Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3142 results about "Pulse current" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phase change-type memory element and process for producing the same

InactiveUS6859389B2Improve integration densityEasy to produceTransistorSolid-state devicesPhase statePhase change

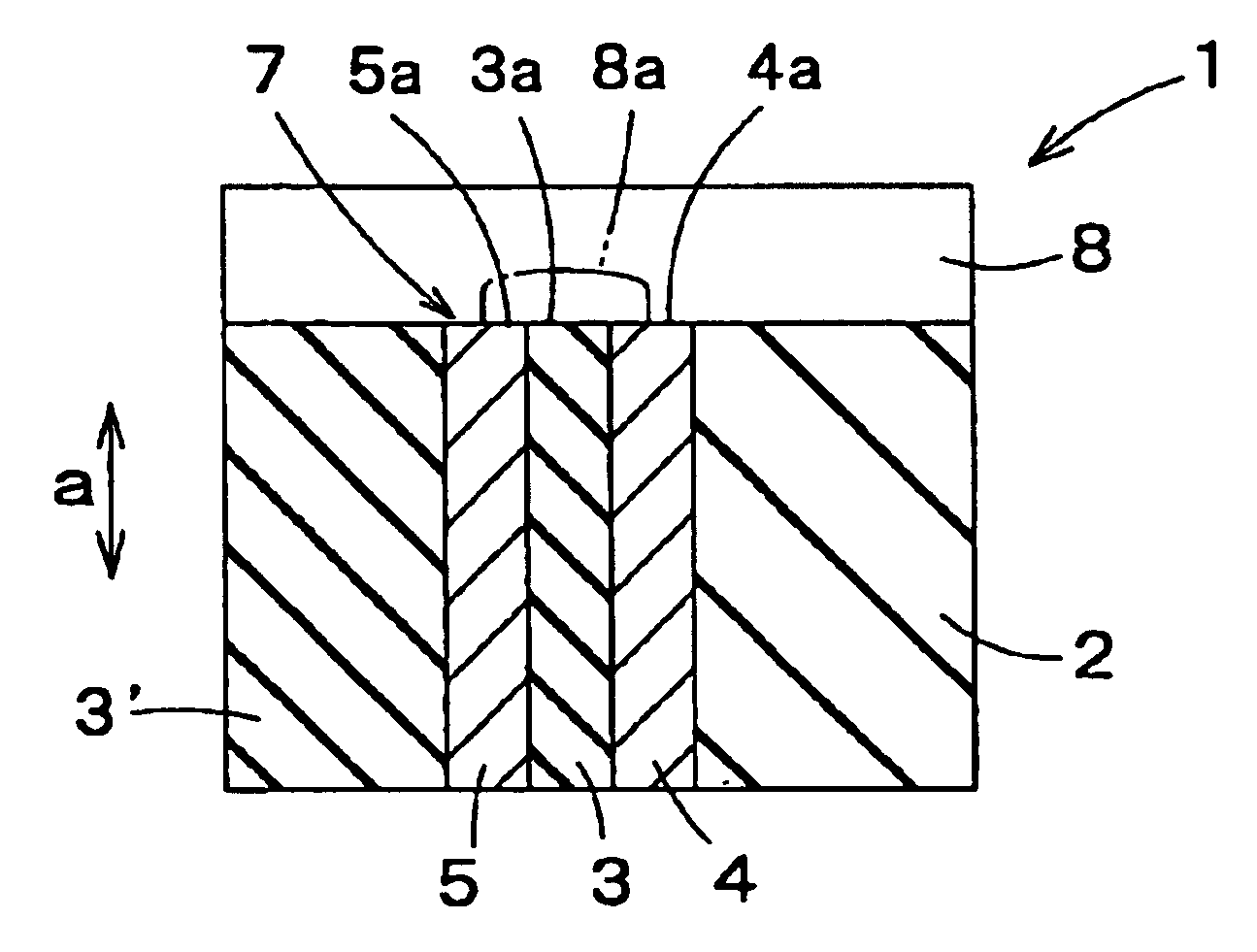

There are provided a phase change-type memory element, which can reduce a reset pulse current value necessary for returning the phase state from an ON state to an OFF state, can improve integration density, is not restricted by the process temperature at the time of the production thereof, and can be simply produced, and a process for producing the same. The phase change-type memory element comprises: two or more electrodes provided opposite to each other through an insulating layer; an exposed surface on which at least a part of the insulating layer and at least a part of each of the electrodes are exposed; and a phase change recording material layer provided, on the exposed surface, in contact with the at least two electrodes. The production process of the phase change-type memory element comprises the steps of: providing two or more electrodes opposite to each other through an insulating material; forming an exposed surface on which at least a part of the insulating material and at least a part of each of the electrodes are exposed; and forming a phase change recording material layer on the exposed surface so as to be in contact with at least two of the electrodes.

Owner:DAI NIPPON PRINTING CO LTD

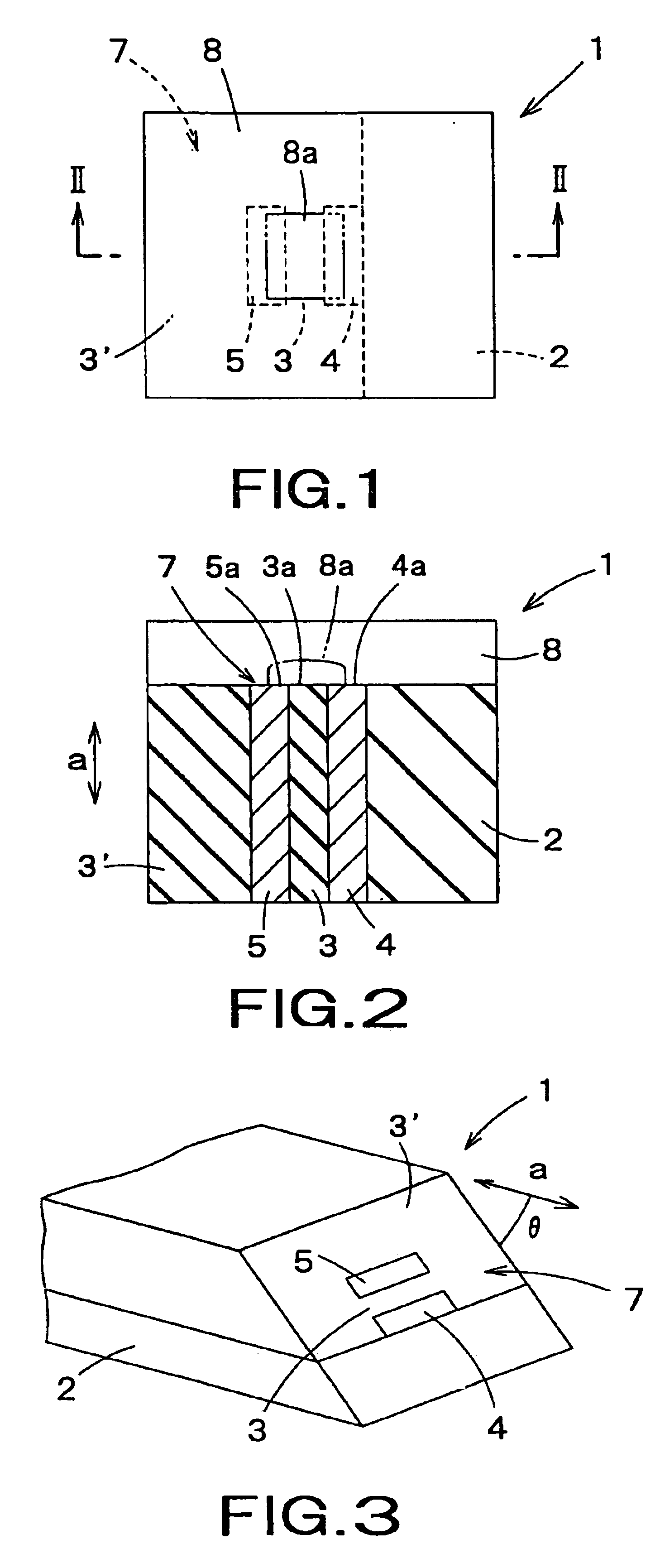

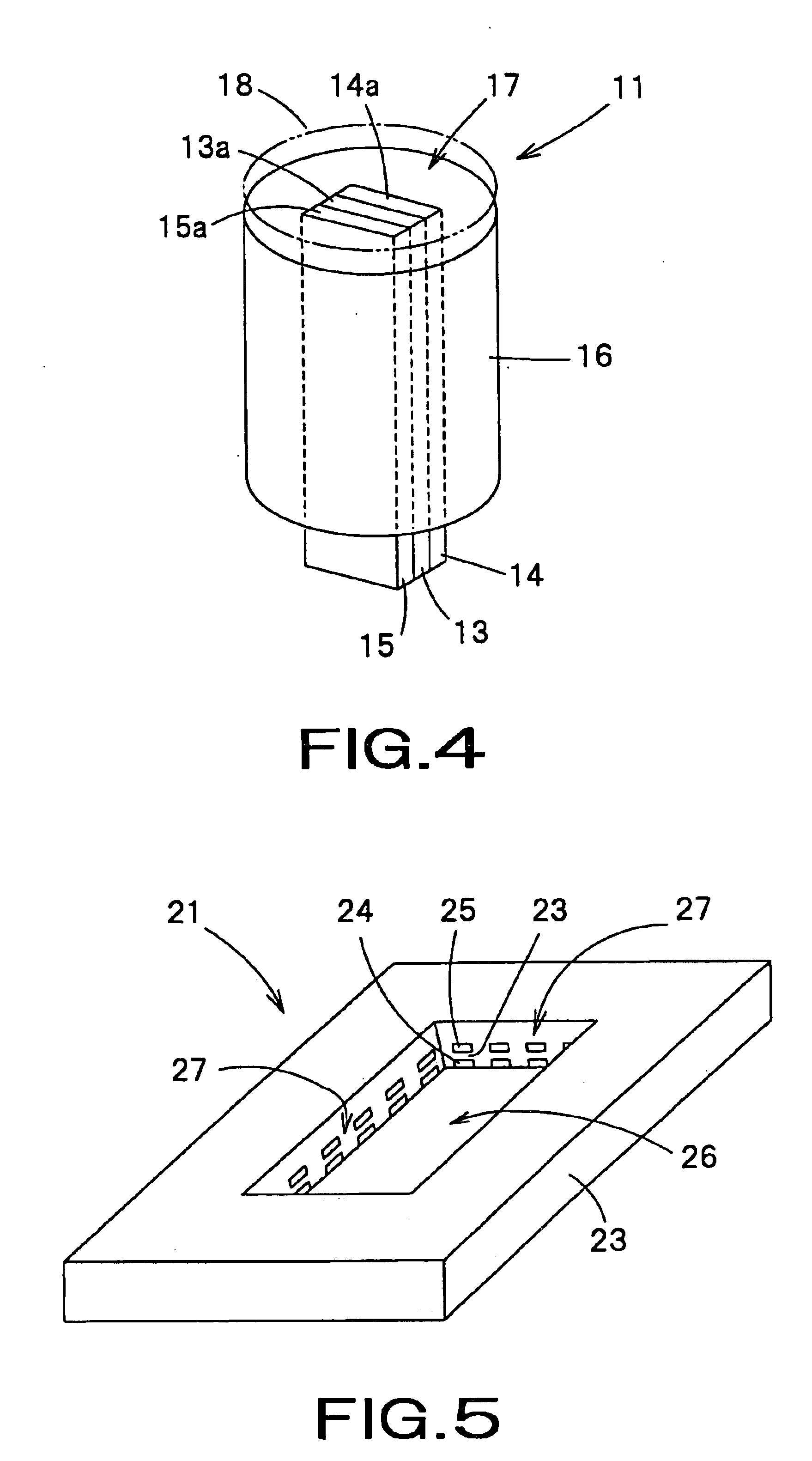

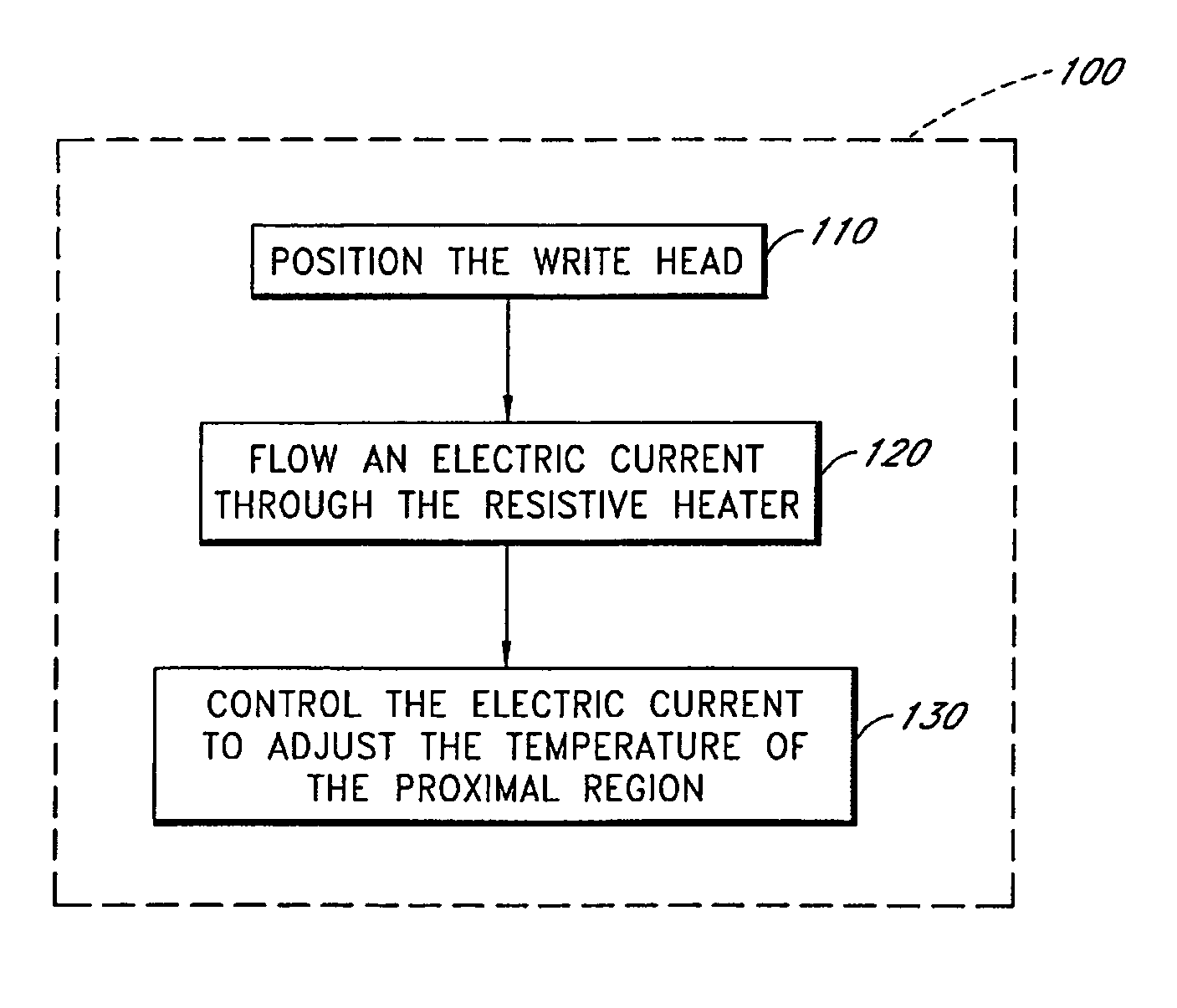

Method of using a magnetic write head having an internal heater

A method adjusts a flying-height distance between a magnetic write head and a magnetic medium. The method includes positioning the write head in a location spaced from the magnetic medium by the flying-height distance. The write head includes a magnetic yoke and a proximal region in proximity to the magnetic medium. The write head further includes a resistive heater and at least a portion of the resistive heater is within the magnetic yoke and is in proximity to the proximal region. The resistive heater is configured to heat the proximal region. The proximal region has a coefficient of thermal expansion. The proximal region is configured to expand and to contract in response to a temperature of the proximal region. The method further includes flowing an electric current through the resistive heater. The method further includes controlling the electric current to adjust the temperature of the proximal region to selectively expand and contract the proximal region and thereby control the flying-height distance. Controlling the electric current includes pulsing the electrical current and adjusting a time interval between pulses.

Owner:WESTERN DIGITAL TECH INC

Process for the electrolytic deposition of metal layers

InactiveUS6099711AOptimize allocationImpairing propertyCellsElectrolysisHigh current densityMetal coating

PCT No. PCT / EP96 / 05140 Sec. 371 Date Apr. 23, 1998 Sec. 102(e) Date Apr. 23, 1998 PCT Filed Nov. 21, 1996 PCT Pub. No. WO97 / 19206 PCT Pub. Date May 29, 1997The invention relates to a method for the electrolytic deposition of metal coatings, in particular of copper coatings with certain physical-mechanical and optical properties and uniform coating thickness. According to known methods using soluble anodes and applying direct current, only uneven metal distribution can be attained on complex shaped workpieces. By using a pulse current or pulse voltage method, the problem of the coatings being of varying thickness at various places on the workpiece surfaces can indeed be reduced. However, the further problem of the geometric ratios being changed continuously during the depositing process by dissolving of the anodes is not resolved thus. This can be avoided by using insoluble anodes. In order to guarantee sufficient stability of the anodes and a bright coating even at those points on the workpiece surfaces, onto which the metal is deposited with high current density, it is essential to add compounds of an electrochemically reversible redox system to the depositing solution.

