Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

636 results about "Tubular membrane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tubular membranes are an effective way of removing contaminants from water and are thus widely used in wastewater treatment and to maintain a zero liquid discharge across a wide range of industries. Tubular membranes have a low packing density. This is the reason behind higher prices per module of tubular membranes.

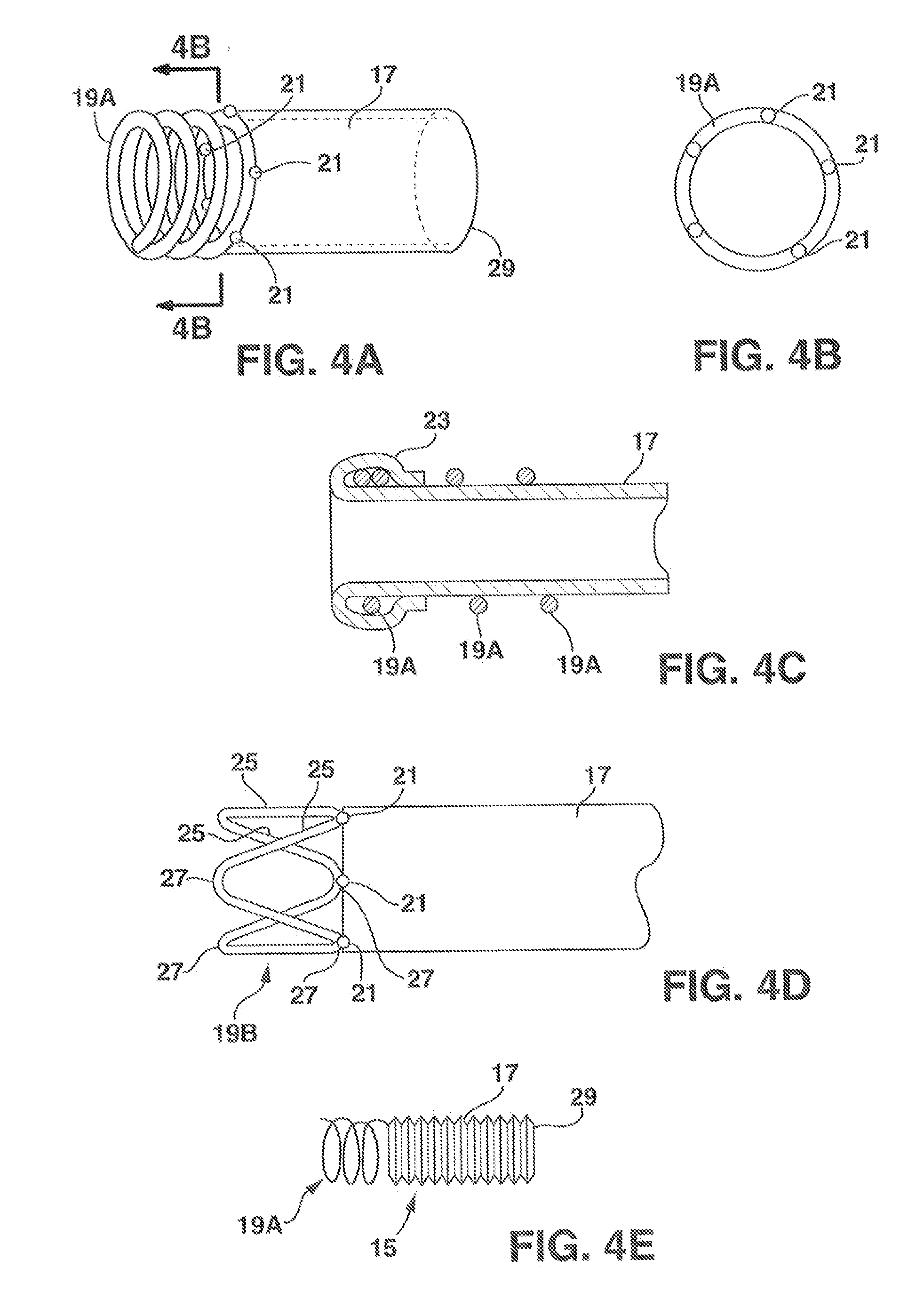

Stent mounted valve

ActiveUS20050137682A1Prevent backflowSmall amount of regurgitationHeart valvesBlood vesselsProsthetic valveInsertion stent

