Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

9180 results about "Chemical physics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemical physics is a subdiscipline of chemistry and physics that investigates physicochemical phenomena using techniques from atomic and molecular physics and condensed matter physics; it is the branch of physics that studies chemical processes from the point of view of physics. While at the interface of physics and chemistry, chemical physics is distinct from physical chemistry in that it focuses more on the characteristic elements and theories of physics. Meanwhile, physical chemistry studies the physical nature of chemistry. Nonetheless, the distinction between the two fields is vague, and workers often practice in both fields during the course of their research.

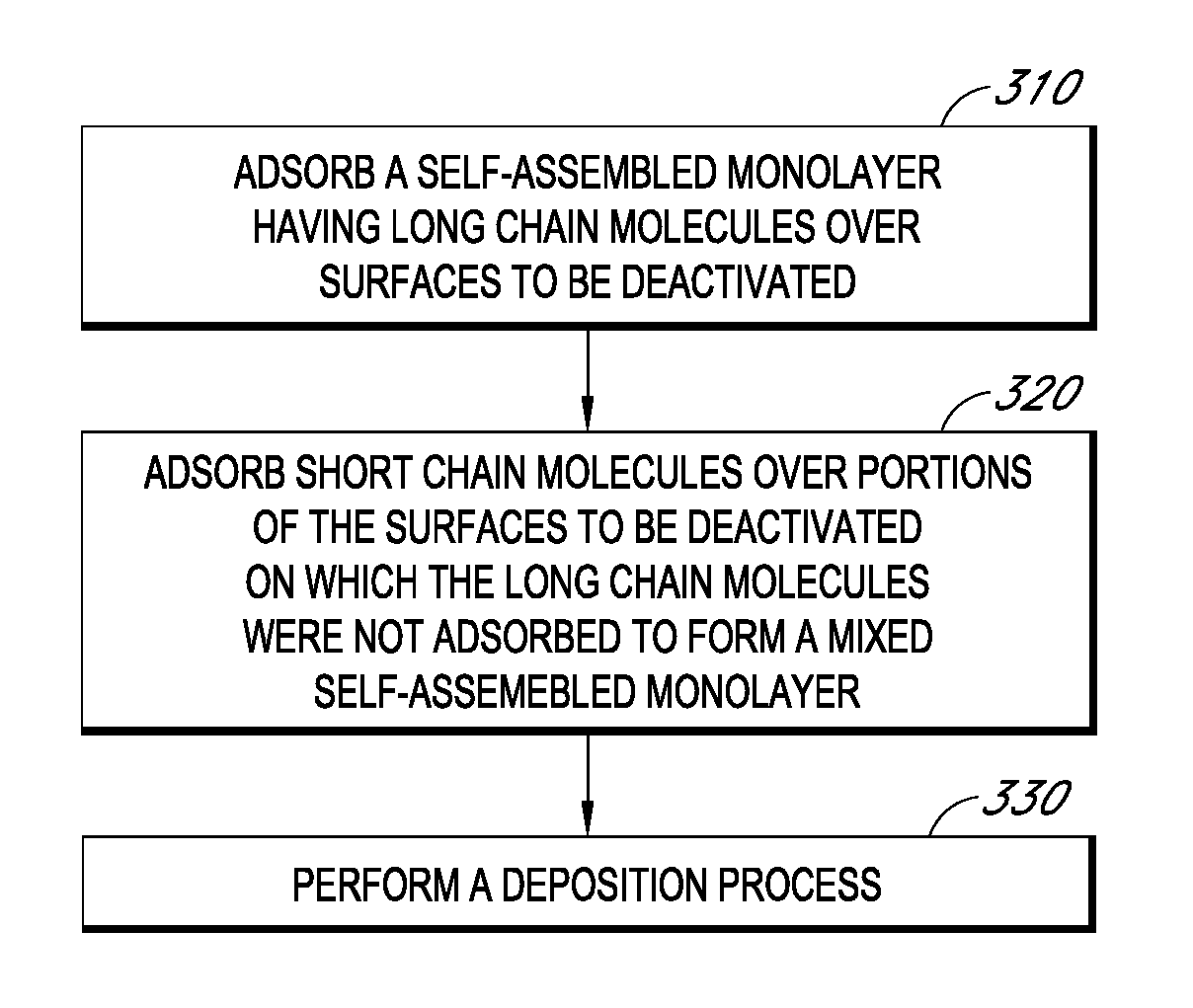

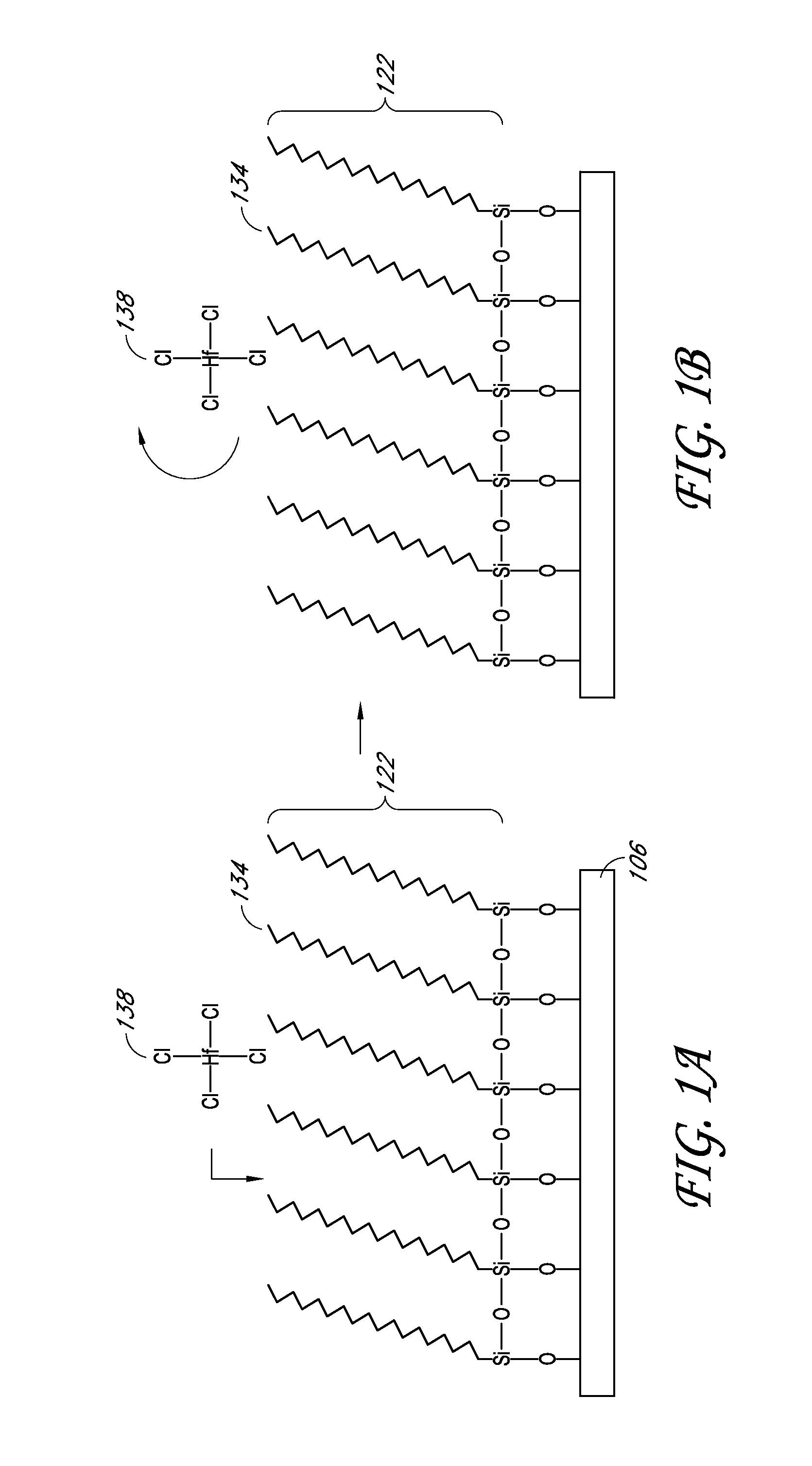

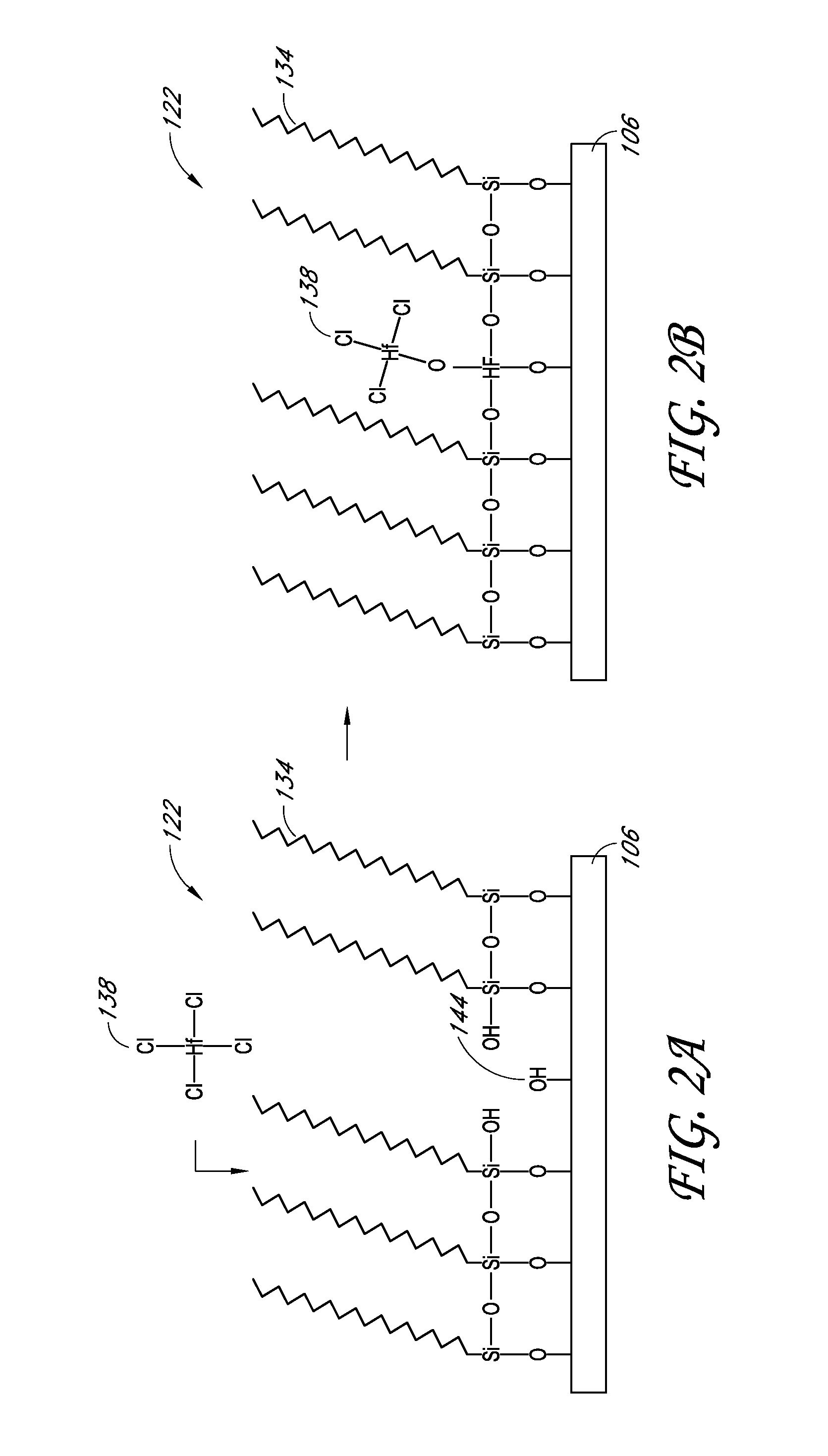

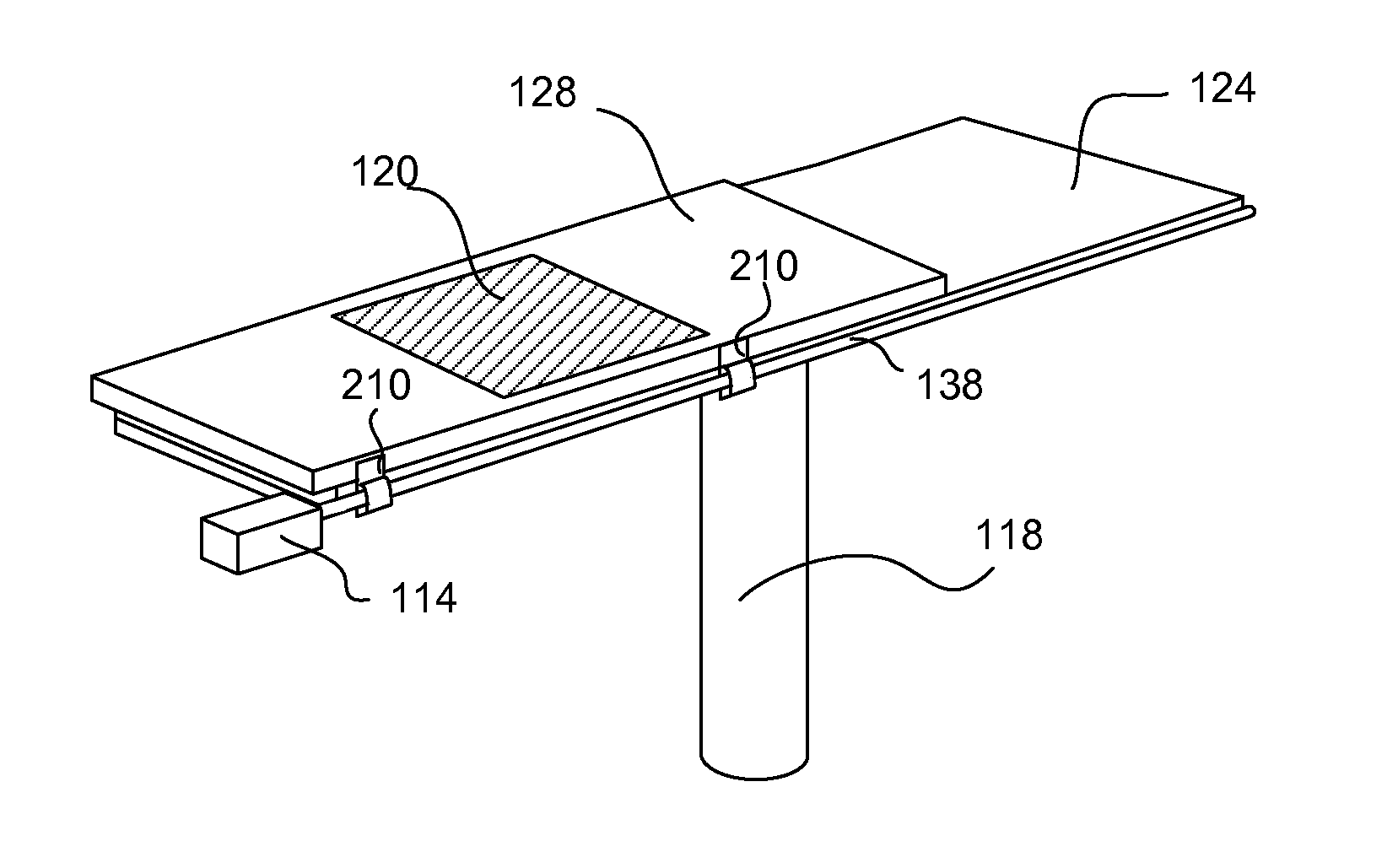

Reactive site deactivation against vapor deposition

Methods and structures relating to the formation of mixed SAMs for preventing undesirable growth or nucleation on exposed surfaces inside a reactor are described. A mixed SAM can be formed on surfaces for which nucleation is not desired by introducing a first SAM precursor having molecules of a first length and a second SAM precursor having molecules of a second length shorter than the first. Examples of exposed surfaces for which a mixed SAM can be provided over include reactor surfaces and select surfaces of integrated circuit structures, such as insulator and dielectric layers.

Owner:ASM IP HLDG BV

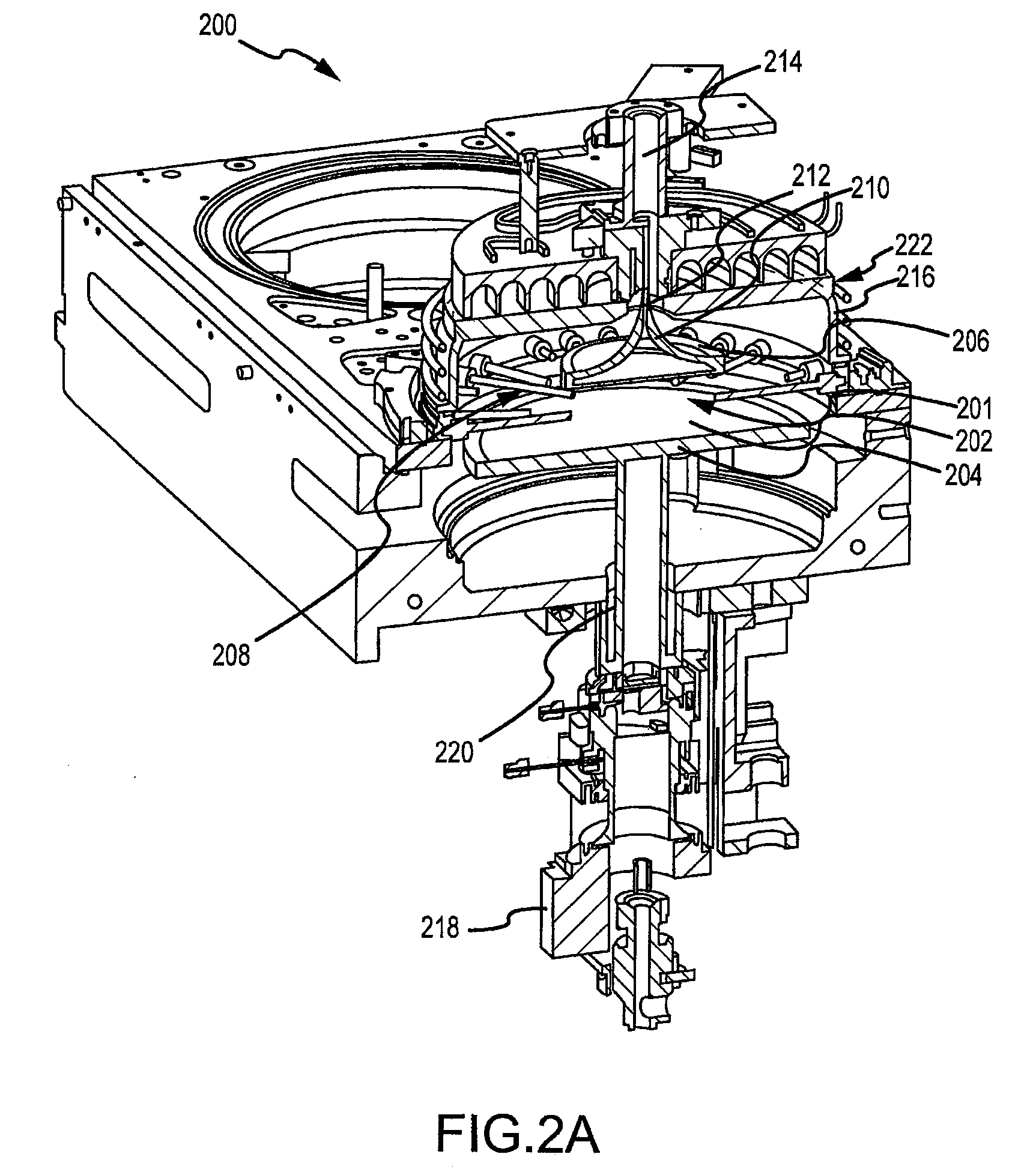

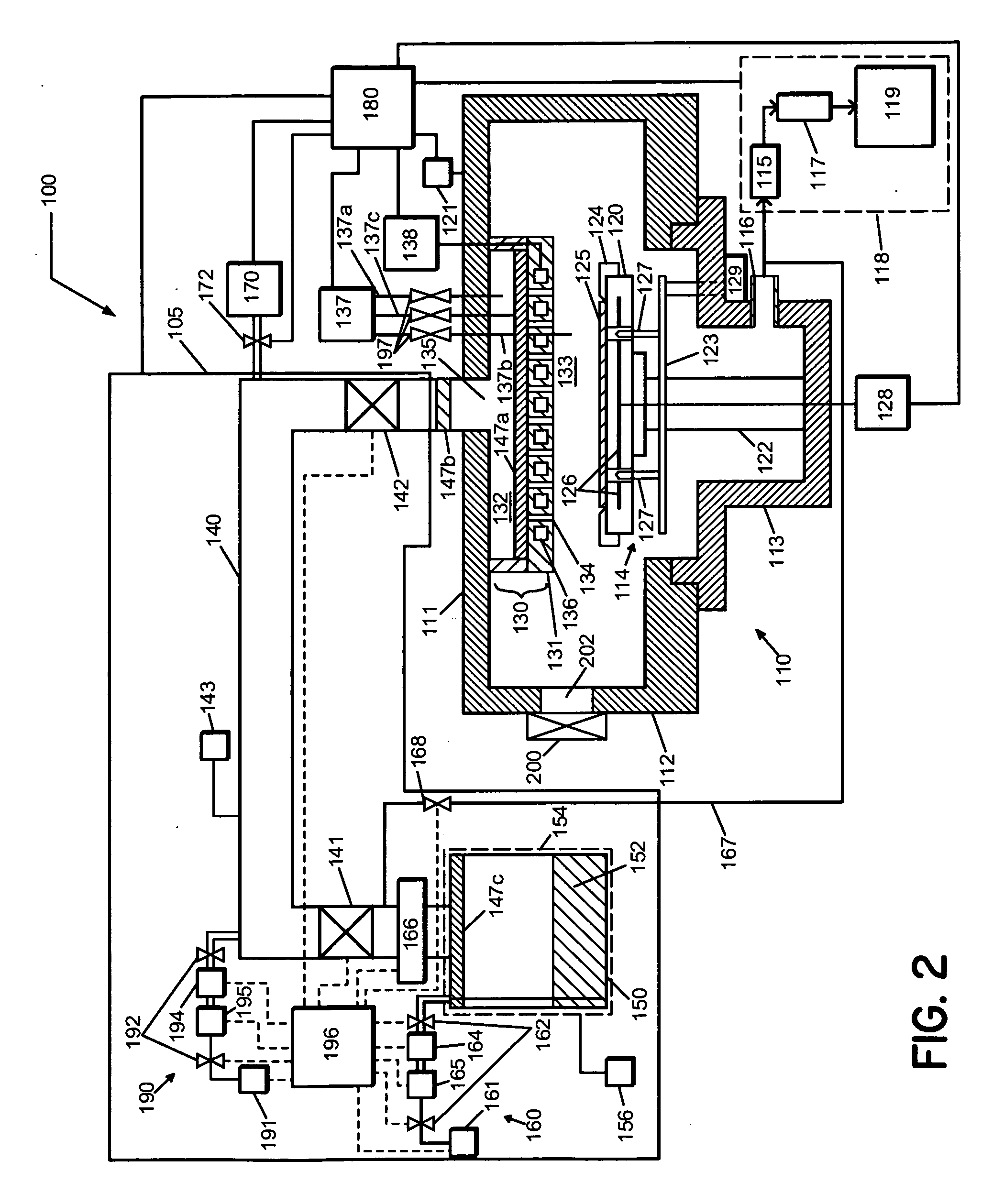

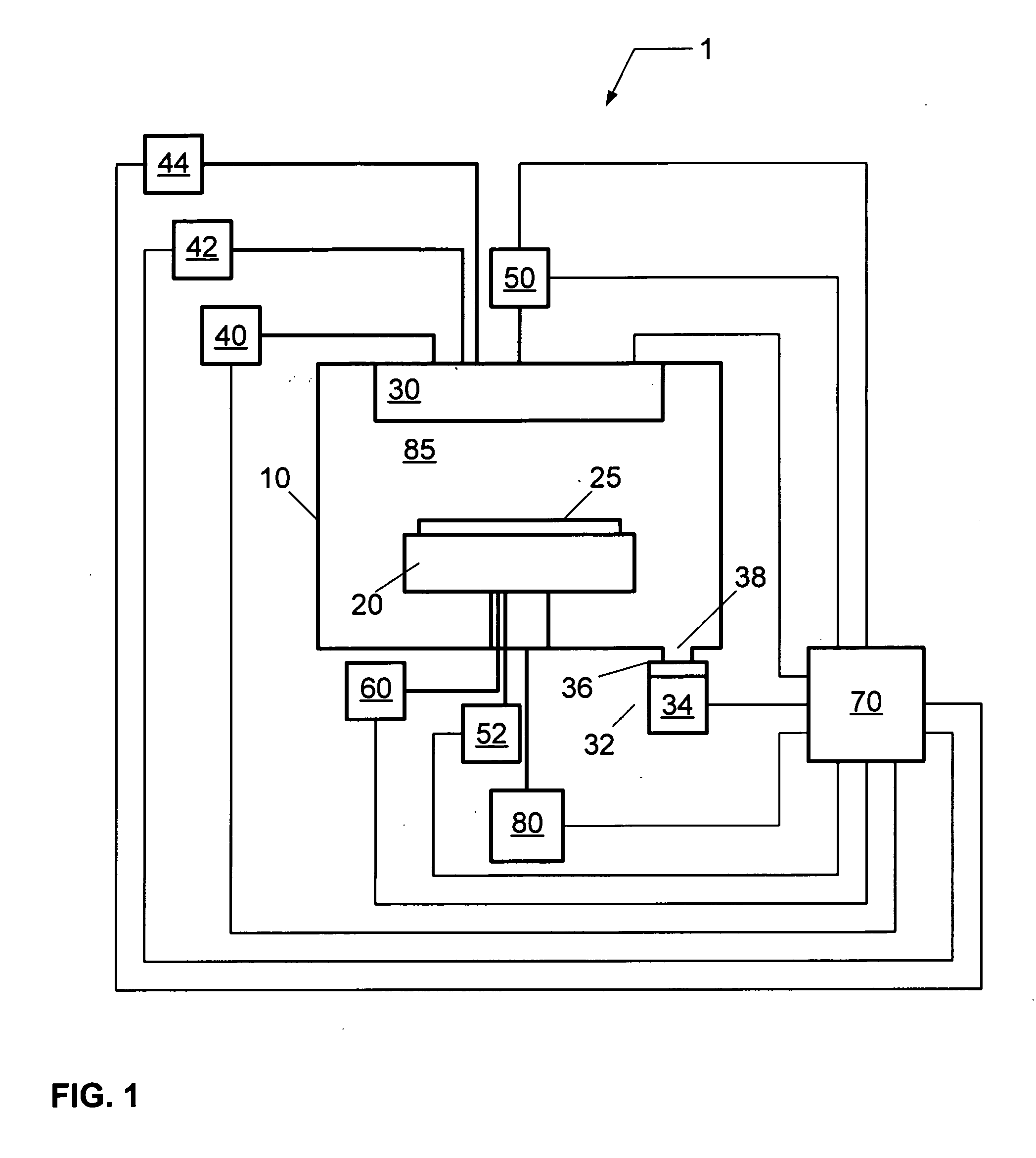

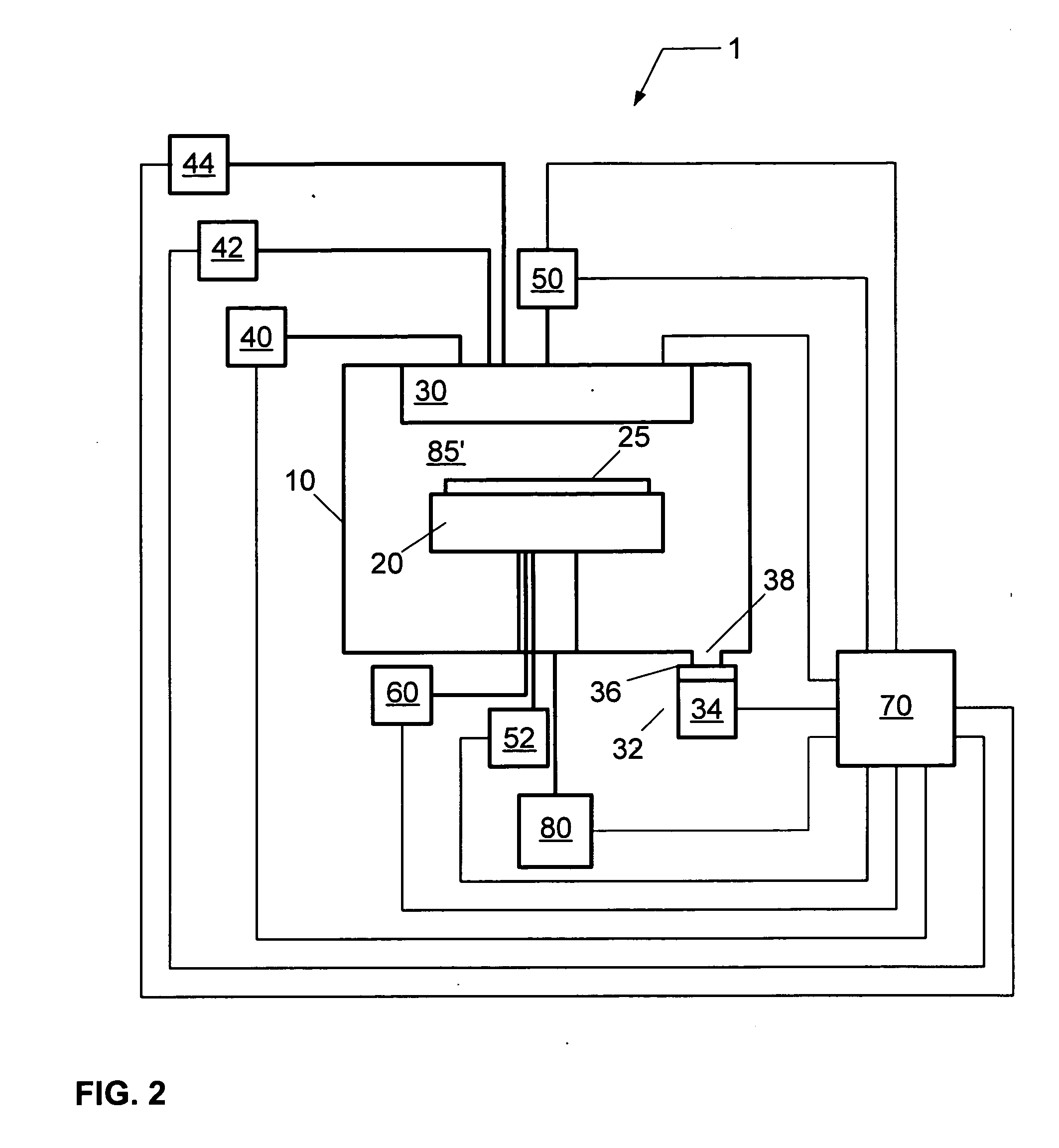

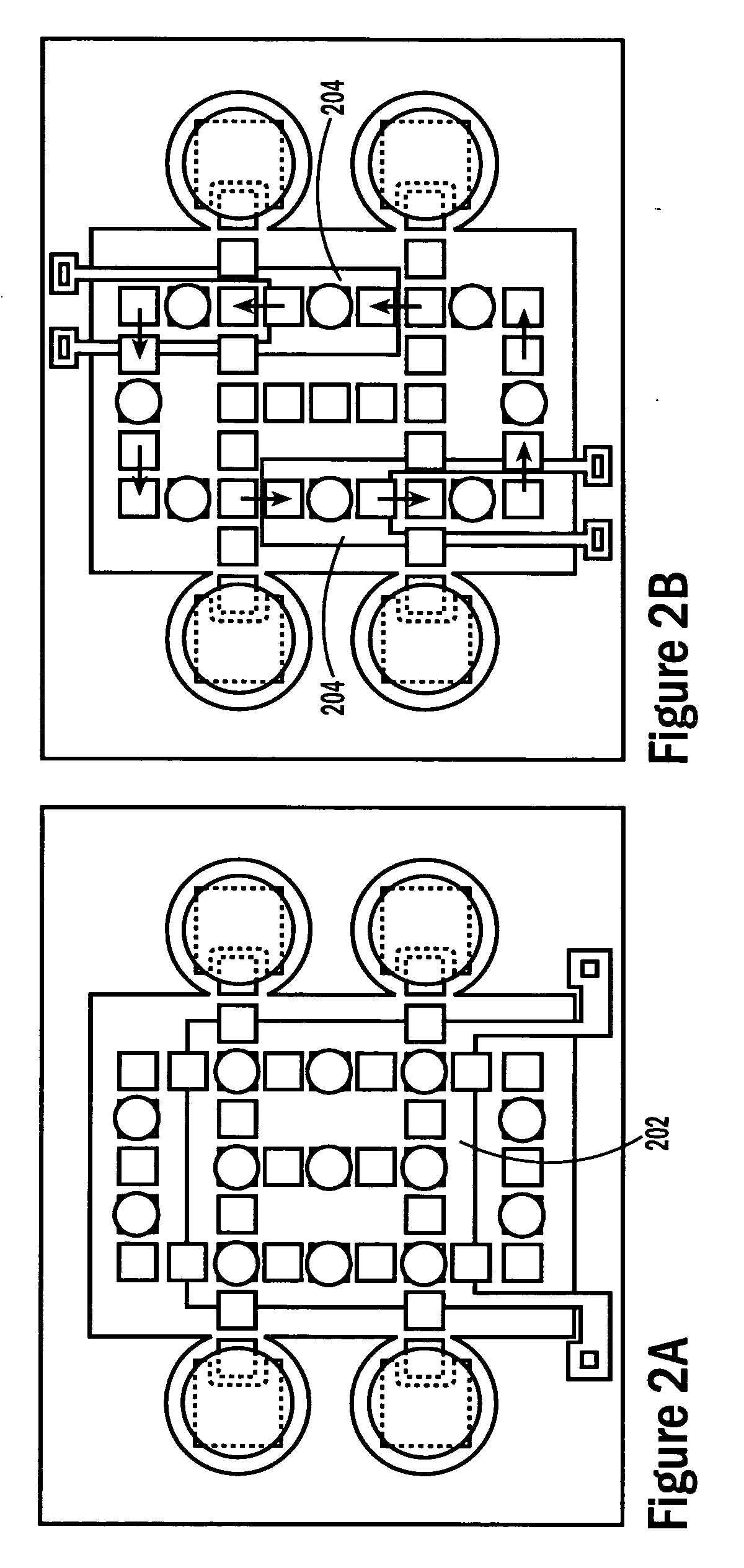

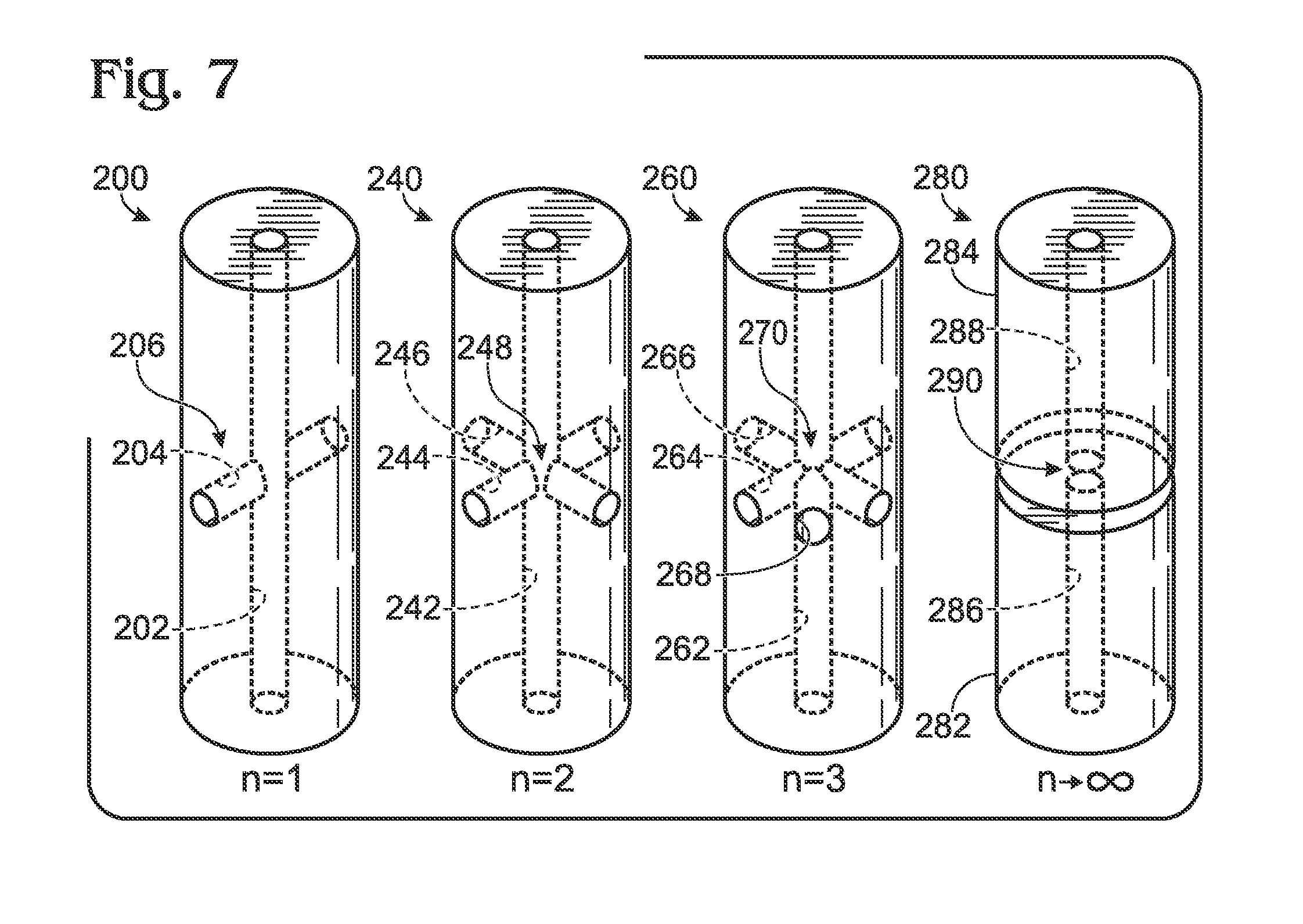

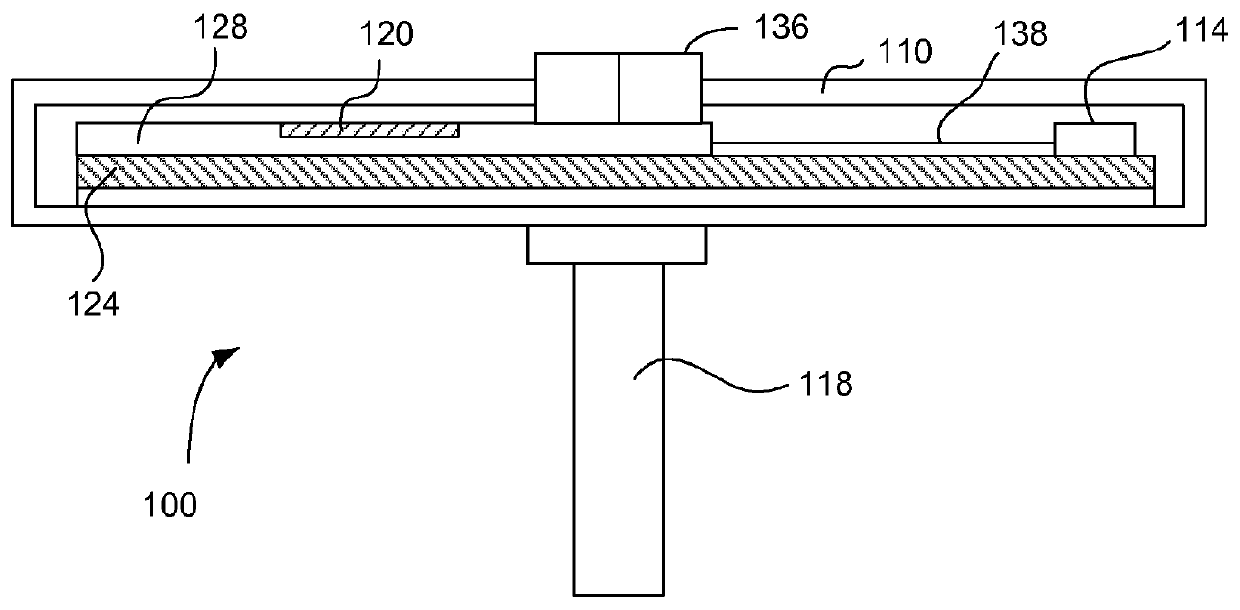

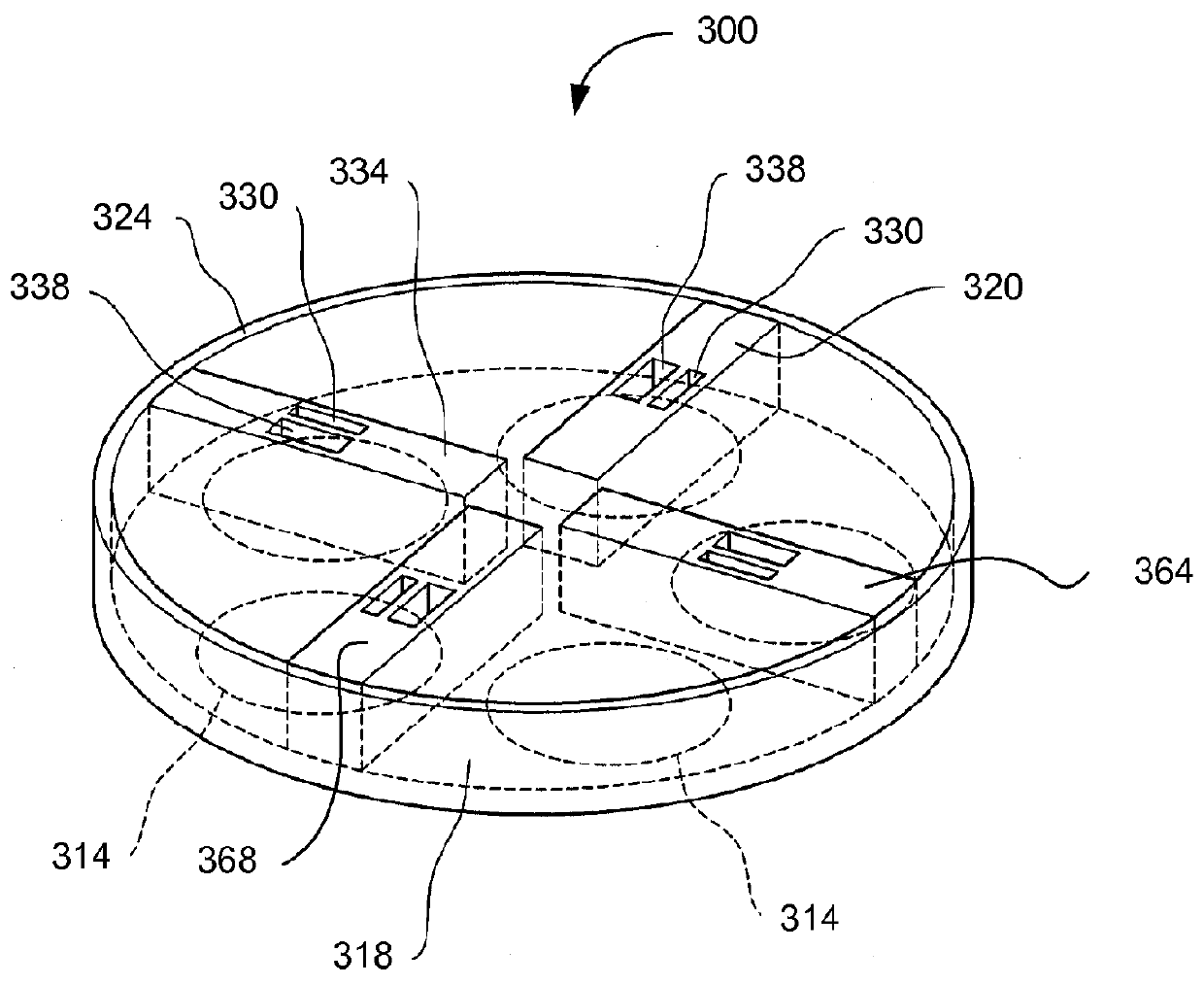

Radical Reactor with Multiple Plasma Chambers

InactiveUS20120114877A1Well mixedElectric discharge tubesChemical vapor deposition coatingAtomic layer depositionPlasma chamber

