Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1549 results about "Welding power supply" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

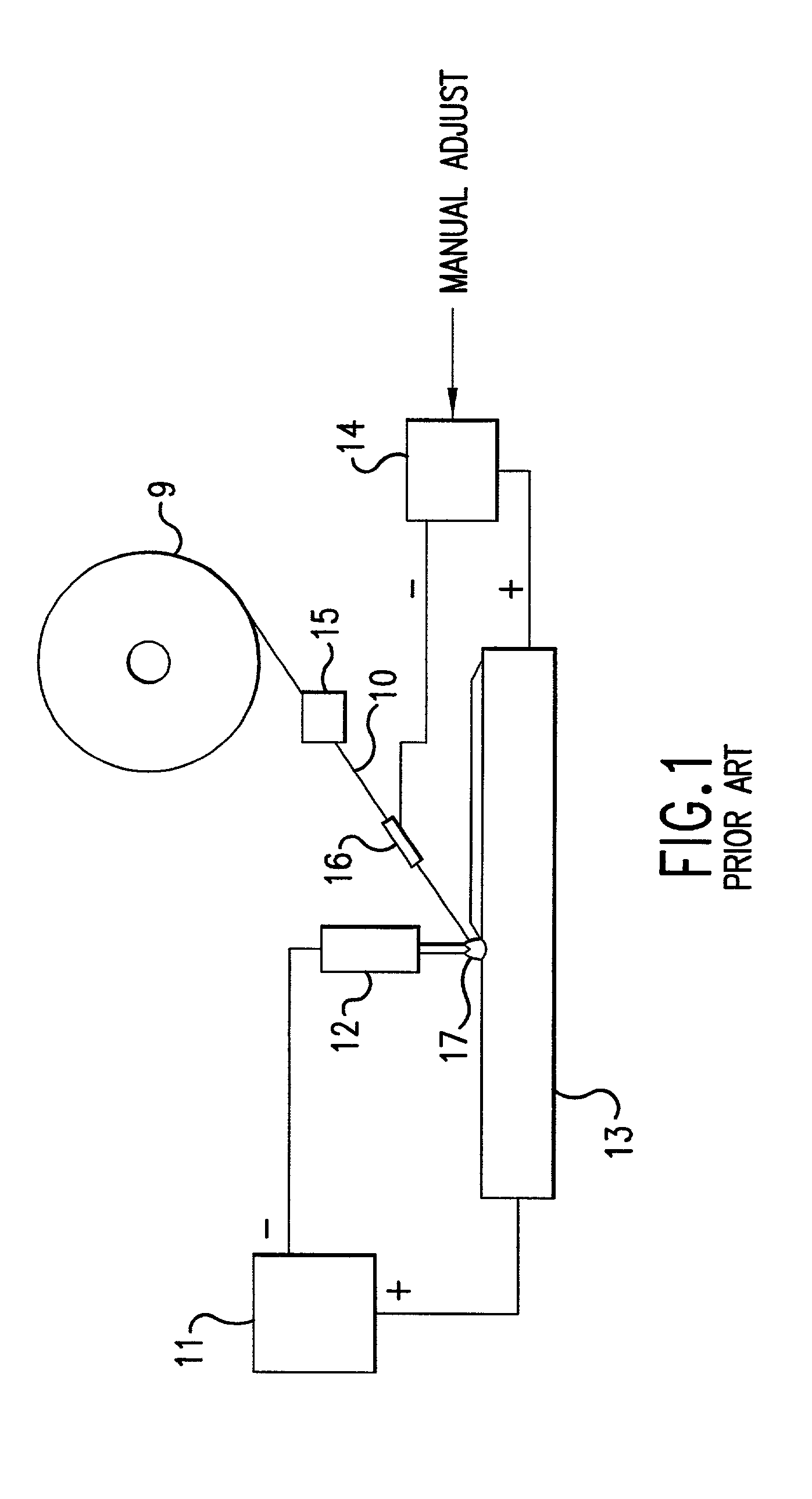

A welding power supply is a device that provides an electric current to perform welding. Welding usually requires high current (over 80 amperes) and it can need above 12,000 amperes in spot welding. Low current can also be used; welding two razor blades together at 5 amps with gas tungsten arc welding is a good example. A welding power supply can be as simple as a car battery and as sophisticated as a high-frequency inverter using IGBT technology, with computer control to assist in the welding process.

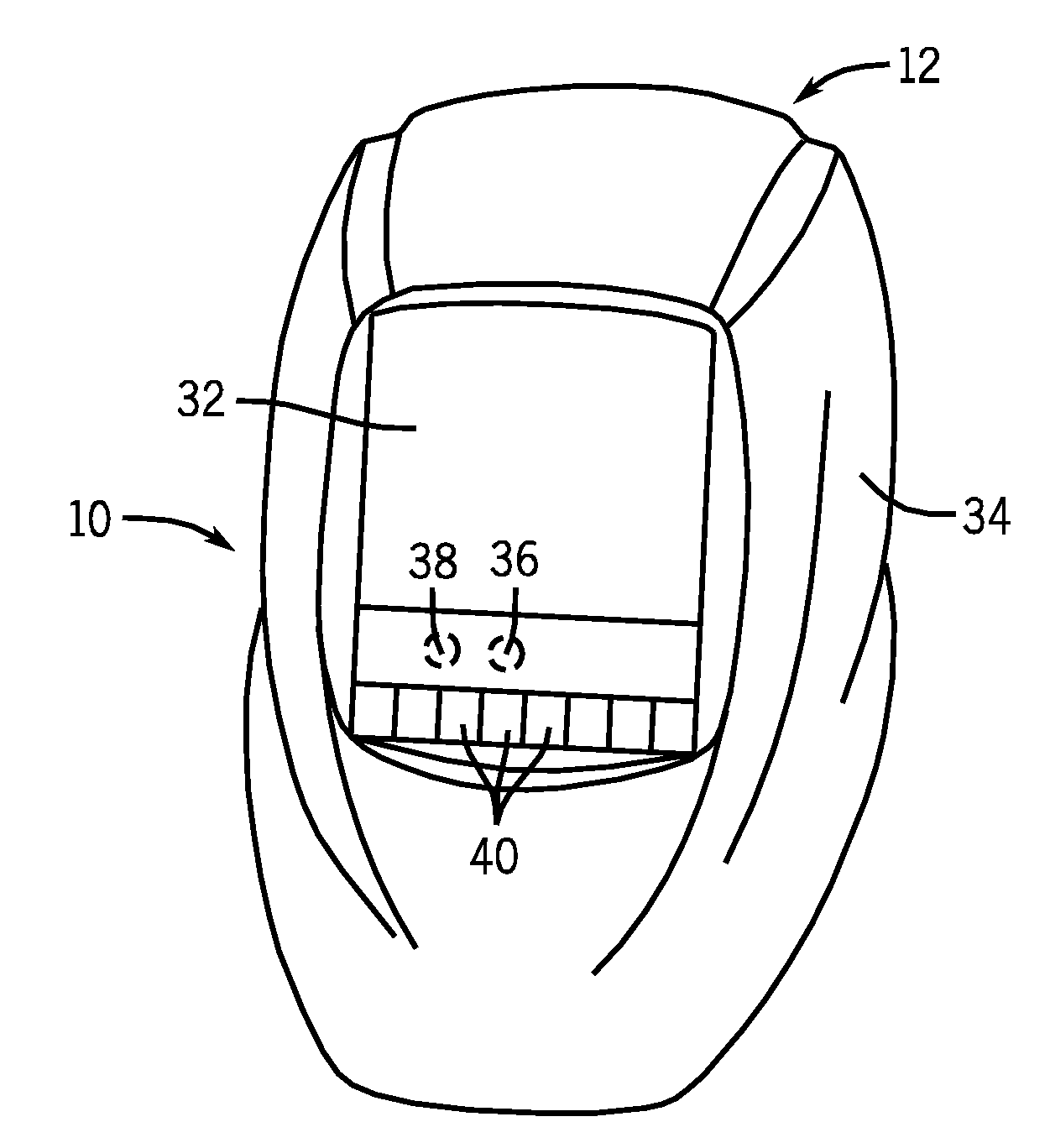

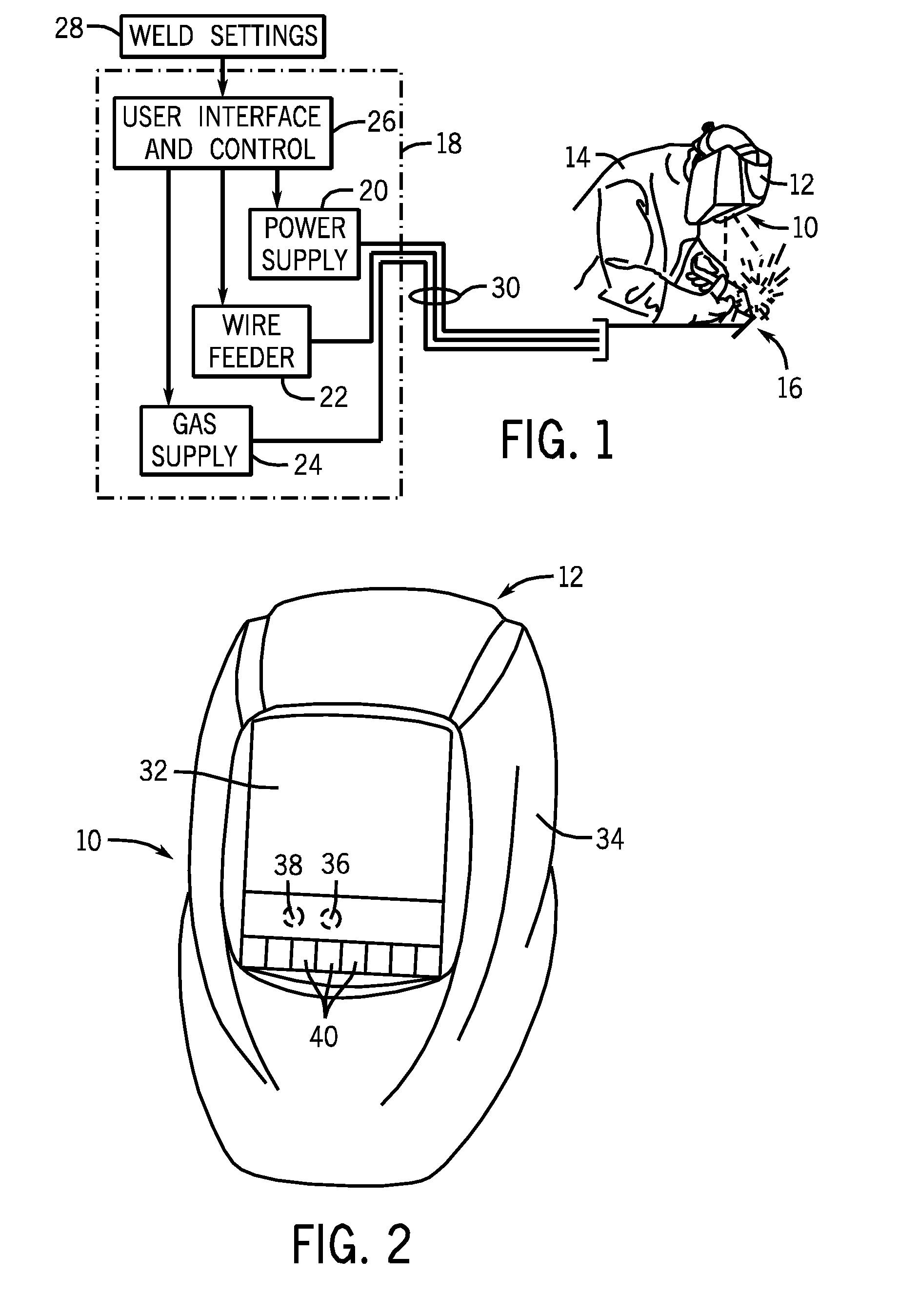

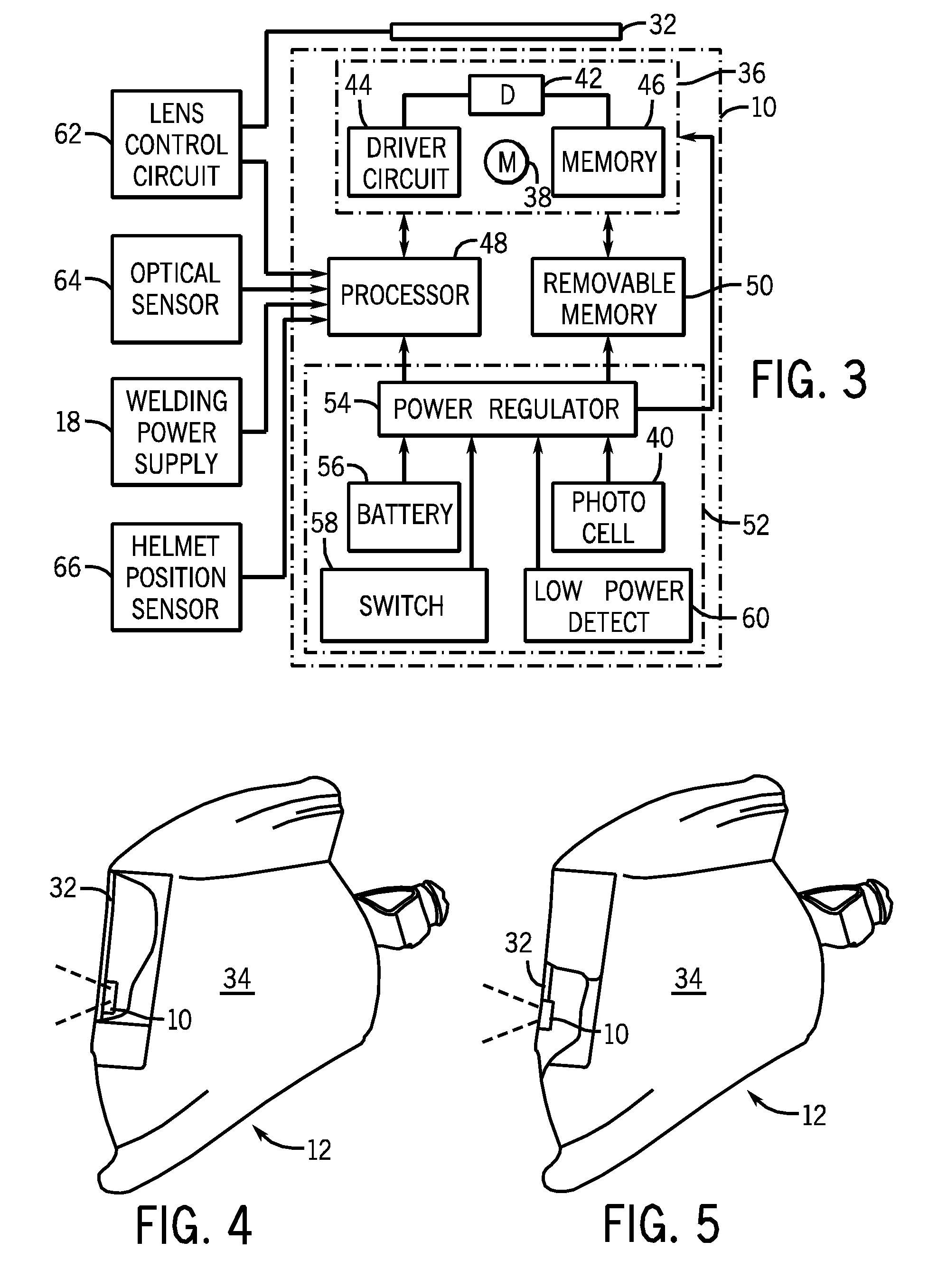

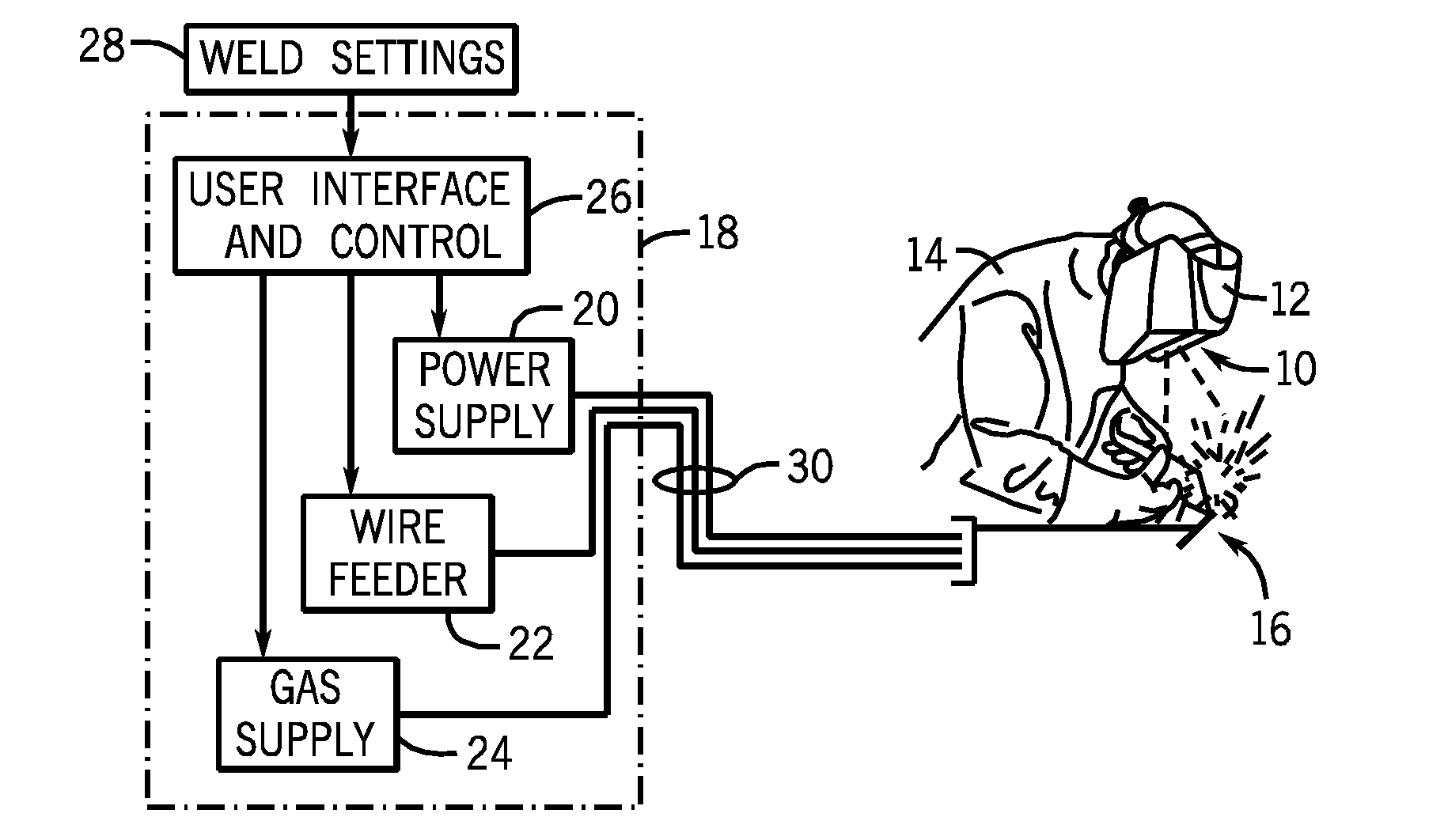

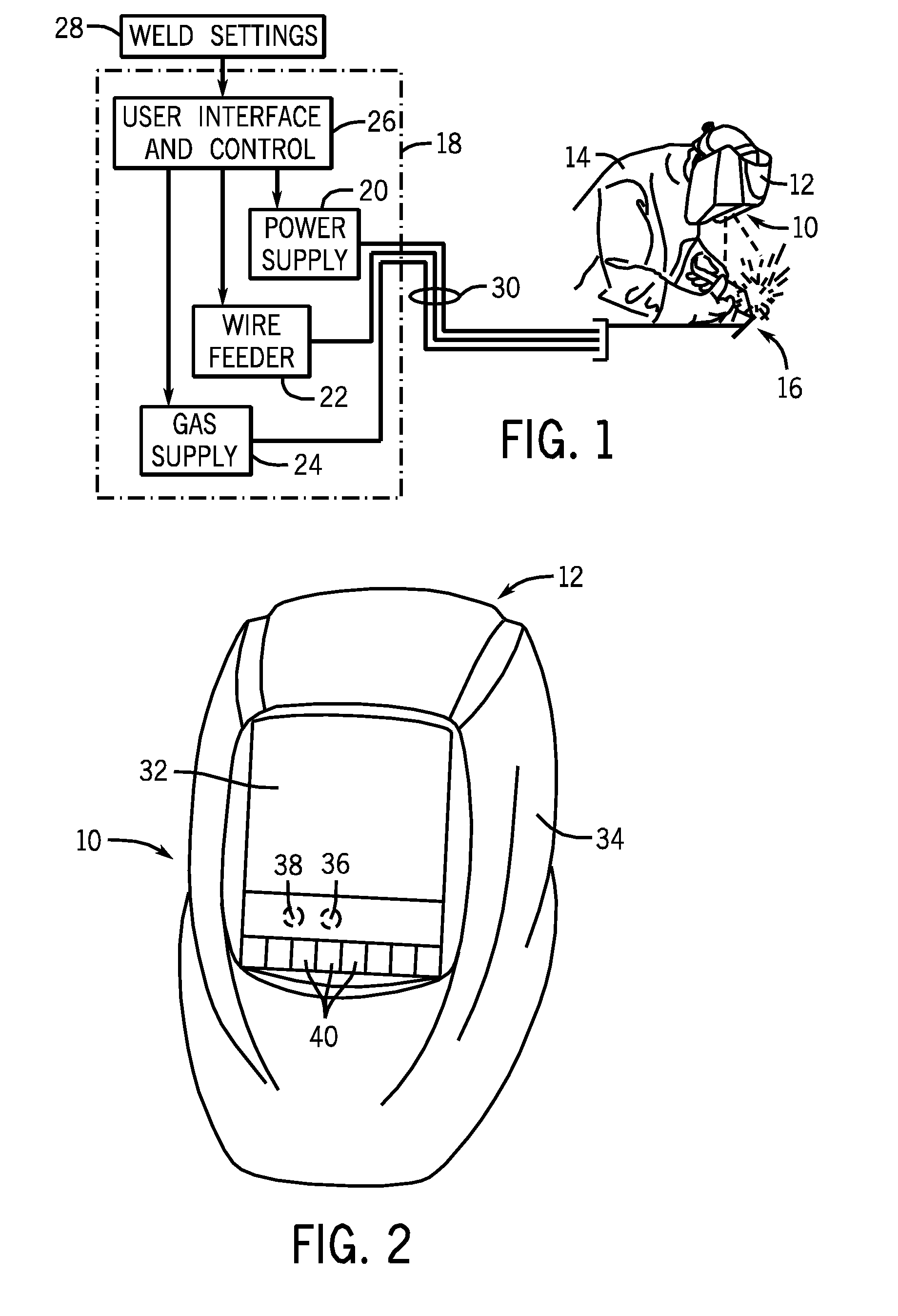

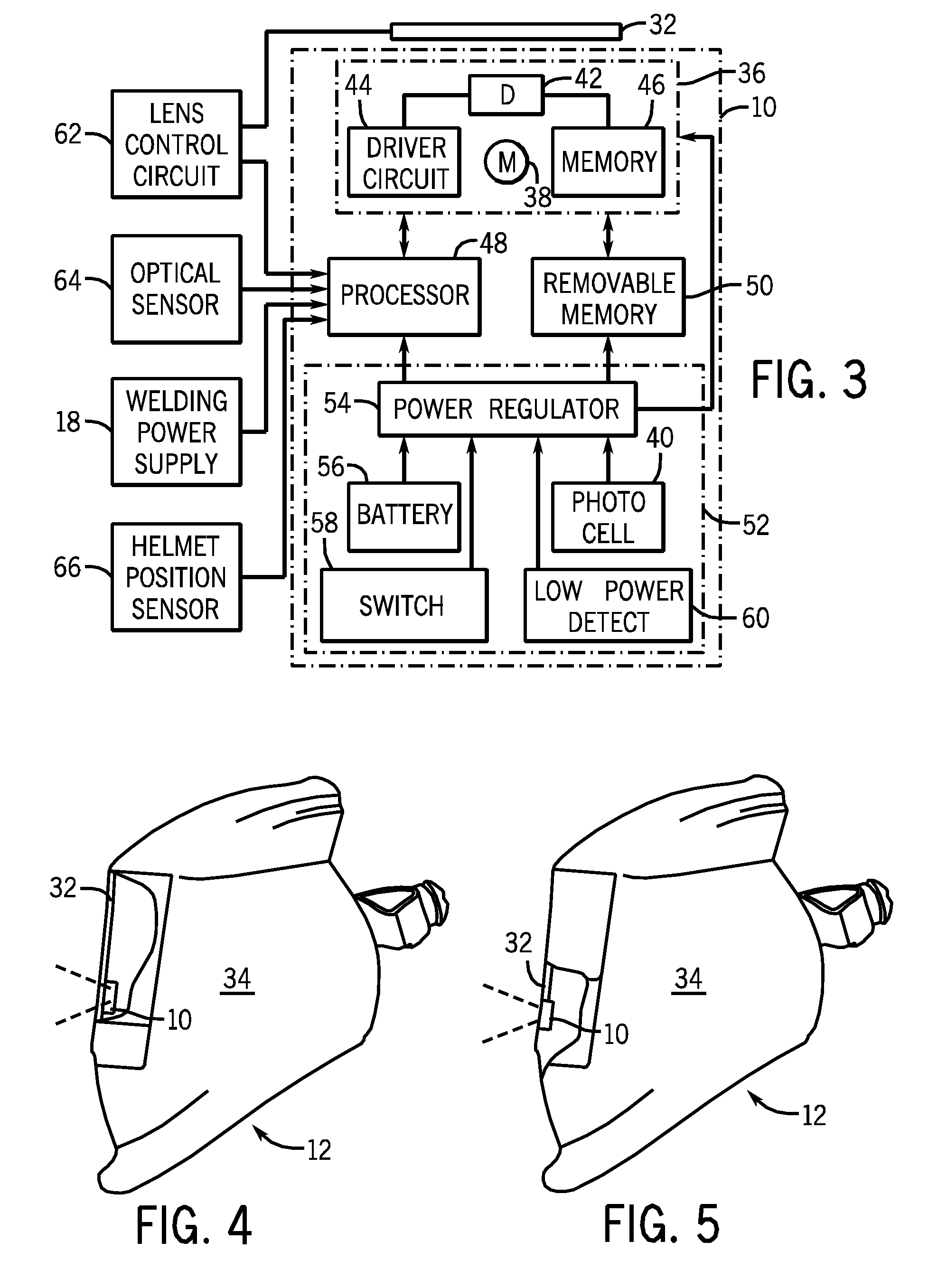

Video recording device for a welder's helmet

ActiveUS20090231423A1Television system detailsColor television signals processingComputer hardwareVideo record

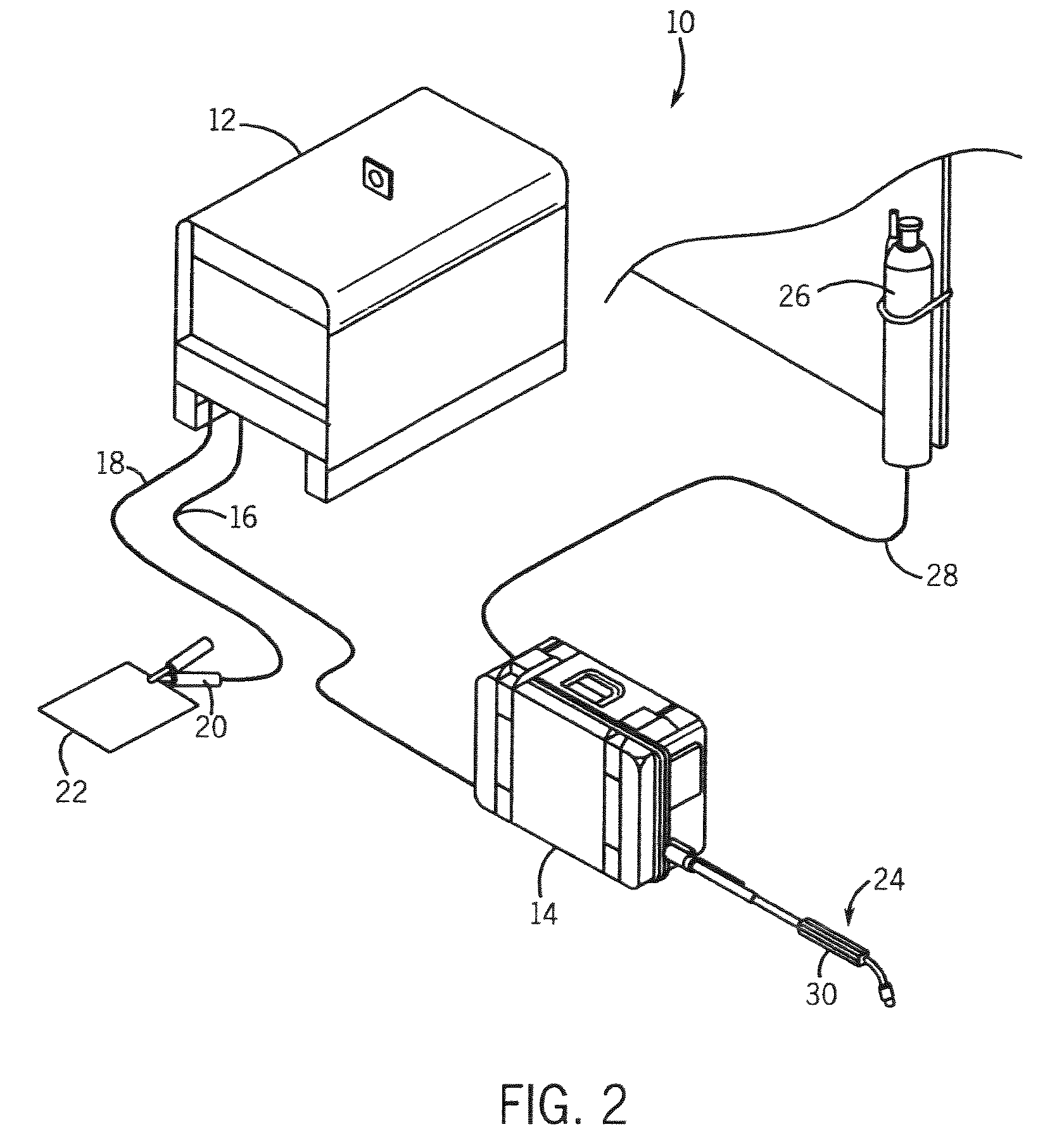

A weld recording system mounted in or on a welding helmet is provided. The weld recording system includes a camera assembly unit, a power supply unit, a processor, and removable memory. The weld recording system interfaces with lens control circuitry, an optical sensor, a welding power supply, and a helmet position sensor. Logic is provided for the triggering and recording of video and audio signals, which are eventually stored in a file for future reference. Transmission of signals from one or more welders to a monitoring station for eventual display is presented. An image processing algorithm is provided to combine multiple images with varied exposure times into a visual image of the weld and its surroundings.

Owner:ILLINOIS TOOL WORKS INC

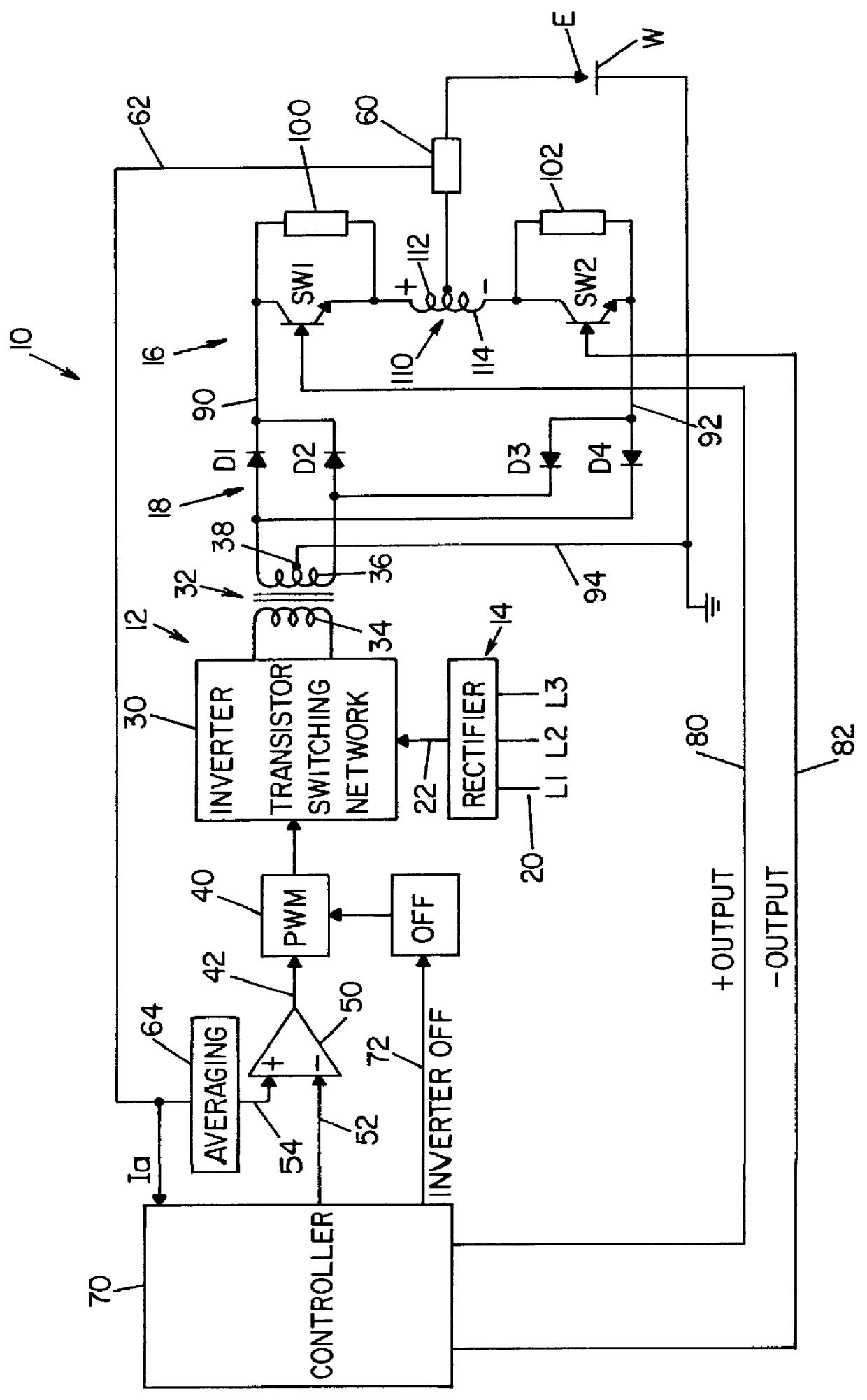

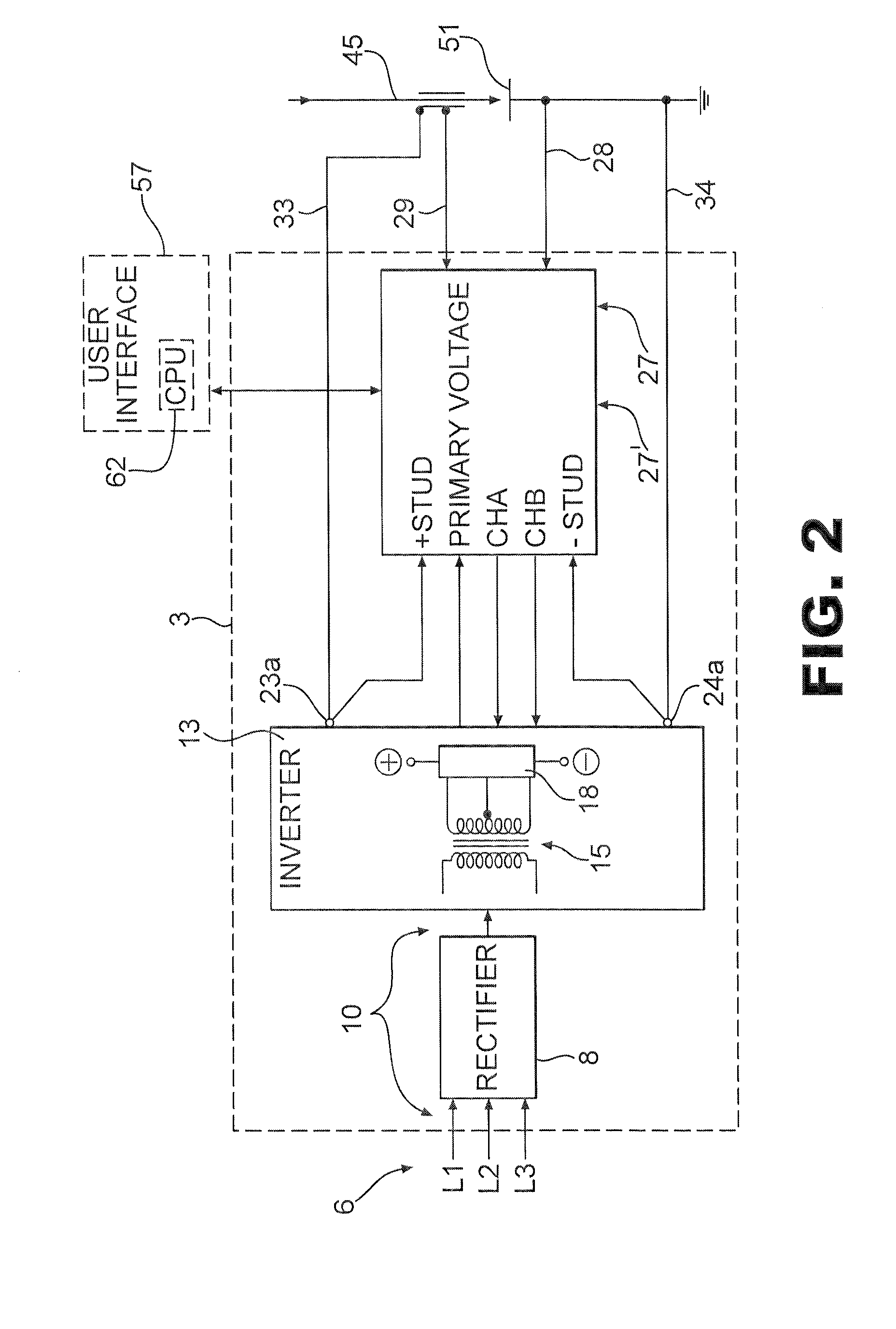

High current welding power supply

InactiveUS6111216AEasy to adjustIncrease supplyInterconnection arrangementsArc welding apparatusPower inverterPower flow

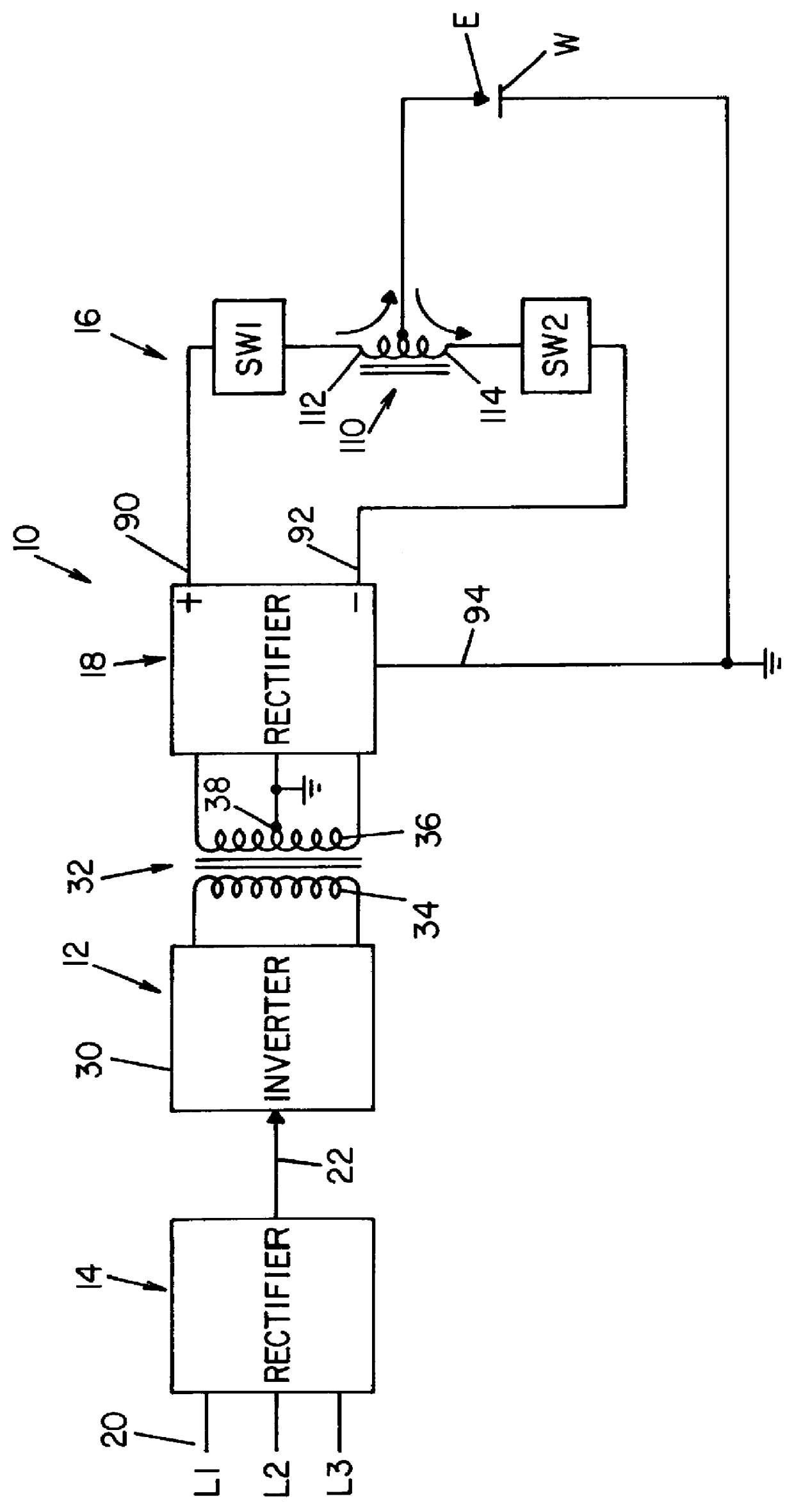

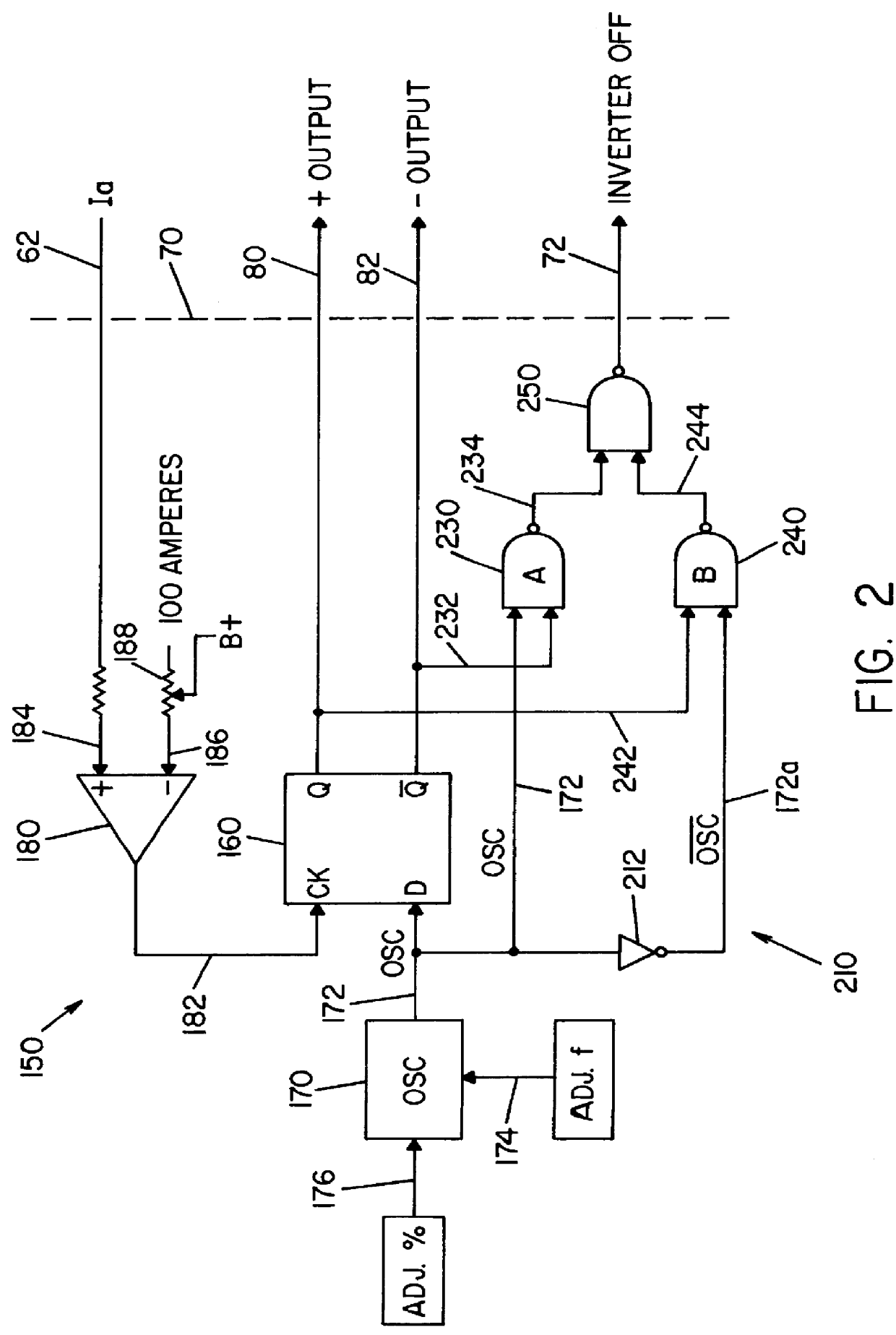

In a welding power supply for creating welding current in a succession of current pulses with a maximum current level and a trailing off state which current pulses passing through a series circuit including an inductor and electrode in welding relationship with a workpiece wherein the power supply has (a) an inverter stage with an input to be connected to a power source, a first terminal at a first electrical polarity when the inverter is on, a second terminal at a second electrical polarity when the inverter is on, and a control to generate an off signal to turn the inverter off and remove current from the terminals to shift said current pulse toward an off state; and, (b) a power switching stage including a transistor based switch having a conduction condition passing current from the first terminal upon creation of a first logic signal and a non-conduction condition blocking current upon creation of a second logic signal, the improvement comprising: a sensor for measuring the instantaneous value of the welding current, a comparator for producing a low current signal when the instantaneous current is at a selected value substantially below the maximum current level and a circuit or program for creating the second logic signal upon production of a low current signal after generation of an off signal whereby the transistor based switch is switched from the conduction condition to the non-conduction condition when the welding current is generally at the selected value.