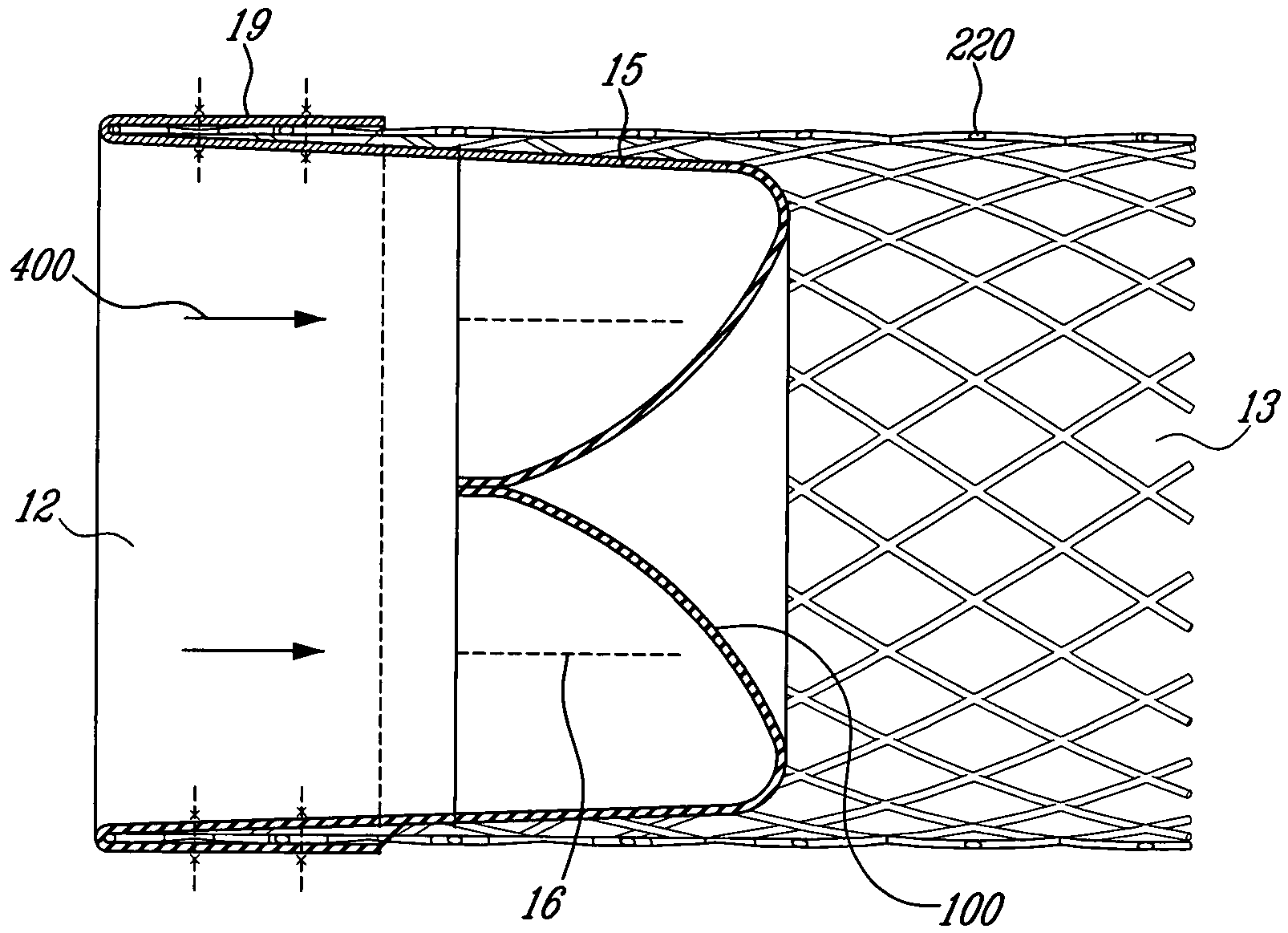

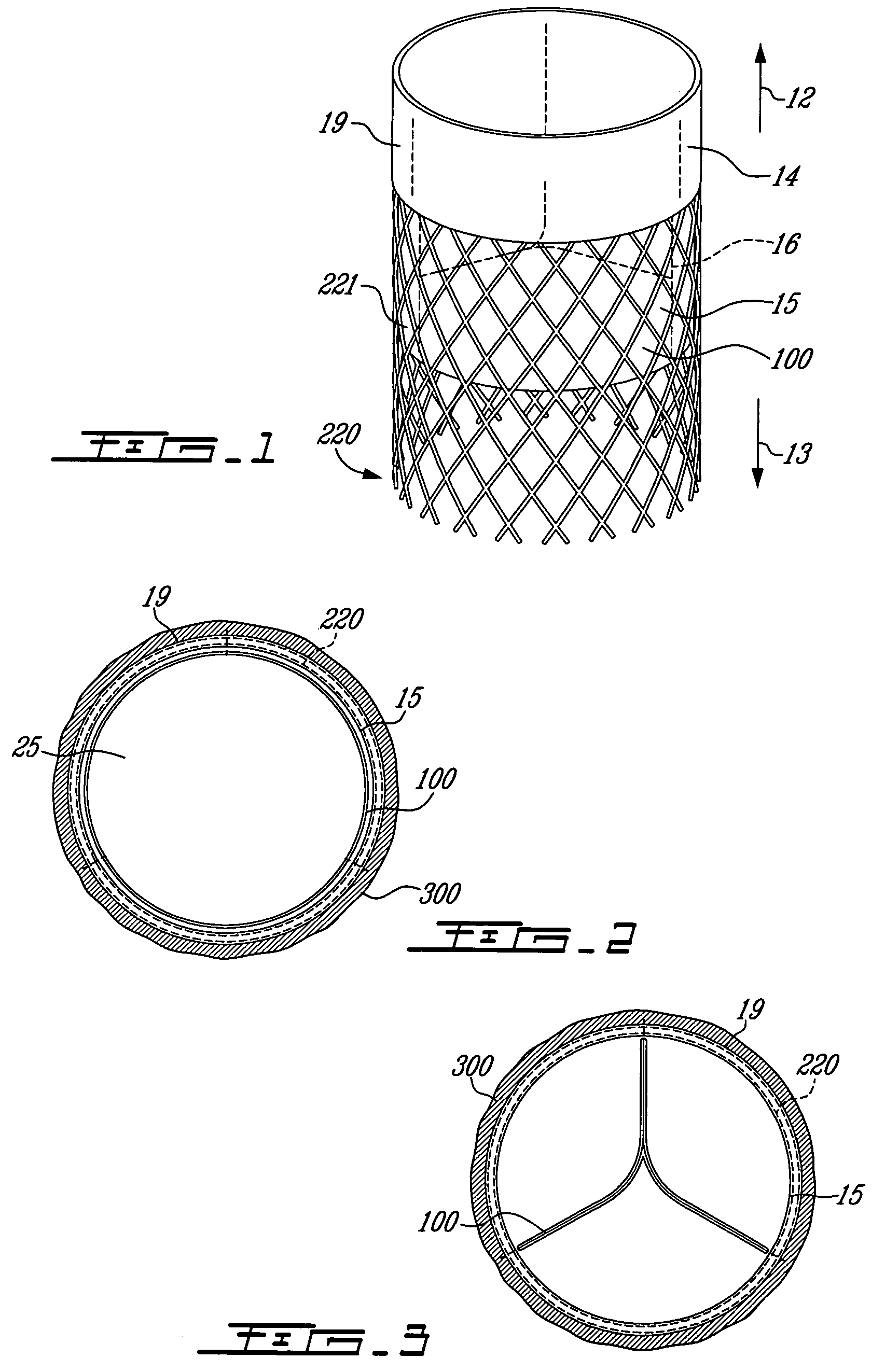

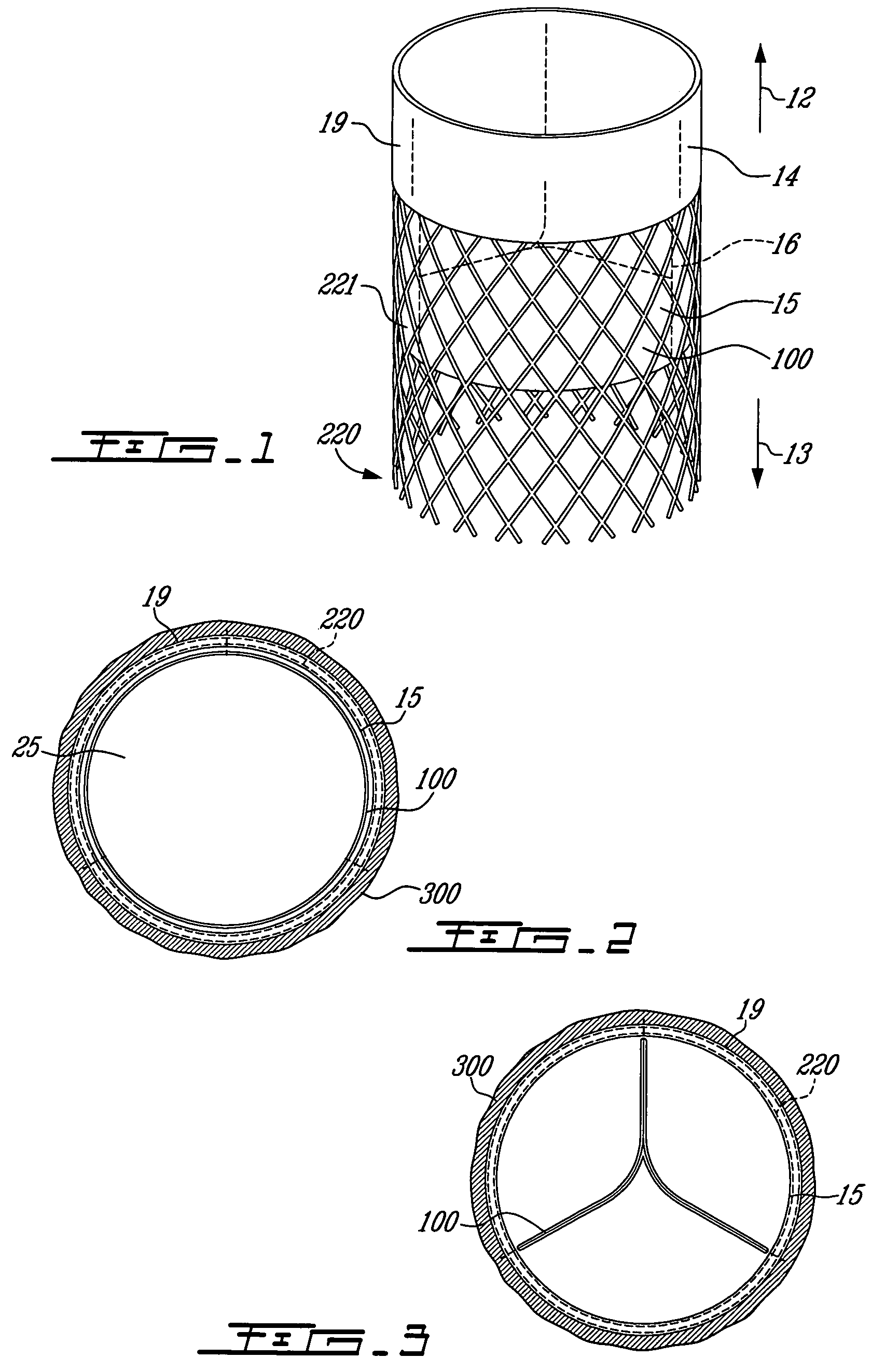

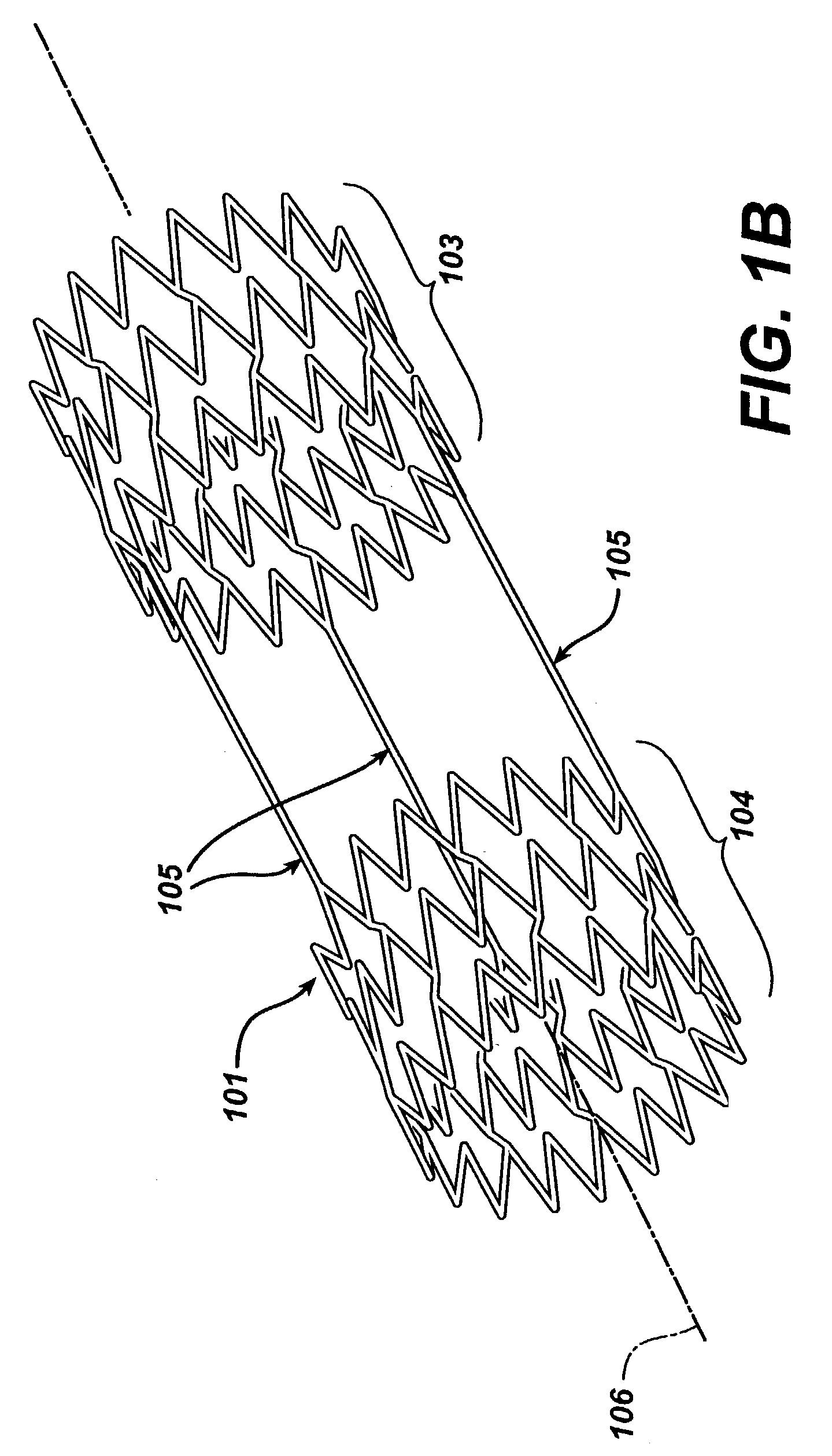

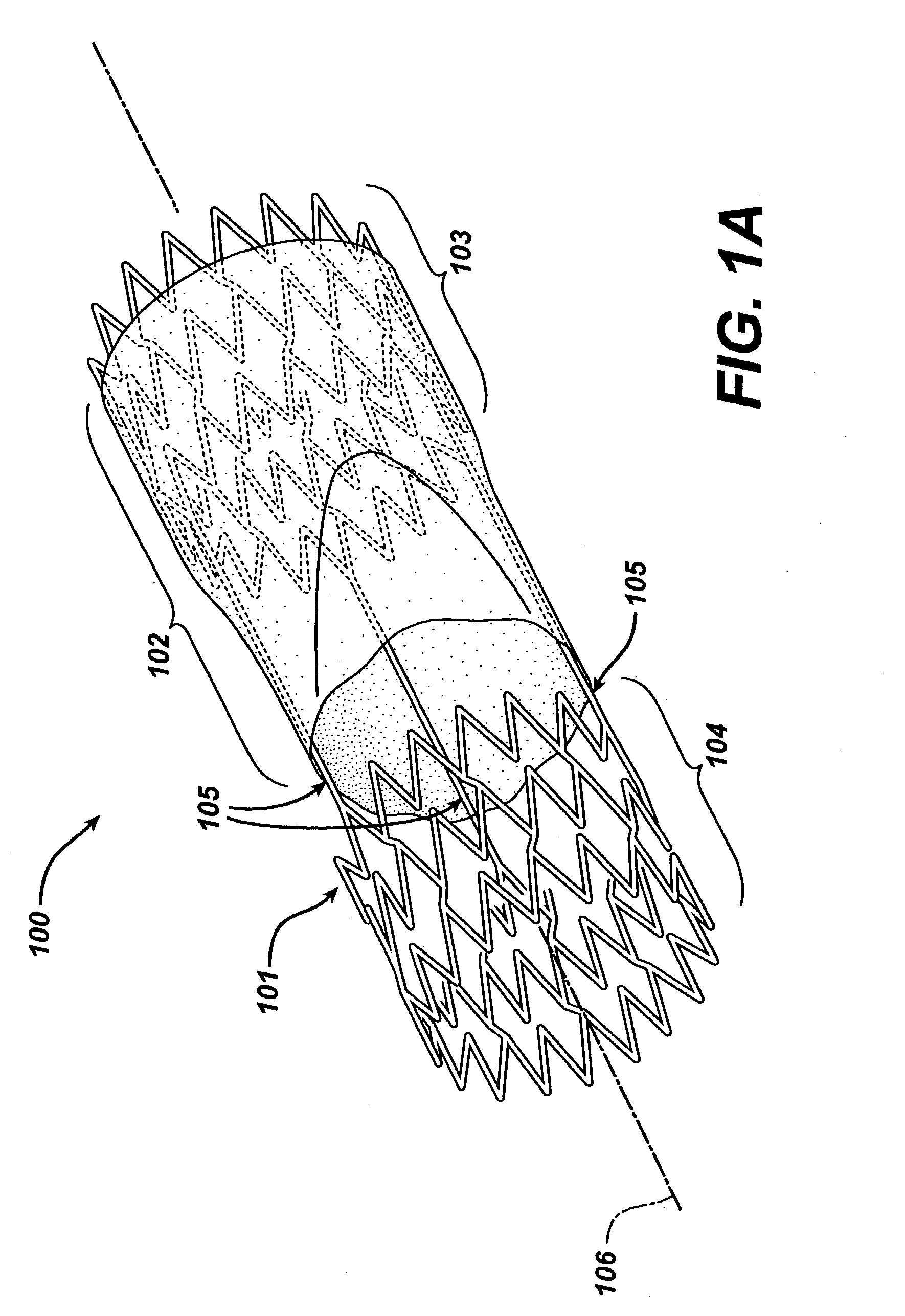

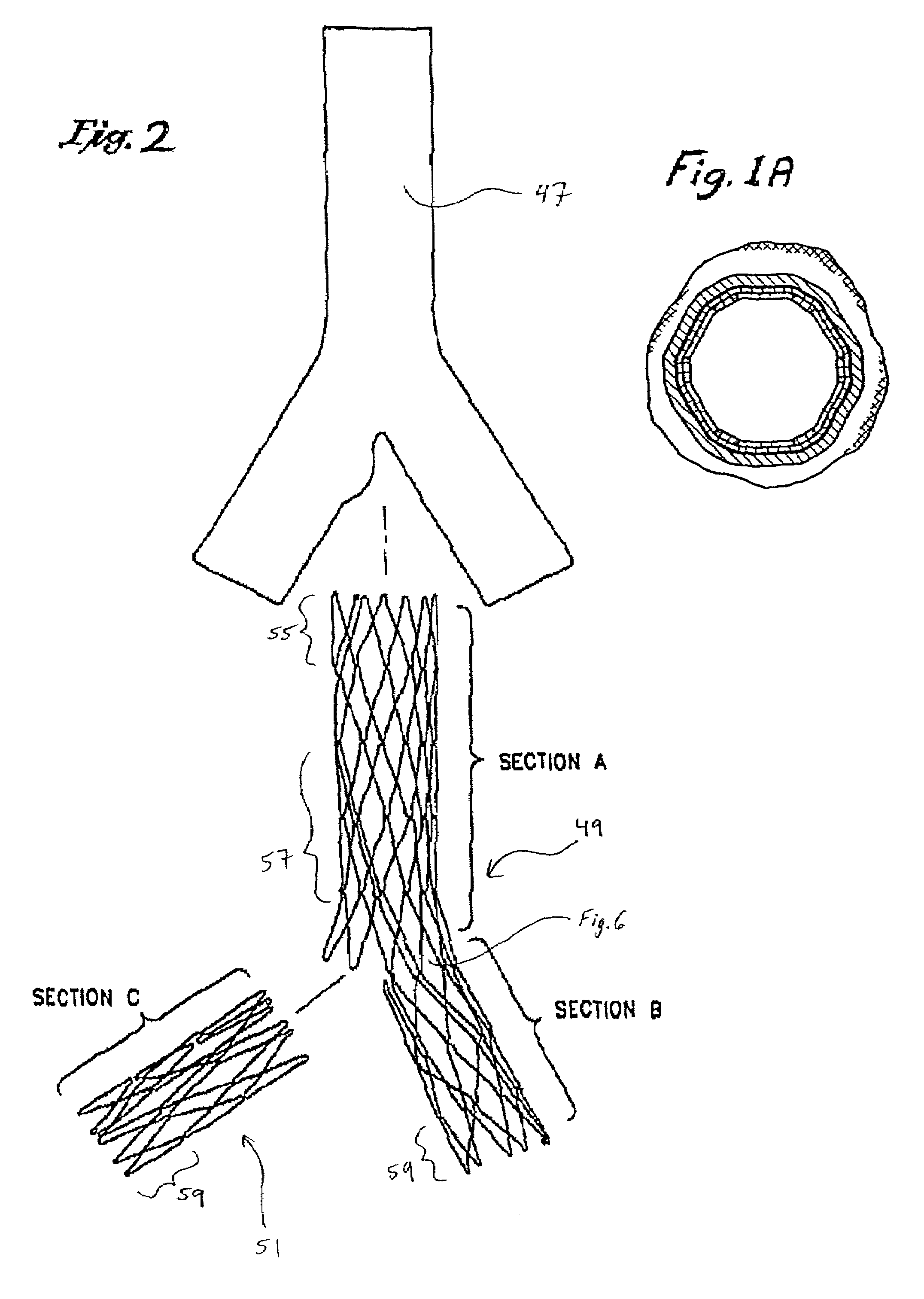

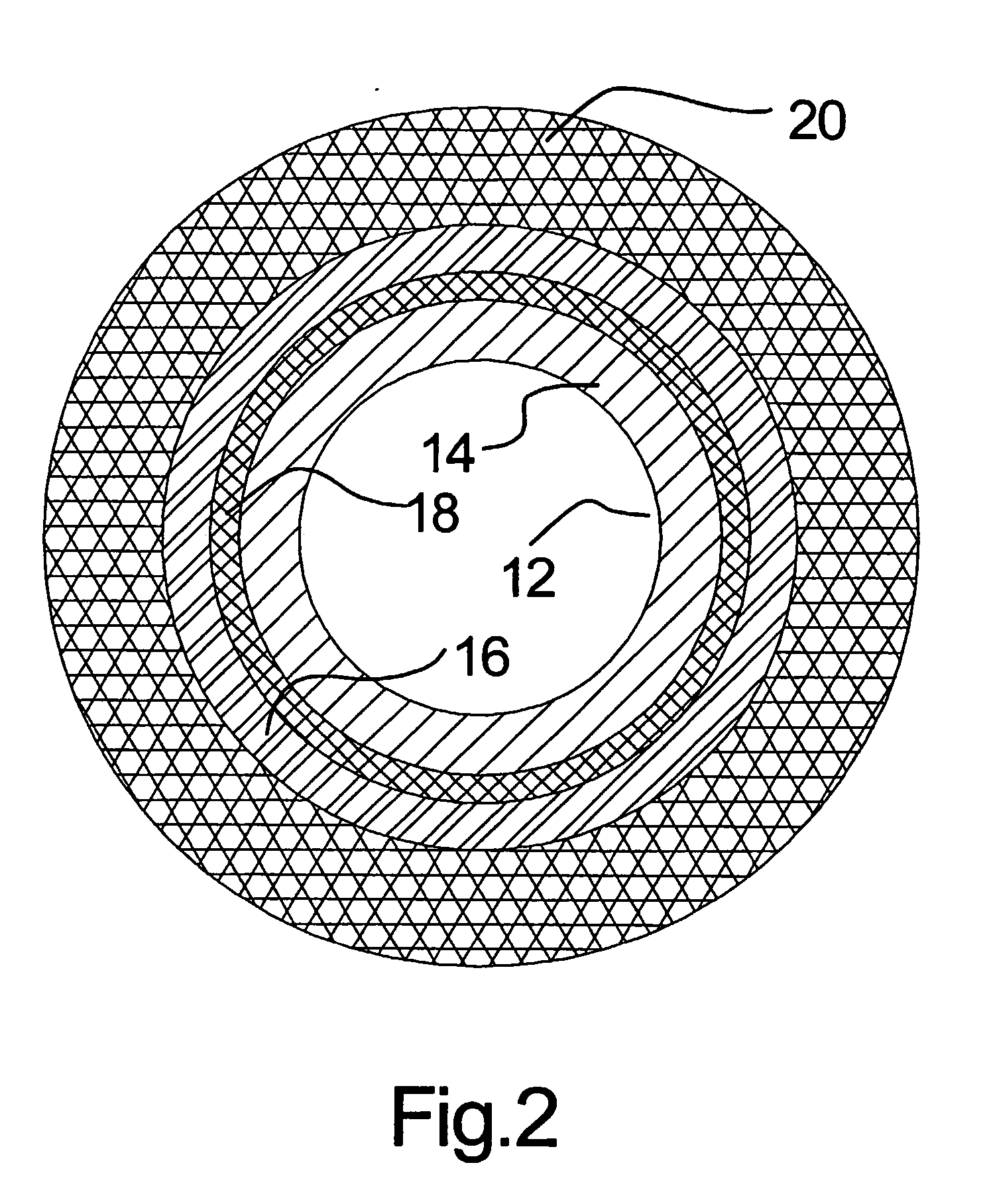

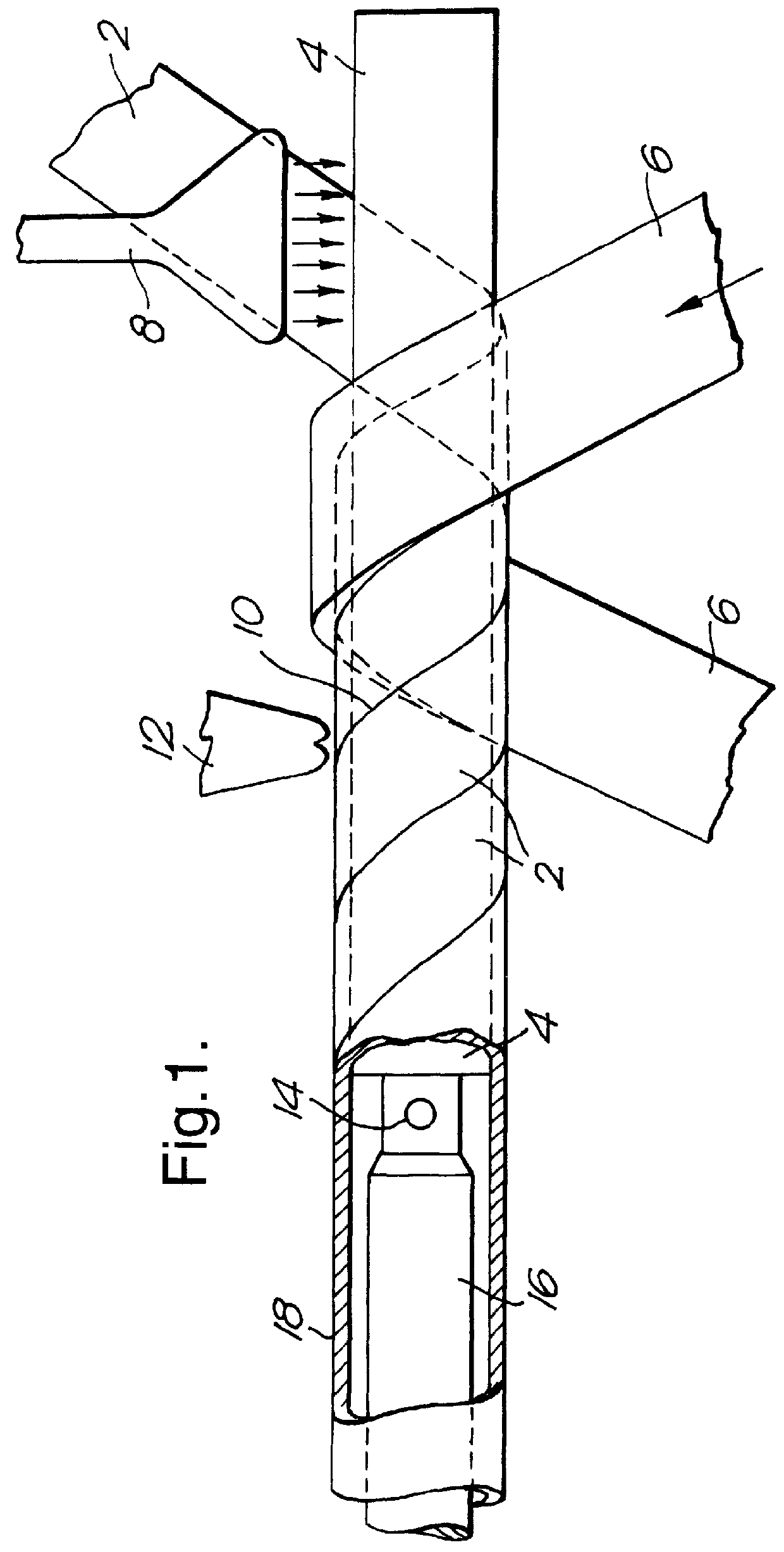

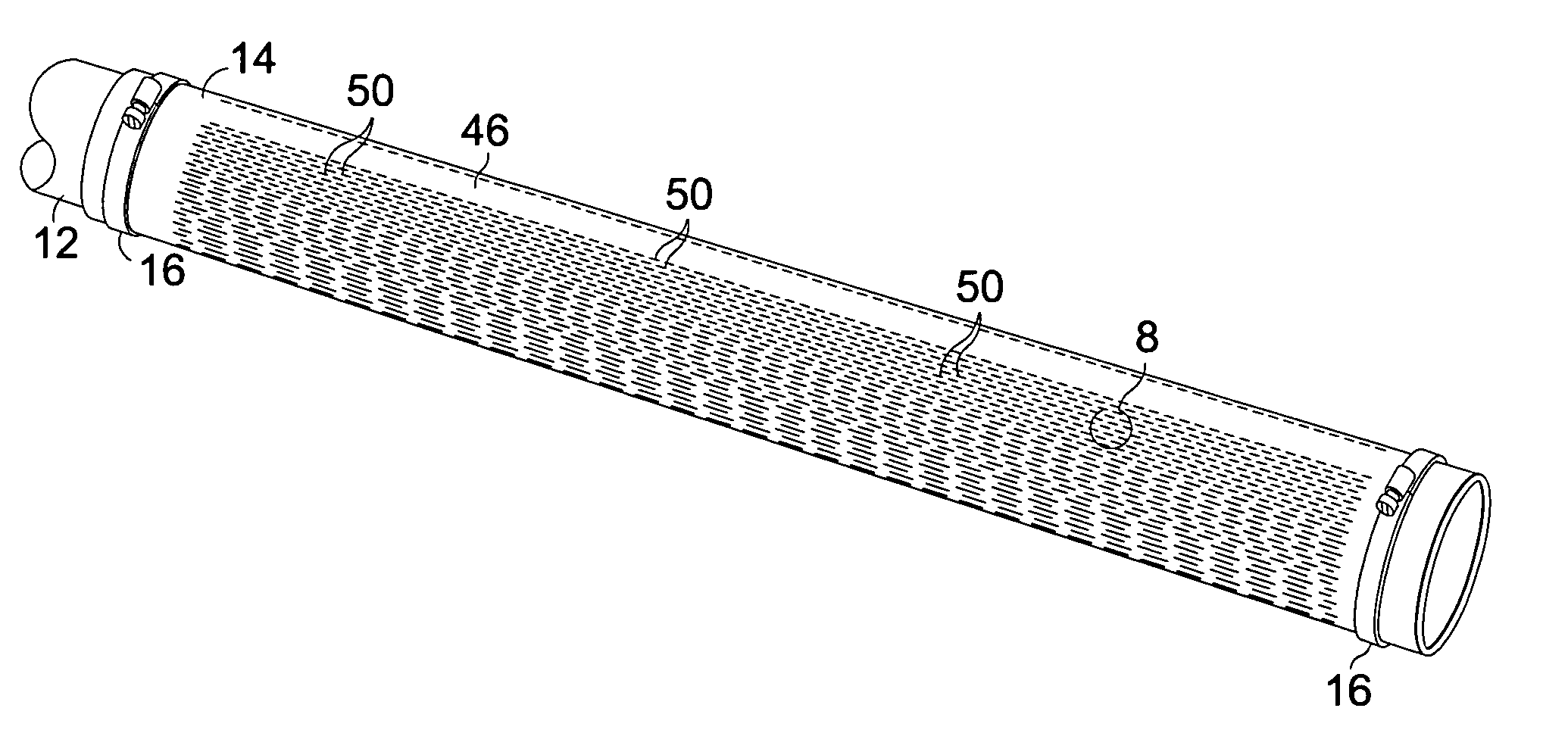

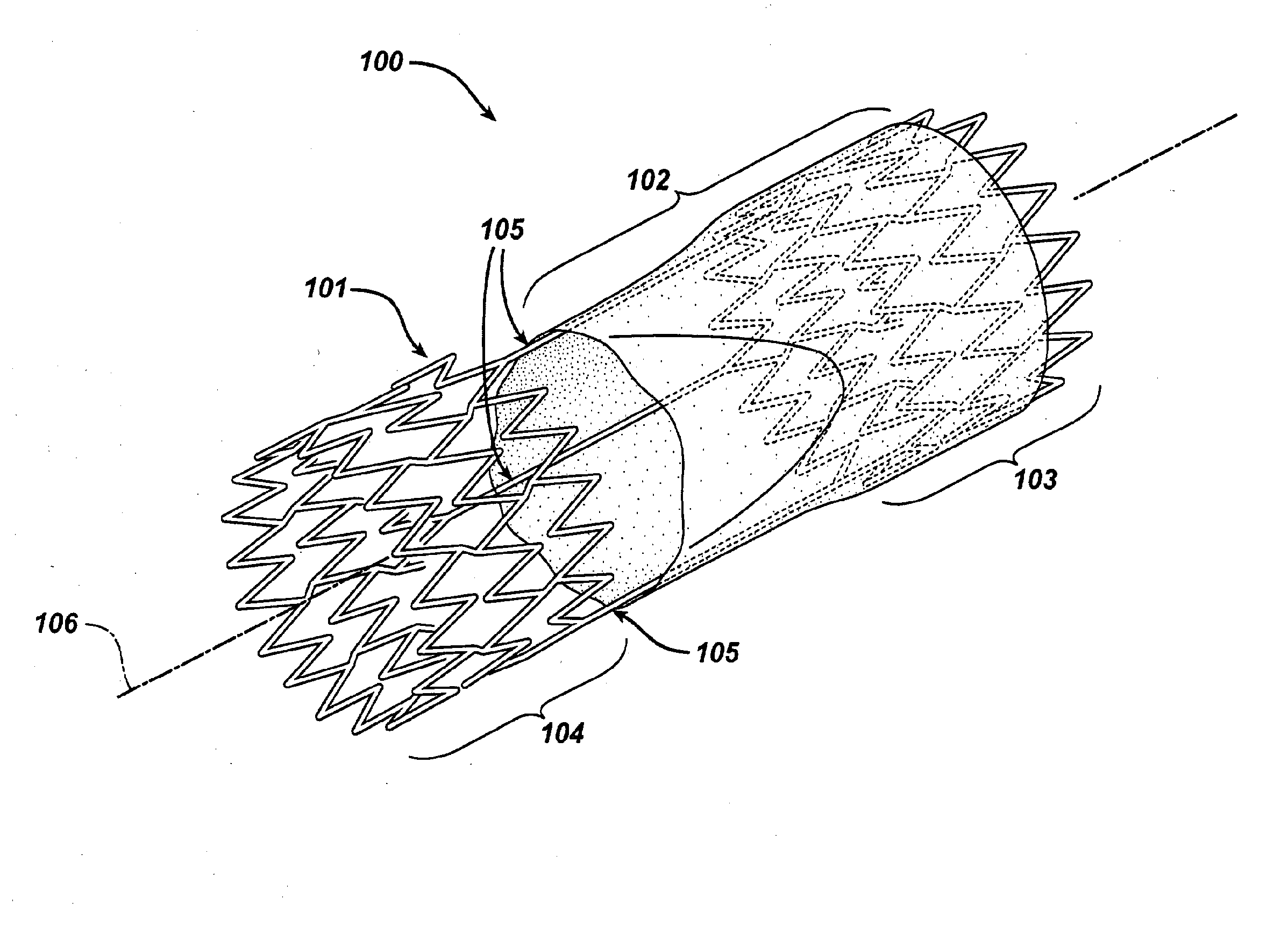

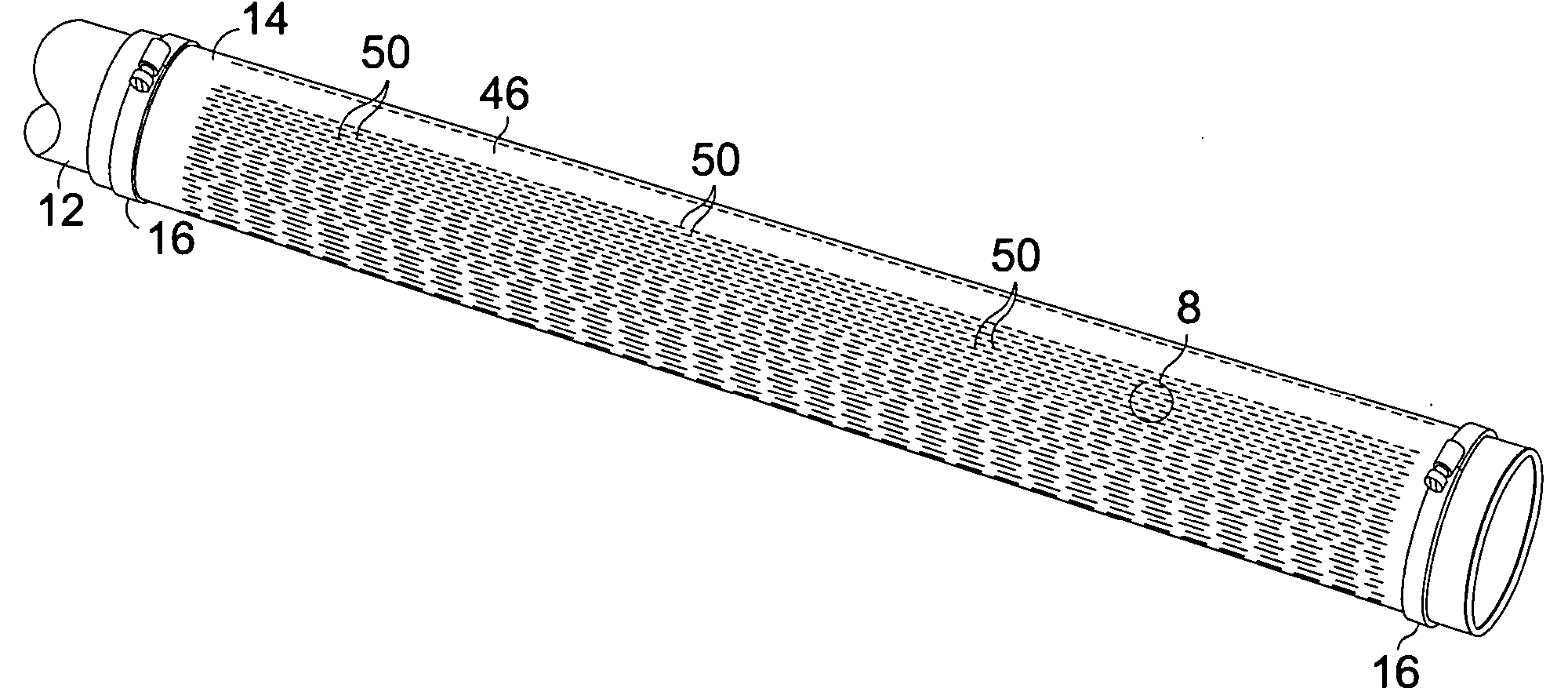

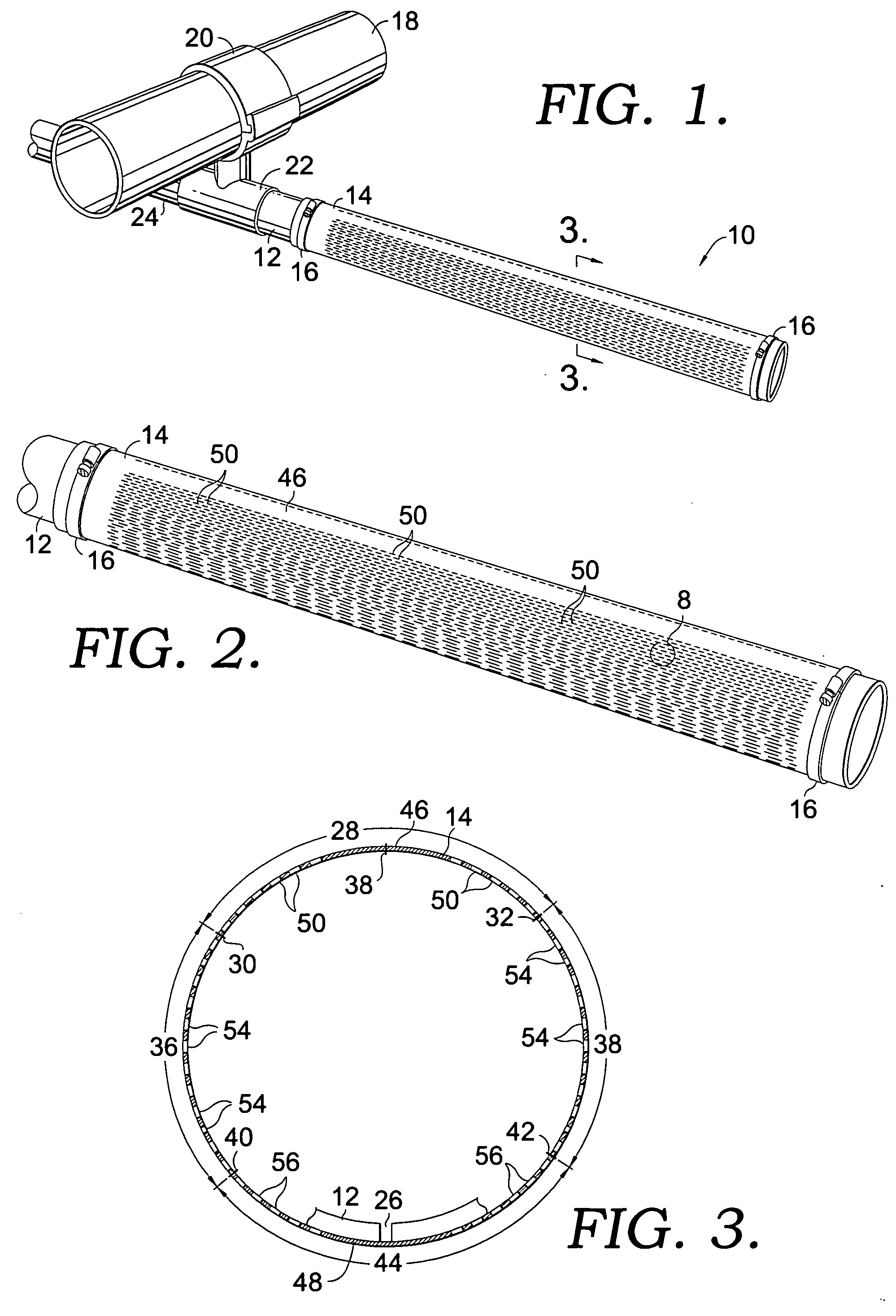

There is described a prosthetic valve to be inserted into a body lumen, the valve having leaflets that are spread apart during forward flow of fluid to create an orifice, and the leaflets coming into contact with each other during reverse flow of fluid, thereby impeding the reverse flow of fluid, the valve comprising: a hollow, cylindrical stent having an inner surface and an outer surface, and having a first and a second open end; and valve means formed from a single tubular membrane, the membrane mounted to the stent, the membrane having a graft portion internally folded and bonded to itself at a plurality of points to form pouches such that the leaflets extend from the pouches, and a sleeve portion on an outer surface of the stent to secure the membrane thereto.

