Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

9848 results about "Vacuum cleaner" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

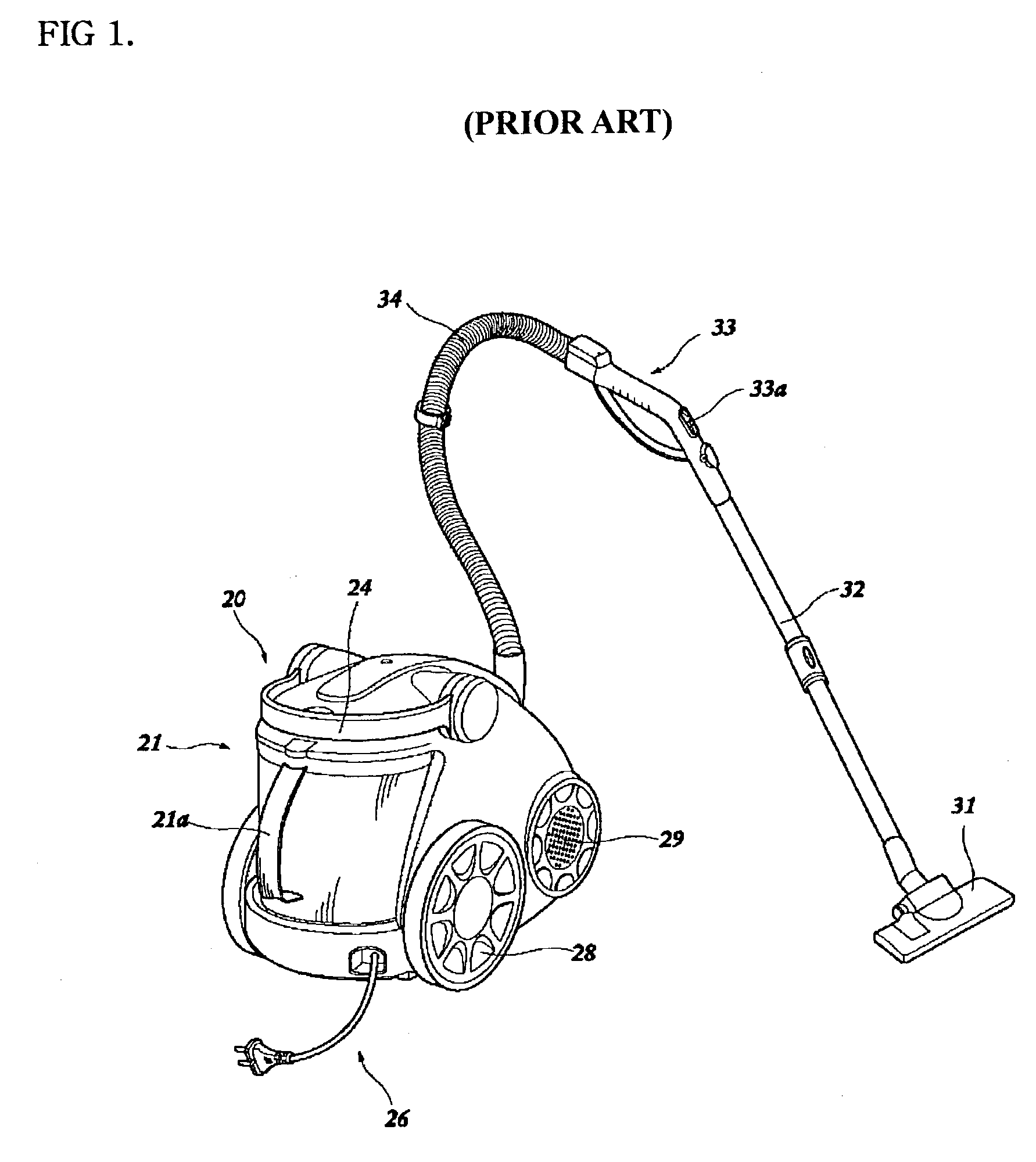

Inventor

A vacuum cleaner, also known simply as a vacuum, is a device that causes suction in order to remove debris from floors, upholstery, draperies and other surfaces. It is generally electrically driven. The dirt is collected by either a dustbag or a cyclone for later disposal. Vacuum cleaners, which are used in homes as well as in industry, exist in a variety of sizes and models—small battery-powered hand-held devices, wheeled canister models for home use, domestic central vacuum cleaners, huge stationary industrial appliances that can handle several hundred litres of dust before being emptied, and self-propelled vacuum trucks for recovery of large spills or removal of contaminated soil. Specialized shop vacuums can be used to suck up both dust and liquids.