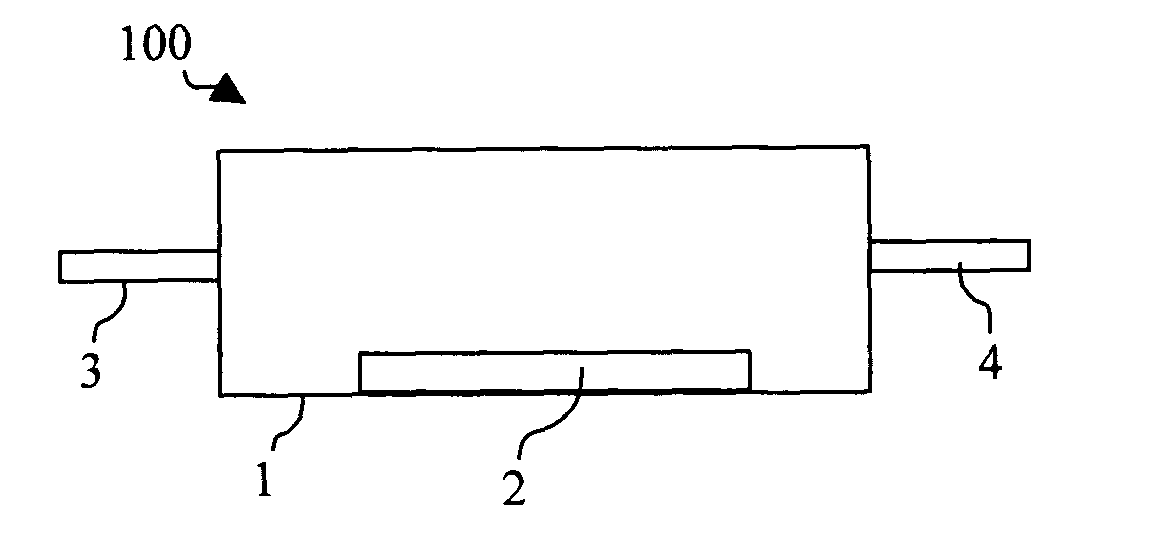

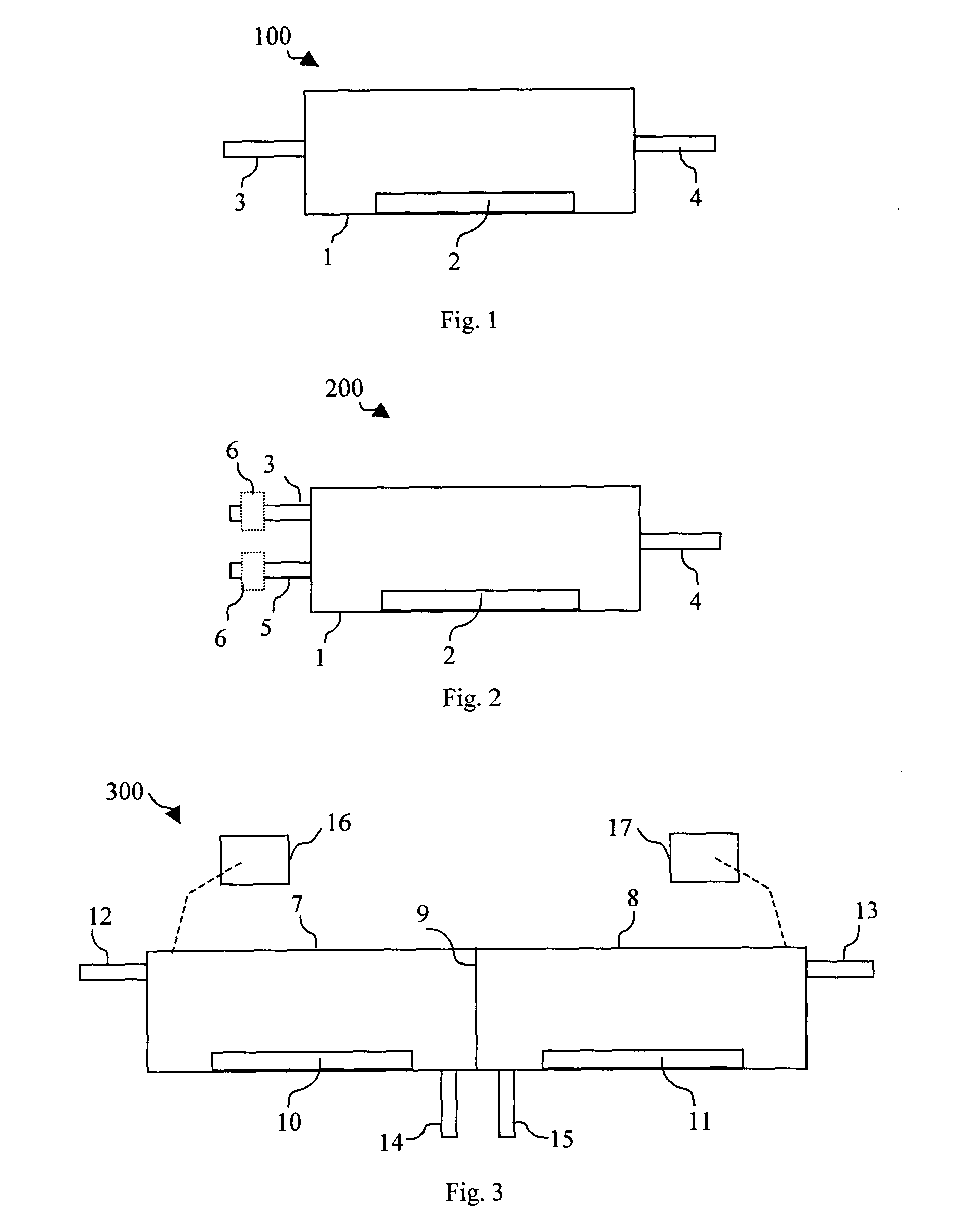

Two or more plasma chambers are provided in a radical reactor to generate radicals of gases under different conditions for use in atomic layer deposition (ALD) process. The radical reactor has a body with multiple channels and corresponding process chambers. Each plasma chamber is surrounded by an outer electrode and has an inner electrode extending through the chamber. When voltage is applied across the outer electrode and the inner electrode with gas present in the plasma chamber, radicals of the gas is generated in the plasma chamber. The radicals generated in the plasma chamber are then injected into a mixing chamber for mixing with radicals of another gas from another plasma chamber, and injected onto the substrate. By providing two or more plasma chambers, different radicals of gases can be generated within the same radical reactor, which obviates the need for separate radical generators.

Owner:VEECO ALD

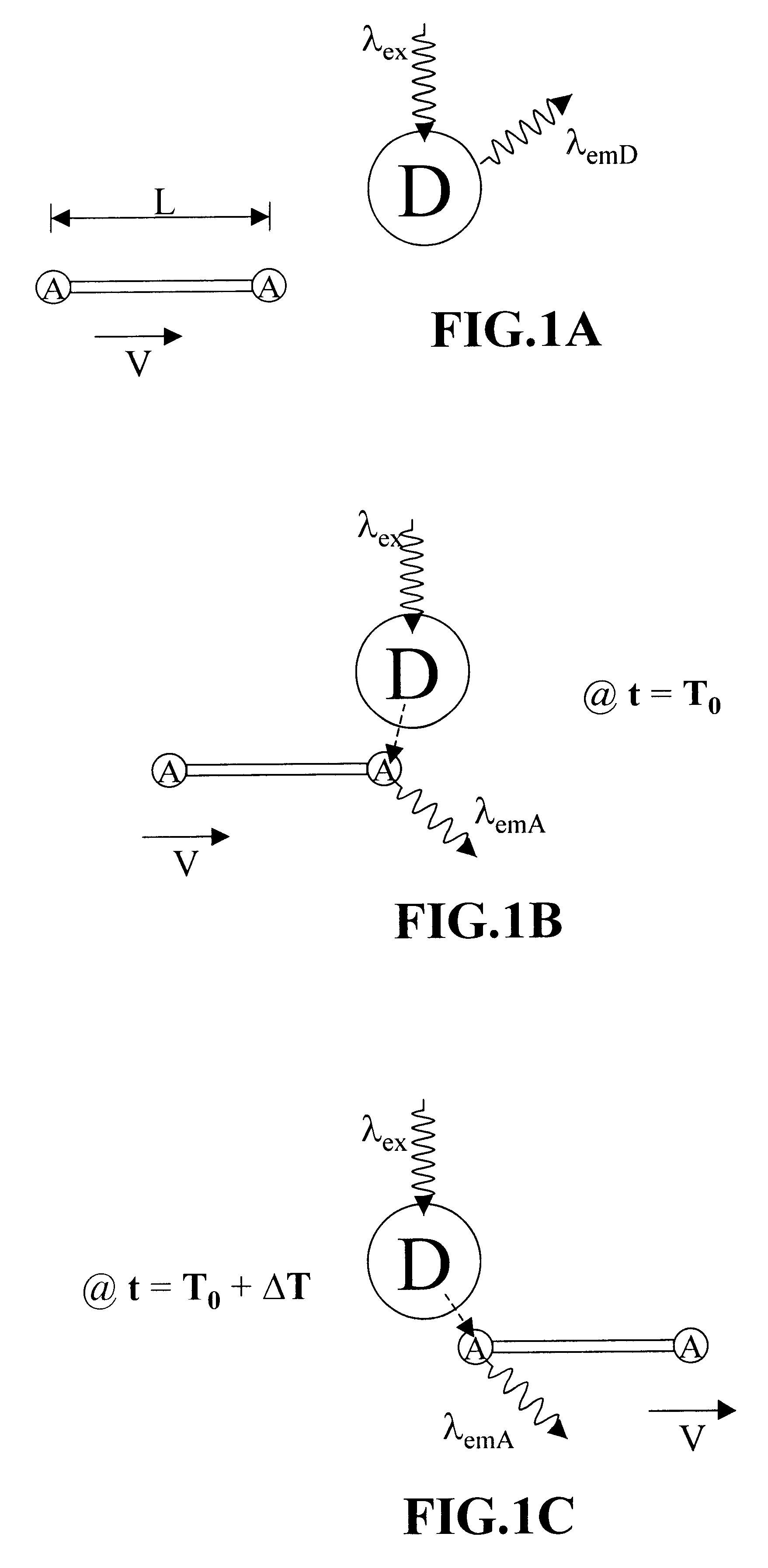

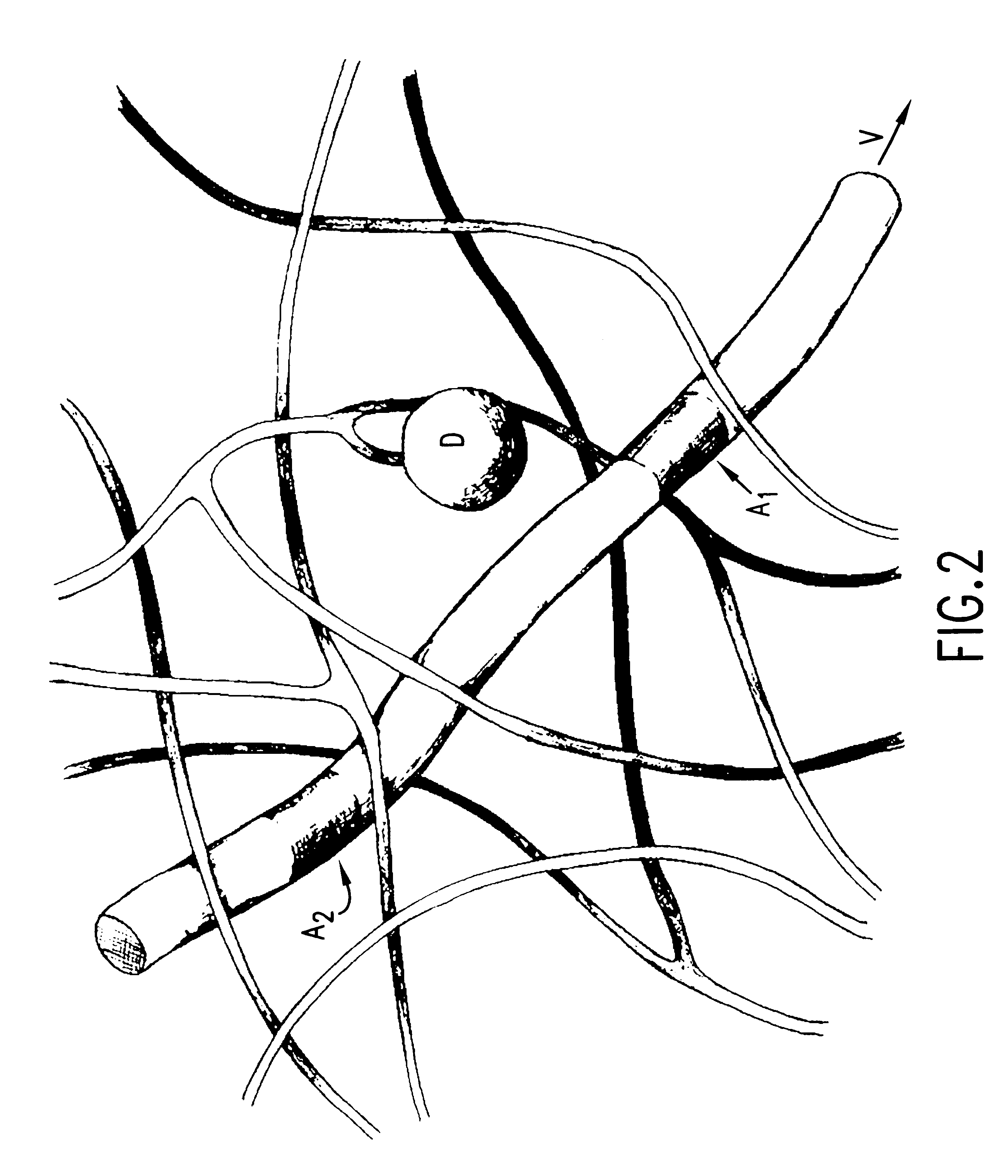

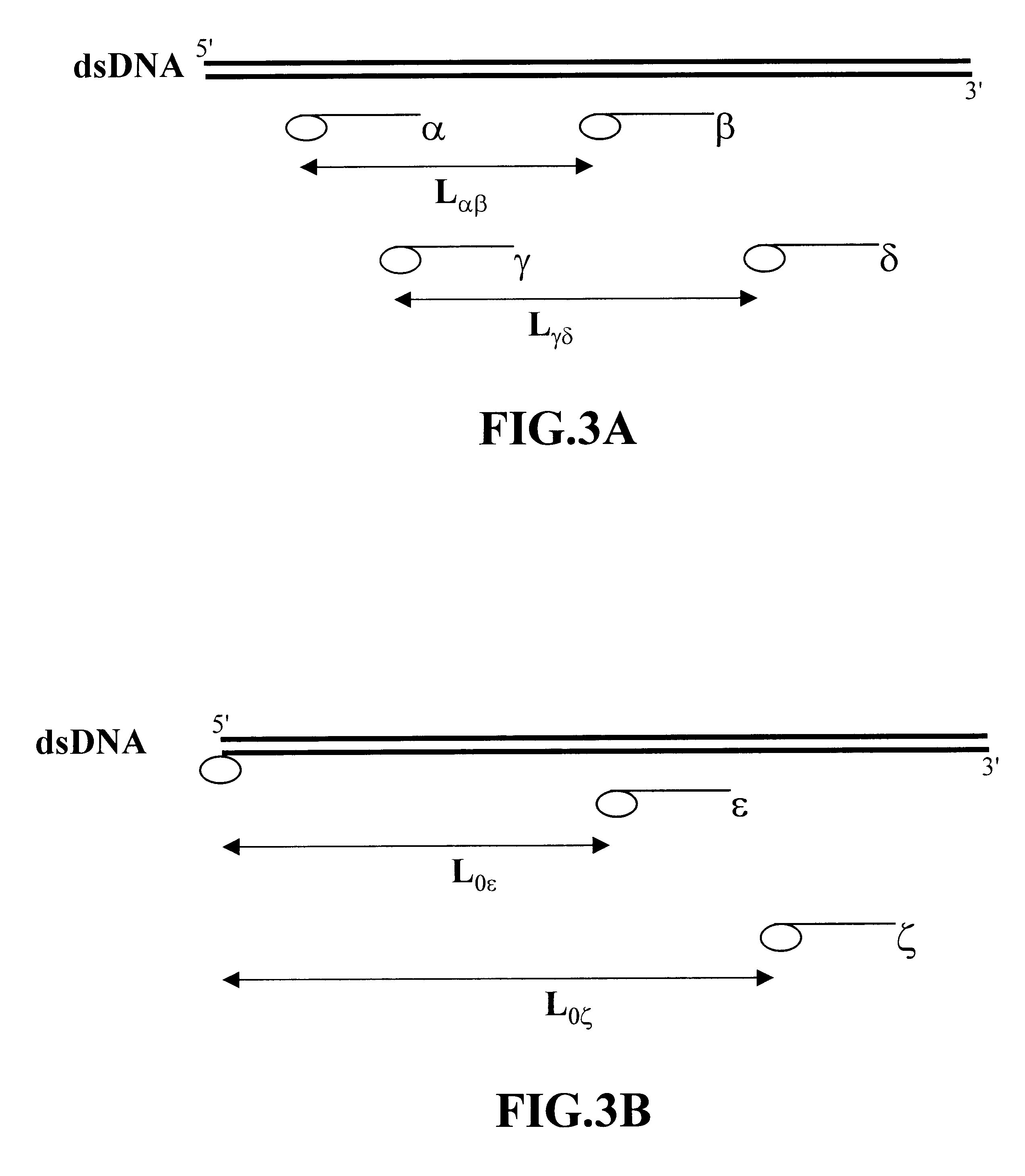

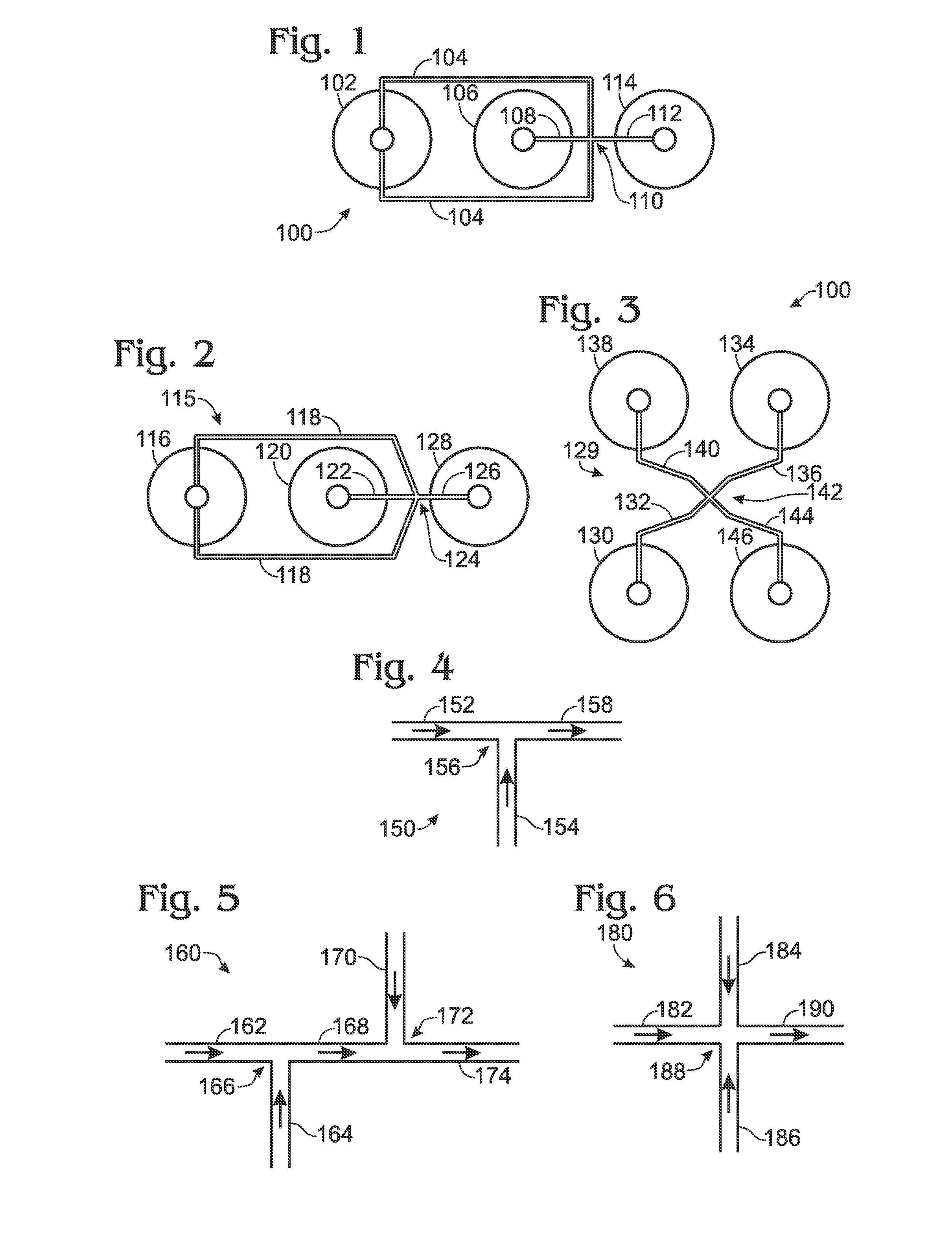

Methods of analyzing polymers using a spatial network of fluorophores and fluorescence resonance energy transfer

InactiveUS6263286B1Easy to analyze and useMicrobiological testing/measurementLaboratory glasswaresEnergy transferResonance

The present invention relates to methods and apparatuses for analyzing molecules, particularly polymers, and molecular complexes with extended or rod-like conformations. In particular, the methods and apparatuses are used to identify repetitive information in molecules or molecular ensembles, which is interpreted using an autocorrelation function in order to determine structural information about the molecules. The methods and apparatuses of the invention are used for, inter alia, determining the sequence of a nucleic acid, determining the degree of identity of two polymers, determining the spatial separation of specific sites within a polymer, determining the length of a polymer, and determining the velocity with which a molecule penetrates a biological membrane.

Owner:U S GENOMICS INC

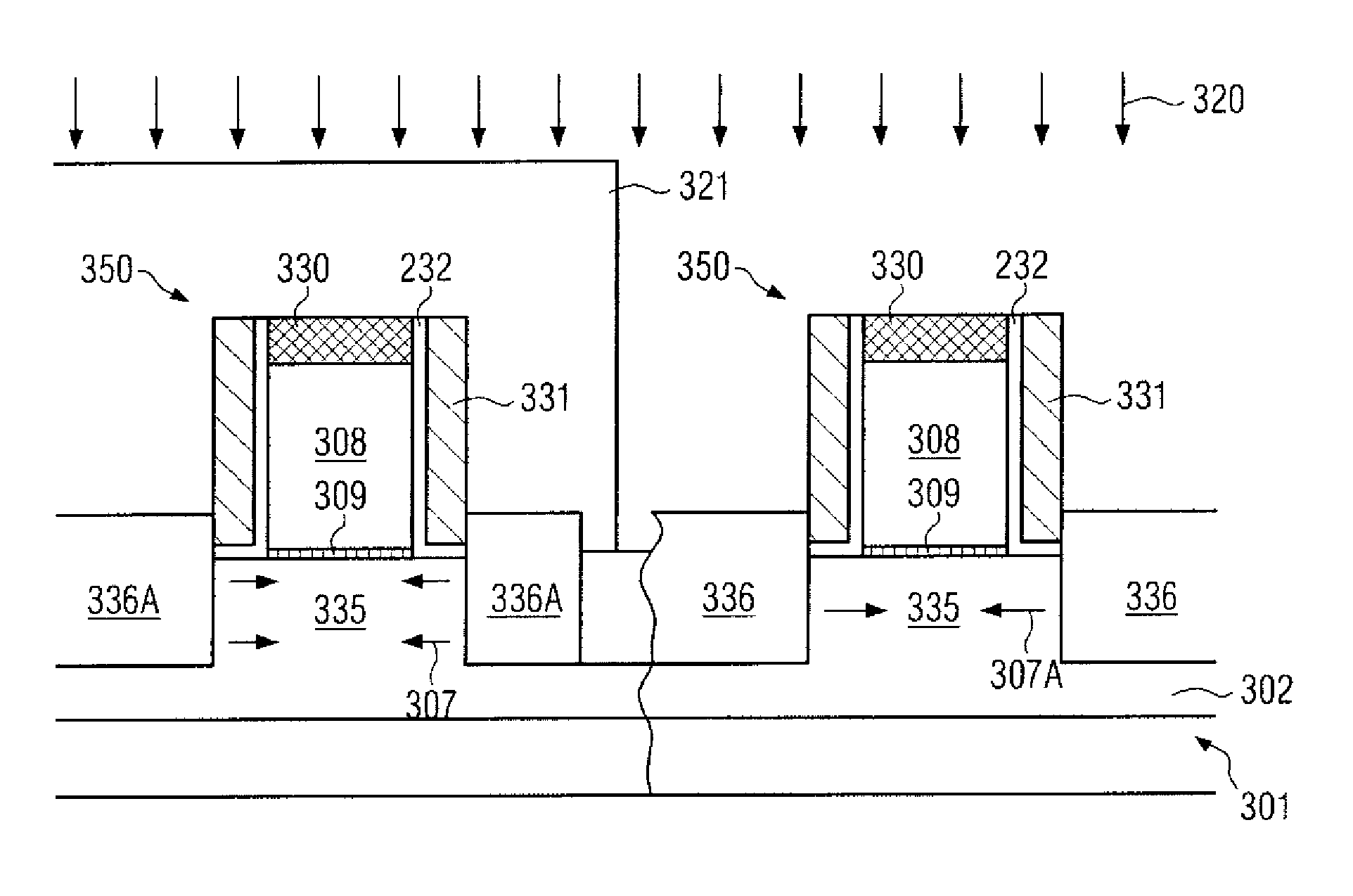

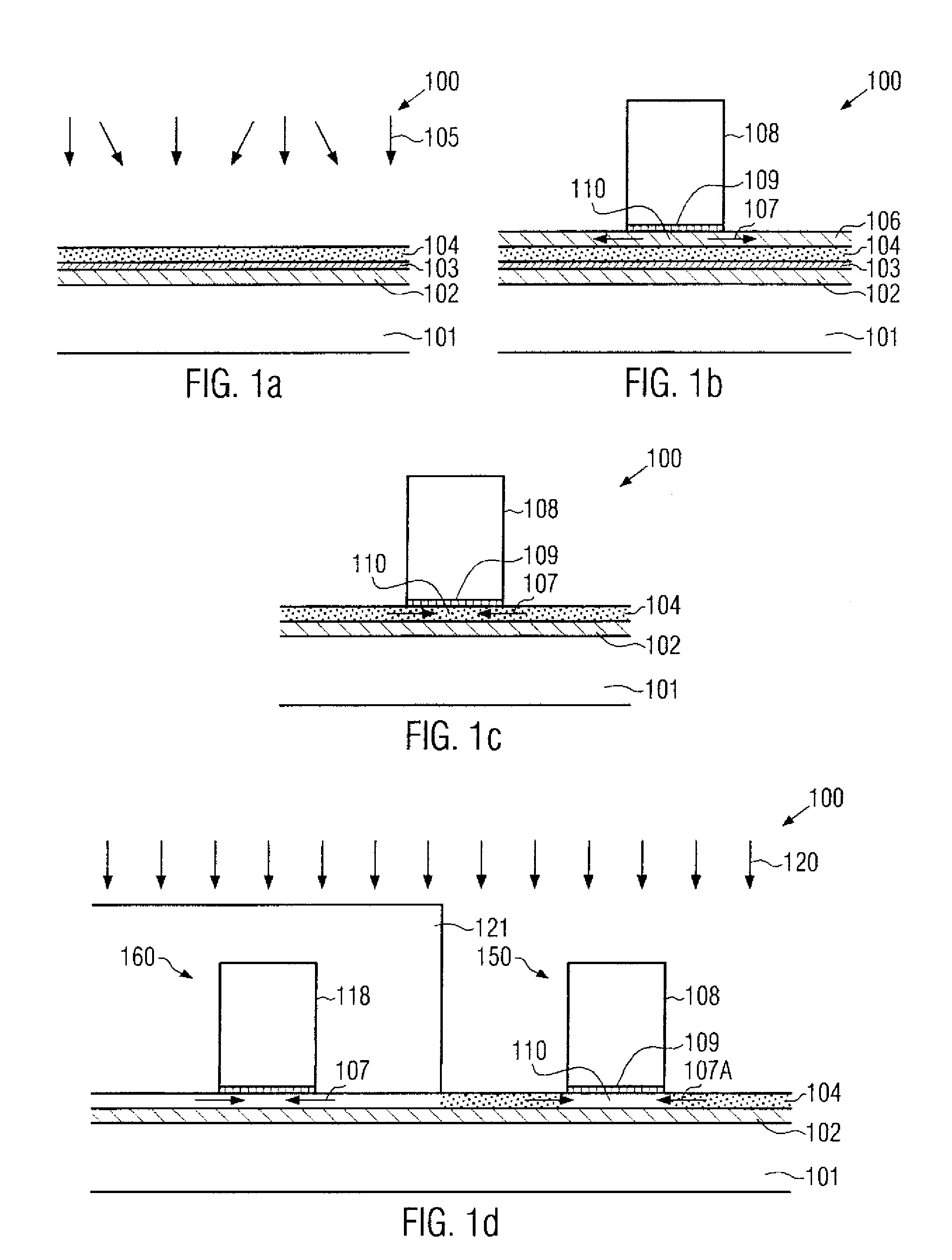

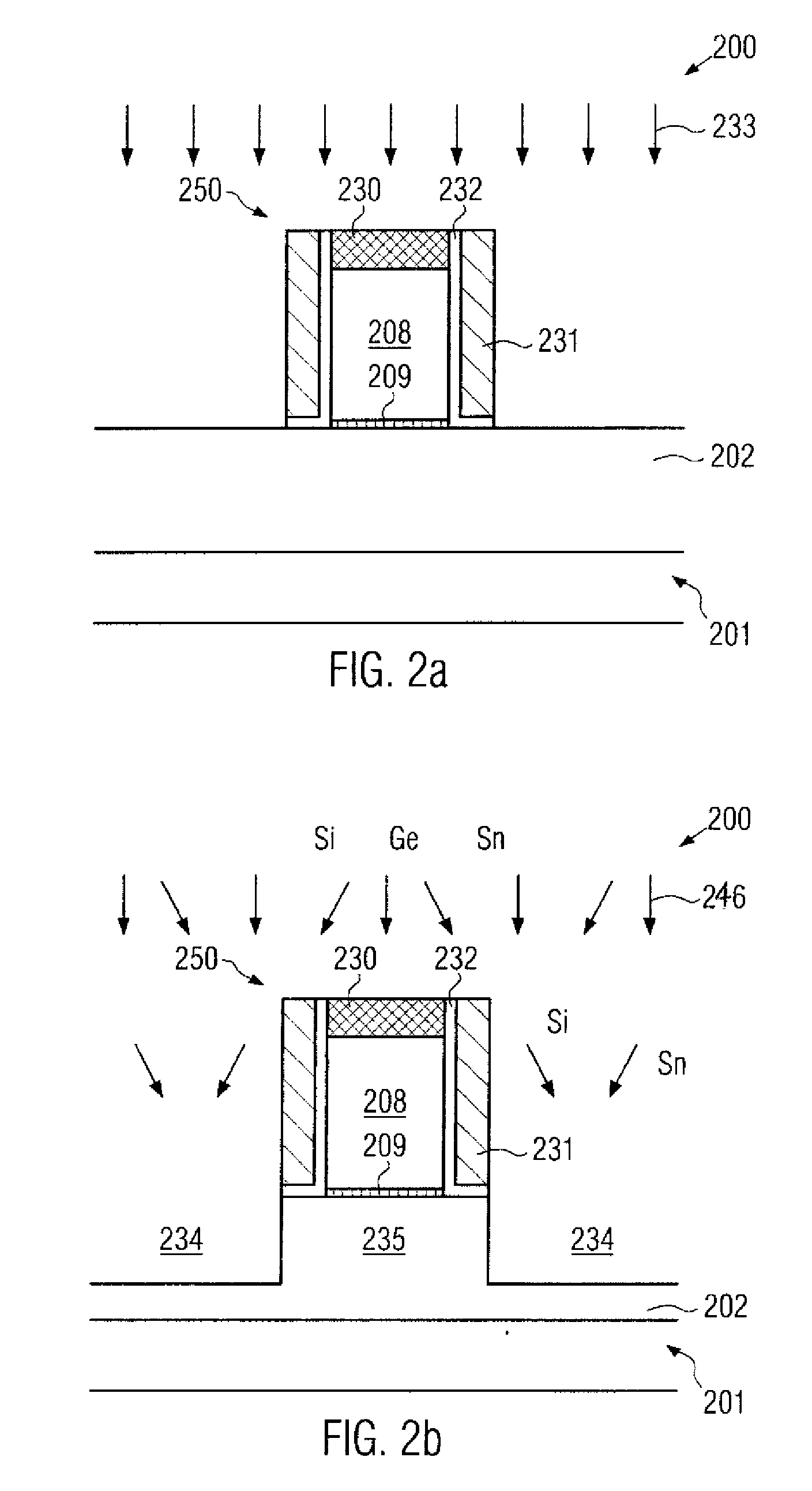

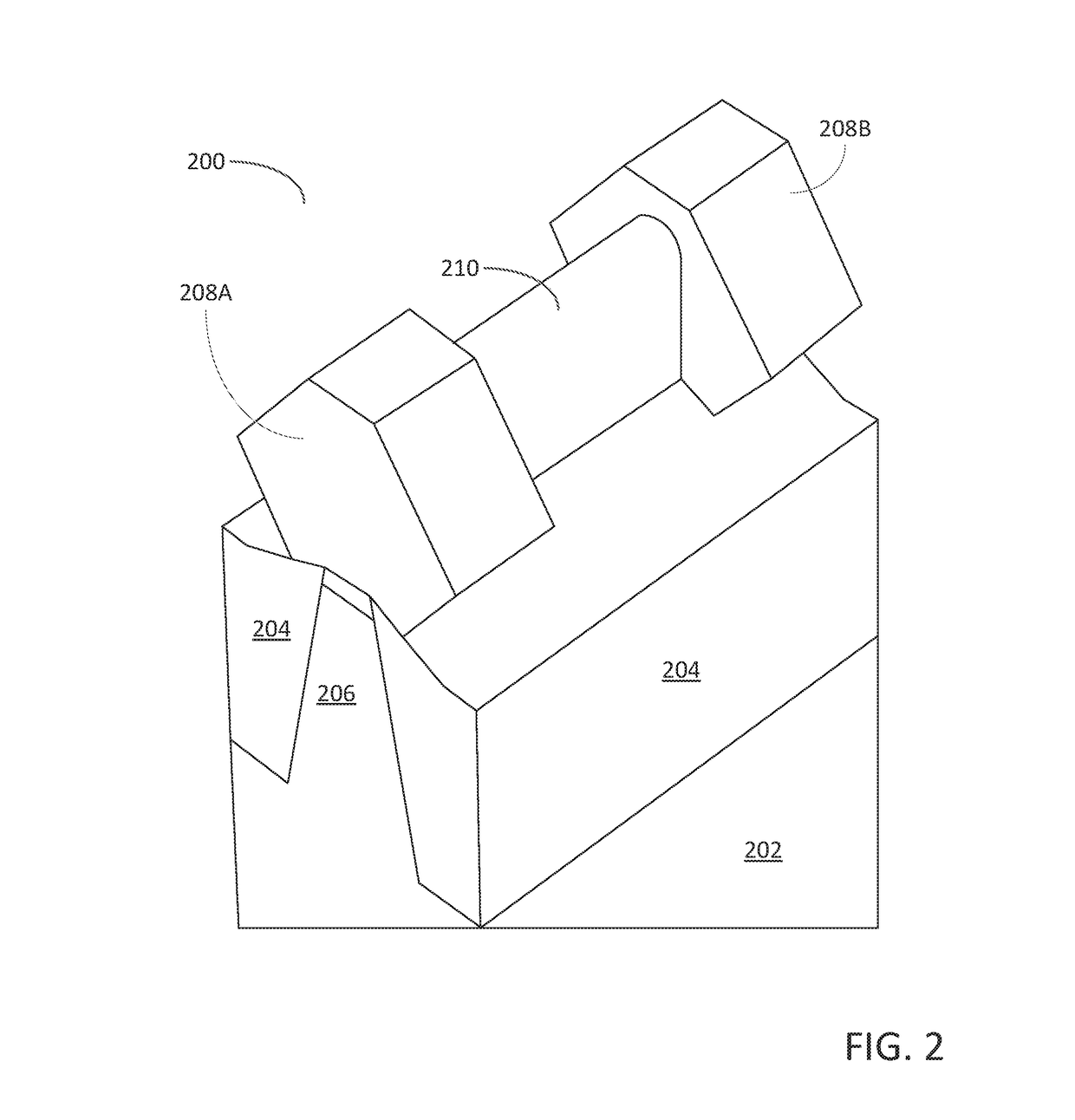

Technique for strain engineering in si-based transistors by using embedded semiconductor layers including atoms with high covalent radius

By incorporating an atomic species of increased covalent radius, which may at least partially substitute germanium, a highly efficient strain mechanism may be provided, in which the risk of stress relief due to germanium conglomeration and lattice defects may be reduced. The atomic species of increased radius, such as tin, may be readily incorporated by epitaxial growth techniques on the basis of tin hydride.

