Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1356 results about "Unit operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In chemical engineering and related fields, a unit operation is a basic step in a process. Unit operations involve a physical change or chemical transformation such as separation, crystallization, evaporation, filtration, polymerization, isomerization, and other reactions. For example, in milk processing, homogenization, pasteurization, and packaging are each unit operations which are connected to create the overall process. A process may require many unit operations to obtain the desired product from the starting materials, or feedstocks.

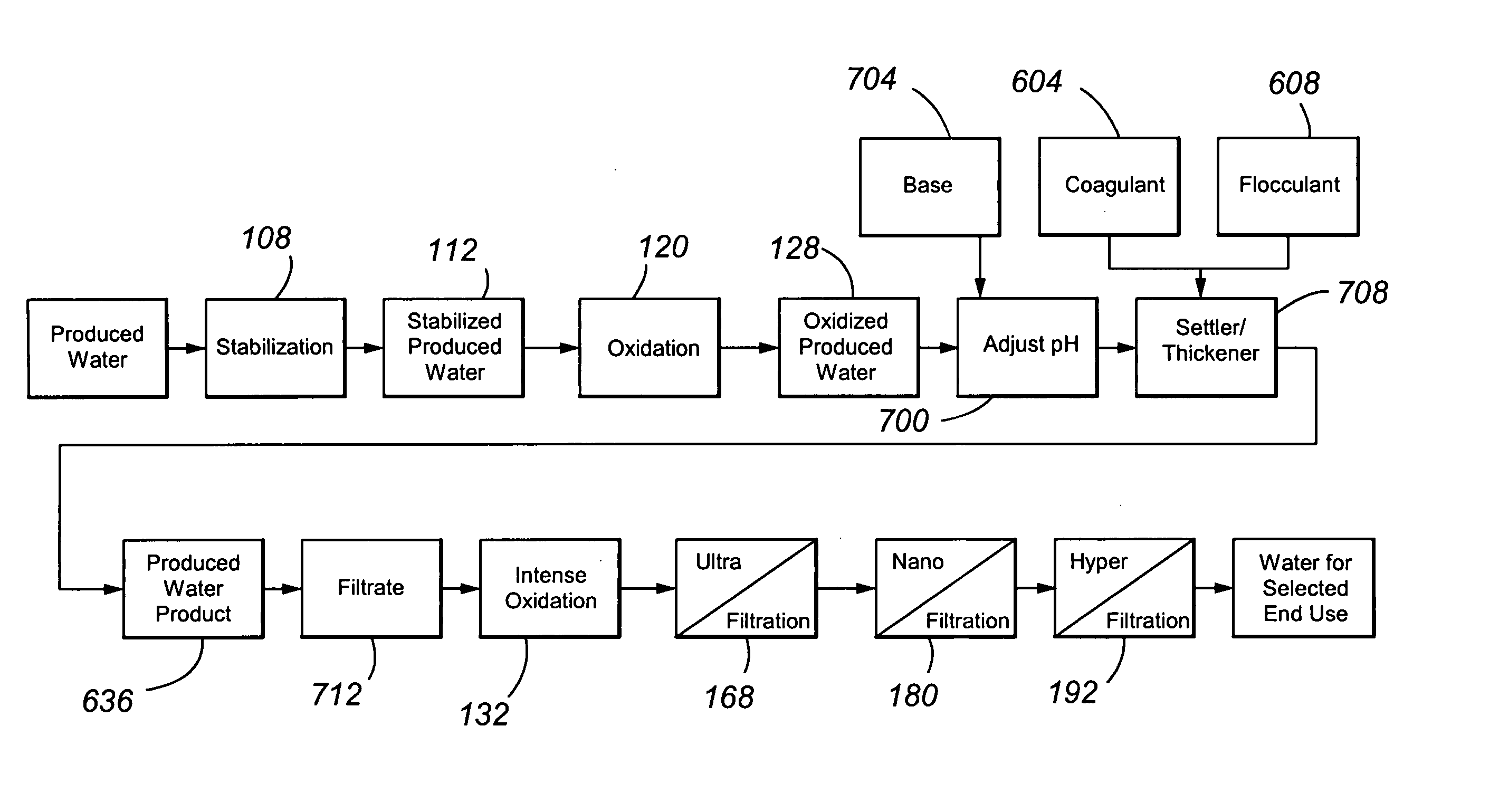

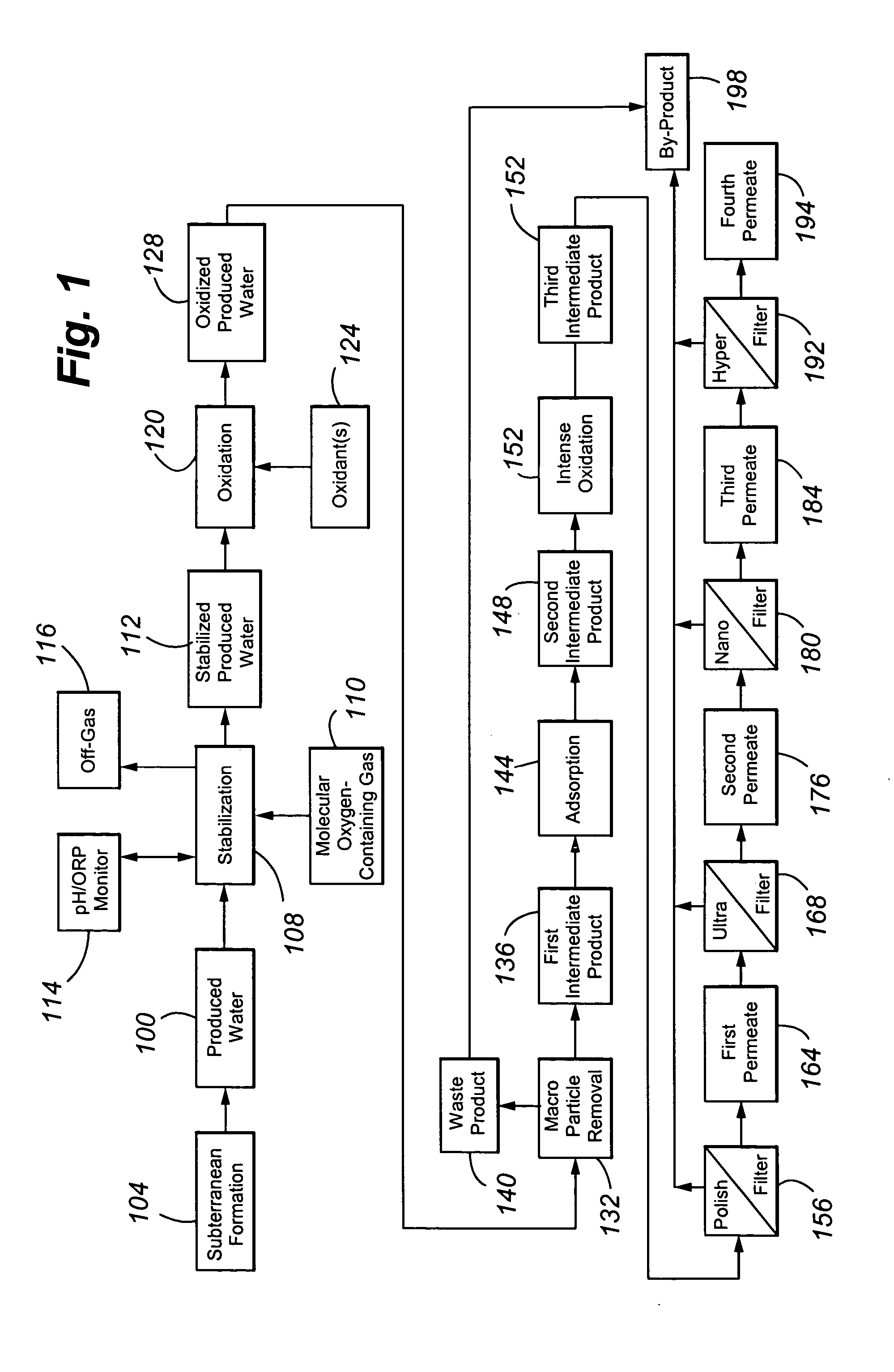

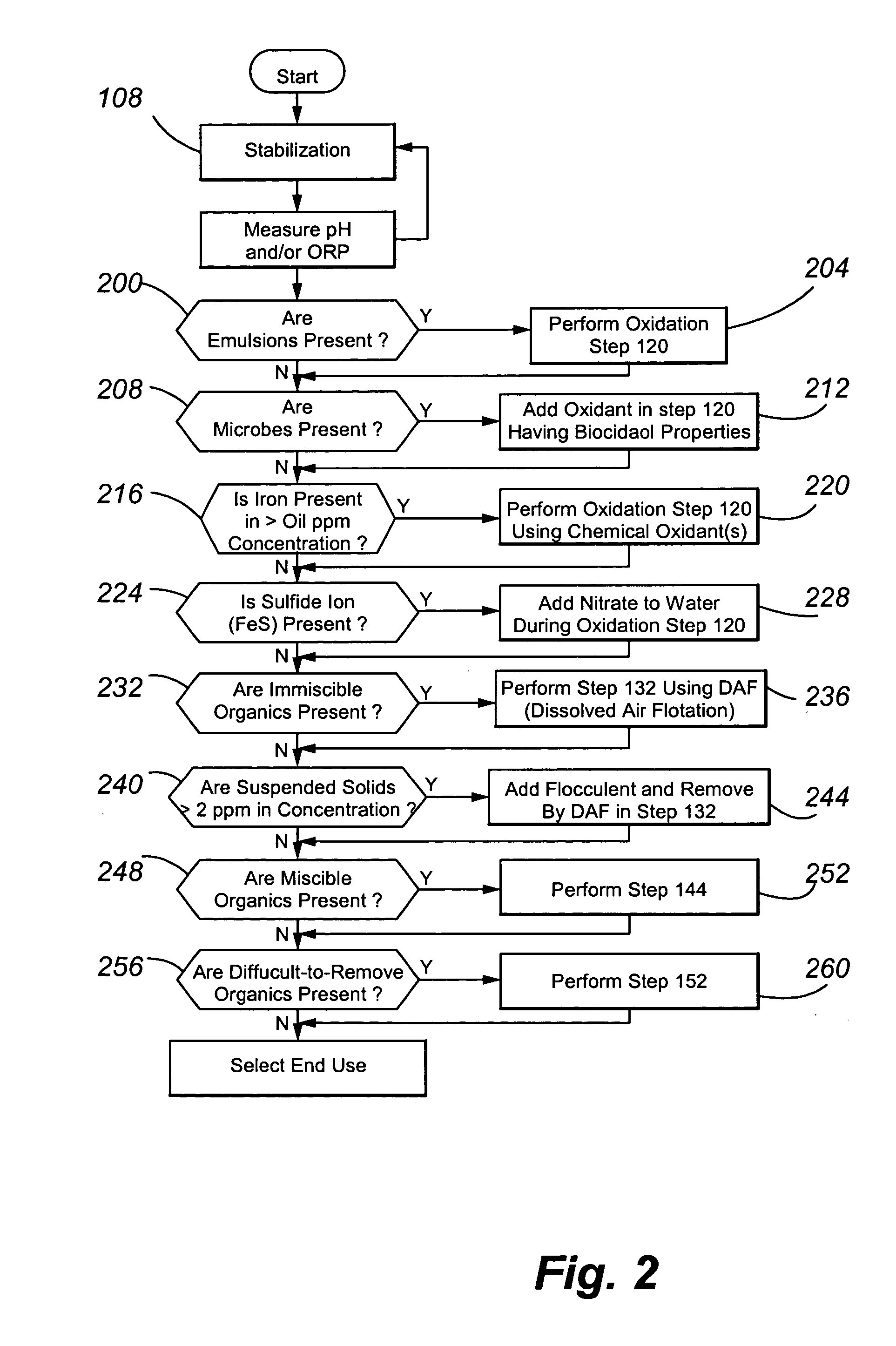

Treating produced waters

InactiveUS20070102359A1Complicate purificationIncrease ratingsUltrafiltrationTreatment involving filtrationEmulsionUnit operation

The present invention is directed to various sets of unit operations for treating aqueous effluents and logic for designing and effecting the treatment. The unit operations include stabilization of subterranean waters, sequential oxidation steps to alter selected target materials, oxidation to break up emulsions prior to removal of the emulsion components, and intense oxidation to break up difficult-to-remove organic target materials.

Owner:HW PROCESS TECH

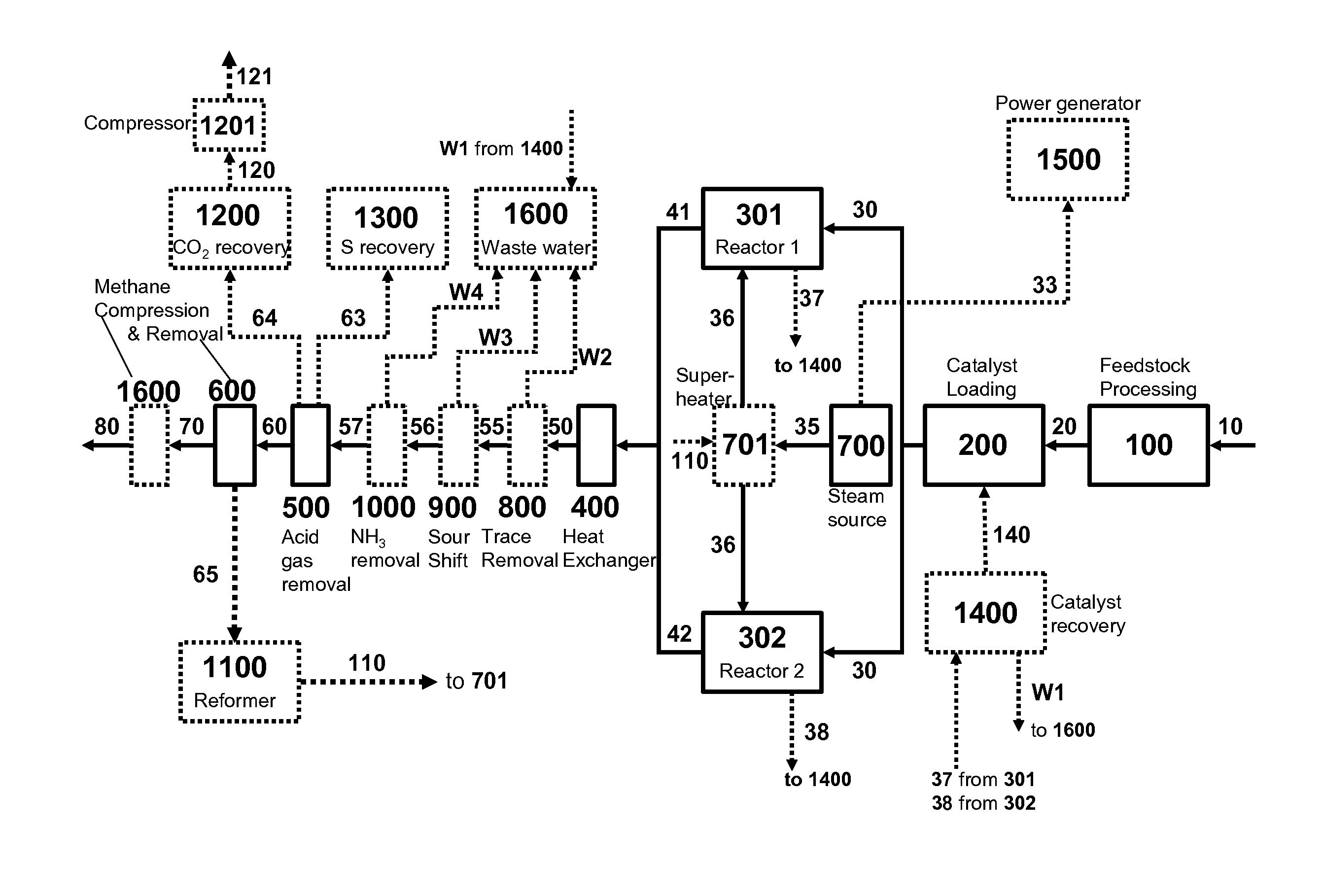

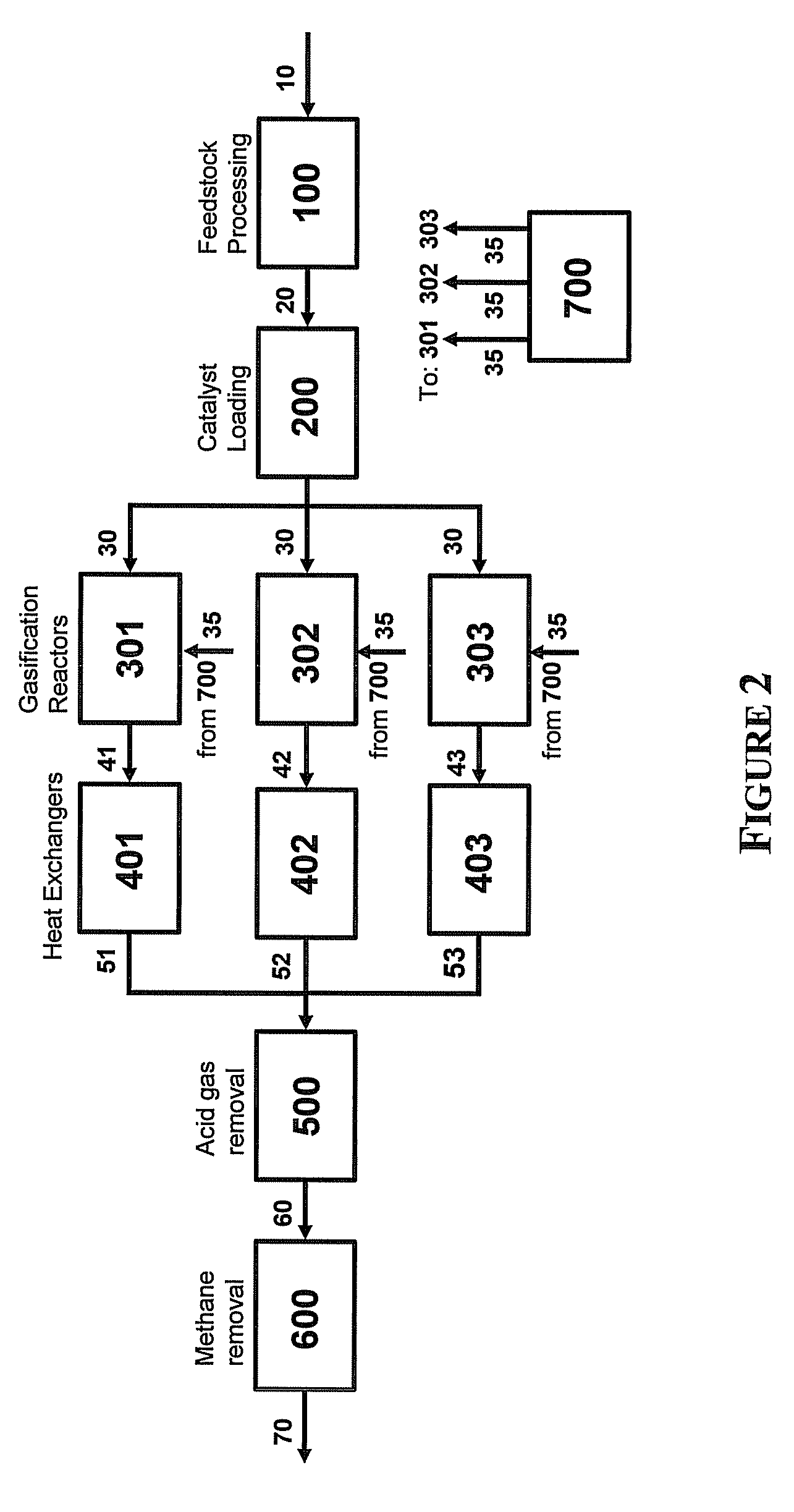

Two-Train Catalytic Gasification Systems

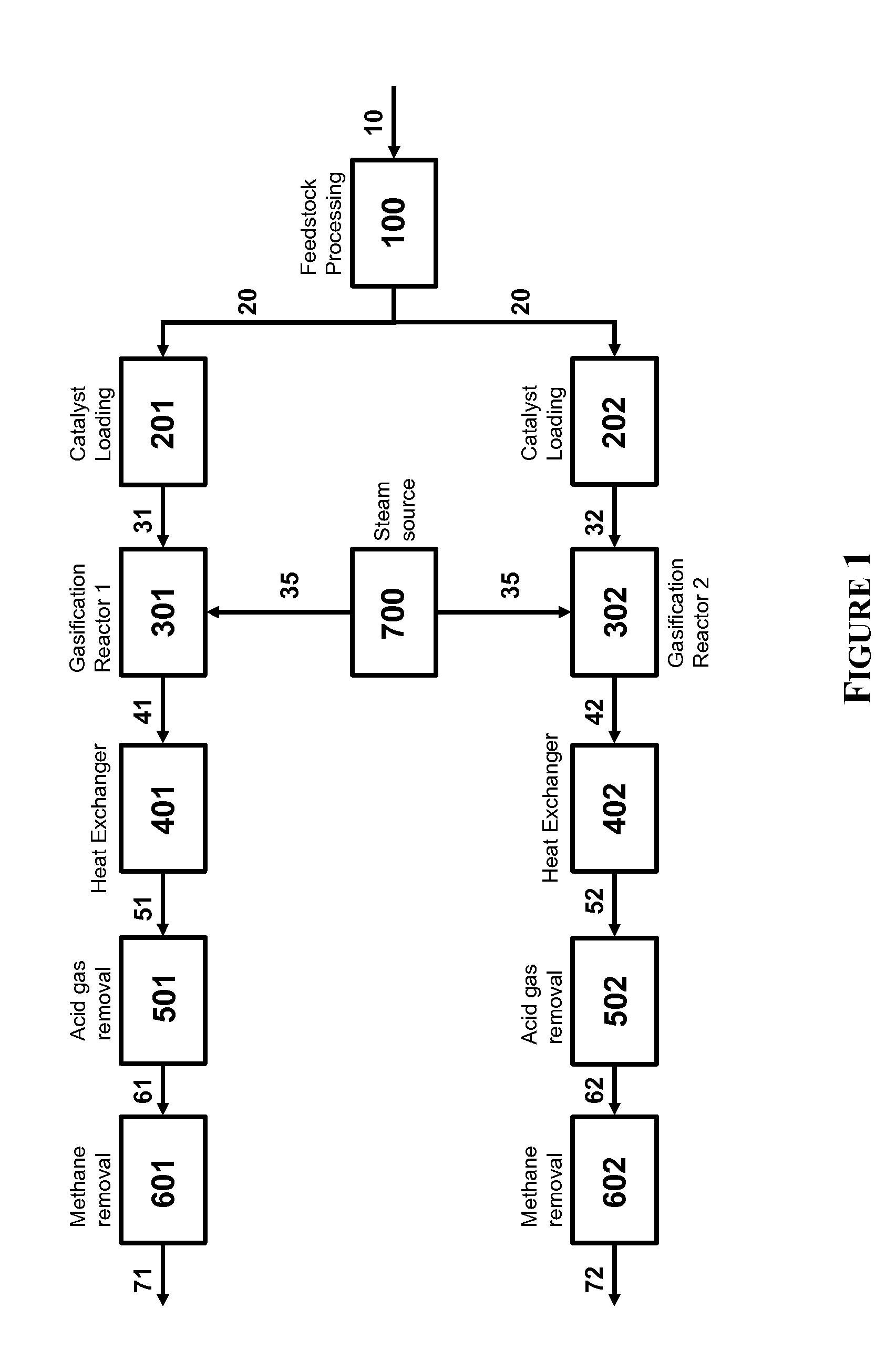

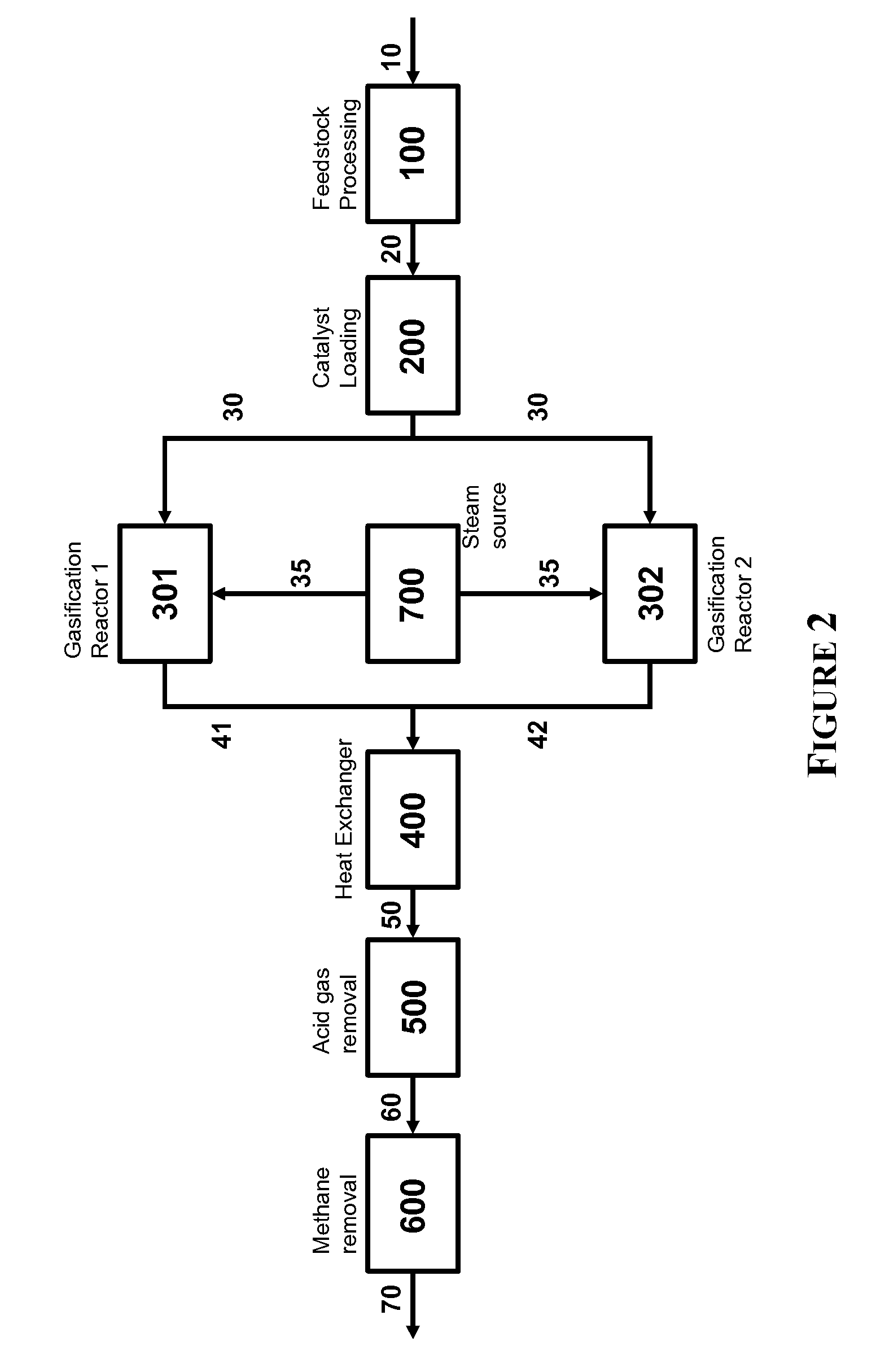

InactiveUS20090324458A1Reduce moisture contentGasifier mechanical detailsCombustible gas catalytic treatmentUnit operationAmmonia

Systems for converting a carbonaceous feedstock into a plurality of gaseous products are described. The systems include, among other units, two separate gasification reactors to convert a carbonaceous feedstock in the presence of an alkali metal catalyst into the plurality of gaseous products including at least methane. Each of the gasification reactors may be supplied with the feedstock from a single or separate catalyst loading and / or feedstock preparation unit operations. Similarly, the hot gas streams from each gasification reactor may be purified via their combination at a heat exchanger, acid gas removal, or methane removal unit operations. Product purification may comprise trace contaminant removal units, ammonia removal and recovery units, and sour shift units.

