Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

165results about How to "High film forming rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

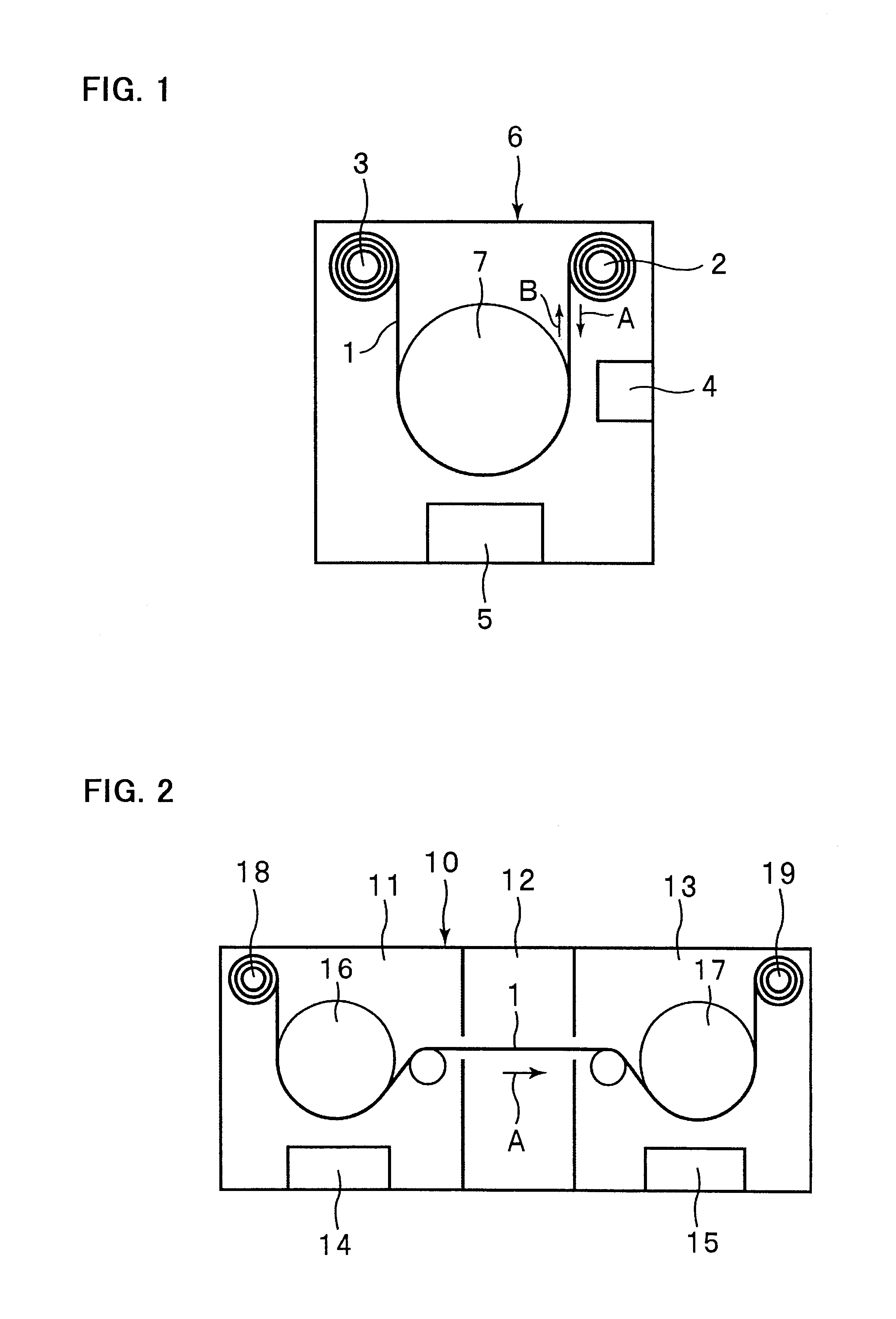

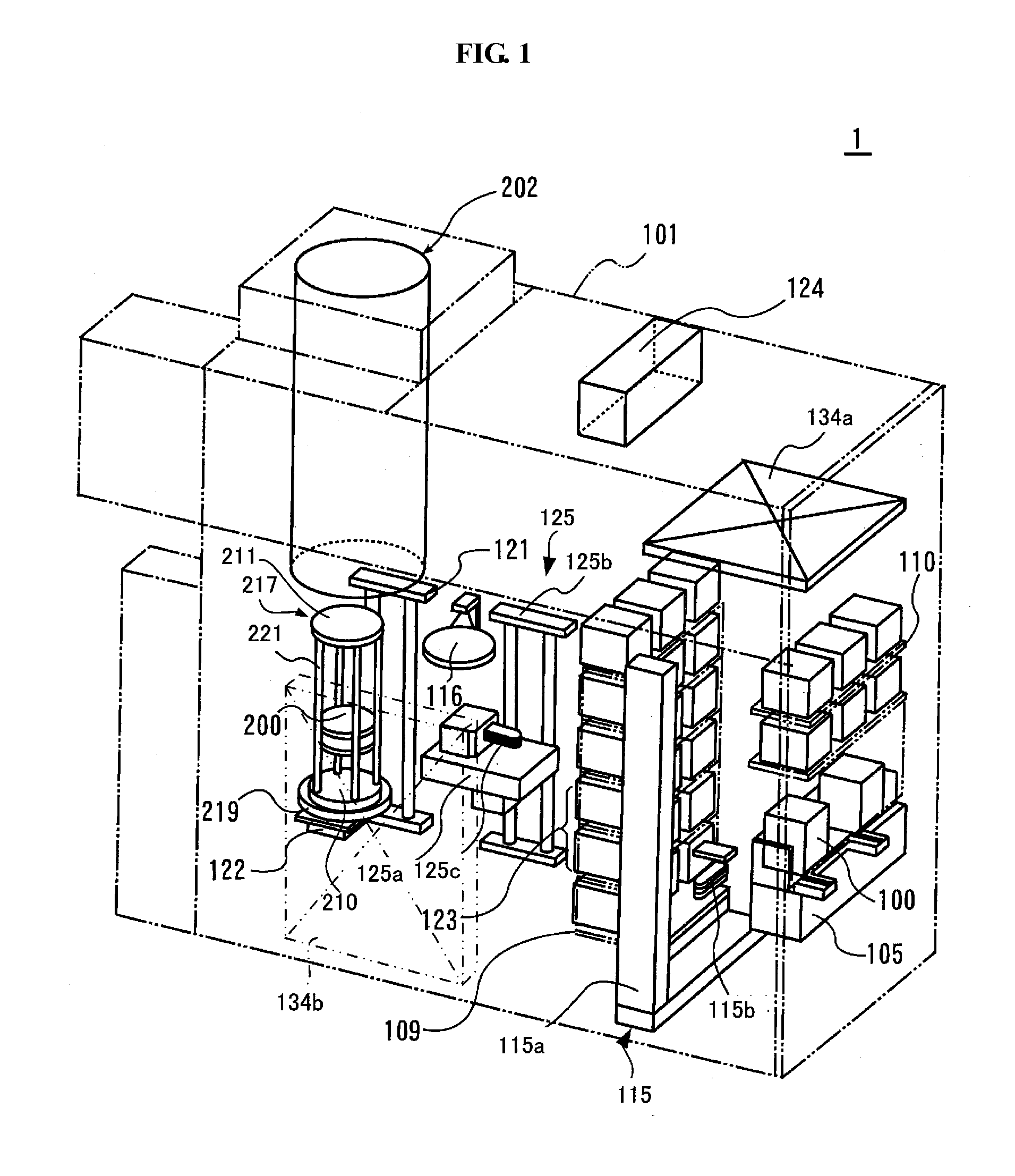

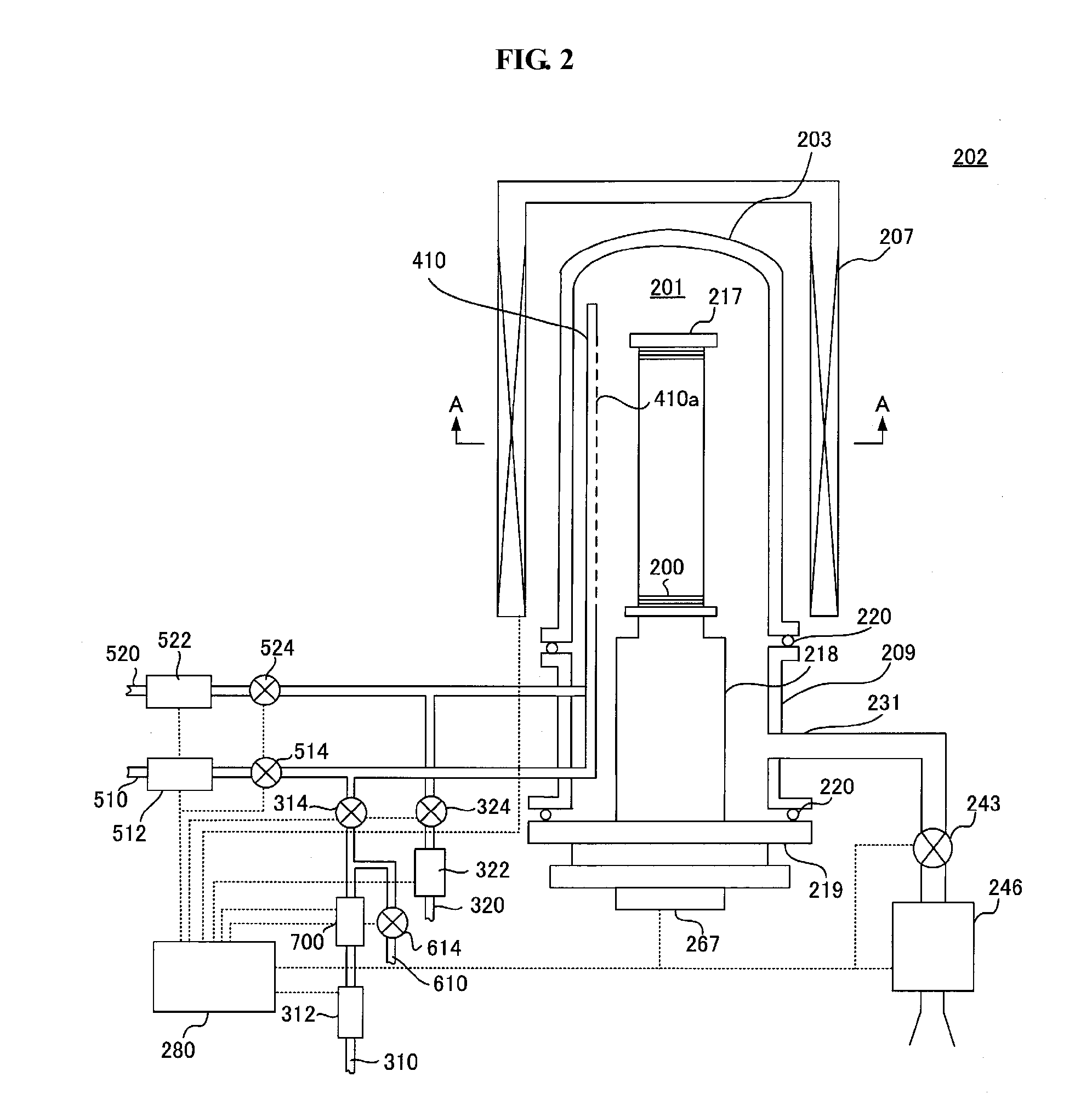

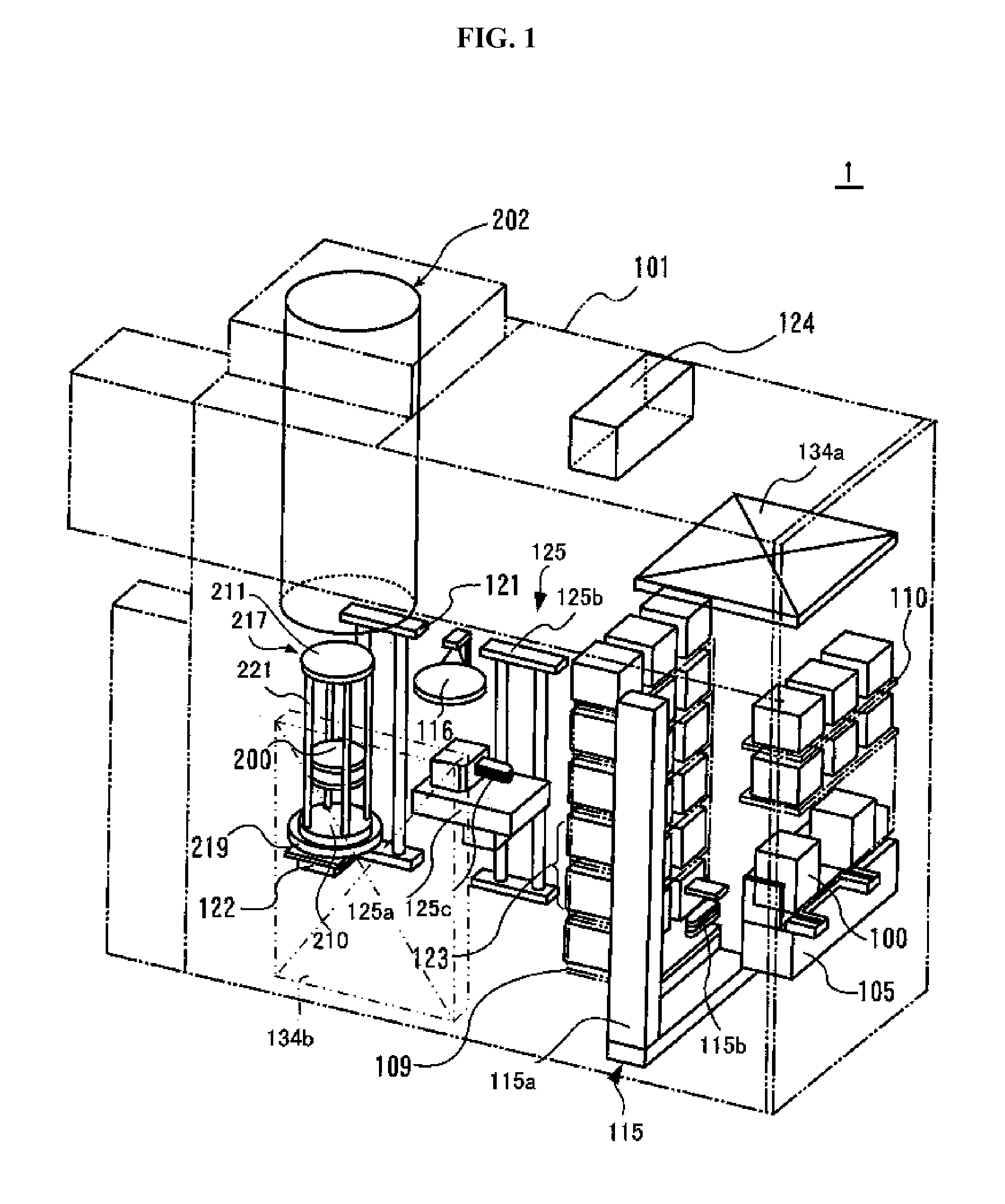

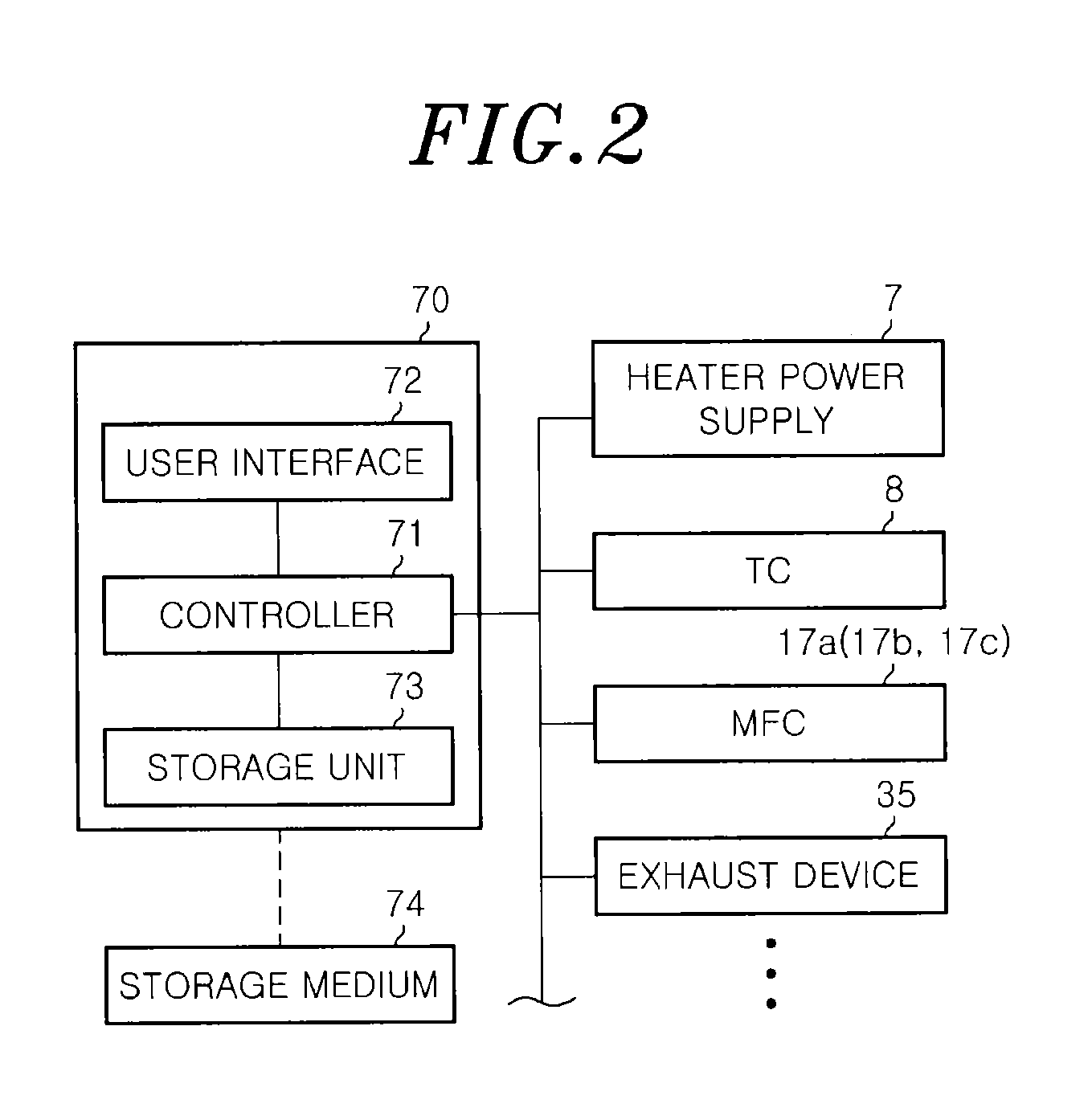

Substrate processing apparatus and method of manufacturing semiconductor device

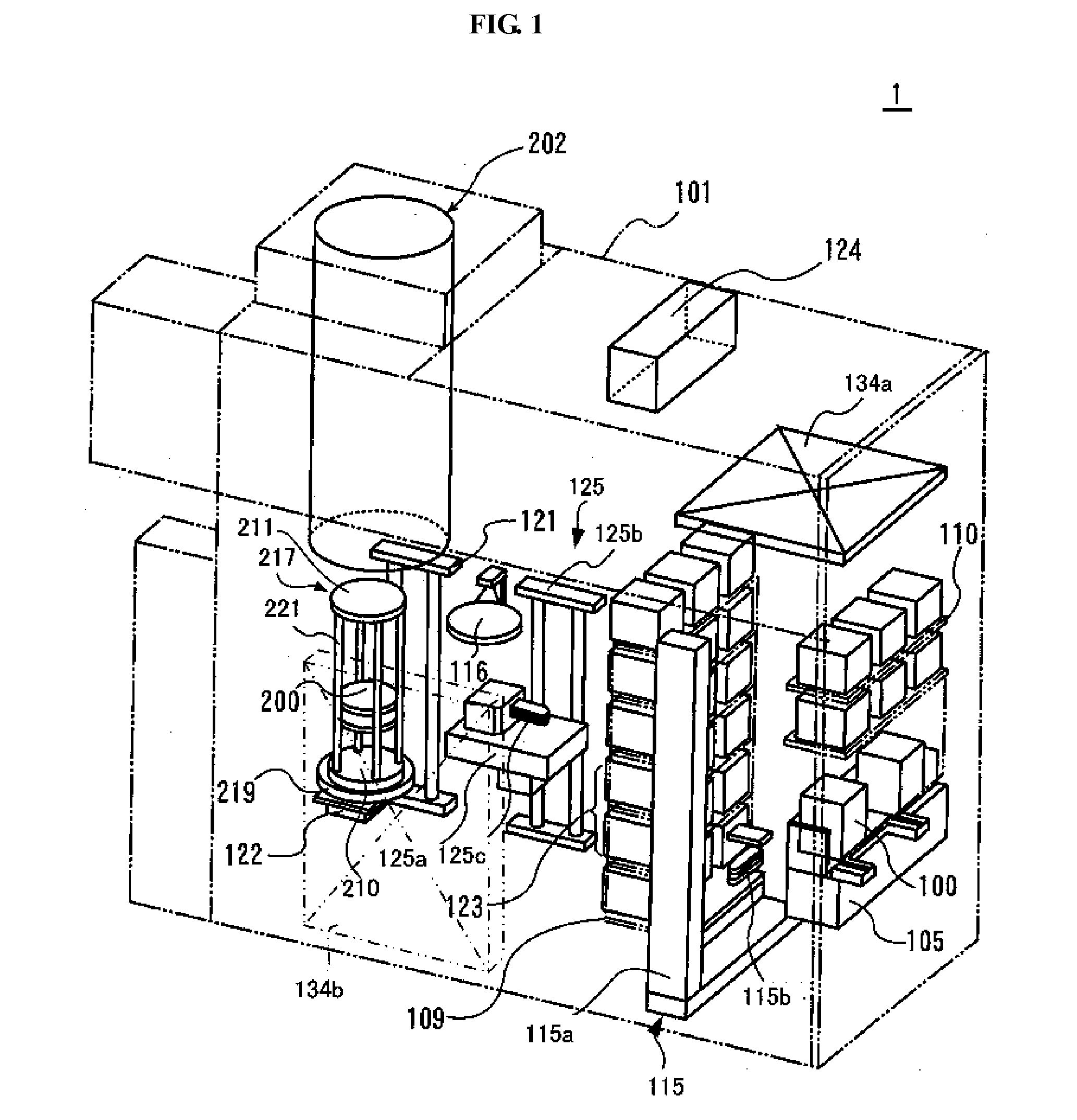

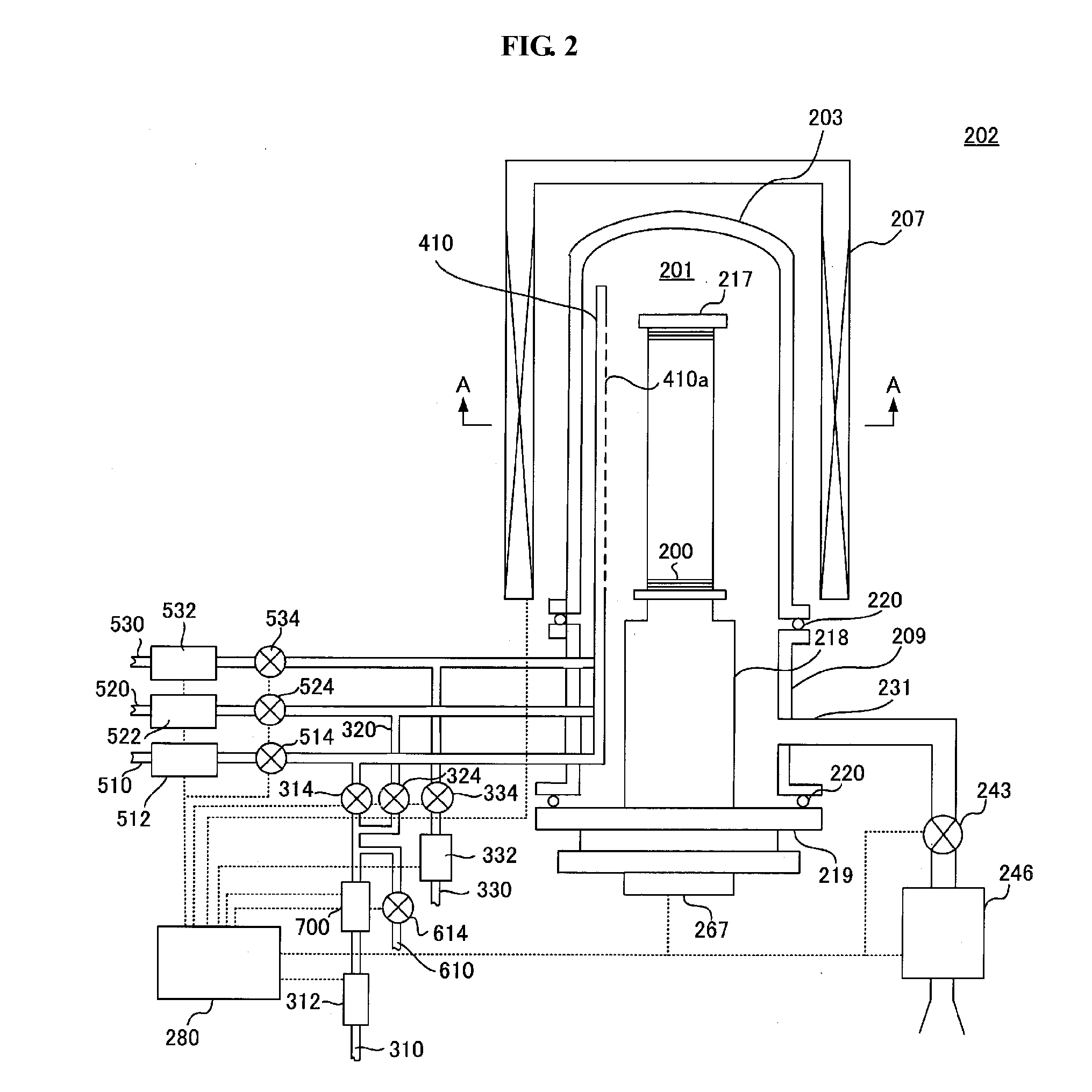

ActiveUS20110186984A1Quality improvementHigh film forming rateSemiconductor/solid-state device detailsSolid-state devicesProcess engineeringGas supply