Owner:GLOBALFOUNDRIES INC

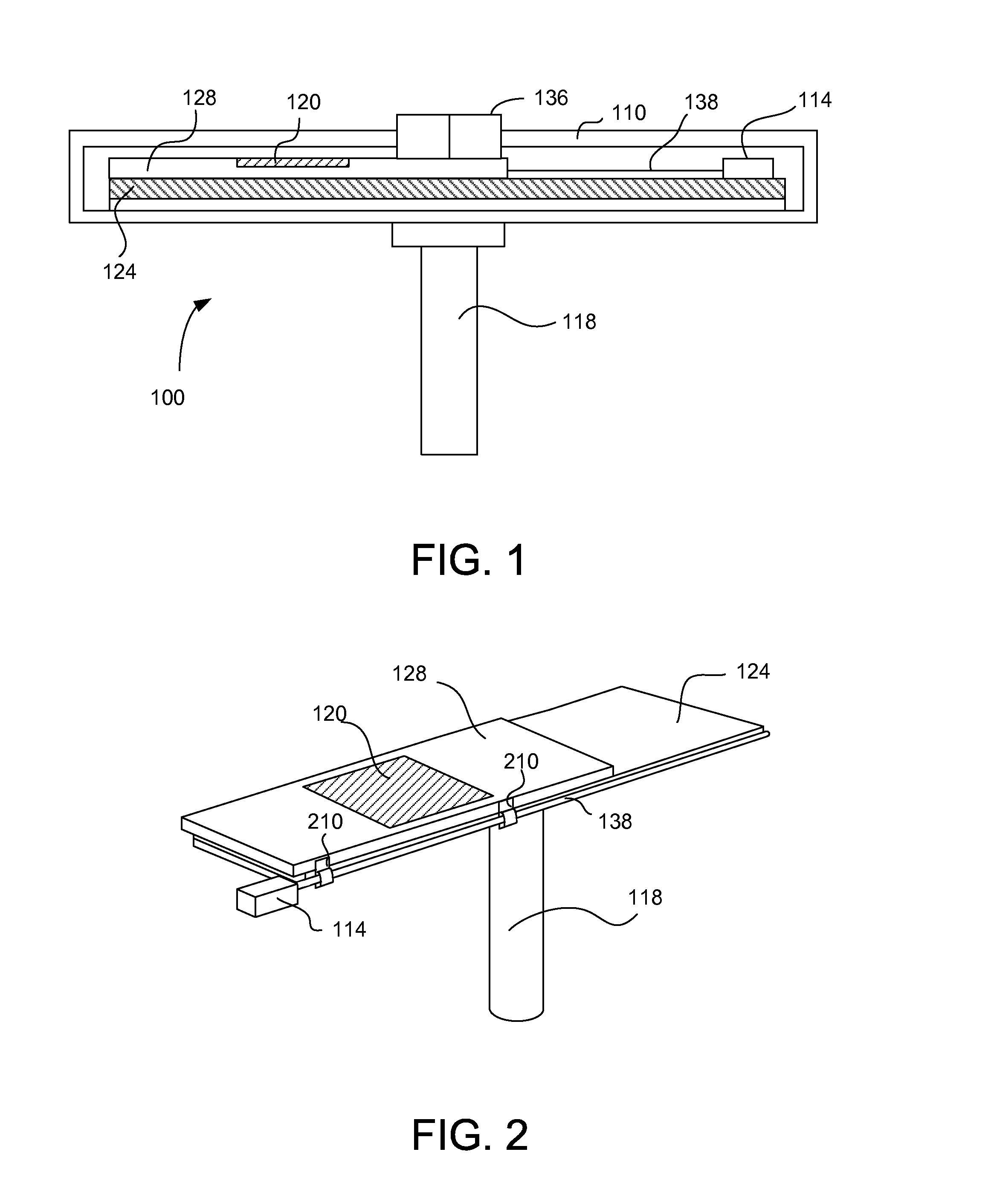

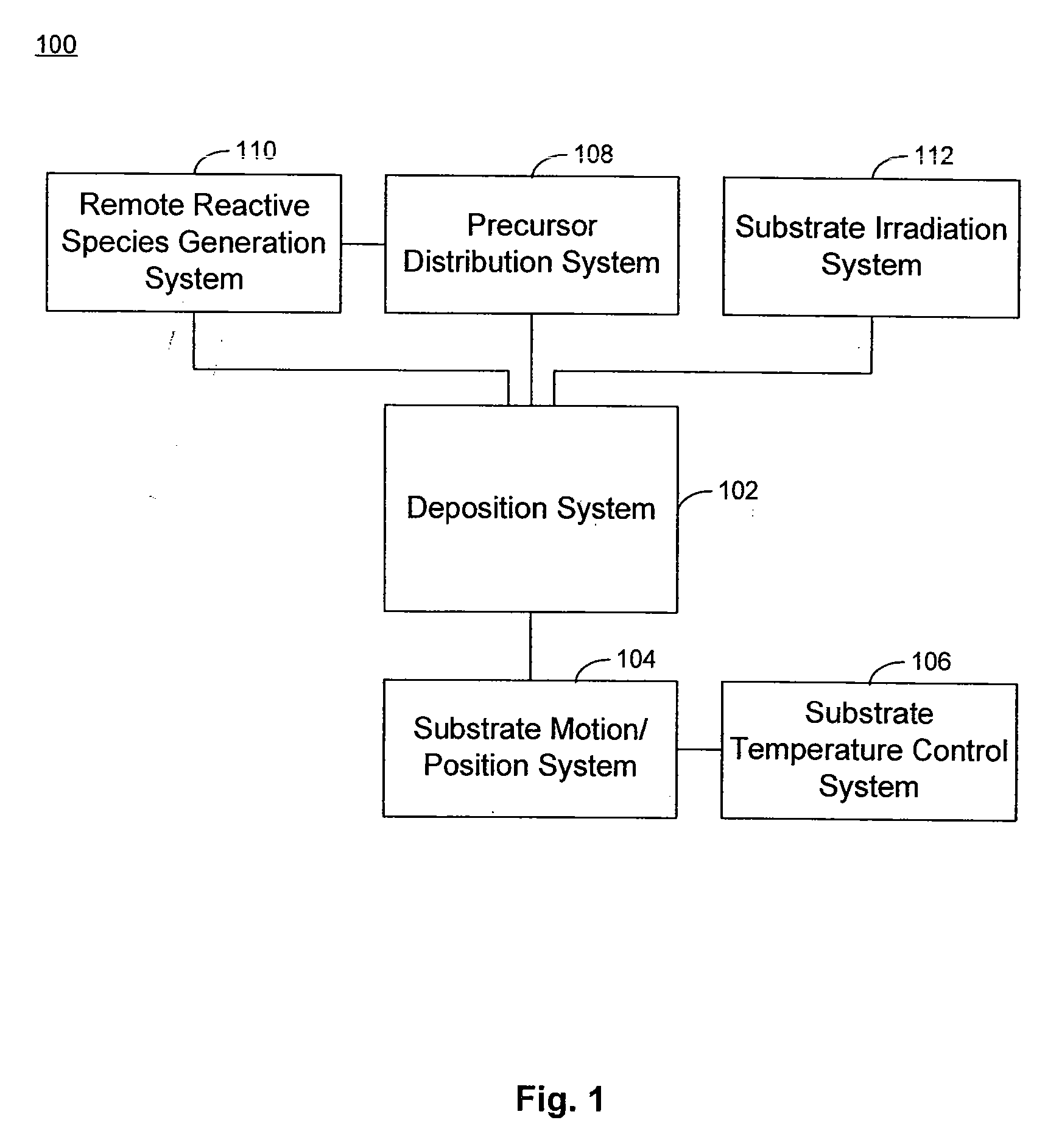

Process chamber for dielectric gapfill

InactiveUS20070281106A1Electric discharge tubesSemiconductor/solid-state device manufacturingRemote plasmaDistribution system

A system to form a dielectric layer on a substrate from a plasma of dielectric precursors is described. The system may include a deposition chamber, a substrate stage in the deposition chamber to hold the substrate, and a remote plasma generating system coupled to the deposition chamber, where the plasma generating system is used to generate a dielectric precursor having one or more reactive radicals. The system may also include a precursor distribution system that includes at least one top inlet and a plurality of side inlets. The top inlet may be positioned above the substrate stage and the side inlets may be radially distributed around the substrate stage. The reactive radical precursor may be supplied to the deposition chamber through the top inlet. An in-situ plasma generating system may also be included to generate the plasma in the deposition chamber from the dielectric precursors supplied to the deposition chamber.

Owner:APPLIED MATERIALS INC

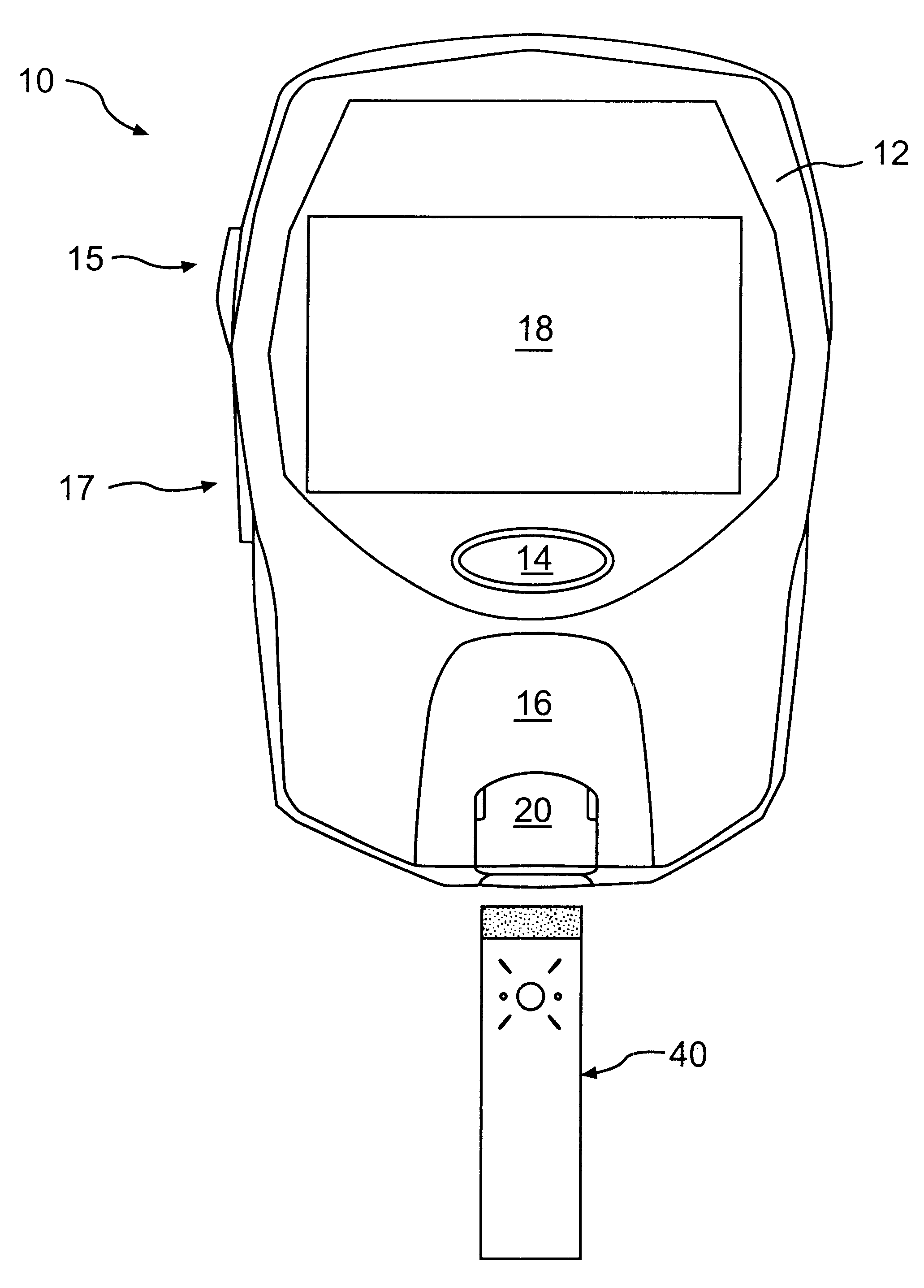

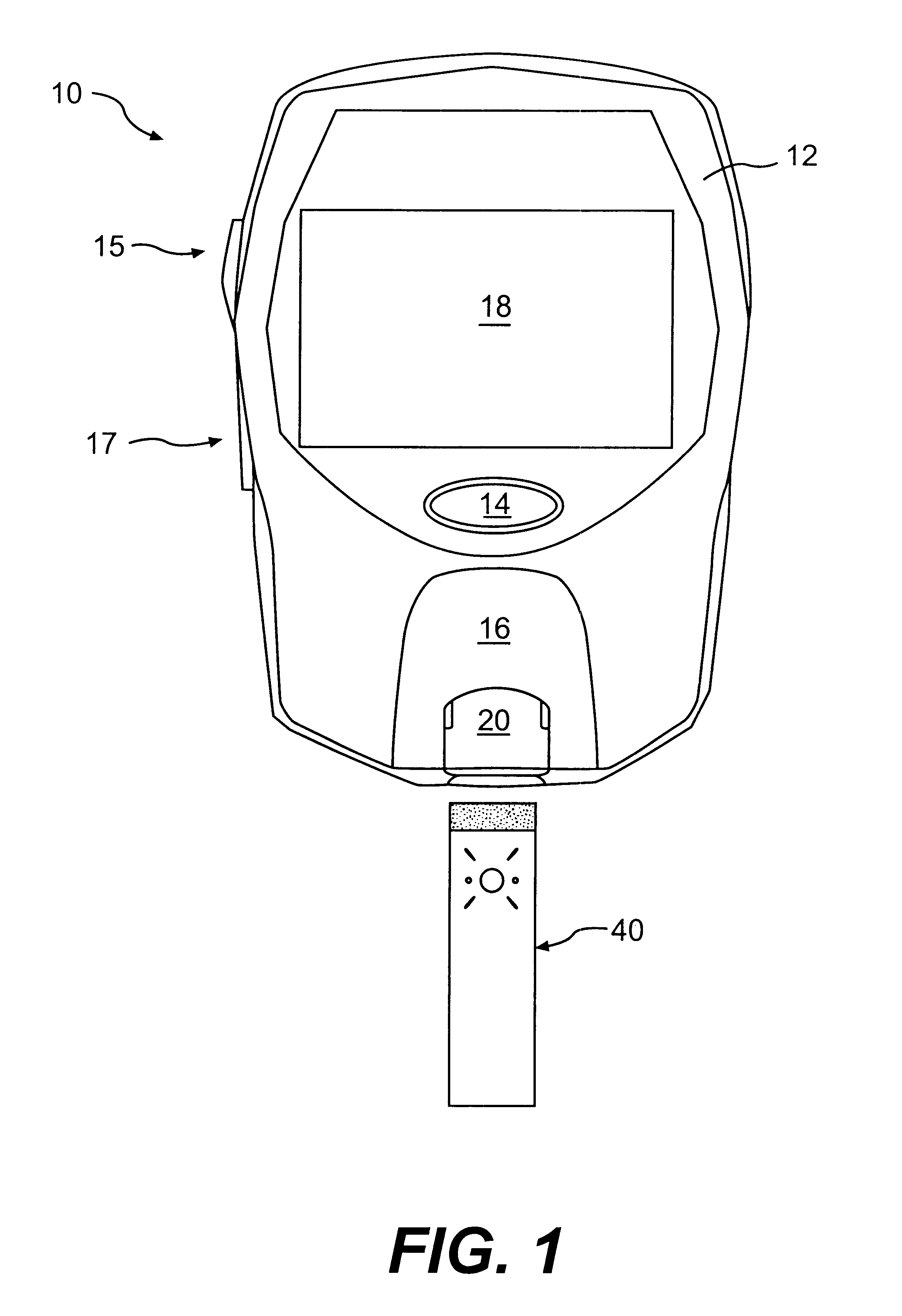

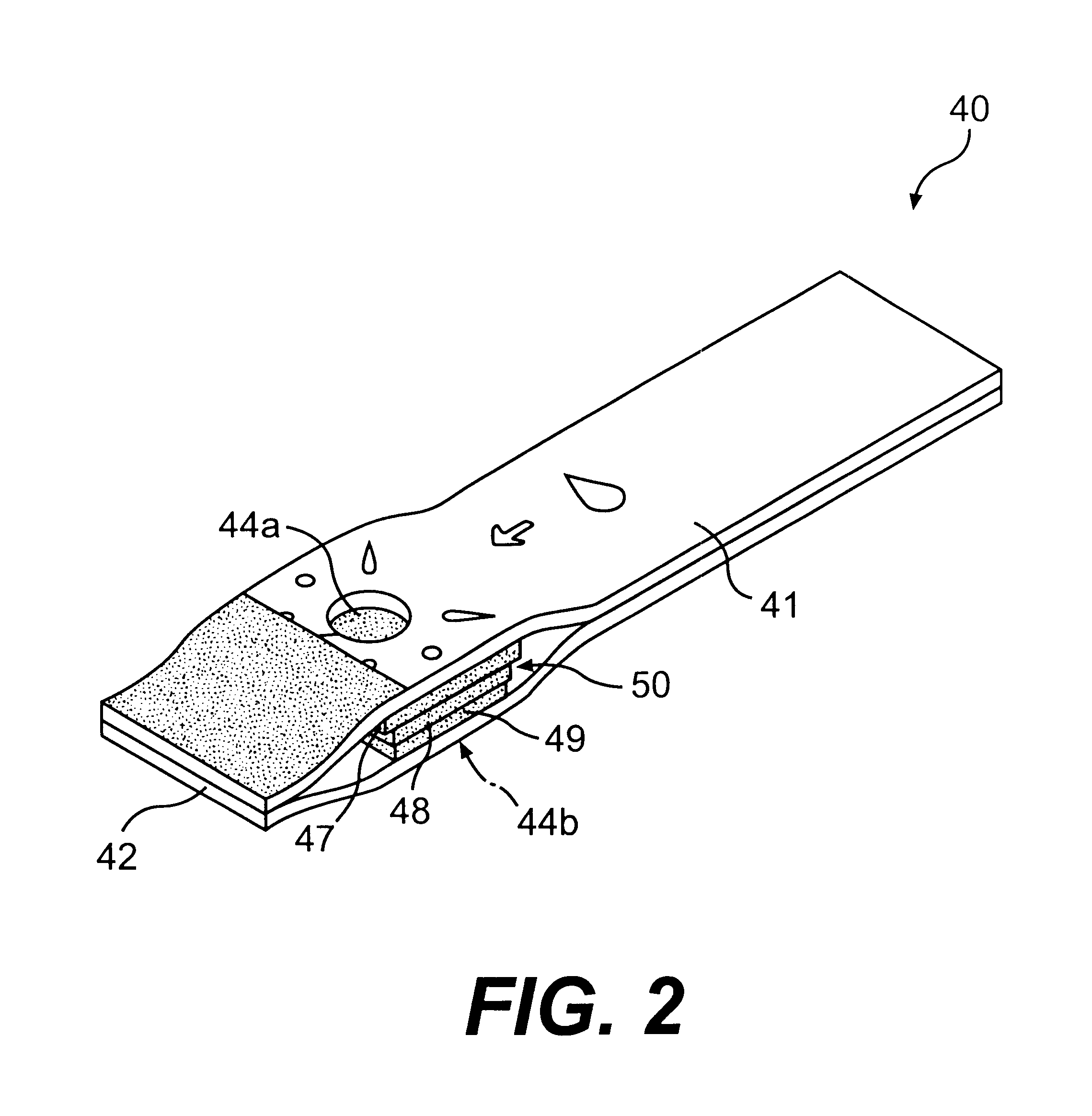

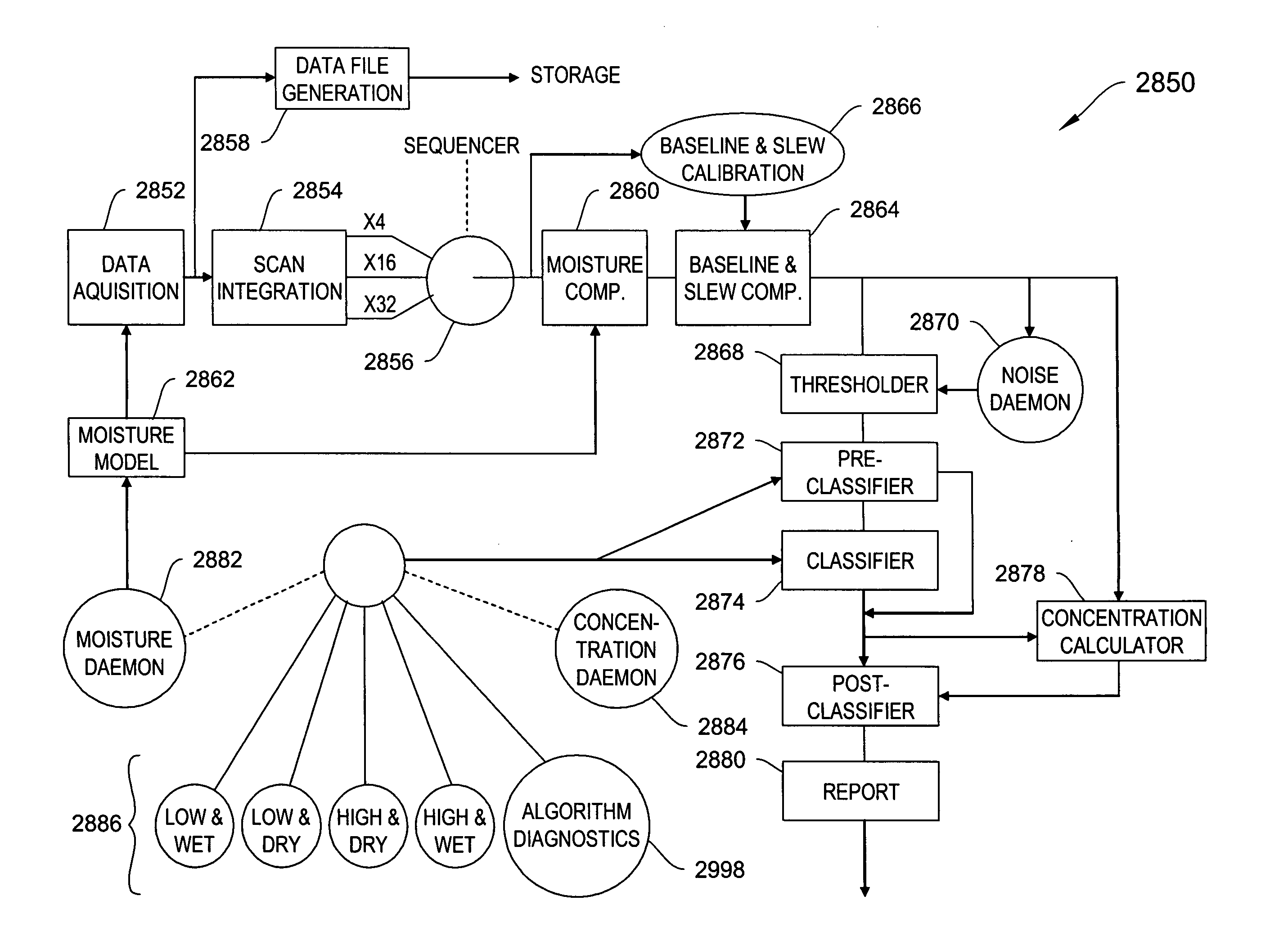

Method for determining concentration of an analyte in a test strip

InactiveUS6541266B2Analysis using chemical indicatorsMaterial analysis by observing effect on chemical indicatorTarget analysisAnalyte

The present invention provides a method of measuring an analyte, such as glucose in a fluid sample, such as whole blood, by a reflectance reading device. The method includes making periodic intermediate calculations of analyte level and dynamically ascertaining when an analytical reaction has reached an end point. Once stable, the process stops making periodic calculations and reports the final, actual glucose concentration. According to an exemplary embodiment, the method is performed by a reflectance photometer using an analytical test strip containing reagents that react with an analyte of interest in the test fluid. The end point is determined by calculating an intermediate analyte level of the testing element at predetermined intervals and calculating a ratio value corresponding to the (n)th measurement to an (n-5)th measurement. When two consecutive ratio values are less than or equal to a predetermined value, the end point is deemed reached and the final analyte level ascertained.

Owner:TRIVIDIA HEALTH

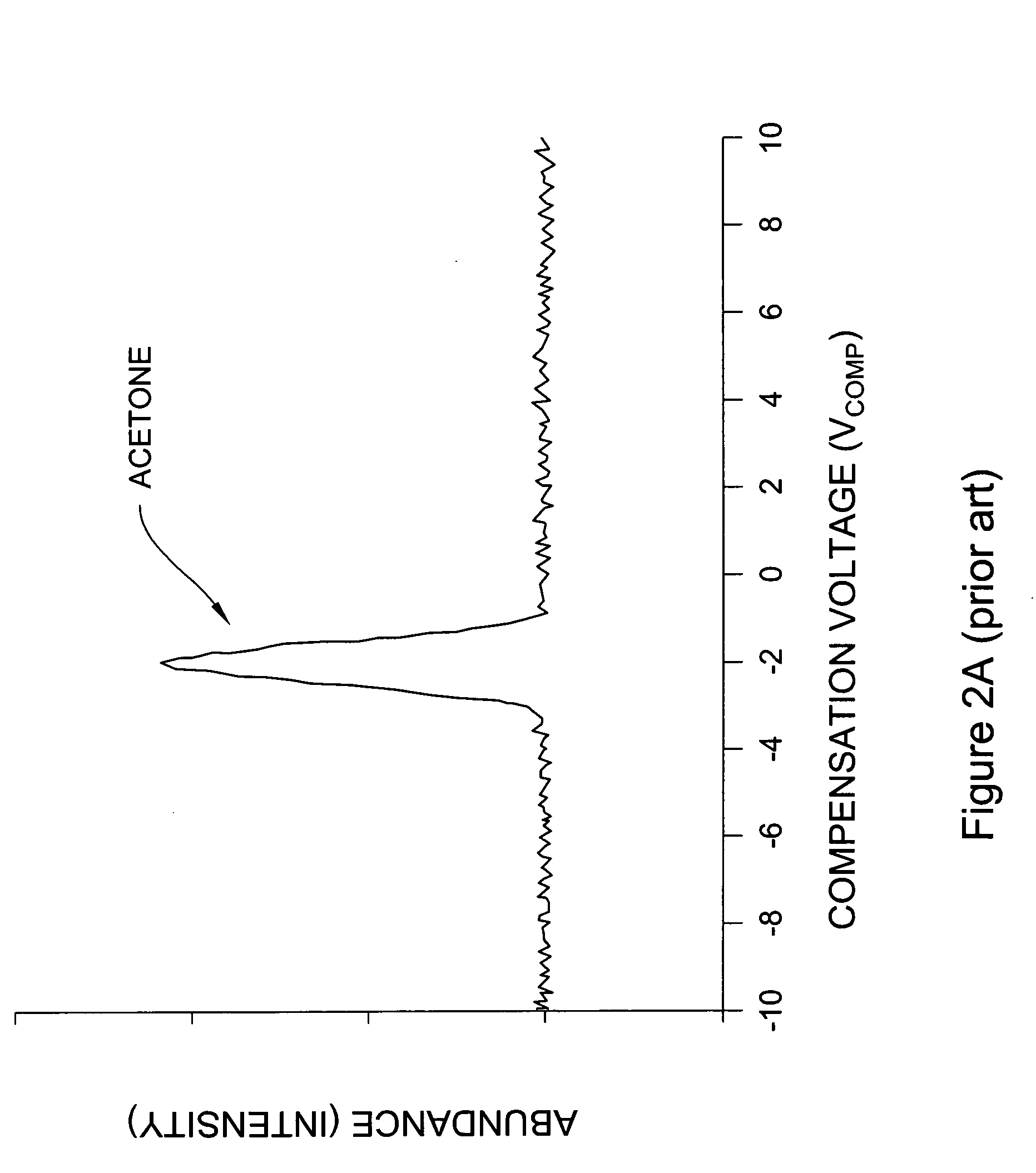

Systems and methods for ion species analysis with enhanced condition control and data interpretation

ActiveUS20050253061A1Reduces spectral peak overlapHigh resolutionTime-of-flight spectrometersMaterial analysis by electric/magnetic meansSystems approachesComputer science

The invention relates generally to ion mobility based systems, methods and devices for analyzing samples and, more particularly, to sample detection using enhanced condition control and data interpretation.

Owner:DH TECH DEVMENT PTE

Sequential UV induced chemical vapor deposition

Ion-induced, UV-induced, and electron-induced sequential chemical vapor deposition (CVD) processes are disclosed where an ion flux, a flux of ultra-violet radiation, or an electron flux, respectively, is used to induce the chemical reaction in the process. The process for depositing a thin film on a substrate includes introducing a flow of a first reactant gas in vapor phase into a process chamber where the gas forms an adsorbed saturated layer on the substrate and exposing the substrate to a flux of ions, a flux of ultra-violet radiation, or a flux of electrons for inducing a chemical reaction of the adsorbed layer of the first reactant gas to form the thin film. A second reactant gas can be used to form a compound thin film. The ion-induced, UV-induced, and electron-induced sequential CVD process of the present invention can be repeated to form a thin film of the desired thickness.

Owner:NOVELLUS SYSTEMS

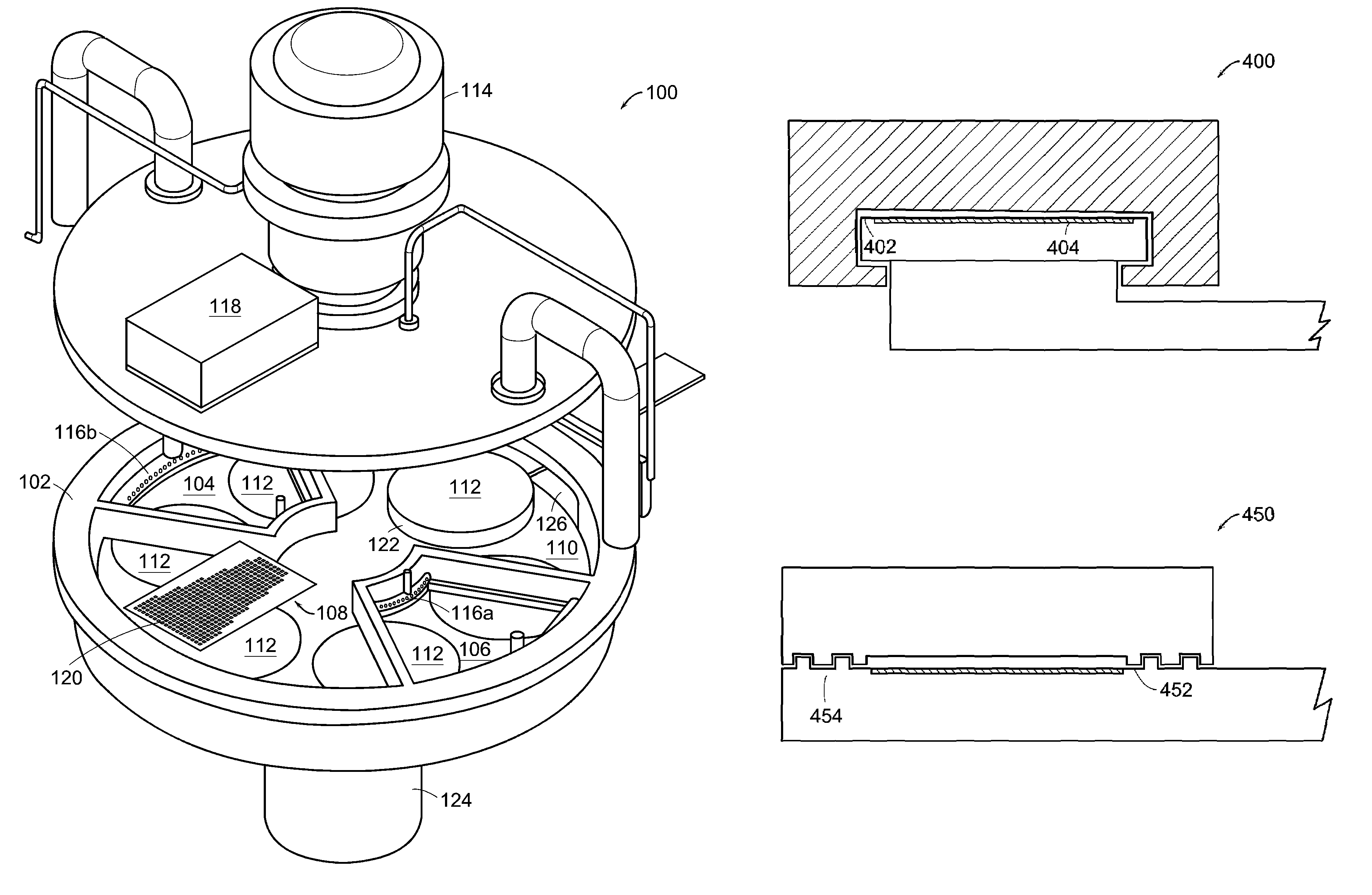

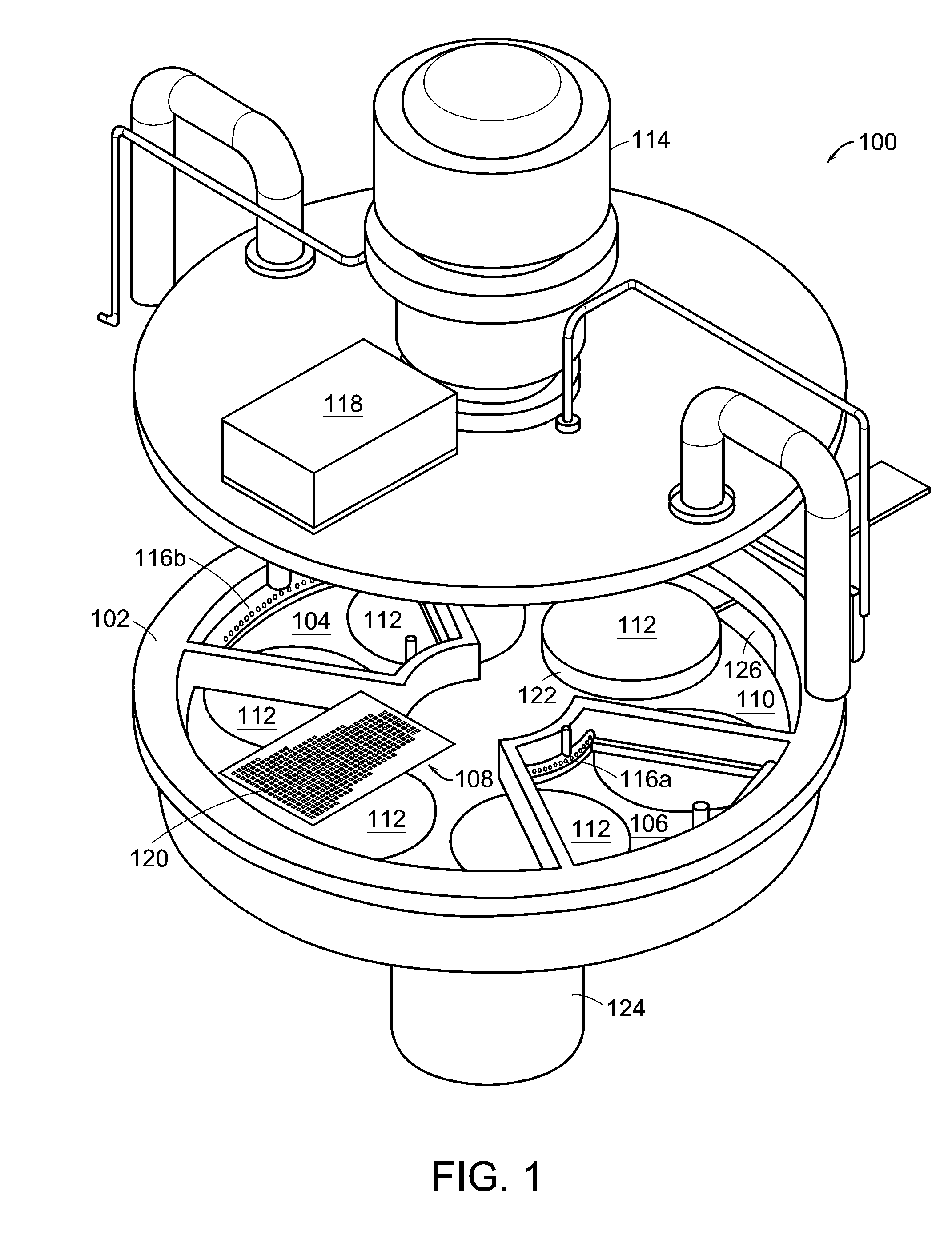

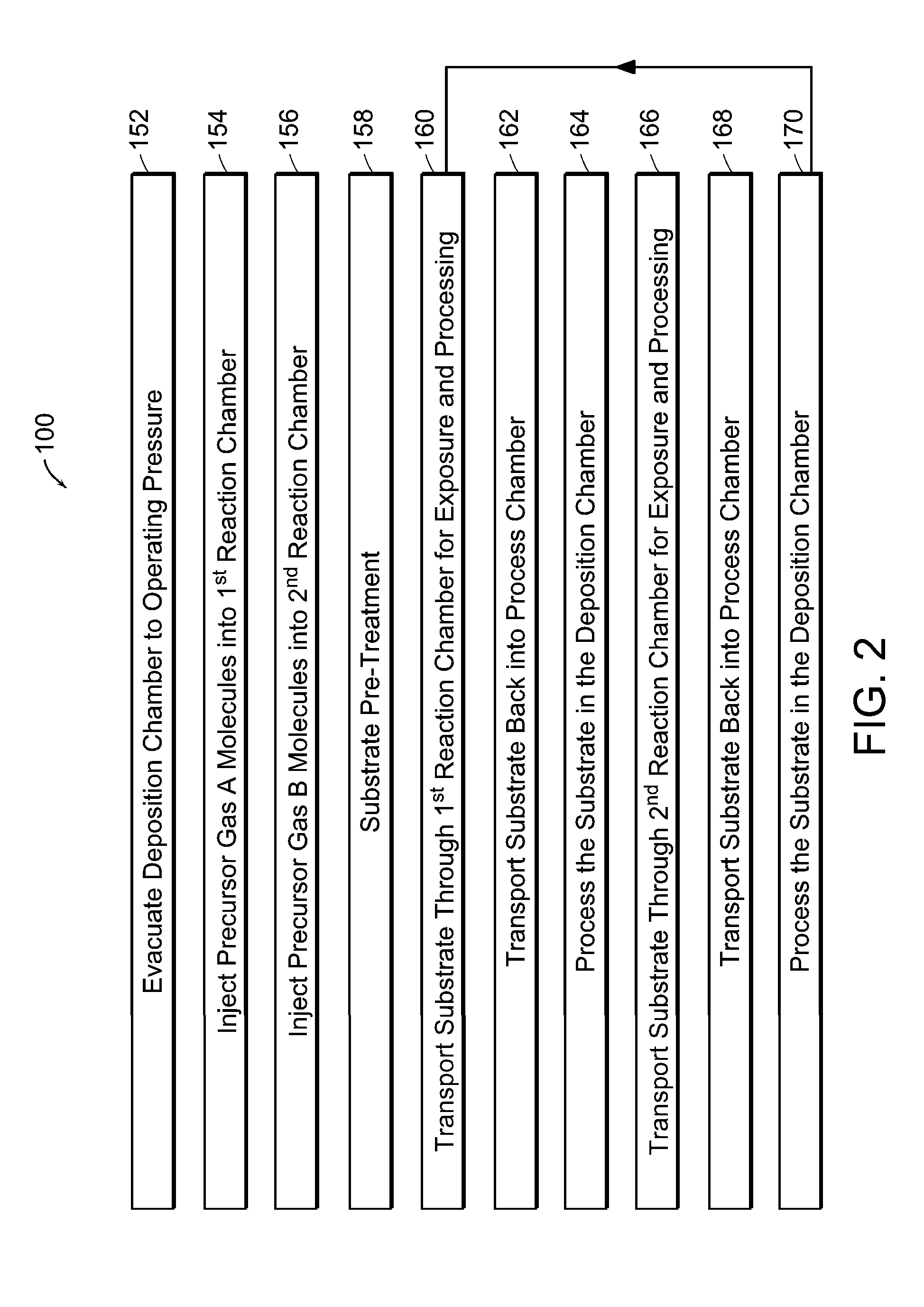

Continuous flow deposition system

An atomic layer deposition system is described that includes a deposition chamber. A first and second reaction chamber are positioned in the deposition chamber and contain a first and a second reactant species, respectively. A monolayer of the first reactant species is deposited on a substrate passing through the first reaction chamber. A monolayer of the second reactant species is deposited on a substrate passing through the second reaction chamber. A transport mechanism transports a substrate in a path through the first reaction chamber and through the second reaction chamber, thereby depositing a film on the substrate by atomic layer deposition. The shape of the first and the second reaction chambers are chosen to achieve a constant exposure of the substrate to reactant species when the transport mechanism transports the substrate in the path through the respective reaction chambers at the constant transport rate.

