Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4590results about How to "Low resistivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

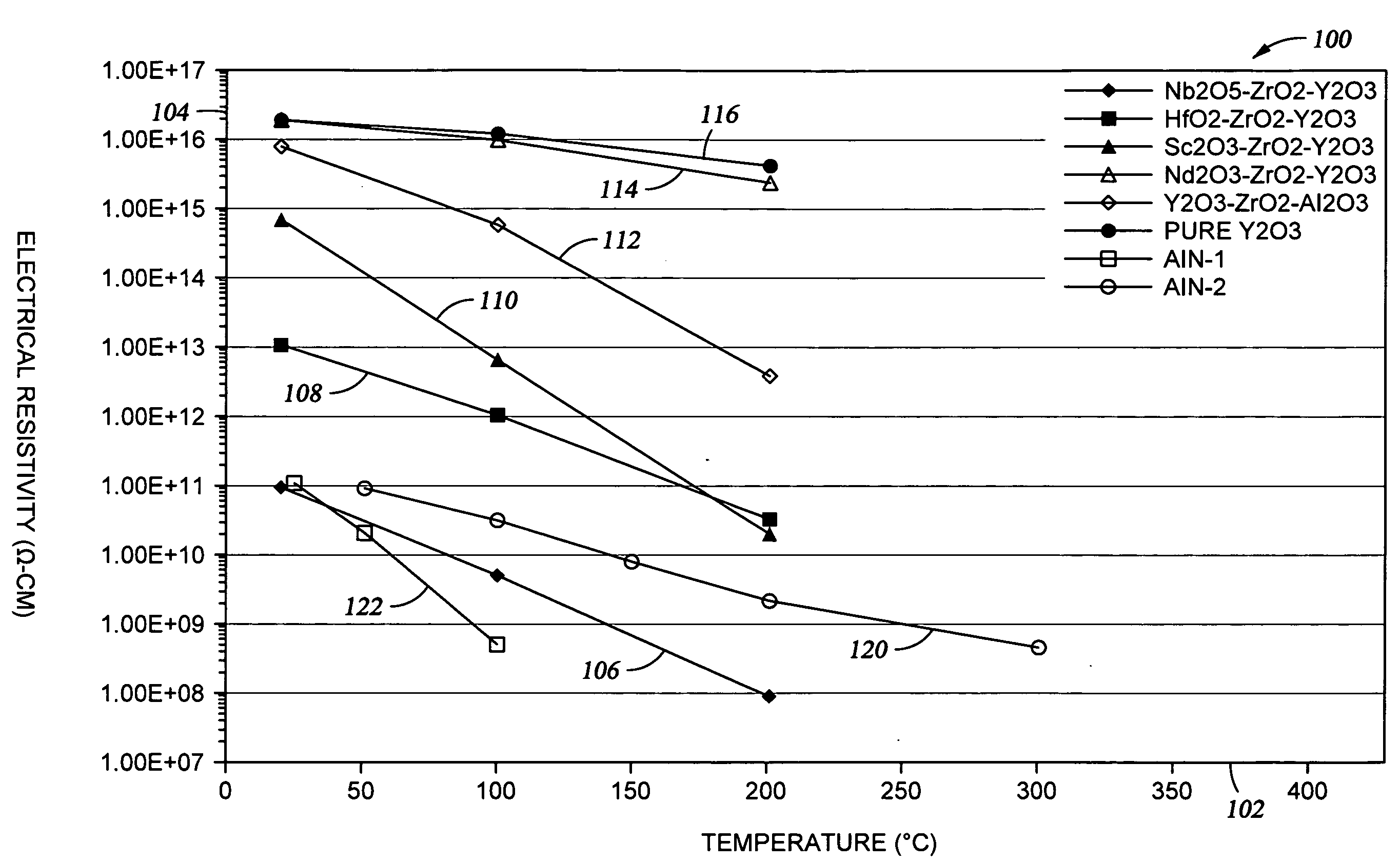

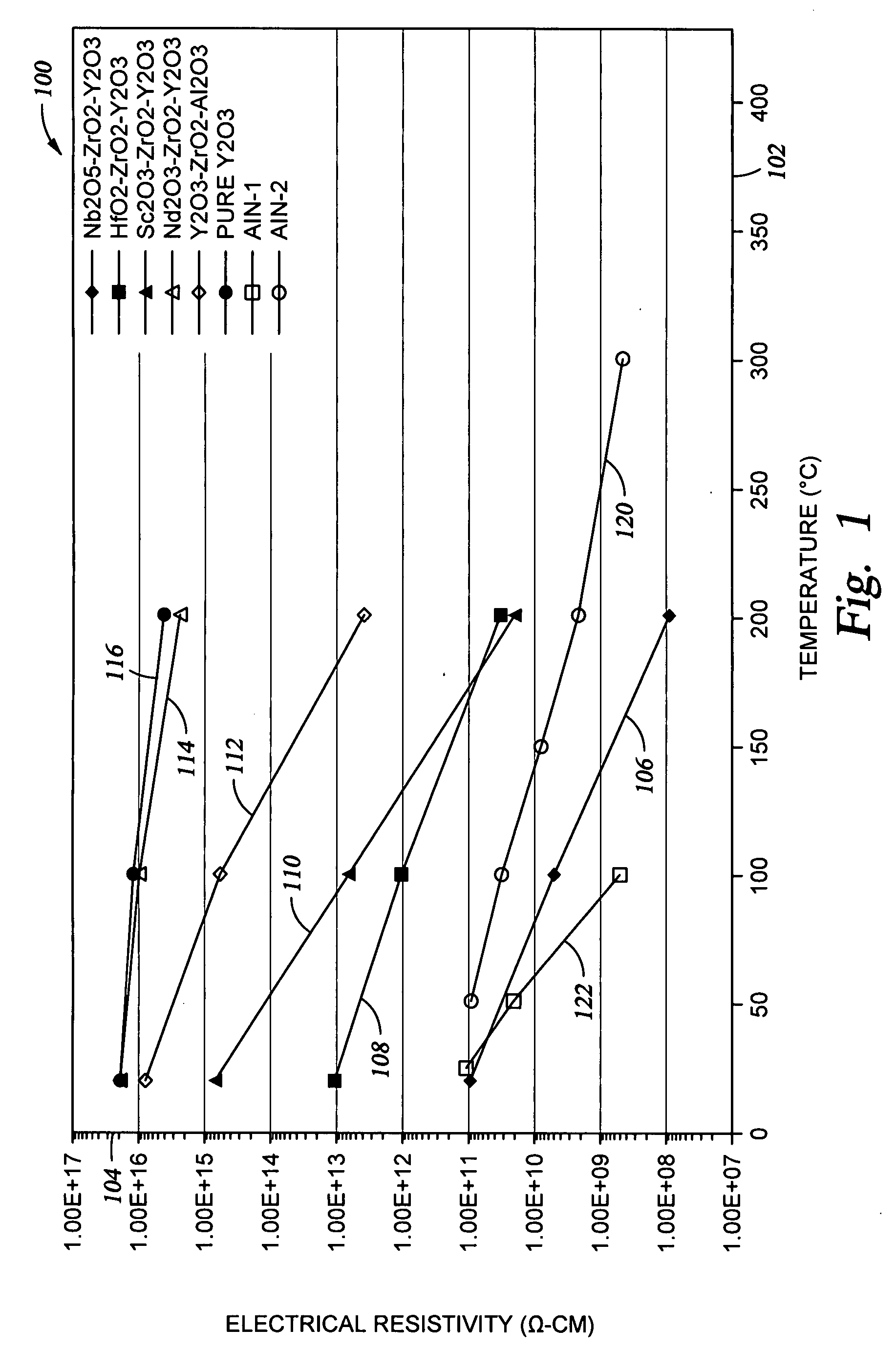

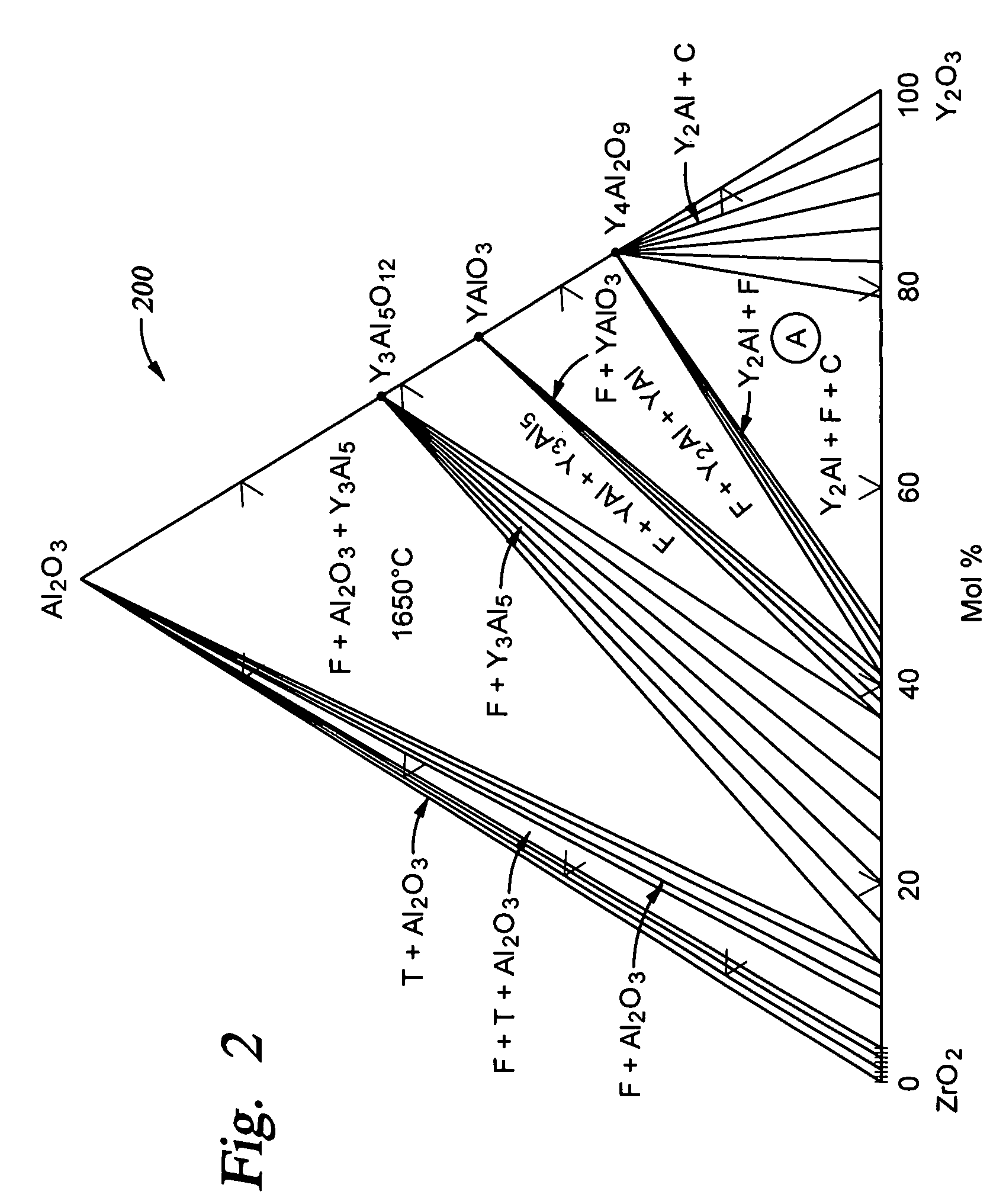

Plasma-resistant ceramics with controlled electrical resistivity

ActiveUS20090036292A1Improve plasma resistanceTailored mechanical propertiesSemiconductor/solid-state device manufacturingGlass/slag layered productsHalogenCeramic

Specialty ceramic materials which resist corrosion / erosion under semiconductor processing conditions which employ a corrosive / erosive plasma. The corrosive plasma may be a halogen-containing plasma. The specialty ceramic materials have been modified to provide a controlled electrical resistivity which suppresses plasma arcing potential.

Owner:APPLIED MATERIALS INC

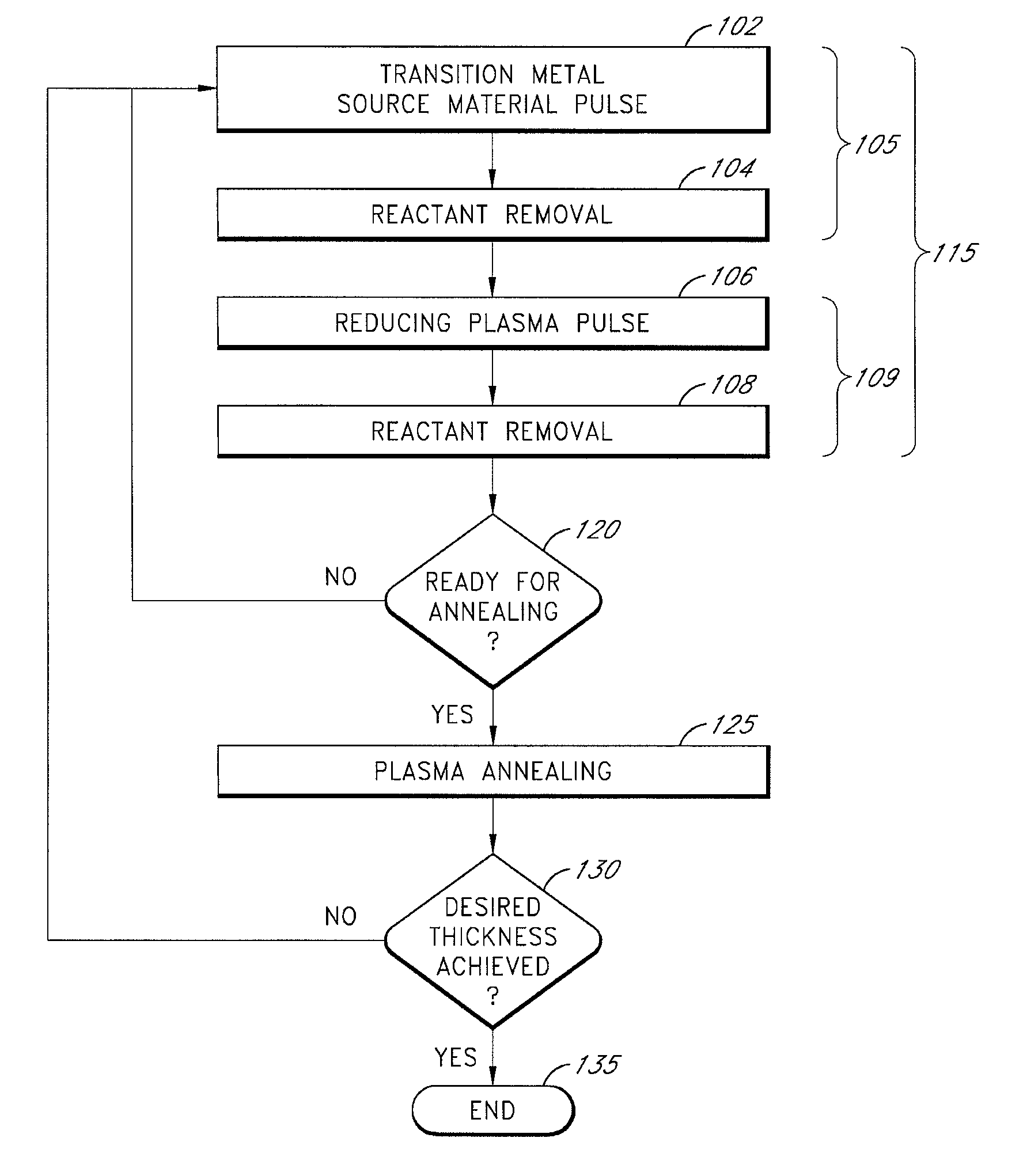

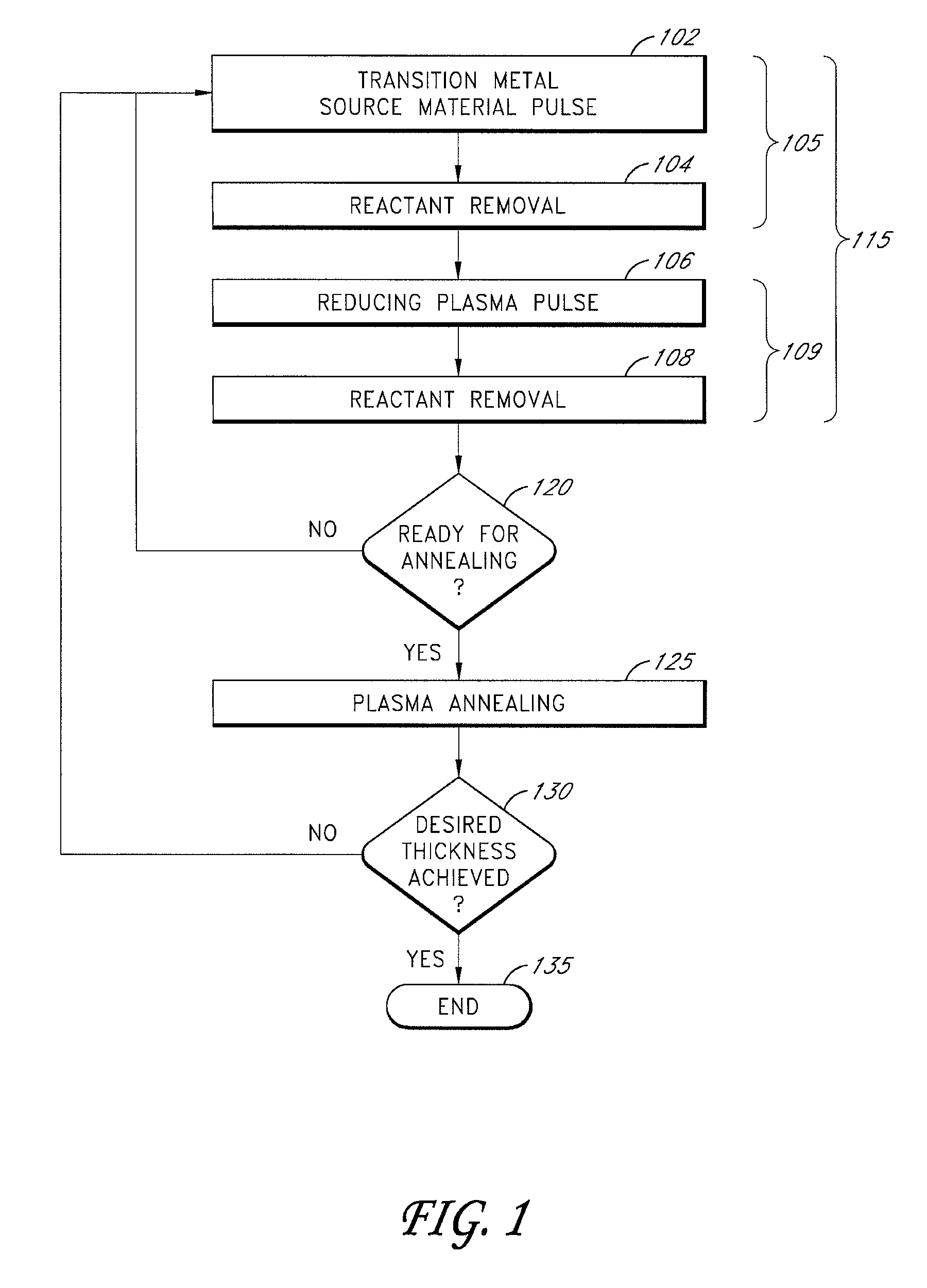

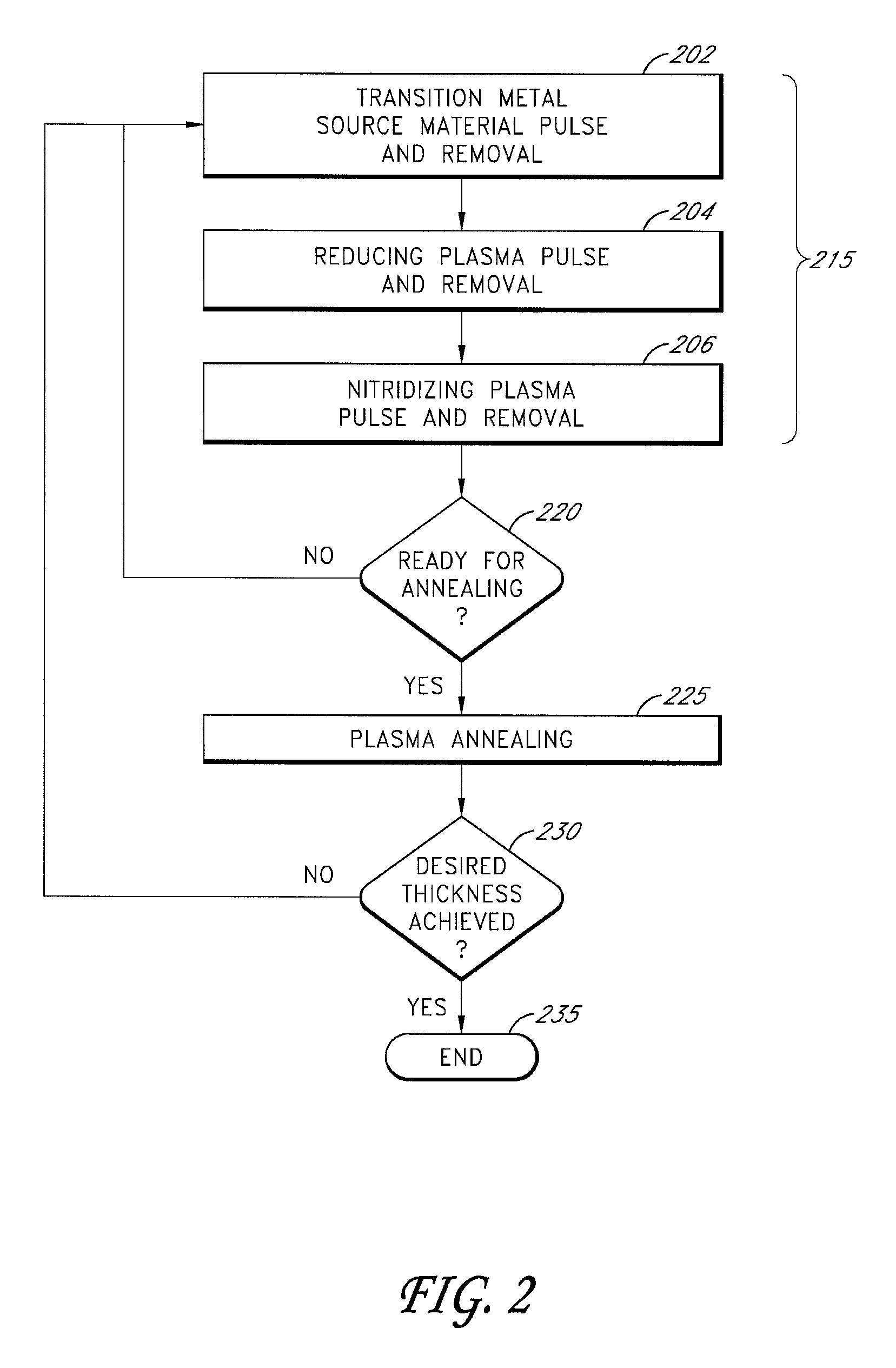

Periodic plasma annealing in an ALD-type process

ActiveUS7713874B2Increase probabilityReduce susceptibility to oxidationPolycrystalline material growthSemiconductor/solid-state device manufacturingGas phaseVapor phase

Methods for performing periodic plasma annealing during atomic layer deposition are provided along with structures produced by such methods. The methods include contacting a substrate with a vapor-phase pulse of a metal source chemical and one or more plasma-excited reducing species for a period of time. Periodically, the substrate is contacted with a vapor phase pulse of one or more plasma-excited reducing species for a longer period of time. The steps are repeated until a metal thin film of a desired thickness is formed over the substrate.

Owner:ASM IP HLDG BV

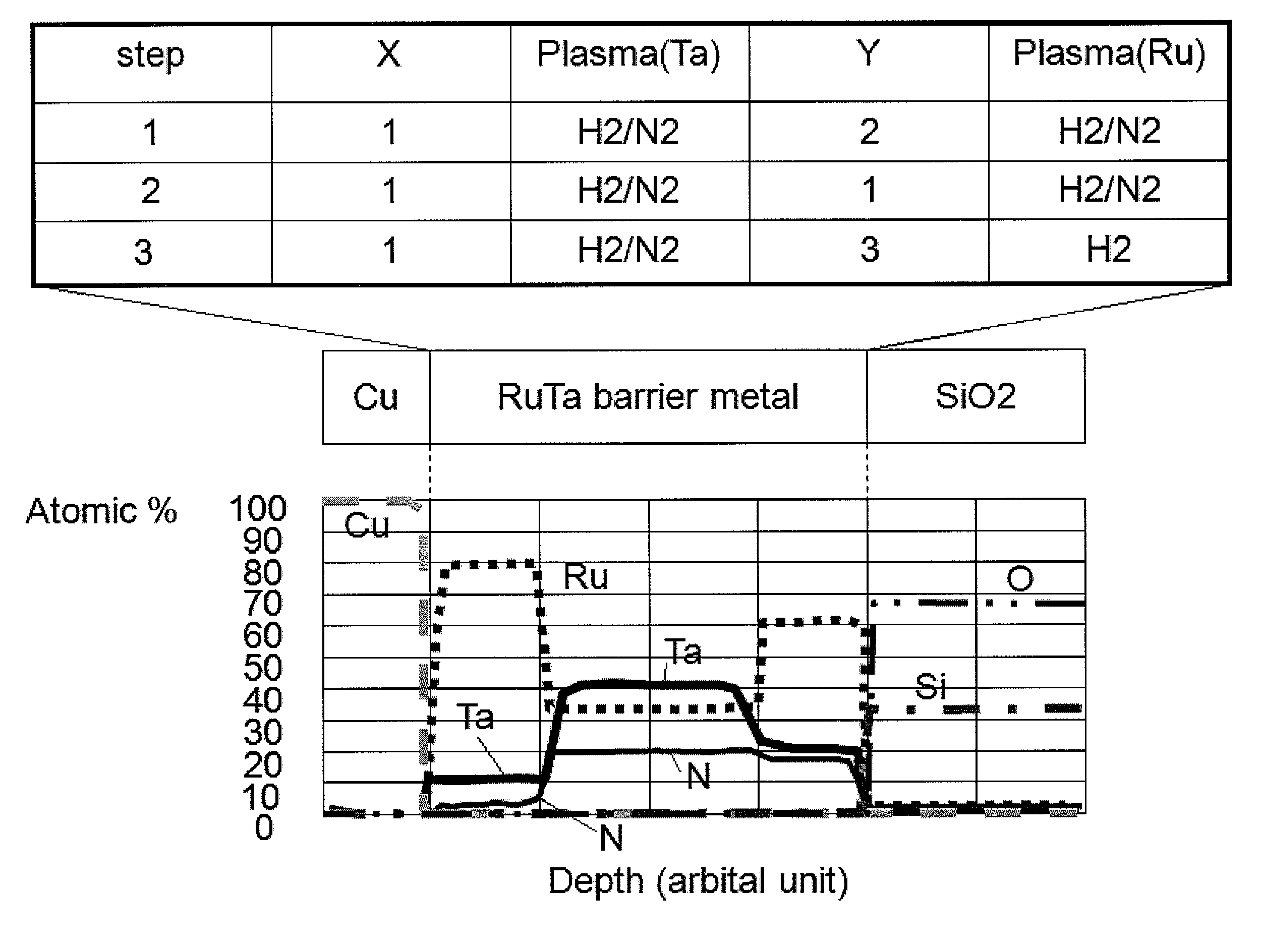

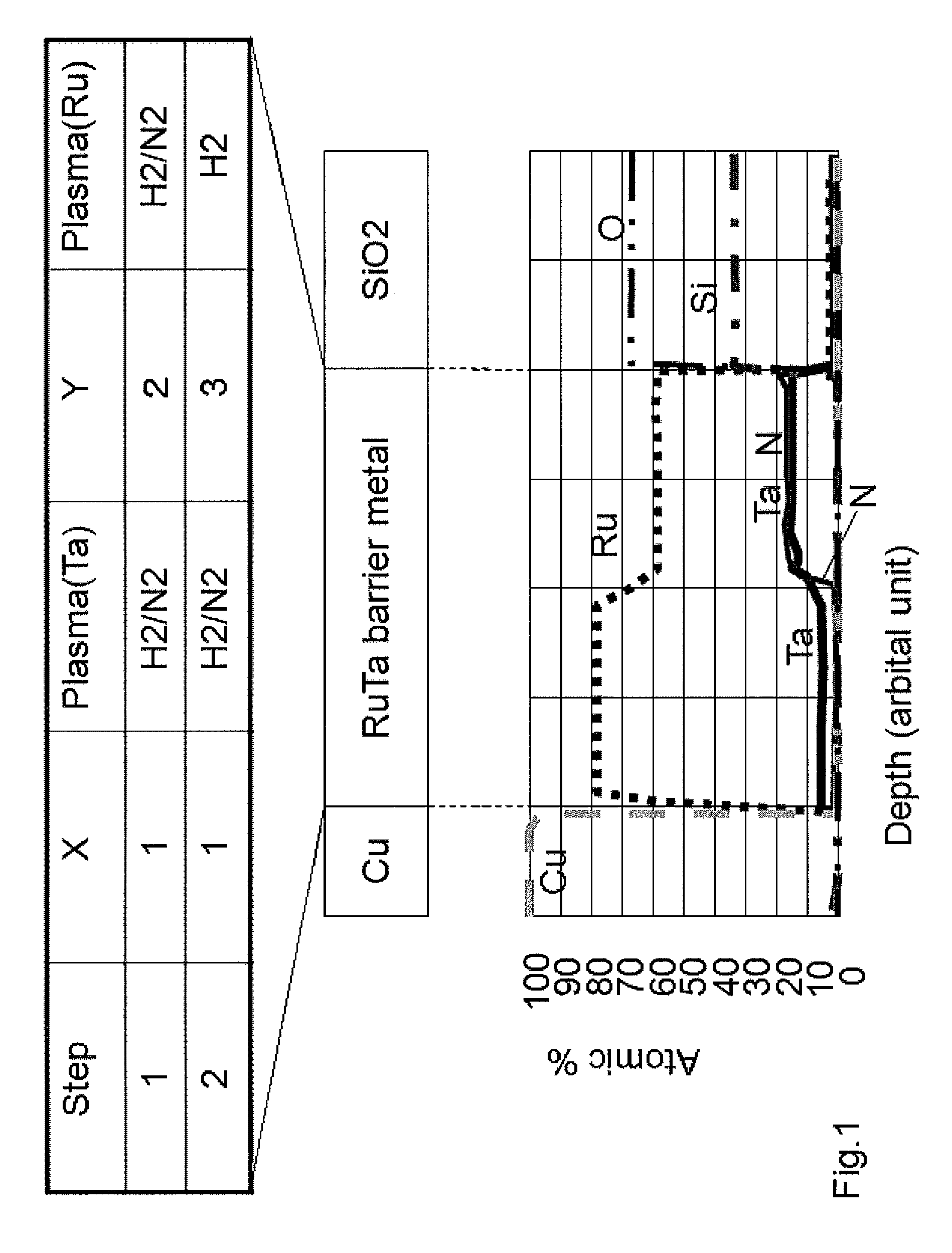

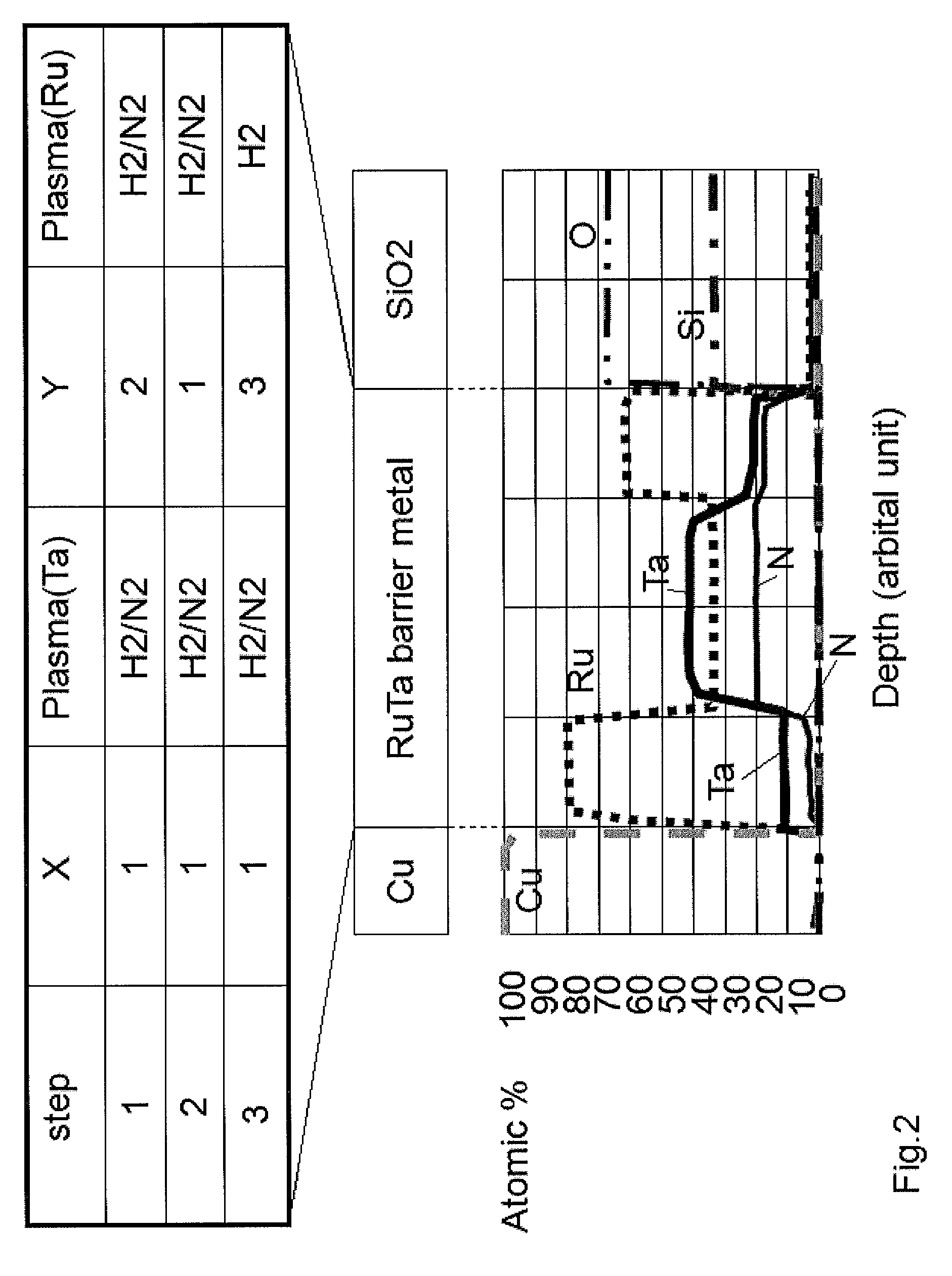

Atomic composition controlled ruthenium alloy film formed by plasma-enhanced atomic layer deposition

ActiveUS8084104B2Reduce resistanceLow densitySemiconductor/solid-state device detailsSynthetic resin layered productsRutheniumAlloy

A metal film composed of multiple atomic layers continuously formed by atomic layer deposition of Ru and Ta or Ti includes at least a top section and a bottom section, wherein an atomic composition of Ru, Ta or Ti, and N varies in a thickness direction of the metal film. The atomic composition of Ru, Ta or Ti, and N in the top section is represented as Ru(x1)Ta / Ti(y1)N(z1) wherein an atomic ratio of Ru(x1) / (Ta / Ti(y1)) is no less than 15, and z1 is 0.05 or less. The atomic composition of Ru, Ta or Ti, and N in the bottom section is represented as Ru(x2)Ta / Ti(y2)N(z2) wherein an atomic ratio of Ru(x2) / (Ta / Ti(y2)) is more than zero but less than 15, and z2 is 0.10 or greater.