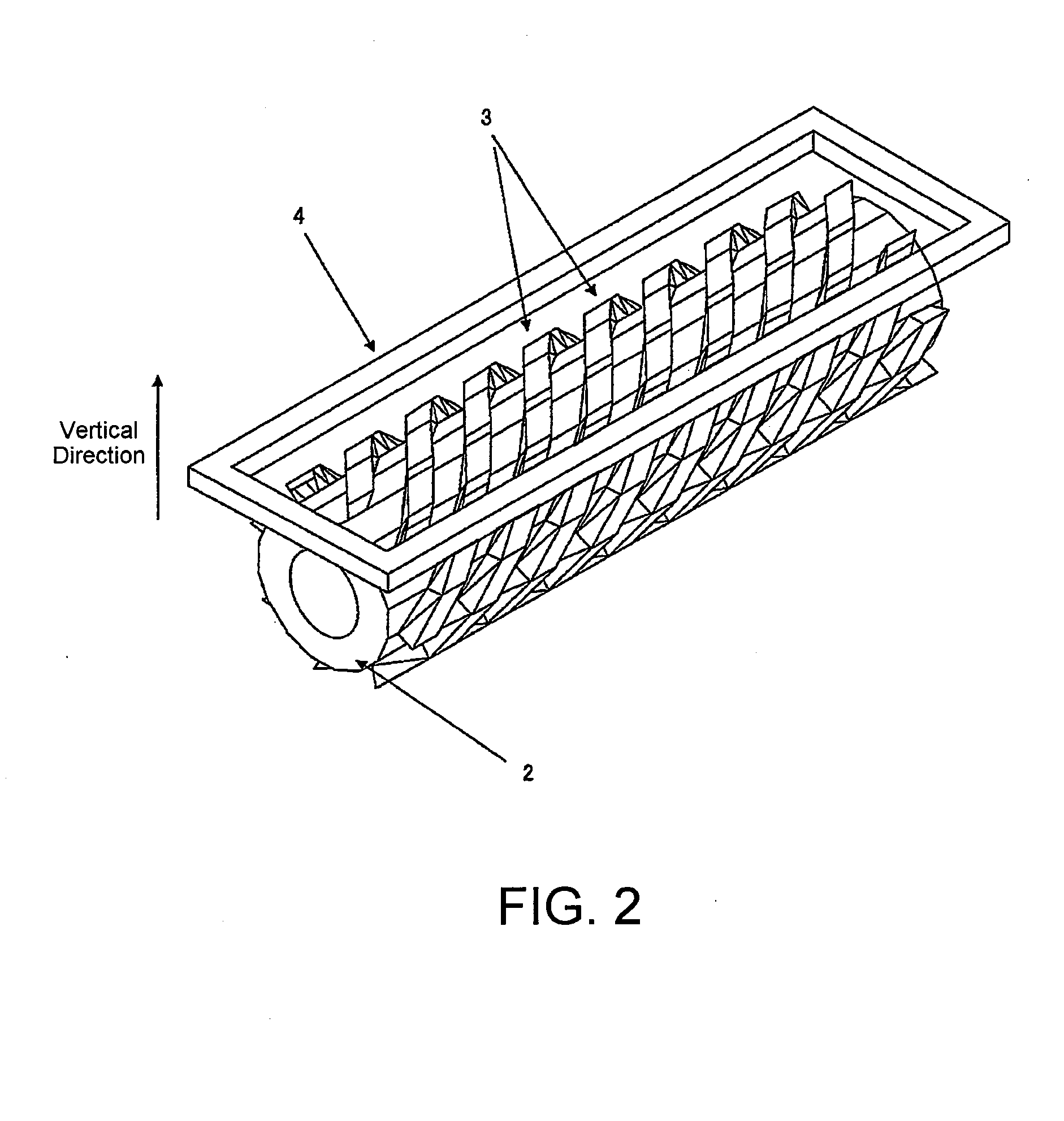

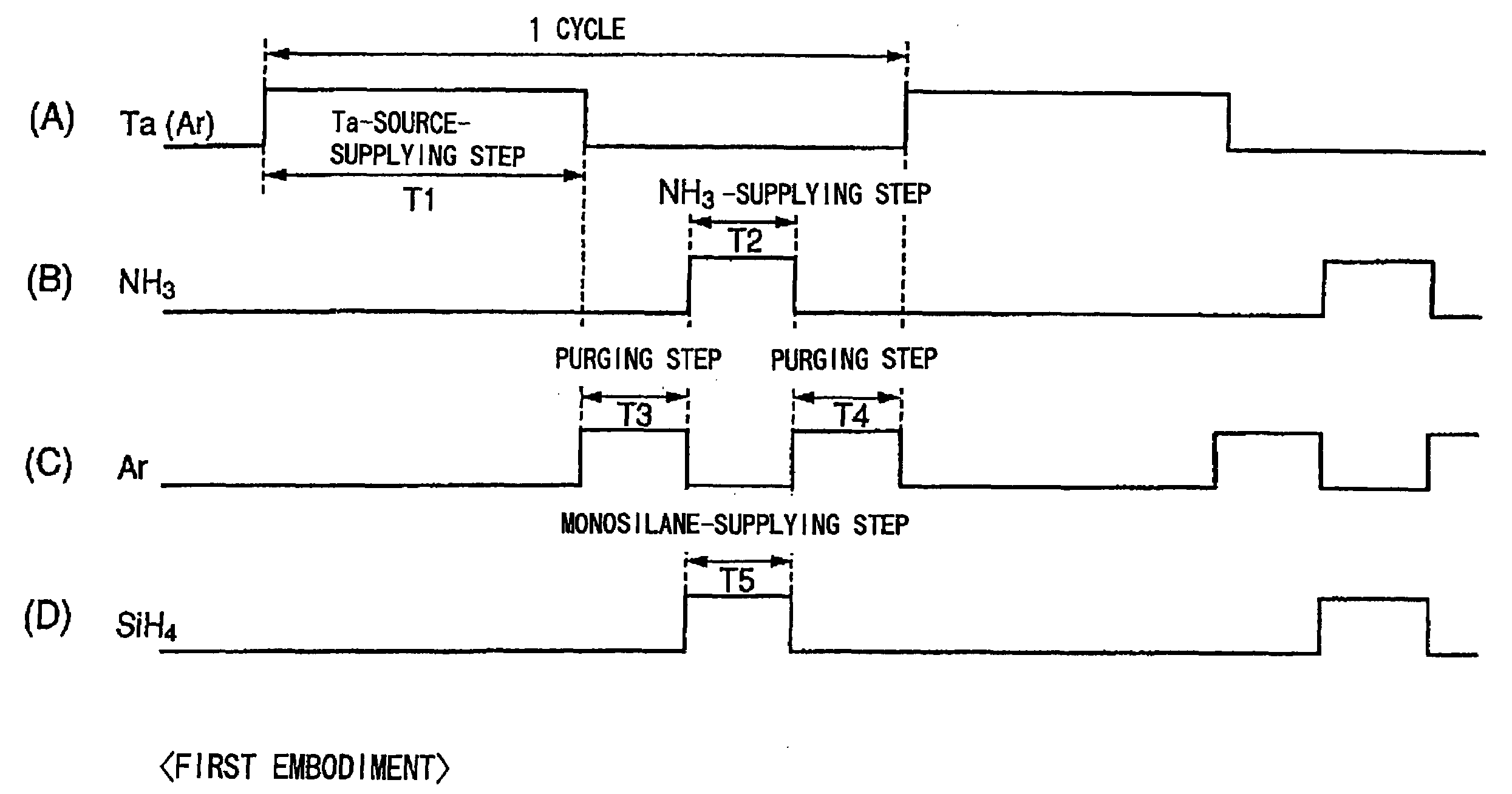

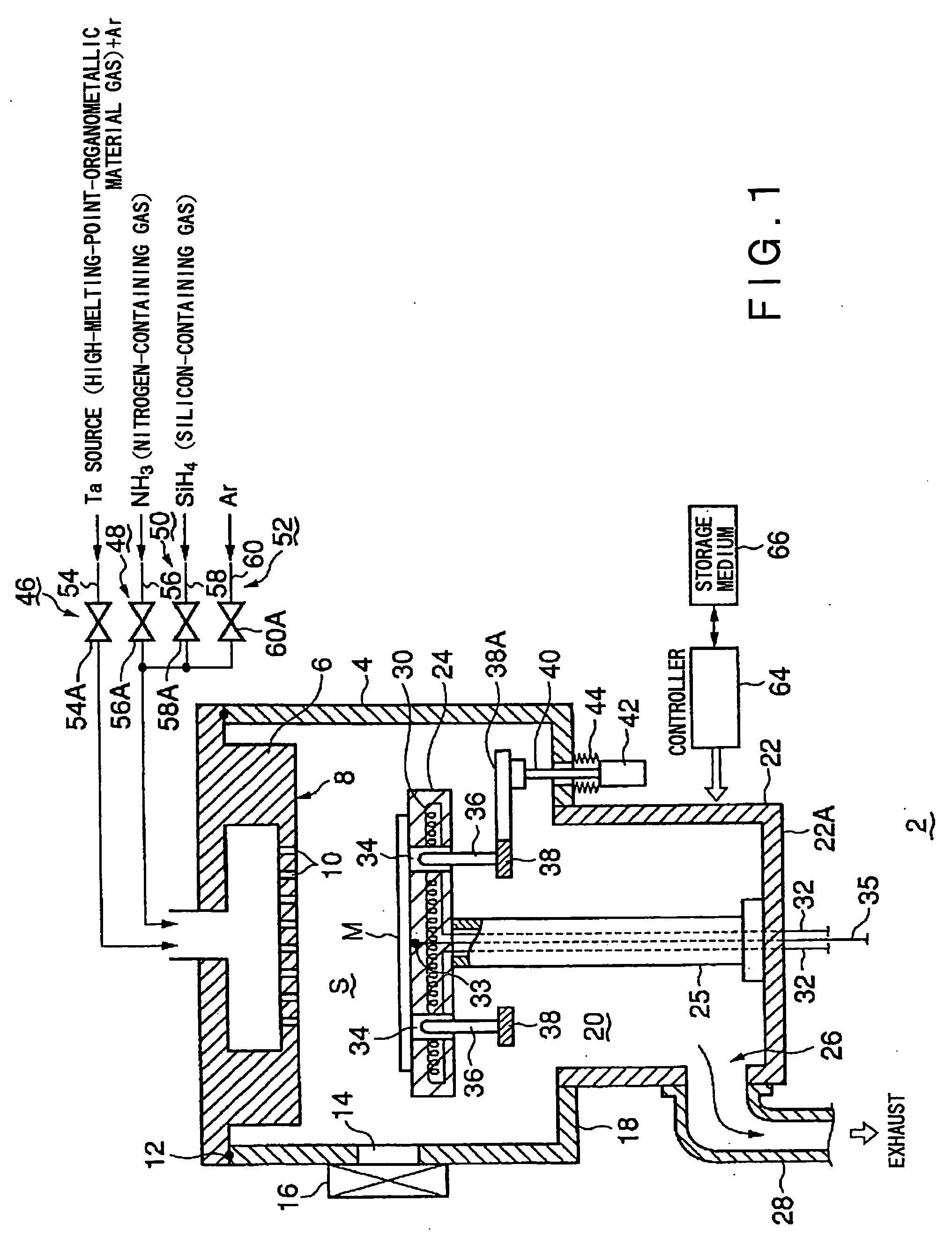

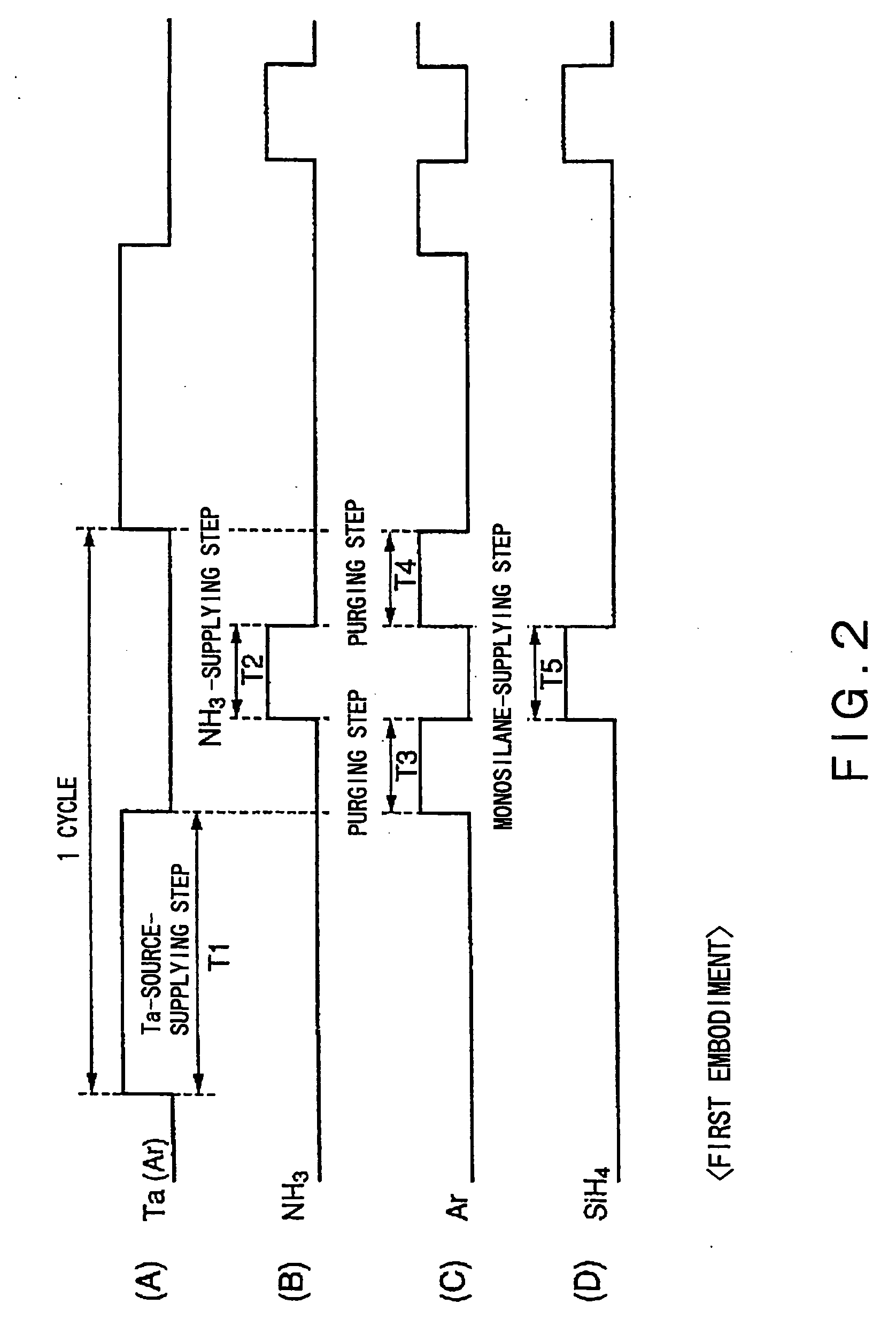

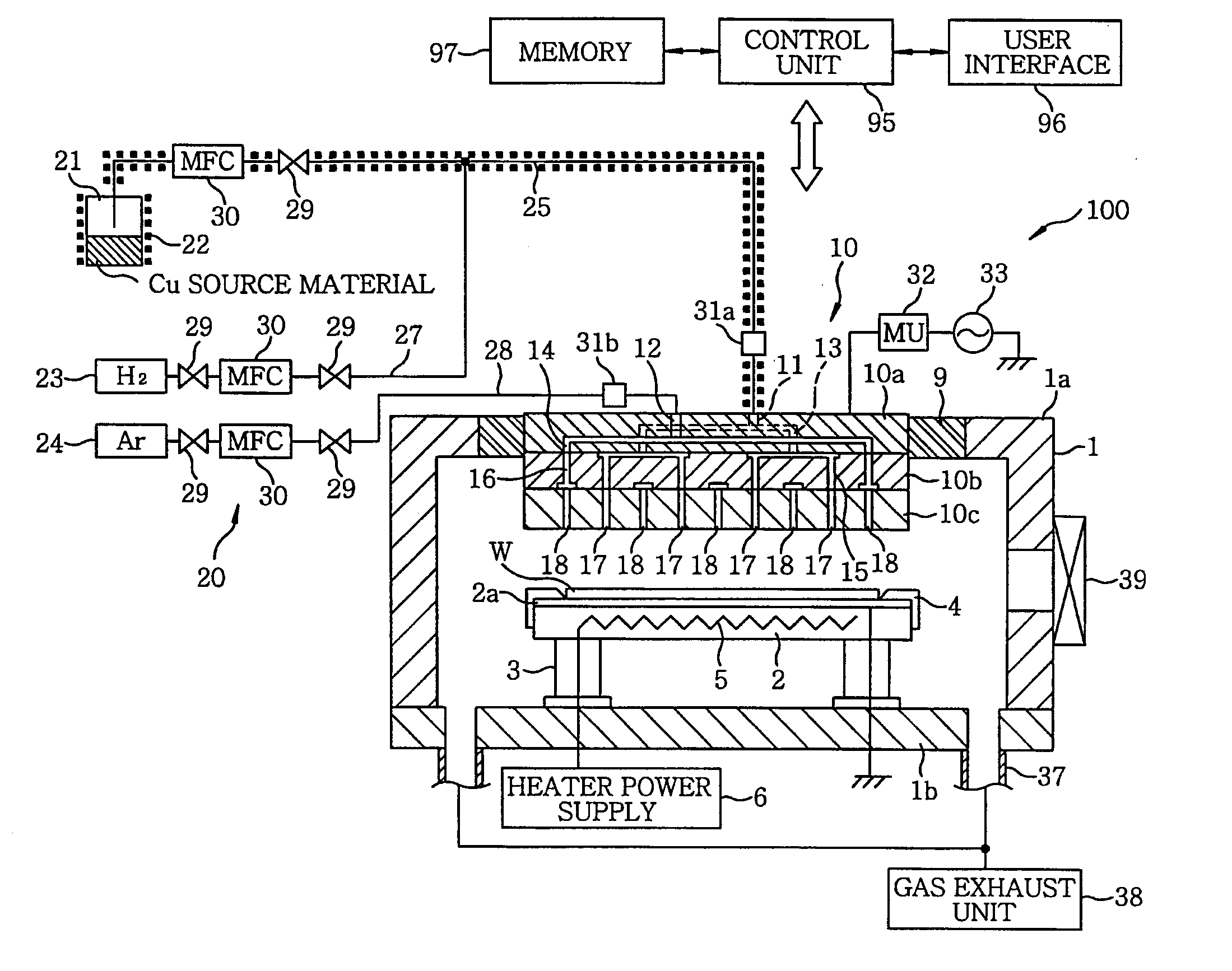

Provided are a substrate processing apparatus and a method of manufacturing a semiconductor device which are able to form a conductive film, which is dense, includes a low concentration of source-derived impurities and has low resistivity, at a higher film-forming rate. The substrate processing apparatus includes a processing chamber configured to stack and accommodate a plurality of substrates; a first processing gas supply system configured to supply a first processing gas into the processing chamber; a second processing gas supply system configured to supply a second processing gas into the processing chamber; and a control unit configured to control the first processing gas supply system and the second processing gas supply system. Here, at least one of the first processing gas supply system and the second processing gas supply system includes two nozzles which are vertically arranged in a stacking direction of the substrates and have different shapes, and the control unit is configured to supply at least one of the first processing gas and the second processing gas into the processing chamber through the two nozzles having different shapes when films are formed on the substrates by supplying the first processing gas and the second processing gas into the processing chamber at pulses having different film-forming rates.

Owner:KOKUSA ELECTRIC CO LTD

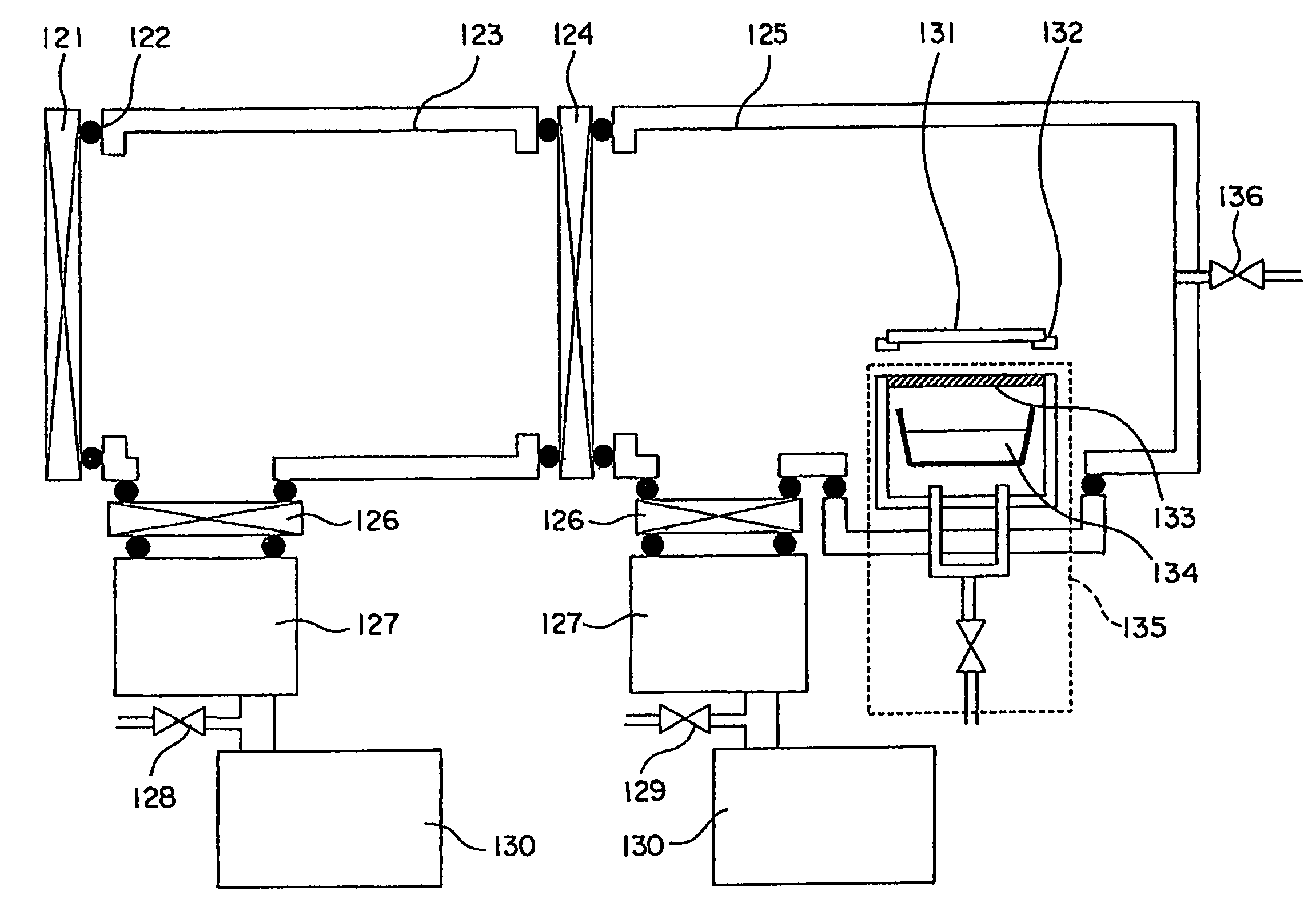

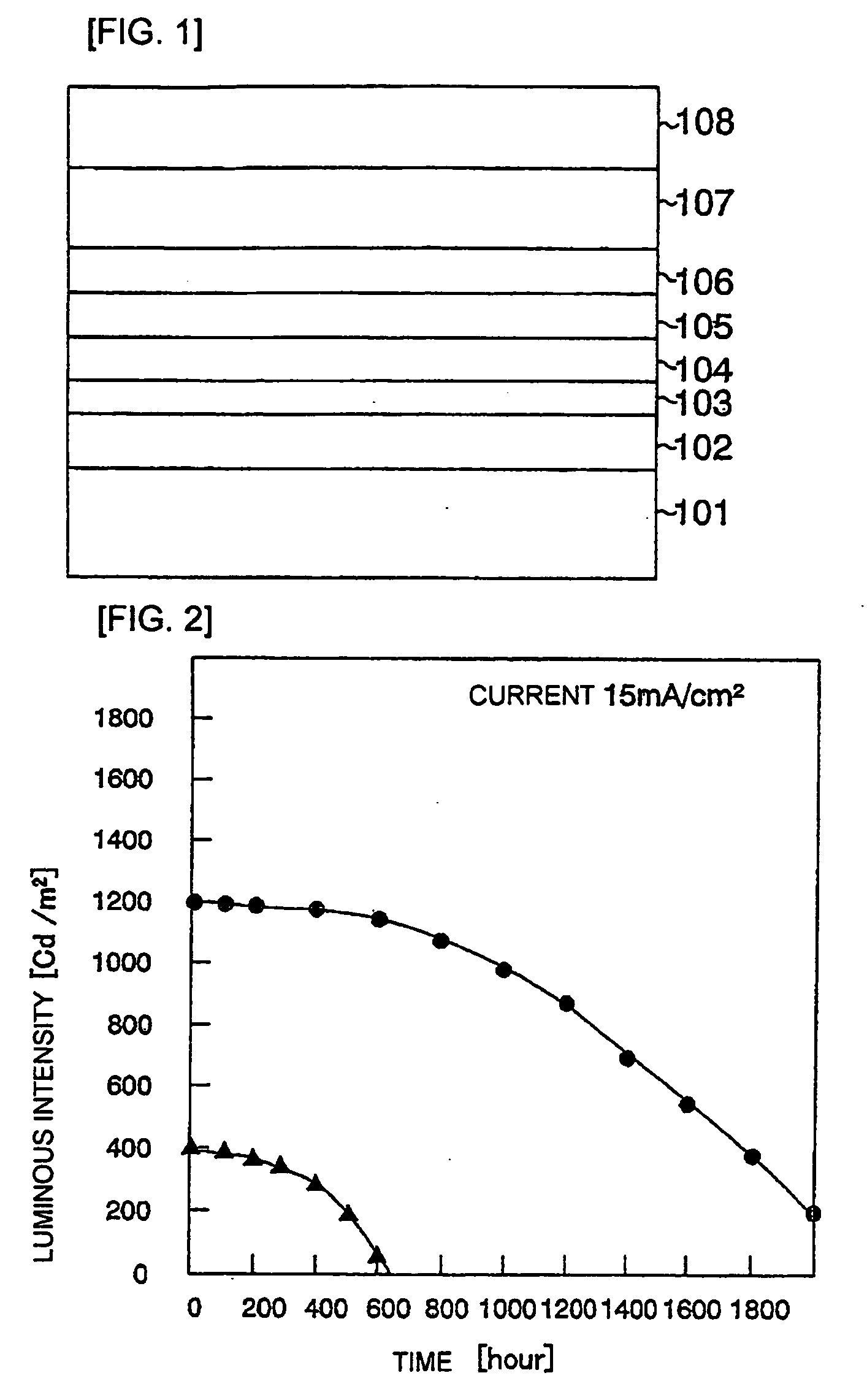

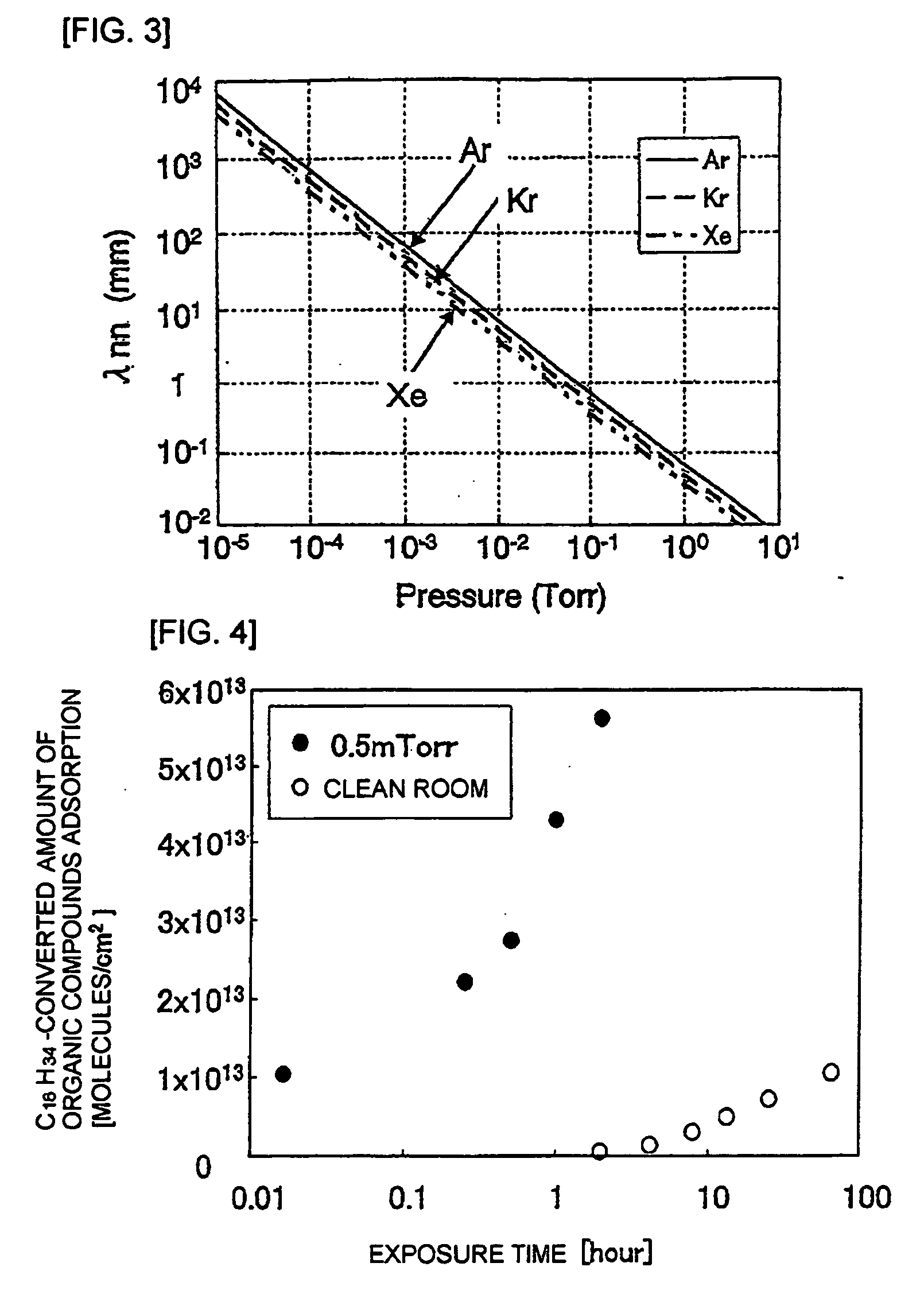

Method of forming silicon-based thin film, silicon-based thin film, and photovoltaic element

InactiveUS7074641B2Improve featuresLow costPolycrystalline material growthFrom solid stateLuminous intensityHydrogen