Owner:VEECON INSTR

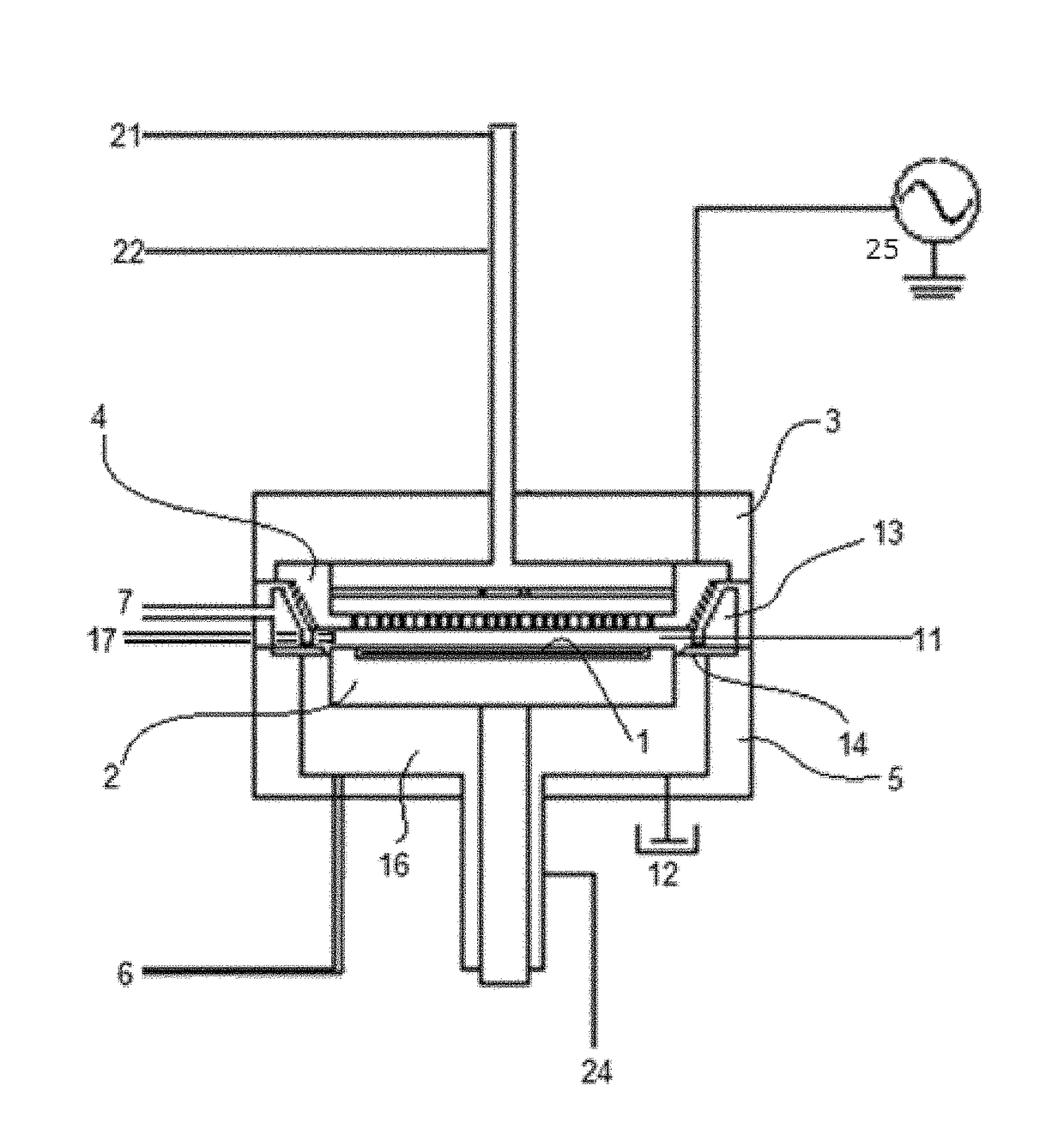

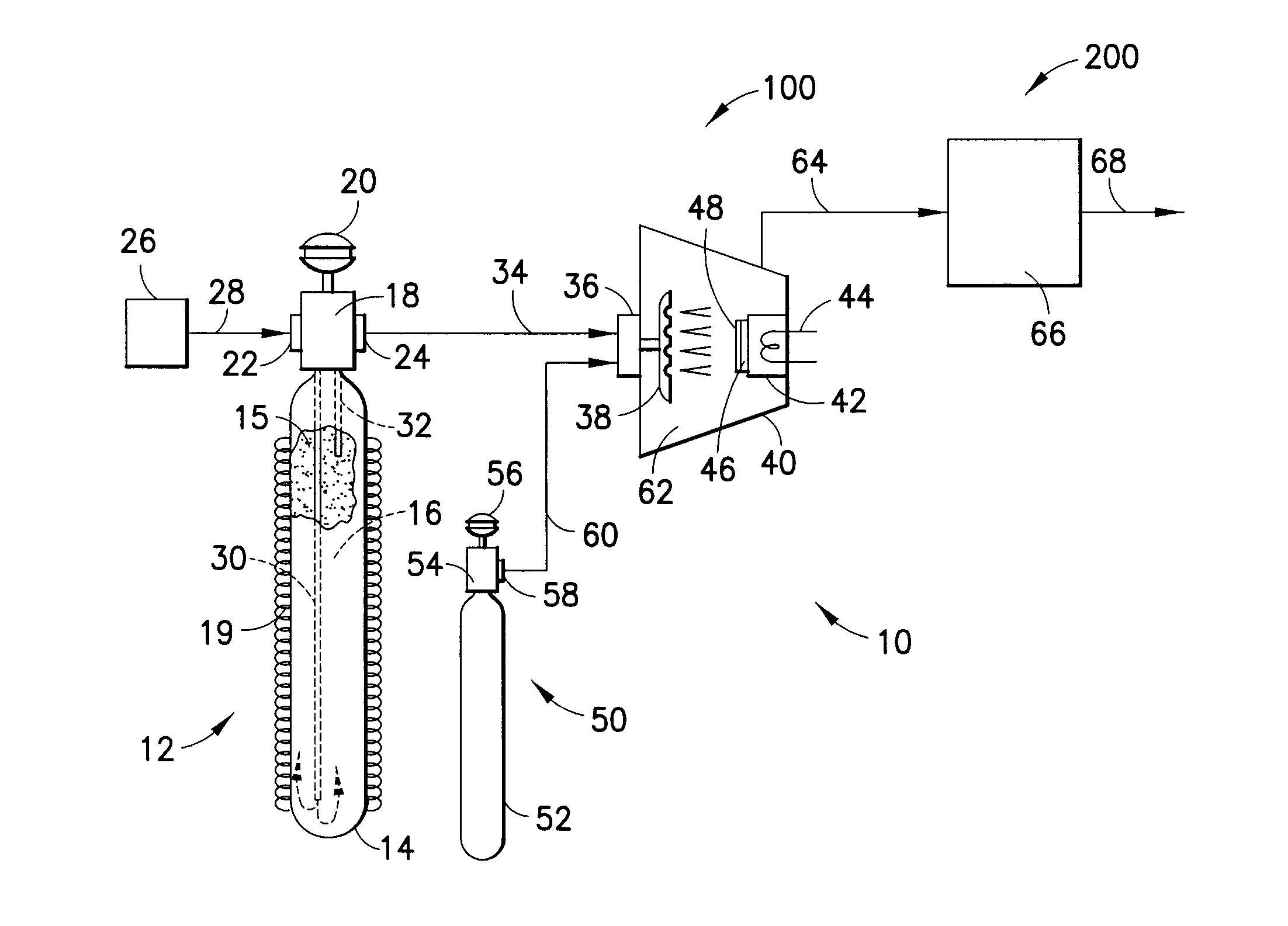

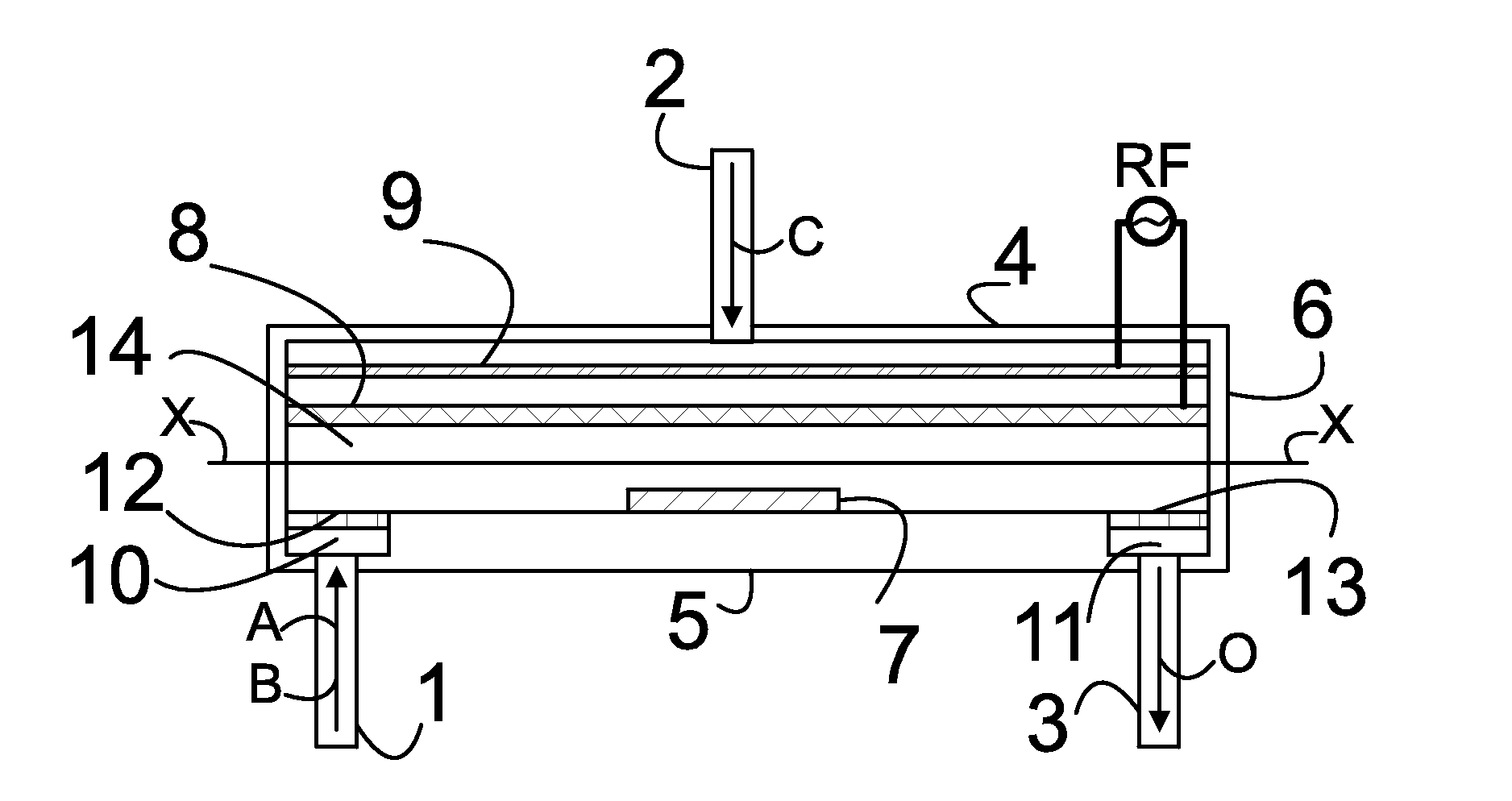

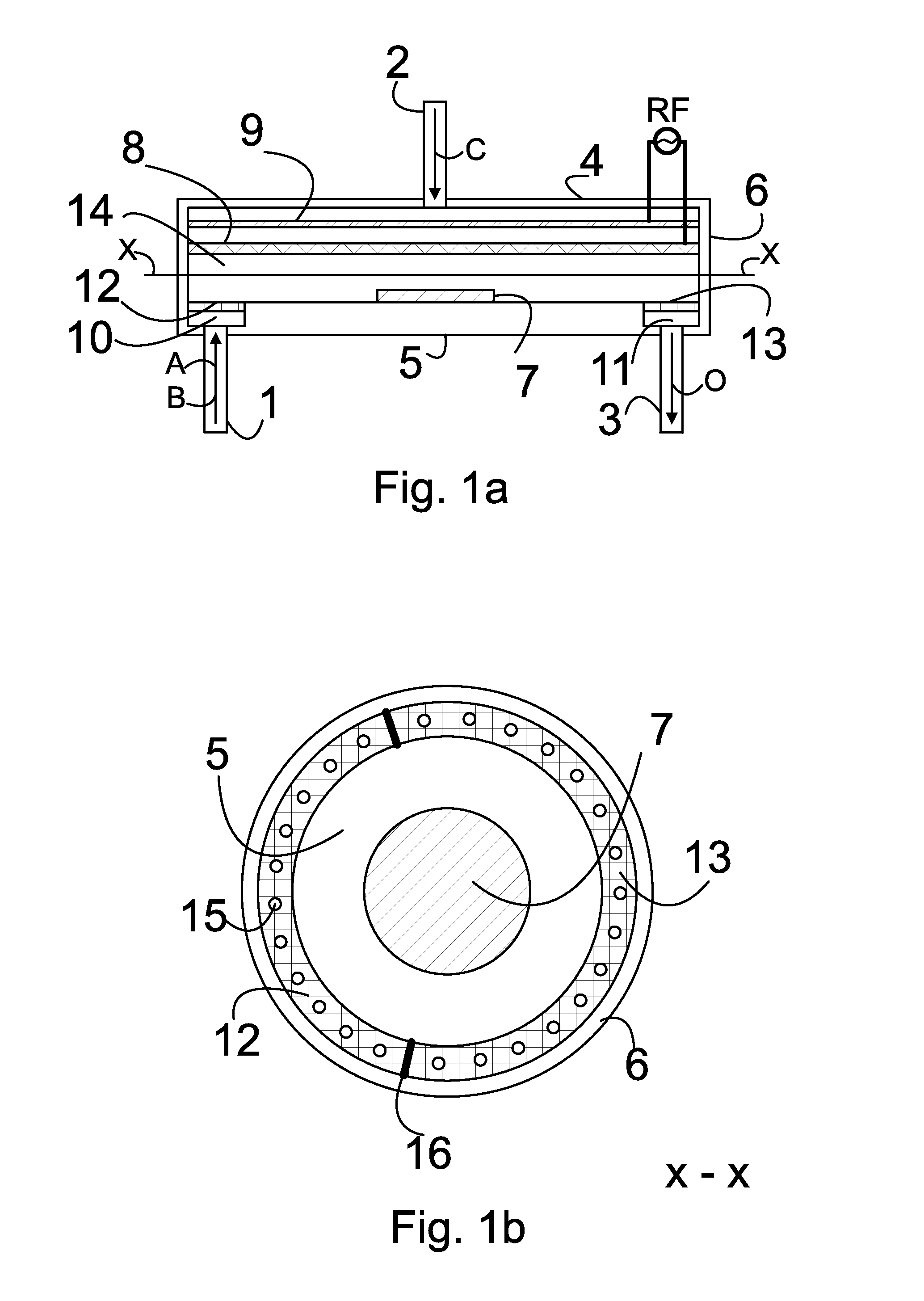

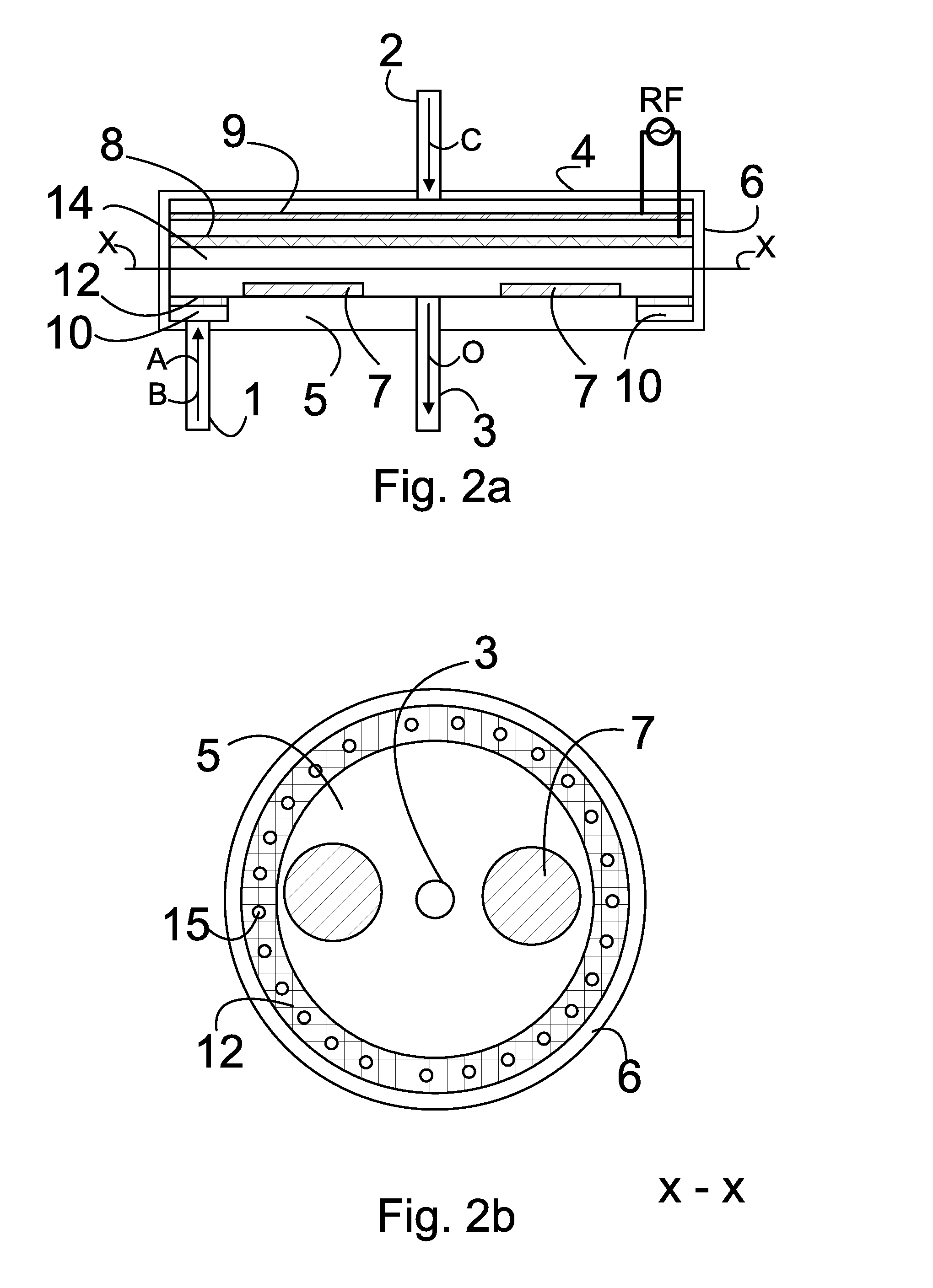

Method and apparatus for atomic layer deposition using an atmospheric pressure glow discharge plasma

InactiveUS20100255625A1Comparable and good performanceSemiconductor/solid-state device manufacturingChemical vapor deposition coatingPlasma generatorProduct gas

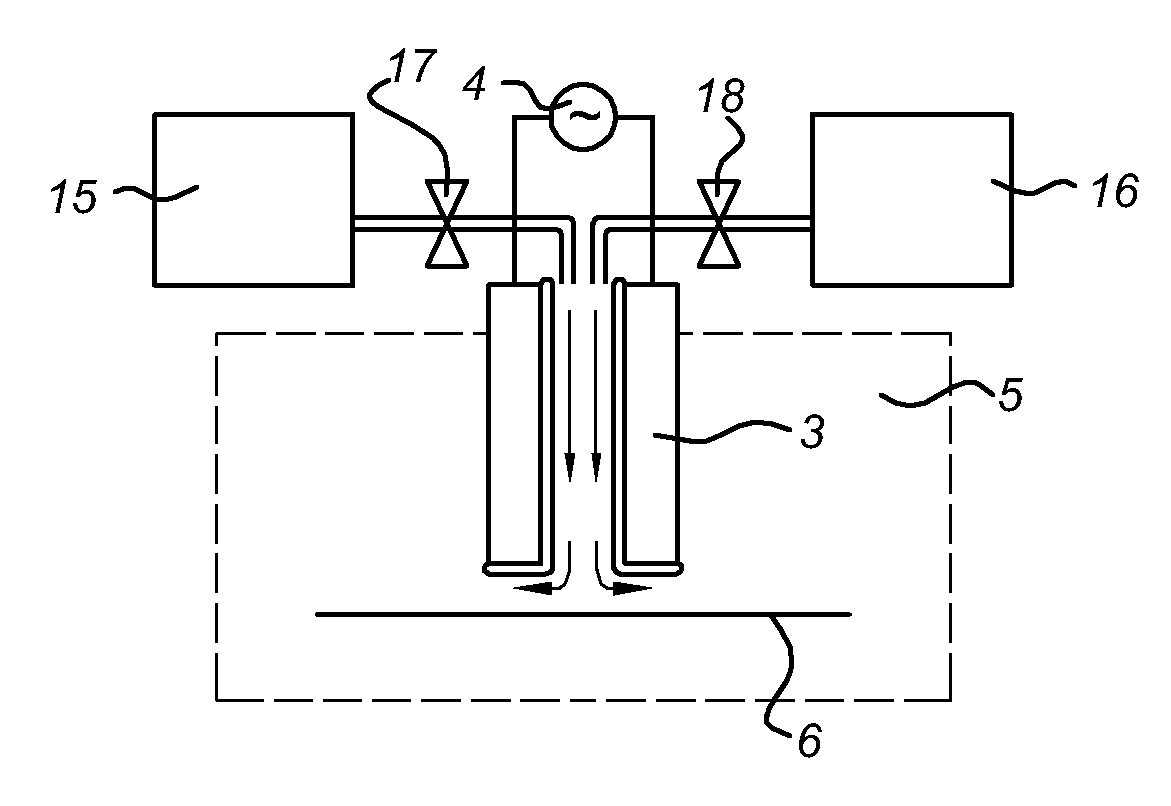

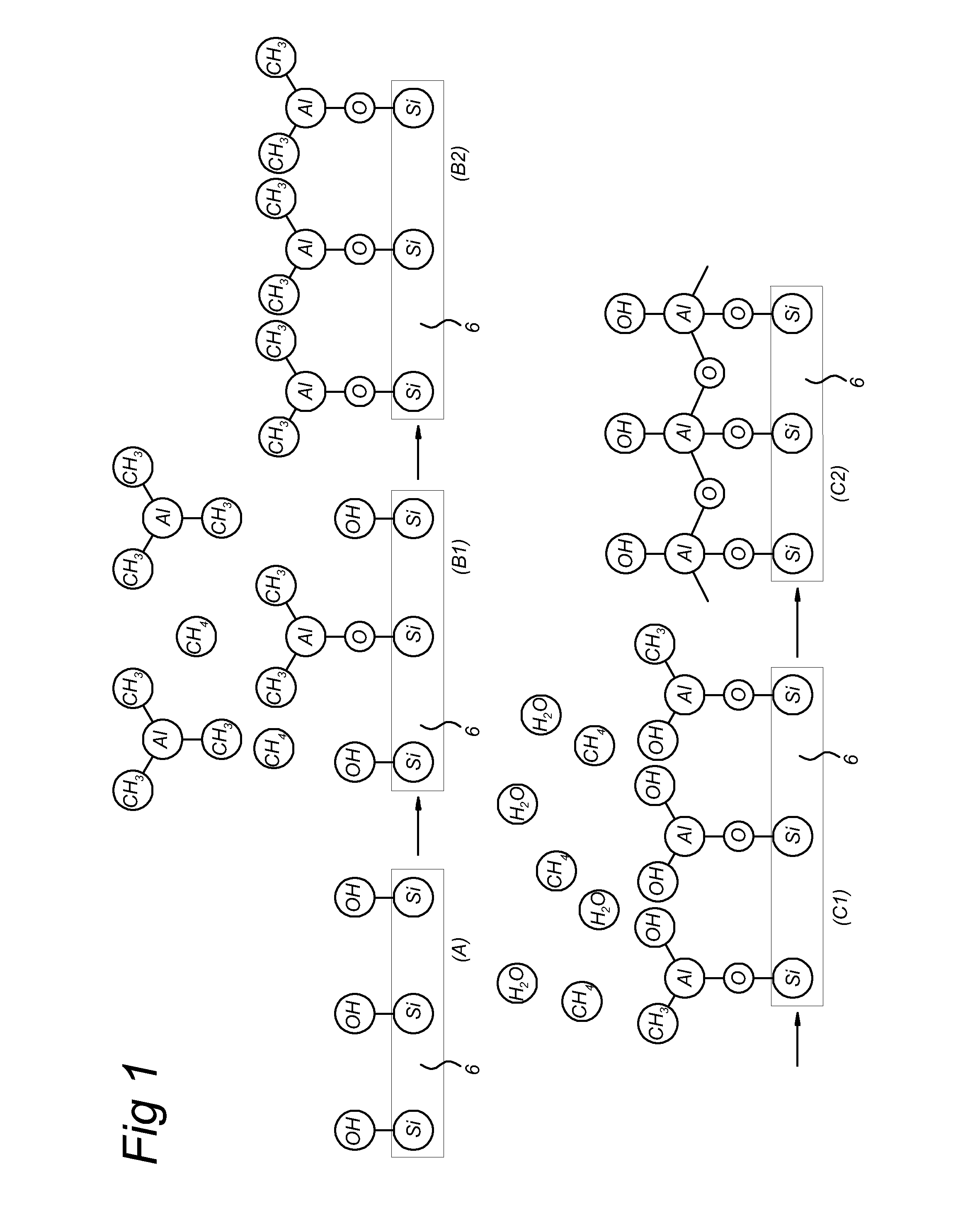

Apparatus and method for atomic layer deposition on a surface of a substrate (6) in a treatment space. A gas supply device (15, 16) is present for providing various gas mixtures to the treatment space (1, 2). The gas supply device (15, 16) is arranged to provide a gas mixture with a precursor material to the treatment space for allowing reactive surface sites to react with precursor material molecules to give a surface covered by a monolayer of precursor molecules attached via the reactive sites to the surface of the substrate. Subsequently, a gas mixture comprising a reactive agent capable to convert the attached precursor molecules to active precursor sites is provided. A plasma generator (10) is present for generating an atmospheric pressure plasma in the gas mixture comprising the reactive agent, the plasma generator being arranged remote from the treatment space (1, 2).

