Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1000 results about "Removal Units" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A Removal Unit (RMU) is a tradable carbon credit or 'Kyoto unit' representing an allowance to emit one metric tonne of greenhouse gases absorbed by a removal or Carbon sink activity in an Annex I country.

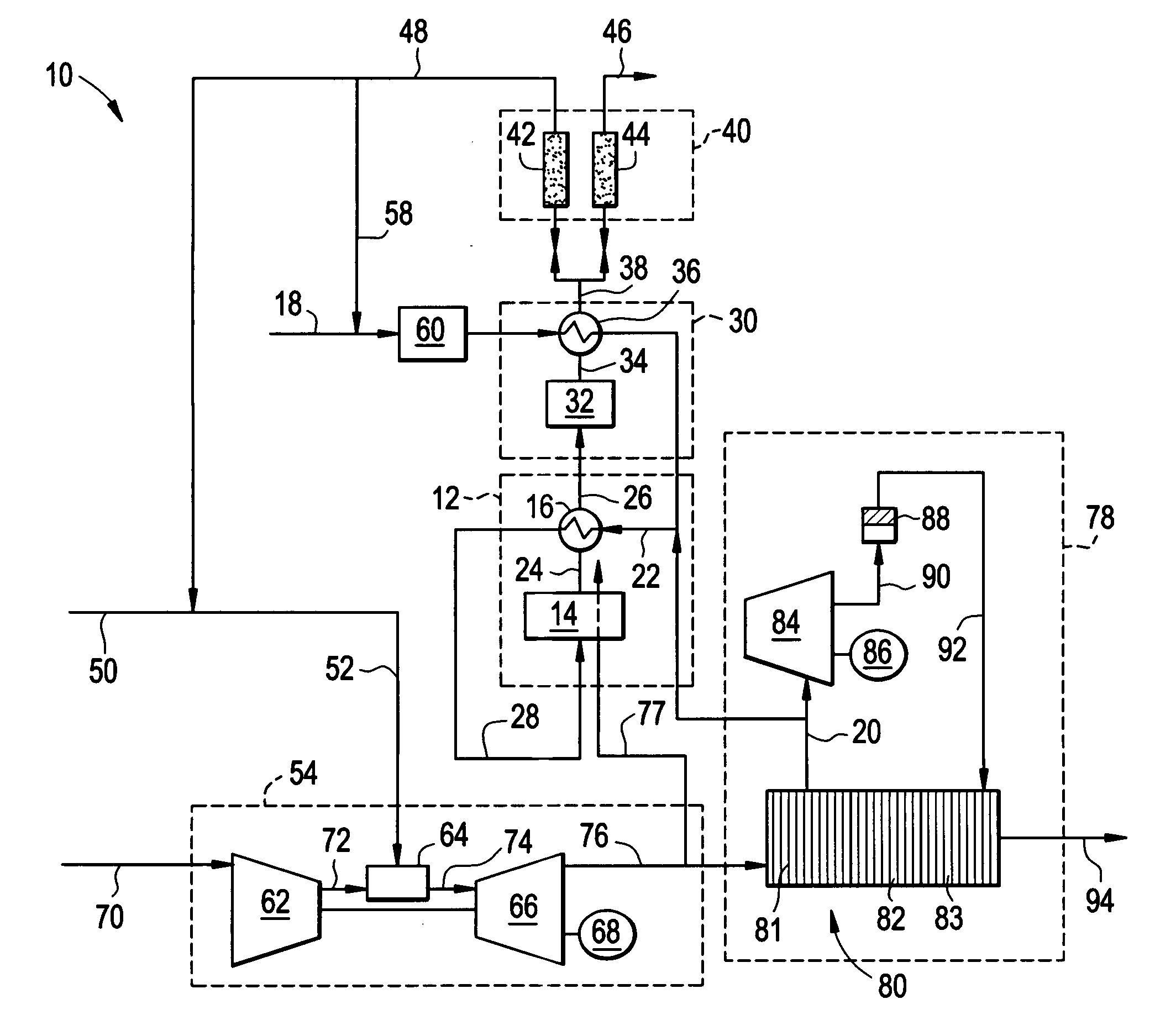

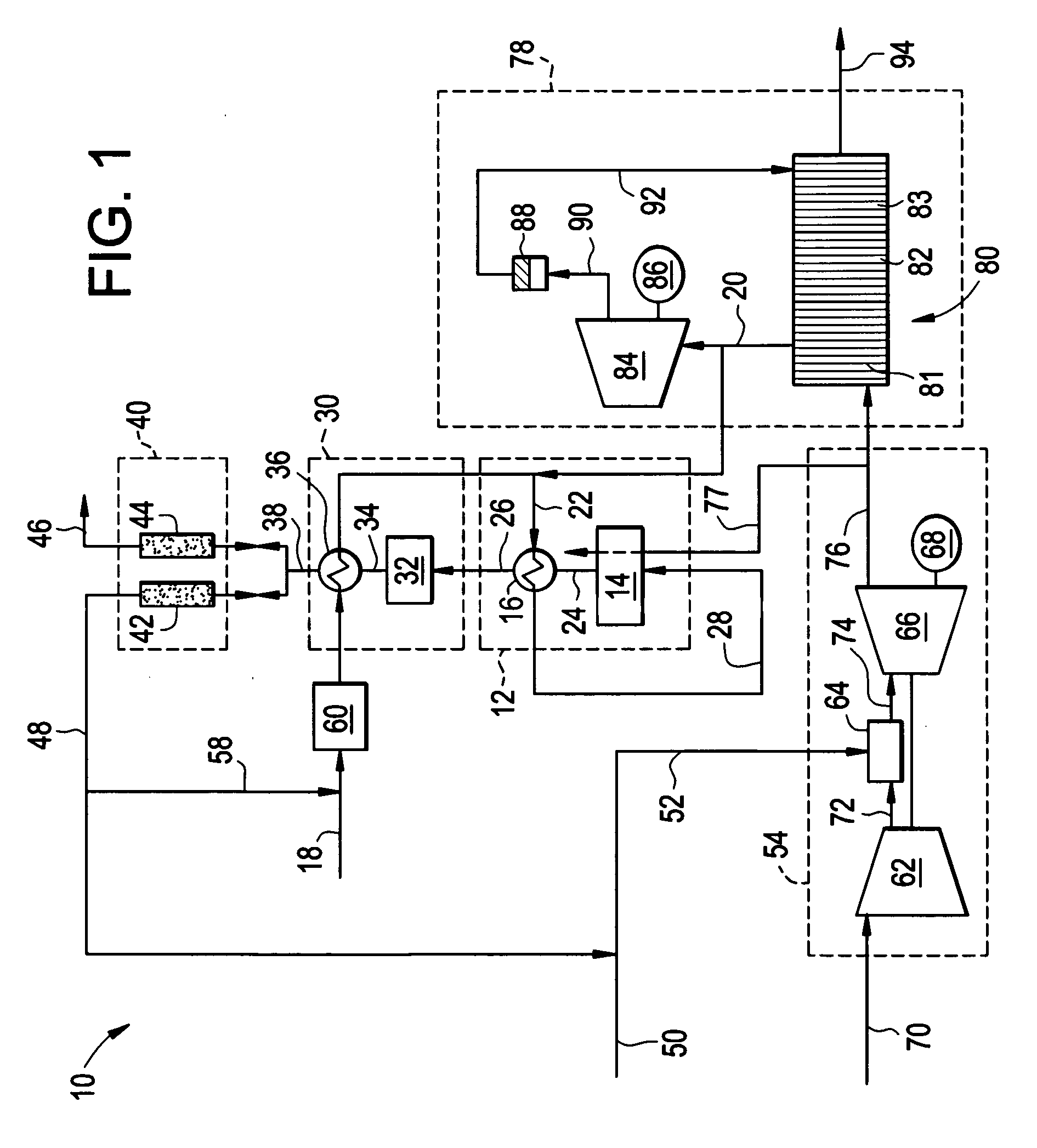

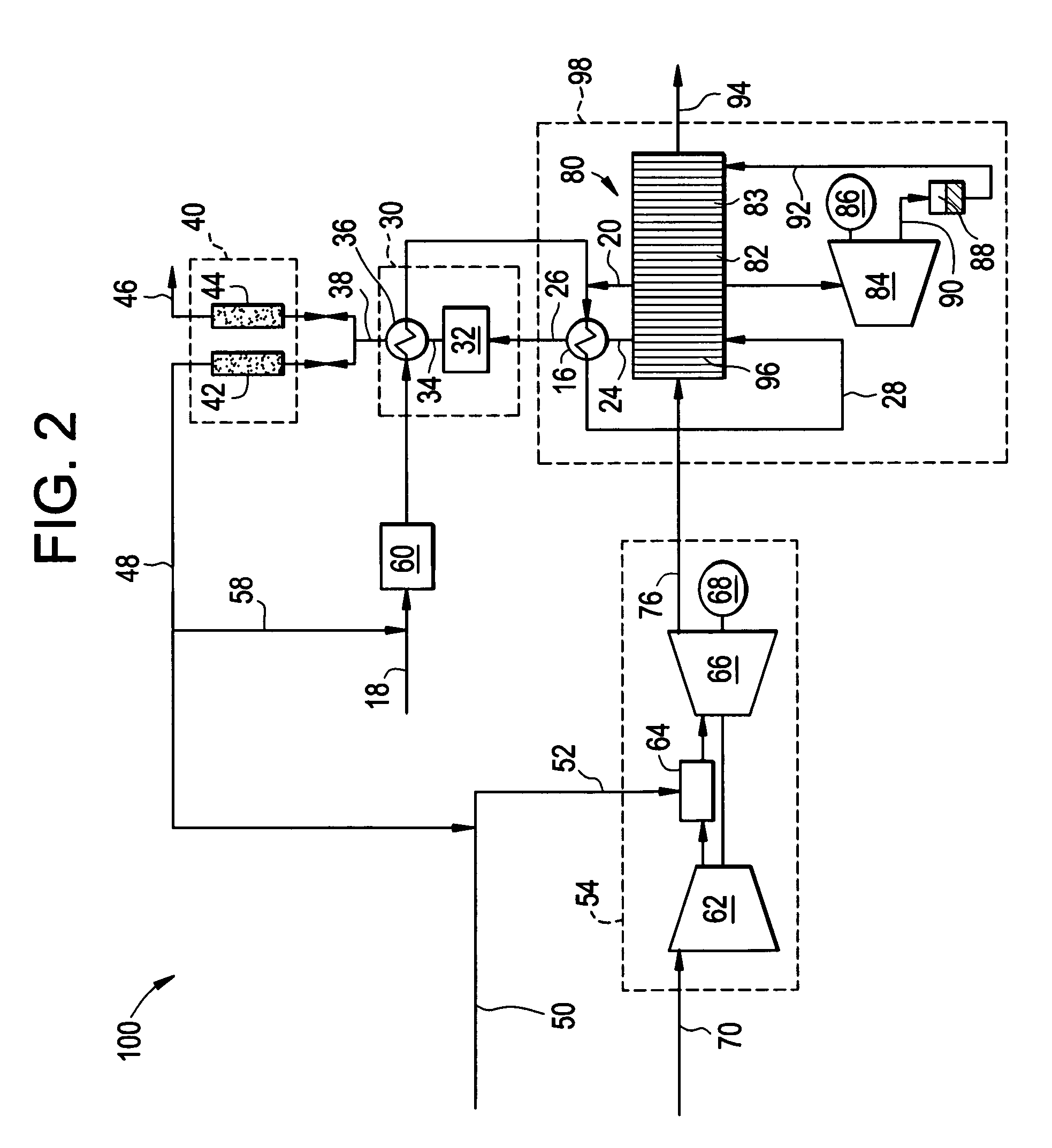

Reforming system for combined cycle plant with partial CO2 capture

A combined cycle system includes, a pre-steam-methane-reformer operating at a temperature of less than about 800 degrees Celsius to reform a mixed fuel stream to generate a first reformate stream, a water-gas-shift reactor to convert carbon monoxide in the first reformate stream to carbon dioxide and form a second reformate stream, a carbon dioxide removal unit for removing carbon dioxide from the second reformate stream and form a carbon dioxide stream and a third reformate stream; wherein less than about 50 percent of the carbon contained in the mixed fuel stream is recovered as carbon dioxide by the removal unit, a gas turbine unit for generating power and an exhaust stream, and a steam generator unit configured to receive the exhaust stream, wherein the heat of the exhaust stream is transferred to a water stream to generate the steam for the mixed fuel stream and for a steam turbine.