Owner:CANON KK

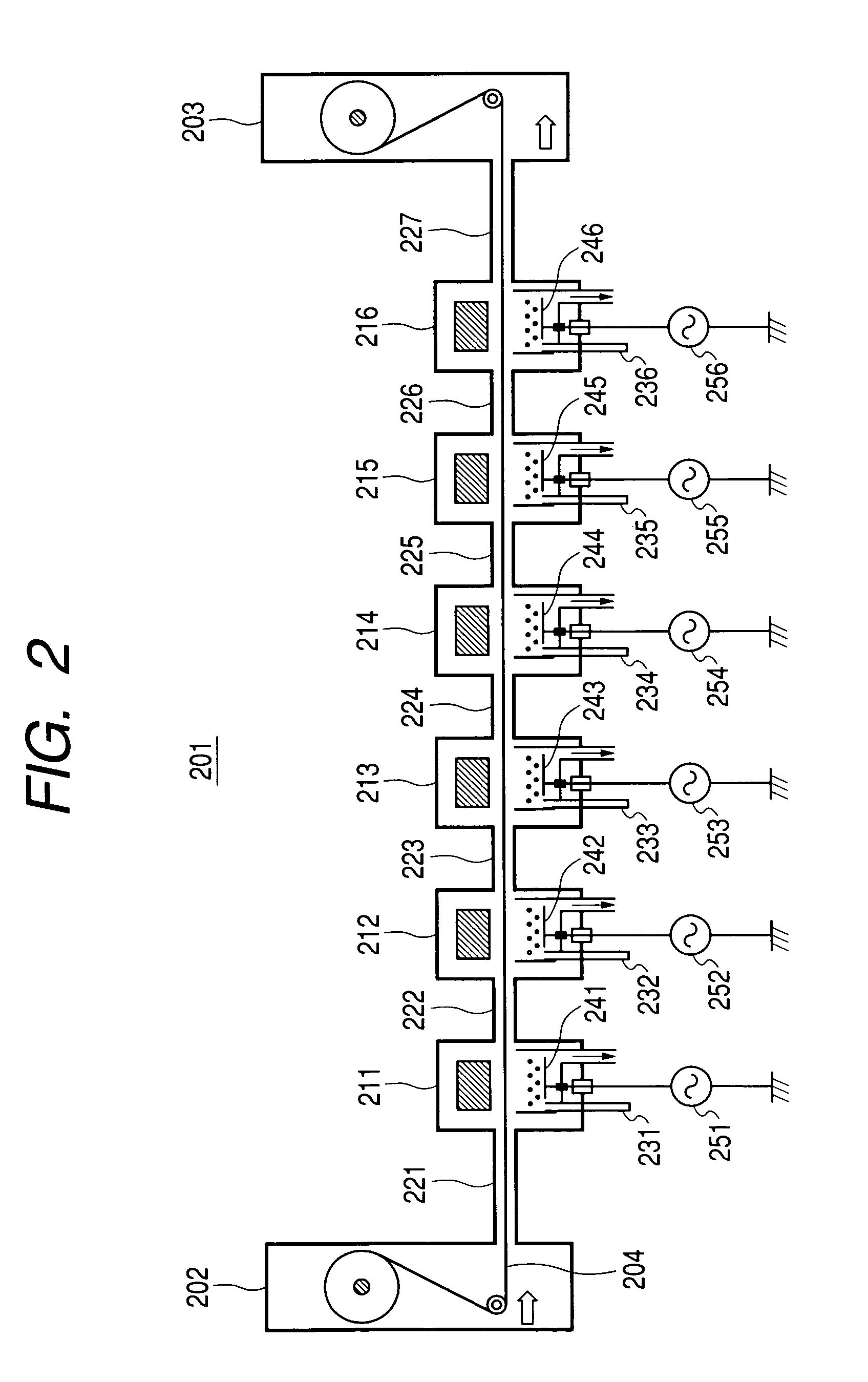

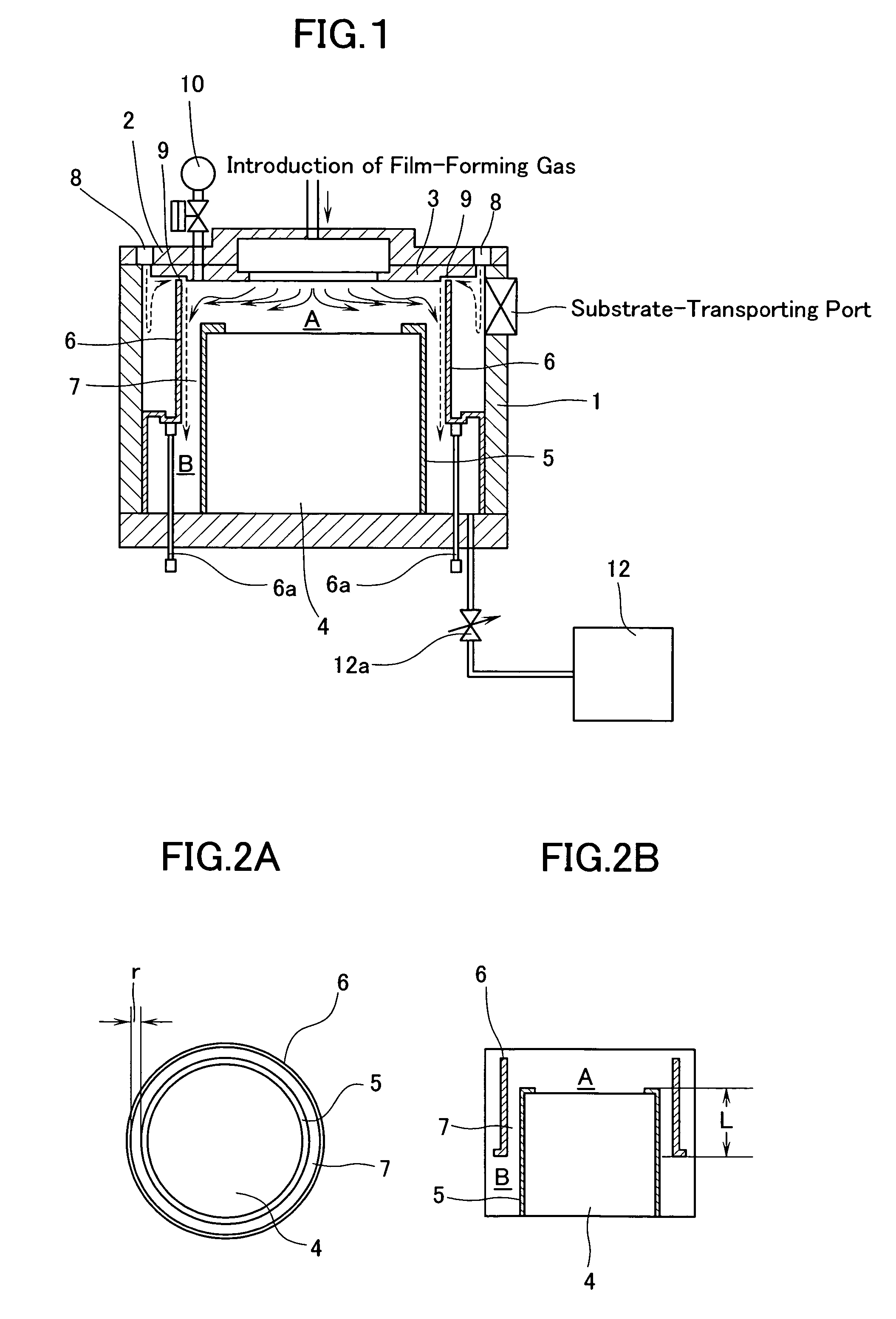

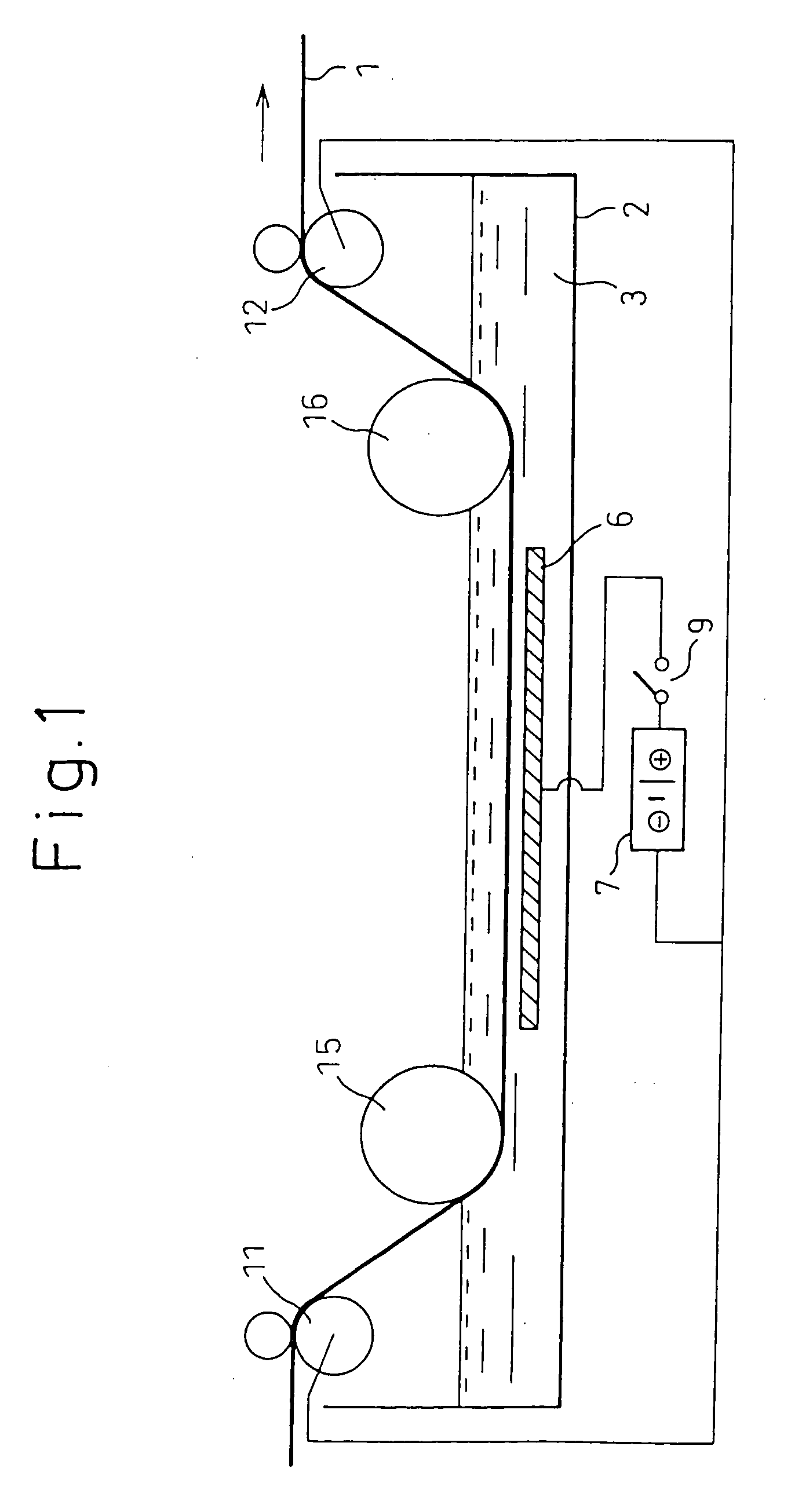

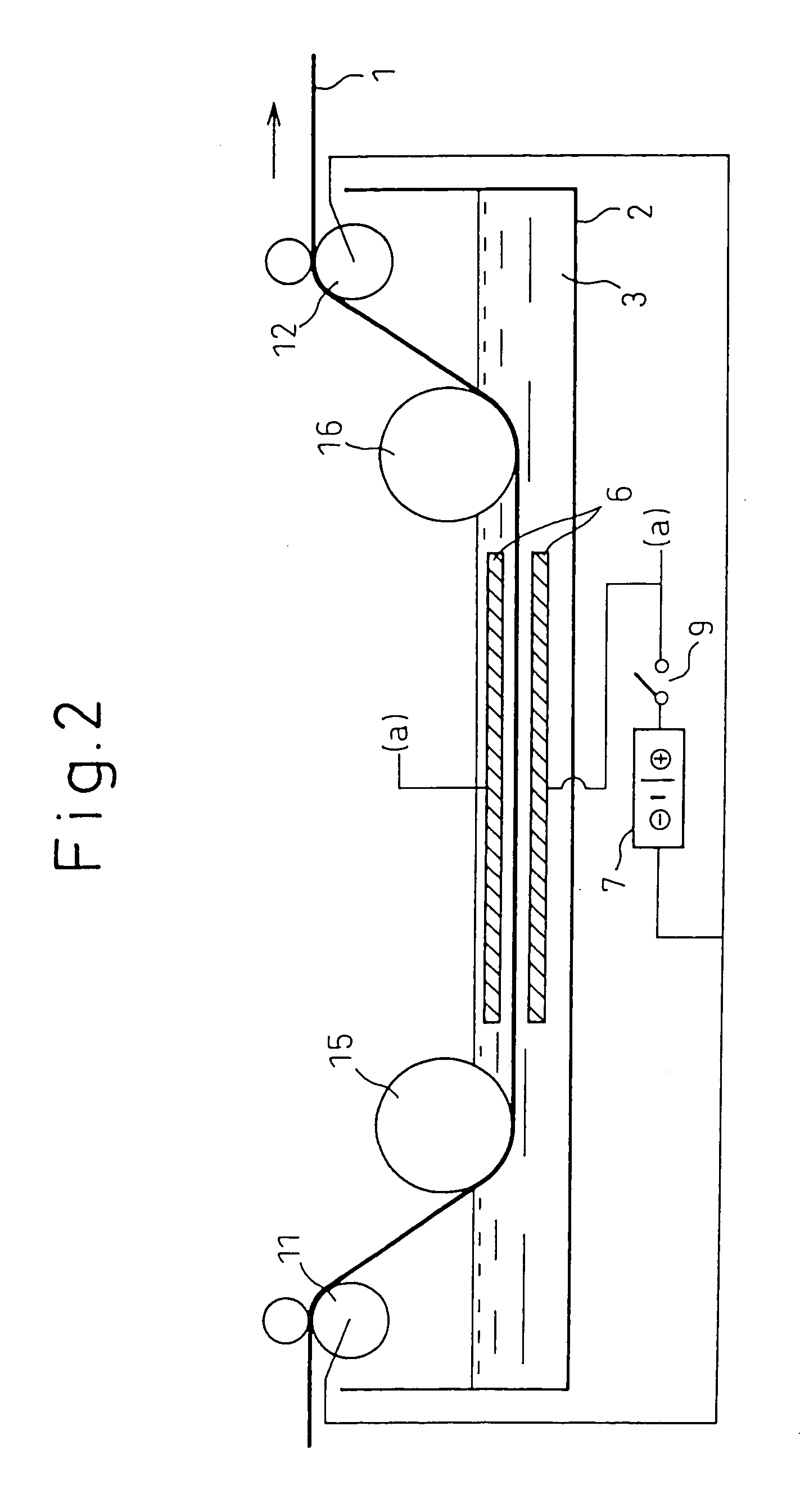

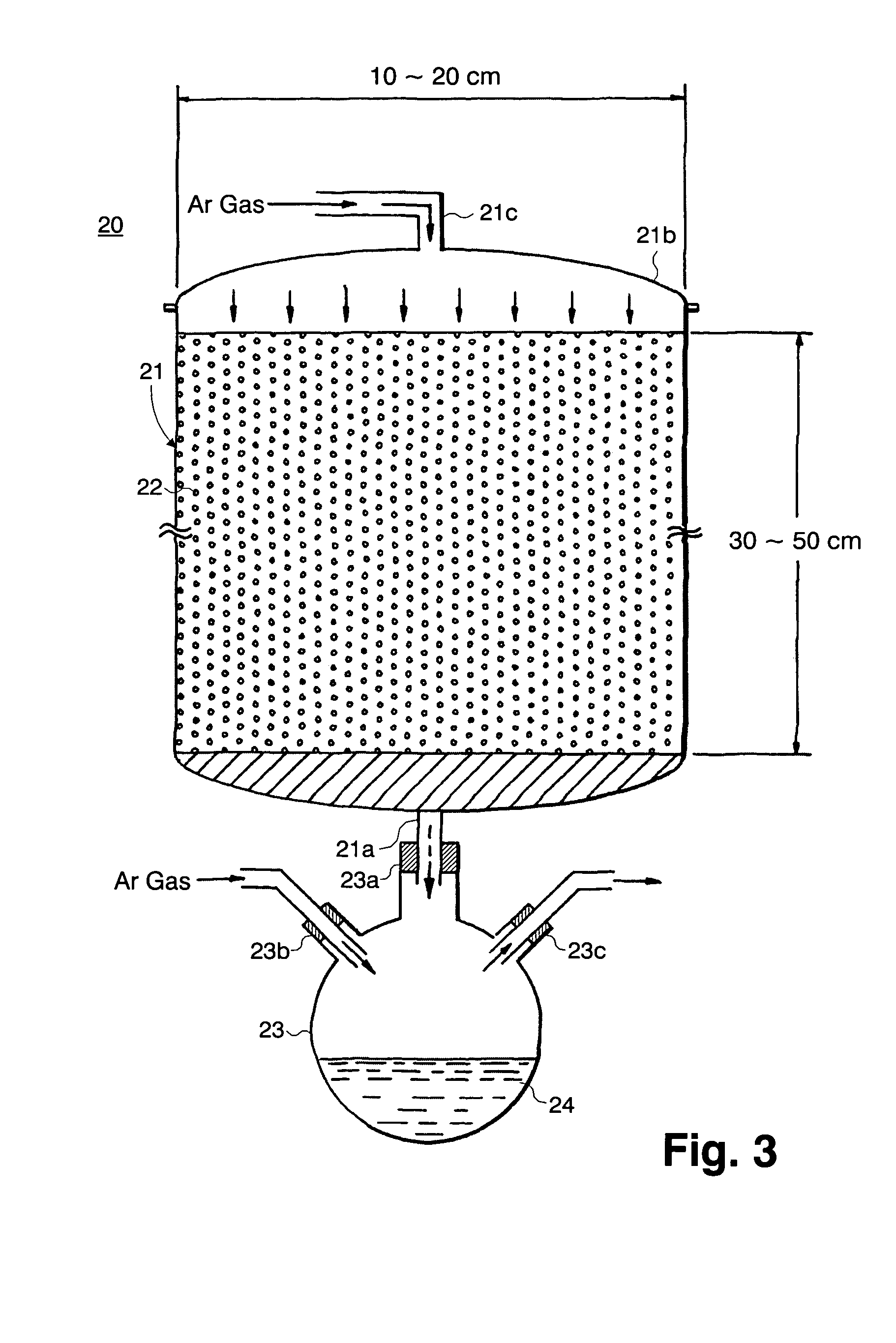

Film-Forming Apparatus And Film-Forming Method

InactiveUS20080241587A1High film forming rateUniform film formationDischarge tube luminescnet screensElectroluminescent light sourcesEngineeringRaw material

For increasing the film-forming rate and enabling uniform film formation and waste elimination of raw material, a film-forming method and a film-forming apparatus can reach an evaporated film-forming material to a surface of a substrate by the flow of a transport gas so as to control the film-forming conditions by the flow of the gas. Thereby a uniform thin film can be deposited on the large-area substrate. That is, by directing the evaporated raw material toward the substrate, it is possible to increase the film-forming rate and achieve uniform film formation.

Owner:OHMI +1

Method for producing electrode for lithium secondary battery

InactiveUS6649033B2Simple interfaceImprove adhesionElectrode carriers/collectorsVacuum evaporation coatingSputteringEvaporation

Owner:SANYO ELECTRIC CO LTD

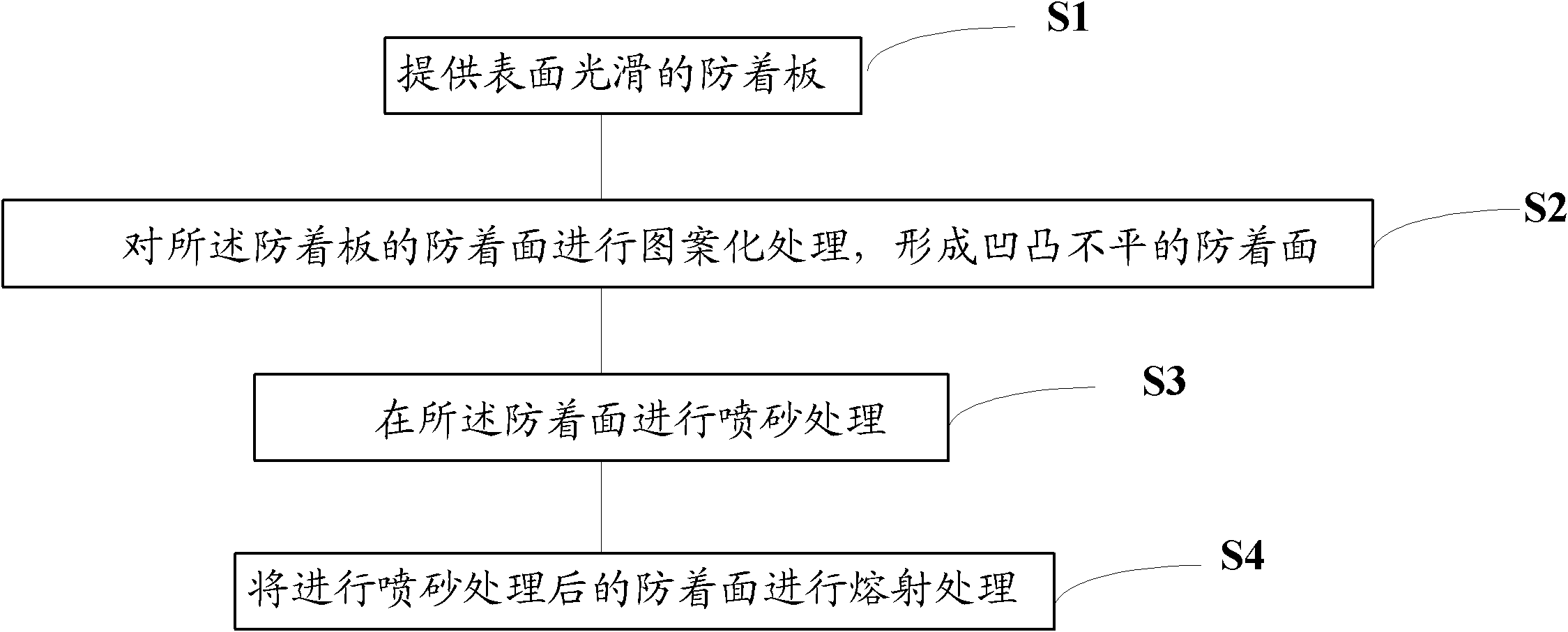

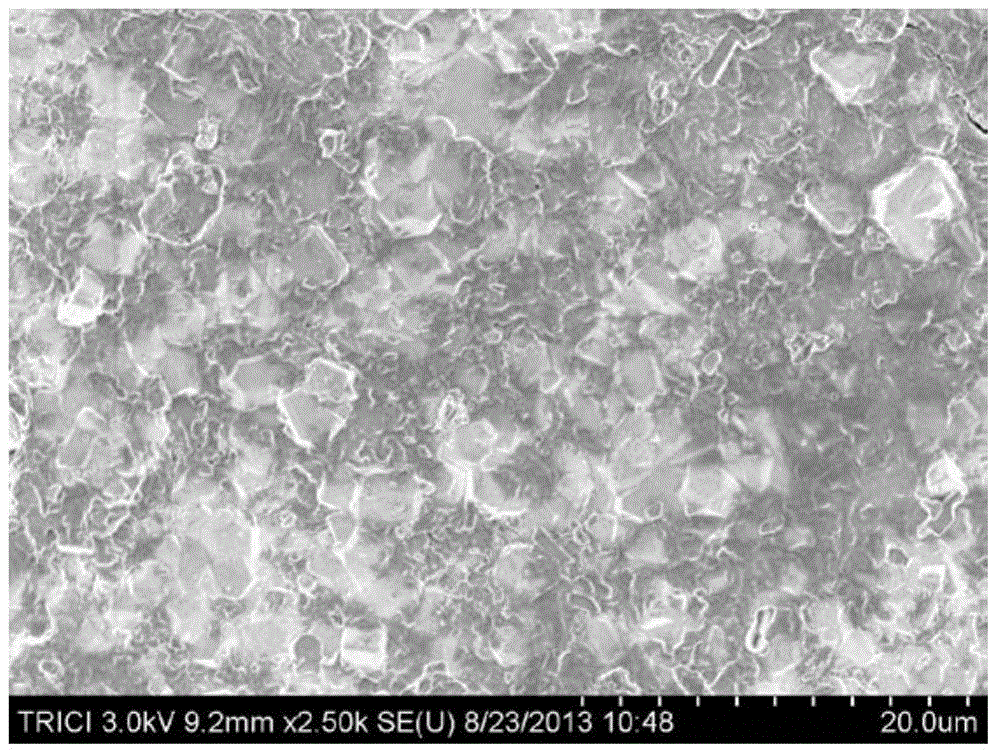

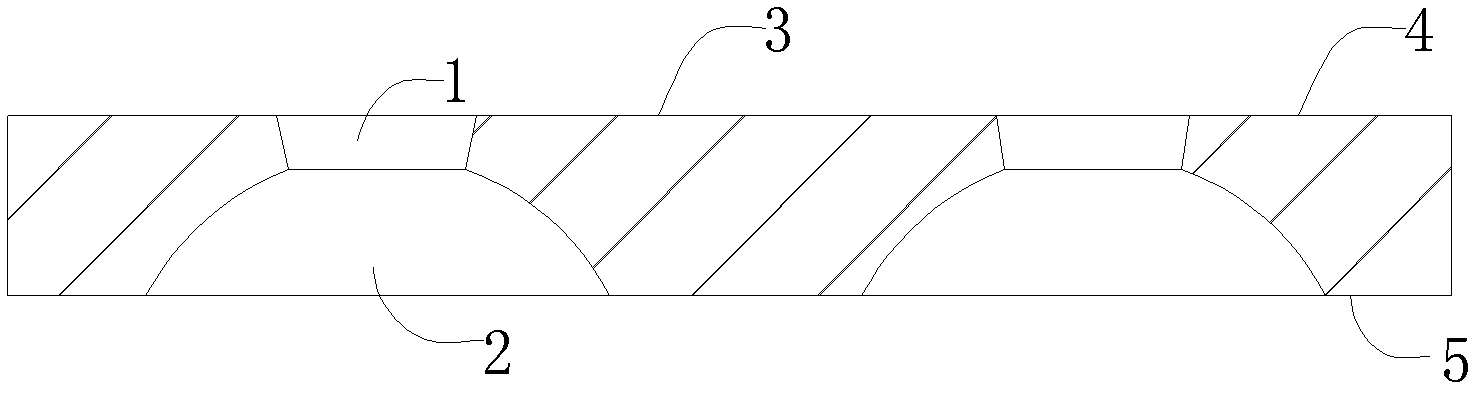

Method for processing surface of attachment-resisting plate

ActiveCN102011085AImprove corrosion resistanceImprove precipitation effectMolten spray coatingAbrasive blastingSputtering

The invention discloses a method for processing the surface of an attachment-resisting plate. The method comprises the following steps: providing an attachment-resisting plate with a smooth surface; patterning the attachment-resisting surface of the attachment-resisting plate with a smooth surface to form an uneven attachment-resisting surface; blasting the attachment-resisting surface; and meltallizing the attachment-resisting surface after blasting. The smooth surface of the attachment-resisting plate is subject to the patterning, the blasting and the meltallizing so that the surface of theattachment-resisting plate has corrosion resistance, rust prevention, abrasion resistance, lubrication, roughness, adsorption, insulation, heat insulation and other properties; the attachment-resisting surface of the attachment-resisting plate achieves even roughness; and the attachment-resisting plate can easily absorb target atoms or large-sized particles so that the target atoms or large-sizedparticles do not fall on a substrate, thereby increasing the sediment capability of the attachment-resisting plate, improving the cleanness of the inner wall of a sputtering machine, improving the filming rate of sputtering and prolonging the service life of the attachment-resisting plate.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

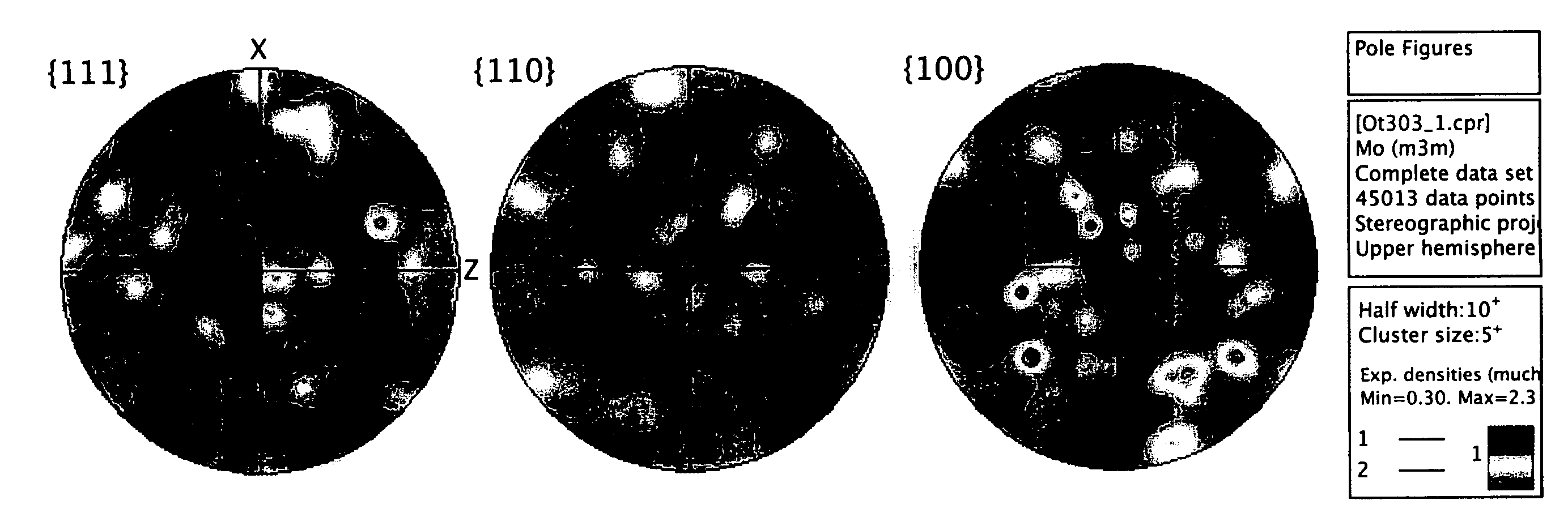

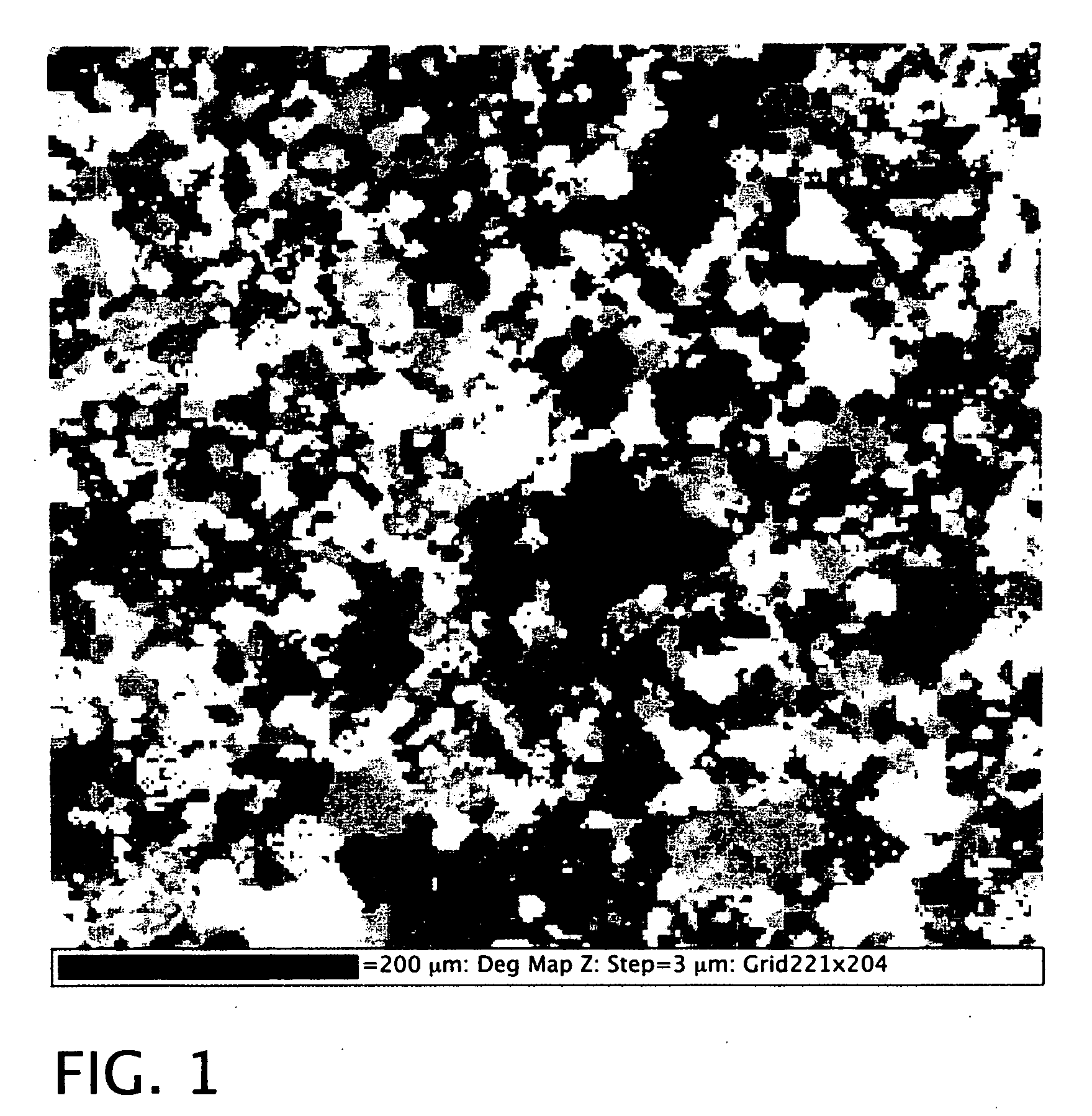

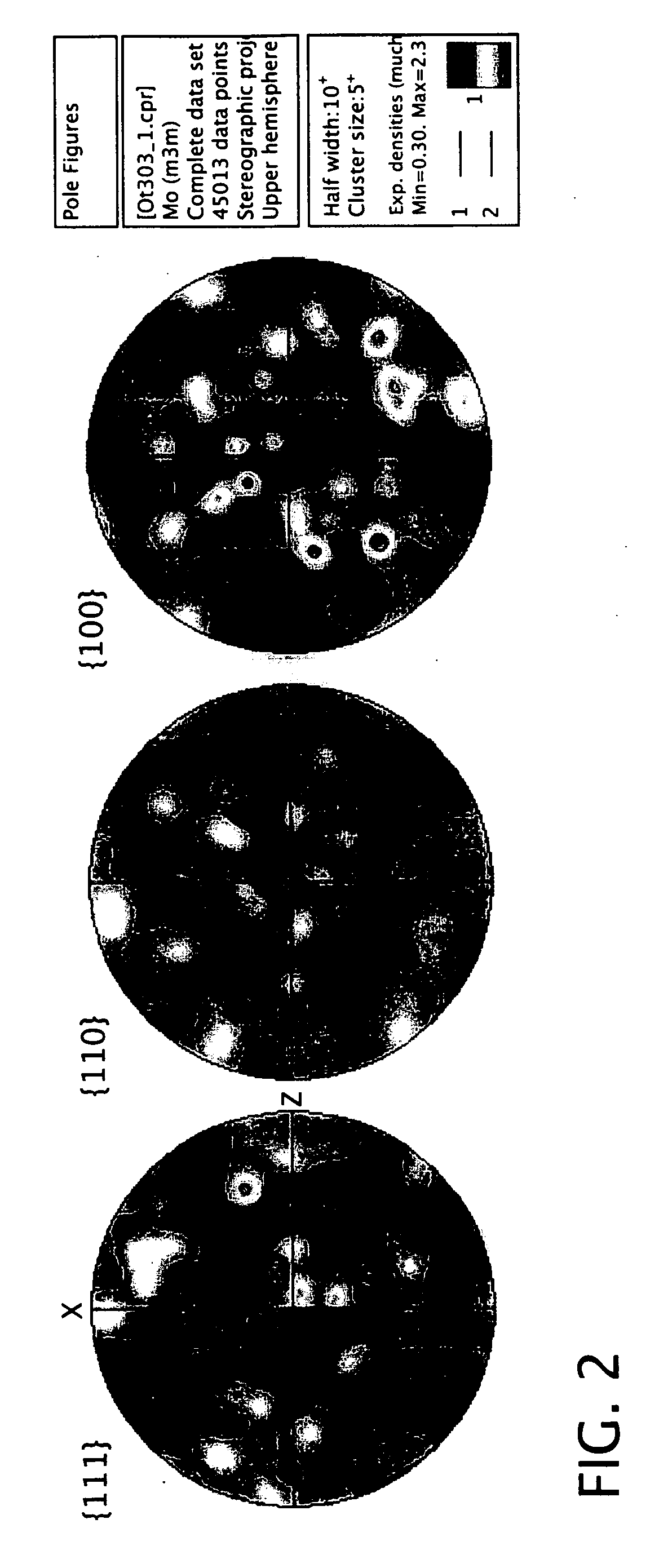

High density refractory metals & alloys sputtering targets

ActiveUS20080171215A1High film forming rateLow resistivityVacuum evaporation coatingSputtering coatingHigh densityAlloy

The present invention is directed to a process for producing high density, refractory metal products via a press / sintering process. The invention is also directed to a process for producing a sputtering target and to the sputtering target so produced.