Owner:FUJIFILM MFG EURO

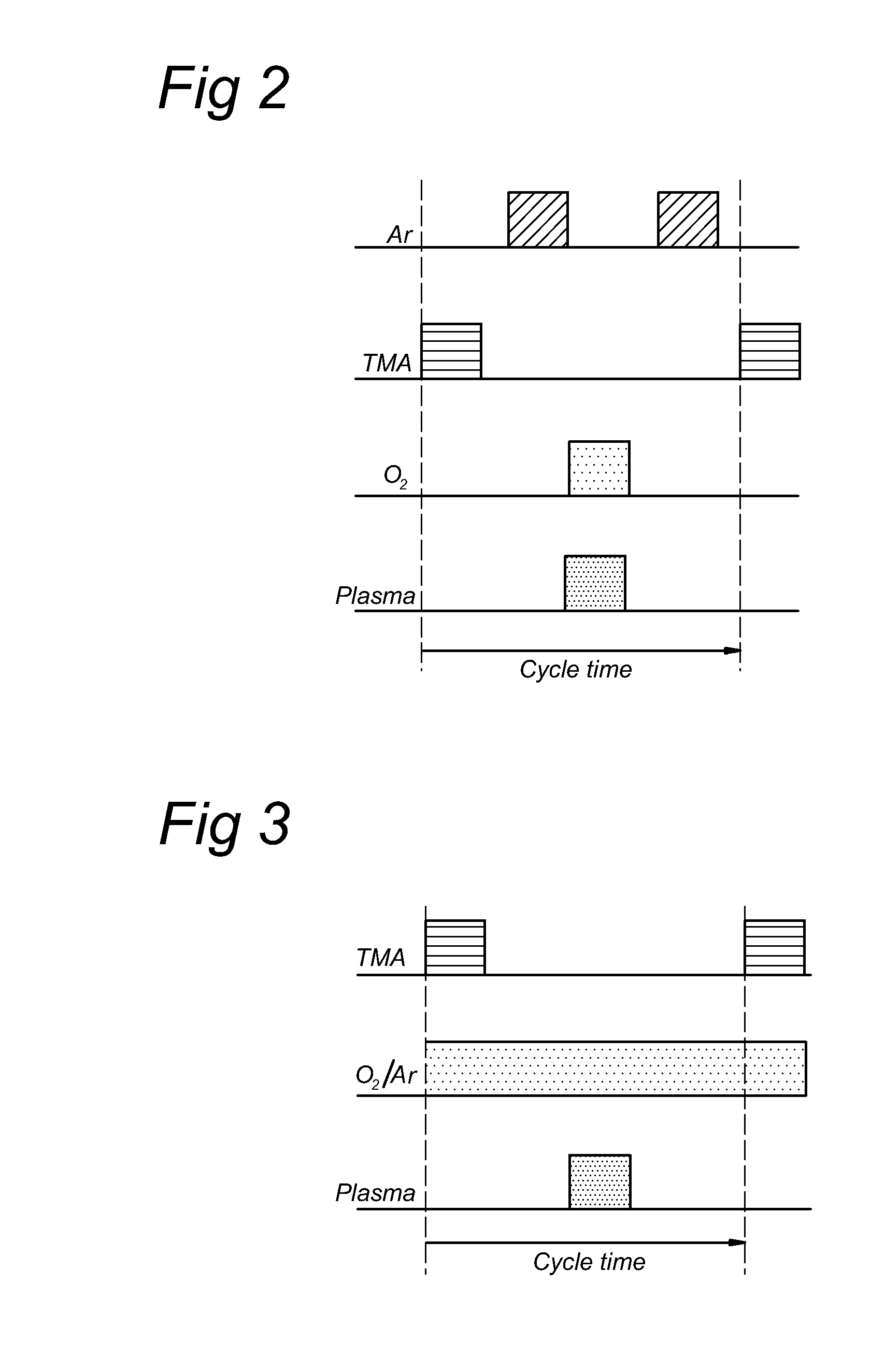

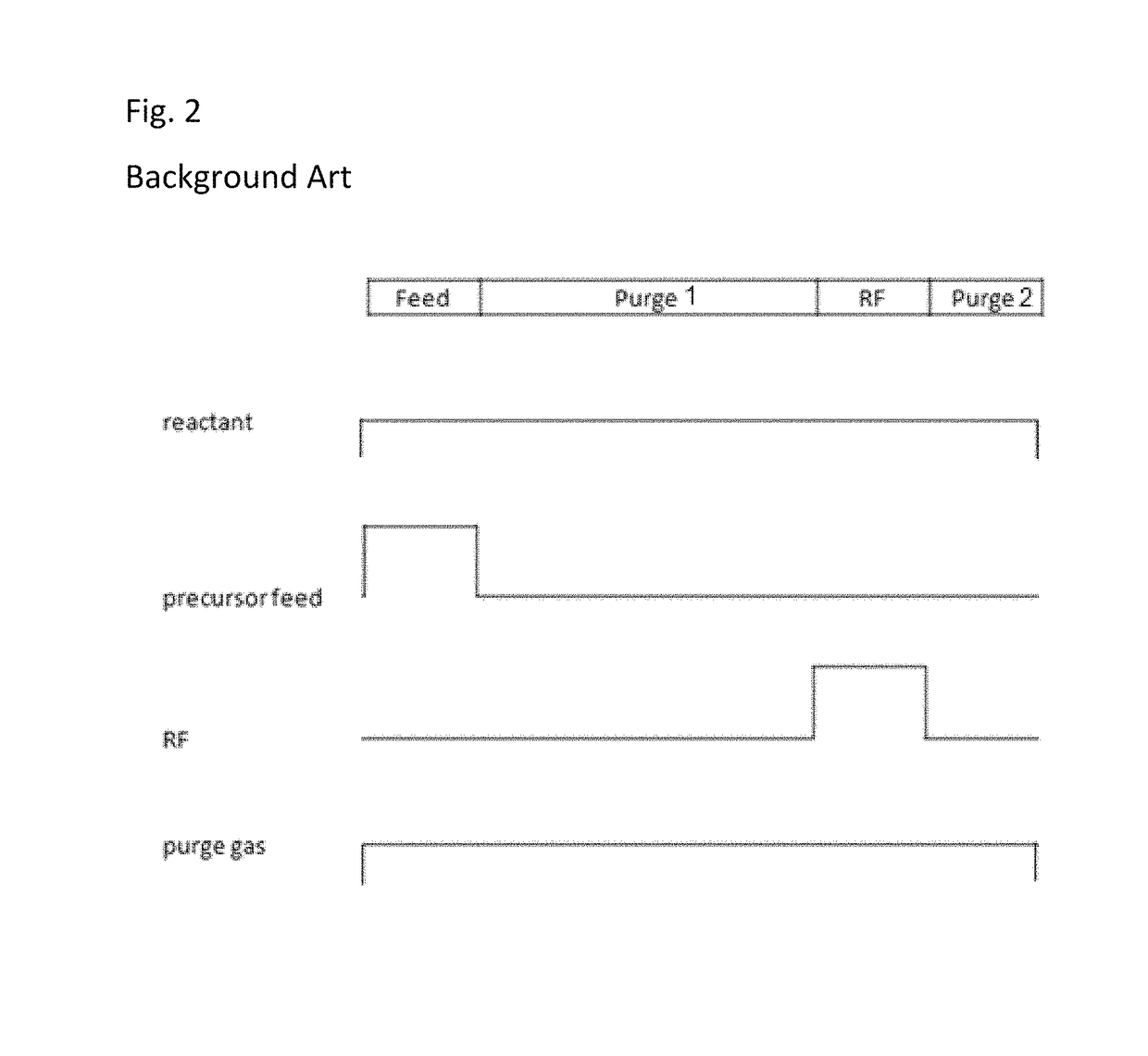

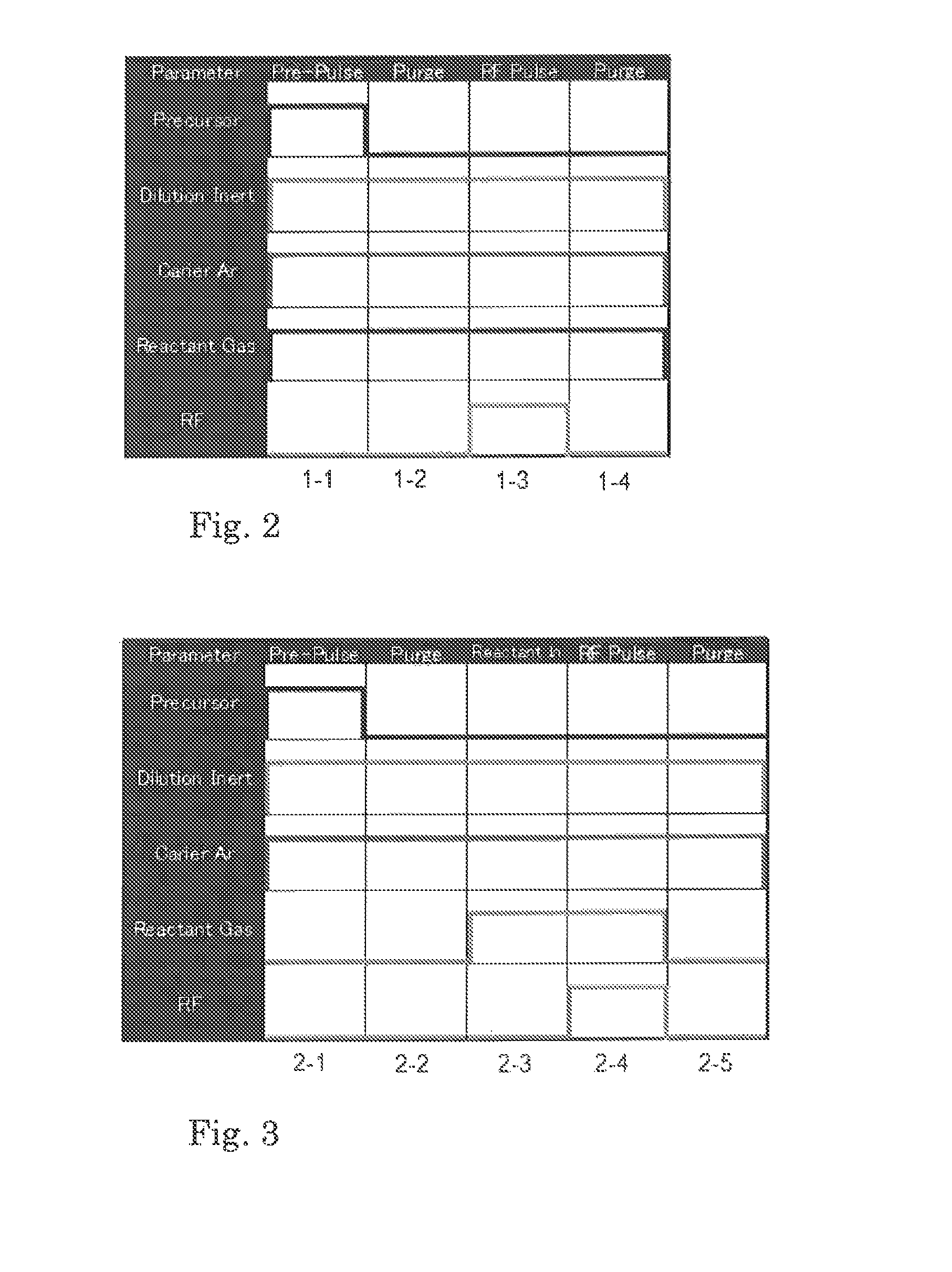

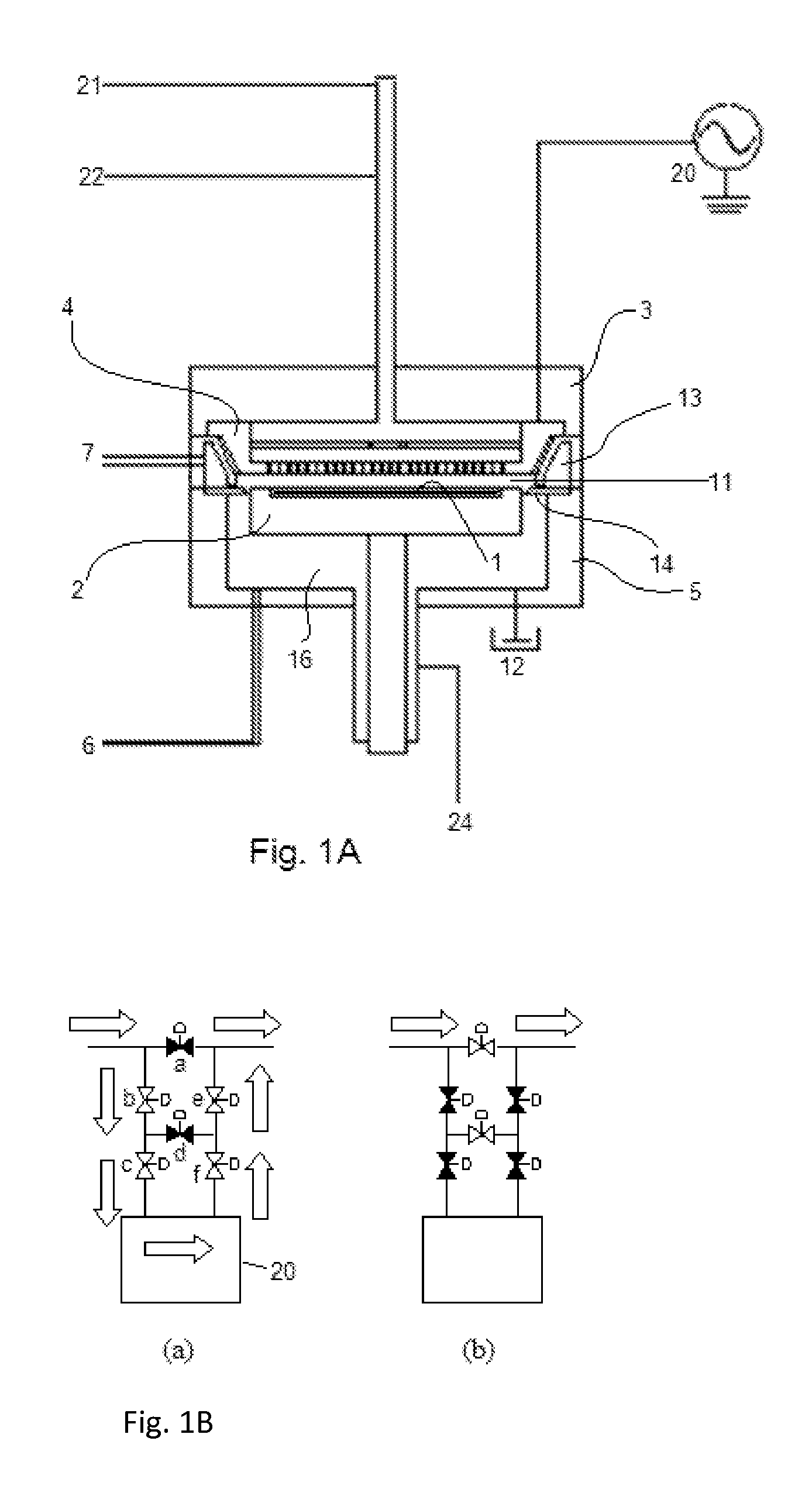

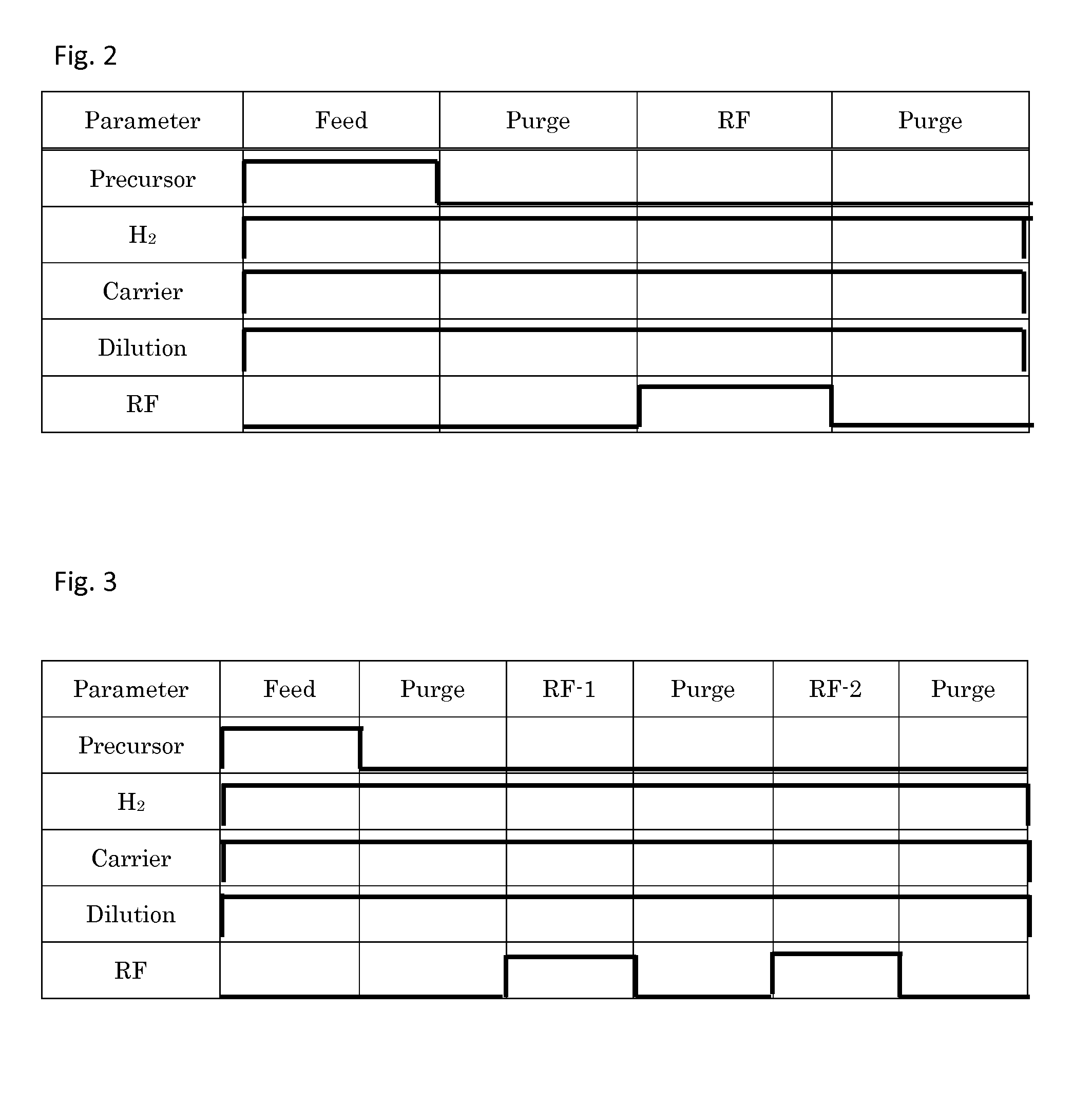

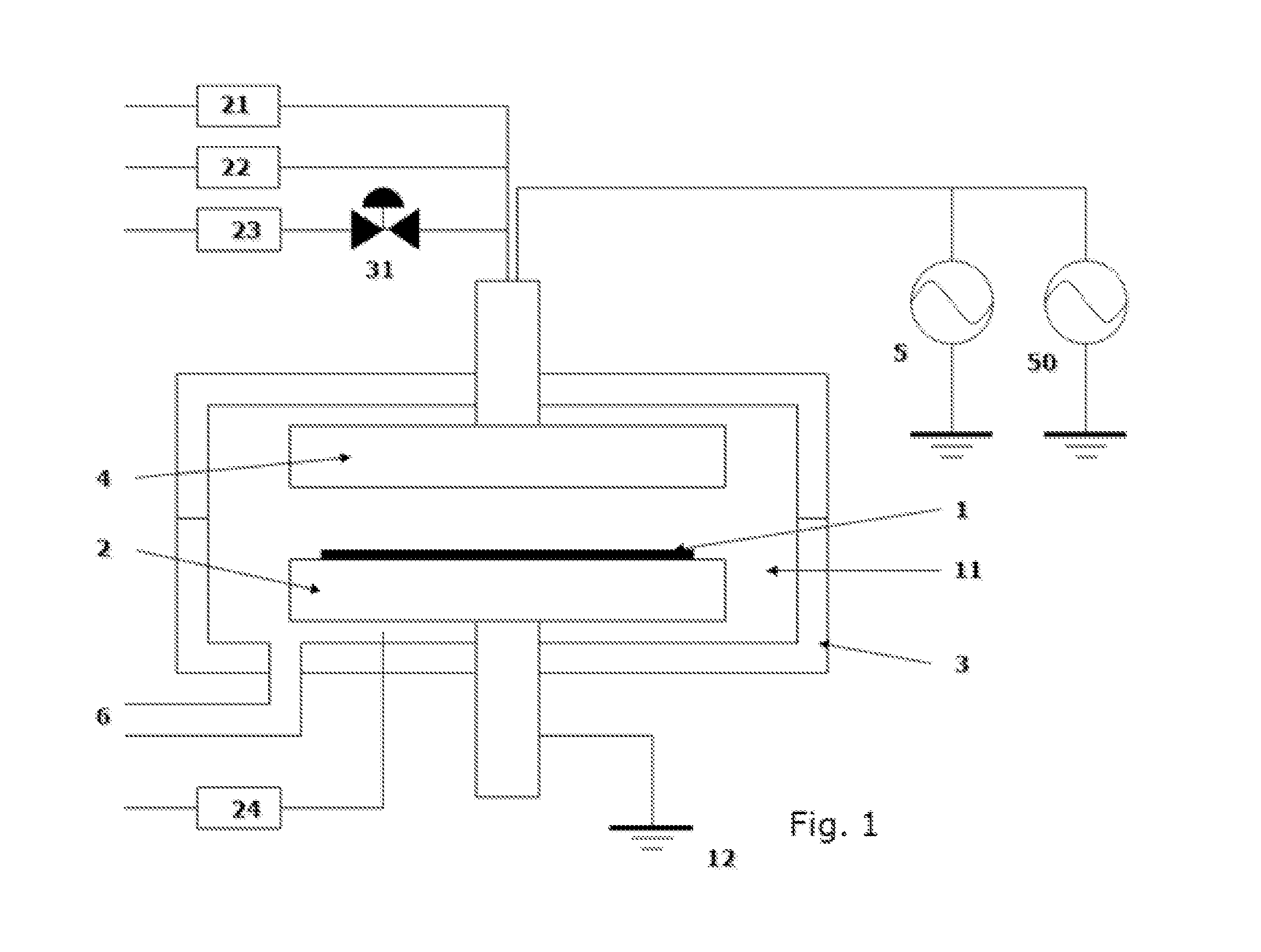

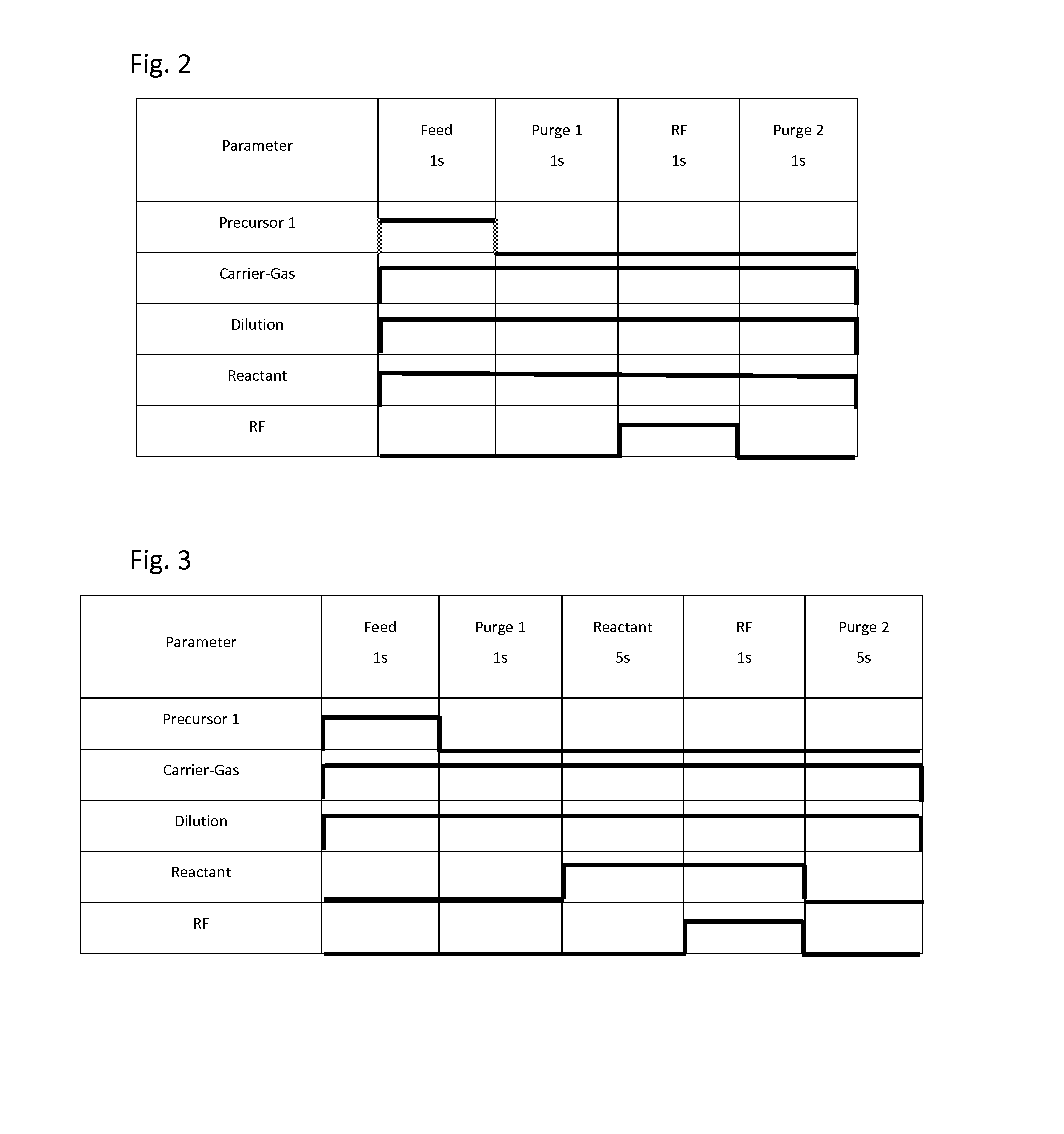

Method of plasma-assisted cyclic deposition using ramp-down flow of reactant gas

ActiveUS9984869B1Electric discharge tubesSemiconductor/solid-state device manufacturingHydrogenOxygen

A method is for forming a nitride or oxide film by plasma-assisted cyclic deposition, one cycle of which includes: feeding a first reactant, a second reactant, and a precursor to a reaction space where a substrate is placed, wherein the second reactant flows at a first flow ratio wherein a flow ratio is defined as a ratio of a flow rate of the second reactant to a total flow rate of gases flowing in the reaction space; and stopping feeding the precursor while continuously feeding the first and second reactants at a flow ratio which is gradually reduced from the first flow ratio to a second flow ratio while applying RF power to the reaction space to expose the substrate to a plasma. The second reactant is constituted by a hydrogen-containing compound or oxygen-containing compound.

Owner:ASM IP HLDG BV

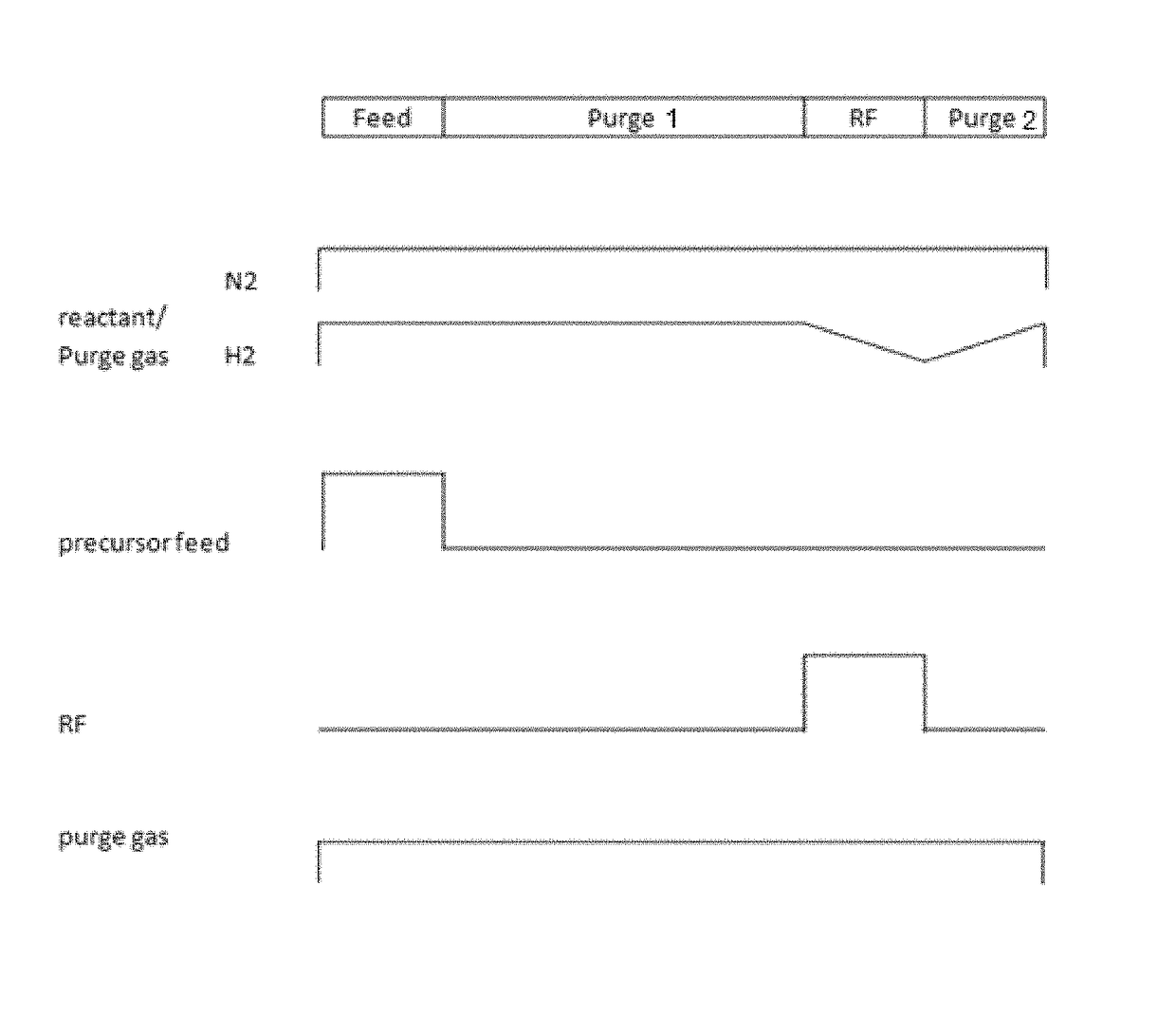

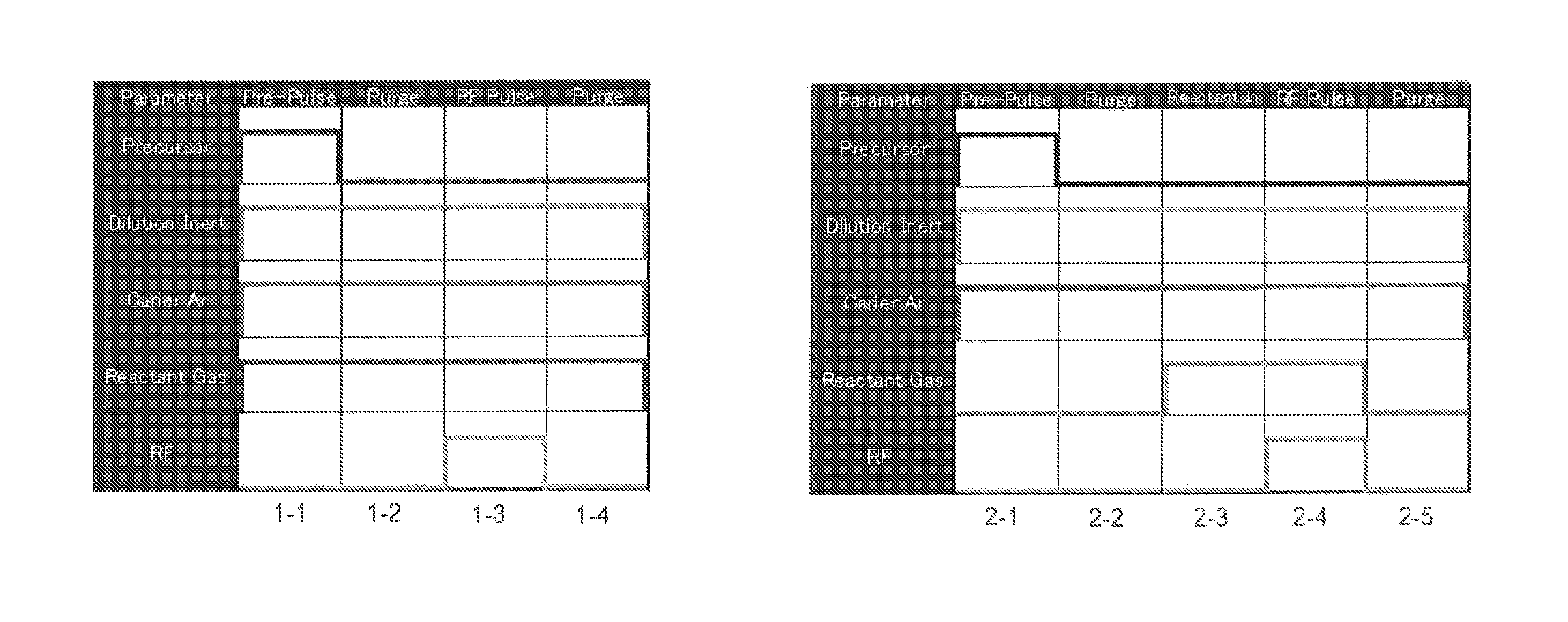

Method for forming insulation film using non-halide precursor having four or more silicons

ActiveUS8784951B2Improving chemical adsorptionGood step coverageSemiconductor/solid-state device manufacturingChemical vapor deposition coatingOxygenAtomic layer deposition

A method of forming an insulation film on a semiconductor substrate by plasma enhanced atomic layer deposition (PEALD), includes: (i) adsorbing a non-excited non-halide precursor having four or more silicon atoms in its molecule onto a substrate placed in a reaction space; (ii) supplying an oxygen-free reactant to the reaction space without applying RF power so as to expose the precursor-adsorbed substrate to the reactant; and (iii) after step (ii), applying RF power to the reaction space while the oxygen-free reactant is supplied in the reaction space; and (iv) repeating steps (i) to (iii) as a cycle, thereby depositing an insulation film on the substrate.

Owner:ASM IP HLDG BV

Method and apparatus for reducing particle formation in a vapor distribution system

InactiveUS20070218200A1Reduce particle pollutionChemical vapor deposition coatingDistribution systemEvaporation

A method and system is described for reducing particle contamination in a vapor distribution system. The vapor distribution system comprises a housing and a vapor distribution head comprising a plurality of openings configured to introduce a film precursor vapor to a deposition system. The housing and vapor distribution head define a plenum coupled to a film precursor evaporation system, and configured to receive the film precursor vapor from the evaporation system and distribute the film precursor vapor within the deposition system through the plurality of openings. In order to reduce particle contamination, the vapor distribution system is designed to reduce the difference, or ratio, between the pressure in the plenum and the pressure in the deposition system. For example, the plenum pressure can be less than twice the pressure in the process space, or can be less than 50 mTorr, 30 mTorr or even 20 mTorr than the pressure in the process space.

Owner:TOKYO ELECTRON LTD

Method for forming dielectric film in trenches by PEALD using H-containing gas

ActiveUS9455138B1Increase deposition rateHigh film thicknessSemiconductor/solid-state device manufacturingChemical physicsNoble gas

A method for forming a dielectric film in a trench on a substrate by plasma-enhanced atomic layer deposition (PEALD) performs one or more process cycles, each process cycle including: (i) feeding a silicon-containing precursor in a pulse; (ii) supplying a hydrogen-containing reactant gas at a flow rate of more than about 30 sccm but less than about 800 sccm in the absence of nitrogen-containing gas; (iii) supplying a noble gas to the reaction space; and (iv) applying RF power in the presence of the reactant gas and the noble gas and in the absence of any precursor in the reaction space, to form a monolayer constituting a dielectric film on a substrate at a growth rate of less than one atomic layer thickness per cycle.

Owner:ASM IP HLDG BV

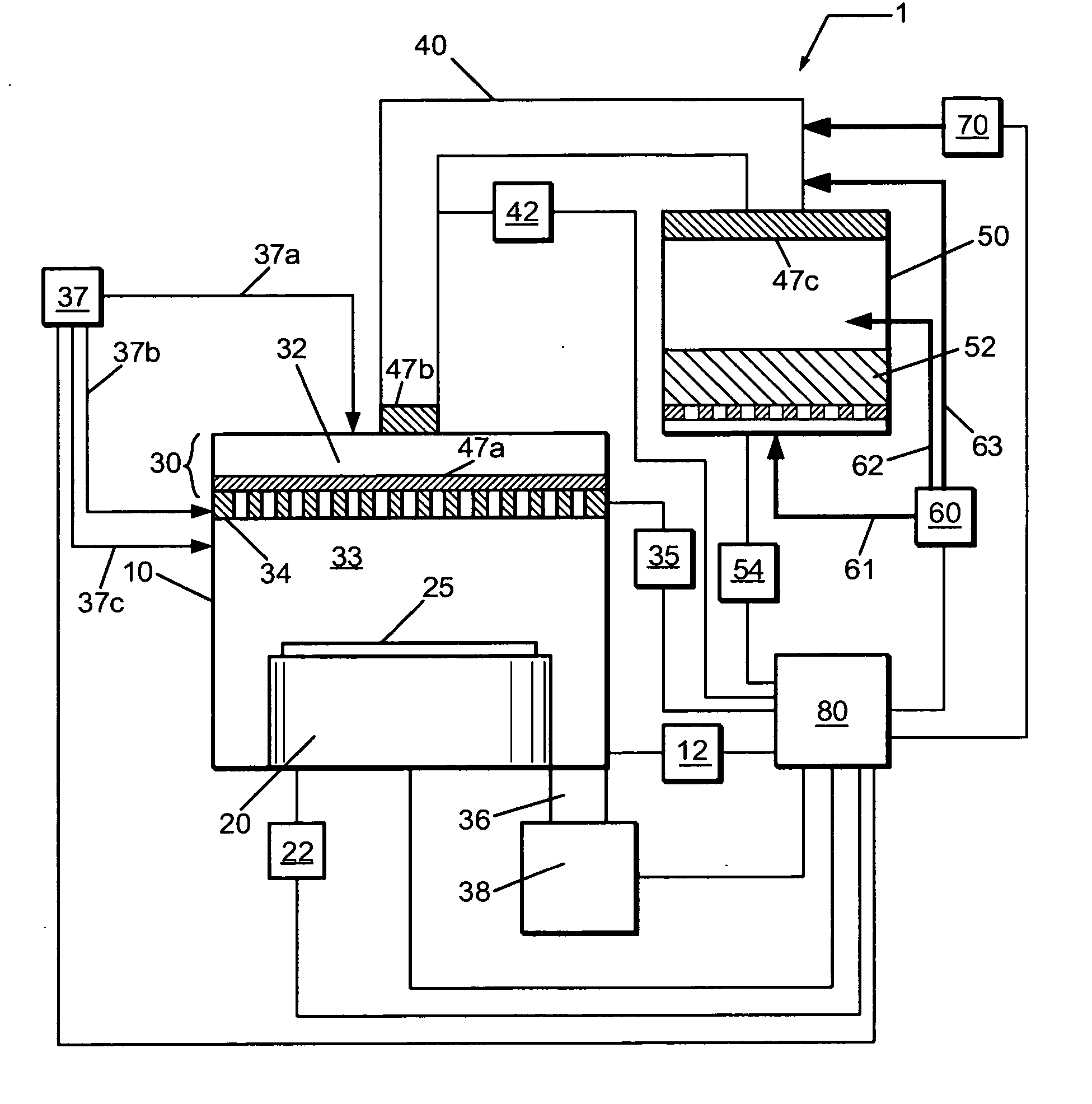

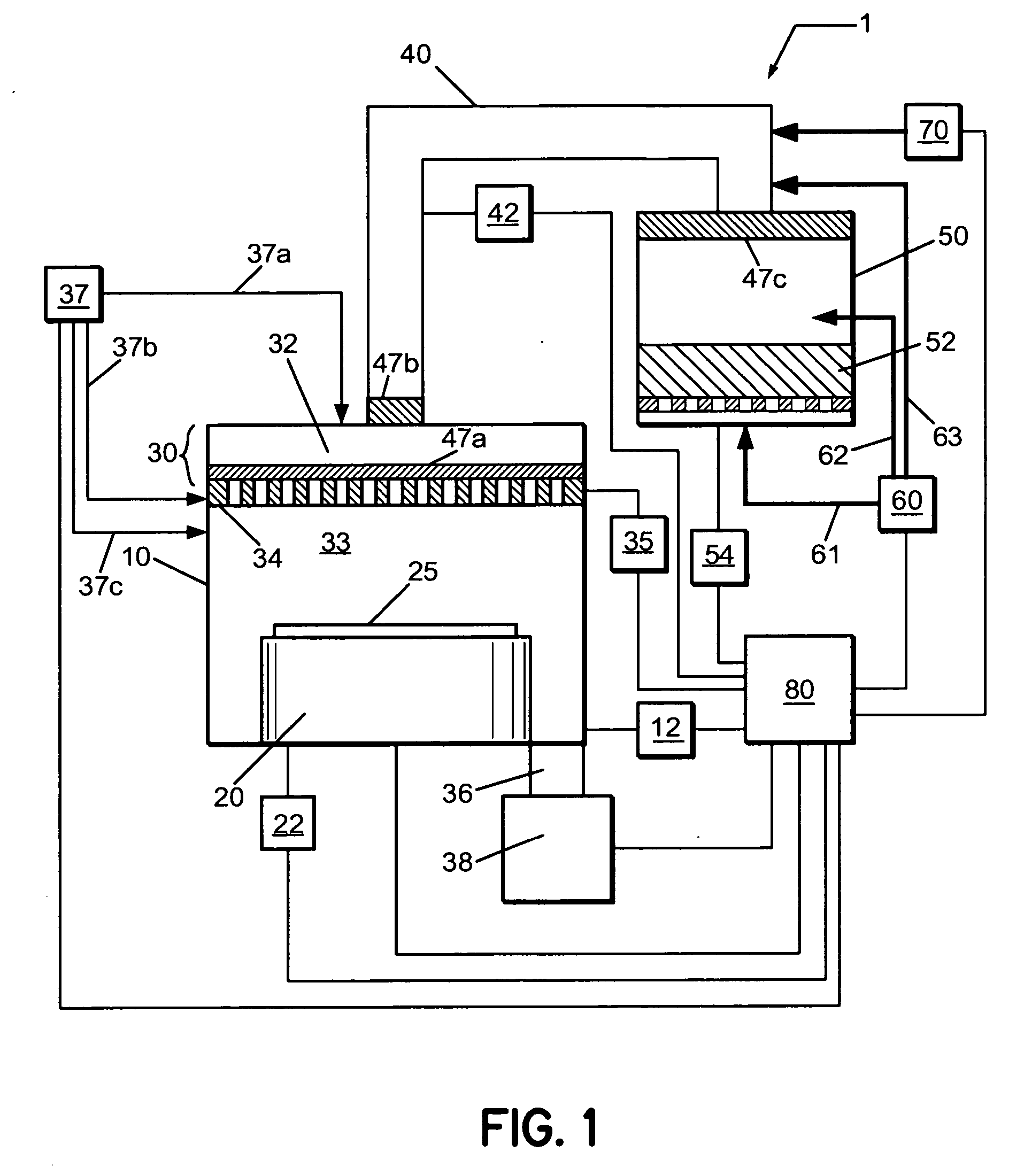

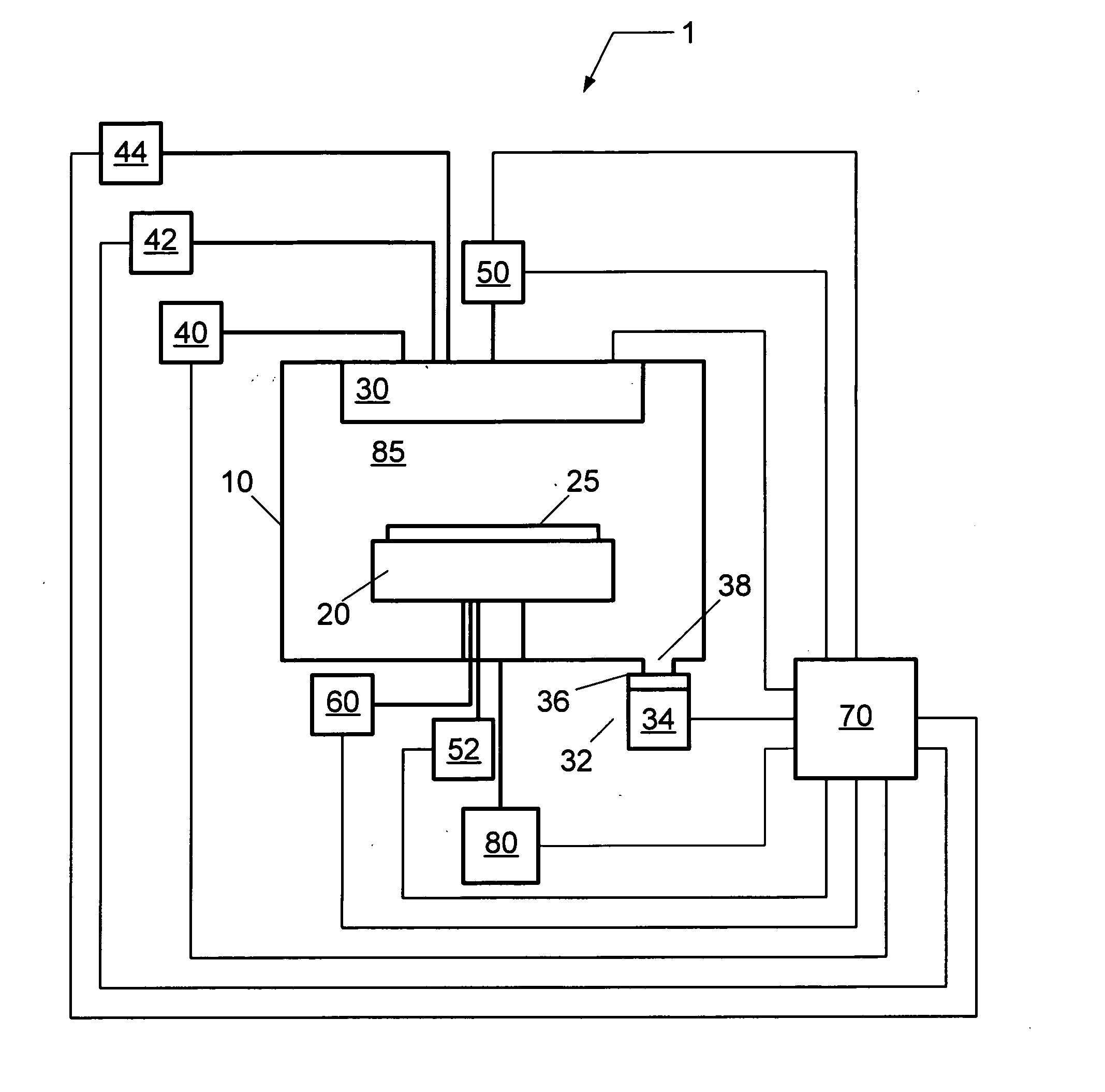

Method and system for performing plasma enhanced atomic layer deposition

InactiveUS20070116887A1Reduce pollutionReduce depositionElectric discharge tubesChemical vapor deposition coatingGas phaseProcess engineering

A method, computer readable medium, and system for vapor deposition on a substrate that introduce a gaseous film precursor to a process space, increase the volume of the process space from a first size to a second size to form an enlarged process space, introduce a reduction gas to the enlarged process space, and form a reduction plasma from the reduction gas. The system for vapor deposition includes a process chamber including a first process space and further including a second process space that includes the first process space and that has a second volume that exceeds the first volume. The first process space is configured for atomic layer deposition, and the second process space is configured for plasma reduction of a layer deposited in the first process space.

Owner:TOKYO ELECTRON LTD

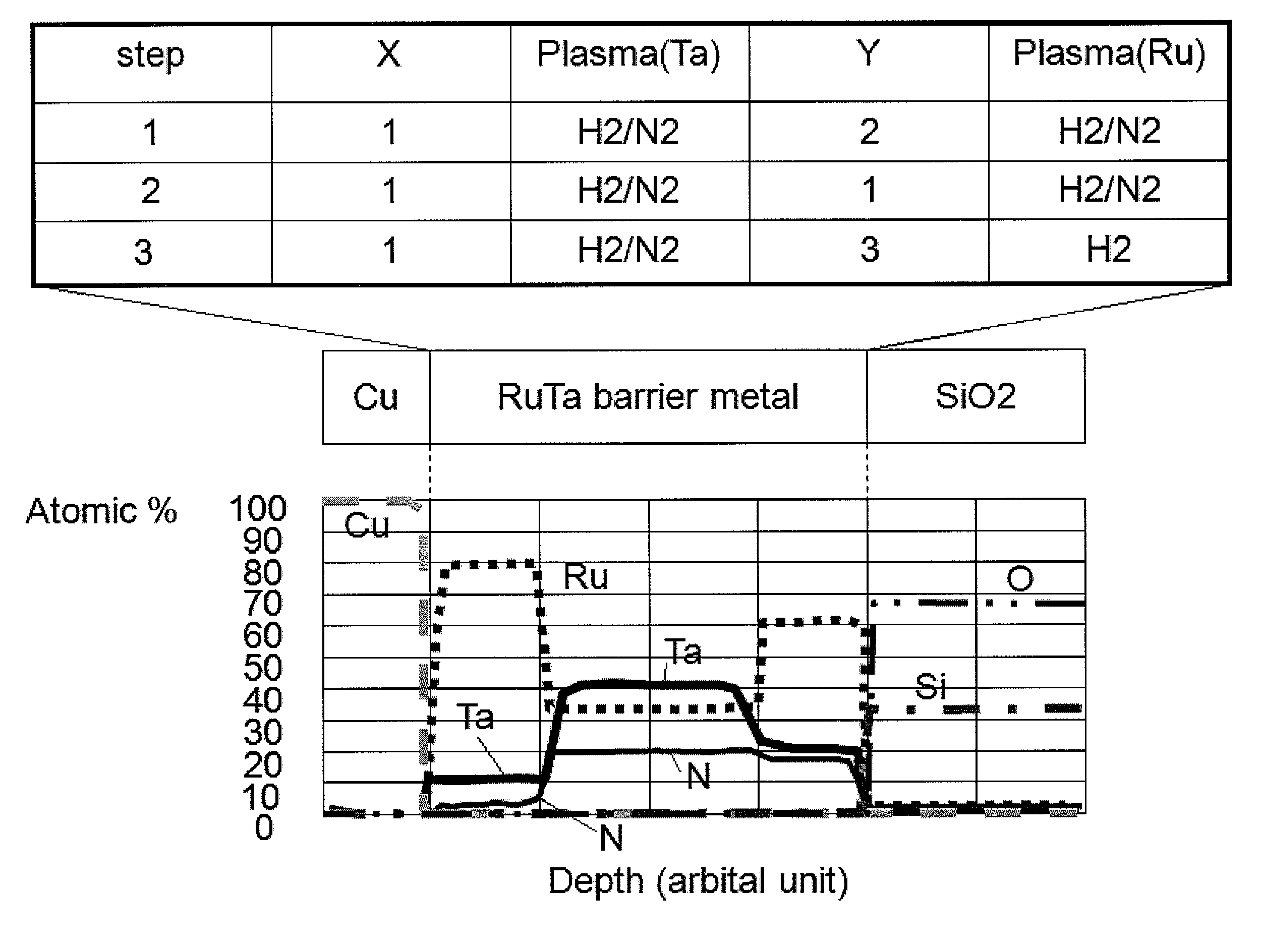

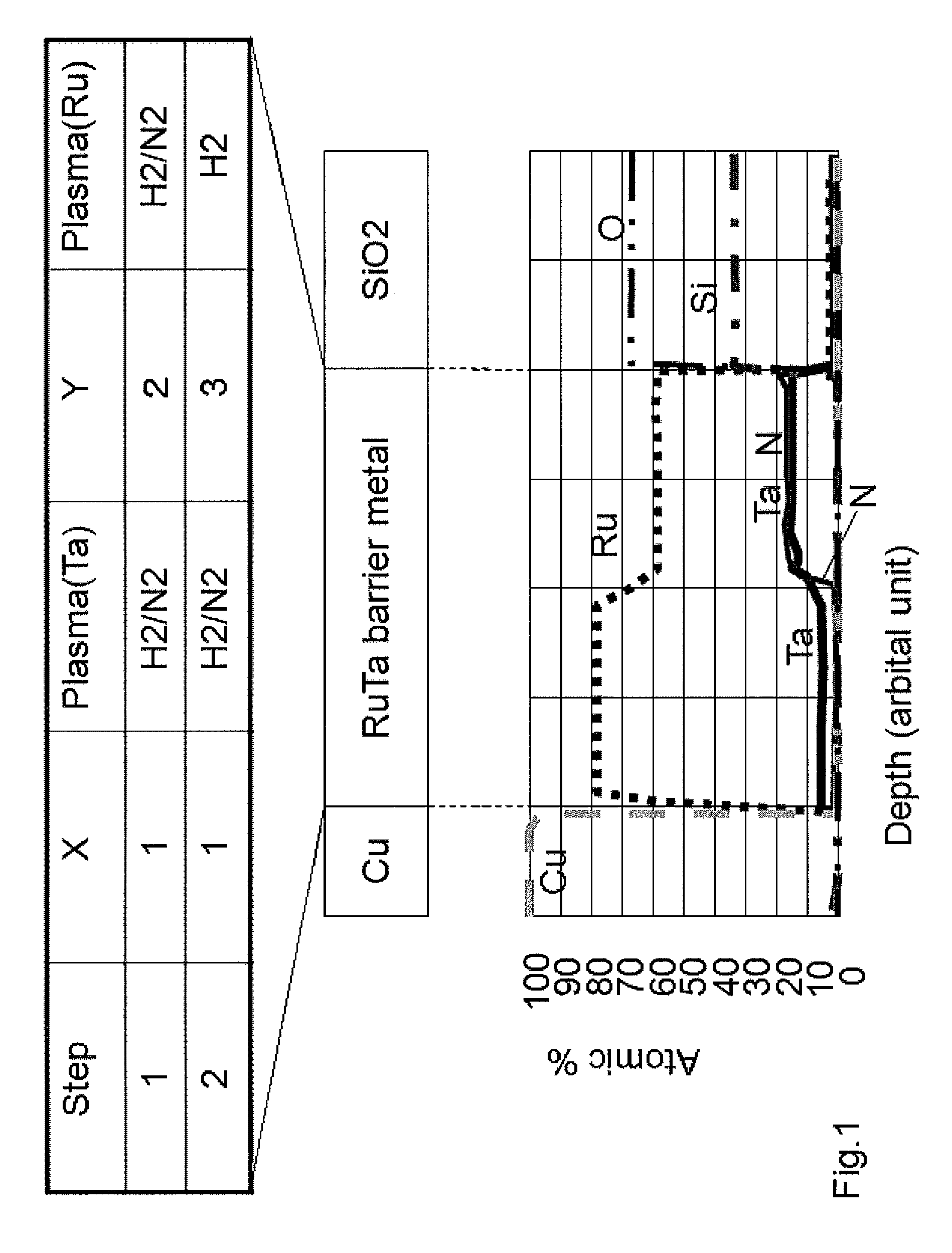

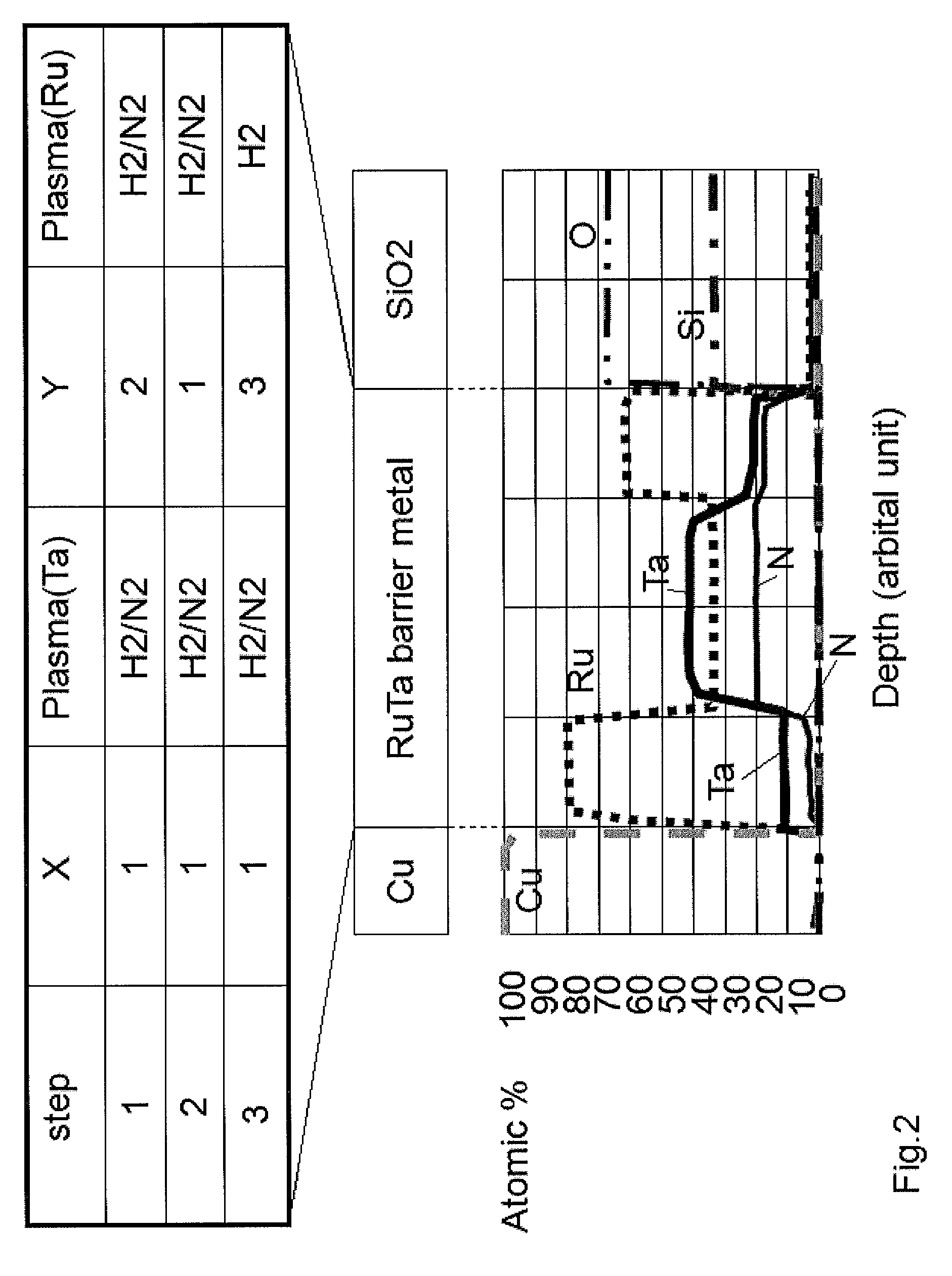

Atomic composition controlled ruthenium alloy film formed by plasma-enhanced atomic layer deposition

ActiveUS8084104B2Reduce resistanceLow densitySemiconductor/solid-state device detailsSynthetic resin layered productsRutheniumAlloy

A metal film composed of multiple atomic layers continuously formed by atomic layer deposition of Ru and Ta or Ti includes at least a top section and a bottom section, wherein an atomic composition of Ru, Ta or Ti, and N varies in a thickness direction of the metal film. The atomic composition of Ru, Ta or Ti, and N in the top section is represented as Ru(x1)Ta / Ti(y1)N(z1) wherein an atomic ratio of Ru(x1) / (Ta / Ti(y1)) is no less than 15, and z1 is 0.05 or less. The atomic composition of Ru, Ta or Ti, and N in the bottom section is represented as Ru(x2)Ta / Ti(y2)N(z2) wherein an atomic ratio of Ru(x2) / (Ta / Ti(y2)) is more than zero but less than 15, and z2 is 0.10 or greater.