Owner:GENERAL ELECTRIC CO

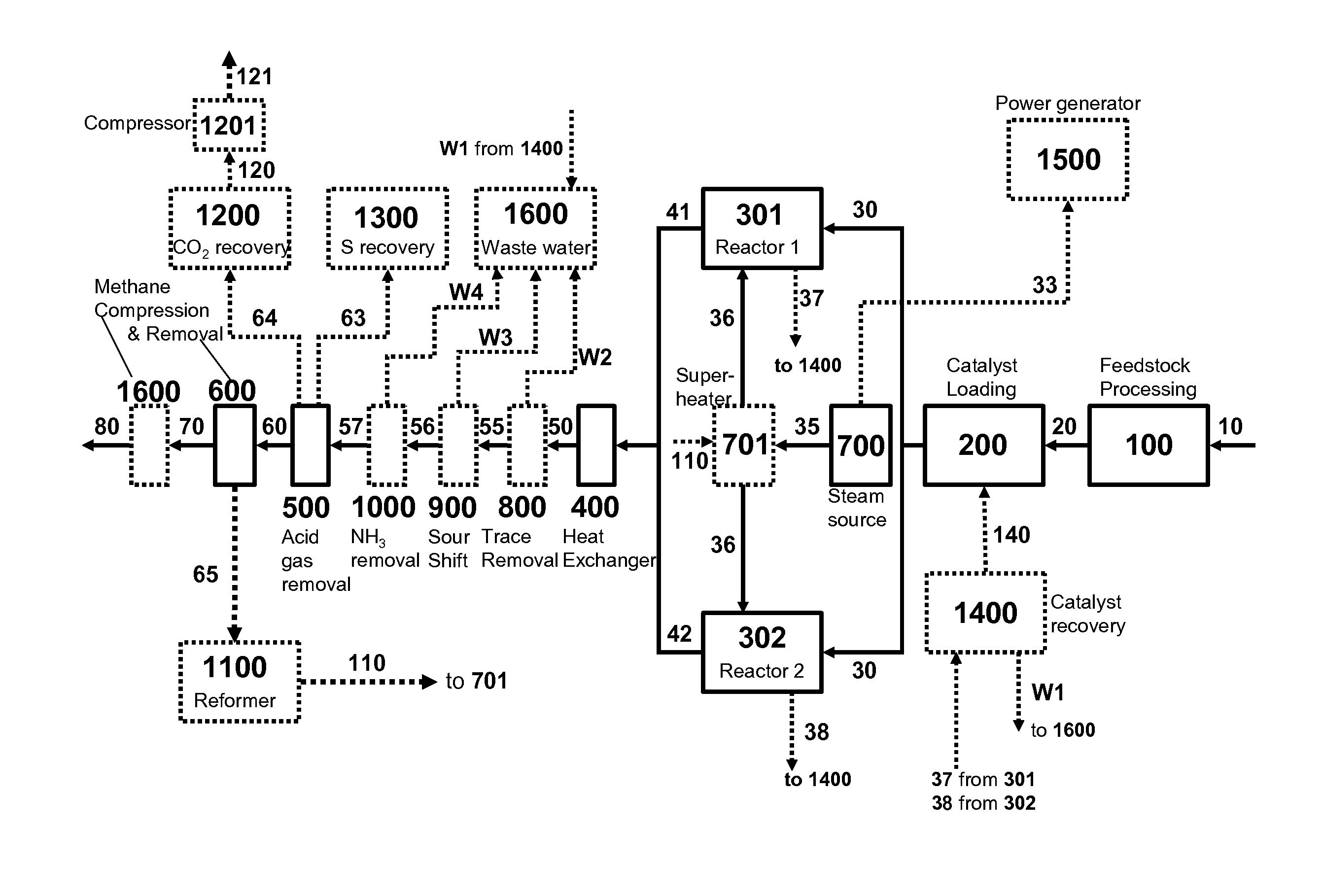

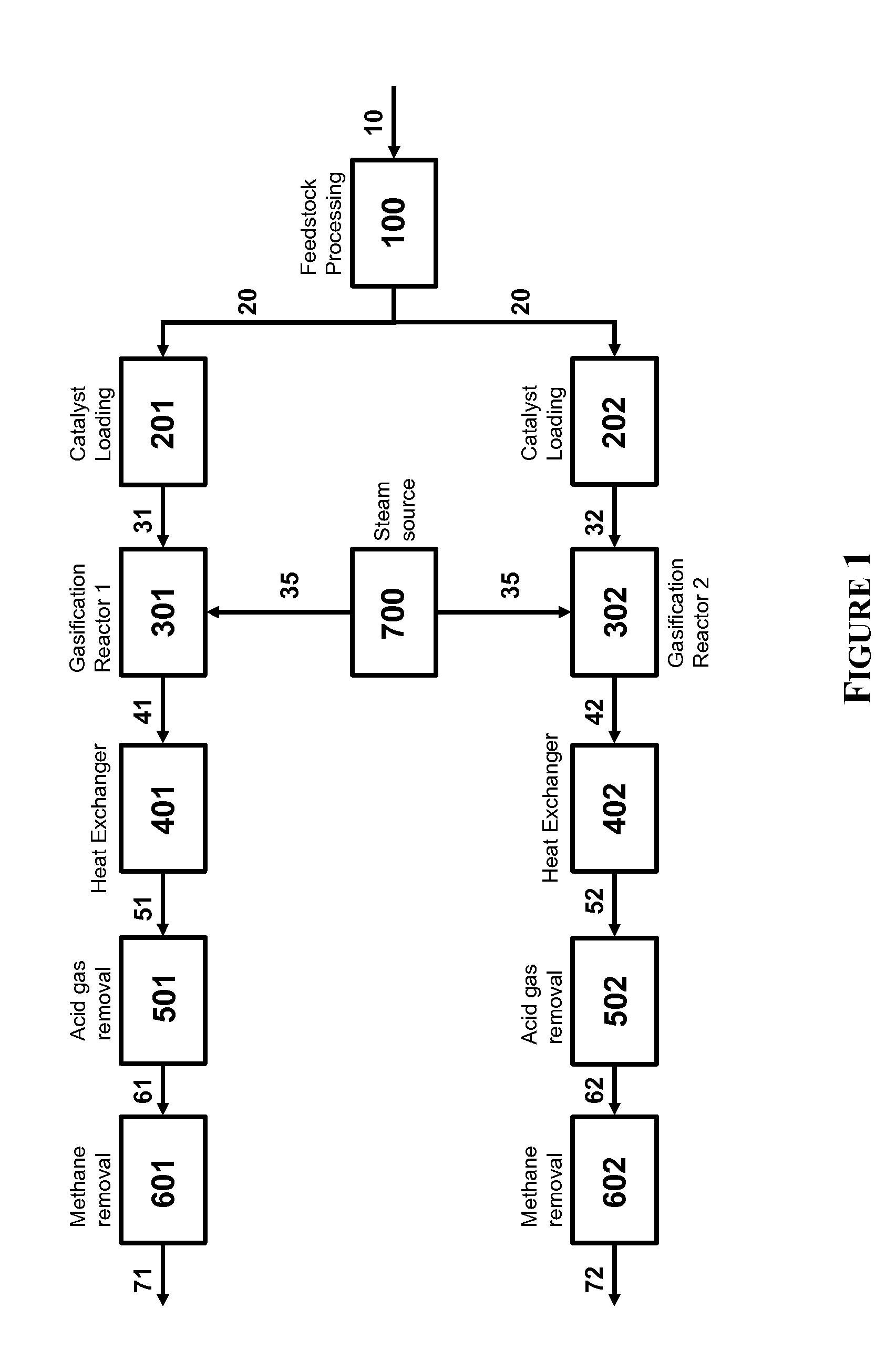

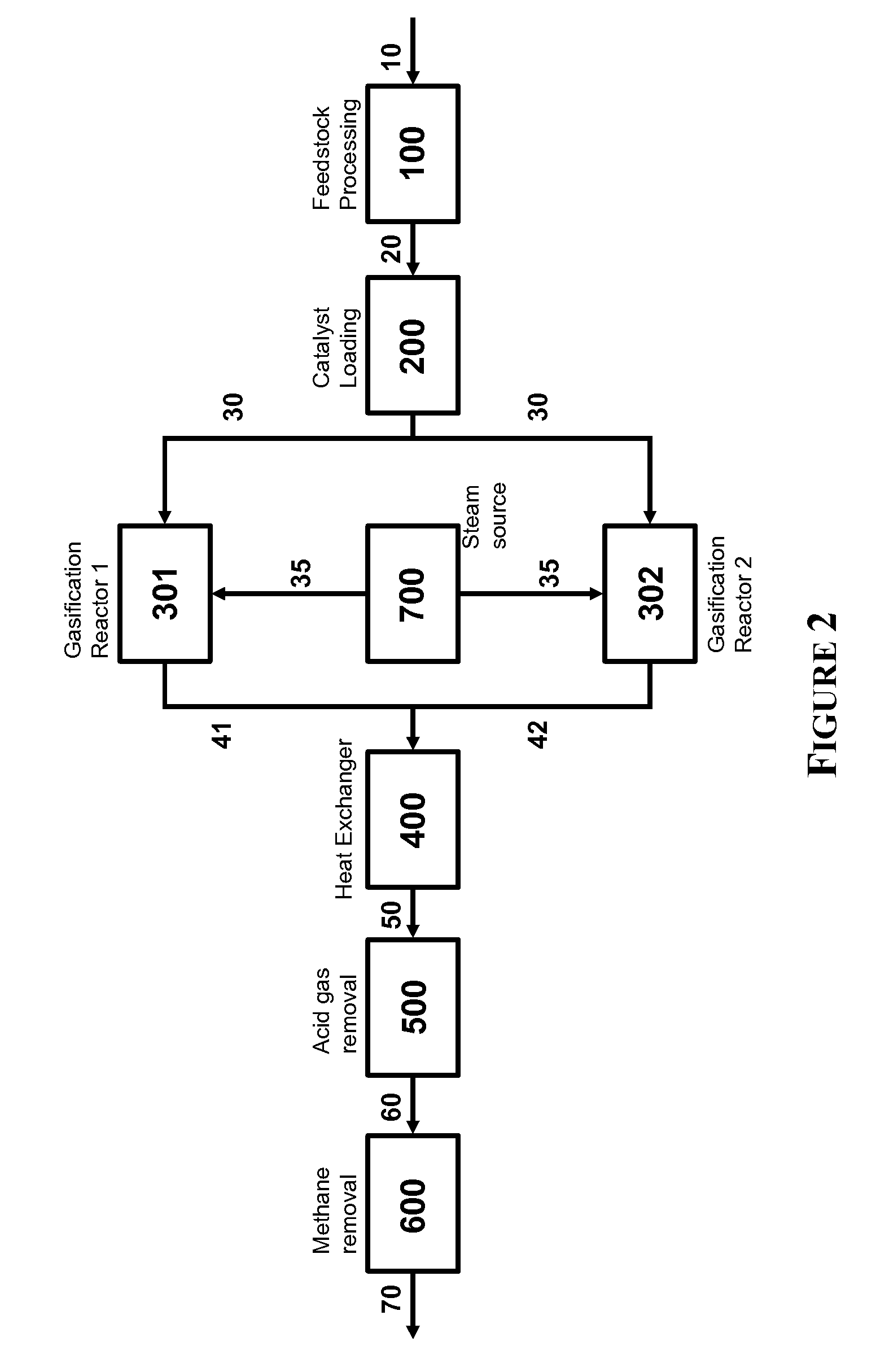

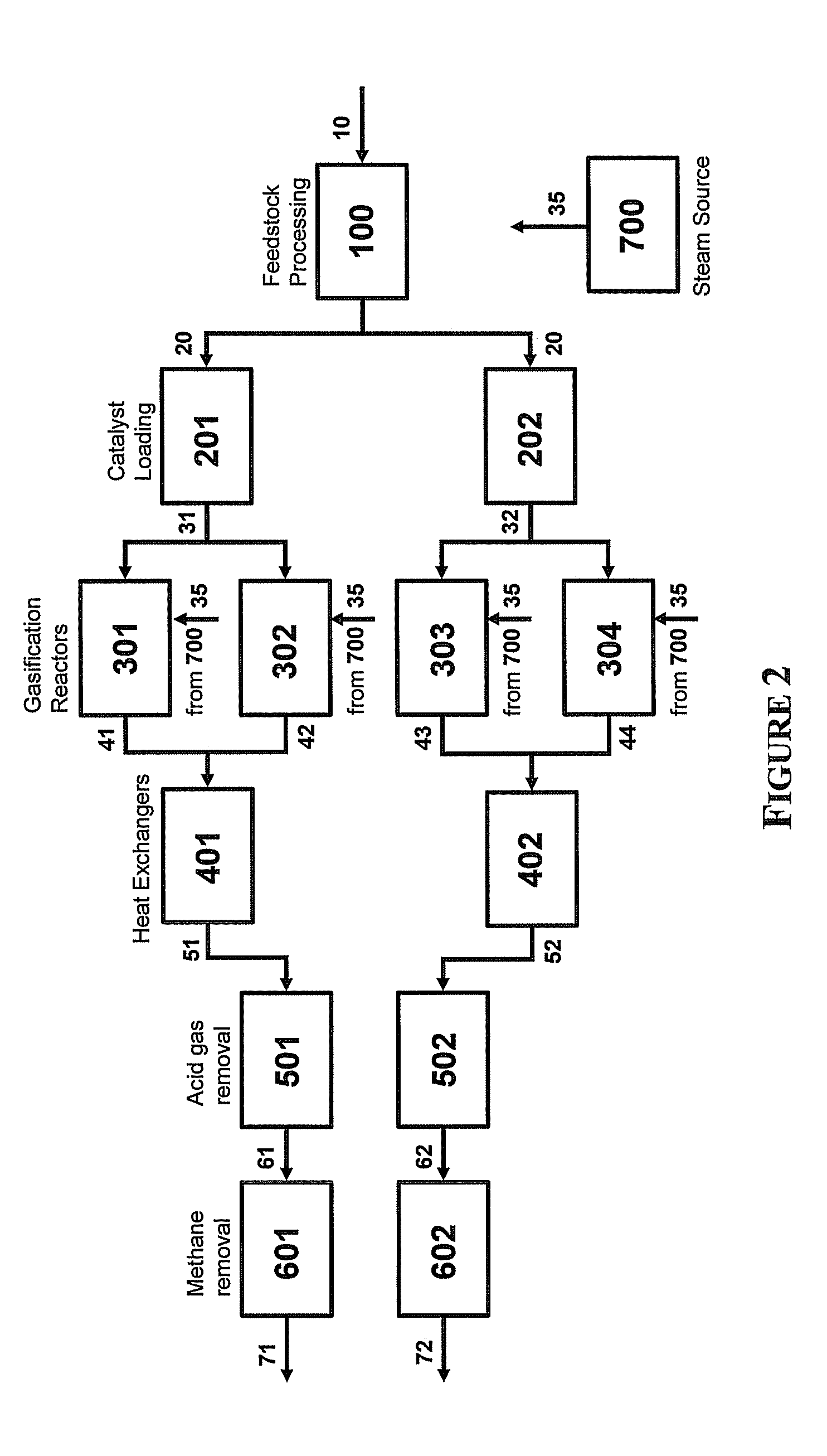

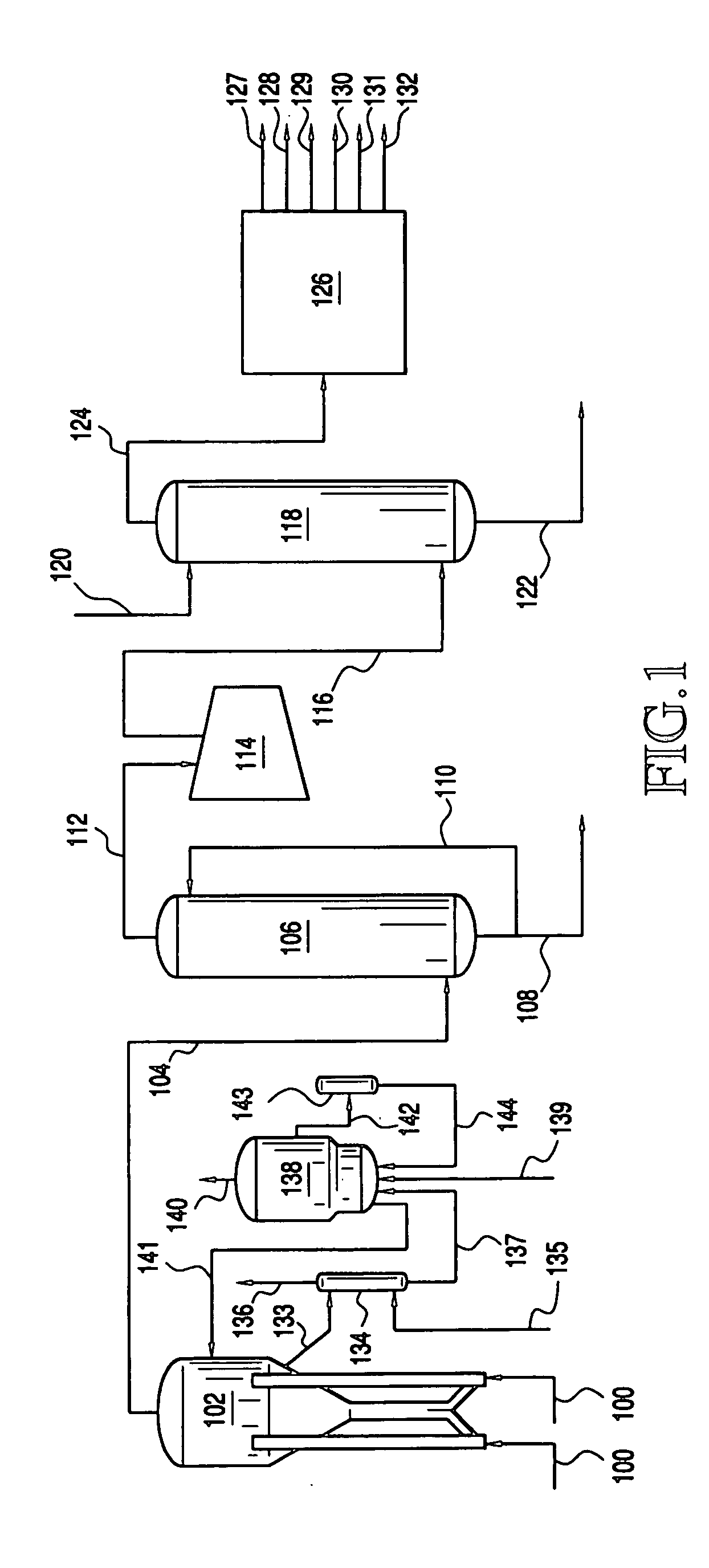

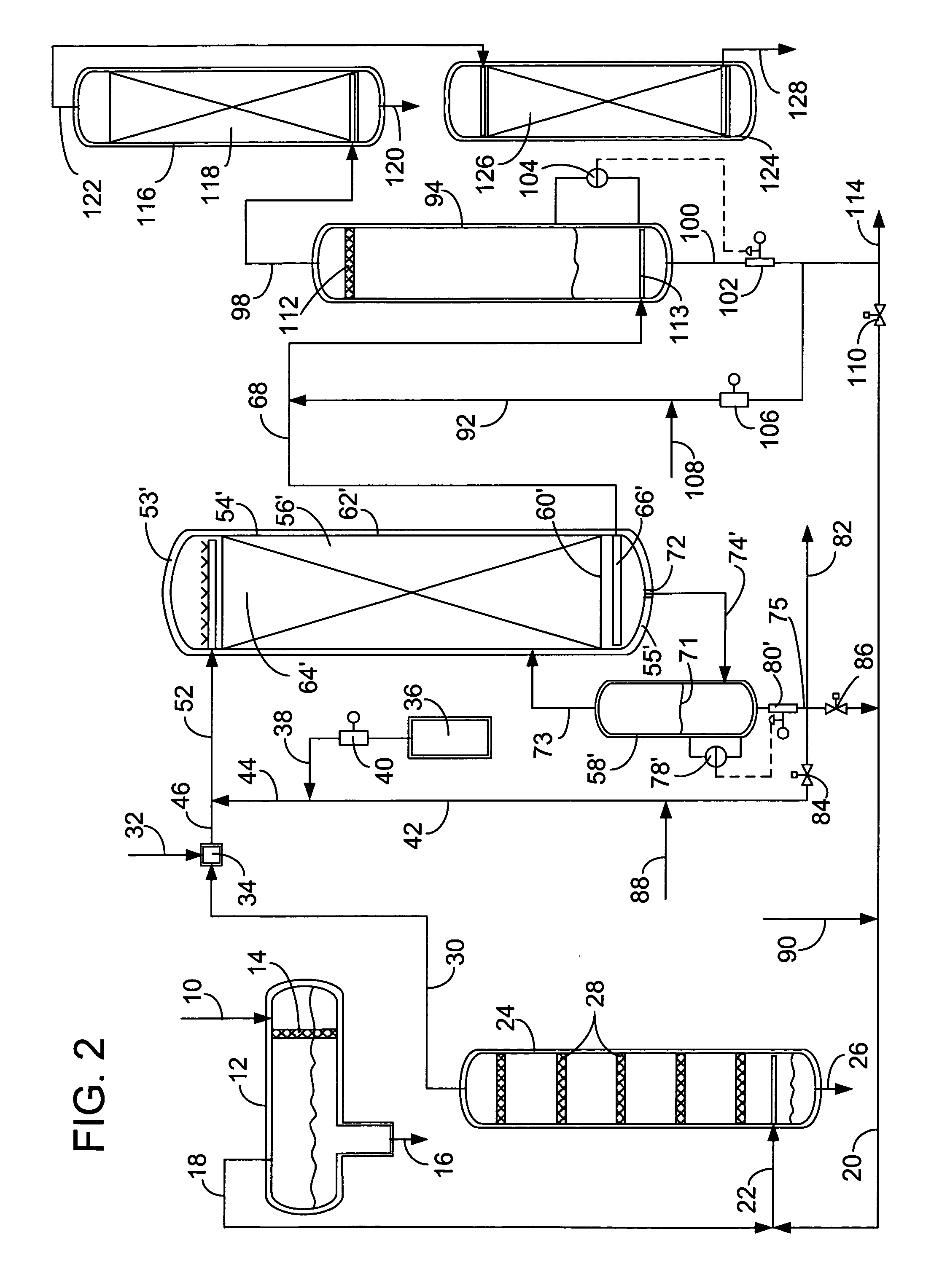

Two-Train Catalytic Gasification Systems

InactiveUS20090324458A1Reduce moisture contentGasifier mechanical detailsCombustible gas catalytic treatmentUnit operationAmmonia

Systems for converting a carbonaceous feedstock into a plurality of gaseous products are described. The systems include, among other units, two separate gasification reactors to convert a carbonaceous feedstock in the presence of an alkali metal catalyst into the plurality of gaseous products including at least methane. Each of the gasification reactors may be supplied with the feedstock from a single or separate catalyst loading and / or feedstock preparation unit operations. Similarly, the hot gas streams from each gasification reactor may be purified via their combination at a heat exchanger, acid gas removal, or methane removal unit operations. Product purification may comprise trace contaminant removal units, ammonia removal and recovery units, and sour shift units.

Owner:SURE CHAMPION INVESTMENT LTD

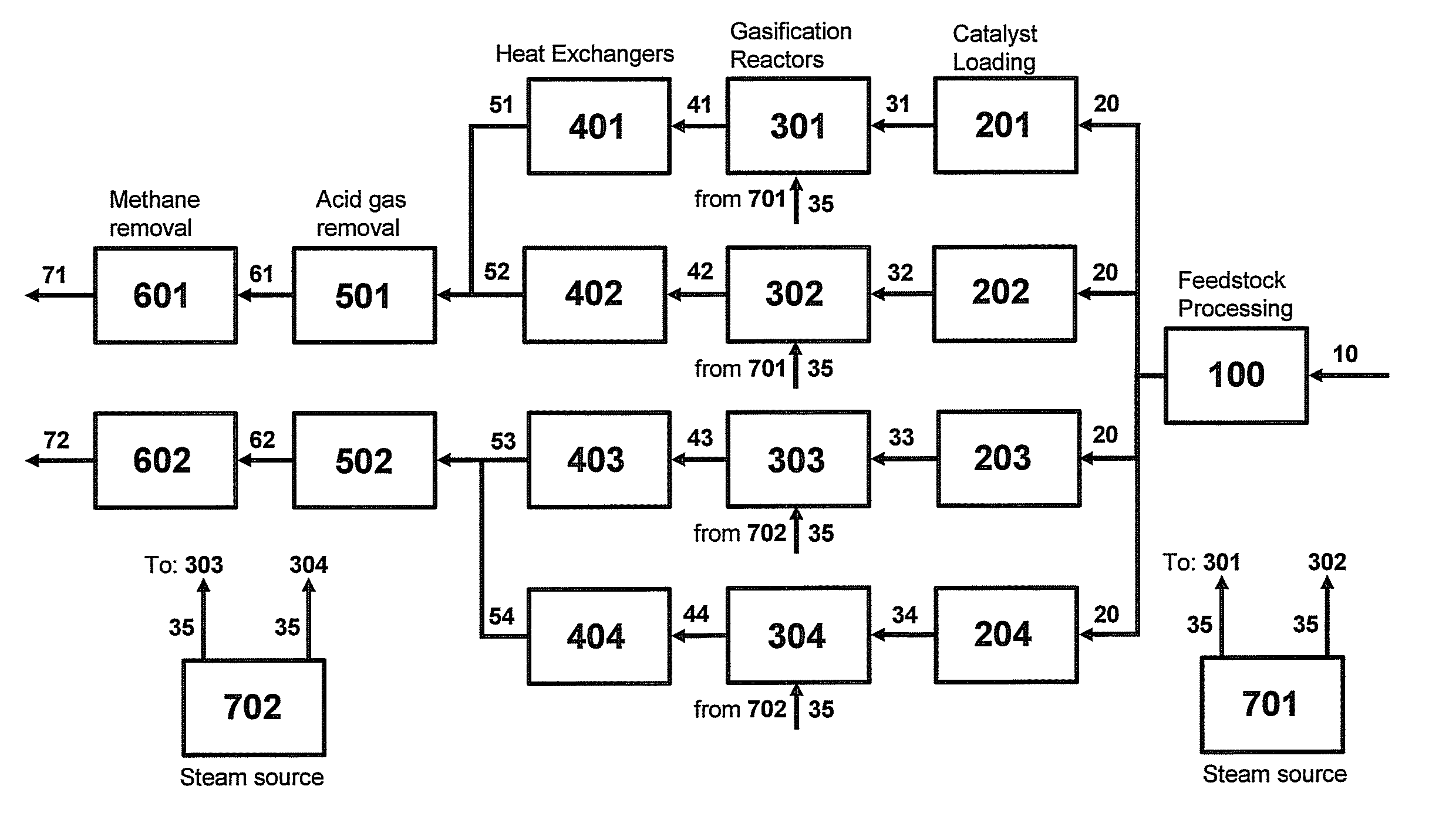

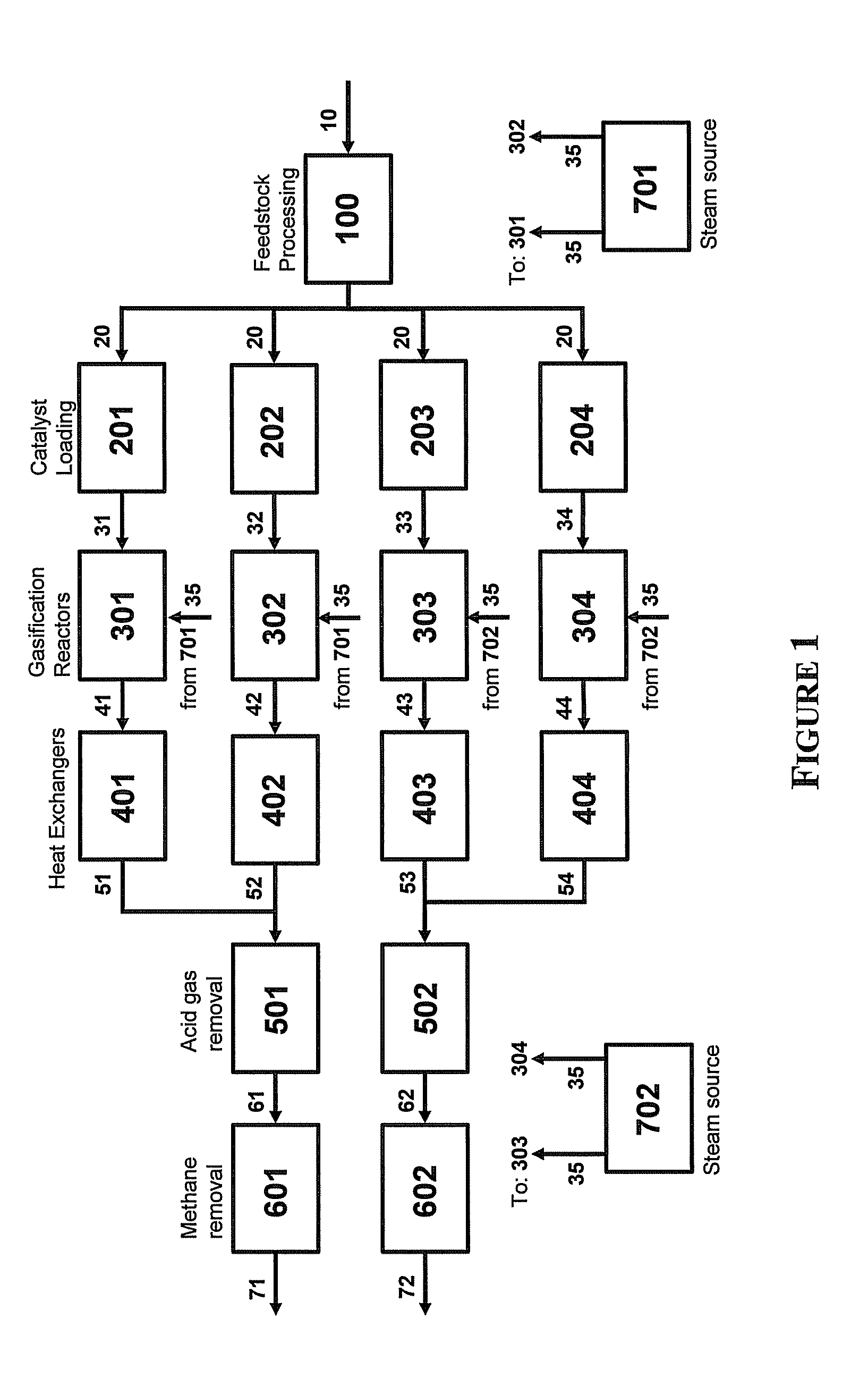

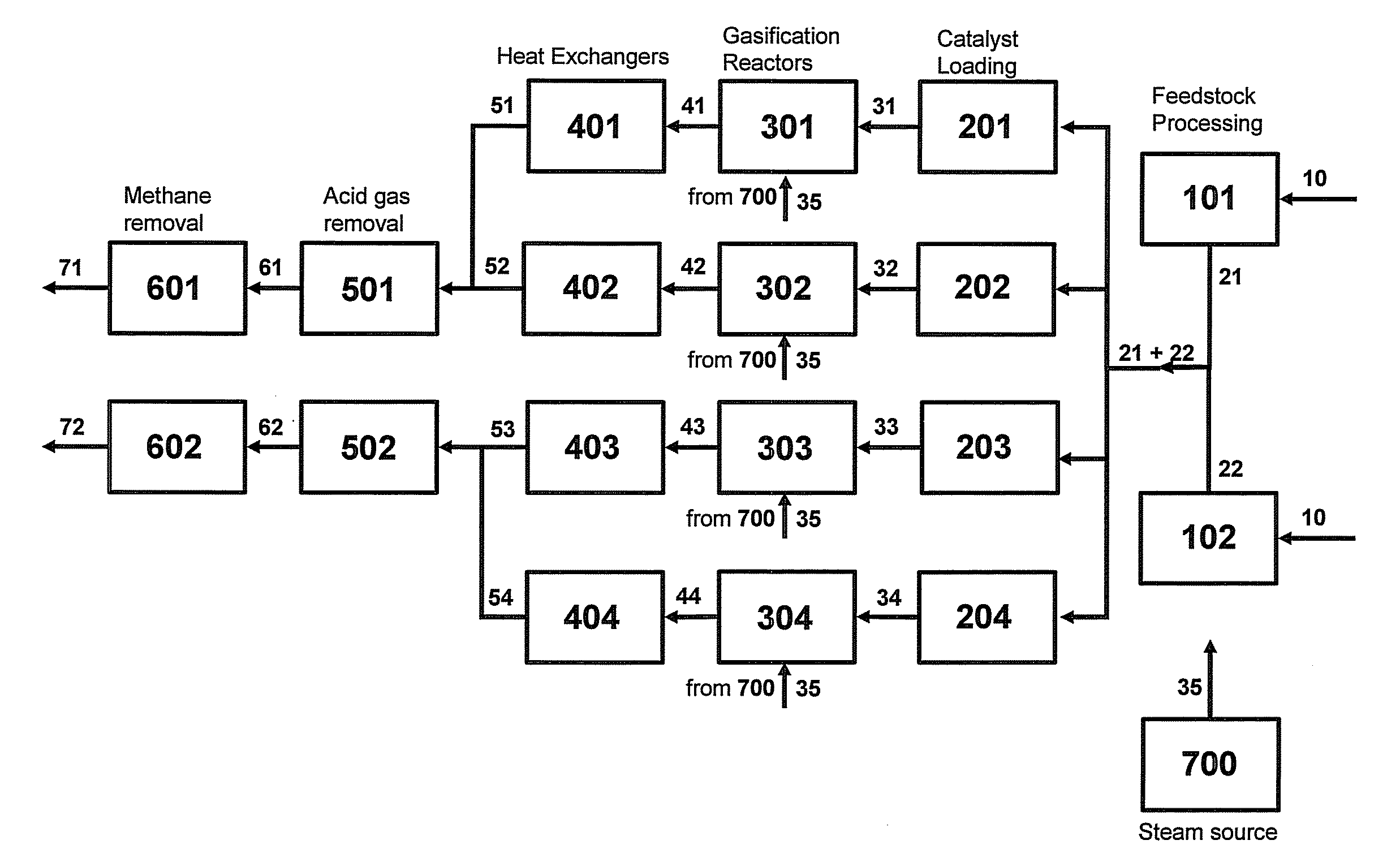

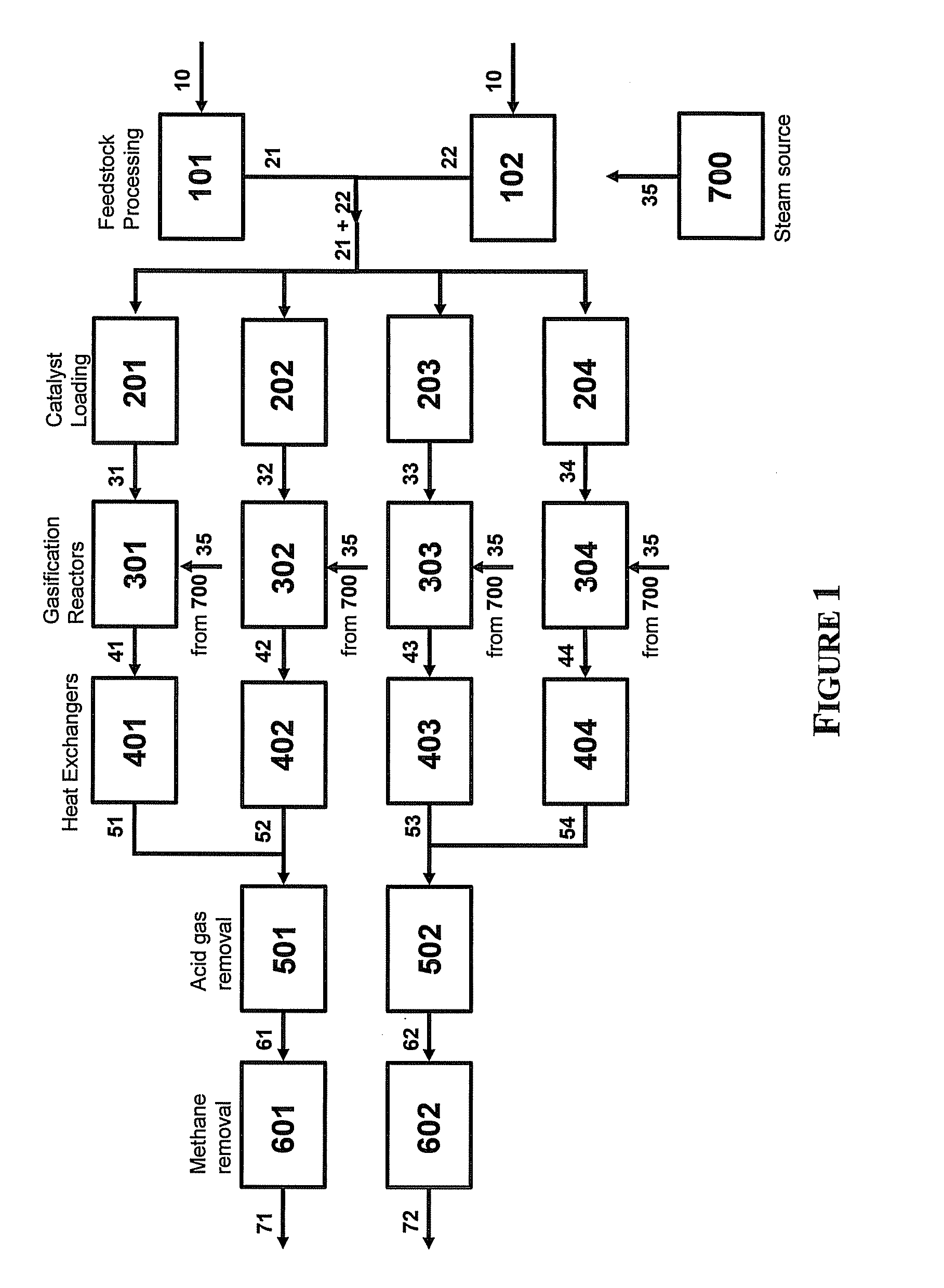

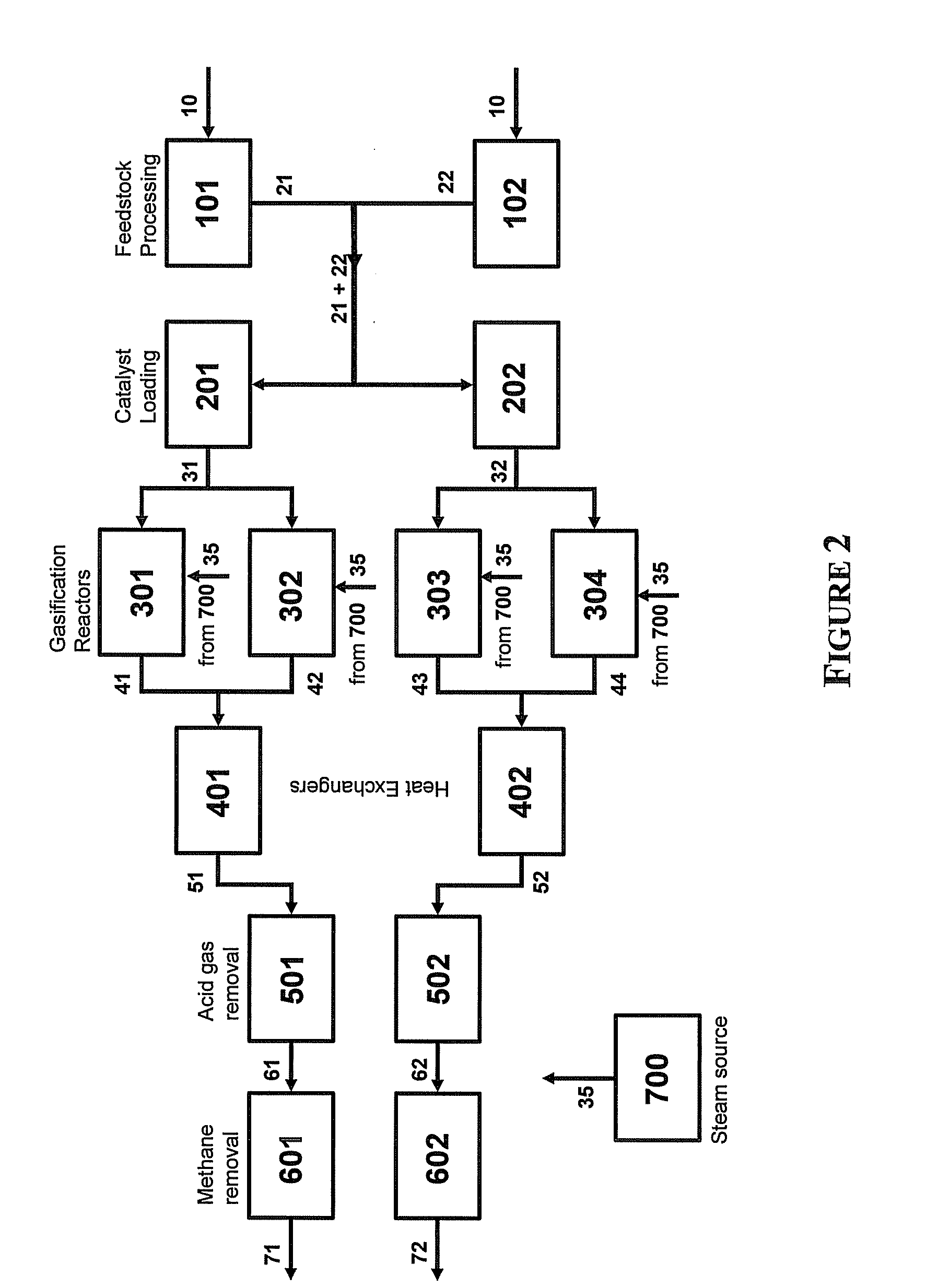

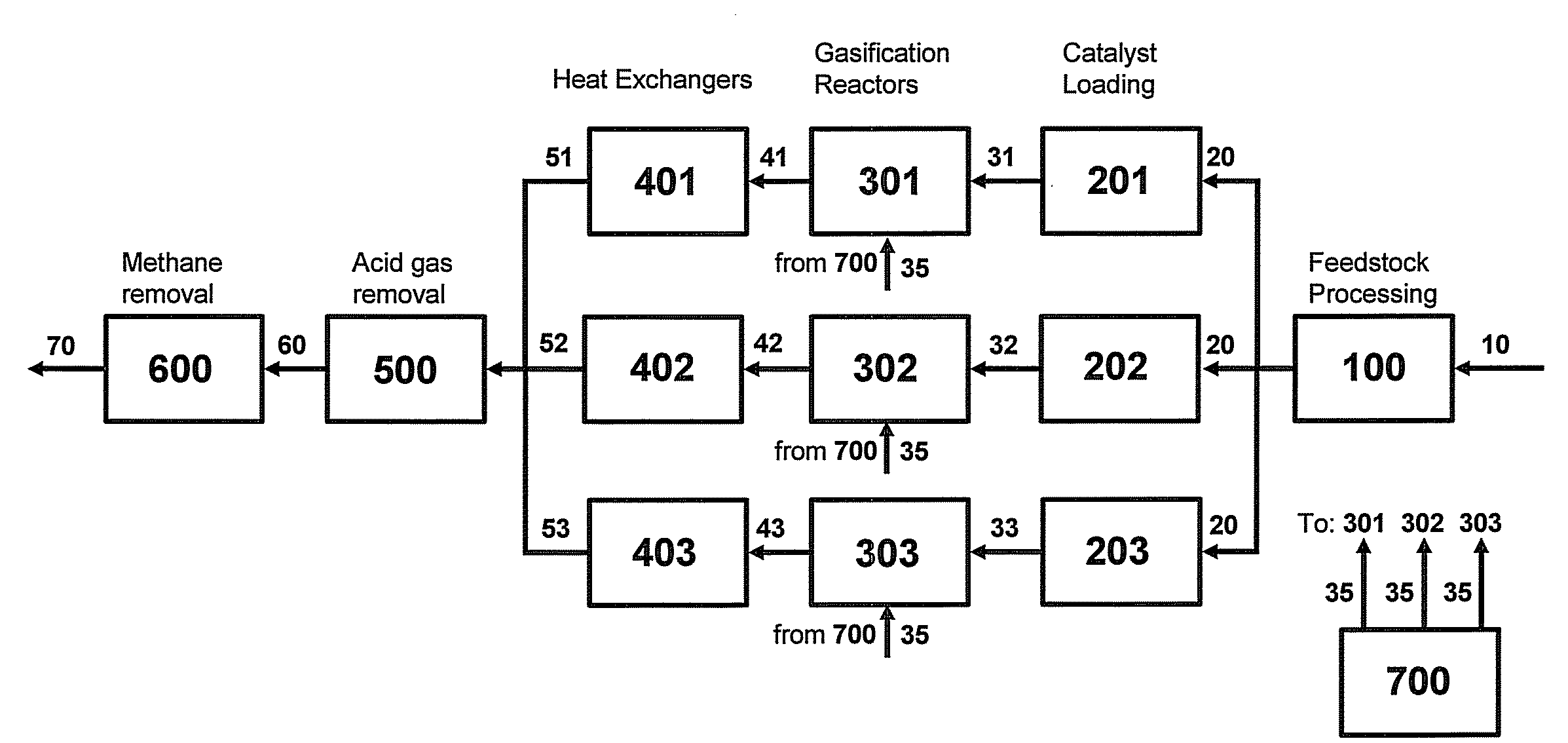

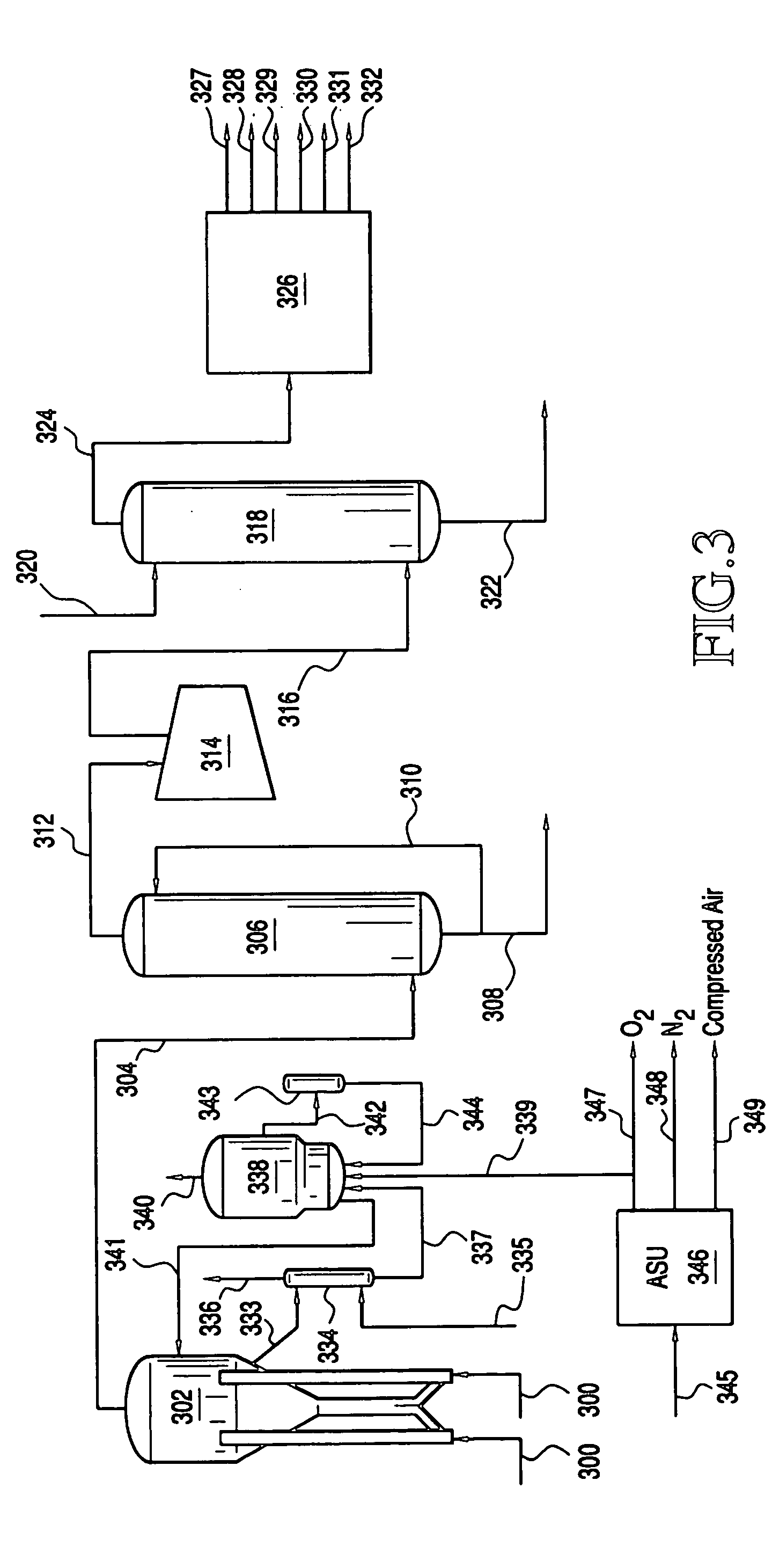

Four-Train Catalytic Gasification Systems

InactiveUS20090324460A1Reduce moisture contentHydrogen separation at low temperatureHydrogen separation using liquid contactUnit operationAmmonia

Systems to convert a carbonaceous feedstock into a plurality of gaseous products are described. The systems include, among other units, four separate gasification reactors for the gasification of a carbonaceous feedstock in the presence of an alkali metal catalyst into the plurality of gaseous products including at least methane. Each of the gasification reactors may be supplied with the feedstock from a single or separate catalyst loading and / or feedstock preparation unit operations. Similarly, the hot gas streams from each gasification reactor may be purified via their combination at a heat exchanger, acid gas removal, or methane removal unit operations. Product purification may comprise trace contaminant removal units, ammonia removal and recovery units, and sour shift units.

