Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1738 results about "Directional drilling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

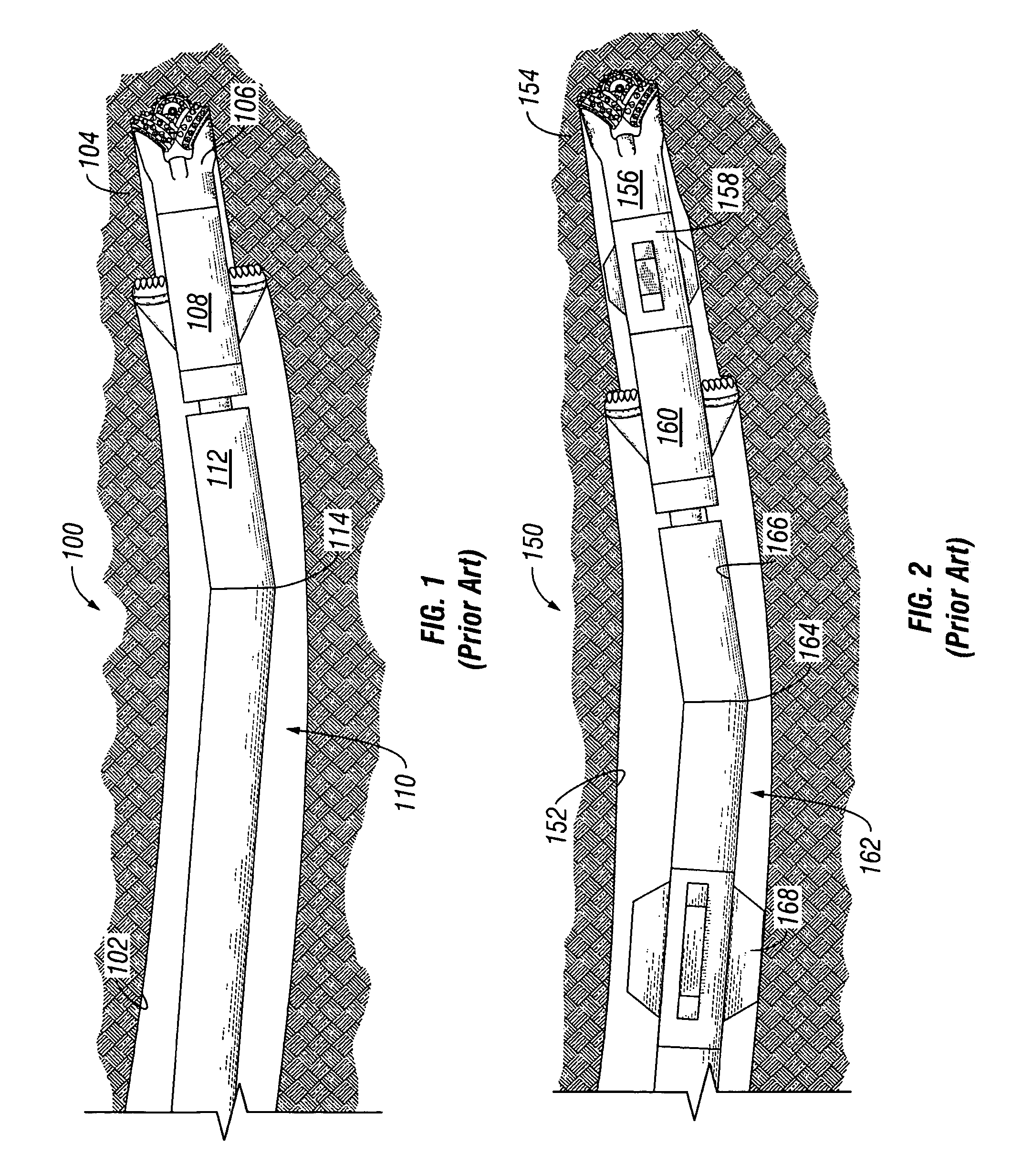

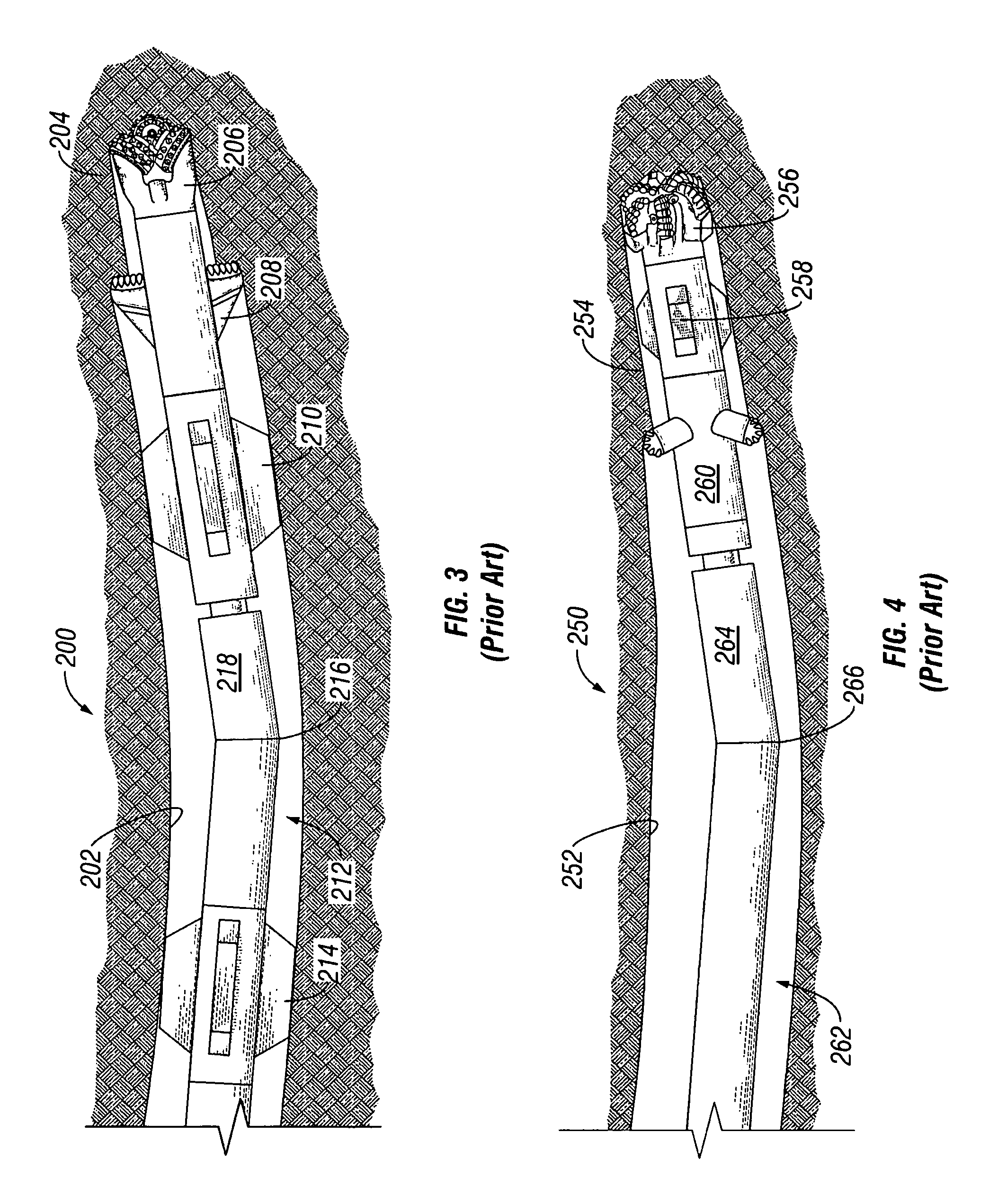

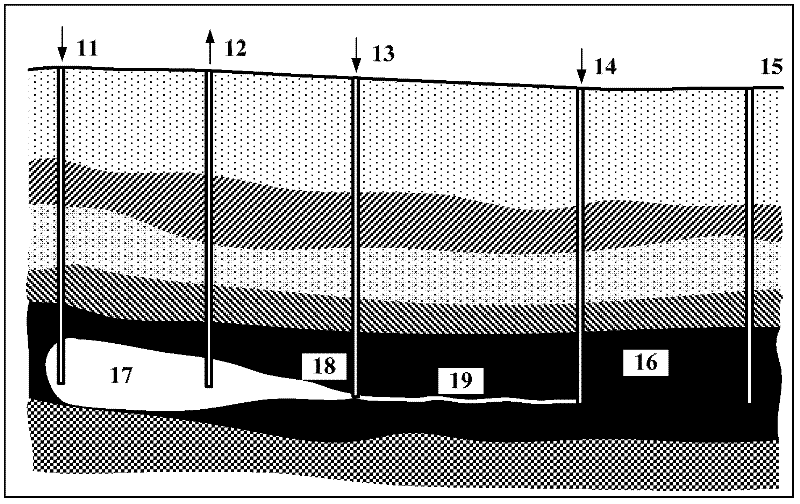

Directional drilling (or slant drilling) is the practice of drilling non-vertical wells. It can be broken down into four main groups: oilfield directional drilling, utility installation directional drilling (horizontal directional drilling), directional boring, and surface in seam (SIS), which horizontally intersects a vertical well target to extract coal bed methane.