Owner:GLAS TRUST +1

Polyimide film, and method for production thereof

InactiveUS20090197068A1Increase production capacityImprove productivitySynthetic resin layered productsPrinted circuit aspectsToluenediamineCarboxylic acid

Disclosed is a polyimide film prepared from an aromatic tetracarboxylic acid component consisting essentially of 3,3′,4,4′-biphenyltetracarboxylic dianhydride and an aromatic diamine component consisting essentially of not less than 65 mol phenylenediamine % but less than 97 mol % of p-phenylenediamine and not less than 3 mol % but less than 35 mol % of 2,4-toluenediamine.

Owner:UBE IND LTD

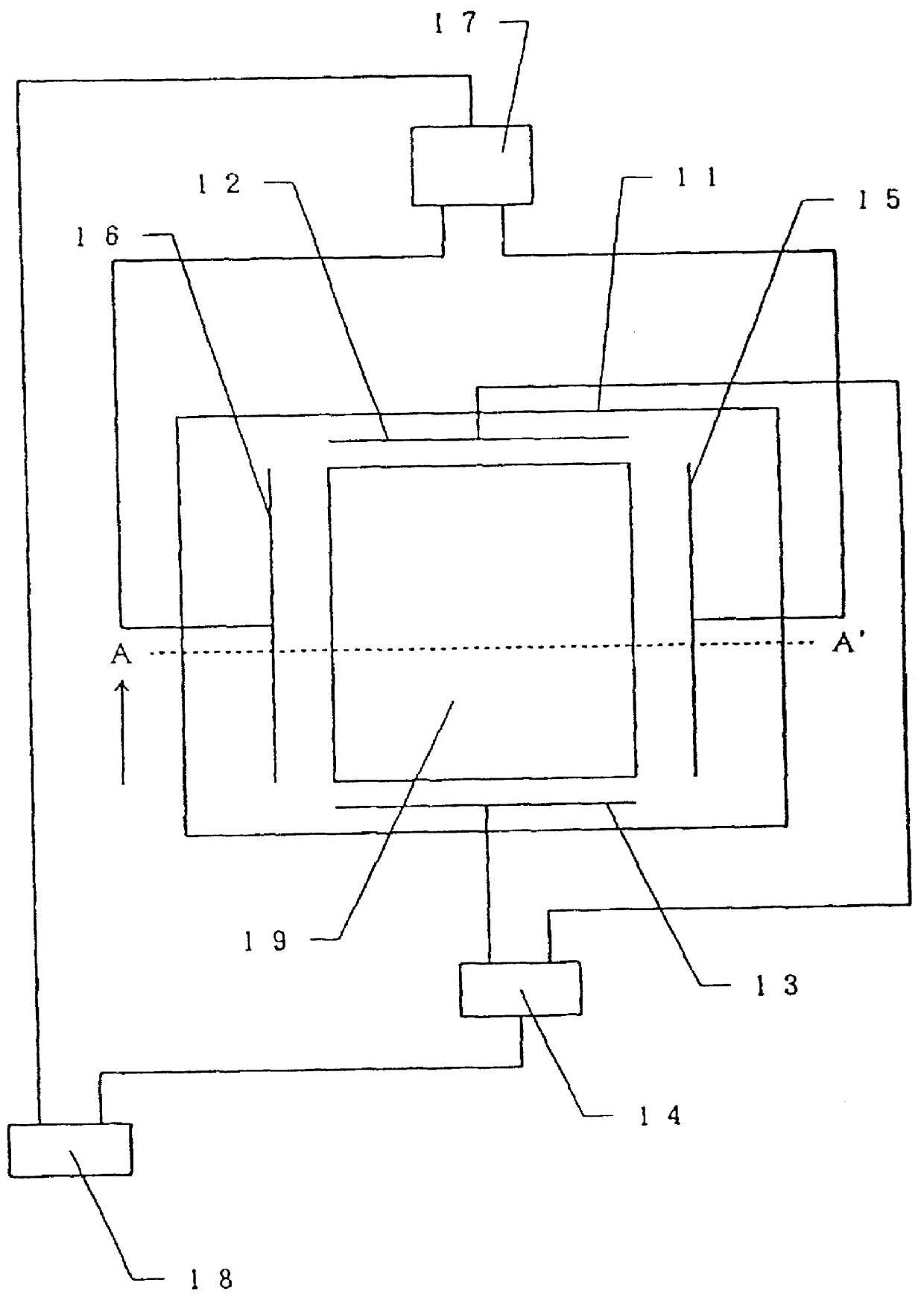

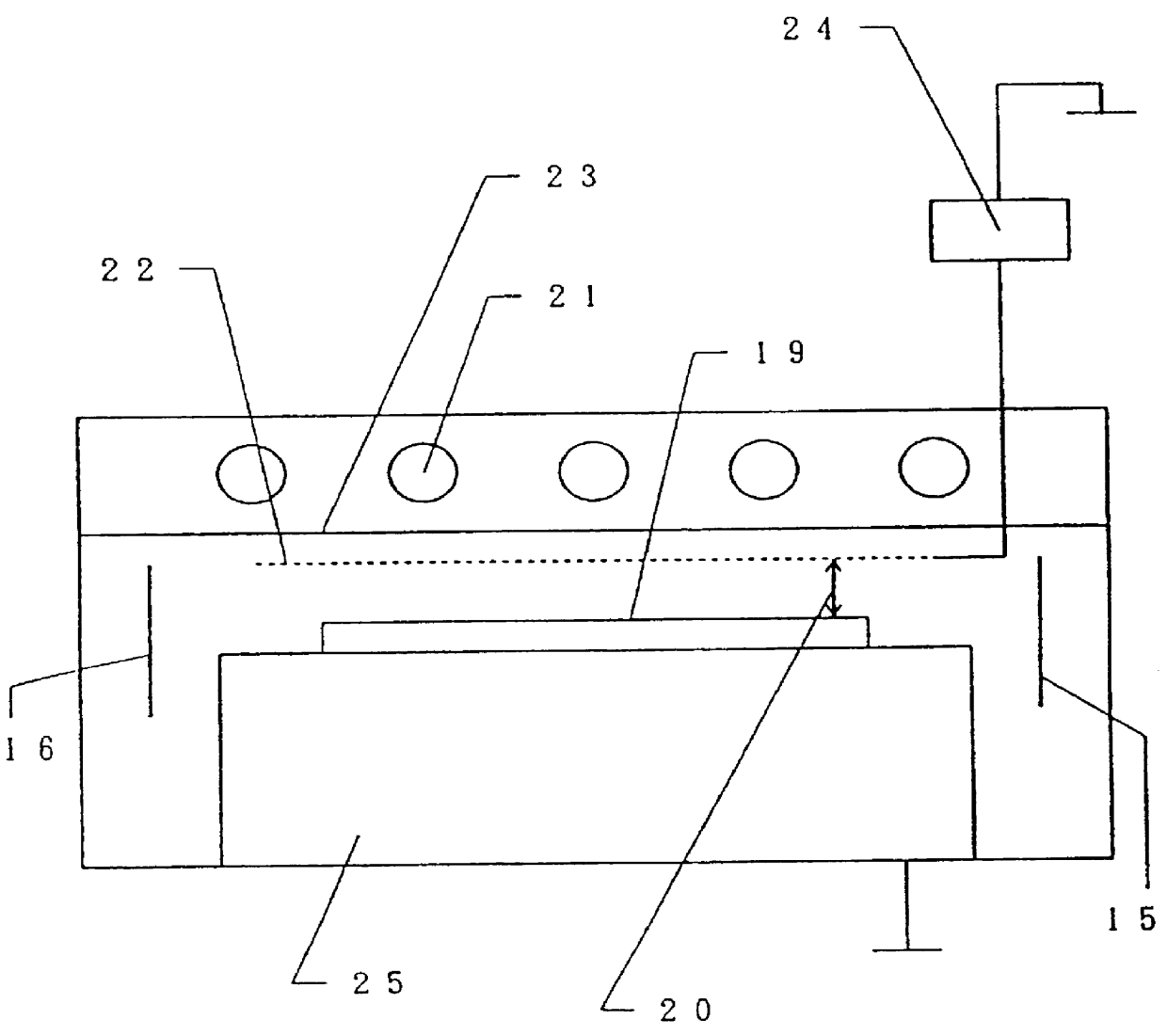

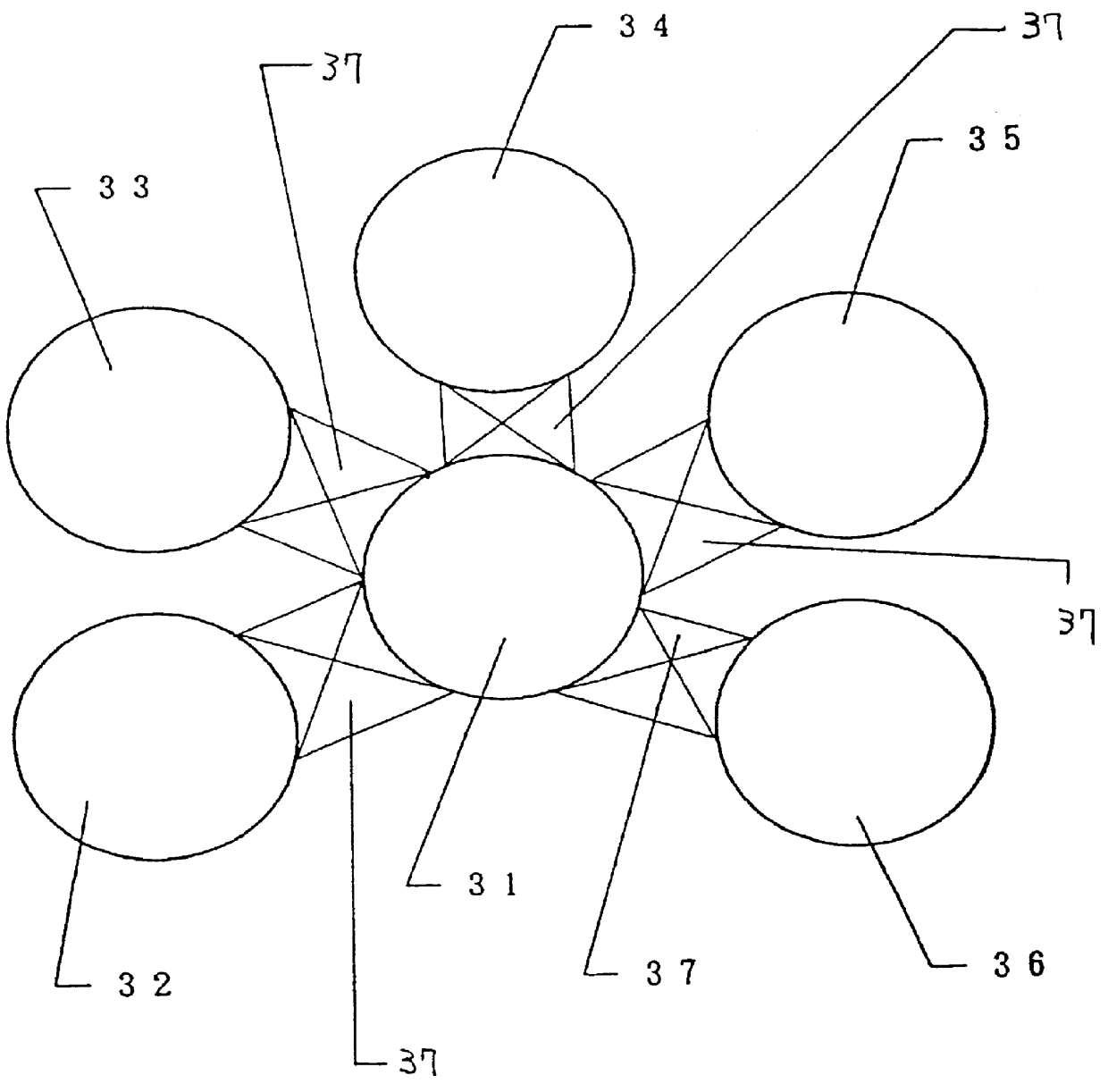

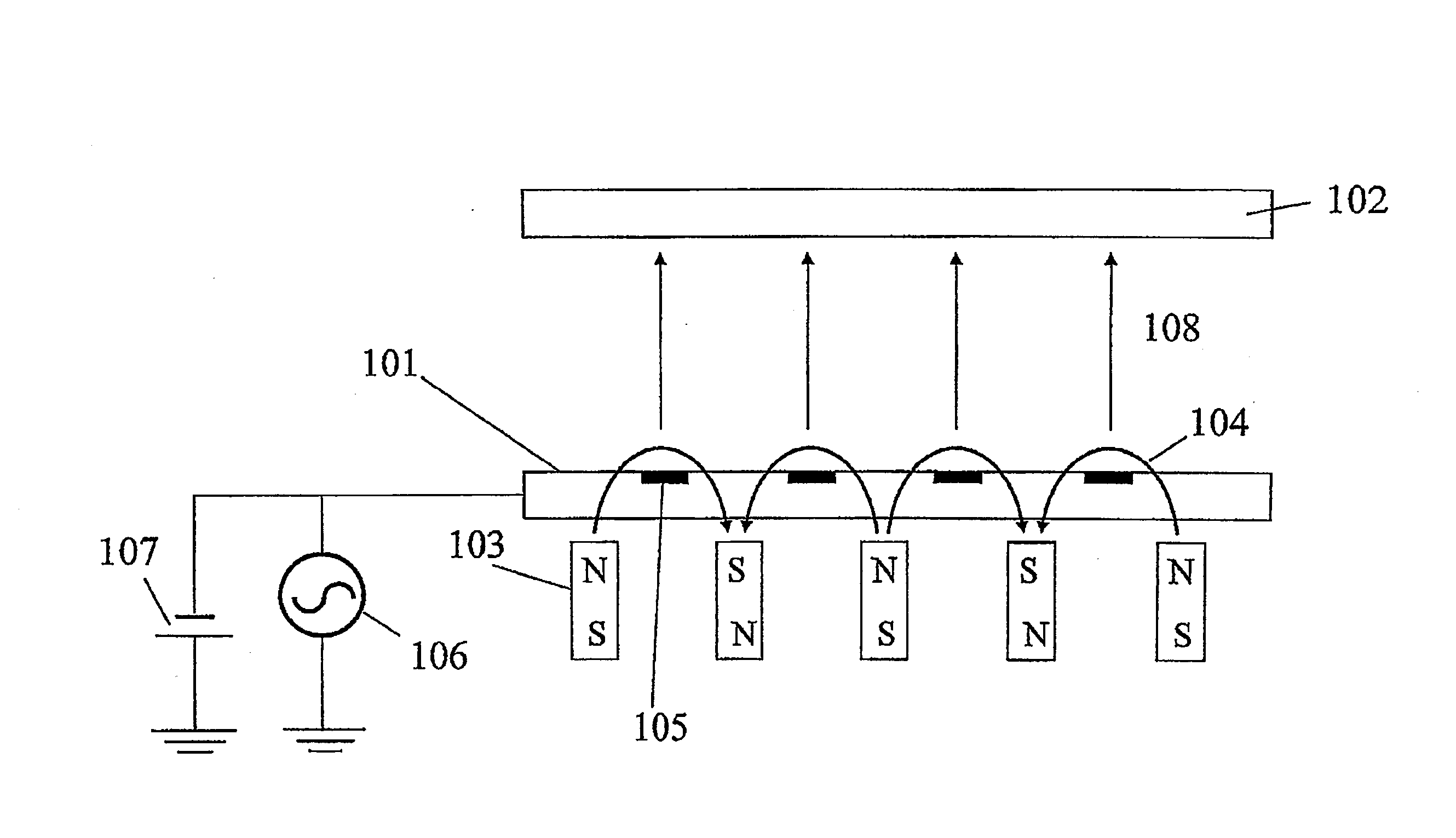

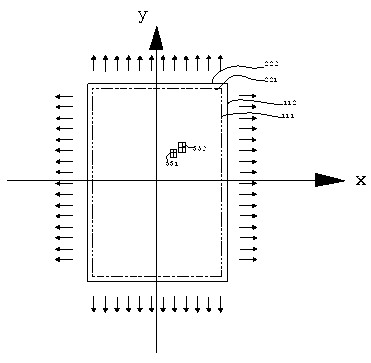

Plasma reaction apparatus and plasma reaction

InactiveUS6130118AGood step coverageIncreased film deposition rateElectric discharge tubesSemiconductor/solid-state device manufacturingHigh frequency powerHigh rate

A process for depositing a film at a high rate and with superior step coverage properties, which comprises installing a pair of electrodes crossing with another pair of electrodes making a right angle with respect to the another pair, and applying a high frequency power differing in phase to the electrodes in order to apply a high frequency power having a Lissajous' waveform in the reaction space during the deposition of a film on a substrate.

