Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

17627 results about "Motor control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Motor control is the regulation of movement in organisms that possess a nervous system. Motor control includes reflexes as well as directed movement. To control movement, the nervous system must integrate multimodal sensory information (both from the external world as well as proprioception) and elicit the necessary signals to recruit muscles to carry out a goal. This pathway spans many disciplines, including multisensory integration, signal processing, coordination, biomechanics, and cognition. Successful motor control is crucial to interacting with the world to carry out goals as well as to regulate balance and stability.

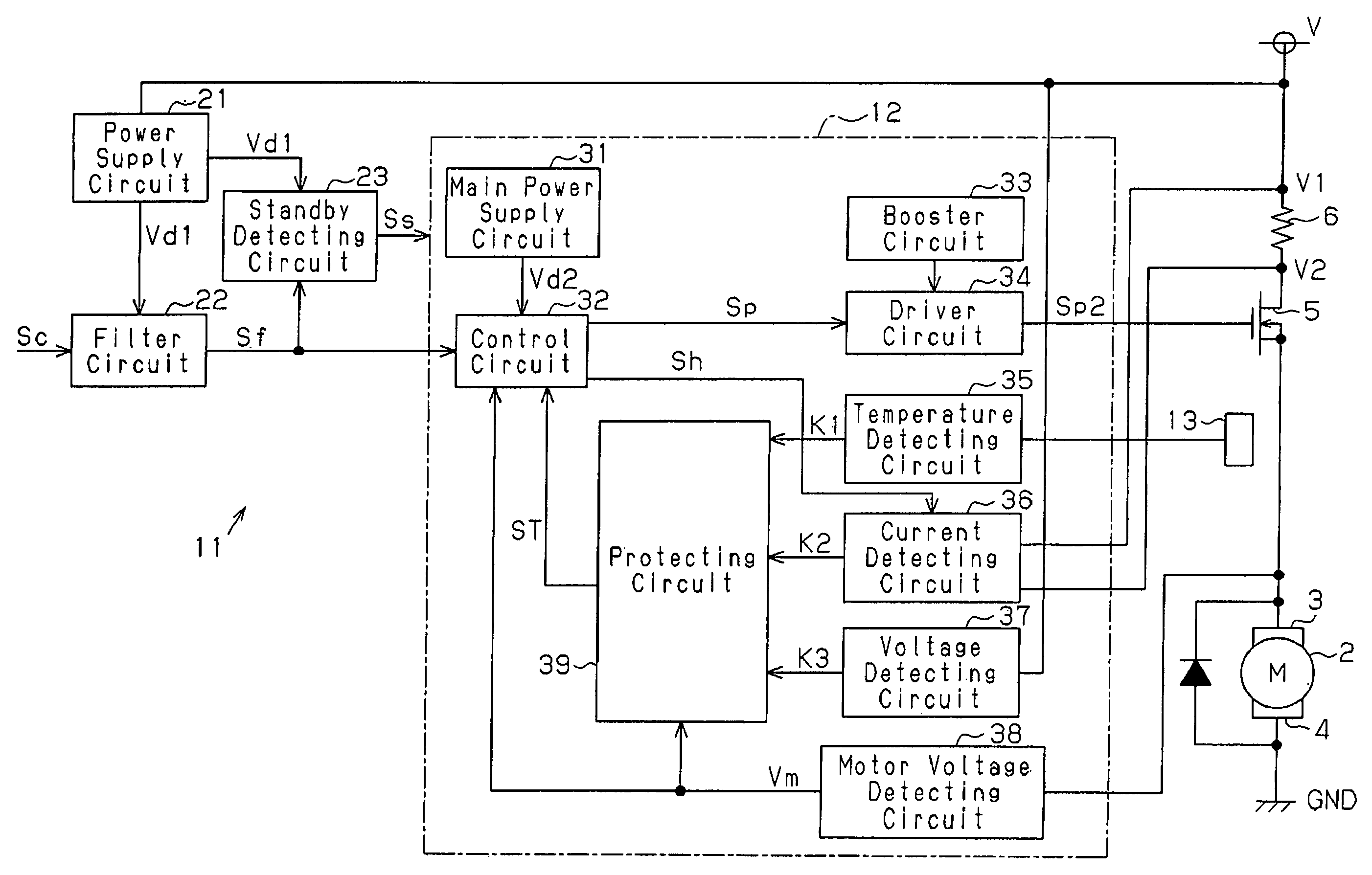

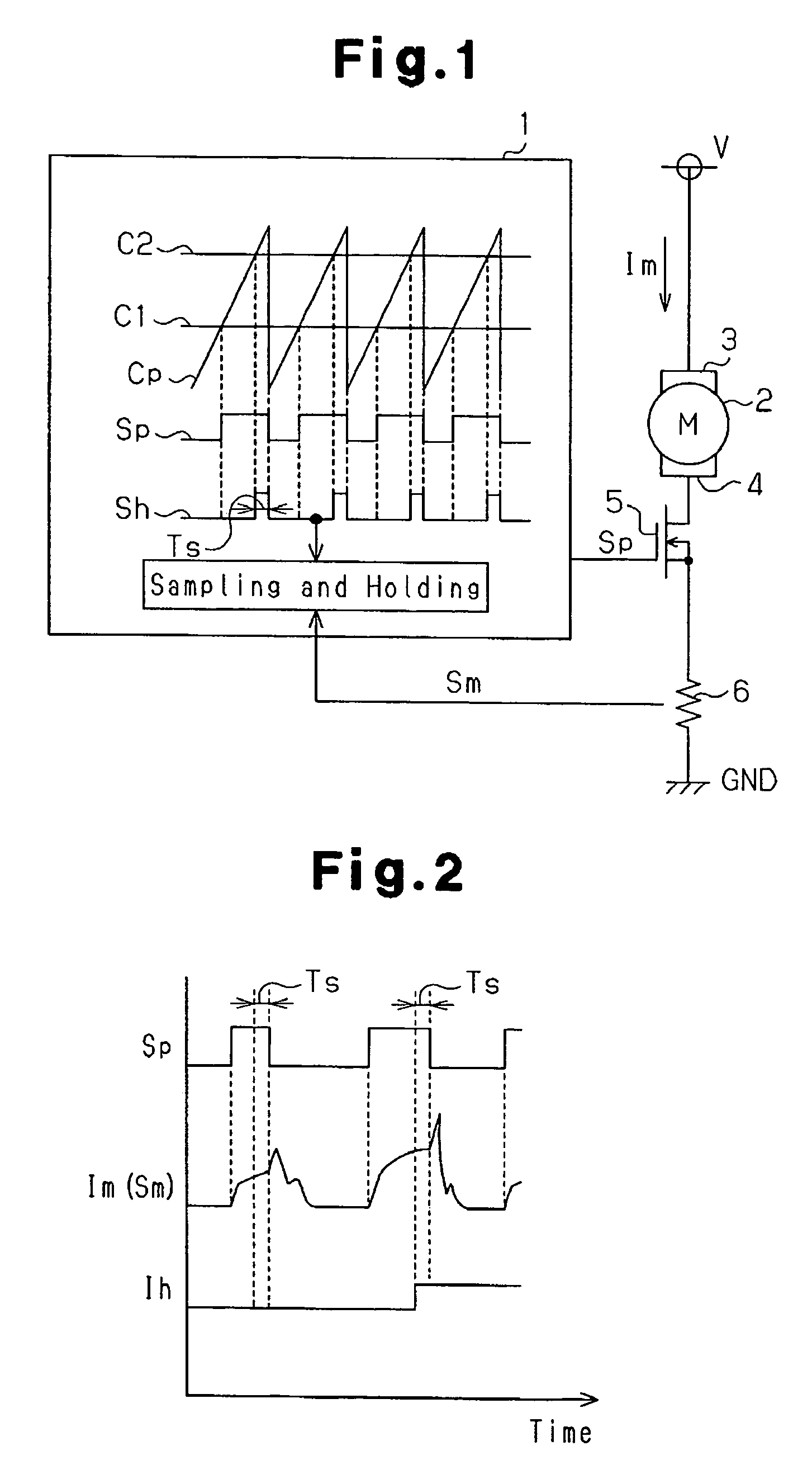

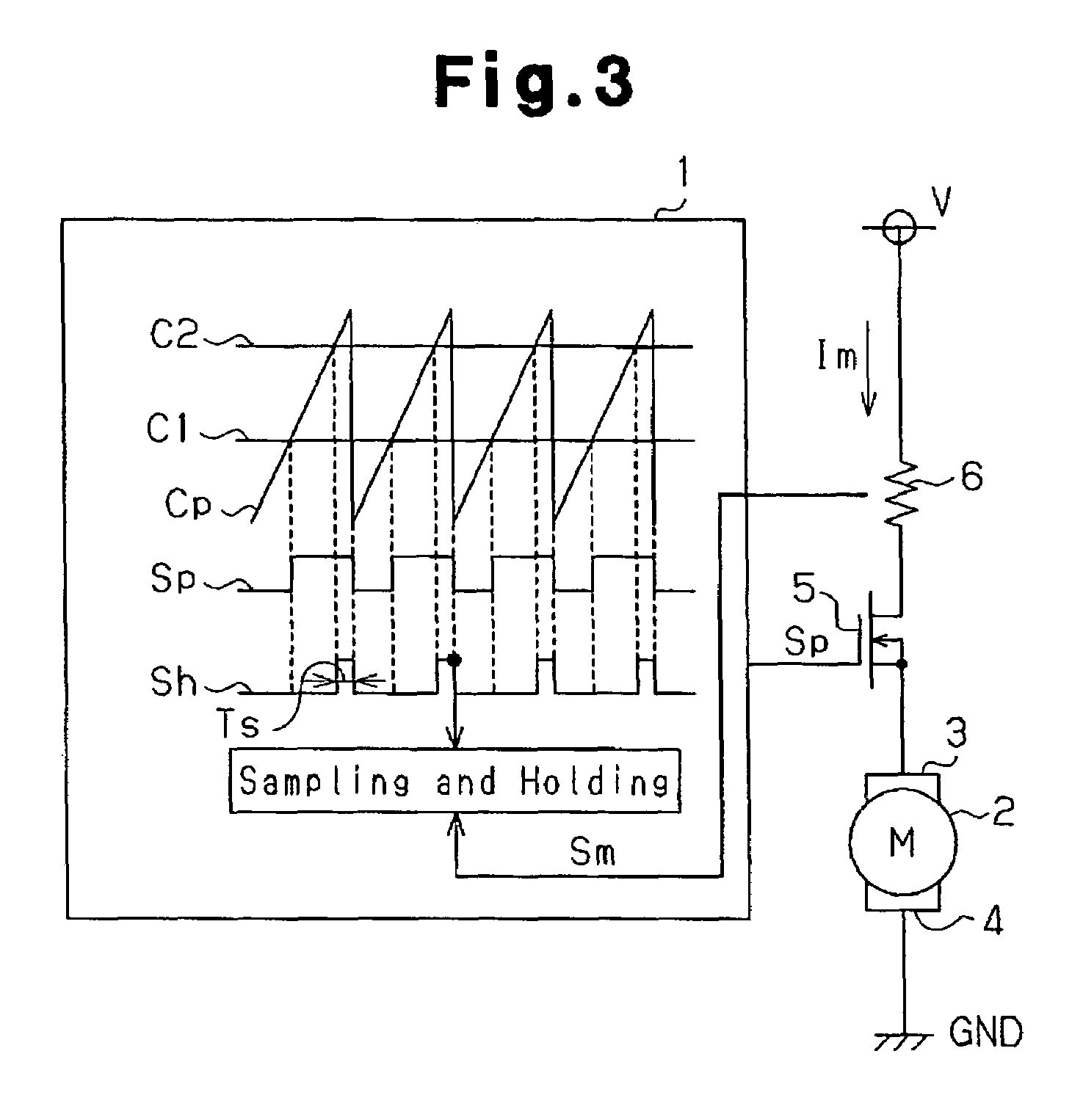

Motor control device and motor control method

InactiveUS7183737B2Improve accuracyCurrent detectionAC motor controlElectric motor controlDriving currentControl signal

A motor control device selectively turns on or off a drive transistor in-accordance with a PWM control signal Sp, such that a drive current Im supplied to a motor is adjusted. The device also samples and holds a motor current Sm for obtaining a motor current value Ih. With reference to the motor current value Ih, the device protects the motor from an overcurrent. Sampling and holding of the motor current Sm is performed for a sampling and holding time Ts. The sampling and holding time Ts corresponds to a time period between a first point in time when the level of the PWM control signal Sp is switched for turning off the drive transistor and a second point in time that precedes the first point in time by a predetermined period. As a result, the motor current value Ih is detected with high accuracy.

Owner:ASMO CO LTD

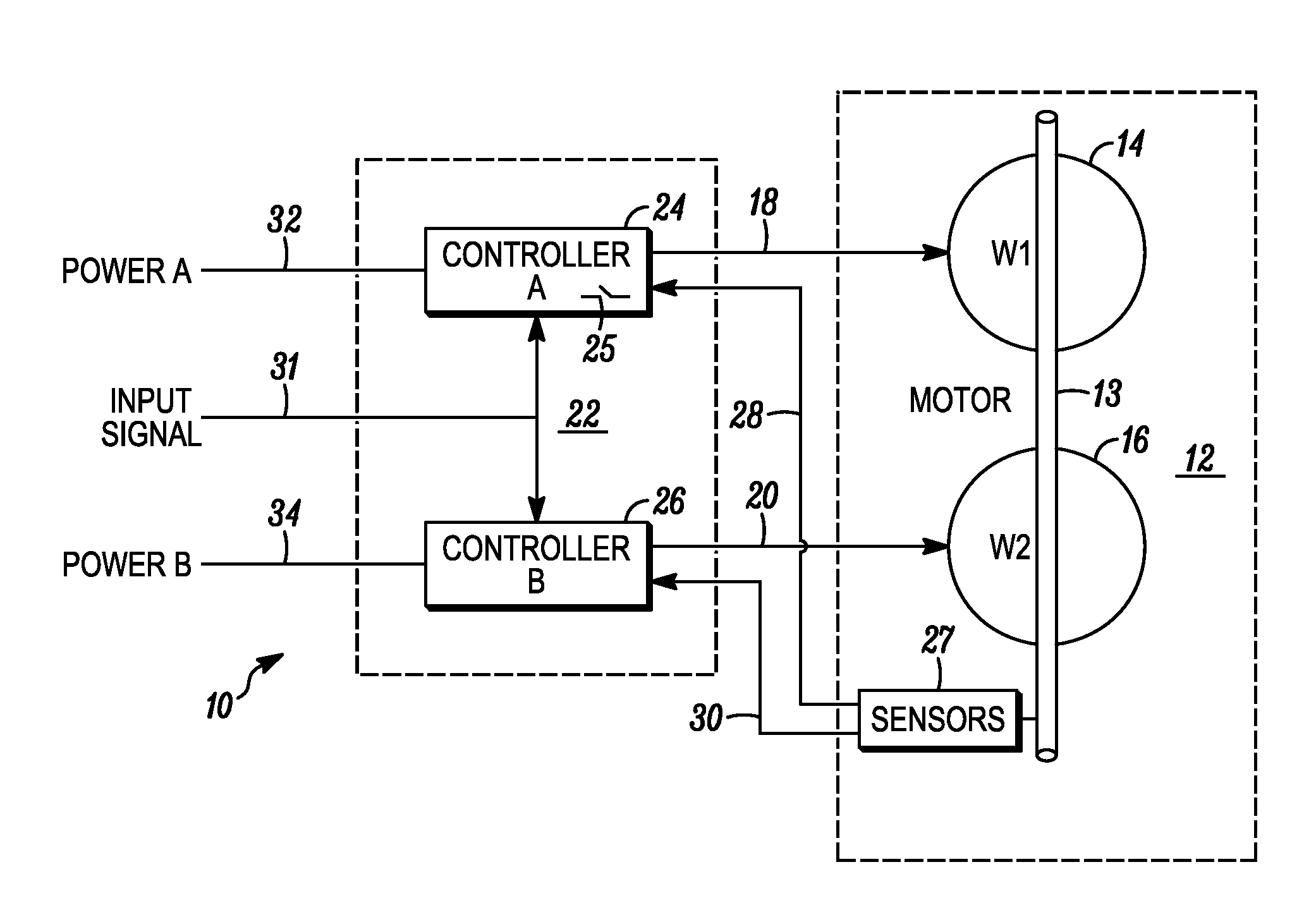

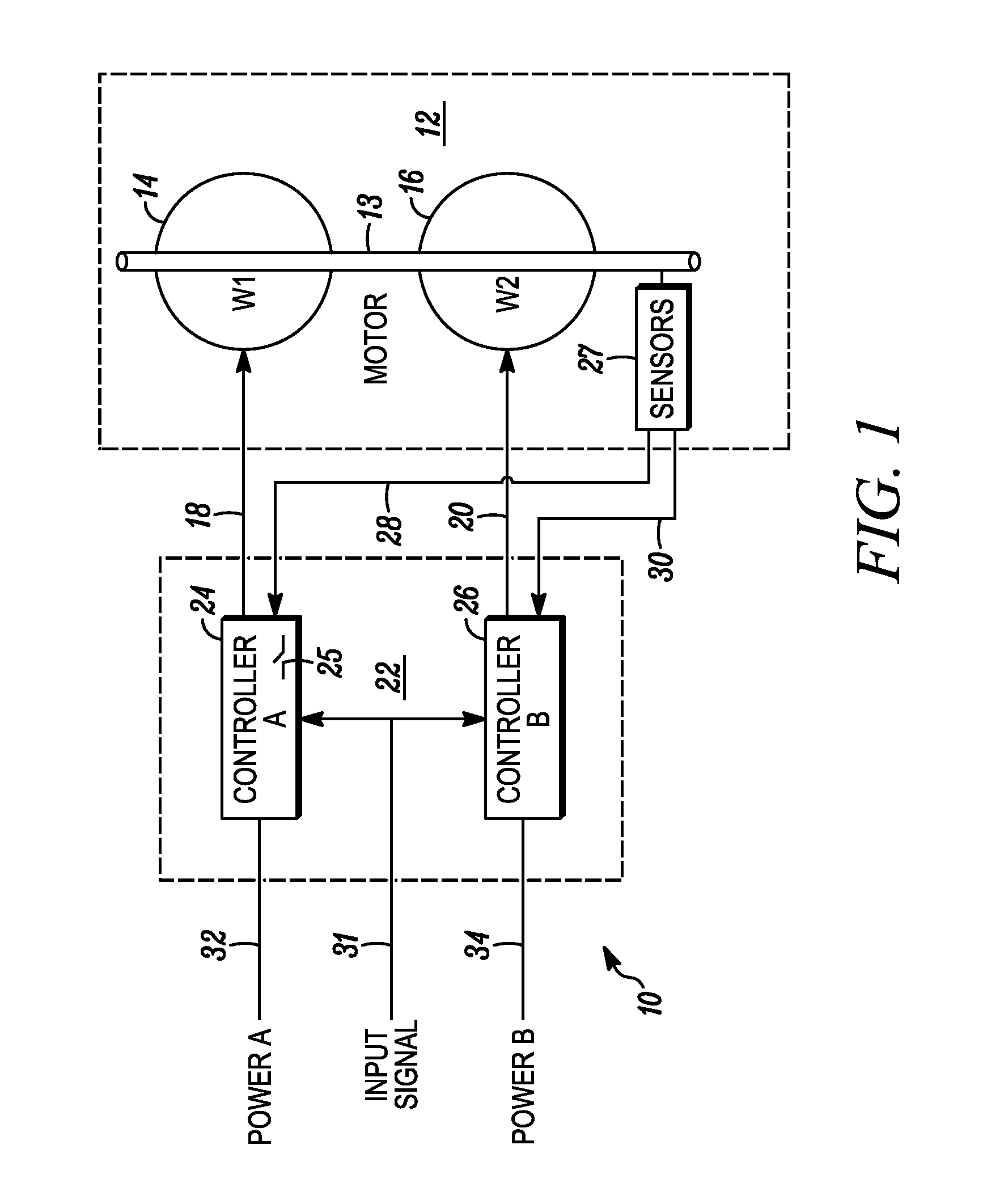

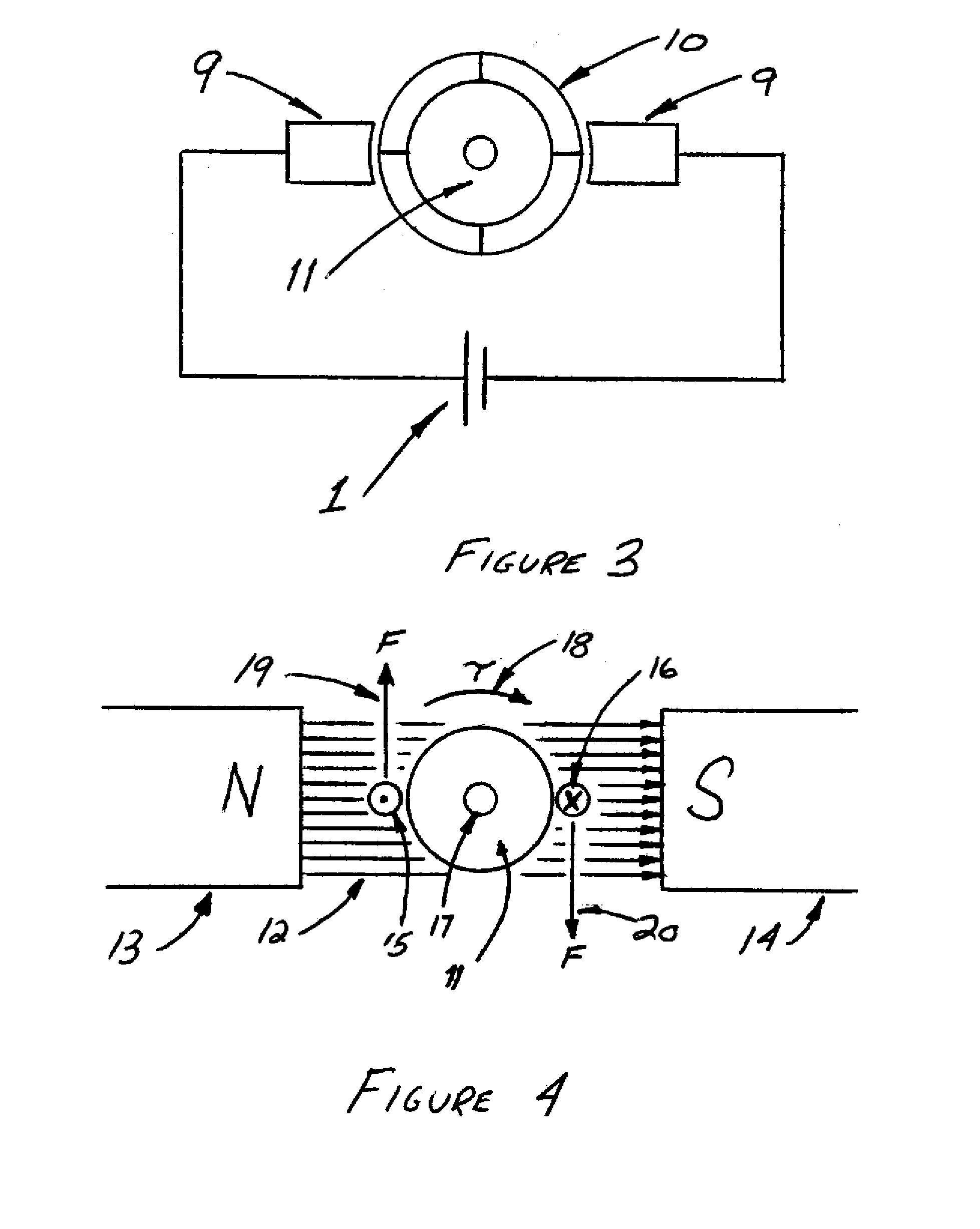

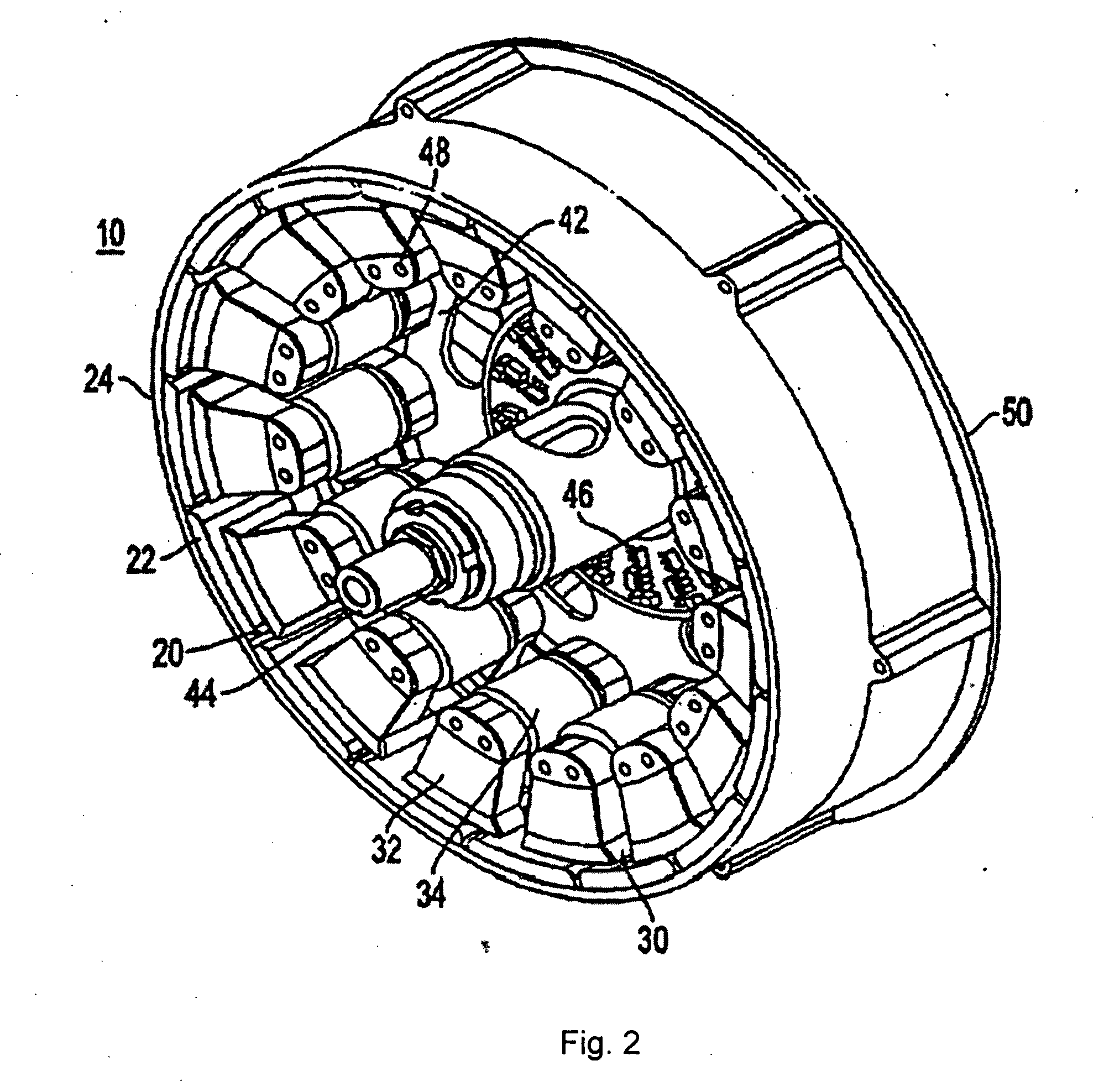

Motor having controllable torque

InactiveUS8125168B2Single-phase induction motor startersCommutation monitoringMotor controlElectric motor

A controllable motor includes a rotor. A first stator winding set is operable, upon being energized, to generate and apply a first torque to the rotor. A second stator winding set independent of the first stator winding set is operable, upon being energized, to generate and apply a second torque to the rotor. A motor control is coupled to the first and second stator winding sets. The motor control is operable to selectively energize one of the first or second stator winding sets to thereby generate and apply one of the first or second torques to the rotor, and simultaneously energize both the first and second stator winding sets to thereby generate and apply a third torque greater than the first or the second torque.

Owner:HONEYWELL INT INC

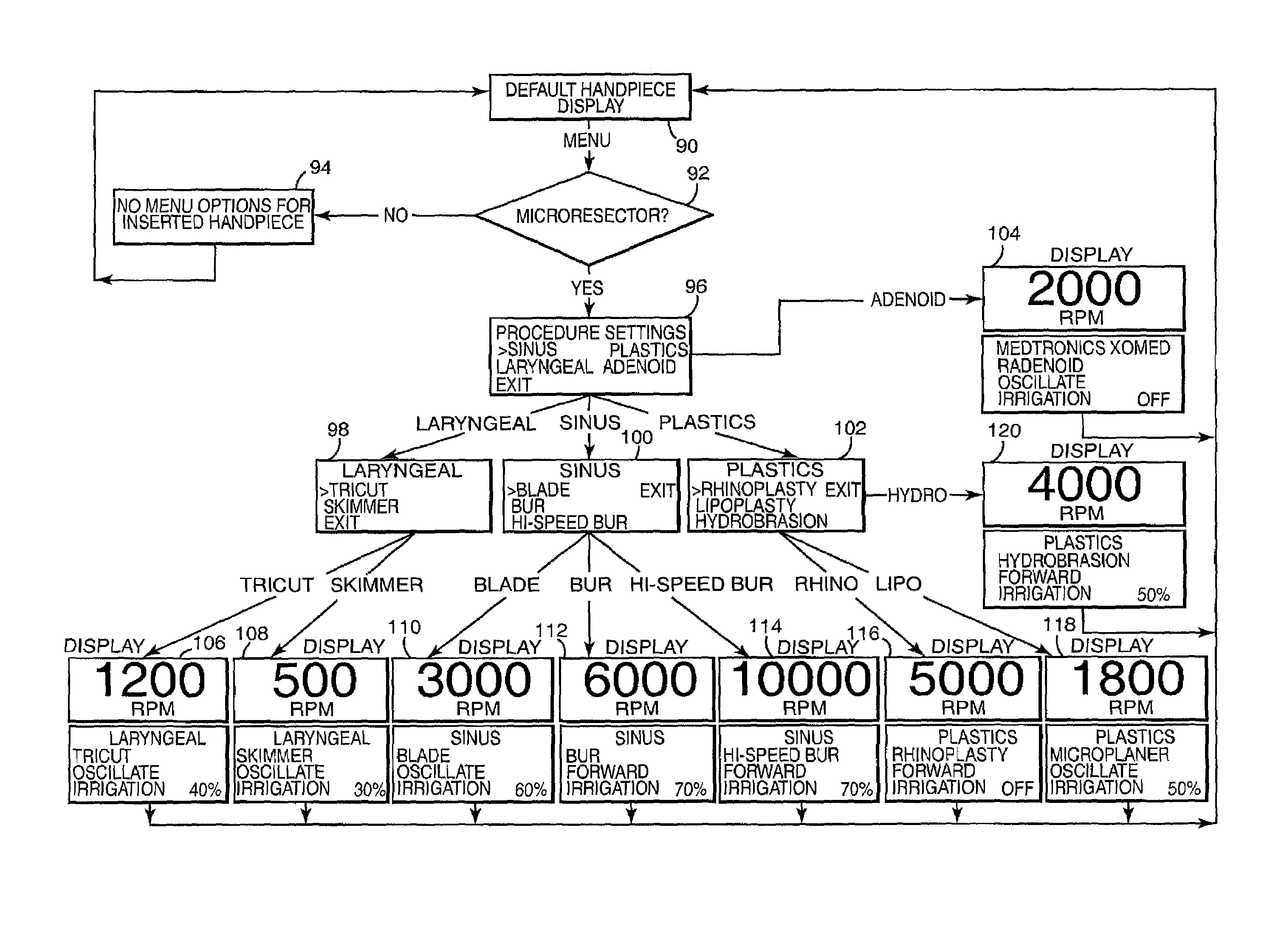

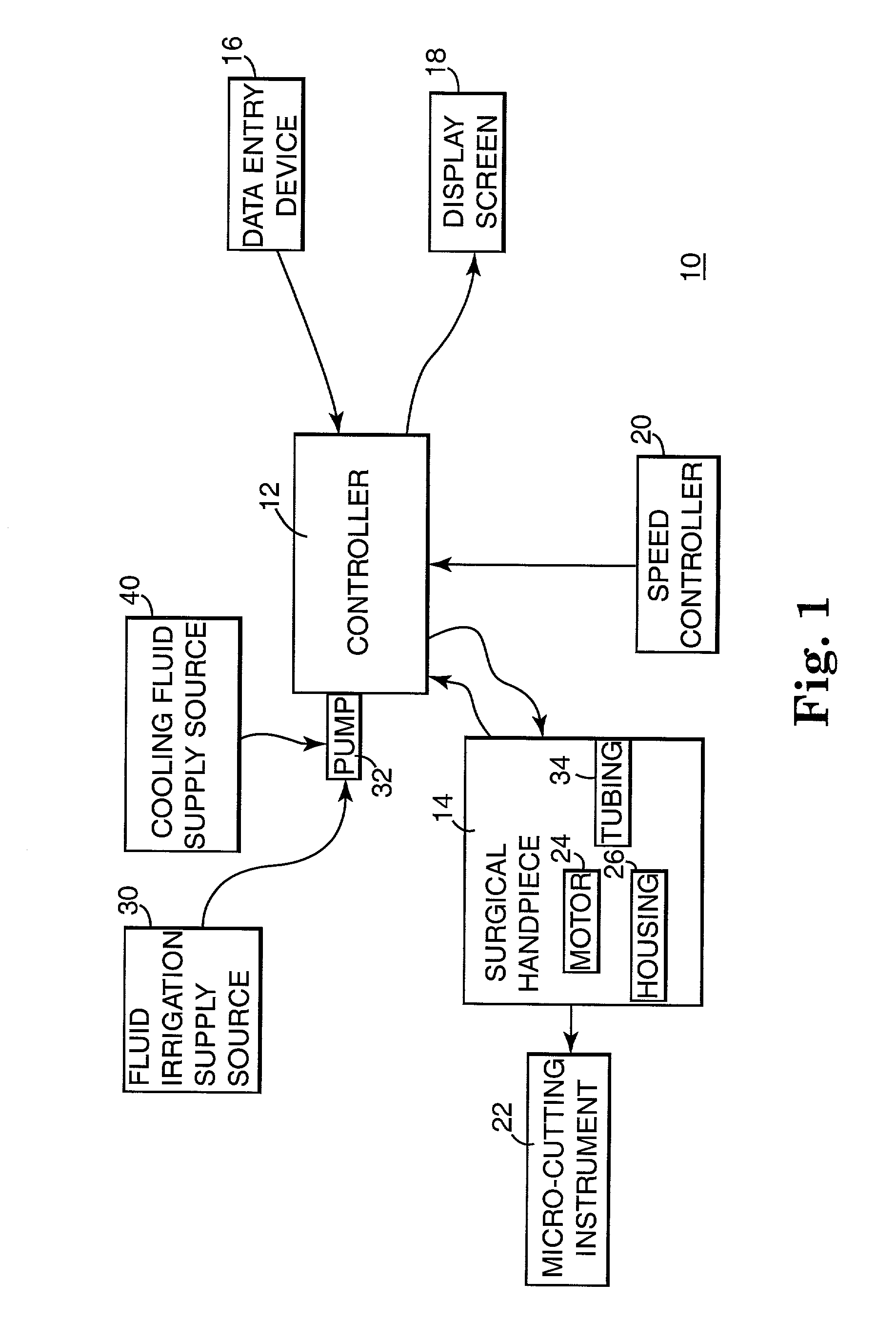

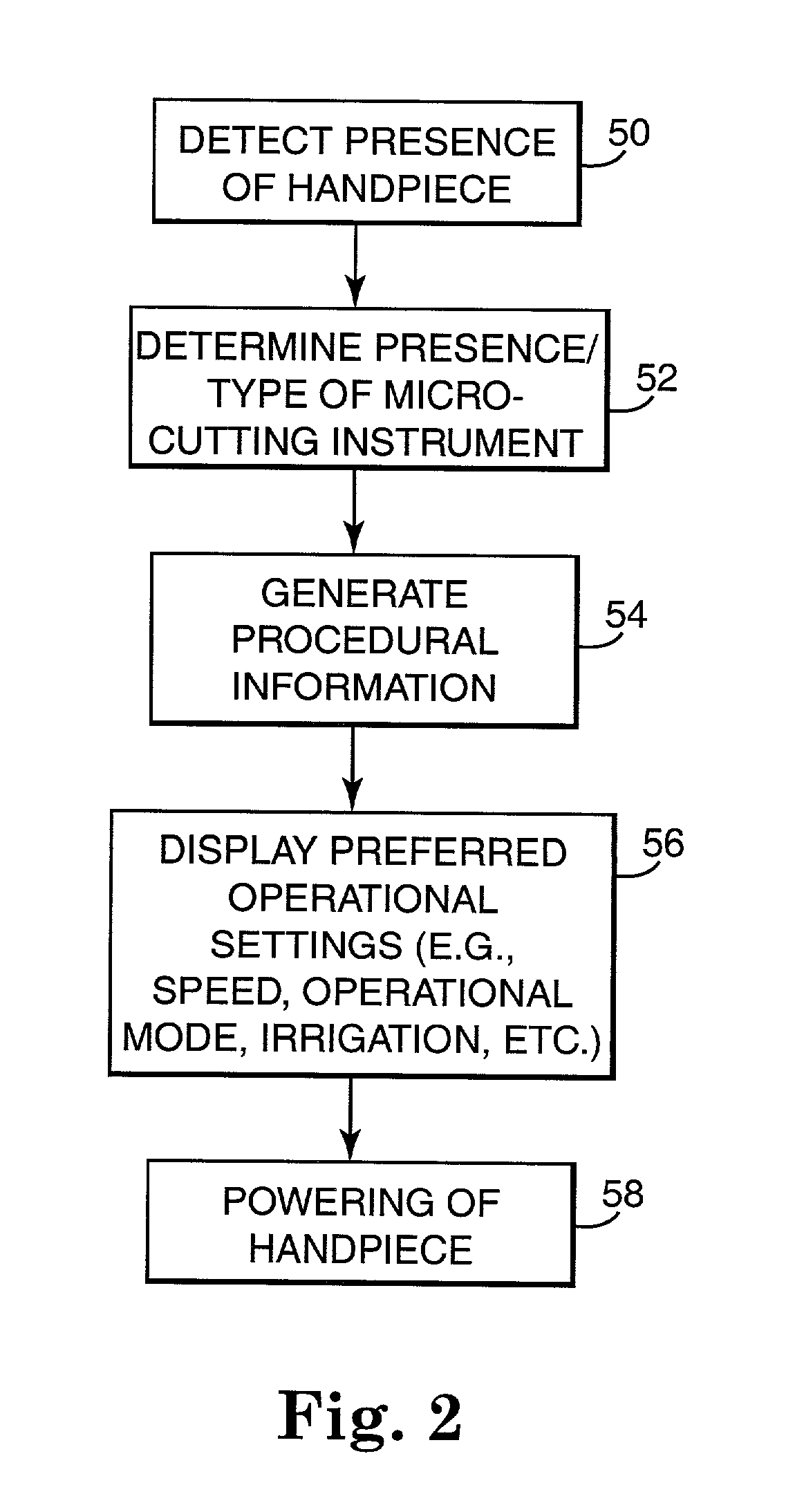

Motor control system for a surgical handpiece

A system and method for powered surgical handpiece capable of powering various micro-cutting instruments is described. The system is comprised of a controller adapted for controlling / interfacing with a powered surgical handpiece based upon user-defined procedural information. A data entry device is used for entering the user-defined procedural information used by the controller for configuring and operating the motor control system.