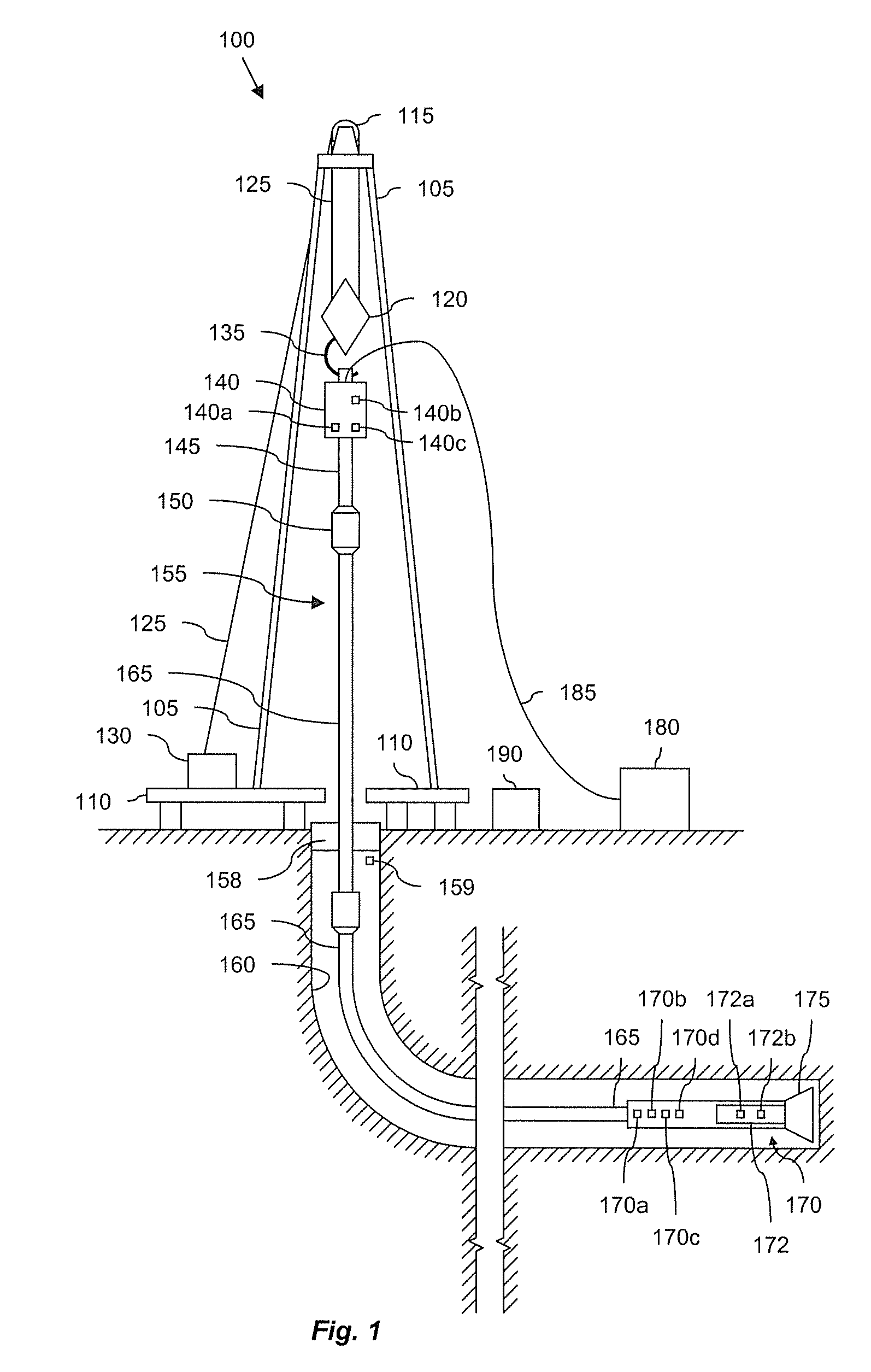

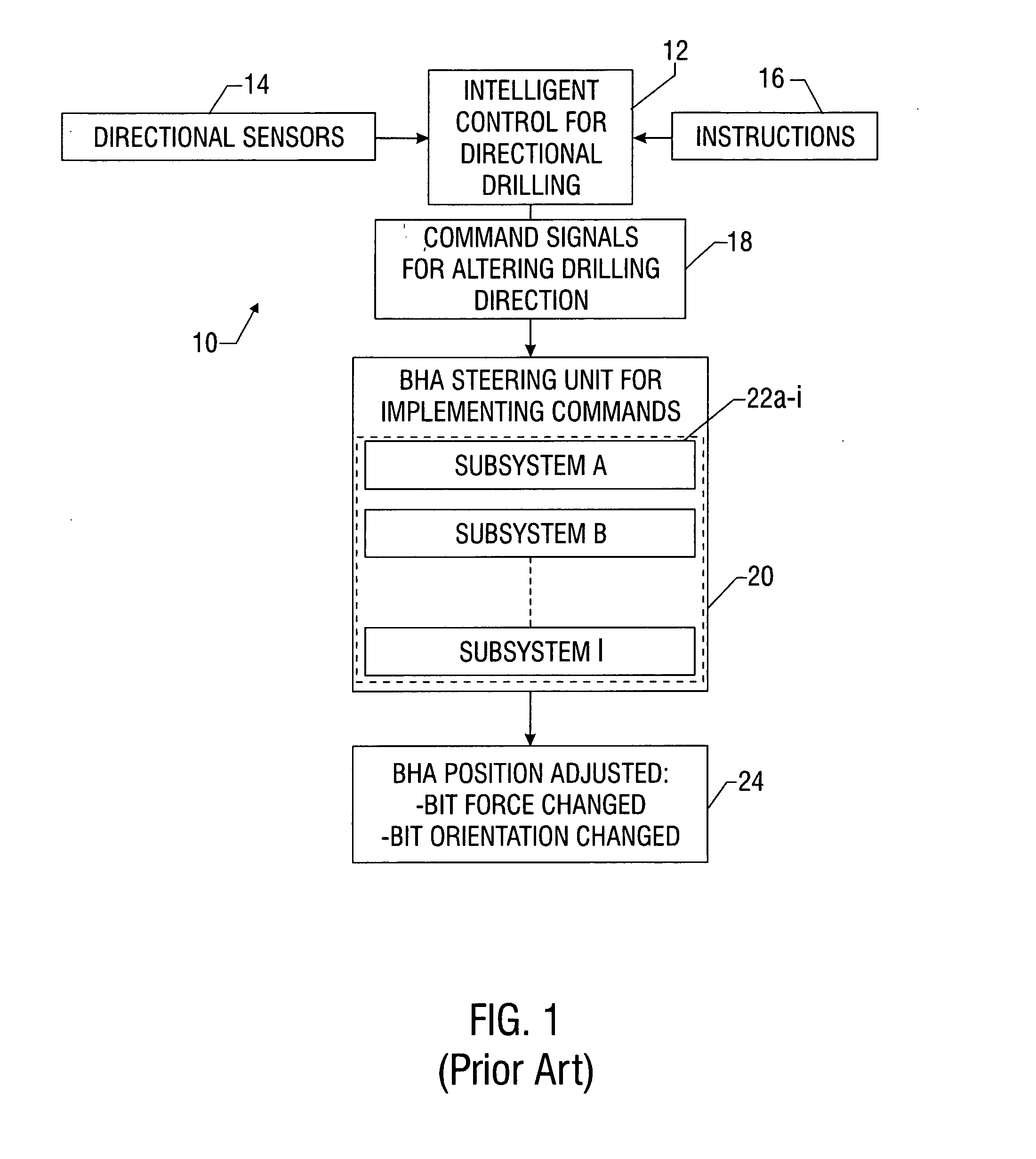

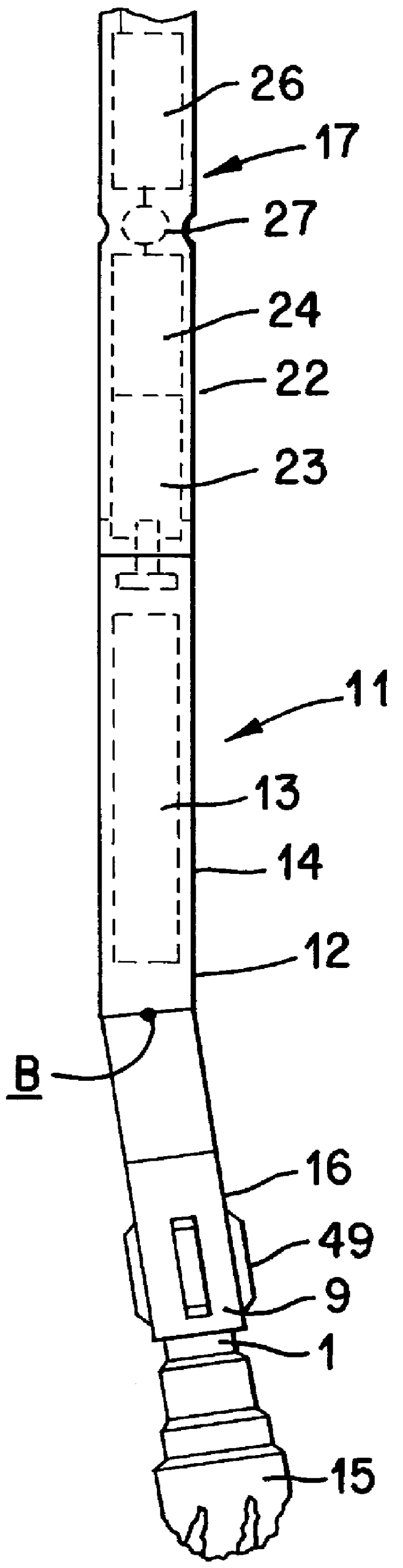

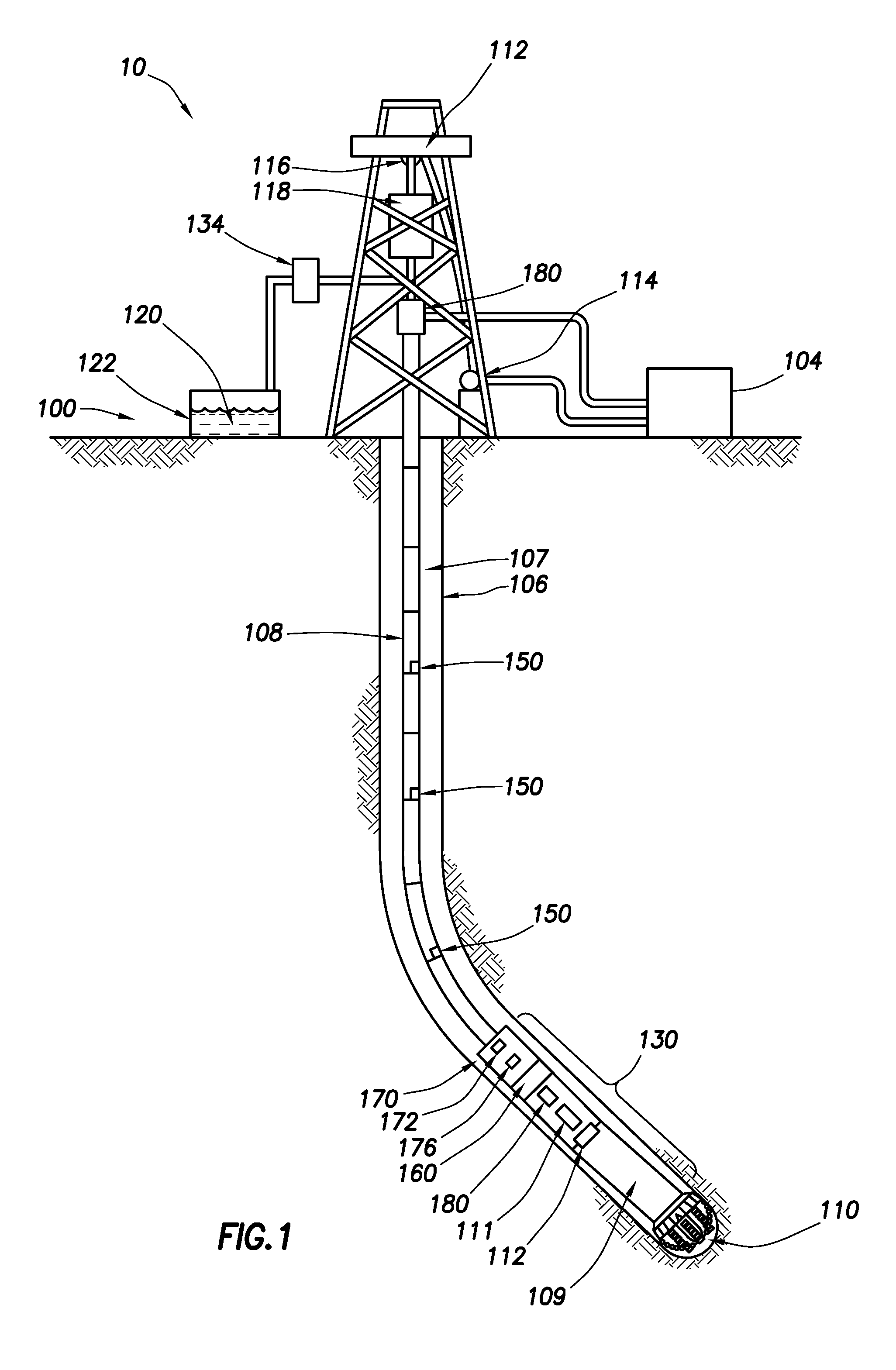

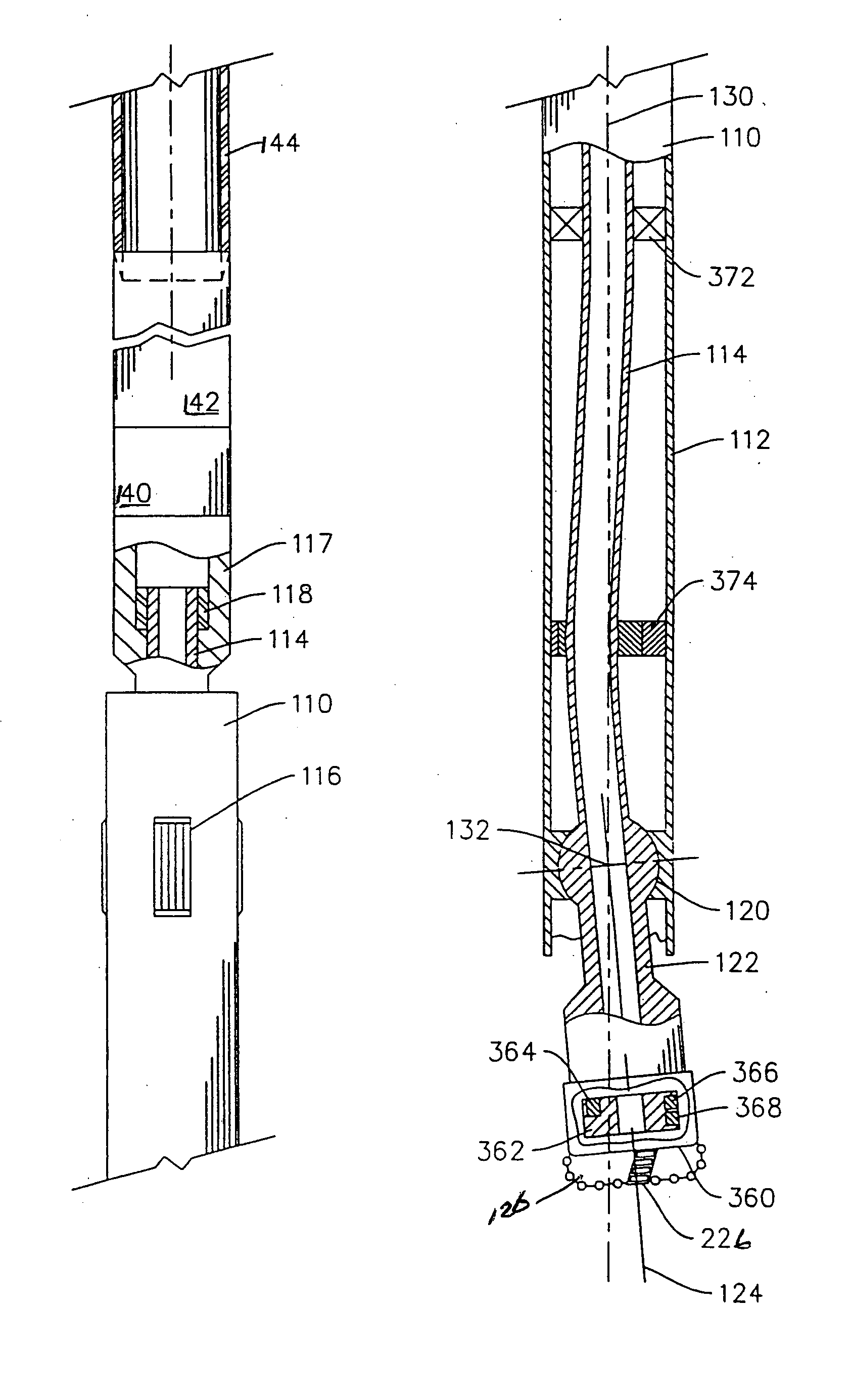

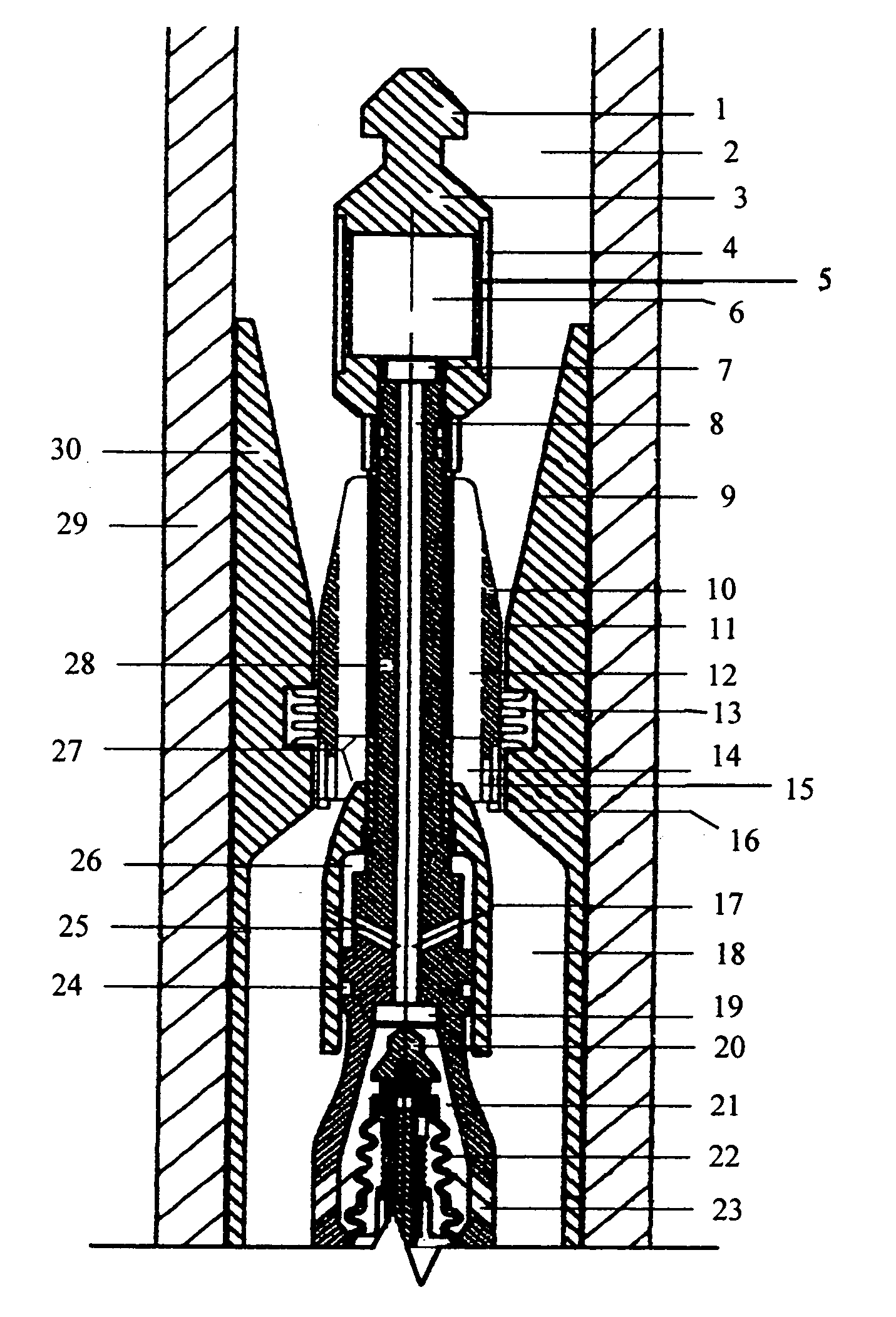

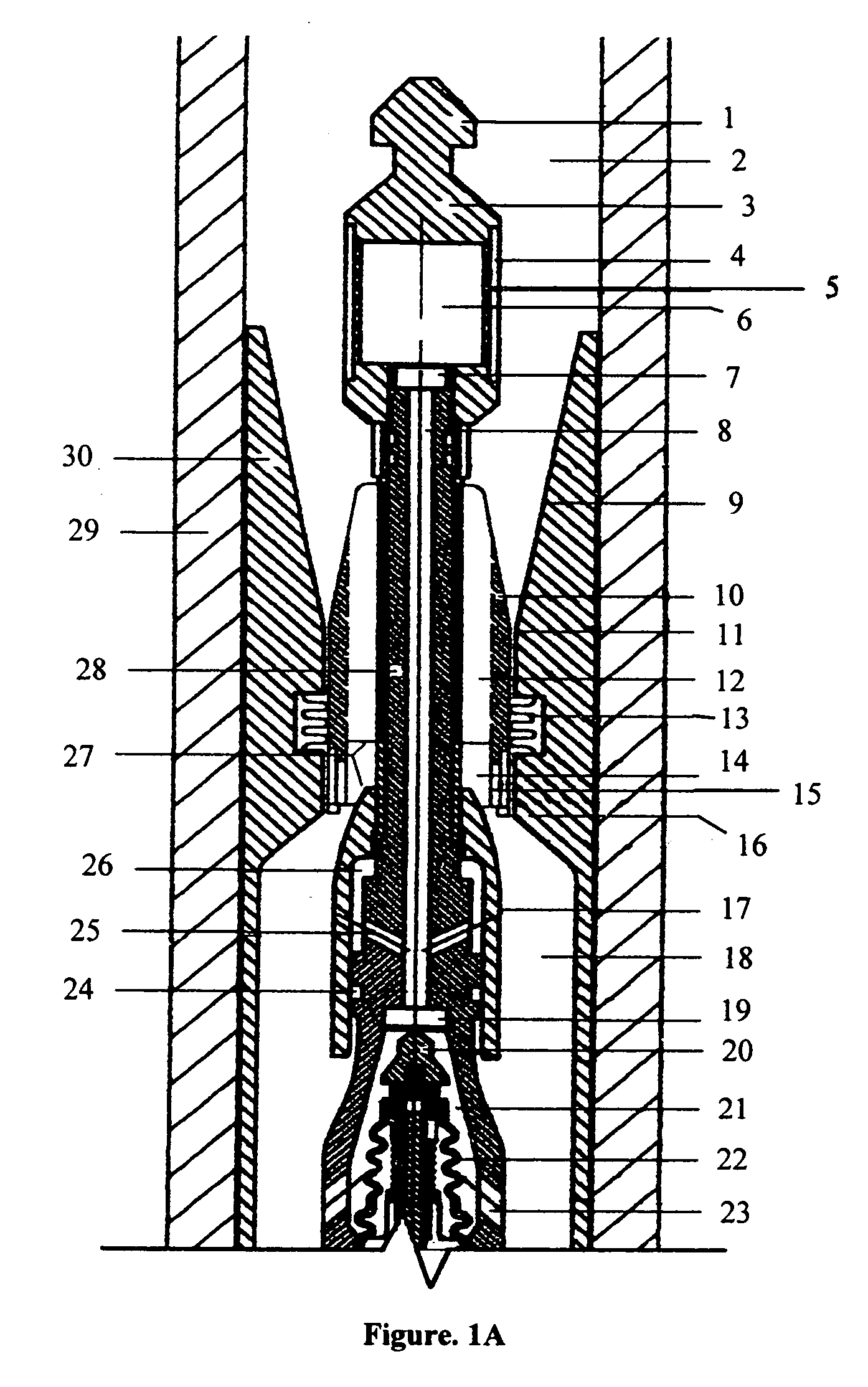

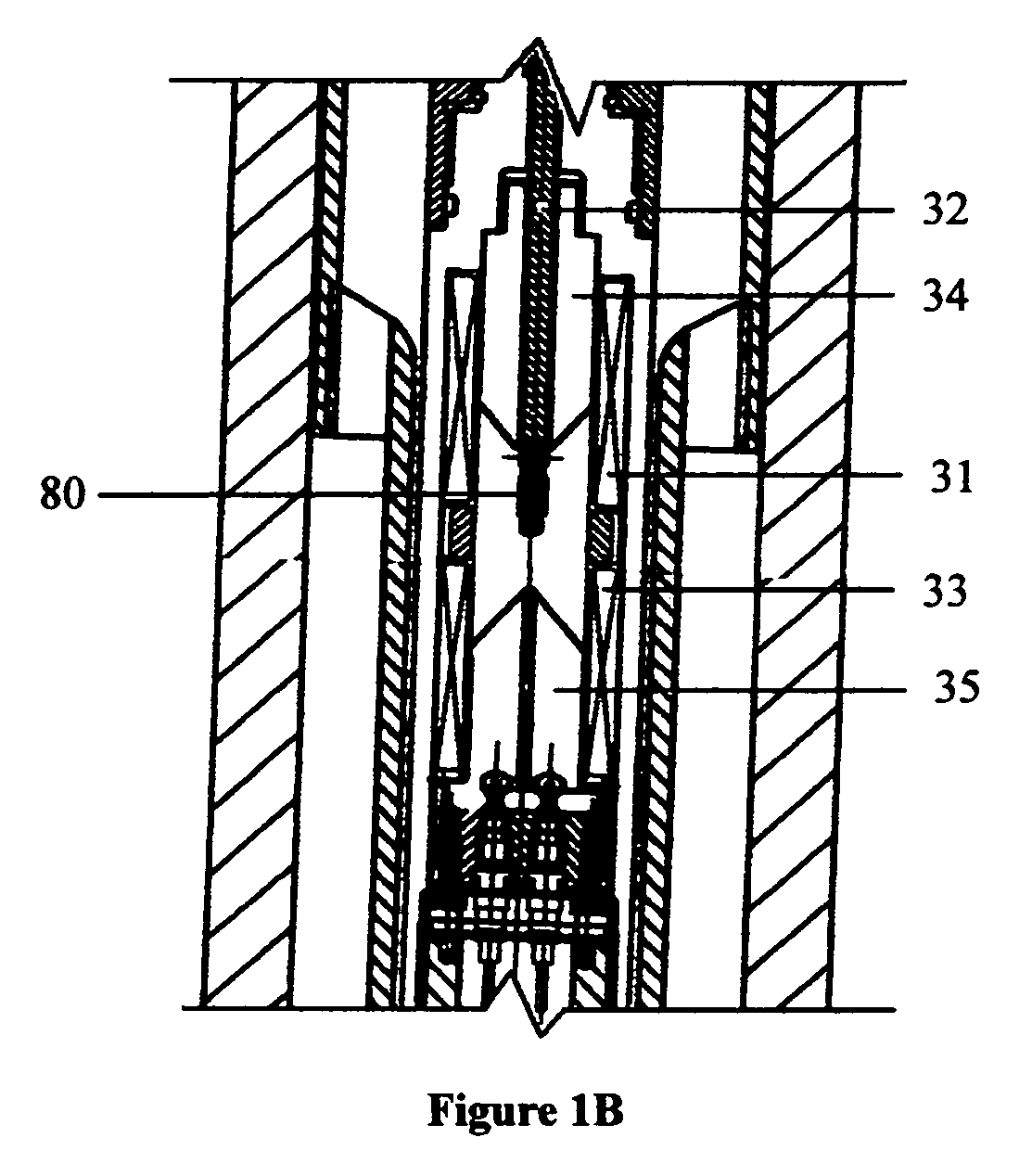

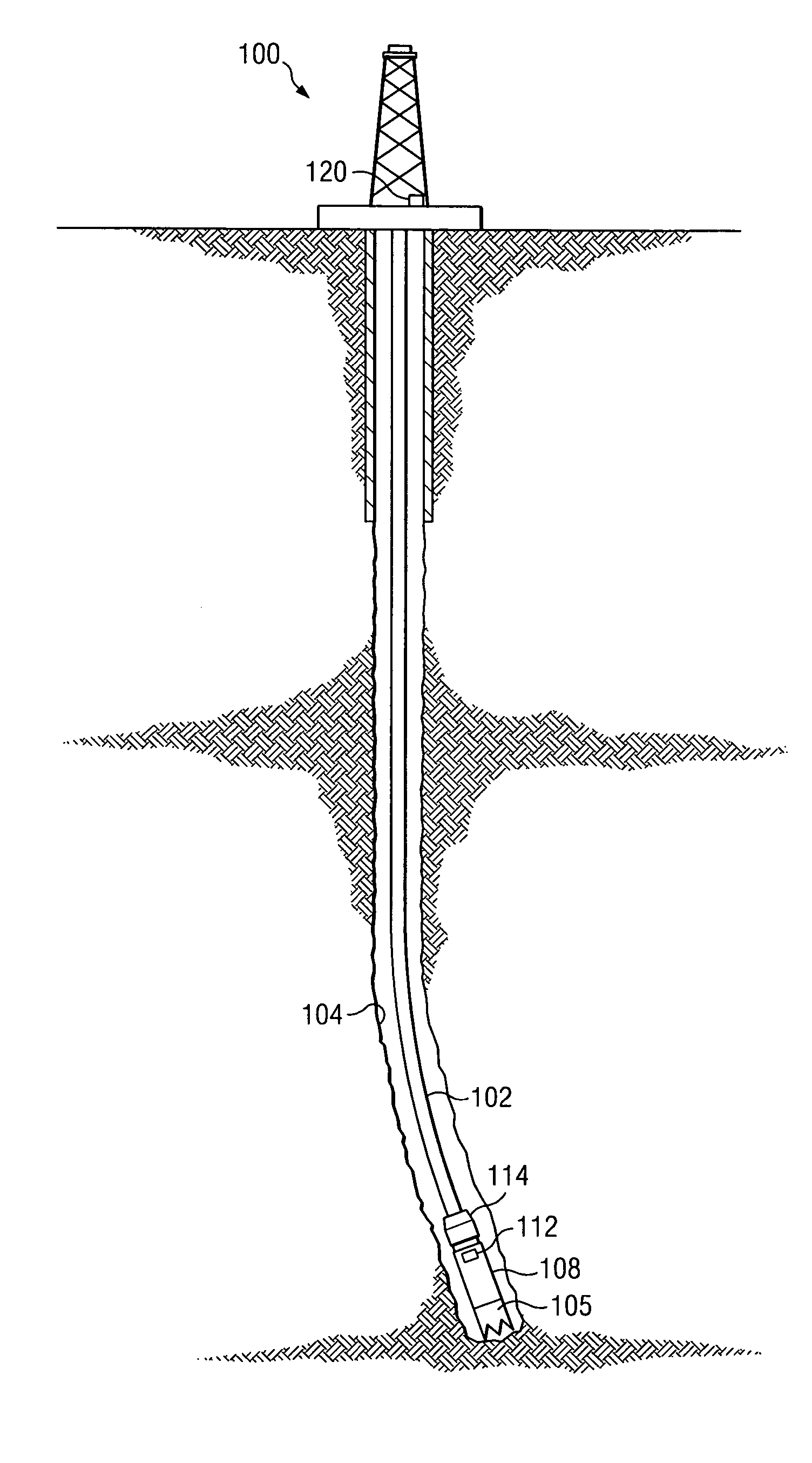

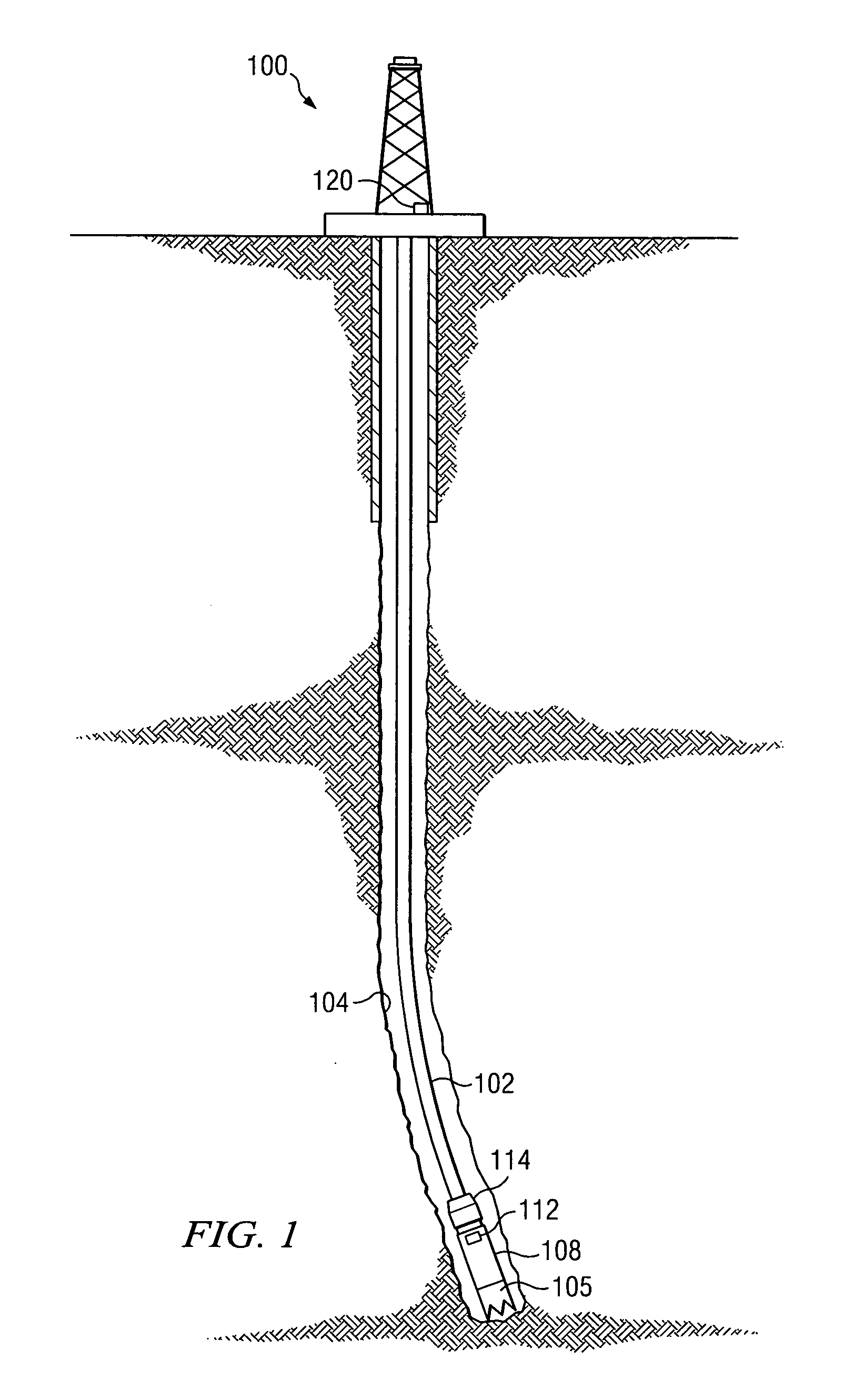

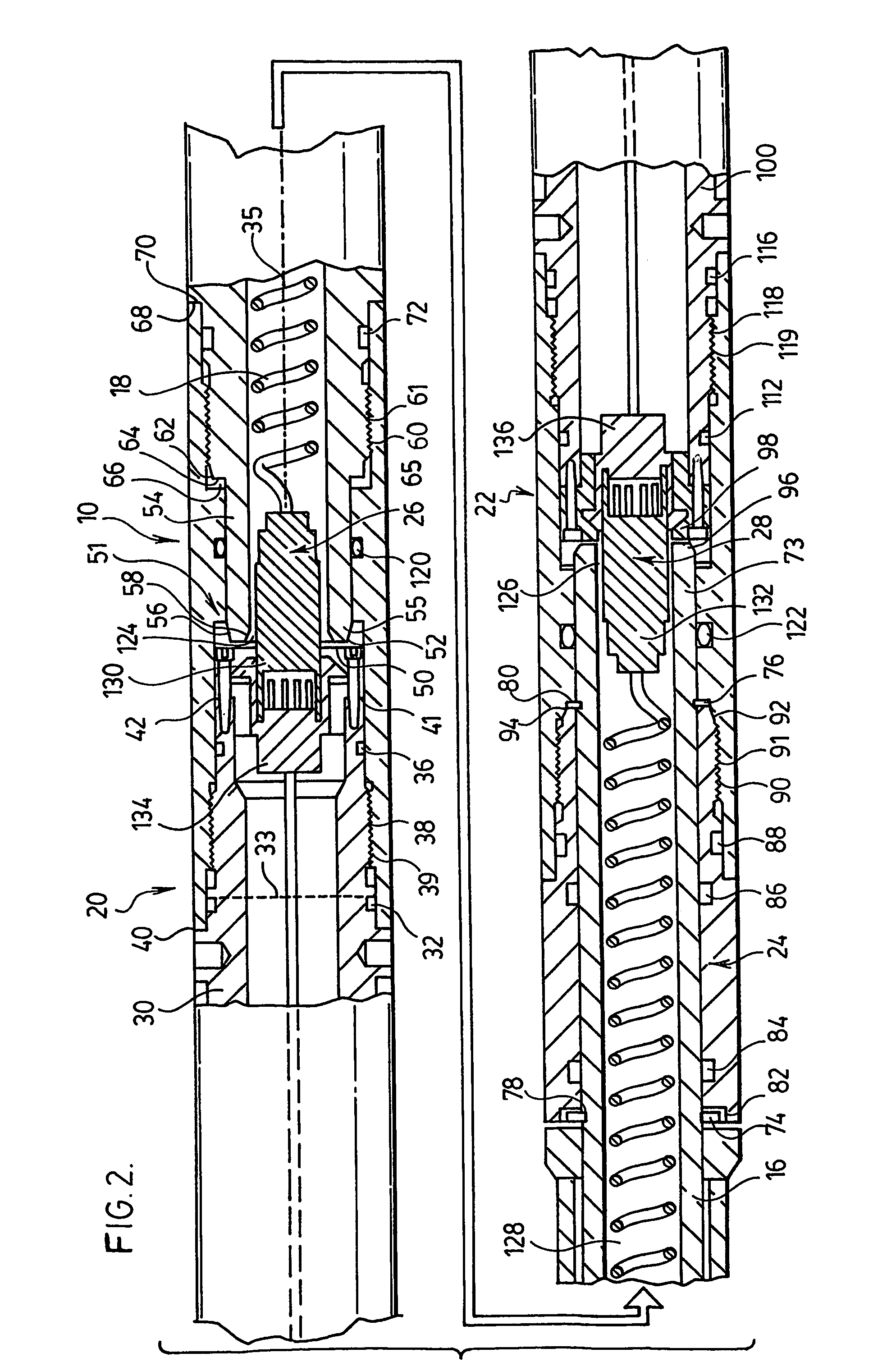

Actively controlled rotary steerable system and method for drilling wells

InactiveUS6092610AEfficient rotary speedPromote productionDrilling rodsConstructionsAccelerometerDirectional drilling

An actively controlled rotary steerable drilling system for directional drilling of wells having a tool collar rotated by a drill string during well drilling. A bit shaft has an upper portion within the tool collar and a lower end extending from the collar and supporting a drill bit. The bit shaft is omni-directionally pivotally supported intermediate its upper and lower ends by a universal joint within the collar and is rotatably driven by the collar. To achieve controlled steering of the rotating drill bit, orientation of the bit shaft relative to the tool collar is sensed and the bit shaft is maintained geostationary and selectively axially inclined relative to the tool collar during drill string rotation by rotating it about the universal joint by an offsetting mandrel that is rotated counter to collar rotation and at the same frequency of rotation. An electric motor provides rotation to the offsetting mandrel with respect to the tool collar and is servo-controlled by signal input from position sensing elements such as magnetometers, gyroscopic sensors, and accelerometers which provide real time position signals to the motor control. In addition, when necessary, a brake is used to maintain the offsetting mandrel and the bit shaft axis geostationary. Alternatively, a turbine is connected to the offsetting mandrel to provide rotation to the offsetting mandrel with respect to the tool collar and a brake is used to servo-control the turbine by signal input from position sensors.

Owner:SCHLUMBERGER TECH CORP

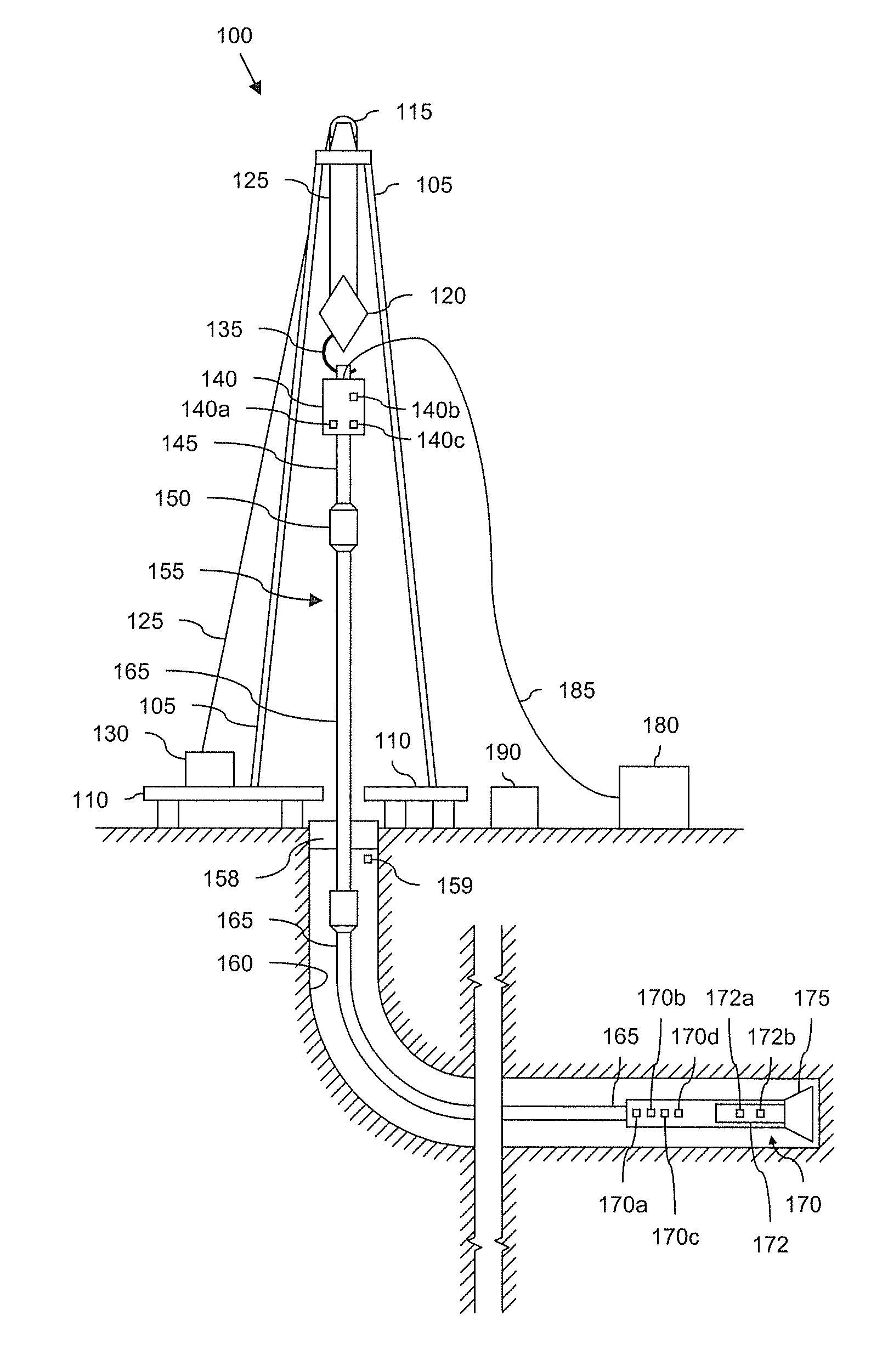

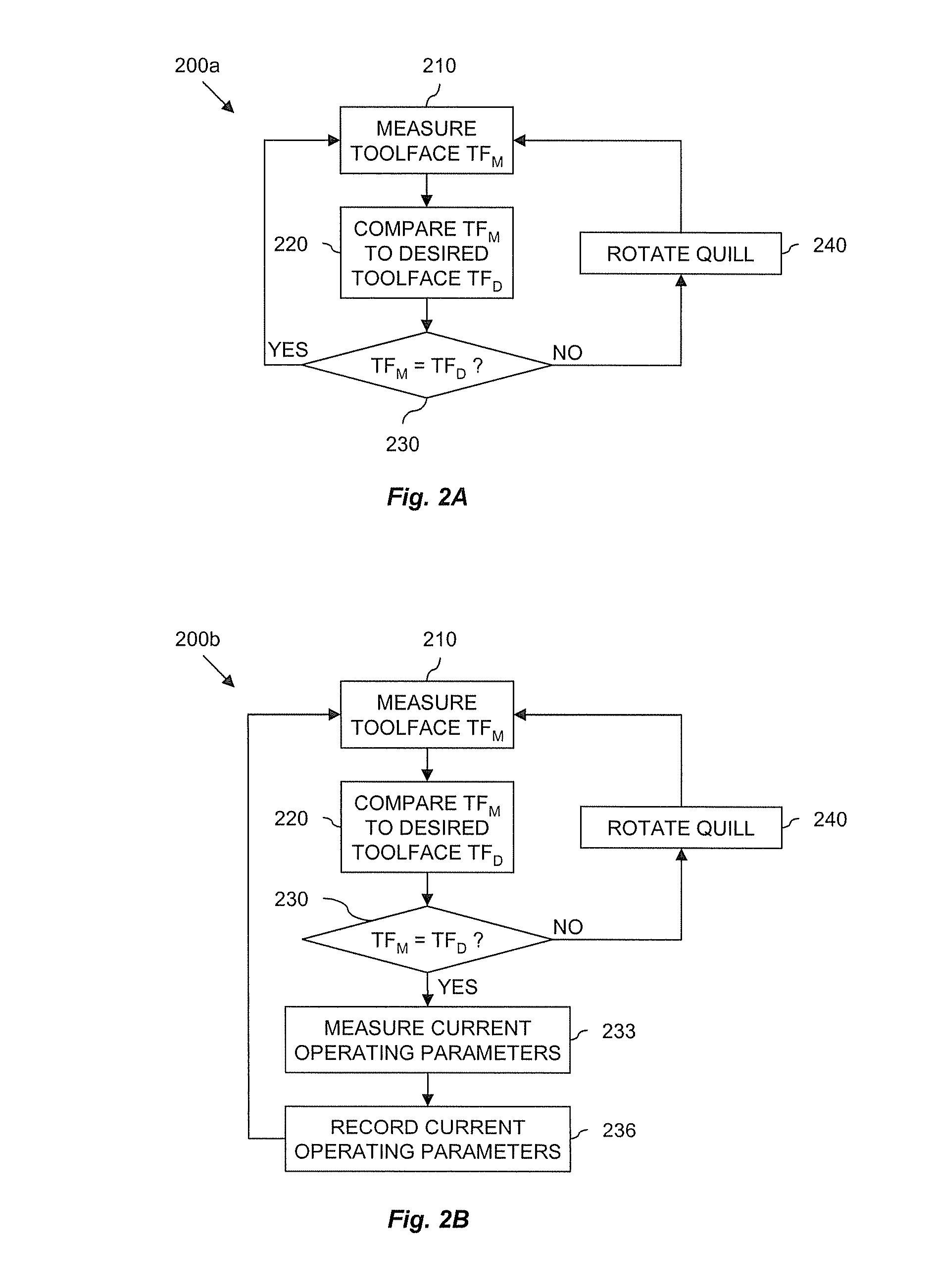

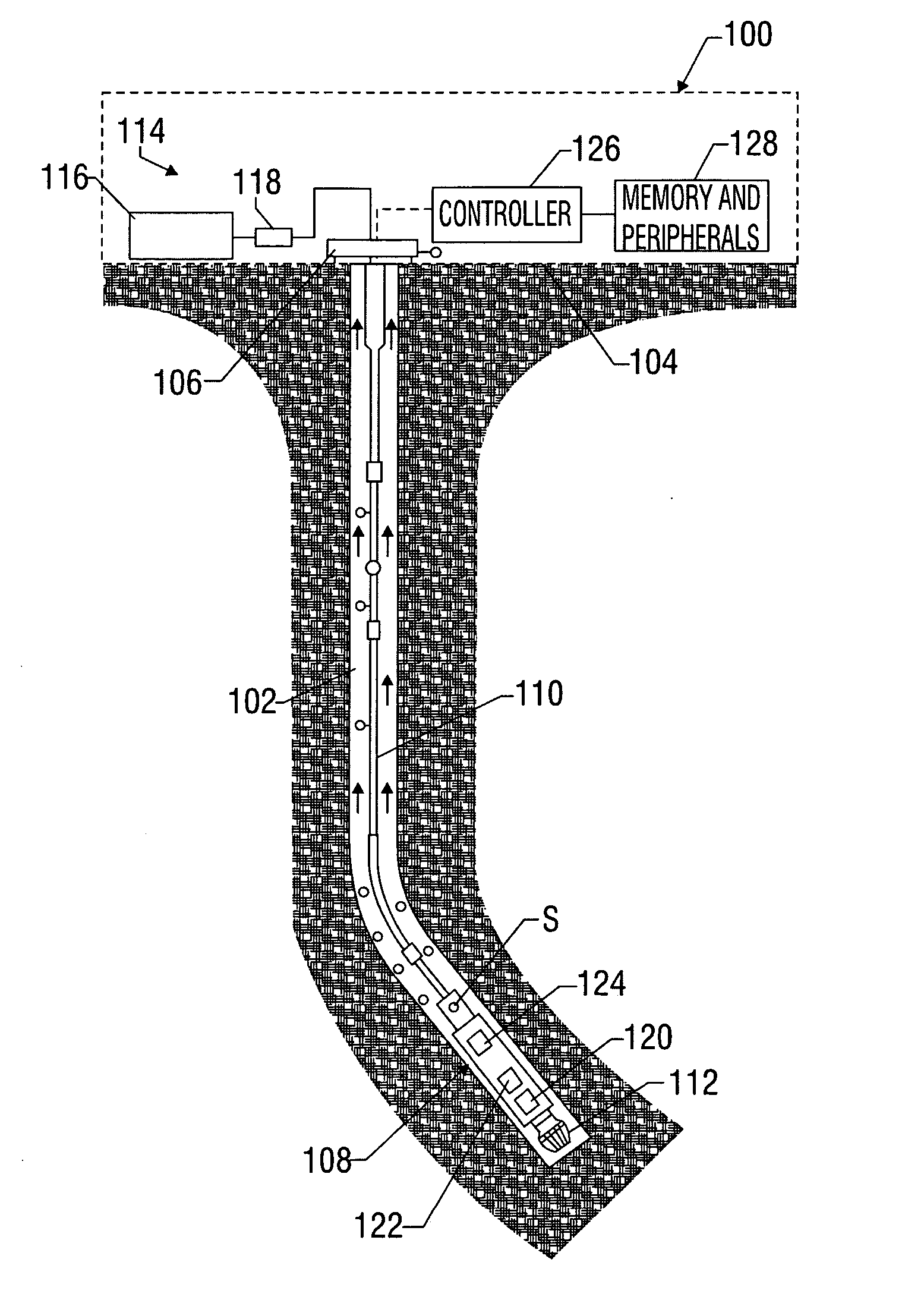

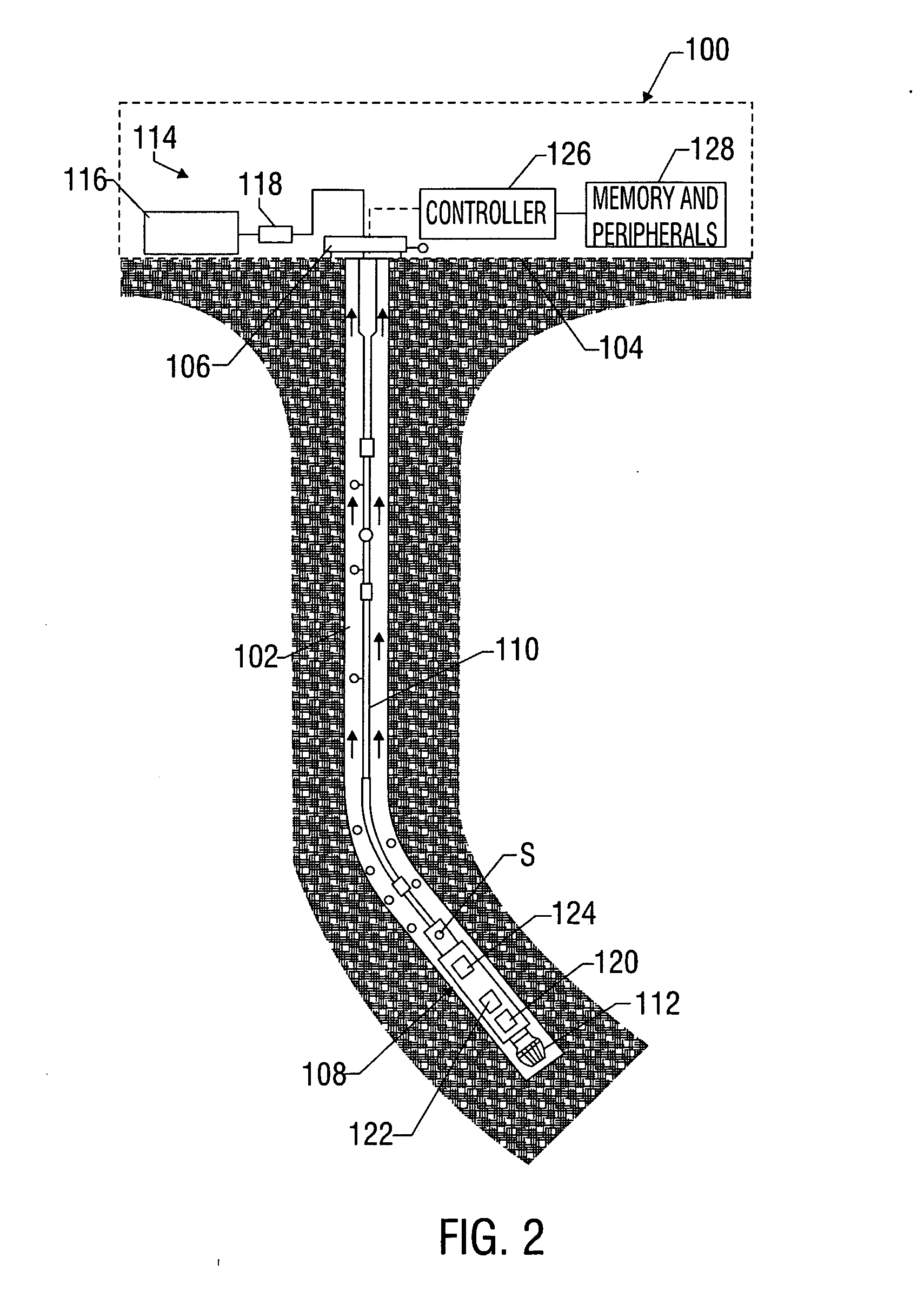

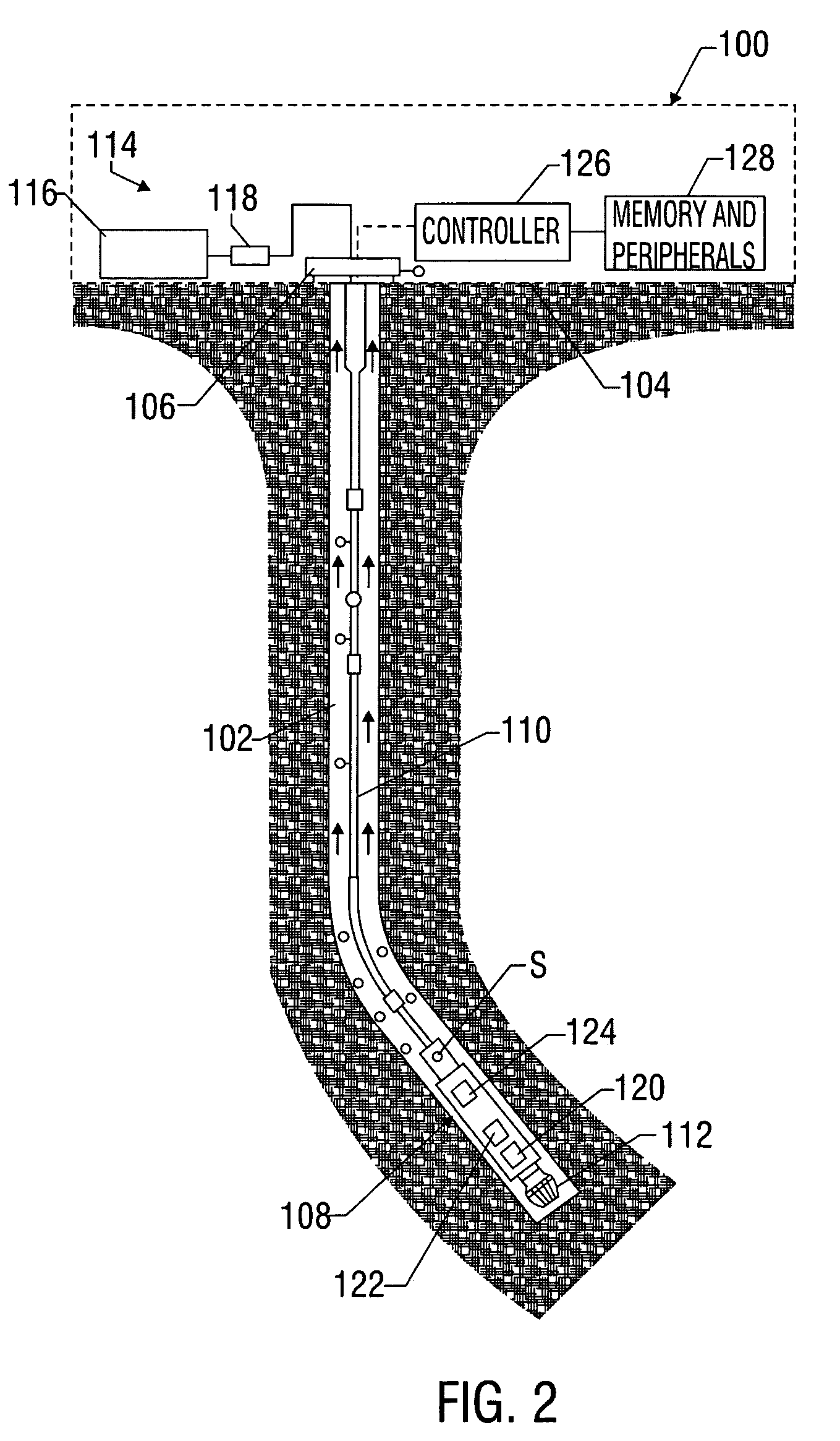

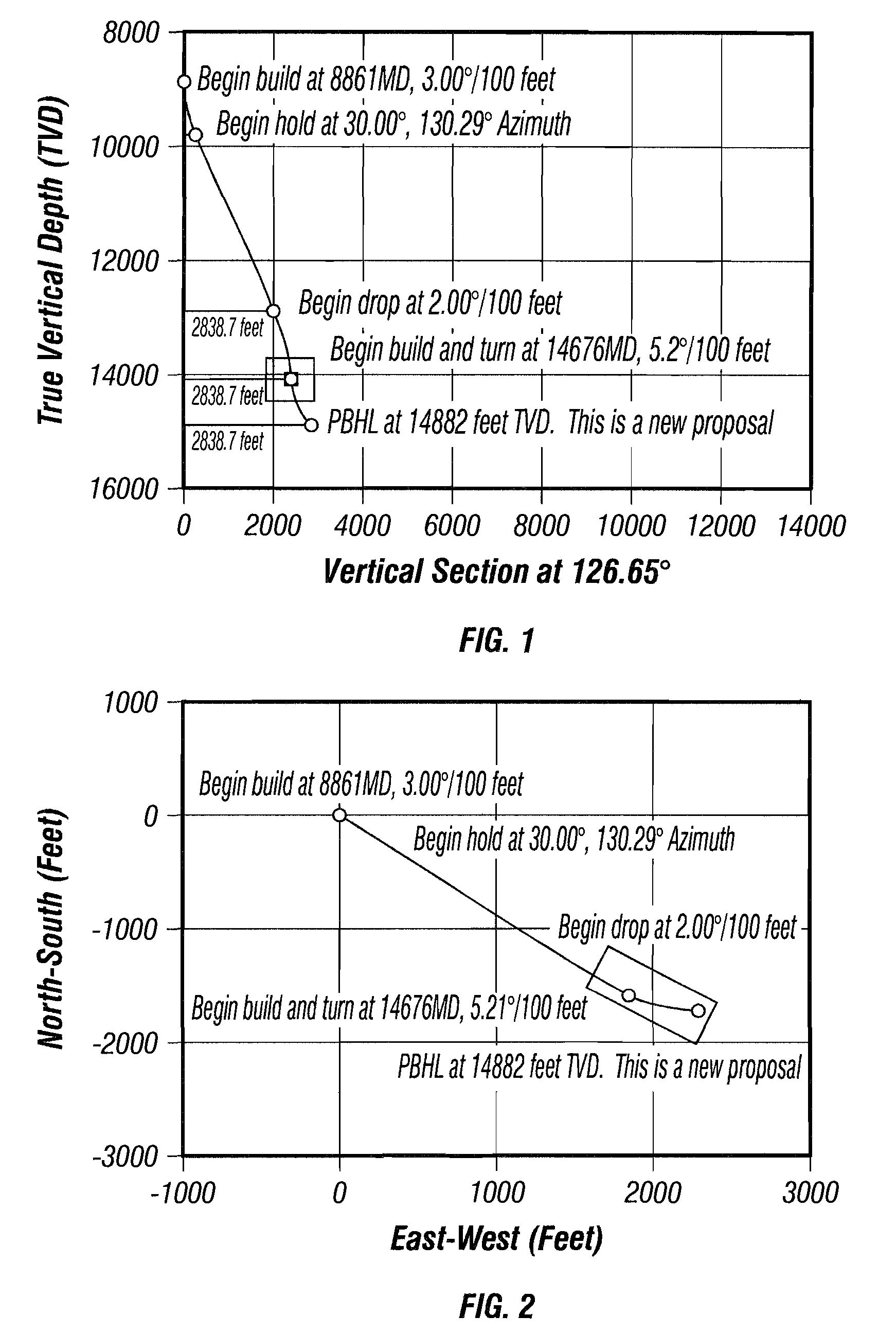

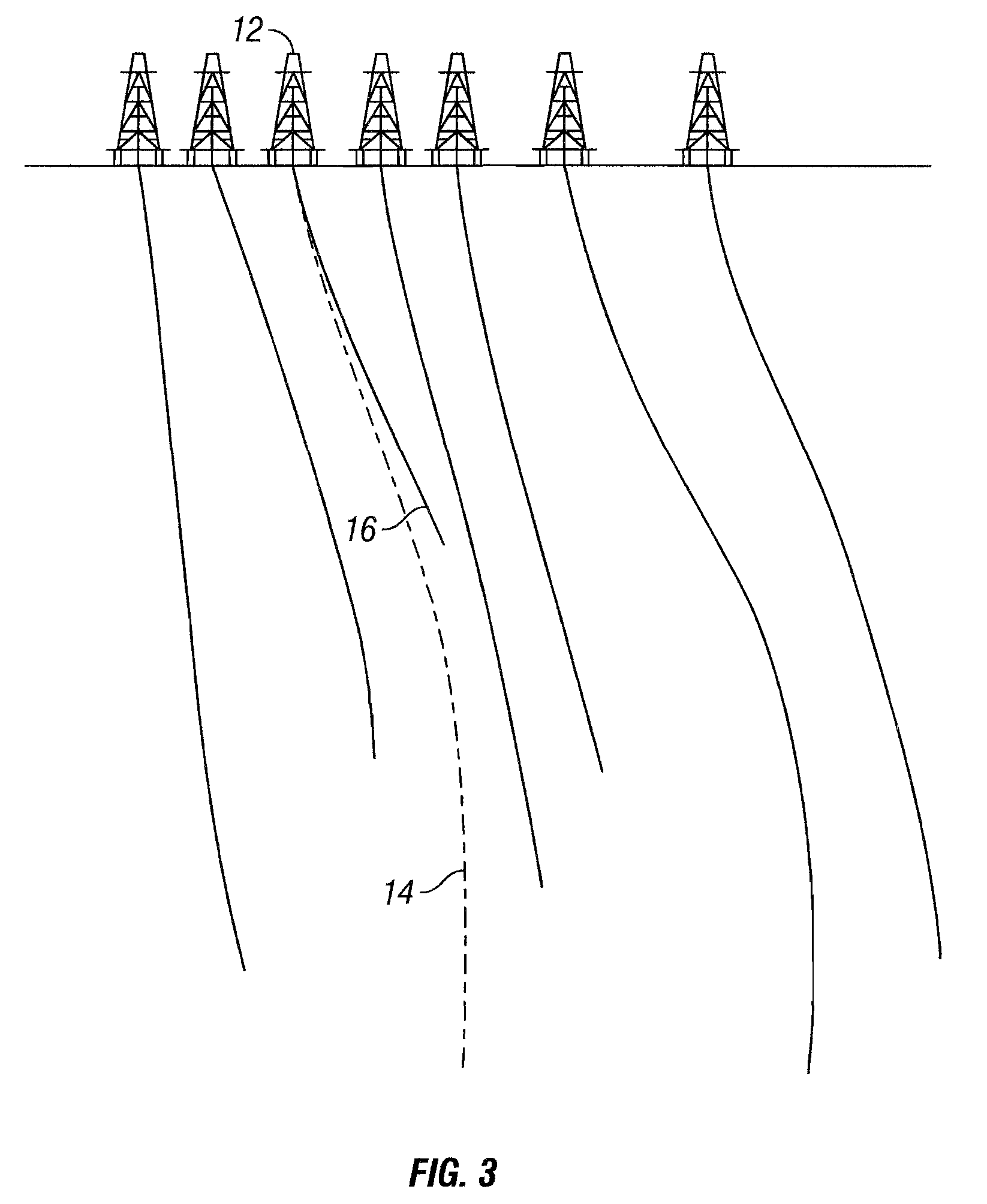

Automated directional drilling apparatus and methods

Methods and systems for drilling to a target location include a control system that receives an input comprising a planned drilling path to a target location and determines a projected location of a bottom hole assembly of a drilling system. The projected location of the bottom hole assembly is compared to the planned drilling path to determine a deviation amount. A modified drilling path is created to the target location as selected based on the amount of deviation from the planned drilling path, and drilling rig control signals that steer the bottom hole assembly of the drilling system to the target location along the modified drilling path are generated.

Owner:NABORS DRILLING TECH USA INC

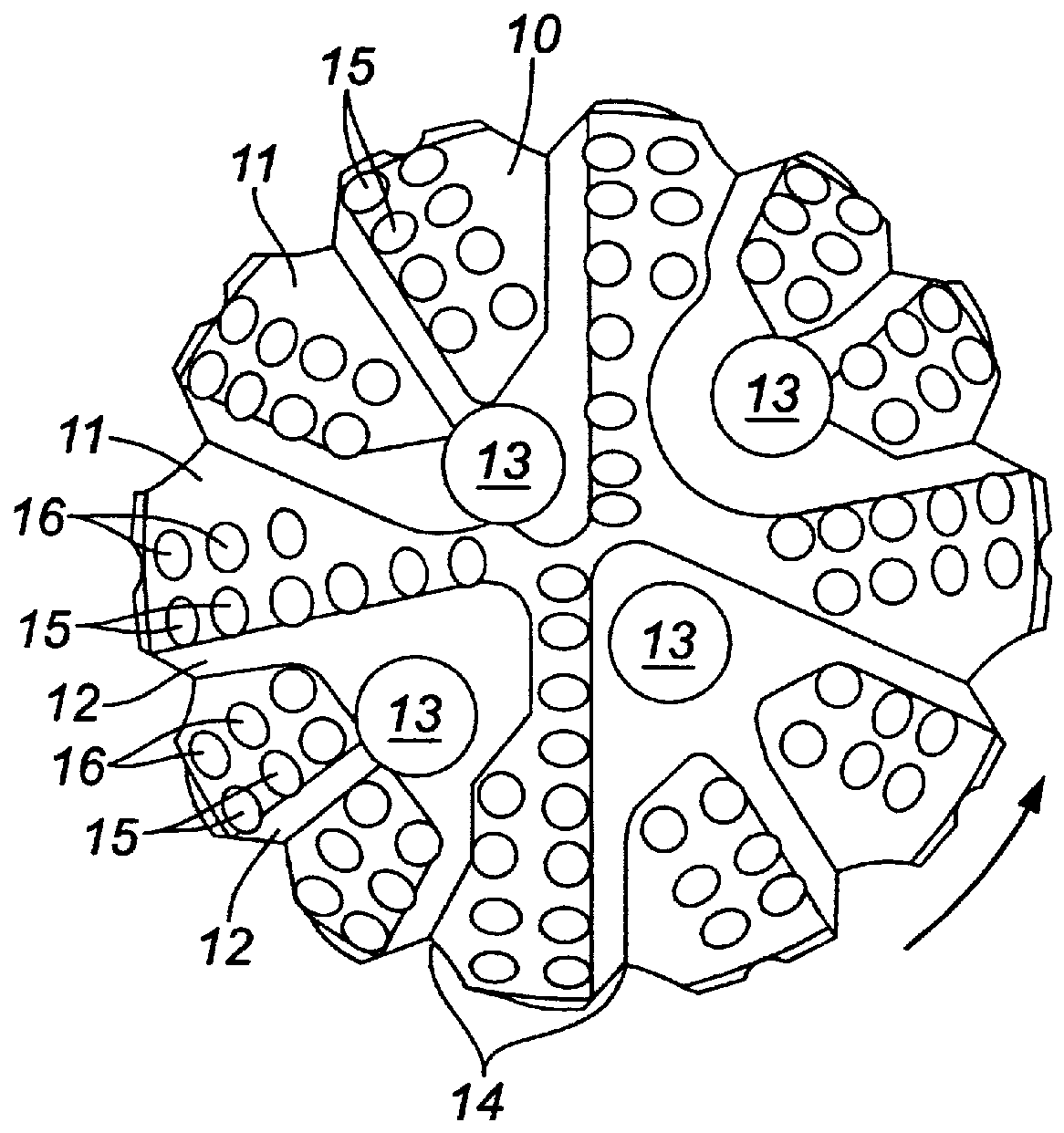

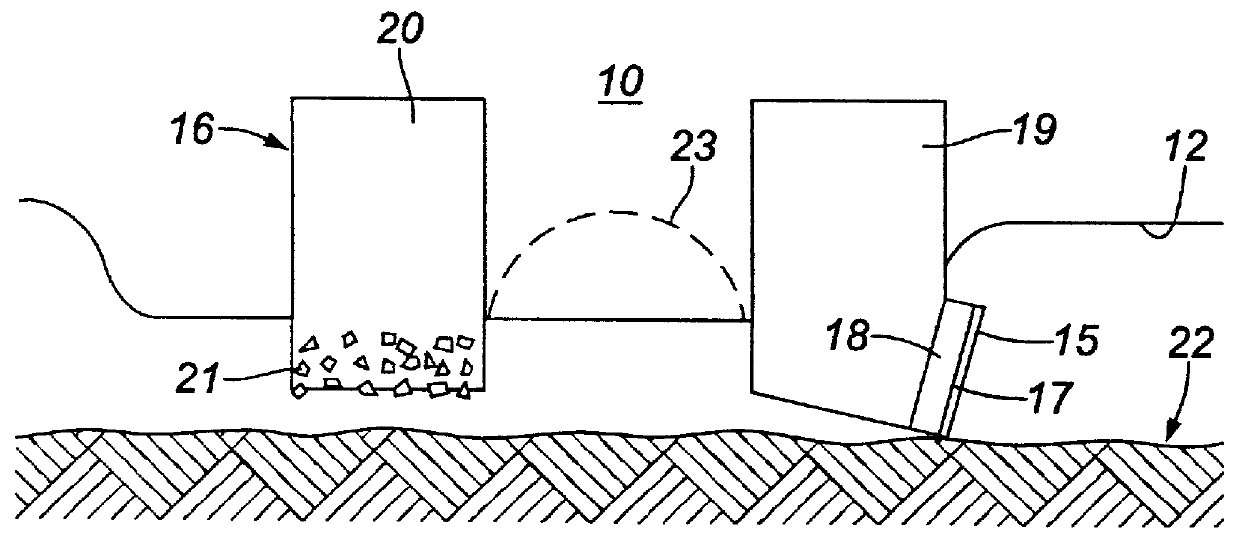

Rotary drill bit having moveable formation-engaging members

Formation engaging elements are moveably mounted onto a drill bit. Such elements may be used to protect other rigidly mounted formation engaging elements from impacts that occur during use of the drill bit, or they may be used to alter the aggressiveness of the drill bit when used in directional drilling operations.

