Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1533results about How to "Increase deposition rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for depositing thin films by mixed pulsed CVD and ald

ActiveUS20080317972A1Easy to customizeImprove responseSemiconductor/solid-state device manufacturingChemical vapor deposition coatingChemical vapor depositionAtomic layer deposition

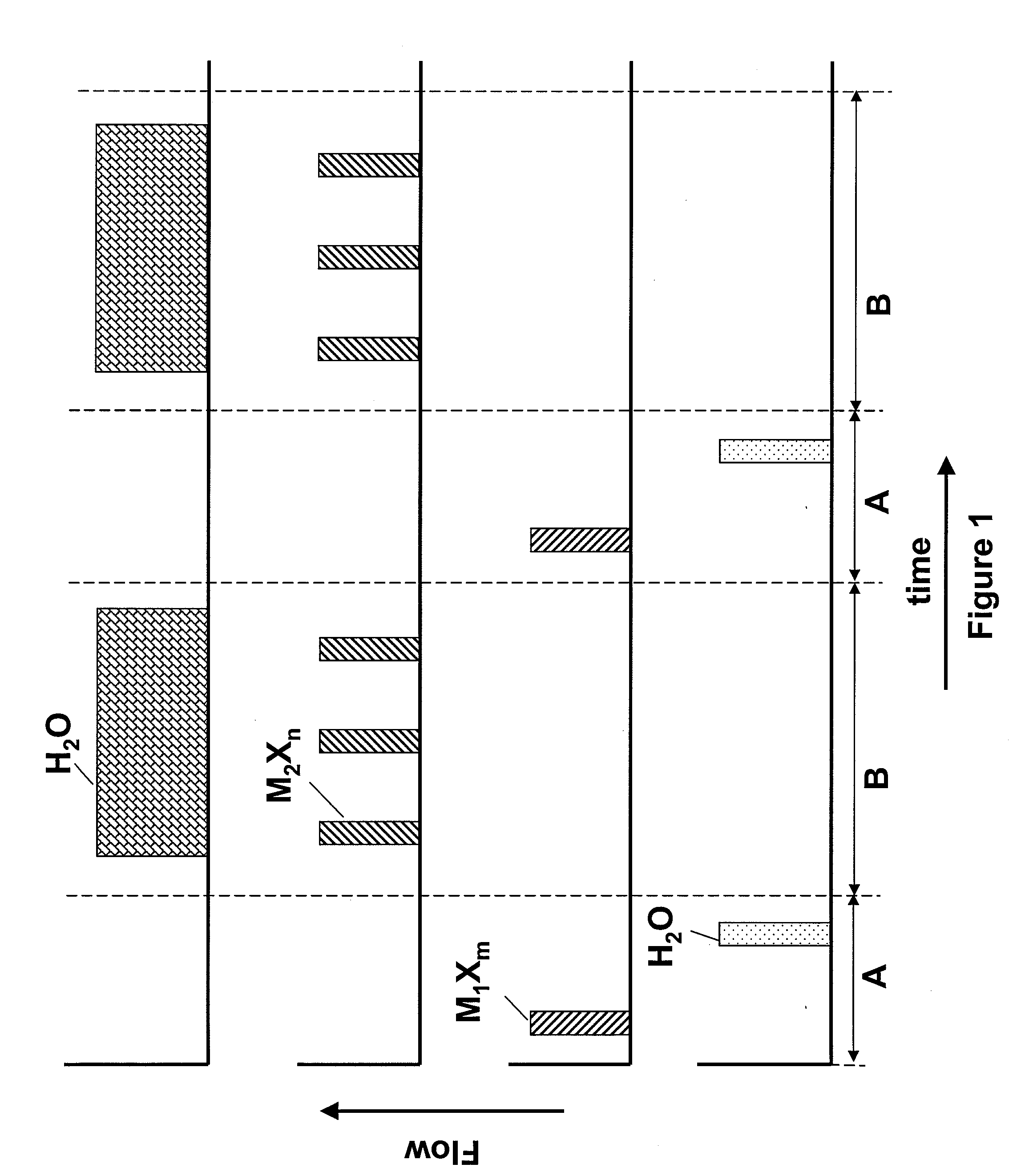

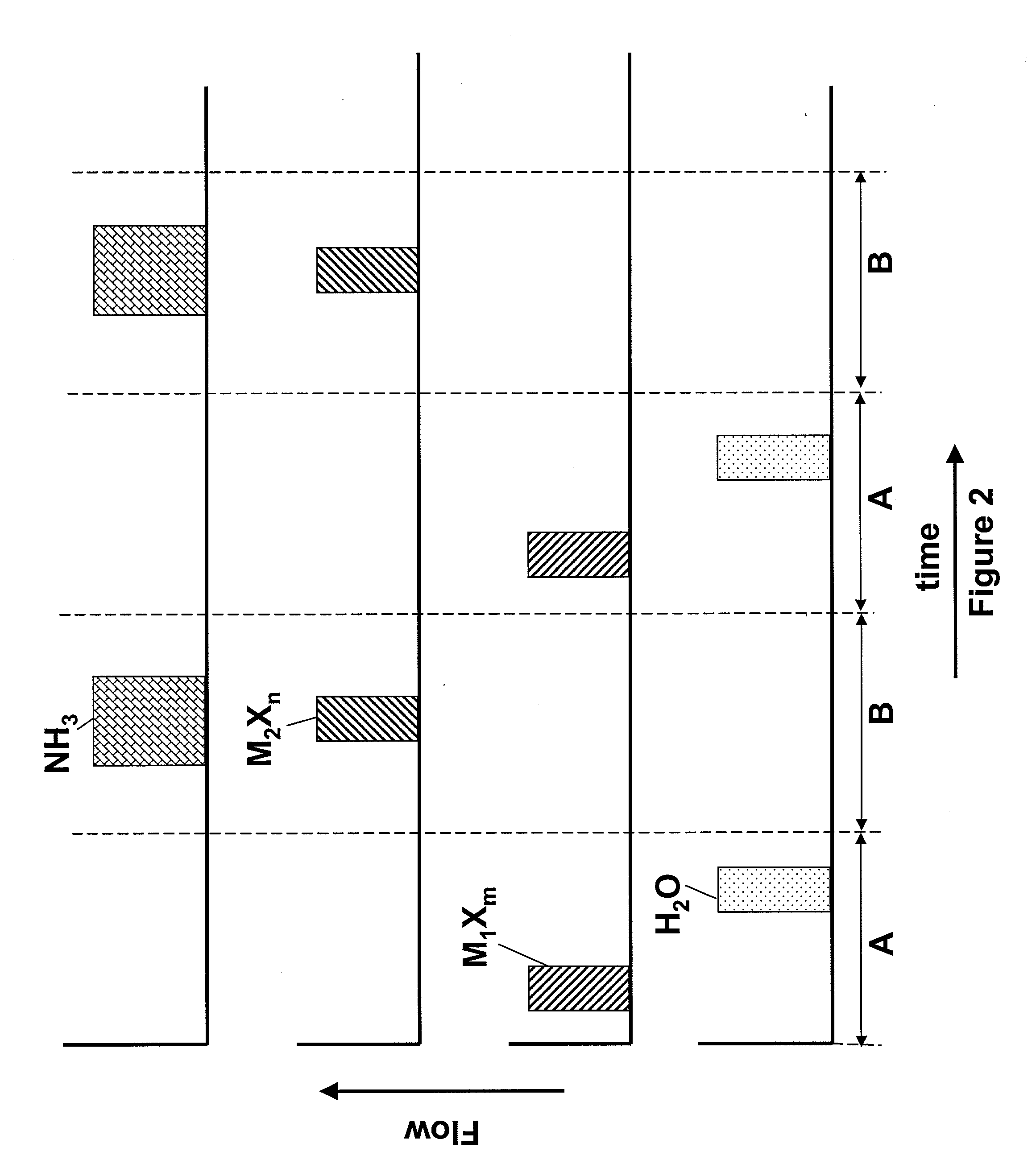

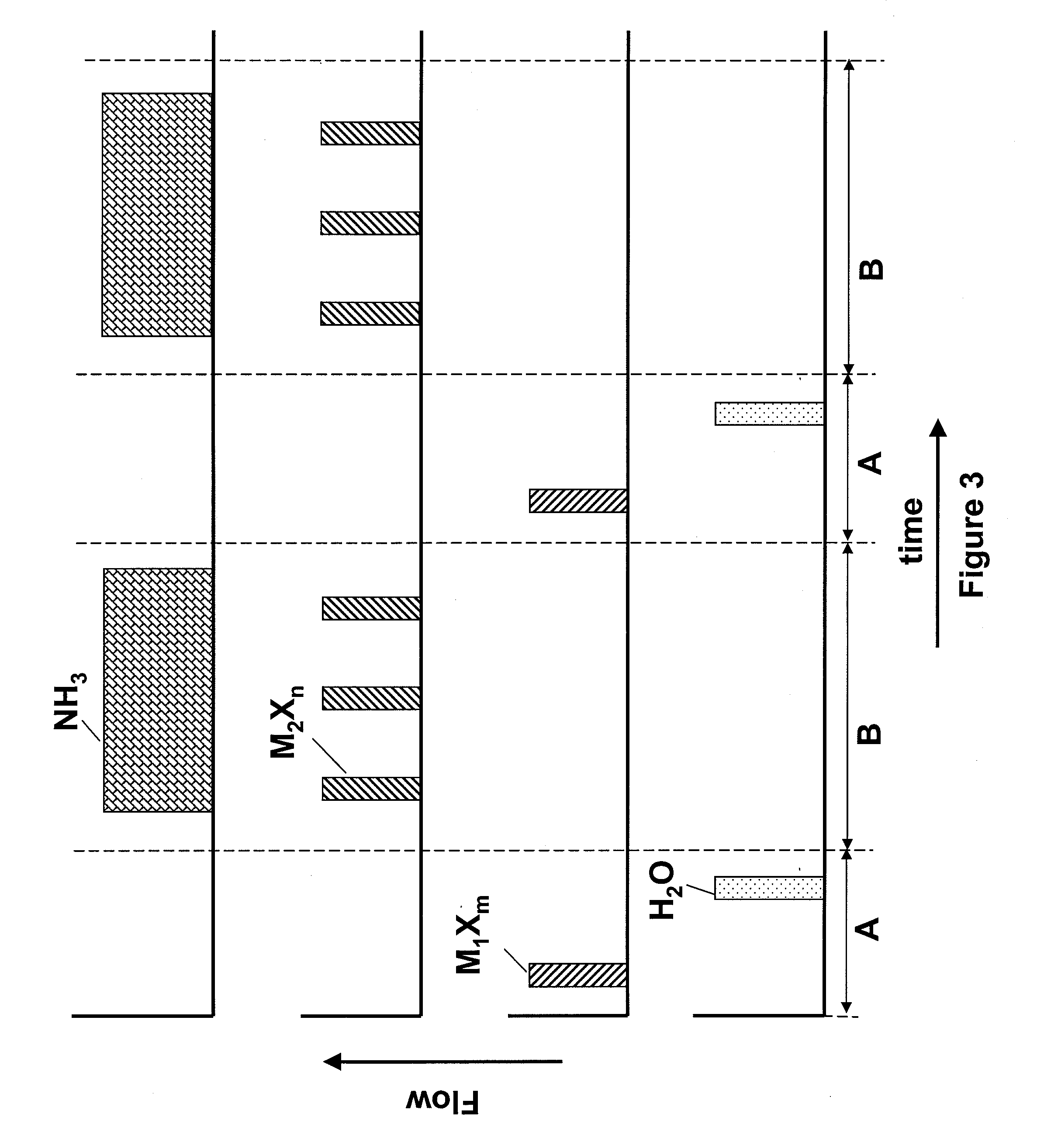

Films are deposited on a substrate by a process in which atomic layer deposition (ALD) is used to deposit one layer of the film and pulsed chemical vapor deposition (CVD) is used to deposit another layer of the film. During the ALD part of the process, a layer is formed by flowing sequential and alternating pulses of mutually reactive reactants that deposit self-limitingly on a substrate. During the pulsed CVD part of the process, another layer is deposited by flowing two CVD reactants into a reaction chamber, with at least a first of the CVD reactants flowed into the reaction chamber in pulses, with those pulses overlapping at least partially with the flow of a second of the CVD reactants. The ALD and CVD parts of the process ca be used to deposit layers with different compositions, thereby forming, e.g., nanolaminate films. Preferably, high quality layers are formed by flowing the second CVD reactant into the reaction chamber for a longer total duration than the first CVD reactant. In some embodiments, the pulses of the third reactant at separated by a duration at least about 1.75 times the length of the pulse. Preferably, less than about 8 monolayers of material are deposited per pulse of the first CVD reactant.

Owner:ASM INTERNATIONAL

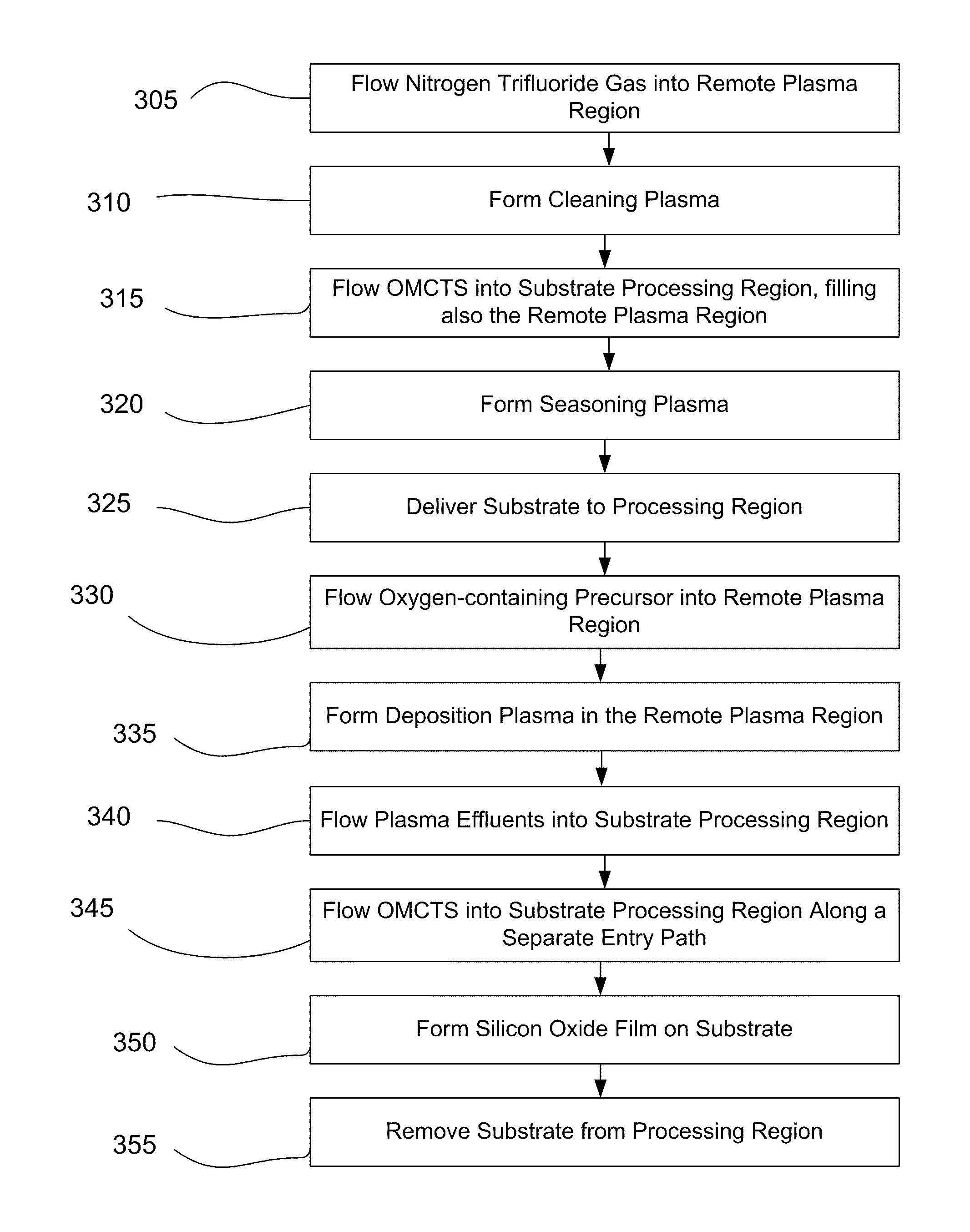

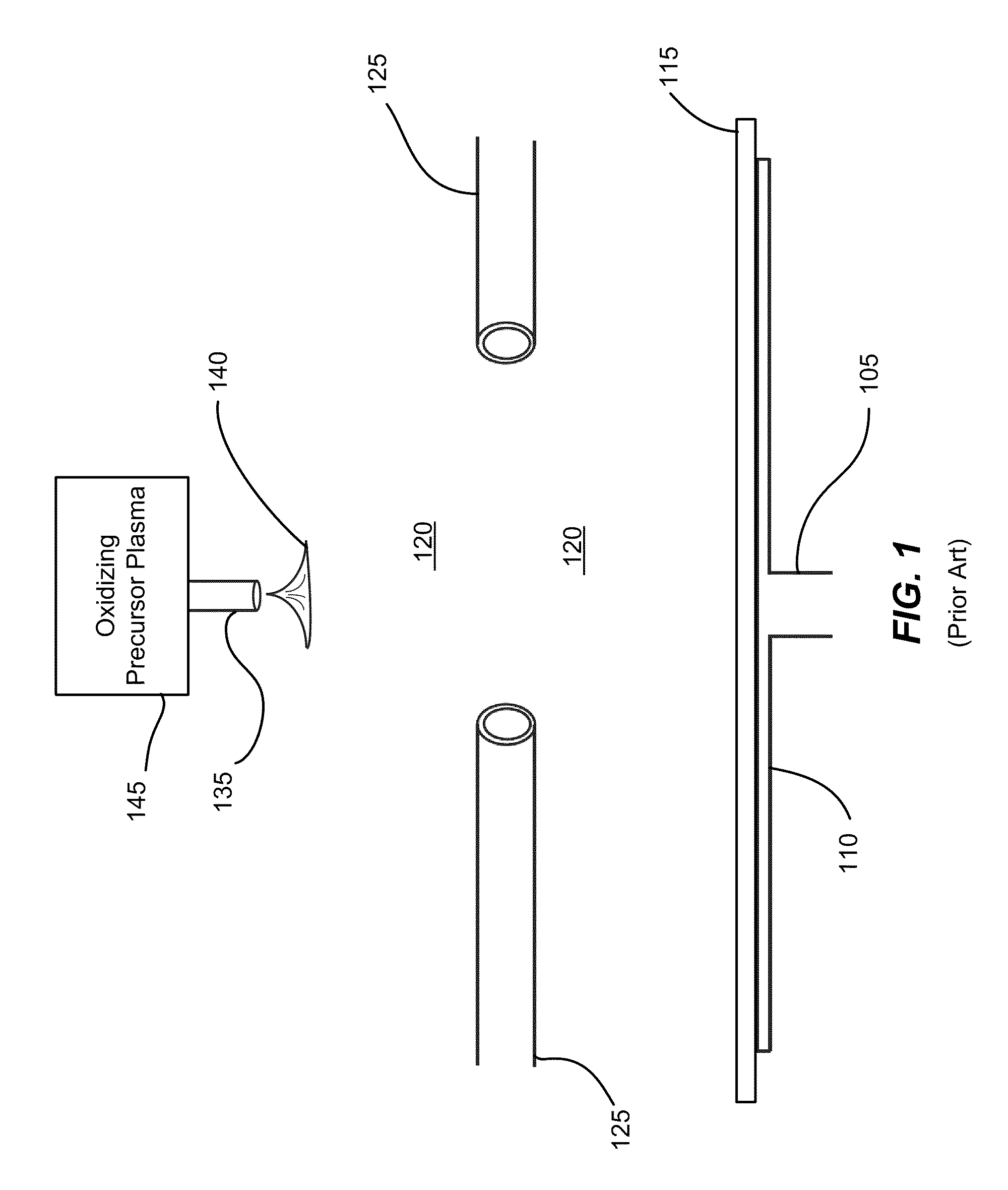

Remote plasma source seasoning

ActiveUS7989365B2Increase deposition rateImprove uniformityElectric discharge tubesSemiconductor/solid-state device manufacturingRemote plasmaDeposition process

Methods of seasoning a remote plasma system are described. The methods include the steps of flowing a silicon-containing precursor into a remote plasma region to deposit a silicon containing film on an interior surface of the remote plasma system. The methods reduce reactions with the seasoned walls during deposition processes, resulting in improved deposition rate, improved deposition uniformity and reduced defectivity during subsequent deposition.