Owner:ASM JAPAN

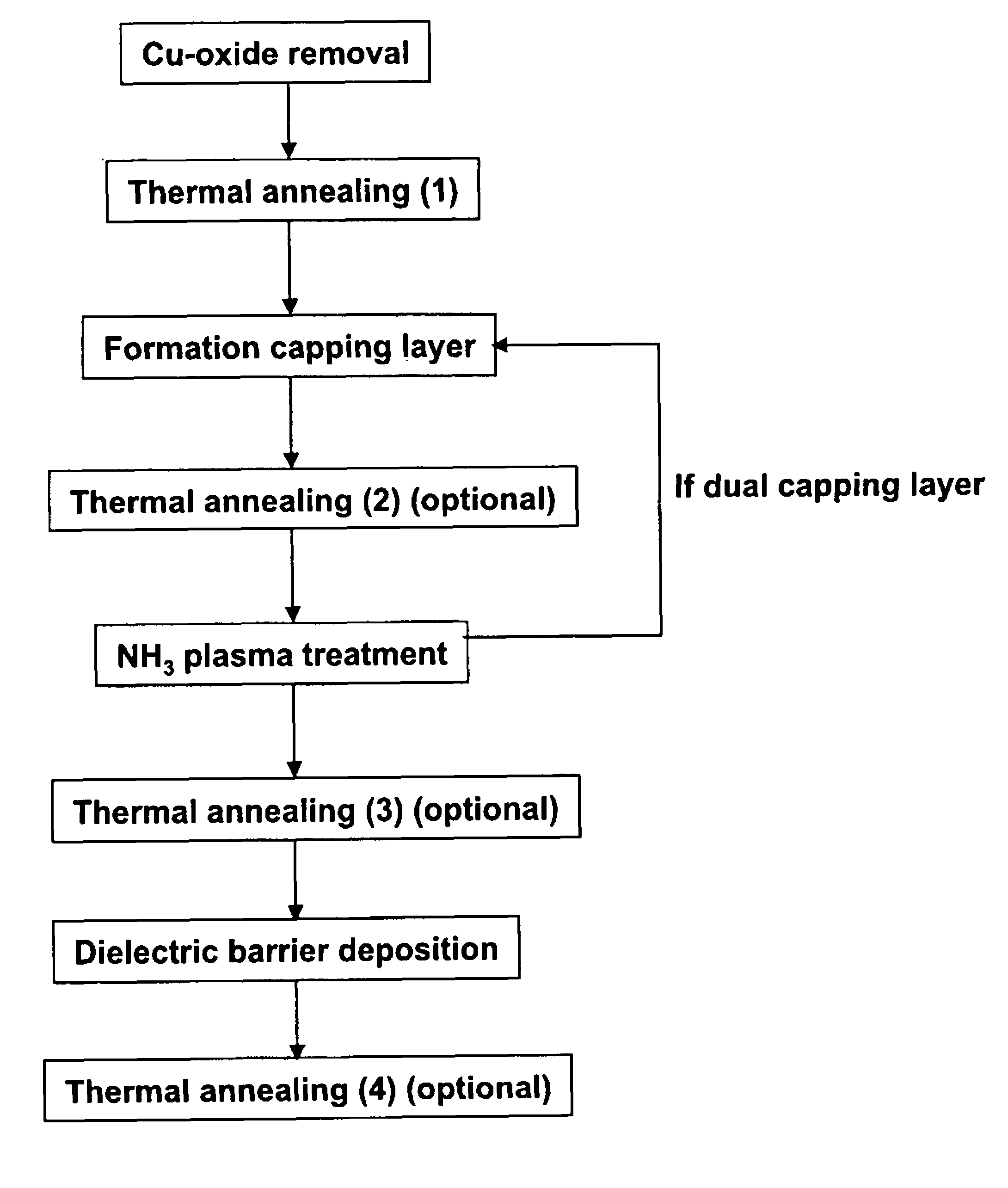

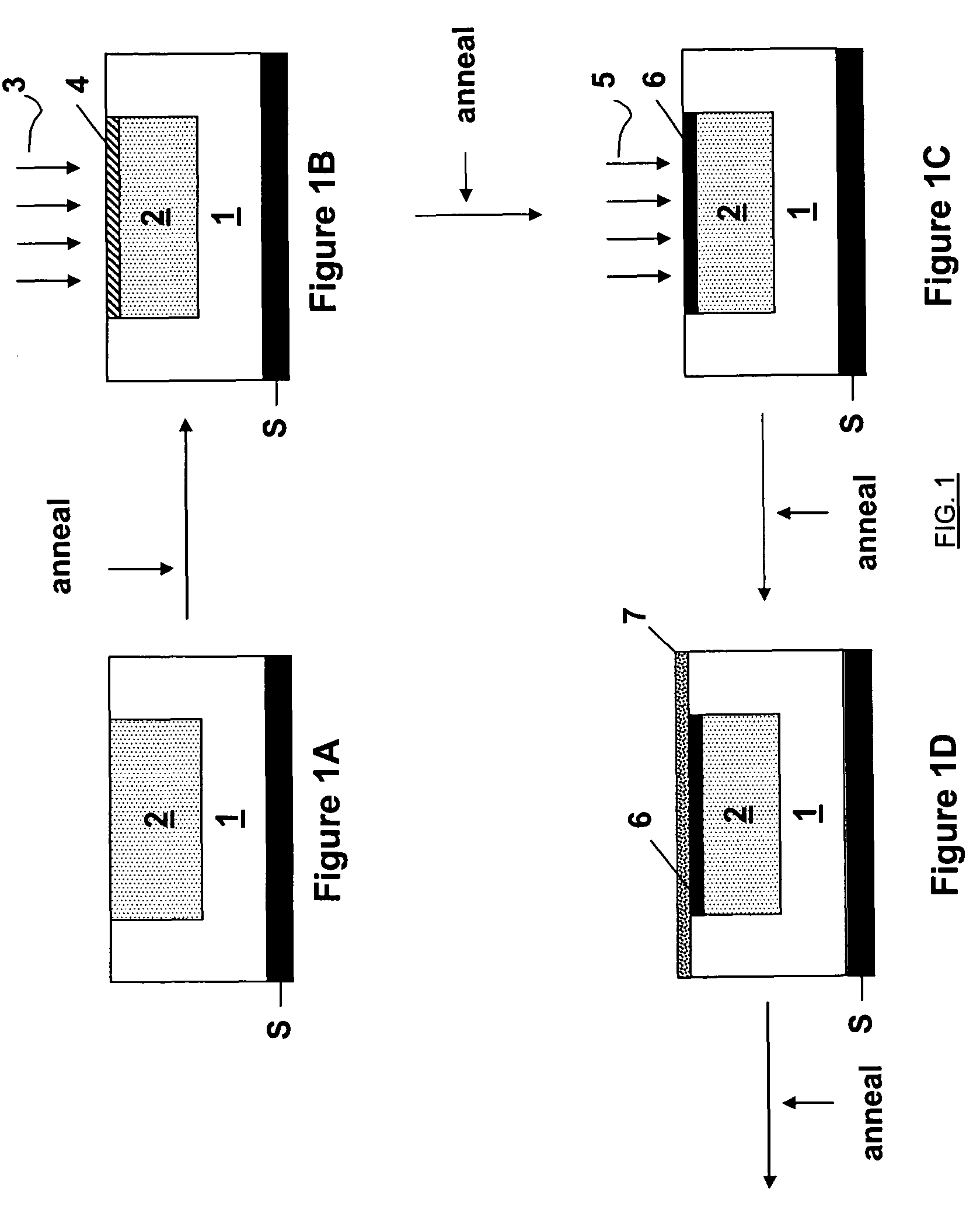

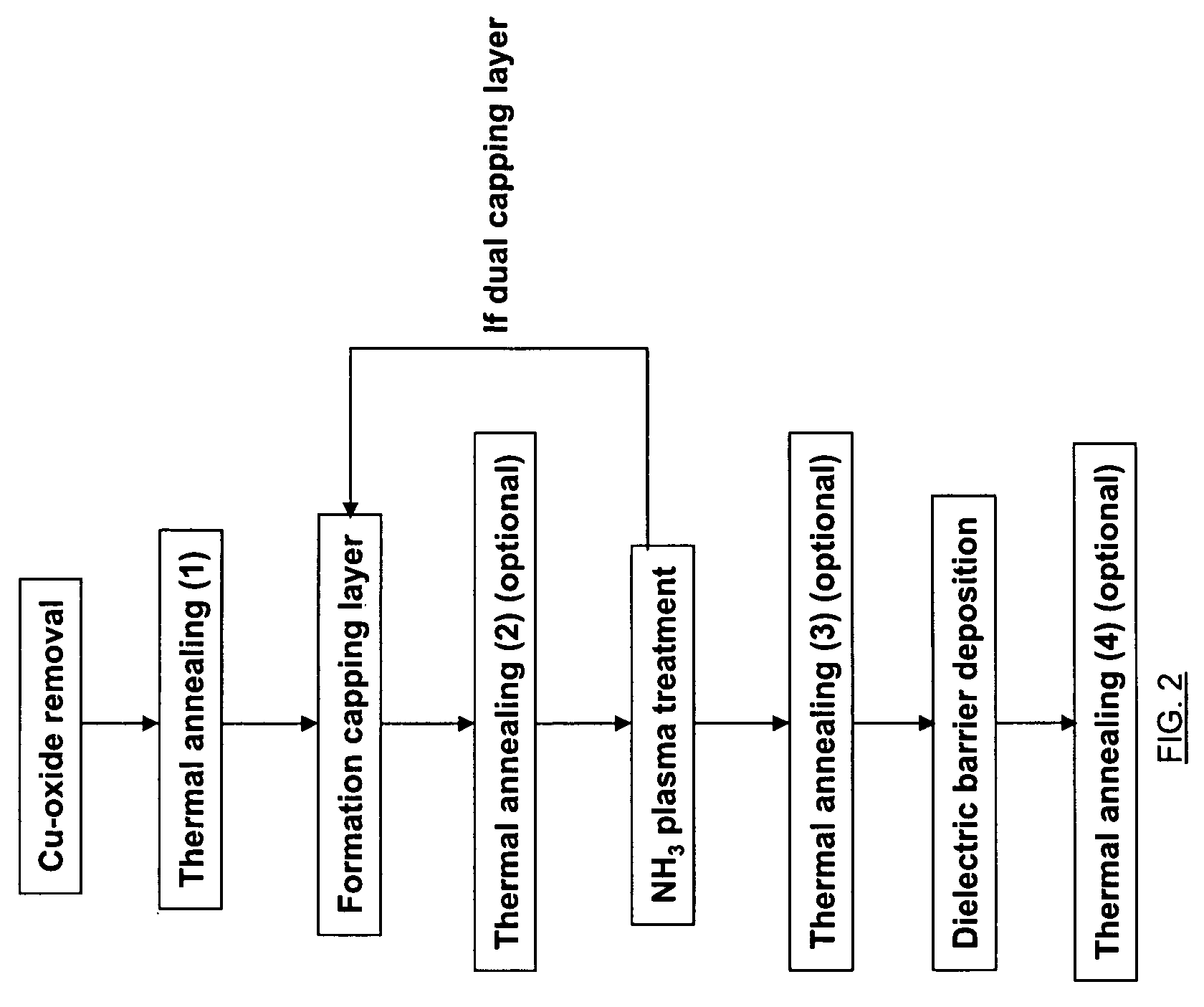

Integrated circuit and manufacturing method of copper germanide and copper silicide as copper capping layer

ActiveUS7858519B2Improve barrier propertiesAvoiding Cu out diffusingSemiconductor/solid-state device detailsSolid-state devicesGermanideCopper silicide

A method is provided for forming a capping layer comprising Cu, N, and also Si and / or Ge onto a copper conductive structure, said method comprising the sequential steps of: forming, at a temperature range between 200° C. up to 400° C., at least one capping layer onto said copper conductive structure by exposing said structure to a GeH4 and / or a SiH4 comprising ambient, performing a NH3 plasma treatment thereby forming an at least partly nitrided capping layer, forming a dielectric barrier layer onto said at least partly nitrided capping layer, wherein prior to said step of forming said at least one capping layer a pre-annealing step of said copper conductive structure is performed at a temperature range between 250° C. up to 450° C.

Owner:TAIWAN SEMICON MFG CO LTD +1

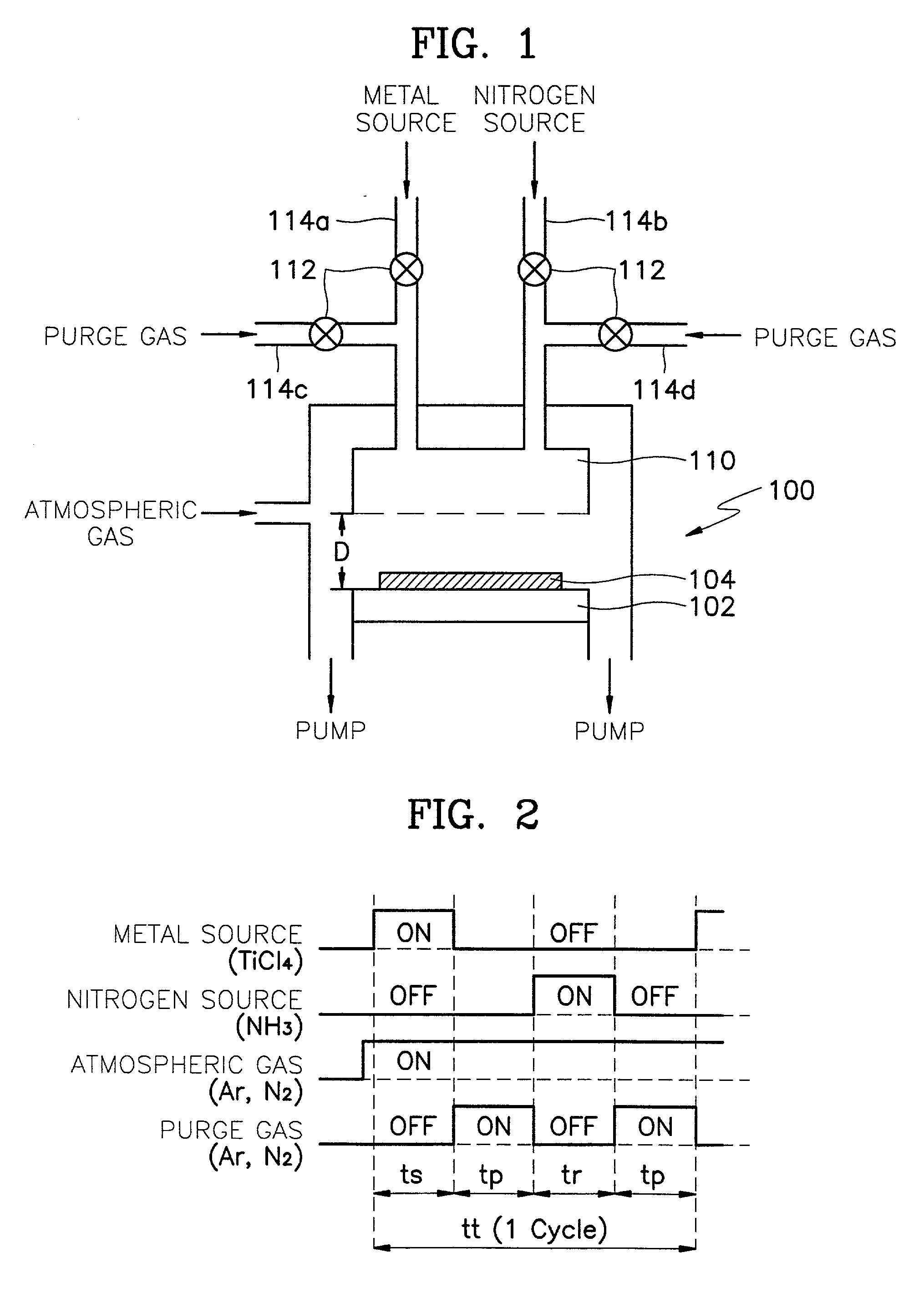

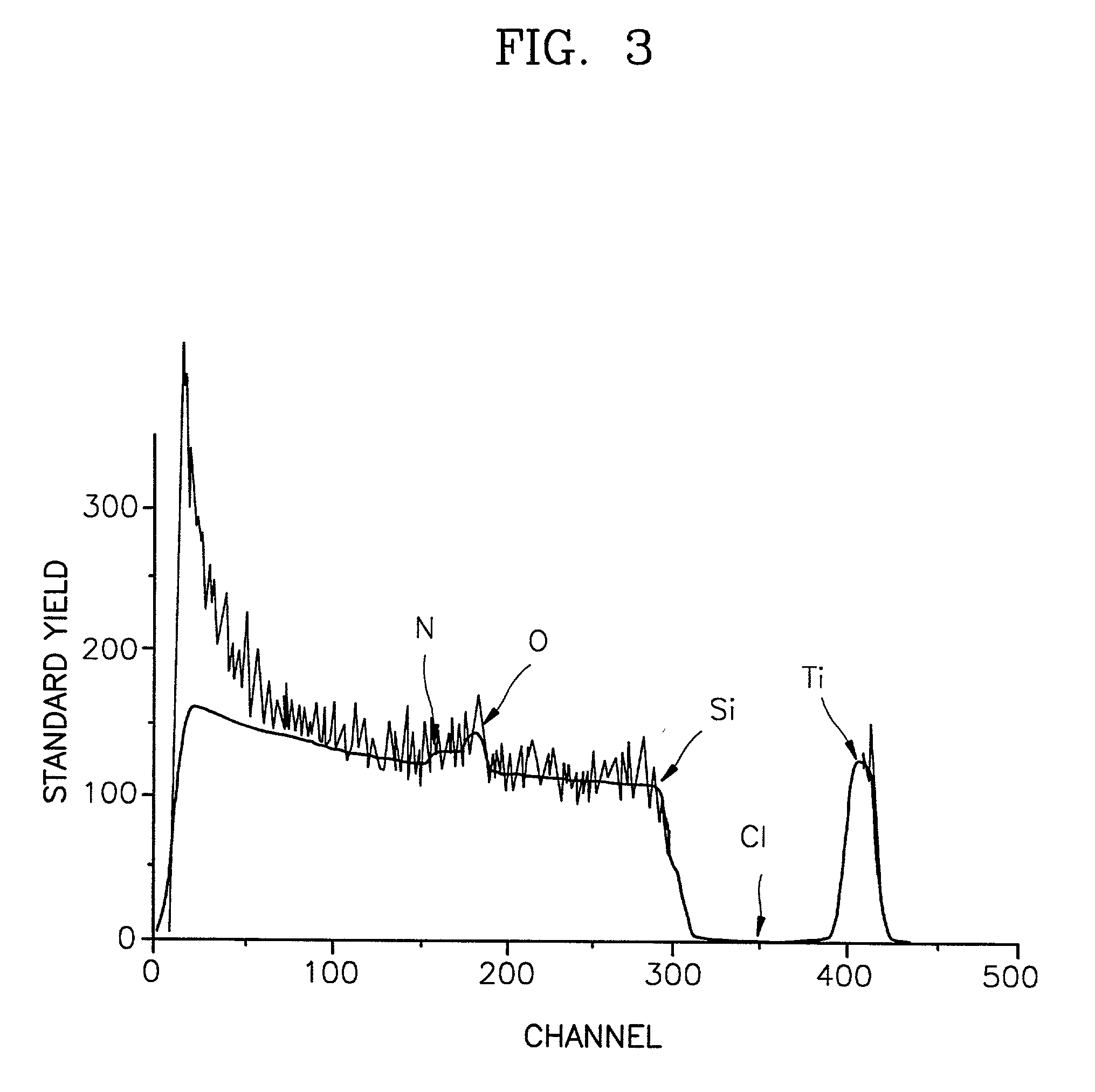

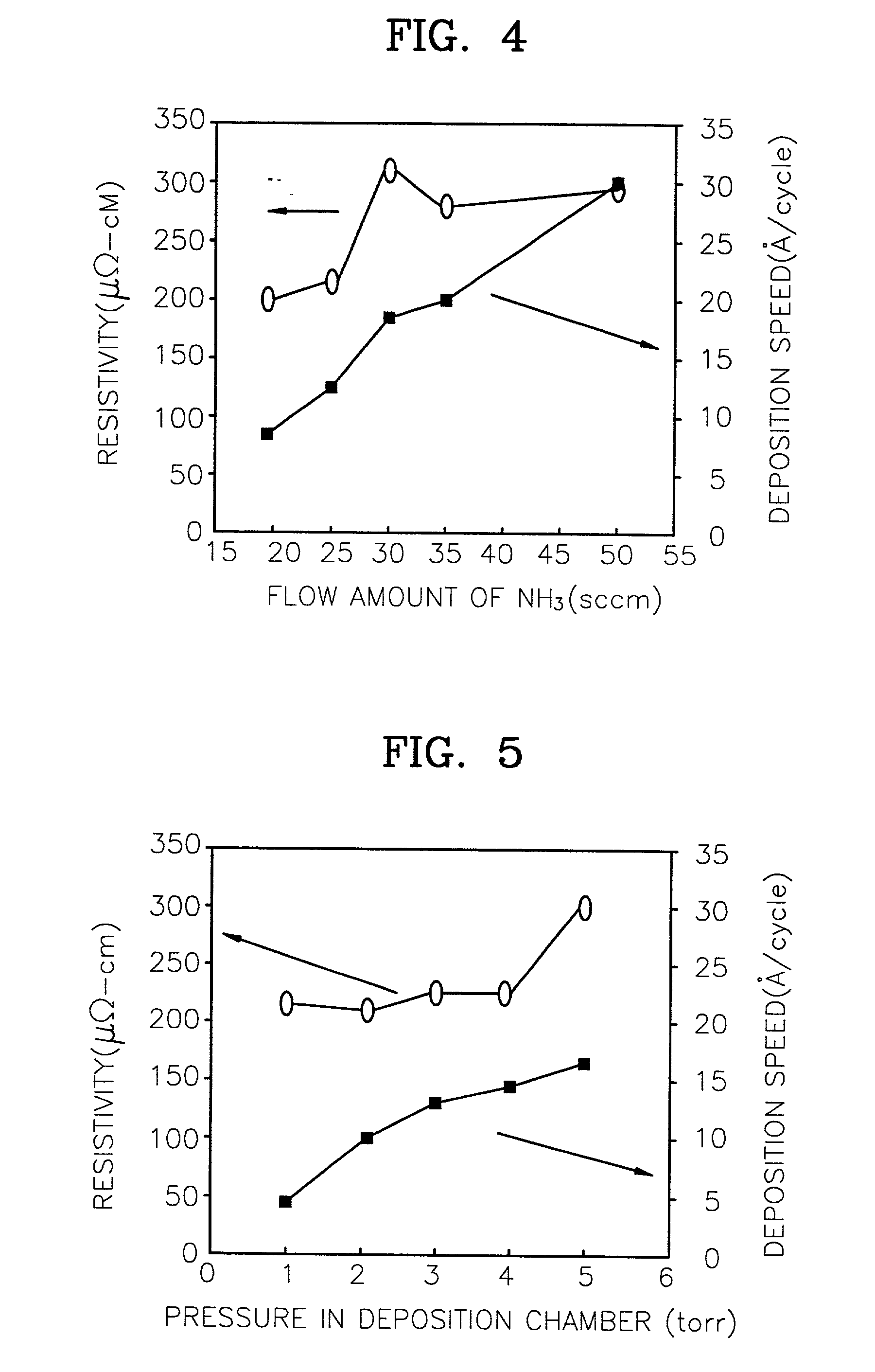

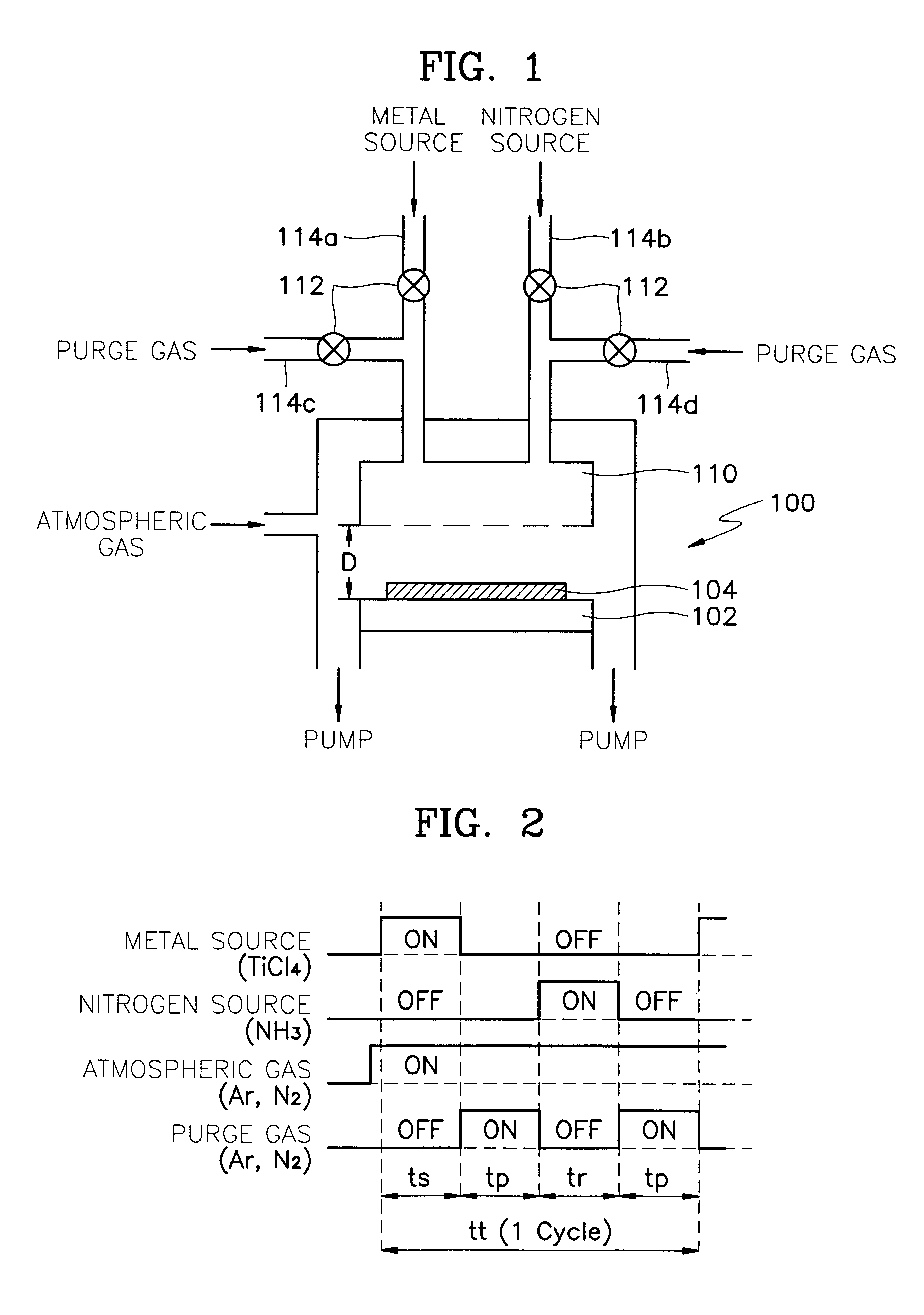

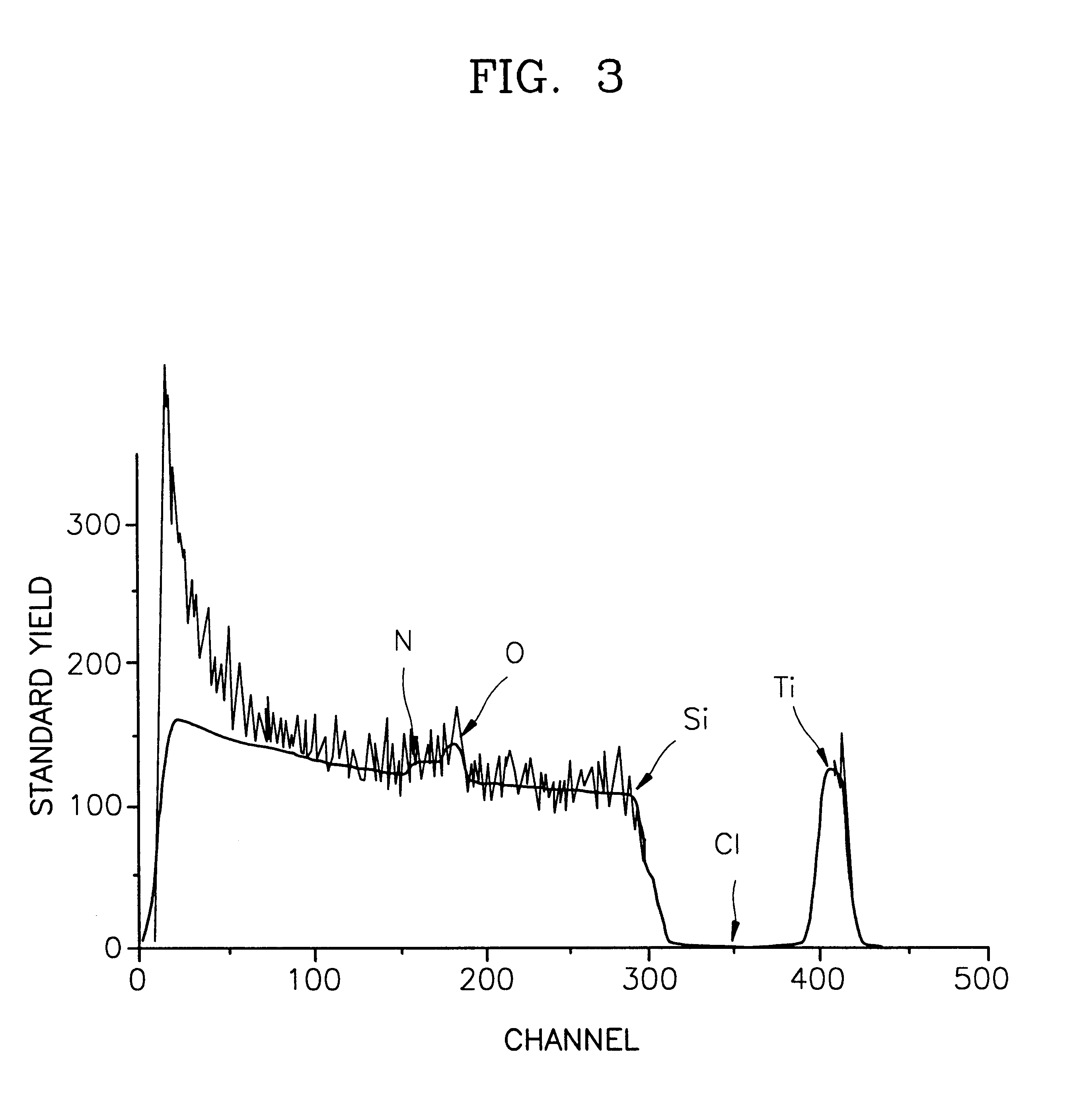

Method of forming metal nitride film by chemical vapor deposition and method of forming metal contact and capacitor of semiconductor device using the same

InactiveUS20010034097A1Good step coverageLow resistivitySemiconductor/solid-state device manufacturingCapacitorsChemical physicsDevice material

A method of forming a metal nitride film using chemical vapor deposition (CVD), and a method of forming a metal contact and a semiconductor capacitor of a semiconductor device using the same, are provided. The method of forming a metal nitride film using chemical vapor deposition (CVD) in which a metal source and a nitrogen source are used as a precursor, includes the steps of inserting a semiconductor substrate into a deposition chamber, flowing the metal source into the deposition chamber, removing the metal source remaining in the deposition chamber by cutting off the inflow of the metal source and flowing a purge gas into the deposition chamber, cutting off the purge gas and flowing the nitrogen source into the deposition chamber to react with the metal source adsorbed on the semiconductor substrate, and removing the nitrogen source remaining in the deposition chamber by cutting off the inflow of the nitrogen source and flowing the purge gas into the deposition chamber. Accordingly, the metal nitride film having low resistivity and a low content of Cl even with excellent step coverage can be formed at a temperature of 500° C. or lower, and a semiconductor capacitor having excellent leakage current characteristics can be manufactured. Also, a deposition speed, approximately 20 A / cycle, is suitable for mass production.