Owner:ATOTECH DEUT GMBH

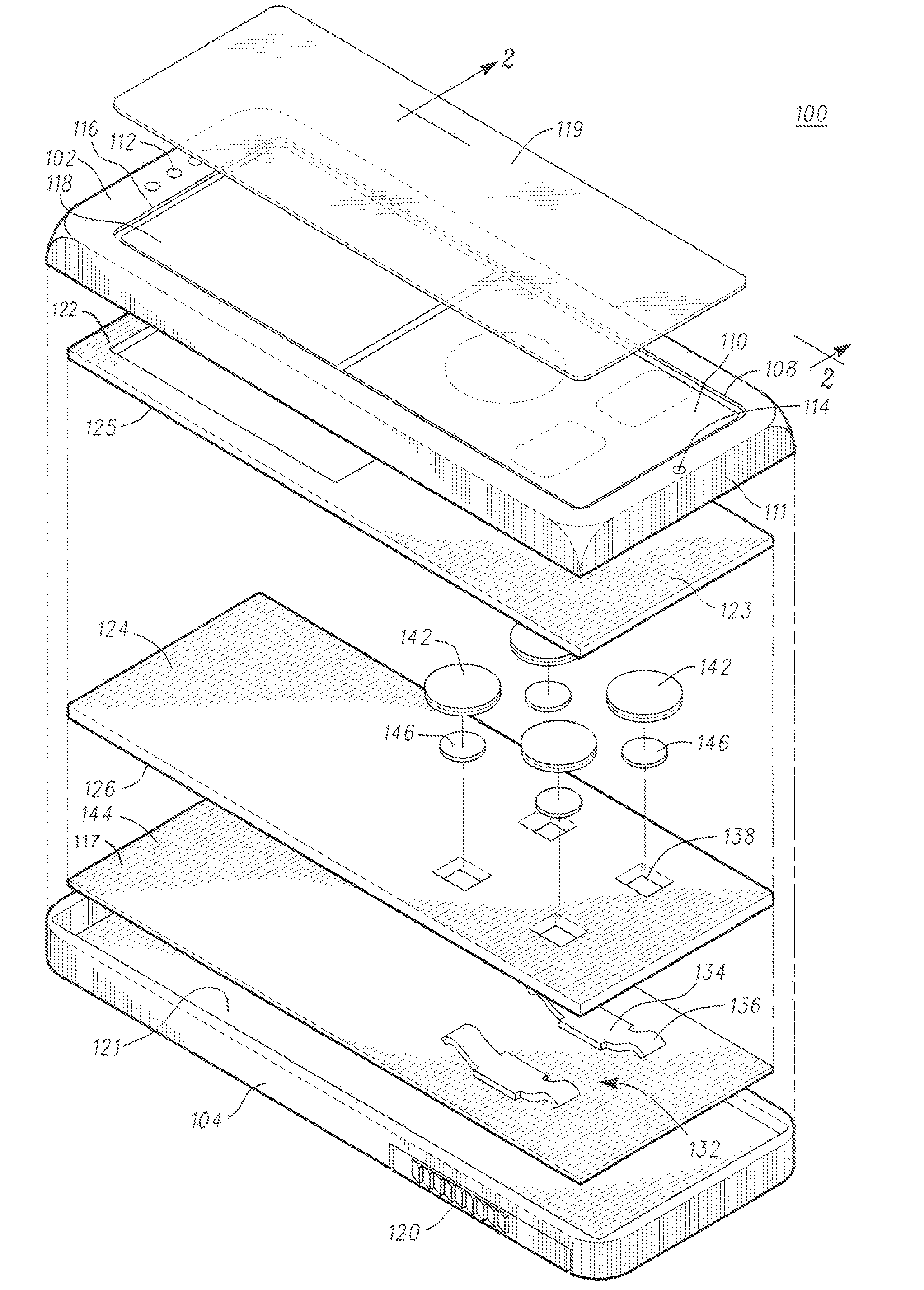

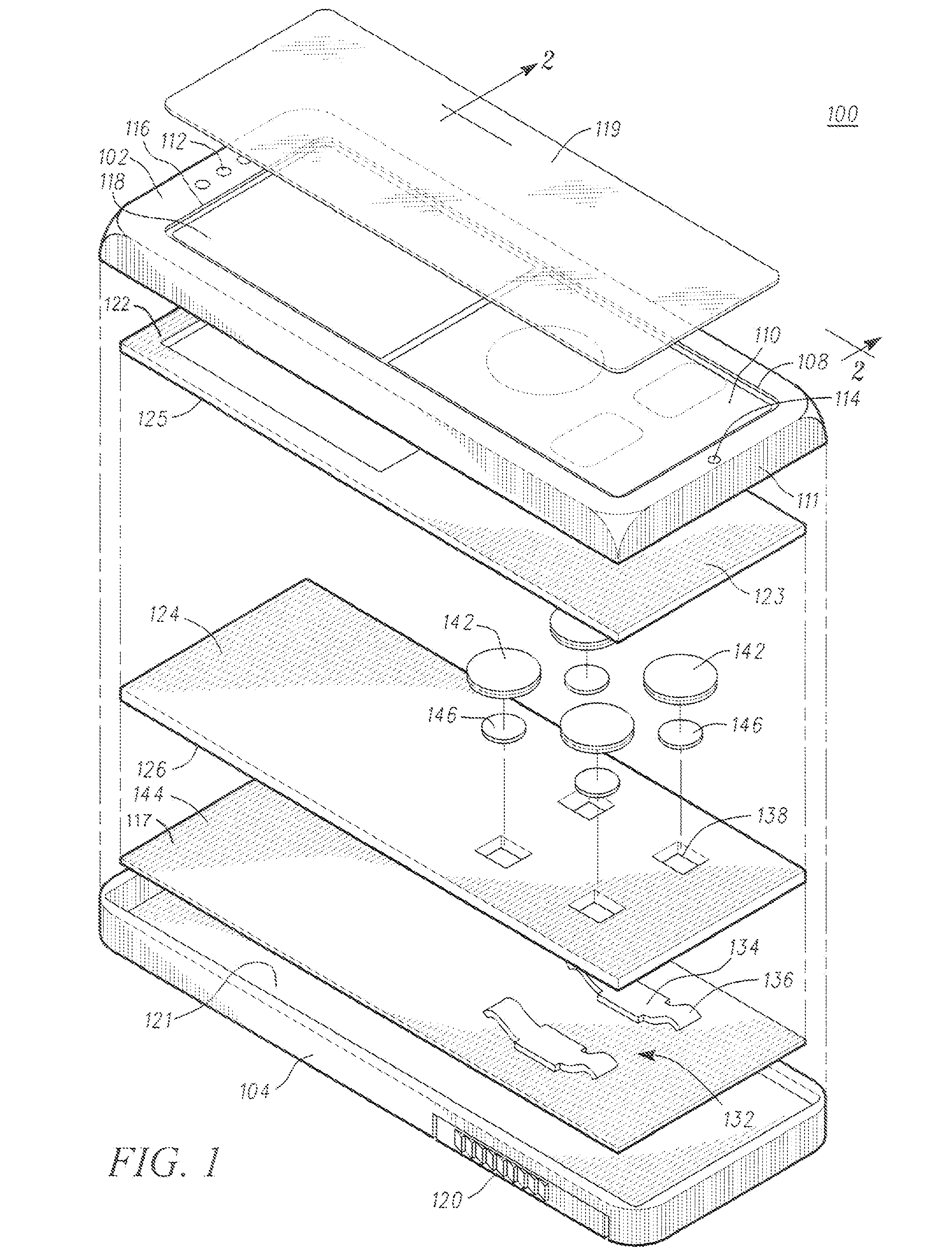

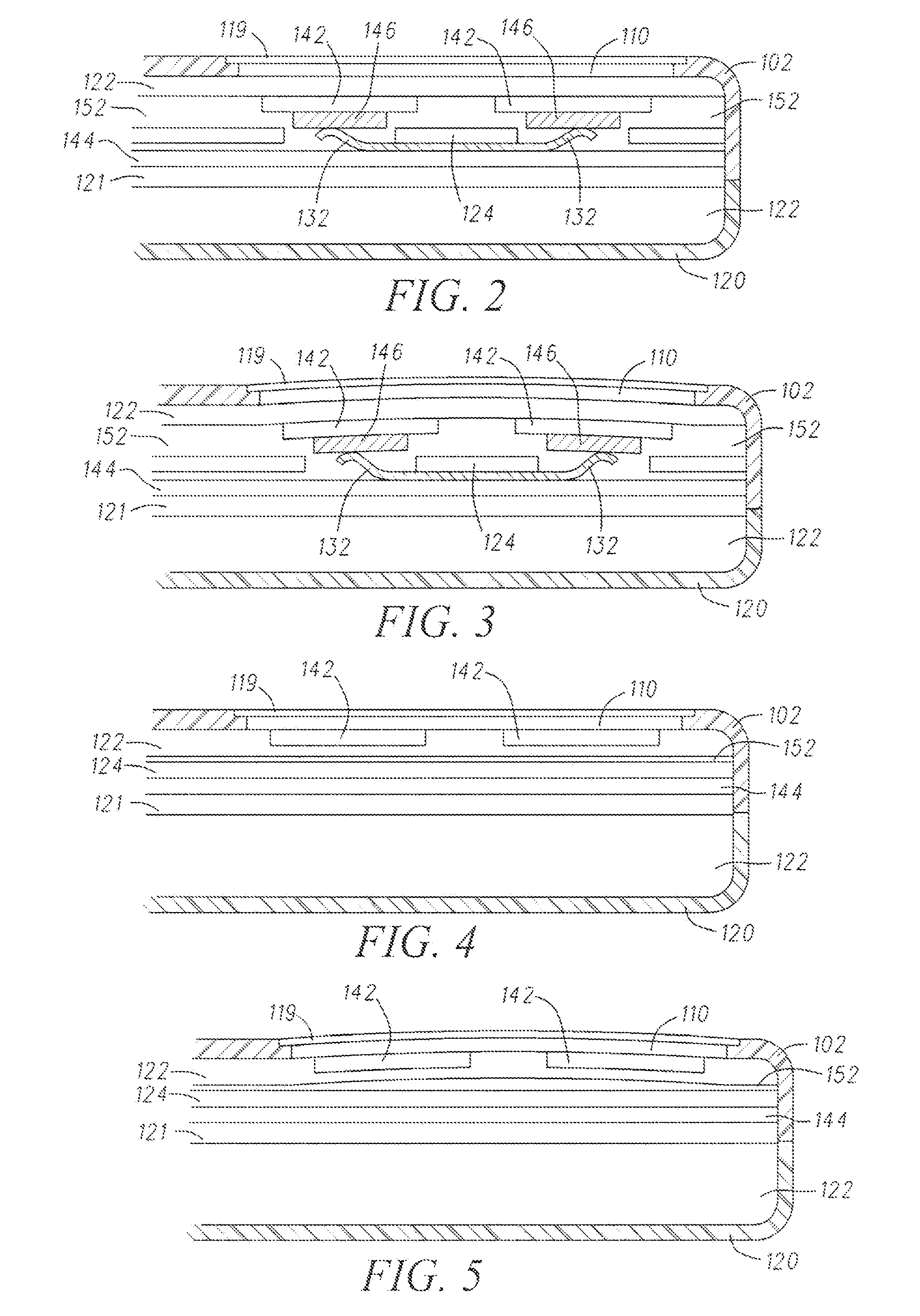

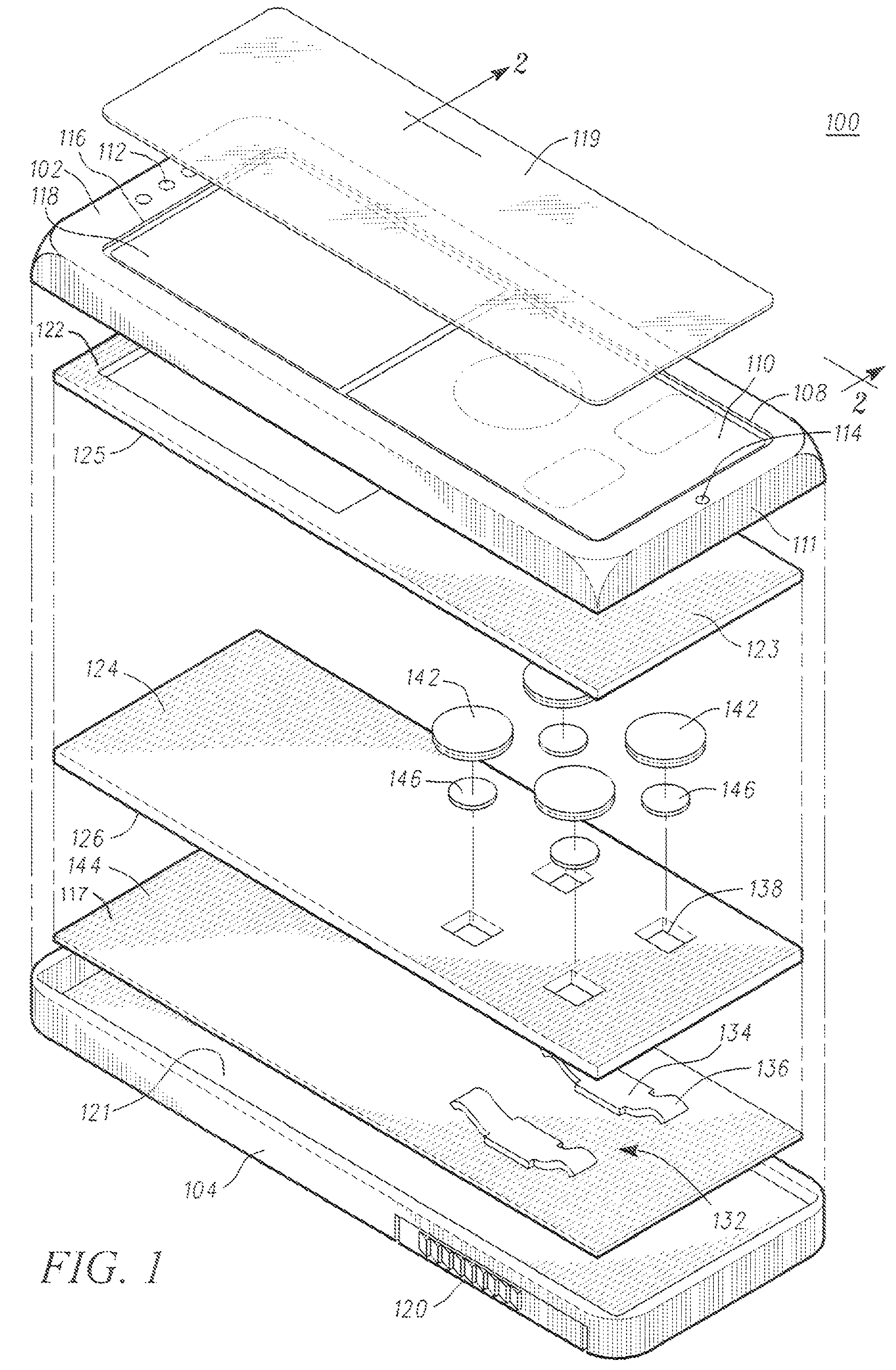

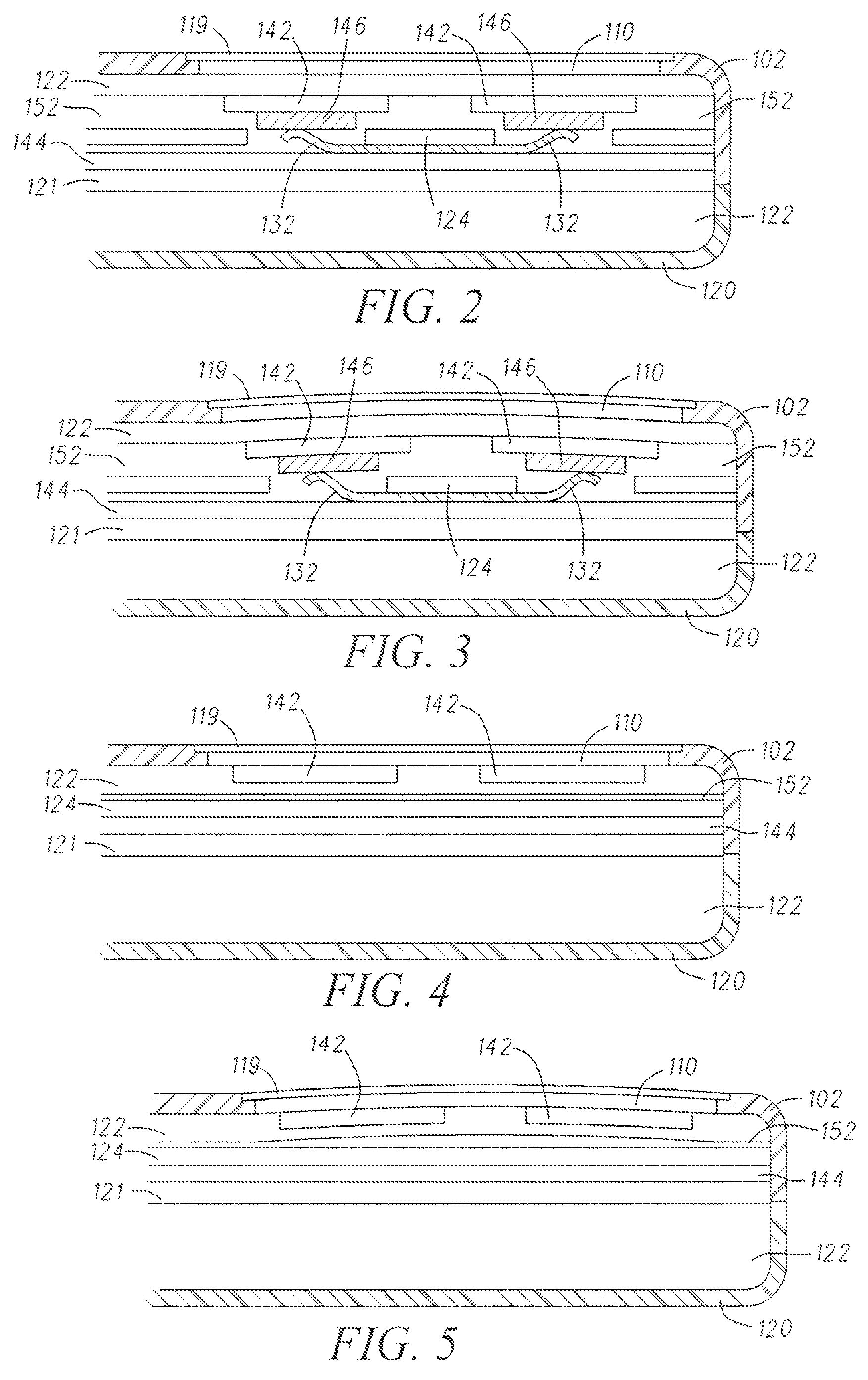

Electronic device and circuit for providing tactile feedback

ActiveUS20090072662A1Low costPiezoelectric/electrostriction/magnetostriction machinesDigital data processing detailsElectricityControl signal

A circuit (800) for controlling at least one piezoelectric actuator (142) includes a piezoelectric drive circuit (802) that generates unidirectional voltage drive signal, also referred to as Vout, at node (804). The piezoelectric actuator drive circuit (802) includes a boost switcher circuit or charging circuit (806), a buck switcher circuit or pulsed current sink discharge circuit (808) and a control signal generating circuit (810) that receives an input control signal (812) from, for example, a keyboard processor or other suitable processor (604) indicating that the device has requested generation of haptic feedback utilizing the piezoelectric actuator (142). The control signal generating circuit (810) provides at least two pulse-with-modulated control signals, one to control the charging circuit and one to control the discharging circuit to produce the unidirectional voltage drive signal, that in one example is a raised cosine drive signal (904).

Owner:GOOGLE TECH HLDG LLC

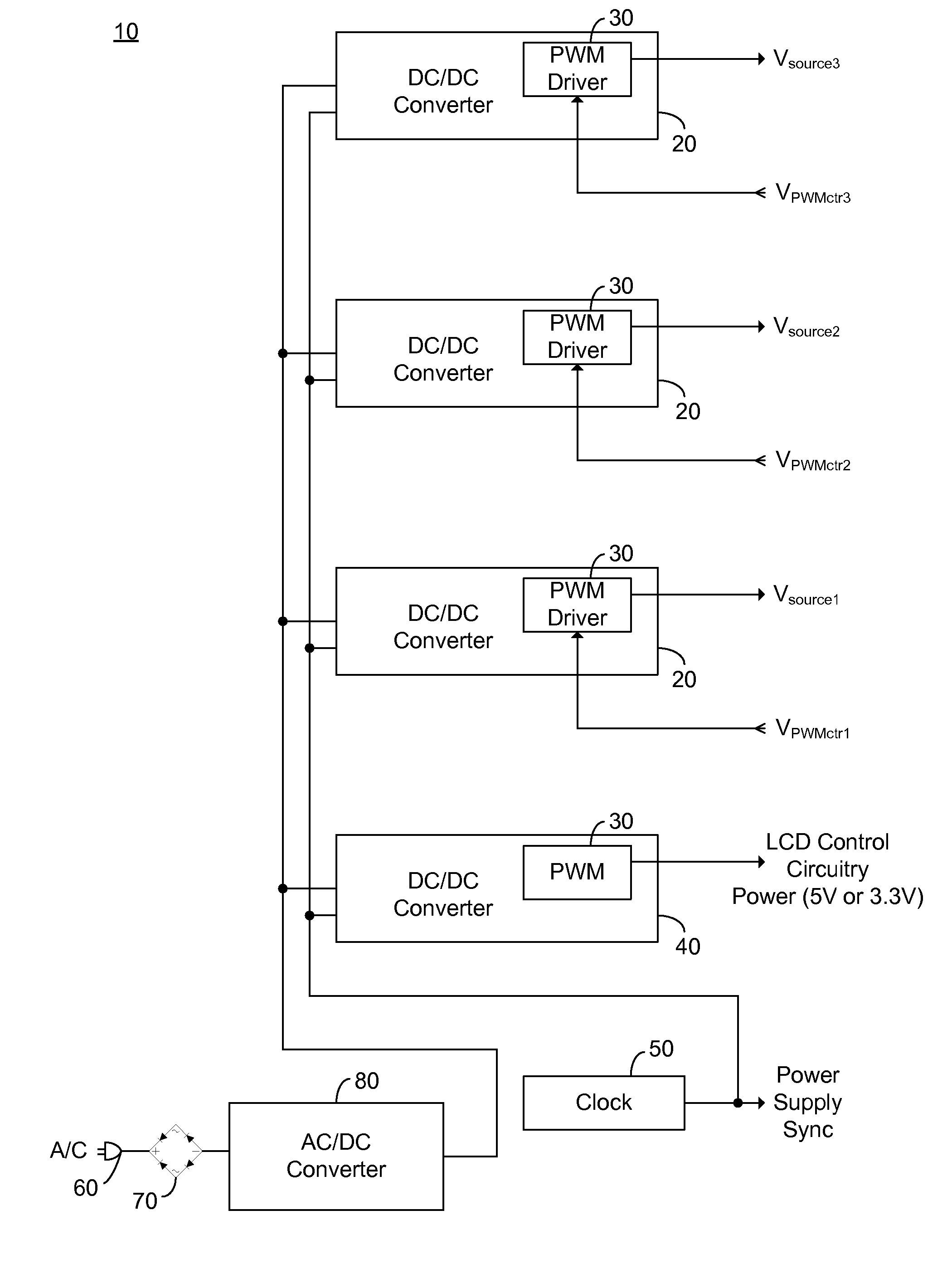

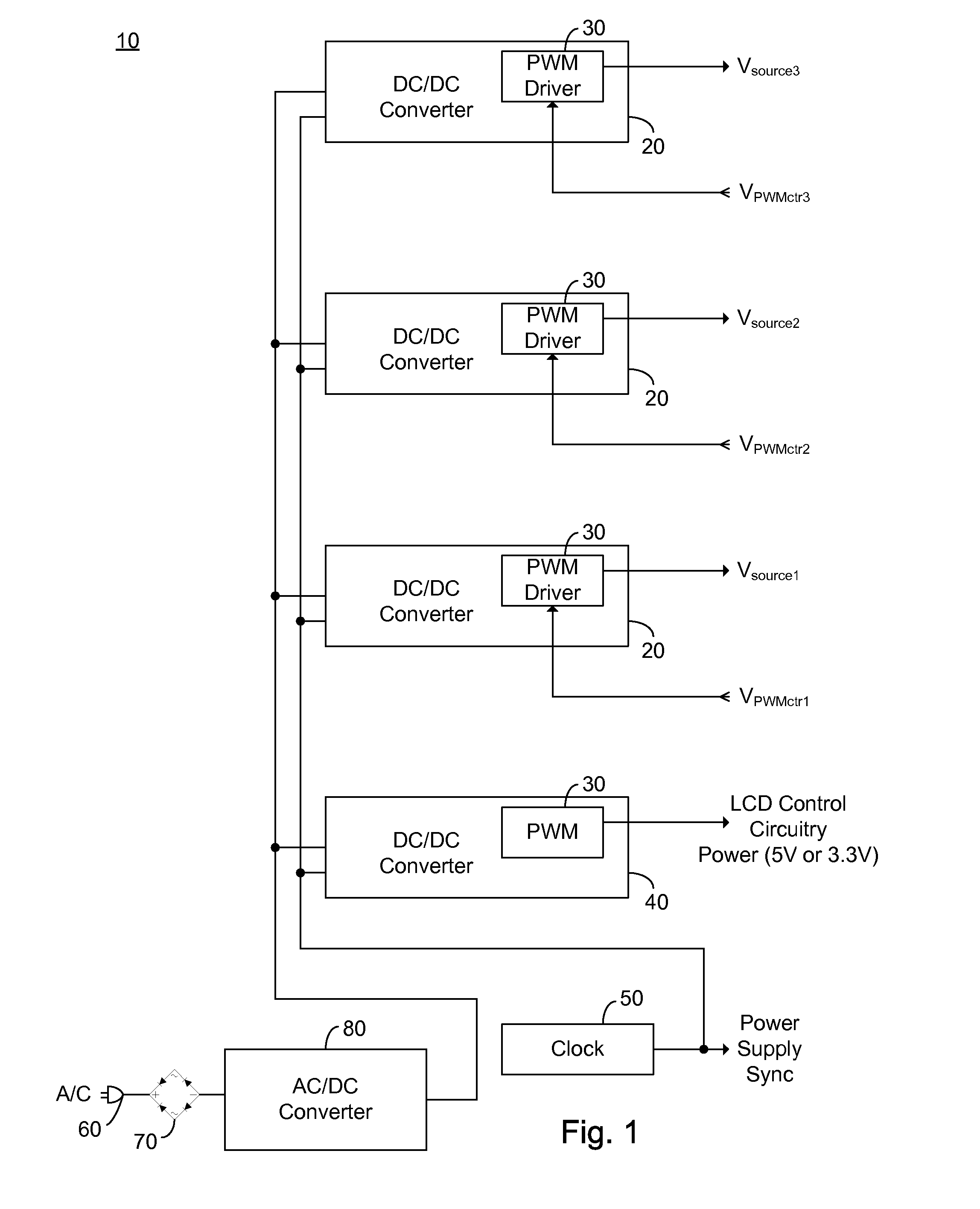

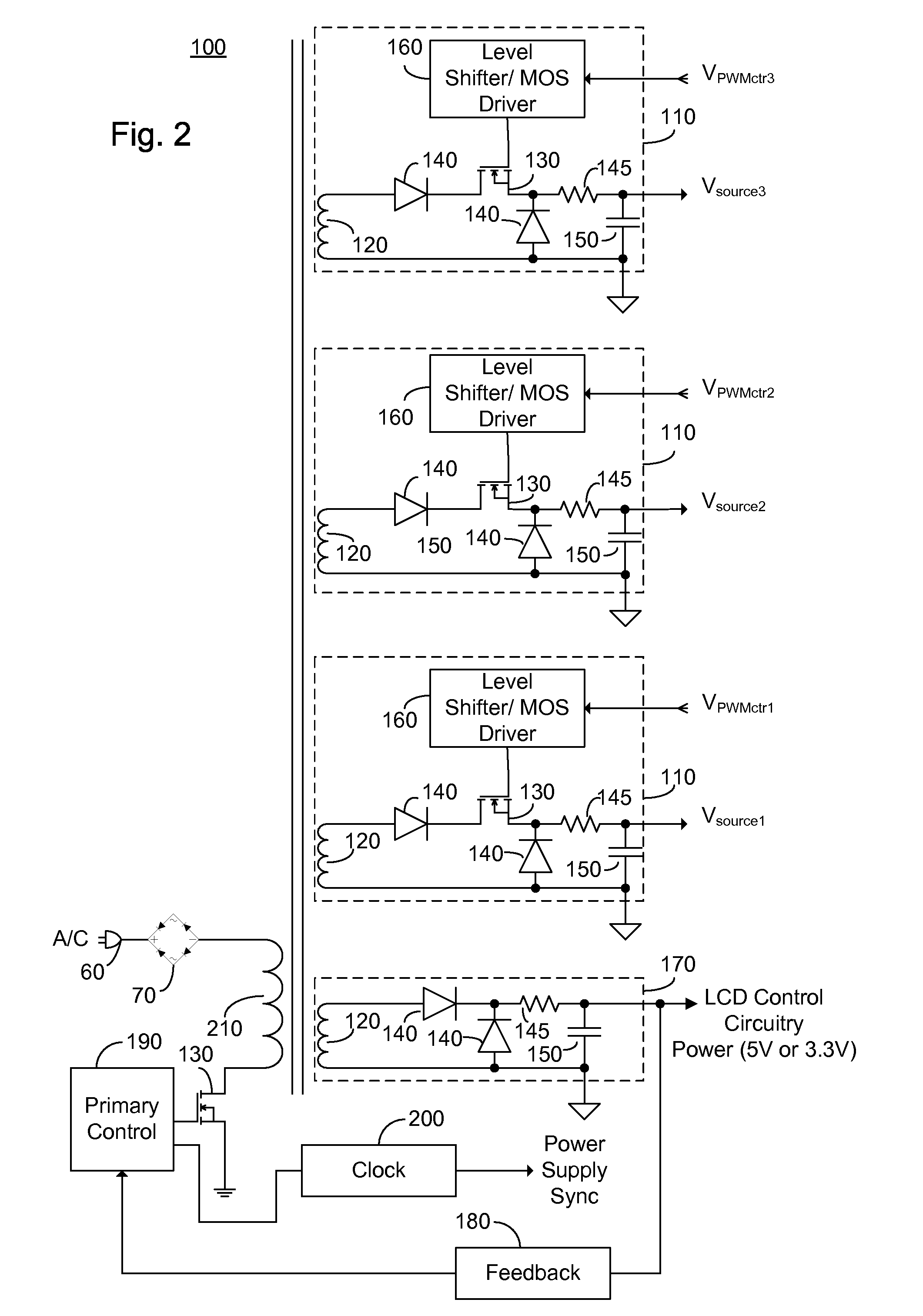

Secondary Side Post Regulation for LED Backlighting

A secondary side post regulator arrangement for a plurality of LED strings. For each secondary winding, a first electronically controlled switch is provided arranged to control the power output, and a LED string is connected thereto. A second electronically controlled switch is further connected in series with the LED string, arranged to receive a PWM signal, thereby pulsing current through the LED string. A current sensing element is further provided outputting a voltage representation of the current through the LED string, and a synchronized sampling circuit is provided arranged to sample the voltage representation during the on period of the second electronically controlled switch. The sampled and held voltage representation is compared with a reference signal and fed back to control the first electronically controlled switch. The voltage output associated with each secondary winding is controlled, responsive to the reference voltage.