Owner:SURE CHAMPION INVESTMENT LTD

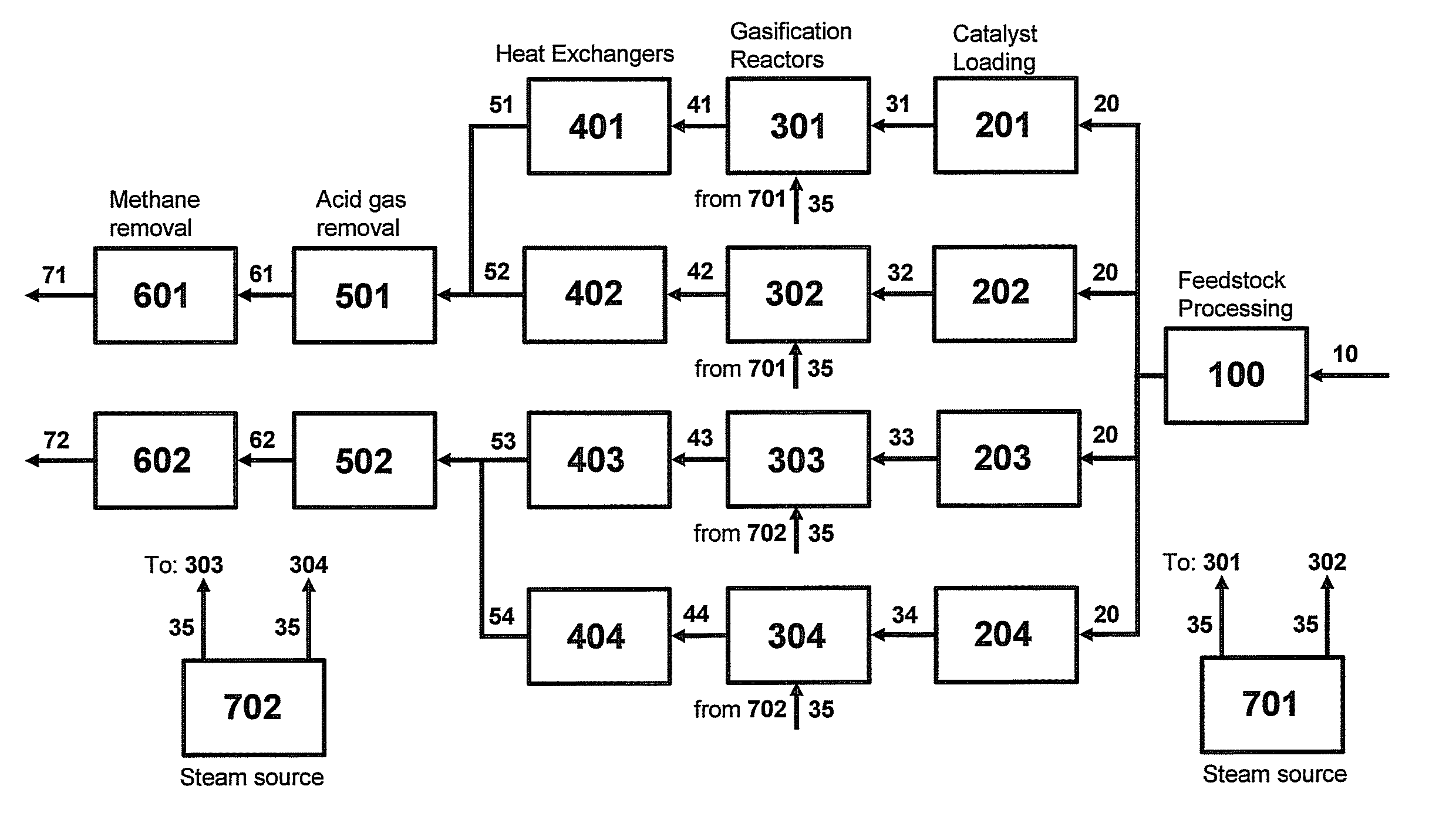

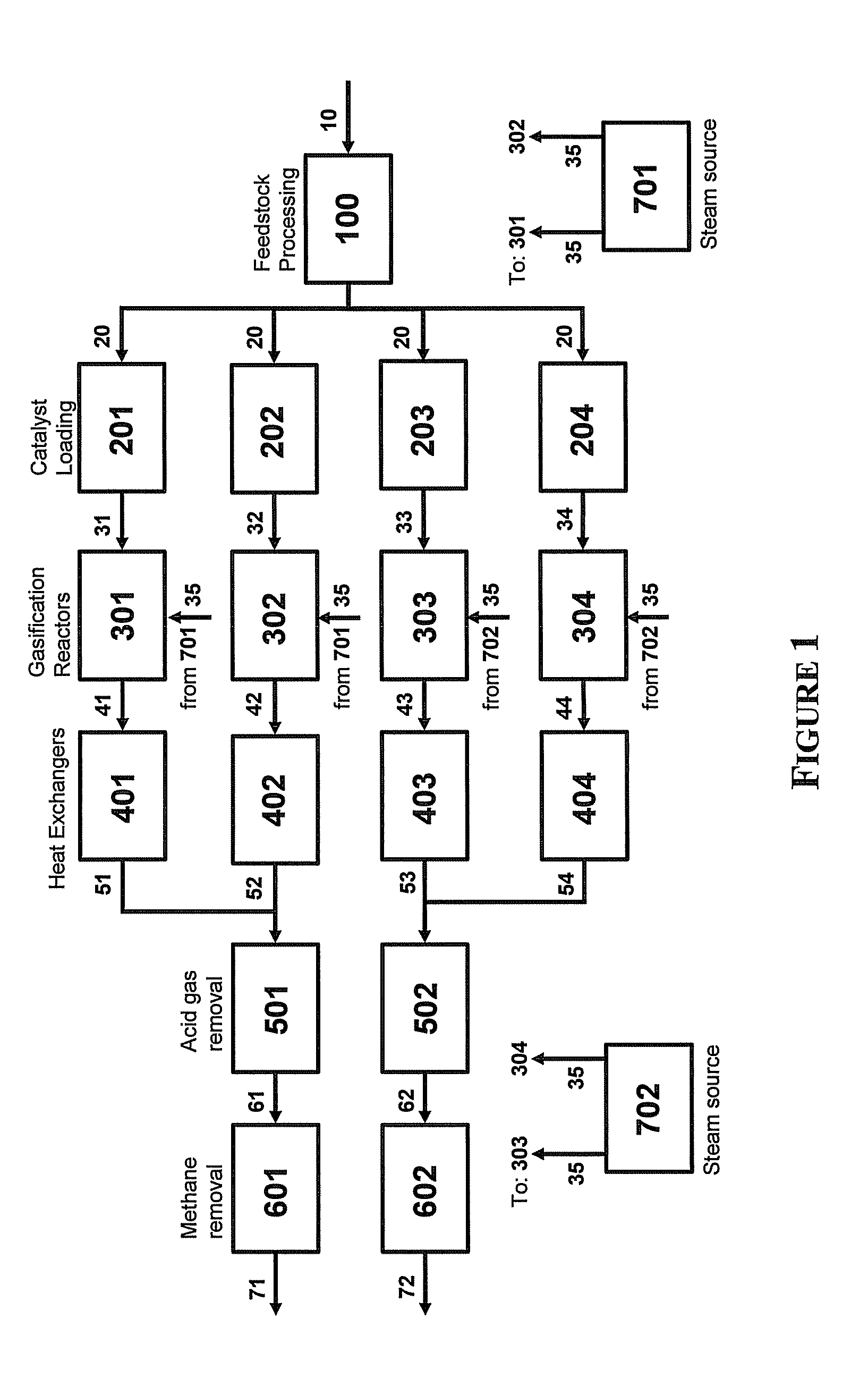

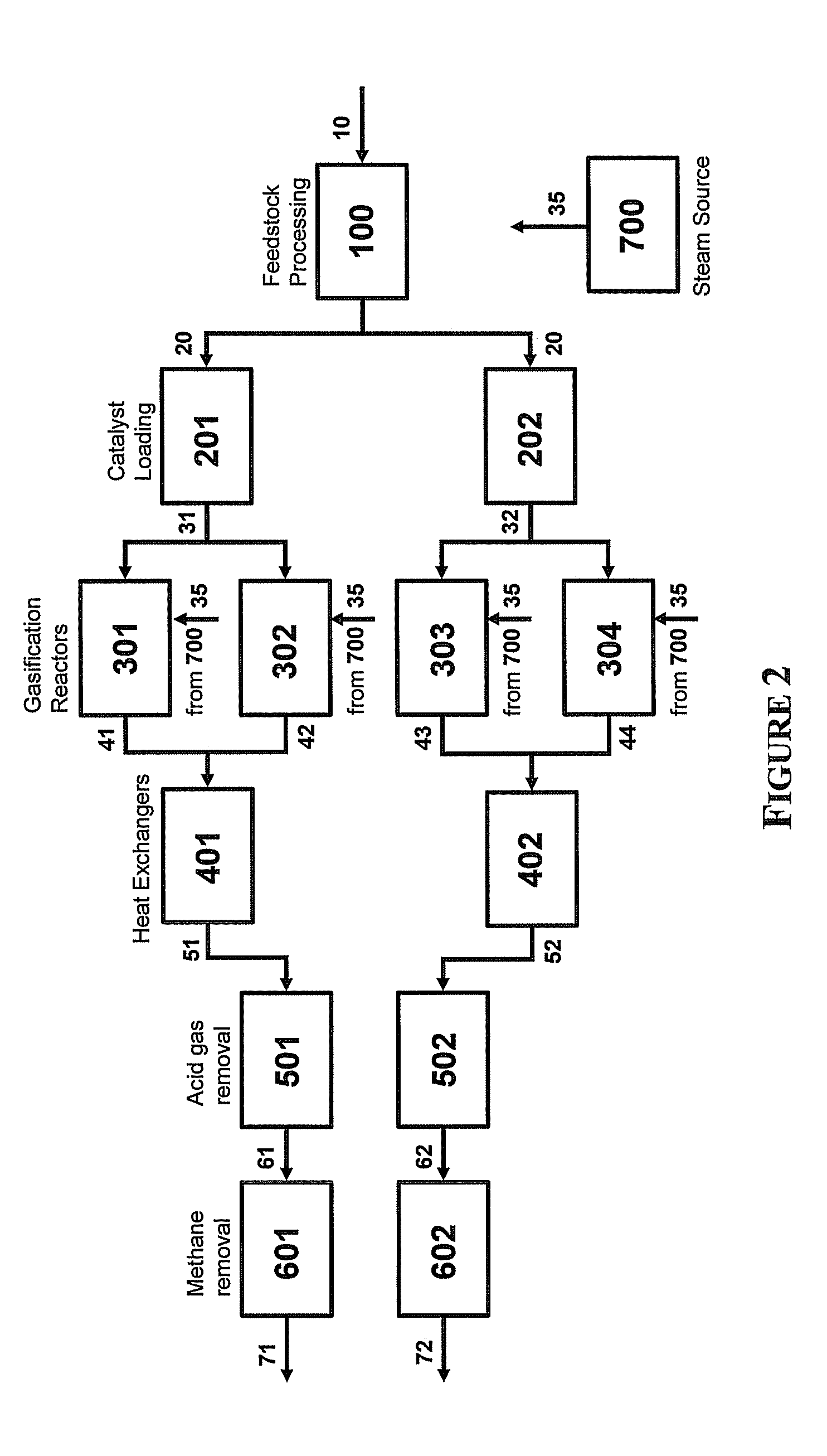

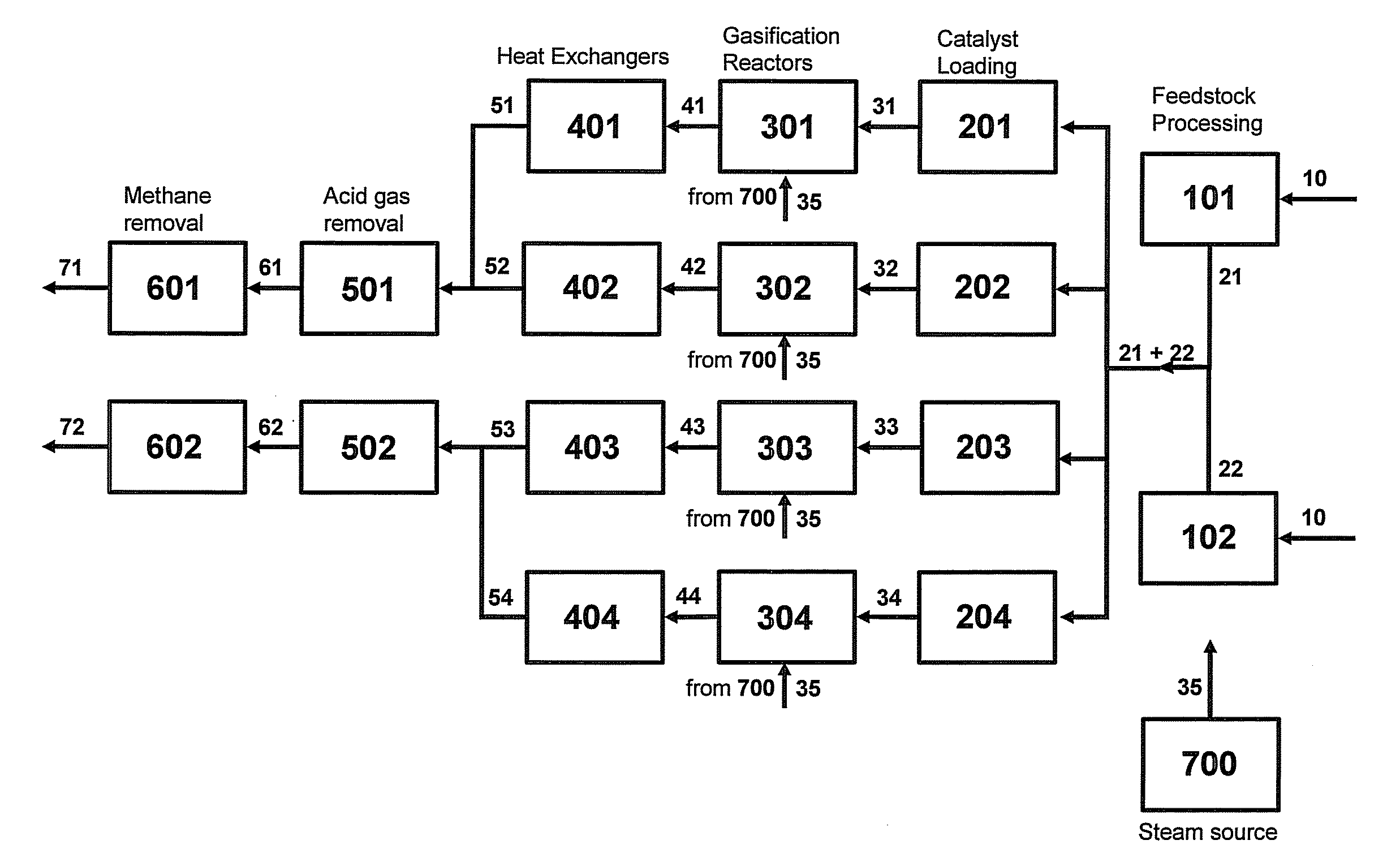

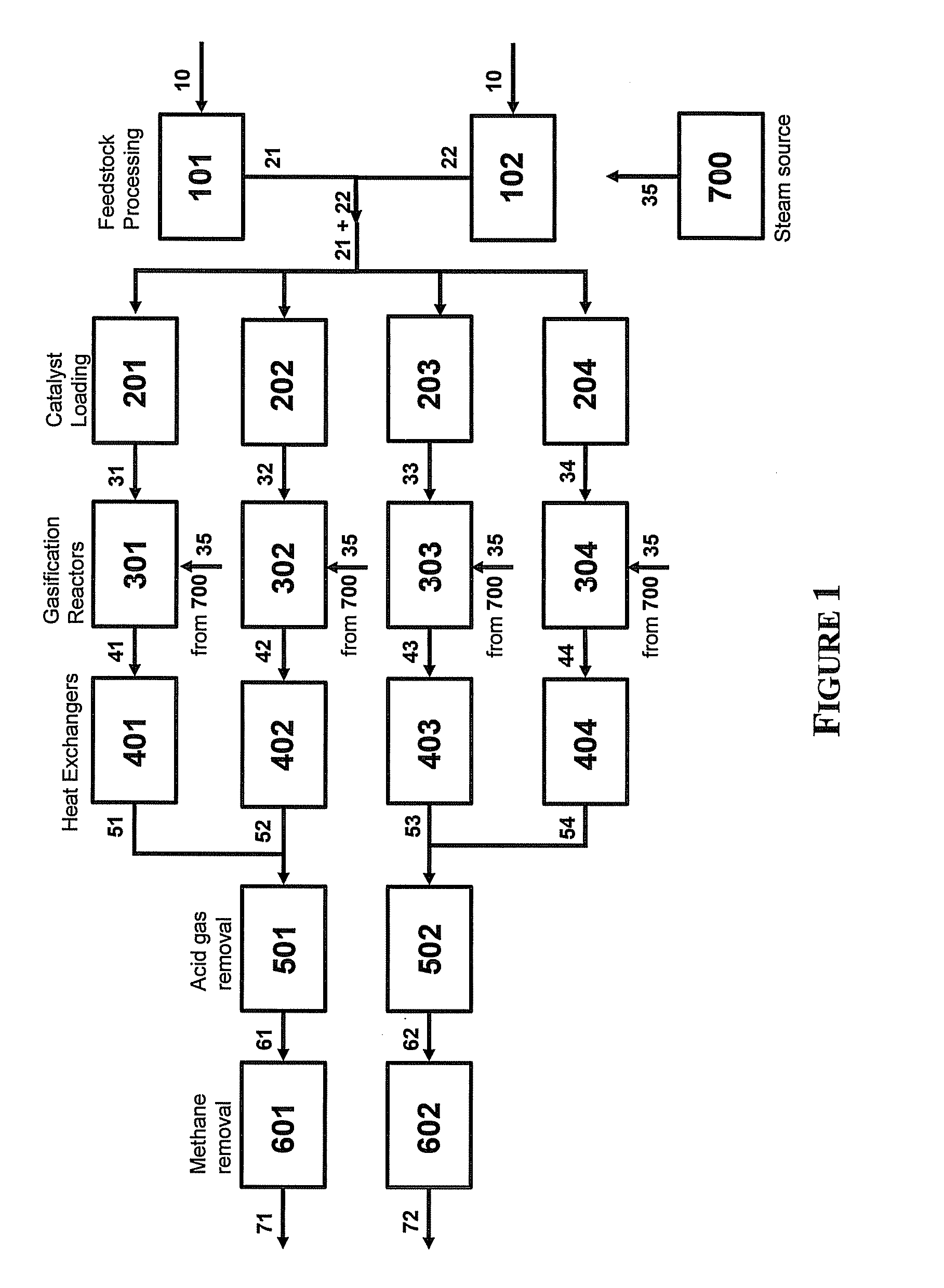

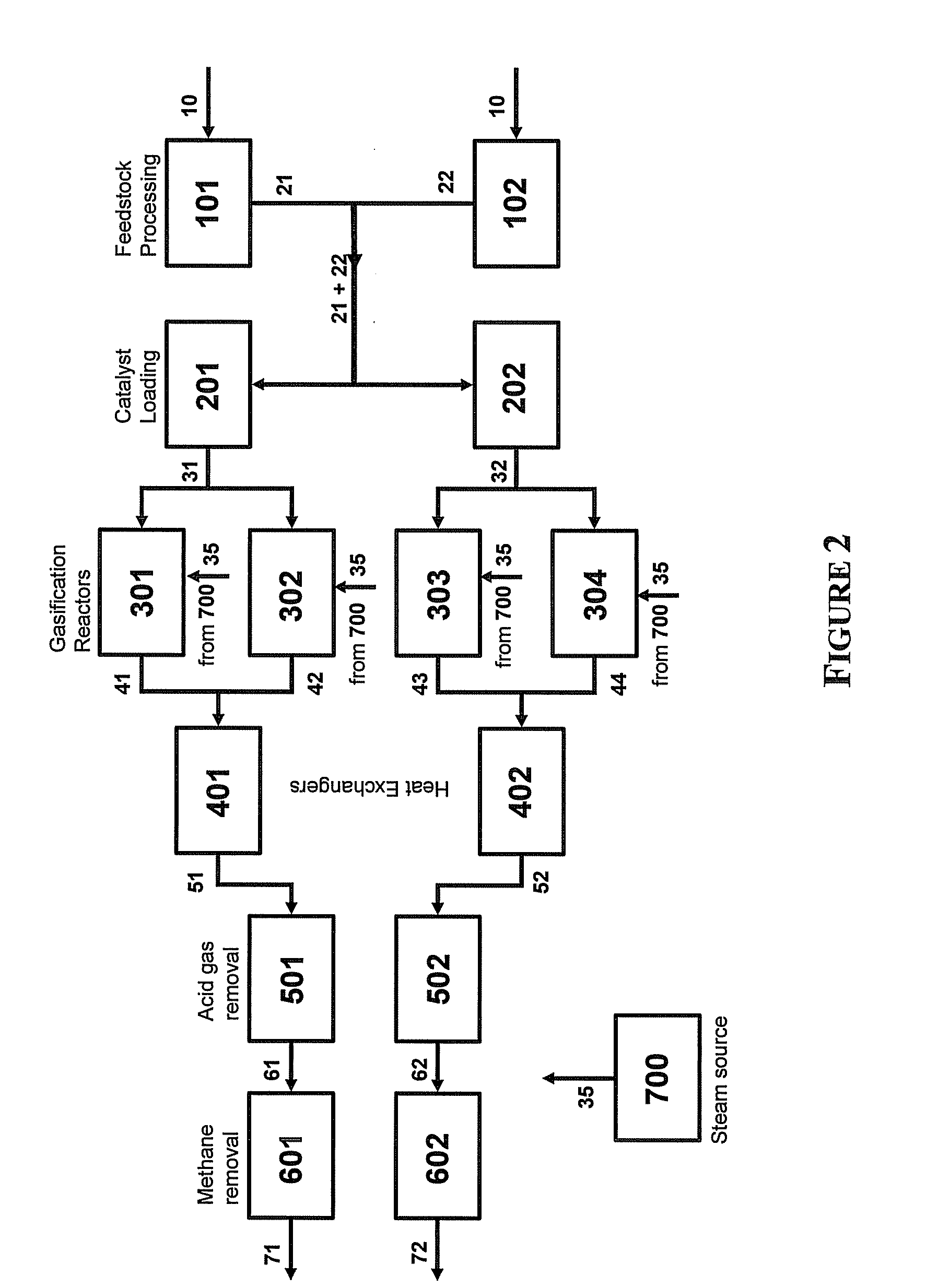

Four-Train Catalytic Gasification Systems

InactiveUS20090324460A1Reduce moisture contentHydrogen separation at low temperatureHydrogen separation using liquid contactUnit operationAmmonia

Systems to convert a carbonaceous feedstock into a plurality of gaseous products are described. The systems include, among other units, four separate gasification reactors for the gasification of a carbonaceous feedstock in the presence of an alkali metal catalyst into the plurality of gaseous products including at least methane. Each of the gasification reactors may be supplied with the feedstock from a single or separate catalyst loading and / or feedstock preparation unit operations. Similarly, the hot gas streams from each gasification reactor may be purified via their combination at a heat exchanger, acid gas removal, or methane removal unit operations. Product purification may comprise trace contaminant removal units, ammonia removal and recovery units, and sour shift units.

Owner:SURE CHAMPION INVESTMENT LTD

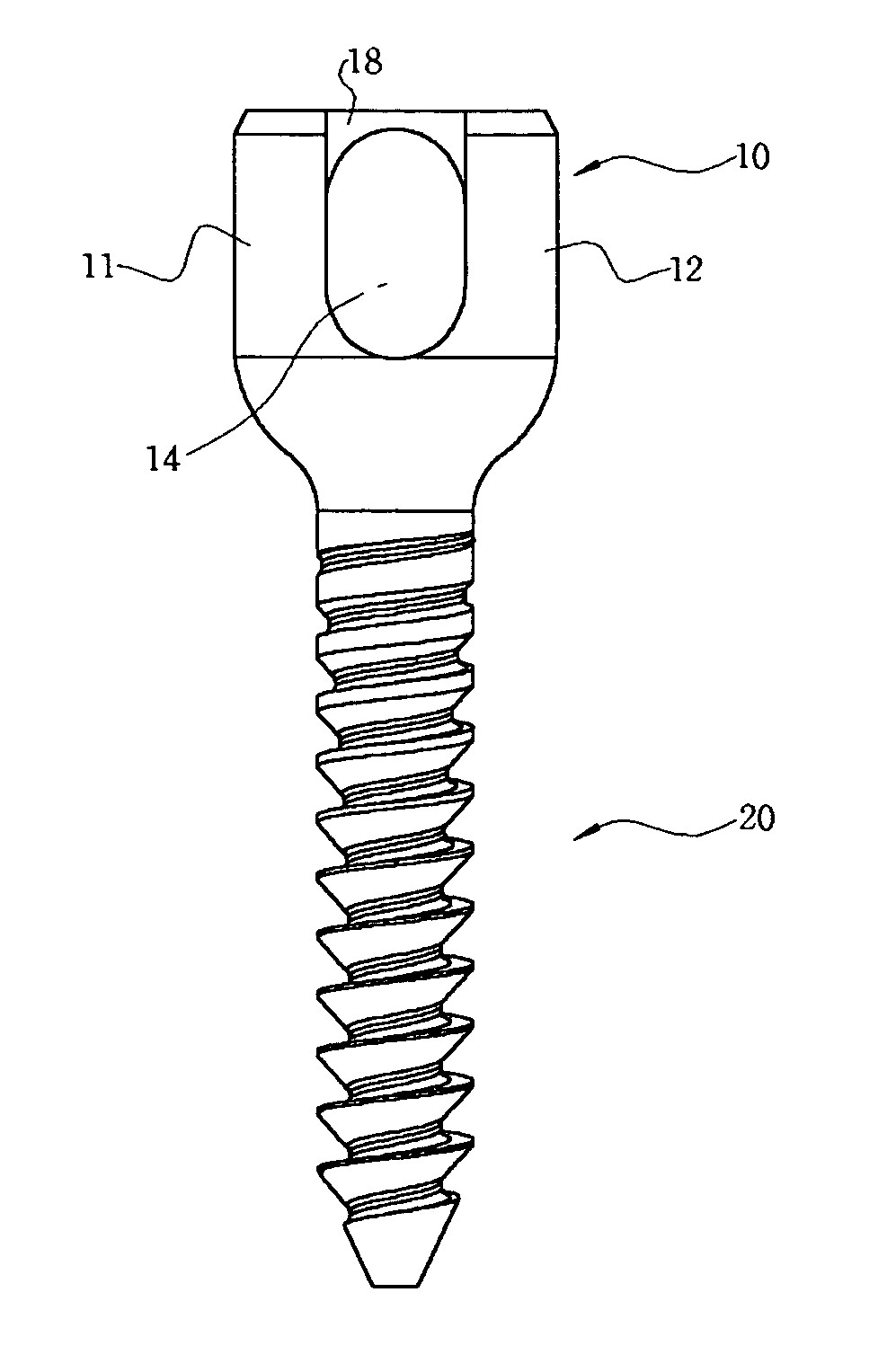

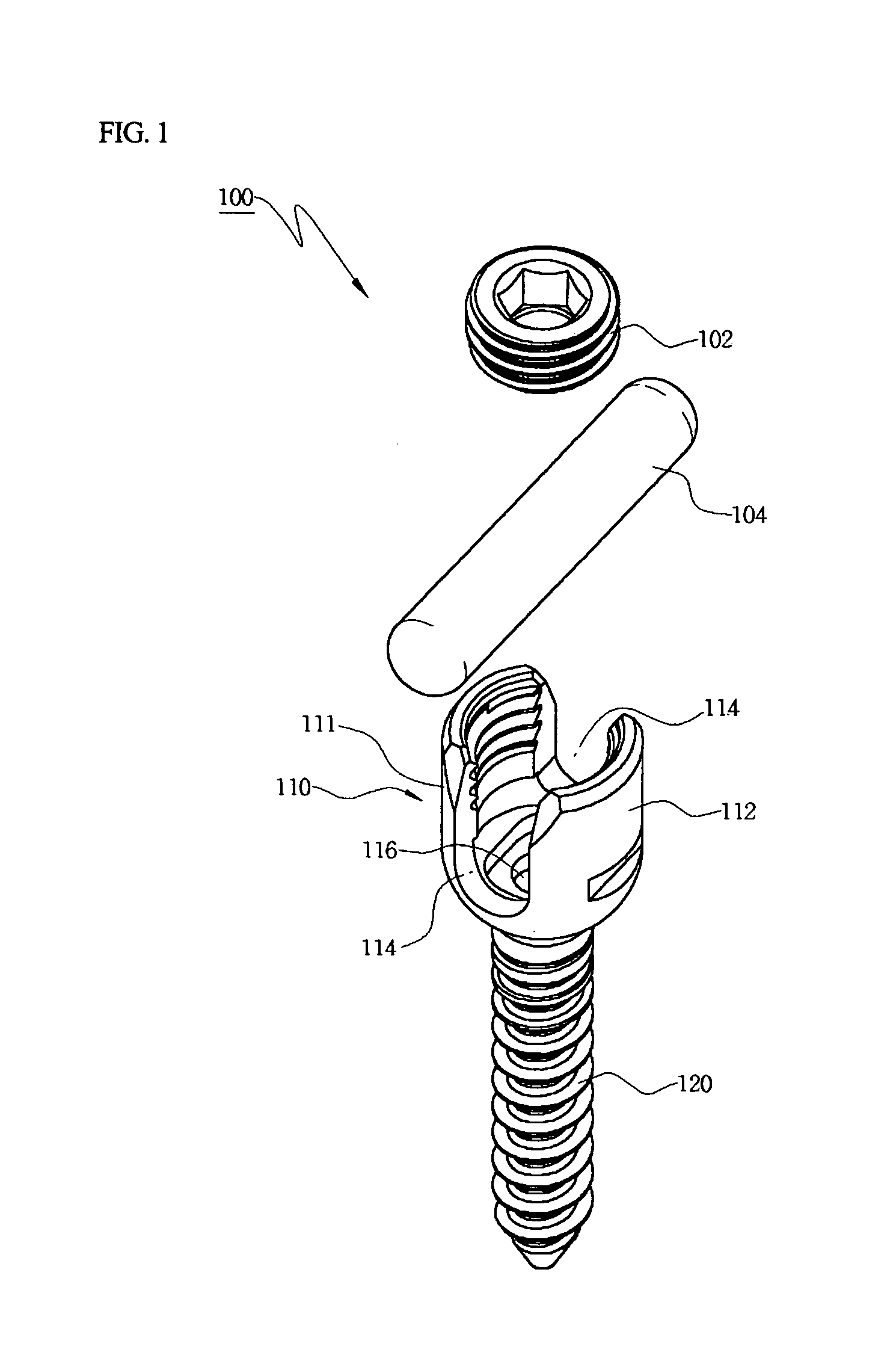

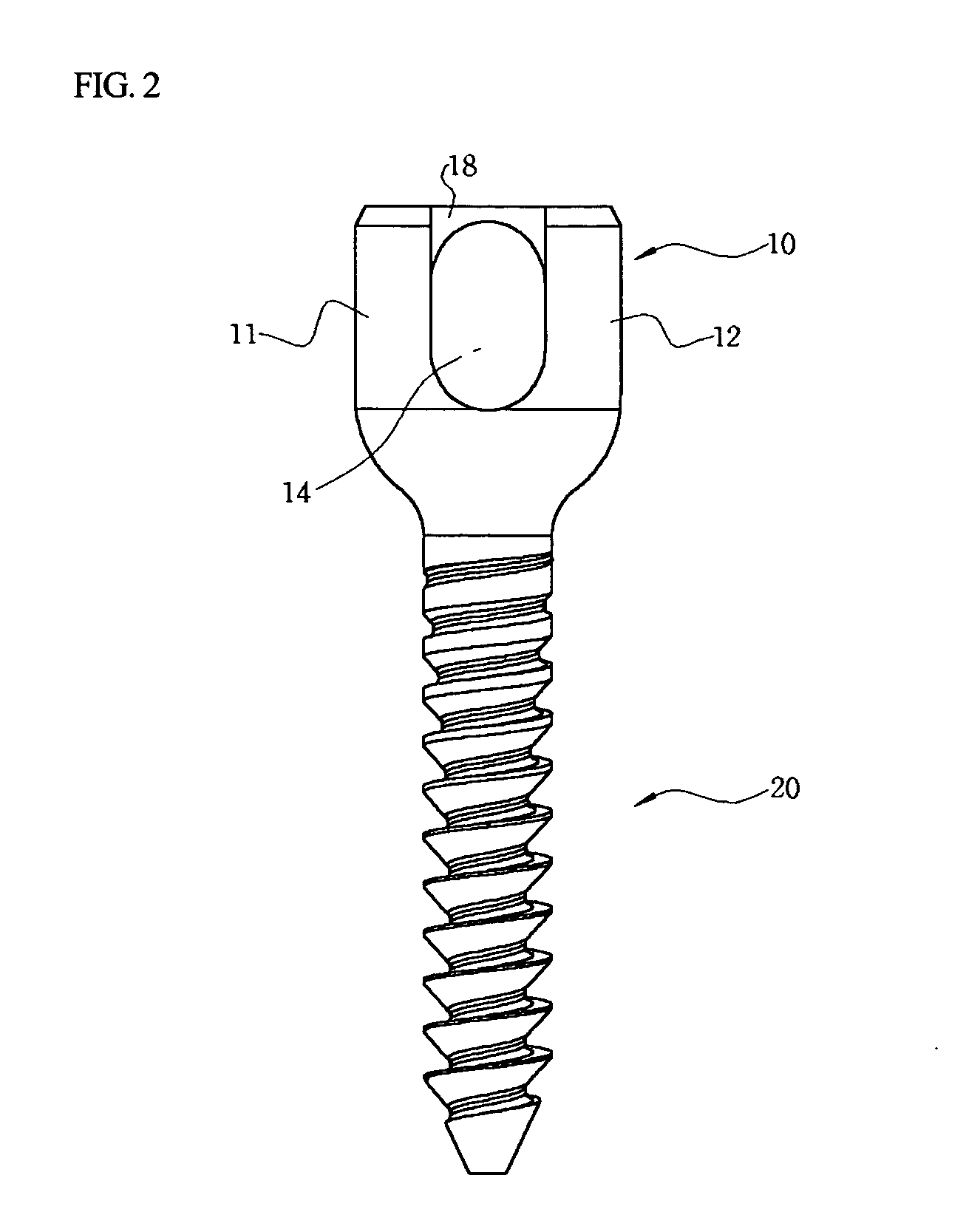

Pedicle screw and operating device thereof

ActiveUS20060030839A1Avoid separationAccurately indicatedInternal osteosythesisNon-surgical orthopedic devicesCouplingUnit operation

Disclosed is a spine fixation apparatus, more particularly, a pedicle screw implanted into a spine and an operating device for the pedicle screw capable of easily inserting a rod to a head section of the pedicle screw in order to securely fix the spine. The pedicle screw has a head section including a recess part defined by first and second sidewalls, a screw section, and a support unit formed at an upper portion of the recess part of the head section while connecting the first sidewall to the second sidewall. The operating device has a screw coupling rod having an elongated pipe shape, a body having a first side coupled to the screw coupling rod, a rotating member having a first end coupled to a second side of the body in such a manner that a second end of the rotating member rotates about the first end thereof, and a rod receiver coupled to the second end of the rotating member. Due to the support unit, the rod is prevented from being easily separated from the pedicle screw, thereby facilitating minimum incision surgery. The operating device for the pedicle screw allows an operator to easily perform minimum incision surgery while making several incisions for the pedicle screws and the rod in the back of the patient and keeping the size of incisions quite a small.

Owner:SOLCO BIOMEDICAL +1

Four-Train Catalytic Gasification Systems

InactiveUS20090324461A1Reduce moisture contentGaseous fuelsGasification processes detailsUnit operationAmmonia

Systems to convert a carbonaceous feedstock into a plurality of gaseous products are described. The systems include, among other units, four separate gasification reactors for the gasification of a carbonaceous feedstock in the presence of an alkali metal catalyst into the plurality of gaseous products including at least methane. Each of the gasification reactors may be supplied with the feedstock from a single or separate catalyst loading and / or feedstock preparation unit operations. Similarly, the hot gas streams from each gasification reactor may be purified via their combination at a heat exchanger, acid gas removal, or methane removal unit operations. Product purification may comprise trace contaminant removal units, ammonia removal and recovery units, and sour shift units.

Owner:SURE CHAMPION INVESTMENT LTD

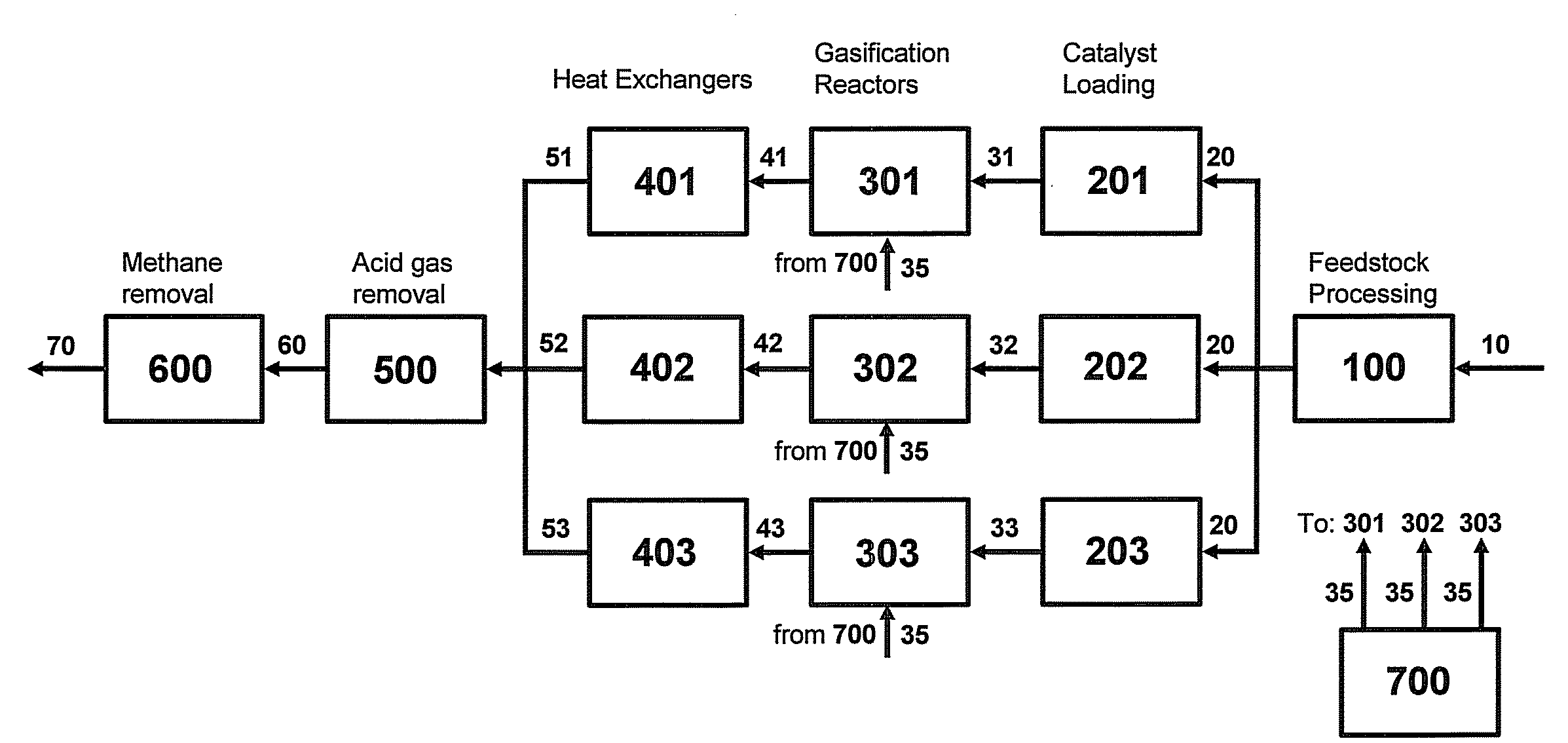

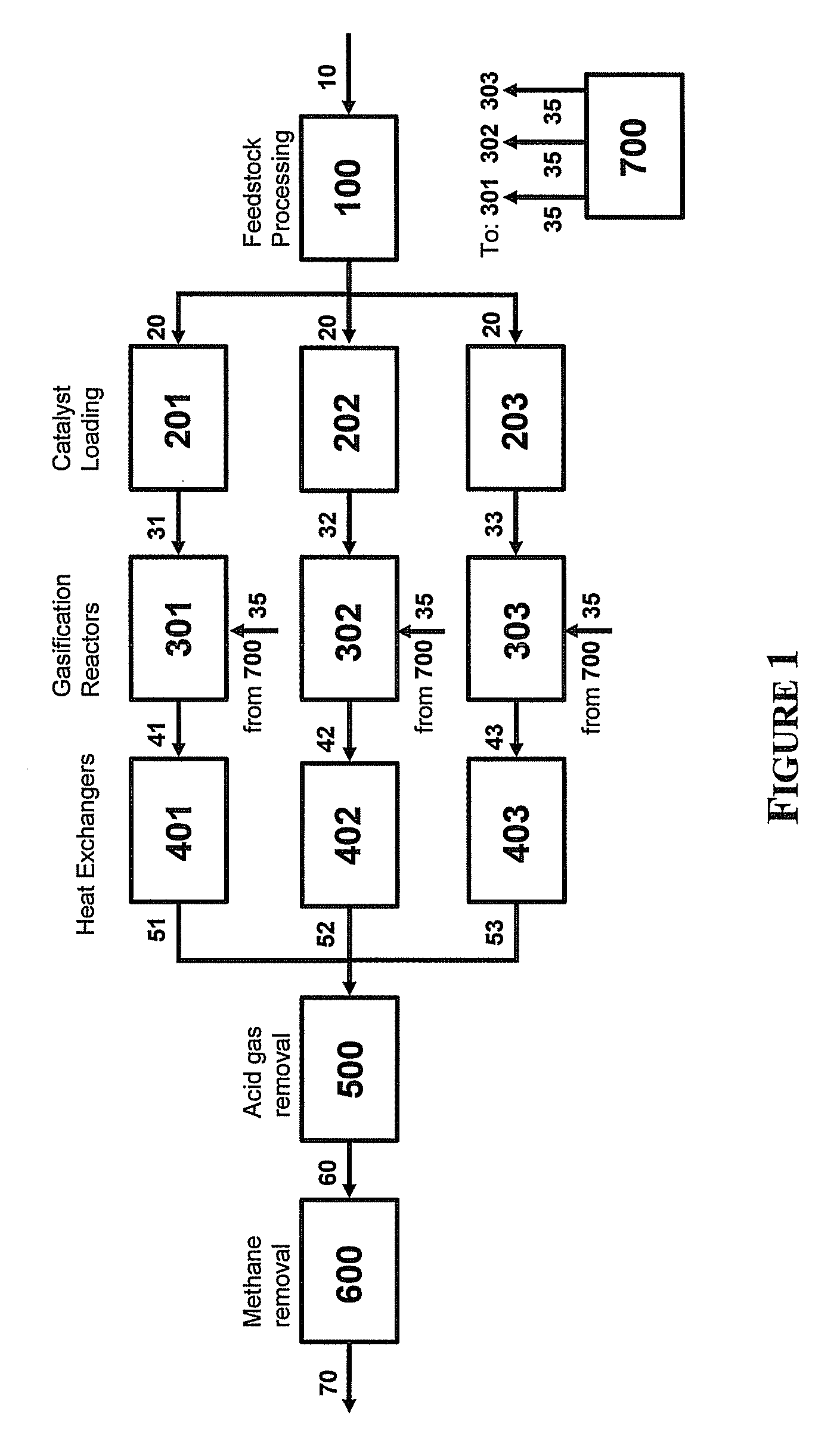

Three-Train Catalytic Gasification Systems

InactiveUS20090324459A1Reduce moisture contentCombustible gas catalytic treatmentGaseous fuelsUnit operationAmmonia

Systems to convert a carbonaceous feedstock into a plurality of gaseous products are described. The systems include, among other units, three separate gasification reactors for the gasification of a carbonaceous feedstock in the presence of an alkali metal catalyst into the plurality of gaseous products including at least methane. Each of the gasification reactors may be supplied with the feedstock from a single or separate catalyst loading and / or feedstock preparation unit operations. Similarly, the hot gas streams from each gasification reactor may be purified via their combination at a heat exchanger, acid gas removal or methane removal unit operations. Product purification may comprise trace contaminant removal units, ammonia removal and recovery units, and sour shift units.