Owner:JUSTINO HENRI

Stent mounted valve

ActiveUS7261732B2Prevent backflowSmall amount of regurgitationHeart valvesBlood vesselsProsthetic valveProsthesis

There is described a prosthetic valve to be inserted into a body lumen, the valve having leaflets that are spread apart during forward flow of fluid to create an orifice, and the leaflets coming into contact with each other during reverse flow of fluid, thereby impeding the reverse flow of fluid, the valve comprising: a hollow, cylindrical stent having an inner surface and an outer surface, and having a first and a second open end; and valve means formed from a single tubular membrane, the membrane mounted to the stent, the membrane having a graft portion internally folded and bonded to itself at a plurality of points to form pouches such that the leaflets extend from the pouches, and a sleeve portion on an outer surface of the stent to secure the membrane thereto.

Owner:JUSTINO HENRI

Virtual channel enabling device for use in endoscopic instrument insertion and body cavity cleansing

InactiveUS20100256447A1Maintain good propertiesFacilitate surgical procedureCannulasEndoscopesSurface mountingEndoscope

Owner:JETPREP

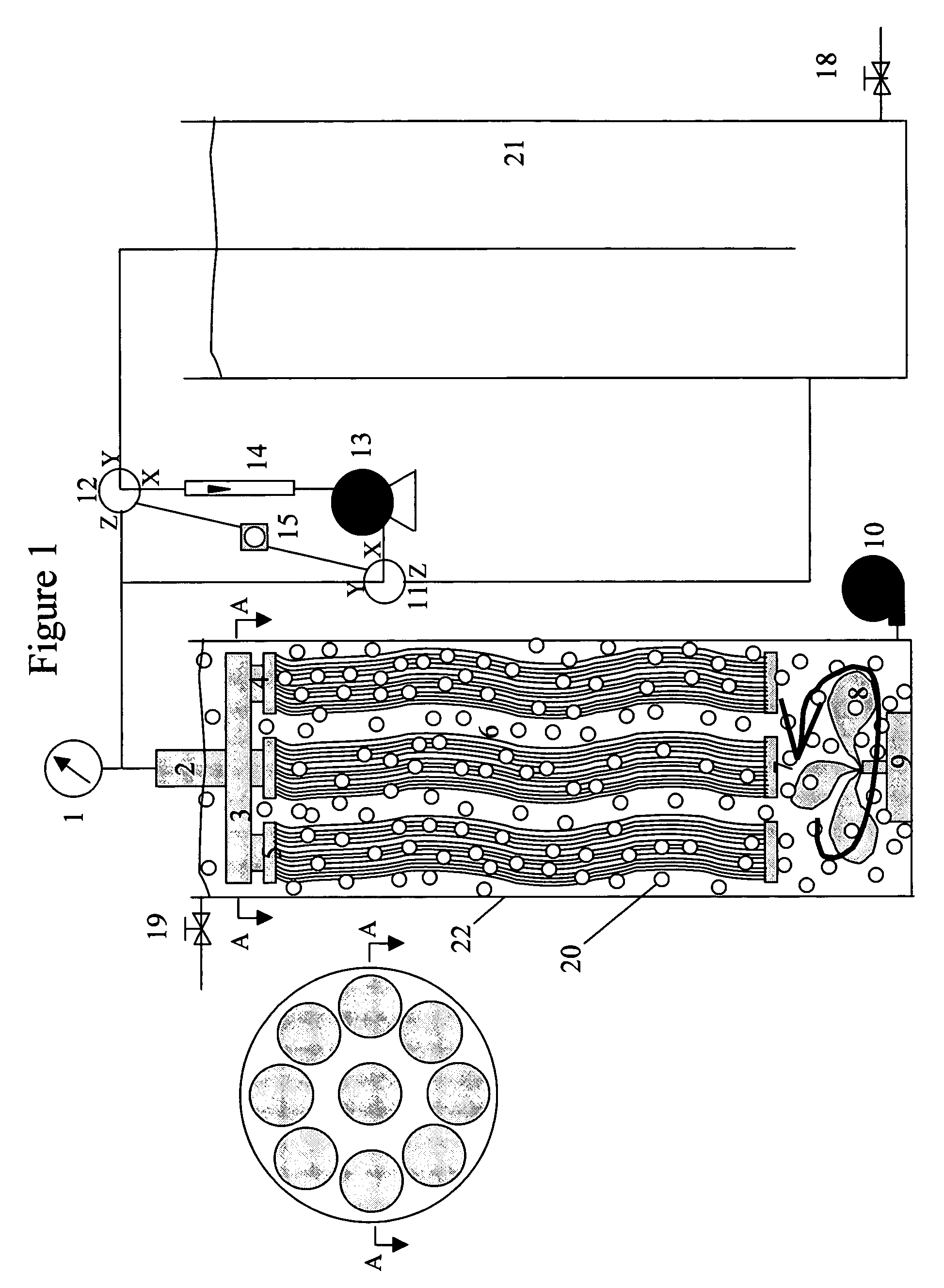

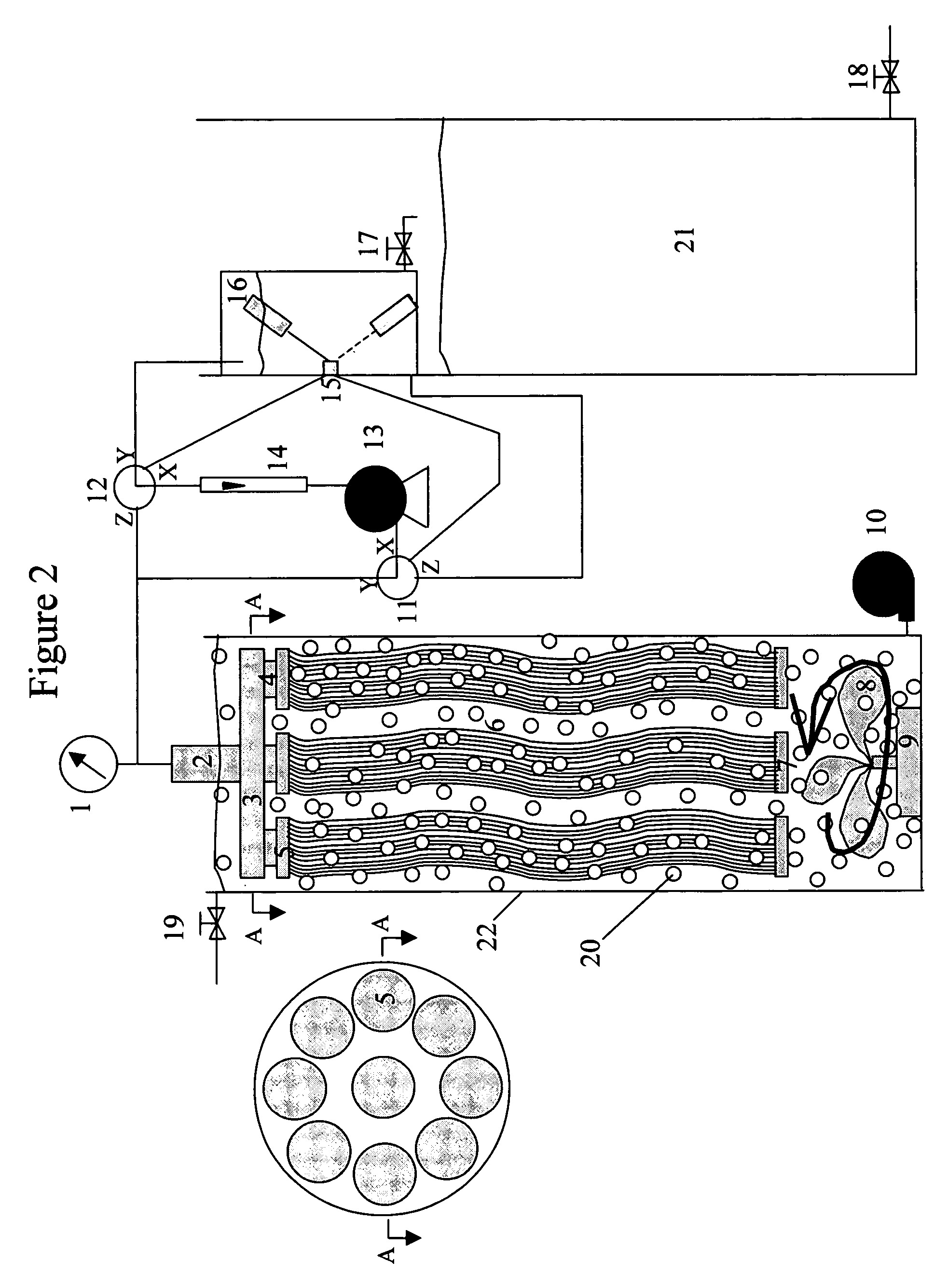

Advanced submerged membrane modules, systems and processes

Advanced submerged membrane systems are provided. Said submerged membrane systems have multiple membrane modules comprising of strips of flat sheet membrane, bundles of self-support hollow fiber membranes braided together for reinforcement, tubular membranes, and braid supported hollow fiber membranes. Said submerged membrane systems have alternating relay, or two-way floating switch or computer to control filtration and back flush / pulse cleaning. Said submerged membrane systems have an oscillating motor, and aerator which can generate liquid vortex (whirlpool) flow around membrane to keep membrane from fouling. The present invention provides advanced submerge membrane systems at very low cost for drinking water production, wastewater treatment and membrane bioreactors for biotech, pharmaceutical and other industries.

Owner:JI JIANG

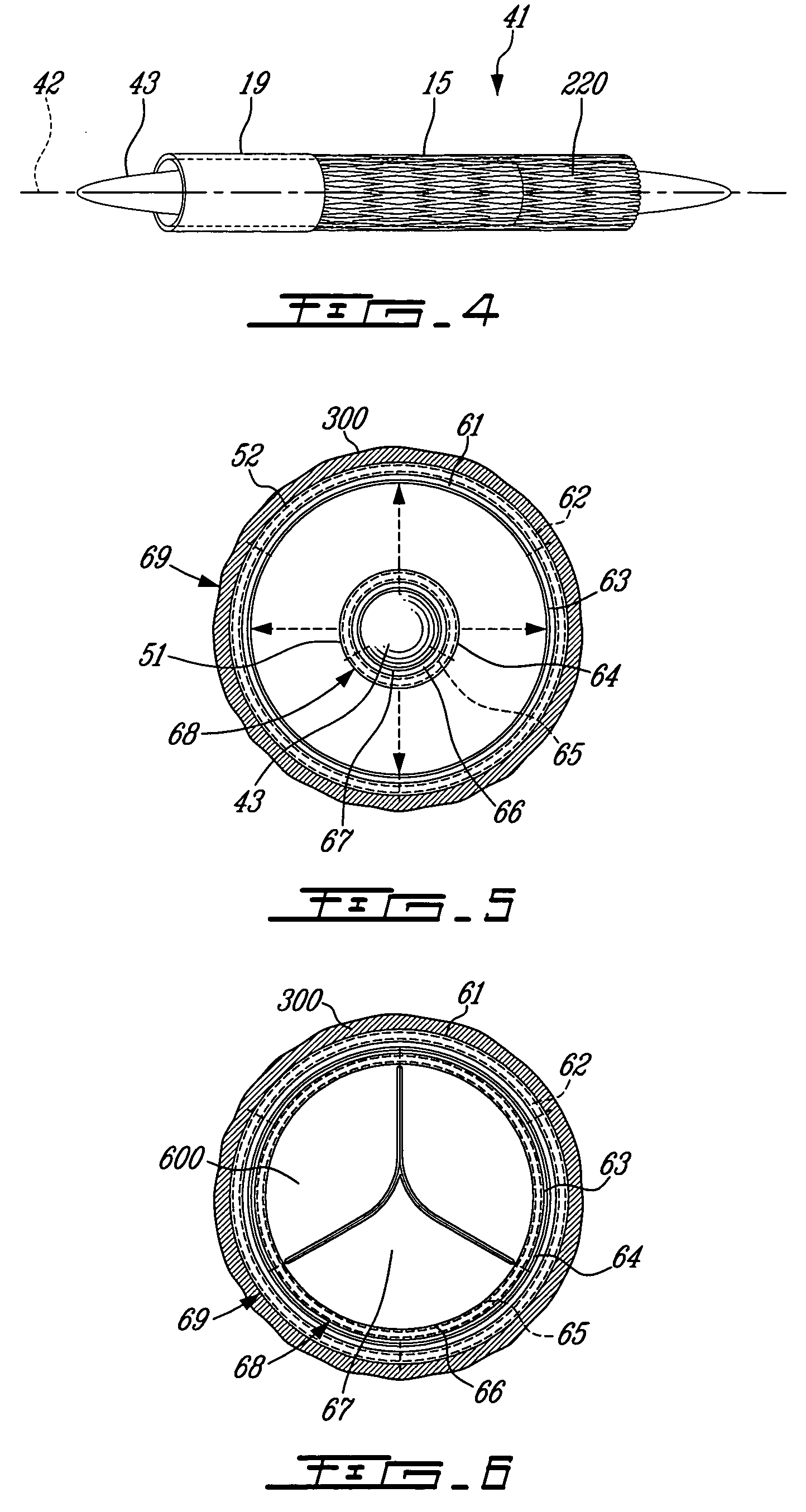

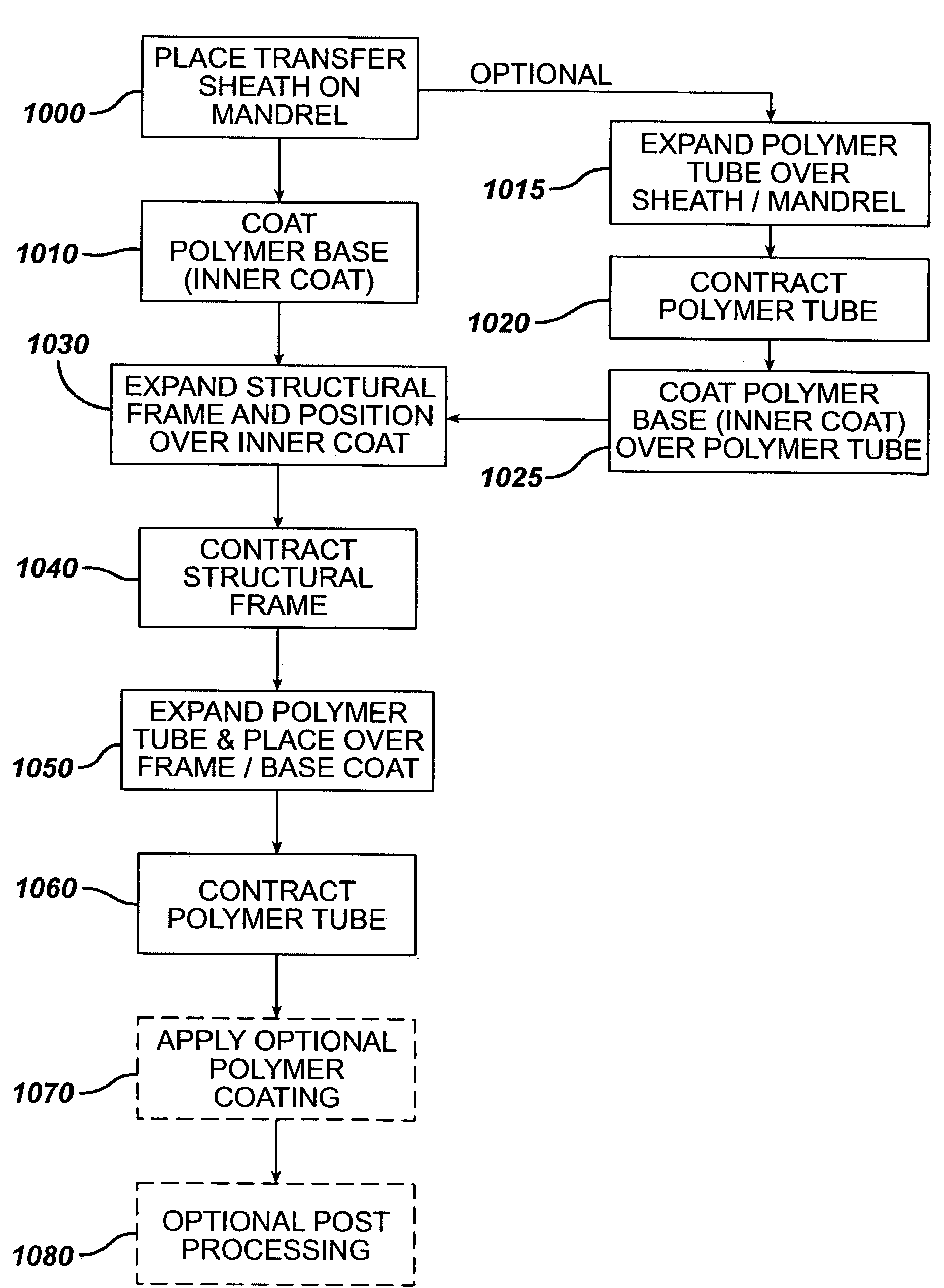

Method of placing a tubular membrane on a structural frame

The present invention relates to a medical device, and more particularly to a method of forming a tubular membrane on a radially expandable structural frame. In one aspect, a structural frame is placed over a spinning mandrel and a fiber is electro-statically spun over at least a portion of the structural frame forming a membrane. A transfer sheath may be used between the mandrel and structural frame to prevent the electrostatically spun fiber from adhering to the mandrel. In another aspect, a first membrane is spun over the mandrel before the structural frame is placed over the mandrel. In this aspect, at least a portion of the structural frame is sandwiched between the membranes. The membrane or membranes and structural frame form a fiber spun frame assembly. The fiber spun frame assembly may be coated with an elastic polymer. In addition, the membrane or membranes may go through some post processing to achieve desired characteristics or configurations.