Owner:SEMICON ENERGY LAB CO LTD

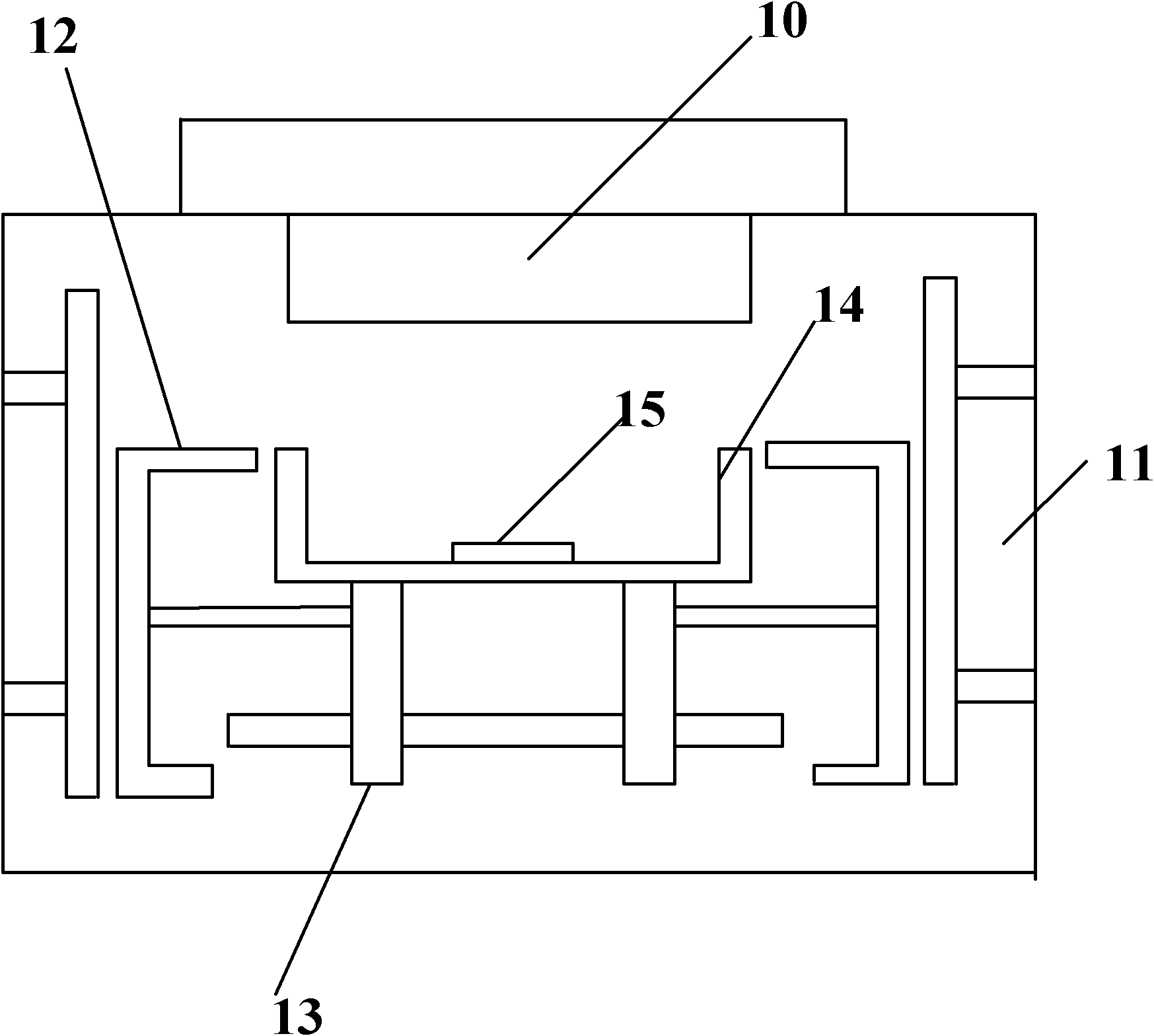

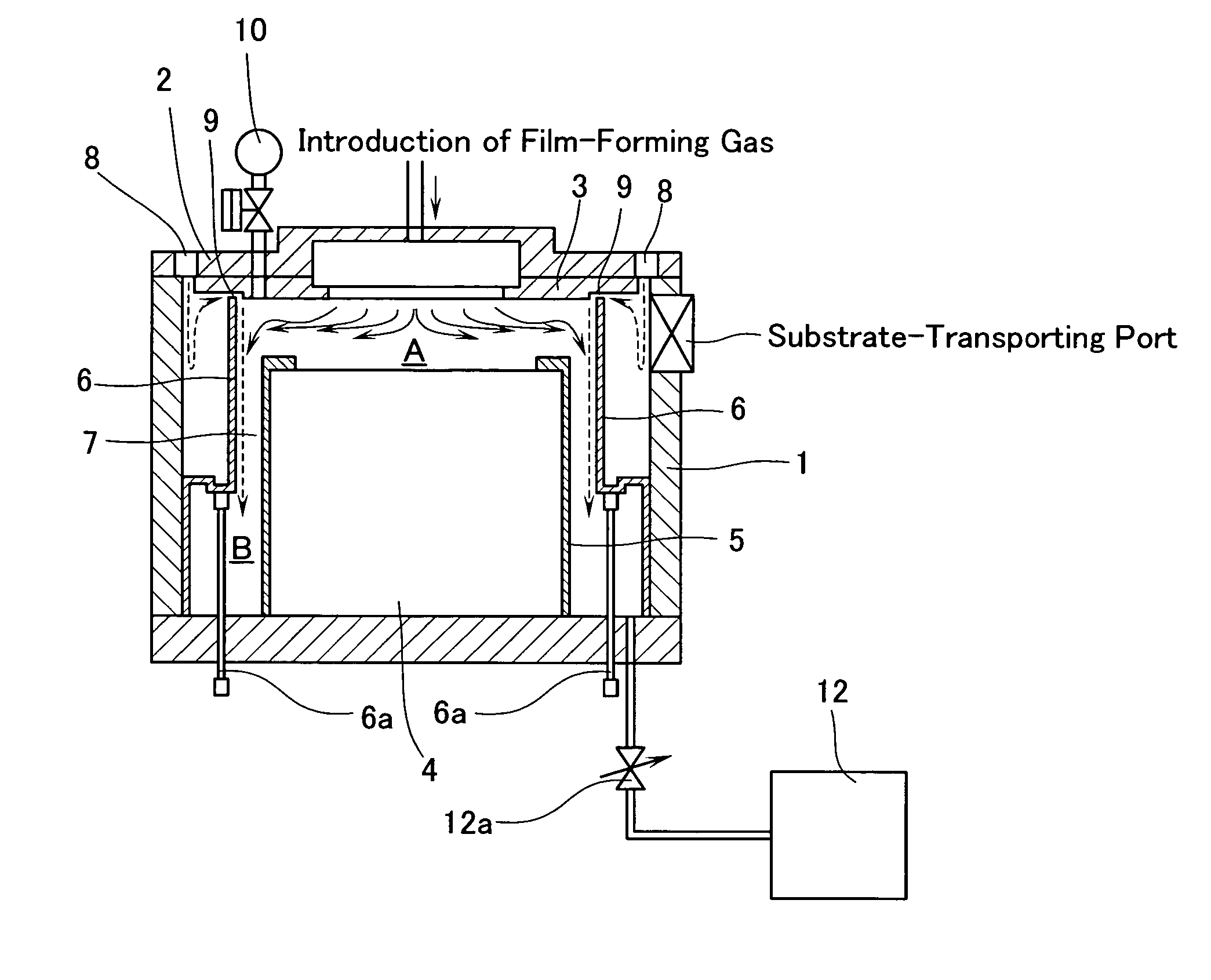

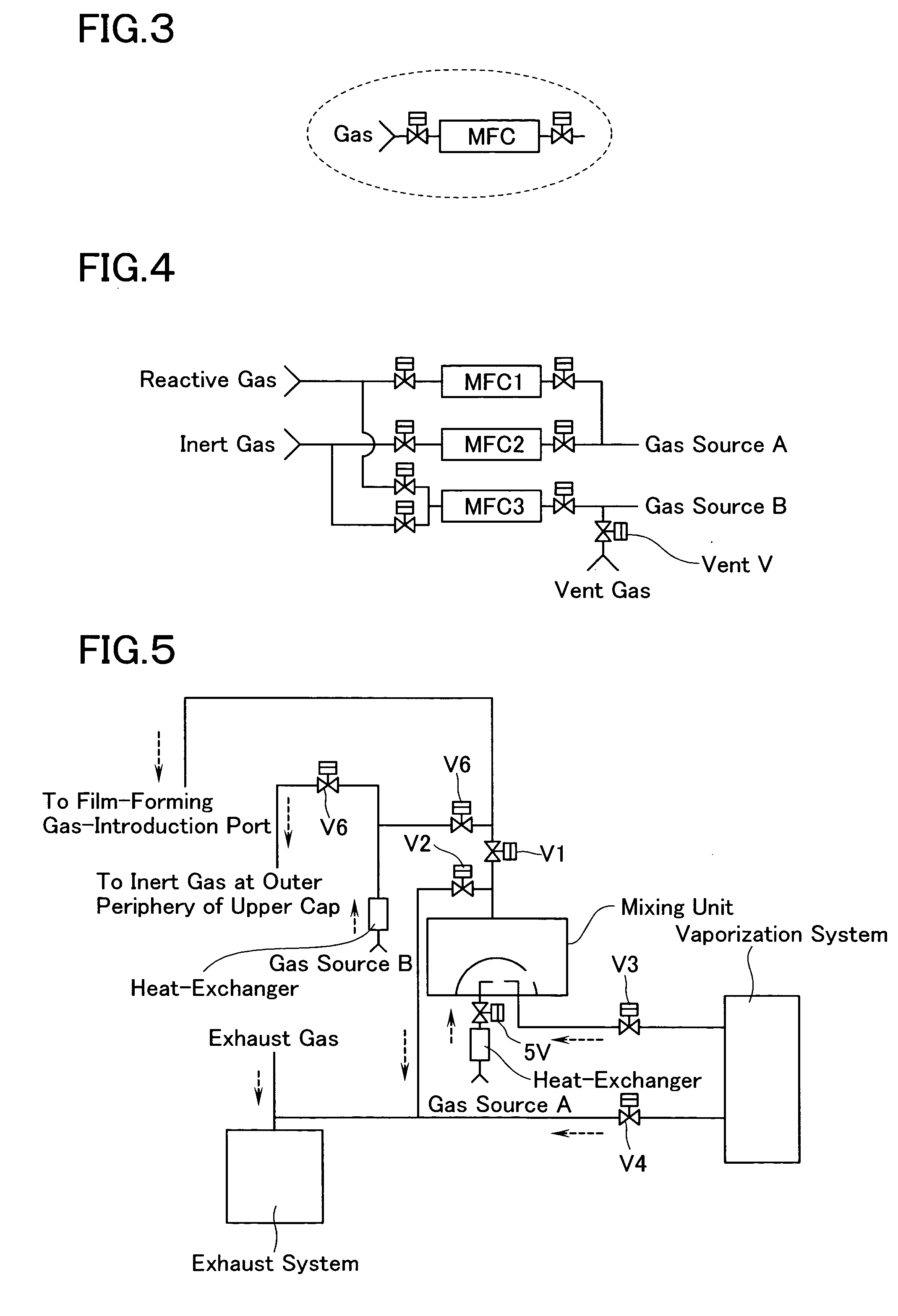

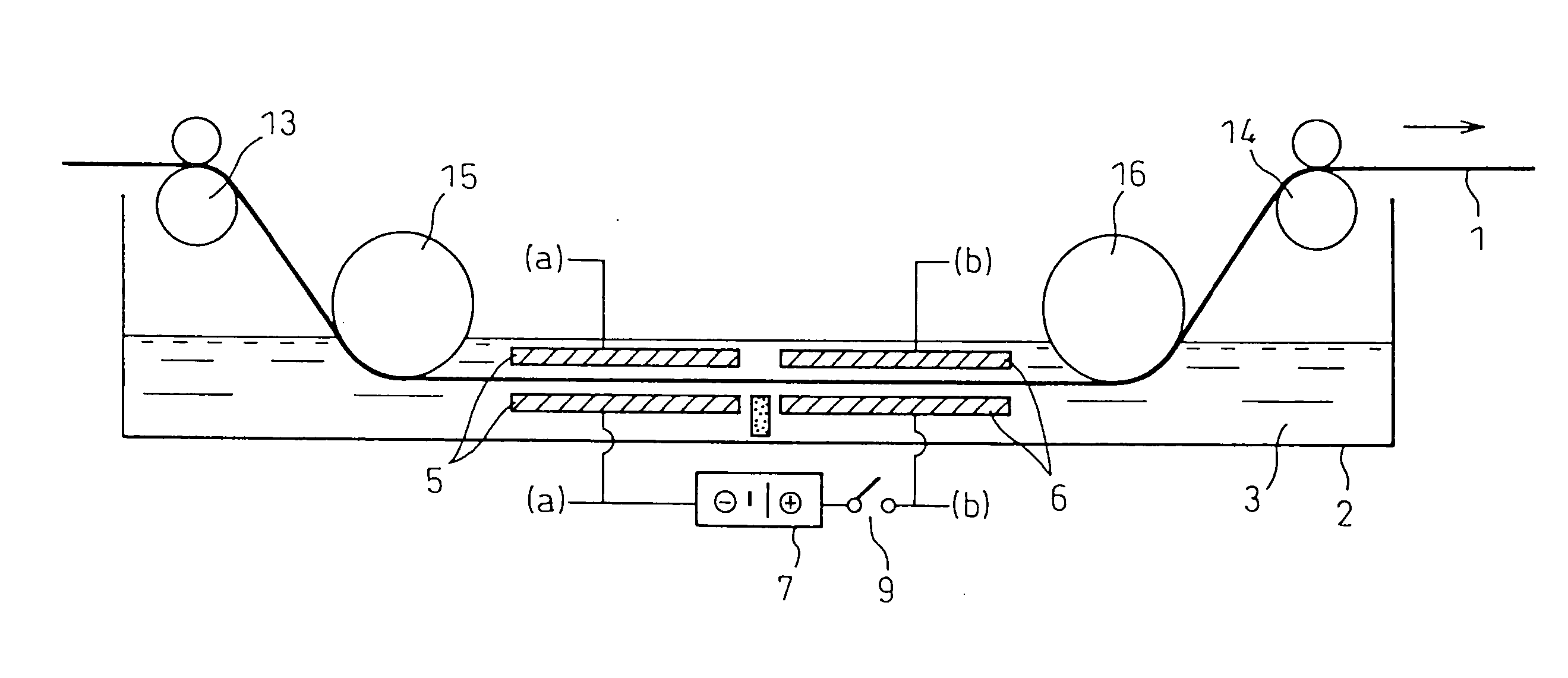

Device and method for manufacturing thin films

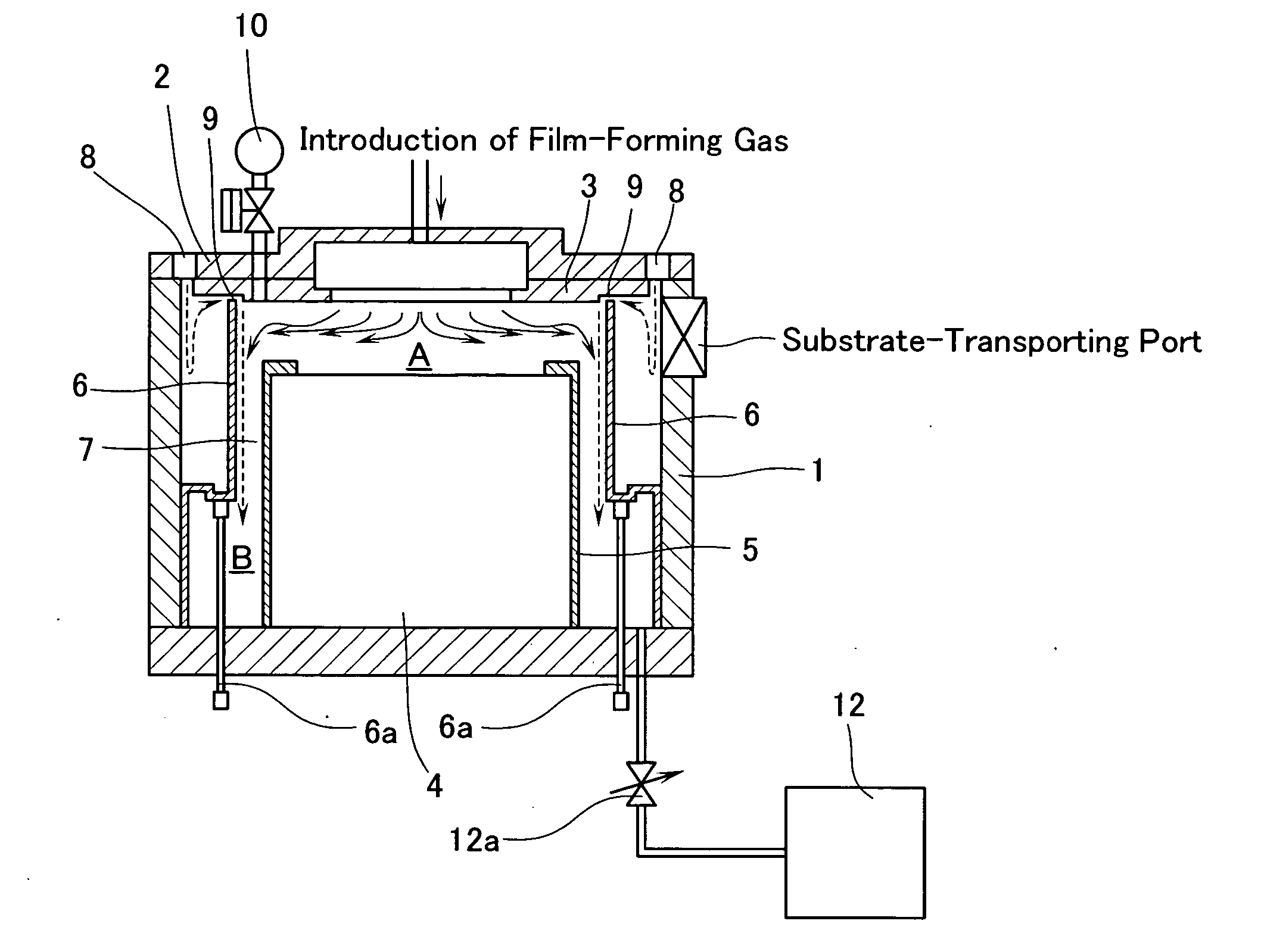

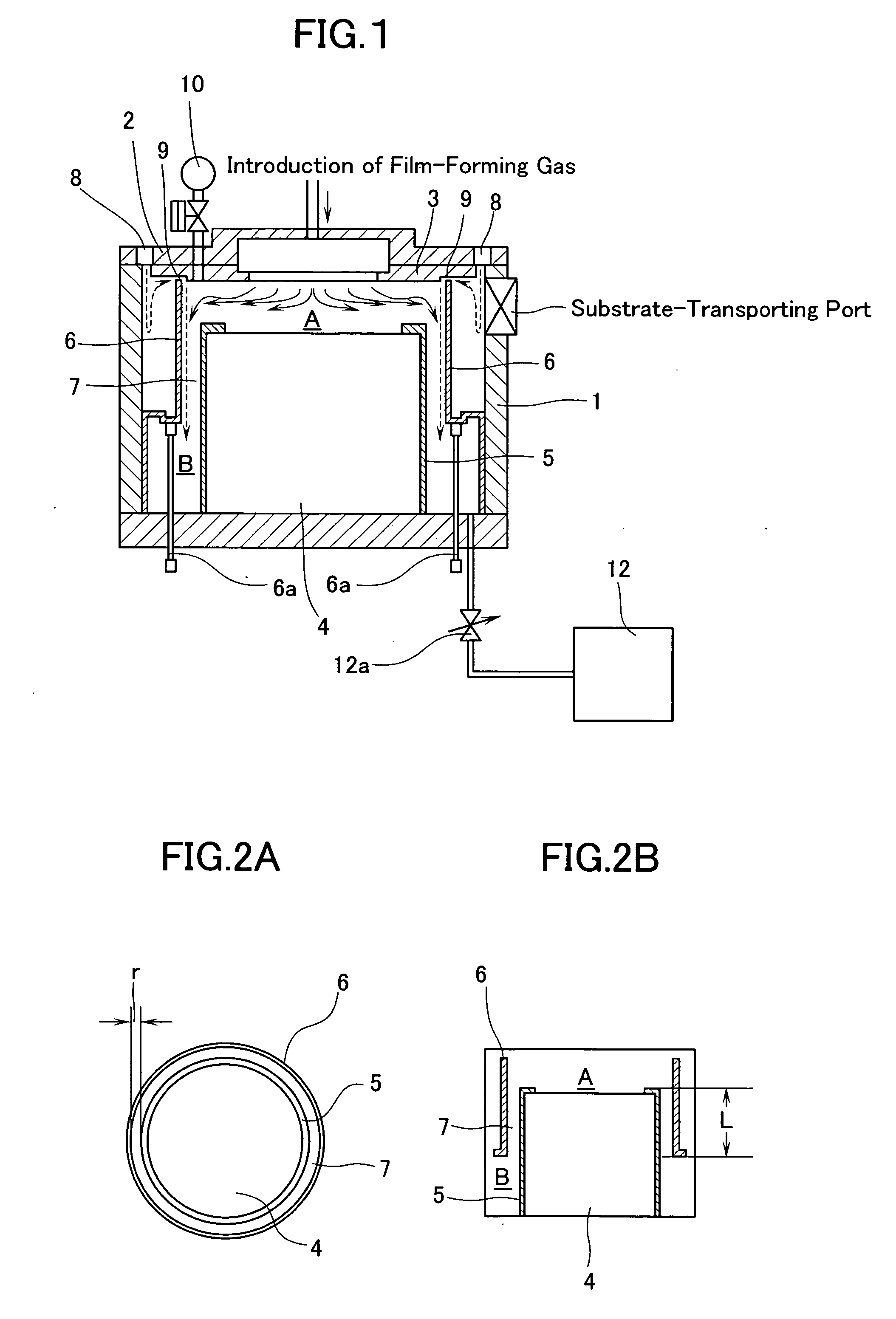

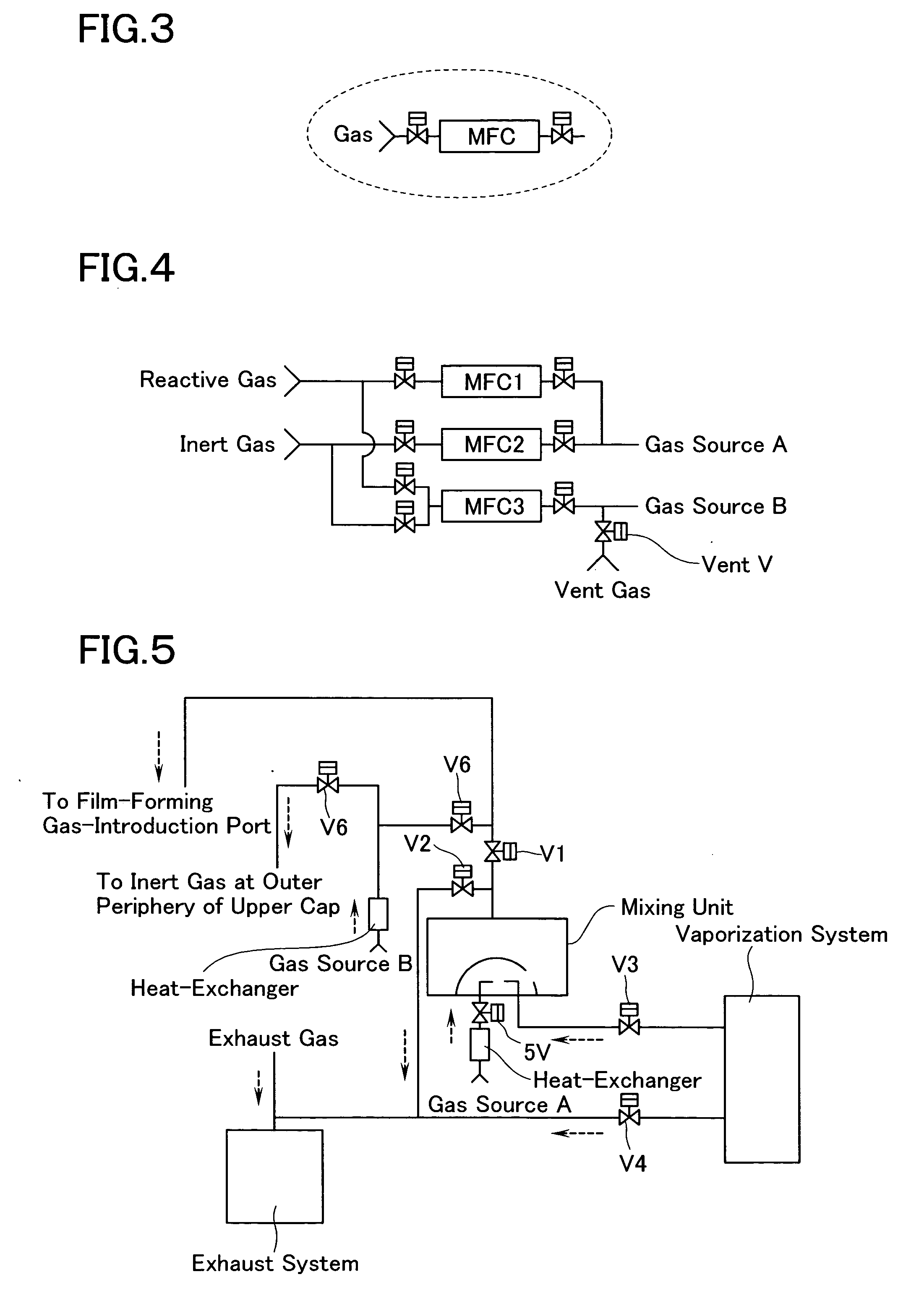

ActiveUS20050059246A1Stable and continuous formationGood film thickness distributionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingProduction rateForming gas

The present invention herein provide a thin film-manufacturing device and a thin film-manufacturing method which are excellent in the mass-production ability and productivity, which permit the stable and continuous production of films over a long period of time while reproducing a good film thickness distribution, a good compositional distribution and a high film-forming rate and controlling the number of particles generated during the film-formation to a lower level. The device is one serving as a CVD device in which a film-forming gas is introduced into a reaction chamber from the upper portion of the chamber serving as a reaction space, through a shower head and a film is formed on a heated substrate, wherein the device is so designed that the upper reaction space is constructed by the substrate-supporting stage which is free of any rotational motion or free of any elevating motion, the shower head and a deposition-inhibitory plate, that the substrate-supporting stage and the deposition-inhibitory plate are so arranged as to form, between them, a concentric gap or interstice serving as a gas-exhaust path through which an inert gas can flow from the upper portion of the gas-exhaust path along the deposition-inhibitory plate and that a lower space is formed on the secondary side of the gas-exhaust path.

Owner:ULVAC INC

Method for synthesizing NaA zeolite membrane with high membrane forming efficiency

ActiveCN103599709AHigh film forming rateSuitable for large-scale industrial productionSemi-permeable membranesMolecular sieveZeolite

The invention provides a method for synthesizing a NaA zeolite membrane with high membrane forming efficiency. The method is characterized by comprising the following steps: coating nano NaA molecular sieve crystal seeds by a thermal impregnation method, wiping the crystal seed layer of the surface of a carrier under an evacuated condition to ensure that the thickness of the crystal seed layer is uniform and the crystal seeds are coated evenly and continuously, and synthesizing for 2-6h at 80-100 DEG C by hydrothermal crystallization, so as to prepare the NaA zeolite membrane with high pass and preferable separation effect; due to the adoption of the method, the problems that the crystals are coated for several times, repeated hydrothermal synthesizes are required and the membrane forming efficiency is low when preparing the NaA membrane in the prior art are solved mainly.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

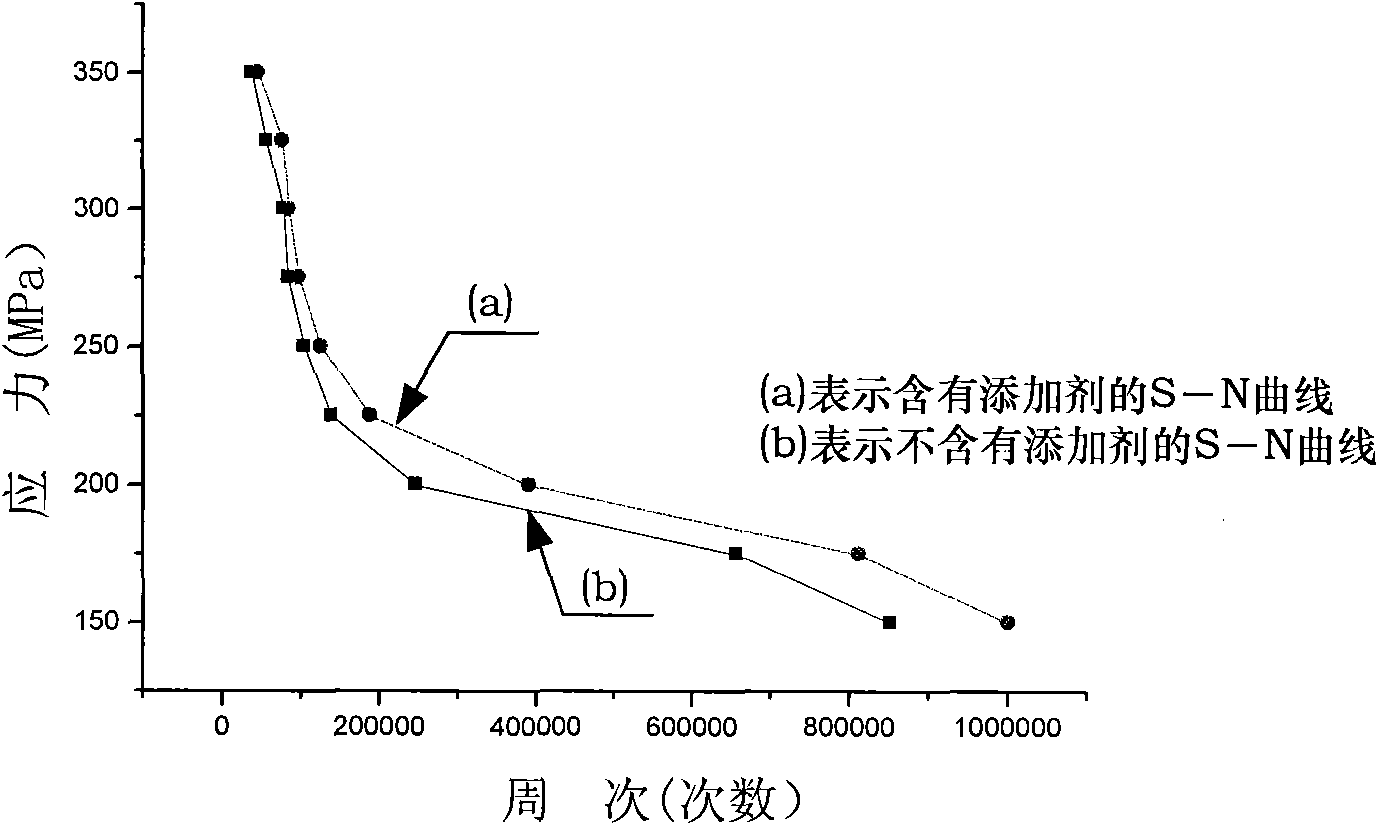

Chromizing-free anodic oxidation treatment method of surface of aviation 2 department and 7 department aluminium alloy

The invention discloses a chromizing-free anodic oxidation treatment method of the surfaces of an aviation 2 series and 7 series aluminium alloys, which is an improvement of a surface anodic oxidation treatment method of a sample in a standard aluminium and an aluminium alloy sulfuric acid anodic oxidation technology (HB / Z 233-93) of the PRC aviation industry, a processing solution contains no chromium in an anodic oxidation step, and an anodic oxidation solution comprises sulfuric acid and a modifier. The film weight of a prepared anodic oxidation film is within a range from 10 mg / dm <2> to 75 mg / dm <2> through the matching of anodic oxidation technology conditions, and in addition, the invention meets the corrosion resistance of a film layer and the combination property of the anodic oxidation film and an organic coating and also prolongs the fatigue life of workpieces manufactured by the aviation 2 series and 7 series aluminium alloys.

Owner:BEIHANG UNIV

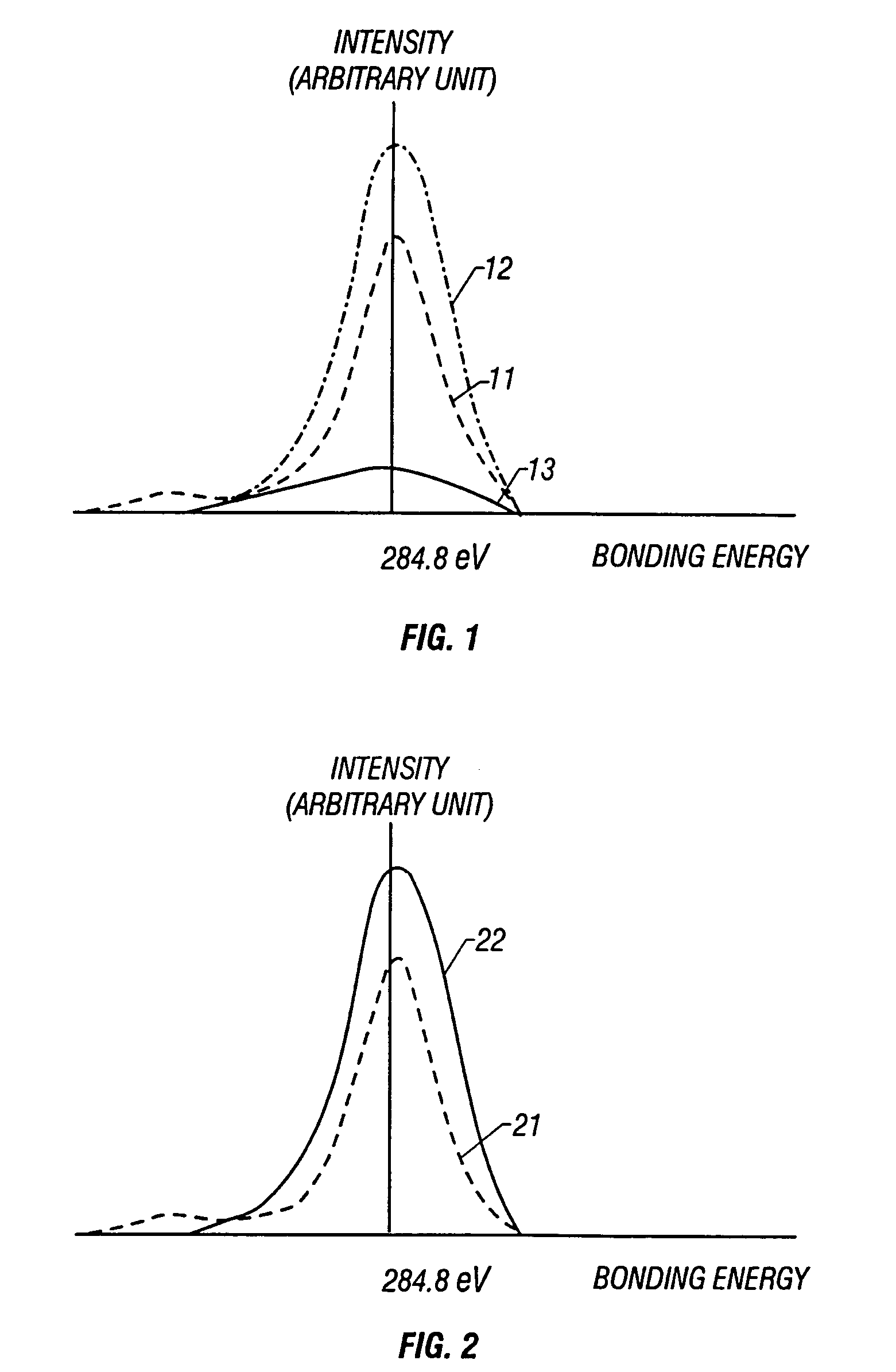

Method of manufacturing a semiconductor device

InactiveUS7393723B2Improving decarbonizationImproving step coverage propertyTransistorSolid-state devicesHydrogenEngineering

A method of manufacturing a semiconductor device that forms laminate layers includes the steps of reducing contamination containing the single bond of carbon on at least one part of a surface on which the laminate films are formed by activated hydrogen before the laminate films are formed, and forming the laminate films on the surface on which the laminate films are formed.

Owner:SEMICON ENERGY LAB CO LTD

Titanium dioxide film adulterated with rare soil and the preparing method

InactiveCN101036879AFast preparationImprove photocatalytic activityCatalyst activation/preparationSpecial surfacesSocial benefitsOptical property

The present invention discloses a Tio2 film adulterated with rare earth, wherein the molecule percentage content of titanium and rare earth are as follows: titanium 85%-99%, rare earth 1%-15%. The preparation of the film adopts normal pressure thermal decomposition chemical vapor deposition method, wherein a propodosoma combination is deposited onto a glass substrate. The Tio2 film adulterated with rare earth of the present invention has excellent photocatalysis activity, hydrophilicity and optical property, and can be widely used for glass external wall, indoor decorating, etc,. The present invention greatly enlarges the application area of Tio2 film, and is hopeful for generating great economy, environment and social benefits.