Owner:SURE CHAMPION INVESTMENT LTD

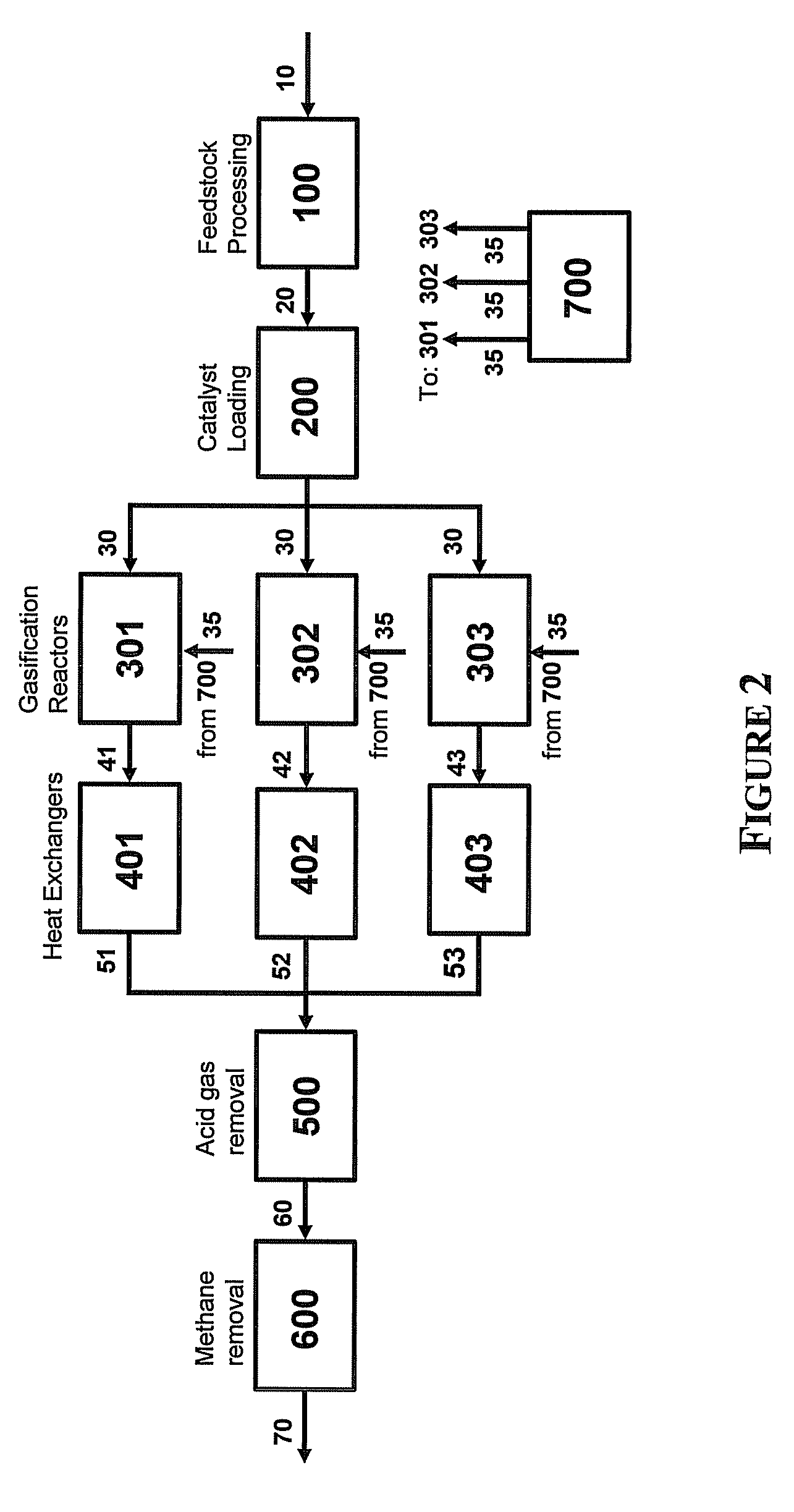

Four-Train Catalytic Gasification Systems

InactiveUS20090324461A1Reduce moisture contentGaseous fuelsGasification processes detailsUnit operationAmmonia

Systems to convert a carbonaceous feedstock into a plurality of gaseous products are described. The systems include, among other units, four separate gasification reactors for the gasification of a carbonaceous feedstock in the presence of an alkali metal catalyst into the plurality of gaseous products including at least methane. Each of the gasification reactors may be supplied with the feedstock from a single or separate catalyst loading and / or feedstock preparation unit operations. Similarly, the hot gas streams from each gasification reactor may be purified via their combination at a heat exchanger, acid gas removal, or methane removal unit operations. Product purification may comprise trace contaminant removal units, ammonia removal and recovery units, and sour shift units.

Owner:SURE CHAMPION INVESTMENT LTD

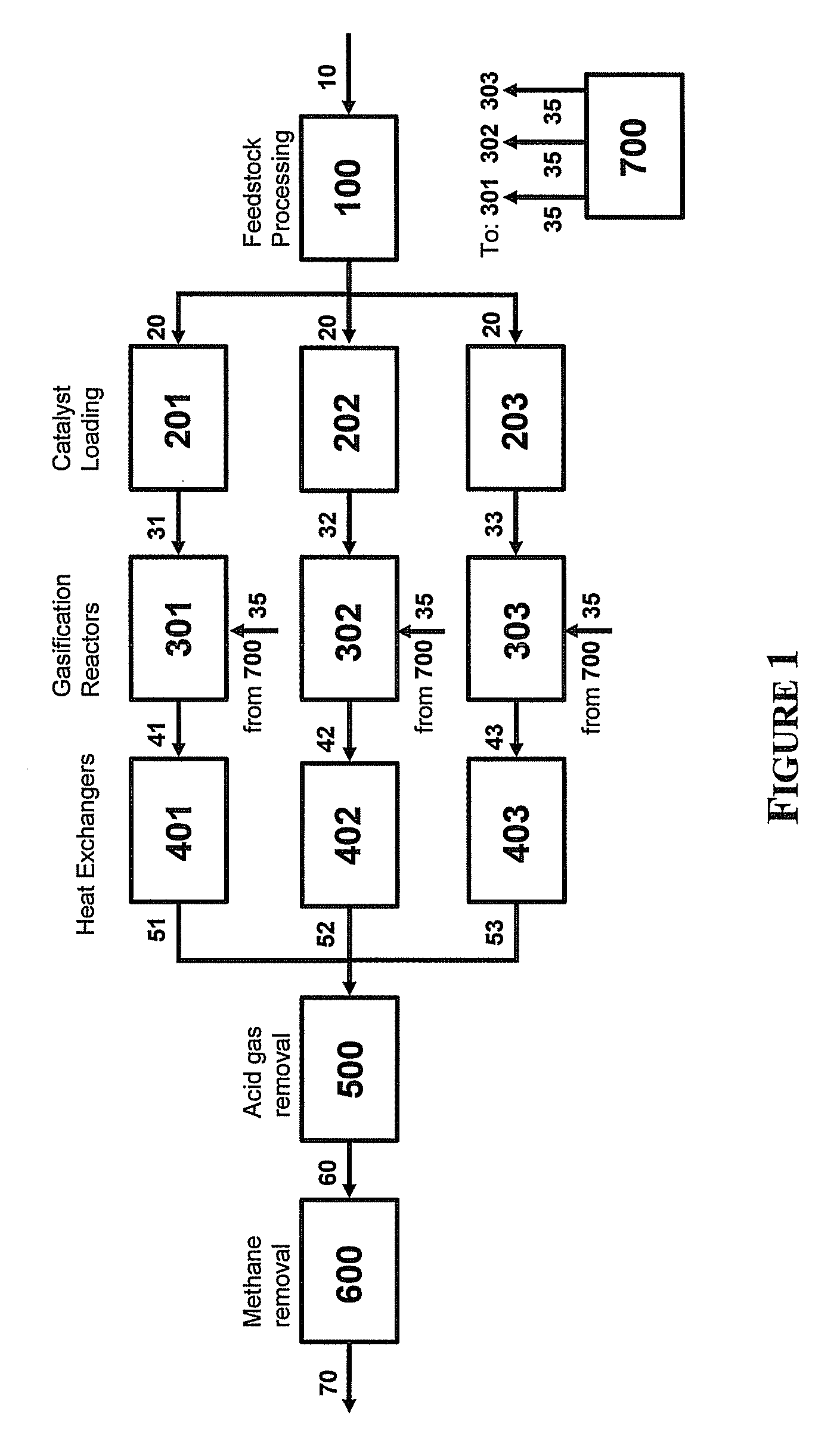

Three-Train Catalytic Gasification Systems

InactiveUS20090324459A1Reduce moisture contentCombustible gas catalytic treatmentGaseous fuelsUnit operationAmmonia

Systems to convert a carbonaceous feedstock into a plurality of gaseous products are described. The systems include, among other units, three separate gasification reactors for the gasification of a carbonaceous feedstock in the presence of an alkali metal catalyst into the plurality of gaseous products including at least methane. Each of the gasification reactors may be supplied with the feedstock from a single or separate catalyst loading and / or feedstock preparation unit operations. Similarly, the hot gas streams from each gasification reactor may be purified via their combination at a heat exchanger, acid gas removal or methane removal unit operations. Product purification may comprise trace contaminant removal units, ammonia removal and recovery units, and sour shift units.

Owner:SURE CHAMPION INVESTMENT LTD

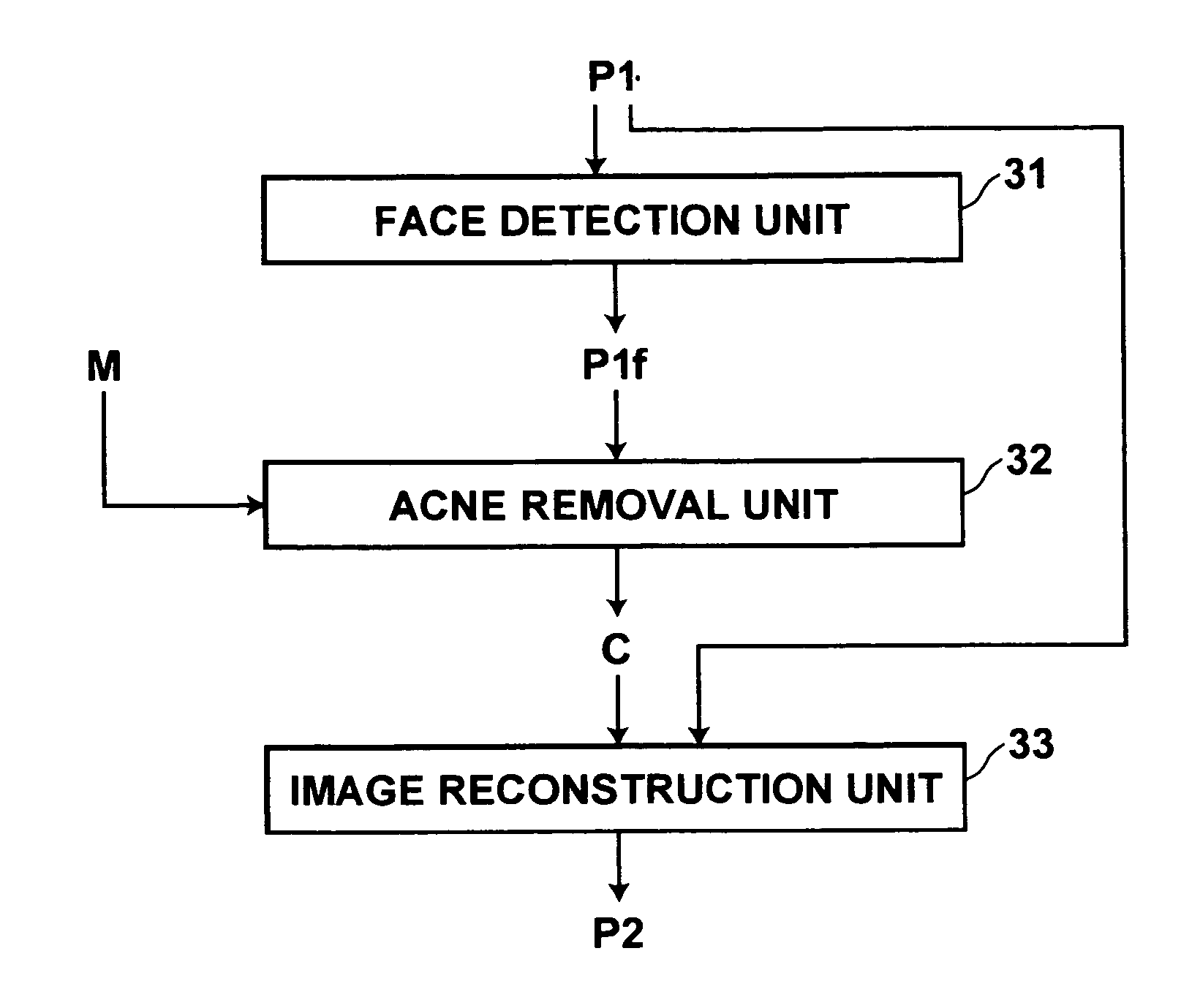

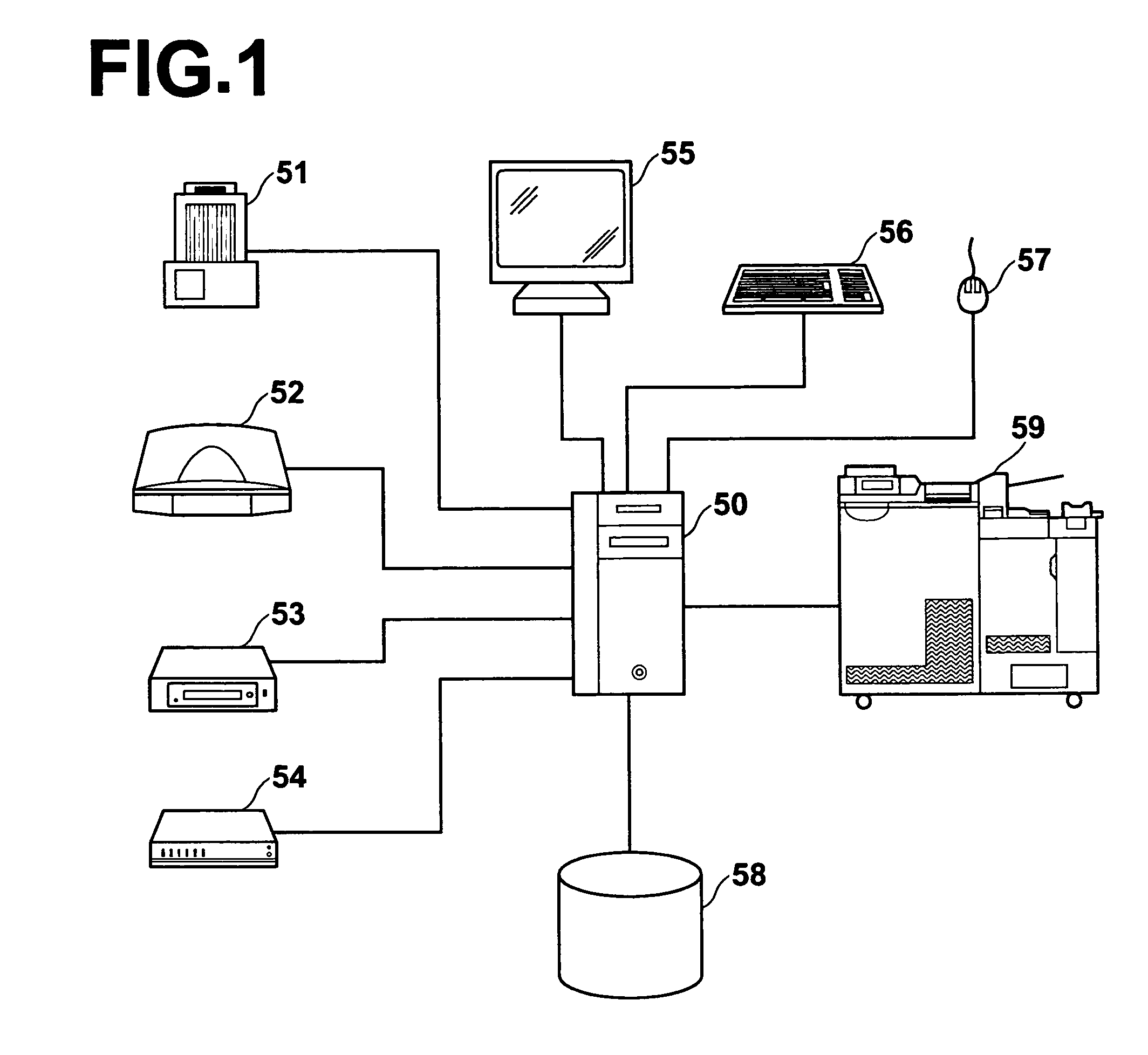

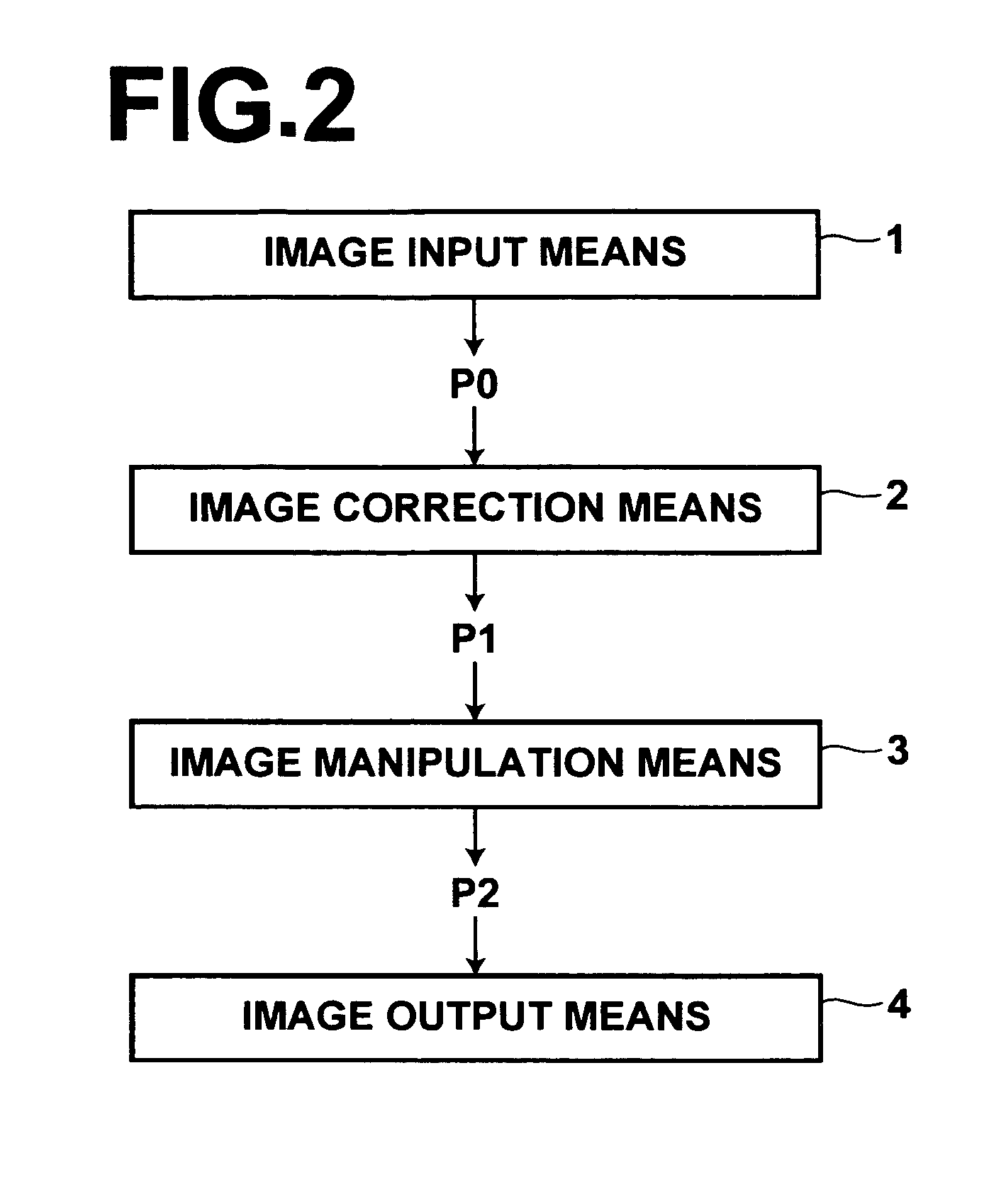

Image processing method, image processing apparatus, and computer-readable recording medium storing image processing program

ActiveUS20070071347A1Quality improvementImprove machining accuracyImage enhancementImage analysisImaging processingMathematical model

An unnecessary component such as acne is removed completely from a predetermined structure such as a face in a photograph image without manual operation and skills. An acne removal unit fits to a face region as the structure in the image a mathematical model generated according to a statistical method such as AAM using sample images representing the structure without the component to be removed, and an image reconstruction unit reconstructs an image of the face region based on parameters corresponding to the face region obtained by the fitting of the model. An image is then generated by replacing the face region with the reconstructed image. Since the mathematical model has been generated from the sample images of human faces without acne, the model does not include acne. Therefore, the reconstructed face image generated by fitting the model to the face region does not include acne.