Owner:MEDTRONIC INC

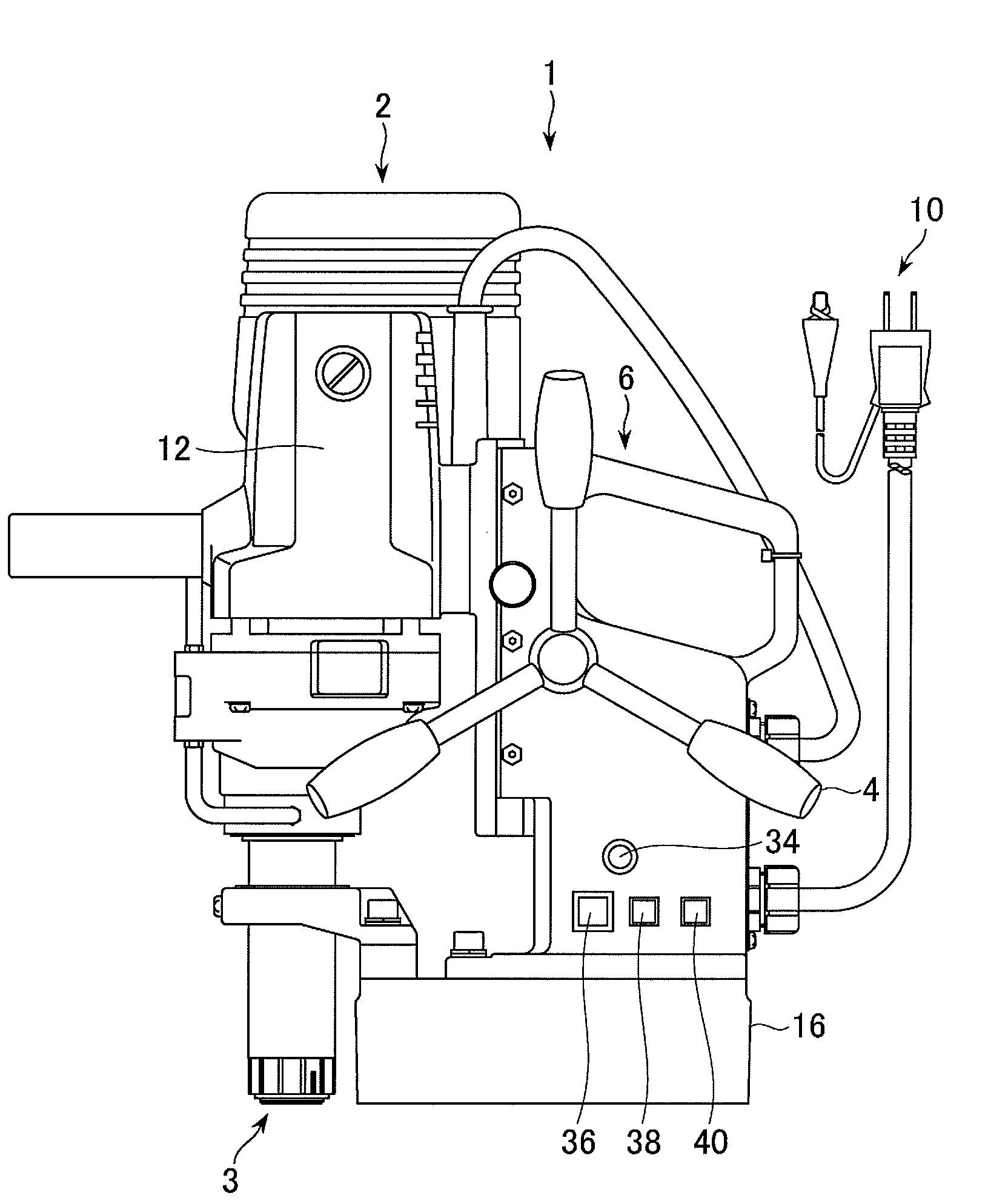

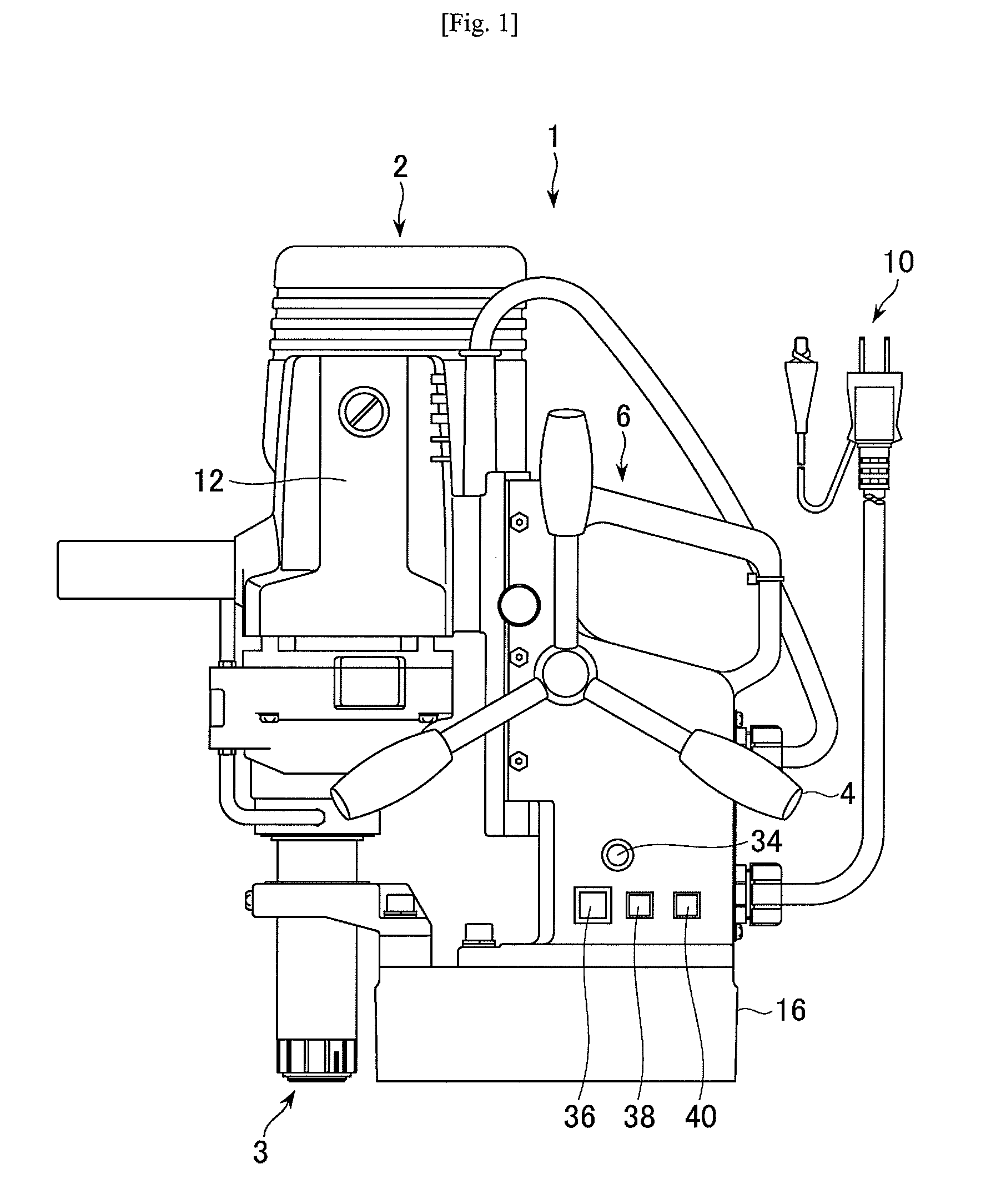

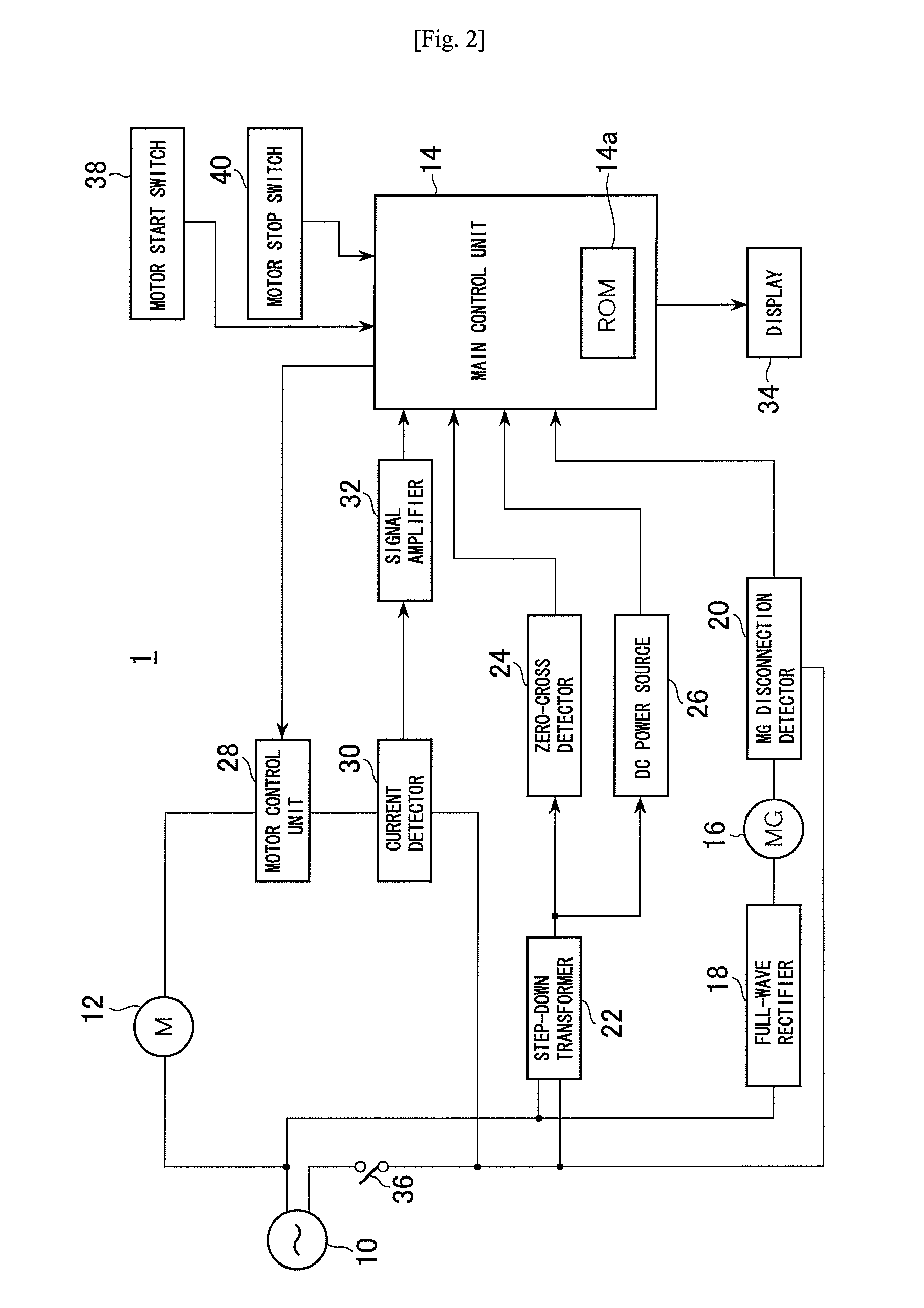

Portable drilling device

ActiveUS7936142B2Easy to operateImprove securityAC motor controlDC motor speed/torque controlFull waveEngineering

A drilling device prevents recurrence of an overload condition after occurrence of the overload condition, thereby improving operability and safety in the drilling device. A motor for rotating a drill is connected to an AC power source through a motor control unit, a current detector, and a power switch. A magnet is also connected to the AC power source through the power switch and a full-wave rectifier. The motor control unit rotationally drives the motor on the basis of a signal sent from a main control unit according to a state in which a motor start switch is on. The main control unit controls the motor control unit to gradually reduce a supply voltage to the motor when the motor becomes overloaded, to gradually increase the voltage to the normal power supply condition when the overload condition is vanished, and to stop power supply to the motor if the overload condition continues for a predetermined period.

Owner:NITTO KOHKI CO LTD

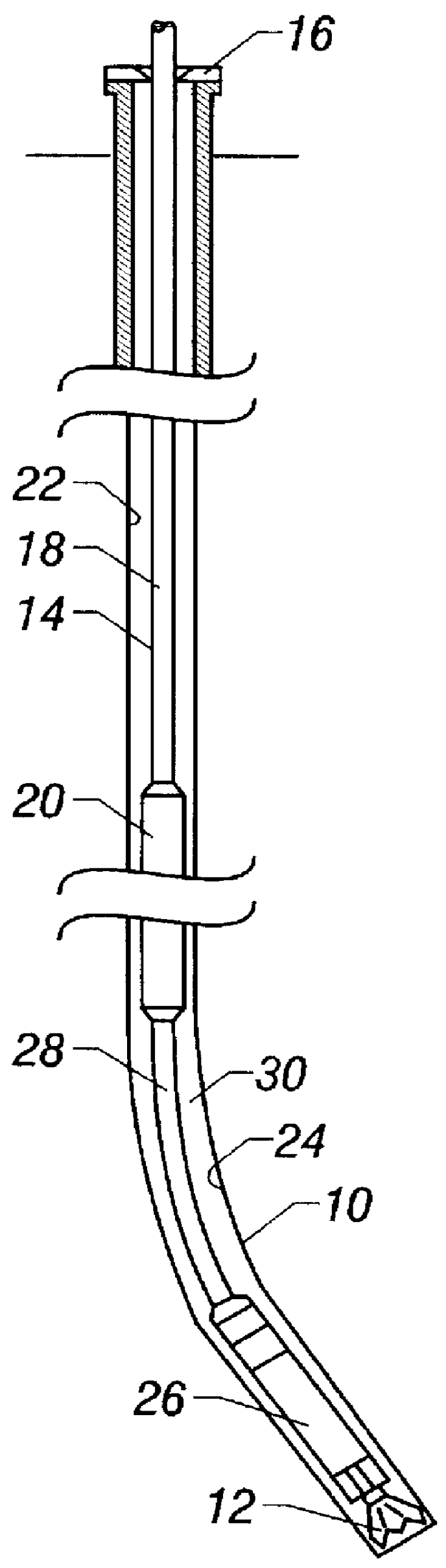

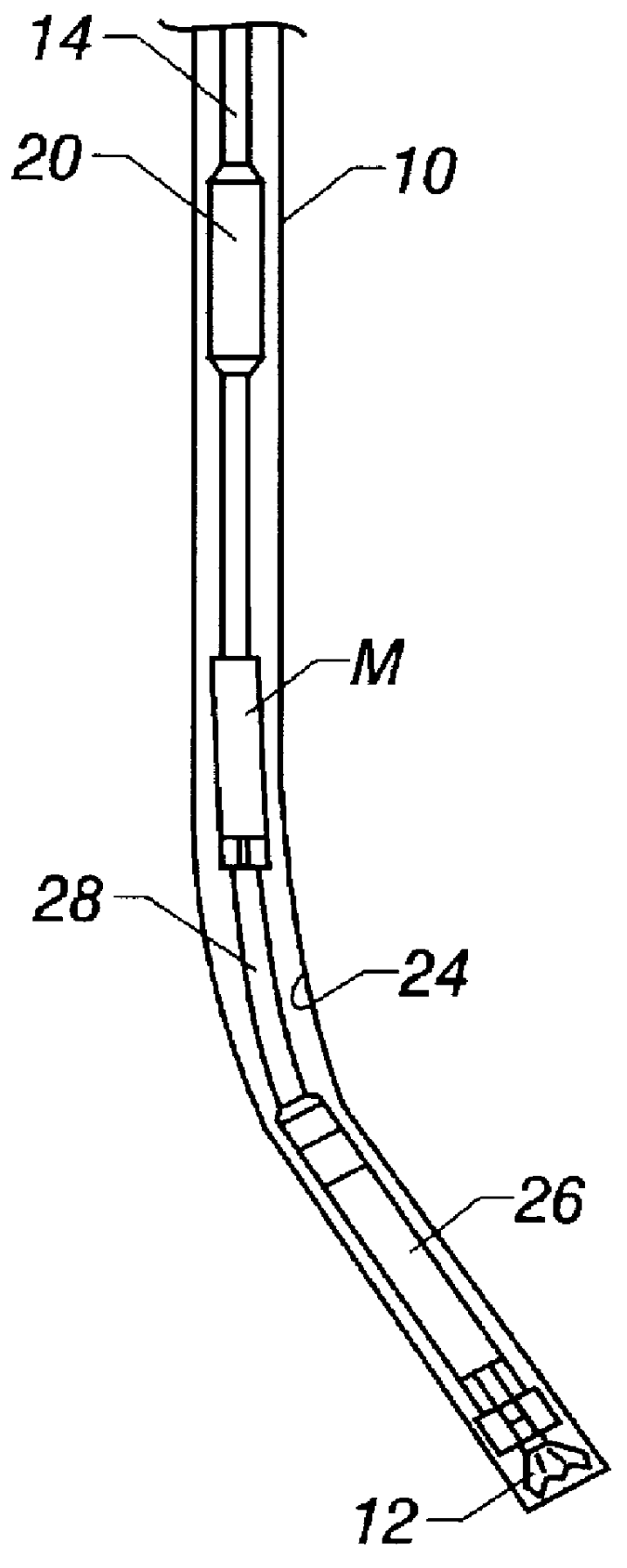

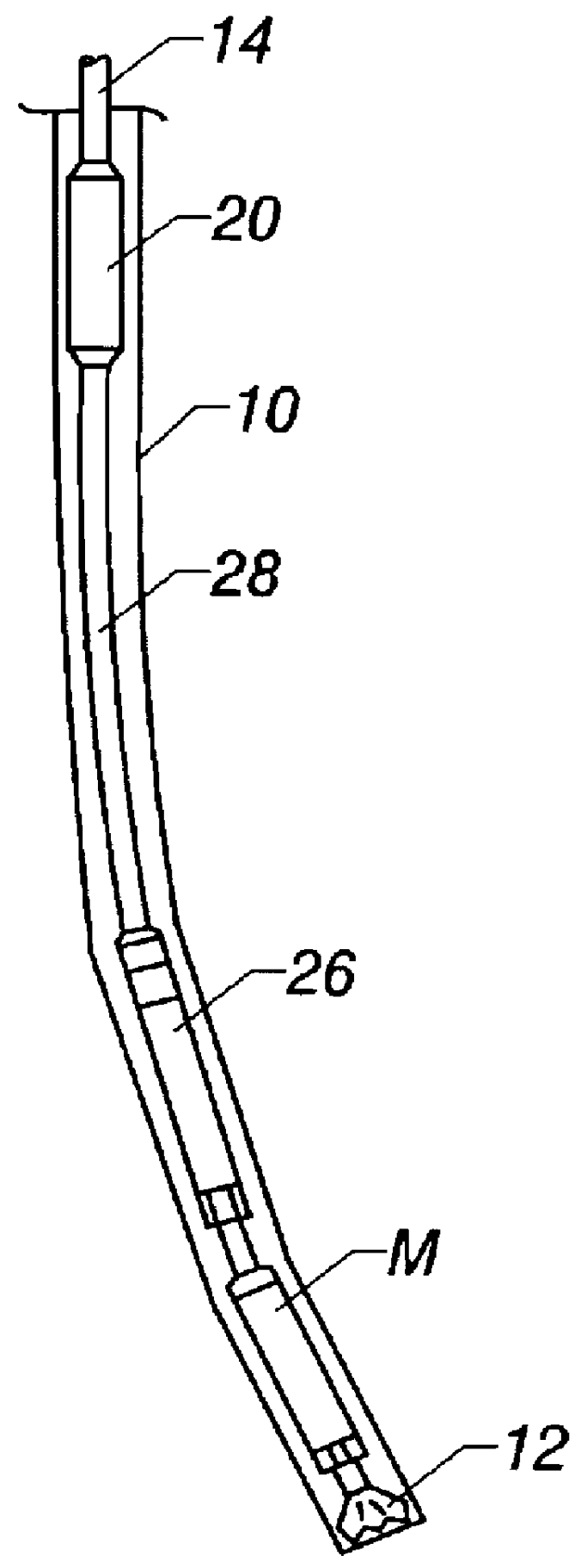

Actively controlled rotary steerable system and method for drilling wells

InactiveUS6092610AEfficient rotary speedPromote productionDrilling rodsConstructionsAccelerometerDirectional drilling

An actively controlled rotary steerable drilling system for directional drilling of wells having a tool collar rotated by a drill string during well drilling. A bit shaft has an upper portion within the tool collar and a lower end extending from the collar and supporting a drill bit. The bit shaft is omni-directionally pivotally supported intermediate its upper and lower ends by a universal joint within the collar and is rotatably driven by the collar. To achieve controlled steering of the rotating drill bit, orientation of the bit shaft relative to the tool collar is sensed and the bit shaft is maintained geostationary and selectively axially inclined relative to the tool collar during drill string rotation by rotating it about the universal joint by an offsetting mandrel that is rotated counter to collar rotation and at the same frequency of rotation. An electric motor provides rotation to the offsetting mandrel with respect to the tool collar and is servo-controlled by signal input from position sensing elements such as magnetometers, gyroscopic sensors, and accelerometers which provide real time position signals to the motor control. In addition, when necessary, a brake is used to maintain the offsetting mandrel and the bit shaft axis geostationary. Alternatively, a turbine is connected to the offsetting mandrel to provide rotation to the offsetting mandrel with respect to the tool collar and a brake is used to servo-control the turbine by signal input from position sensors.

Owner:SCHLUMBERGER TECH CORP

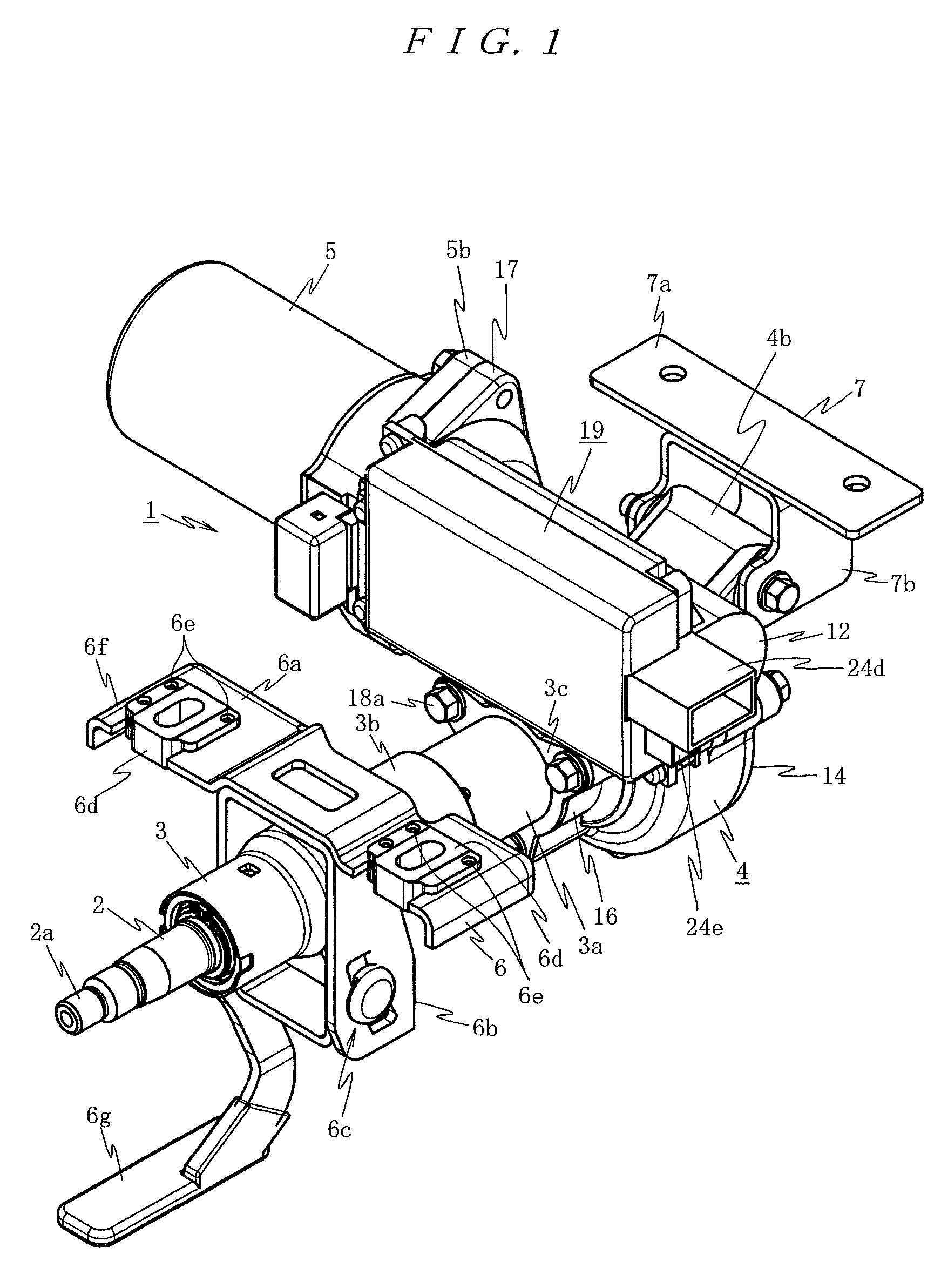

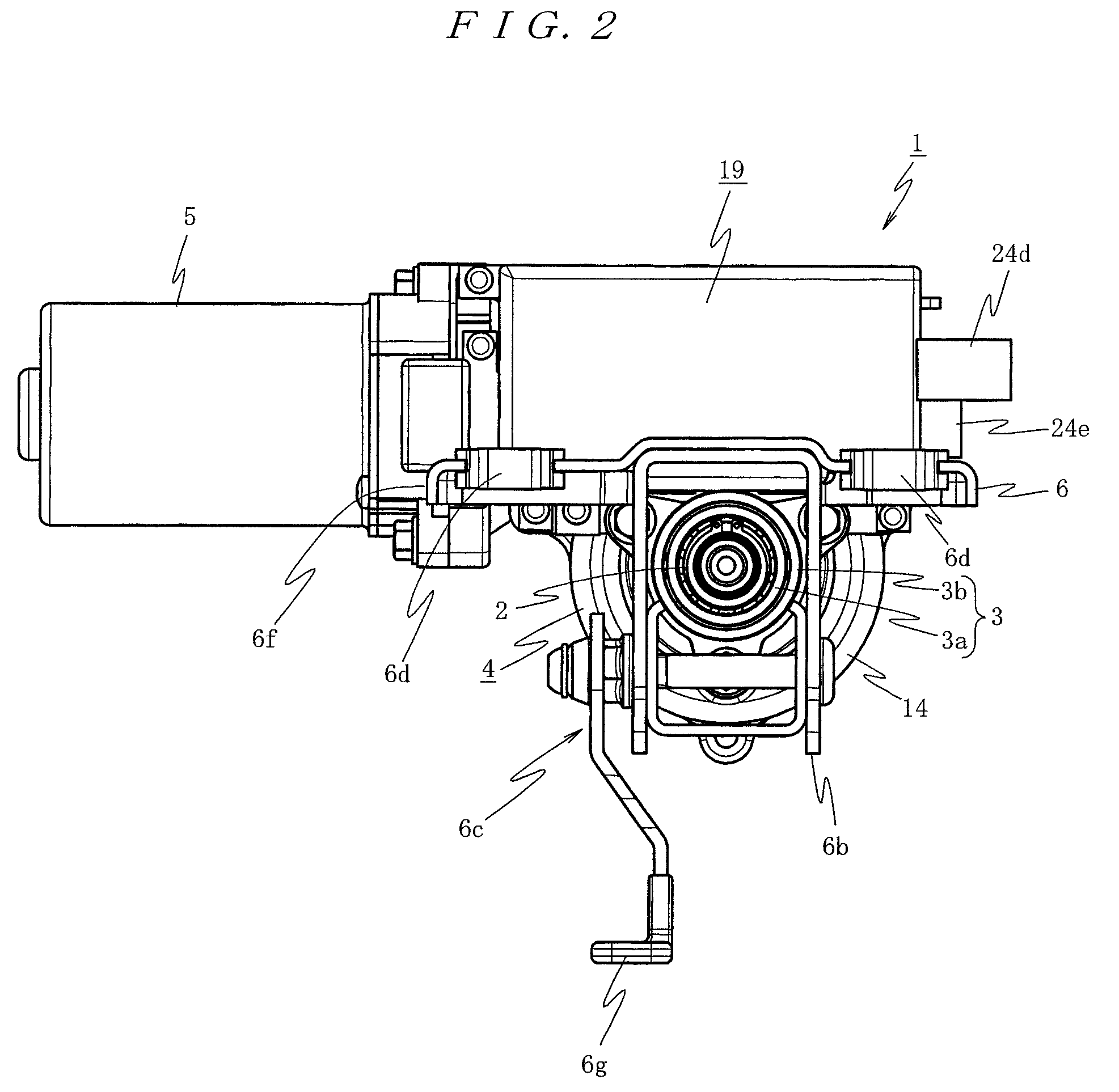

Electric power steering apparatus and method of assembling the same

ActiveUS8102138B2Large massDC motor speed/torque controlElement comparisonElectricityElectric power steering

A motor control apparatus includes a steering column having inserted therein a steering shaft to which steering torque is transmitted, a reduction gear box coupled to the steering shaft, and an electric motor that transmits a steering assisting force to the steering shaft via a reduction mechanism in the reduction gear box. The electric motor and its control unit including a control board mounted with a control circuit, are provided side by side in the reduction gear box. A connection terminal of the electric motor is electrically connected to the control unit directly. This minimizes a connection distance between the control unit and the electric motor.

Owner:NSK LTD

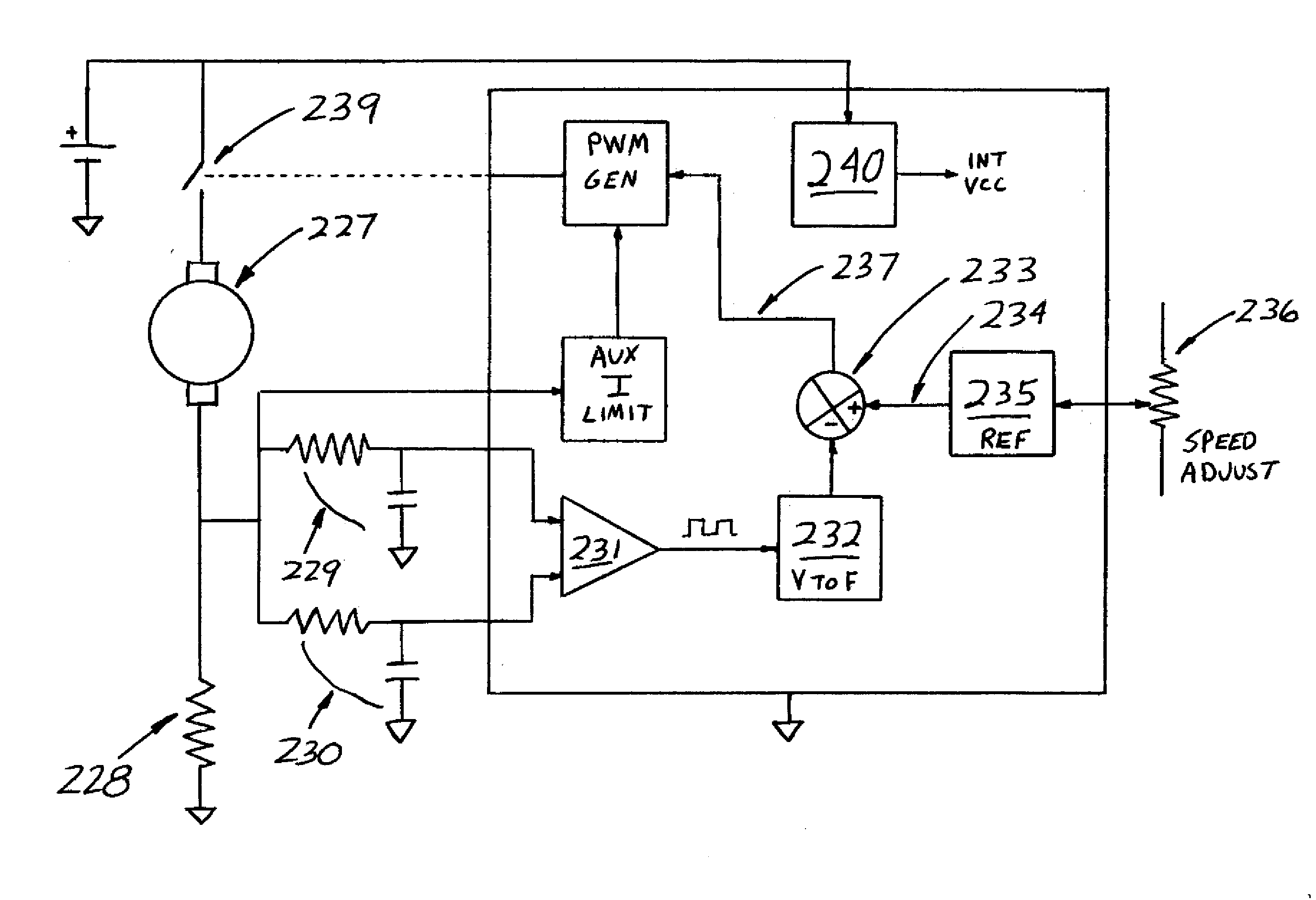

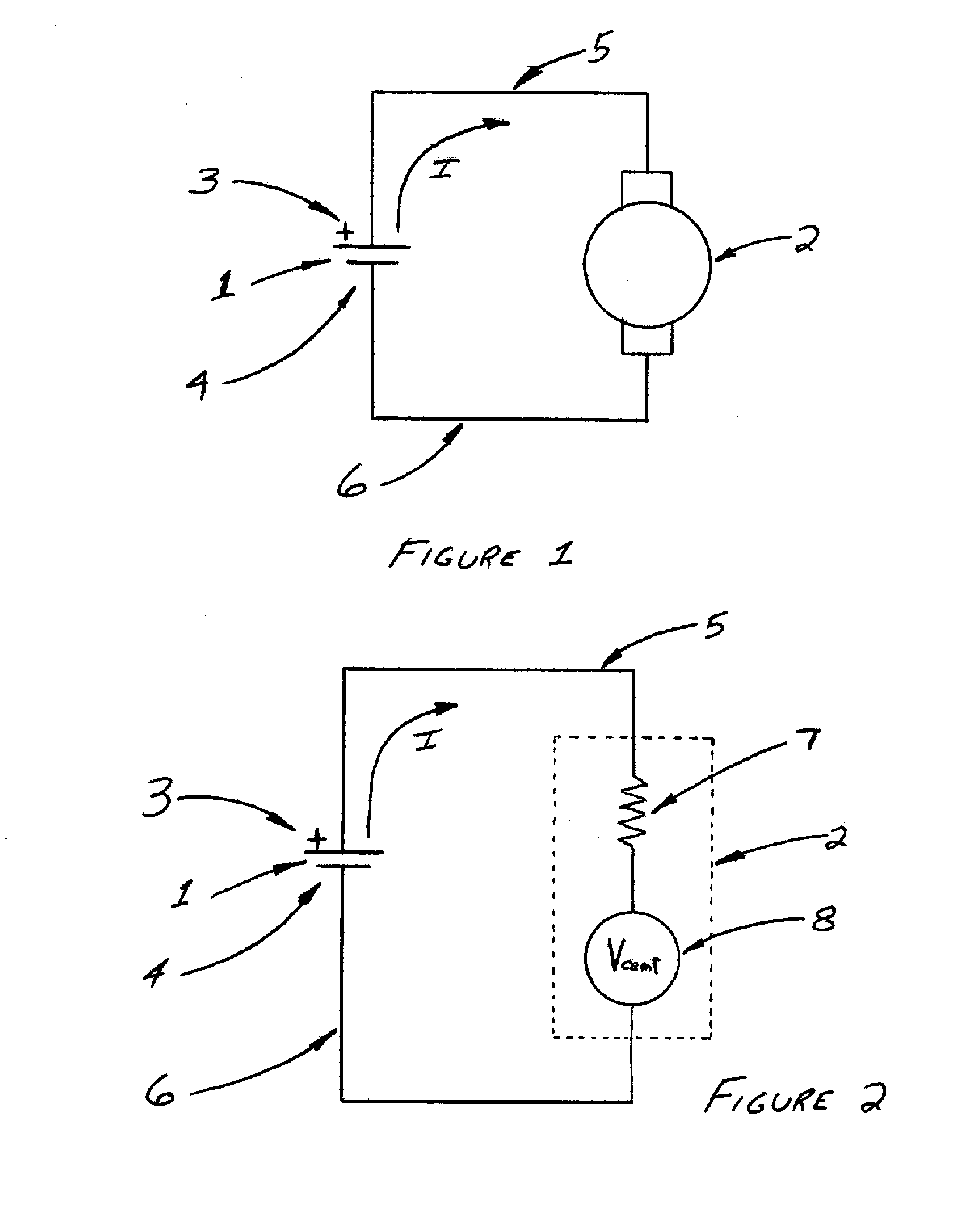

Method of Sensing Speed of Electric Motors and Generators

InactiveUS20080298784A1Simple and inexpensiveLow costMotor/generator/converter stoppersField or armature current controlMotor speedMotor control

A method and circuit for determining the speed and / or counting the revolutions of brush and commutator motors is described. The method and circuitry detects signals present on the windings of the motor due to commutation that occurs at the brushes and commutator of the motor. This method can be used to simply monitor & indicate the motor speed and revolutions or to form the basis of a motor control.

