Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

18675results about "Arc welding apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

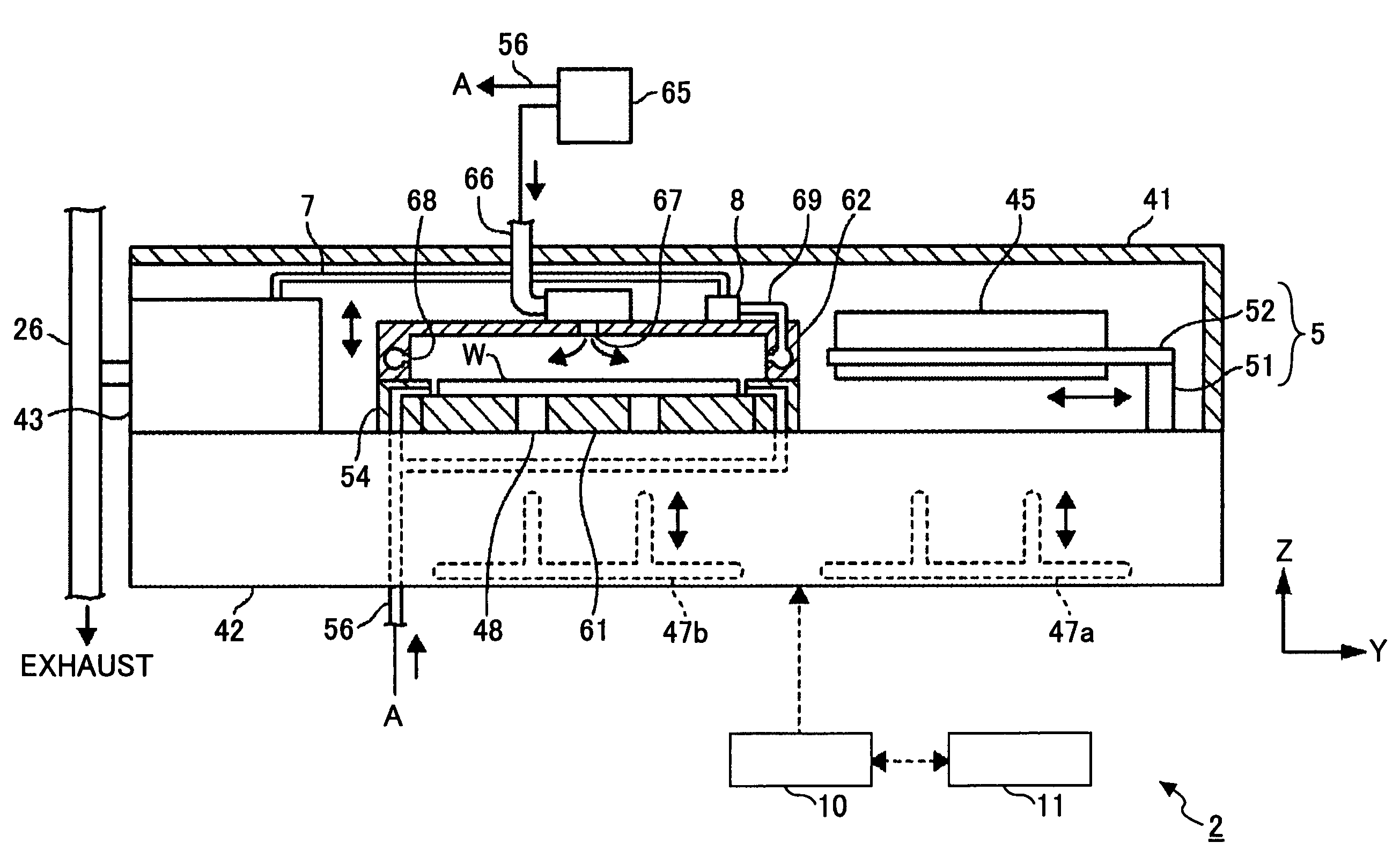

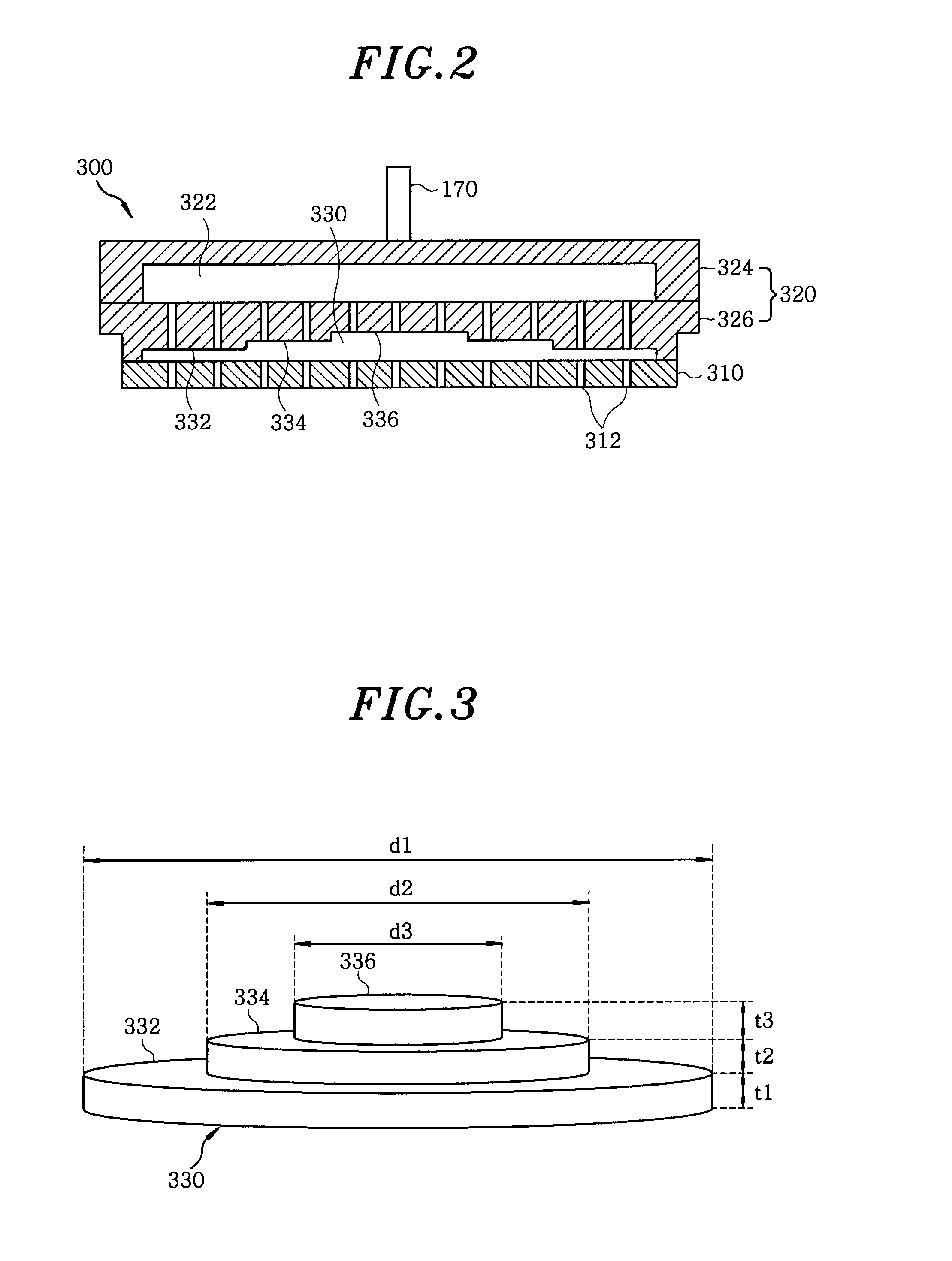

Heating apparatus, heating method, and computer readable storage medium

ActiveUS7992318B2Improve temperature uniformityDryer sectionDrying gas arrangementsProcess engineeringGas supply

A disclosed heating apparatus for heating a substrate on which a film is coated includes a process chamber having a gas supply opening for supplying a first gas to the process chamber and a gas evacuation opening for evacuating the first gas from the process chamber; a heating plate that is arranged in the process chamber and includes a heating element for heating the substrate; plural protrusions arranged on the heating plate so as to support the substrate; plural suction holes formed in the heating plate so as to attract by suction the substrate toward the heating plate; and a gas inlet adapted to supply a second gas to a gap between the heating plate and the substrate supported by the plural protrusions.

Owner:TOKYO ELECTRON LTD

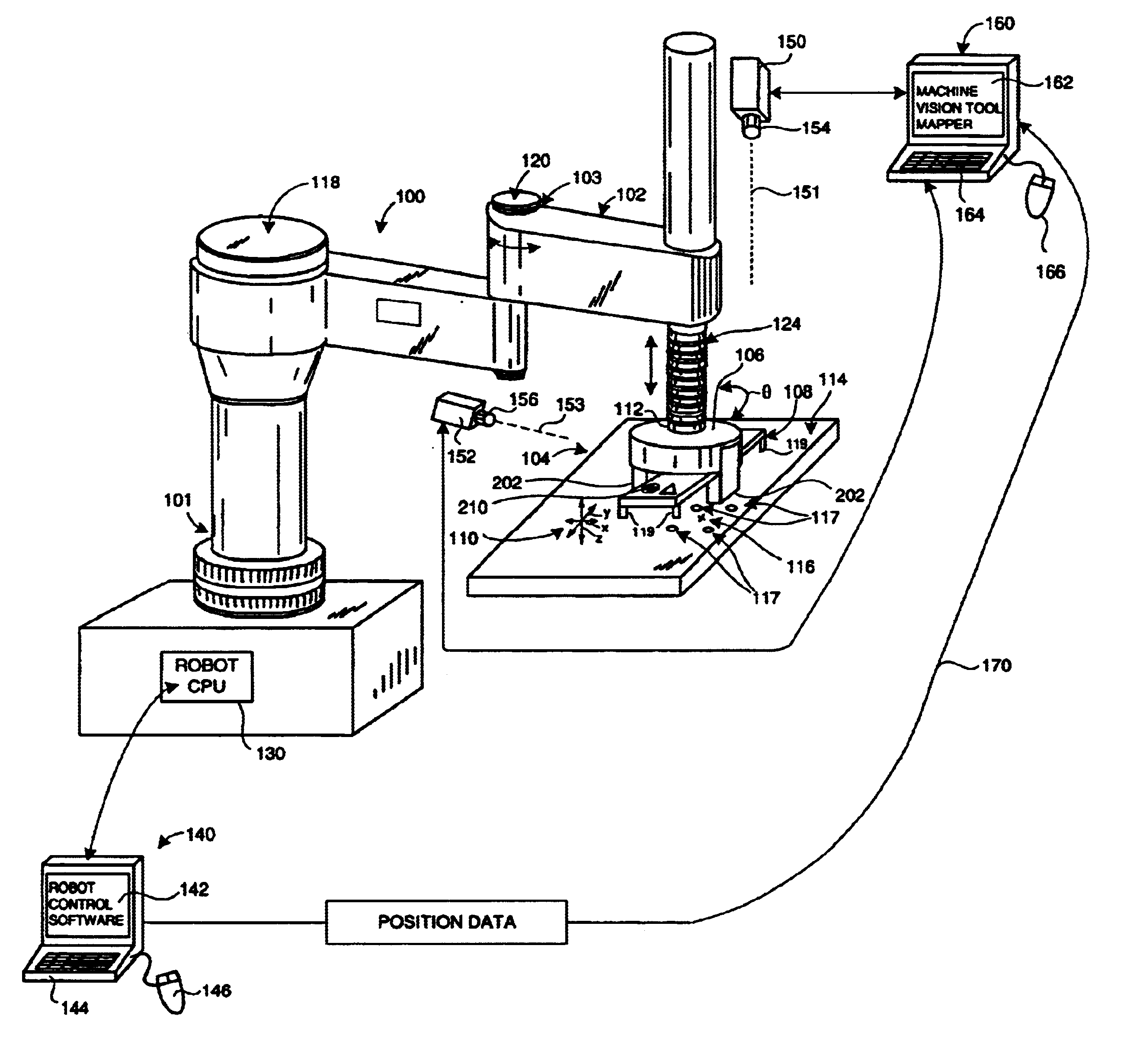

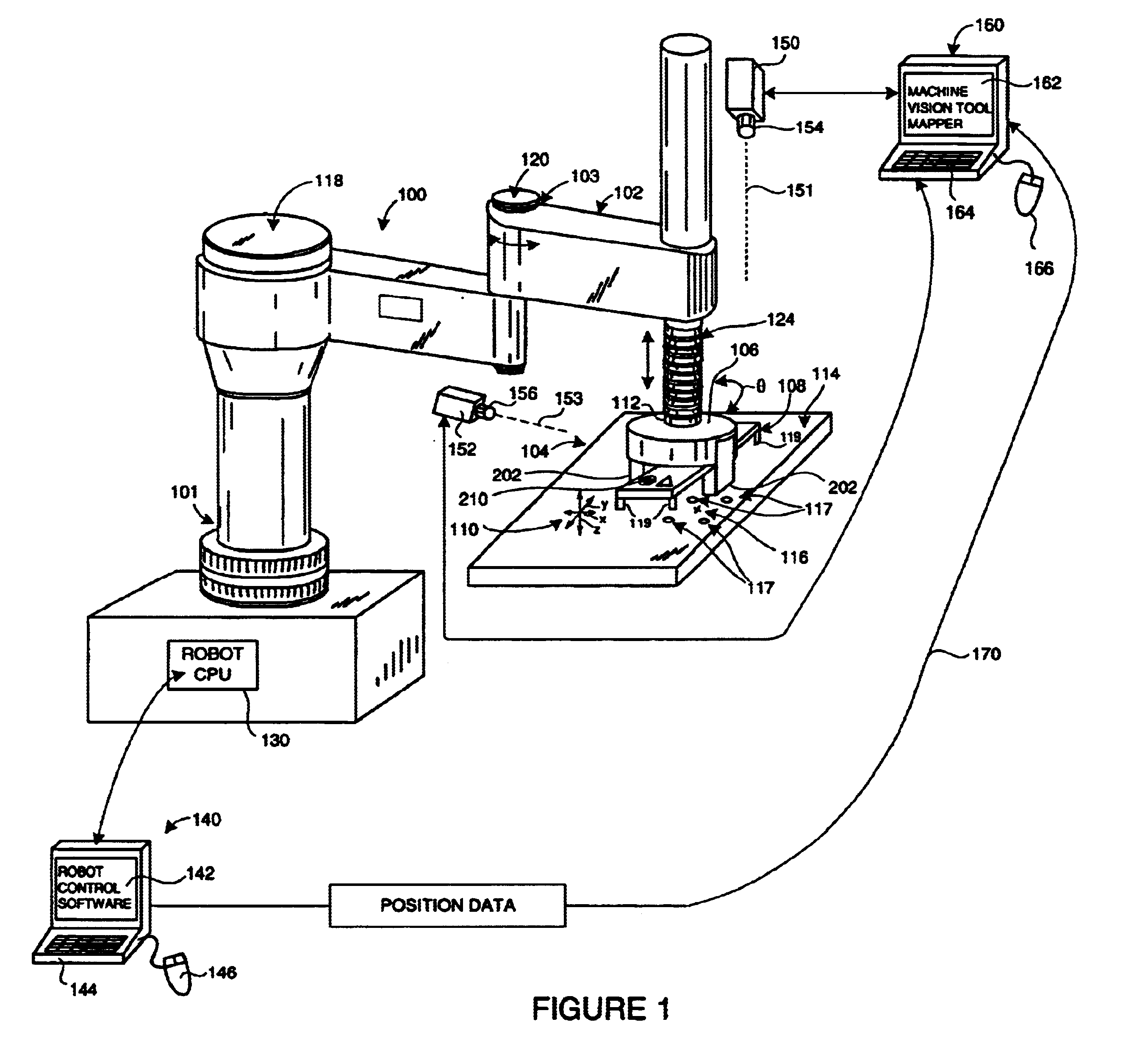

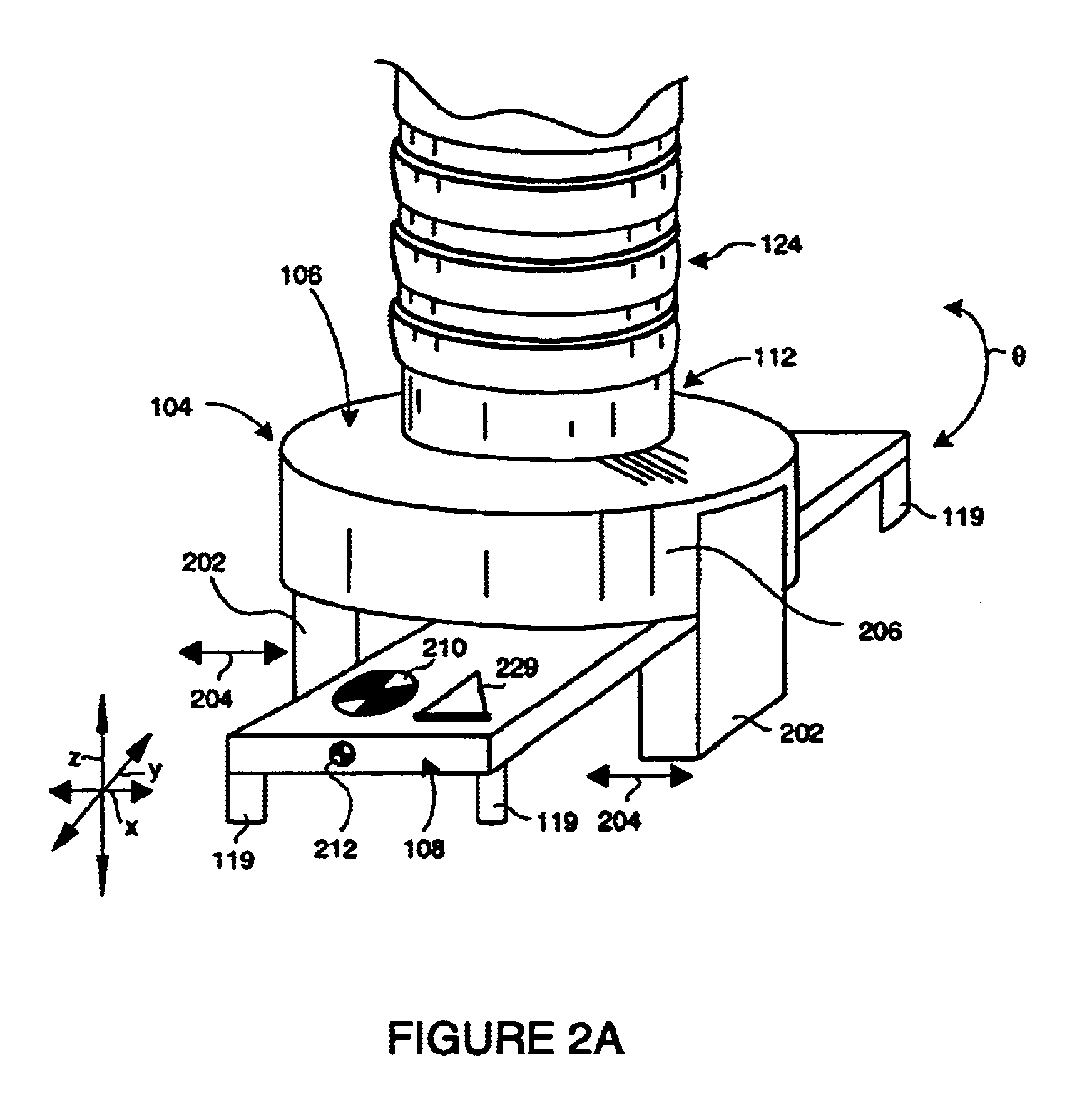

System and method for servoing robots based upon workpieces with fiducial marks using machine vision

InactiveUS6681151B1Sure easyLocated reliablyProgramme-controlled manipulatorPhotometry using reference valueEngineeringDegrees of freedom

A system and method for servoing robot marks using fiducial marks and machine vision provides a machine vision system having a machine vision search tool that is adapted to register a pattern, namely a trained fiducial mark, that is transformed by at least two translational degrees and at least one mon-translational degree of freedom. The fiducial is provided to workpiece carried by an end effector of a robot operating within a work area. When the workpiece enters an area of interest within a field of view of a camera of the machine vision system, the fiducial is recognized by the tool based upon a previously trained and calibrated stored image within the tool. The location of the work-piece is derived by the machine vision system based upon the viewed location of the fiducial. The location of the found fiducial is compared with that of a desired location for the fiducial. The desired location can be based upon a standard or desired position of the workpiece. If a difference between location of the found fiducial and the desired location exists, the difference is calculated with respect to each of the translational axes and the rotation. The difference can then be further transformed into robot-based coordinates to the robot controller, and workpiece movement is adjusted based upon the difference. Fiducial location and adjustment continues until the workpiece is located the desired position with minimum error.

Owner:COGNEX TECH & INVESTMENT

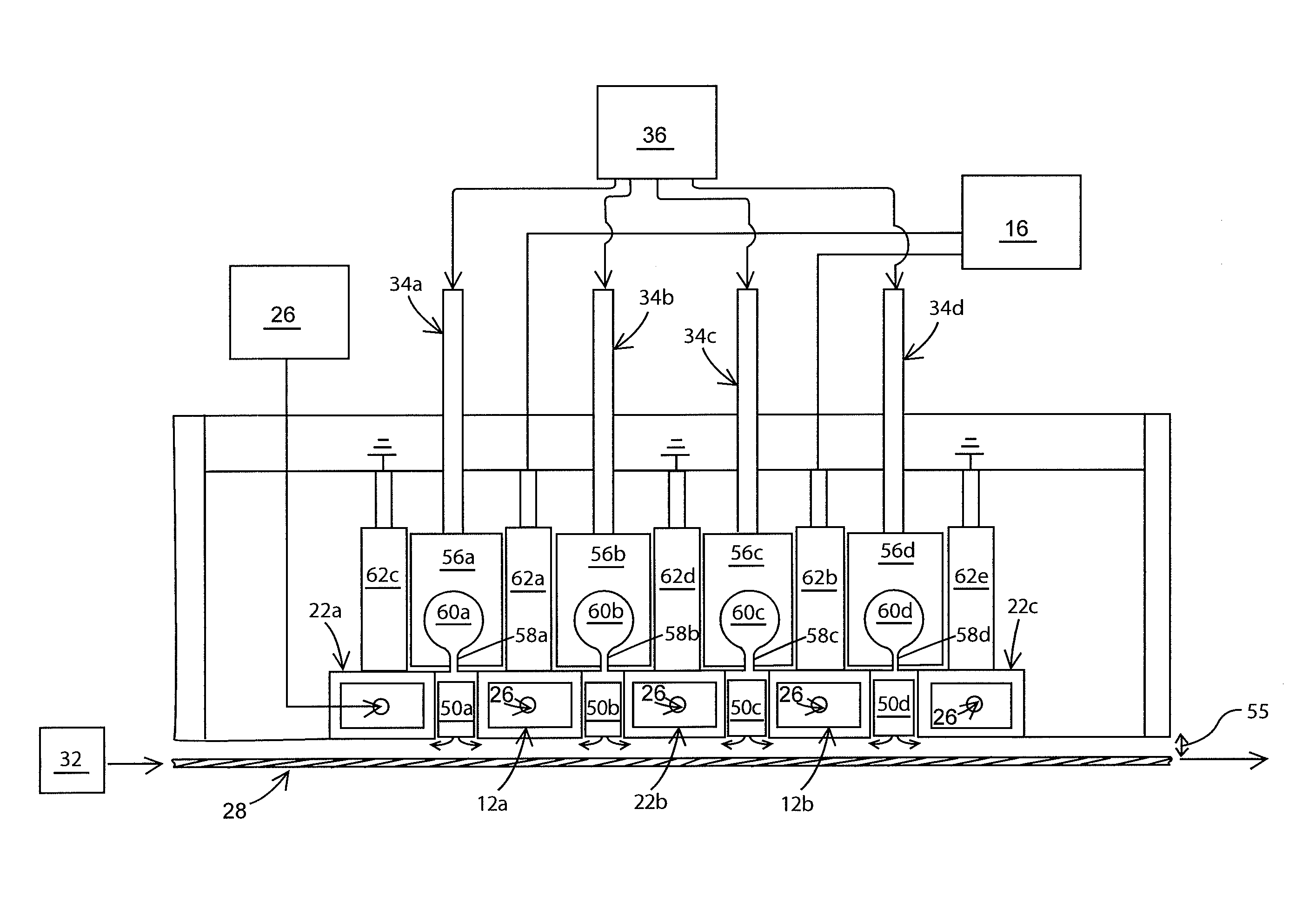

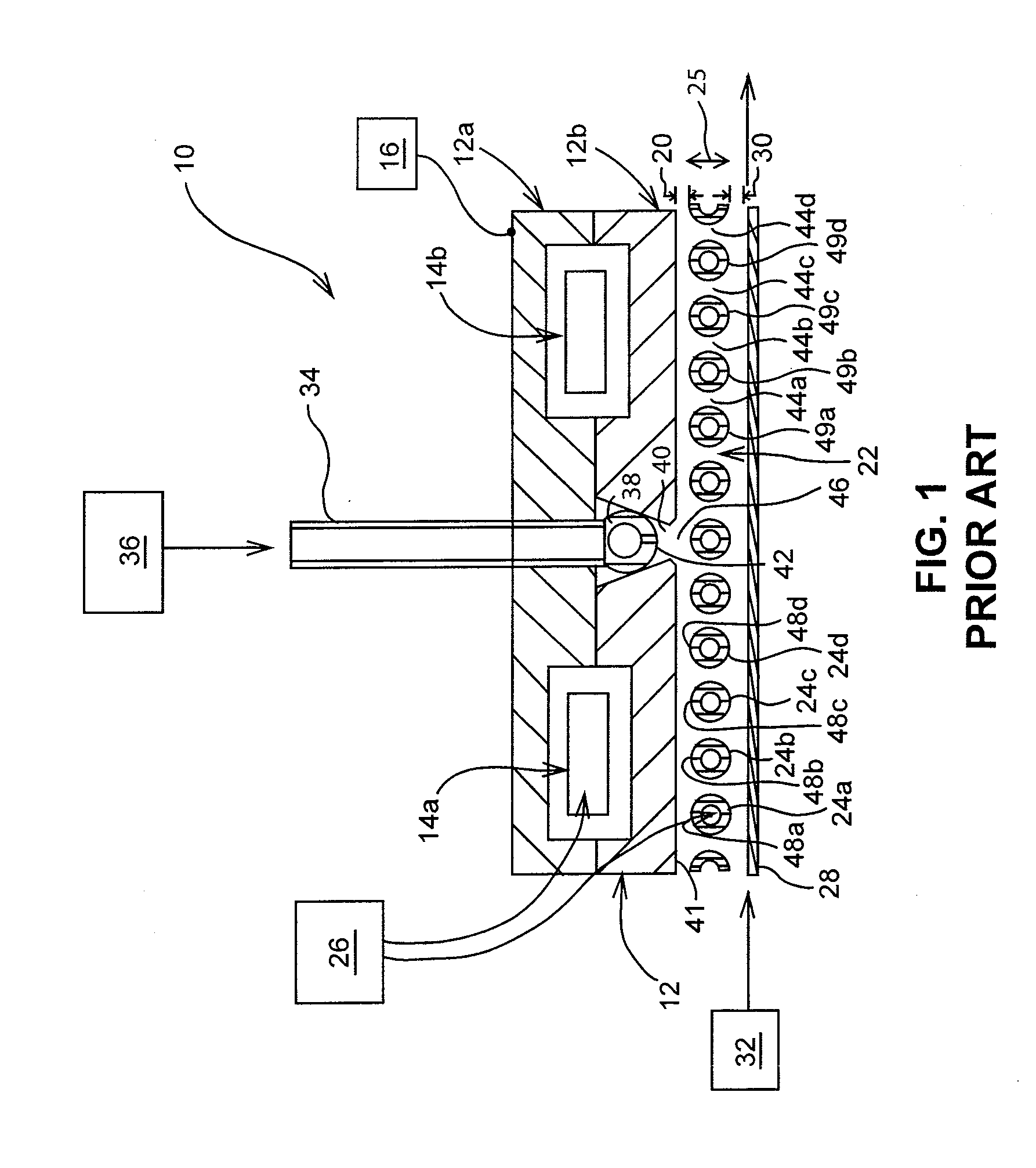

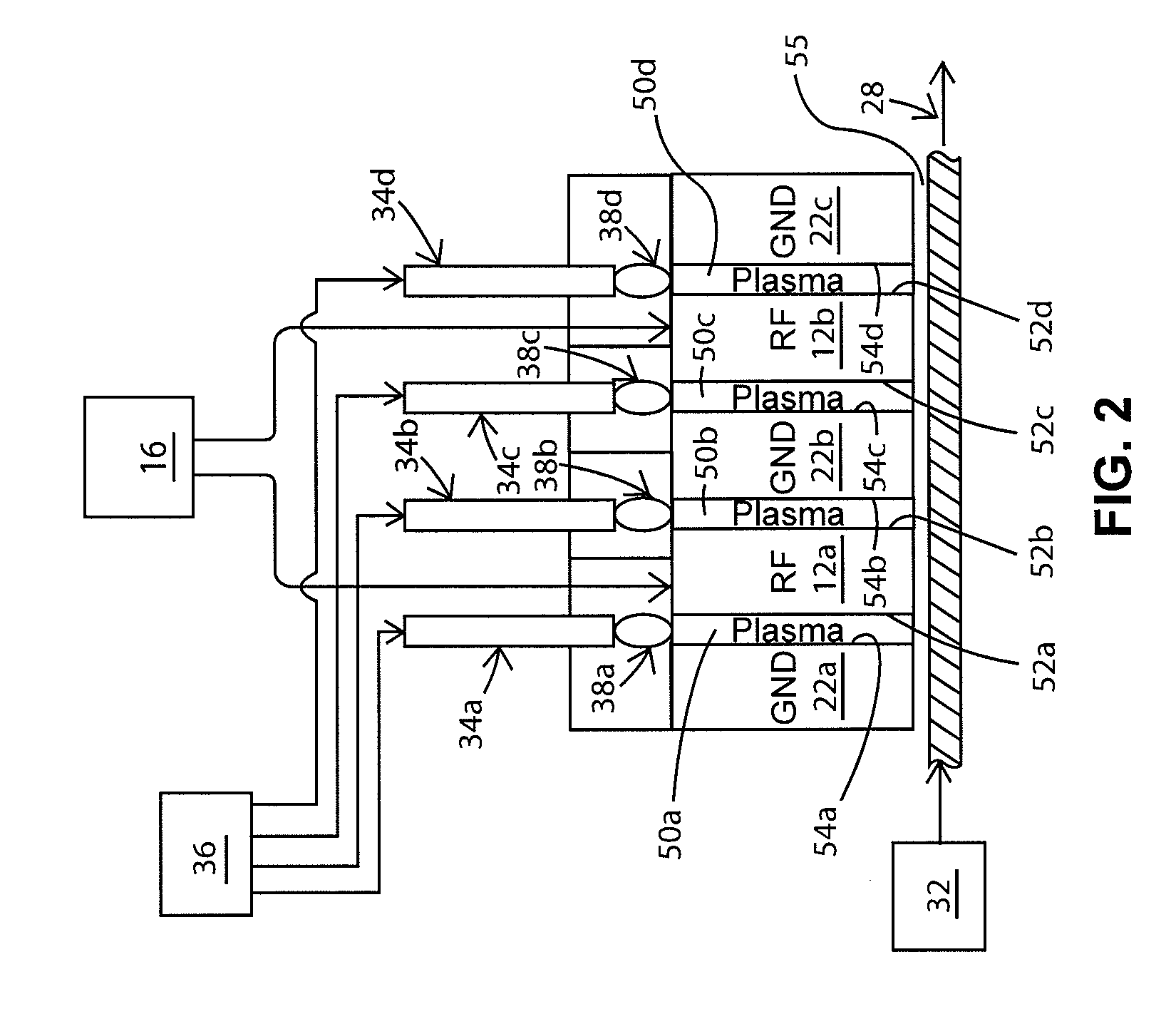

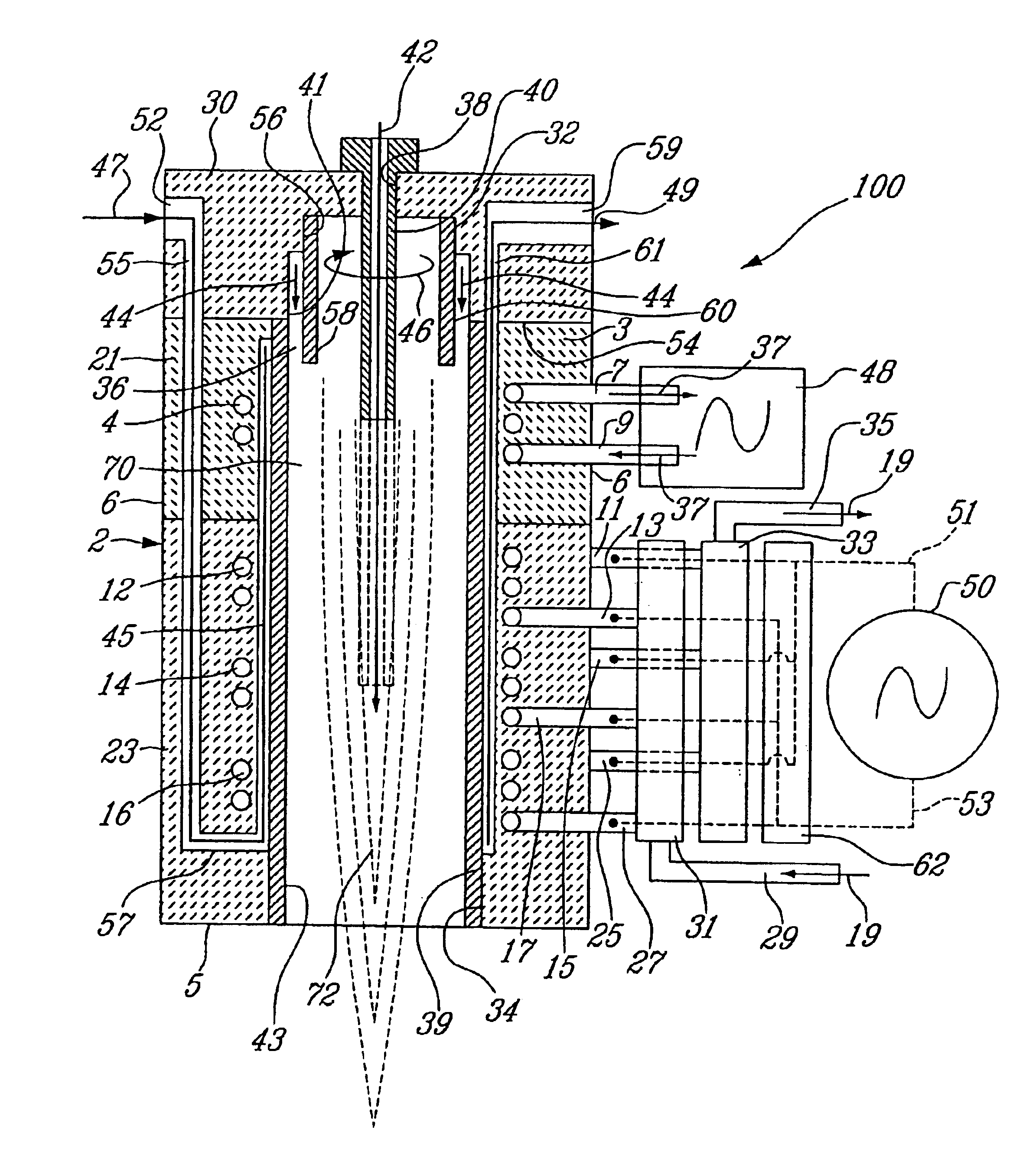

Atmospheric-pressure plasma processing apparatus and method

ActiveUS20140076861A1Faster plasma processing speedMinimum distanceChemical fixing of textilesArc welding apparatusEngineeringAtmospheric pressure

A plasma processing apparatus including powered electrodes having elongated planar surfaces; grounded electrodes having elongated planar surfaces parallel to and coextensive with the elongated surfaces of the powered electrodes, and spaced-apart a chosen distance therefrom, forming plasma regions, is described. RF power is provided to the at least one powered electrode, both powered and grounded electrodes may be cooled, and a plasma gas is flowed through the plasma regions at atmospheric pressure; whereby a plasma is formed in the plasma regions. The material to be processed may be moved into close proximity to the exit of the plasma gas from the plasma regions perpendicular to the gas flow, and perpendicular to the elongated electrode dimensions, whereby excited species generated in the plasma exit the plasma regions and impinge unimpeded onto the material.