Owner:APPLIED MATERIALS INC

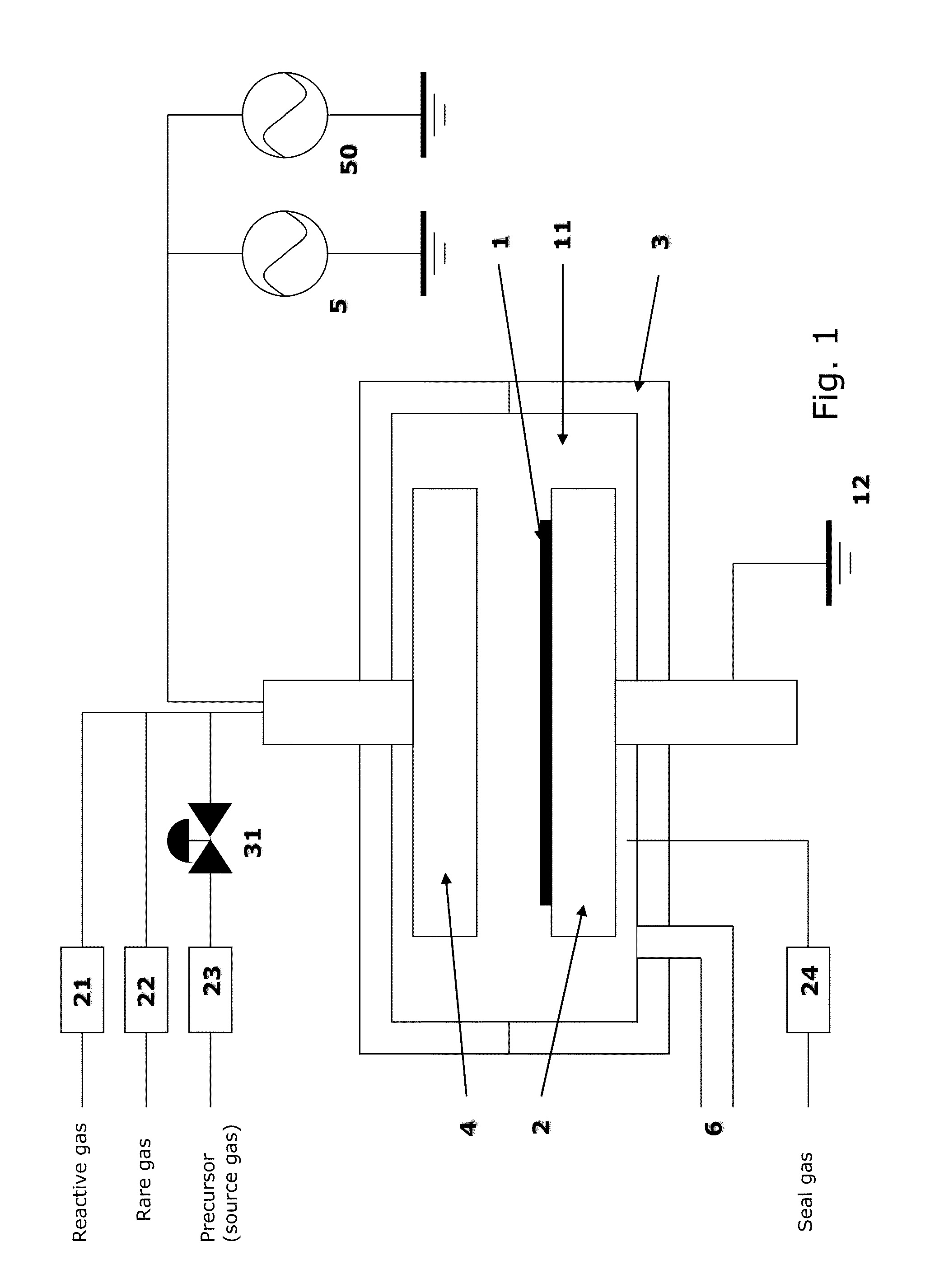

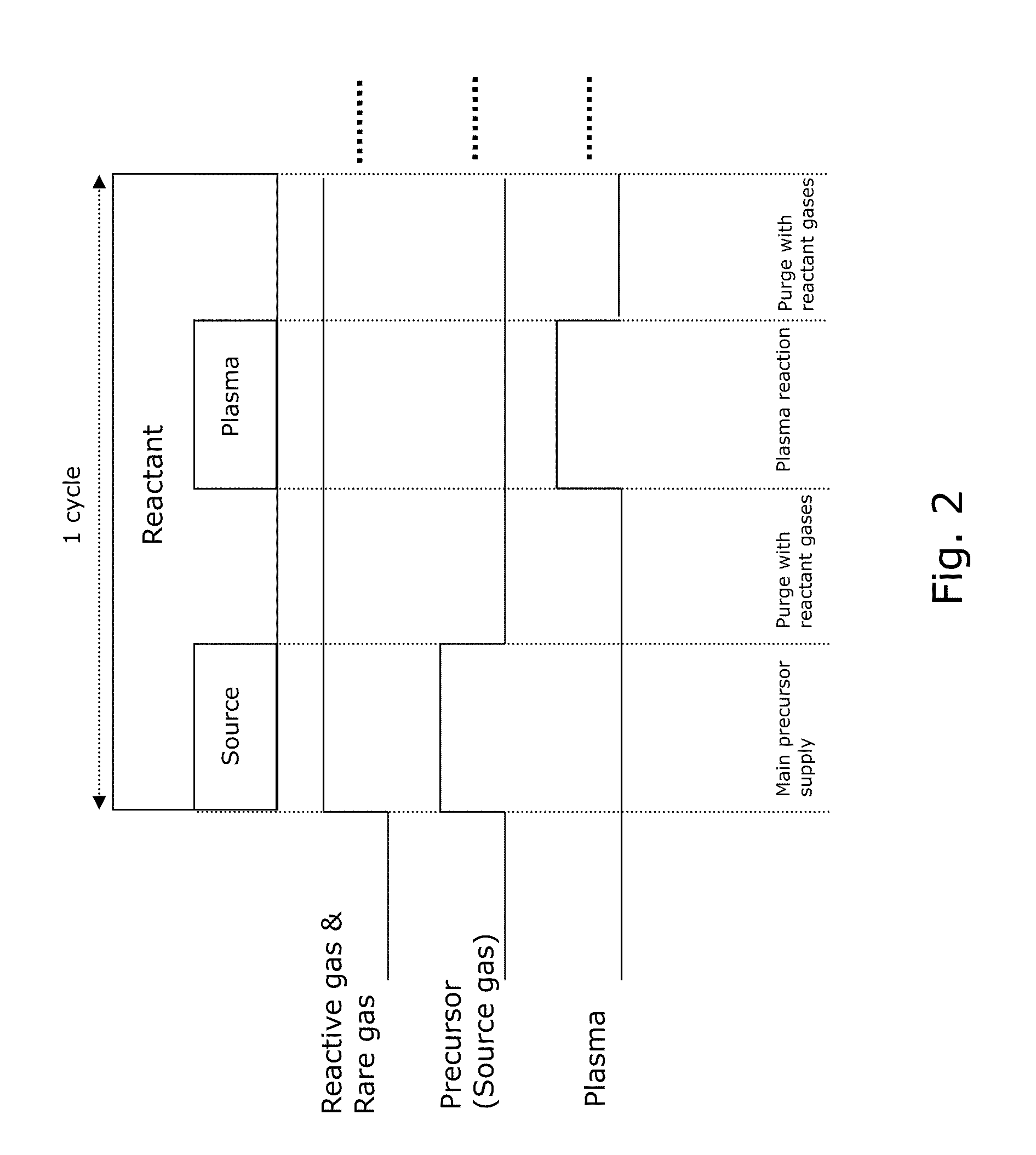

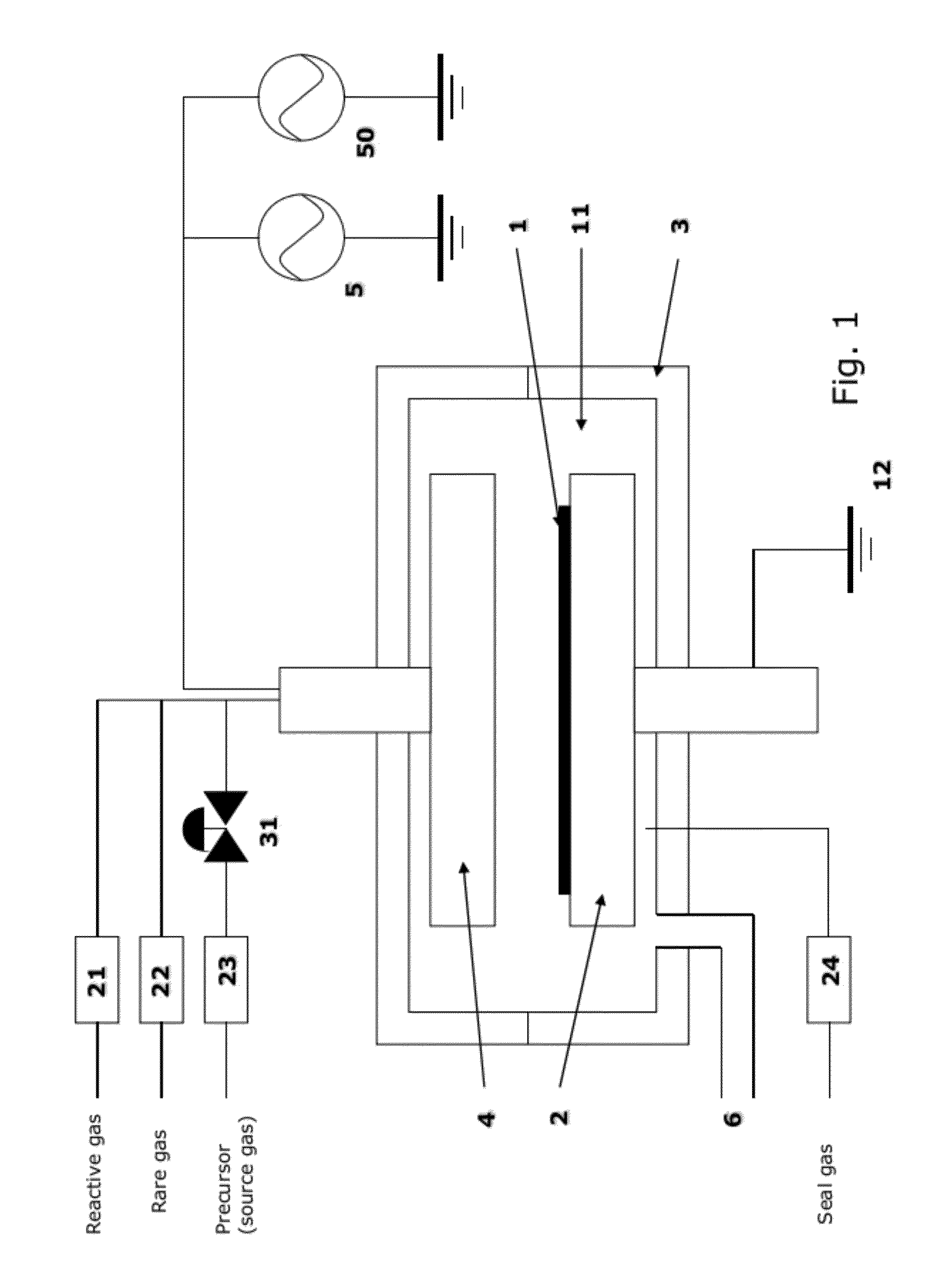

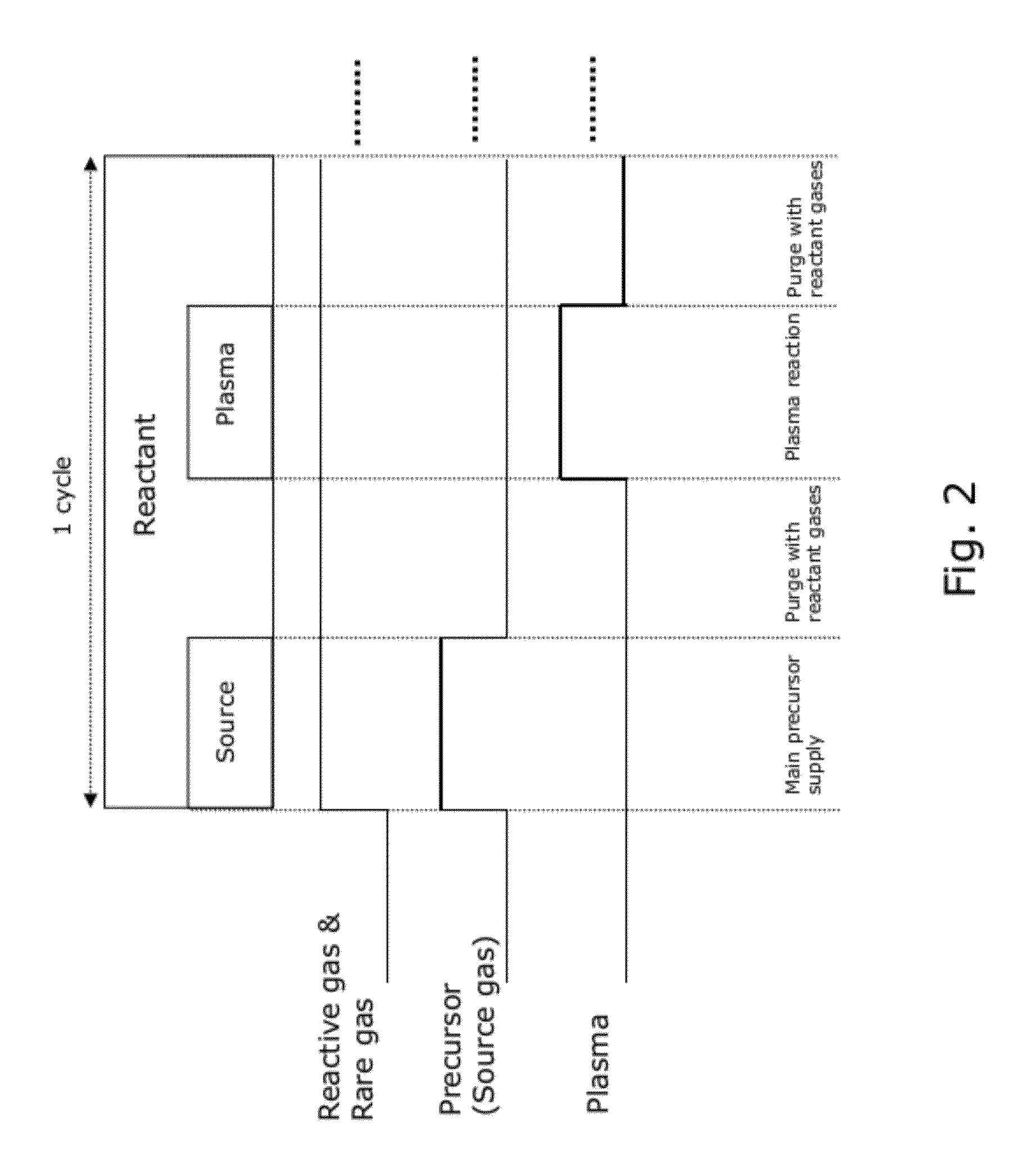

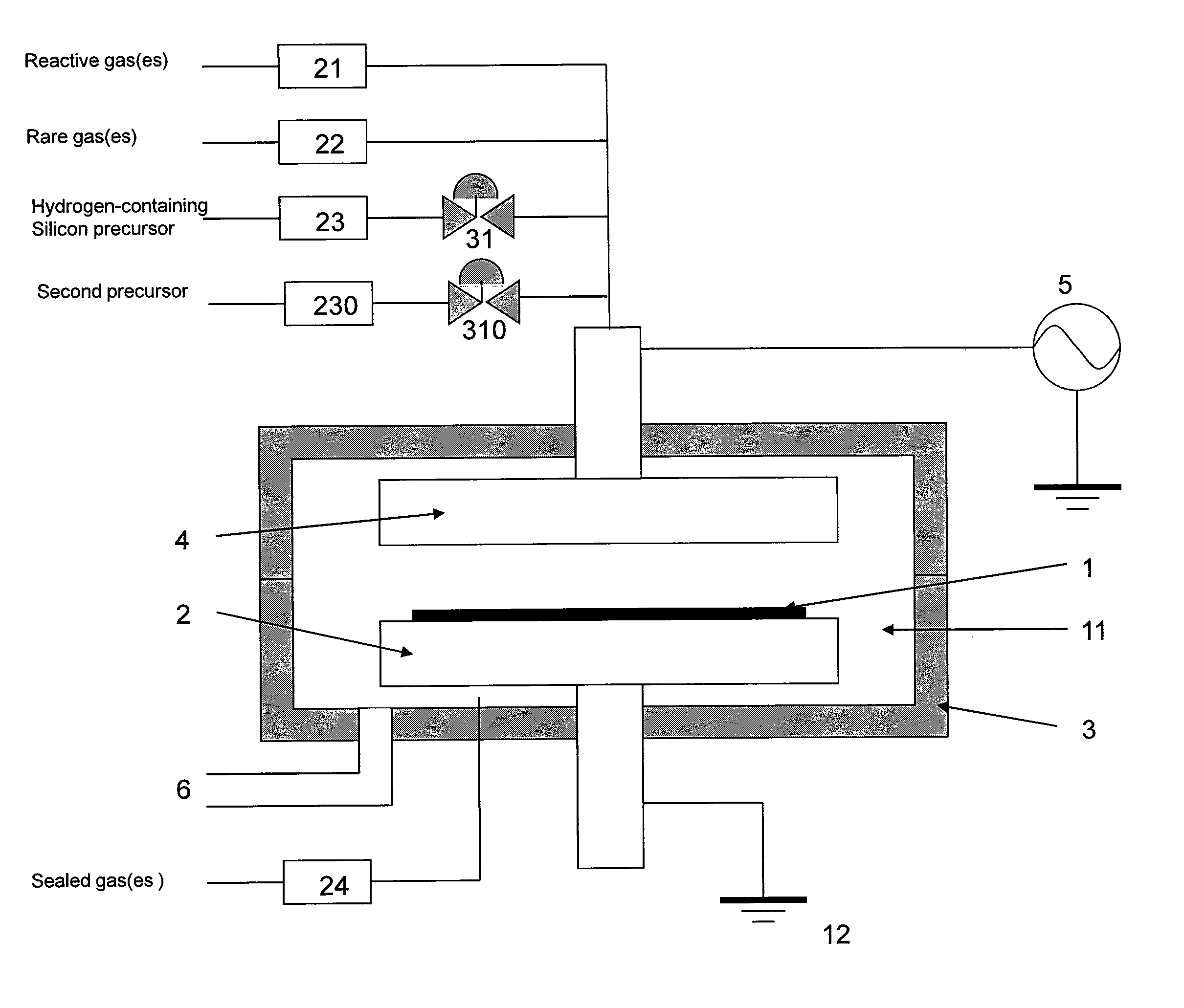

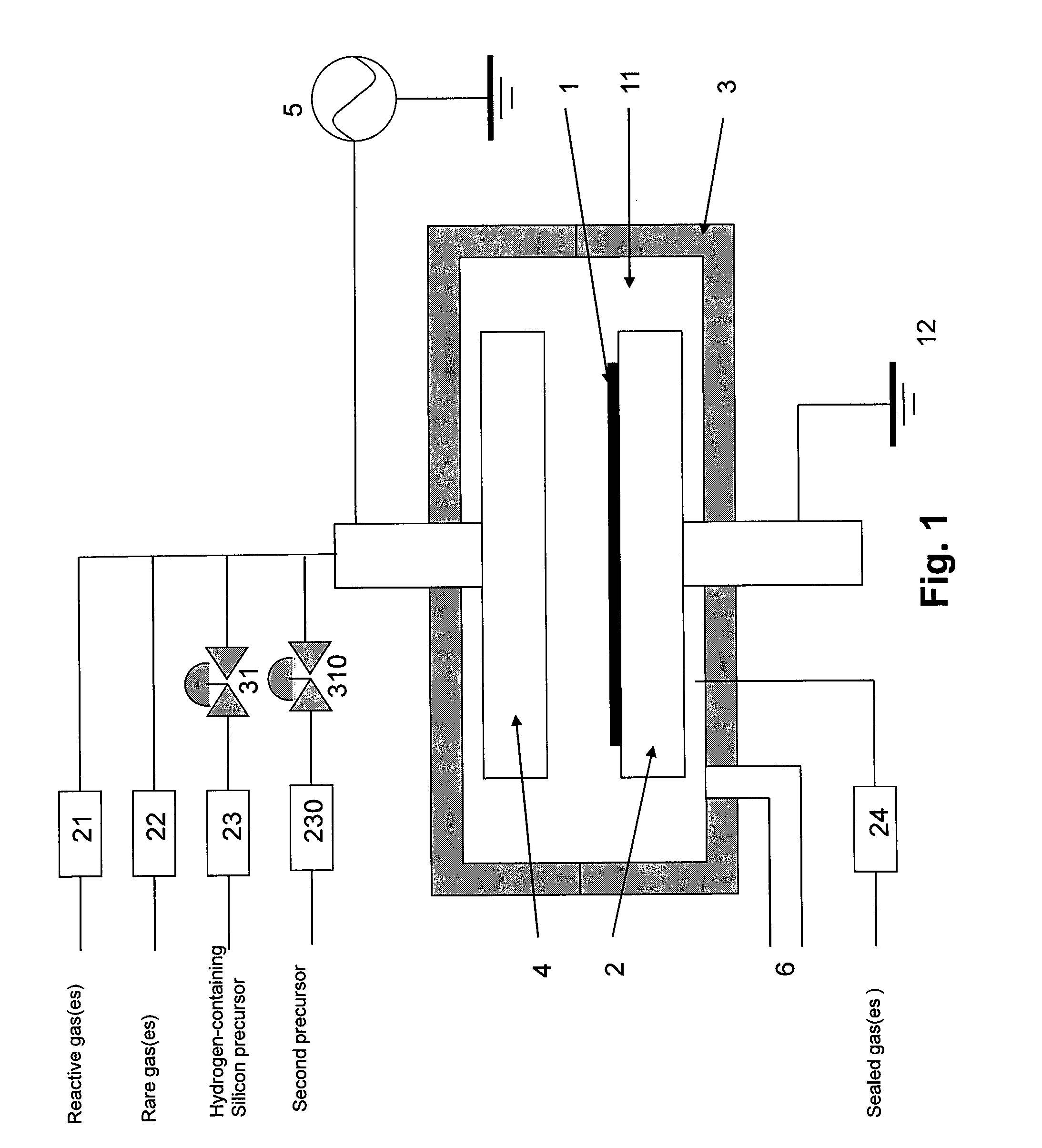

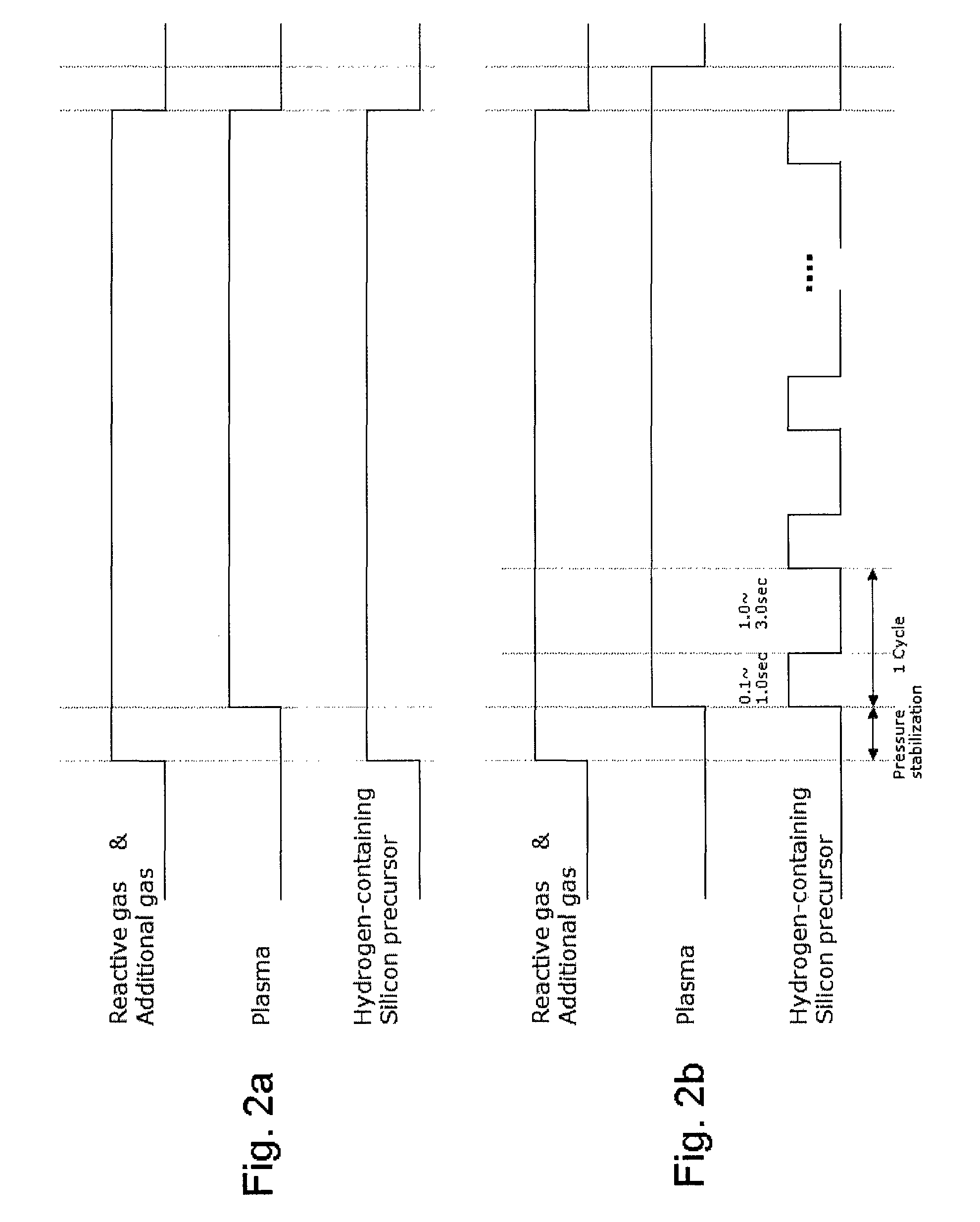

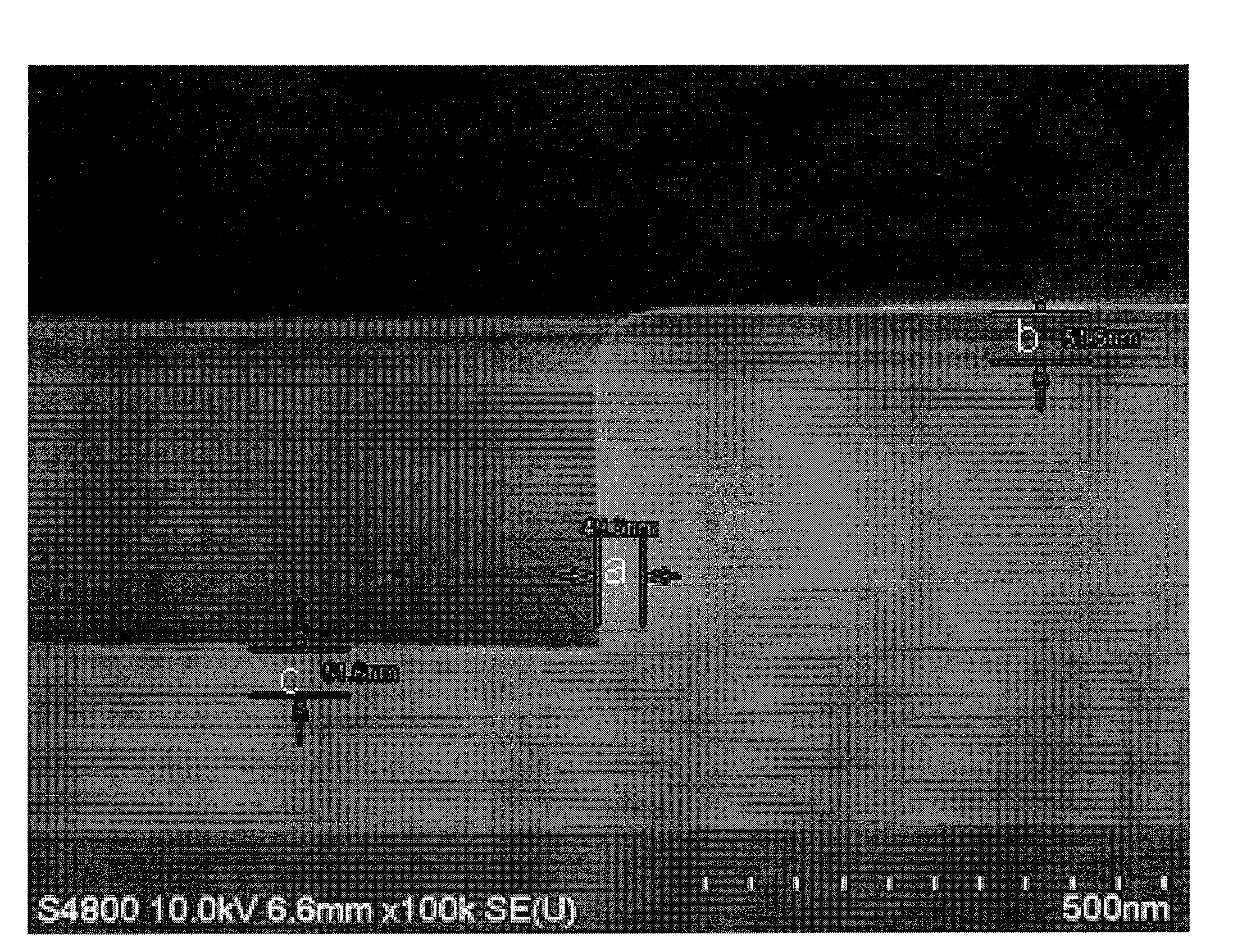

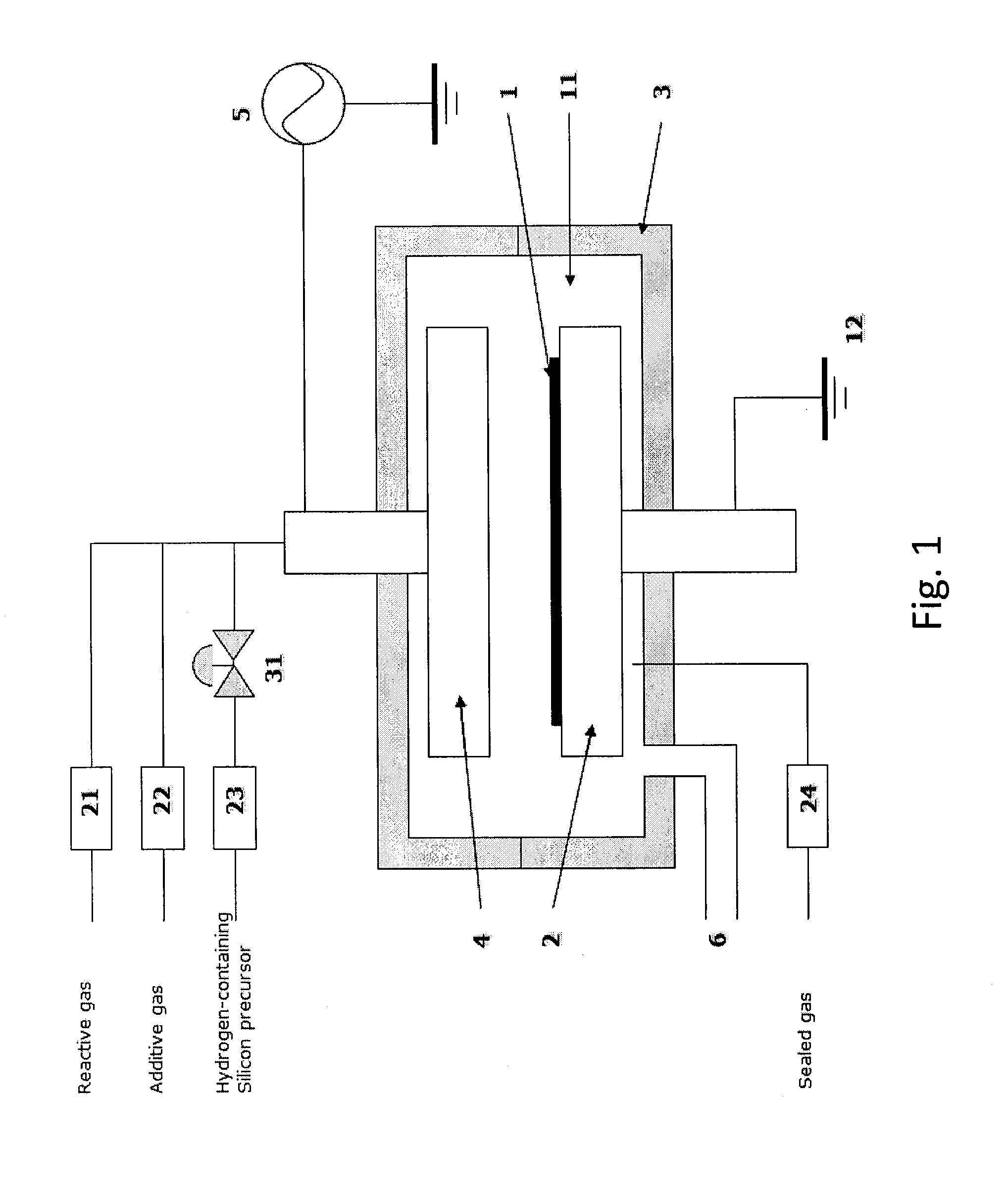

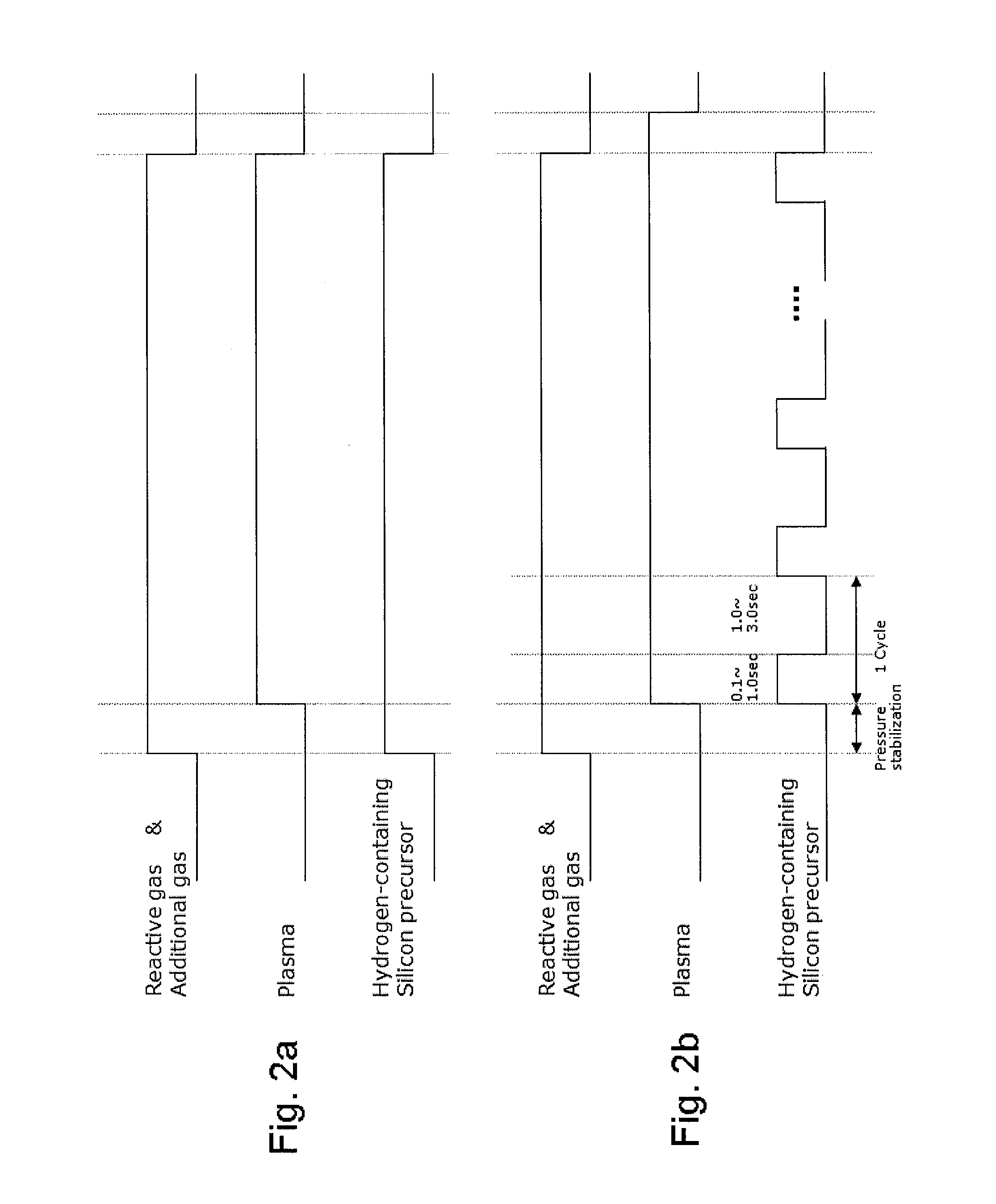

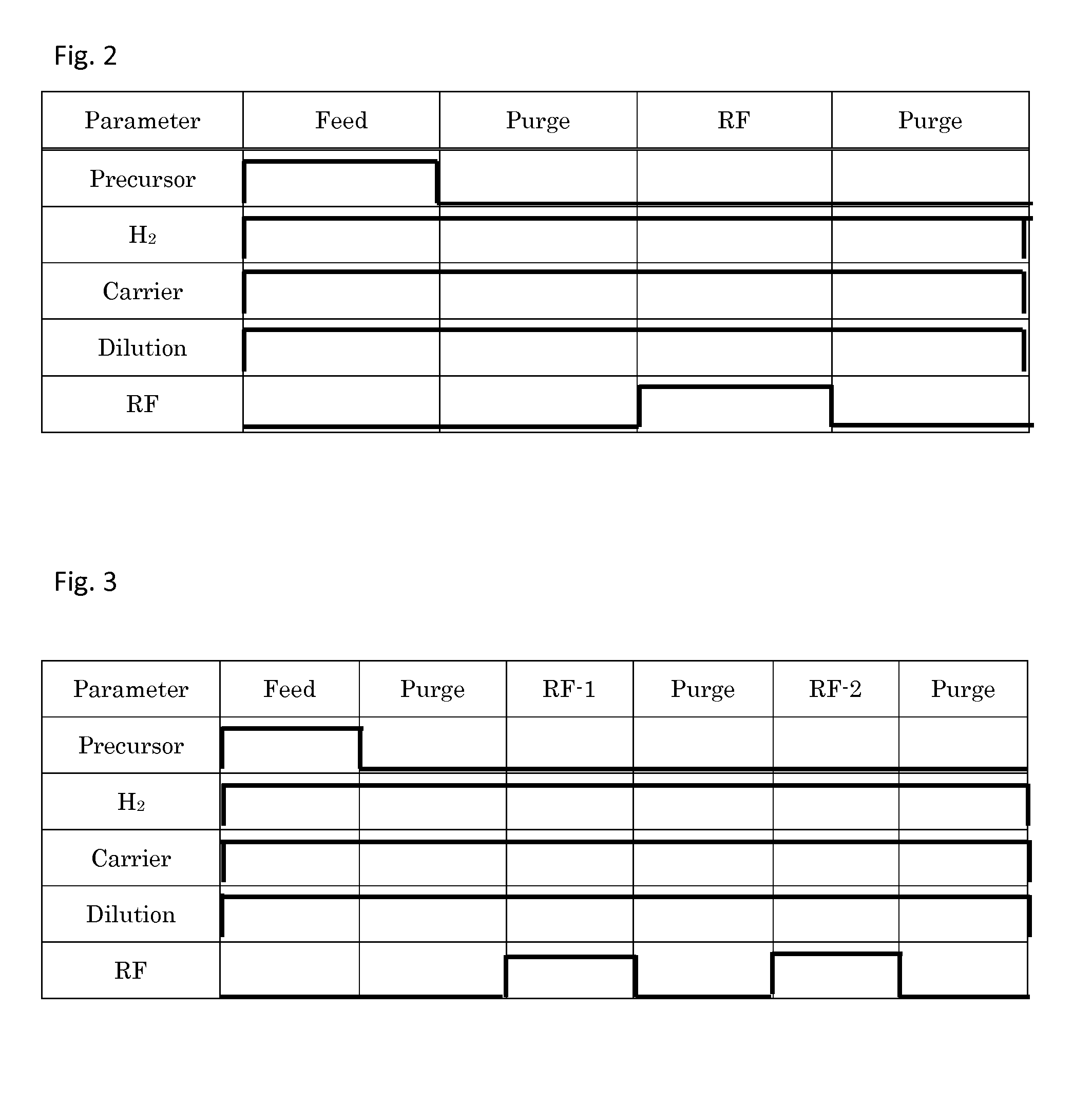

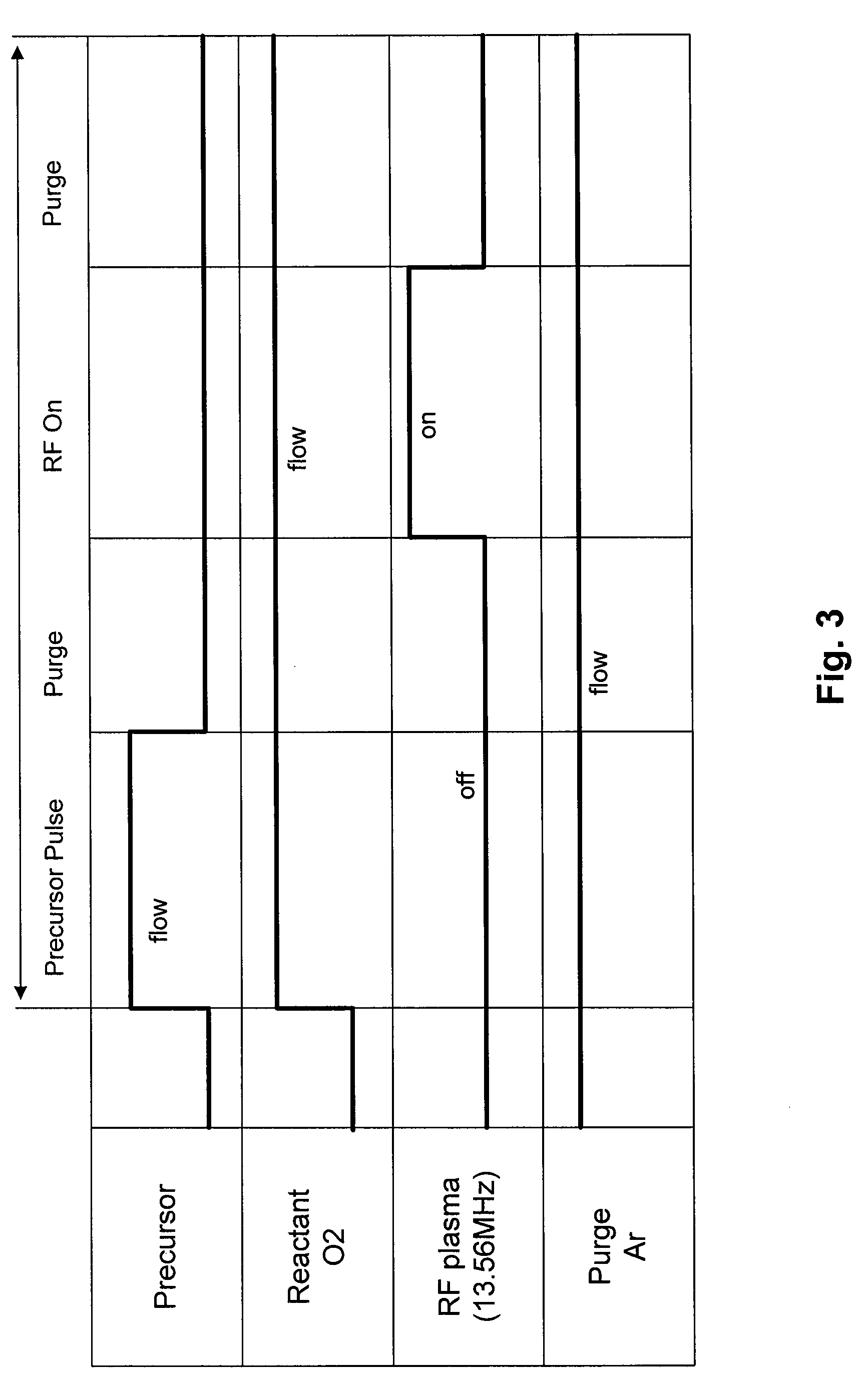

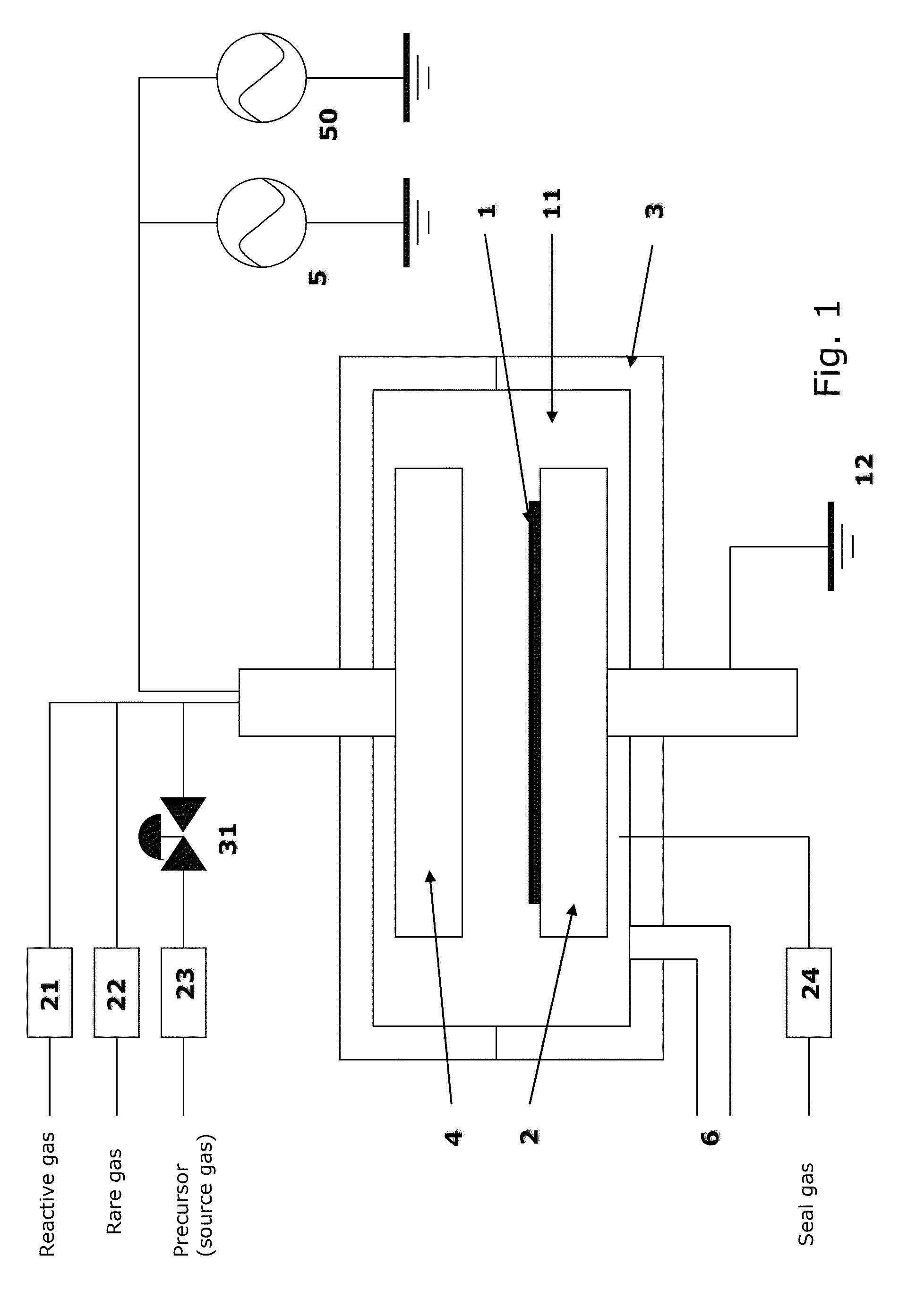

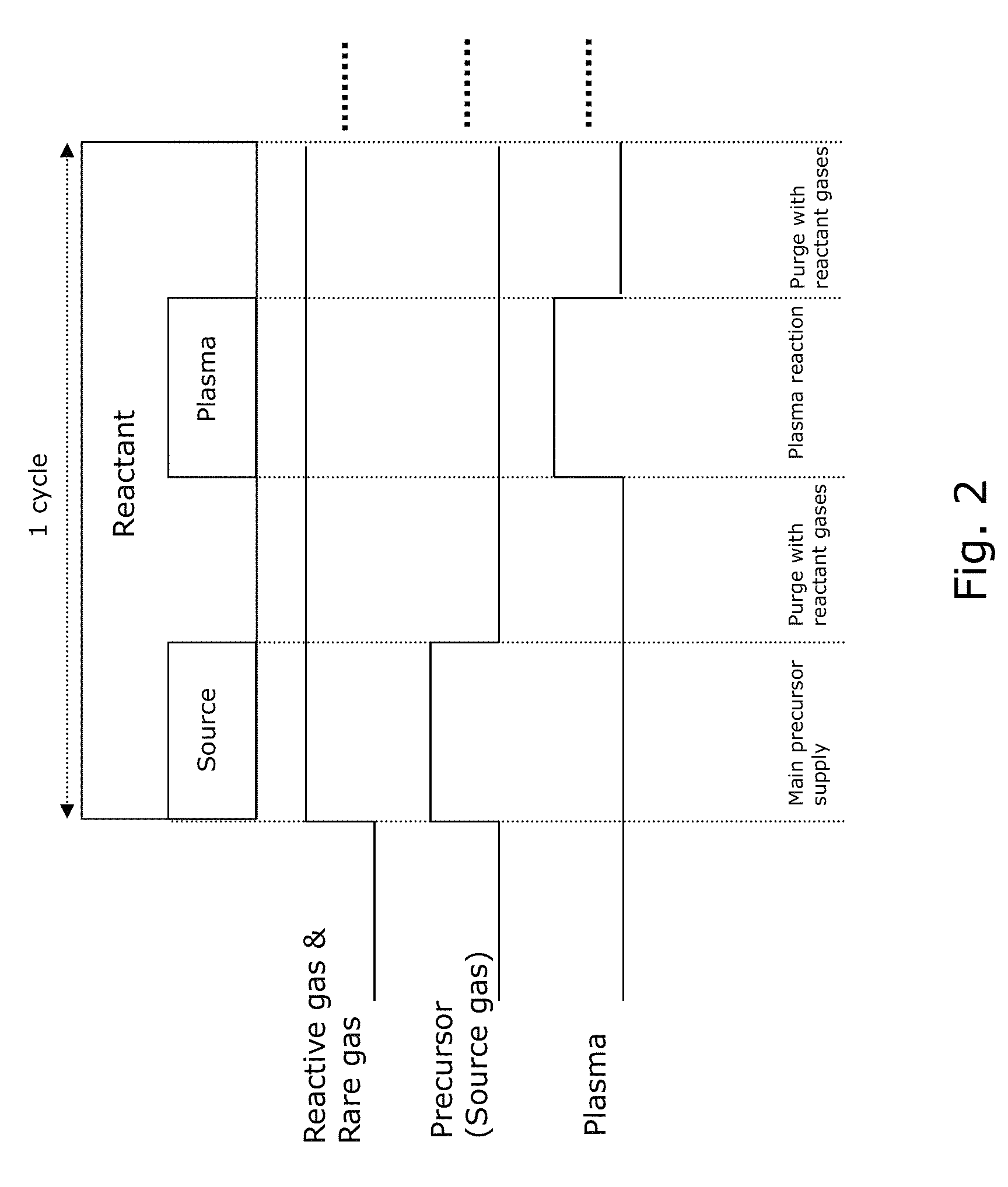

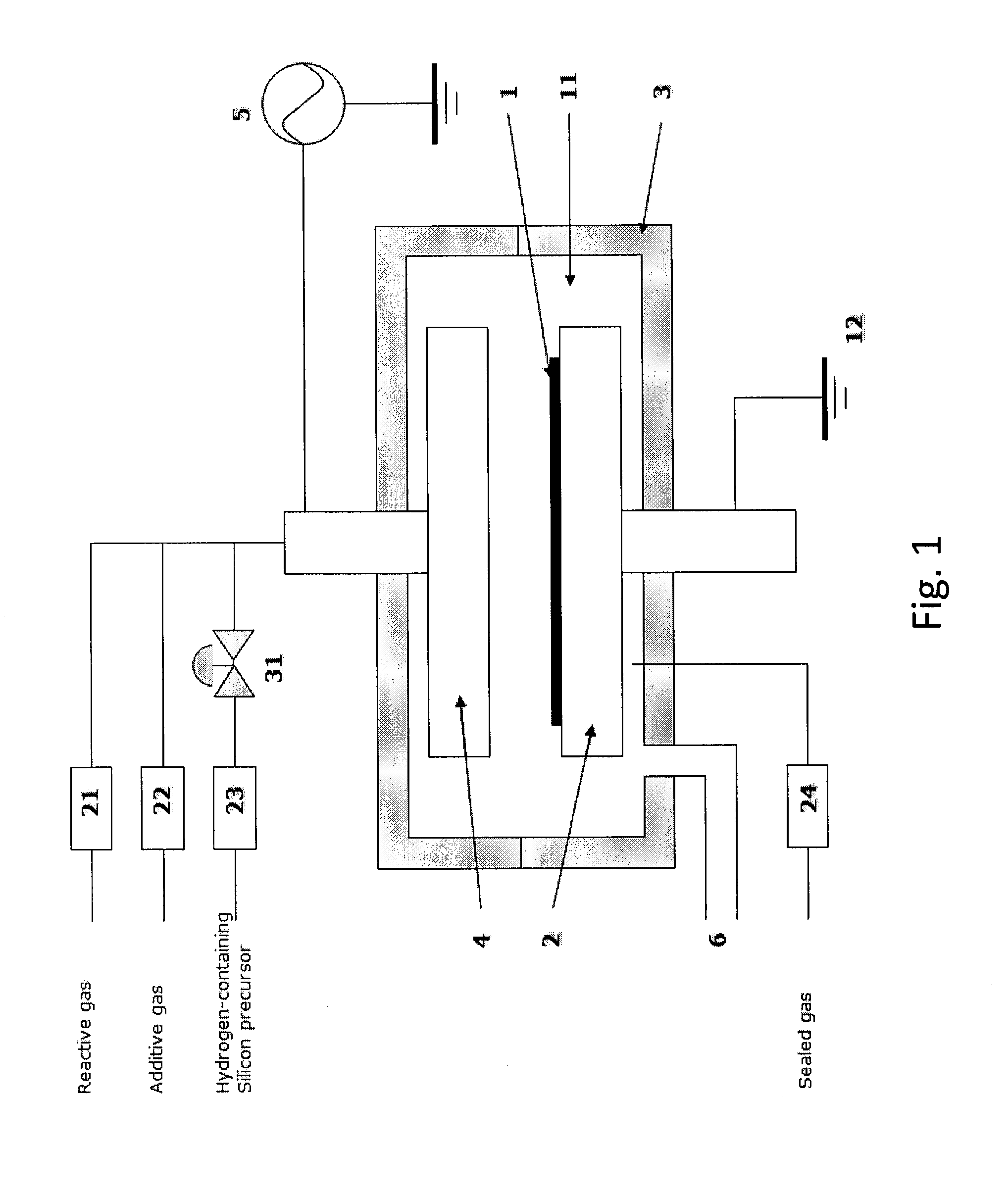

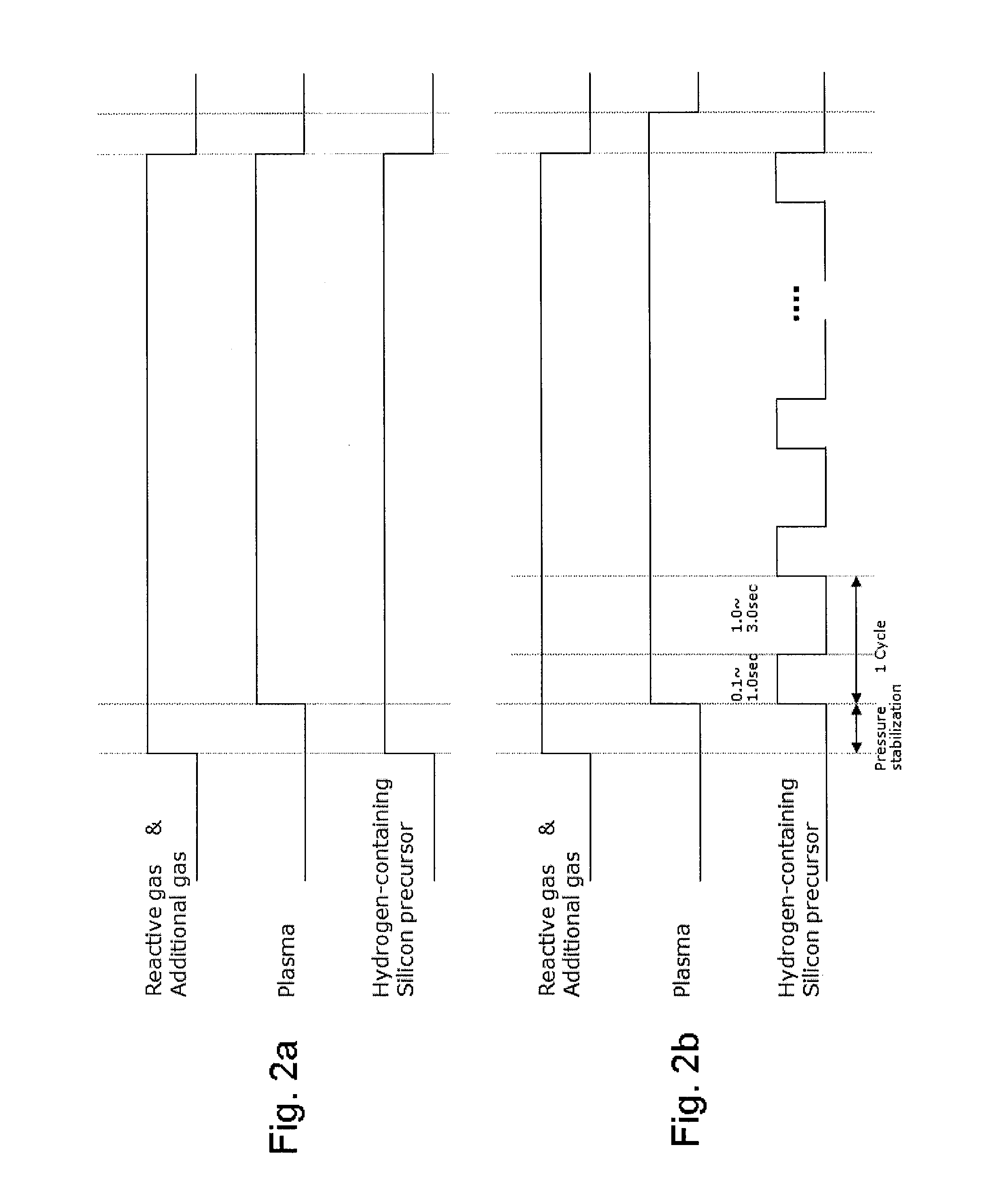

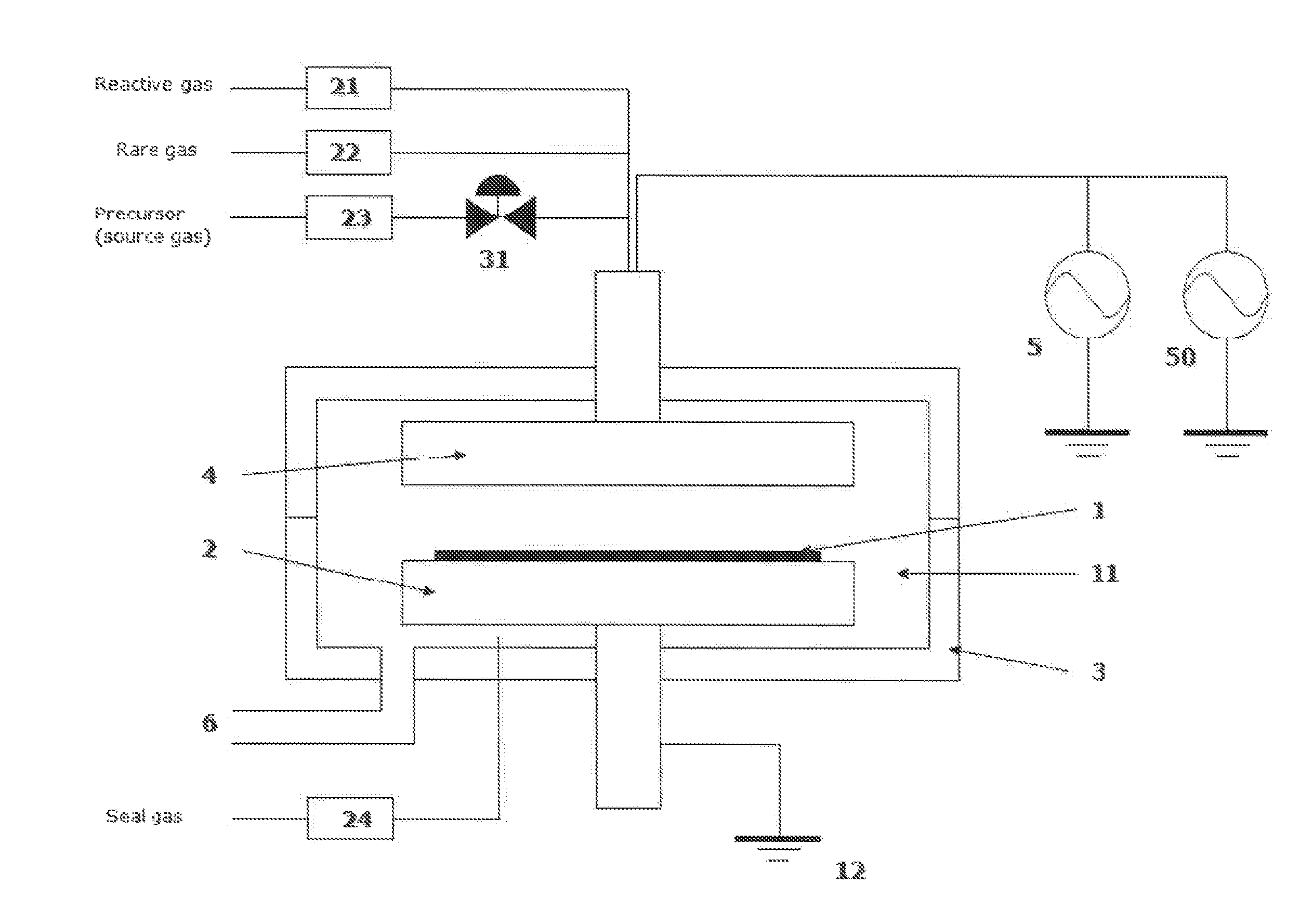

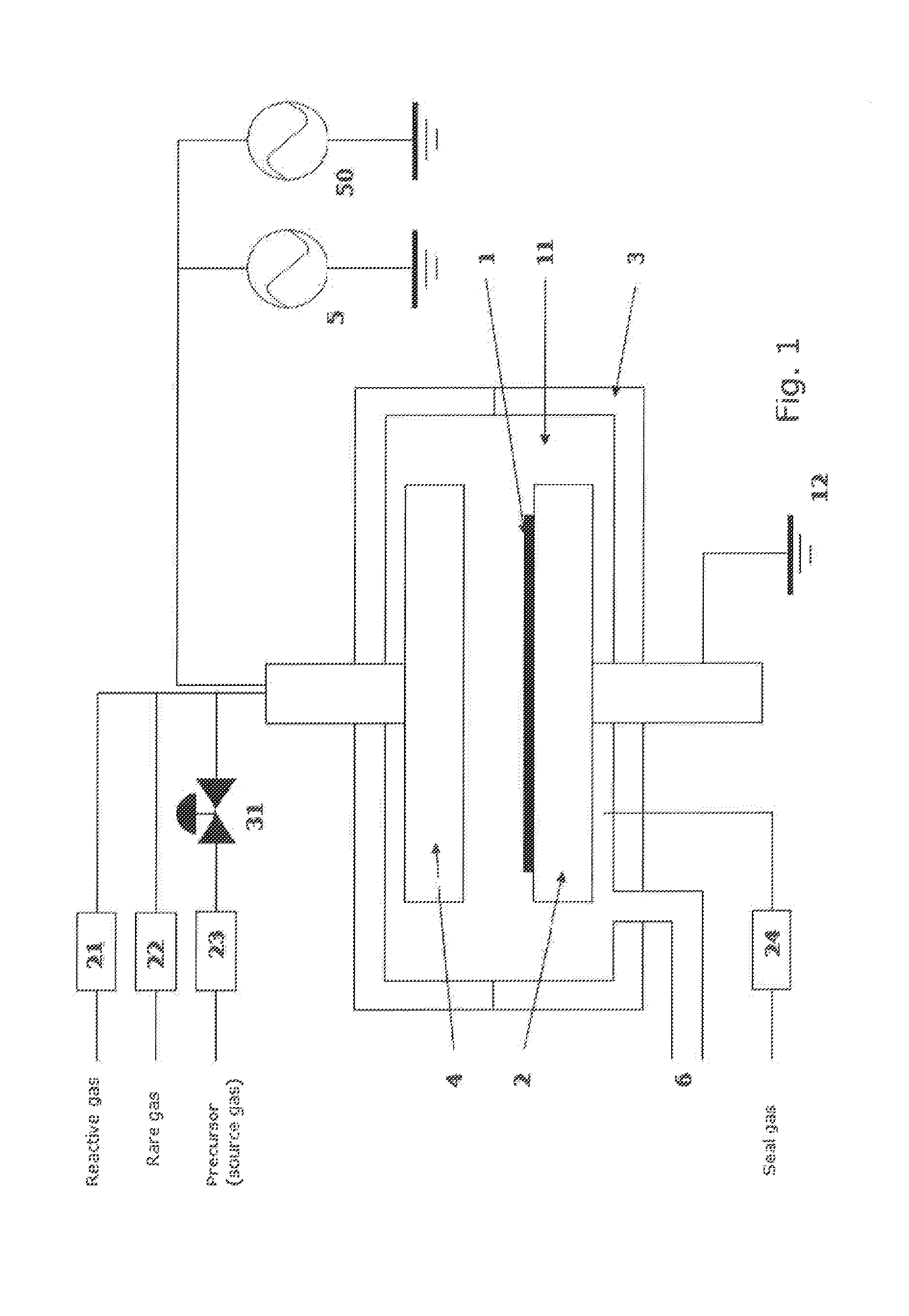

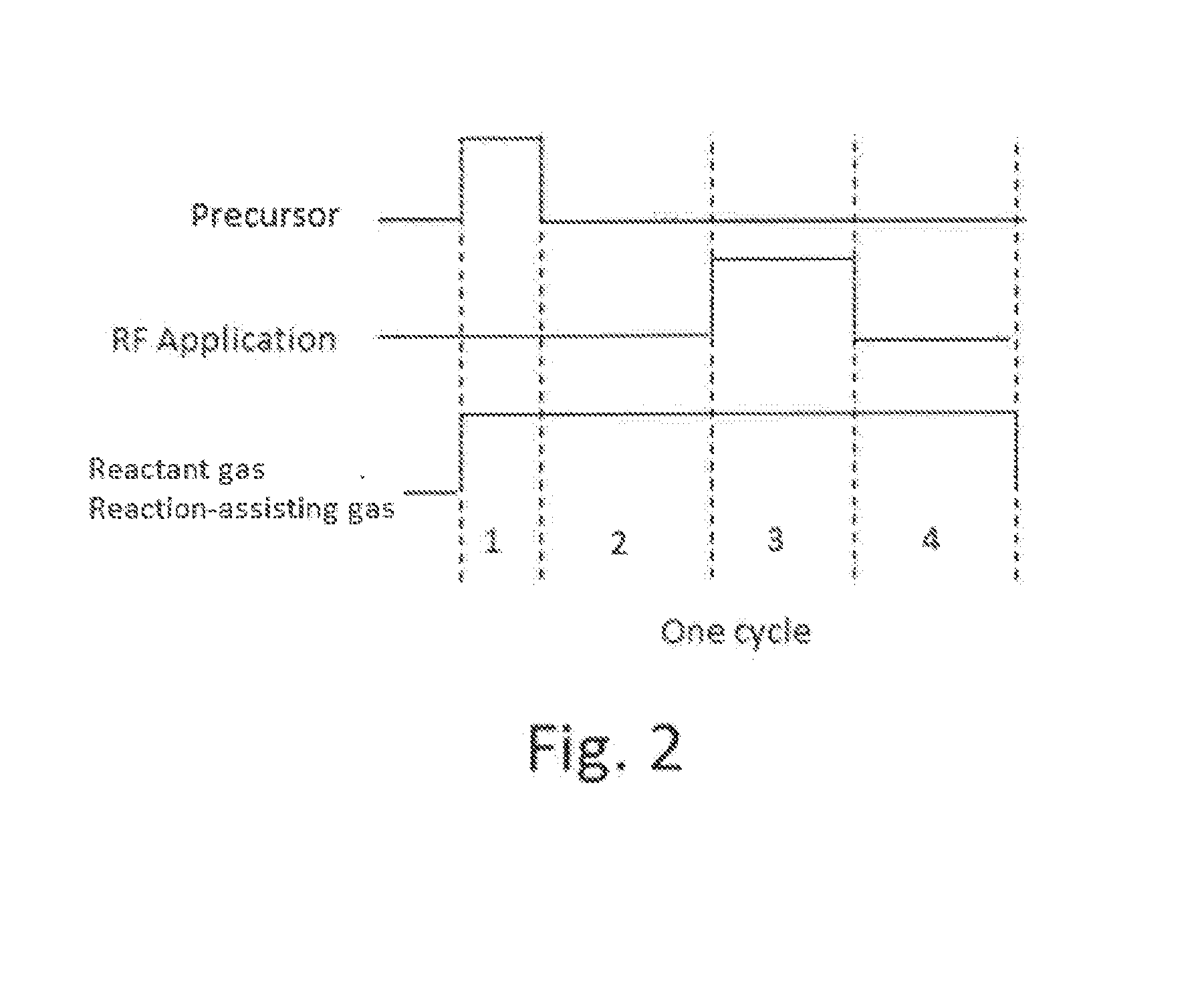

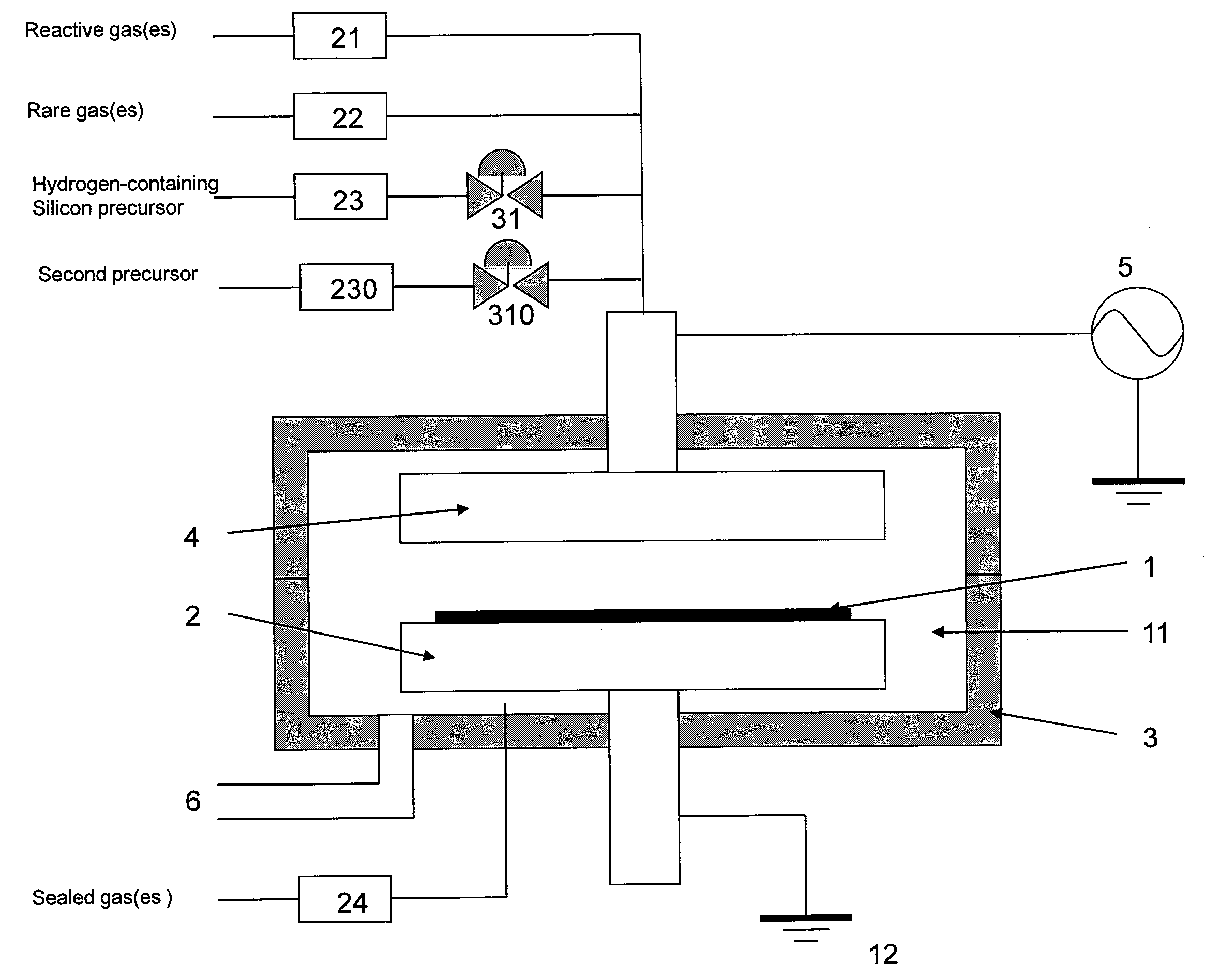

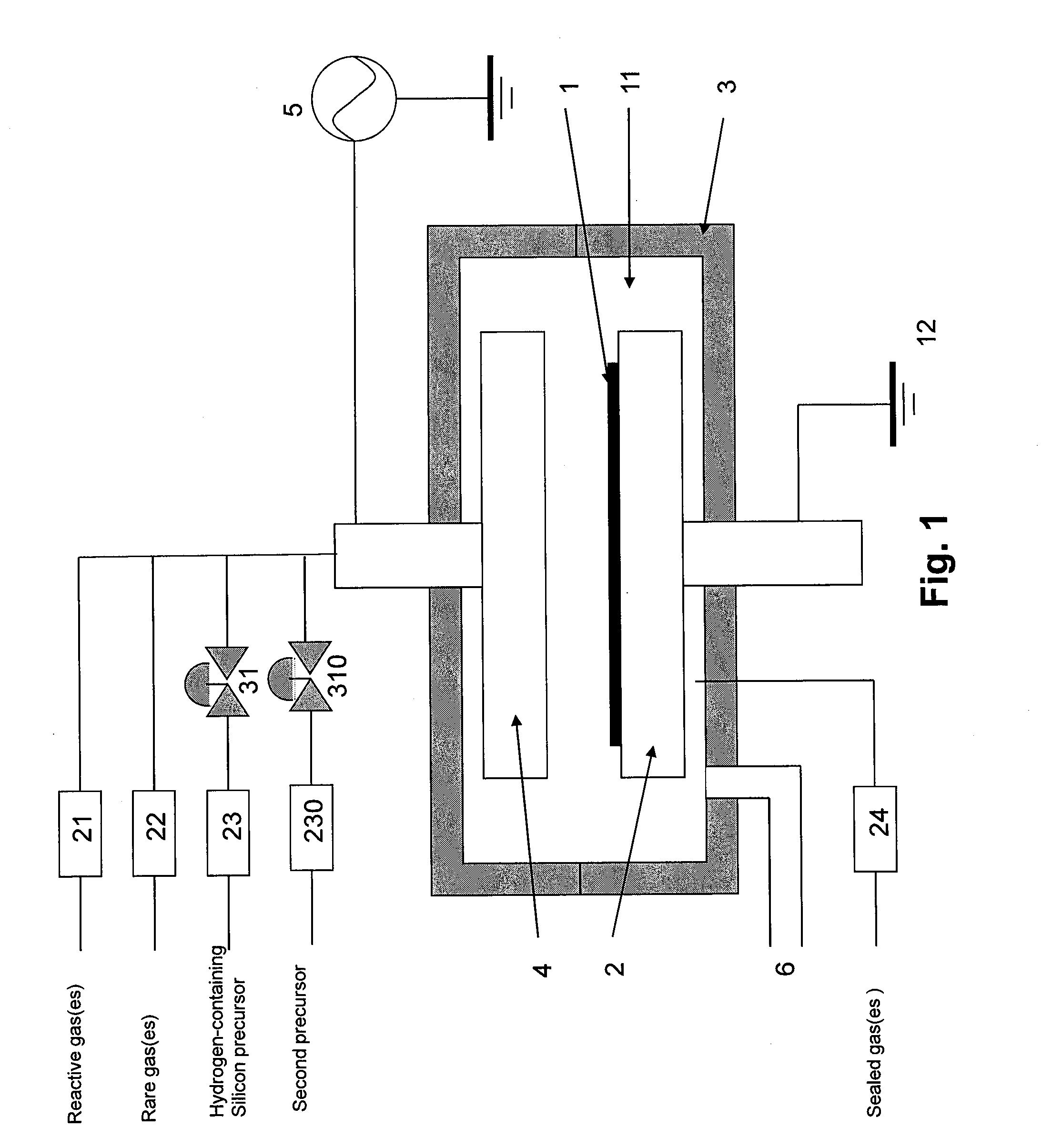

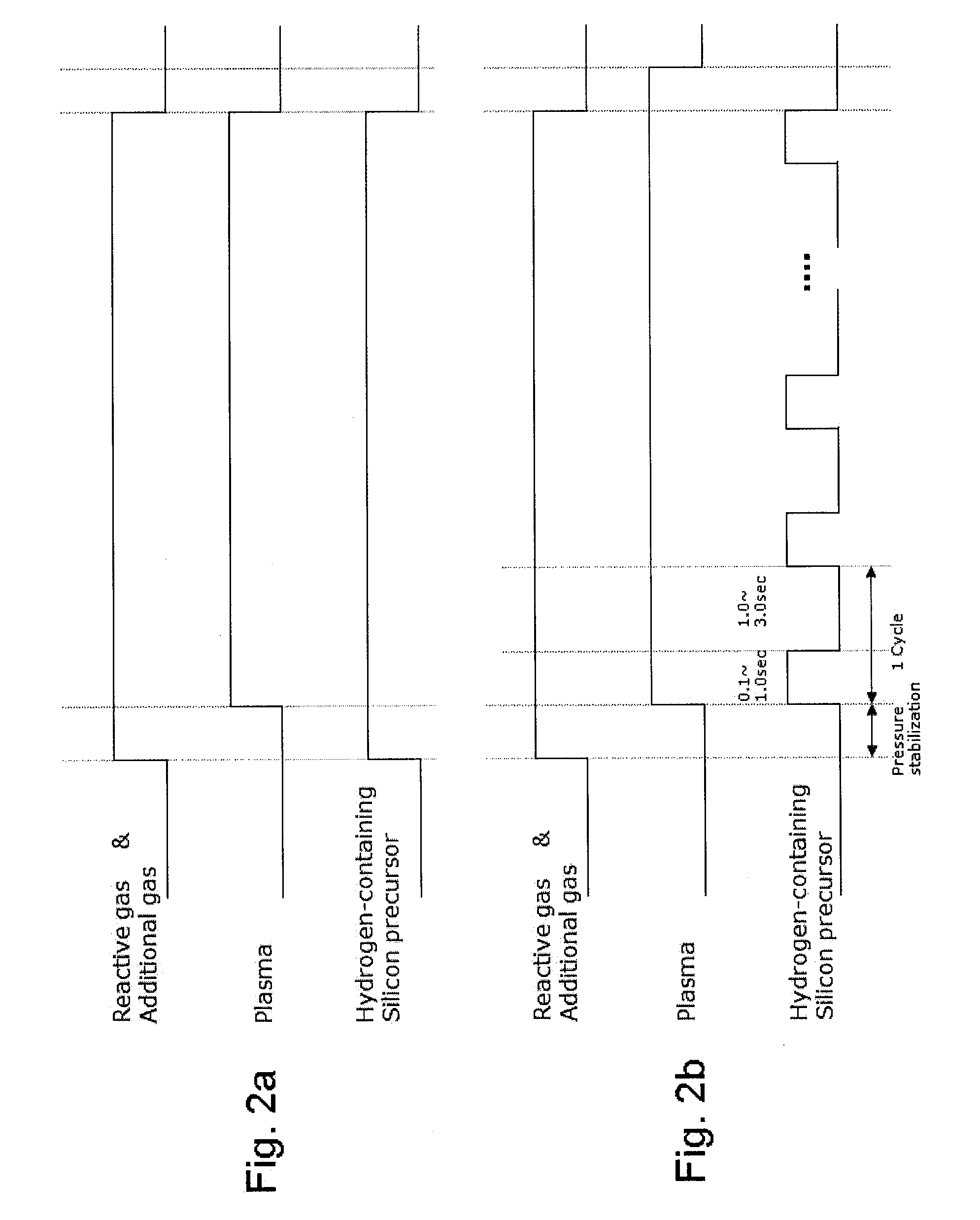

Method of depositing dielectric film having Si-N bonds by modified peald method

ActiveUS8173554B2Increase deposition rateHigh conformalitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectricHydrogen

A method of forming dielectric film having Si—N bonds on a semiconductor substrate by plasma enhanced atomic layer deposition (PEALD), includes: introducing a nitrogen- and hydrogen-containing reactive gas and a rare gas into a reaction space inside which the semiconductor substrate is placed; introducing a hydrogen-containing silicon precursor in pulses of less than 1.0-second duration into the reaction space wherein the reactive gas and the rare gas are introduced; exiting a plasma in pulses of less than 1.0-second duration immediately after the silicon precursor is shut off; and maintaining the reactive gas and the rare gas as a purge of less than 2.0-second duration.

Owner:ASM JAPAN

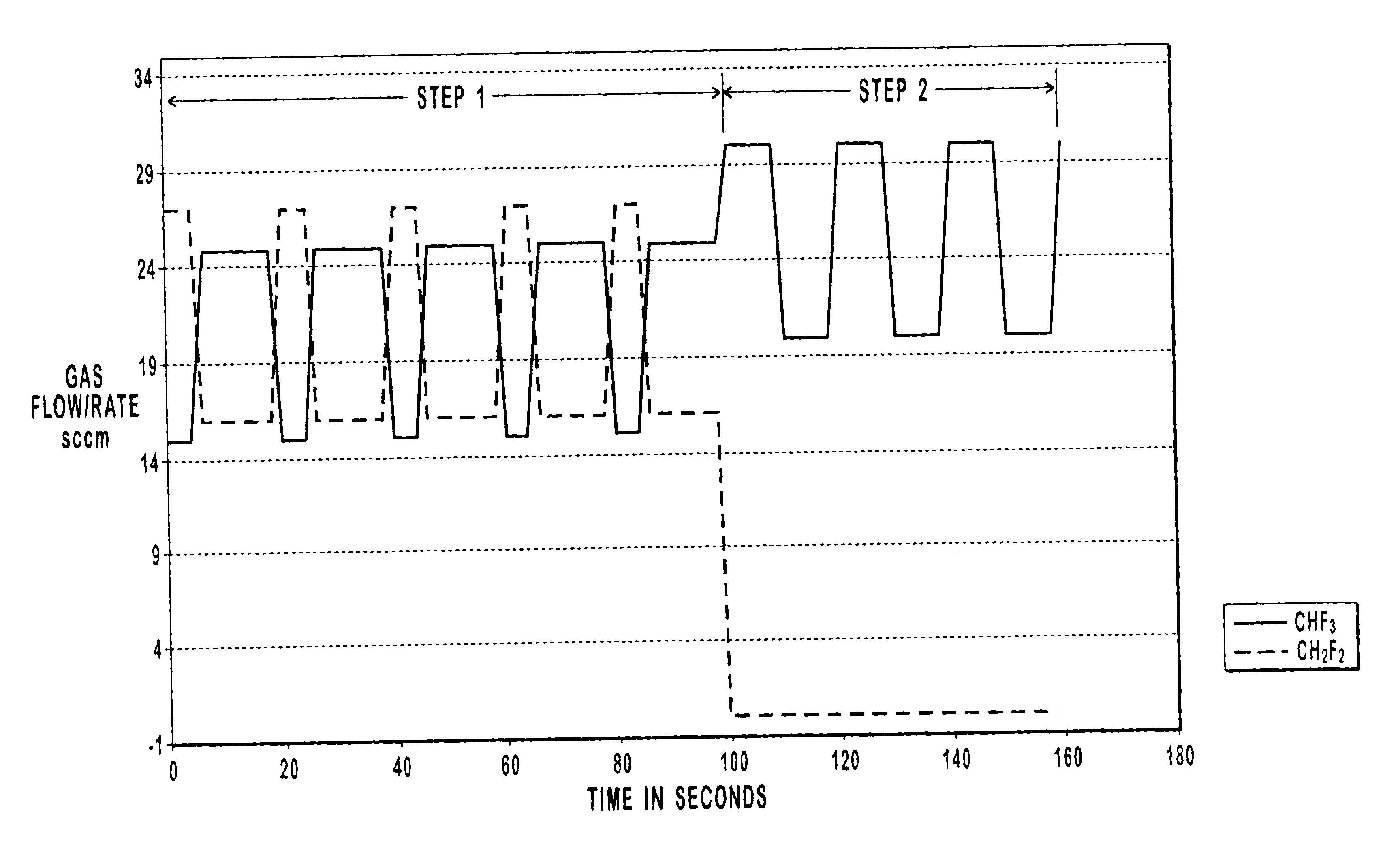

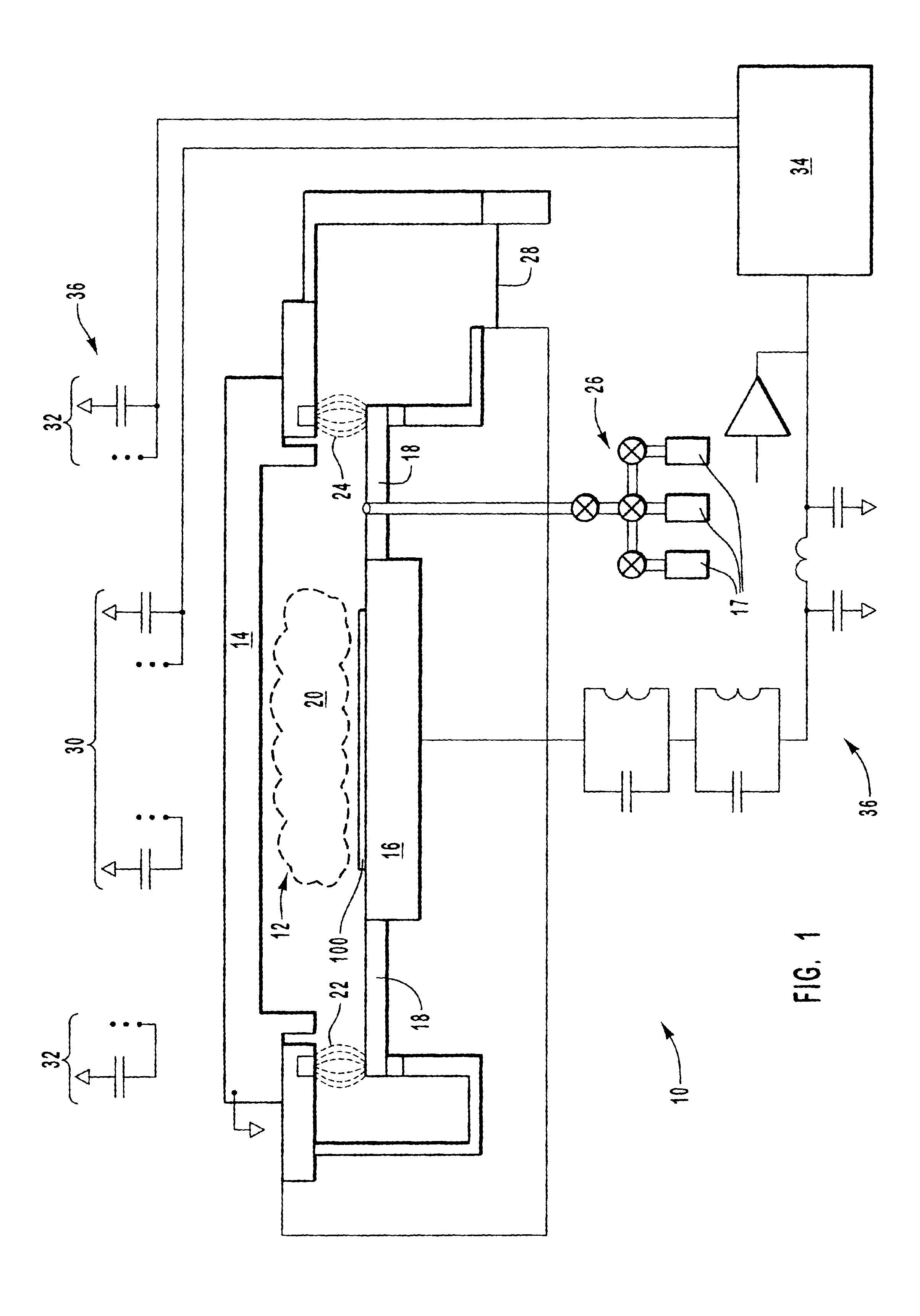

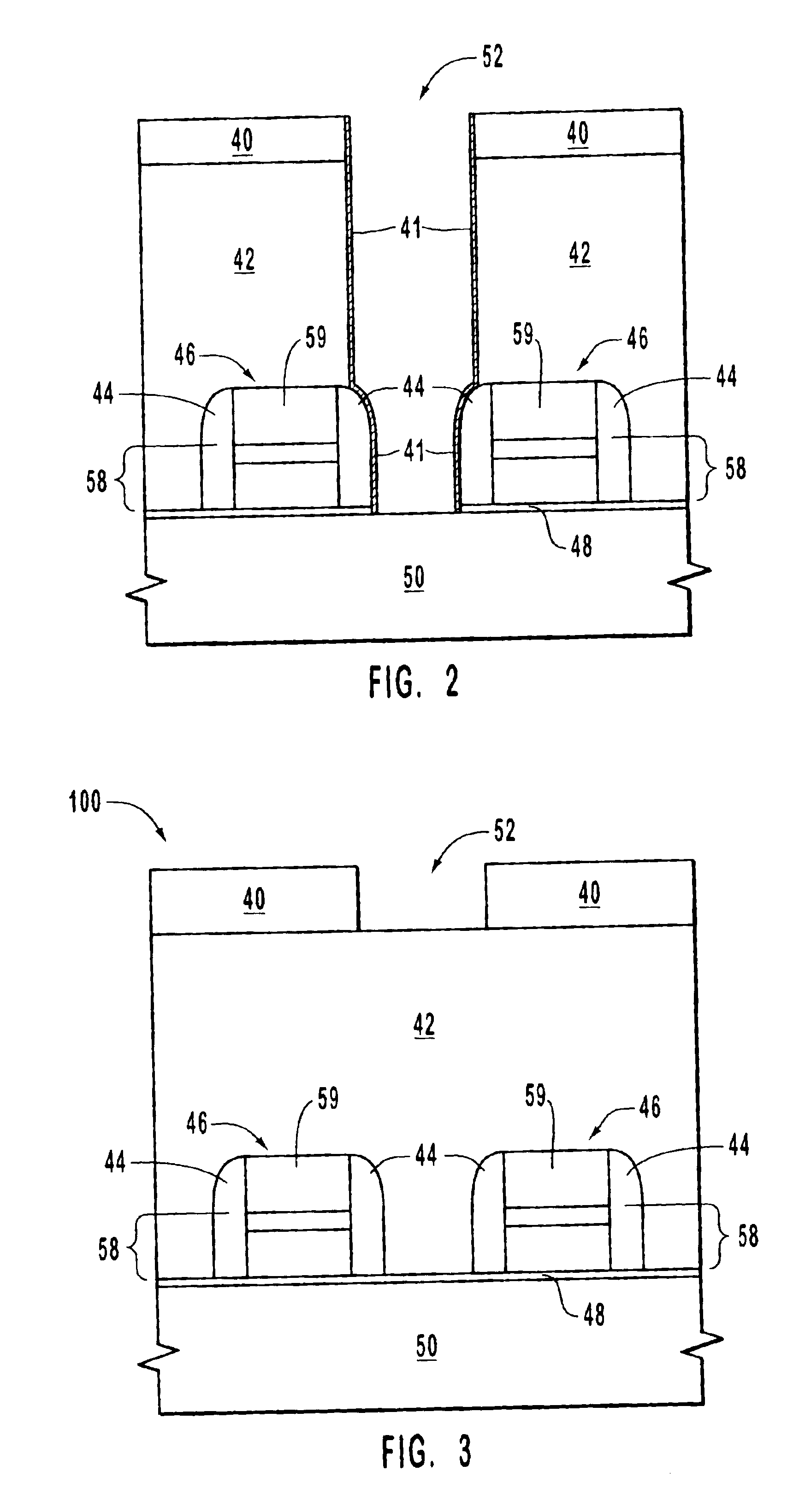

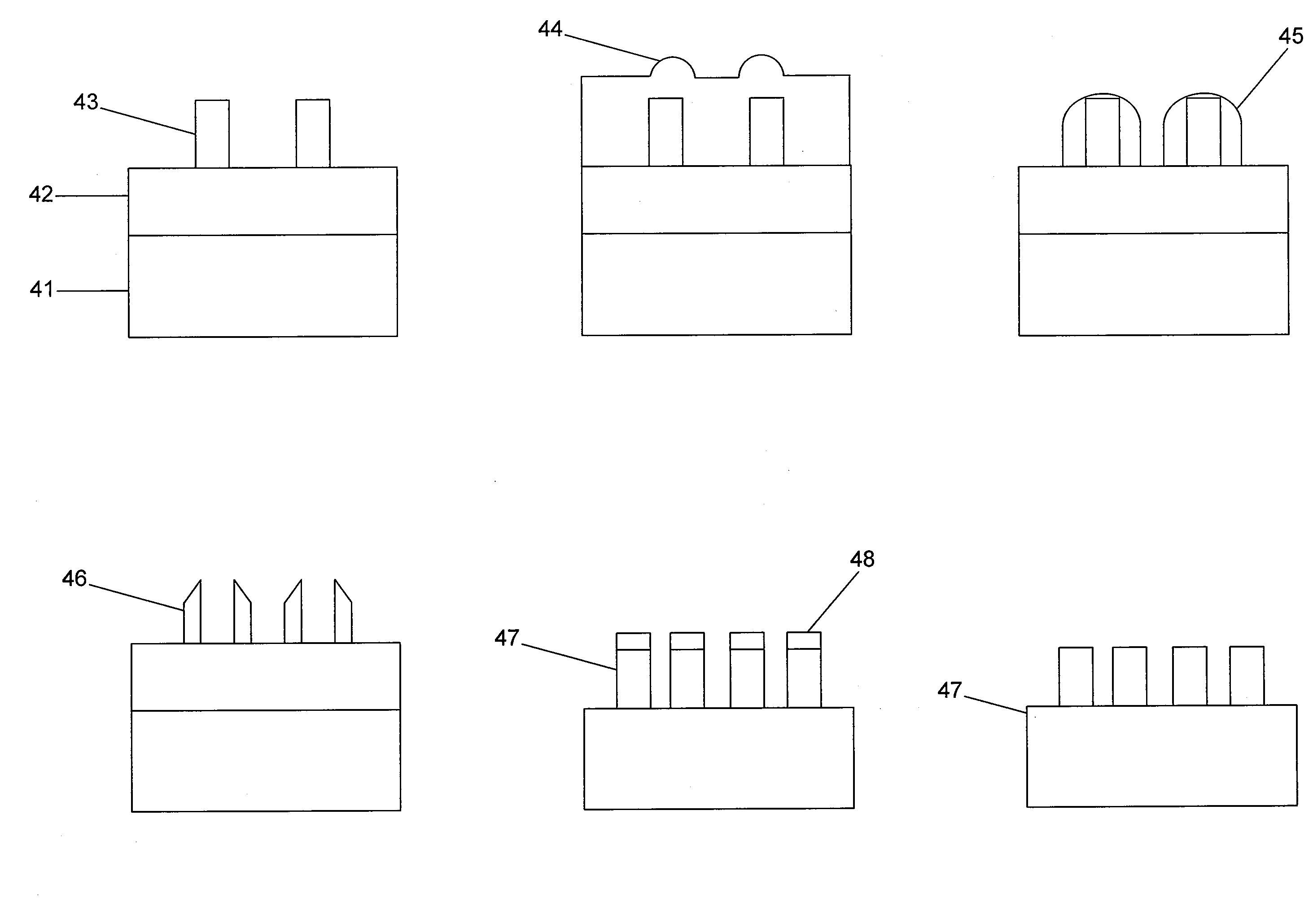

Gas pulsing for etch profile control

InactiveUS6784108B1Increase flow rateReduce flow rateElectric discharge tubesDecorative surface effectsEngineeringAnisotropic etching