Owner:REEDHYCALOG UK

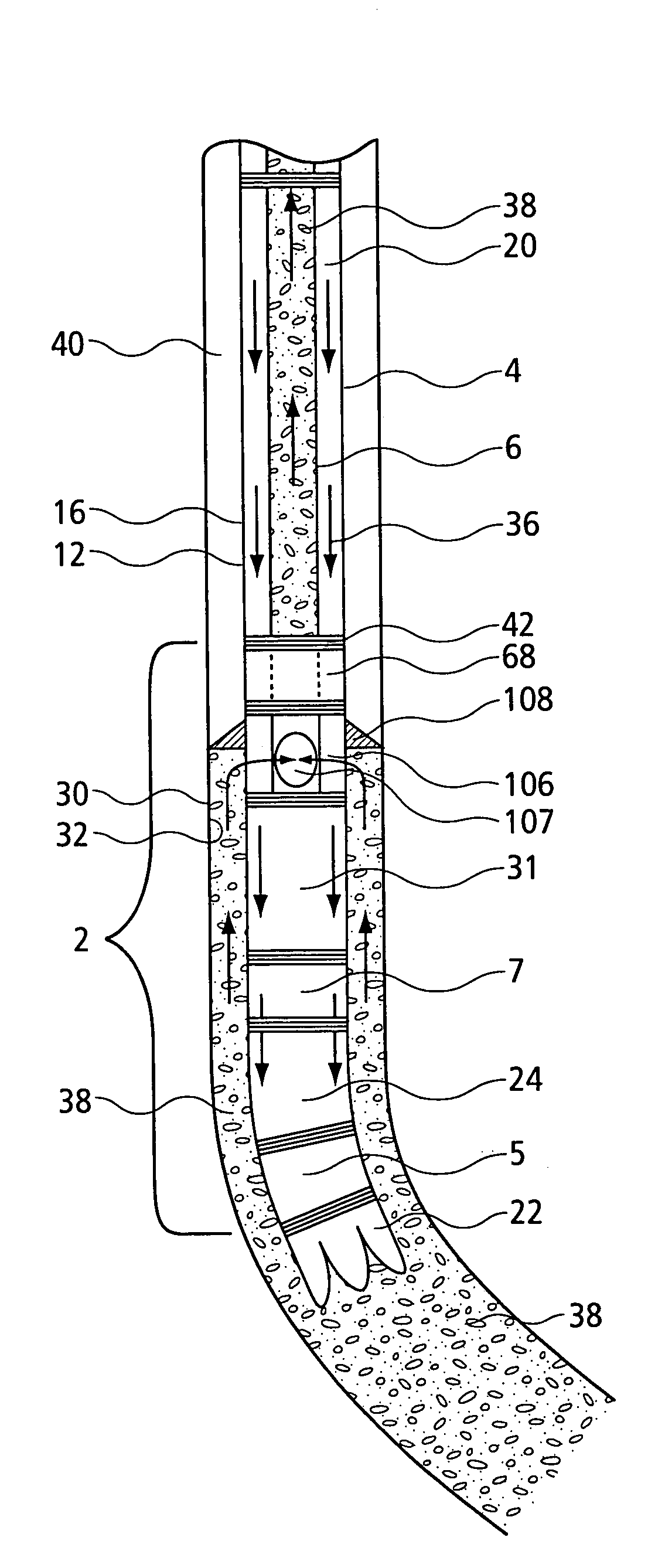

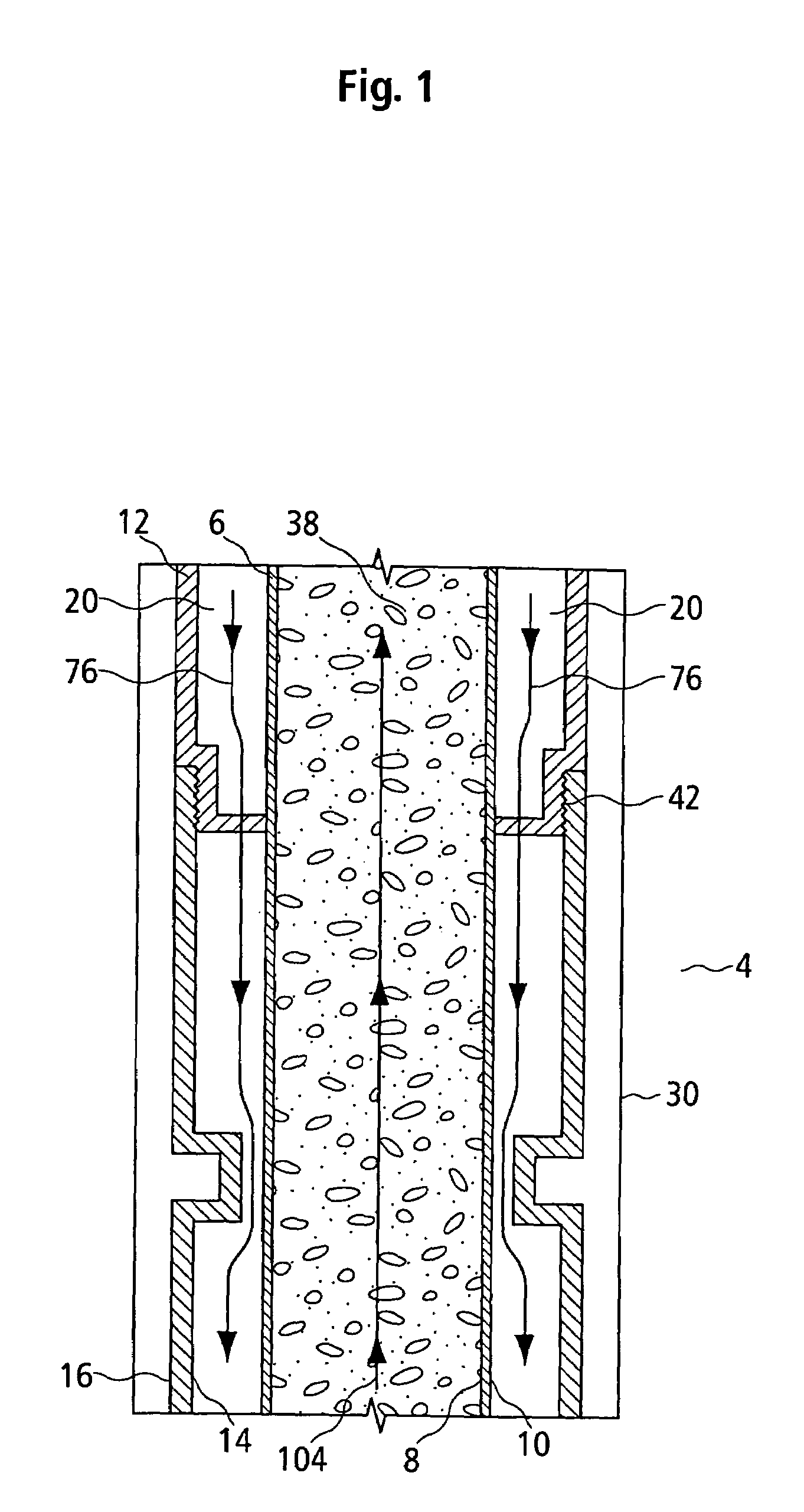

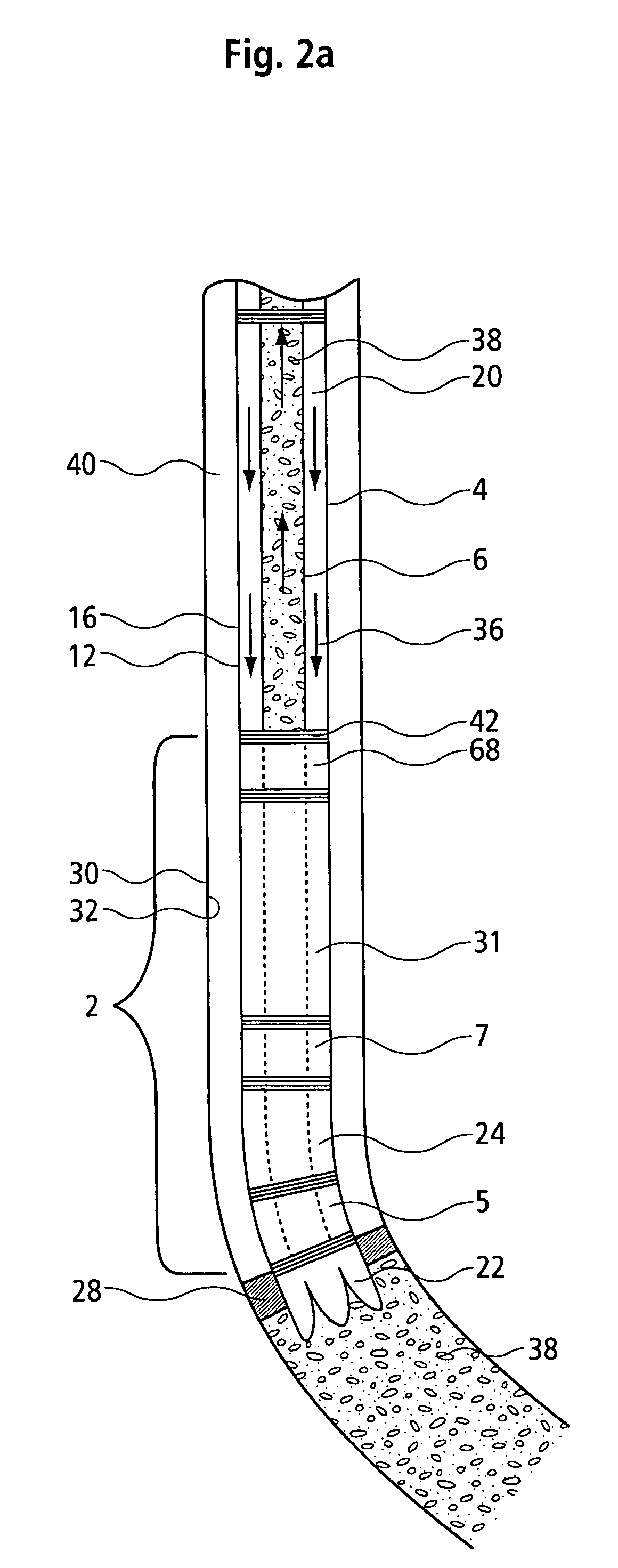

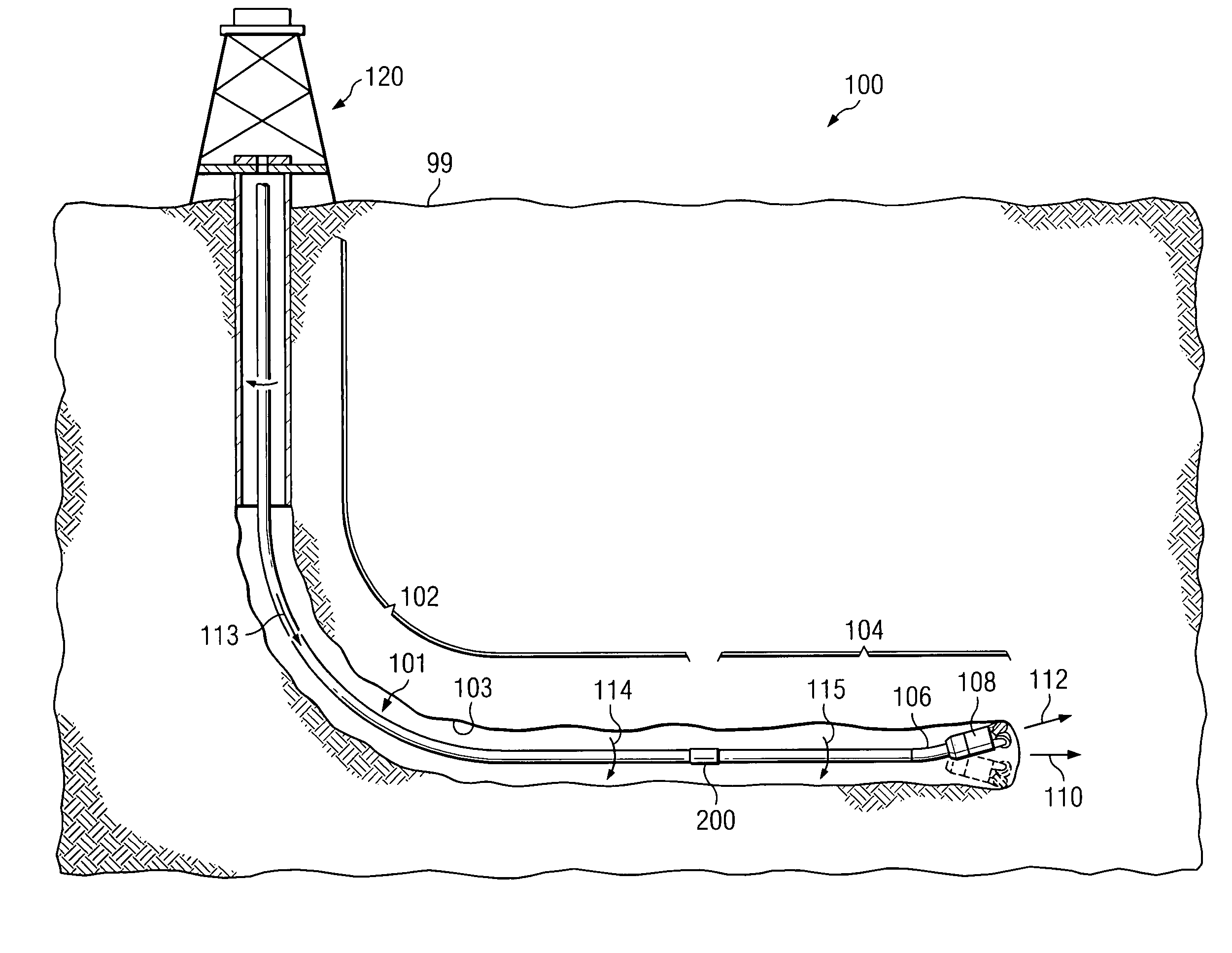

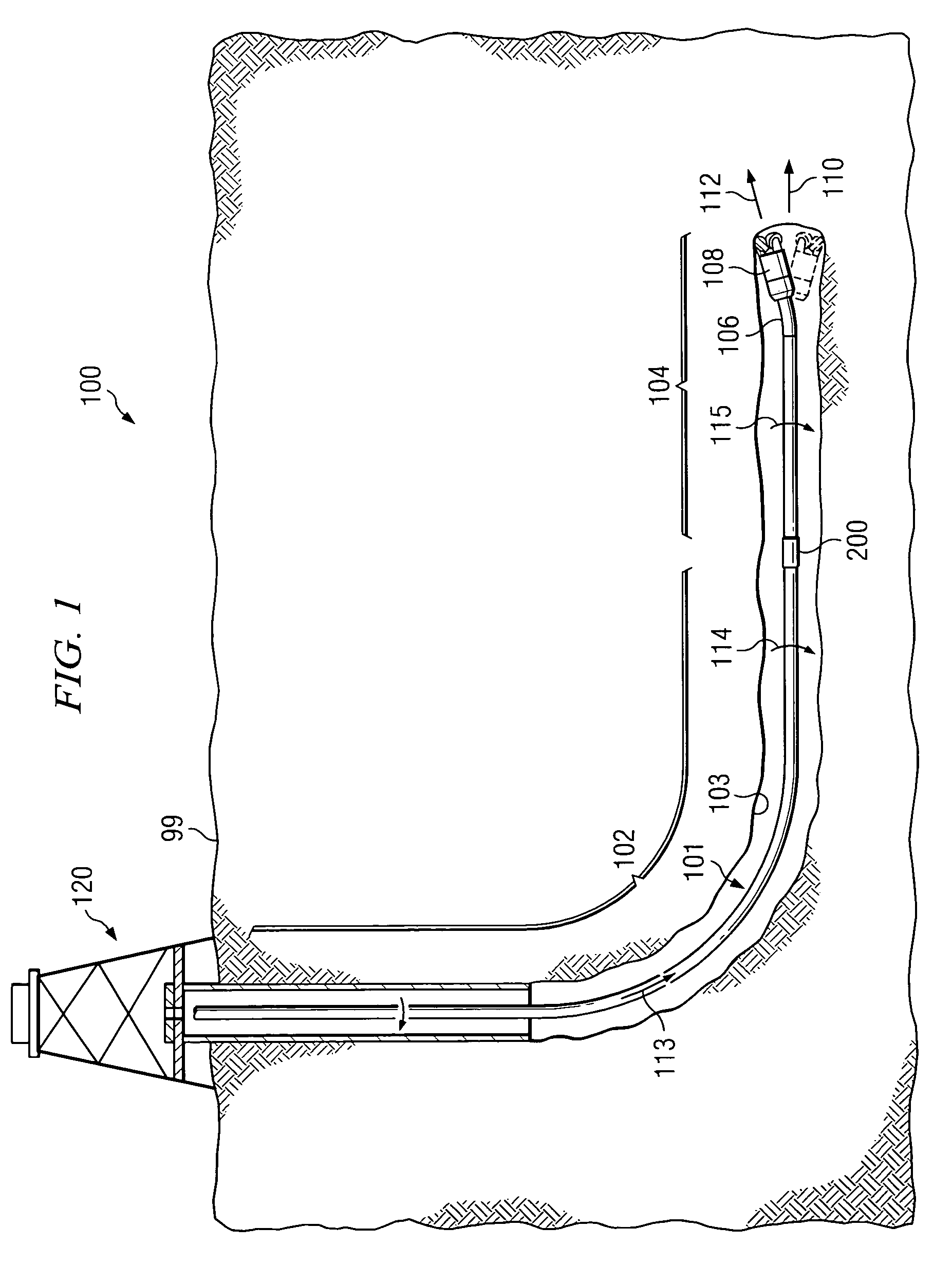

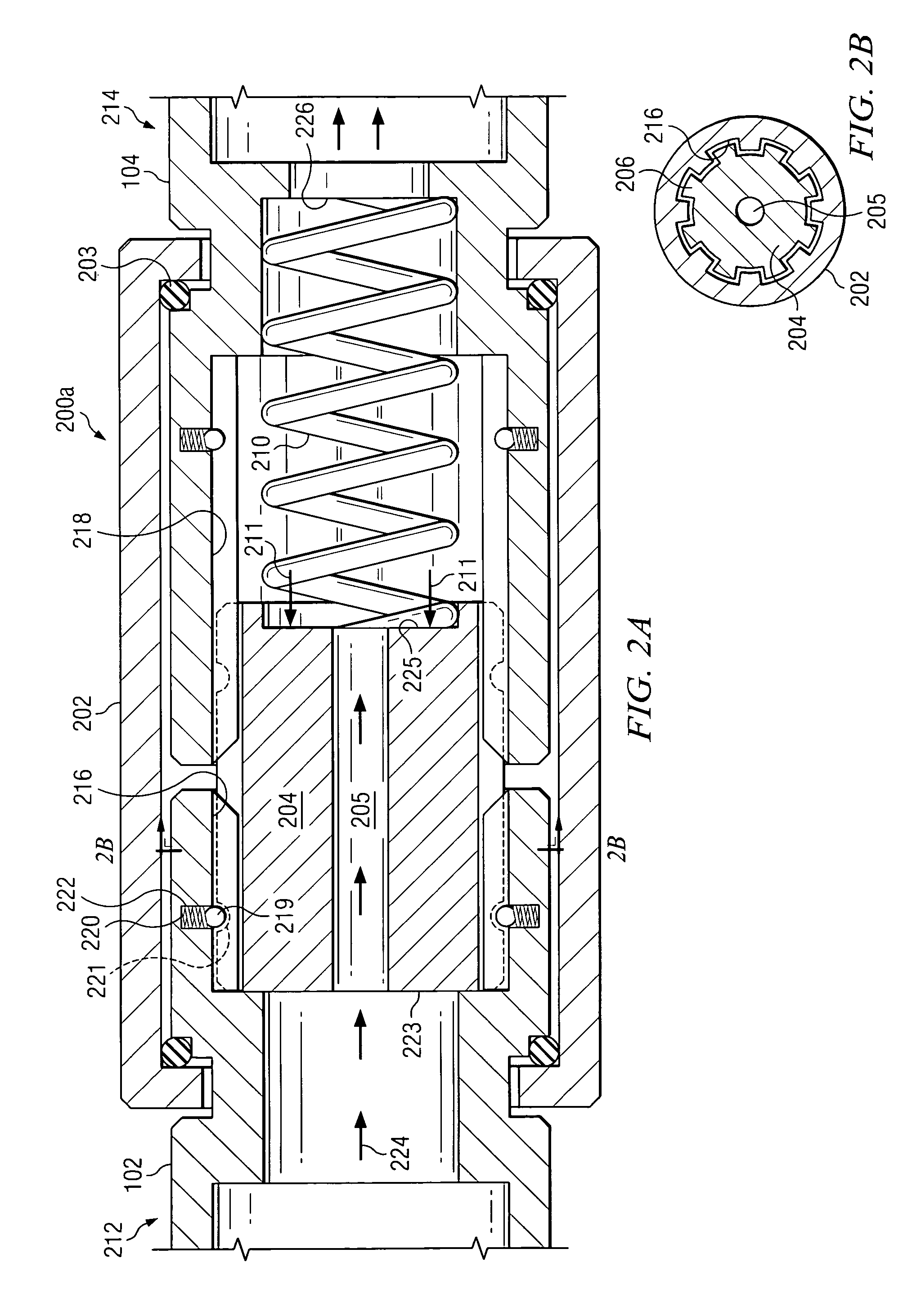

Reverse circulation directional and horizontal drilling using concentric drill string

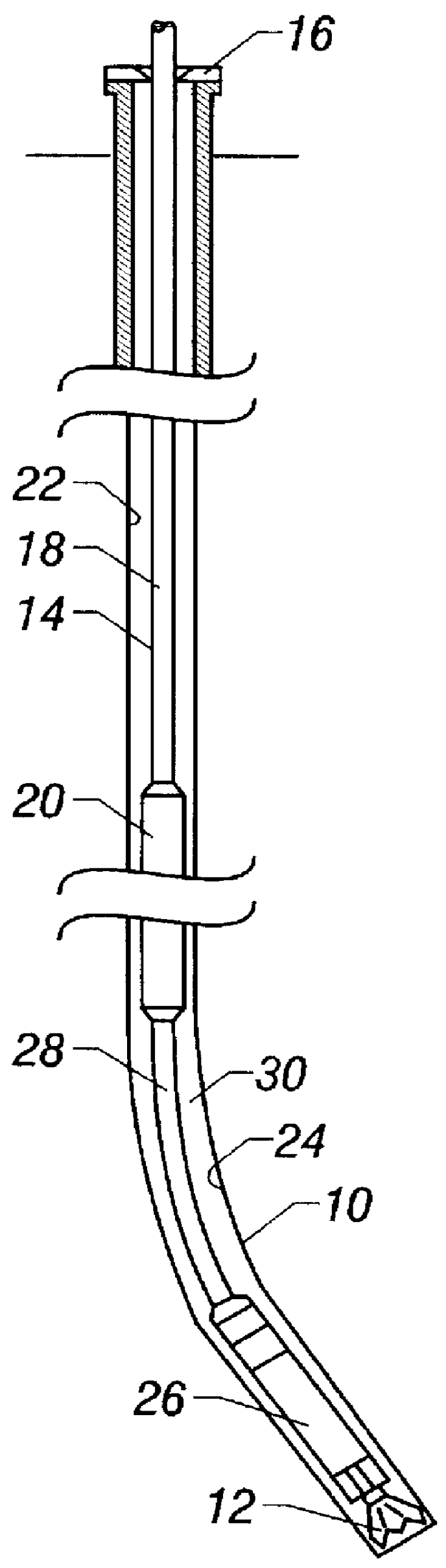

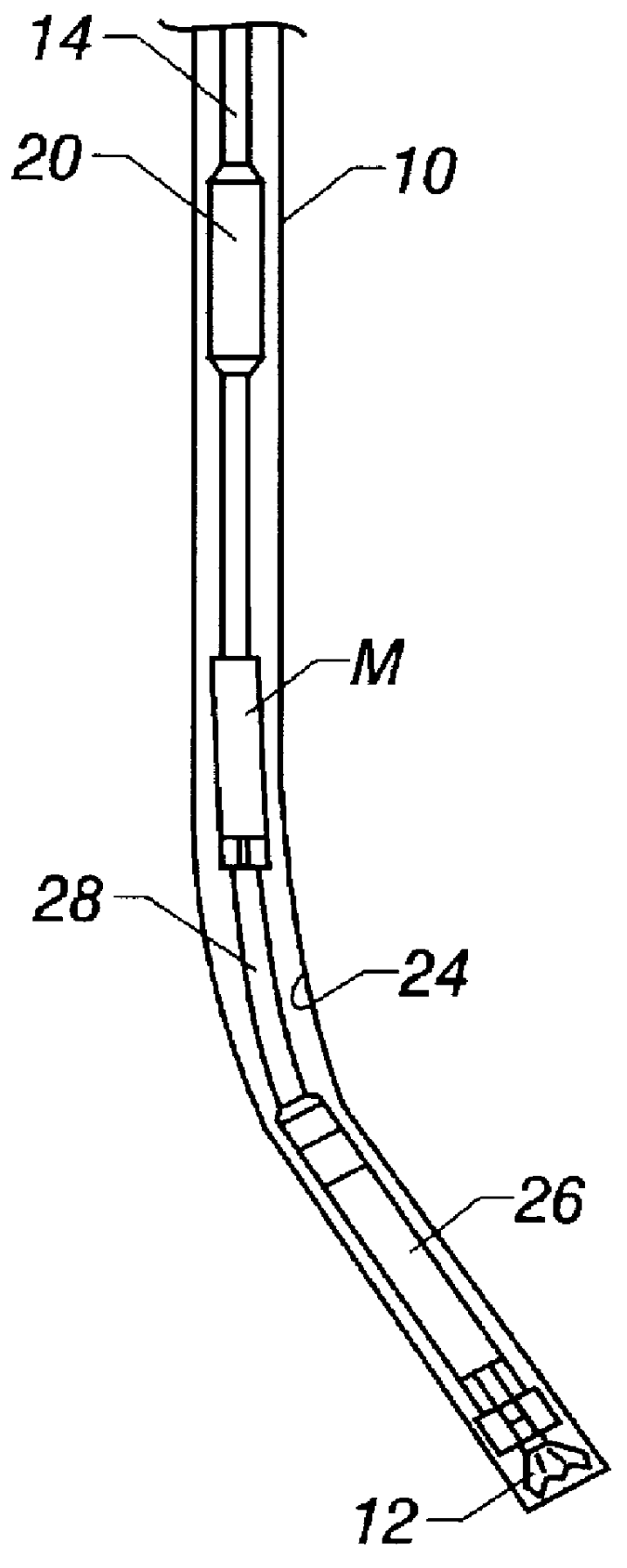

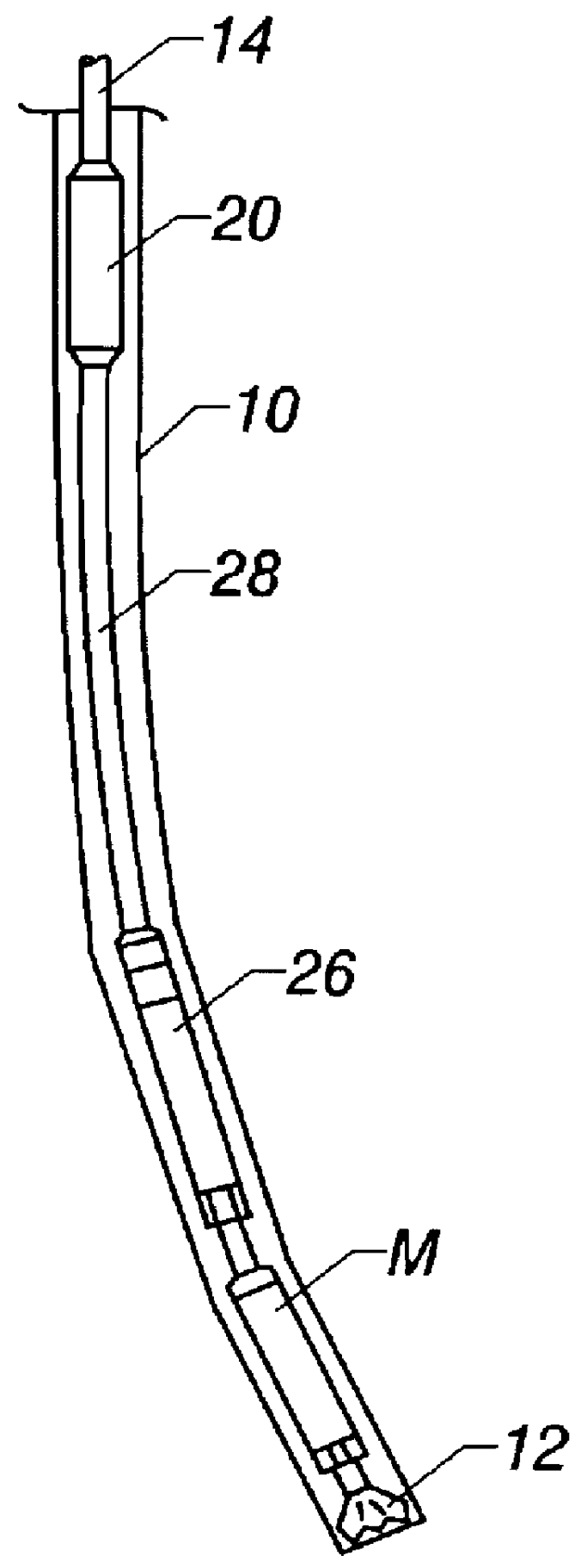

InactiveUS7204327B2Avoid damageSafe and economical mannerDrilling rodsDirectional drillingWell drillingDirectional drilling

Method and apparatus for drilling a directional or horizontal wellbore in a hydrocarbon formation using concentric drill string having an inner pipe and an outer pipe defining an annulus there between. A bottomhole assembly comprising a directional drilling means such as an air hammer or a rotary drill bit and driving system is provide at the lower end of the concentric drill string and drilling medium is delivered through the annulus or inner pipe for operating the directional drilling means to form a borehole. Exhaust drilling medium, drilling cutting and hydrocarbon are removed from the wellbore by extracting the exhaust drilling medium, drilling cutting and hydrocarbon through the other of the annulus or inner pipe.

Owner:PRESSSOL

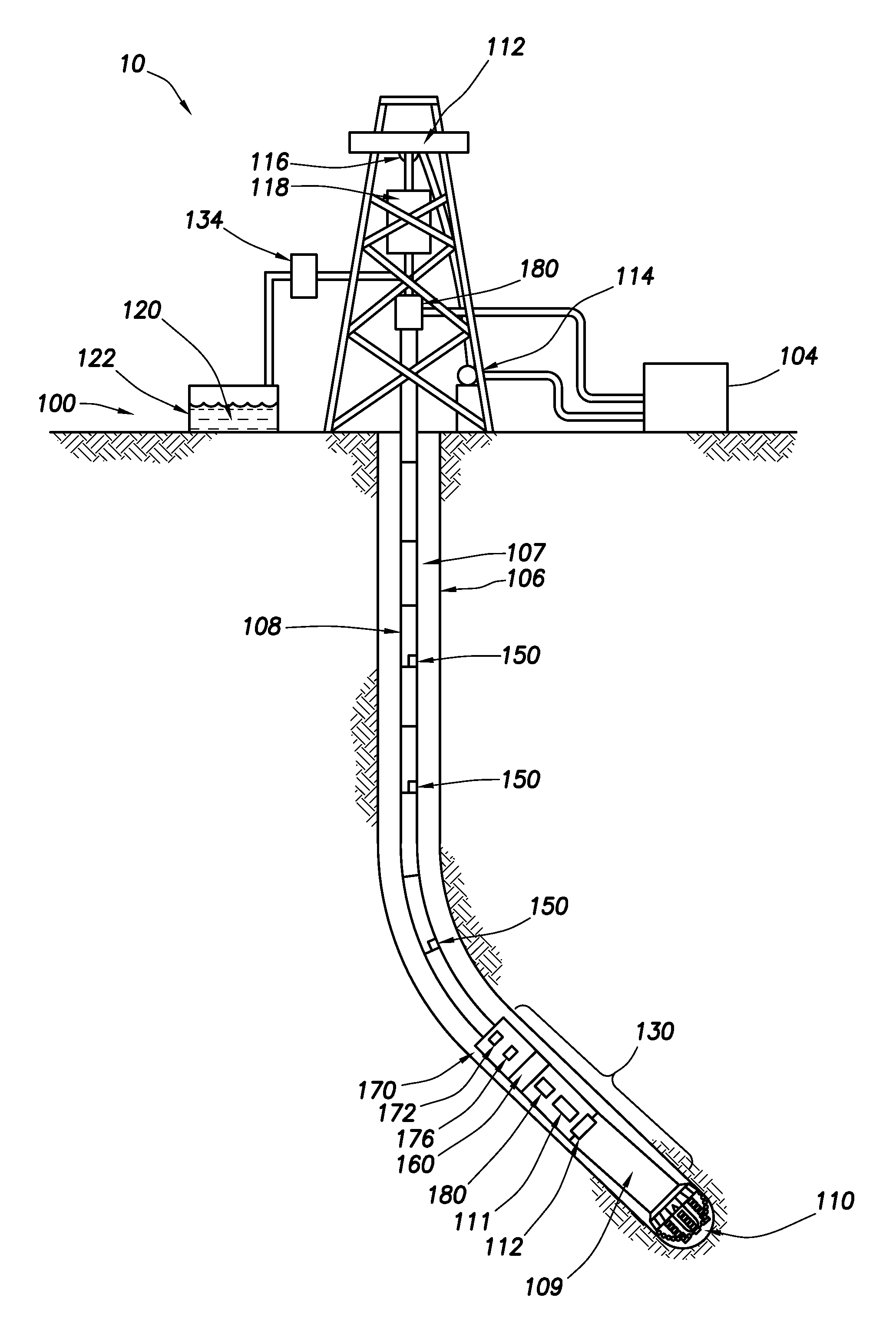

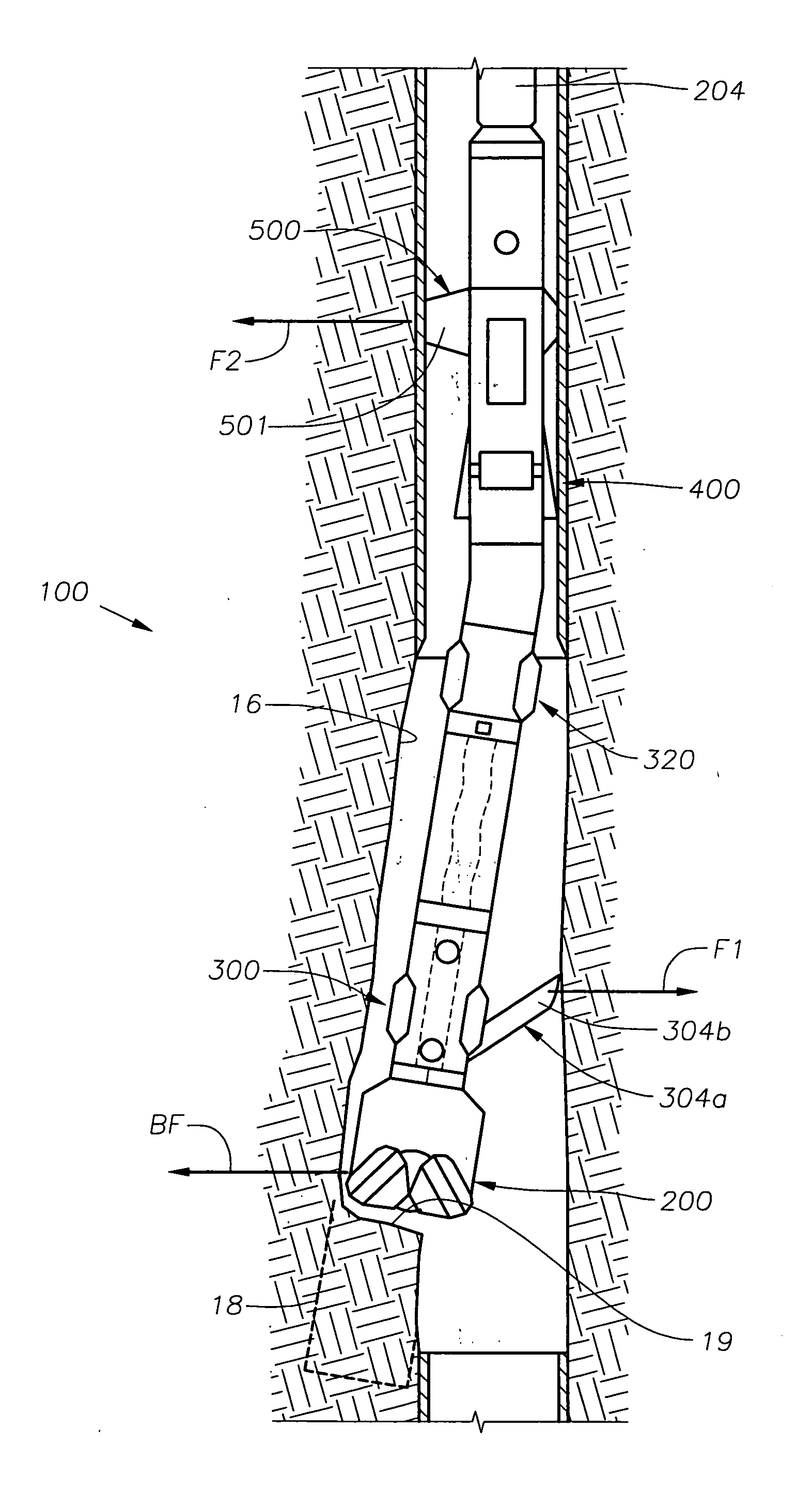

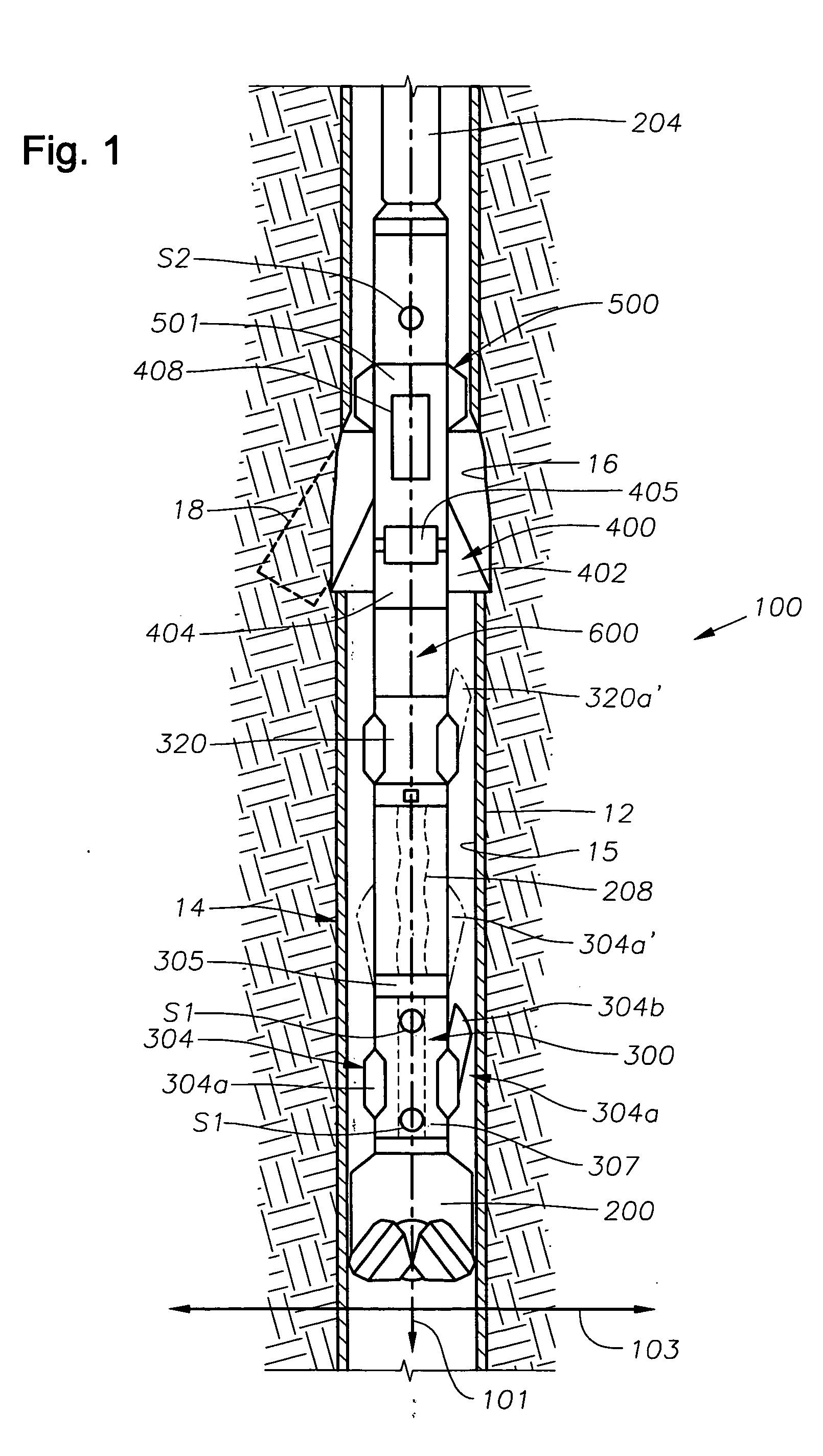

Steerable bit assembly and methods

ActiveUS20050056463A1Efficient and cost-effectiveFaster and less mechanically complexDrill bitsDrilling rodsShape changeExternal reference

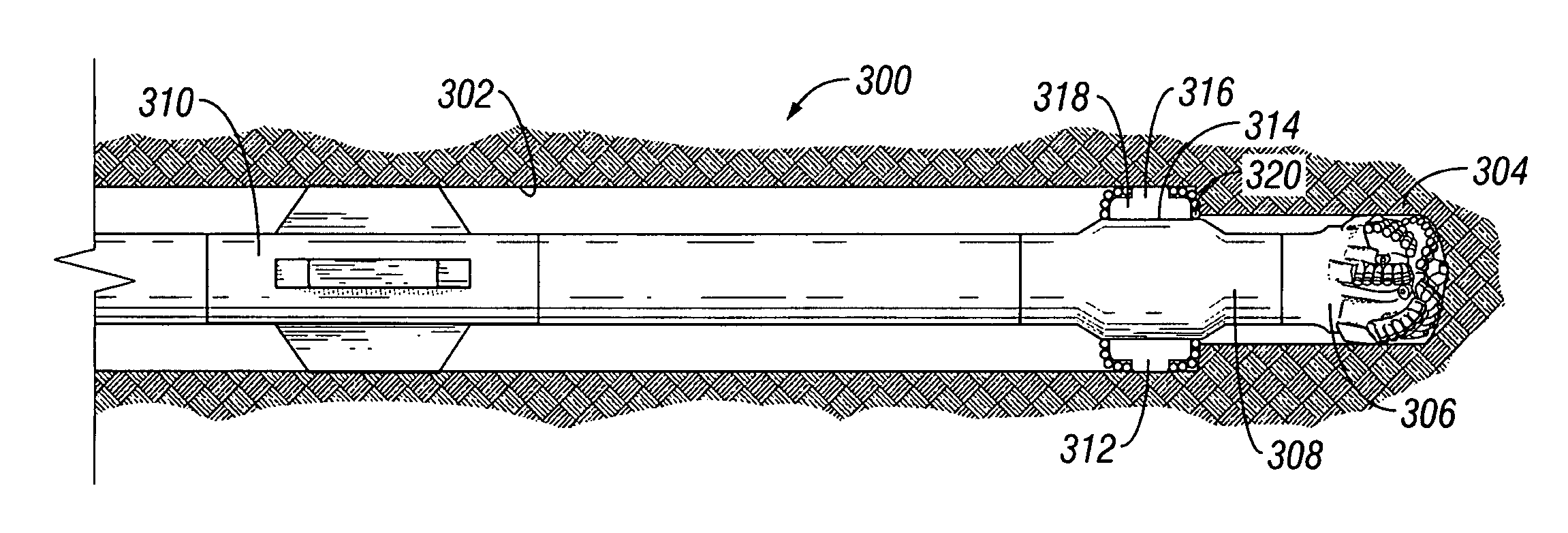

A drilling system includes a steerable bottomhole assembly (BHA) having a steering unit and a control unit that provide dynamic control of drill bit orientation or tilt. Exemplary steering units can adjust bit orientation at a rate that approaches or exceeds the rotational speed of the drill string or drill bit, can include a dynamically adjustable articulated joint having a plurality of elements that deform in response to an excitation signal, can include adjustable independently rotatable rings for selectively tilting the bit, and / or can include a plurality of selectively extensible force pads. The force pads are actuated by a shape change material that deforms in response to an excitation signal. A method of directional drilling includes continuously cycling the position of the steering unit based upon the rotational speed of the drill string and / or drill bit and with reference to an external reference point.