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

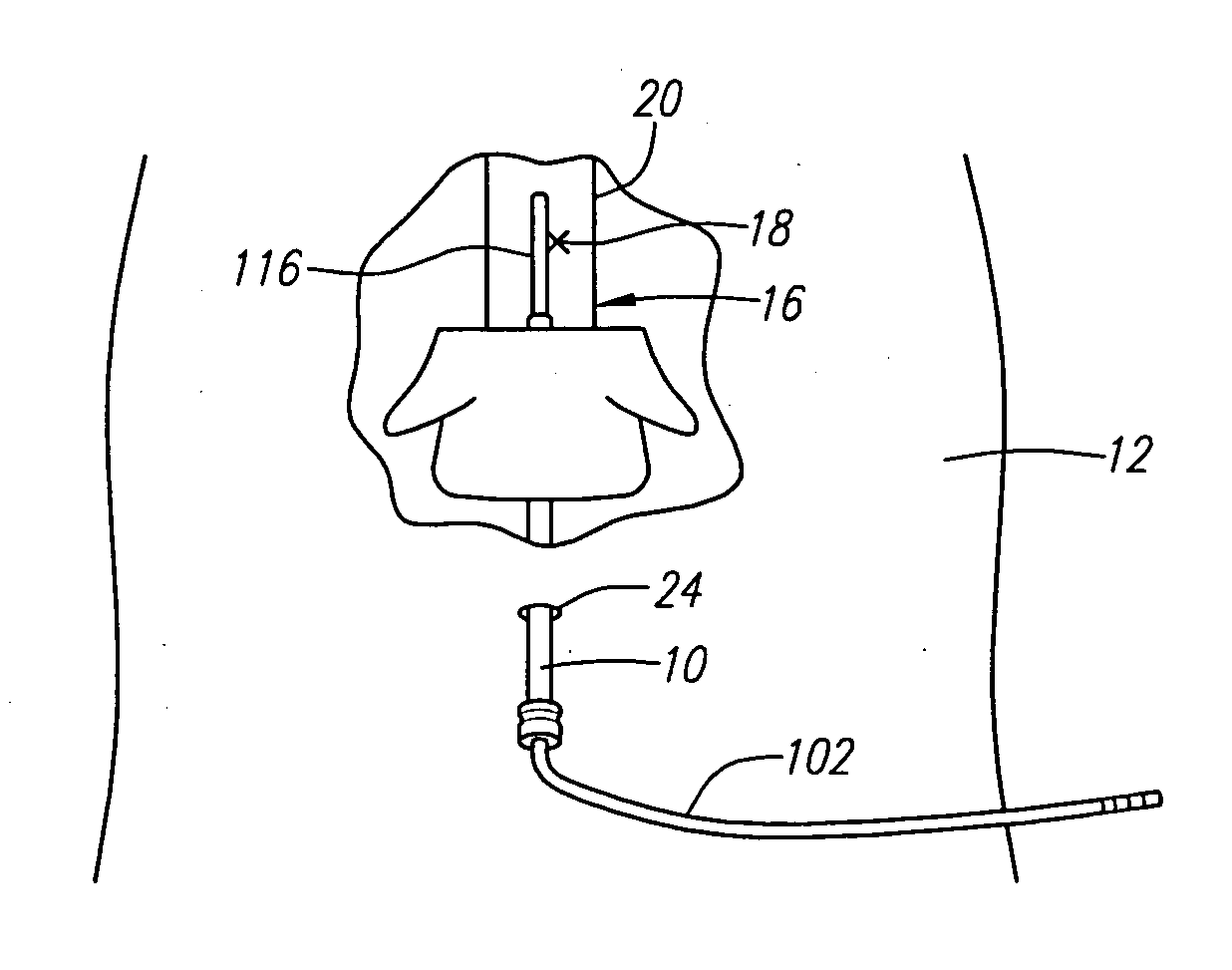

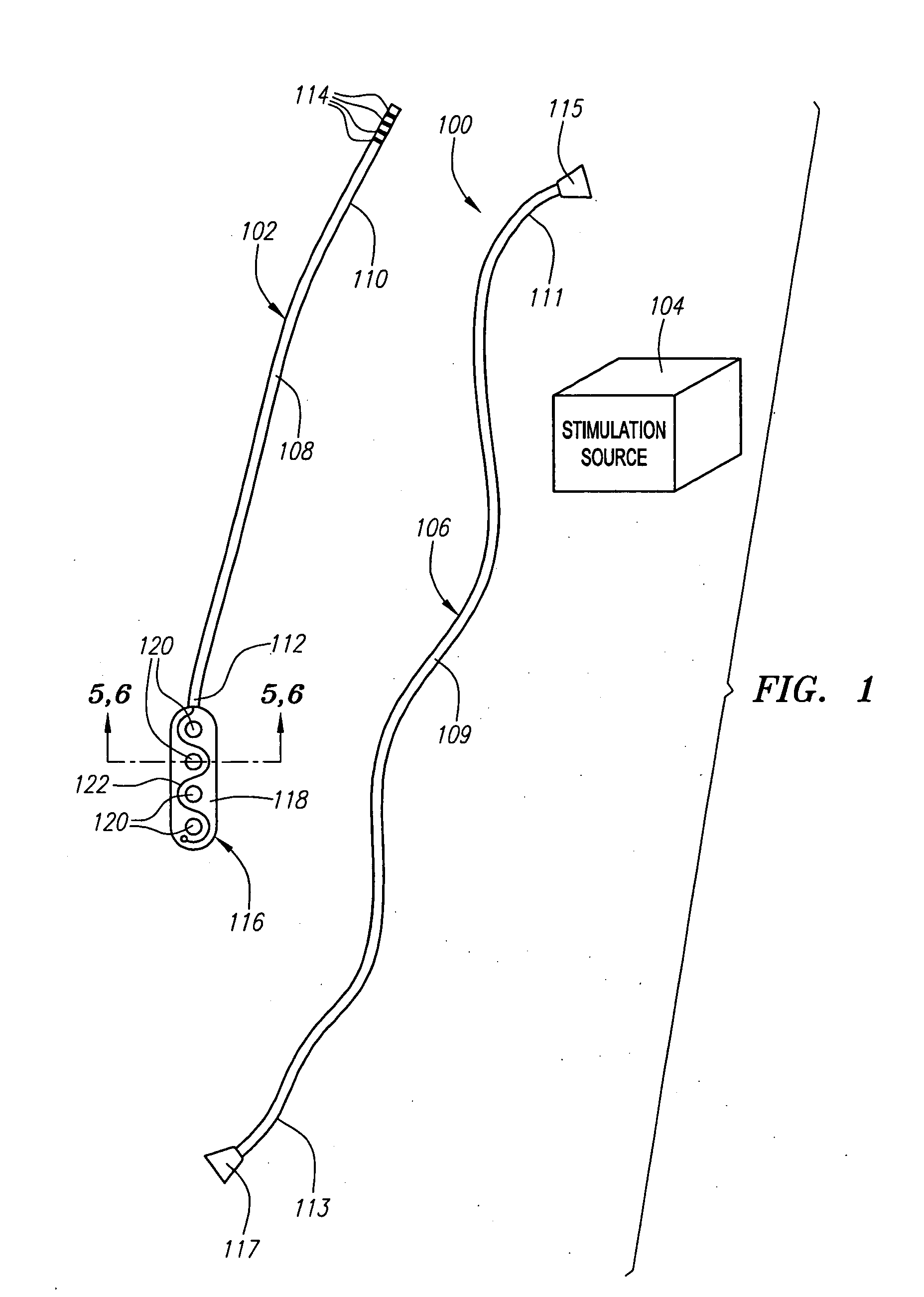

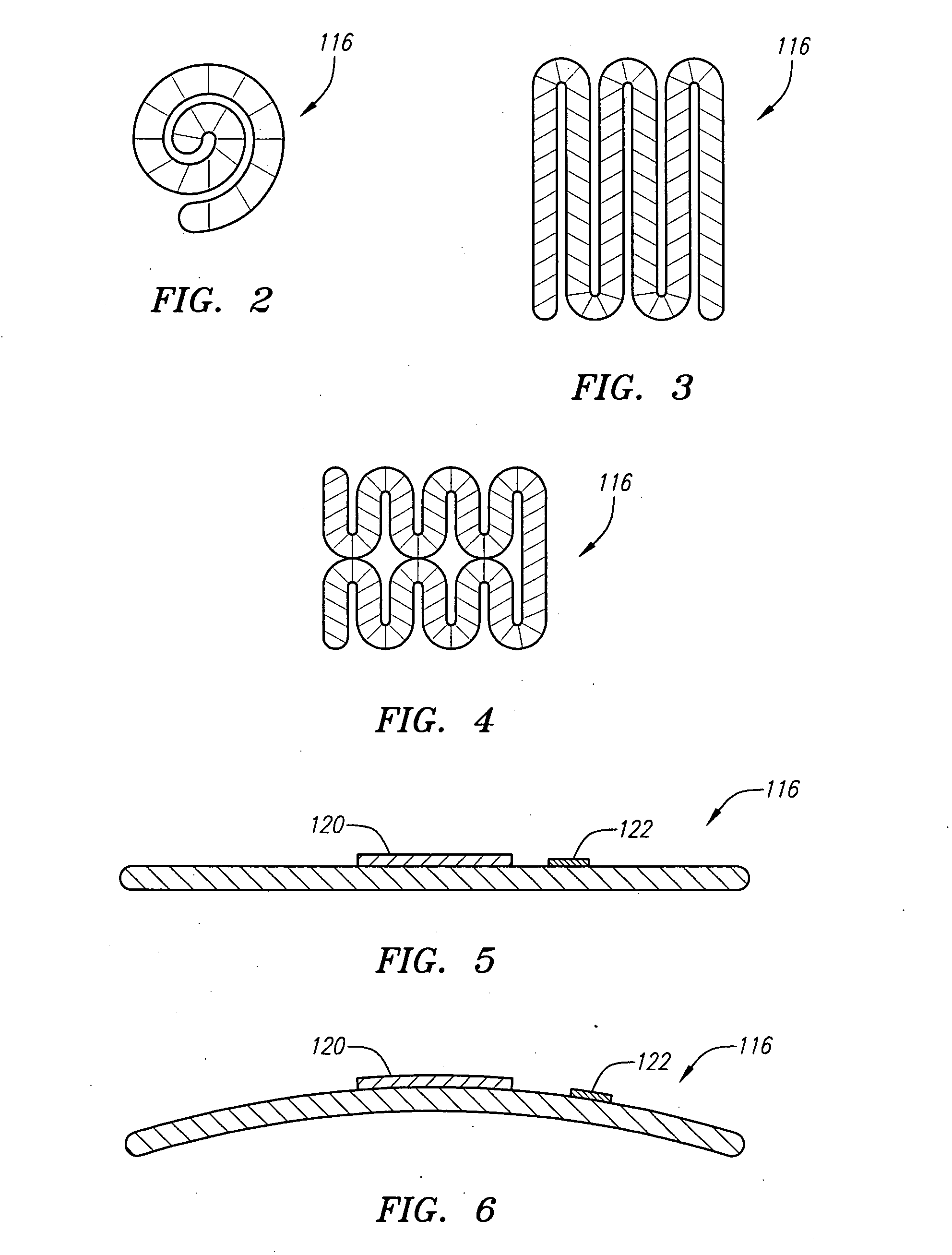

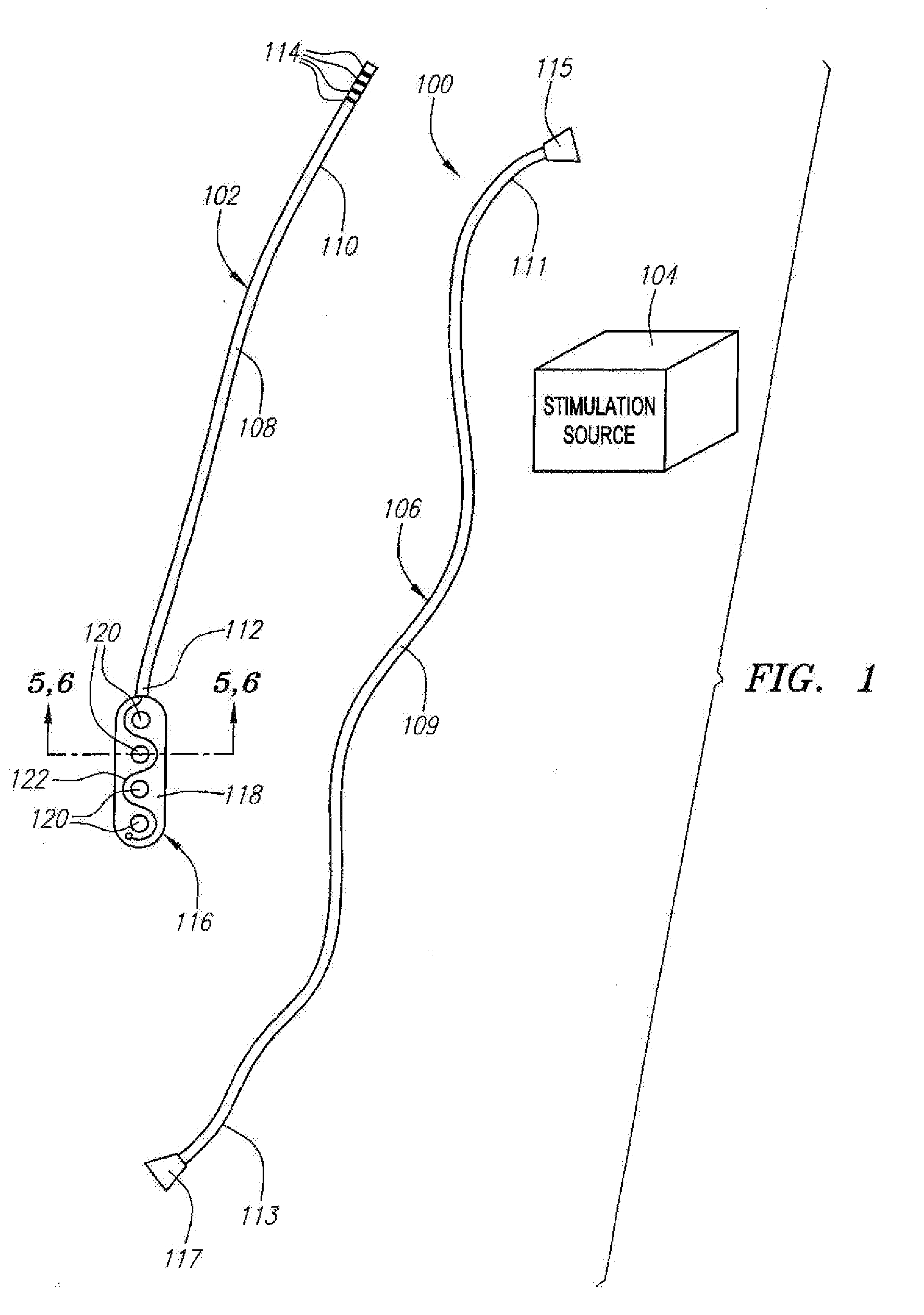

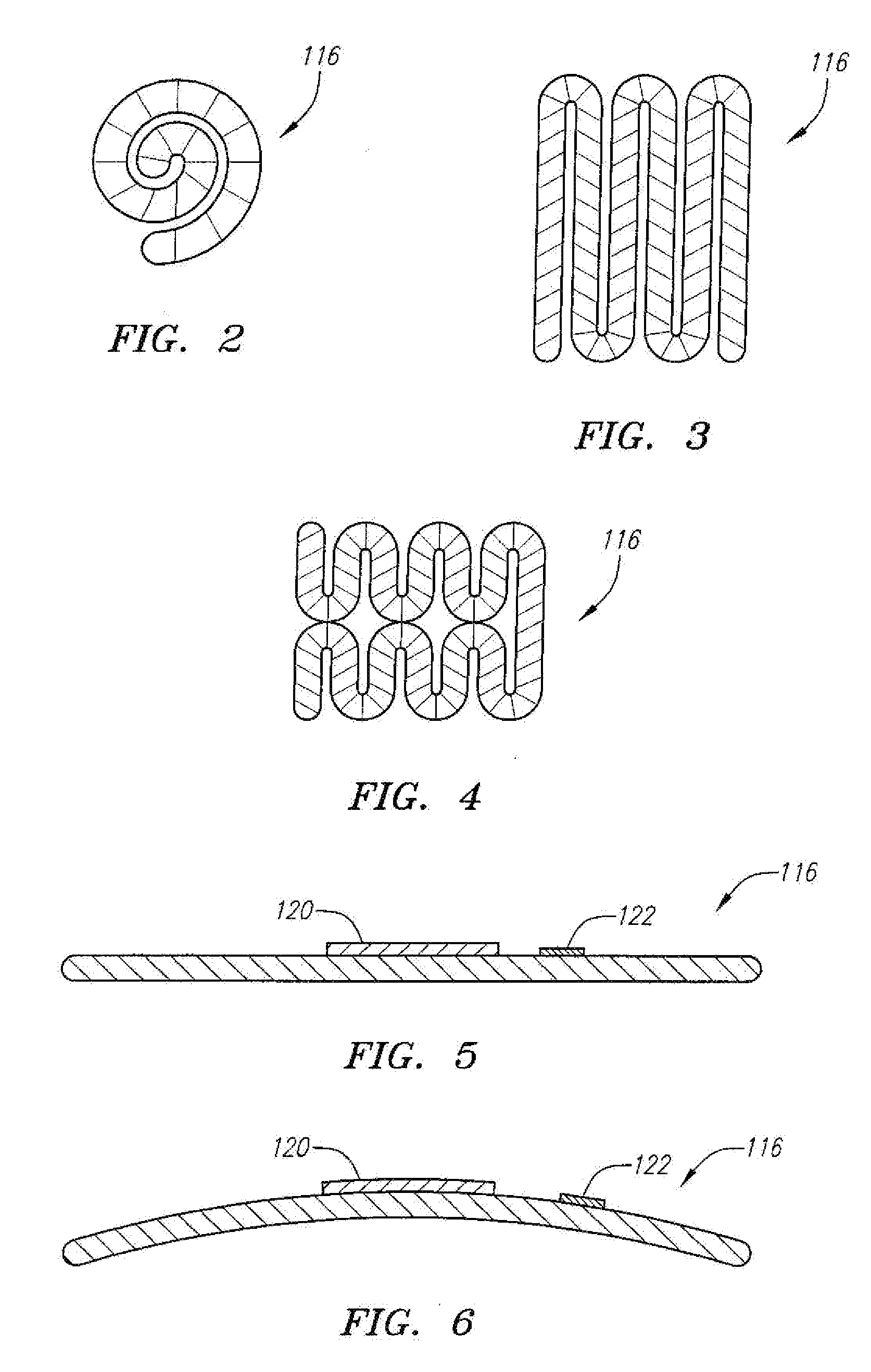

Collapsible/expandable tubular electrode leads

InactiveUS20050203600A1Inhibit tissue growthEasy retrievalSpinal electrodesExternal electrodesSpinal cordSurgical department

A medical lead and method of treating a patient are provided. The medical lead comprises an electrically insulative tubular membrane, a resilient spring element associated with the insulative membrane, and at least one electrode associated with the insulative membrane. In the preferred embodiment, the tubular membrane has a non-circular cross-sectional shape. The spring layer is configured to urge that insulative membrane into an expanded geometry. The medical lead is configured to be collapsed into a compact form for percutaneous delivery into the patient, thereby obviating the need to perform an invasive surgical procedure on the patient. The body formed by these elements, when expanded, can be sized to fit within the epidural space of a patient. The patient can be treated by placing the medical lead into a collapsed state by applying a compressive force to the medical lead, percutaneously delivering the collapsed medical lead into the patient adjacent tissue to be treated, and placing the medical lead into an expanded state by releasing the compressive force. In one preferred method, the stimulation lead is used to stimulate tissue, such as spinal cord tissue.

Owner:BOSTON SCI SCIMED INC

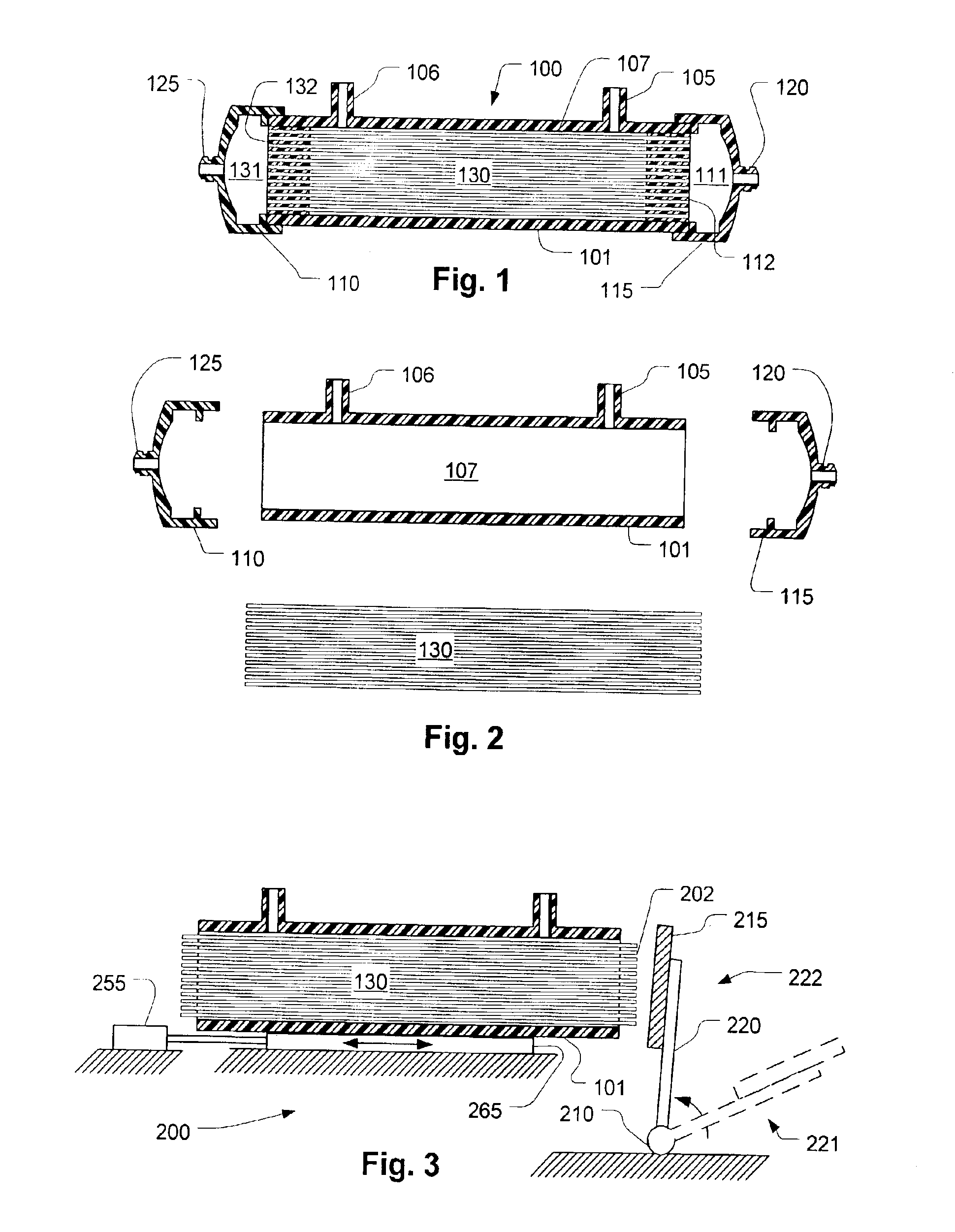

Method of forming a tubular membrane on a structural frame

The present invention relates to a medical device and method of forming the medical device. In particular, the present invention relates to a medical device having a tubular membrane structure over a radially expandable structural frame, and to a method of forming the tubular membrane on the radially expandable structural frame. In one aspect, a structural frame is placed over a spinning mandrel and a fiber is electro-statically spun over at least a portion of the structural frame forming a membrane. A transfer sheath may be used between the mandrel and structural frame to prevent the electro-statically spun fiber from adhering to the mandrel. In another aspect, a first membrane is spun over the mandrel before the structural frame is placed over the mandrel. In this aspect, at least a portion of the structural frame is sandwiched between the membranes. The membrane or membranes and structural frame form a fiber spun frame assembly. The fiber spun frame assembly may be coated with an elastic polymer. In addition, the membrane or membranes may go through some post processing to achieve desired characteristics or configurations.

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

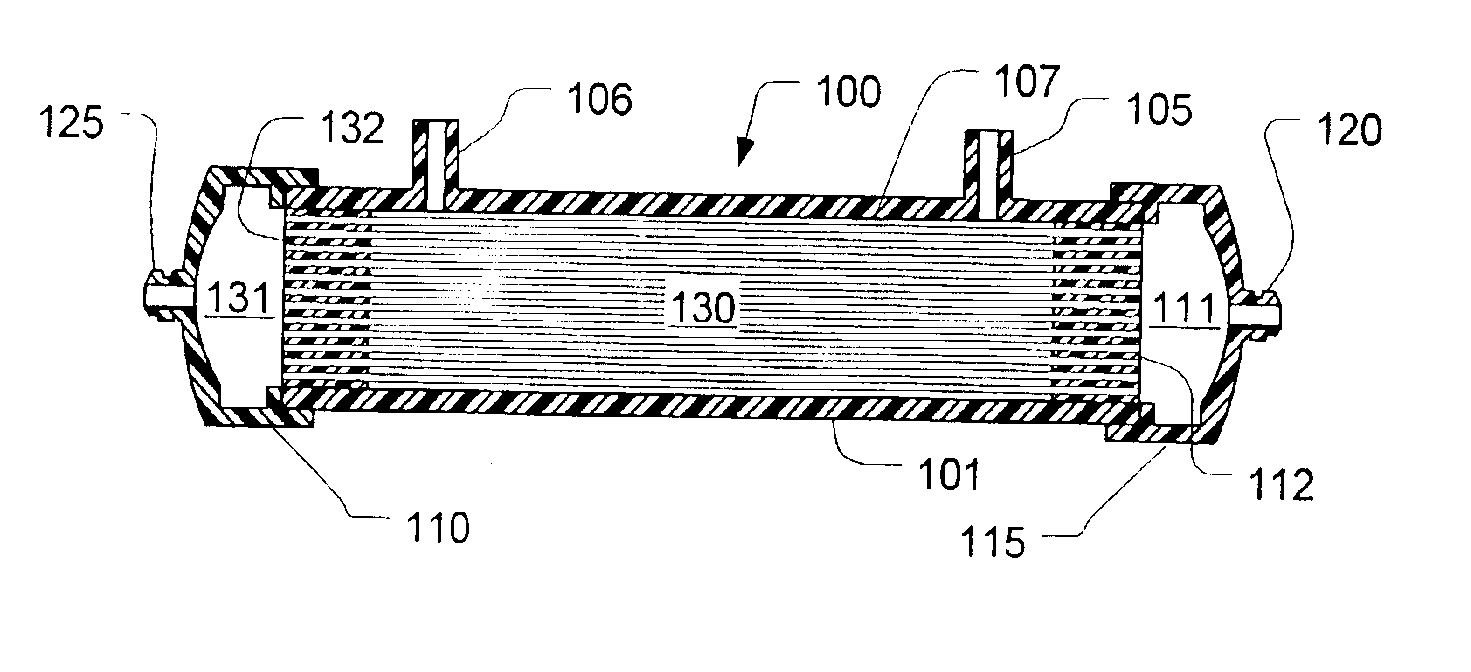

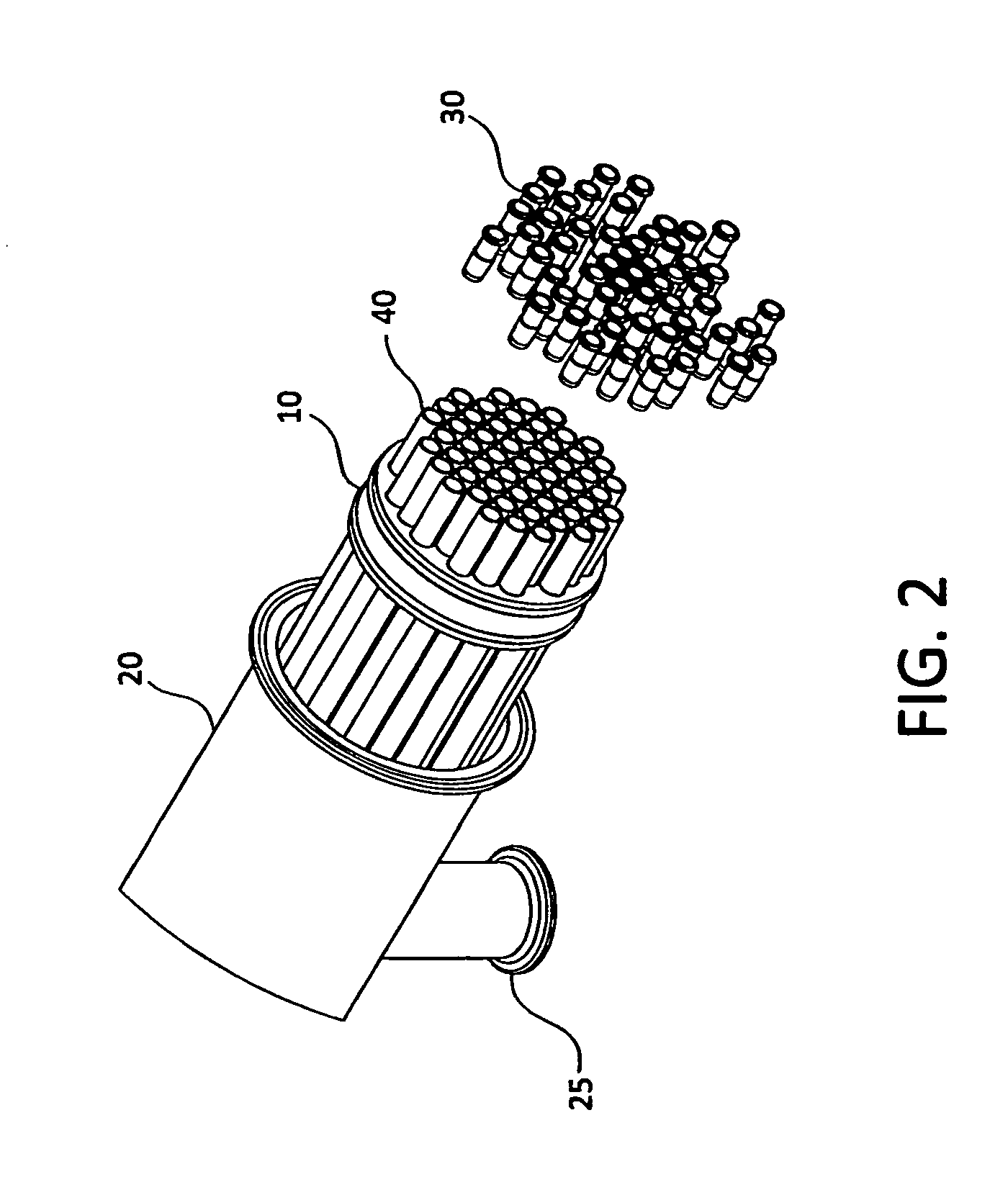

Method and apparatus for manufacturing filters

InactiveUS6872346B2Speed productionShort amount of timeSemi-permeable membranesTailstocks/centresEngineeringMechanical engineering

A problem in the manufacture of filters using tubular membrane bundles is keeping potting material from flowing into the openings at the ends of the tubes. A preferred embodiment of a method for manufacturing a tubular membrane filter employs a non-contact heat source such as radiant heating to melt the tips of the tubular membranes. This prevents the migration of potting material into the tubes when the potting material is flowed into the ends of tube bundles during the manufacturing process for a filter.