Owner:LINCOLN GLOBAL INC

Welding power supply with neural network controls

InactiveUS20090200281A1Biological neural network modelsArc welding apparatusWelding power supplyNetwork control

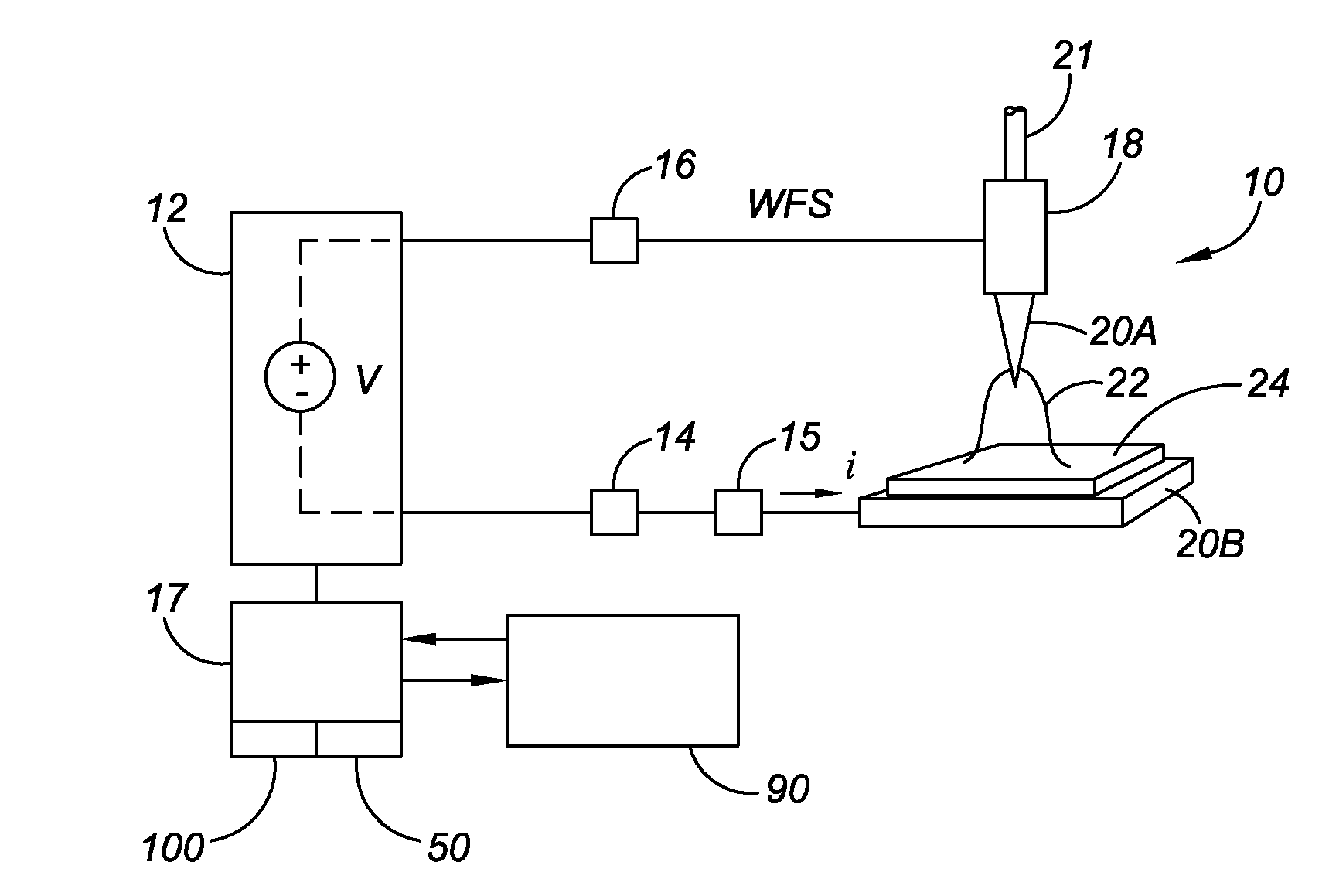

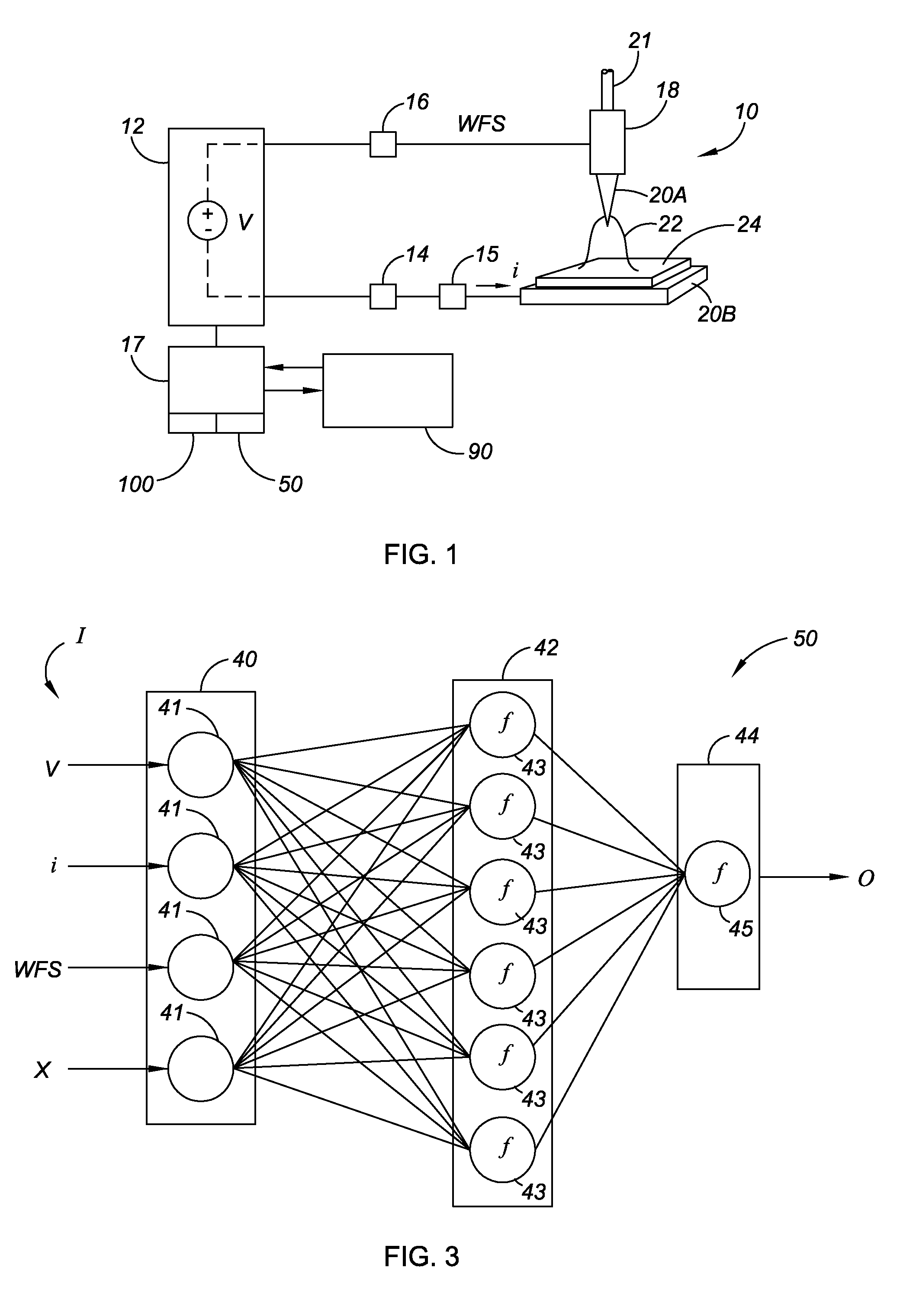

A method controls a welding apparatus by using a neural network to recognize an acceptable weld signature. The neural network recognizes a pattern presented by the instantaneous weld signature, and modifies the instantaneous weld signature when the pattern is not acceptable. The method measures a welding voltage, current, and wire feed speed (WFS), and trains the neural network using the instantaneous weld signature when the instantaneous weld signature is different from each of the different training weld signatures. A welding apparatus for controlling a welding process includes a welding gun, a power supply for supplying a welding voltage and current, and a sensor for detecting values of a plurality of different welding process variables. A controller of the apparatus has a neural network for receiving the welding process variables and for recognizing a pattern in the weld signature. The controller modifies the weld signature when the pattern is not recognized.

Owner:GM GLOBAL TECH OPERATIONS LLC

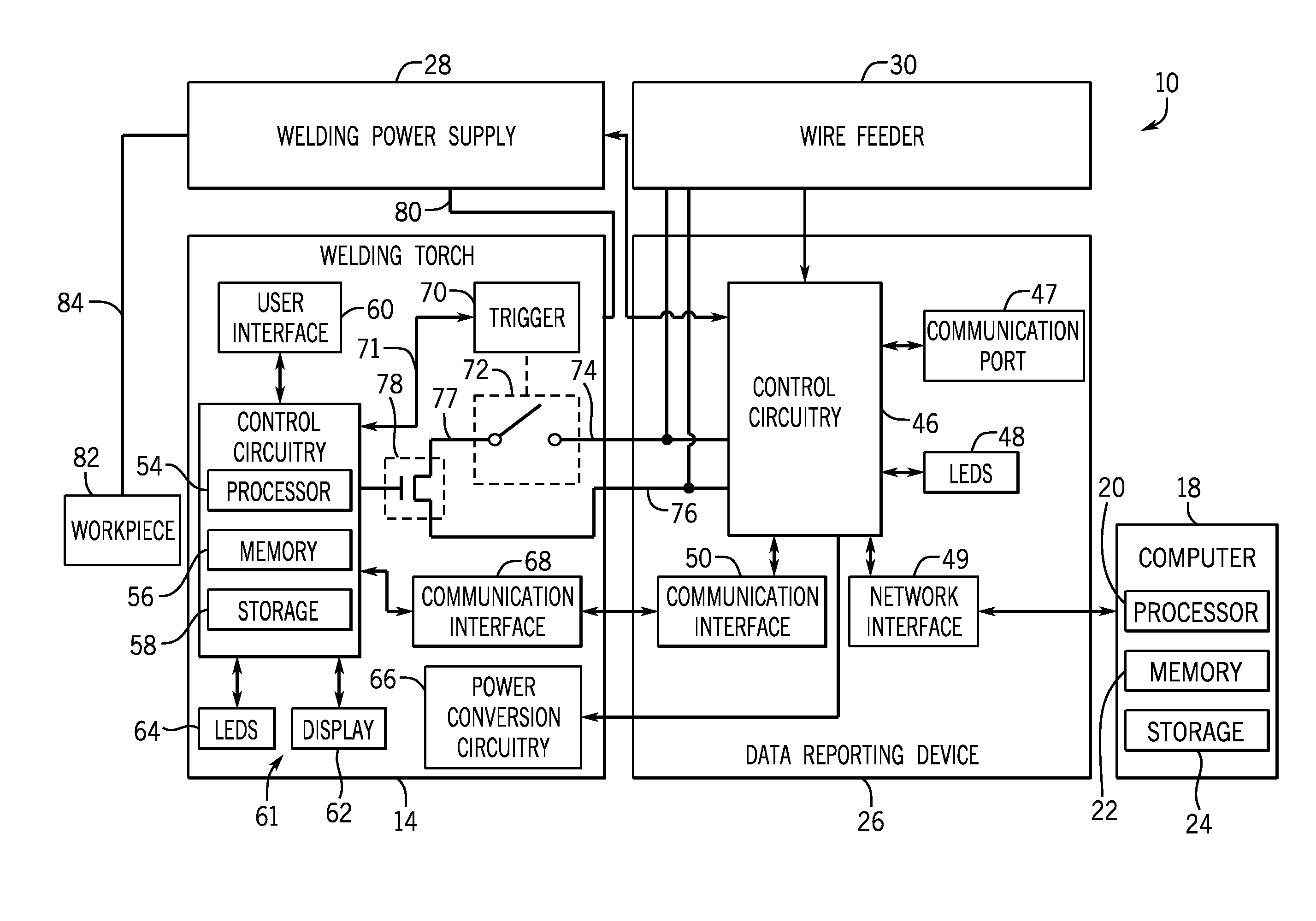

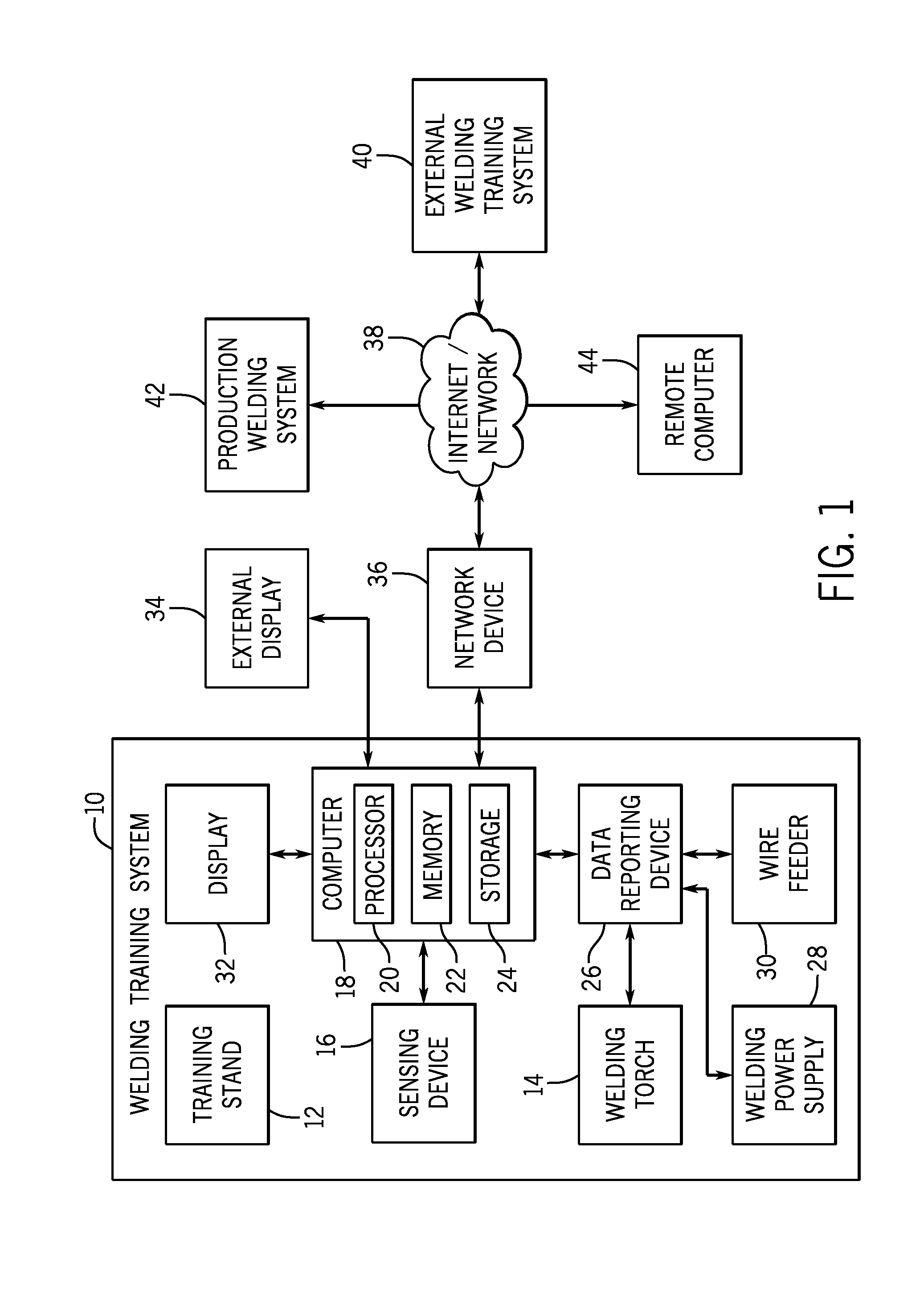

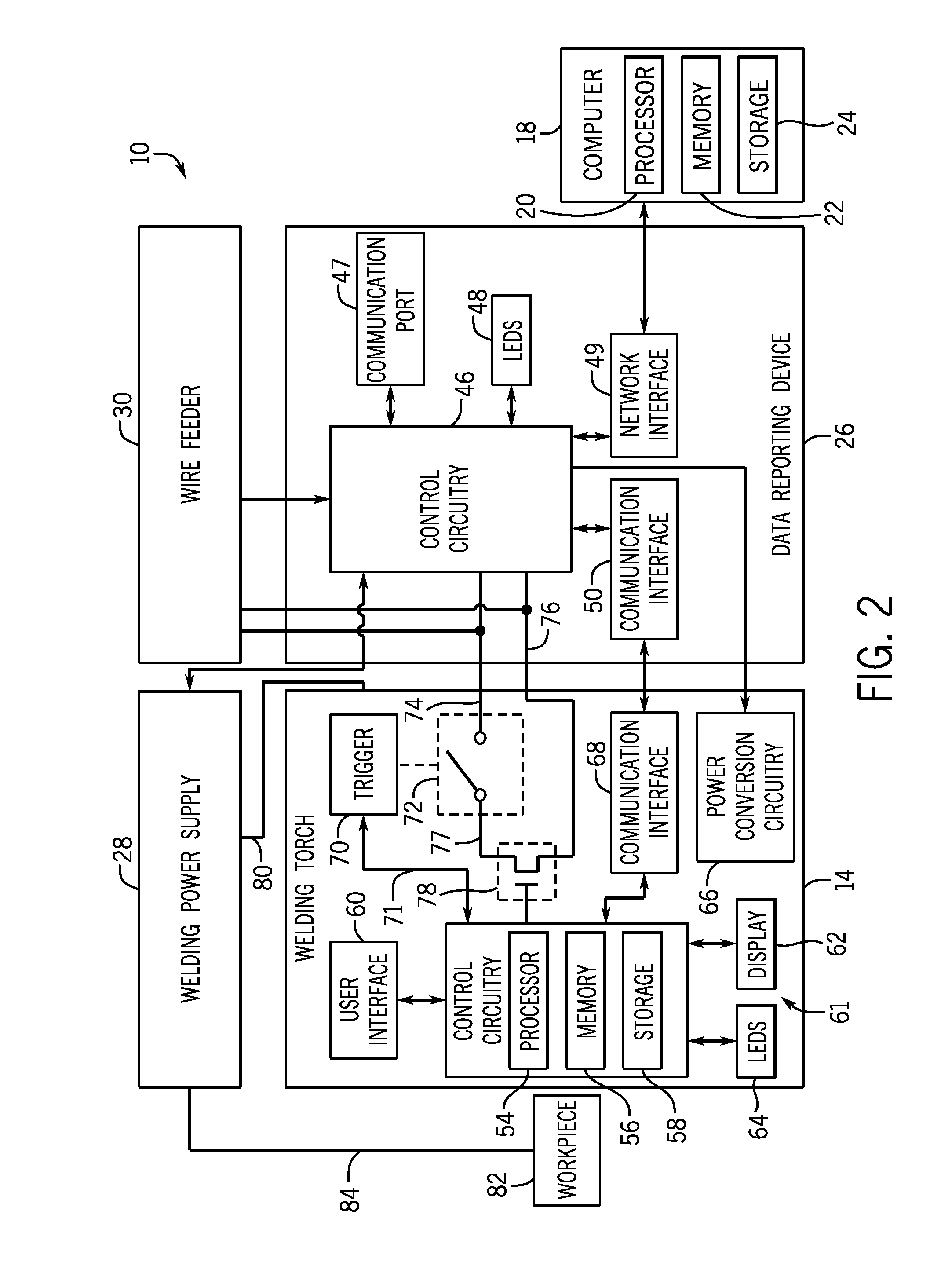

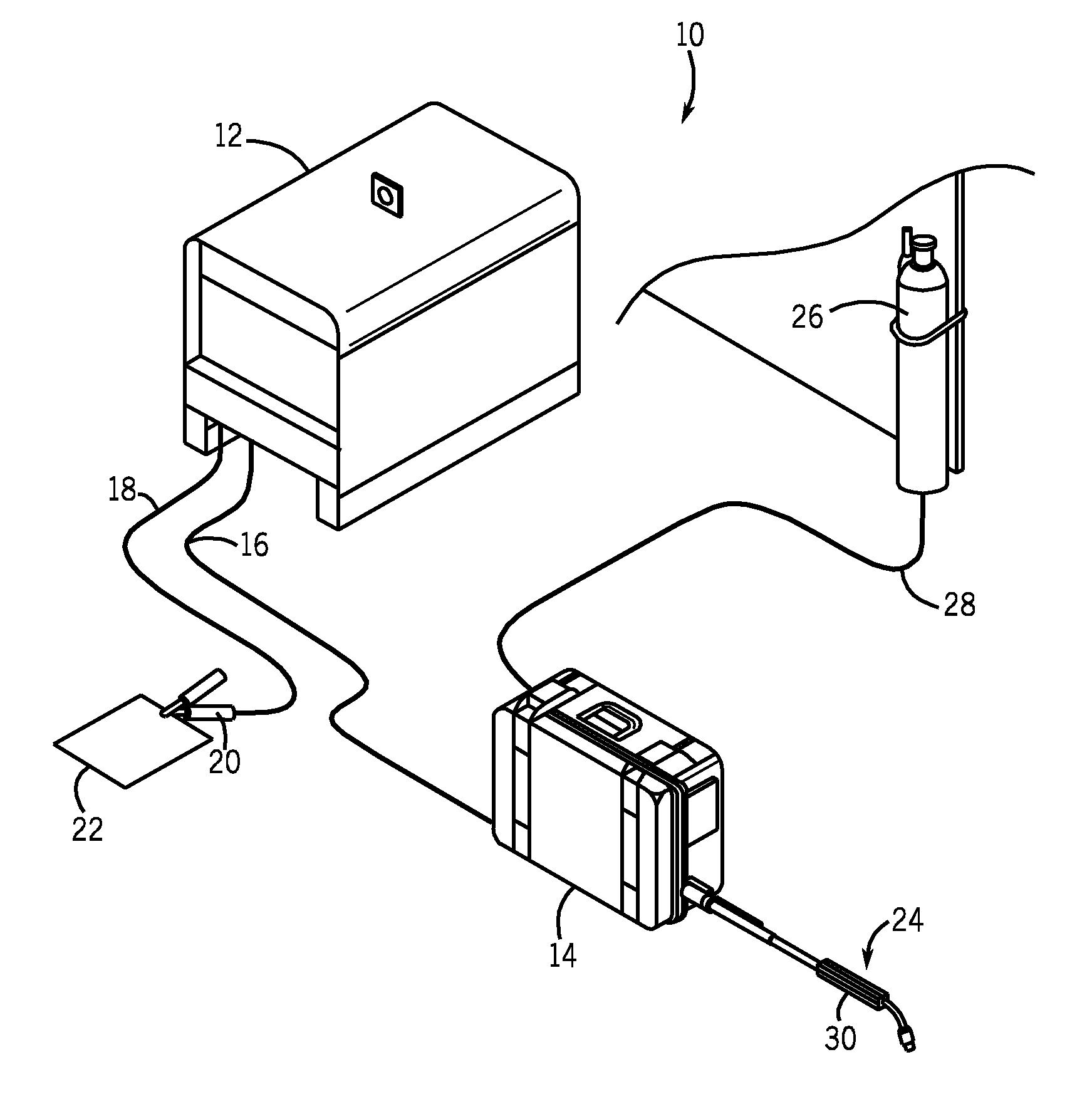

Welding torch for a welding training system

A welding training system includes a welding training software having a first training mode configured to simulate a welding arc and a second training mode configured to use a live welding arc. The welding training system is configured to block welding power flow between a welding power supply and a welding torch while the welding training software is in the first training mode. The welding training system is also configured to enable the welding power to flow between the welding power supply and the welding torch while the welding training software is in the second training mode.

Owner:ILLINOIS TOOL WORKS INC

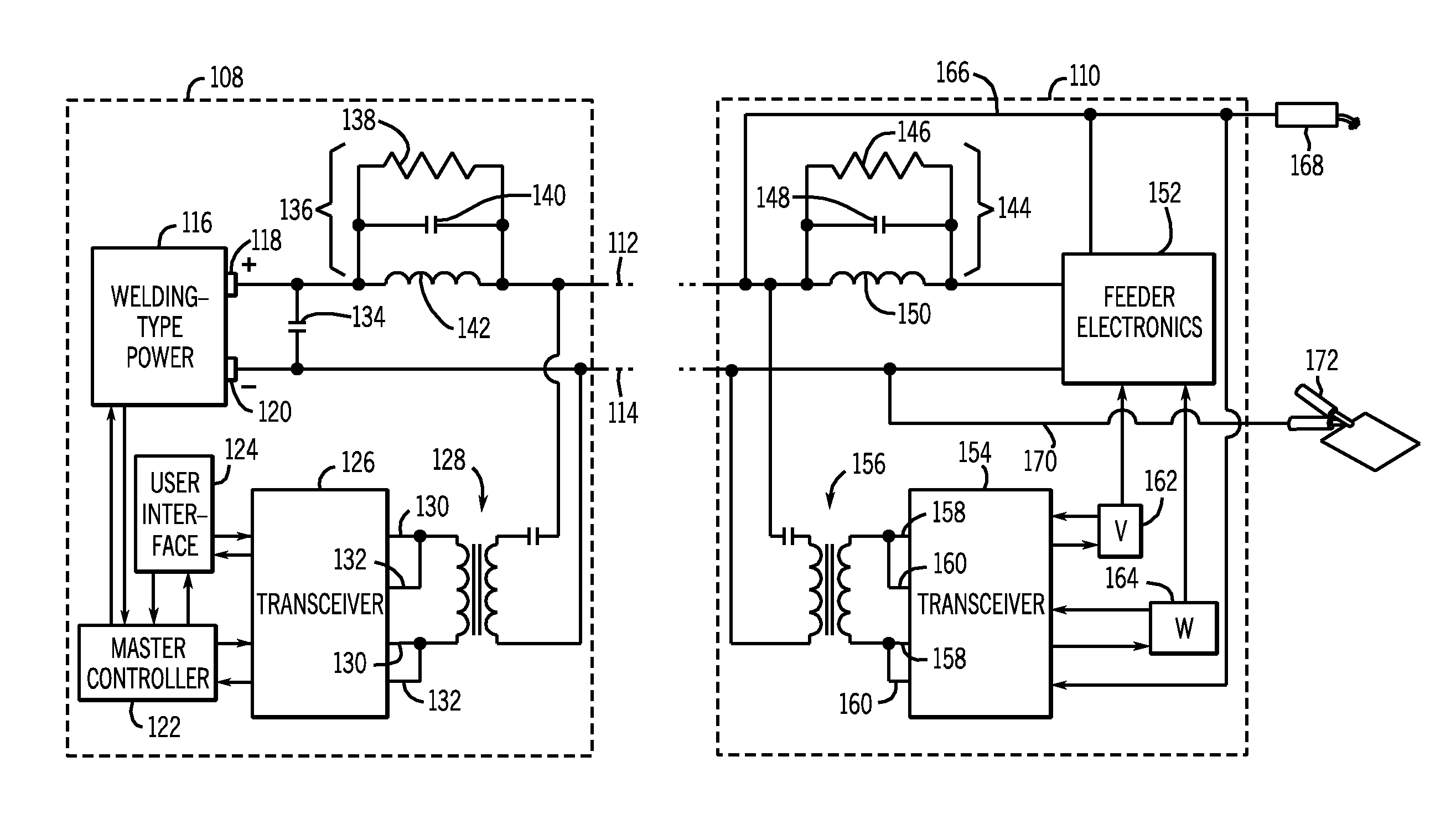

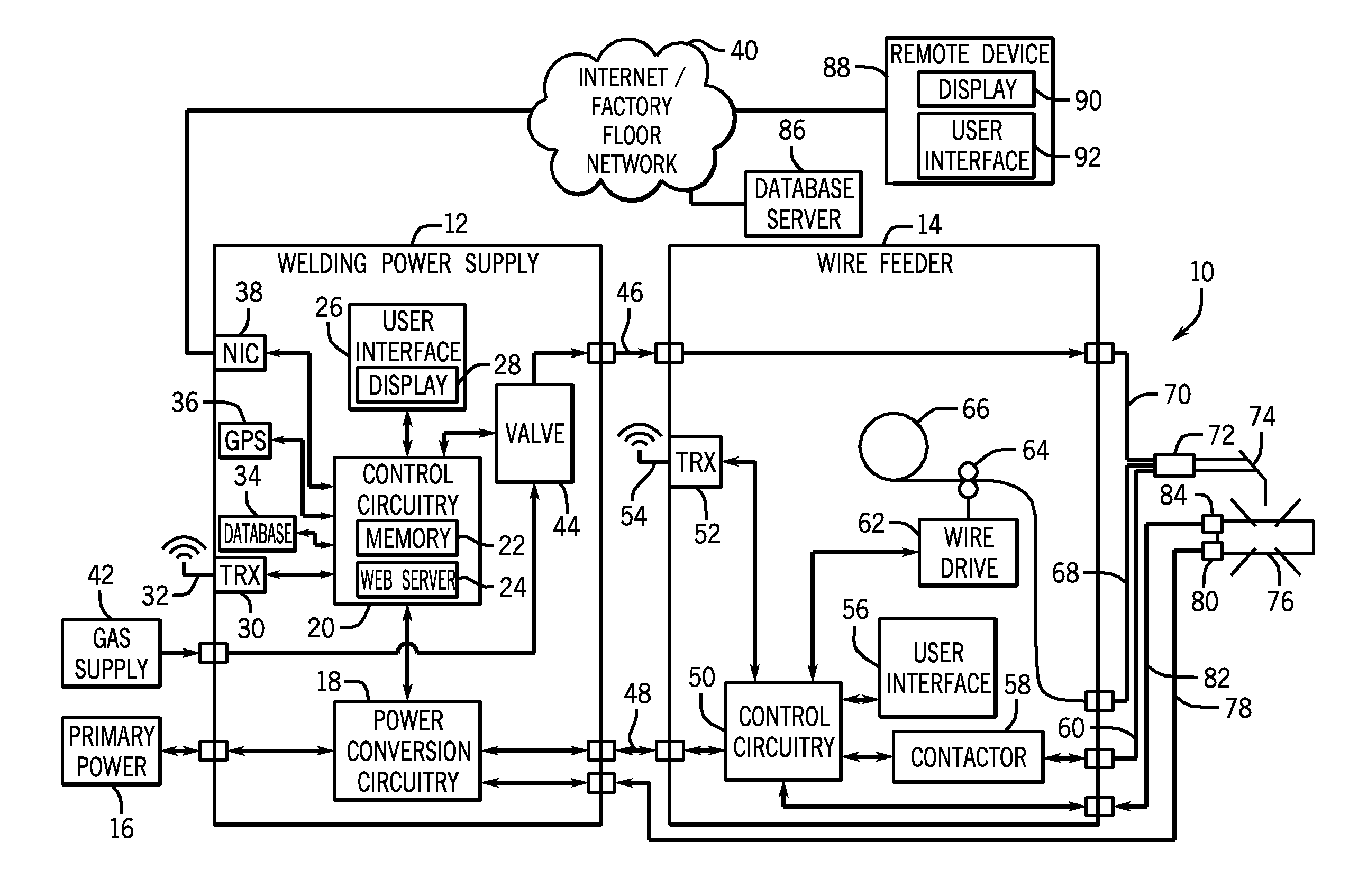

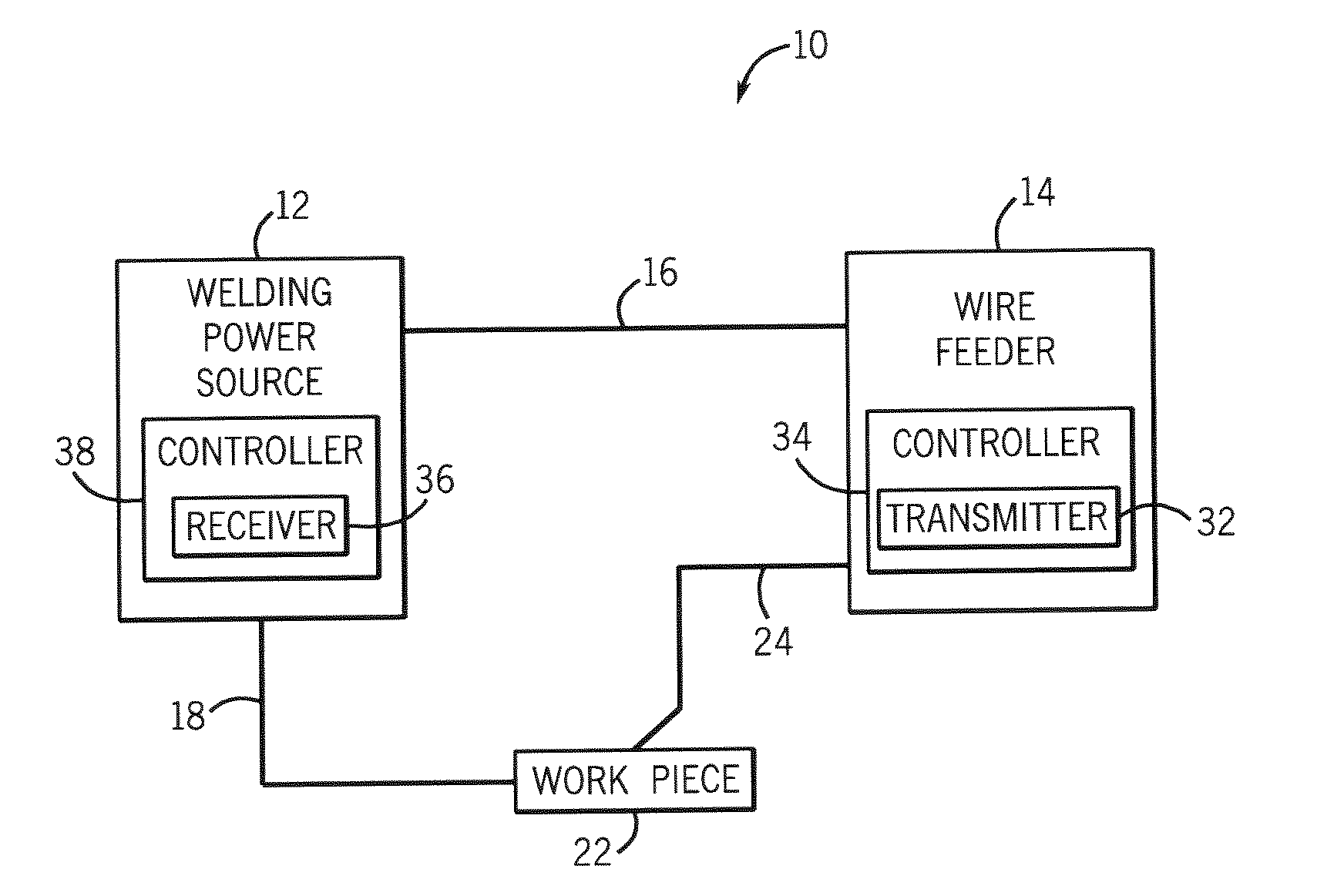

Remote wire feeder using binary phase shift keying to modulate communications of command/control signals to be transmitted over a weld cable

ActiveUS20060138113A1Overcomes drawbackElectric discharge heatingArc welding apparatusControl signalWelding power supply