Owner:BAKER HUGHES INC

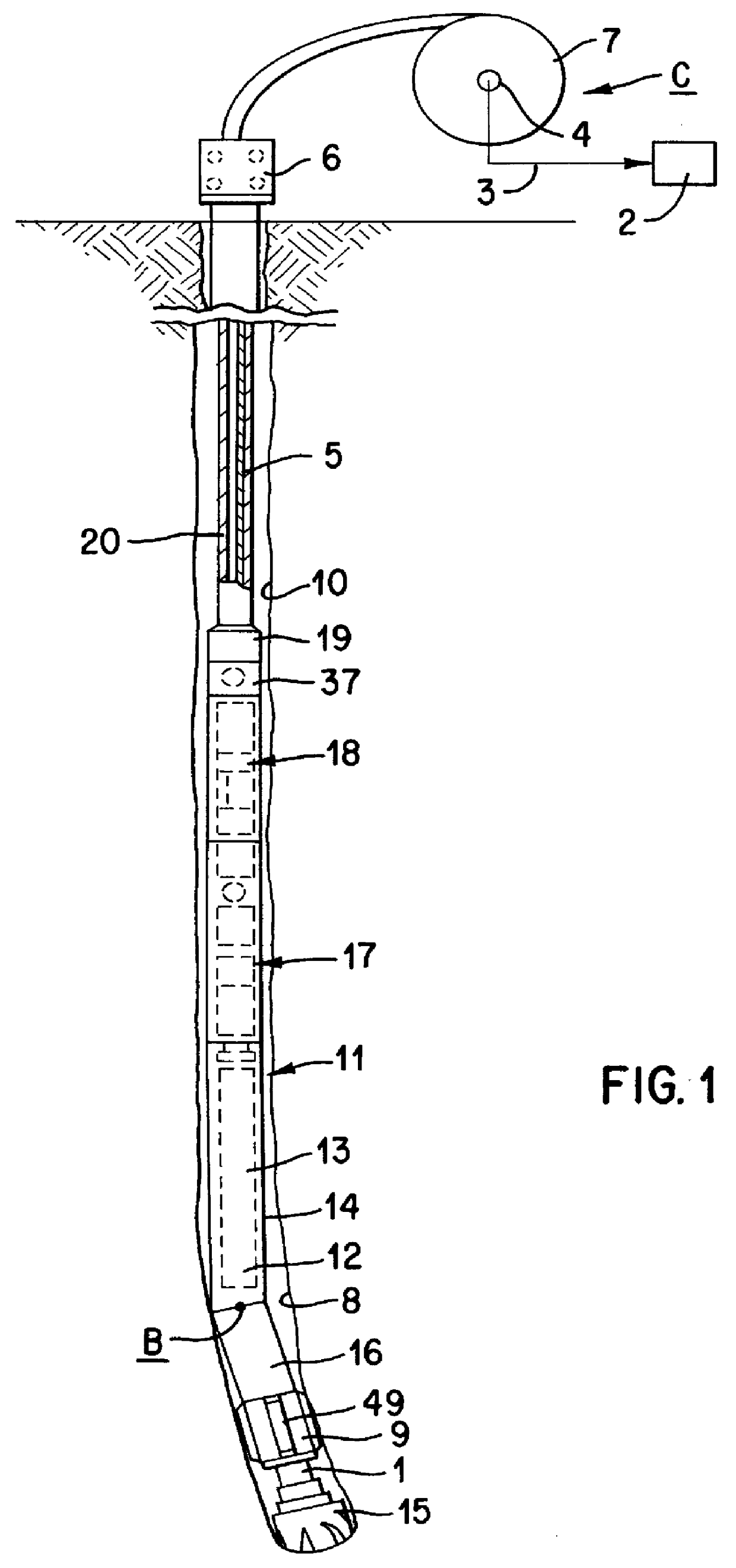

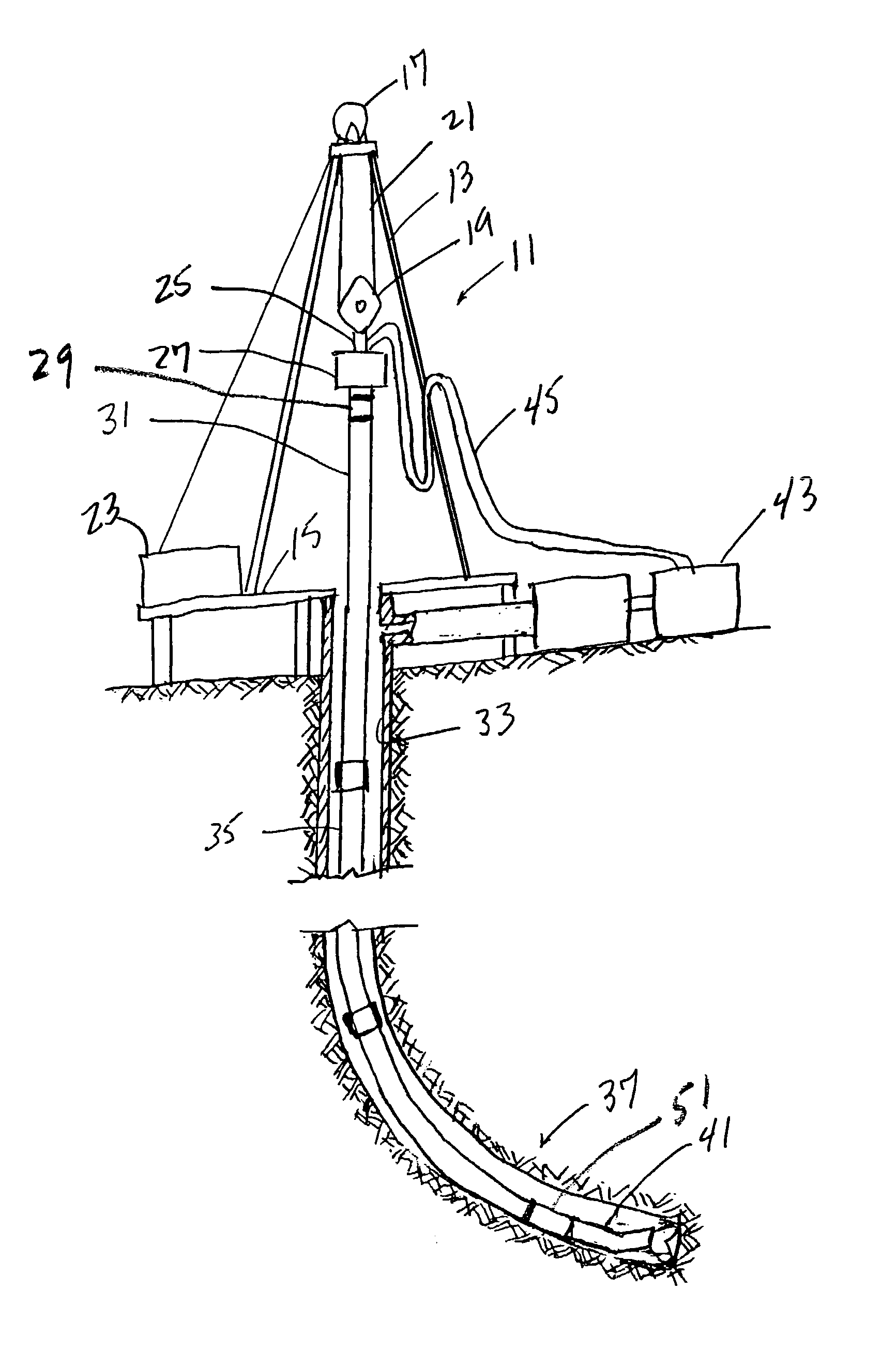

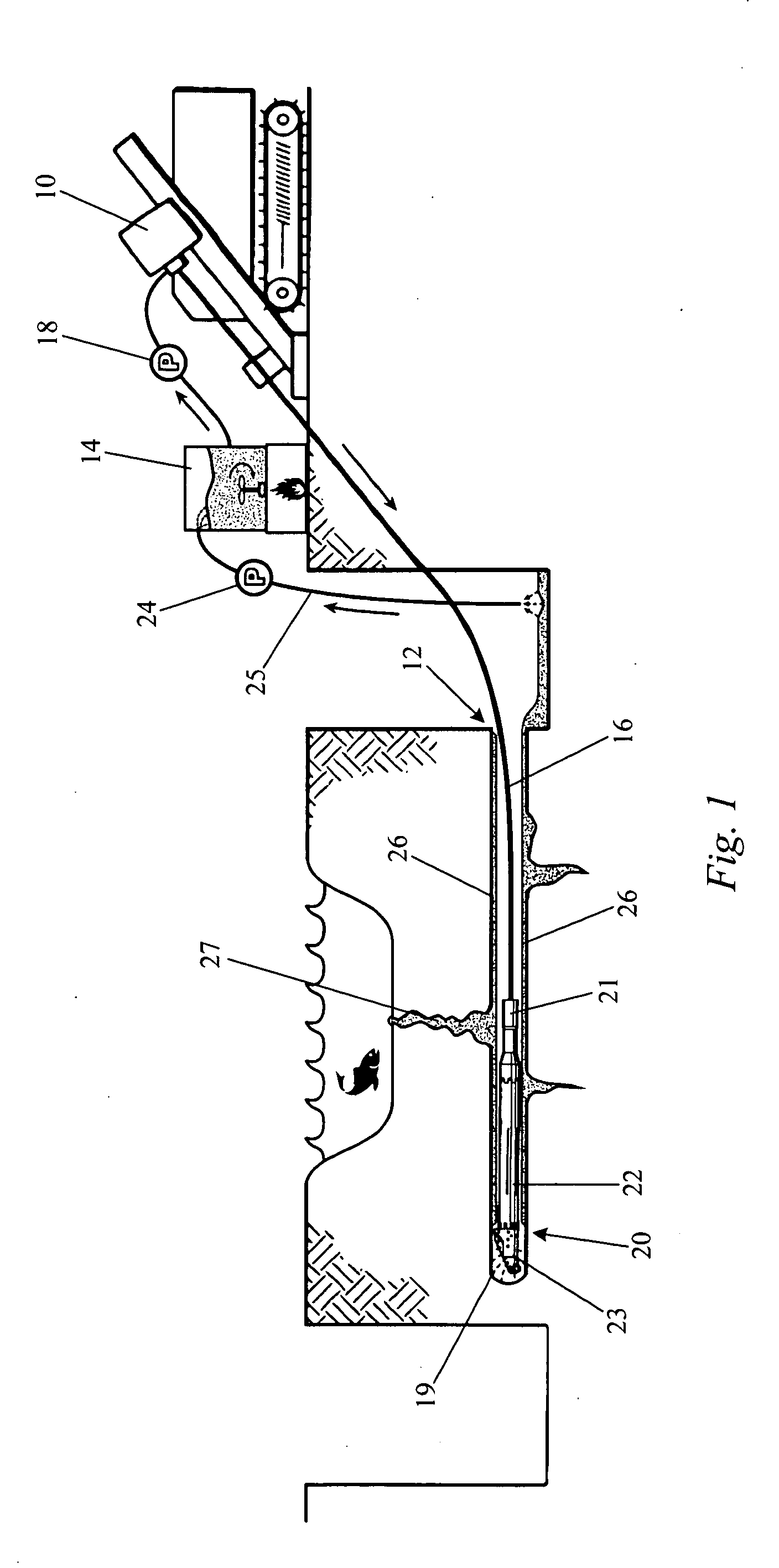

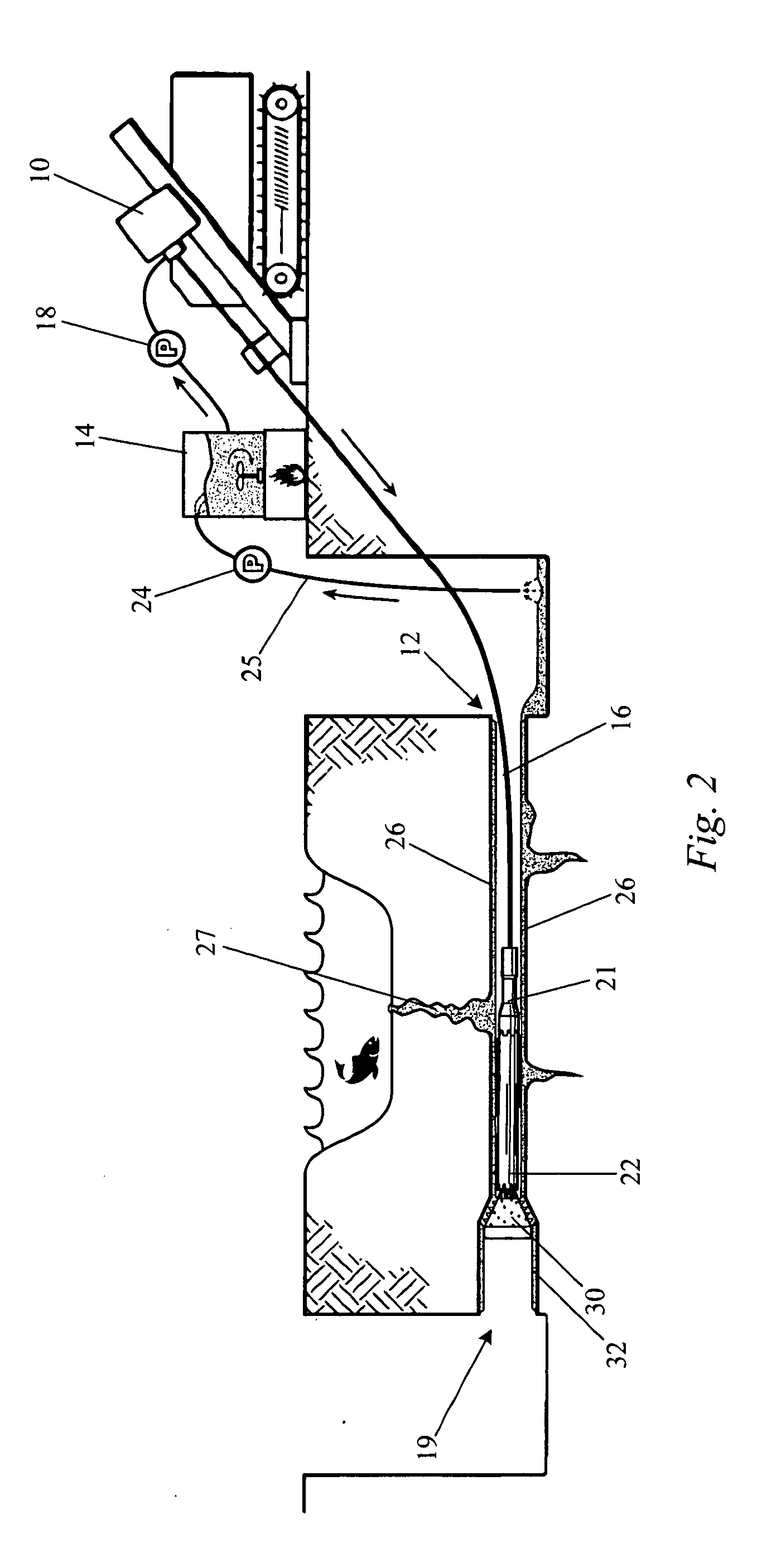

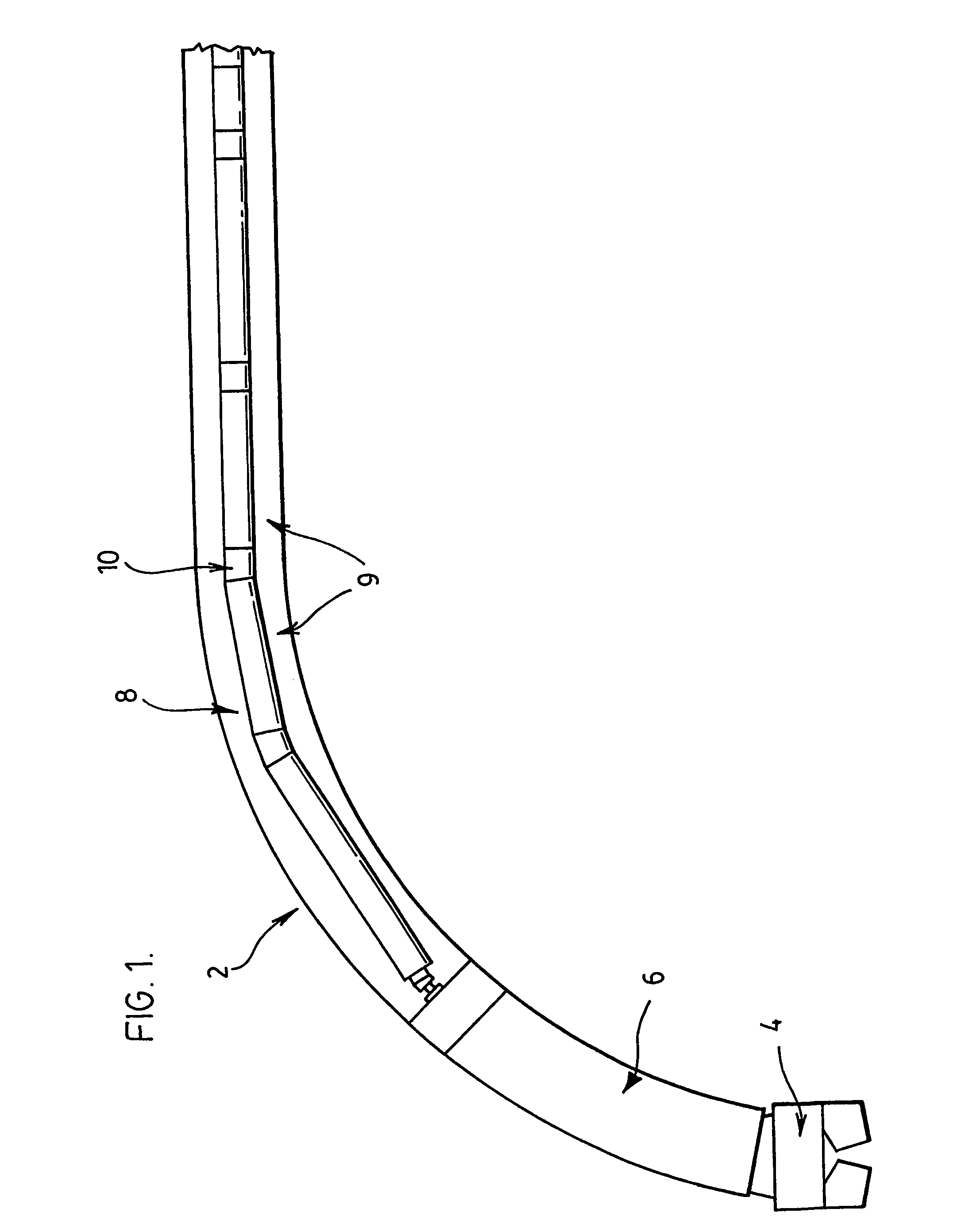

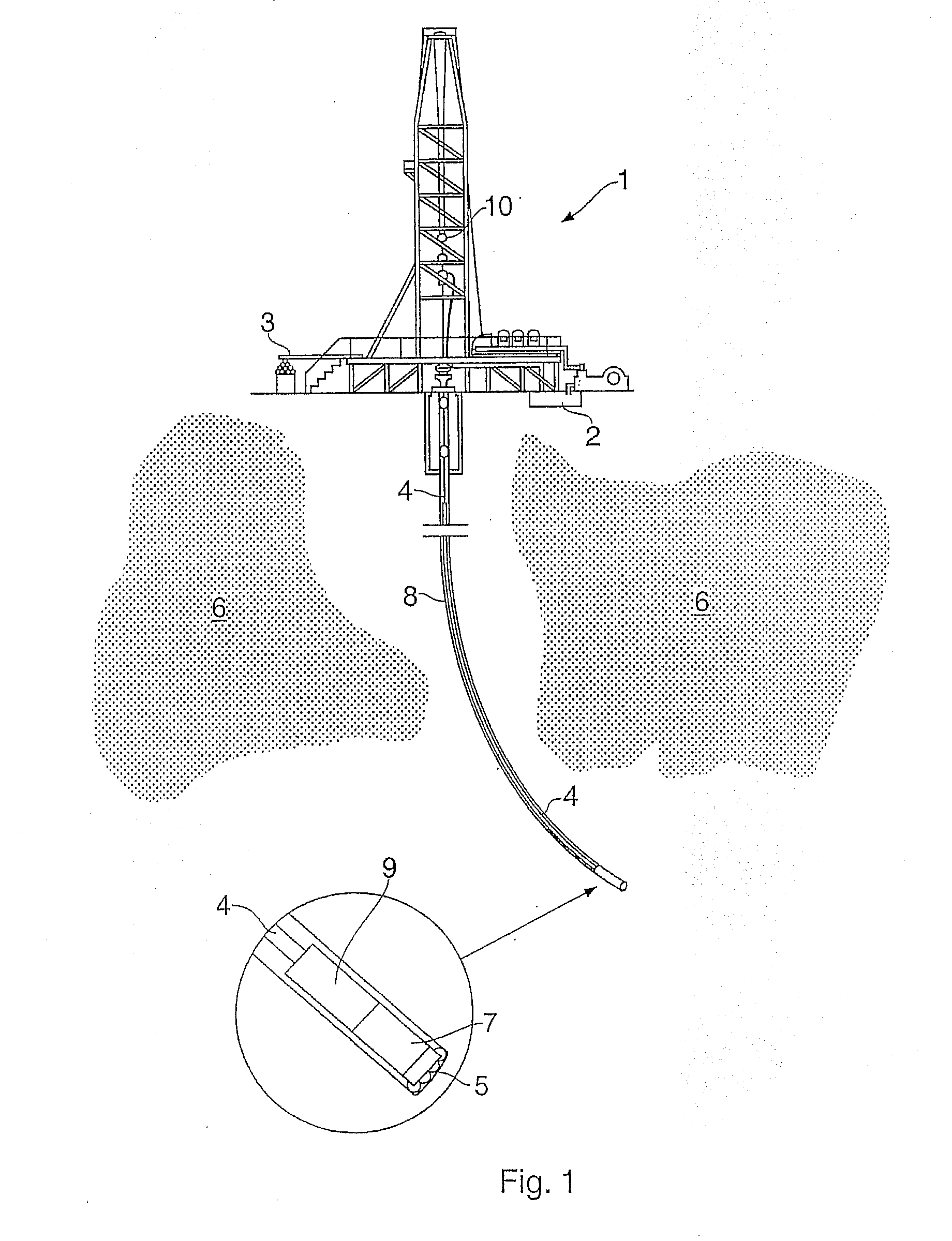

Apparatus and method for directional drilling using coiled tubing

A steerable directional drilling tool assembly includes a bent housing defining a bend angle and having a mud motor in its upper section and a drill bit below its lower section, an orienting tool rotatably coupled to such upper section and suspended on coiled tubing that extends upward to the surface, an electric motor in the orienting tool operable to rotate the bent housing in either hand direction to change or adjust the tool face angle of the bit, or continuously rotate the bent housing so that the bit drills straight-ahead, and an electric cable extending throughout the coiled tubing to furnish power from the surface to the electric motor and transmit electric signals to and from the surface. A logging tool can be included in the assembly for measuring characteristics of the formation, the borehole, and the tool assembly.