Owner:SURE CHAMPION INVESTMENT LTD

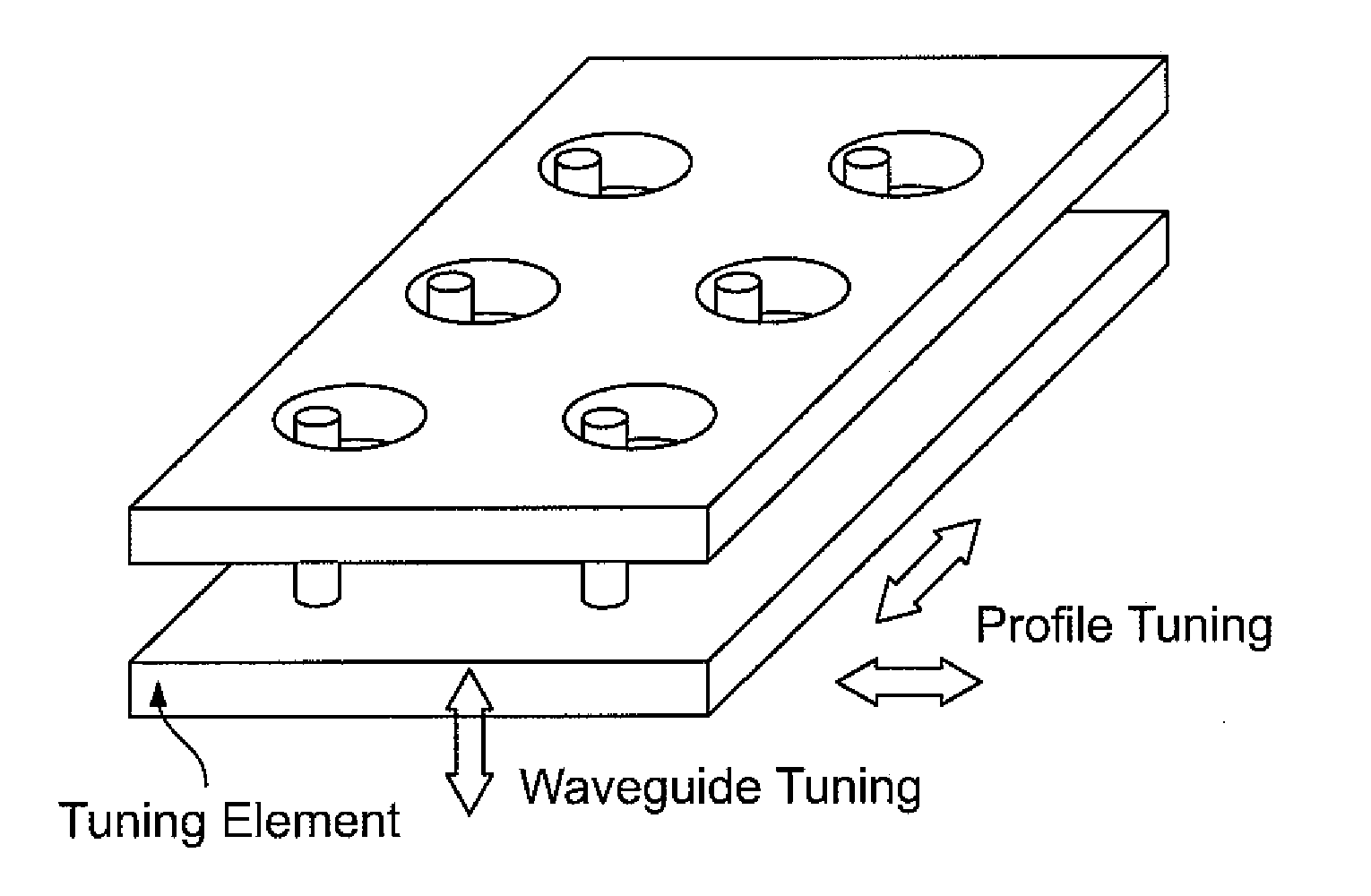

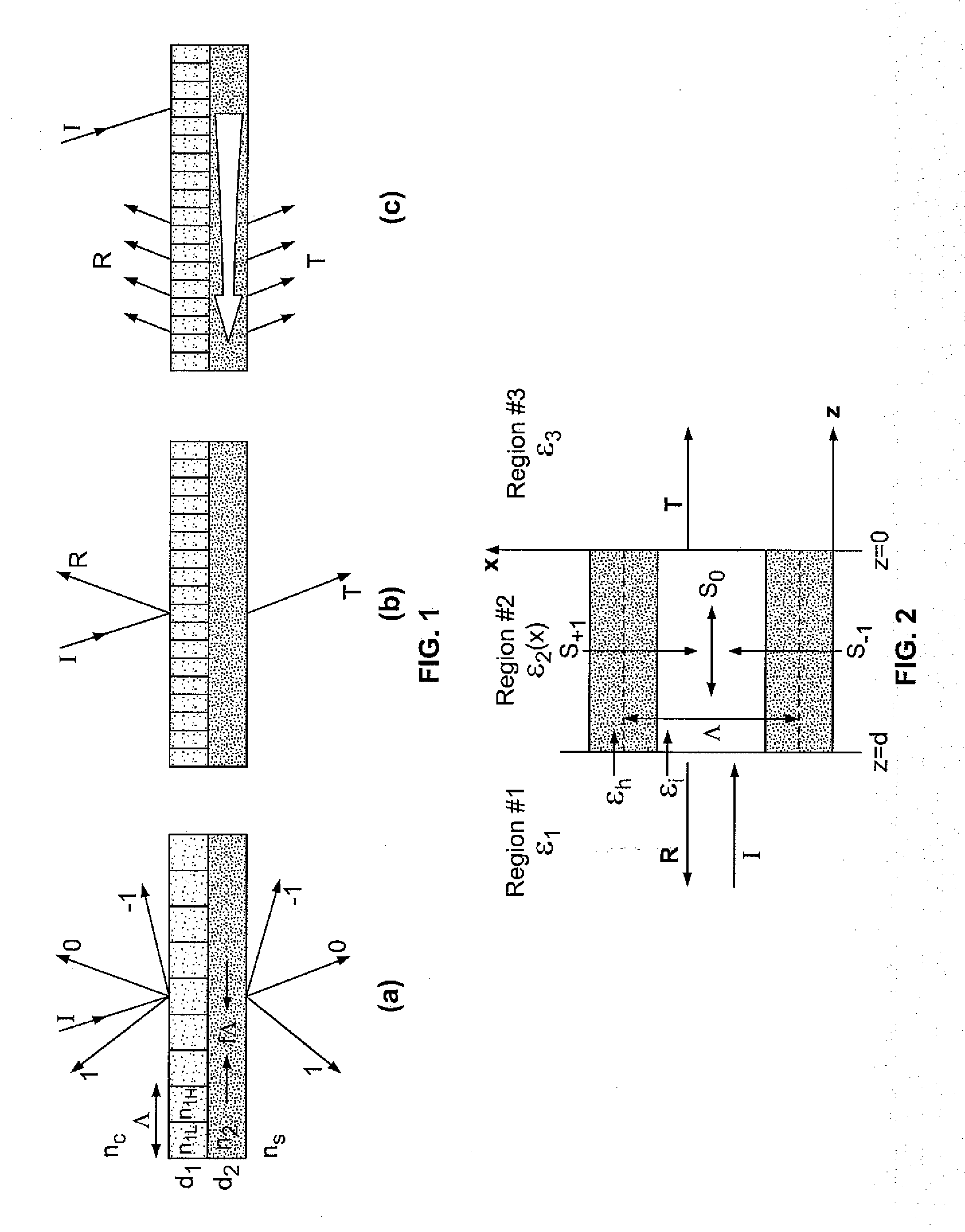

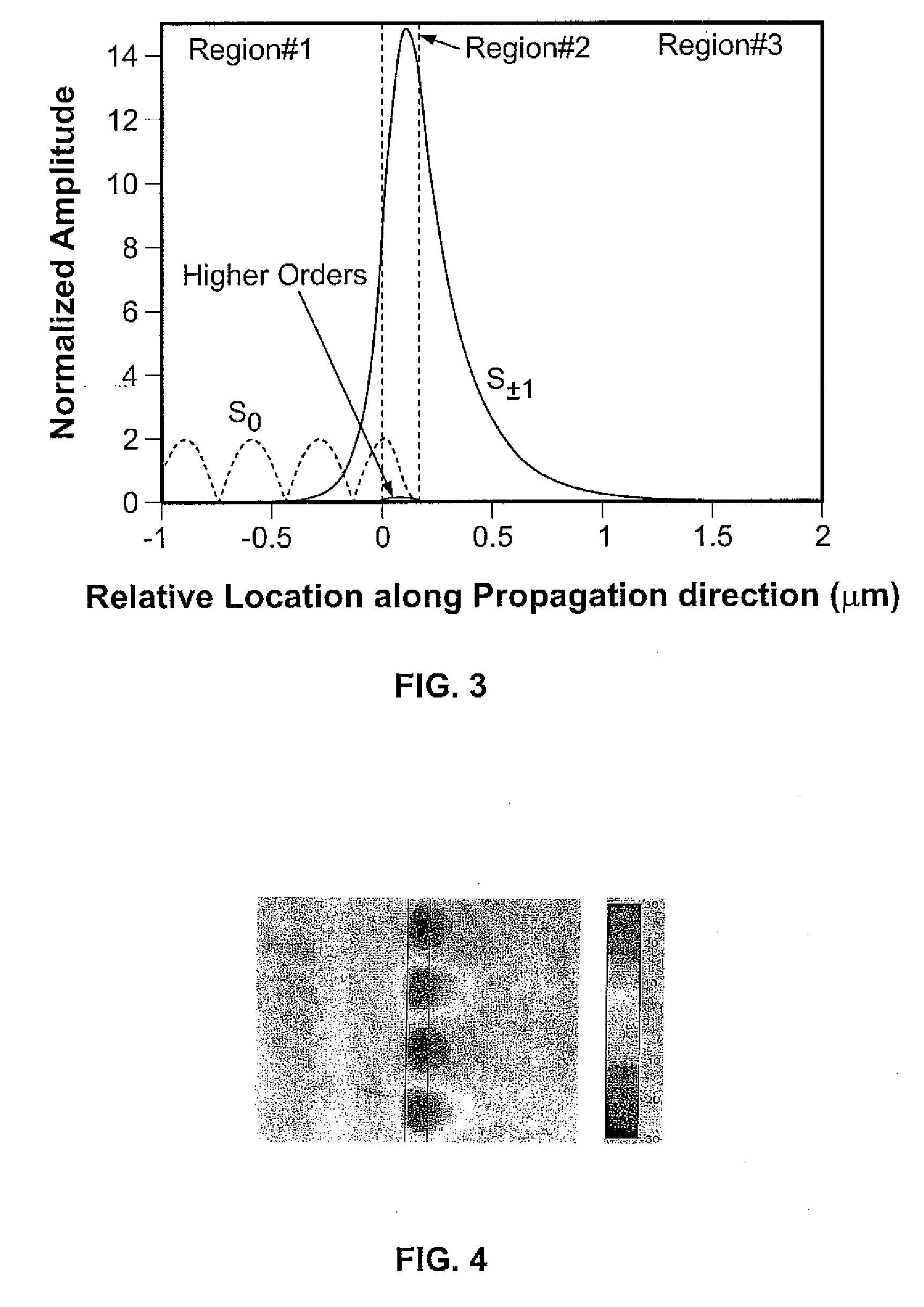

Tunable resonant leaky-mode N/MEMS elements and uses in optical devices

ActiveUS20090067774A1Increase varietyImprove utilizationLaser detailsNanoopticsDielectricUnit operation

Mechanically tunable electromagnetic and photonic devices featuring enhanced spectral tunability with minimal mechanical movement are provided. These nano / micro-electromechanically (N / MEMS) tunable elements, including filters and pixels, rely on leaky-mode resonance effects in subwavelength photonic lattices that constitute periodic wavelengths. Such elements can operate in reflection (bandstop) or transmission (bandpass) modes, and can be arranged in one-dimensional or two-dimensional arrays, or operated as single units, and their spectral regions are controlled by the element design. Input electromagnetic radiation illuminates the element and is then filtered, modulated, analyzed or tuned by the element. Mechanical motion alters the structural symmetry, and therefore, the tuning properties, of the nanostructured subwavelength resonance elements. Further, incorporating metals and dielectrics to generate coexisting plasmonic and leaky-mode resonance effects adds to the versatility of the potential applications.

Owner:UNIV OF CONNECTICUT

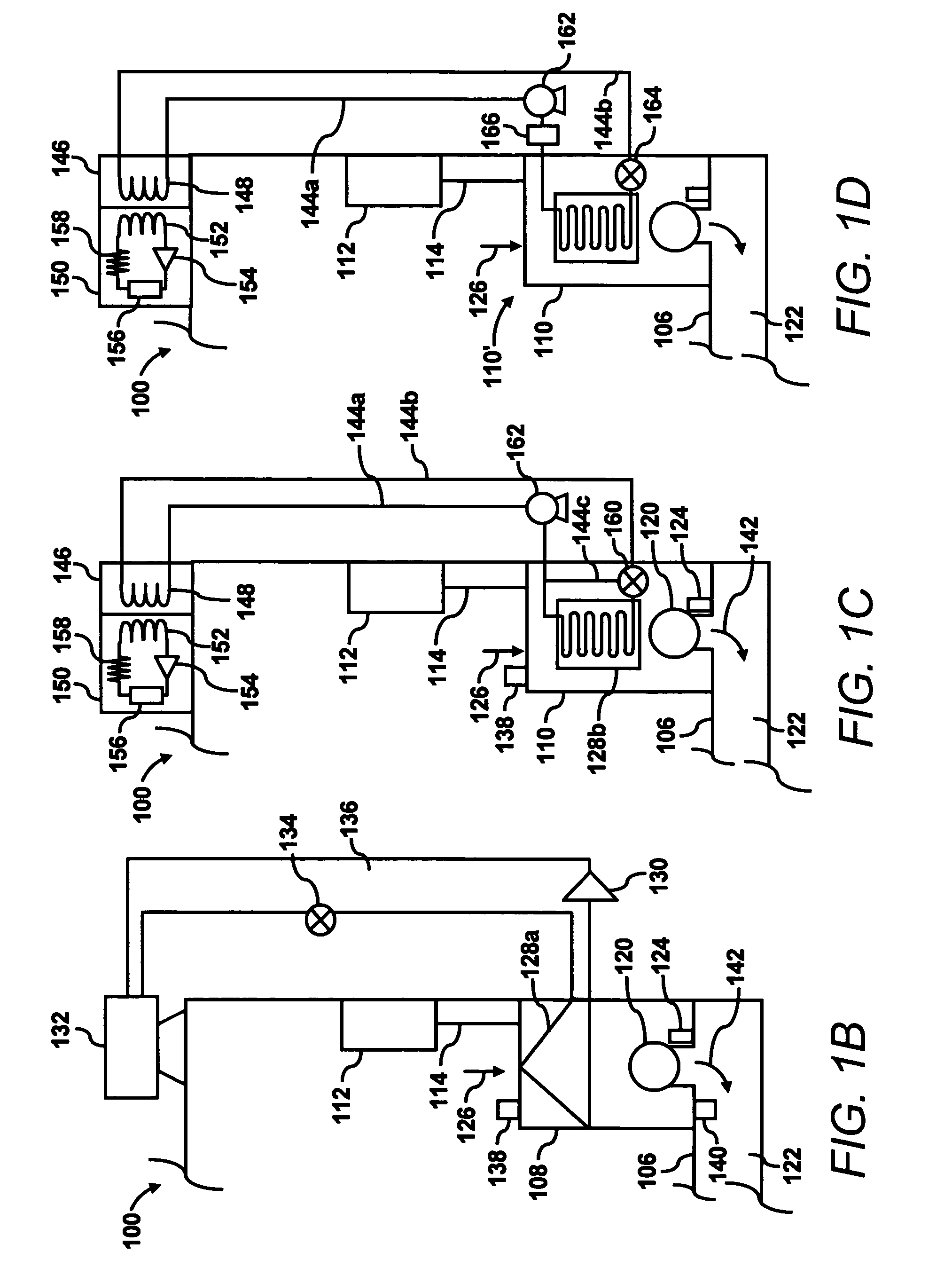

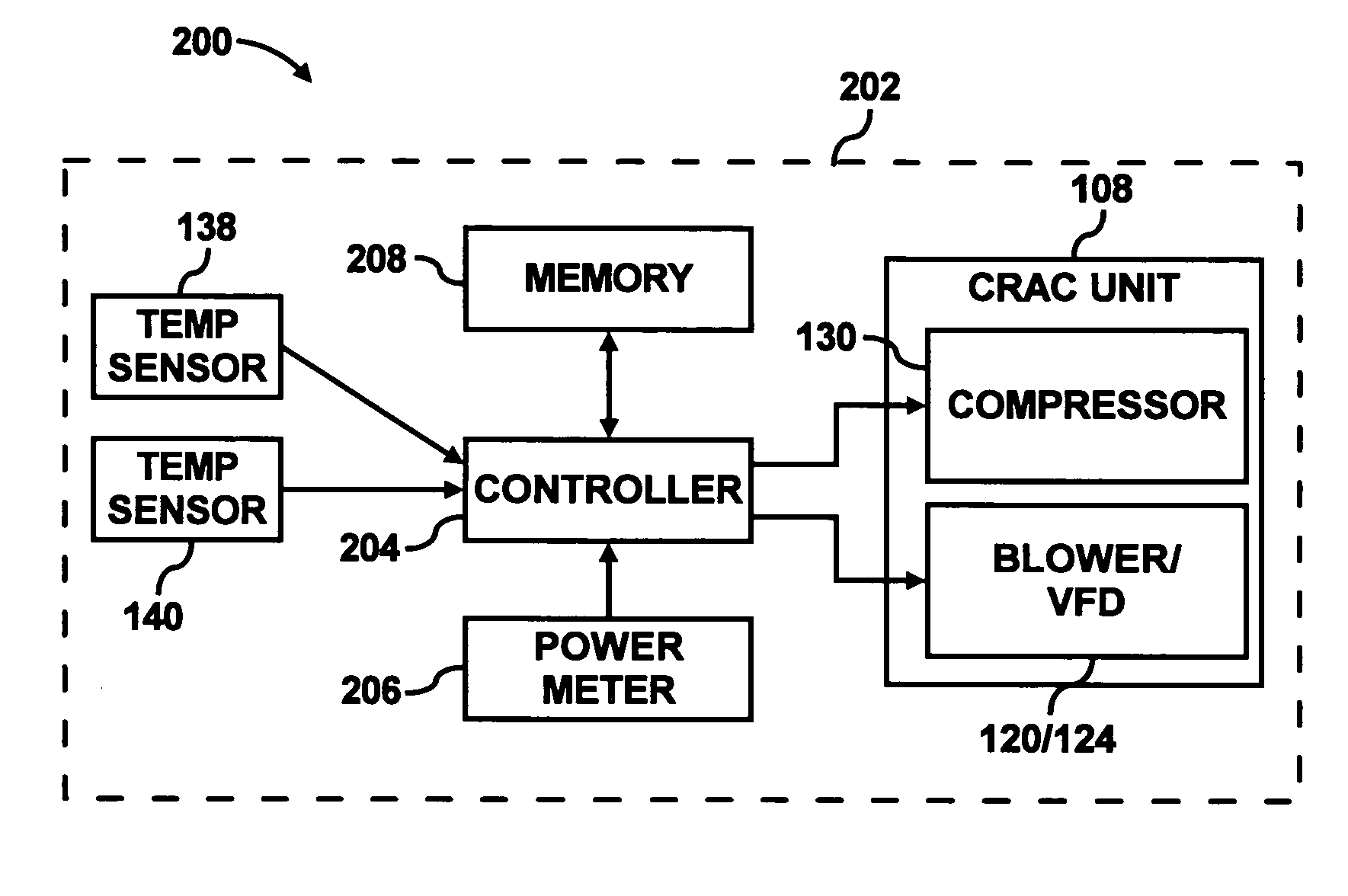

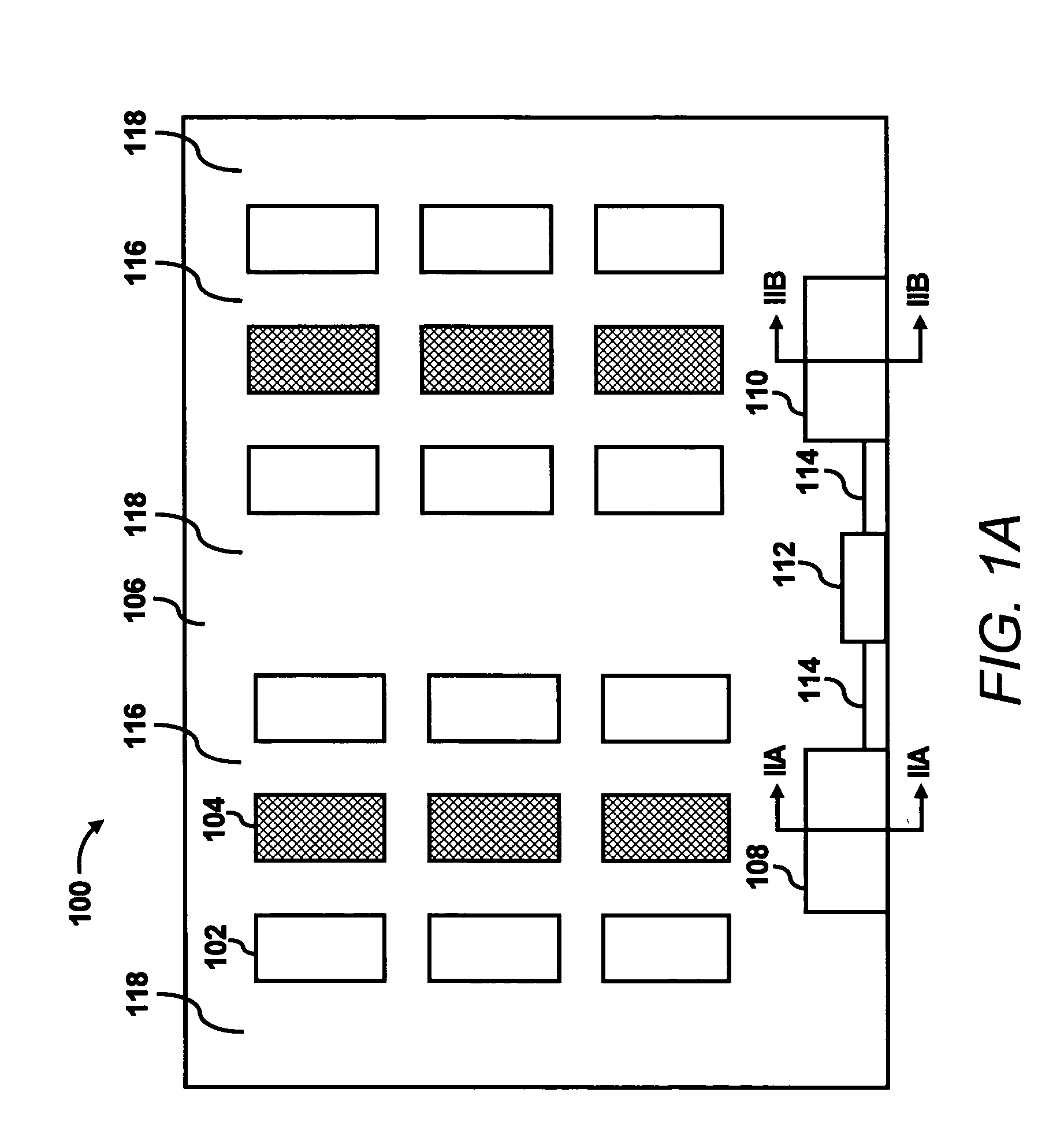

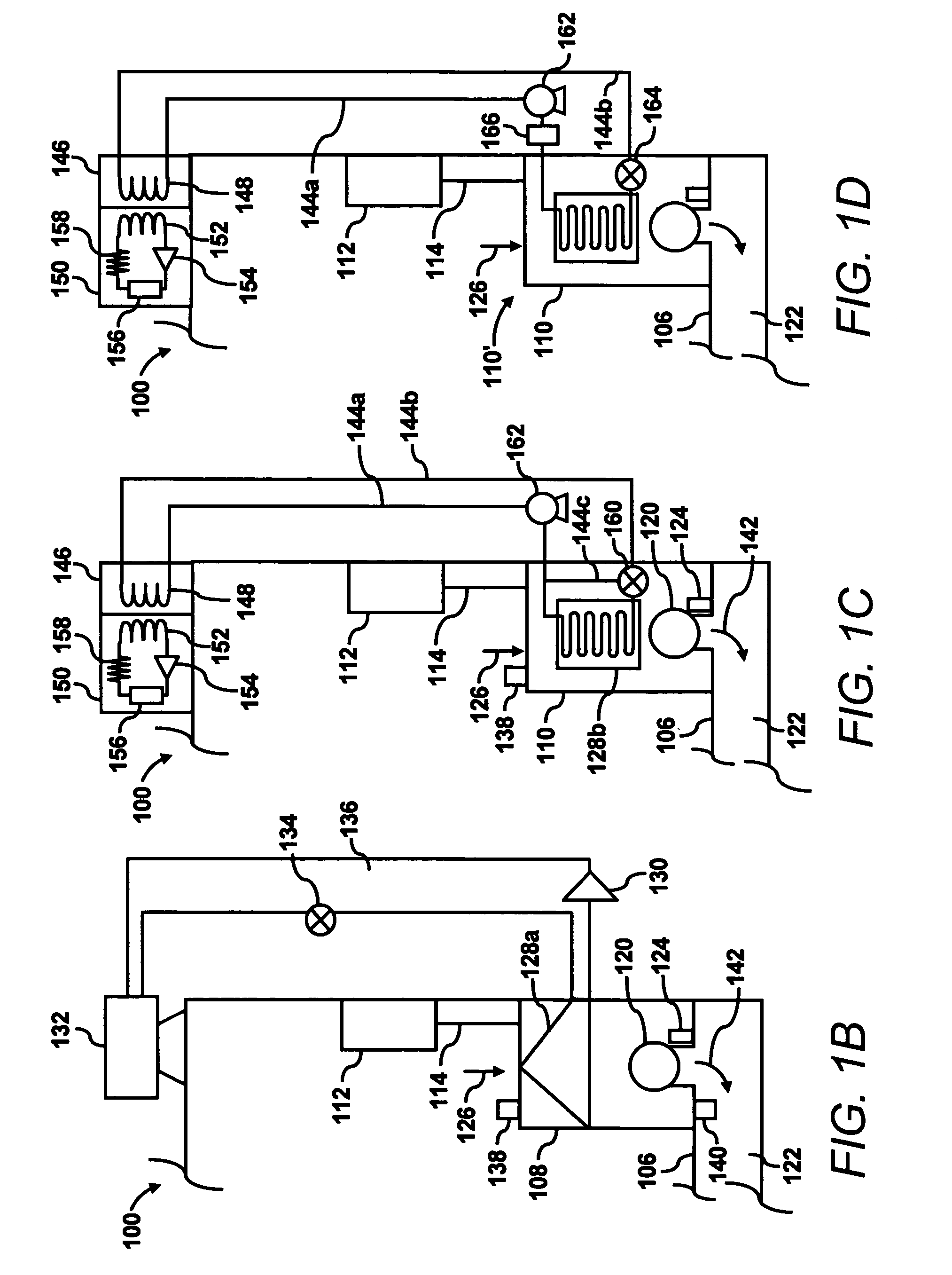

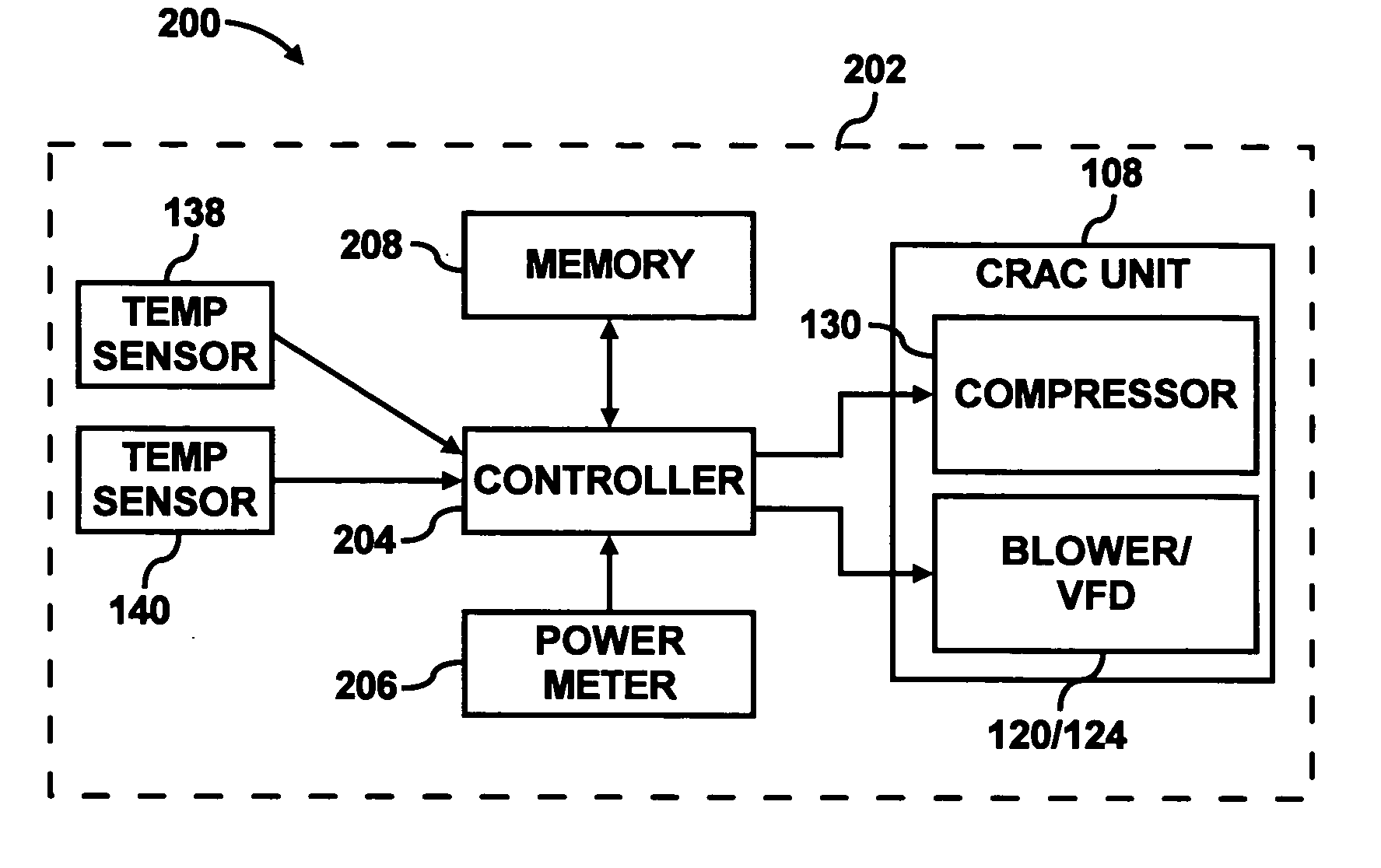

Energy efficient CRAC unit operation using heat transfer levels

ActiveUS7010392B2Improve efficiencyEasy to operateMechanical apparatusLevel controlUnit operationEngineering

A method for controlling one or more computer room air conditioning (CRAC) units for energy efficient operation, in which, the temperature of the air returned (Trat) into the one or more CRAC units and the temperature of the air supplied (Tsat) by the one or more CRAC units is detected. The caloric heat transfer level (Q) is calculated based upon the Trat and the Tsat and it is determined whether the Q is within a predetermined setpoint caloric heat transfer range. In addition, at least one operation of the one or more CRAC units is reduced in response to the Q being within the predetermined setpoint caloric heat transfer range to thereby increase the efficiencies of the one or more CRAC units.