Owner:KASTNER MARK ALLEN

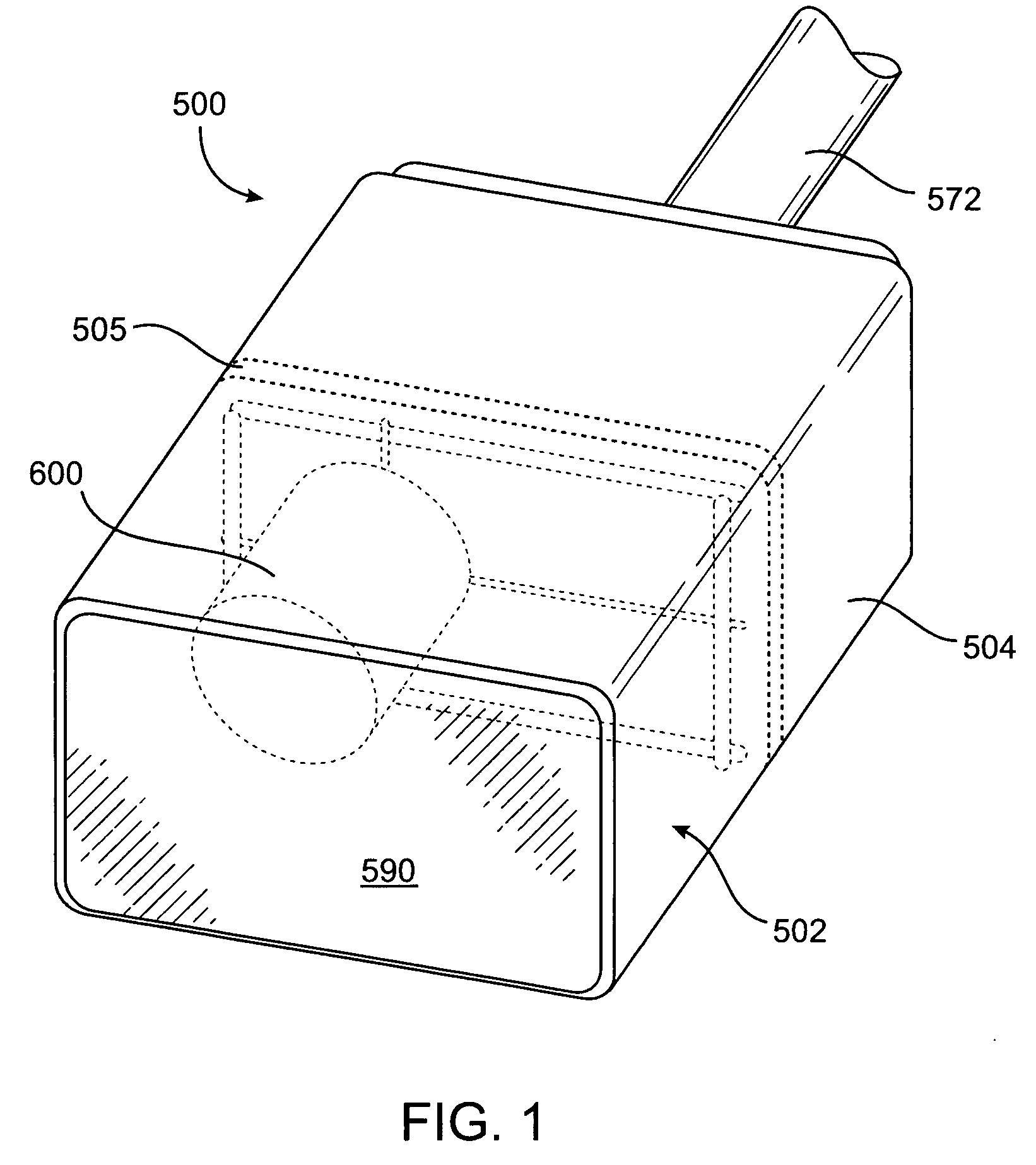

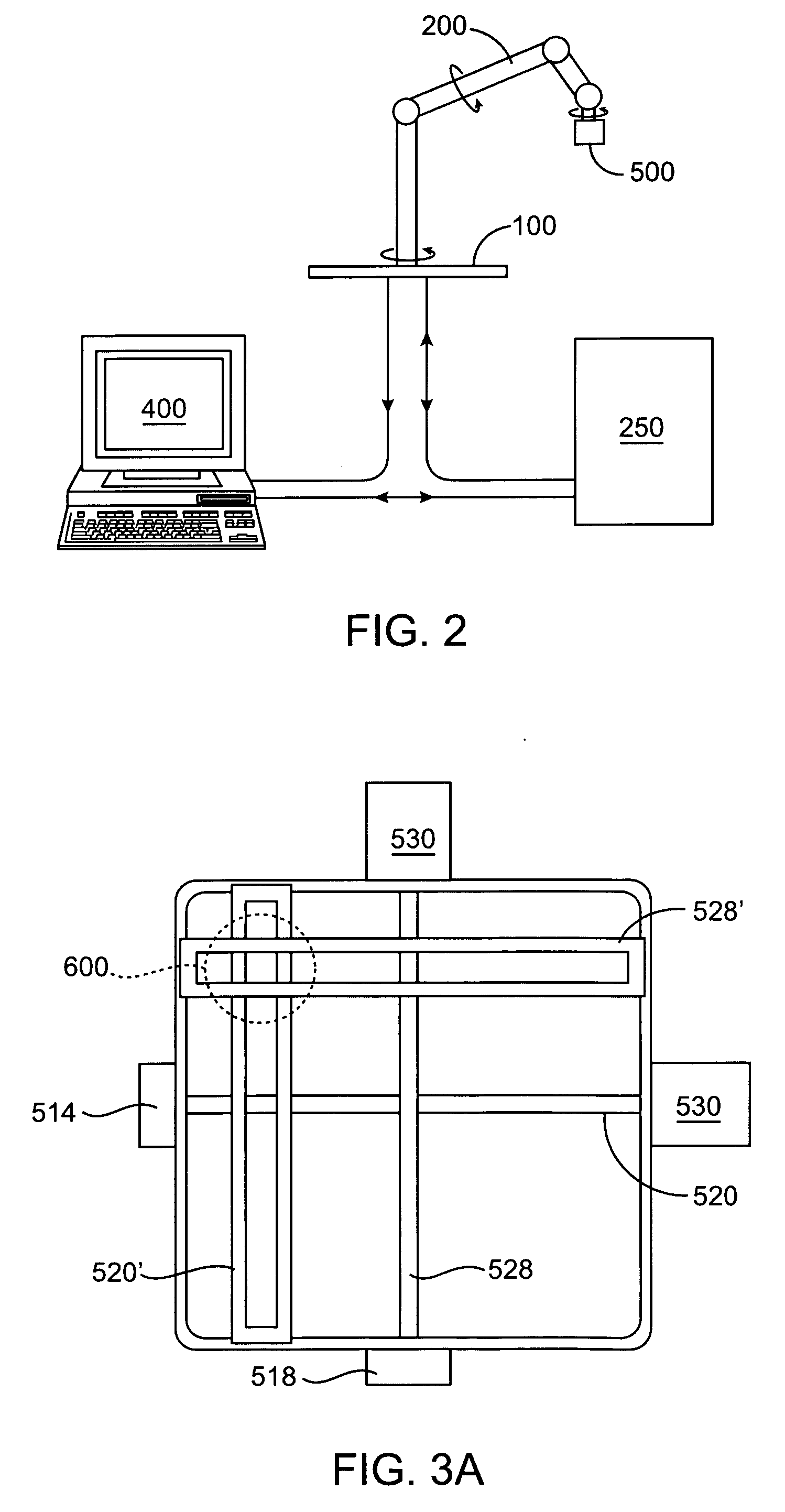

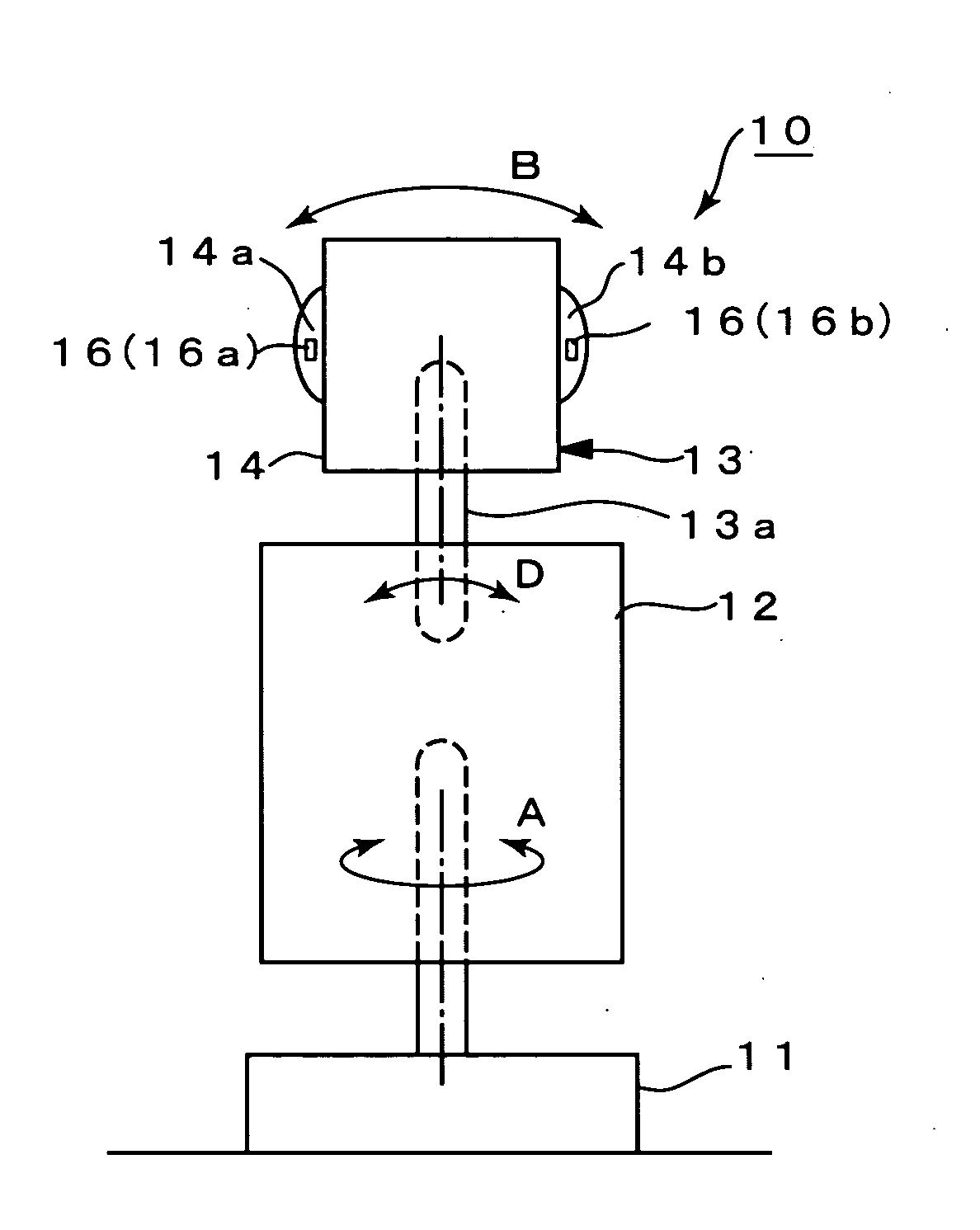

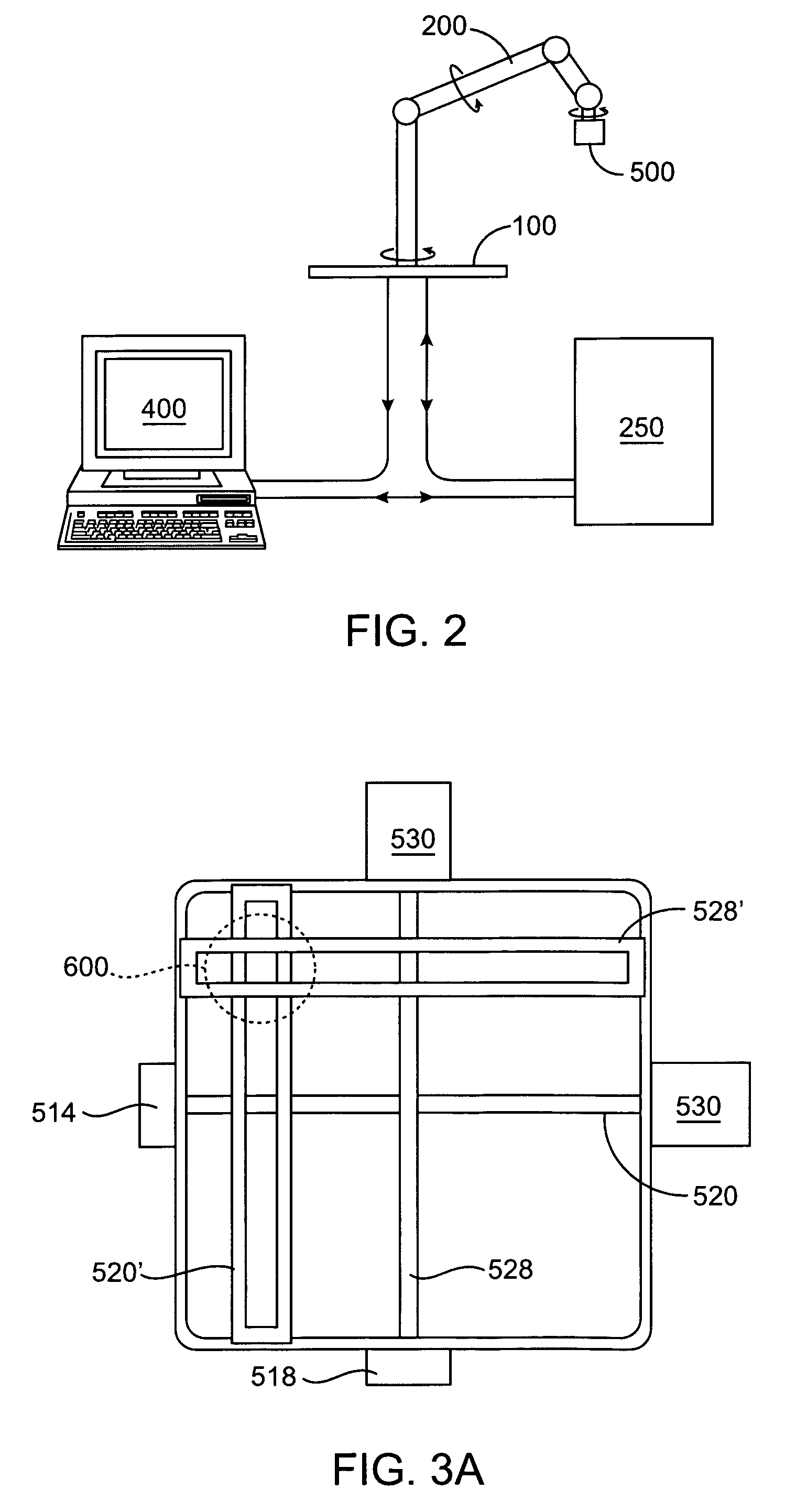

Ultrasound therapy head with movement control

ActiveUS20050187495A1Easy to operateReliable treatmentUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyUltrasonic sensorEnergy applicator

A therapy head for use in HIFU procedures is described. The therapy head has an enclosure with a window, an energy applicator and a means of moving the energy applicator within the enclosure. The therapy head uses motors and actuators to move the energy applicator, usually an ultrasound transducer, inside the enclosure. A controller is provided either internally or externally that allows the therapy head to identify and distinguish locations where the therapy head should be to radiate energy into a patient. The controller uses the motors and actuators to move the energy applicator into the desired locations.

Owner:SOLTA MEDICAL

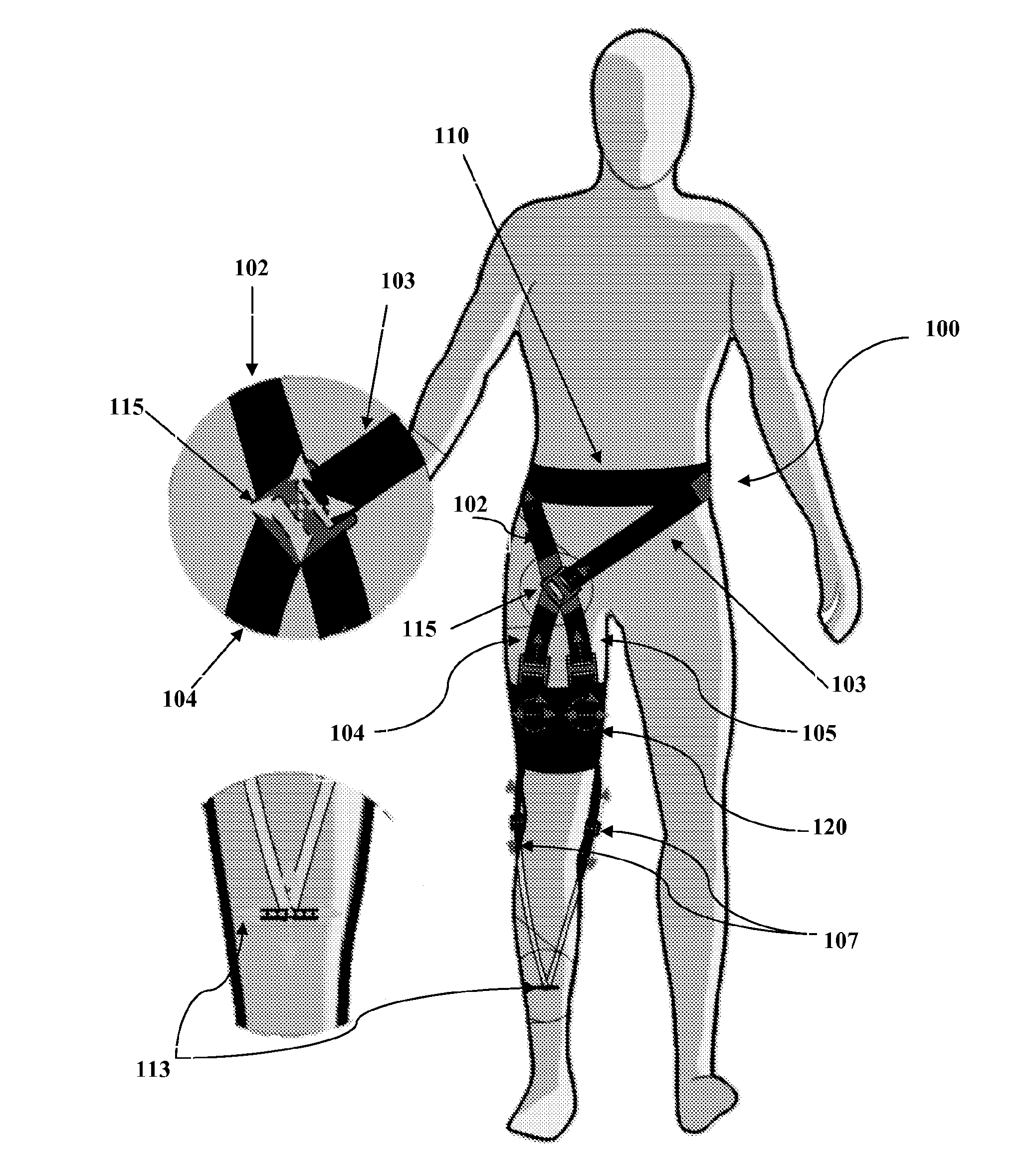

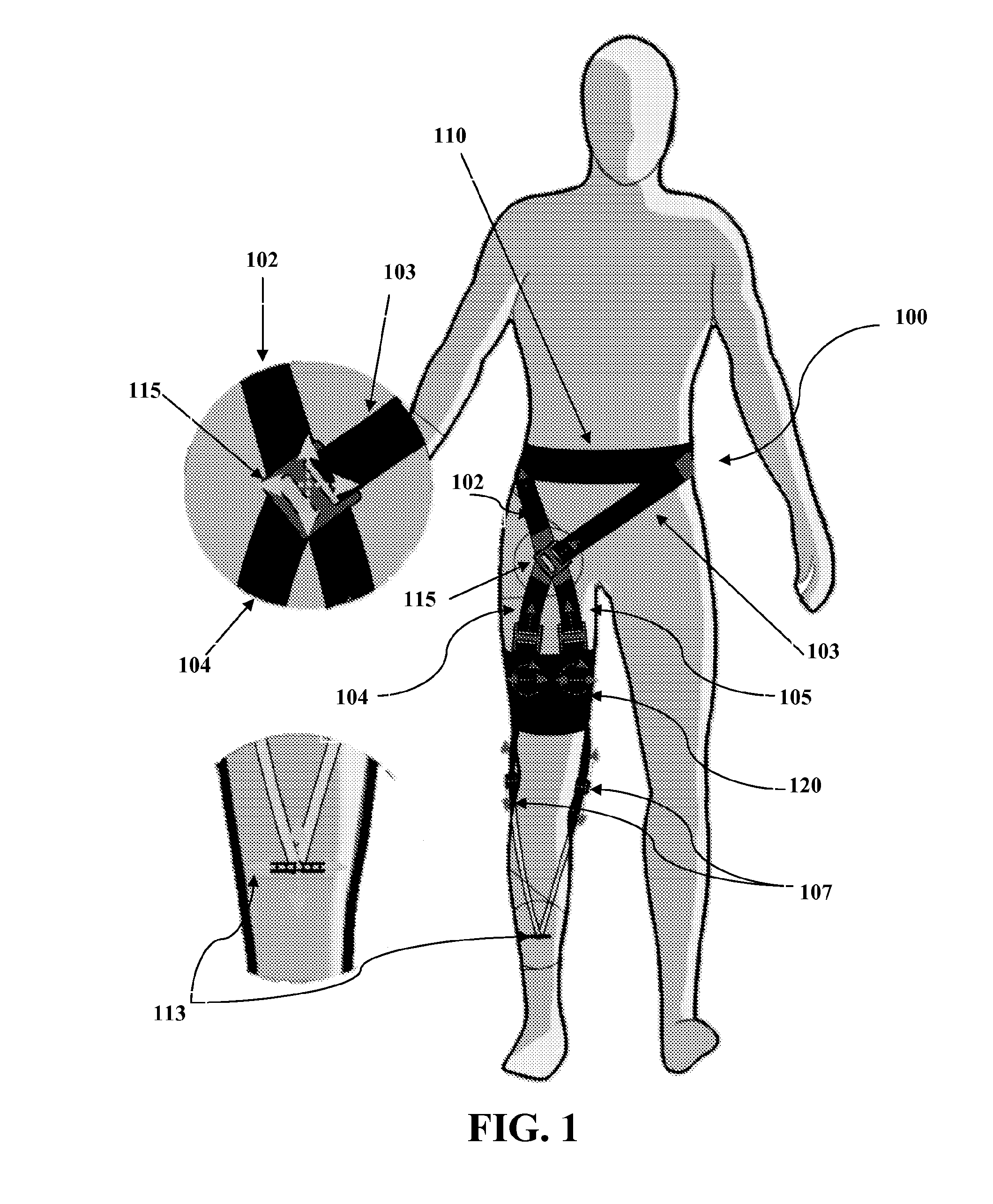

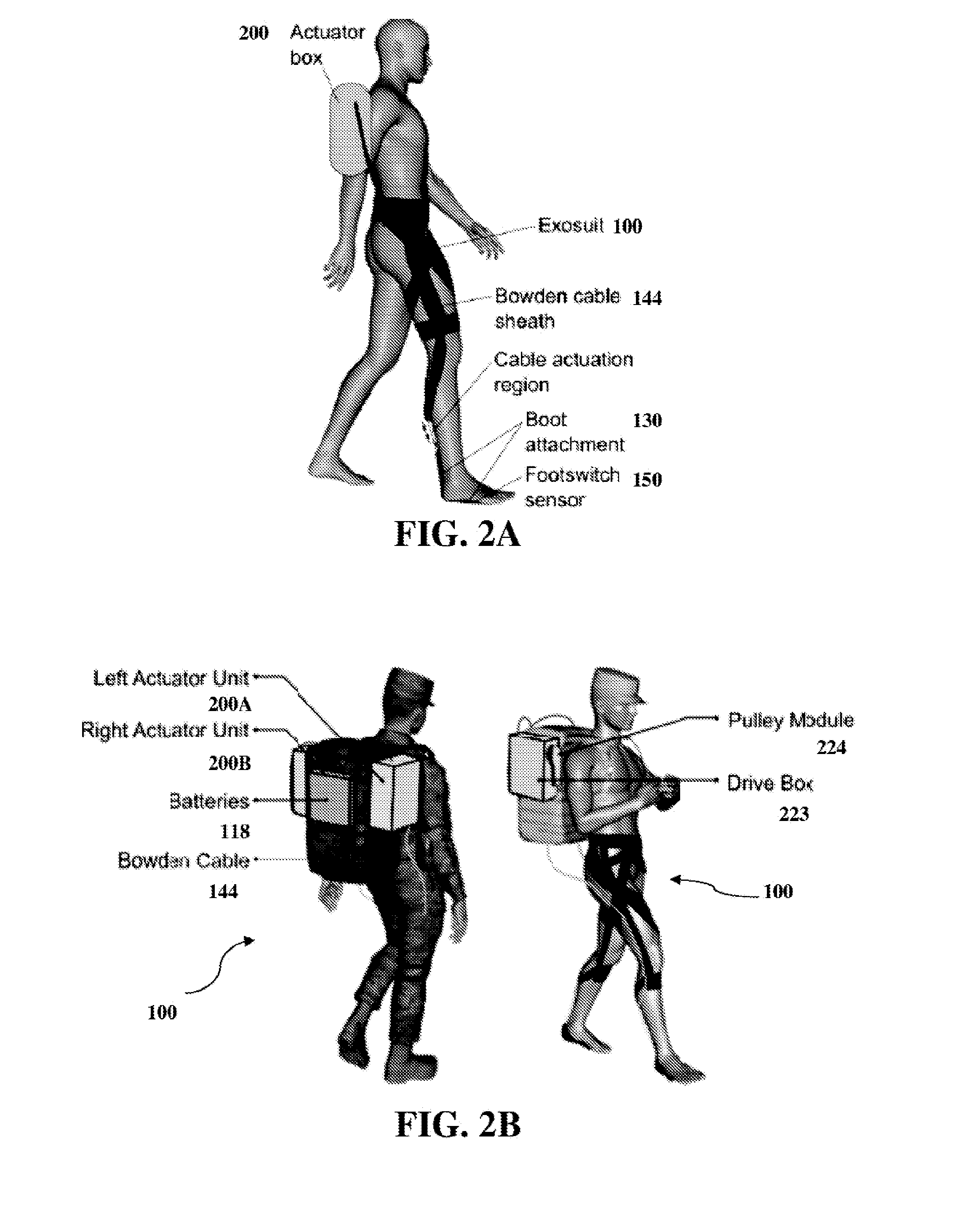

Soft Exosuit for Assistance with Human Motion

ActiveUS20160107309A1Beneficial reduction in metabolic consumption of energyReduce loadProgramme-controlled manipulatorChiropractic devicesControl systemHuman motion

A motion control system includes an actuator having an actuation member, the actuation member having a proximal end attached to the actuator on a first side of a joint and a distal end attached to an anchor element attachment point on a second side of the joint. A first sensor is configured to output signals defining a gait cycle and a second sensor is configured to output signals representing a tensile force in the at least one actuation member. A controller receives the output signals from the sensors and actuates the actuator, during a first portion of the gait cycle, to apply a force greater than a predetermined threshold tensile force to the anchor element attachment point via the actuation member to generate a beneficial moment about the joint and to automatically actuate the actuator.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

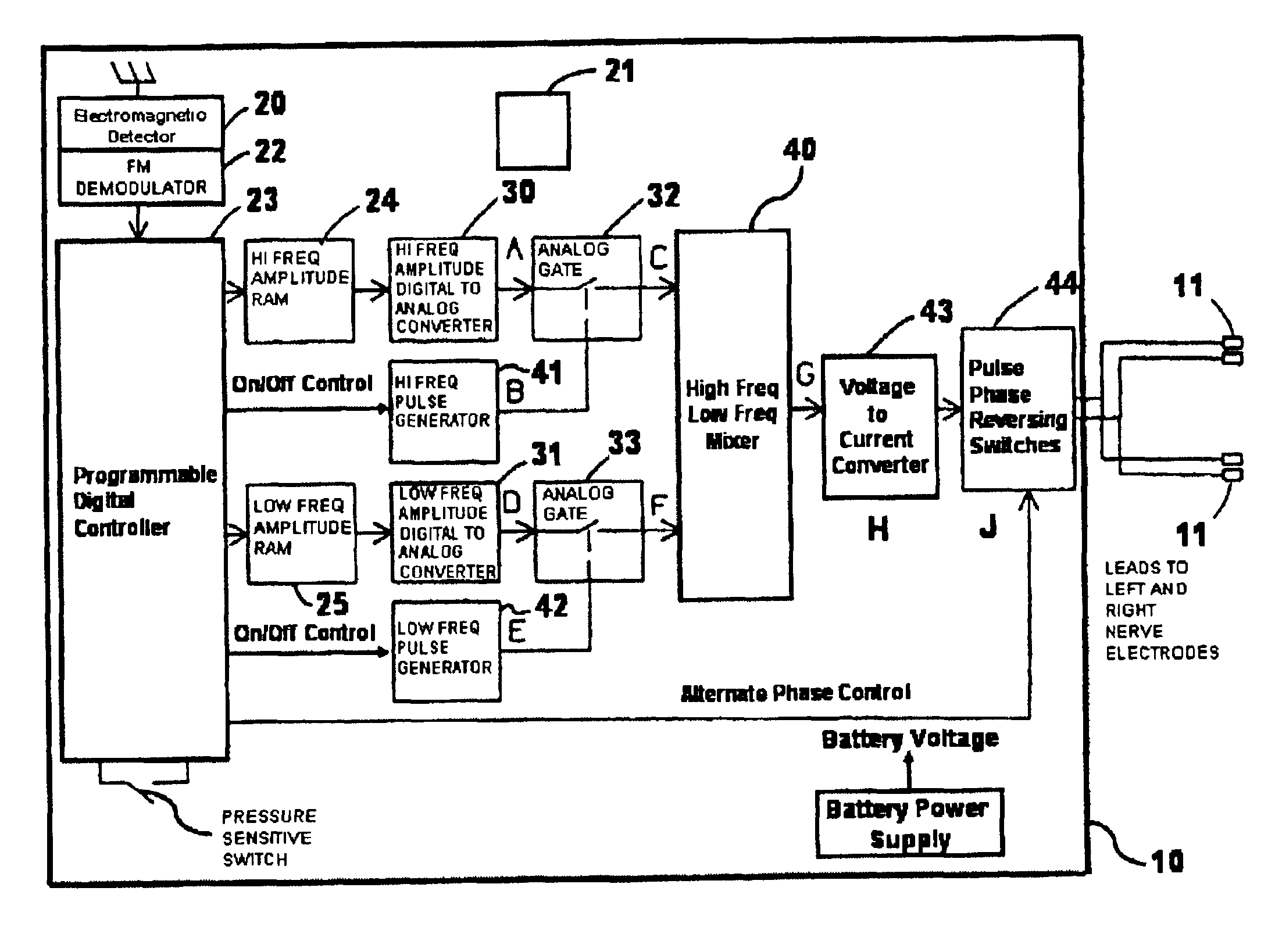

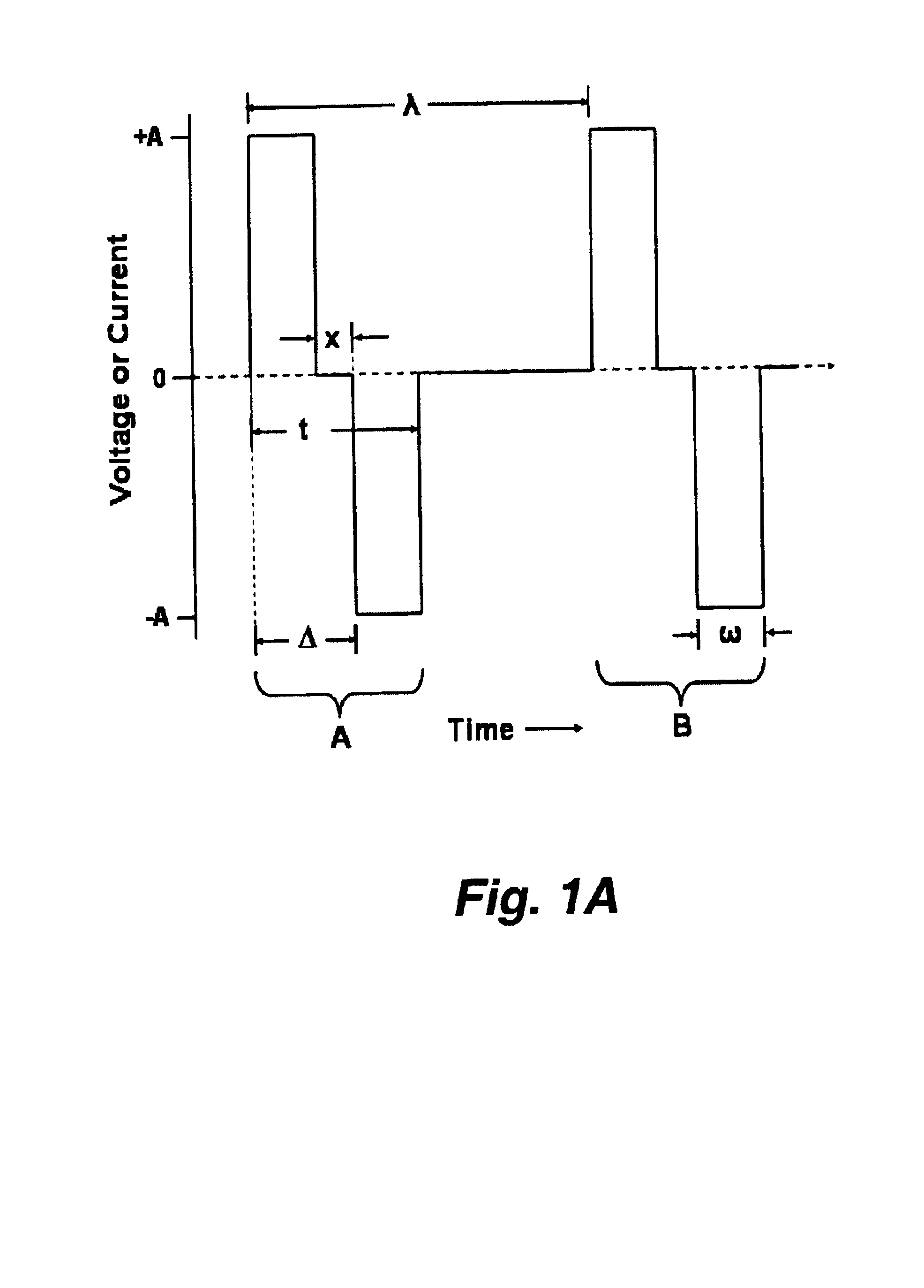

Methods and systems for selective control of bladder function

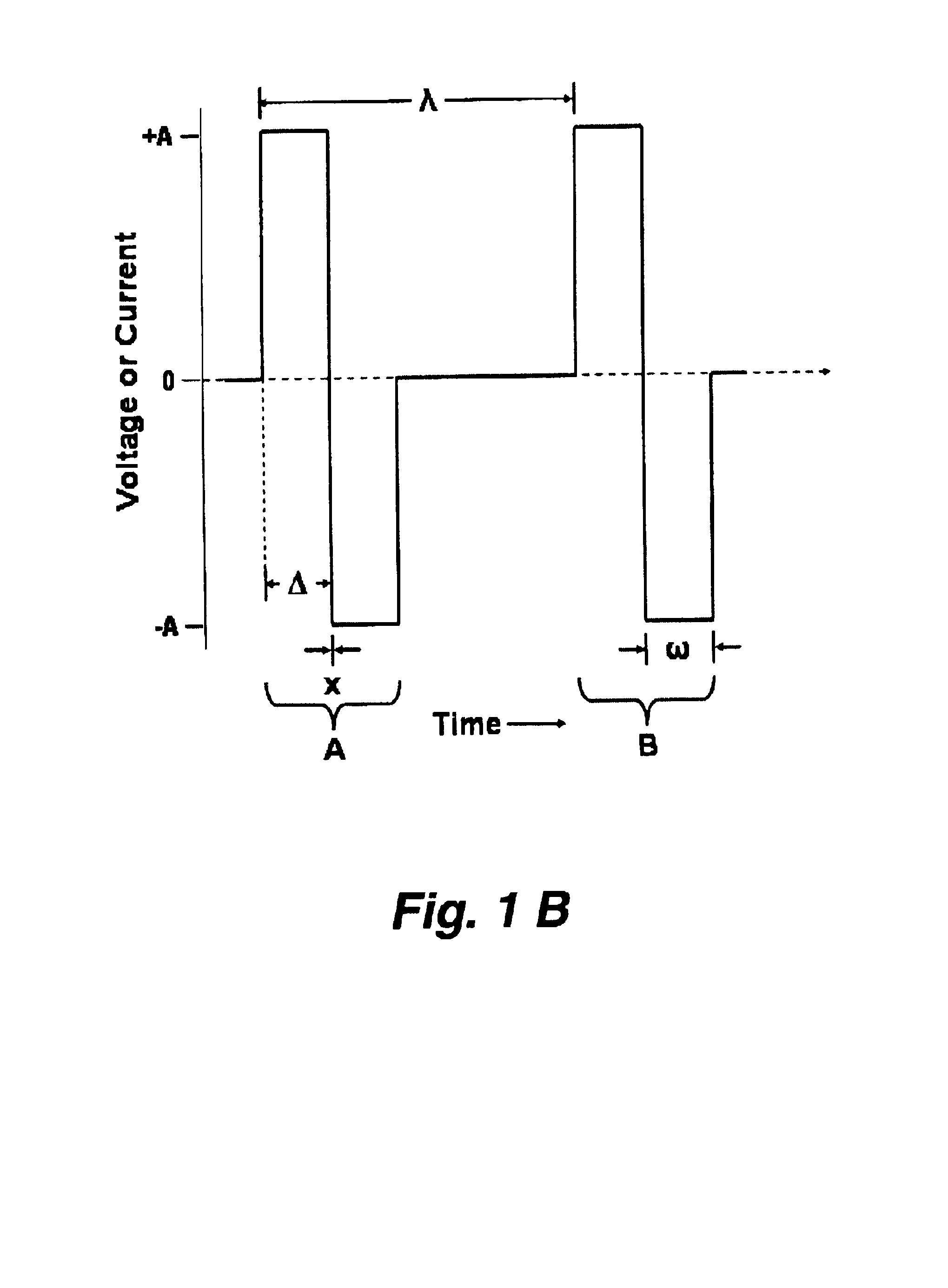

InactiveUS6990376B2Inhibiting neural transmissionStimulating neural transmissionElectrotherapyArtificial respirationNerve fibreHigh amplitude

A method and system for selective inhibition of somatic nerve fibers in a mixed nerve containing both somatic and autonomic nerve fibers where the method finds use in treatment of chronic pain, spastic muscles and for sensory and motor control of a bladder. The methods and systems utilize alternate phase rectangular electrical pulses. An electrical pulse generator is coupled to a nerve. An alternate phase high frequency, low amplitude pulse is first applied to selectively inhibit somatic nerves when present in a mixed nerve. An alternate phase low frequency, high amplitude phase pulse subsequently supplied to stimulate the autonomic nerve fibers and in the case of the sacral root will permit a controlled voiding of the bladder and bowel.