Owner:HEWLETT PACKARD CO +1

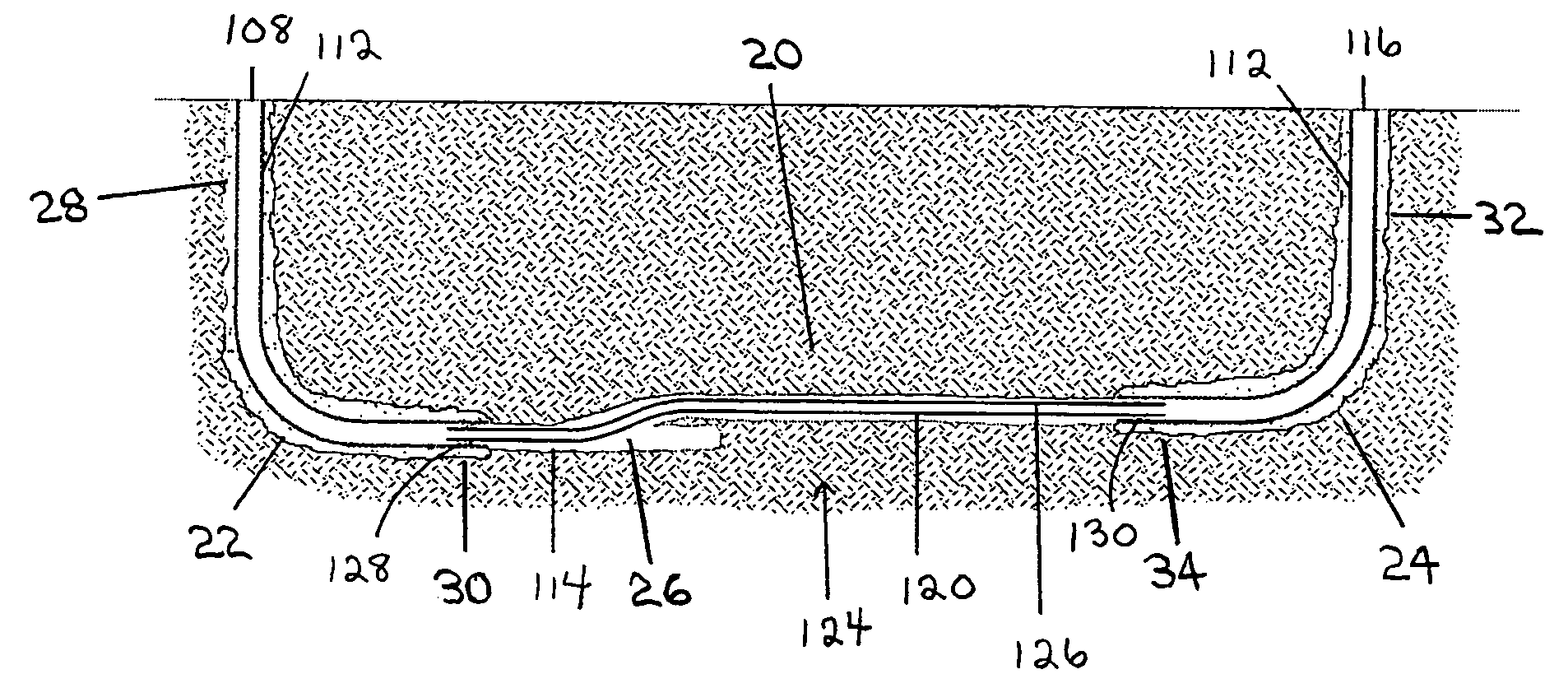

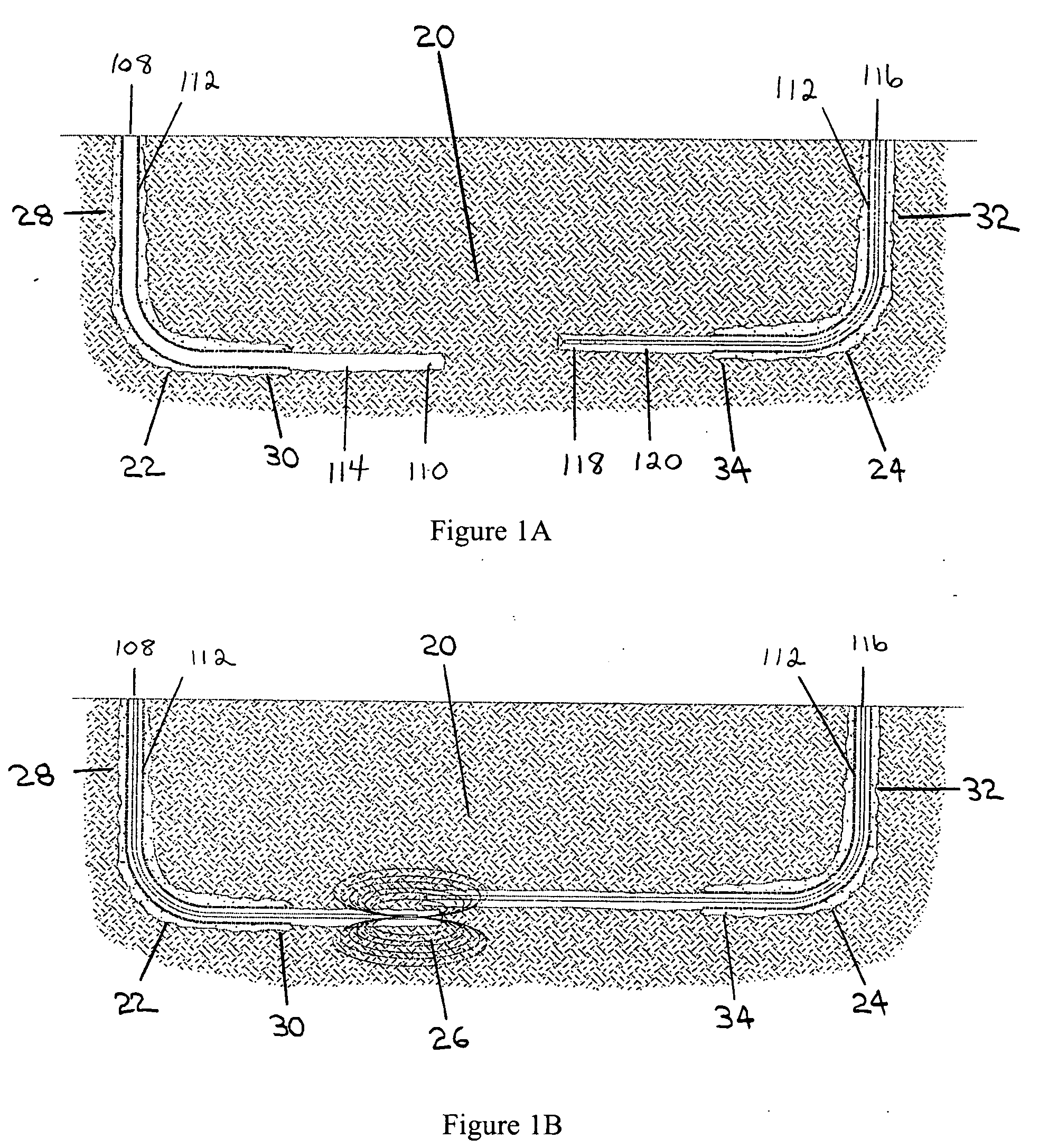

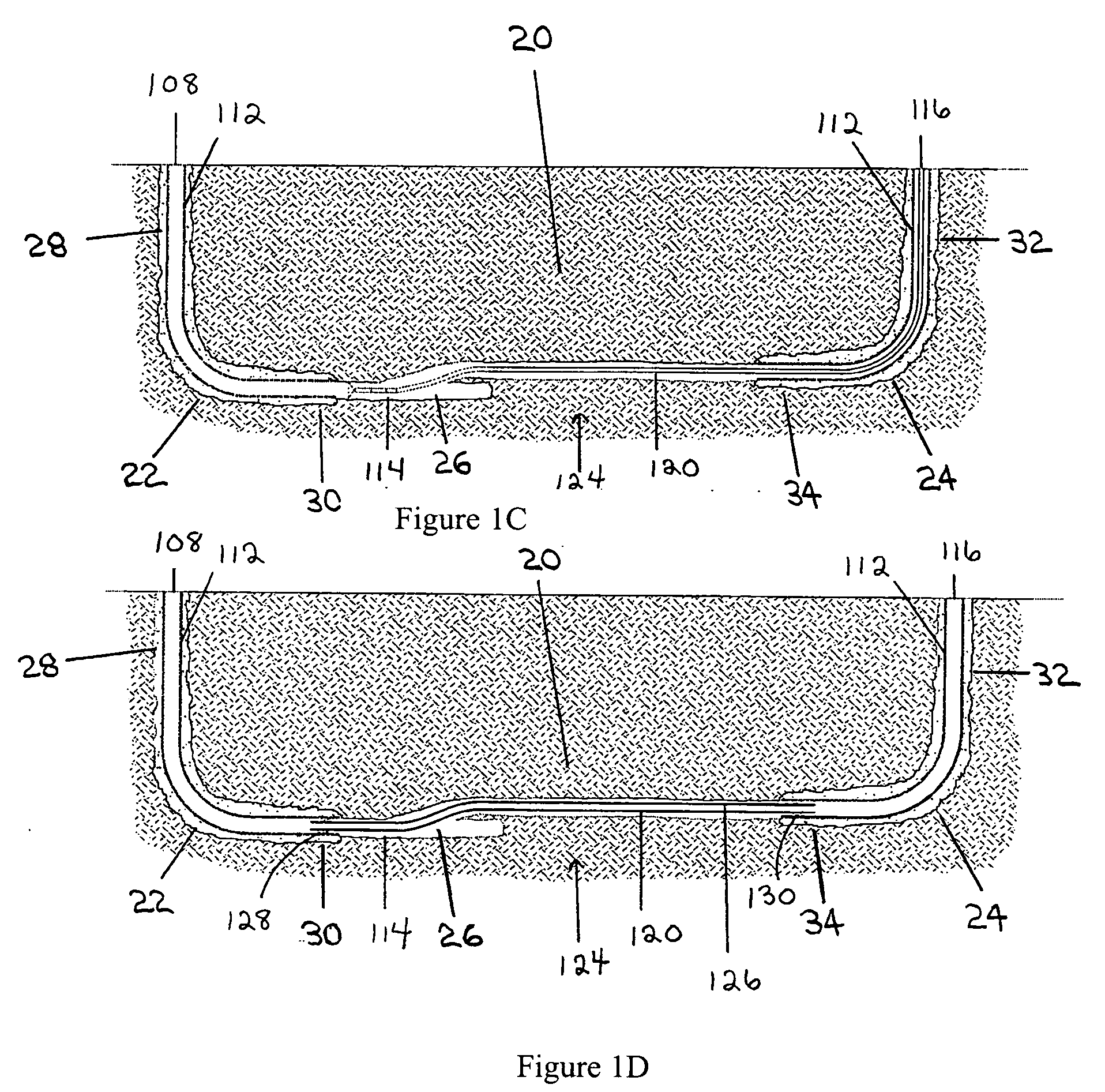

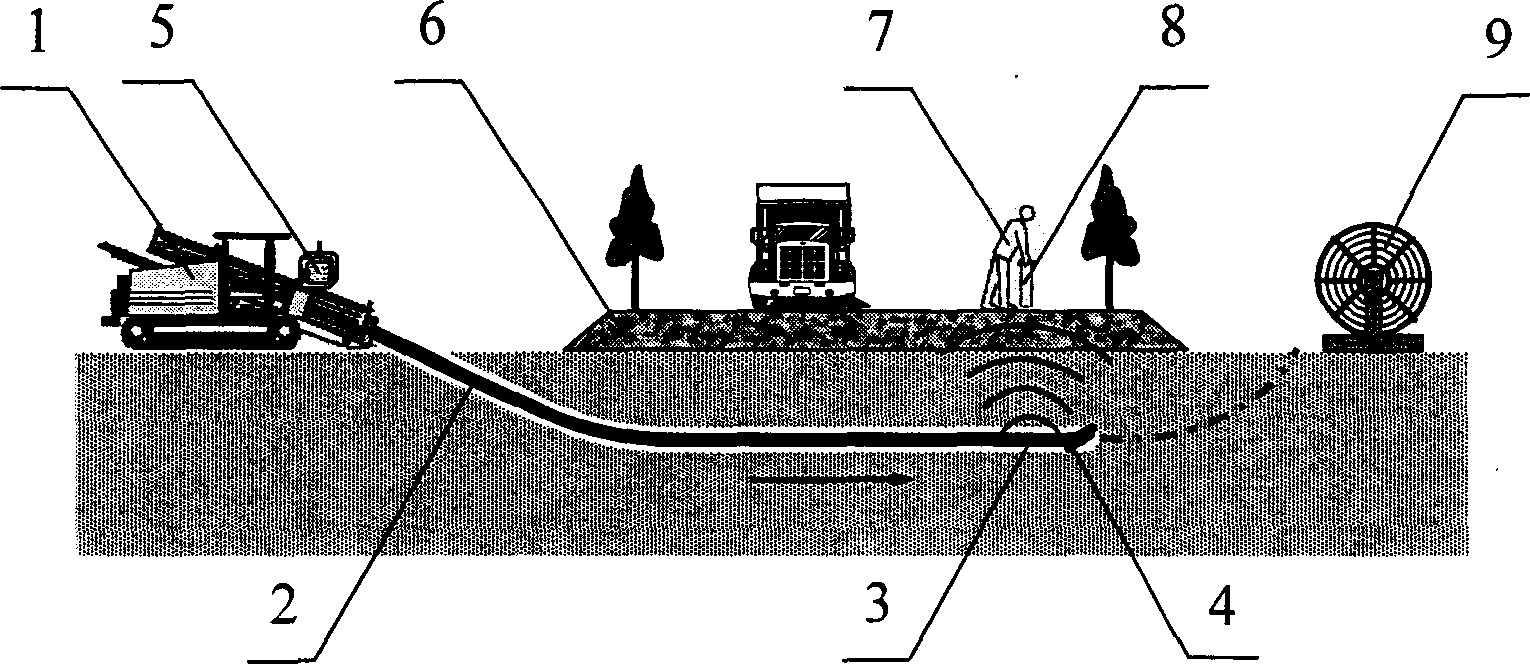

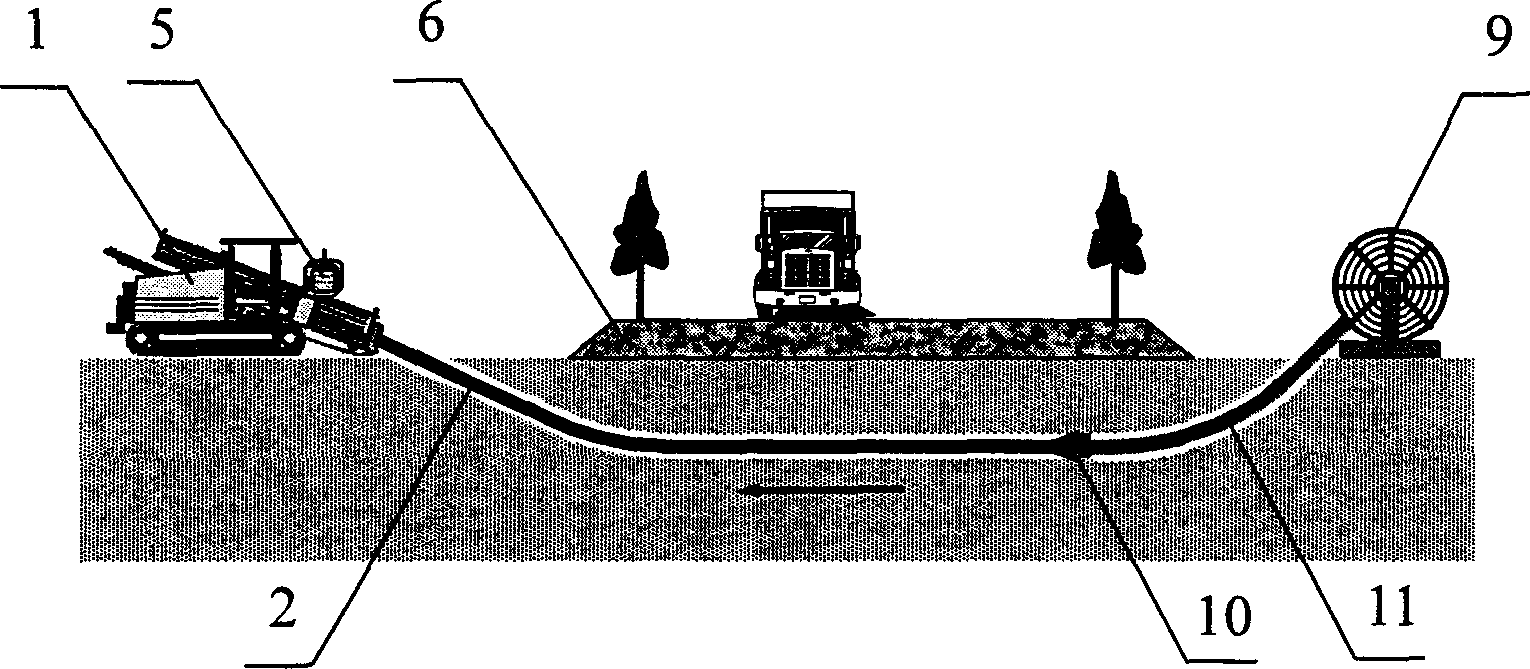

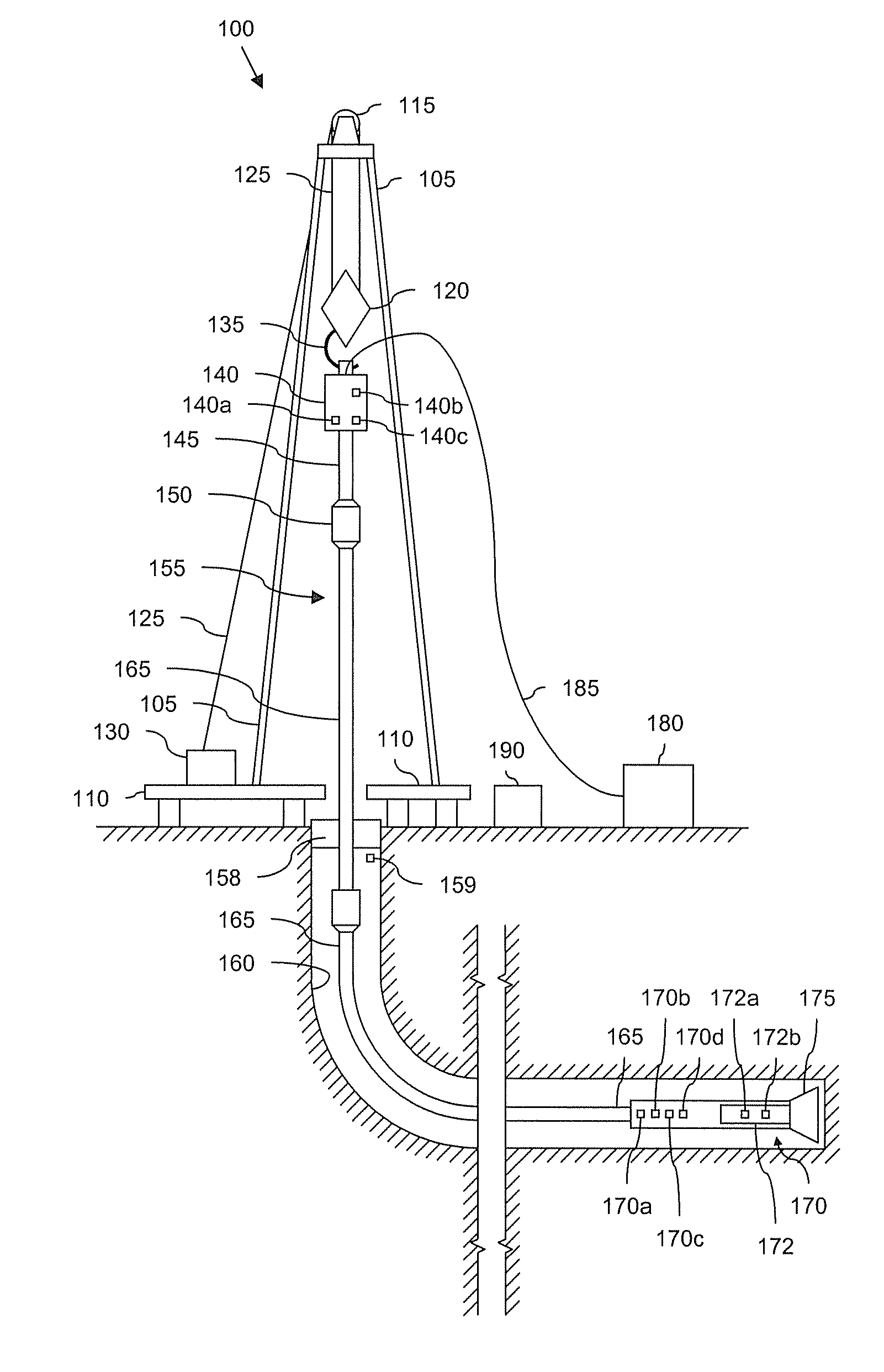

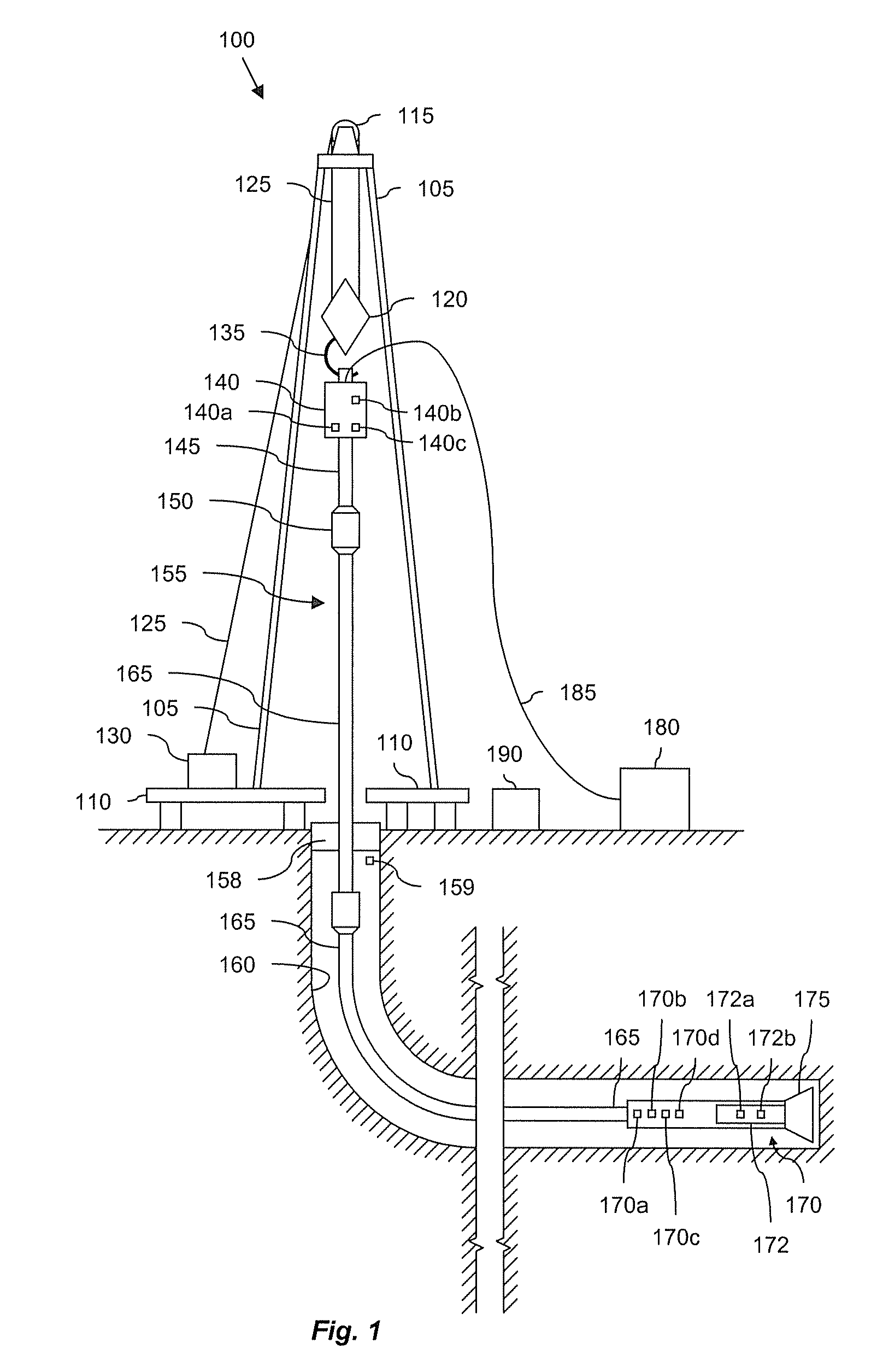

Methods and apparatus for drilling, completing and configuring U-tube boreholes

A borehole network including first and second end surface locations and at least one intermediate surface location interconnected by a subterranean path, and a method for connecting a subterranean path between a first borehole including a directional section and a second borehole including a directional section. A directional drilling component is drilled in at least one of the directional sections to obtain a required proximity between the first and second boreholes. An intersecting component is drilled, utilizing magnetic ranging techniques, from one directional section to provide a borehole intersection between the first and second boreholes, thereby connecting the subterranean path.

Owner:HALLIBURTON ENERGY SERVICES INC

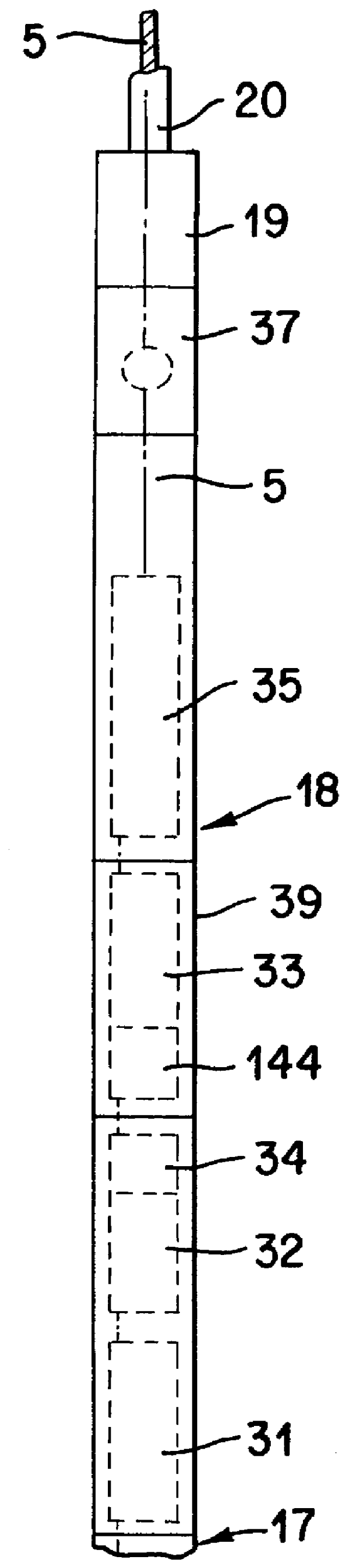

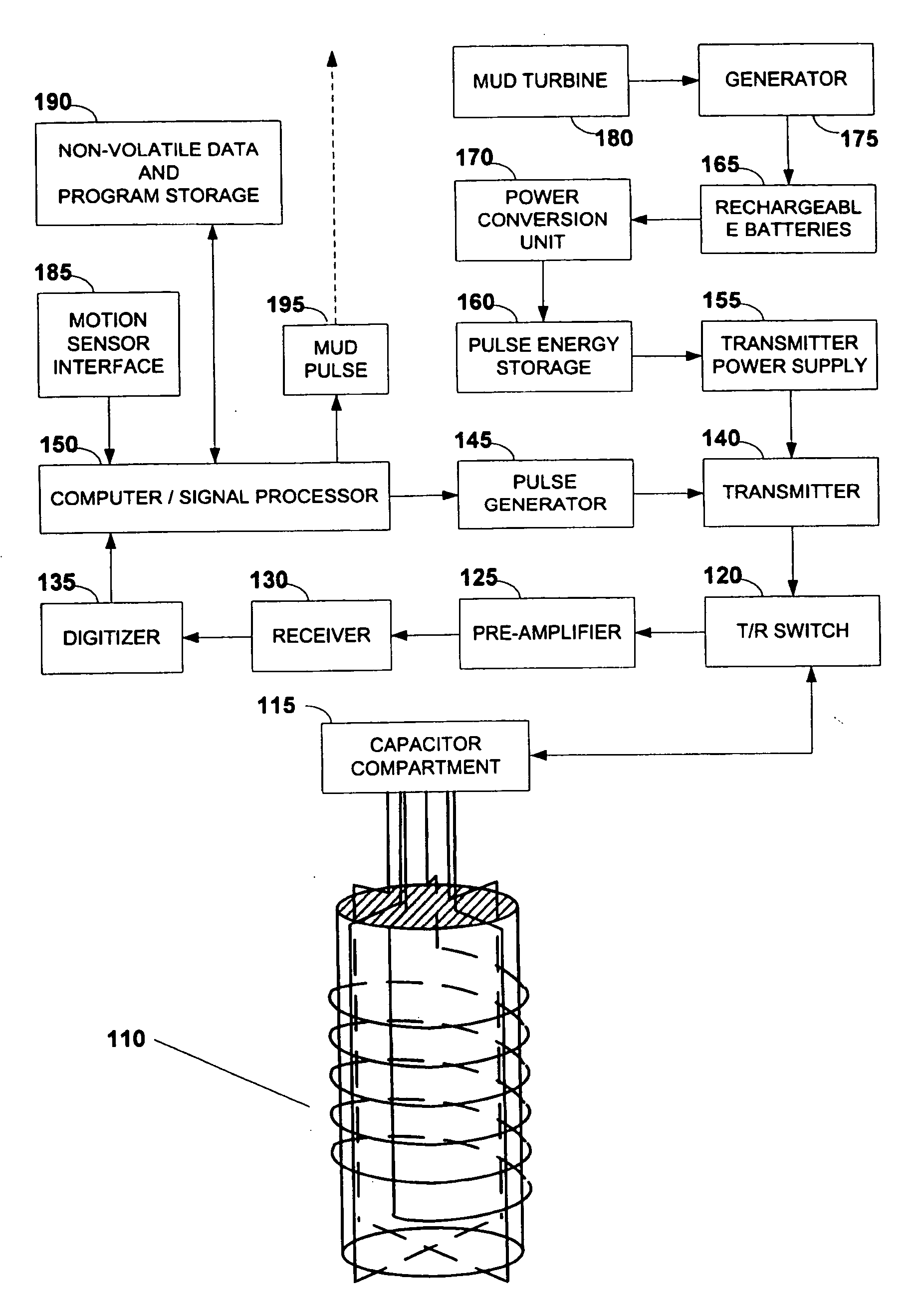

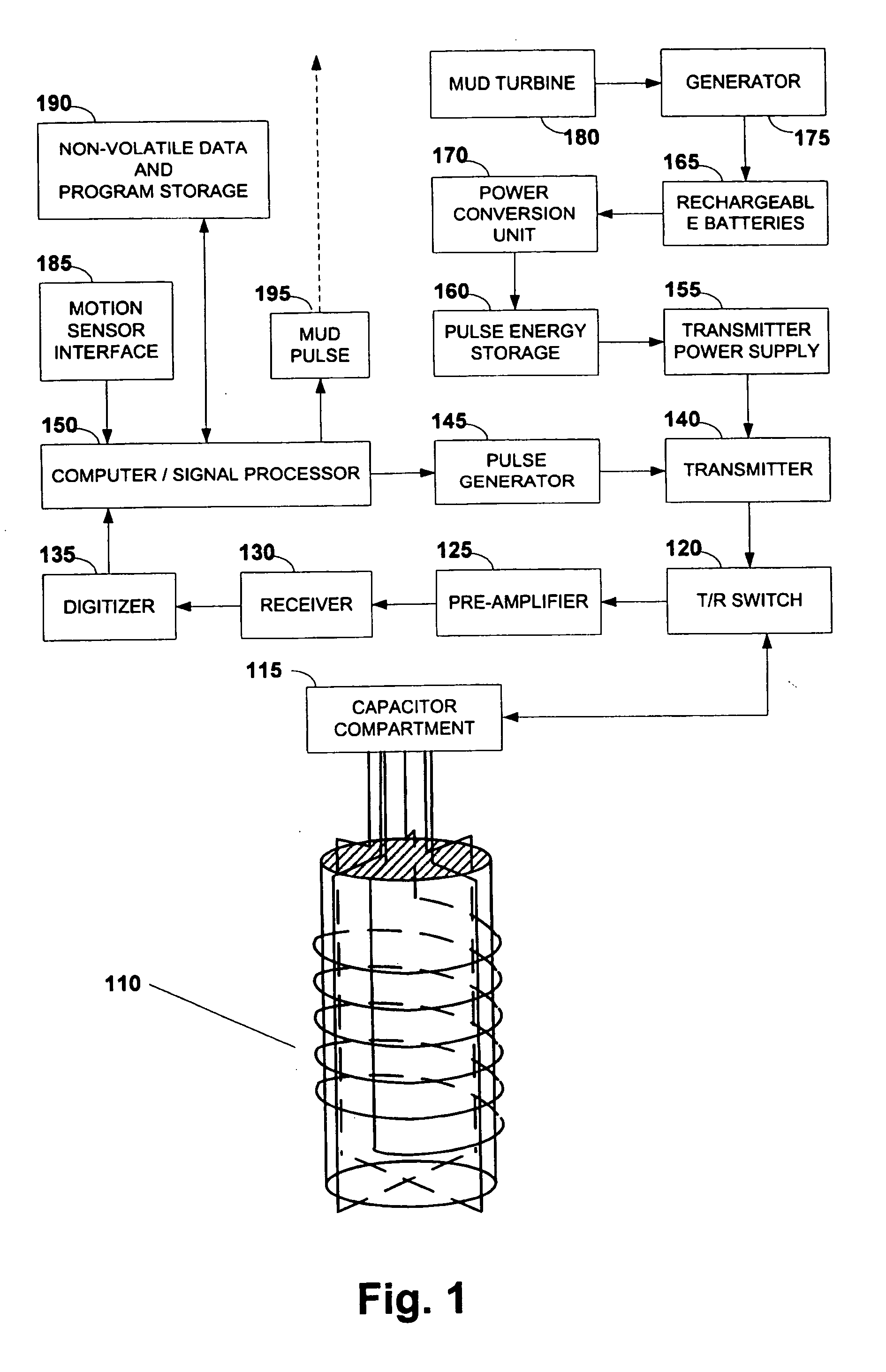

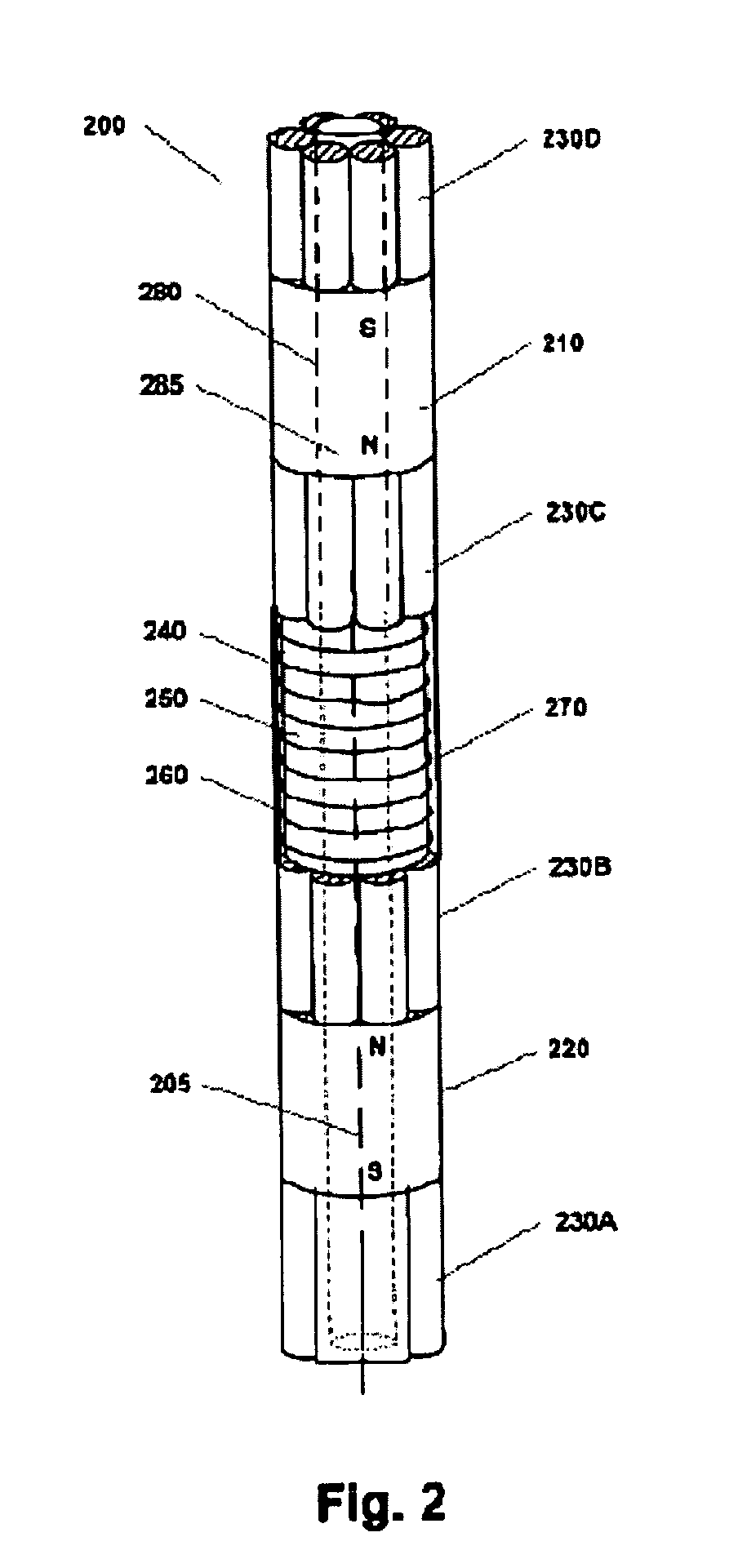

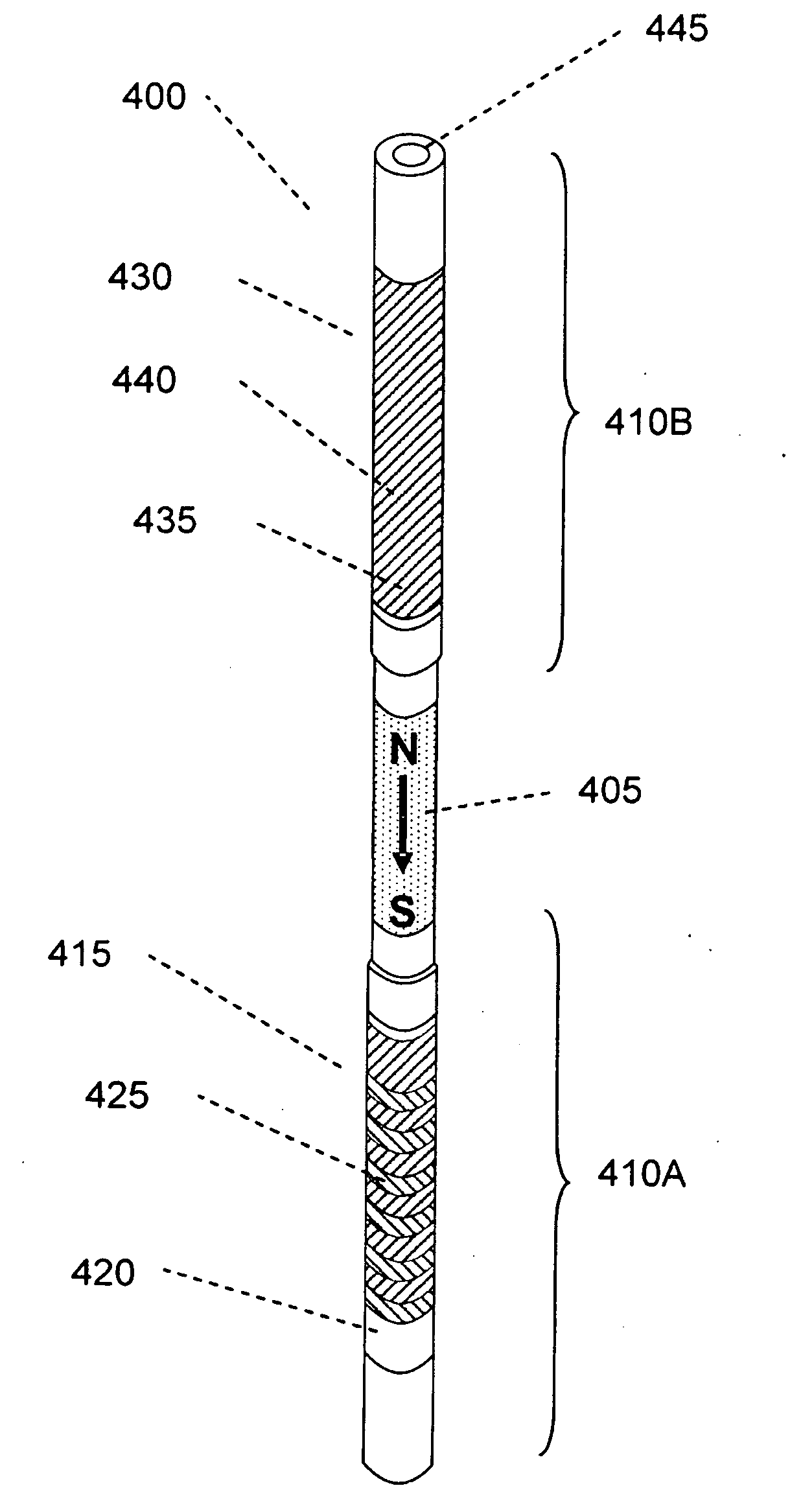

Systems and methods for NMR logging

ActiveUS20050030021A1Add depthAccurate estimateElectric/magnetic detection for well-loggingMaterial analysis by using resonanceEngineeringPole piece

An NMR logging tool for conducting NMR measurements in a plurality of sensitive volumes ranging up to a meter from the tool. The tool comprises a magnetic assembly using one or more permanent magnets and at least one pole piece for extending a magnet pole and shaping the magnetic field to simulate a magnetic monopole in a sensitive volume within the formation. Different embodiments of a segmented antenna enable directional NMR logging. The tool embodiments and methods of their use are suitable for wireline or LWD logging, and can be used for directional drilling.

Owner:HALLIBURTON ENERGY SERVICES INC

Steerable bit assembly and methods

ActiveUS7287604B2Efficient and cost-effectiveFaster and less mechanically complexDrill bitsDrilling rodsShape changeWell drilling

Owner:BAKER HUGHES INC

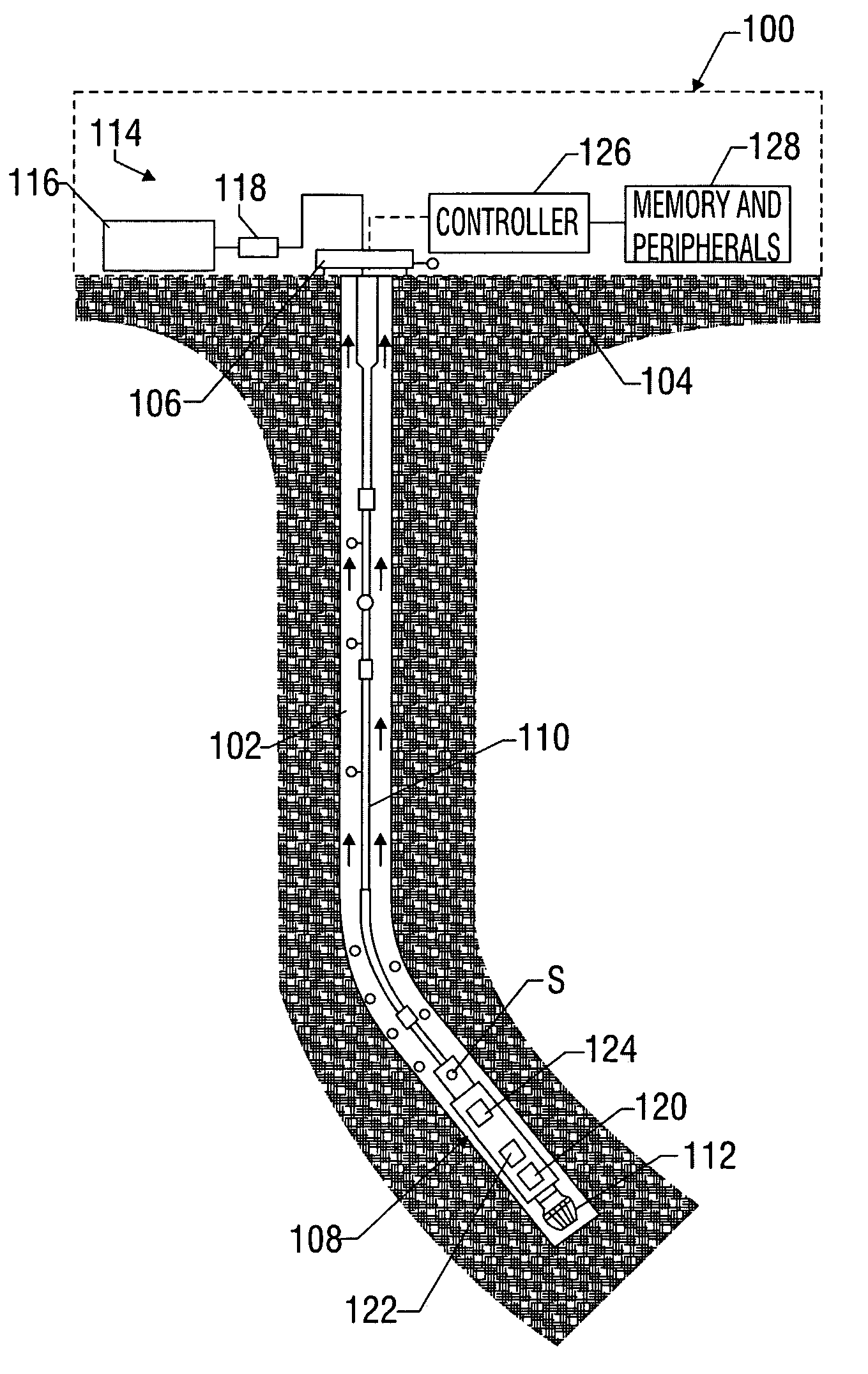

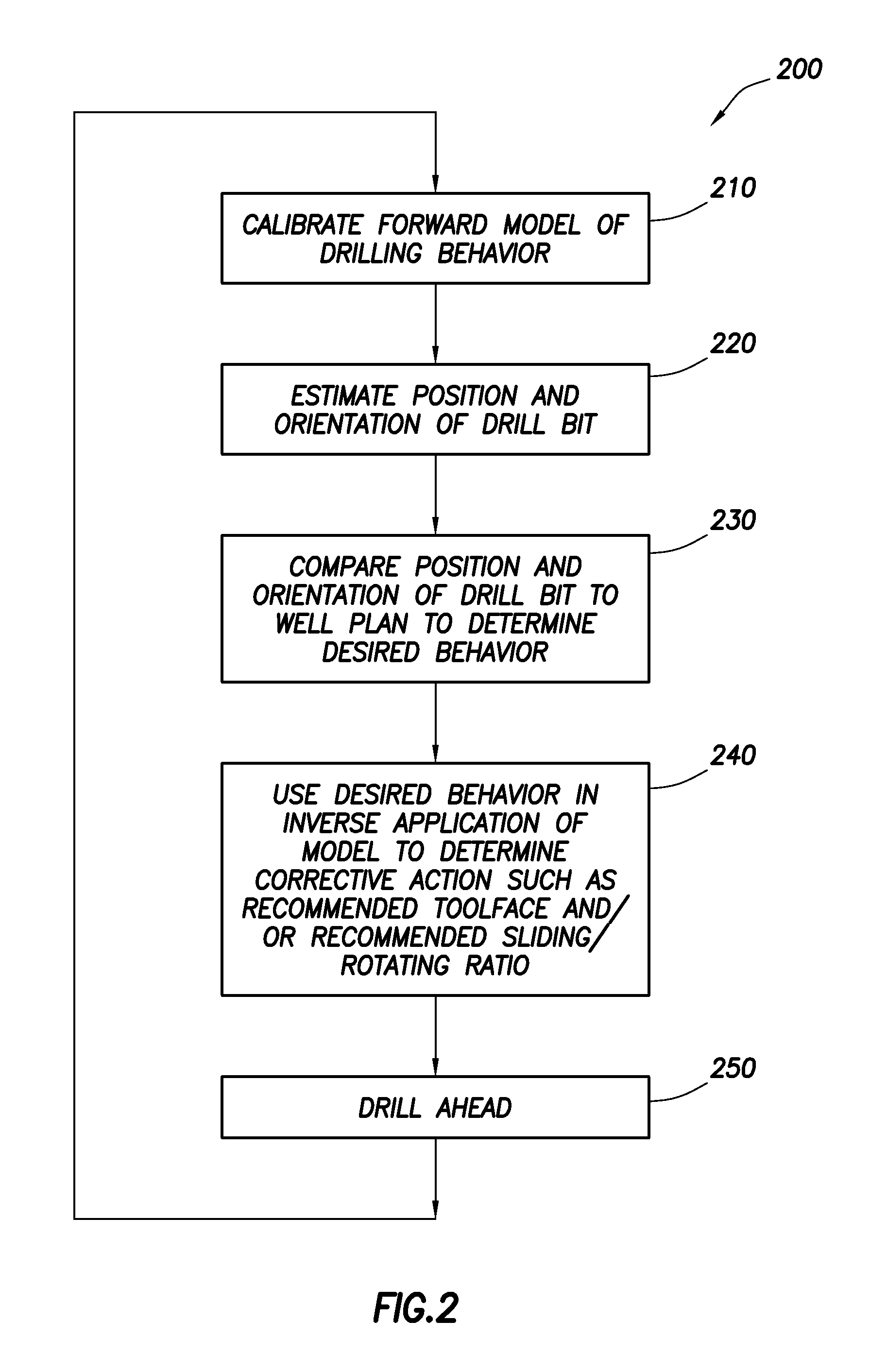

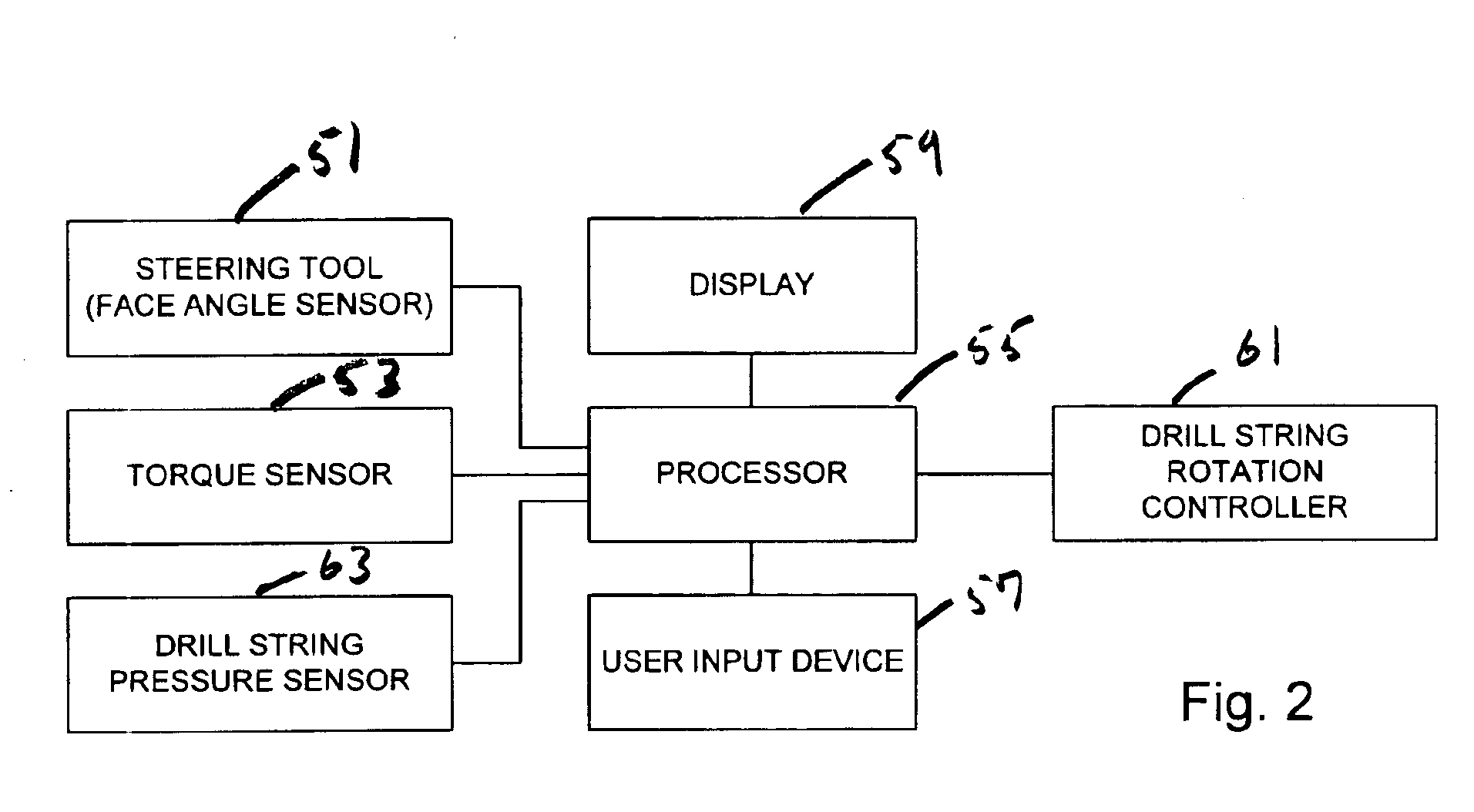

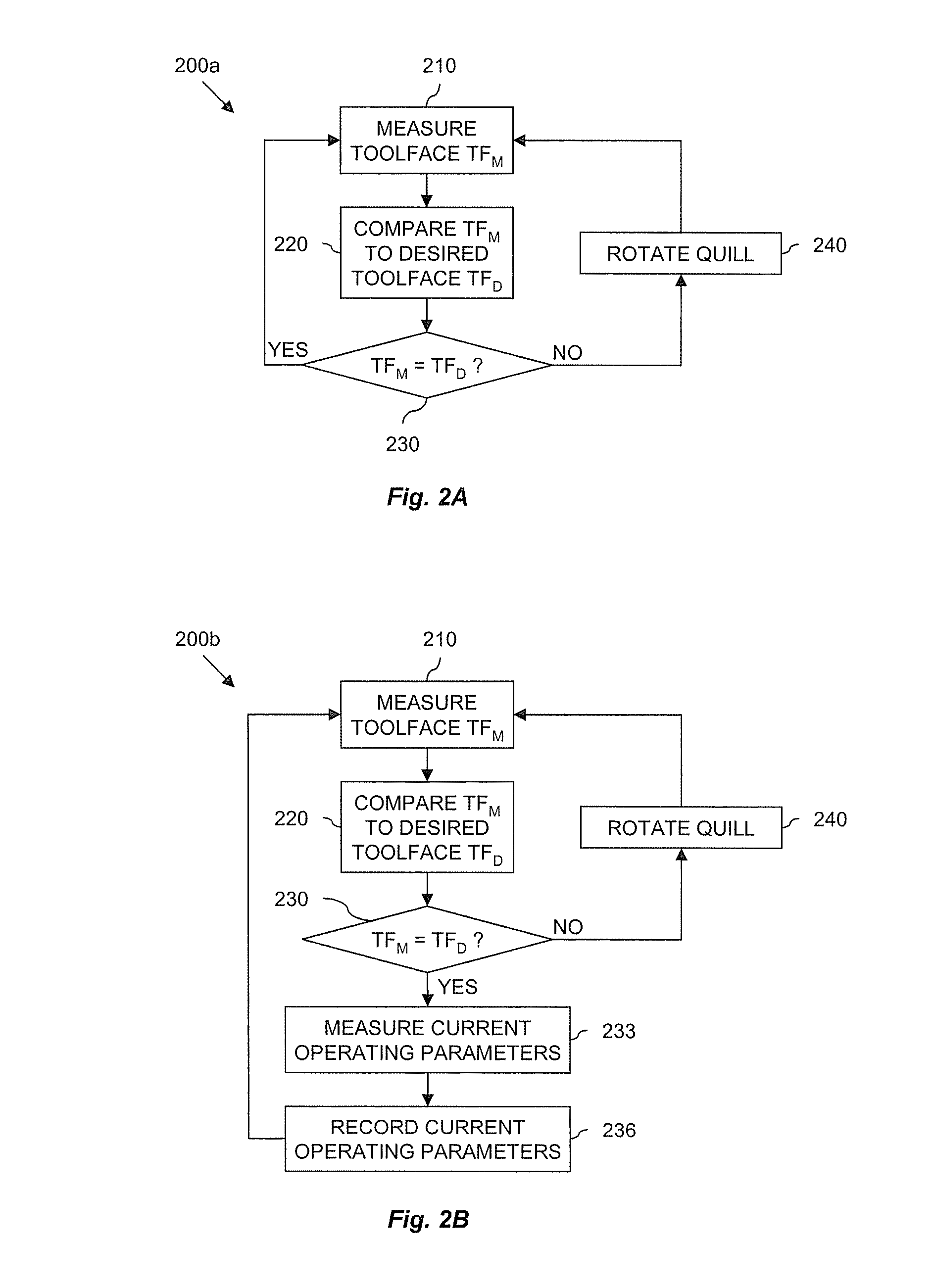

System and method for direction drilling

InactiveUS20120024606A1SurveyNavigation by speed/acceleration measurementsDirectional drillingDrill bit

A system and a method for directional drilling may generate a model of steering behavior which may be used to estimate a position and an orientation of the drill bit during directional drilling. The estimated position and the estimated orientation may be compared to the well plan to determine desired drilling behavior, and the desired drilling behavior may be used to determine a recommended toolface orientation and / or recommended intervals of sliding and rotating to conform the directional drilling to the well plan.