Owner:HEWLETT PACKARD DEV CO LP

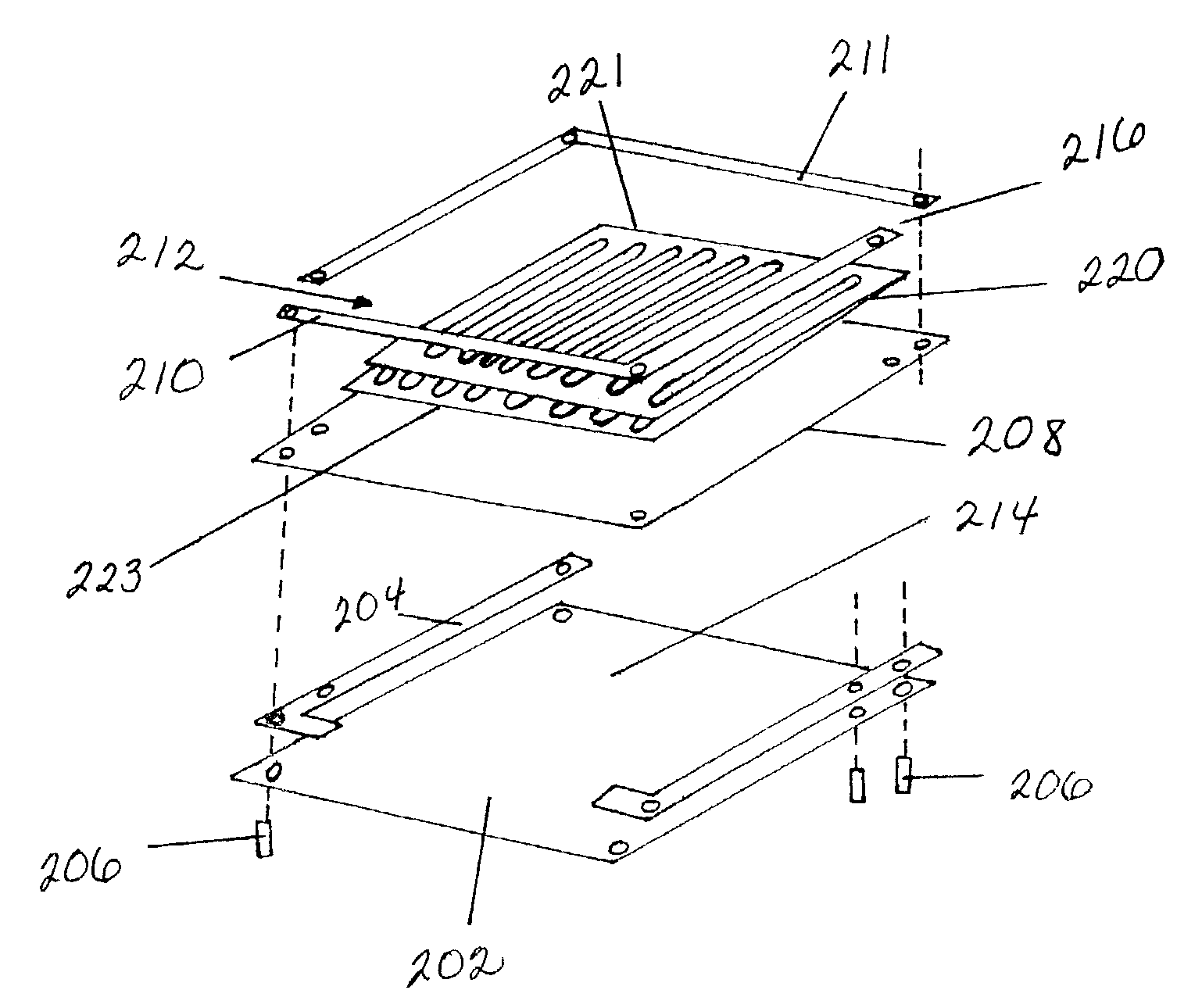

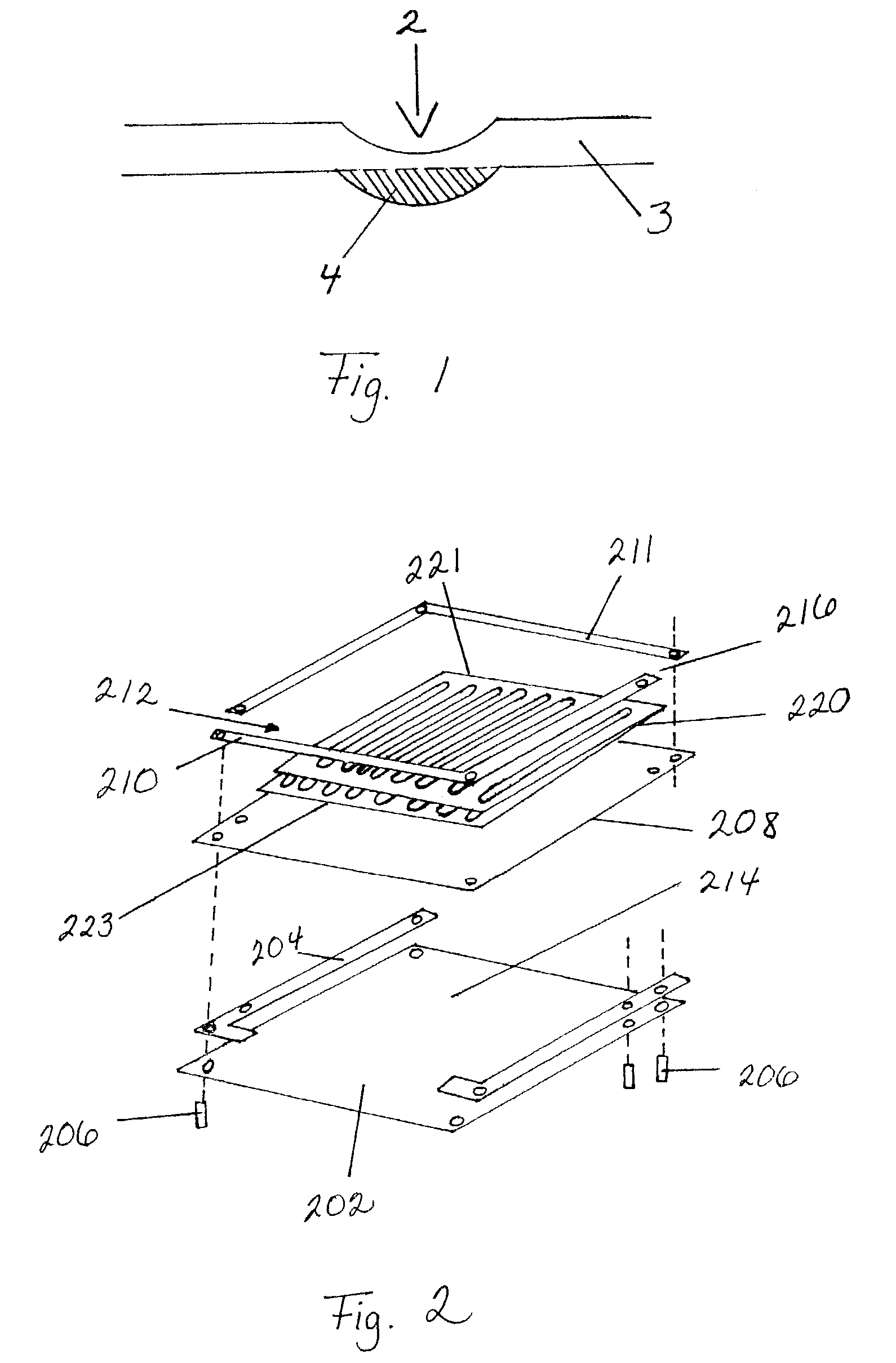

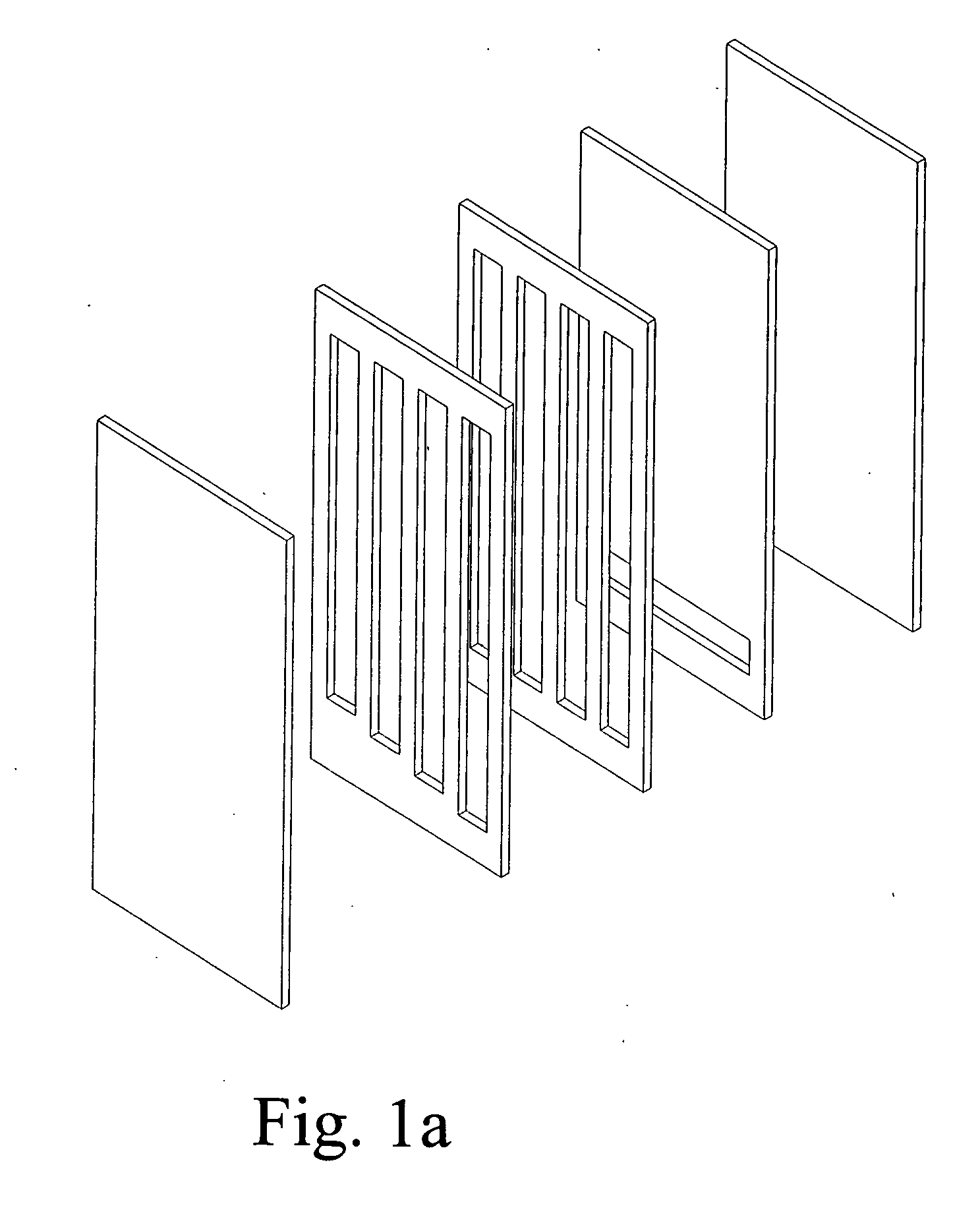

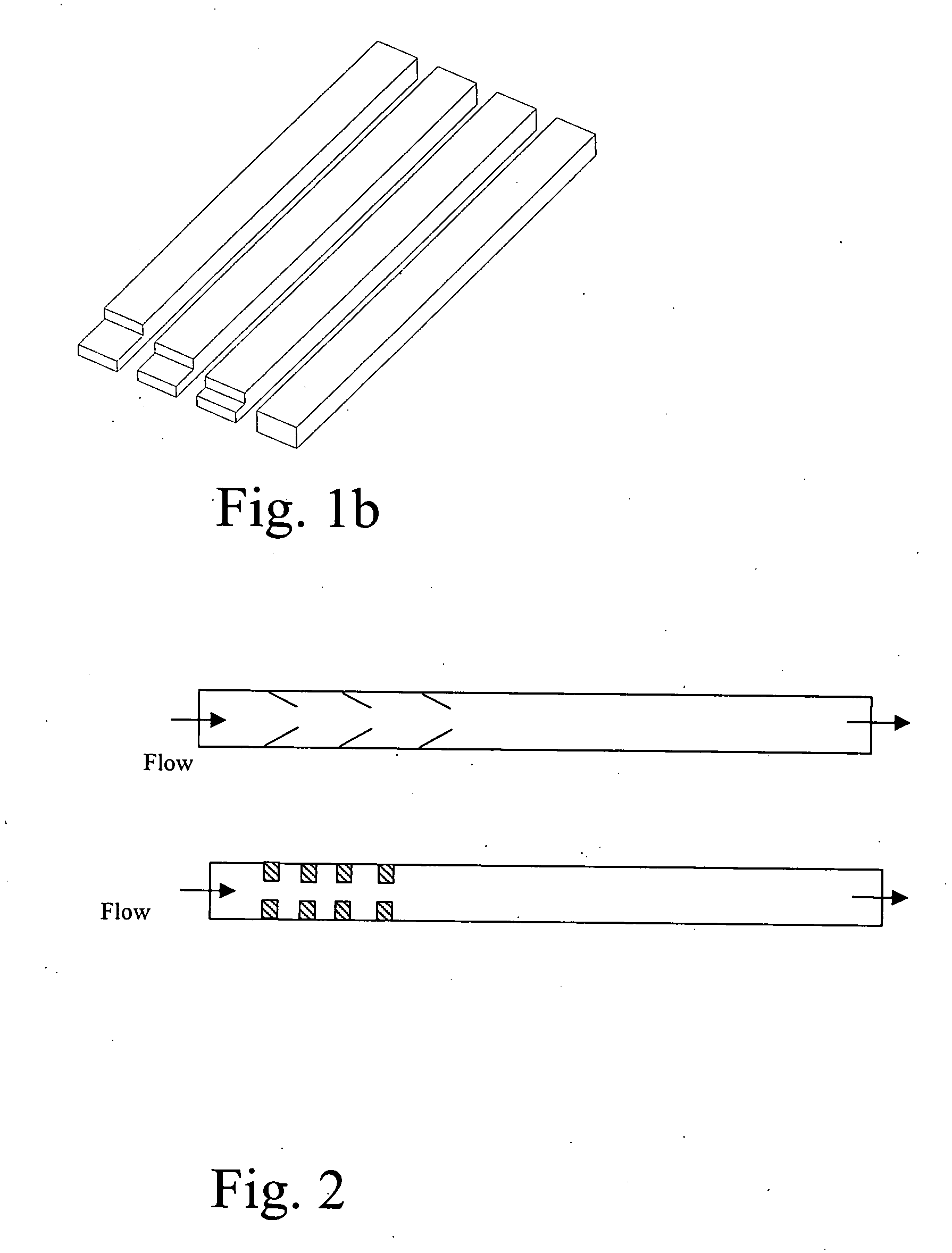

Microchannel apparatus, methods of making microchannel apparatus, and processes of conducting unit operations

InactiveUS6989134B2Low costReduce wasteFlow mixersTransportation and packagingUnit operationEngineering

Novel methods of making laminated, microchannel devices are described. Examples include: assembly from thin strips rather than sheets; and hot isostatic pressing (HIPing) to form devices with a hermetically sealed wall. Laminated microchannel articles having novel features are also described. The invention includes processes conducted using any of the articles described.