Owner:ZHEJIANG UNIV

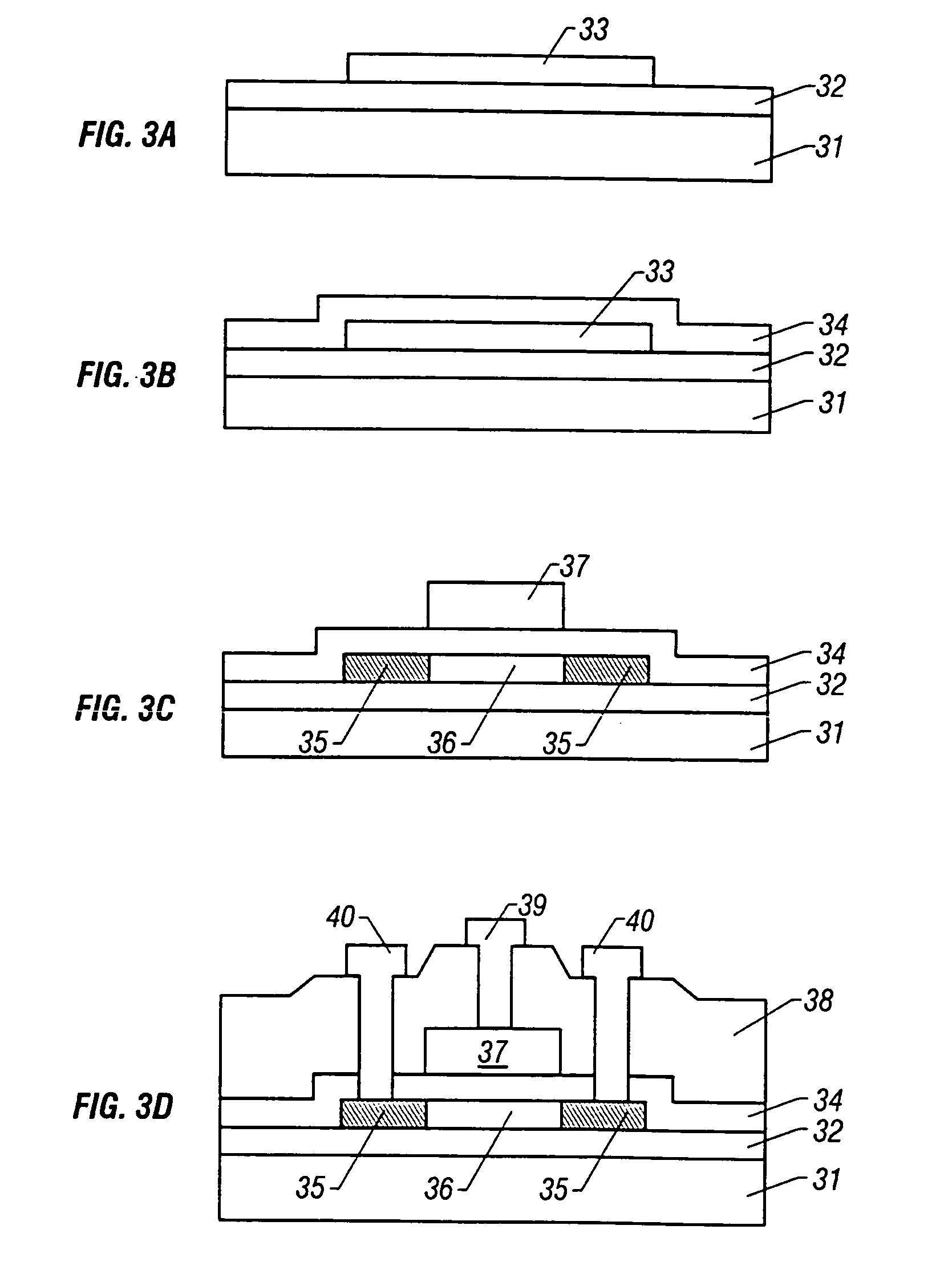

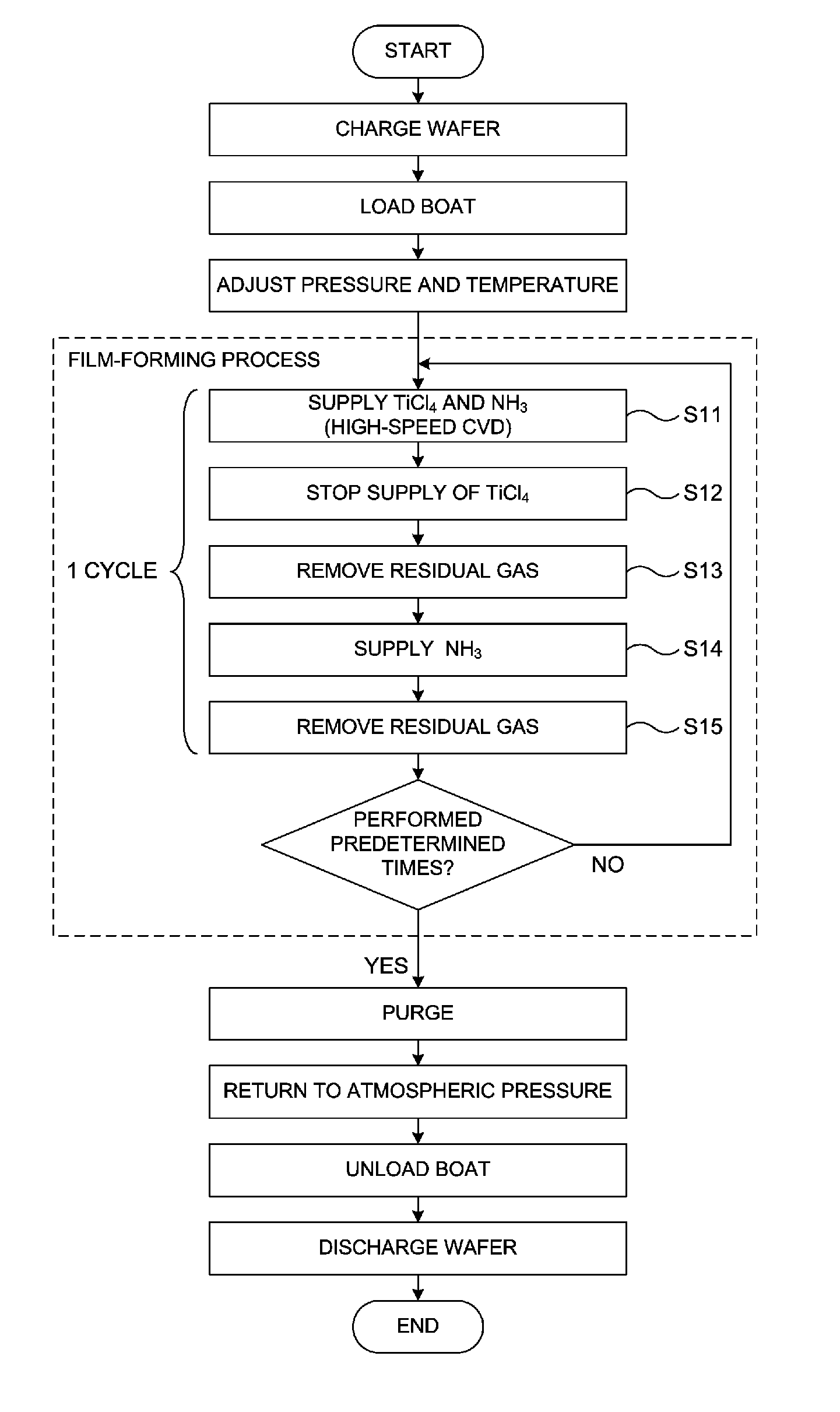

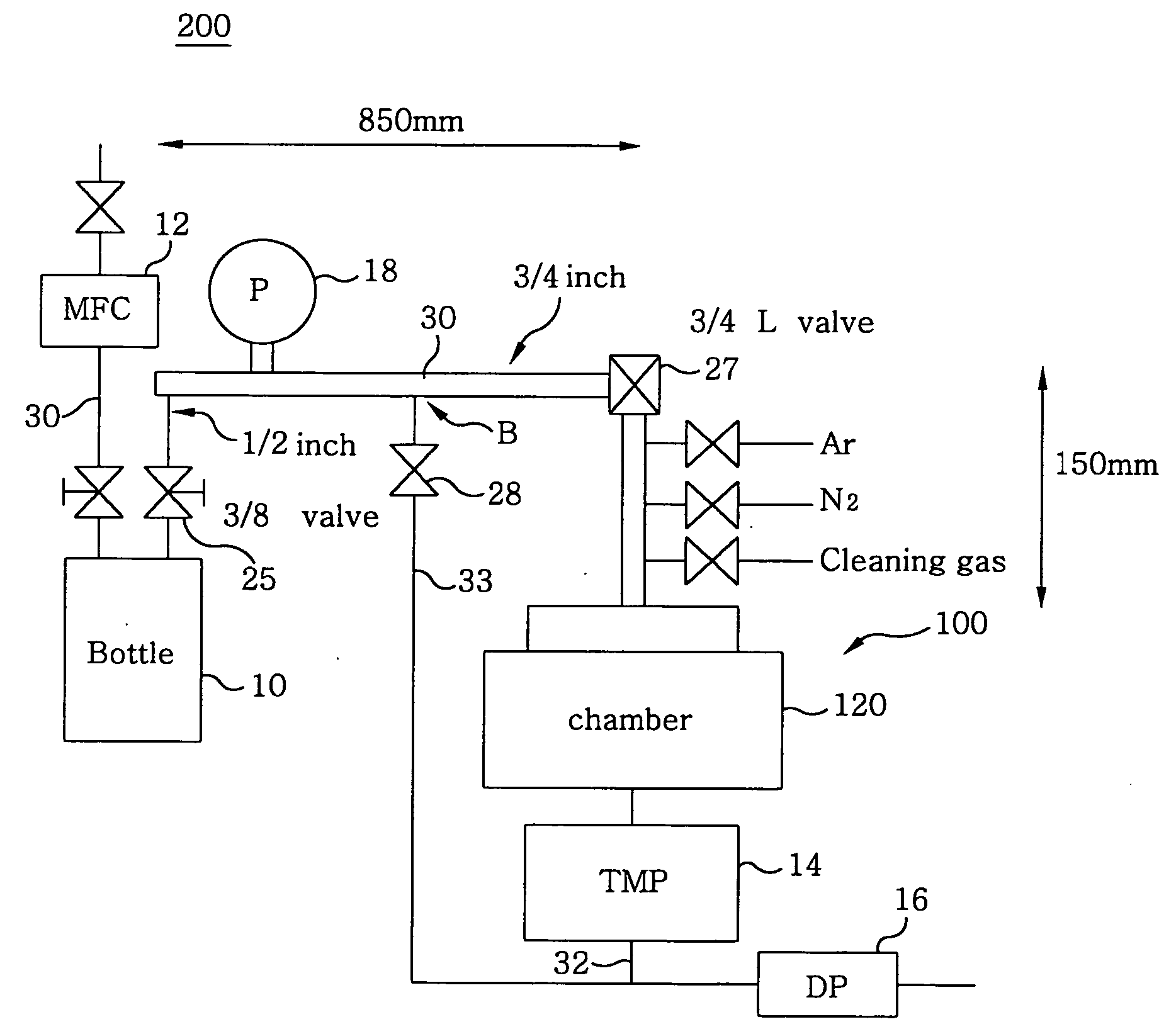

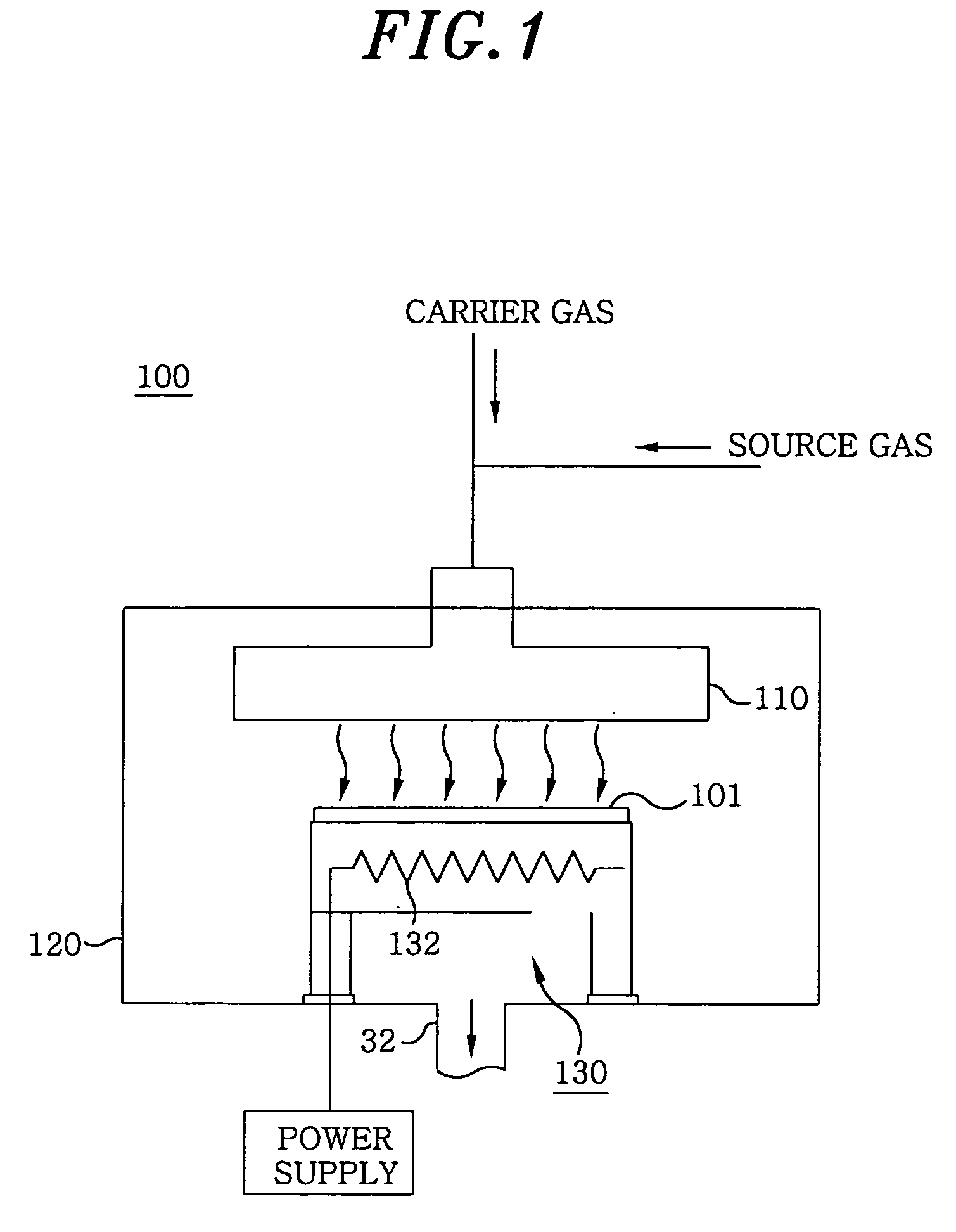

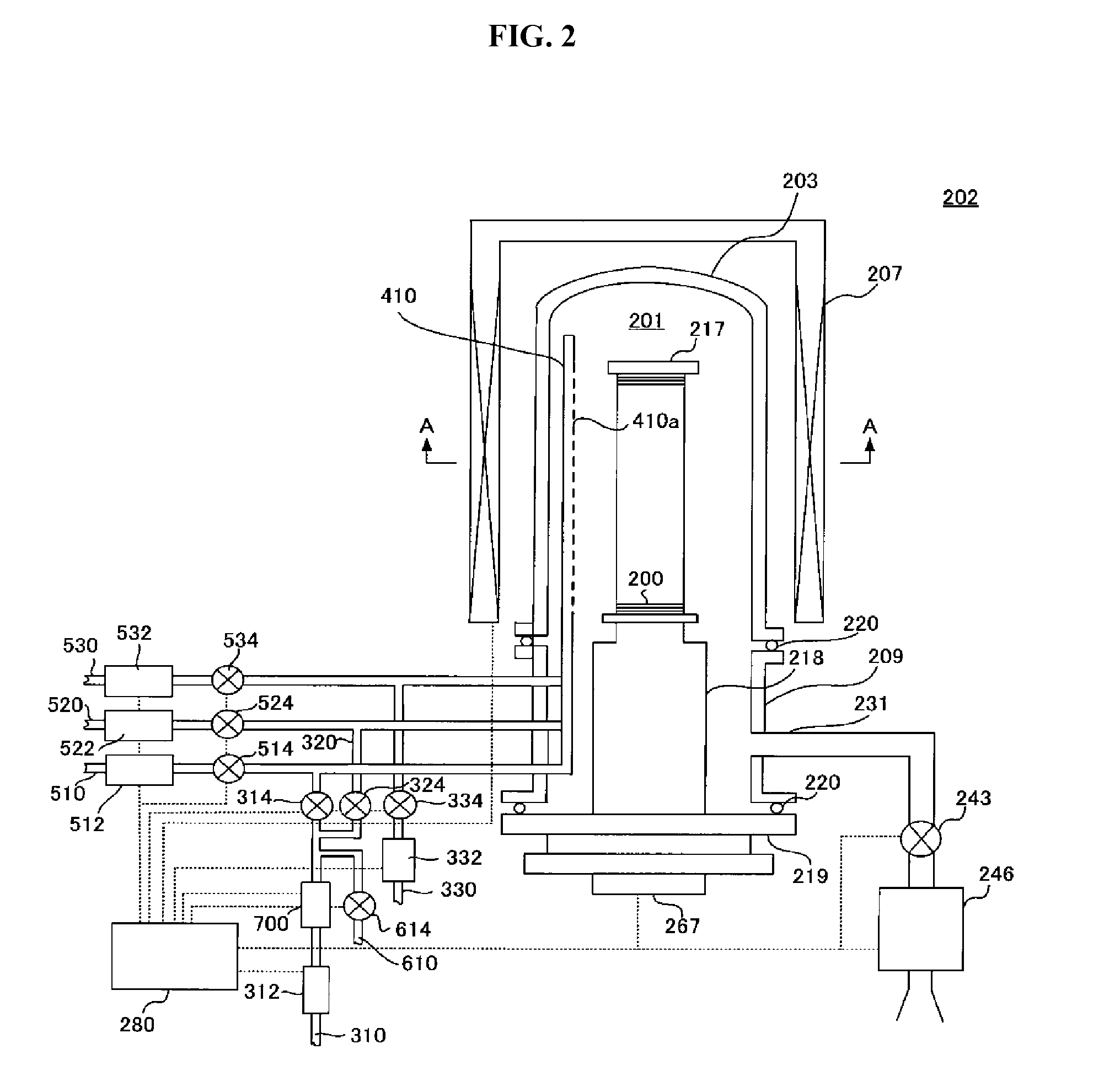

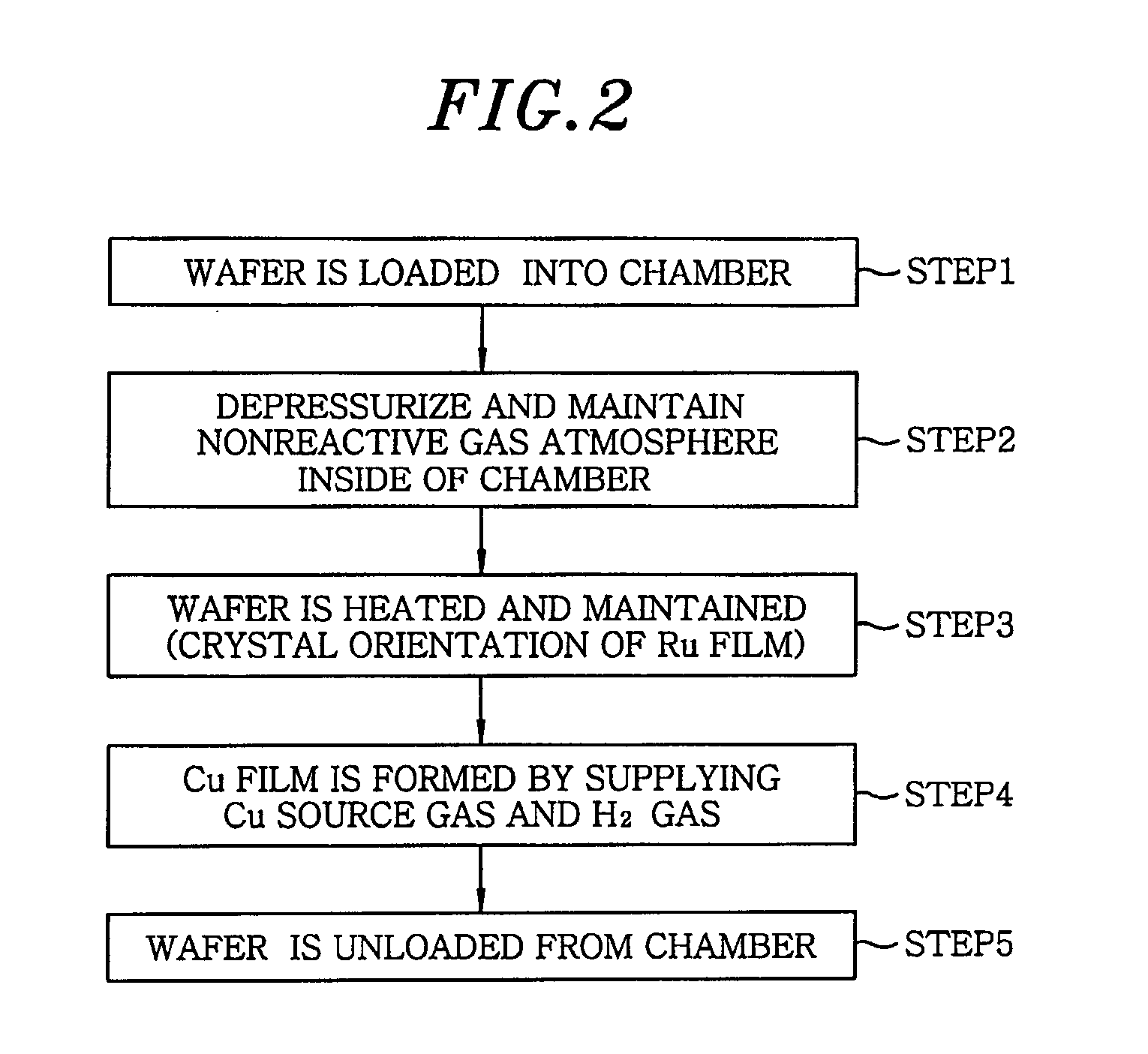

Method of manufacturing semiconductor device and substrate processing apparatus

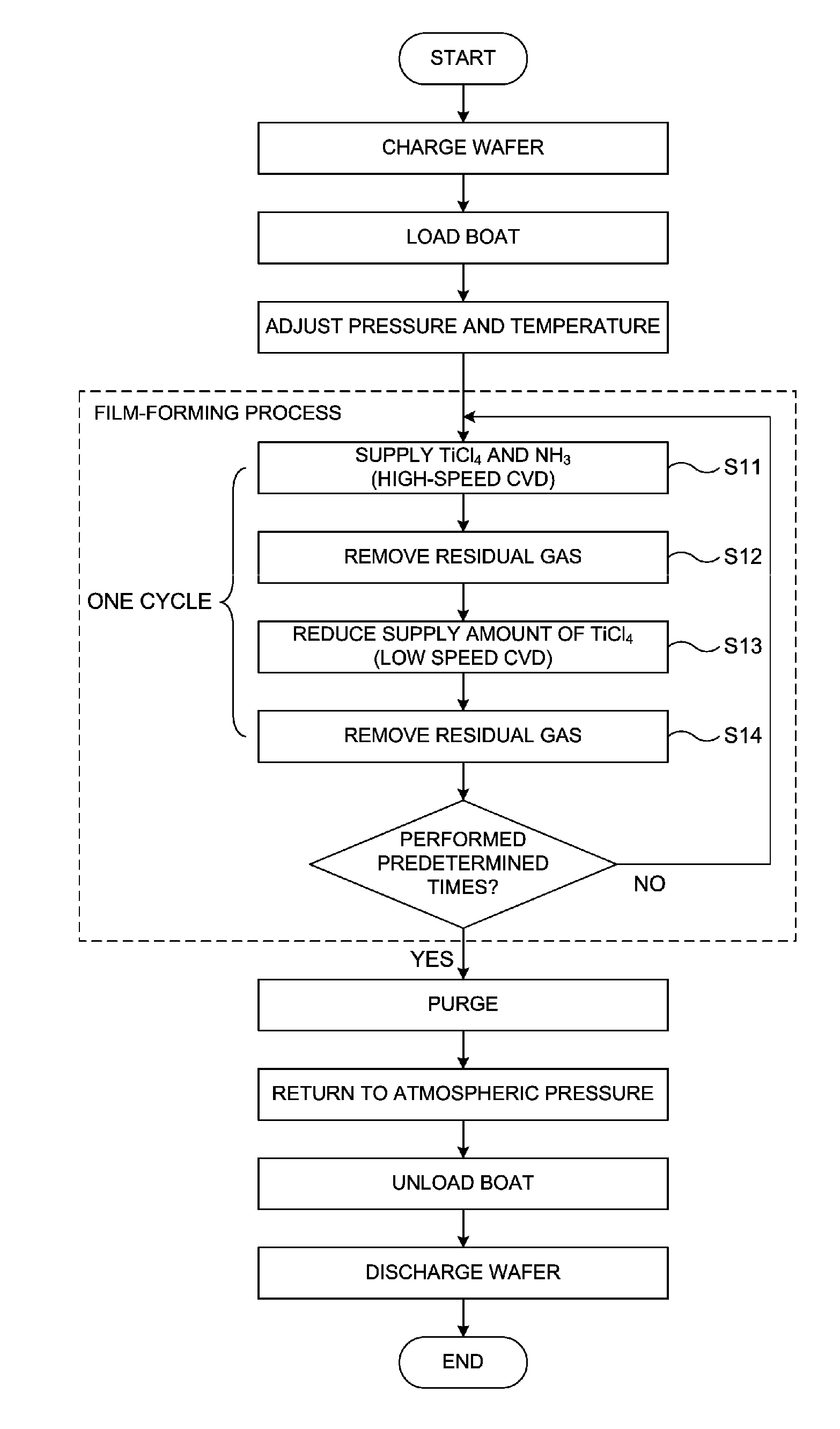

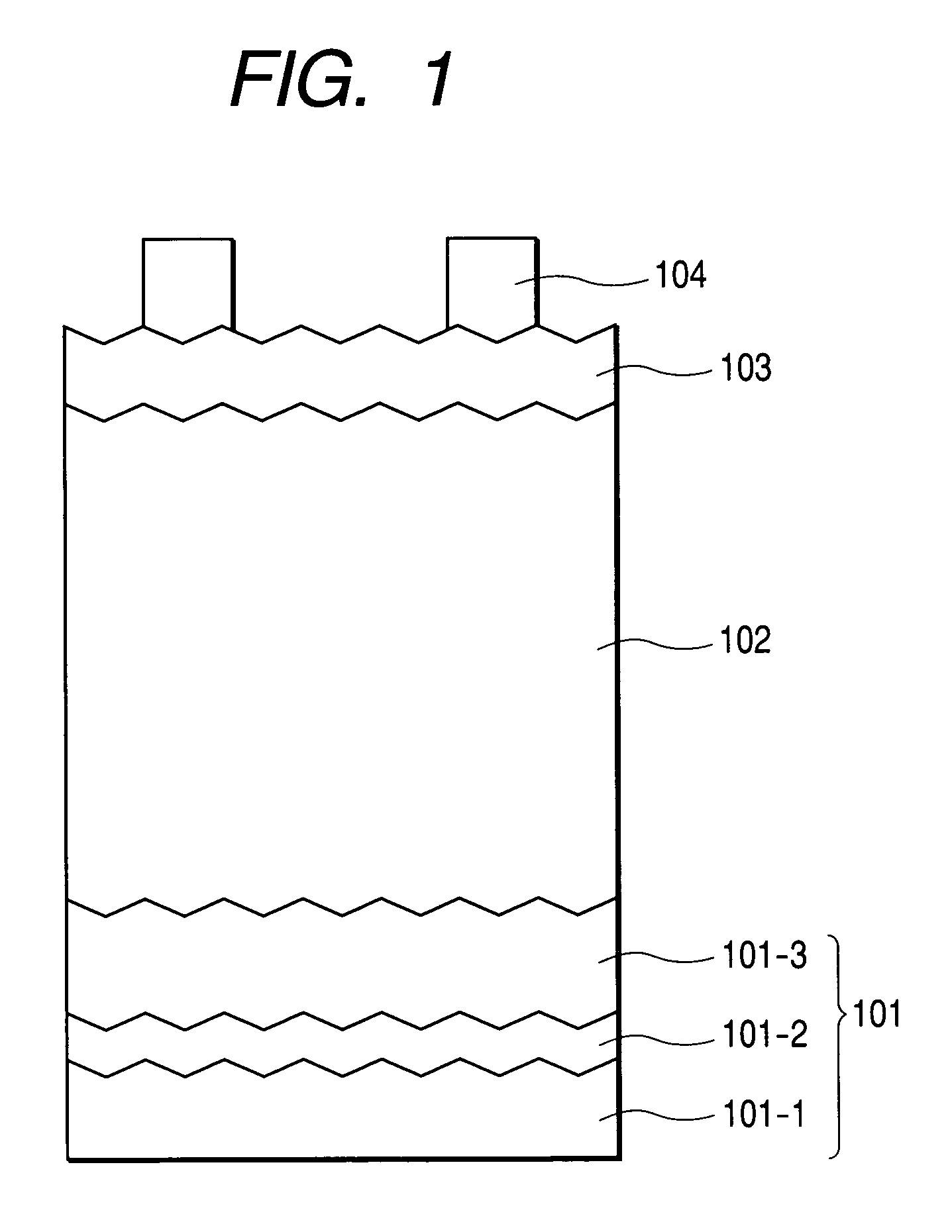

ActiveUS20110183519A1Long period of timeQuality improvementLiquid surface applicatorsSemiconductor/solid-state device manufacturingProduction rateProcess engineering

A method of manufacturing a semiconductor device and a substrate processing apparatus capable of providing a TiN film that is higher in quality than a TiN film formed by a conventional CVD method at a higher film-forming rate, that is, with a higher productivity than a TiN film formed by an ALD method. The method includes steps of: (a) loading a substrate into a processing chamber; (b) forming a predetermined film on the substrate by simultaneously supplying the first processing gas and the second processing gas into the processing chamber; (c) stopping the supply of the first processing gas and the second processing gas and removing the first processing gas and the second processing gas remaining in the processing chamber; (d) modifying the film formed on the substrate by supplying the second processing gas into the processing chamber after the step (c); and (e) unloading the substrate from the processing chamber, wherein, in the step (b), a time period for supplying the second processing gas into the processing chamber is longer than a time period for supplying the first processing gas into the processing chamber.

Owner:KOKUSA ELECTRIC CO LTD

Device and method for manufacturing thin films

ActiveUS7618493B2Stable continuous productionImprove abilitiesSemiconductor/solid-state device manufacturingChemical vapor deposition coatingProduction rateForming gas

Owner:ULVAC INC

Film forming apparatus

InactiveUS20050120955A1High film forming rateIncrease flow rateChemical vapor deposition coatingEngineeringSystem structure

A film forming unit includes a source vessel for receiving a raw material from which source gas is produced, a processing vessel for applying a film forming process on a semiconductor substrate, a source supply line for supplying the source gas from the source vessel to the processing vessel, a gas exhaust line for exhausting gas from the processing vessel, having a vacuum pump system structured by a turbo molecular pump and a dry pump, and a pre-flow line branching off from the source supply line while bypassing the processing vessel and the turbo molecular pump, and joining to the gas exhaust line. Moreover, the source supply line includes piping having an inner diameter greater than 6.4 mm, and a turbo molecular pump is provided in the pre-flow line.

Owner:TOKYO ELECTRON LTD

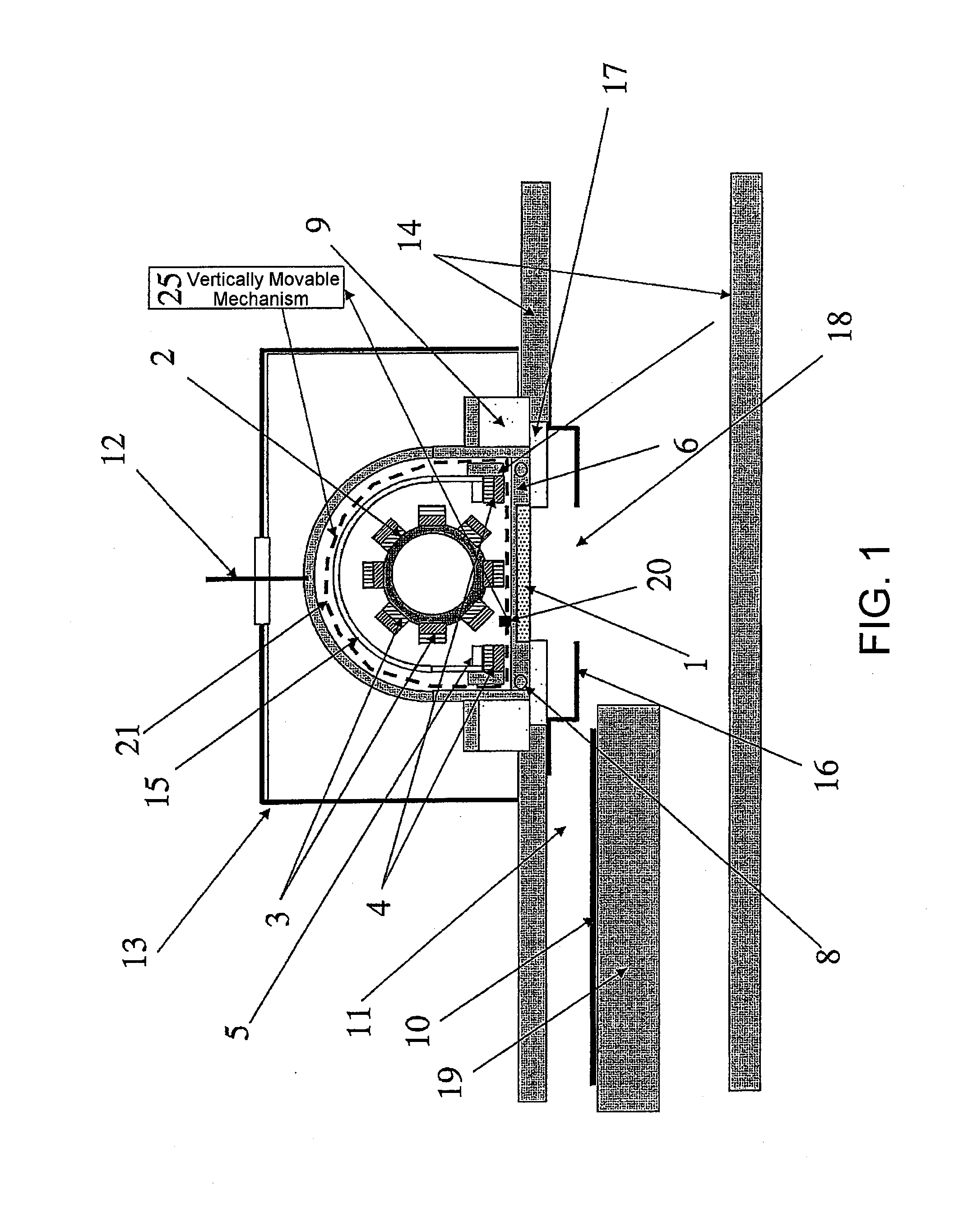

Rotary magnet sputtering apparatus

InactiveUS20100126852A1Improve utilization efficiencyProlong lifeCellsElectric discharge tubesTarget surfaceSputtering

In a rotary magnet sputtering apparatus, a target consumption displacement quantity is measured, and corresponding to the measurement results, a distance between a rotating magnet group and a target is adjusted, and uniform film forming rate is achieved over a long period of time so as to reduce the change of a target surface due to consumption of the target and to reduce the change of the film forming rate with time. An ultrasonic sensor or a laser transmitting / receiving device may be used as a means for measuring the consumption displacement quantity of the target.

Owner:TOHOKU UNIV +1

Method of Film Deposition and Film Deposition System

InactiveUS20090142491A1Increase coverageHigh film forming rateSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDecompositionNitrogen

The present invention is a method of film deposition that comprises a first gas-supplying step of supplying a high-melting-point organometallic material gas to a processing vessel that can be evacuated, and a second gas-supplying step of supplying, to the processing vessel, a gas consisting of one, or two or more gases selected from a nitrogen-containing gas, a silicon-containing gas, and a carbon-containing gas, wherein a thin metallic compound film composed of one, or two or more compounds selected from a high-melting-point metallic nitride, a high-melting-point metallic silicate, and a high-melting-point metallic carbide is deposited on the surface of an object to be processed, placed in the processing vessel. The first and second gas-supplying steps are alternately carried out, and in these steps, the object to be processed is held at a temperature equal to or higher than the decomposition-starting temperature of the high-melting-point organometallic material.