Owner:SCHLUMBERGER TECH CORP

Directional cased hole side track method applying rotary closed loop system and casing mill

InactiveUS20050150692A1Easy to operateEasy to controlDrill bitsDrilling rodsWell drillingClosed loop

A bottomhole assembly (BHA) for single trip sidetracking operations has a mill for forming an open hole section in a cased wellbore and a steering unit for controlling drill bit orientation. During use, the drilling system is assembled at the surface and tripped into the wellbore. The mill is positioned adjacent a kick-off point and operated to form an open hole section. Thereafter, the drill bit is positioned adjacent the open hole section. An exemplary steering unit includes one or more force application members that, when energized, displace the drill bit such that the bit is pointed in a specified direction into the open hole section. The steering unit also includes one or more force application members that facilitate directional drilling through the open hole section. Other suitable steering units can employ devices that alter the BHA centerline geometry.

Owner:BAKER HUGHES INC

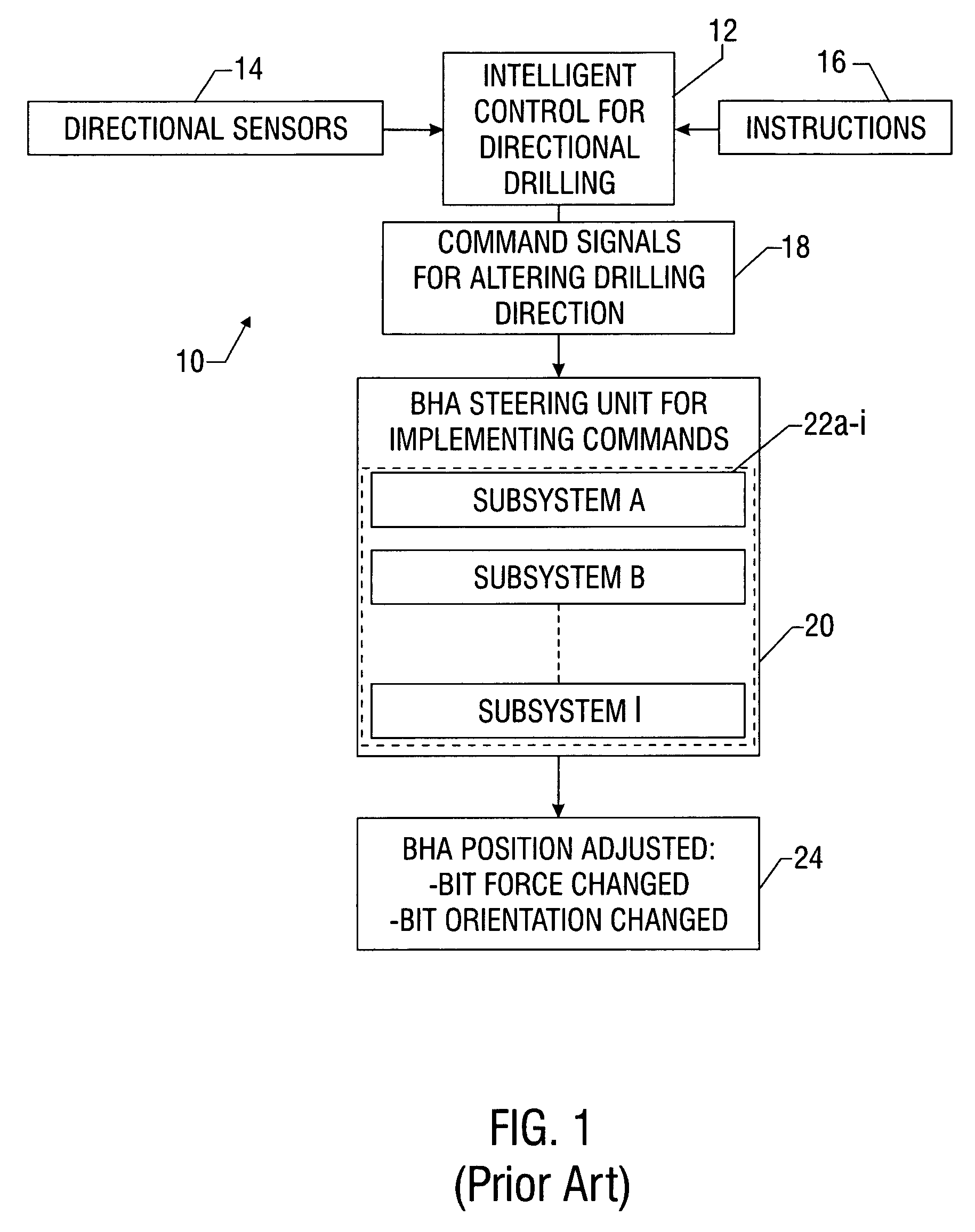

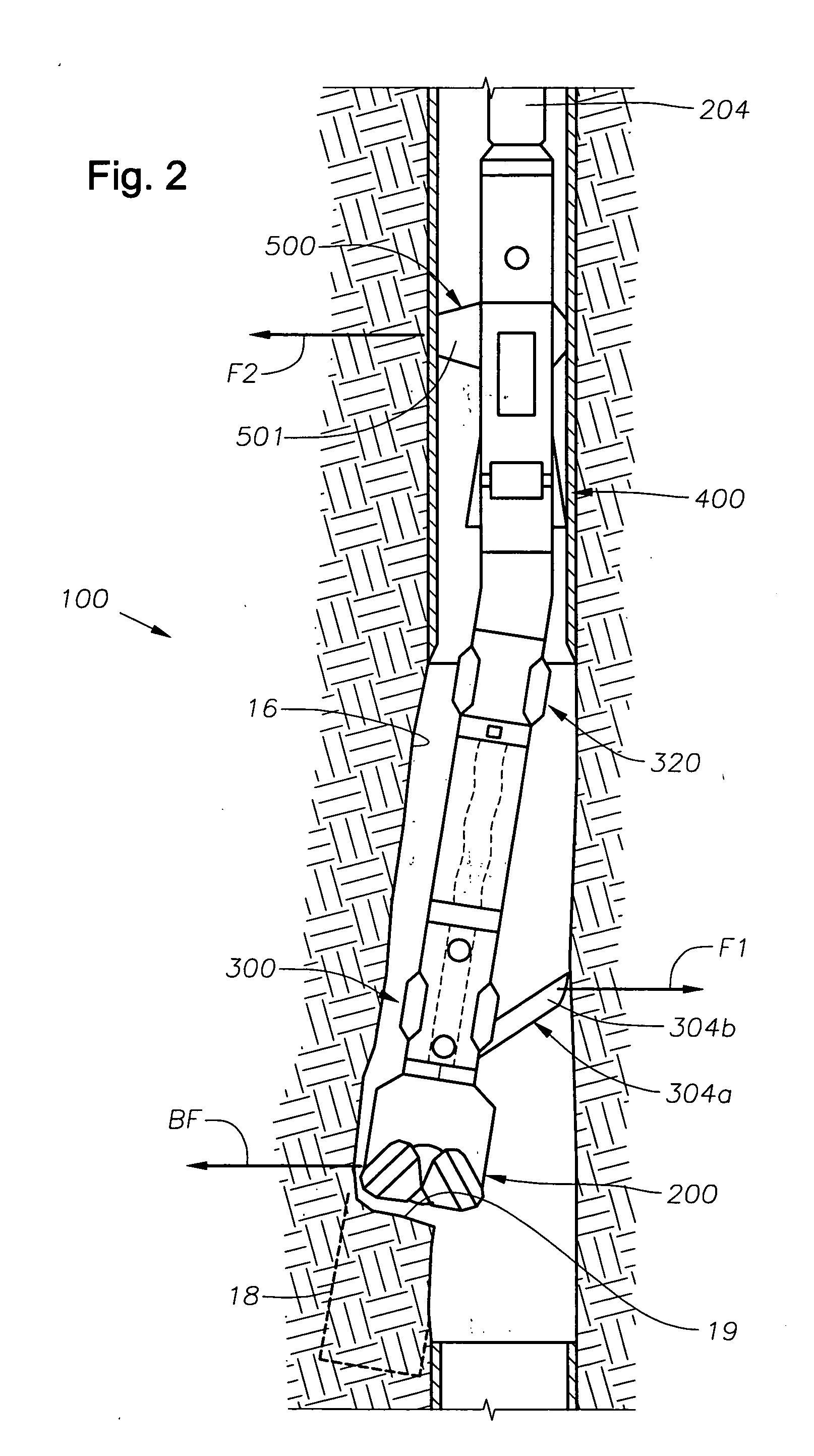

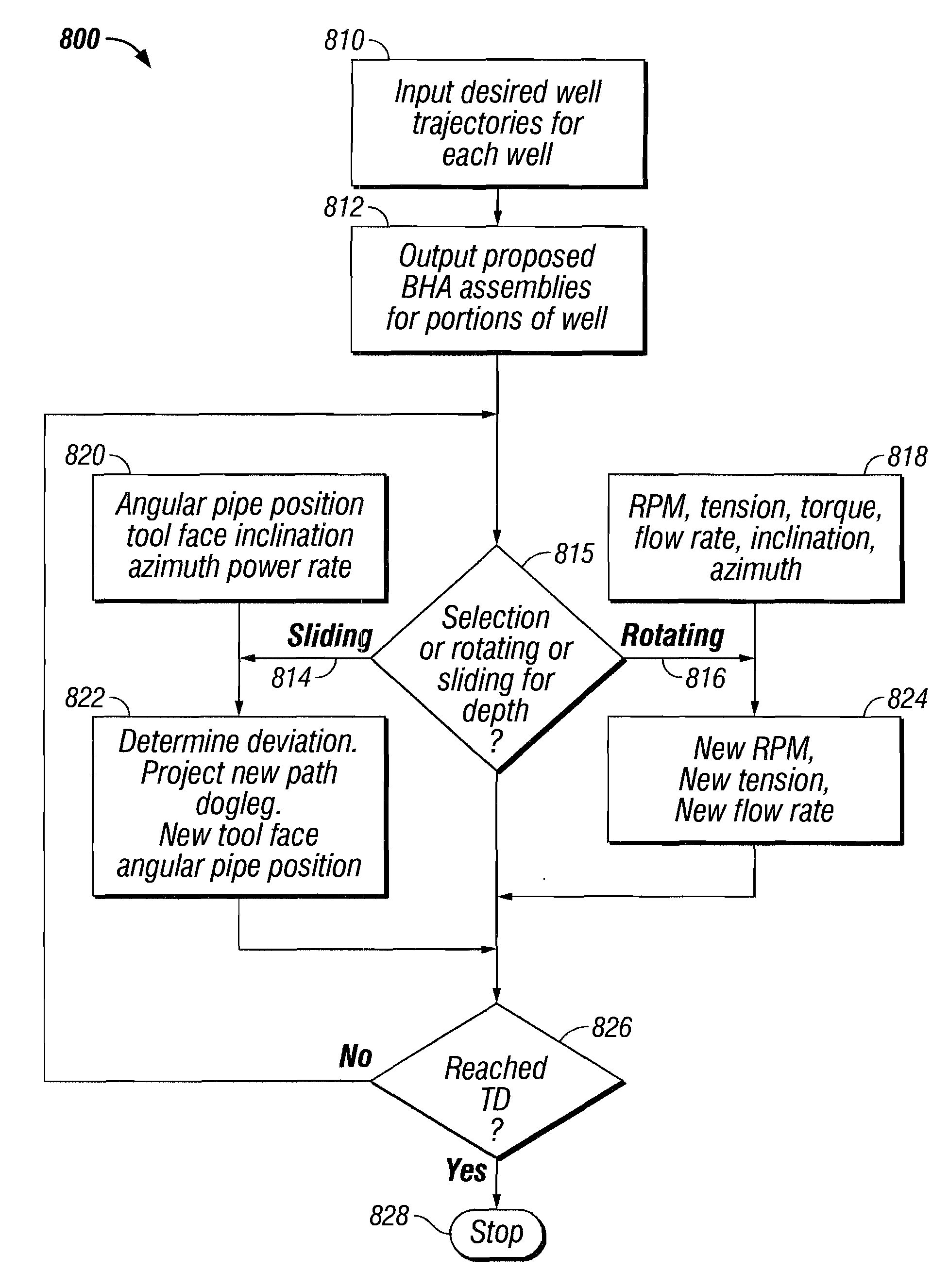

Directional Drilling System and Software Method

InactiveUS20080314641A1Eliminate needSurveyDirectional drillingBottom hole assemblyDirectional drilling

A software method for directionally drilling a plurality of wells capable of providing directional drilling services to hundreds of wells. The software method may comprise steps from determining a BHA for a portion of a well, determining a deviation between the desired trajectory of the well bore and an actual trajectory of the well bore as measured at the nonmagnetic measurement portion of the bottom hole assembly, determining a dogleg of the actual trajectory, and determining a correction trajectory to reduce the deviation between the desired trajectory and the actual trajectory which produces a dogleg less than a predetermined value. The trajectory may be projected to the bit even though the nonmagnetic measurement portion of the bottom hole assembly is often separated therefrom by significant distances.

Owner:MCCLARD KEVIN

Steerable underreamer/stabilizer assembly and method

A bottom hole assembly includes a drill bit, a stabilized underreamer assembly located behind the drill bit, and a drilling assembly. A method to drill a formation includes positioning a stabilized underreamer assembly behind a drill bit, positioning a drilling assembly behind the stabilized underreamer assembly, and rotating the drill bit and stabilized underreamer assembly with the drilling assembly. A stabilized underreamer located between a directional drilling assembly and a drill bit includes at least one arm assembly extending from the stabilized underreamer assembly, wherein the arm assembly includes a stabilizer portion and an underreamer cutting structure.

Owner:SMITH INT INC

Continuous on-bottom directional drilling method and system

A method of and system for directional drilling alternate between rotary drilling and sliding drilling with the bit remaining in continuous contact with the bottom of the bore hole.

Owner:SCHLUMBERGER TECH CORP

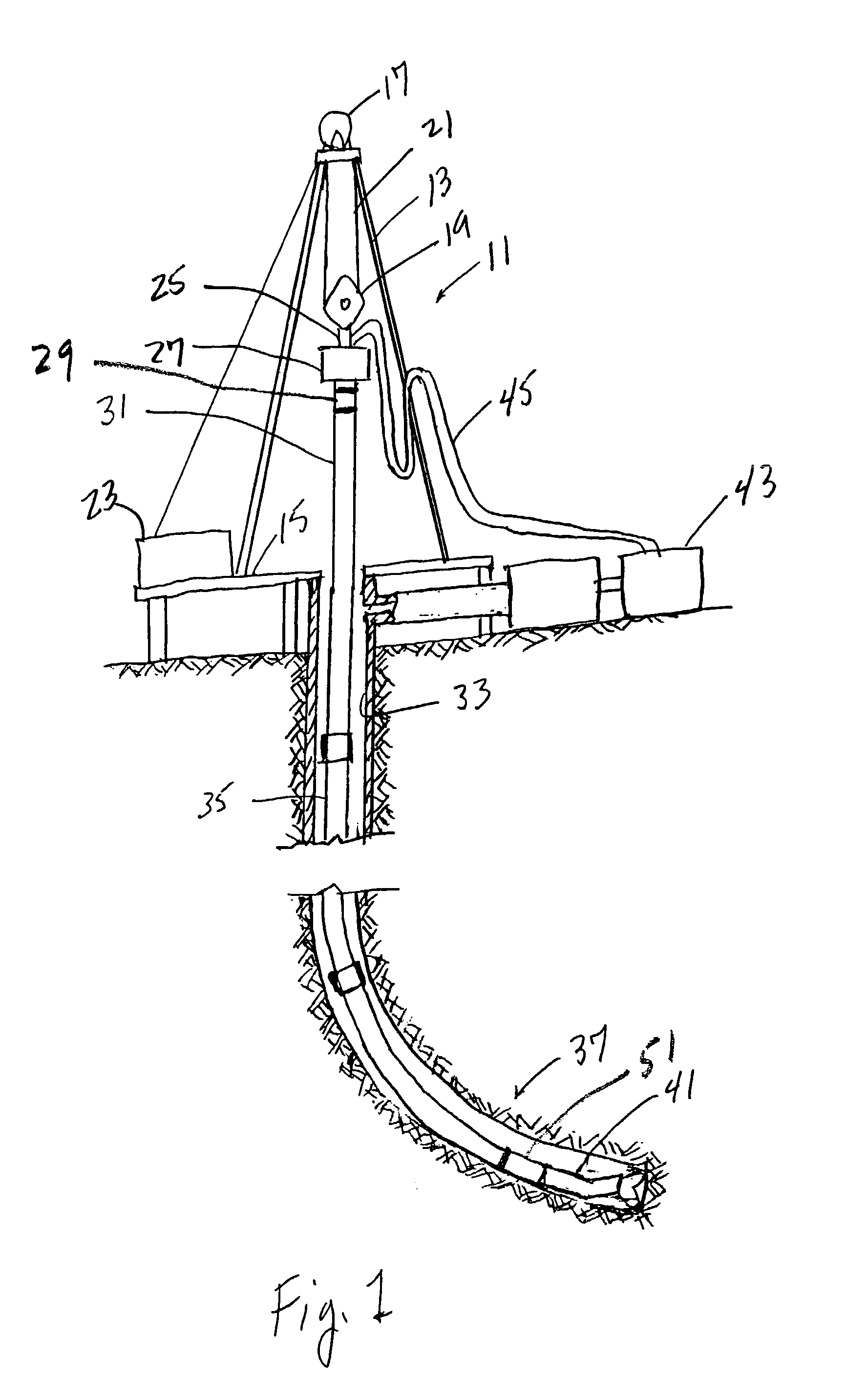

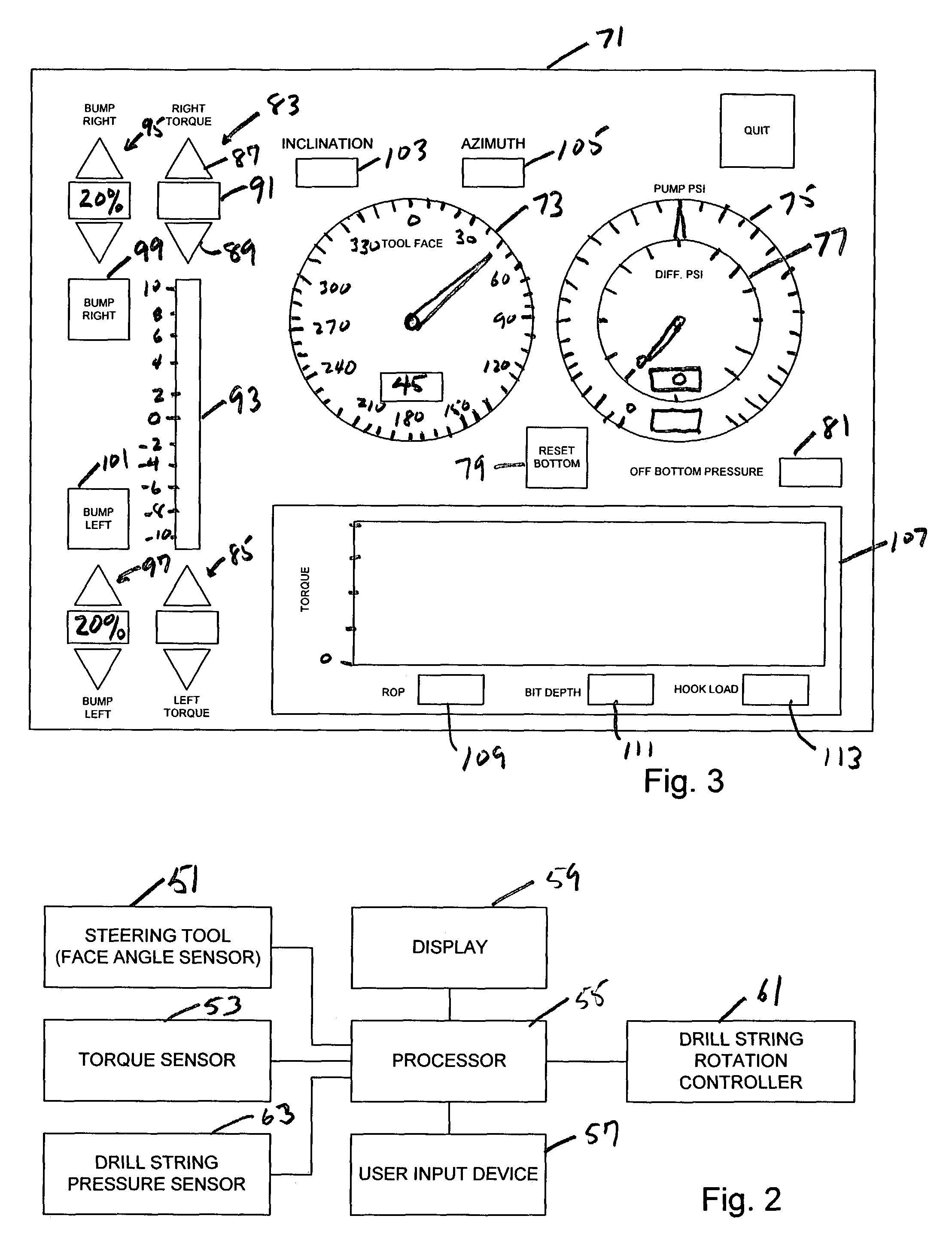

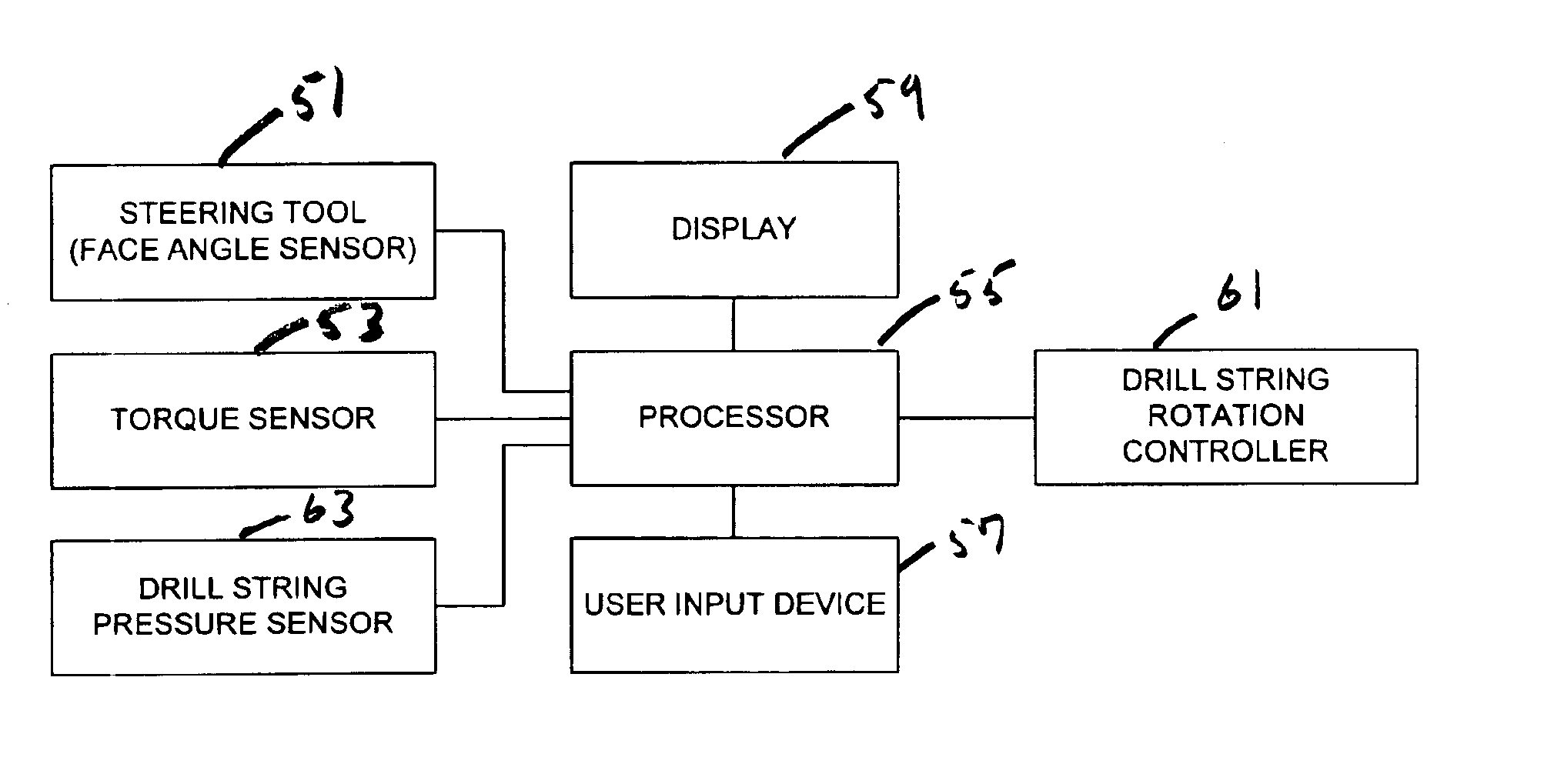

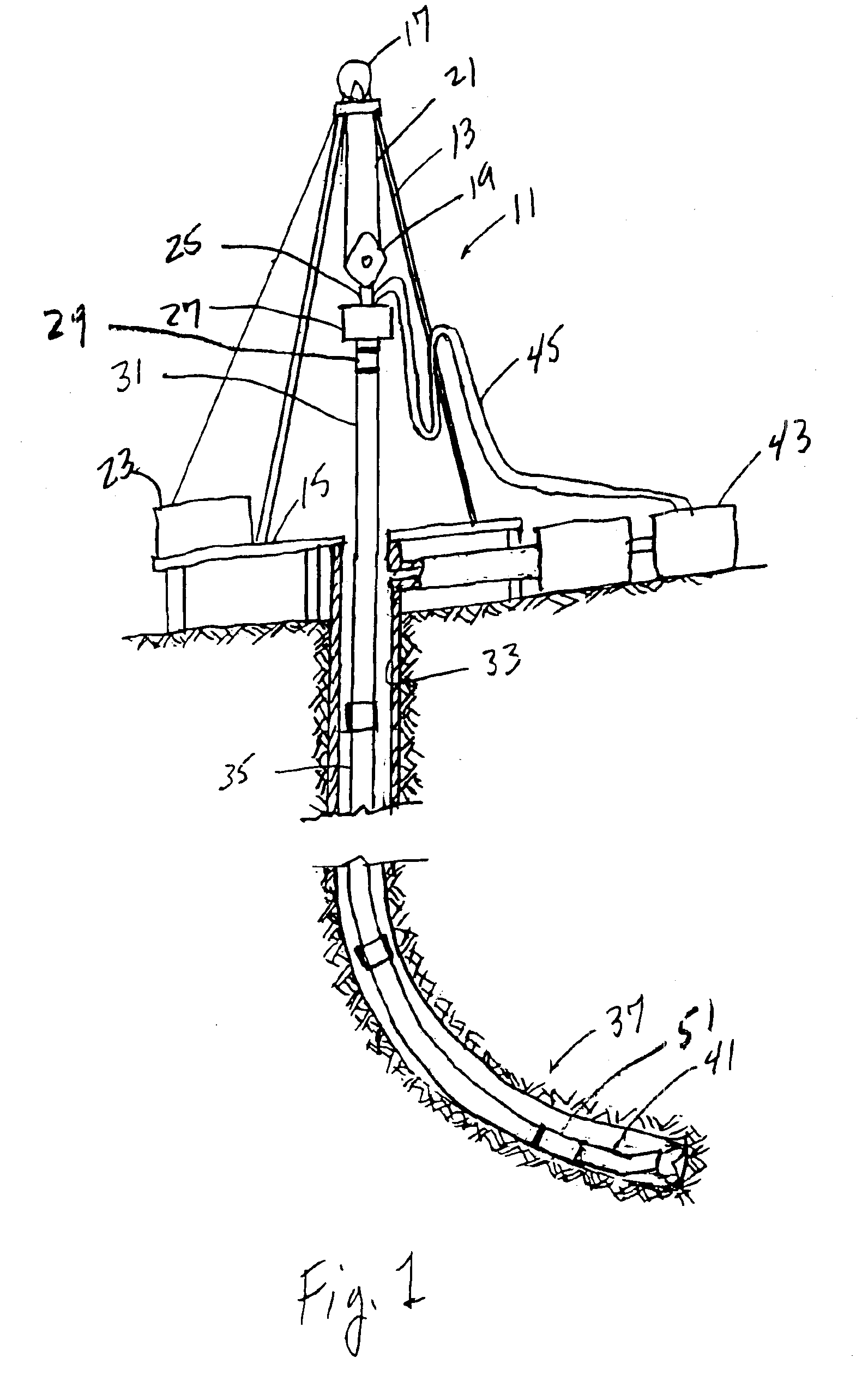

Method of and apparatus for directional drilling

InactiveUS6918453B2Reduce frictionDerricks/mastsDirectional drillingWell drillingDirectional drilling

A method of and system for directional drilling reduces the friction between the drill string and the well bore. A downhole drilling motor is connected to a drilling rig at the surface by a drill string. The drilling motor is oriented at a selected tool face angle. The drill string is rotated at the surface in a first direction until a first torque magnitude is reached without changing the tool face angle. The drill string is then rotated in the opposite direction until a second torque magnitude is reached, again without changing the tool face angle. The drill string is rotated back and forth between the first and second torque magnitudes. Pressure inside the drill string is measured, and the first and second torque magnitudes are adjusted in response to changes in the pressure.