Owner:NXSTAGE MEDICAL

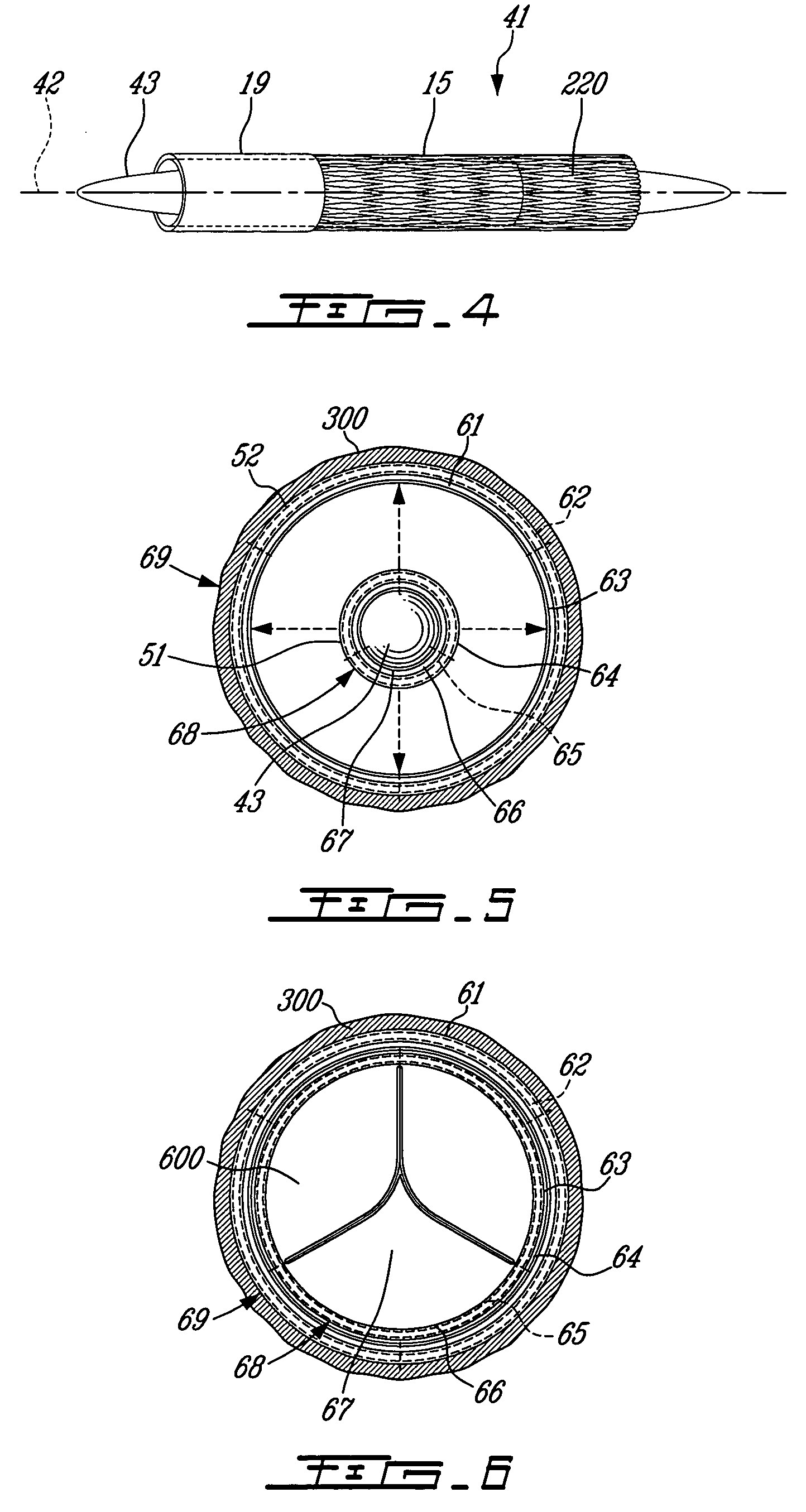

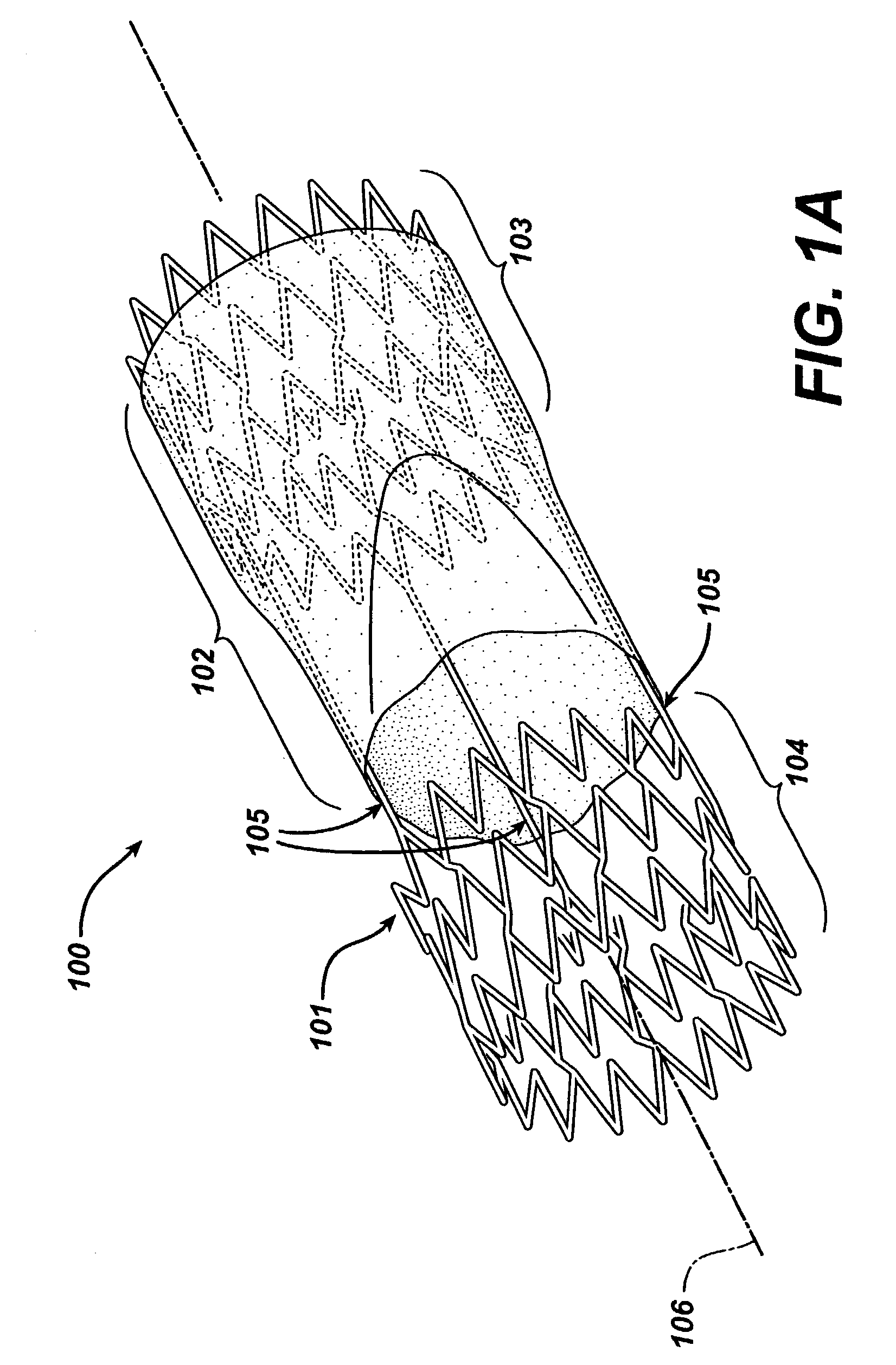

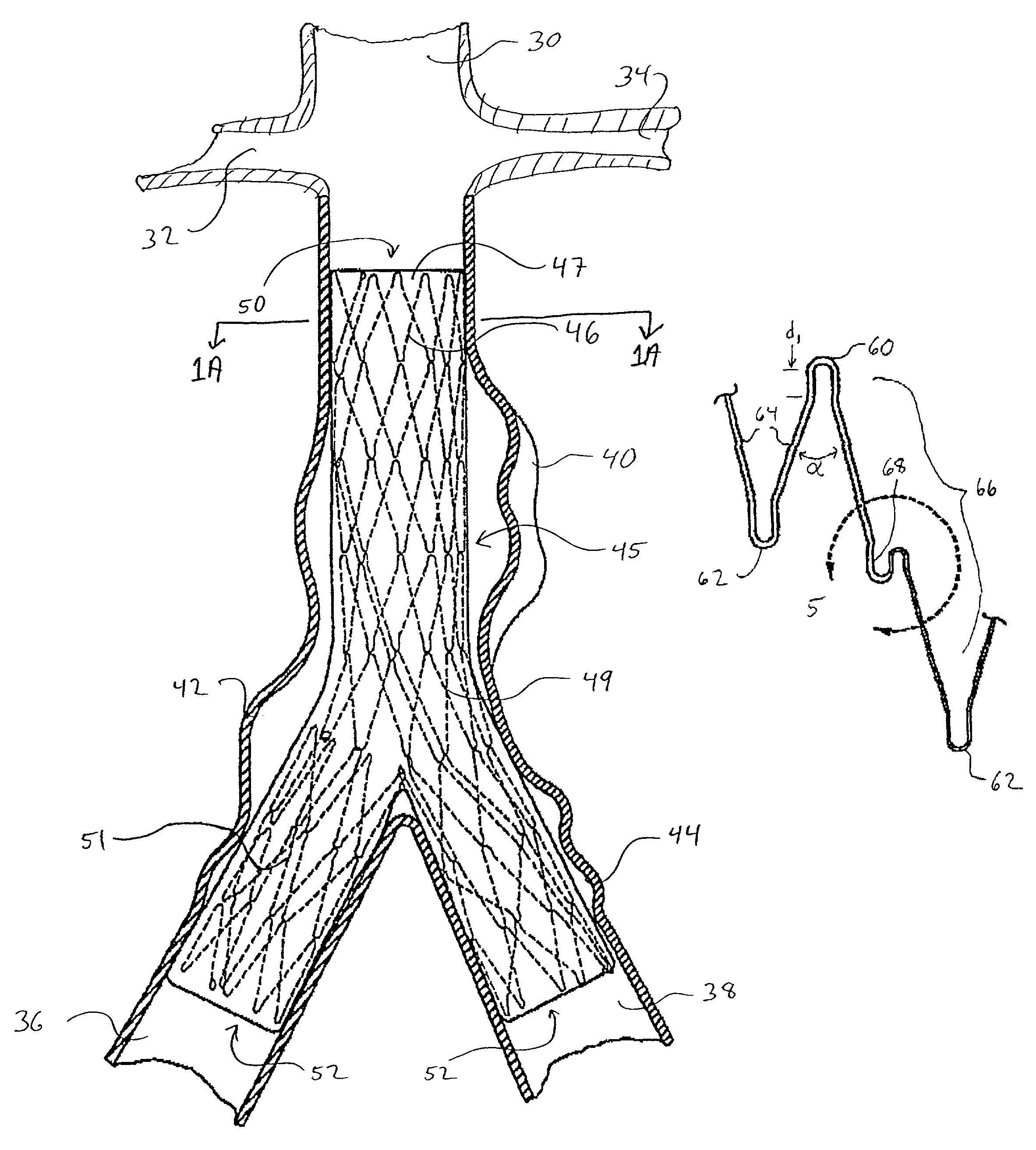

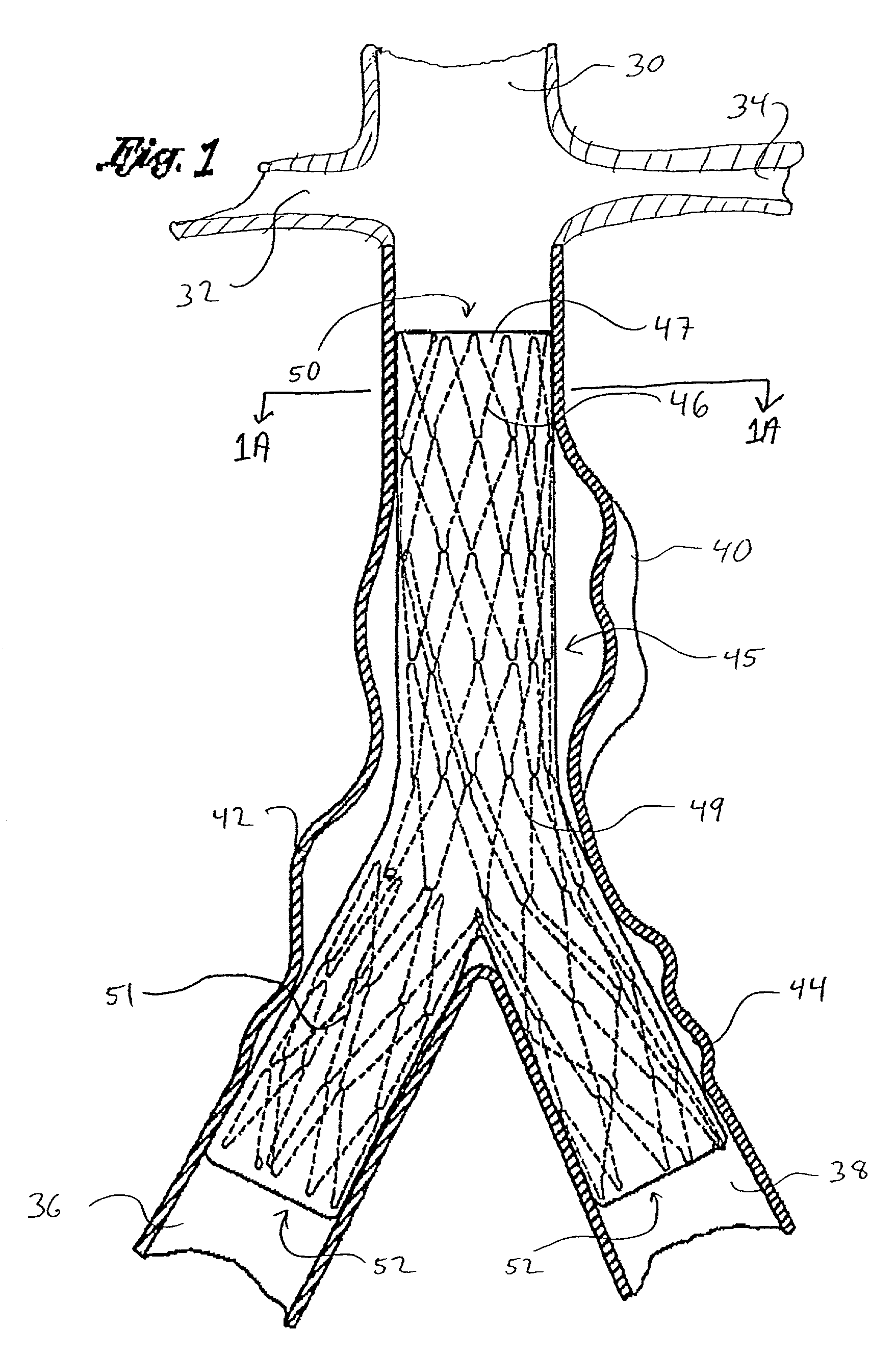

Self expanding bifurcated endovascular prosthesis

Disclosed is a bifurcated tubular endoluminal vascular prosthesis, useful in treating, for example, an abdominal aortic aneurysm. The prosthesis comprises a self expandable wire support structure surrounded at least in part by a flexible tubular membrane. A delivery catheter and methods are also disclosed.

Owner:ENDOLOGIX LLC

Tubular solid oxide fuel cell stack

This invention relates to a stack comprising a continuous solid-phase matrix and tubular fuel cells embedded in the matrix. Each fuel cell comprises an inner electrode layer, an outer electrode layer, and an electrolyte layer sandwiched between the inner and outer electrode layers. The matrix is sufficiently porous to allow a first reactant to flow through the matrix and to the outer electrode of each fuel cell, and have sufficient mechanical strength to support the fuel cells in the stack. The fuel cells are embedded such that a second reactant may be flowed through the inside of each tubular fuel cell and to the inner electrode thereof. Alternatively, a stack of tubular separation membranes or a stack of tubular membrane reactors may be embedded in the matrix. The matrix material may comprise solid state foam, metal filament, or metal, cermet, or ceramic wool.

Owner:INNOTECH ALBERTA INC

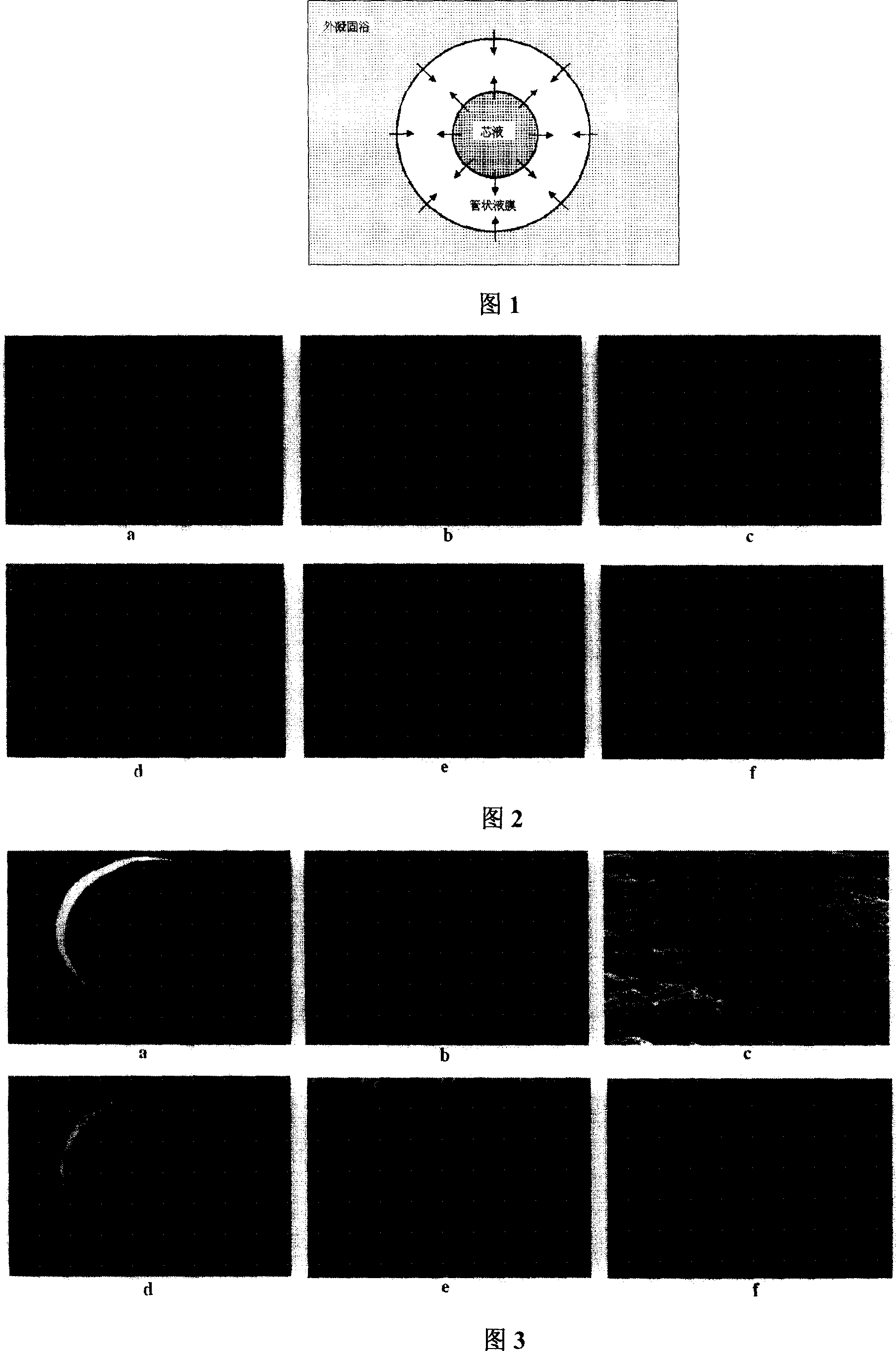

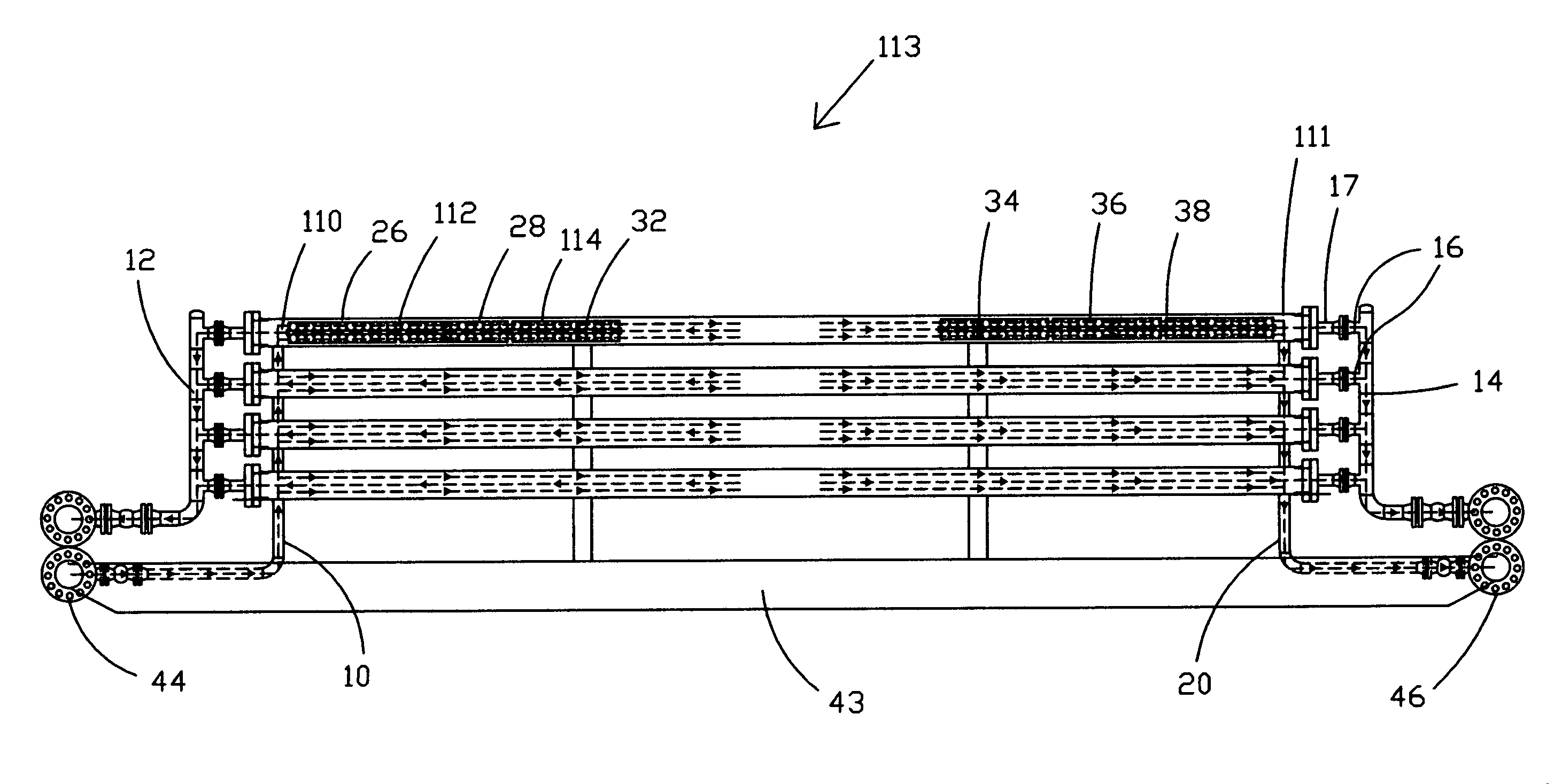

Porous polyvinylidene blending porous membrane and process for producing same

InactiveCN101015773AAchieve hydrophilicImprove throughputSemi-permeable membranesSolventWater treatment

The invention discloses a plate-tubular porous membrane based on polyvinylidene fluoride mixture, and relative production. The membrane substantially comprises polyvinylidene fluoride, dual-block amphipathic epoxyethane, and inorganic particles. And the preparation comprises that mixing polyvinylidene fluoride, dual-block amphipathic epoxyethane, inorganic particles, aperture adjusting agent and polarity solvent to obtain the membrane preparing liquid, using said membrane preparing liquid into plate or tubular liquid membrane, immerging the liquid membrane into solidifying bath mainly comprising water to be solidified into plate or tubular membrane. And the apertures of plate membrane and tubular membrane are 0.01-5.0 and 0.01-0.2 micrometers. The hydrophilic chain section of amphipathic epoxyethane is abundant at the face or aperture walls of the membrane, while said two membranes are both better in hydrophilic property and permeable property, with significant resistance on organic adsorption, to be used as ultra-filter membrane and micro-filter membrane in membrane water treatment.