Owner:RGT UNIV OF CALIFORNIA

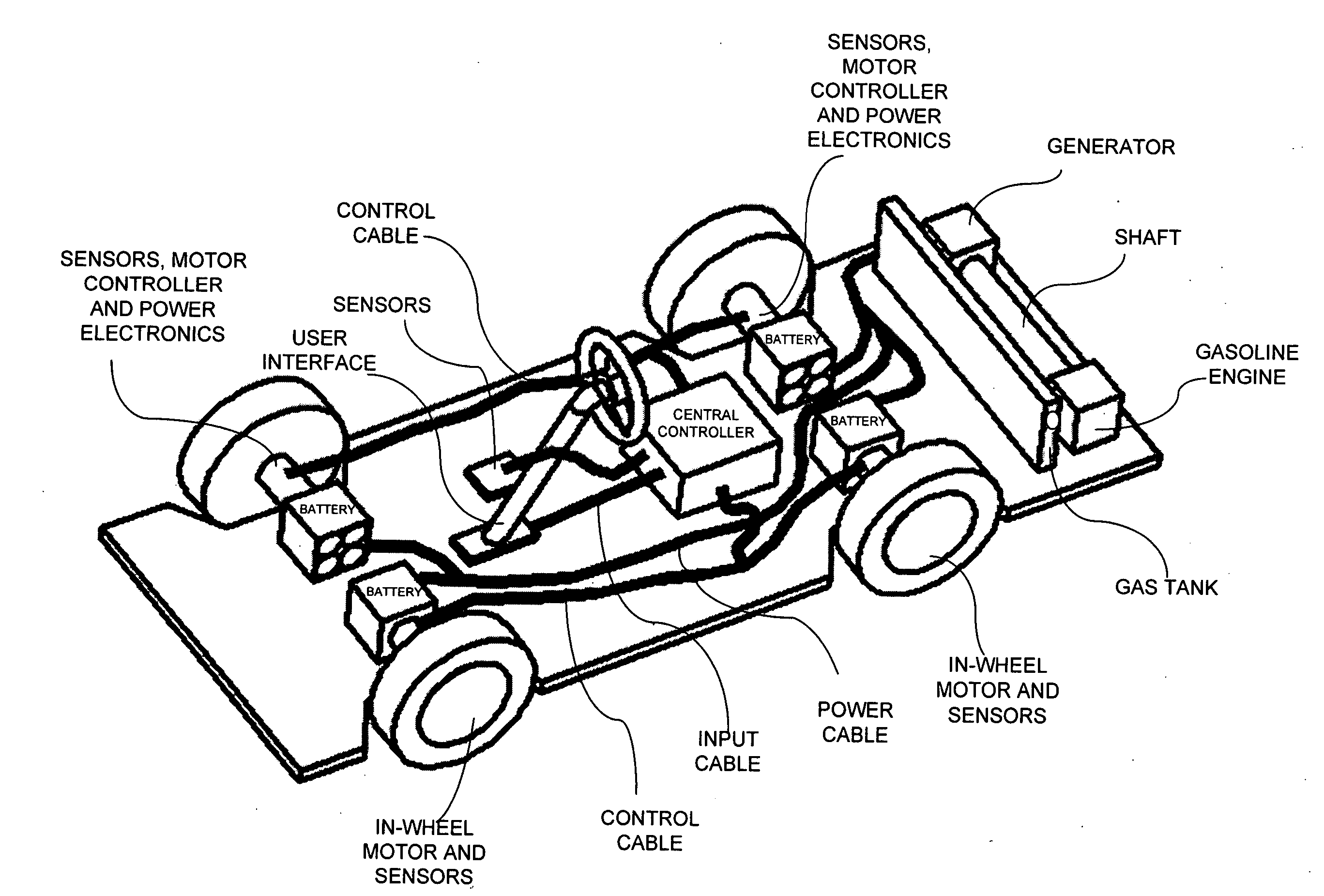

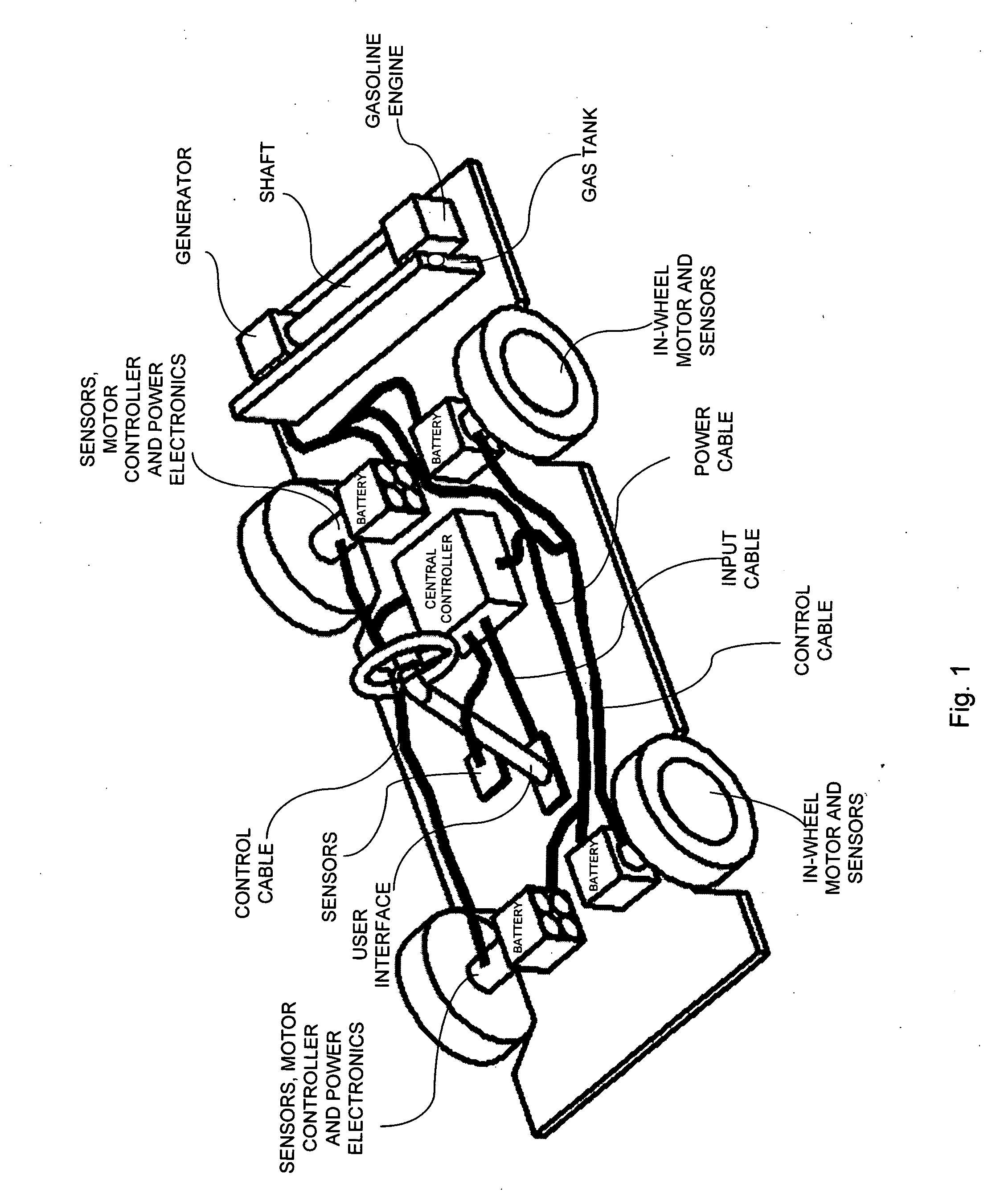

Adaptive electric car

InactiveUS20050052080A1Eliminate electromagneticEliminate electrical interferenceRailway vehiclesAc-dc conversionGasolineMotor control

An adaptive electric car or other vehicle with potentially better performance—power, efficiency, range—than a gasoline vehicle, at a competitive cost. The motor control system can dynamically adapt to the vehicle's operating conditions (starting, accelerating, turning, braking, cruising at high speeds) and other inputs and parameters. That consistently provides better performance. Isolating the vehicle's motor or generator electromagnetic circuits allows effective control of more independent parameters. That gives great freedom to optimize. Adaptive motors and generators for an electric vehicle are cheaper, smaller, lighter, more powerful, and more efficient than conventional designs. An electric vehicle with in-wheel adaptive motors delivers high power with low unsprung mass and high torque and power-density. Total energy management of the vehicles entire electrical system allows for large-scale optimization. An adaptive architecture improves performance of a wide variety of vehicles, particularly those that need optimal efficiency over a range of operating conditions.

Owner:BLUWAV SYST LLC

Robotics visual and auditory system

InactiveUS20090030552A1Accurate collectionAccurately localizeProgramme controlComputer controlSound source separationPhase difference

It is a robotics visual and auditory system provided with an auditory module (20), a face module (30), a stereo module (37), a motor control module (40), and an association module (50) to control these respective modules. The auditory module (20) collects sub-bands having interaural phase difference (IPD) or interaural intensity difference (IID) within a predetermined range by an active direction pass filter (23a) having a pass range which, according to auditory characteristics, becomes minimum in the frontal direction, and larger as the angle becomes wider to the left and right, based on an accurate sound source directional information from the association module (50), and conducts sound source separation by restructuring a wave shape of a sound source, conducts speech recognition of separated sound signals from respective sound sources using a plurality of acoustic models (27d), integrates speech recognition results from each acoustic model by a selector, and judges the most reliable speech recognition result among the speech recognition results.

Owner:JAPAN SCI & TECH CORP

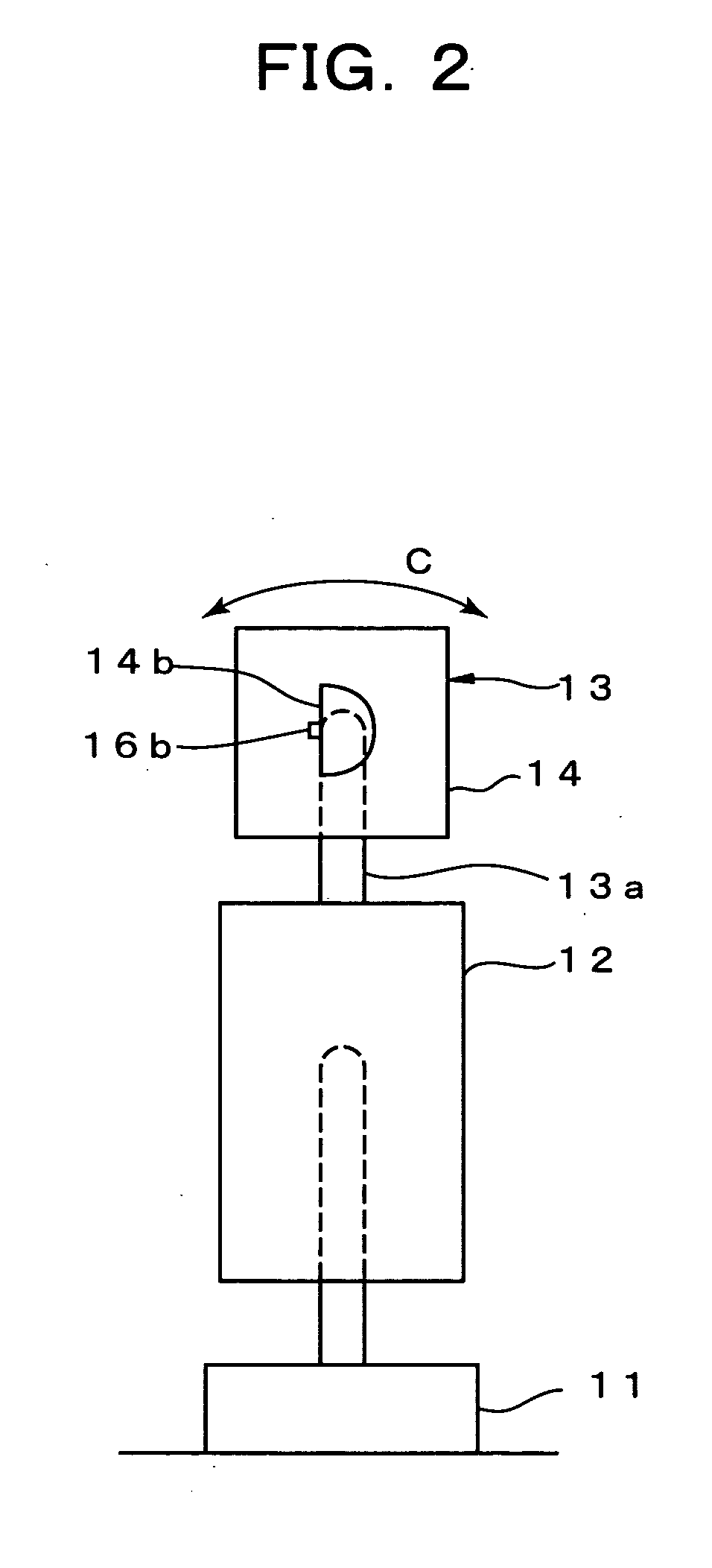

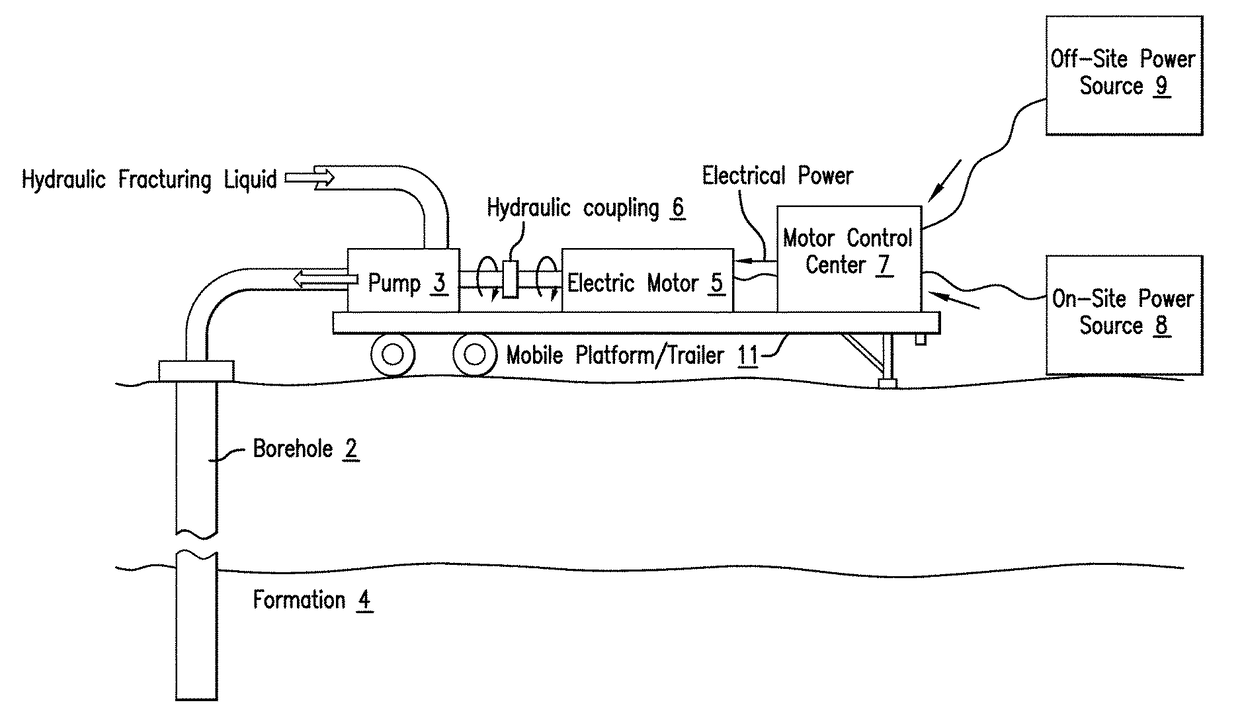

Fixed frequency high-pressure high reliability pump drive

An apparatus configured to hydraulically fracture an earth formation, includes a pump configured to hydraulically fracture the earth formation by pumping a fracturing liquid into a borehole penetrating the earth formation and an electric motor having a rotor coupled to the pump and a stator. A motor control center is configured to apply an alternating electrical voltage having a fixed-frequency to the stator in order to power the electric motor, wherein the apparatus and motor control center do not have a variable frequency drive.

Owner:BJ ENERGY SOLUTIONS LLC FORMERLY TES ASSET ACQUISITION LLC

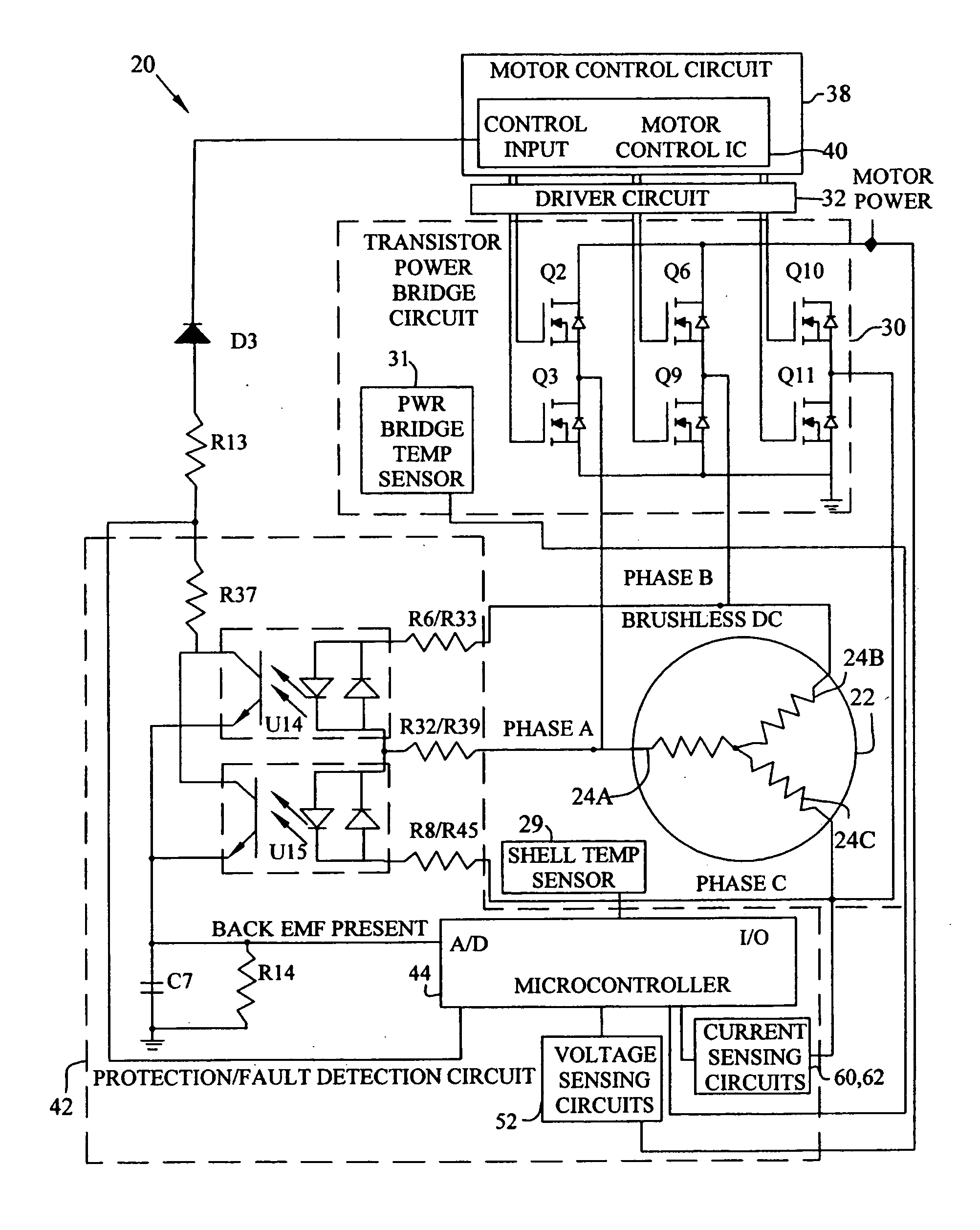

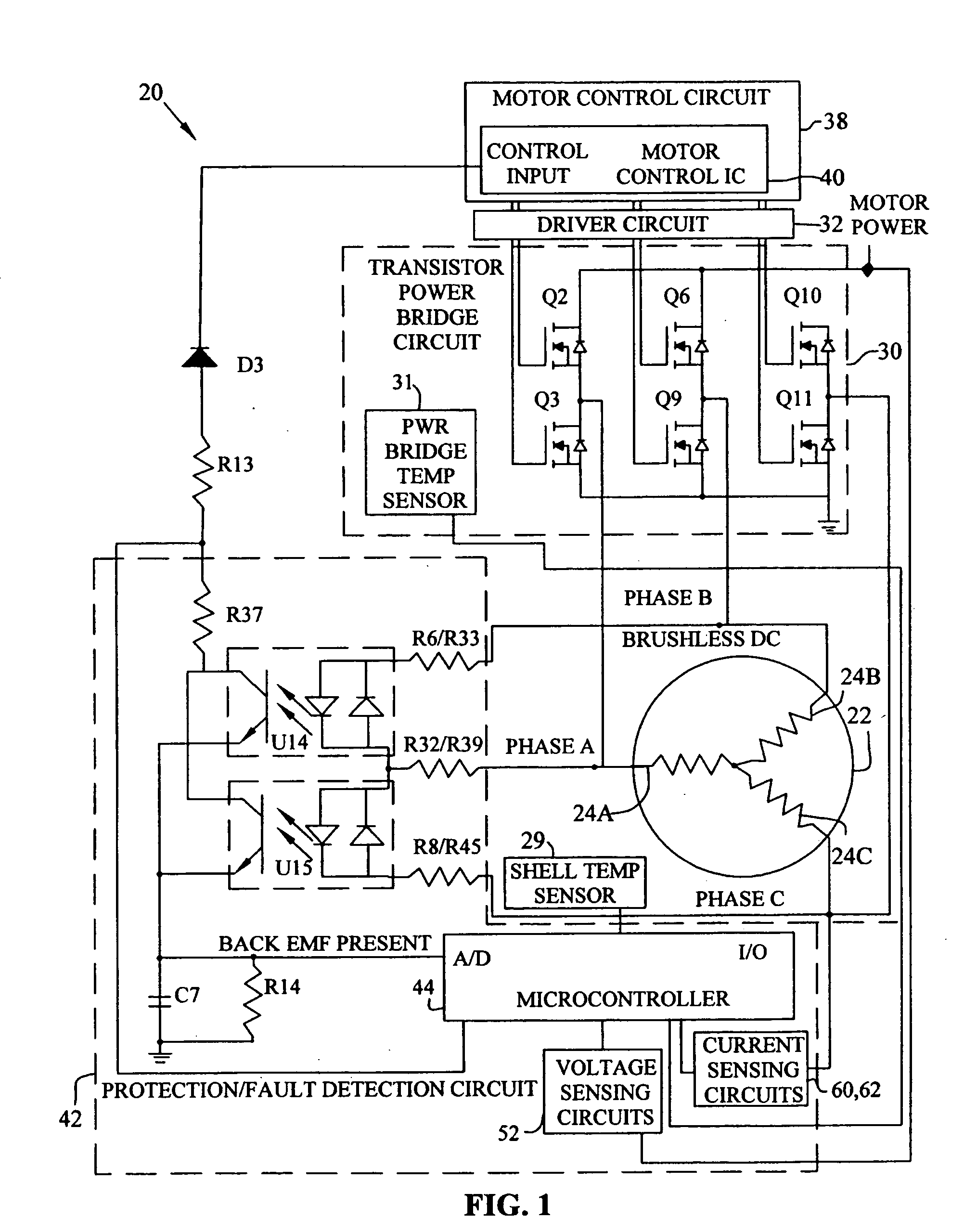

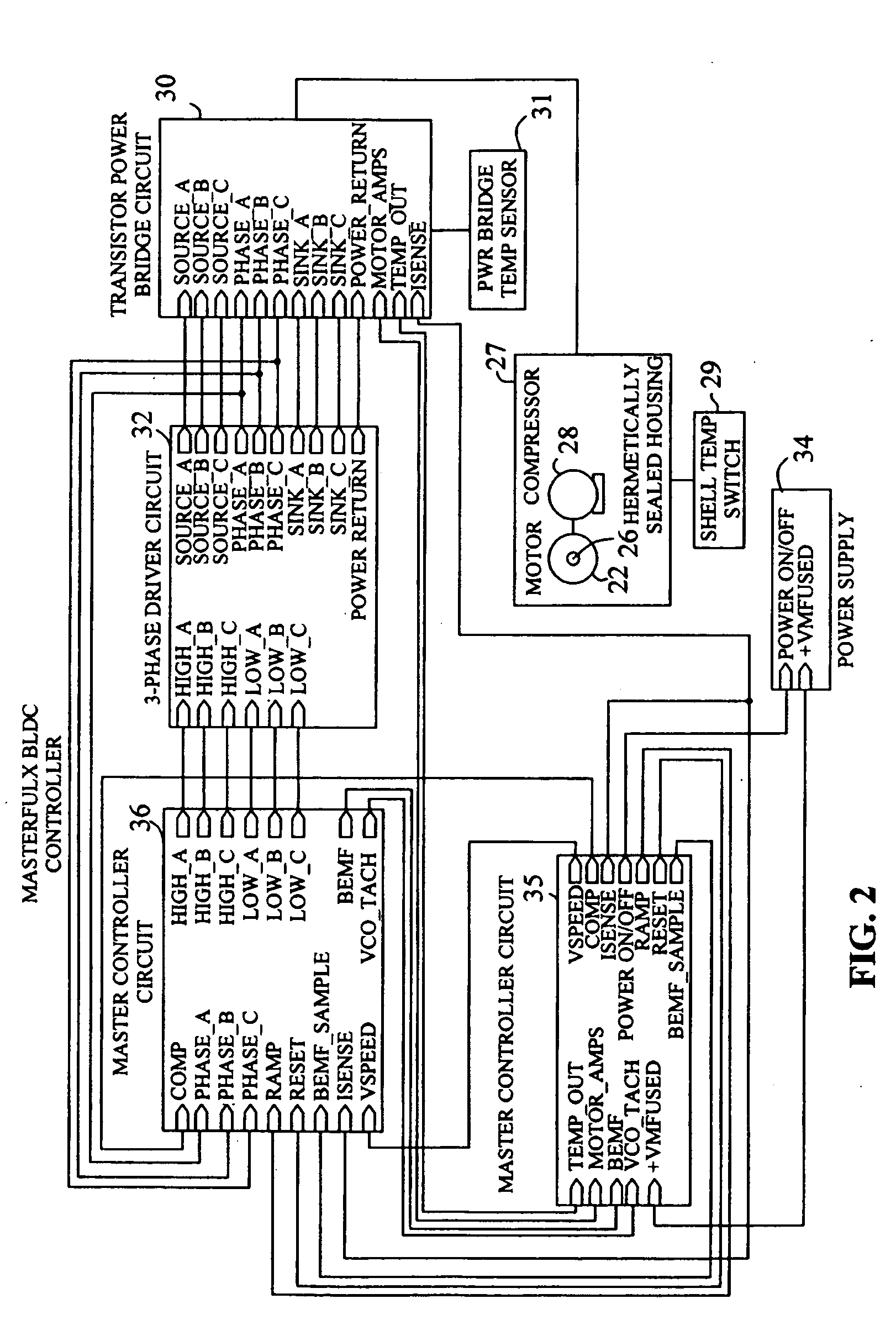

Brushless and sensorless DC motor control system with locked and stopped rotor detection

ActiveUS20050029976A1Easy to modifyEasily interfaceCommutation monitoringDC motor speed/torque controlMotor speedDc motor control

A motor control system for a brushless and sensorless DC motor for driving a compressor, pump or other application, includes a protection and fault detection circuit for detecting a locked rotor and a rotor which has stopped because of lost rotor phase lock. The motor control system also includes an off-the-shelf motor control integrated circuit having an input for disabling power outputs to the motor phase coils. The protection and fault detection circuit uses a back EMF sampling circuit coupled to the motor phase coils and momentarily disables power to the motor phase coils, via the motor control integrated circuit input, to determine if the motor rotor is rotating. The system also monitors supply voltage, supply current, temperature, and motor speed limits to detect faults and protect system components.