Owner:VELOCYS CORPORATION

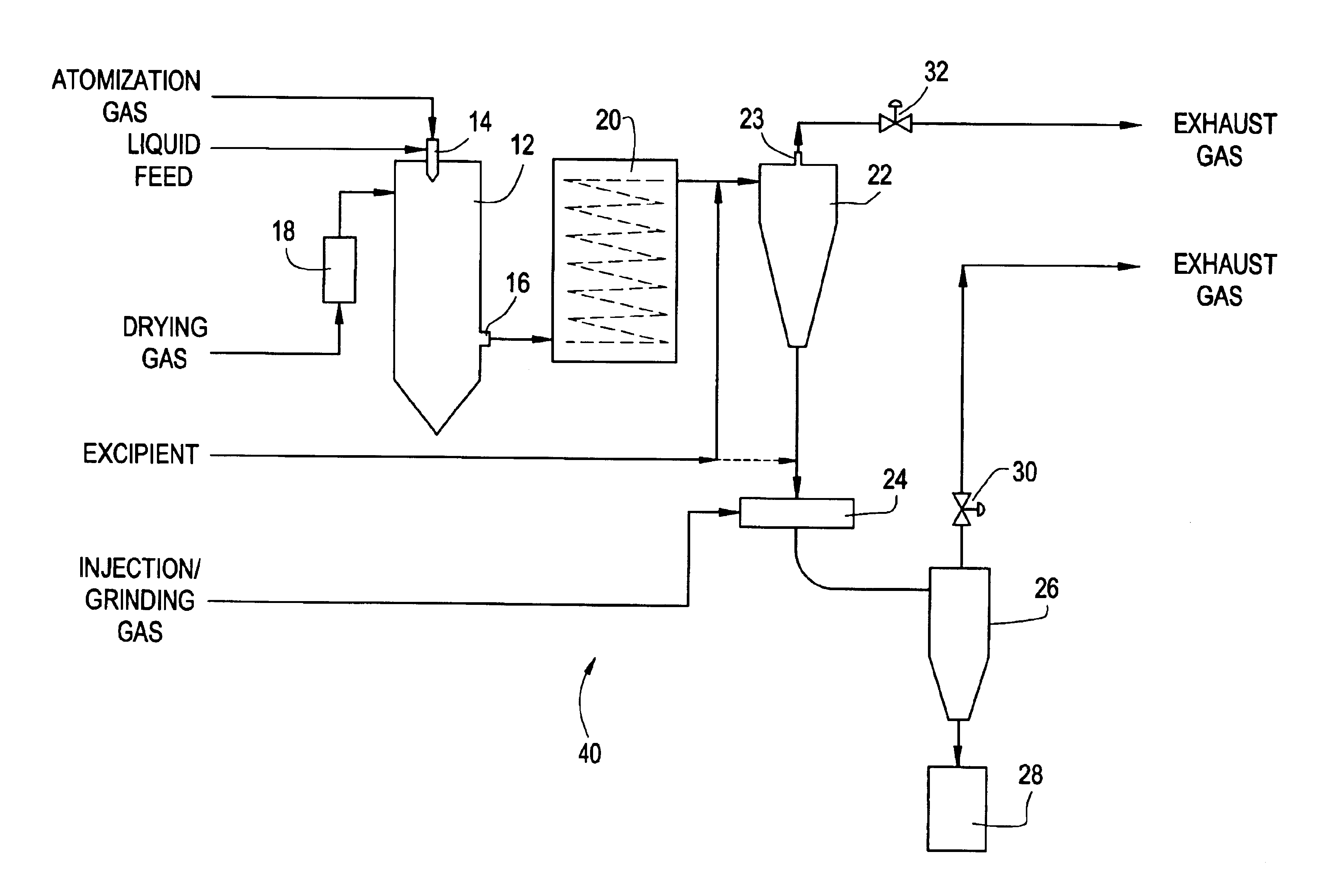

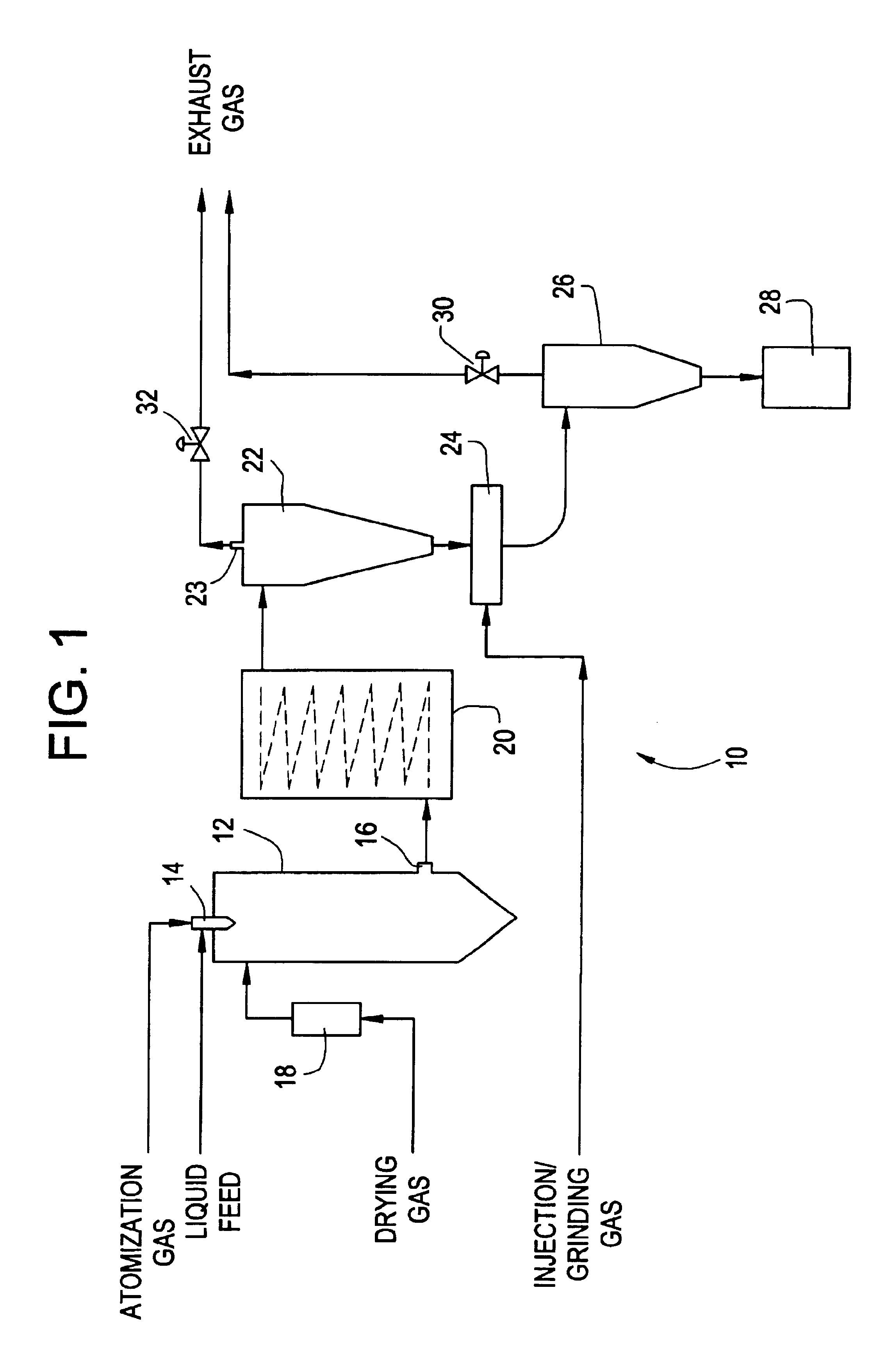

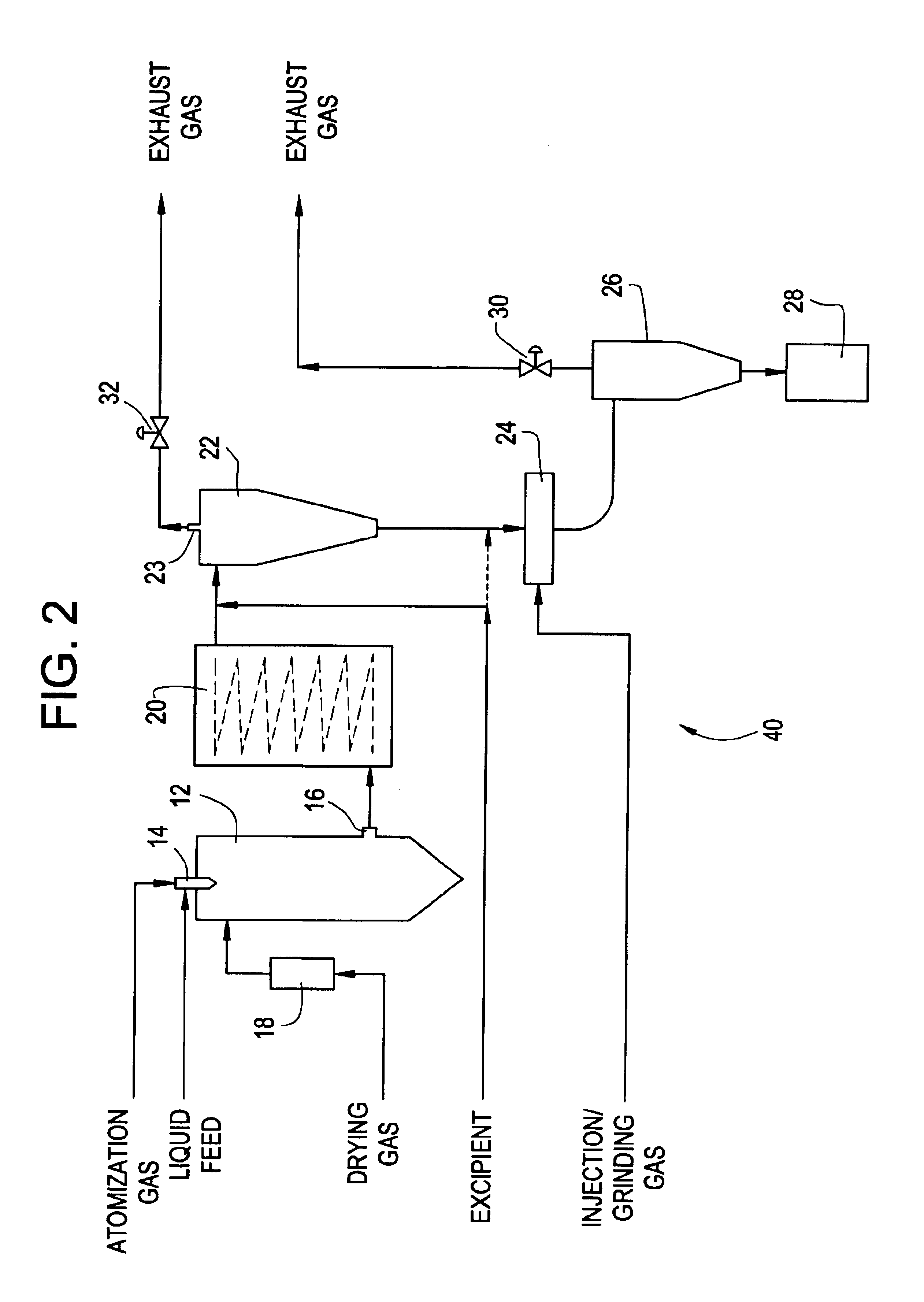

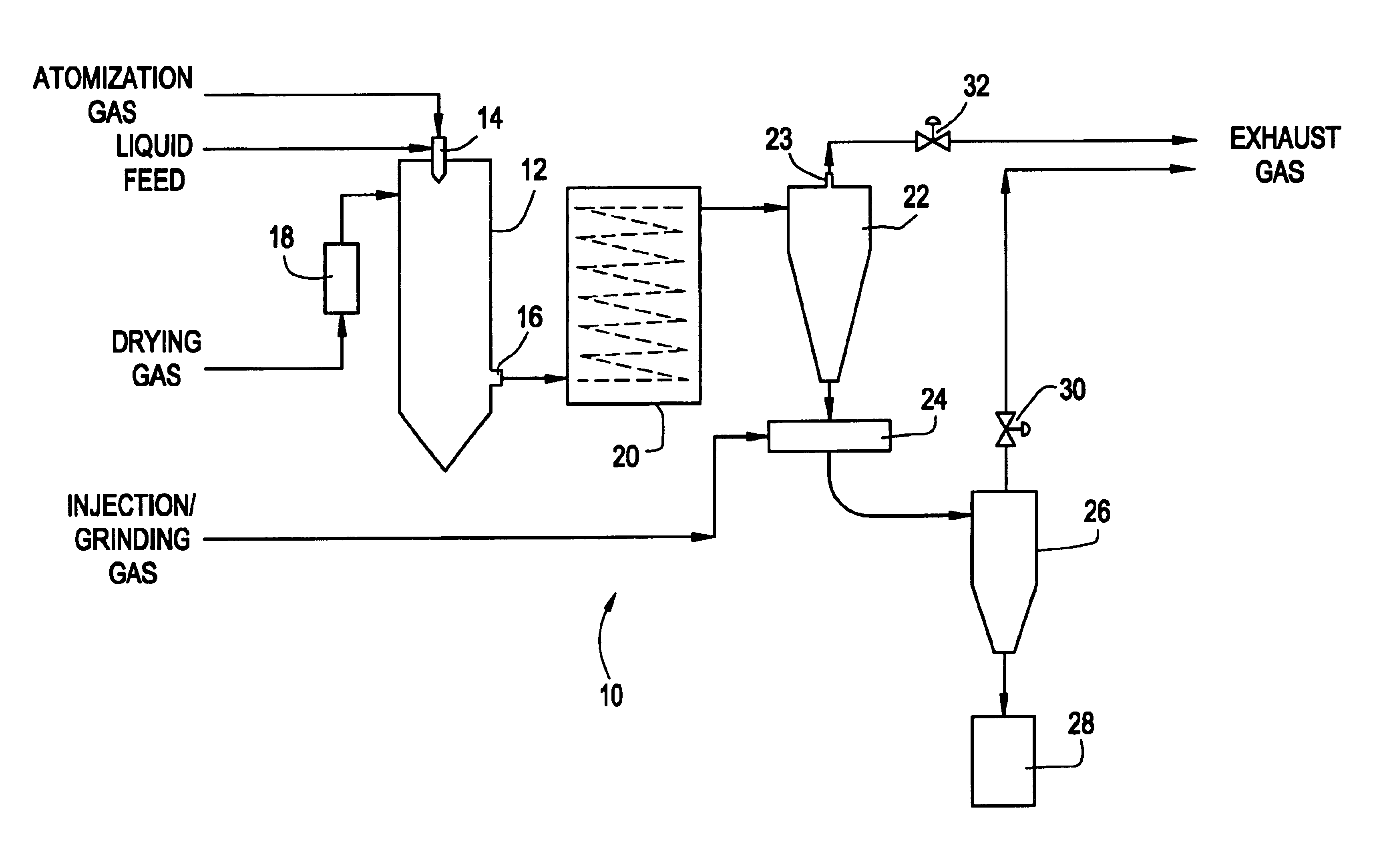

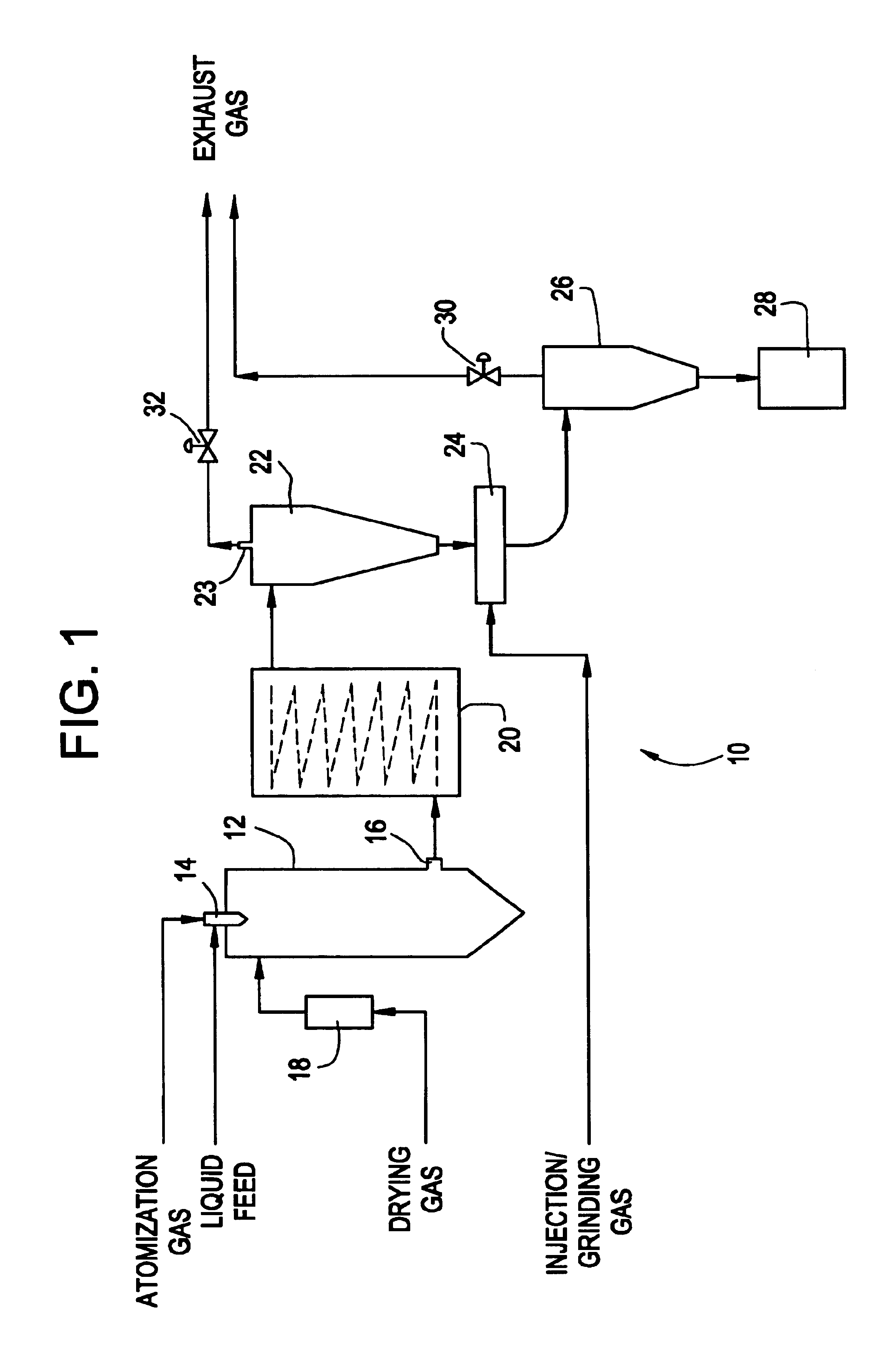

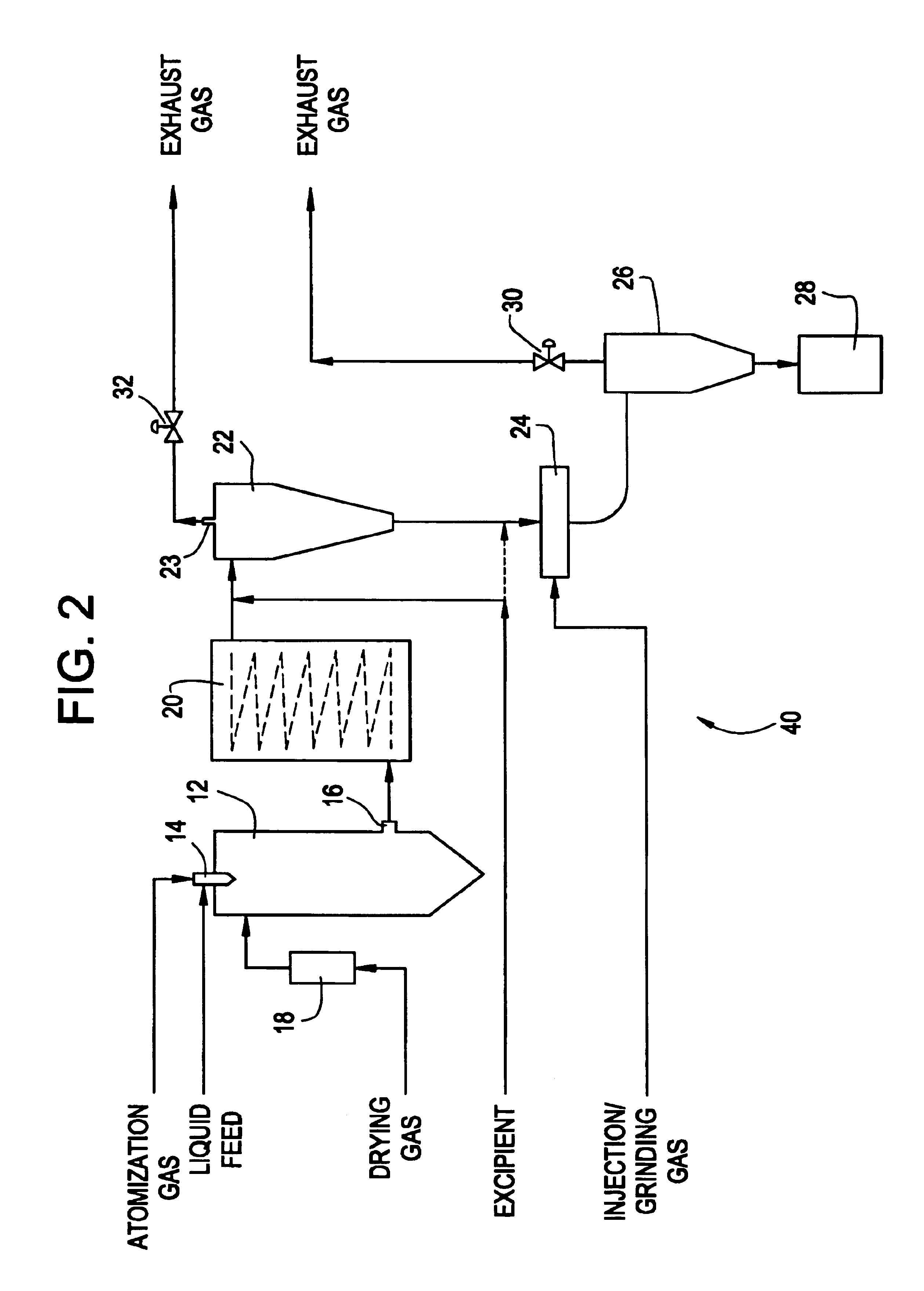

Methods and apparatus for making particles using spray dryer and in-line jet mill

InactiveUS6918991B2Reduce processing timeDrying solid materials with heatGranulation by liquid drop formationPolymer scienceEmulsion

Methods and apparatus are provided for making particles comprising: (a) spraying an emulsion, solution, or suspension, which comprises a solvent and a bulk material (e.g., a pharmaceutical agent), through an atomizer and into a primary drying chamber, having a drying gas flowing therethrough, to form droplets comprising the solvent and bulk material dispersed in the drying gas; (b) evaporating, in the primary drying chamber, at least a portion of the solvent into the drying gas to solidify the droplets and form particles dispersed in drying gas; and (c) flowing the particles and at least a portion of the drying gas through a jet mill to deagglomerate or grind the particles. By coupling spray drying with “in-line” jet milling, a single step process is created from two separate unit operations, and an additional collection step is advantageously eliminated. The one-step, in-line process has further advantages in time and cost of processing.

Owner:ACUSPHERE INC

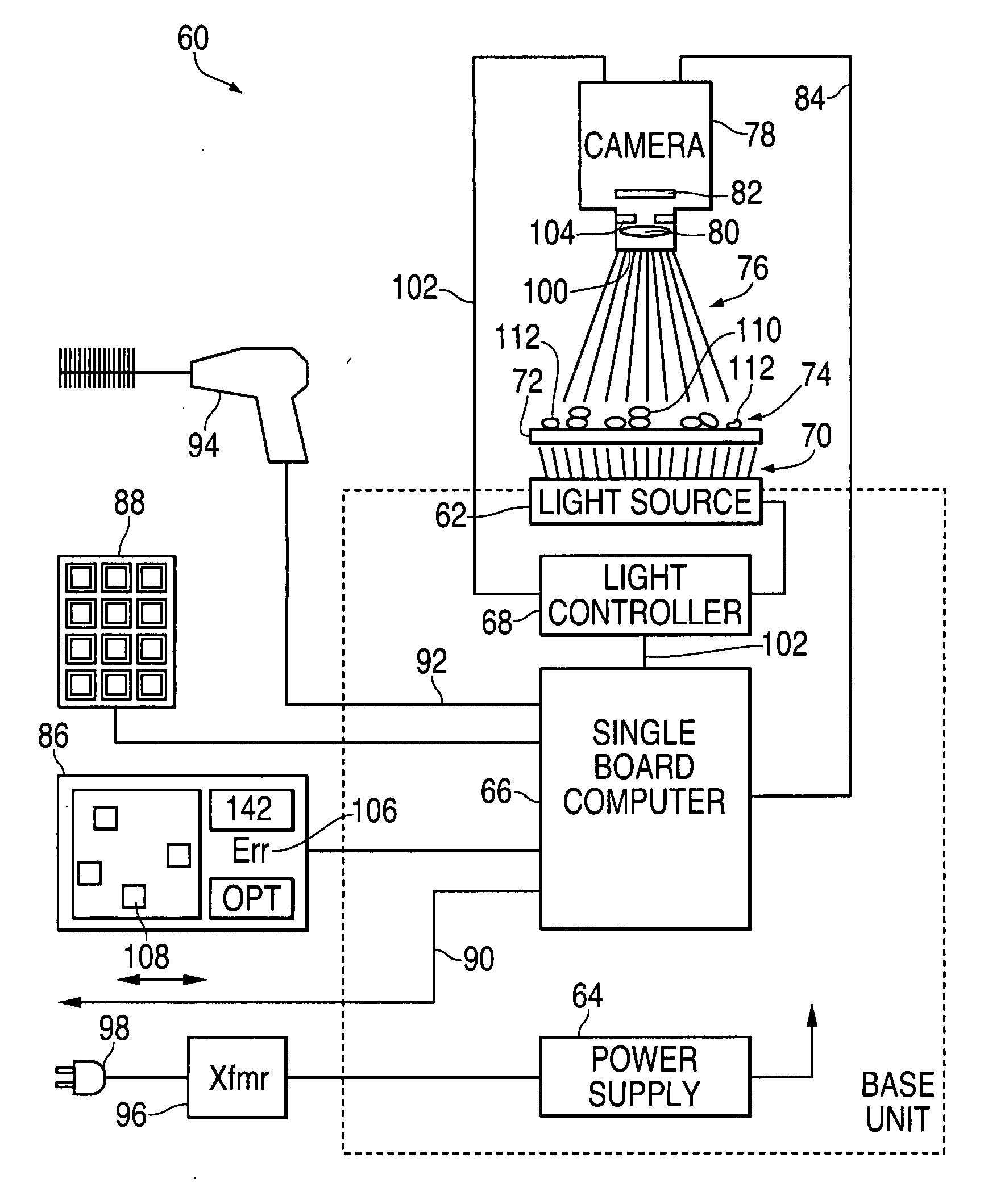

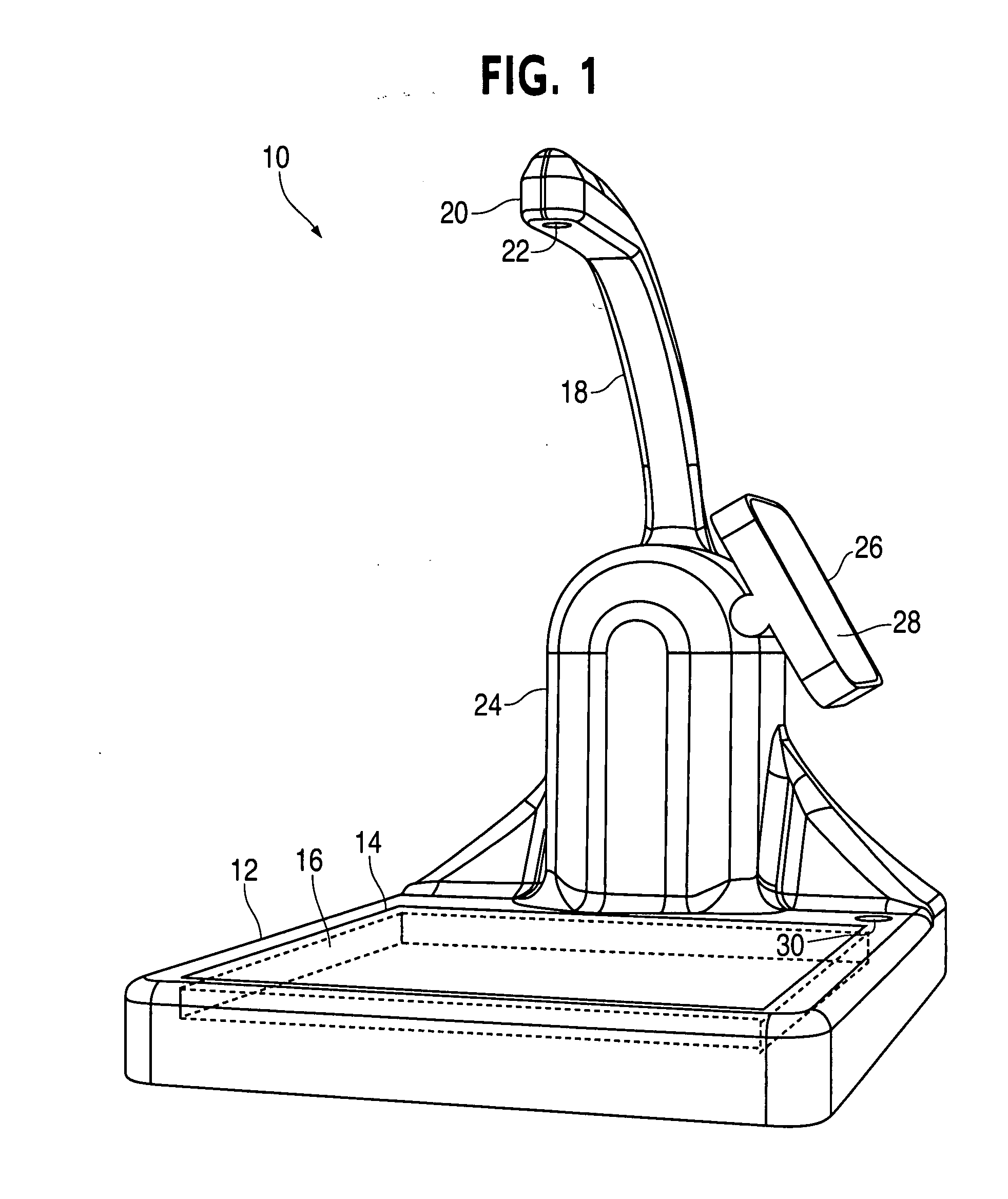

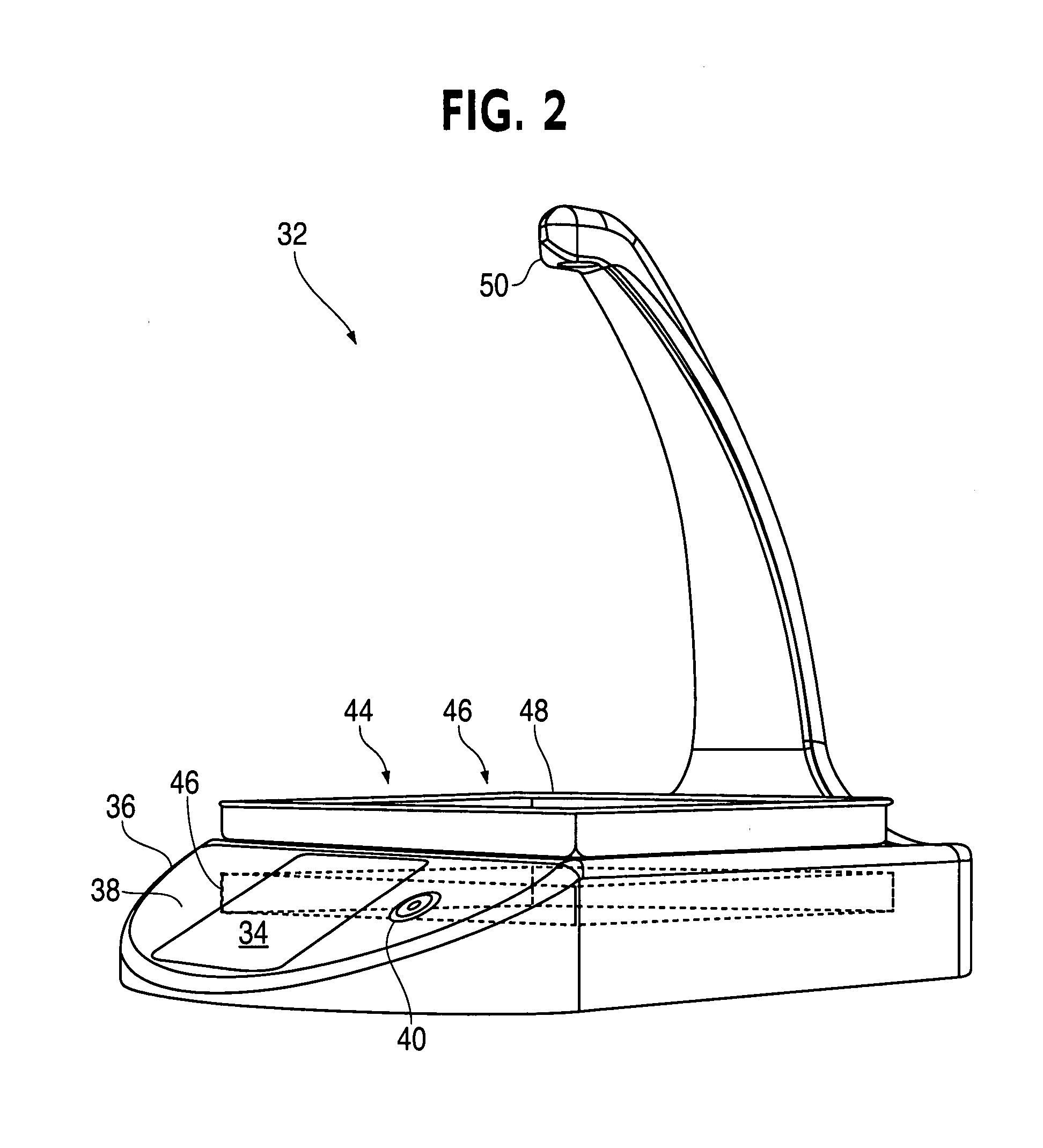

Machine vision counting system apparatus and method

InactiveUS20070189597A1Character and pattern recognitionOral administration deviceOperator interfaceMachine vision

A machine-vision-based counter includes an image acquisition component (imager), wherein light provides discrimination between a background field and imageable units located away from the imager. The imager outputs data representing the field and units; an image processor receiving imager data finds countable units therein. An operator interface accepts command inputs and presents count output. A controller manages image acquisition, processor, and operator interface functions. A counting method includes configuring an imager to detect light, directing light from a source to units positioned to be detected by the imager, and directing the light to the imager. The method includes discriminating between a background field and imageable units; providing, as an imager output, data representing the field and units; configuring an image processor to receive imager data; configuring the processor to interpret the data as counted units on a background field; and configuring an operator interface to present a count result.

Owner:ILLINOIS TOOL WORKS INC

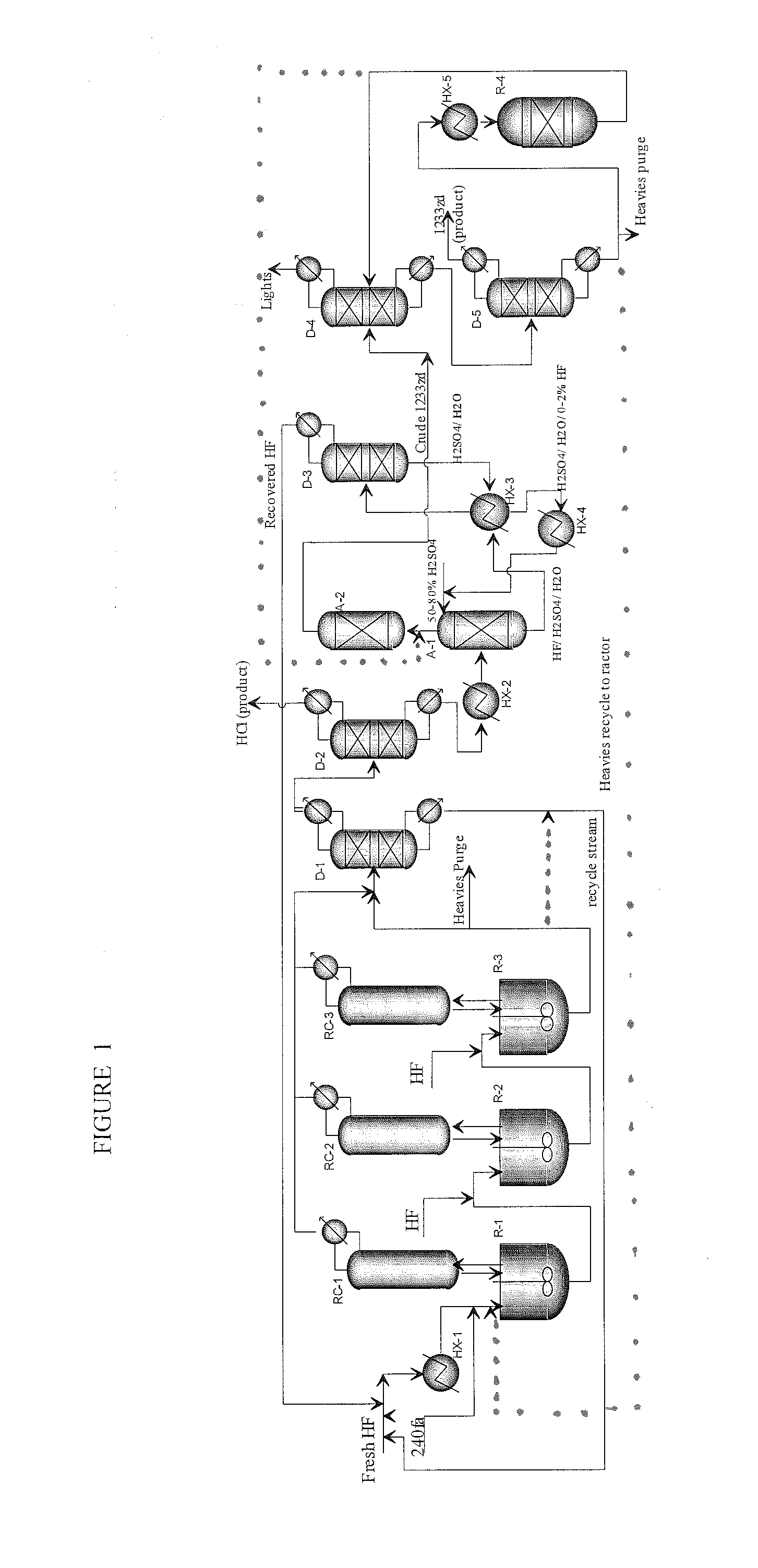

Continuous low-temperature process to produce trans-1-chloro-3,3,3-trifluoropropene

ActiveUS20120059199A1Slow reaction rateYield maximizationChlorine/hydrogen-chloridePreparation by hydrogen halide split-offIsomerizationUnit operation

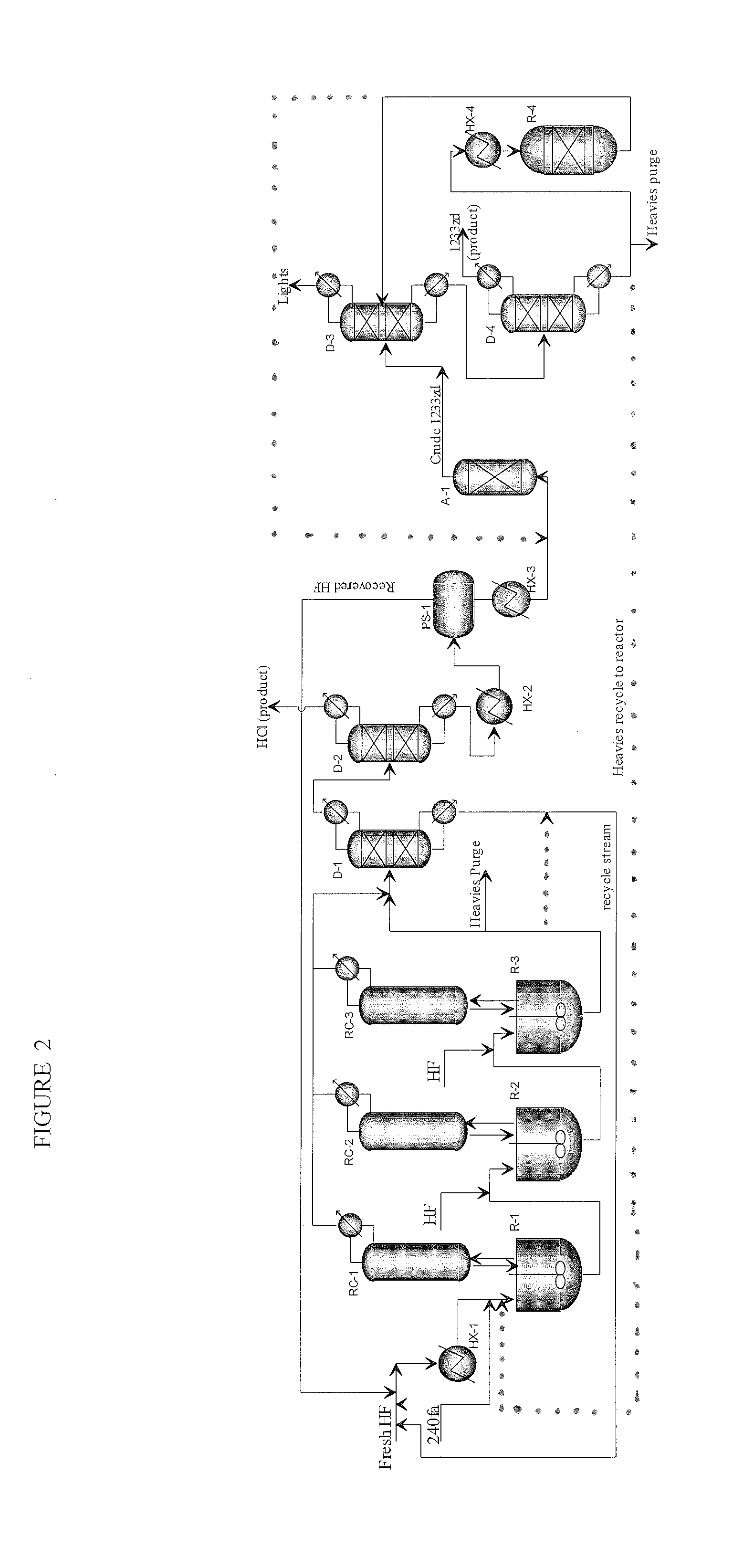

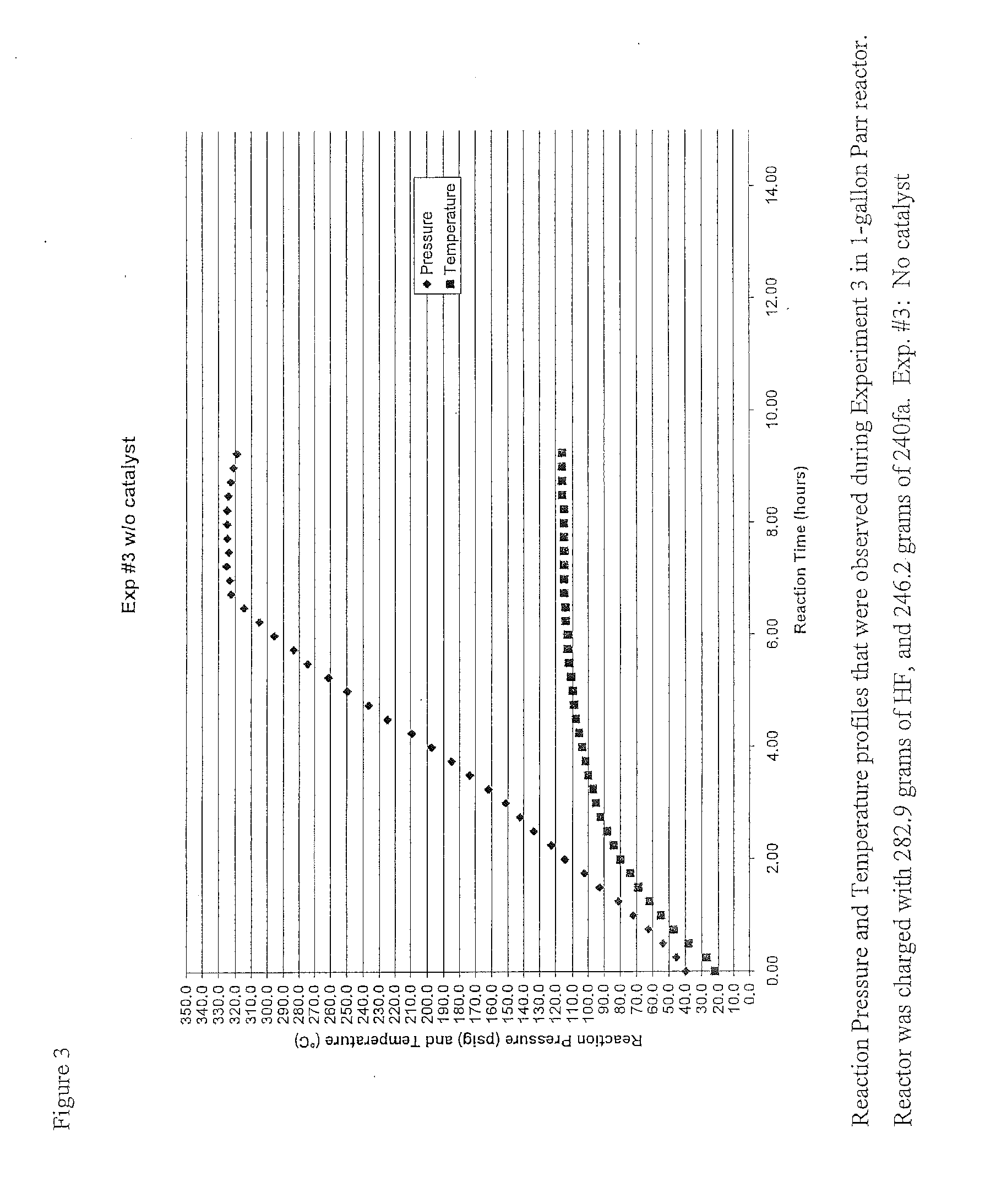

Disclosed is process for the production of (E) 1-chloro-3,3,3-trifluoropropene (HCFO-1233zd(E)) by conducting a continuous reaction without the use of a catalyst. Also disclosed is an integrated system for producing hydrofluoro olefins, particularly 1233zd(E). The manufacturing process includes six major unit operations: (1) a fluorination reaction of HCC-240fa (in continuous or semi-batch mode) using HF with simultaneous removal of by-product HCl and the product 1233zd(E); (2) recycle of unreacted HCC-240fa and HF together with under-fluorinated by-products back to (1); (3) separation and purification of by-product HCl; (4) separation of excess HF back to (1); (5) purification of final product, 1233zd(E); and (6) isomerization of by-product 1233zd(Z) to 1233zd(E) to maximize the process yield.