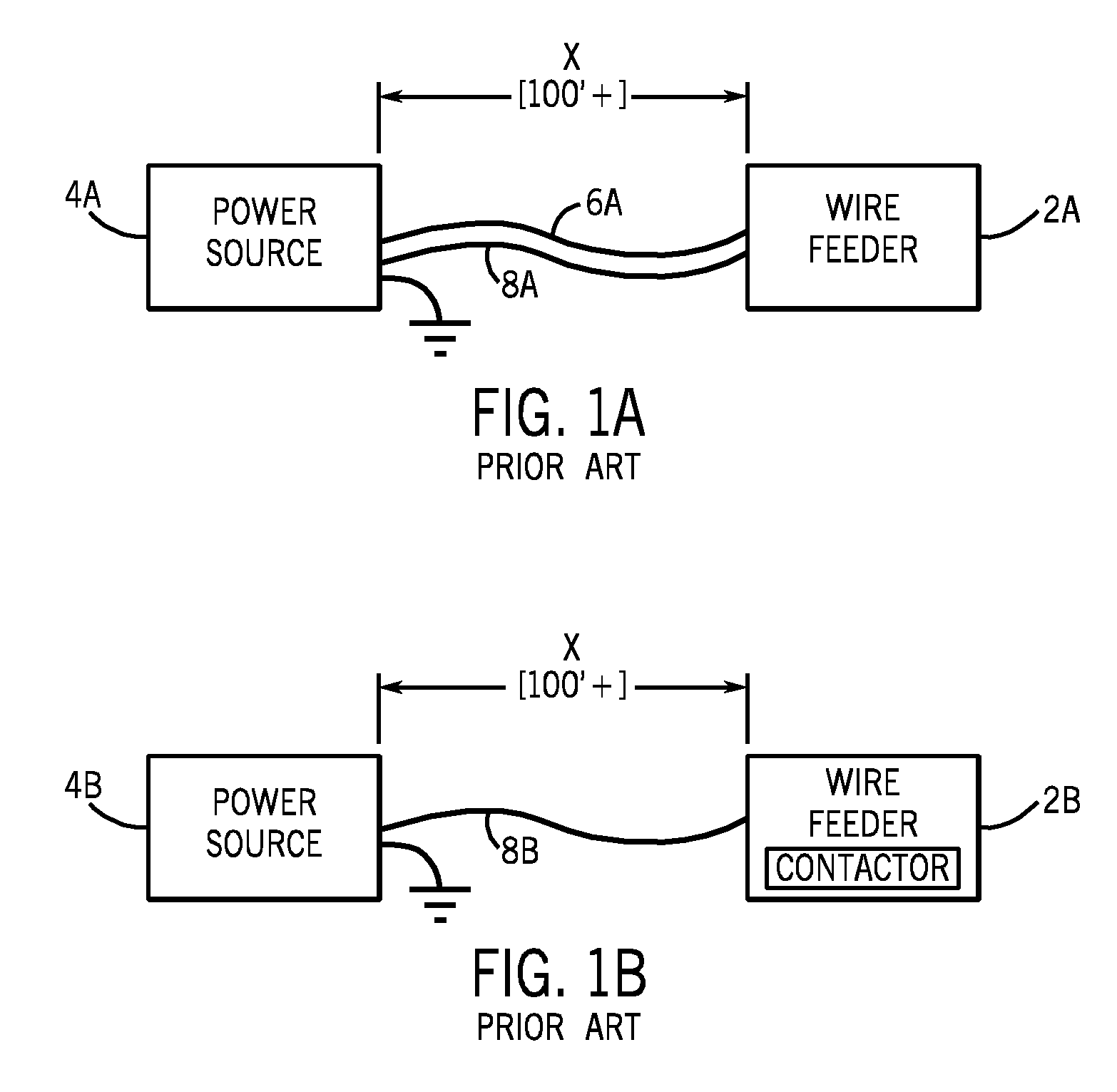

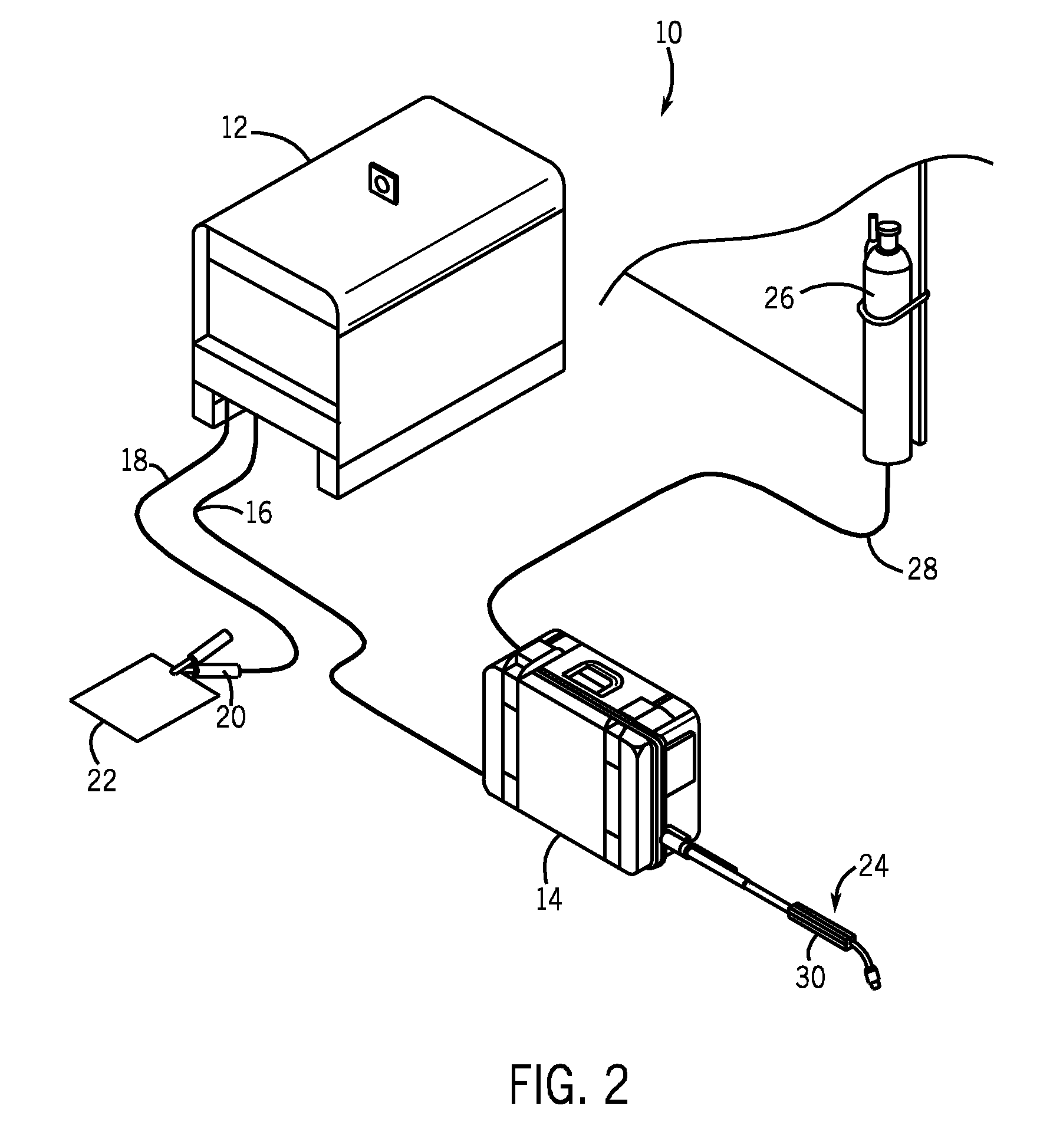

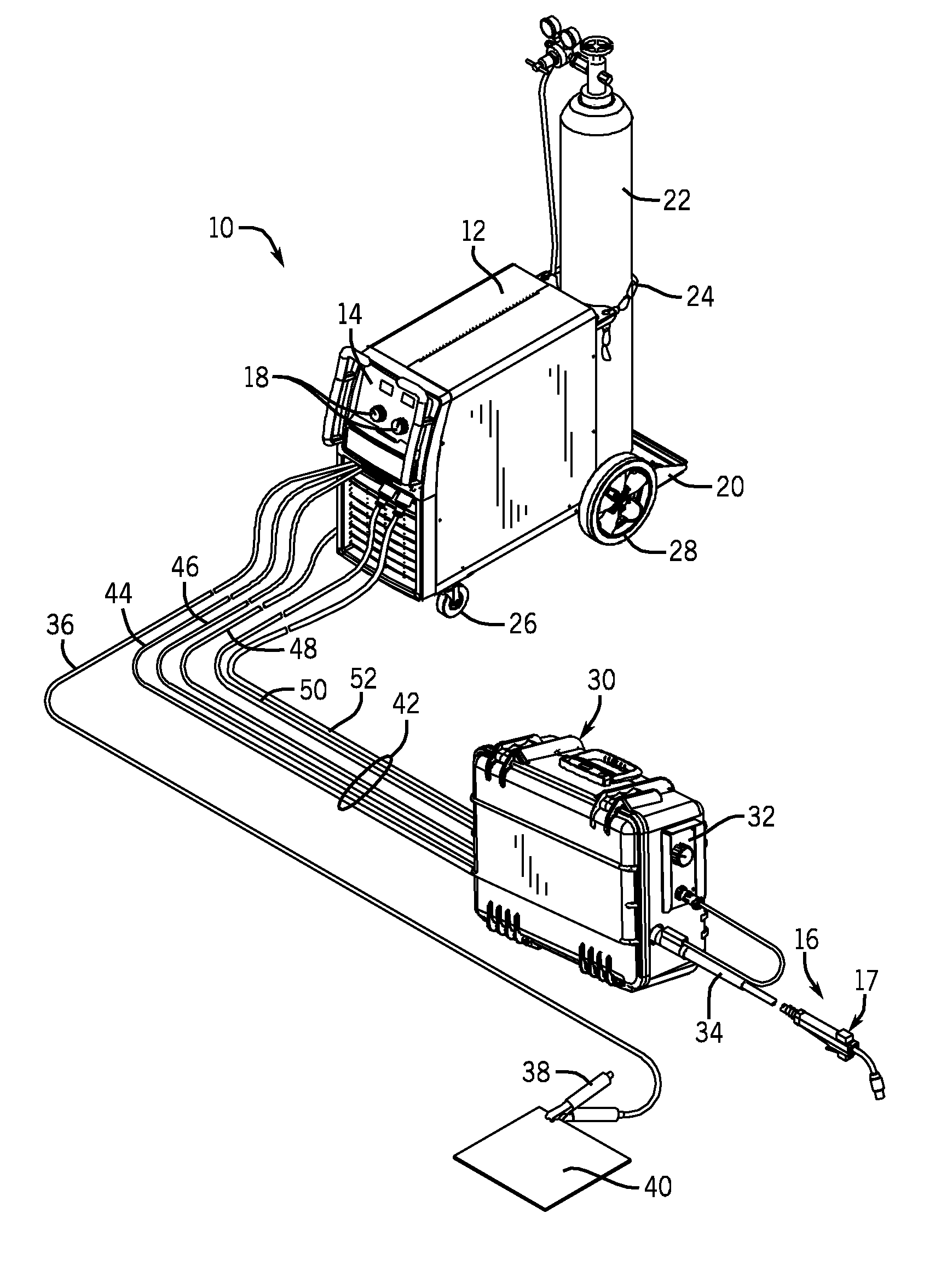

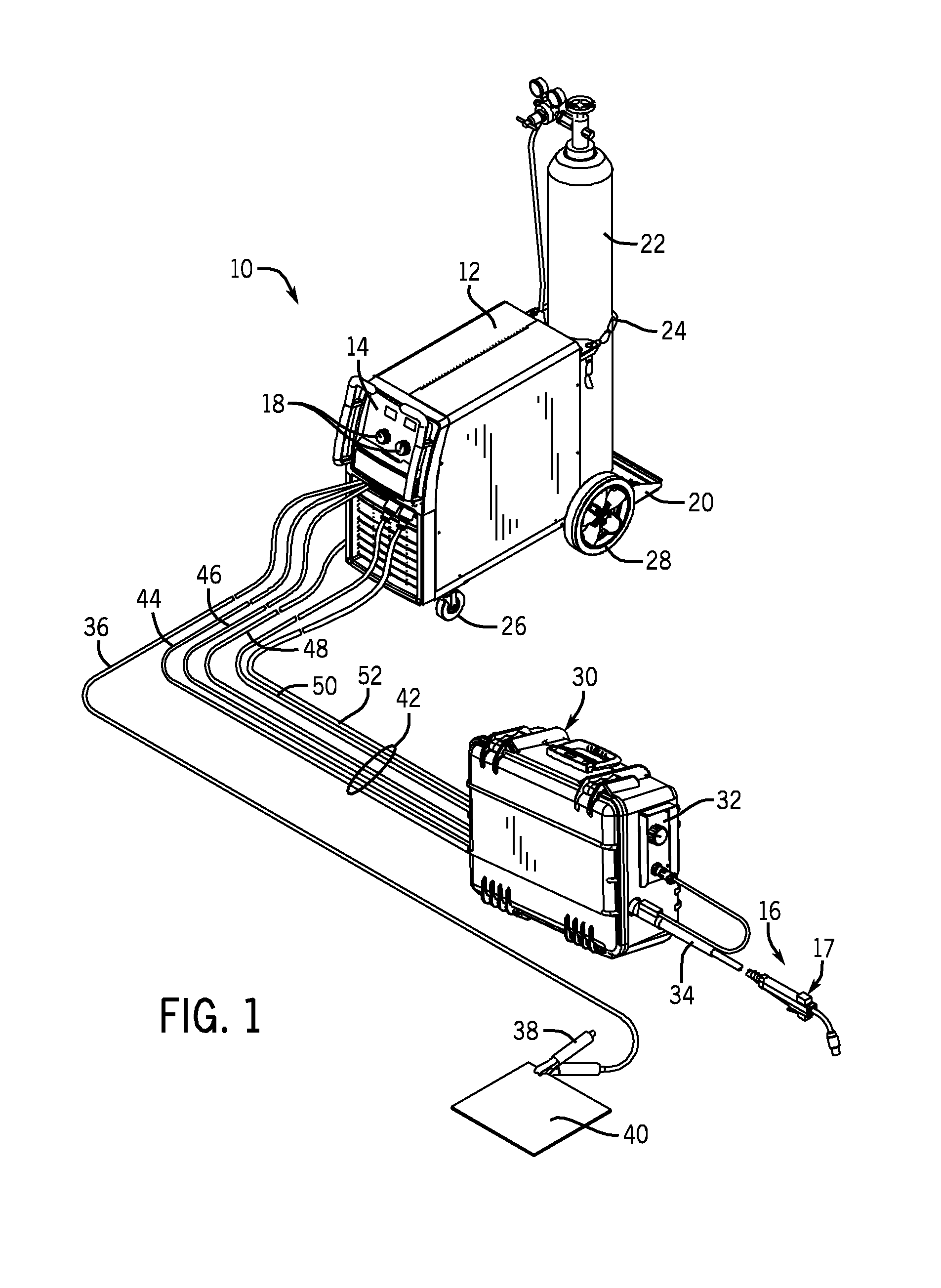

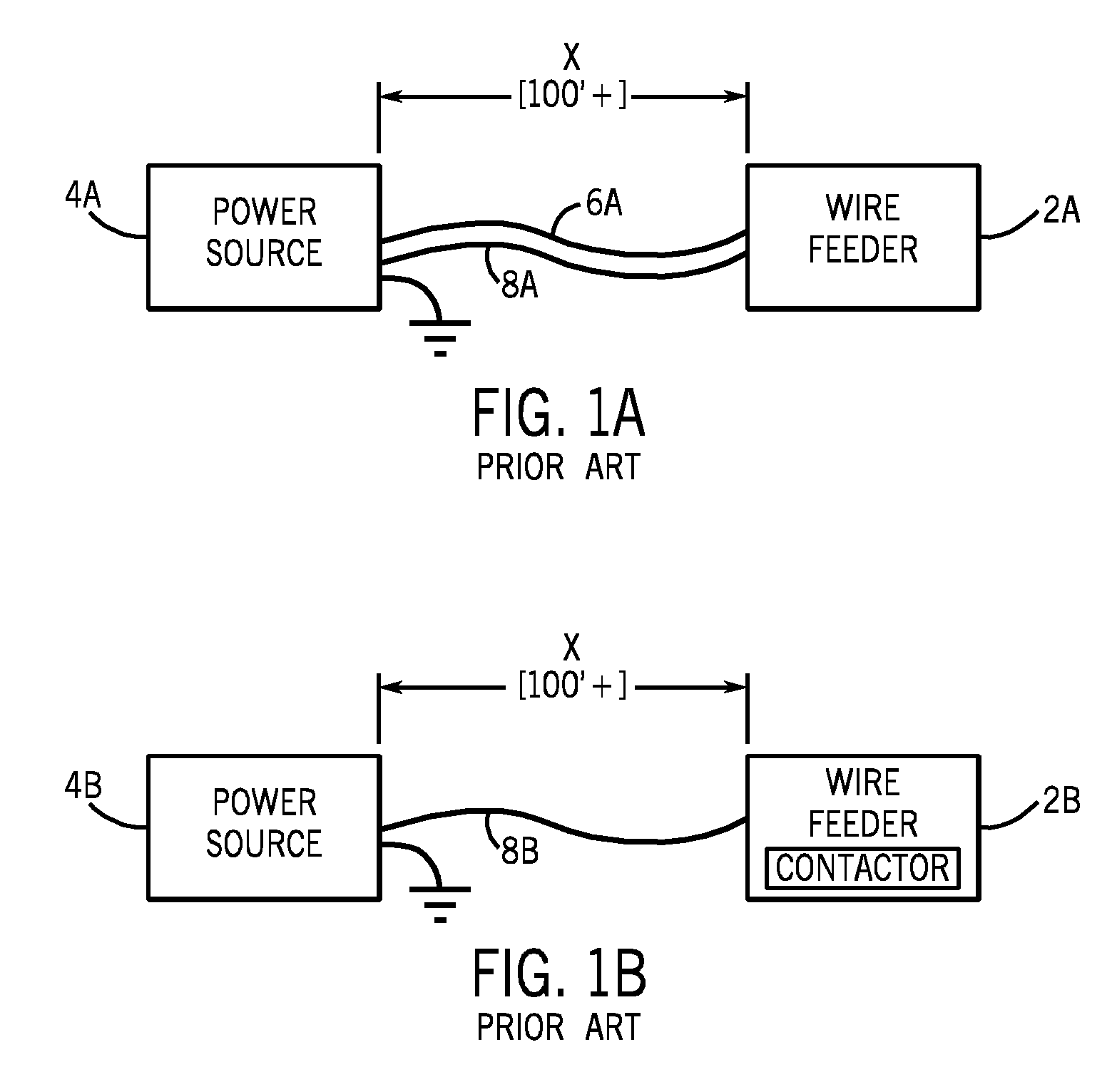

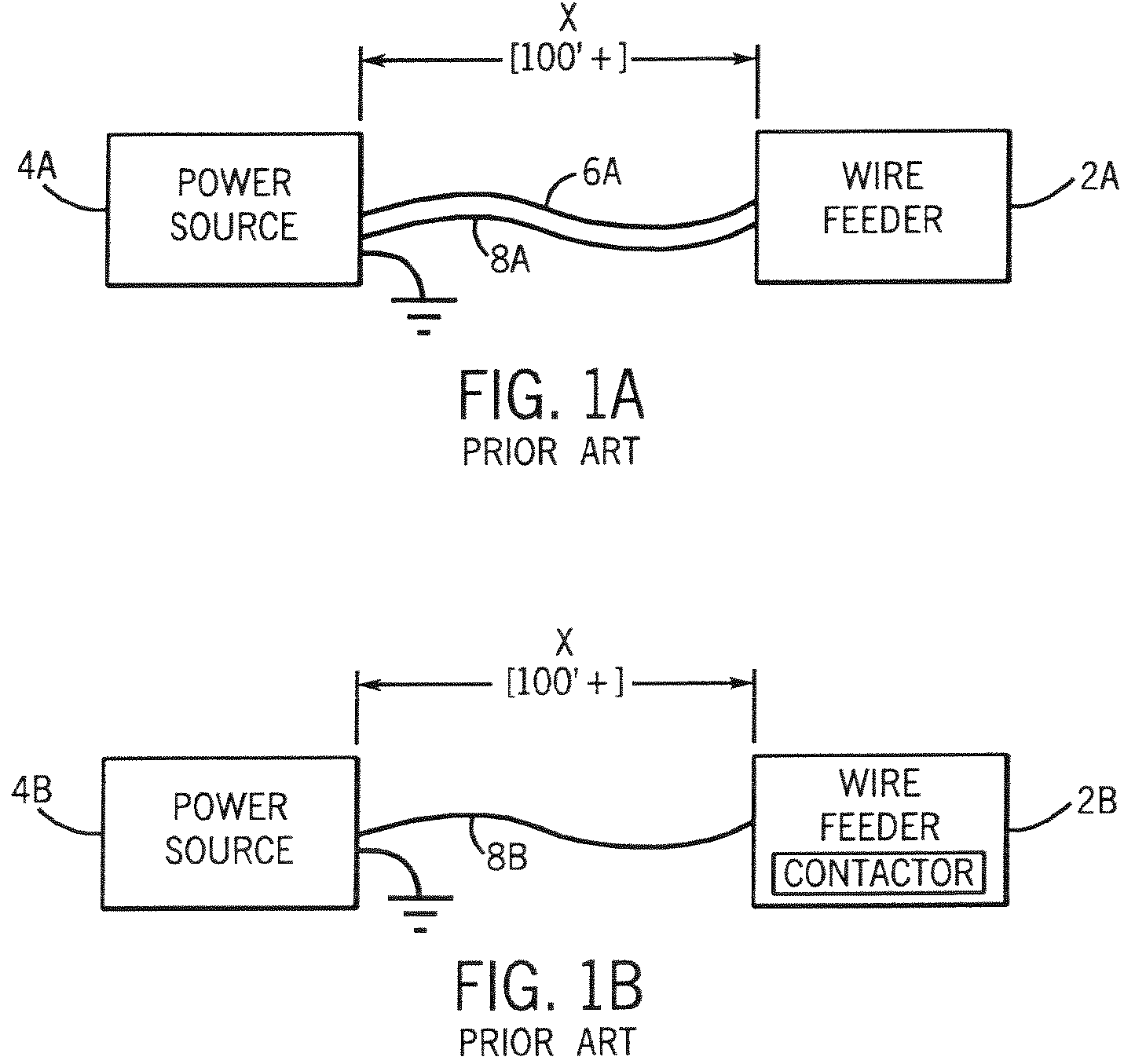

The present invention is directed to a system and method of remotely controlling a welding machine with command signals transmitted to the welding power source across a weld cable connecting the power source to a remote device, such a wire feeder. A transmitter transmits the control commands containing desired welding operational parameters to a receiver disposed in the power source across a weld cable also designed to carry welding power from the power source to the wire feeder.

Owner:ILLINOIS TOOL WORKS INC

Remote wire feeder using binary phase shift keying to modulate communications of command/control signals to be transmitted over a weld cable

ActiveUS20070080154A1Improve signal qualityImprove transmission qualitySimultaneous amplitude and angle modulationSystems using filtering and bypassingControl signalWelding power supply

The present invention is directed to a system and method of remotely controlling a welding machine with command signals transmitted to the welding power source across a weld cable connecting the power source to a remote device, such a wire feeder. A transmitter transmits the control commands containing desired welding operational parameters to a receiver disposed in the power source across a weld cable also designed to carry welding power from the power source to the wire feeder.

Owner:ILLINOIS TOOL WORKS INC

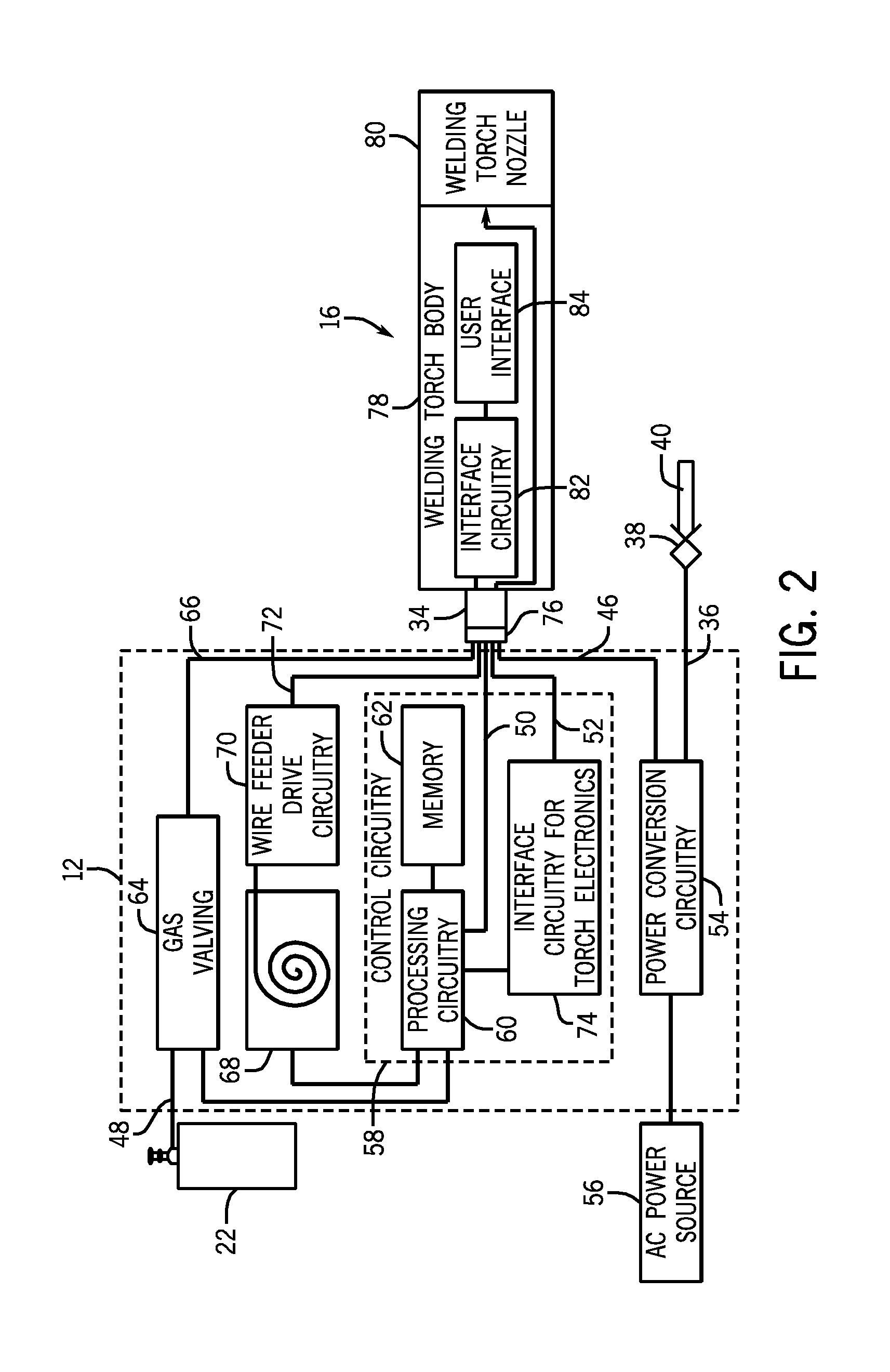

Welding device with integral user interface

InactiveUS20110220616A1Arc welding apparatusWelding/cutting media/materialsGraphical user interfaceWelding power supply

Welding torch assemblies including a torch body having a user interface module integrally formed therewith, a welding nozzle, and a torch lead assembly are provided. The user interface module may enable a user to control one or more parameters of a welding operation. The welding nozzle may be coupled to a first end of the torch body. The torch lead assembly may be coupled to a second end of the torch body opposite the first end and may include a weld power lead and a weld control lead.

Owner:ILLINOIS TOOL WORKS INC

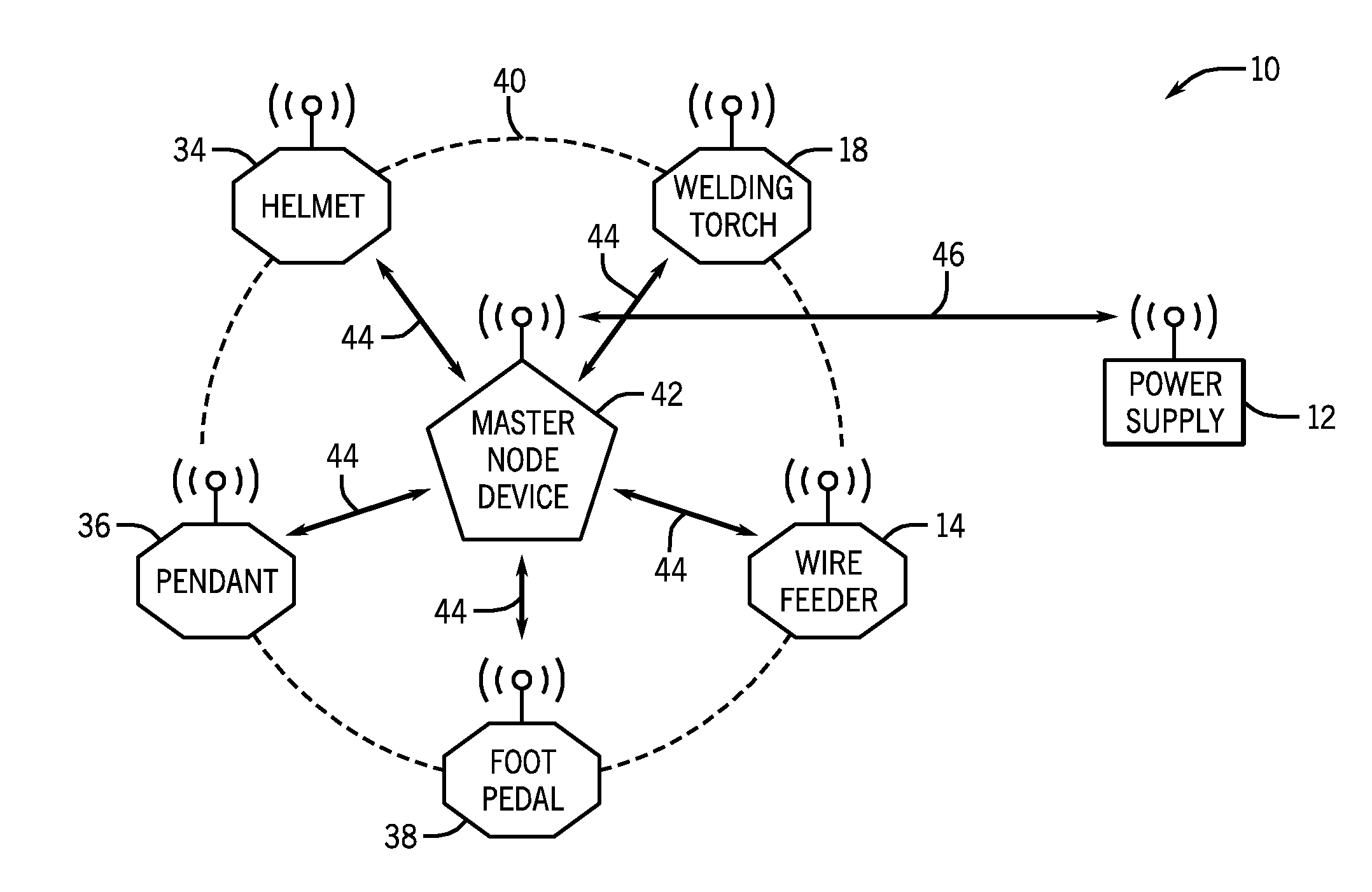

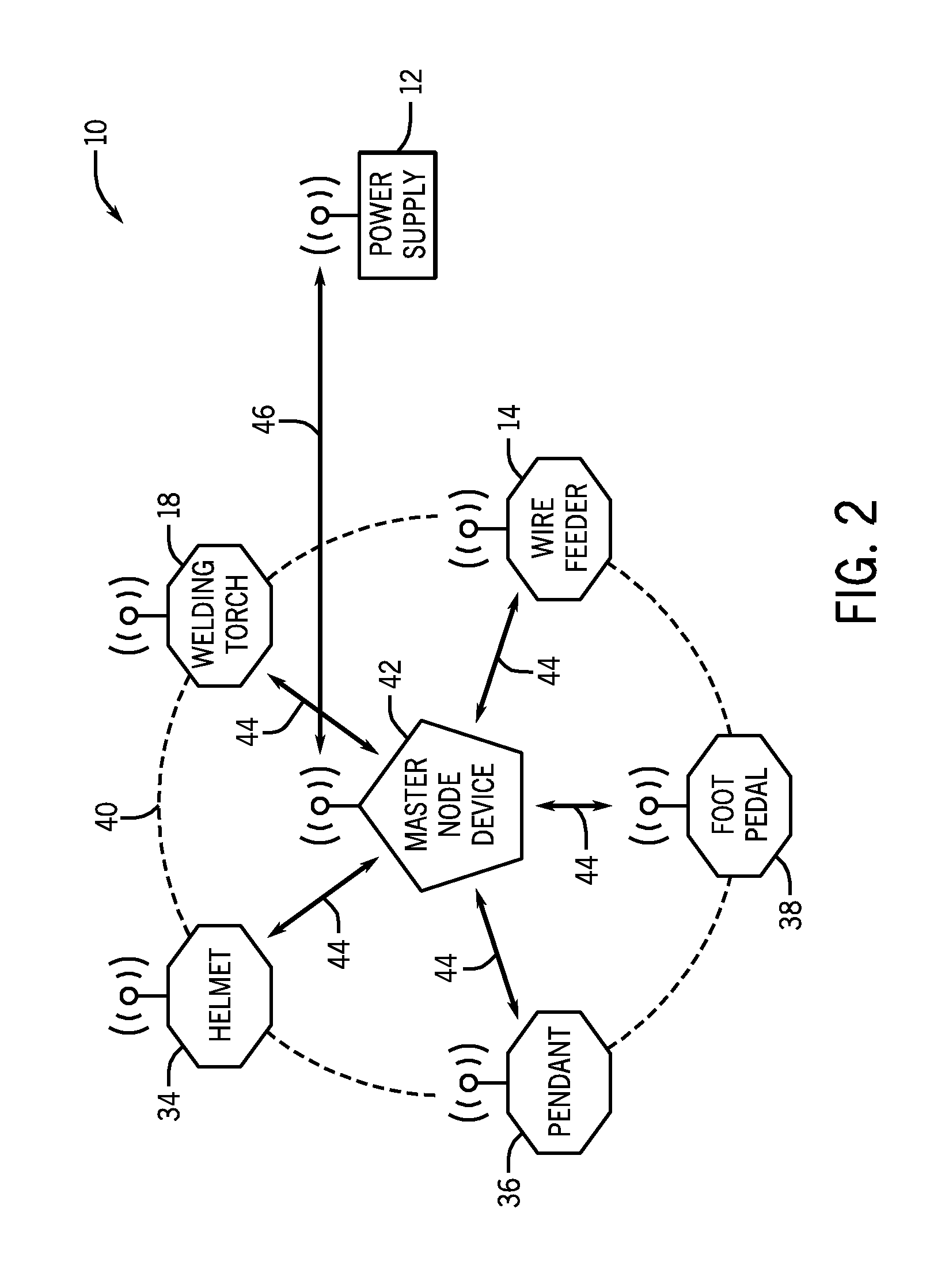

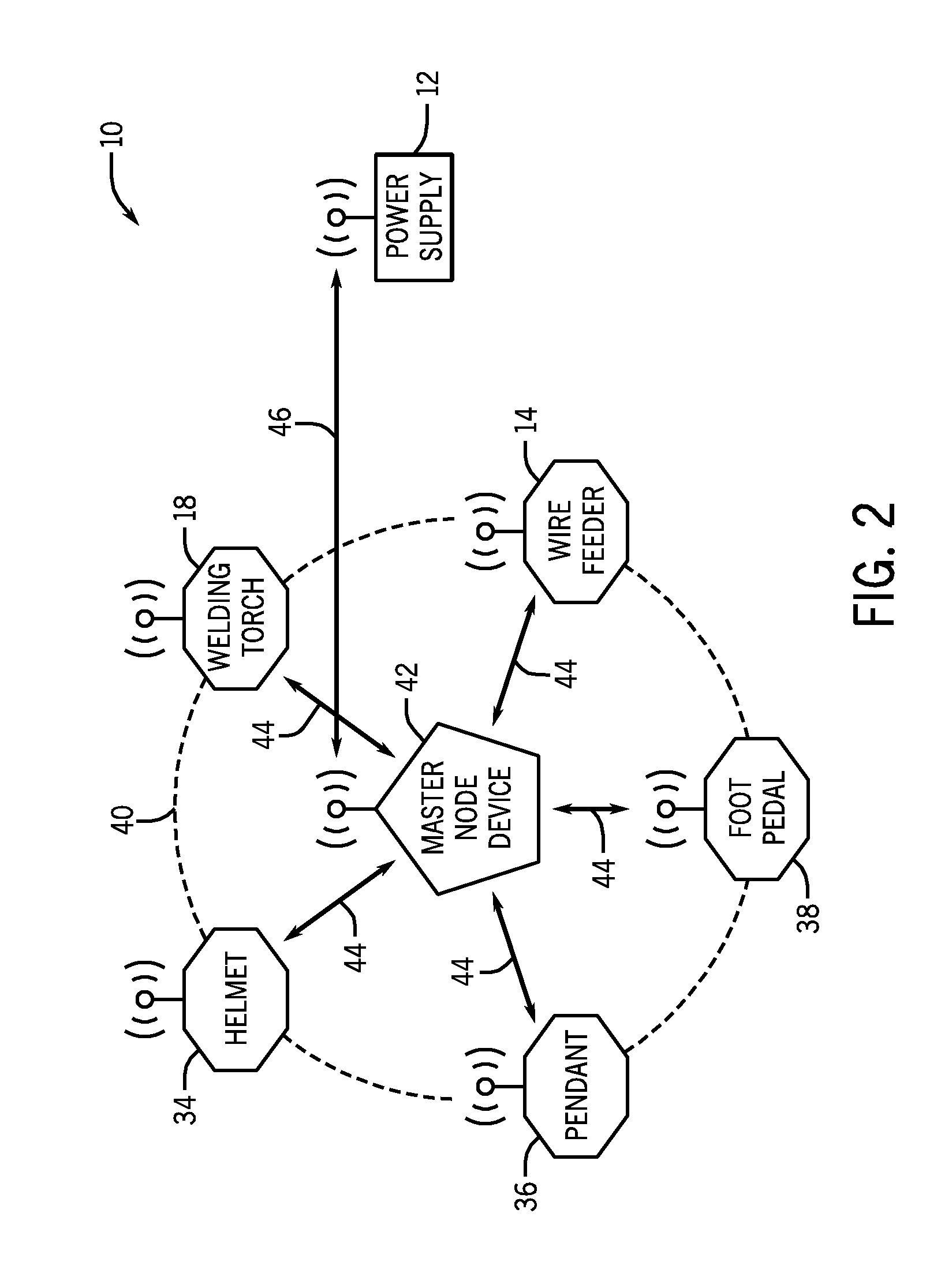

Wireless communication network sensor information for control of industrial equipment in harsh environments

ActiveUS20140052832A1Network topologiesDigital computer detailsTelecommunicationsWelding power supply

In certain embodiments, a system includes a master node device. The master node device includes communication circuitry configured to facilitate communication with a welding power supply unit via a long-range communication link, and to facilitate wireless communication with one or more welding-related devices via a short-range wireless communication network. The master node device also includes control circuitry configured to receive sensor data from one or more sensors within a physical vicinity of the short-range wireless communication network, and to route the sensor data to final destinations for the one or more sensors.

Owner:ILLINOIS TOOL WORKS INC

Video recording device for a welder's helmet

A weld recording system mounted in or on a welding helmet is provided. The weld recording system includes a camera assembly unit, a power supply unit, a processor, and removable memory. The weld recording system interfaces with lens control circuitry, an optical sensor, a welding power supply, and a helmet position sensor. Logic is provided for the triggering and recording of video and audio signals, which are eventually stored in a file for future reference. Transmission of signals from one or more welders to a monitoring station for eventual display is presented. An image processing algorithm is provided to combine multiple images with varied exposure times into a visual image of the weld and its surroundings.