Etch profile control with pulsed gas flow and its applications to etching such as anisotropic etching of high aspect ratio features and etching of self-aligned contact structures in various processes. Pulsing can be applied according to this invention to the flow rate of a gas such as an etchant gas, a gas that leads to the deposition of a protective layer, a gas that modifies the deposition of a protective layer, and a gas that modifies etching.

Owner:MICRON TECH INC

Method of depositing dielectric film by modified peald method

ActiveUS20120220139A1Increase deposition rateHigh conformalitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingNoble gasHydrogen

A method of forming a film on a semiconductor substrate by plasma enhanced atomic layer deposition (PEALD), includes: introducing a nitrogen- and hydrogen-containing reactive gas and a rare gas into a reaction space inside which the semiconductor substrate is placed; introducing a precursor in pulses of less than 1.0-second duration into the reaction space wherein the reactive gas and the rare gas are introduced; exiting a plasma in pulses of less than 1.0-second duration immediately after the precursor is shut off; and maintaining the reactive gas and the rare gas as a purge of less than 2.0-second duration.

Owner:ASM JAPAN

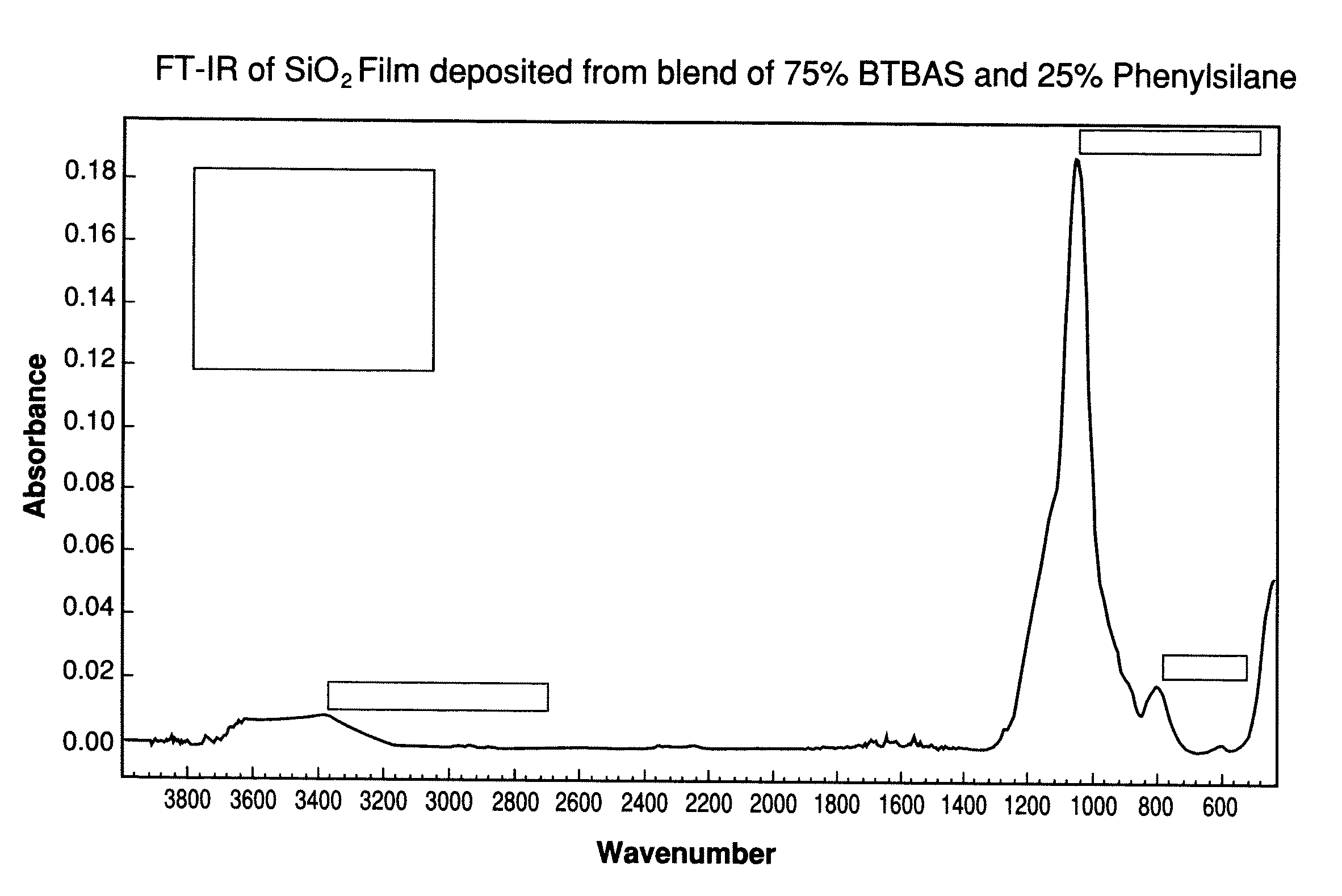

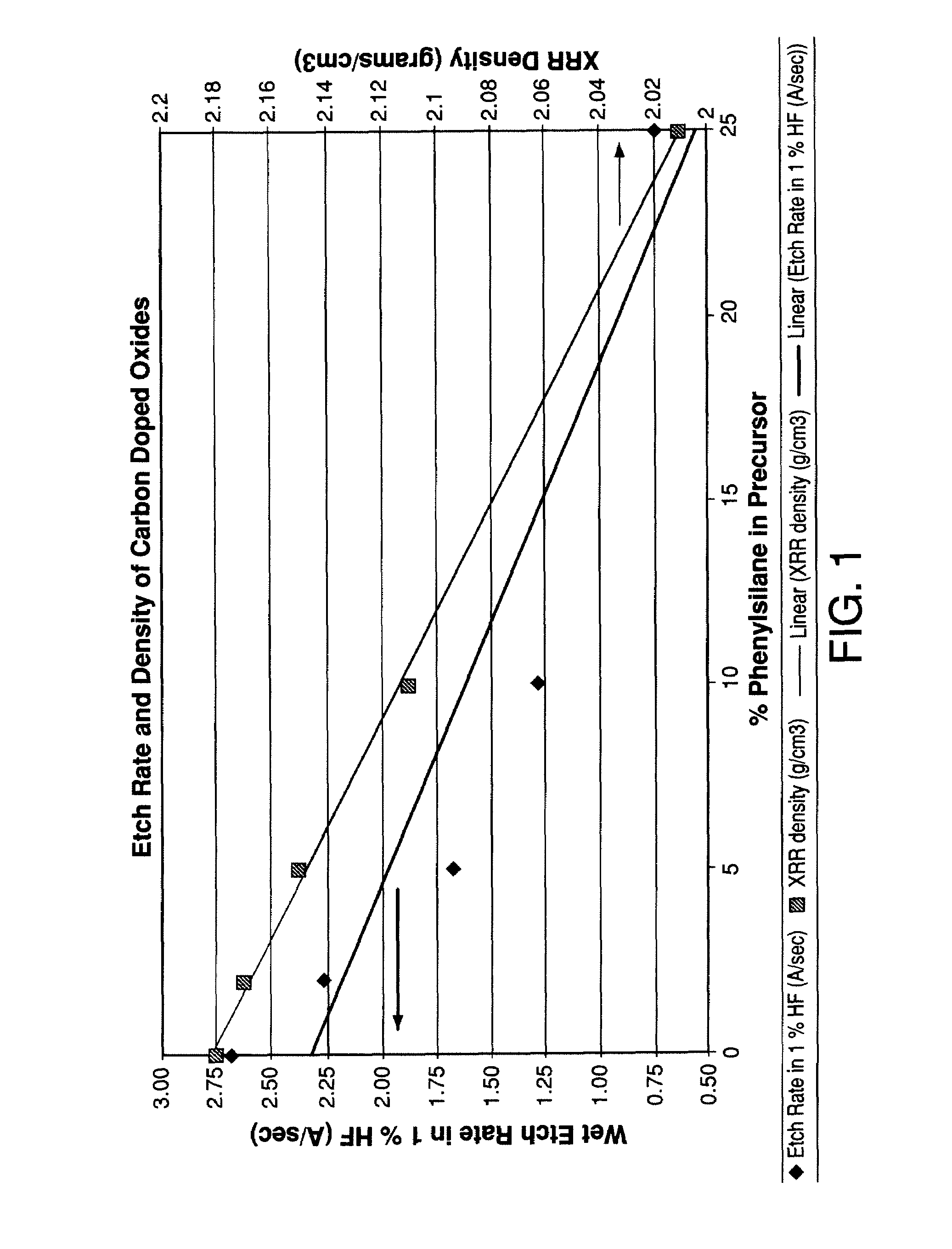

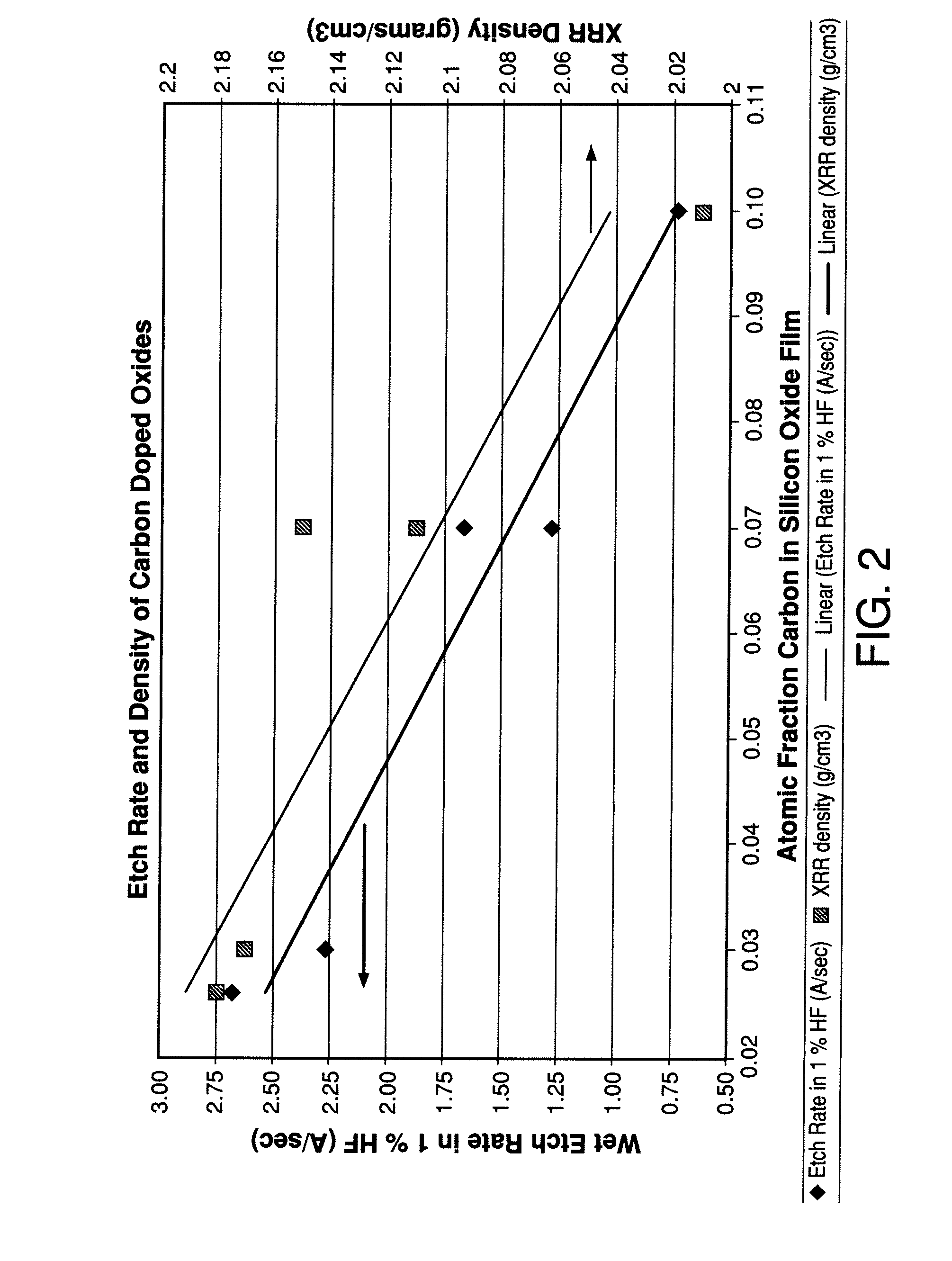

Organosilane compounds for modifying dielectrical properties of silicon oxide and silicon nitride films

InactiveUS20080124946A1Excellent etch resistanceIncreasing flow ratioSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSilicon oxideChemical Modifier

The present invention discloses a process for depositing a carbon containing silicon oxide film, or a carbon containing silicon nitride film having enhanced etch resistance. The process comprises using a silicon containing precursor, a carbon containing precursor and a chemical modifier. The present invention also discloses a process for depositing a silicon oxide film, or silicon nitride film having enhanced etch resistance comprising using an organosilane precursor and a chemical modifier.