Owner:APJET INC

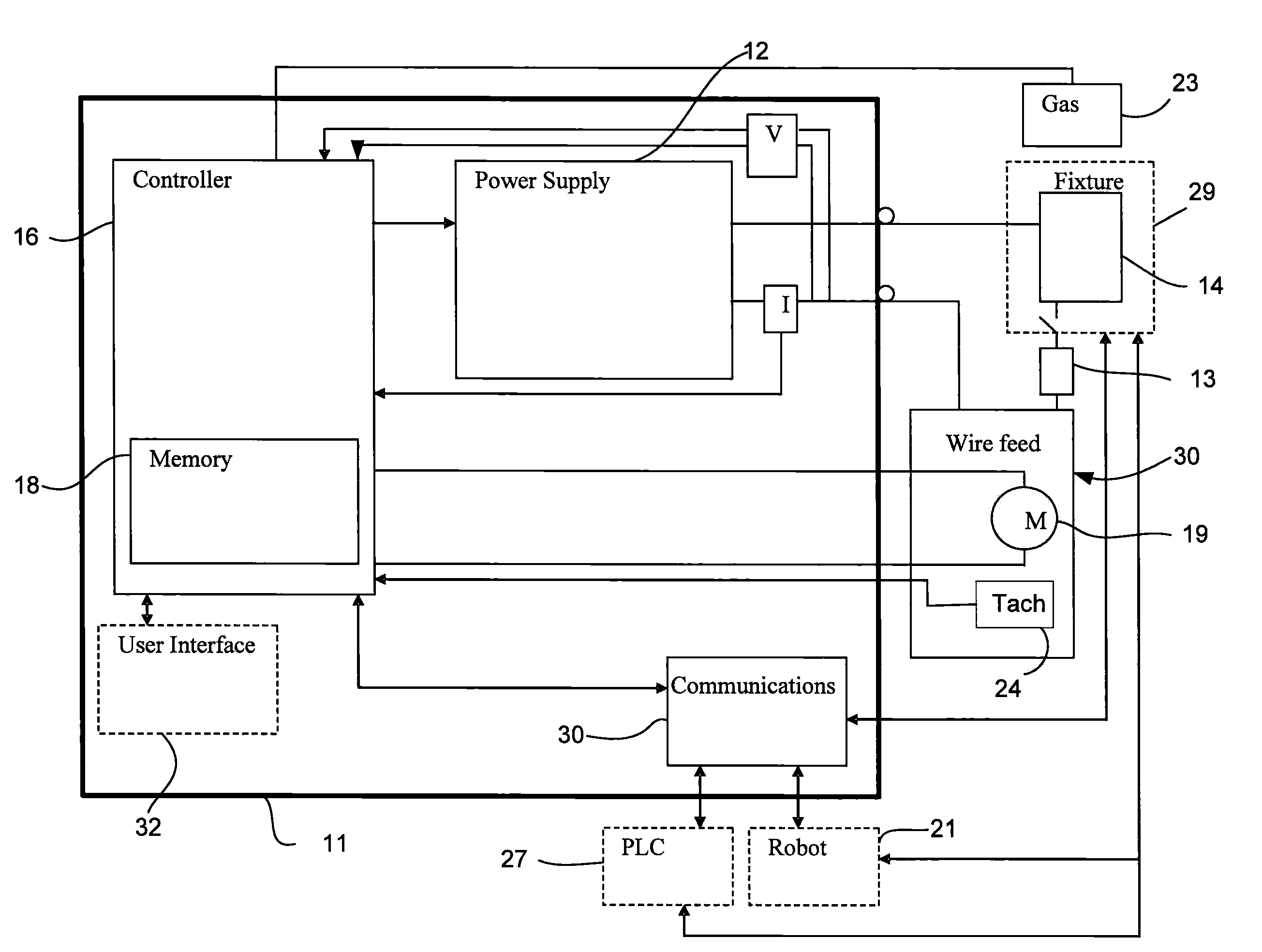

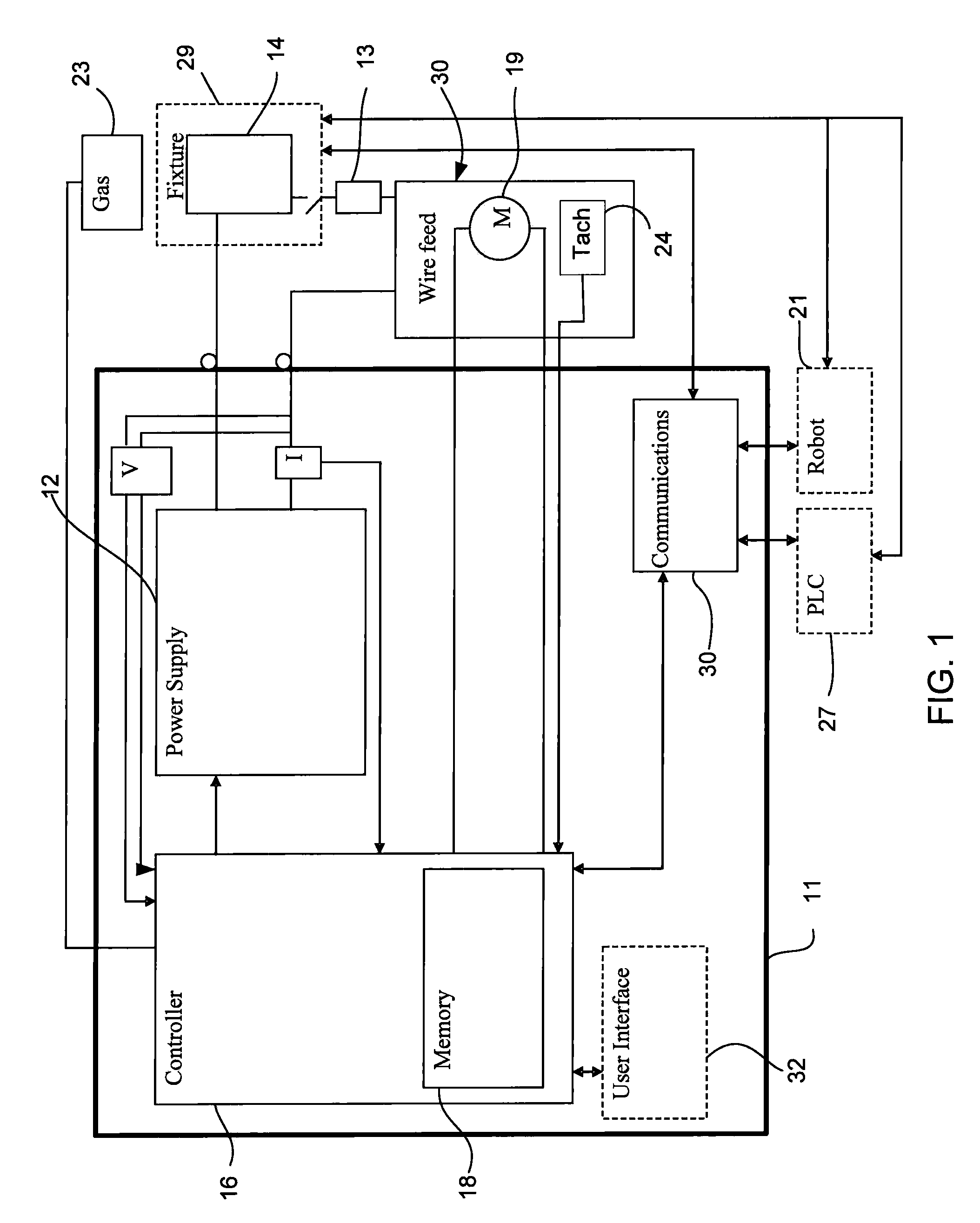

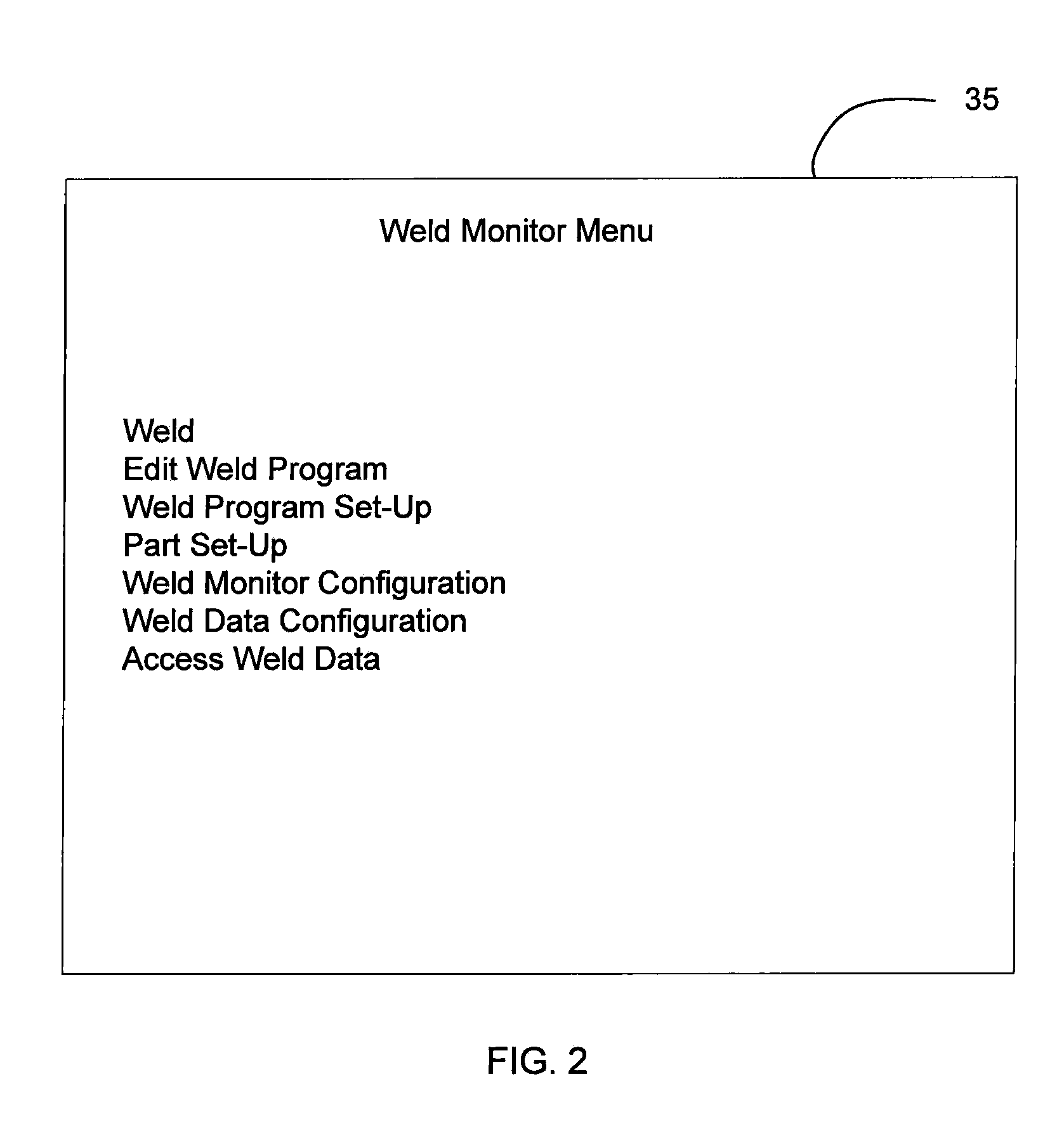

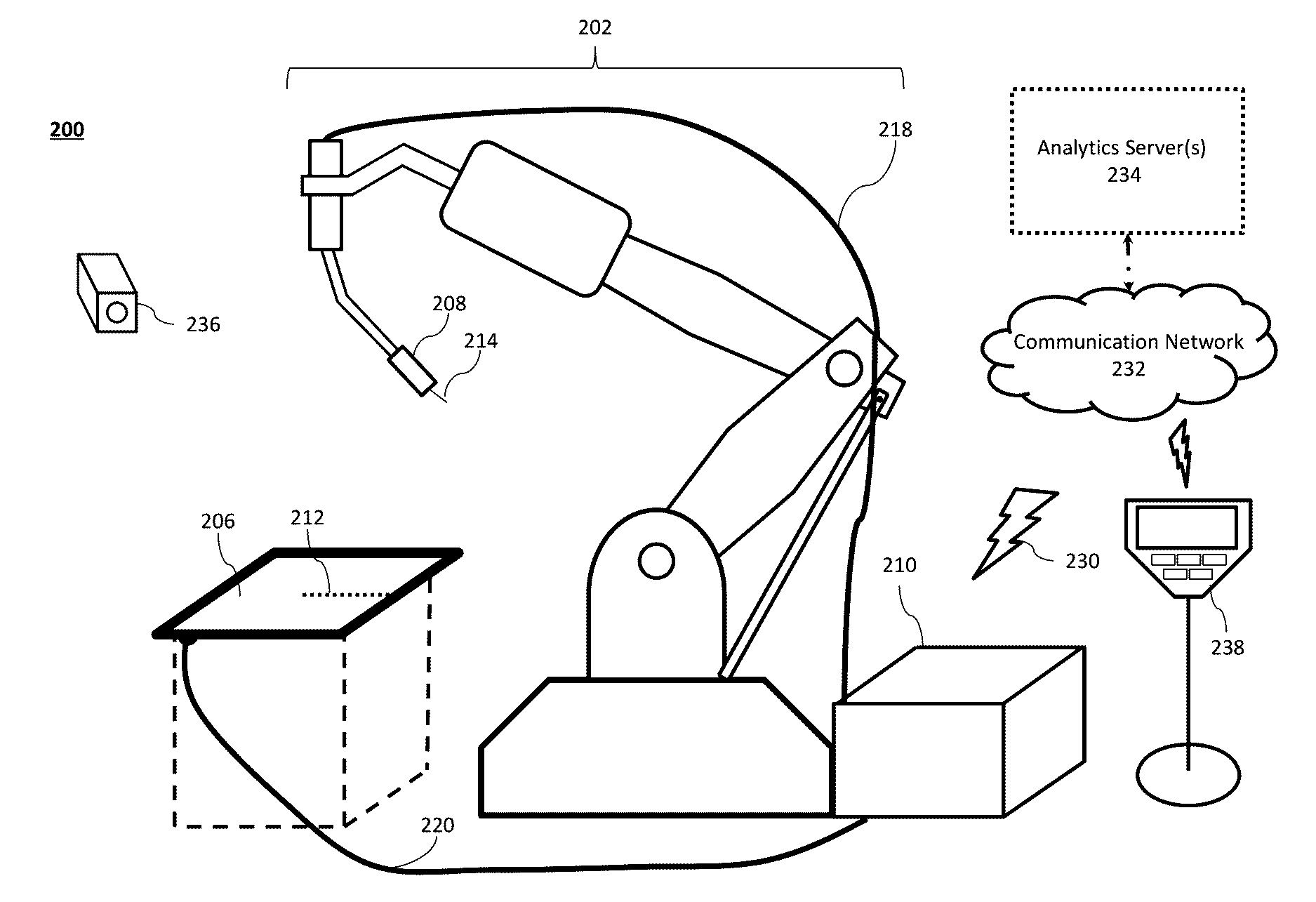

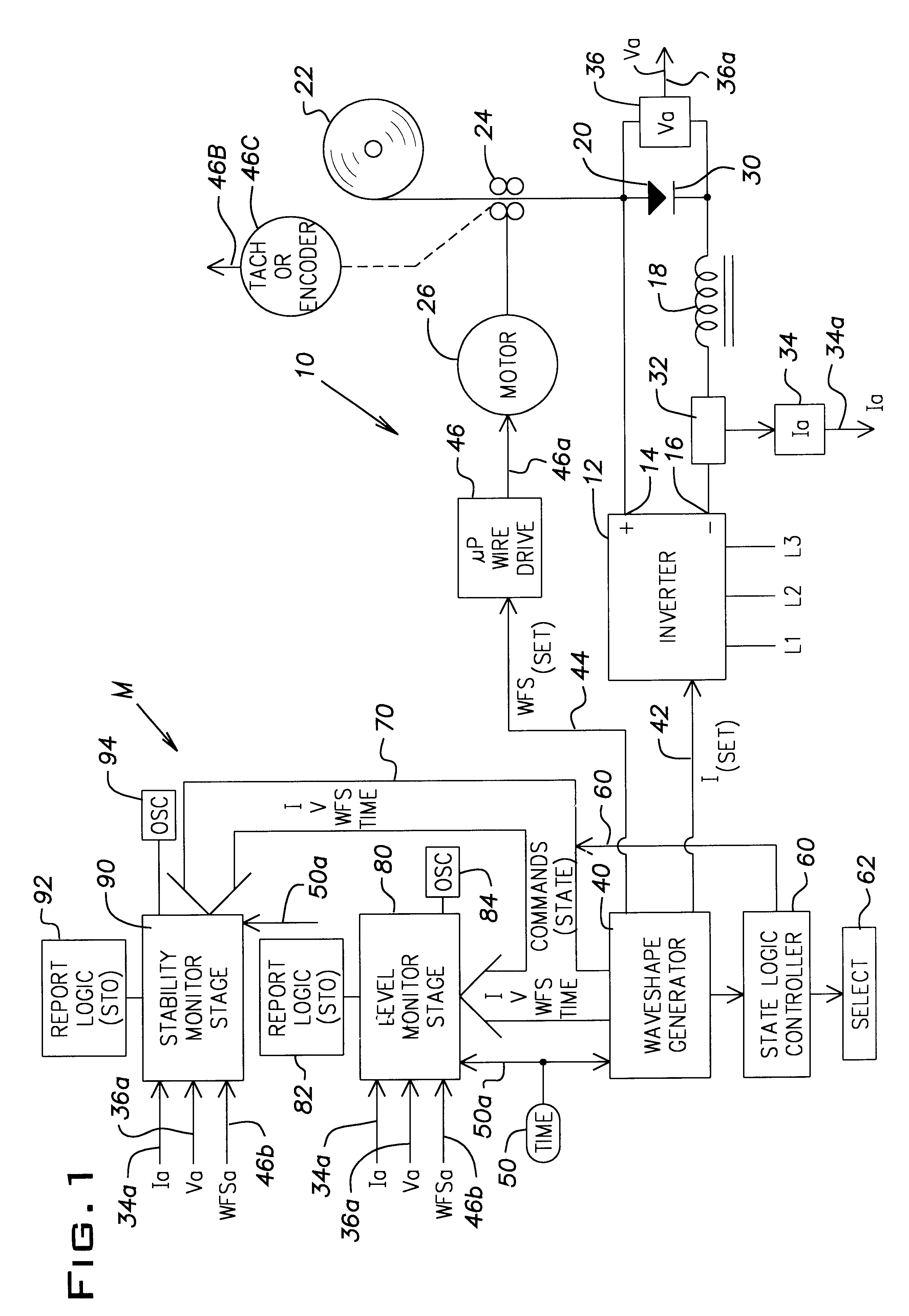

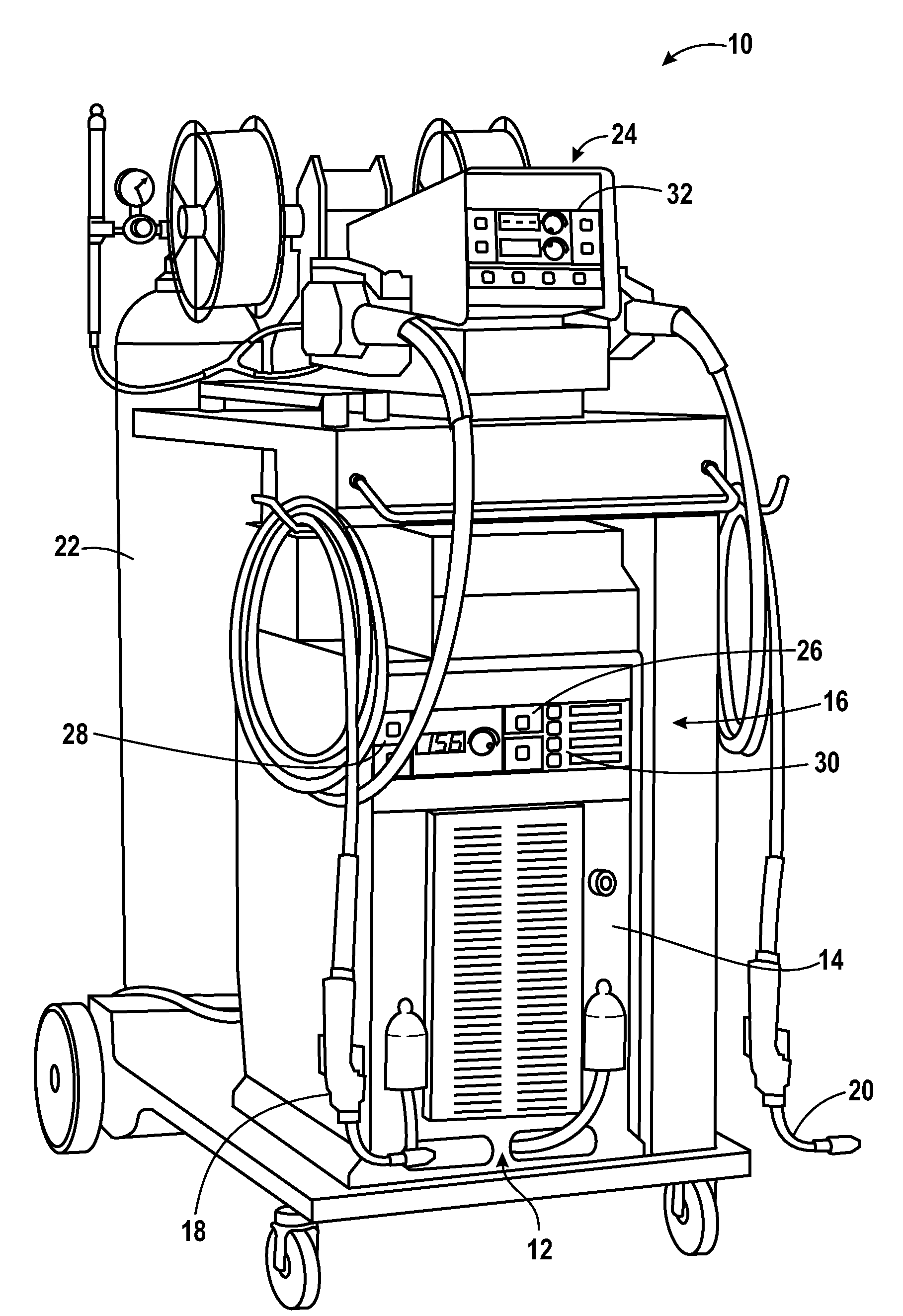

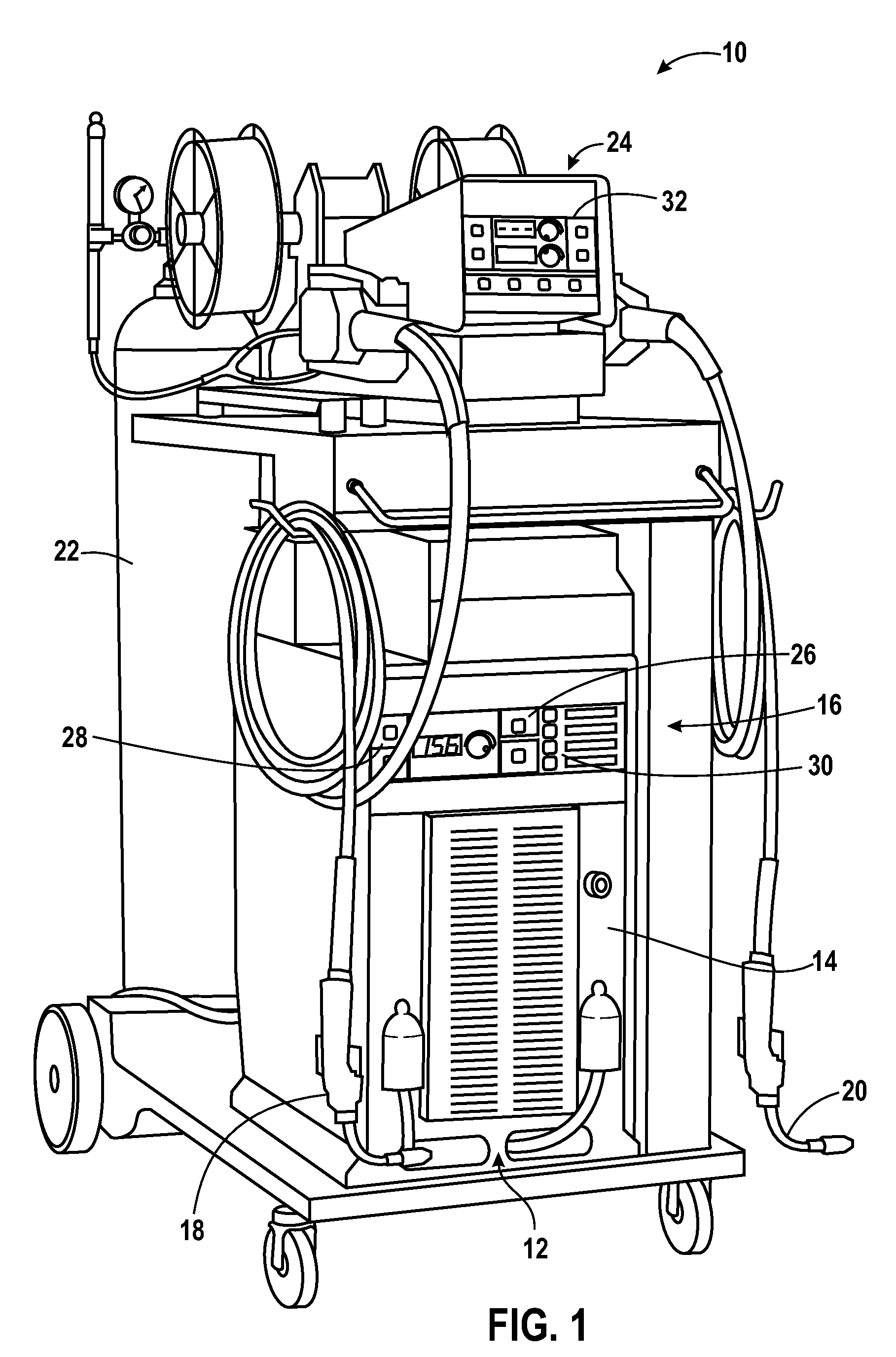

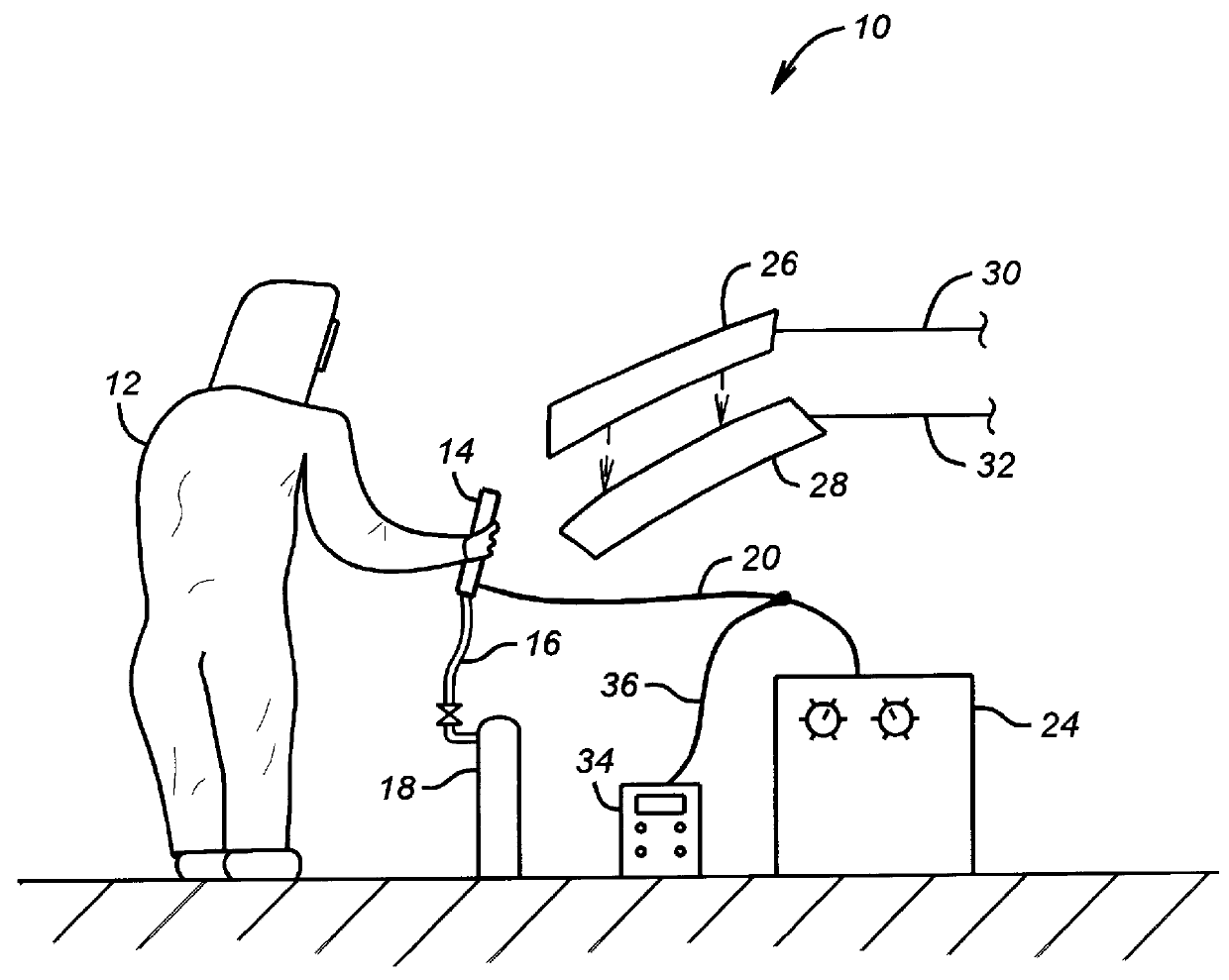

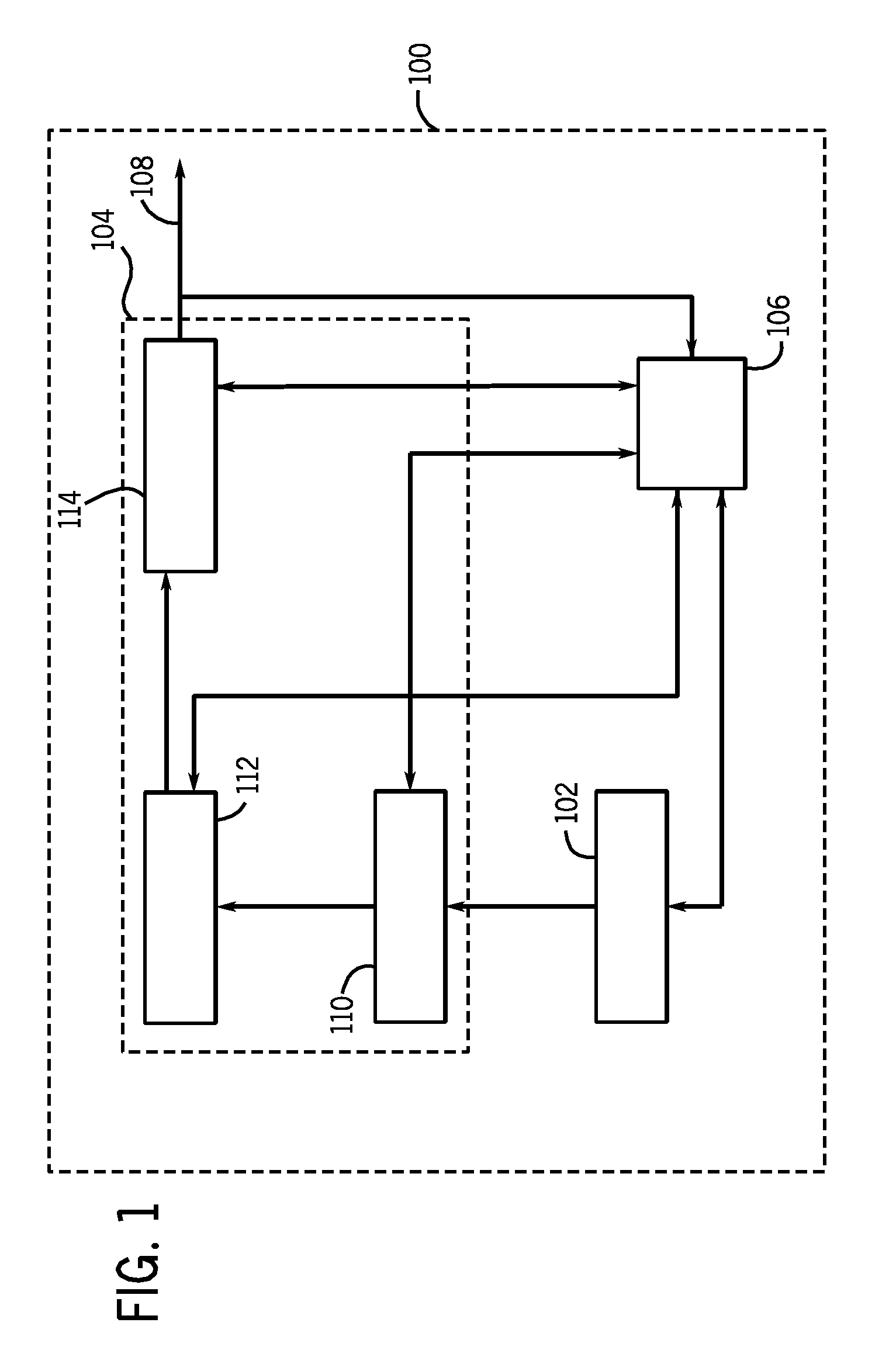

Automatic Weld Arc Monitoring System

A welding system including an arc monitoring, training, and control system is disclosed. The welding system includes a power supply, controller, and associated memory. When a weld is performed, the weld command and weld feedback parameters can be stored in the memory, along with associated alarm limit values. During subsequent welds, the input weld commands and actual feedback values can be compared to the established limits, and a fault signal provided to an operator or supervisor when the value exceeds the established limits. The fault signals can be used for training operators, as well as providing monitoring signals, and can be stored with weld data in a database for later analysis. In addition, collected weld data can be used to determine when to clean, repair, or replace consumables, including, for example, contact tips, wire drive liners, and drive rolls, and to monitor usage of wire and gas.

Owner:ILLINOIS TOOL WORKS INC

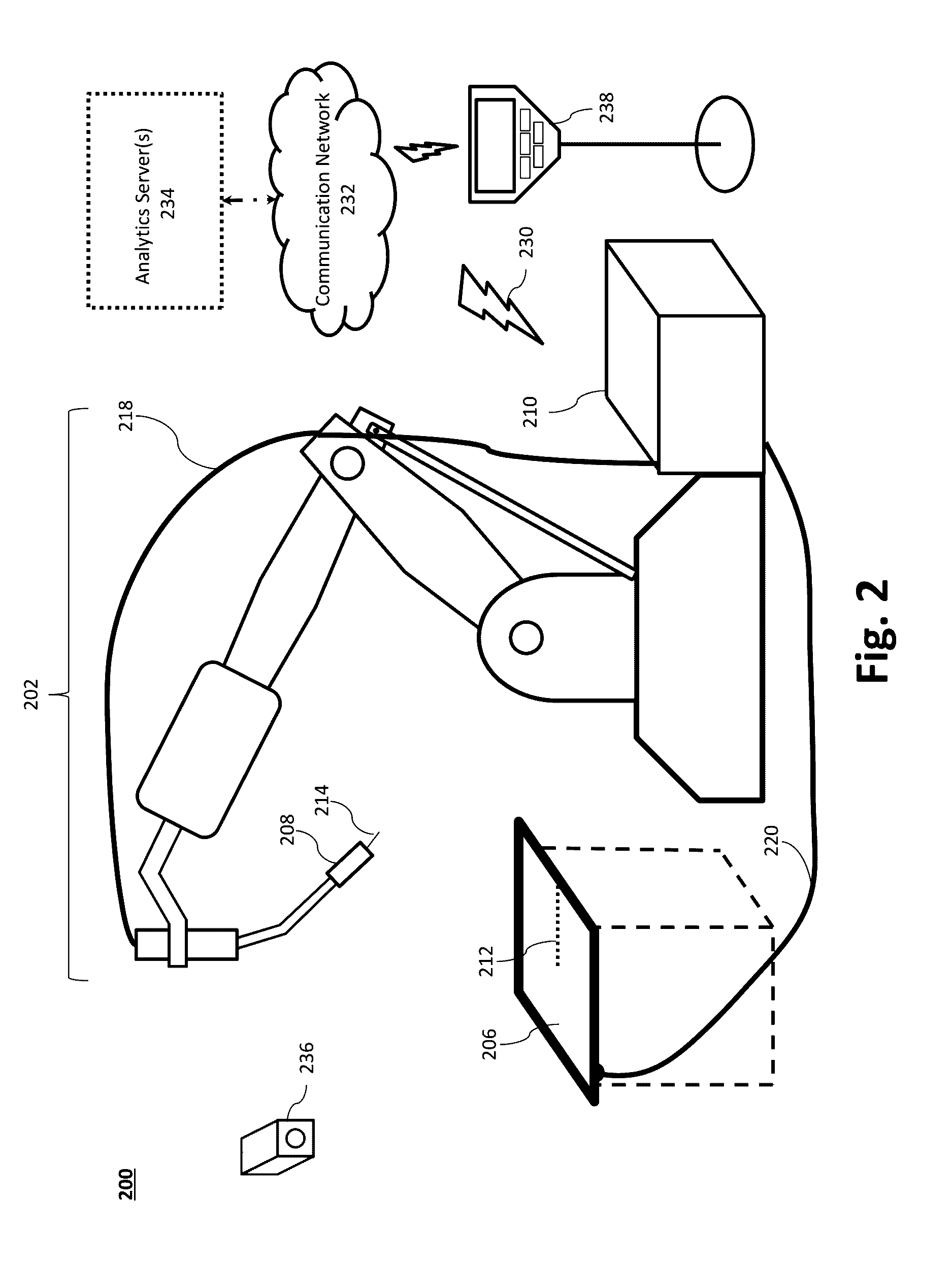

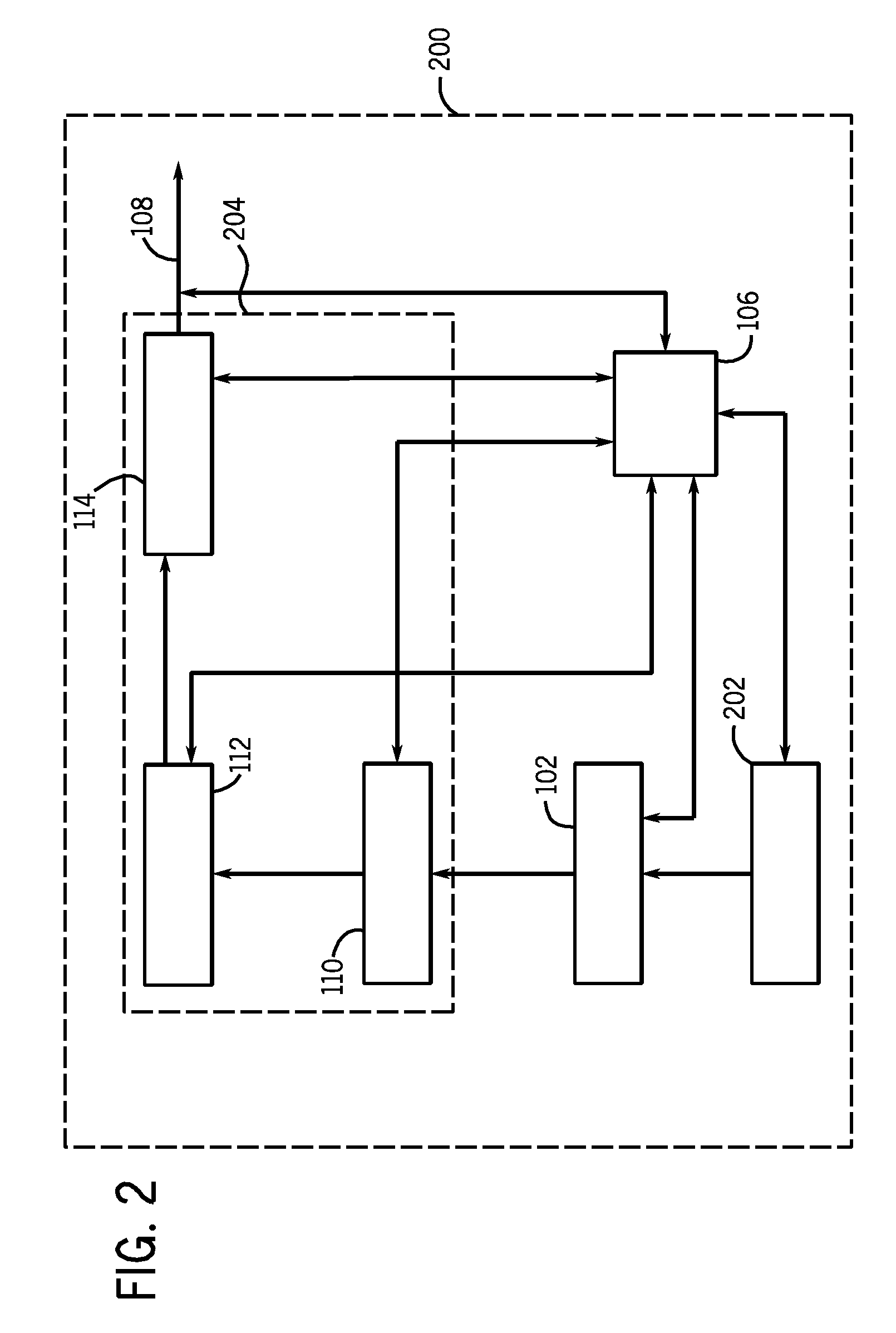

System and Method to Facilitate Welding Software as a Service

ActiveUS20170032281A1Minimizing human interactionScalable and cost-effective mass customization approachProgramme controlTesting/monitoring control systemsCommunication interfaceData set

A weld production knowledge system for processing welding data collected from one of a plurality of welding systems, the weld production knowledge system comprising a communication interface communicatively coupled with a plurality of welding systems situated at one or more physical locations. The communication interface may be configured to receive, from one of said plurality of welding systems, welding data associated with a weld. The weld production knowledge system may comprise an analytics computing platform operatively coupled with the communication interface and a weld data store. The weld data store employs a dataset comprising (1) welding process data associated with said one or more physical locations, and / or (2) weld quality data associated with said one or more physical locations. The analytics computing platform may employ a weld production knowledge machine learning algorithm to analyze the welding data vis-à-vis the weld data store to identify a defect in said weld.

Owner:ILLINOIS TOOL WORKS INC

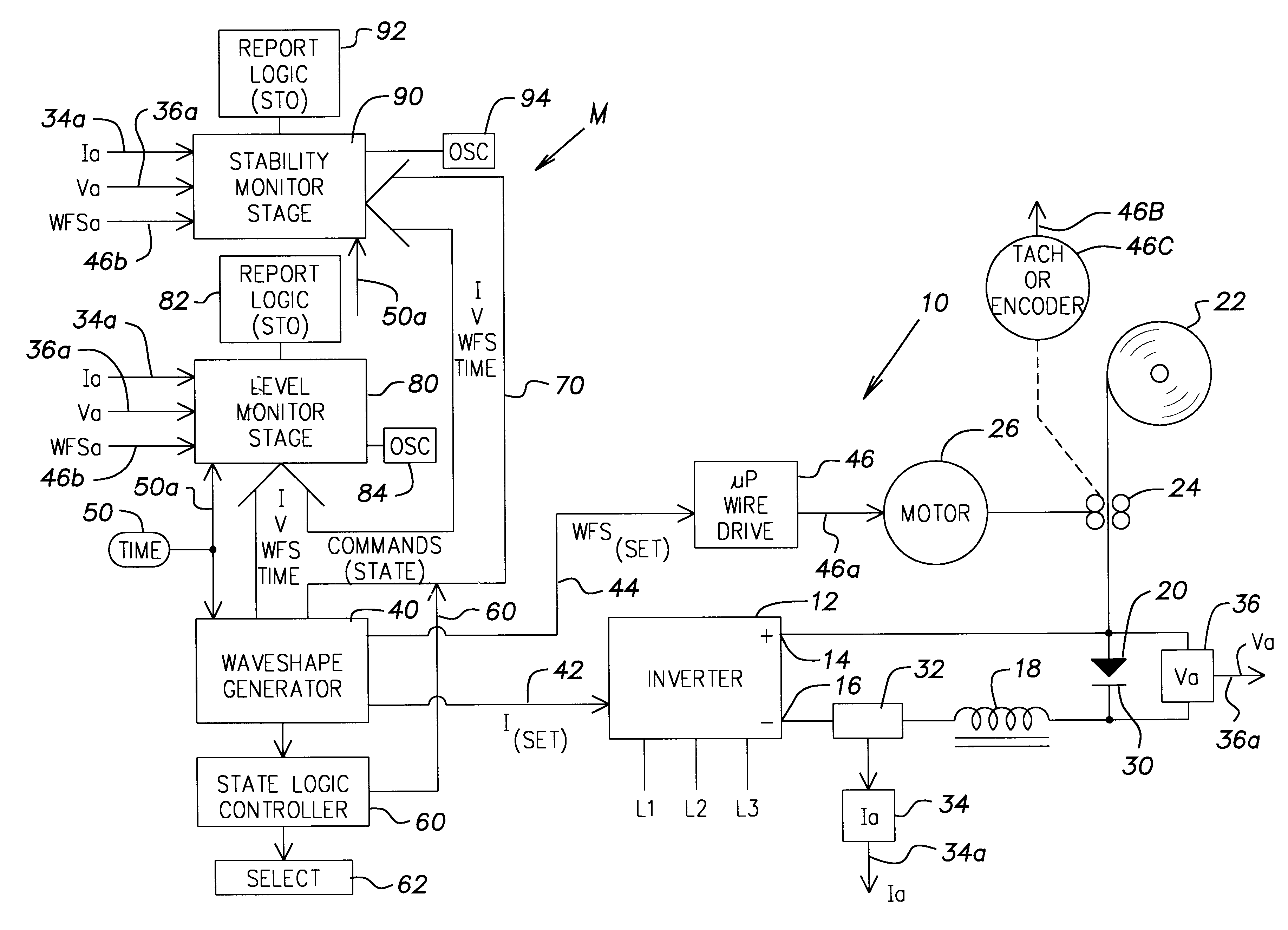

Monitor for electric arc welder

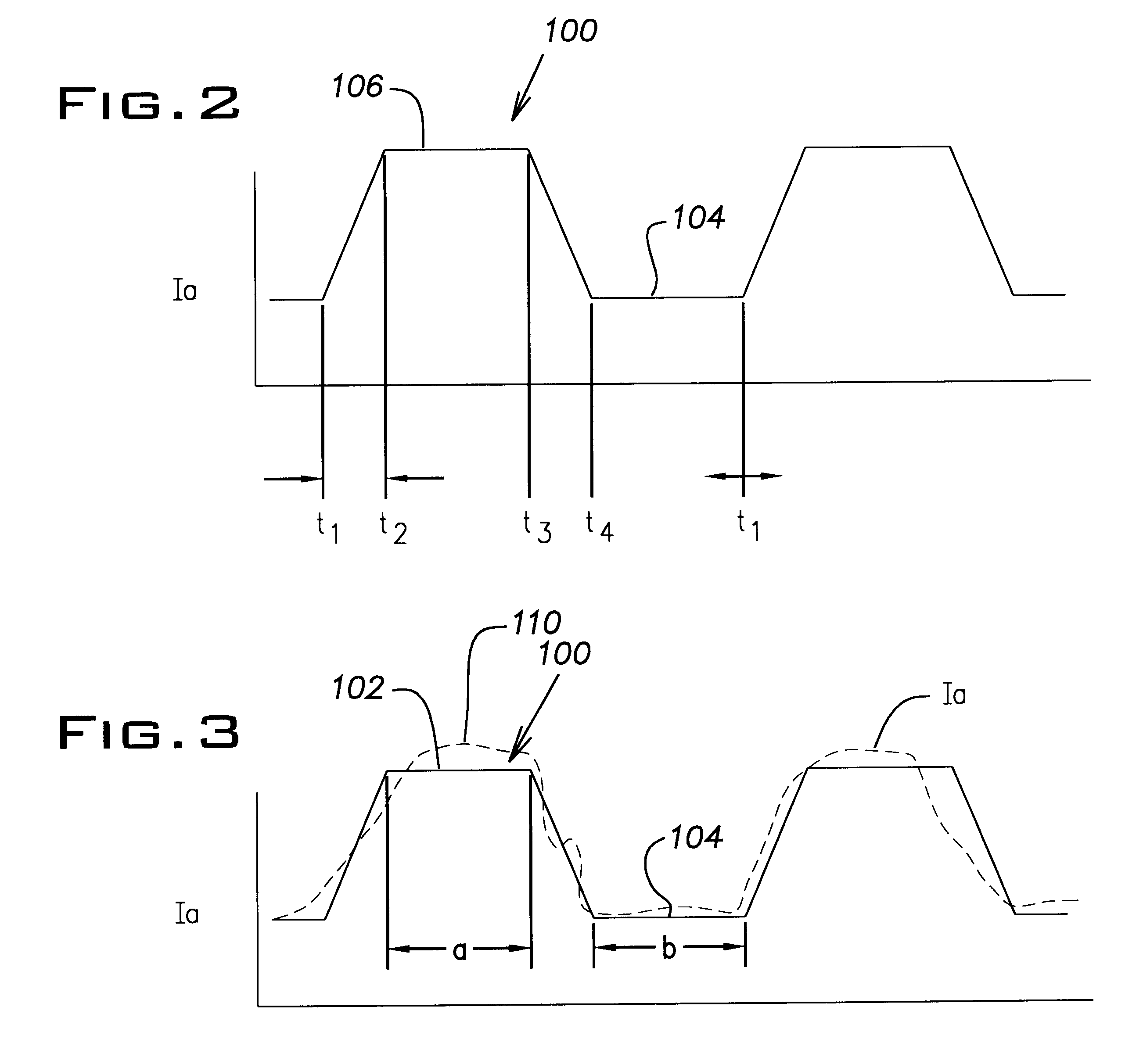

InactiveUS6441342B1Rapid data acquisition rateSufficient memoryArc welding apparatusWave shapeSimulation

A monitor for an electric arc welder as the welder performs a selected arc welding process by creating actual welding parameters, such as arc current and arc voltage, between an advancing welding wire and a workpiece, where the process involves an arc and is defined by a series of rapidly repeating wave shapes constituting a weld cycle with a cycle time, the wave shapes are each segmented into time states having command signals corresponding to the actual parameters and a time duration. The monitor selects a specific wave shape state, reads one of the actual parameters, compares the actual read parameter with a function of the command signal corresponding to the actual parameter, and uses-the comparison to generate a characteristic of the welding process during the selected state.