Owner:POLARIS POWERLED TECH LLC

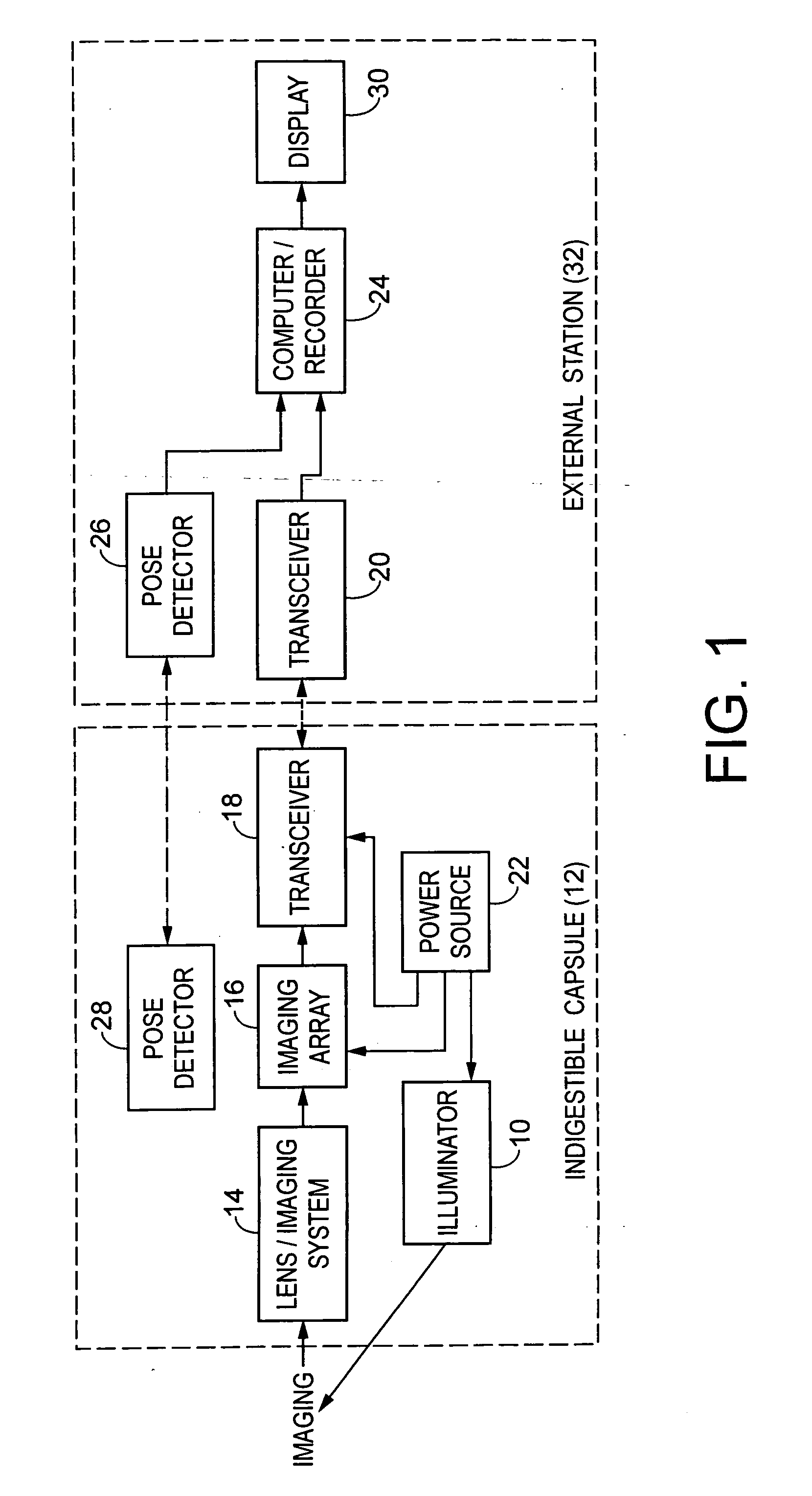

Miniature ingestible capsule

Owner:NAIR PADMANABHAN P +1

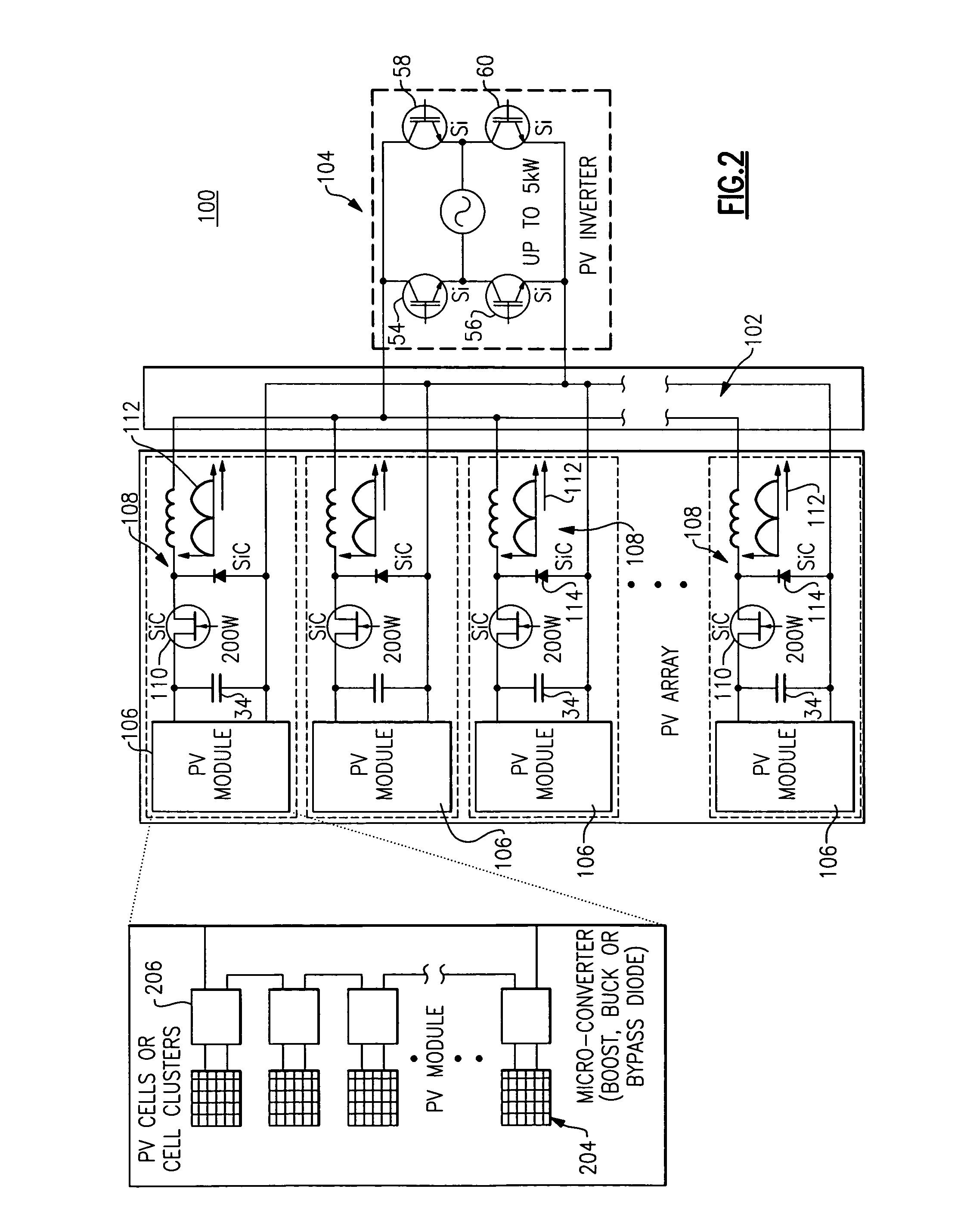

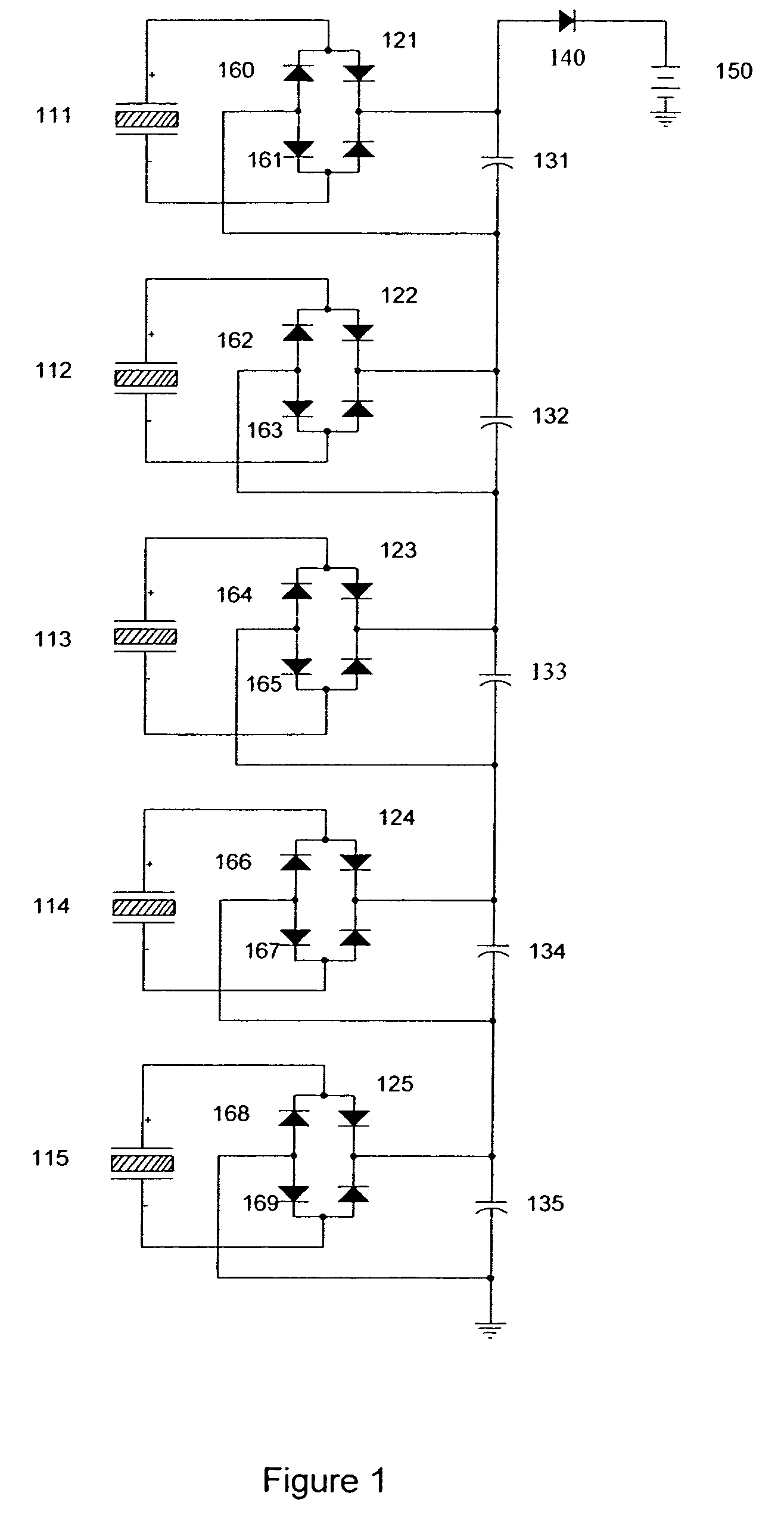

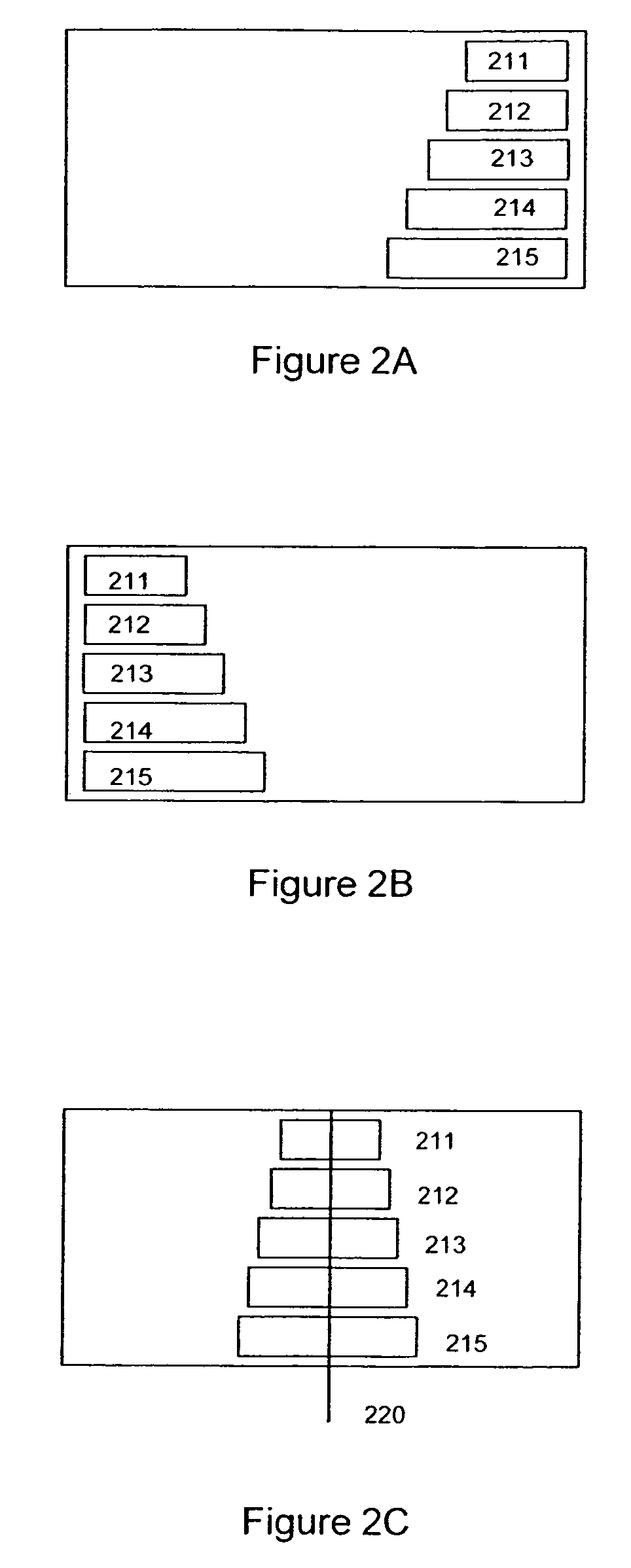

Quasi-AC, photovoltaic module for unfolder photovoltaic inverter

A photovoltaic (PV) energy system includes a pulsed bus defined by a non-zero average value voltage that is proportional to a rectified utility grid AC supply voltage. The PV energy system also includes a plurality of PV modules, each PV module including a bucking circuit configured to convert a corresponding PV voltage into a pulsing current, wherein the pulsating bus is configured to sum the pulsing currents produced via the plurality of PV modules such that a resultant pulsing current is injected into the pulsating bus in phase with the non-zero average value voltage. A current unfolding circuit is configured to control the amount of AC current injected into the utility grid in response to the resultant pulsing current.