Owner:SAMSUNG ELECTRONICS CO LTD

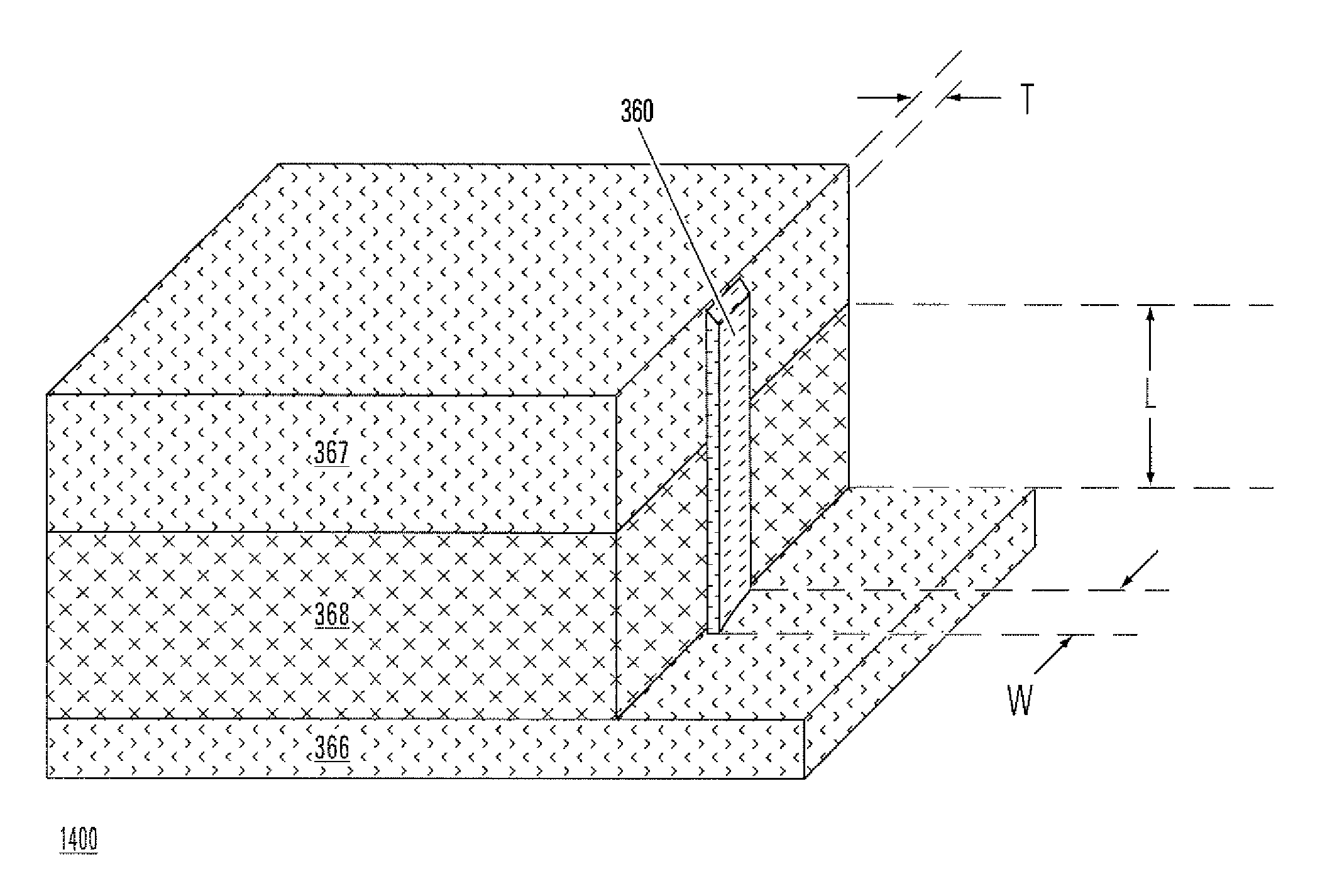

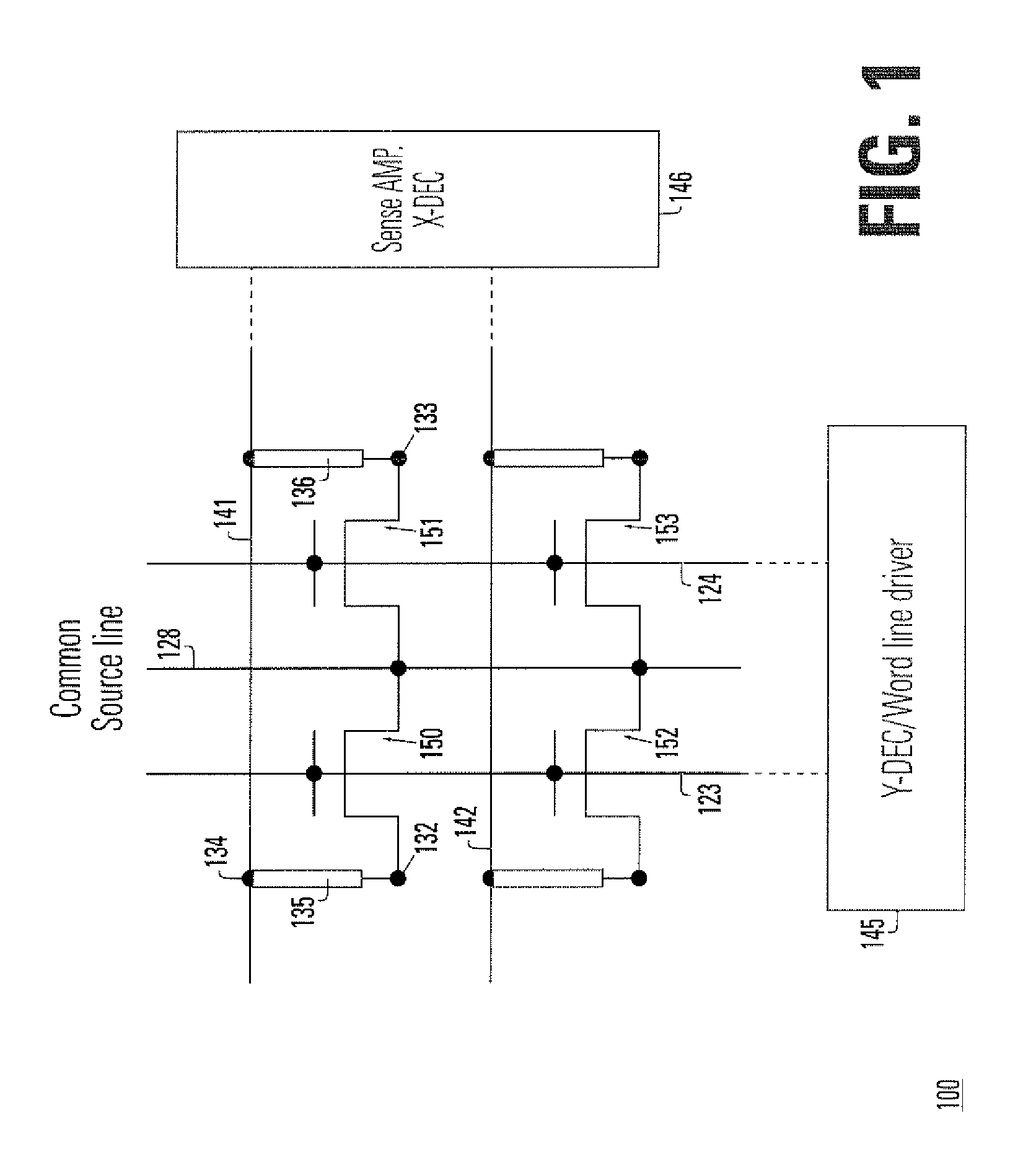

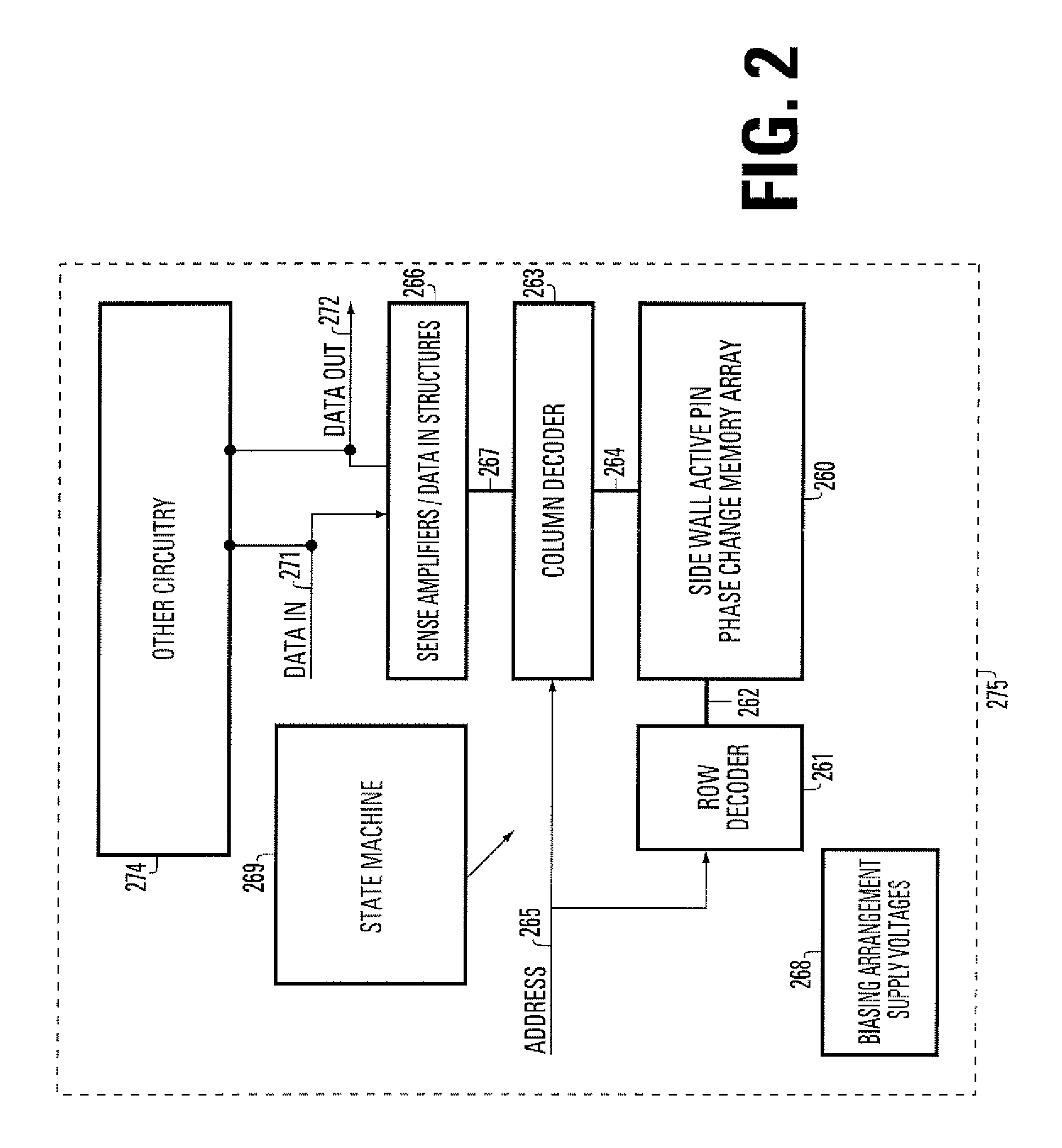

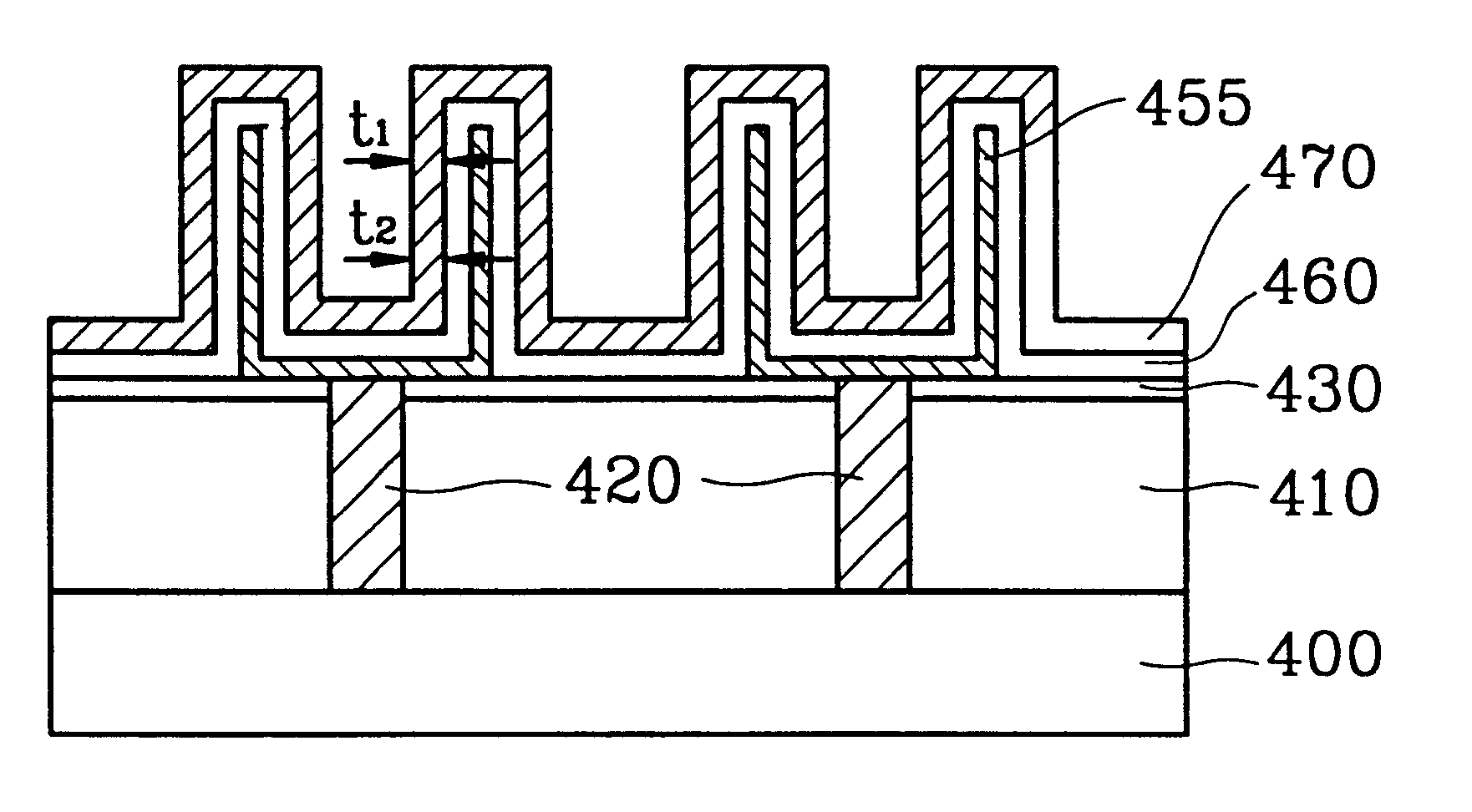

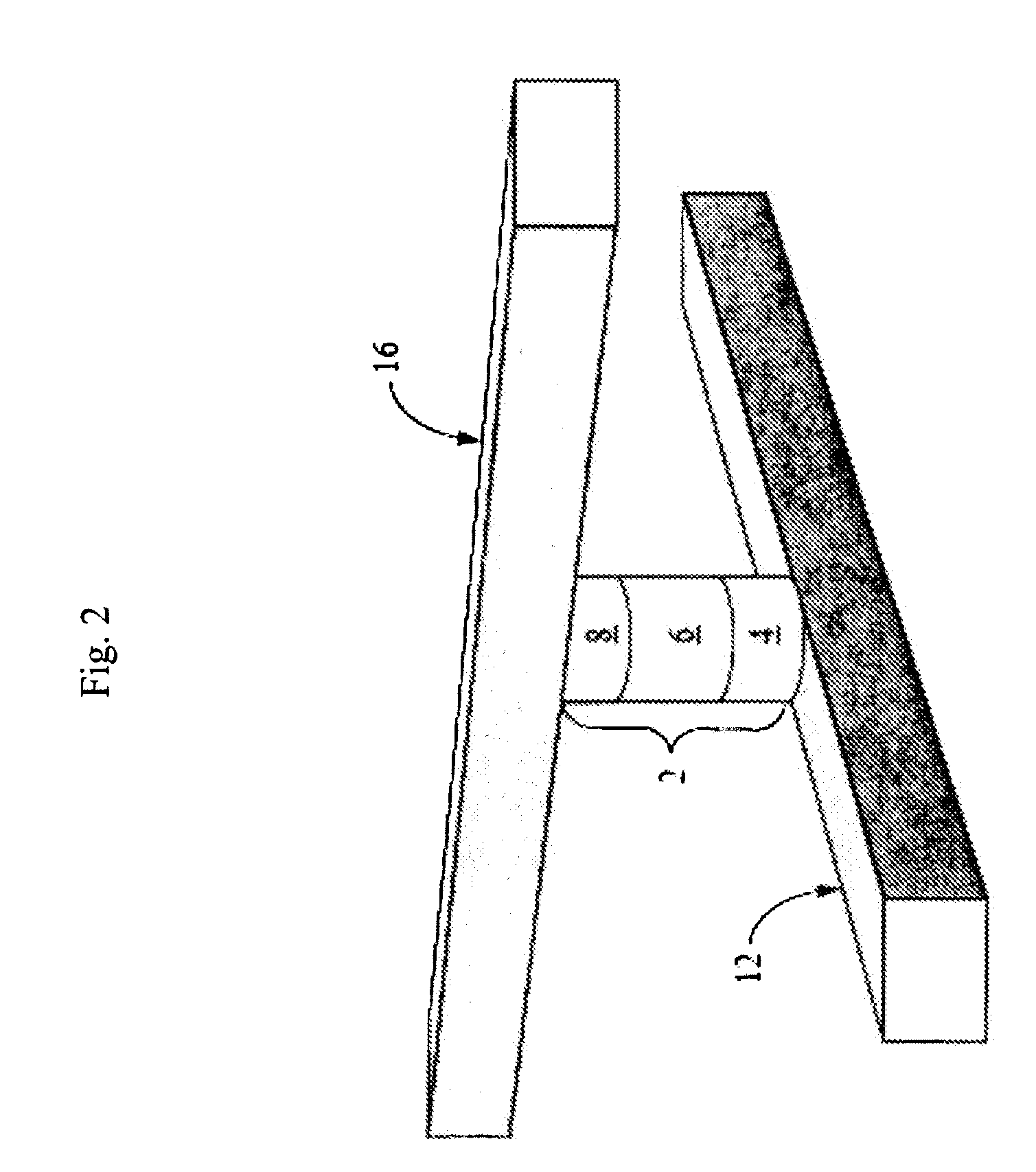

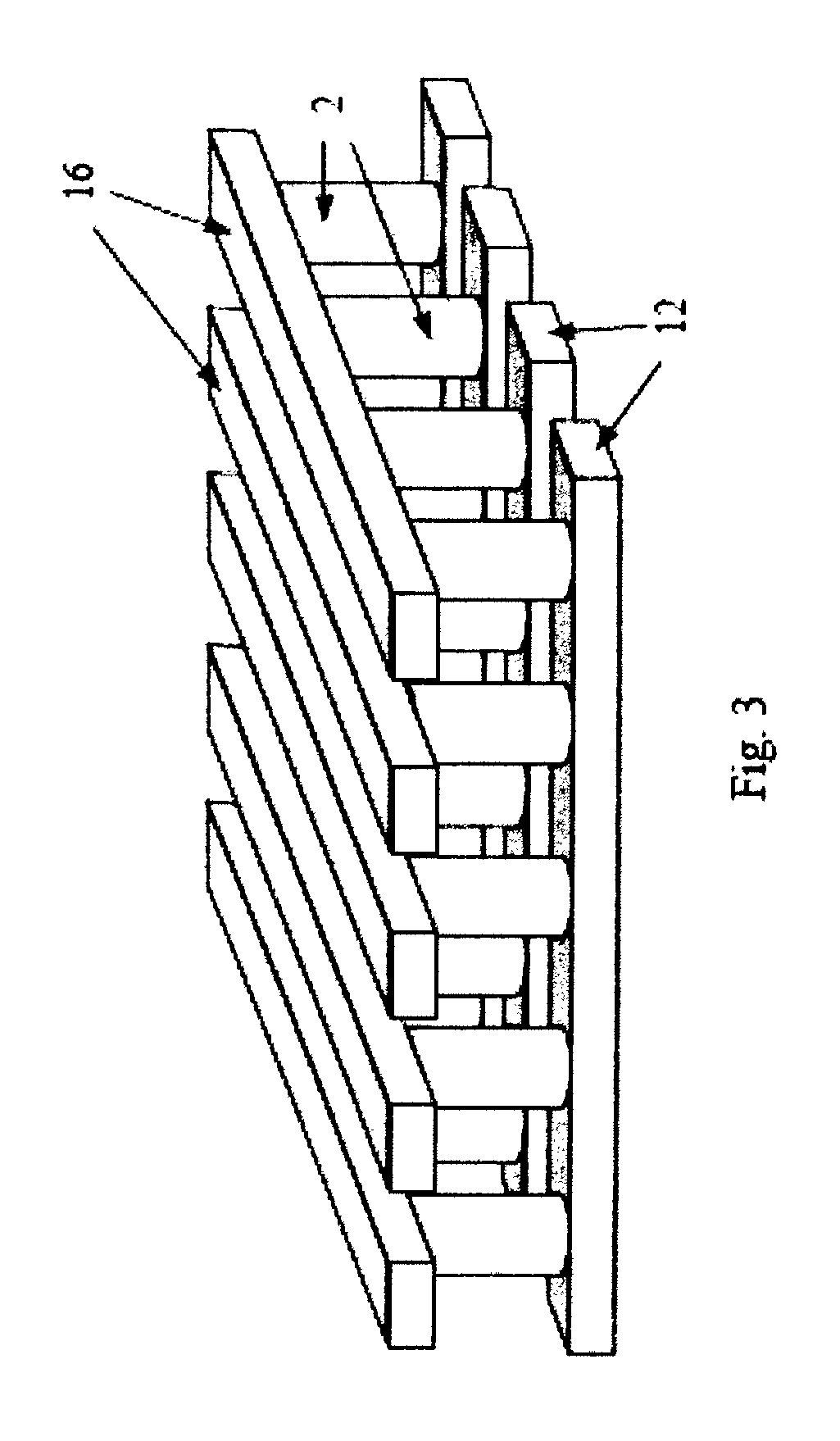

Vertical Side Wall Active Pin Structures in a Phase Change Memory and Manufacturing Methods

ActiveUS20070176261A1Reduce electrical currentLow resistivitySolid-state devicesSemiconductor devicesEngineeringPhase-change material

A programmable resistor memory, such as a phase change memory, with a memory element comprising narrow vertical side wall active pins is described. The side wall active pins comprise a programmable resistive material, such as a phase change material. In a first aspect of the invention, a method of forming a memory cell is described which comprises forming a stack comprising a first electrode having a principal surface with a perimeter, an insulating layer overlying a portion of the principal surface of the first electrode, and a second electrode vertically separated from the first electrode and overlying the insulating layer. Side walls on the insulating layer and on the second electrode are positioned over the principle surface of the first electrode with a lateral offset from the perimeter of the first electrode.

Owner:MACRONIX INT CO LTD

Method of forming metal nitride film by chemical vapor deposition and method of forming metal contact and capacitor of semiconductor device using the same

InactiveUS6348376B2Good step coverageLow resistivitySemiconductor/solid-state device manufacturingCapacitorsDevice materialNitrogen source

A method of forming a metal nitride film using chemical vapor deposition (CVD), and a method of forming a metal contact and a semiconductor capacitor of a semiconductor device using the same, are provided. The method of forming a metal nitride film using chemical vapor deposition (CVD) in which a metal source and a nitrogen source are used as a precursor, includes the steps of inserting a semiconductor substrate into a deposition chamber, flowing the metal source into the deposition chamber, removing the metal source remaining in the deposition chamber by cutting off the inflow of the metal source and flowing a purge gas into the deposition chamber, cutting off the purge gas and flowing the nitrogen source into the deposition chamber to react with the metal source adsorbed on the semiconductor substrate, and removing the nitrogen source remaining in the deposition chamber by cutting off the inflow of the nitrogen source and flowing the purge gas into the deposition chamber. Accordingly, the metal nitride film having low resistivity and a low content of Cl even with excellent step coverage can be formed at a temperature of 500° C. or lower, and a semiconductor capacitor having excellent leakage current characteristics can be manufactured. Also, a deposition speed, approximately 20 A / cycle, is suitable for mass production.

Owner:SAMSUNG ELECTRONICS CO LTD

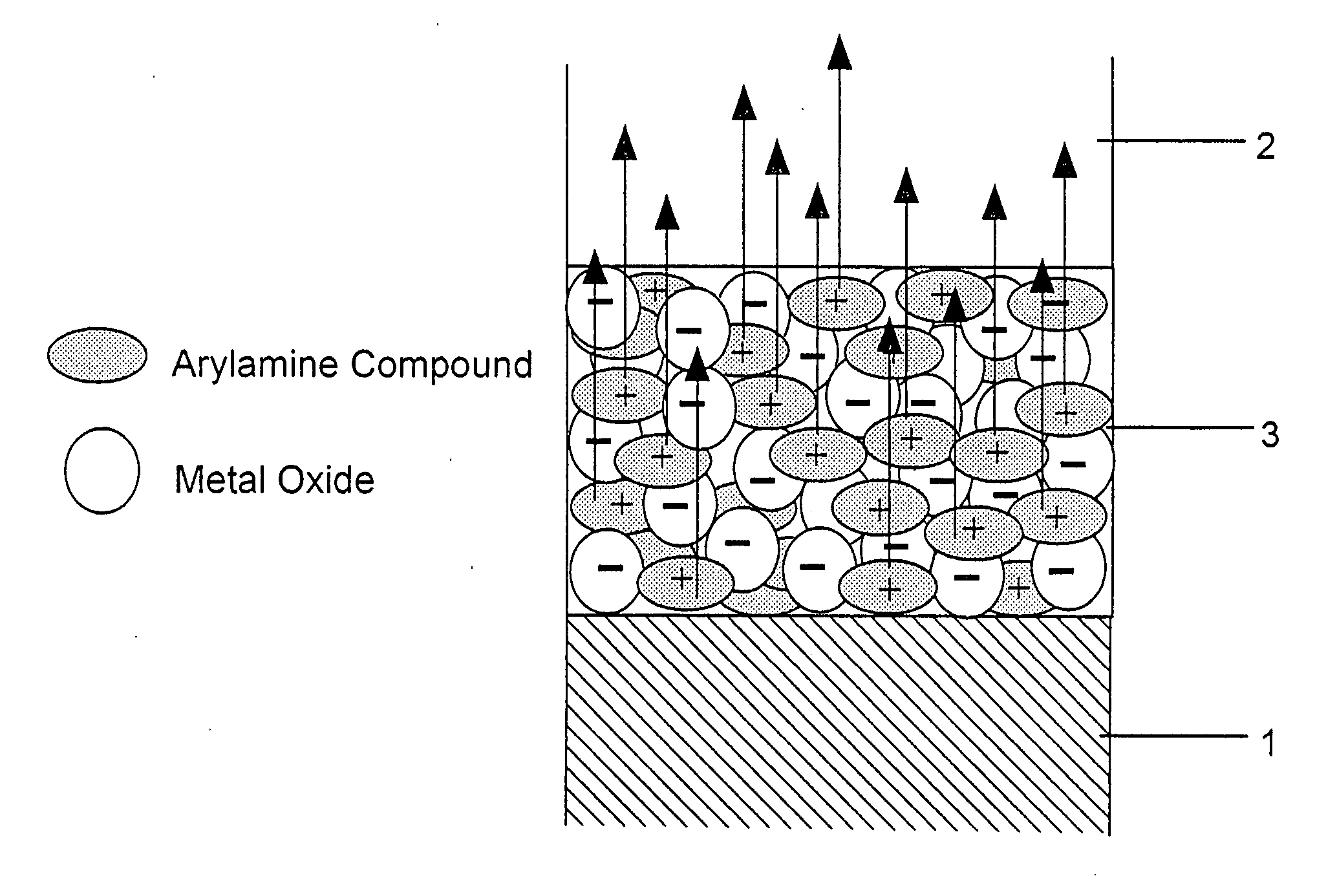

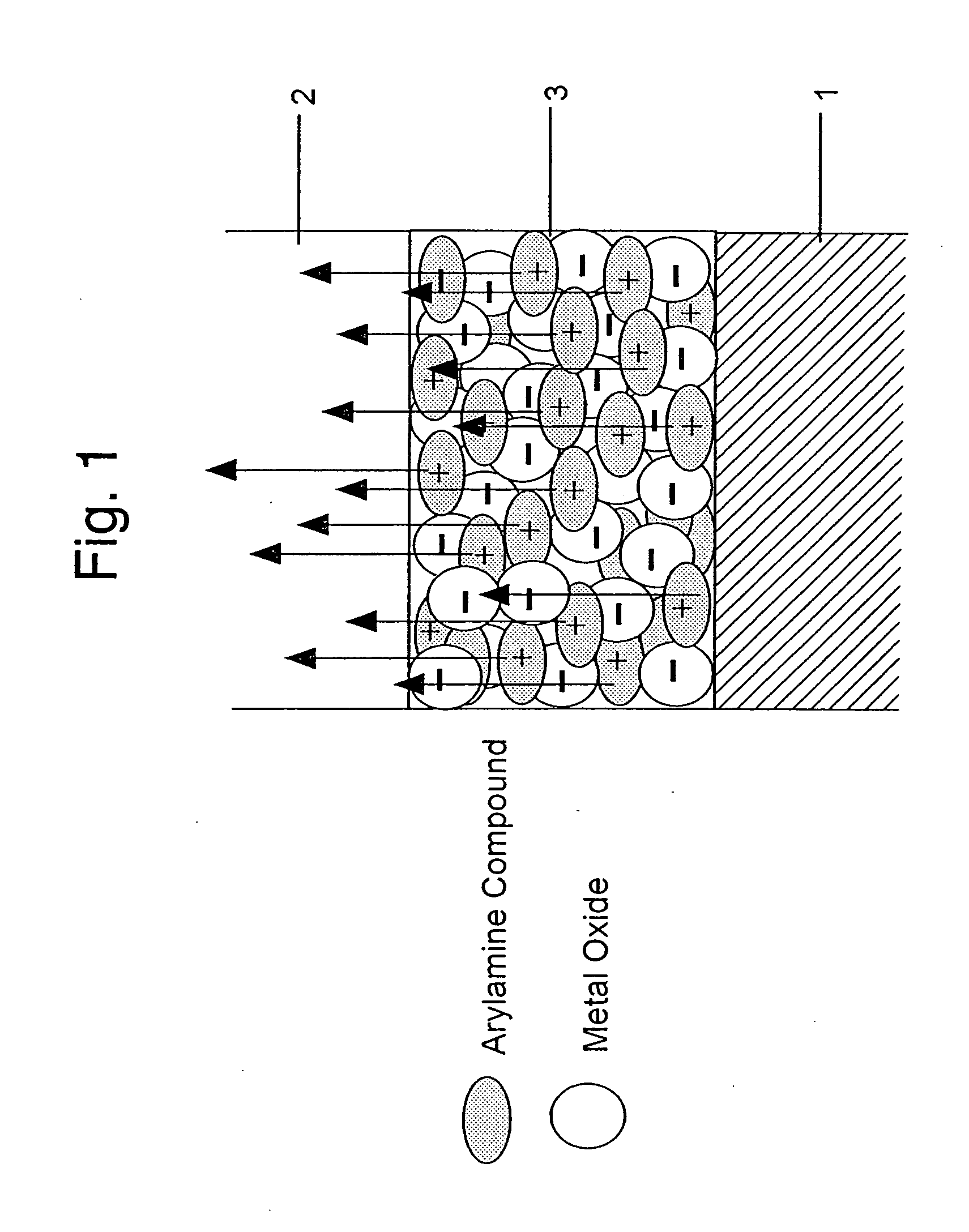

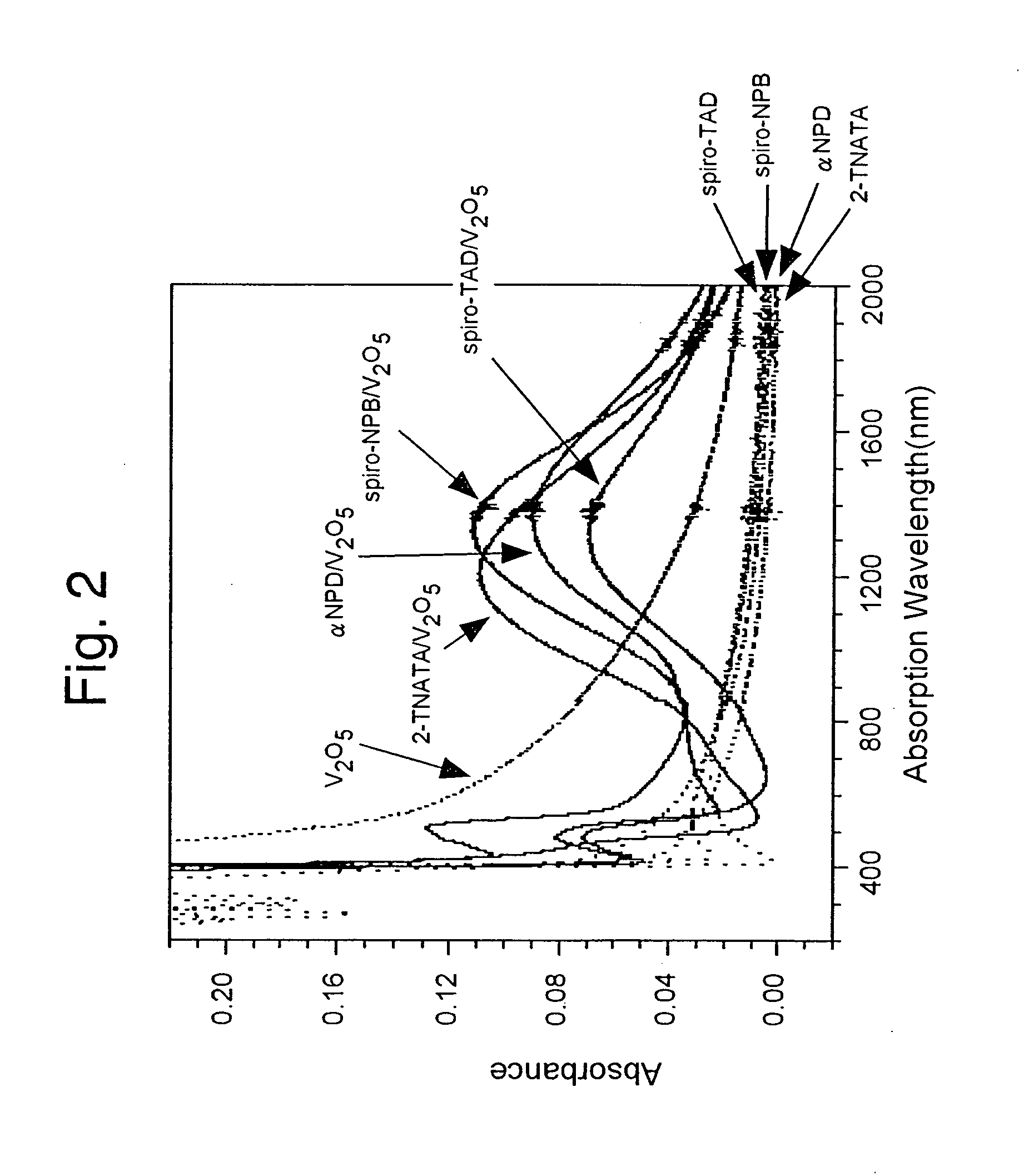

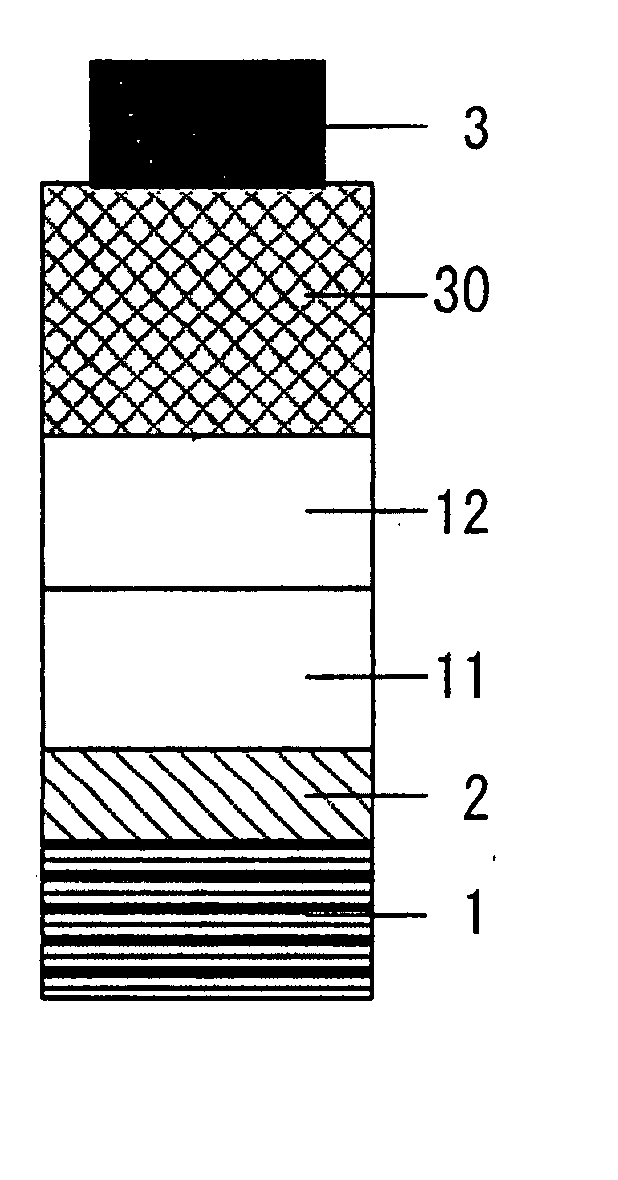

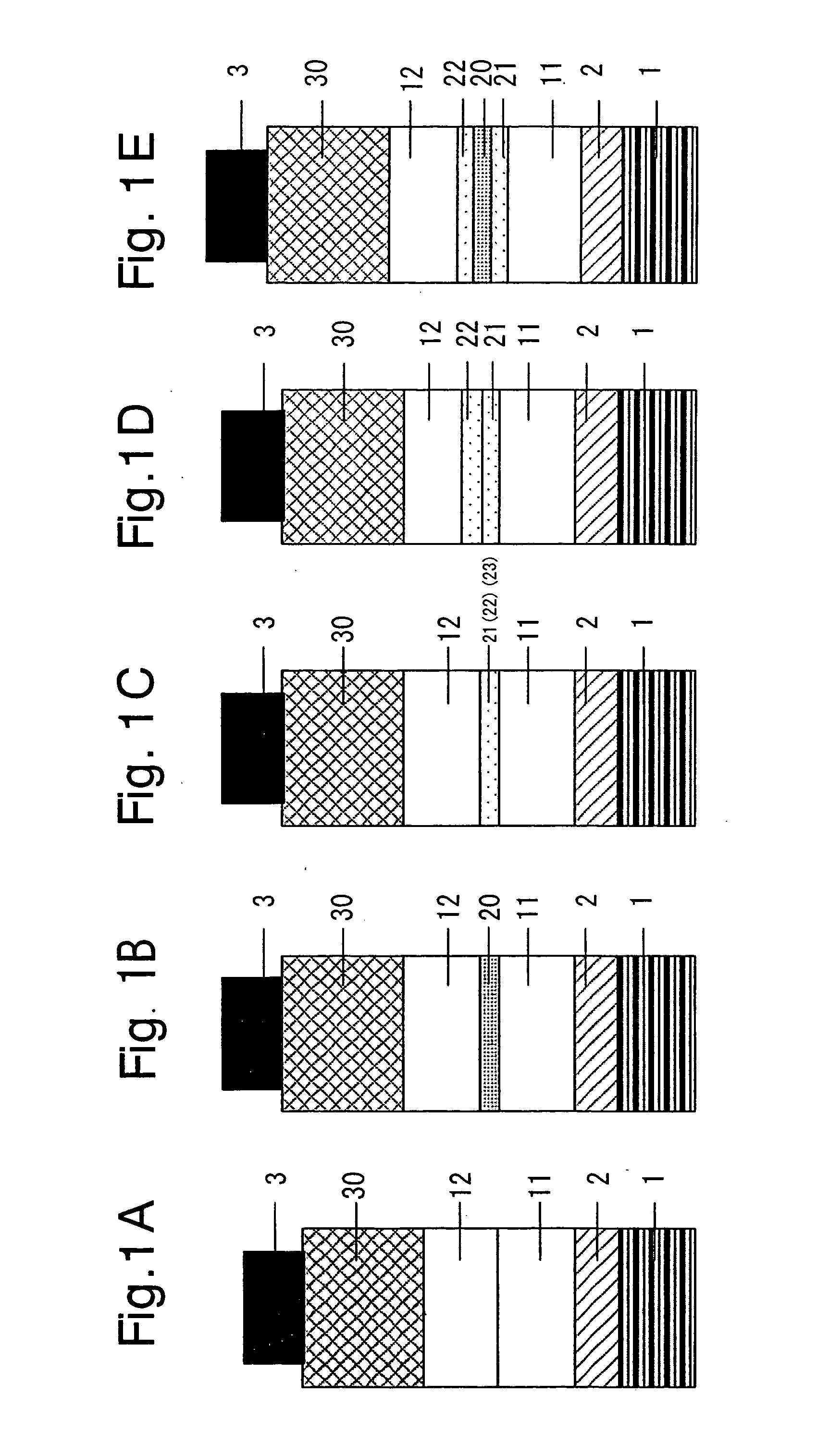

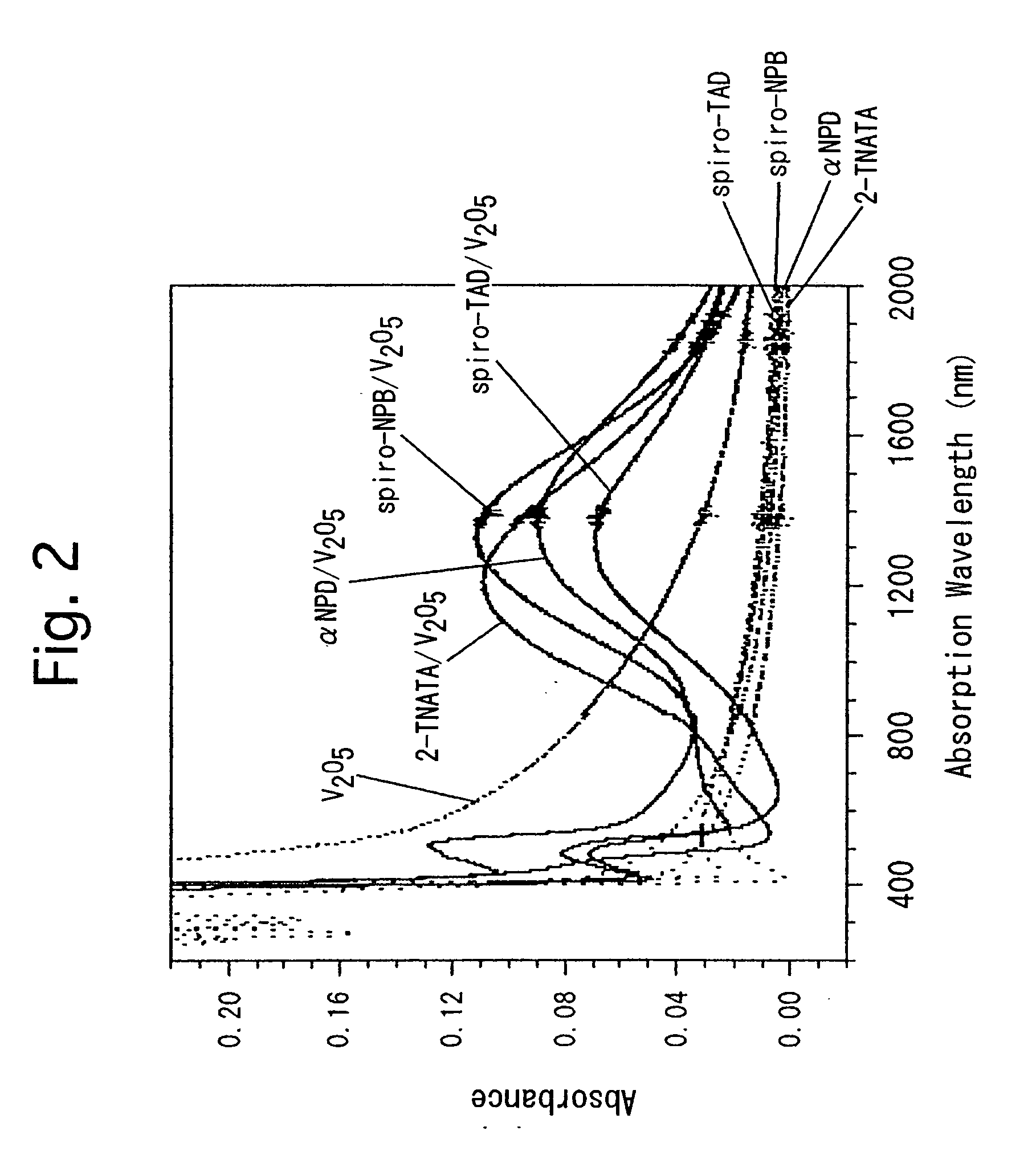

Organic electroluminescent device

ActiveUS20050084712A1Lower energy barrierLow voltage driveDischarge tube luminescnet screensElectroluminescent light sourcesOrganic structureSimple Organic Compounds

An organic electroluminescent device includes an anode electrode layer; a cathode electrode layer opposed to the anode electrode layer; a hole injection layer provided adjacent to the anode electrode layer an organic structure including at least one light-emissive layer_or at least one light-emissive unit having at least one light-emissive layer; between the anode electrode layer and the cathode electrode layer. At least one of the anode electrode layer and the cathode electrode layer is transparent. The hole injection layer includes a mixed layer of a metal oxide and an organic compound. The mixed layer is formed upon co-deposition of the metal oxide and the organic compound.