Owner:SCHLUMBERGER TECH CORP

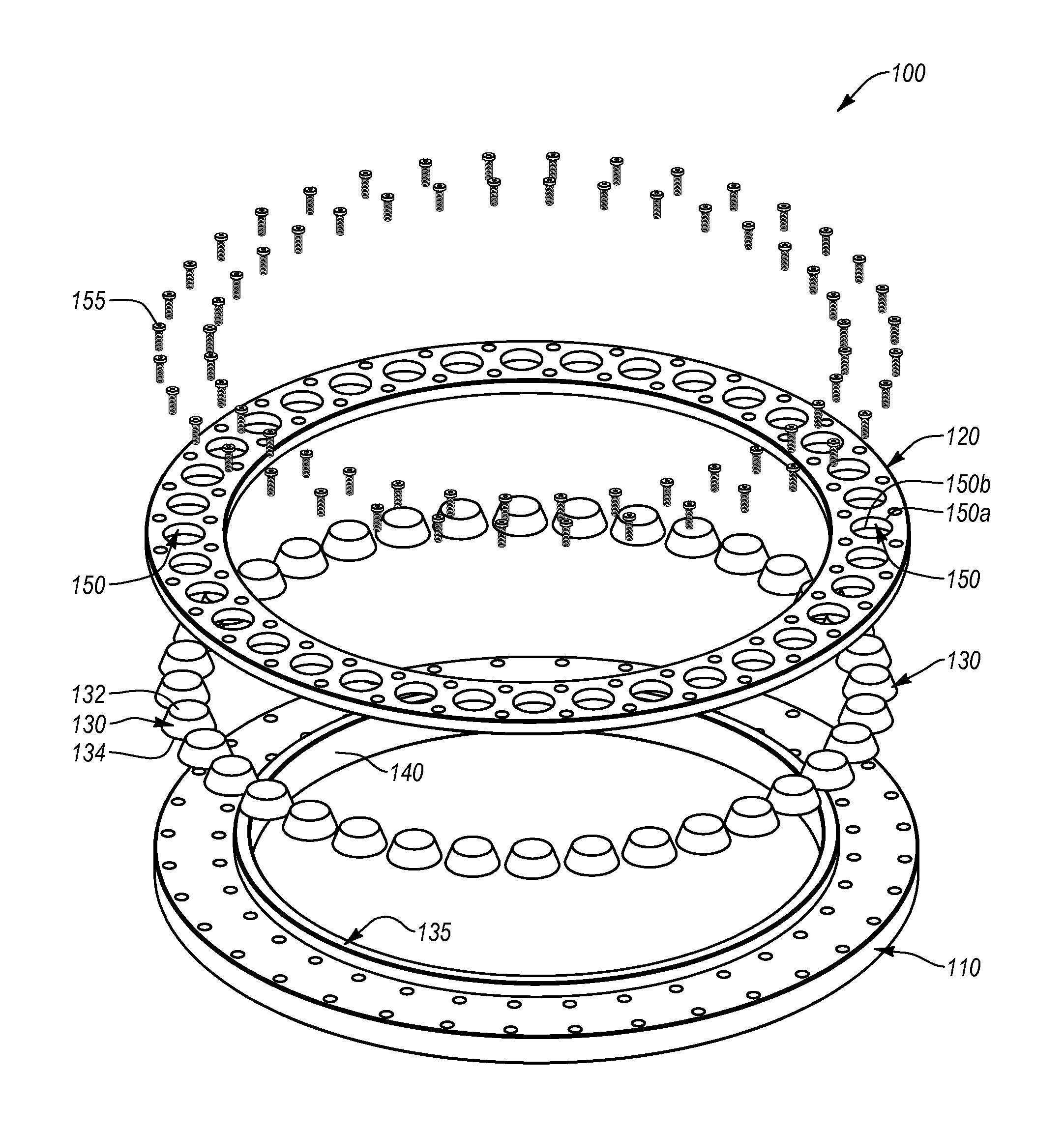

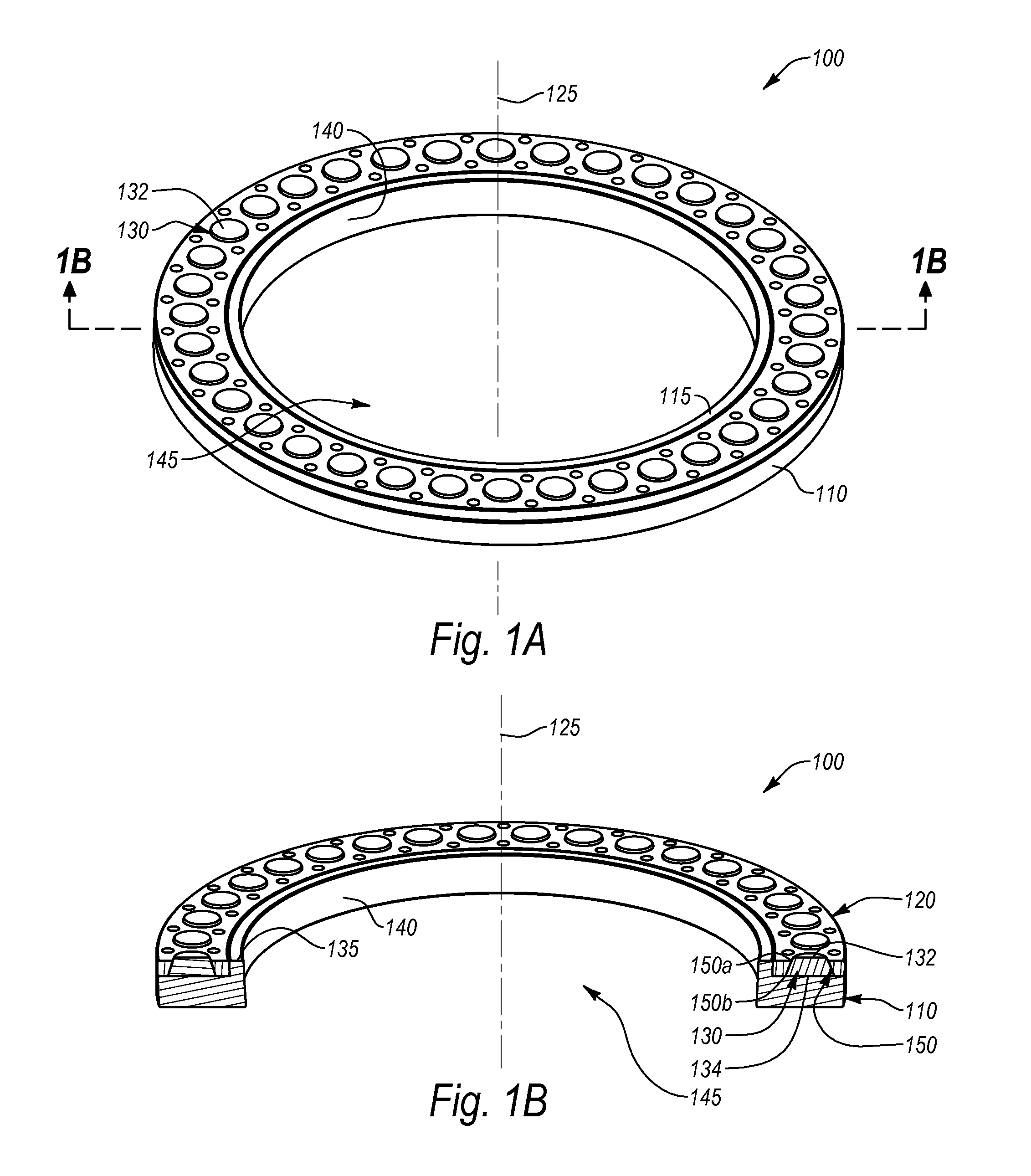

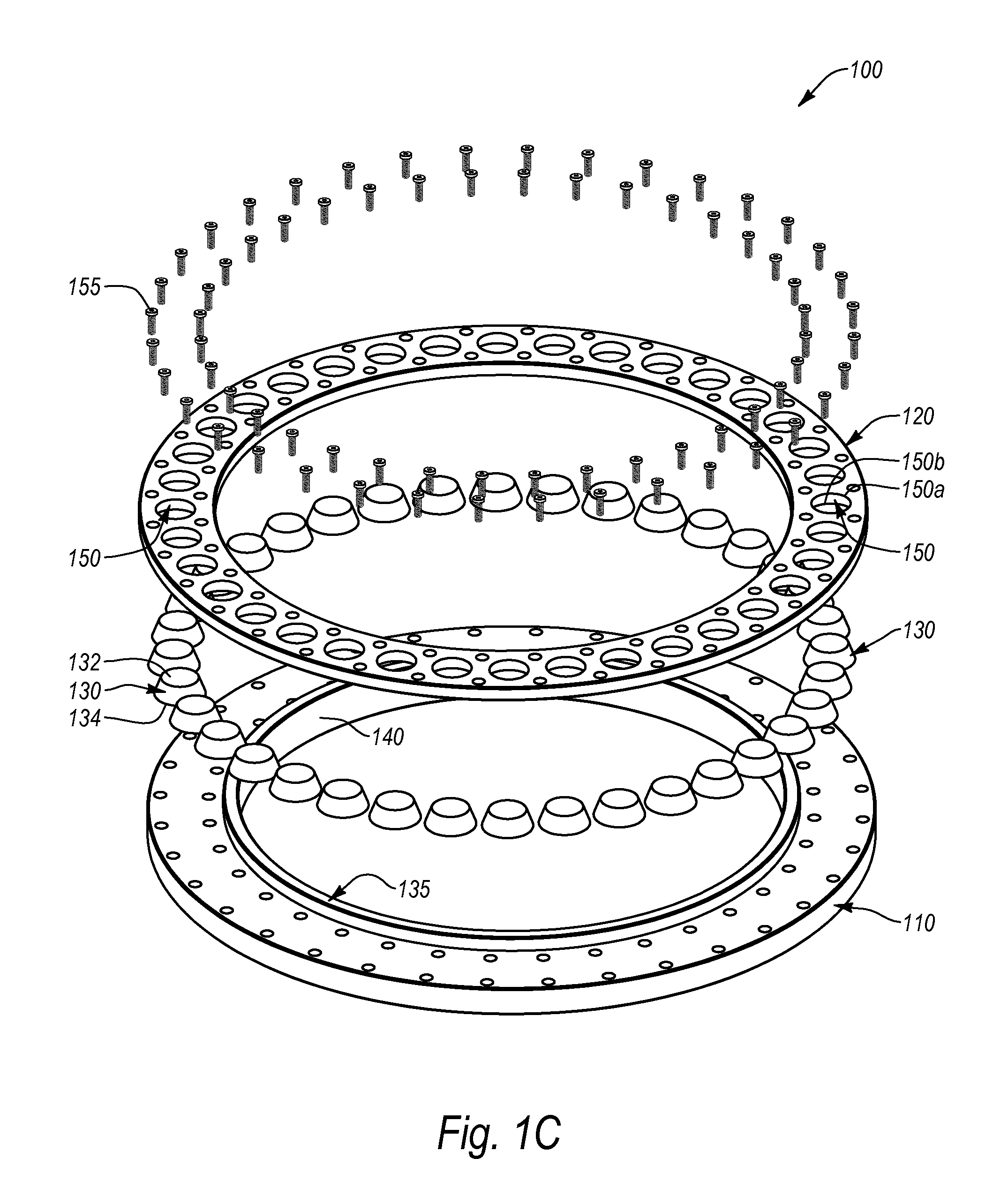

Bearing Assemblies, Bearing Apparatuses Using the Same, and Related Methods

Various embodiments relate to bearing assemblies configured to enable removal and replacement of superhard bearing elements, and bearing apparatuses that may utilize such bearing assemblies. The disclosed bearing assemblies may be used in a number of applications, such as downhole motors in subterranean drilling systems, directional drilling systems, roller-cone drill bits, and many other applications. In an embodiment, a bearing assembly includes a support ring and a retention ring assembled with the support ring. The retention ring includes a plurality of through holes. The bearing assembly further includes a plurality of superhard bearing elements, with each superhard bearing element inserted partially through and projecting from a corresponding one of the through holes of the retention ring. The retention ring and each superhard bearing element are collectively configured to restrict displacement of each superhard bearing element beyond a selected position in a direction away from the support ring.

Owner:US SYNTHETIC CORP

System and method for directional drilling utilizing clutch assembly

InactiveUS7178611B2Reduces and eliminates any static frictionPrevent rotationDrilling rodsDirectional drillingEngineeringDirectional drilling

According to one embodiment of the invention, a system for directional drilling within a wellbore includes a drill string having an upper portion, a lower portion, a bent motor coupled to the lower portion, and a drill bit coupled to bent motor, and a clutch assembly disposed between the upper and lower portions. The clutch assembly is operable to disengage the upper and lower portions of the drill string and allow the upper portion to rotate while the lower portion does not rotate.

Owner:EFFECTIVE EXPLORATION

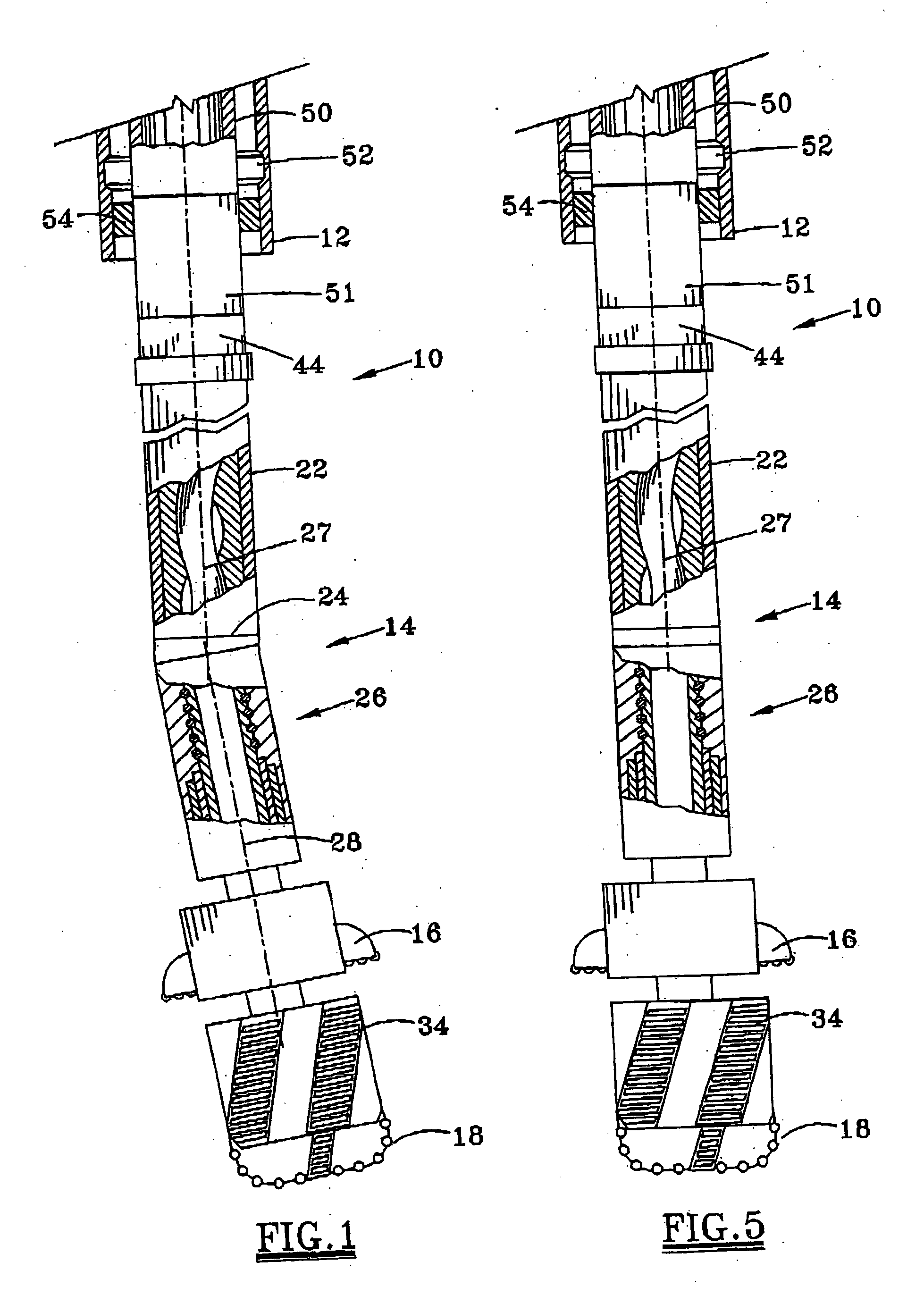

Drilling with casing

A borehole may be drilled utilizing the bottom hole assembly 10, 50 with a downhole motor 14, 110, which may offset at a selected bend angle. A bend for directional drilling may be provided by a PDM, or by a RSD. A gauge section 36 secured to the pilot bit 18 has a uniform diameter bearing surface along an axial length of at least 60% of the pilot bit diameter. The bit or reamer 16 has a bit face defining the cutting diameter of the drilled hole. The axial spacing between the bend and the bit face is controlled to less than fifteen times the bit diameter. The downhole motor, pilot bit and bit may be retrieved from the well while leaving the casing string in the well.

Owner:HALLIBURTON ENERGY SERVICES INC

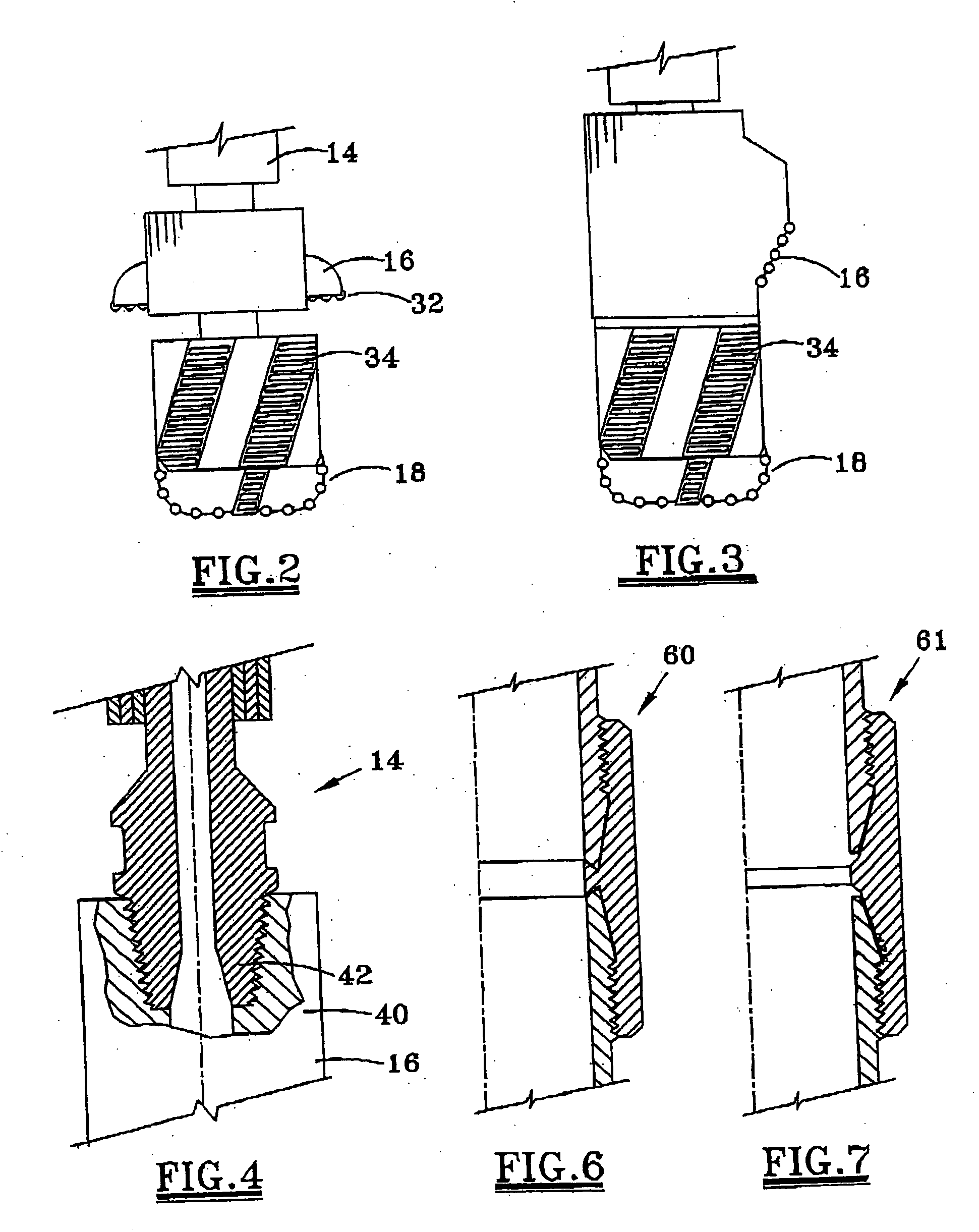

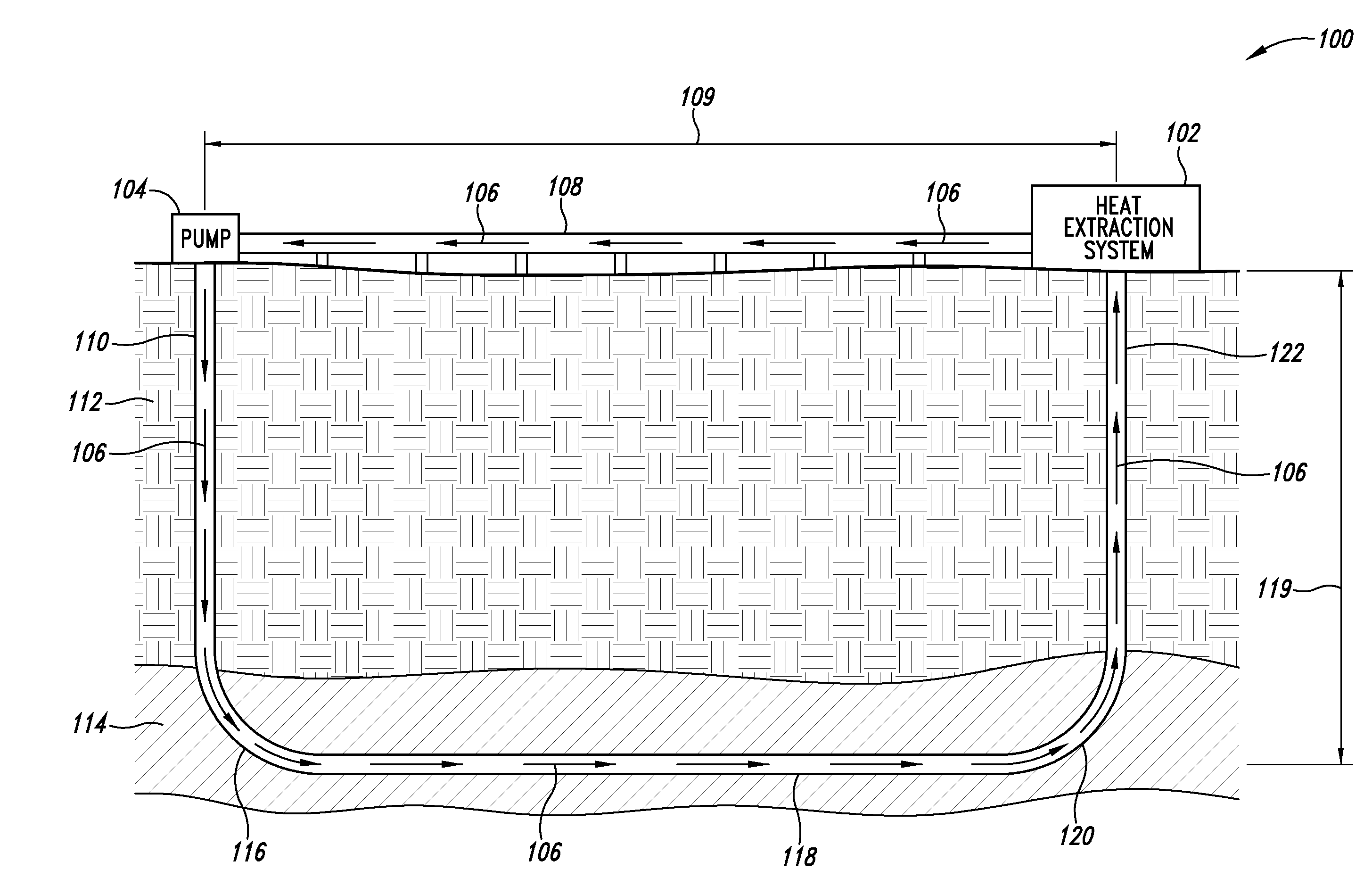

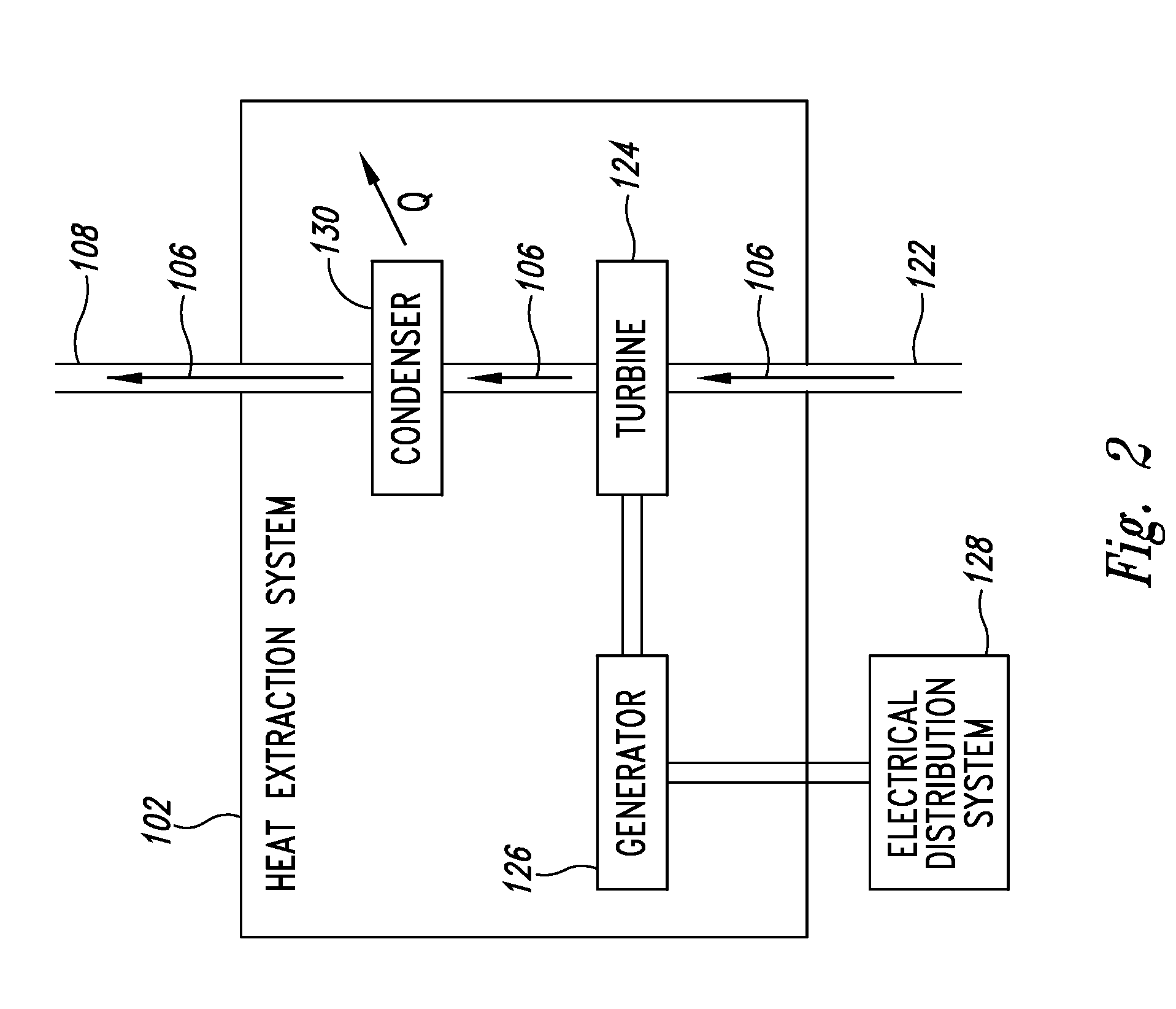

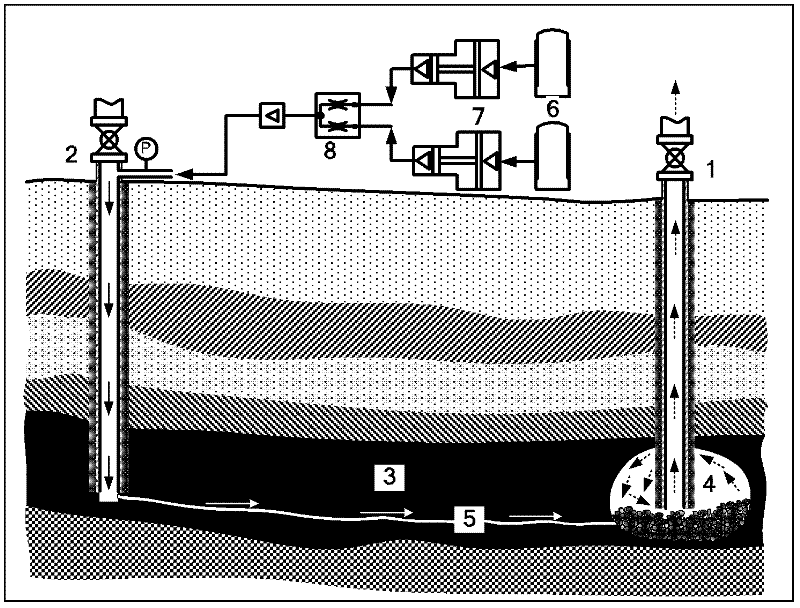

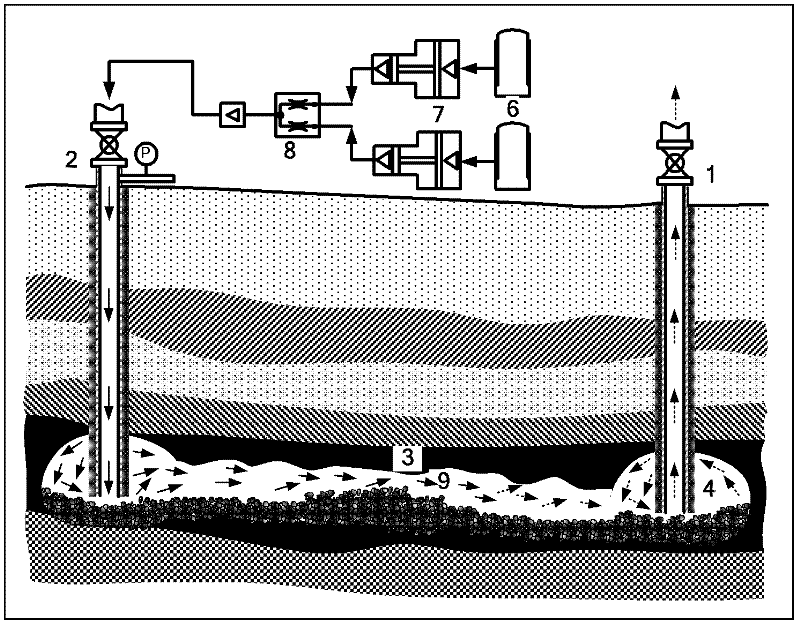

Directional geothermal energy system and method

InactiveUS20070245729A1Collector components/accessoriesGeothermal energy generationMultiple injectionTransport time

A directional geothermal energy system and method helps to increase control in paths to be taken by geo-fluid flow through hot rock to create engineered geothermal reservoirs and networks to mine heat from hot rock resources. The system uses directional drilling techniques to create a spanning borehole extending between an injection borehole and a production borehole. The spanning borehole typically extends through hot rock for a distance on the order of kilometers to allow the geo-fluid flowing through the spanning borehole adequate transit time and surface contact to obtain sufficient heat given a certain flow rate for the geo-fluid. In some implementations, multiple injection boreholes can supply geo-fluid to a single production borehole. Individual geo-fluid networks can be so sized, shaped, and located with respect to one another to form a collection of geo-fluid networks to mine heat from very large hot rock resources.

Owner:MICKLESON D LYNN

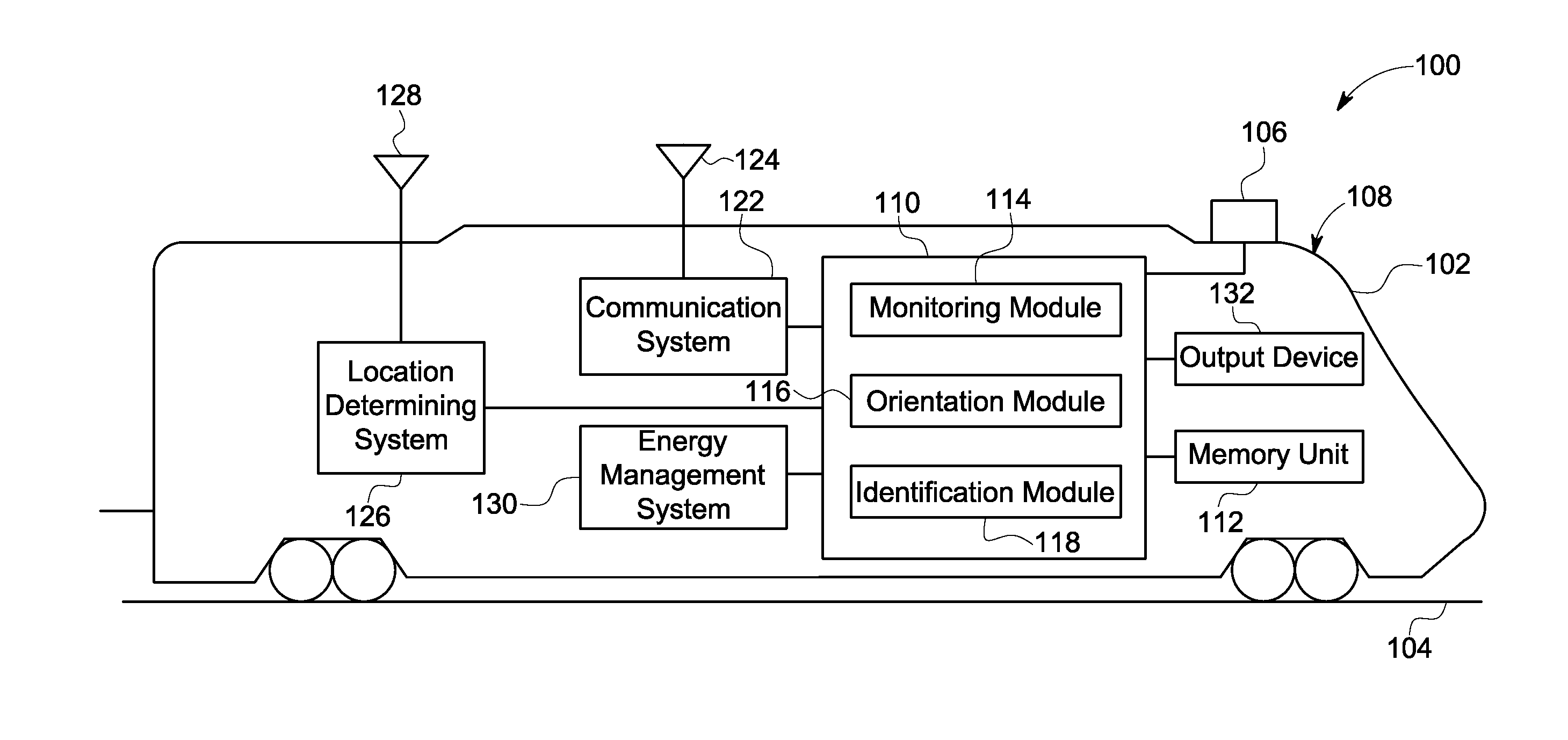

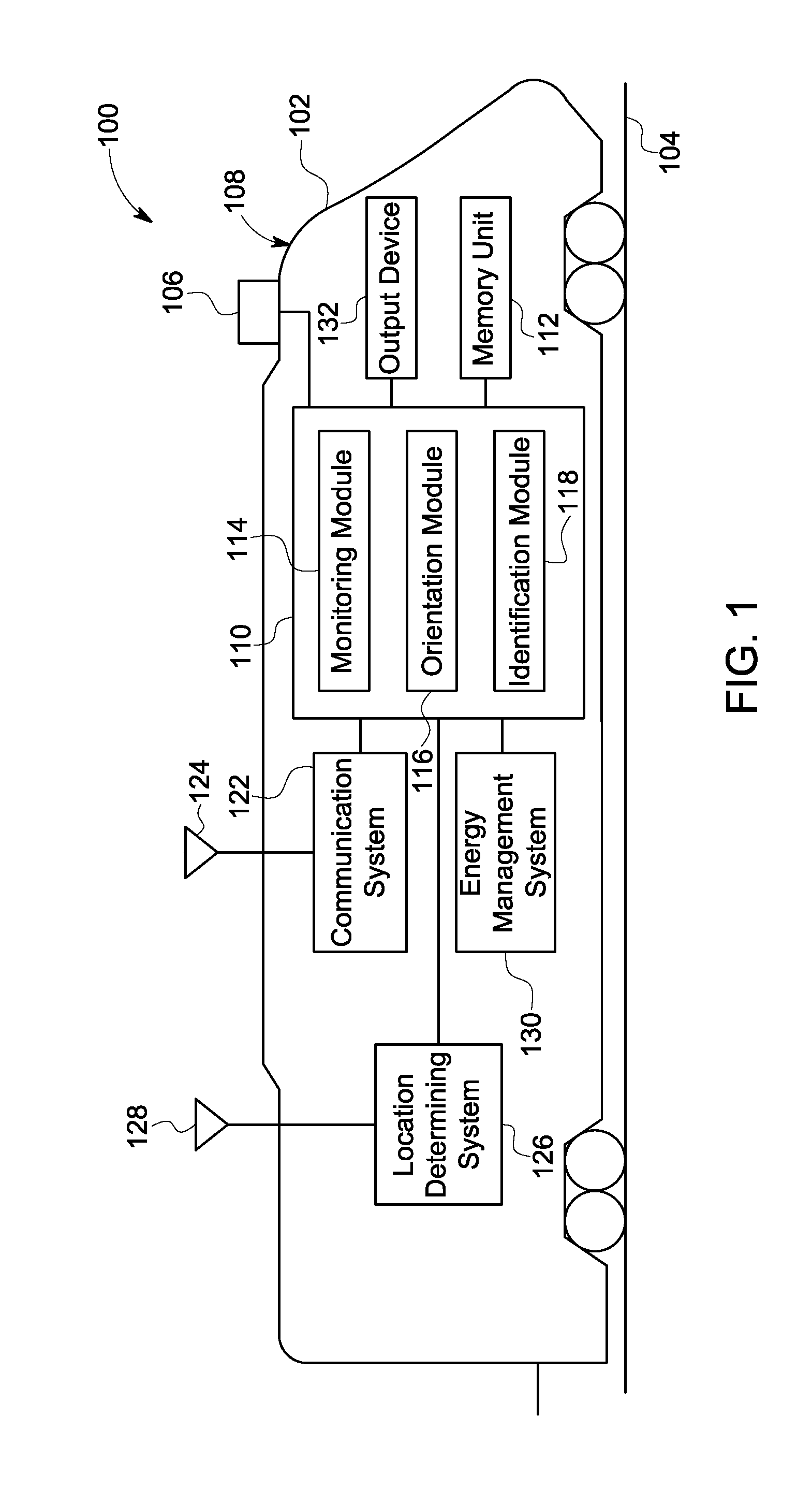

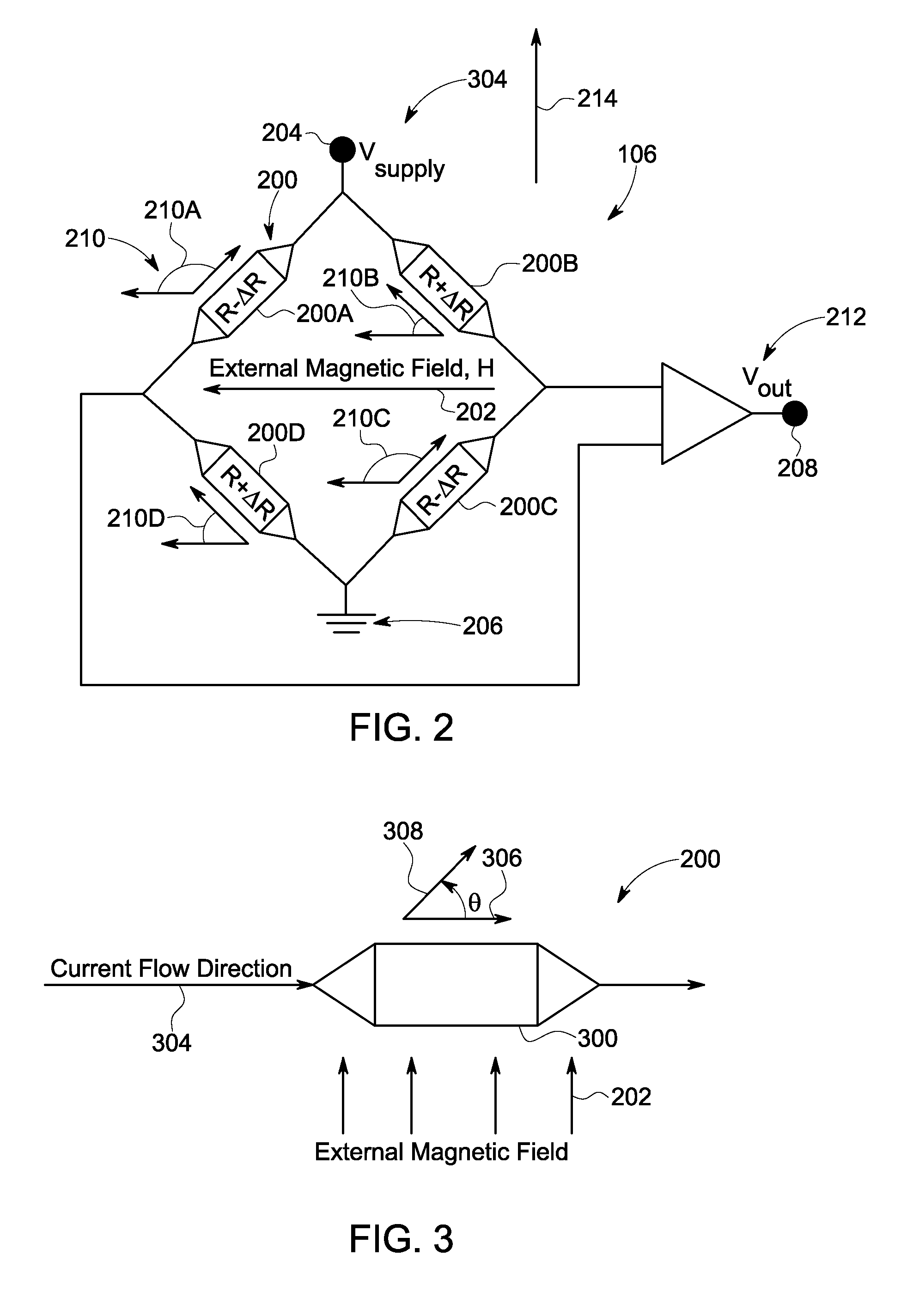

Method and system for identifying a directional heading of a vehicle

ActiveUS20130261856A1Instruments for road network navigationDigital data processing detailsInput selectionEngineering

A system for confirming a direction of travel of a vehicle includes a location determining system and a control unit. The location determining system is configured to be coupled to a vehicle that travels in a network of plural route segments having fixed positions. The location determining system also is configured to obtain data representative of a measured heading of the vehicle. The measured heading represents a direction of travel of the vehicle. The control unit is configured to receive a designated route segment that is at least one of selected by operator input or provided by a trip plan that designates operational settings of the vehicle for a trip. The control unit is configured to compare the measured heading of the vehicle with one or more designated headings associated with the route segments to verify whether the vehicle is actually traveling on the designated route segment.