Owner:ILLINOIS TOOL WORKS INC

Remote wire feeder using binary phase shift keying to modulate communications of command/control signals to be transmitted over a weld cable

ActiveUS9012807B2Improve signal qualityImproving impedanceSimultaneous amplitude and angle modulationError prevention/detection by using return channelControl signalWelding power supply

Owner:ILLINOIS TOOL WORKS INC

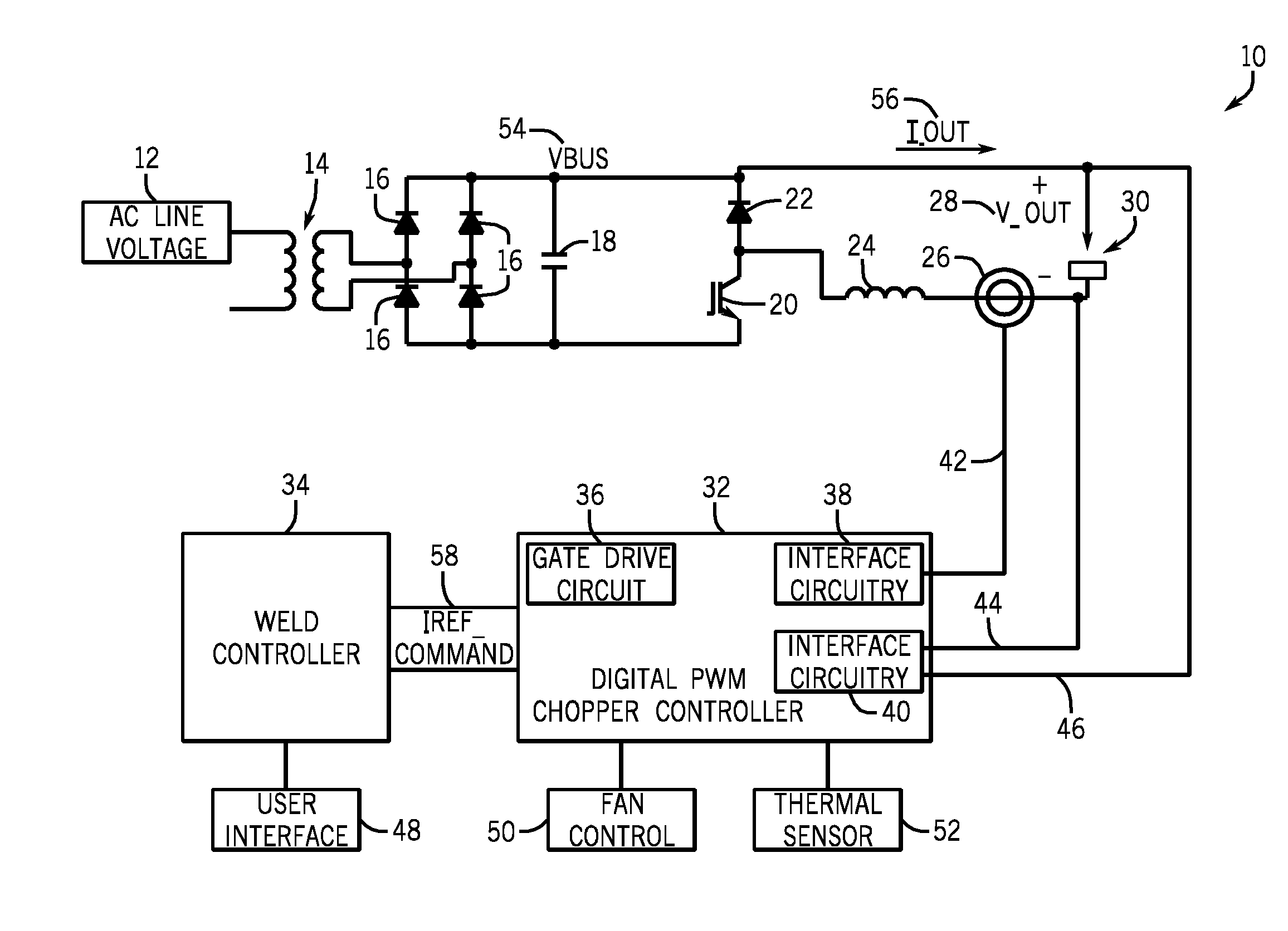

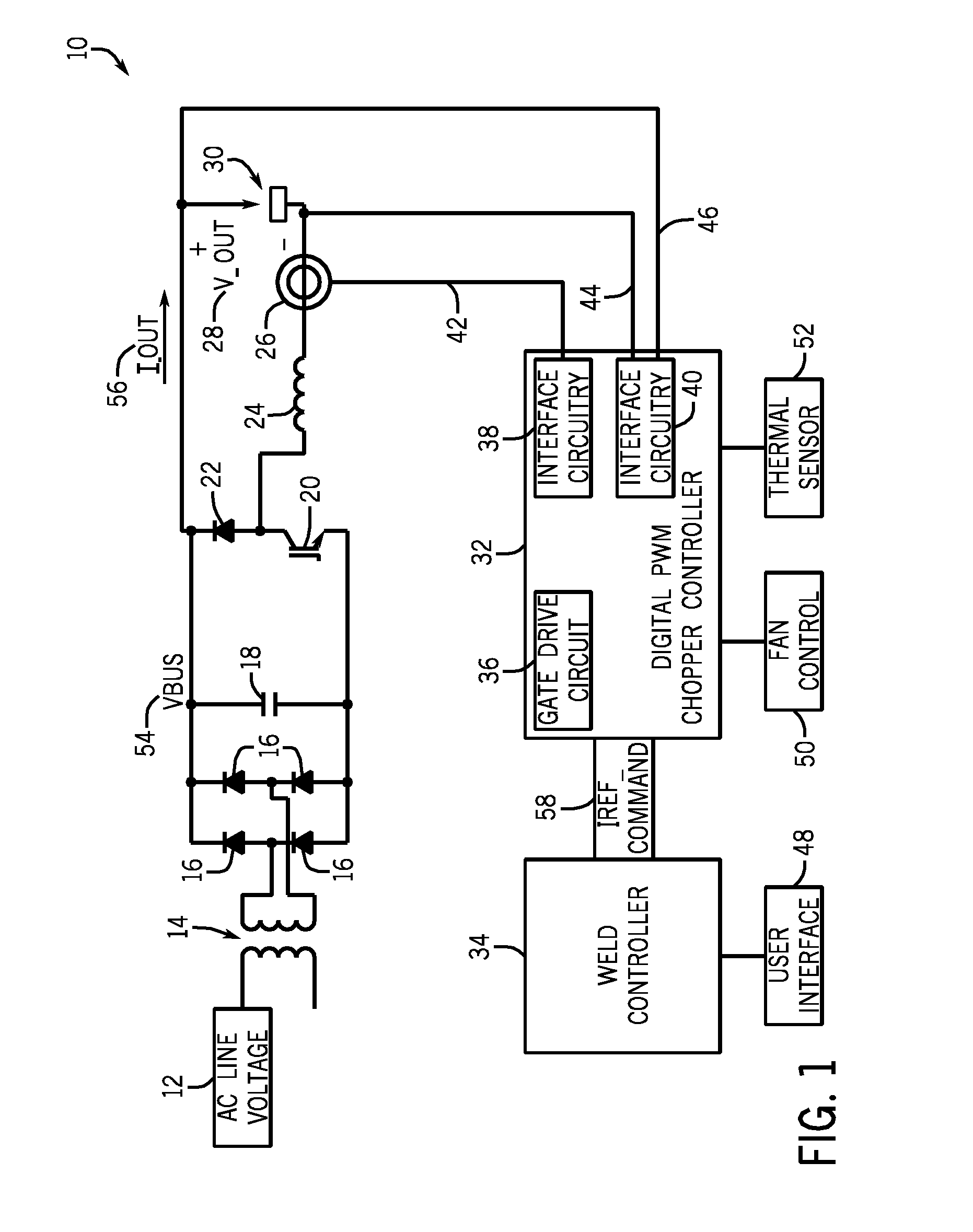

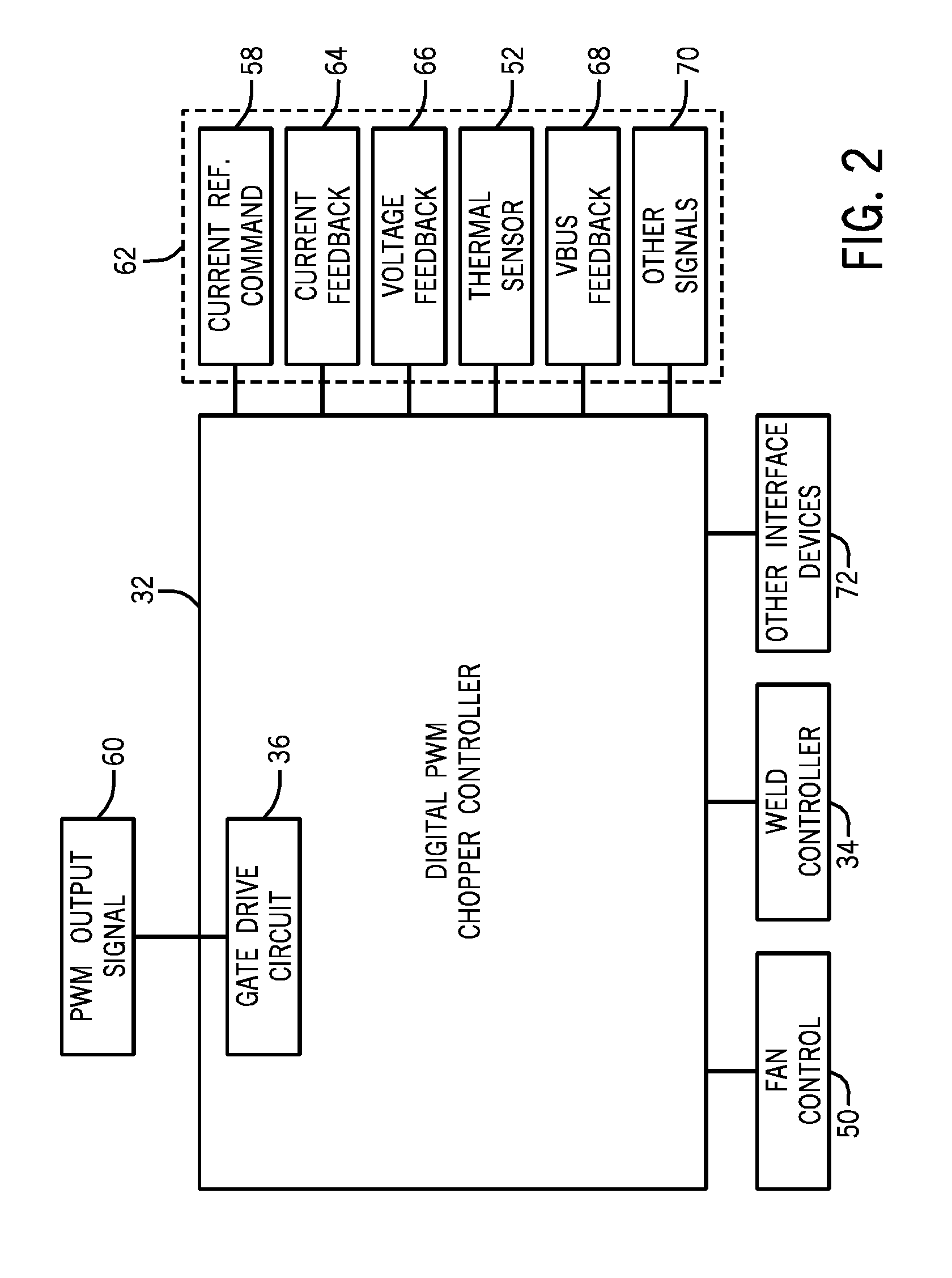

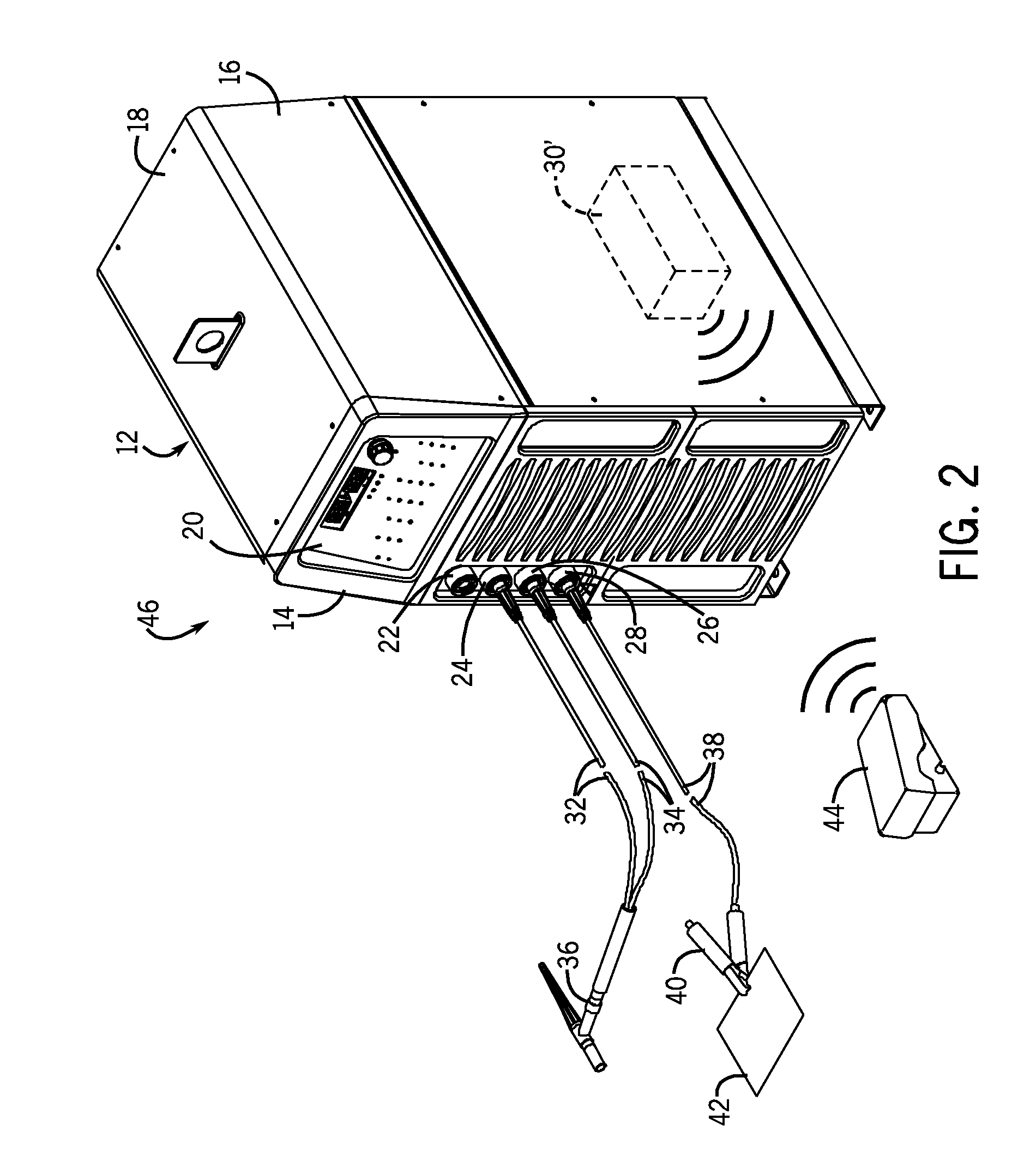

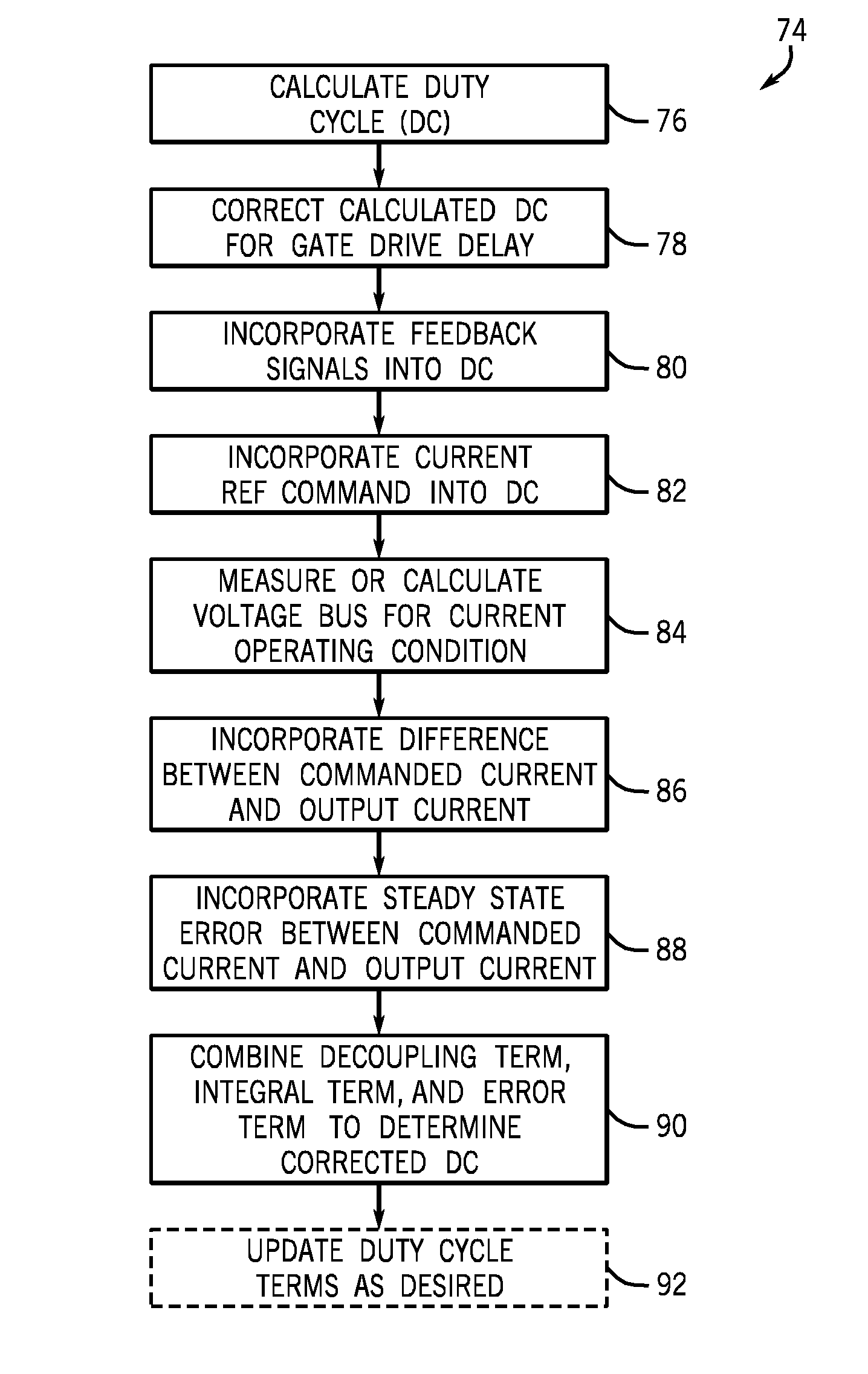

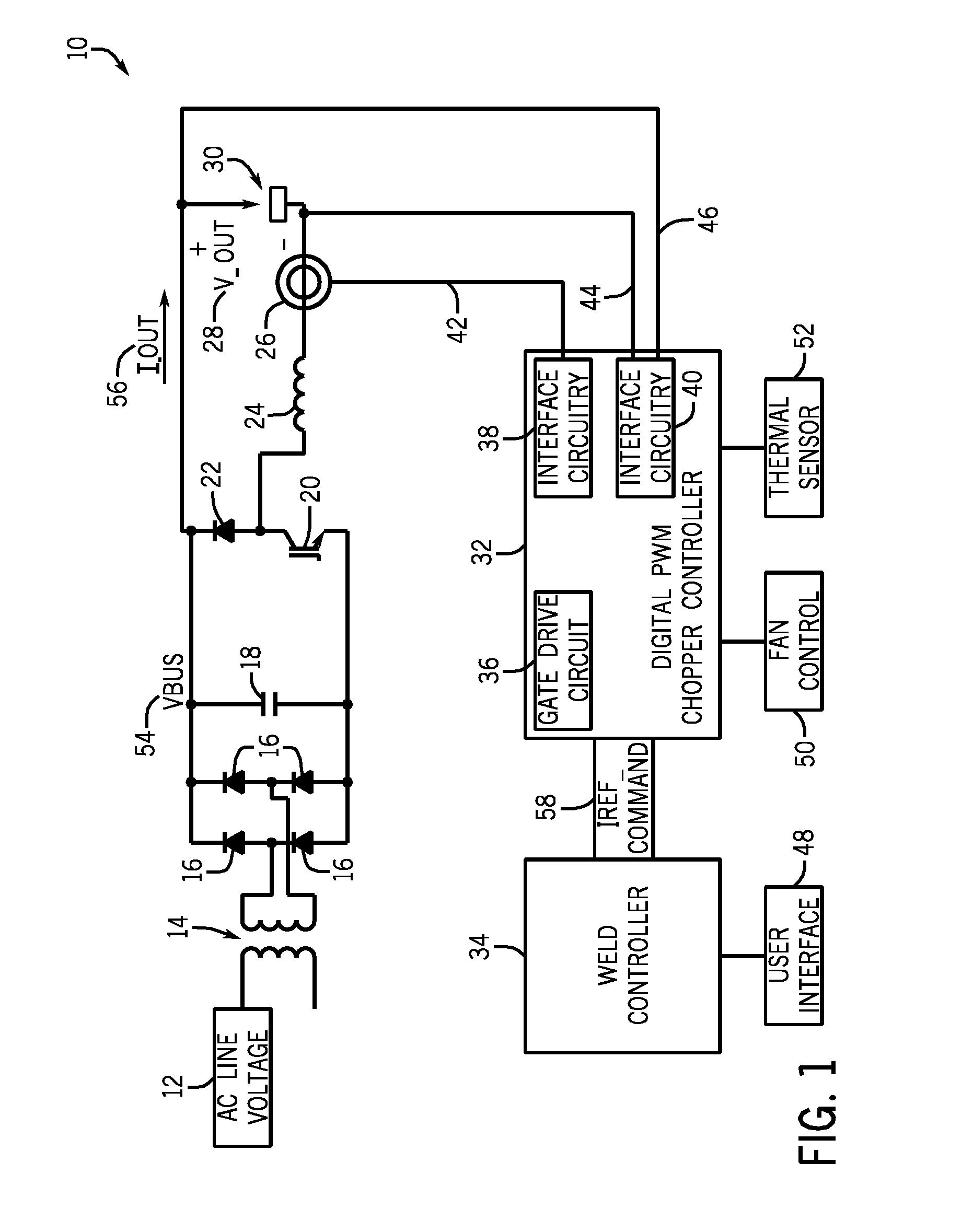

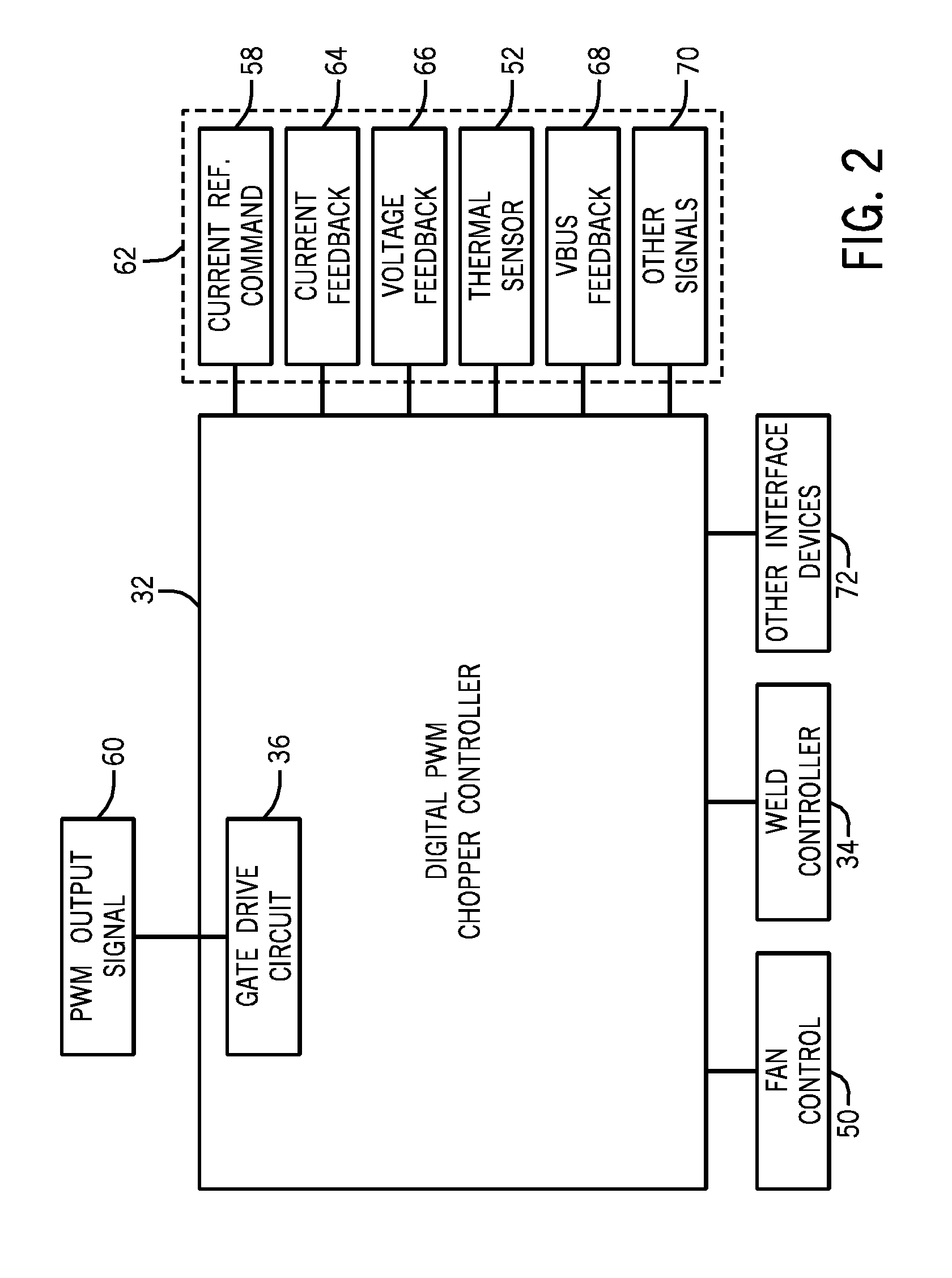

Welding power supply with digital control of duty cycle

A welding power supply including power conversion circuitry adapted to receive a primary source of power, to utilize one or more power semiconductor switches to chop the primary source of power, and to convert the chopped power to a welding output is provided. The provided welding power supply includes a pulse width modulated (PWM) digital controller including gate drive circuitry that generates a PWM output signal that controls the switching of the one or more power semiconductor switches. The PWM output signal includes a duty cycle term corrected for one or more sources of error in the welding system.