Owner:ZHEJIANG UNIV

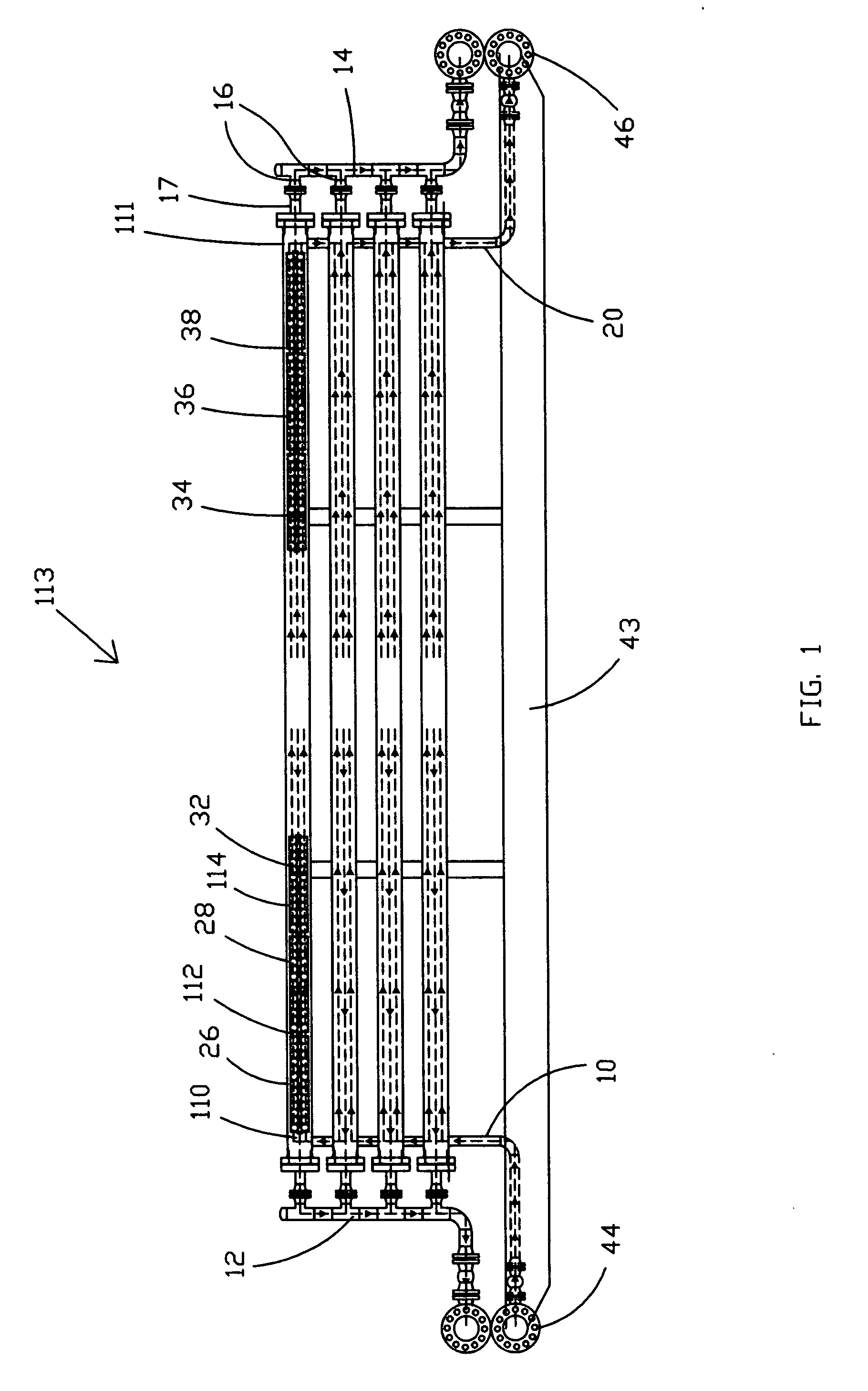

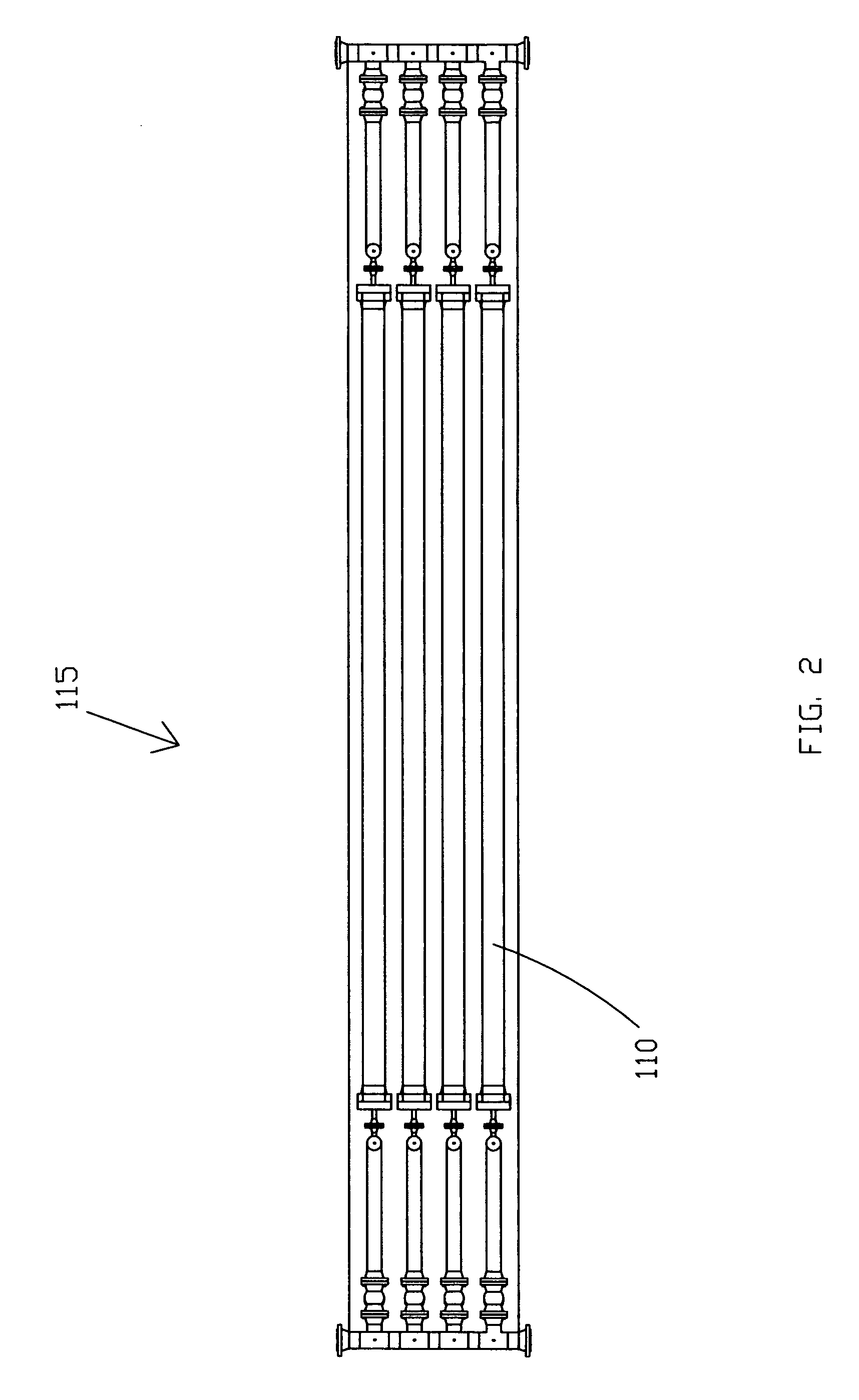

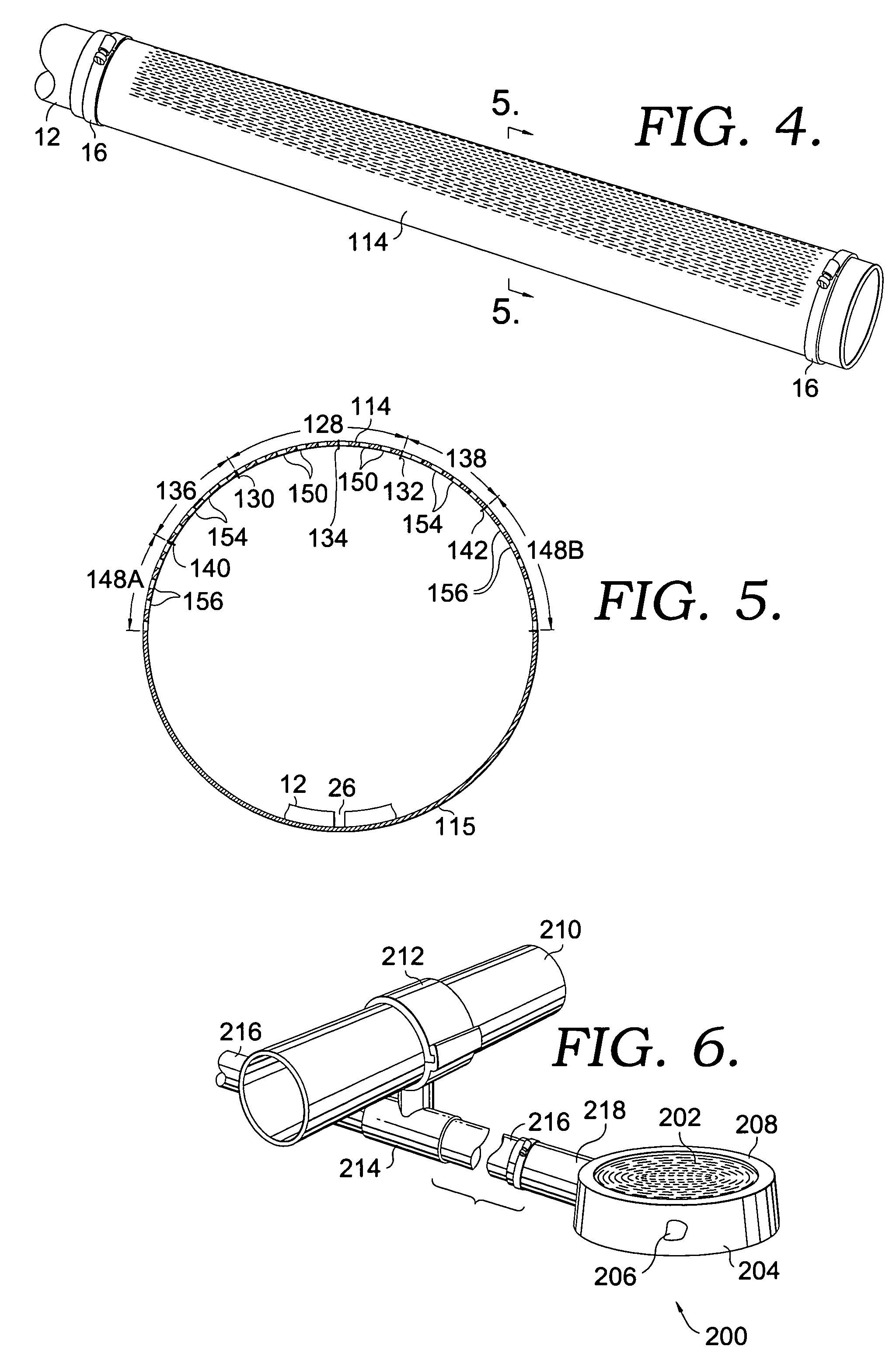

Compact membrane unit and methods

InactiveUS20070039889A1Reduce frictionHigh outputMembranesUltrafiltrationBiomedical engineeringMembrane configuration

Modular or cartridge-type membrane units utilize hollow, cylindrical tubular housings or receivers to house strings of removable membrane modules (elements) and normally comprise arrays of pipes that act as membrane module housings. A pseudo header for fluidly interconnecting the array of pipes reduces weight and cost. The pseudo header may comprise portions that are buried within skid components such as the toe bar. An internal low friction coating permits a larger number of membrane cartridges to be utilized in any cylindrical tubular membrane housing. A center feed pseudo header permits flow in two directions through the tubular membrane housing to double hydraulic capacity.

Owner:ASHFORD EDMUNDO R

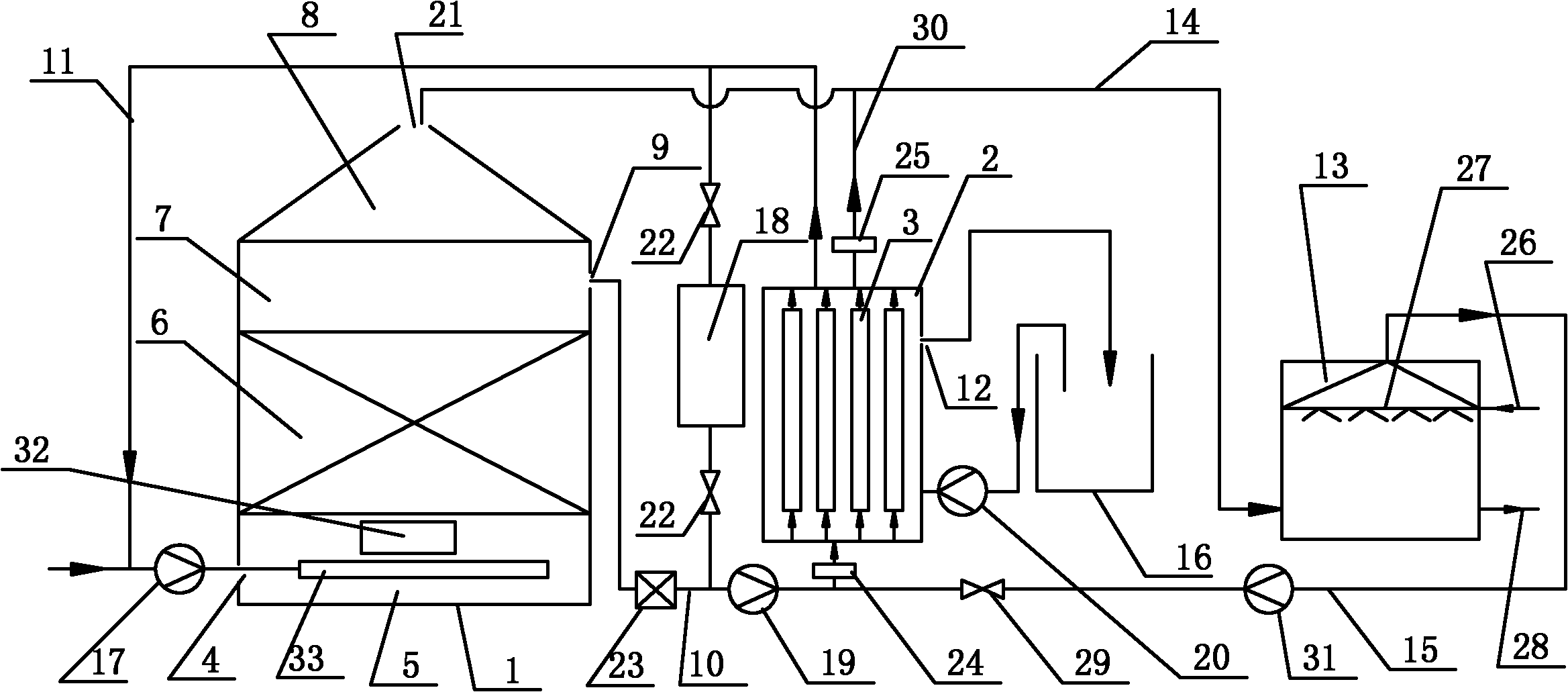

Flexible tube type solid-liquid processing machine with filtering, heat-exchange and hot compression function

InactiveCN1966129ALow costSimplify equipment componentsSemi-permeable membranesStationary filtering element filtersSlagEngineering

The invention relates to a flexible tubular solid liquid processor, with filter, heat exchange and thermal extraction functions, wherein the filter element at least comprises one flexible tubular membrane unit, upper flange room and lower flange room; the hydraulic extracting system comprises pressure container, extract pump and tubes; the material liquid of container can be filtered by the tubular filter membrane of membrane unit, and said material liquid can be used as work medium to extract the concentrated material liquid in the filter room of membrane unit and discharge filter slag; the pressure container or the filter room of membrane unit can be filled with medium to exchange heat, to realize thermal filter or extraction; the filter element is arranged on the bearing base inside the pressure container; the filter rotator can rotate the filter element to realize cross-flow filter; and the invention can be arranged with gas or water reverse tube and vacuum filter tube; the slag discharge system comprises slag discharger or tubular inner / outer membrane scraper, or vibration slag discharger, or compression slag discharger.

Owner:张民良

Process for producing a tubular membrane assembly

InactiveUS6077376ALow selectivityMinimizes problemSemi-permeable membranesPaper/cardboard wound articlesFiberSemipermeable membrane

The invention provides a process for producing a tubular membrane assembly comprising helically winding at least one strip of fibrous material on a mandrel to produce at least a single ply tubular support member for a semi-permeable membrane, characterized by passing the strip through a heated section of the mandrel during the helical winding thereof to flatten and smooth fibers protruding along the cross-sectional width of the strip, whereby a tube with a smooth inner bore along its entire length is formed.

Owner:MEMBRANE PRODS KIRYAT WEIZMANN

Polyvinylidene fluoride nanometer composite super low pressure ultrafiltering membrane and preparation method thereof

InactiveCN101164679AIncreased pure water fluxSolve pollutionSemi-permeable membranesFiberHollow fibre membrane

The present invention relates to a polyvinylidene fluoride nano composite super low pressure ultrafiltration membrane and its preparation method. The invented product is made up by using (by weight portion) 20-150 portions of PVDF, 0.1-20 portions of nano powder body, 10-1000 portions of dispersion medium, 10-50 portions of organic additive and 0.1-30 portions of inorganic additive. Is preparation method includes the following steps: making nano powder body, inorganic additive, organic additive and PVDF be successively added into the dispersion medium, dissolving for 3-48hr, standing still and defoaming for 5-24h to obtain membrane-moulding liquor, can make it into plate membrane, tubular membrane or hollow fibre membrane and correspondent membrane component.

Owner:HARBIN INST OF TECH

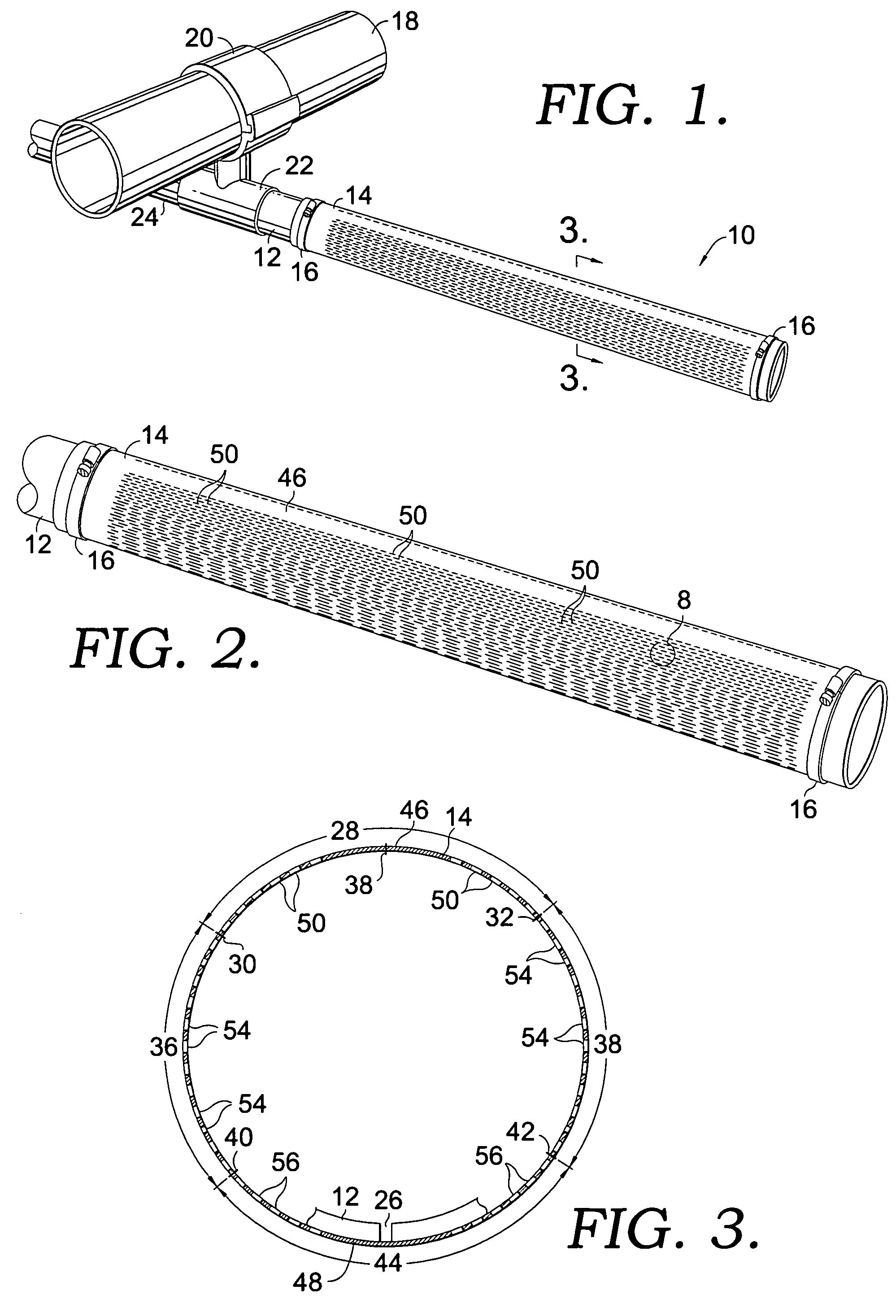

Membrane diffuser with uniform gas distribution

InactiveUS7044453B2Improve distribution uniformityImprove transmission efficiencyCarburetting airTransportation and packagingMembrane surfaceMaterial Perforation

A flexible diffuser membrane is provided with a unique system of perforations arranged to result in uniform distribution of gas even though the membrane deflects to different extents or the submergence varies in different parts of the membrane. The perforations are arranged to provide less perforation area per unit of perforated membrane surface area in the membrane parts that deflect the most or are submerged least and greater perforation area in membrane parts that deflect the least or are submerged most. The perforations can be slits arranged in parallel rows on a tubular membrane, in concentric circles or another pattern on a disk membrane, or in still a different pattern on a flat panel diffuser membrane. The slit length or separation can be varied between different zones on the membrane surface or the spacing between rows or circles can be varied.

Owner:ENVIRONMENTAL DYNAMICS INC

Downhole membrane separation system with sweep gas

InactiveUS20030051874A1Easy to driveWater cleaningCentrifugal force sediment separationChemical physicsSeparation system

One configuration of a separation system for separating hydrocarbons from contaminants downhole includes a tubular membrane having a fluid inlet end and a fluid outlet end. Between the fluid inlet end and the fluid outlet end of the membrane tube the membrane material selectively permeates contaminants, such as carbon dioxide, through the membrane while preventing the hydrocarbon from passing through the membrane achieving the downhole separation. A driving force of the membrane is increased by passing a sweep gas past the output side of the membrane during membrane separation to remove or dilute the contaminant at the output side of the membrane. The sweep gas improves the driving force of the membrane by increasing a partial pressure difference across the membrane.

Owner:CHEVROU USA INC

Membrane treatment method of landfill leachate concentrate

InactiveCN103964609ALess investmentReduce processing costsSludge treatment by de-watering/drying/thickeningGeneral water supply conservationFiltrationReverse osmosis

The invention discloses a membrane treatment method of a landfill leachate concentrate. The method comprises the steps of adding lime and sodium carbonate into the landfill leachate concentrate, removing calcium, magnesium and heavy metal ions in the concentrate, performing tubular membrane filtration, then performing nano-filtration and reverse osmosis treatment, and discharging permeated liquid under standards so as to realize reduction of the landfill leachate concentrate. The membrane treatment method can be used for realizing the reduction of the landfill leachate concentrate, reducing the investment and treatment cost, and removing most pollutants in the concentrate at the same time.

Owner:TIANJIN HIPURE MEMBRANE TECH CO LTD

Garbage percolate treatment technology

ActiveCN102167479AEfficient degradationStrong pollutionSludge treatment by de-watering/drying/thickeningWaste based fuelTubular membraneContamination control

The invention relates to a garbage percolate treatment technology belonging to the technical field of the treatment of high-concentration organic wastewater. The treatment technology comprises six steps of pretreating, anaerobically treating, treating by a tubular membrane bioreactor, performing nano-filtration / reverse osmosis deep treatment, treating concentrated liquor, treating sludge and thelike. The technology can be used for degrading COD (chemical oxygen demand), total nitrogen and total phosphorus in the high-concentration wastewater, removing heavy metal ions from the high-concentration wastewater, and the like. After the technology is used, the defect in the prior art is overcome, wherein the defect mainly refers to the problems of unstable system or high maintenance cost and the like, and a core unit of the technology is a gas-reinforced ceramic membrane bioreactor. High-concentration garbage percolate treated by the technology is better than the emission requirement of the household garbage landfill and pollution control standard (GB16889-2008), and the quality of purified water meets the recycle requirement, so that the near-zero emission of the garbage percolate can be realized.