Owner:VERSUM MATERIALS US LLC

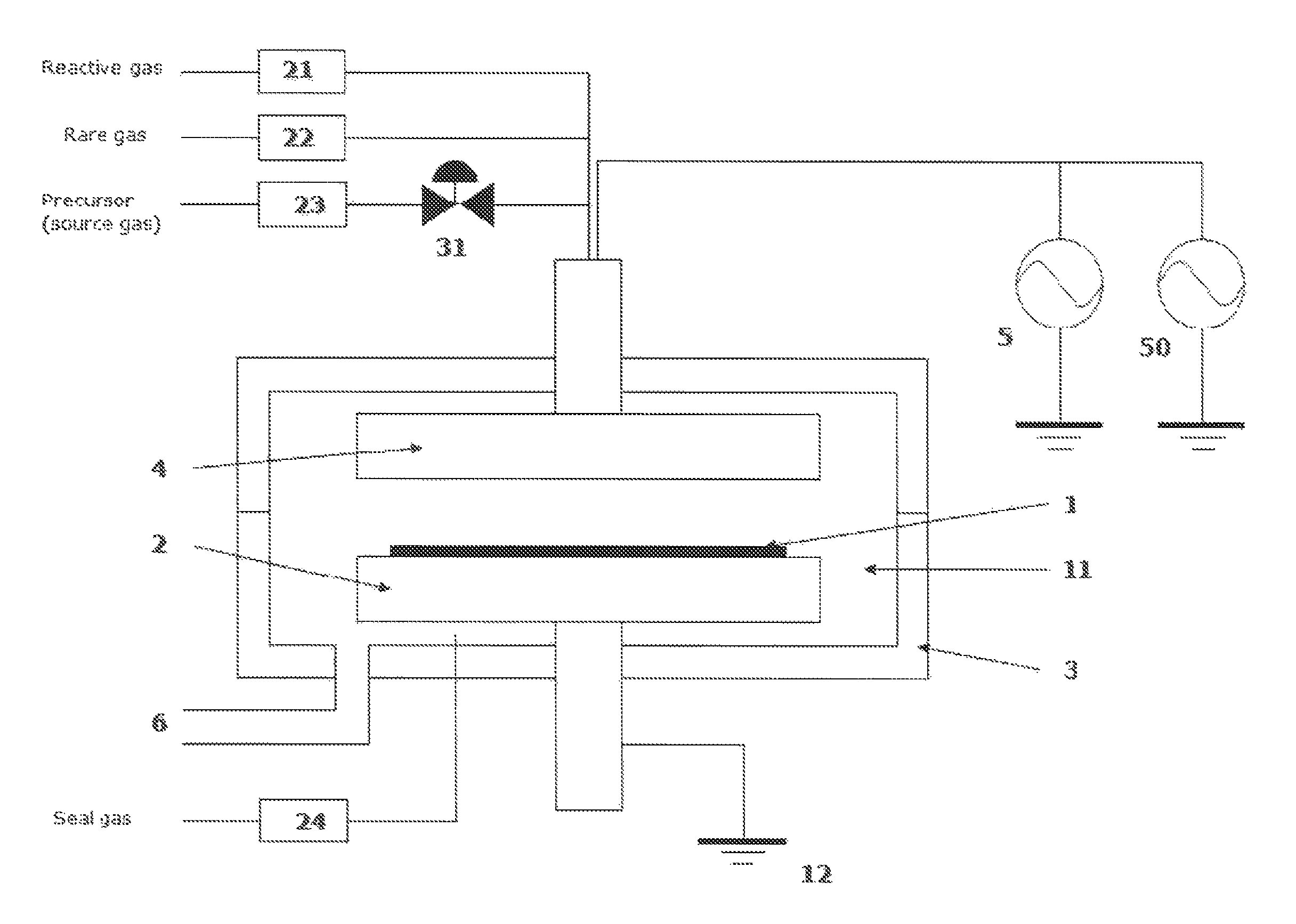

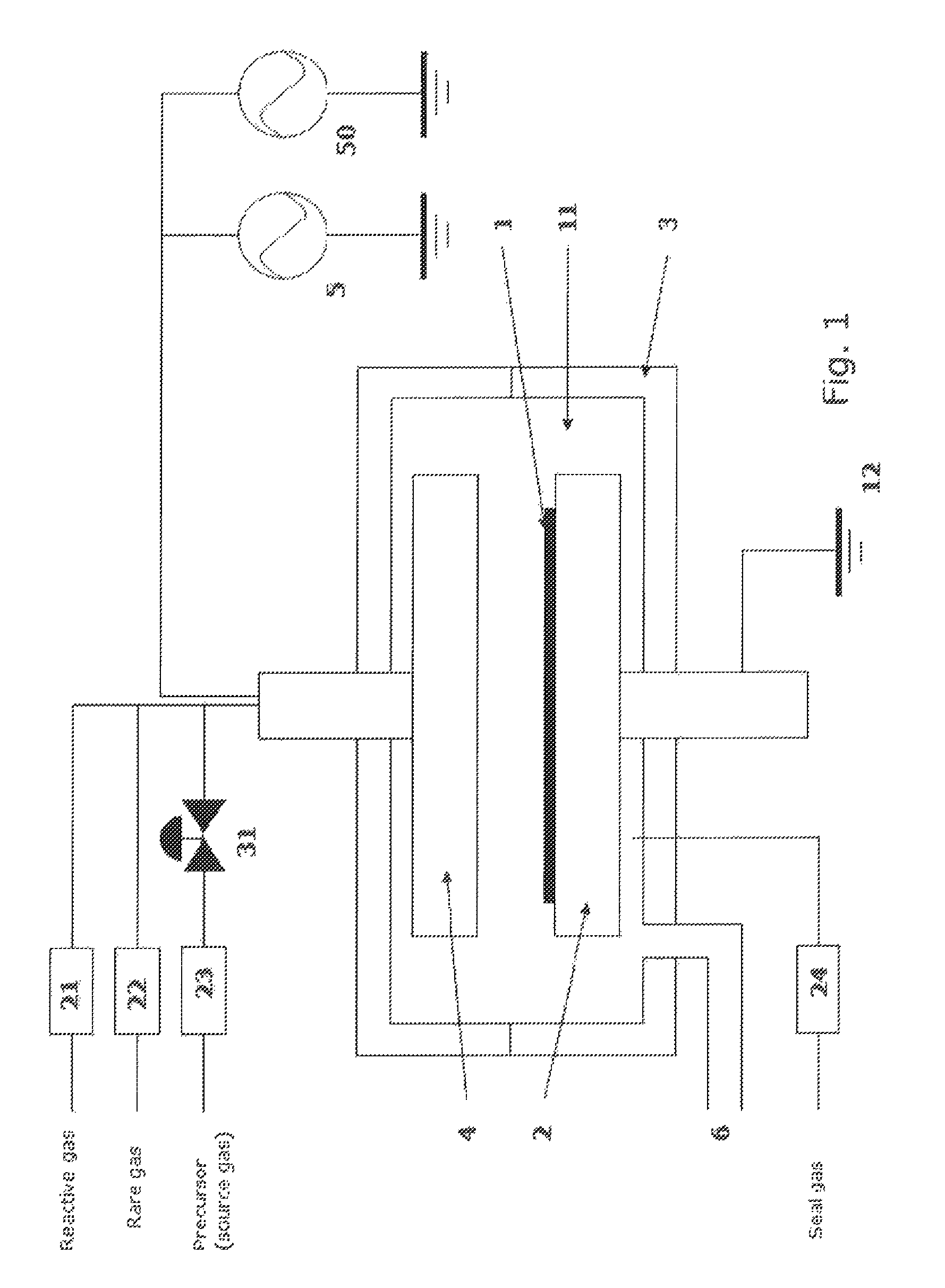

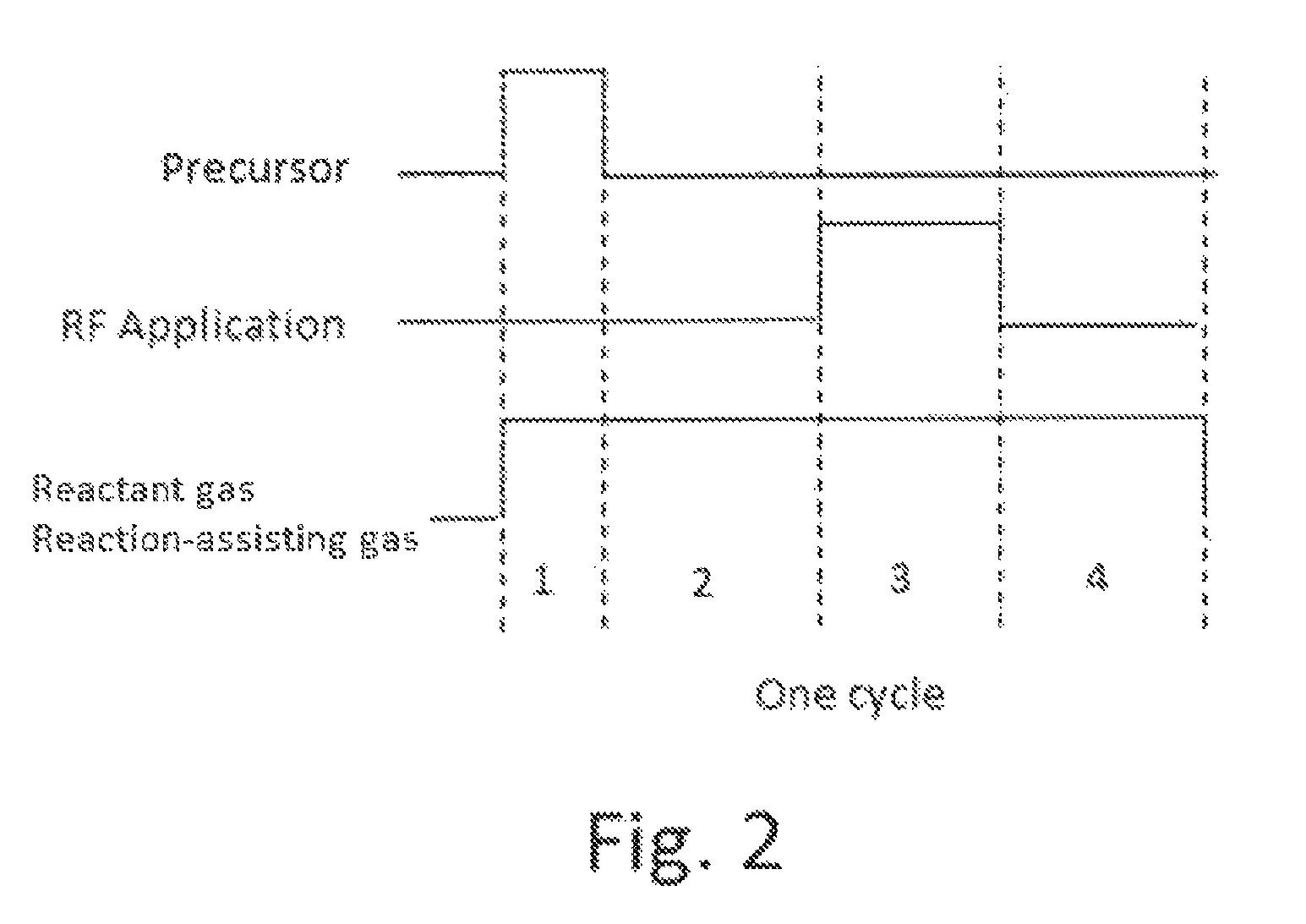

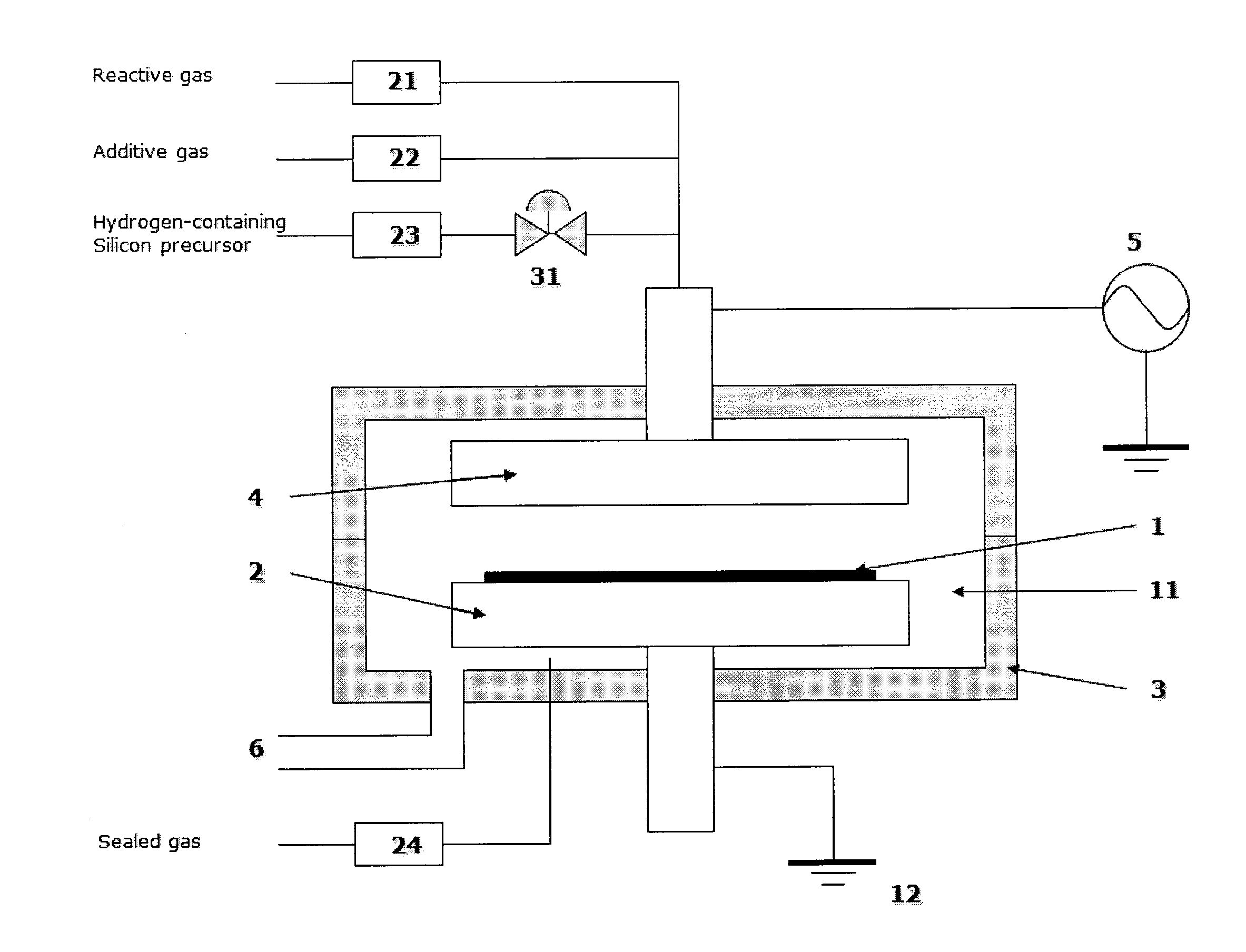

Method of forming conformal dielectric film having Si-N bonds by PECVD

ActiveUS7972980B2Increase deposition rateHigh conformalitySemiconductor/solid-state device detailsSolid-state devicesDielectricNoble gas

Owner:ASM JAPAN

METHOD OF FORMING CONFORMAL DIELECTRIC FILM HAVING Si-N BONDS BY PECVD

ActiveUS20100144162A1Reduce the temperatureIncrease deposition rateSemiconductor/solid-state device manufacturingSolid state diffusion coatingDielectricHydrogen

A method of forming a conformal dielectric film having Si—N bonds on a semiconductor substrate by plasma enhanced chemical vapor deposition (PECVD) includes: introducing a nitrogen- and hydrogen-containing reactive gas and an additive gas into a reaction space inside which a semiconductor substrate is placed; applying RF power to the reaction space; and introducing a hydrogen-containing silicon precursor in pulses into the reaction space wherein a plasma is excited, thereby forming a conformal dielectric film having Si—N bonds on the substrate.

Owner:ASM JAPAN

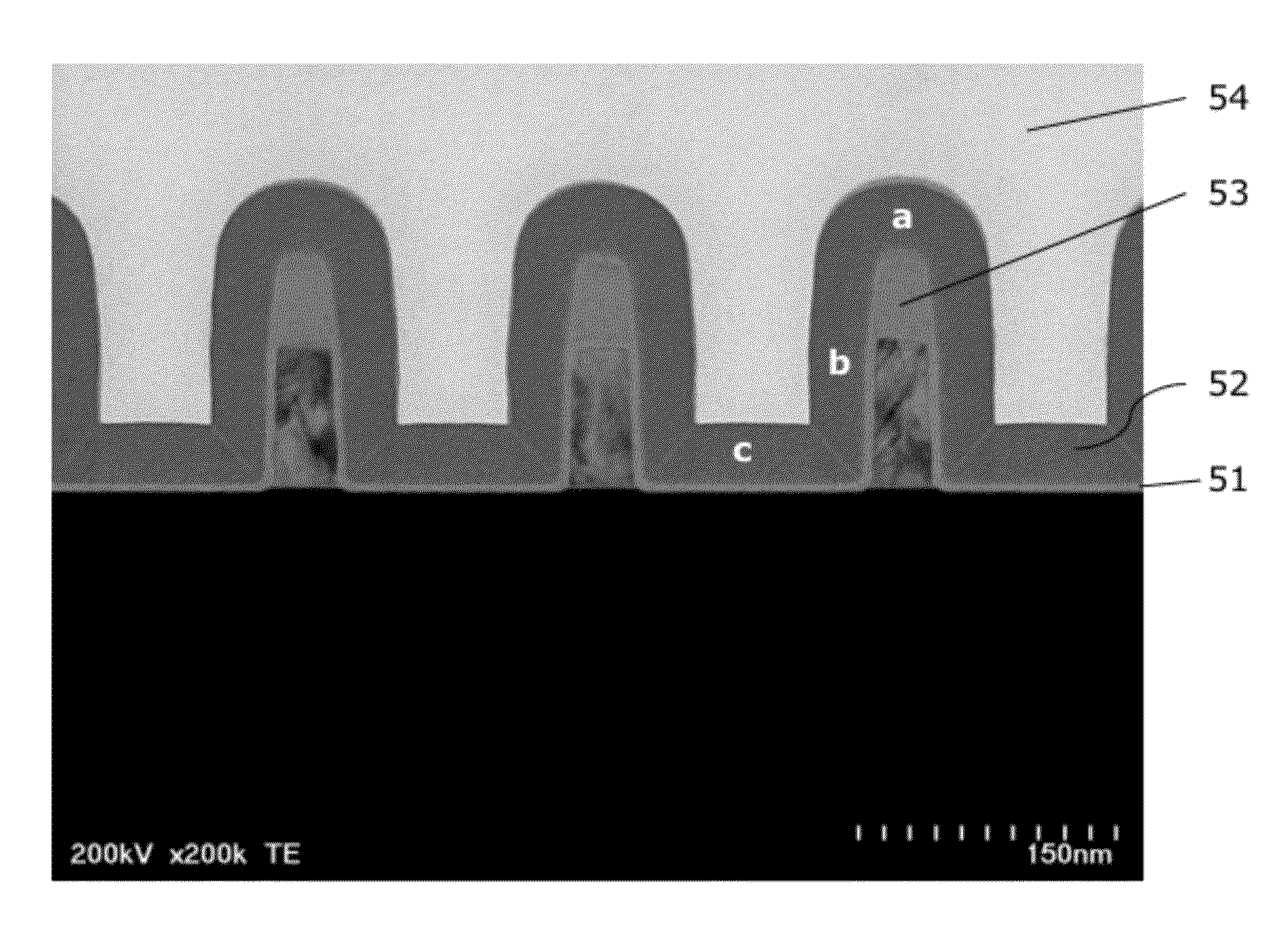

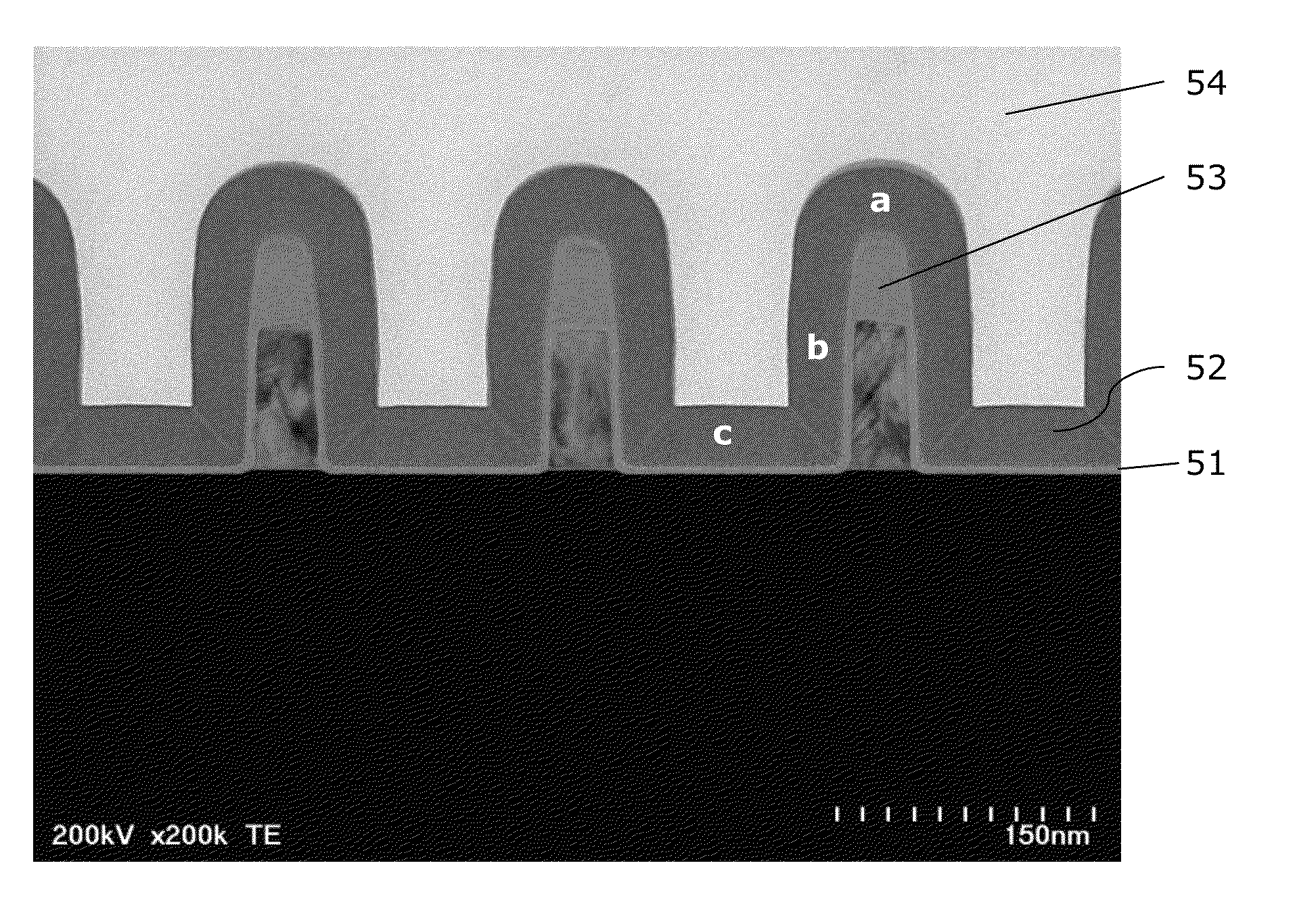

Method for forming dielectric film in trenches by PEALD using H-containing gas

ActiveUS9455138B1Increase deposition rateHigh film thicknessSemiconductor/solid-state device manufacturingChemical physicsNoble gas

A method for forming a dielectric film in a trench on a substrate by plasma-enhanced atomic layer deposition (PEALD) performs one or more process cycles, each process cycle including: (i) feeding a silicon-containing precursor in a pulse; (ii) supplying a hydrogen-containing reactant gas at a flow rate of more than about 30 sccm but less than about 800 sccm in the absence of nitrogen-containing gas; (iii) supplying a noble gas to the reaction space; and (iv) applying RF power in the presence of the reactant gas and the noble gas and in the absence of any precursor in the reaction space, to form a monolayer constituting a dielectric film on a substrate at a growth rate of less than one atomic layer thickness per cycle.

Owner:ASM IP HLDG BV

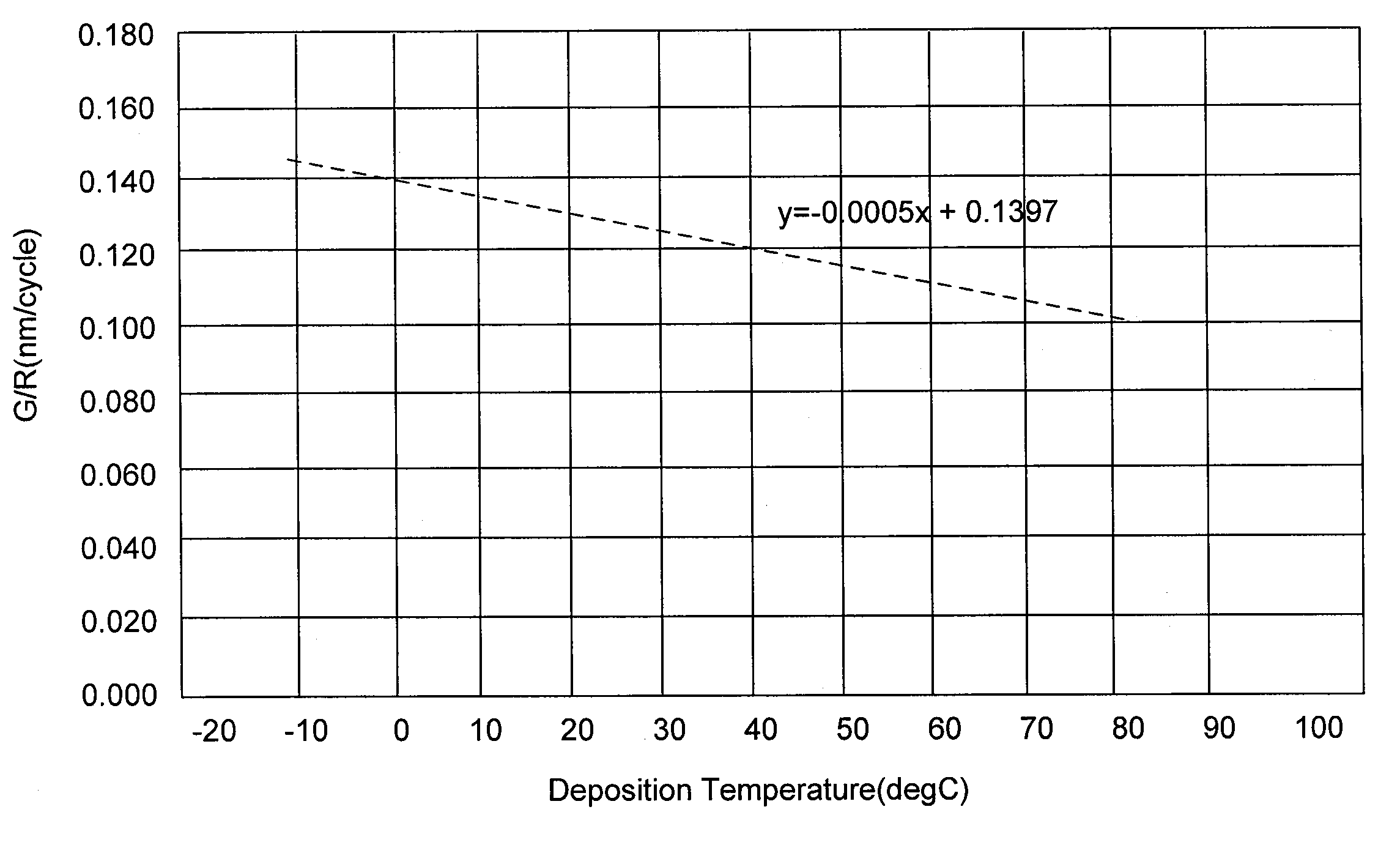

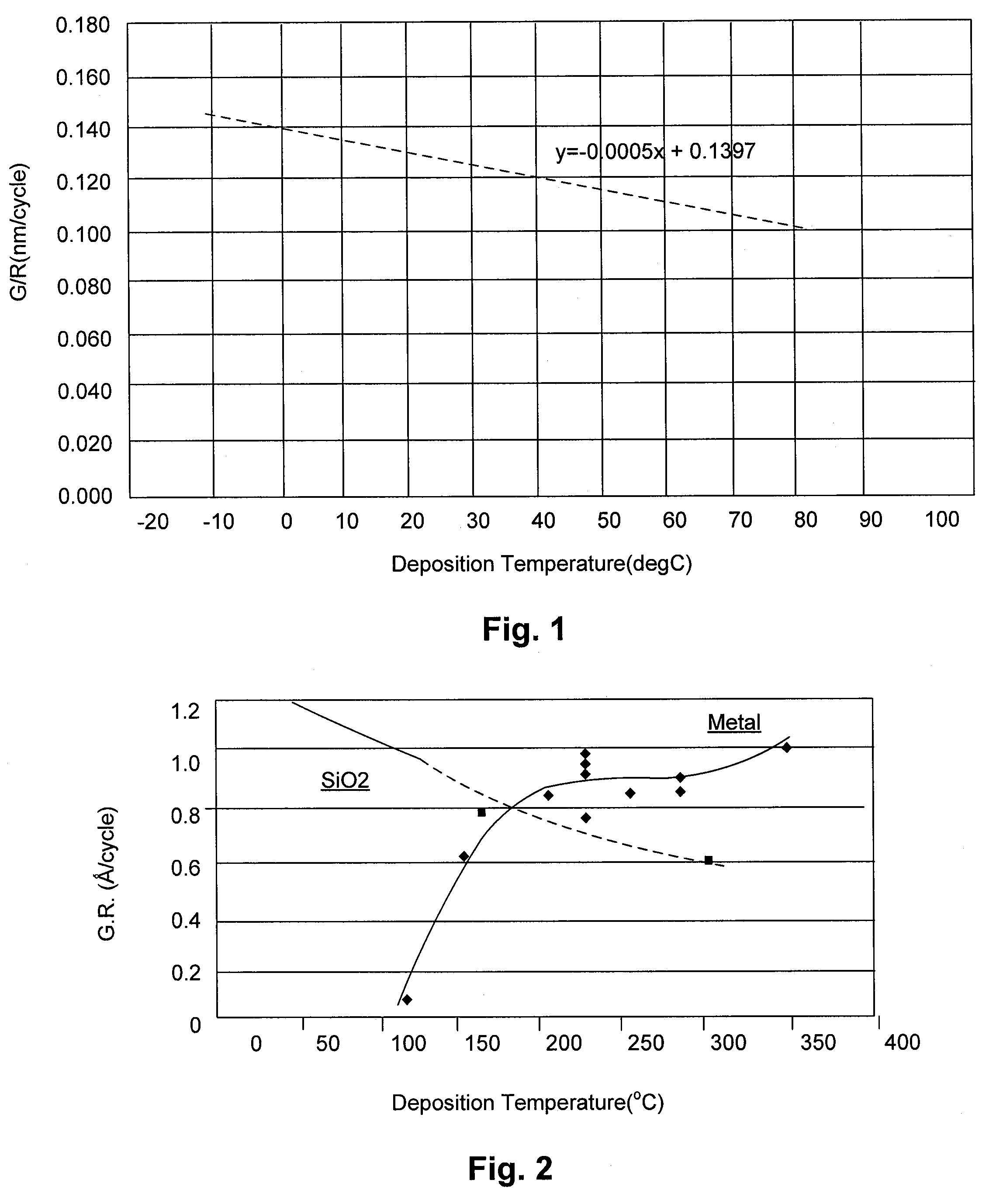

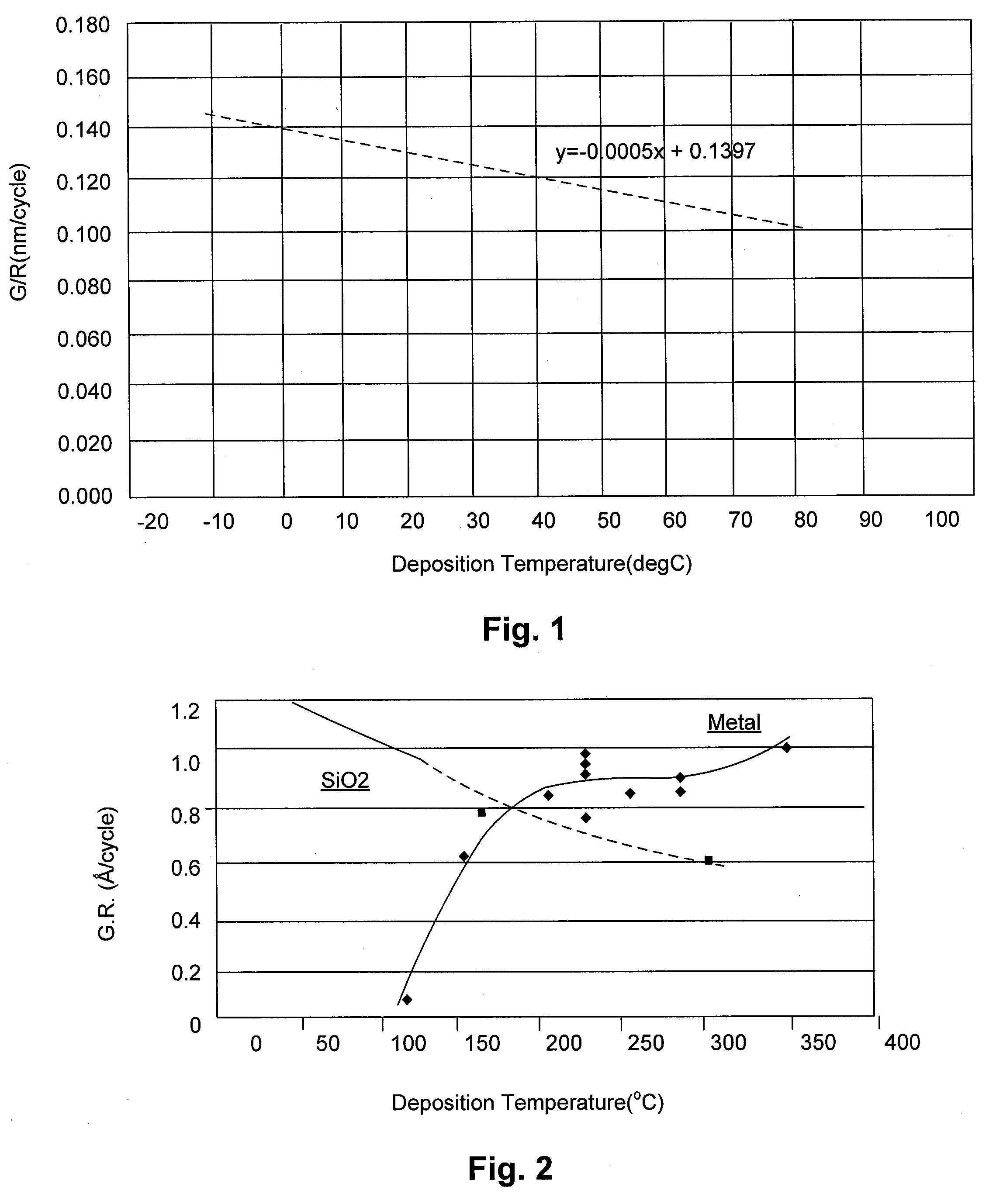

Method of depositing silicon oxide film by plasma enhanced atomic layer deposition at low temperature

ActiveUS8197915B2Increase deposition rateInhibition is effectiveSemiconductor/solid-state device manufacturingPhotosensitive material processingResistDeposition temperature

Owner:ASM JAPAN

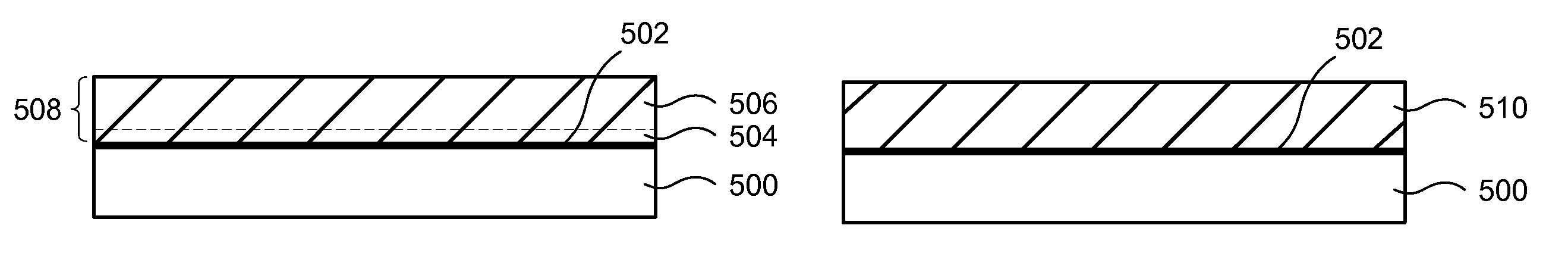

Method for forming aluminum oxide film using Al compound containing alkyl group and alkoxy or alkylamine group

ActiveUS8784950B2Safety with regard to handling and storage of the precursor can be ensuredDamage is causedChemical vapor deposition coatingPlasma techniqueProduct gasPhotochemistry

A method for forming a conformal film of aluminum oxide on a substrate having a patterned underlying layer by PEALD includes: adsorbing an Al precursor containing an Al—C bond and an Al—O—C or Al—N—C bond; providing an oxidizing gas and an inert gas; applying RF power to the reactant gas and the reaction-assisting gas to react the adsorbed precursor with the reactant gas on the surface, thereby forming a conformal film of aluminum oxide on the patterned underlying layer of the substrate, wherein the substrate is kept at a temperature of about 200° C. or lower.

Owner:ASM IP HLDG BV

Method of depositing dielectric film by modified PEALD method

ActiveUS8415259B2Increase deposition rateHigh conformalitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingElectricityNoble gas

A method of forming a film on a semiconductor substrate by plasma enhanced atomic layer deposition (PEALD), includes: introducing a nitrogen- and hydrogen-containing reactive gas and a rare gas into a reaction space inside which the semiconductor substrate is placed; introducing a precursor in pulses of less than 1.0-second duration into the reaction space wherein the reactive gas and the rare gas are introduced; exiting a plasma in pulses of less than 1.0-second duration immediately after the precursor is shut off; and maintaining the reactive gas and the rare gas as a purge of less than 2.0-second duration.