Owner:ILLINOIS TOOL WORKS INC

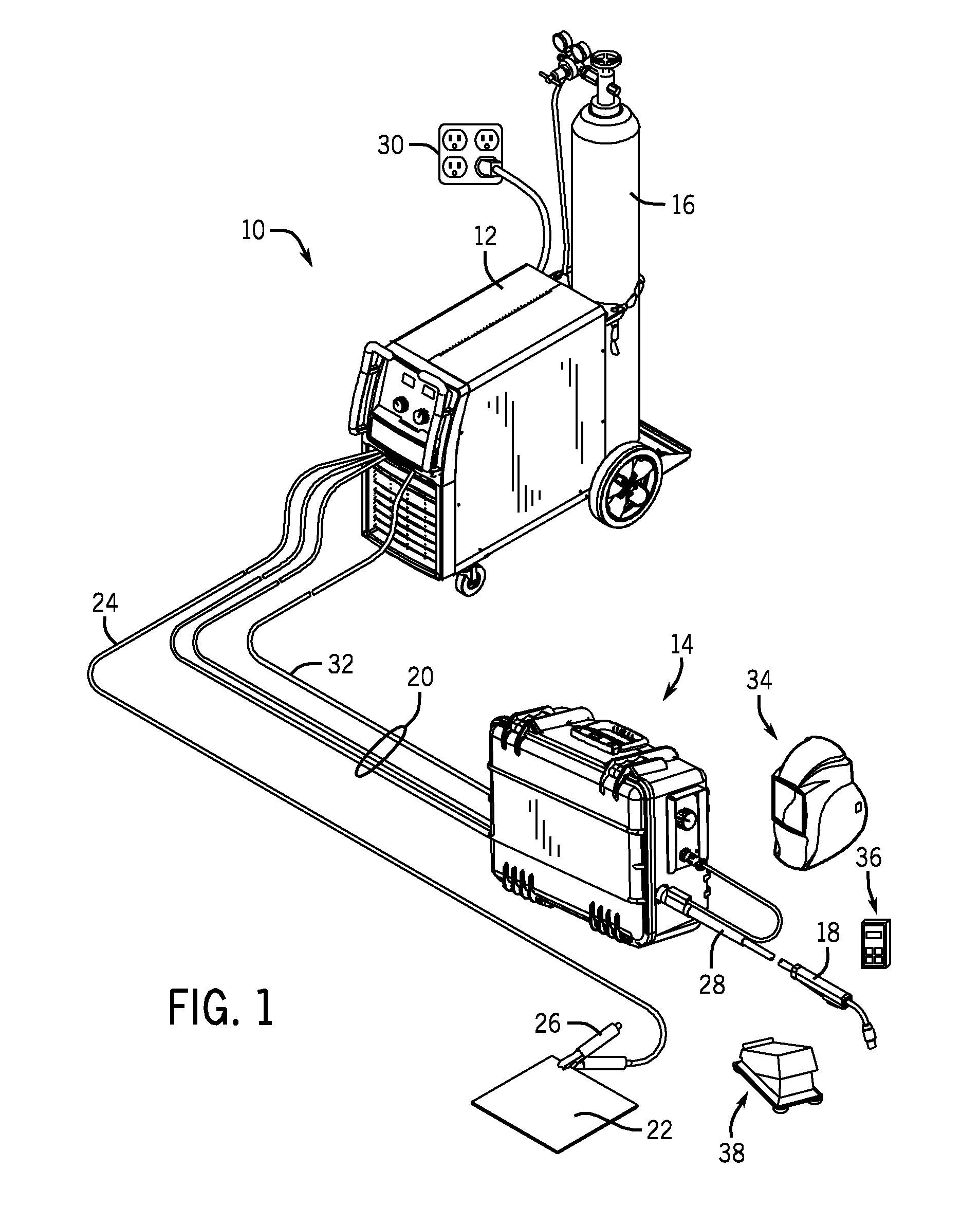

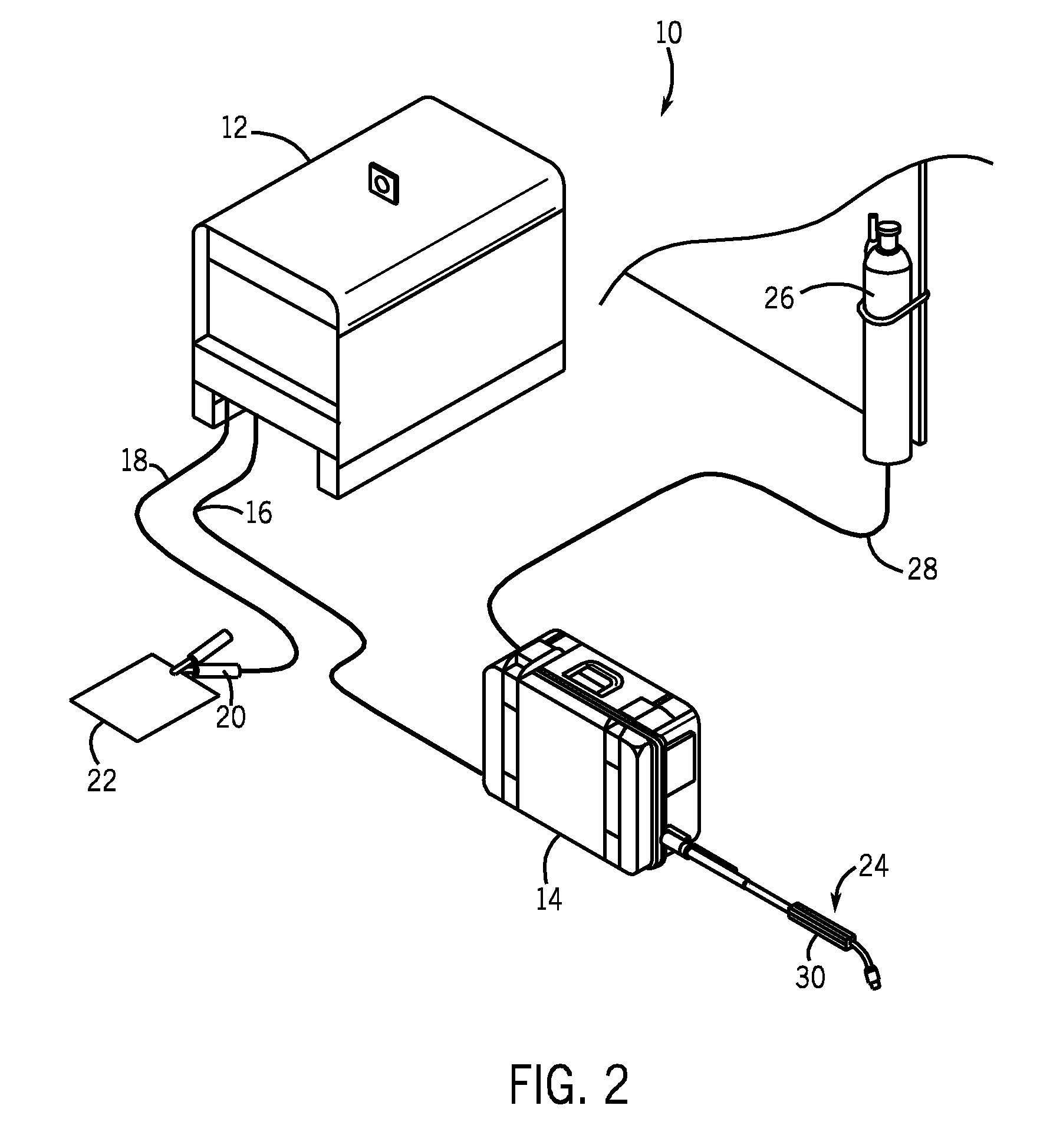

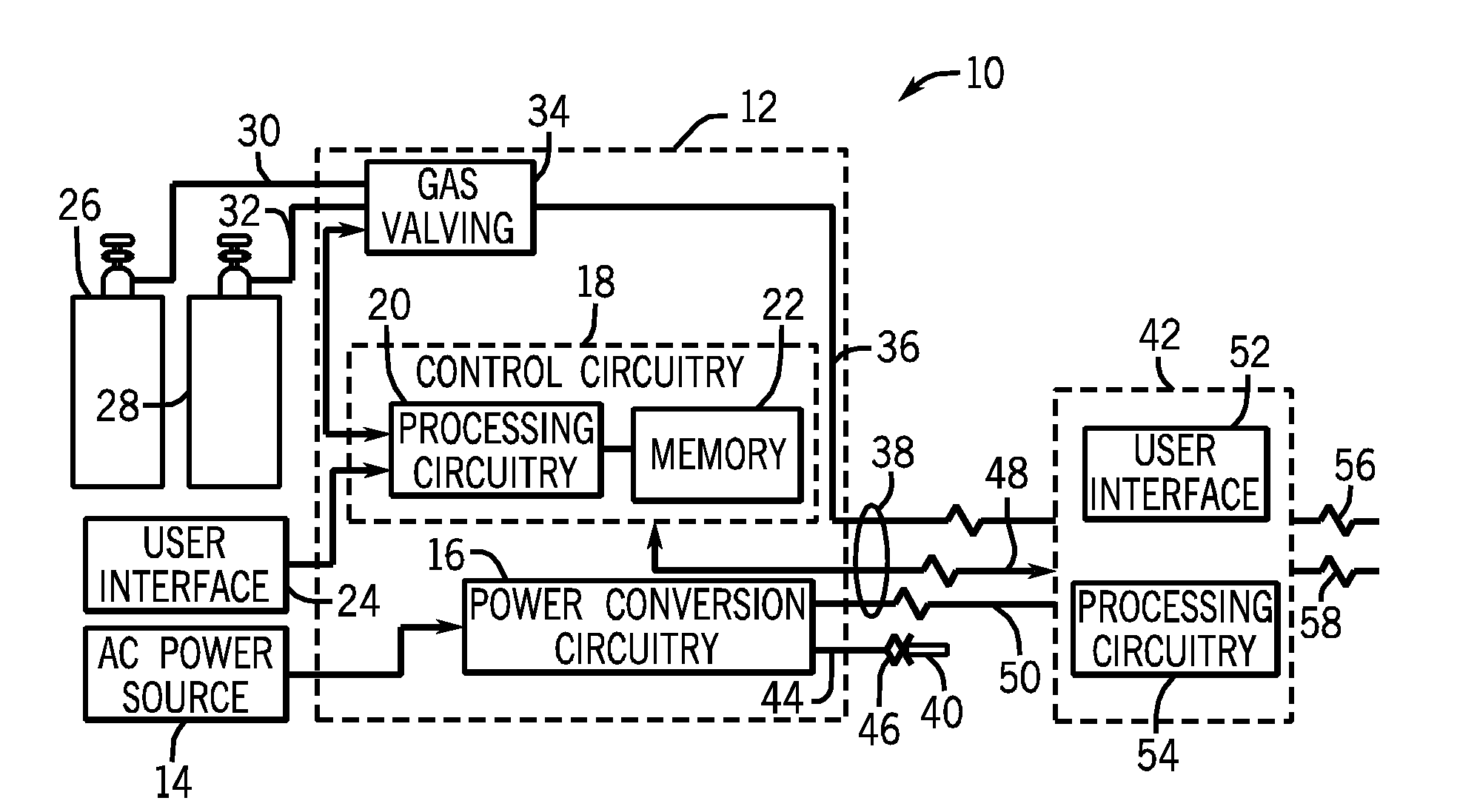

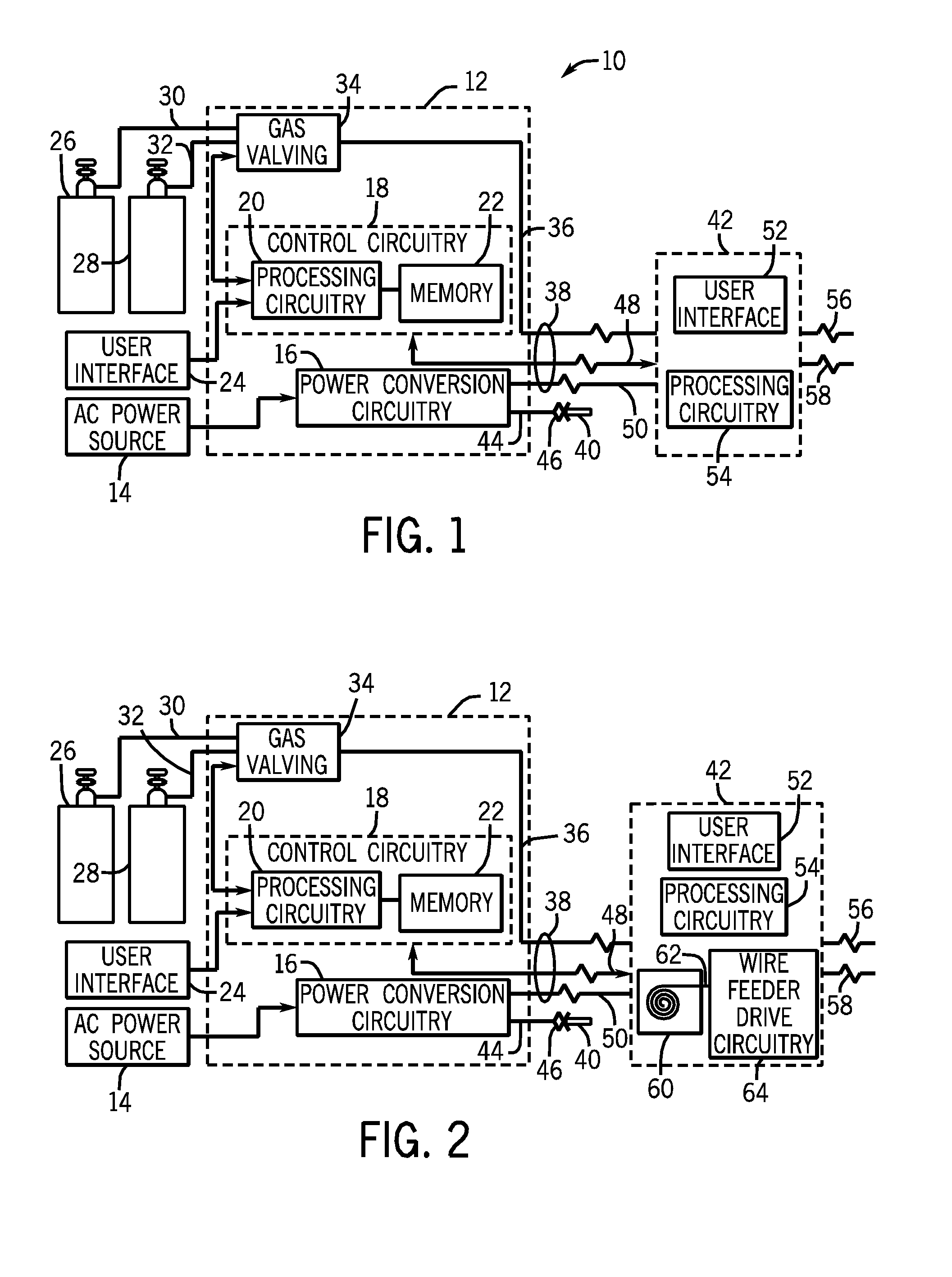

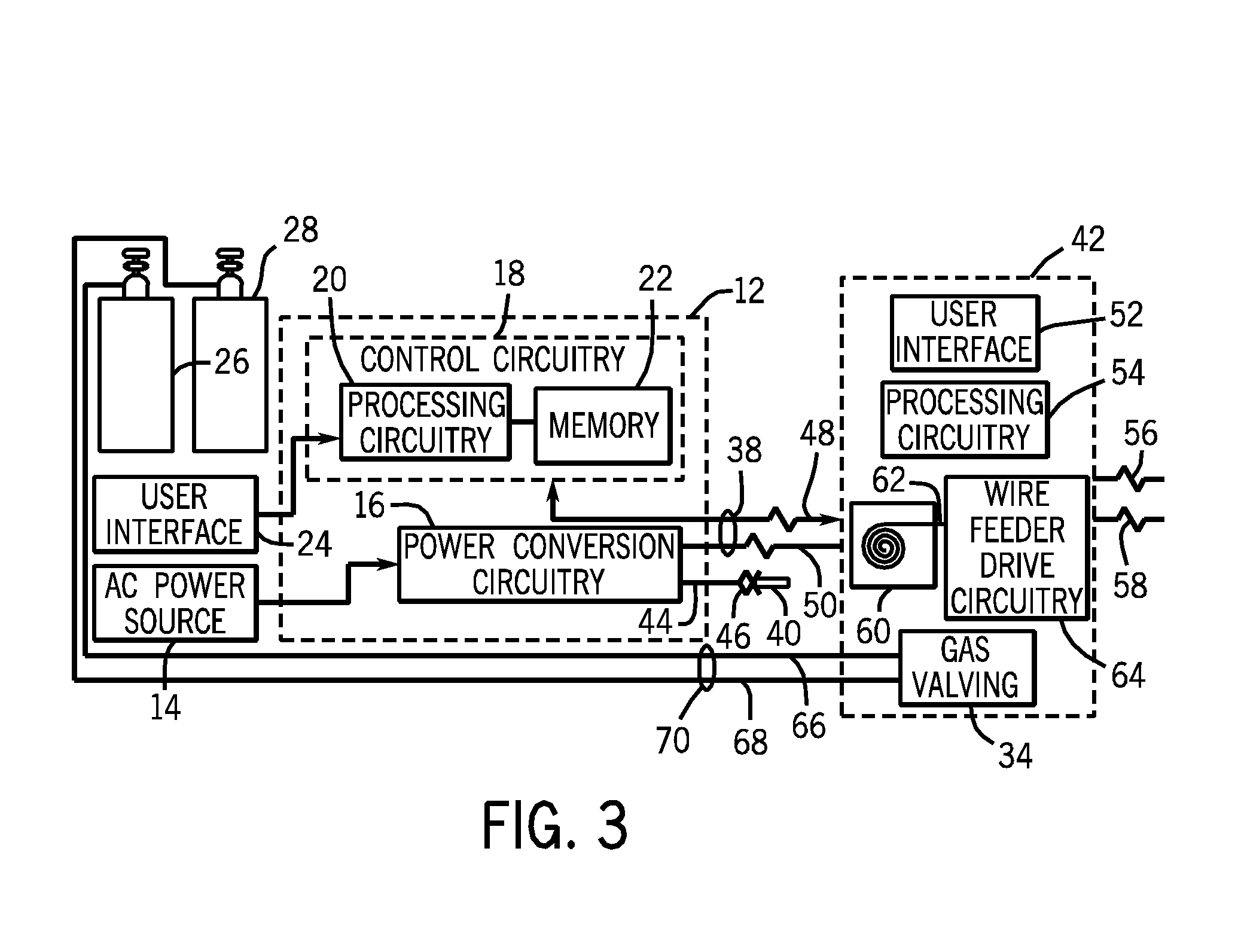

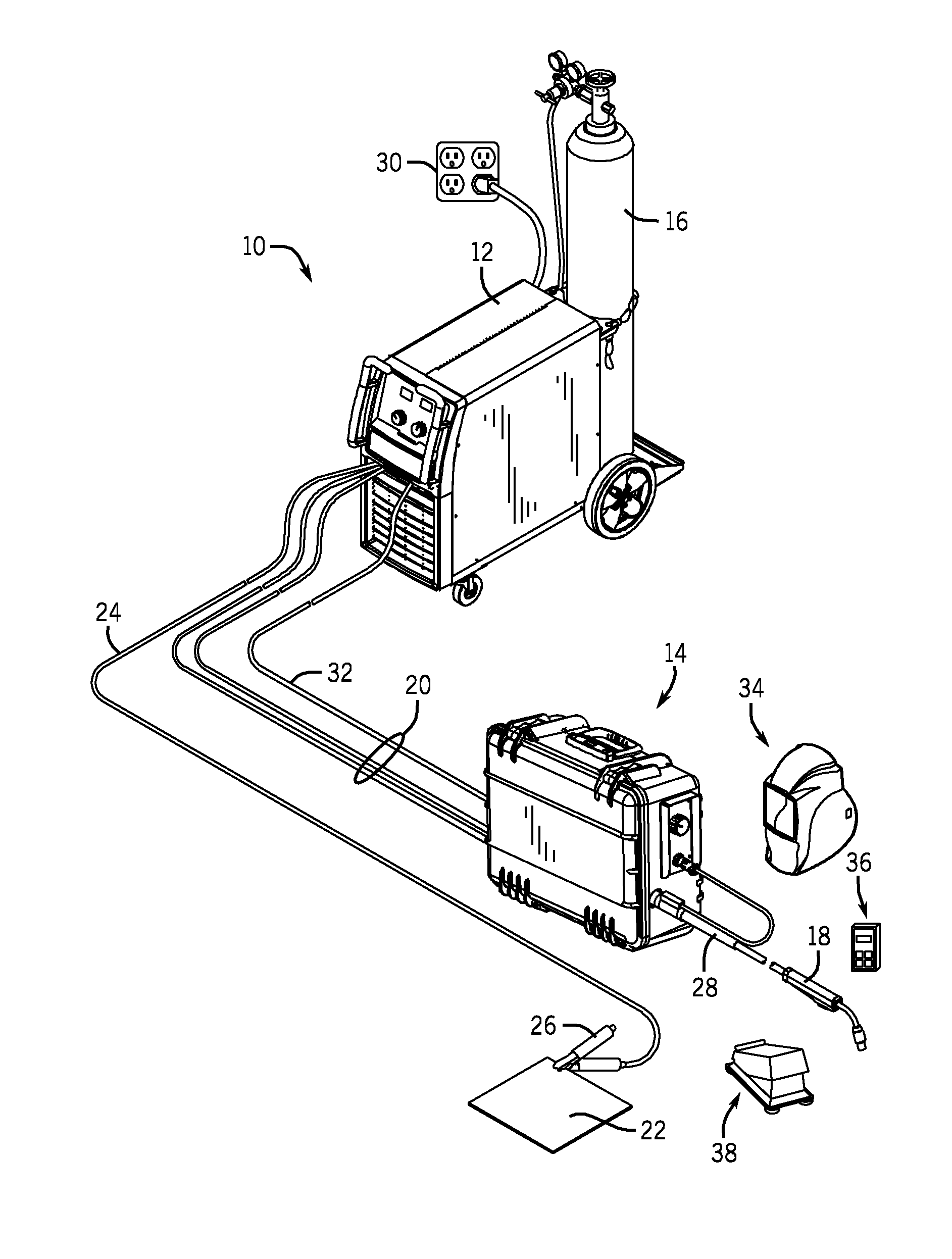

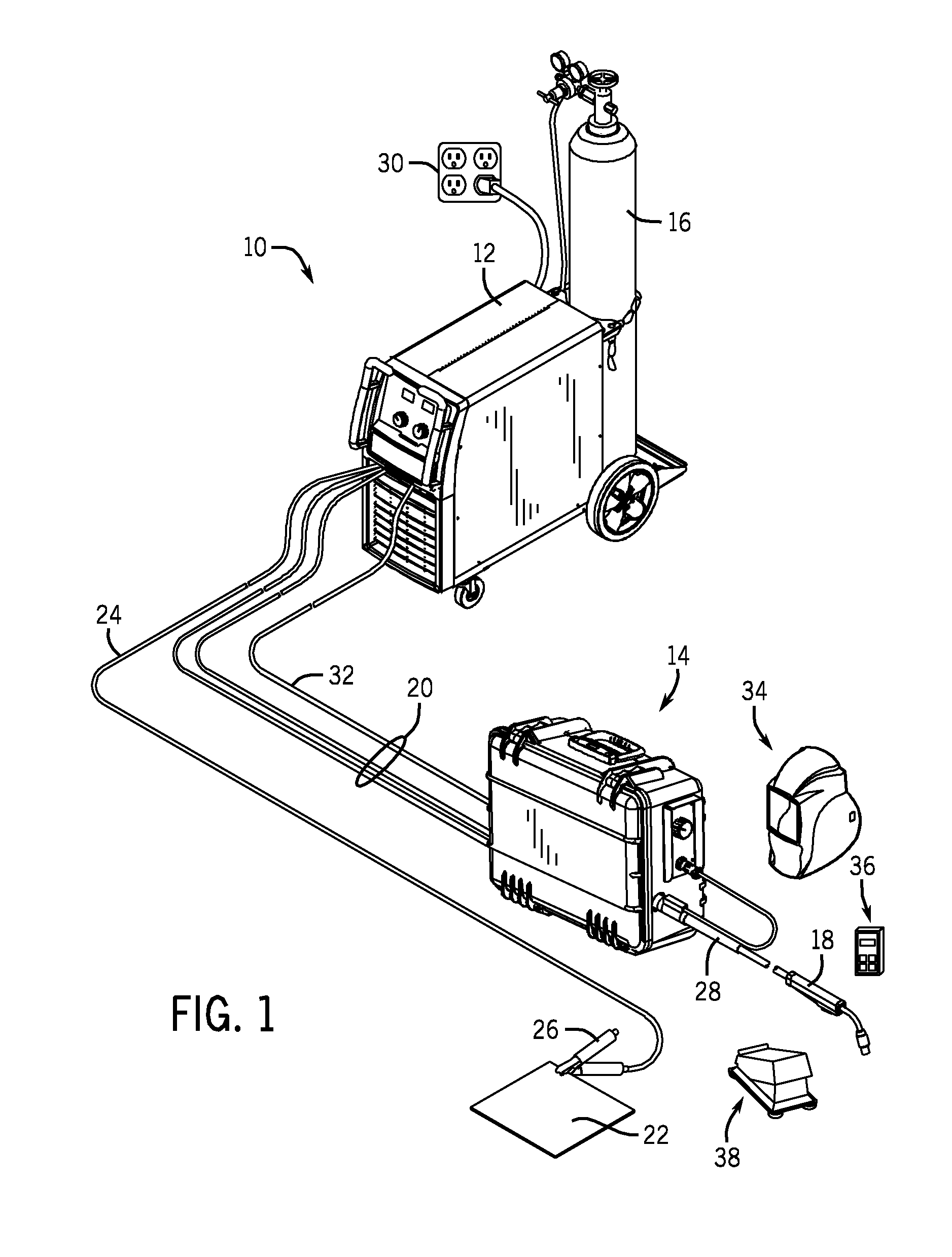

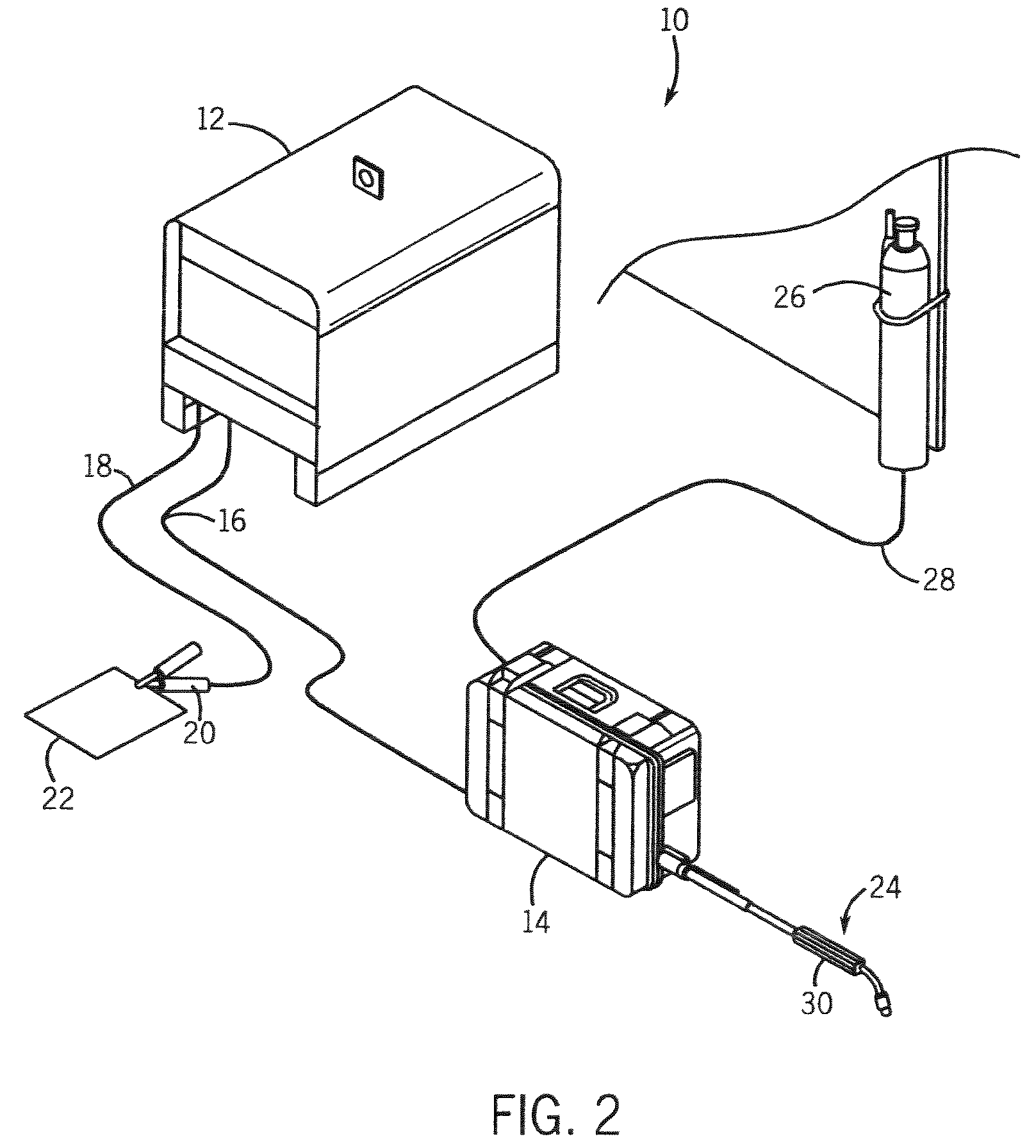

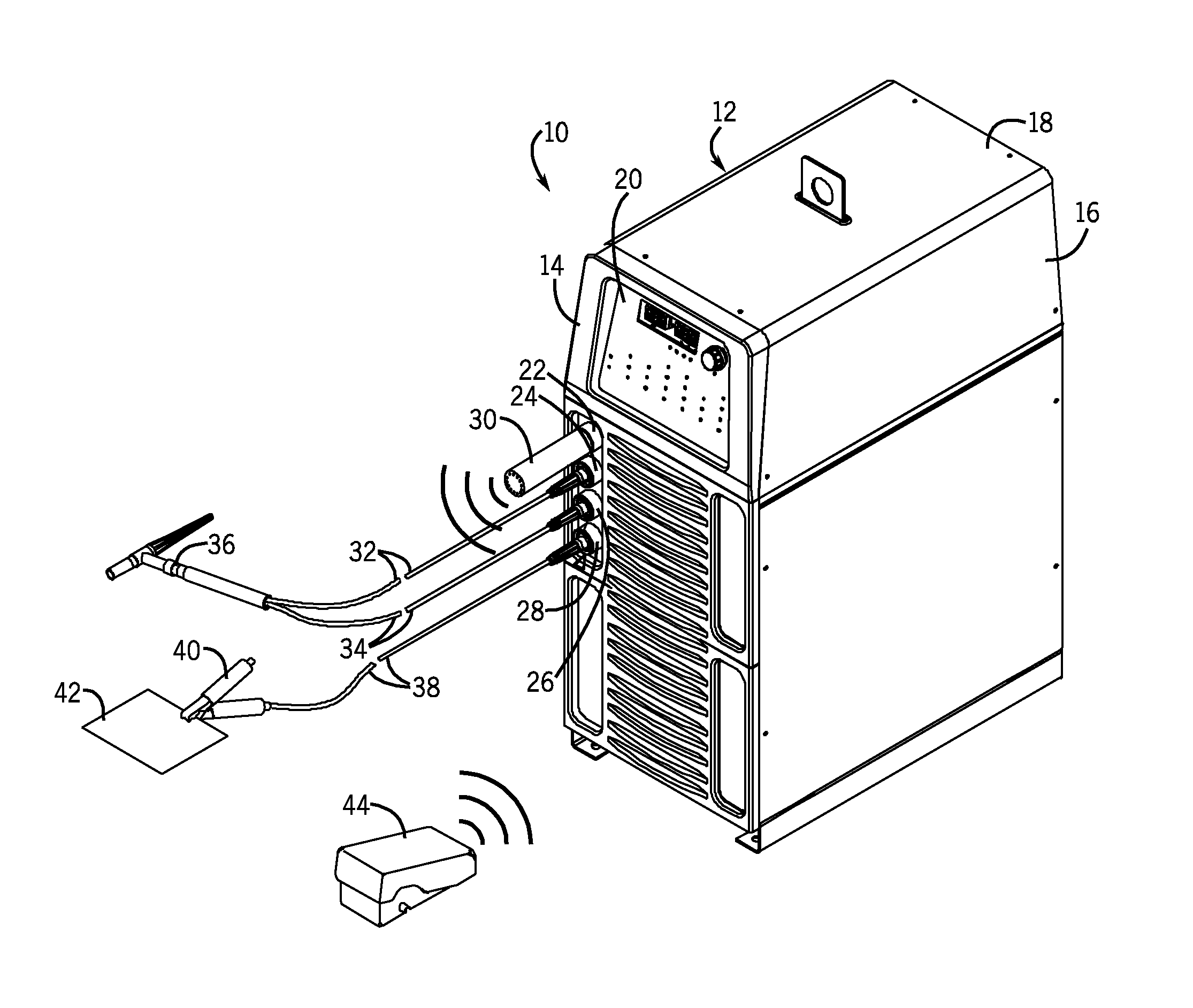

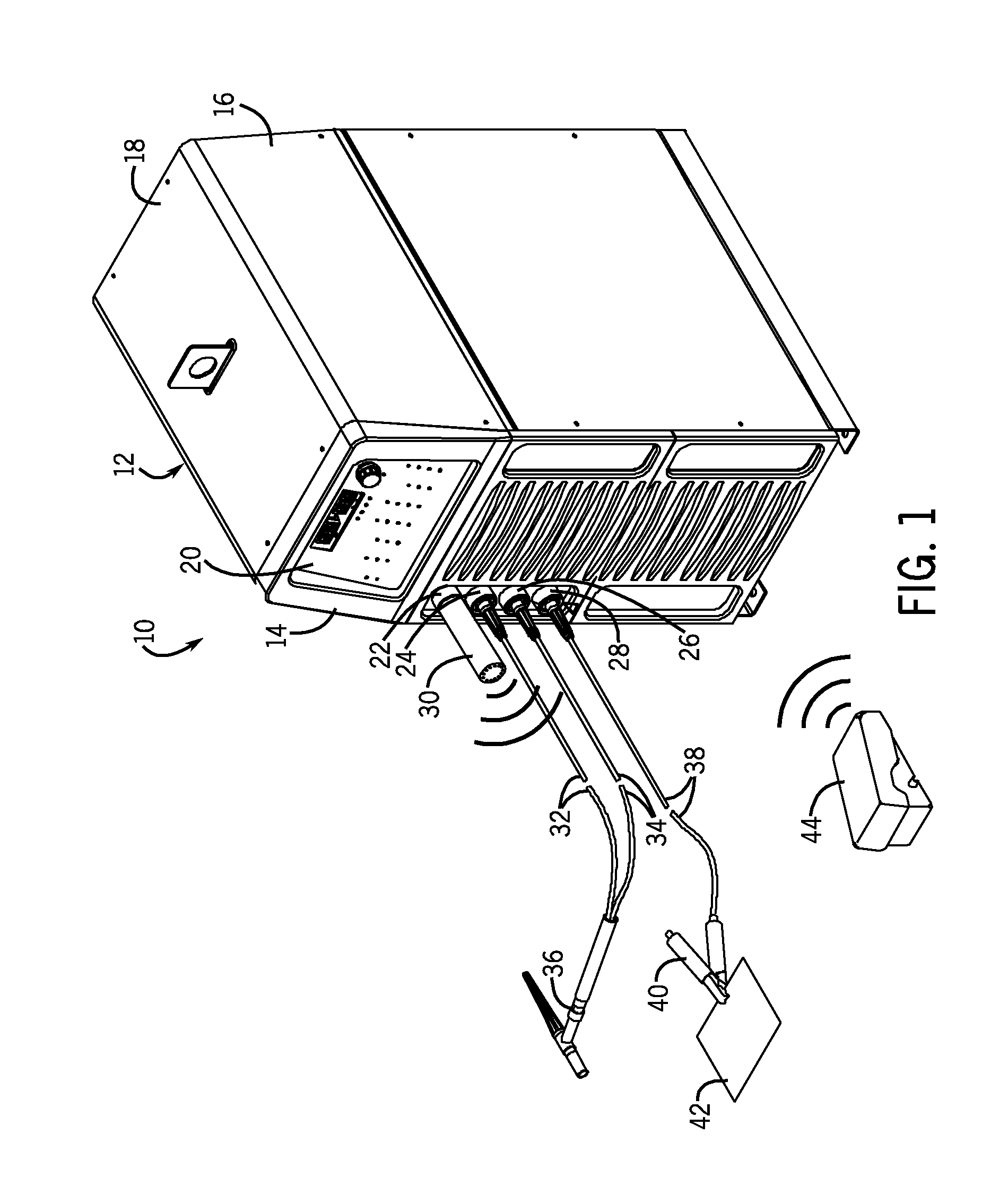

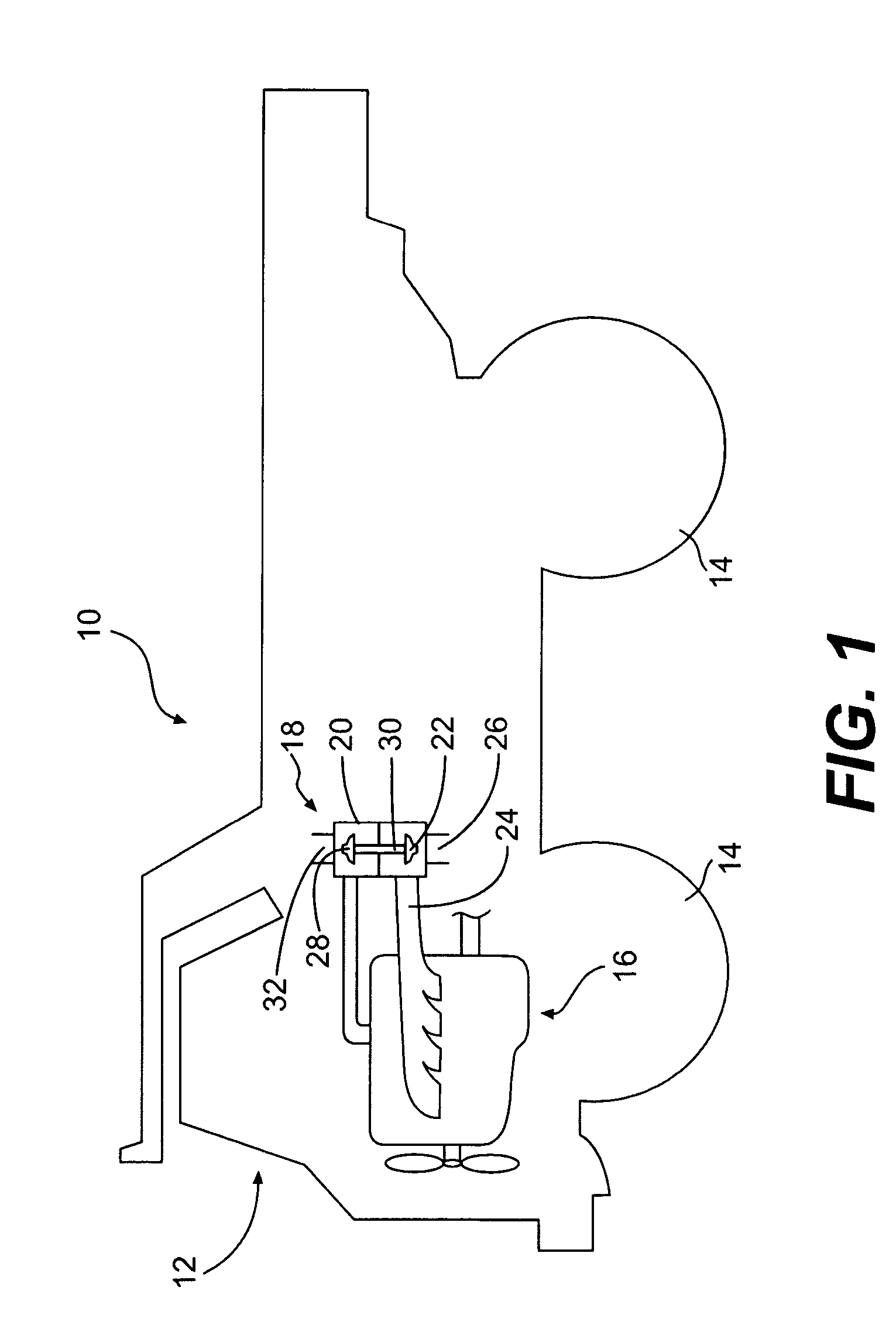

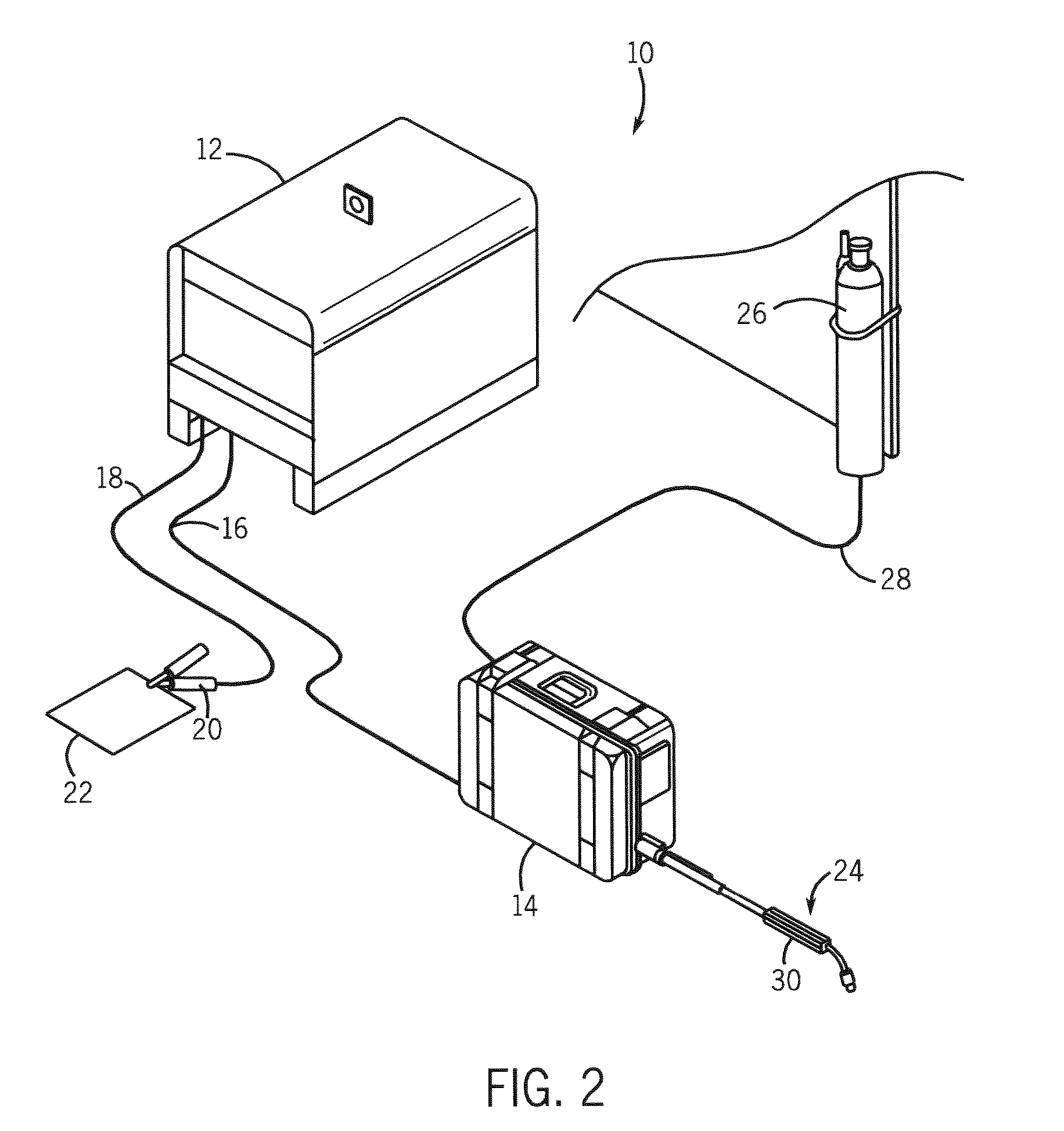

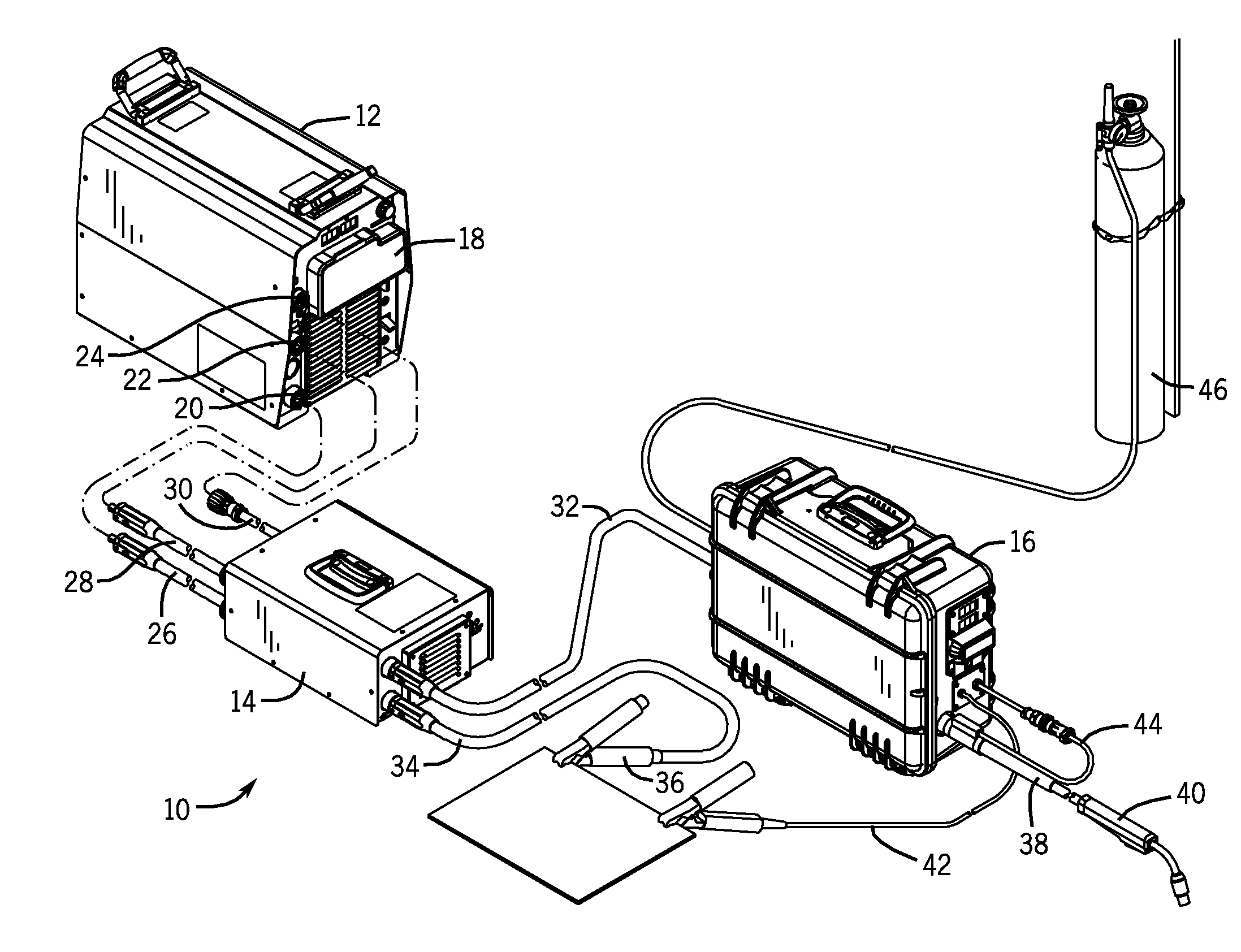

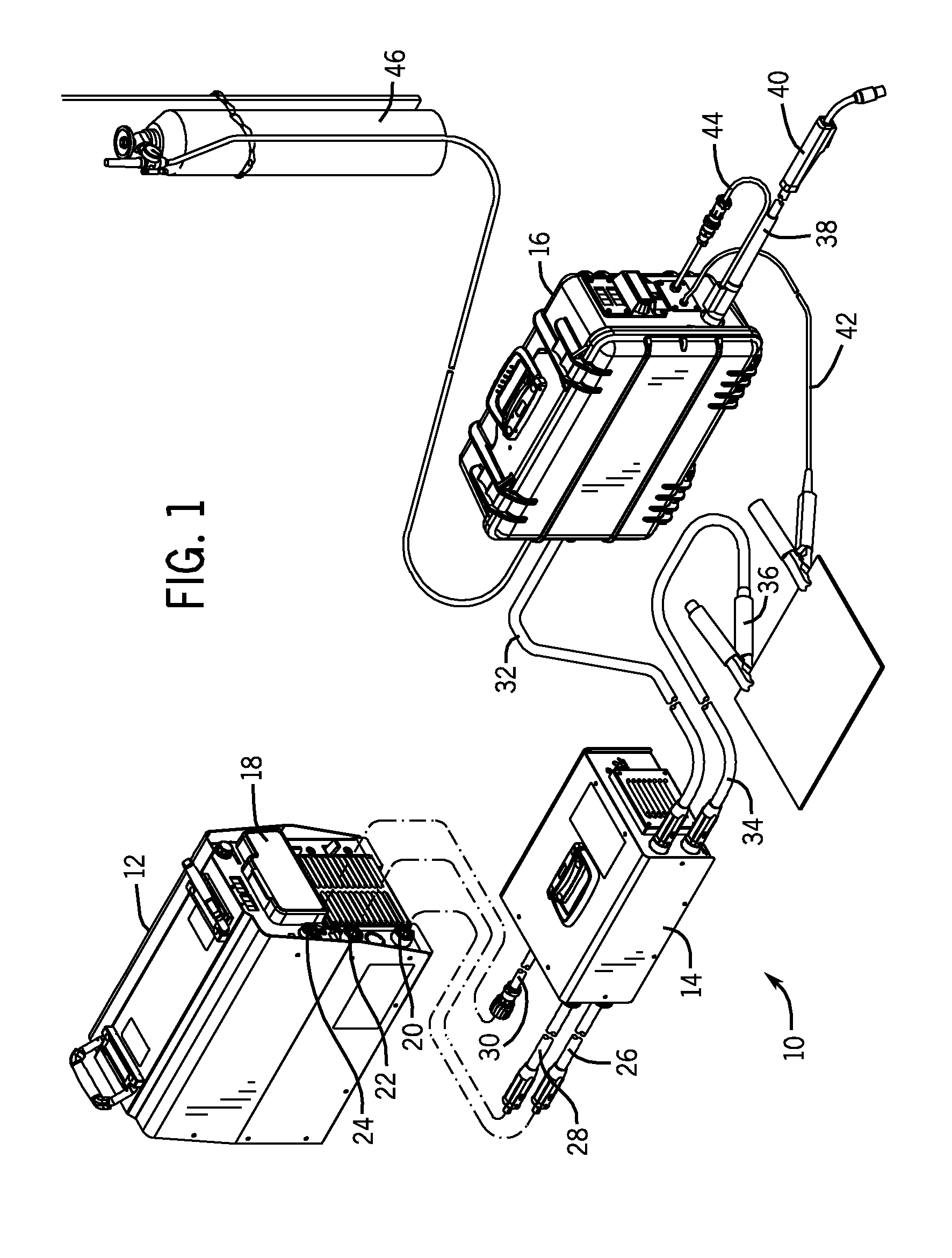

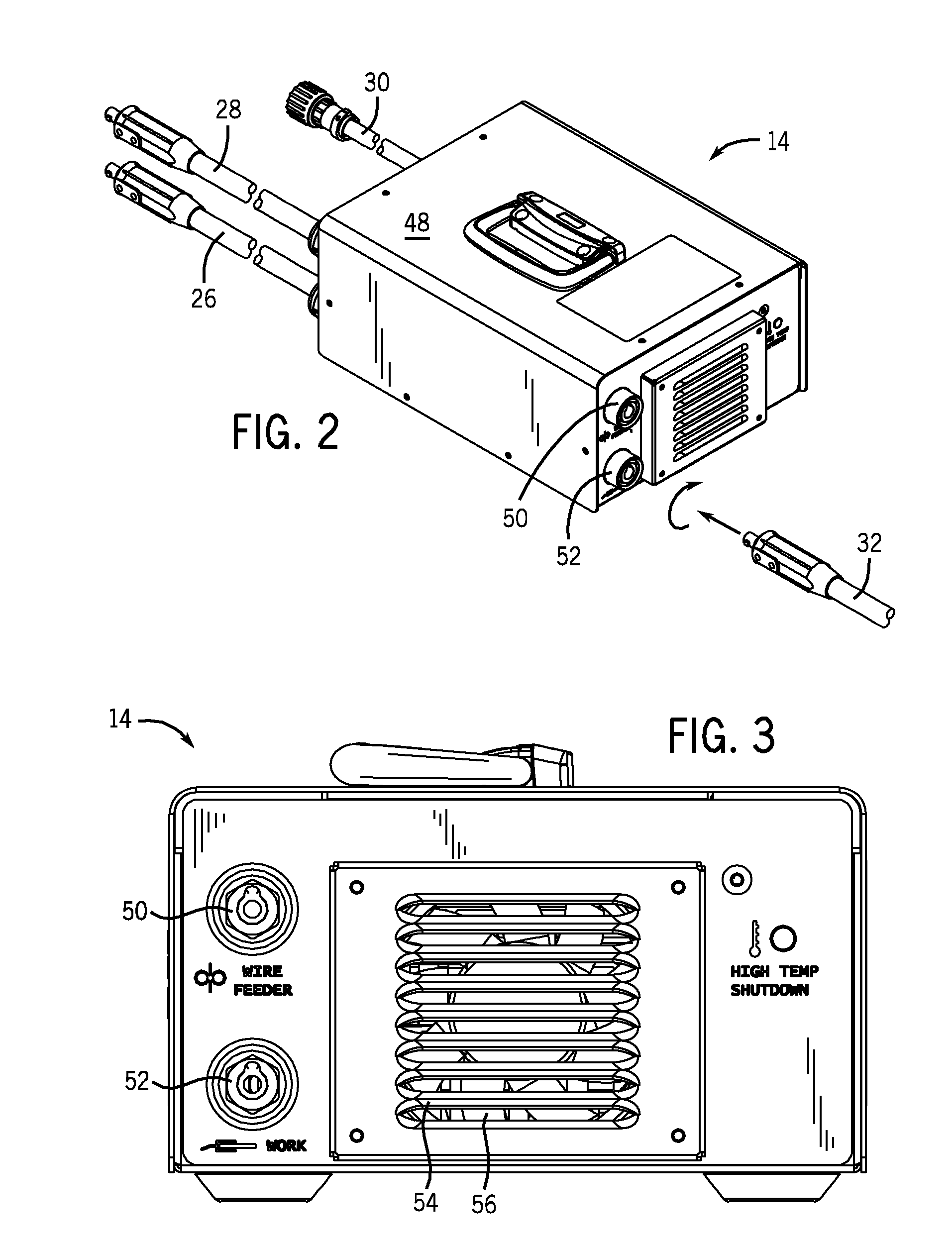

Remote welding system and method

Embodiments of a pendant associated with a multi-process welding power supply that allows a user to switch processes and reverse an output polarity while located remotely from a power supply unit are provided. Certain embodiments include a pendant with a wire spool and wire feeder drive circuitry that is configured to activate spooling during MIG welding. Control circuitry that may include processing circuitry and memory is provided. The control system may disable redundant controls on the power supply unit user interface when the power supply unit is connected to the pendant via a supply cable. Additionally, the control system may set the process, set the polarity, enable or disable a wire feed, and enable or disable gas flow according to inputs received via a user interface on either the power supply unit or the pendant.