Owner:JIANGSU JIUWU HITECH +1

Synthesis gas method and apparatus

A method and apparatus for producing a synthesis gas product having one or more oxygen transport membrane elements thermally coupled to one or more catalytic reactors such that heat generated from the oxygen transport membrane element supplies endothermic heating requirements for steam methane reforming reactions occurring within the catalytic reactor through radiation and convention heat transfer. A hydrogen containing stream containing no more than 20 percent methane is combusted within the oxygen transport membrane element to produce the heat and a heated combustion product stream. The heated combustion product stream is combined with a reactant stream to form a combined stream that is subjected to the reforming within the catalytic reactor. The apparatus may include modules in which tubular membrane elements surround a central reactor tube.

Owner:PRAXAIR TECH INC

Method of forming a tubular membrane on a structural frame

The present invention relates to a medical device and method of forming the medical device. In particular, the present invention relates to a medical device having a tubular membrane structure over a radially expandable structural frame, and to a method of forming the tubular membrane on the radially expandable structural frame. In one aspect, a structural frame is placed over a spinning mandrel and a fiber is electro-statically spun over at least a portion of the structural frame forming a membrane. A transfer sheath may be used between the mandrel and structural frame to prevent the electro-statically spun fiber from adhering to the mandrel. In another aspect, a first membrane is spun over the mandrel before the structural frame is placed over the mandrel. In this aspect, at least a portion of the structural frame is sandwiched between the membranes. The membrane or membranes and structural frame form a fiber spun frame assembly. The fiber spun frame assembly may be coated with an elastic polymer. In addition, the membrane or membranes may go through some post processing to achieve desired characteristics or configurations.

Owner:CORDIS CORP

Collapsible/Expandable Tubular Electrode Leads

ActiveUS20060259110A1Inhibit tissue growthEasy retrievalSpinal electrodesExternal electrodesSpinal cordSurgical department

A medical lead and method of treating a patient are provided. The medical lead comprises an electrically insulative tubular membrane, a resilient spring element associated with the insulative membrane, and at least one electrode associated with the insulative membrane. The medical lead is configured to be collapsed into a compact form for percutaneous delivery into the patient, thereby obviating the need to perform an invasive surgical procedure on the patient. The body formed by these elements, when expanded, can be sized to fit within the epidural space of a patient. The patient can be treated by placing the medical lead into a collapsed state by applying a compressive force to the medical lead, percutaneously delivering the collapsed medical lead into the patient adjacent tissue to be treated, and placing the medical lead into an expanded state by releasing the compressive force. In one preferred method, the stimulation lead is used to stimulate tissue, such as spinal cord tissue.

Owner:BOSTON SCI NEUROMODULATION CORP

Membrane diffuser with uniform gas distribution

InactiveUS20050151281A1Improve distribution uniformityIncrease gas transfer efficiencyCarburetting airMixing methodsCircular discMembrane surface

A flexible diffuser membrane is provided with a unique system of perforations arranged to result in uniform distribution of gas even though the membrane deflects to different extents or the submergence varies in different parts of the membrane. The perforations are arranged to provide less perforation area per unit of perforated membrane surface area in the membrane parts that deflect the most or are submerged least and greater perforation area in membrane parts that deflect the least or are submerged most. The perforations can be slits arranged in parallel rows on a tubular membrane, in concentric circles or another pattern on a disk membrane, or in still a different pattern on a flat panel diffuser membrane. The slit length or separation can be varied between different zones on the membrane surface or the spacing between rows or circles can be varied.

Owner:ENVIRONMENTAL DYNAMICS INC

Method for preparing hollow fiber membranes and tubular membranes with microporous PTFE hybrid flat membrane wrapping method

ActiveCN103386256AHigh hardnessEasy to cutSemi-permeable membranesPolymer sciencePolyvinylidene difluoride

The invention discloses a method for preparing hollow fiber membranes and tubular membranes with a microporous PTFE hybrid flat membrane wrapping method. Dispersed PTFE resin and polyvinylidene fluoride resin are mixed with a liquid lubricant, and microporous PTFE hybrid flat membranes are prepared from the mixture through extrusion, calendaring, stretching and sintering. Then the microporous PTFE hybrid flat membranes are cut into membrane strips which wrap around supporting tubes, and finally the wrapped supporting tubes are sintered to obtain the hollow fiber membranes and the tubular membranes. The polyvinylidene fluoride resin added into the products of the invention has a melting point around 160 DEG C, fuses while sintered at a temperature between 250 and 340 DEG C, and can largely increase the hardness of the flat membranes after solidification, which facilitates slitting of the flat membranes. During the process of sintering after wrapping, the polyvinylidene fluoride resin contained in the flat membranes fuses again when sintered at a temperature between 260 and 340 DEG C, and thus can be used as overlapping parts between the wrapped flat membranes and as binders between the flat membranes and the microporous supporting tubes, so that the bonding strength is substantially improved.

Owner:ZHEJIANG SCI-TECH UNIV

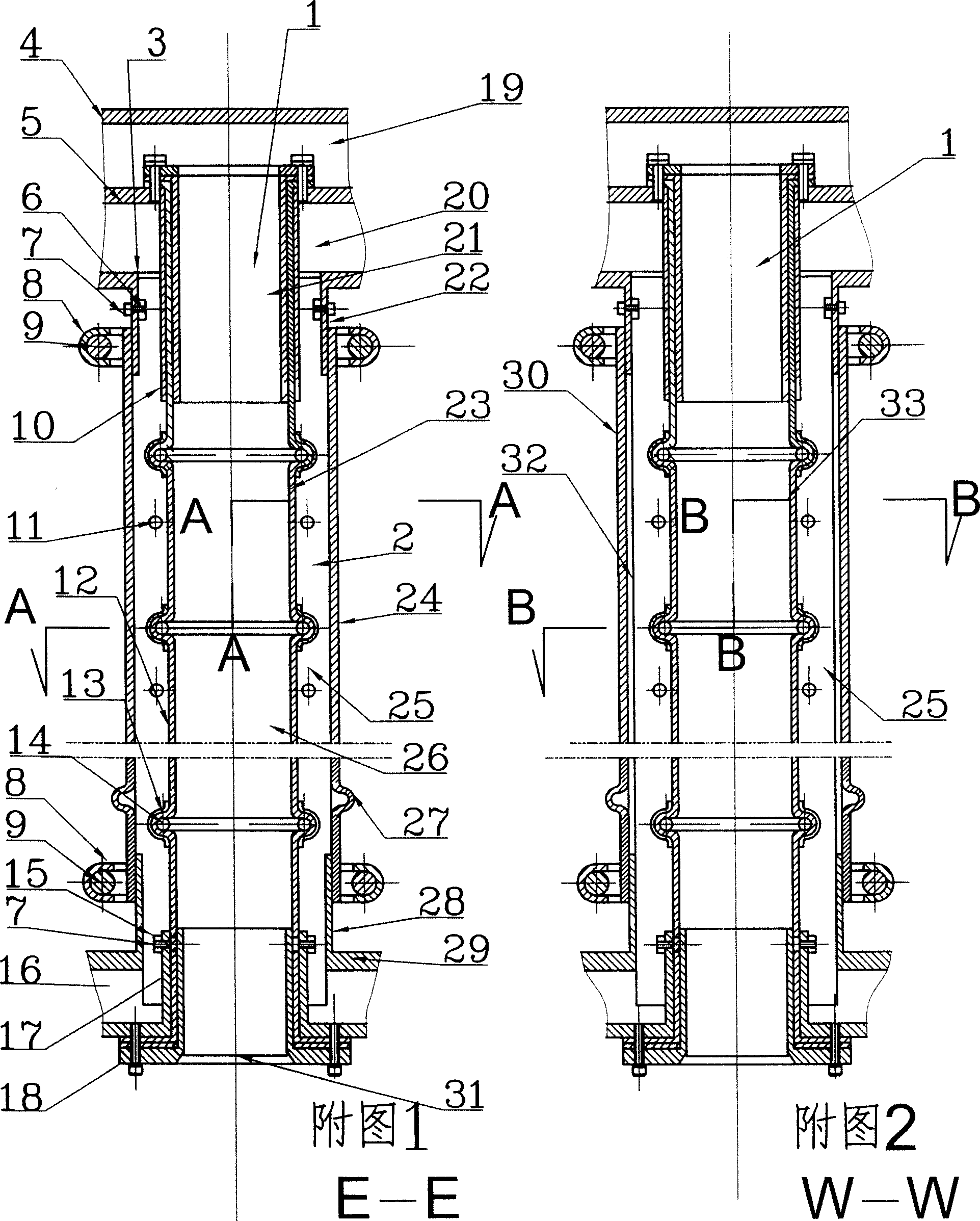

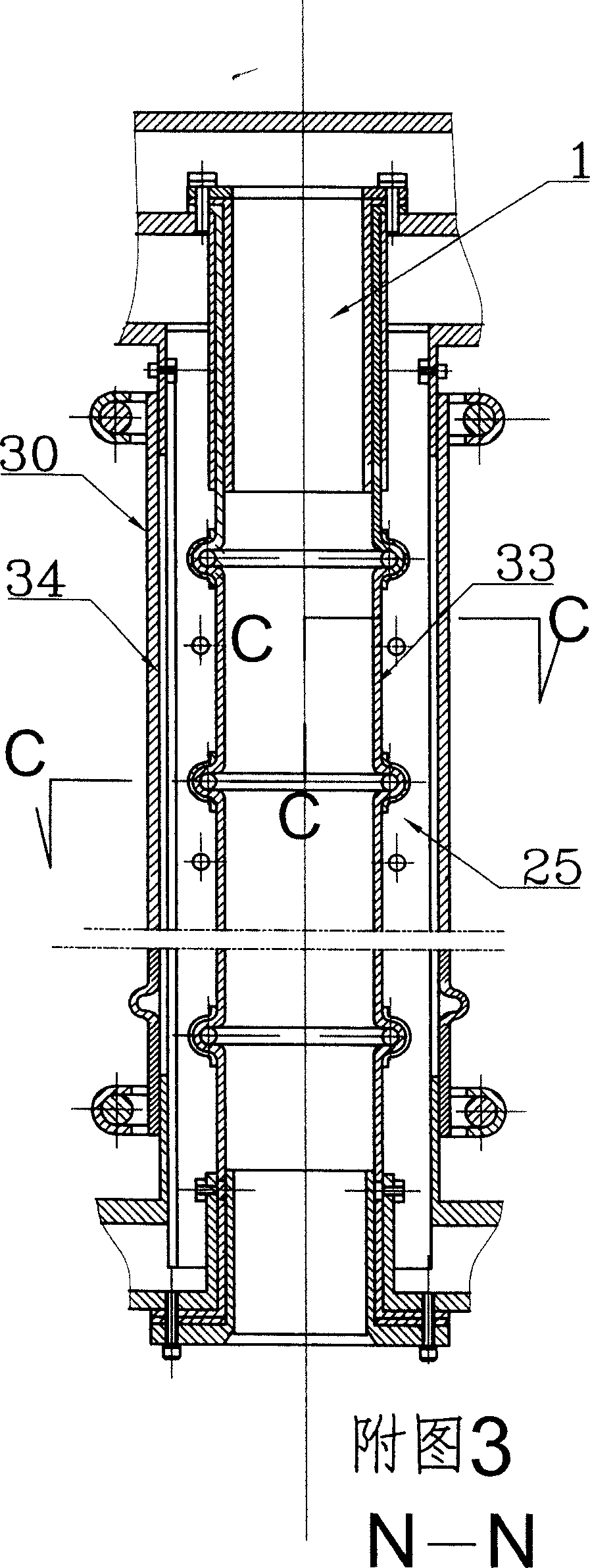

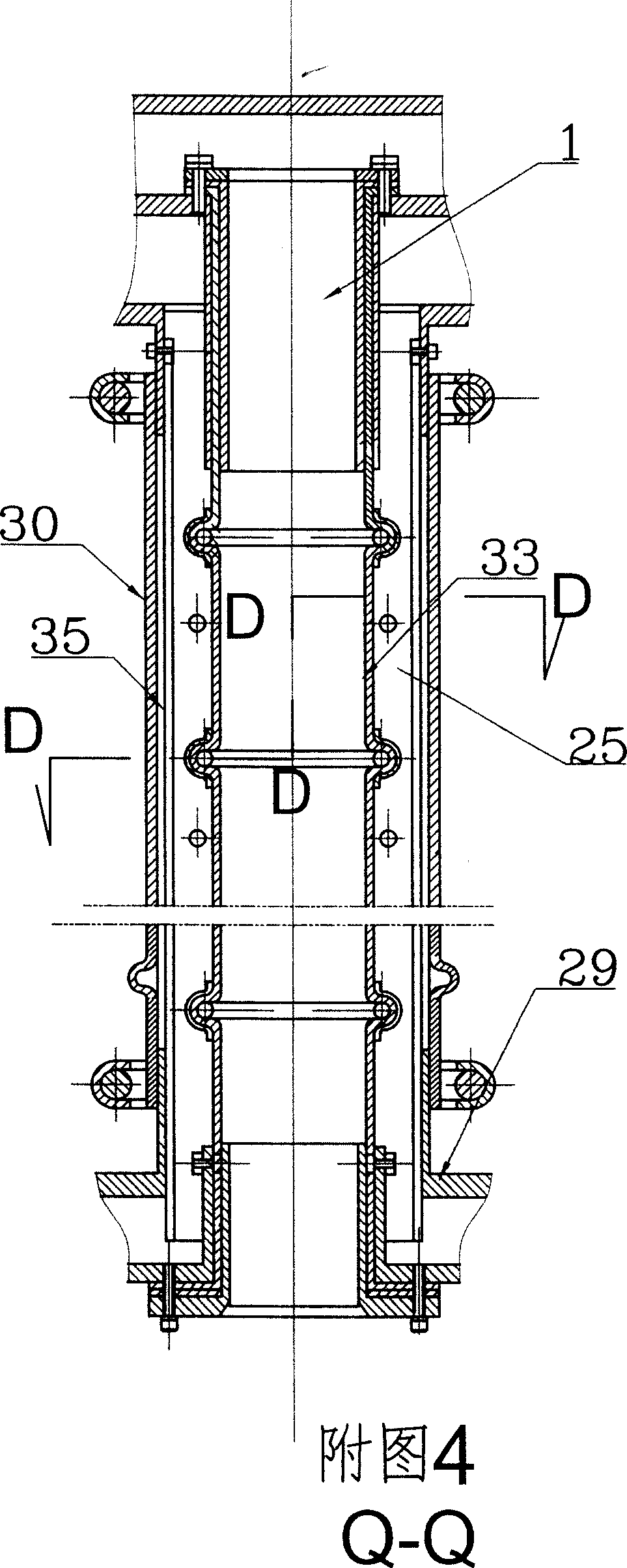

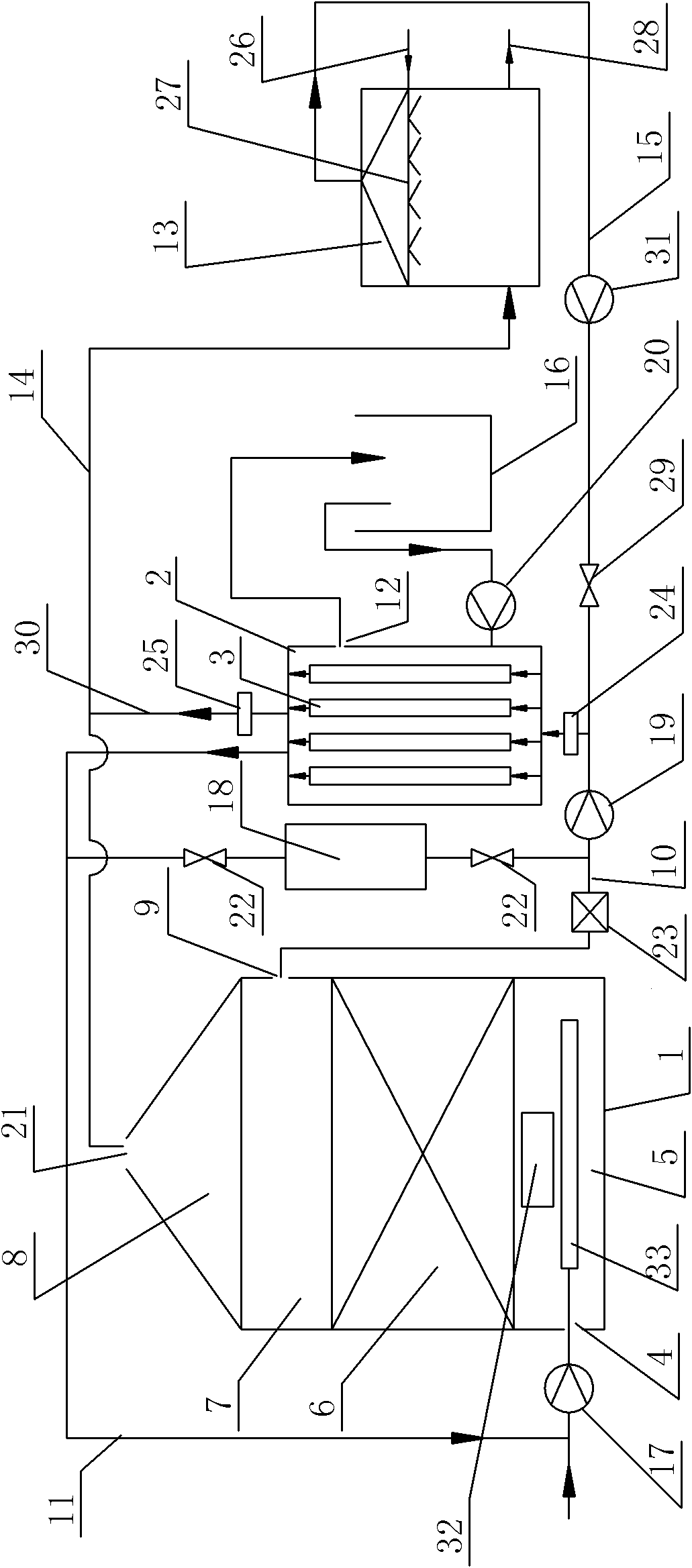

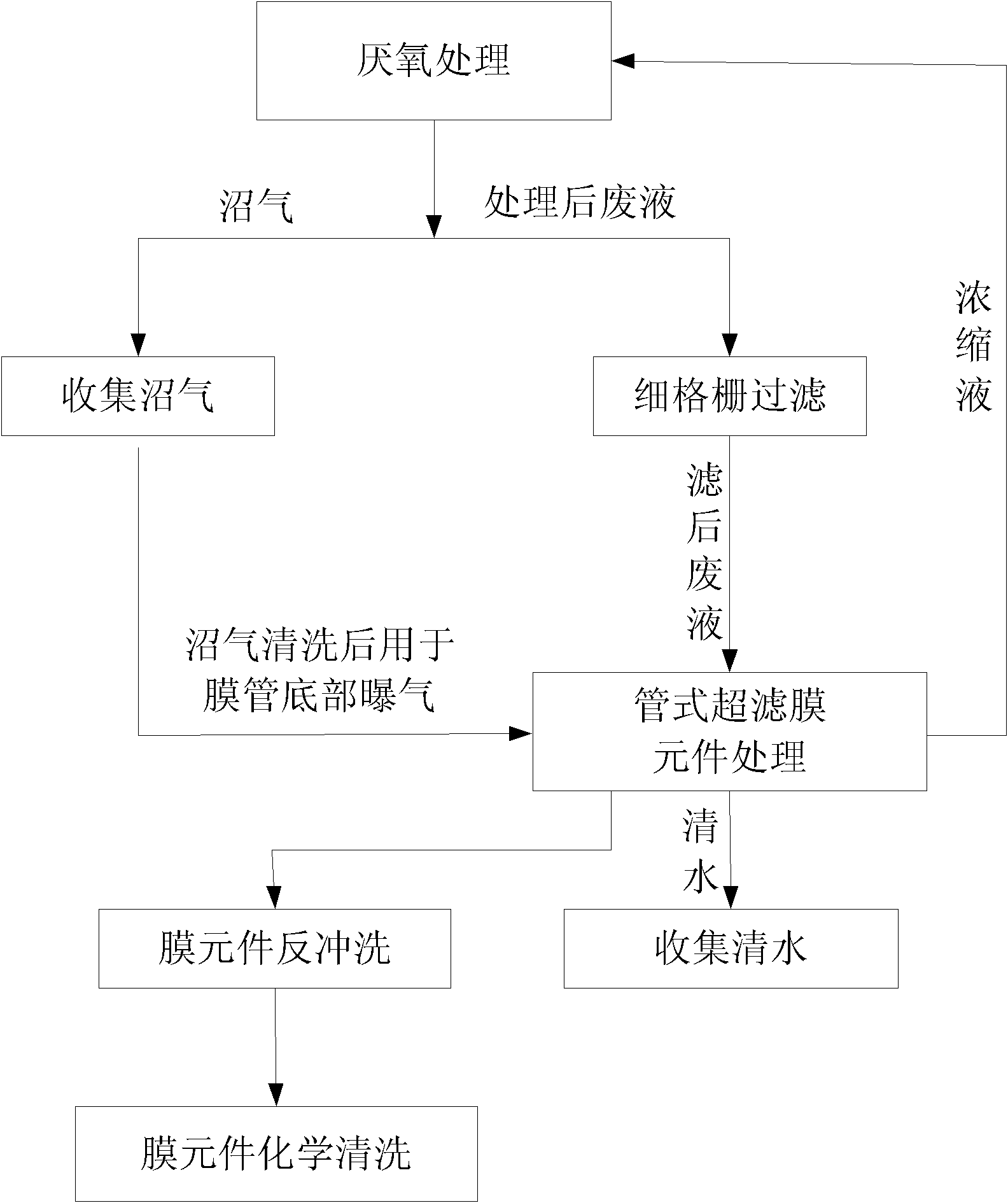

External anaerobic membrane bioreactor and waste water purification technology thereof

InactiveCN102153251AReduce operating energy consumptionImprove degradation efficiencyWaste based fuelTreatment with anaerobic digestion processesGratingAfter treatment

The invention provides an external anaerobic membrane bioreactor comprising an anaerobic tank, a tubular membrane component, tubular ultrafiltration membrane elements and a clear water tank, wherein the tubular ultrafiltration membrane elements are vertically arranged in parallel in the tubular membrane component. The invention also provides a corresponding waste water purification technology of the external anaerobic membrane bioreactor. The waste water purification technology includes the steps as follows: firstly conducting purification treatment on waste water to be treated in the anaerobic tank, collecting biogas which is generated after treatment, filtering and separating the treated waste water in sequence by a fine grating and the tubular ultrafiltration membrane elements, at last leading out the leached clear water, backwashing and chemically washing the tubular ultrafiltration membrane elements at time intervals, drip-washing the collected biogas, and then pumping the biogas together with sewage into the tubular ultrafiltration membrane elements, so that the washing effect of the inner walls of the tubular ultrafiltration membrane elements can be improved. As for the external anaerobic membrane bioreactor and the waste water purification technology thereof, the energy consumption in operation is low, the quality of effluent is good, and blockage does not happen easily.

Owner:上海膜达克环保工程有限公司

Self sealing membrane contactor with PTFE tubular membranes

ActiveUS20130075321A1Reliably and rapidly seal and isolateResilienceMembranesSemi-permeable membranesEpoxyAdhesive

A tubular membrane module and its method of manufacture are disclosed wherein tubular membranes form an interference self-sealing fit with hard tube sheets with the aid of a hard hollow mandrel inserted at the end of the tubular membranes. The tubular membranes are comprised of porous, compressible PTFE and / or fluorocopolymers. The self-sealing method described herein requires no heat treatment, allows for ease of manufacture without destruction of the tubular membranes and without the processing complexity of utilizing any additional potting agent, extrusion, or chemical cross-linking of any polymeric adhesives. The self sealing PTFE tubular membranes have superb chemical resistance and temperature resistance, and through the benefits of this invention, offer higher pull-out resistance than typically observed with potting materials such as polyurethane and epoxy. In addition, the self-sealing method is reversible and non-destructive (whereas chemical potting and sealing methods using heat are not), as one can easily remove one or more damaged tubes and replace them.