Owner:ASM JAPAN

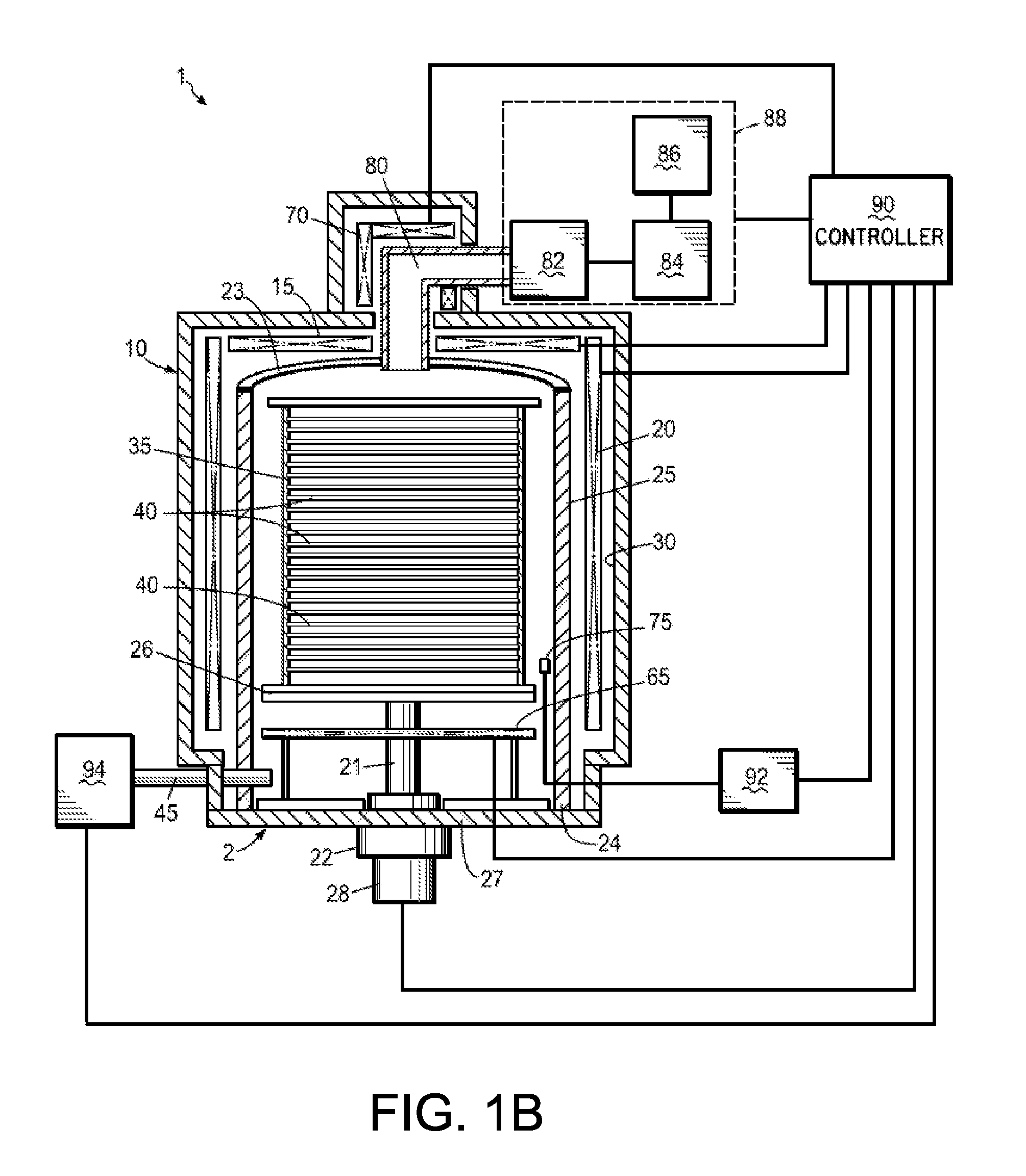

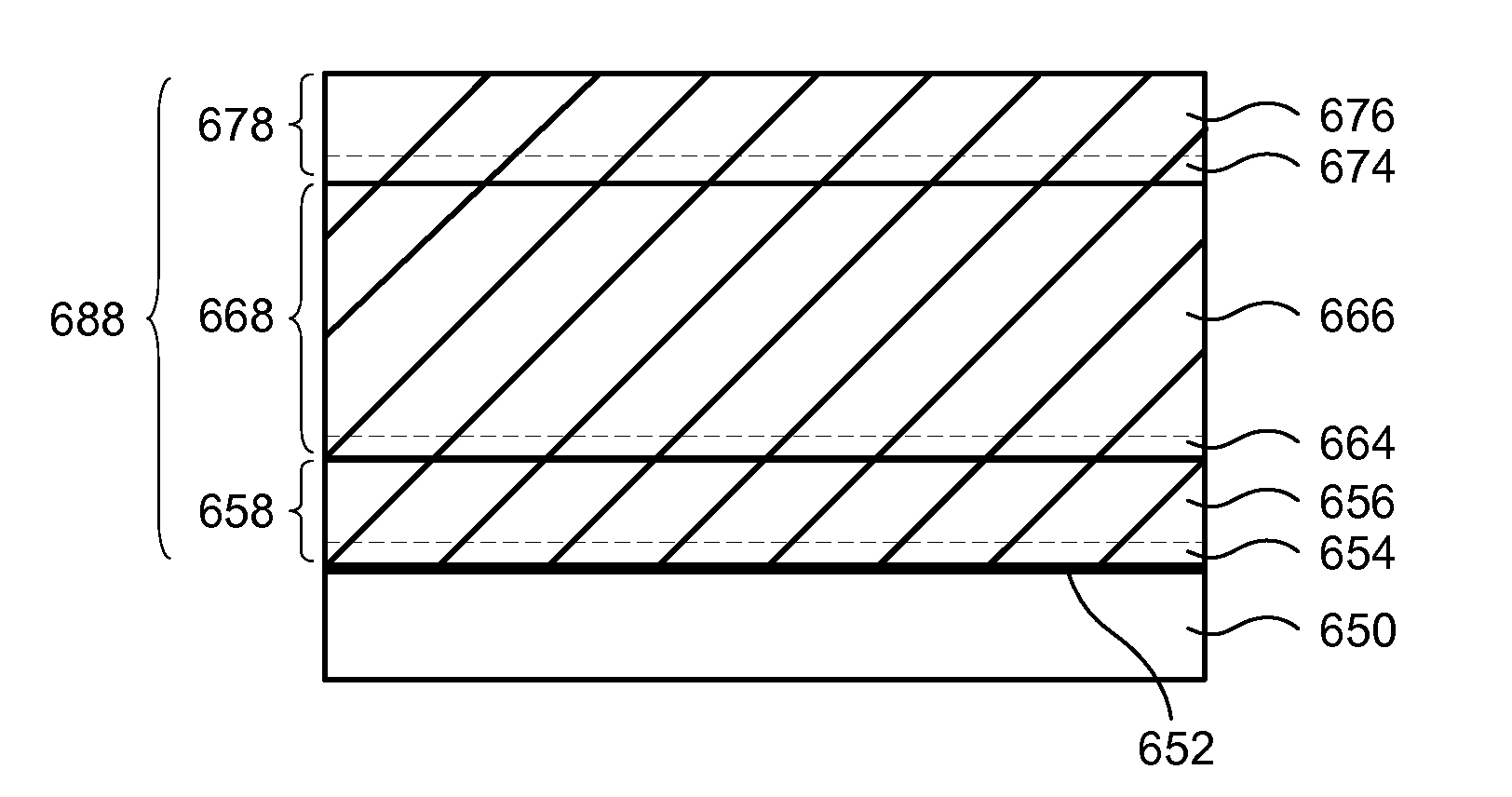

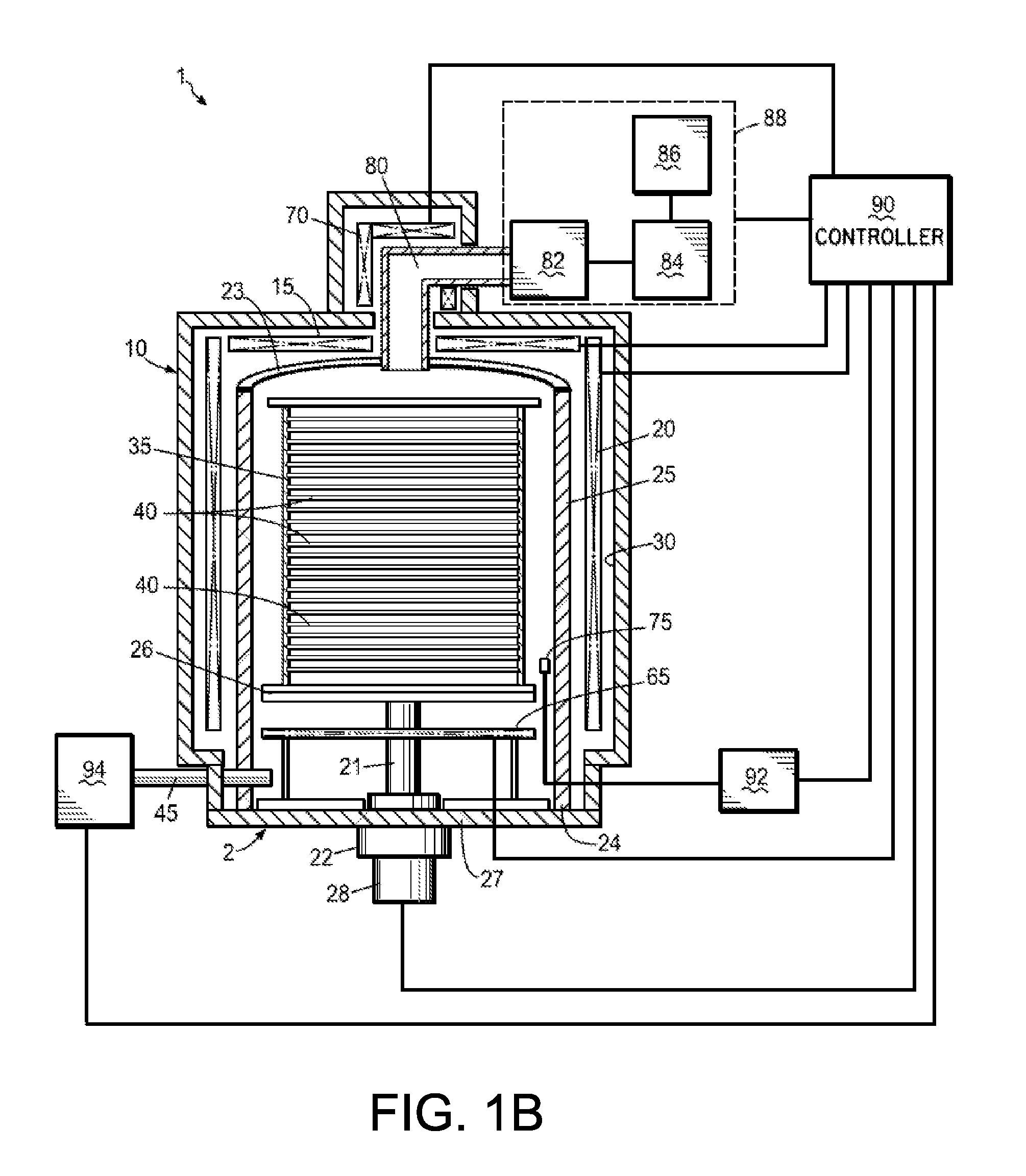

In-situ hybrid deposition of high dielectric constant films using atomic layer deposition and chemical vapor deposition

InactiveUS7816278B2Rapid temperature measurementIncrease deposition rateSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectricBatch processing

An in-situ hybrid film deposition method for forming a high-k dielectric film on a plurality of substrates in a batch processing system. The method includes loading the plurality of substrates into a process chamber of the batch processing system, depositing by atomic layer deposition (ALD) a first portion of a high-k dielectric film on the plurality of substrates, after depositing the first portion, and without removing the plurality of substrates from the process chamber, depositing by chemical vapor deposition (CVD) a second portion of the high-k dielectric film on the first portion, and removing the plurality of substrates from the process chamber. The method can further include alternatingly repeating the deposition of the first and second portions until the high-k dielectric film has a desired thickness. The method can still further include pre-treating the substrates and post-treating the high-k dielectric film in-situ prior to the removing.

Owner:TOKYO ELECTRON LTD

Method of forming conformal dielectric film having Si-N bonds by PECVD

ActiveUS8142862B2Increase deposition rateHigh conformalitySemiconductor/solid-state device manufacturingSolid state diffusion coatingDielectricElectricity

A method of forming a conformal dielectric film having Si—N bonds on a semiconductor substrate by plasma enhanced chemical vapor deposition (PECVD) includes: introducing a nitrogen- and hydrogen-containing reactive gas and an additive gas into a reaction space inside which a semiconductor substrate is placed; applying RF power to the reaction space; and introducing a hydrogen-containing silicon precursor in pulses into the reaction space wherein a plasma is excited, thereby forming a conformal dielectric film having Si—N bonds on the substrate.

Owner:ASM JAPAN

Method of Depositing Silicon Oxide Film by Plasma Enhanced Atomic Layer Deposition at Low Temperature

ActiveUS20100255218A1Increase deposition rateInhibition is effectiveLiquid surface applicatorsSemiconductor/solid-state device manufacturingResistDeposition temperature

A method of depositing a silicon oxide film on a resist pattern or etched lines formed on a substrate by plasma enhanced atomic layer deposition (PEALD) includes: providing a substrate on which a resist pattern or etched lines are formed in a PEALD reactor; controlling a temperature of a susceptor on which the substrate is placed at less than 50° C. as a deposition temperature; introducing a silicon-containing precursor and an oxygen-supplying reactant to the PEALD reactor and applying RF power therein in a cycle, while the deposition temperature is controlled substantially or nearly at a constant temperature of less than 50° C., thereby depositing a silicon oxide atomic layer on the resist pattern or etched lines; and repeating the cycle multiple times substantially or nearly at the constant temperature to deposit a silicon oxide atomic film on the resist pattern or etched lines.

Owner:ASM JAPAN

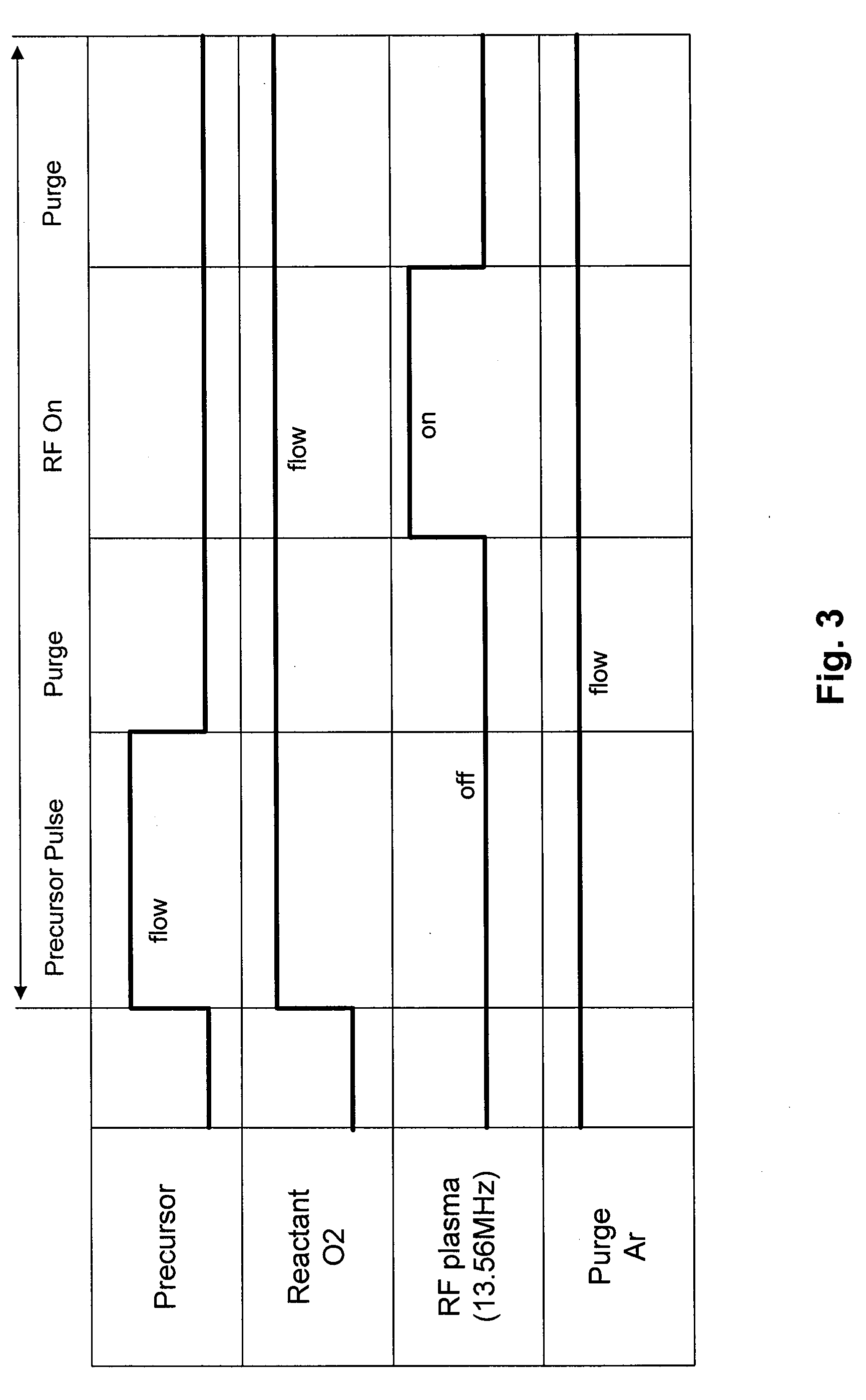

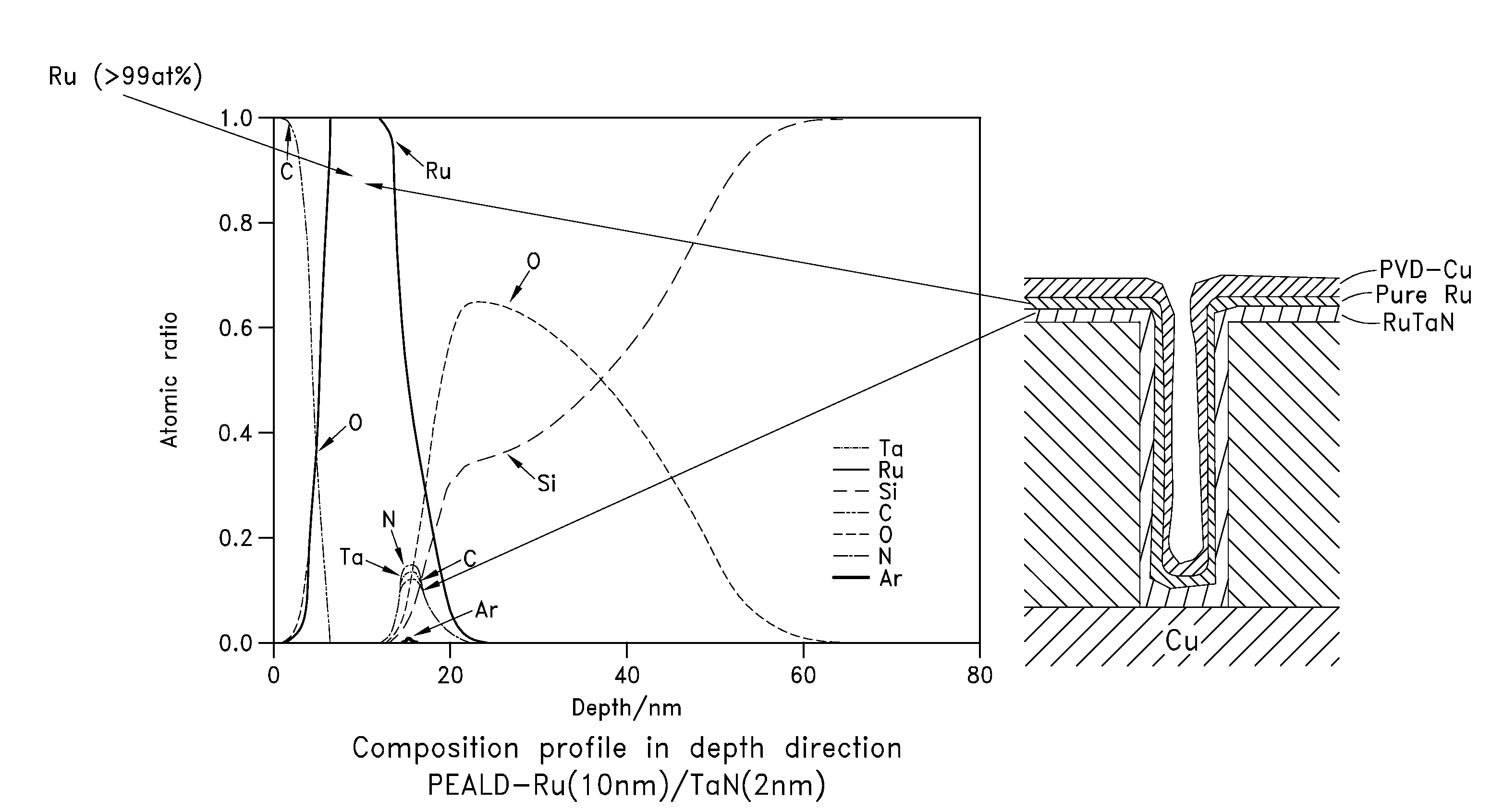

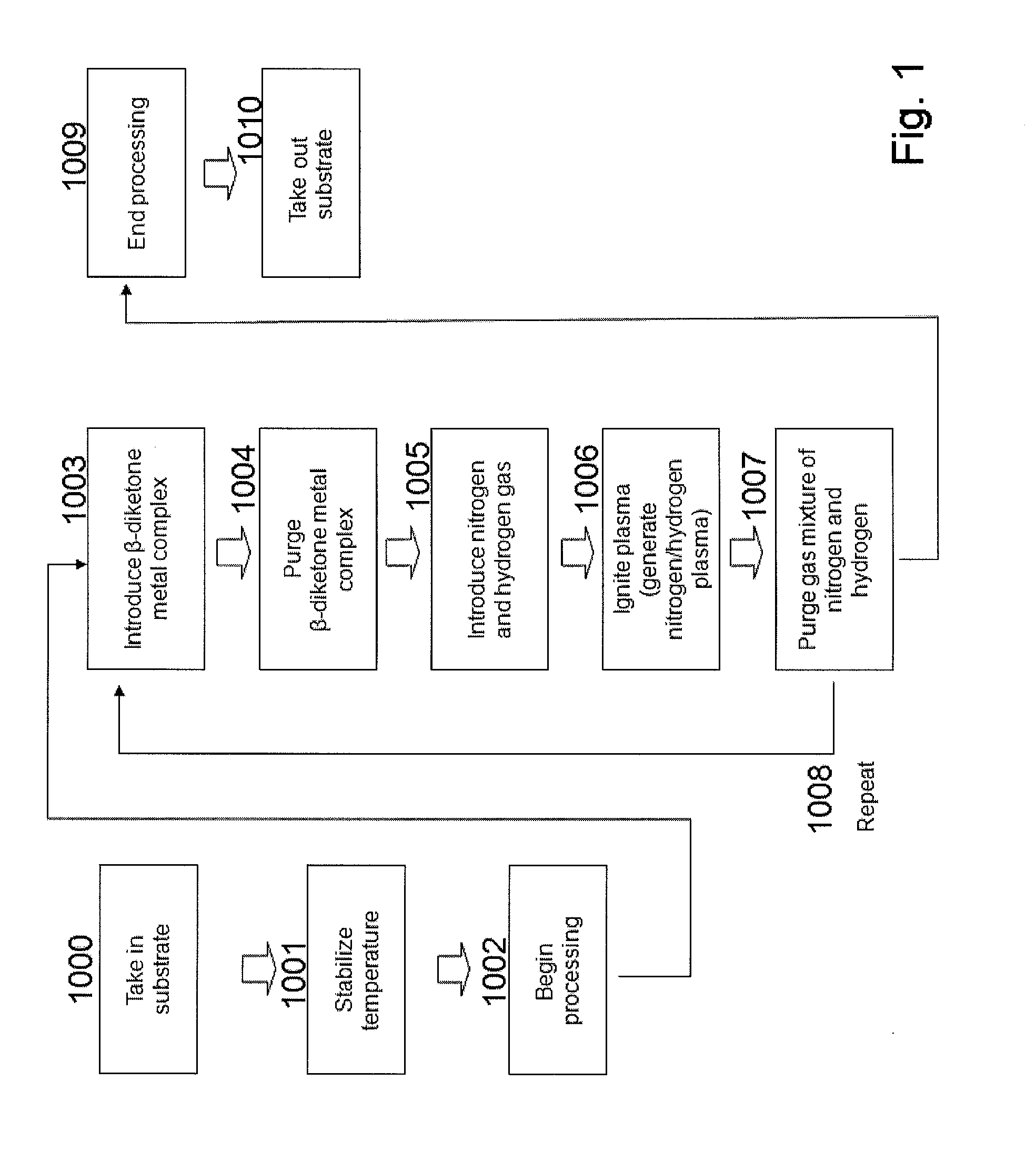

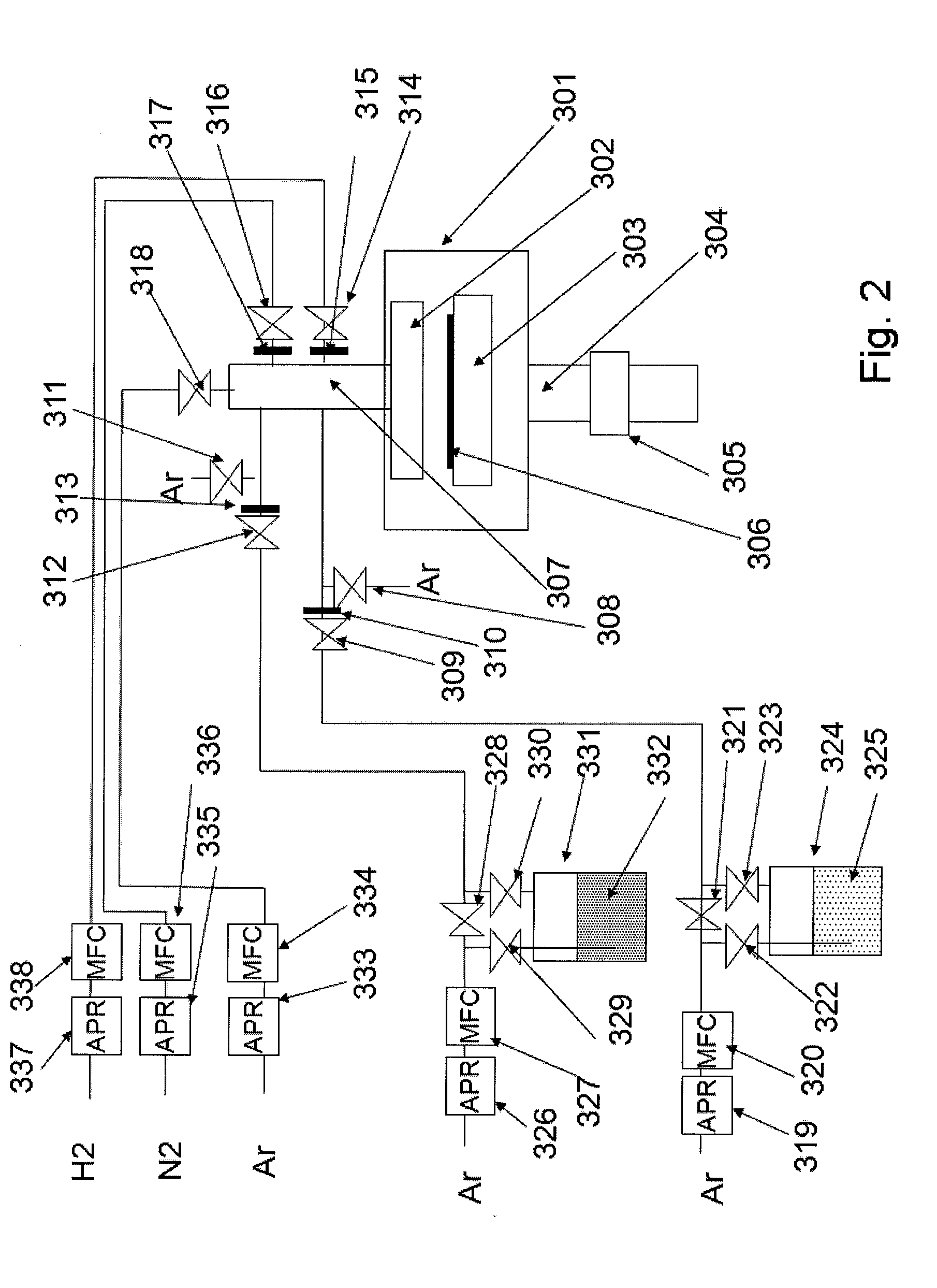

Method for forming metal film by ald using beta-diketone metal complex

ActiveUS20100092696A1Improve shielding effectRapid and reliable mannerVacuum evaporation coatingPretreated surfacesDiketoneHydrogen

A method of forming a single-metal film on a substrate by plasma ALD includes: contacting a surface of a substrate with a β-diketone metal complex in a gas phase; exposing molecule-attached surface to a nitrogen-hydrogen mixed plasma; and repeating the above steps, thereby accumulating atomic layers to form a single-metal film on the substrate.

Owner:ASM JAPAN

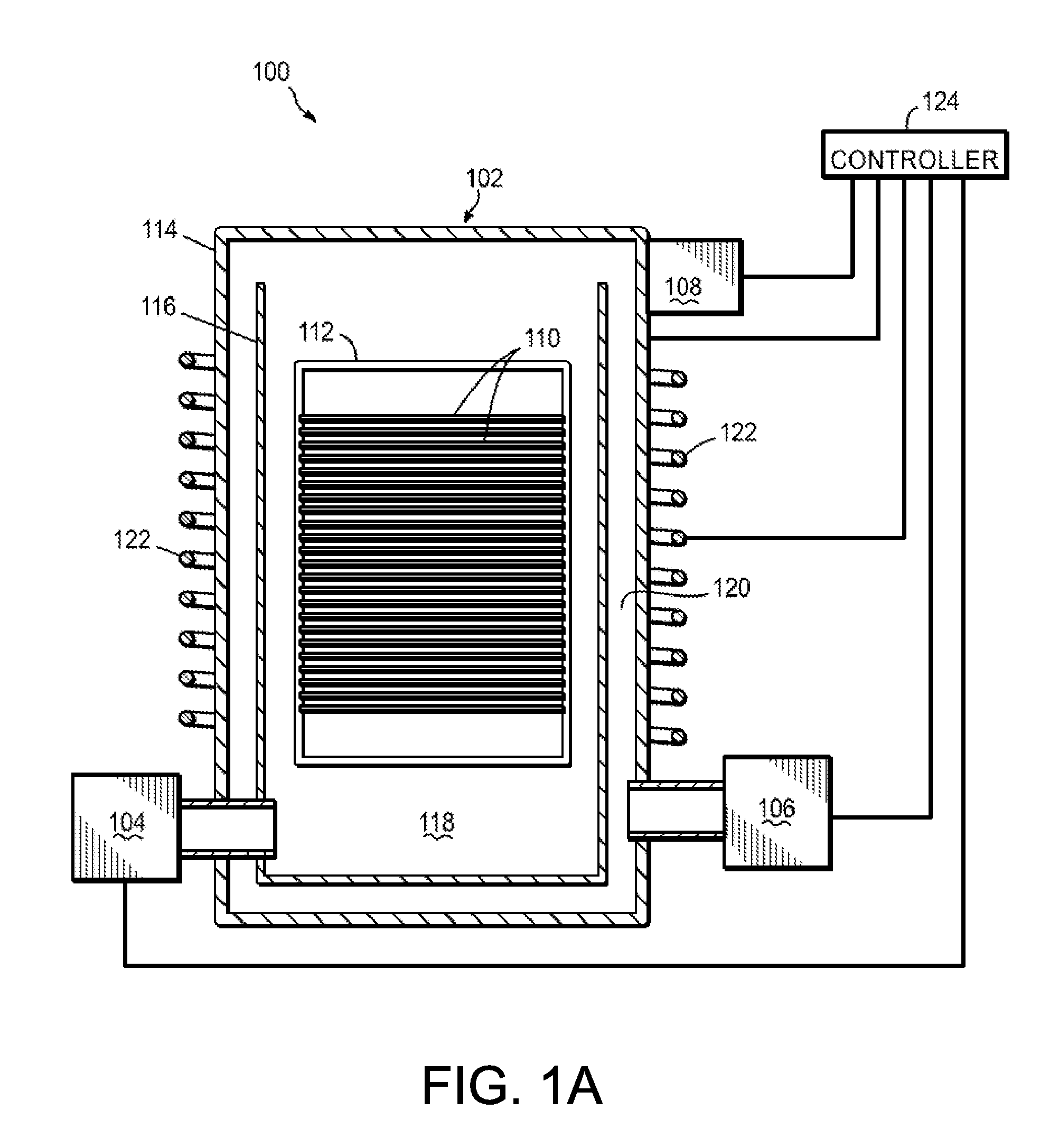

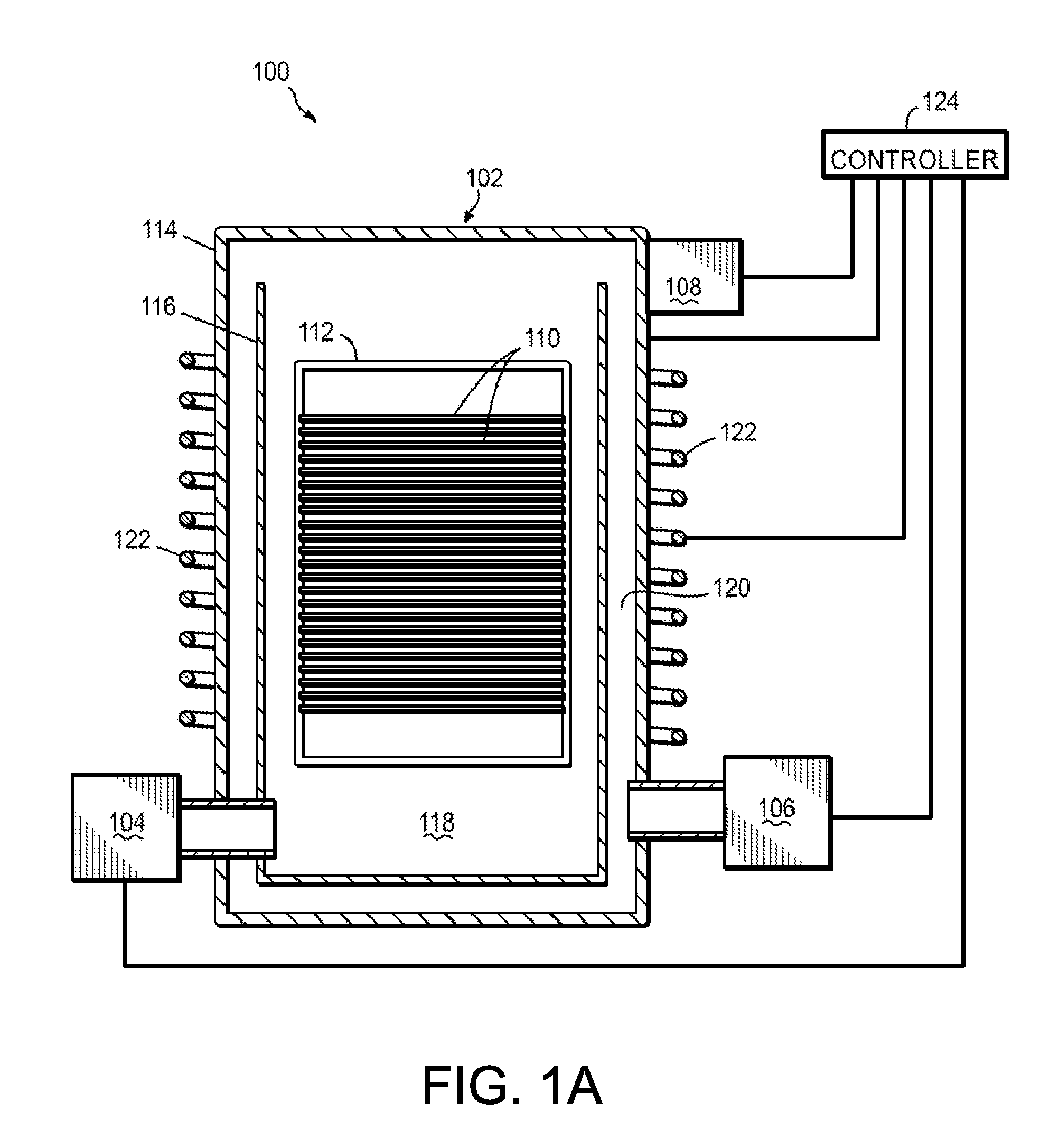

In-situ hybrid deposition of high dielectric constant films using atomic layer deposition and chemical vapor deposition

InactiveUS20090246971A1Cost-effectiveHigh deposition rateSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringHigh dielectric permittivity

An in-situ hybrid film deposition method for forming a high-k dielectric film on a plurality of substrates in a batch processing system. The method includes loading the plurality of substrates into a process chamber of the batch processing system, depositing by atomic layer deposition (ALD) a first portion of a high-k dielectric film on the plurality of substrates, after depositing the first portion, and without removing the plurality of substrates from the process chamber, depositing by chemical vapor deposition (CVD) a second portion of the high-k dielectric film on the first portion, and removing the plurality of substrates from the process chamber. The method can further include alternatingly repeating the deposition of the first and second portions until the high-k dielectric film has a desired thickness. The method can still further include pre-treating the substrates and post-treating the high-k dielectric film in-situ prior to the removing.

Owner:TOKYO ELECTRON LTD

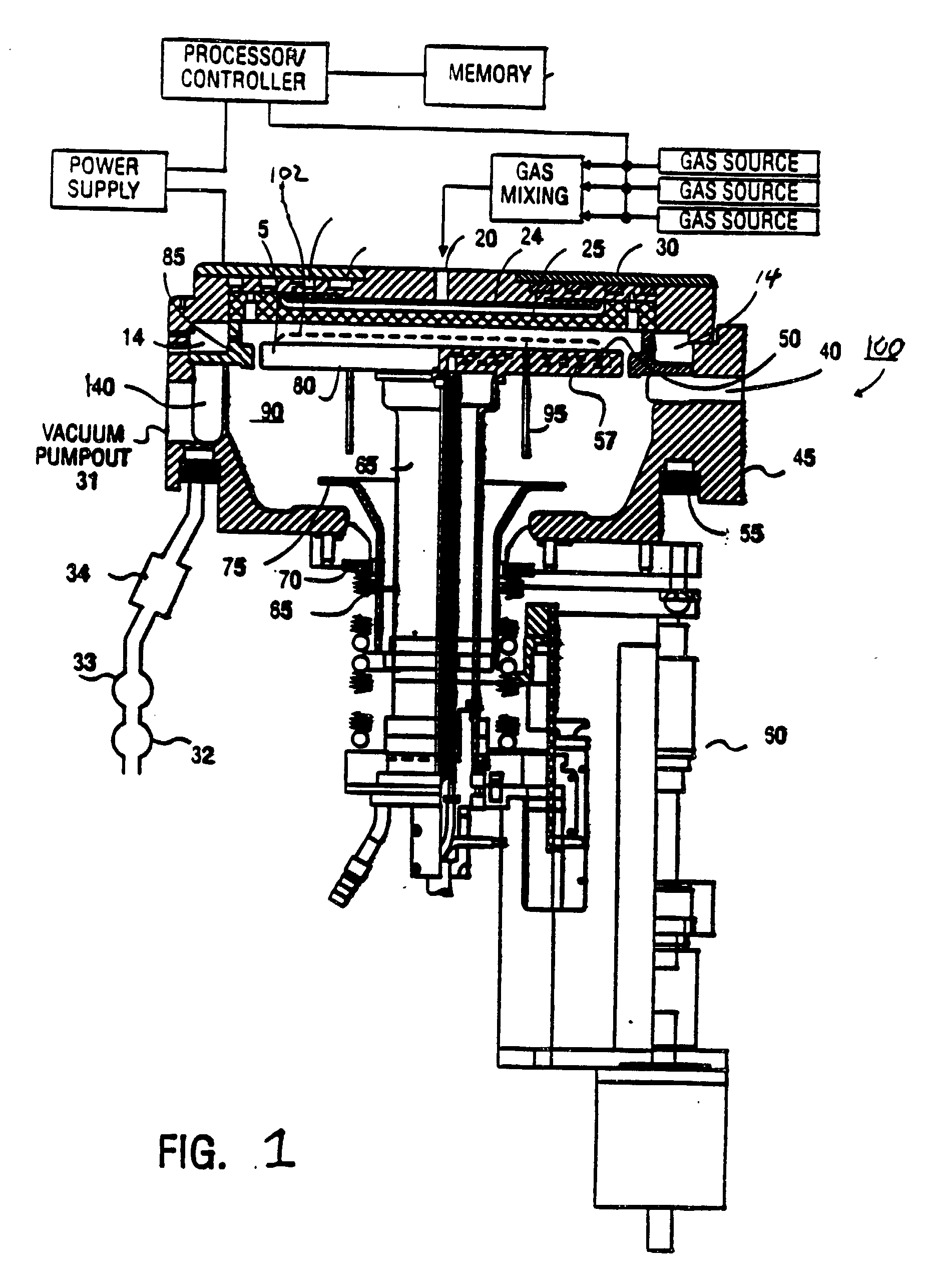

Method and apparatus for forming silicon containing films

InactiveUS20030124818A1Lower activation energyDecomposes faster and more efficientlyFrom solid stateSemiconductor/solid-state device manufacturingElectrical resistance and conductanceActivation energy

The present invention describes a method and apparatus for forming a uniform silicon containing film in a single wafer reactor. According to the present invention, a silicon containing film is deposited in a resistively heated single wafer chamber utilizing a process gas having a silicon source gas and which provides an activation energy less than 0.5 eV at a temperature between 750° C.-550° C.

Owner:APPLIED MATERIALS INC

Method for Forming Aluminum Oxide Film Using Al Compound Containing Alkyl Group and Alkoxy or Alkylamine Group

ActiveUS20140017414A1Increase deposition rateDamage is causedChemical vapor deposition coatingPlasma techniquePhotochemistryConformal film

A method for forming a conformal film of aluminum oxide on a substrate having a patterned underlying layer by PEALD includes: adsorbing an Al precursor containing an Al—C bond and an Al—O—C or Al—N—C bond; providing an oxidizing gas and an inert gas; applying RF power to the reactant gas and the reaction-assisting gas to react the adsorbed precursor with the reactant gas on the surface, thereby forming a conformal film of aluminum oxide on the patterned underlying layer of the substrate, wherein the substrate is kept at a temperature of about 200° C. or lower.