Owner:ASM JAPAN

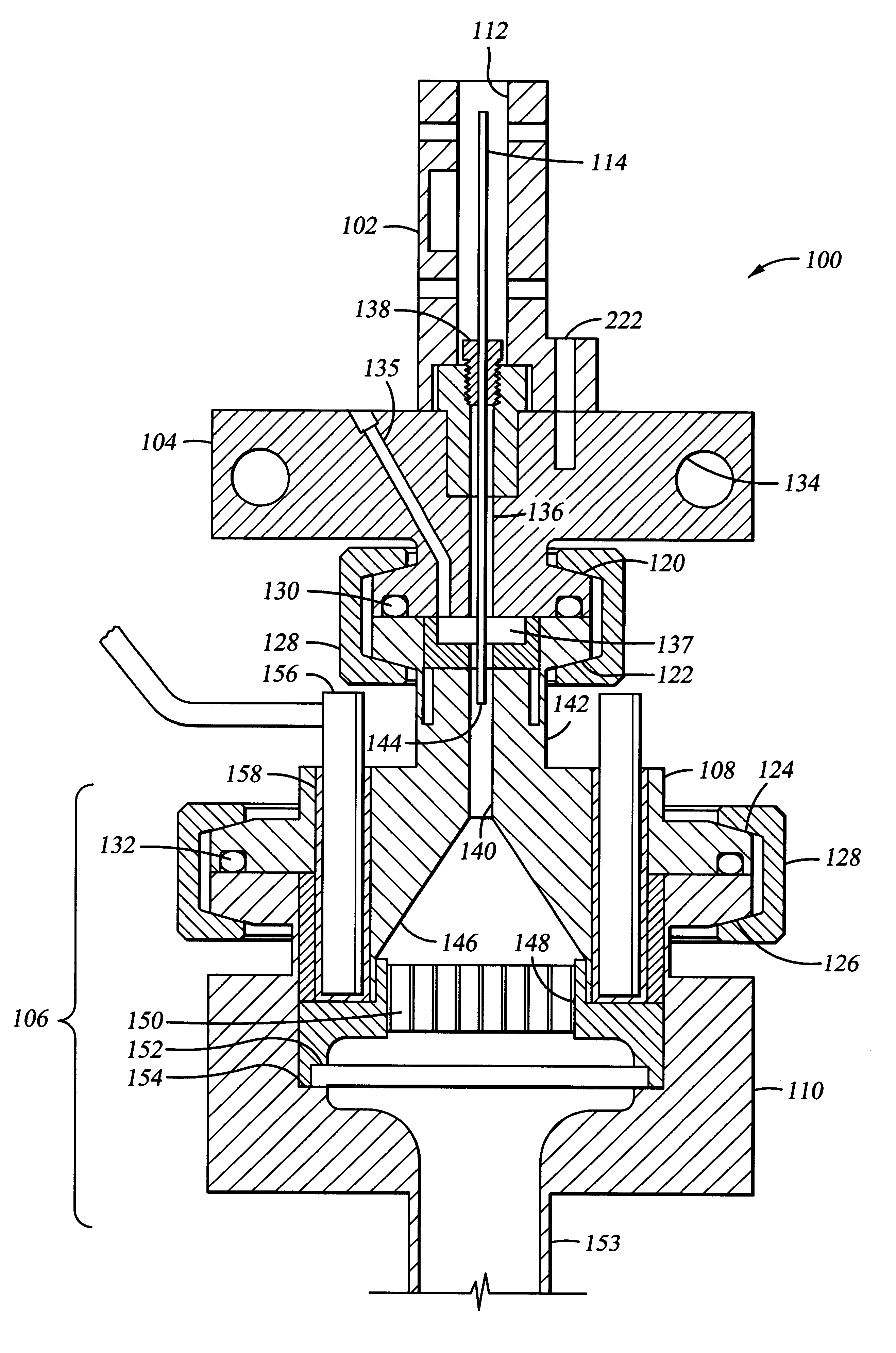

Chemical vapor deposition vaporizer

InactiveUS6210485B1Semiconductor/solid-state device manufacturingMachines/enginesIntegrated circuitEvaporator

The invention relates to an apparatus and process for the vaporization of liquid precursors and deposition of a film on a suitable substrate. Particularly contemplated is an apparatus and process for the vaporization of a metal-oxide film, such as a barium, strontium, titanium oxide (BST) film, for deposition on a silicon wafer to make integrated circuit capacitors useful in high capacity dynamic memory modules. The vaporizer comprises thermally controlled components which are adapted for easy assembly and disassembly. A main vaporizing section provides a large heated surface for flash vaporization. A high conductance blocker is disposed at a lower end of the vaporizer to provide an extended vaporization surface. Optionally, a filter may be employed to capture unvaporized precursor droplets.

Owner:APPLIED MATERIALS INC

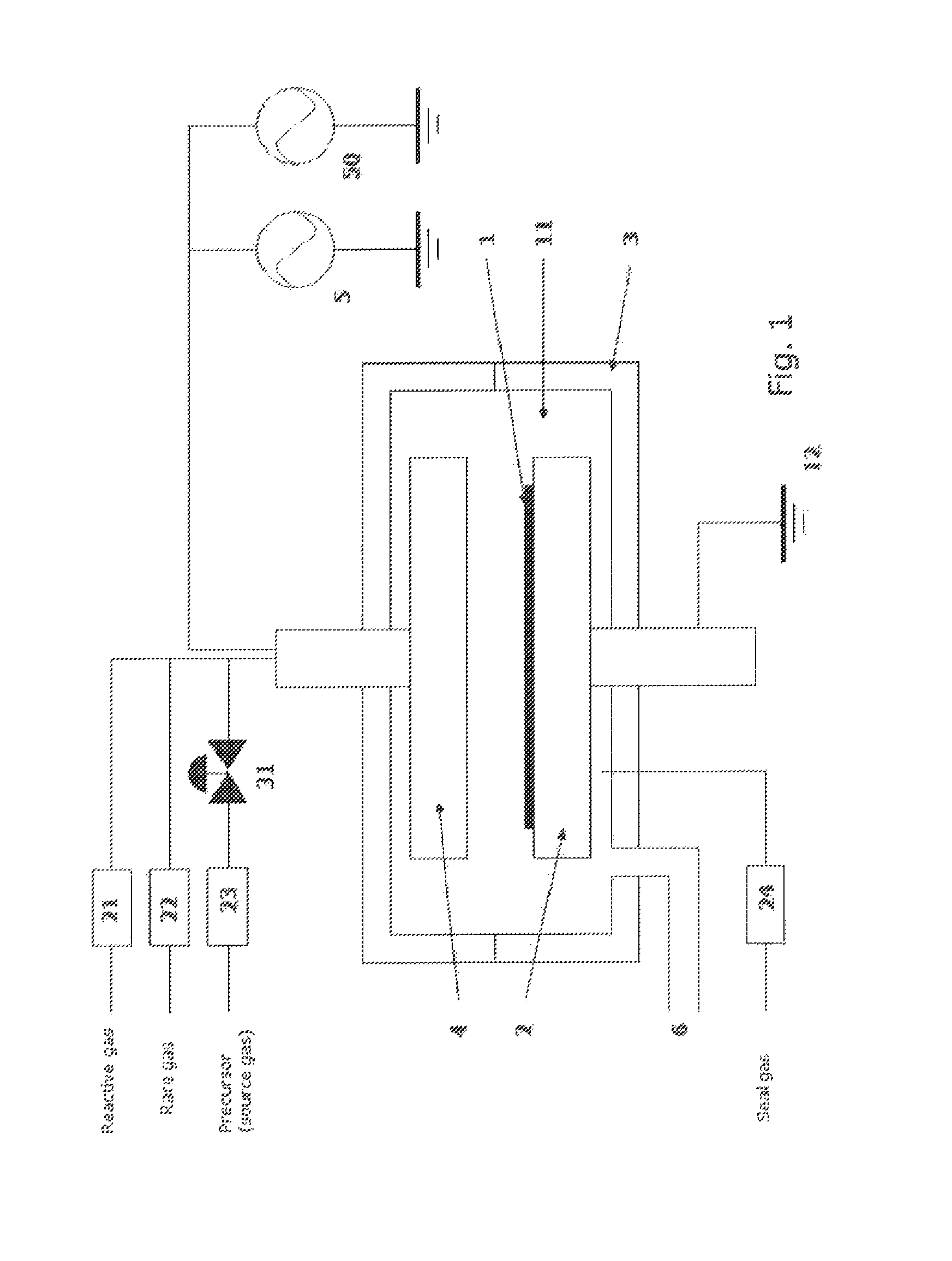

Method for depositing metal-containing film using particle-reduction step

InactiveUS20160168699A1Reduce surface roughnessSolve the lack of resistanceChemical vapor deposition coatingPlasma techniqueAMINO BASENitride

A method for forming a metal oxide or nitride film on a substrate by plasma-enhanced atomic layer deposition (PEALD), includes: introducing an amino-based metal precursor in a pulse to a reaction space where a substrate is placed, using a carrier gas; and continuously introducing a reactant gas to the reaction space; applying RF power in a pulse to the reaction space wherein the pulse of the precursor and the pulse of RF power do not overlap, wherein conducted is at least either step (a) comprising passing the carrier gas through a purifier for reducing impurities before mixing the carrier gas with the precursor, or step (b) introducing the reactant gas at a flow rate such that a partial pressure of the reactant gas relative to the total gas flow provided in the reaction space is 15% or less.

Owner:ASM IP HLDG BV

Droplet-based particle sorting

InactiveUS20080053205A1Large facilityEasy to testSludge treatmentVolume/mass flow measurementChemical physicsParticle sorting

Owner:ADVANCED LIQUID LOGIC

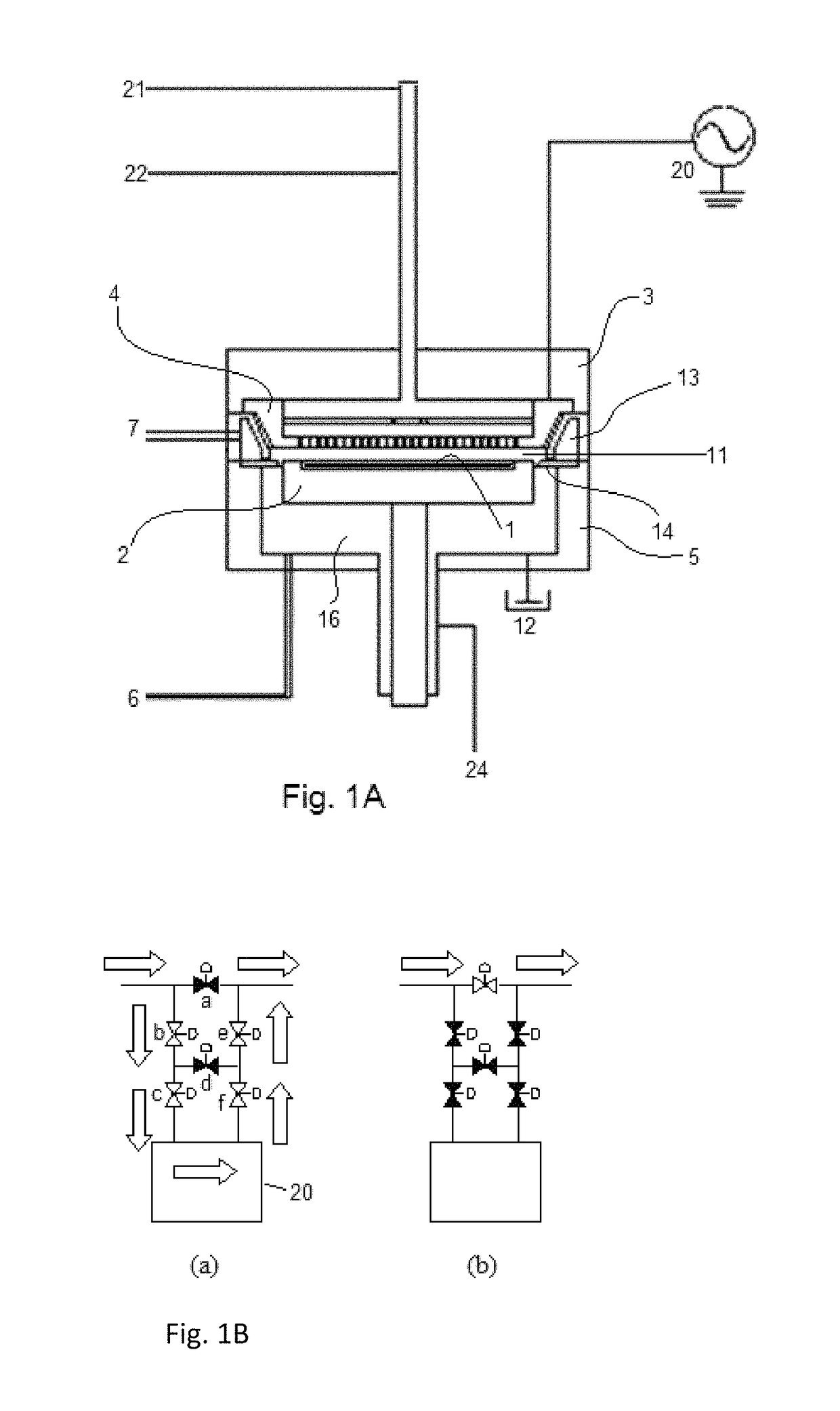

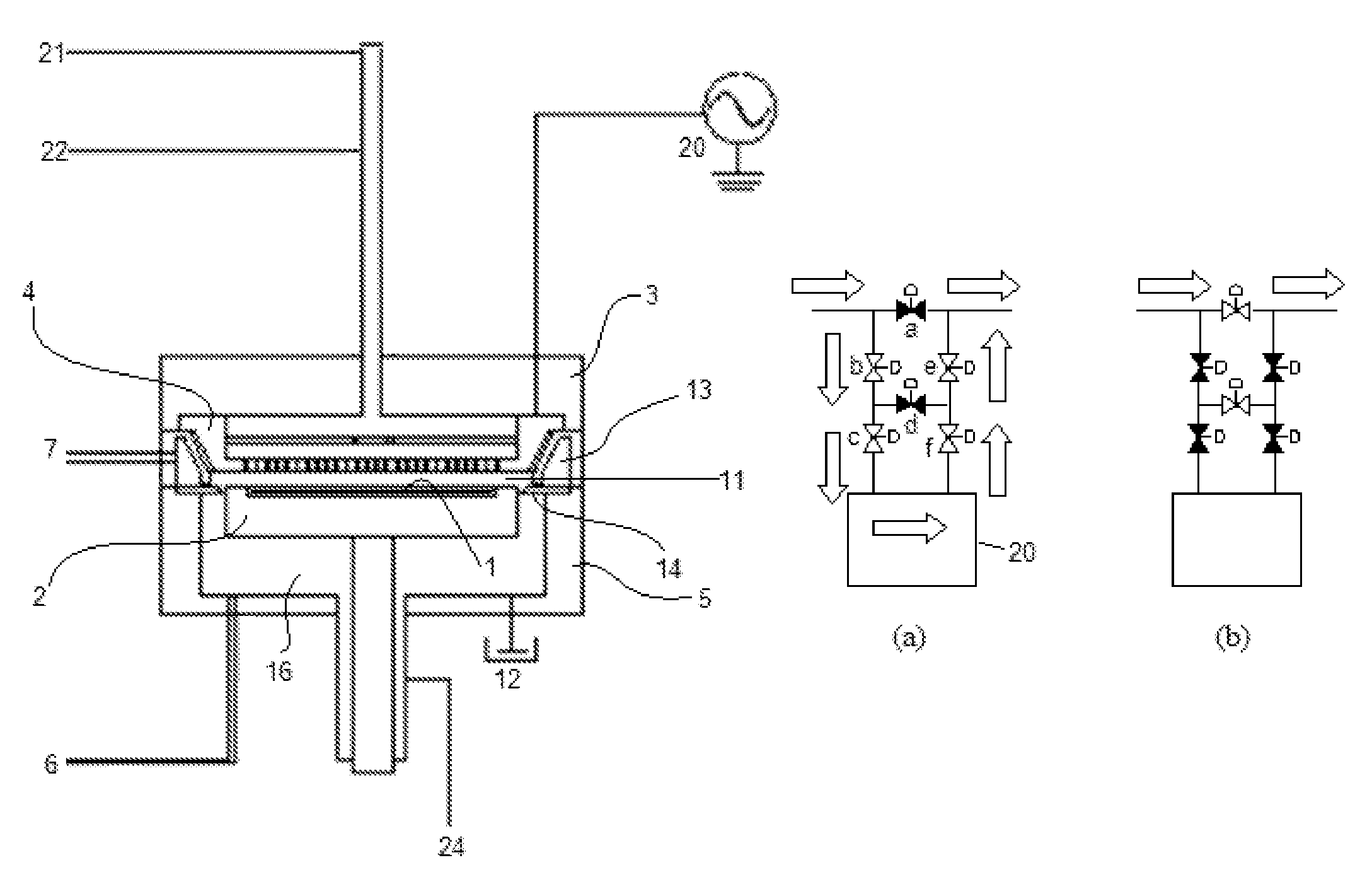

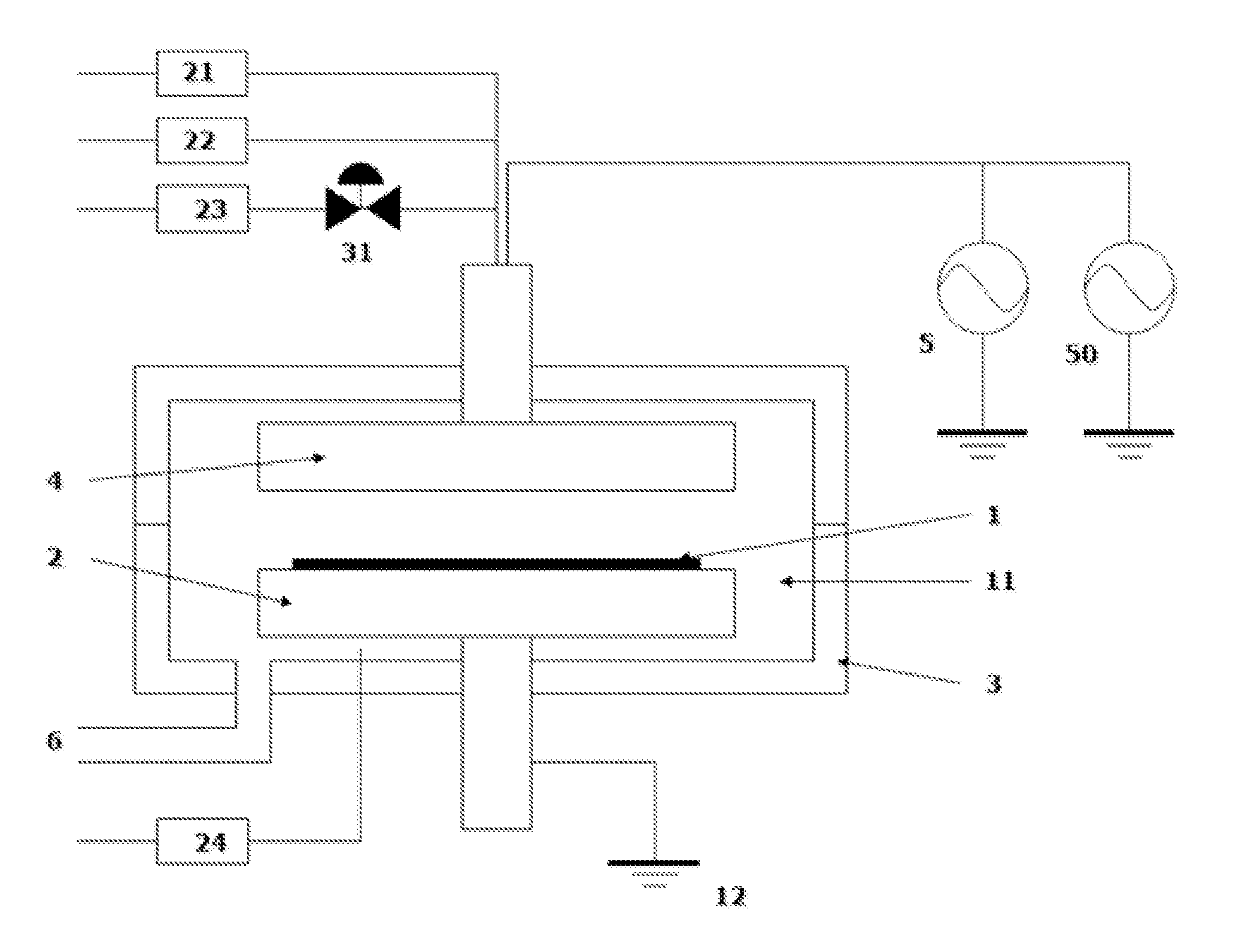

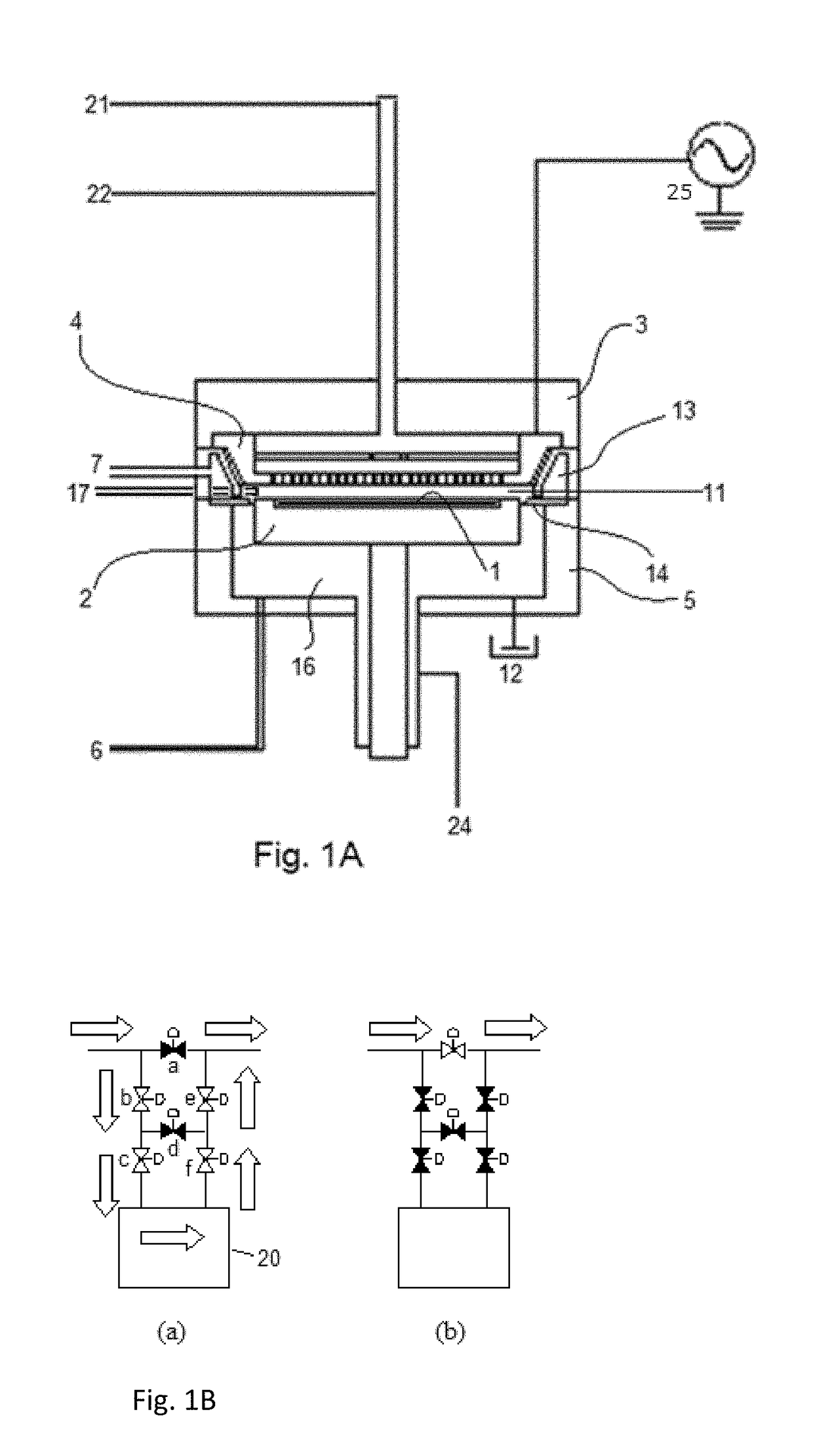

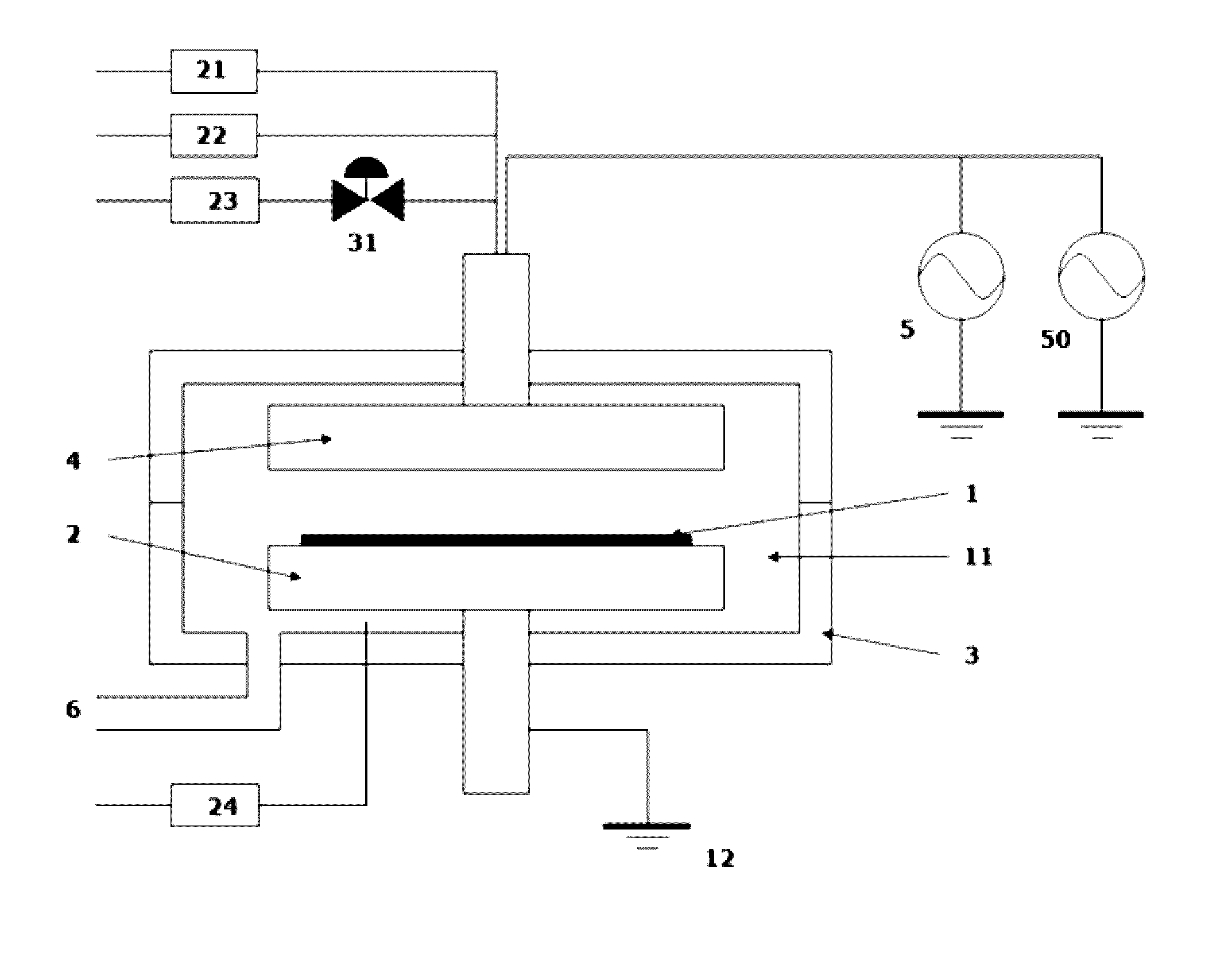

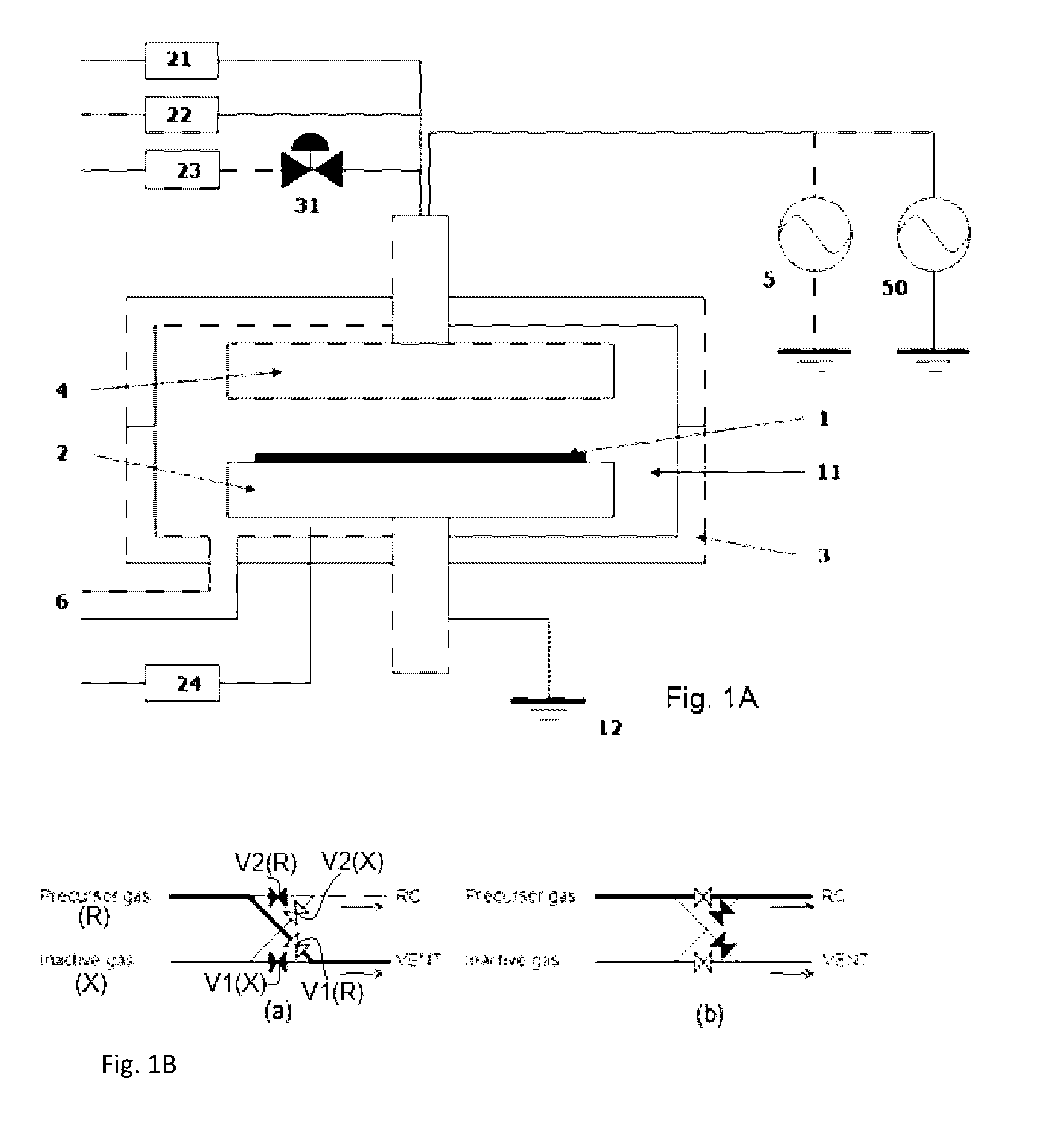

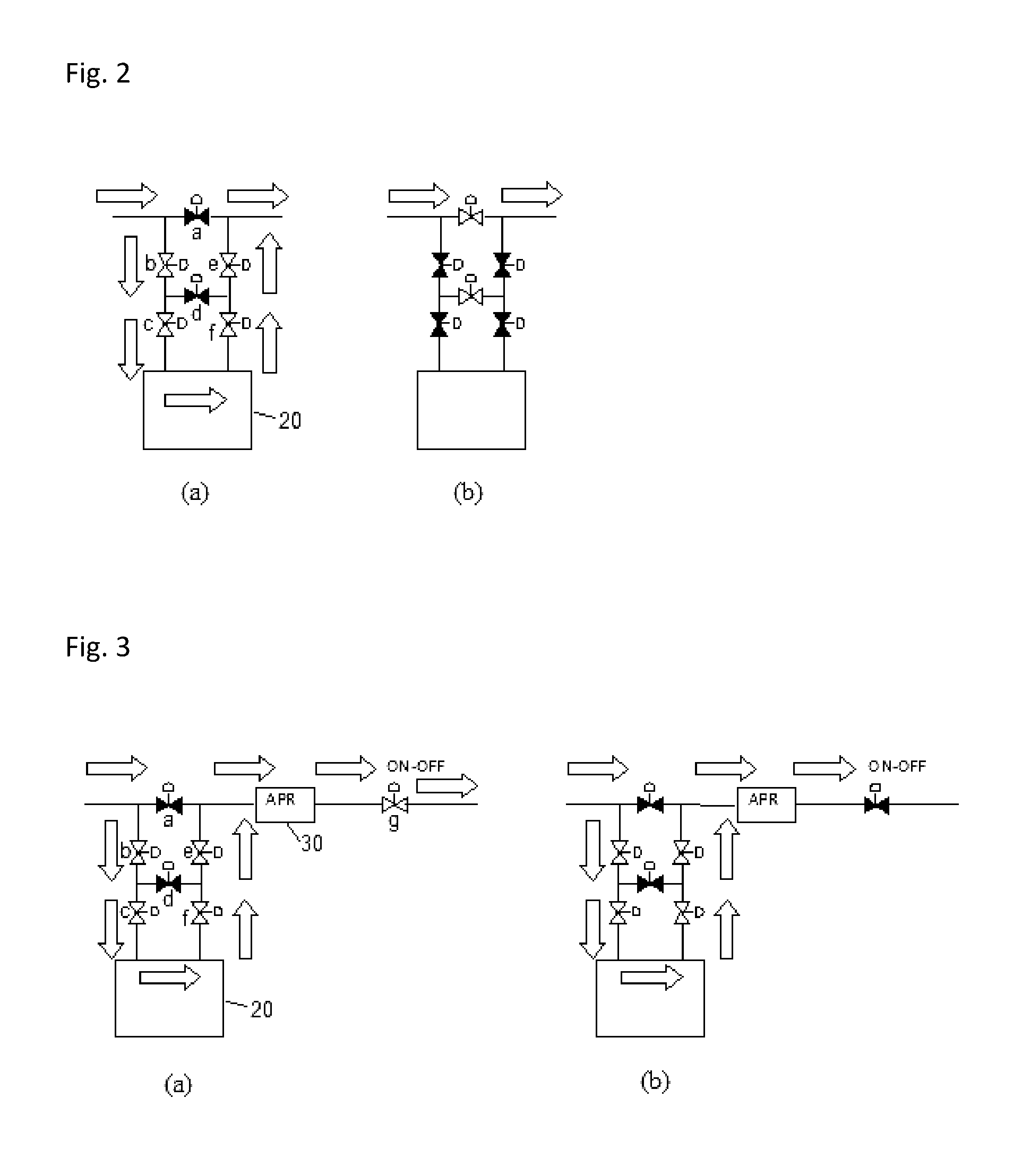

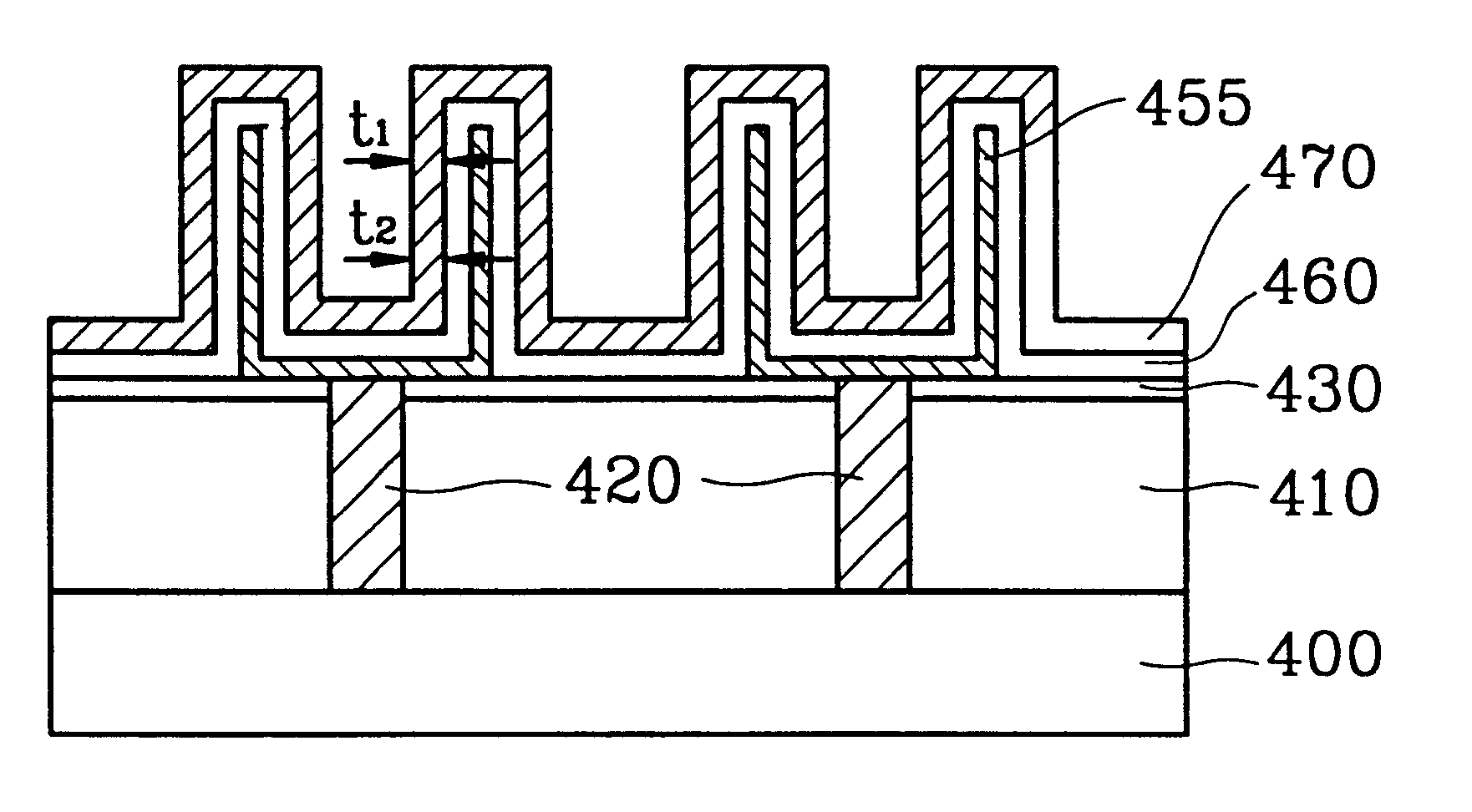

Method of subatmospheric plasma-enhanced ald using capacitively coupled electrodes with narrow gap

ActiveUS20180119283A1Poor conformalityGood shape retentionElectric discharge tubesChemical vapor deposition coatingCapacitanceParallel plate

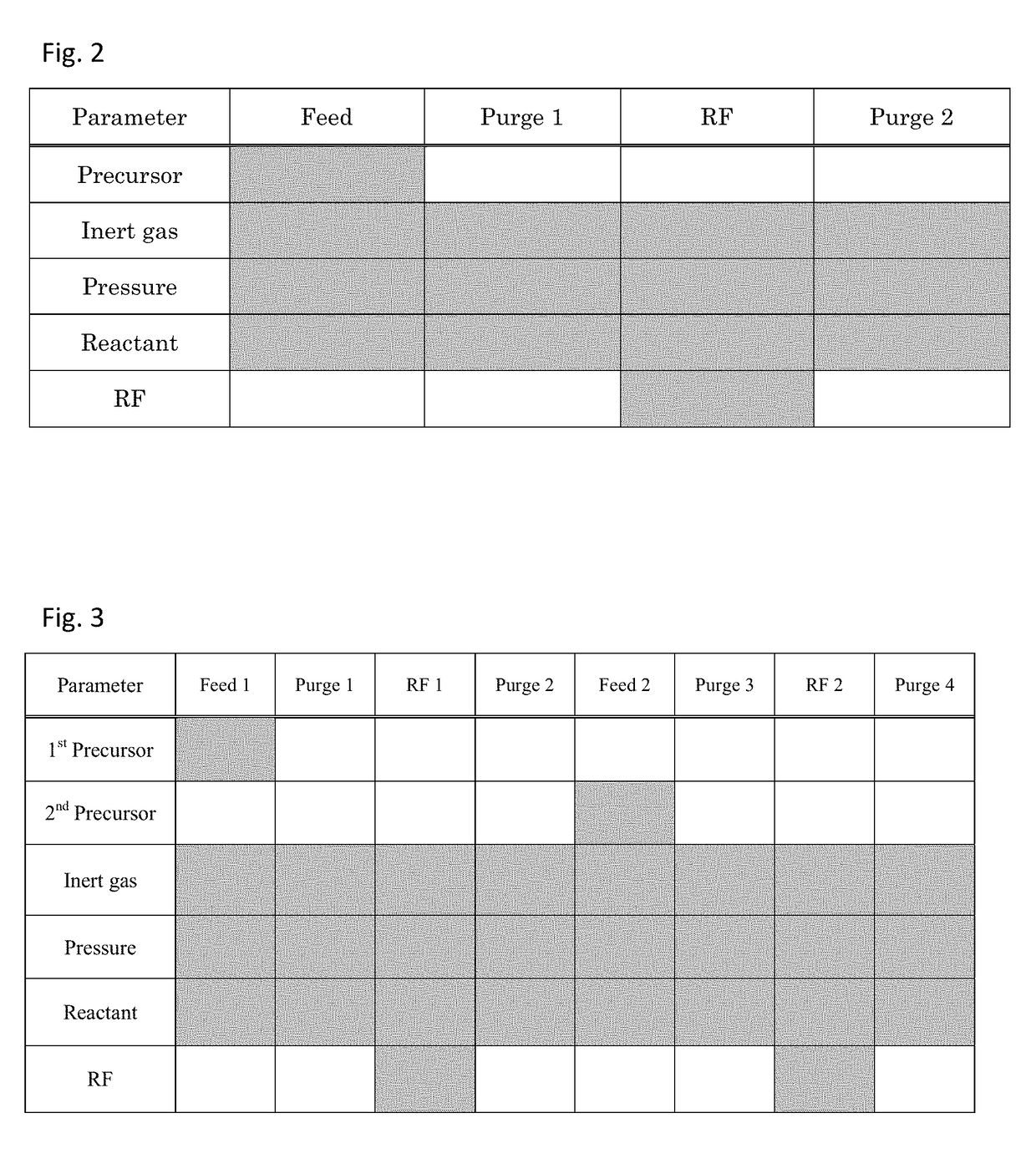

A method for depositing a film by plasma-enhanced subatmospheric-pressure atomic layer deposition (subatmospheric PEALD) is conducted using capacitively coupled parallel plate electrodes with a gap of 1 mm to 5 mm, wherein one cycle of subatmospheric PEALD includes: supplying a precursor in a pulse to the reaction chamber; continuously supplying a reactant to the reaction chamber; continuously supplying an inert gas to the reaction chamber; continuously controlling a pressure of the reaction chamber in a range of 15 kPa to 80 kPa; and applying RF power for glow discharge in a pulse to one of the parallel plate electrodes.