Owner:LINCOLN GLOBAL INC

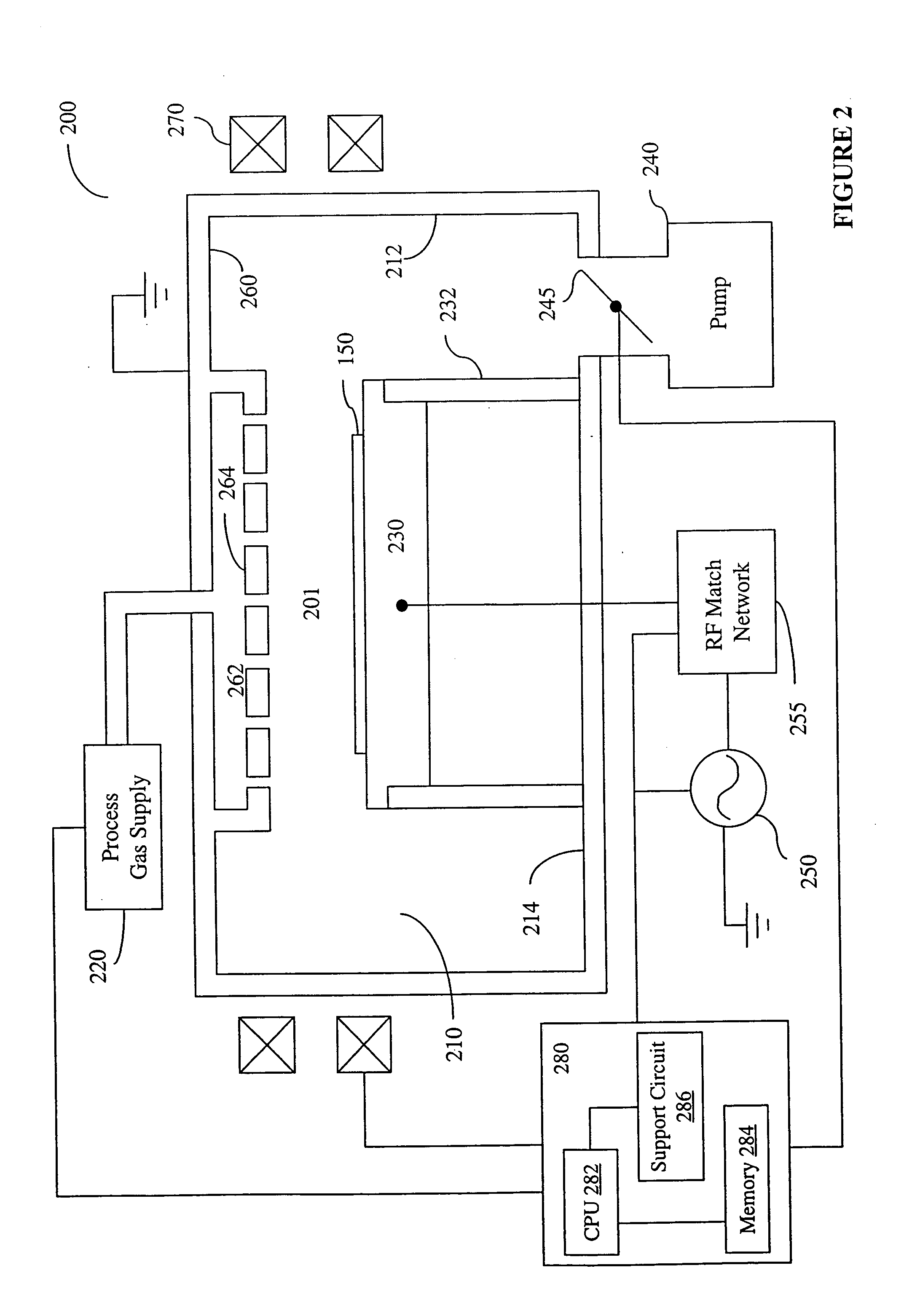

Selective etching of carbon-doped low-k dielectrics

InactiveUS20050026430A1High selectivityReducing micro-loadingDecorative surface effectsVacuum evaporation coatingPlasma etchingChemistry

The present invention includes a process for selectively etching a low-k dielectric material formed on a substrate using a plasma of a gas mixture in a plasma etch chamber. The gas mixture comprises a fluorine-rich fluorocarbon or hydrofluorocarbon gas, a nitrogen-containing gas, and one or more additive gases, such as a hydrogen-rich hydrofluorocarbon gas, an inert gas and / or a carbon-oxygen gas. The process provides a low-k dielectric to a photoresist mask etching selectivity ratio greater than about 5:1, a low-k dielectric to a barrier / liner layer etching selectivity ratio greater about 10:1, and a low-k dielectric etch rate higher than about 4000 Å / min.

Owner:APPLIED MATERIALS INC

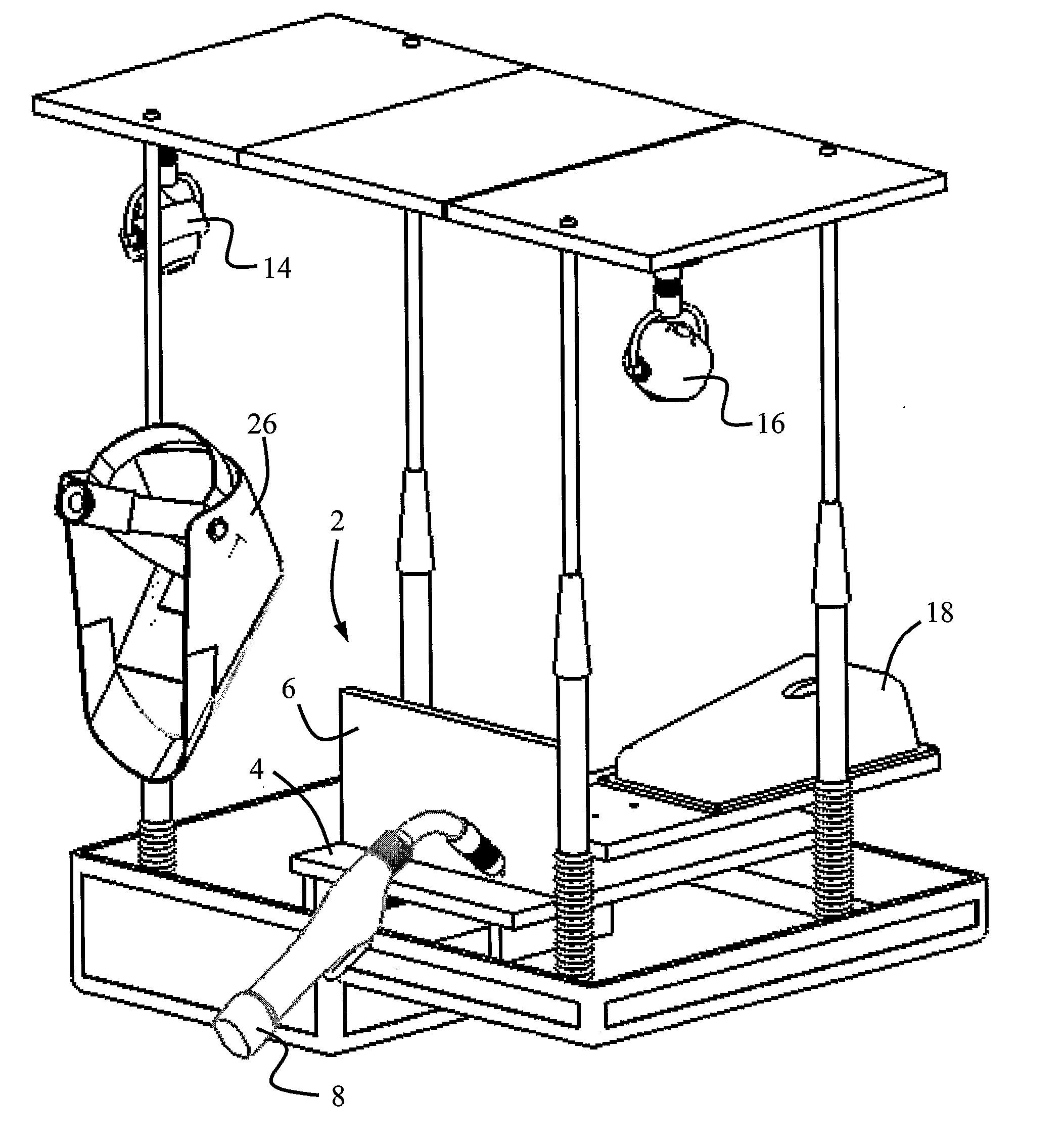

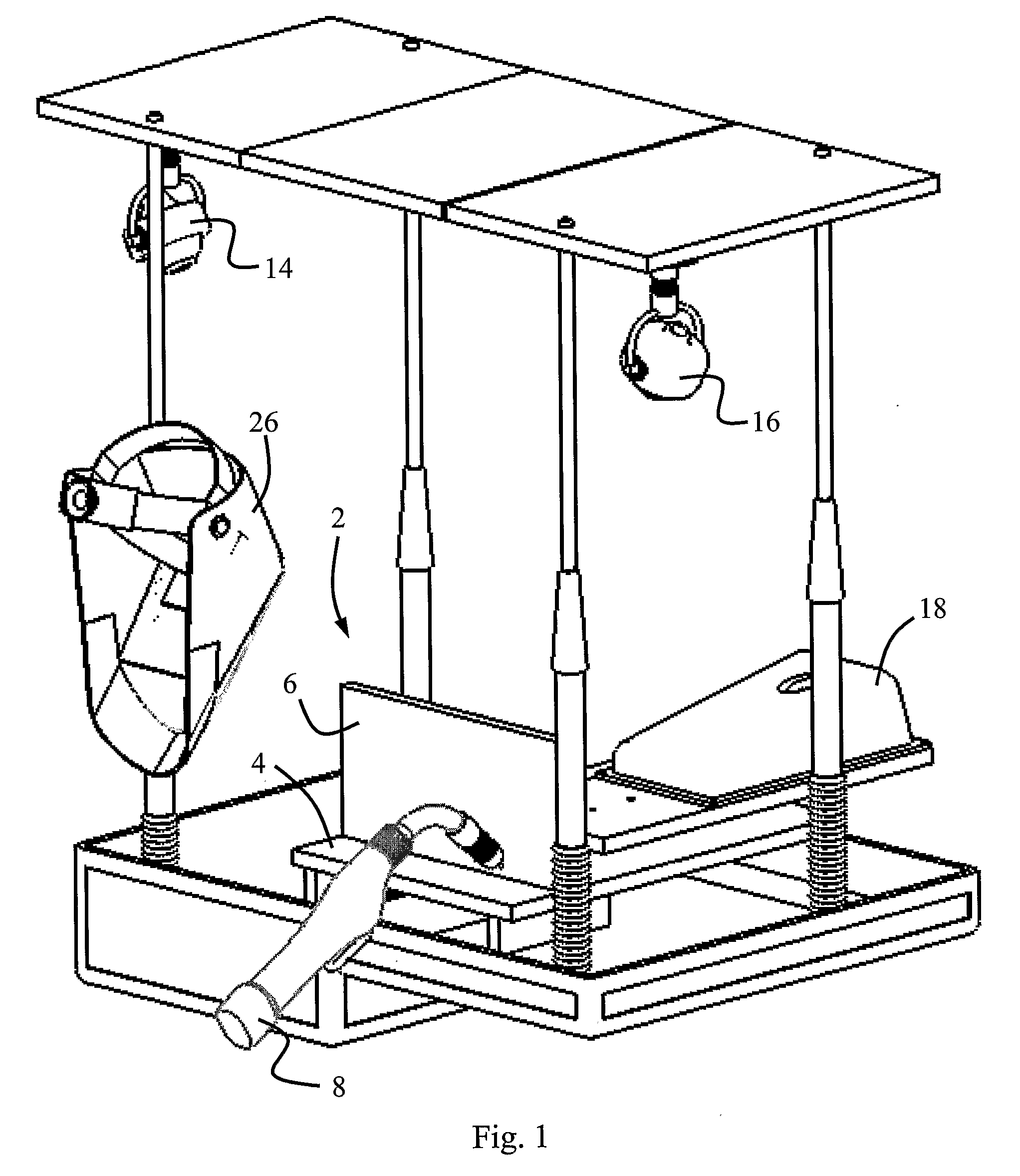

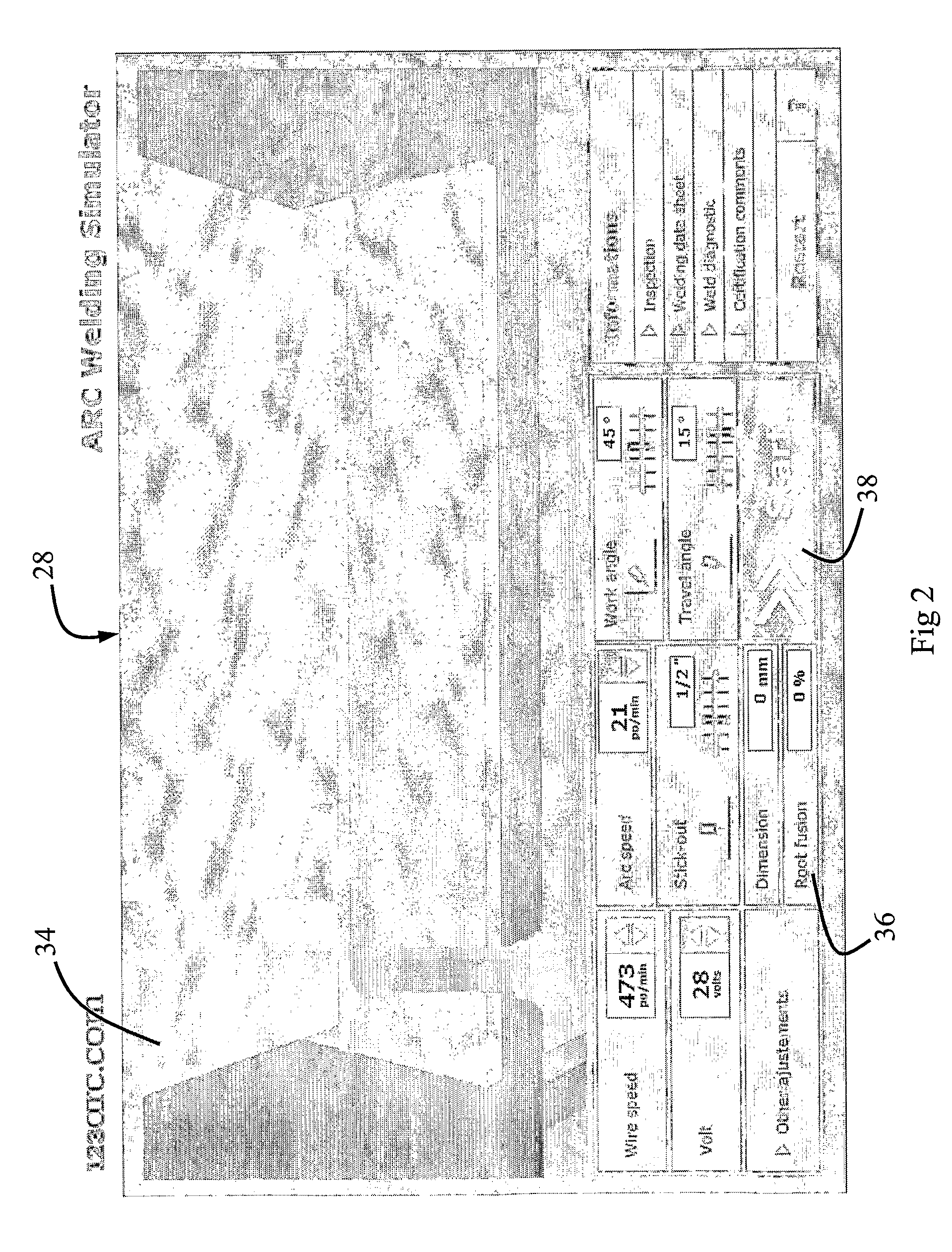

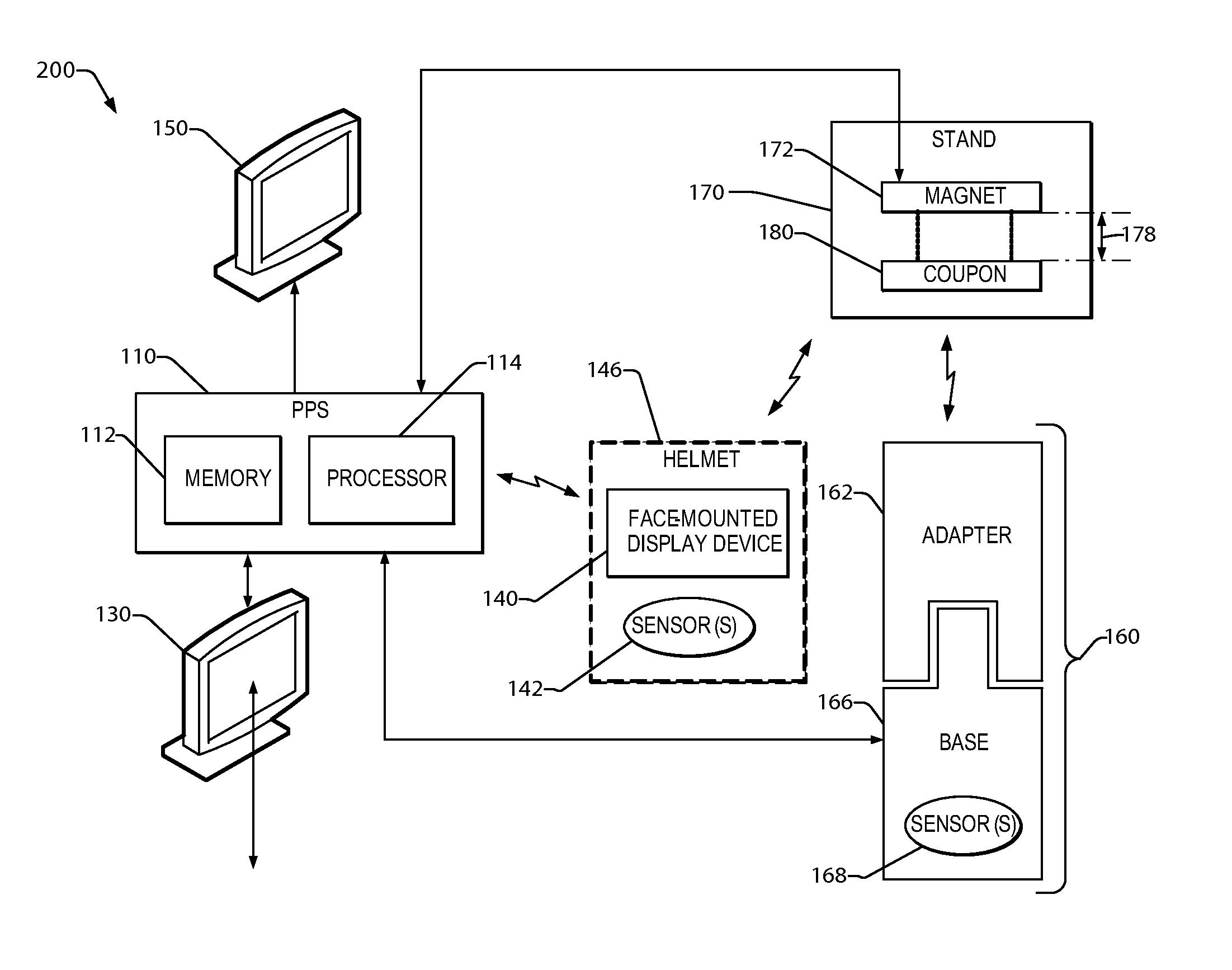

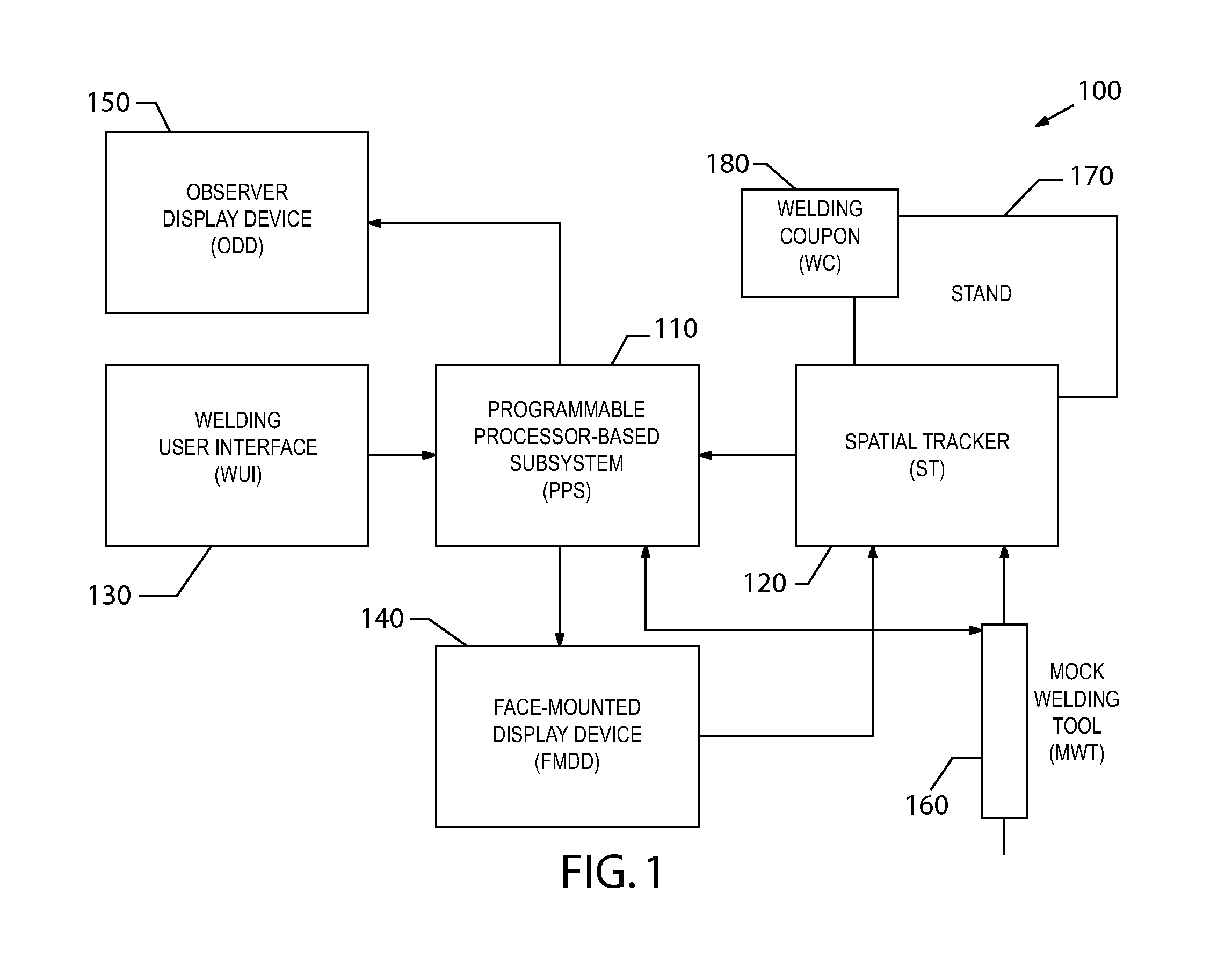

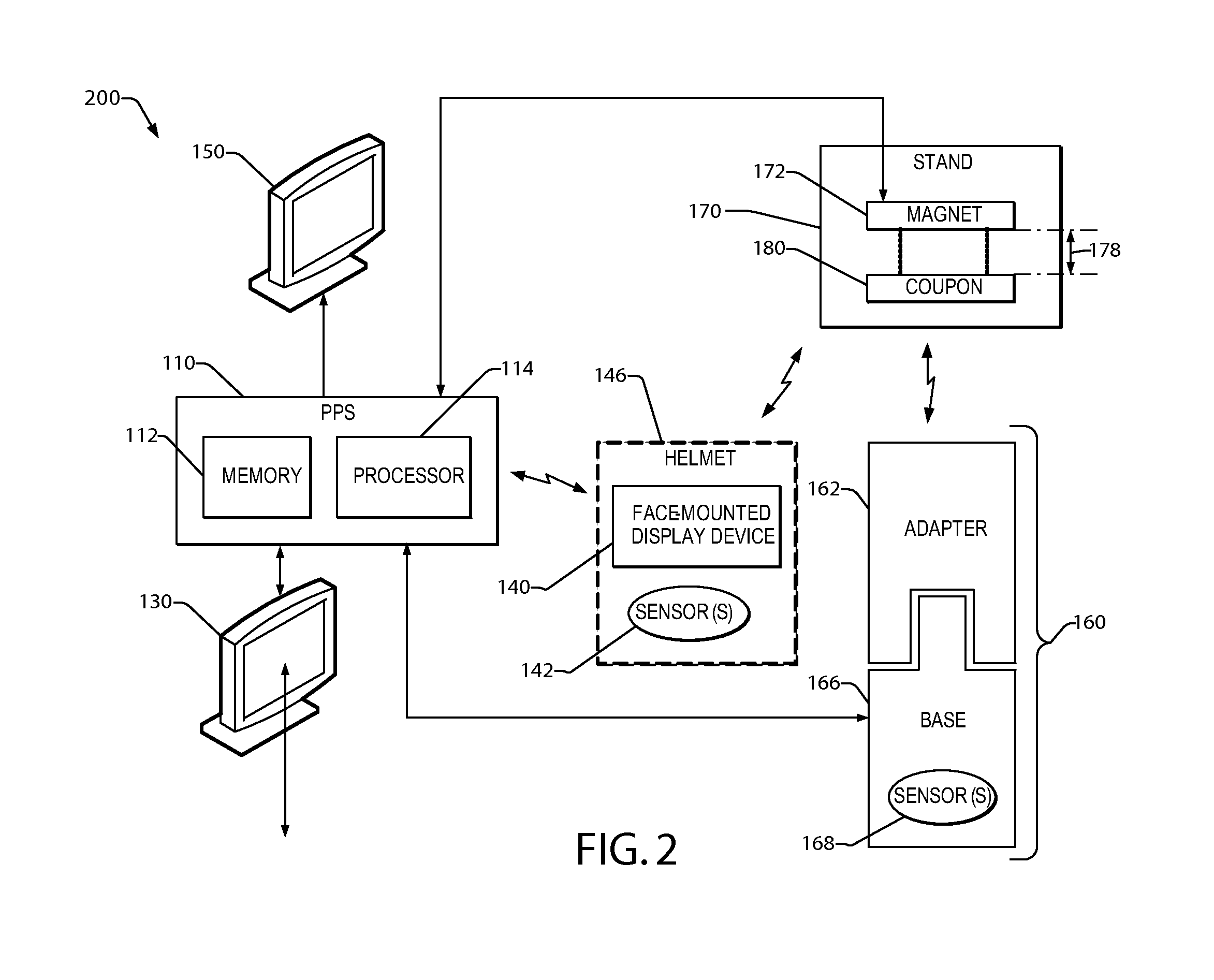

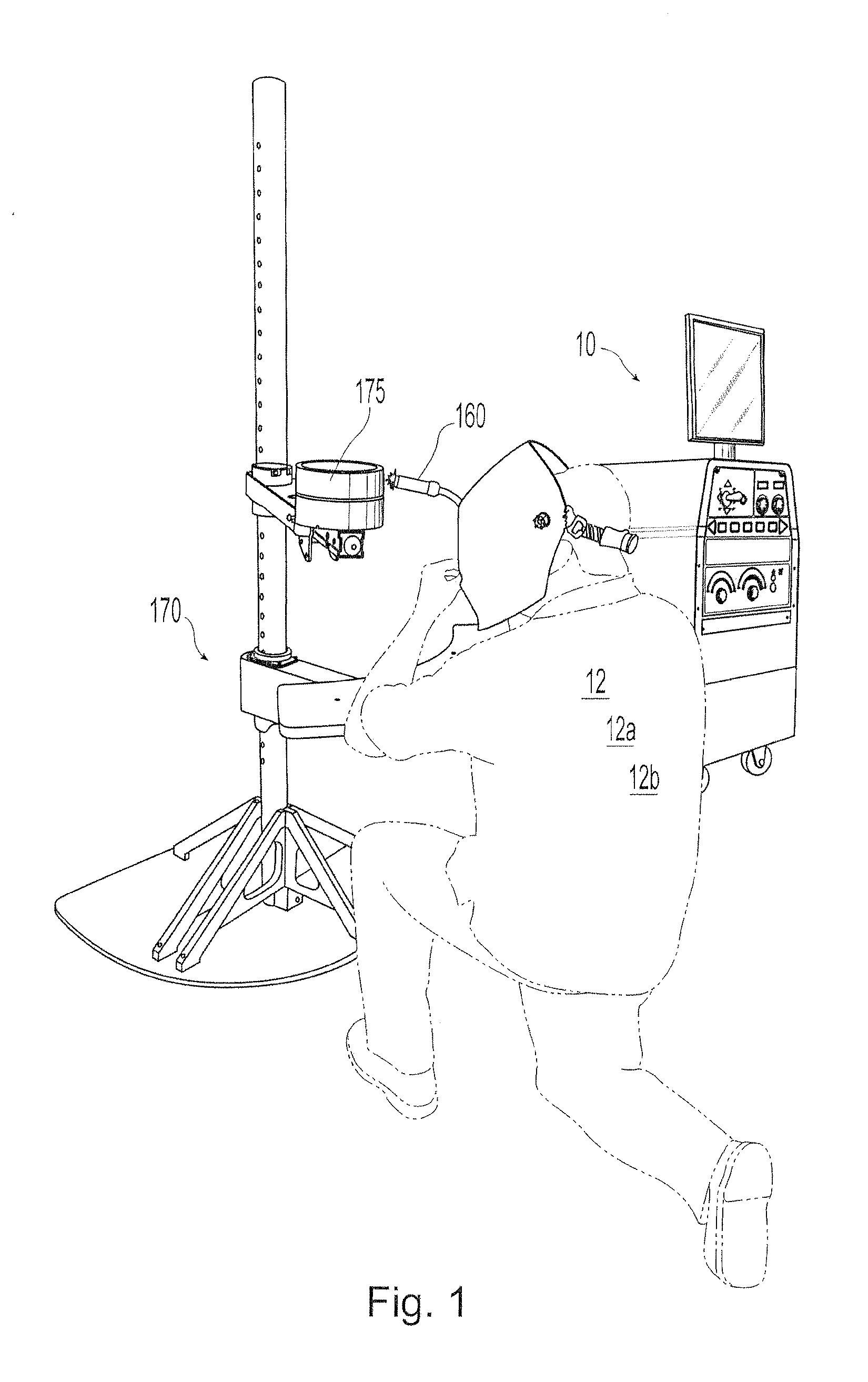

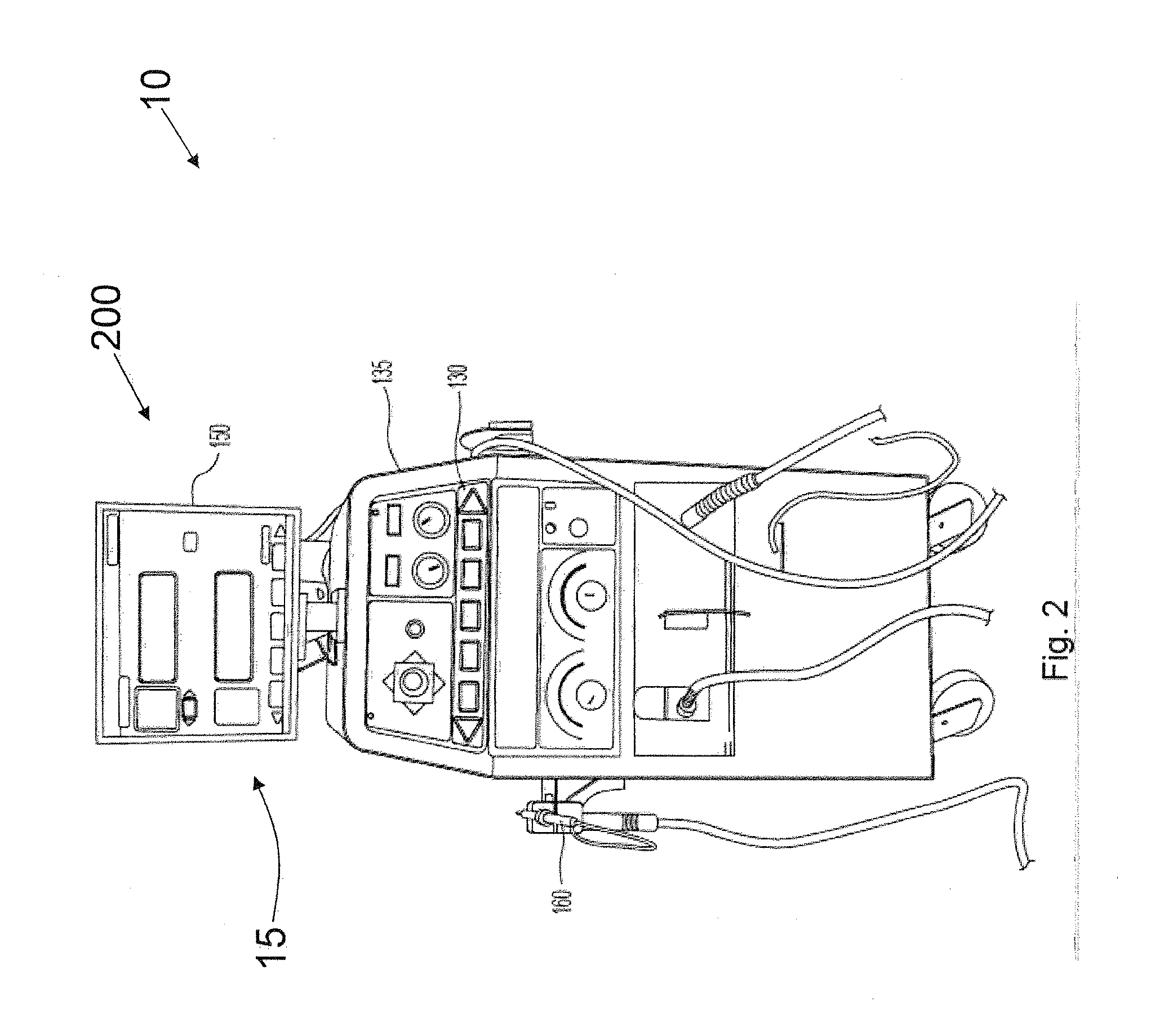

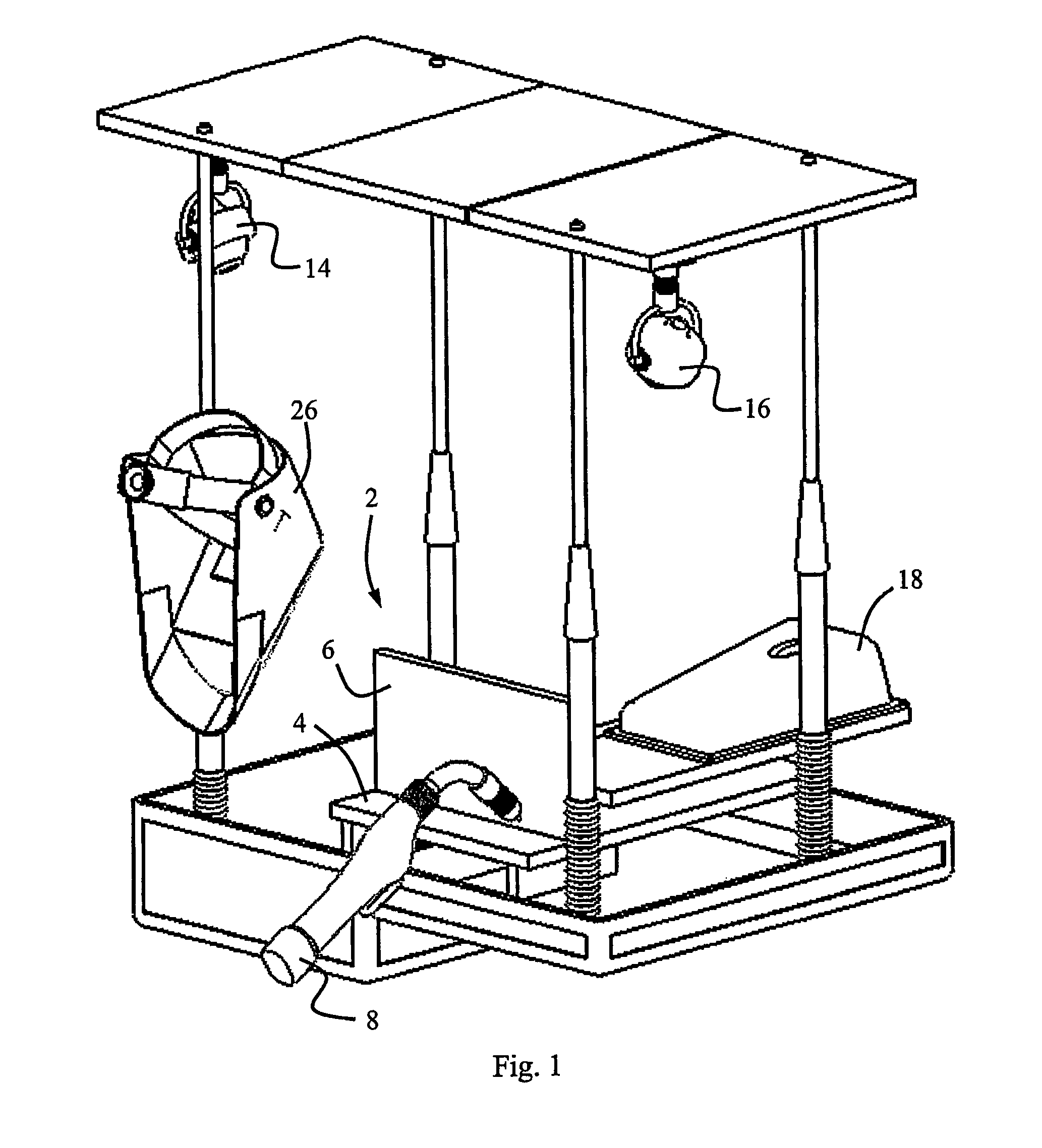

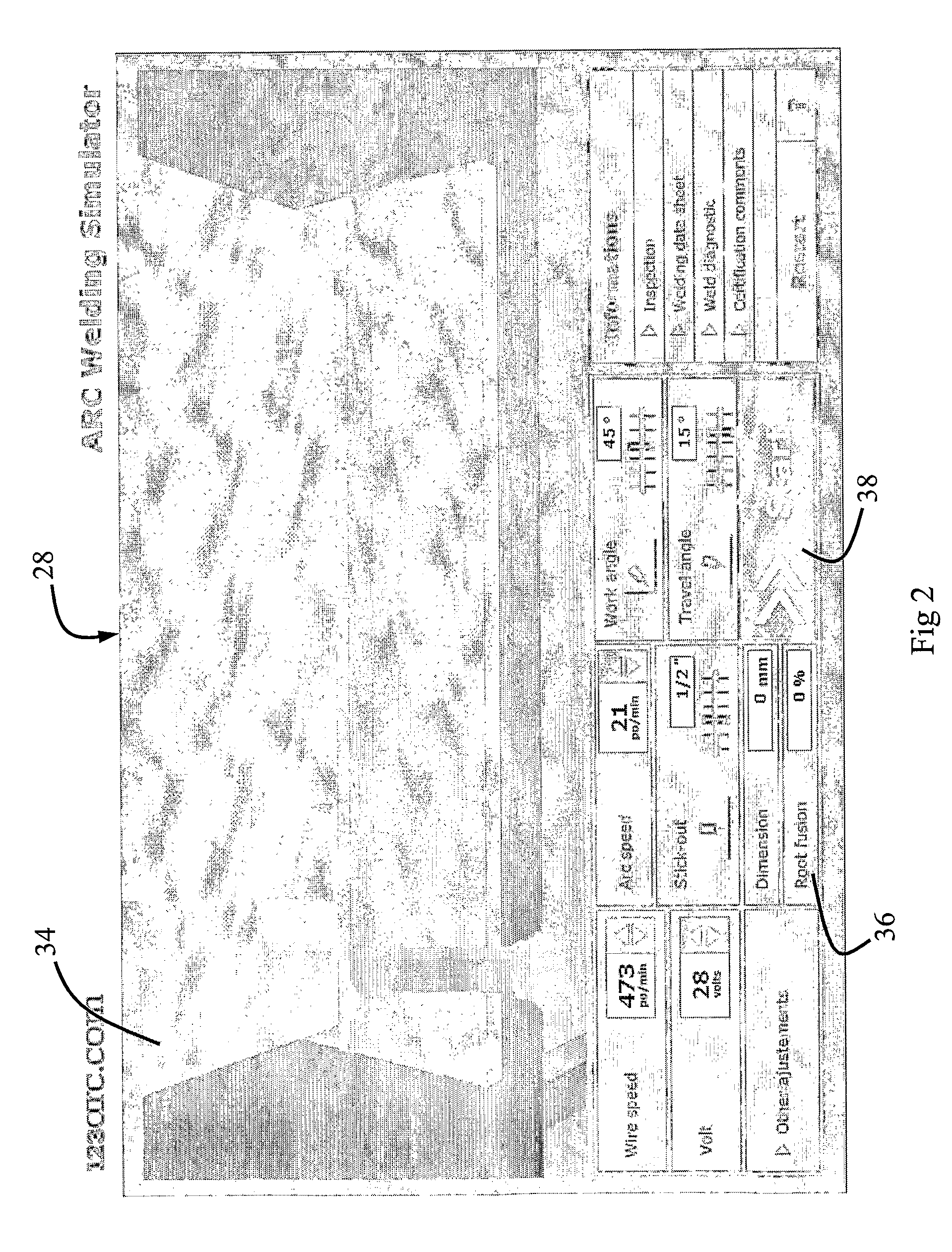

Body Motion Training and Qualification System and Method

InactiveUS20080038702A1Defective reproductionCosmonautic condition simulationsElectric discharge heatingSimulationDisplay device

The system allows training and qualification of a user performing a skill-related training exercise involving body motion in a workspace. A training environment is selected through a computer apparatus, and variables, parameters and controls of the training environment and the training exercise are adjusted. Use of an input device by the user is monitored. The 3D angles and spatial coordinates of reference points related to the input device are monitored through a detection device. A simulated 3D dynamic environment reflecting effects caused by actions performed by the user on objects is computed in real time as a function of the training environment selected. Images of the simulated 3D dynamic environment in real time are generated on a display device viewable by the user as a function of a computed organ of vision-object relation. Data indicative of the actions performed by the user and the effects of the actions are recorded and user qualification is set as a function of the recorded data.