Owner:FUJIFILM CORP +1

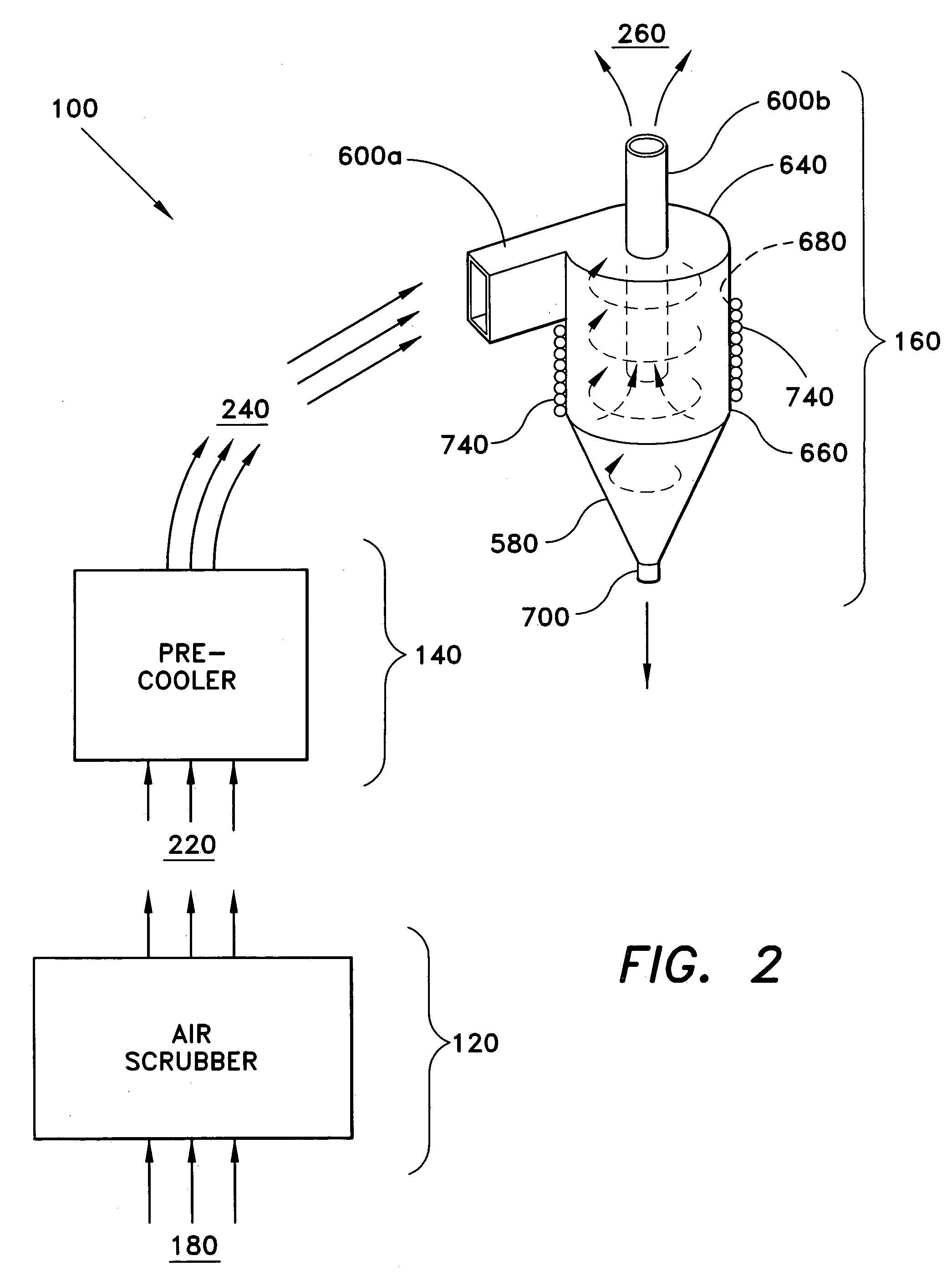

Air purification system and method

Owner:LEE DAVID B

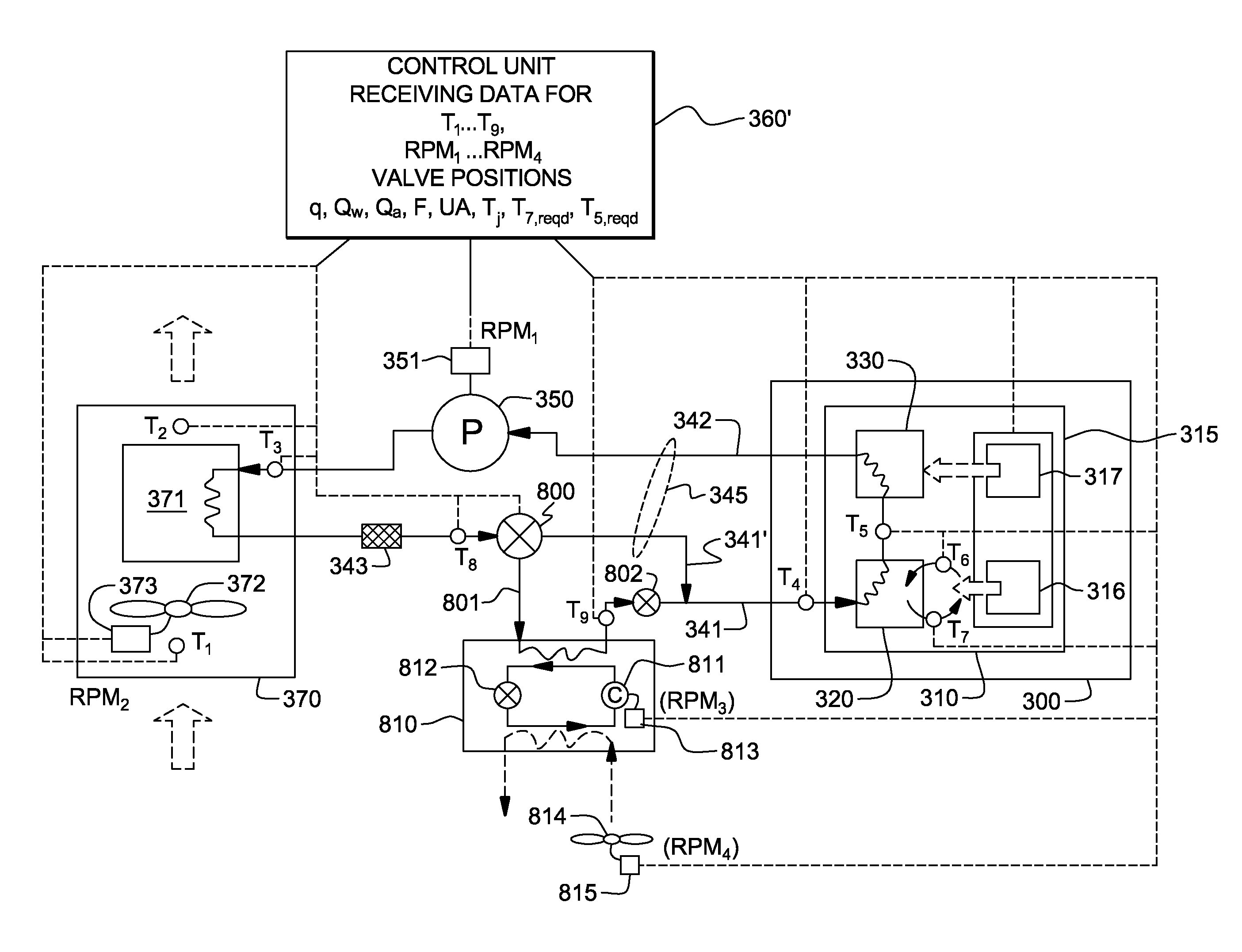

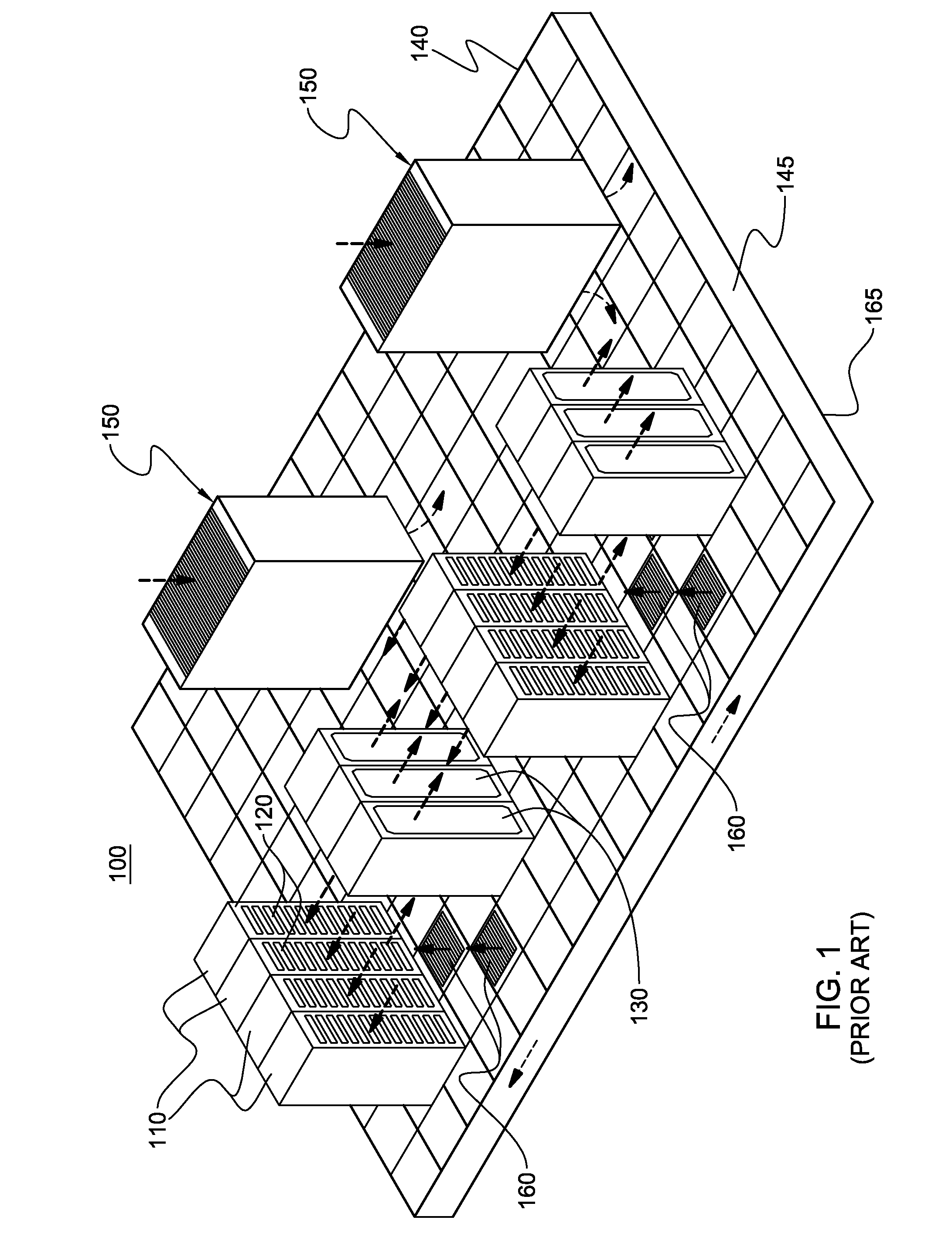

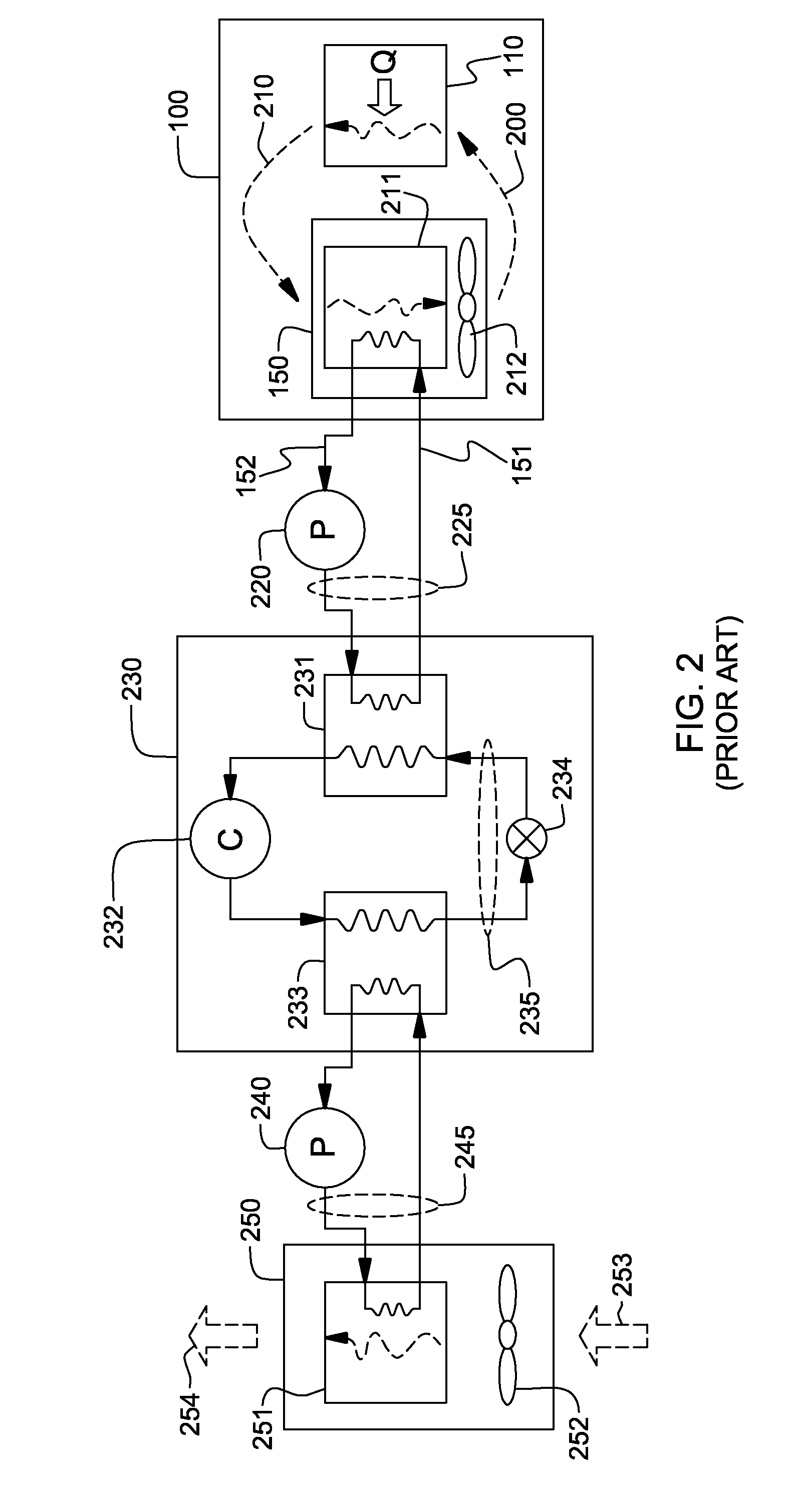

Energy efficient apparatus and method for cooling an electronics rack

InactiveUS7791882B2Overcomes shortcomingImprove cooling effectDomestic cooling apparatusDigital data processing detailsNuclear engineeringEnergy expenditure

Apparatus and method are provided for cooling an electronics rack in an energy efficient, dynamic manner. The apparatus includes one or more extraction mechanisms for facilitating cooling of the electronics rack, an enclosure, a heat removal unit, and a control unit. The enclosure has an outer wall, a cover coupled to the outer wall and a central opening sized to surround the electronics rack and the heat extraction mechanism. A liquid coolant loop couples the heat removal unit in fluid communication with the heat extraction mechanism, which removes heat from liquid coolant passing therethrough. The control unit is coupled to the heat removal unit for dynamically adjusting energy consumption of the heat removal unit to limit its energy consumption, while providing a required cooling to the electronics rack employing the liquid coolant passing through the heat extraction mechanism.

Owner:INT BUSINESS MASCH CORP

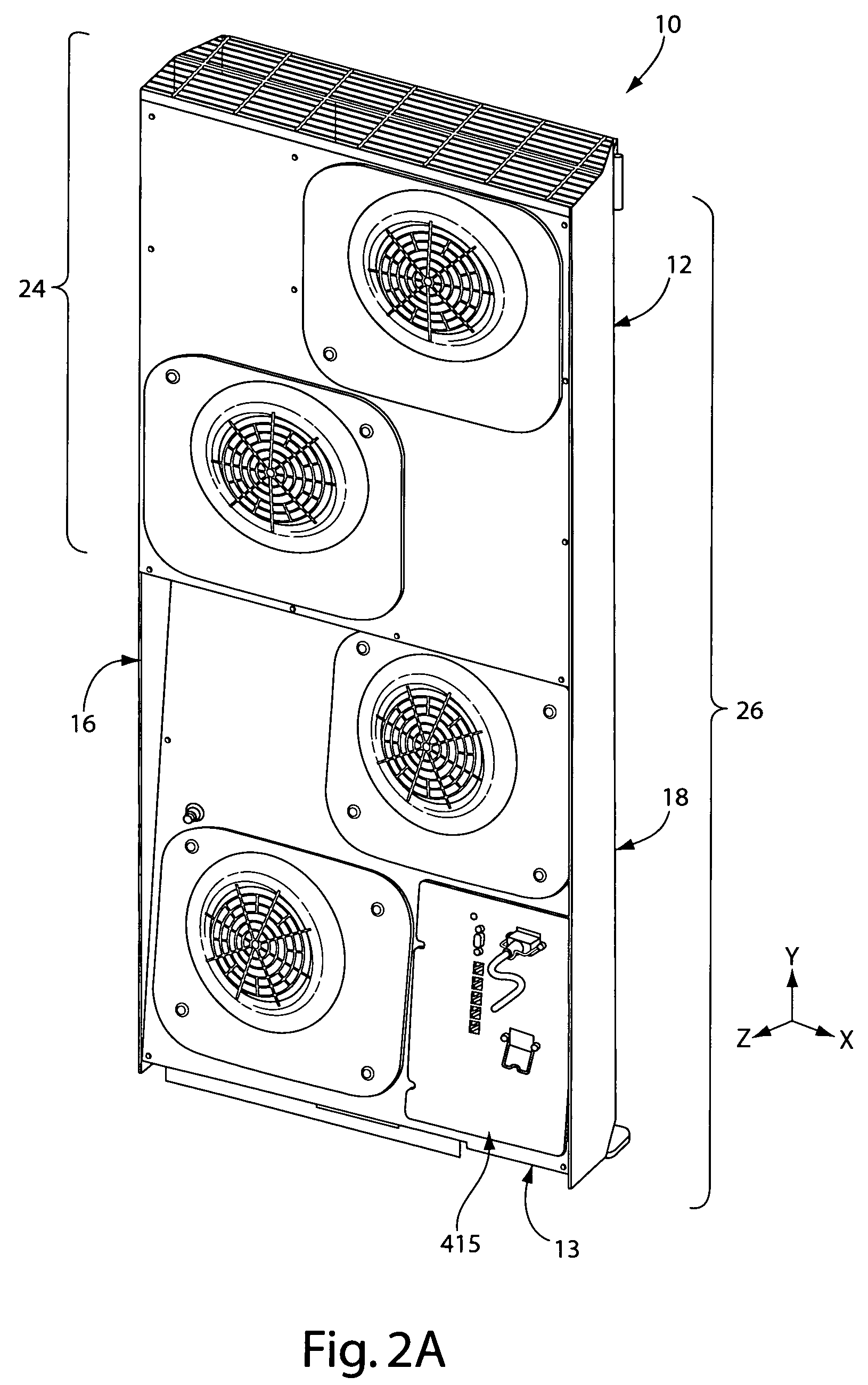

Air removal unit

ActiveUS7862410B2Minimize loss of airMinimize air flowCooling/ventilation/heating modificationsElectrical apparatus casings/cabinets/drawersData centerEngineering

An air removal unit configured for removing exhaust air from an equipment rack or enclosure includes multiple fans to achieve a high airflow capacity while defining a compact and portable structure. The unit removably installs along an exhaust side of an equipment rack or enclosure to provide capabilities for managing the thermal output of equipment, such as servers, CPUs, communications, internetworking and other types of equipment. The unit includes one or more upper fan modules and one or more lower fan modules positioned below the upper fan modules. The upper and the lower fan modules are arranged in a stacked configuration along the depth of the unit with the lower fan modules positioned in an offset orientation relative to the upper fan modules. The stacked configuration and the offset orientation of the fan modules help to incorporate multiple fans with the unit while maintaining the compact and portable design. The unit is further configured to serve as a door of an equipment rack or enclosure to thereby provide access to the unit and the rack or enclosure during operation. The unit can be incorporated with a ventilation system or a cooling air system associated with an equipment room or data center.