Owner:TOKYO ELECTRON LTD

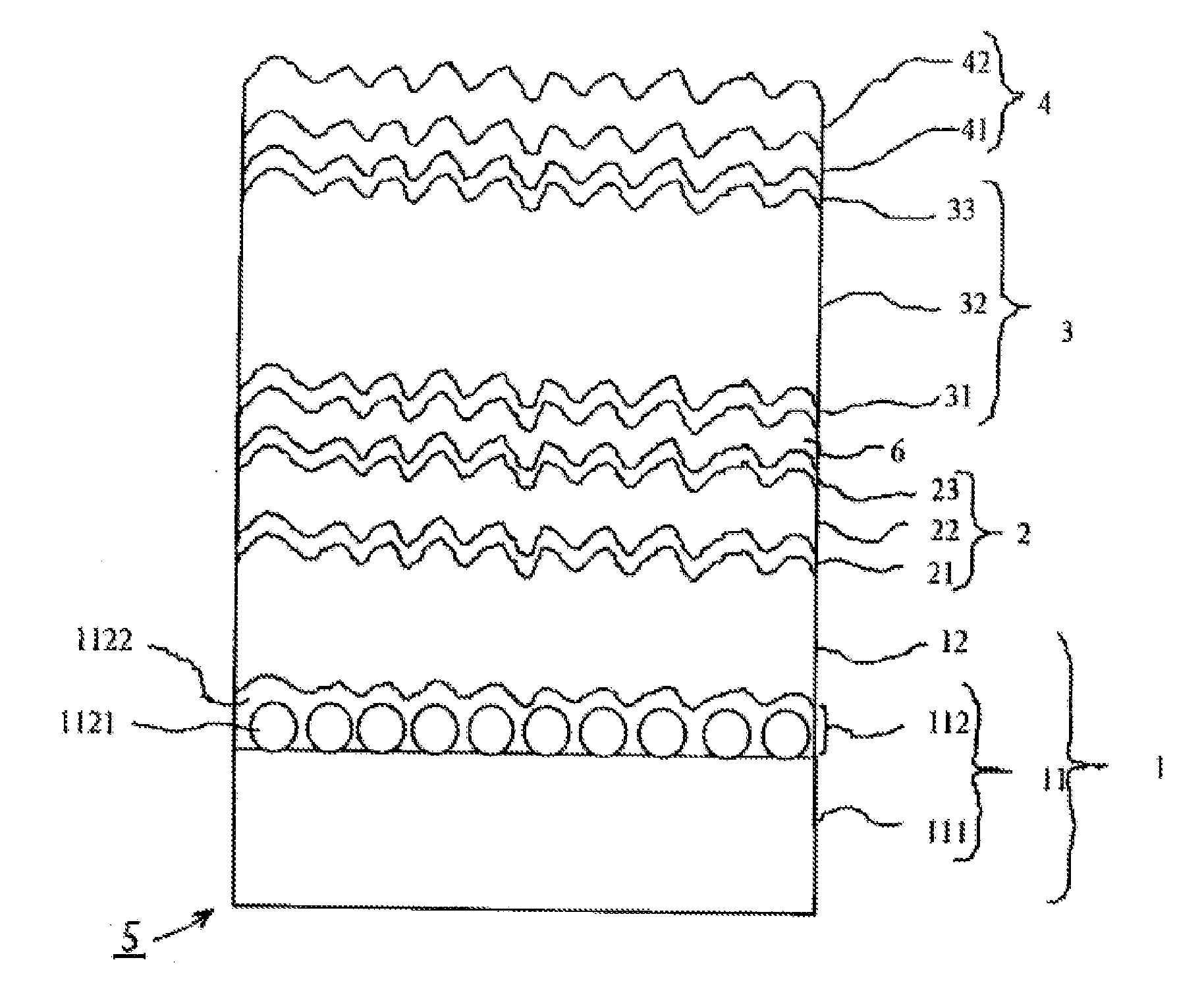

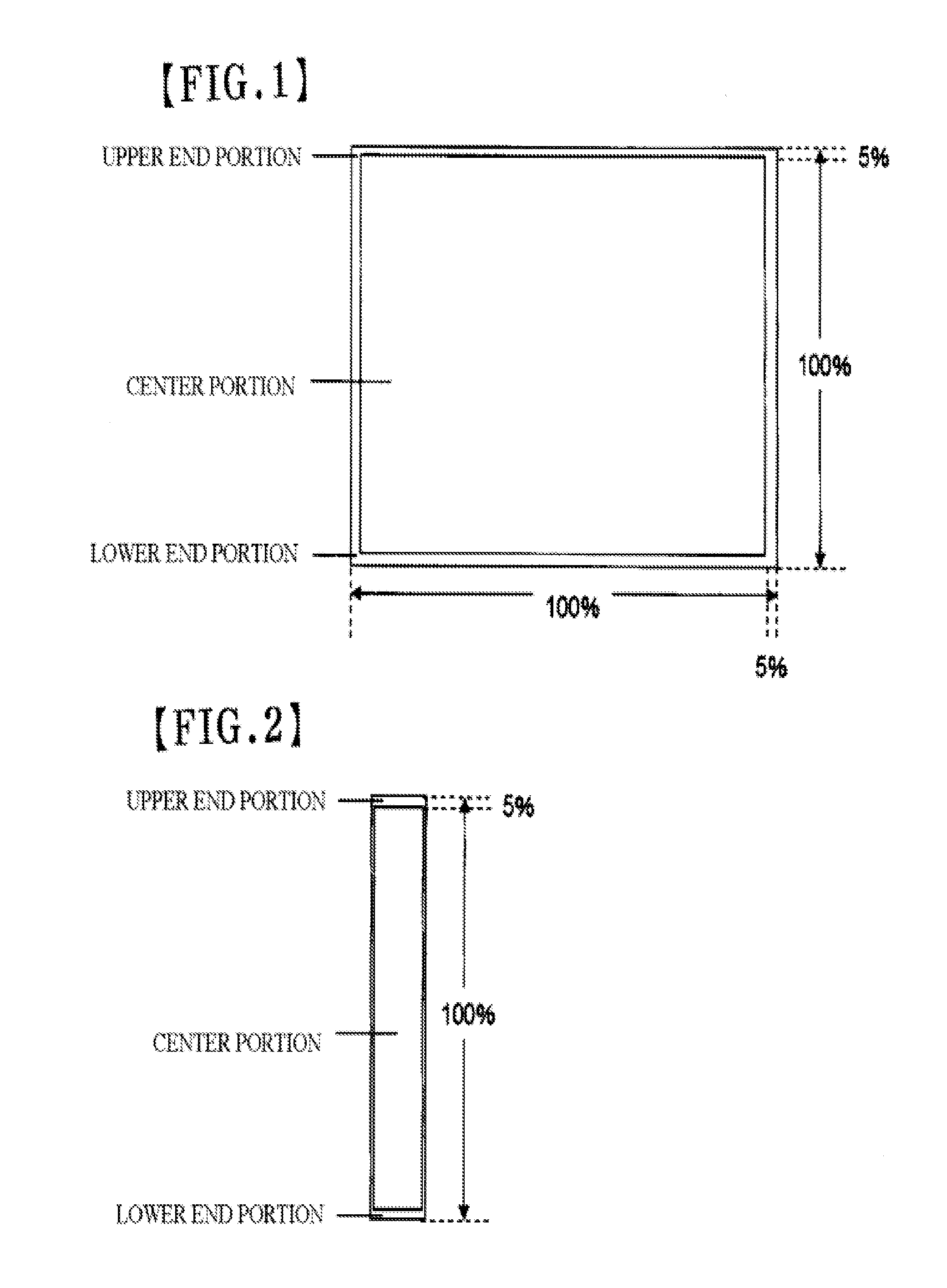

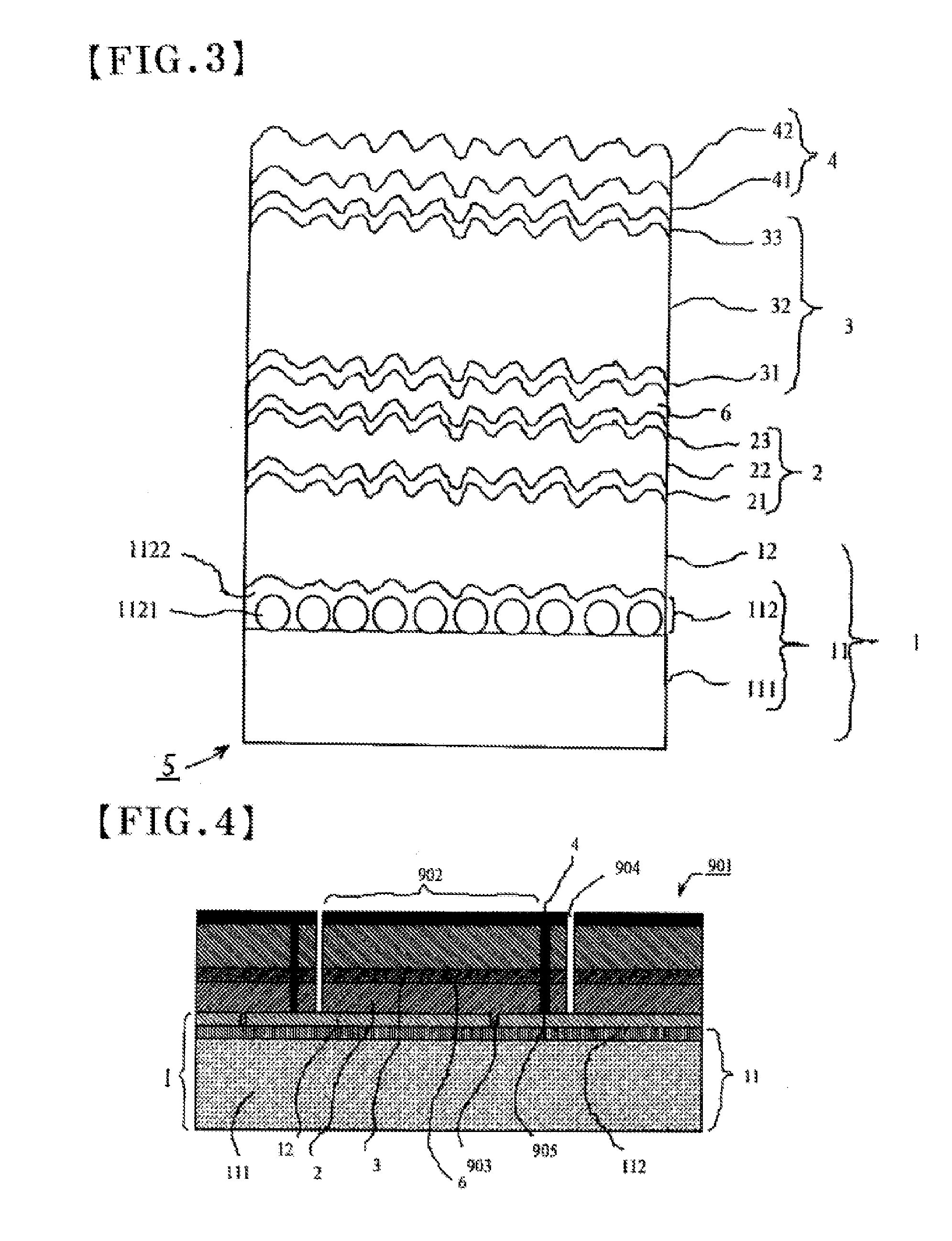

Substrate for thin-film photoelectric conversion device, thin-film photoelectric conversion device including the same, and method for producing substrate for thin-film photoelectric conversion device

InactiveUS20110073162A1Improve adhesionImprove FFFinal product manufacturePV power plantsProduction ratePhotoelectric conversion

Provided is a substrate for a thin-film photoelectric conversion device which makes it possible to produce the device having improved characteristics at low cost and high productivity. The substrate includes a transparent base member, with a transparent underlying layer and a transparent electrode layer successively stacked on one main surface of the transparent base member. The underlying layer includes transparent insulating fine particles and transparent binder, and the particles are dispersed to cover the one main surface with a coverage factor of particles—ranging from 30% or more to less than 80%. An antireflection layer is provided on the other main surface of the transparent base. The antireflection layer includes transparent insulating fine particles and transparent binder, and the particles are dispersed to cover the other main surface with a coverage factor greater than the underlying layer. The transparent electrode layer contains zinc oxide deposited by low-pressure CVD method.

Owner:KANEKA CORP

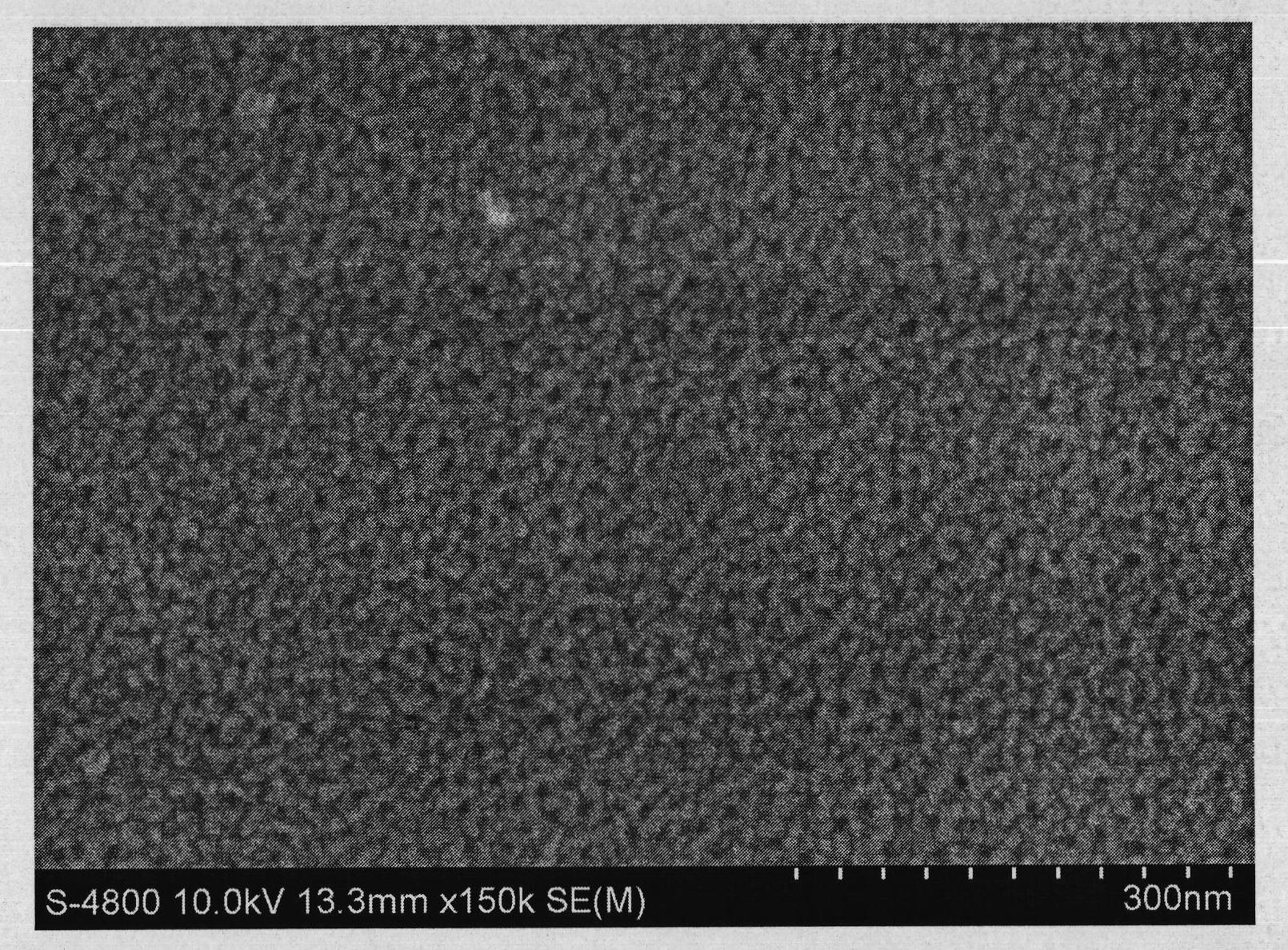

Metal material coated with metal oxide and/or metal hydroxide coating film and method for production thereof

InactiveUS20050067056A1Easy to controlIncrease deposition rateElectrolytic inorganic material coatingSurface reaction electrolytic coatingElectrolysisConductive materials

It is an object of the invention to provide a method for production of various oxide and / or hydroxide coatings with various functions and constructions on metal materials from aqueous solutions, and metal materials having such coatings. There are provided specifically a method for production of a metal oxide and / or metal hydroxide coated metal material characterized by immersing a metal material or electrolyzing a conductive material in an aqueous treatment solution at pH 2-7 containing metal ion and fluorine ion in a 4-fold molar ratio with respect to the metal ion, and / or containing a complex ion comprising at least a metal and fluorine in a 4-fold molar ratio with respect to the metal, to form on the surface of the metal material a metal oxide and / or metal hydroxide coating containing the metal ion, as well as a metal oxide and / or metal hydroxide coated metal material characterized by having a metal oxide and / or metal hydroxide coating produced by the method.

Owner:NIPPON STEEL CORP

Biodegradable composite film and preparation method thereof

InactiveCN102719104AImprove mechanical propertiesImprove barrier propertiesFlexible coversWrappersPEG 400Plasticizer

The invention provides a biodegradable composite film, which is prepared from a plasticizer, a reinforcing agent, a crosslinking agent, egg white protein and nano SiOx which serve as raw materials, wherein the plasticizer consists of glycerol and polyethylene glycol 400 with volume ratio of 3 to 1; the reinforcing agent is CMC-Na (sodium carboxymethylcellulose); and the crosslinking agent is epichlorohydrin. The biodegradable composite film has excellent mechanical performance and isolation performance, has the use performance of a plastic coating film, and can completely replace a conventional plastic package film.

Owner:SOUTHWEST UNIV

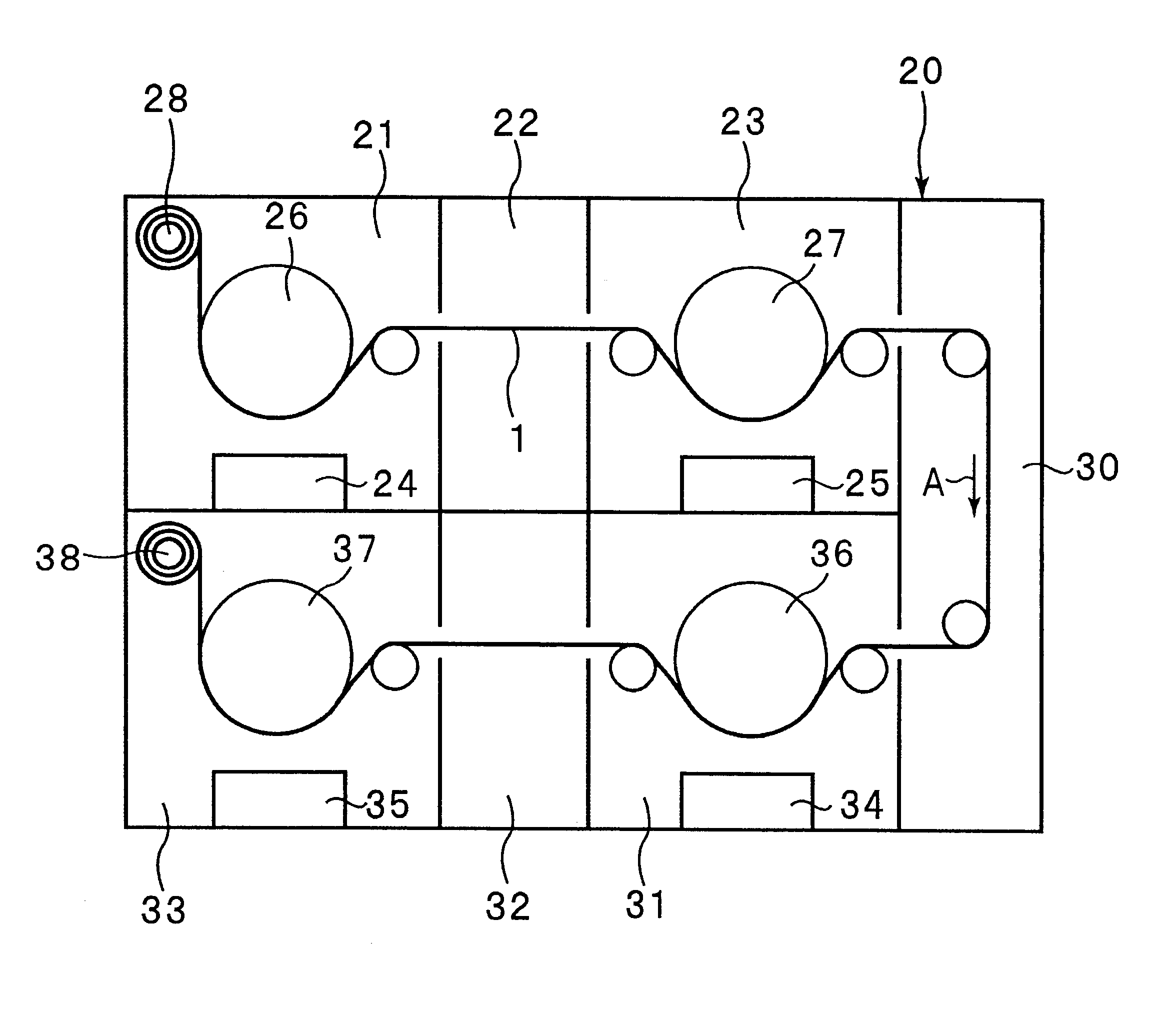

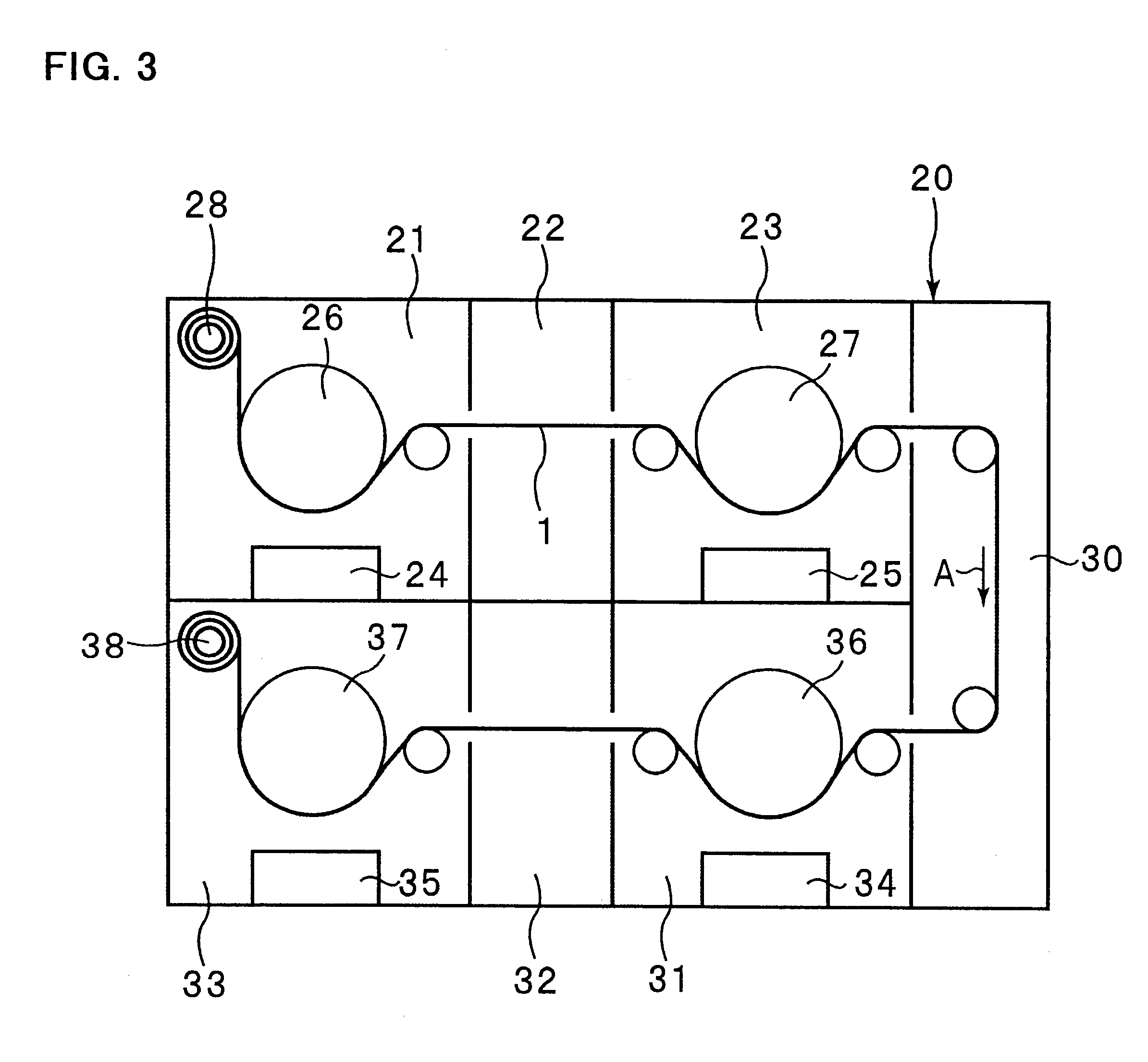

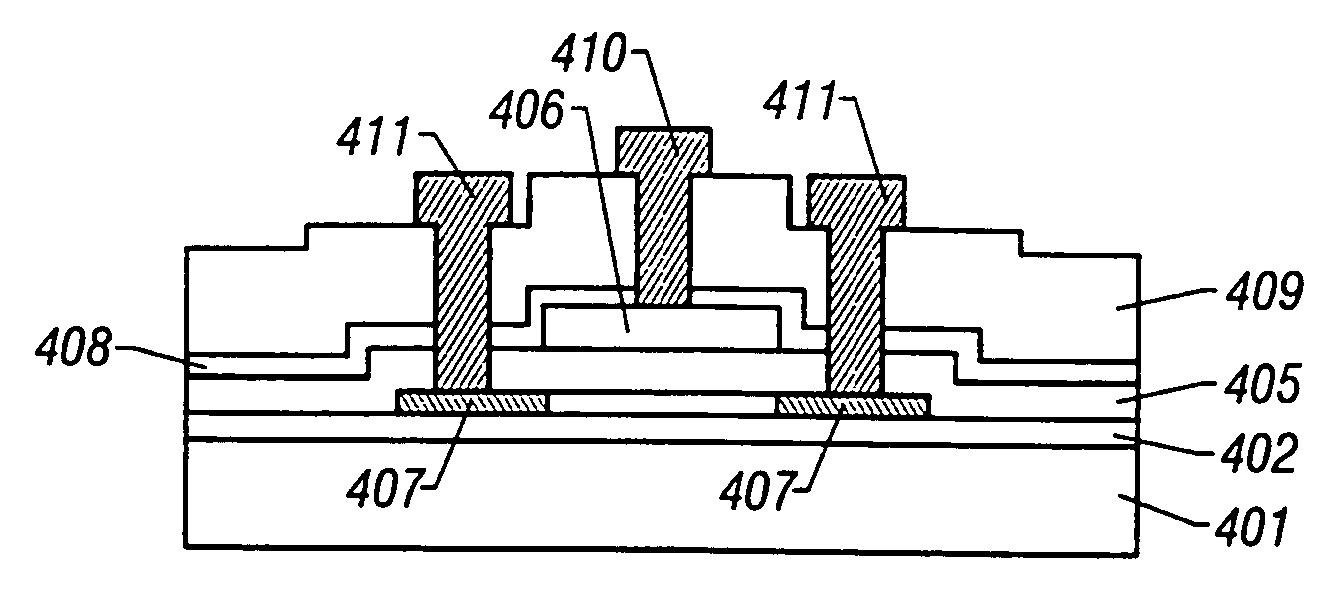

Substrate processing apparatus and method of manufacturing semiconductor device

ActiveUS8808455B2Low resistivityHigh film forming rateLiquid surface applicatorsSemiconductor/solid-state device detailsSpray nozzleProcess engineering

Owner:KOKUSA ELECTRIC CO LTD

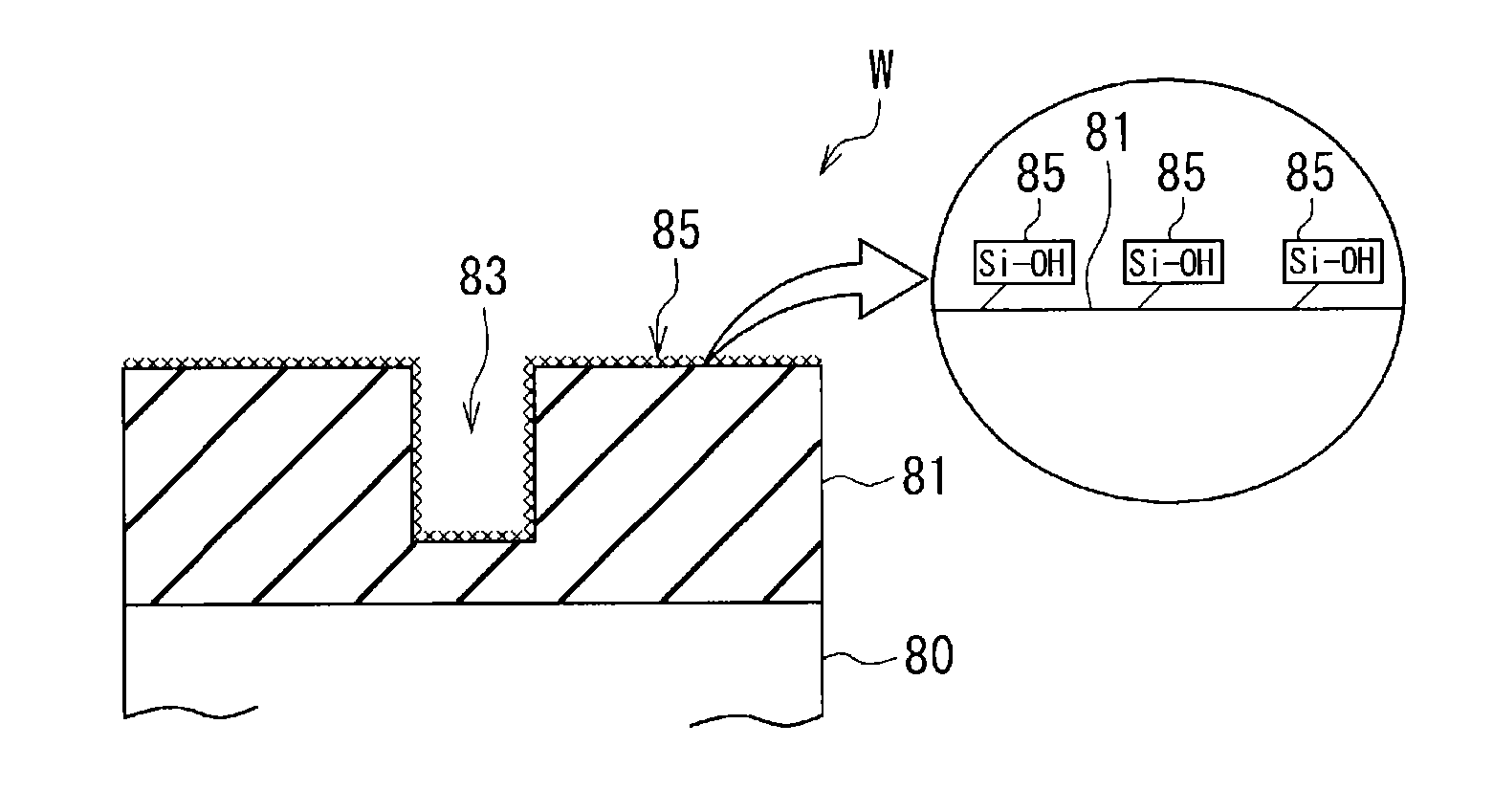

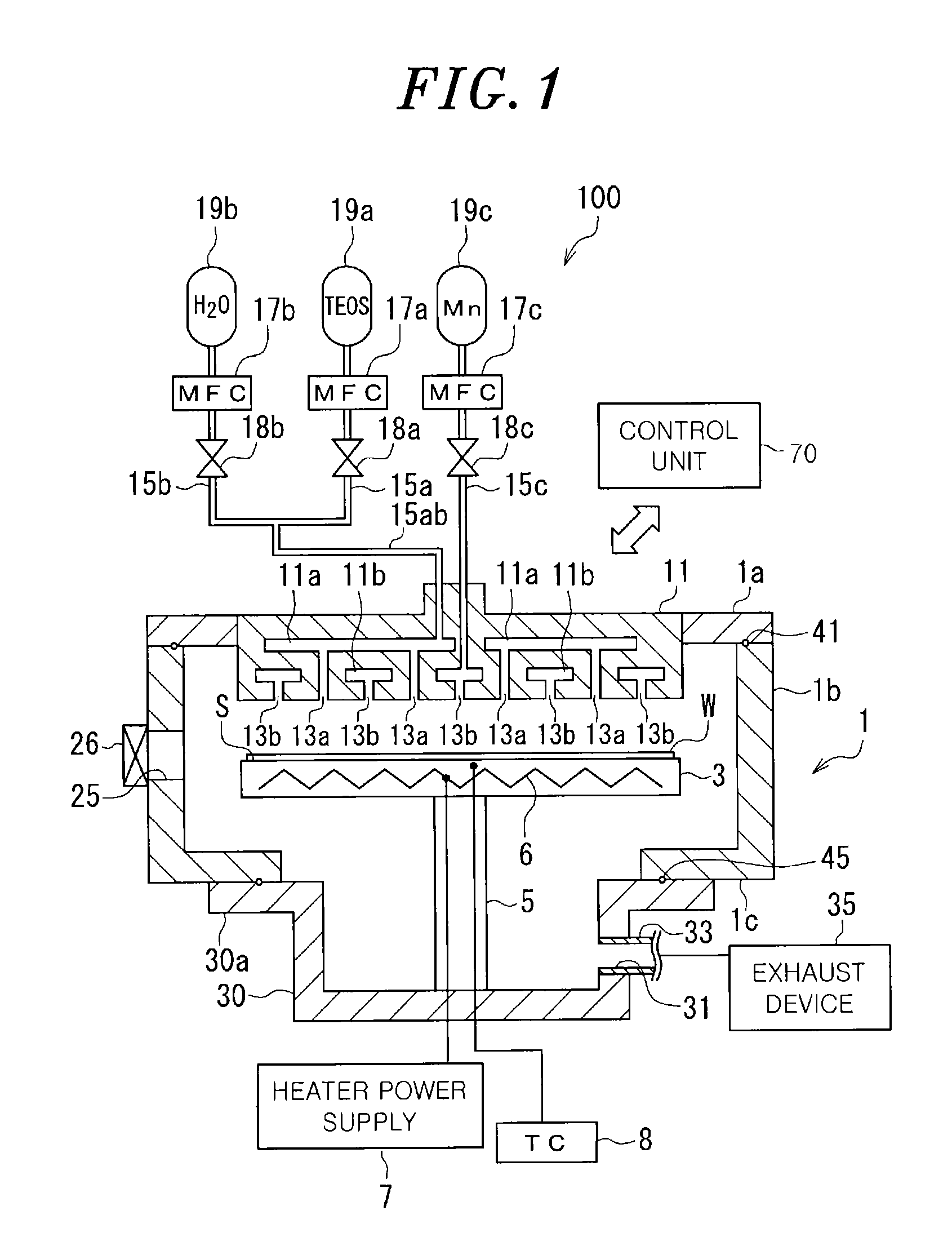

Film forming method and film forming apparatus

InactiveUS20130017328A1Improve adhesionGood step coverageSemiconductor/solid-state device detailsSolid-state devicesForming gasManganese

A film forming method includes a step of arranging a wafer, on which an insulating film is formed, in a processing chamber of a film forming apparatus and a surface modification step of supplying a compound gas containing silicon atoms and an OH group-donating gas into the processing chamber so that Si—OH groups are formed on the surface of the insulating film. The film forming method further includes a film forming step of supplying a film forming gas containing a manganese-containing material into the processing chamber so that a manganese-containing film is formed on the surface of the insulating film on which the Si—OH groups have been formed through a CVD method.