Owner:123 CERTIFICATION

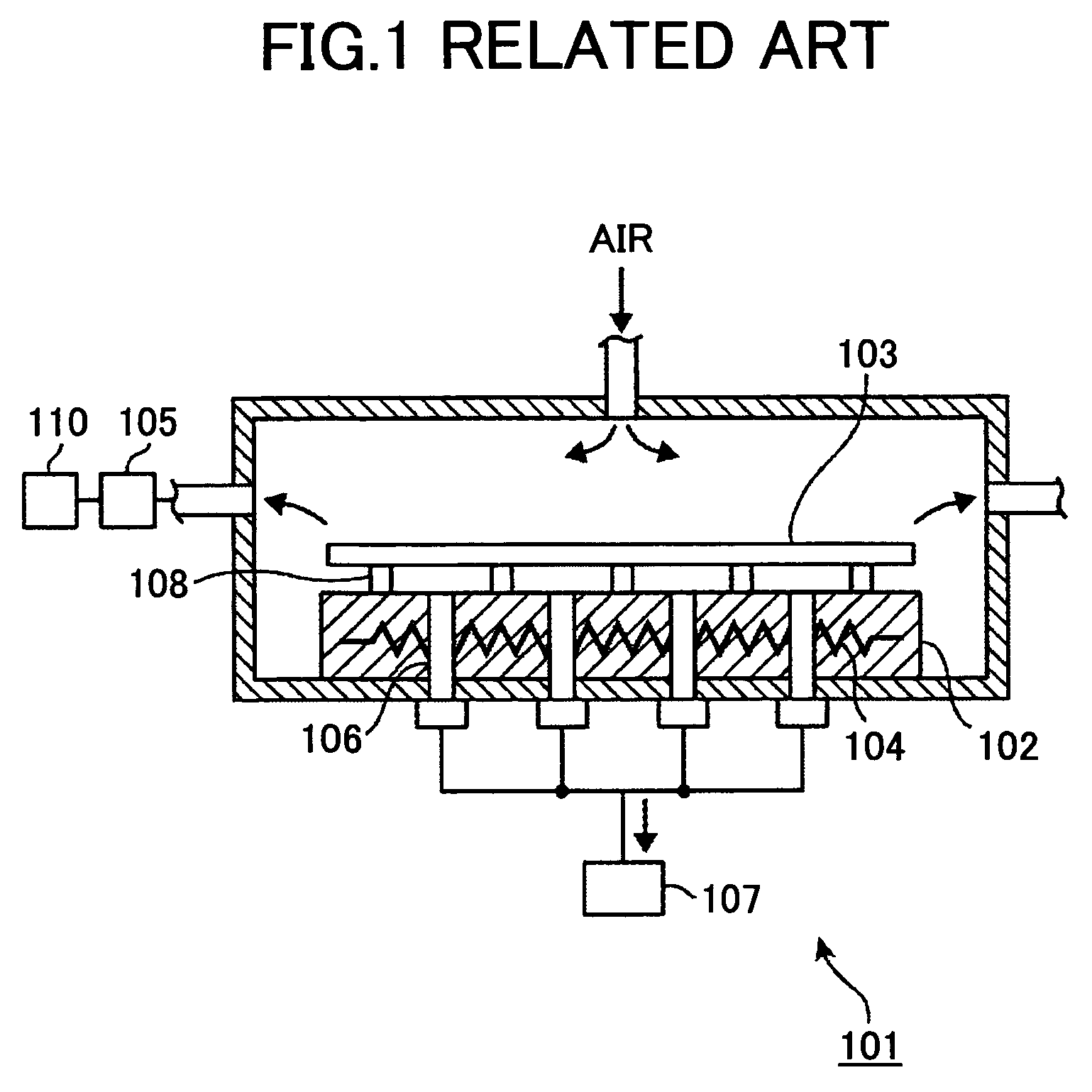

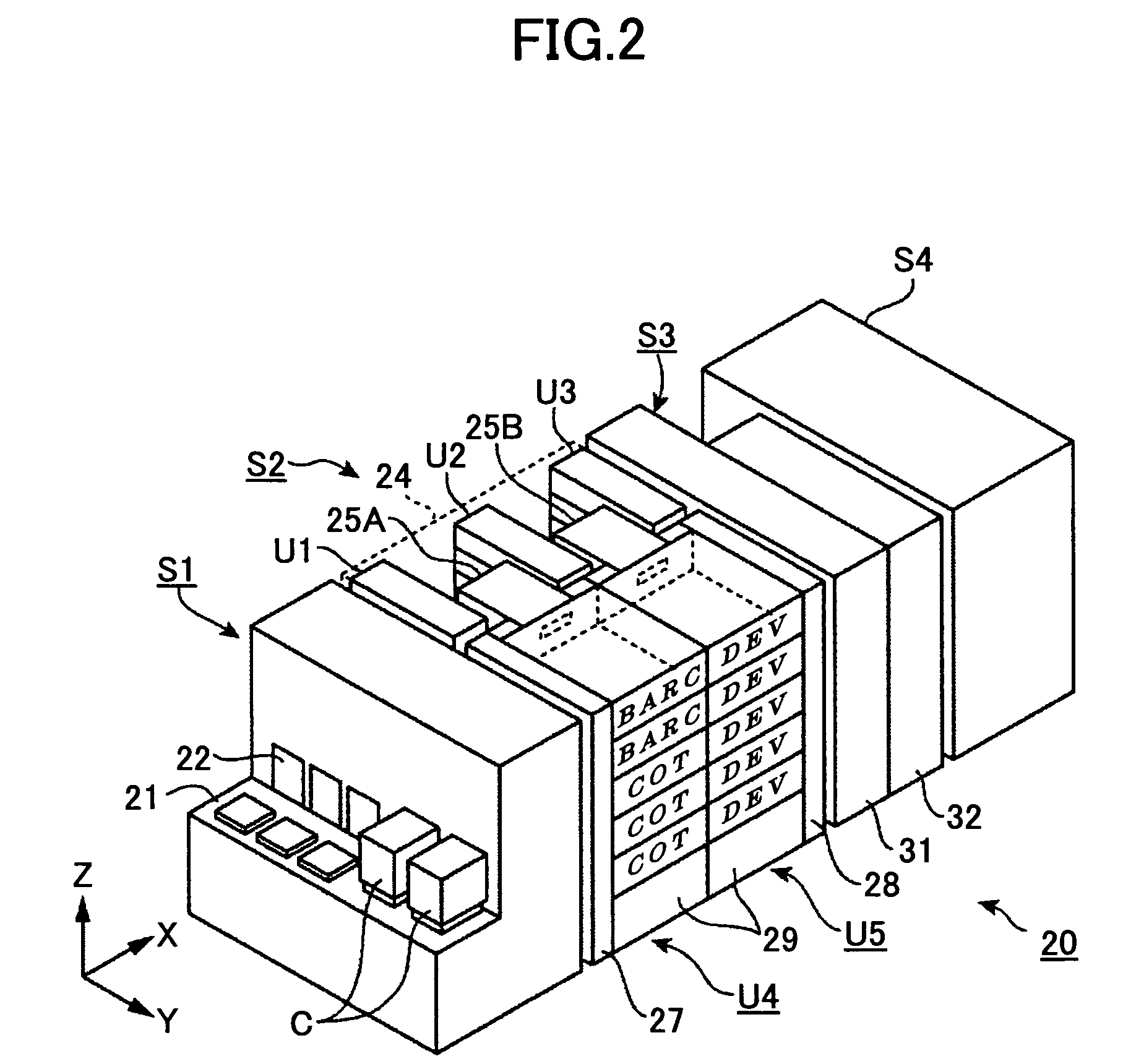

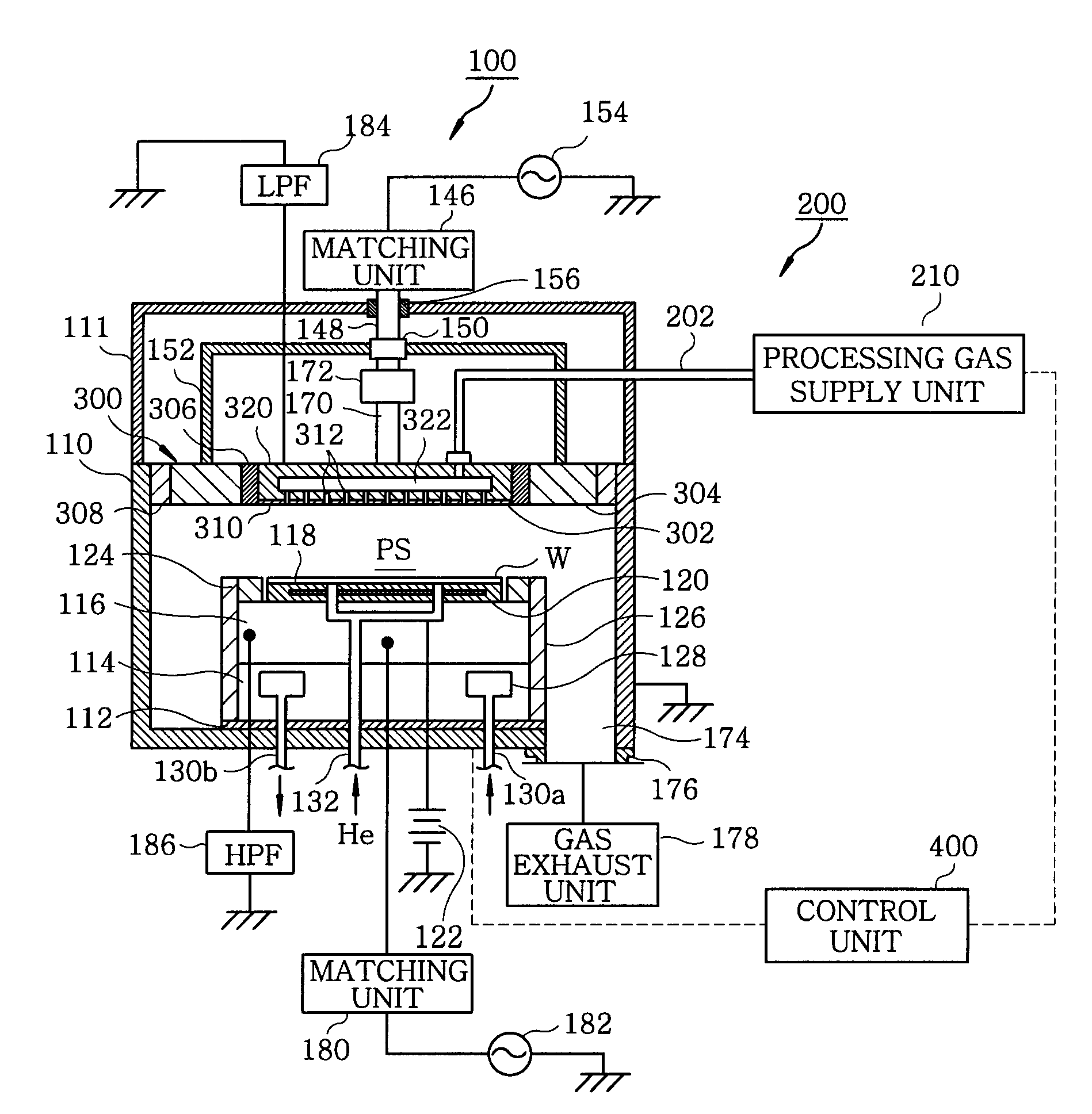

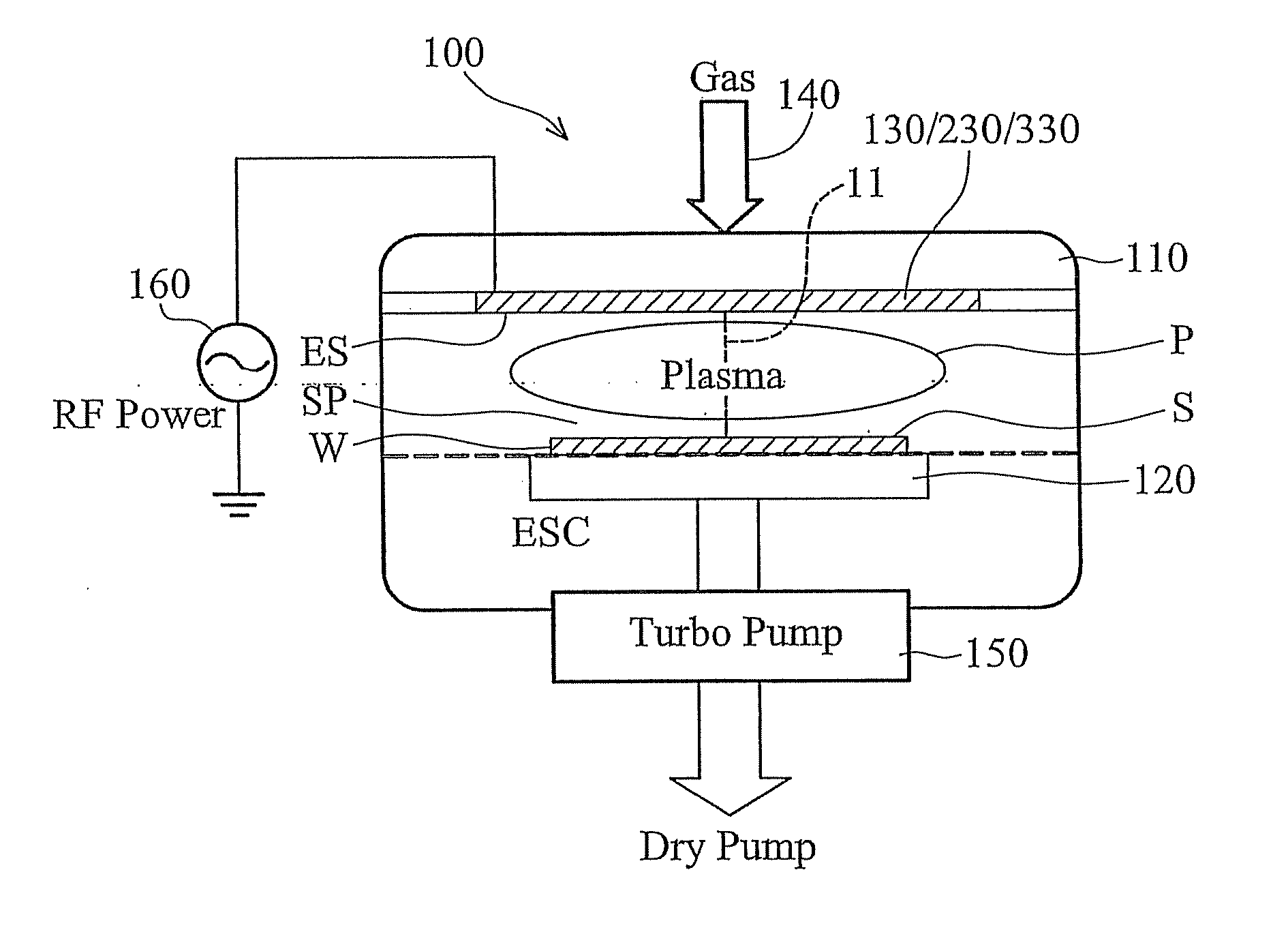

Plasma processing apparatus and plasma processing method

InactiveUS20060108331A1Reduce defectsPollution suppressionElectric discharge tubesSemiconductor/solid-state device manufacturingEtchingPre treatment

A plasma processing apparatus comprising at least a plasma processing chamber for plasma-processing an object; object-holding means for disposing the object in the plasma processing chamber; and plasma-generating means for generating a plasma in the plasma processing chamber. The inner wall of the plasma processing chamber is at least partially covered with an oxide film based on a pre-treating plasma. A plasma processing apparatus and a plasma processing method effectively prevent the spluttering and the etching of the inner wall of the plasma processing chamber while suppressing contamination to the object.

Owner:TOKYO ELECTRON LTD

Virtual welding system

ActiveUS20120189993A1Easy to useArc welding apparatusEducational modelsComputer scienceHuman language

Owner:LINCOLN GLOBAL INC

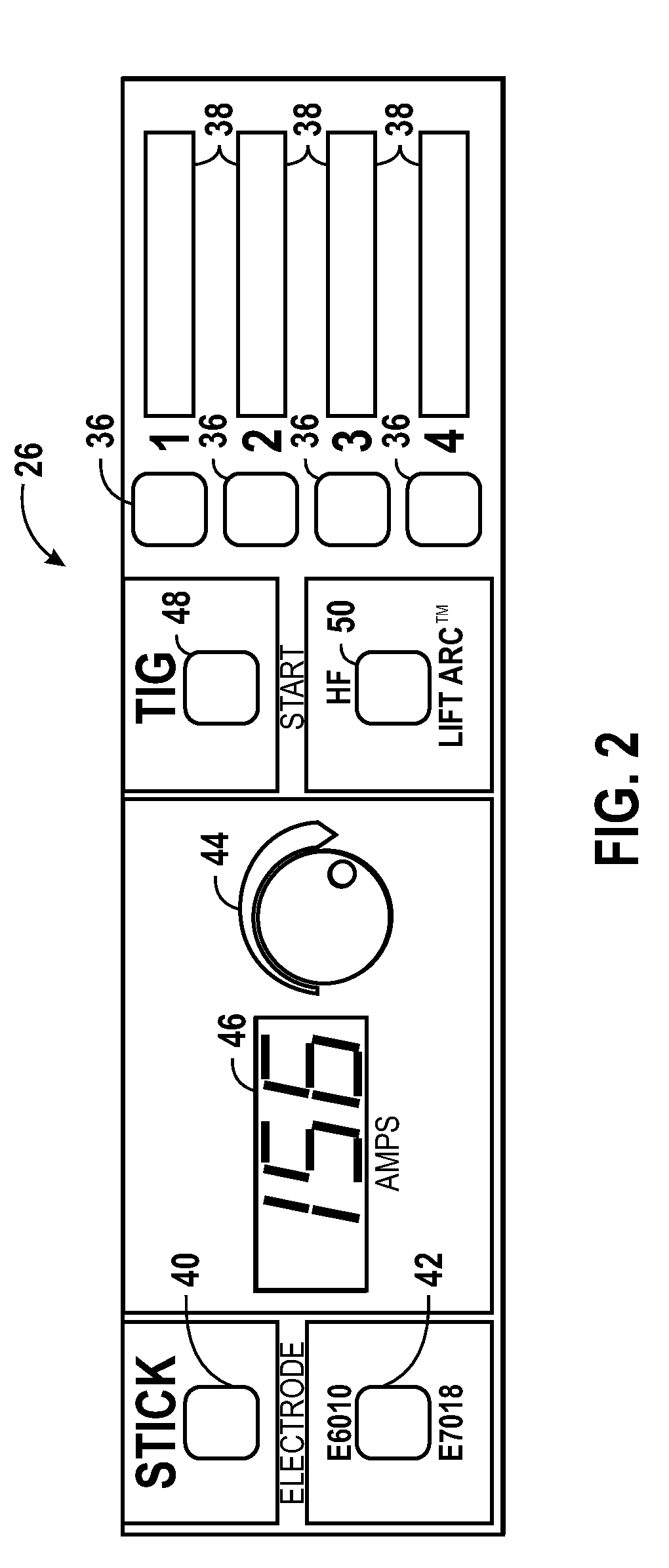

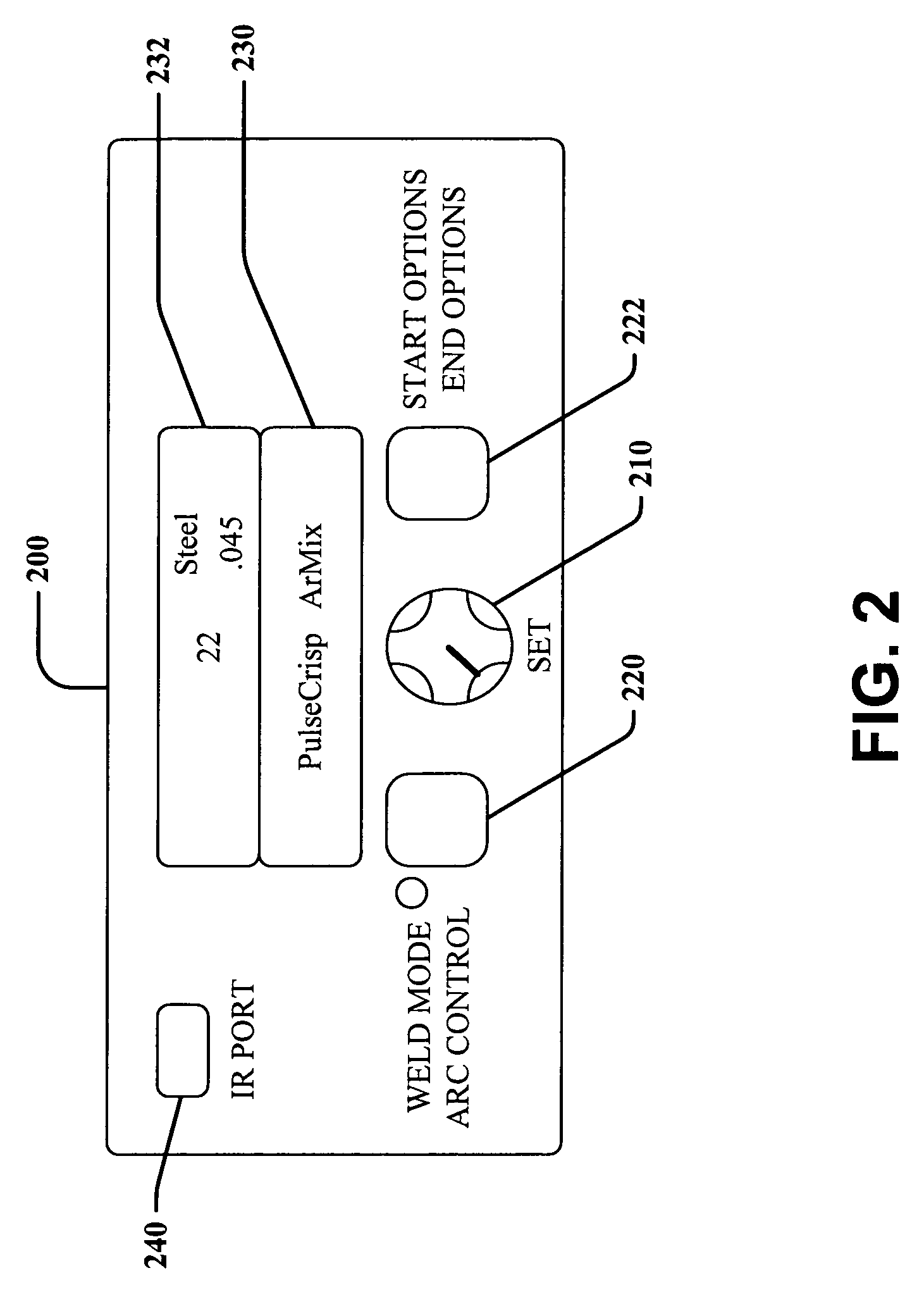

Personalized interface for torch system and method

There is provided a system and method for quick identification and selection of torch processes based on a profile scheme. In an illustrated embodiment, a profile selectable via a one-click process may define operational parameters for one or more torch processes. Multiple profiles may be identified by corresponding labels that are visible on the face of the system. Furthermore, in an illustrated embodiment, the profiles and associated torch processes may be automatically stored in the system upon user configuration of the operational parameters. For example, in one embodiment, the user may select a profile and configure a welding process. Upon changing an operational parameter, it may be automatically saved to the selected profile and process. Reselection of that profile may recall the last used process and its associated parameters. The operational parameters of other configured processes may then be retrieved by selecting the desired process within the selected profile.

Owner:ILLINOIS TOOL WORKS INC

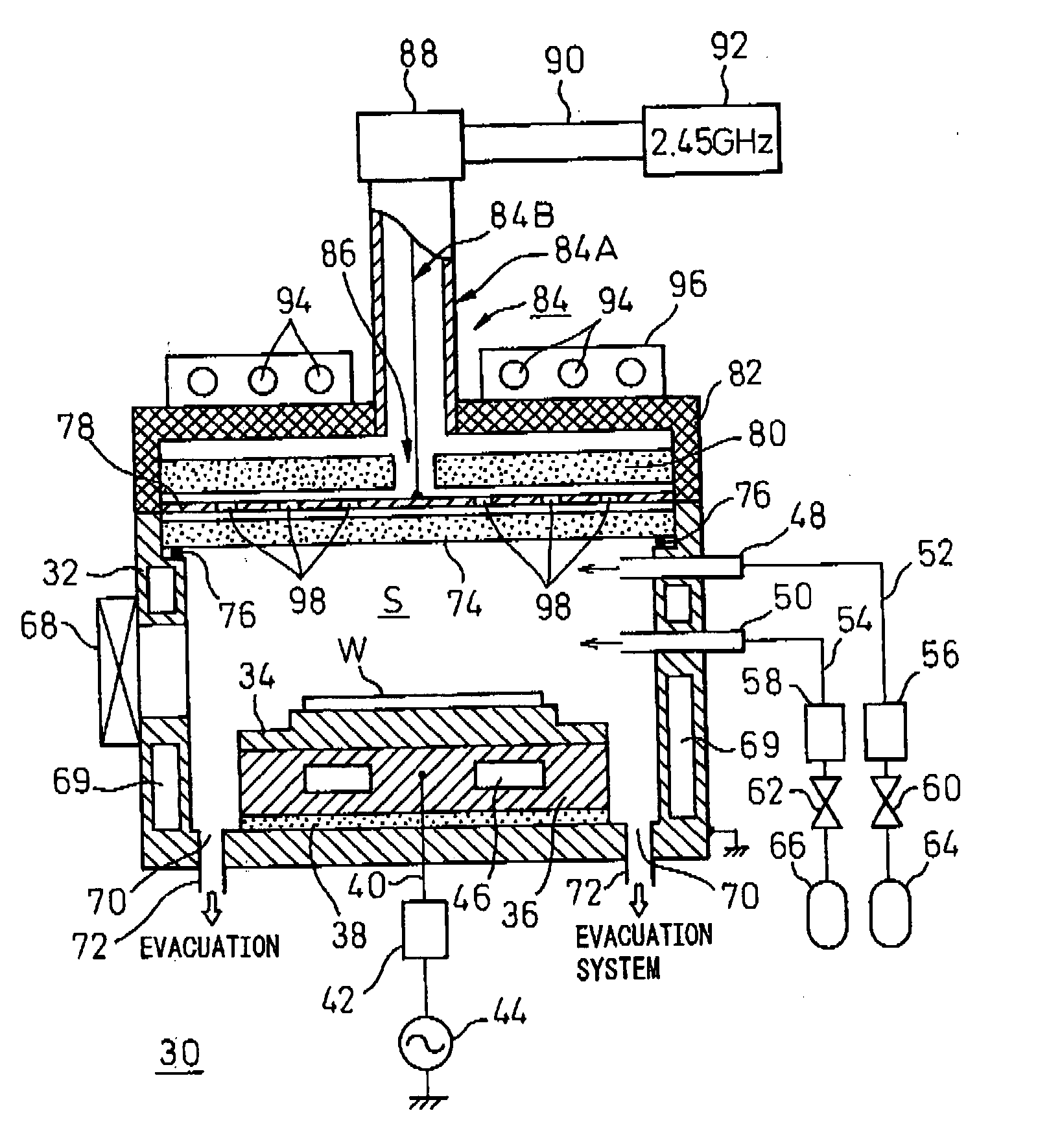

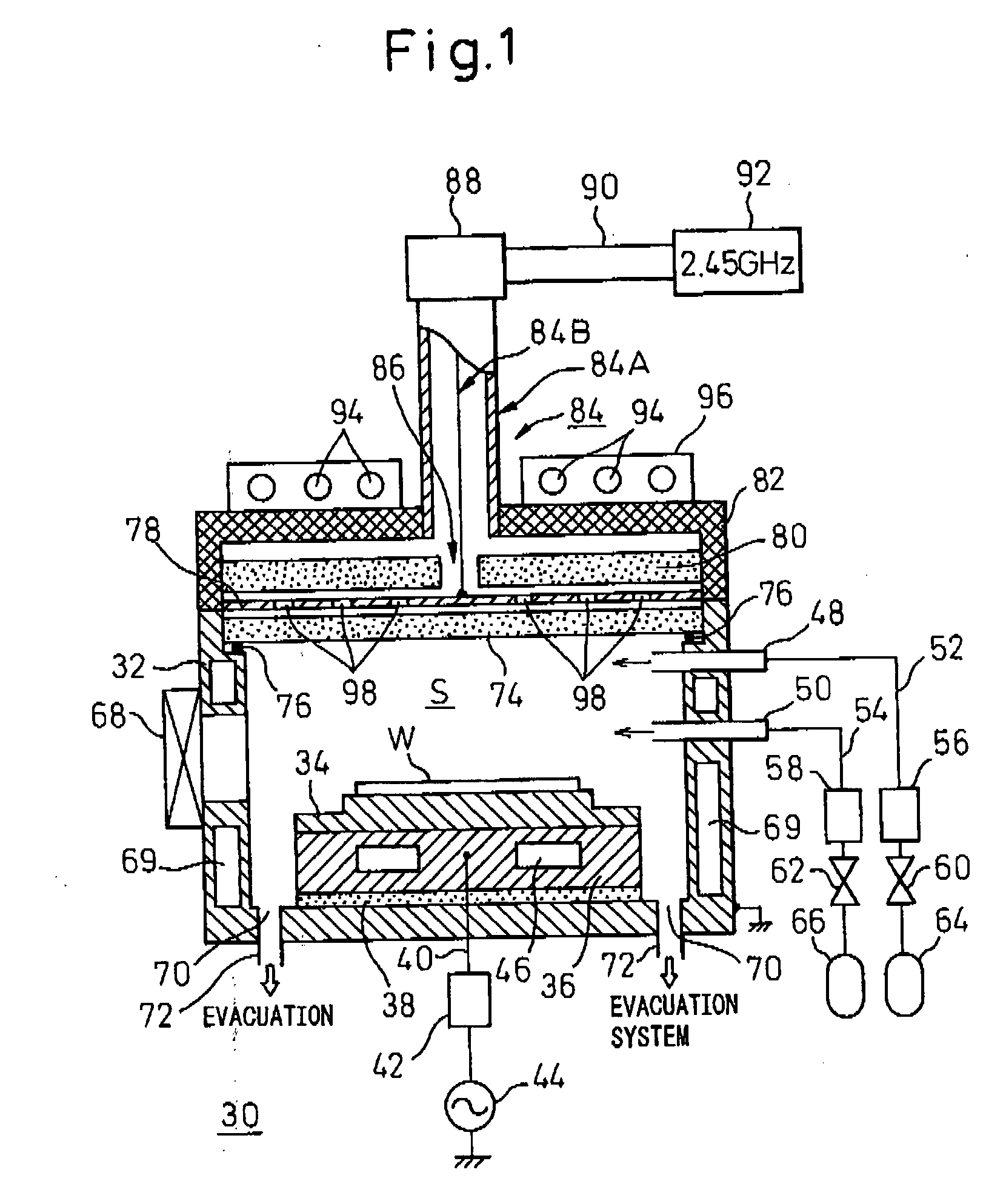

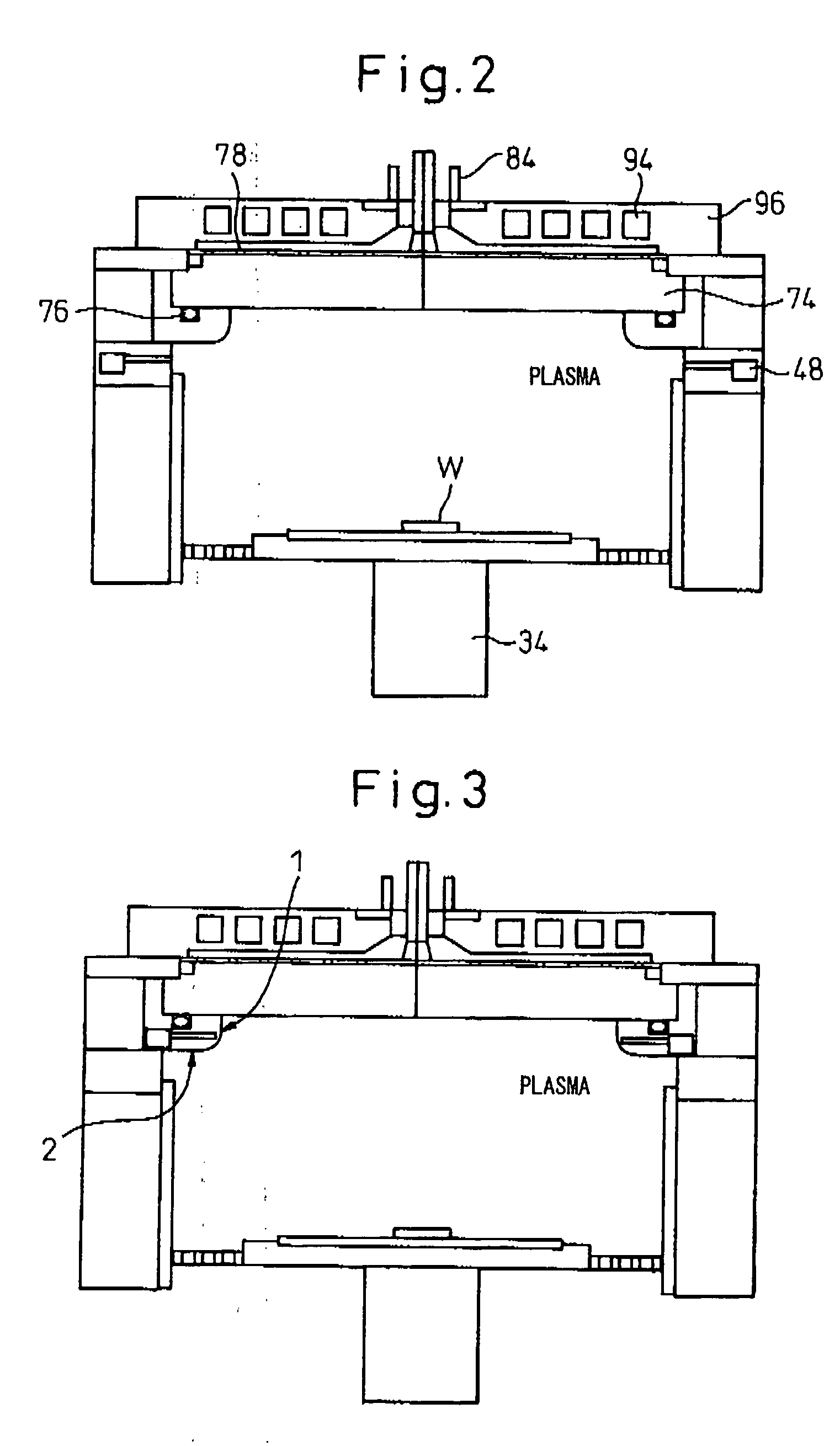

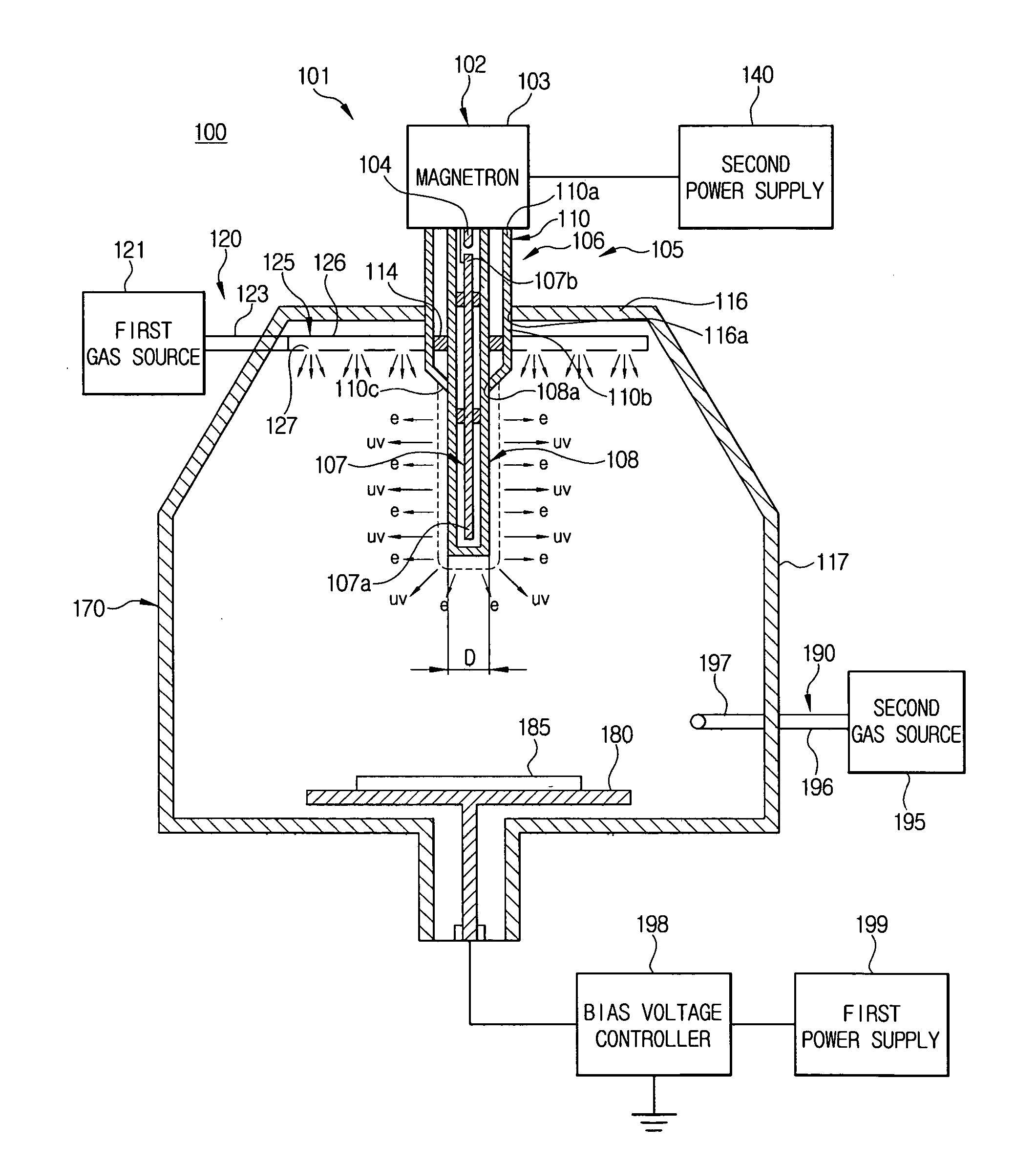

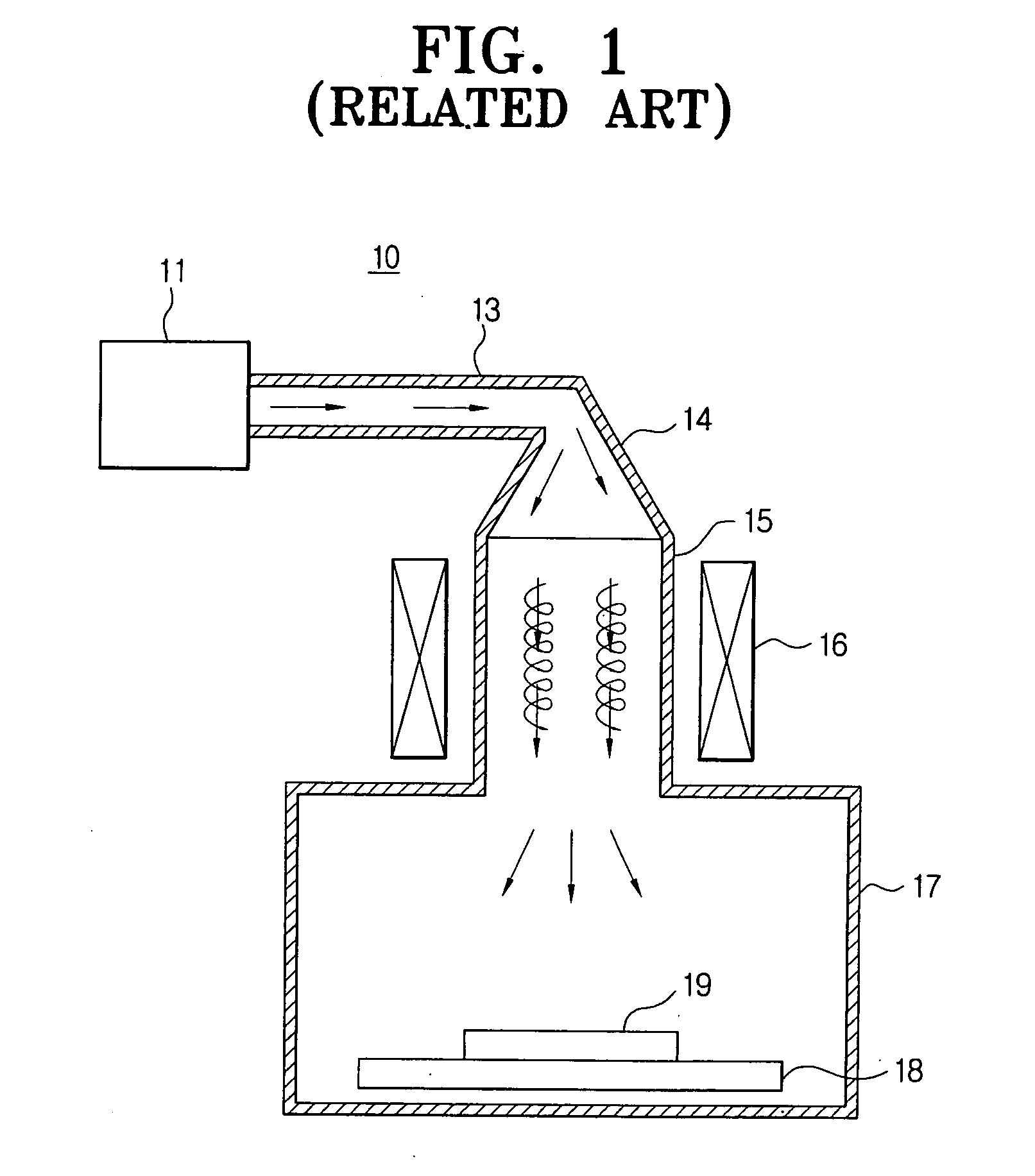

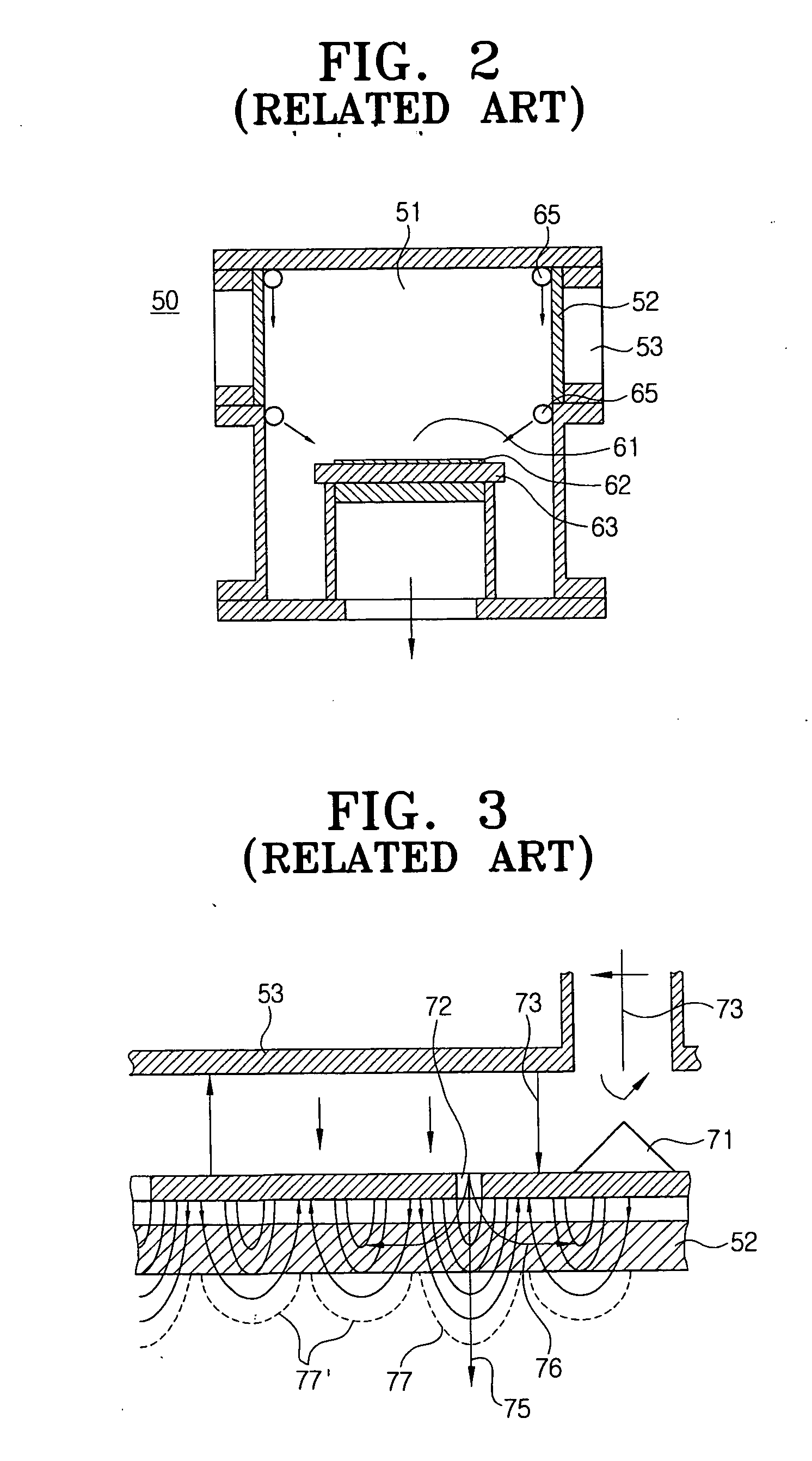

Microwave resonance plasma generating apparatus and plasma processing system having the same

ActiveUS20070045244A1Increase plasma producing efficiencySimple structureElectric discharge tubesElectric arc lampsHigh energyCoaxial waveguides

A microwave resonance plasma generating apparatus, a plasma processing system having the same and a method of generating a microwave resonance plasma are provided. The apparatus includes a microwave generating unit which generates a microwave, and a plasma producing unit which produces electrons and photons of high energy using the microwave generated from the microwave generating unit. The plasma producing unit includes a coaxial waveguide having an inner electrode disposed adjacent to the microwave generating unit, an outer electrode connected to the microwave generating unit and disposed to coaxially surround a portion of the inner electrode, the outer electrode being shorter than the inner electrode, and a dielectric tube disposed between the inner electrode and the outer electrode to insulate between the inner electrode and the outer electrode. The coaxial waveguide utilizes a principle of “cut or truncated electrode of coaxial waveguide” and a resonance phenomenon of Langmiur.