Owner:AMERICA POWER CONVERSION CORP

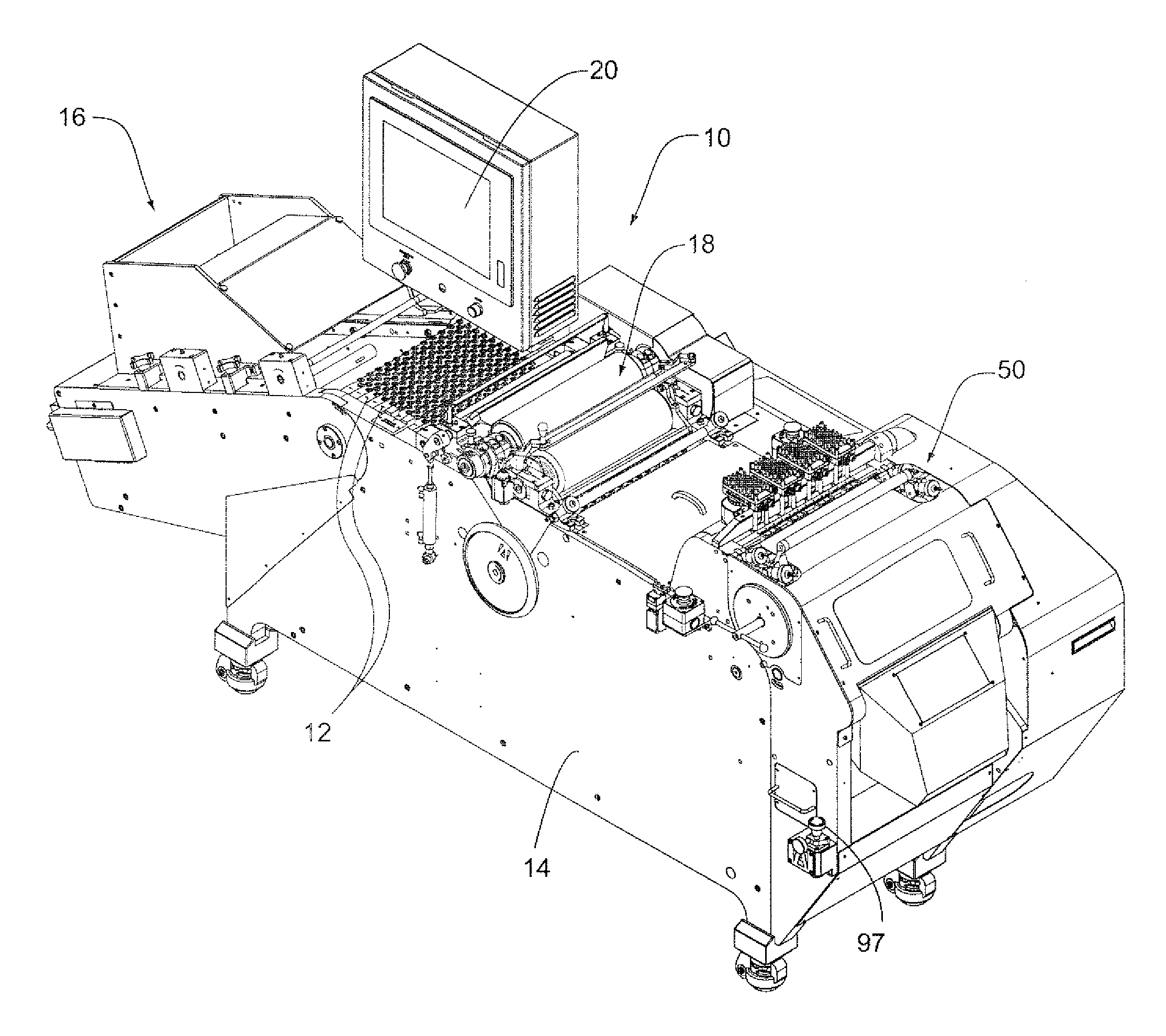

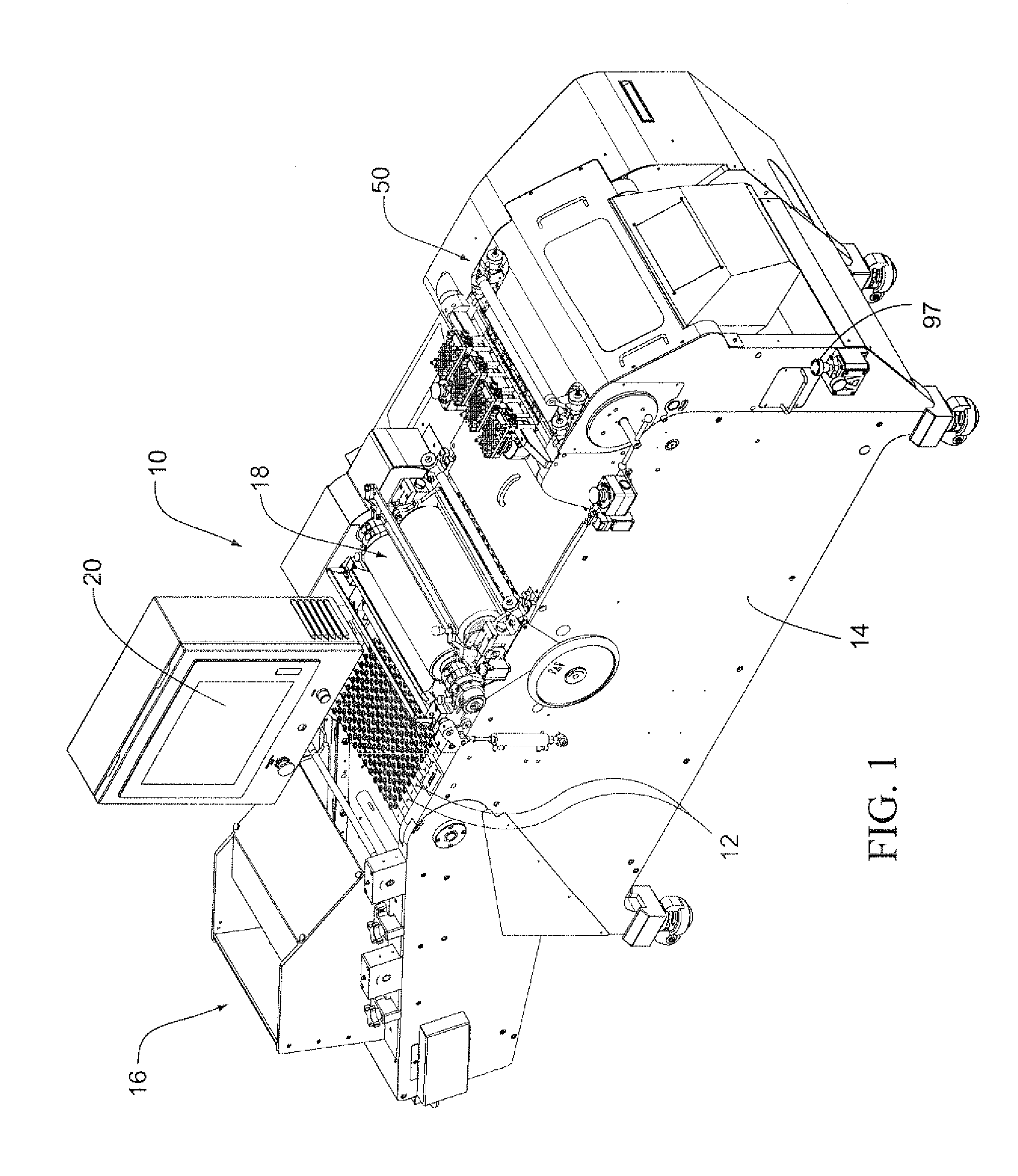

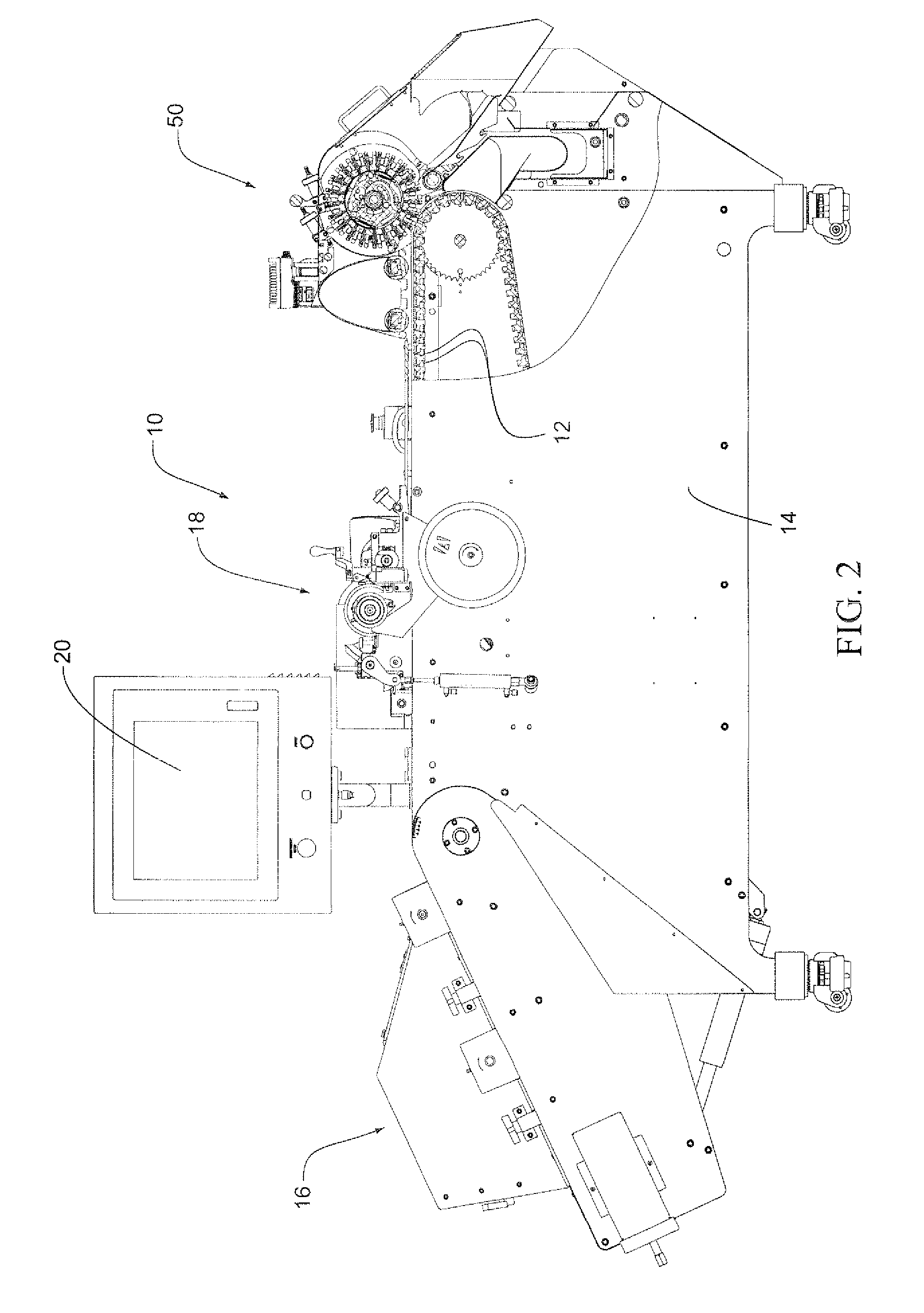

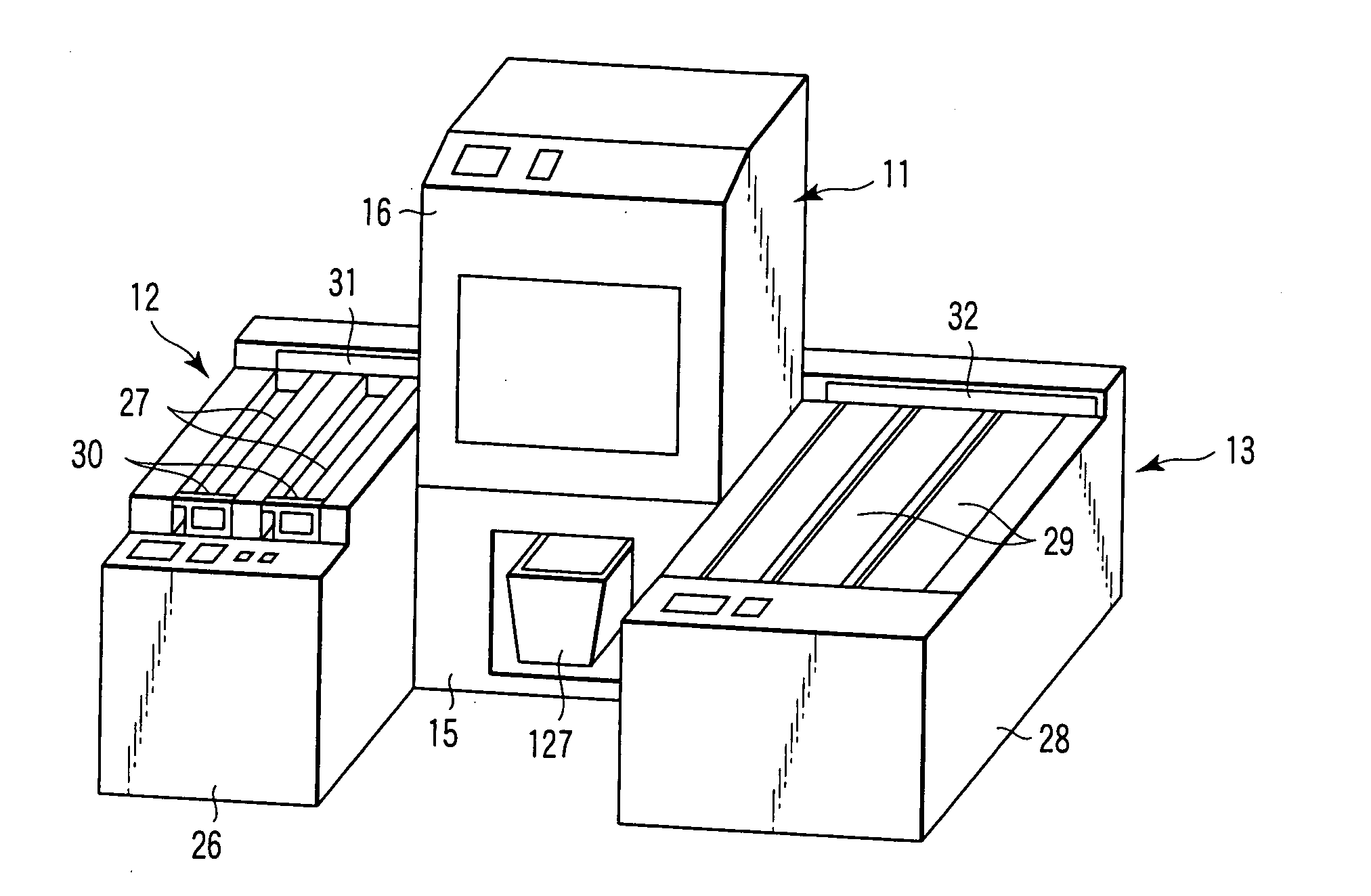

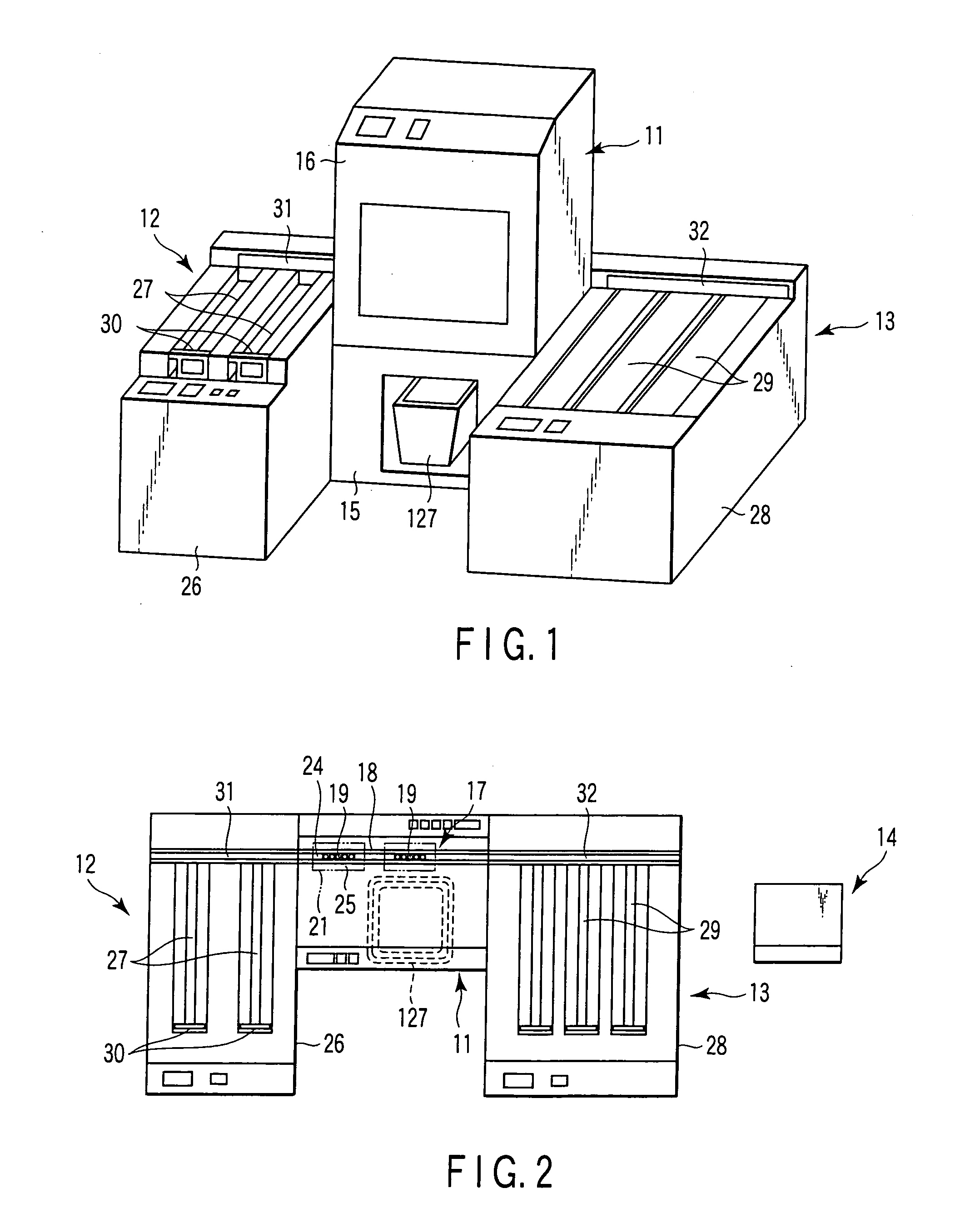

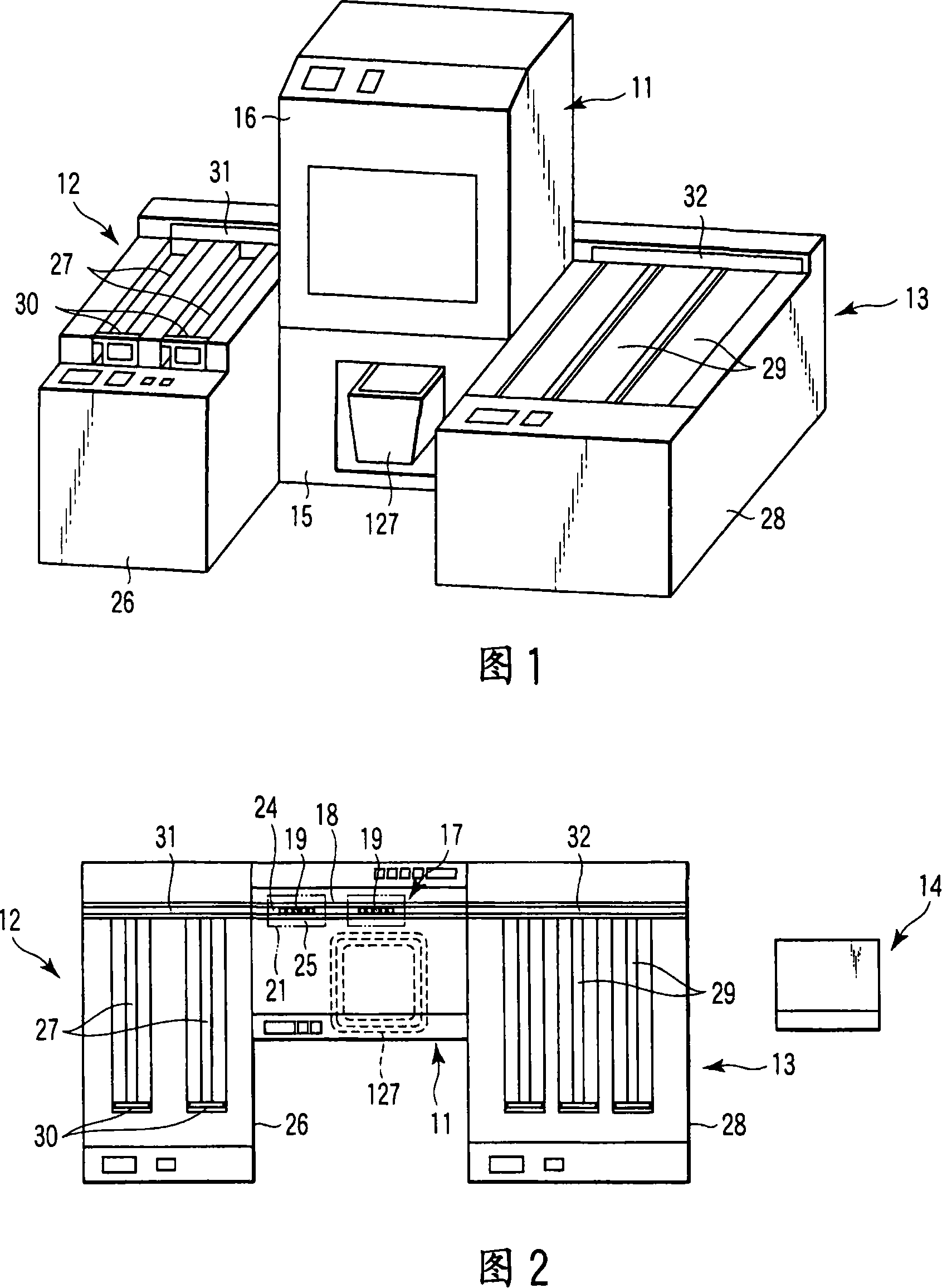

Inspection system

ActiveUS20110297590A1Facilitates softwareFacilitates hardware changeoverInvestigating moving fluids/granular solidsCharacter and pattern recognitionRemoval UnitsNozzle

An inspection system is configured for use with a conveyer apparatus including carrier bars. Each carrier bar conveys pellet-shaped articles along a predetermined path. The inspection system includes at least one camera unit for sensing a predetermined characteristic of the pellet-shaped articles, a removal unit, and a controller. The removal unit, downstream from the at least one camera unit, removes selected pellet-shaped article(s) from the carrier bar(s) depending on whether the characteristic is sensed by the at least one camera unit. The controller is in communication with the at least one camera unit and the removal unit. The controller provides a signal to the removal unit in accordance with the sensed characteristic. The removal unit includes a rotatable ejection drum having extended vacuum nozzles along its length, equal to the number of articles conveyed in each carrier bar. Each vacuum nozzle selectively removes article(s) from the carrier bar(s) by suction.

Owner:ACKLEY MACHINE

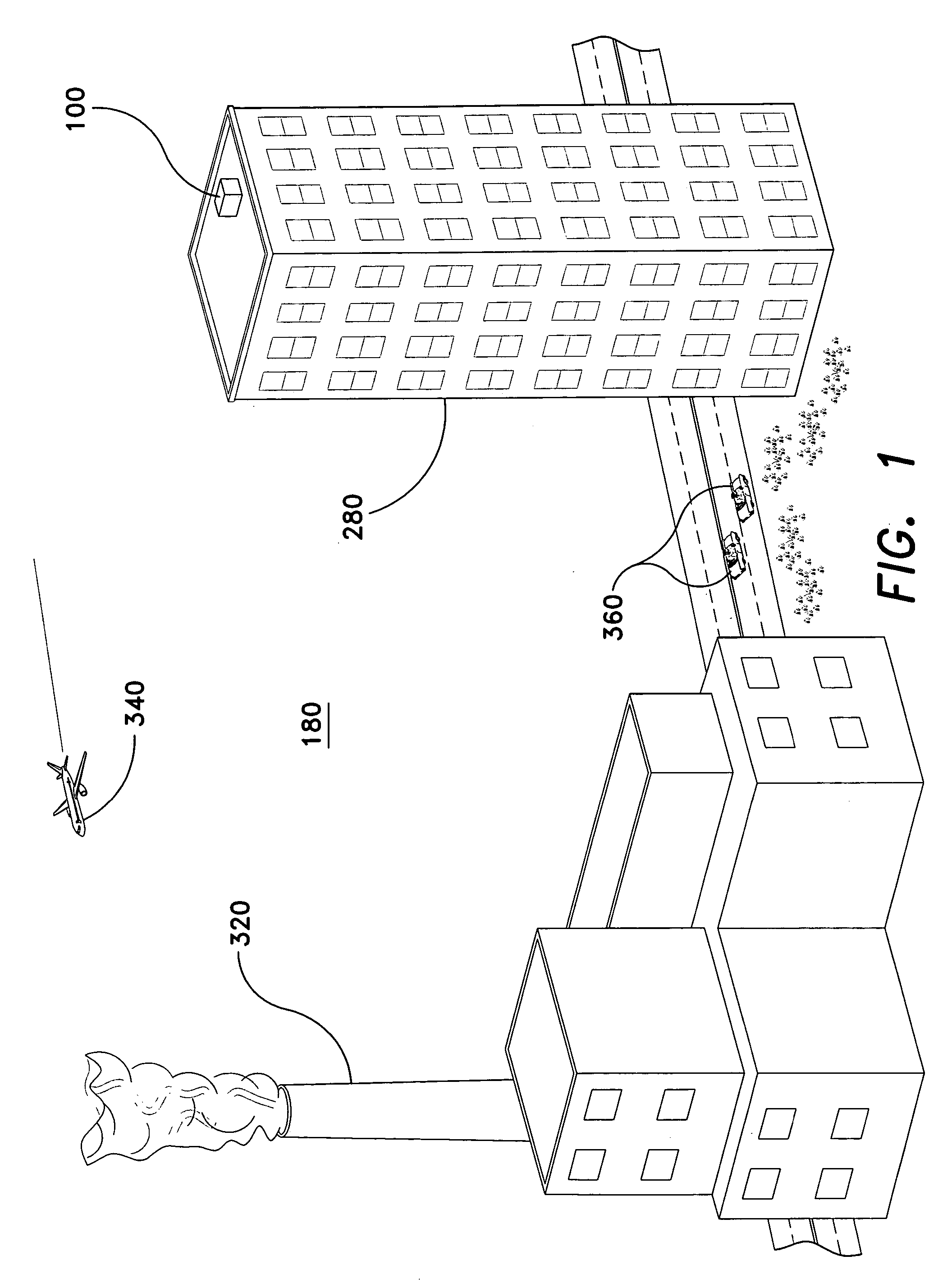

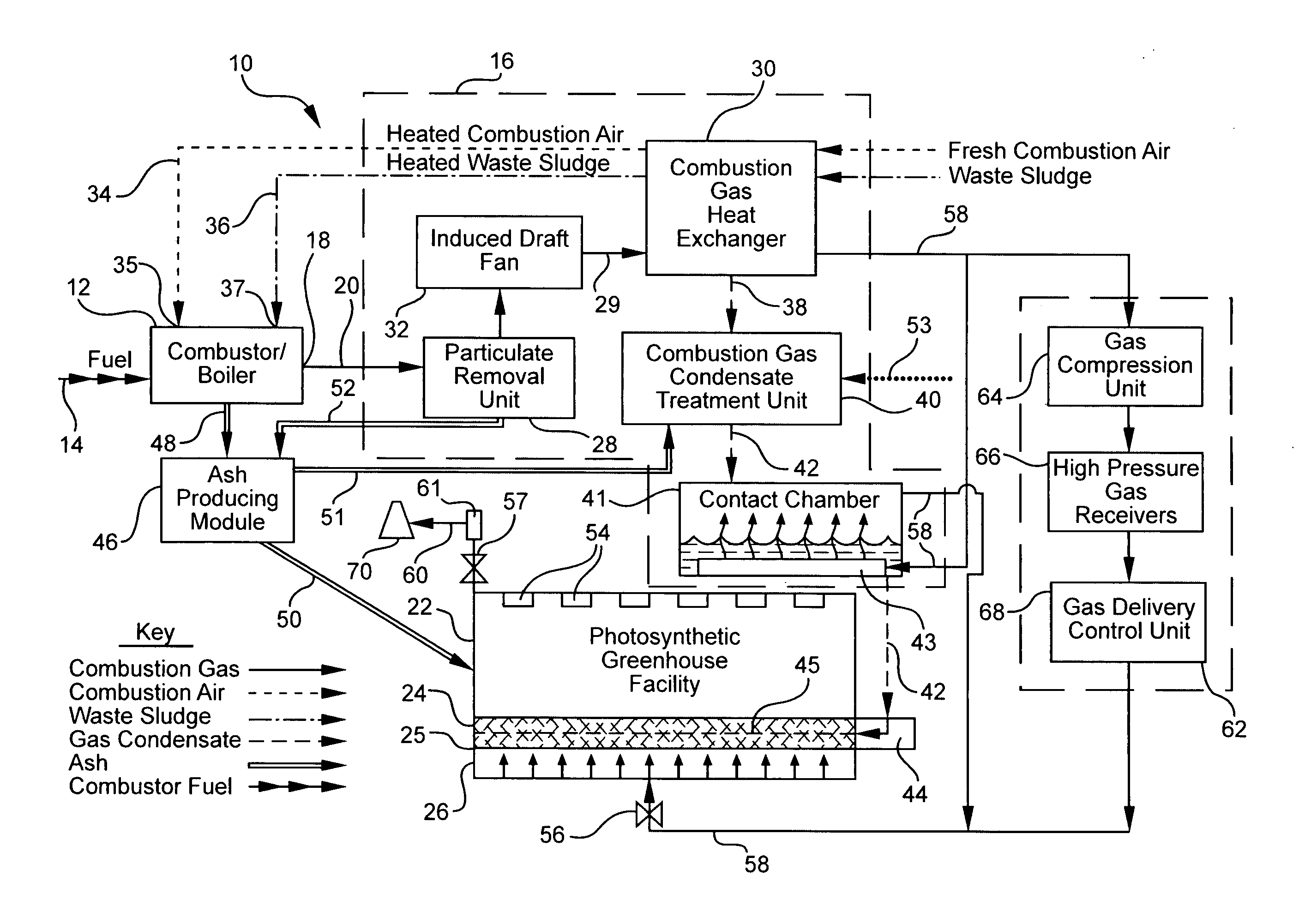

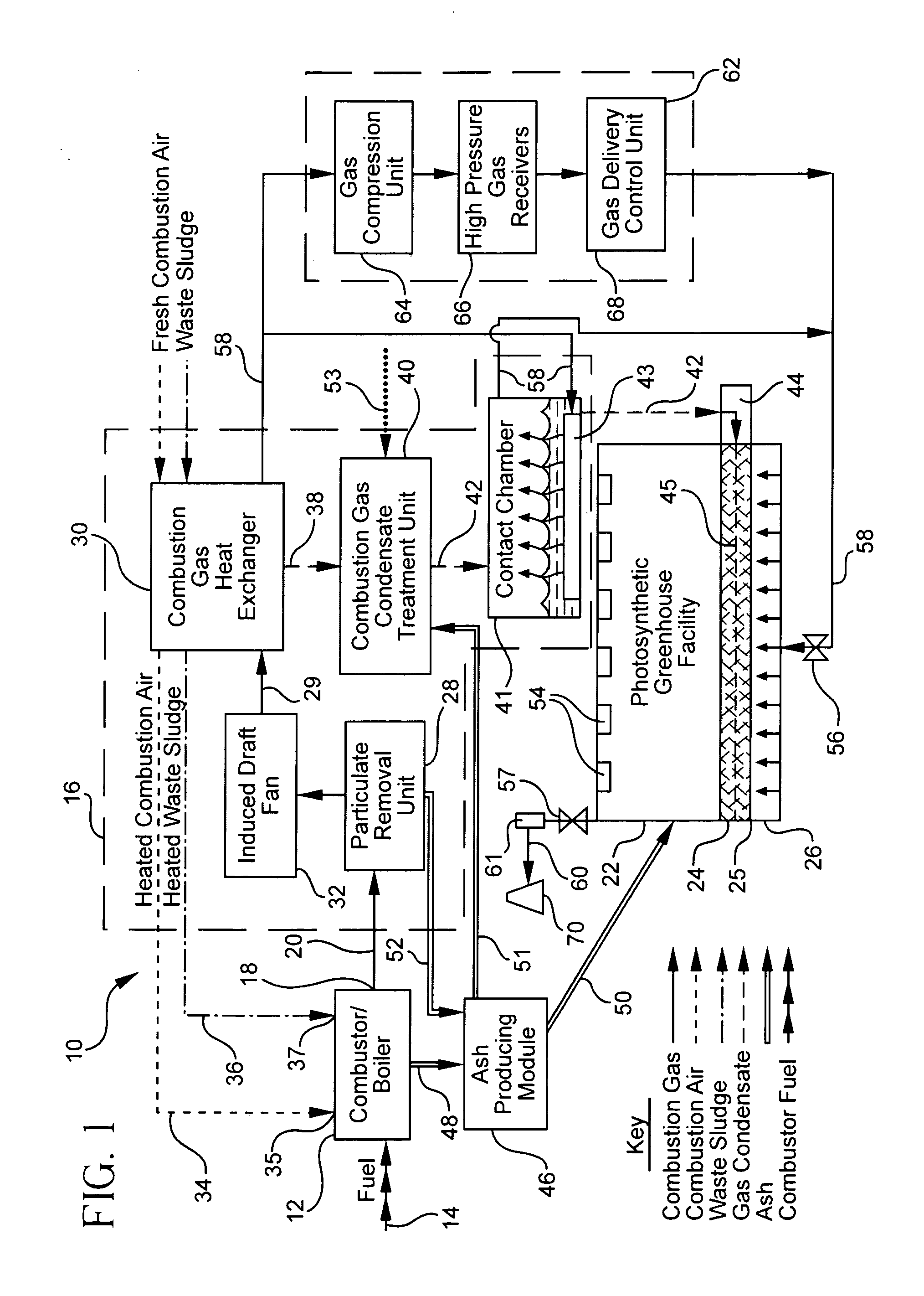

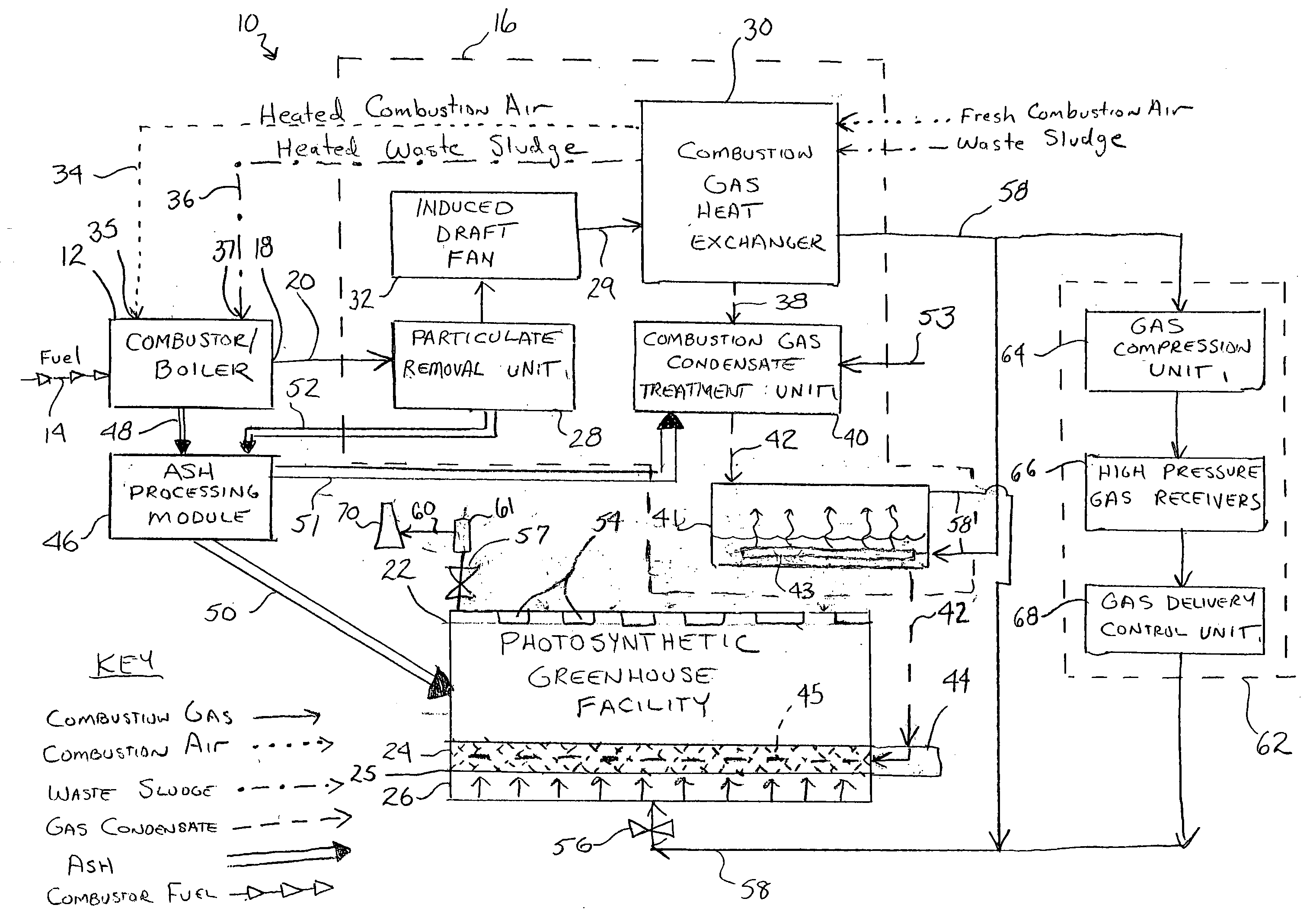

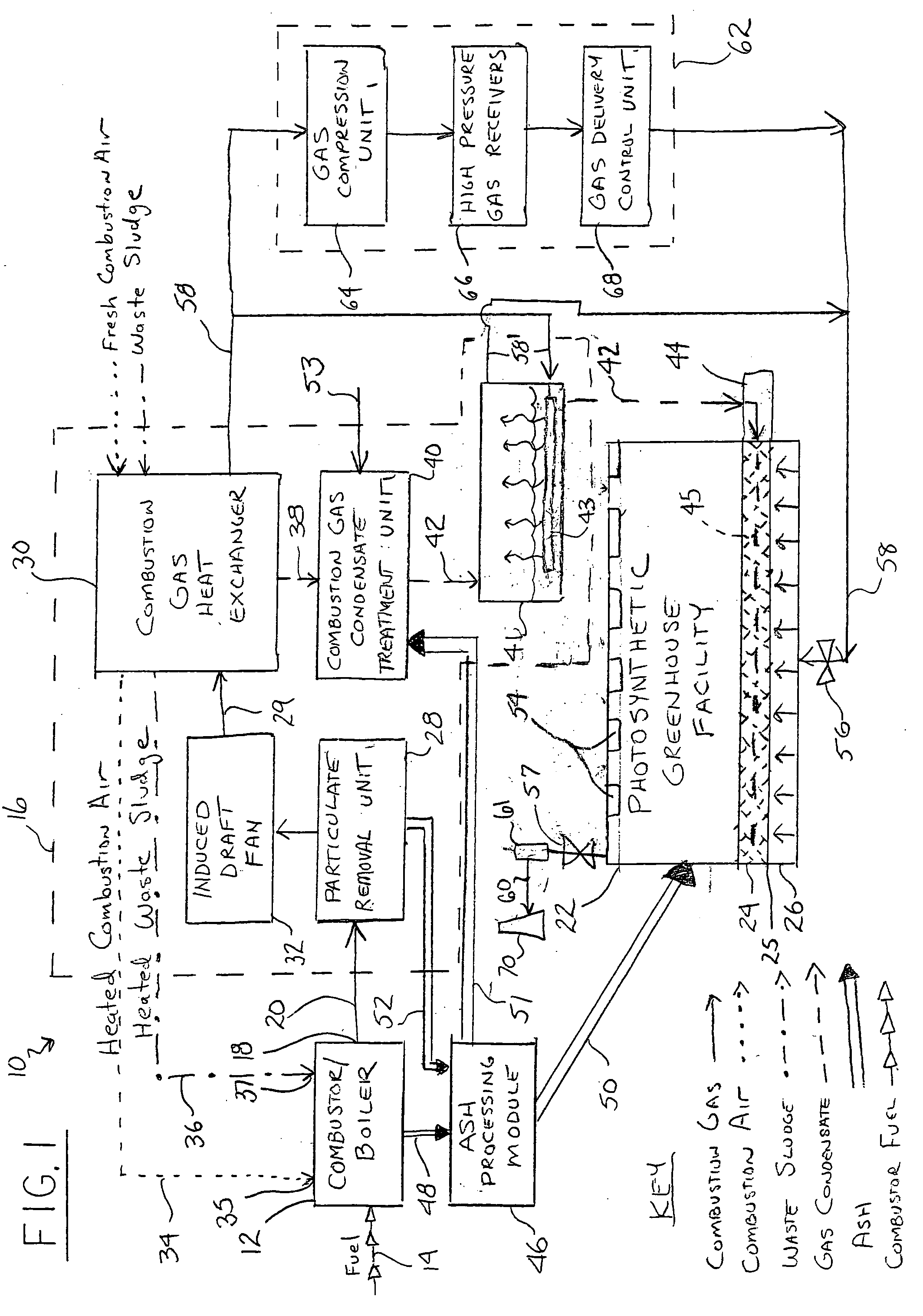

Method and system for sequestering carbon emissions from a combustor/boiler

A system for sequestering carbon emissions from a fuel combustor generally includes a combustion gas extraction module for extracting combustion gas from a fuel combustor and a greenhouse facility for receiving the extracted combustion gas and having at least one vegetation supporting soil bed for absorbing carbon dioxide from the received combustion gas. The extraction module includes a particulate removal unit for removing pollutants from the extracted combustion gas and a heat exchanger in downstream fluid communication with the particulate removal unit for cooling the extracted combustion gas.

Owner:ECO TECH LLC

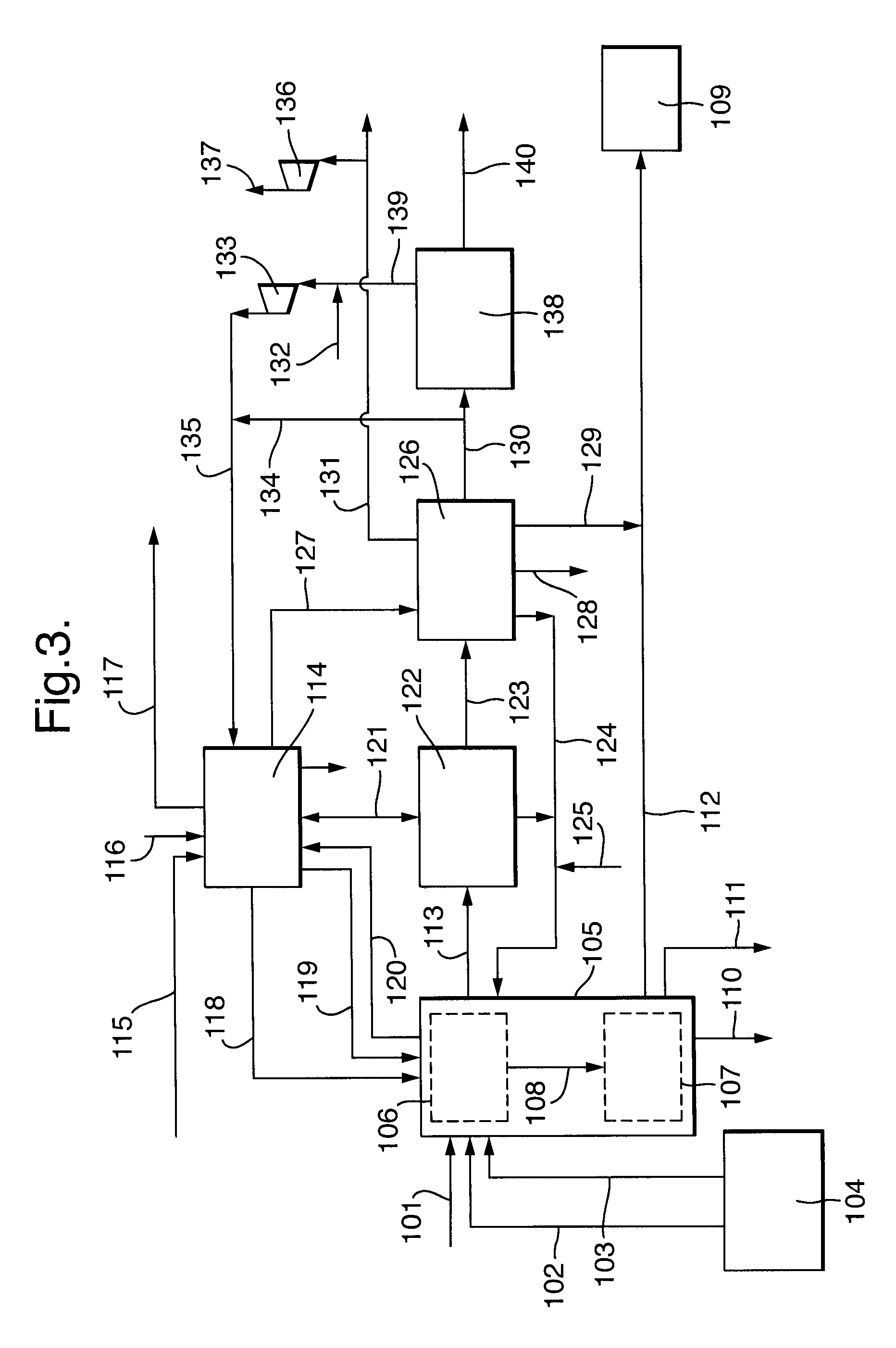

Integrated Fischer-Tropsch and power production plant with low CO2 emissions

A plant for producing Fischer-Tropsch liquids and electrical power with greatly reduced emissions of carbon dioxide to the atmosphere is made up of a syngas generator unit, an air separation unit, a Fischer-Tropsch unit, a CO2 removal unit, and a combined cycle electricity generation unit. Each of Fischer-Tropsch liquids, carbon dioxide, and electrical power can be recoverable under proper economic conditions. Electrical power is recoverable by the use of a gas turbine fueled by predominantly hydrogen and a steam turbine powered by steam generated by cooling exhaust gases from the gas turbine. Sequestration of CO2 and fueling the gas turbine with hydrogen reduces the amount of greenhouse gases emitted to the atmosphere.