Owner:GENERAL ELECTRIC CO

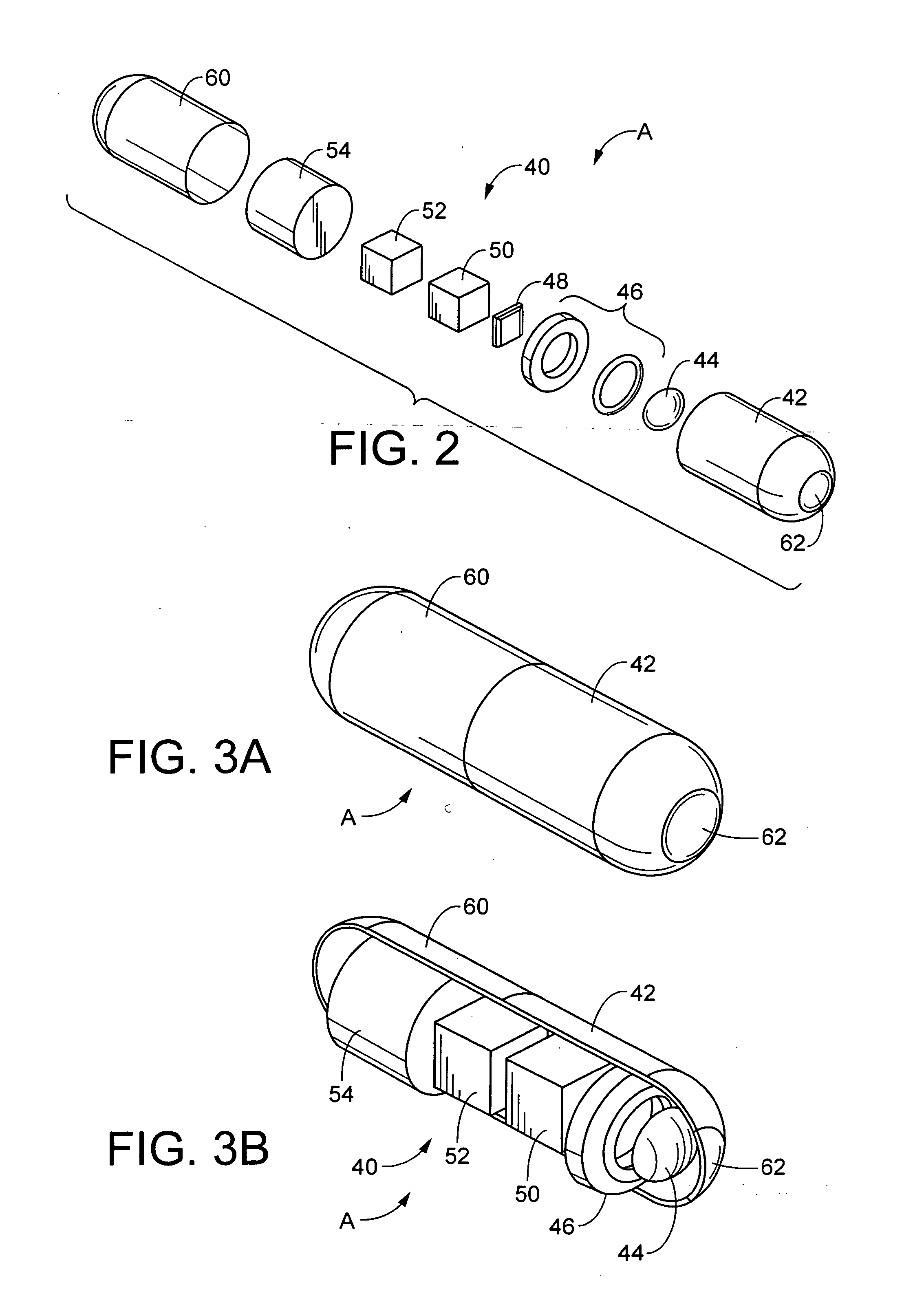

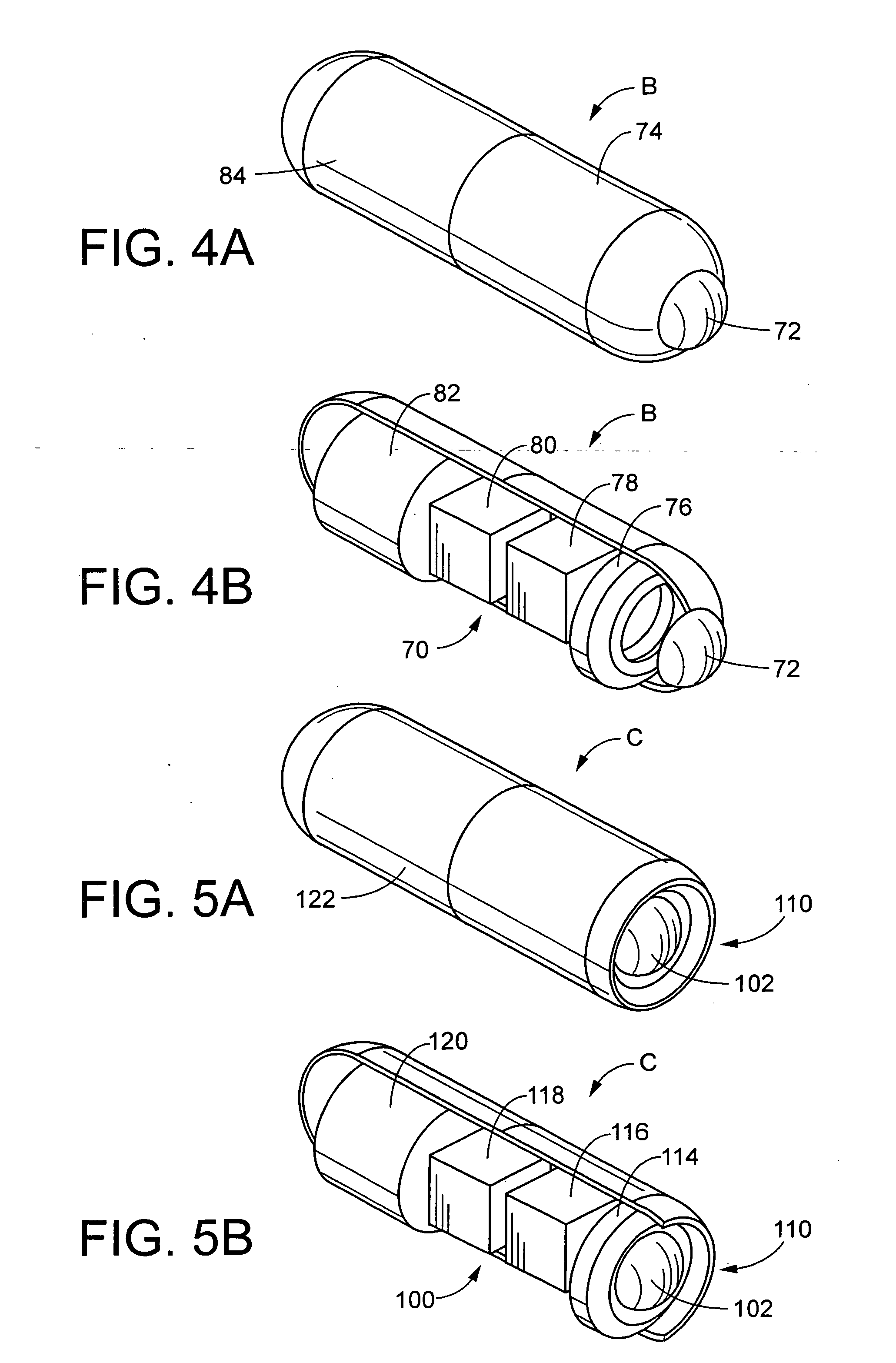

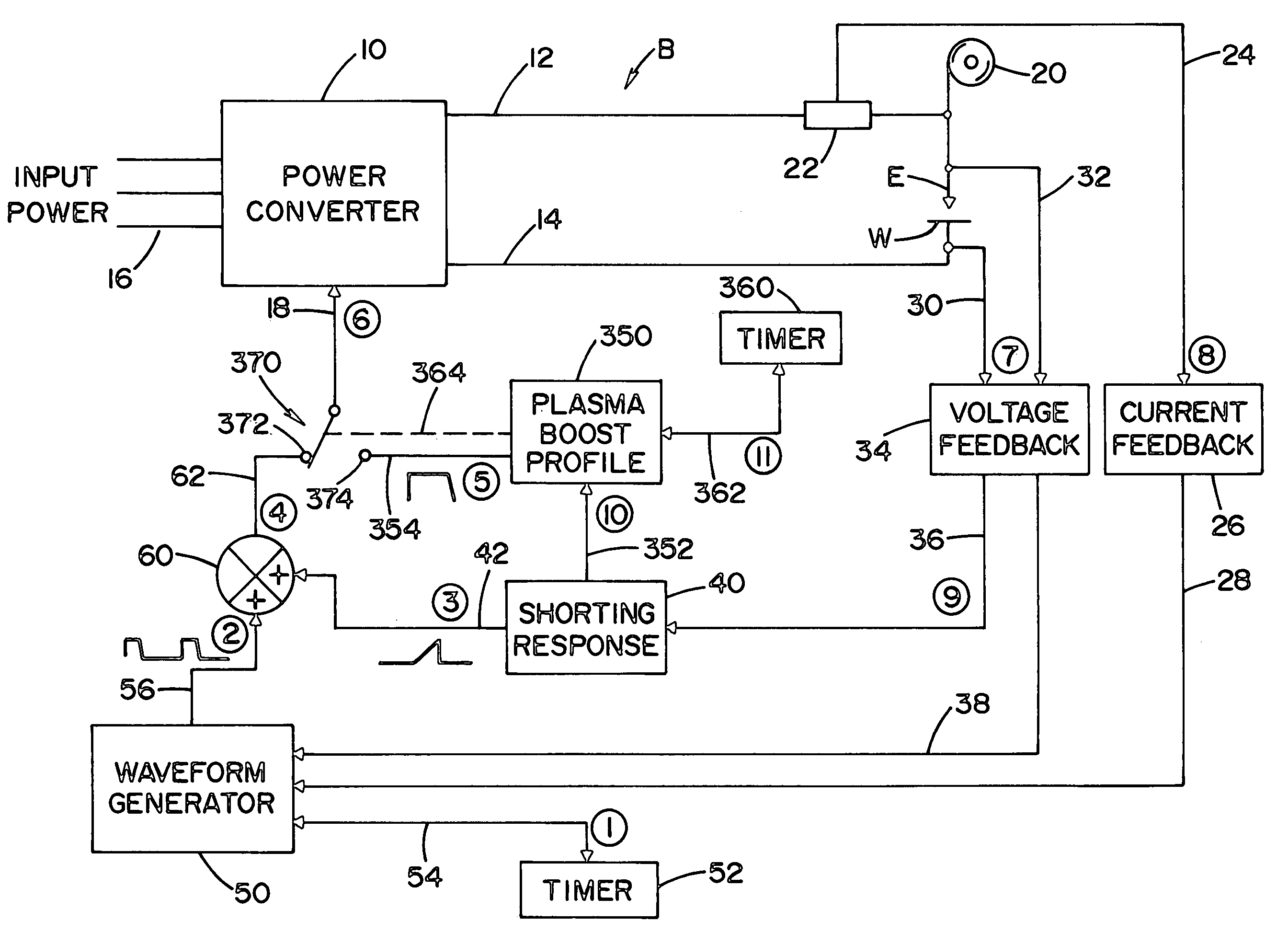

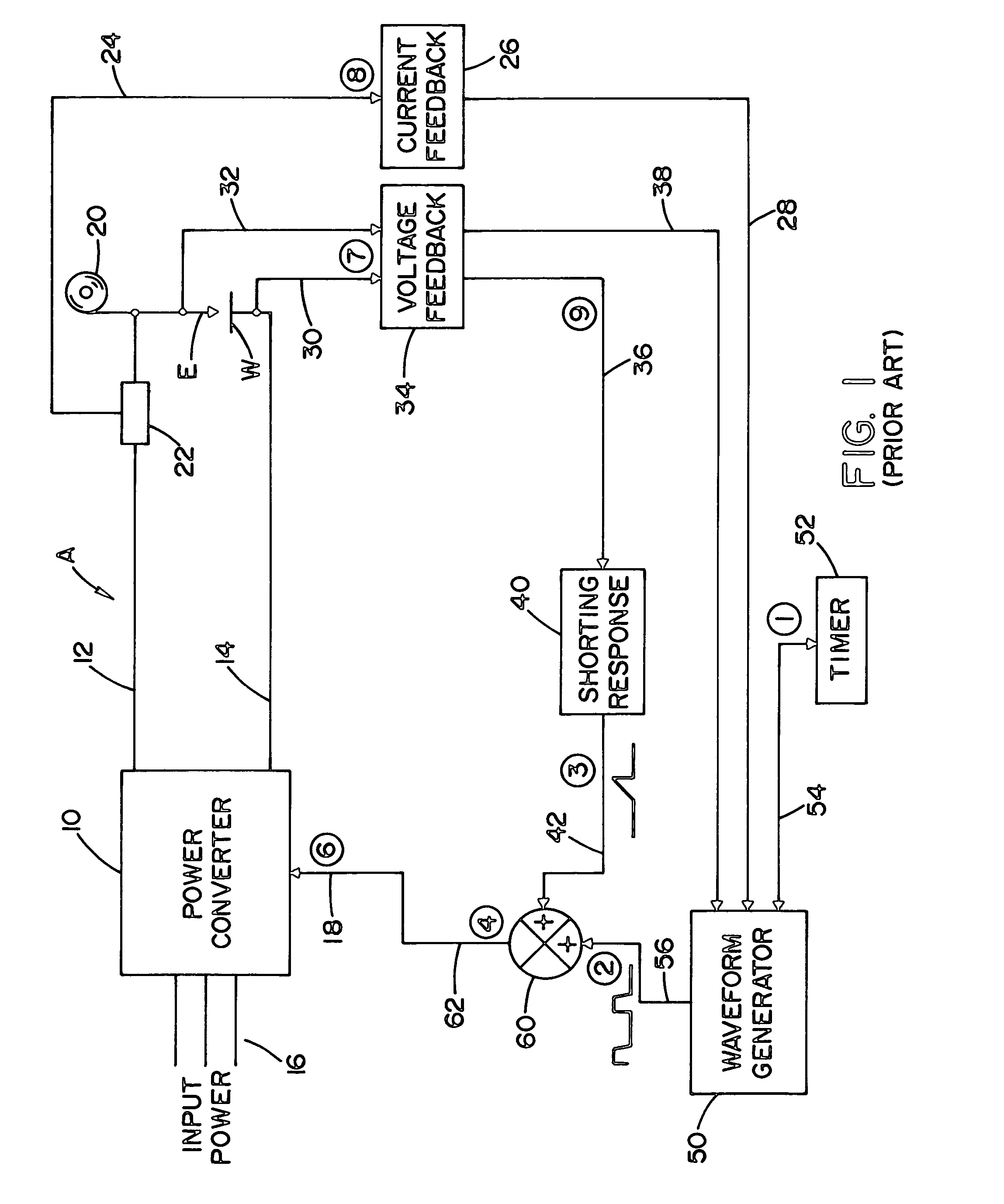

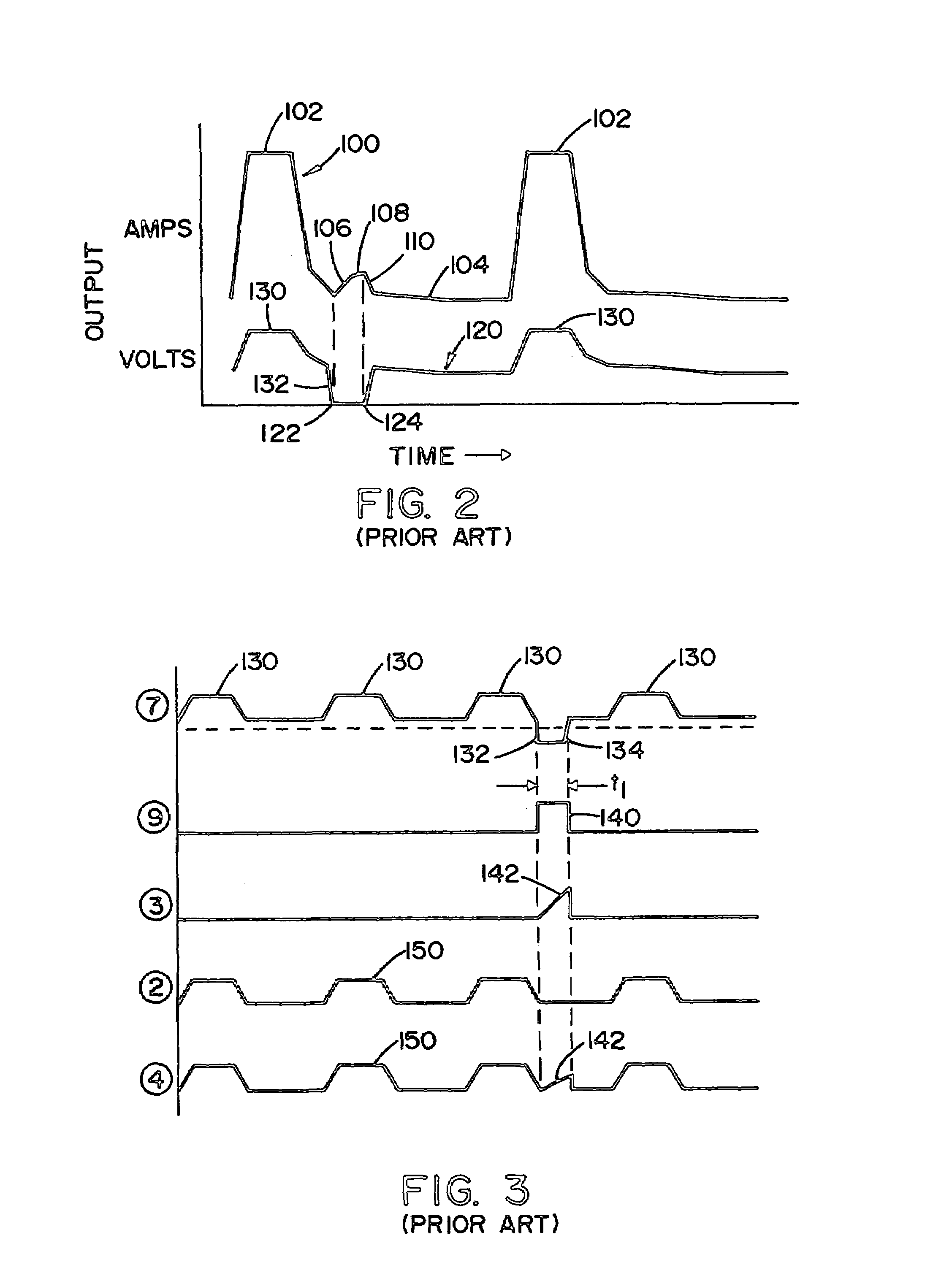

Pulse welder and method of using same

ActiveUS7304269B2Reduce arc forcePromote shorting eventsCoin-freed apparatus detailsArc welding apparatusPower flowEngineering

An electric arc welder for performing a pulse welding process by a current between an advancing electrode and workpiece where the welder comprises a short detecting circuit for creating a short signal upon occurrence of a short circuit between the advancing electrode and the workpiece and a boost circuit to create a plasma boost pulse after the short circuit is cleared during the time period when the welder is not outputting the peak pulse current.

Owner:LINCOLN GLOBAL INC

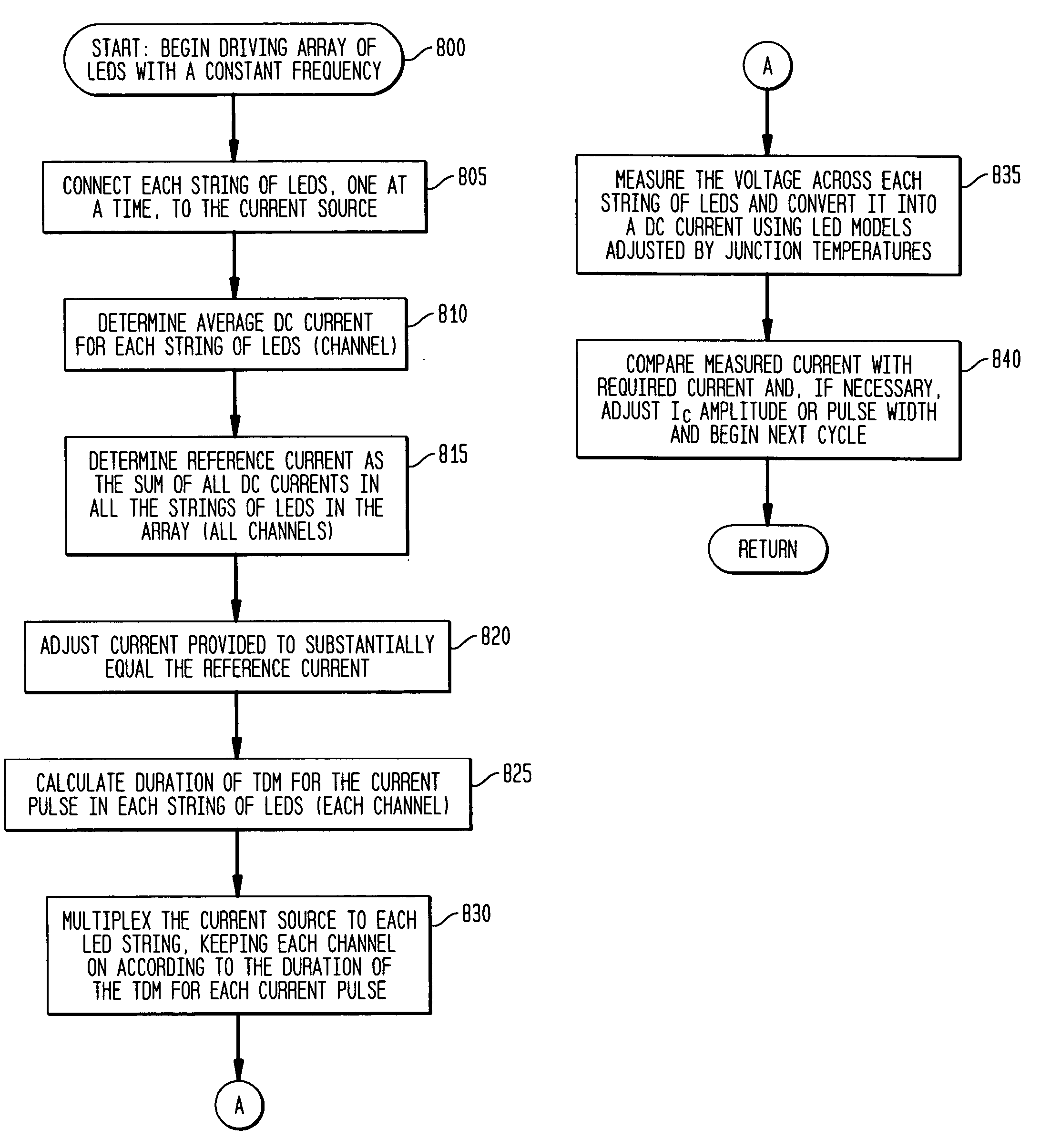

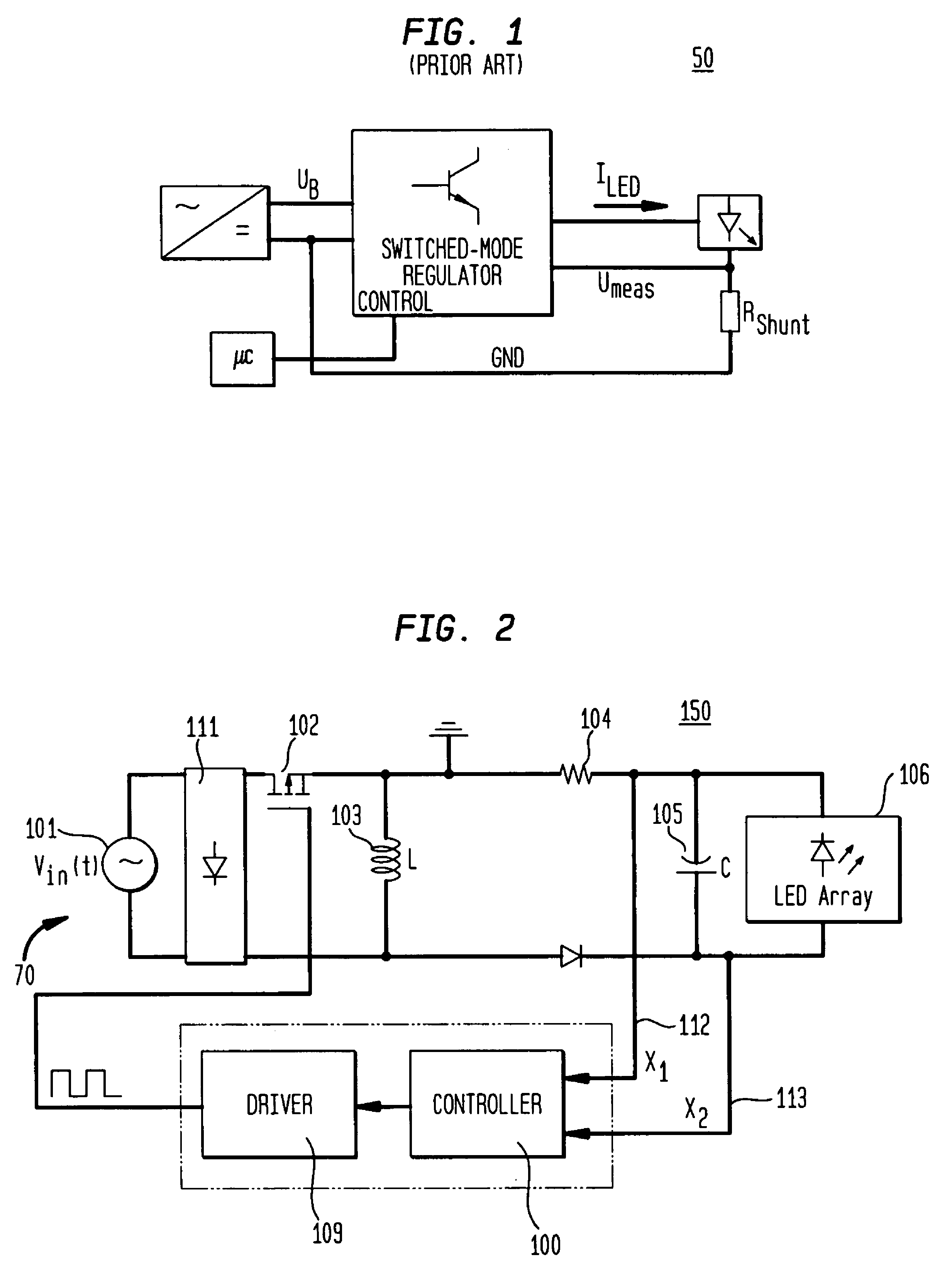

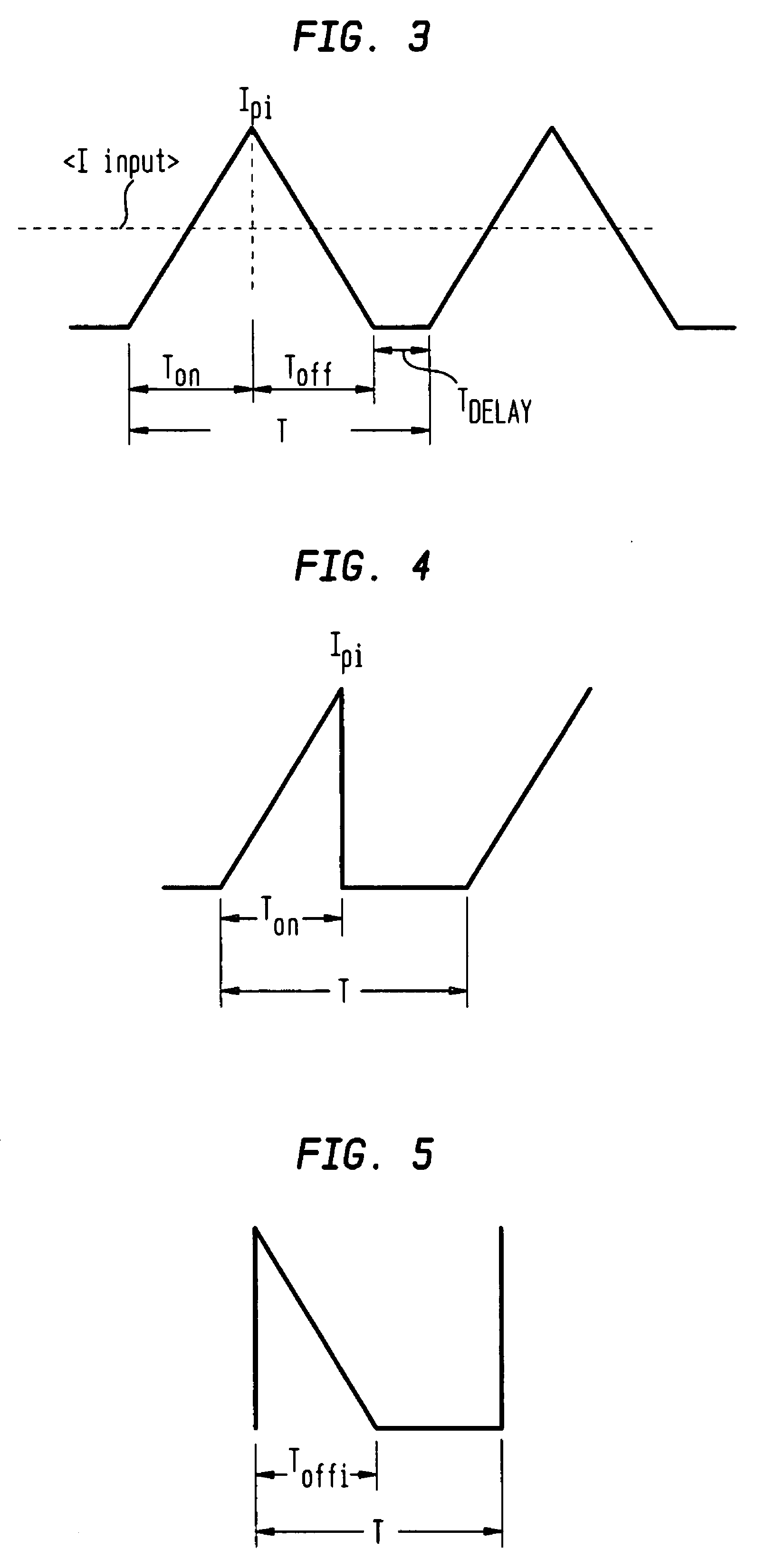

Pulsed current averaging controller with amplitude modulation and time division multiplexing for arrays of independent pluralities of light emitting diodes

ActiveUS7888881B2Improve efficiencySmall sizeElectrical apparatusElectroluminescent light sourcesSwitched currentAverage current

Exemplary embodiments provide a system, method and apparatus for regulating current in loads, such as in an array of independent pluralities of light emitting diodes (“LEDs”). An exemplary system comprises a multiplexer adapted to switch current to each independent string of LEDs; a first controller to maintain a substantially constant average current level to the plurality of LEDs; and a second controller to modulate a current amplitude and duration of time division multiplexing for each independent string of LEDs. Another aspect of the system provides for modulating the on time for switching current to maintain a substantially constant average current level and to respond and converge quickly to changing current reference levels.