Owner:MITSUBISHI HEAVY IND LTD +1

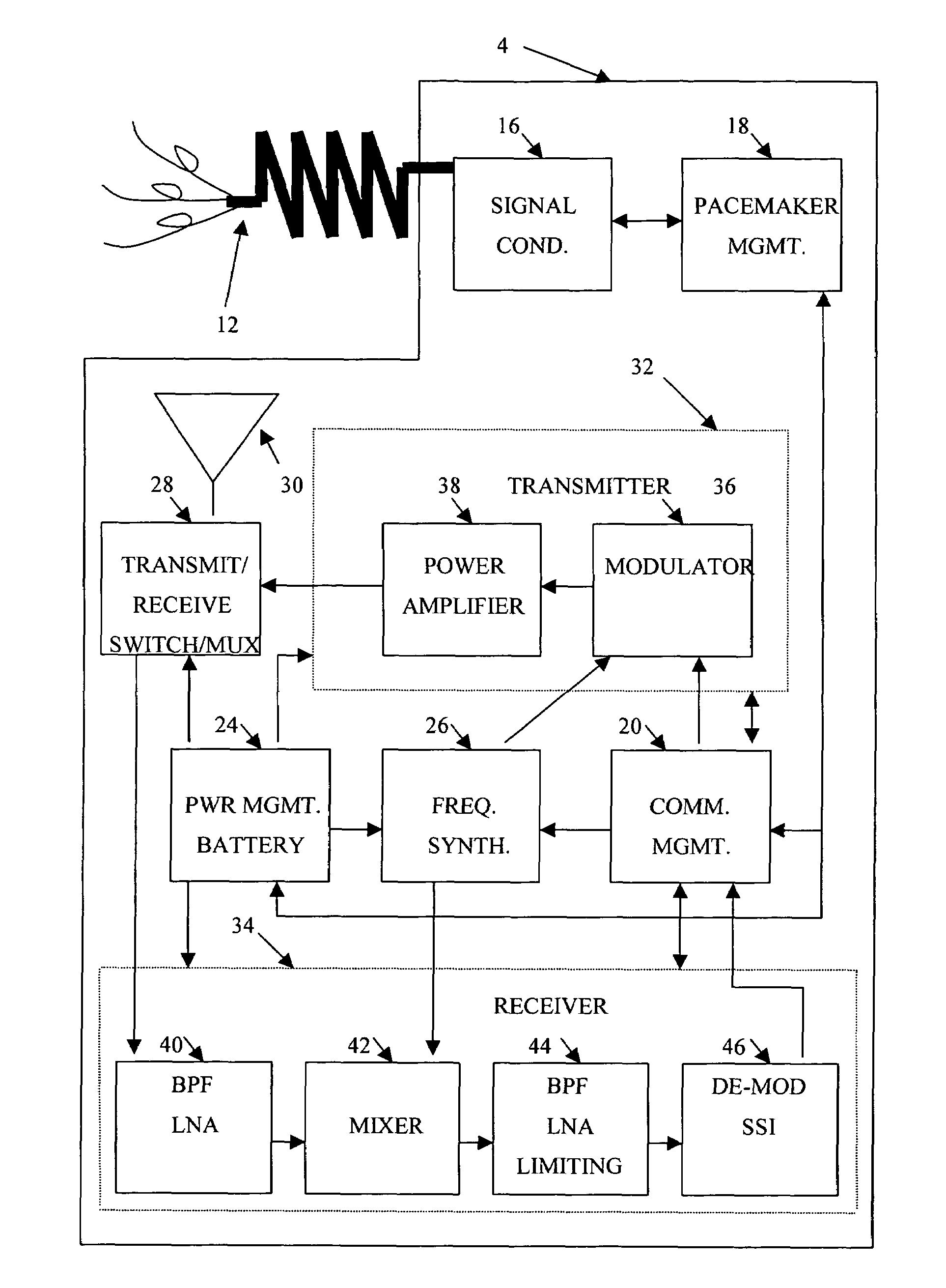

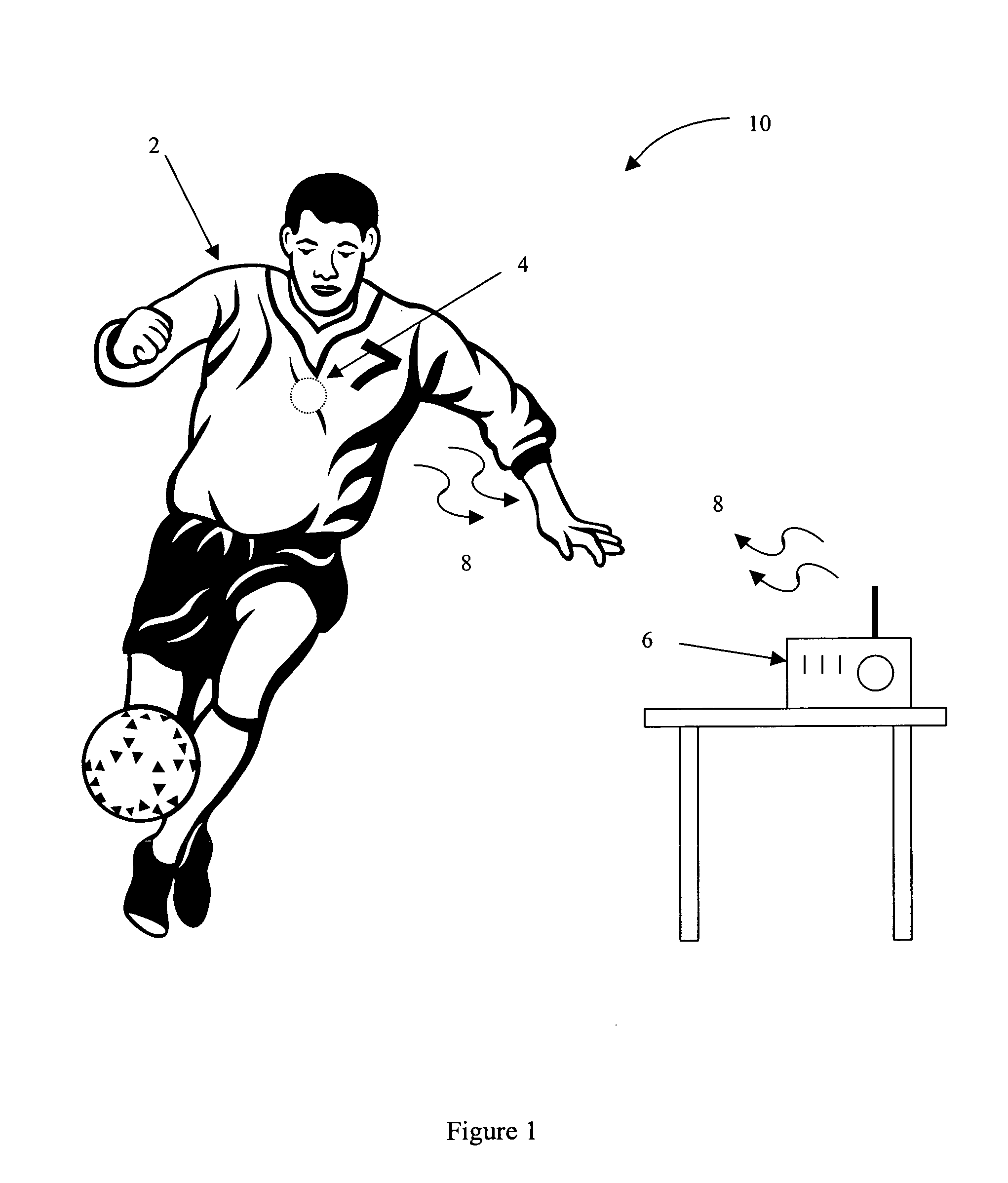

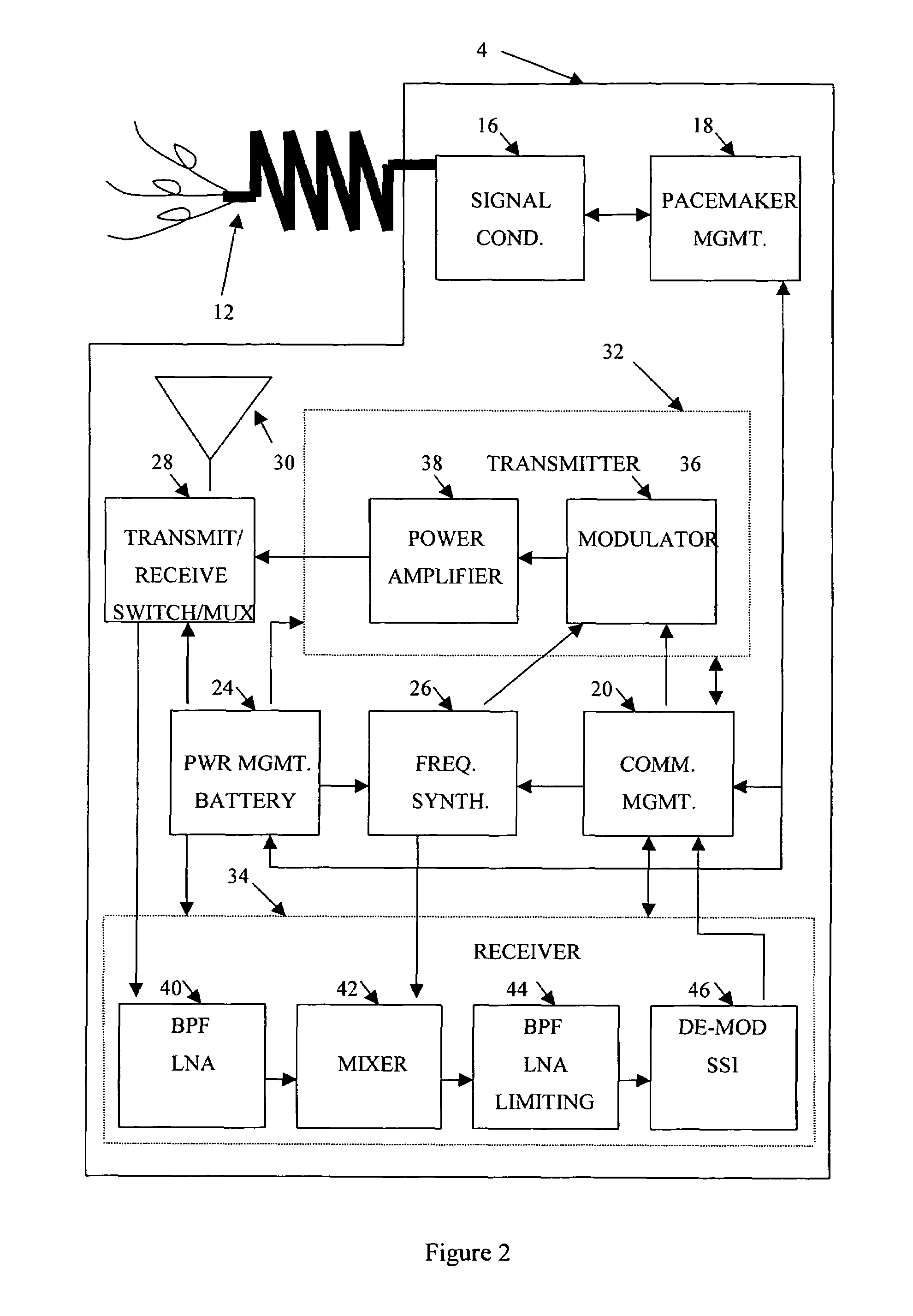

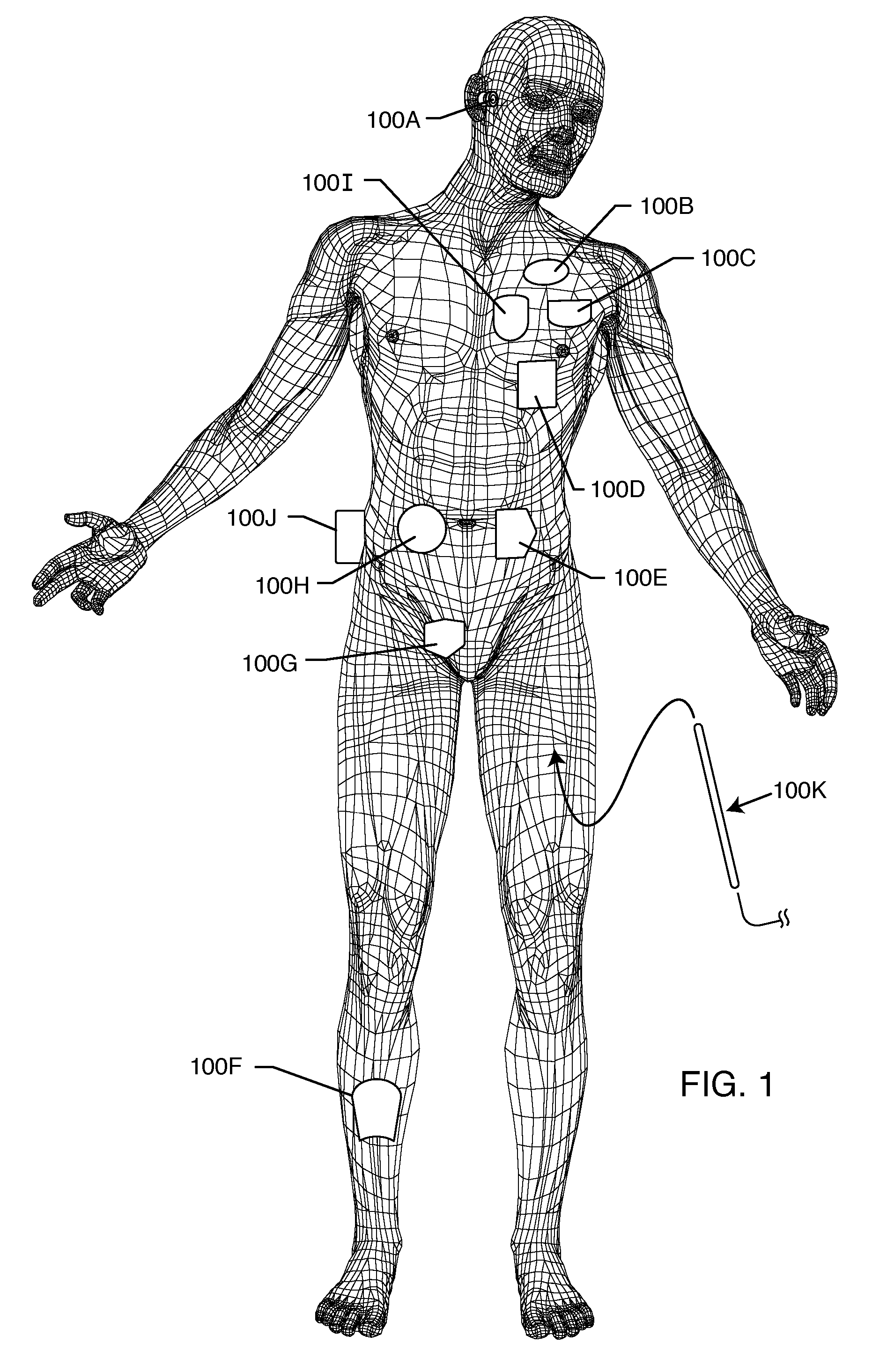

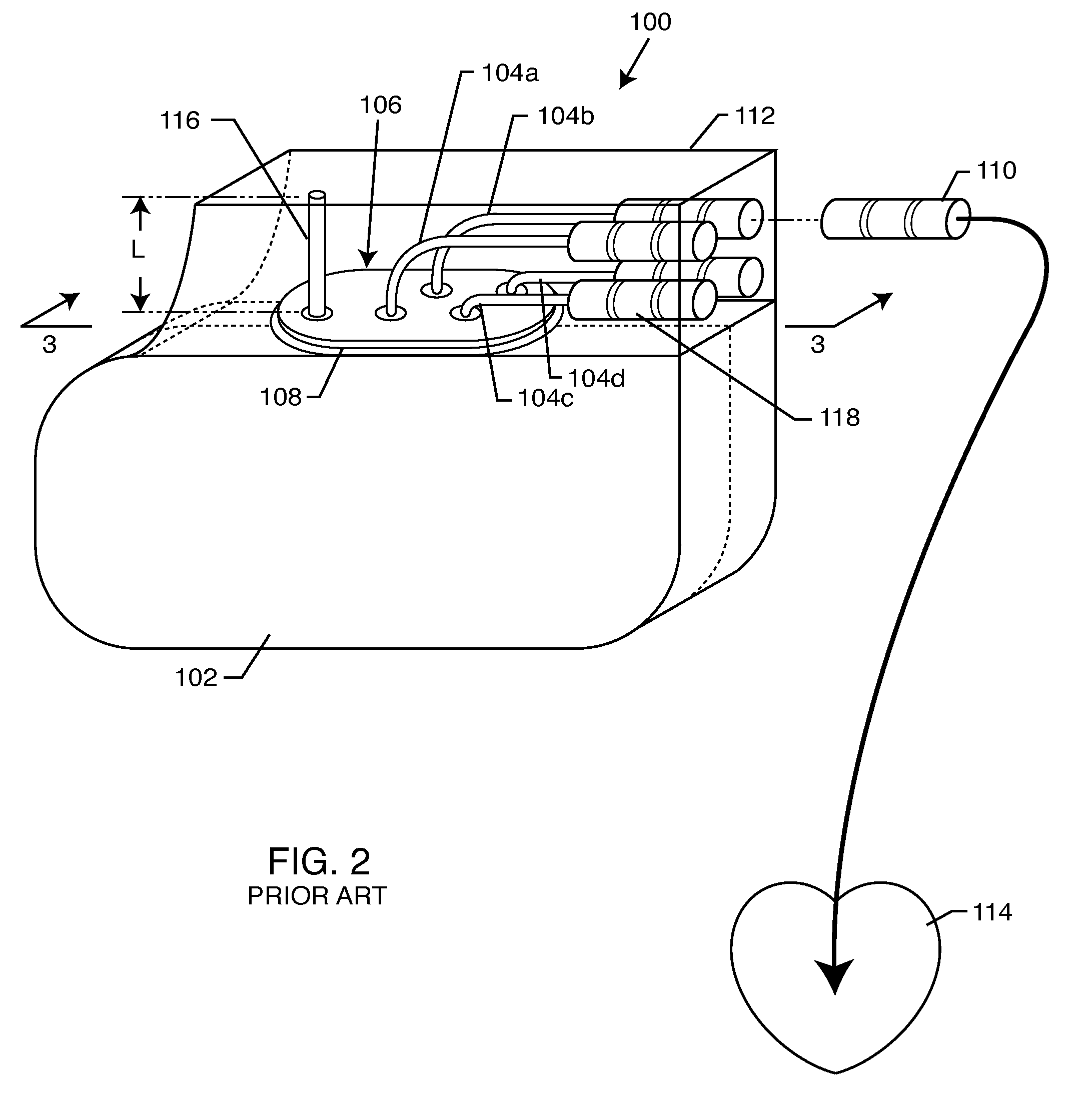

High frequency wireless pacemaker

InactiveUS7289853B1High-frequency operationLow pacemaker power consumptionHeart stimulatorsCommunications systemCardiac pacemaker electrode

A wireless communications system optimizes performance by dividing communications functionality between a wireless pacemaker and a wireless monitoring base station according to the design constraints imposed by the system elements. Typical design constraints include high frequency operation, low pacemaker power consumption, reasonable range, high data rate, minimal RF radiation of internal circuitry, small pacemaker antenna system, simple pacemaker RF circuit design, high reliability, low pacemaker cost, and use of existing pacemaker construction methodologies.

Owner:CAMPBELL DAVID +1

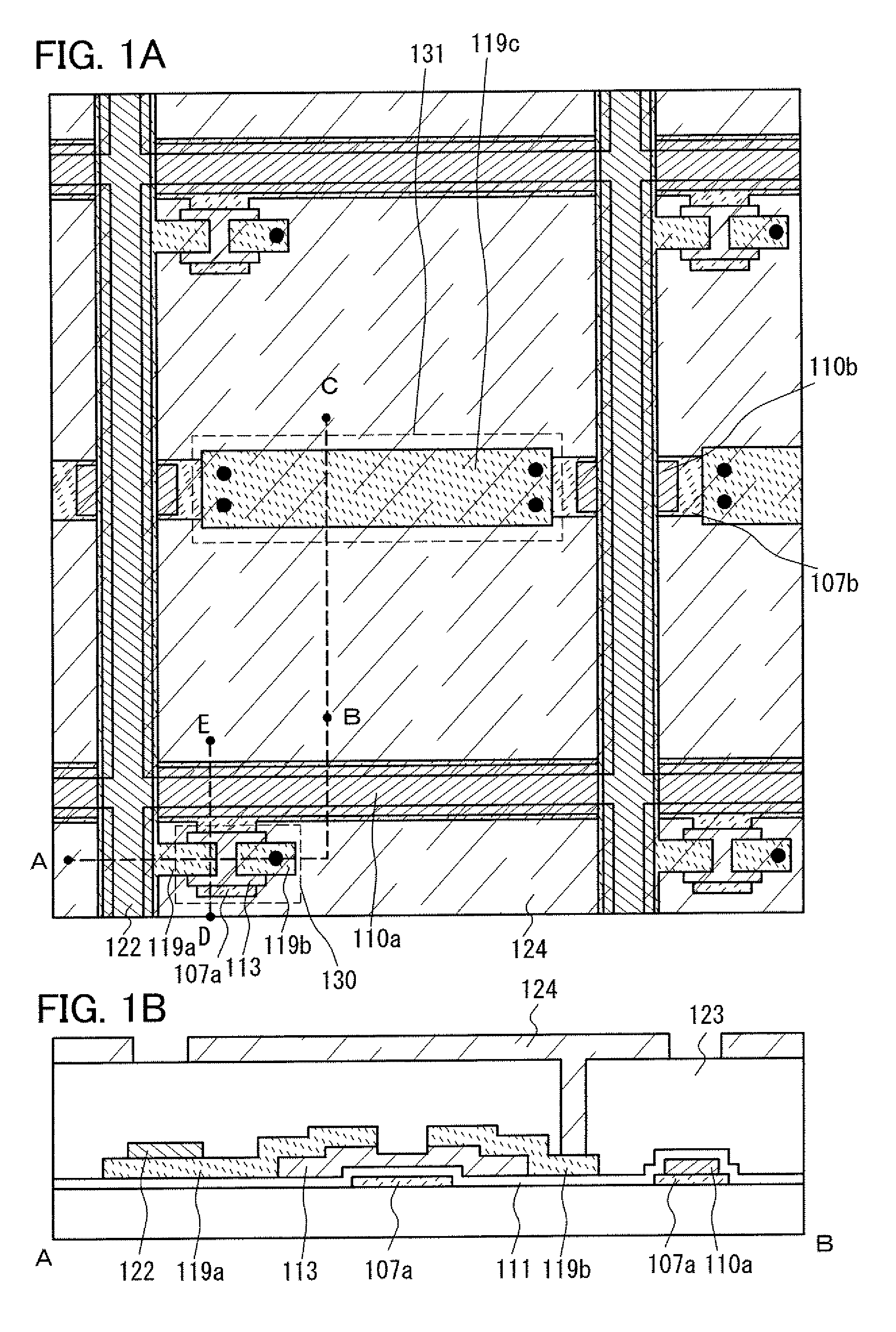

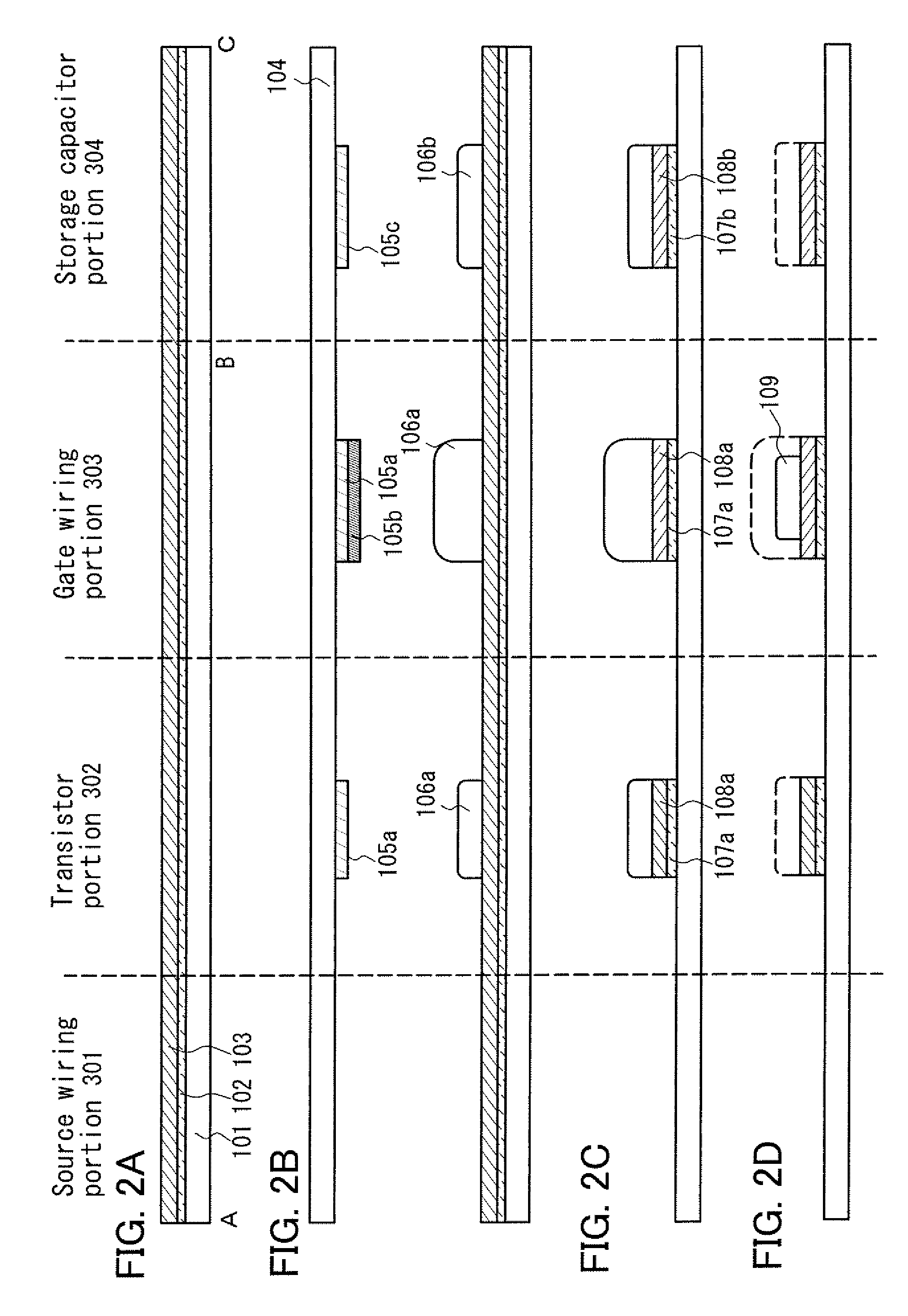

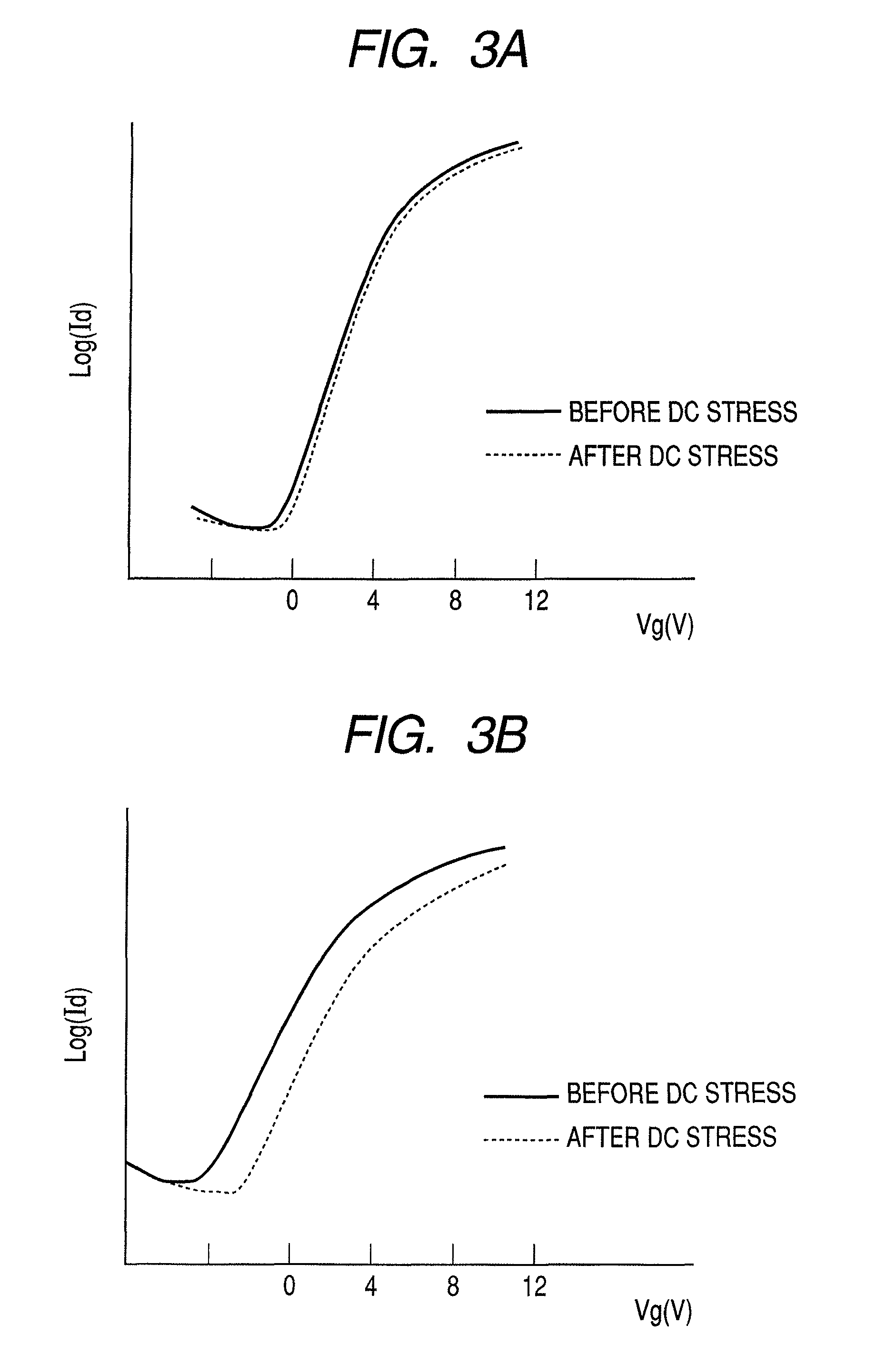

Semiconductor device and manufacturing method of the same

ActiveUS20090283762A1Reduce the ratioLow resistivityTransistorSemiconductor/solid-state device detailsSemiconductorAperture ratio

An object is to provide a semiconductor device with high aperture ratio or a manufacturing method thereof. Another object is to provide semiconductor device with low power consumption or a manufacturing method thereof. A light-transmitting conductive layer which functions as a gate electrode, a gate insulating film formed over the light-transmitting conductive layer, a semiconductor layer formed over the light-transmitting conductive layer which functions as the gate electrode with the gate insulating film interposed therebetween, and a light-transmitting conductive layer which is electrically connected to the semiconductor layer and functions as source and drain electrodes are included.

Owner:SEMICON ENERGY LAB CO LTD

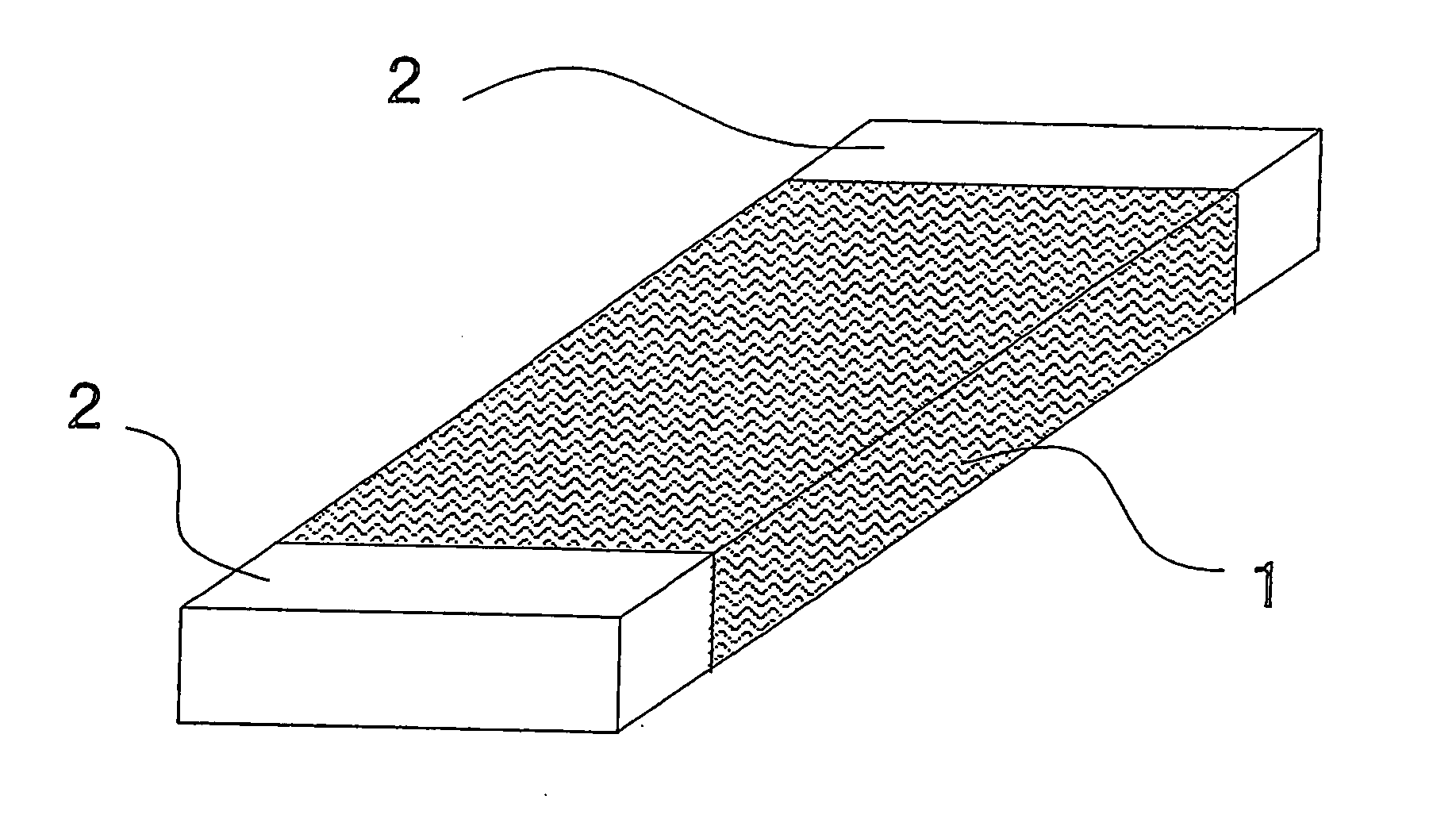

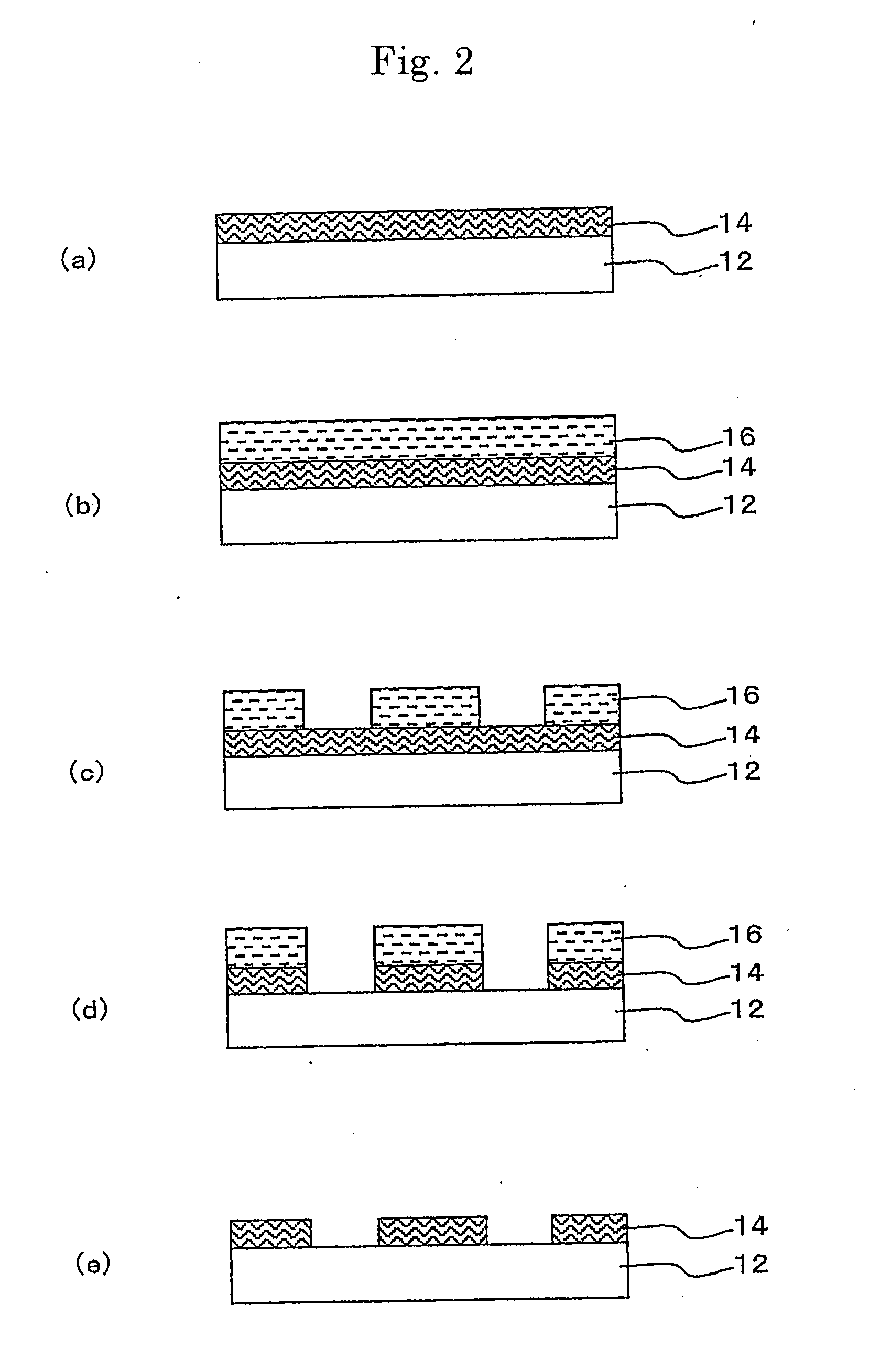

Resistance element, method of manufacturing the same, and thermistor

InactiveUS20050040371A1Easy and stable coatingLow resistivityMaterial nanotechnologyCurrent responsive resistorsResistive elementCarbon nanotube

To provide a resistance element having an electric resistance body with excellent stability and a method of manufacturing the same. The resistance element includes an electric resistance body, on a base body surface, consisting of a carbon nanotube structure layer 14, which configures a mesh structure in which at least plural carbon nanotubes are cross-linked to one another. The method of manufacturing the resistance element includes: an applying step of applying the base body surface 12 with a liquid solution containing carbon nanotubes having functional groups; and a cross-linking step of forming the carbon nanotube structure layer 14, used as an electric resistance body, that configures a mesh structure in which the plural carbon nanotubes are cross-linked to one another through curing of the liquid solution after application.