Owner:RES USA LLC

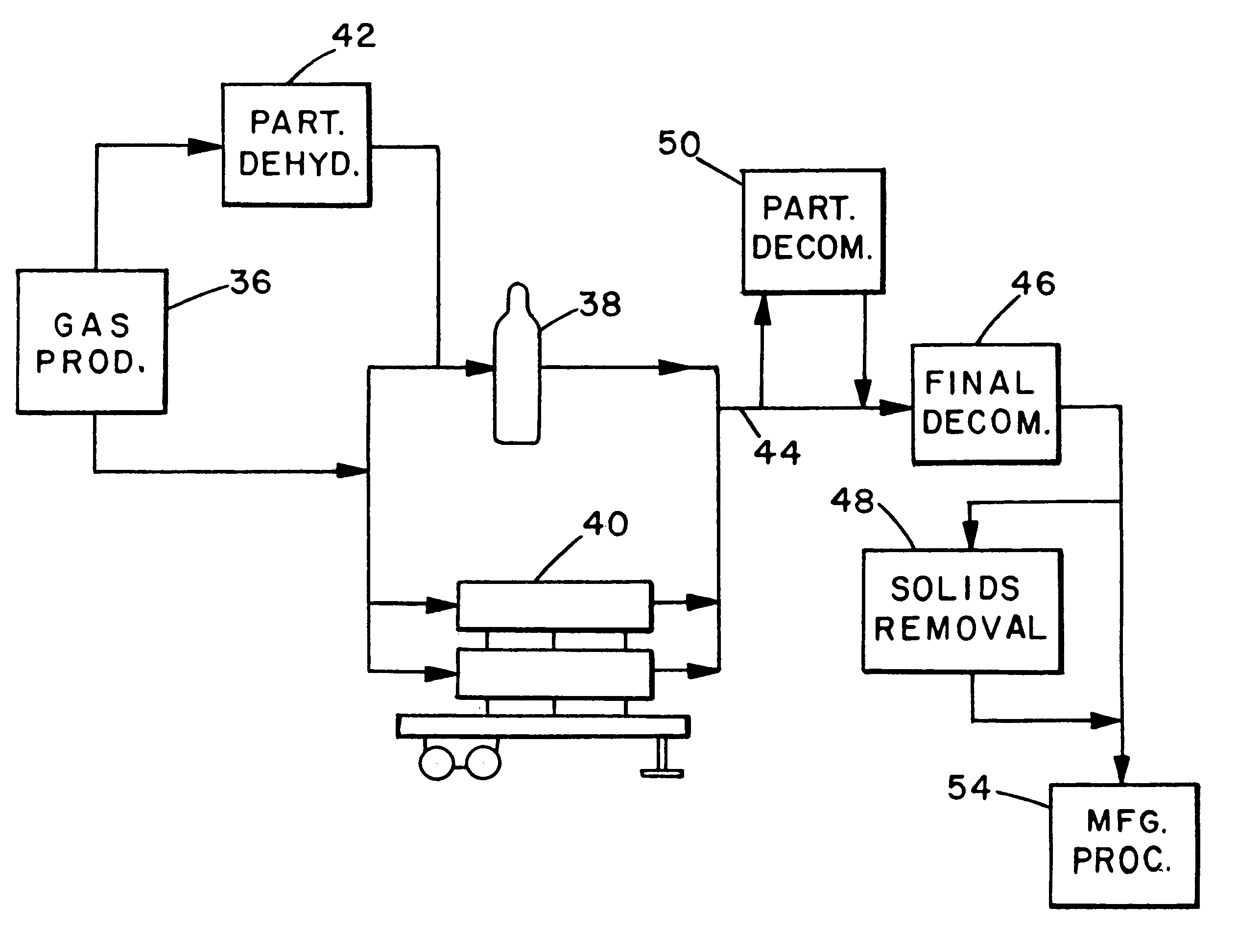

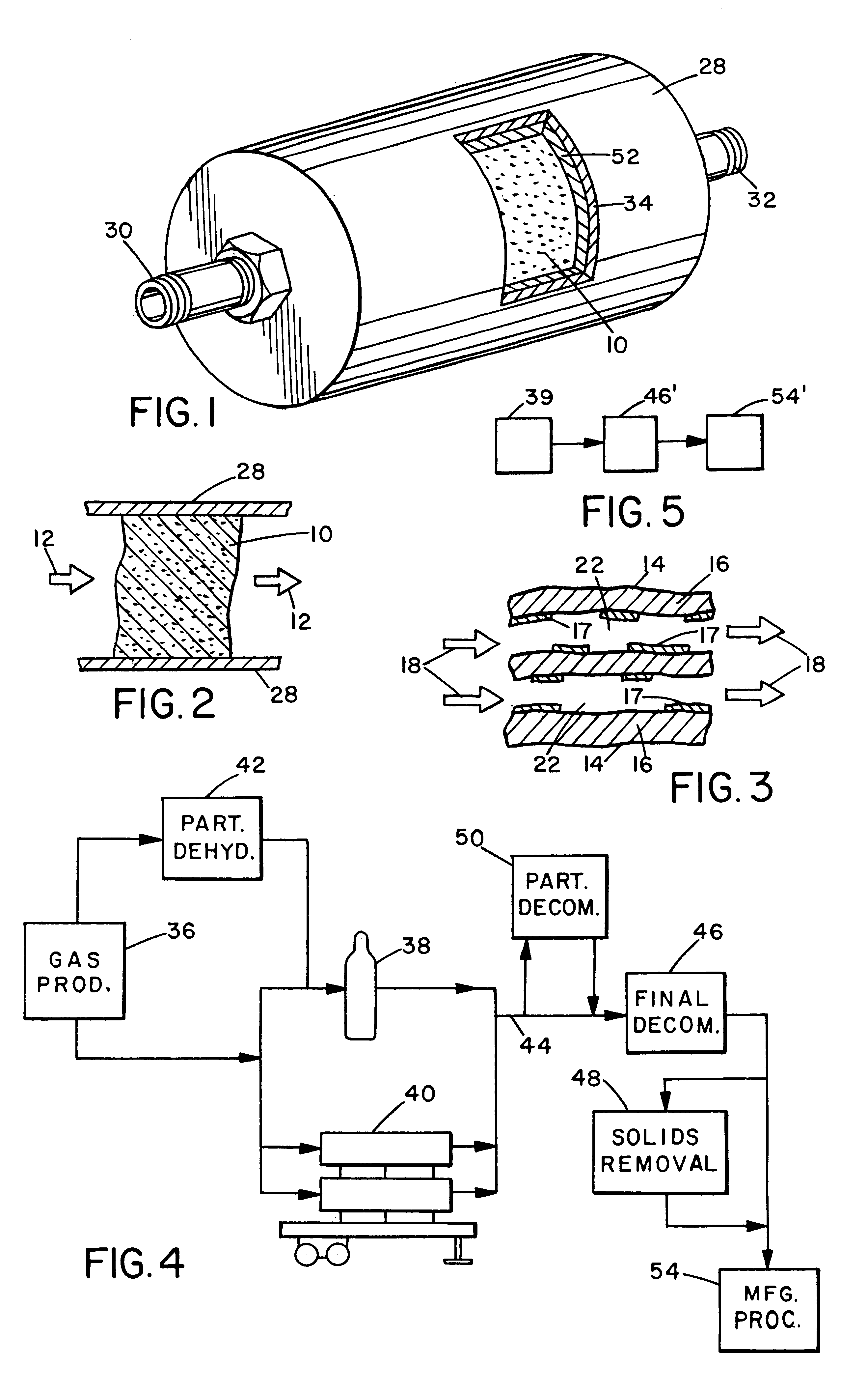

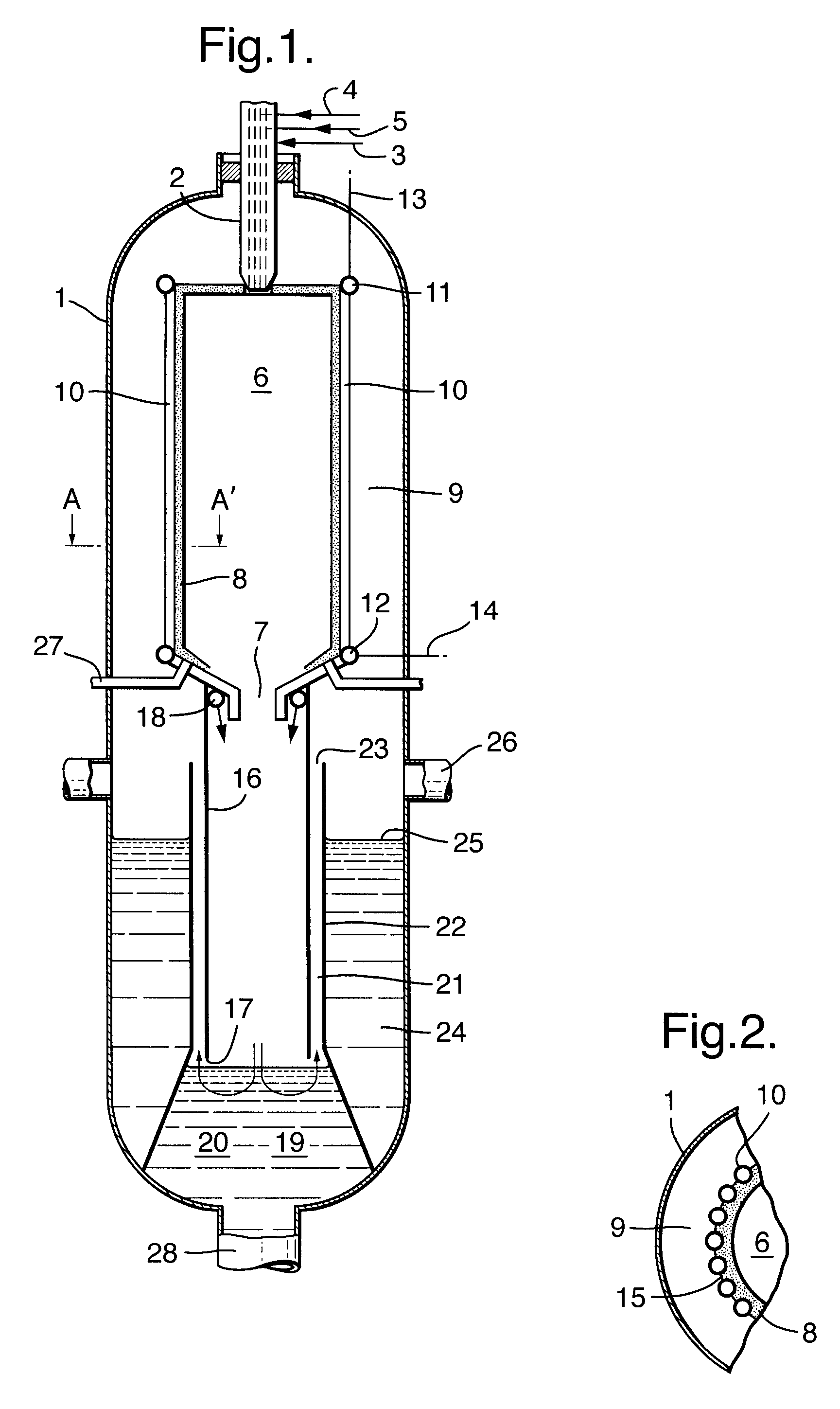

Method and apparatus for purification of hydride gas streams

A process and apparatus for the decontamination of gaseous contaminants (especially oxygen, carbon dioxide and water vapor) from hydride gases (including their lower alkyl analogs) down to <=100 ppb contaminant concentration are described. The critical component is a high surface area metal oxide substrate with reduced metal active sites, which in various physical forms is capable of decontaminating such gases to <=100 ppb, <=50 ppb or <=10 ppb level without being detrimentally affected by the hydride gases. The surface area of the substrate will be >=100 m2 / g, and preferably 200-800 m2 / g. Oxides of various metals, especially manganese or molybdenum, can be used, and mixtures of integrated oxides, or one type of oxide coated on another, may be used. The substrate is preferably retained in a hydride-gas-resistant container which is installed in a gas supply line, such as to a gas- or vapor-deposition manufacturing unit. The invention provides final decontamination for hydride gas streams intended for gas- or vapor-deposition formation of high purity LED, laser (especially blue laser), electronic, optical or similar products, and can be used in combination with upstream preliminary decontamination process and / or upstream or downstream solid particulate removal units.

Owner:SAES PURE GAS

Method and system for sequestering carbon emissions from a combustor/boiler

A system for sequestering carbon emissions from a fuel combustor generally includes a combustion gas extraction module for extracting combustion gas from a fuel combustor and a greenhouse facility for receiving the extracted combustion gas and having at least one vegetation supporting soil bed for absorbing carbon dioxide from the received combustion gas. The extraction module includes a particulate removal unit for removing pollutants from the extracted combustion gas and a heat exchanger in downstream fluid communication with the particulate removal unit for cooling the extracted combustion gas.

Owner:ECO TECH LLC

Key agreement system, shared-key generation apparatus, and shared-key recovery apparatus

ActiveUS20040165726A1Hinders derivationKey distribution for secure communicationPublic key for secure communicationContent distributionHash function

Provided is a content distribution system that prevents different keys to be derived between an encryption apparatus and a decryption apparatus. A random-number generating unit 112d, in an encryption apparatus 110d, generates a random number s, and a first function unit 113d generates a functional value G(s) of the random number s, and generates a verification value a and a shared key K from the functional value G(s). An encryption unit 114d generates a first cipher text c1 of the verification value a using a public-key polynomial h, and a second function unit 115d generates a functional value H(a,c1) of the verification value a and the first cipher text c1, and a random-number mask unit 116d generates a second cipher text c2=s xor H(a,c1). A decryption unit 123d, in a decryption apparatus 120d, decrypts the first cipher text c1 using a secret-key polynomial f, to generate a decryption verification value a'. A third function unit 124d generates a functional value H(a',c1) of the decryption verification value a' and the first cipher text c1, and a random-number mask removal unit 125d generates a decryption random number s'=c2 xor H(a',c1). A fourth function unit 126d generates a hash functional value G(s') of the decryption random number s', and generates a verification value a'' and a shared key K' from the functional value G(s') A comparison unit 127d outputs the shared key K' if the decryption verification value a' is equal to the verification value a''.

Owner:SAMARIA CO LTD

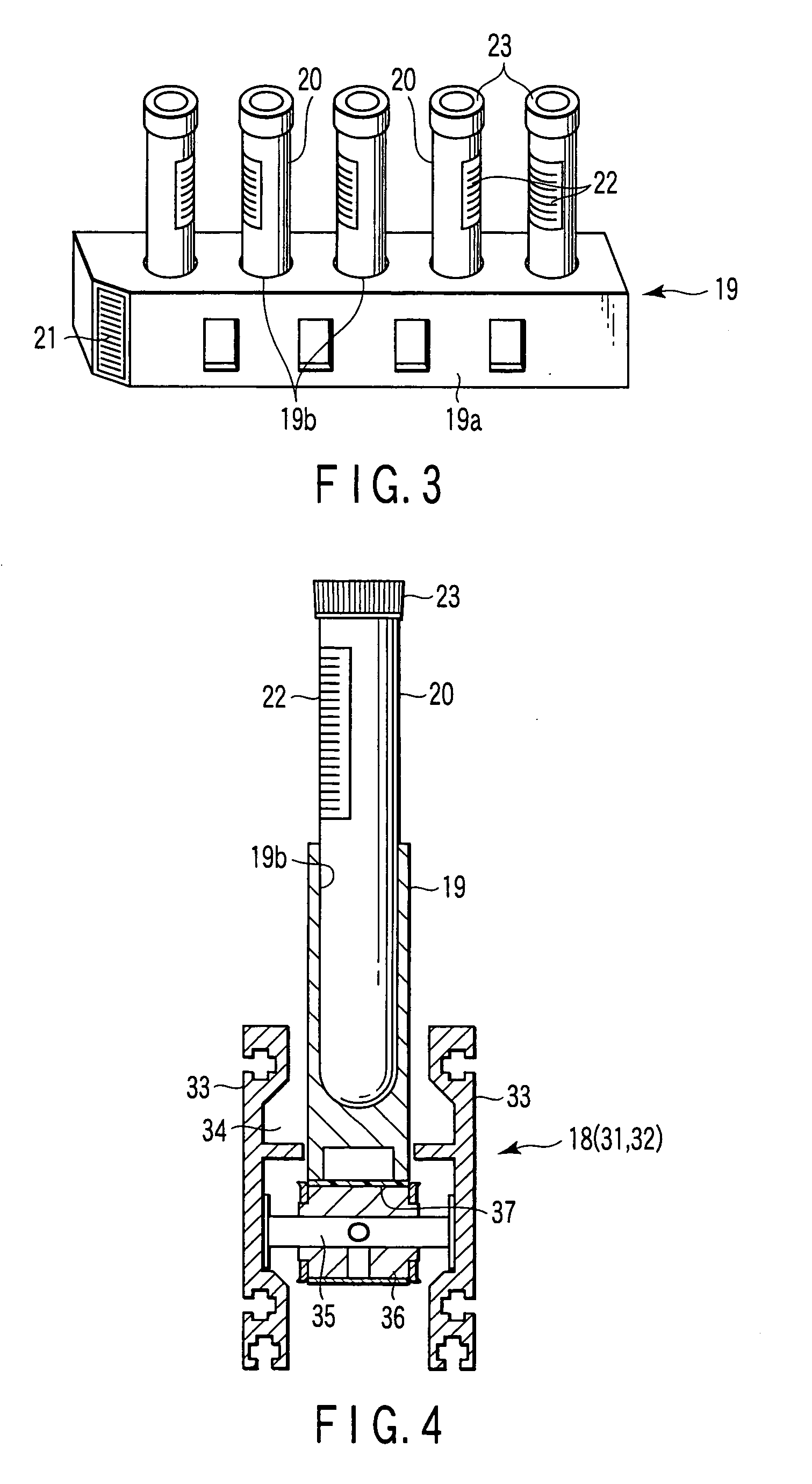

Automated test tube cap removal apparatus

ActiveUS20080170967A1Analysis using chemical indicatorsStopper removalBiomedical engineeringTest tube

A automated test tube cap removal apparatus includes, a cap remover, a test tube rack which holds a plurality of capped test tubes upright in a row, a clamping mechanism which is disposed in the cap removing position and clamps the plurality of test tubes, and a cap removal unit disposed in the cap removing position and configured to move upward to remove caps from some of a plurality of test tubes and move upward to remove caps from the remaining test tubes. The cap removal unit includes engaging members which are capable of advance and retreat with respect to the caps and clamp each cap, a lift mechanism which raises the engaging members while alternately moving the engaging members upward, thereby removing the cap from each test tube, a cap guide member which separates the cap and guides the cap for dropping.

Owner:IDS CO LTD

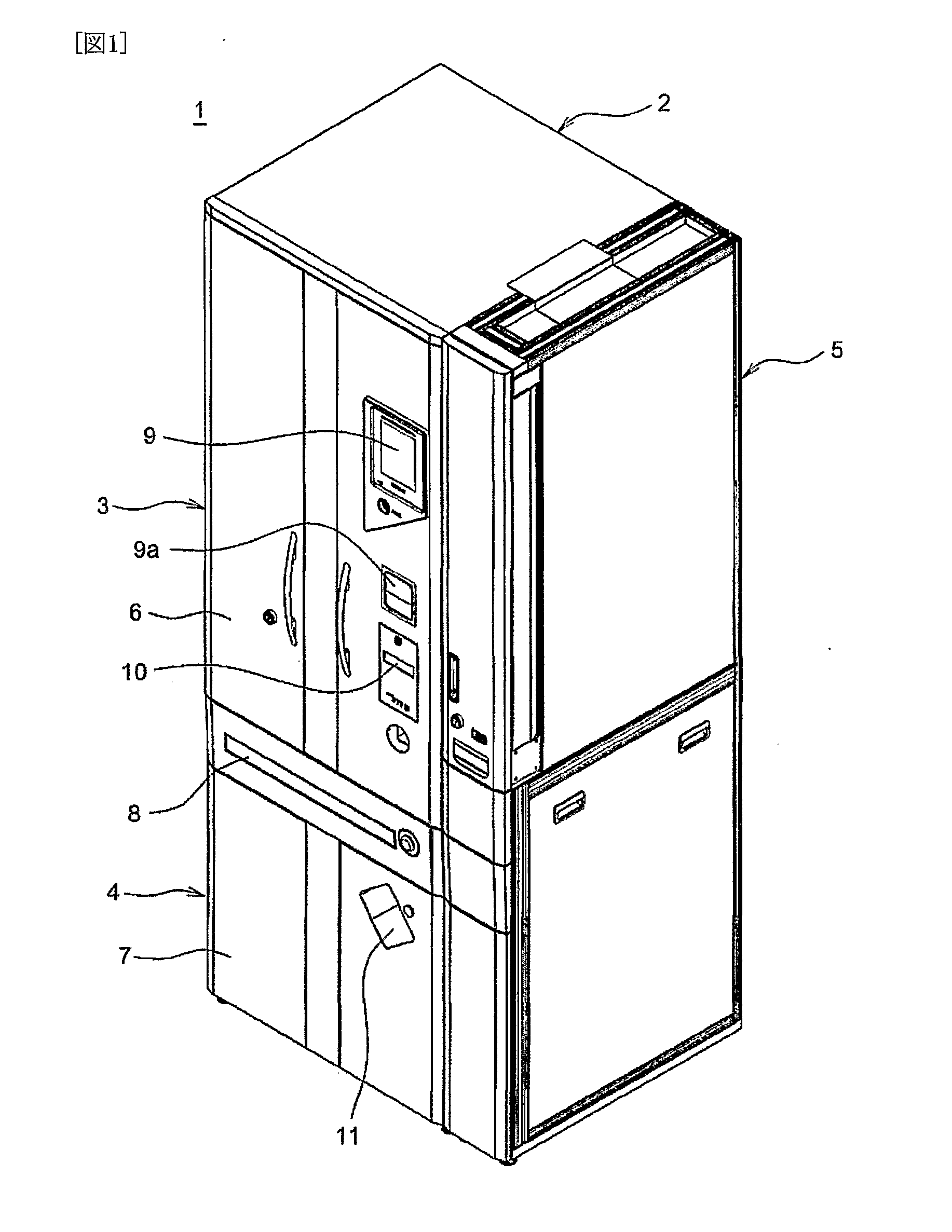

Medicine Delivering Device

InactiveUS20080029530A1Easy to insertGood adhesionInking apparatusManual label dispensersBiomedical engineeringMedical treatment

A medicine delivering device permits additional medicine cassettes to be provided at low cost without greatly enlarging the installation space. The medicine delivering device includes a medicine storage and removal unit in which many medicine cassettes each containing a medicine are detachably provided to the outer surface of a drum whose upper and lower ends are rotatable supported by the device body and a medicine packaging unit that packages medicine removed through a collecting hopper from the medicine cassette of the medicine storage and removal unit. There is provided on the side surface of the device body a sub medicine storage and removal unit including: a body; a drawer body provided to be capable of being pulled out from the body and that is detachably provided with a plurality of medicine cassettes each containing the medicine; and a guide that guides the medicine taken out from the medicine cassette to the collecting hopper.