Owner:REGAL BELOIT AMERICA

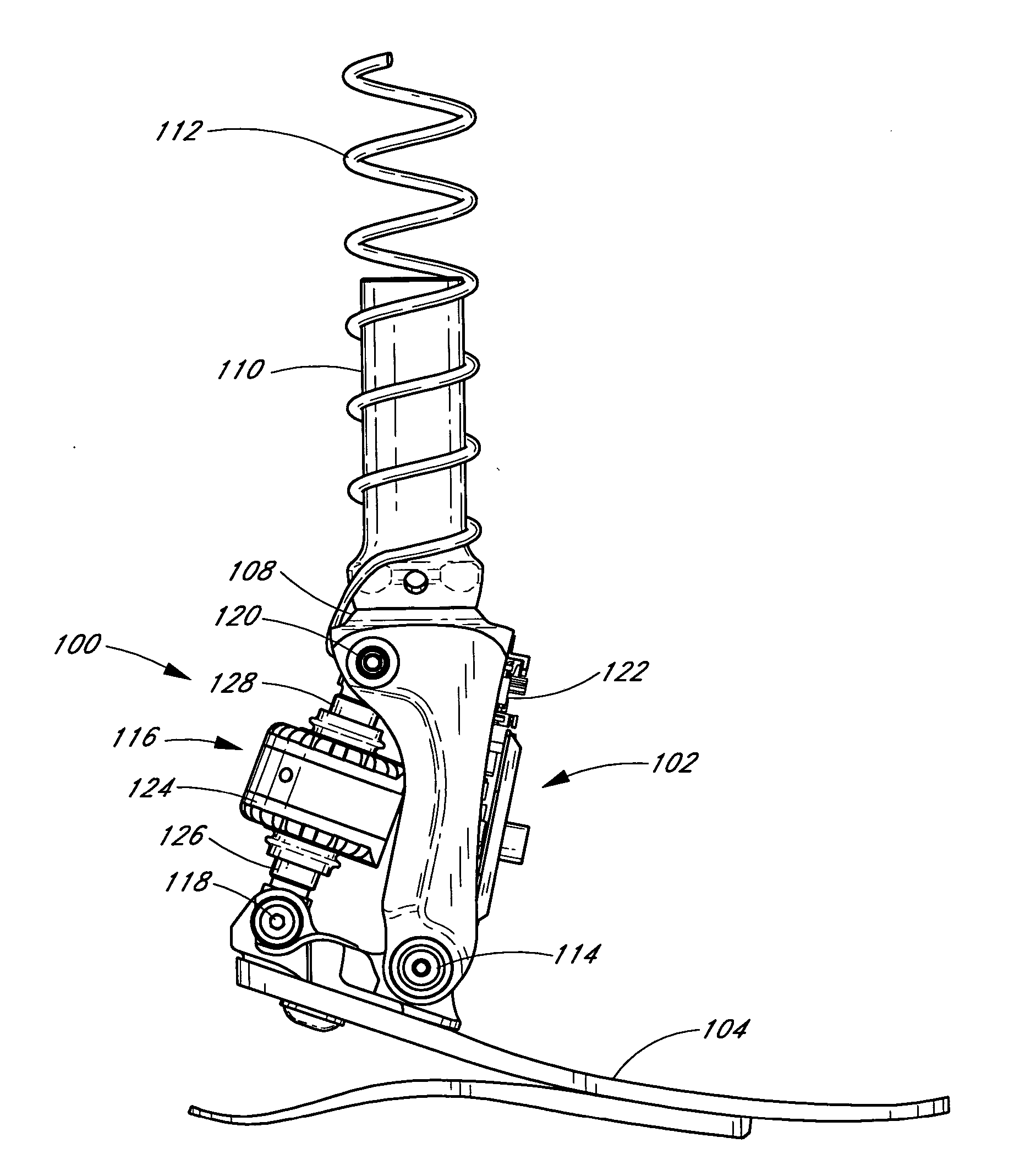

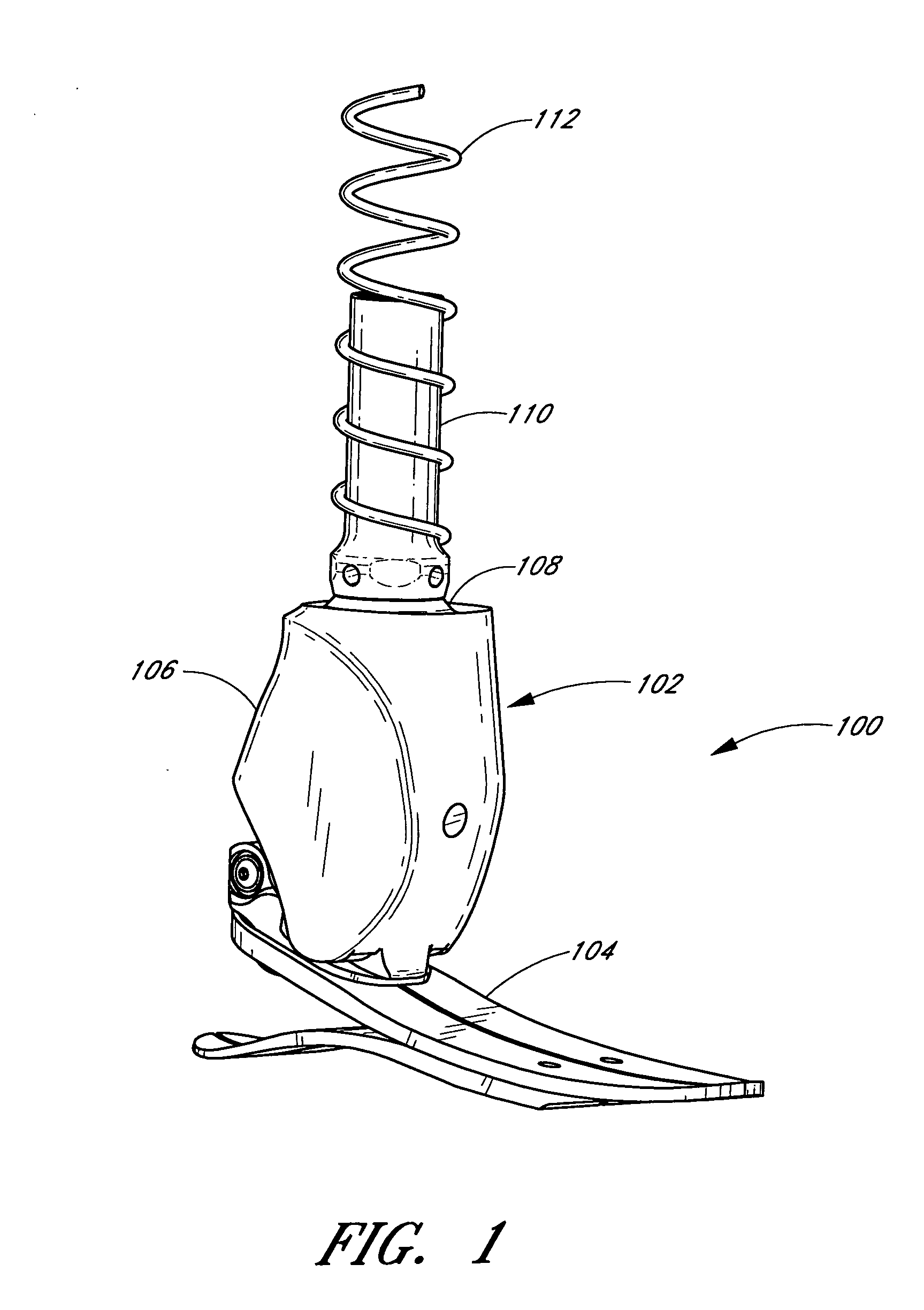

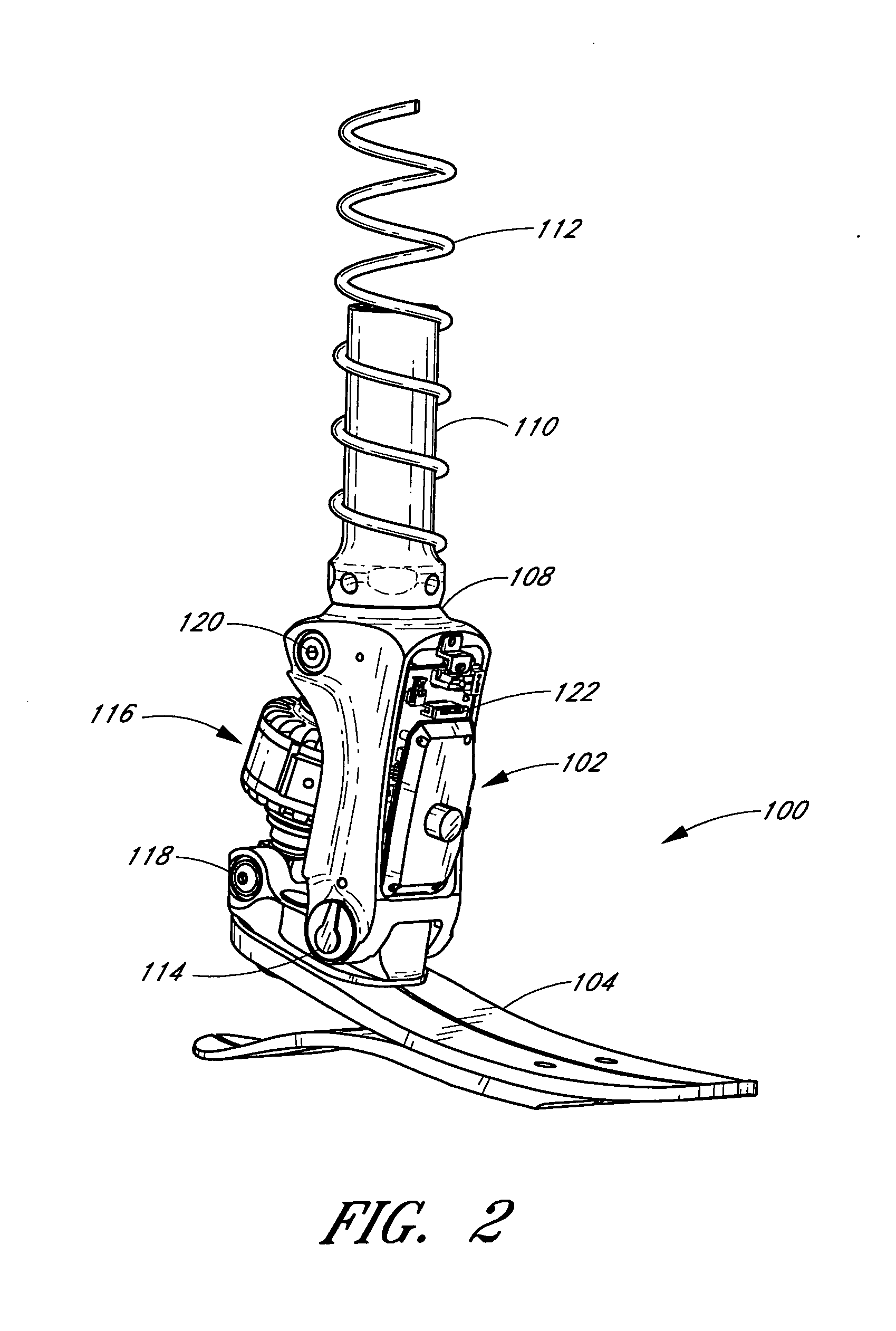

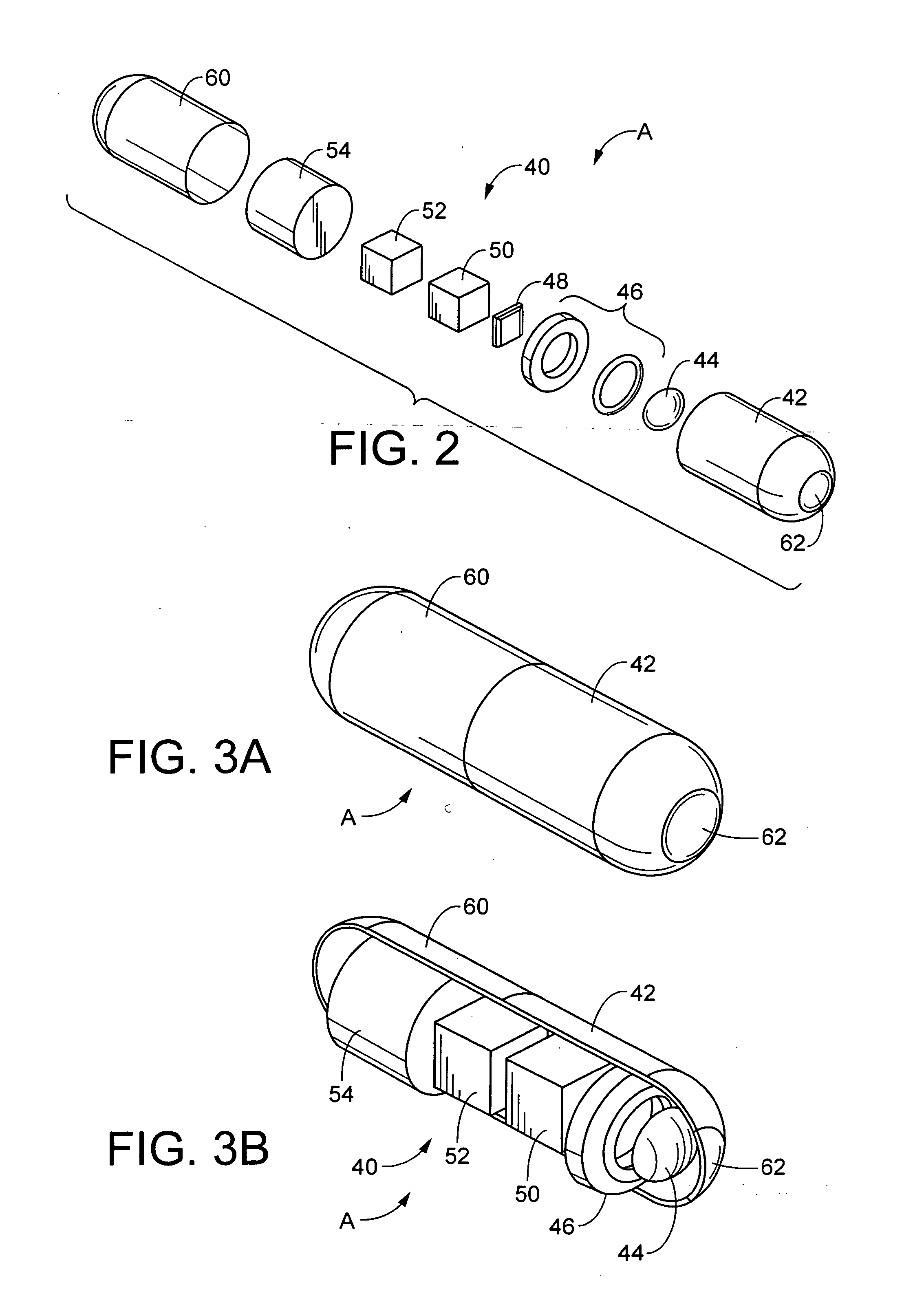

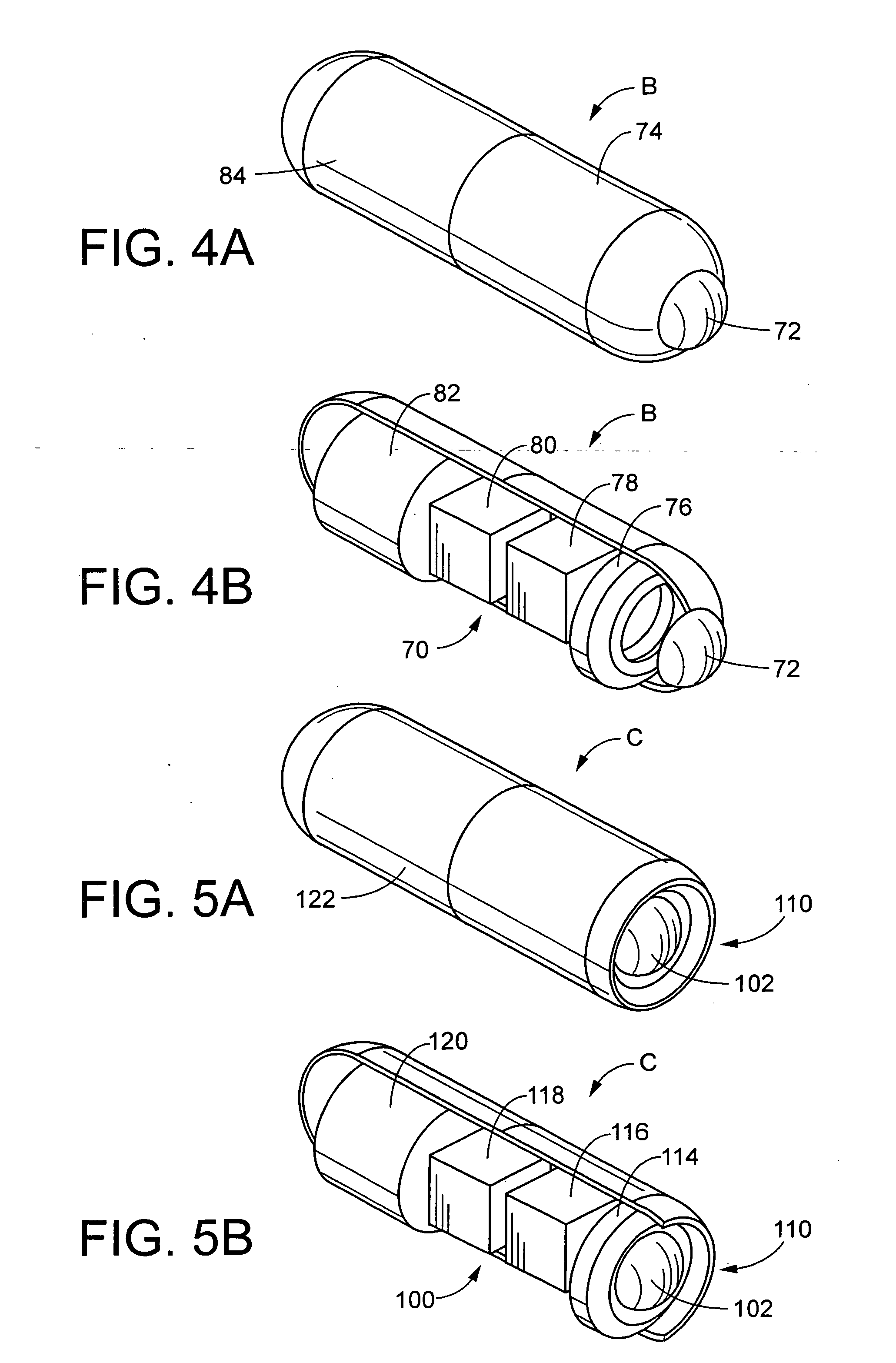

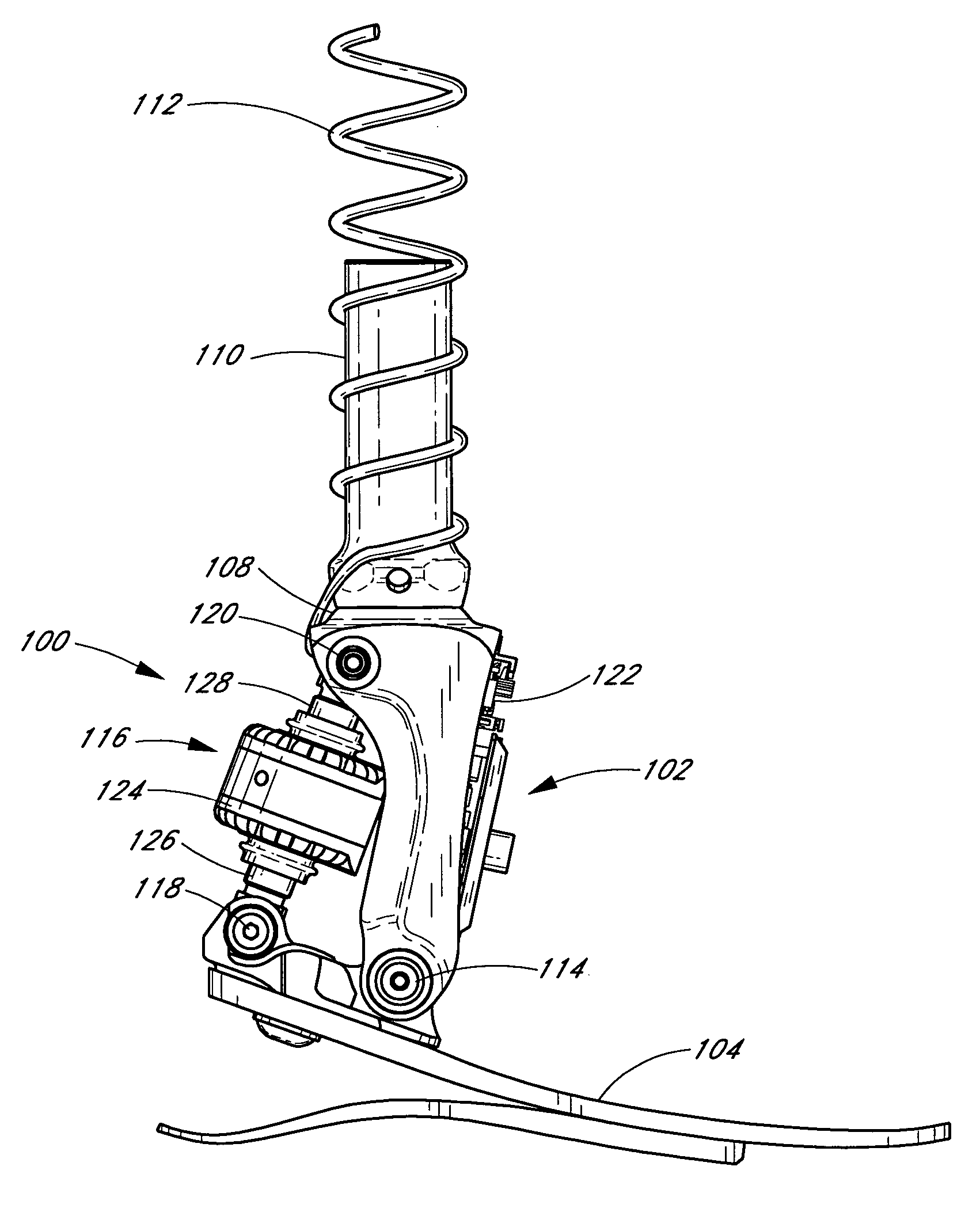

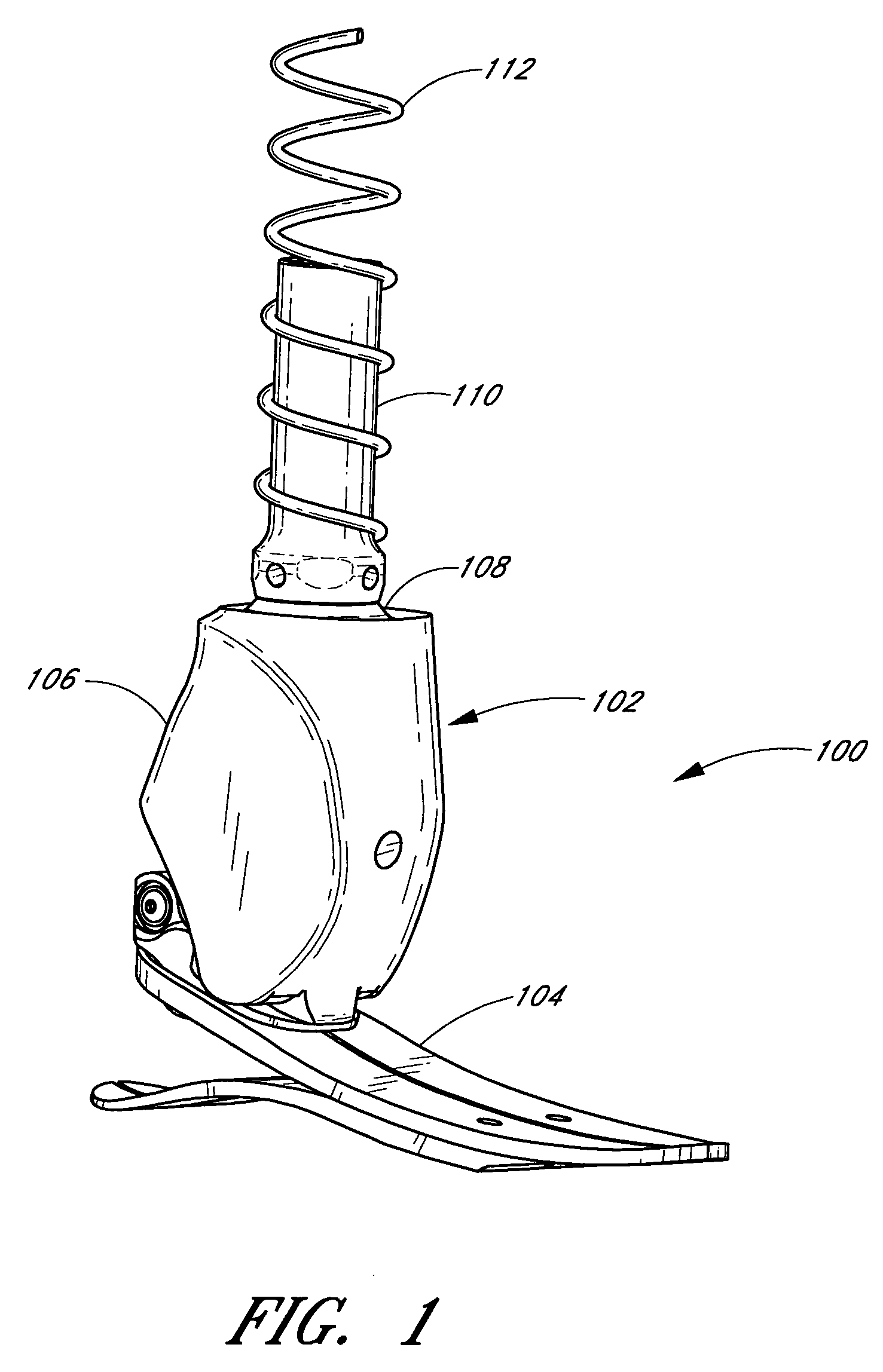

System and method for motion-controlled foot unit

A system and method associated with the movement of a limb. In one example, the system, such as a prosthetic or orthotic system, includes an actuator that actively controls, or adjusts, the angle between a foot unit and a lower limb member. A processing module may control movement of the actuator based on data obtained from a sensor module. For instance, sensing module data may include information relating to the gait of a user and may be used to adjust the foot unit to substantially mimic the movement of a natural, healthy ankle. The system may further accommodate, for example, level ground walking, traveling up / down stairs, traveling up / down sloped surfaces, and various other user movements. In addition, the processing module may receive user input or display output signals through an external interface. For example, the processing module may receive a heel height input from the user.

Owner:OSSUR HF

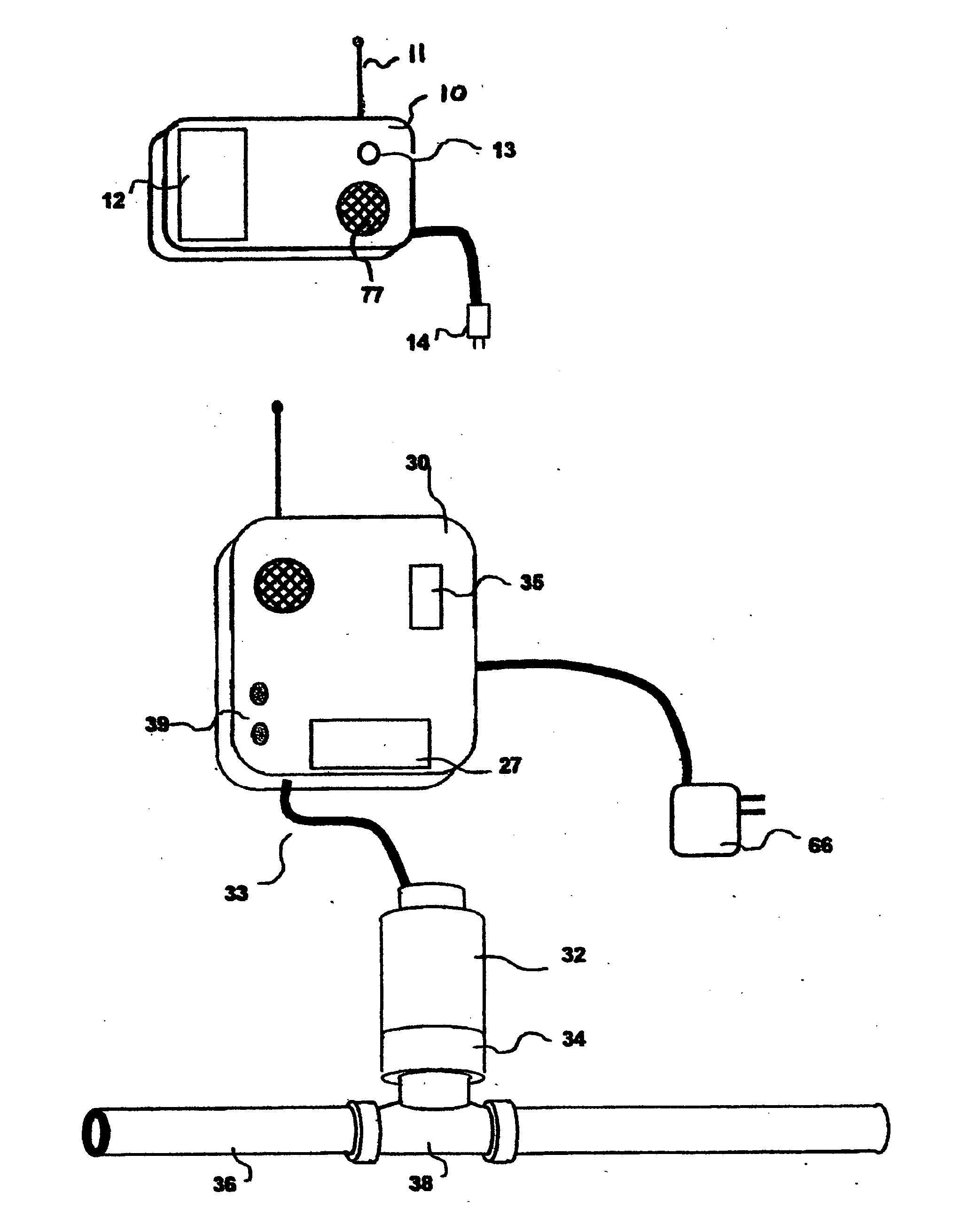

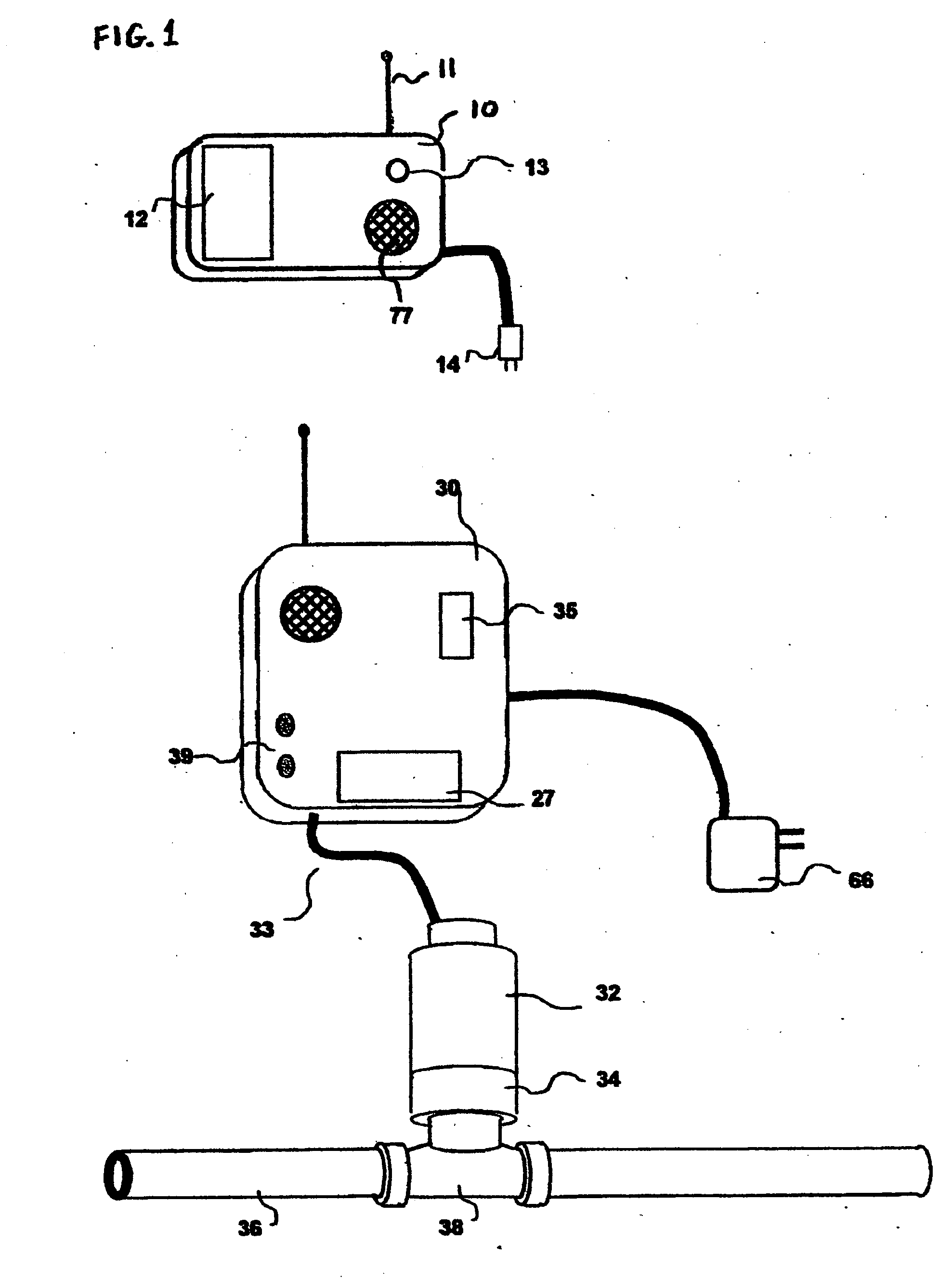

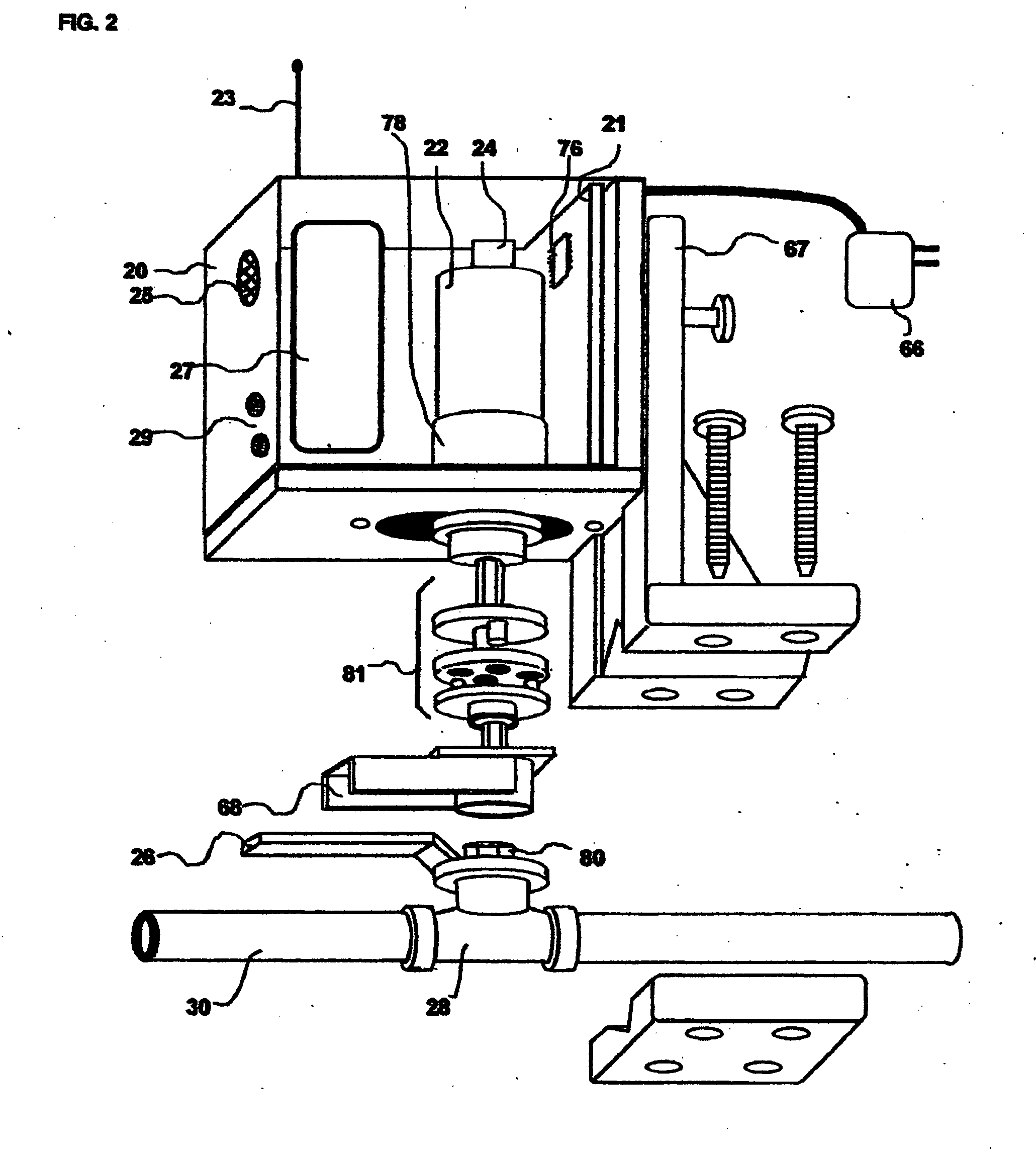

Secure wireless leak detection system

InactiveUS20070289635A1Easy to installReduce power consumptionDetection of fluid at leakage pointOperating means/releasing devices for valvesTransceiverMotor control

Supervised wireless leak detection system, having a leak detection sensor unit, capable of transmitting a uniquely coded signal in response to a detected leak, a supervised wireless valve control transceiver unit having a receiver, capable of receiving said uniquely coded signal, and a transmitter for feeding the uniquely coded signal within the system, a valve shut-off mechanism in communication with said valve control transceiver unit said valve shut-off mechanism having a motor attached to a valve, said motor creating a rotation pulse used to close and open said valve, and a processor having an electronic circuitry containing sensor(s), detecting said motor rotation pulse count during a motorized valve closure or open process. Said processor functions in a setup process to memorize (learn) said motor rotation pulse count, required, to close and or to open the valve. Wherein said processor upon receipt of said uniquely coded signal in response to a detected leak, applies power to the motor to close the valve, the motor controlled to stop turning the valve in response to a processor received motor rotation pulse count number, substantially equal to a previously stored number needed to close or open said valve. A digital, voice, or SMS text message phone dialer is add to dispatch the detected leak signals, and notify monitoring personnel supervised system operation, end provide user access to turn on or off a valve(s) from a remote location(s).

Owner:RUGGIERI MONICA L +1

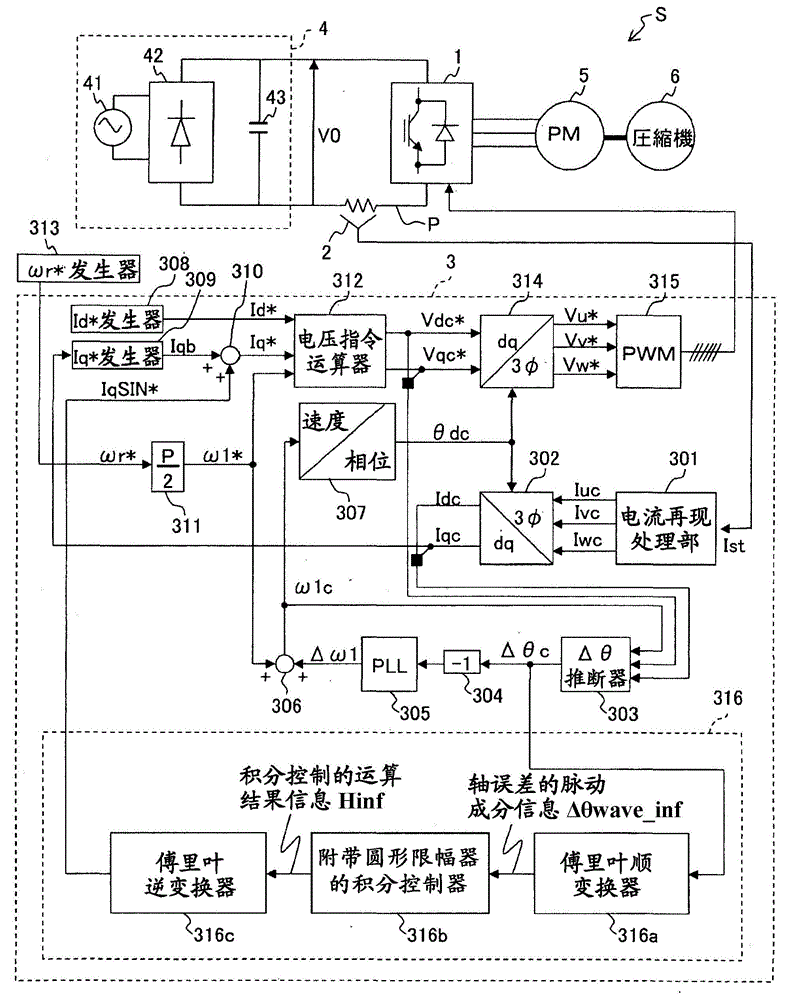

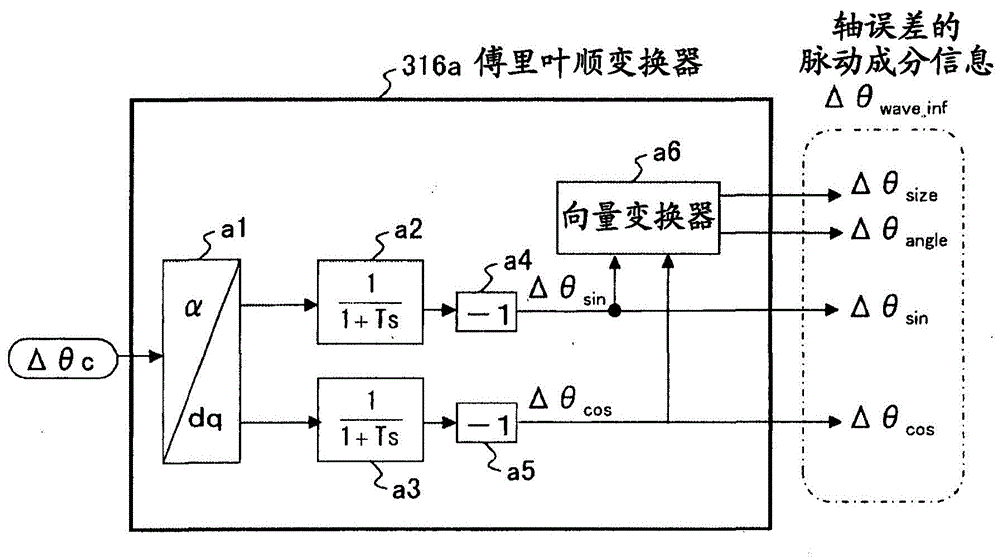

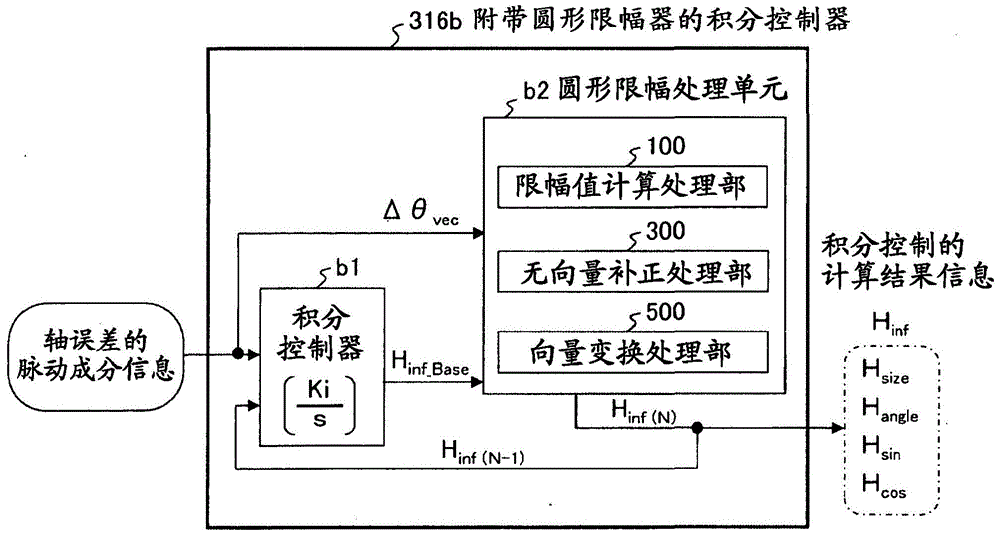

Motor control device

ActiveCN104038127ASuppression of pulsating torqueVector control systemsDynamo-electric converter controlCurrent sensorIntegral controller

A motor control device capable of suitably inhibiting the pulsating torque of an alternating-current motor is provided. The motor control device comprises an axis error inference machine (30) which infers an axis error based on a current value of an inverter, detected by a current sensor (2); a Fourier rectification machine (316a) which extracts an axis error vector from the time-base changes of the axis error; an integral control machine (316b) additionally provided with a circular amplitude limiter, which is used to calculate a correction current vector for offsetting the pulsating torque, wherein a circle with a set amplitude limiting value serving as the radius is used as the base for limiting the movement of the correction current vector, and the integral control machine (316b) additionally provided with the circular amplitude limiter performs the circular amplitude limiting for limiting the movement of the correction current vector so as to enable the deflection angle of the correction current vector to be close to the deflection angle of the axis error vector.

Owner:HITACHI JOHNSON CONTROLS AIR CONDITIONING INC

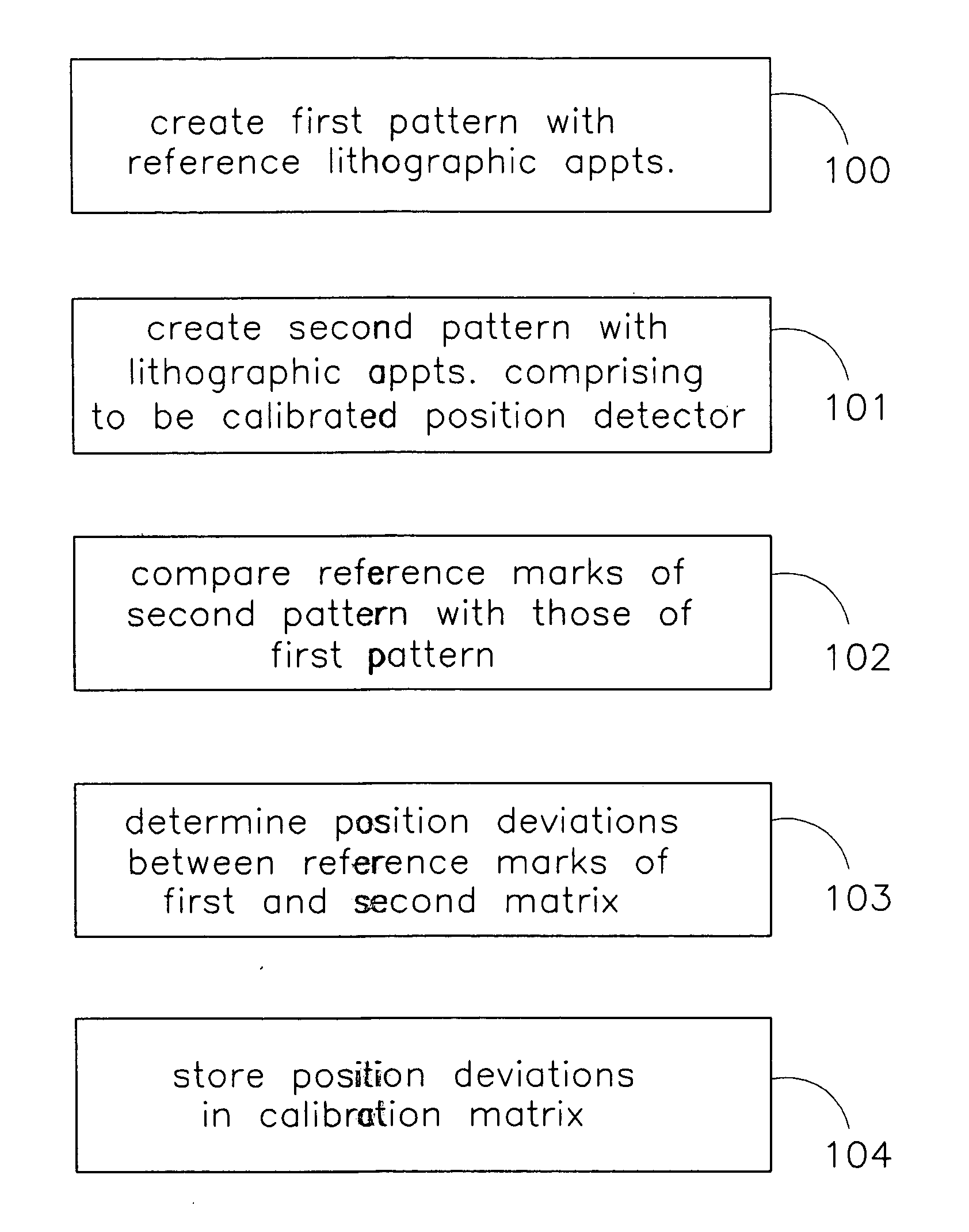

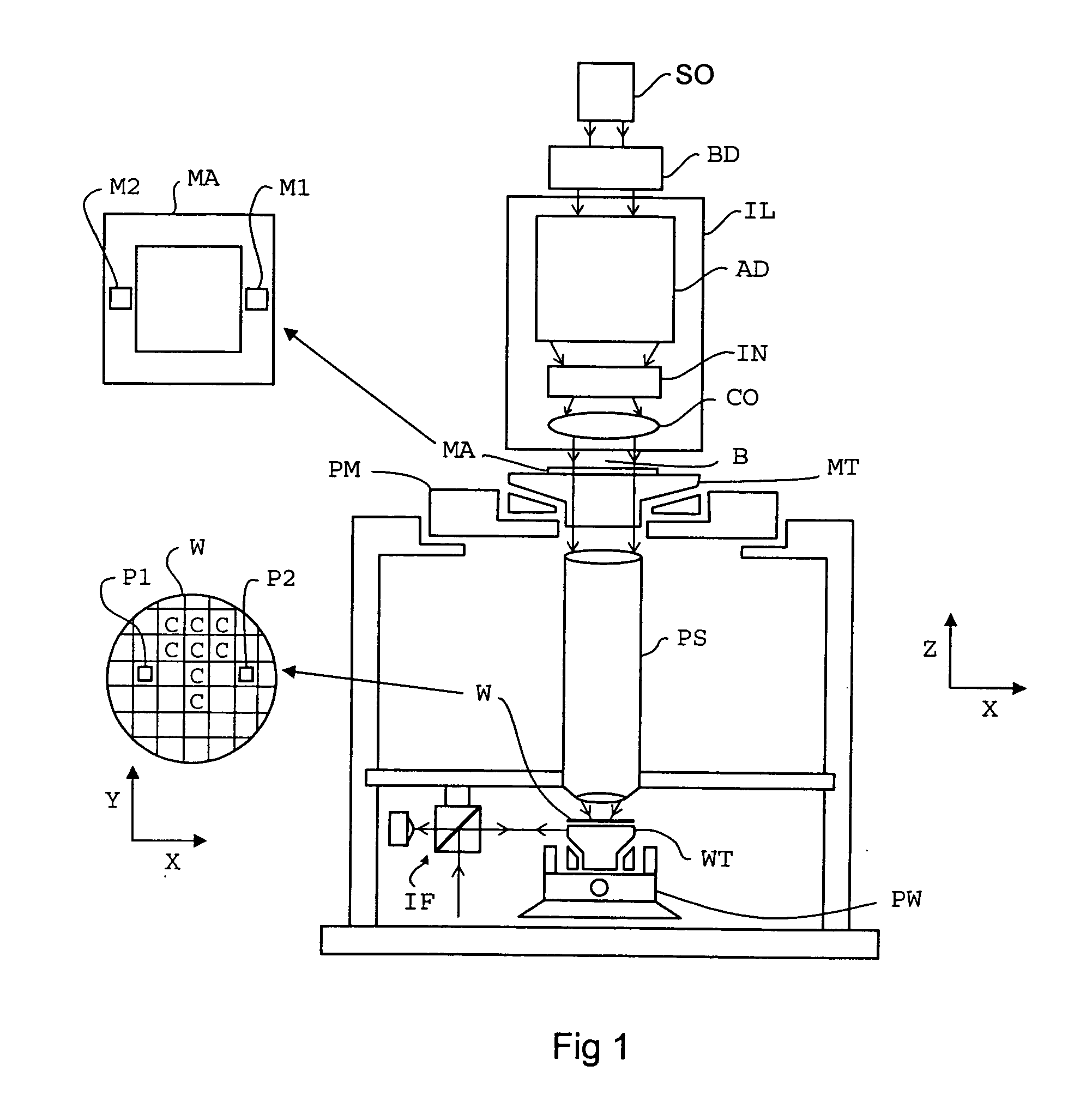

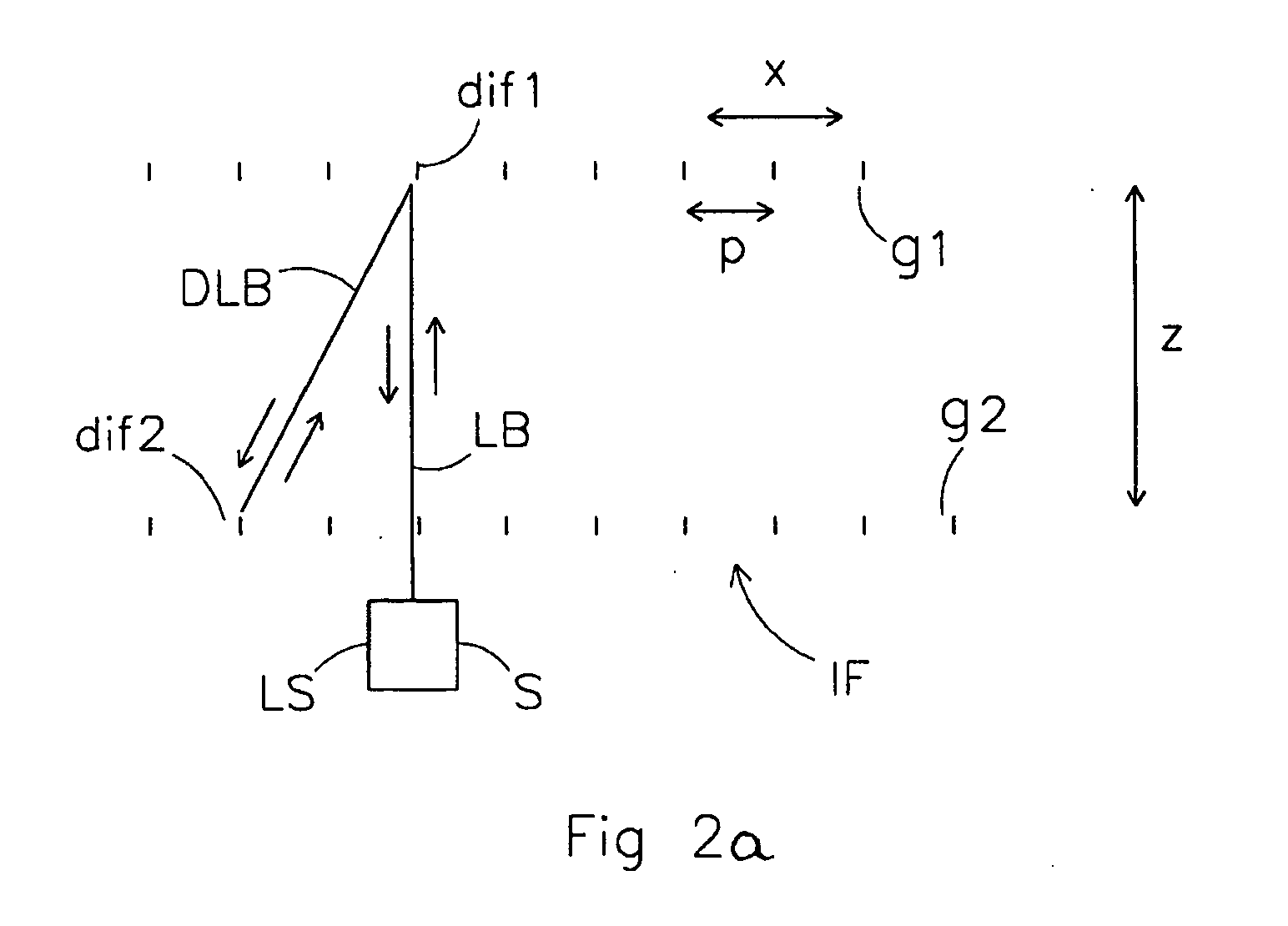

Lithographic apparatus and method for calibrating the same

ActiveUS20060023178A1Photomechanical apparatusSemiconductor/solid-state device manufacturingControl systemMotor control