Owner:SAMSUNG ELECTRONICS CO LTD

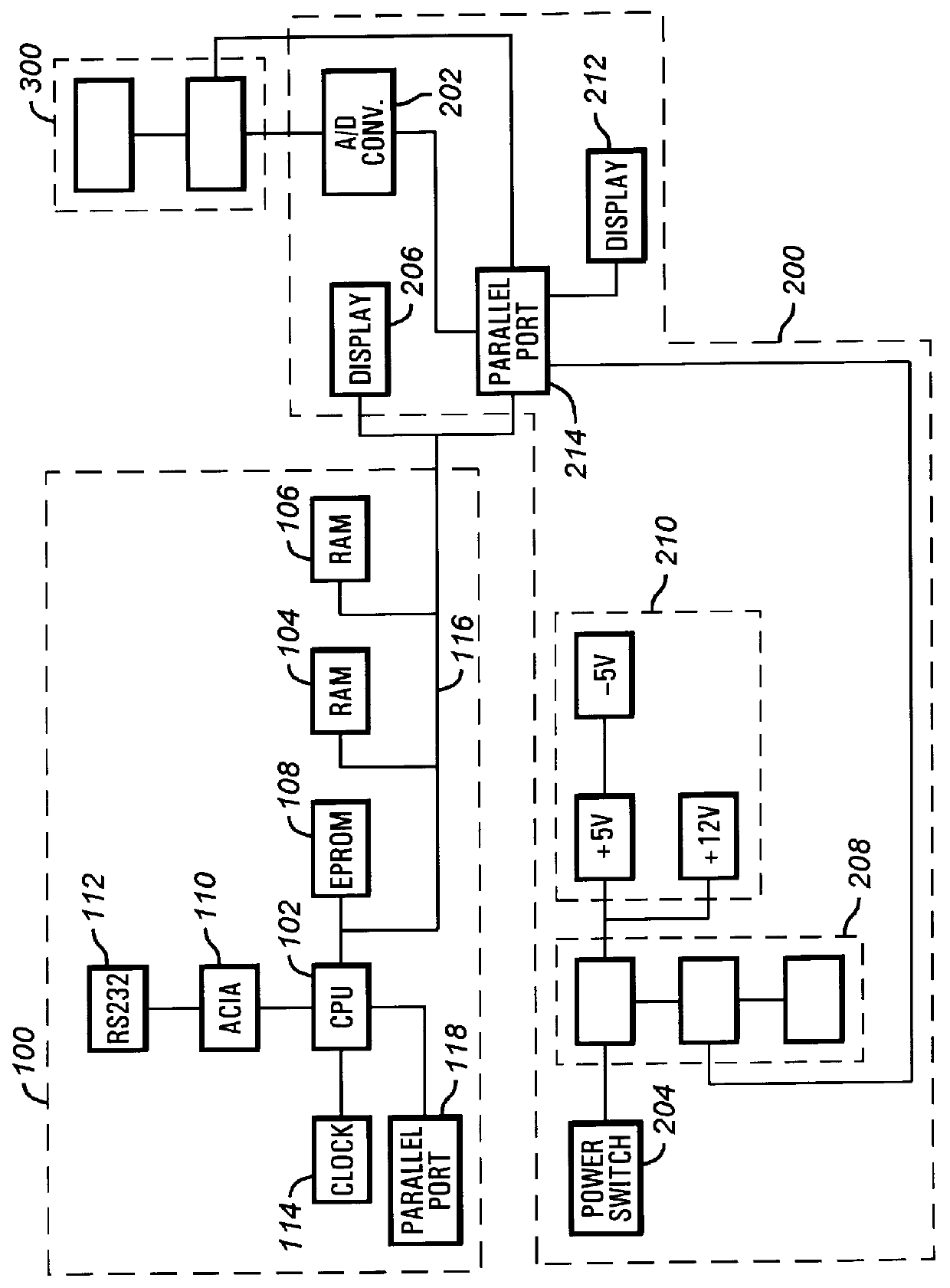

Methods and apparatus for welding performance measurement

InactiveUS6051805AStreamlined operationMaximize efficiencyArc welding apparatusAverage currentControl circuit

Methods and apparatus are provided for determining the duty cycle, average amperage, and / or the number of arc starts during a welding operation. The apparatus comprises first and second circuits, the first circuit being a CPU control circuit, and the second circuit being an arc time sensor circuit which is programmed to measure amperage, welding wire feed speed and preferably gas flow rates while welding. A ratio of the cumulative welding time during the audit to the total on-time provides a measurement of the efficiency of the welding arc. The welding deposition efficiency may then be calculated using the average amperage and welding duty cycle as measured and calculated by the apparatus. The number of arc starts where the arc on-time is in excess of one second may also provide a useable measurement in giving secondary information on the overall efficiency of the welding operation.

Owner:AIR LIQUIDE CANADA

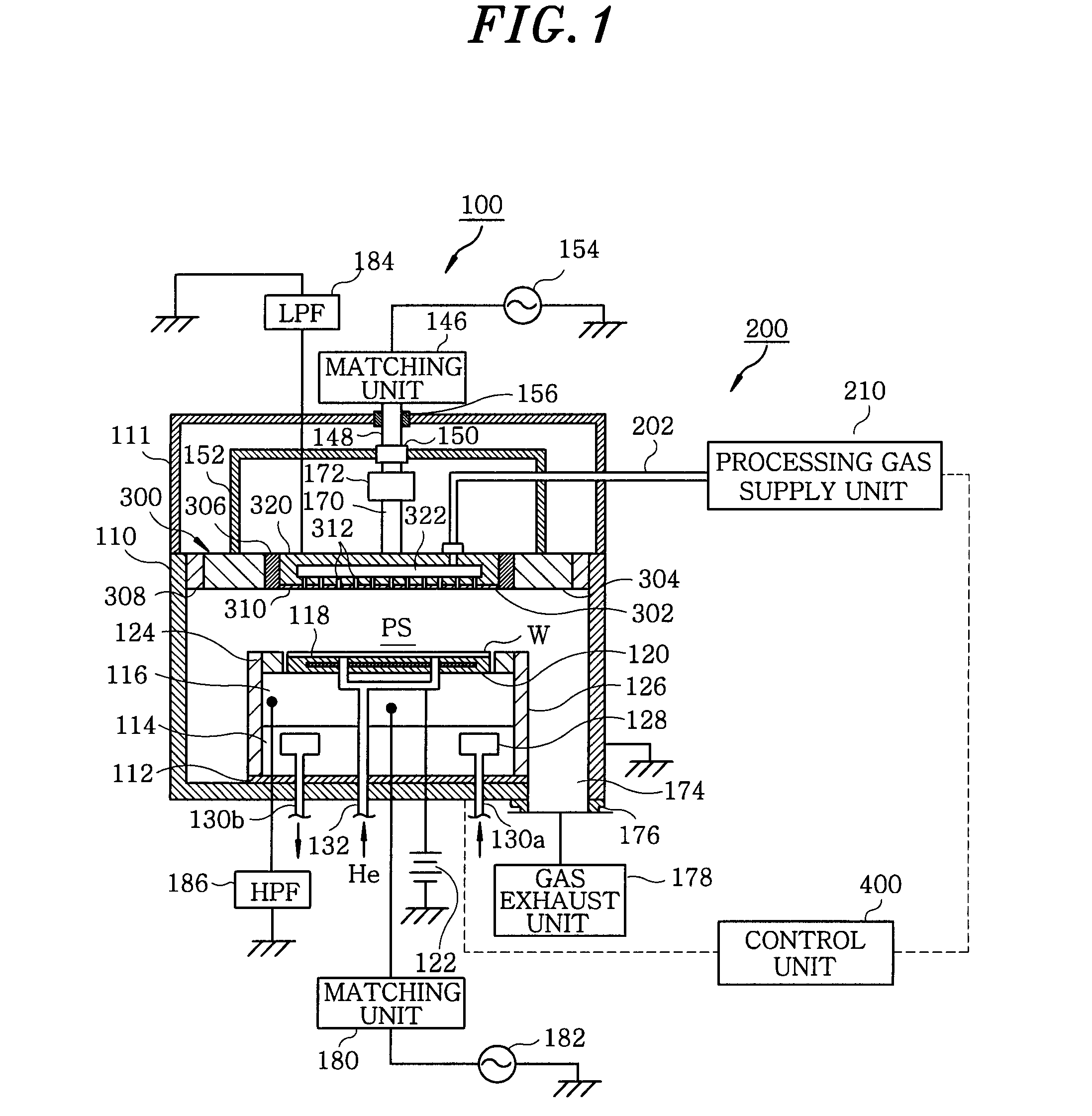

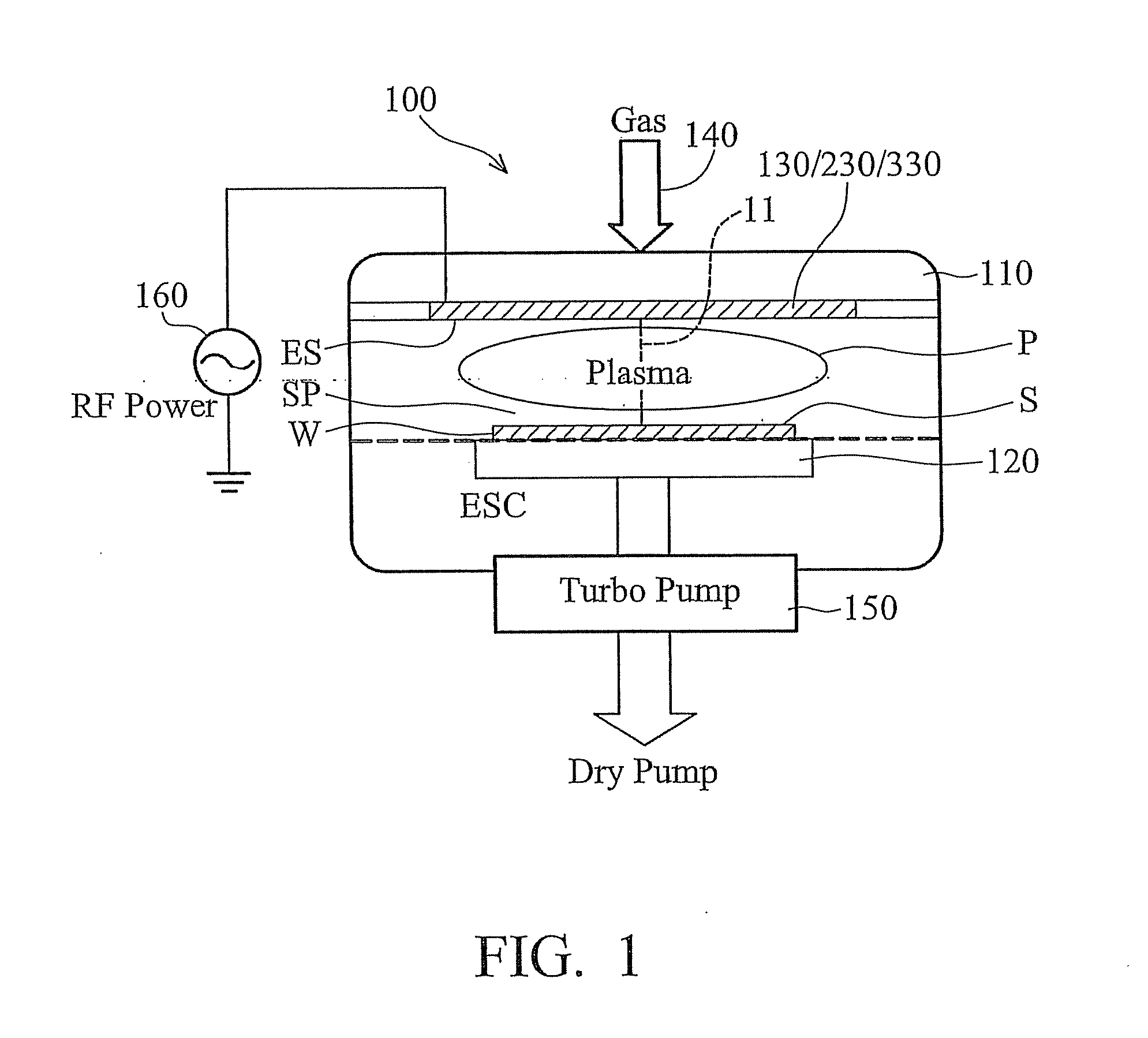

Plasma processing apparatus and electrode used therein

ActiveUS20070215580A1Improve uniformityReduce unevennessElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringElectric power

A plasma processing apparatus performs a specific plasma processing on a target substrate by disposing a first and a second electrode to face each other in a processing chamber, and supplying high-frequency electric power to at least one of the first and the second electrodes to thereby generate a plasma while introducing a processing gas onto the target substrate supported by the second electrode. The electrode for use as the first electrode includes: an electrode plate facing the second electrode; a support for supporting the electrode plate, wherein the support is in contact with a surface of the electrode plate and the surface is opposite to the second electrode; and a dielectric portion, provided on a contact surface of the support with the electrode plate, and having a shape in which a center portion thereof has a height different from that of an edge portion thereof.

Owner:TOKYO ELECTRON LTD

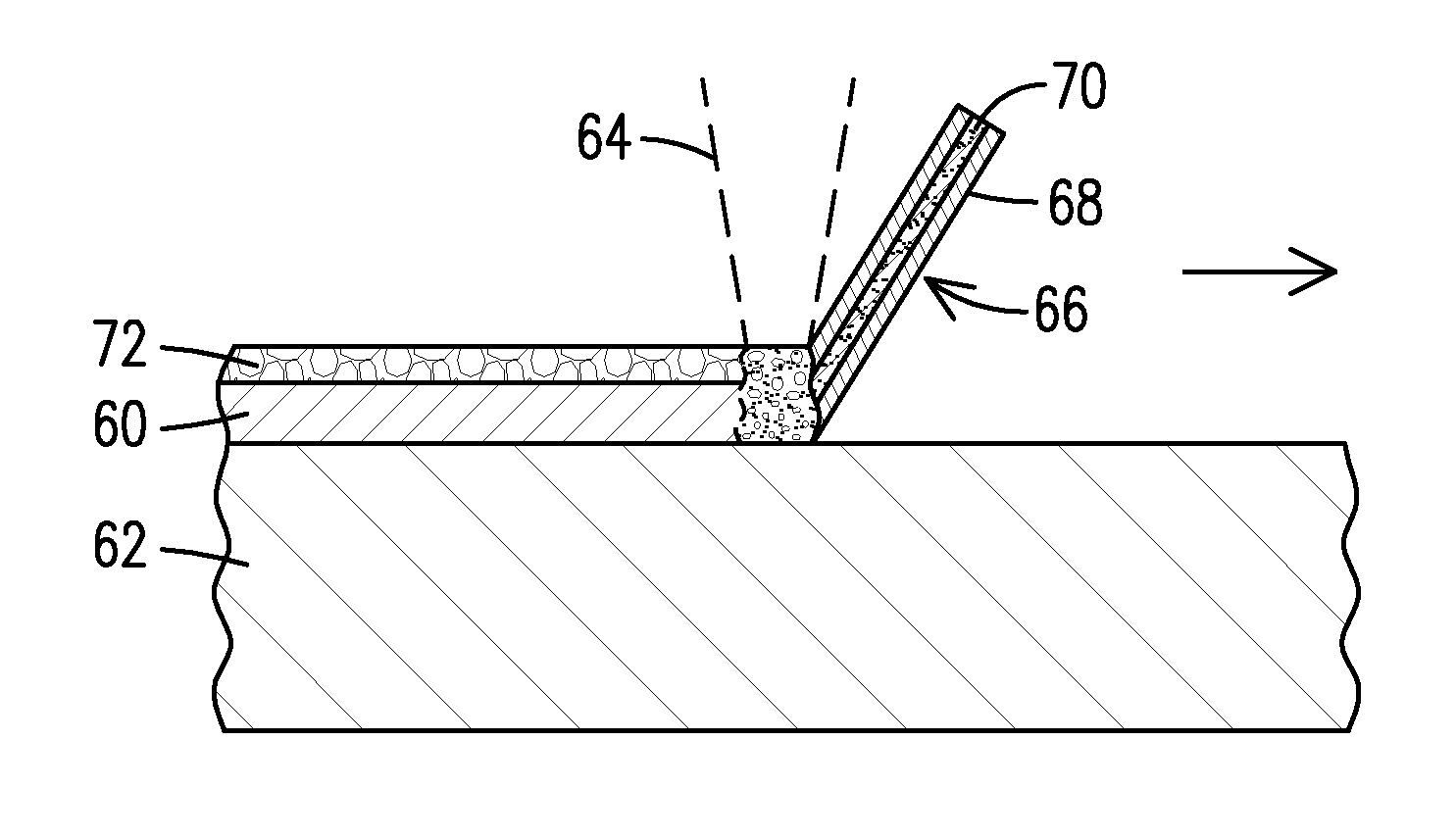

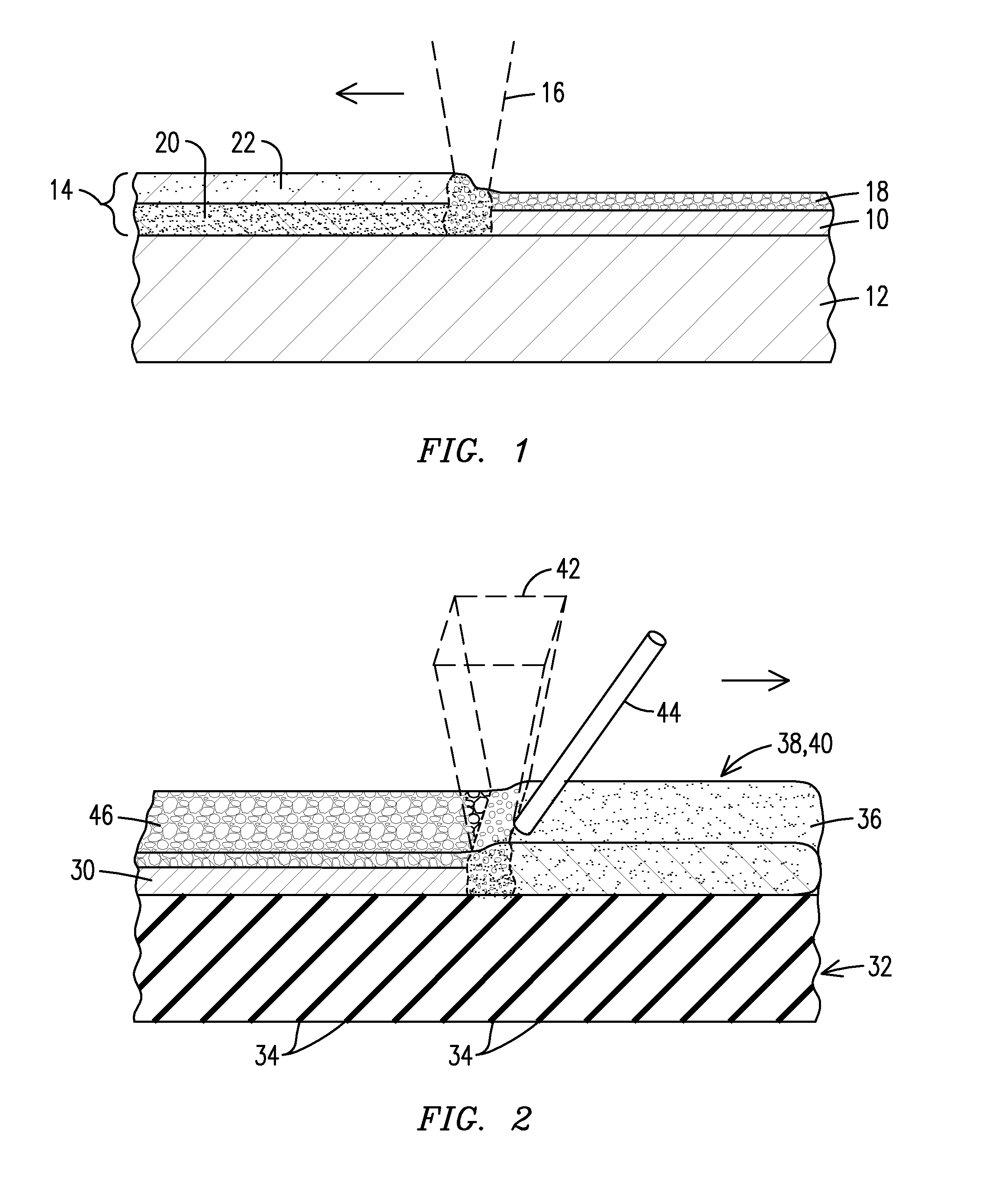

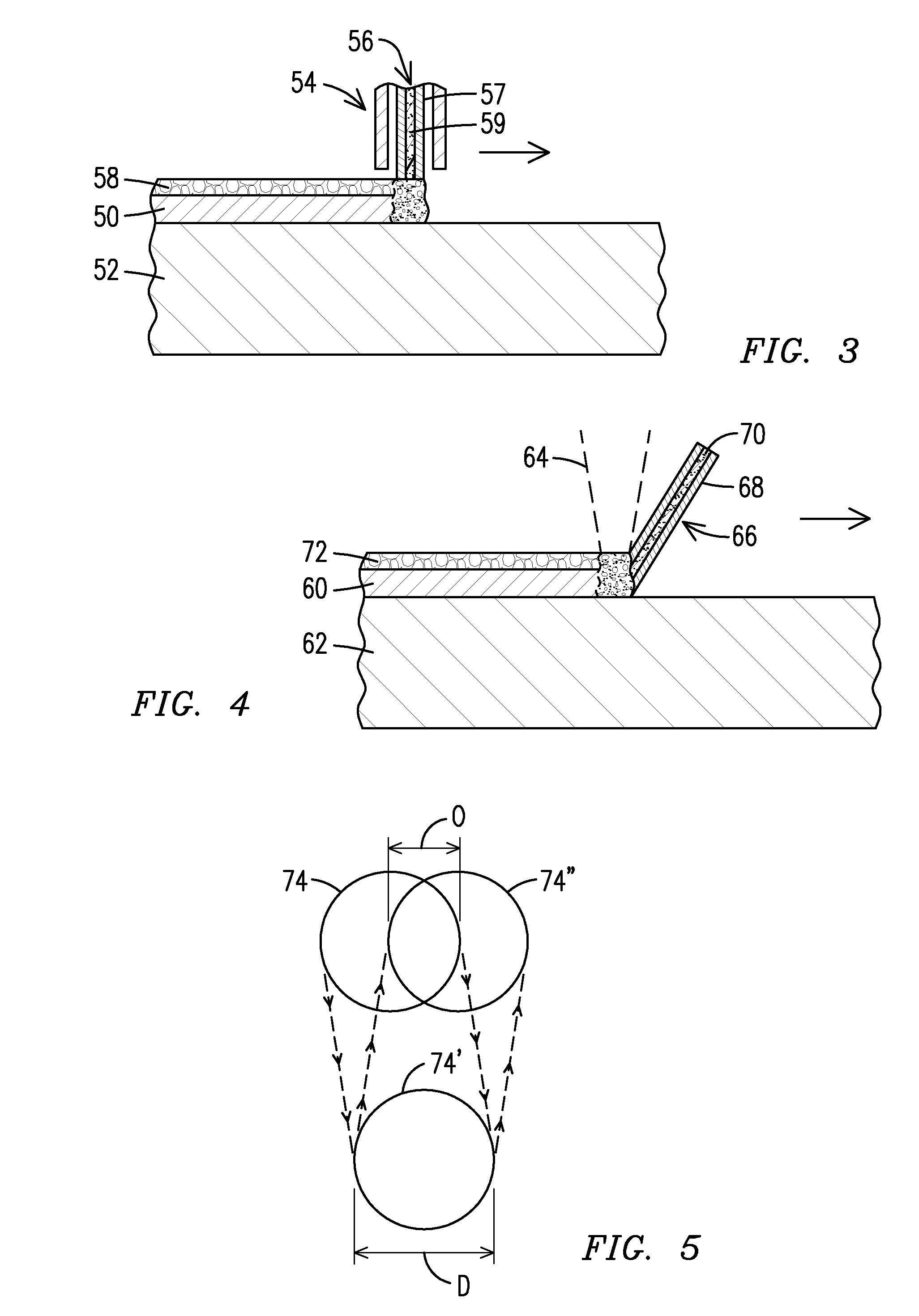

Selective laser melting / sintering using powdered flux

InactiveUS20130136868A1TurbinesRadiation applicationsSelective laser meltingSelective laser sintering

An additive manufacturing process (110) wherein a powder (116) including a superalloy material and flux is selectively melted in layers with a laser beam (124) to form a superalloy component (126). The flux performs a cleaning function to react with contaminants to float them to the surface of the melt to form a slag. The flux also provides a shielding function, thereby eliminating the need for an inert cover gas. The powder may be a mixture of alloy and flux particles, or it may be formed of composite alloy / flux particles.

Owner:SIEMENS ENERGY INC

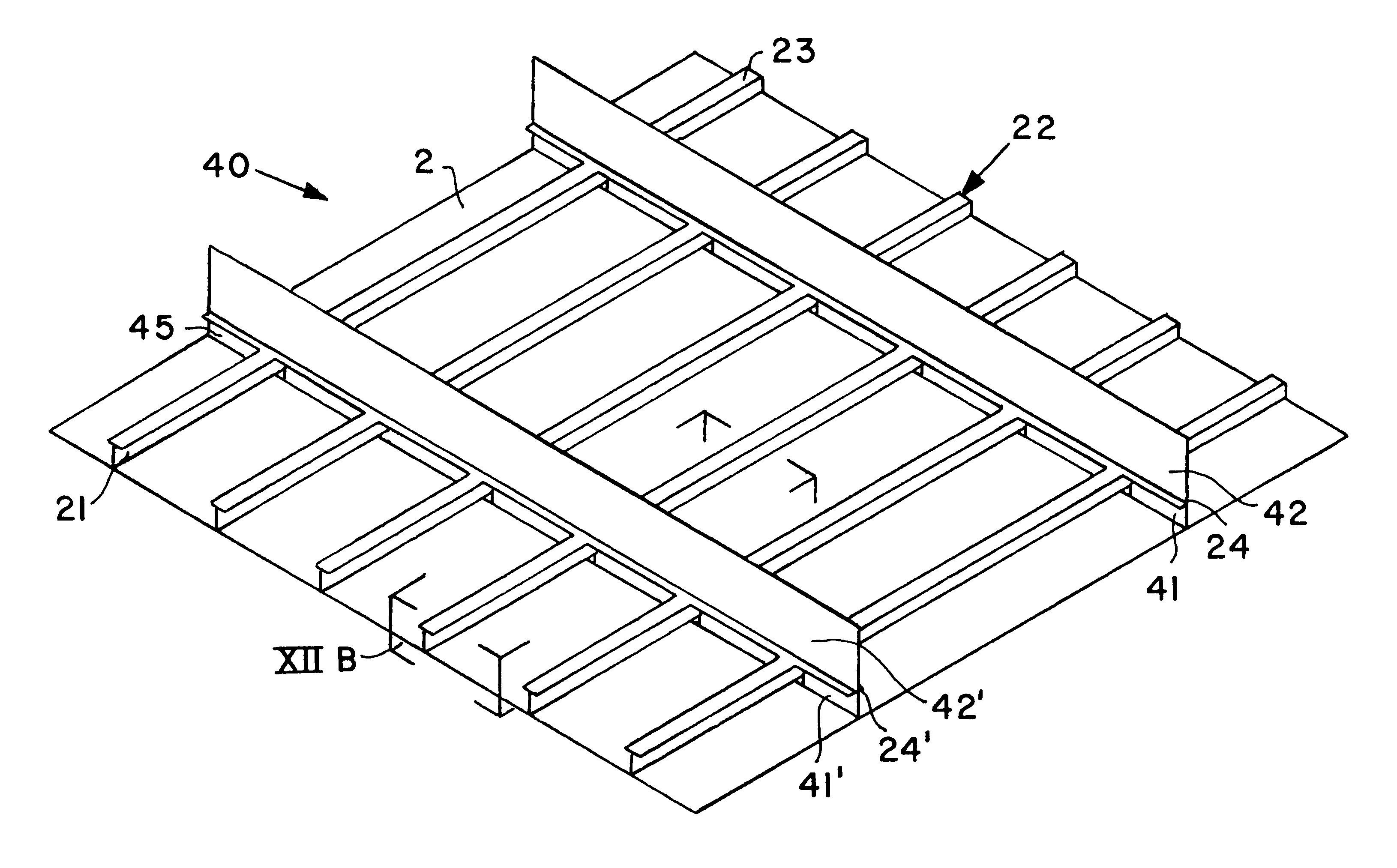

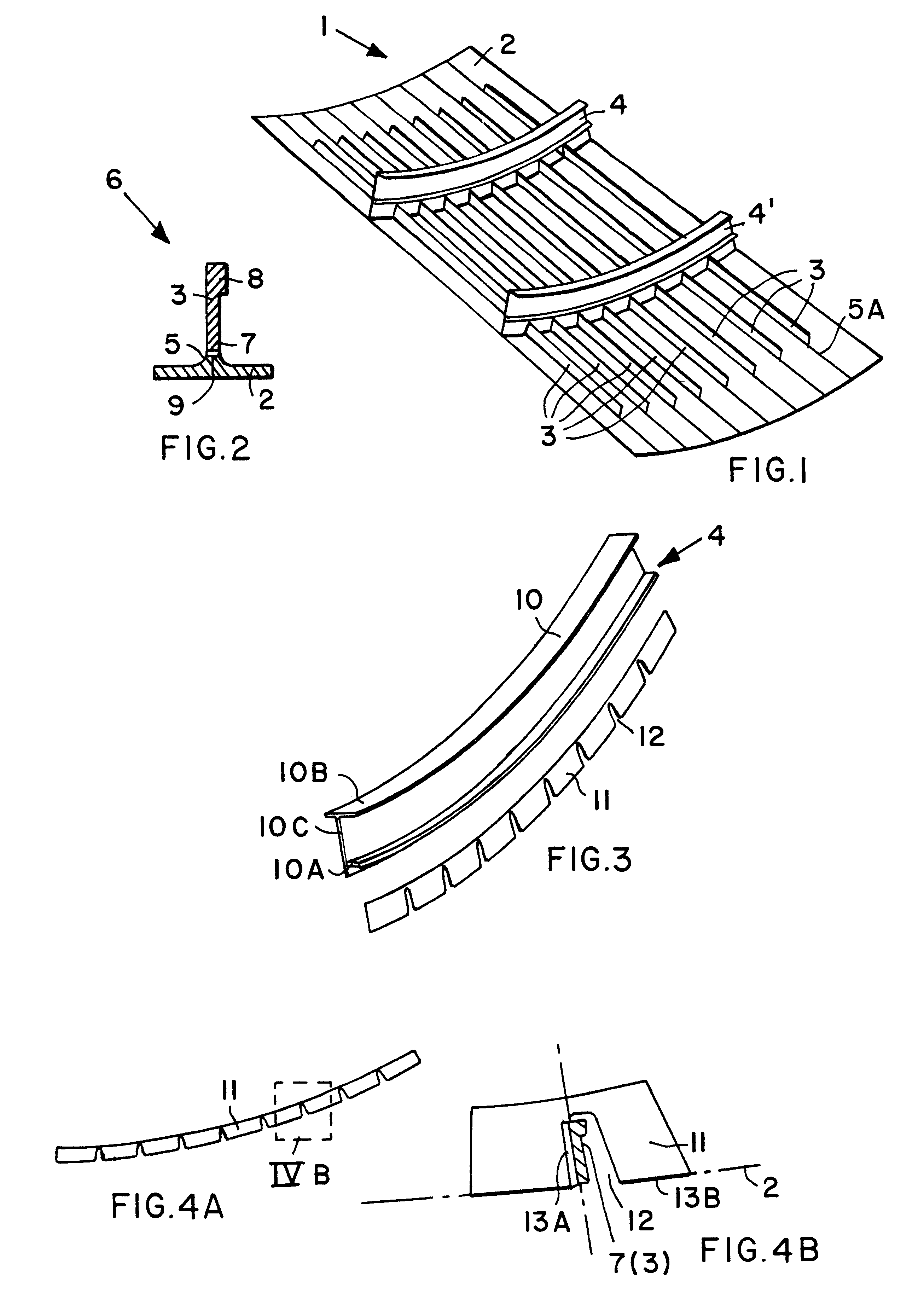

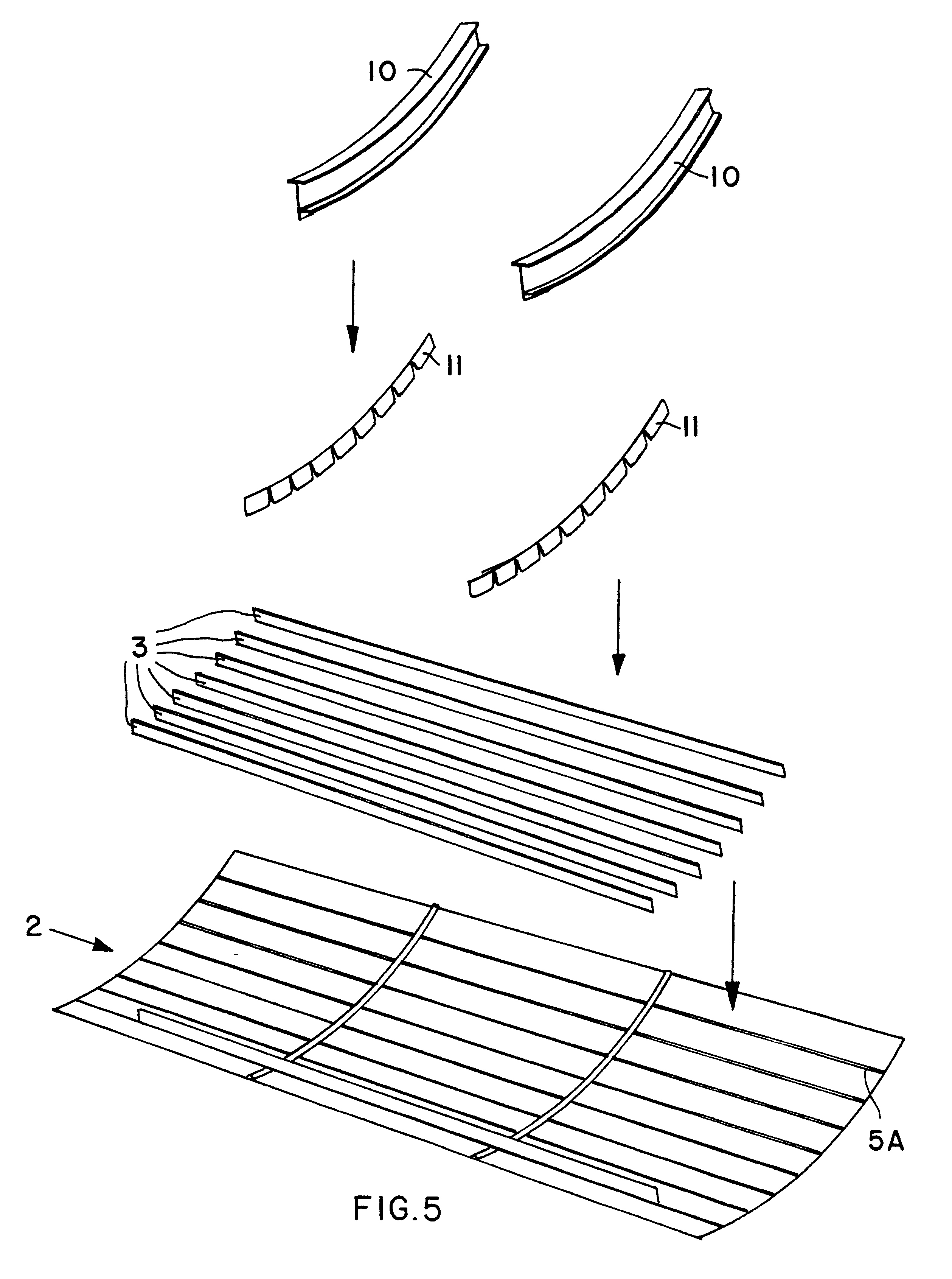

Shell component for an aircraft fuselage and method of manufacturing the same

A shell component for an aircraft fuselage includes a fuselage skin panel, a plurality of stringers extending in an aircraft lengthwise direction, and a plurality of frames extending crosswise relative to the stringers. The stringers and the frames are respectively welded onto the skin panel with the addition of a weld filler material. Each frame includes a frame root portion and a frame profile portion connected to each other. The frame root portion has cut-out notches receiving the stringers passing therethrough. The frame root portion is welded to the skin panel at the areas between the cut-out notches, and may be welded to the respective stringer in each cut-out notch. The stringers and frames are fabricated from webs and flanges, whereby a premanufactured grid of flanges may be used. The result is a very strong, yet simple shell component structure, that may be manufactured with a simple welding process, at a low cost and with low effort.