Owner:HONEYWELL INT INC

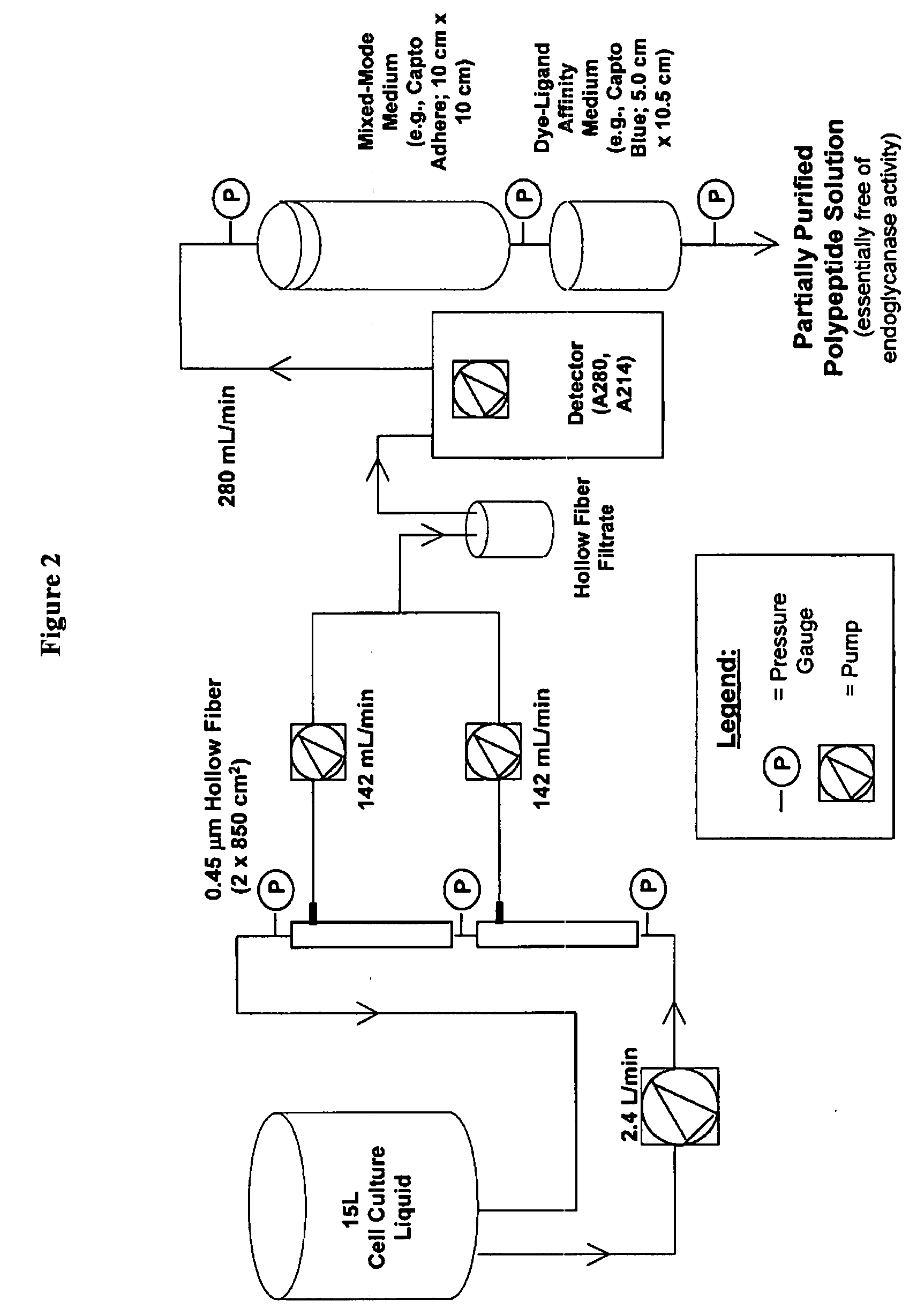

Manufacturing process for the production of polypeptides expressed in insect cell-lines

InactiveUS20080207487A1Promote recoveryReduce manufacturing costPeptide/protein ingredientsDepsipeptidesFiberCulture fluid

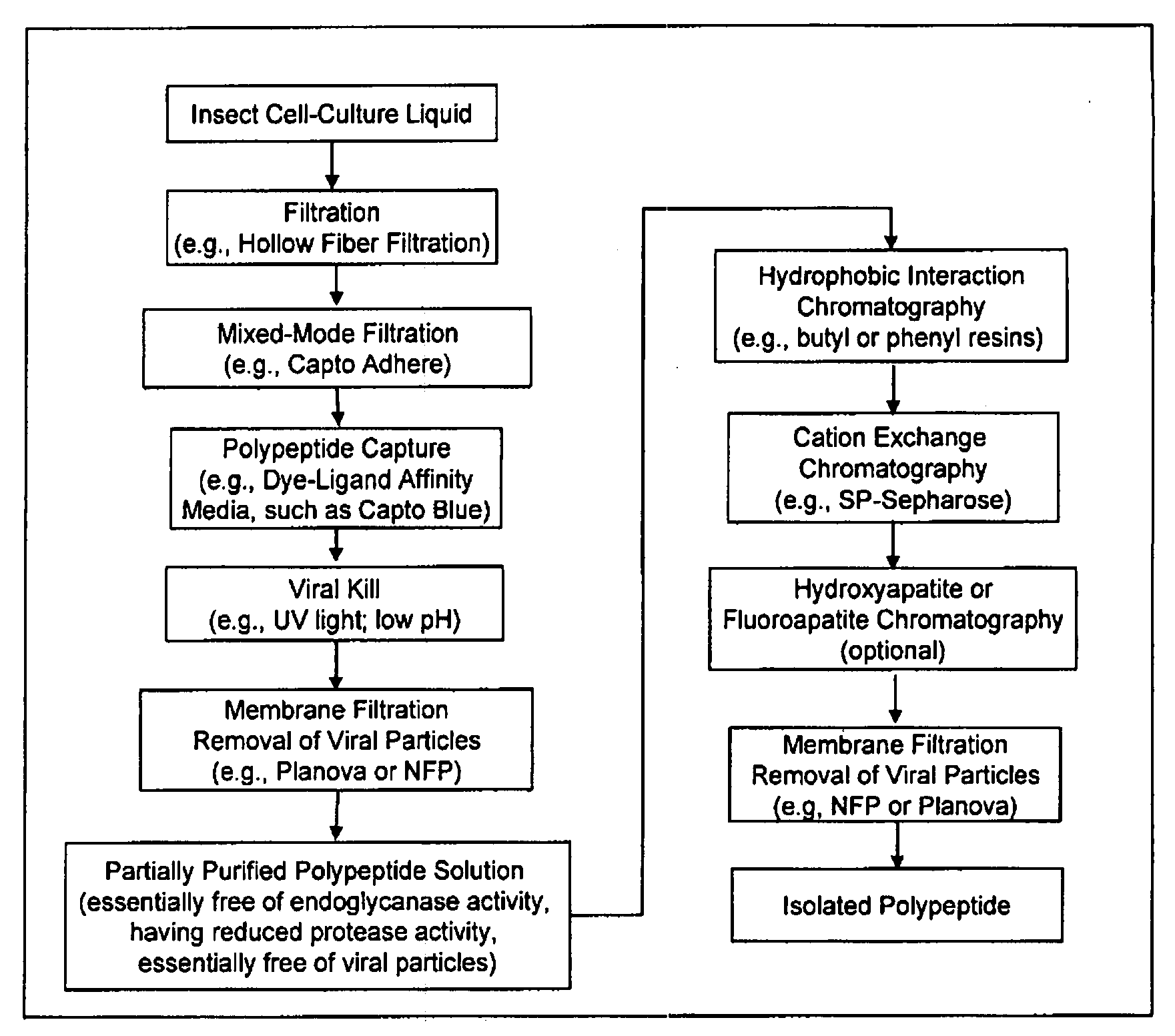

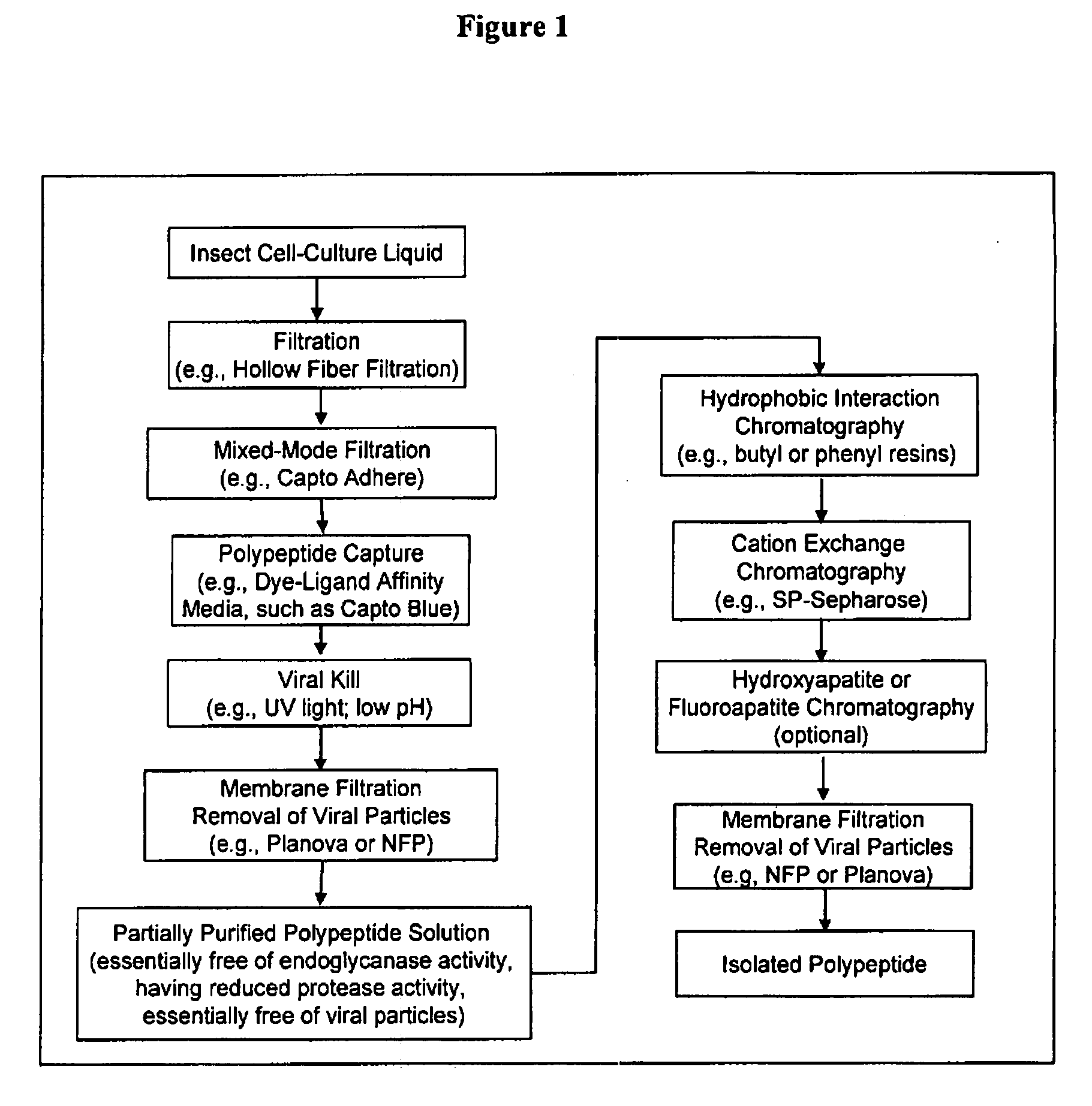

The present invention provides a manufacturing method for polypeptides that are produced in insect cells using a baculoviral expression system. In one example, the insect cell culture is supplemented with a lipid mixture immediately prior to infection (e.g., one hour prior to infection). The polypeptides are isolated from the insect cell culture using a method that employs anion exchange or mixed-mode chromatography early in the purification process. This process step is useful to remove insect-cell derived endoglycanases and proteases and thus reduces the loss of desired polypeptide due to enzymatic degradation. In another example, mixed-mode chromatography is combined with dye-ligand affinity chromatography in a continuous-flow manner to allow for rapid processing of the insect-cell culture liquid and capture of the polypeptide. In yet another example, a polypeptide is isolated from an insect cell culture liquid using a process that combines hollow fiber filtration, mixed-mode chromatography and dye-ligand affinity in a single unit operation producing a polypeptide solution that is essentially free of endoglycanase and proteolytic activities. In a further example, the isolated polypeptides are glycopeptides having an insect specific glycosylation pattern, which are optionally conjugated to a modifying group, such as a polymer (e.g., PEG) using a glycosyltransferase and a modified nucleotide sugar.

Owner:NOVO NORDISK AS

Energy efficient CRAC unit operation using heat transfer levels

ActiveUS20050278069A1Improve efficiencyEasy to operateMechanical apparatusLevel controlUnit operationEngineering

A method for controlling one or more computer room air conditioning (CRAC) units for energy efficient operation, in which, the temperature of the air returned (Trat) into the one or more CRAC units and the temperature of the air supplied (Tsat) by the one or more CRAC units is detected. The caloric heat transfer level (Q) is calculated based upon the Trat and the Tsat and it is determined whether the Q is within a predetermined setpoint caloric heat transfer range. In addition, at least one operation of the one or more CRAC units is reduced in response to the Q being within the predetermined setpoint caloric heat transfer range to thereby increase the efficiencies of the one or more CRAC units.

Owner:HEWLETT PACKARD DEV CO LP

Process for the preparation of fatty acid methyl ester from triglyceride oil by transesterification

InactiveUS20060080891A1Produced cost-effectivelyReduce water contentFatty oils/acids recovery from wasteFatty acid esterificationTransesterificationUnit operation

The present invention relates to an improved process for the preparation of biodiesel from triglyceride oils through transesterification, particularly the fatty acid methyl ester of oil mechanically expelled from whole seeds of Jatropha curcas, a plant with potential for cultivation on wastelands in India and other countries, all unit operations being carried out at ambient temperature.

Owner:COUNCIL OF SCI & IND RES

Energy efficient CRAC unit operation

ActiveUS20050278070A1Easy to operateImprove efficiencyLevel controlLighting and heating apparatusUnit operationProcess engineering

A method for controlling one or more computer room air conditioning (CRAC) units configured to receive return air for energy efficient operation. In the method, the temperature of the air returned (Trat) into the one or more CRAC units is detected. It is determined whether the Trat is within a predetermined setpoint temperature range and at least one operation of the one or more CRAC units is reduced in response to the Trat being within the predetermined setpoint temperature range to thereby increase the efficiencies of the one or more CRAC units.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

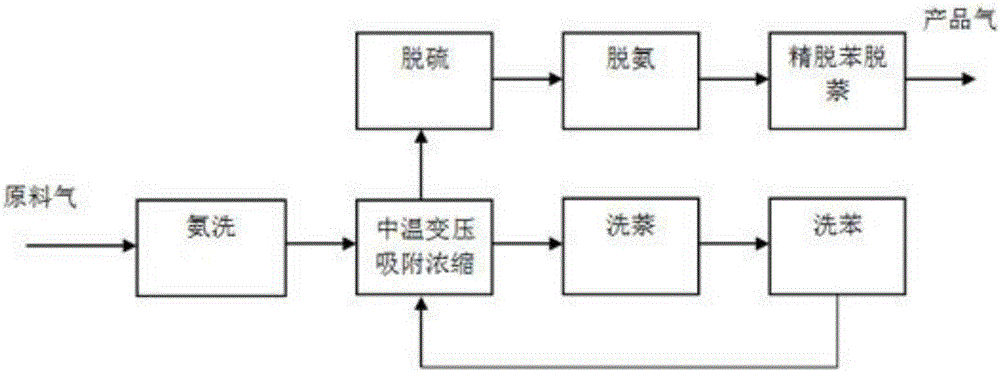

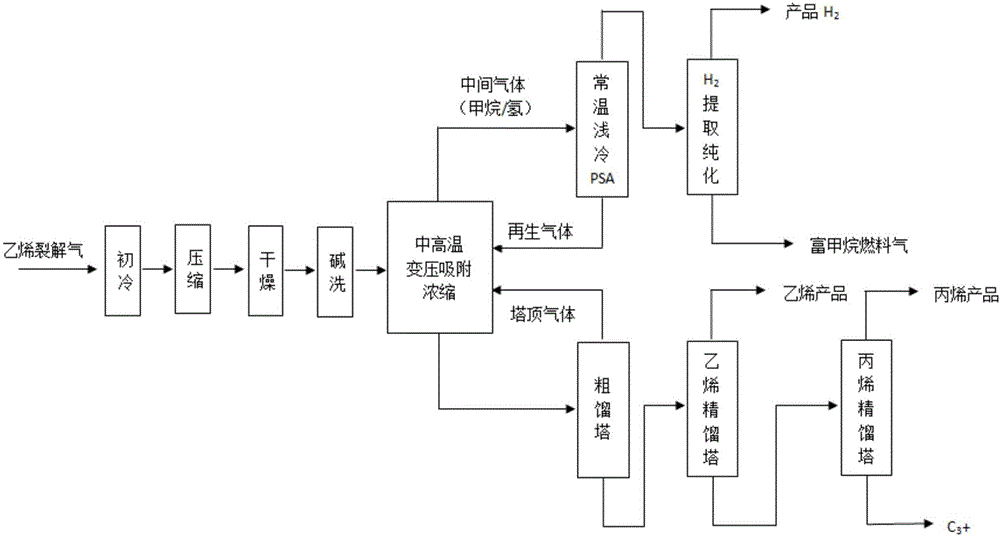

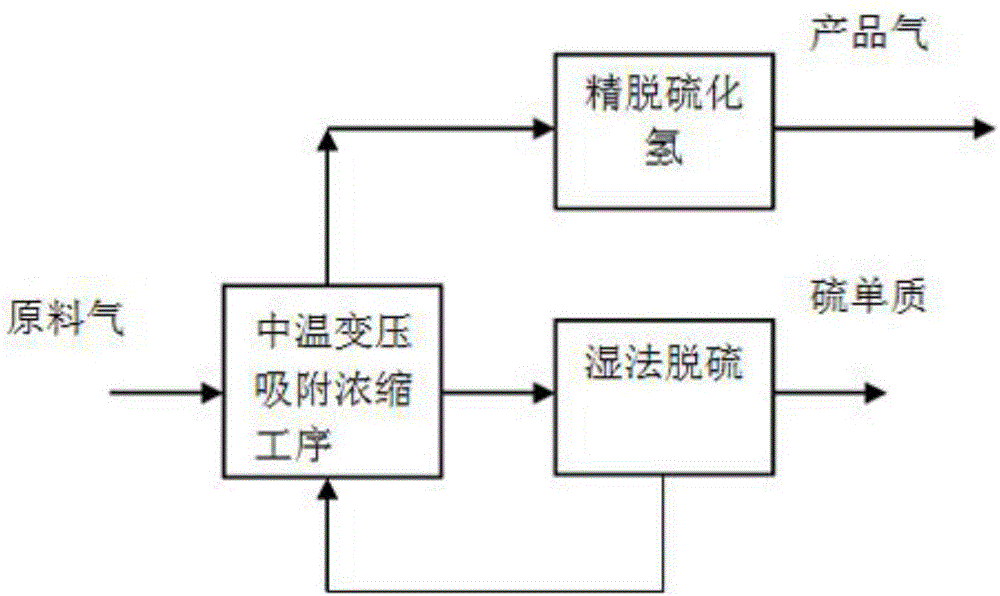

Full-temperature-range pressure swing adsorption gas separation, refinement and purification method

ActiveCN105749699AReduce energy consumptionBroaden the scope of adsorption separation applicationsSolidificationLiquefactionEnergy gradientPurification methods

The invention discloses a full-temperature-range pressure swing adsorption gas separation, refinement and purification method.By means of the difference of the temperatures and pressures of different raw material gases and the difference of the adsorption separation coefficients and physical chemistry properties of all components in the raw material gases in the temperature range of 80-200 DEG C and the pressure range of 0.03-4.0 MPa, the adsorption or desorption regeneration operation of the pressure swing adsorption circulation process is adjusted by coupling all separation methods, the adsorption theory that the pressure or temperature swing adsorption separation process is only limited to the adsorption and desorption regeneration circulation operation through pressure or temperature changes is expanded, and therefore all raw material gases are separated, refined and purified by achieving the energy gradient utilization in the gas separation, refinement and purification process and achieving the circulation operation, where adsorption, desorption and regeneration are easily matched and balanced, in the moderate to low cold and moderate to high temperature pressure swing adsorption separation process, and it is changed that a traditional adsorption method is only limited to the auxiliary effect of refinement and purification, and adsorption becomes the basic separation unit operation just as important as refinement, absorption and extraction separation.

Owner:SICHUAN TECHAIRS

Flow control through plural, parallel connecting channels to/from a manifold

InactiveUS20060275185A1Chemical/physical/physico-chemical microreactorsSemiconductor/solid-state device manufacturingControl flowStream flow

The invention provides apparatuses and techniques for controlling flow between a manifold and two or more connecting microchannels. Flow between plural connecting microchannels, that share a common manifold, can be made more uniform by the use of flow straighteners and distributors that equalize flow in connecting channels. Alternatively, flow can be made more uniform by sections of narrowed diameter within the channels. Methods of making apparatus and methods of conducting unit operations in connecting channels are also described.

Owner:VELOCYS CORPORATION

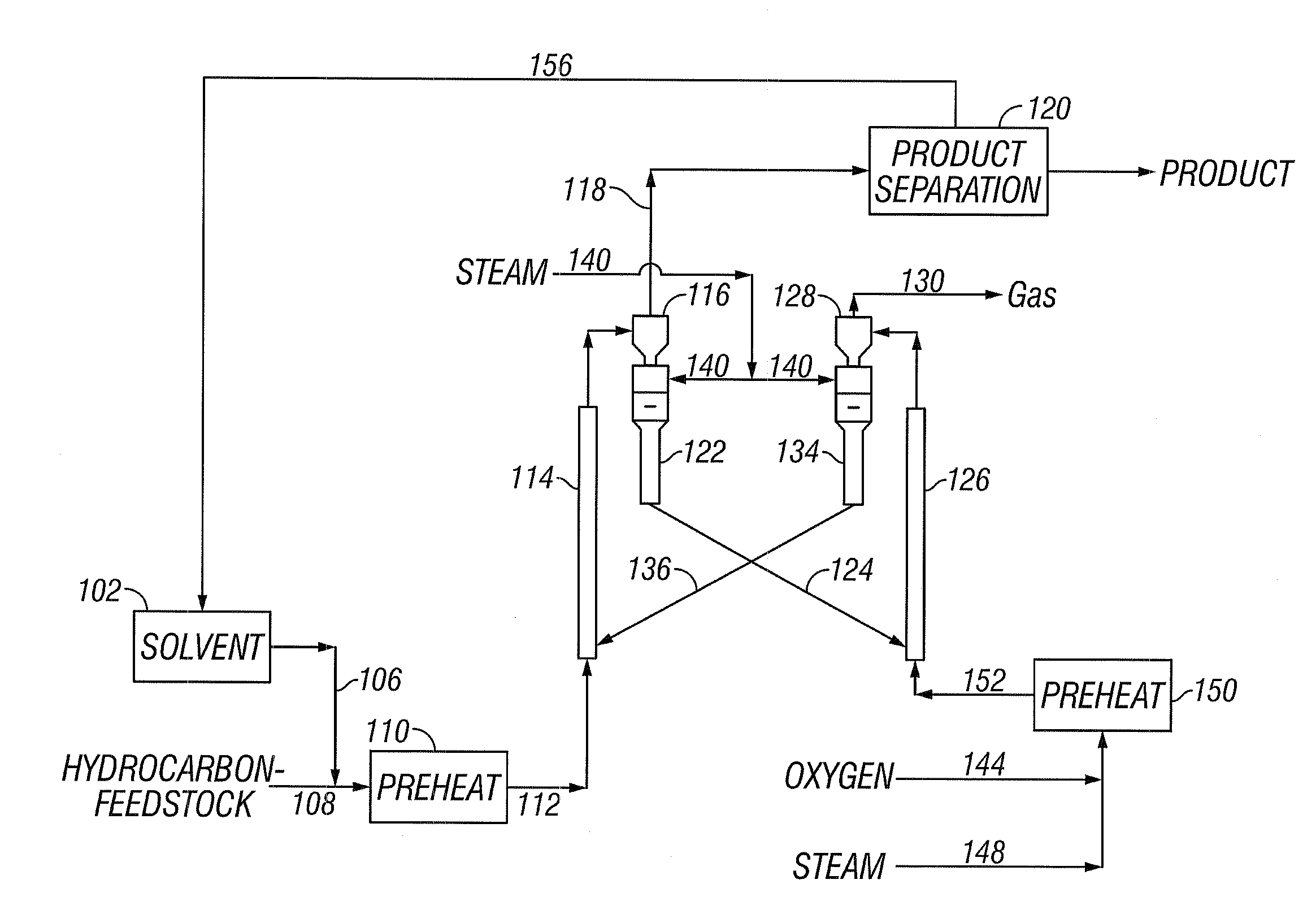

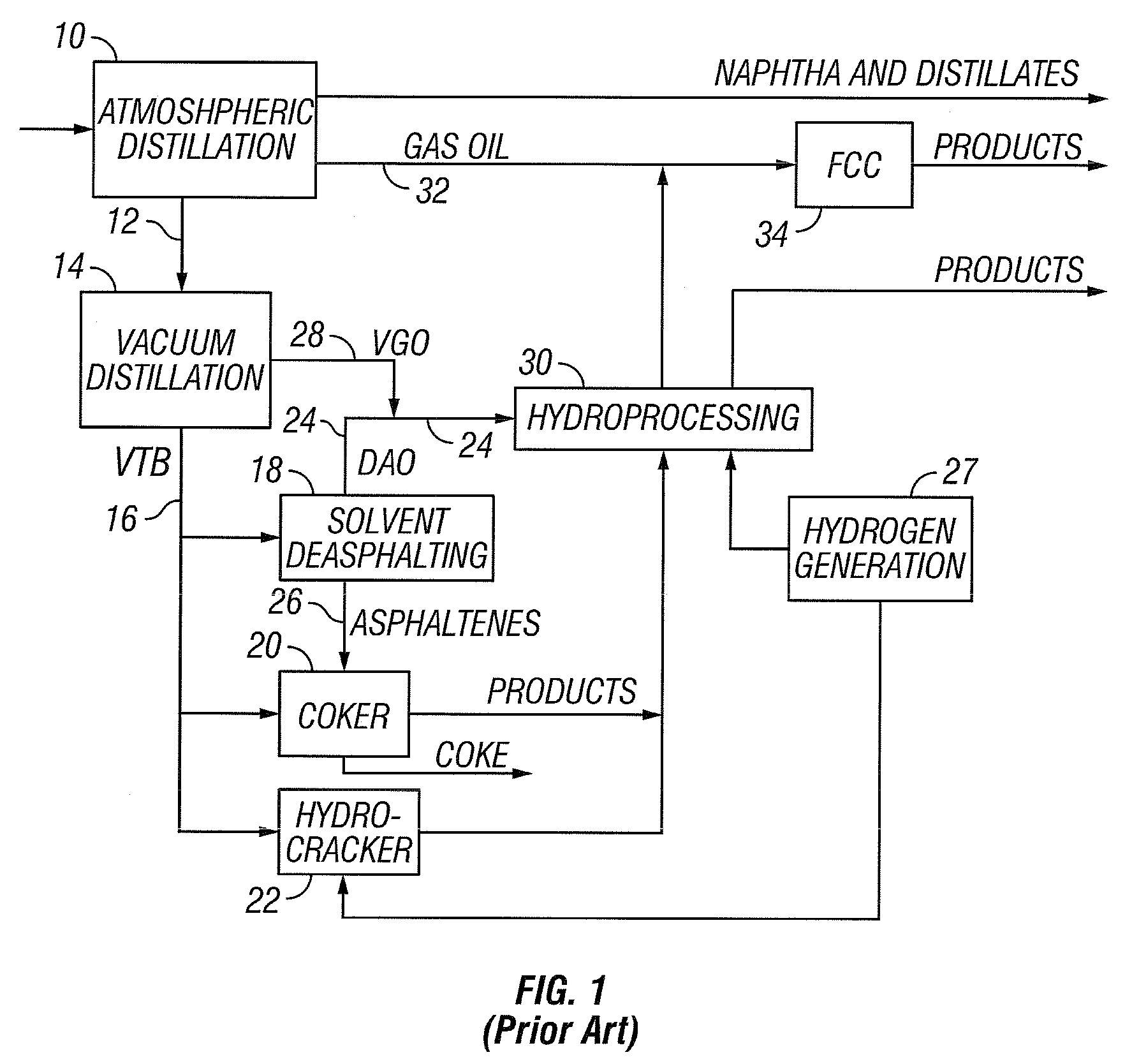

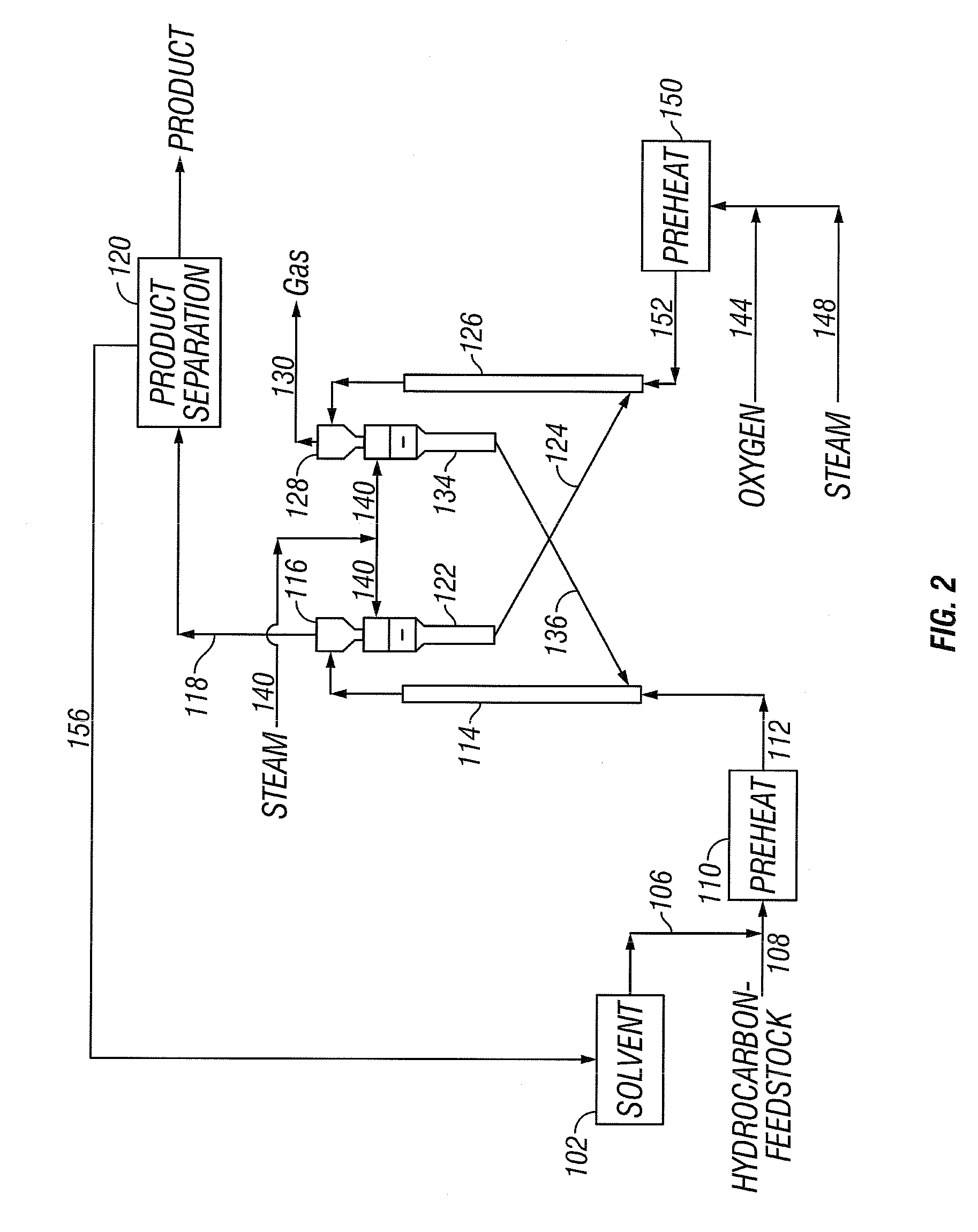

Supercritical hydrocarbon conversion process

ActiveUS7144498B2Thermal non-catalytic crackingTreatment with plural serial cracking stages onlyReaction temperatureUnit operation

Supercritical conversion of hydrocarbons boiling above 538° C. (1000° F.) with a solvating hydrocarbon at a weight ratio of solvating hydrocarbon to high-boiling hydrocarbons of at least 2:1 and at conditions above the critical temperature and pressure of the high-boiling hydrocarbons-solvent mixture, in the presence of hot fluidized solids. The hydrocarbons are supplied to a reaction zone at a temperature below that of the hot solids supplied thereto, whereby the resulting hydrocarbons-solids suspension has a thermal equilibrium temperature corresponding to the reaction temperature. The conversion has high rates of sulfur, nitrogen and metals removal, nearly complete conversion to lower molecular weight products, high naphtha and distillate selectivity, and low coke formation. The supercritical conversion can replace crude distillation, vacuum distillation, solvent deasphalting, coking, hydrocracking, hydrotreating, and / or fluid catalytic cracking, and / or used in parallel with such unit operations for debottle-necking or increasing capacity.