Lithographic apparatus includes a substrate table and a motion control system for controlling a movement of the substrate table. The motion control system includes at least 3 position detectors constructed for detecting a position of the substrate table. For measuring a position and orientation of the substrate table, each position detector comprises an optical encoder of a single dimensional or multi dimensional type, the optical encoders being arranged for providing together at least 6 position values, at least one position value being provided for each of the 3 dimensions. Some of the optical encoders may be connected to the substrate table at different locations in the 3 dimensional coordinate system. The motion control system is arranged to calculate the position of the substrate table in the 3 dimensional coordinate system from a subset of at least 3 of the 6 position values and to calculate an orientation of the substrate table with respect to the coordinate system from another subset of at least 3 of the 6 position values. Further, a method for calibrating the position detectors is presented.

Owner:ASML NETHERLANDS BV

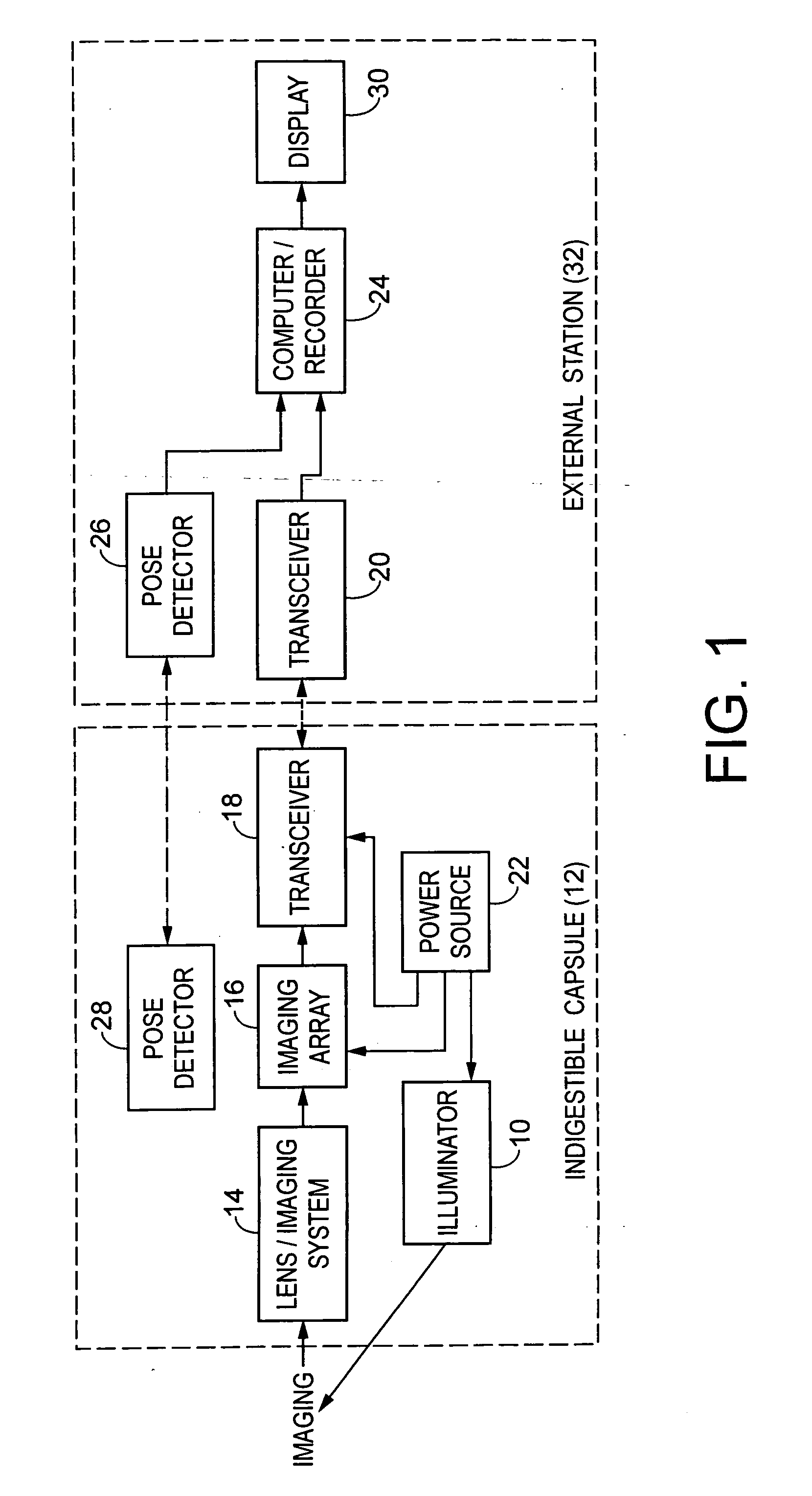

Miniature ingestible capsule

Owner:NAIR PADMANABHAN P +1

System and method for motion-controlled foot unit

A system and method associated with the movement of a limb. In one example, the system, such as a prosthetic or orthotic system, includes an actuator that actively controls, or adjusts, the angle between a foot unit and a lower limb member. A processing module may control movement of the actuator based on data obtained from a sensor module. For instance, sensing module data may include information relating to the gait of a user and may be used to adjust the foot unit to substantially mimic the movement of a natural, healthy ankle. The system may further accommodate, for example, level ground walking, traveling up / down stairs, traveling up / down sloped surfaces, and various other user movements. In addition, the processing module may receive user input or display output signals through an external interface. For example, the processing module may receive a heel height input from the user.

Owner:OSSUR HF

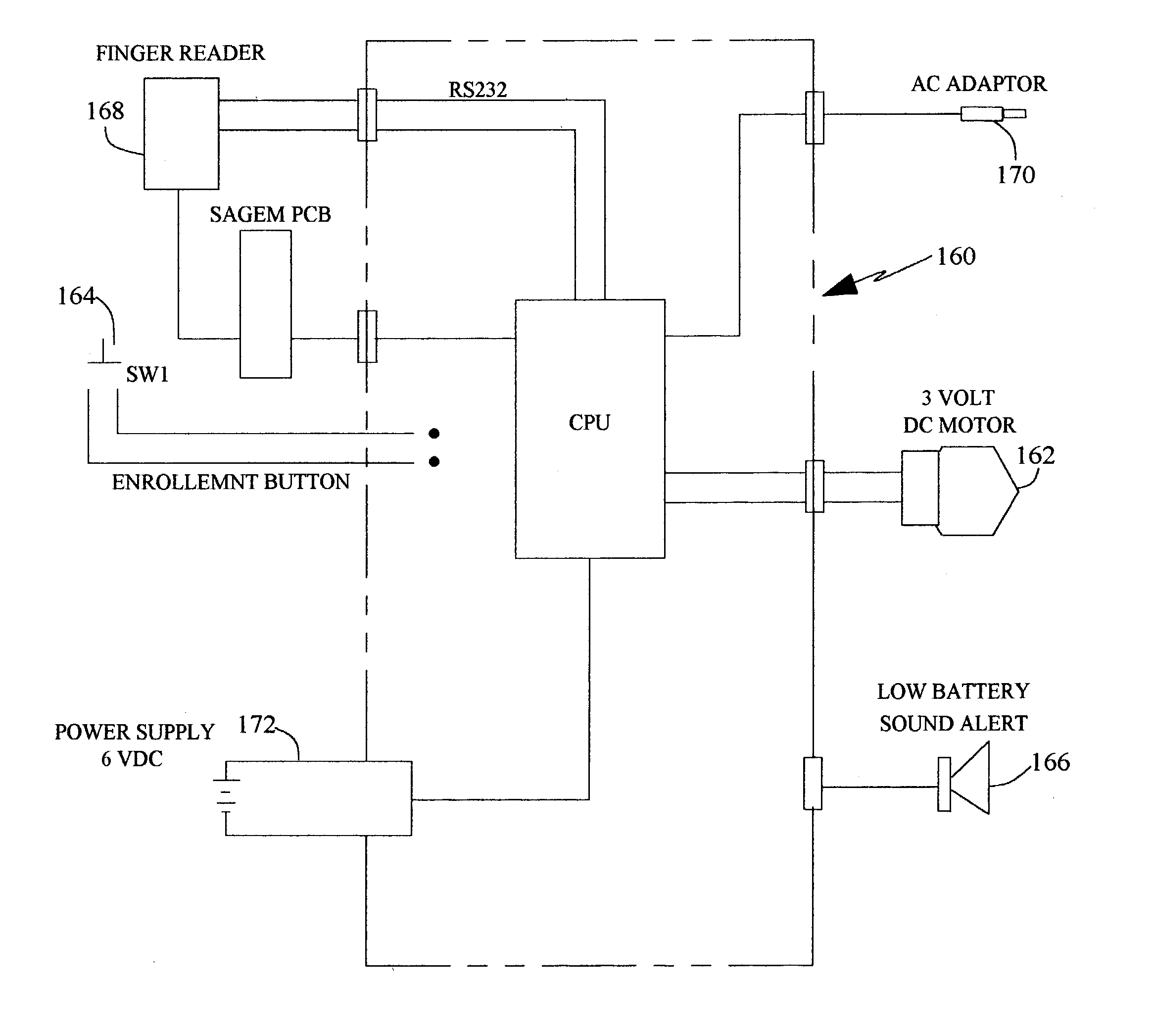

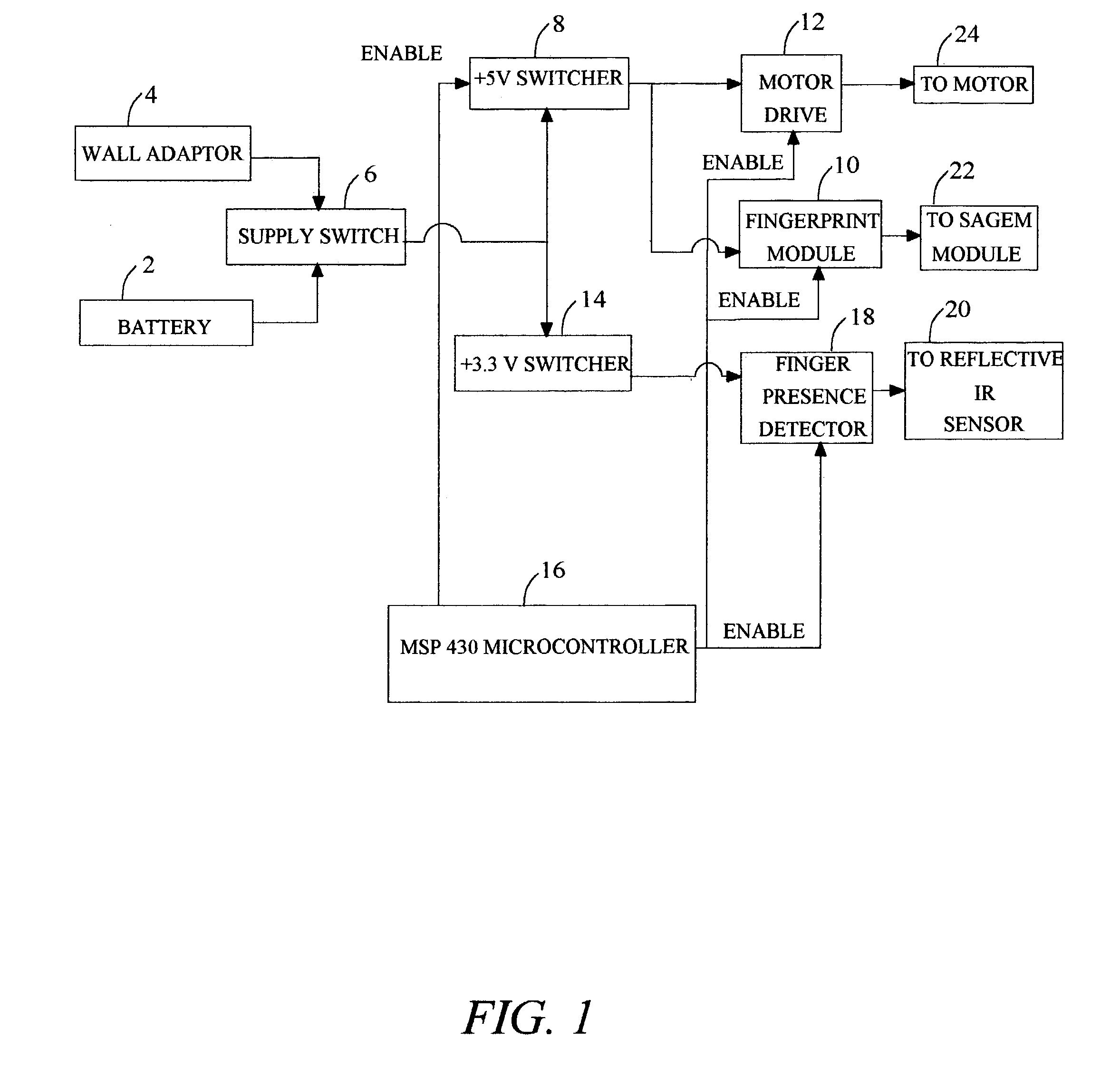

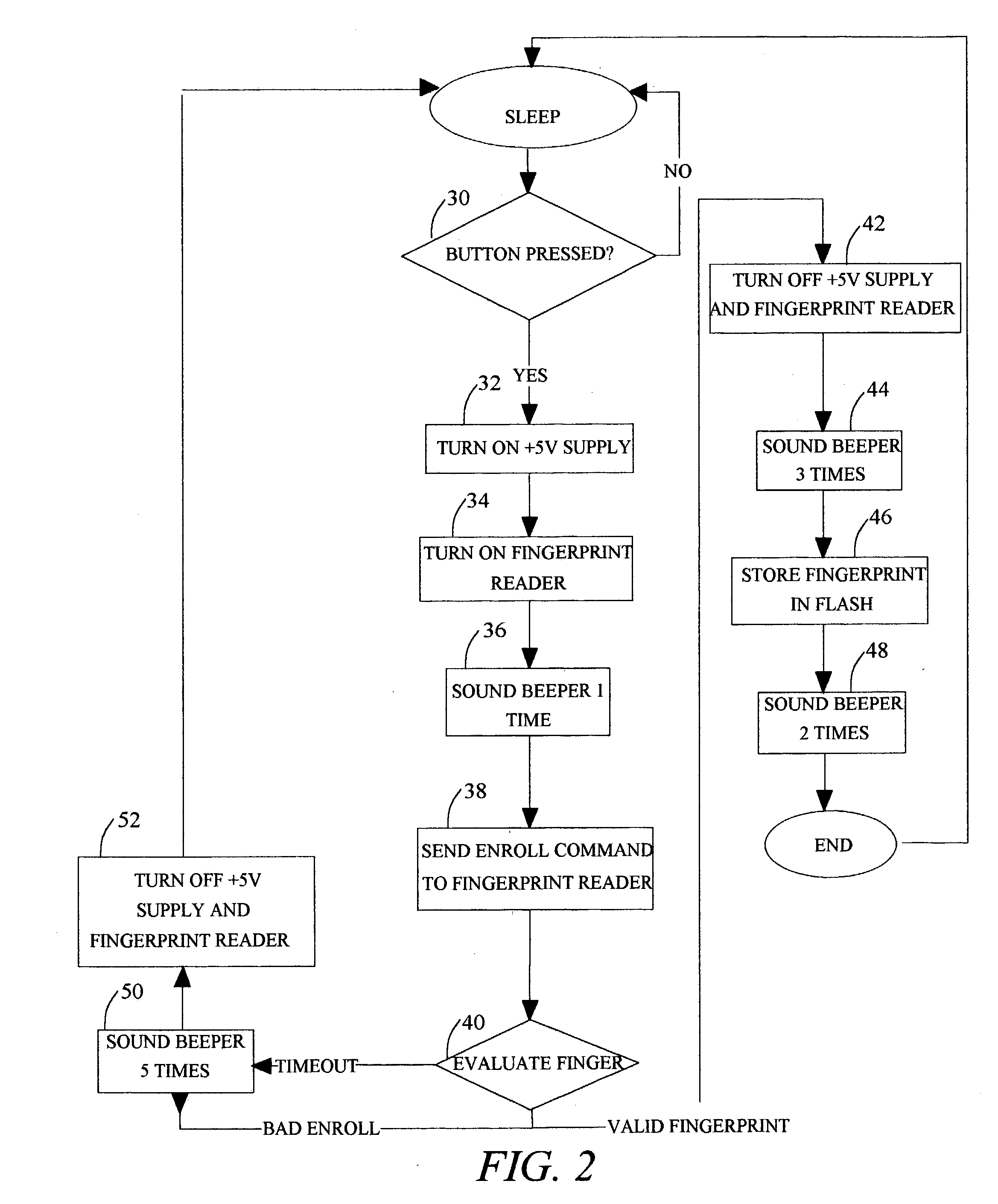

Fingerprint biometric lock

InactiveUS20030141959A1Electric signal transmission systemsImage analysisLocking mechanismMovement restriction

A fingerprint biometric lock is provided which includes a locking mechanism that restricts the movement of an object that is to be unlocked, a movement restriction electronic circuit that restricts the unlocking of the object by the locking mechanism, a fingerprint sensor that detects a fingerprint pattern, a memory device that stores an enrolled fingerprint code data, a verifying unit that determines whether an offered fingerprint code, created from the fingerprint pattern sensed by the sensor, matches with any of the enrolled fingerprint codes stored in the memory device, a motor control unit that unlocks the locking mechanism through the movement restricting electronic circuit, when the offered and enrolled fingerprint codes match, and, a finger presence detector for powering a direct current to the sensor and the motor control unit.

Owner:SEQUIAM BIOMETRICS INC +1

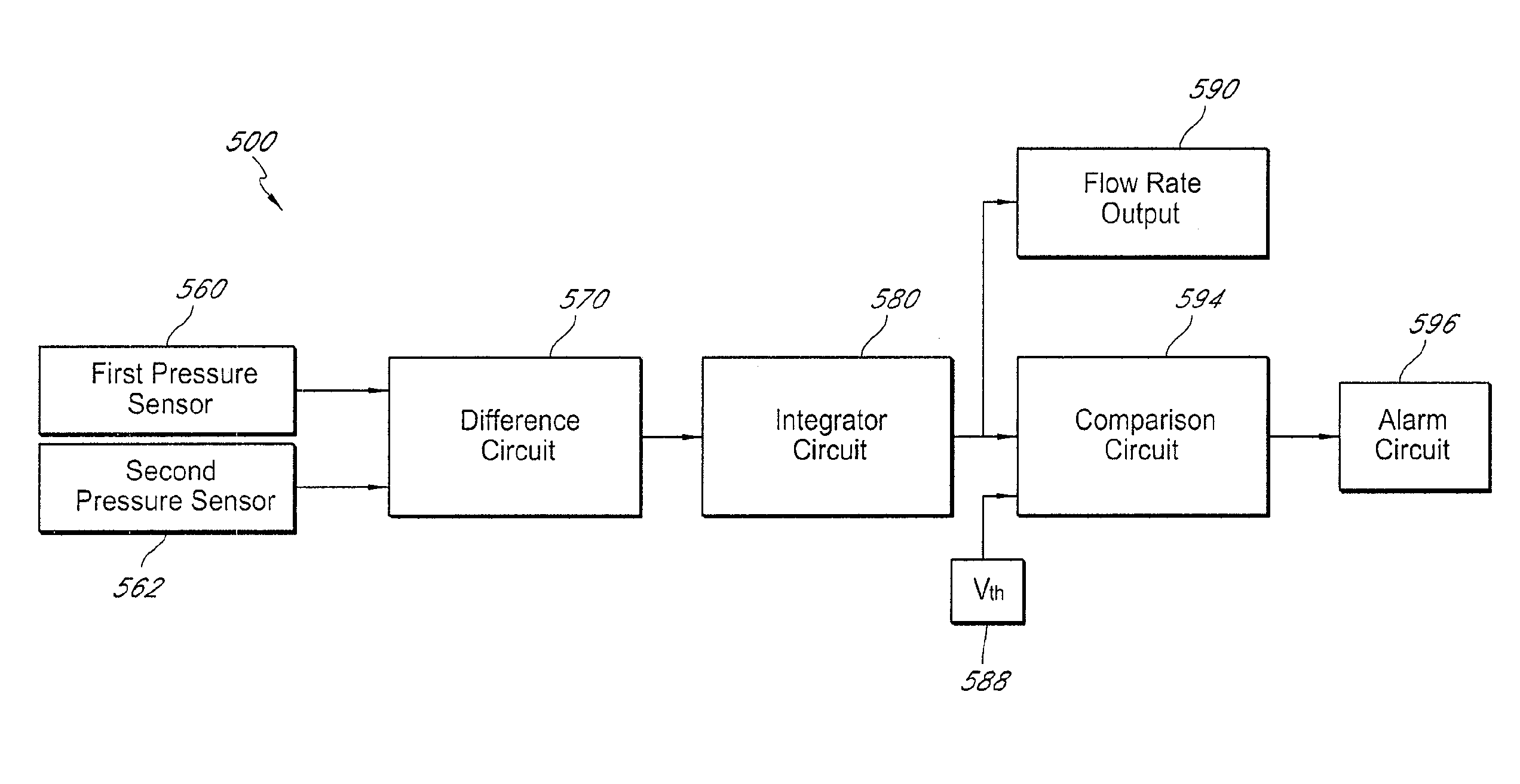

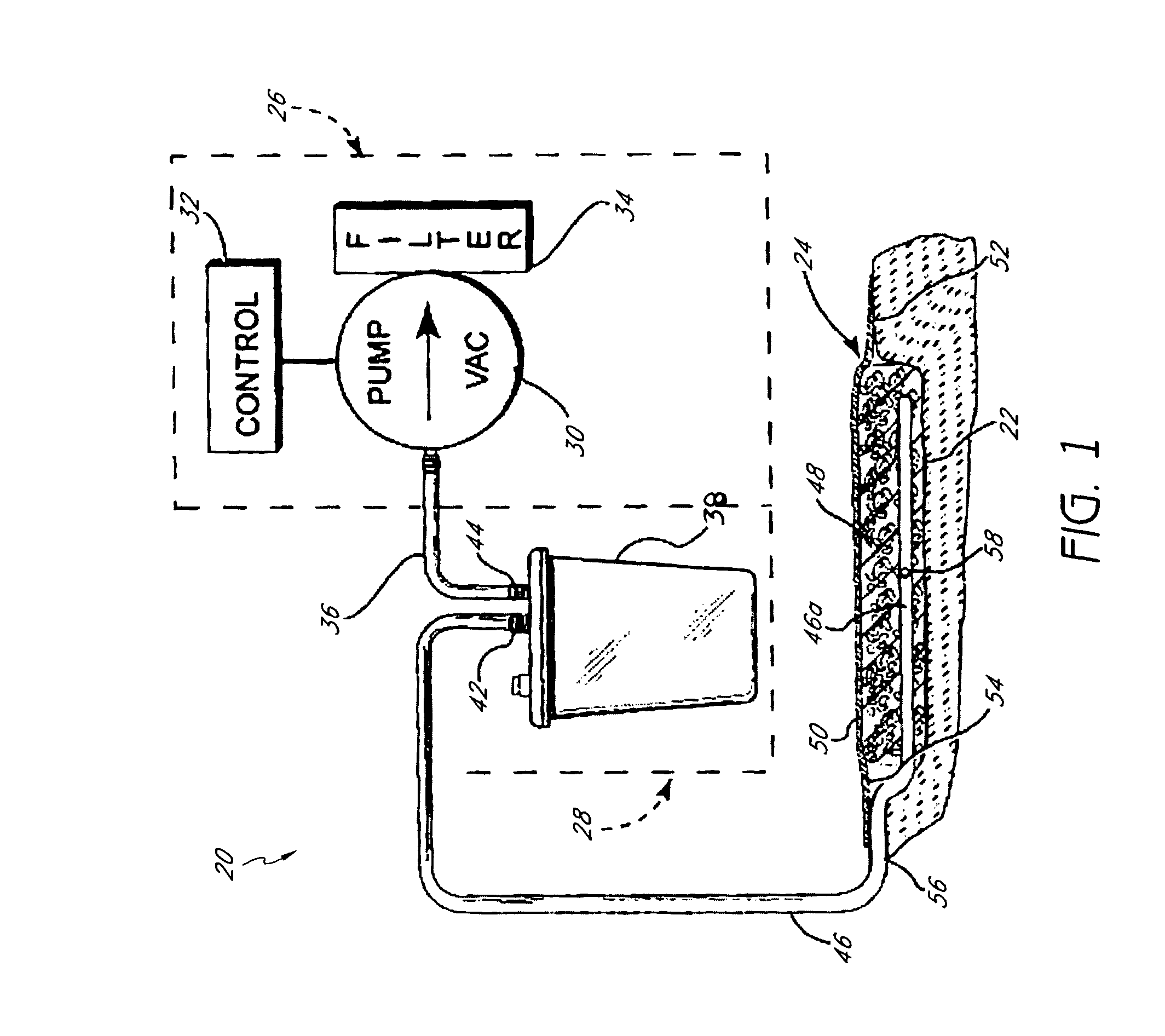

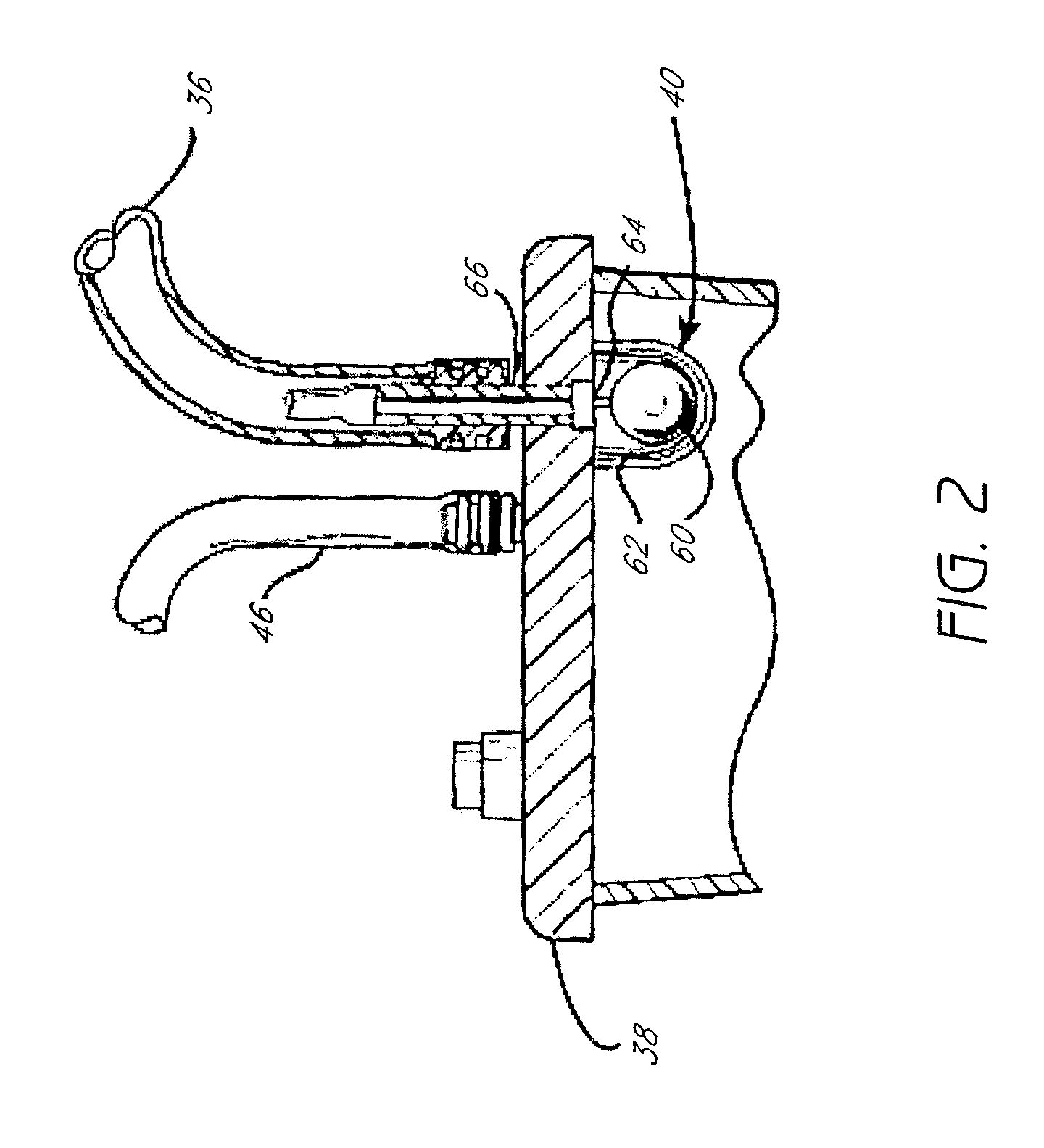

Control circuit and method for negative pressure wound treatment apparatus

ActiveUS8308714B2Avoid procrastinationAvoid runningWound drainsMedical devicesWound dressingControl signal

A negative pressure wound therapy apparatus can include a wound dressing, a fluid collection container, a vacuum pump comprising a pump motor, and tubing. Additionally, the apparatus can include a pressure sensor that measures a pressure in the tubing. One or more tubes can channel a fluid between the wound dressing, the fluid collection canister, and the pump. In addition, first and second control circuits can be provided for controlling the pump motor without using a processor. The first control circuit can generate a difference signal between a desired pressure input and a pressure sensor input, and can further generate a motor control signal responsive to the difference signal. Moreover, a second control circuit can provide an override signal based at least in part on the difference signal and at least one reference signal. The override signal beneficially overrides the motor control signal to prevent the pump motor from stalling.

Owner:SMITH & NEPHEW INC

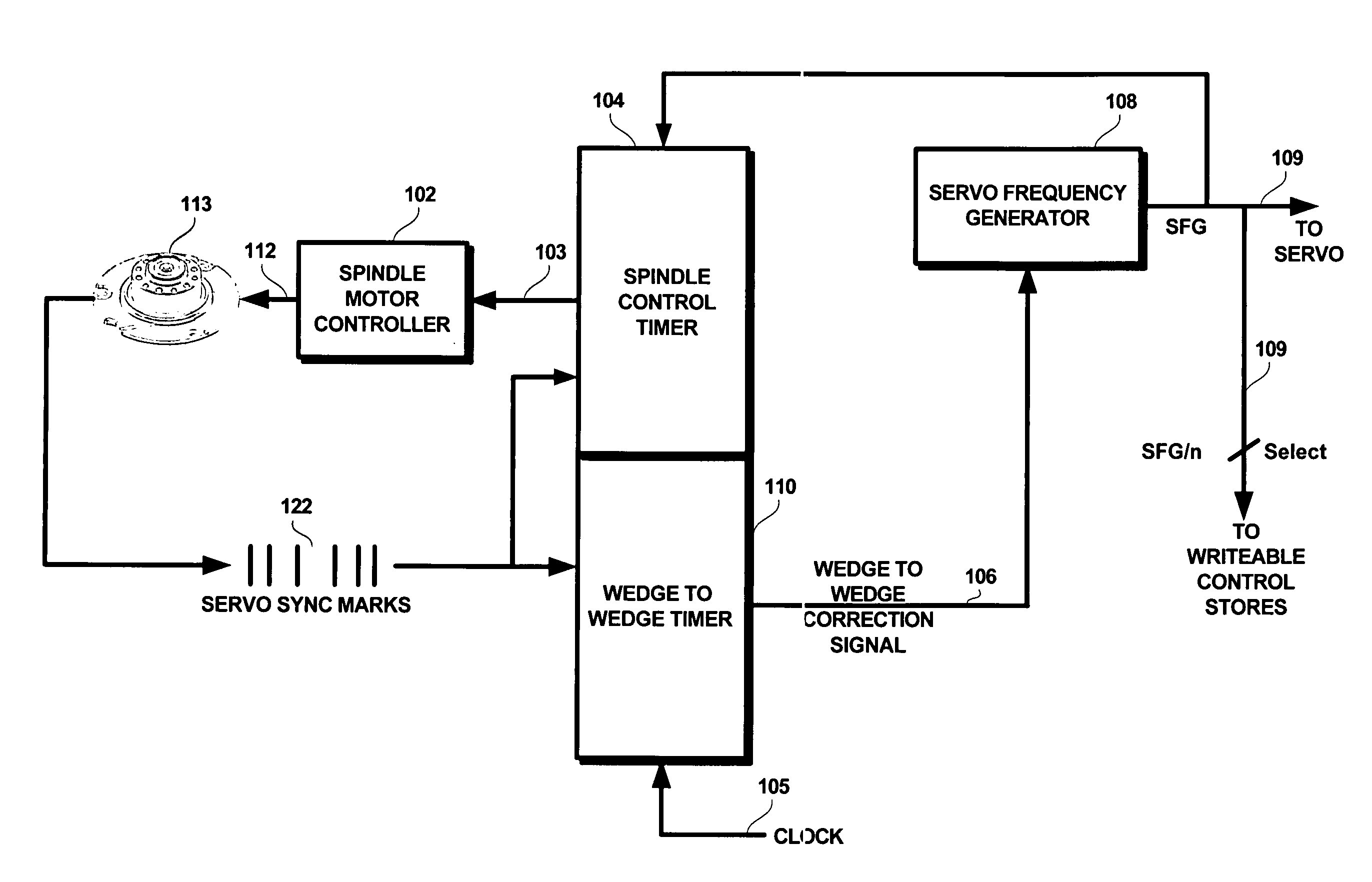

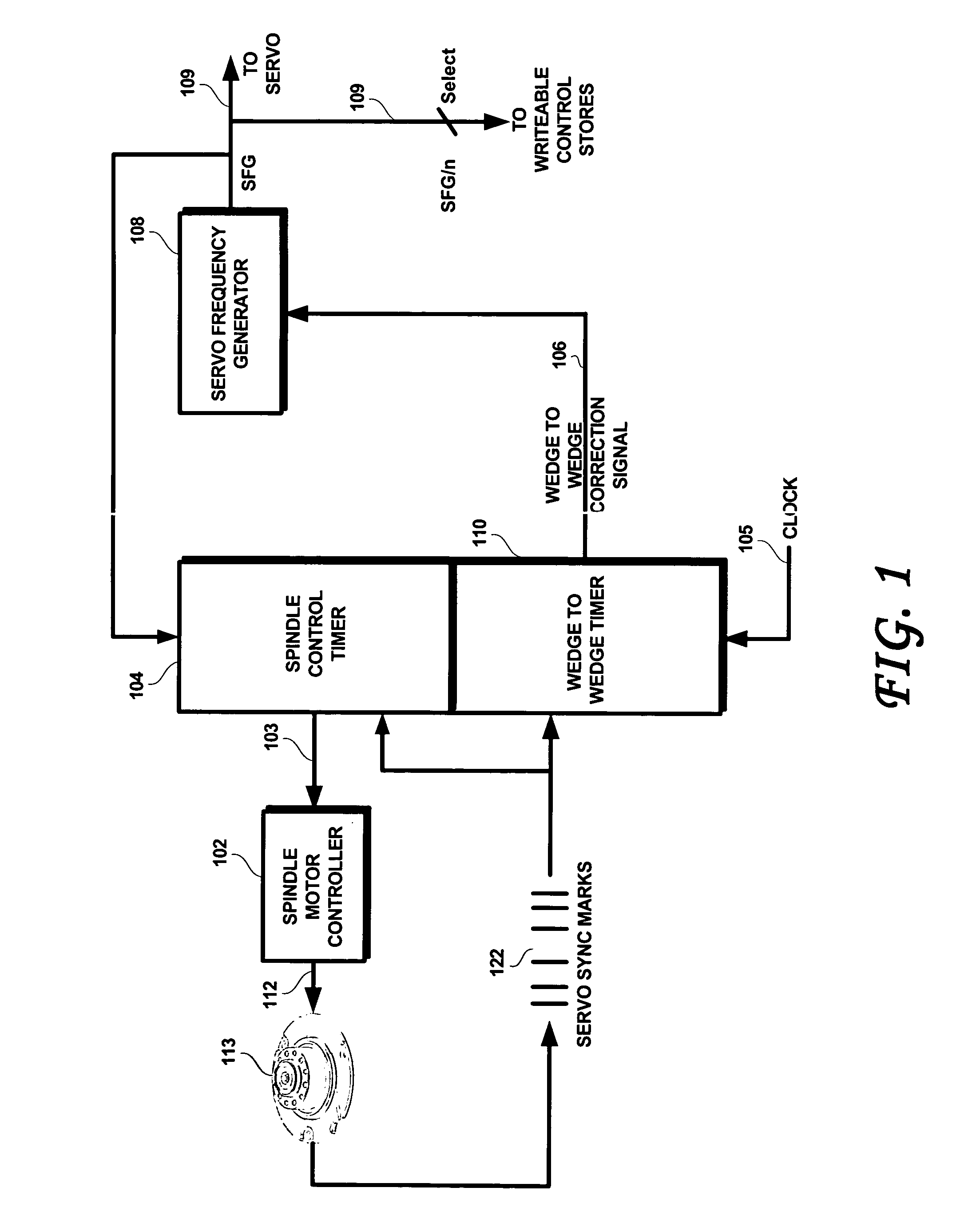

Disk drives and disk drive containing devices that include a servo frequency generator and spindle control timer that compensate for disk eccentricity

InactiveUS7075746B1Record information storageAlignment for track following on disksElectric machineControl signal

A disk includes an actuator assembly, a spindle motor and a disk that defines a plurality of servo wedges. A wedge to wedge timer is configured to measure the time elapsed between at least two circumferentially adjacent servo wedges and to output a wedge to wedge correction signal that defines a count between circumferentially adjacent servo wedges that is dependent upon the measured elapsed time. A servo frequency generator is configured to output a servo frequency generator signal having a frequency that is modulated by the wedge to wedge correction signal. A spindle motor control timer outputs a spindle control timer signal that is dependent upon the servo frequency generator signal and upon the time elapsed between at least two successive detections of circumferentially adjacent servo wedges. A spindle motor controller controls the spindle motor with a control signal that changes according to the spindle control timer signal.