Owner:ASM IP HLDG BV

Method for forming sin or sicn film in trenches by peald

InactiveUS20170051405A1Step-coverage is poorImprove responseChemical vapor deposition coatingHalogenAtomic layer deposition

A method for forming a SiN or SiCN film in a trench on a substrate by plasma-enhanced atomic layer deposition (PEALD) conducts one or more process cycles, each process cycle including: (i) feeding a precursor in a pulse to a reaction space where the substrate is place, said precursor having a Si—N—Si bond in its skeletal structure to which at least one halogen group is attached; and (ii) applying RF power to the reaction space in the presence of a reactant gas and in the absence of any precursor to form a monolayer constituting a SiN or SiCN film.

Owner:ASM IP HLDG BV

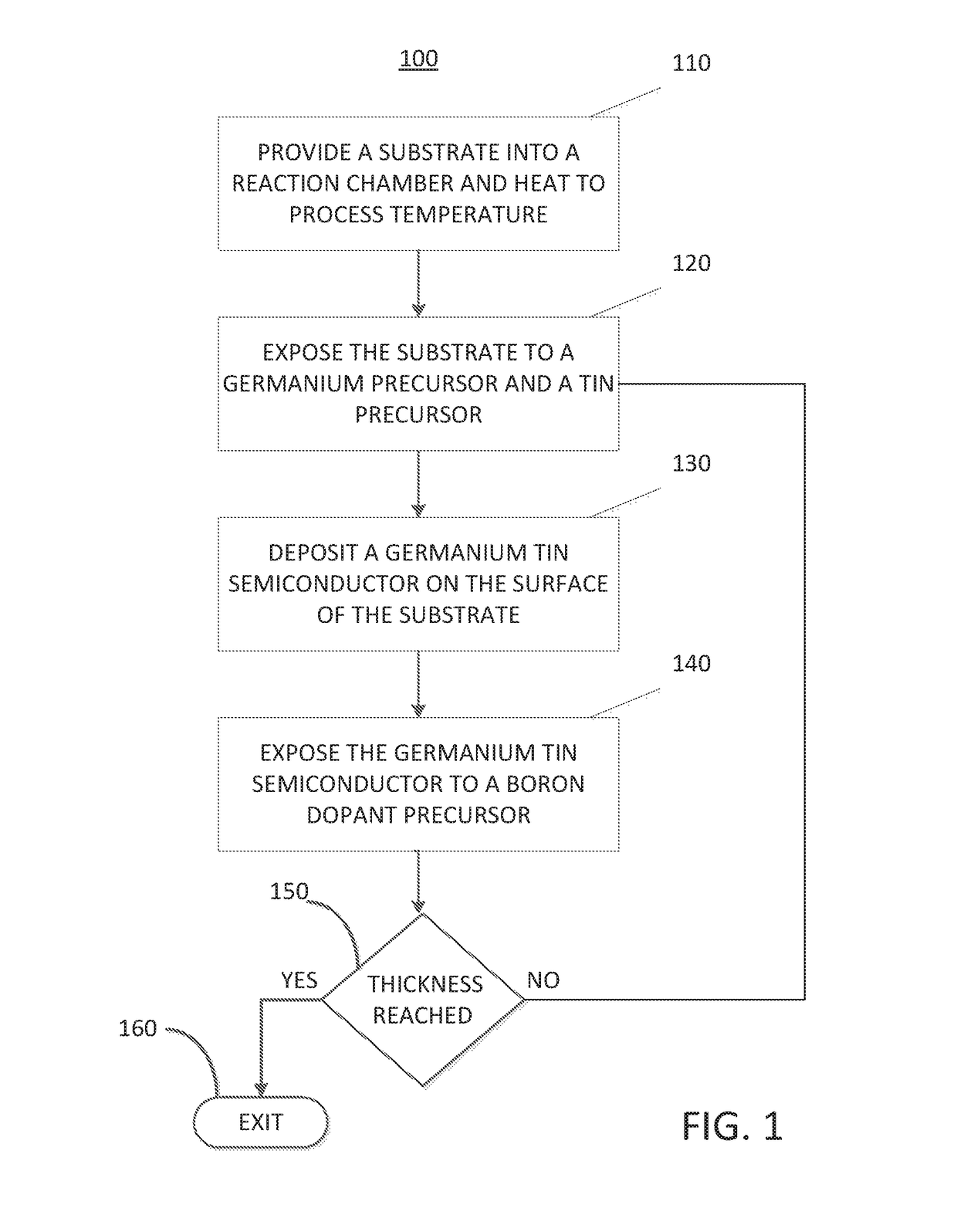

Methods for depositing a doped germanium tin semiconductor and related semiconductor device structures

ActiveUS10236177B1Polycrystalline material growthAfter-treatment detailsDopantDeposition temperature

A method for depositing a germanium tin (Ge1-xSnx) semiconductor is disclosed. The method may include; providing a substrate within a reaction chamber, heating the substrate to a deposition temperature and exposing the substrate to a germanium precursor and a tin precursor. The method may further include; depositing a germanium tin (Ge1-xSnx) semiconductor on the surface of the substrate, and exposing the germanium tin (Ge1-xSnx) semiconductor to a boron dopant precursor. Semiconductor device structures including a germanium tin (Ge1-xSnx) semiconductor formed by the methods of the disclosure are also provided.

Owner:ASM IP HLDG BV

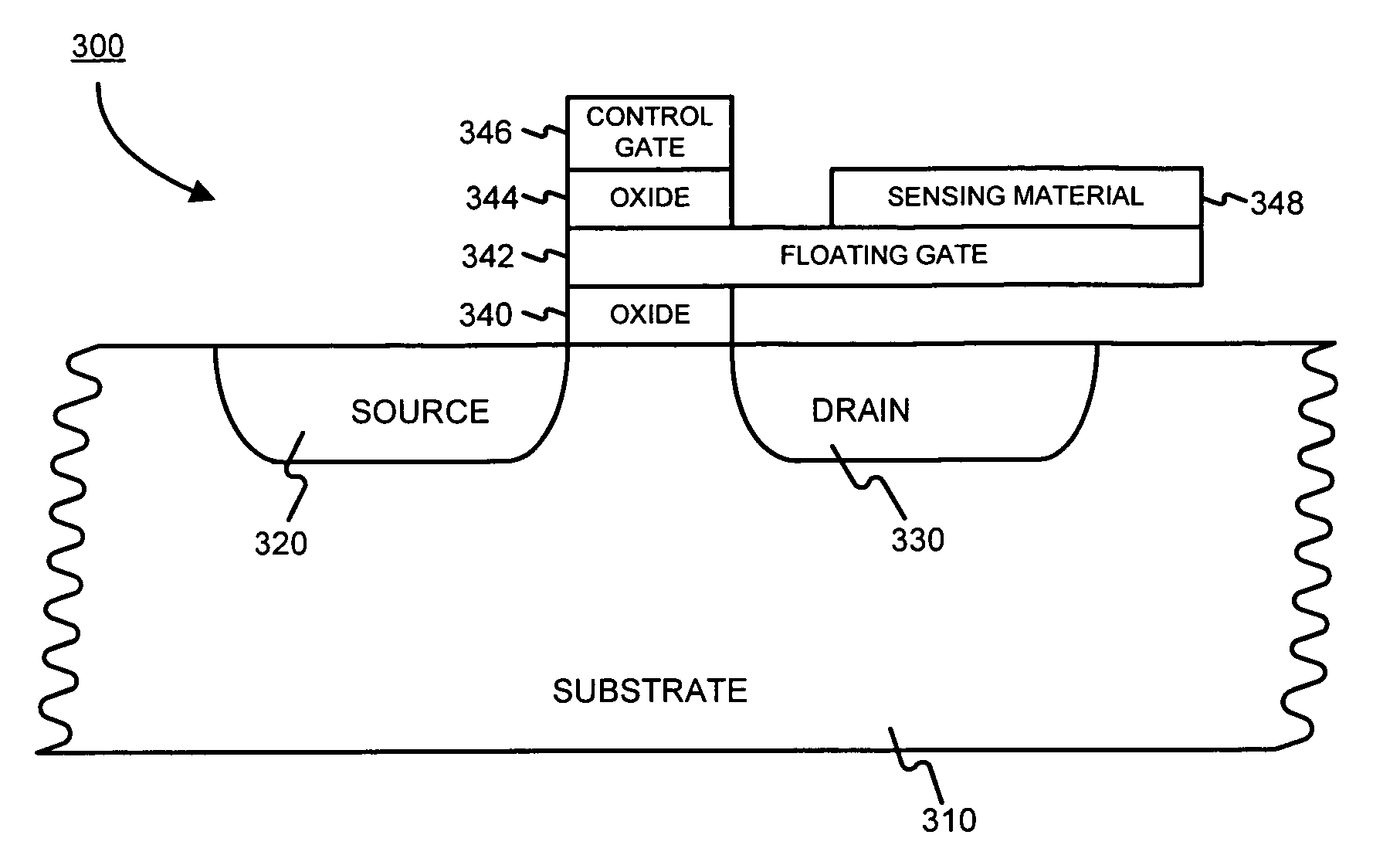

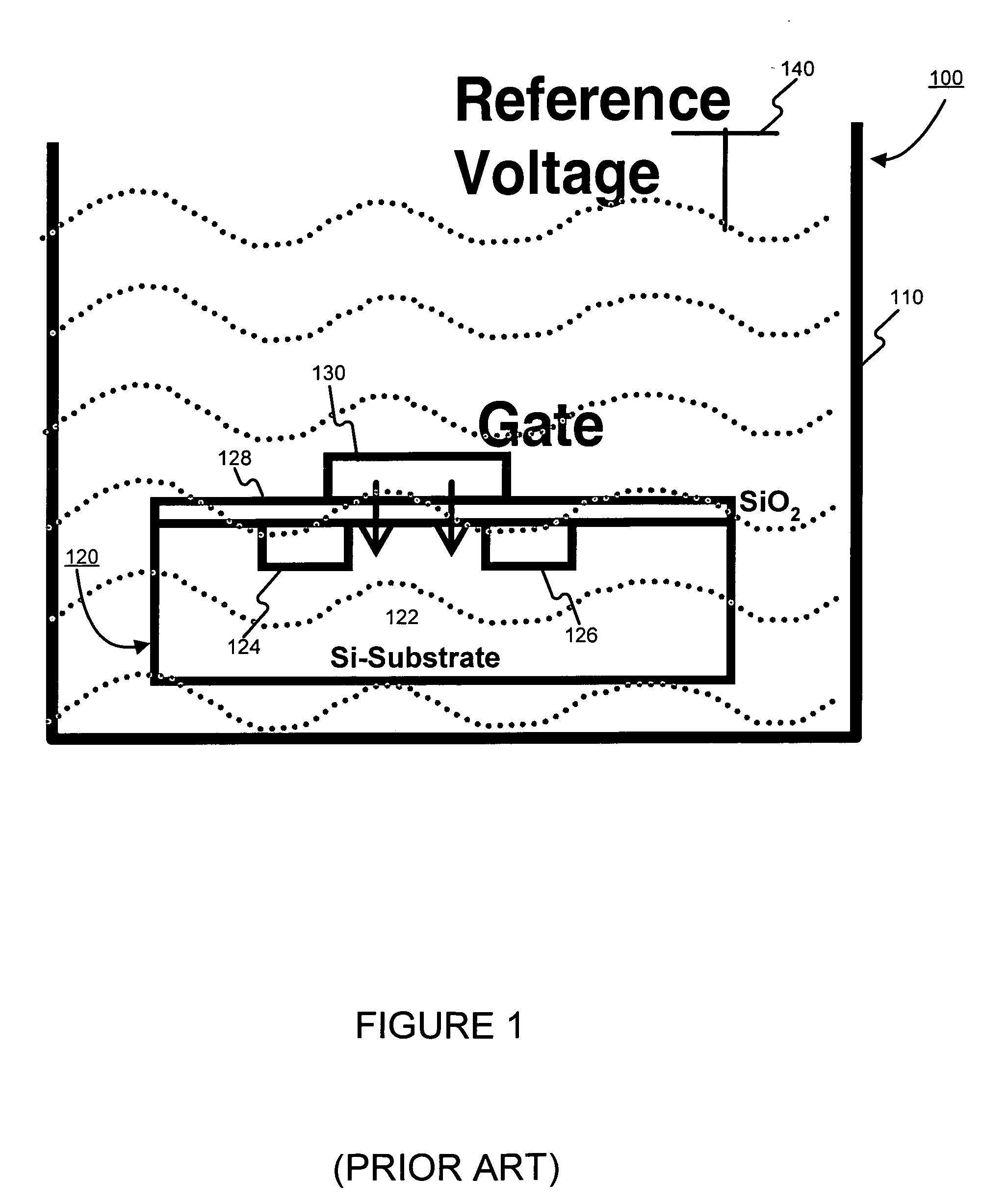

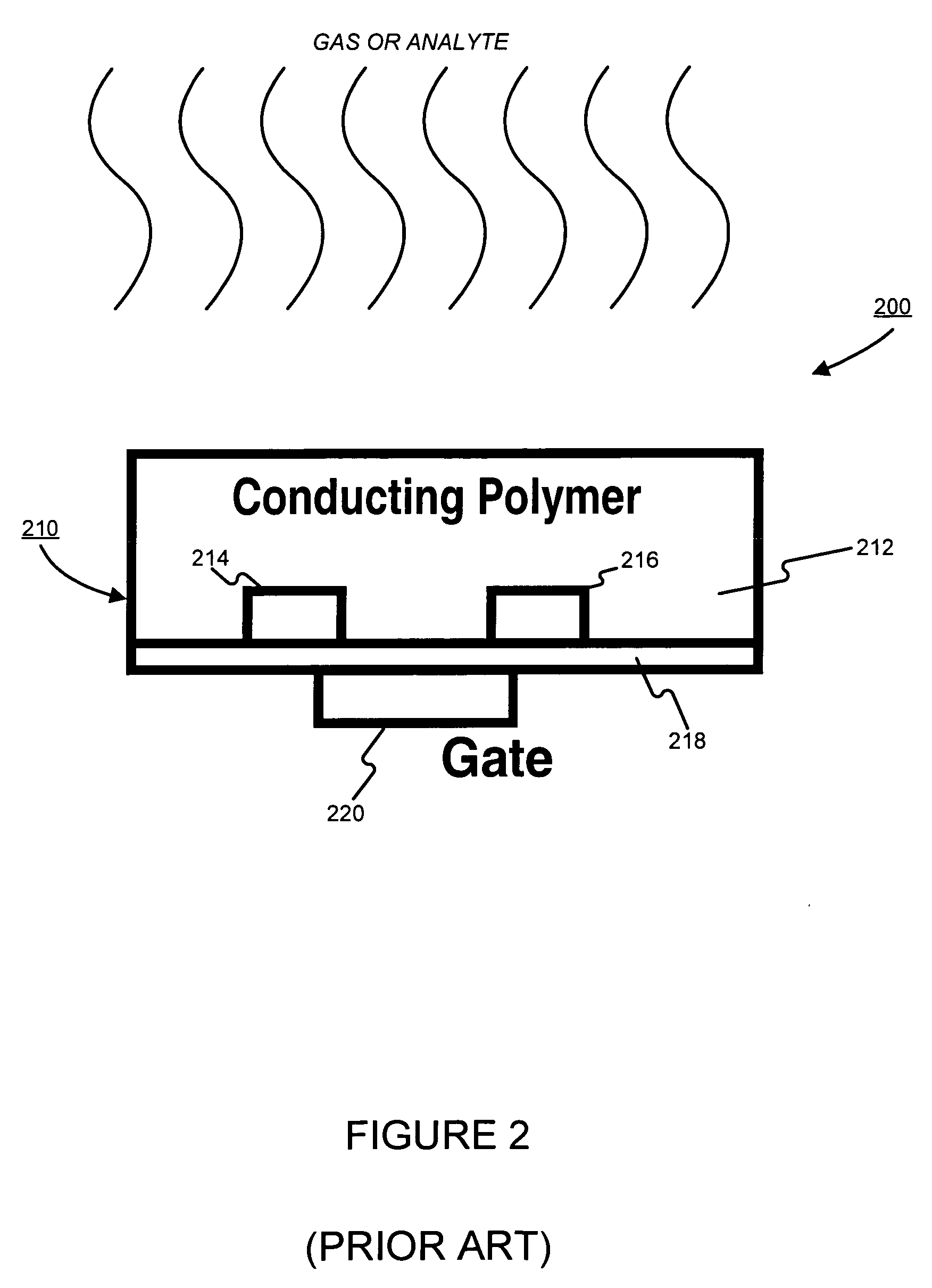

Floating gate field effect transistors for chemical and/or biological sensing

ActiveUS20050230271A1Weather/light/corrosion resistanceVolume/mass flow measurementChemical physicsEngineering

Specific ionic interactions with a sensing material that is electrically coupled with the floating gate of a floating gate-based ion sensitive field effect transistor (FGISFET) may be used to sense a target material. For example, an FGISFET can use (e.g., previously demonstrated) ionic interaction-based sensing techniques with the floating gate of floating gate field effect transistors. The floating gate can serves as a probe and an interface to convert chemical and / or biological signals to electrical signals, which can be measured by monitoring the change in the device's threshold voltage, VT.

Owner:POLYTECHNIC INSTITUTE OF NEW YORK UNIVERSITY

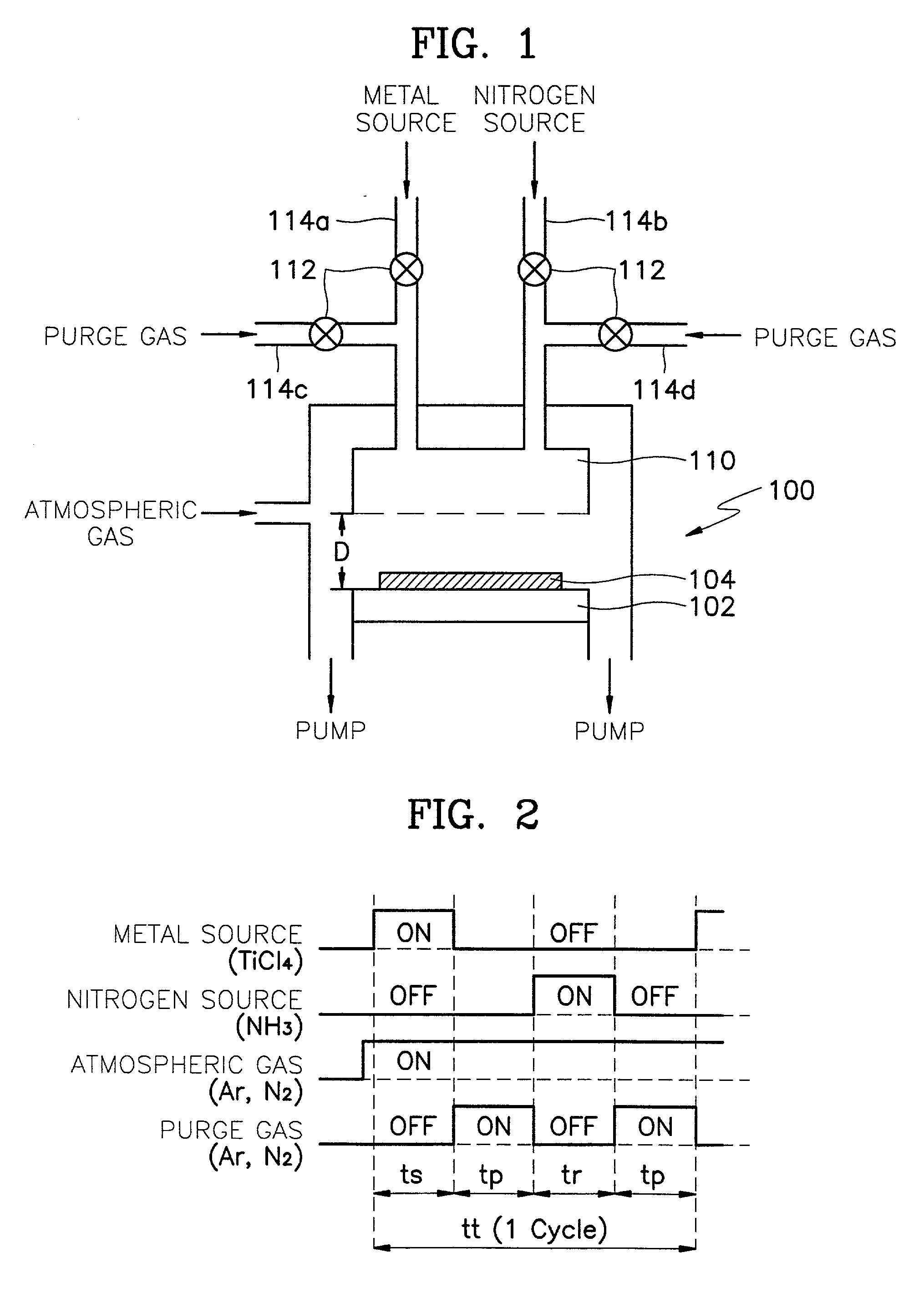

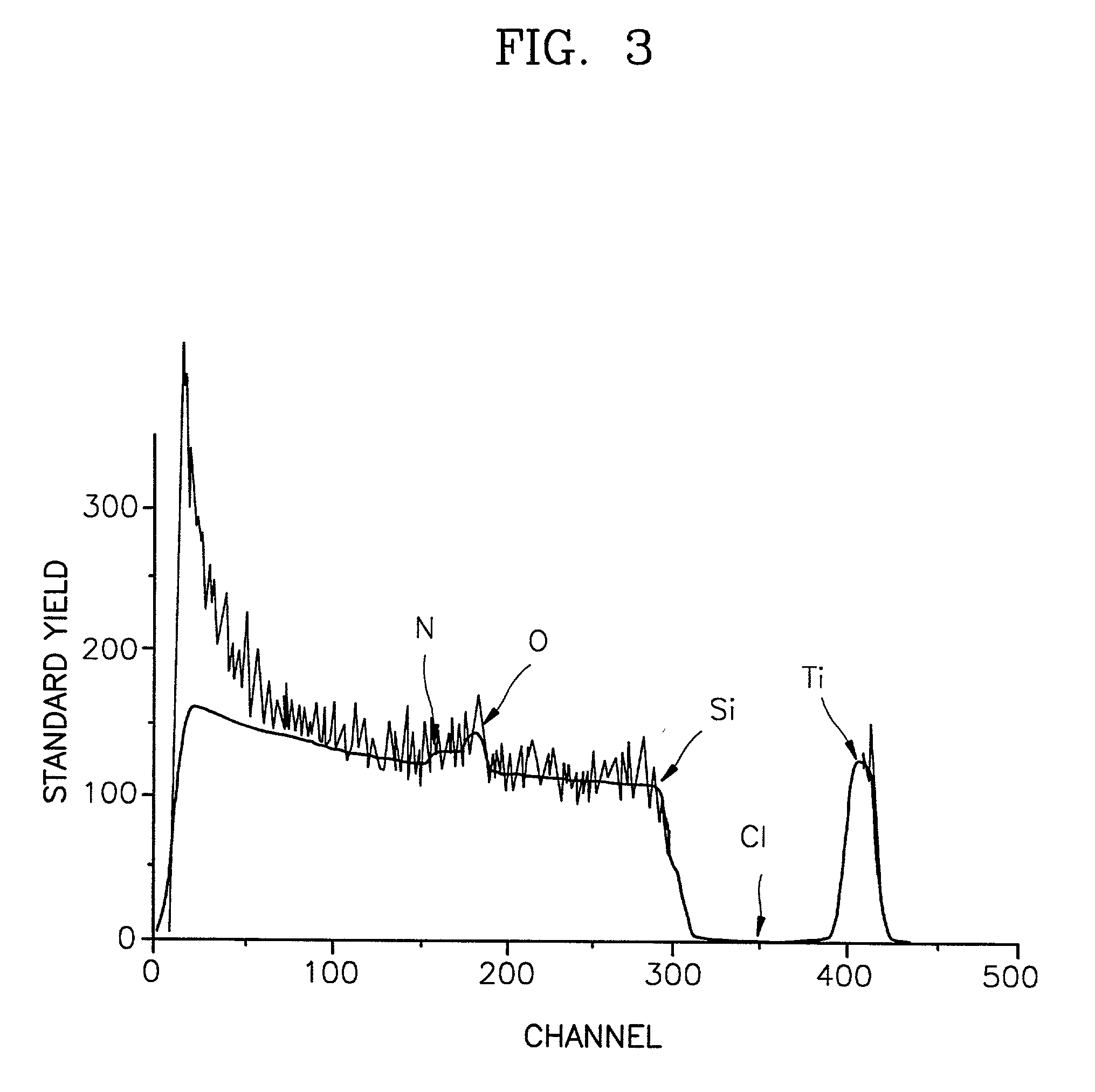

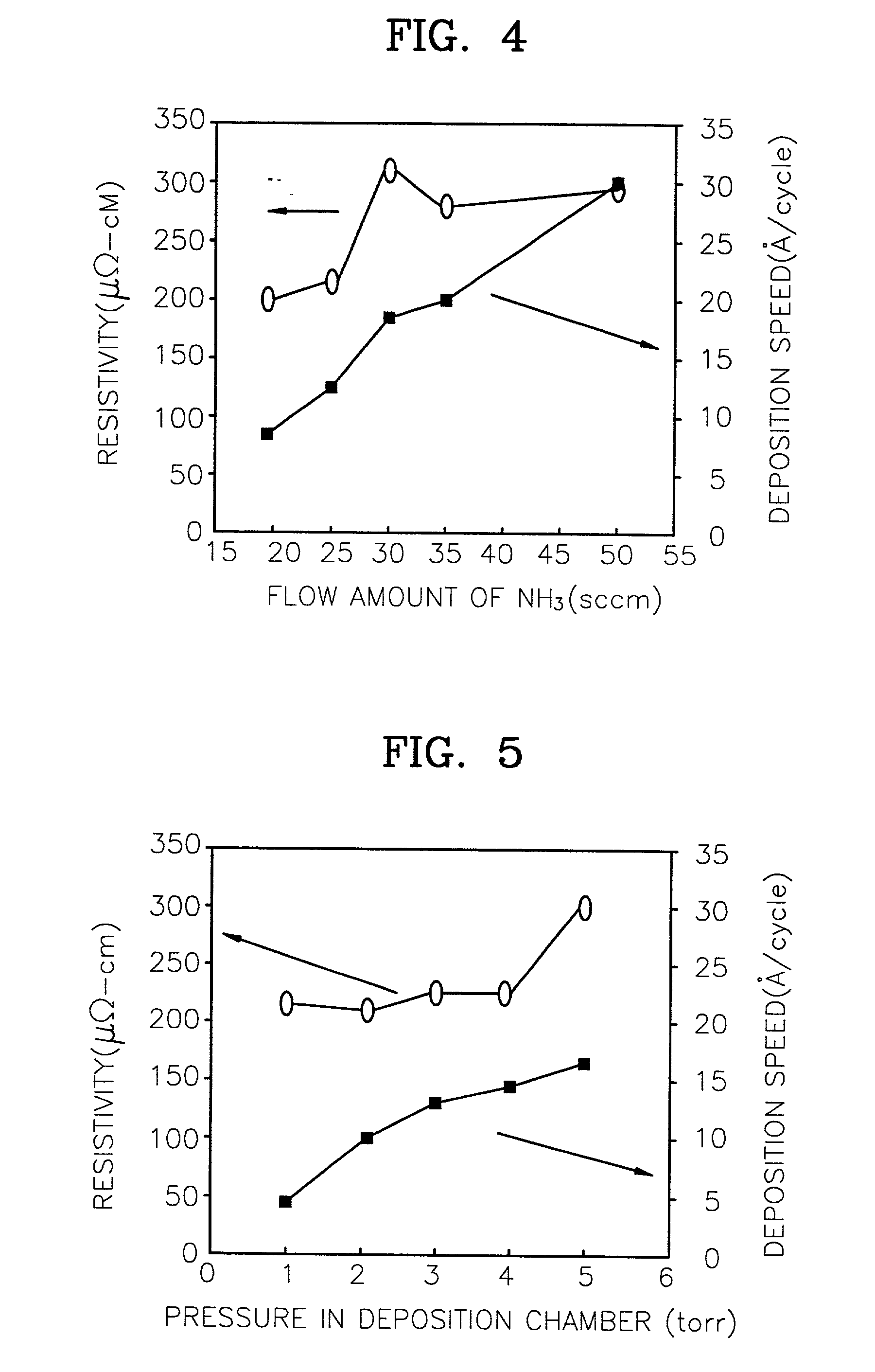

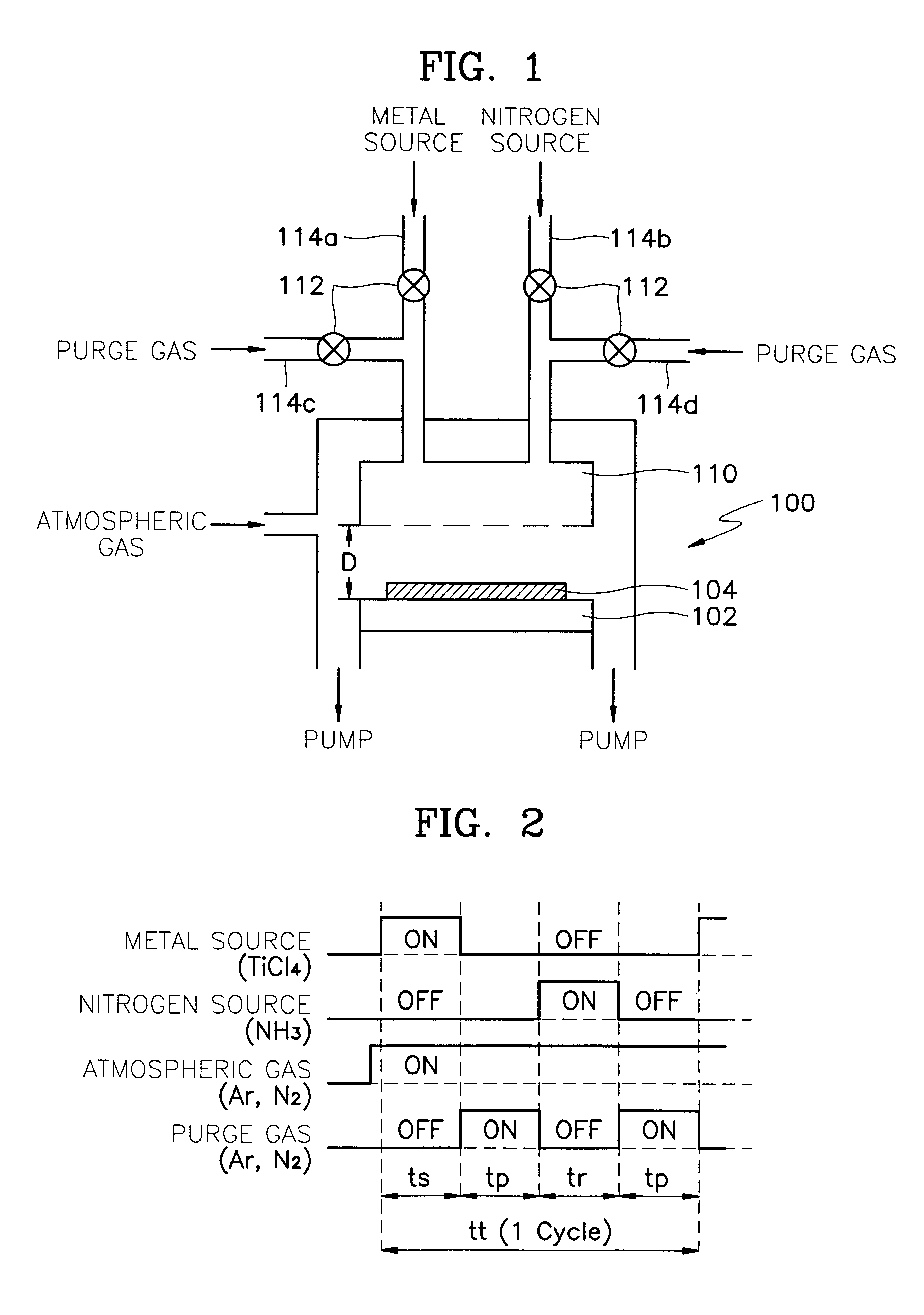

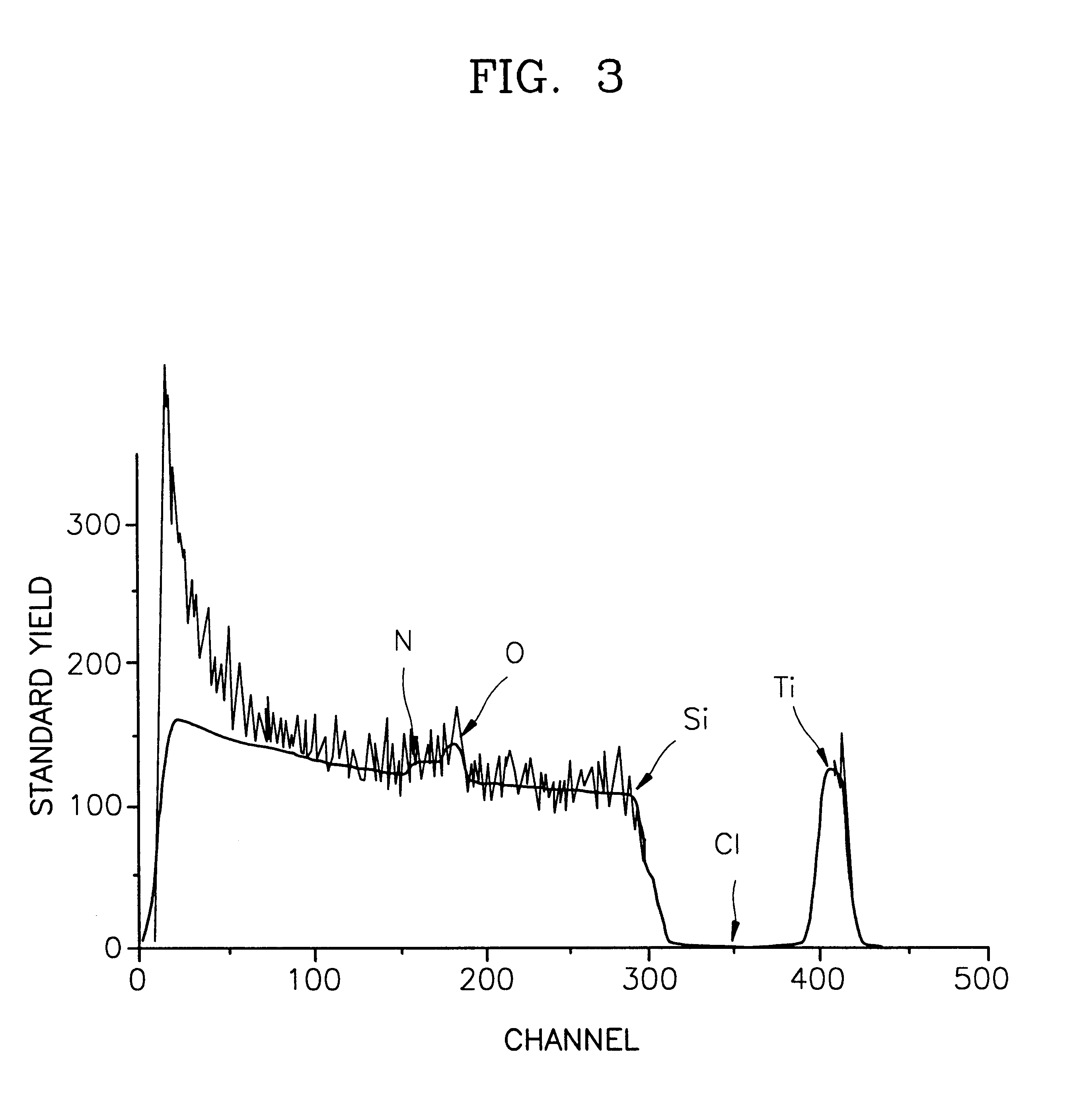

Method of forming metal nitride film by chemical vapor deposition and method of forming metal contact and capacitor of semiconductor device using the same

InactiveUS20010034097A1Good step coverageLow resistivitySemiconductor/solid-state device manufacturingCapacitorsChemical physicsDevice material

A method of forming a metal nitride film using chemical vapor deposition (CVD), and a method of forming a metal contact and a semiconductor capacitor of a semiconductor device using the same, are provided. The method of forming a metal nitride film using chemical vapor deposition (CVD) in which a metal source and a nitrogen source are used as a precursor, includes the steps of inserting a semiconductor substrate into a deposition chamber, flowing the metal source into the deposition chamber, removing the metal source remaining in the deposition chamber by cutting off the inflow of the metal source and flowing a purge gas into the deposition chamber, cutting off the purge gas and flowing the nitrogen source into the deposition chamber to react with the metal source adsorbed on the semiconductor substrate, and removing the nitrogen source remaining in the deposition chamber by cutting off the inflow of the nitrogen source and flowing the purge gas into the deposition chamber. Accordingly, the metal nitride film having low resistivity and a low content of Cl even with excellent step coverage can be formed at a temperature of 500° C. or lower, and a semiconductor capacitor having excellent leakage current characteristics can be manufactured. Also, a deposition speed, approximately 20 A / cycle, is suitable for mass production.