Owner:ASM IP HLDG BV

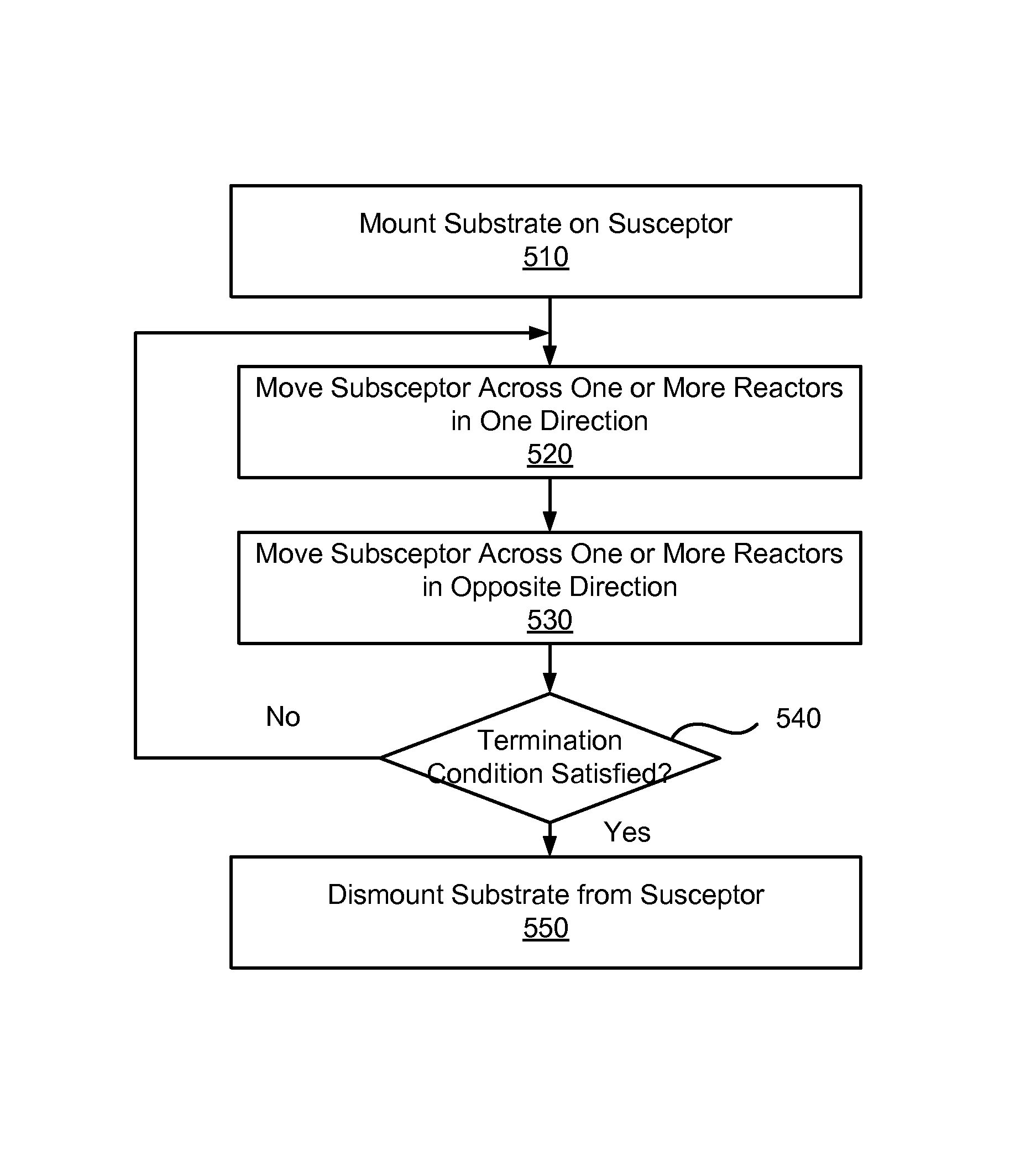

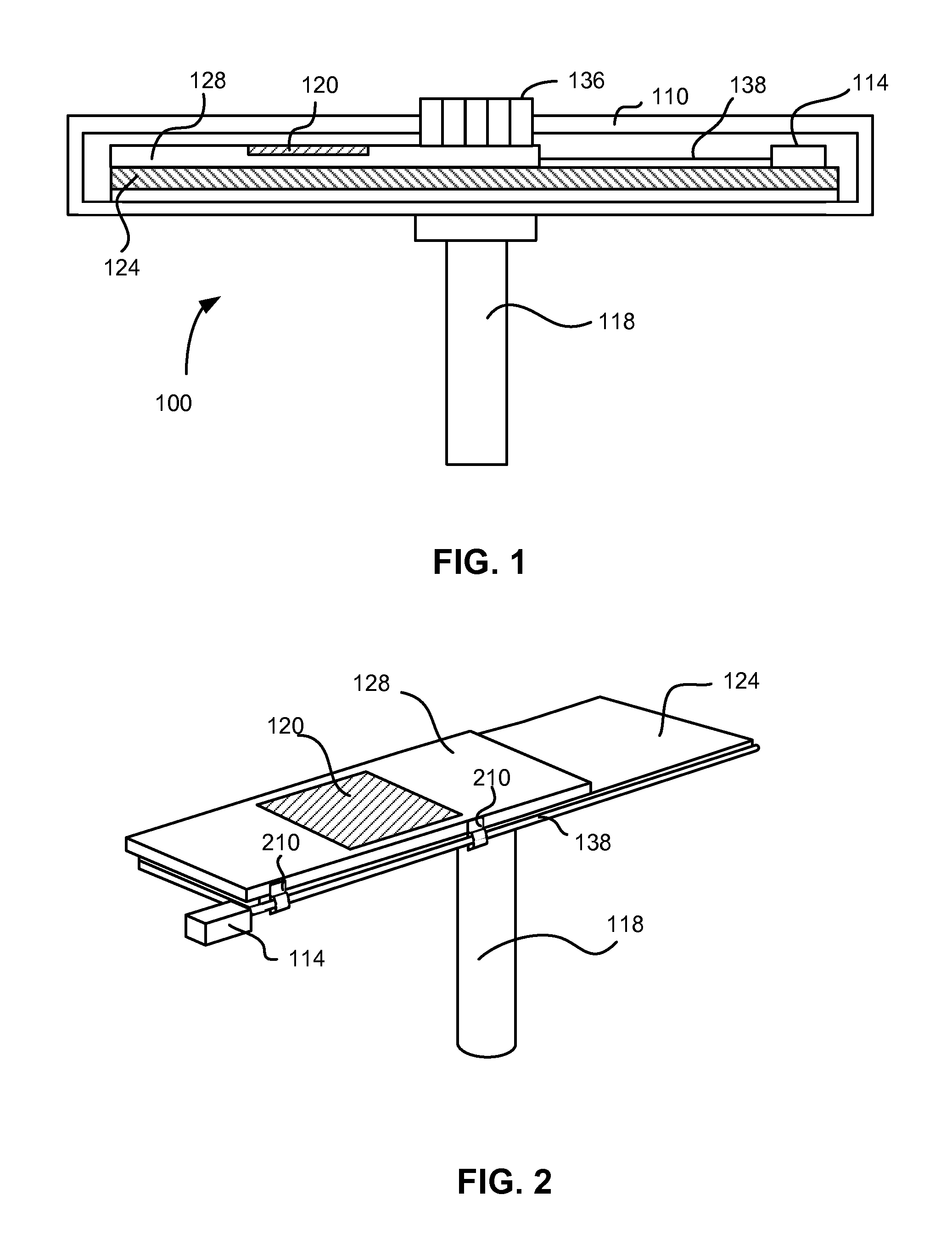

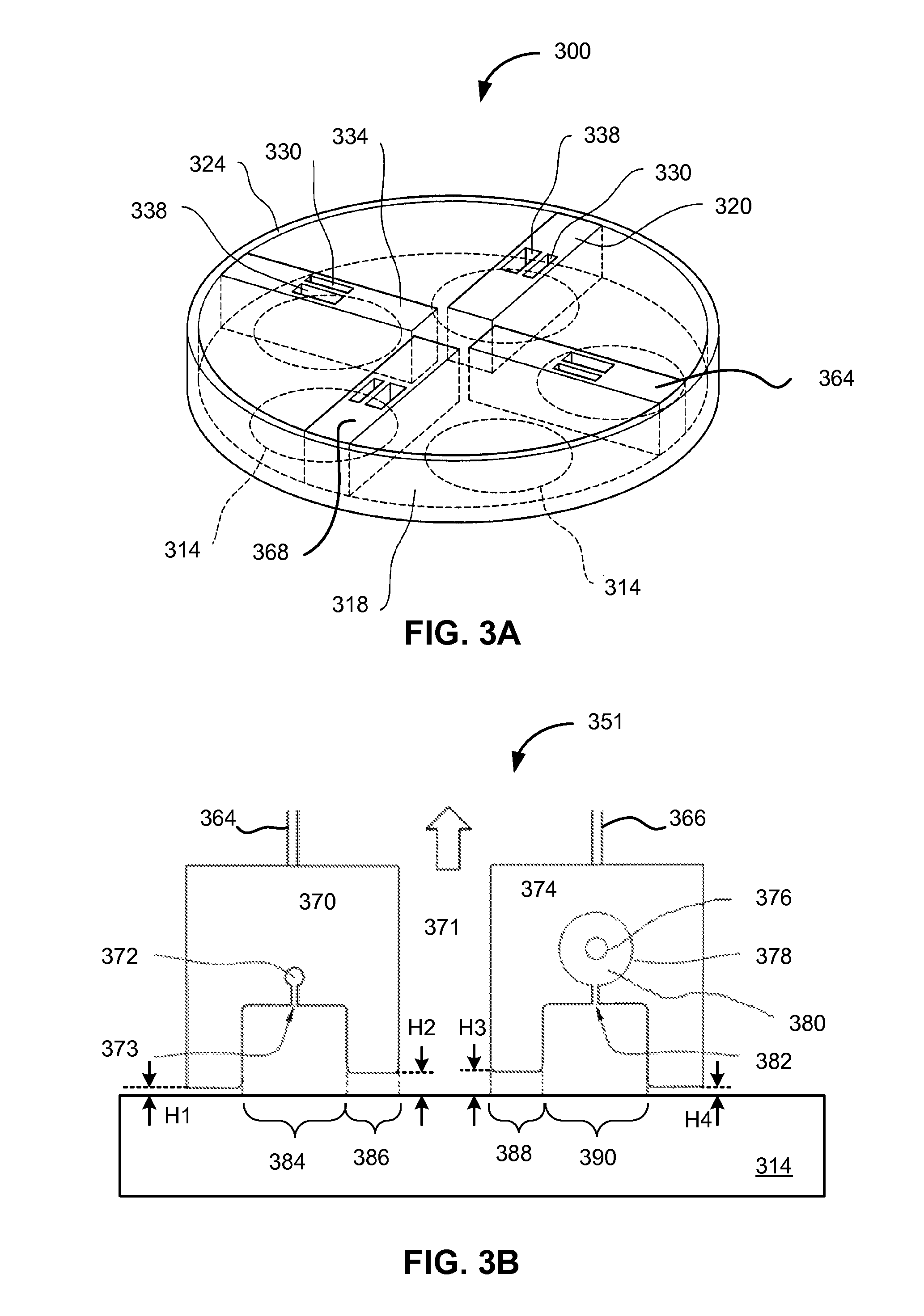

Deposition of layer using depositing apparatus with reciprocating susceptor

InactiveUS8771791B2Improve absorption rateIncrease deposition ratePretreated surfacesNatural mineral layered productsSusceptorReciprocating motion

Atomic layer deposition is performed by reciprocating a susceptor in two directions, subjecting a substrate on the susceptor to two different sequences of processes. By subjecting the susceptor to different sequences of processes, the substrate undergoes different processes that otherwise would have required an additional set of injectors or reactors. The reduced number of injectors or reactors enables a more compact deposition device, and reduces the cost associated with the deposition device.

Owner:VEECO ALD

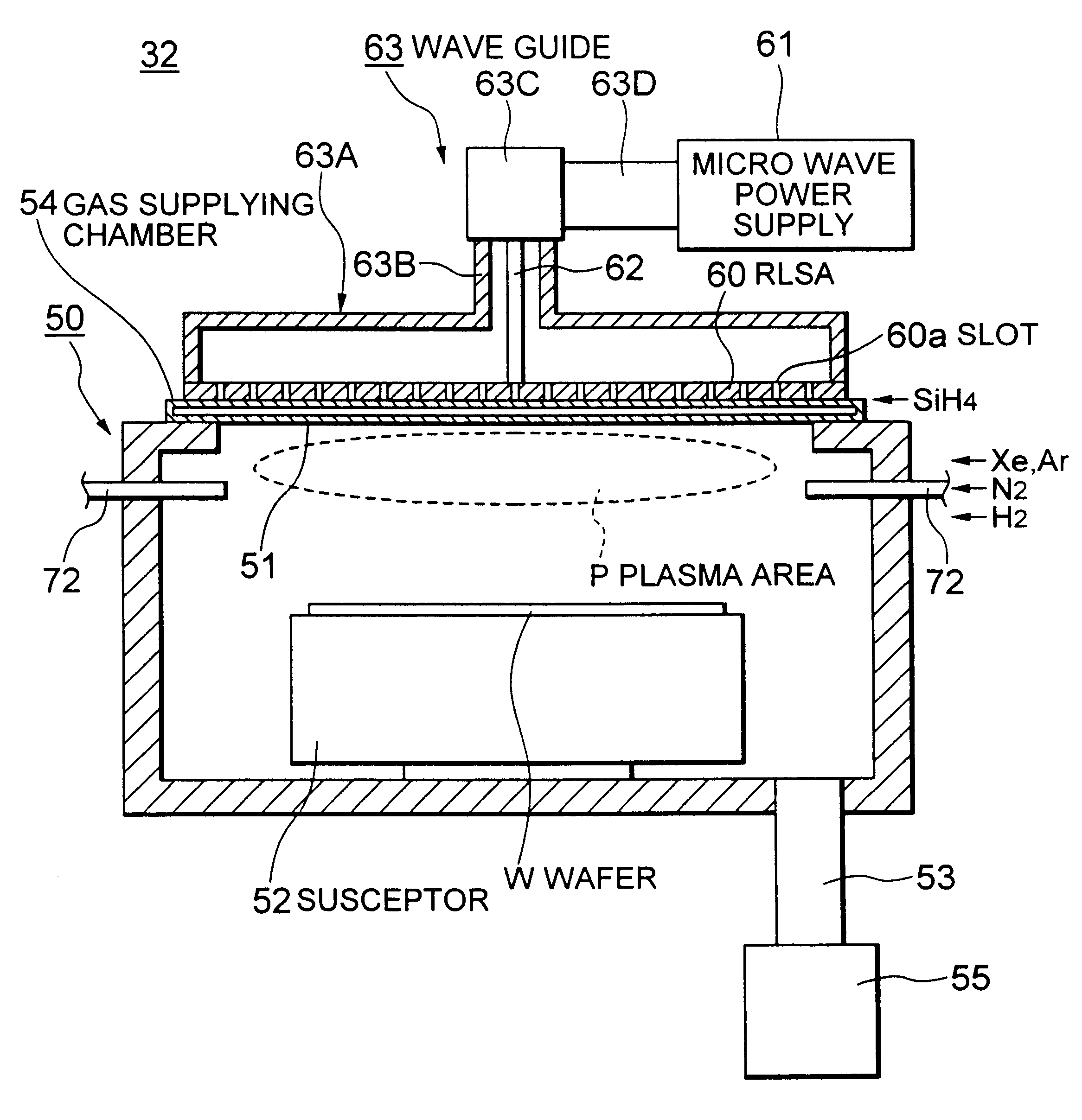

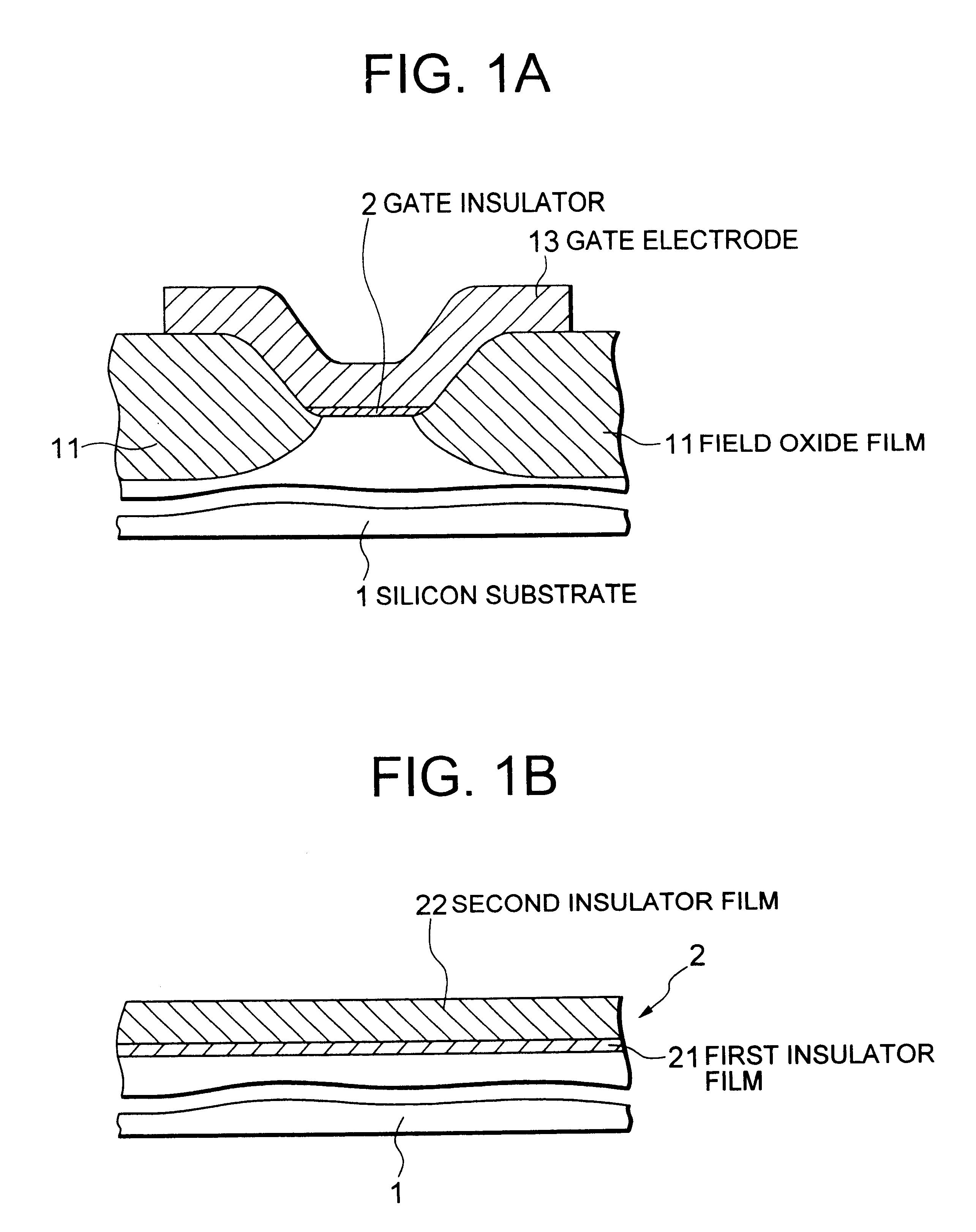

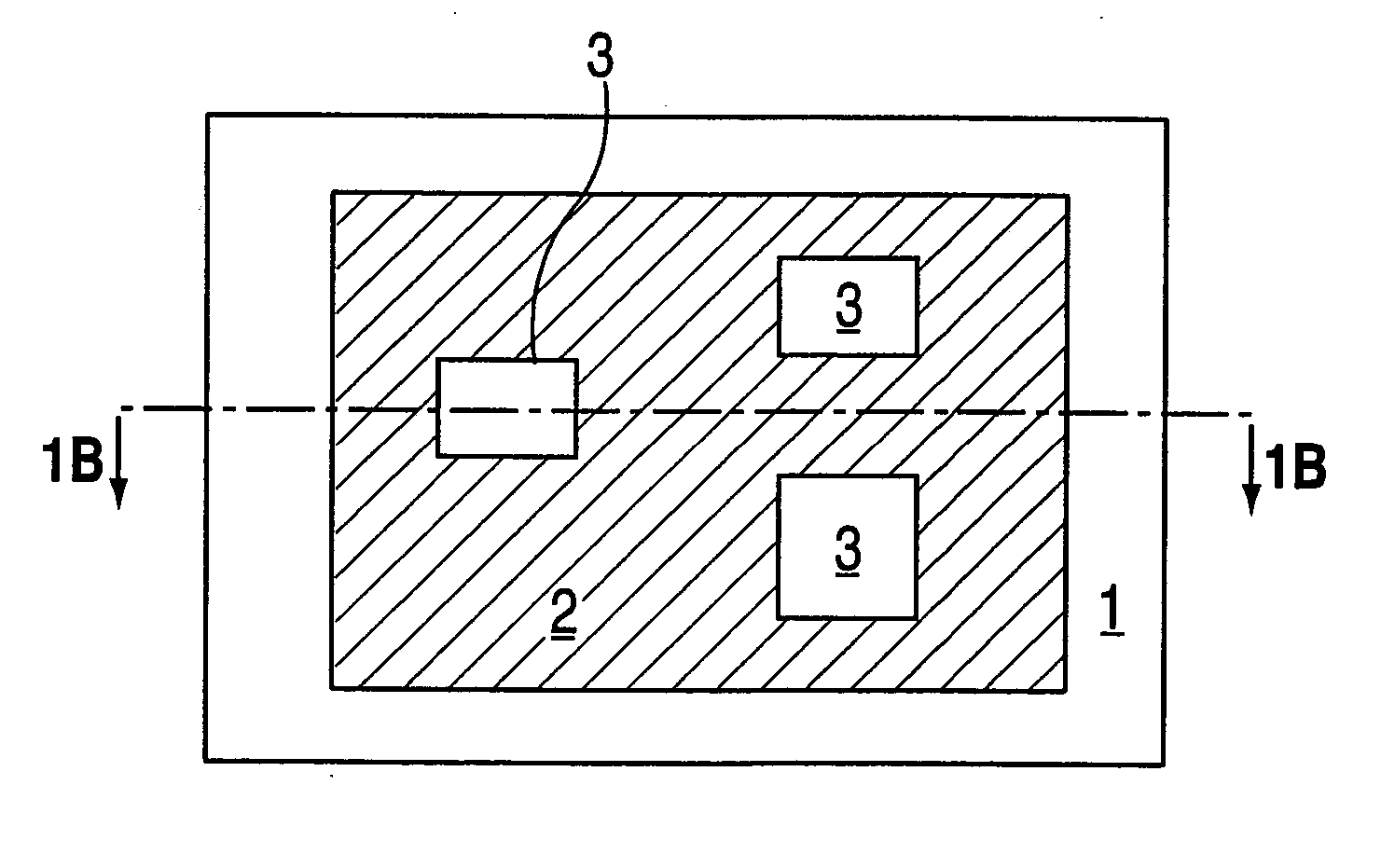

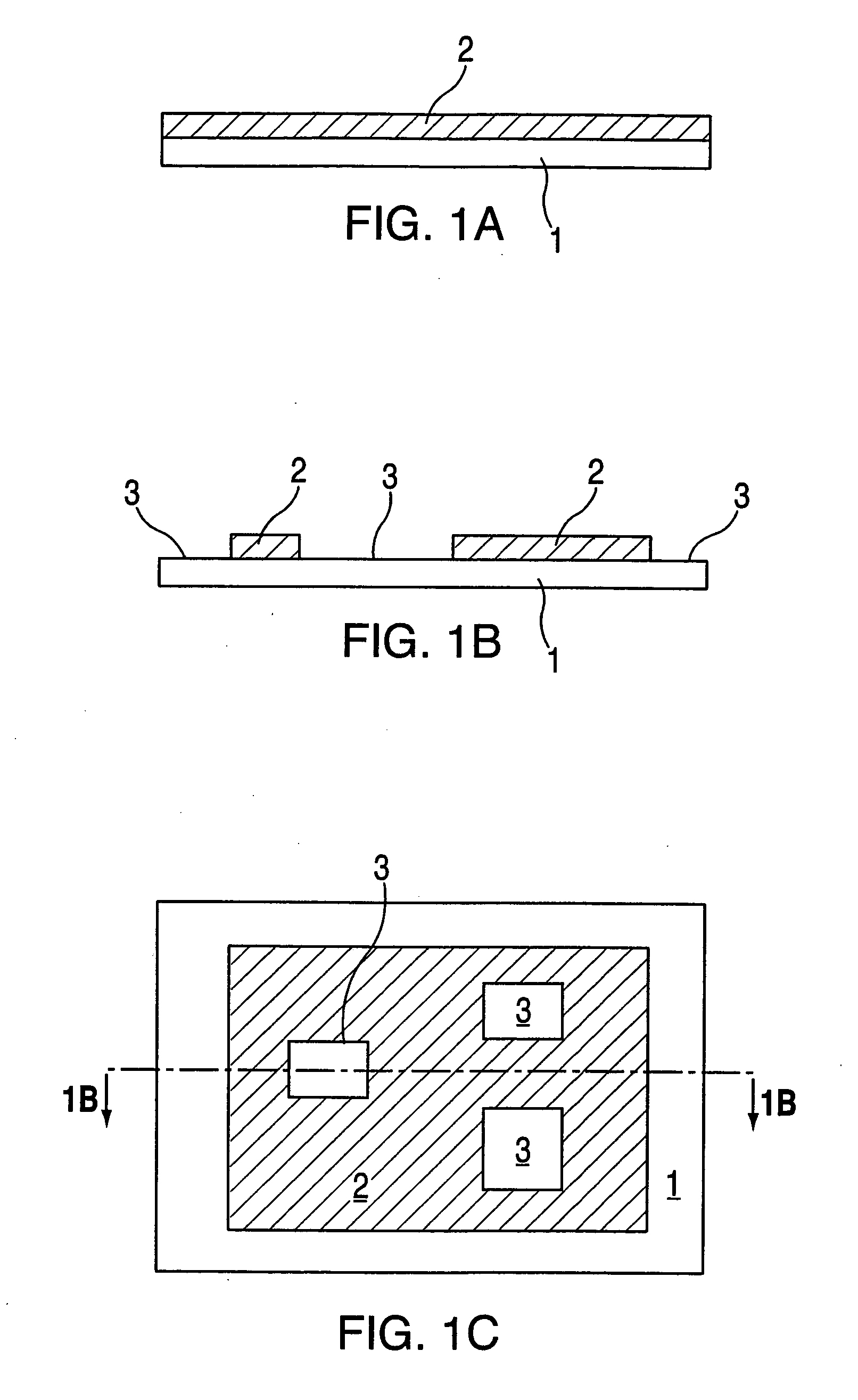

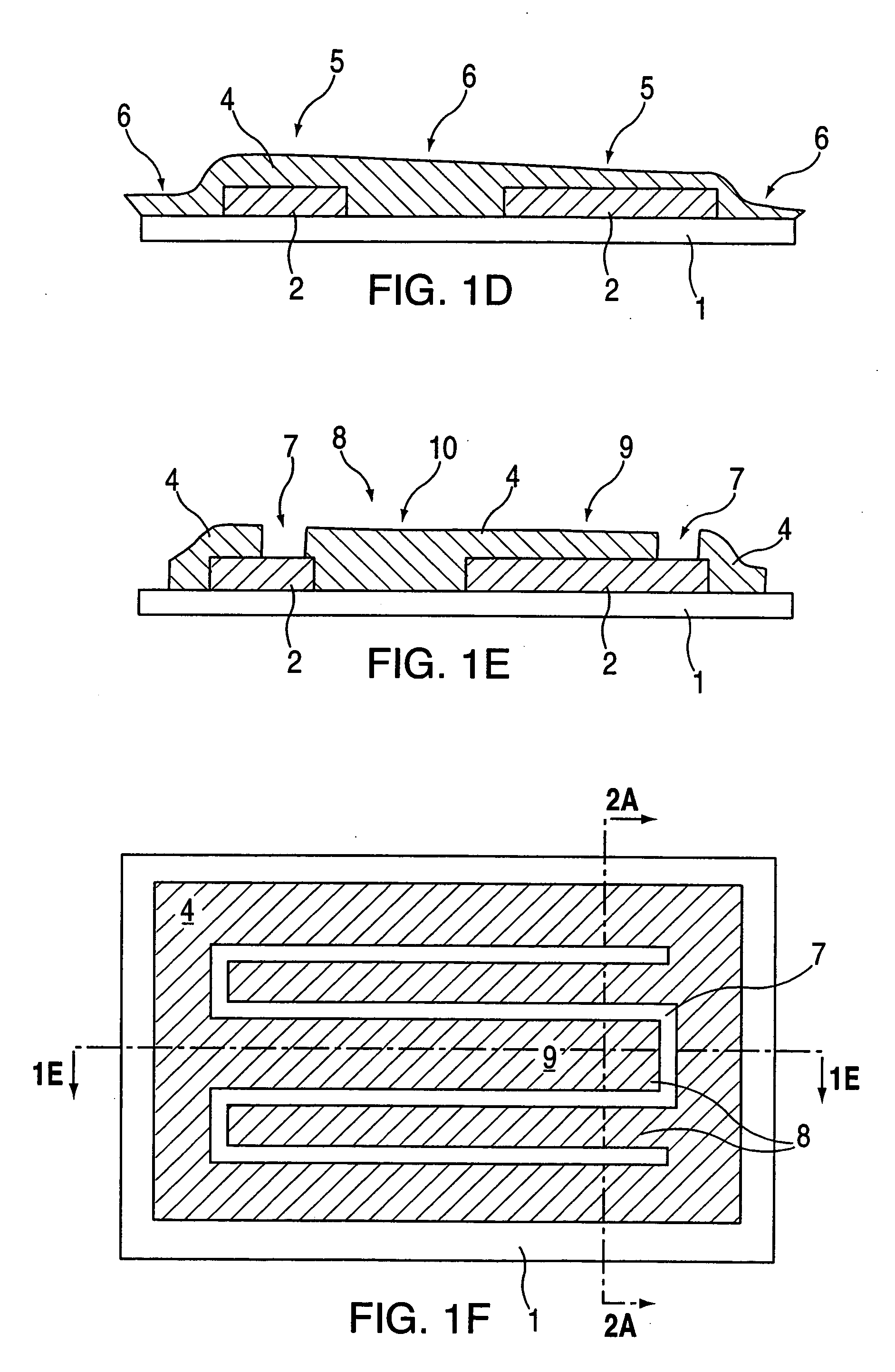

Semiconductor manufacturing method and semiconductor manufacturing apparatus

InactiveUS6399520B1Quality improvementShort timeElectric discharge tubesSemiconductor/solid-state device manufacturingMicrowaveWafering

In an atmosphere of processing gas, on a wafer W consisting mainly of silicon, through a planar-array antenna RLSA 60 having a plurality of slits, microwaves are irradiated to generate plasma containing oxygen, or nitrogen, or oxygen and nitrogen and to implement therewith on the surface of the wafer W direct oxidizing, nitriding, or oxy-nitriding to deposit an insulator film 2 of a thickness of 1 nm or less in terms of oxide film. A manufacturing method and apparatus of semiconductors that can successfully regulate film quality of the interface between a silicon substrate and a SiN film and can form SiN film of high quality in a short time can be obtained.

Owner:TOKYO ELECTRON LTD

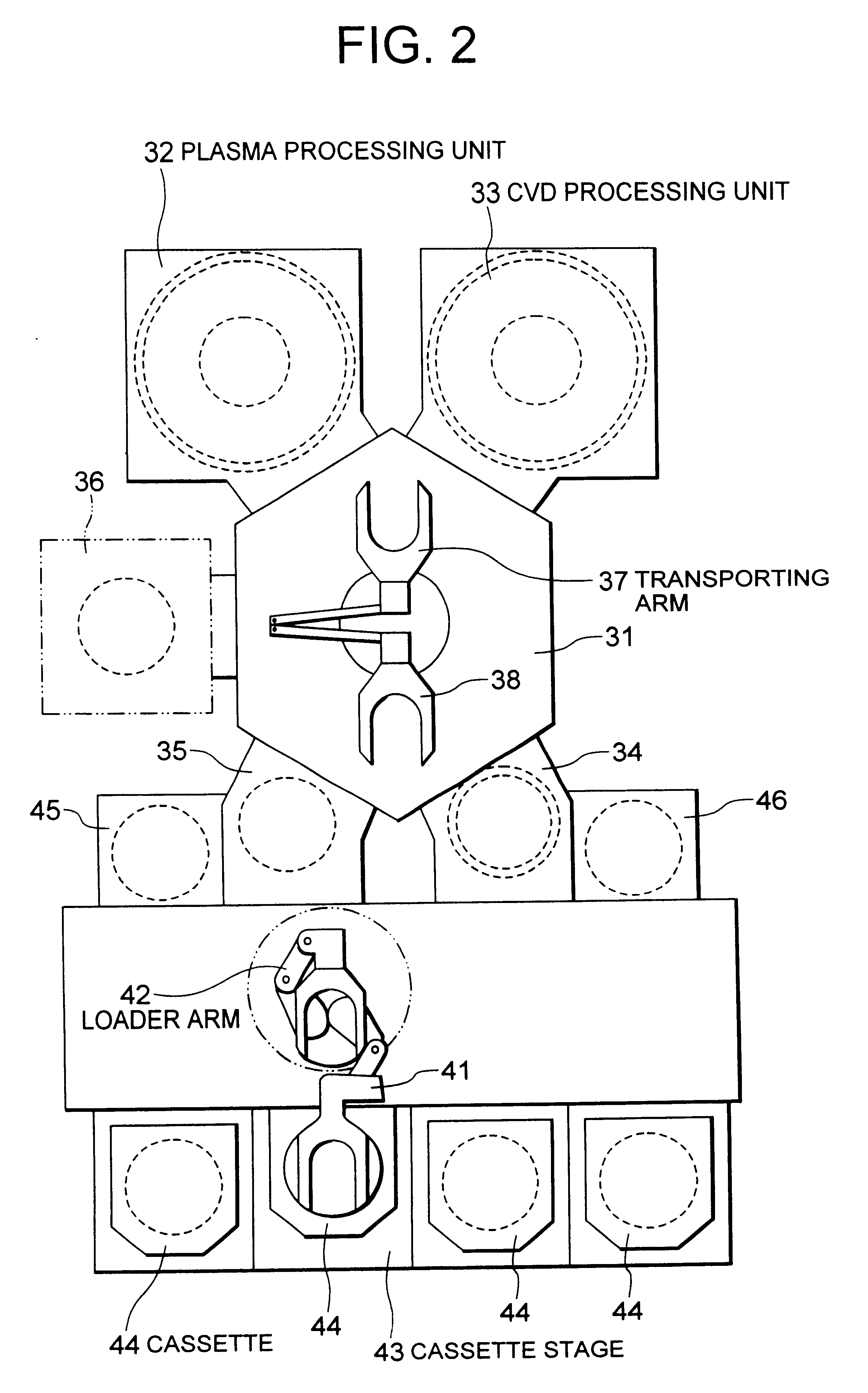

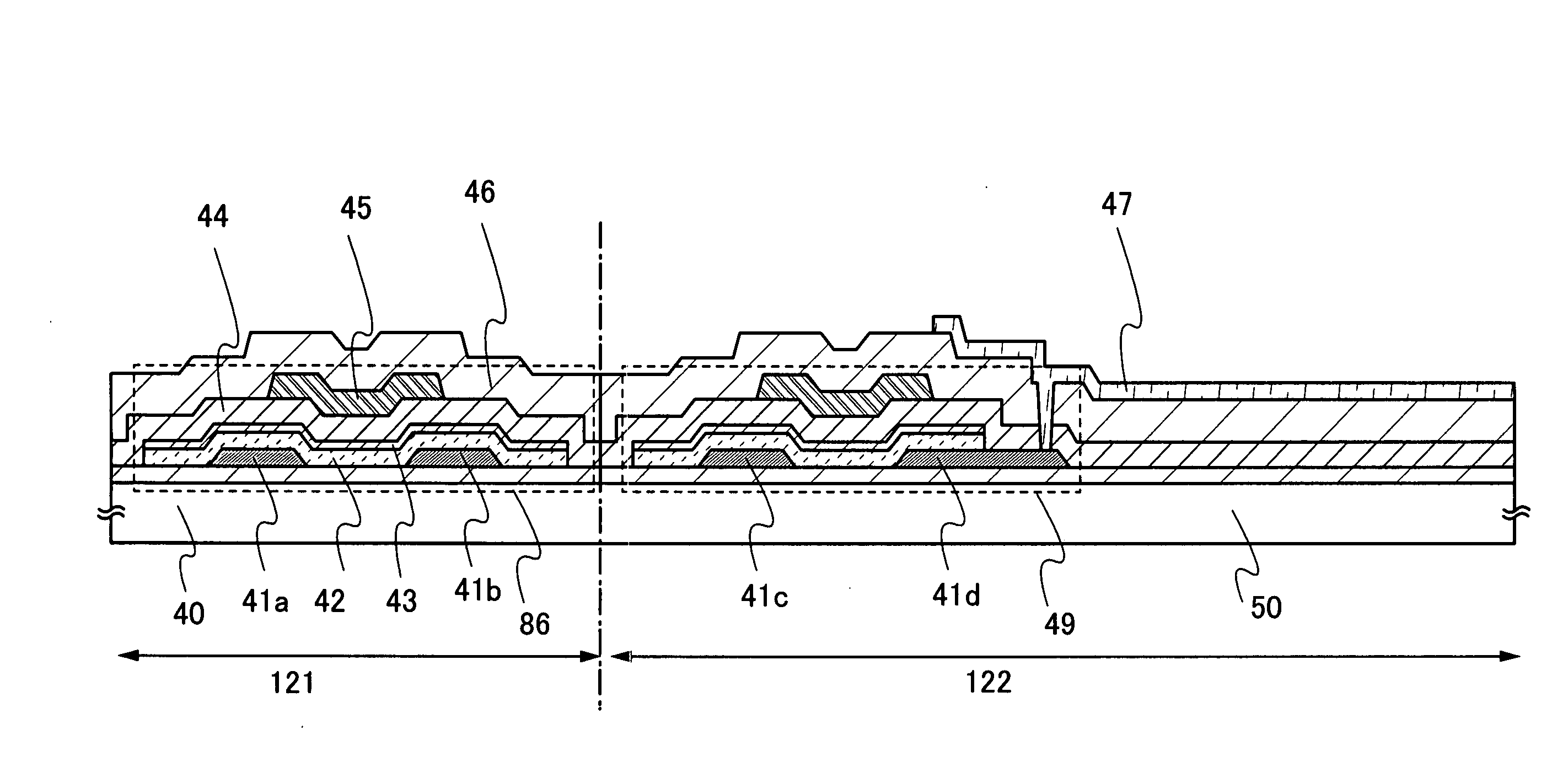

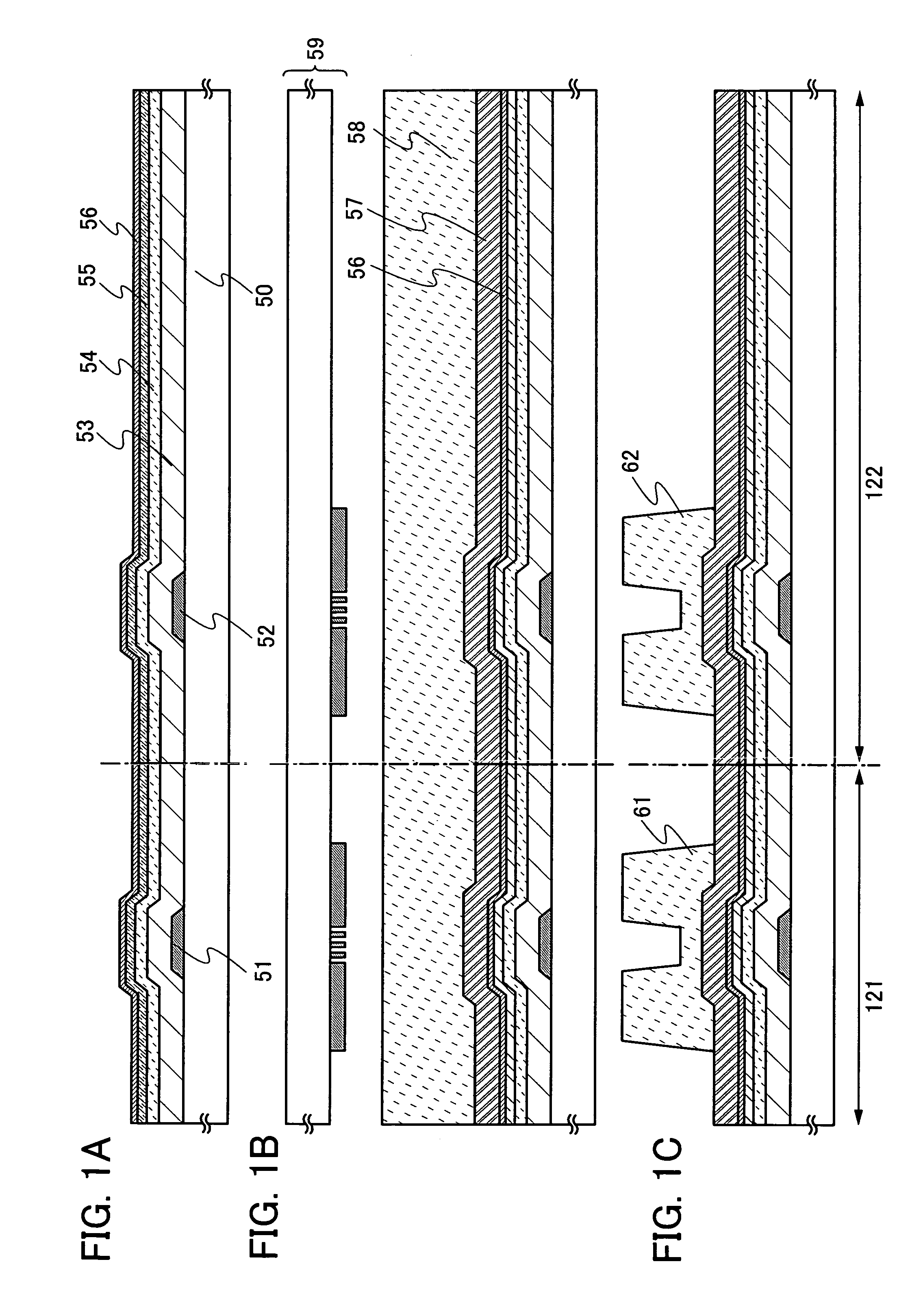

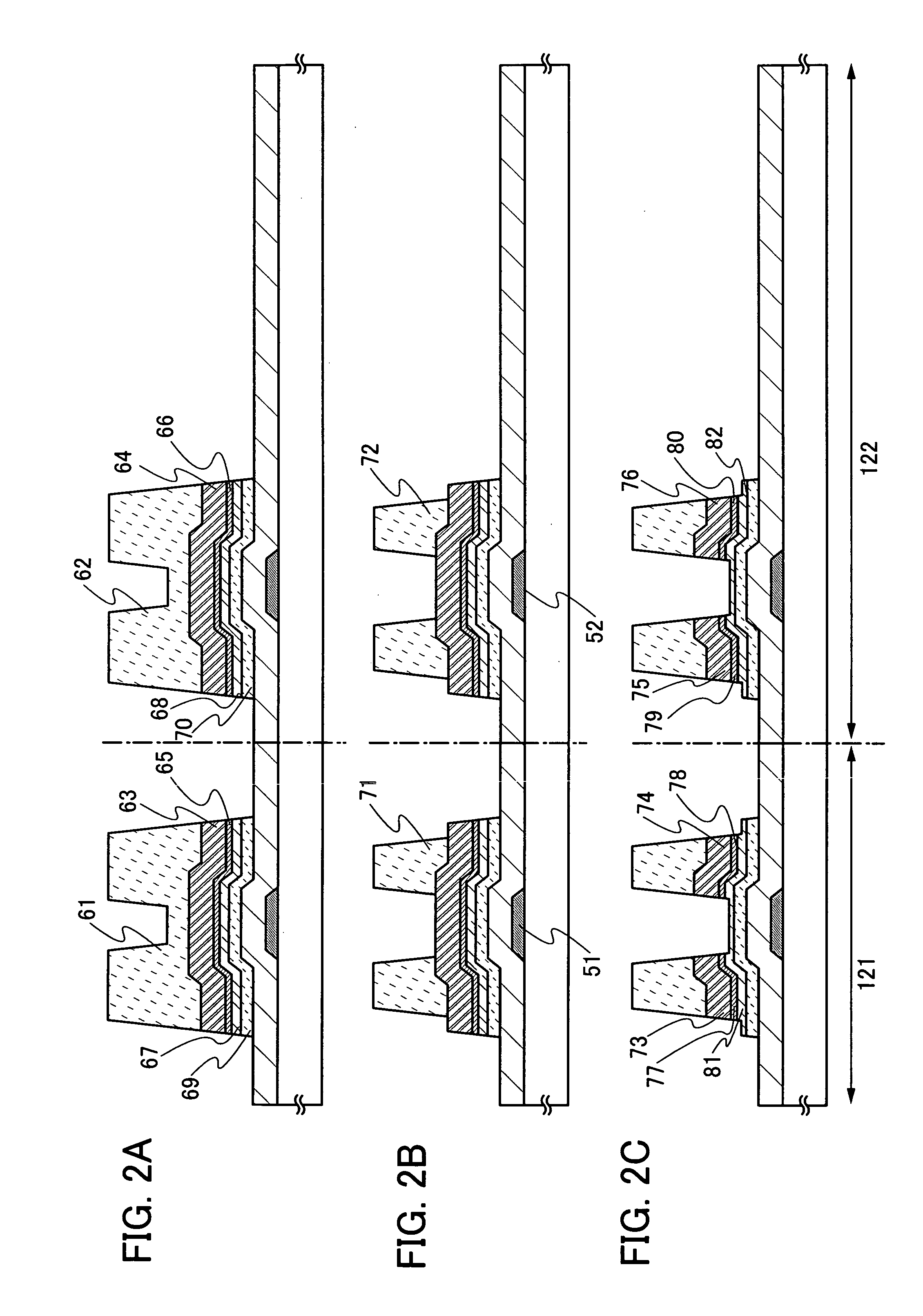

Display device and manufacturing method thereof

InactiveUS20080308807A1Inhibition of mobilityReduce oxidationSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

It is an object to provide a manufacturing method by which display devices can be manufactured in quantity without degrading the characteristics of thin film transistors. In a display device including a thin film transistor in which a microcrystalline semiconductor film, a gate insulating film in contact with the microcrystalline semiconductor film, and a gate electrode overlap with each other, an antioxidant film is formed on a surface of the microcrystalline semiconductor film. The antioxidant film on the surface of the microcrystalline semiconductor film can prevent a surface of a microcrystal grain from being oxidized, thereby preventing the mobility of the thin film transistor from decreasing.