Owner:WESTERN DIGITAL TECH INC

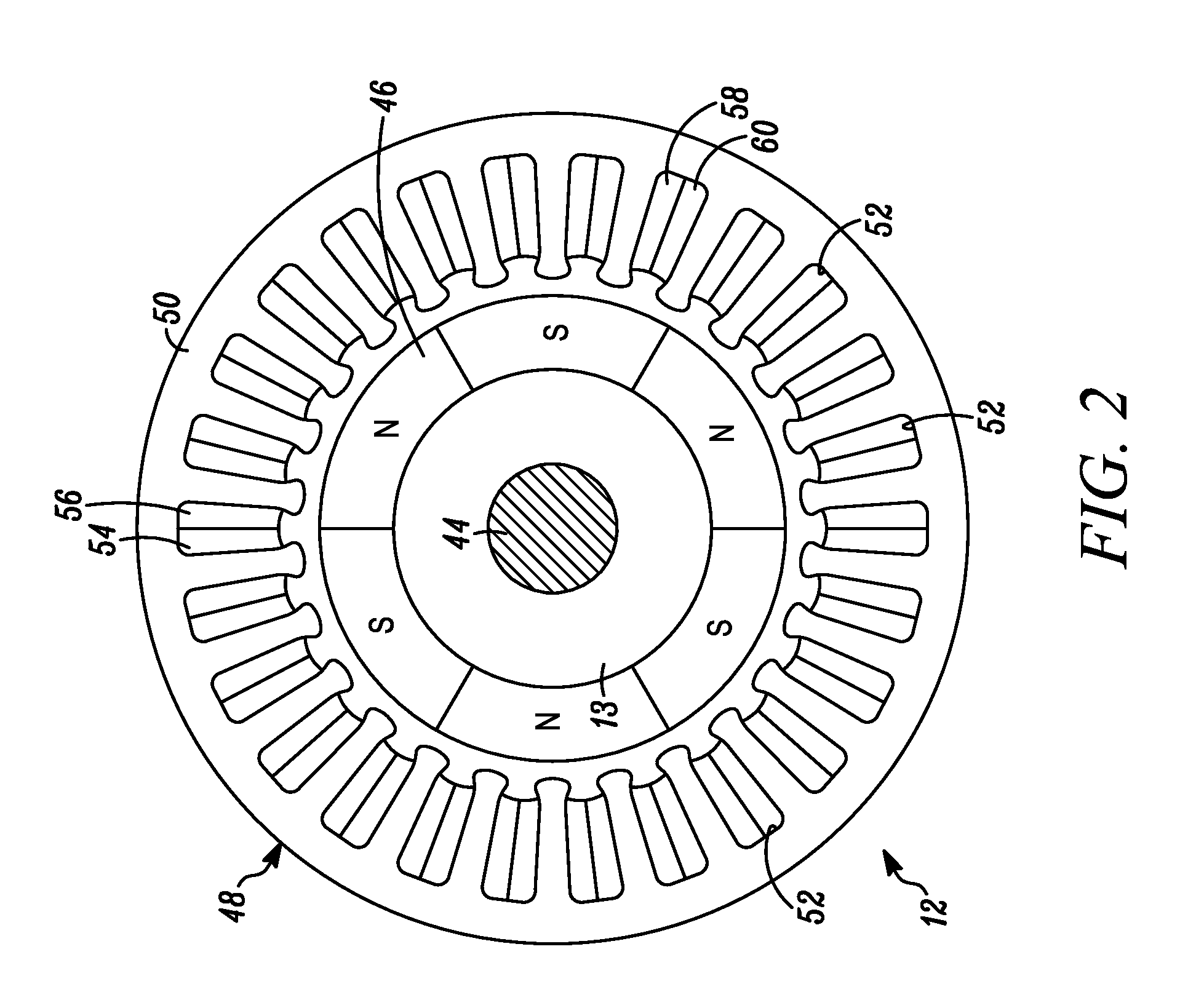

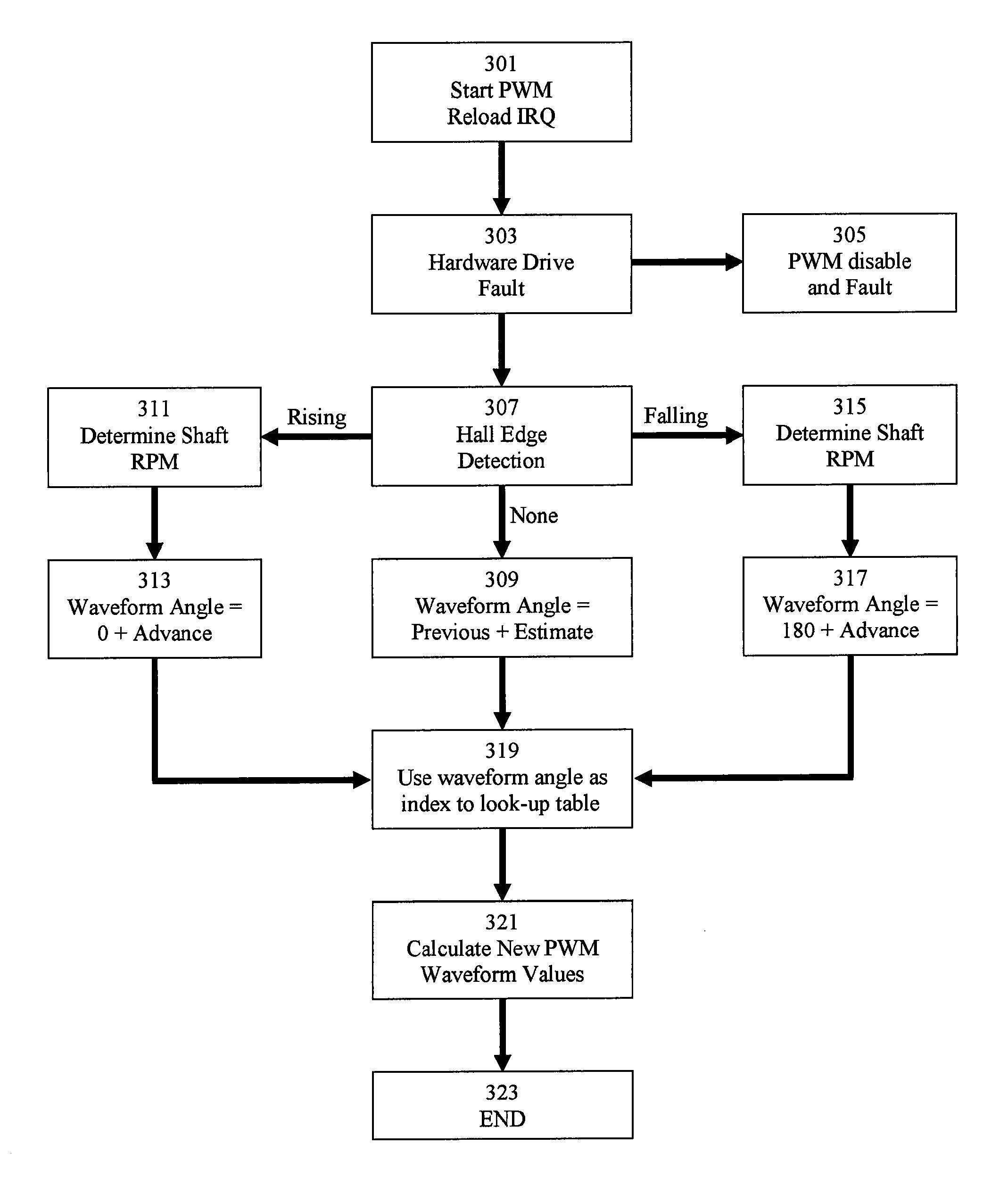

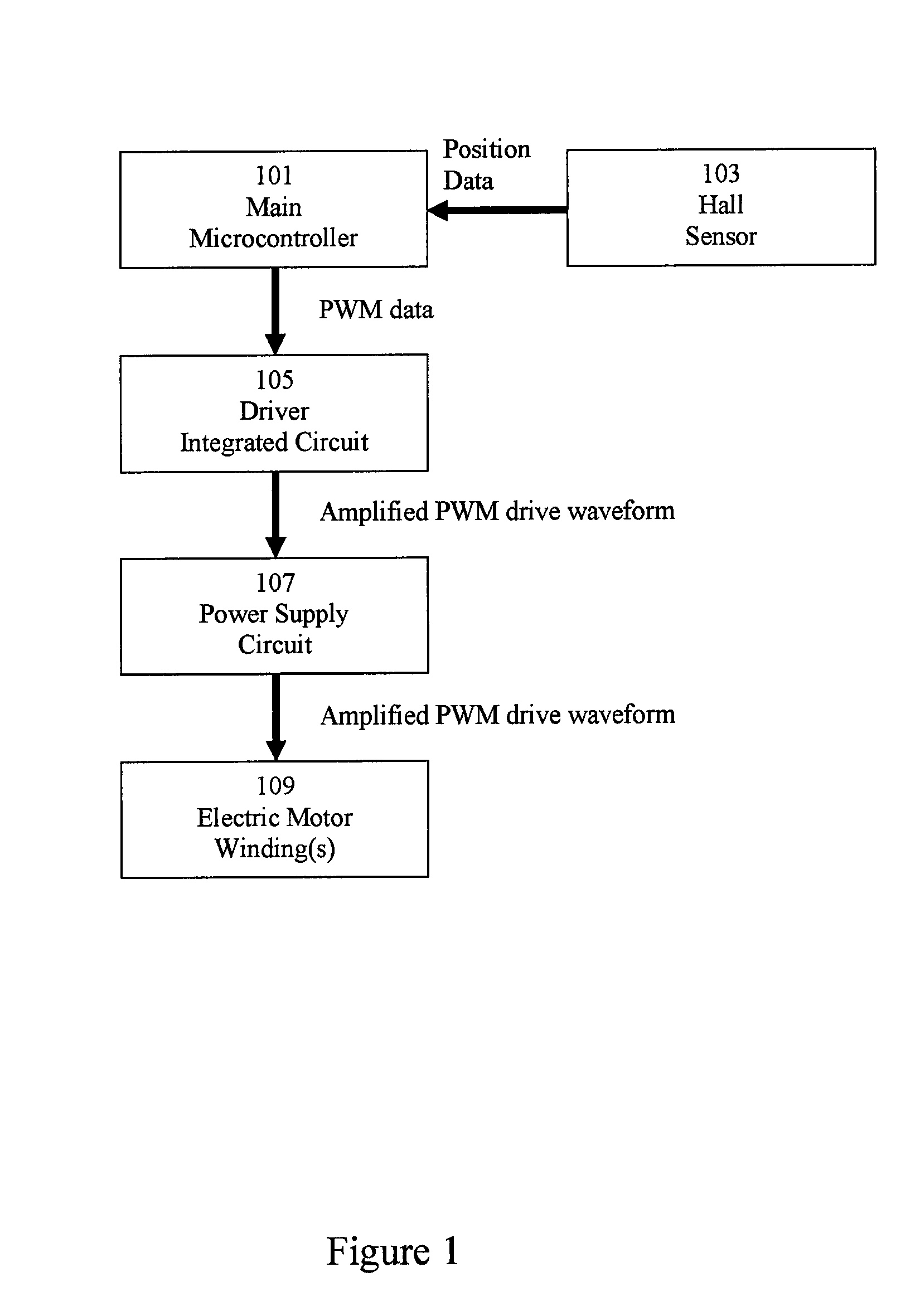

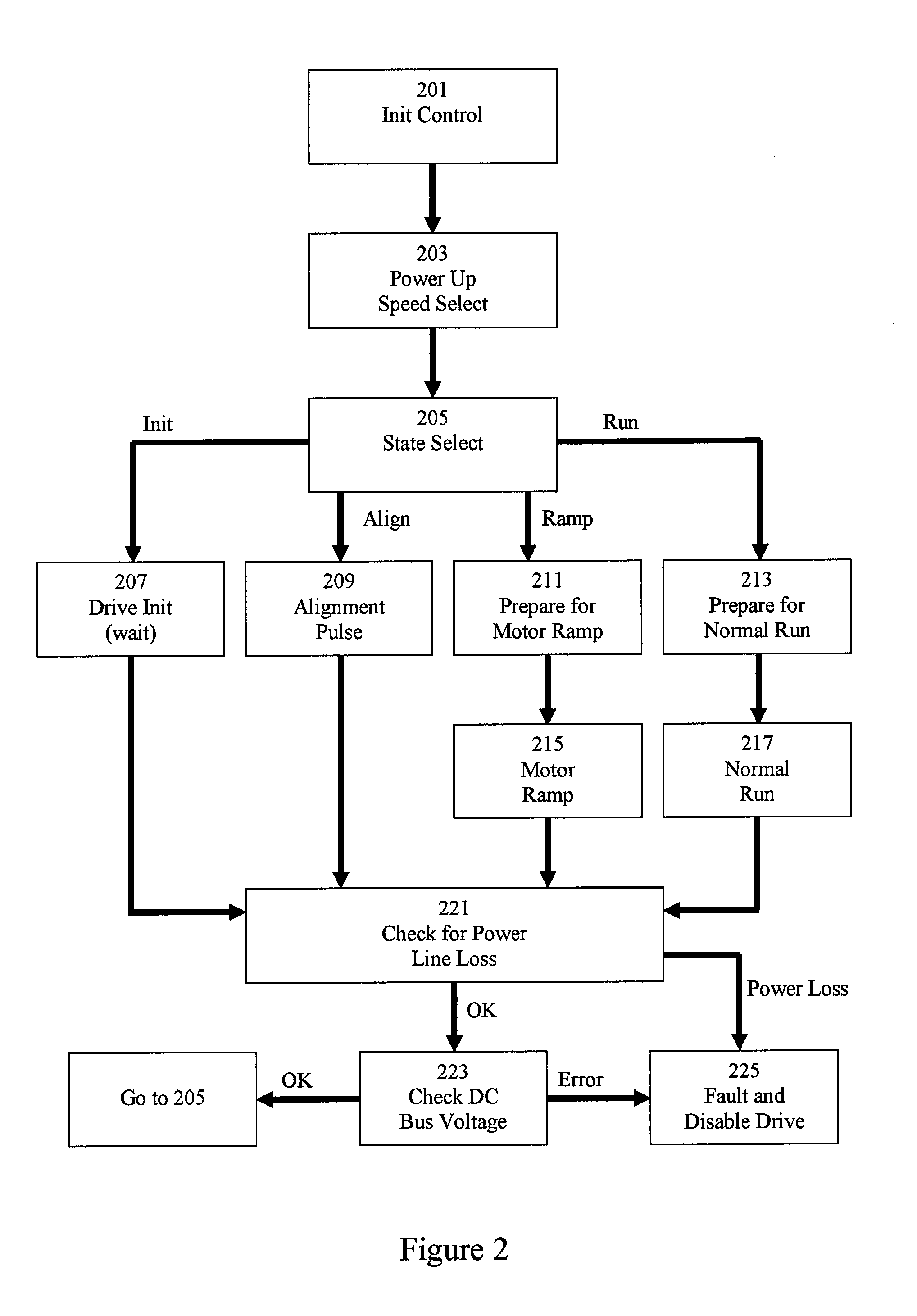

Electric motor and motor control

InactiveUS8575873B2Reduce noiseHigh complexitySingle-phase induction motor startersTorque ripple controlElectric machinePermanent magnet motor

Various embodiments of an electric motor and electronic control for an electric motor are disclosed. An exemplary electric motor comprises a single-phase brushless permanent magnet electric motor. In exemplary embodiments, the electronic motor control is configured to commutate an electric motor at a frequency other than line frequency, perform pulse width modulation, and drive the electric motor with a drive waveform that approximates the counter-electromotive force of the motor.

Owner:NIDEC MOTOR CORP

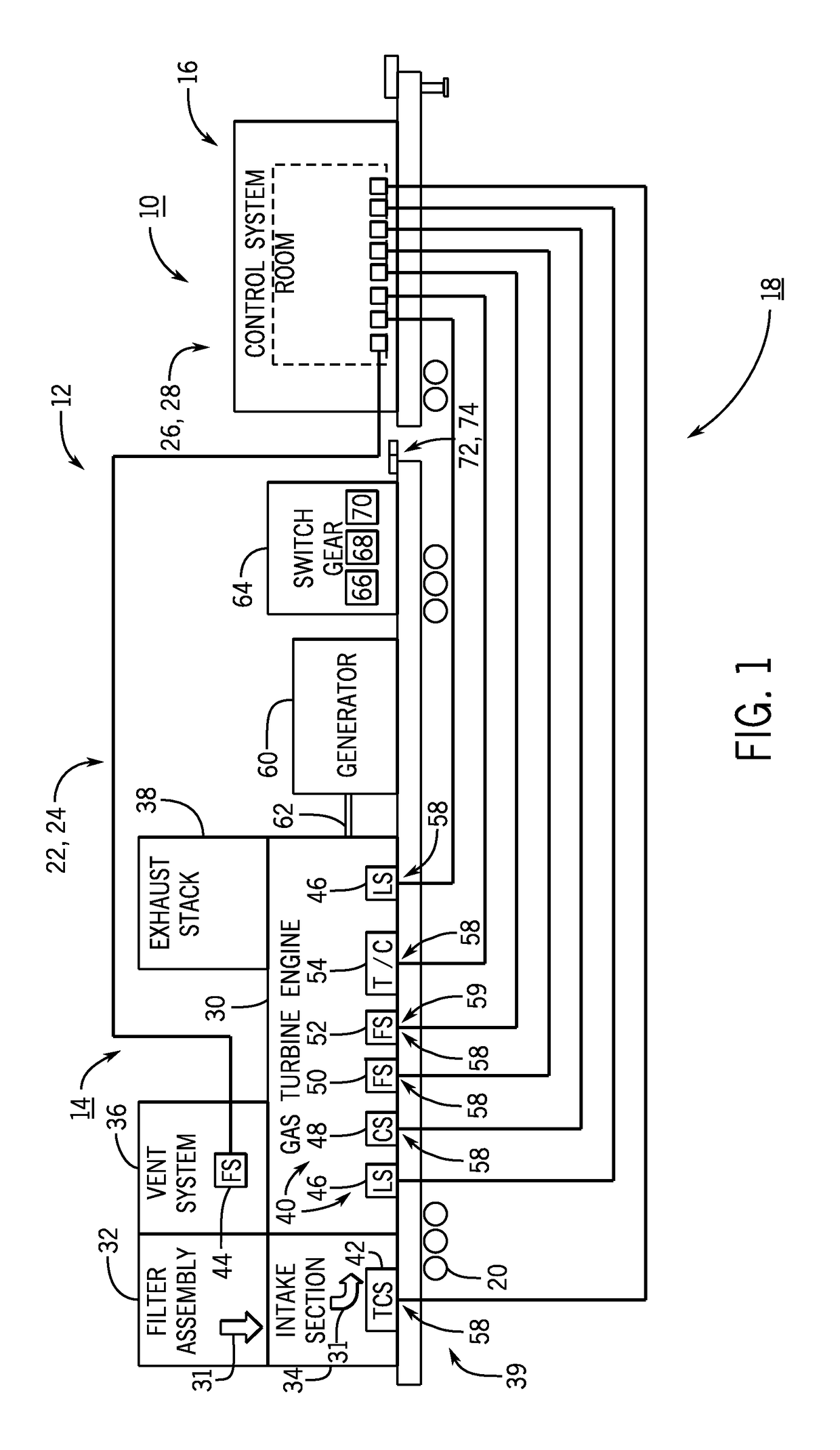

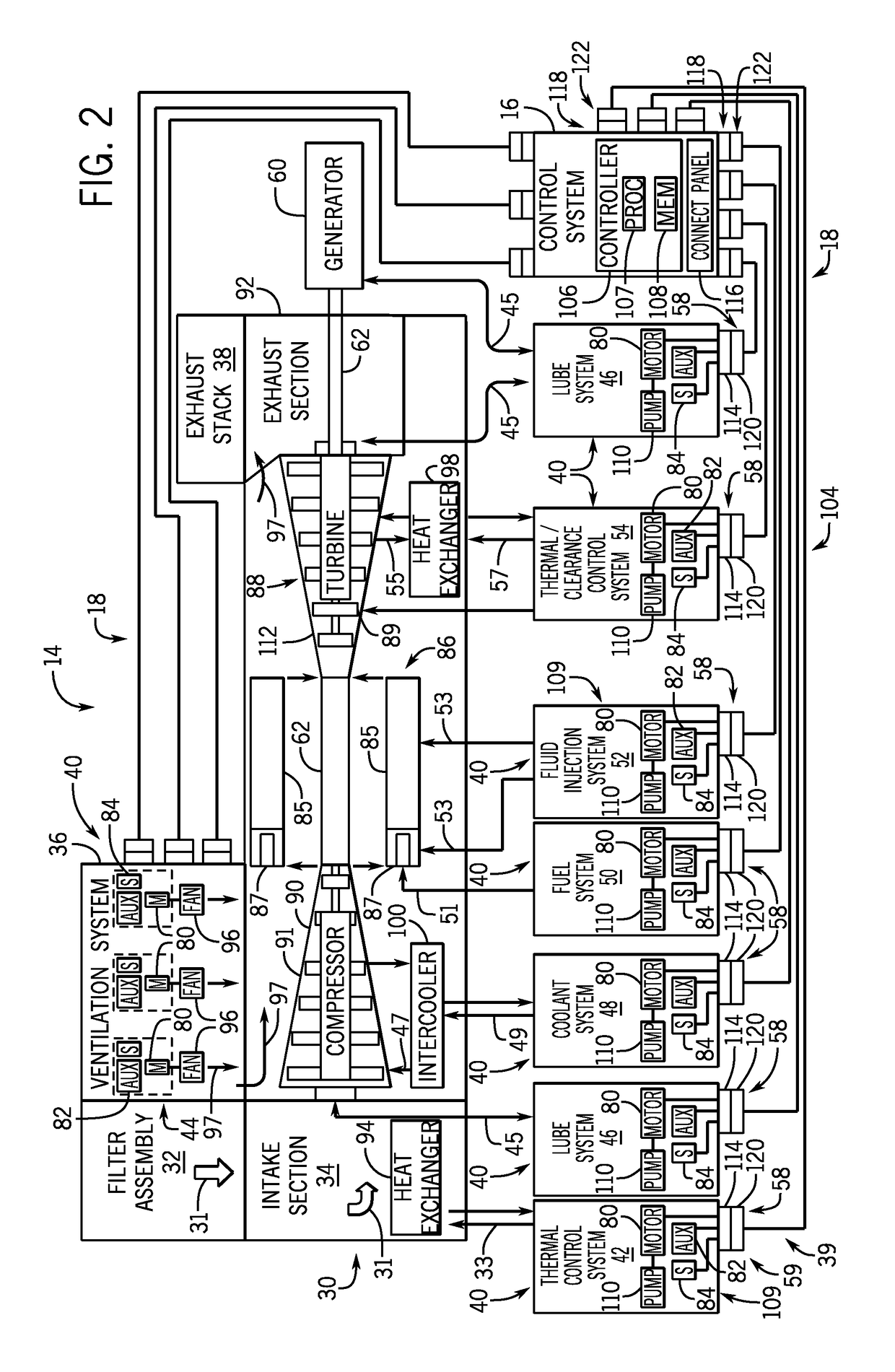

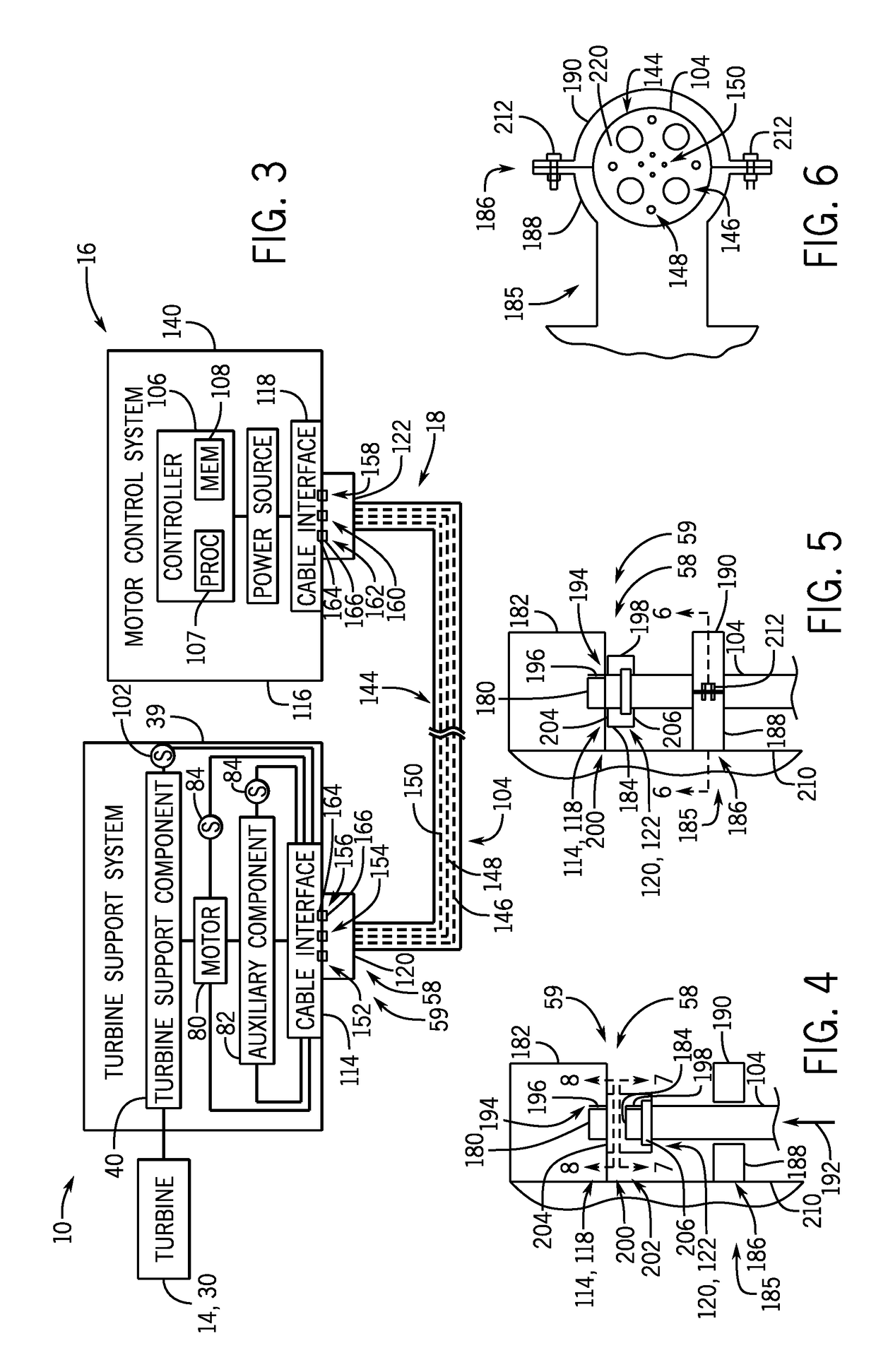

System and method for coupling components of a turbine system with cables

Owner:GE INFRASTRUCTURE TECH INT LLC

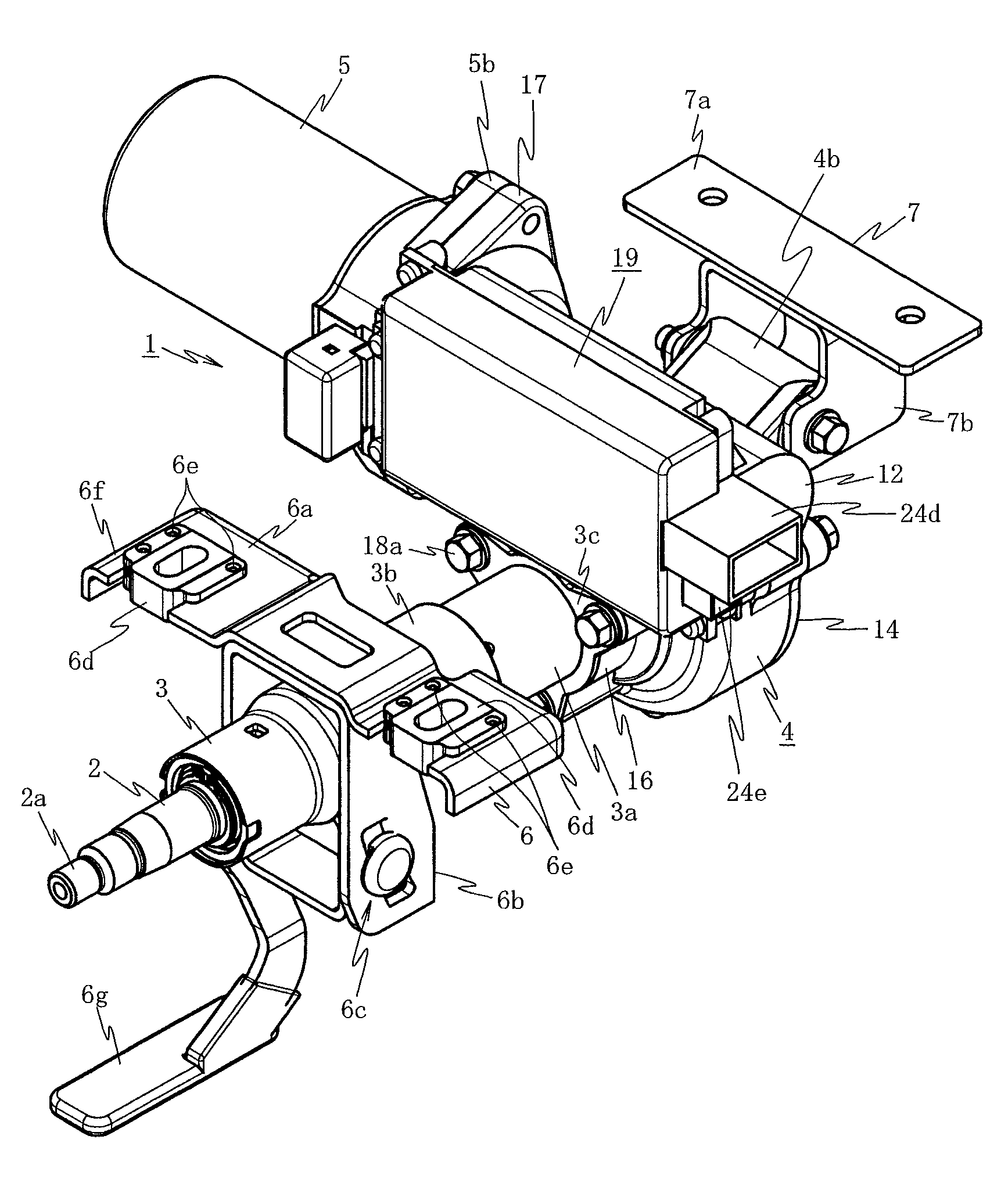

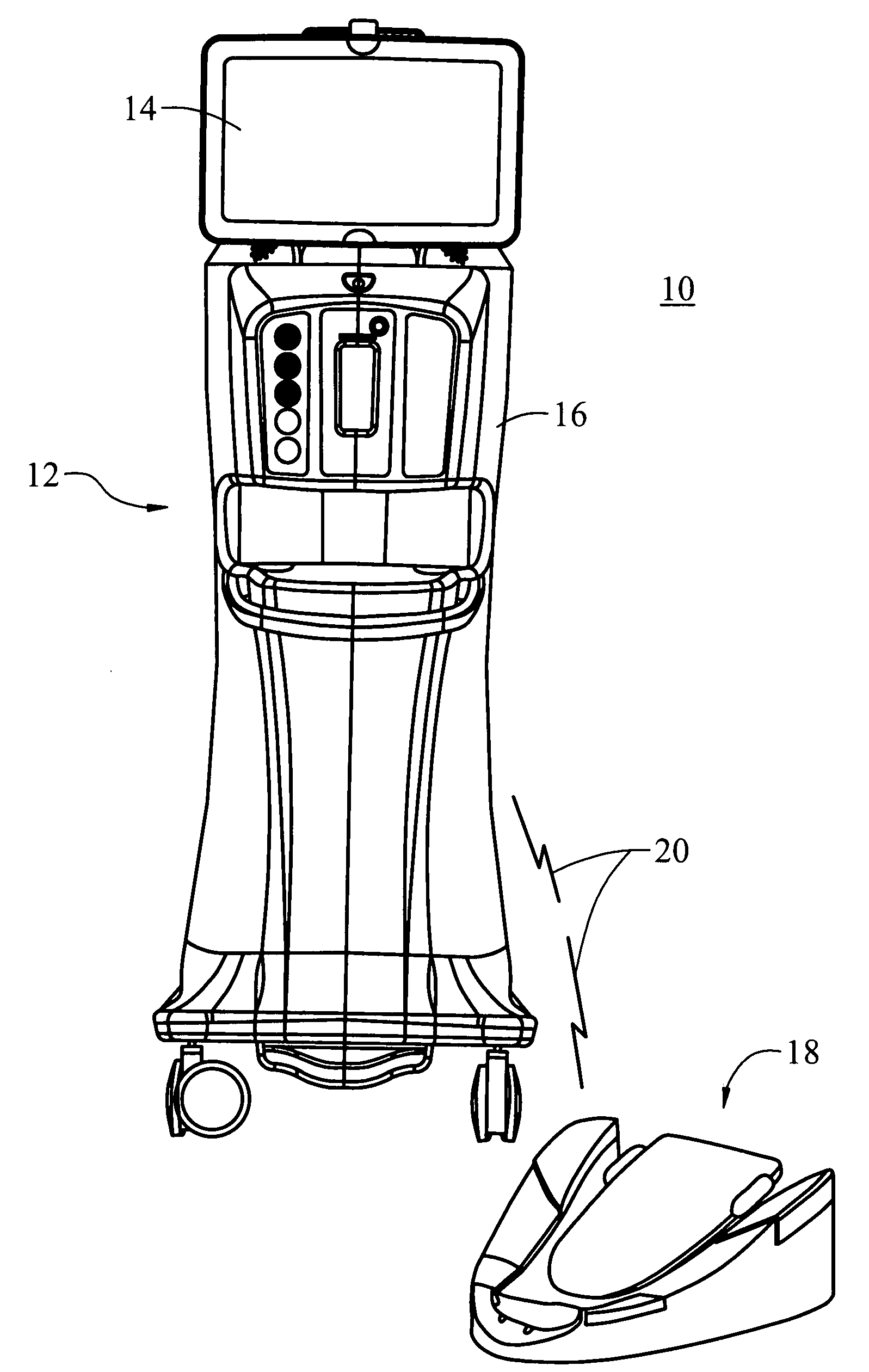

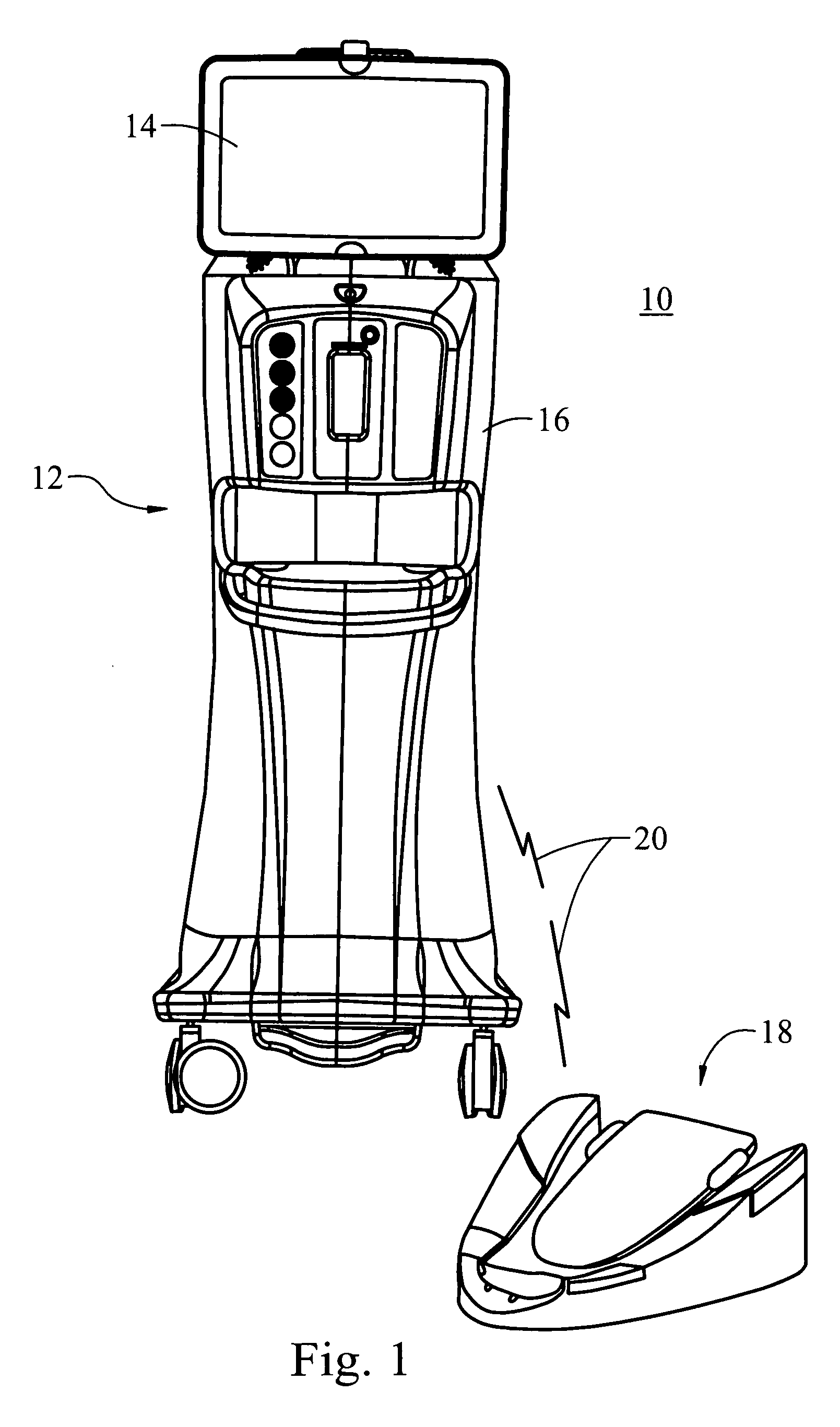

Dual linear ultrasound control

An ophthalmic surgical control system 10 includes a surgical console 12 for controlling a variety of surgical instruments. A foot controller 18 is connected to the surgical console 12 including a pedal 24 for movement by a user over a pre-determined range in pitch 26 and yaw 28. The system 10 allows the foot controller 18 to independently control two parameters for a single function where a first parameter is controlled by movement of the pedal 24 in pitch 26 and a second parameter is controlled by movement of the pedal 24 in yaw 28.