Owner:FUJIFILM BUSINESS INNOVATION CORP

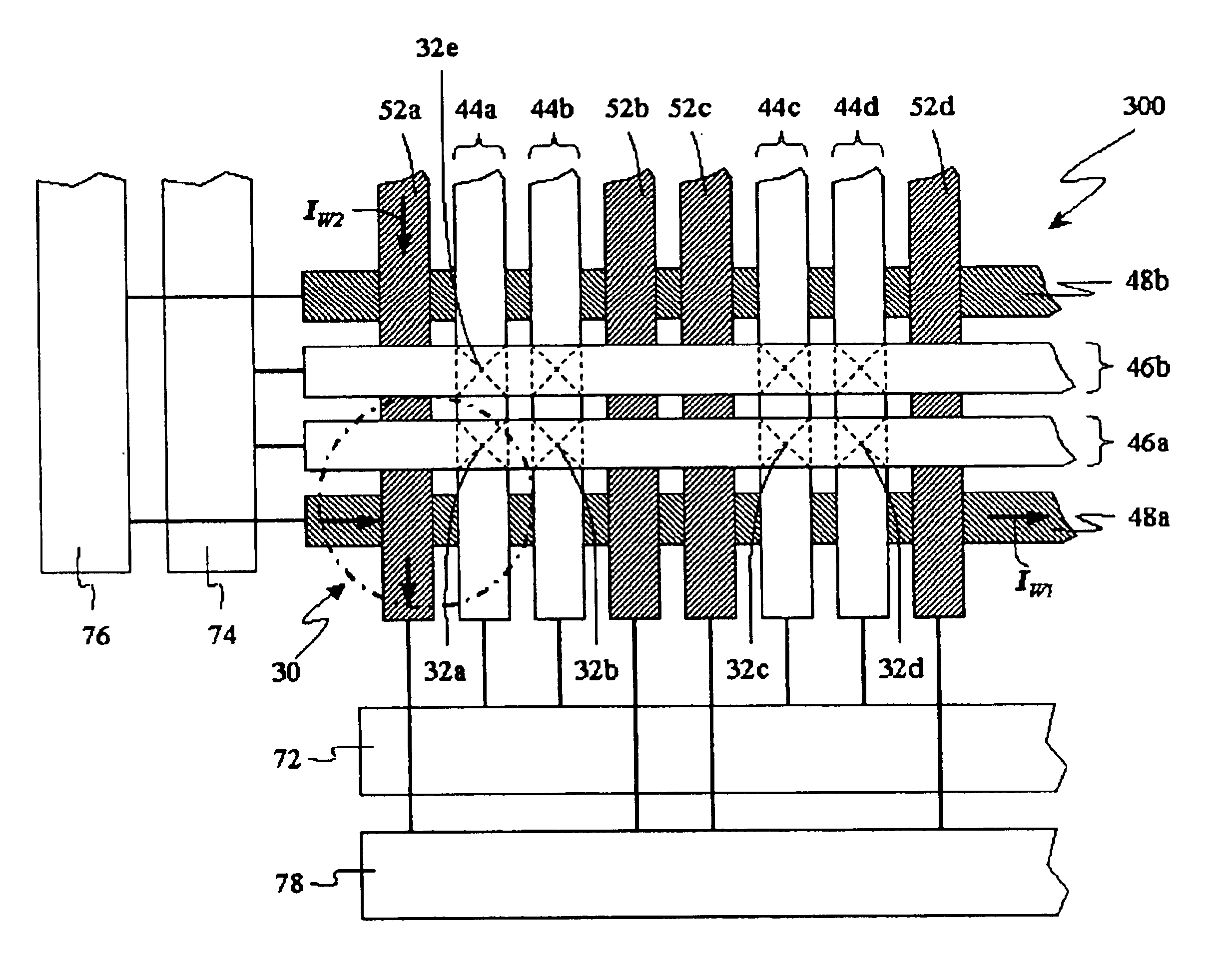

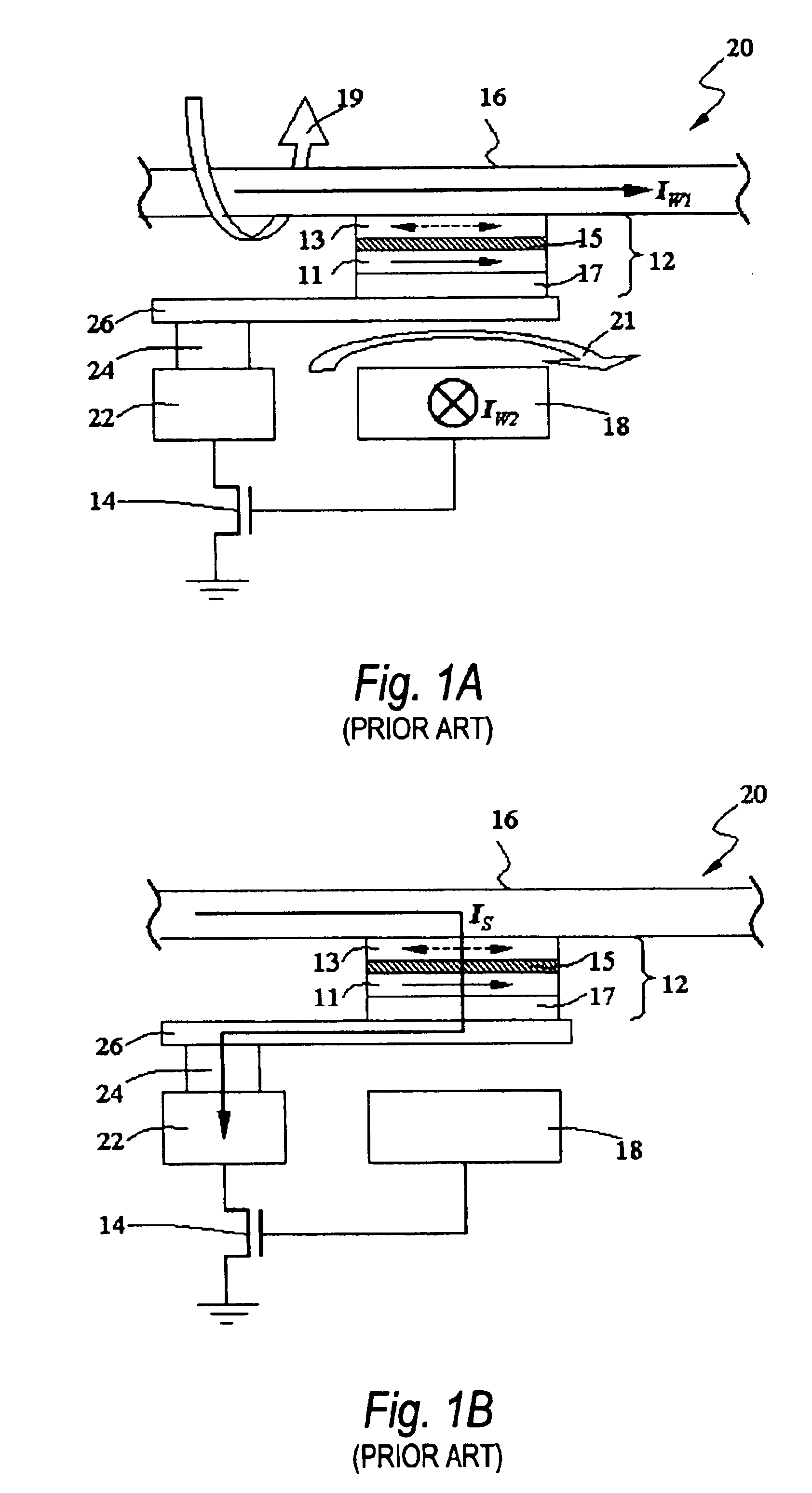

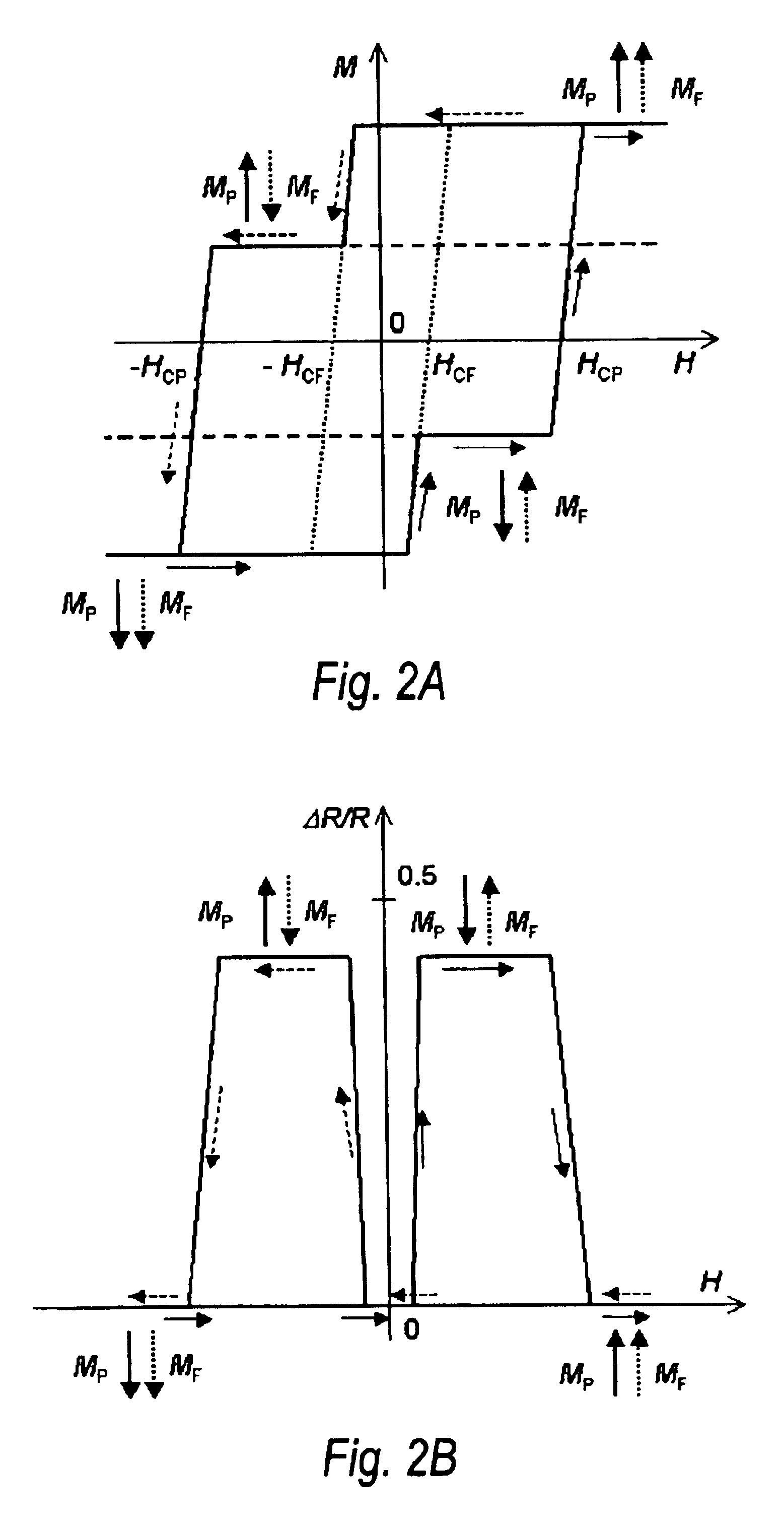

Magnetic tunnel junction memory device

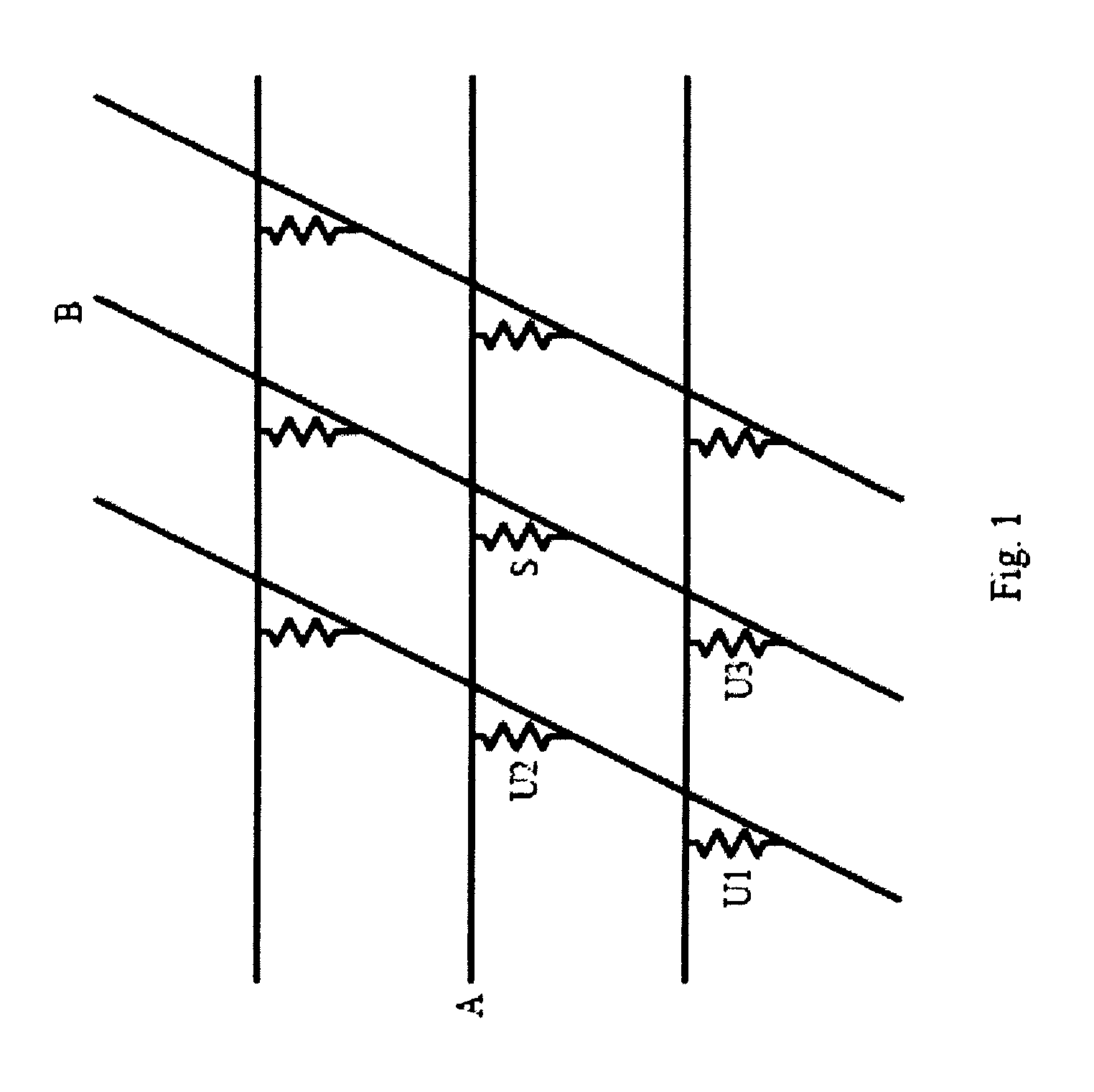

InactiveUS6845038B1Improve permeabilityLow resistivityDigital storageBit linePerpendicular magnetization

A memory cell for magnetic random access memory devices based on a magnetic tunnel junction (MTJ) memory element with a perpendicular orientation of magnetization in pinned and free magnetic layers, and a tunnel barrier layer sandwiched between the pinned and free layers. The memory cell can include the MTJ memory element, a magnetic flux guide in series with selection devices, such as a bit line, a word line, and a transistor. The magnetic flux guide can have two electrically conductive magnetic portions with the MTJ memory element positioned between the magnetic portions. The MTJ memory element is magnetically isolated from the magnetic flux guide by thin non-magnetic conductive spacers. The MTJ memory element is arranged in a vertical space between the intersecting bit and word lines at their intersection region. The memory cell also includes write and excitation lines. The write line is parallel to the bit line and the excitation line is parallel to the word line. The write and excitation lines also intersect each other and define a corner. The MTJ memory element is positioned in the corner of the intercepting write and excitation lines.

Owner:SHUKH ALLA MIKHAILOVNA

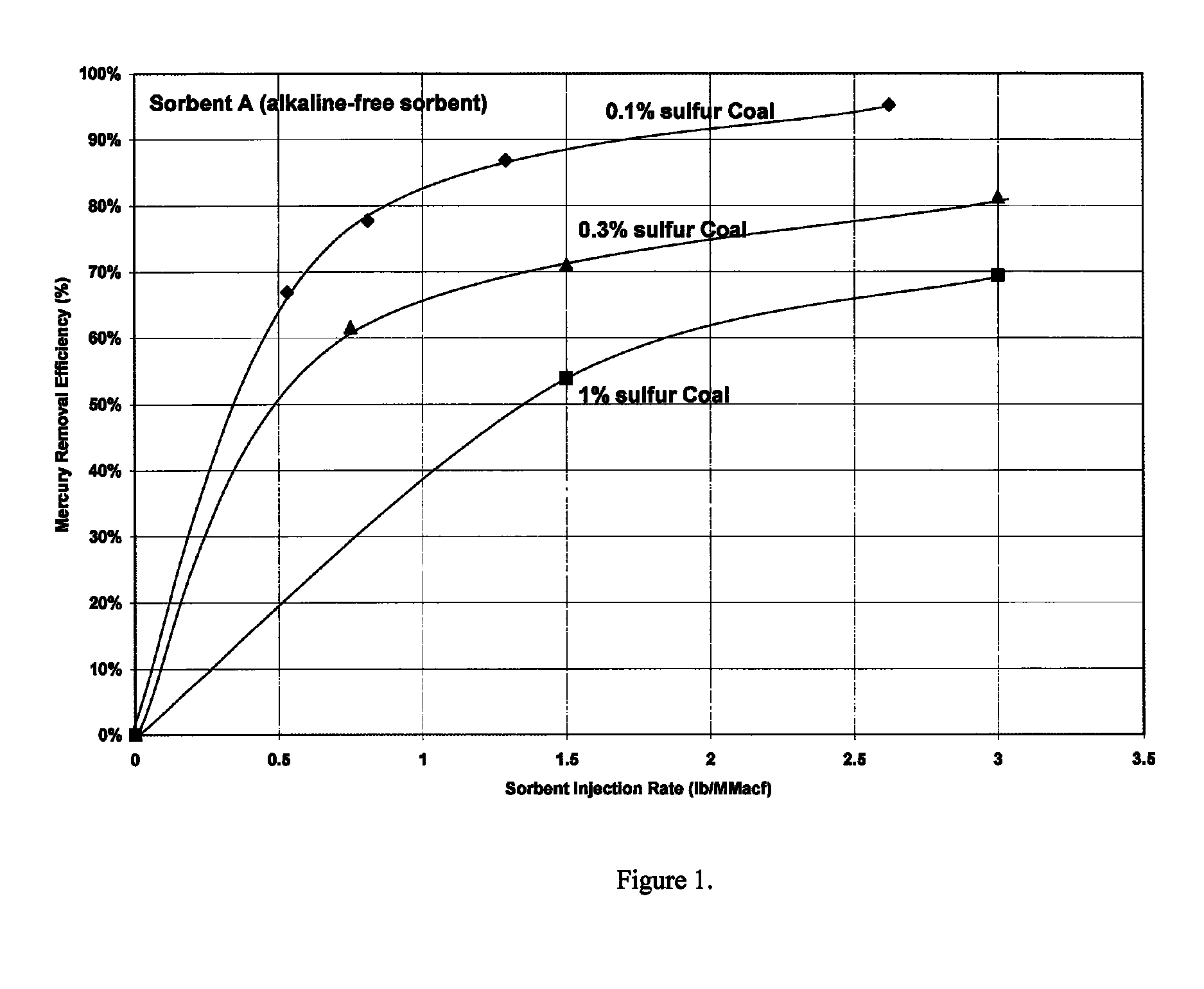

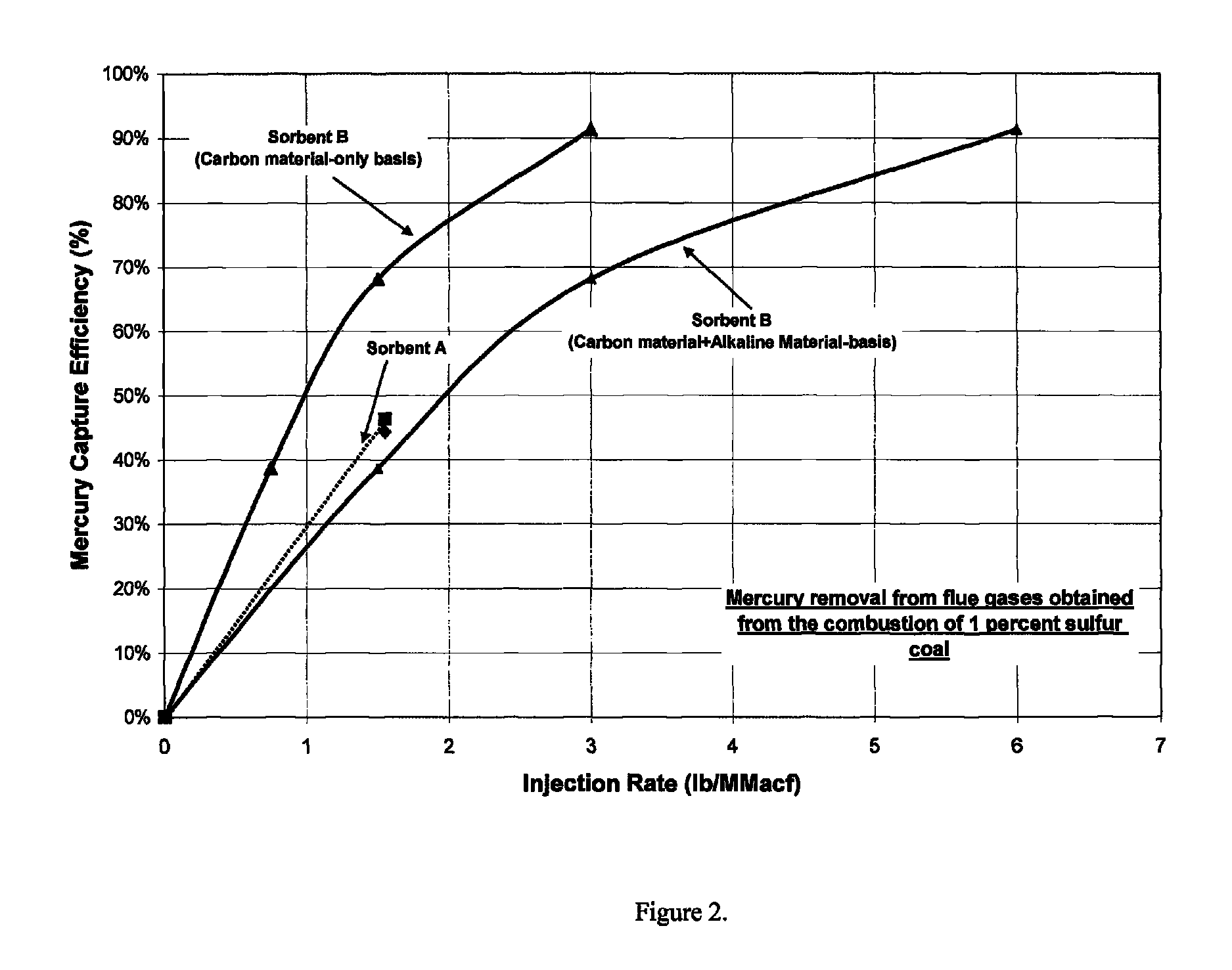

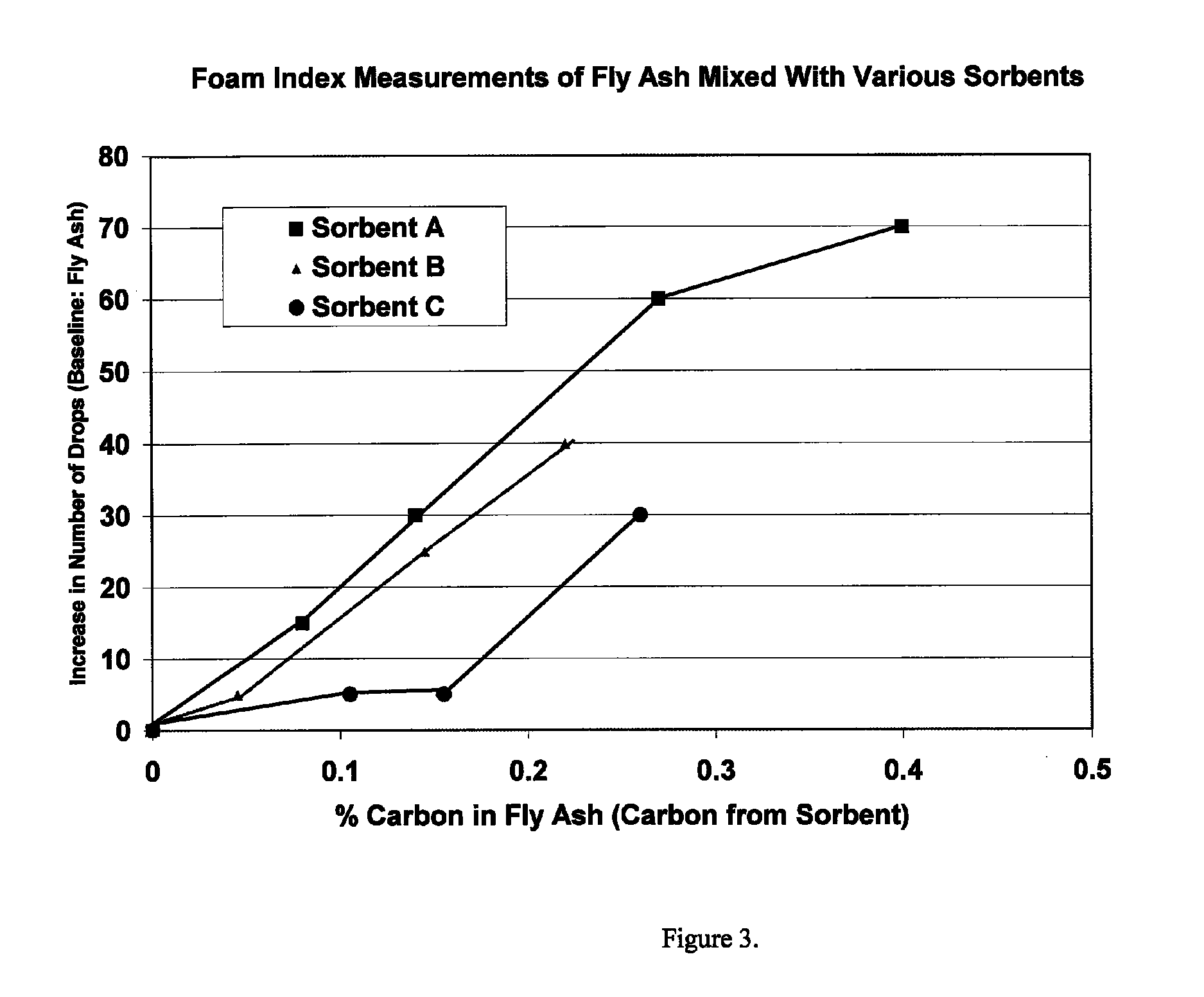

Flue gas mercury control

ActiveUS8080088B1Enhance particulate collectionReducing fly ash resistivityGas treatmentIsotope separationActivated carbonHalogen

An adsorbent composition for removing mercury from a flue gas stream, and a method of its use. The composition is a powdered activated carbon having at least one of a halogen-containing component and an alkaline component dispersed thereon. A flow agent can be composited with the material to maintain flowability in situ.

Owner:SRINIVASACHAR SRIVATS

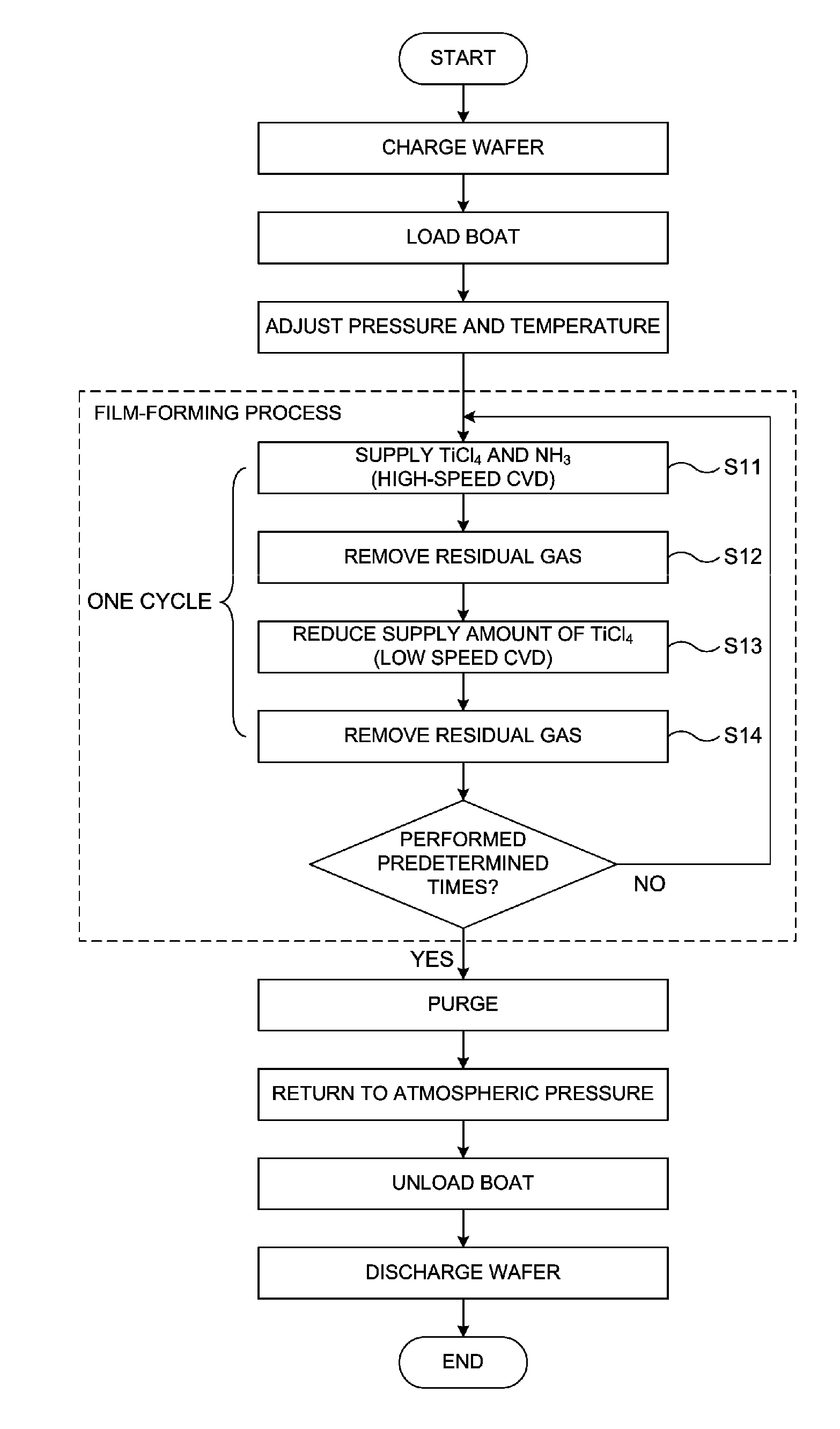

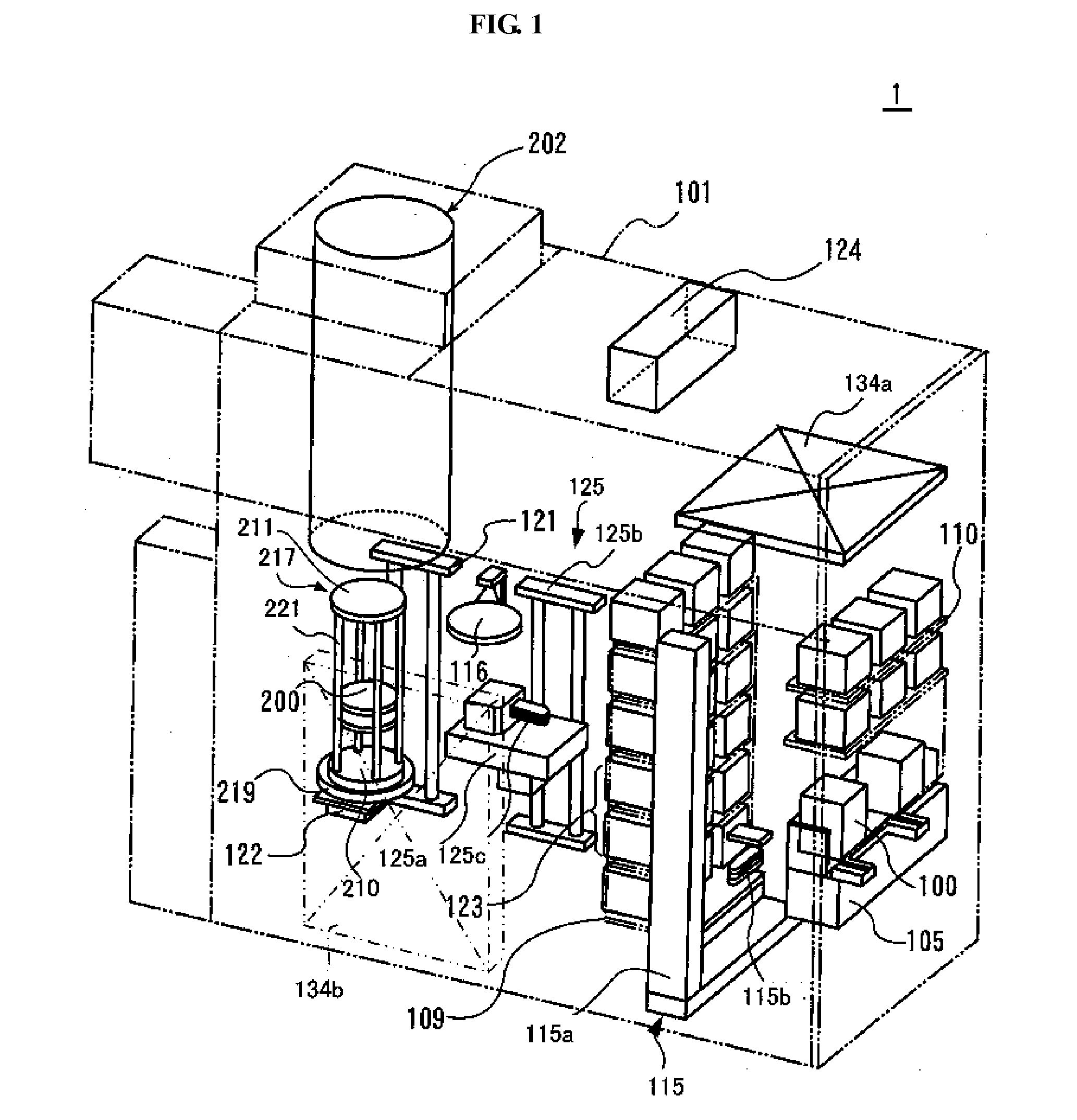

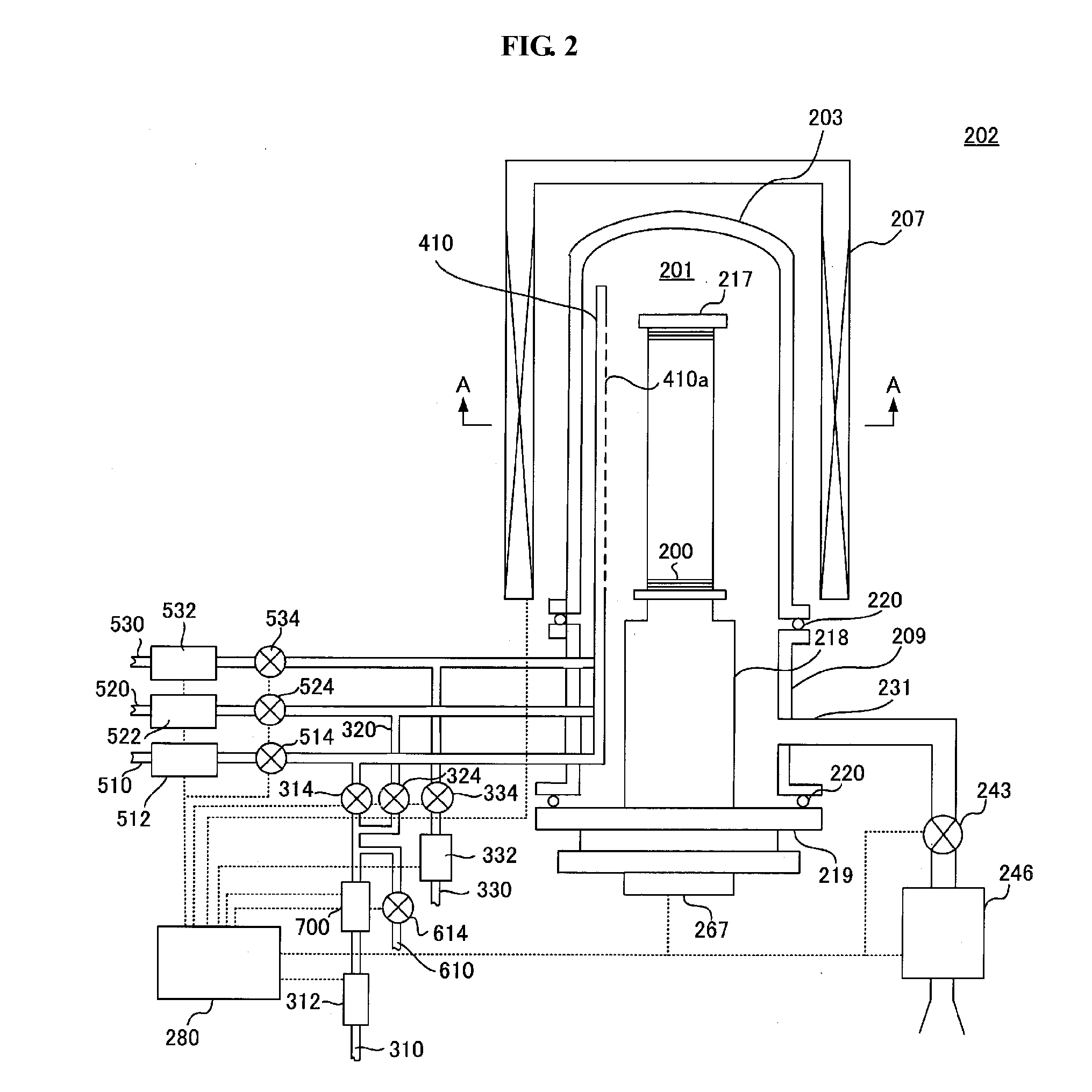

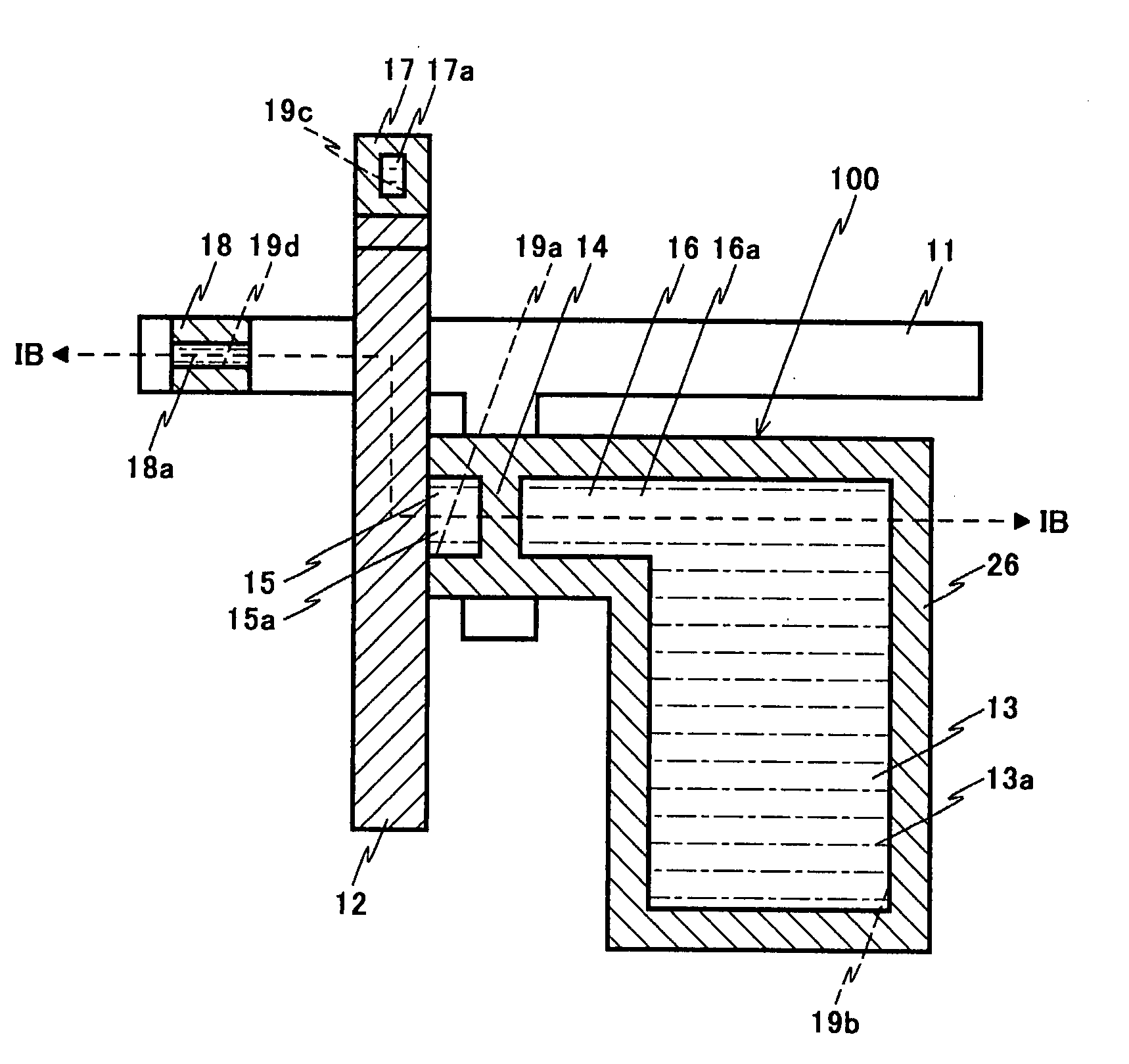

Substrate processing apparatus and method of manufacturing semiconductor device

ActiveUS20110186984A1Quality improvementHigh film forming rateSemiconductor/solid-state device detailsSolid-state devicesProcess engineeringGas supply

Provided are a substrate processing apparatus and a method of manufacturing a semiconductor device which are able to form a conductive film, which is dense, includes a low concentration of source-derived impurities and has low resistivity, at a higher film-forming rate. The substrate processing apparatus includes a processing chamber configured to stack and accommodate a plurality of substrates; a first processing gas supply system configured to supply a first processing gas into the processing chamber; a second processing gas supply system configured to supply a second processing gas into the processing chamber; and a control unit configured to control the first processing gas supply system and the second processing gas supply system. Here, at least one of the first processing gas supply system and the second processing gas supply system includes two nozzles which are vertically arranged in a stacking direction of the substrates and have different shapes, and the control unit is configured to supply at least one of the first processing gas and the second processing gas into the processing chamber through the two nozzles having different shapes when films are formed on the substrates by supplying the first processing gas and the second processing gas into the processing chamber at pulses having different film-forming rates.