Owner:SEMICON ENERGY LAB CO LTD

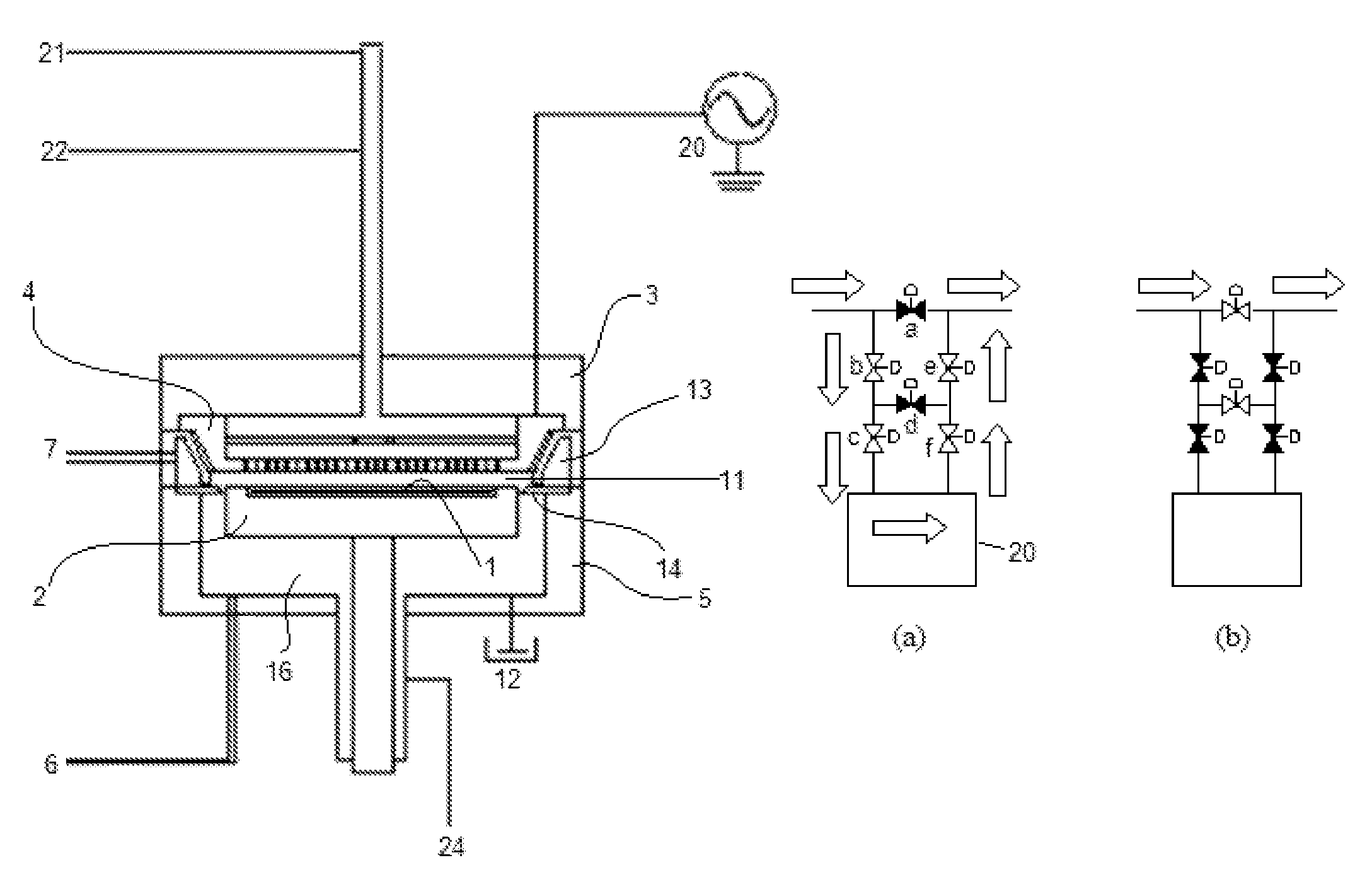

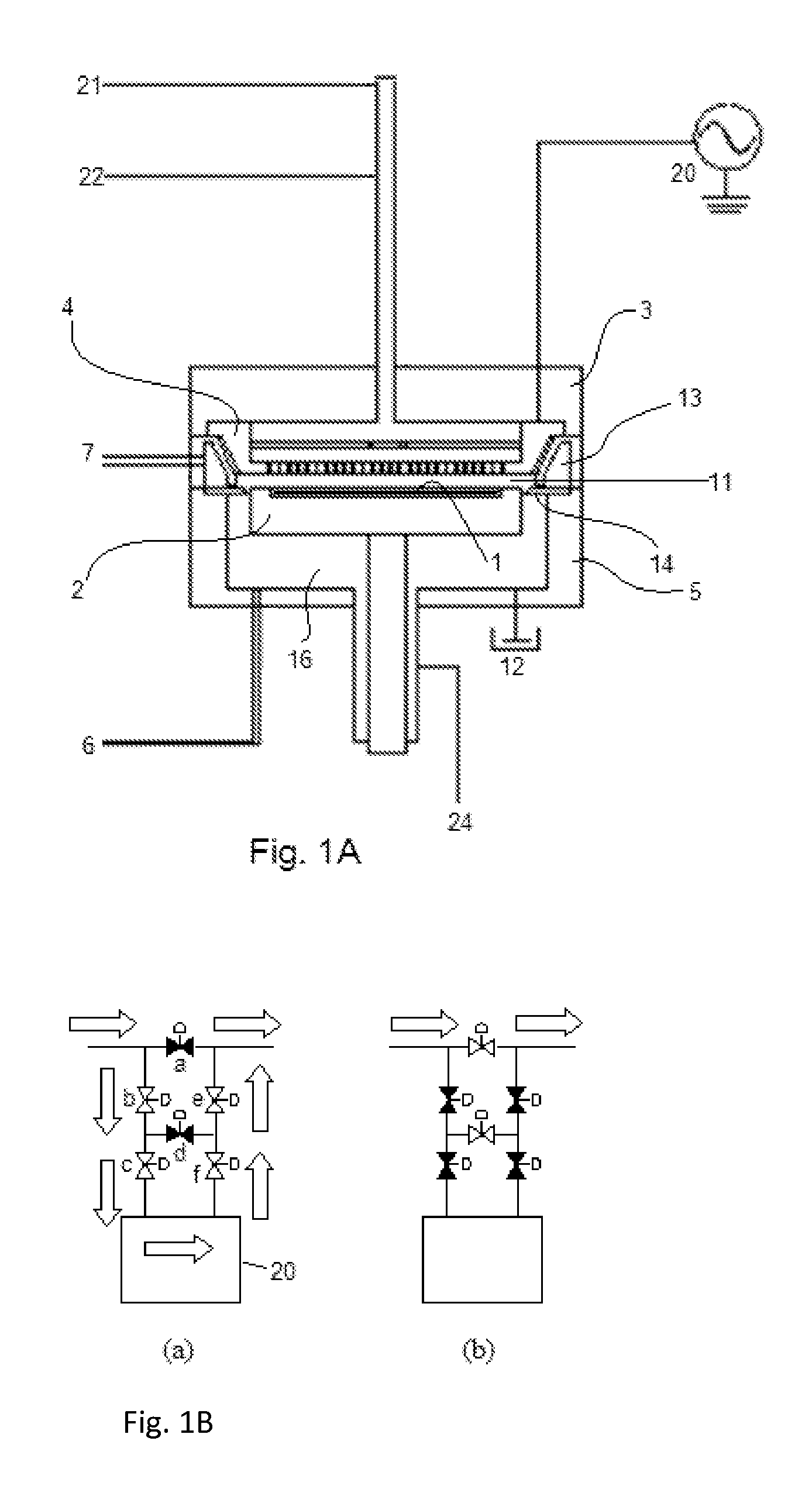

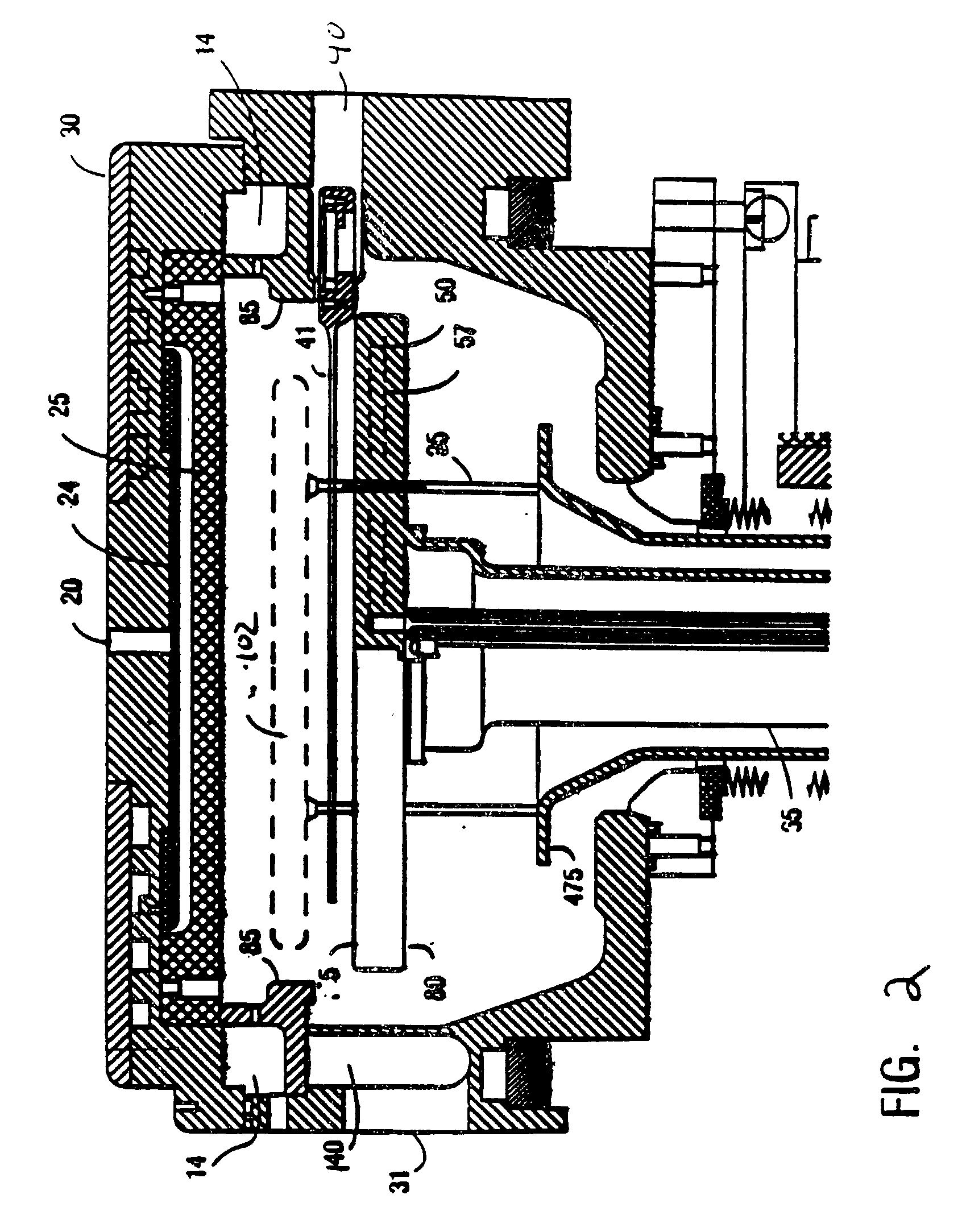

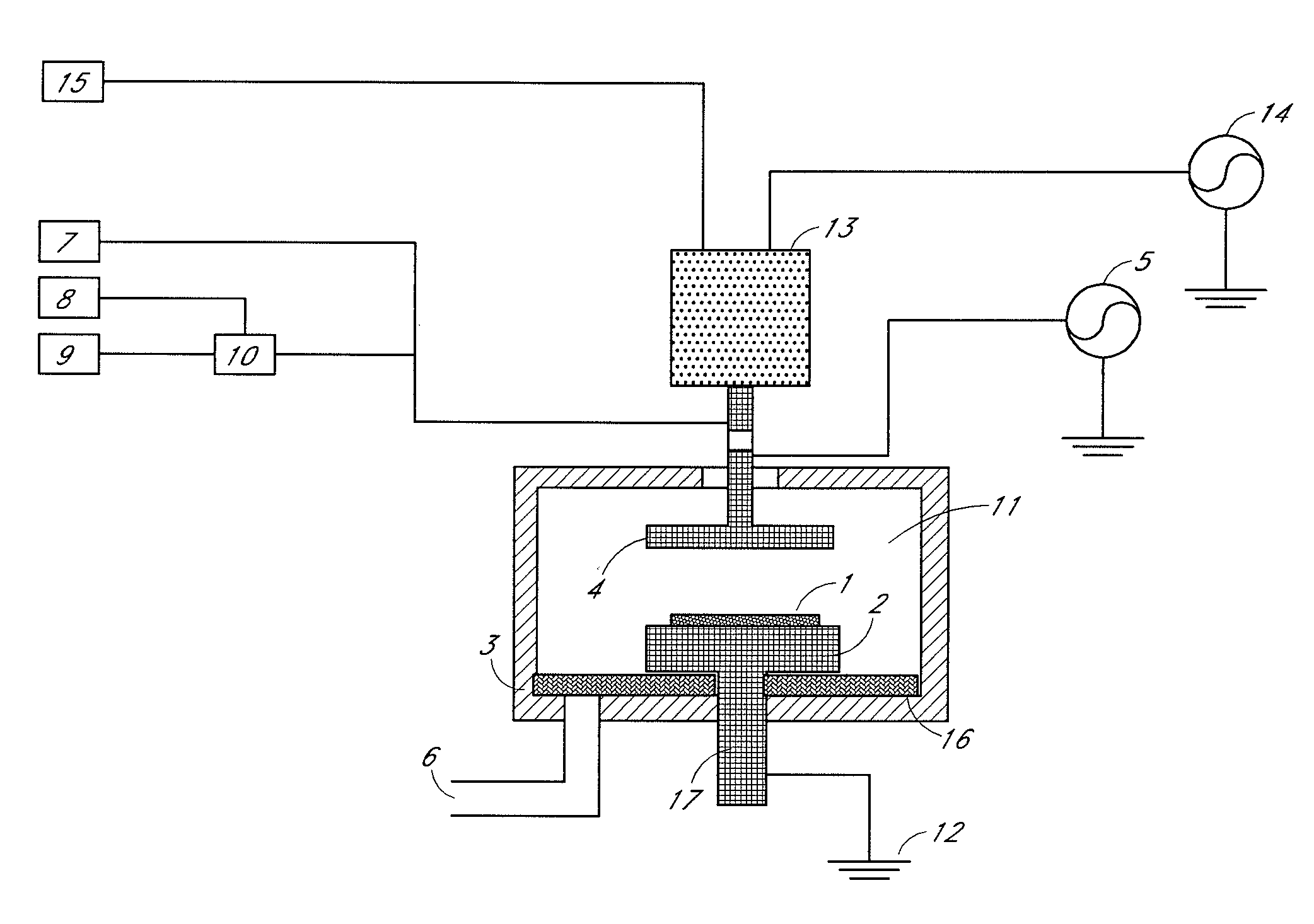

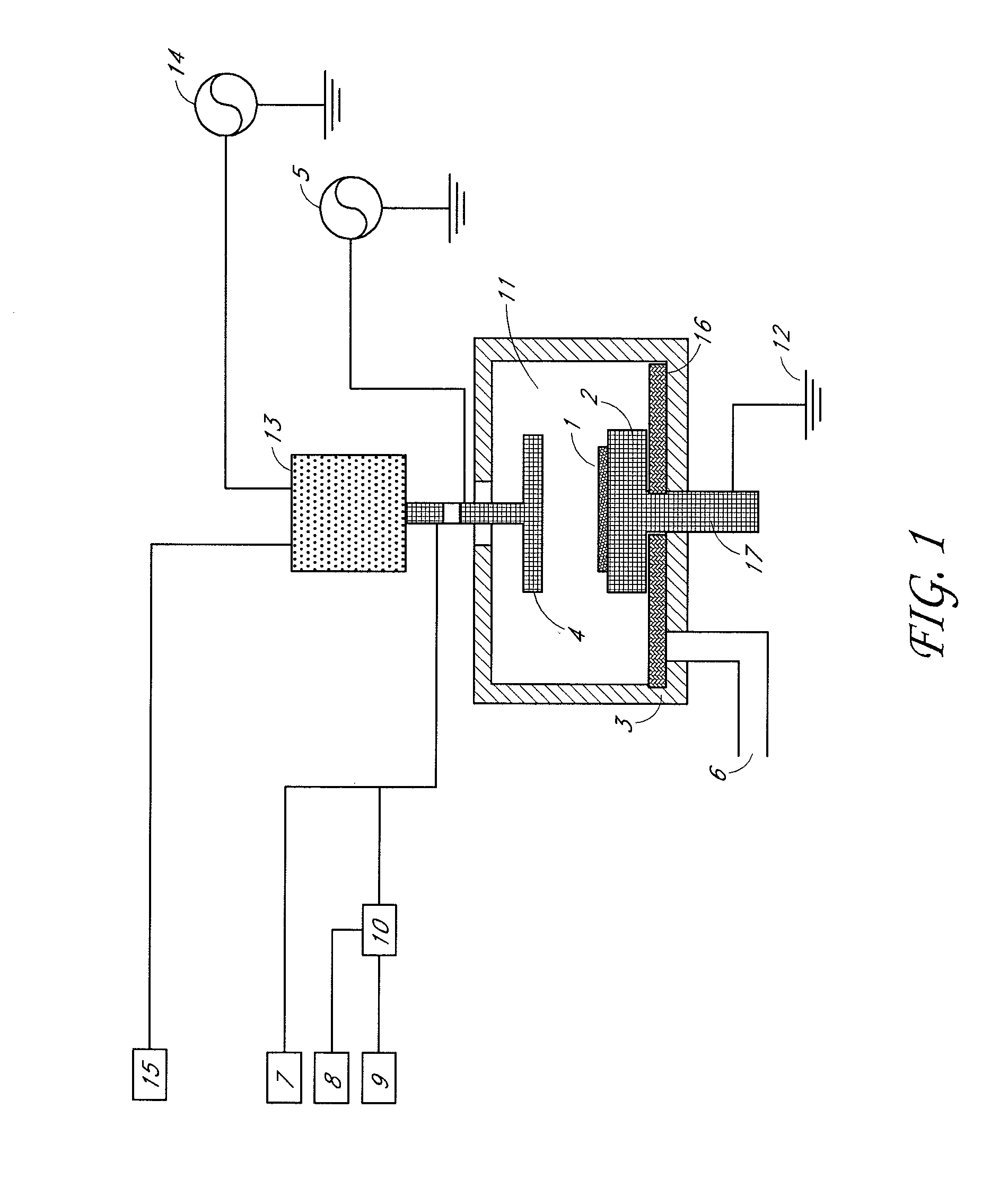

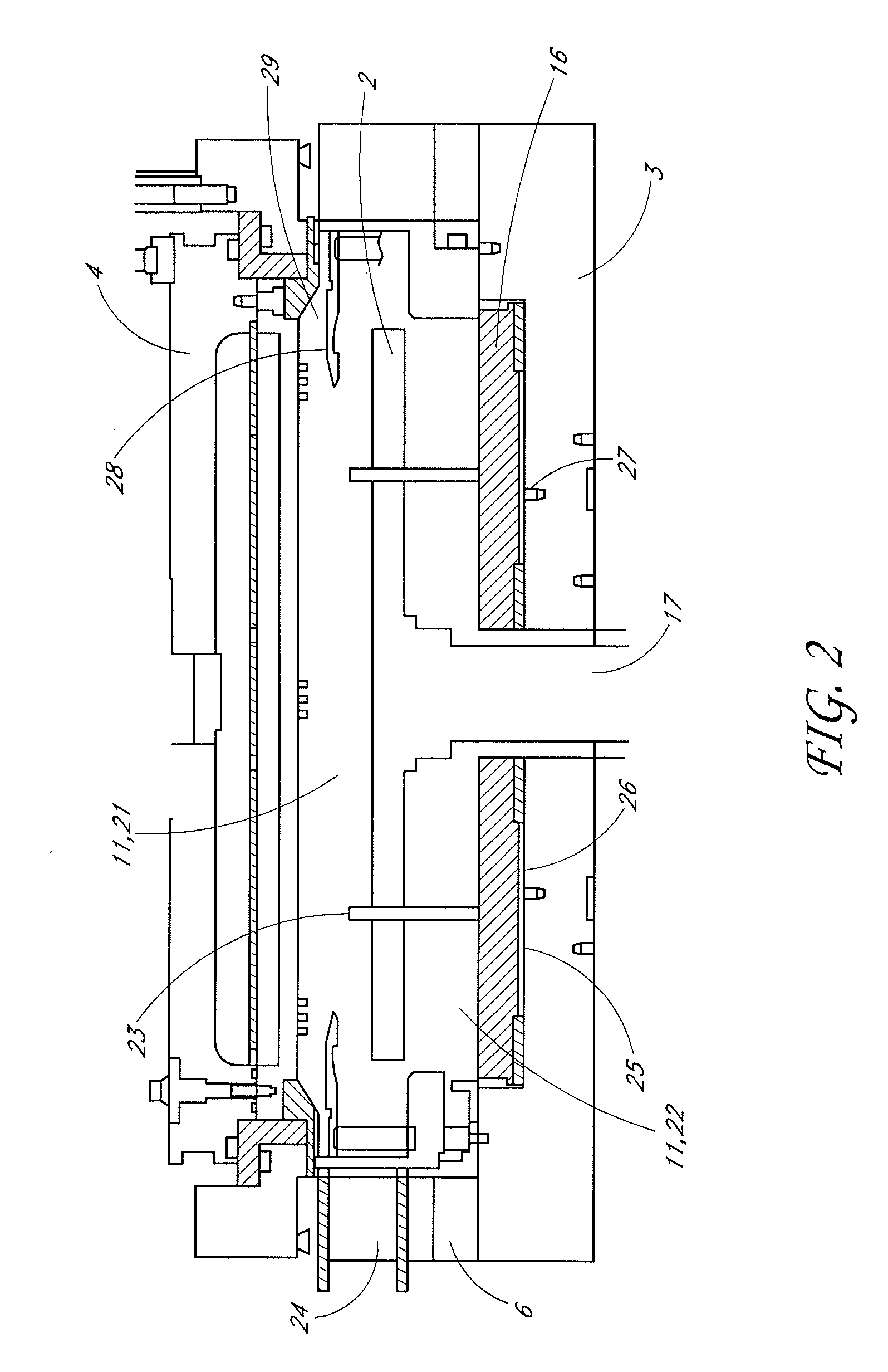

Apparatus and method for improving production throughput in CVD chamber

InactiveUS20090297731A1Prevent penetrationIncrease deposition rateElectric discharge tubesChemical vapor deposition coatingCapacitanceCapacitive coupling

A plasma CVD apparatus for forming a film on a substrate includes: an evacuatable reaction chamber; capacitively-coupled upper and lower electrodes disposed inside the reaction chamber; and an insulator for inhibiting penetration of a magnetic field of radio frequency generated during substrate processing. The insulator is placed on the bottom surface of the reaction chamber under the lower electrode.

Owner:ASM JAPAN

Method for atomic layer deposition (ALD) of silicon oxide film

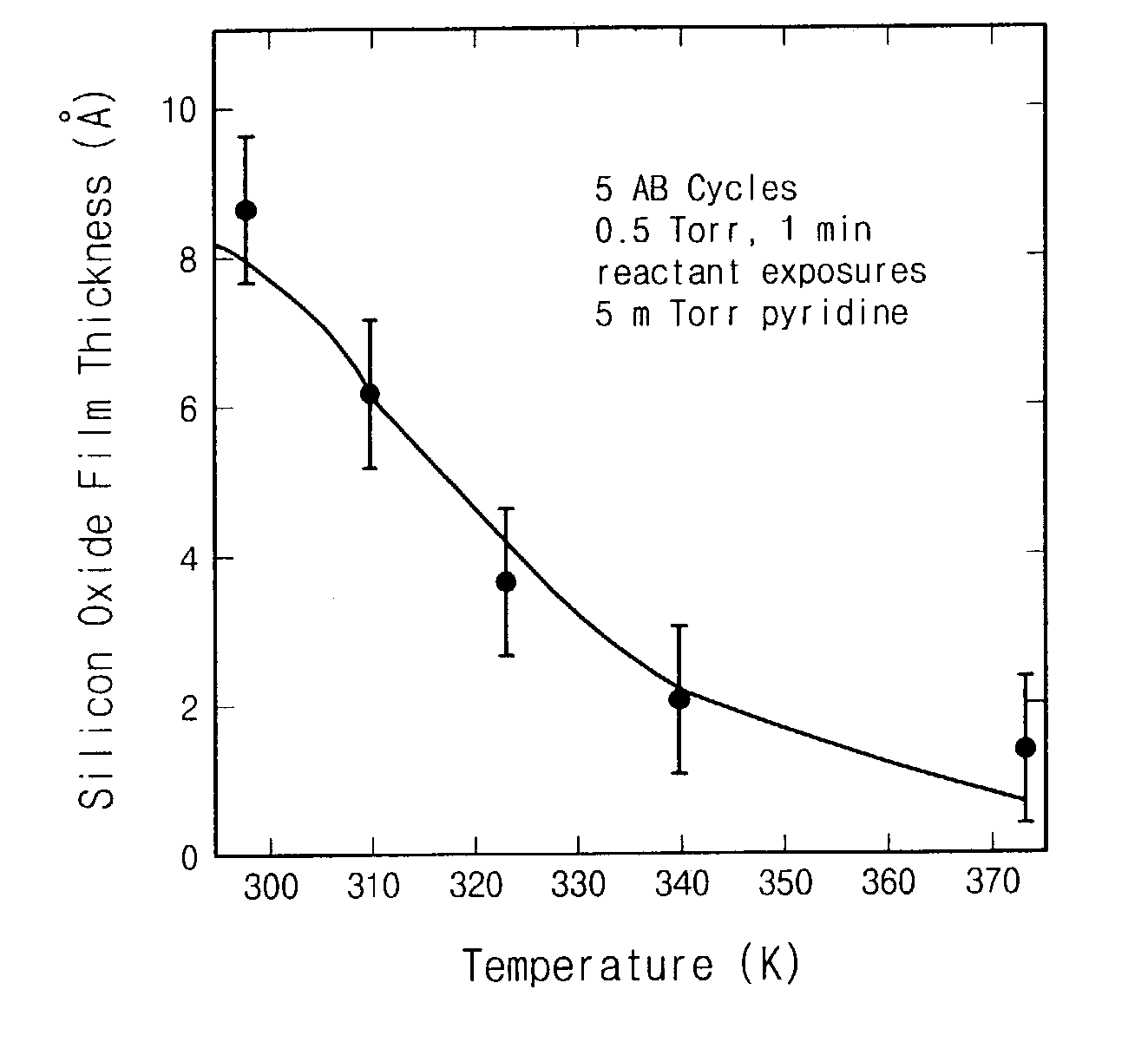

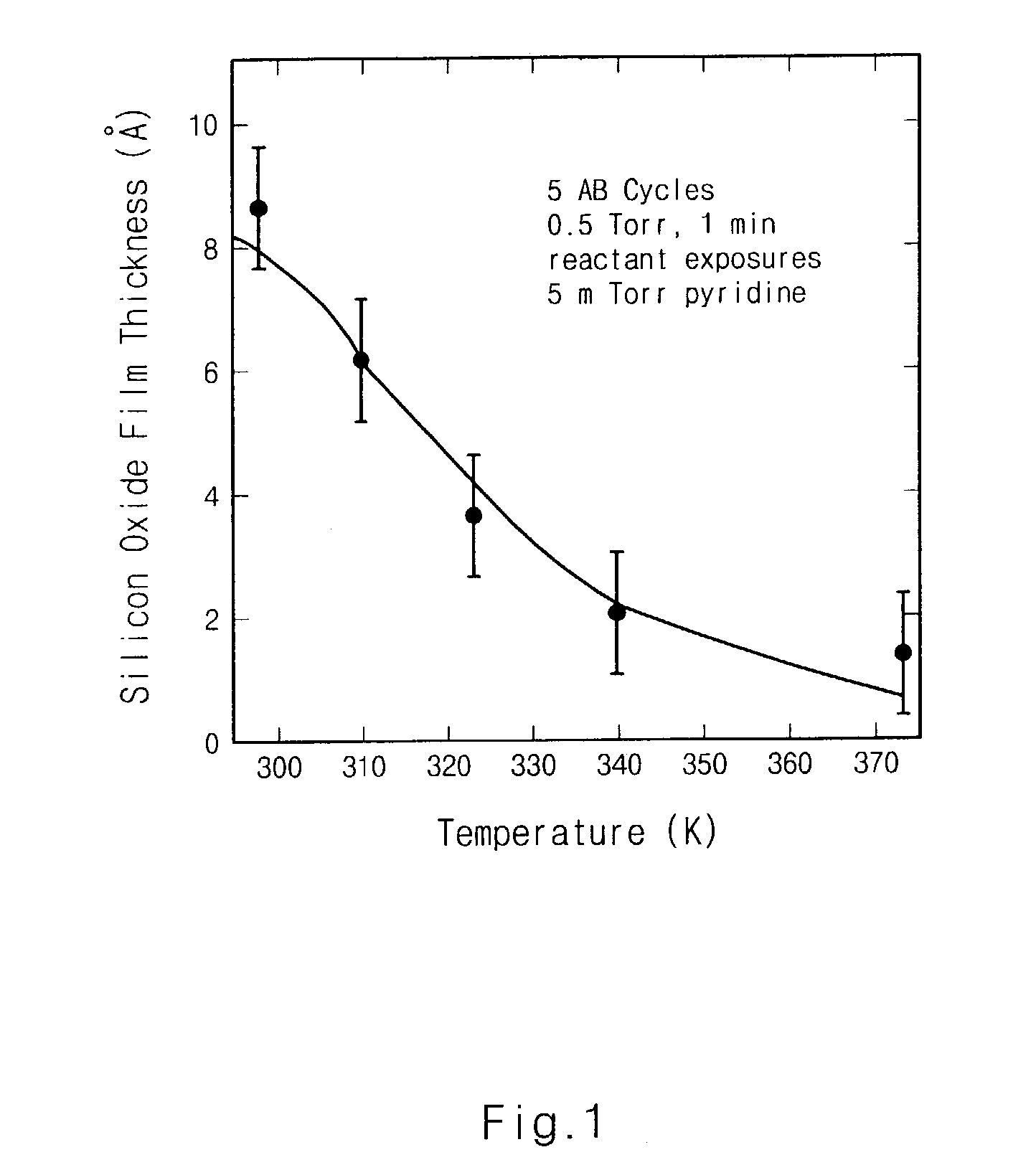

InactiveUS7077904B2Increase deposition rateReduce the temperaturePolycrystalline material growthFrom chemically reactive gasesSilicon oxideAtomic layer deposition

The present invention relates to a method for forming silicon oxide films on substrates using an atomic layer deposition process. Specifically, the silicon oxide films are formed at low temperature and high deposition rate via the atomic layer deposition process using a Si2Cl6 source unlike a conventional atomic layer deposition process using a SiCl4 source. The atomic layer deposition apparatus used in the above process can be in-situ cleaned effectively at low temperature using a HF gas or a mixture gas of HF gas and gas containing —OH group.

Owner:SAMSUNG ELECTRONICS CO LTD

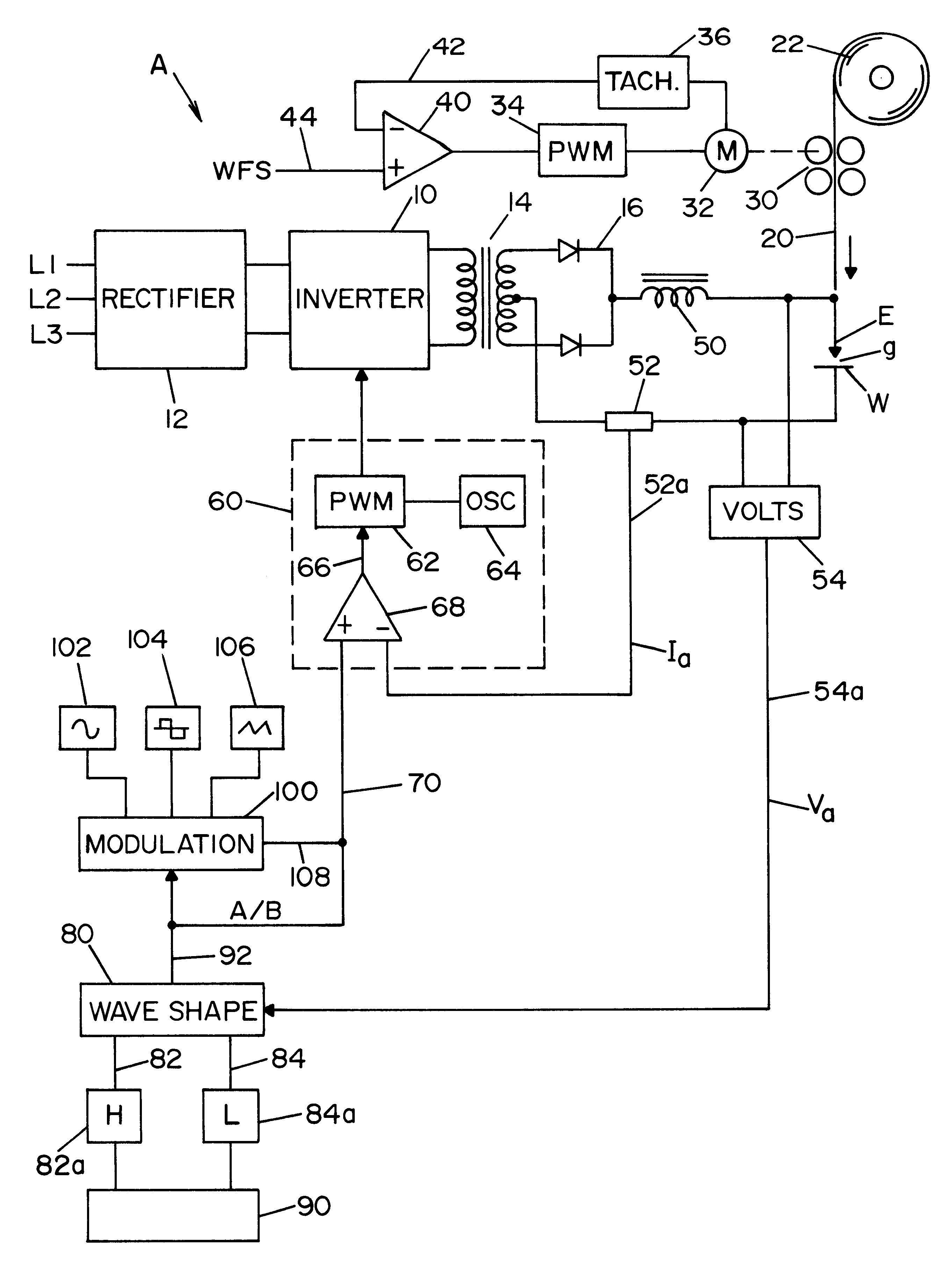

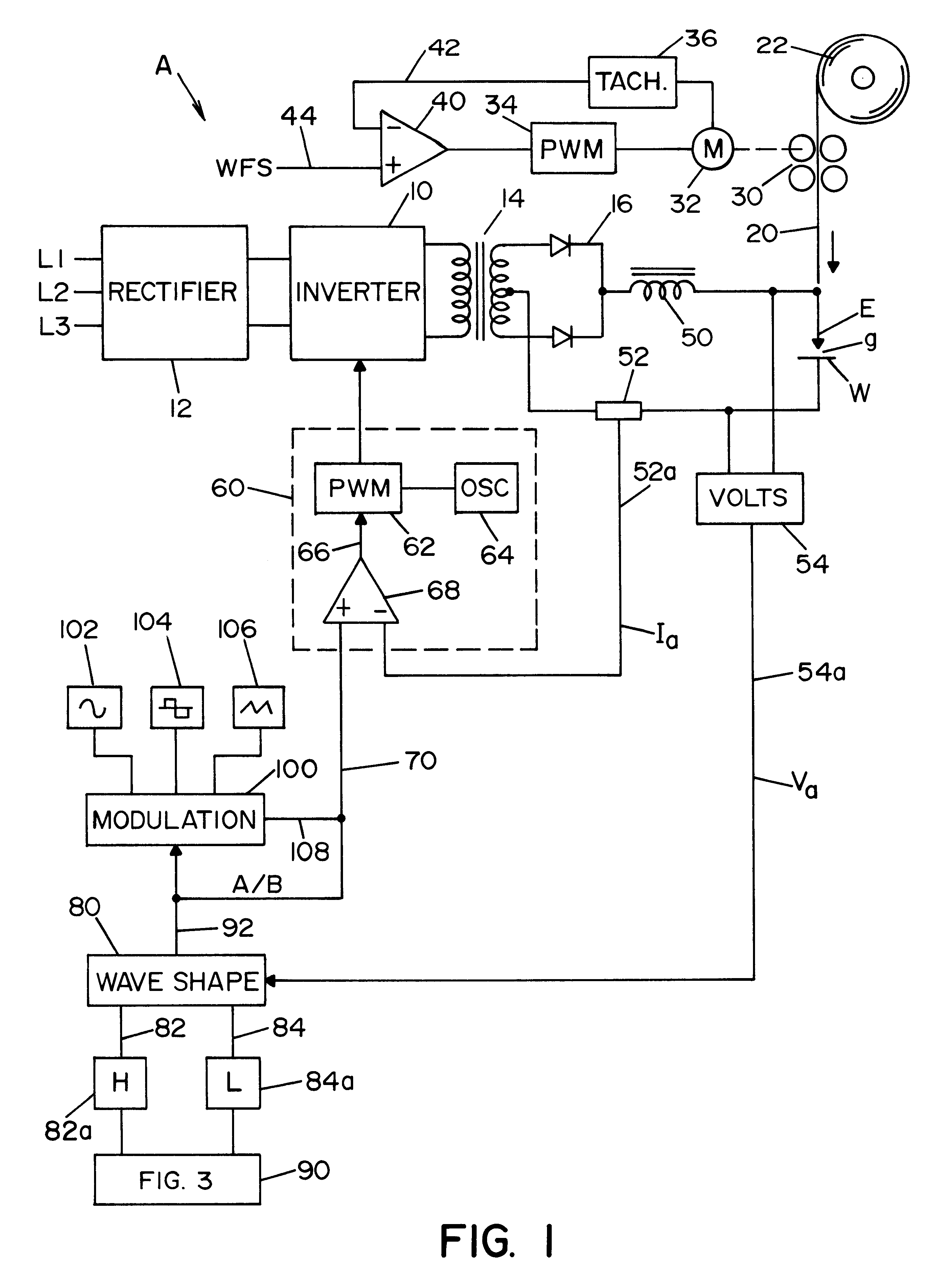

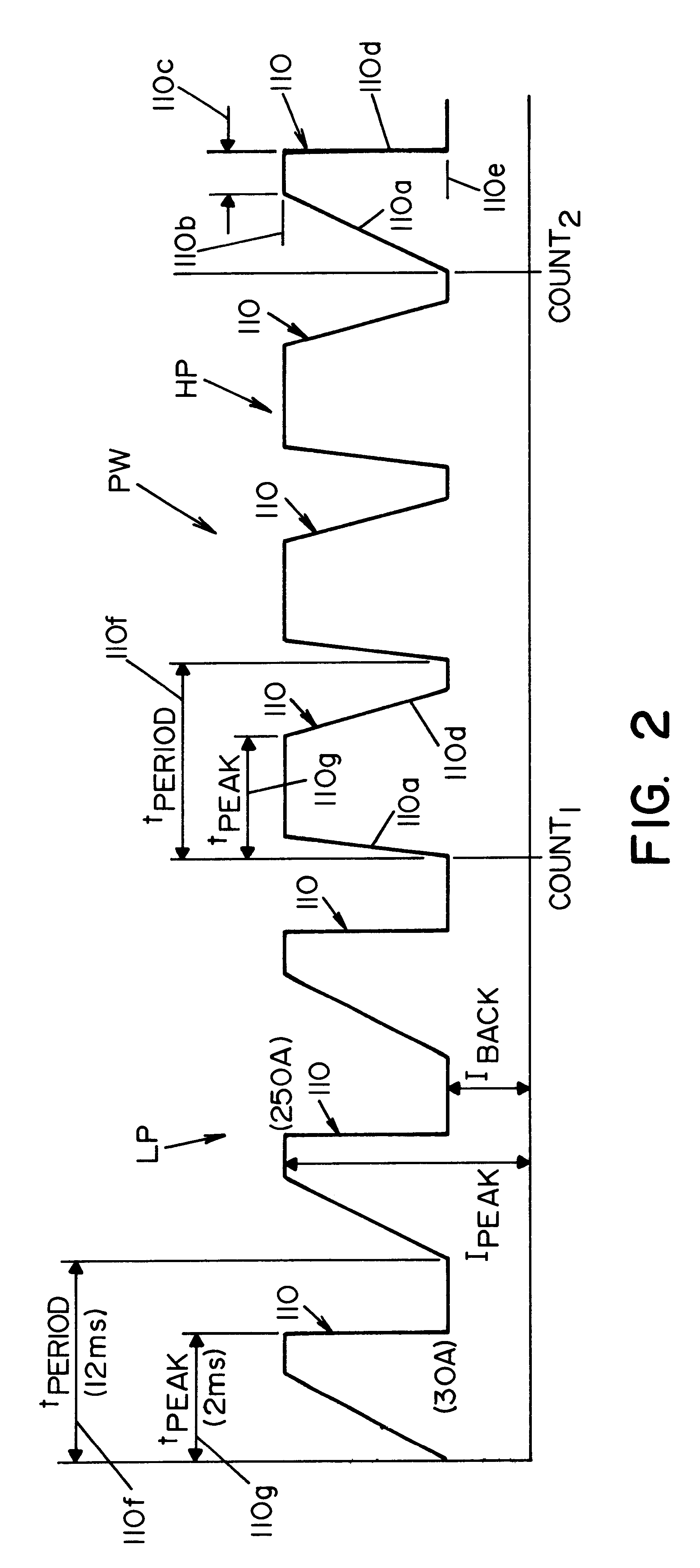

Electric arc welder using high frequency pulses

InactiveUS6515259B1Efficiently transferredMaximized efficiency and heatArc welding apparatusWave shapeElectric arc

An electric arc welder including a high speed switching power supply with a controller for creating high frequency current pulses through the gap between a workpiece and a welding wire advancing toward the workpiece, where the pulses and a background current defining a series of weld cycles. A wave shape generator defines the shape of the pulses and the background current including a controlled ramp up and / or ramp down in each of said cycles and a circuit to change the shapes of the pulses and / or background current in a repeating pattern in each of the weld cycles. The shape change in a cycle can be between first and second shapes or by a rhythmic AC modulation.