Owner:CHEMTRON RES

Quasi-AC, photovoltaic module for unfolder photovoltaic inverter

Owner:GENERAL ELECTRIC CO

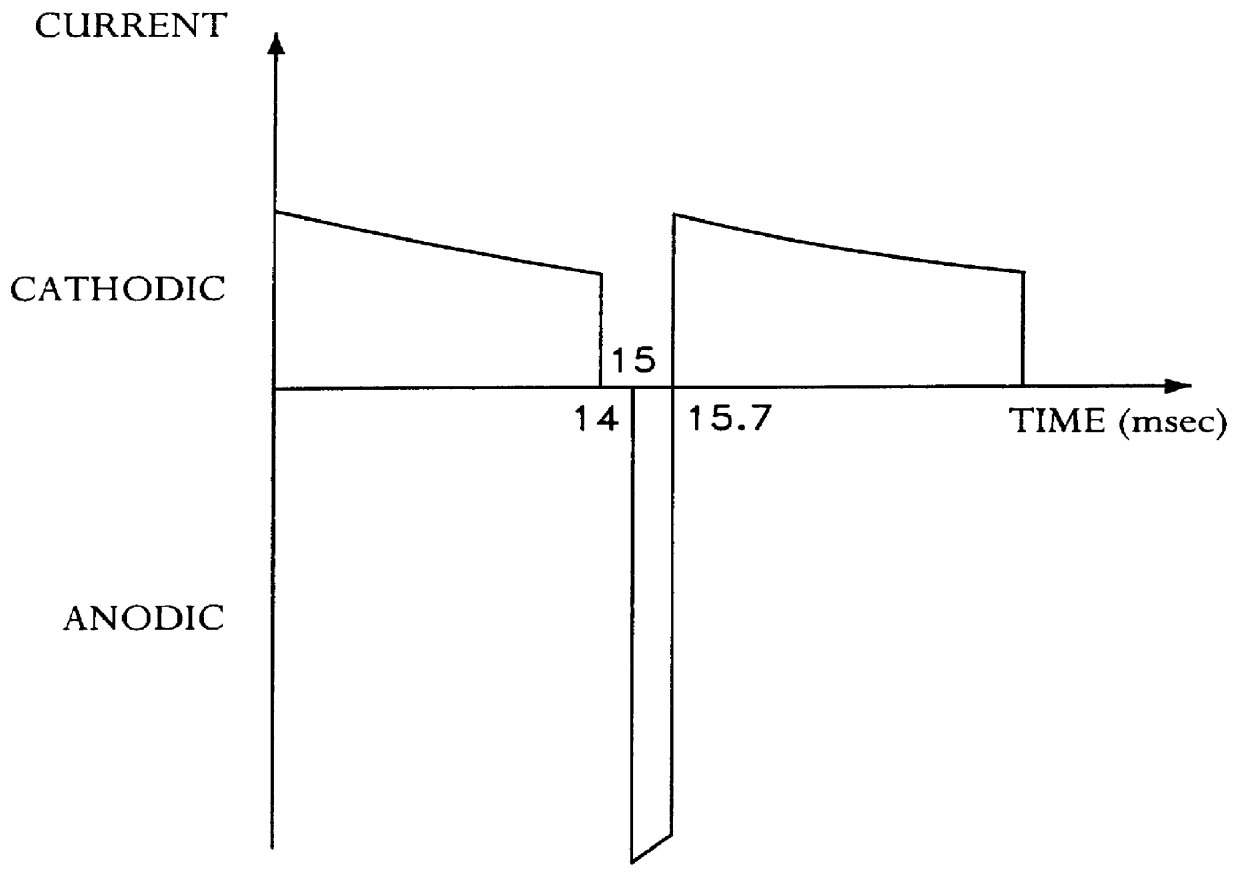

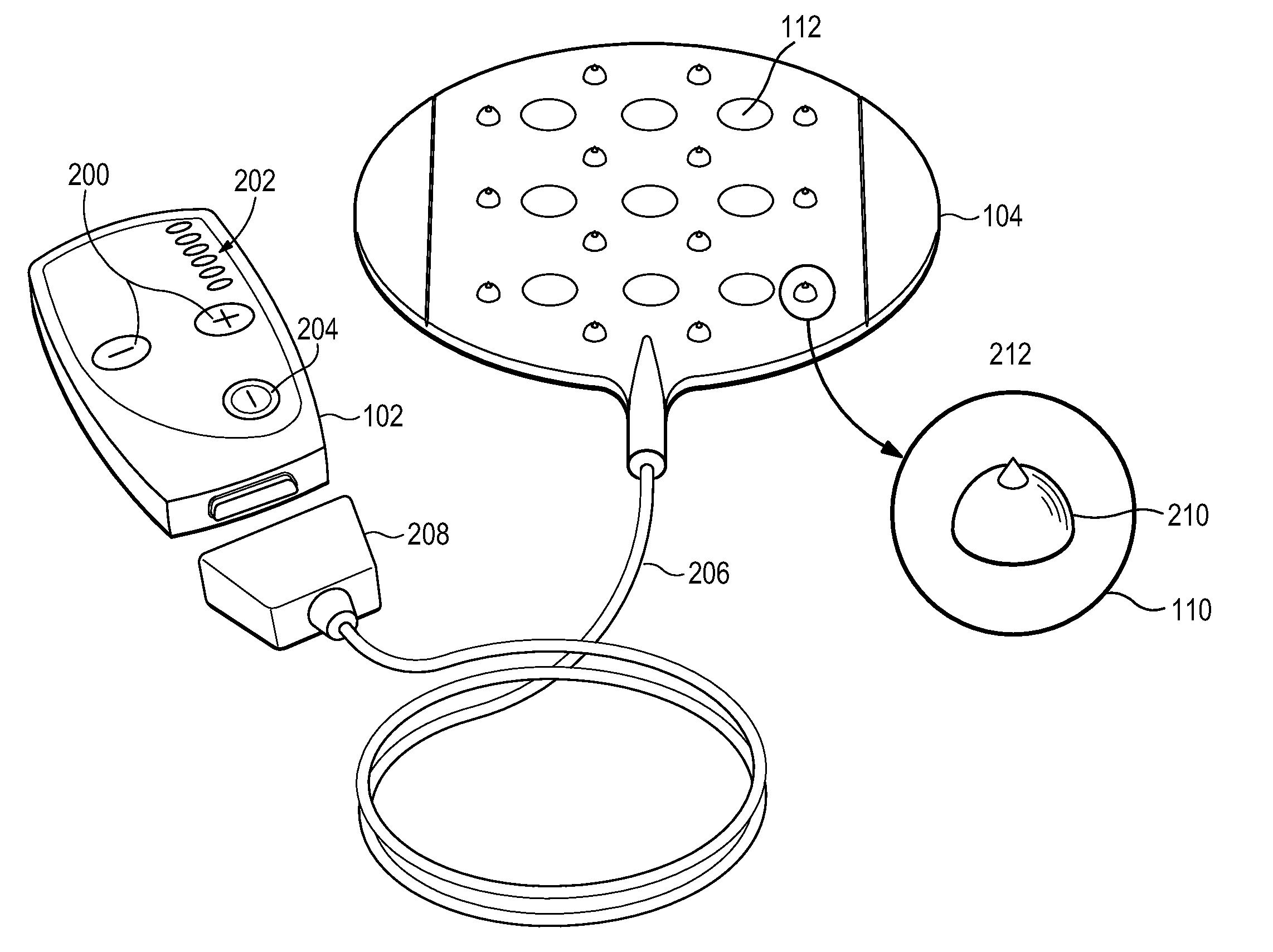

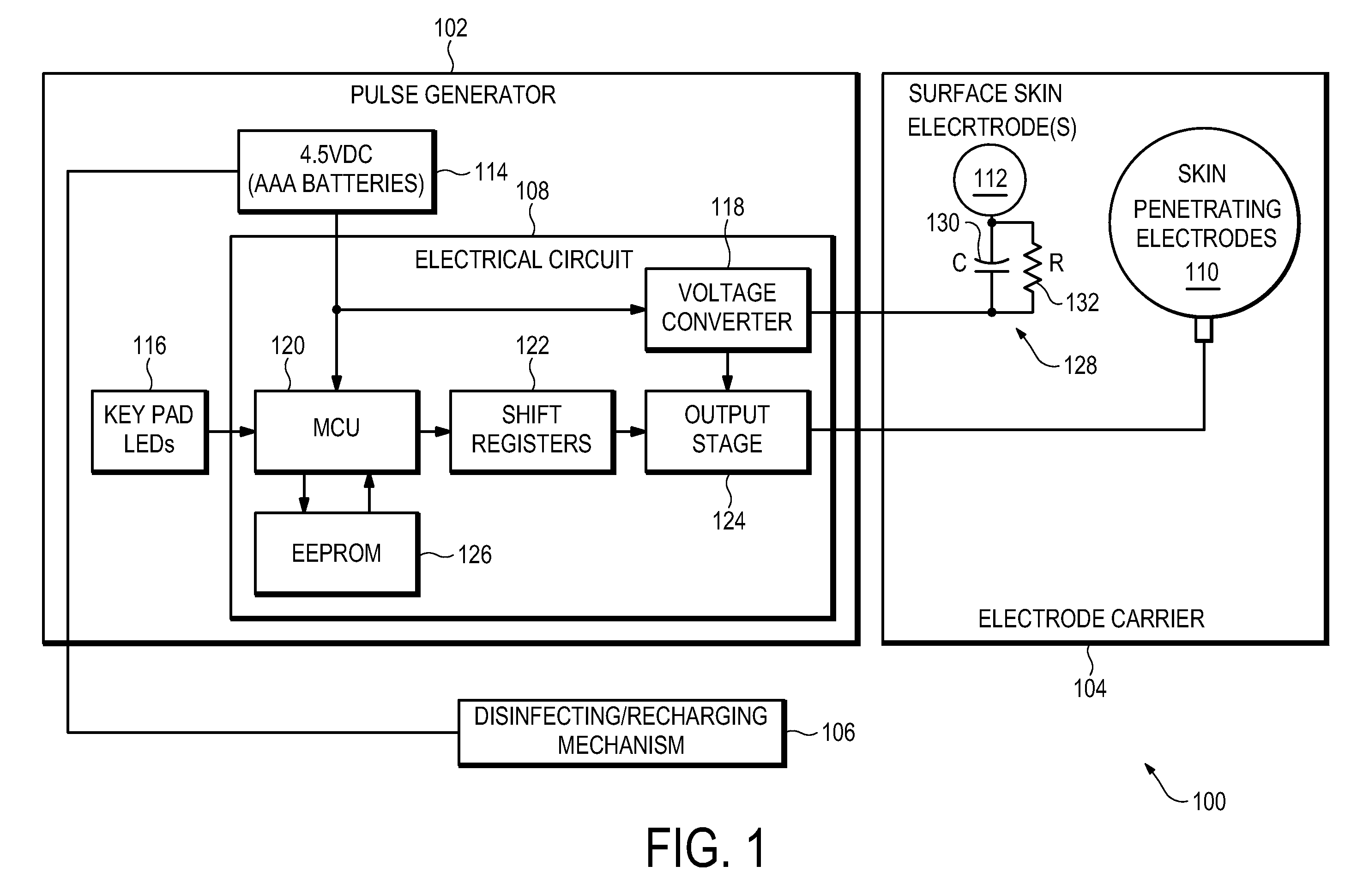

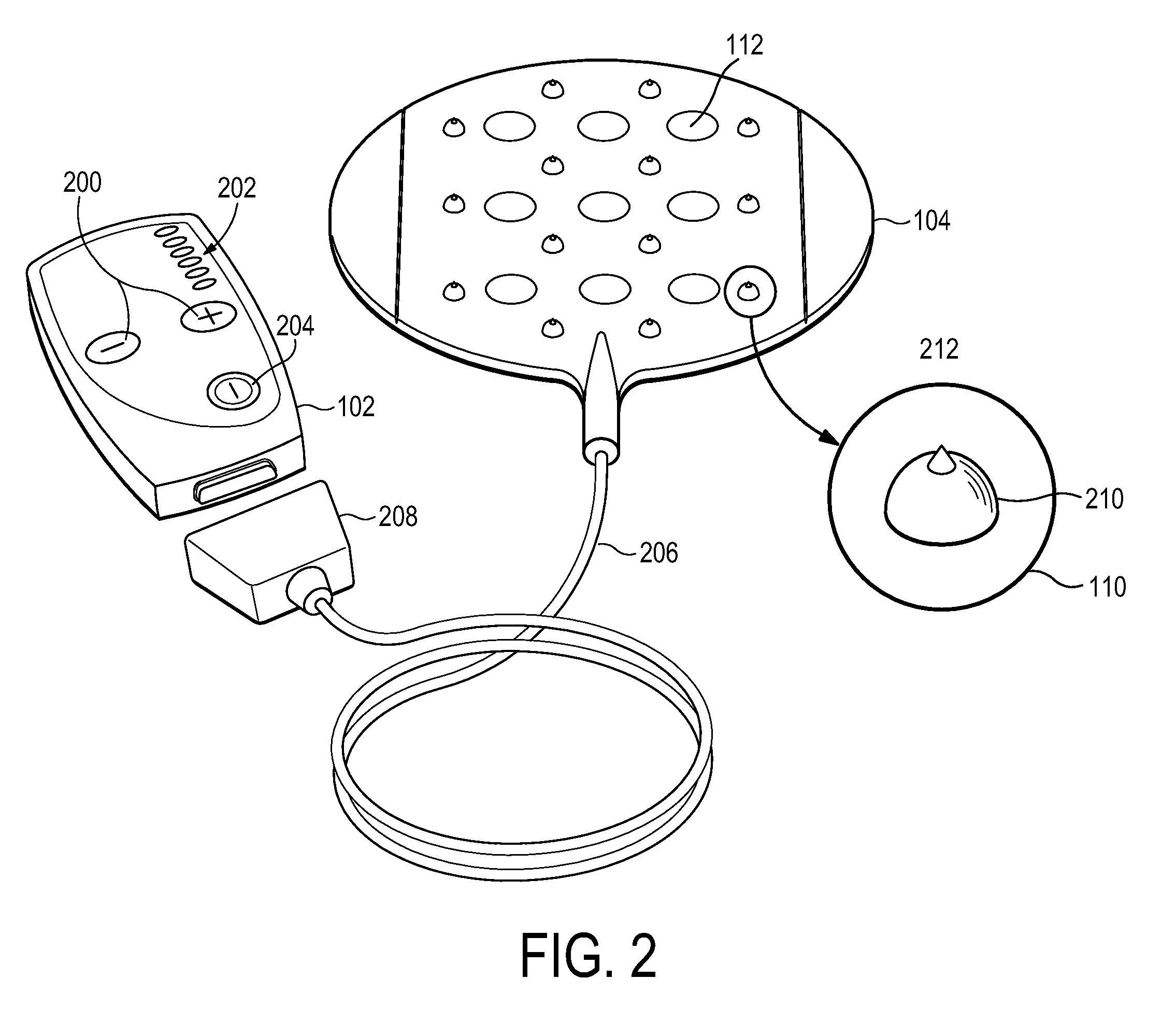

System and method for stimulating sensory nerves

An electrotherapy system for stimulating sensory nerves within skin tissue includes a electrode carrier, a pulse generator, an array of skin-penetrating electrodes and surface skin electrodes, a pulse conditioning circuit, and a power source. The system administers biphasic pulsed current at the surface skin electrodes and monophasic pulsed current at each skin-penetrating electrode. The skin-penetrating surfaces and skin contact surfaces of the electrotherapy system may be sterilized or may be replaceable for outpatient reusability.

Owner:MEAGAN MEDICAL

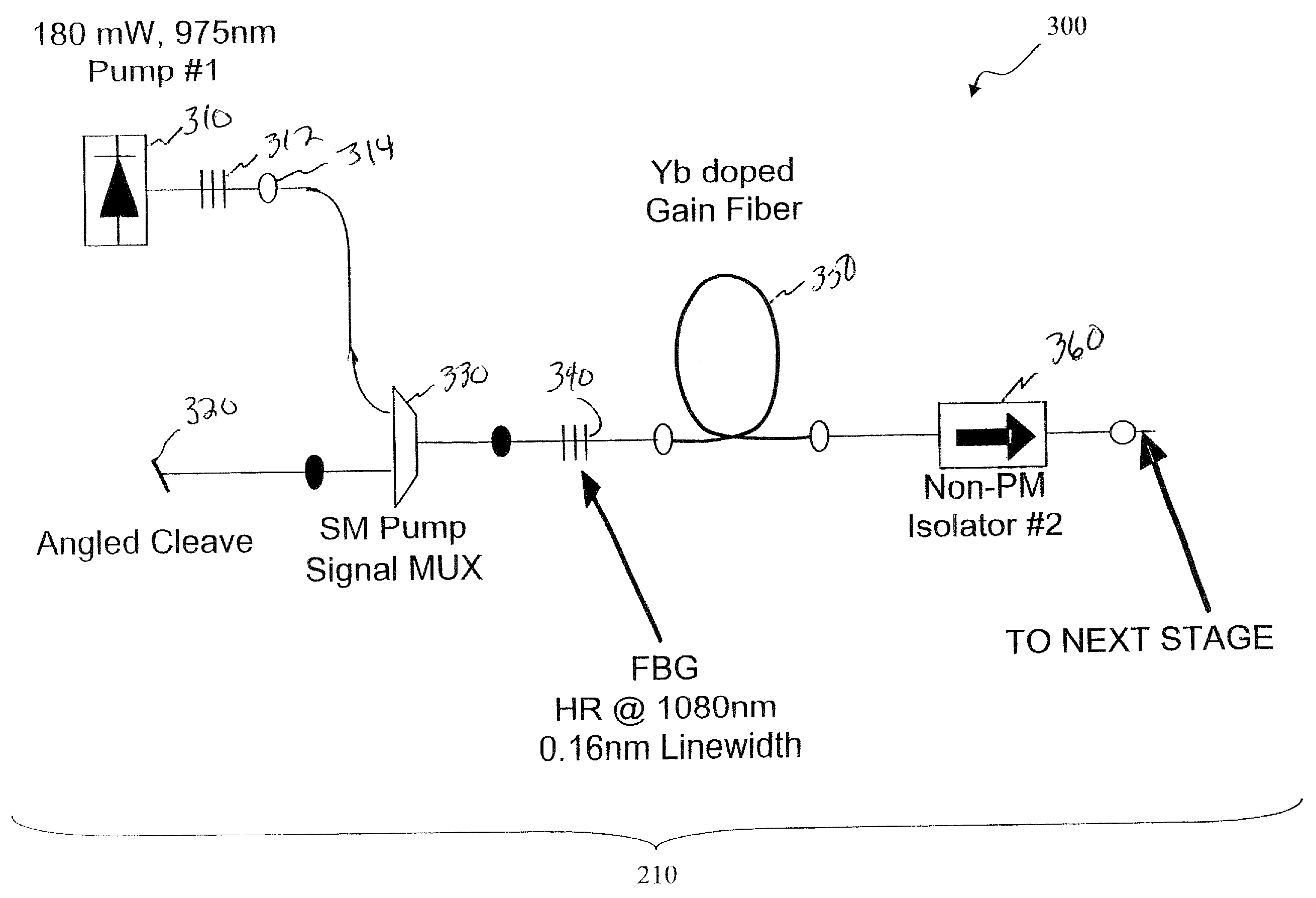

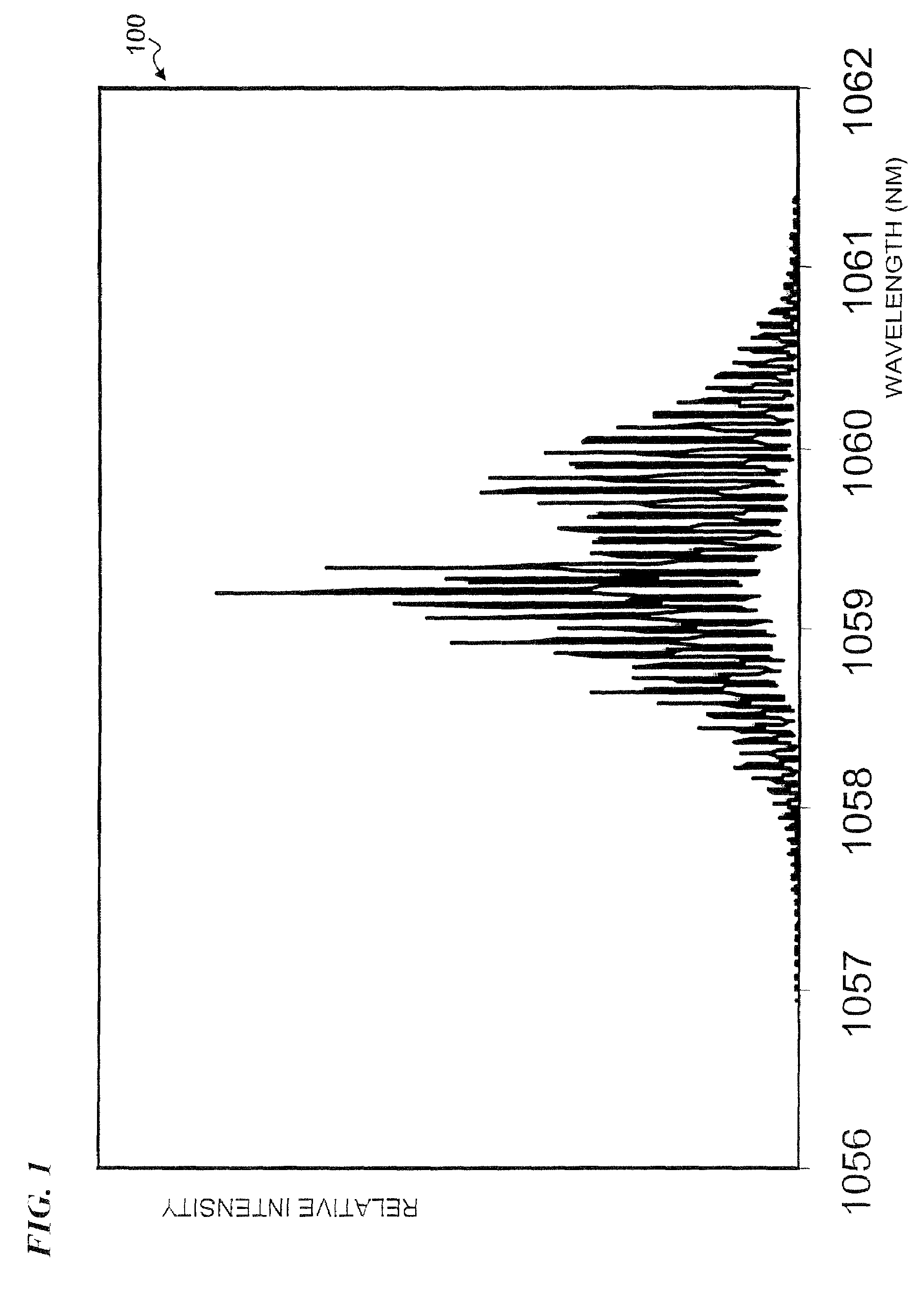

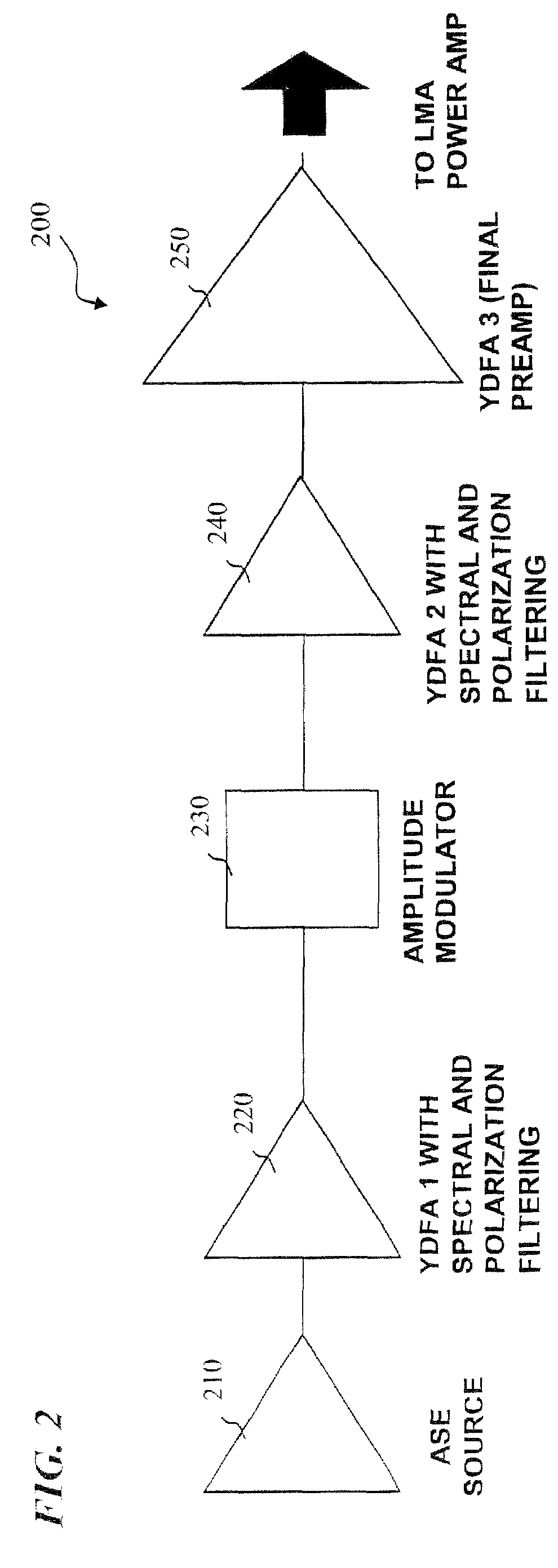

Apparatus and method for generating controlled-linewidth laser-seed-signals for high-powered fiber-laser amplifier systems

Apparatus and method for generating controlled-linewidth laser-seed-signals for high-powered fiber-laser amplifier systems. In some embodiments, the natural chirp (frequency change of laser light over a short start-up time) of a DBR laser diode when driven by pulsed current is used to broaden the linewidth of the laser output, while adjusting the peak current and / or the pulse duration to obtain the desired linewidth.

Owner:LOCKHEED MARTIN CORP

Method and apparatus for an ambient energy battery or capacitor recharge system

InactiveUS7088031B2Improve the environmentChange powerPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive devicesMassive gravityInfrared

The present invention relates to the field of battery and capacitor charging. In particular, the present invention provides pulsed current charging using changes, regardless of polarity, in the local energy environment to obtain power. The present invention relates, for example, to ambient energy charging thin film batteries, other batteries, or capacitors, via, for example, polyvinyladine fluoride homopolymer (PVDF), PVDF bi-axially poled, or other piezoelectric materials. Ambient energy may be defined as any change in energy within the local environment. Charging can be accomplished with, and is not limited to, positive or negative changes of the following energy types: thermal; visible light, including infrared and ultraviolet; mechanical motion or impact; triboelectric, including airflow or physical contact; movement in relation to a gravitational plane (increase or decrease in gravitational potential energy); and radio frequency (RF) electromagnetic energy, regardless of specific frequency.

Owner:SAPURAST RES

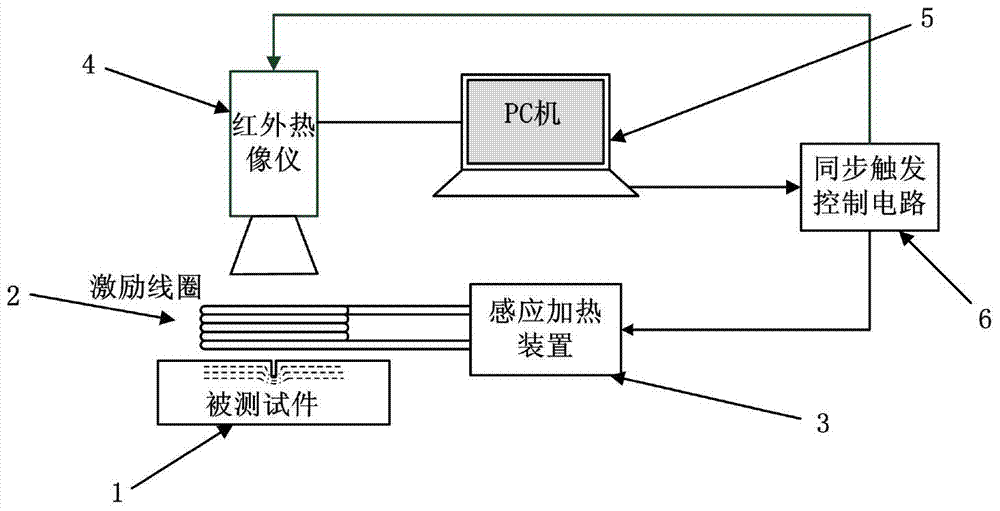

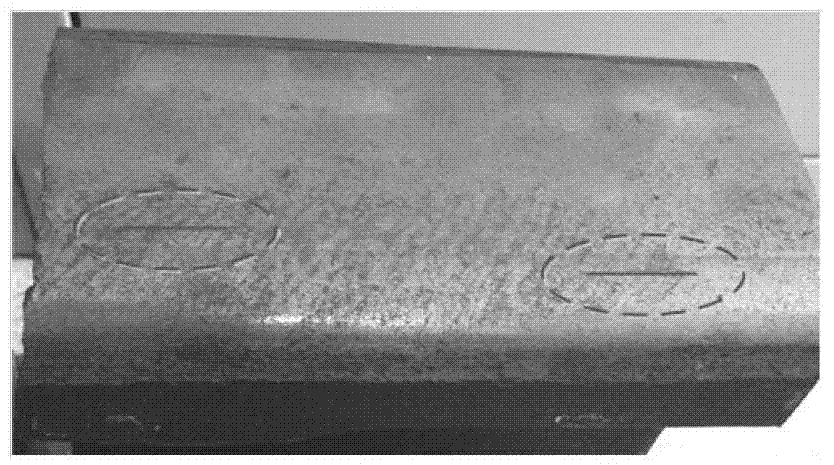

Pulsed eddy current infrared thermal imaging detection system and method for steel rail cracks

InactiveCN104764770AConvenient and intuitive detection meansThe energy of the pulse signal is largeMaterial flaws investigationThermodynamicsImage resolution

The invention discloses a pulsed eddy current infrared thermal imaging detection system and method for steel rail cracks. The system comprises an excitation device, an induction heating device, an infrared thermal imager and a PC, wherein the induction heating device is used for generating a pulse current signal; the pulse current signal is exerted to a tested part through the excitation device; eddy current is induced from the surface of the tested part and a thermal effect is generated, so that the surface temperature distribution changes; the infrared thermal imager is used for recording the surface temperature change process of the tested part and transmitting to the PC to process and analyze. The pulsed eddy current infrared thermal imaging detection system is characterized by also comprising a synchronous trigger control circuit, which is used for synchronously controlling the excitation and recording time of the induction heating device and the infrared thermal imager, so that the heating and cooling processes after complete induction of the tested part are accurately recorded; and the condition that the PC obtains accurate data to analyze and treat is ensured. The pulsed eddy current infrared thermal imaging detection system is high in detection efficiency and high in image resolution ratio; excitation of an excitation source and the infrared thermal imager can be synchronously carried out; and the detection result is not affected by human factors.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Semiconductor integrated device

Owner:RENESAS ELECTRONICS CORP

Electronic device and circuit for providing tactile feedback

ActiveUS7667371B2Low costPiezoelectric/electrostriction/magnetostriction machinesDigital data processing detailsControl signalPiezoelectric actuators

A circuit (800) for controlling at least one piezoelectric actuator (142) includes a piezoelectric drive circuit (802) that generates unidirectional voltage drive signal, also referred to as Vout, at node (804). The piezoelectric actuator drive circuit (802) includes a boost switcher circuit or charging circuit (806), a buck switcher circuit or pulsed current sink discharge circuit (808) and a control signal generating circuit (810) that receives an input control signal (812) from, for example, a keyboard processor or other suitable processor (604) indicating that the device has requested generation of haptic feedback utilizing the piezoelectric actuator (142). The control signal generating circuit (810) provides at least two pulse-with-modulated control signals, one to control the charging circuit and one to control the discharging circuit to produce the unidirectional voltage drive signal, that in one example is a raised cosine drive signal (904).