Owner:KOKUSA ELECTRIC CO LTD

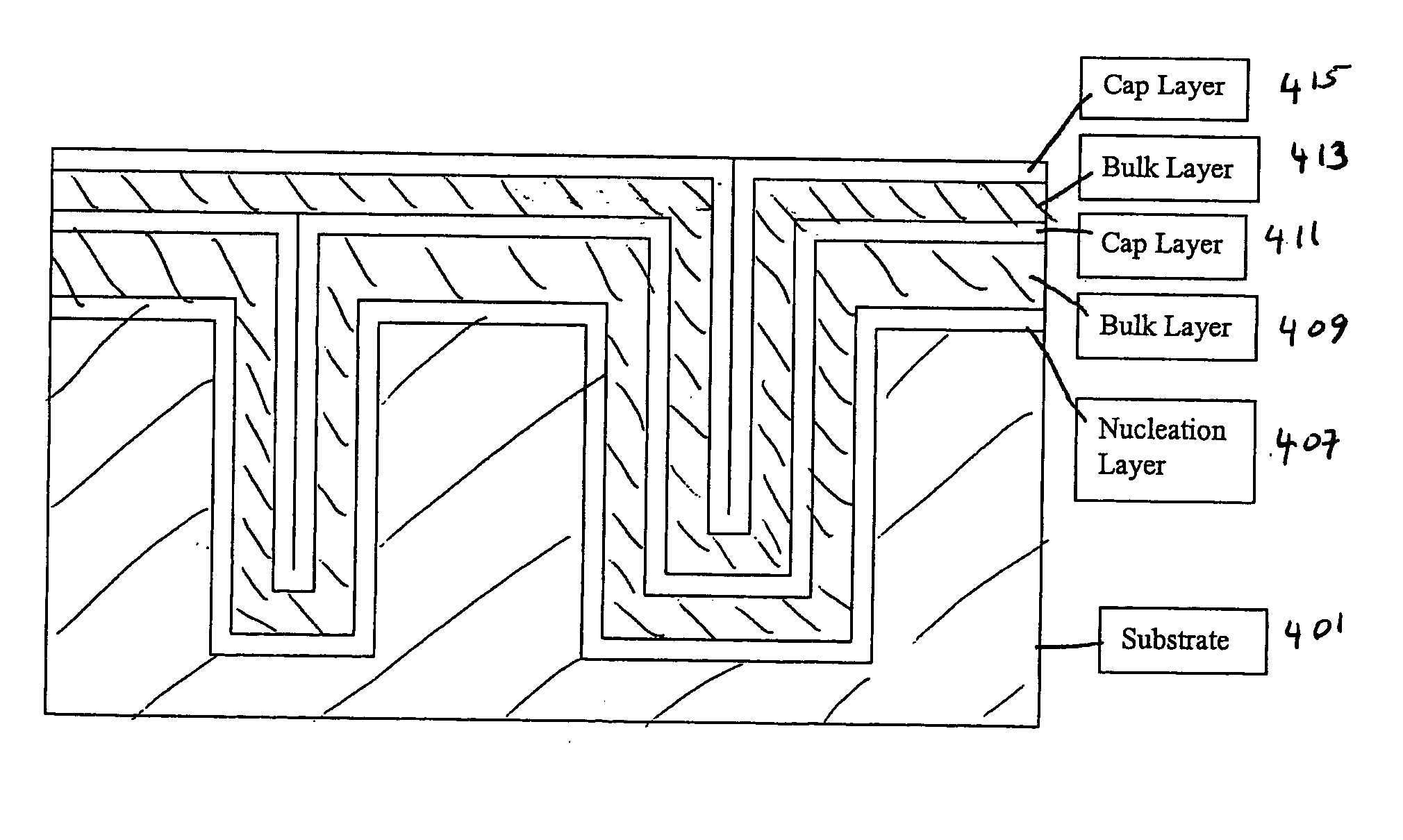

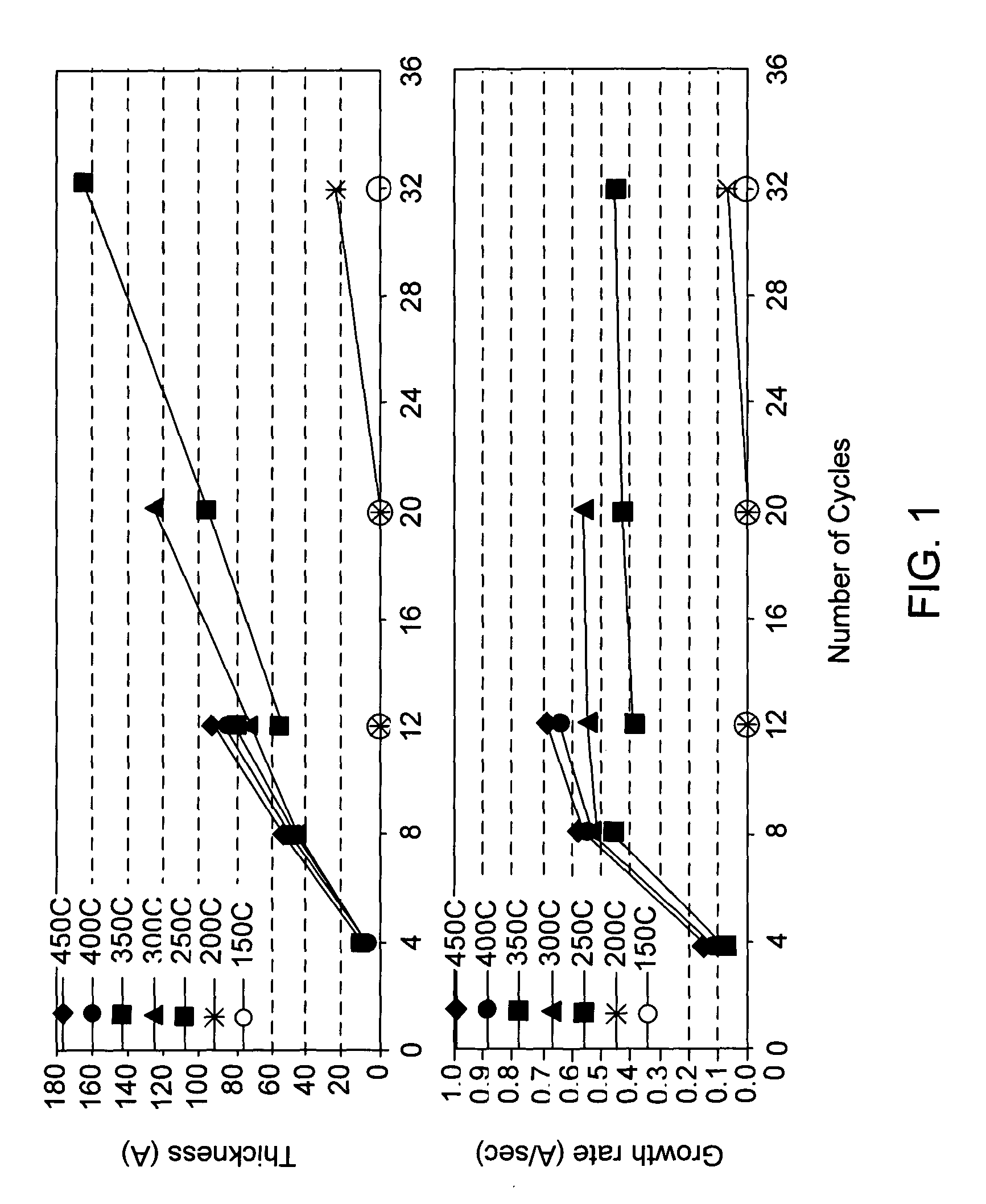

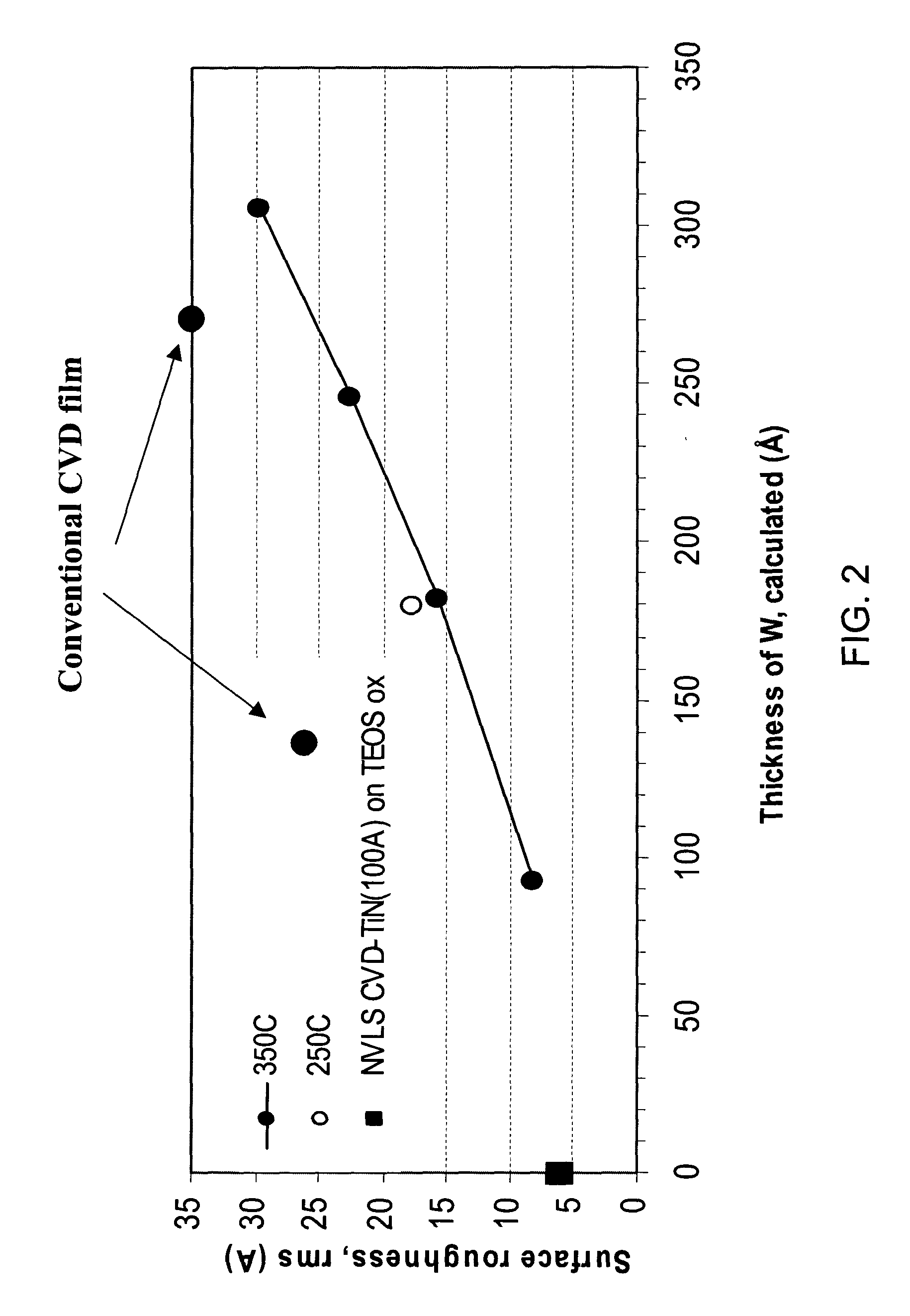

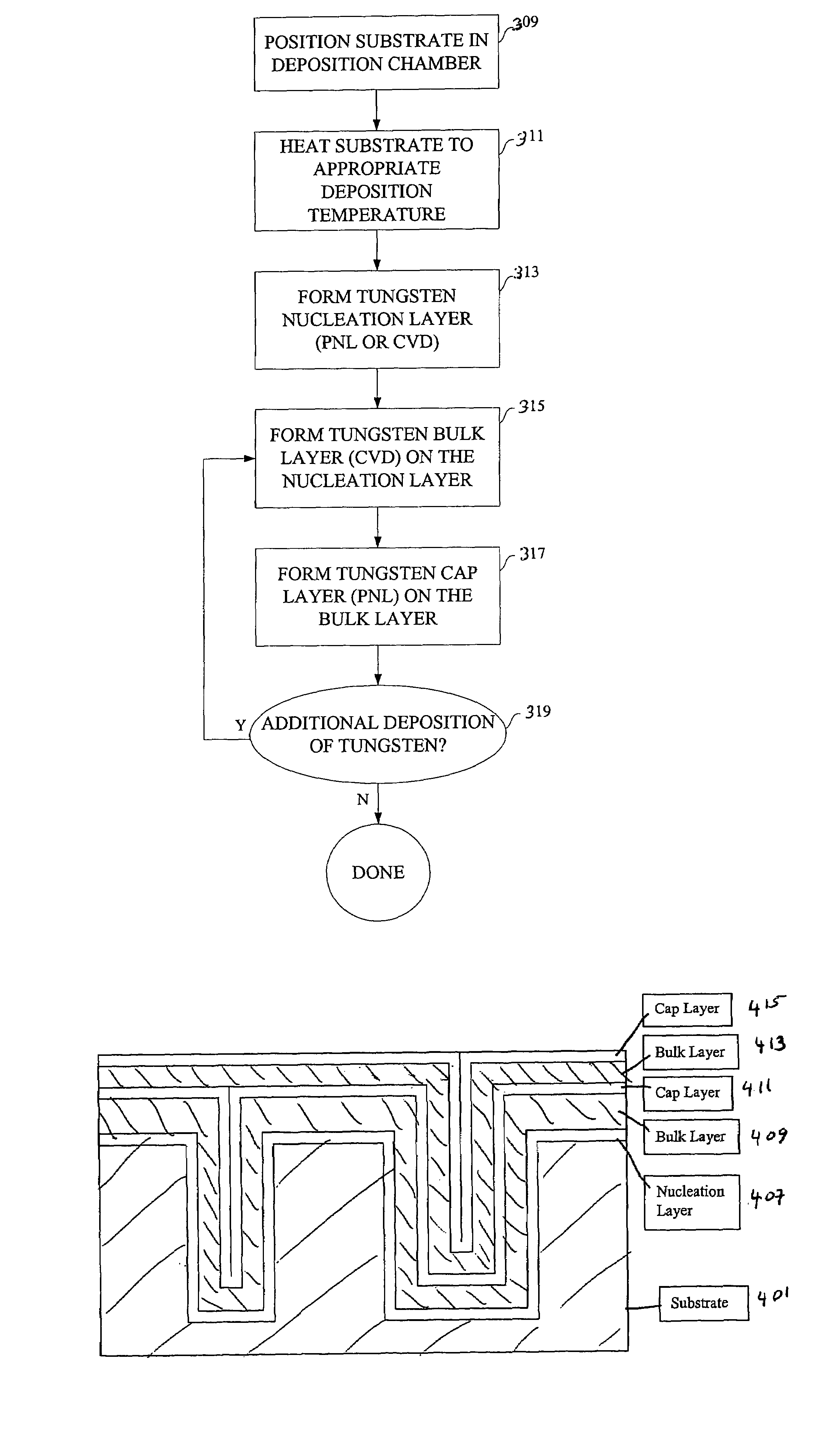

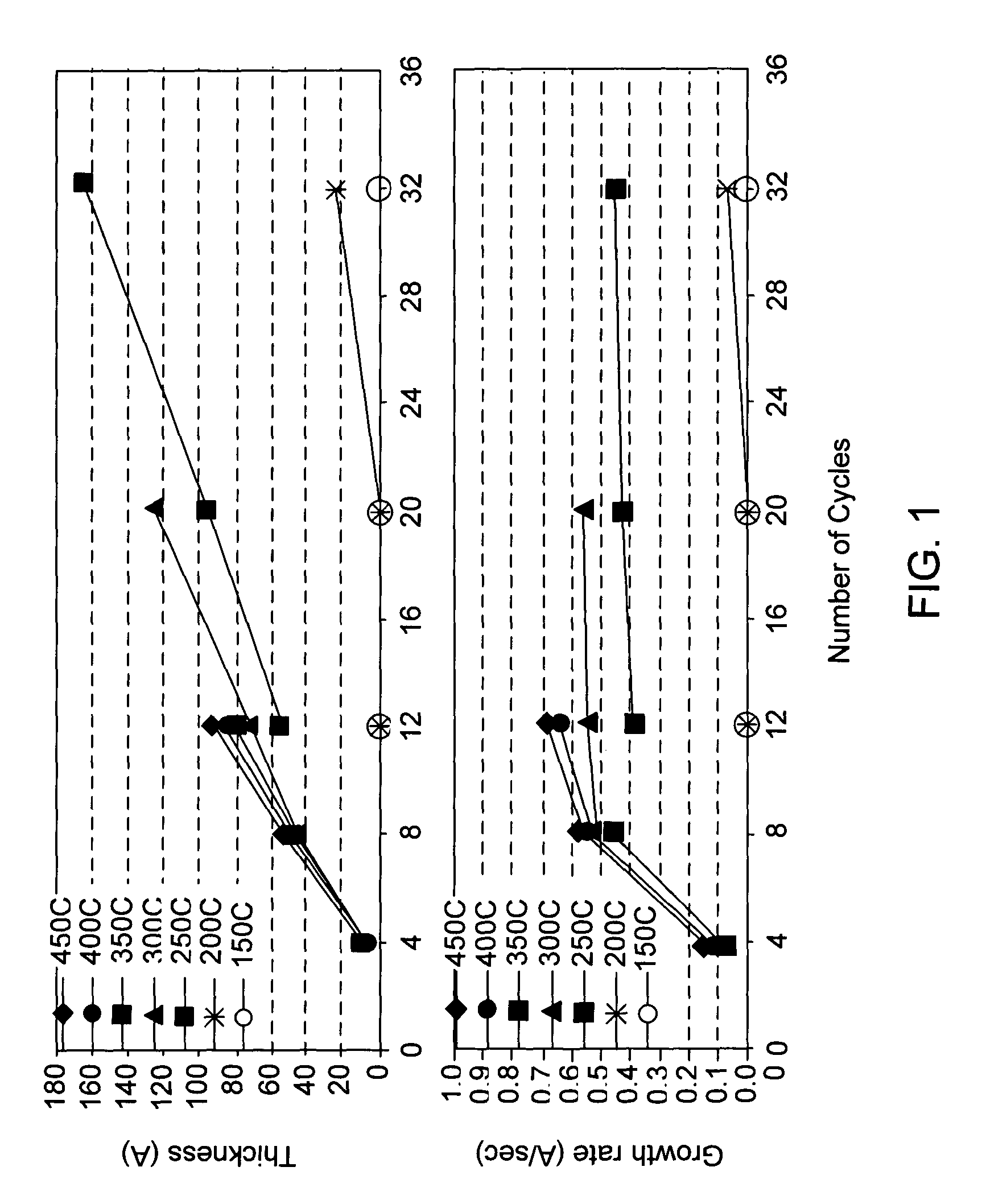

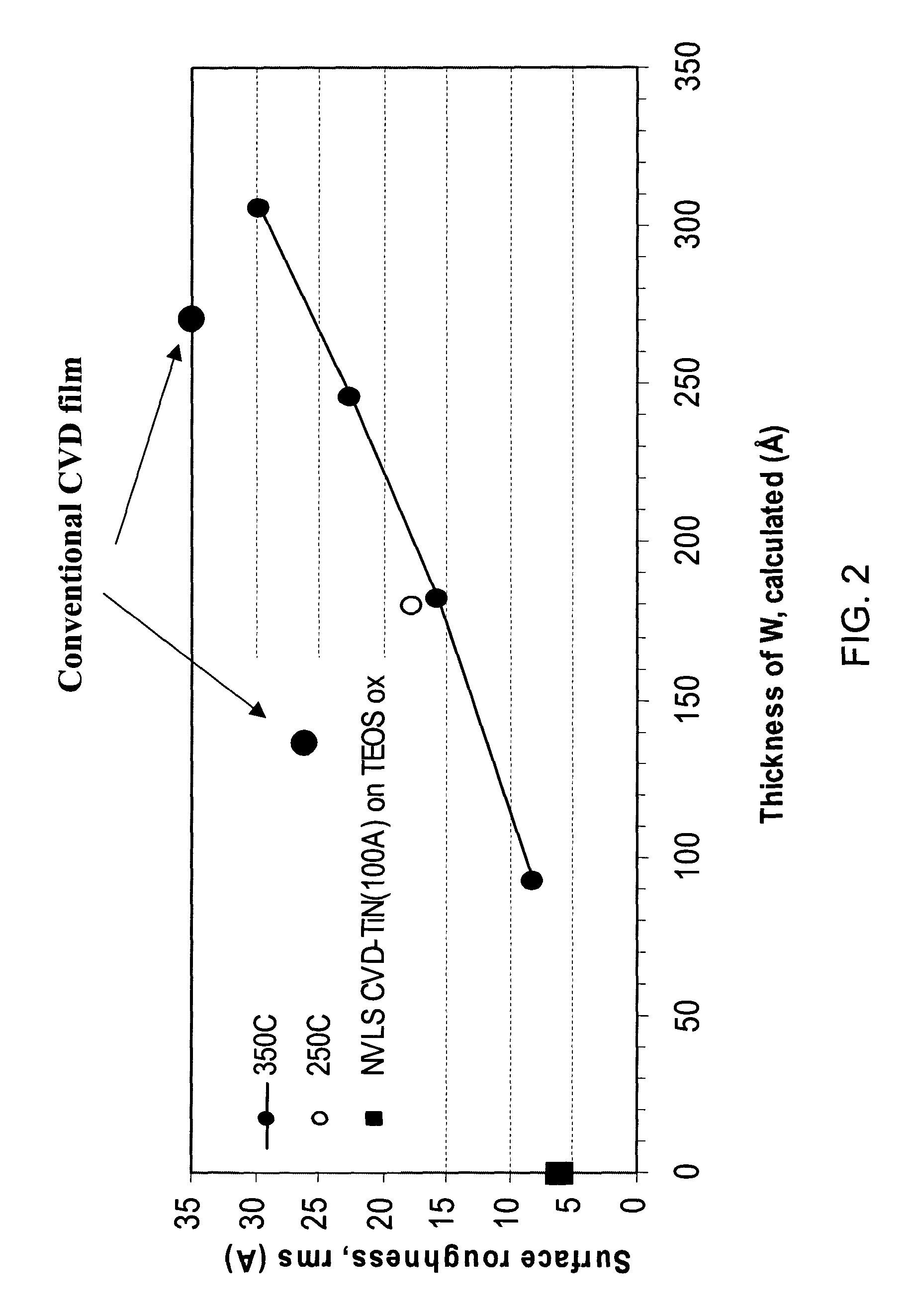

Method for reducing tungsten film roughness and improving step coverage

InactiveUS20050031786A1Increase probabilityLow resistivitySemiconductor/solid-state device manufacturingRefuse receptaclesNucleationSemiconductor

A tungsten nucleation film is formed on a surface of a semiconductor substrate by alternatively providing to that surface, reducing gases and tungsten-containing gases. Each cycle of the method provides for one or more monolayers of the tungsten film. The film is conformal and has improved step coverage, even for a high aspect ratio contact hole.

Owner:NOVELLUS SYSTEMS

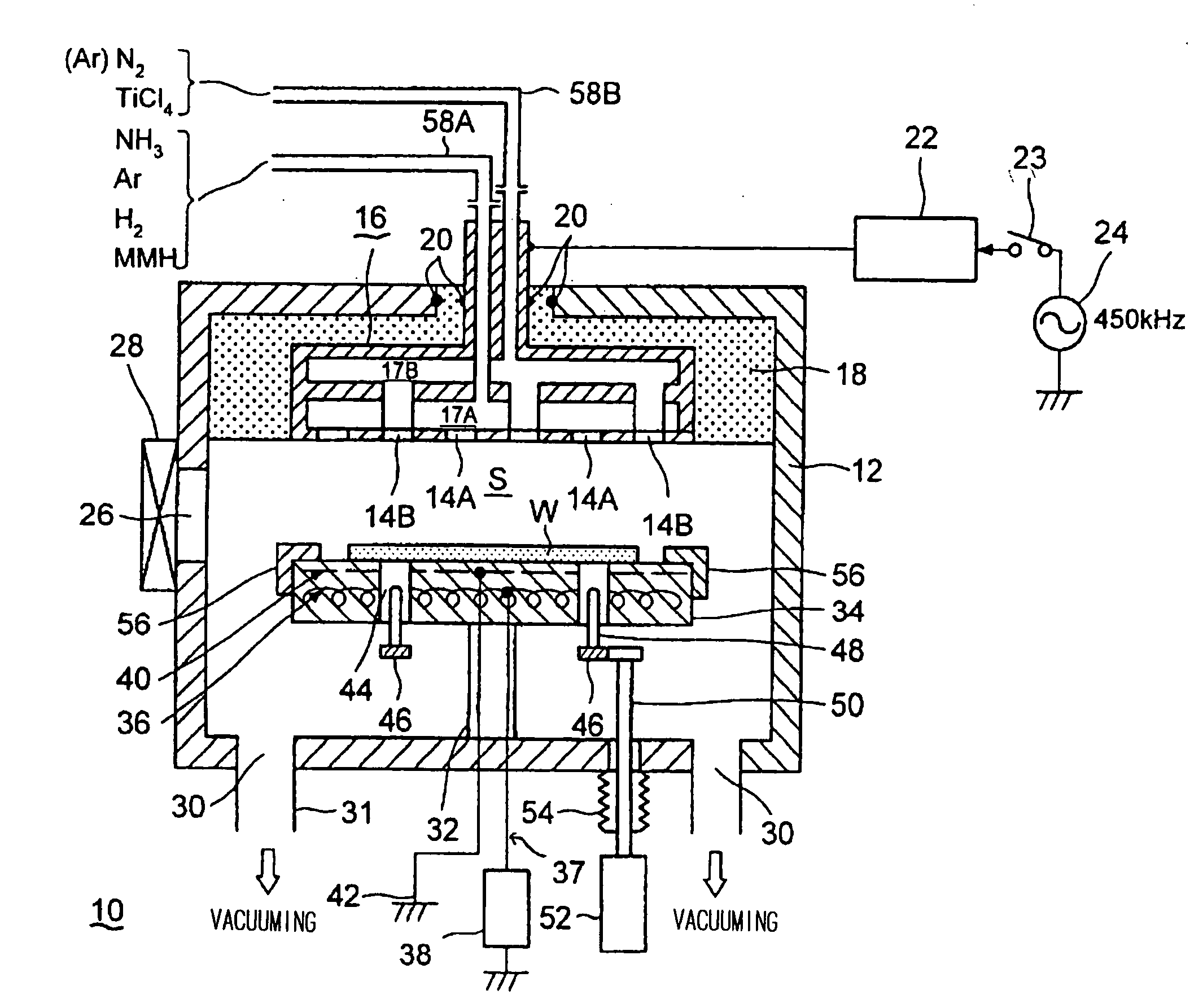

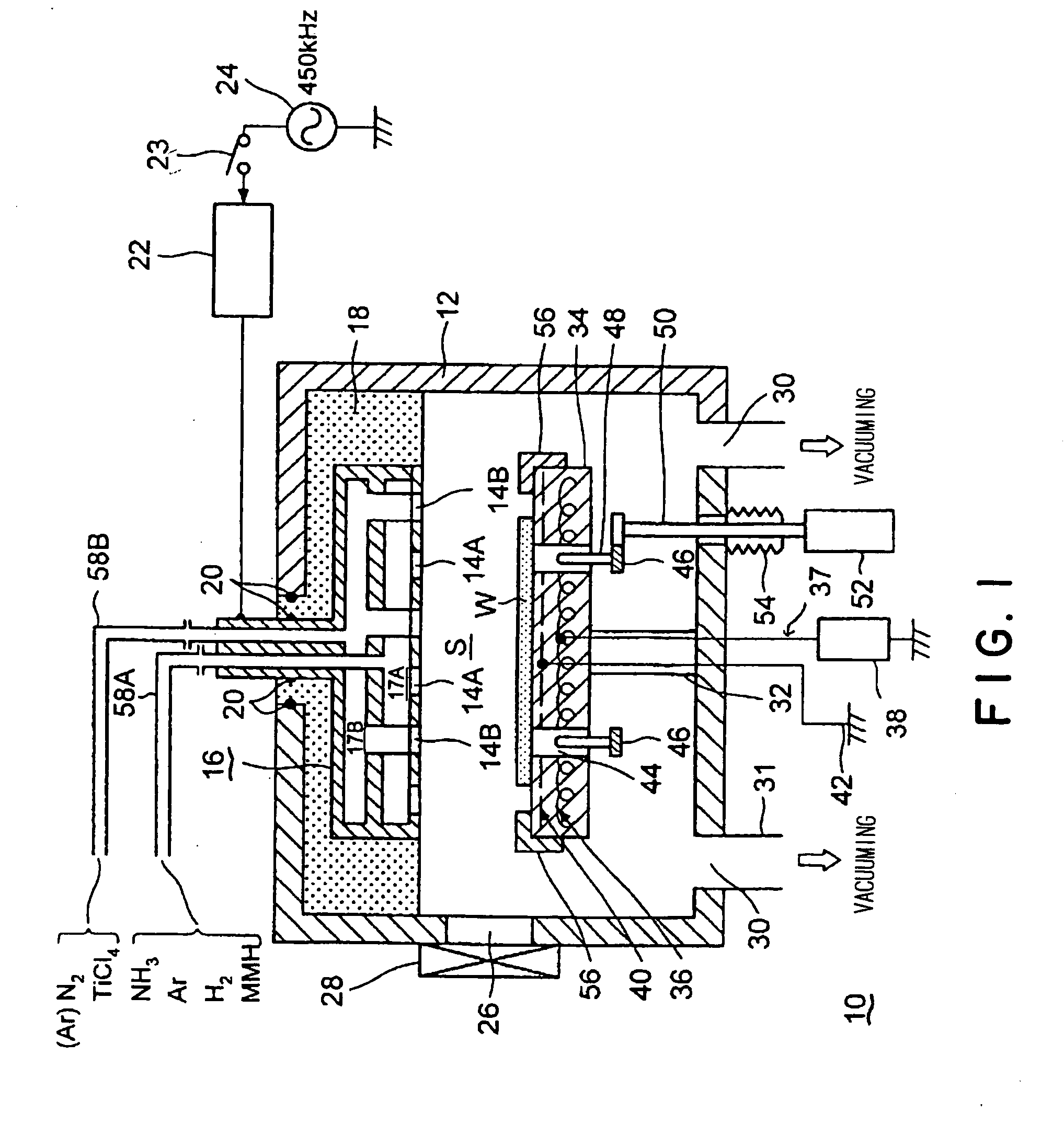

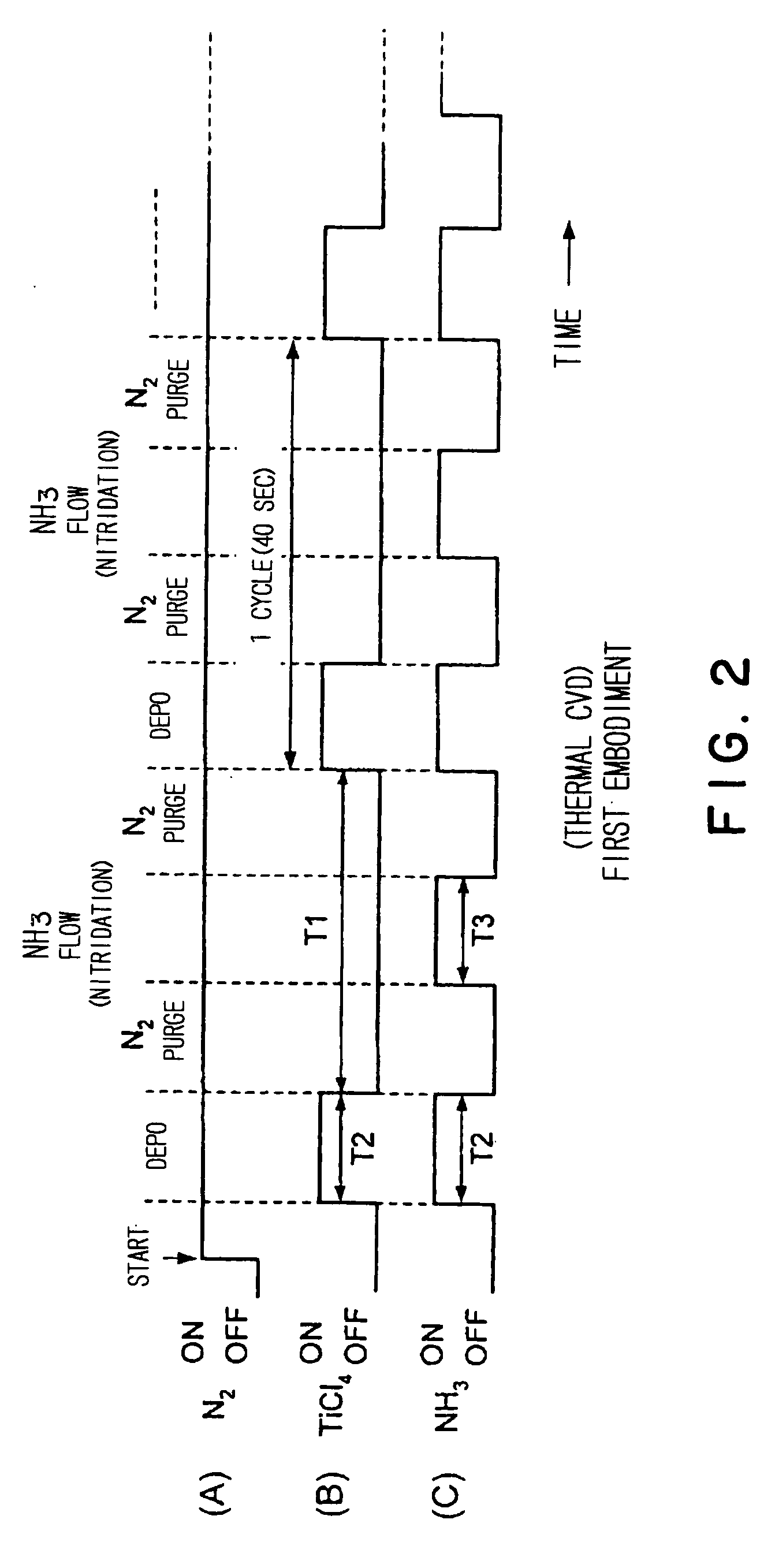

Method for forming film

InactiveUS20060193980A1Less micro crackEfficient solutionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingNitrogenProduct gas

The present invention relates to a method of forming a metal-nitride film onto a surface of an object to be processed in a processing container in which a vacuum can be created. The method of the invention includes: a step of continuously supplying an inert gas into a processing container set at a high film-forming temperature; and a step of intermittently supplying a metal-source gas into the processing container, during the step of continuously supplying the inert gas. During the step of intermittently supplying the metal-source gas, a nitrogen-including reduction gas is supplied into the processing container at the same time that the metal-source gas is supplied, during a supply term of the metal-source gas. The nitrogen-including reduction gas is also supplied into the processing container for a term shorter than a non-supply term of the metal-source gas, during the non-supply term of the metal-source gas. A film thickness of the metal-nitride film formed during the one supply term of the metal-source gas is not more than 60 nm. According to the invention, although the film-forming process is conducted at a relatively high temperature, a metal-nitride film can be deposited whose chlorine density is low, whose resistivity is low, and in which fewer cracks may be generated.

Owner:TOKYO ELECTRON LTD

Organic electroluminescent devices

InactiveUS20050106419A1Low resistivityReduced stabilityDischarge tube luminescnet screensElectroluminescent light sourcesSimple Organic CompoundsElectron injection

An organic electroluminescent device includes an anode electrode layer, a cathode electrode layer opposed to the anode electrode layer, and a luminous layer containing an organic compound disposed between the anode electrode layer and the cathode electrode layer. An excitation state of the organic compound in the luminous layer is created upon a hole injection from the anode electrode layer, and an electron injection from the cathode electrode layer, thereby causing light emission in the organic electroluminescent device. An electron-accepting material is provided in at least one hole transportation layer capable of transporting holes injected from the anode electrode layer disposed between the anode electrode layer and the cathode electrode layer, and the electron-accepting material is positioned at a site which is not adjacent to the anode electrode layer.

Owner:ROHM CO LTD

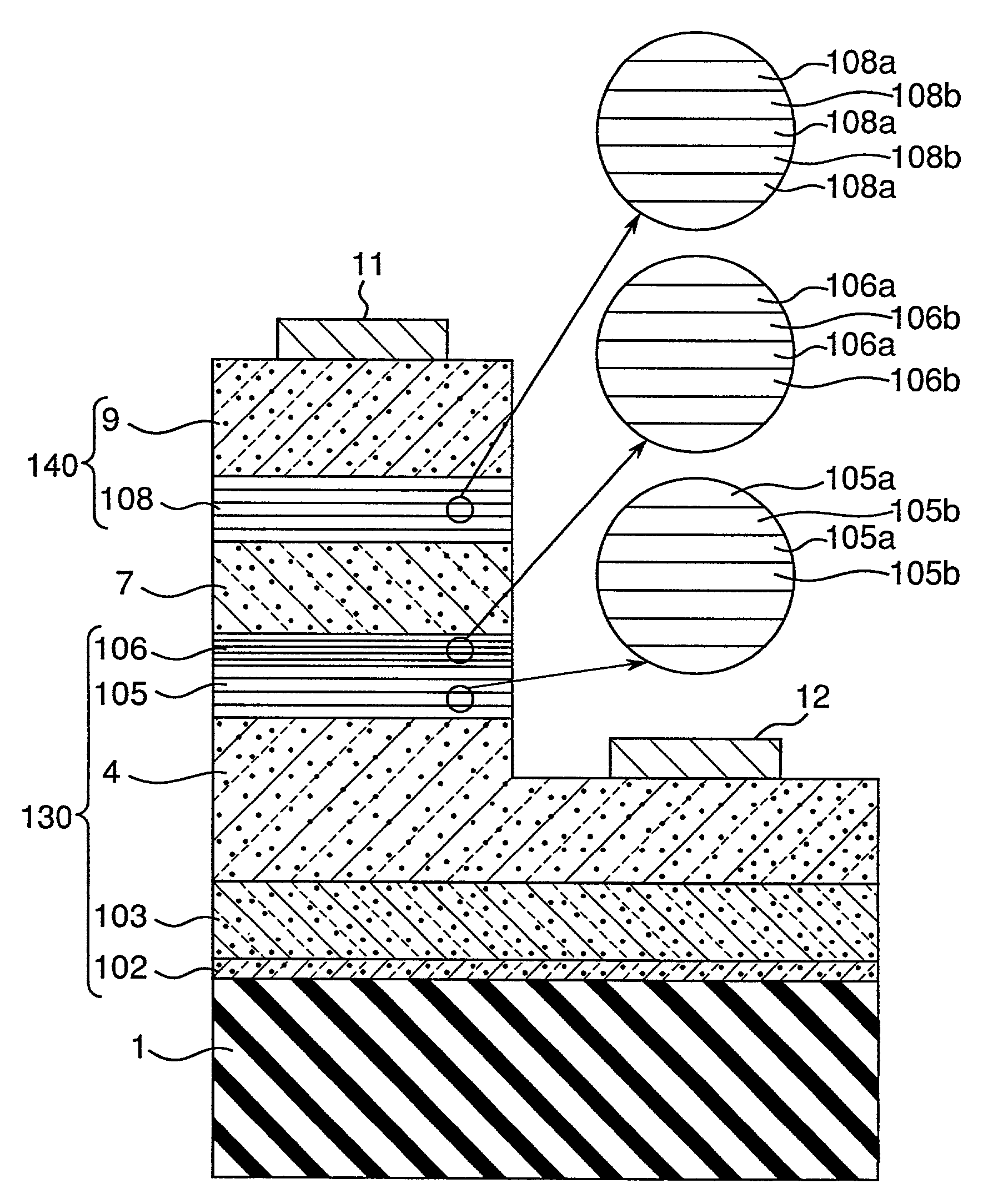

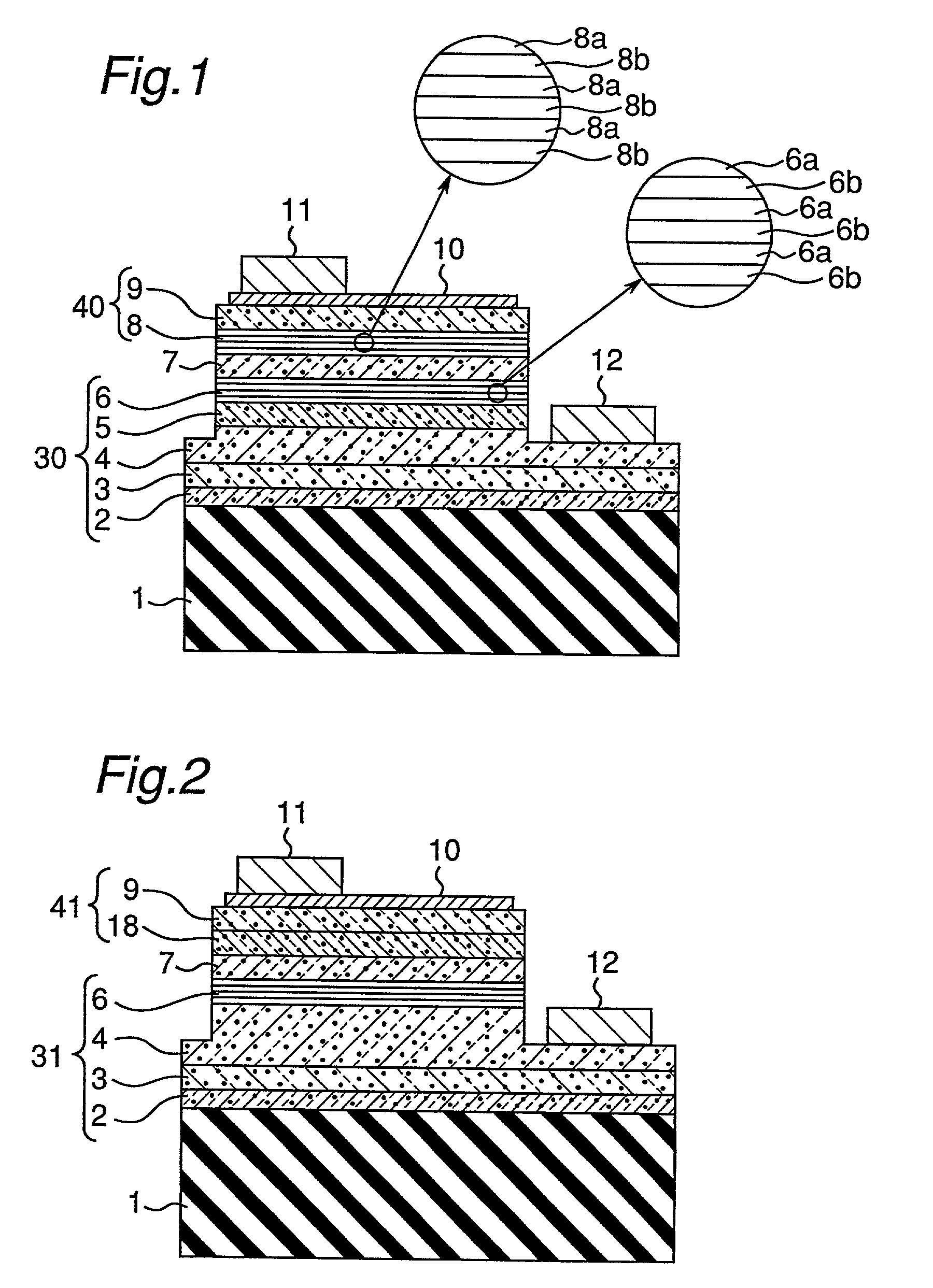

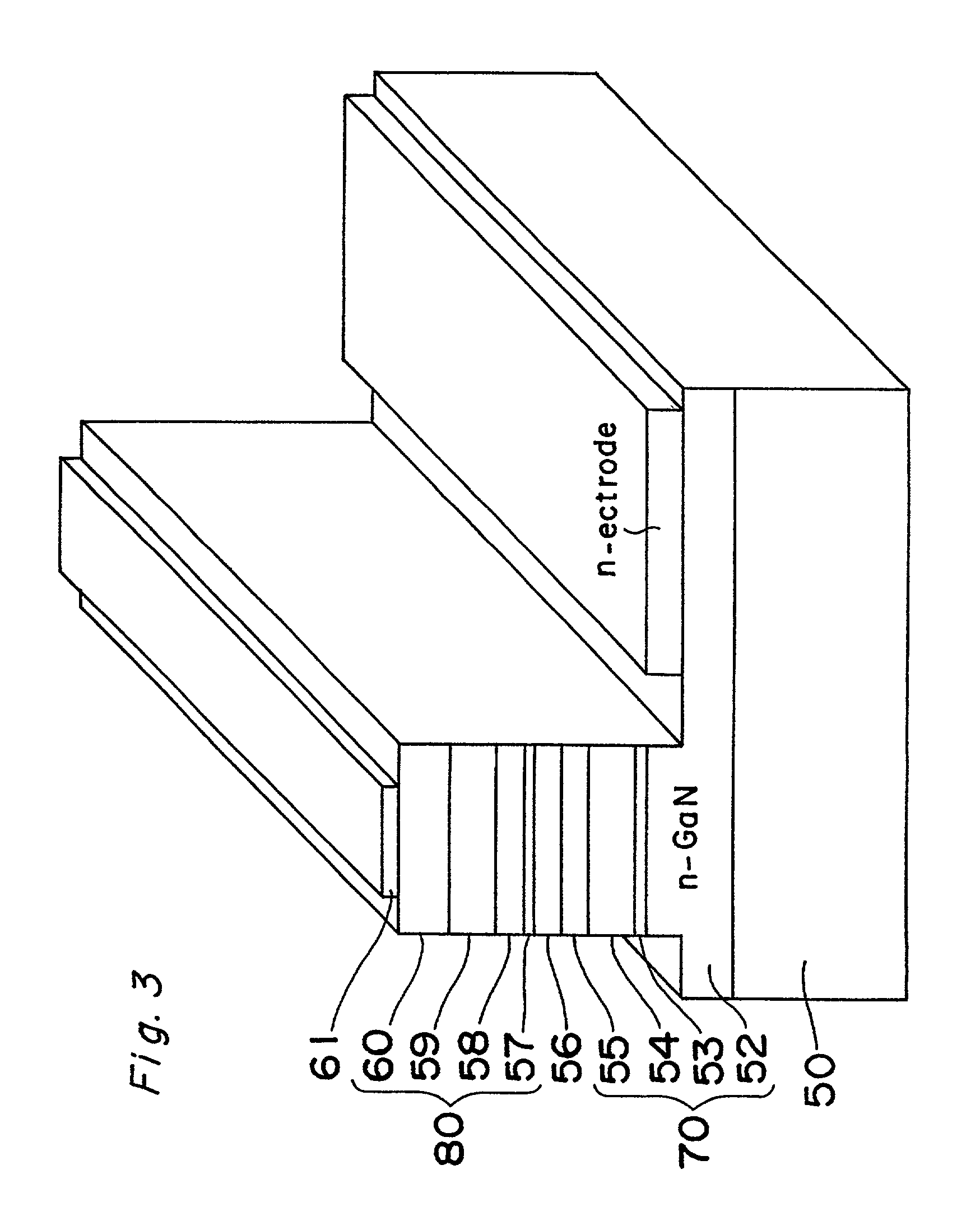

Nitride semiconductor device

InactiveUS7193246B1Light emission efficiencyHigh luminous outputOptical wave guidanceLaser detailsMultiple quantumNitride semiconductors

According to the nitride semiconductor device with the active layer made of the multiple quantum well structure of the present invention, the performance of the multiple quantum well structure can be brought out to intensify the luminous output thereof thereby contributing an expanded application of the nitride semiconductor device. In the nitride semiconductor device comprises an n-region having a plurality of nitride semiconductor films, a p-region having a plurality of nitride semiconductor films, and an active layer interposed therebetween, a multi-film layer with two kinds of the nitride semiconductor films is formed in at least one of the n-region or the p-region.