Owner:MARKEL CORPORATION

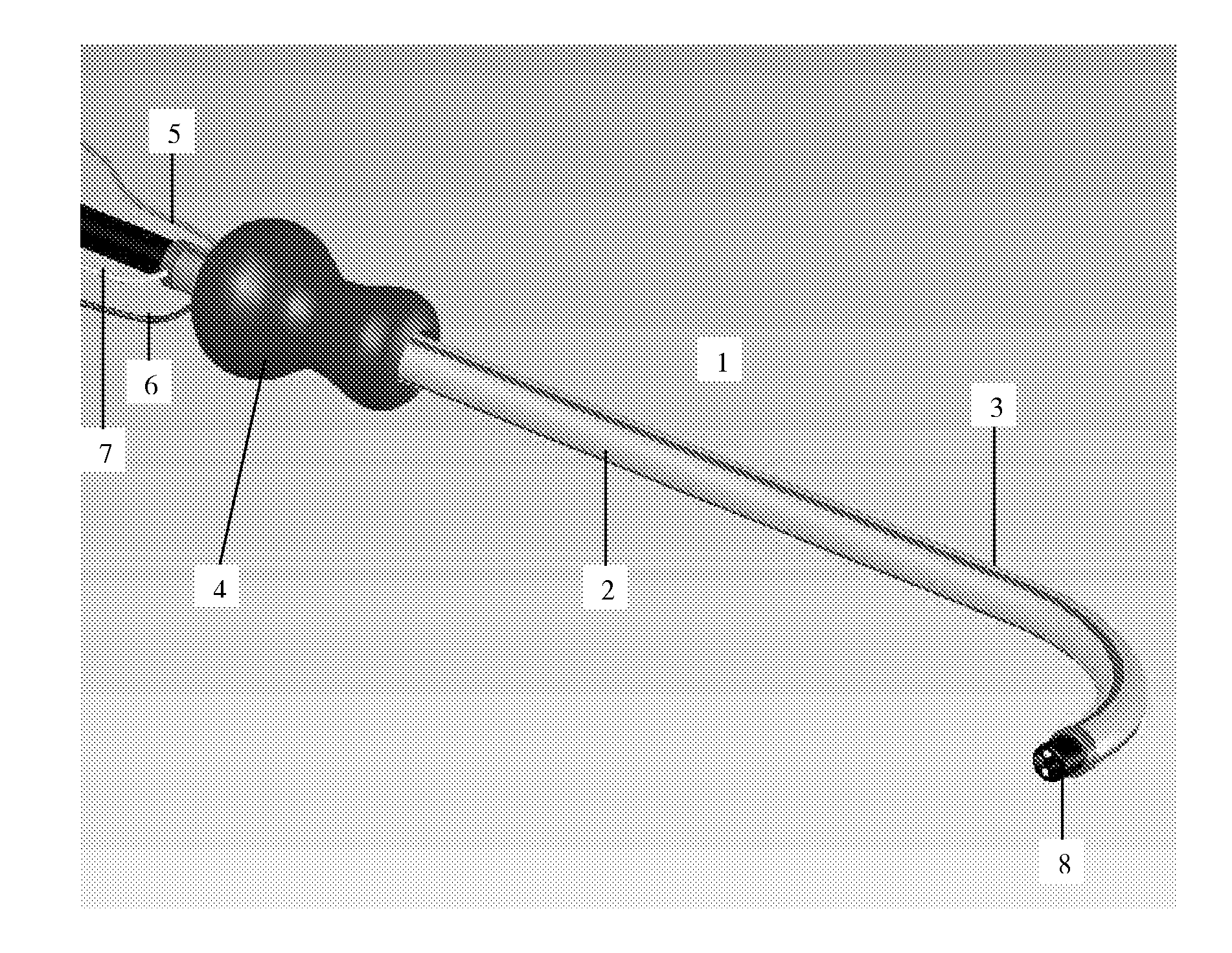

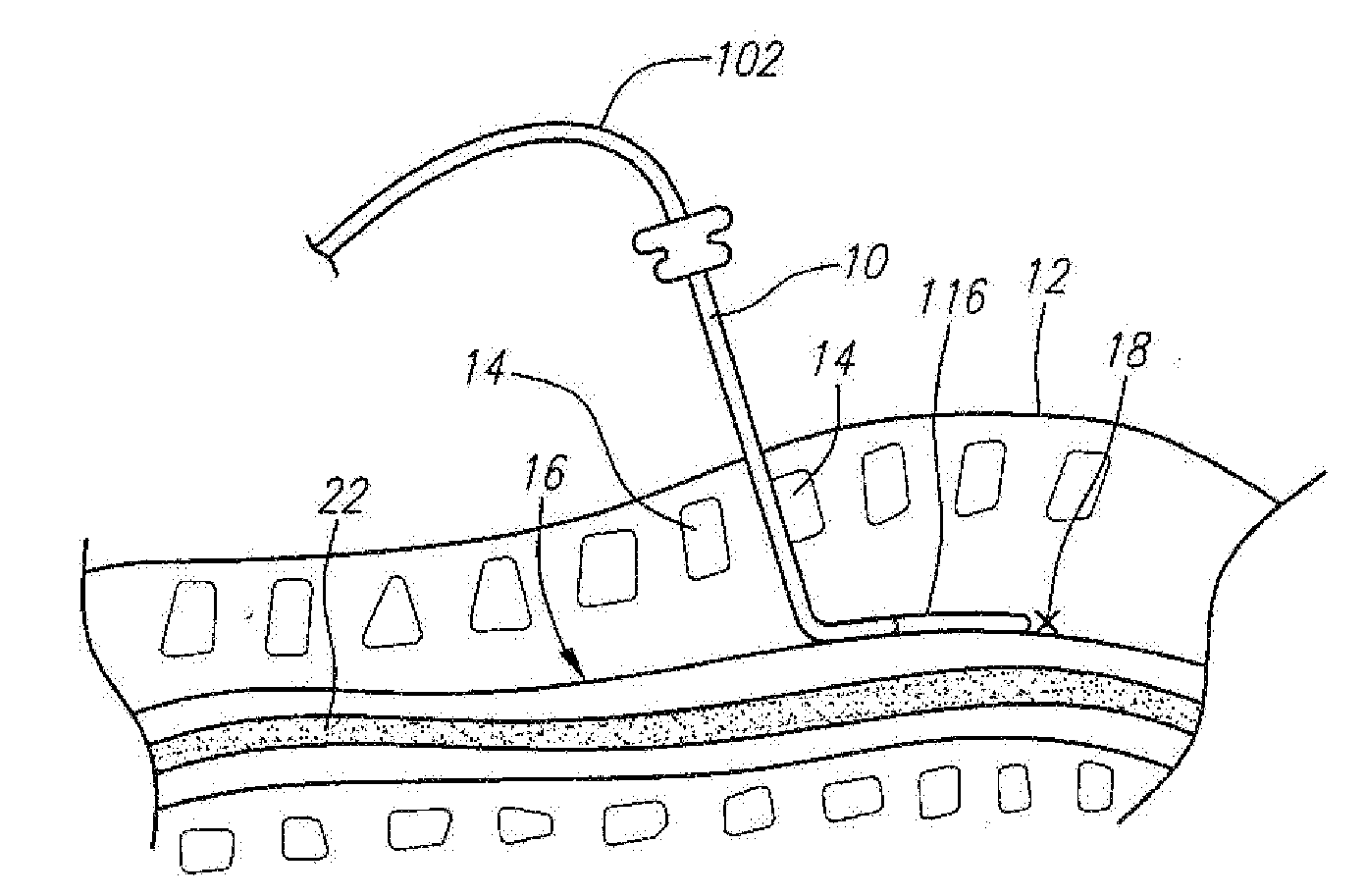

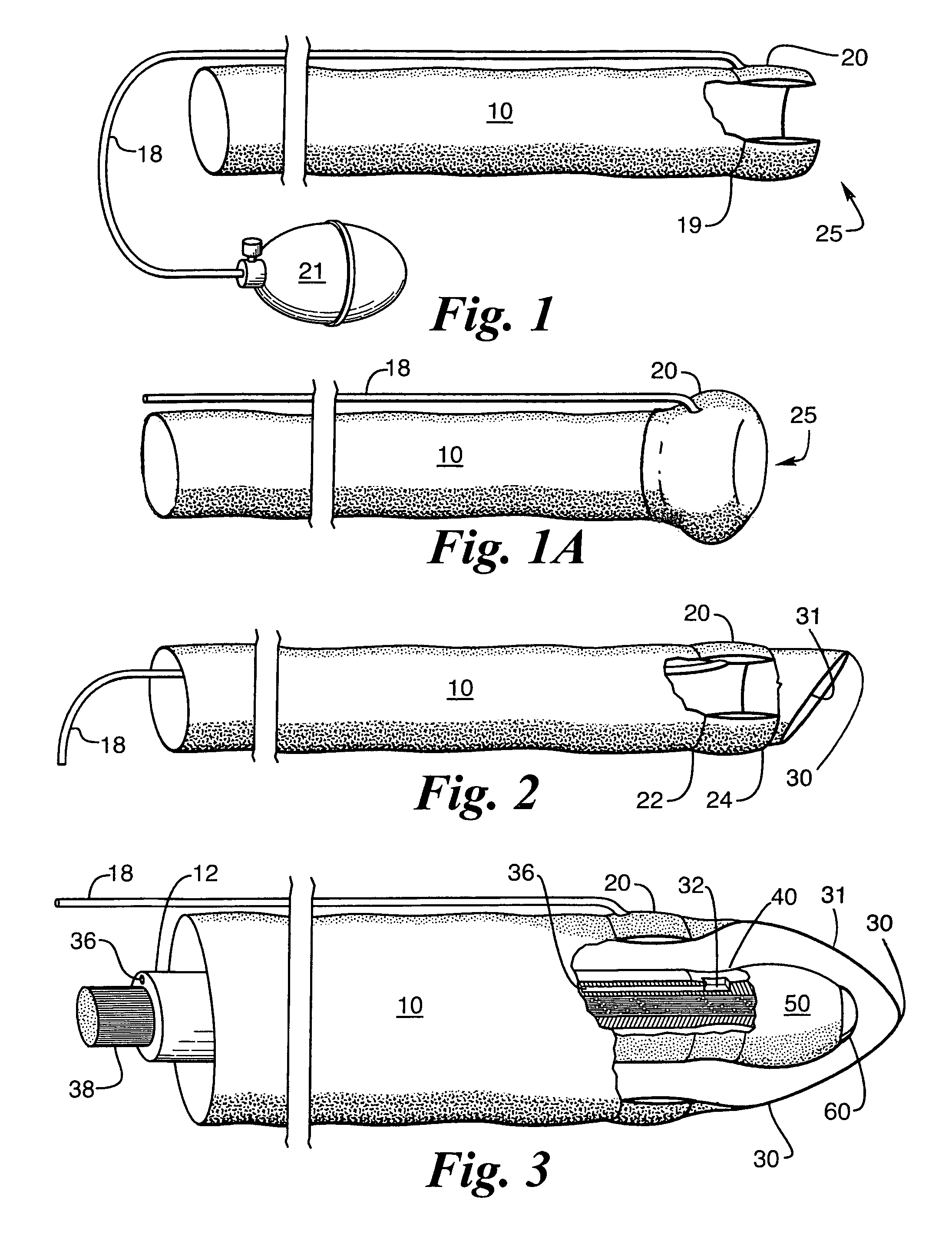

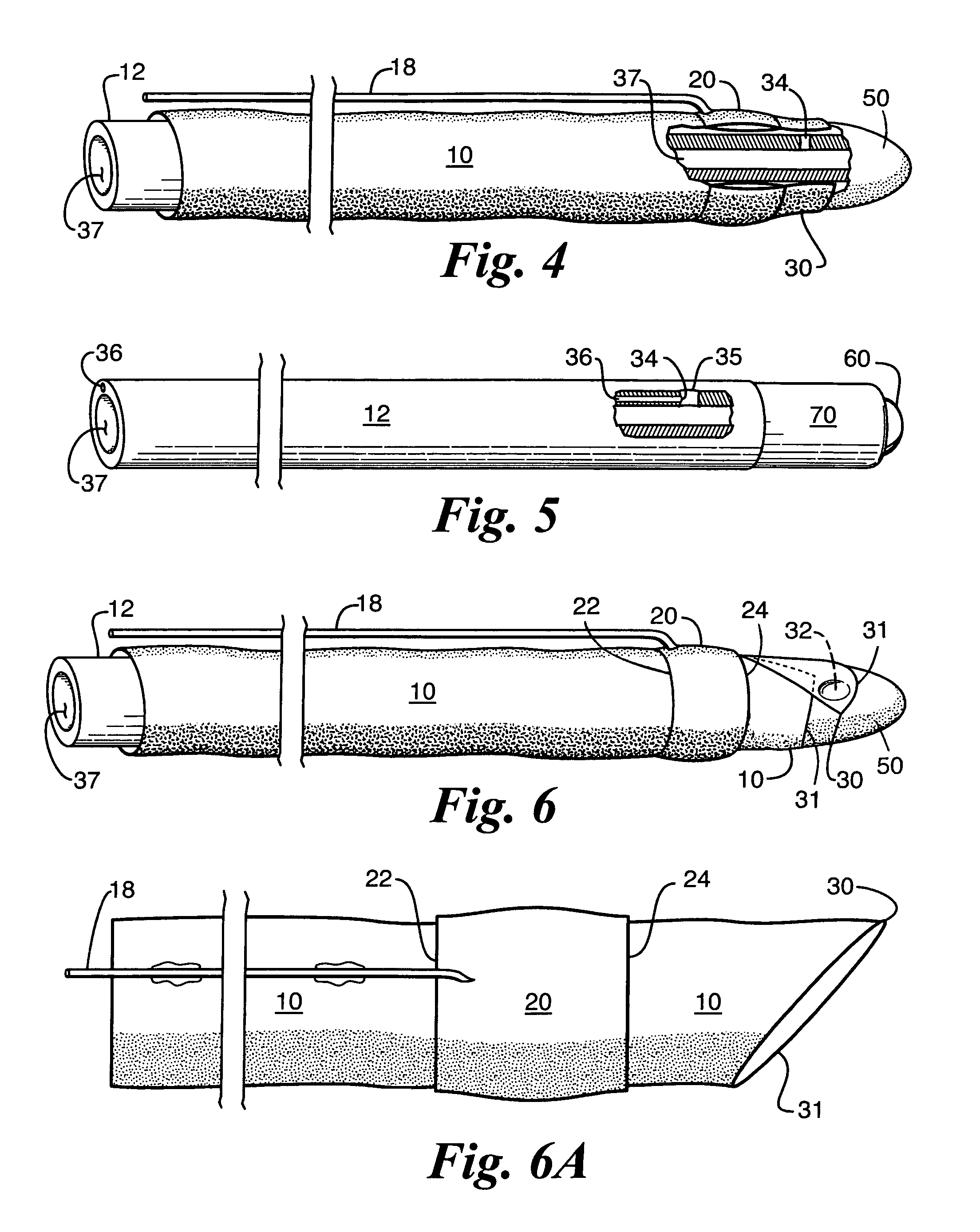

Flaccid tubular membrane and insertion appliance for surgical intubation and method

InactiveUS7862542B1Protect from harmEasy procedureBalloon catheterCannulasHuman patientSurgical department

A thin sheath of flexible, flaccid material is introduced through openings in the body of an animal or human patient to permit surgical tools or fluids to be inserted and removed, or debris removed, during surgeries anywhere in the body to protect the tissue of the body from the instruments used. The sheath is inserted by an obturator which holds the sheath thereon by suction through an aperture in the obturator at its distal end. Once the sheath is inserted, suction is removed to release the sheath. Then a balloon on the distal end of the sheath is expanded to hold the sheath in place in the body while the obturator is removed. The sheath then remains in place with the balloon holding the distal end in the open position to enable fluids to flow through the sheath. After a procedure, the balloon is deflated and the sheath removed.

Owner:HARMON SR JAMES V

Electric heating textile based on carbon nano tubular membrane

InactiveCN104589714AHigh insulation requirementsThin and flexibleLayered productsOhmic-resistance heatingCarbon nanotubeEngineering

The invention relates to an electric heating textile based on a carbon nano tubular membrane. The electric heating textile based on the carbon nano tubular membrane comprises a heating layer, textile protection layers and bonding layers, wherein the upper and lower surfaces of the heating layer are stuck with the textile protection layers by the bonding layers; and the heating layer is the carbon nano tubular membrane. The electric heating textile has the characteristics of stability of heating, uniform temperature, safety, comfort, lightness, portability and the like.

Owner:DONGHUA UNIV

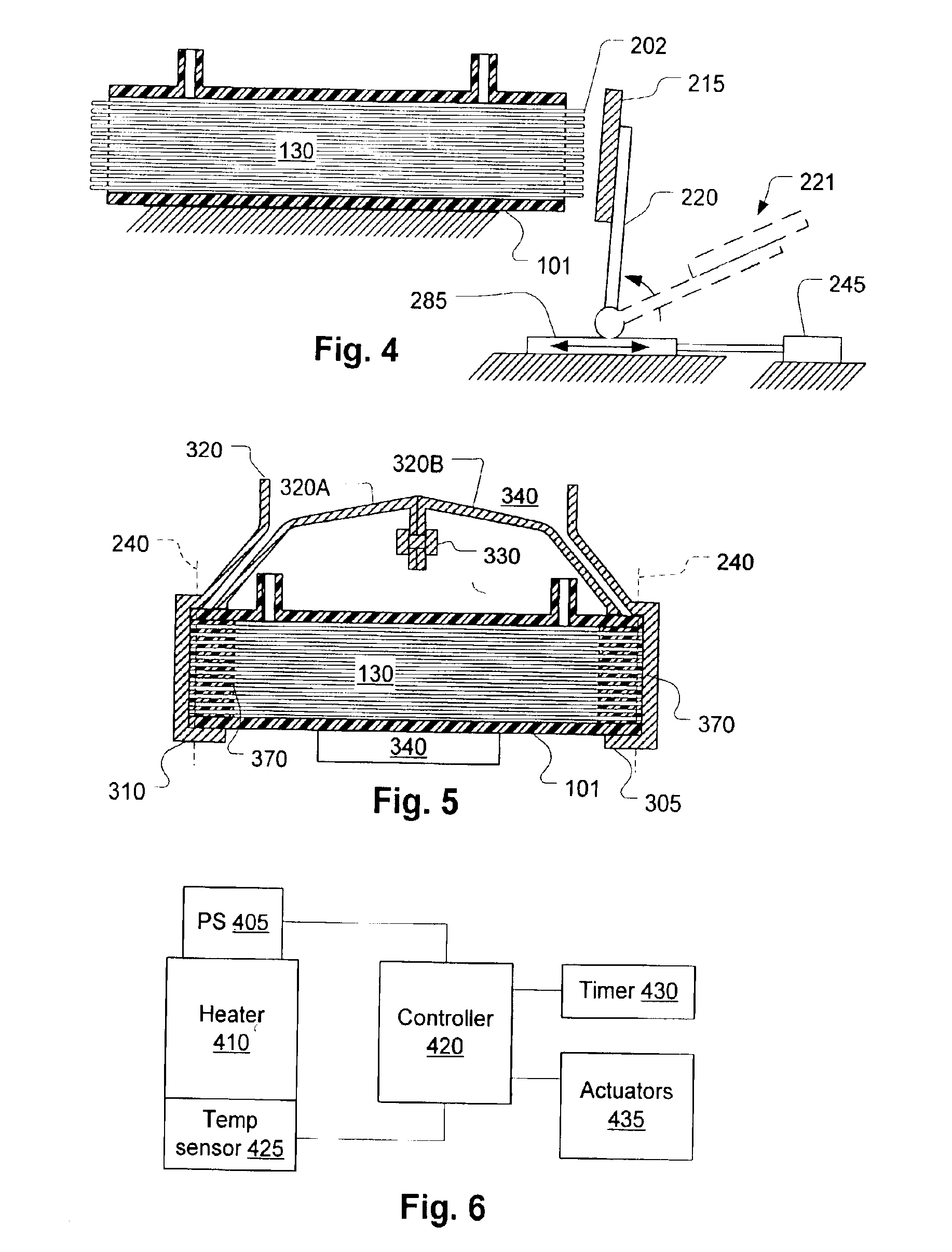

Oxygen separation module and apparatus

A module and an apparatus incorporating such module utilizing a plurality of tubular membrane elements, each configured to separate oxygen from an oxygen containing feed stream when an electric potential difference is applied to induce oxygen ion transport in an electrolyte thereof. The tubular membrane elements can be arranged in a bundle that is held in place by end insulating members. The insulating members can be positioned within opposed openings of end walls of a heated enclosure and can incorporate bores to allow an oxygen containing feed stream to flow past exposed ends of the tubular membrane elements for cooling the end seals of such elements. Further, first and second manifolds can be provided in a module in accordance with the present invention to collect separated oxygen from two separate portions of the tubular membrane elements.

Owner:PRAXAIR TECH INC

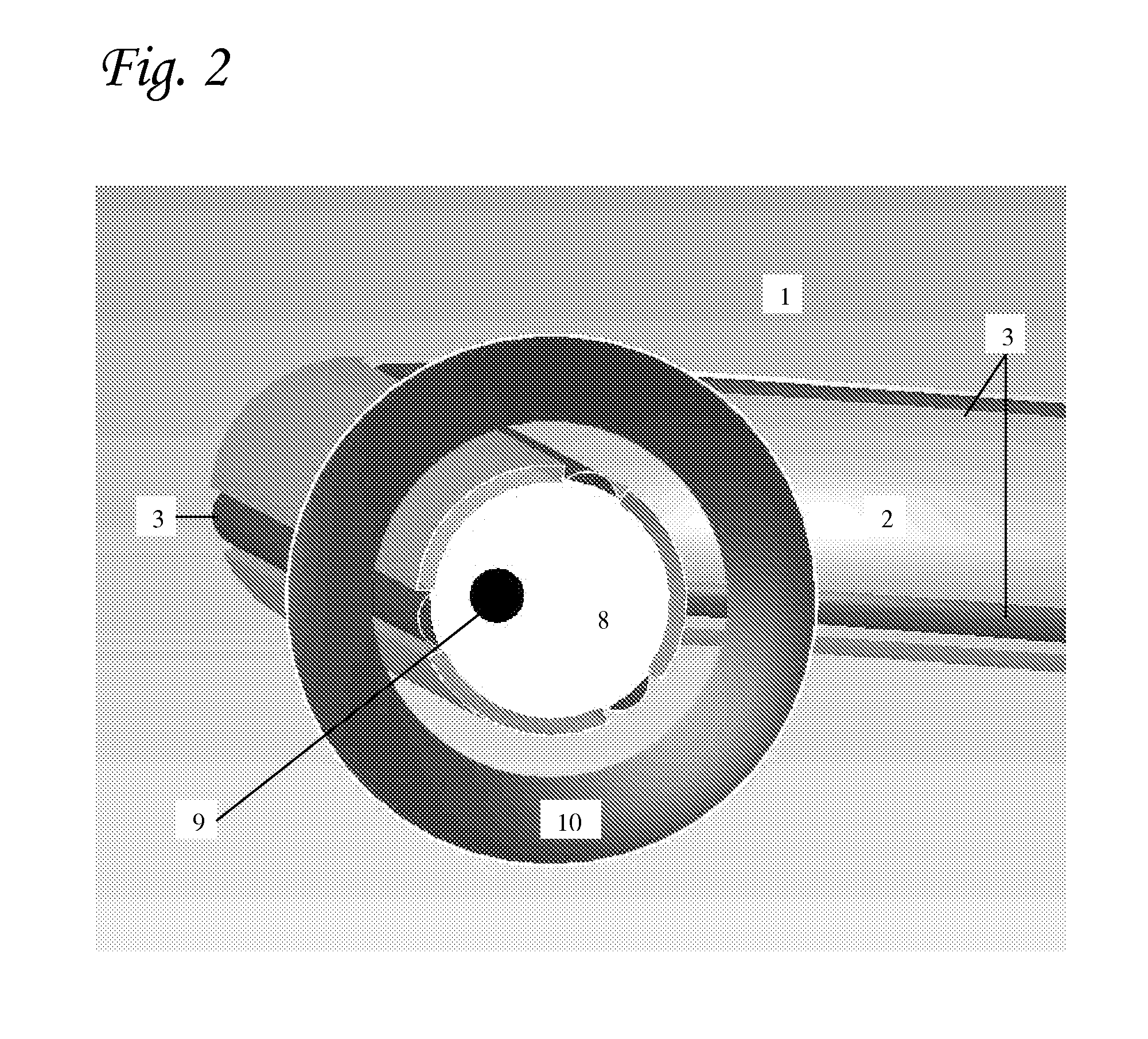

Systems and Methods for Closing a Percutaneous Vascular Puncture

A system and method for closing a percutaneous vessel puncture at the conclusion of a vascular catheterization procedure includes placement of an intravascular closure device having a radially and axially expandable tubular membrane and a radially expandable anchor at the distal sad of the membrane. The closure device is placed, by a delivery catheter extending through the puncture site, with its anchor radially expanded in a location upstream of the puncture site to enable the force of a patient's blood flow to deploy the tubular membrane to a proximally extended configuration closing the puncture from within the vessel.

Owner:MEDTRONIC VASCULAR INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com