Owner:GOOGLE TECHNOLOGY HOLDINGS LLC

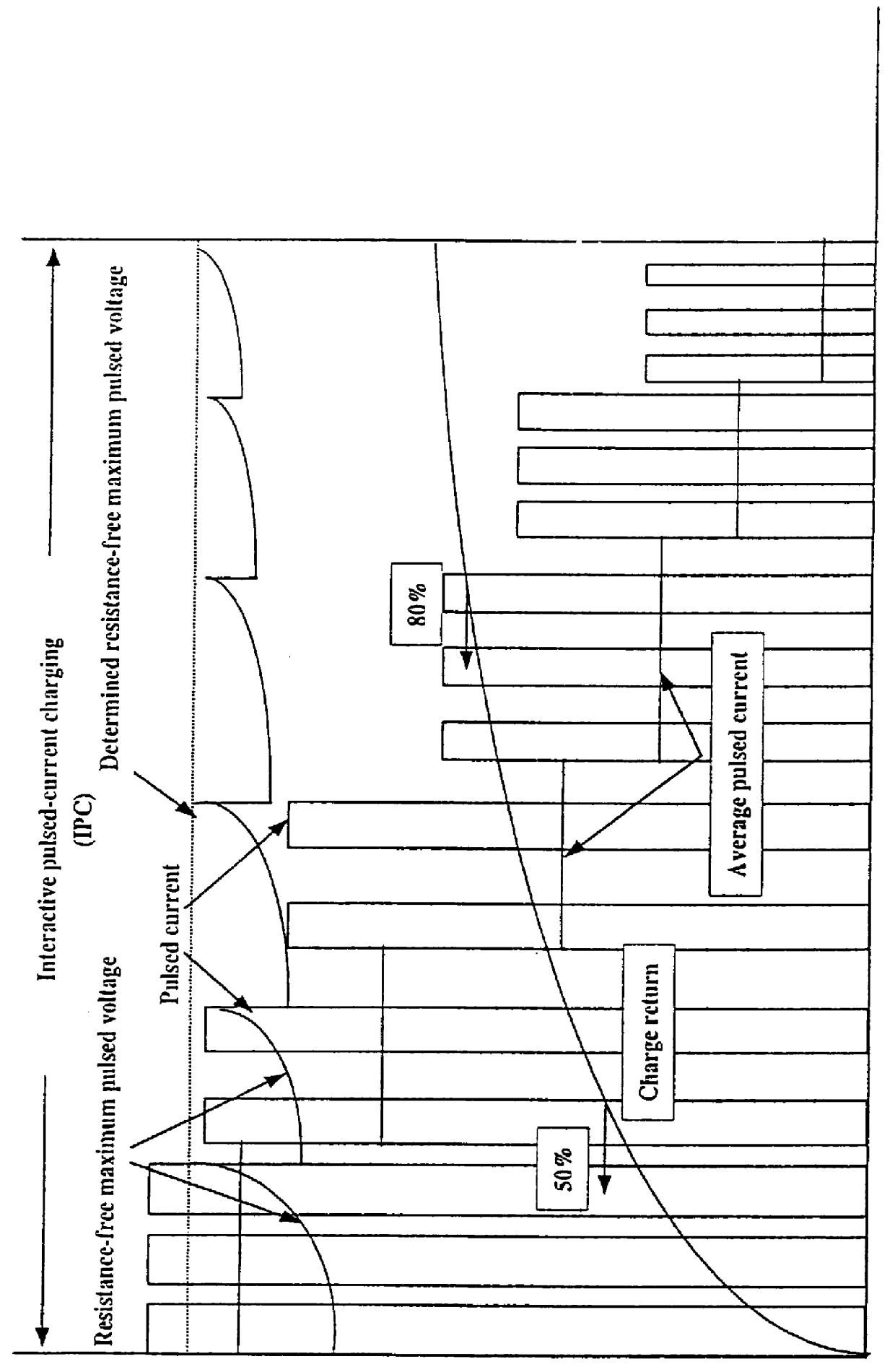

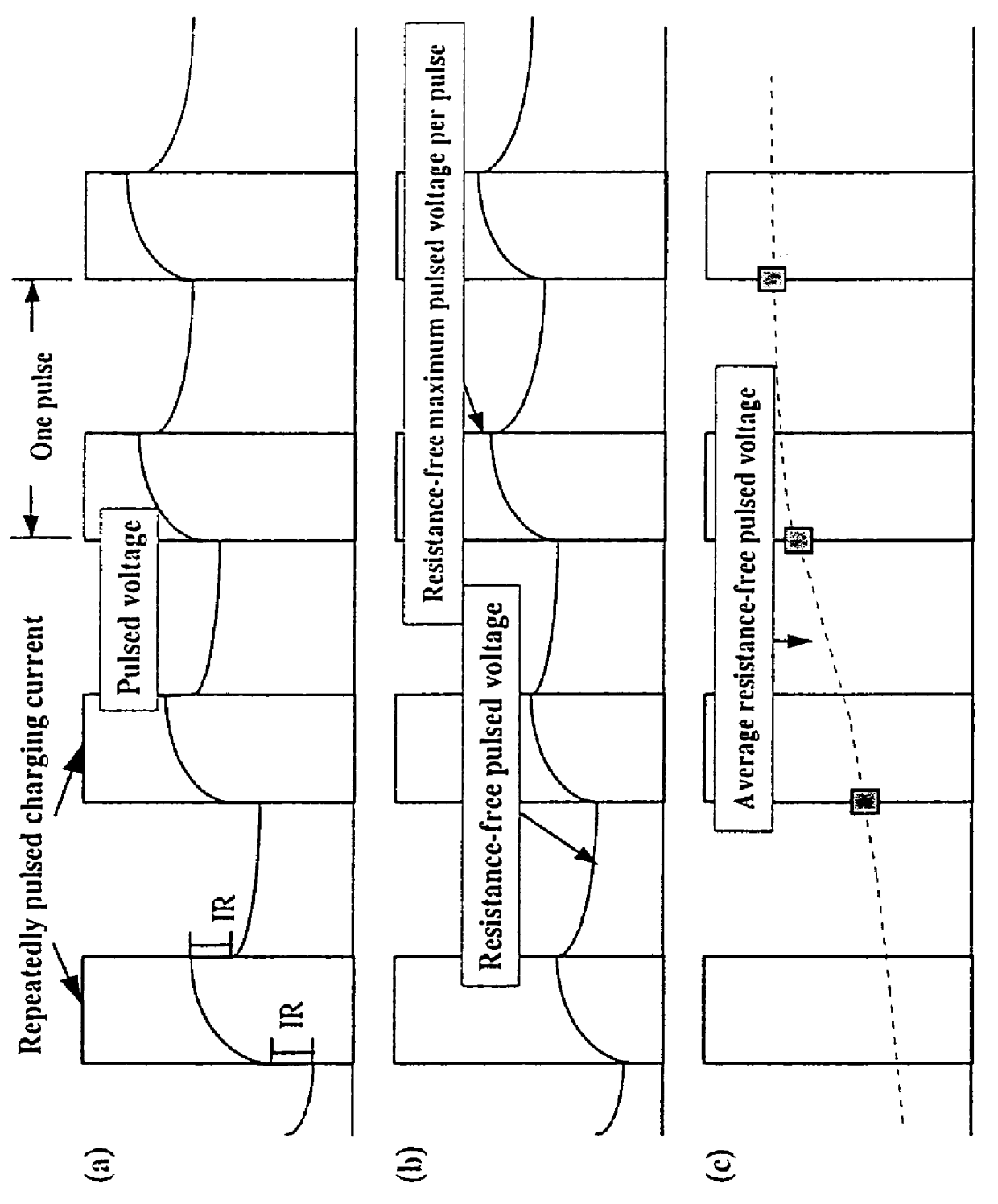

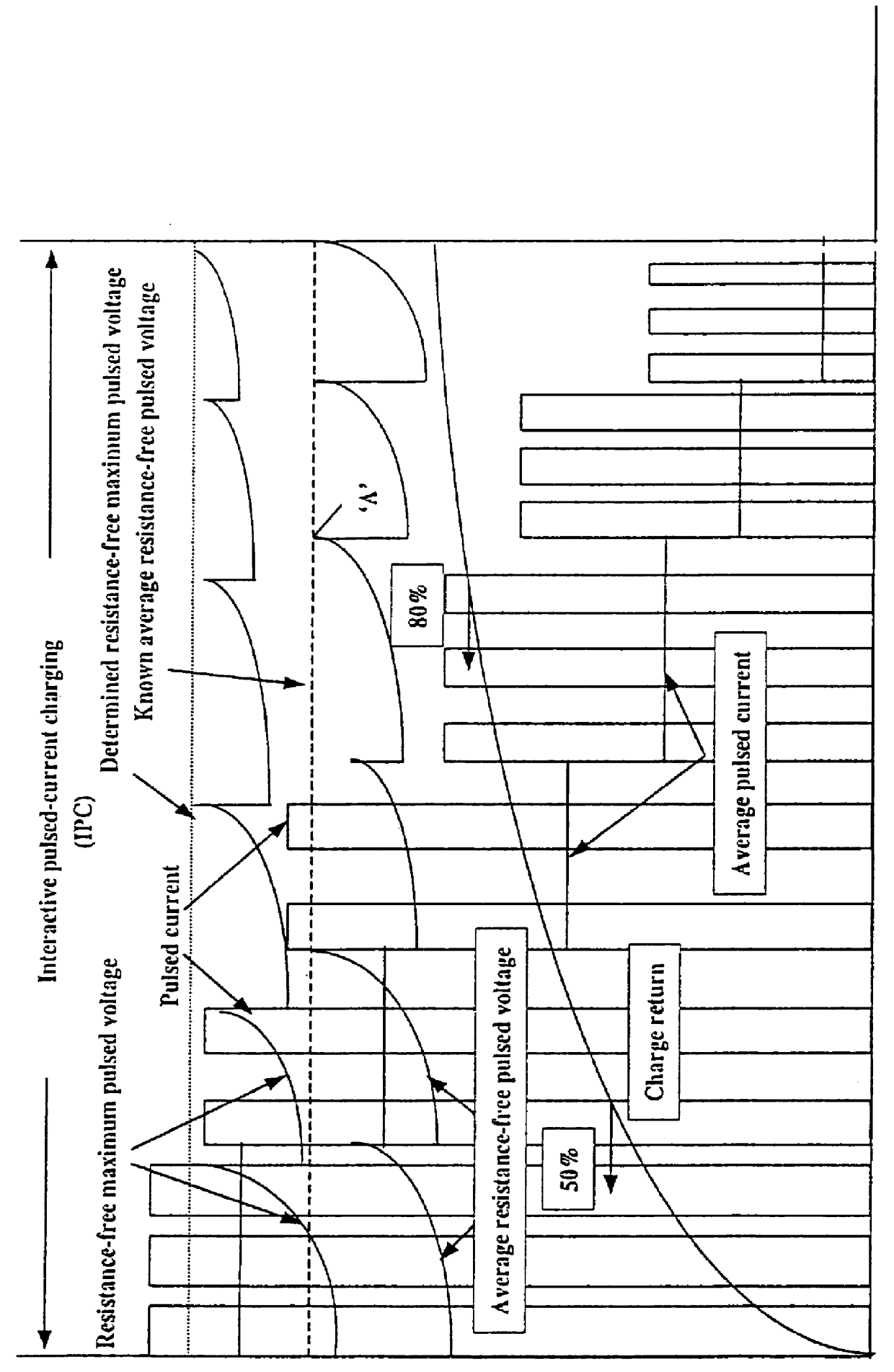

Charging of batteries

InactiveUS6154011AFast chargingExtend battery lifeBatteries circuit arrangementsCharging stationsElectrical resistance and conductanceCharge current

A method and apparatus for fast charging of batteries such as lead acid batteries is provided. A repeatedly pulsed current is applied to the battery to enable a determined resistance free maximum pulsed voltage to be reached where the determined resistance free maximum pulsed voltage is below that at which unacceptable gassing will occur. The determined resistance free maximum pulsed voltage is above that of a known average resistance free pulsed voltage for the battery type. When the determined maximum pulsed voltage is reached the pulsed current is continued to be applied to maintain the resistance free maximum pulsed voltage at approximately the determined resistance free maximum pulsed voltage by at least one of: (I) reducing the amplitude of the pulsed charging current, (II) increasing the OFF-time of pulses of the pulsed charging current, (III) decreasing the ON-time of pulses of the pulsed charging current, (IV) a combination of any two or more of (I), (II) or (III). In addition, the present invention may employ a combination of stages to charge the battery. Alternatively or in combination, the system may use a repeatedly pulsed charging current or a repeatedly pulsed charge voltage to control and adjust the charging of the battery.

Owner:COMMONWEALTH SCI & IND RES ORG

Touch screen calibration and update methods

A method of calibrating optical components in a light-based touch screen, including providing (i) a display, (ii) a row of light pulse emitters that sequentially transmit light pulses over the display according to calibrated pulse current and pulse duration controls, and (iii) a row of light pulse receivers that receive the light pulses and that output values representing the received light pulses, each receiver having expected values for emitter-receiver pairs when the light pulses are not blocked, determining if each receiver output value for a receiver-emitter pair is within a respective designated range from the corresponding receiver expected value, and when a receiver output value for a receiver-emitter pair is outside the designated range, recalibrating the emitter, including adjusting at least one of the emitter pulse current and pulse duration such that subsequent receiver output values are within the designated range, and updating the receiver expected value for the receiver-emitter pair based on subsequent output values of the receiver.

Owner:NEONODE

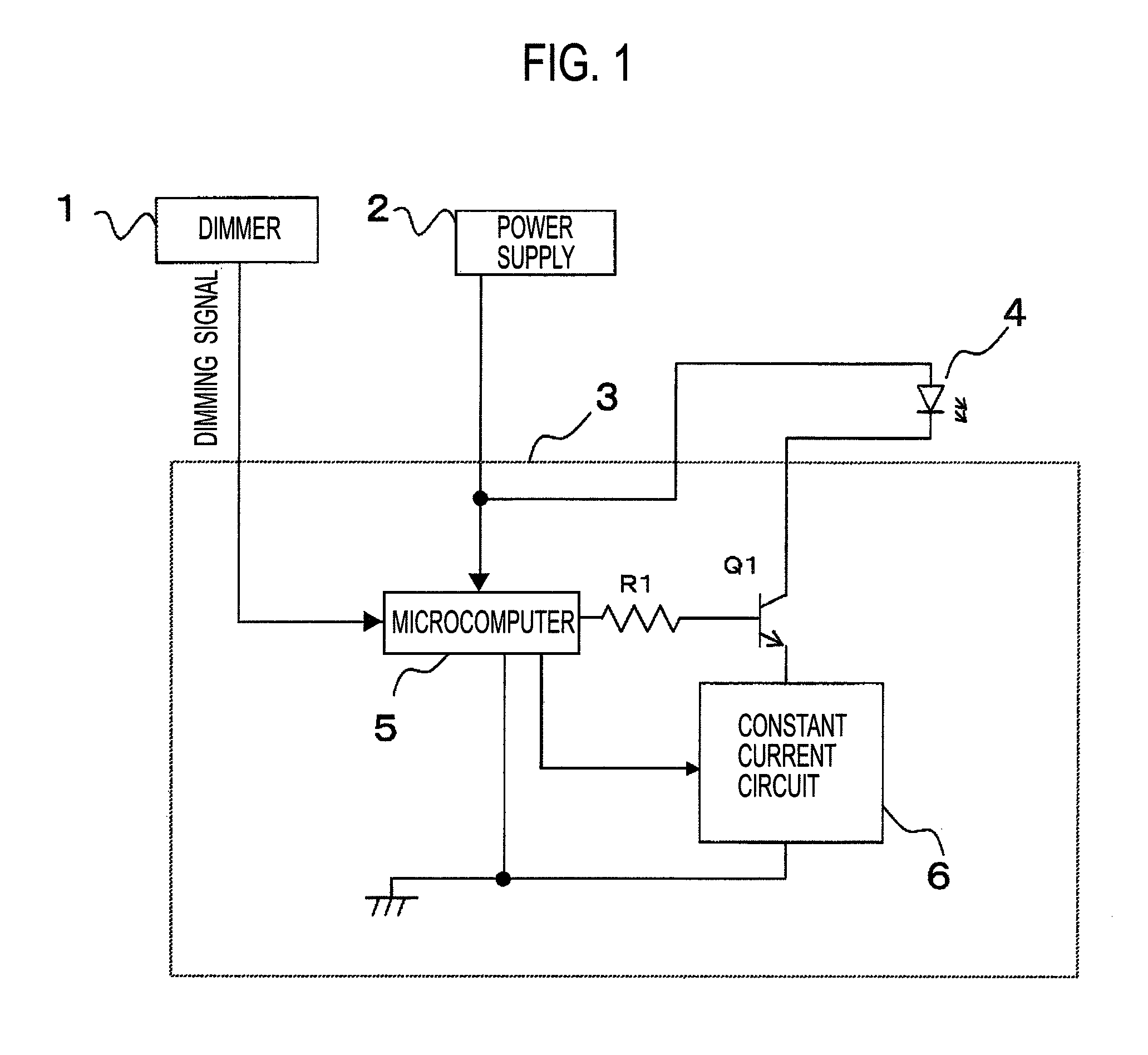

LED dimming apparatus

ActiveUS20100219764A1Electroluminescent light sourcesSemiconductor lamp usageMicrocomputerLuminosity

An LED dimming includes: current adjusting means (constant current circuit) for variably controlling a magnitude of a current flowing through an LED load; switching means (transistor) for intermittently controlling the current flowing through the LED load; and dimming controlling means (microcomputer) for controlling the current adjusting means and the switching means upon receiving a dimming signal outputted from a dimmer. In a case where the dimming signal outputted from the dimmer is on a higher brightness side than a predetermined level, the dimming controlling means flows a continuous current though the LED load, and dims the LED load based on a magnitude of the flowing current, and in a case where the dimming signal outputted from the dimmer is on a lower brightness side than the predetermined level, the dimming controlling means flows a pulse current through the LED load, and changes a mean value of waveforms of the pulse current, thereby dims the LED load. In this LED dimming apparatus, noise is less likely to occur even in a case where such an LED current is large, and brightness is less likely to vary even in a case where a dimming degree is increased.

Owner:PANASONIC CORP

LED dimming apparatus

An LED dimming includes: current adjusting means (constant current circuit) for variably controlling a magnitude of a current flowing through an LED load; switching means (transistor) for intermittently controlling the current flowing through the LED load; and dimming controlling means (microcomputer) for controlling the current adjusting means and the switching means upon receiving a dimming signal outputted from a dimmer. In a case where the dimming signal outputted from the dimmer is on a higher brightness side than a predetermined level, the dimming controlling means flows a continuous current though the LED load, and dims the LED load based on a magnitude of the flowing current, and in a case where the dimming signal outputted from the dimmer is on a lower brightness side than the predetermined level, the dimming controlling means flows a pulse current through the LED load, and changes a mean value of waveforms of the pulse current, thereby dims the LED load. In this LED dimming apparatus, noise is less likely to occur even in a case where such an LED current is large, and brightness is less likely to vary even in a case where a dimming degree is increased.

Owner:PANASONIC CORP

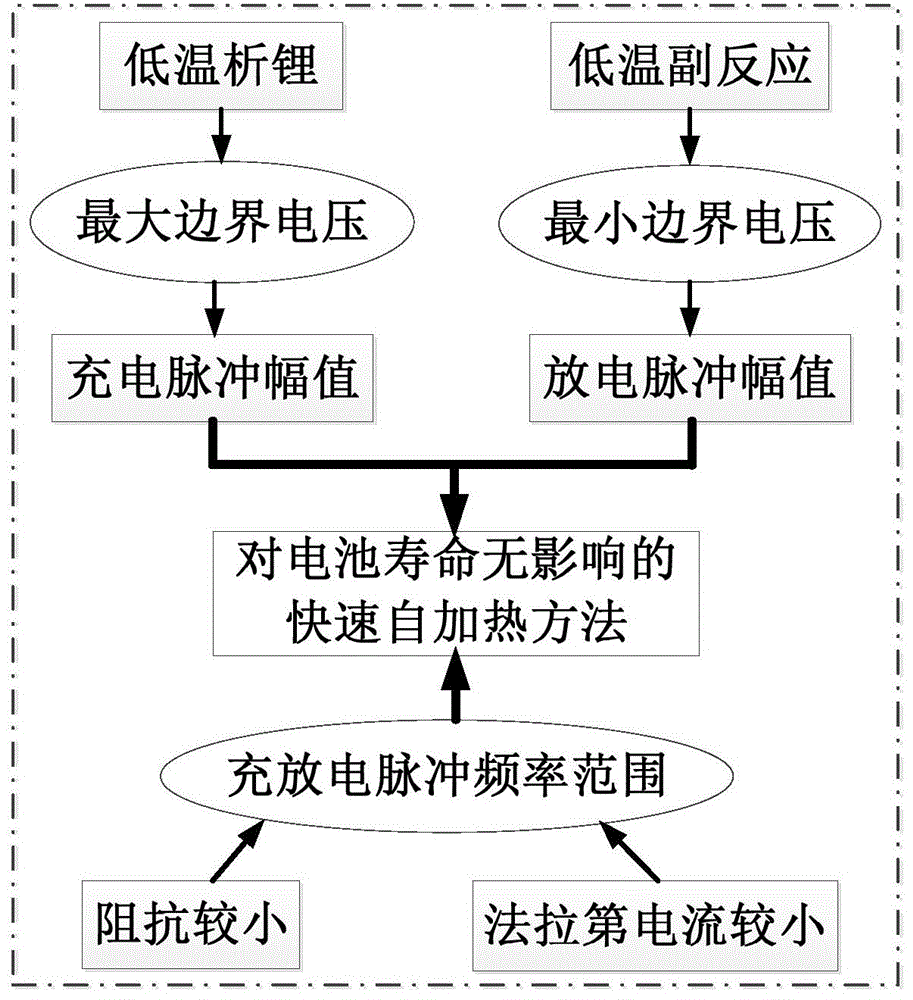

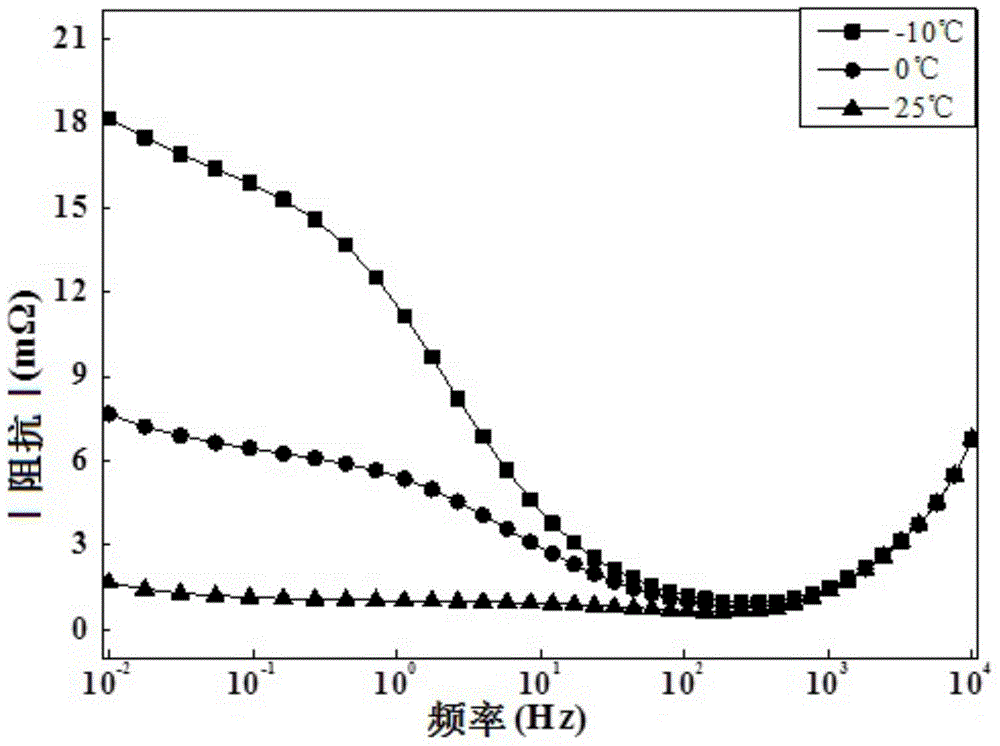

Low-temperature self-heating method for lithium ion battery

ActiveCN104064836ANo effect on service lifeReduced service lifeCell temperature controlInternal resistanceEngineering

The invention discloses a low-temperature self-heating method for a lithium ion battery. The method comprises the steps of determining a frequency range in which the service life of the lithium ion battery cannot be affected, and selecting frequencies of charging and discharging pulses according to the range; setting a pulse current amplitude value selection basis under a selected charging and discharging mode, and calculating a charging current amplitude value Ic and a discharging current amplitude value Id; performing no-life-loss heating on the battery to be heated according to charging and discharging pulse signals of the determined frequencies and the amplitude values, wherein the inner resistance of the self-heated battery is greatly reduced, and the charging performance is greatly improved. According to the technical scheme, the low-temperature self-heating method has the effects of high self-heating speed, obvious low-temperature performance improvement and no influence on the service life of the battery.

Owner:BEIJING BEIJIAO NEW ENERGY TECH CO LTD

Multistage and multidirectional electromagnetic forming method and device

The invention provides a multistage and multidirectional electromagnetic forming method comprising the following steps of: establishing a stable magnetic field area by adopting quasi-steady state current; generating induced eddy current in a workpiece by using pulse current; driving the part of the workpiece, which is positioned outside a female die, to be deformed away from the direction of the female die by using an electromagnetic force between the induced eddy current and the pulse current and driving the part of the workpiece, which is positioned inside the female die, to be deformed towards the direction close to the female die; and when the part inside the female die is deformed to an area of a stable magnetic field area, driving the workpiece to do accelerated motion to be attached to the female die under the action of induced eddy current in the stable magnetic field and the woprkpiece to finish the forming. The invention also provides a device for realizing the method, mainly comprising an edge pressing ring and coils arranged at different positions of the female die. According to the method and device disclosed by the invention, the workpiece is accelerated in a multistage and multidirectional electromagnetic forming manner, the forming, the processing and the manufacturing in a longer time and larger space range are realized and the forming depth of the workpiece is effectively increased.

Owner:HUAZHONG UNIV OF SCI & TECH

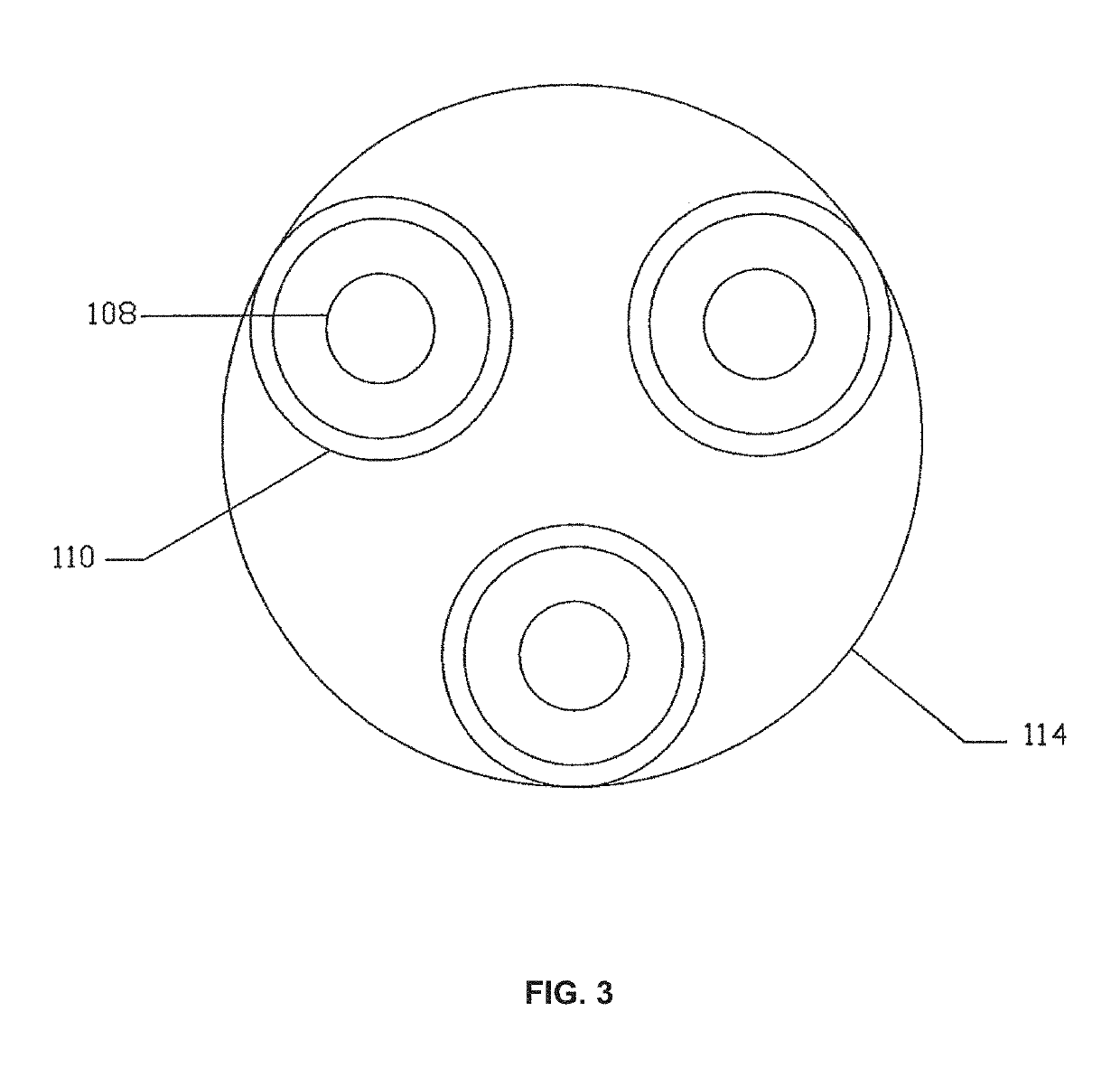

Repetitive pulsed electric discharge drills including downhole formation evaluation

ActiveUS10407995B2Solve insufficient bandwidthReduce lossesDrilling rodsThermal drillingElectricityElectric discharge

Electrocrushing drills and methods for operating electrocrushing drills. Electrocrushing drill bits comprise one or more high voltage electrodes surrounded by a ground or current return structure, which can be a ring or a comprise rod shaped electrodes. Openings in the rim of the current return structure facilitate removal of drilling debris and bubbles created by the electrocrushing process out from the bottom face of the bit and up the wellbore. The high voltage electrodes can be arranged in a circle. The current return structure may partially cover the bottom face of the drill bit, thereby enclosing the high voltage electrodes in openings that may be sector shaped. The drill may comprise one or more conducting loops, in each of which pulsed current creates a pulsed magnetic field. The loops can be oriented in particular directions to provide a pulsed magnetic field with the desired configuration and orientation in space. The formation ahead of the drill can then be evaluated with the appropriate sensors.