Owner:YUYAMA MFG CO LTD

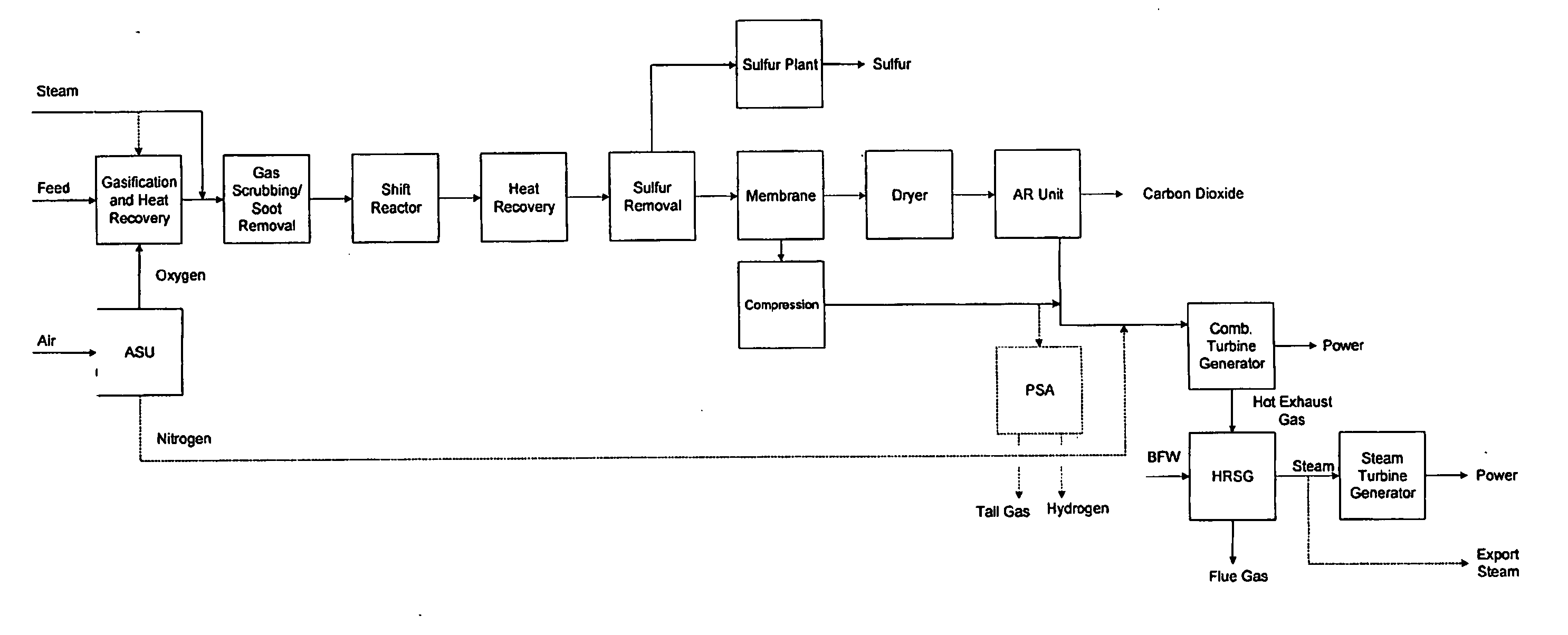

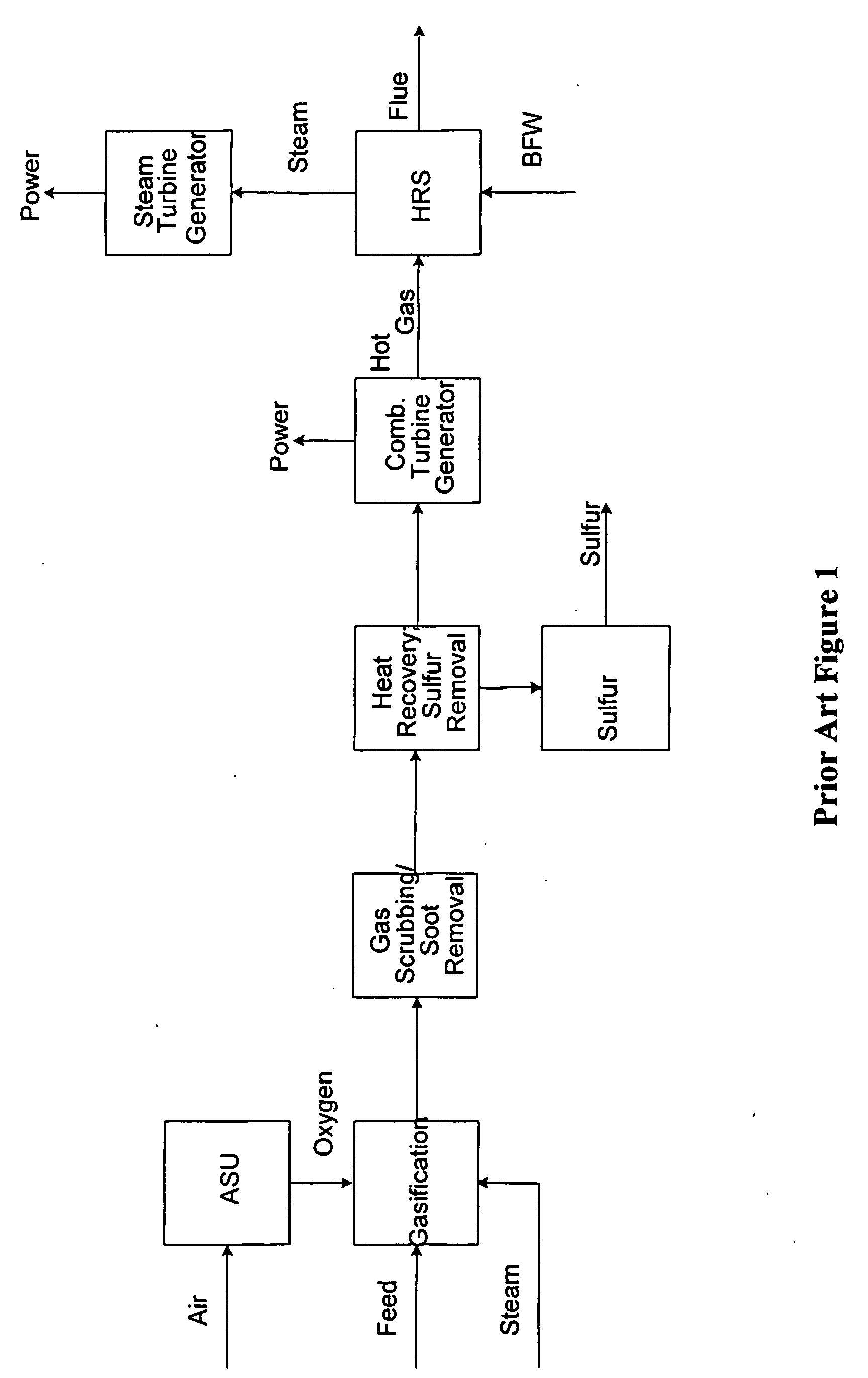

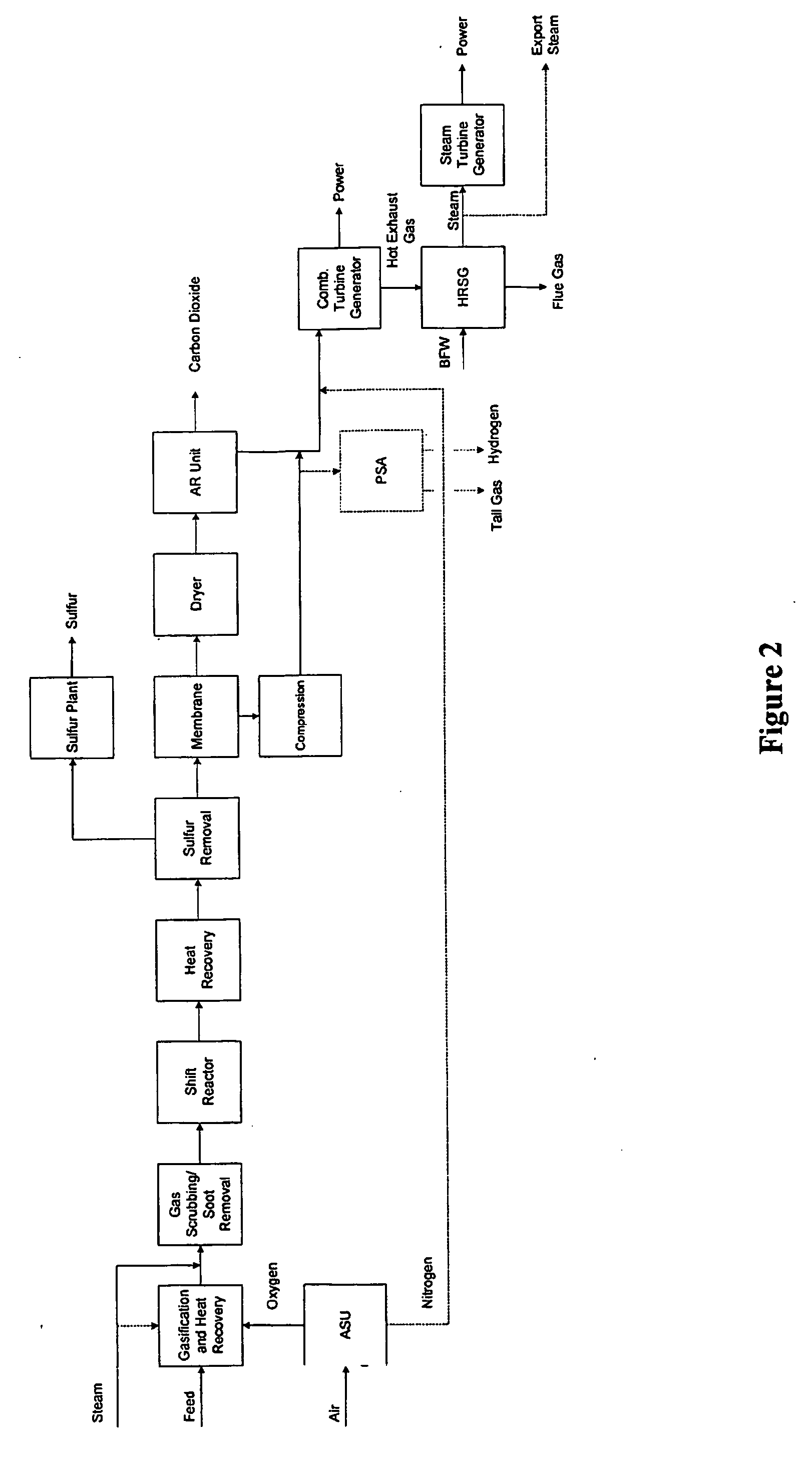

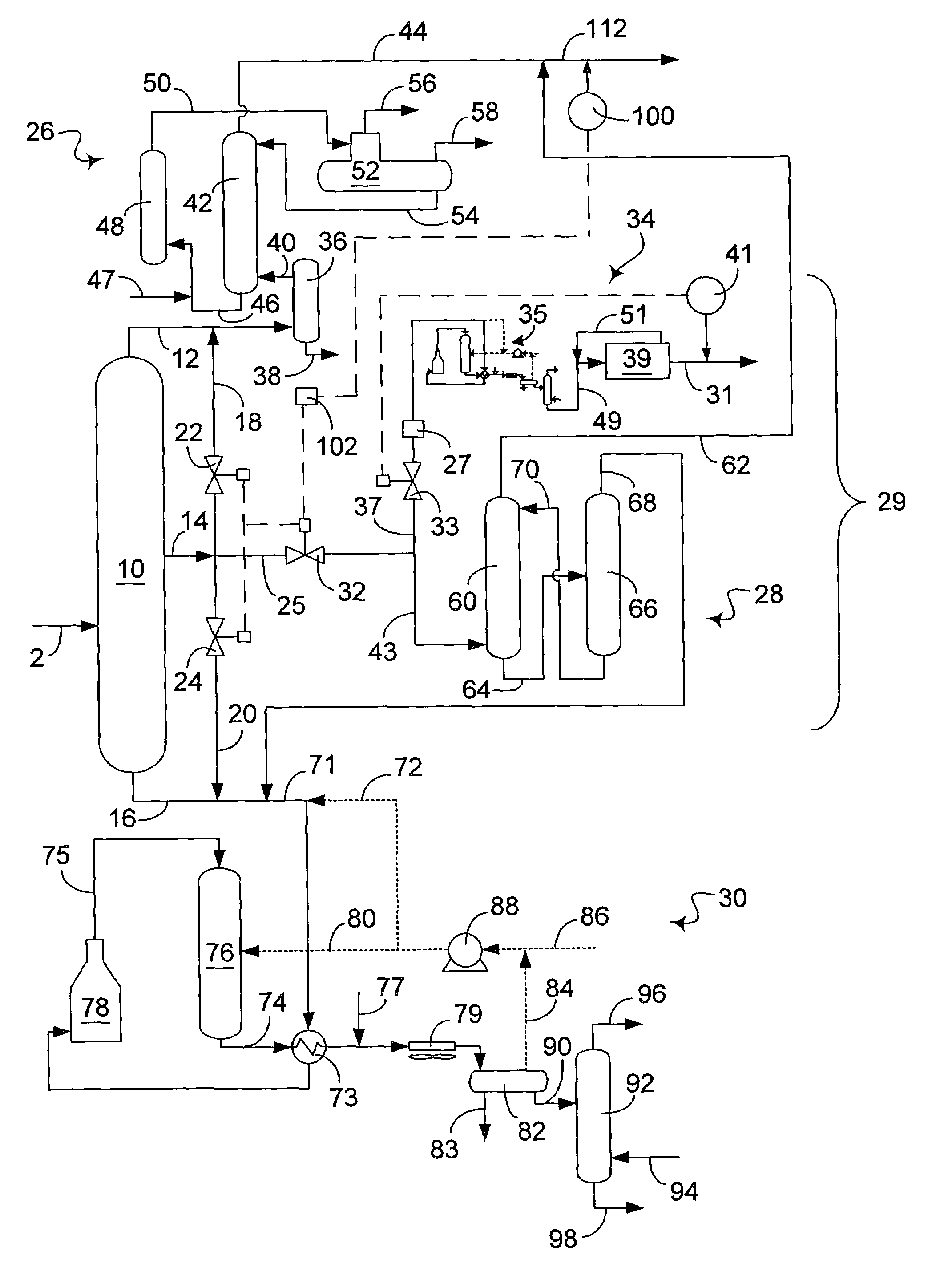

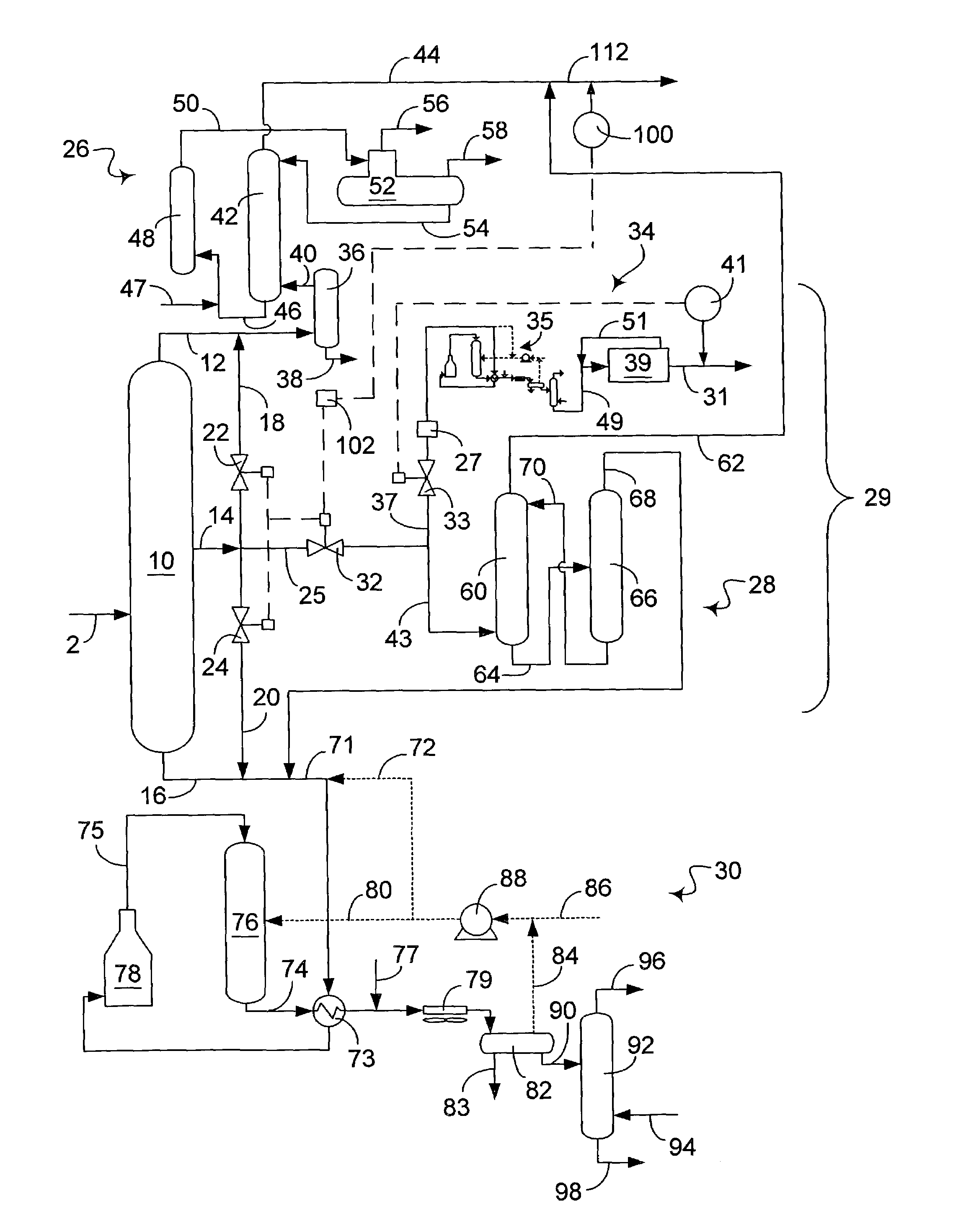

Configurations and methods of carbon capture

An IGCC plant has a precombustion decarbonization unit in which acid gas is removed from a combustion gas before the combustion gas enters a combustion turbine. In one preferred configuration, a sulfur removal unit removes hydrogen sulfide from a feed gas before the desulfurized feed gas enters an autorefrigeration unit in which carbon dioxide is removed. In another preferred configuration, hydrogen sulfide is converted to carbonyl sulfide in a dryer, and the carbonyl sulfide is absorbed in the liquid carbon dioxide that is prepared from the feed gas using autorefrigeration.

Owner:FLUOR TECHSE CORP

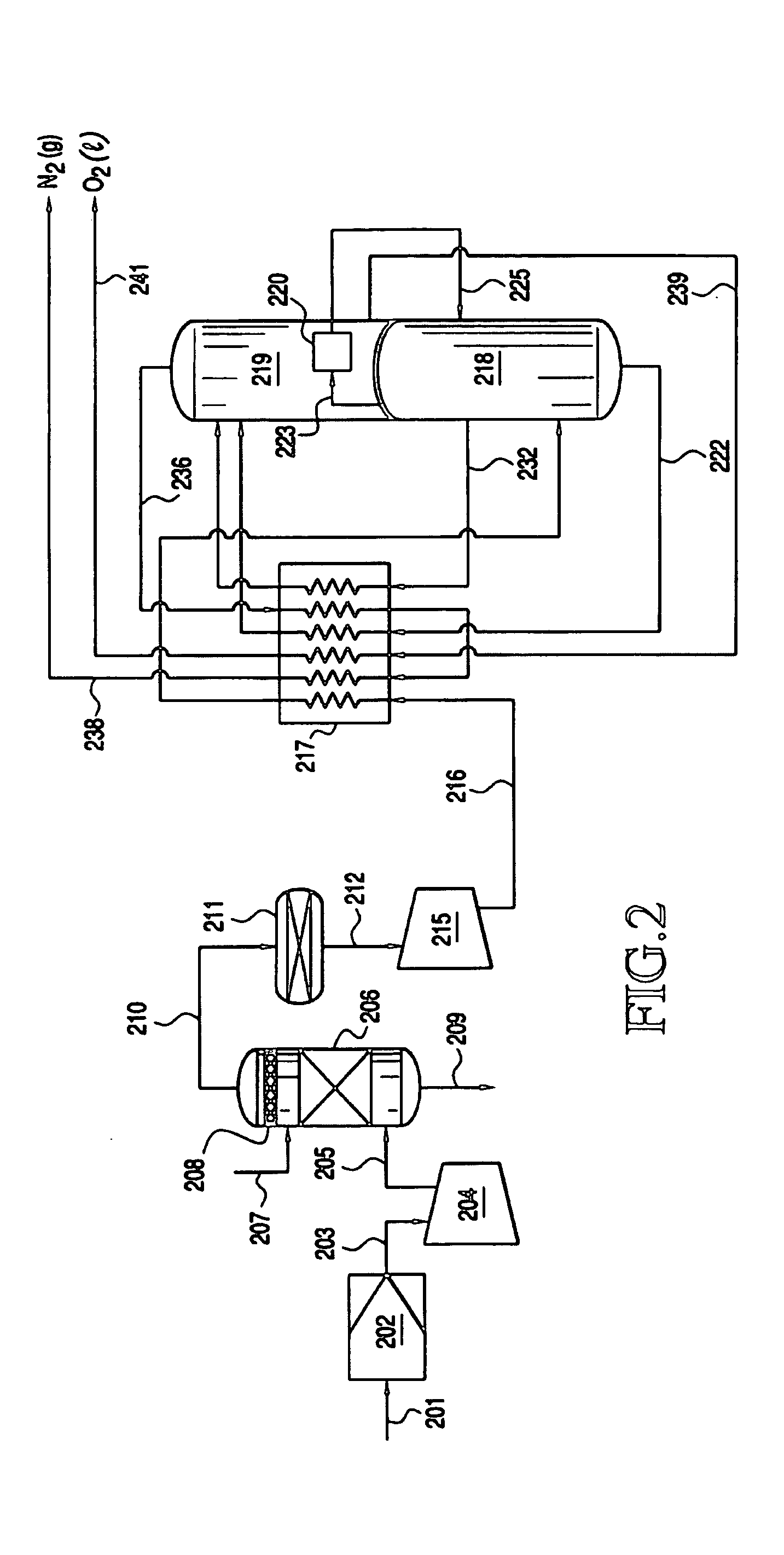

Integrating an air separation unit into an oxygenate-to-olefins reaction system

ActiveUS20050234278A1Reduce the amount of solutionSmall sizeSolidificationLiquefactionOxygen compoundPolymer

This invention provides an integrated system and process for forming light olefins and polymers from oxygenates, and optionally from natural gas. The integrated system includes an air separation unit, which separates air components into an oxygen stream and a nitrogen stream, and which also forms a compressed air stream. According to the present invention, the oxygen stream, the nitrogen stream and / or the compressed air stream from the air separation unit may serve as a reactant in syngas generation, as a regeneration medium in the methanol-to-olefins reaction system, as a fluidizing stream, as a blanketing medium, as a stripping medium, as instrument air, and / or as a reactant in a sulfur removal unit.

Owner:EXXONMOBIL CHEM PAT INC

Process and apparatus for removing sulfur from hydrocarbons

ActiveUS7005058B1Reduce operating expensesDelay capital expenditureRefining to eliminate hetero atomsCatalytic reformingBoiling point

Disclosed is an apparatus and process for controlling the sulfur content of effluent from a hydrocarbon fractionation column. The effluent includes a low boiling stream, a middle boiling stream and a high boiling stream. Either of the feed or the low boiling stream may be subjected to a mercaptan removal treatment such as thioetherification or mercaptan oxidation treatment. The high boiling stream is subjected to hydrotreatment which will rid the high boiling stream of almost all organic sulfur compounds. The middle boiling stream may be subjected to a sulfur treatment complex which may comprise a sulfur removal unit and / or a catalytic reforming unit which may already be present in the refinery. Control valves govern the flow of adding the middle boiling stream to the low boiling stream and the high boiling stream in response to the sulfur concentration of the overhead stream downstream of the mercaptan removal treatment.

Owner:UOP LLC

Reactor and process for mercaptan oxidation and separation in the same vessel

ActiveUS7223332B1Sweetening hydrocarbon streamSmall volumeRefining with oxygen compoundsLiquid displacementThiolKerosene

The present invention is an apparatus and process for oxidizing mercaptans in a preferably kerosene stream. By using a catalyst promoter, sufficient separation of hydrocarbon and aqueous alkali occurs in the reactor vessel to obviate the need for a settling tank. Hence, the sweetened kerosene can be withdrawn from the reactor vessel and sent directly to a residual alkali removal unit such as a sand filter vessel or to a water wash vessel if jet grade fuel is desired. In an embodiment, the reactor vessel used for this purpose includes a reaction section and a separation section in the same reactor vessel and an aqueous alkali outlet and a sweetened hydrocarbon outlet in the separation section.

Owner:UOP LLC

Vacuum cleaner

An upright cleaner removes dust from a drum brush. The upright cleaner includes a case having a suction port, a drum brush rotatably provided in the case to sweep and guide foreign matter to the suction port, a dust removal unit provided in the case so that the dust removal unit is moved between a first position where one side of the dust removal unit contacts the drum brush and a second position where the side of the dust removal unit is separated from the drum brush, and a lever connected to the dust removal unit to actuate the dust removal unit.

Owner:SAMSUNG ELECTRONICS CO LTD

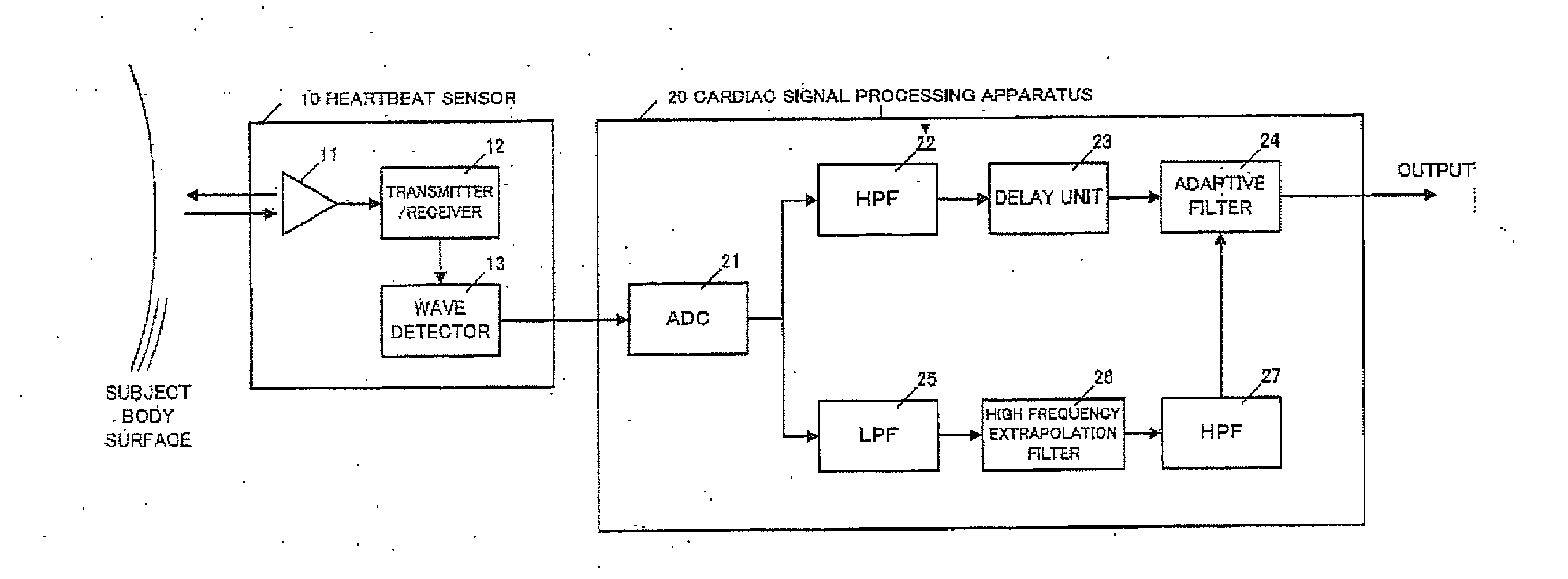

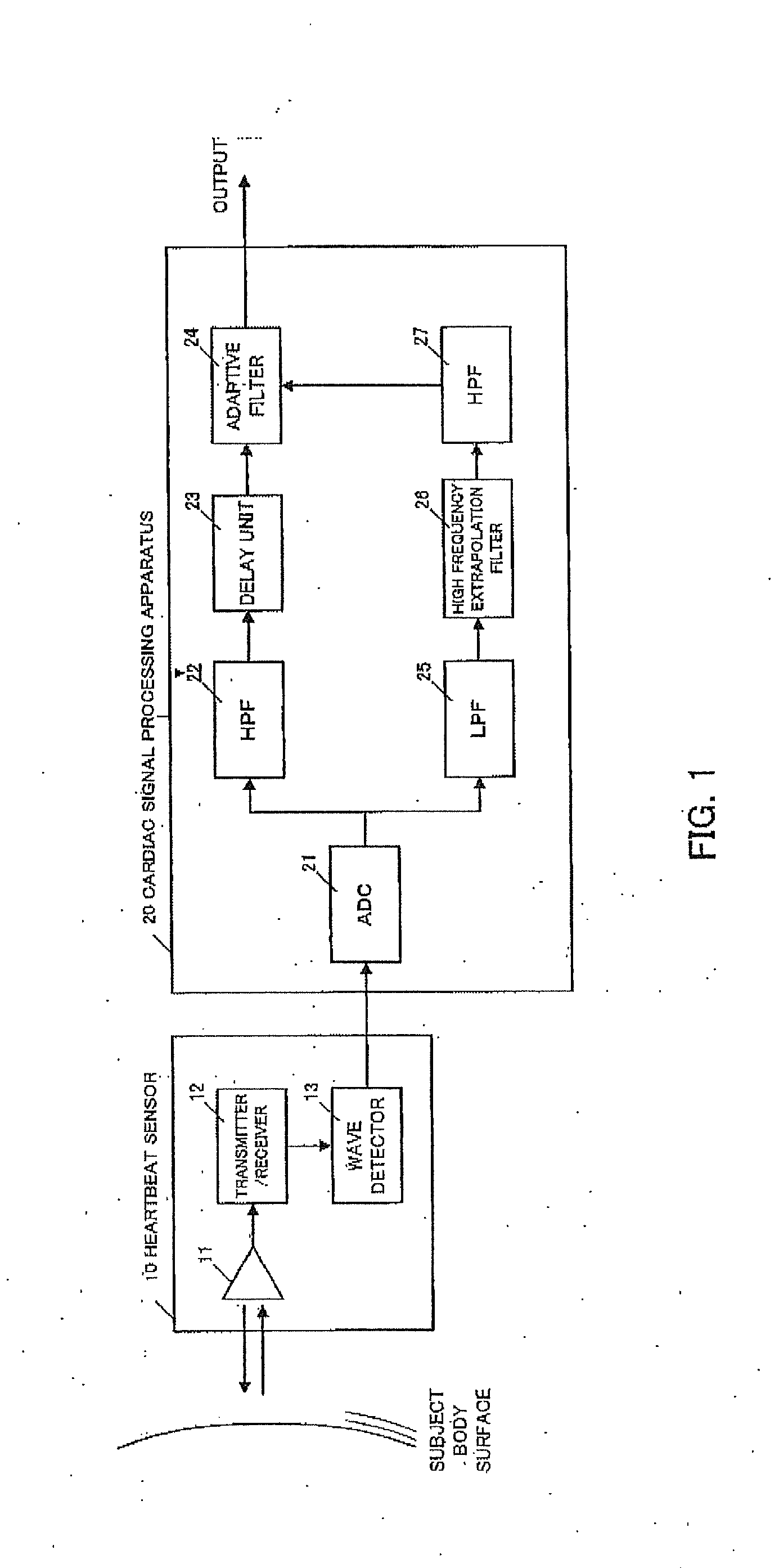

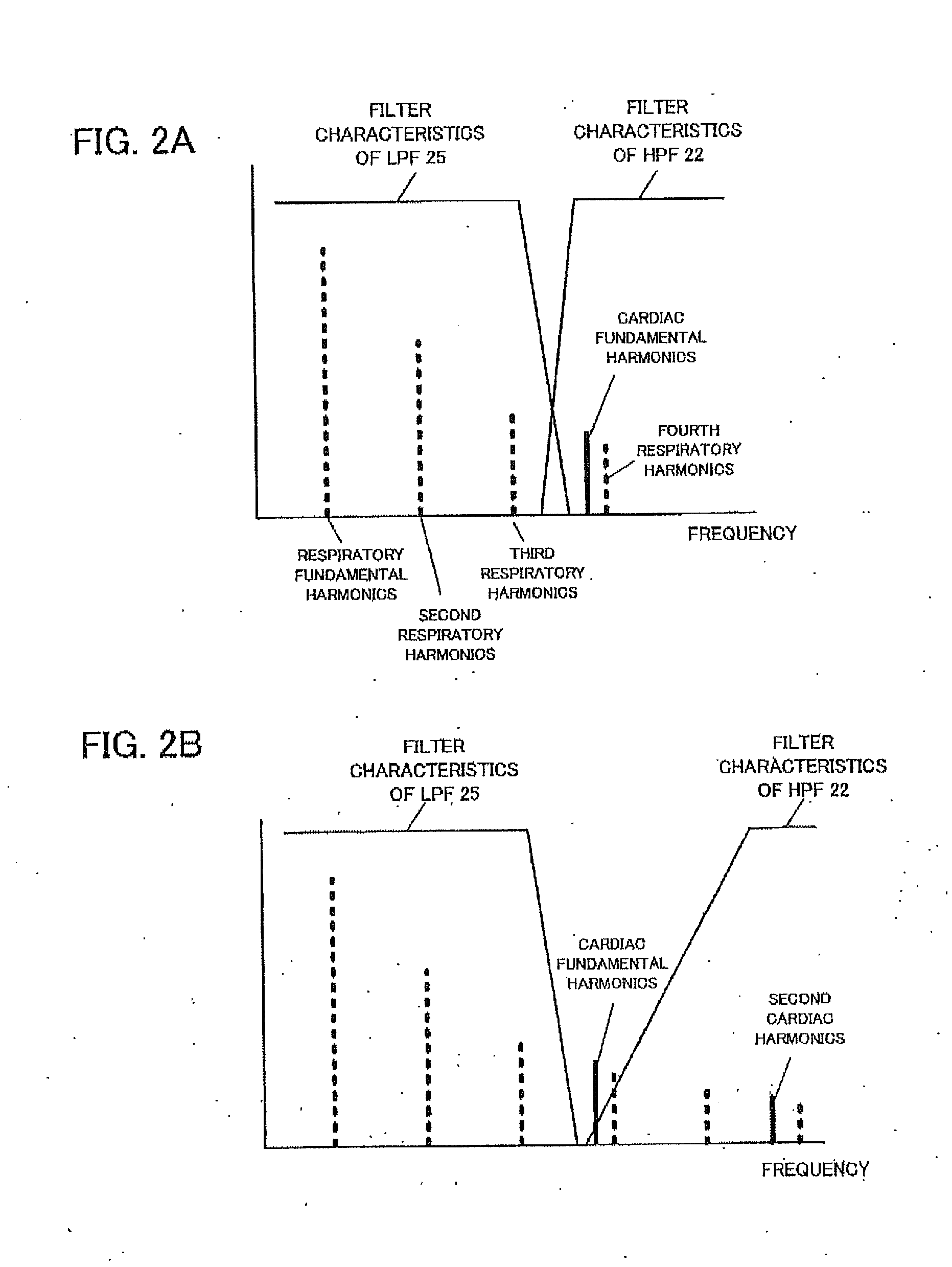

Cardiac signal processing apparatus and cardiac signal processing method

ActiveUS20130197377A1Eliminate distractionsComponent with highCatheterSensorsBand-pass filterEngineering

A cardiac signal processing apparatus includes: a unit for acquiring, from a heartbeat sensor, cardiac signals relating to heartbeats of a subject; a low-pass filter for allowing passage of those cardiac signals having a first predetermined frequency or lower, among the cardiac signals; higher harmonic noise acquisition unit for acquiring harmonic signals of low-frequency noise by performing high frequency extrapolation on the signals output from the low-pass filter; a high-pass filter for allowing passage of those cardiac signals having a second predetermined frequency or higher, among the cardiac signals; and higher harmonic noise removal unit for removing the harmonic signals of low-frequency noise from the signals output from the high-pass filter. It is thus made possible to remove noise from the cardiac signals and to obtain desirable heartbeat detection characteristics.