Owner:KELLOGG BROWN & ROOT LLC

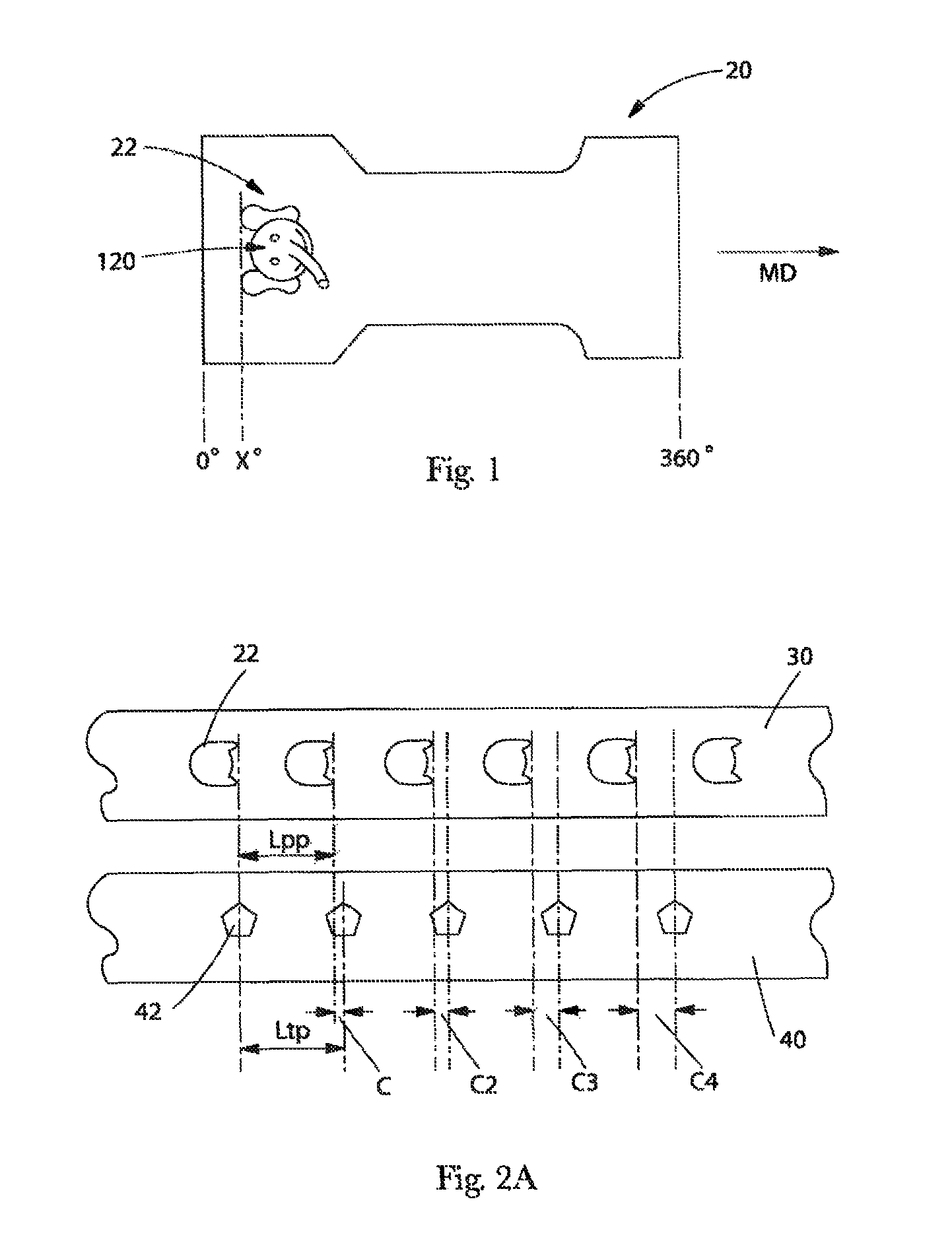

System and methods for registering a controlled web to a pitched unit operation

ActiveUS8244393B2Absorbent padsTesting/calibration of speed/acceleration/shock measurement devicesUnit operationWorld Wide Web

Owner:PROCTER & GAMBLE CO

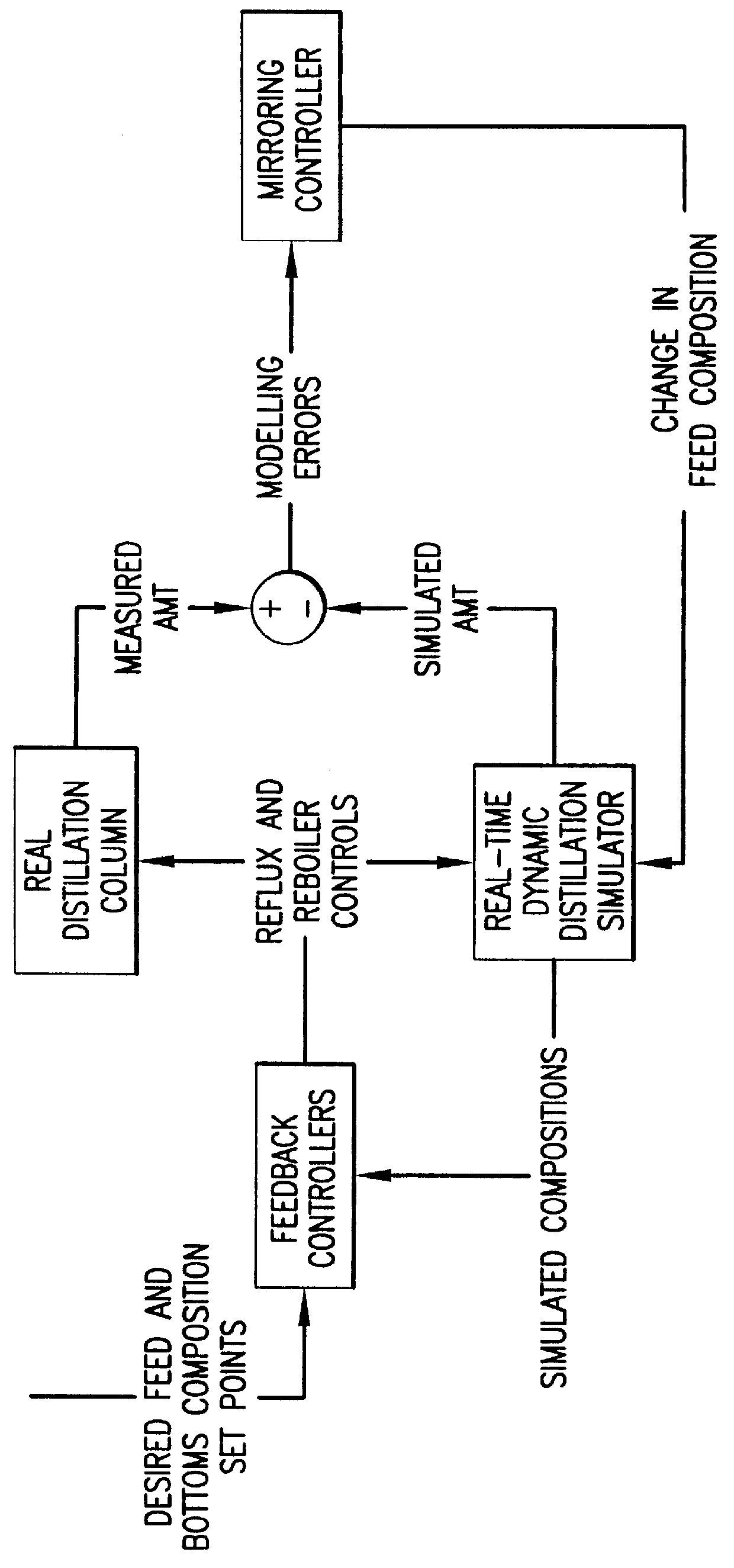

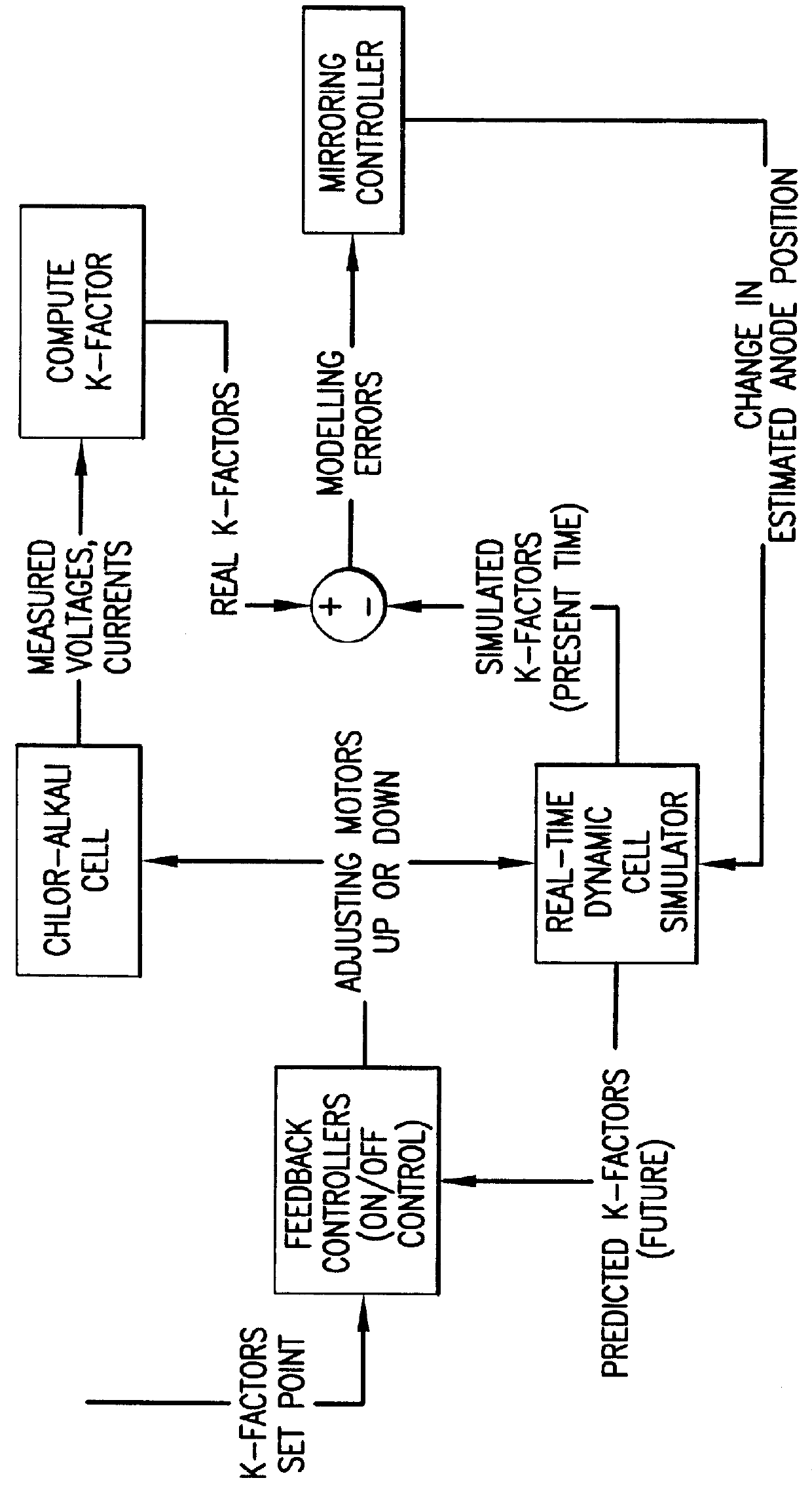

Automatic control system for unit operation

InactiveUS6088630AImprove stabilityAccurate predictionSampled-variable control systemsPhotography auxillary processesAutomatic controlAutomatic train control

Automatic control systems, and corresponding processes, for controlling either an anode adjuster in a chlor / alkali cell or at least one average middle temperature of a distillation column wherein the combination of feedback control from at least one real unit operation variable and an embedded real-time dynamic simulation of that variable are used.

Owner:OLIN CORP

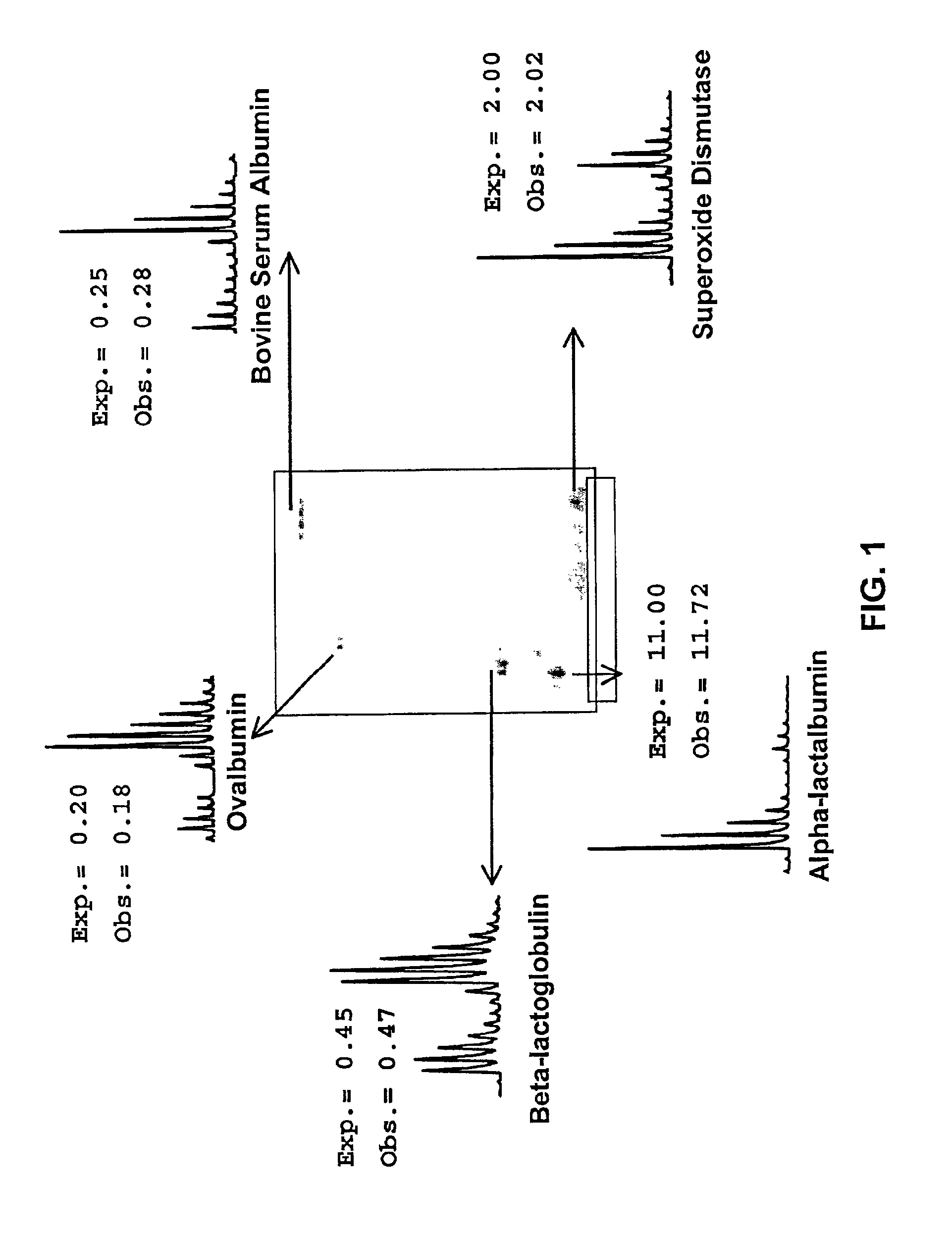

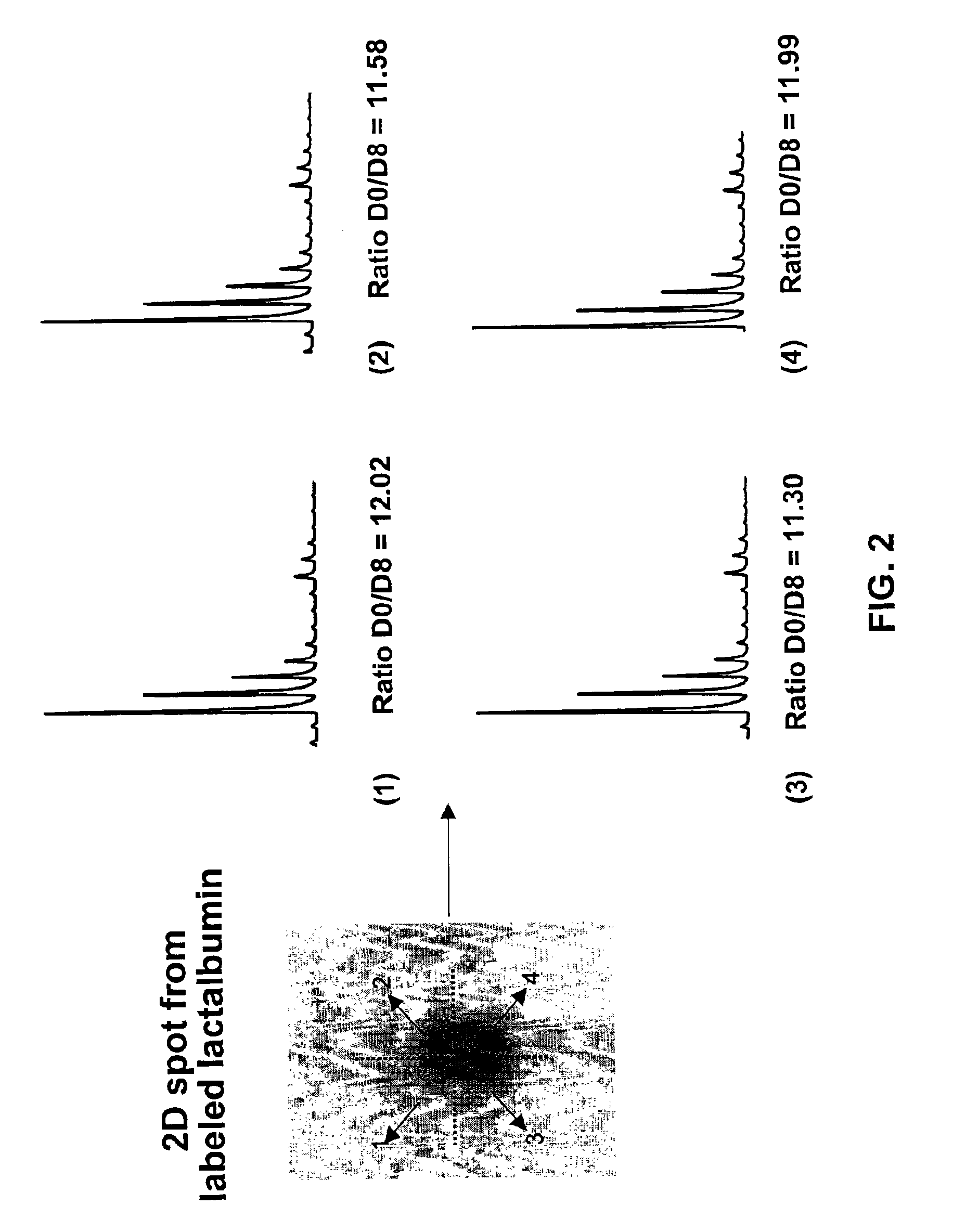

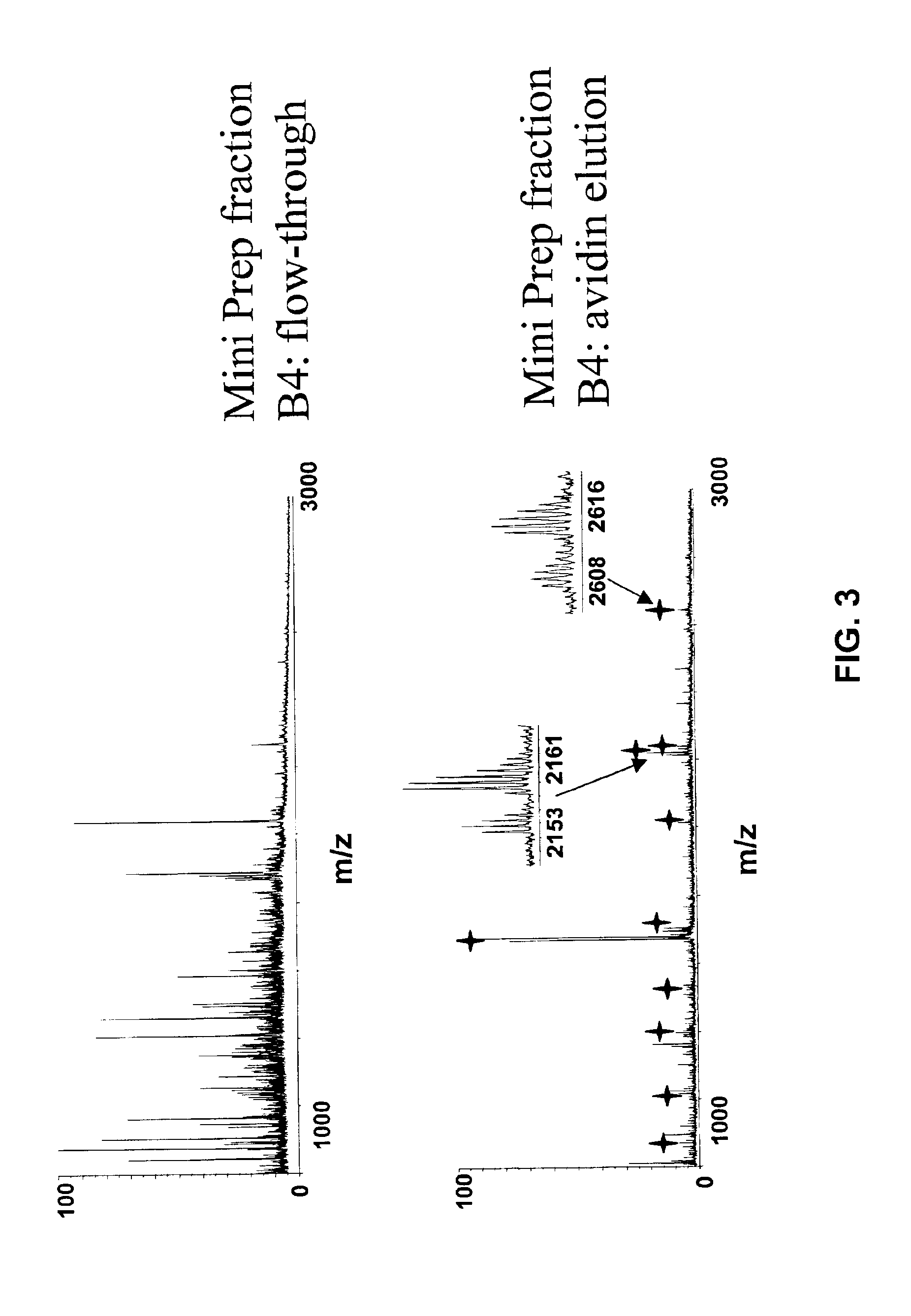

Process for analyzing protein samples

InactiveUS7045296B2Reduce disulfide bondEasy labelingSamplingMicrobiological testing/measurementProtein expression profileUnit operation

Methods using gel electrophoresis and mass spectrometry for the rapid, quantitative analysis of proteins or protein function in mixtures of proteins derived from two or more samples in one unit operation are disclosed. In one embodiment the method includes (a) preparing an extract of proteins from each of at least two different samples; (b) providing a set of substantially chemically identical and differentially isotopically labeled protein reagents; (c) reacting the extract of proteins from different samples of step (a) with a different isotopically labeled reagent from the set of step (b) to provide two or more sets of isotopically differentially labeled proteins; (d) mixing each of the two or more sets of isotopically labeled proteins to form a single mixture of isotopically differentially labeled proteins; (e) electrophoresing the mixture of step (d) by an electrophoresing method capable of separating proteins within the mixture; (f) digesting at least a portion of one or more separated proteins of step (e) and (g) detecting the difference in the expression levels of the proteins in the two samples by mass spectrometry based on one or more peptides in the sample of labeled peptides. The analytical method can be used for qualitative and particularly for quantitative analysis of global protein expression profiles in cells and tissues, i.e. the quantitative analysis of proteomes.

Owner:DH TECH DEVMENT PTE +1

Methods and apparatus for making particles using spray dryer and in-line jet mill

InactiveUS6921458B2Reduce processing timeDrying solid materials with heatGranulation by liquid drop formationPolymer scienceEmulsion

Methods and apparatus are provided for making particles comprising: (a) spraying an emulsion, solution, or suspension, which comprises a solvent and a bulk material (e.g., a pharmaceutical agent), through an atomizer and into a primary drying chamber, having a drying gas flowing therethrough, to form droplets comprising the solvent and bulk material dispersed in the drying gas; (b) evaporating, in the primary drying chamber, at least a portion of the solvent into the drying gas to solidify the droplets and form particles dispersed in drying gas; and (c) flowing the particles and at least a portion of the drying gas through a jet mill to deagglomerate or grind the particles. By coupling spray drying with “in-line” jet milling, a single step process is created from two separate unit operations, and an additional collection step is advantageously eliminated. The one-step, in-line process has further advantages in time and cost of processing.

Owner:ACUSPHERE INC

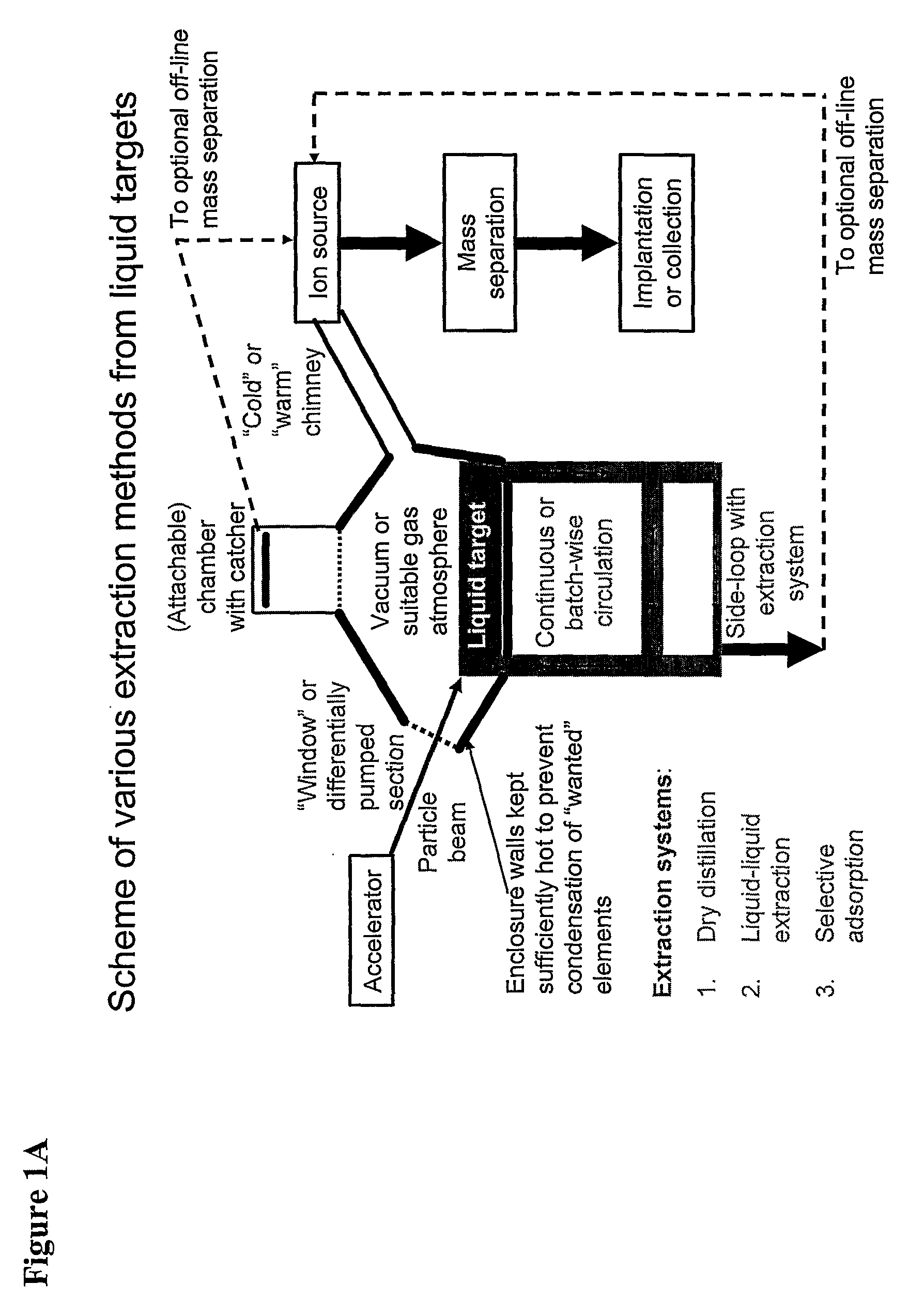

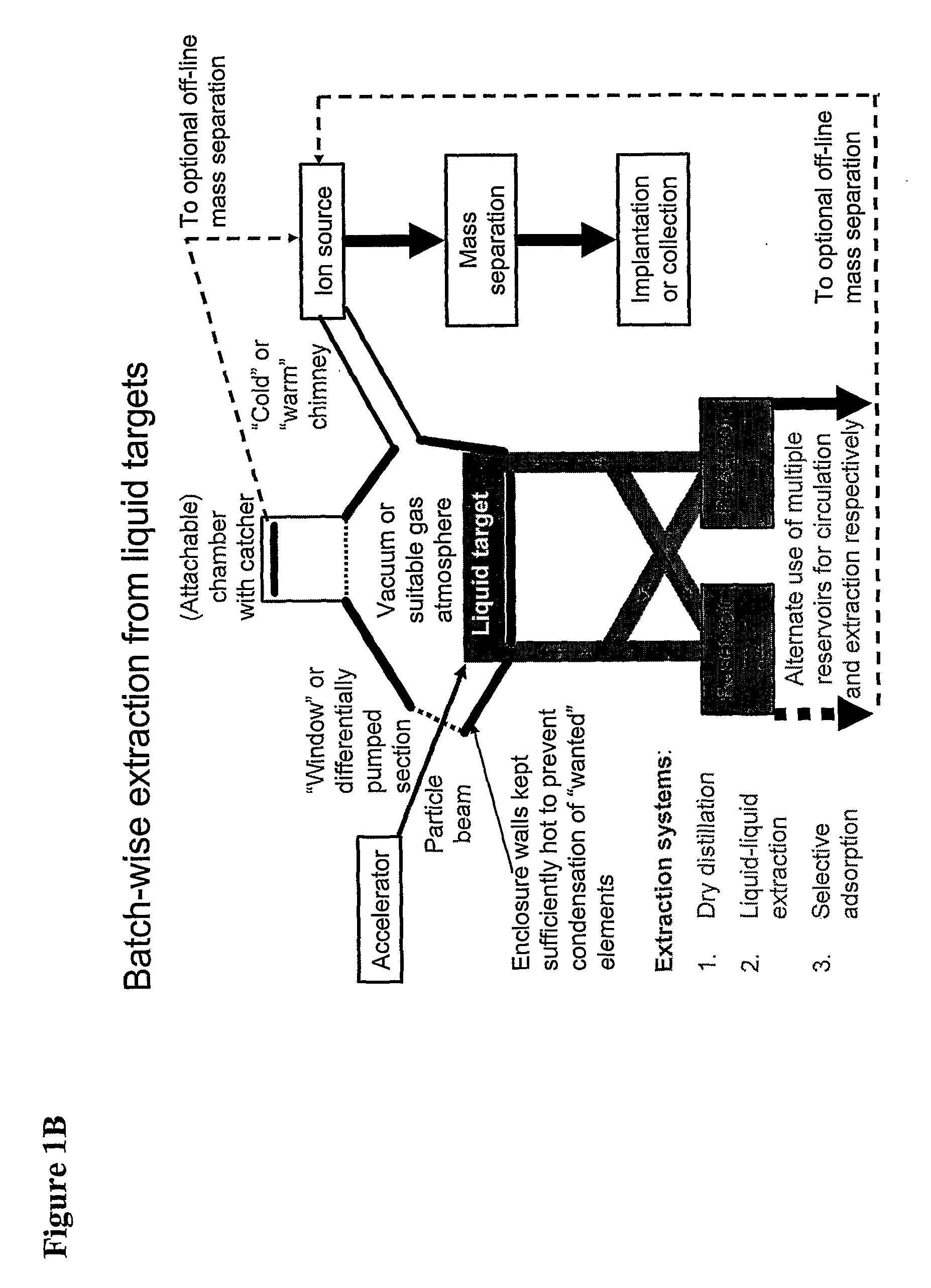

Method for Production of Radioisotope Preparations and Their Use in Life Science, Research, Medical Application and Industry

The present invention relates to an universal method for the large scale production of high-purity carrier free or non carrier added radioisotopes by applying a number of “unit operations” which are derived from physics and material science and hitherto not used for isotope production. A required number of said unit operations is combined, selected and optimised individually for each radioisotope production scheme. The use of said unit operations allows a batch wise operation or a fully automated continuous production scheme. The radioisotopes produced by the inventive method are especially suitable for producing radioisotope-labelled bioconjugates as well as particles, in particular nanoparticles and microparticles.

Owner:EUROPEAN ORGANIZATION FOR NUCLEAR RESEARCH +1

Multiuse reactors and related methods

InactiveUS20120231504A1Bioreactor/fermenter combinationsPeptide/protein ingredientsUnit operationProduct gas