Owner:SDG LLC

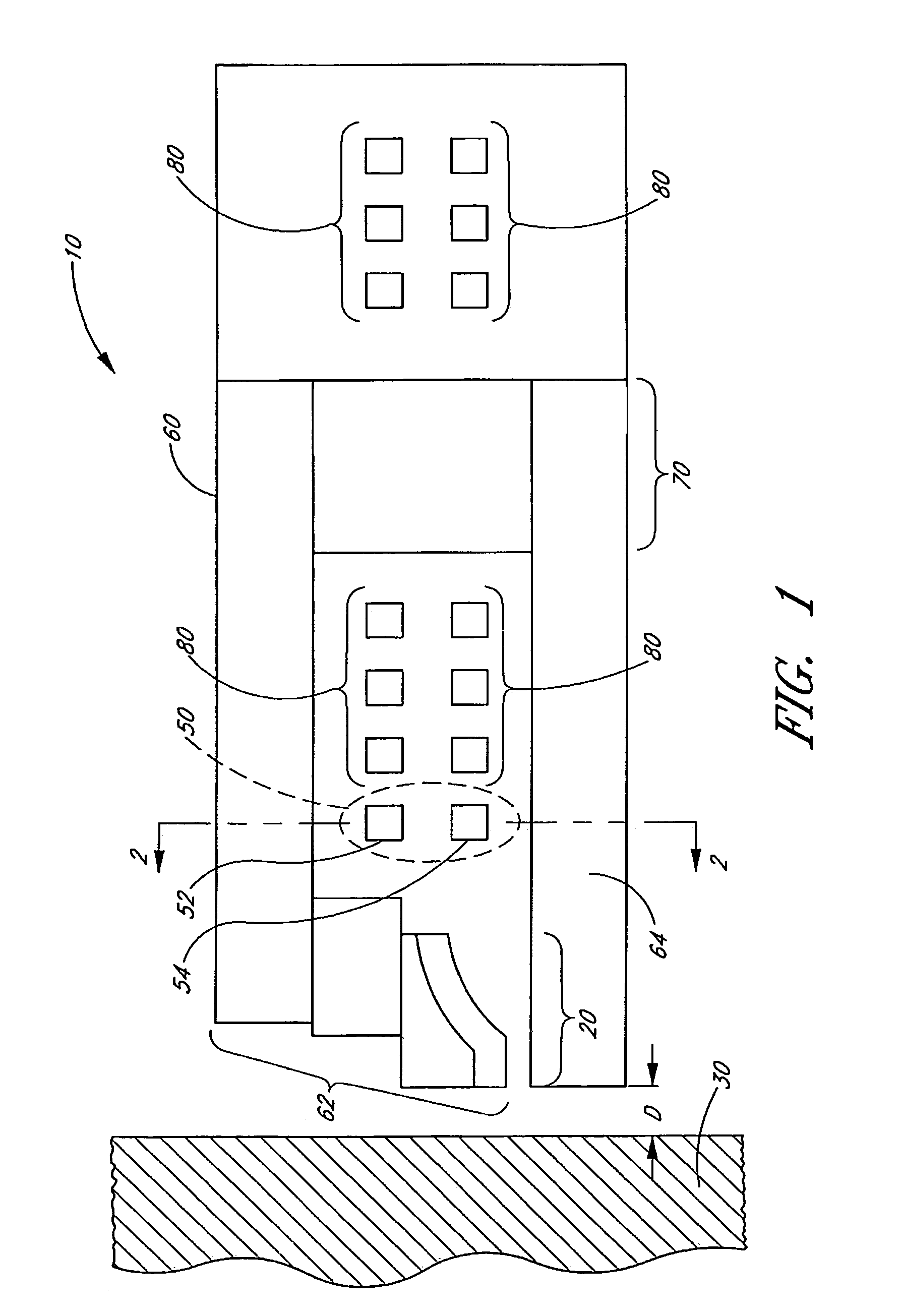

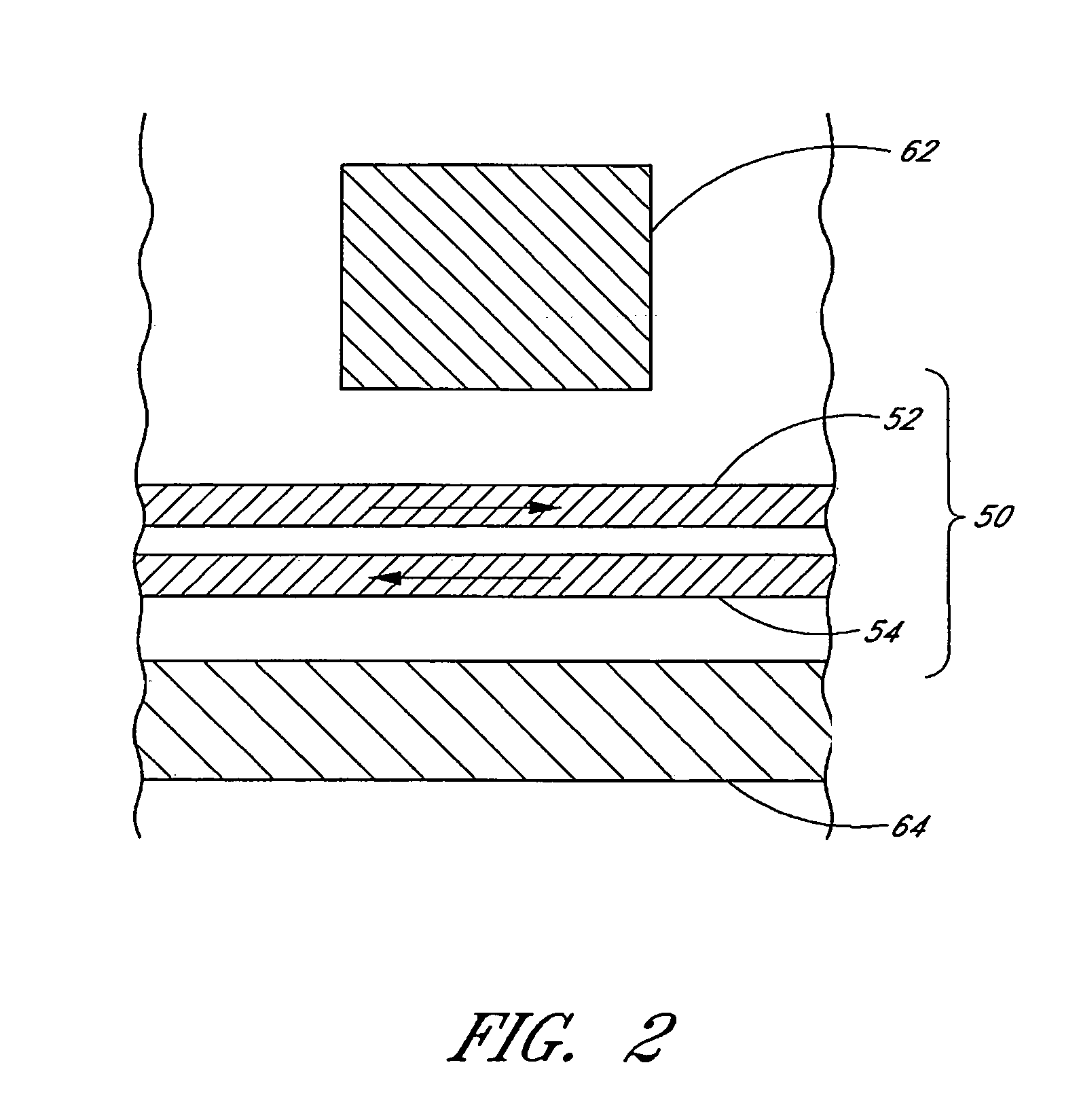

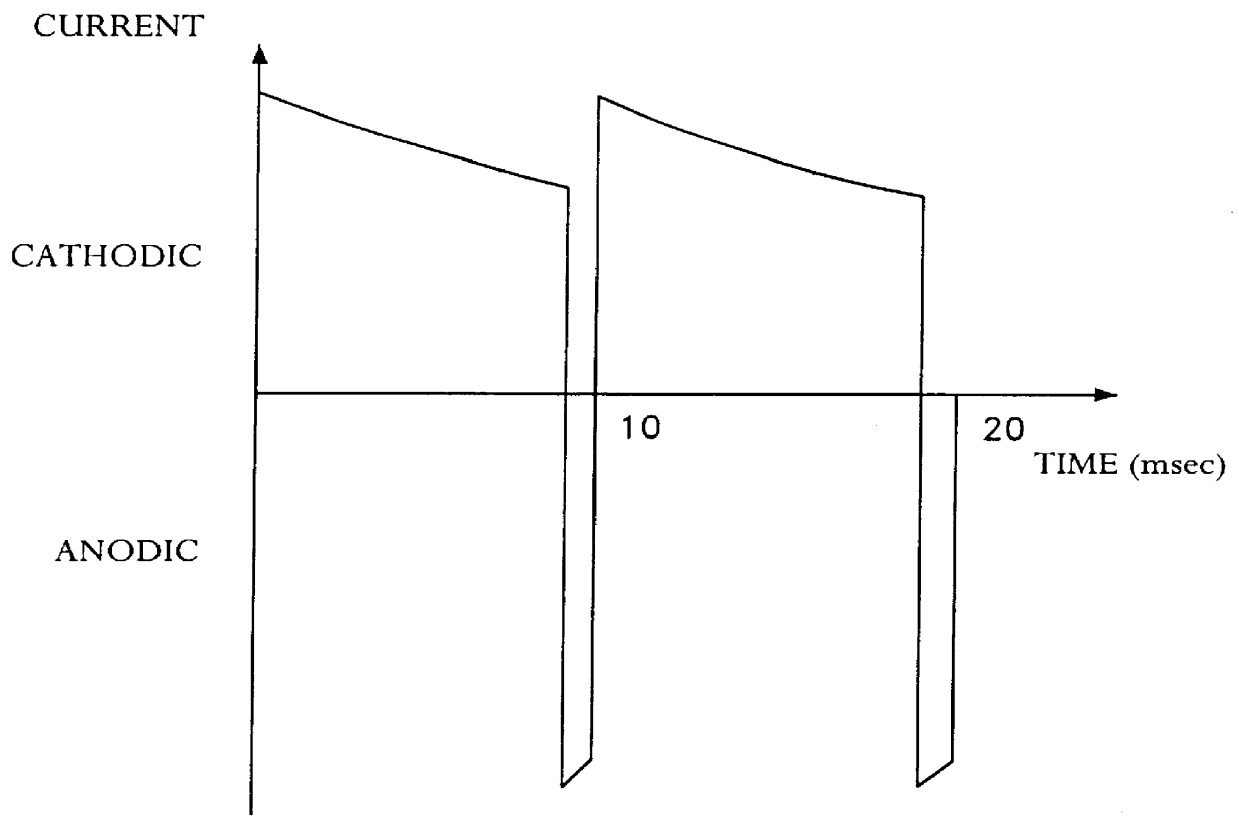

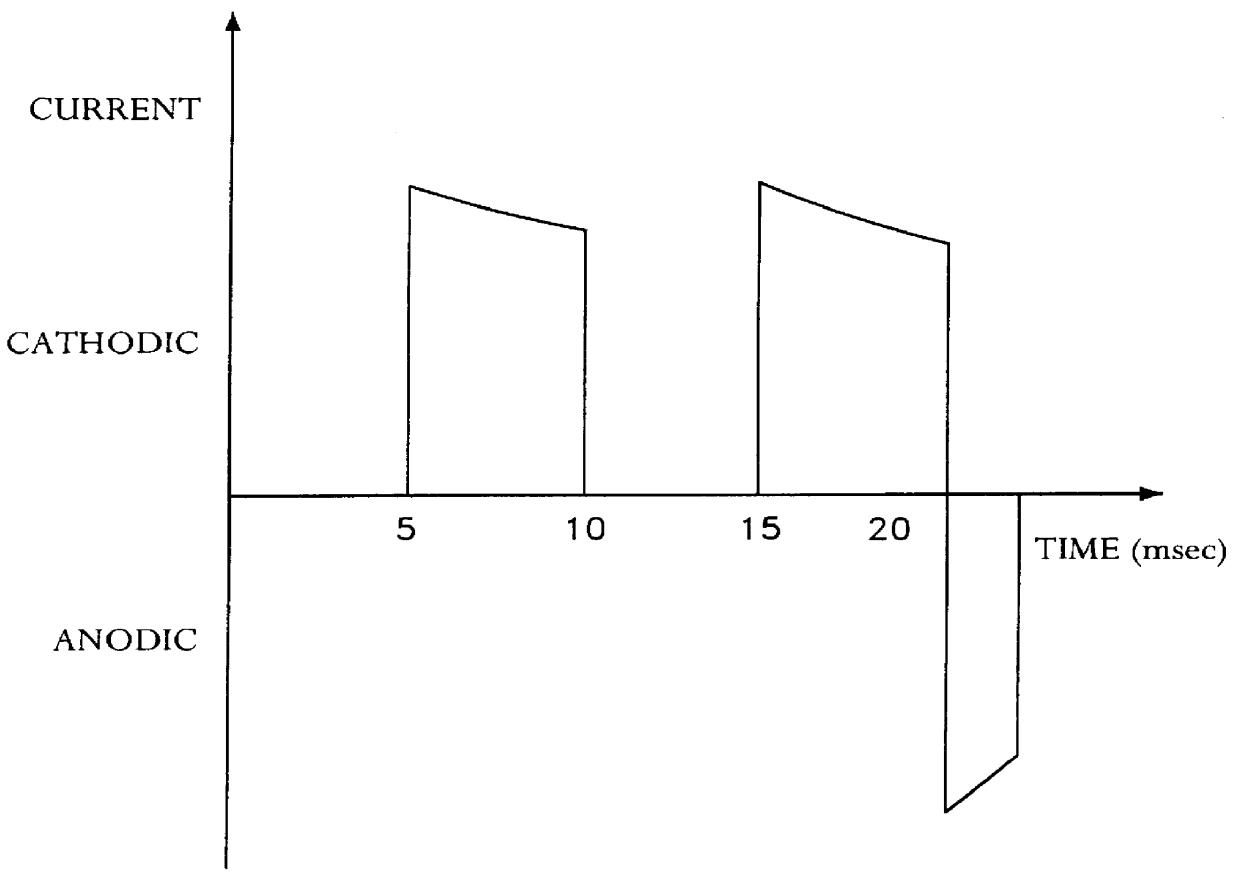

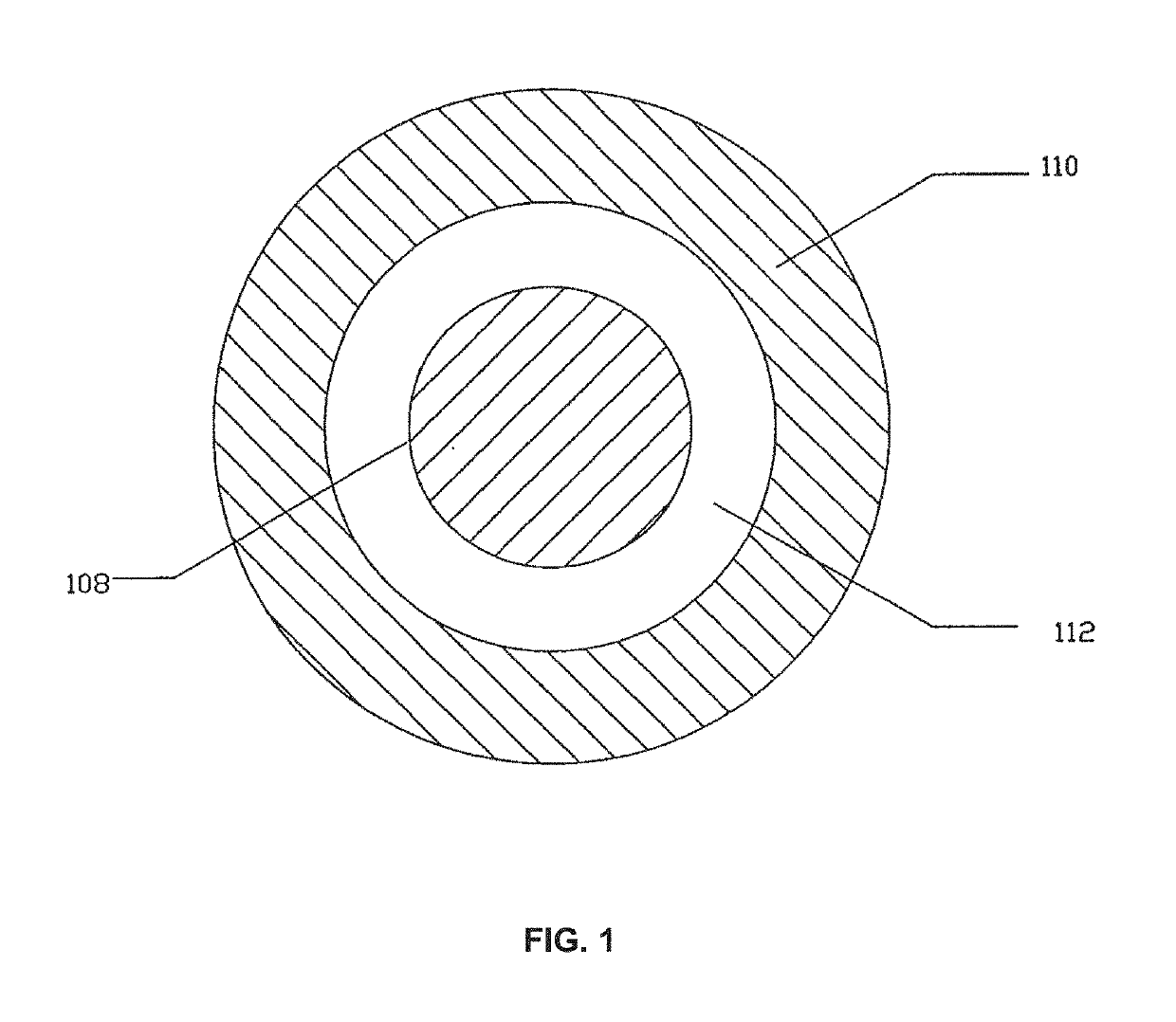

Pulsed current sintering for surfaces of medical implants

A porous medical implant and a method of making same is described. The medical implant comprises a porous surface formed by application of pulsed electrical energy ins such a way as to cause a localized heating in the surface of the material comprising portions of the implant. The method comprises a pulsed current sintering technique.