Owner:TOKYO ELECTRON LTD

A mask assembly

InactiveCN103205693ASmall amount of deformationReduce dimensional accuracy deviationVacuum evaporation coatingSputtering coatingInvar alloyThermal dilatation

The invention provides a mask assembly. The mask assembly includes a mask body and a mask frame; under tension state, the mask body is fixed on the mask frame; and both the mask body and the mask frame are made of Invar alloy 4J36. The Invar alloy 4J36 is adopted to make both the mask body and the mask frame of the mask assembly, because the invar alloy 4J36 has anomalous thermal expansion of an invar effect, and an average expansion coefficient thereof is generally 1.5*10<-6> DEG C, reaches 1.8*10<-8> DEG C when the nickel content of the material is 36%, and is invariable at the temperature range of -80 DEG C to +100 DEG C. Thus, the deformation of the mask body and the mask frame made from the material is small in a vapor deposition chamber, effectively reducing the dimensional accuracy deviation of a pattern opening and the positional accuracy deviation of the pattern opening, effectively improving vapor deposition quality, and increasing the film-forming rate of an organic vapor deposition material.

Owner:KUN SHAN POWER STENCIL

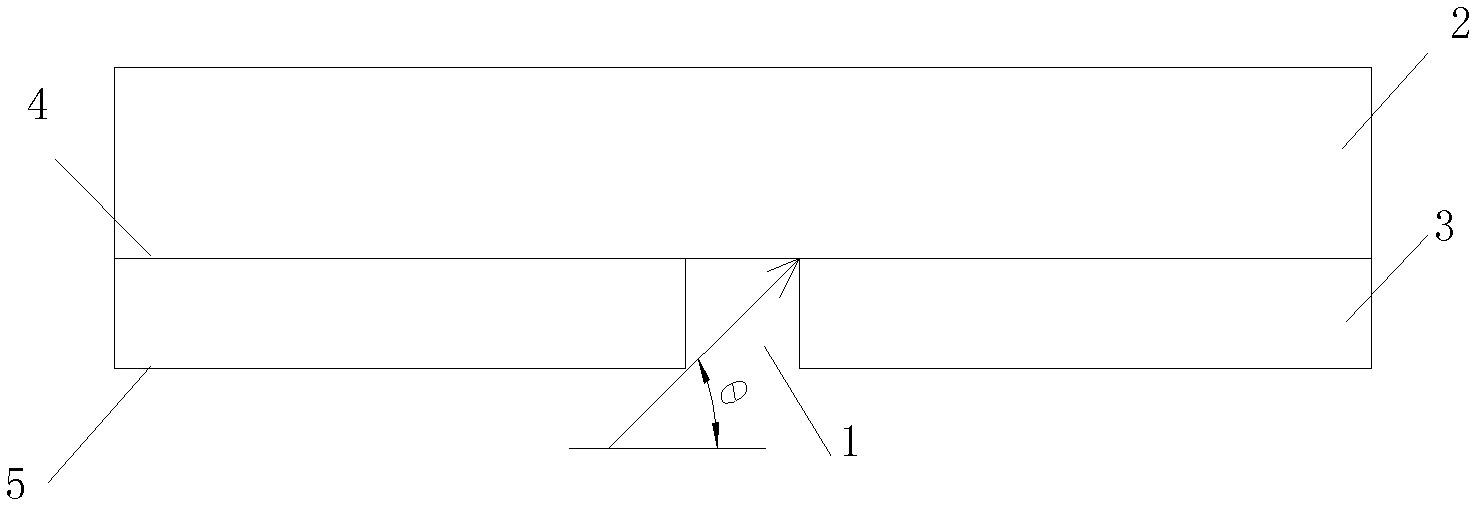

Vapor deposition mask

InactiveCN103205704AWide thickness rangeExtended service lifeVacuum evaporation coatingSputtering coatingManufacturing technologyIndium tin oxide

The invention relates to a vapor deposition mask, and mainly solves the technical problem that organic particles can not reach a substrate during vapor deposition due to the shielding of a mask opening wall, in a conventional OLED manufacturing technology. The problem is relatively well solved by adopting a technical solution that the vapor deposition mask is a quadrilateral metal plate and comprises an ITO surface contacting with an indium tin oxide (ITO) substrate and a vapor deposition surface; the mask is provided with a through hole penetrating through the ITO surface and the vapor deposition surface; and the opening size of the through hole on the ITO surface is less than the opening size on the vapor deposition surface. The vapor deposition mask can be applied in industrial production of organic light emitting diodes.

Owner:KUN SHAN POWER STENCIL

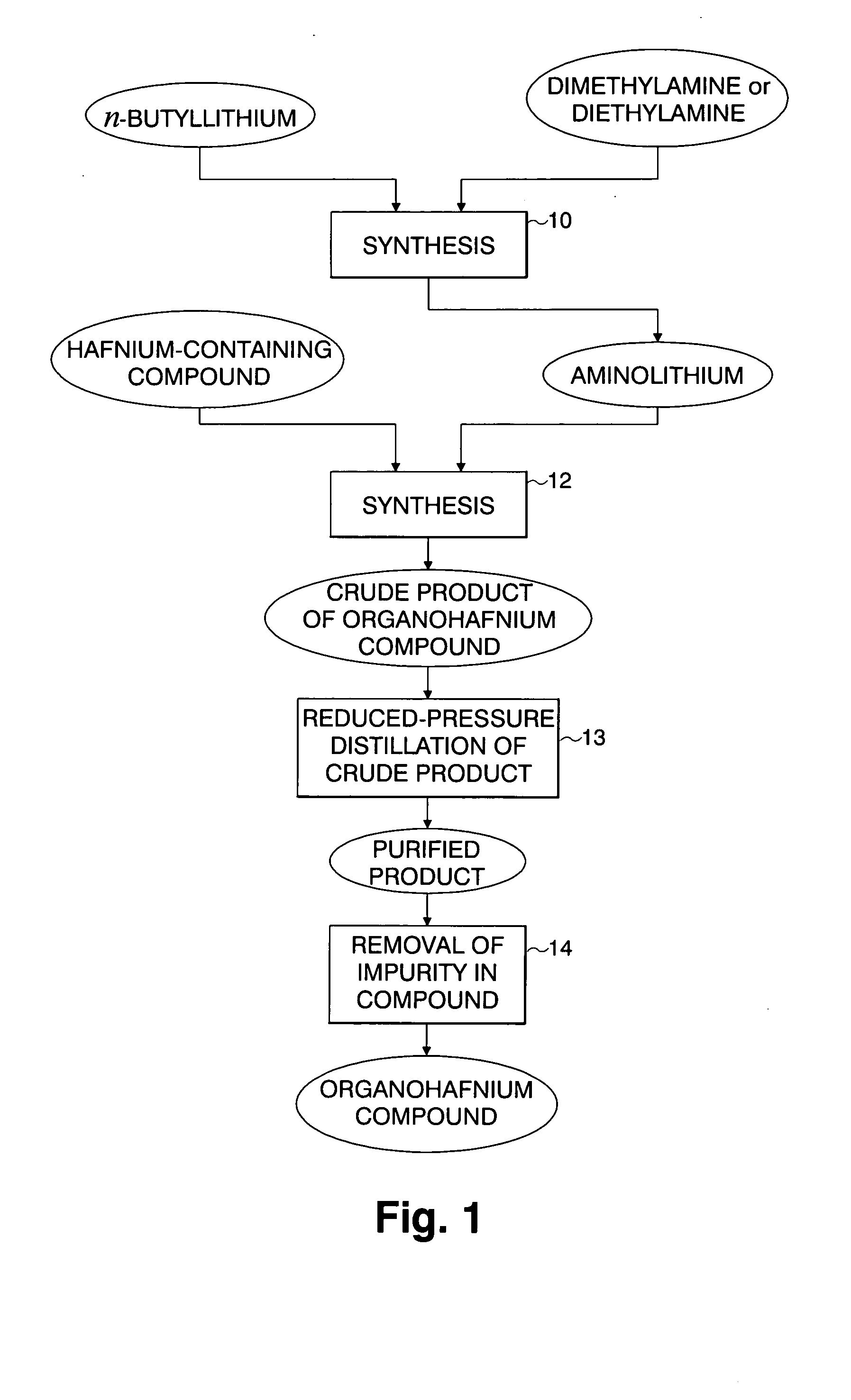

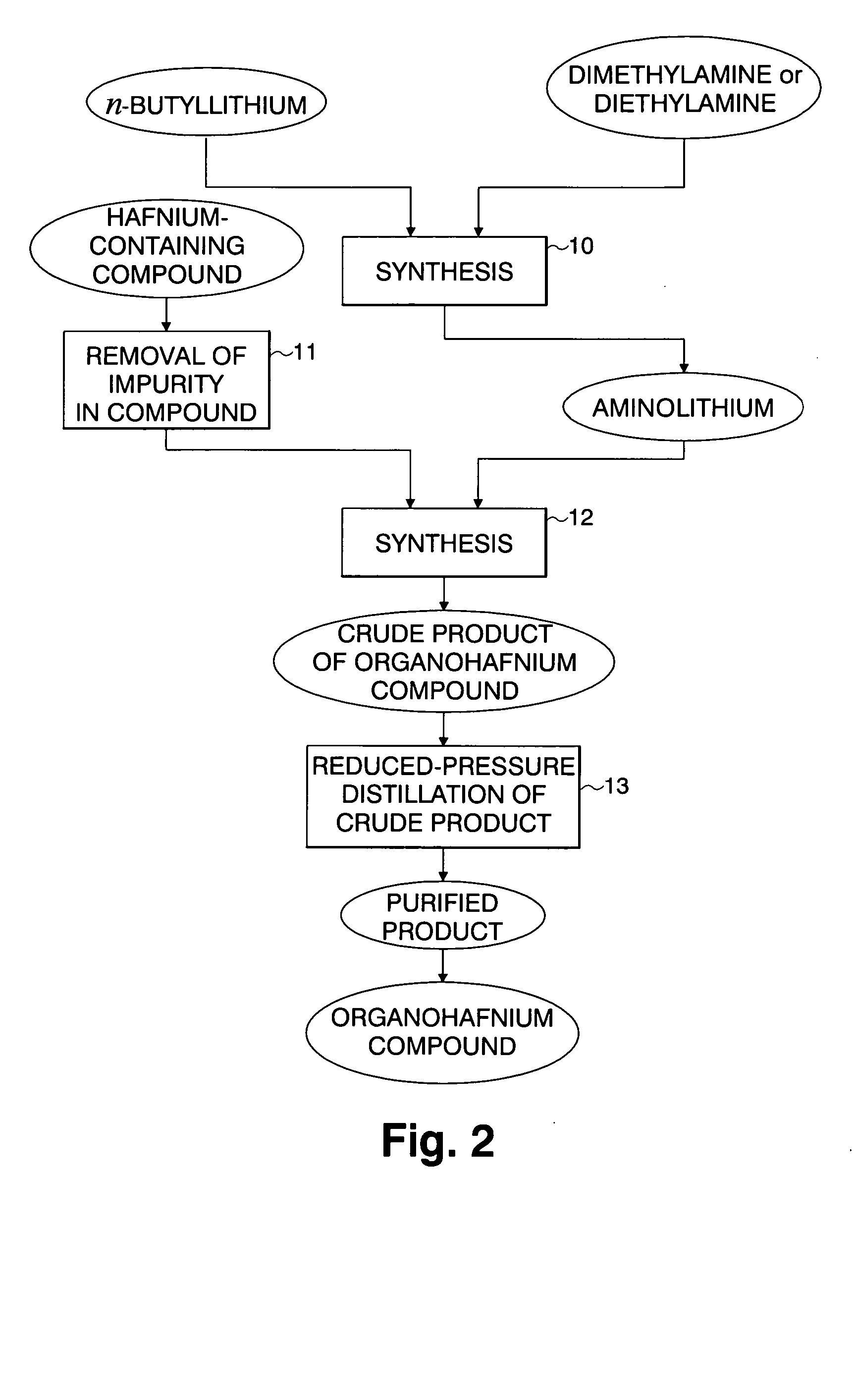

Hafnium-containing material for film formation, method for producing the same, and method for producing hafnium-containing thin film using the same

InactiveUS20050065358A1Good step coverageExcellent vaporization stabilityGroup 4/14 organic compounds without C-metal linkagesZirconium compoundsNitrogenHafnium

A hafnium-containing material is presented for forming a film having excellent vaporization stability and higher film formation rate. Also a method for producing the film is presented. The hafnium-containing material for film formation has a bond of a hafnium atom with a nitrogen atom, or a bond of a hafnium atom and an oxygen atoms. Zr content contained in the material is equal to or less than 650 ppm.

Owner:MITSUBISHI MATERIALS CORP

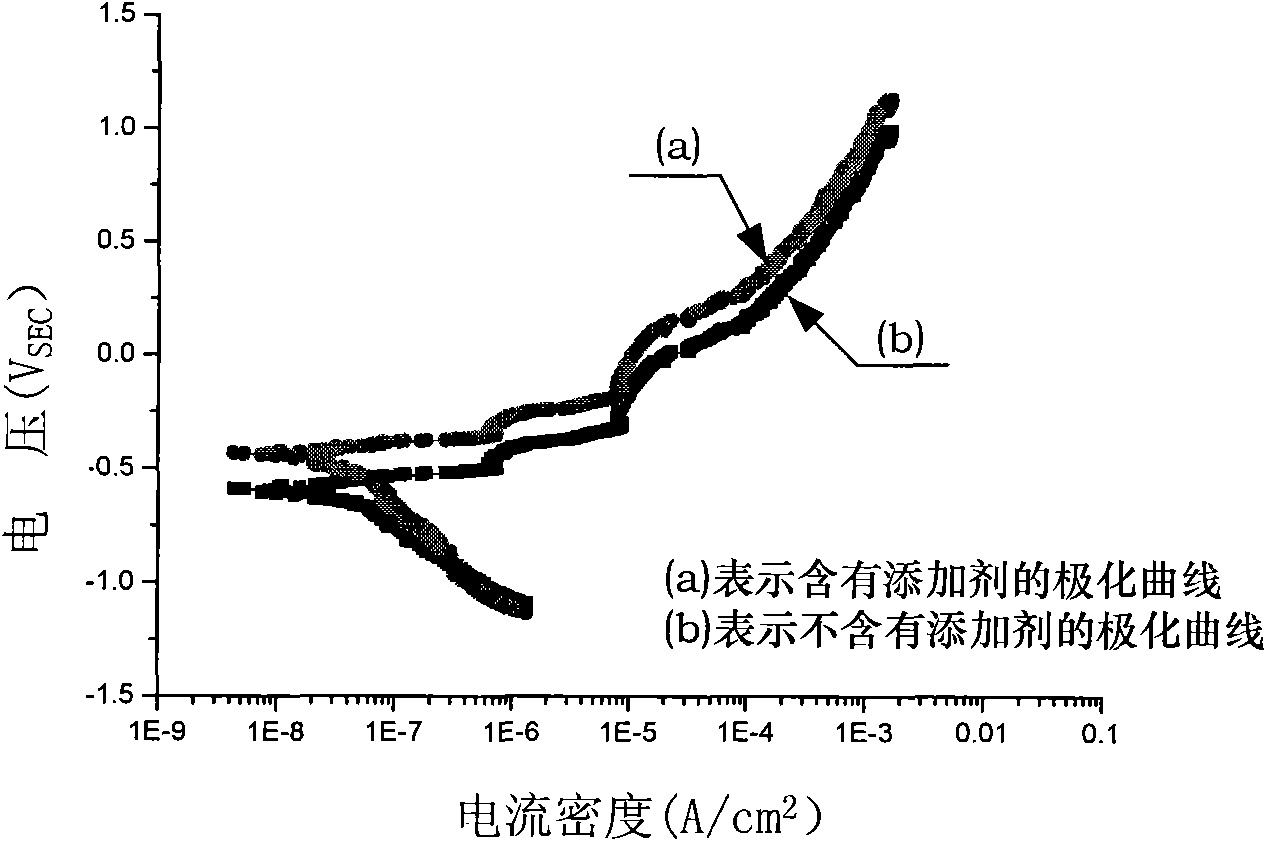

Anodic oxidation treating fluid containing corrosion inhibition additive

InactiveCN101792919AImprove fatigue lifeHigh film forming rateAnodisationAdipic acid8-Hydroxyquinoline

The invention discloses anodic oxidation treating fluid containing corrosion inhibition additive; the treating fluid is formed by adding 1.6-7.6ml of sulfuric acid, 5-30g of modifier and 10-100mg of corrosion inhibition additive in 100ml of deionized water; the modifier is adipic acid or adipate; the corrosion inhibition additive is benzotriazole, 2-mercaptobenzothiazole, dithizone or 8-oxyquinoline; the anodic oxidation treating fluid reduces the concentration of the sulfuric acid, reduces dissolving of bath solution to aerometal basal body and a generated oxidation film, and the corrosion inhibition additive is added for inhibiting excessive expansion of an oxidation film hole defect at the position of copper-bearing alloy phase particles. In the invention, the adipic acid or adipate which is environmental-protection and has low price replaces the using amount of the sulfuric acid, the film forming rate, the film layer compactness and uniformity of the anodic oxidation film are improved.

Owner:BEIHANG UNIV

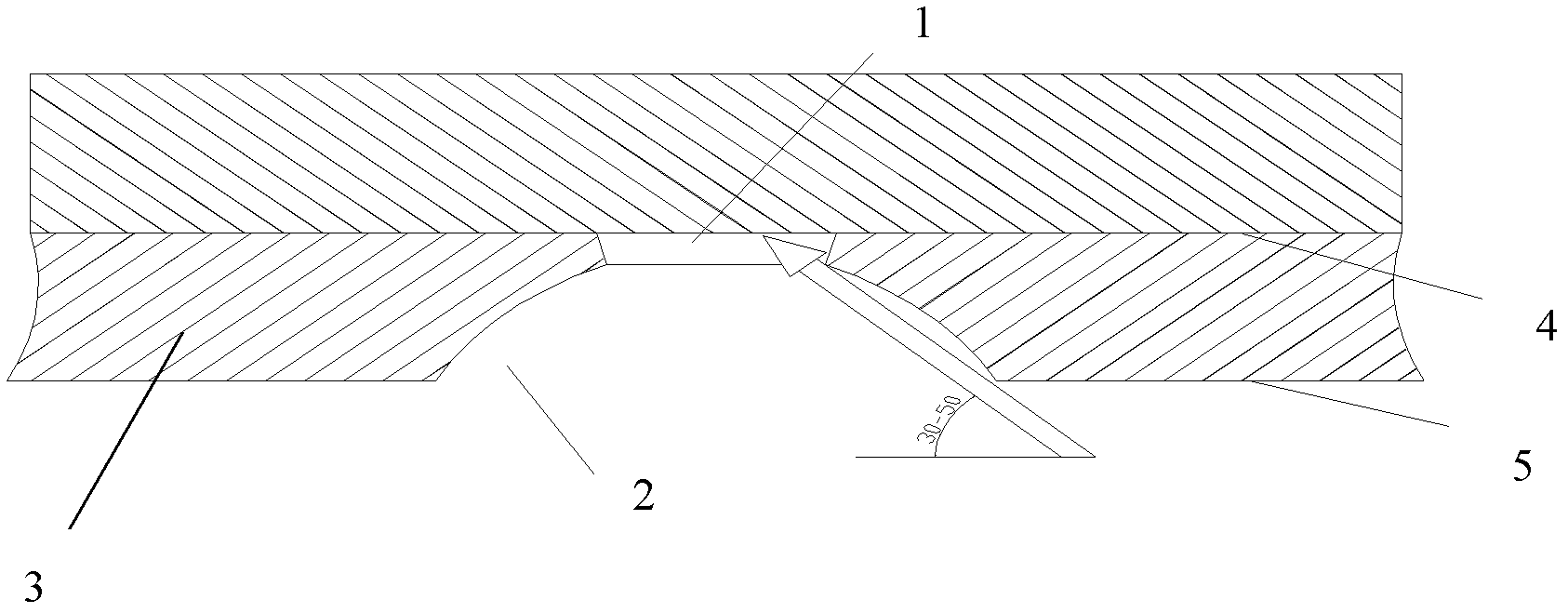

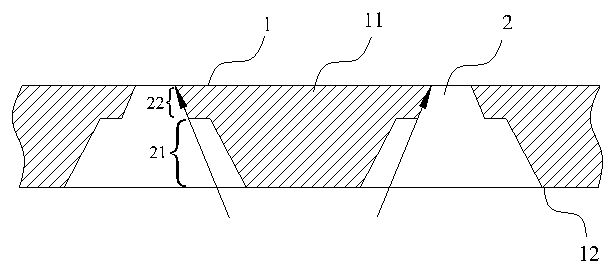

Mask plate and processing method thereof

InactiveCN103014619AImprove machining accuracyImprove processing efficiencyVacuum evaporation coatingSolid-state devicesEvaporationIndium tin oxide

The invention relates to a mask plate and a processing method thereof. The mask plate comprises an indium tin oxide (ITO) contact surface and an evaporation surface, wherein a plurality of evaporation holes are formed on the evaporation surface; the evaporation holes penetrate through the ITO contact surface from the evaporation surface, and the section of the evaporation holes is in a step shape; the evaporation holes comprise first sections and second sections which are coaxially arranged; the sizes of the evaporation holes are gradually shrunk from the first sections to the second sections. The processing of the evaporation holes is finished through a laser process only, the required secondary detachment and clamping process are saved in the process of processing the evaporation holes through multiple processes, and the mounting error brought by the operation of processing the evaporation holes through multiple processes is avoided, so that the processing precision and processing efficiency of the evaporation holes can be effectively improved, and the production cost of the mask plate is reduced; and the manufacturing cost of an organic light emitting diode (OLED) display screen is reduced, and the mask plate has wide market prospect.

Owner:南京澄超光电科技有限公司

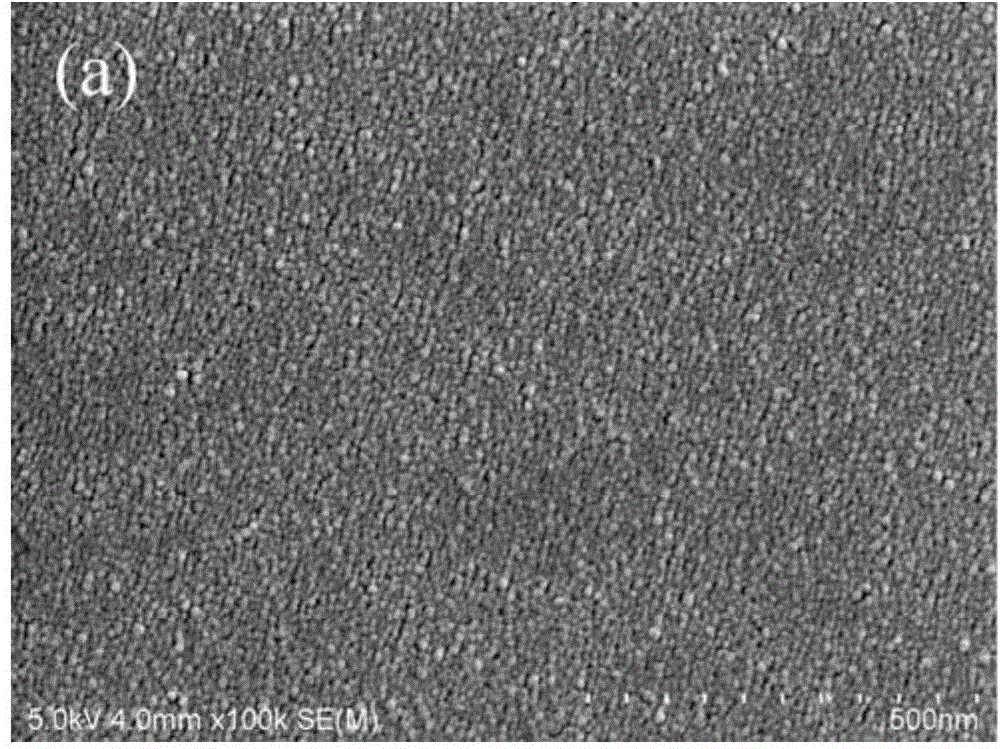

Substrate treatment method and film forming method, film forming apparatus, and computer program

InactiveUS20080020934A1High film forming rateAdhesivenessSemiconductor/solid-state device manufacturingSuperconductor device manufacture/treatmentLattice mismatchOptoelectronics

There is provided a substrate treatment method performed on a substrate before forming a Cu film on a surface of a base material of the substrate. In the substrate treatment method, a substrate on which a Cu film is to be formed is prepared; and a specific treatment is performed on the substrate so that a crystalline orientation of the surface of the base material of the substrate has a small lattice mismatch with the Cu film.

Owner:TOKYO ELECTRON LTD

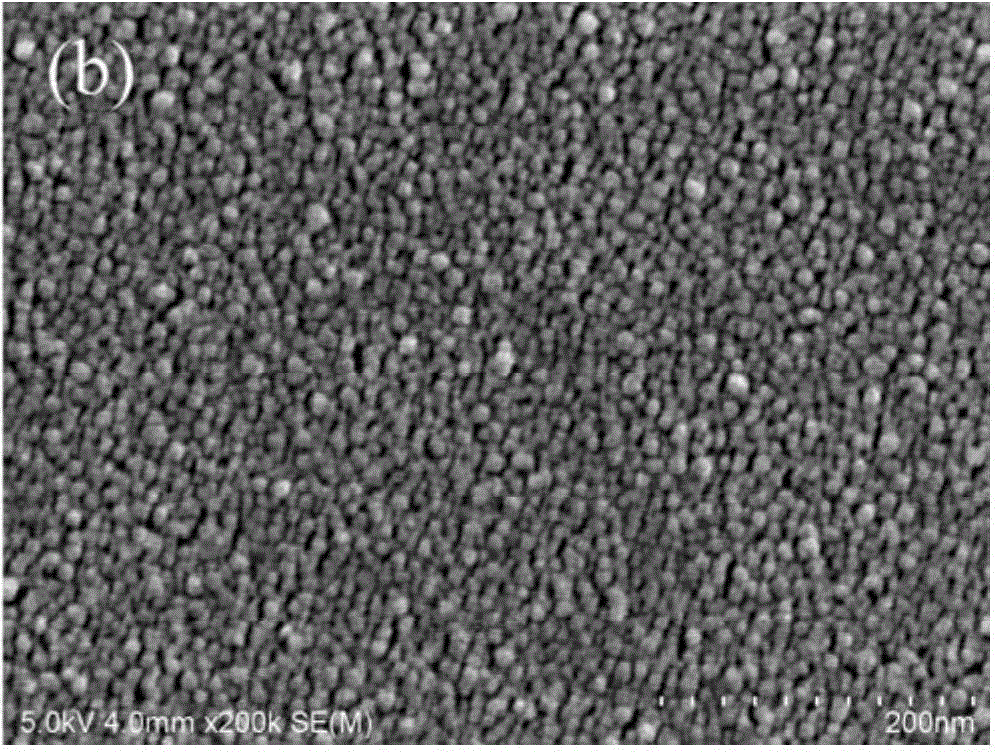

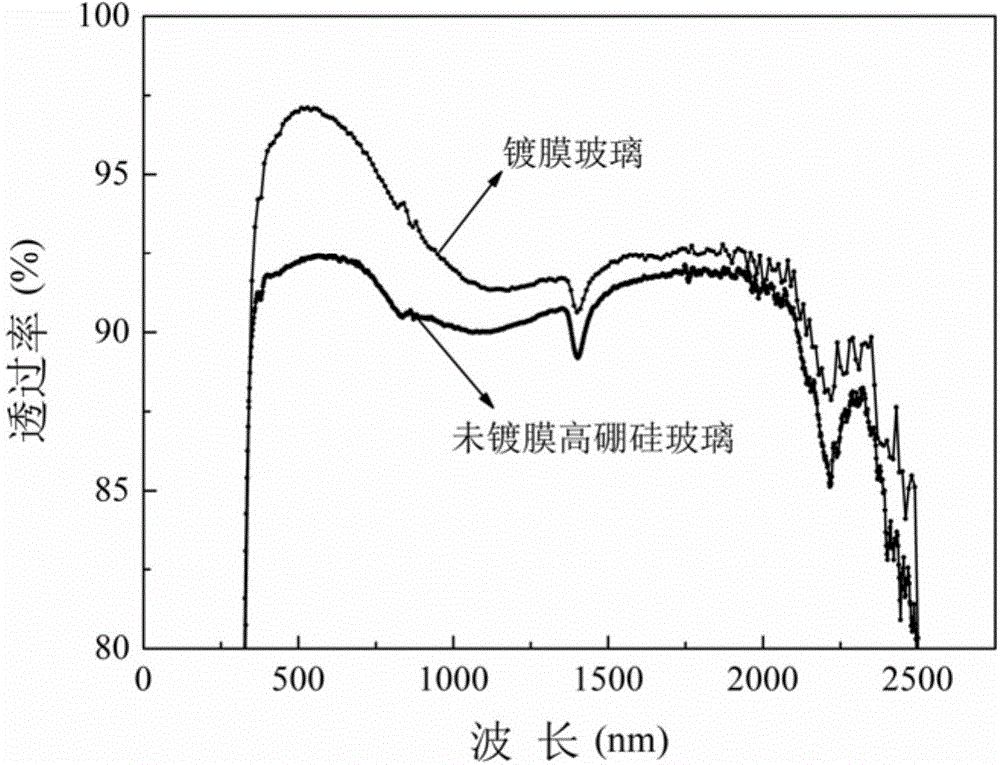

Method used for increasing silicon dioxide antireflection film hole stability

The invention relates to a method used for increasing silicon dioxide antireflection film hole stability, and belongs to the technical field of optical thin film preparation. Sol-gel method is adopted for preparing a silicon dioxide antireflection film, and comprises following steps: a sol is prepared firstly; high borosilicate glass is subjected to cleaning and surface treatment; film preparation is carried out through pulling; and thin film heat treatment and thin film surface hydrophobic treatment are carried out; wherein 1) organic siloxane R'xSi(OR)4-x is added into the sol so as to modify the sol; and 2) in thin film heat treatment processes, a gel thin film is subjected to step thermal insulation heat processing at 90 to 350 DEG C. The method is capable of increasing film forming rate of porous silicon dioxide thin films, and ensuring transmittance of workpieces provided with antireflection films.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com