Owner:NICHIA CORP

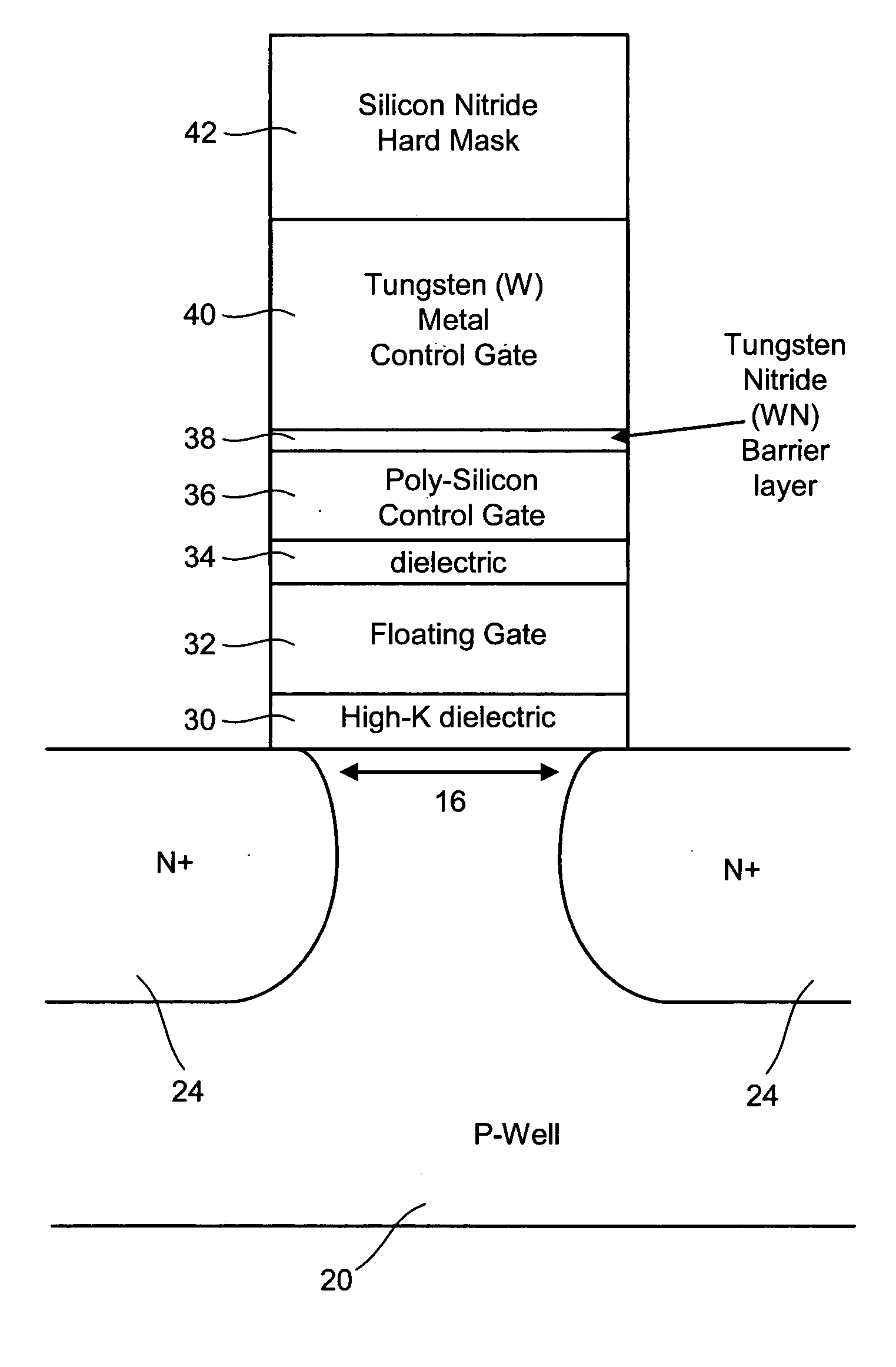

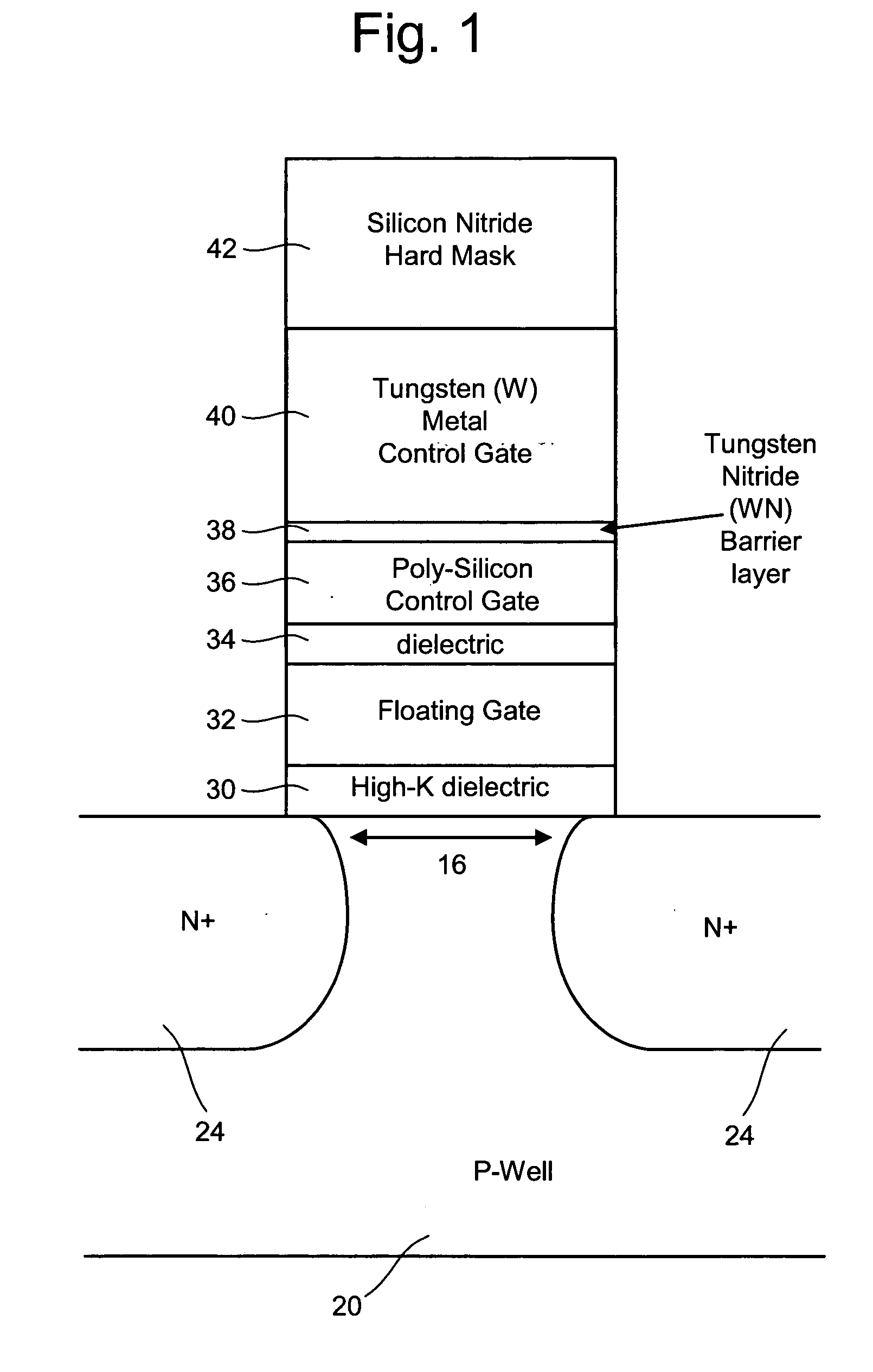

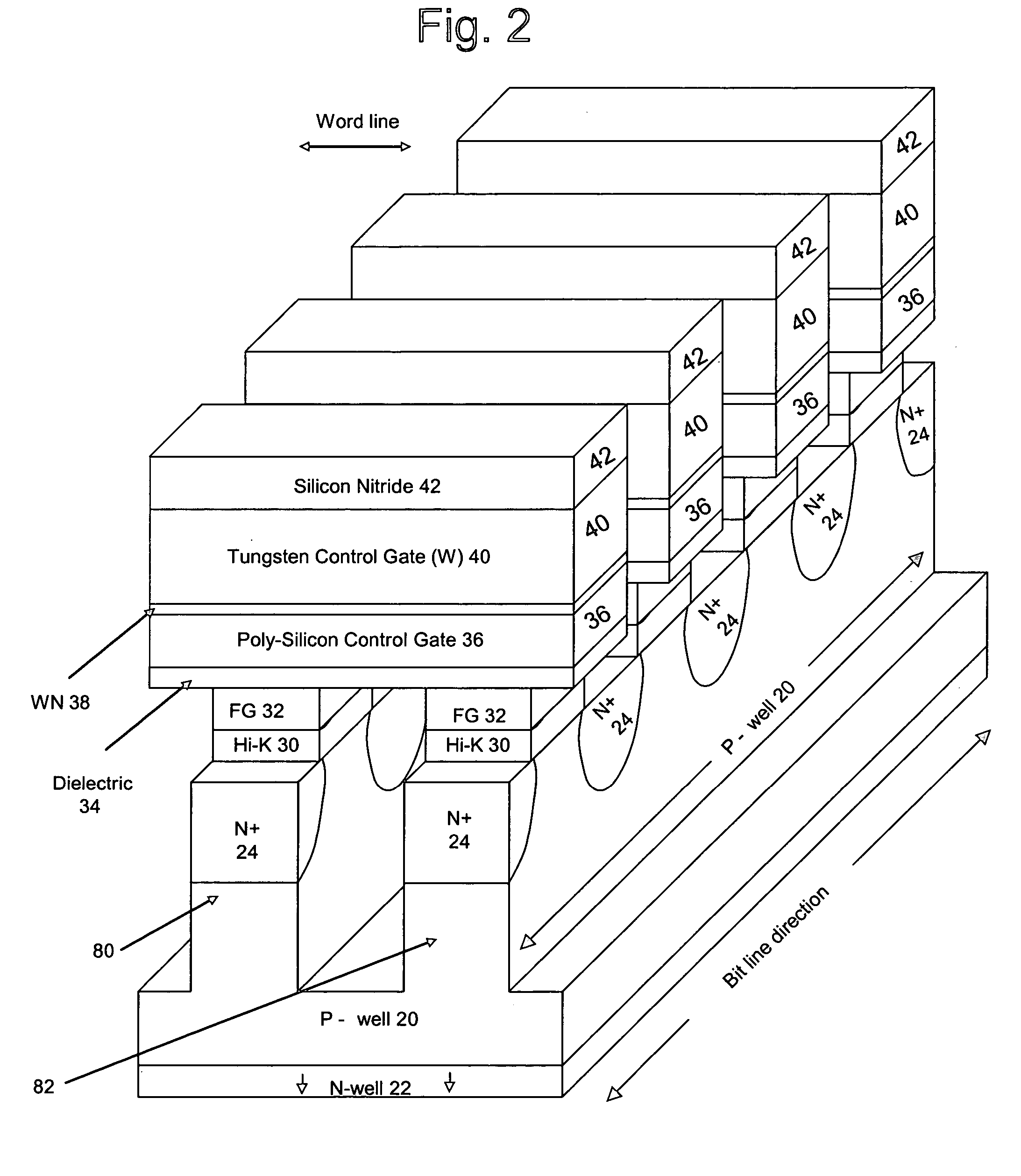

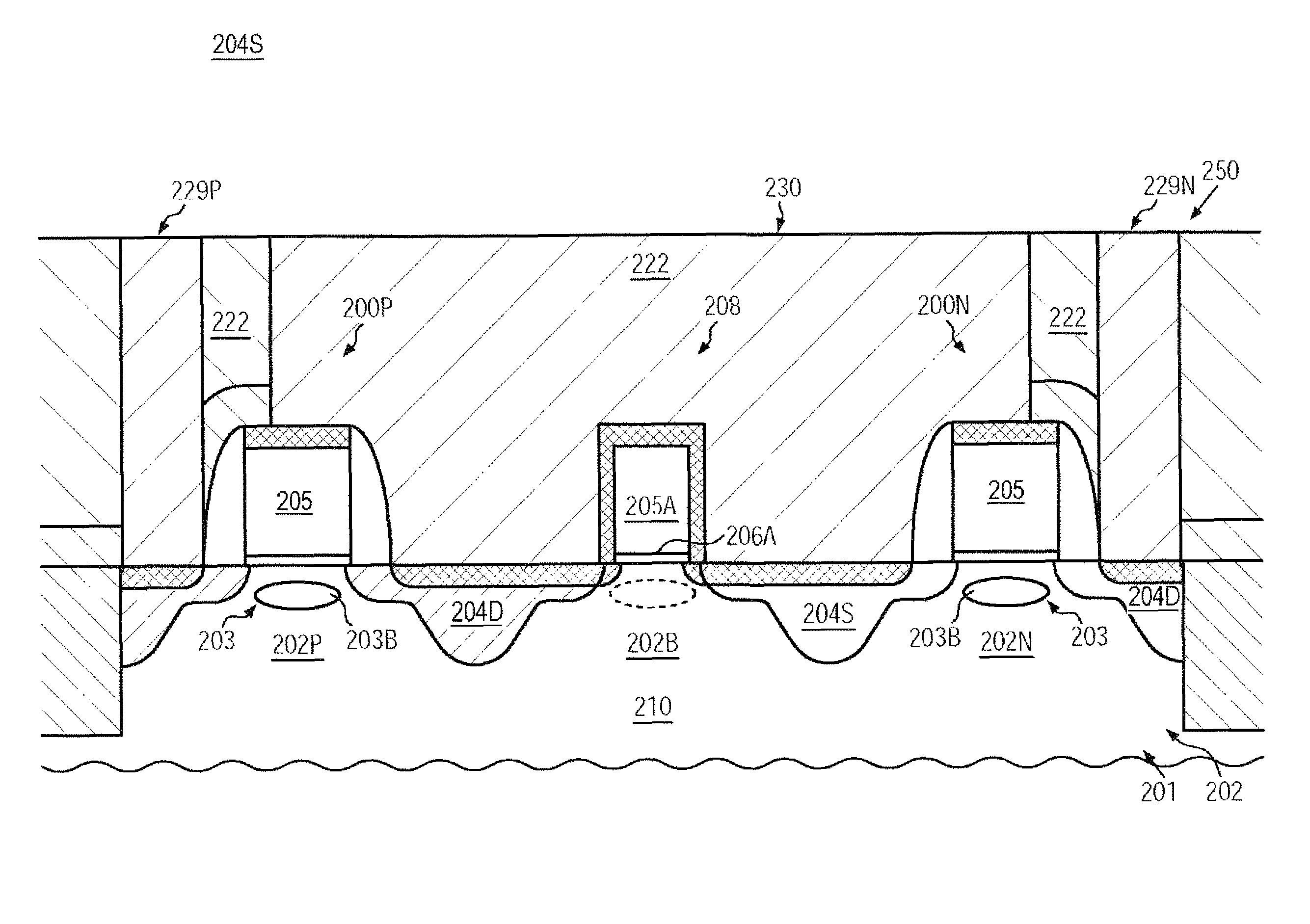

Non-volatile memory cell using high-k material and inter-gate programming

ActiveUS20050157549A1Improve performanceReduce Shrinkage ProblemsTransistorSolid-state devicesDielectricNon-volatile memory

A non-volatile memory device has a channel region between source / drain regions, a floating gate, a control gate, a first dielectric region between the channel region and the floating gate, and a second dielectric region between the floating gate and the control gate. The first dielectric region includes a high-K material. The non-volatile memory device is programmed and / or erased by transferring charge between the floating gate and the control gate via the second dielectric region.

Owner:SANDISK TECH LLC

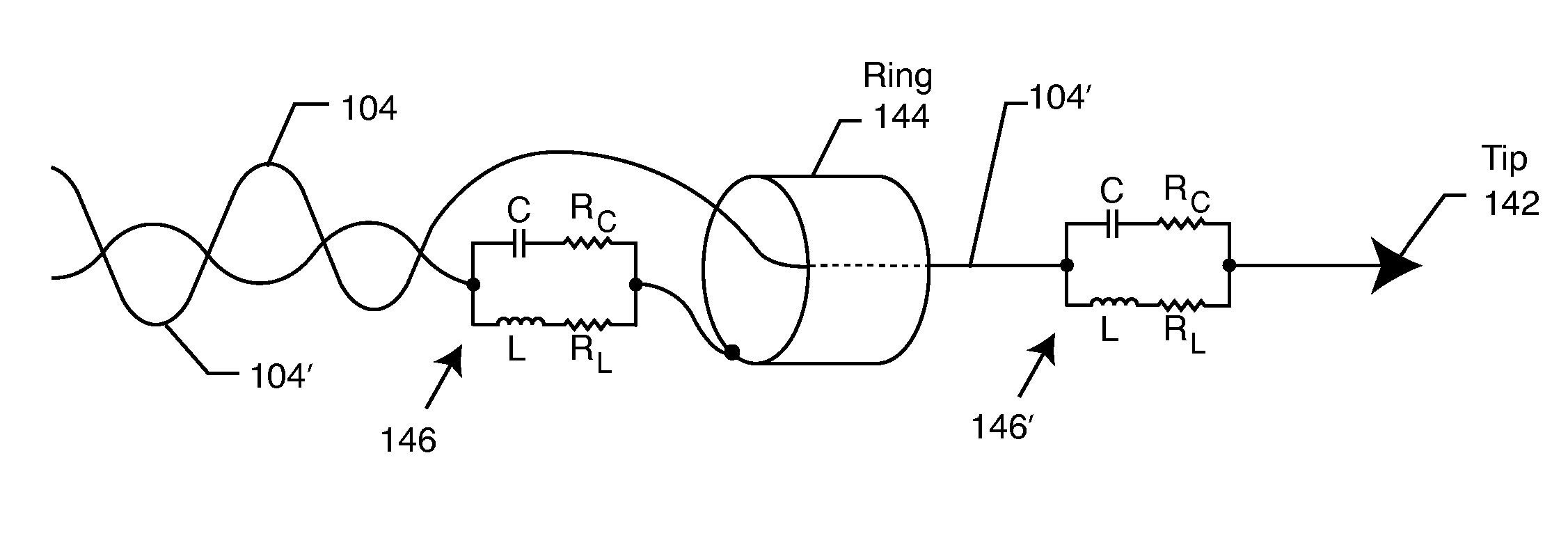

Band stop filter employing a capacitor and an inductor tank circuit to enhance MRI compatibility of active medical devices

InactiveUS20060247684A1Decrease QCapacitor is relatively minimizedMultiple-port networksInternal electrodesCapacitanceEngineering

A band stop filter is provided for a lead wire of an active medical device (AMD). The band stop filter includes a capacitor in parallel with an inductor. The parallel capacitor and inductor are placed in series with the lead wire of the AMD, wherein values of capacitance and inductance are selected such that the band stop filter is resonant at a selected frequency. The Q of the inductor may be relatively maximized and the Q of the capacitor may be relatively minimized to reduce the overall Q of the band stop filter to attenuate current flow through the lead wire along a range of selected frequencies. In a preferred form, the band stop filter is integrated into a TIP and / or RING electrode for an active implantable medical device.

Owner:WILSON GREATBATCH LTD

Method for reducing tungsten film roughness and improving step coverage

InactiveUS7141494B2Increase probabilityLow resistivitySemiconductor/solid-state device manufacturingRefuse receptaclesNucleationTungsten film

A tungsten nucleation film is formed on a surface of a semiconductor substrate by alternatively providing to that surface, reducing gases and tungsten-containing gases. Each cycle of the method provides for one or more monolayers of the tungsten film. The film is conformal and has improved step coverage, even for a high aspect ratio contact hole.

Owner:NOVELLUS SYSTEMS

Thin-film transistor array, method of fabricating the same, and liquid crystal display device including the same

ActiveUS20080035920A1Improve electrical connection reliabilityReduce conductivitySolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayEngineering

A thin-film transistor array includes an electrically insulating substrate, a plurality of thin-film transistors arranged in a matrix on the substrate, and each including a channel, a source, and a drain each comprised of an oxide-semiconductor film, a pixel electrode integrally formed with the drain, a source signal line through which a source signal is transmitted to a group of thin-film transistors, a gate signal line through which a gate signal is transmitted to a group of thin-film transistors, a source terminal formed at an end of the source signal line, and a gate terminal formed at an end of the gate signal line. The source terminal and the gate terminal are formed in the same layer as a layer in which the channel is formed. The source terminal and the gate terminal have the same electric conductivity as that of the pixel electrode.

Owner:NEC LCD TECH CORP

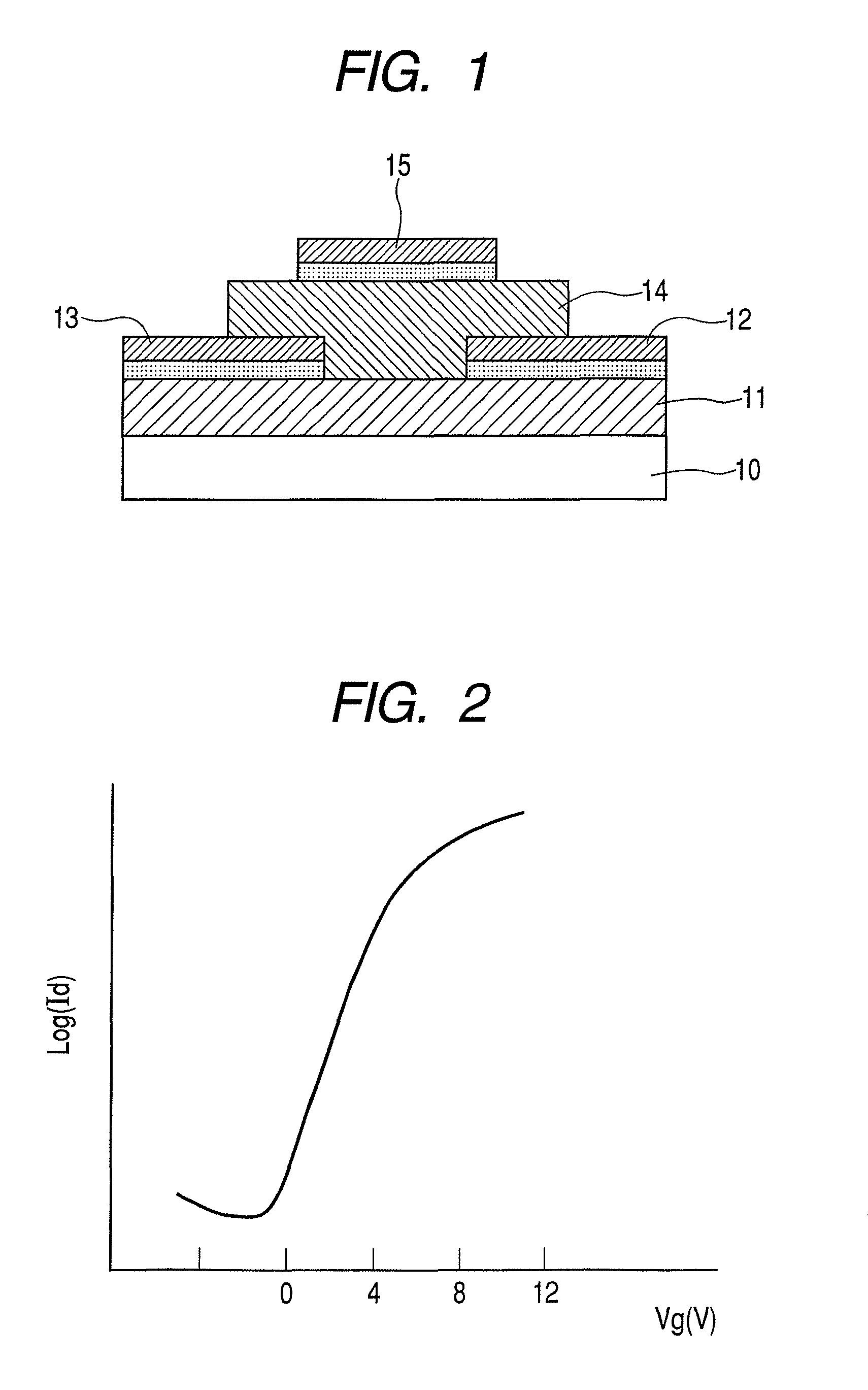

Production method of thin film transistor using amorphous oxide semiconductor film

ActiveUS8415198B2Satisfactory characteristicEffective controlSemiconductor/solid-state device manufacturingSemiconductor devicesActive layerPartial pressure

A production method of a thin film transistor including an active layer including an amorphous oxide semiconductor film, wherein a step of forming the active layer includes a first step of forming the oxide film in an atmosphere having an introduced oxygen partial pressure of 1×10−3 Pa or less, and a second step of annealing the oxide film in an oxidative atmosphere after the first step.

Owner:CANON KK

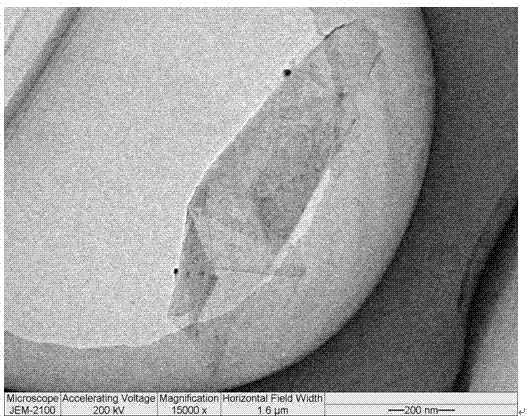

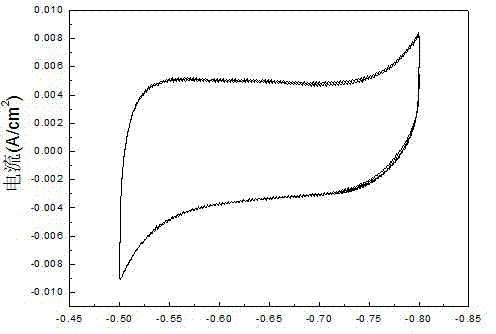

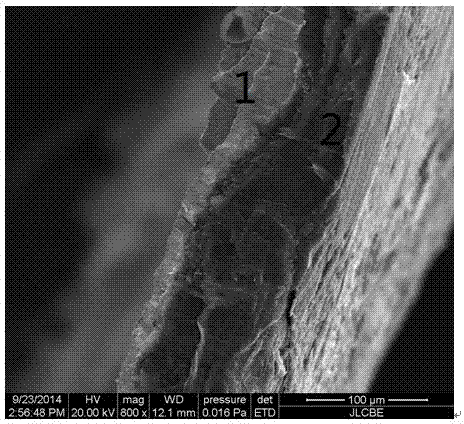

Graphene composite material and preparation method thereof

ActiveCN104495811ALarge specific surface areaImprove conductivityMaterial nanotechnologyPtru catalystElectrical battery

The invention relates to a graphene composite material and a preparation method thereof. The graphene composite material provided by the invention is characterized in that a graphene material plate fixed on a metallic matrix serves as a carrier, and the elementary substance and / or a compound are compounded on the graphene surface. Meanwhile, the invention also discloses a method for preparing the graphene composite material. The graphene composite material prepared by the invention is opened between graphene sheets and is compounded with a chemical substance under the condition that a space body structure is formed, and the obtained material has high conductivity, high specific surface area and excellent performance of low electrical resistivity between the sheets, and can be widely applied to the fields of energy storage materials such as lithium ion batteries, super-capacitors, super lead carbon batteries, super nickel-carbon electrodes, solar energy and fuel cells, the field of heat dissipation materials, the field of environment-friendly adsorbing materials, the field of sea water desalination materials, the field of photoelectric sensor materials, the biological relevance field, the field of catalyst materials and the fields of conductive ink and coating materials.

Owner:YANCHENG TEACHERS UNIV

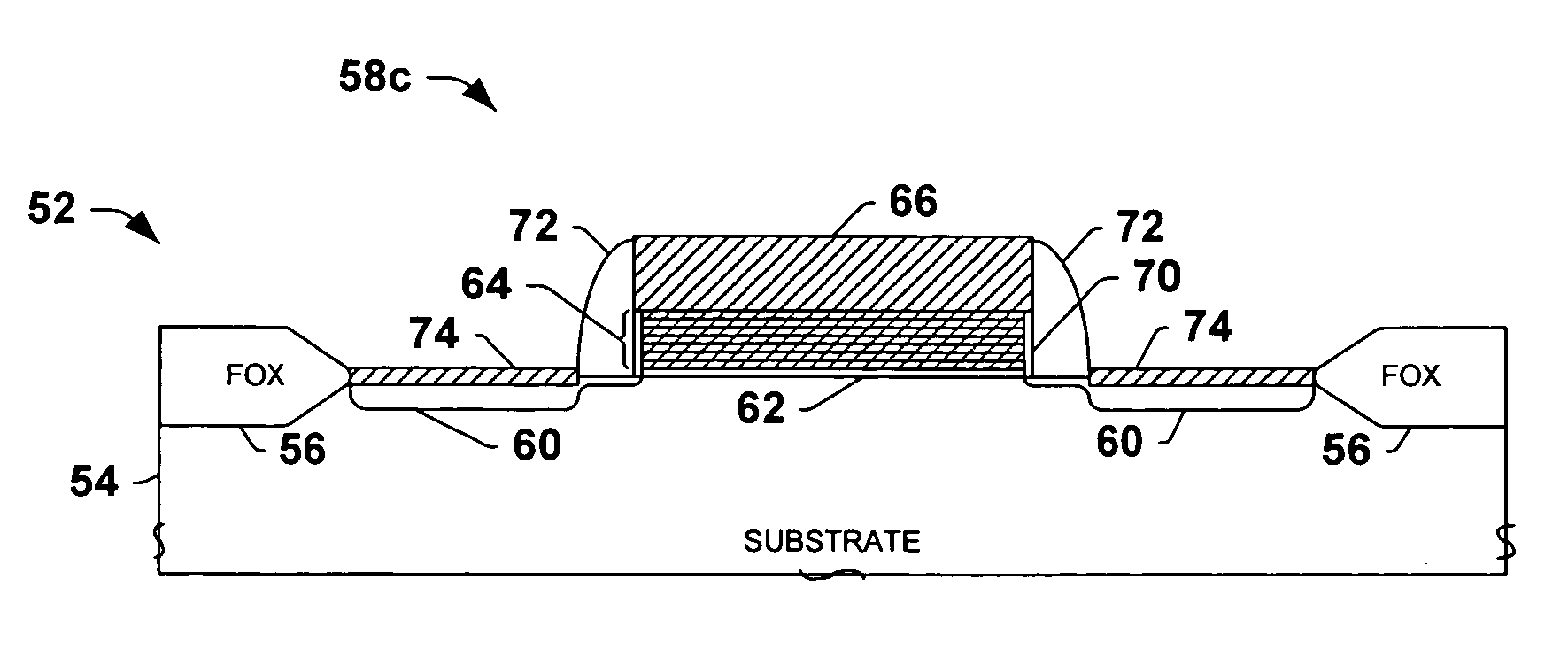

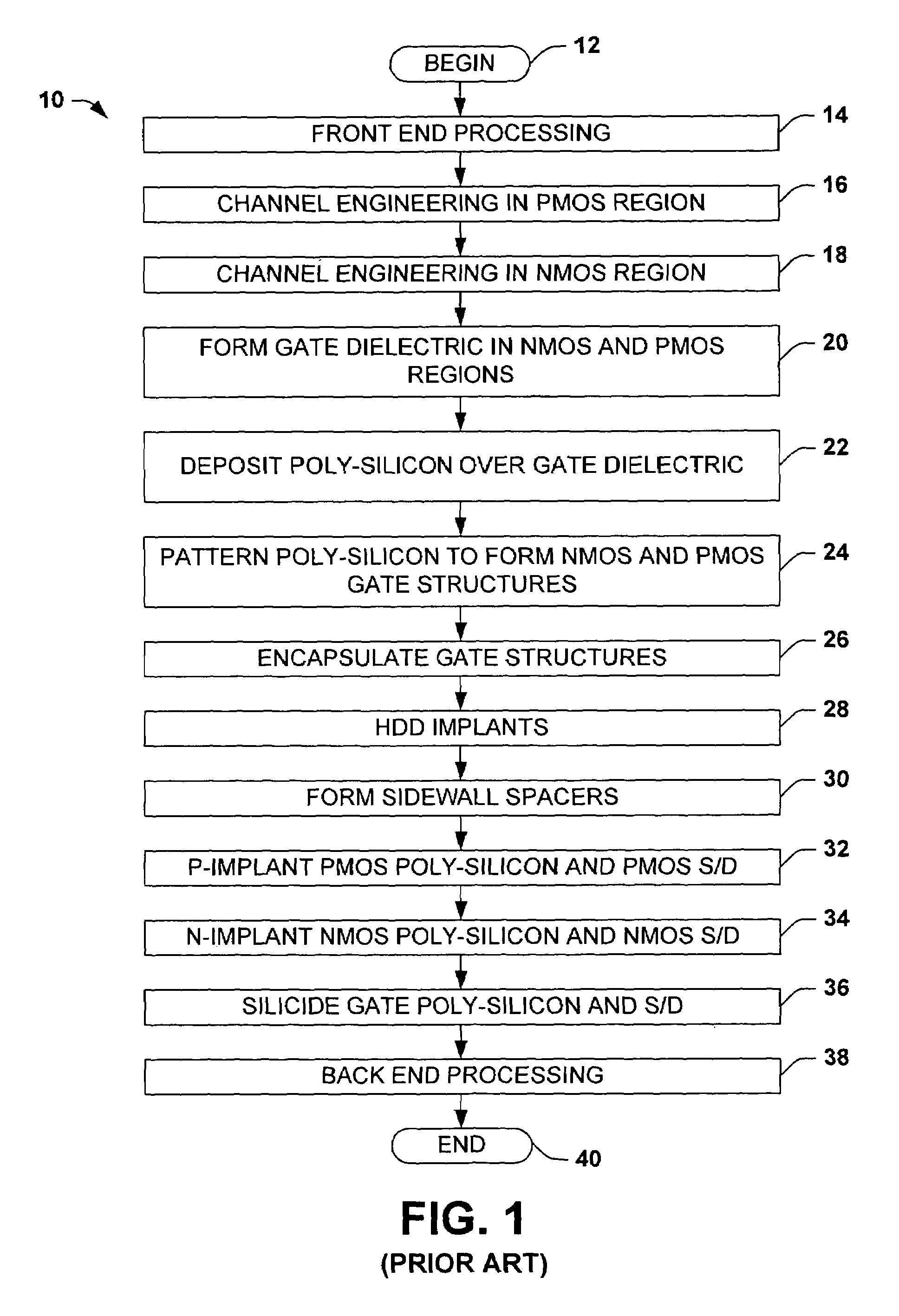

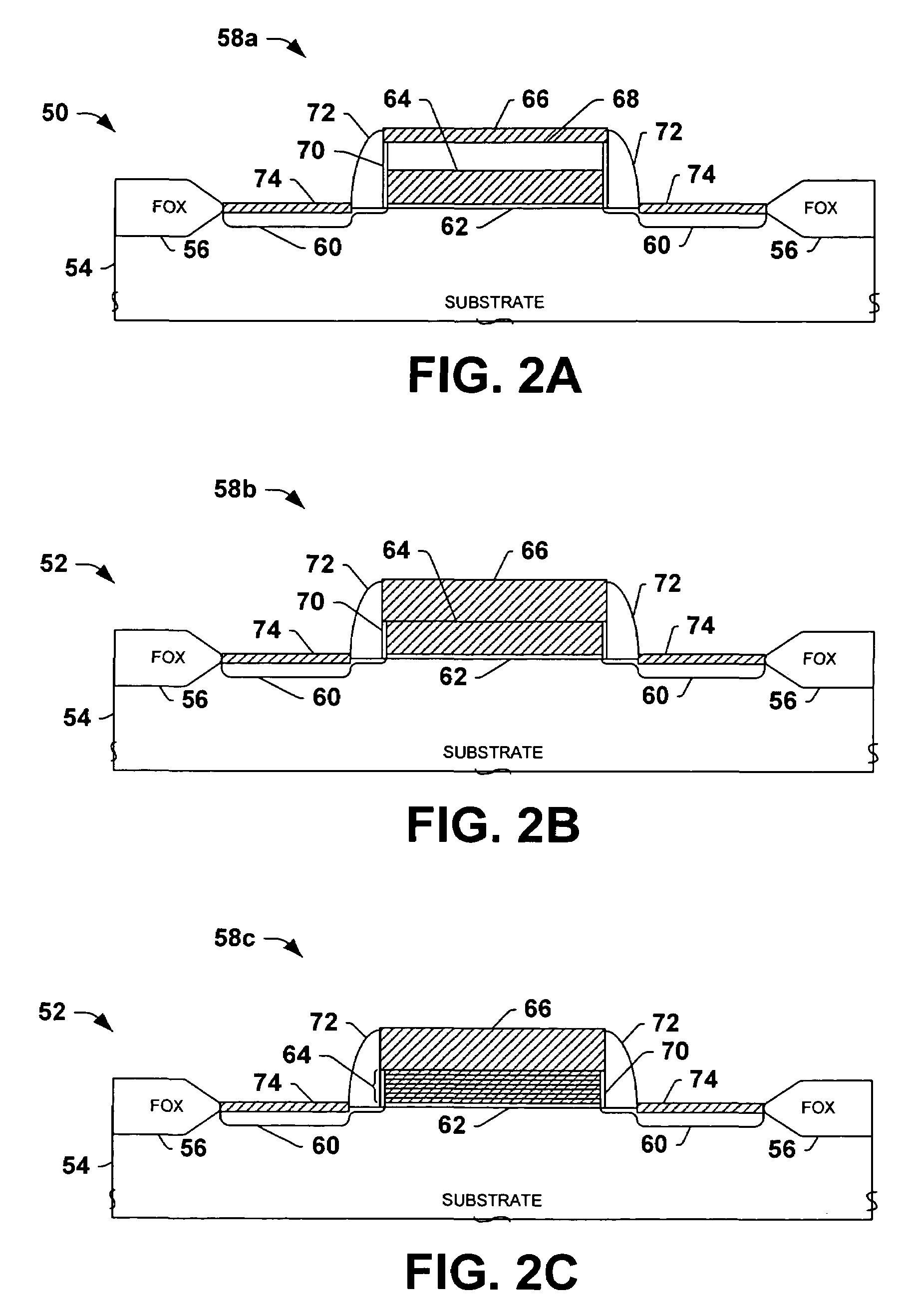

MOS transistor gates with thin lower metal silicide and methods for making the same

ActiveUS7045456B2Easy to implantEasy to controlTransistorSemiconductor/solid-state device manufacturingSalicideGate dielectric

Methods are presented for fabricating transistor gate structures, wherein upper and lower metal suicides are formed above a gate dielectric. In one example, the lower silicide is formed by depositing a thin first silicon-containing material over the gate dielectric, which is implanted and then reacted with a first metal by annealing to form the lower silicide. A capping layer can be formed over the first metal prior to annealing, to prevent oxidation of the metal prior to silicidation, and a barrier layer can be formed over the lower silicide to prevent reaction with subsequently formed silicon material. In another example, the lower silicide is a multilayer silicide structure including a plurality of metal silicide sublayers.