Owner:LINCOLN GLOBAL INC

METHOD OF FORMING CONFORMAL DIELECTRIC FILM HAVING Si-N BONDS BY PECVD

ActiveUS20100221925A1Reduce the temperatureIncrease deposition rateSemiconductor/solid-state device detailsSolid-state devicesDielectricHydrocotyle bowlesioides

A method of forming a conformal dielectric film having Si—N bonds on a semiconductor substrate by plasma enhanced chemical vapor deposition (PECVD) includes: introducing a nitrogen- and hydrogen-containing reactive gas and a rare gas into a reaction space inside which a semiconductor substrate is placed; applying RF power to the reaction space; and introducing a hydrogen-containing silicon precursor as a first precursor and a hydrocarbon gas as a second precursor in pulses into the reaction space wherein a plasma is excited, thereby forming a conformal dielectric film doped with carbon and having Si—N bonds on the substrate.

Owner:ASM JAPAN

Gap tuning for surface micromachined structures in an epitaxial reactor

InactiveUS20050014374A1Increase chanceIncrease deposition rateDecorative surface effectsSemiconductor/solid-state device manufacturingEngineeringSilicon dioxide

A method for adjusting with high precision the width of gaps between micromachined structures or devices in an epitaxial reactor environment. Providing a partially formed micromechanical device, comprising a substrate layer, a sacrificial layer including silicon dioxide deposited or grown on the substrate and etched to create desired holes and / or trenches through to the substrate layer, and a function layer deposited on the sacrificial layer and the exposed portions of the substrate layer and then etched to define micromechanical structures or devices therein. The etching process exposes the sacrificial layer underlying the removed function layer material. Cleaning residues from the surface of the device, then epitaxially depositing a layer of gap narrowing material selectively on the surfaces of the device. The selection of deposition surfaces determined by choice of materials and the temperature and pressure of the epitaxy carrier gas. The gap narrowing epitaxial deposition continues until a desired gap width is achieved, as determined by, for example, an optical detection arrangement. Following the gap narrowing step, the micromachined structures or devices may be released from their respective underlying sacrificial layer.

Owner:ROBERT BOSCH GMBH

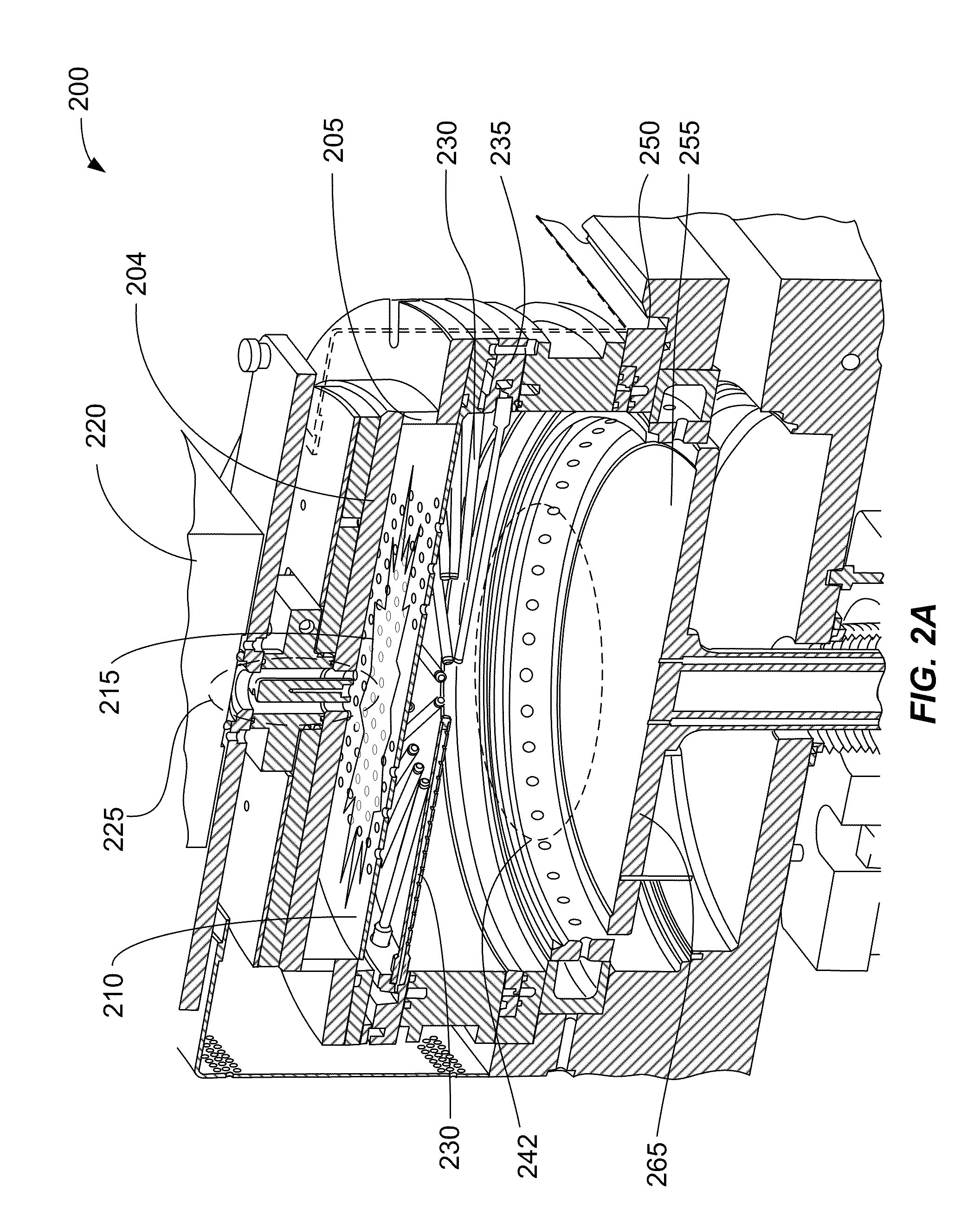

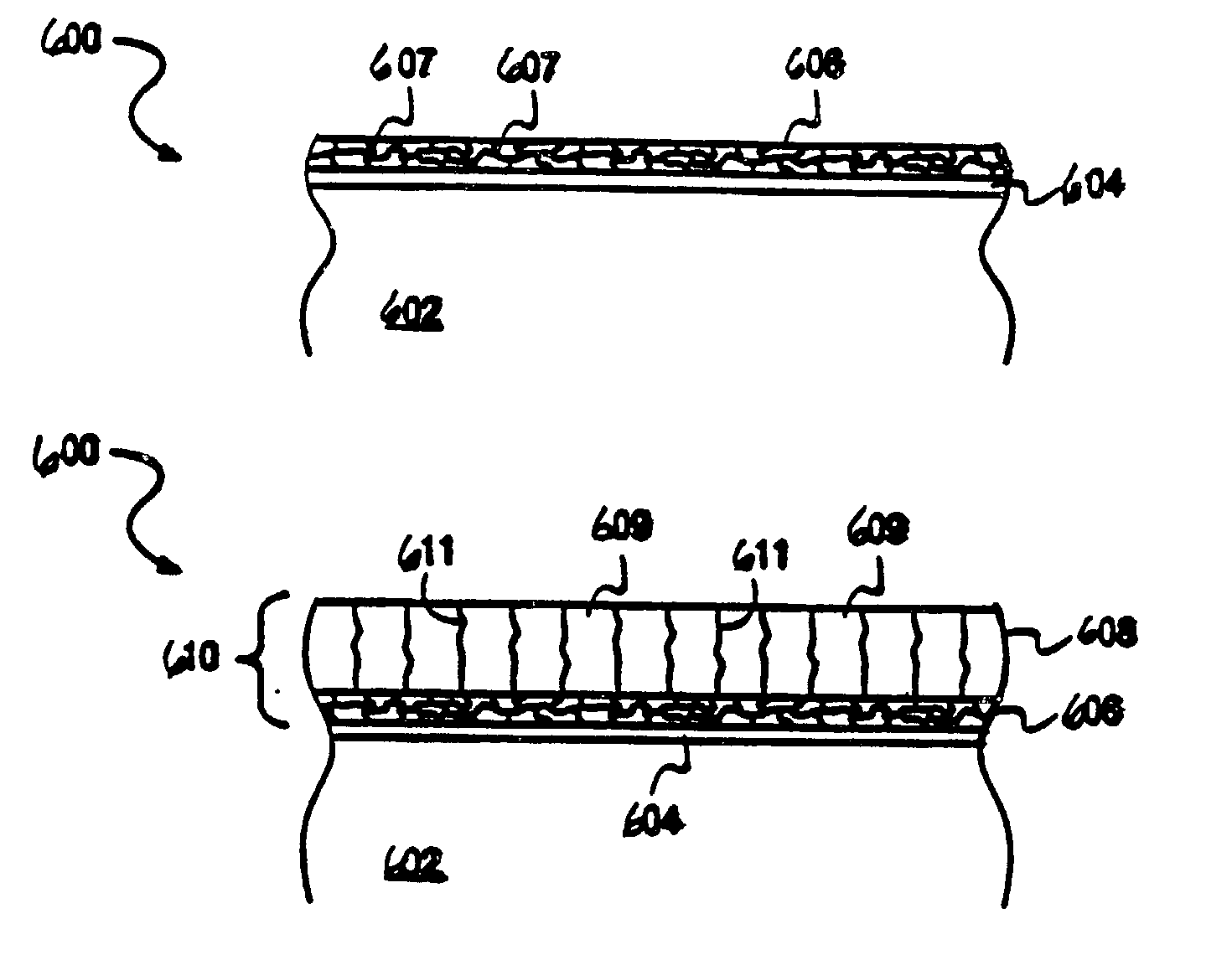

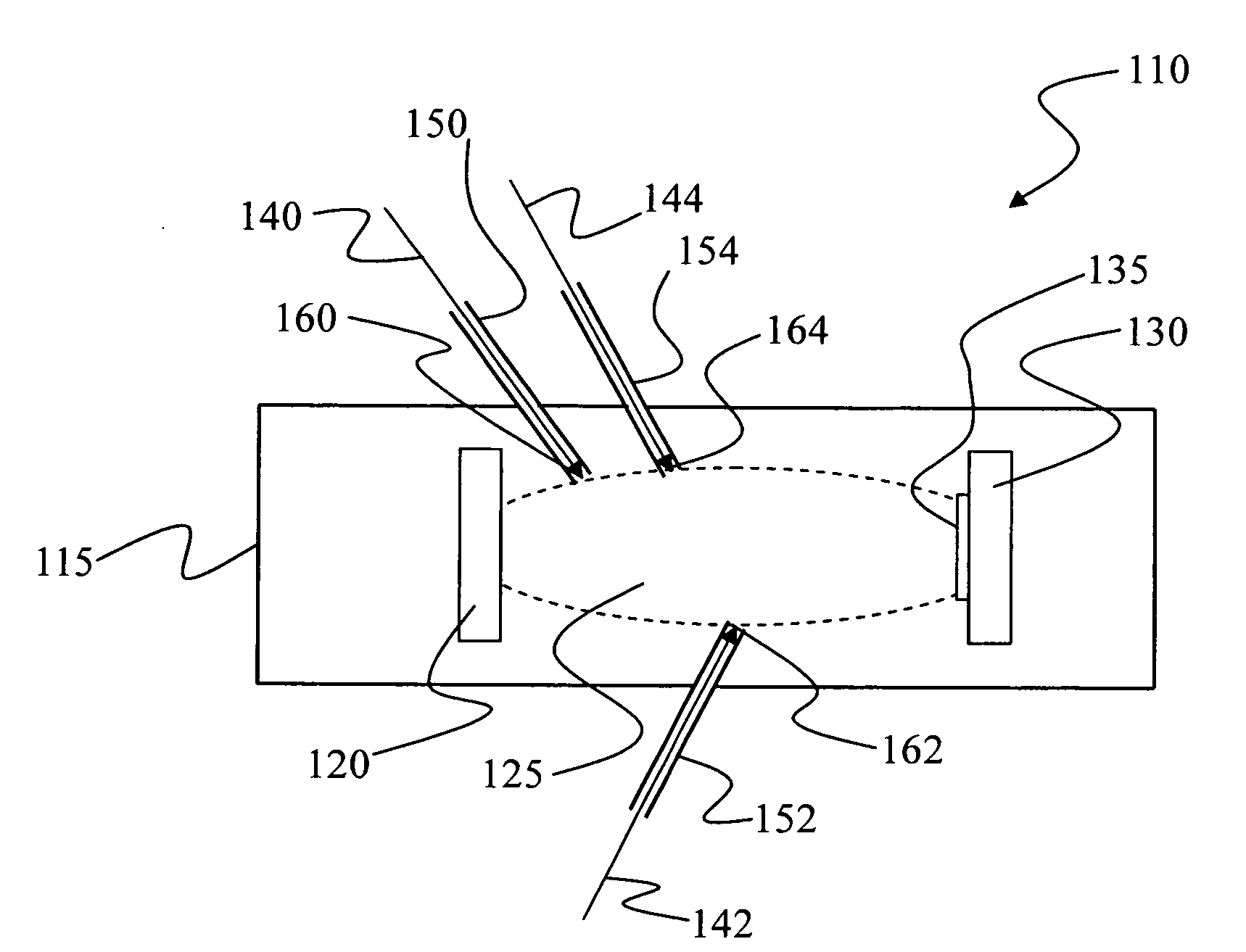

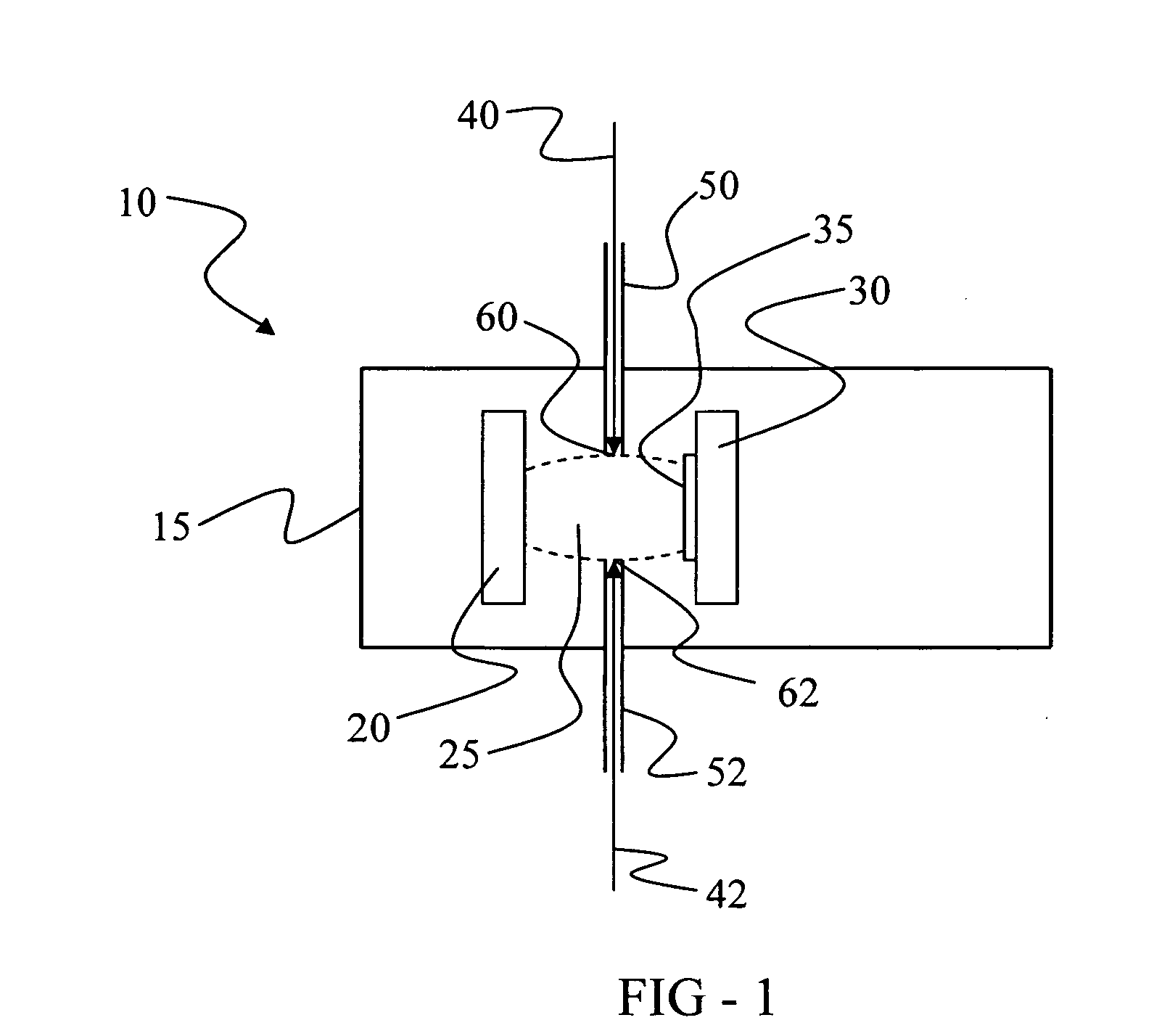

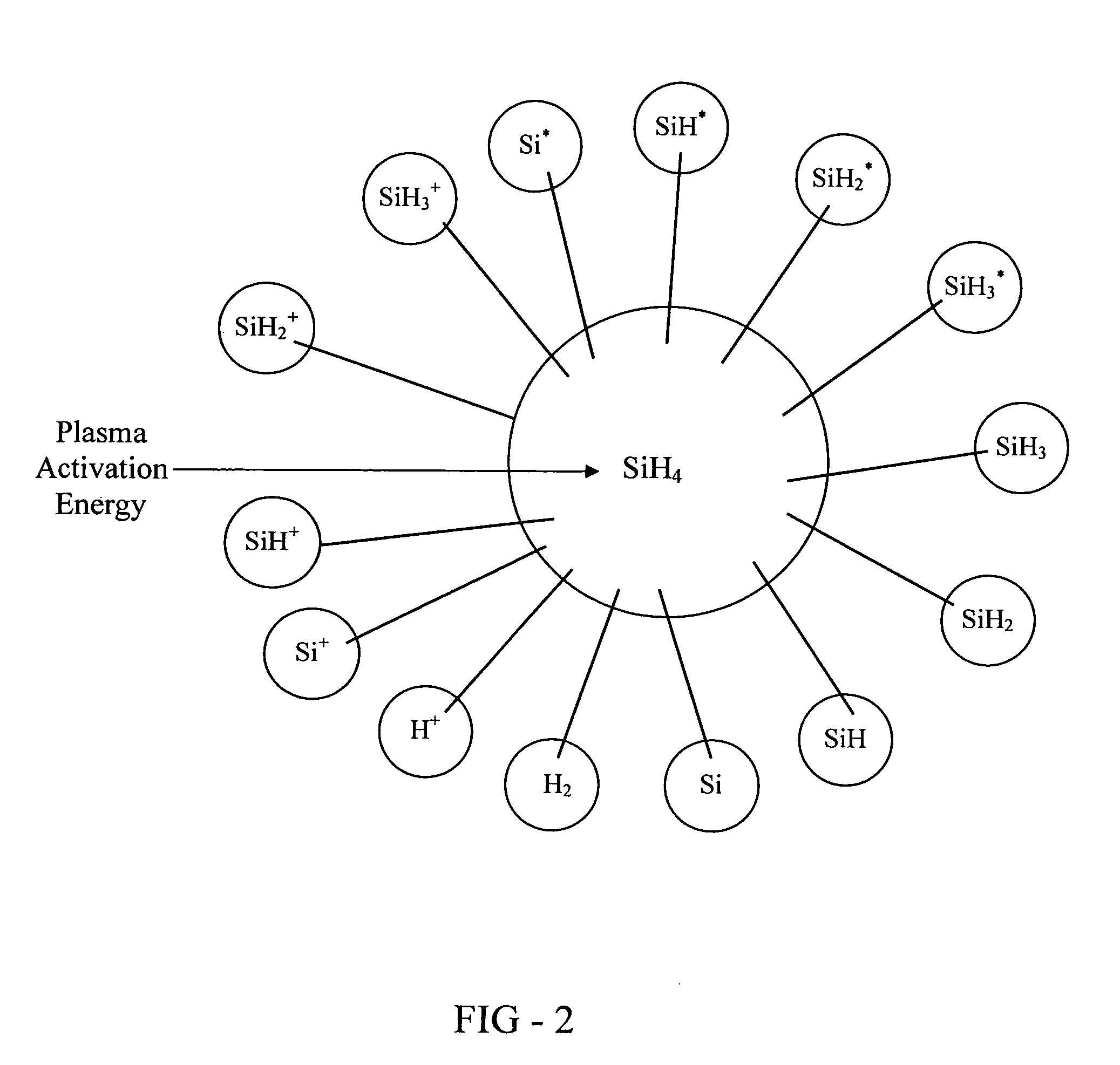

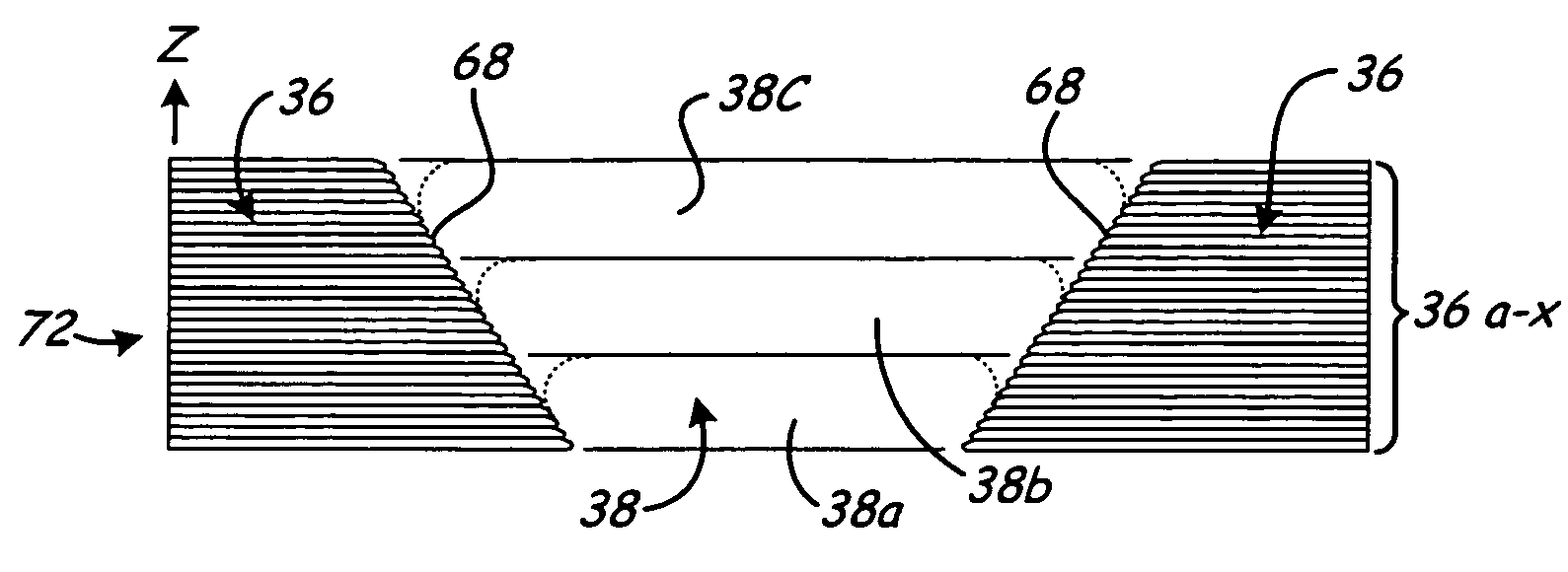

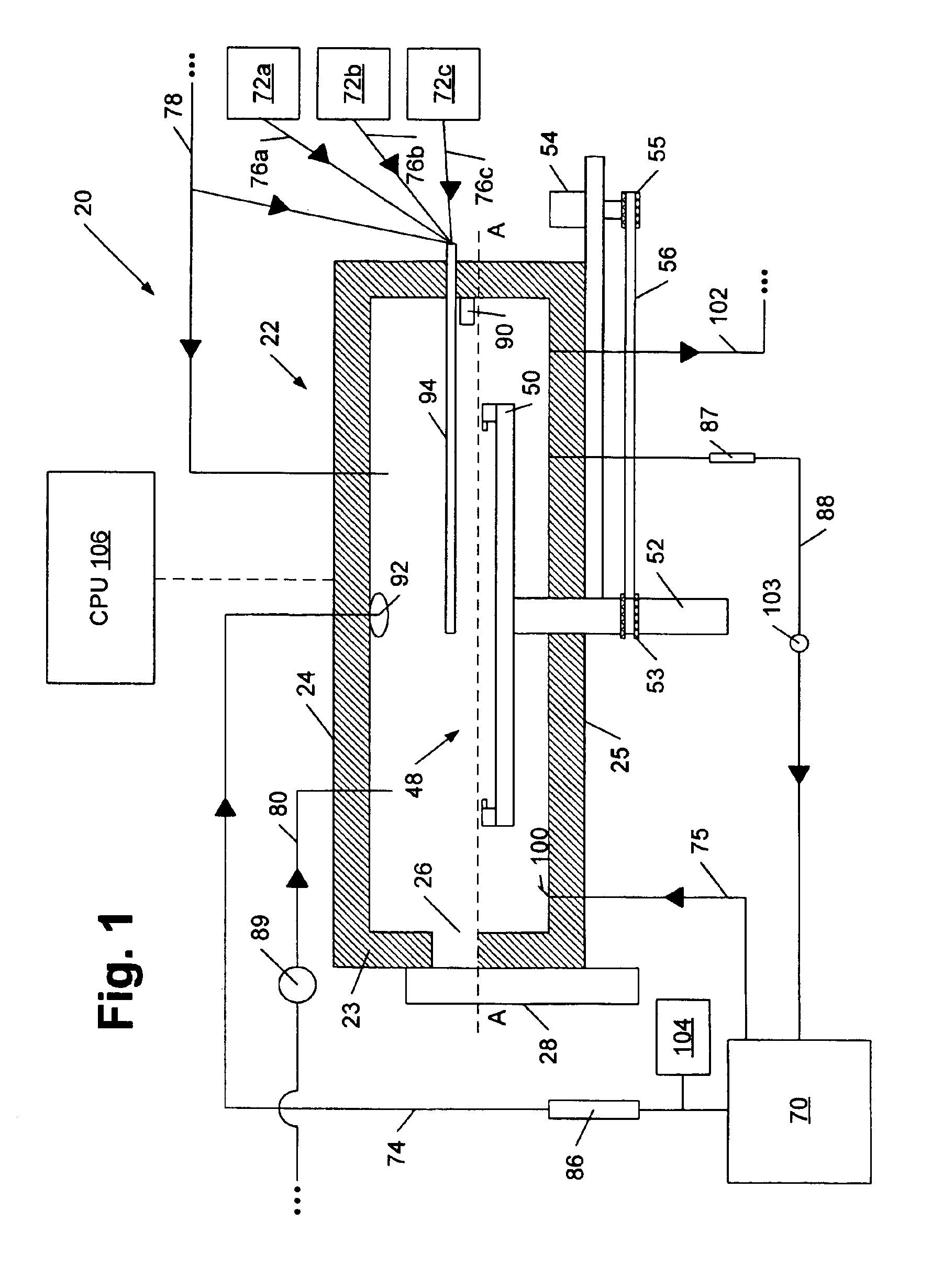

Thin film deposition via a spatially-coordinated and time-synchronized process

InactiveUS20100151149A1Increase deposition rateImprove photovoltaic efficiencyFinal product manufacturePretreated surfacesRemote plasmaSource material

A deposition system and process for the formation of thin film materials. In one embodiment, the process includes forming an initial plasma from a first material stream and allowing the plasma to evolve in space and / or time to extinguish species that are detrimental to the quality of the thin film material. After the initial plasma evolves to an optimum state, a second material stream is injected into the deposition chamber to form a composite plasma that contains a distribution of species more conducive to formation of a high quality thin film material. The deposition system includes a deposition chamber having a plurality of delivery points for injecting two or more streams (source materials or carrier gases) into a plasma region. The delivery points are staggered in space to permit an upstream plasma formed from a first material stream deposition source material to evolve before combining a downstream material stream with the plasma. Injection of different material streams is also synchronized in time. The net effect of spatial coordination and time synchronization of material streams is a plasma whose distribution of species is optimized for the deposition of a thin film photovoltaic material at high deposition rates. Delivery devices include nozzles and remote plasma sources.

Owner:OVSHINSKY TECH

High-resolution rapid manufacturing

ActiveUS7236166B2Fast preparationGood physical propertiesAdditive manufacturing apparatusWood working apparatusStructural engineeringRapid manufacturing

The present invention is a method for forming an object, the method comprising jetting a first material to form a plurality of layers that define a support structure increment, and extruding a second material to form a layer of the object. The layer of the object substantially conforms to an interior surface of the support structure increment.

Owner:STRATSYS INC

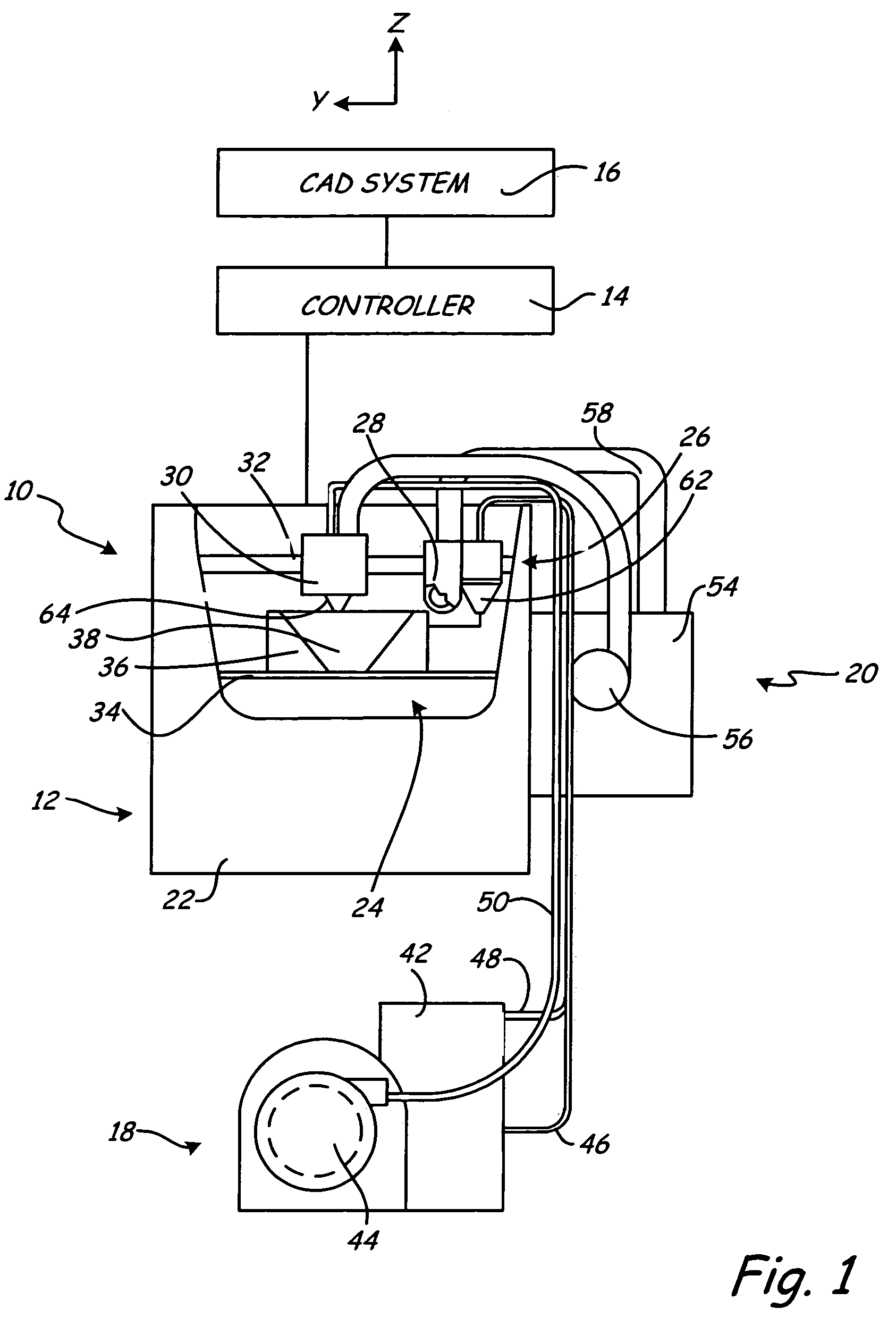

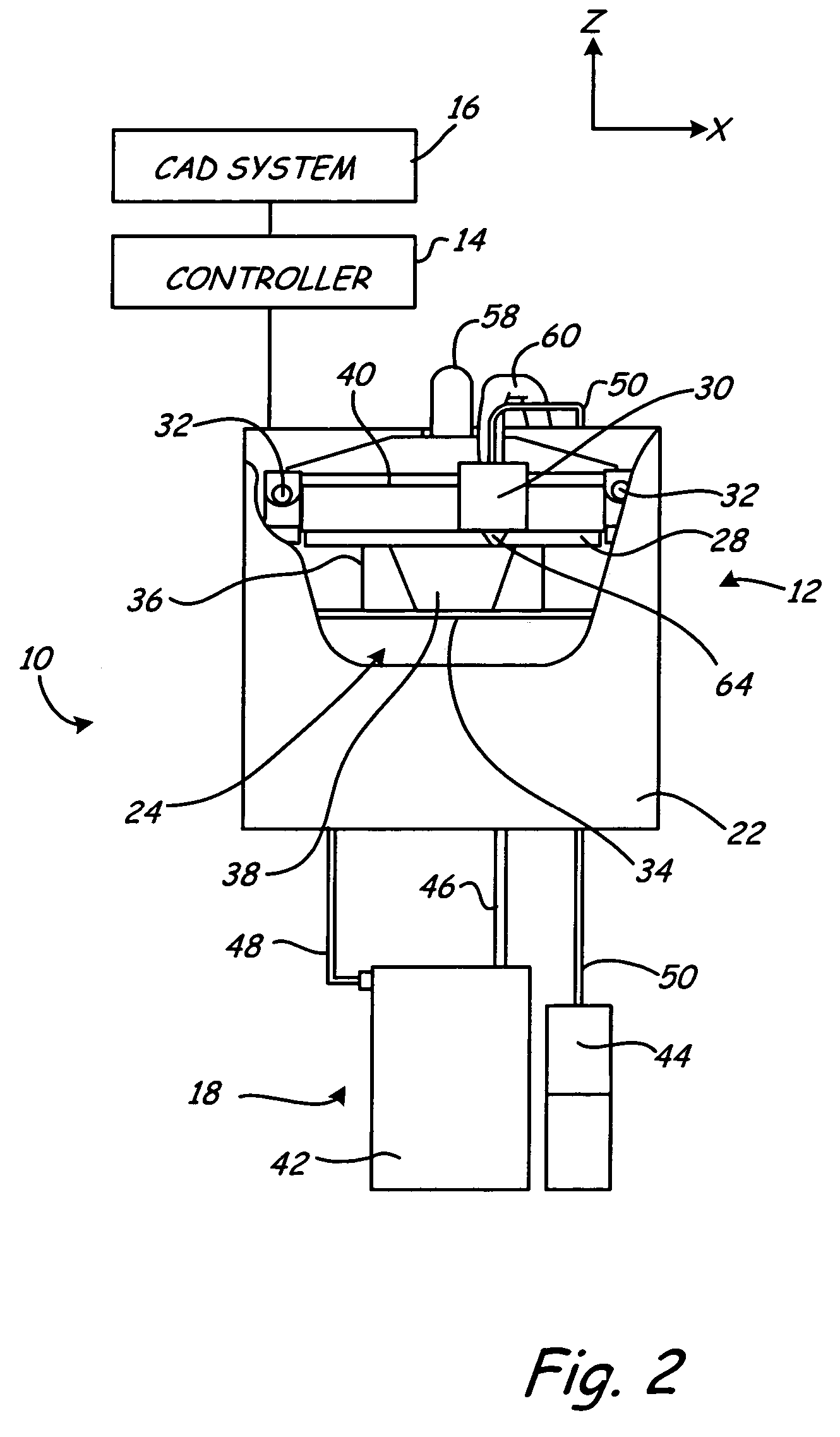

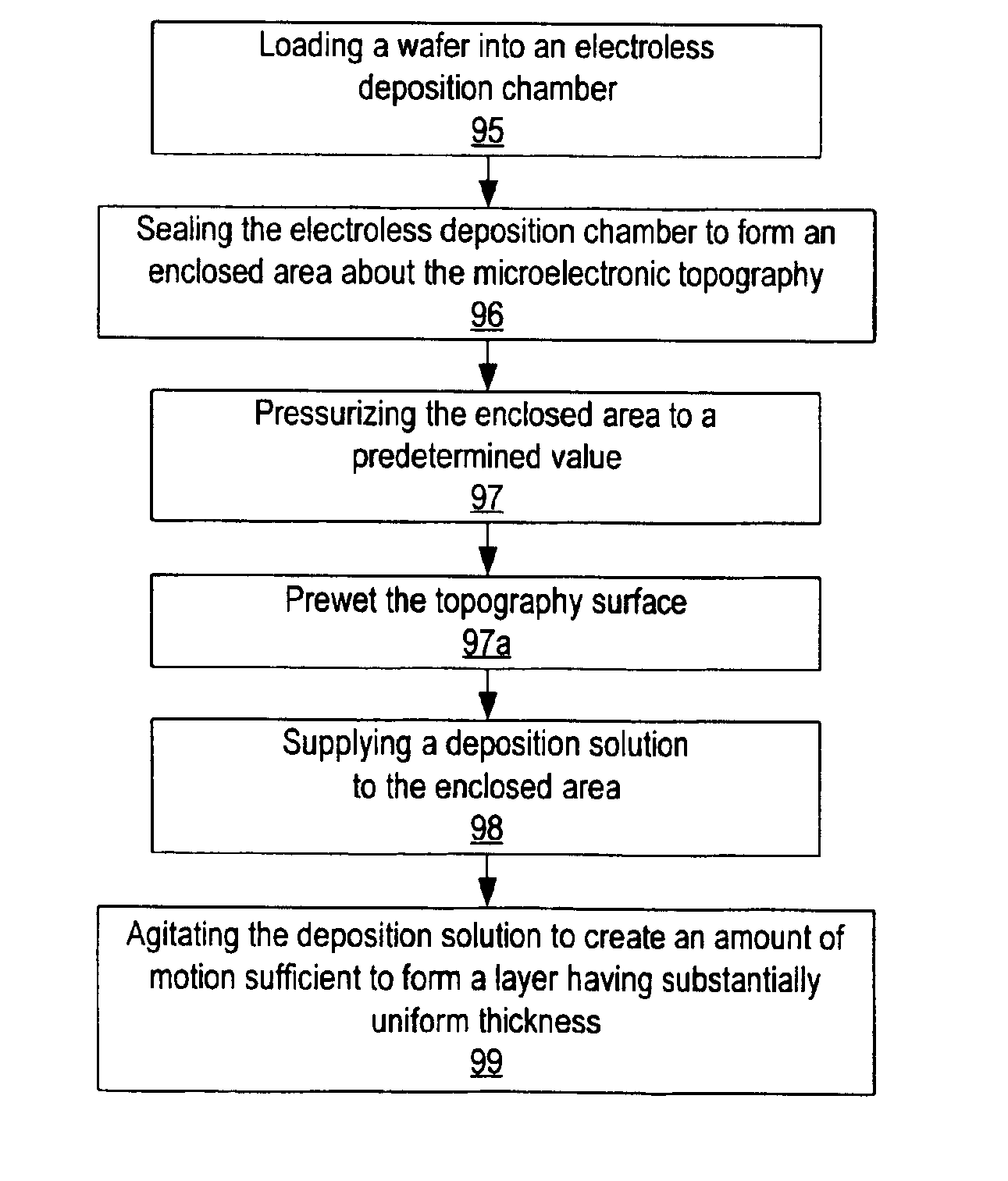

Methods and system for processing a microelectronic topography

InactiveUS6881437B2Avoid flowHigh boiling pointSemiconductor/solid-state device manufacturingPretreated surfacesElectroless depositionTopography

Methods and systems are provided which are adapted to process a microelectronic topography, particularly in association with an electroless deposition process. In general, the methods may include loading the topography into a chamber, closing the chamber to form an enclosed area, and supplying fluids to the enclosed area. In some embodiments, the fluids may fill the enclosed area. In addition or alternatively, a second enclosed area may be formed about the topography. As such, the provided system may be adapted to form different enclosed areas about a substrate holder. In some cases, the method may include agitating a solution to minimize the accumulation of bubbles upon a wafer during an electroless deposition process. As such, the system provided herein may include a means for agitating a solution in some embodiments. Such a means for agitation may be distinct from the inlet / s used to supply the solution to the chamber.

Owner:LAM RES CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com