Owner:SMITH & NEPHEW INC

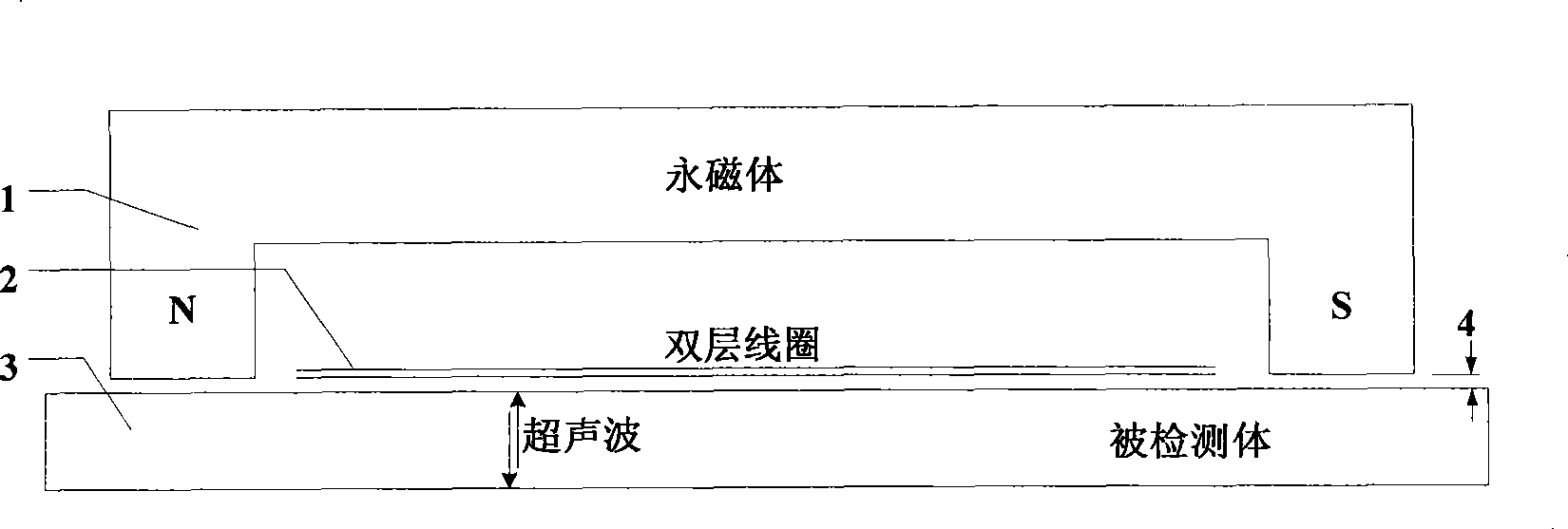

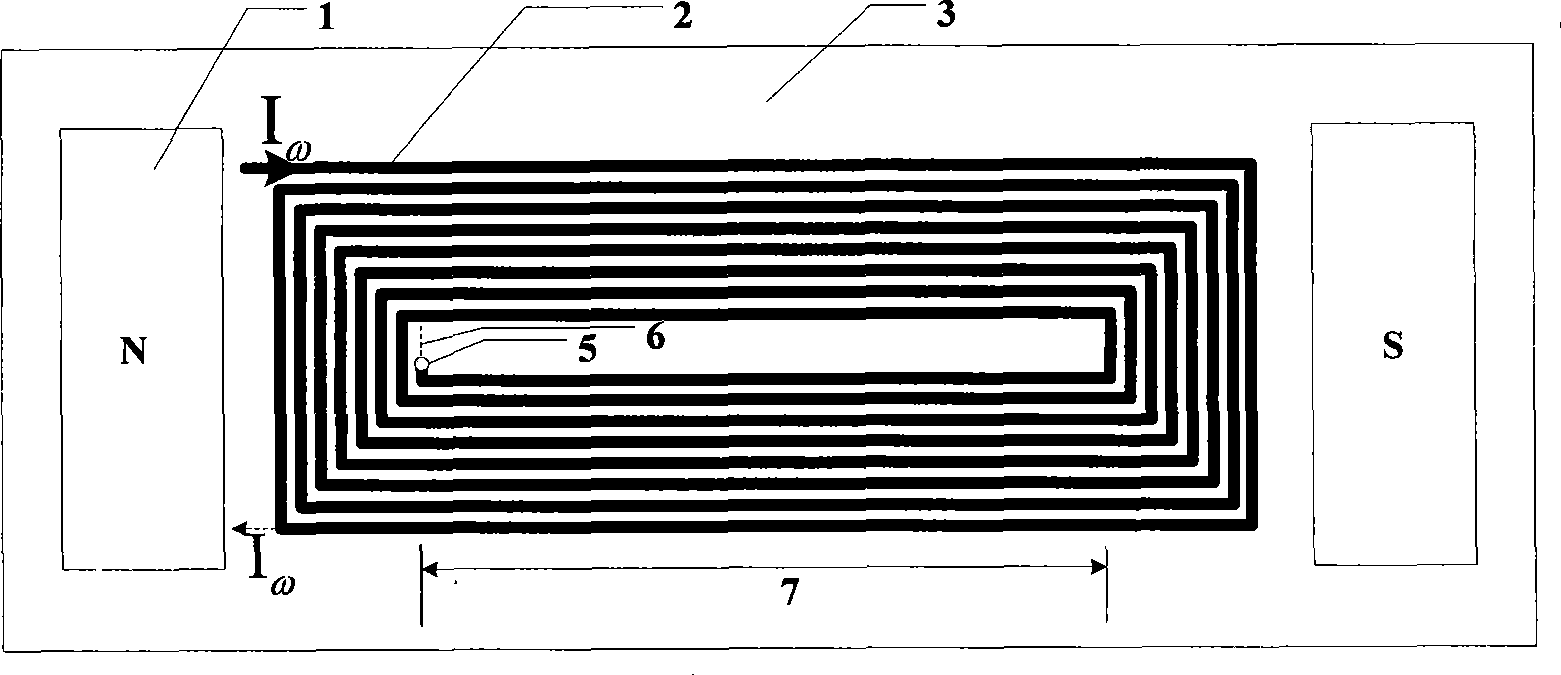

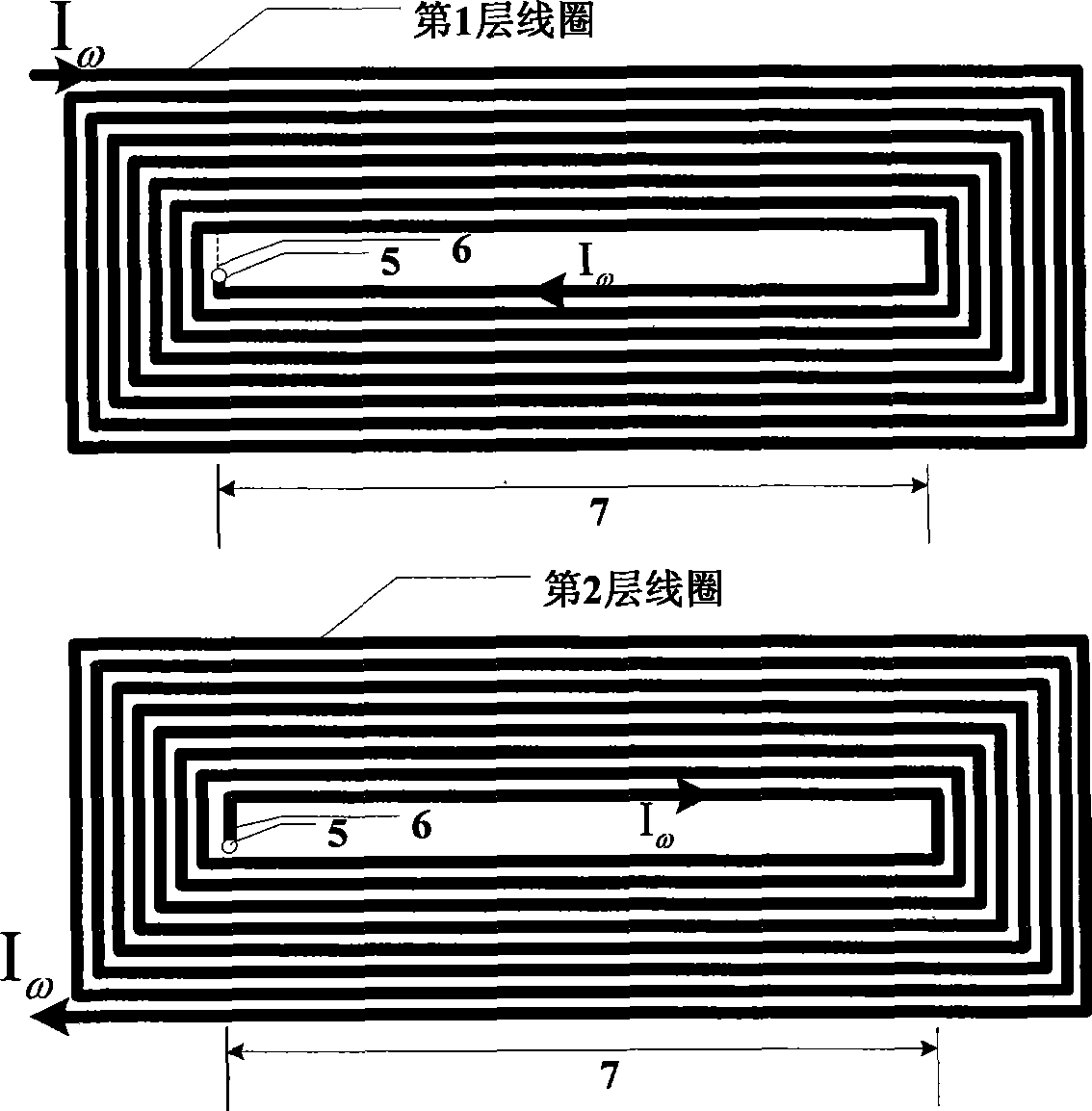

Electromagnetical ultrasonic thickness-measuring method

InactiveCN101398298AWith non-contactUsing subsonic/sonic/ultrasonic vibration meansUltrasonic sensorReflected waves

The invention discloses a method for detecting ferrous magnetic material thickness by utilizing electromagnetic ultrasound, and is characterized in that a magnet inside an electromagnetic ultrasound transducer takes a U-shaped permanent magnet, a coil takes a PCB double-layer coil that takes the shape of a Chinese character, 'Hui' and is positioned at an opening of the permanent magnet, and an effective lead part of the coil is parallel to the direction of a bias magnetic field. In thickness measurement, the electromagnetic ultrasound transducer is positioned on a detected object, high-frequency electric sinusoidal pulse current passes through the coil, according to the magnetostrictive effect, the detected object generates partial stretching deformation and oscillation, and consequently excites ultrasonic transverse wave and leads the ultrasonic transverse wave to spread downwards in a direction vertical to surfaces of the detected object. The ultrasonic wave is reflected by a lower surface of the detected object, and then the reflected wave is received by the coil. A received ultrasonic signal is collected and input into a computer after being amplified. If the ultrasonic wave spreading velocity in the detected object is v, and the spreading time is t, then the thickness of the detected object d is equal to a half of v multiplied by t. The method for detecting ferrous magnetic material thickness by realizing the thickness detection of ferrous magnetic materials, has the non-contact and couplant-free advantages, and can be used in high-temperature environment and for detecting materials with rough surfaces.

Owner:TSINGHUA UNIV

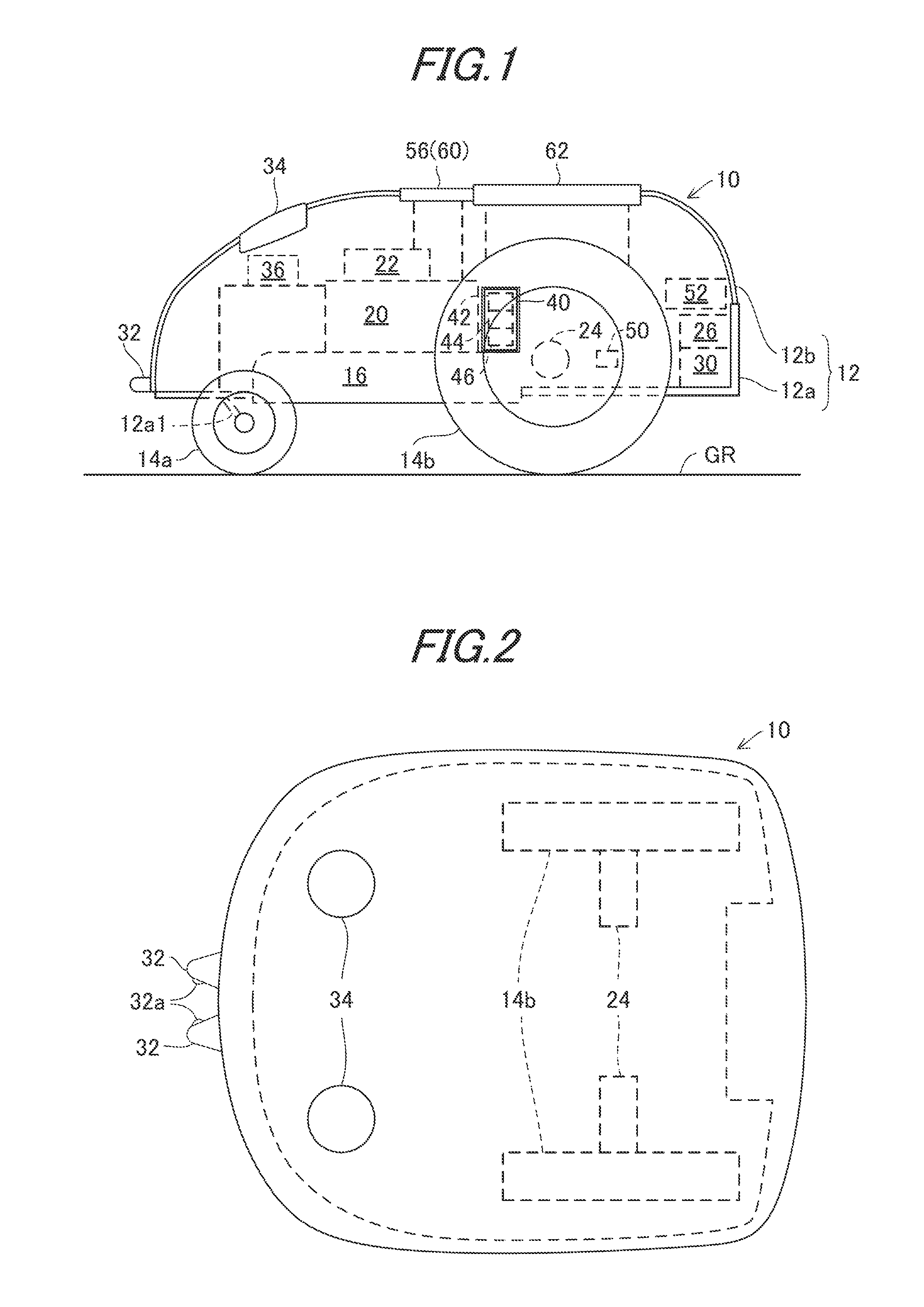

Unmanned autonomous operating system

ActiveUS20130317680A1Accurate identificationDigital data processing detailsMowersMicrocomputerOperational system

In an unmanned autonomous operating system having a station provided with a signal generator for supplying an area signal in electric pulse current to an area wire that defines an operating area, and an unmanned autonomous vehicle having magnetic sensors for detecting a magnetic field generated by the area wire and a microcomputer programmed to recognize the operating area from the detected magnetic field, a selection mechanism is installed at the station that outputs one of area signals from the signal generator in response to a selection of a user, one of the area signals generated from the signal generator is registered, and the operating area is recognized based on the registered area signal.

Owner:HONDA MOTOR CO LTD

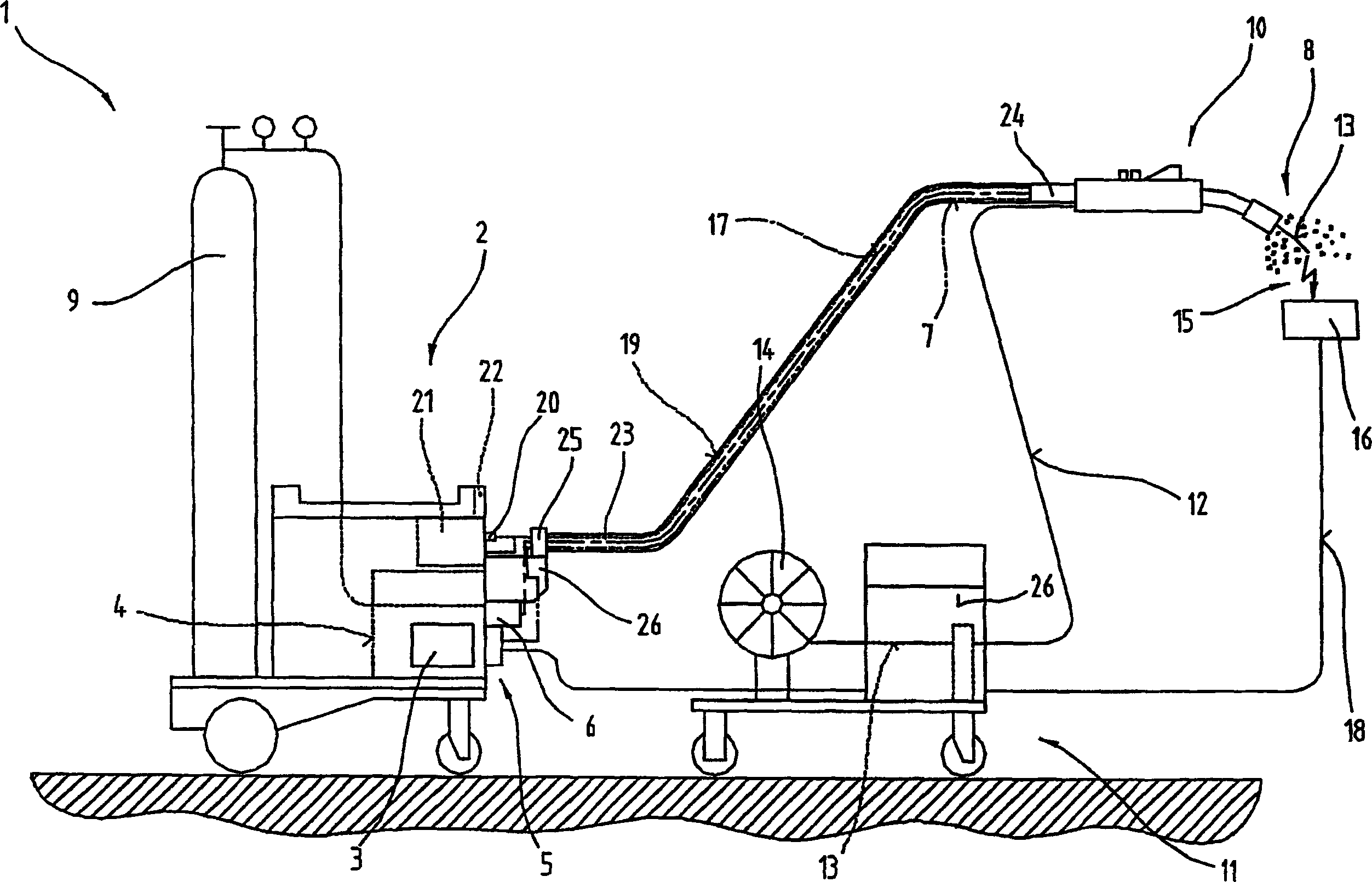

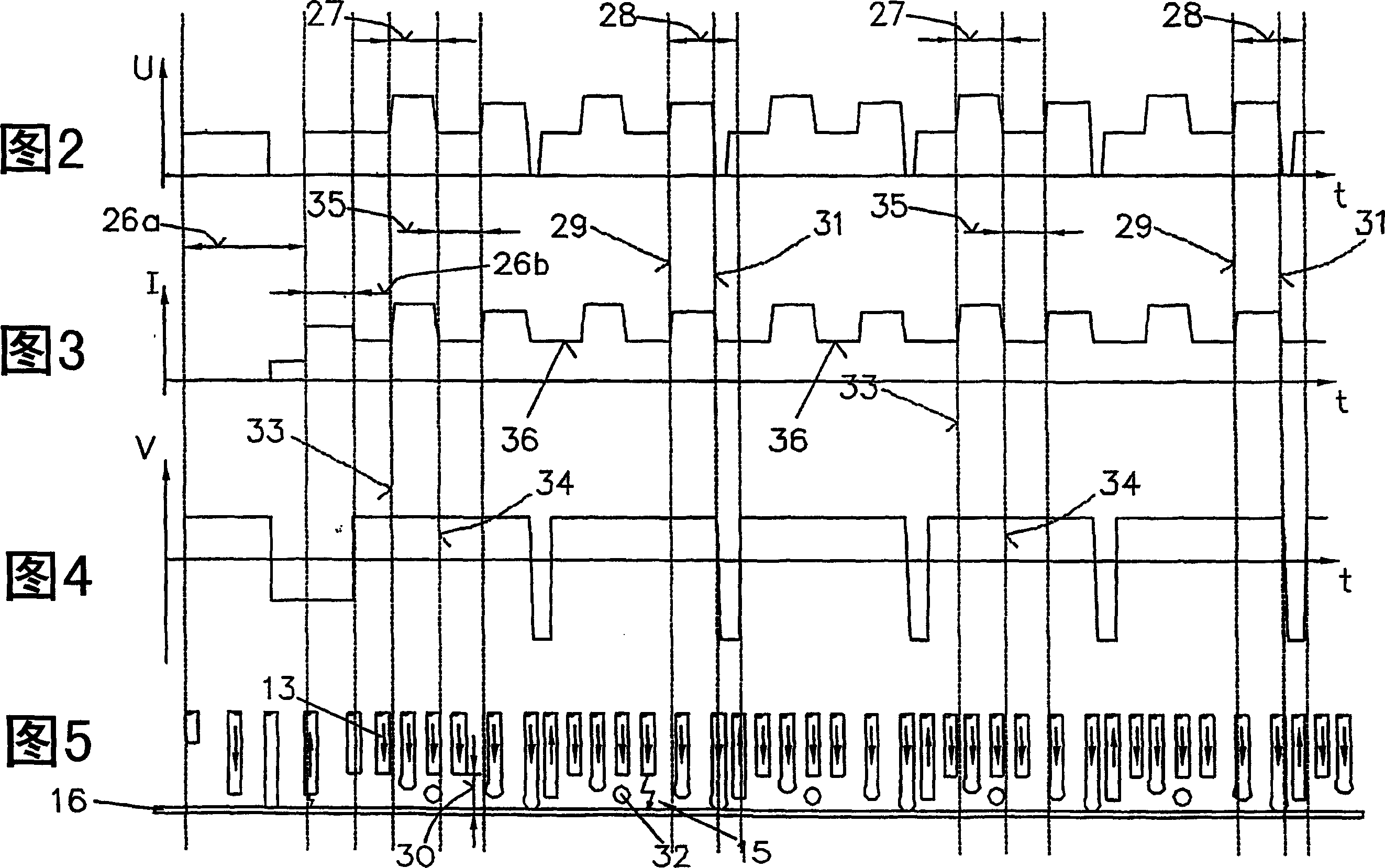

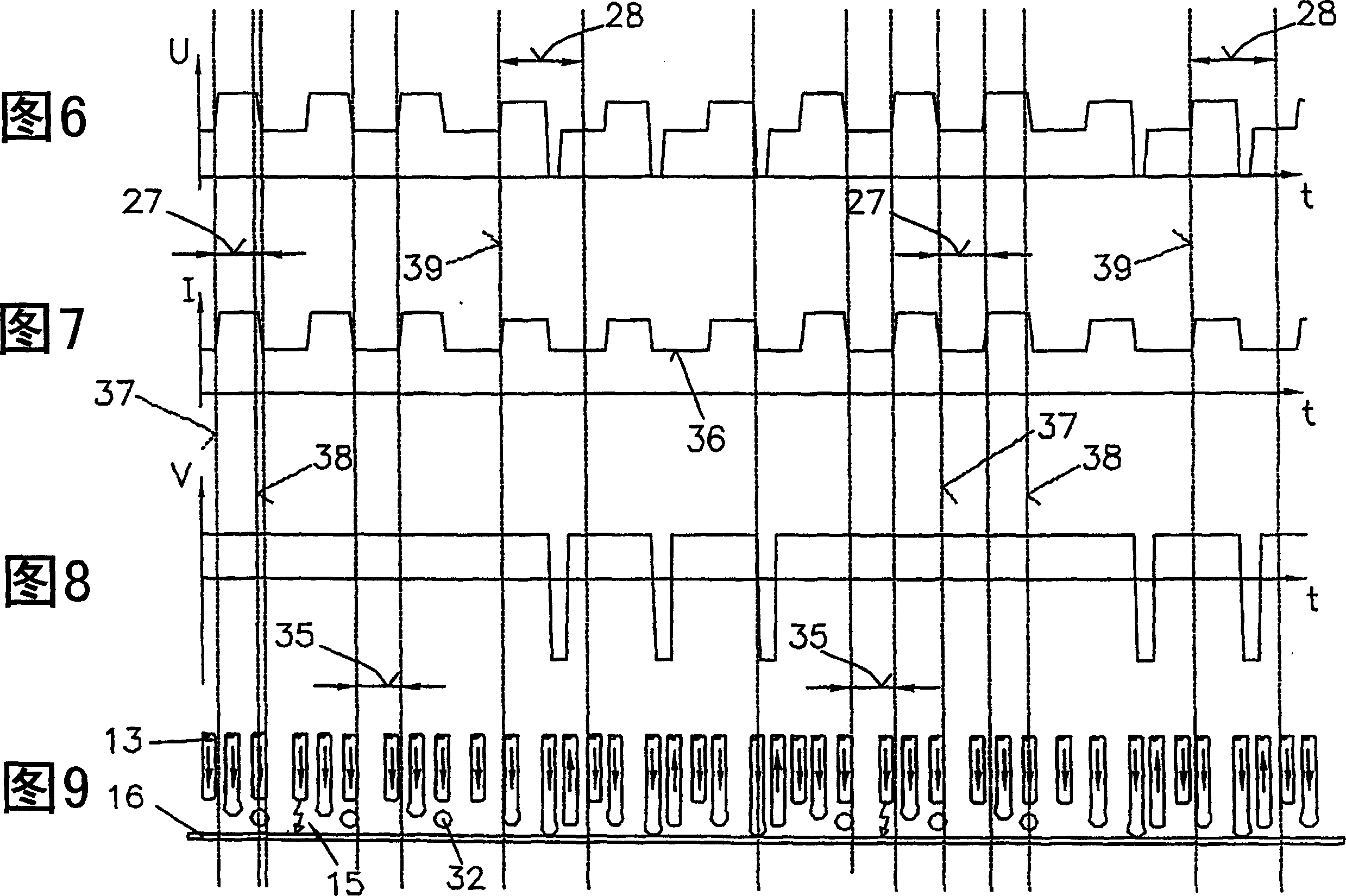

Method for controlling a welding process and welding device for carrying out a welding process

InactiveCN1871093ASimple Heat Balance ControlLow heat inputArc welding apparatusWelding power supplyProcess engineering

The invention relates to a method for controlling and / or adjusting a welding process, using a melting electrode, wherein after ignition of an electric arc, a welding process, which is adjusted on the basis of several different welding parameters, is carried out by means a welding current source (2), said process being controlled or adjusted by a control device (4). The invention also relates to a corresponding welding device used to carry out the process. In order to create said method, wherein the thermal heat economy is adjusted and / or regulated and / or controlled in order to introduce heat into the workpiece (16), at least two different process phases are cyclically combined, said process phases having different inputs of energy via different material transitions and / or arc types, such as a pulse current phase (27) and a cold metal transfer phase (28) in order to influence or control thermal heat economy, particularly the introduction of heat into the workpiece to be processed.

Owner:FRONIUS INTERNATIONAL GMBH

Sequential electromachining and electropolishing of metals and the like using modulated electric fields

A surface of an electrolytically dissolvable material, e.g., an electrolytically dissolvable metal, is smoothed by a two-step electrochemical process wherein a the surface to be smoothed and a counterelectrode are contacted with an electrolyte and an electric current is passed between the substrate and counterelectrode, with the substrate as the anode. In a first step relatively large asperities on the substrate are reduced in height by maintaining a macroprofile regime by using a pulsed electric current with short pulses. In a second step, small asperities and the remainder of the large asperities are reduced or removed by maintaining a microprofile regime by using a pulsed current having longer pulses or a direct current.

Owner:FARADAY TECH INC

LED drive circuit

A drive circuit for LEDs or other light-emitting elements with which the influence of the changes in temperature or power supply voltage and the element variations can be restrained in order to output a pulse current with a constant level. When n-type MOS transistor 10 is on, power is supplied from switching power supply 60 to the LED, and the current of LED is detected by resistor 20. The error signal Serr between said detection signal Sfb and setpoint signal Sref is generated by error signal generating unit 30 and is averaged by signal holding unit 40. The power supplied to the LED is controlled corresponding to the averaged error signal SerrA. When n-type MOS transistor 10 is turned off from the on state, the power supplied to the LED is stopped, and error signal SerrA is held in signal holding unit 40. When n-type MOS transistor 10 is turned on from the off state, the averaging of error signal Serr is started with the signal level of the held error signal SerrA used as the initial level.

Owner:TEXAS INSTR INC

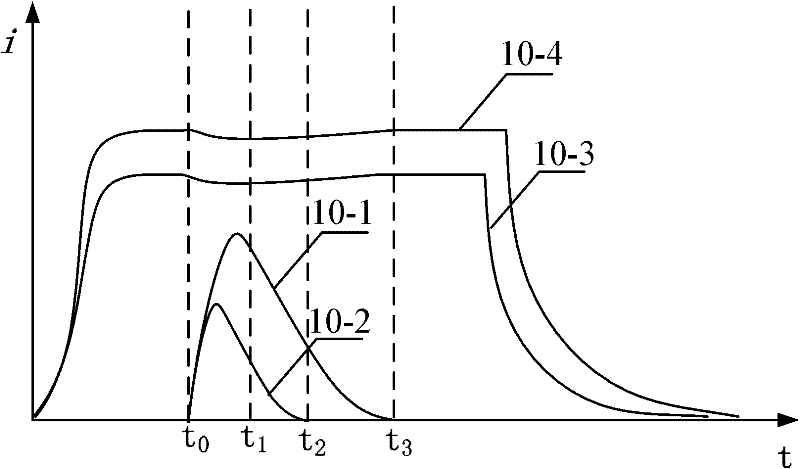

Battery heating method based on battery health status

InactiveCN106532187AInhibition of the effects of agingHigh precisionSecondary cellsElectrical testingElectrical batteryInternal resistance

The invention discloses a battery heating method based on battery health status, and belongs to the technical field of battery heating. The method aims to solve the problem that a battery is incapable of being heated uniformly when the battery is charged and used at a low temperature or that aging of the battery is accelerated due to improper battery low-temperature heating pulse amplitude selection and control caused by the facts that the difference between the charging internal resistance of the battery and the discharging internal resistance of the battery is ignored in the heating process and the influence of the battery health status on battery performance is not taken into account. Alternating-current pulse current is applied to the battery, the battery is heated internally by using the heat generated by the battery internal resistance, the battery internal resistance is finely divided into the charging internal resistance and the discharging internal resistance in the heating process, and the influence of the battery health status on the battery performance is taken into account by using a certain constant polarization voltage as a restricted condition, so that the accuracy of battery low-temperature heating pulse amplitude selection and control is improved, and the influence on the aging of the battery in the heating process of the battery is effectively inhibited.

Owner:HARBIN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com