Owner:DAIMLER CHRYSLER AEROSPACE AIRBUS

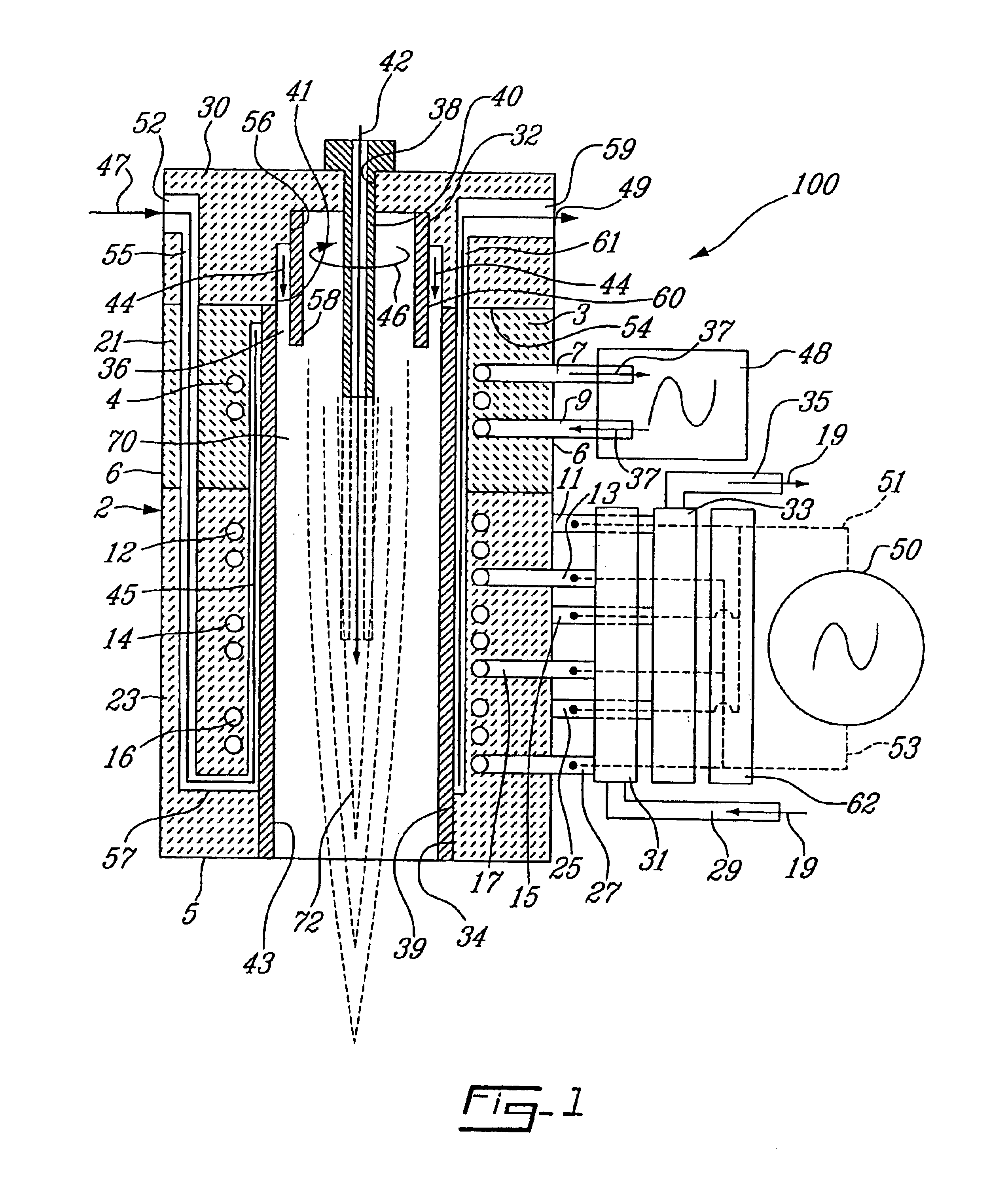

Multi-coil induction plasma torch for solid state power supply

InactiveUS6919527B2Efficient heatingImprove thermal conductivityElectric discharge tubesElectric arc lampsHigh frequency powerInduction plasma technology

Owner:TEKNA PLASMA SYST INC

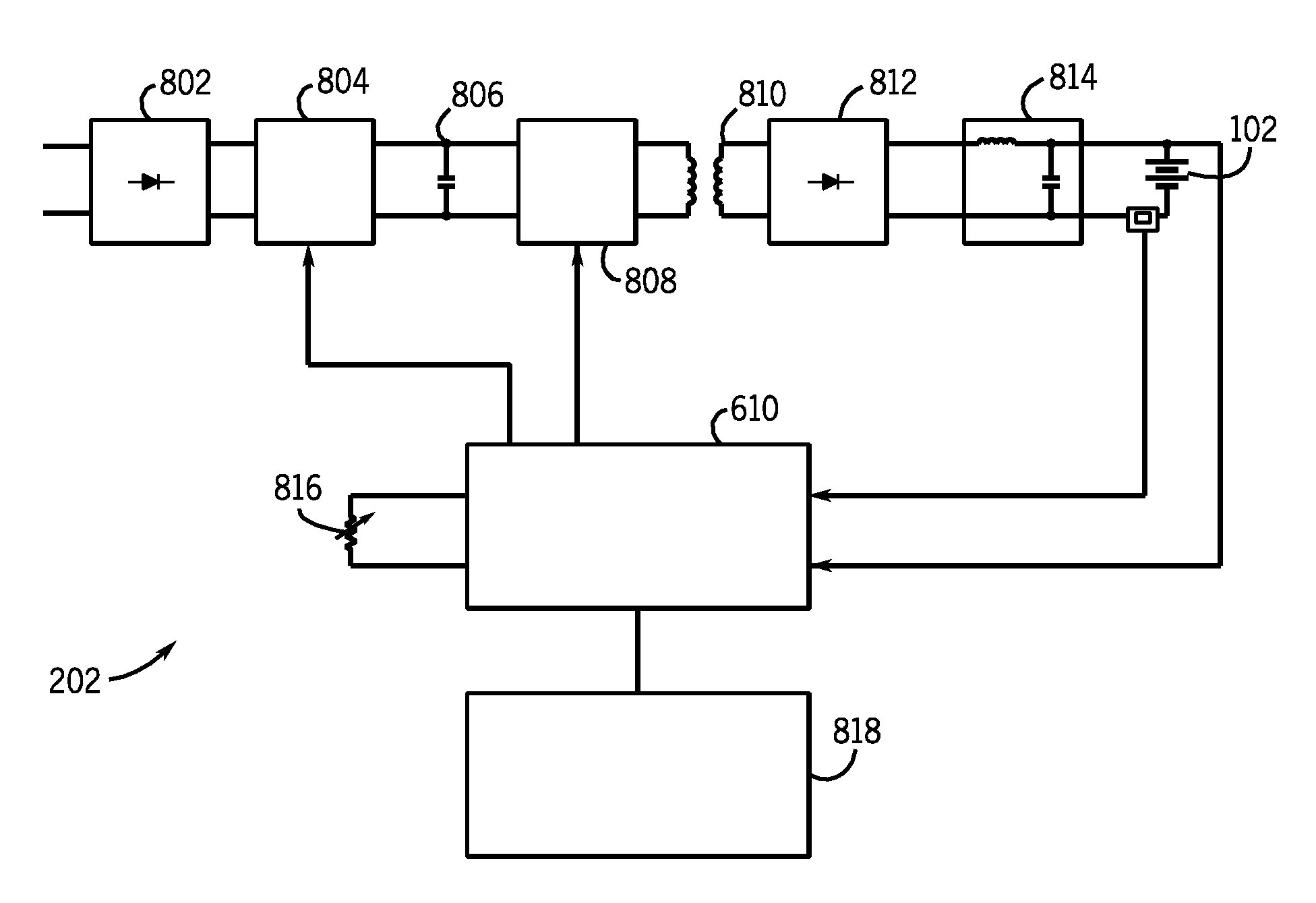

Method and apparatus for welding with battery power

A method and apparatus provides welding-type power and preferably includes a removable battery or other energy storage device, a converter connected to the battery, and a controller. The controller may have a CV and / or a CSC and / or an AC weld control module, and / or an ac auxiliary control module. The converter is a boost converter, a buck converter, a cuk converter, a forward converter, an inverter, a bridge converter, and / or a resonant converter. The controller may include a battery charging control module, and may have one or more charging schedules, and / or data for stored charge, thermal information, expected life of the battery, maximum amp-hour charge for the battery, maximum charging current and / or feedback. The battery charging schedules may include at least 3 phases, such as a phase of increasing voltage and a phase of decreasing current, a substantially constant power phase. The controller can wirelessly provide data to a display or pda. A generator may provide power to the battery, charger, and / or the weld. It can include a vehicle and use its dc power system.

Owner:ILLINOIS TOOL WORKS INC

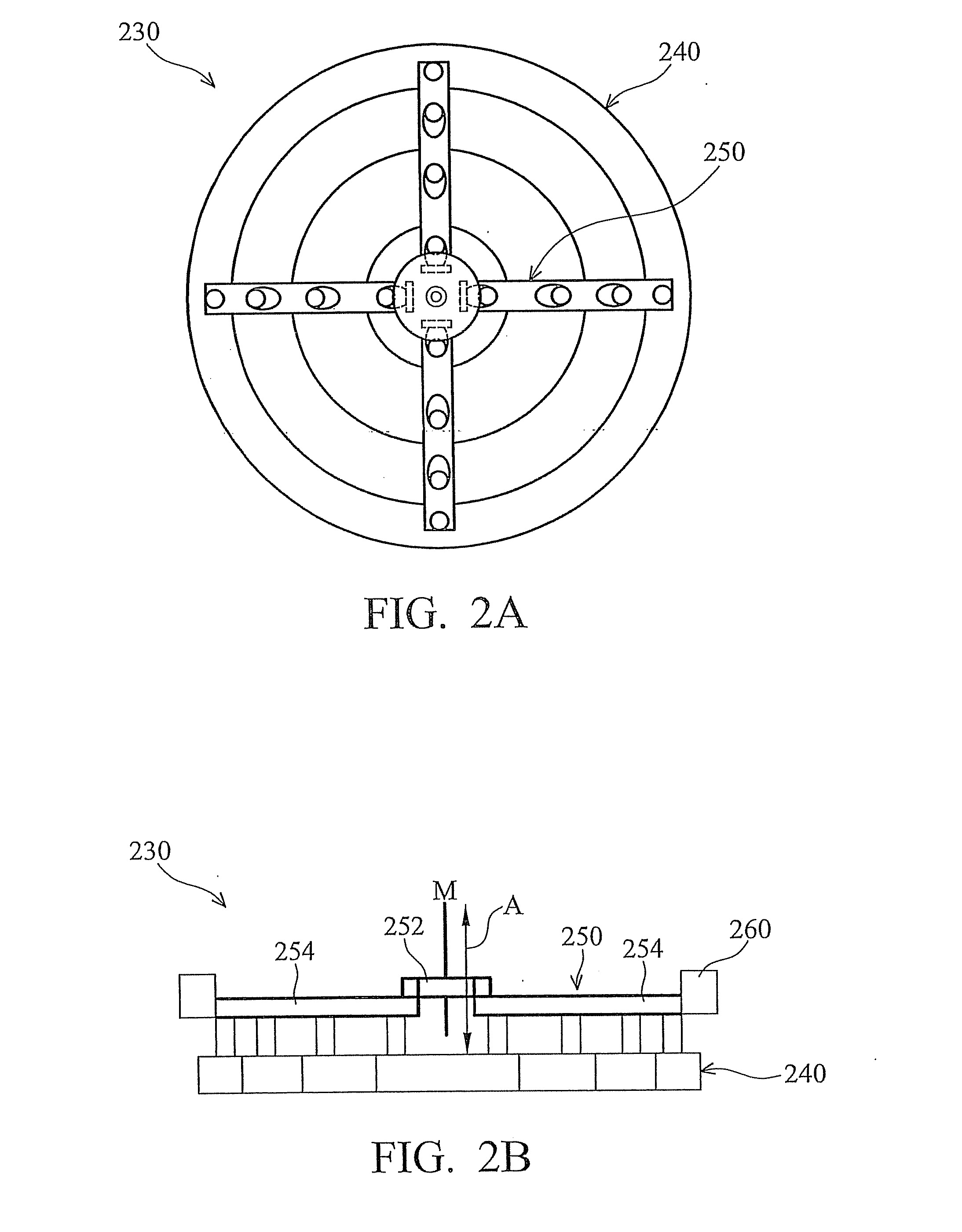

Adjustable electrodes and coils for plasma density distribution control

InactiveUS20080083710A1Electric discharge tubesSemiconductor/solid-state device manufacturingSemiconductorPlasma density distribution

A adjustable upper coil or electrode for a reaction chamber apparatus useable in semiconductor processing, is constructed so that its shape may be selectively changed or so at least two portions thereof may be selectively driven at different power and / or frequencies. The adjustable upper coil or electrode, therefore, enables the plasma density distribution in the reaction chamber apparatus to be selectively controlled.

Owner:TAIWAN SEMICON MFG CO LTD

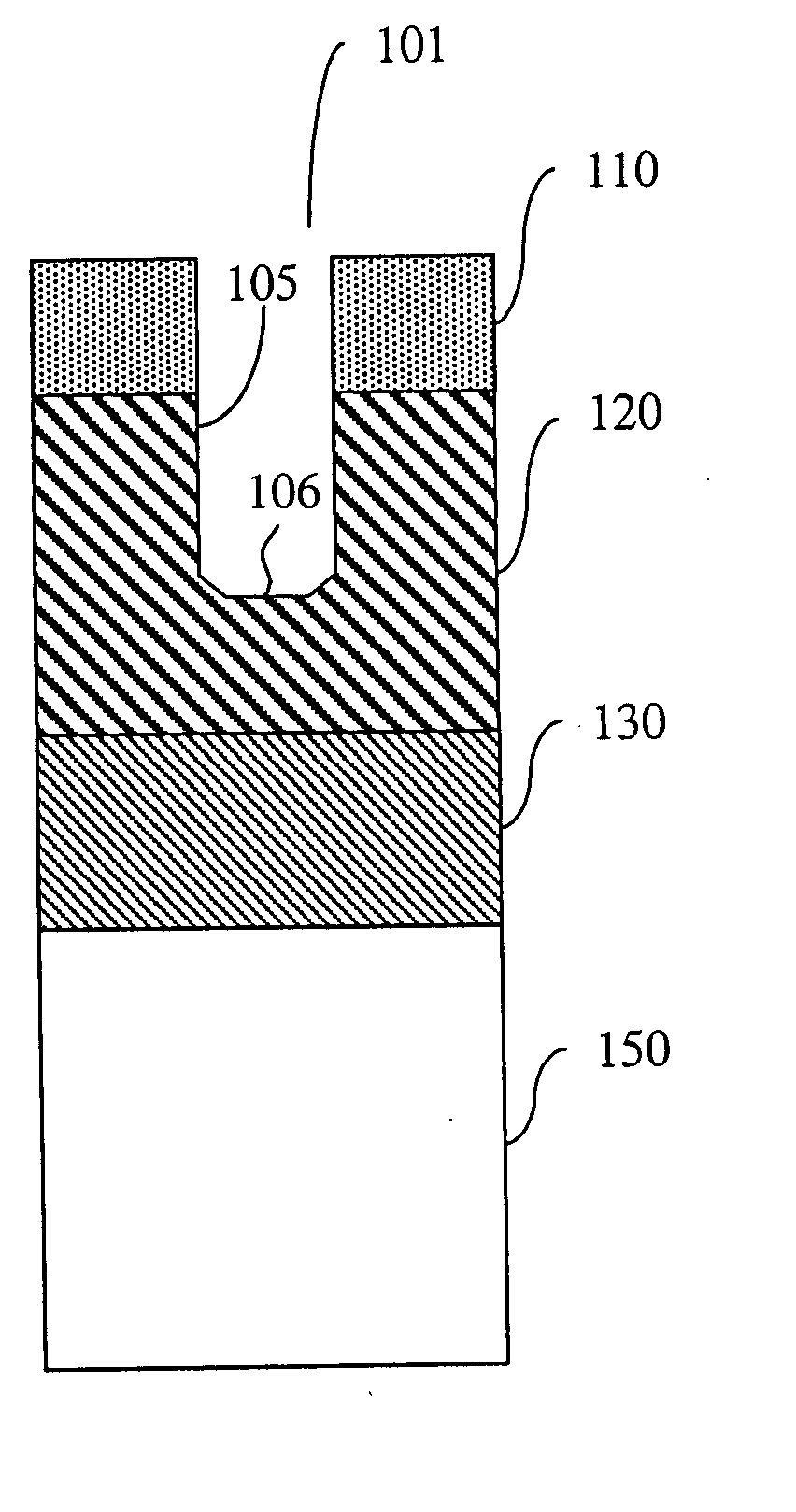

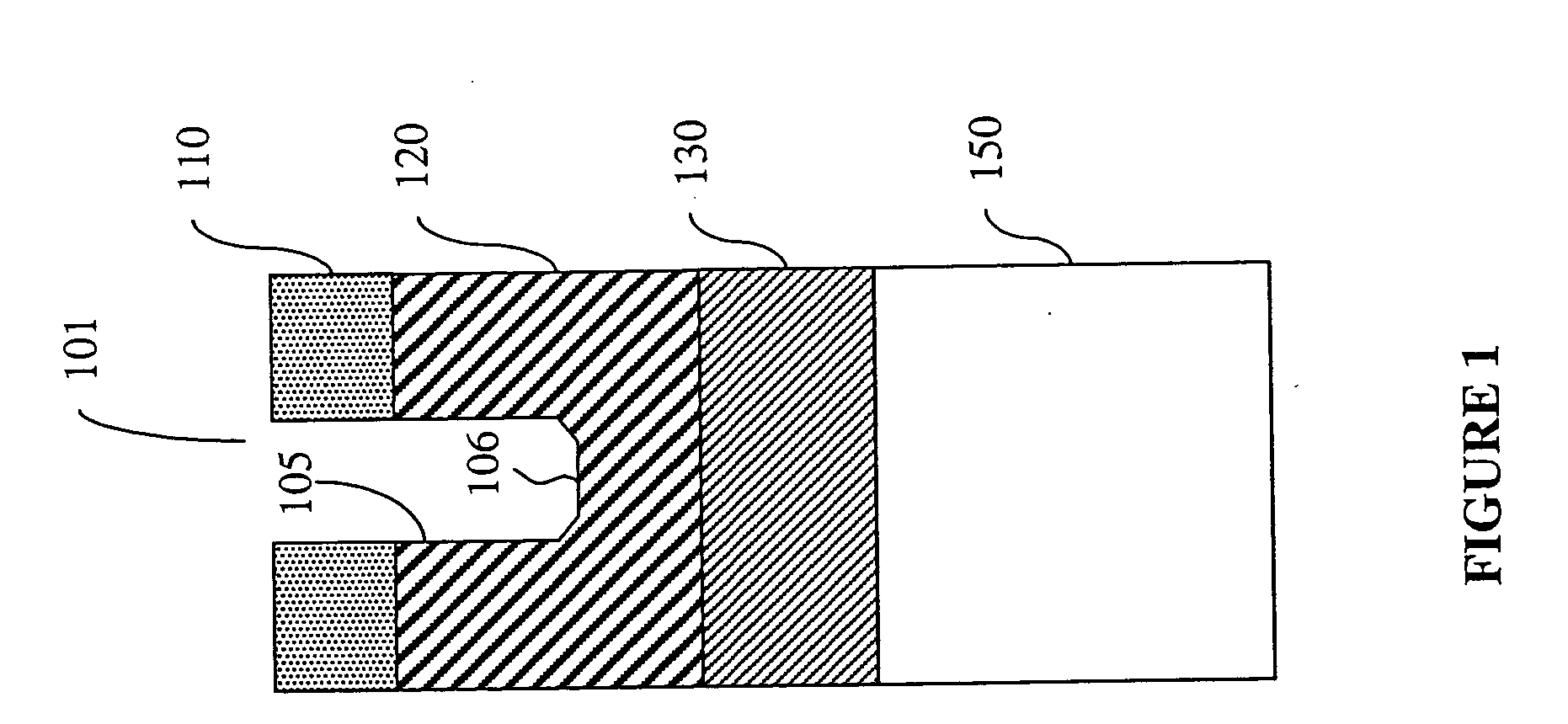

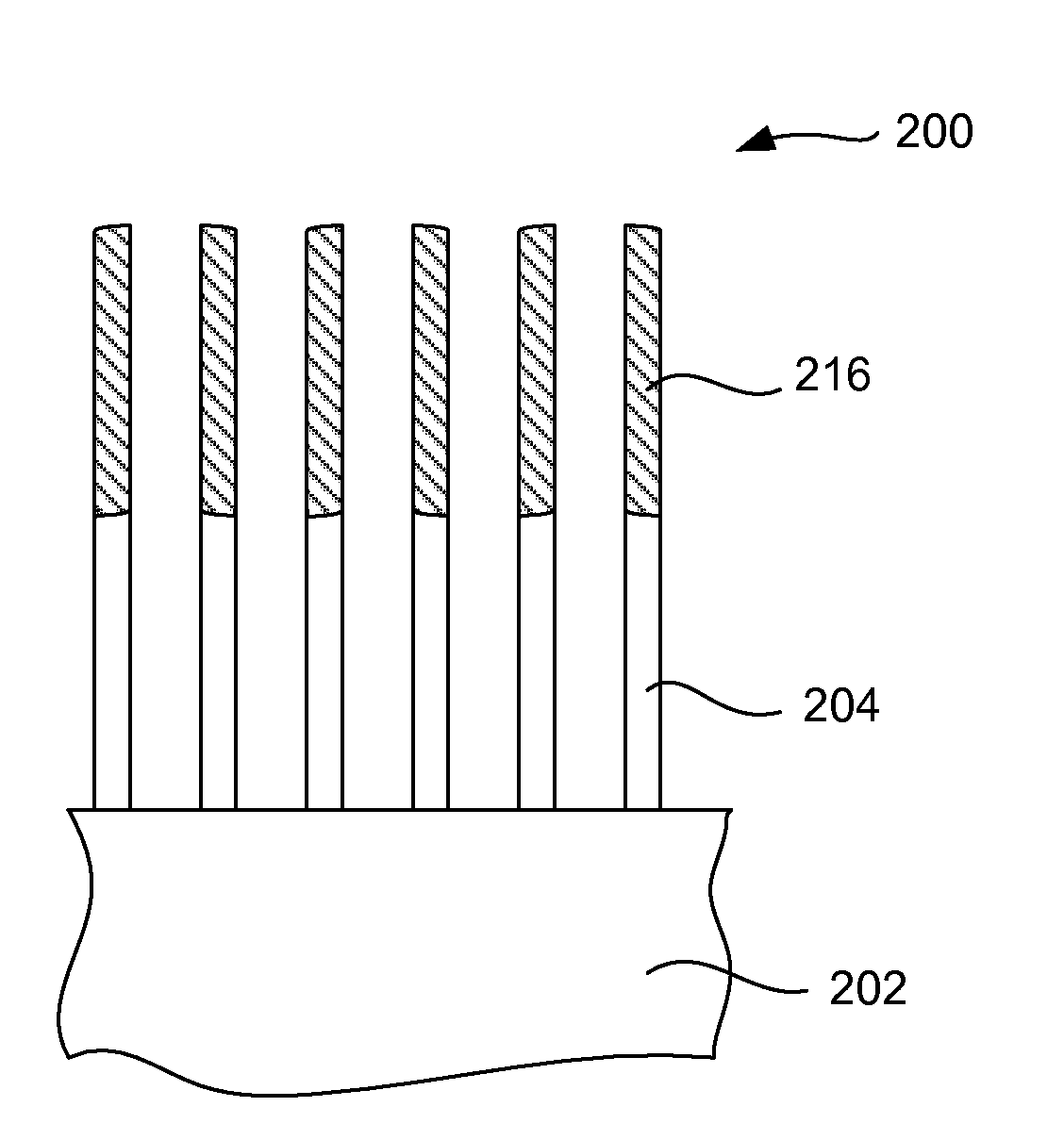

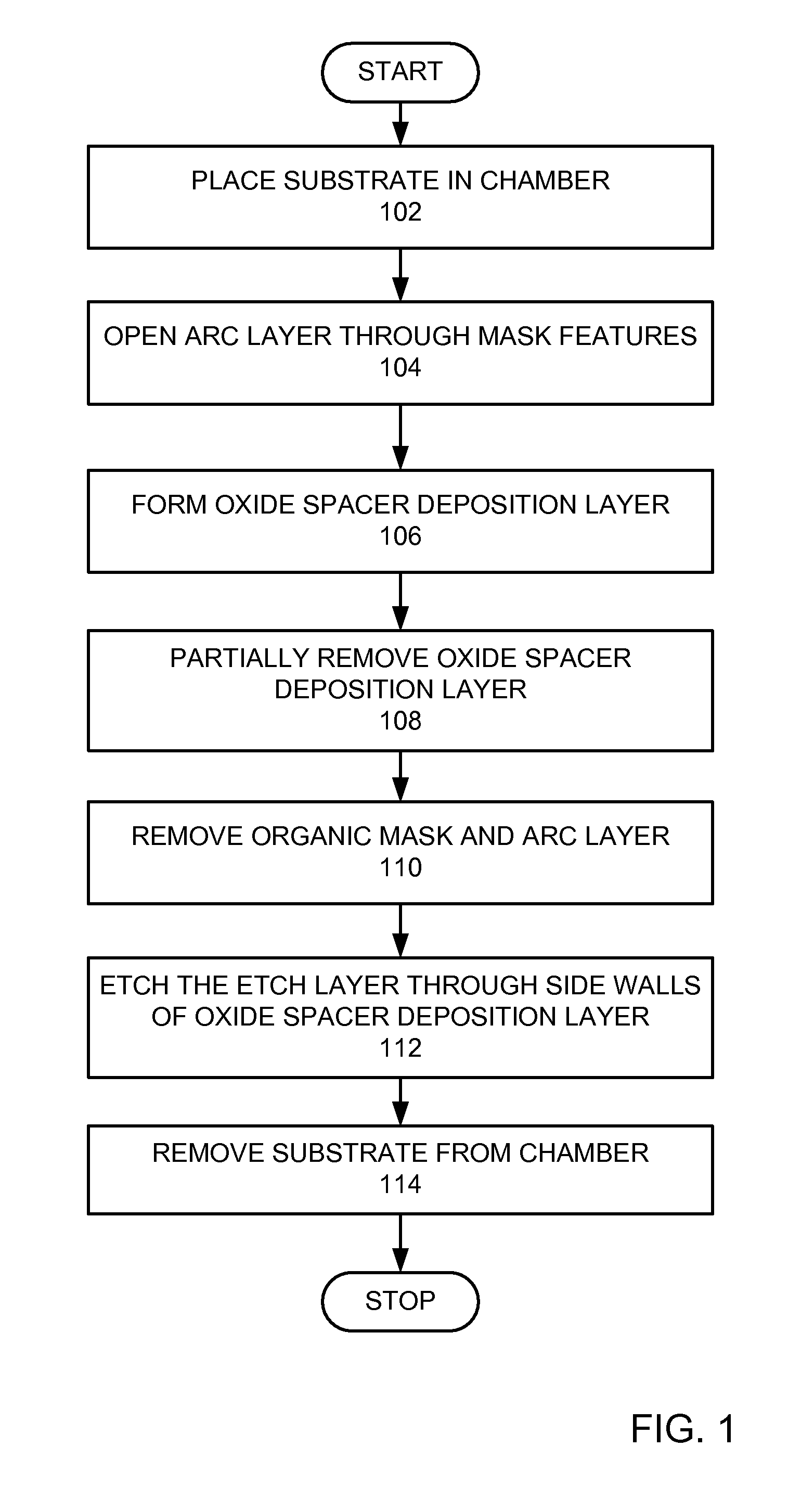

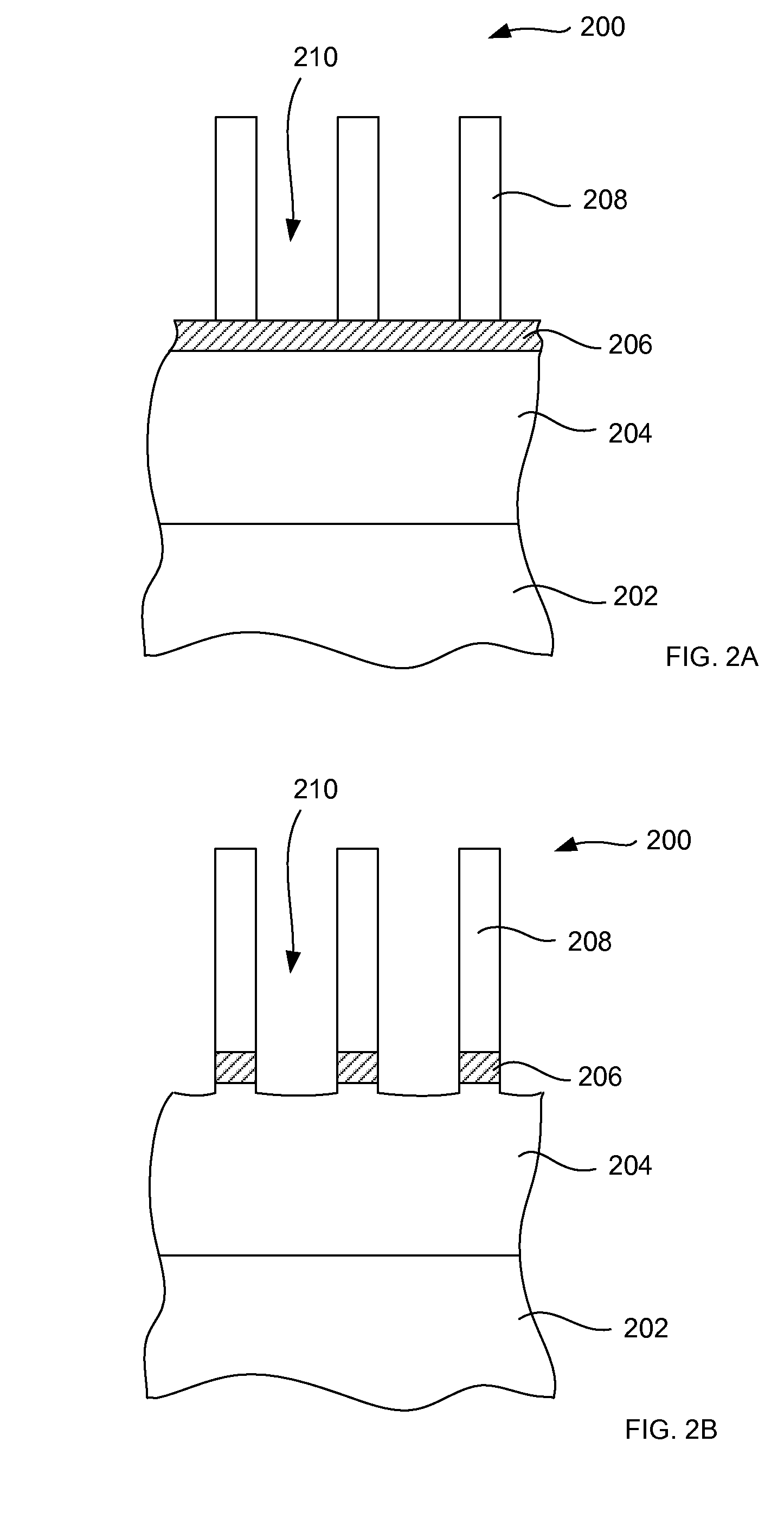

Pitch reduction using oxide spacer

InactiveUS20120052683A1Decorative surface effectsSemiconductor/solid-state device manufacturingOptoelectronicsCoating

A method for etching an etch layer disposed over a substrate and below an antireflective coating (ARC) layer and a patterned organic mask with mask features is provided. The substrate is placed in a process chamber. The ARC layer is opened. An oxide spacer deposition layer is formed. The oxide spacer deposition layer on the organic mask is partially removed, where at least the top portion of the oxide spacer deposition layer is removed. The organic mask and the ARC layer are removed by etching. The etch layer is etched through the sidewalls of the oxide spacer deposition layer. The substrate is removed from the process chamber.

Owner:LAM RES CORP

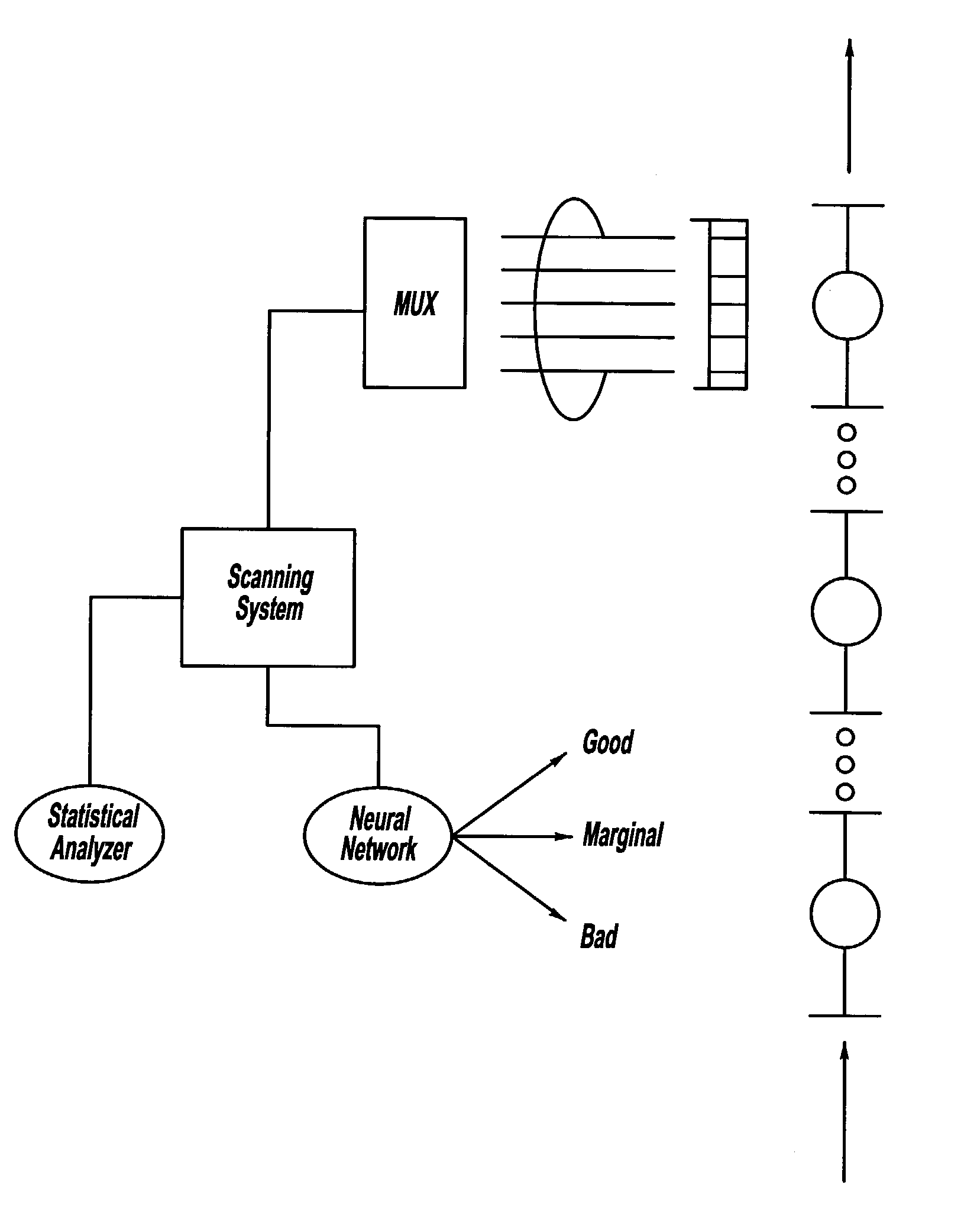

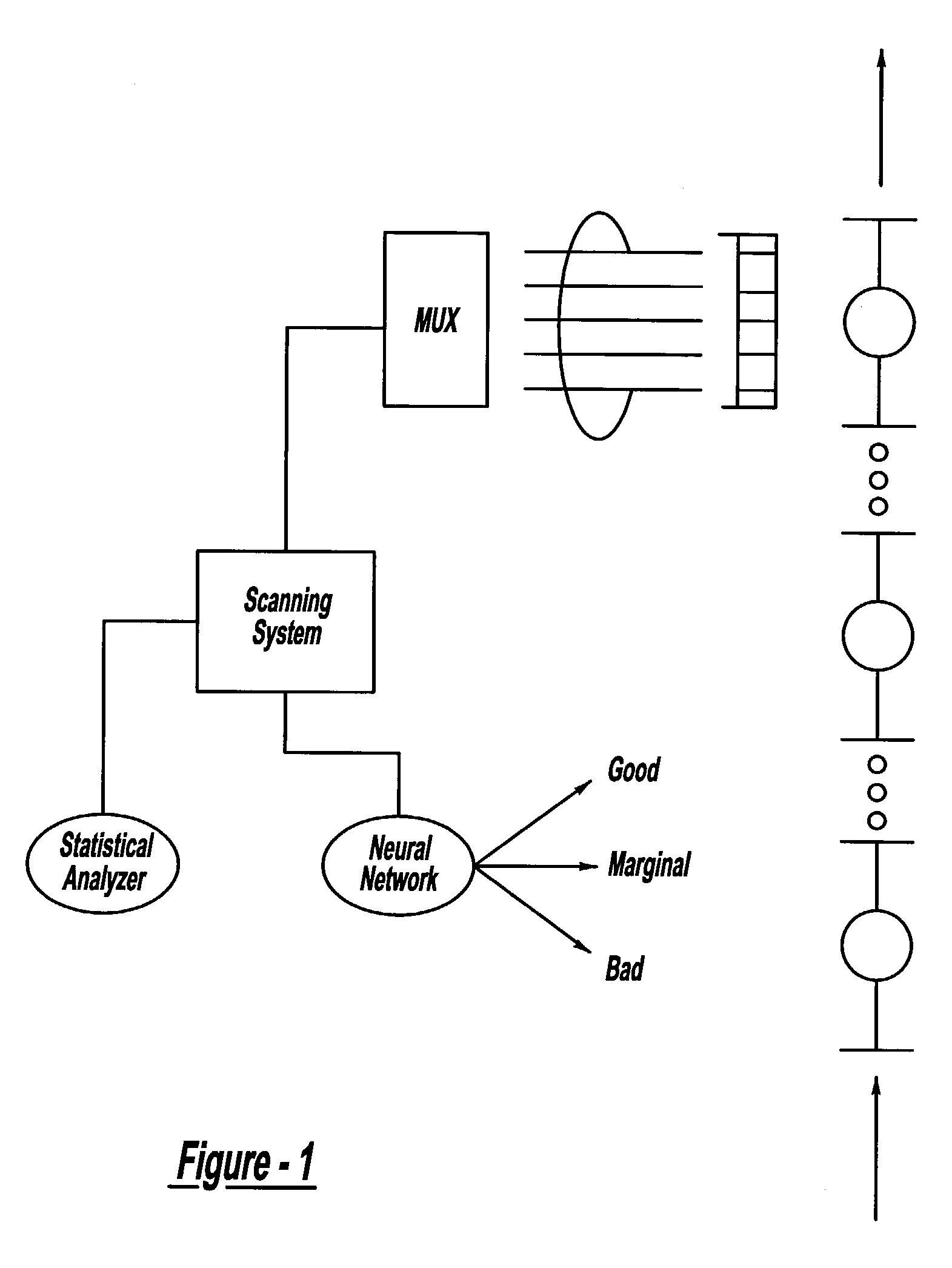

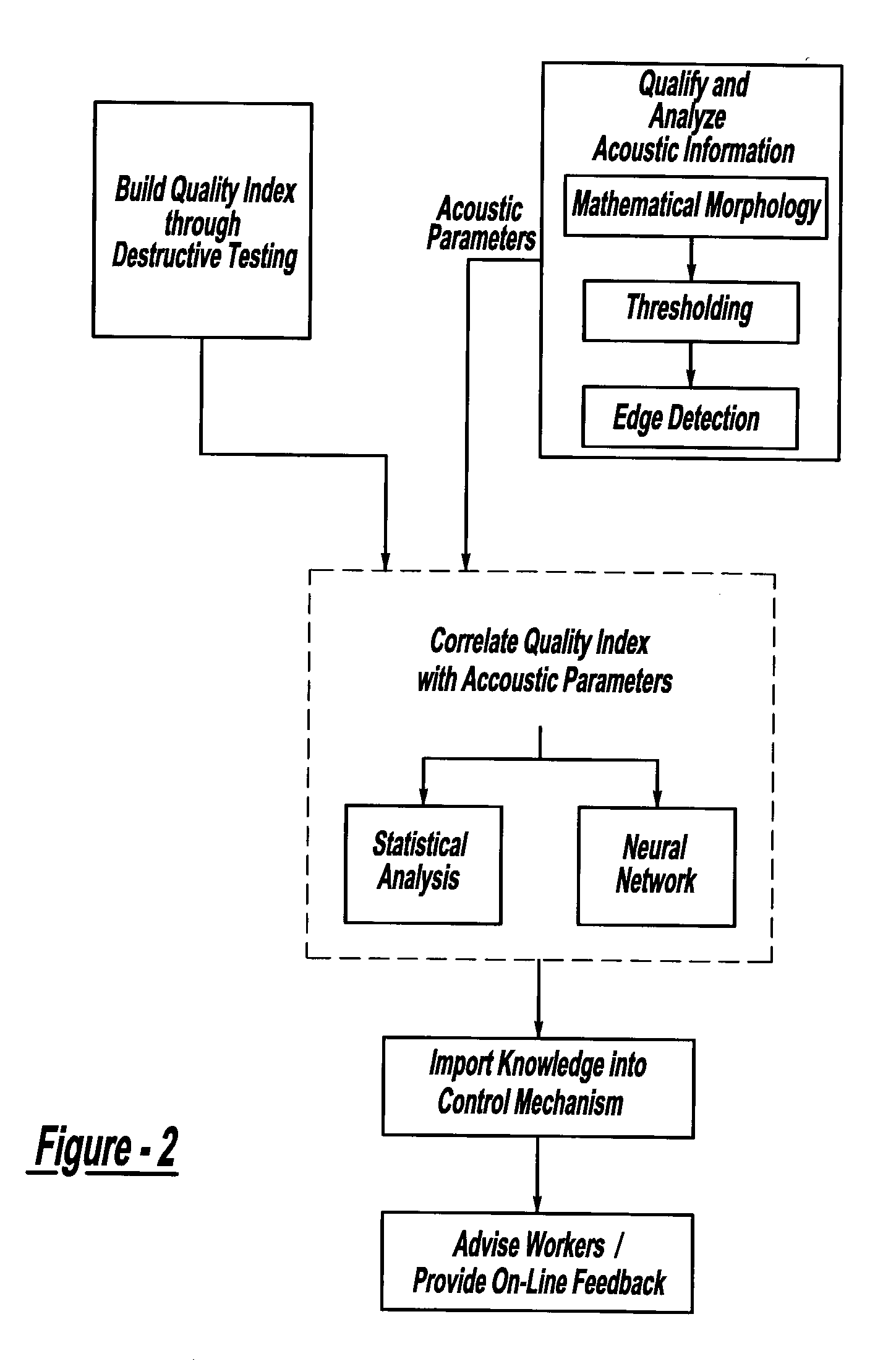

Method and system for assessing quality of spot welds

ActiveUS7132617B2Reduce in quantityReduce manufacturing costAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalDigital dataElectricity

A system and method for assessing the quality of spot weld joints between pieces of metal includes an ultrasound transducer probing a spot weld joint. The ultrasound transducer transmits ultrasonic radiation into the spot weld joint, receives corresponding echoes, and transforms the echoes into electrical signals. An image reconstructor connected to the ultrasound transducer transforms the electrical signals into numerical data representing an ultrasound image. A neural network connected to the image reconstructor analyzes the numerical data and an output system presents information representing the quality of the spot weld joint. The system is trained to assess the quality of spot weld joints by scanning a spot weld joint with an ultrasound transducer to produce the data set representing the joint; then physically deconstructing the joint to assess the joint quality.