Owner:ILLINOIS TOOL WORKS INC

Welding system with power line communication

ActiveUS20110073569A1Convenient control functionalityConvenient powerArc welding apparatusWelding monitoring devicesDriver circuitWelding power supply

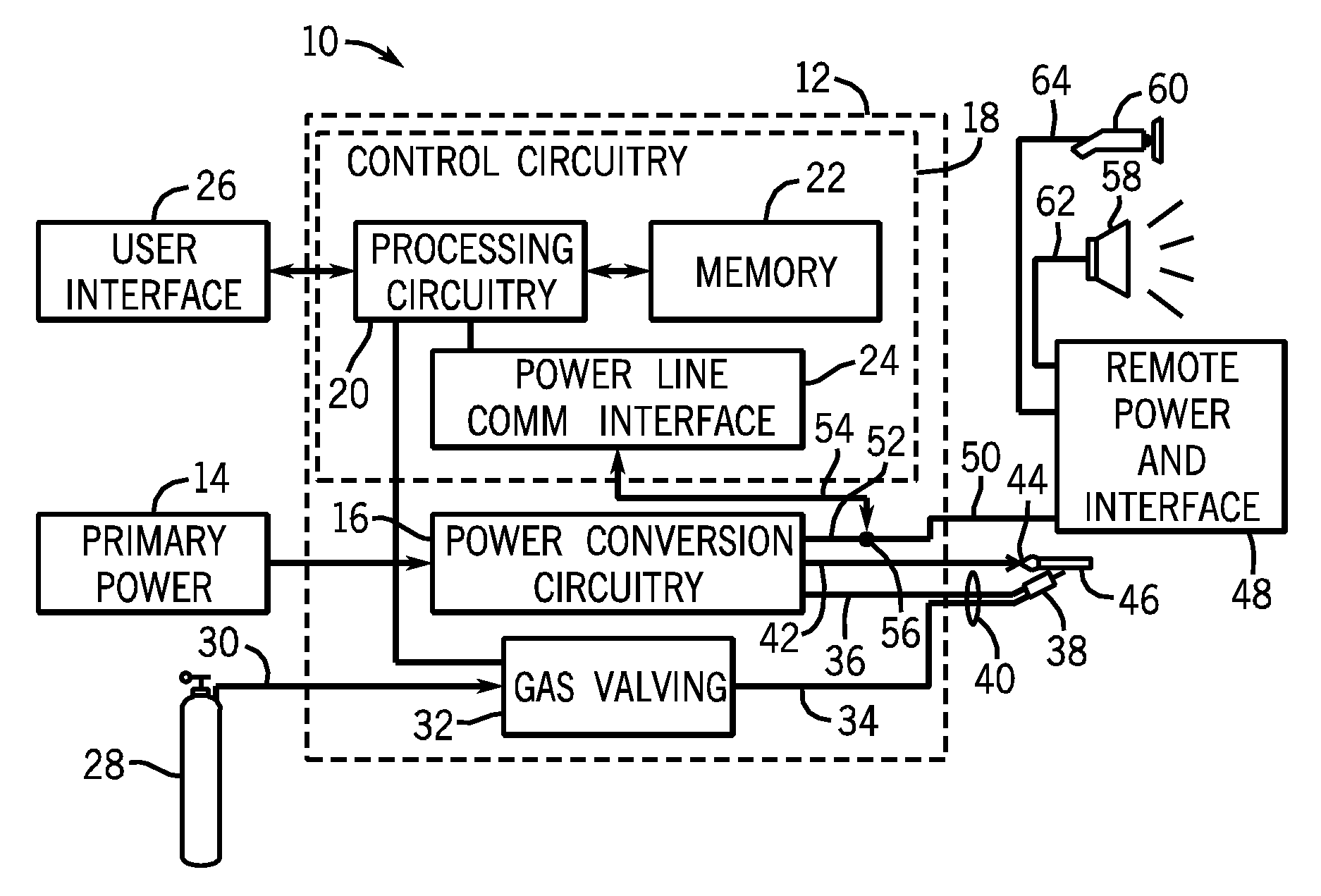

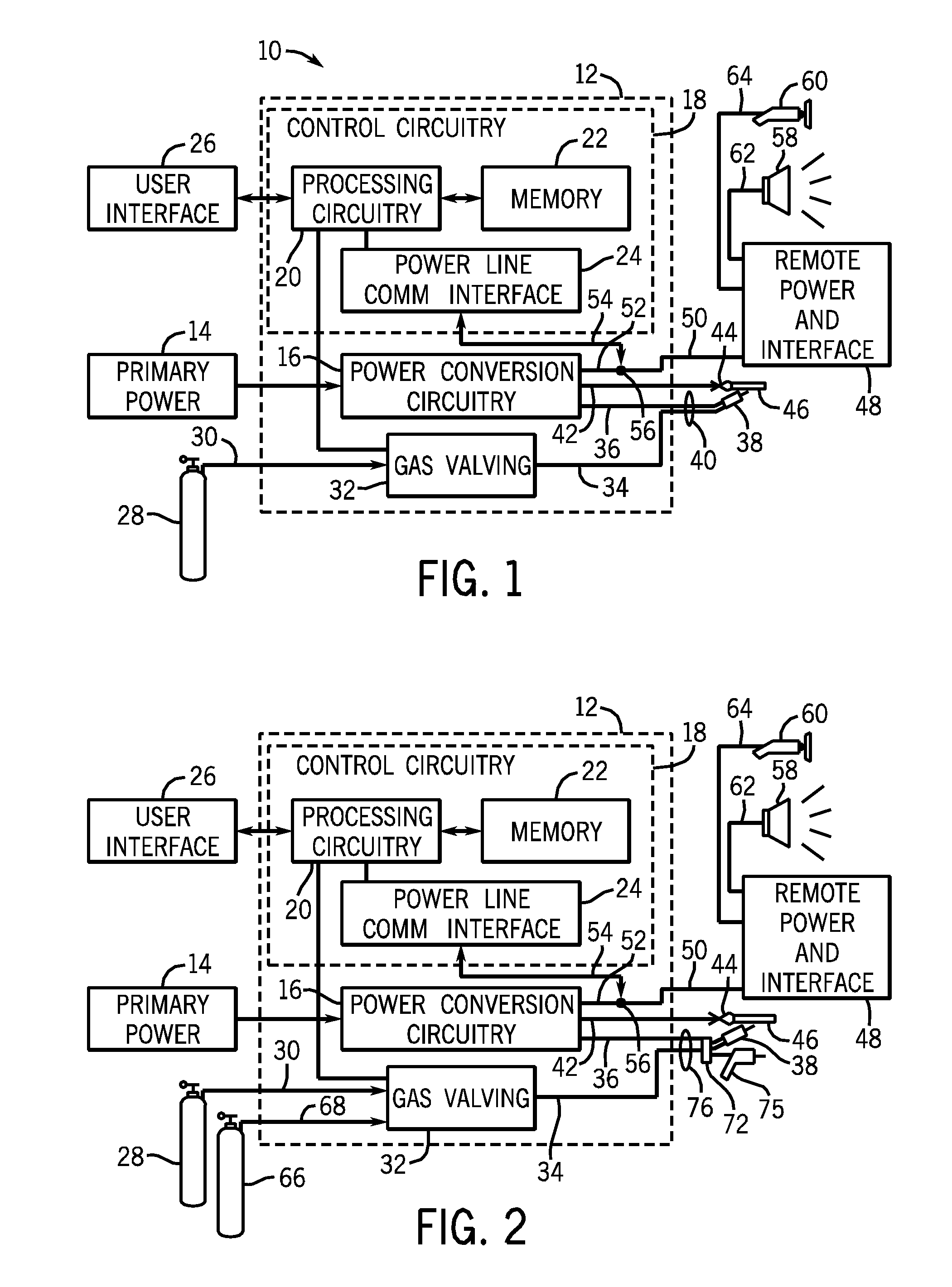

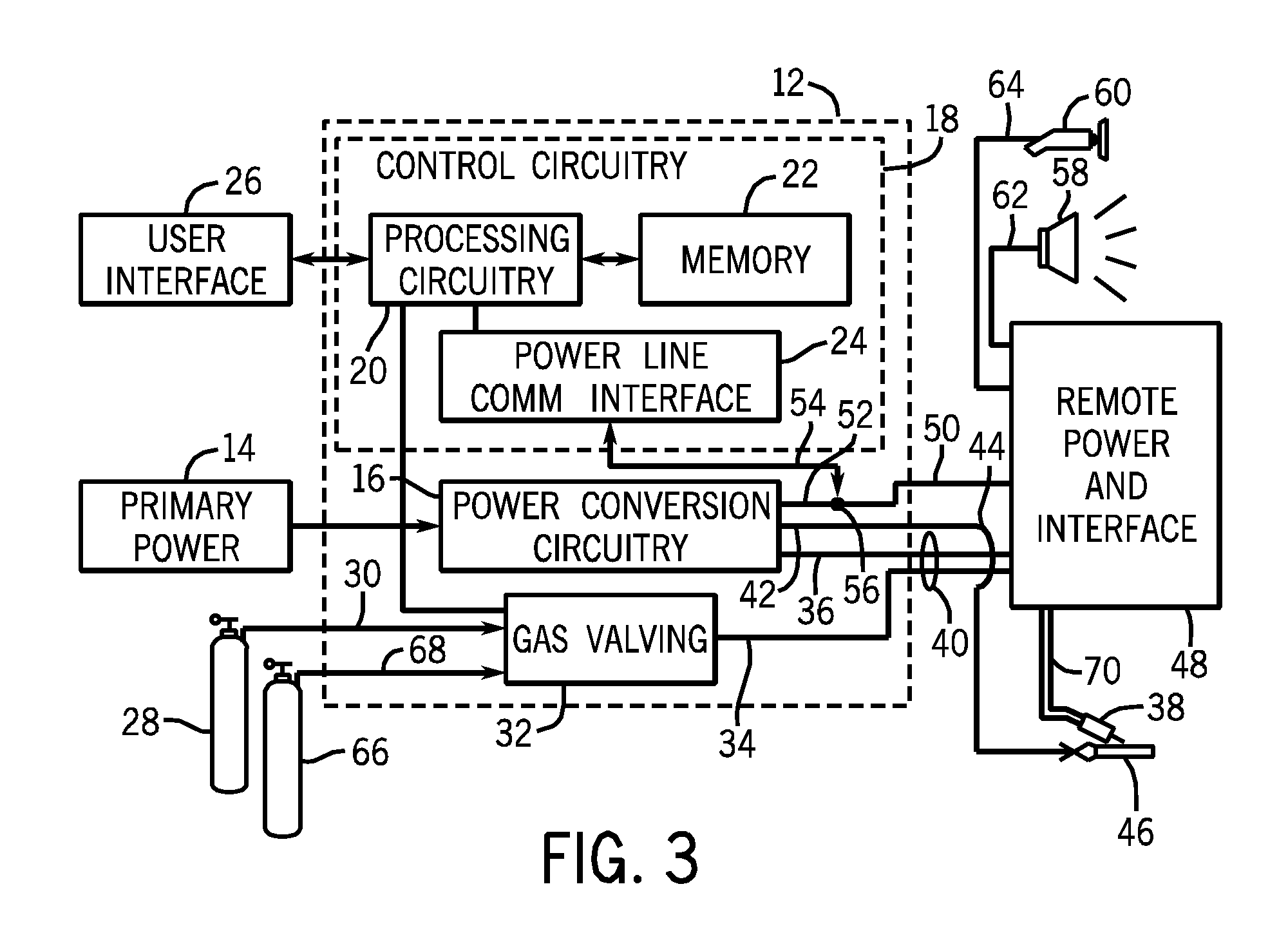

Various welding systems that provide communication over auxiliary or weld power lines are provided. The disclosed embodiments may include a multi-process welding power supply that is communicatively coupled to a pendant via an auxiliary conduit that facilitates the exchange of data and power between components of the welding system. In some embodiments, the pendant may also include auxiliary outlets that allow an operator to power auxiliary devices at the weld location. The disclosed embodiments further include a pendant with a wire spool and wire feeder drive circuitry that is configured to activate spooling during MIG welding. Embodiments are provided that also allow for bidirectional data communication over a power line in networked welding systems.

Owner:ILLINOIS TOOL WORKS INC

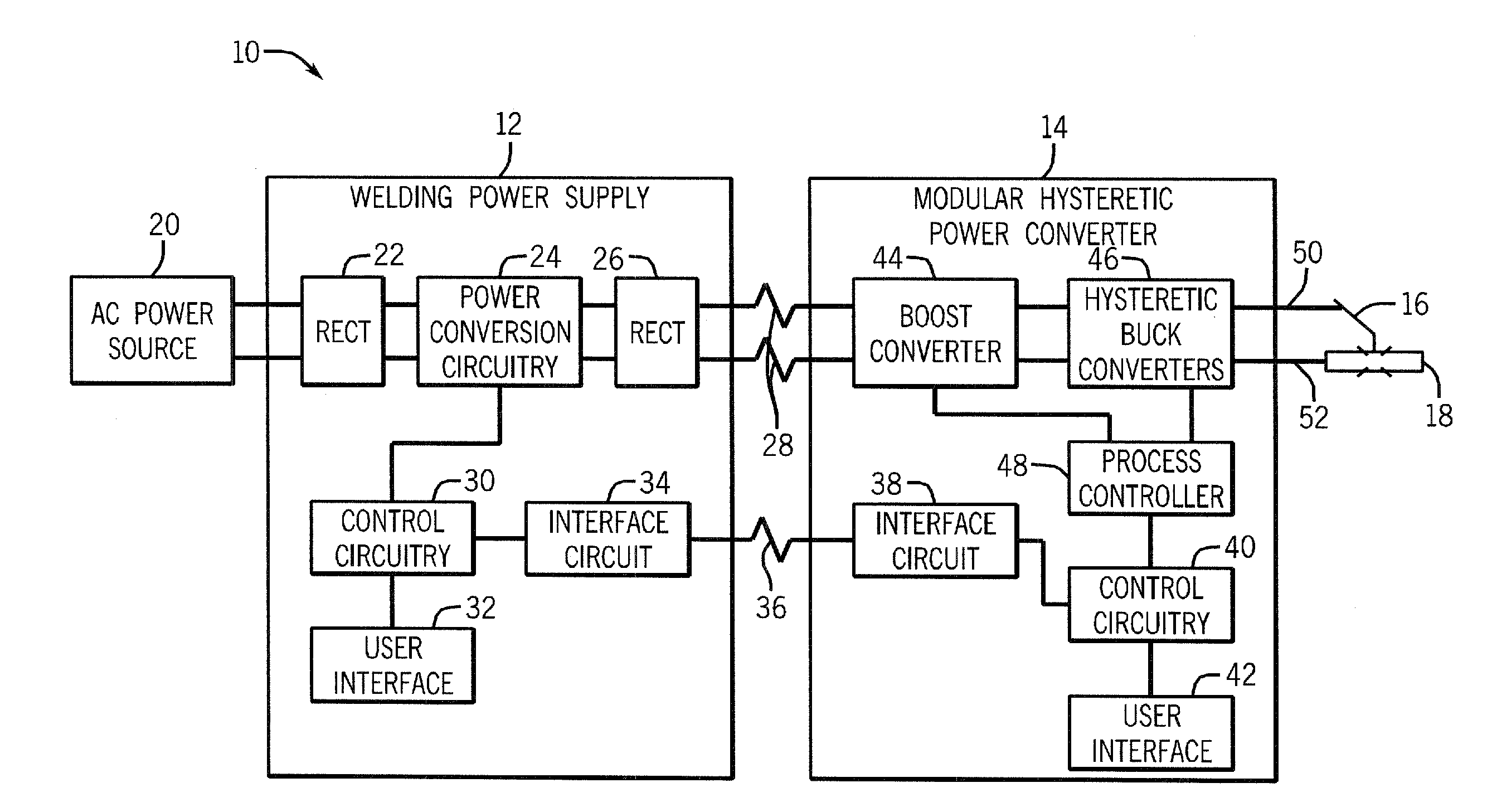

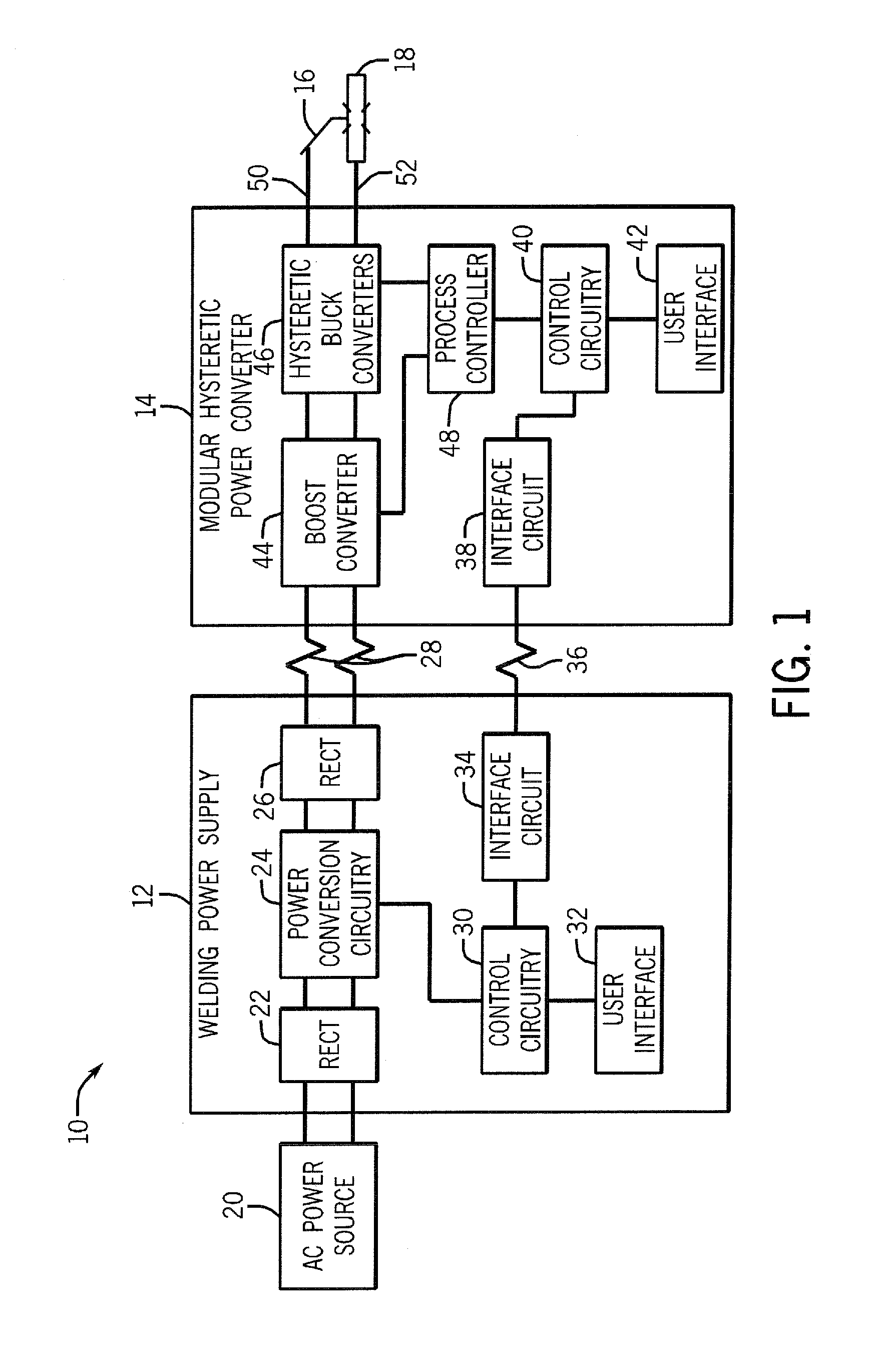

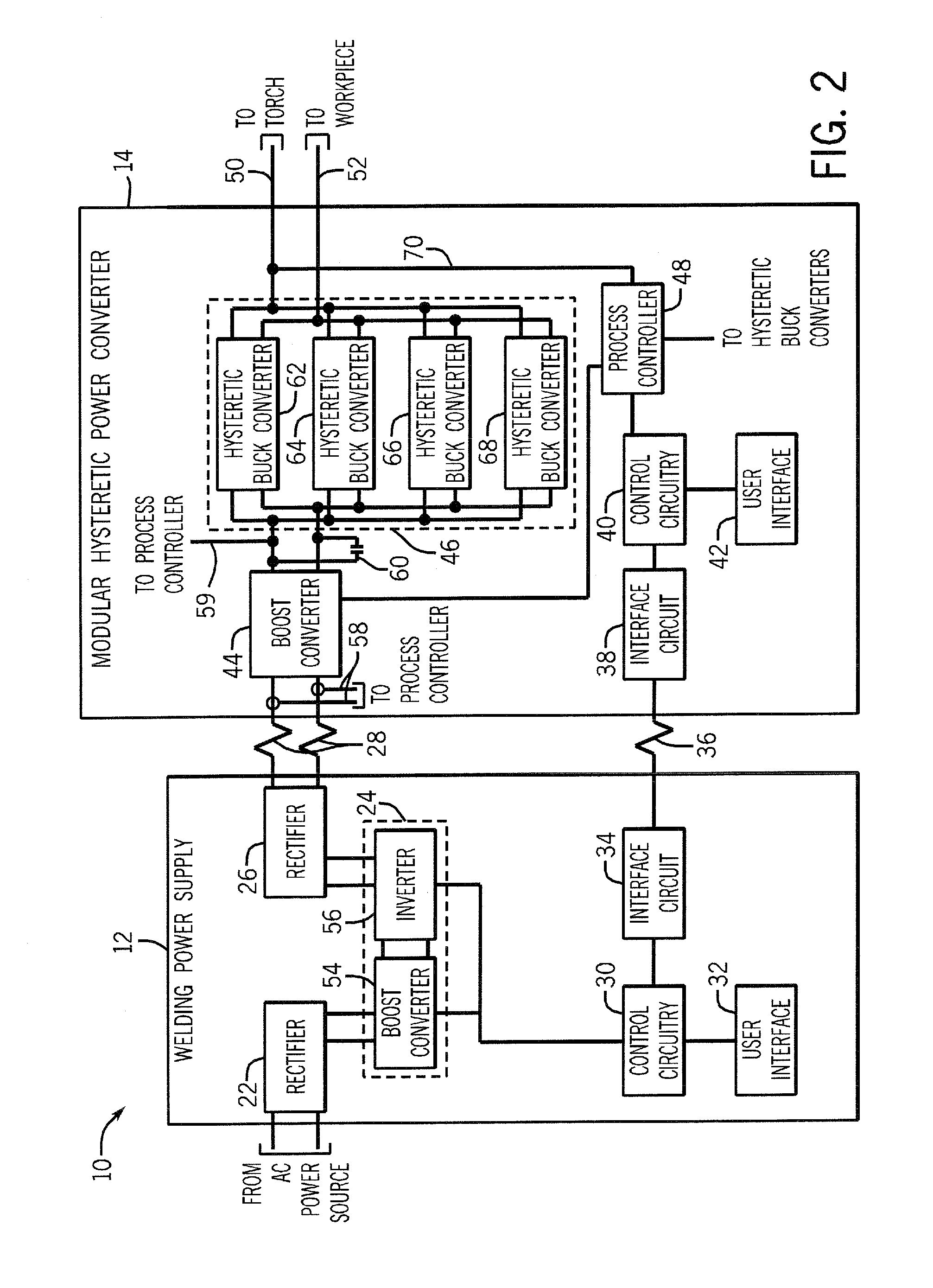

Modular direct current power source

A modular direct current power source is provided. One welding power supply system includes a plurality of hysteretic buck converters coupled in parallel. The hysteretic buck converters are configured to receive a common input and to provide combined output power to a common load based upon the common input.

Owner:ILLINOIS TOOL WORKS INC

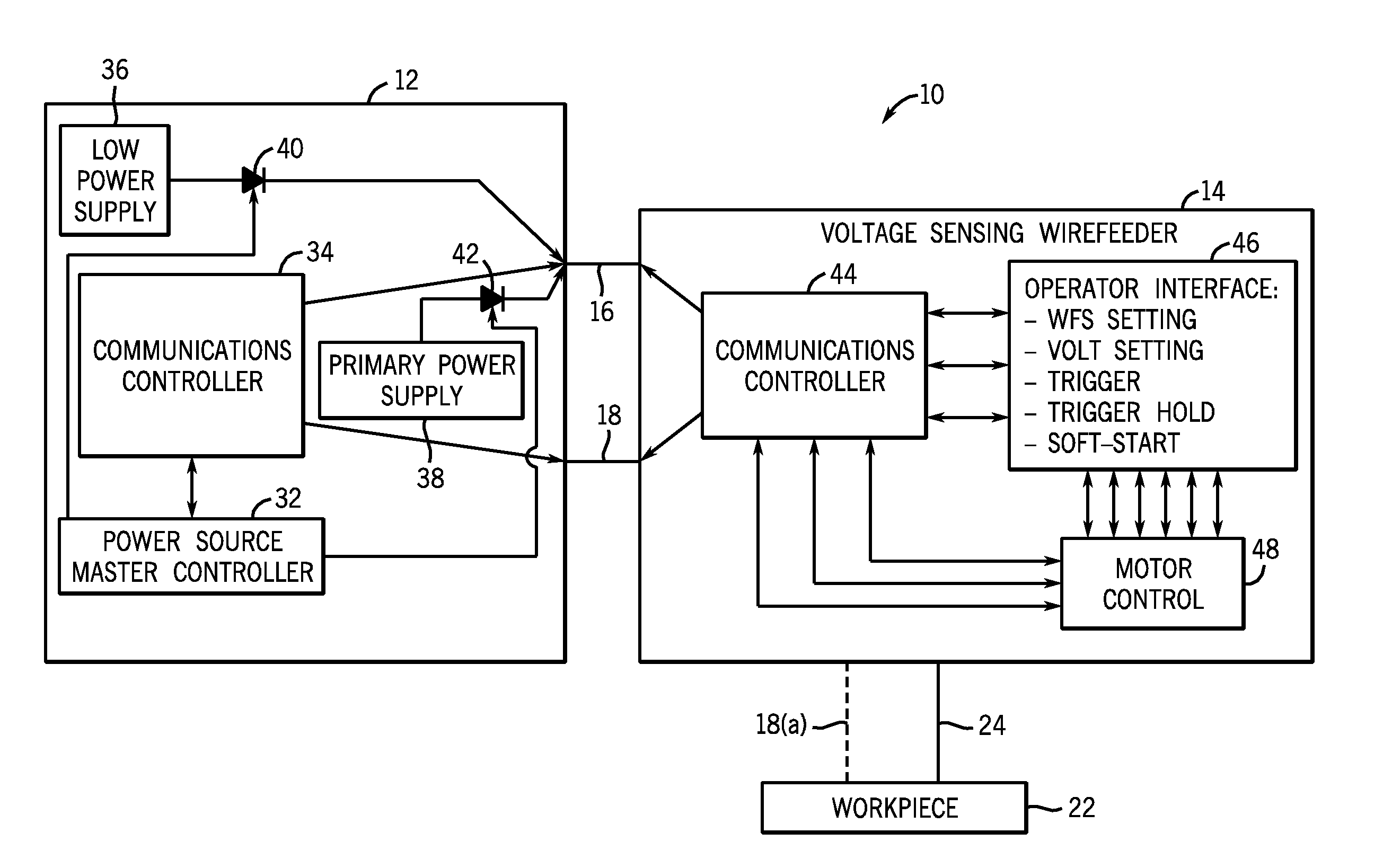

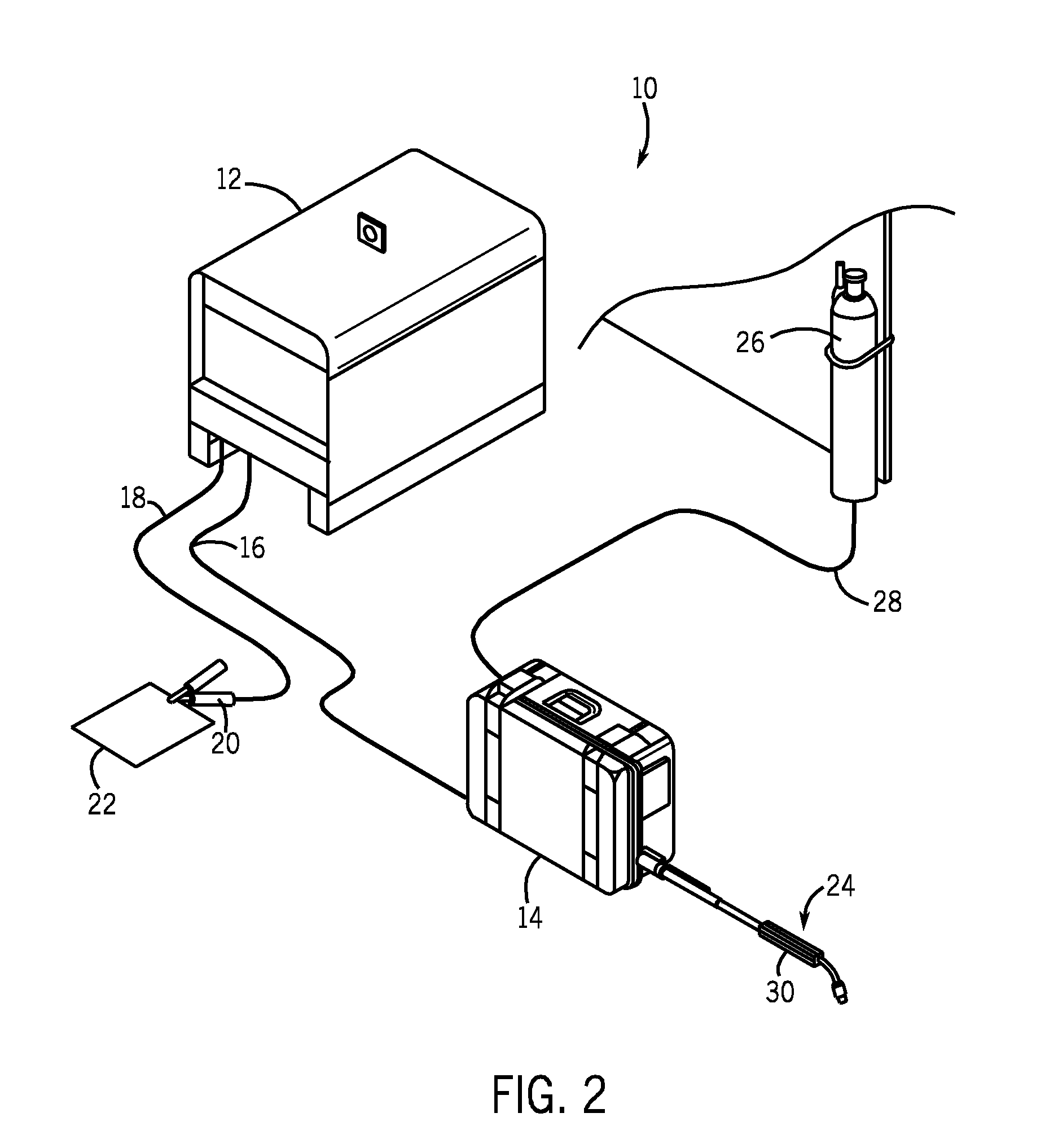

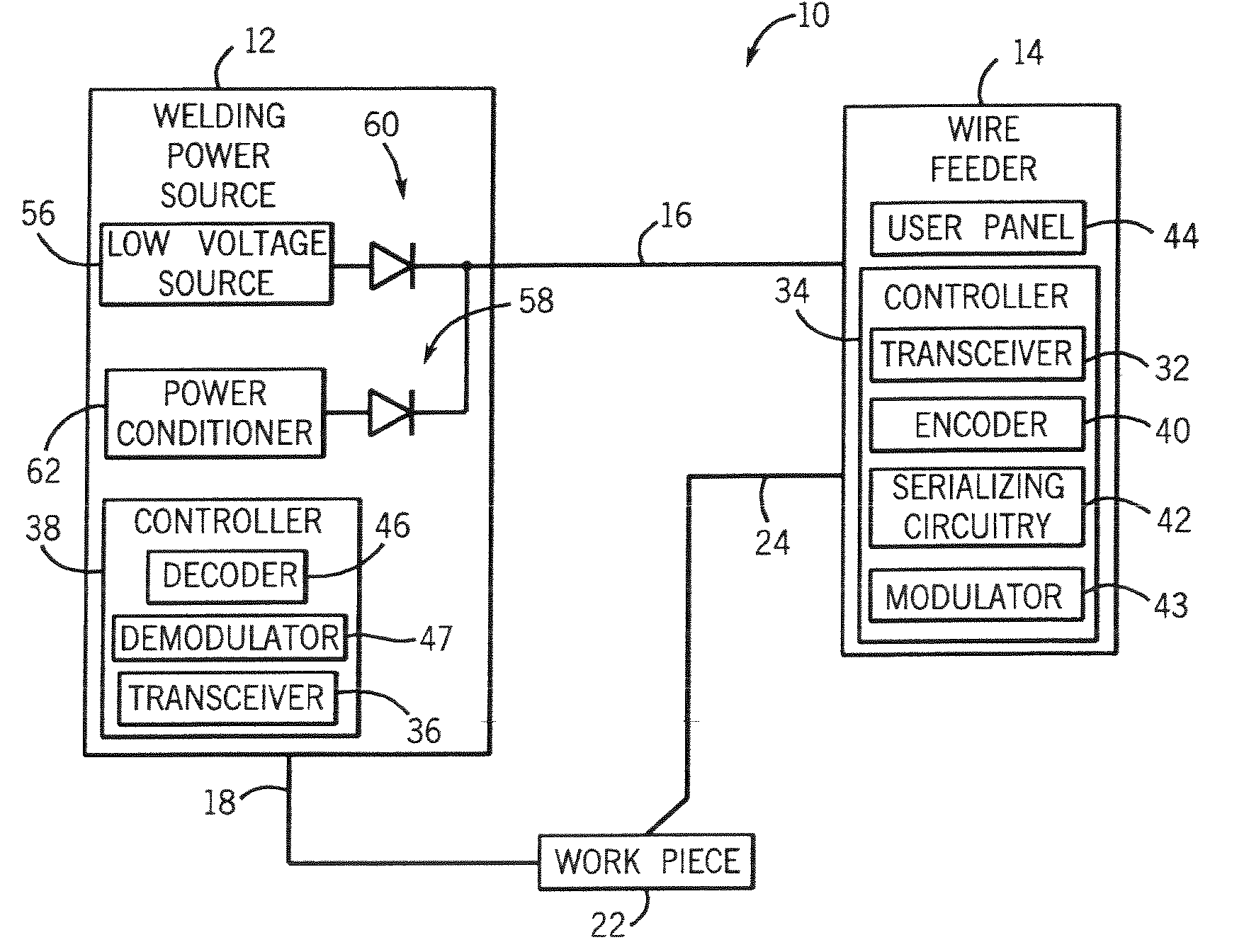

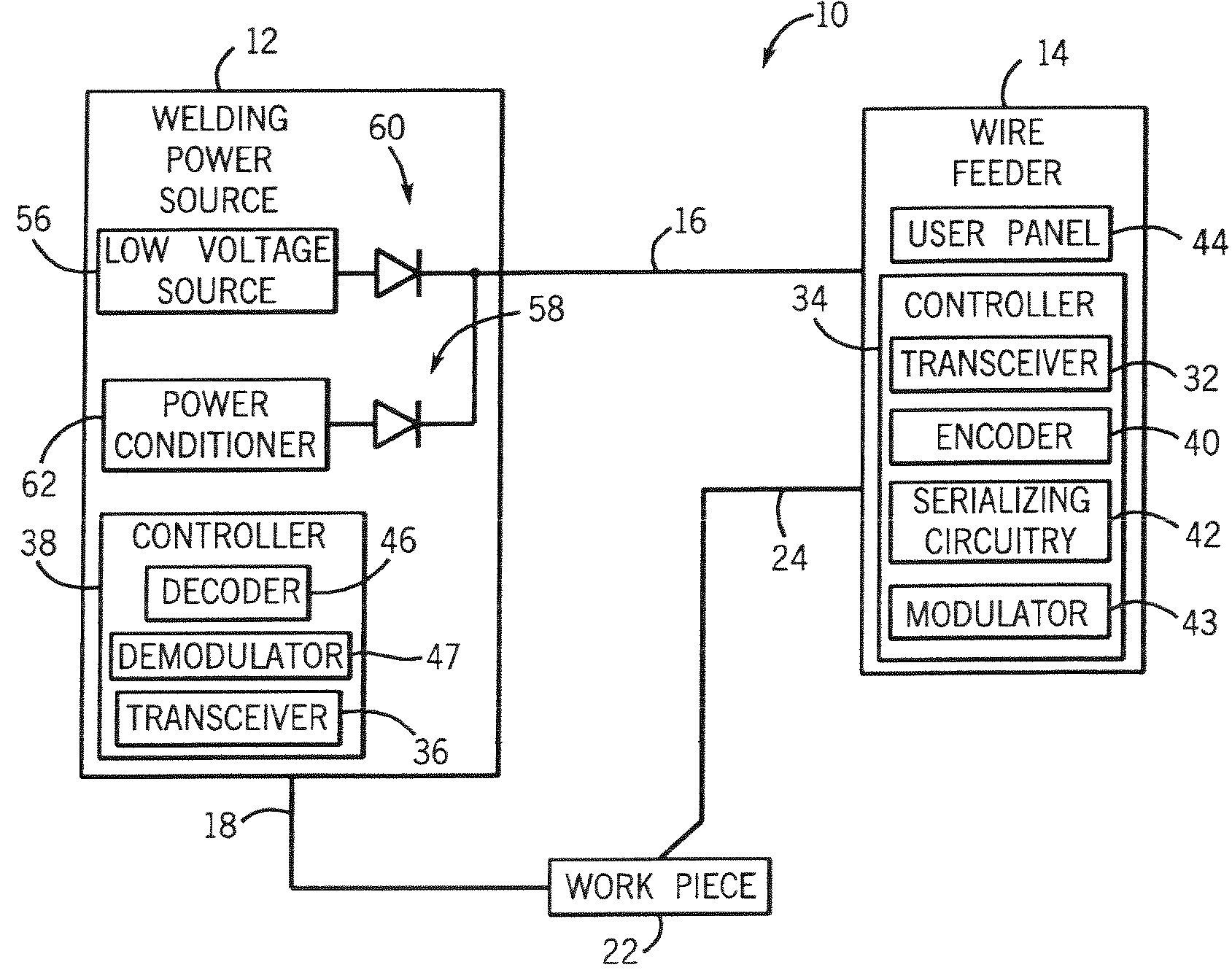

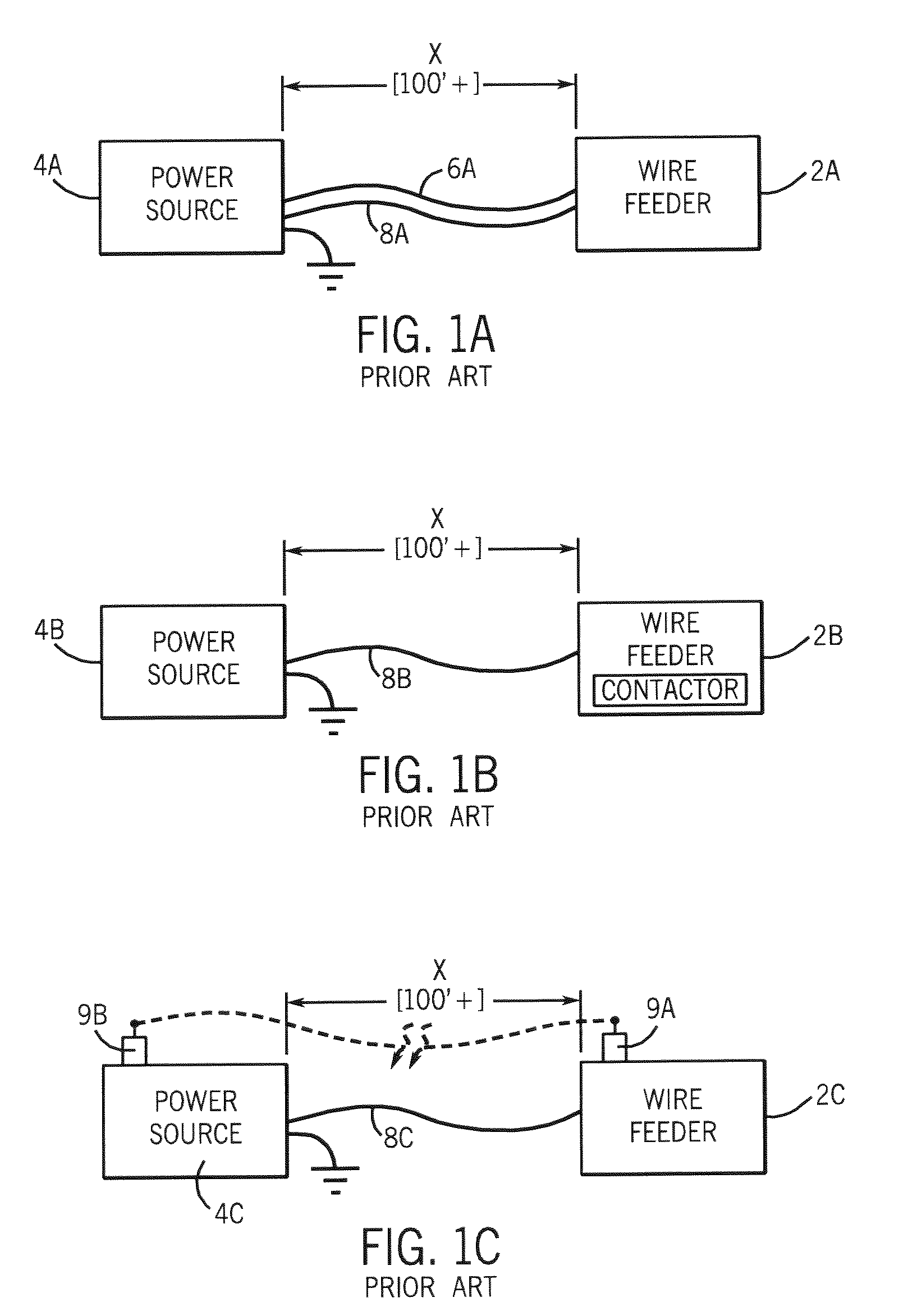

Method and system for a remote wire feeder where standby power and system control are provided via weld cables

ActiveUS20050230372A1Electric discharge heatingArc welding apparatusNetwork packetWelding power supply

The present invention is directed to a remotely controlled welding machine that uses serializing and modulating circuits to transfer modulated data packets to a welding power source across a weld cable. A transmitter transmits the data packets of desired welding operational parameters to a receiver disposed in the power source across a weld cable also designed to carry welding power from the power source to the wire feeder. The transmitter and other electronics of the wire feeder are constructed to use only a small amount of power which, preferably, is supplied by a DC power supply external to the wire feeder. The DC power supply is designed to provide power to the electronics of the wire feeder when the wire feeder is in a standby mode of operation.

Owner:ILLINOIS TOOL WORKS INC

Wireless communication network for control of industrial equipment in harsh environments

ActiveUS20140048522A1Electric discharge heatingArc welding apparatusTelecommunicationsWelding power supply

In certain embodiments, a system includes a master node device. The master node device includes communication circuitry configured to facilitate communication with a welding power supply unit via a long-range communication link, and to facilitate wireless communication with one or more welding-related devices via a short-range wireless communication network.