Owner:SAMSUNG ELECTRONICS CO LTD

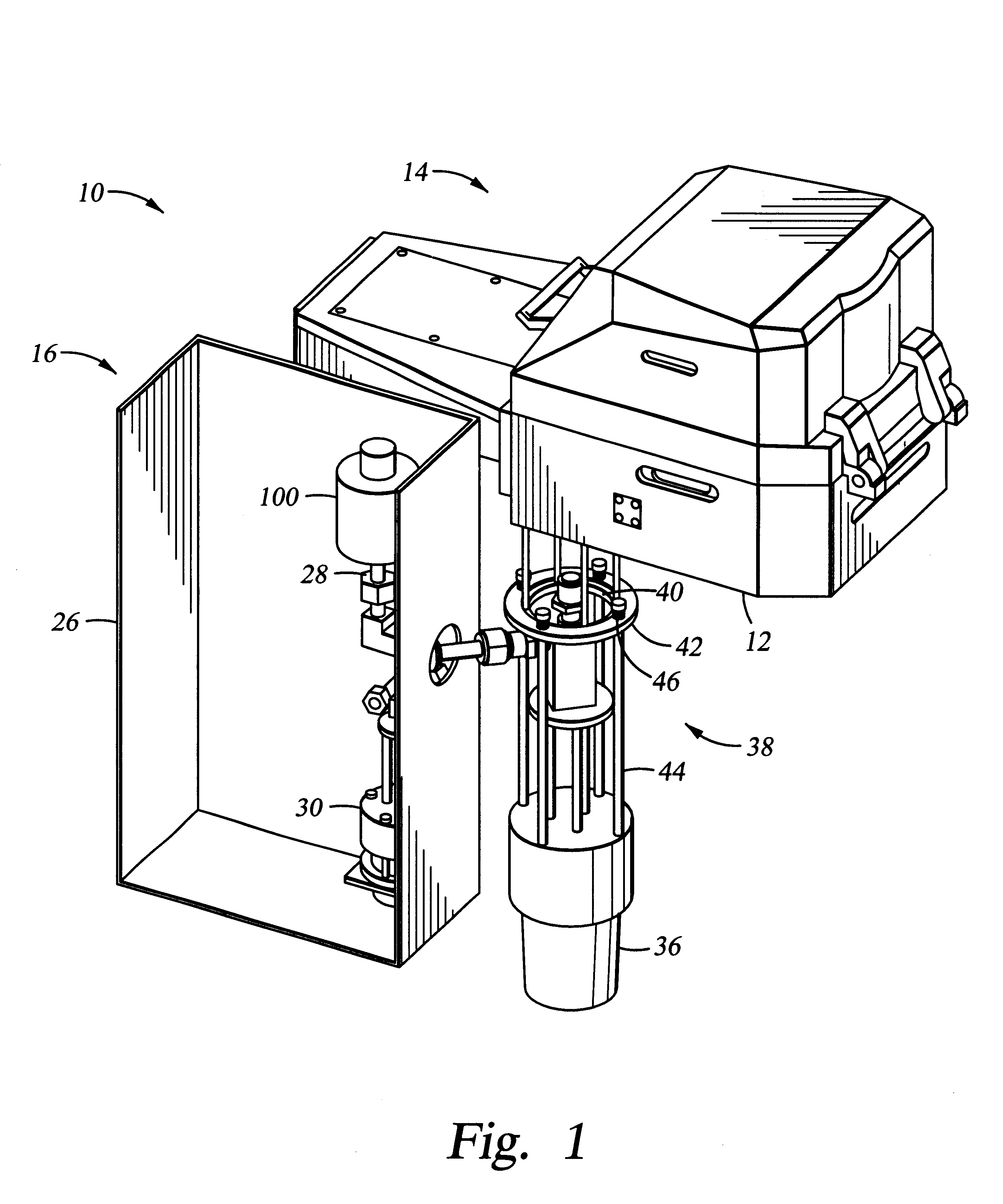

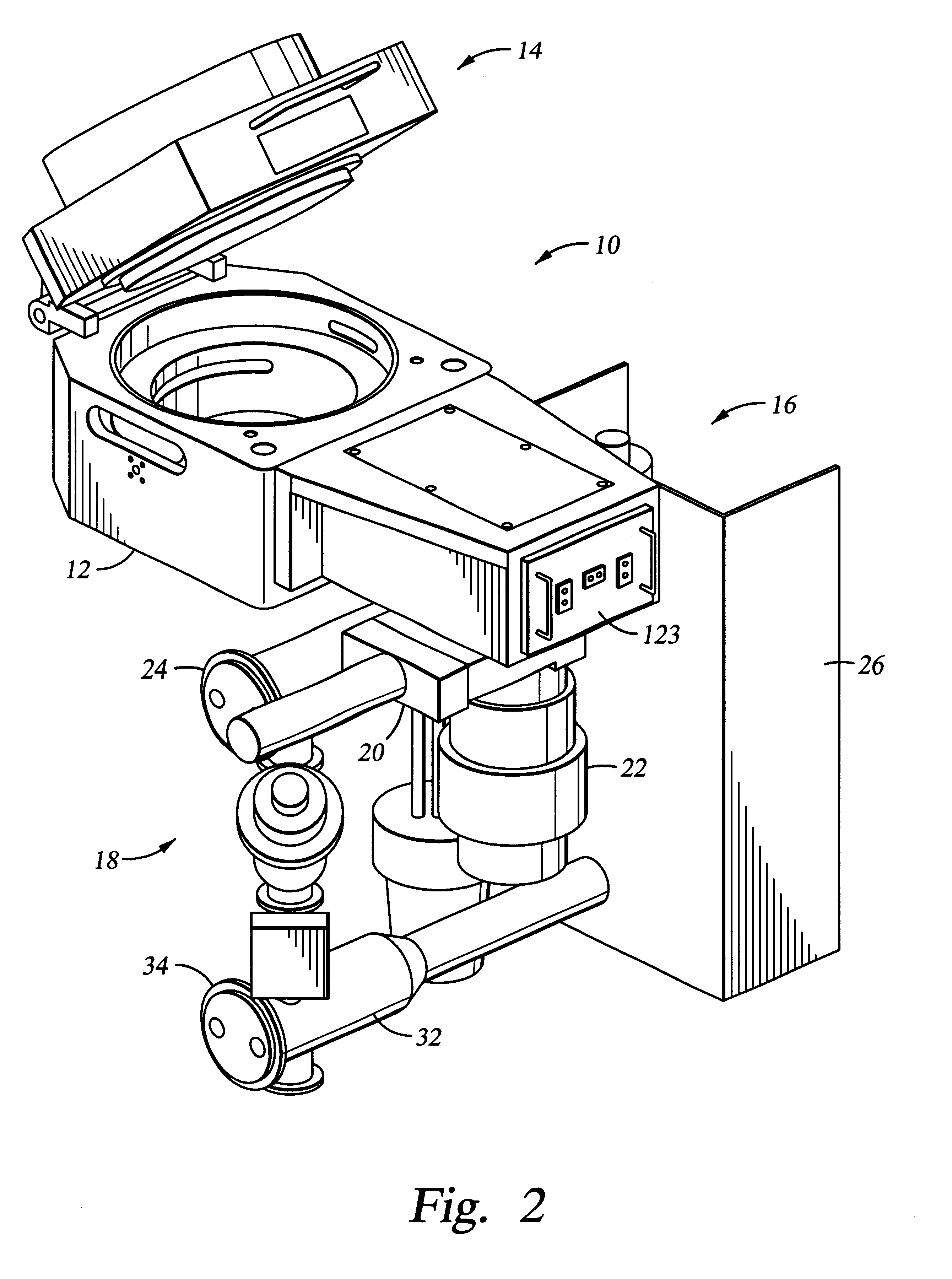

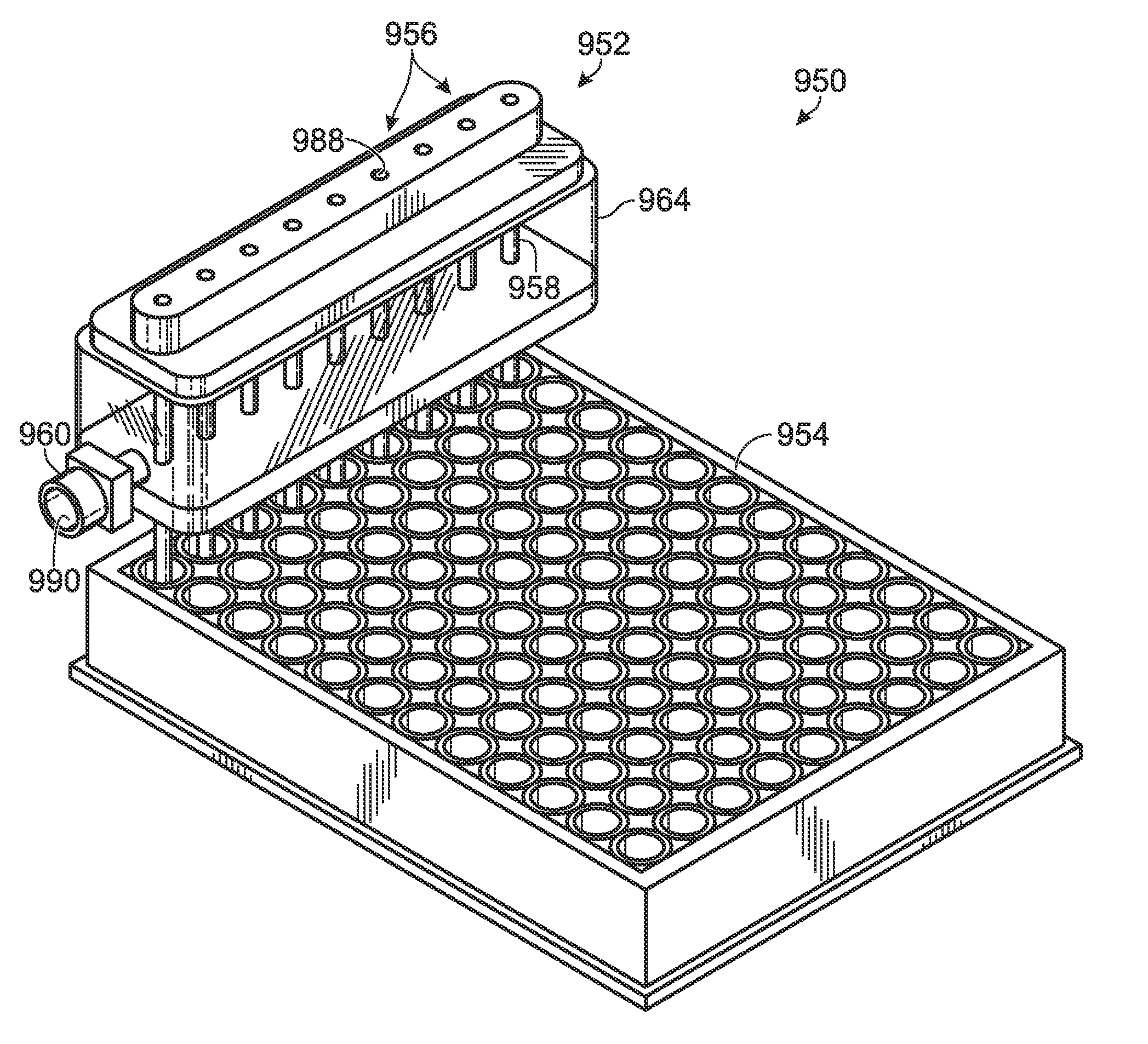

Droplet generation for droplet-based assays

ActiveUS20120190032A1High-confidence resultLower the volumeBioreactor/fermenter combinationsBiological substance pretreatmentsAssayEmulsion

A system, including method and apparatus, for generating droplets suitable for droplet-based assays. The disclosed systems may include either one-piece or multi-piece droplet generation components configured to form sample-containing droplets by merging aqueous, sample-containing fluid with a background emulsion fluid such as oil, to form an emulsion of sample-containing droplets suspended in the background fluid. In some cases, the disclosed systems may include channels or other suitable mechanisms configured to transport the sample-containing droplets to an outlet region, so that subsequent assay steps may be performed.

Owner:BIO RAD LAB INC

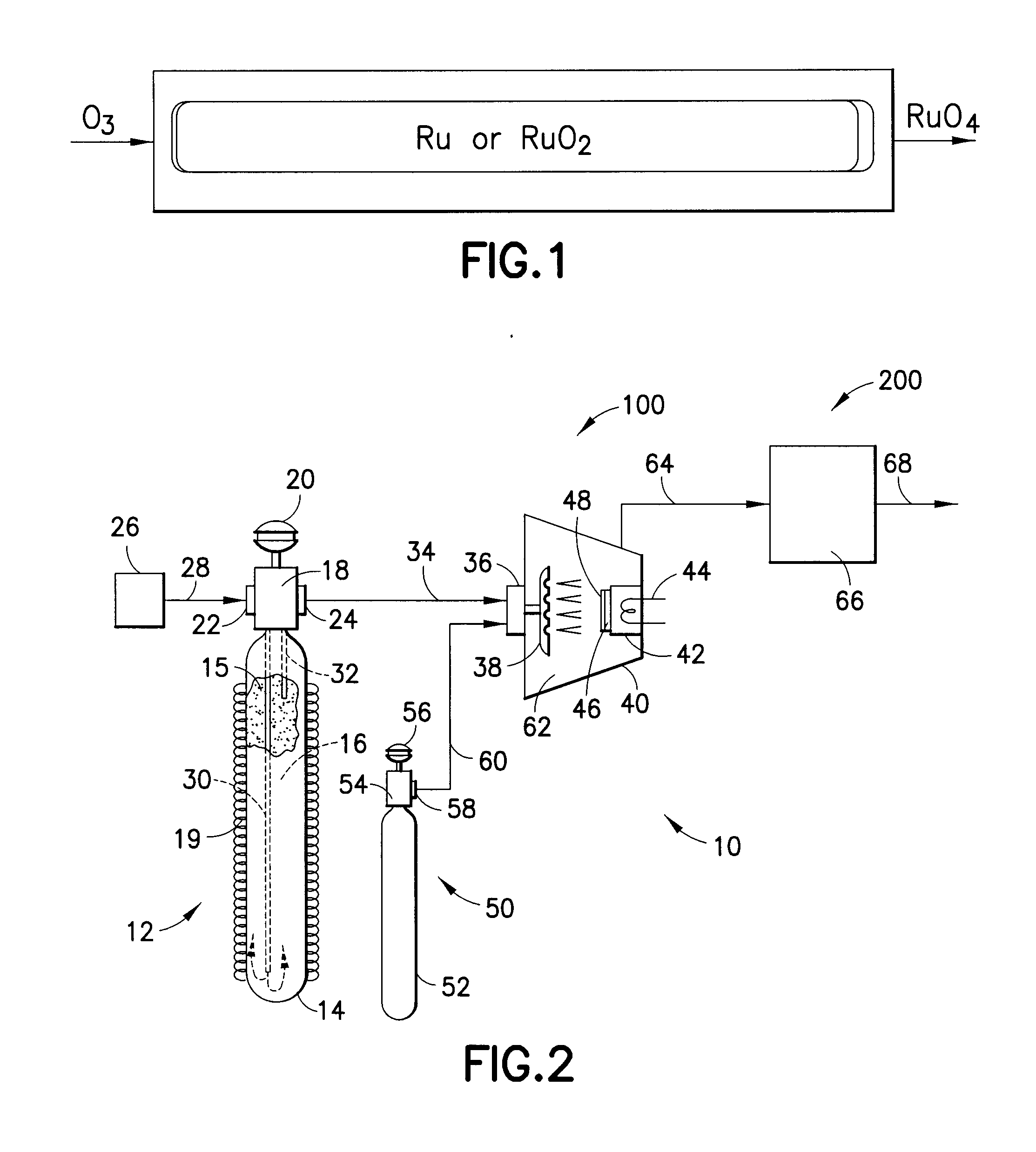

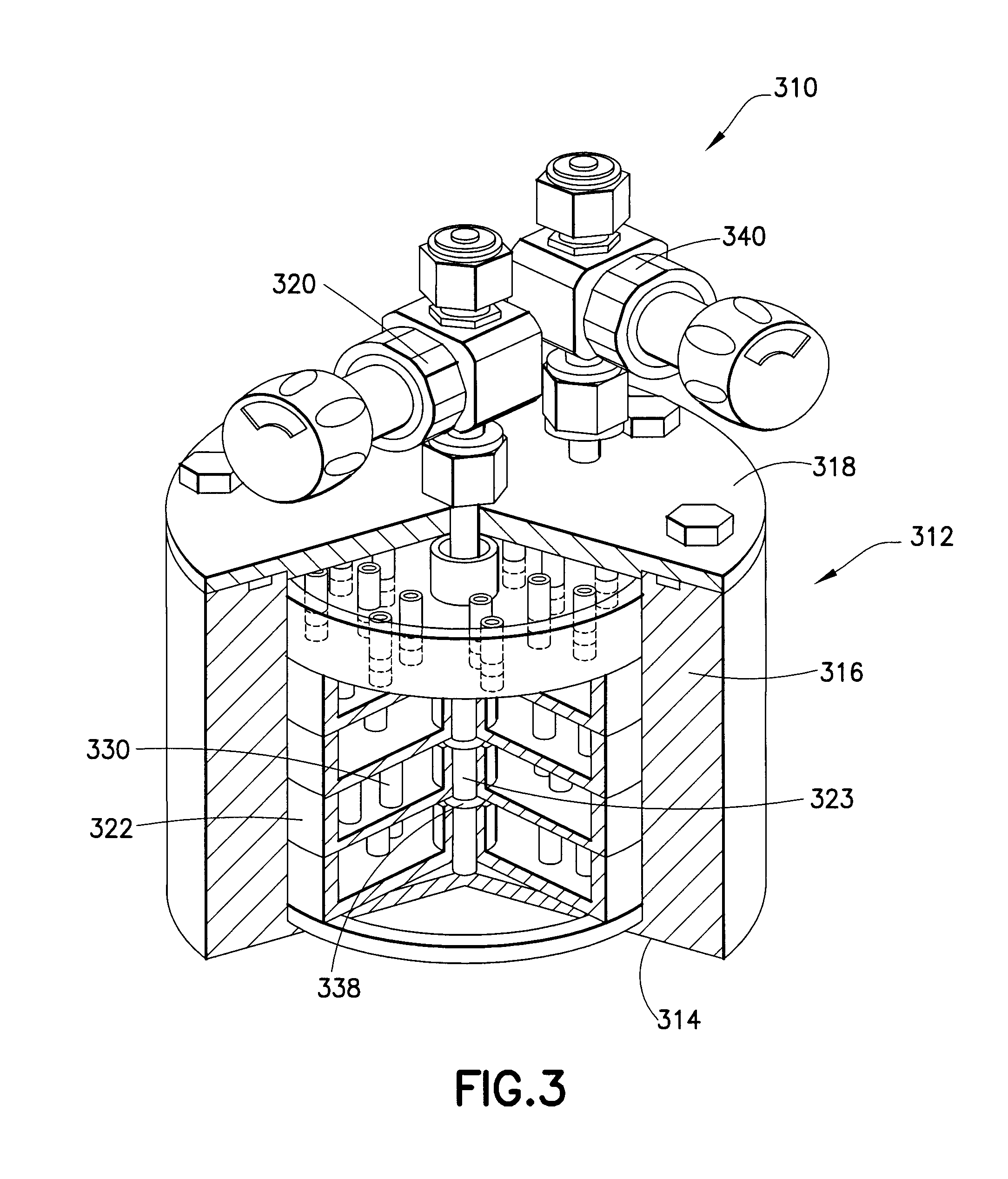

IN SITU GENERATION OF RuO4 FOR ALD OF Ru AND Ru RELATED MATERIALS

Apparatus and method for generating ruthenium tetraoxide in situ for use in vapor deposition, e.g., atomic layer deposition (ALD), of ruthenium-containing films on microelectronic device substrates. The ruthenium tetraoxide can be generated on demand by reaction of ruthenium or ruthenium dioxide with an oxic gas such as oxygen or ozone. In one implementation, ruthenium tetraoxide thus generated is utilized with a strontium organometallic precursor for atomic layer deposition of strontium ruthenate films of extremely high smoothness and purity.

Owner:ENTEGRIS INC

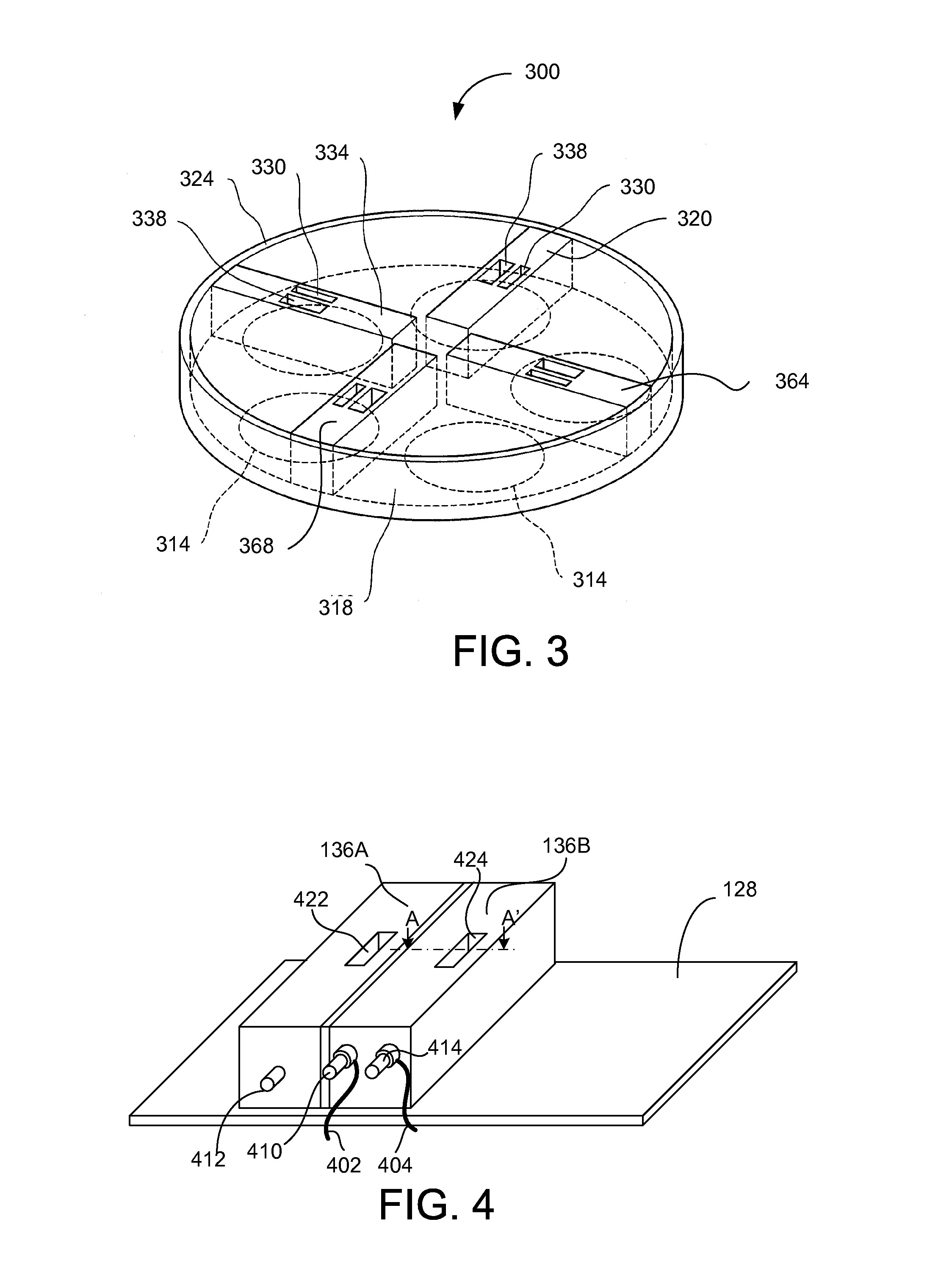

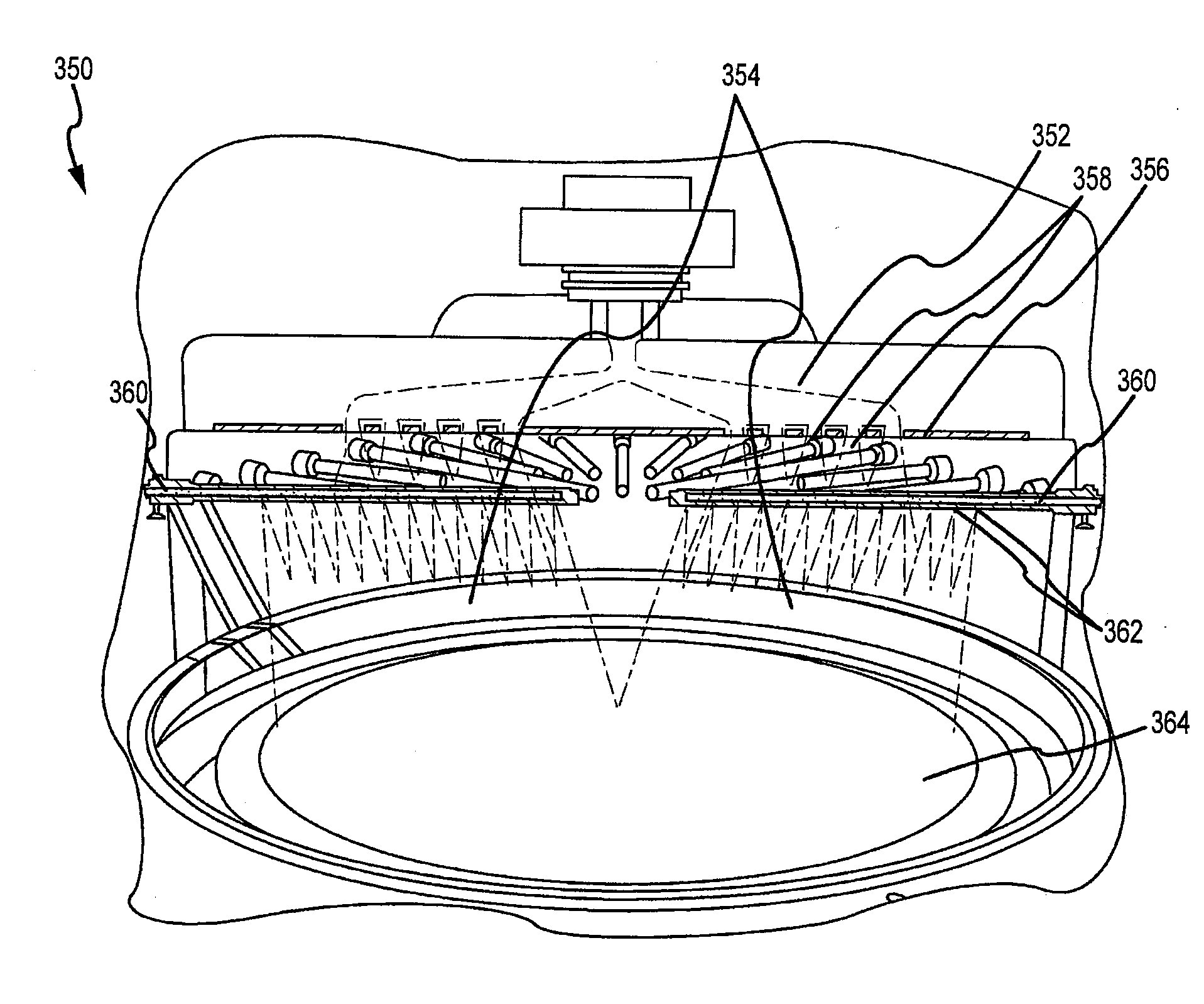

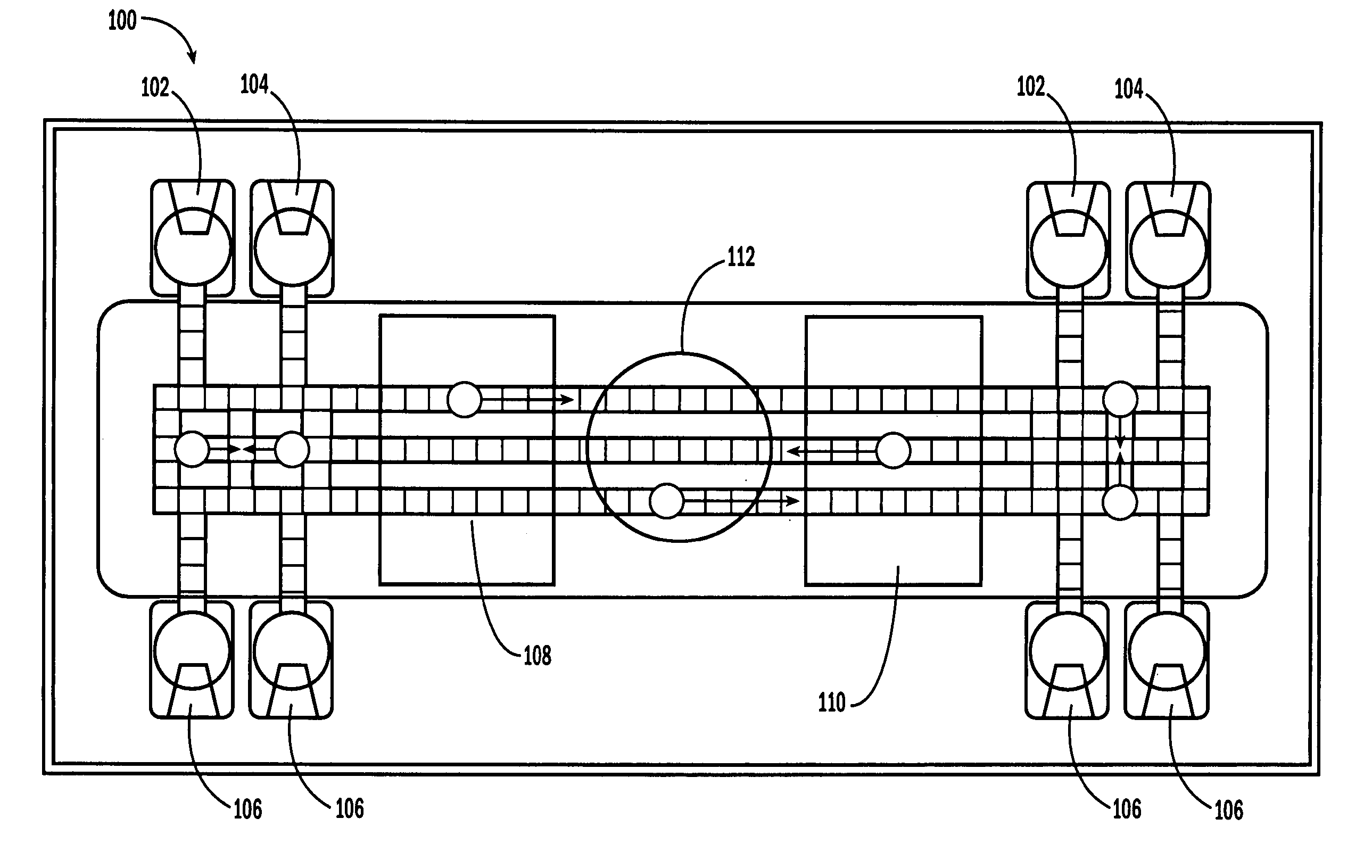

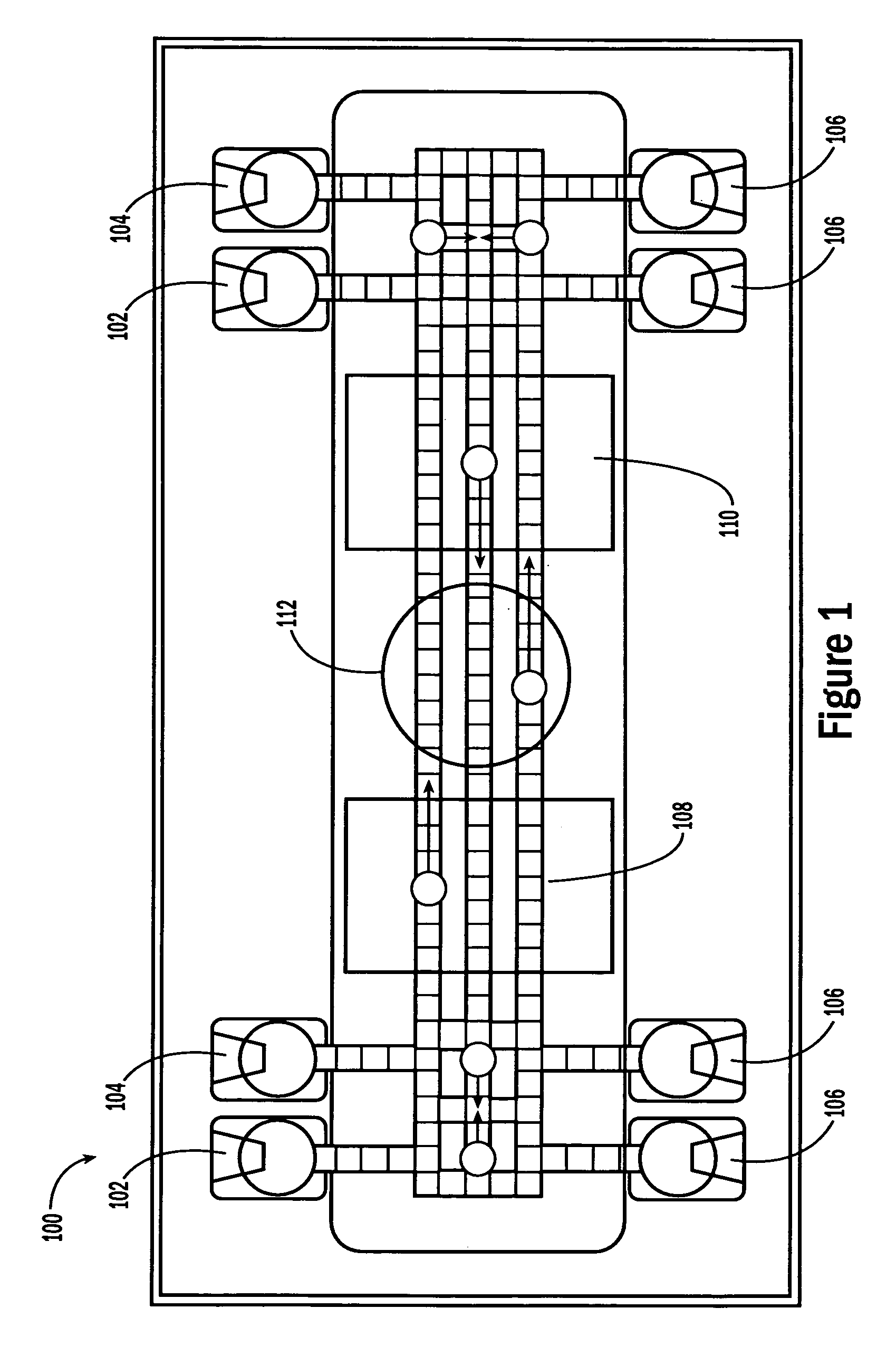

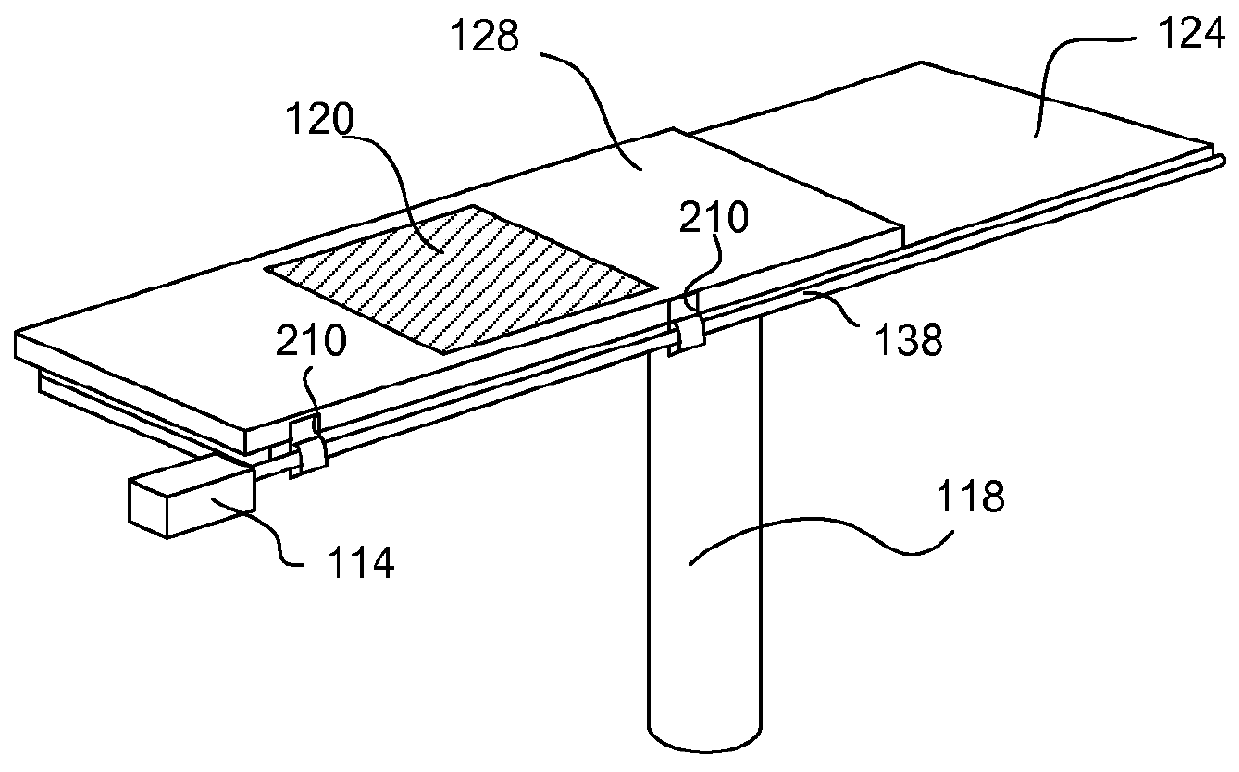

Extended Reactor Assembly with Multiple Sections for Performing Atomic Layer Deposition on Large Substrate

InactiveUS20120125258A1Electric discharge tubesChemical vapor deposition coatingFree-radical reactionInjector

An elongated reactor assembly in a deposition device for performing atomic layer deposition (ALD) on a large substrate. The elongated reactor assembly includes one or more injectors and / or radical reactors. Each injector or radical reactor injects a gas or radicals onto the substrate as the substrate passes the injector or radical reactor as part of the ALD process. Each injector or radical reactor includes a plurality of sections where at least two sections have different cross sectional configurations. By providing different sections in the injector or radical reactor, the injector or radical reactor may inject the gas or the radicals more uniformly over the substrate. Each injector or radical reactor may include more than one outlet for discharging excess gas or radicals outside the deposition device.

Owner:VEECO ALD

Method and apparatus for generating plasma

InactiveUS20110003087A1Easy to controlImprove uniformityElectric discharge tubesChemical vapor deposition coatingSurface reactionGas phase

A reaction chamber of a reactor for coating or treating a substrate by an atomic layer deposition process (ALD) by exposing the substrate to alternately repeated surface reactions of two or more gas-phase reactants. The reaction chamber is configured to generate capacitively coupled plasma and comprises a reaction space within said reaction chamber, a first inlet to guide gases into the reaction chamber and an outlet to lead gases out of the reaction chamber. The reaction chamber is configured to lead the two or more reactants into the reaction chamber such that the two or more reactants may flow through the reaction space across the substrate in a direction essentially parallel to the inner surface of the lower wall.

Owner:BENEQ OY

Atmospheric pressure molecular layer CVD

InactiveUS20050084610A1Reducing physisorptionHigh purityChemical vapor deposition coatingChemical physicsControl system

An Atomic Layer CVD process and apparatus deposits single and or multiple minelayers of material sequentially at atmospheric pressure. Sequential monolayer depositions are separated in time and in space by combinations of physical barriers and / or gas curtains and / or by physical movement of substrates from one deposition chamber or location to another Pulse and / or continuous flows of reactant and purge gases are used in alternate embodiments of the present invention. Reactant injection, purge gas flow and exhaust flows at separated deposition chambers or locations are controlled by coordination of dedicated gas manifolds and control systems for each spatially or temporally separated deposition process or location.

Owner:SELITSER SIMON I

Method of forming metal nitride film by chemical vapor deposition and method of forming metal contact and capacitor of semiconductor device using the same

InactiveUS6348376B2Good step coverageLow resistivitySemiconductor/solid-state device manufacturingCapacitorsDevice materialNitrogen source

A method of forming a metal nitride film using chemical vapor deposition (CVD), and a method of forming a metal contact and a semiconductor capacitor of a semiconductor device using the same, are provided. The method of forming a metal nitride film using chemical vapor deposition (CVD) in which a metal source and a nitrogen source are used as a precursor, includes the steps of inserting a semiconductor substrate into a deposition chamber, flowing the metal source into the deposition chamber, removing the metal source remaining in the deposition chamber by cutting off the inflow of the metal source and flowing a purge gas into the deposition chamber, cutting off the purge gas and flowing the nitrogen source into the deposition chamber to react with the metal source adsorbed on the semiconductor substrate, and removing the nitrogen source remaining in the deposition chamber by cutting off the inflow of the nitrogen source and flowing the purge gas into the deposition chamber. Accordingly, the metal nitride film having low resistivity and a low content of Cl even with excellent step coverage can be formed at a temperature of 500° C. or lower, and a semiconductor capacitor having excellent leakage current characteristics can be manufactured. Also, a deposition speed, approximately 20 A / cycle, is suitable for mass production.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com