Owner:FCA US

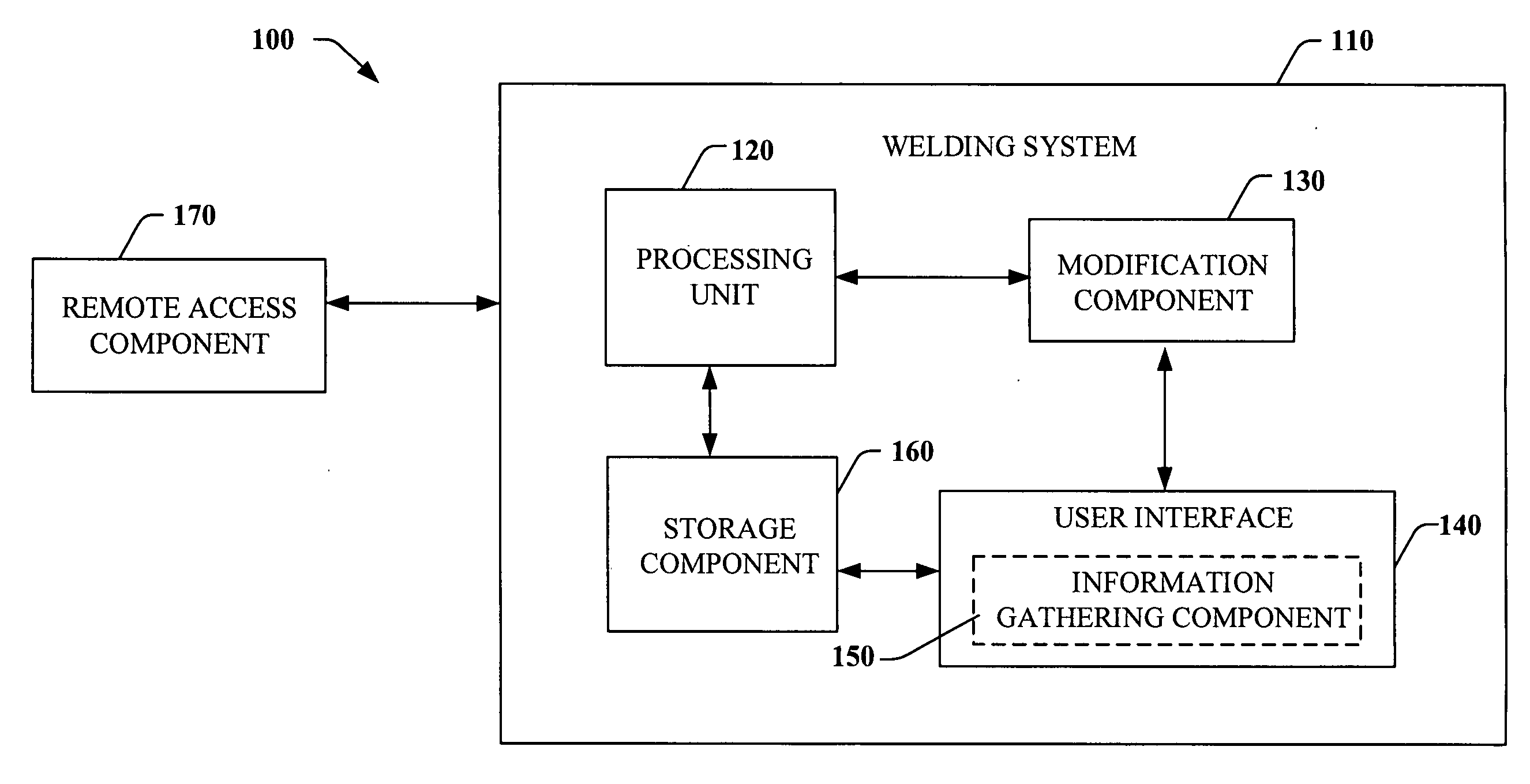

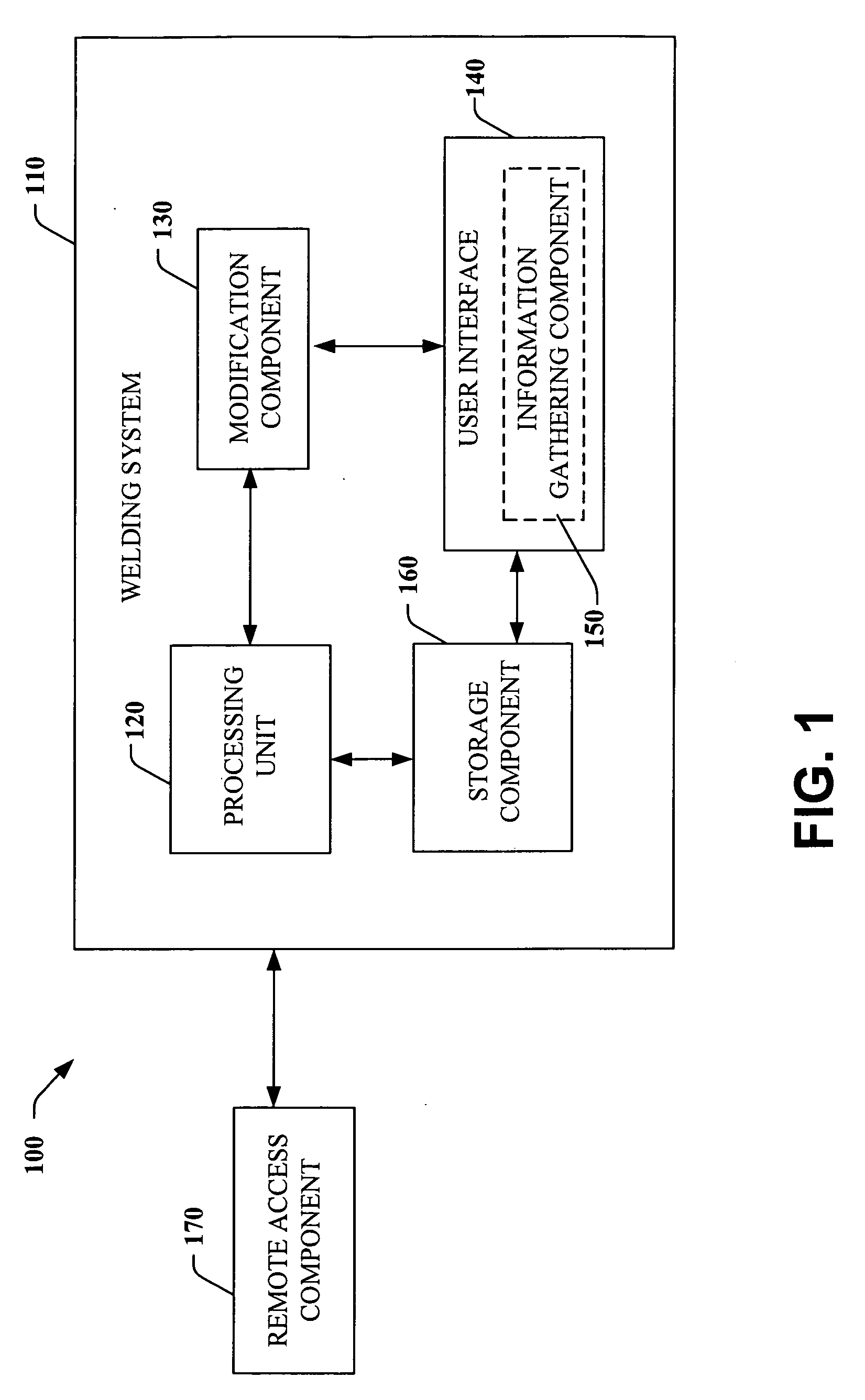

Comprehensive identification and designation of welding procedures

ActiveUS20060207980A1Easy selectionFacilitates namingElectric discharge heatingArc welding apparatusDefined ProcedureWaste management

System(s) and method(s) that facilitates comprehensive identification and designation of welding procedures. A configuration component facilitates configuring the welding system with respect to pre-defined procedures and / or parameters and facilitates naming of the configured welding system. A storage component that stores the configured welding system in a readily accessible memory location. A remote access component can facilitate remotely accessing the welding system, the configuration of the welding system alterable by way of the remote access component.

Owner:LINCOLN GLOBAL INC

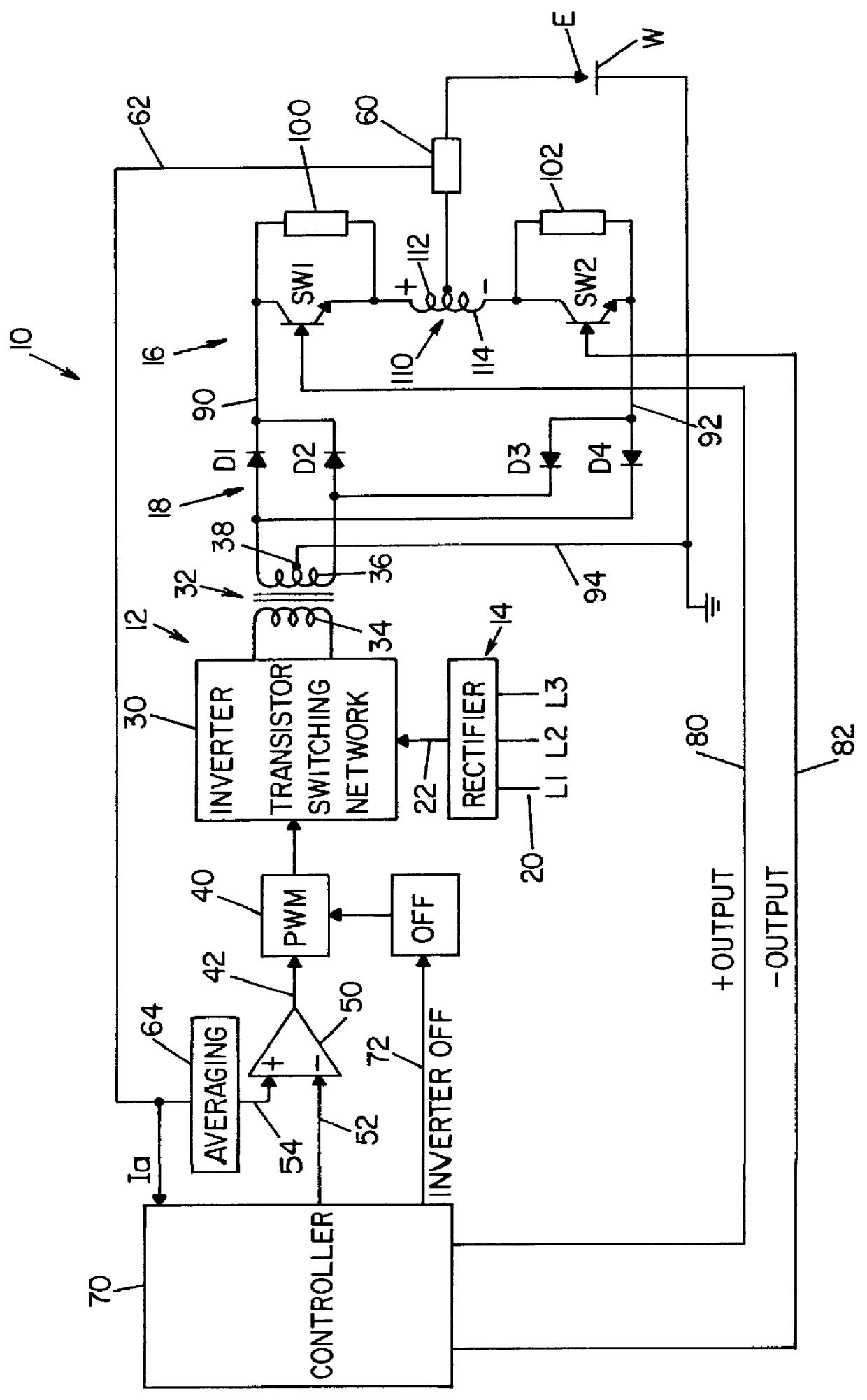

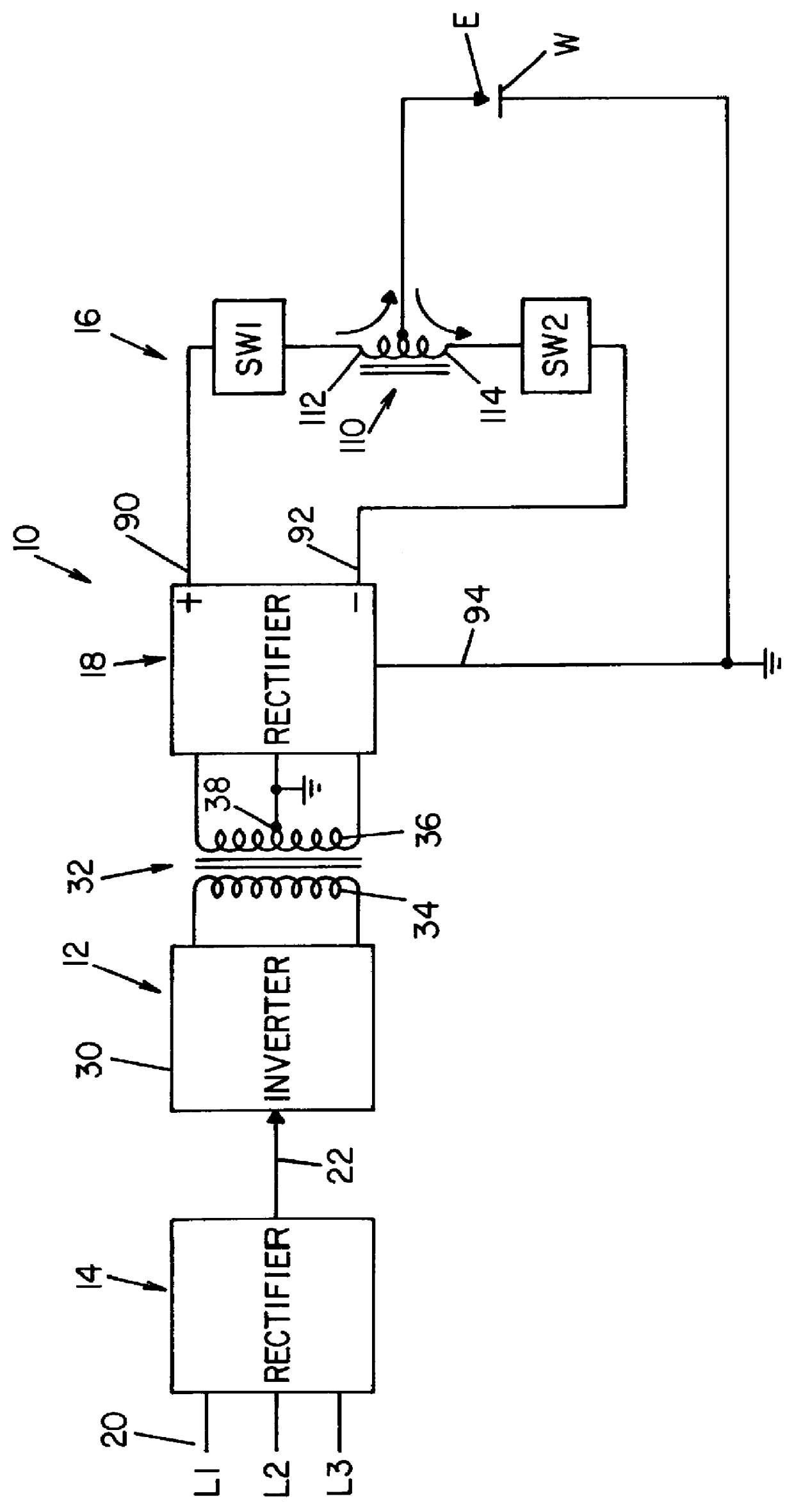

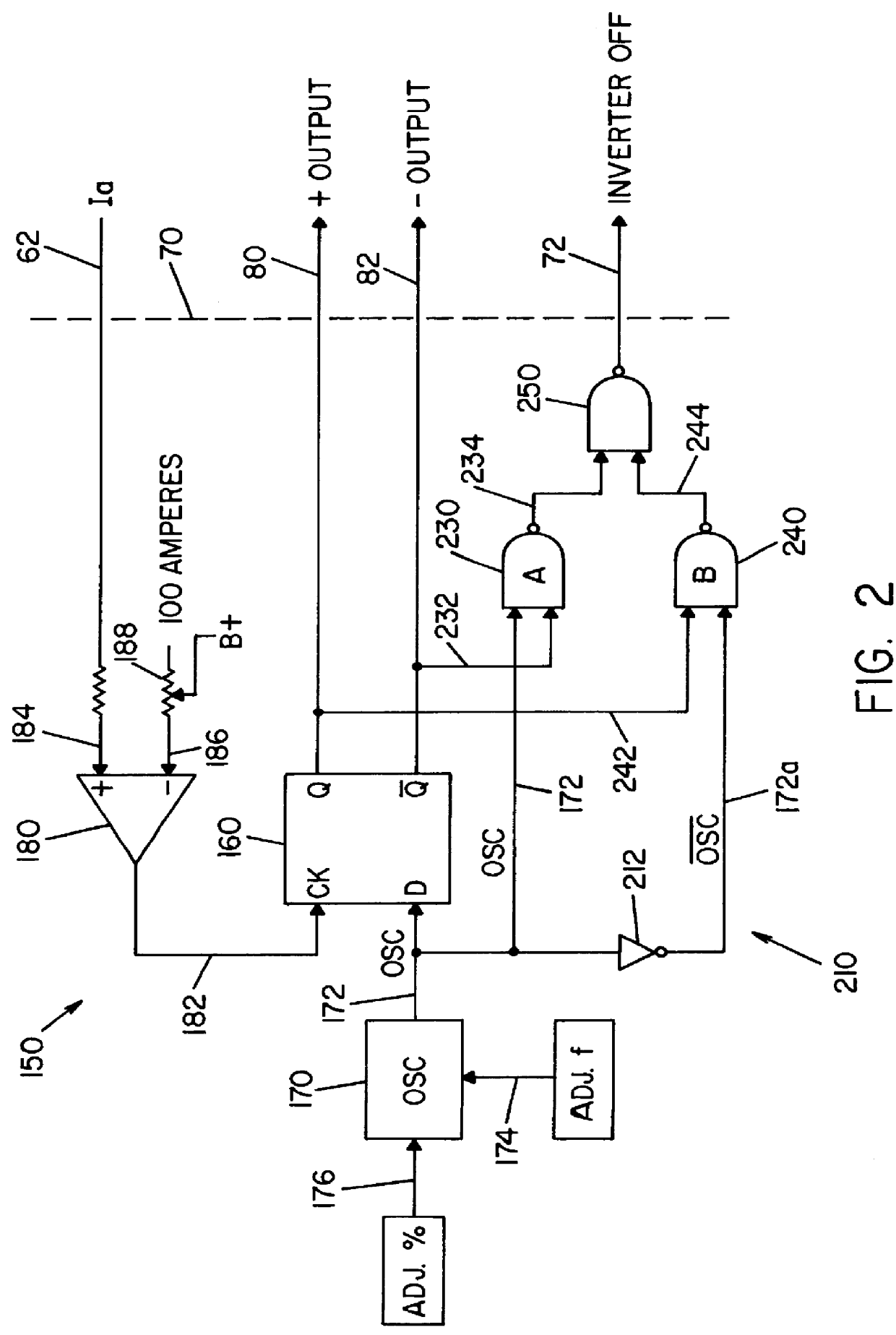

High current welding power supply

InactiveUS6111216AEasy to adjustIncrease supplyInterconnection arrangementsArc welding apparatusPower inverterPower flow

In a welding power supply for creating welding current in a succession of current pulses with a maximum current level and a trailing off state which current pulses passing through a series circuit including an inductor and electrode in welding relationship with a workpiece wherein the power supply has (a) an inverter stage with an input to be connected to a power source, a first terminal at a first electrical polarity when the inverter is on, a second terminal at a second electrical polarity when the inverter is on, and a control to generate an off signal to turn the inverter off and remove current from the terminals to shift said current pulse toward an off state; and, (b) a power switching stage including a transistor based switch having a conduction condition passing current from the first terminal upon creation of a first logic signal and a non-conduction condition blocking current upon creation of a second logic signal, the improvement comprising: a sensor for measuring the instantaneous value of the welding current, a comparator for producing a low current signal when the instantaneous current is at a selected value substantially below the maximum current level and a circuit or program for creating the second logic signal upon production of a low current signal after generation of an off signal whereby the transistor based switch is switched from the conduction condition to the non-conduction condition when the welding current is generally at the selected value.

Owner:LINCOLN GLOBAL INC

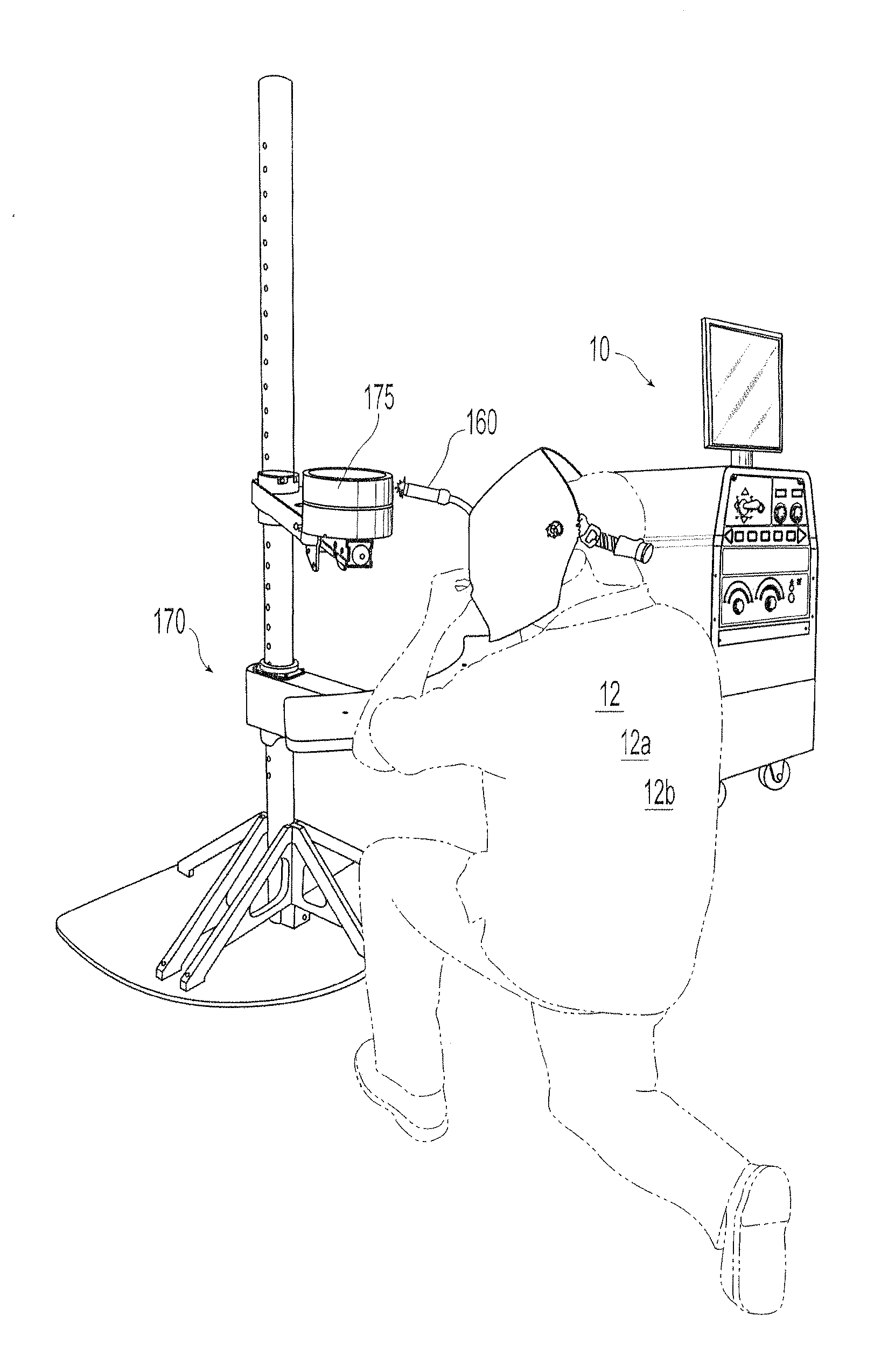

Virtual reality gtaw and pipe welding simulator and setup

ActiveUS20130189657A1Affect characteristicArc welding apparatusEducational modelsSimulationClassical mechanics

Owner:LINCOLN GLOBAL INC

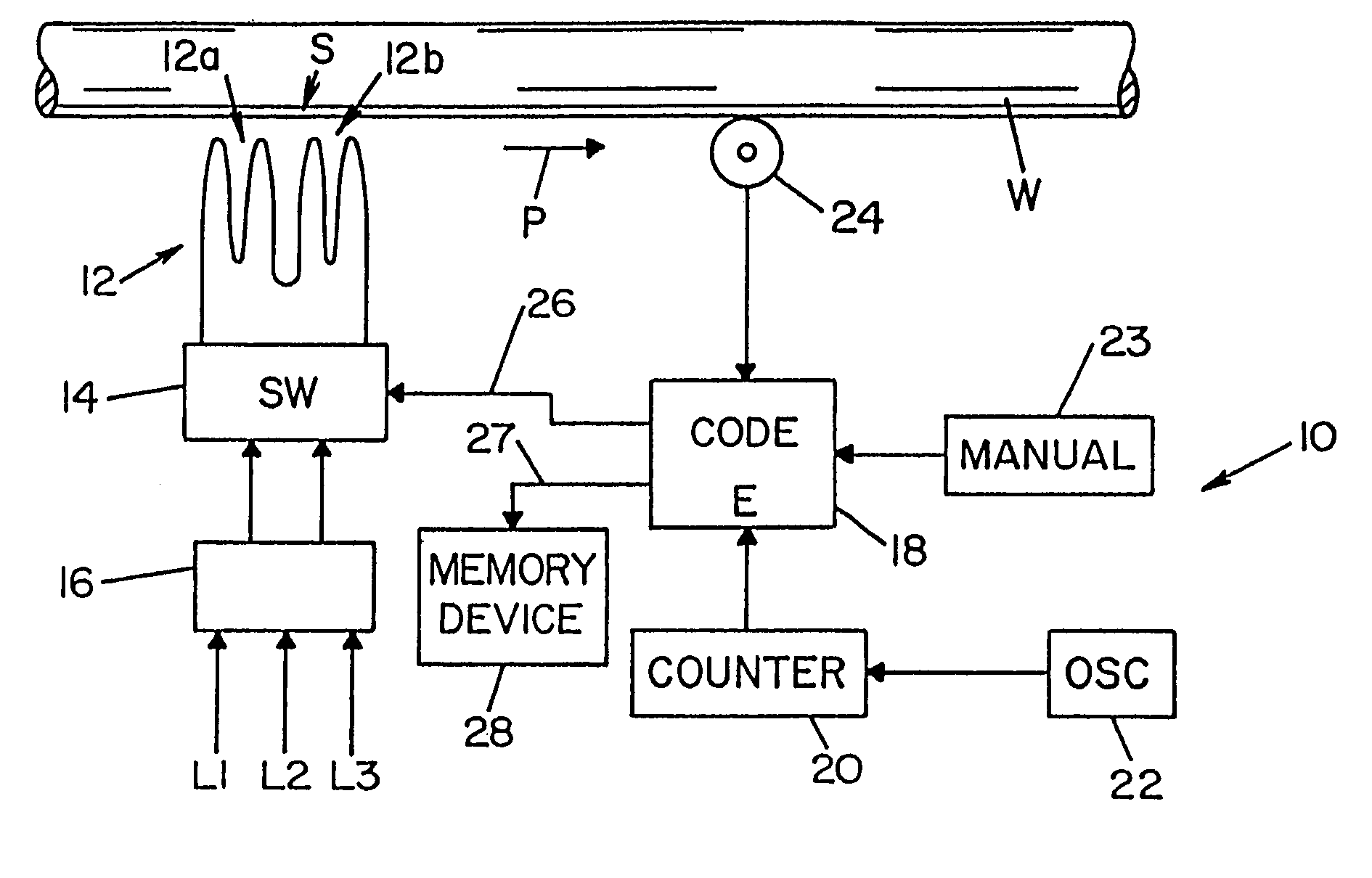

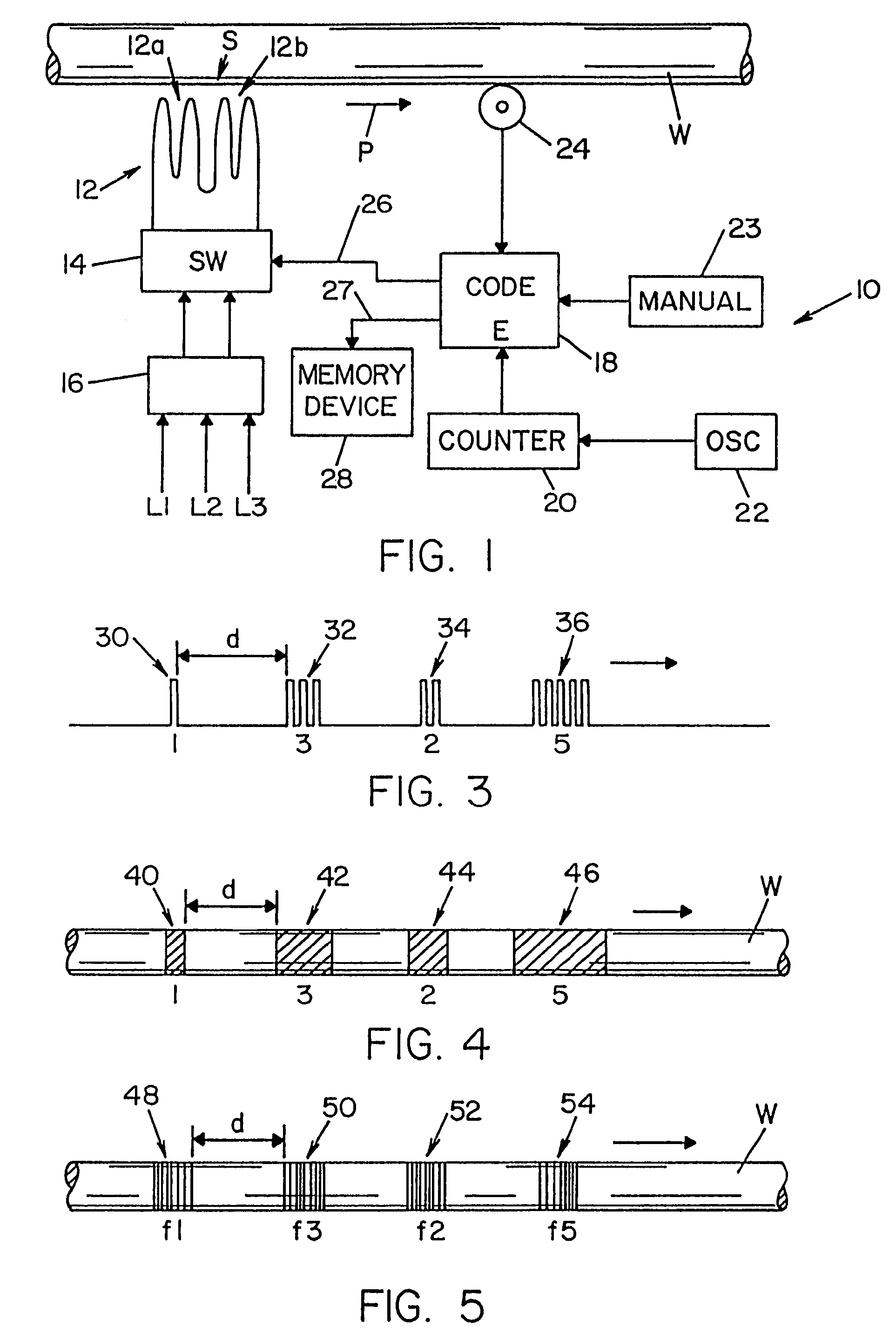

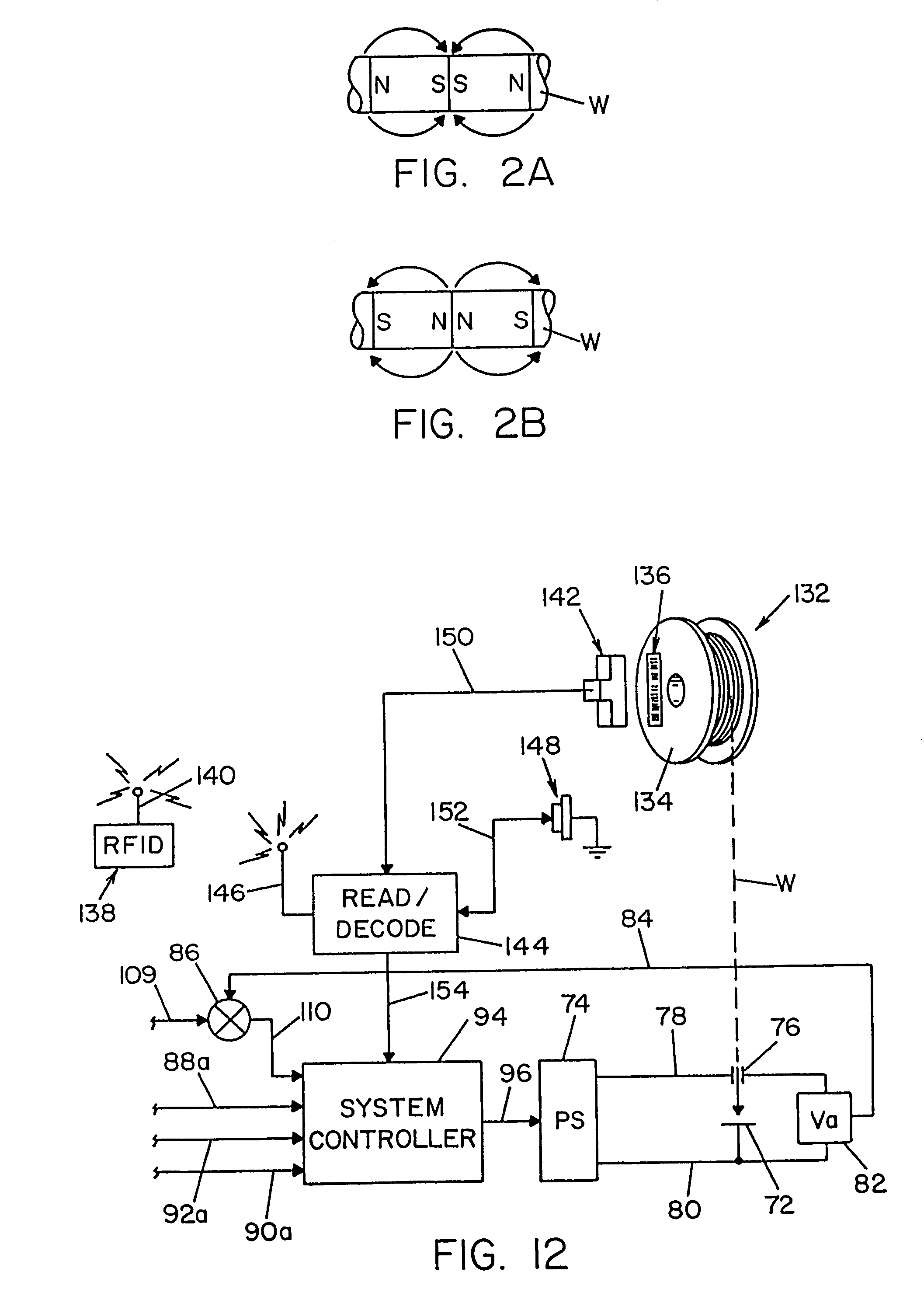

Coded welding consumable

InactiveUS7032814B2Quality improvementImprove welding efficiencyArc welding apparatusCo-operative working arrangementsCarbon Dioxide / HeliumShielding gas

Information pertaining to characteristics of consumables such as metal welding electrode wire and shielding gas and which characteristics are useful in connection with adjusting welding parameters in an arc welding process and / or selecting between operating modes in a welding system are encoded on welding wire and / or on other memory components such as bar code labels and tags, RFID cards and tags, IC cards, and Touch Memory buttons, and the memory device is scanned prior to and / or at the point of use of the welding wire or shielding gas for enabling tracking of product distribution, manual and / or automatic selection of an operating mode for the welding system, manual and / or automatic adjustment of welding parameters in a given operating mode, consumables inventory, and the like.

Owner:LINCOLN GLOBAL INC

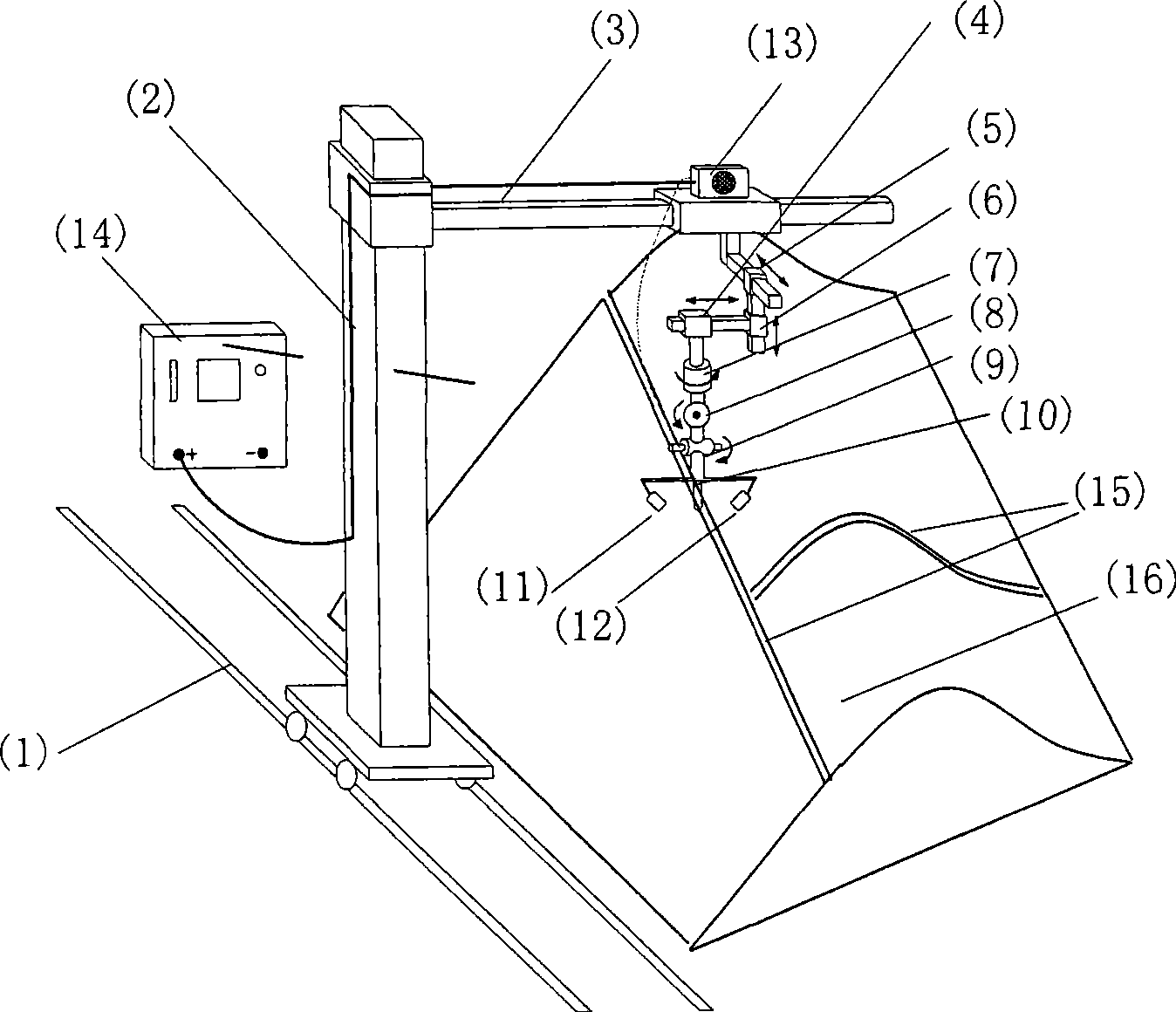

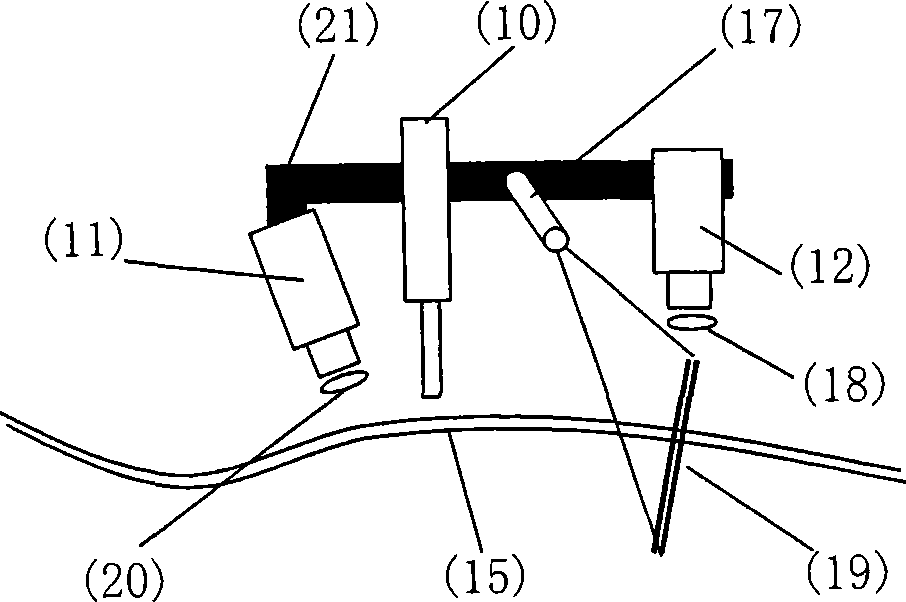

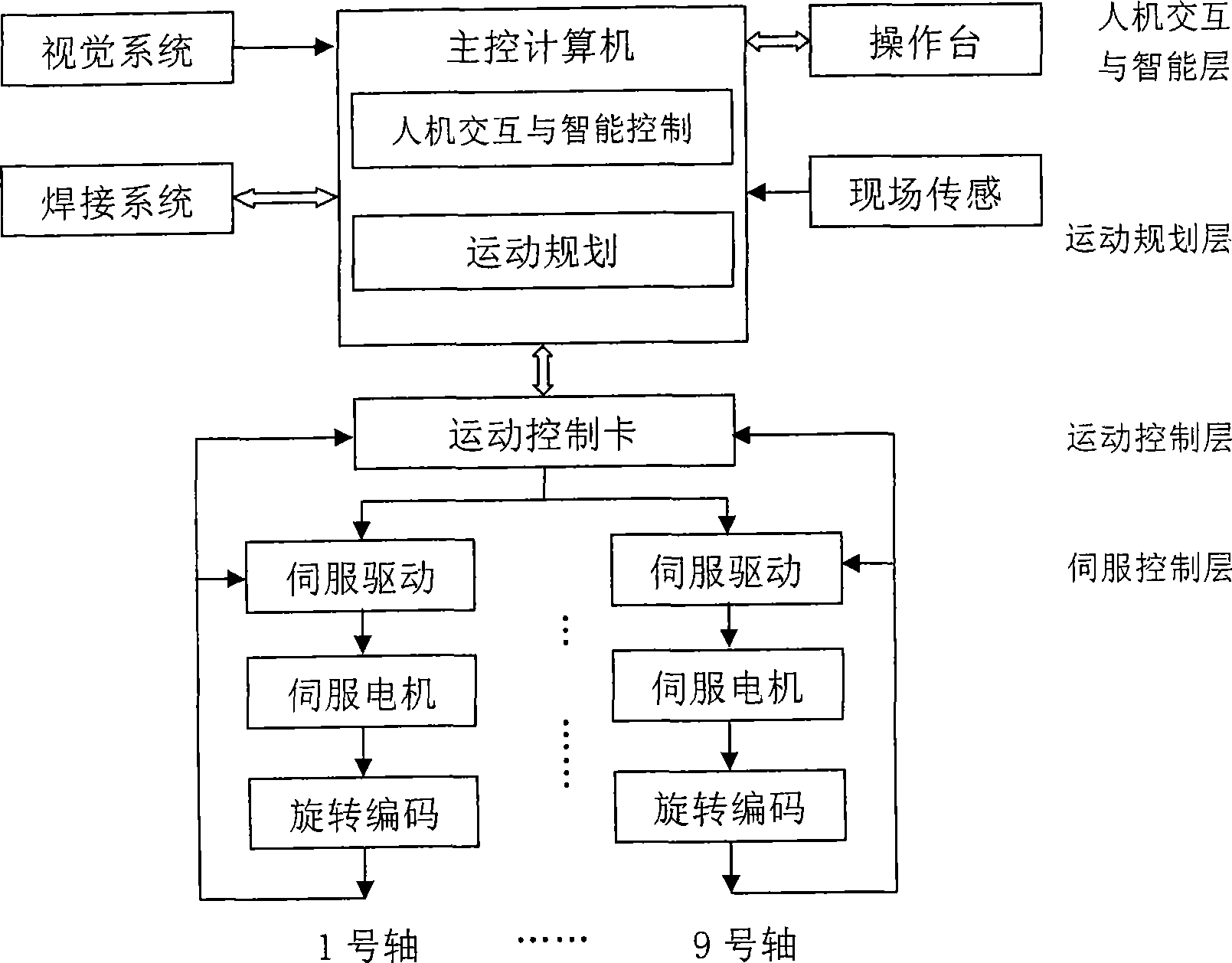

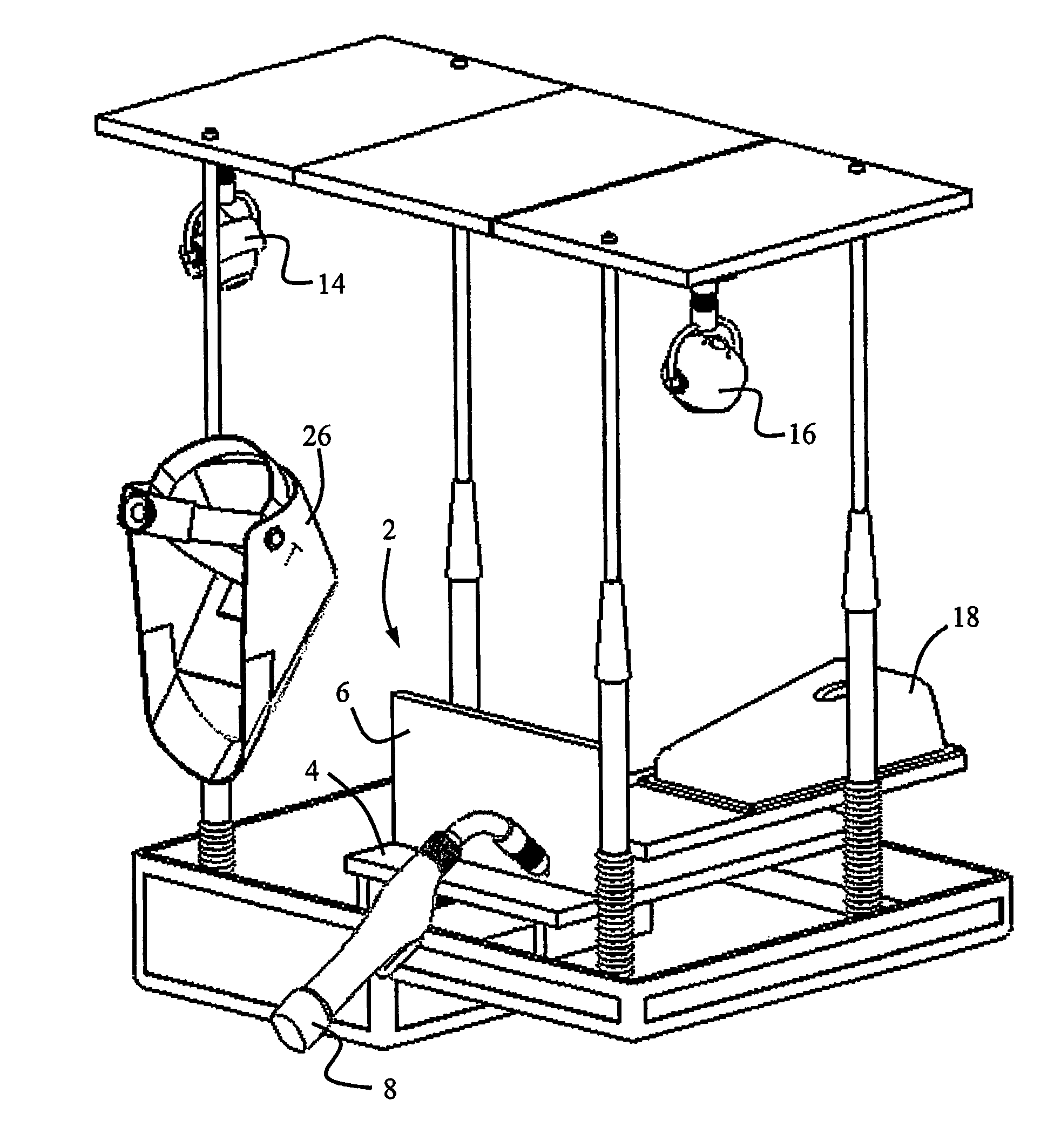

Intelligent robot welding device using large-scale workpiece

InactiveCN101456182AWith visual functionSimple motion controlProgramme-controlled manipulatorArc welding apparatusRotational axisRotational degrees of freedom