Owner:BAUSCH & LOMB INC

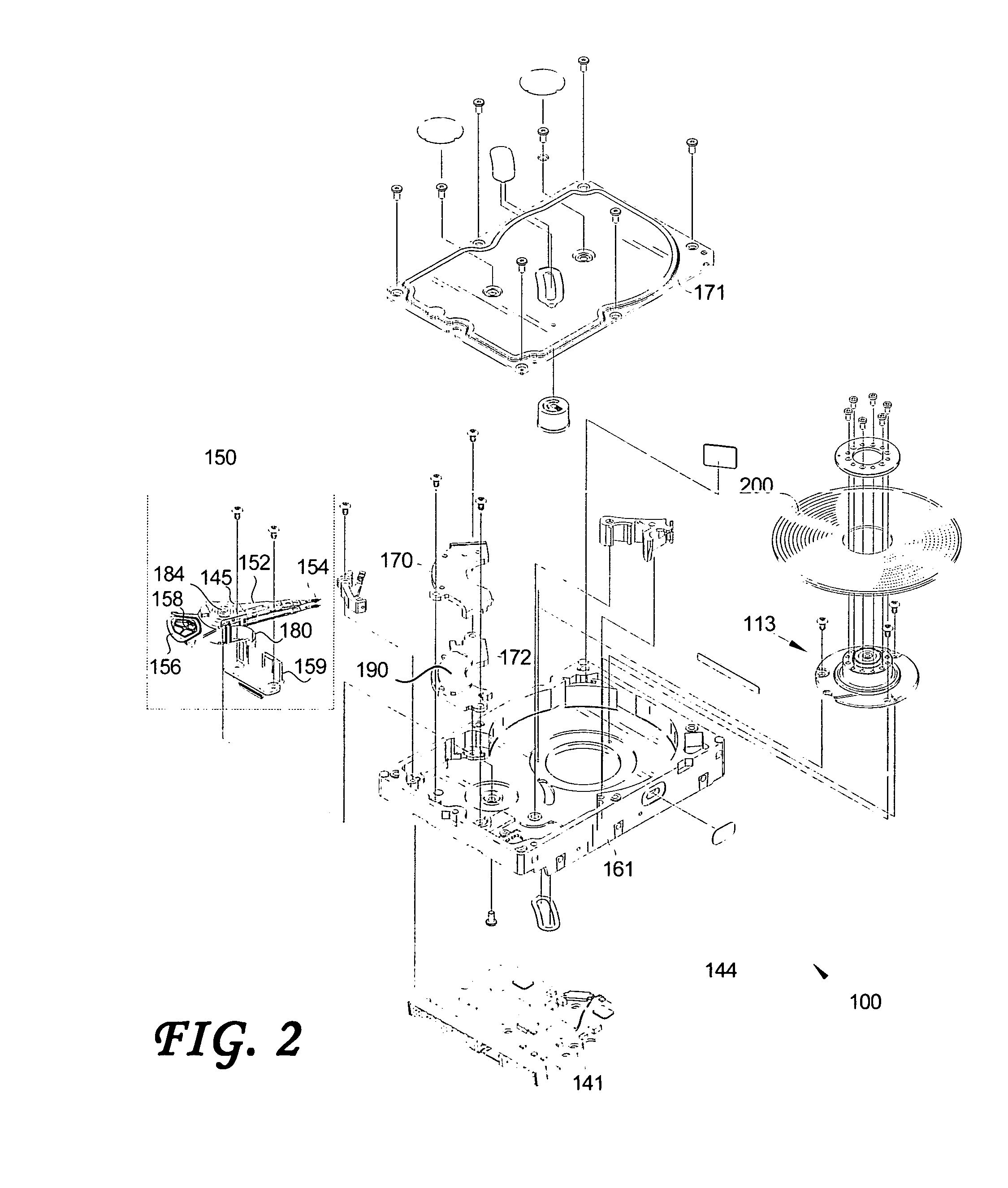

Ultrasound therapy head with movement control

ActiveUS7695437B2Easy to operateReliable treatmentUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyUltrasonic sensorEnergy applicator

A therapy head for use in HIFU procedures is described. The therapy head has an enclosure with a window, an energy applicator and a means of moving the energy applicator within the enclosure. The therapy head uses motors and actuators to move the energy applicator, usually an ultrasound transducer, inside the enclosure. A controller is provided either internally or externally that allows the therapy head to identify and distinguish locations where the therapy head should be to radiate energy into a patient. The controller uses the motors and actuators to move the energy applicator into the desired locations.

Owner:SOLTA MEDICAL

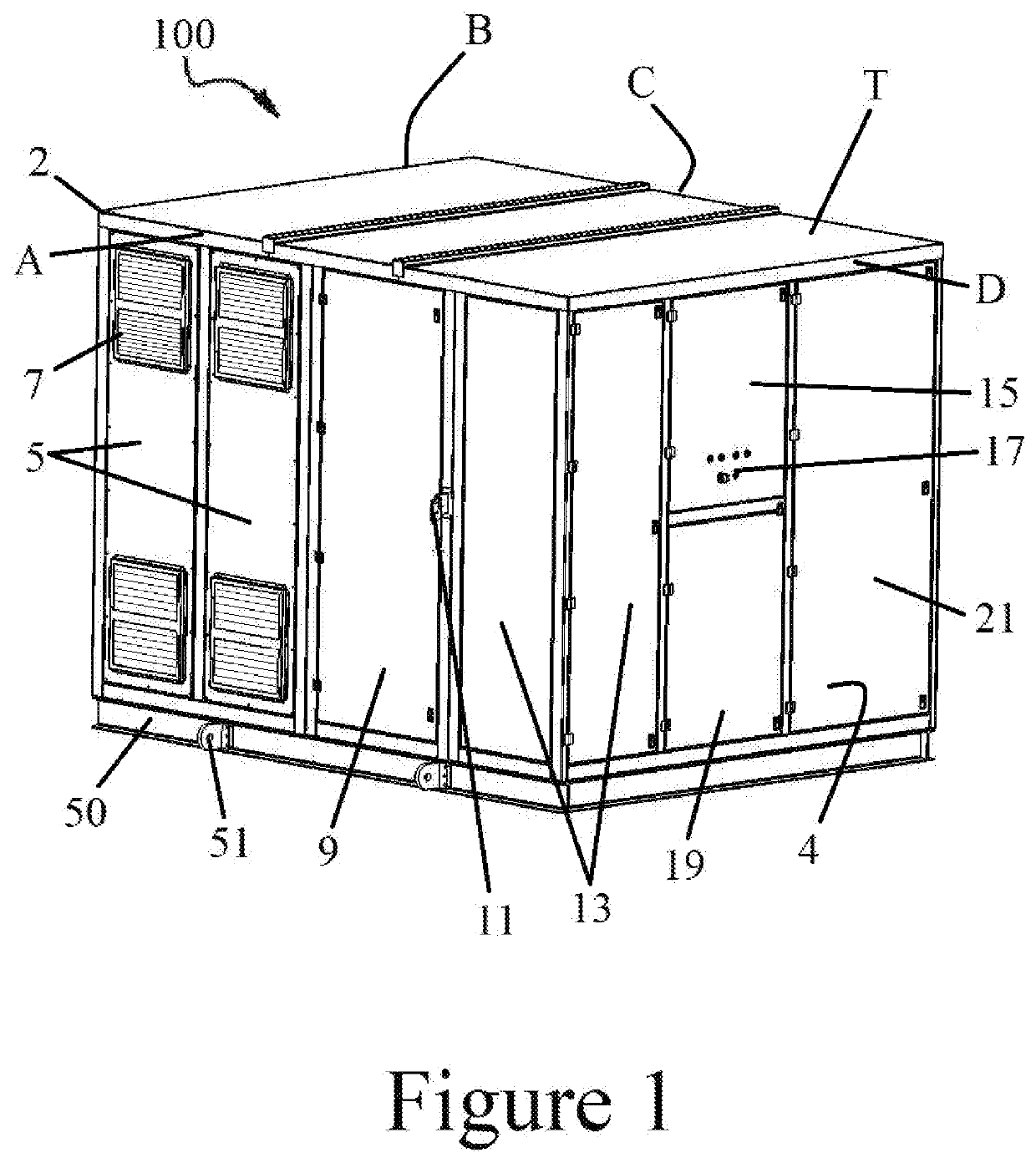

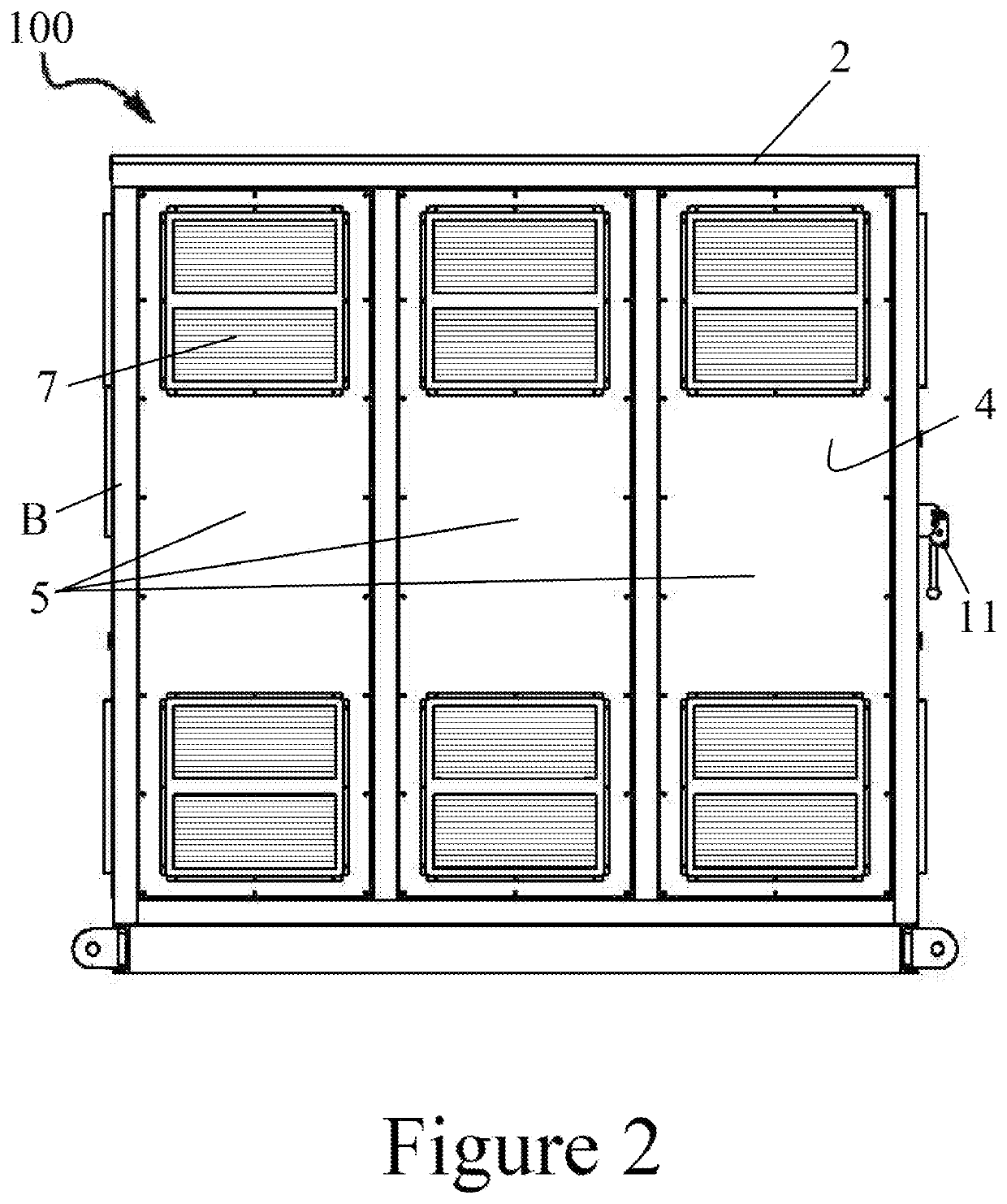

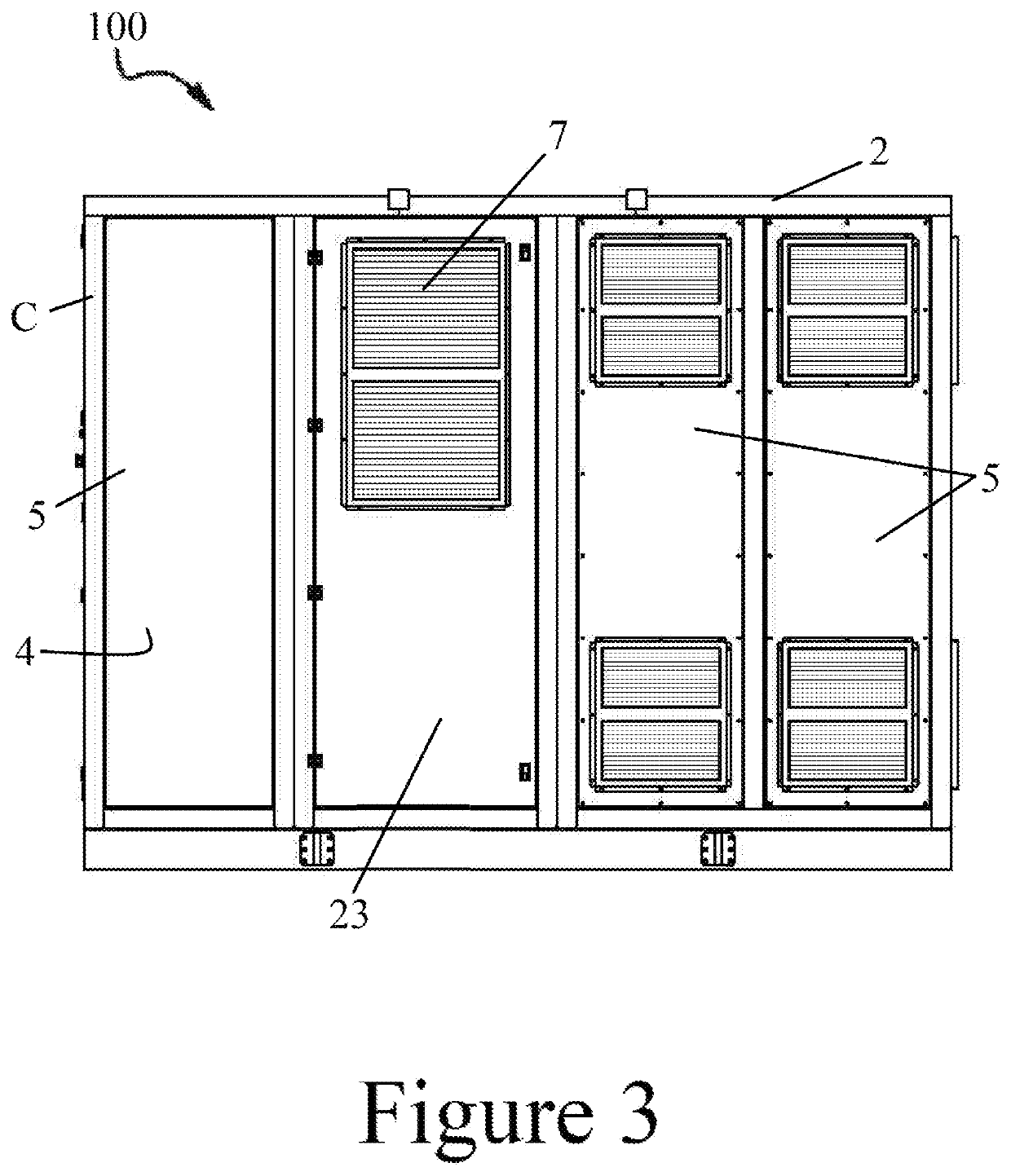

Power System for Oil and Gas Fracking Operations

ActiveUS20200340404A1Turbine/propulsion engine coolingGas turbine plantsElectricity systemLow voltage

Embodiments of a power provision system of the present invention generally include a transformer, a drive assembly, a motor control center, rectifiers, circuit breakers, and a cooling system, all of which are enclosed in a cabinet that is divided into a plurality of compartments that house various components and that is adapted and configured to be skid mounted on a trailer. In one embodiment, high voltage power is supplied to the power provision system, wherein it is stepped down to lower voltages by the transformer and the lower voltage power is utilized to drive a fracking pump motor via the drive assembly, as well as auxiliary equipment, such as the cooling system, via the motor control center. Embodiments of a method of using the power provision system are also provided.

Owner:AMERIMEX MOTOR & CONTROLS LLC

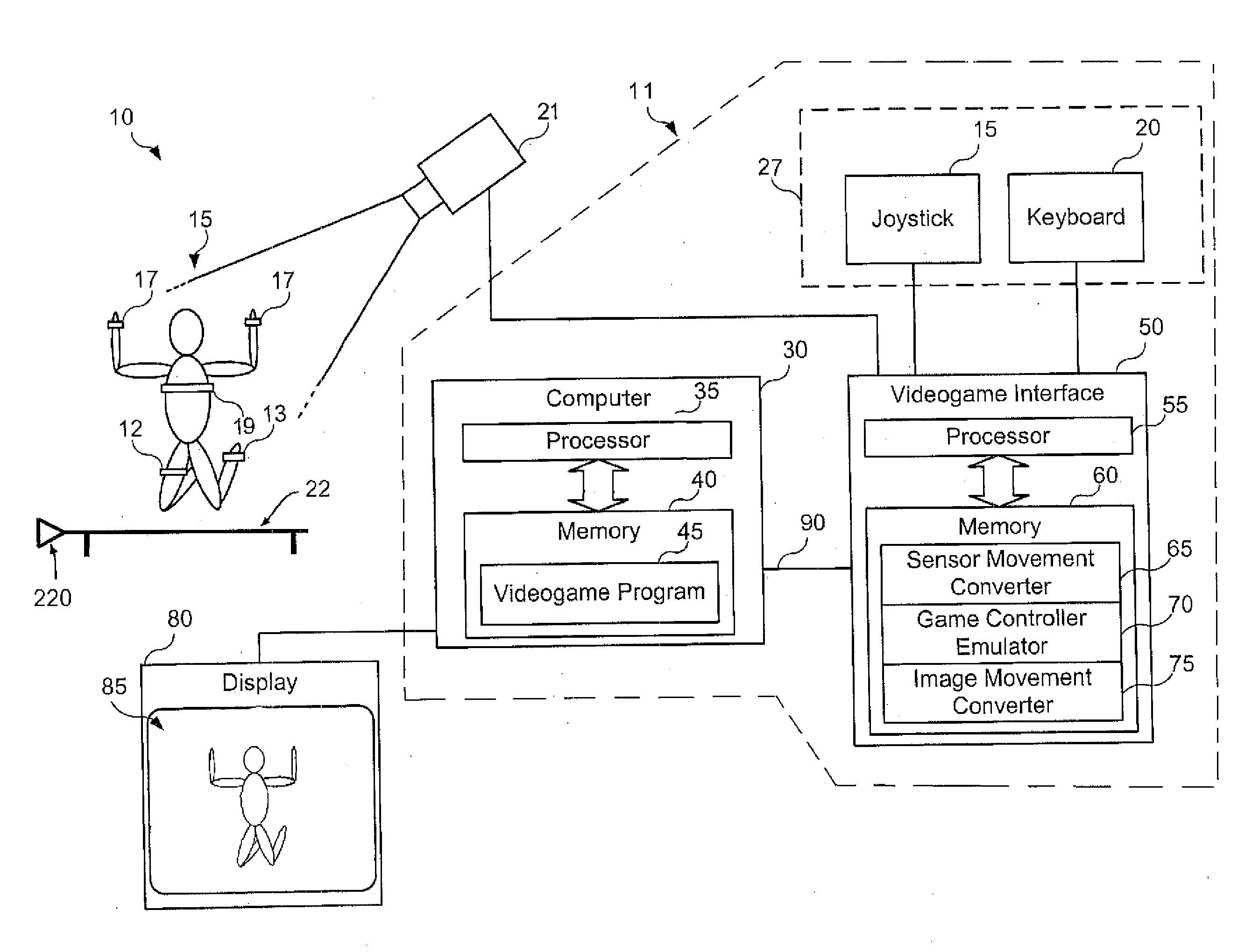

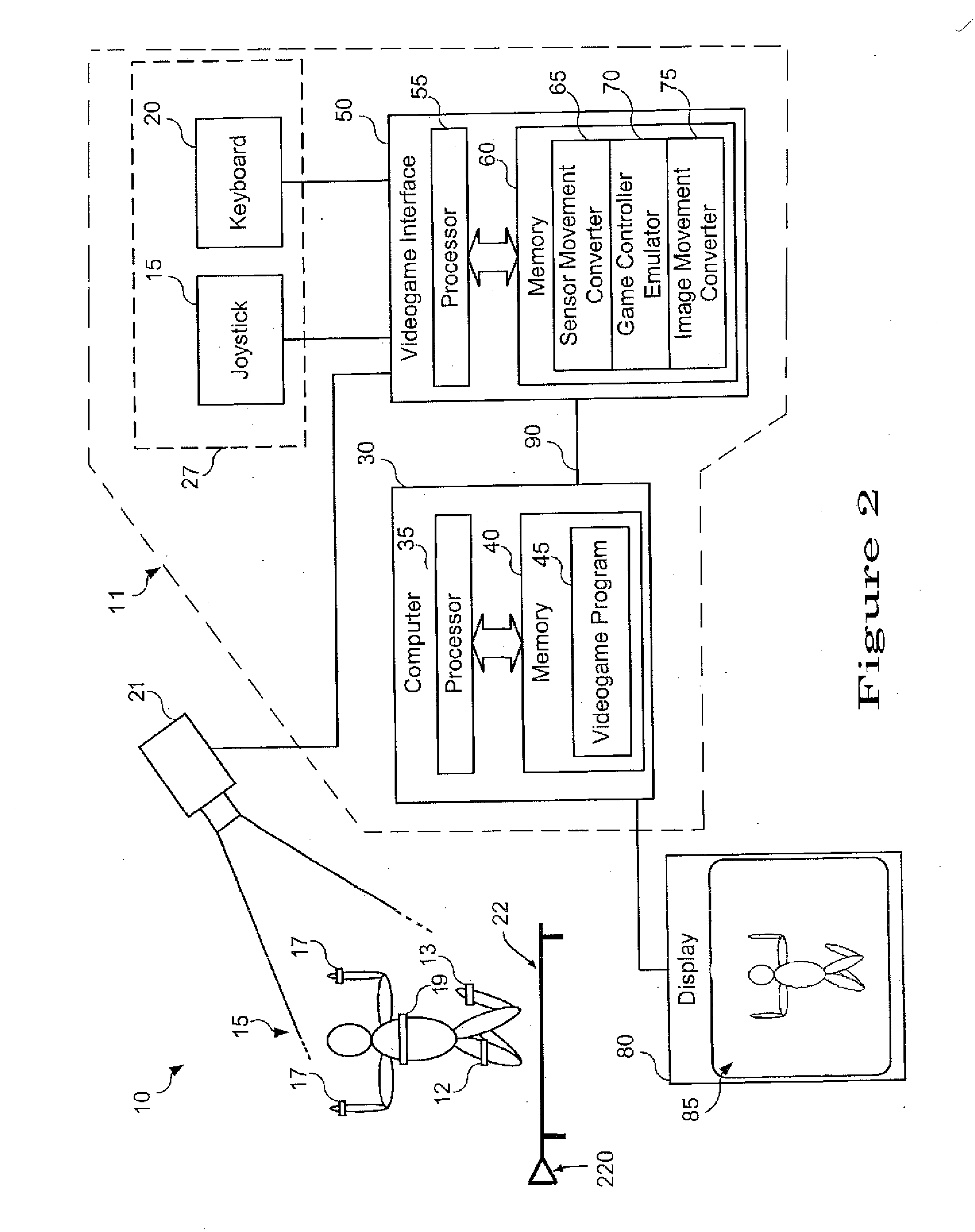

Sensor, Control and Virtual Reality System for a Trampoline

A trampoline exercise system that is designed to show an avatar of a user, which is jumping on a trampoline. The exercise system includes a computer module, a trampoline configured to provide a platform for a user to perform exercises thereon, and a sensor module designed to sense movements of a user performed on the trampoline. The sensor module provides information that is received by the computer module that controls the display of a users' avatar on a video monitor in response to the users' motion on the trampoline. Several types of sensor may be used to sense the movement of the user, including body mounted sensors, trampoline mounted sensors, and remote viewing sensors.

Owner:HALL DAVID

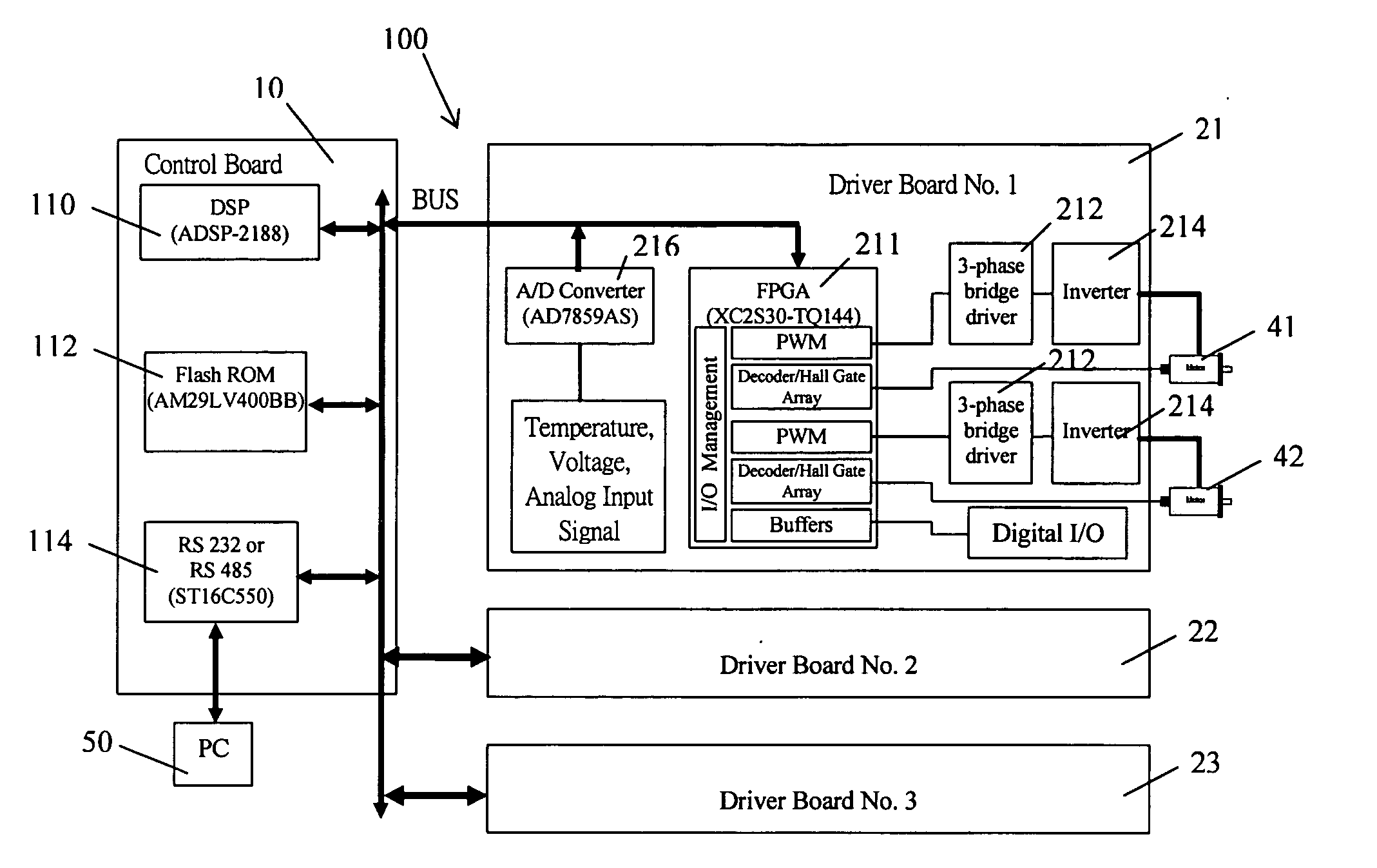

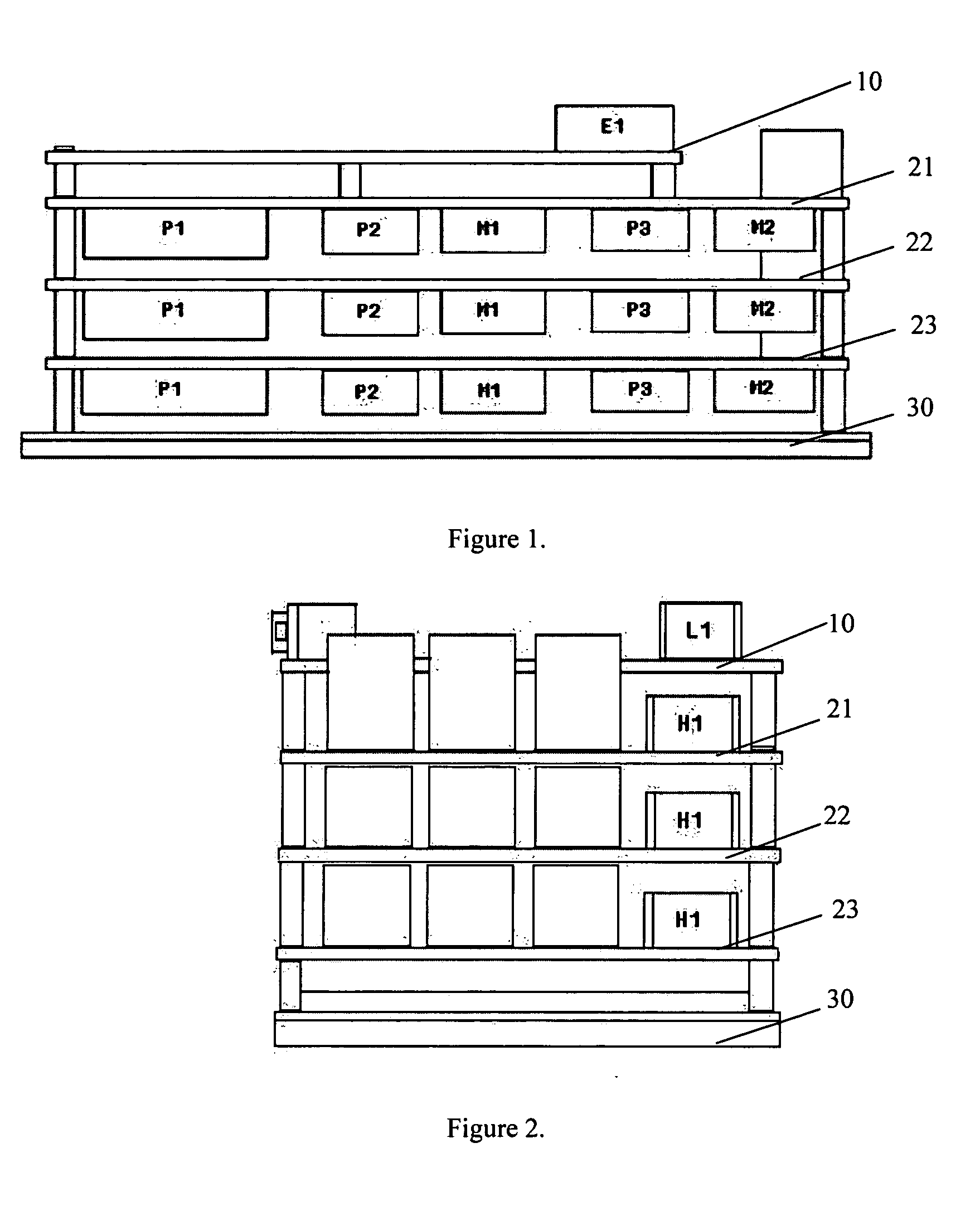

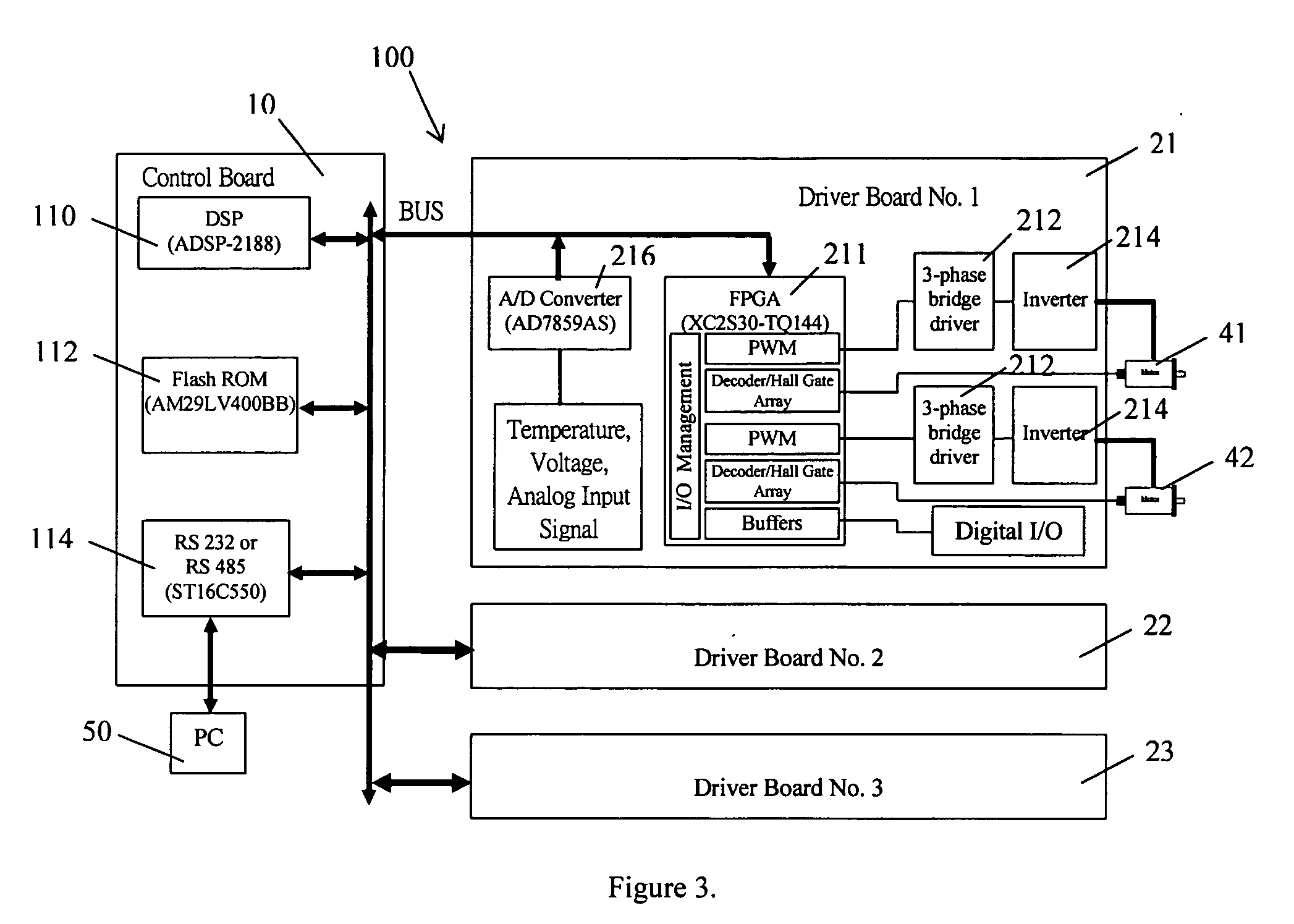

Modular multi-axis motion control and driving system and method thereof

InactiveUS20060100723A1Improve performanceReduced dimensionSynchronous motors startersAC motor controlMOSFETNetwork service

A modular multi-axis motion control and driving system is developed by using advanced Digital Signal Processor (DSP) and Field Programmable Gate Array (FPGA) technologies. A modular multi-axis motion control and driving system comprises: a control board comprising a DSP and Flash ROM connected to each other, for performing position control and current control of said system; a plurality of driver boards, connected to the control board through a bus, each of which comprise a FPGA device and a plurality of MOSFET power amplifier, for driving a plurality of servo motors; a computer, connected to said control board, for providing graphic user interface, through which motor setting, current and position loop tuning and diagnostic can be performed; Wherein, a control program, system parameters and FPGA configuration file are stored in said Flash ROM, when the system power is on, the DSP automatically executes an loader firmware to transfer the control program from said Flash ROM to the memory of DSP for execution, then the DSP reads the FPGA configuration file from the Flash ROM and configure the FPGA in the driver board, after that, the control program runs into a circulation loop to do system diagnose, network service and check command queue, while the current and position controls are implemented in an interrupt service.

Owner:DYNACITY TECH HK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com