Owner:TEXAS INSTR INC

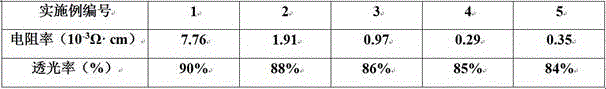

Method for preparing high-uniformity Nb-doped TiO2 transparent conducting thin film through atomic layer deposition

ActiveCN106011785ALow resistivityDisplacemental dopingChemical vapor deposition coatingThin membraneTransmittance

The invention relates to a method for preparing a high-uniformity Nb-doped TiO2 transparent conducting thin film through atomic layer deposition in the technical field of semiconductor photoelectric materials. According to the method, a substrate which is subjected to ultrasonic cleaning and nitrogen blowing-drying is heated; titanium tetrachloride, niobium tris(ethylmethylamido)-tert-butylimino and high purity water serve as precursor sources; and deposition combination is cycled for multiple times, so that the high-uniformity Nb-doped TiO2 transparent conducting thin film is prepared. The transparent conducting thin film prepared through the method is excellent in performance; the refractive index is 2.3 or above; the electrical resistivity can reach 2.9*10<4> omega.cm at a minimum; and at this moment, the light transmittance is still 85% or above.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Method of making a diode read/write memory cell in a programmed state

A method of making a nonvolatile memory device includes fabricating a diode in a low resistivity, programmed state without an electrical programming step. The memory device includes at least one memory cell. The memory cell is constituted by the diode and electrically conductive electrodes contacting the diode.

Owner:SANDISK TECH LLC

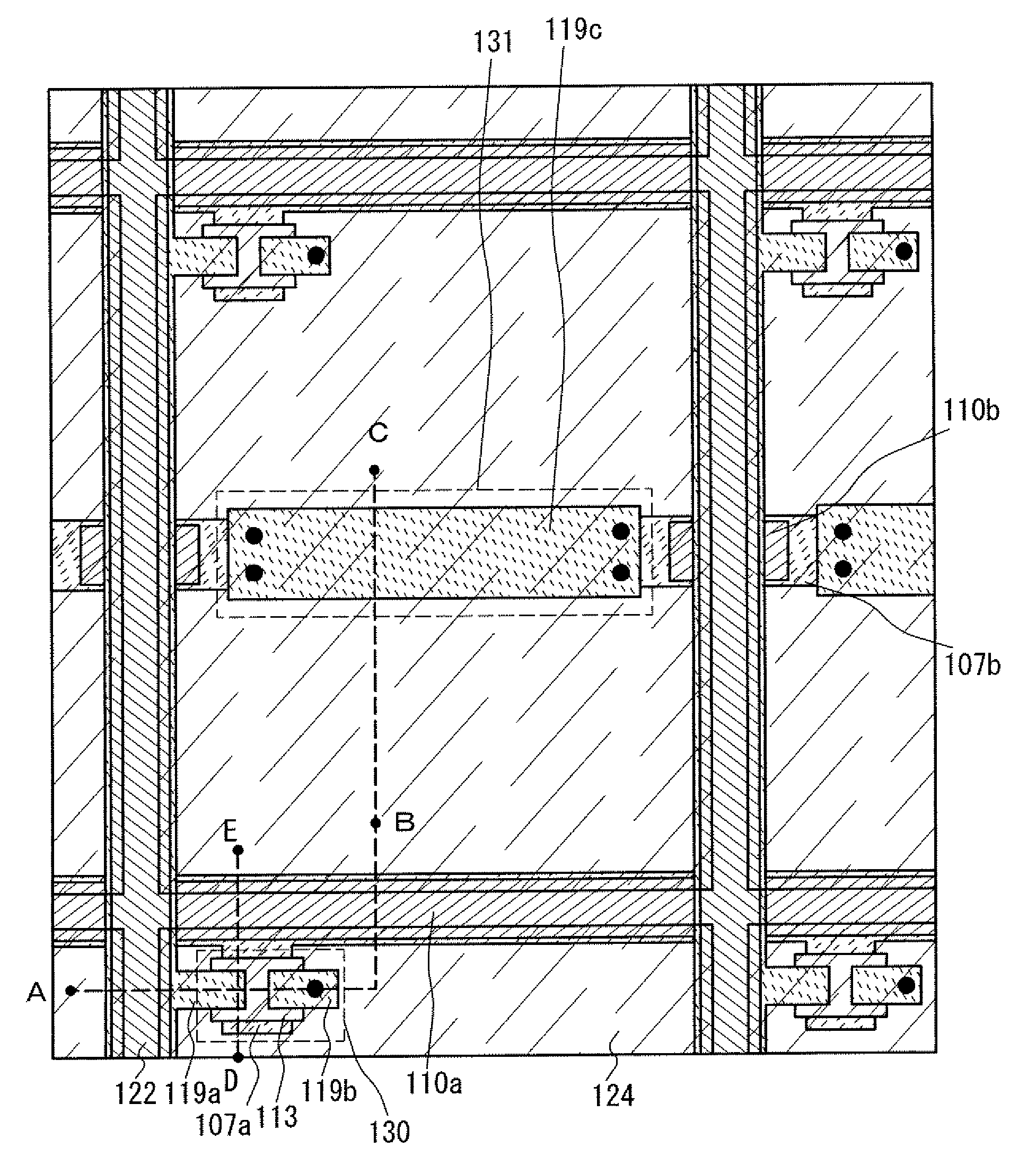

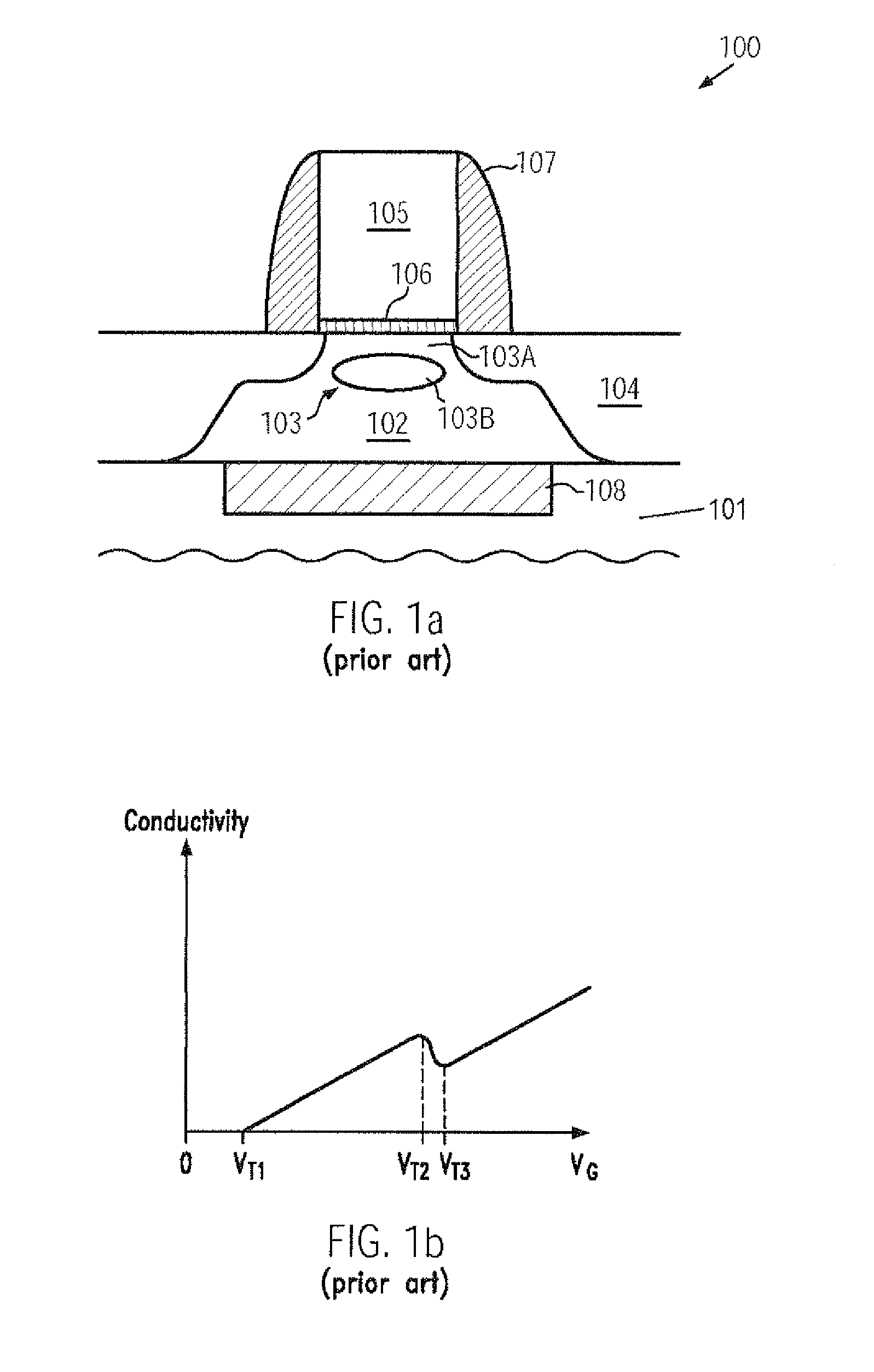

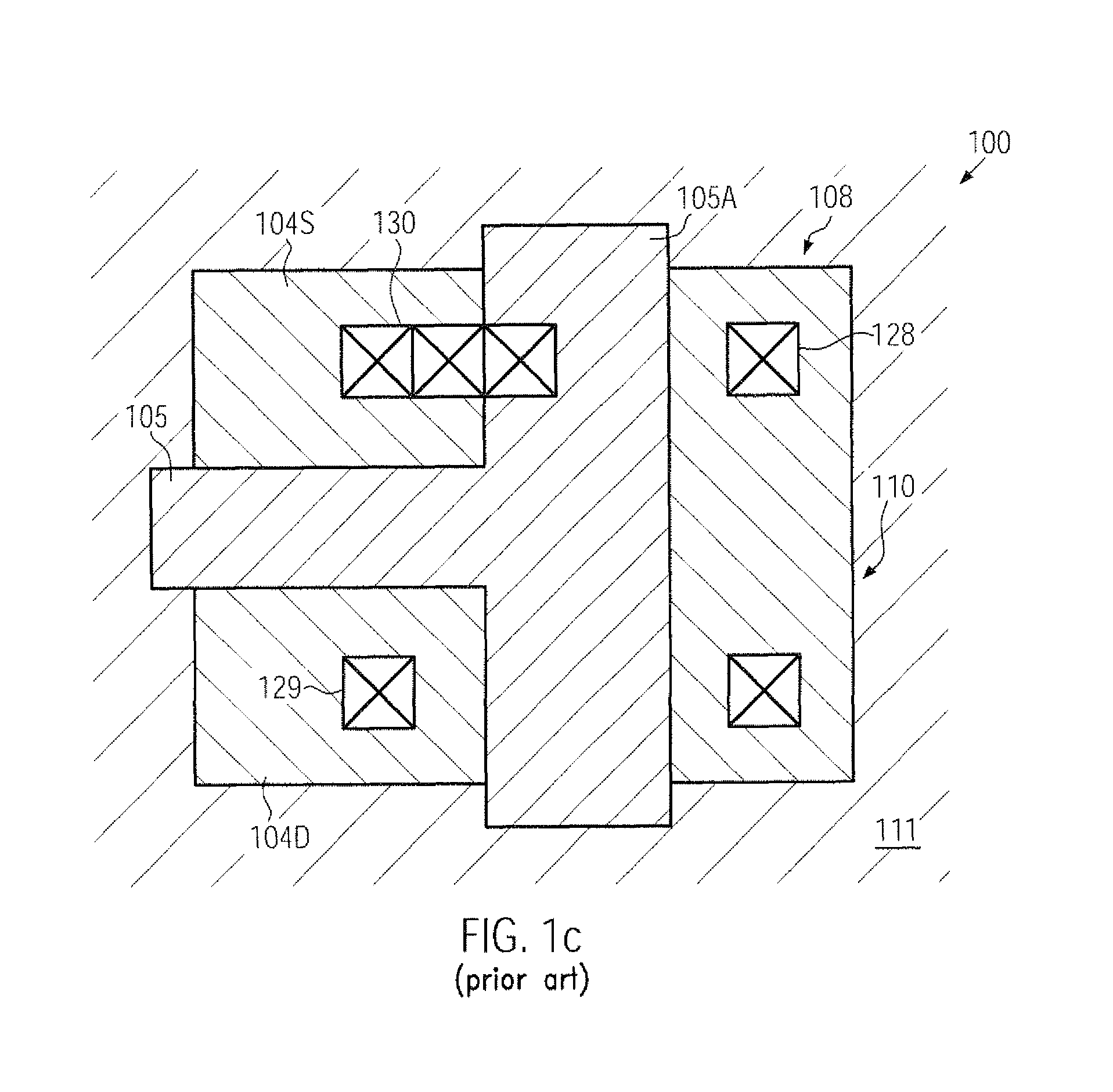

Static RAM cell design and multi-contact regime for connecting double channel transistors

ActiveUS8183096B2Improve space efficiencyLow resistivityTransistorSolid-state devicesBody contactCell design

A static RAM cell may be formed on the basis of two double channel transistors and a select transistor, wherein a body contact may be positioned laterally between the two double channel transistors in the form of a dummy gate electrode structure, while a further rectangular contact may connect the gate electrodes, the source regions and the body contact, thereby establishing a conductive path to the body regions of the transistors. Hence, compared to conventional body contacts, a very space-efficient configuration may be established so that bit density in static RAM cells may be significantly increased.

Owner:ADVANCED MICRO DEVICES INC

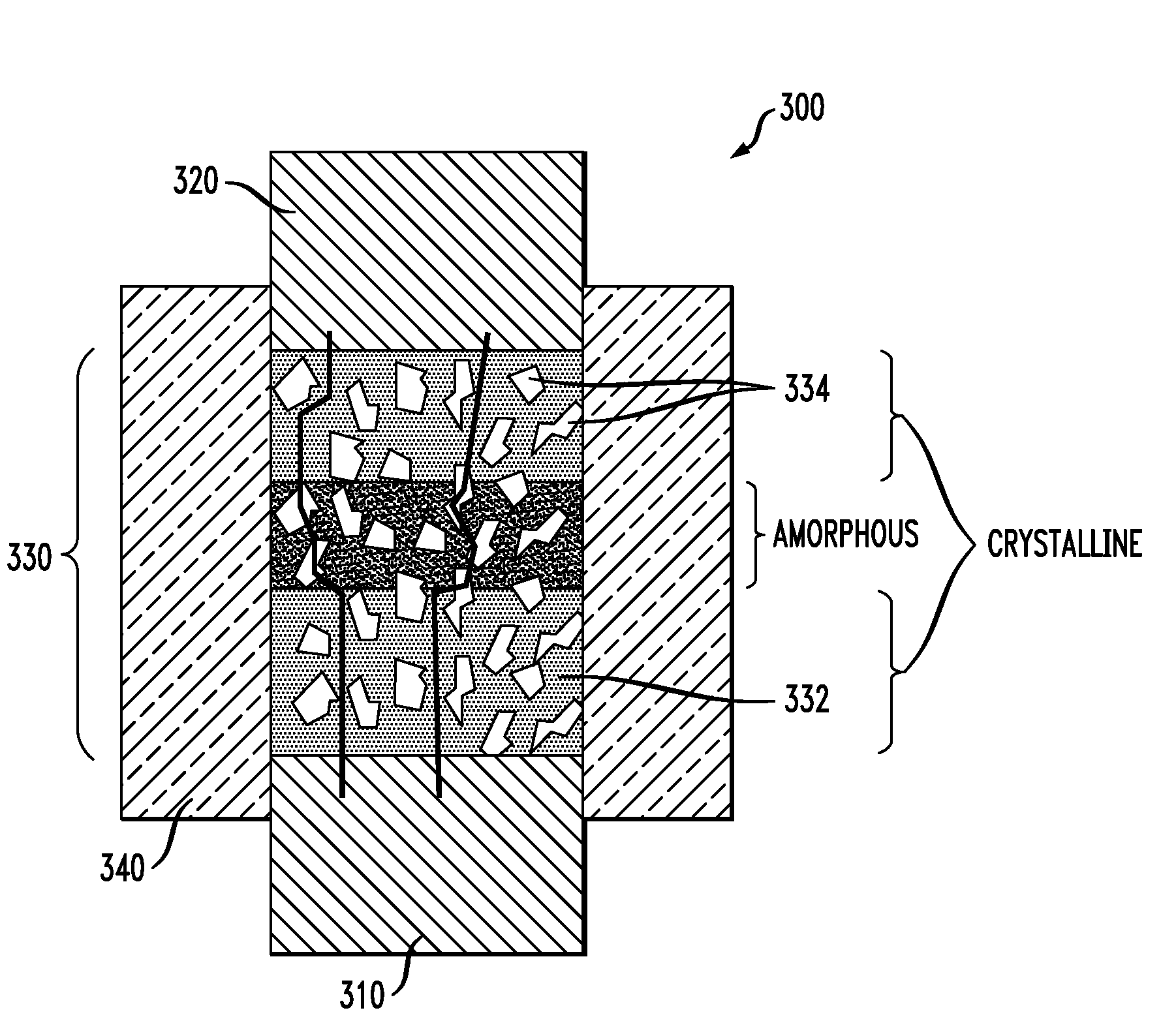

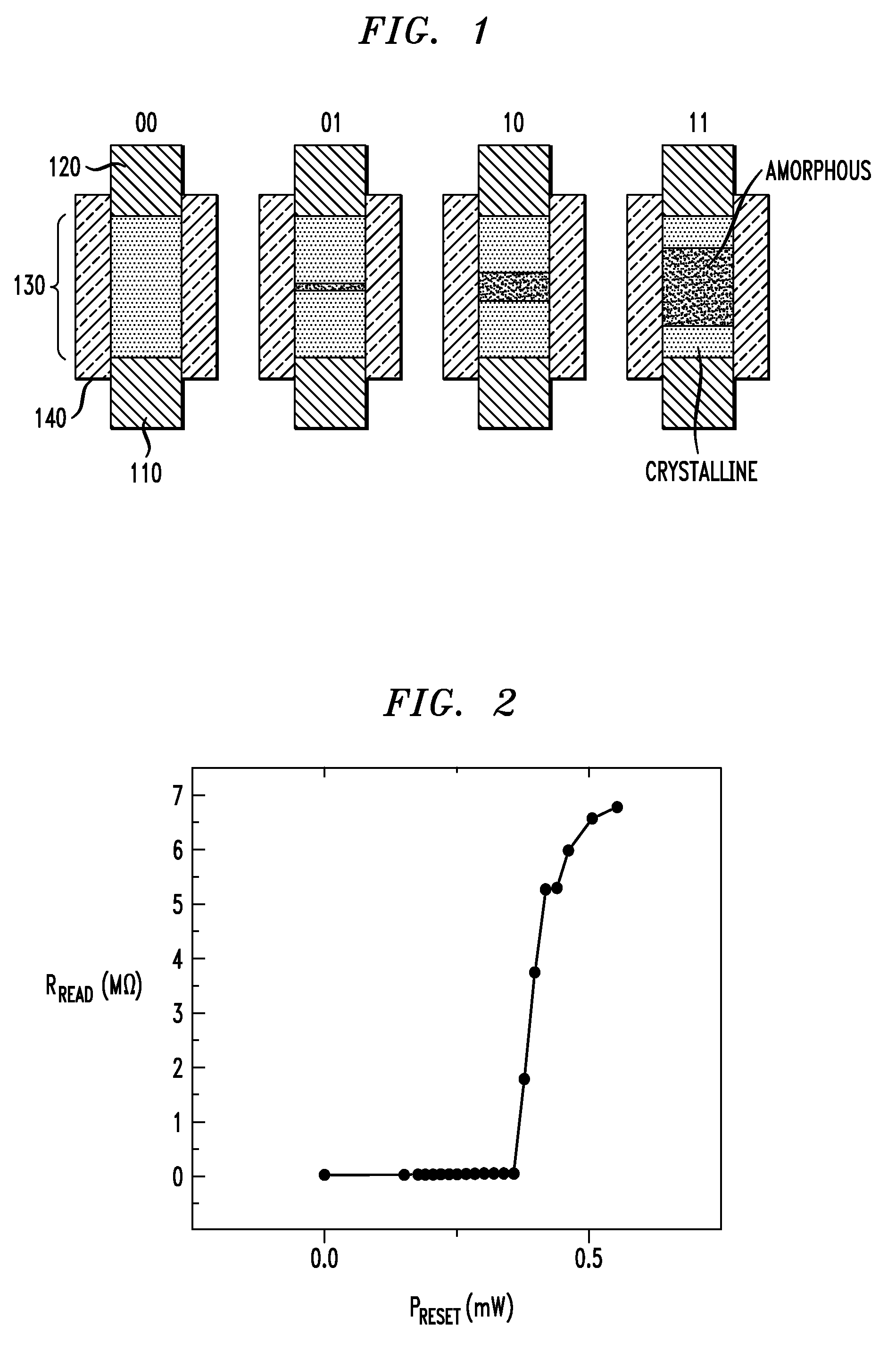

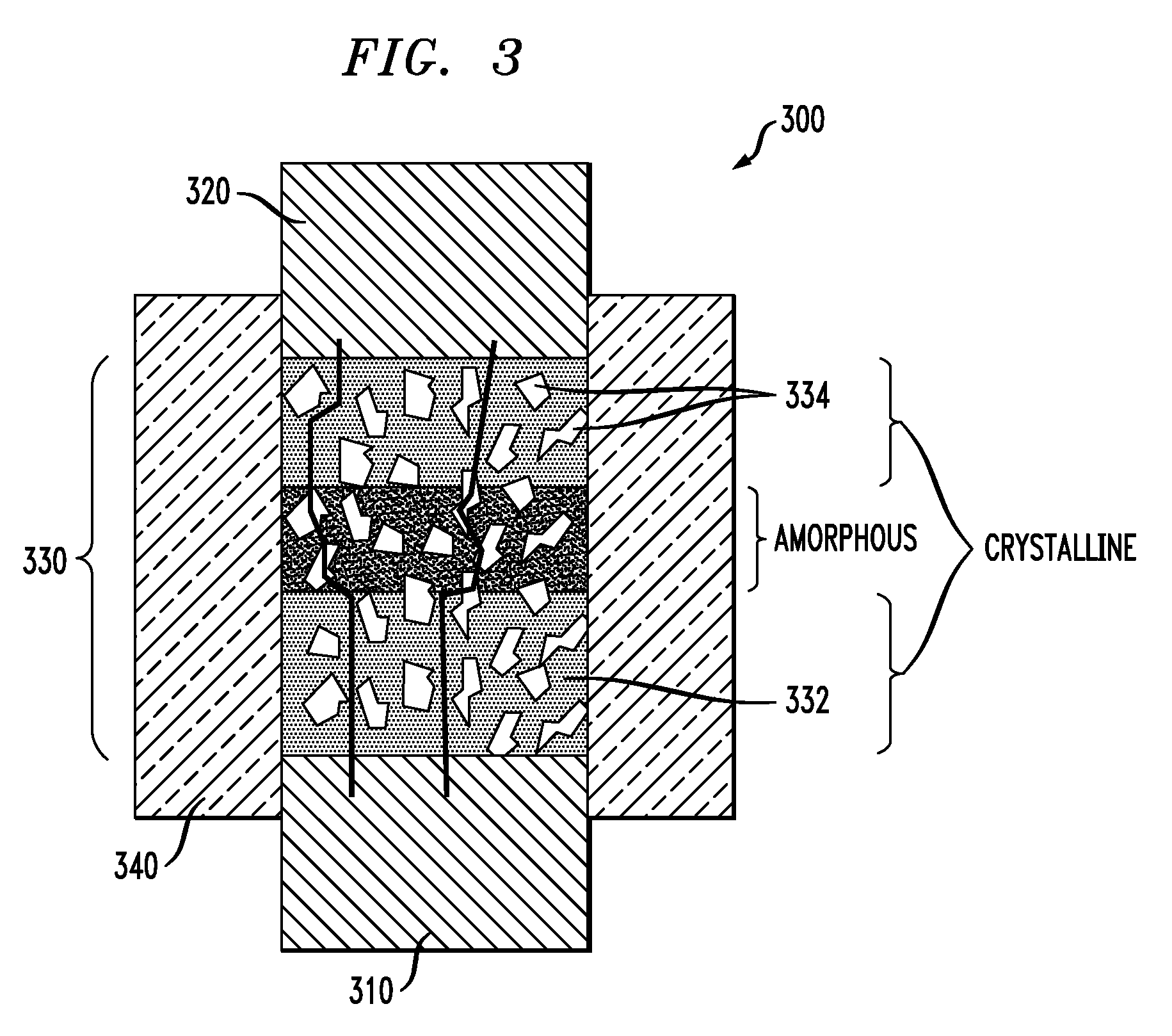

Resistance Limited Phase Change Memory Material

InactiveUS20080165569A1High resistance valueSlow reading speedSemiconductor/solid-state device manufacturingDigital storagePhase-change materialPhase-change memory

A memory cell comprises a first electrode, a second electrode and a composite material. The composite material electrically couples the first electrode to the second electrode. Moreover, the composite material comprises a phase change material and a resistor material. At least a portion of the phase change material is operative to switch between a substantially crystalline phase and a substantially amorphous phase in response to an application of a switching signal to at least one of the first and second electrodes. In addition, the resistor material has a resistivity lower than that of the phase change material when the phase change material is in the substantially amorphous phase.

Owner:IBM CORP +2

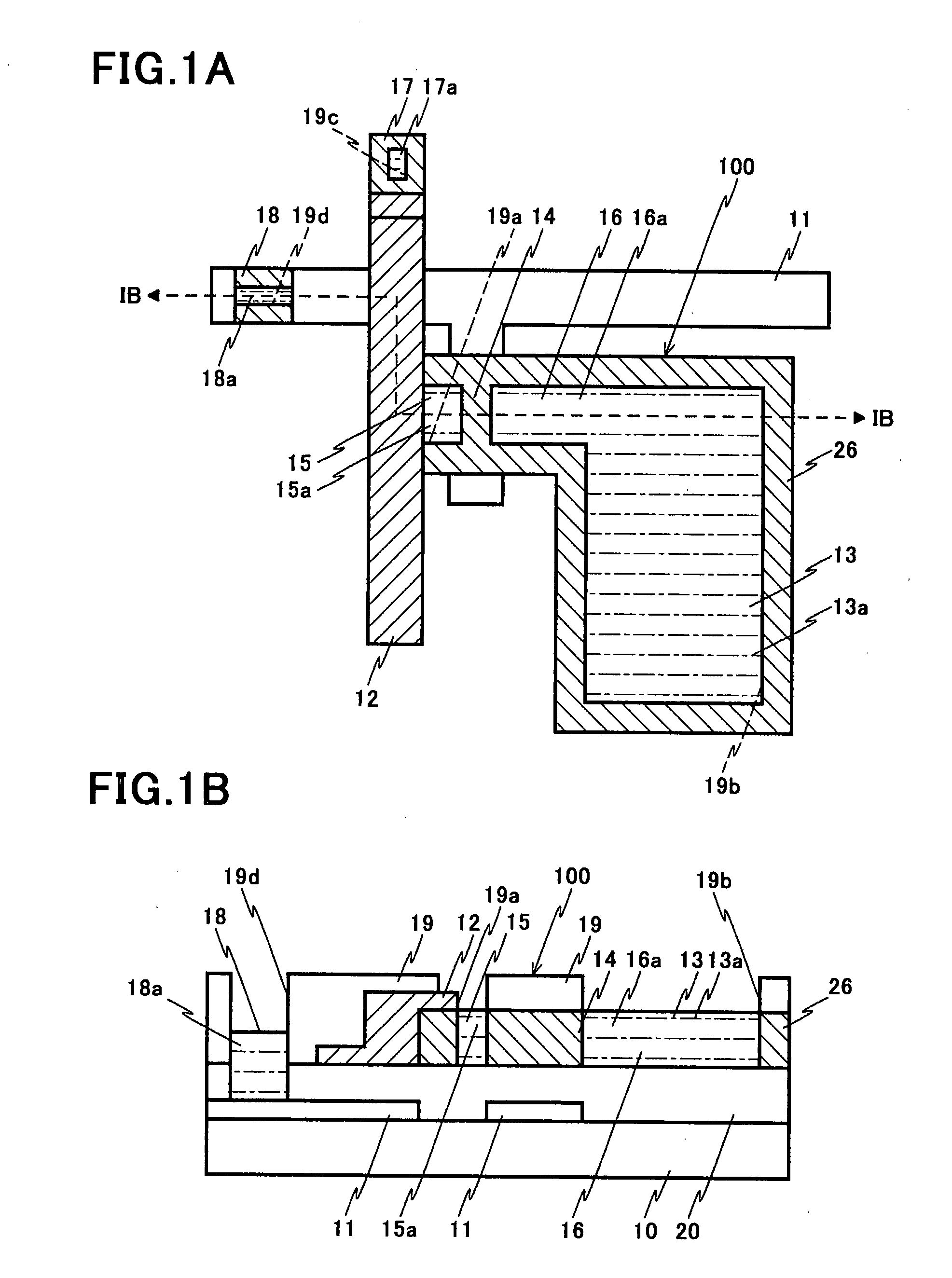

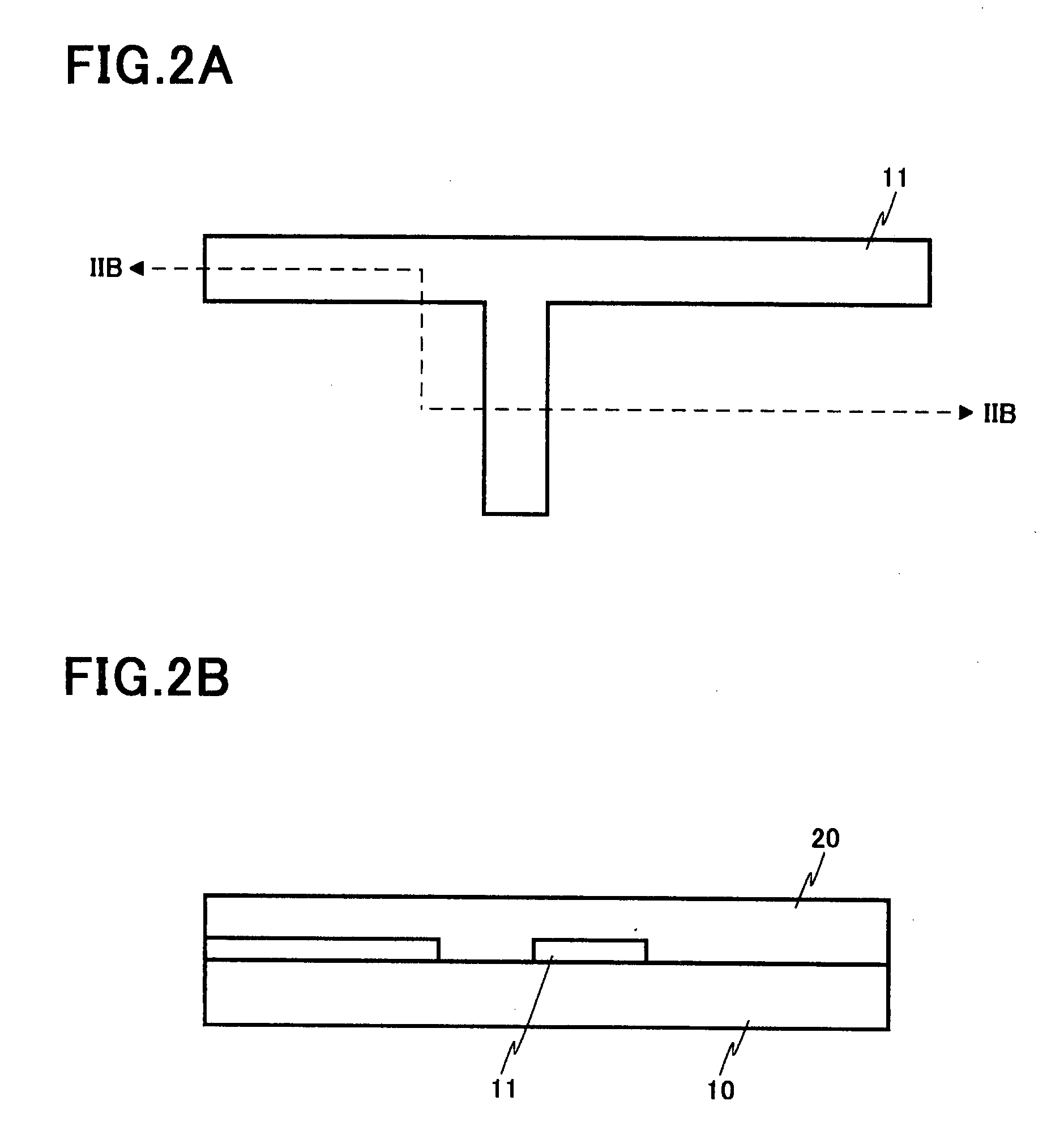

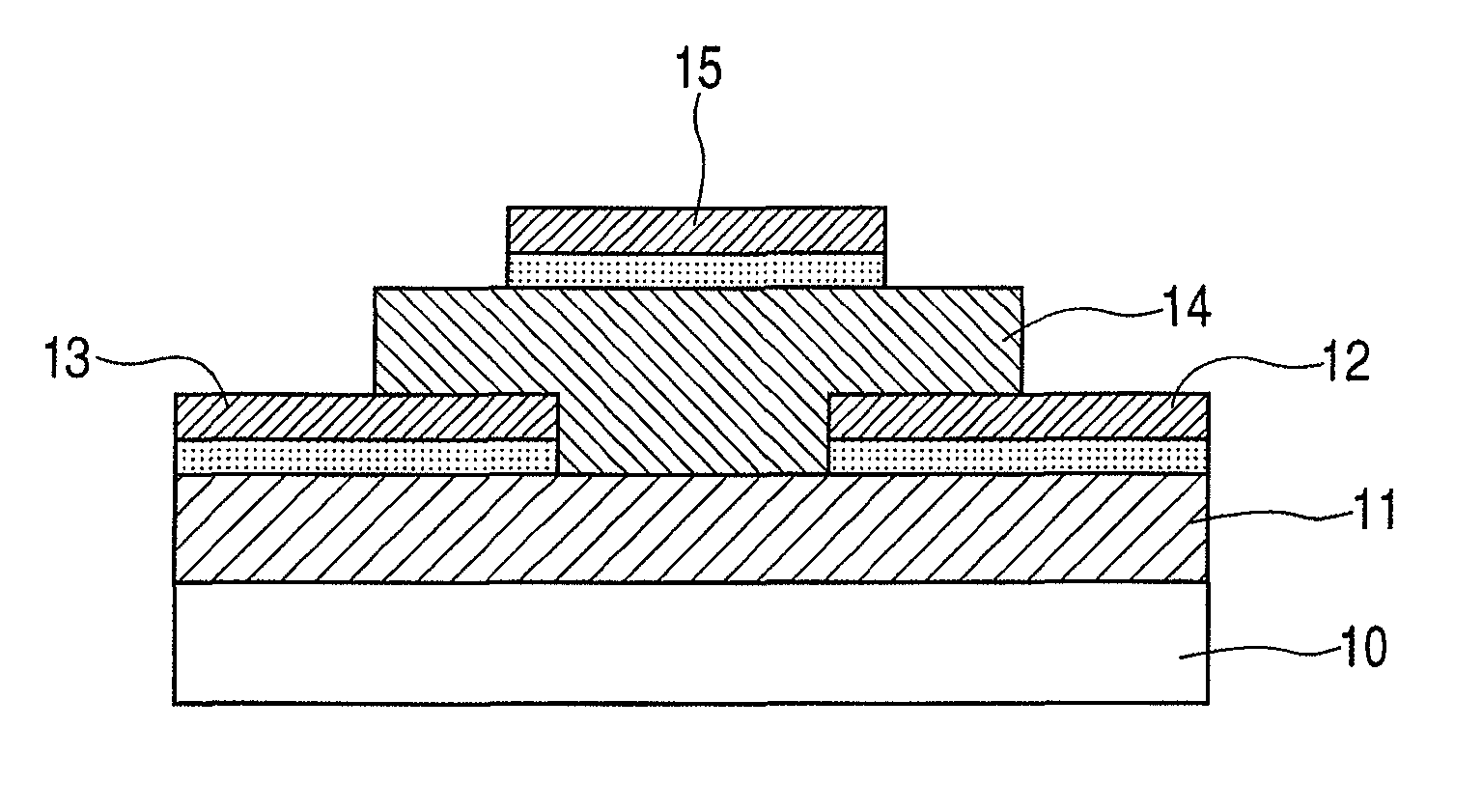

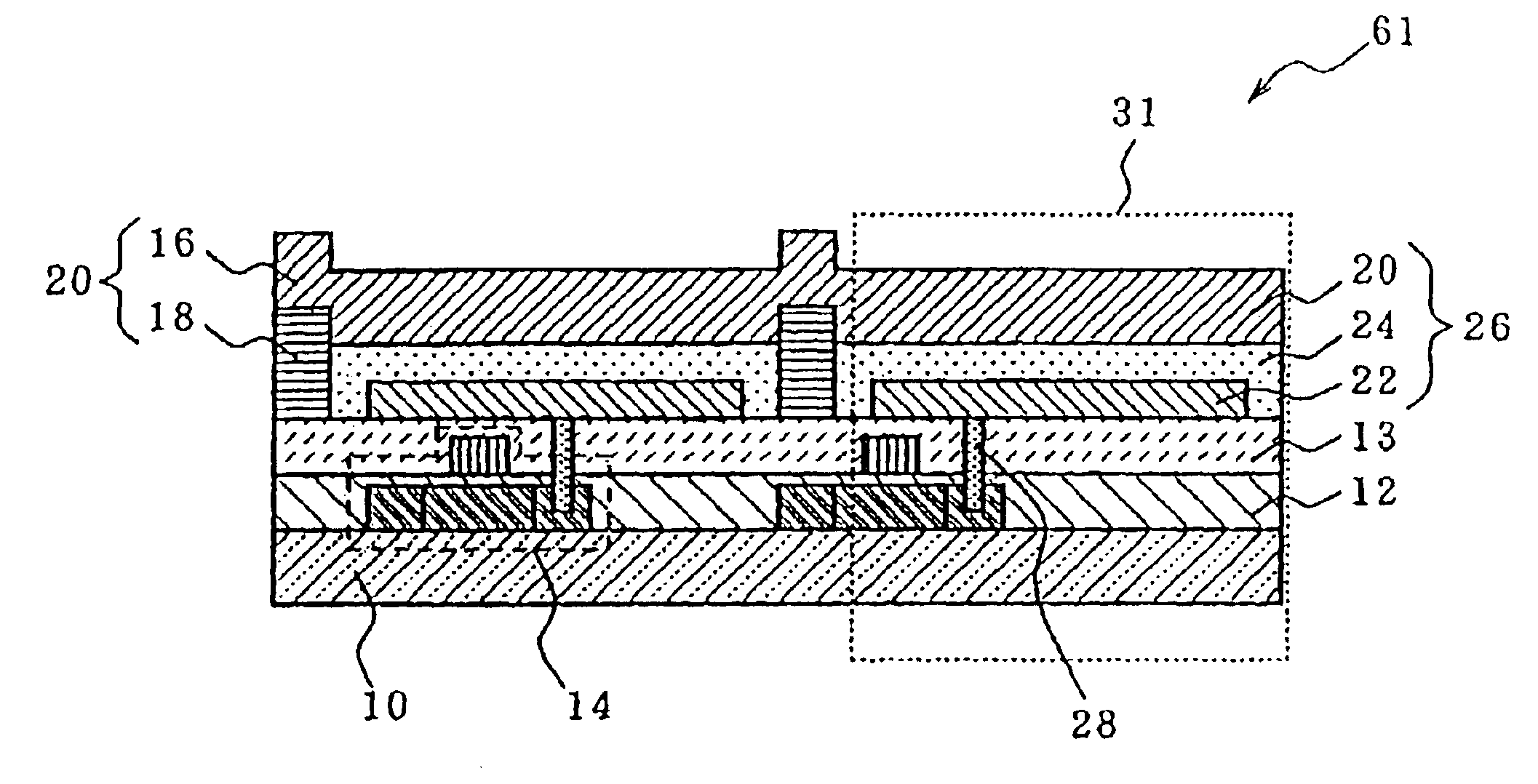

Actively driven organic EL device and manufacturing method thereof

InactiveUS6933672B2Increase the number ofLow resistivityDischarge tube luminescnet screensStatic indicating devicesConductive materialsAuxiliary electrode

The present invention is a active-driving organic EL light emission device comprising an organic EL element comprising an organic luminous medium between an upper electrode and a lower electrode, and a thin film transistor for driving this organic EL element, wherein light emitted from the organic EL element is taken out from the side of the upper electrode, and the upper electrode comprises a main electrode formed of transparent conductive material, and an auxiliary electrode formed of a low-resistance material. According to the active-driving organic EL light emission device of this structure, the numerical aperture can be made large. Additionally, the sheet resistivity of the upper electrode can be made low even if luminescence is taken out from the side of the upper electrode. Thus, it is possible to provide an active-driving organic EL light emission device making it possible to display images having a high brightness and a homogenous brightness; and a method for manufacturing the same.

Owner:IDEMITSU KOSAN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com