Owner:THERAPEUTIC PROTEINS INT

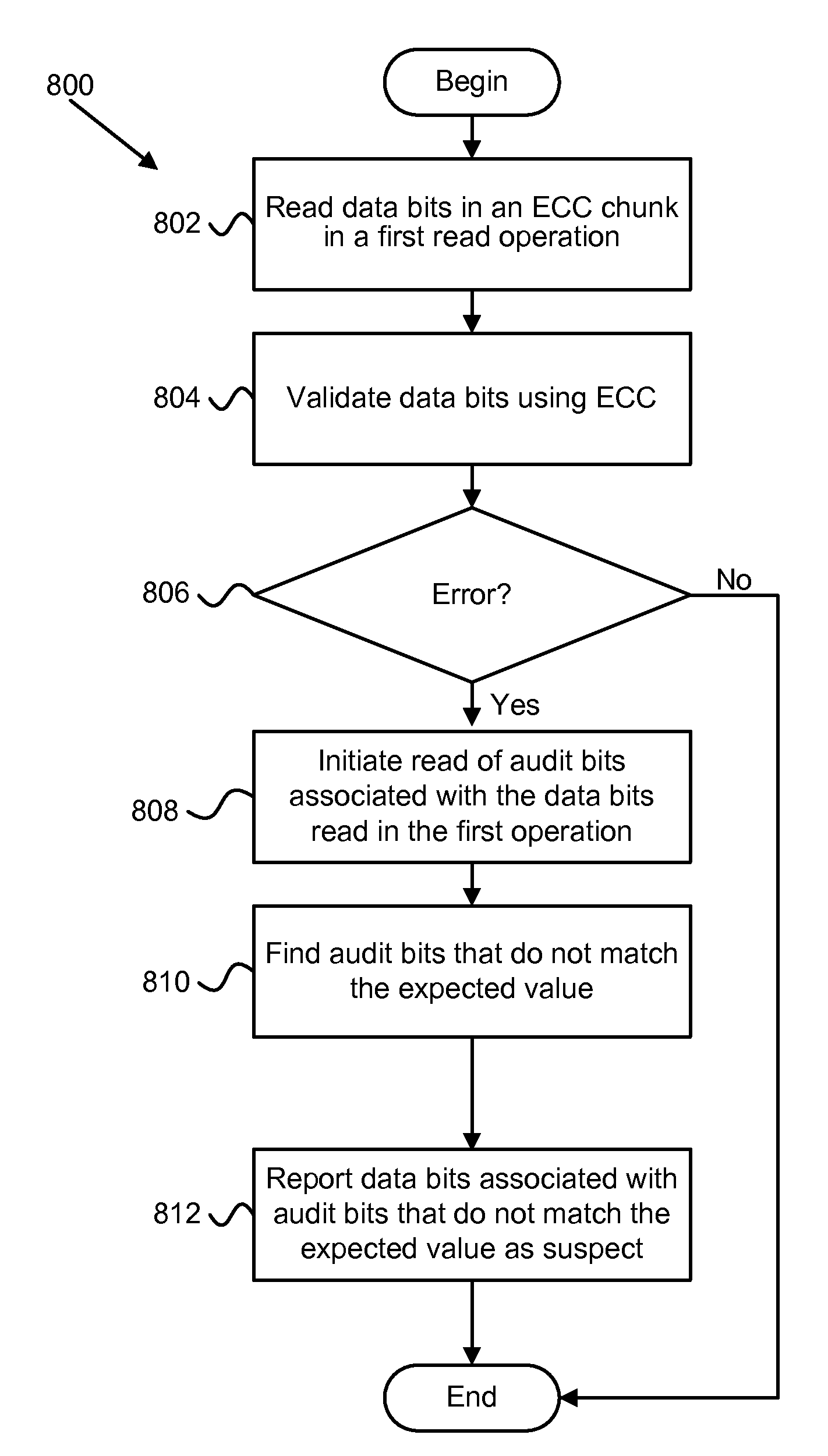

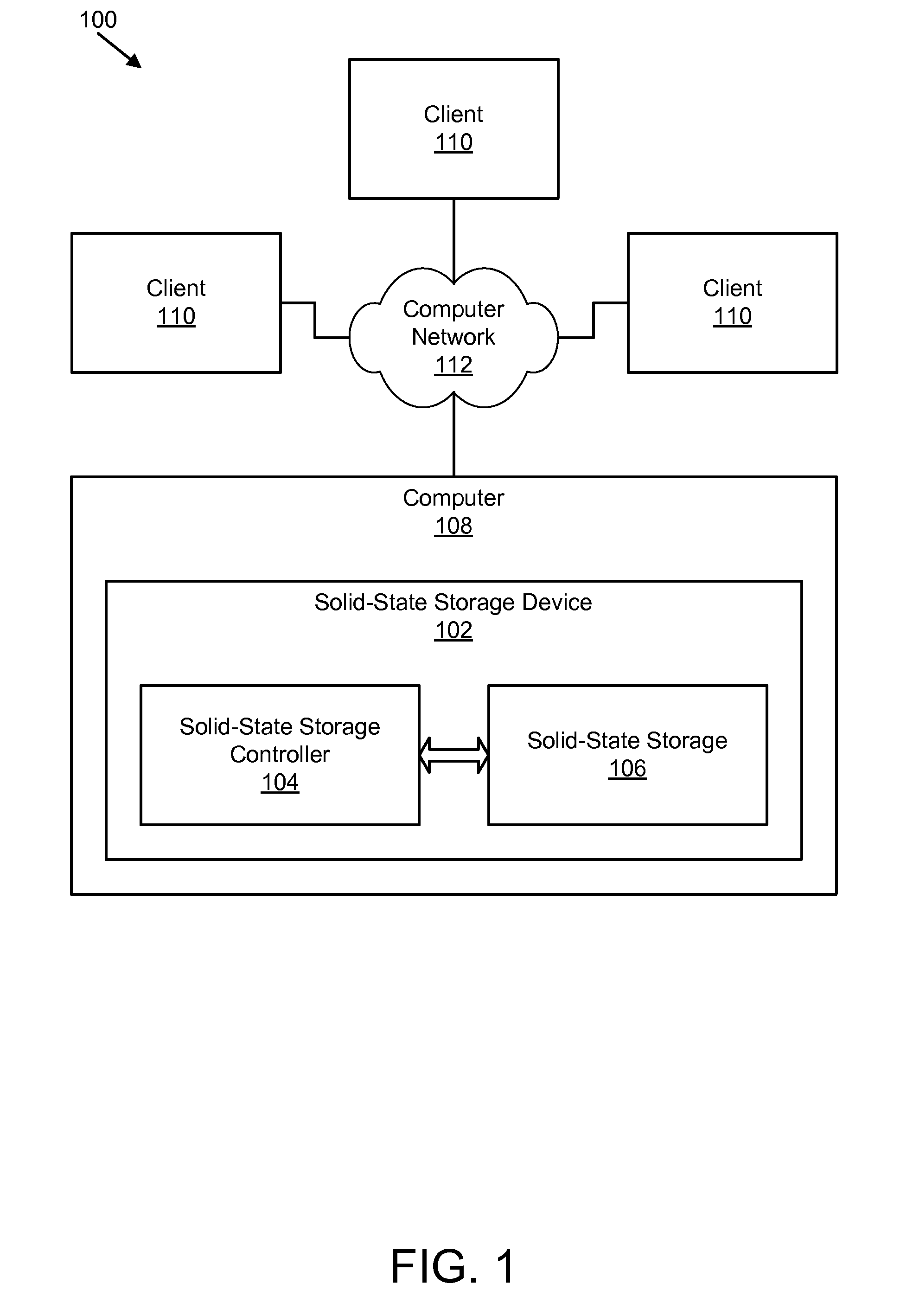

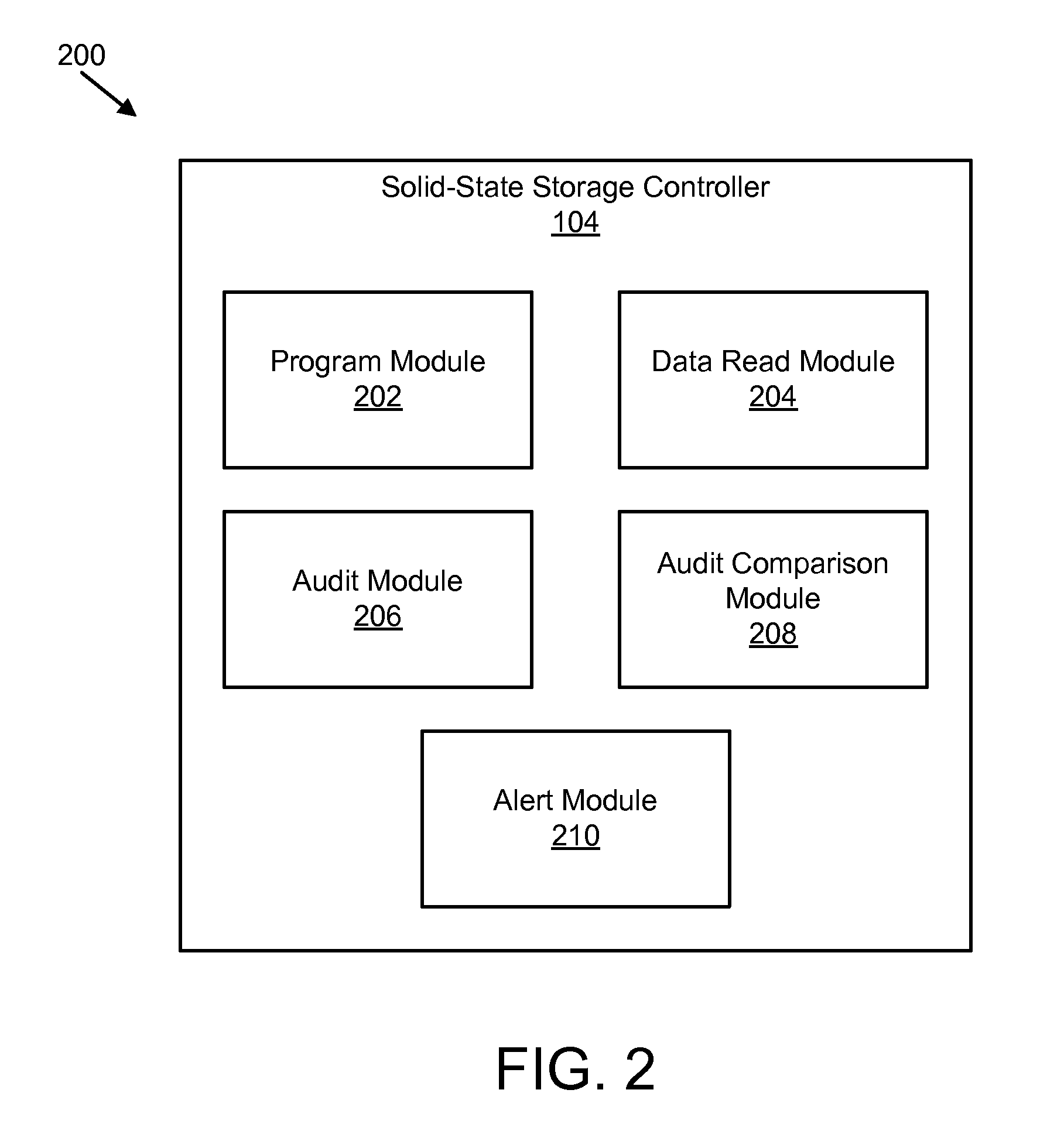

Apparatus, system, and method for using multi-level cell solid-state storage as single-level cell solid-state storage

ActiveUS20100235715A1Increase guard bandLow reliabilityMemory loss protectionRead-only memoriesSolid-state storageMultilevel memory

An apparatus, system, and method are disclosed for storing information in a storage device that includes multi-level memory cells. The method involves storing data that is written to the storage device in the LSBs of the multi-level memory cells, and storing audit data in the MSBs of the multi-level memory cells. The audit data can be read separately from the data and used to determine whether or not there has been any unintended drift between states in the multi-level cells. The audit data may be used to correct data when the errors in the data are too numerous to be corrected using error correction code (ECC). The audit data may also be used to monitor the general health of the storage device. The monitoring process may run as a background process on the storage device. The storage device may transition the multi-level memory cells to operate as single-level memory cells.

Owner:SANDISK TECH LLC

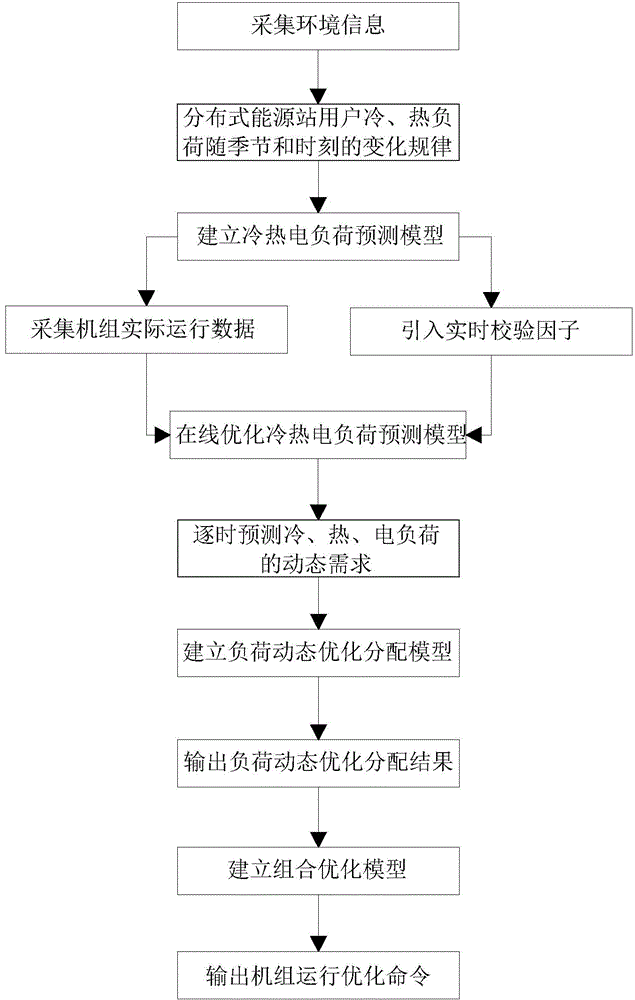

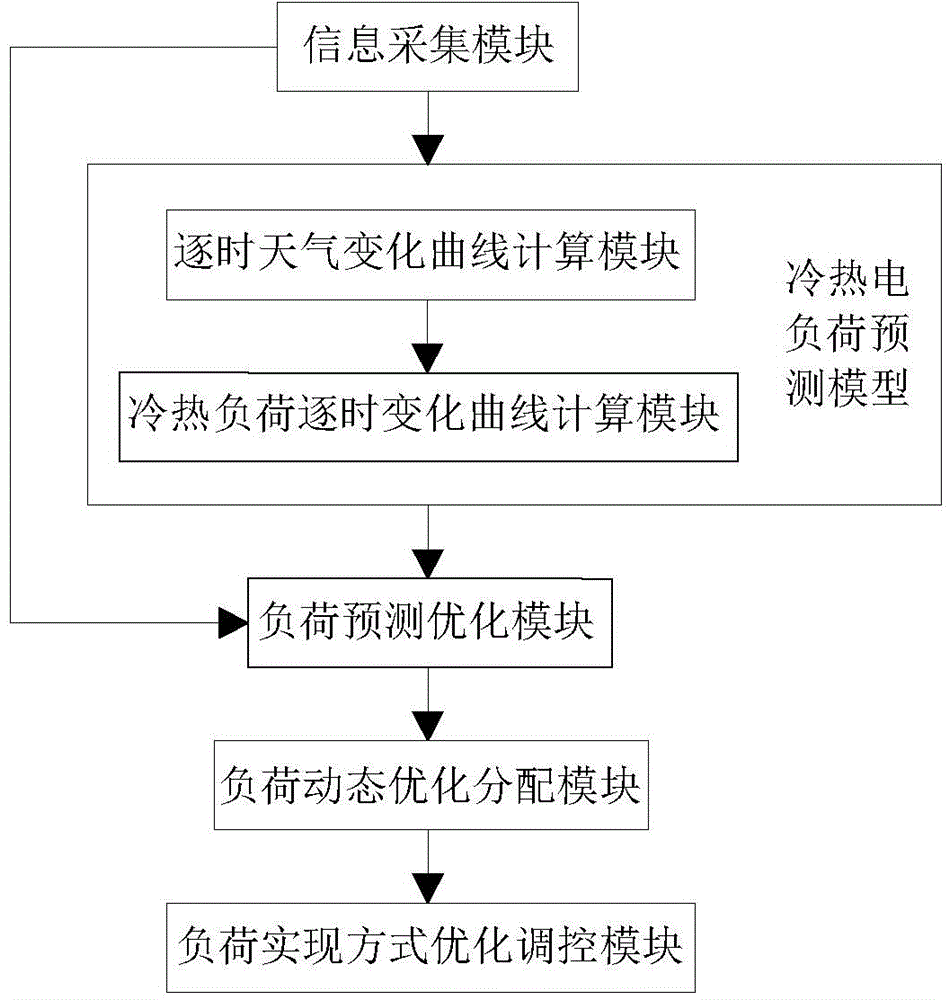

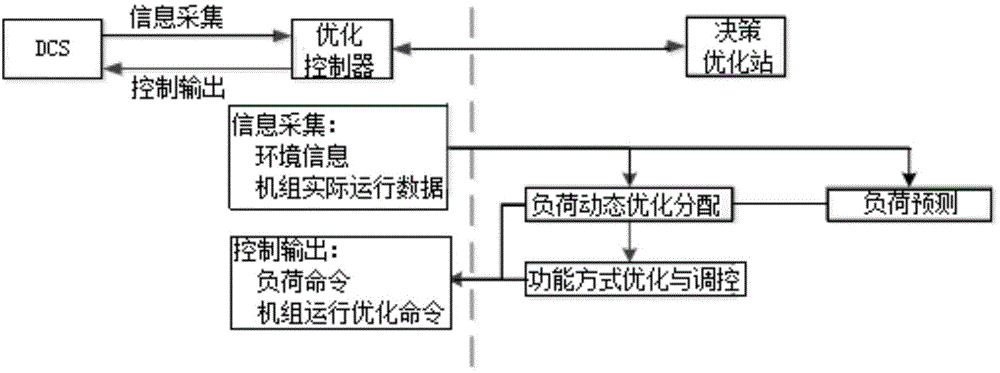

Optimized operation control method and system of distributed energy system

ActiveCN104571068AAchieve optimal allocationIncrease speedTotal factory controlProgramme total factory controlElectricityLoad forecasting

The invention discloses an optimized operation control method and system of a distributed energy system. The method include: S1, collecting environmental information and actual operation data of a unit so as to acquire a change rule of cold and hot load of a distributed energy station user with season and moment, and establishing a cold, hot and electric load prediction model; S2, optimizing the cold, hot and electric load prediction model on line by introducing real-time calibration factors and the actual operation data of the unit; S3, on the premise that the energy utilization efficiency is met, establishing a dynamic optimized load distribution model according to the dynamic requirements of the predicated cold, hot and electric load by taking a whole-plant economic benefit optimization as an objective, and outputting dynamic optimized load distribution results; S4, based on the whole-plant economic benefit optimization, establishing an optimal combination model according to the dynamic optimized load distribution results, and outputting a unit operation optimization command. High-precision load prediction information can be acquired, a corresponding optimization command is formed, and online optimization control is performed on the load dynamics and unit operation.

Owner:CHINA HUADIAN SCI & TECH INST

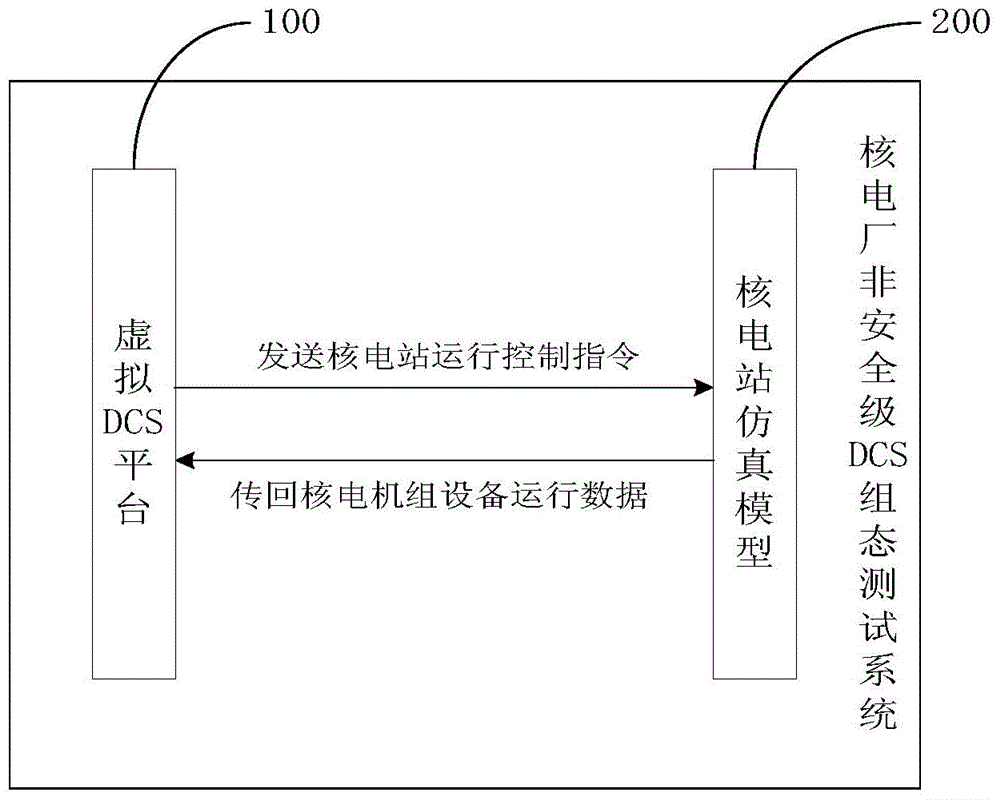

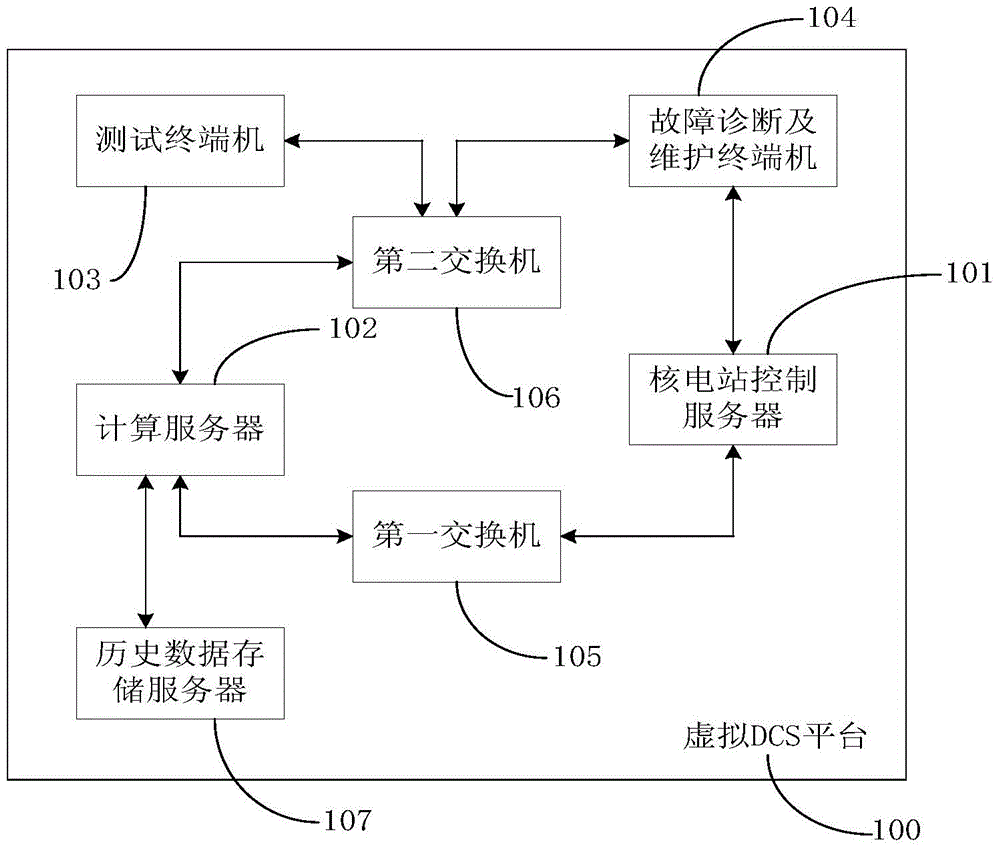

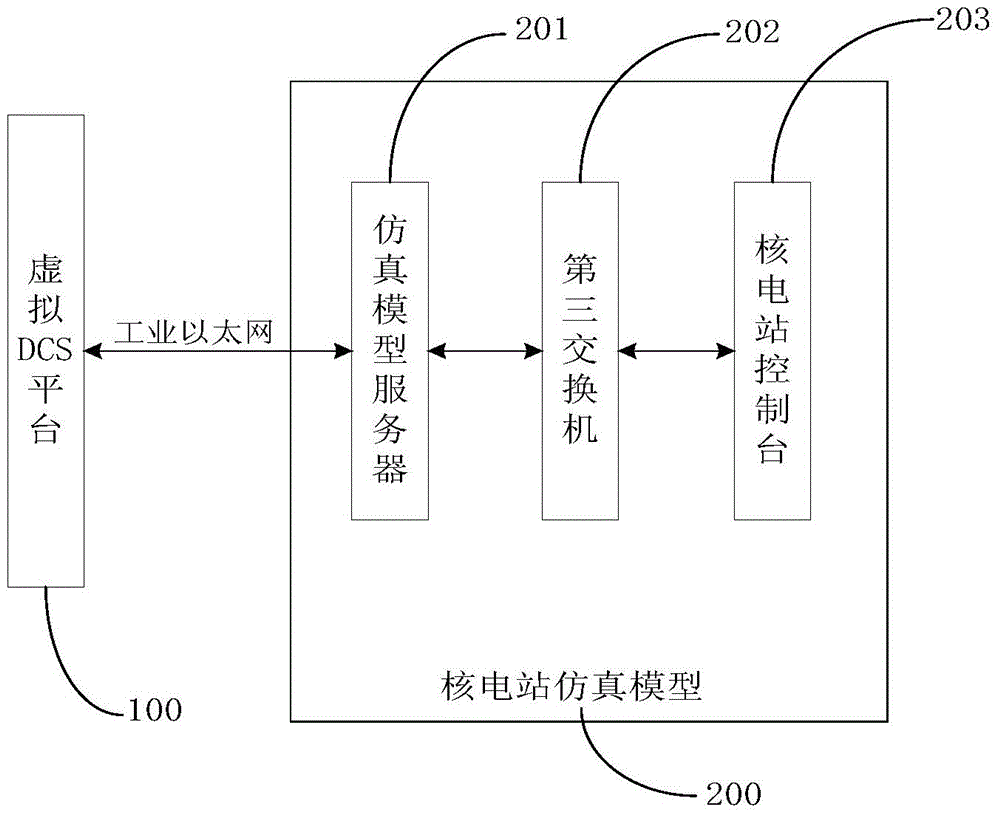

Nuclear power plant non-security-level DCS configuration testing method and system

ActiveCN104898633ALow input costSimple network structureTotal factory controlProgramme total factory controlNuclear powerNuclear engineering

The invention discloses a nuclear power plant non-security-level DCS configuration testing method and system comprising a virtual DCS platform and a nuclear power station simulating model coupled to the virtual DCS platform. The nuclear power station simulating model is used for, according to a nuclear power unit operation control instruction given by the virtual DCS platform, simulating the operation of a real nuclear power station, acquiring the operating data of the nuclear power unit, and returning the acquired data to the virtual DCS platform. The virtual DCS platform is used for, according to the operating data of the nuclear power unit, computing and analyzing the operating condition of the nuclear power unit in real time, evaluating a difference between an analyzed result and a designed operating condition, determining the correctness and the rationality of DCS configuration logic and parameters, giving corresponding logic modification and parameter optimization, and transplanting and applying a tested and modified result to the DCS configuration of a real nuclear power unit. The nuclear power plant non-security-level DCS configuration testing method and system may reduce the investment cost of the nuclear power station, shorten the construction period of nuclear power engineering, and decrease equipment loss.

Owner:中广核工程有限公司 +1

Method and system for storing field replaceable unit operational history information

InactiveUS6892159B2Thermometer detailsThermometers using material expansion/contactionUnit operationField replaceable unit

A method for tracking repair histories includes providing a field replaceable unit having a memory device. Operational history data is collected during the operation of the field replaceable unit. The operational history data is stored in the memory device. A computing system includes a field replaceable unit including a memory device configured to store operational history data associated with the field replaceable unit.

Owner:ORACLE INT CORP

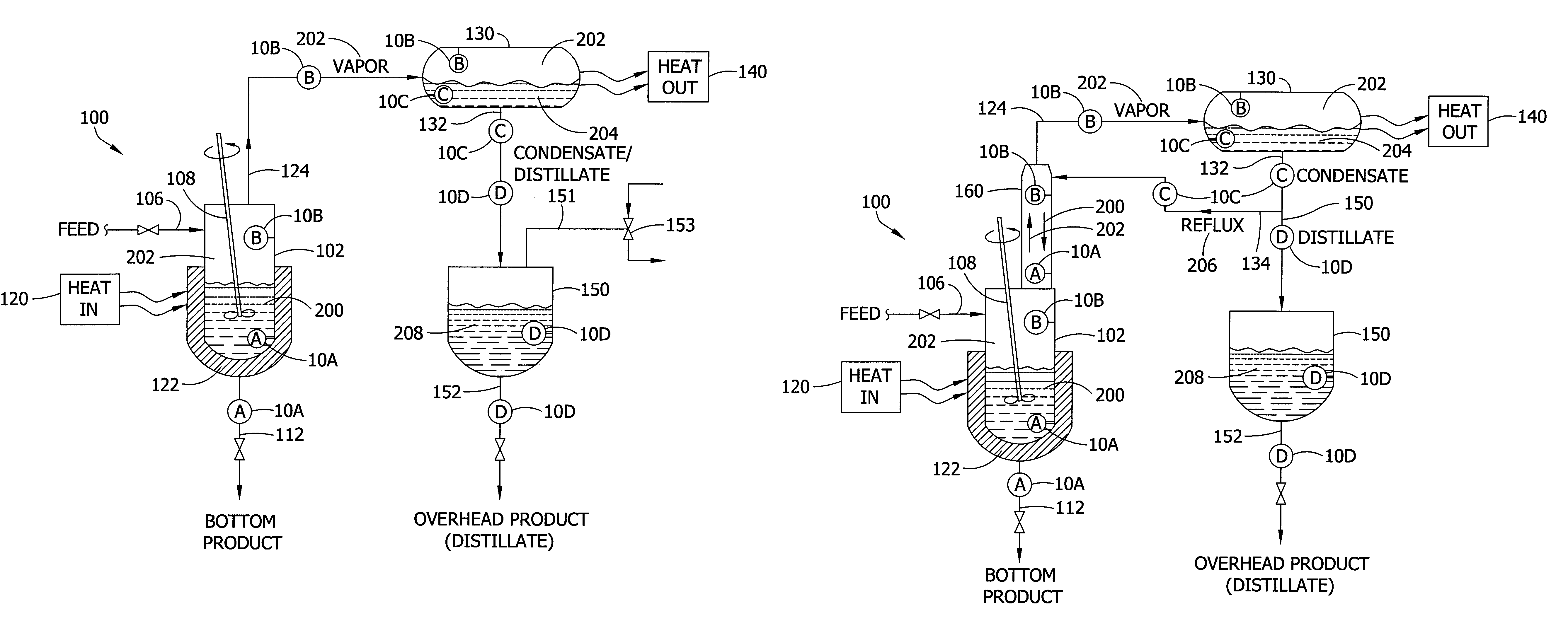

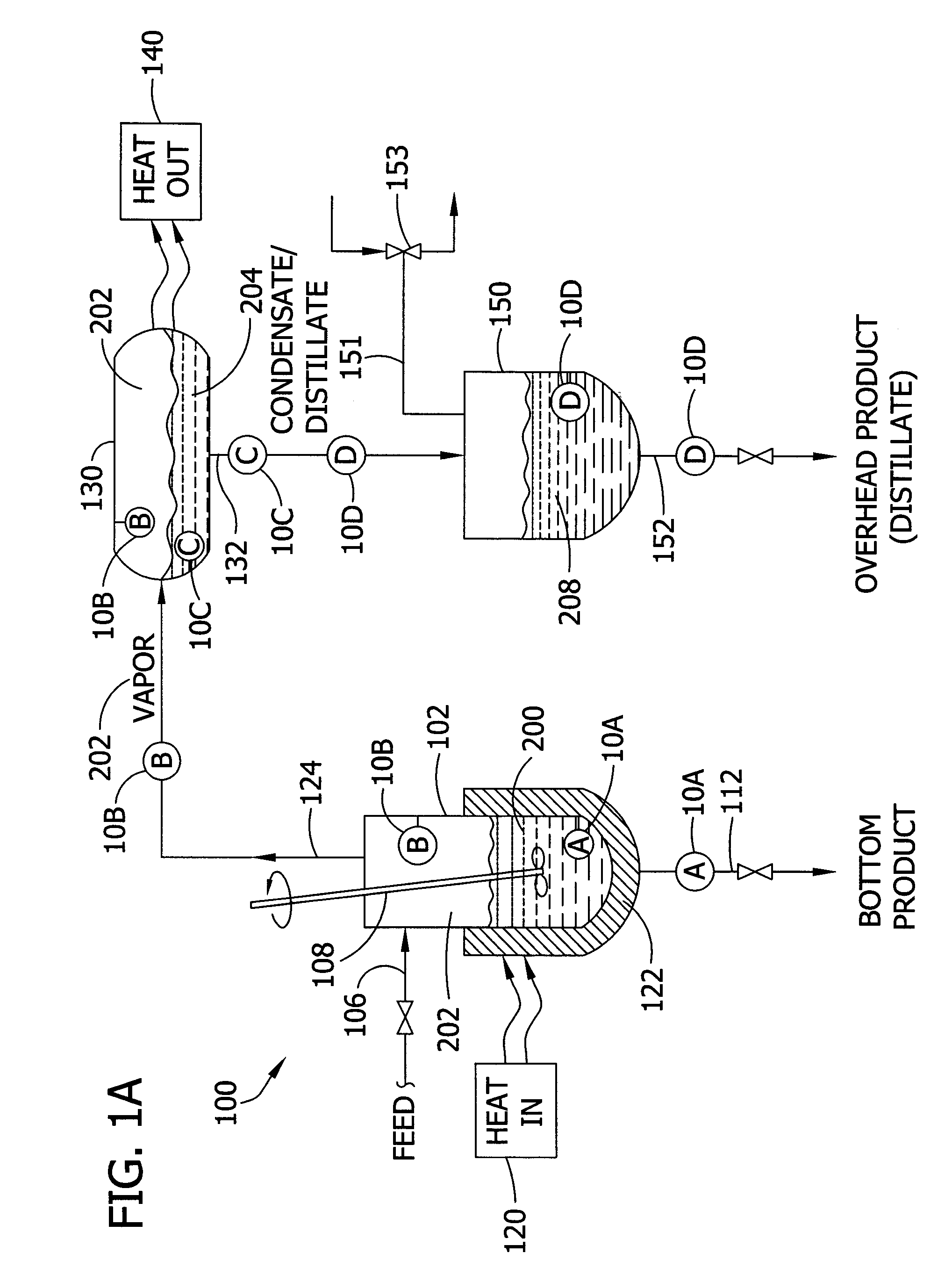

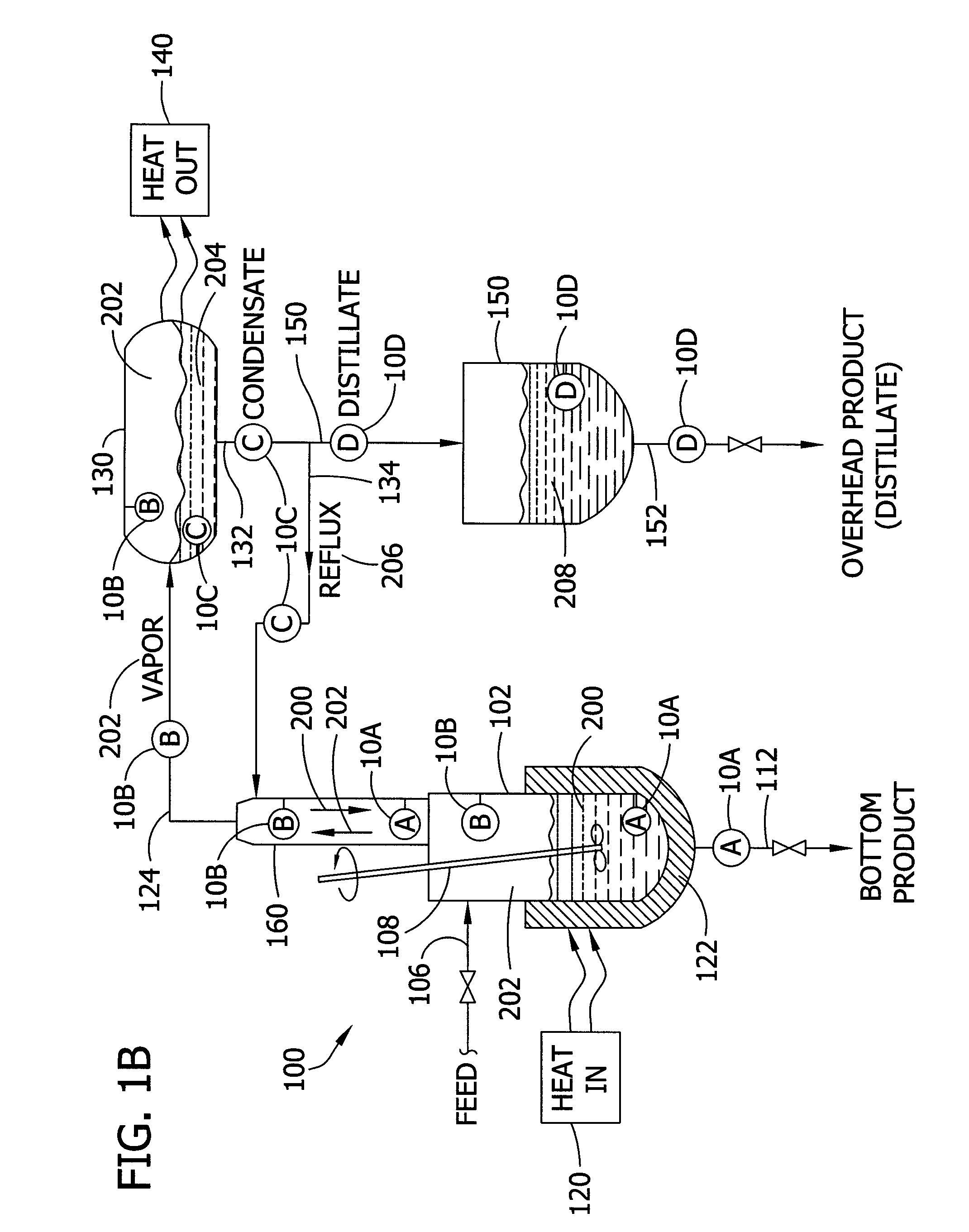

Systems for monitoring and controlling unit operations that include distillation

InactiveUS7603889B2High sensitivityHigh dielectric constantProcess control/regulationAnalysing solids using sonic/ultrasonic/infrasonic wavesDistillationUnit operation

Fluid sensor methods and systems adapted for monitoring and / or controlling distillation operations in fluidic systems, such as batch distillation operations or continuous distillation operations, are disclosed. Preferred embodiments are directed to process monitoring and / or process control for unit operations involving endpoint determination of a distillation, for example, as applied to a liquid-component-switching operation (e.g., a solvent switching operation), a liquid-liquid separation operation, a solute concentration operation, a dispersed-phase concentration operation, among others.

Owner:MEAS FRANCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com