Owner:ILLINOIS TOOL WORKS INC

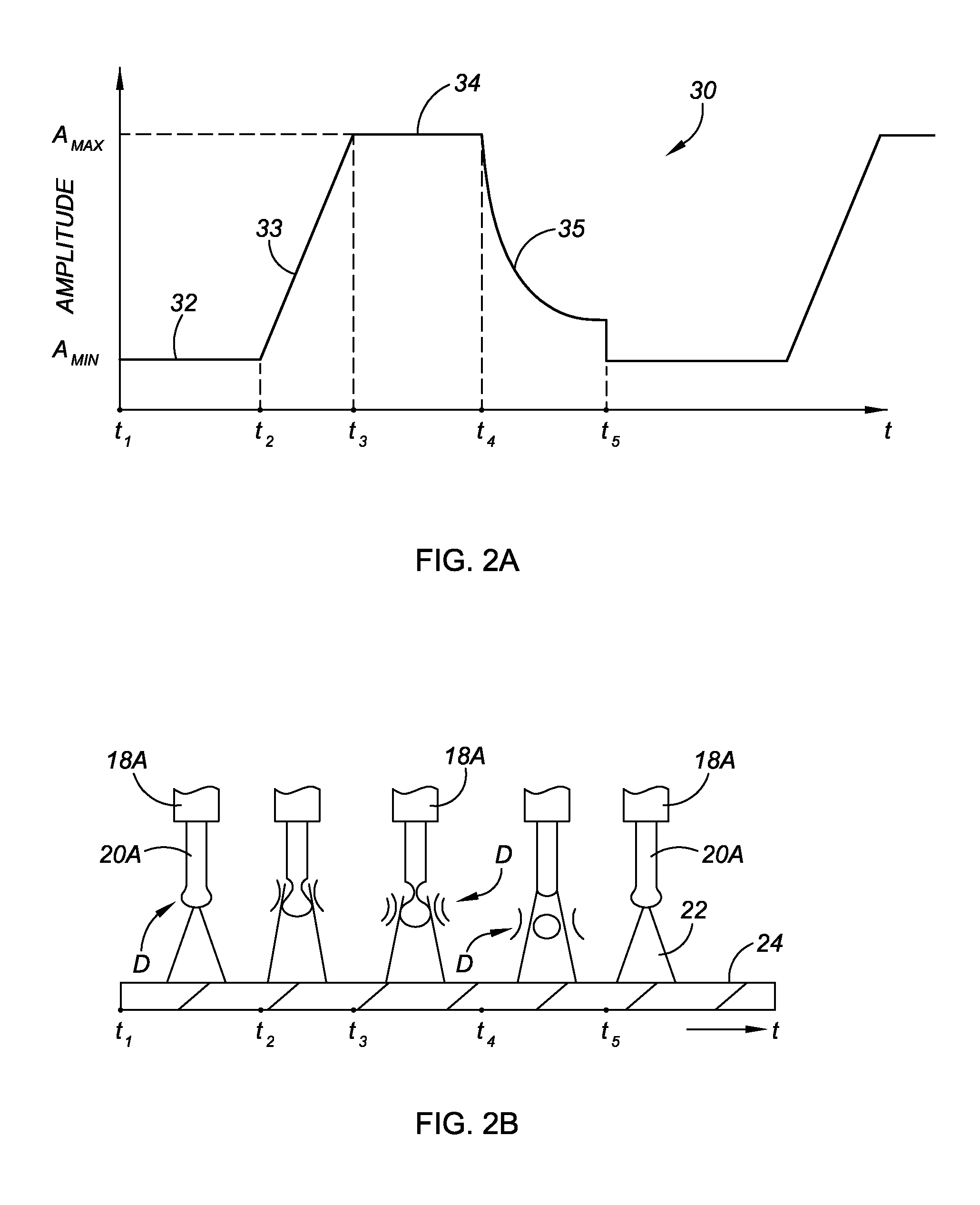

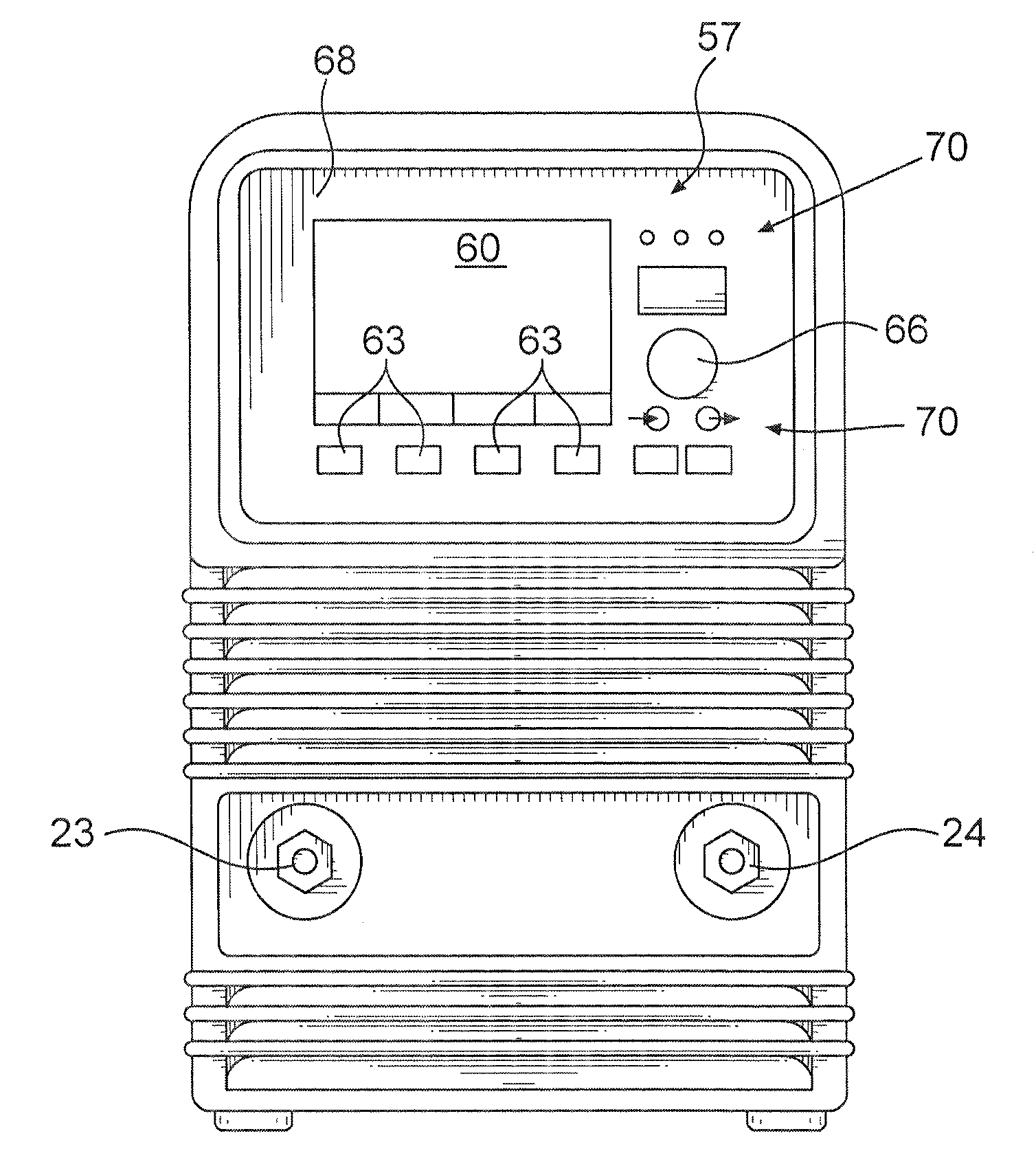

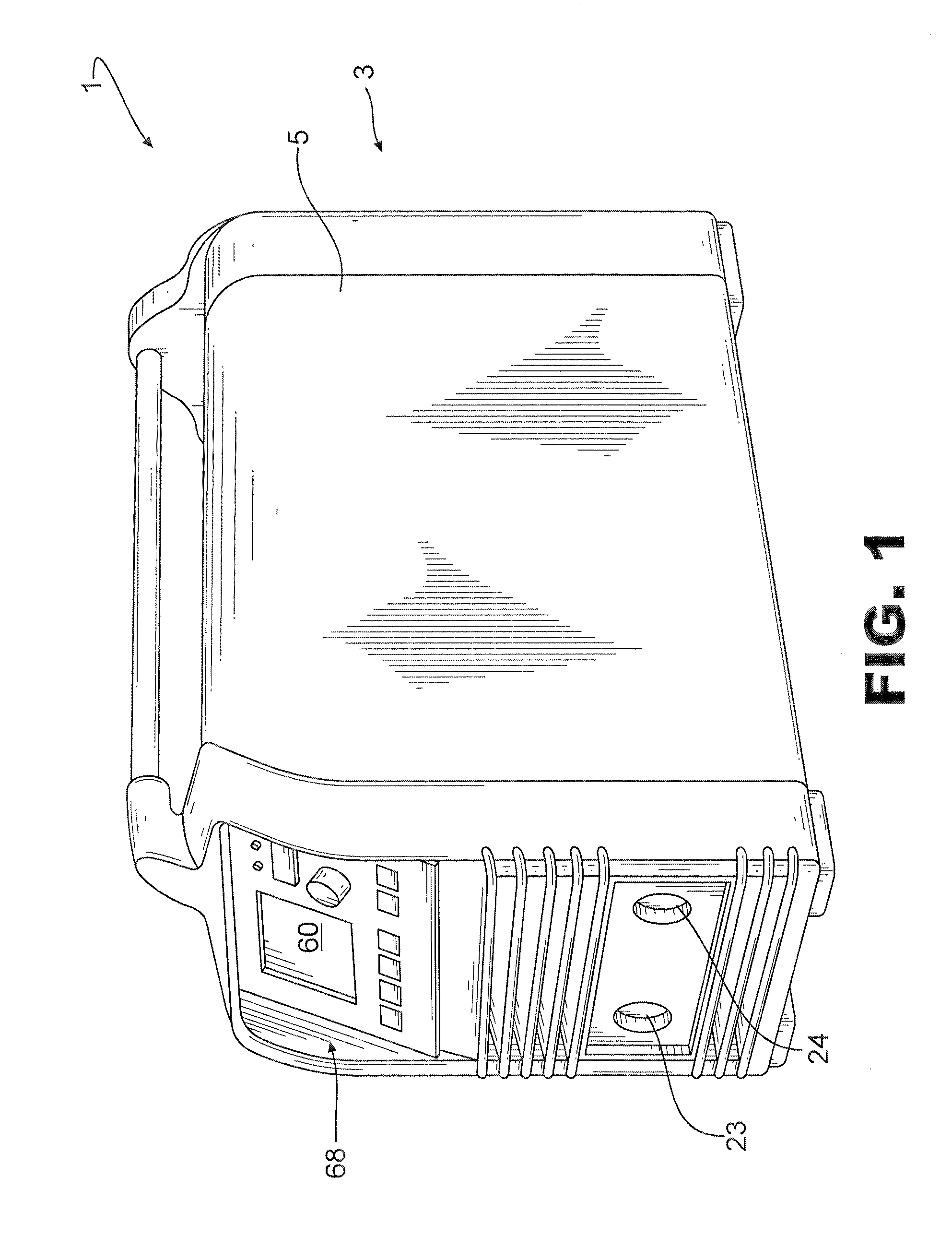

User interface for welding power supply

A welding power supply includes a user interface that allows the operator to adjust one or more welding parameters comprising a welding sequence for a welding process. The user interface may include a display, which may be a graphical display depicting the welding sequence and the one or more welding parameters. The user interface may further dynamically depict a pictograph, icon or other graphical image showing how changes to the one or more welding parameters will affect the welding process, which in an exemplary manner may be the welding bead profile and / or the welding arc profile.

Owner:LINCOLN GLOBAL INC

Method and system for a remote wire feeder where standby power and system control are provided via weld cables

The present invention is directed to a remotely controlled welding machine that uses serializing and modulating circuits to transfer modulated data packets to a welding power source across a weld cable. A transmitter transmits the data packets of desired welding operational parameters to a receiver disposed in the power source across a weld cable also designed to carry welding power from the power source to the wire feeder. The transmitter and other electronics of the wire feeder are constructed to use only a small amount of power which, preferably, is supplied by a DC power supply external to the wire feeder. The DC power supply is designed to provide power to the electronics of the wire feeder when the wire feeder is in a standby mode of operation.

Owner:ILLINOIS TOOL WORKS INC

Methods and systems for binding a wireless control device to a welding power source

InactiveUS20110180517A1Welding electric supplyArc welding apparatusWireless controlWelding power supply

A welding system including a welding power source, a receiver, and a wireless control device are provided. The receiver is adapted to communicate information to and from the welding power source. The wireless control device and / or the receiver is adapted to learn a first address specific to the receiver and the wireless control device pair to exclusively bind the welding power source to the wireless control device during a learning mode. Such a binding may occur when the wireless control device is located a distance from the welding power source that is below a preset threshold. The wireless control device controls operation of the welding power source when the wireless control device is bound to the welding power source.

Owner:ILLINOIS TOOL WORKS INC

Method and apparatus for receiving a universal input voltage in a welding power source

InactiveUS7049546B2Arc welding apparatusElectrical-based machining electrodesOutput transformerControl signal

A method and apparatus for providing a welding current is disclosed. The power source is capable of receiving any input voltage over a wide range of input voltages and includes an input rectifier that rectifies the ac input into a dc signal. A dc voltage stage converts the dc signal to a desired dc voltage and an inverter inverts the dc signal into a second ac signal. An output transformer receives the second ac signal and provides a third ac signal that has a current magnitude suitable for welding. The welding current may be rectified and smoothed by an output inductor and an output rectifier. A controller provides control signals to the inverter and an auxiliary power controller that can receive a range of input voltages and provide a control power signal to the controller.

Owner:ILLINOIS TOOL WORKS INC

Welding power supply with digital control of duty cycle

A welding power supply including power conversion circuitry adapted to receive a primary source of power, to utilize one or more power semiconductor switches to chop the primary source of power, and to convert the chopped power to a welding output is provided. The provided welding power supply includes a pulse width modulated (PWM) digital controller including gate drive circuitry that generates a PWM output signal that controls the switching of the one or more power semiconductor switches. The PWM output signal includes a duty cycle term corrected for one or more sources of error in the welding system.

Owner:ILLINOIS TOOL WORKS INC

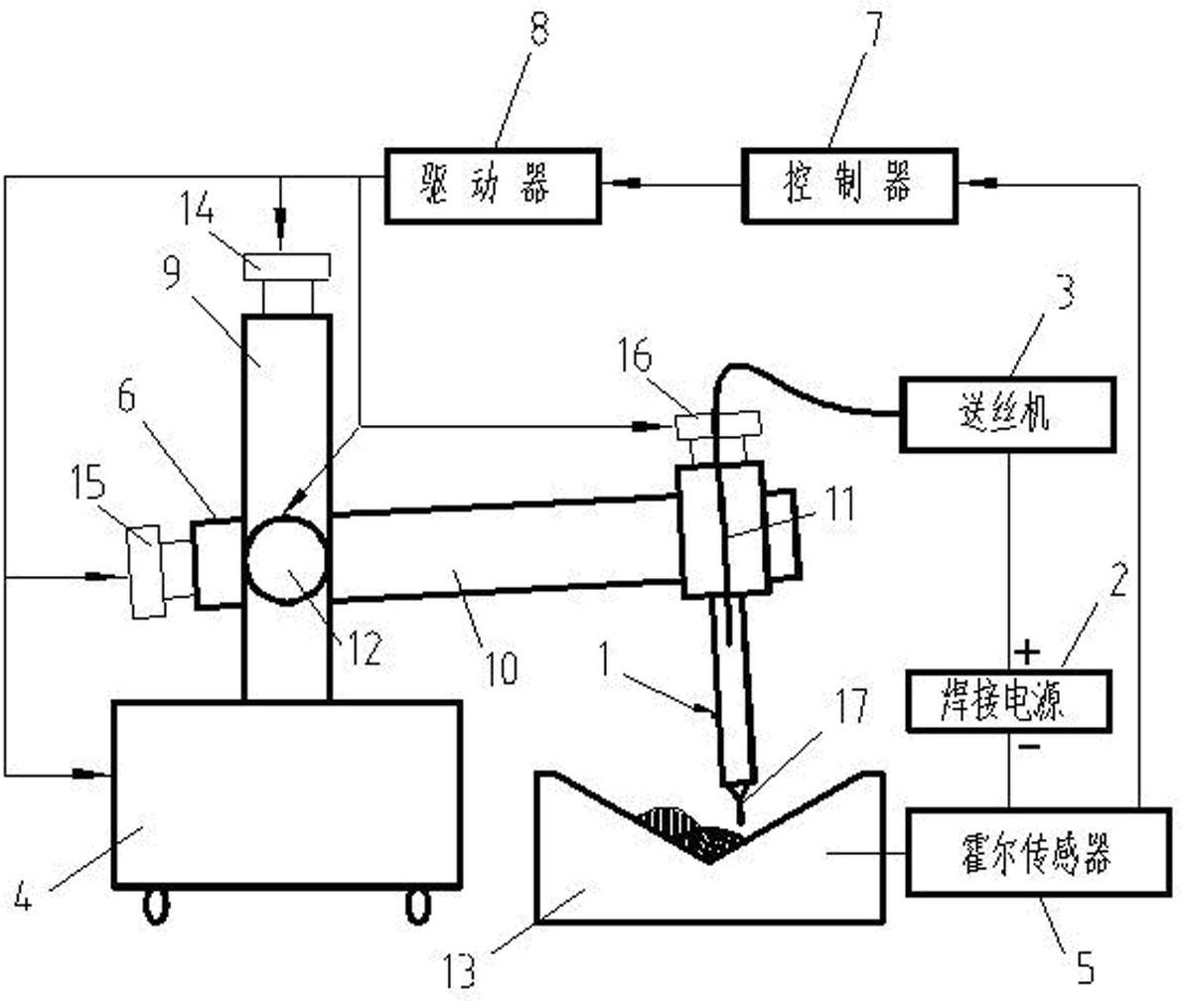

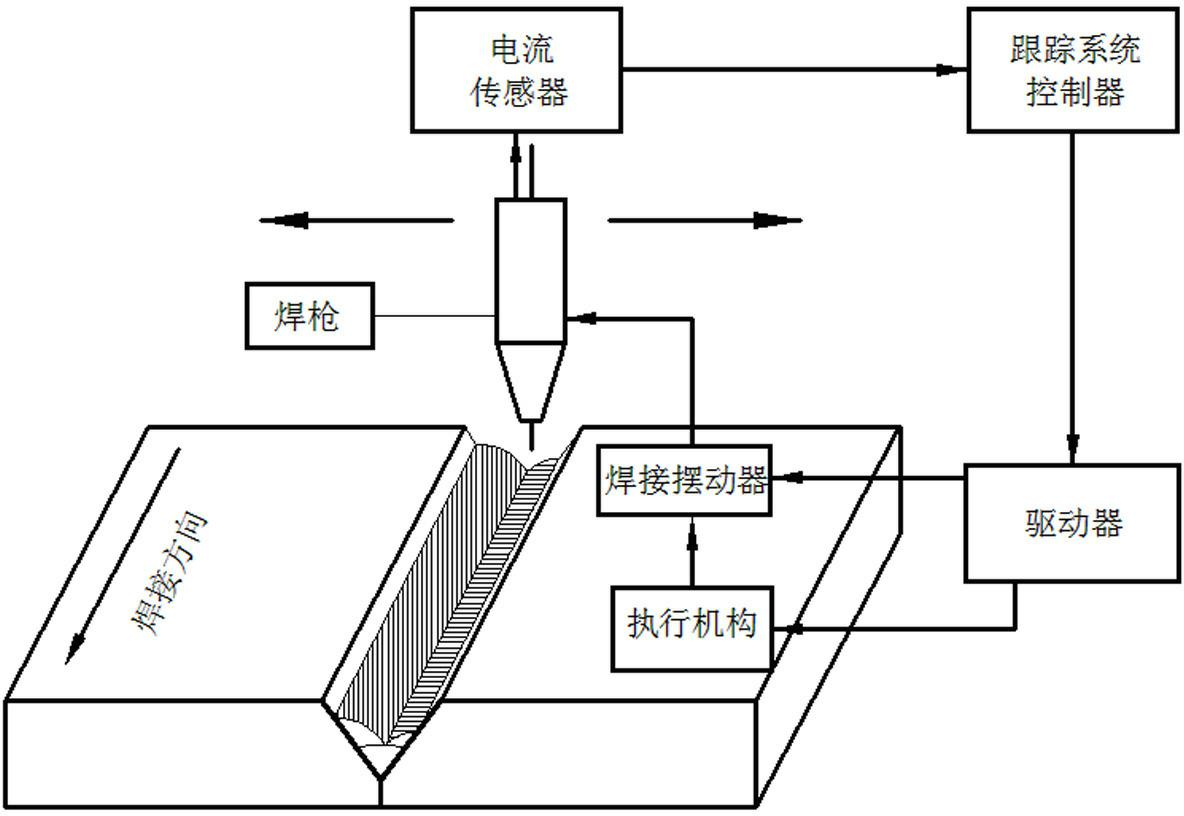

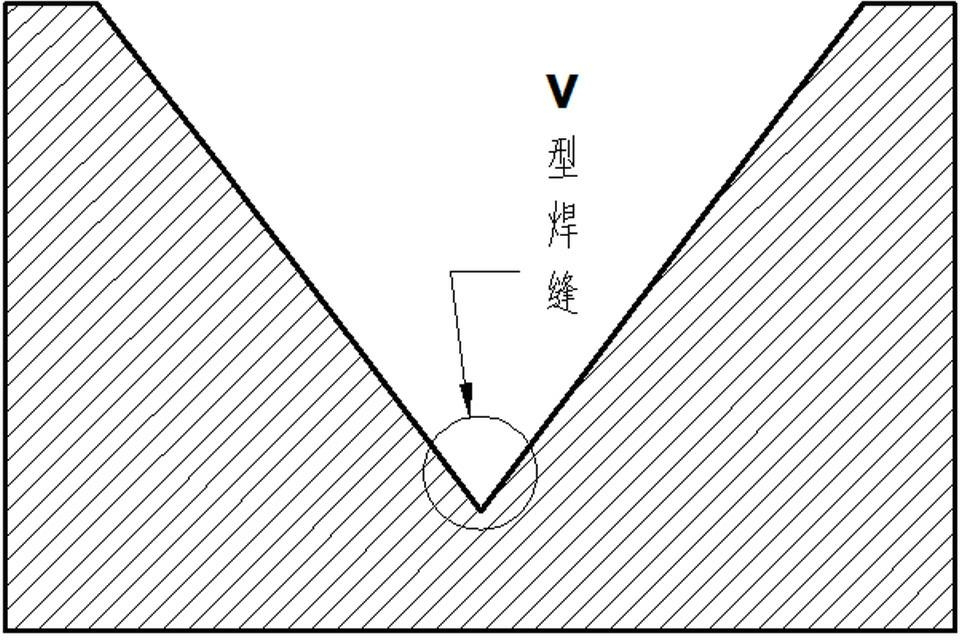

Swing arc-based multi-layer and multi-channel weld tracking system and identification method thereof

InactiveCN102615390AHigh precisionGuaranteed uptimeArc welding apparatusWelding power supplyCurrent sensor

Owner:XIANGTAN UNIV

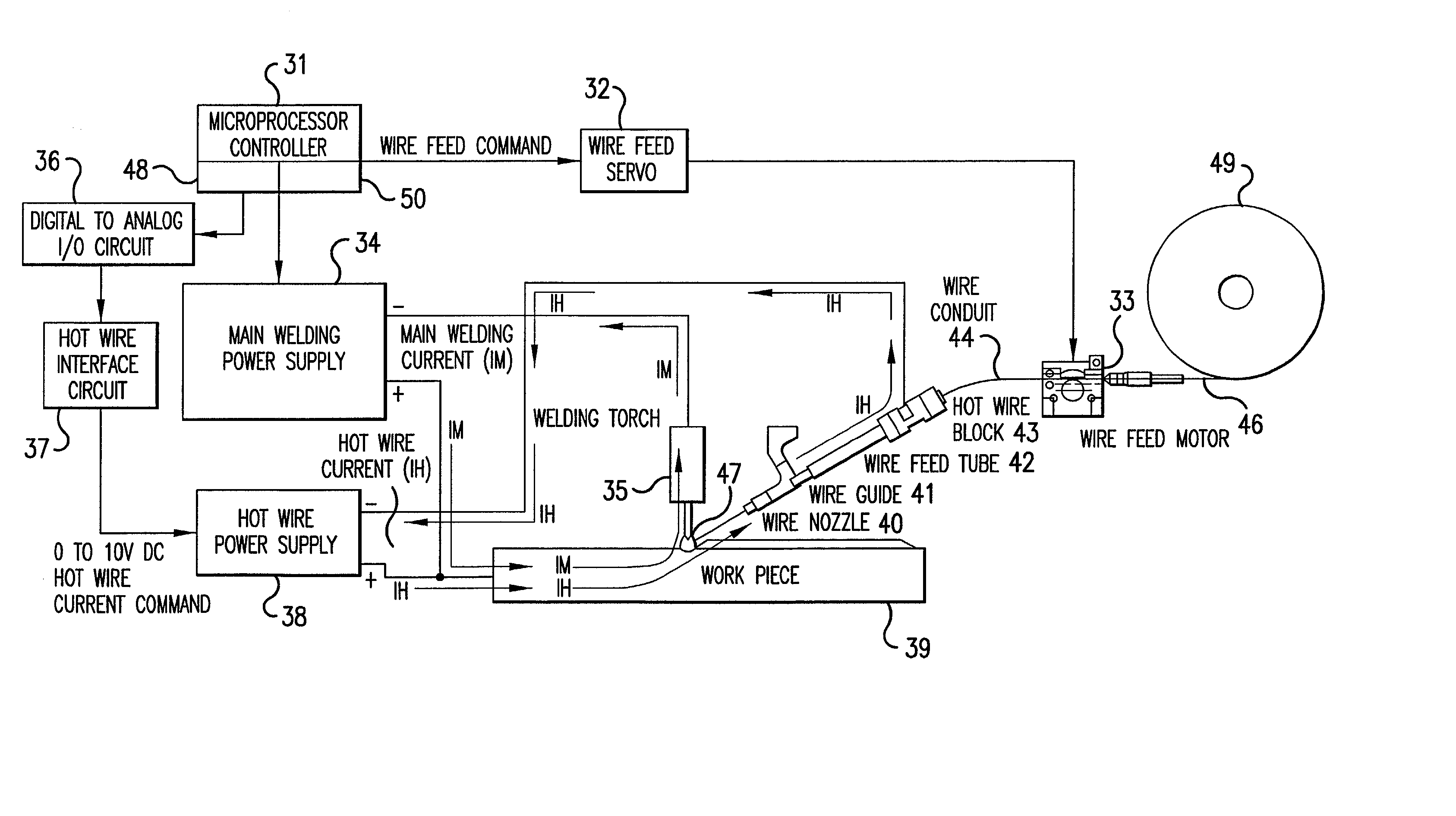

Method and system for hot wire welding

InactiveUS20020117489A1Welding/cutting media/materialsWelding electrode featuresPower flowWelding power supply

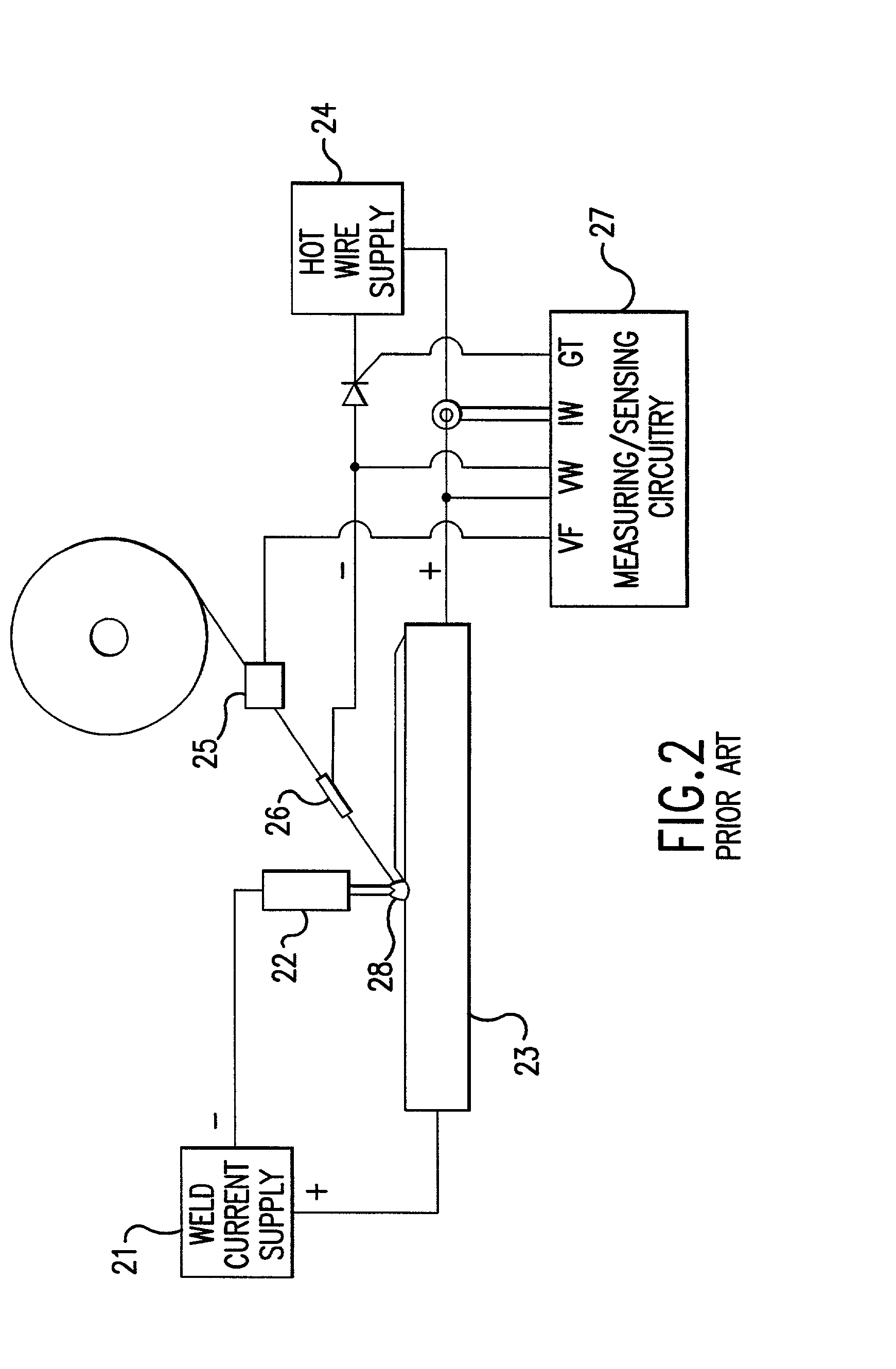

A hot wire welding method and system rely upon a welding torch with a non-melting electrode, a melting metal filler wire that is fed into a weld puddle created by welding arc, a microprocessor controller for controlling (i) current of the main welding arc, (ii) filler wire feed speed, and (iii) hot wire current for heating the filler wire. The method and system also rely upon a main welding power supply for supplying the main welding arc and a secondary DC supply for supplying the hot wire current. The hot wire current is automatically controlled by the microprocessor to supply the correct amount of current to the filler wire in response to changes in wire feed speed.

Owner:ARNDT TONY LEE +2

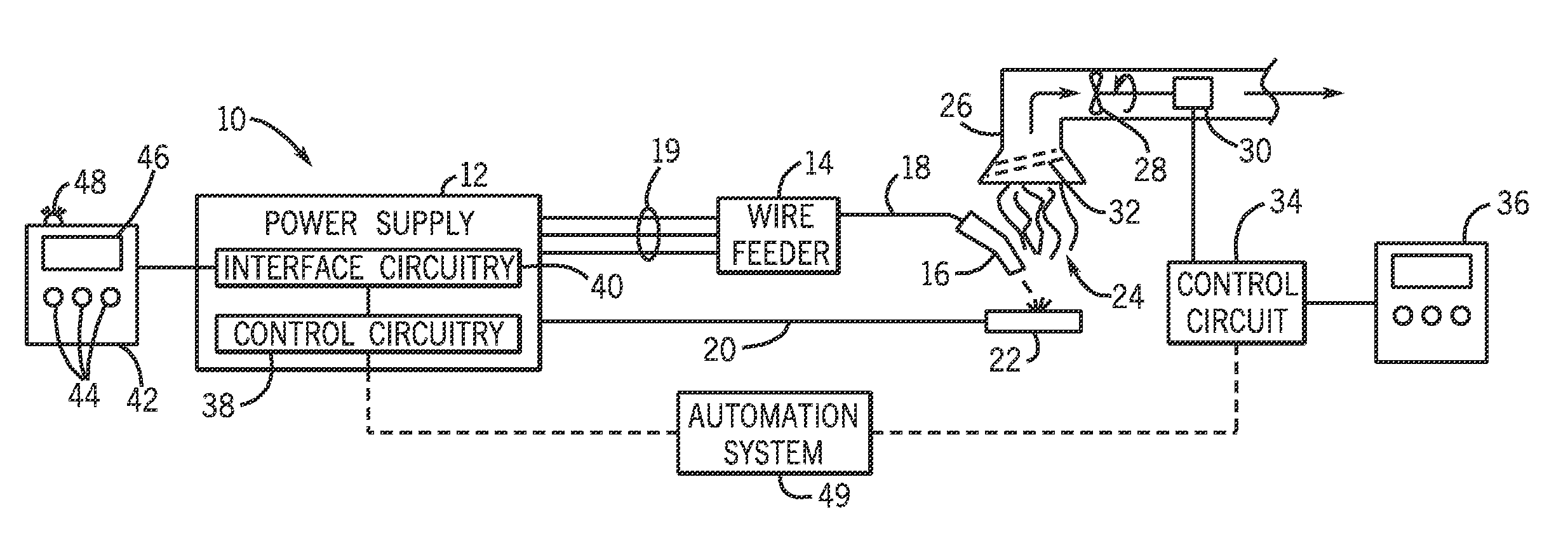

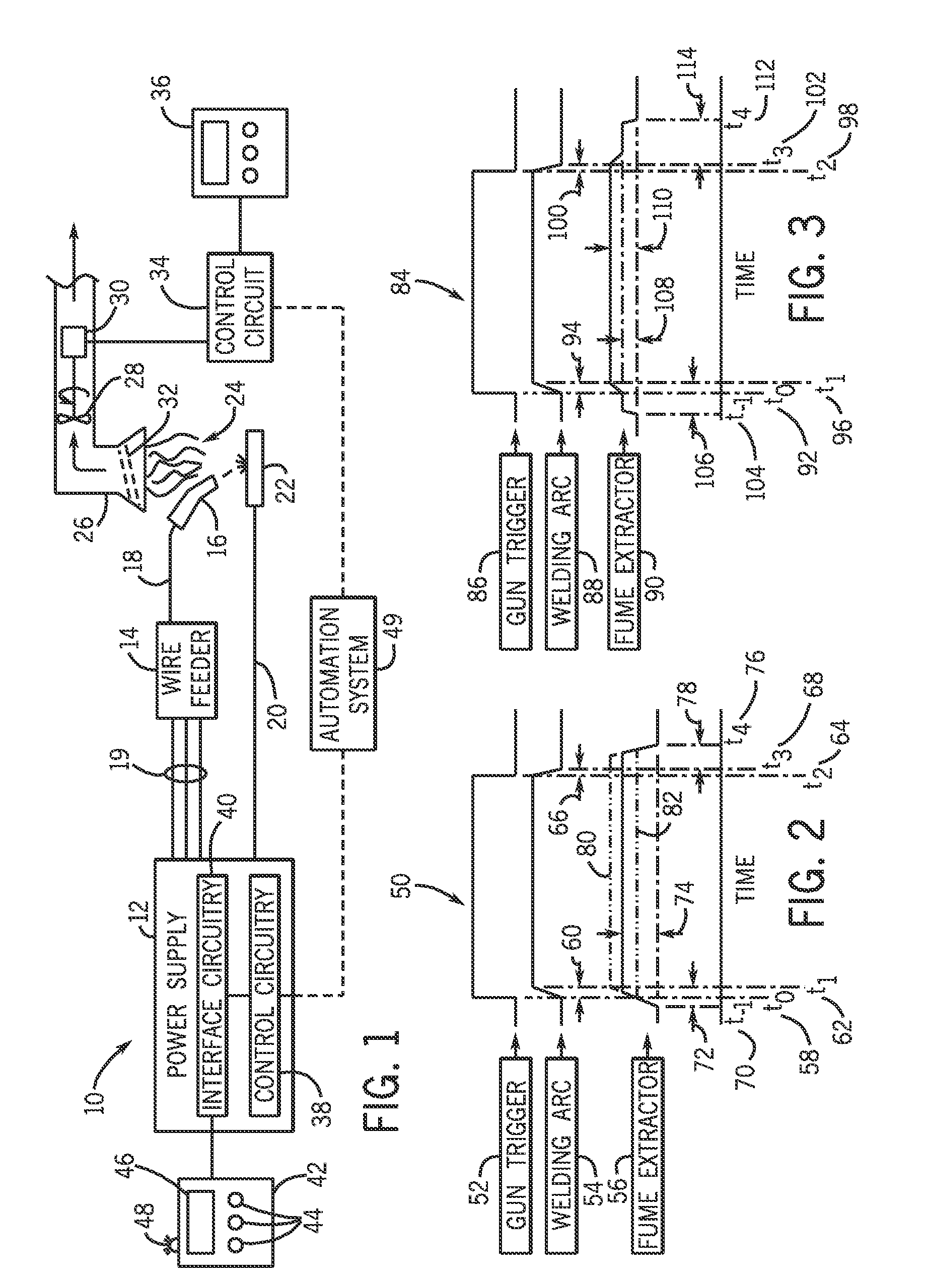

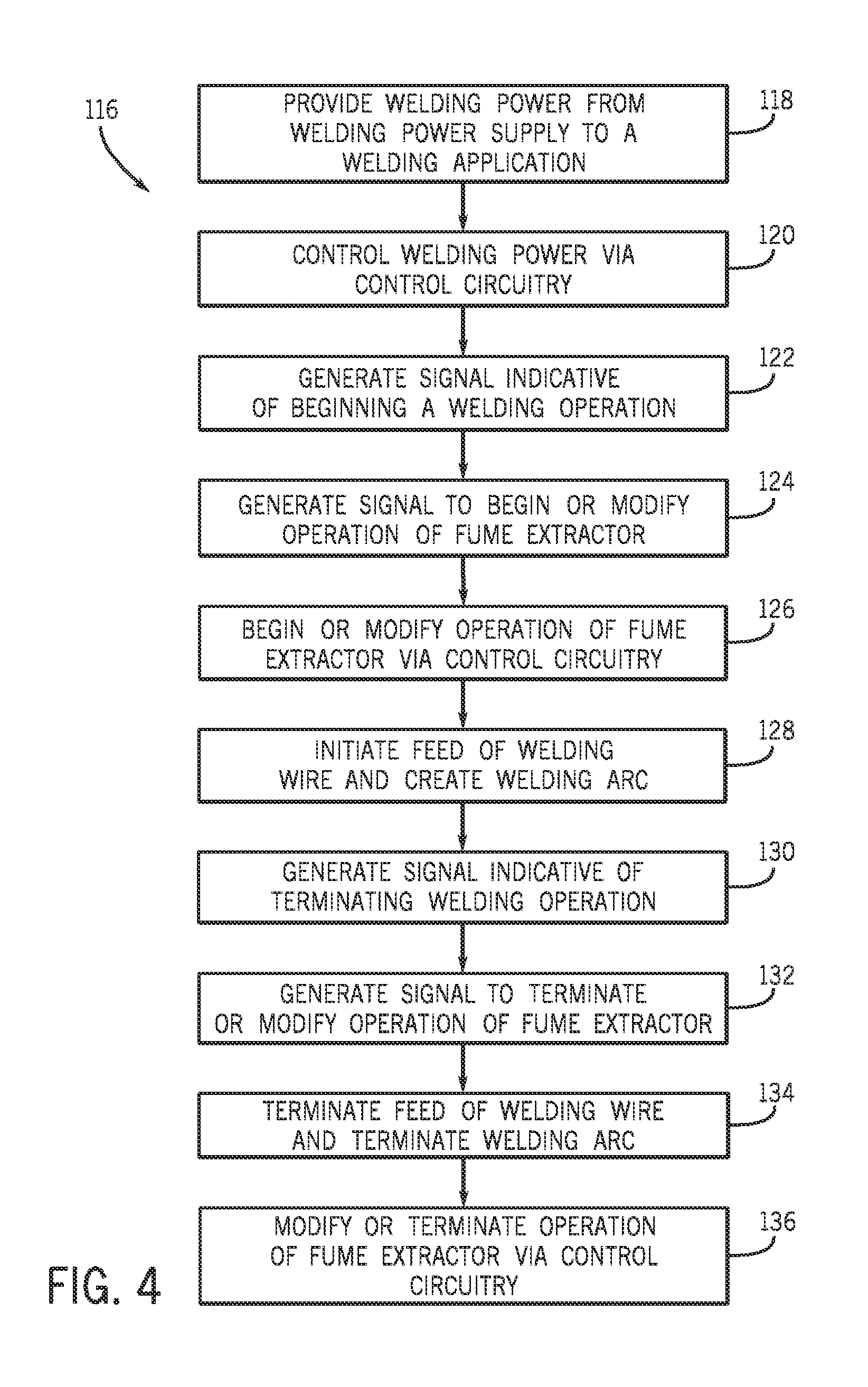

Fume extractor for welding applications

A welding system having a welding power supply coupled to a fume extractor is provided. The fume extractor may be coupled to control circuitry configured to operate the welding power supply. The control circuitry may be configured to begin, terminate or modify the operation of the fume extractor prior to the establishment of a welding arc, after the termination of the welding arc, or both. The control circuitry may be further configured to modify the operation of the fume extractor based upon a type of welding process used.