The invention discloses a large-sized workpiece welded intelligent robot device, relates to robot technology, in particular to the robot device based on visual control technology. The device consists of a robot body, a sensing system, a robot controller and a welding auxiliary mechanism. The welded robot is provided with nine moving shafts, including three macrographic moving translational moving shafts, three microscopic moving translational moving shafts and three rotating shafts. The robot body comprises a robot frame and a robot head which is arranged on a transverse arm of the robot frame, and the robot frame consists of the three macrographic moving translational moving shafts, namely a horizontal lead rail, an upright post and the transverse arm. The robot head consists of the three microscopic moving translational moving shafts, the three rotating shafts and a welding gun. The robot frame provides the large-scale three-dimensional movement of the robot; the precision of macrographic moving movement is compensated by the microscopic moving mechanisms of the robot head which also provides rotating freedom of motion. The robot device can meet the movement requirements of large scale and precise positioning for the welding operation of large-sized workpieces. Through the visual sensing technology and intelligent visual controlling technology, the device can improve the automatic welding quality and efficiency of the welded robot.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

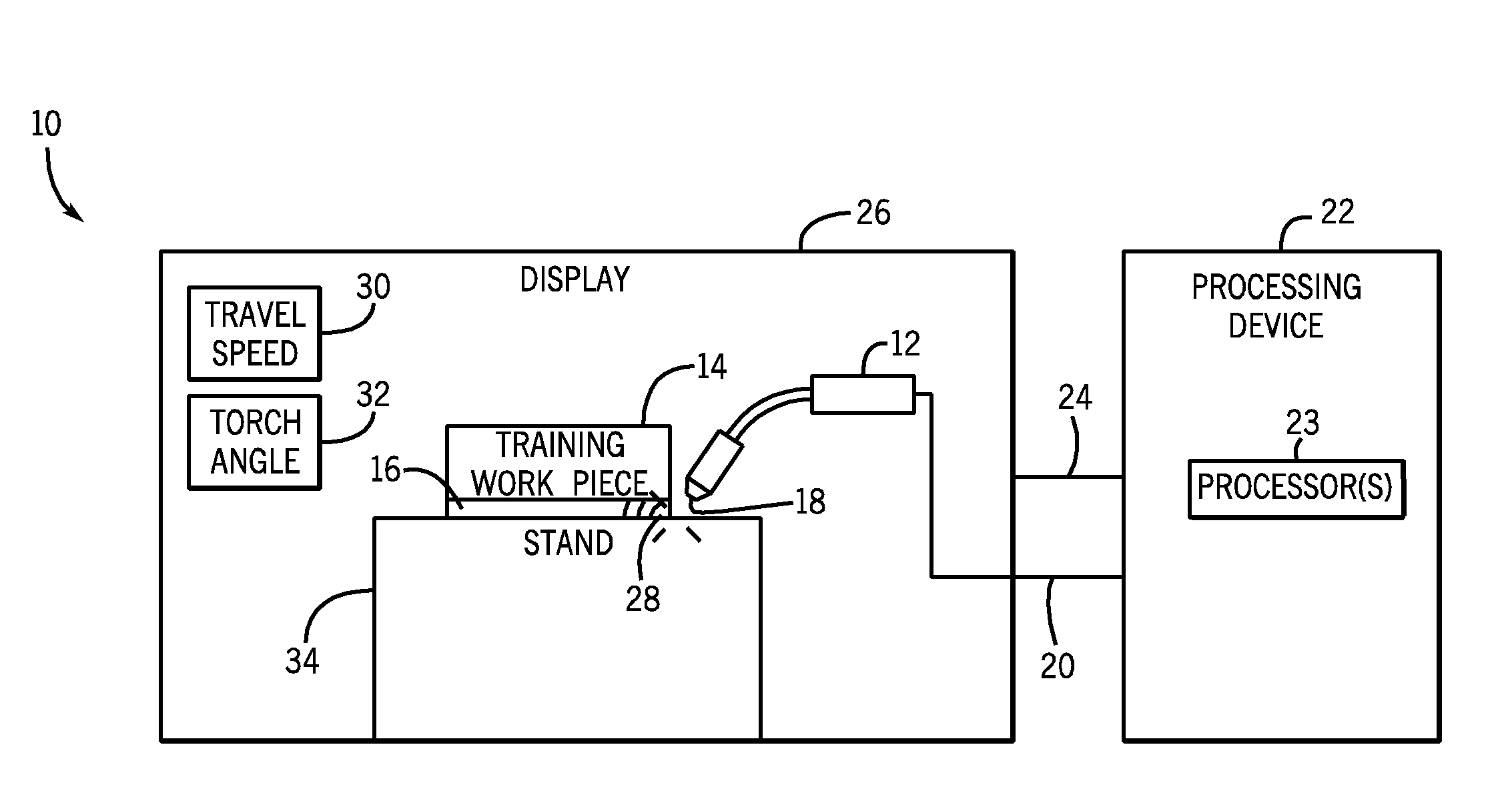

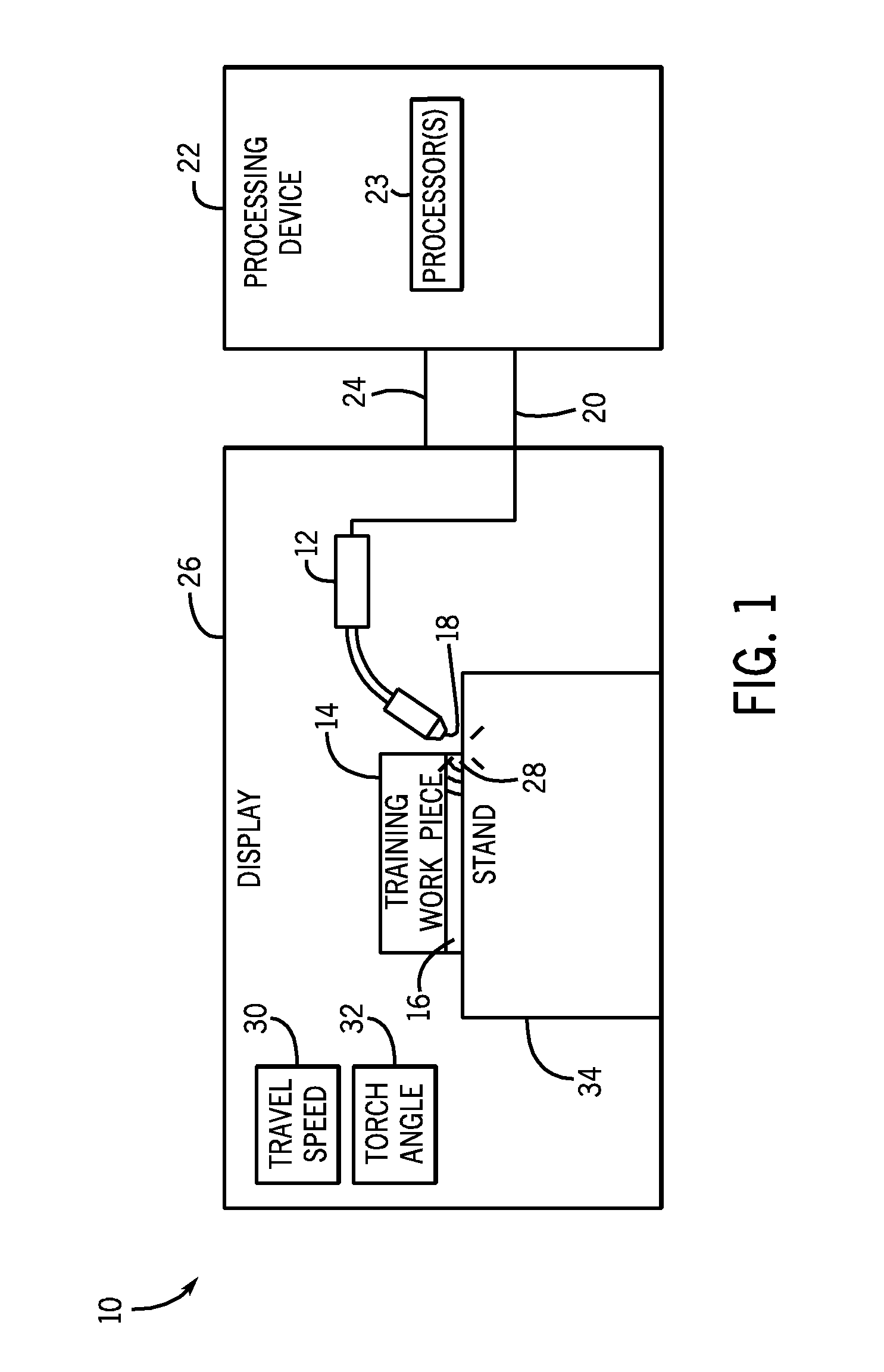

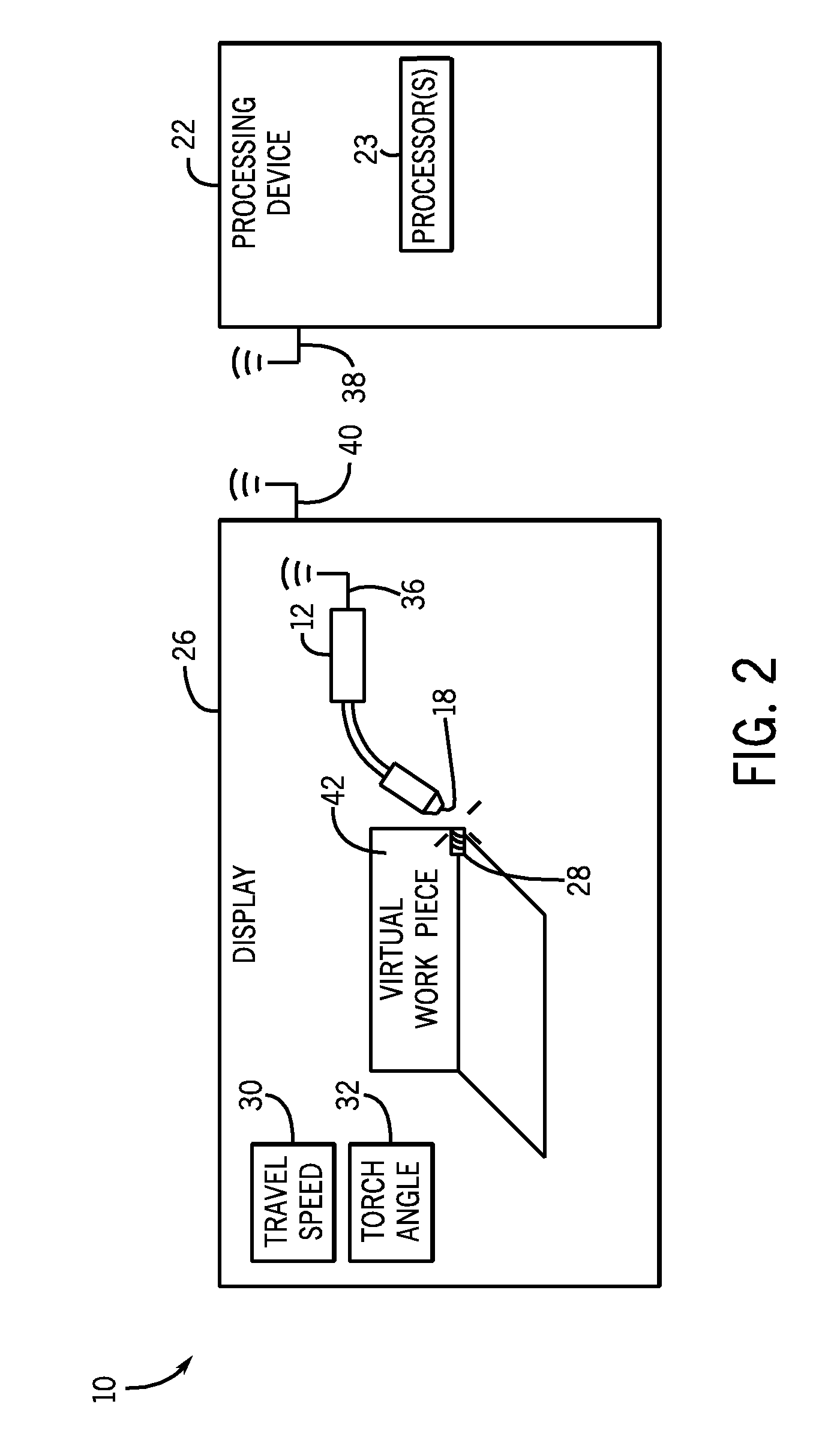

System and device for welding training

A system and device for welding training. In one example, a welding training system includes a display configured to show welding features related to a training welding operation. The system also includes a training workpiece having a substantially transparent weld joint configured to be placed adjacent to the display during the training welding operation. The system includes a processing device coupled to the display and configured to provide welding data relating to the training welding operation to the display. The system also includes a training torch comprising an optical sensor. The training torch is coupled to the processing device and configured to provide the processing device with data from the optical sensor corresponding to a position of the training torch relative to the training workpiece.

Owner:ILLINOIS TOOL WORKS INC

Body motion training and qualification system and method

InactiveUS8512043B2Defective reproductionElectric discharge heatingGymnastic exercisingWorkspaceSimulation

The system allows training and qualification of a user performing a skill-related training exercise involving body motion in a workspace. A training environment is selected through a computer apparatus, and variables, parameters and controls of the training environment and the training exercise are adjusted. Use of an input device by the user is monitored. The 3D angles and spatial coordinates of reference points related to the input device are monitored through a detection device. A simulated 3D dynamic environment reflecting effects caused by actions performed by the user on objects is computed in real time as a function of the training environment selected. Images of the simulated 3D dynamic environment in real time are generated on a display device viewable by the user as a function of a computed organ of vision-object relation. Data indicative of the actions performed by the user and the effects of the actions are recorded and user qualification is set as a function of the recorded data.

Owner:123 CERTIFICATION

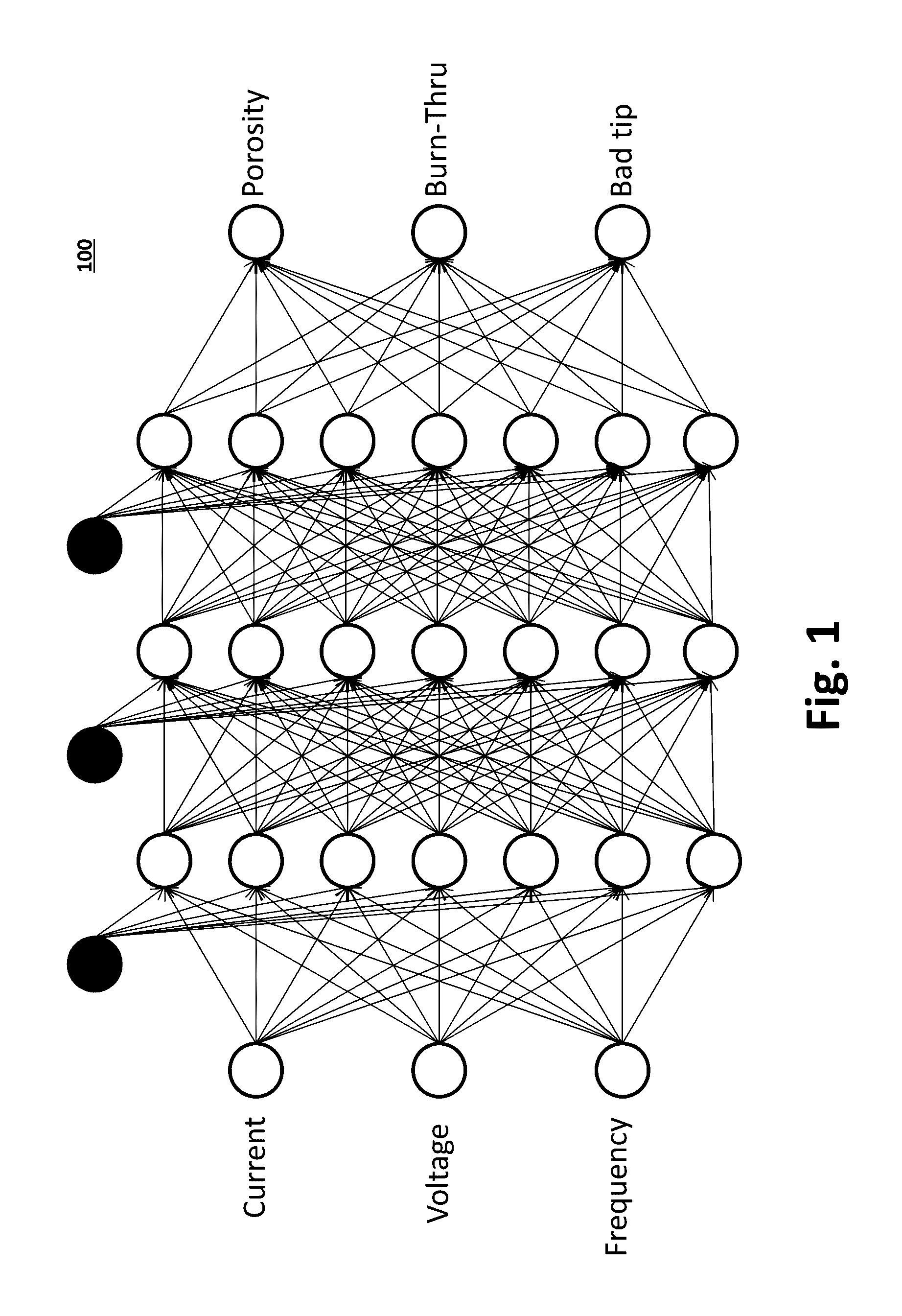

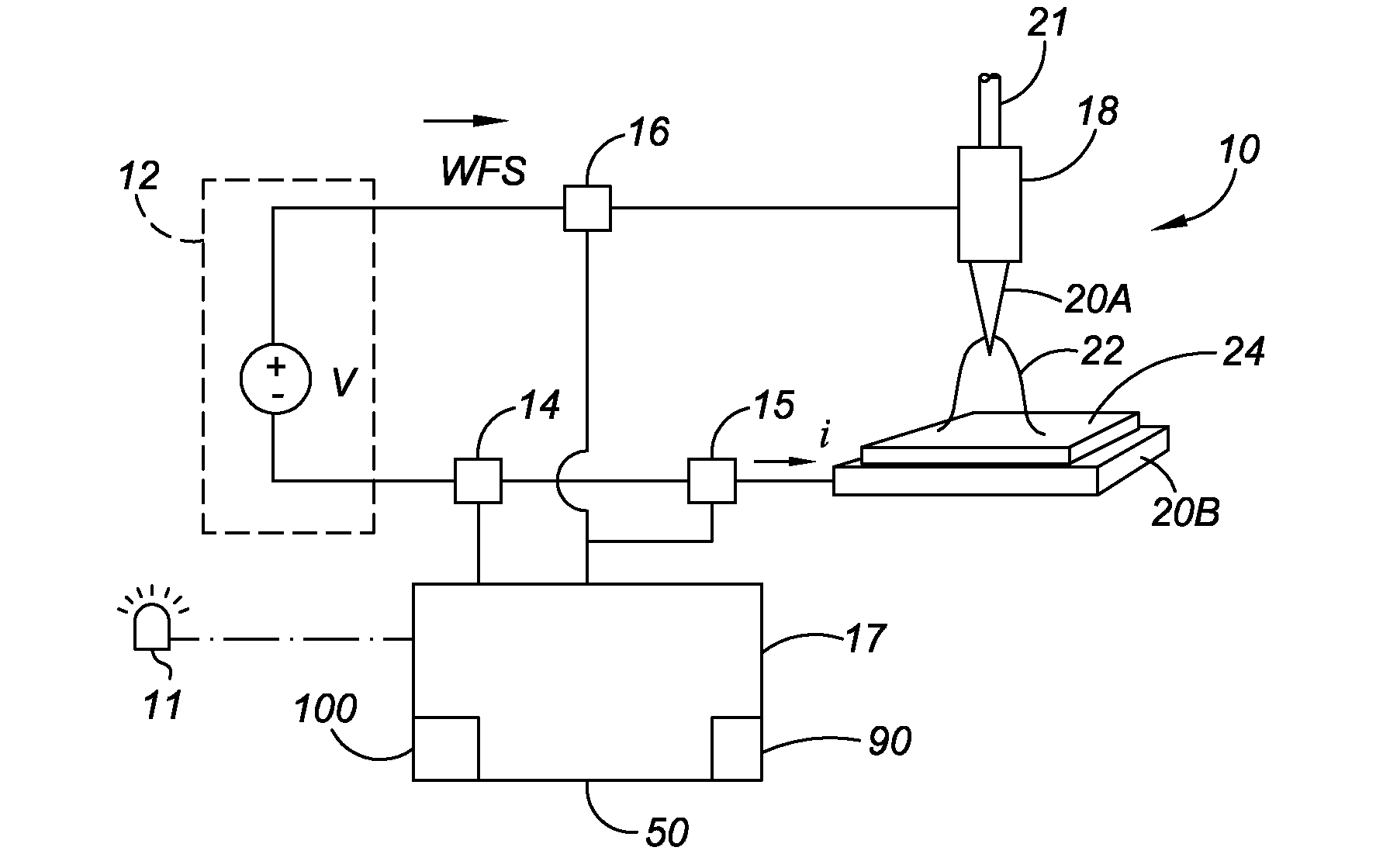

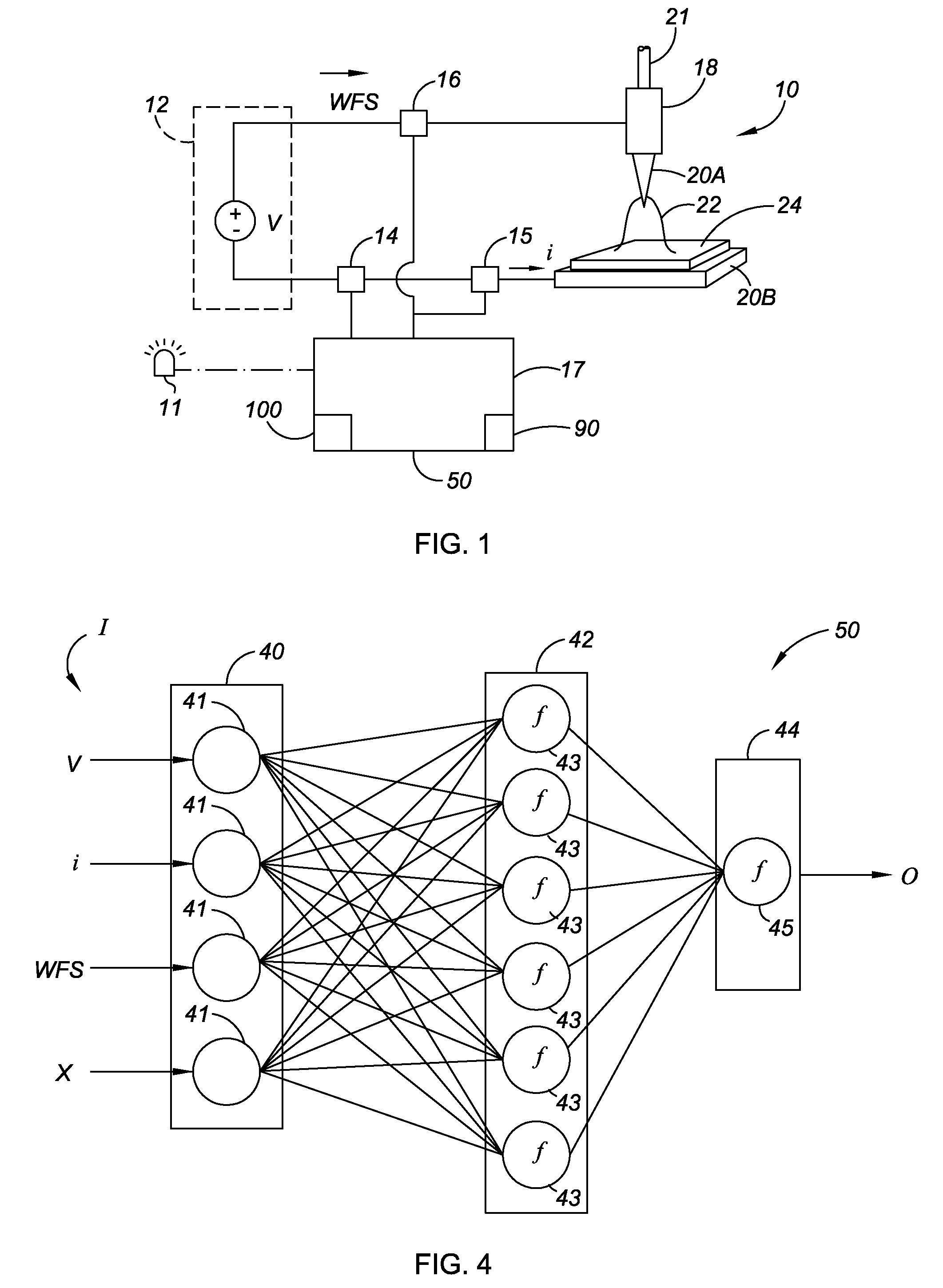

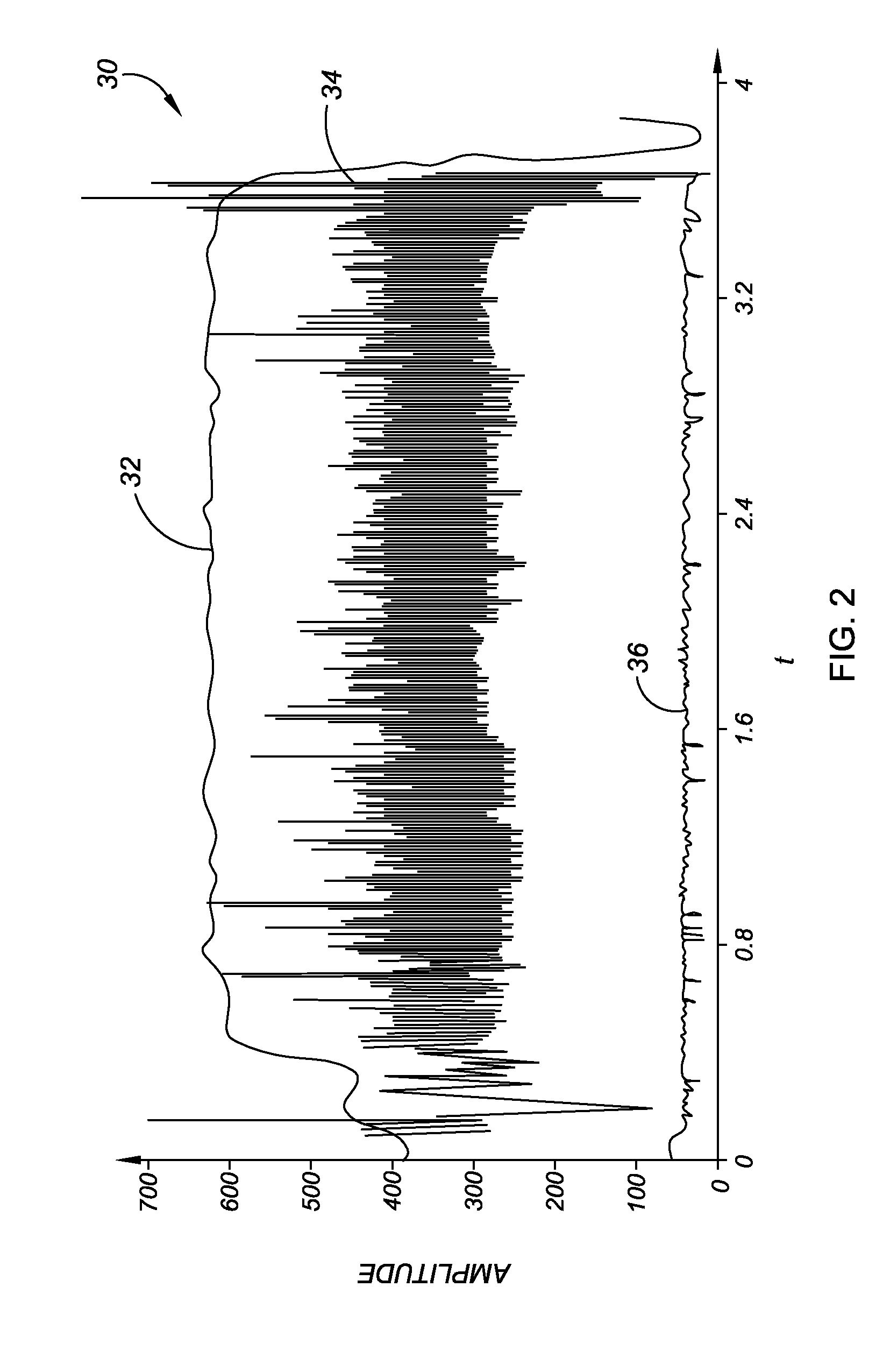

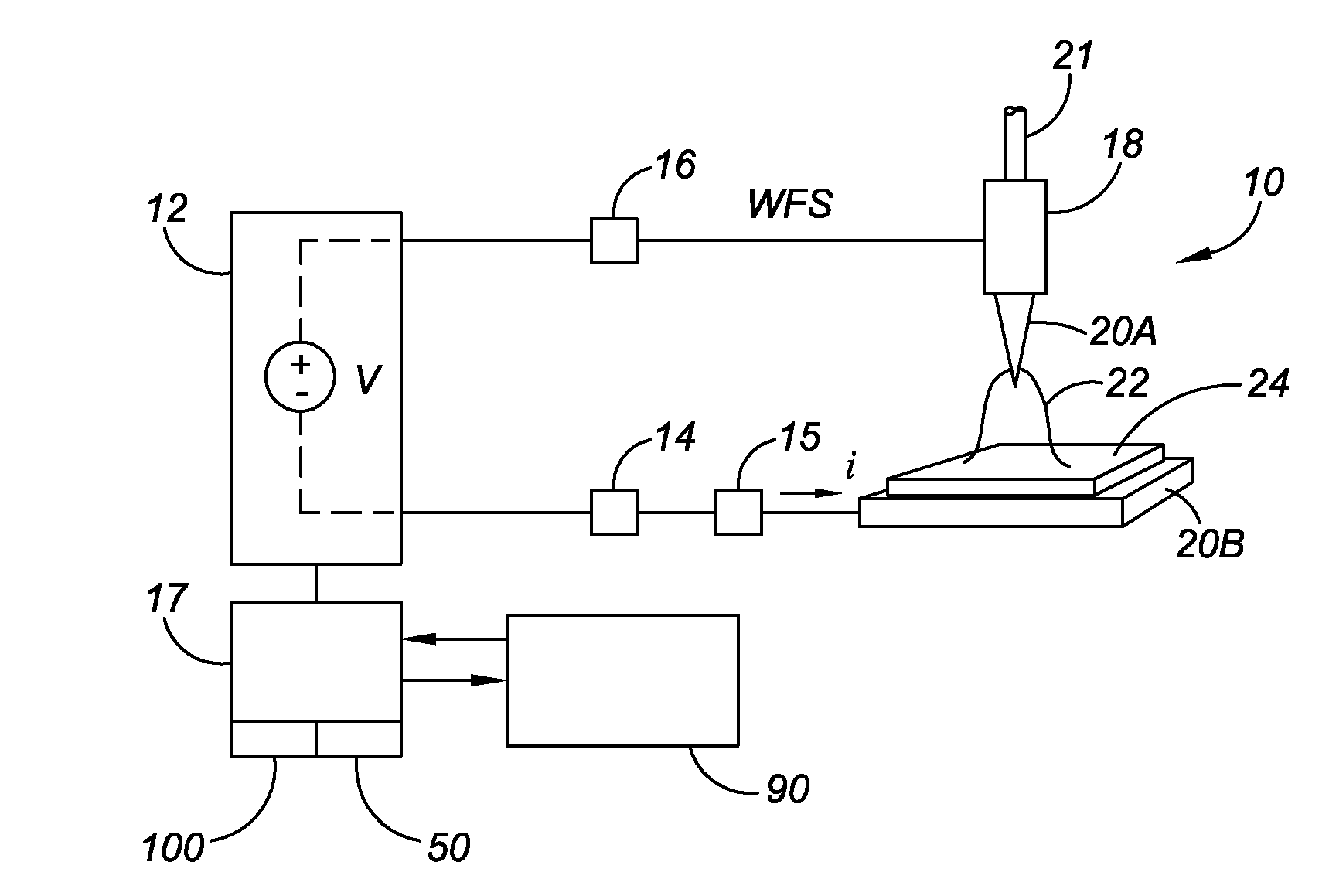

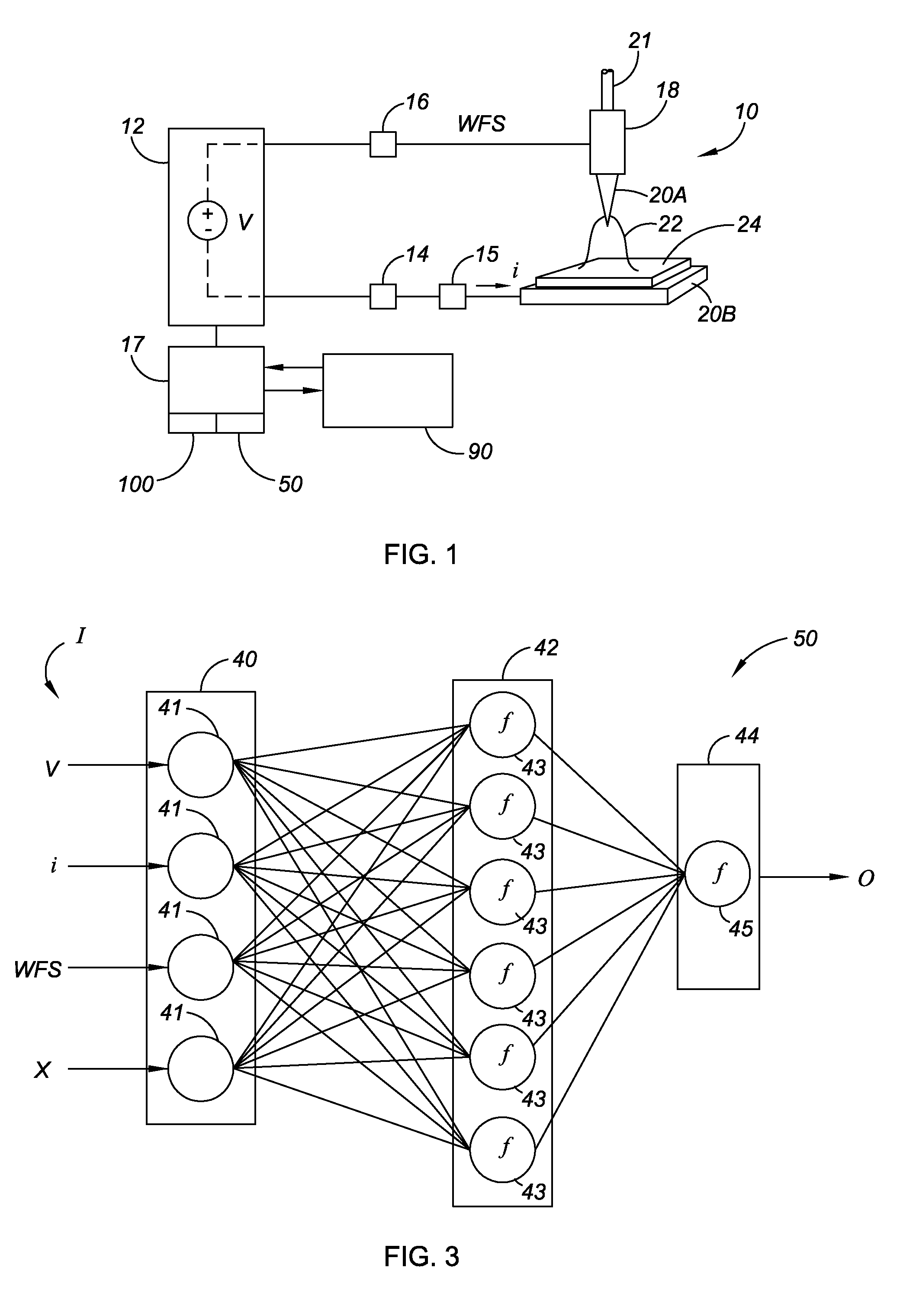

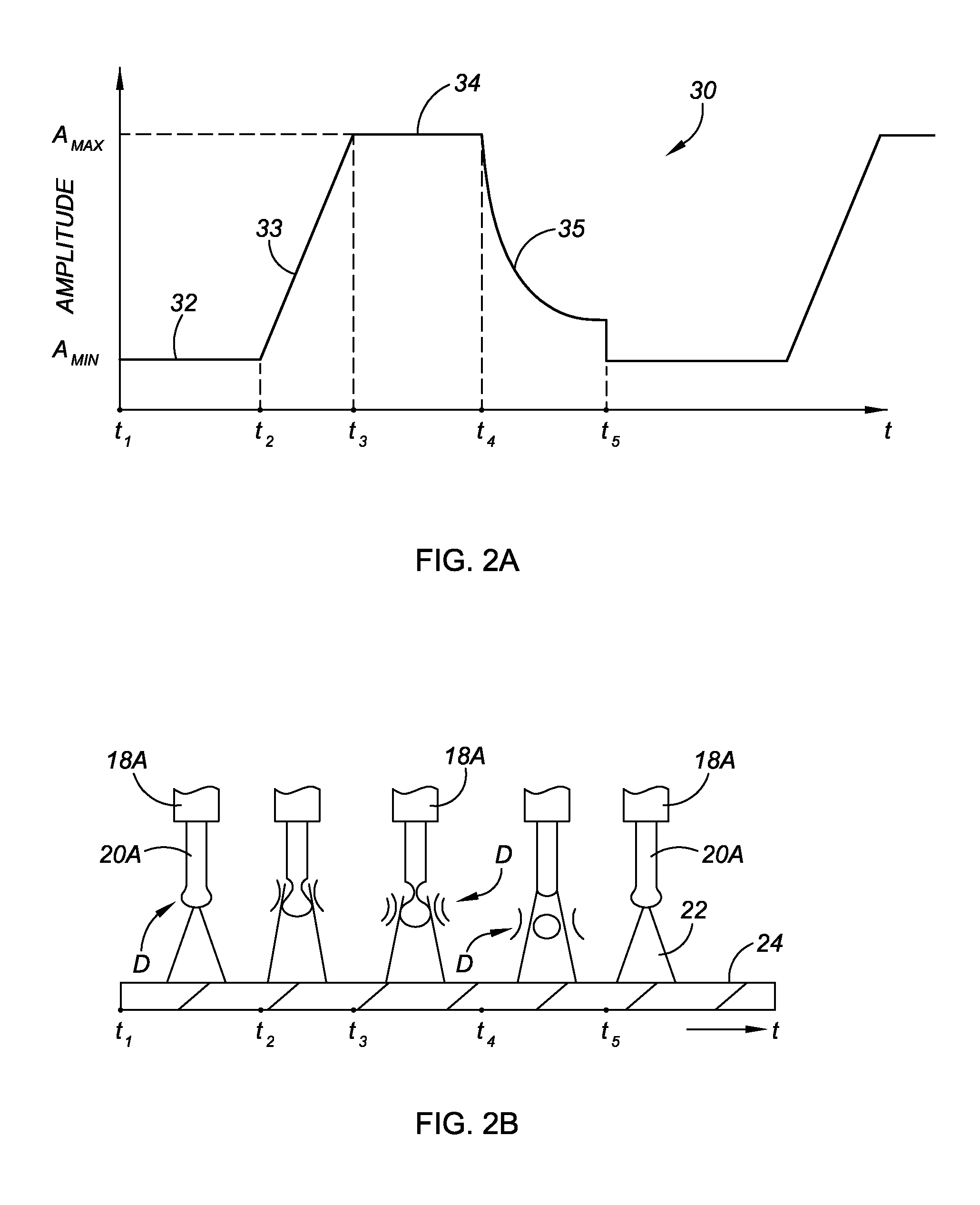

Weld signature monitoring method and apparatus

A method monitors a weld signature of a welding apparatus by processing the signature through a neural network to recognize a pattern, and by classifying the weld signature in response to the pattern. The method determines if the weld signature is sufficiently different from training weld signatures stored in a database, and records the weld signature in the database when sufficiently different. The method tests a weld joint to determine values of different weld joint properties, and then correlates the signature with the weld data to validate the database. An apparatus monitors a weld signature during a welding process to predict welding joint quality, and includes a welding gun, a power supply, and a sensor for detecting welding voltage, current, and wire feed speed (WFS). A neural network receives the welding process values and classifies the signature into different weld classifications each corresponding to a predicted welding joint quality.

Owner:GM GLOBAL TECH OPERATIONS LLC

Welding power supply with neural network controls

InactiveUS20090200281A1Biological neural network modelsArc welding apparatusWelding power supplyNetwork control

A method controls a welding apparatus by using a neural network to recognize an acceptable weld signature. The neural network recognizes a pattern presented by the instantaneous weld signature, and modifies the instantaneous weld signature when the pattern is not acceptable. The method measures a welding voltage, current, and wire feed speed (WFS), and trains the neural network using the instantaneous weld signature when the instantaneous weld signature is different from each of the different training weld signatures. A welding apparatus for controlling a welding process includes a welding gun, a power supply for supplying a welding voltage and current, and a sensor for detecting values of a plurality of different welding process variables. A controller of the apparatus has a neural network for receiving the welding process variables and for recognizing a pattern in the weld signature. The controller modifies the weld signature when the pattern is not recognized.

Owner:GM GLOBAL TECH OPERATIONS LLC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com