Owner:GE GLOBAL SOURCING LLC

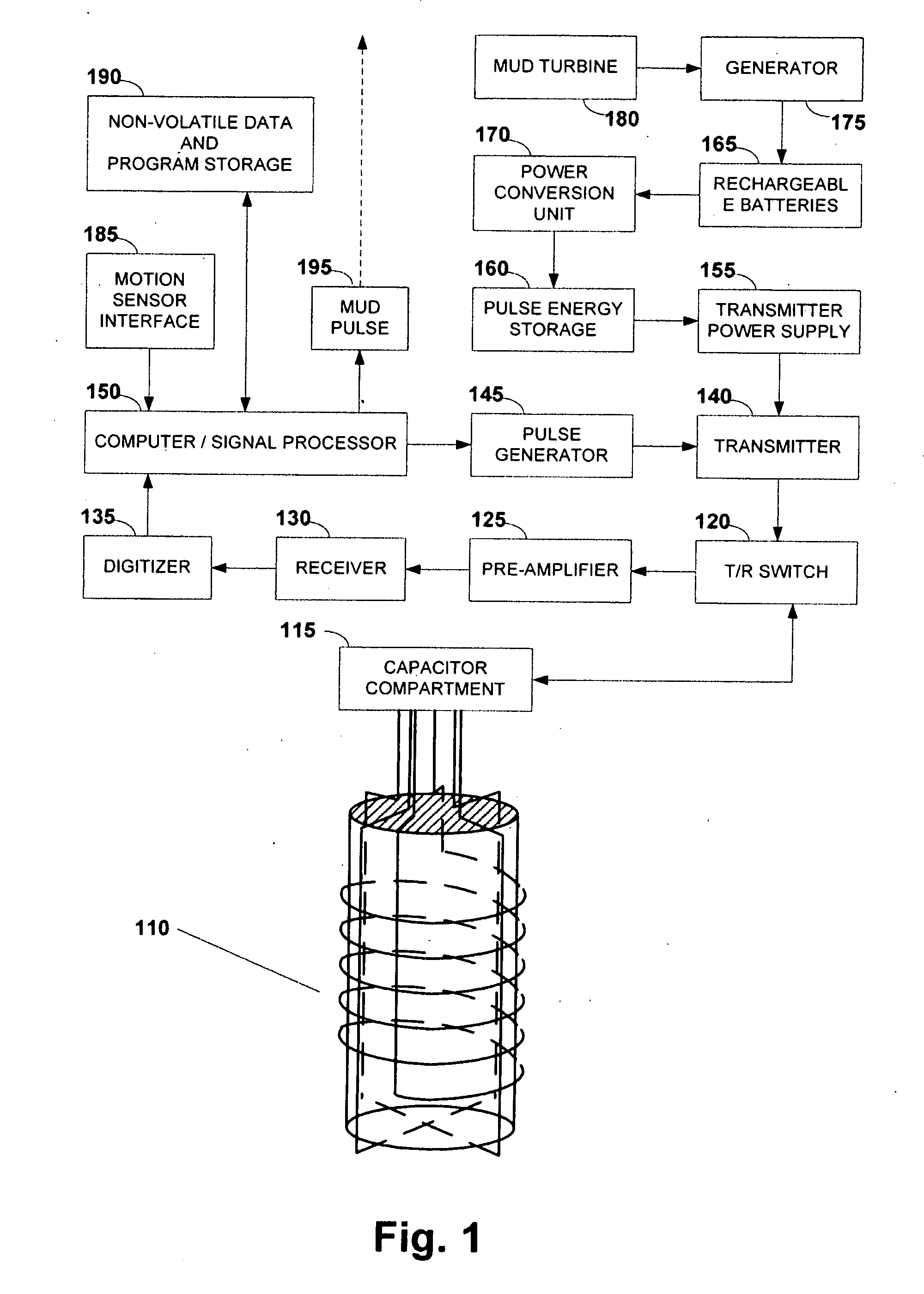

Measurement while drilling bi-directional pulser operating in a near laminar annular flow channel

A device, method, and system for creating a pressure pulse from drilling fluid within a drill string in a down hole drill collar for enabling measurement-while drilling. The device and system are designed such that primarily laminar flow exists in the area surrounding the pulser apparatus. The method associated with the reproducible and essentially noise-free pulses occurs when a pulser bell is manipulated in an upward and downward direction by a combination of the solenoid activation of a bi-directional poppet to redirect the fluid flow from the pressure reservoir to and from a sliding pressure chamber and associated upper and lower flow connecting channels. The pulse or non-pulse is converted into a digital signal uphole by a pressure transducer in conjunction with a decoding algorithm. It is then displayed to the driller and oilfield operators as useful directional and formation information that help the oilfield operator for uphole decision making regarding directional drilling. Additional pulsers can be added to the tool so that higher data bit rates can be accomplished. These higher data bit rates will provide for more comprehensive data collection thereby reducing drilling costs and optimizing oil field yields. The higher bit rate allows for more sensors that can send additional and improved information uphole without the use of open hole wire line logging which is impossible to accommodate while drilling horizontally.

Owner:TELEDRILL

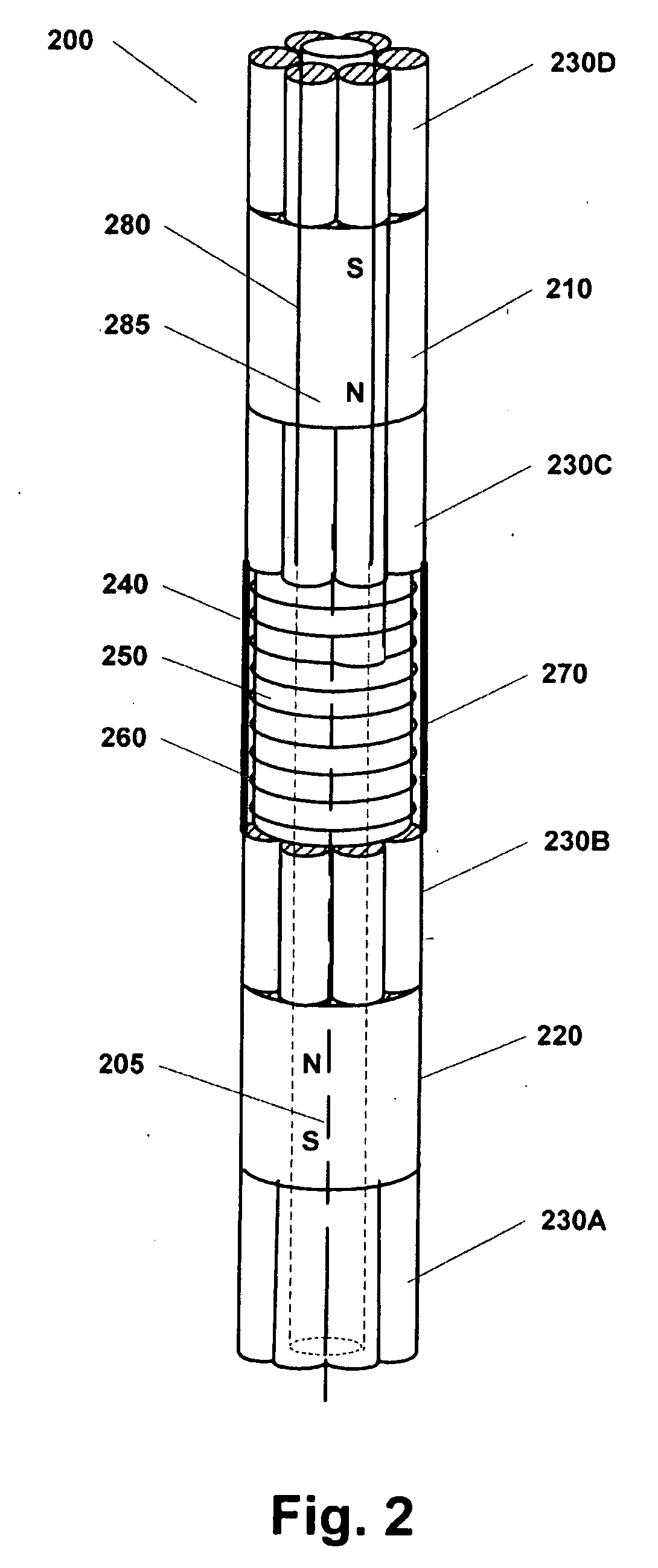

Systems and methods for deep-looking nmr logging

ActiveUS20090072825A1Add depthAccurate estimateElectric/magnetic detection for well-loggingMaterial analysis by using resonanceNMR - Nuclear magnetic resonanceMagnetic poles

An NMR logging tool for conducting NMR measurements in a plurality of sensitive volumes ranging up to a meter from the tool. The tool comprises a magnetic assembly using one or more permanent magnets and at least one pole piece for extending a magnet pole and shaping the magnetic field to simulate a magnetic monopole in a sensitive volume within the formation. Different embodiments of a segmented antenna enable directional NMR logging. The tool embodiments and methods of their use are suitable for wireline or LWD logging, and can be used for directional drilling.

Owner:HALLIBURTON ENERGY SERVICES INC

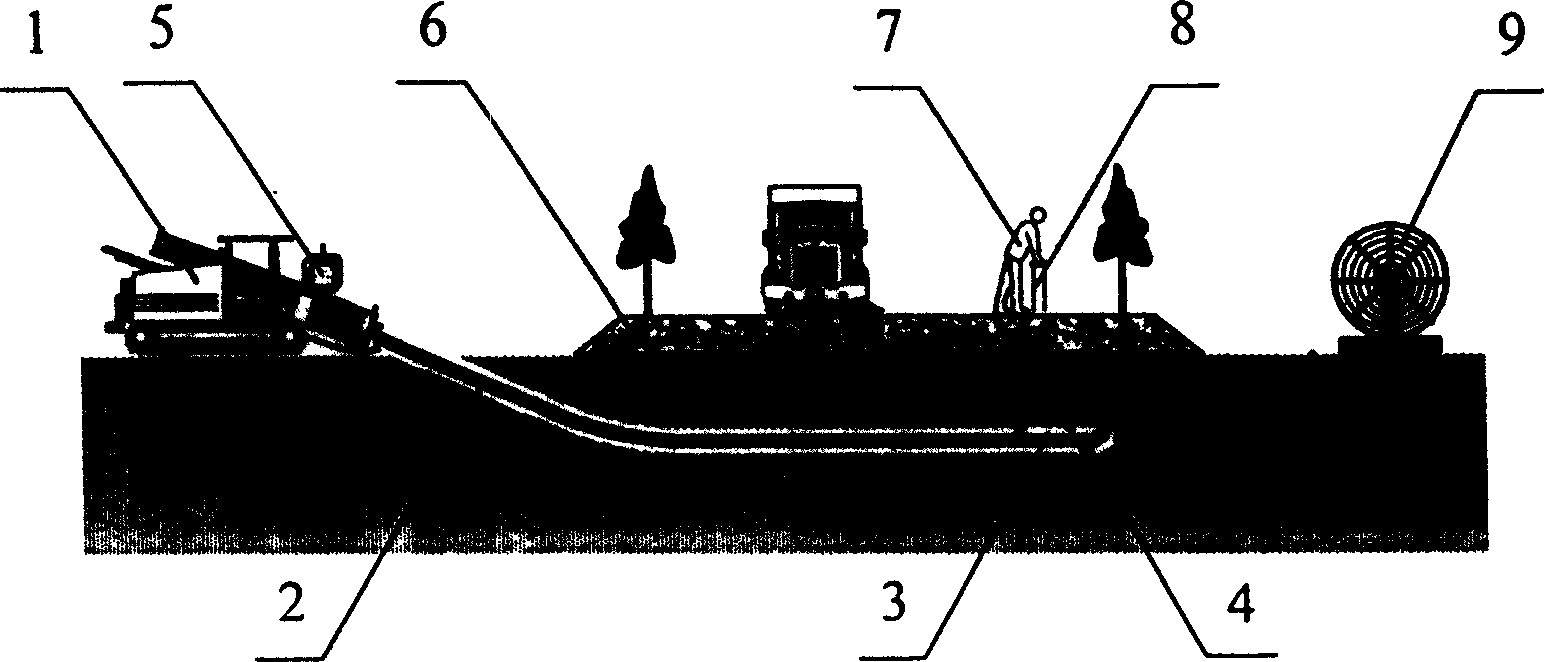

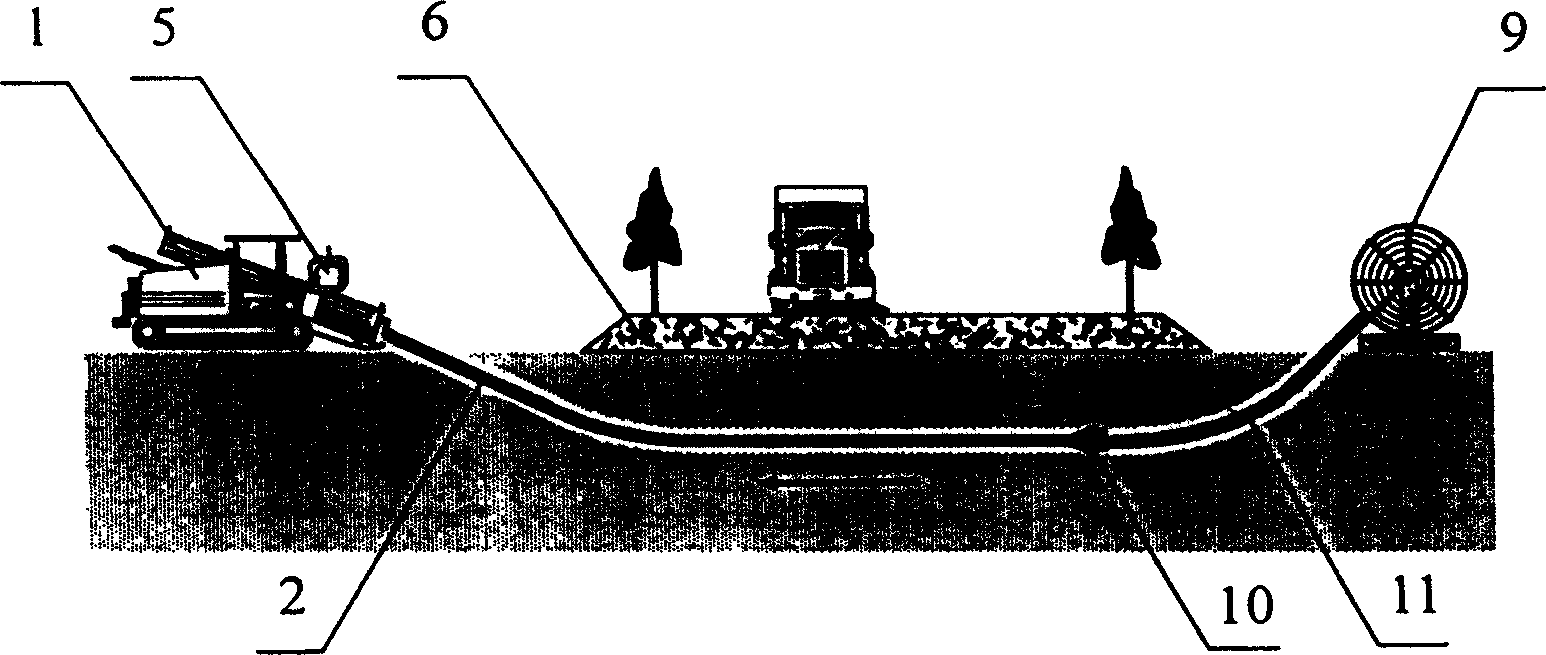

Guide positioning method and positioning instrument for horizontal directional drilling

The invention discloses a horizontal directional drilling guiding position method and position indicator, which comprises the following parts: sensing emission probe in the guiding drilling tool, walking type position follower and driller monitor on the drill, wherein the sensing emission probe is composed of angle sensor, signal disposing and transmitting unit, solenoid coil and battery, which sends the measured the incidence, facing angle, temperature and other parameters to the follower through wireless electromagnetic wave; the position follower calls the parameter of underground probe to measure position and depth according to the signal relative strength distribution, whose final result is sent to the driller display through wireless pattern. The invention is convenient to operate for the driller personnel.

Owner:ZOOMLION HEAVY IND CO LTD +1

Drill string rotation encoding

ActiveUS20050001737A1Quick and accurate communicationReduce the possibilityElectric/magnetic detection for well-loggingSurveyComputer scienceDirectional drilling

A method for communicating with a downhole device is provided. The method includes predefining an encoding language including codes understandable to the device, the codes represented in the language as predefined value combinations of drill string rotation variables such as rotation rate or duration. The method further includes rotating a drill string at first and second rates and measuring the rotation rates downhole. The first measured rotation rate is processed downhole in combination with the second measured rotation rate to acquire a code in the language at the downhole device. Embodiments of the invention are useful, for example, for transmitting commands from the surface to a downhole device such as a directional drilling tool. Exemplary embodiments of this invention advantageously provide for quick and accurate communication with a downhole device without substantially interrupting the drilling process.

Owner:SCHLUMBERGER TECH CORP

Green directional drilling fluid composition

A drilling fluid composition for horizontal directional drilling is a flowable aqueous slurry of biodegradable, non-toxic, preferably edible plant particles. The particle size of the plant-derived particles depends on the drill bit used. The particles should be small enough not to clog the fluid jet orifices in normal use. The slurry is pumped through to the drill bit in a warm or preferably hot state, e.g. 80-100° C. After ejection, the slurry cools rapidly, causing solidification and creating a lining on the tunnel wall.

Owner:HARR TECH

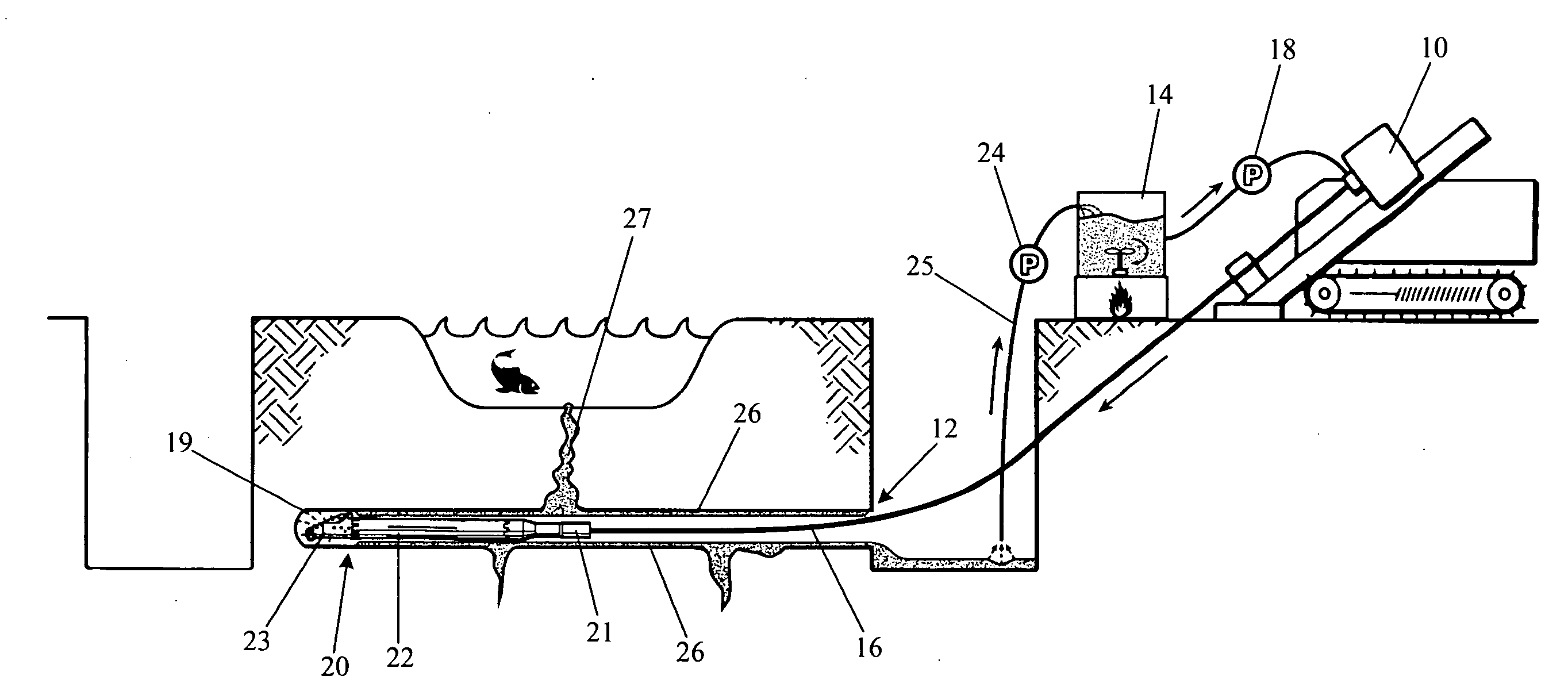

Passage formation method for underground coal gasification

A passage formation method for underground coal gasification is provided. The method comprises the following steps of: (a) building a fire area in the bottom coal bed of a first bore hole; (b) performing mechanical and directional drilling operation in a neighbor coal bed close to the bottom of the first bore hole in the vicinity of the fire area through the lower end of a second bore hole which is another existing bore hole or a newly-drilled bore hole outside the fire area, so as to pre-penetrate the neighbor coal bed and thus to form a directional passage communicated with the fire area in the neighbor coal bed; and (c) delivering an oxygen-containing gas to the fire area through the second bore hole and the directional passage, and thermally processing the directional passage to enlarge the directional passage and thus to form a gasification passage used for a underground coal gasification furnace.

Owner:ENN SCI & TECH DEV

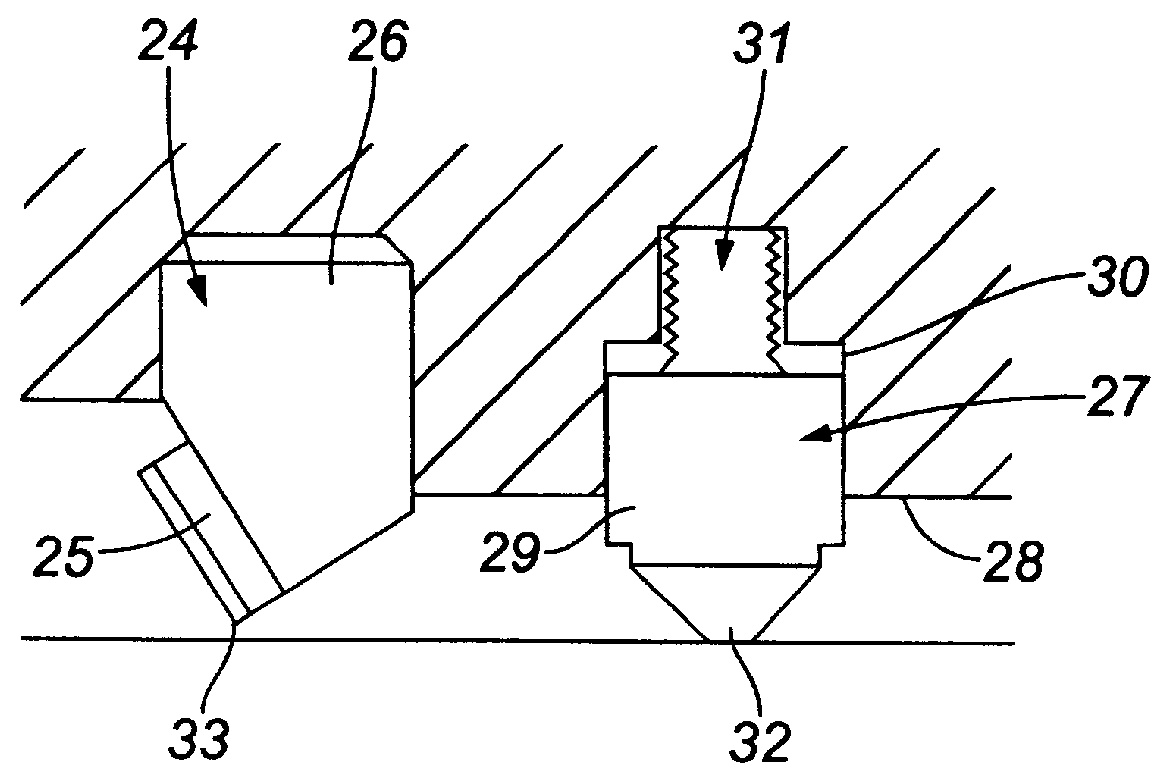

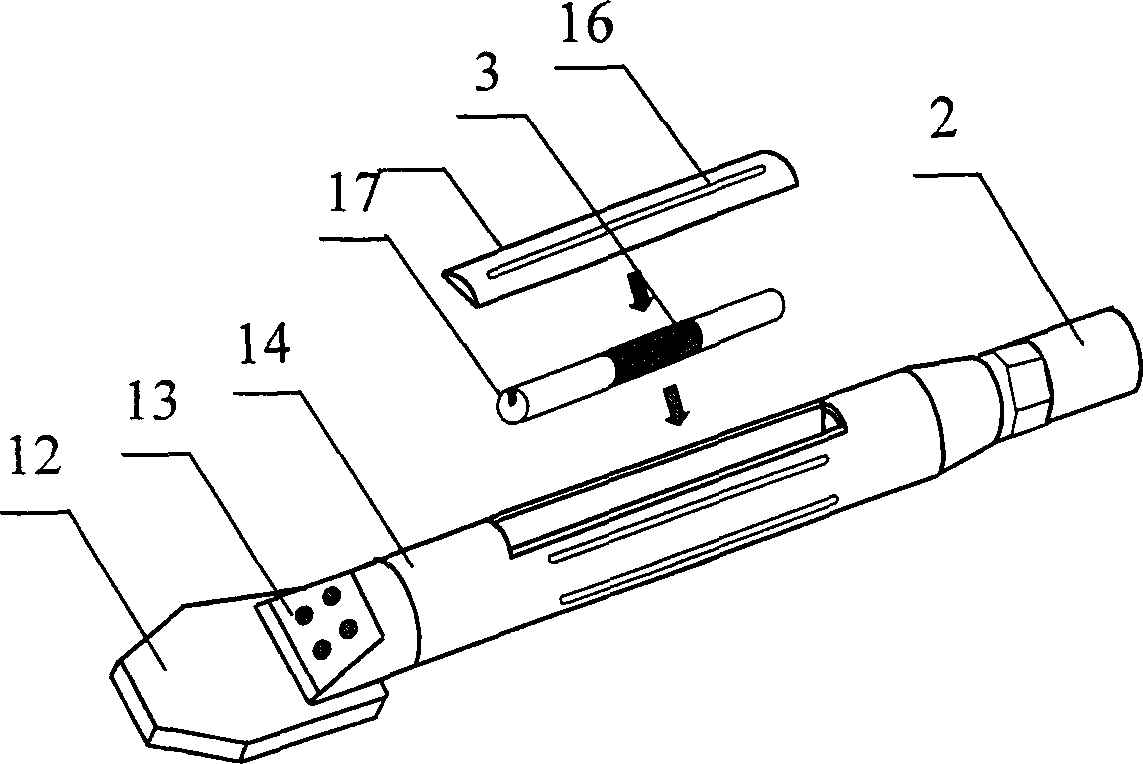

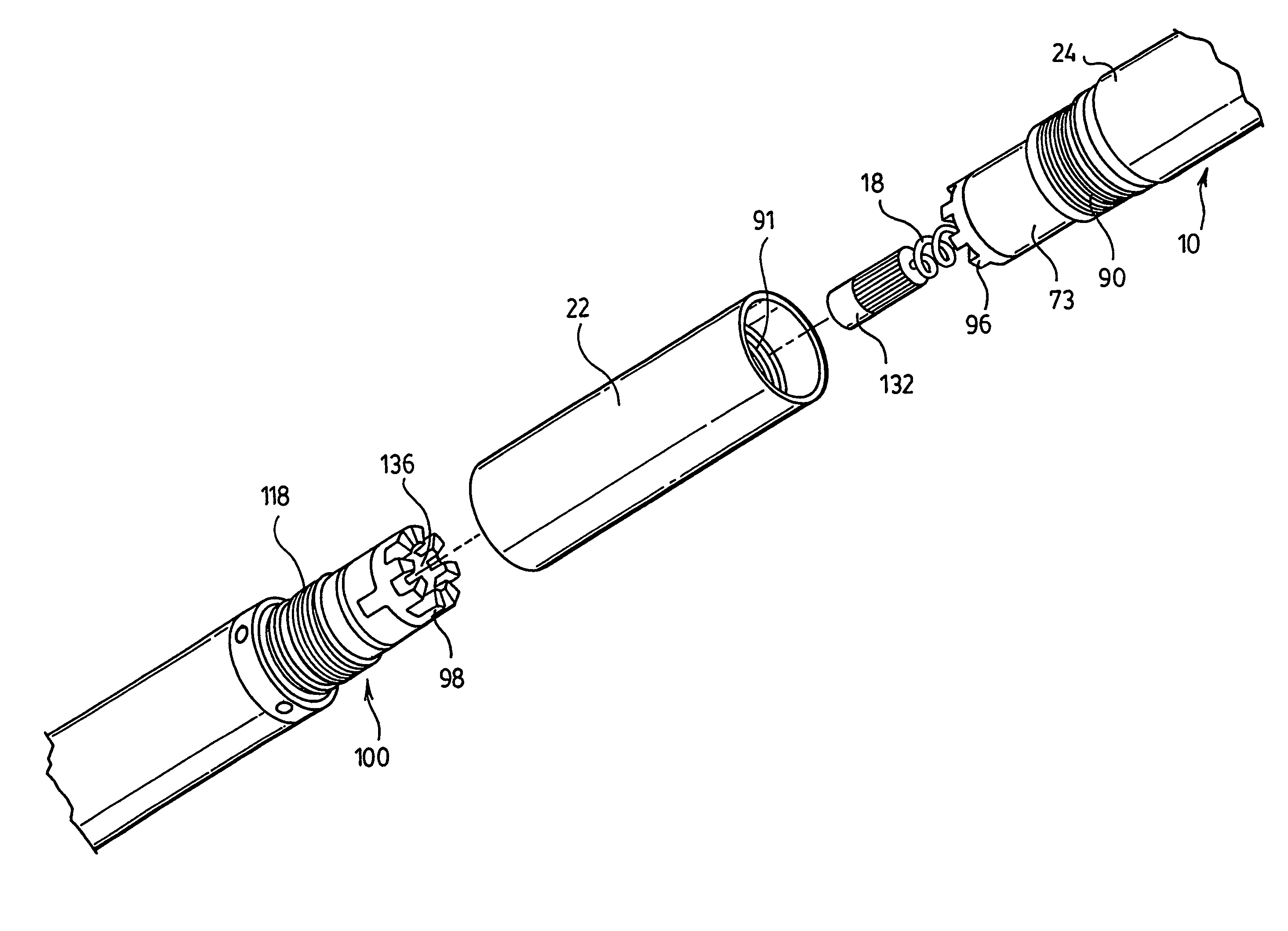

Tool module connector for use in directional drilling

A tool module interconnect (10) for interconnecting to adjoining modules for insertion in a drill string features a system which permits making the electrical interconnection before assembly of the mechanical connections to interconnect the tool modules together. The interconnect comprises a hollow interconnect body (18) open at both ends. A wire harness (18) is provided in the hollow body with terminal end connectors (26, 28) accessible from the respective open end of the interconnect body. The interconnect is adapted for attachment to adjoining modules, where at least one end has a rotatable threaded sleeve (24) for connection to a tool module by a threaded collar.

Owner:RYAN ENERGY TECH

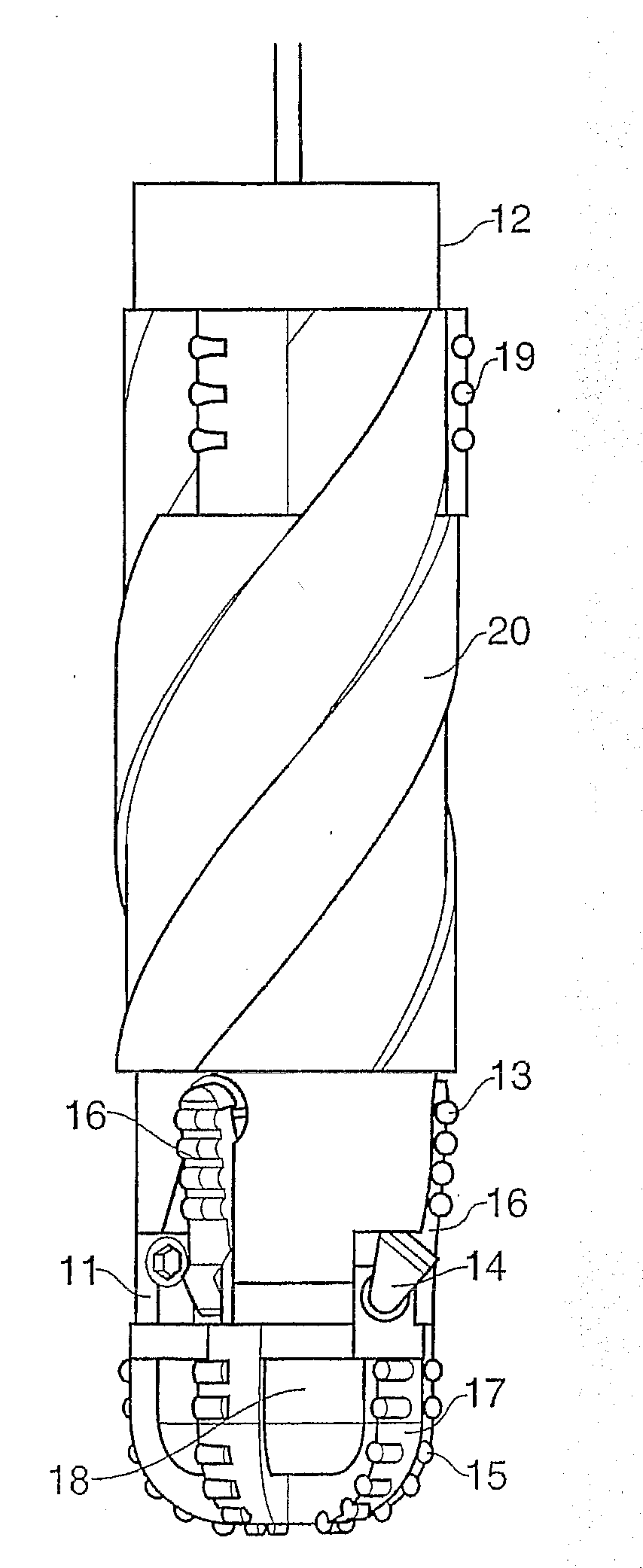

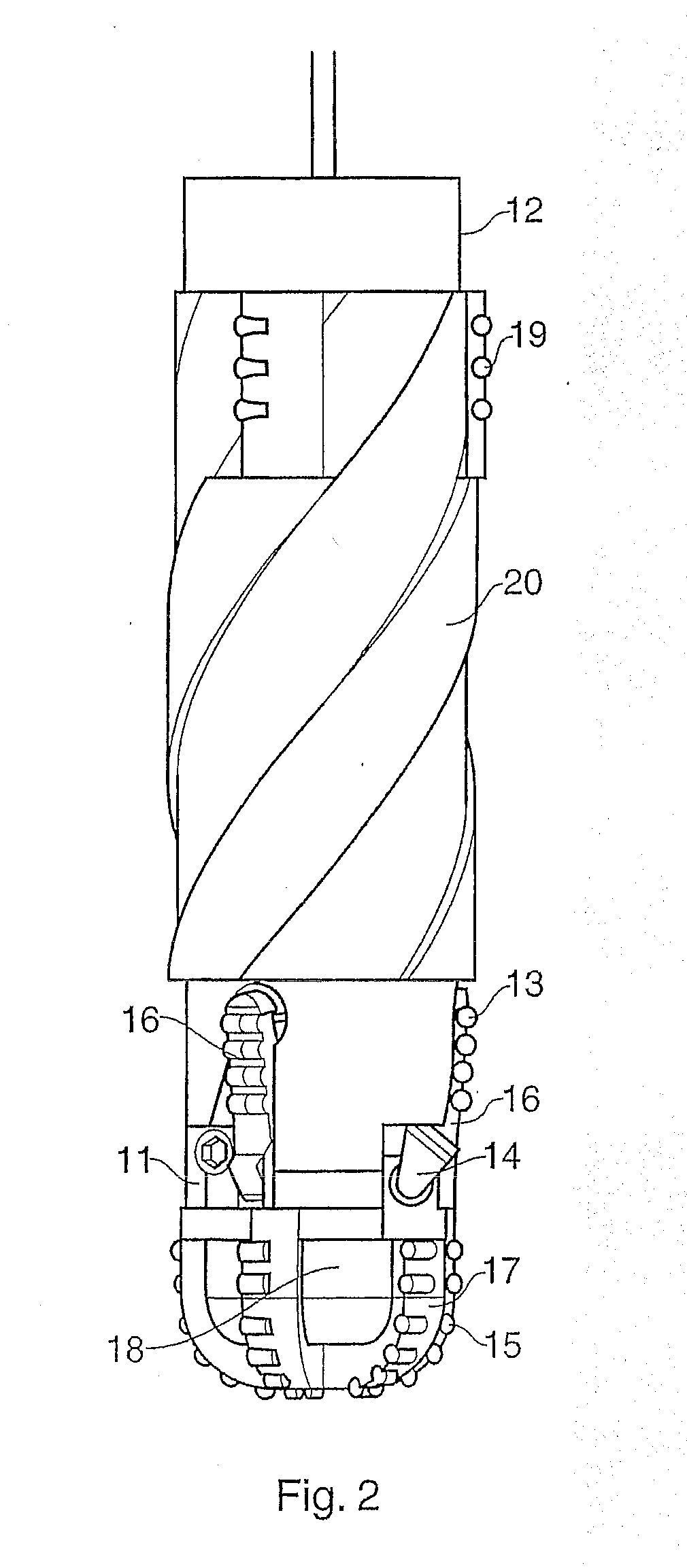

Steerable rotary directional drilling tool for drilling boreholes

The present invention provides a directional drilling apparatus and method for use in drilling bore holes. The apparatus comprises a plurality of movably mounted cutting elements, wherein the cutting elements are movable between radially retracted and extended cutting positions. A rotary valve is provided for synchronizing the movement of the cutting elements between their respective extended and retracted positions. Control of the directional drilling system is affected by synchronized movement of the cutting elements from an inner to an outer radial position in accordance with the angular position of the drill bit. Means are provided for directing high pressure cutting fluid to the region between the cutting elements and the rotatable body to prevent the accumulation of debris that could prevent movement of the cutting elements. The cutting elements enlarge the bore hole formed by the drill bit, so that the cutting elements continuously engage the wall of the bore hole.

Owner:MECIRIA LTD

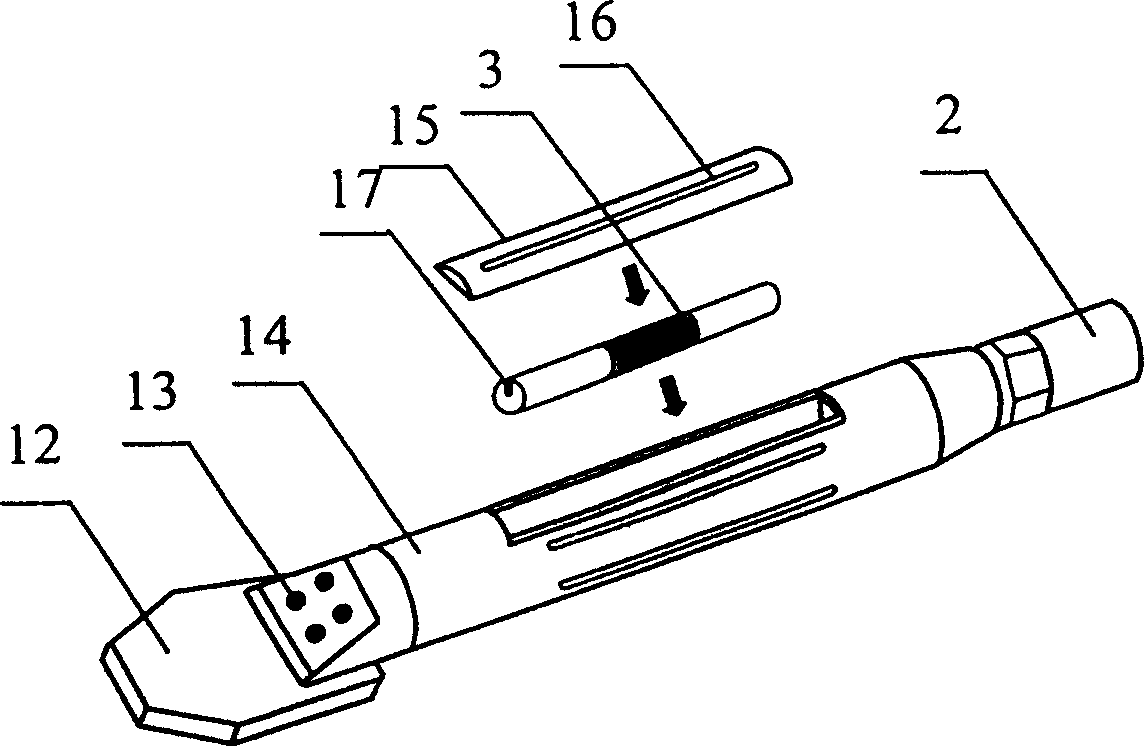

Real time measuring method and apparatus for horizontal directional drilling

InactiveCN1603576AReduce volumeAchieve modularitySurveyDirectional drillingMeasurement deviceUnit operation

One kind of horizontal direction detection sneaks in along with drills the measuring technique and the equipment, uses in the horizontal direction detection sneaks in when the fact to survey underground drilling tool inclining, parameter and so on rotation and temperature, and the measurement result will transmit the ground through the transmitting coil by the radio magnetic wave way. The method use underground drilling tool interior along with drills in the metering equipment the inclination angle, the appearance angle and the temperature sensor surveys the corresponding parameter, after signal processing and transmission unit operation, use wireless launch unit to ground receiver real-time transmission. Its metering equipment has two sections of metals shells and center the compartment insulation shell seal becomes. In an end shell is loaded with the power source; The wireless radiating element installs in the insulator shell; Is loaded with electric circuit of board the signal processing and the transfer element, the inclination angle sensor, the appearance angle sensor and the temperature sensor sets in another end shell. The invention volume small, structure simple, cost inexpensive, the antijamming ability is strong, works reliably under the adverse circumstance, can suit the majority direction detection to sneak in the equipment request.

Owner:ZOOMLION HEAVY IND CO LTD

Automated directional drilling apparatus and methods

Methods and systems for drilling to a target location include a control system that receives an input comprising a planned drilling path to a target location and determines a projected location of a bottom hole assembly of a drilling system. The projected location of the bottom hole assembly is compared to the planned drilling path to determine a deviation amount. A modified drilling path is created to the target location as selected based on the amount of deviation from the planned drilling path, and drilling rig control signals that steer the bottom hole assembly of the drilling system to the target location along the modified drilling path are generated.

Owner:NABORS DRILLING TECH USA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com