Owner:ILLINOIS TOOL WORKS INC

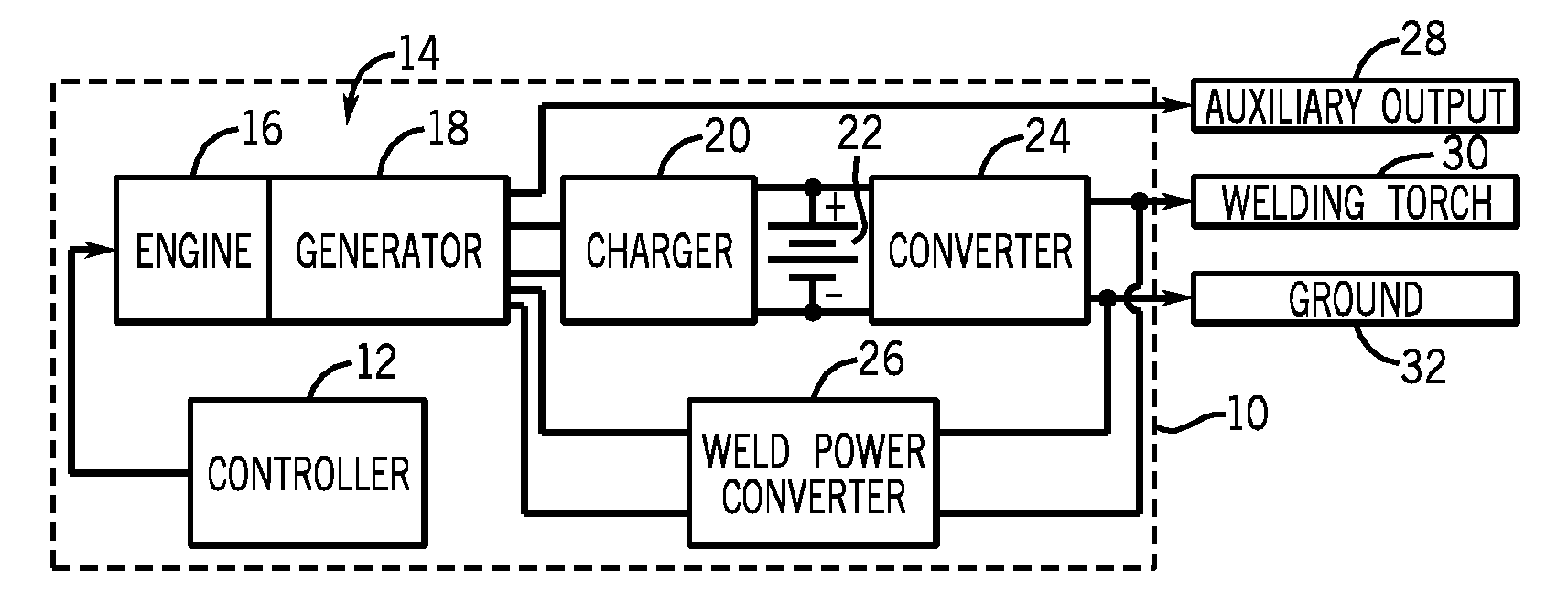

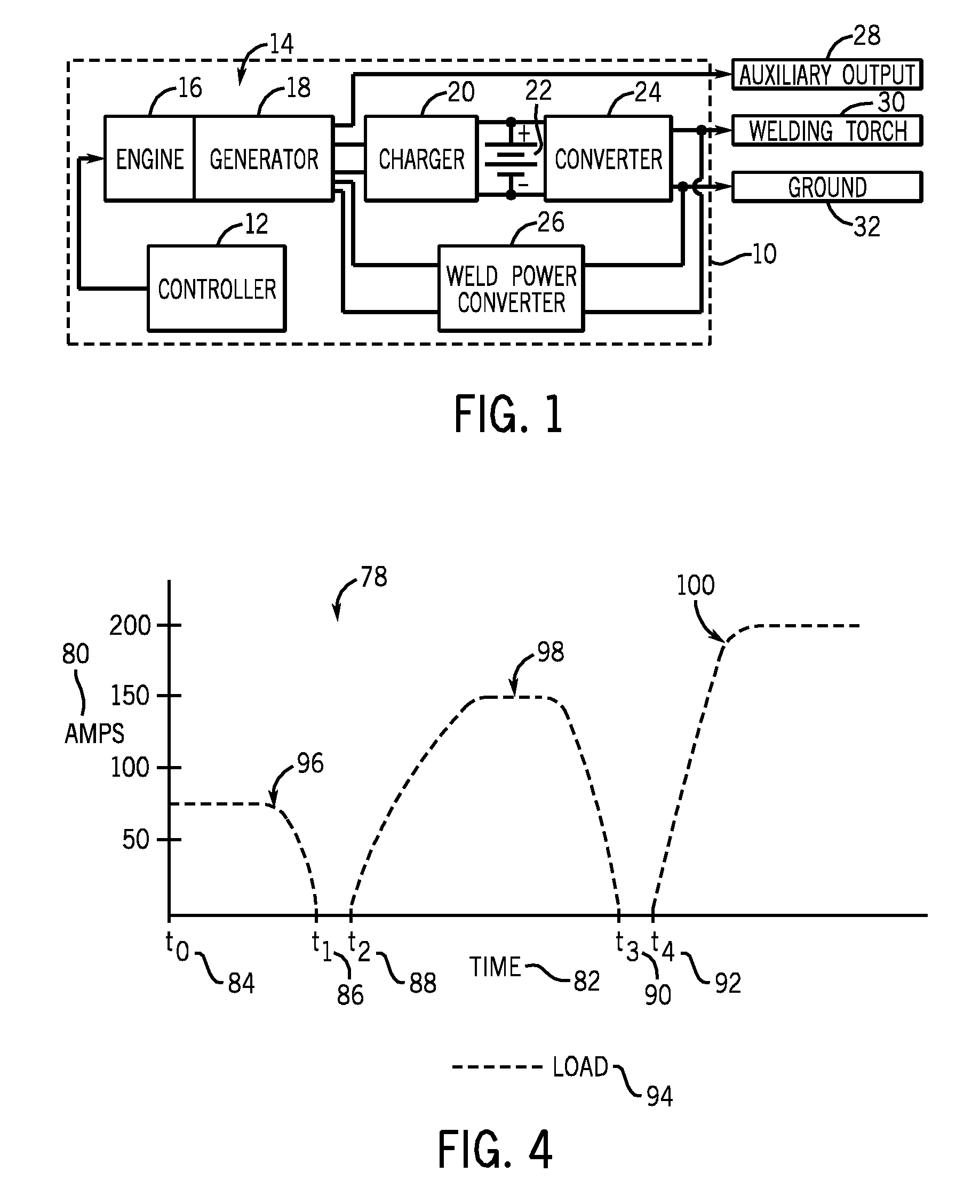

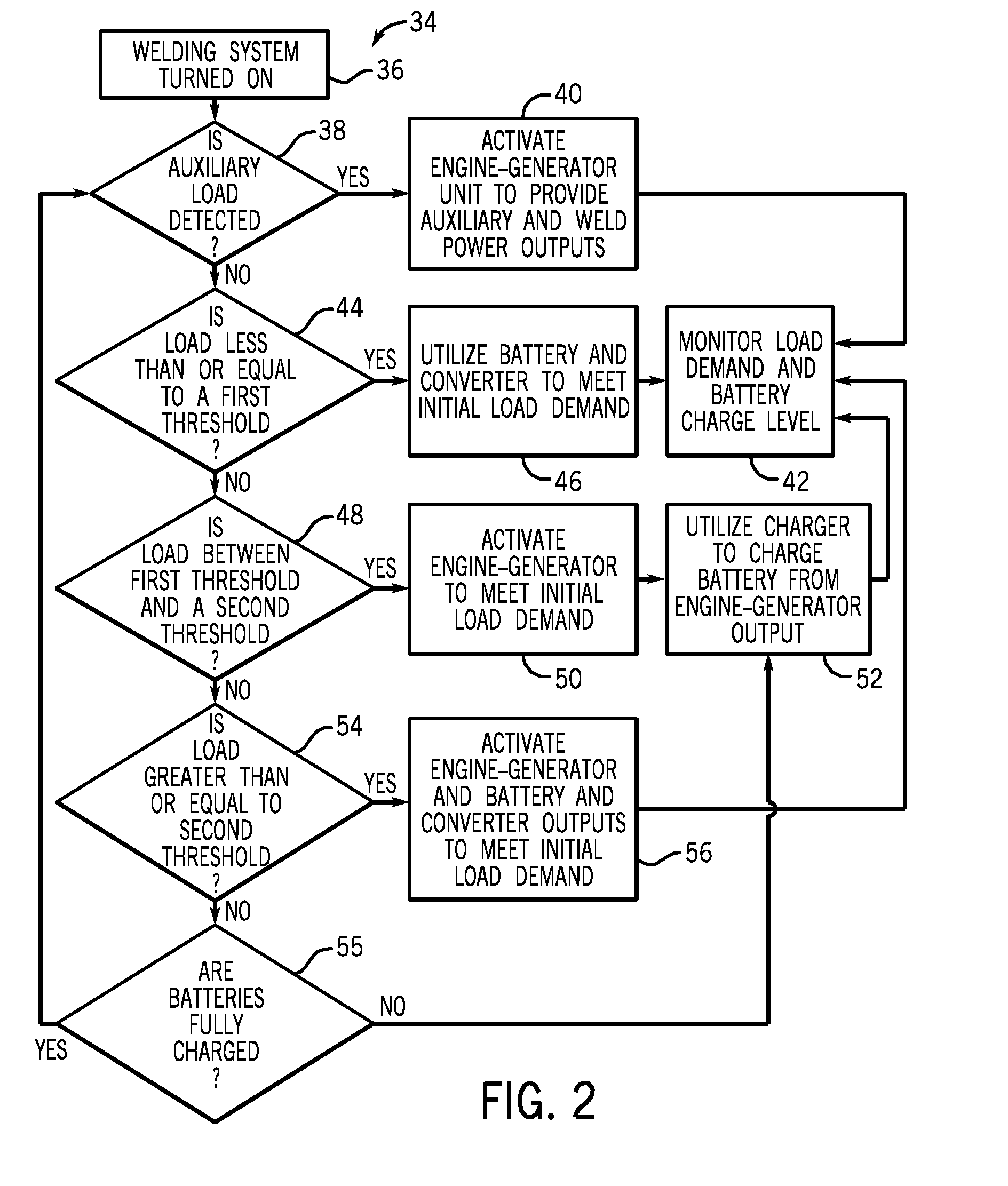

Incremental hybrid welding systems and methods

Owner:ILLINOIS TOOL WORKS INC

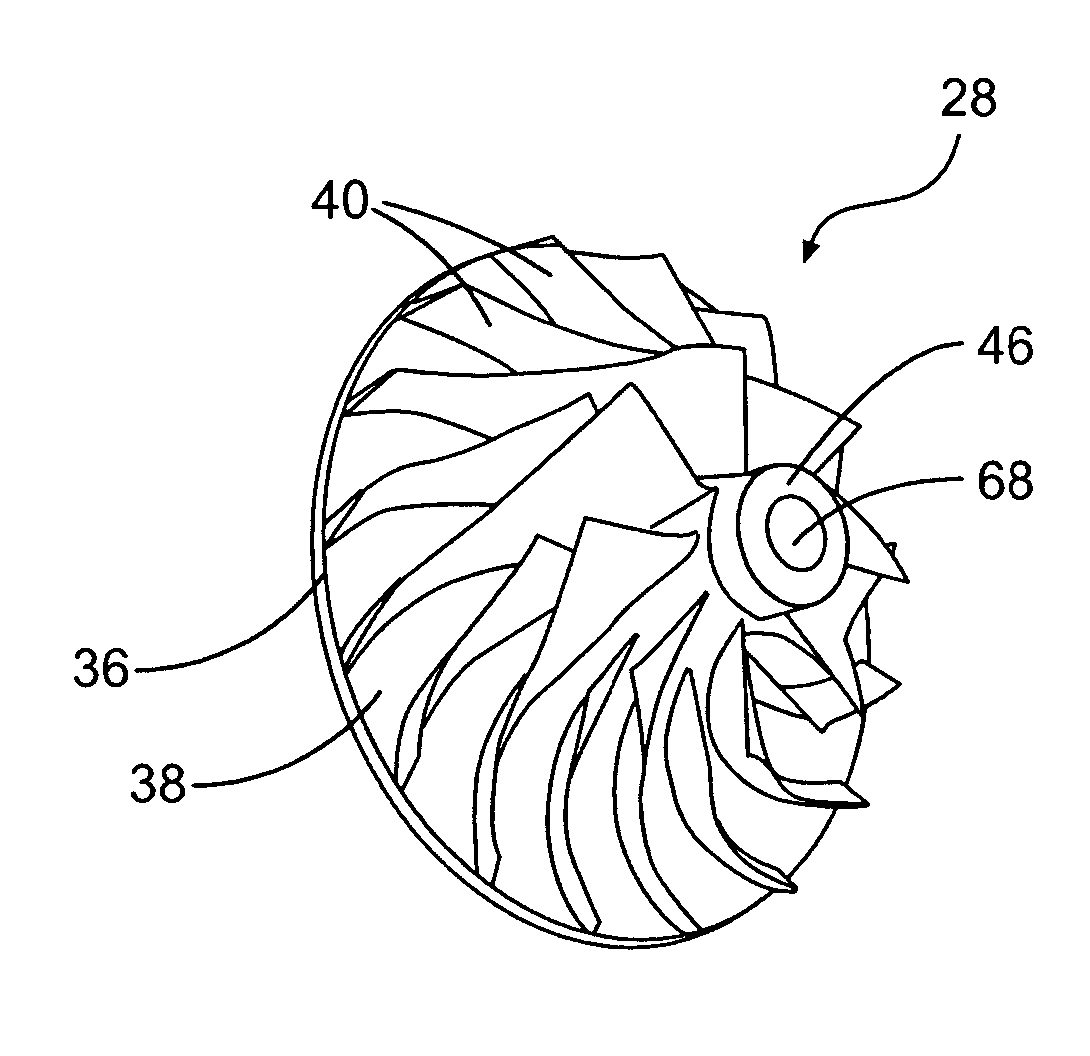

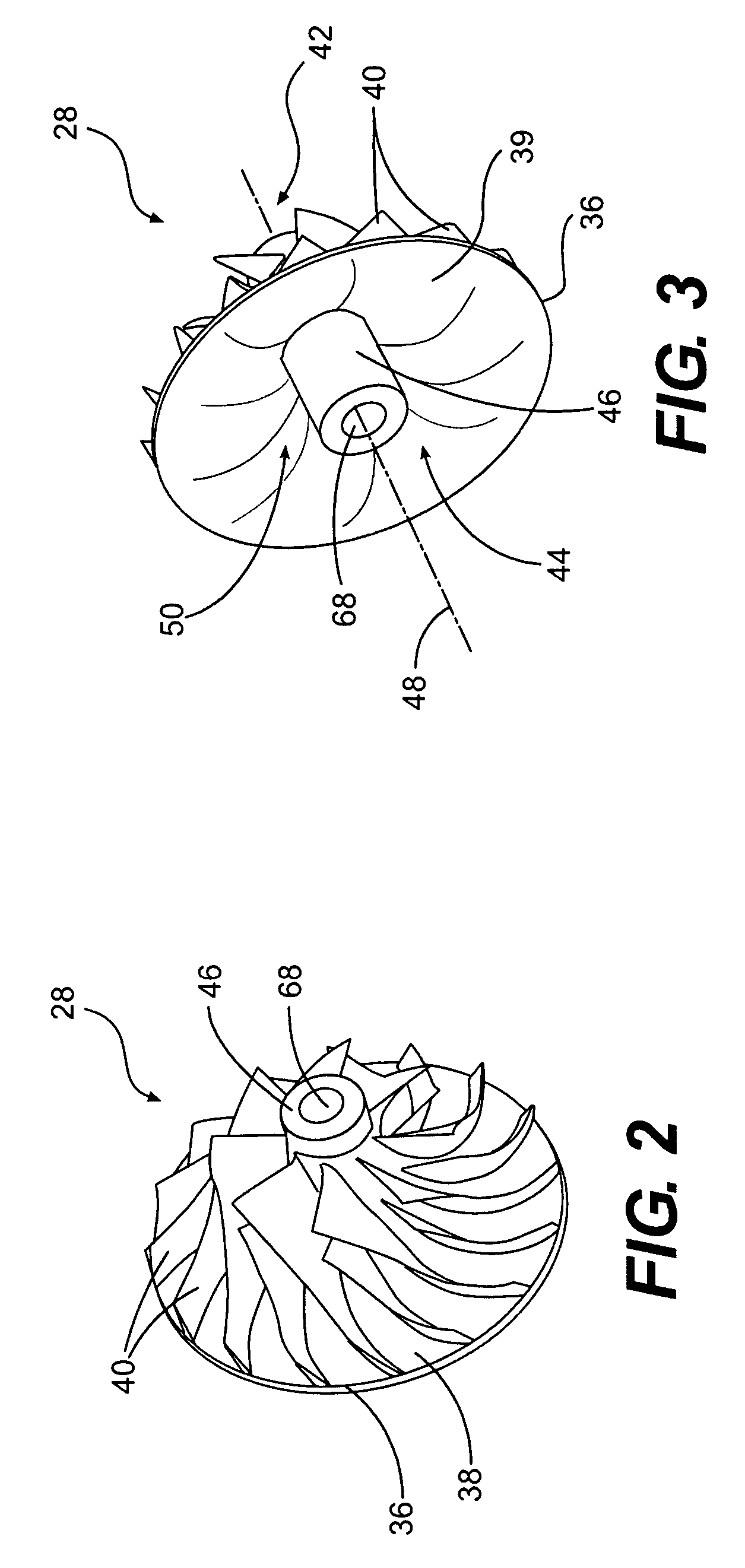

Free-form welded power system component

The present disclosure is directed to a power system component for a work machine. The power system component may include a wheel having one or more free-form welded members. The wheel may include a front end, a back end, and a central, axial spine member extending from the front end to the back end. The wheel may also include an outer shell adjacent the spine member at the front end, extending toward the back end, and flaring radially away from the spine member near the back end. The outer shell may include a front surface, a back surface, and one or more protrusions extending from the front surface. The wheel may further include at least one void defined between the spine member and the back surface of the outer shell and at least one reinforcing structure connecting the outer shell with a portion of the spine member between the front end and the back end.

Owner:CATERPILLAR INC

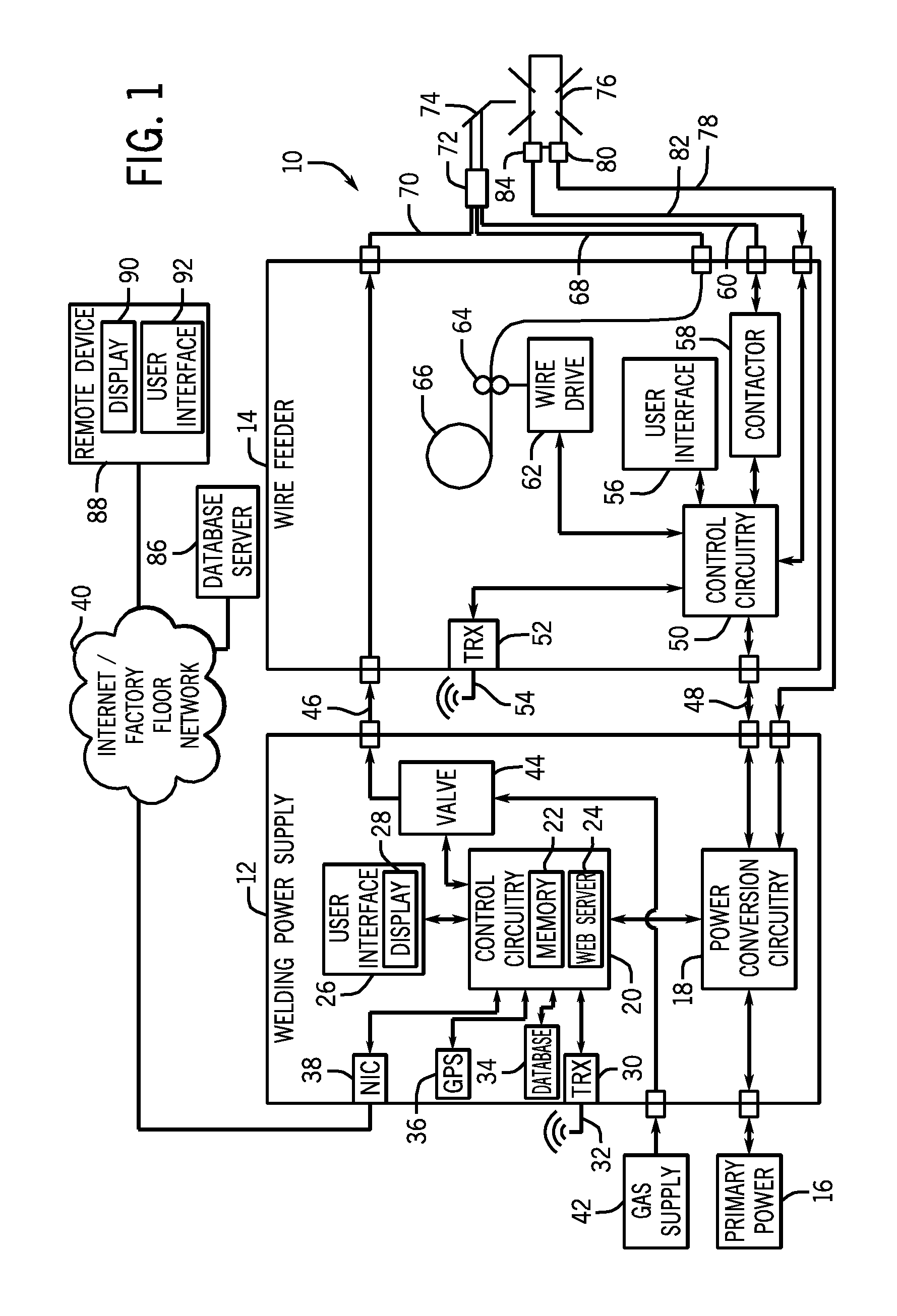

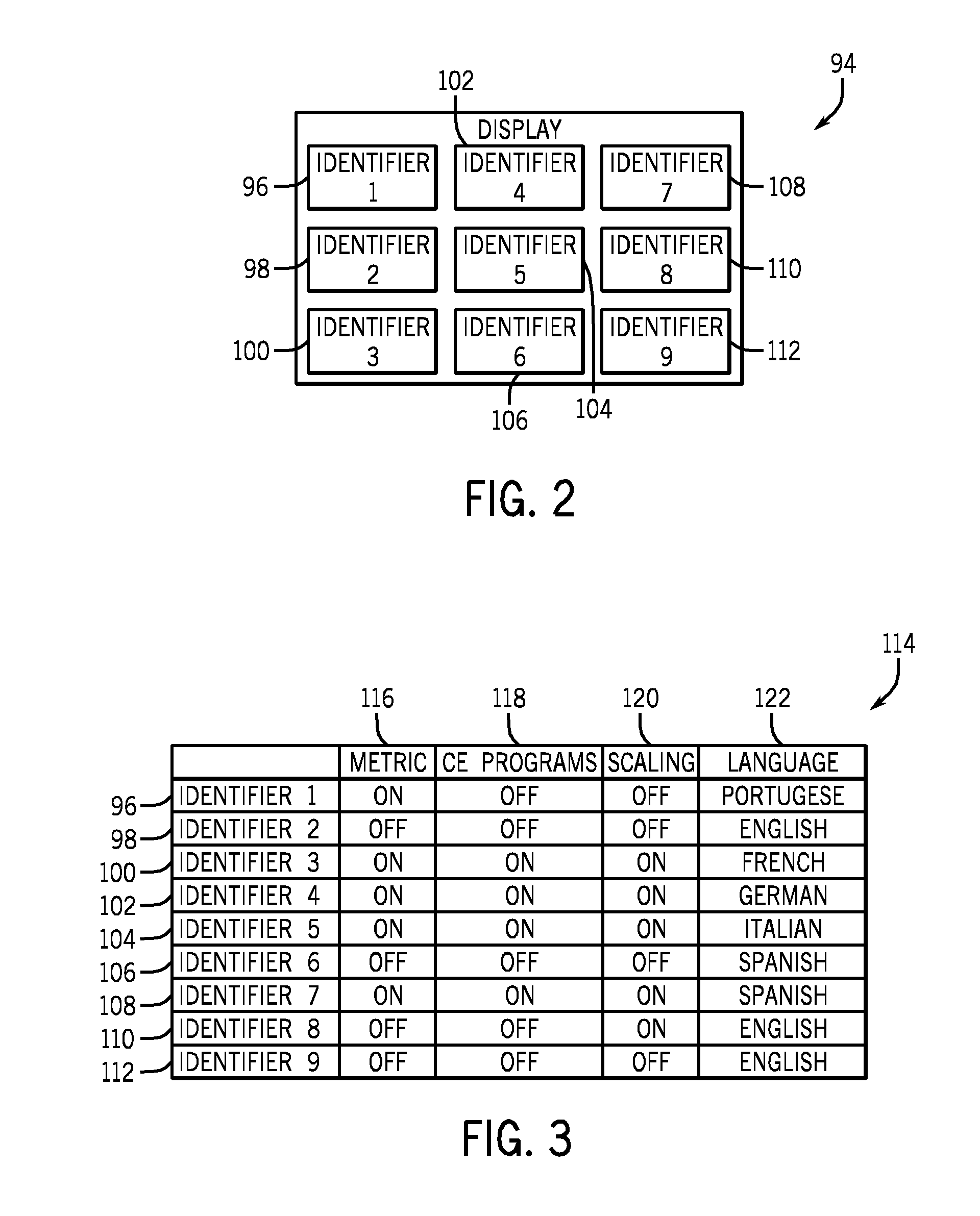

Systems and methods for adjusting multiple settings of a welding power supply

ActiveUS20120241428A1Arc welding apparatusLocation information based serviceWelding power supplyElectrical and Electronics engineering

A method for adjusting multiple settings of a welding power supply is provided. The method includes providing a plurality of selectable identifiers. Each selectable identifier corresponds to a plurality of user adjustable welding power supply settings. The method also includes receiving an indication to select one of the plurality of selectable identifiers. The method includes adjusting the plurality of user adjustable welding power supply settings that correspond to the received indication.

Owner:ILLINOIS TOOL WORKS INC

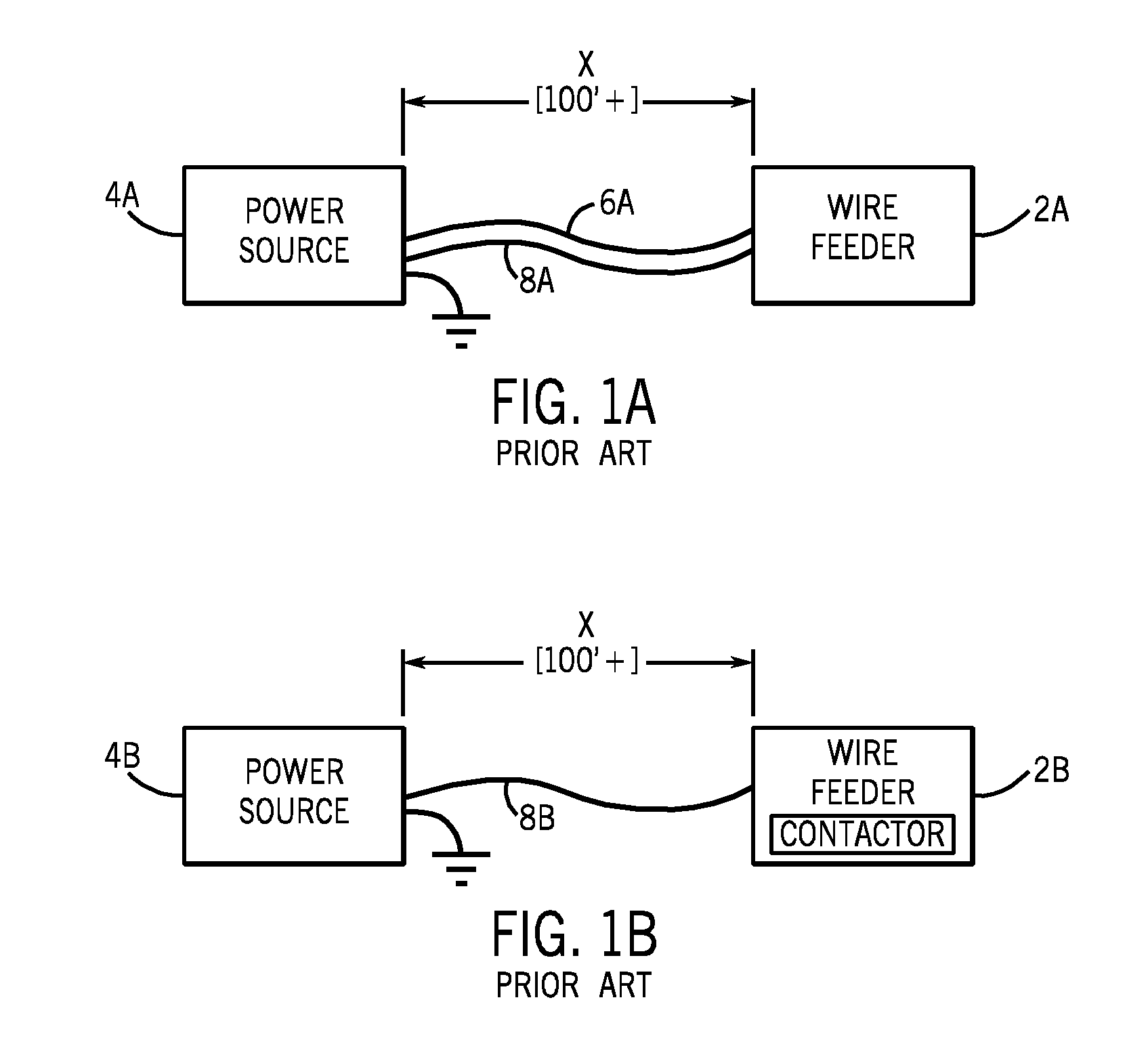

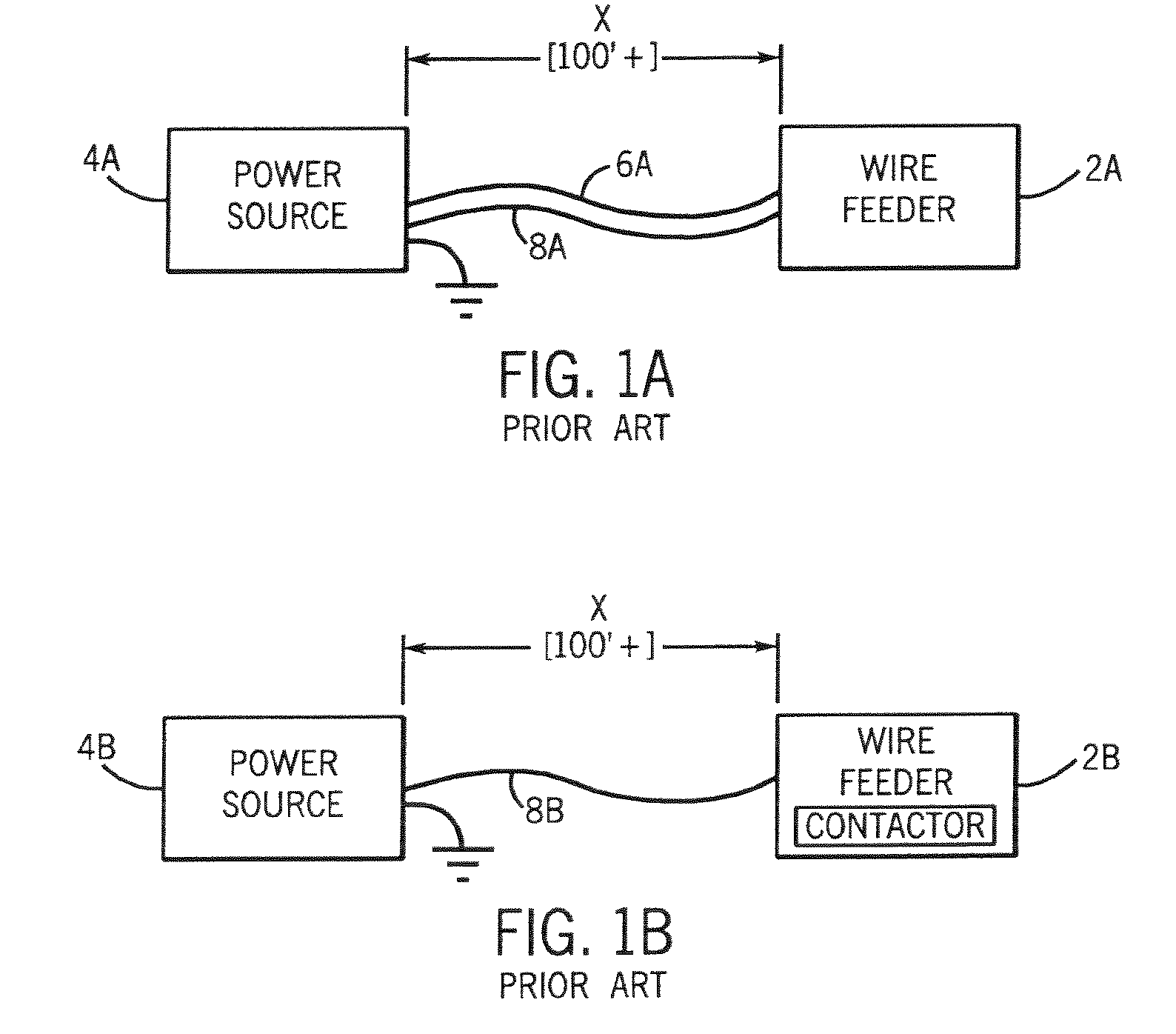

Remotely controlled welding machine

InactiveUS20050016975A1Overcomes drawbackElectric discharge heatingArc welding apparatusLow voltageMode control

The present invention is directed to a remotely controlled welding machine. A remote control uses the welding circuit to transfer information to a welding power source. The information to be communicated to the power source includes welding power source output command information (amperage / voltage control), welding circuit on / off information (power source output contactor control), and power source mode control (constant voltage / constant current). A transmitter transmits the desired welding operational parameters to a receiver disposed in the power source. The transmitter is constructed to use only a small amount of power which, preferably, is supplied by one or two low voltage replaceable and / or rechargeable batteries. Additionally, an open circuit voltage is not created between the power source and an electrode holder when an arc is not present.

Owner:ILLINOIS TOOL WORKS INC

Modular data over power converter for welding power supply

InactiveUS20120097644A1Provide compatibilityWelding electric supplyArc welding apparatusControl signalWelding power supply

An external control module is provided for interfacing a welding power supply with a wire feeder. The welding power supply is designed to exchange control signals, feedback signals, and so forth over a control cable when coupled to a standard wire feeder. However, the external control module allows the power supply to be used with a wire feeder that is designed to exchange data combined in a single cable with welding power. The module is coupled to welding and workpiece cables from the power supply, and to a control cable, such as from a multipin connector on the power supply. The module is further coupled to the wire feeder via a welding cable. The module combines data with welding power for transmission to the wire feeder, and extracts data from welding power for application to the power supply.

Owner:ILLINOIS TOOL WORKS INC

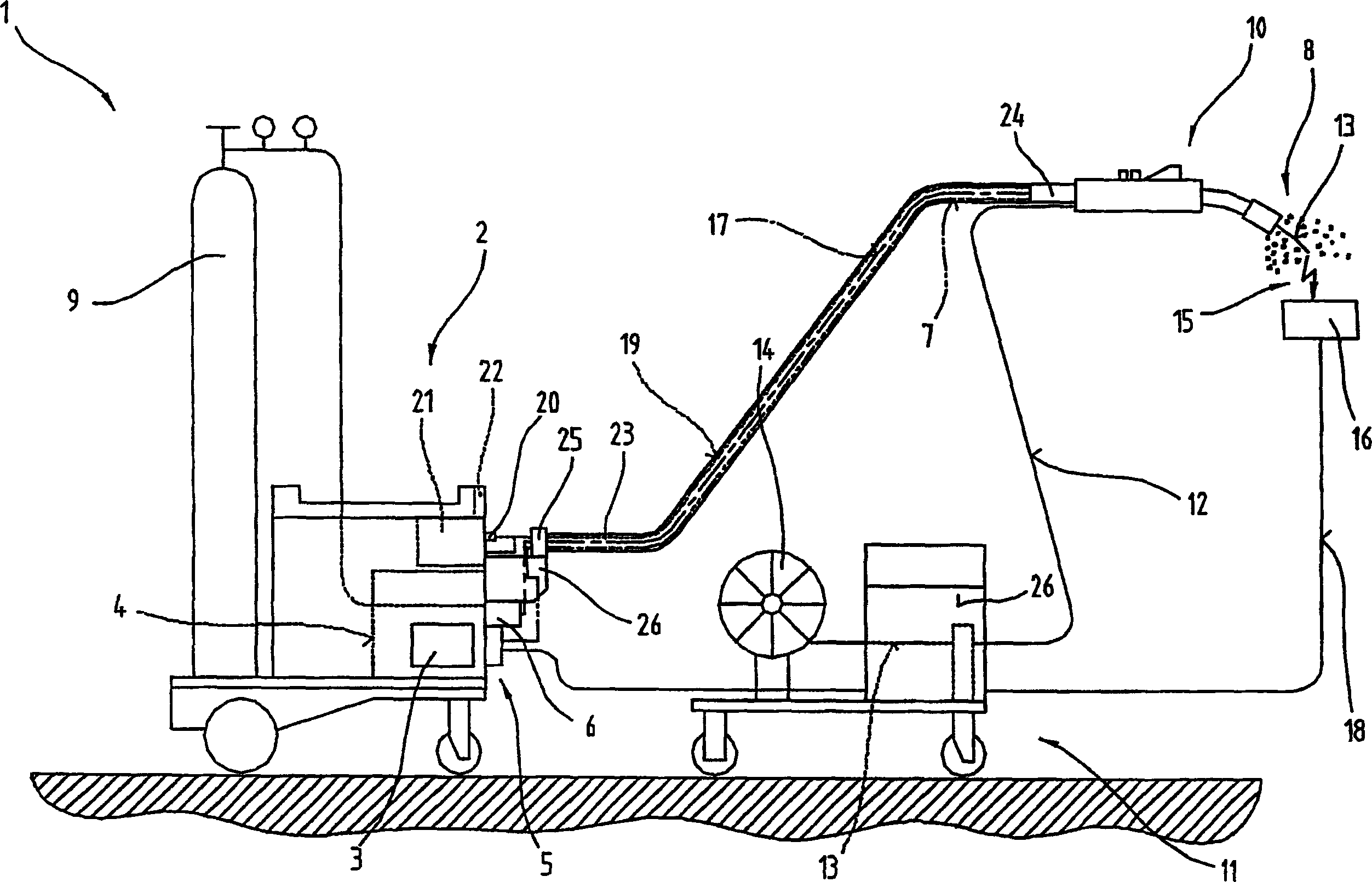

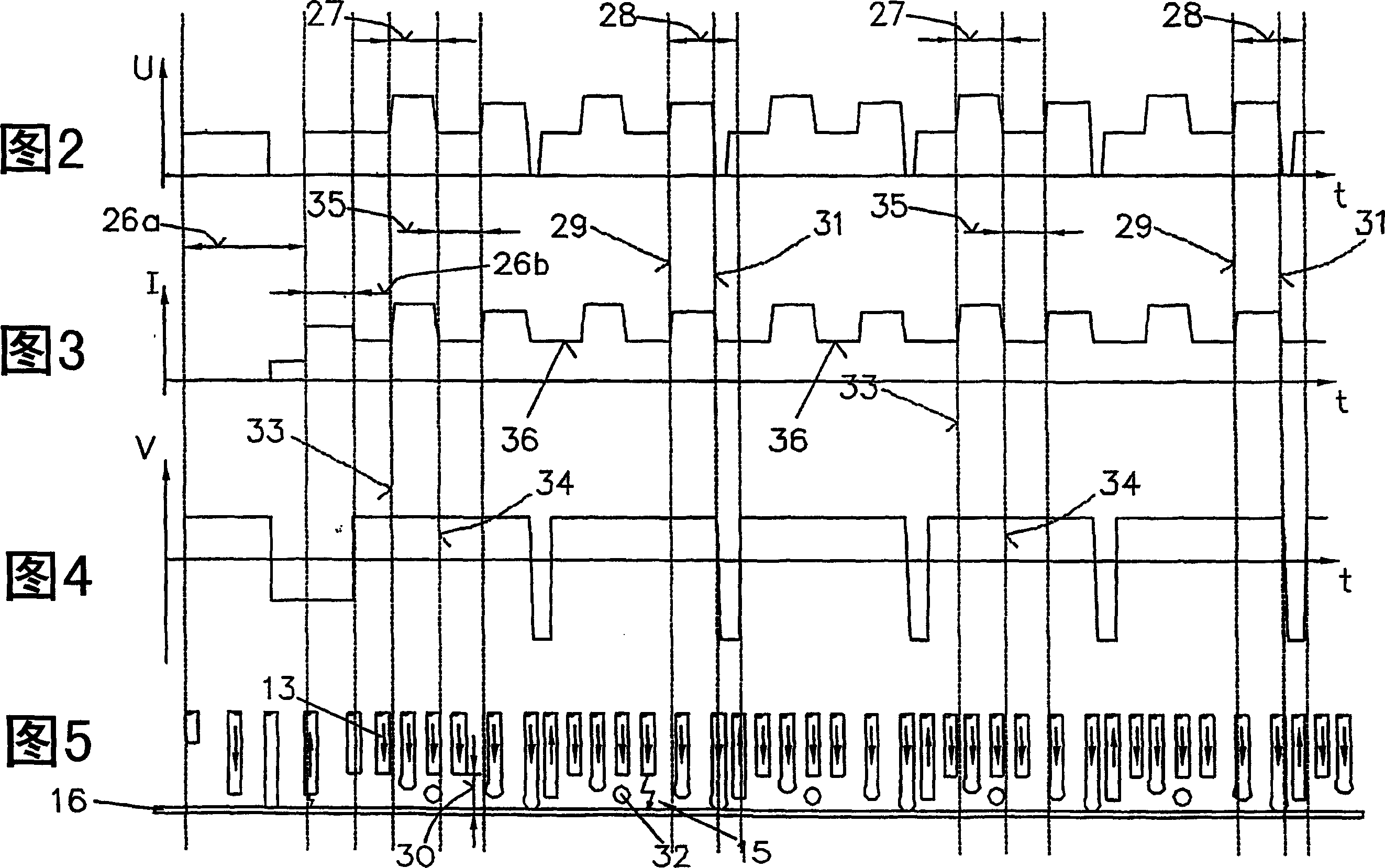

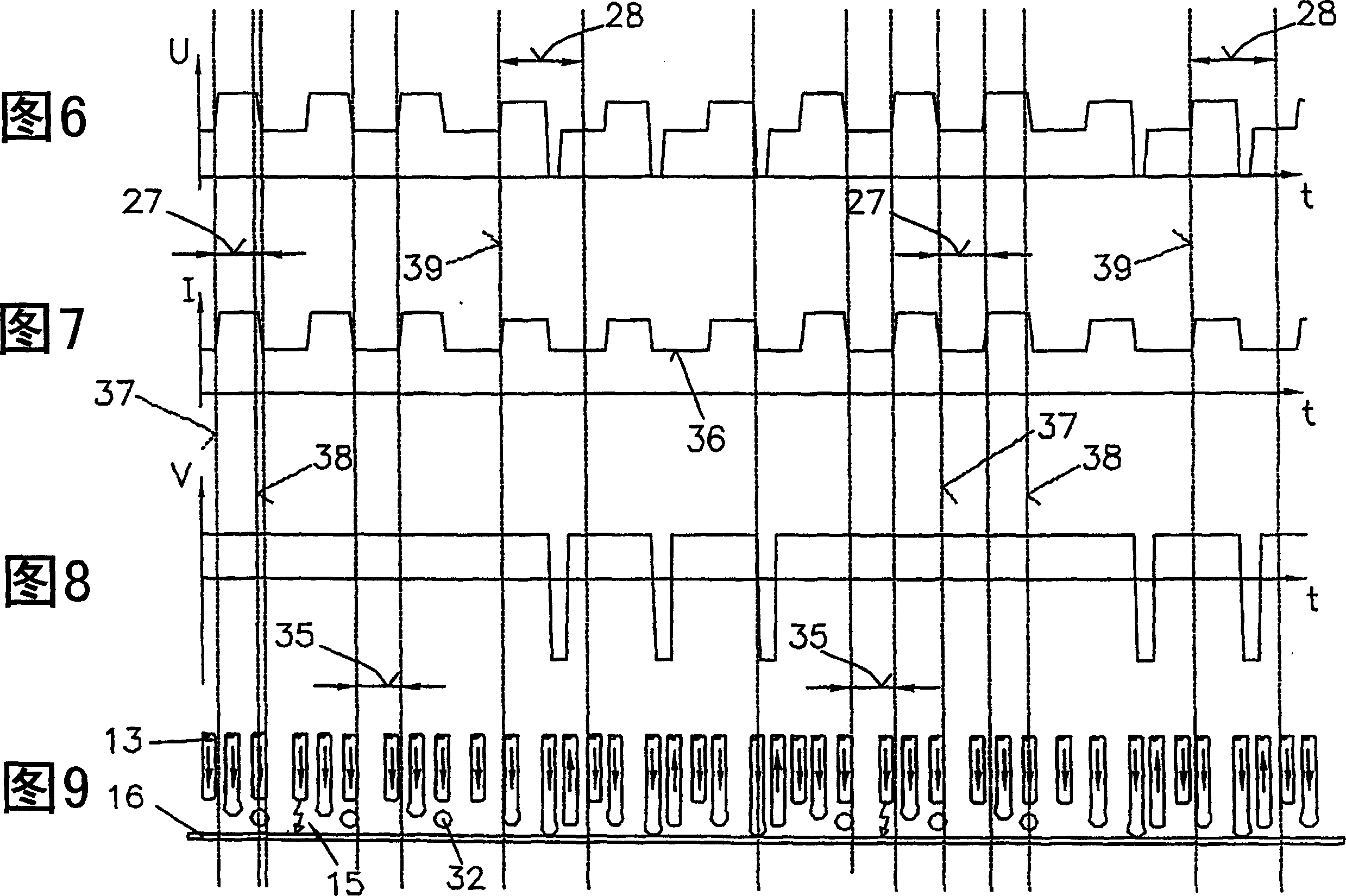

Method for controlling a welding process and welding device for carrying out a welding process

InactiveCN1871093ASimple Heat Balance ControlLow heat inputArc welding apparatusWelding power supplyProcess engineering

The invention relates to a method for controlling and / or adjusting a welding process, using a melting electrode, wherein after ignition of an electric arc, a welding process, which is adjusted on the basis of several different welding parameters, is carried out by means a welding current source (2), said process being controlled or adjusted by a control device (4). The invention also relates to a corresponding welding device used to carry out the process. In order to create said method, wherein the thermal heat economy is adjusted and / or regulated and / or controlled in order to introduce heat into the workpiece (16), at least two different process phases are cyclically combined, said process phases having different inputs of energy via different material transitions and / or arc types, such as a pulse current phase (27) and a cold metal transfer phase (28) in order to influence or control thermal heat economy, particularly the introduction of heat into the workpiece to be processed.

Owner:FRONIUS INTERNATIONAL GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com