Owner:TOYOTA JIDOSHA KK

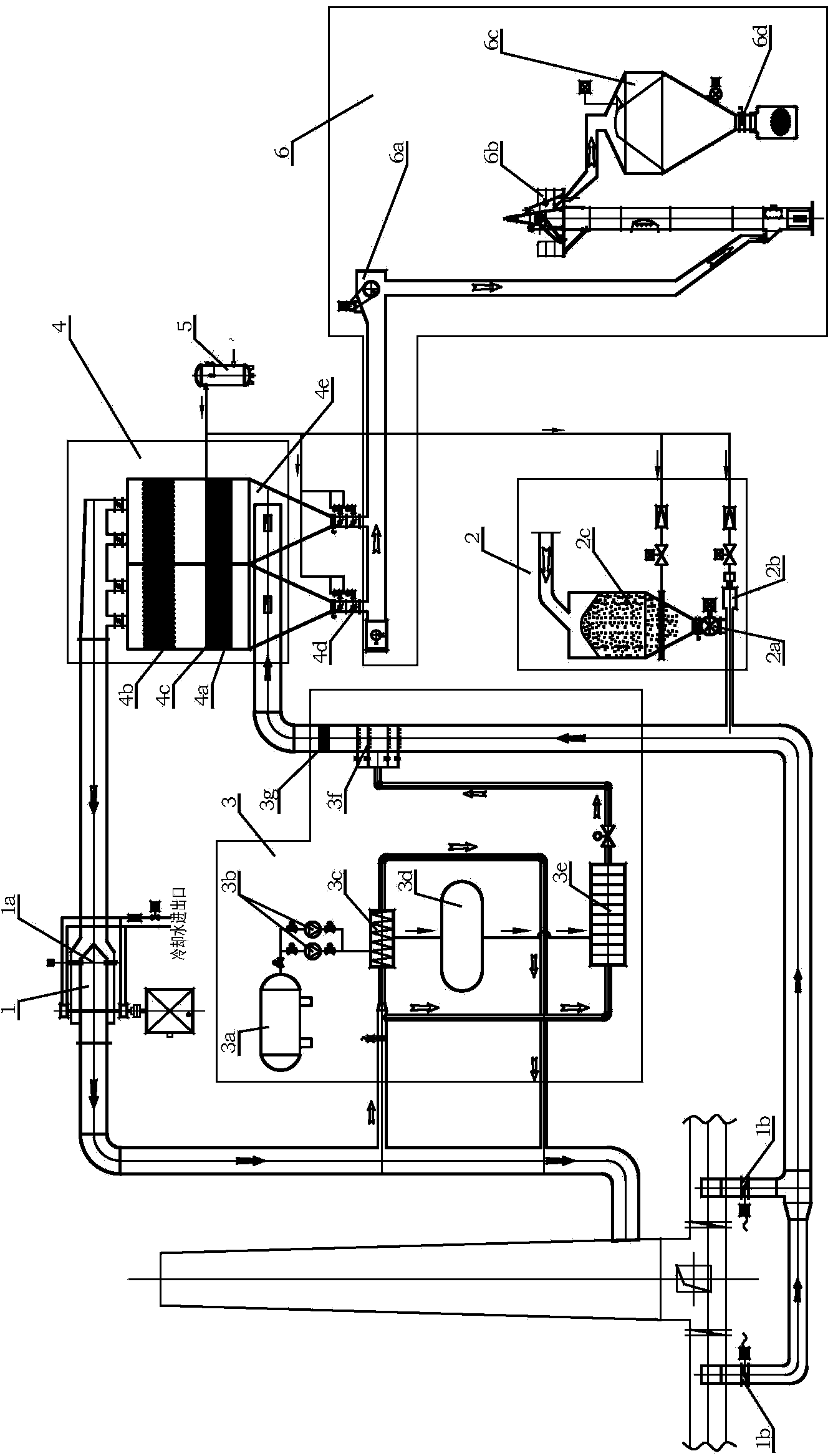

Low-temperature coke oven flue waste gas desulphurization and denitration process

ActiveCN103816796AFully contactedReduce efflux concentrationDispersed particle separationFlue gasCoke oven

The invention relates to a low-temperature coke oven flue waste gas desulphurization and denitration process. According to the process, fluidized NaHCO3 fine powder is jetted into a flue gas conveying pipeline, so as to remove most of SO2 in the flue gas through the dry process; meanwhile, a denitration catalyst structure layer and an ammonia removal catalyst structure layer are combined for use, so that NOx in the coke oven flue gas is effectively removed; a denitration catalyst adopts a filtering-bag-shaped structure, and the ammonia removal catalyst adopts a V-shaped structure. The process utilizes a system consisting of an induced draft unit, a desulphurization unit, an ammonia preparation unit, a denitration and ammonia removal unit, a compressed air unit and a particle conveying unit to realize efficient denitration and desulphurization; compared with the prior art, the process has the benefits that residual ammonia water in a coking plant is fully utilized, a process combining a dry desulphurization method with an SCR (Selective Catalytic Reduction) denitration method is adopted, and the denitration catalyst and the ammonia removal catalyst are combined together, so that the efficient low-temperature coke oven flue gas desulphurization and denitration is realized.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Automated test tube cap removal apparatus

Owner:IDS CO LTD

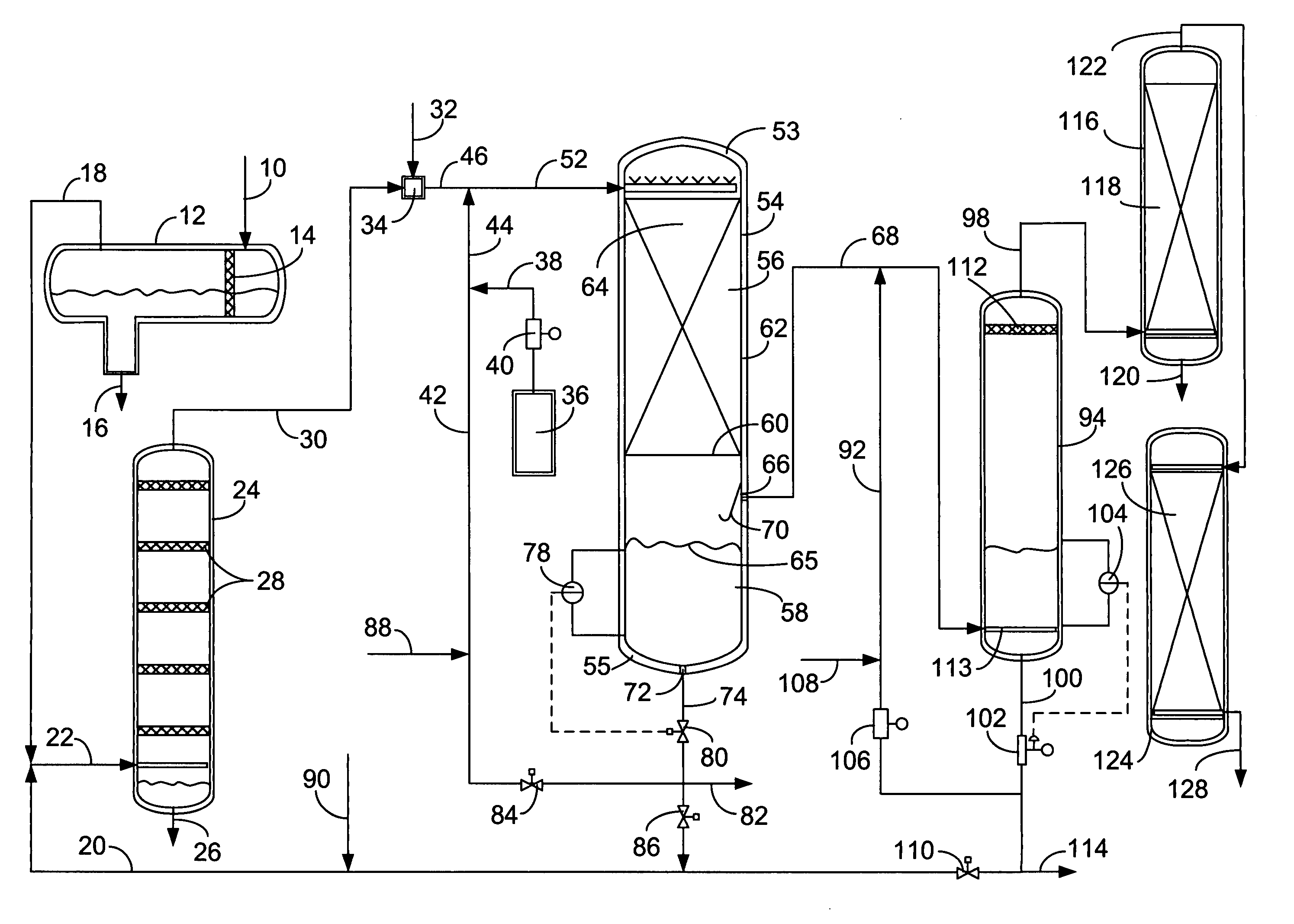

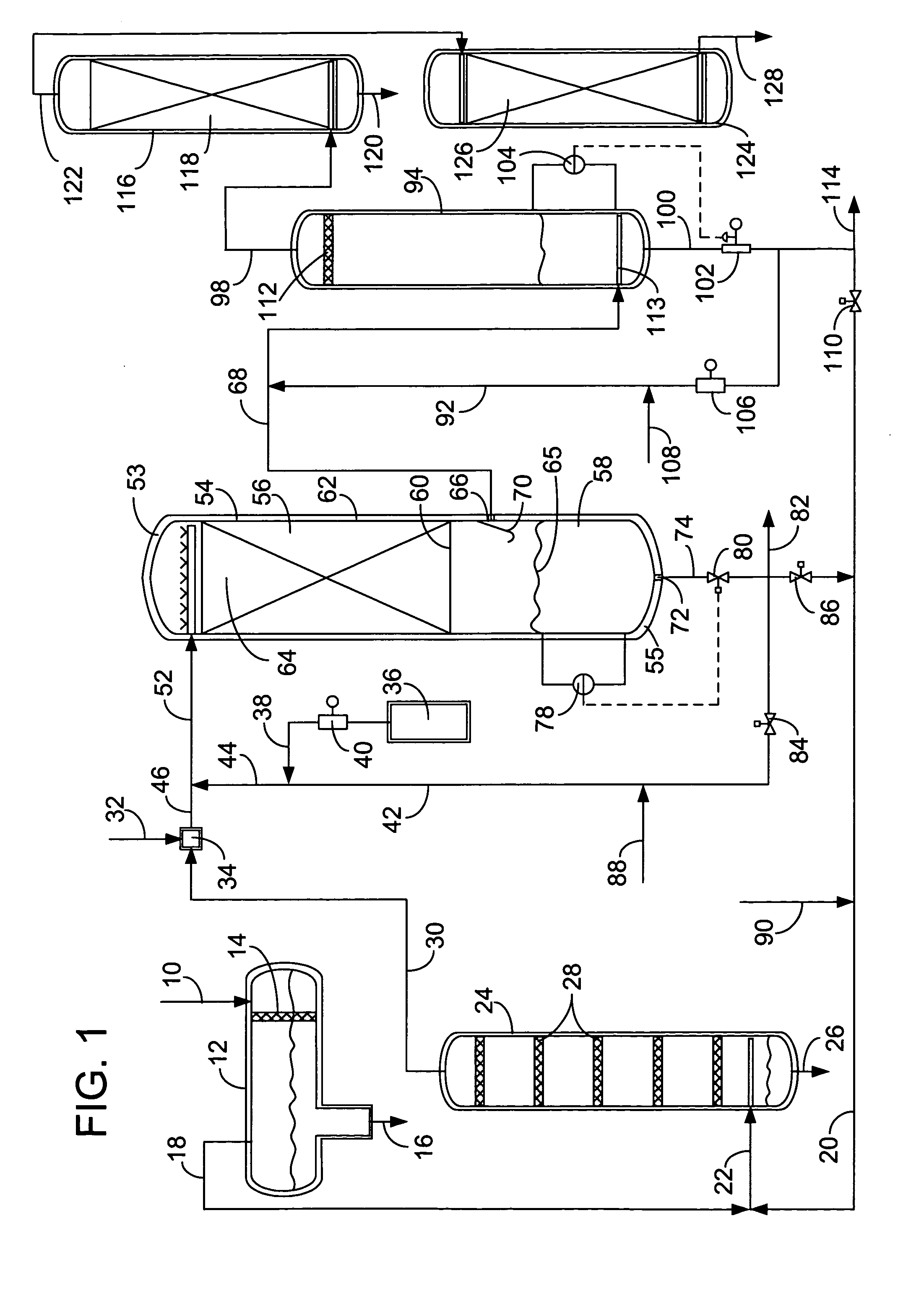

Process to prepare a sweet crude

ActiveUS20080142408A1Hydrocarbon distillationCombustible gas catalytic treatmentOil sandsRemoval Units

A process to prepare a sweet crude from an ash containing and heavy fraction of a tar sand oil by:(a) supplying an atmospheric distillation bottoms of a tar sands originated feed to a vacuum distillation to obtain a vacuum gas oil and a vacuum bottoms,(b) contacting the vacuum gas oil with hydrogen in the presence of a suitable hydrocracking catalyst to obtain a sweet synthetic crude(c) separating the vacuum bottoms obtained in step (a) into an asphalt fraction comprising between 0.1 and 4 wt % ash and a de-asphalted oil,(d) feeding said asphalt fraction to a burner of a gasification reactor where the asphalt fraction is partially oxidized in the presence of an oxidizer gas in a burner to obtain a mixture of hydrogen and carbon monoxide,(e) performing a water gas shift reaction on the mixture of hydrogen and carbon monoxide,(f) separating hydrogen sulphide and carbon dioxide from the shifted gas in an acid removal unit thereby obtaining crude hydrogen,(g) purifying the crude hydrogen to obtain pure hydrogen and(h) using part of the pure hydrogen in step (b), wherein in step (d) the asphalt fraction is provided to the burner in a liquid state and wherein in case separation step (c) fails to provide sufficient feed for step (d), step (d) is performed by feeding the vacuum bottoms of step (a) to the burner in a liquid state.

Owner:AIR PROD & CHEM INC

Control of water treatment system with low level boron detection

ActiveUS7264737B2Improve electricity efficiencyOptimize overall demineralizationSolvent extractionScale removal and water softeningWater treatment systemEngineering

A water treatment system and method including a membrane-based boron removal unit includes a boron analyzer for detecting the concentration of boron in a treatment stream. The boron removal unit can be a reverse osmosis (RO) or electrodeionization (EDI) treatment unit. A controller responds to the detected boron concentration to control an operation of the RO or EDI units. In an EDI system, the controller may adjust current or voltage supplied to match current to changes in ionic load and maintain a portion of the dilute cell in a substantially regenerated state. In an RO system, the controller may control the high pressure side flow rate, the brine blowdown rate, the product water permeation rate, pH, or feed rate of chemicals in response to the detected boron concentration value.

Owner:IONICS INC

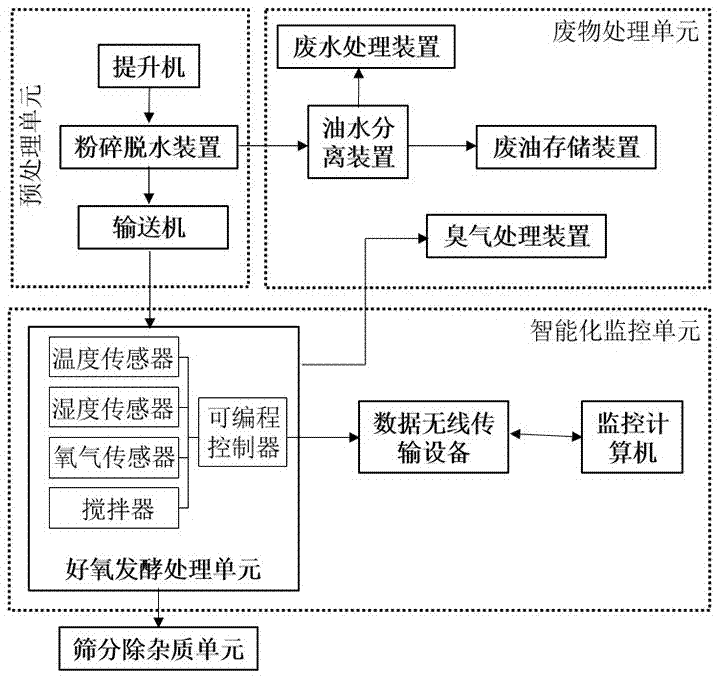

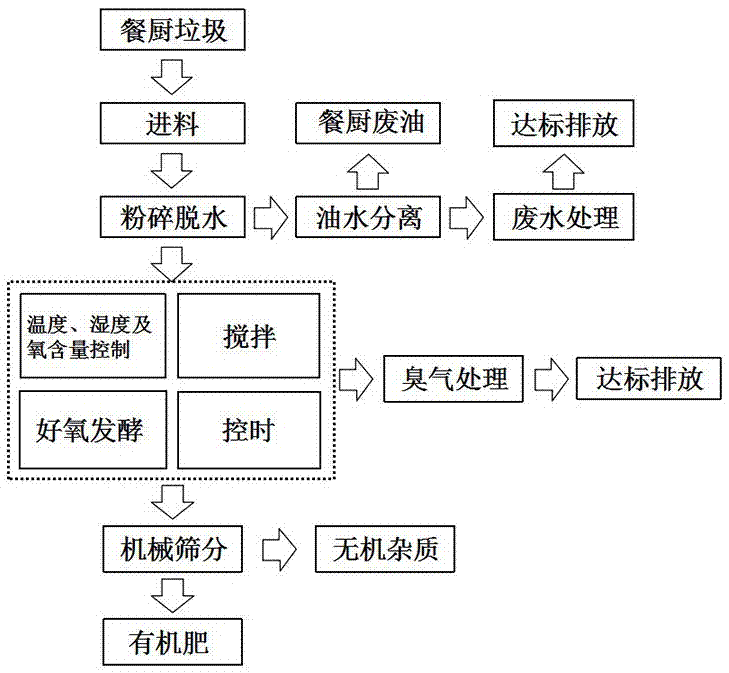

Novel kitchen waste treatment system and technology based on intelligent monitoring

InactiveCN106975645AImprove work efficiencyImprove biological activitySolid waste disposalIntelligent lightingOxygen

The invention discloses a novel food waste treatment system based on intelligent monitoring and a process thereof. The food waste treatment system based on intelligent monitoring of the present invention is characterized in that: the system comprises a pretreatment unit, an aerobic Fermentation processing unit, screening and removing impurities unit, waste processing unit and intelligent monitoring unit. The present invention also provides a kitchen waste treatment process, which is characterized by comprising the following steps: firstly, the collected kitchen waste is pulverized and dehydrated to obtain oil-water mixed liquid and residue particles; then the residue particles enter the aerobic state through a conveyor. The fermentation tank is mixed and stirred with fermentation strains, and aerobic fermentation is carried out at the same time to generate odor and organic materials; finally, the organic materials are mechanically screened by the screening and removal unit to separate organic materials and inorganic impurities to obtain high-quality organic materials. The fertilizer is used for recycling; the waste water obtained from dehydration and the odor generated during the aerobic fermentation process will be properly treated and disposed of by the waste treatment unit and then discharged up to the standard.

Owner:杭州科瑞特环境技术有限公司

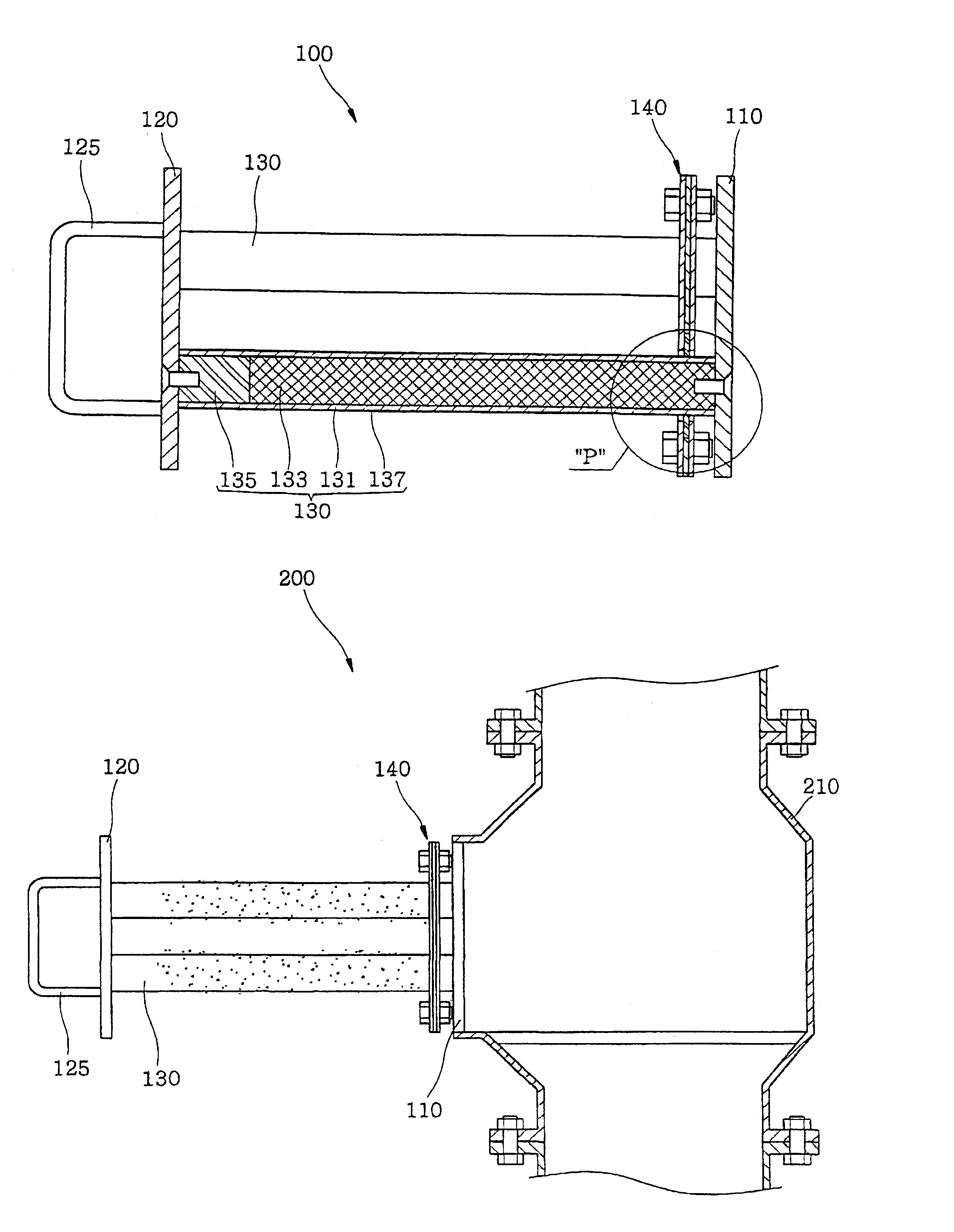

Removal unit for metal alien material removal apparatus

InactiveUS6902066B2Easily and conveniently removeWater/sewage treatment by magnetic/electric fieldsFiltration separationForeign matterMaterial removal

Disclosed is a removal unit for removing metallic alien materials, which is adapted to remove metallic alien materials such as metal fragments contained in powder or liquid raw materials. The removal unit includes an outer plate, an inner plate spaced apart from the outer plate, and magnet members coupled between the inner and outer plates. Each magnet member includes a cylindrical stainless steel rod, a magnet received in the stainless steel rod to extend from one end of the stainless steel rod to at least an intermediate portion of the stainless steel rod, a non-magnetic piece received in the other end of the stainless steel rod and coupled to the outer plate, and a fluorine resin coating formed over an outer peripheral surface of the stainless steel rod. A removal member is arranged to be slidable in a longitudinal direction along the magnet members while being in contact with the outer peripheral surfaces of the magnet members.

Owner:YANG BYEONG GON

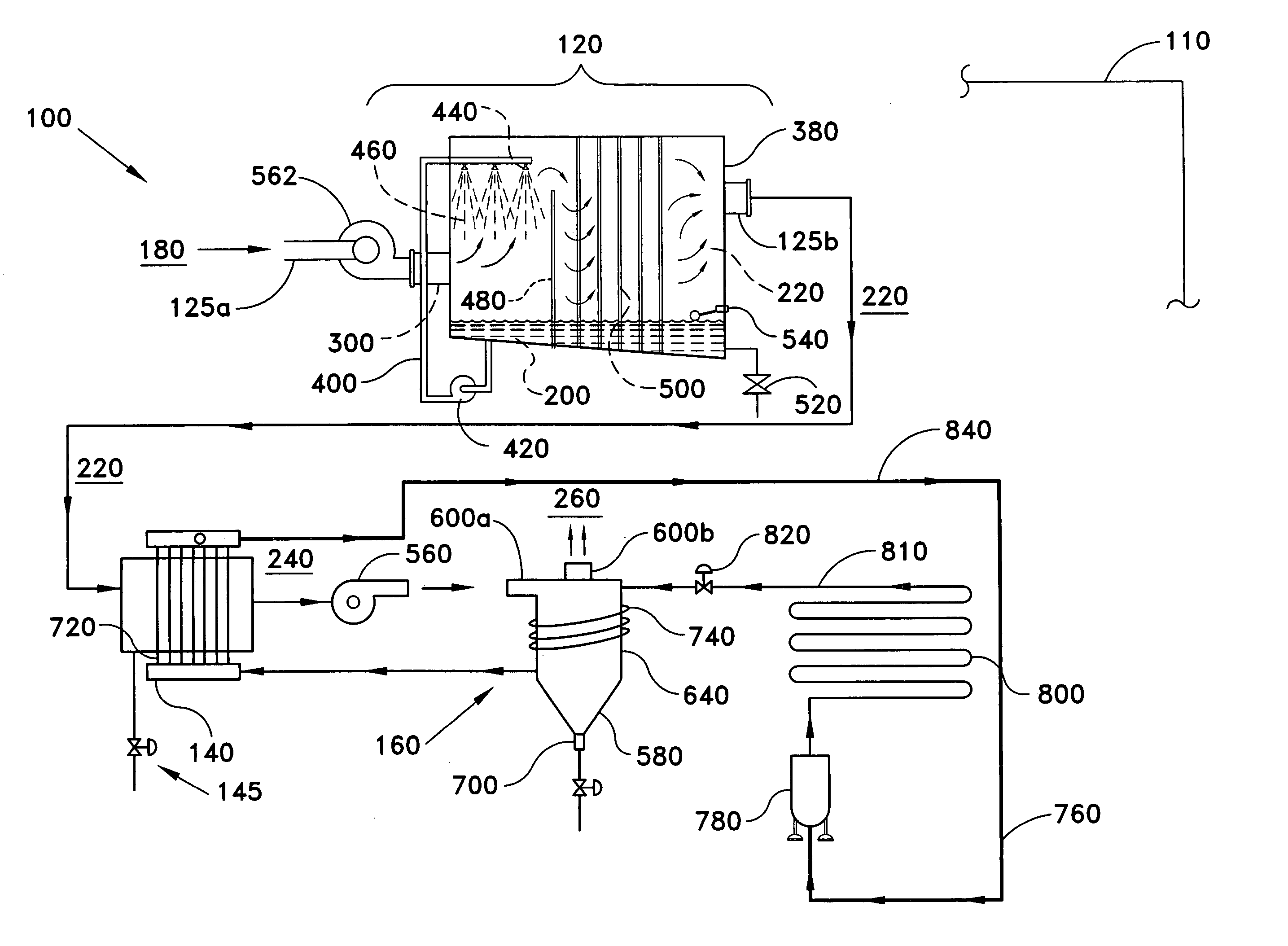

Air purification system and method

InactiveUS20050109209A1Mechanical apparatusLighting and heating apparatusOperating energyAir pollutants

The air purification system and method for purifying and cooling air for use in a building has an air pollutant removal stage, an air pre-cooling unit, and a dual cooling and water removal unit, including a cyclone separator having a cooling coil wrapped around the separator for condensing and removing water from the airflow. The method comprises the steps of removing pollutants from an incoming polluted airflow to provide a substantially pollutant free outgoing moist airflow; pre-cooling the substantially pollutant free moist airflow to provide a clean cool moist airflow; and condensing water out of the clean cool moist airflow to provide a substantially clean dry airflow suitable for use in a building.

Owner:LEE DAVID B

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com