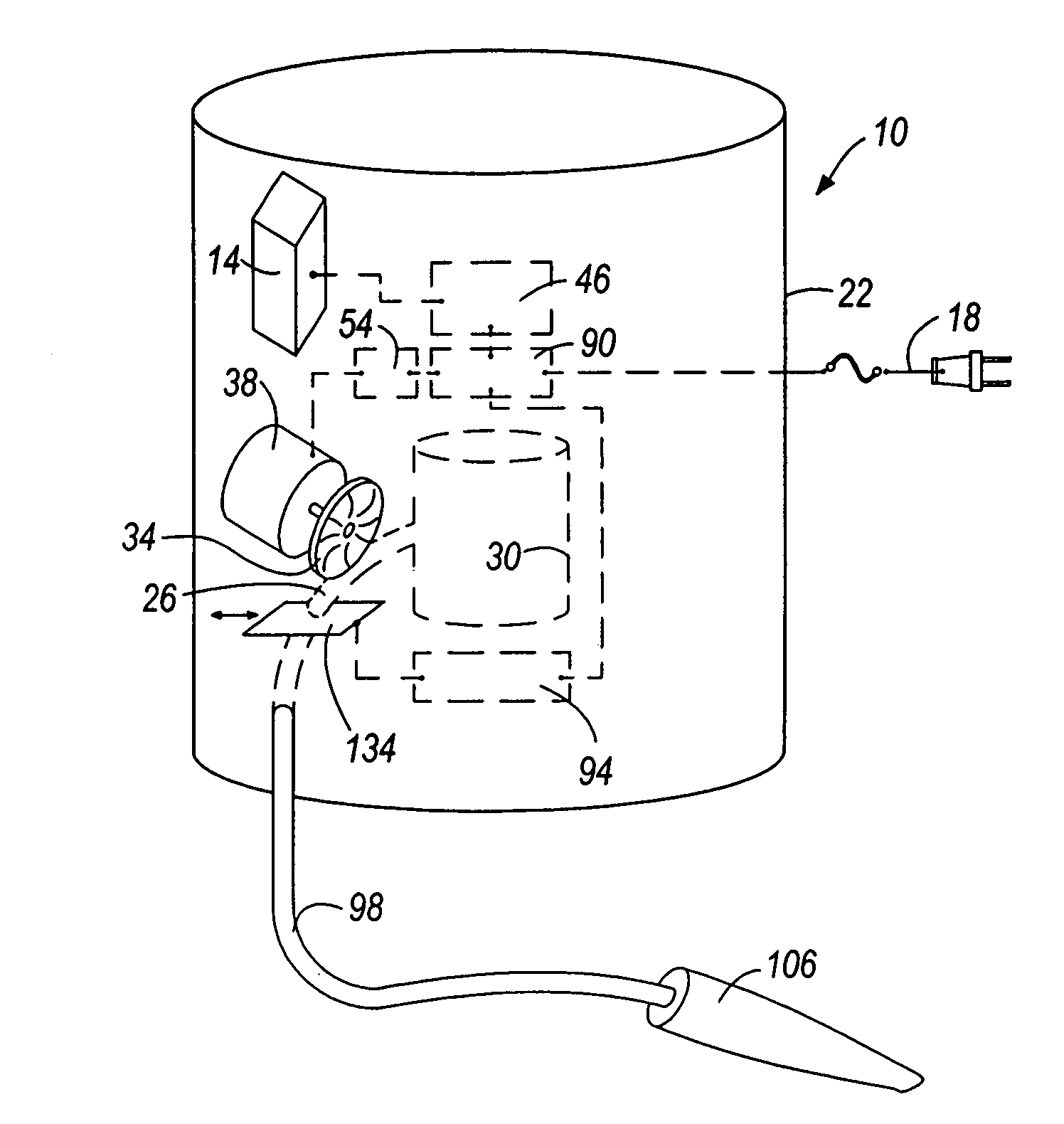

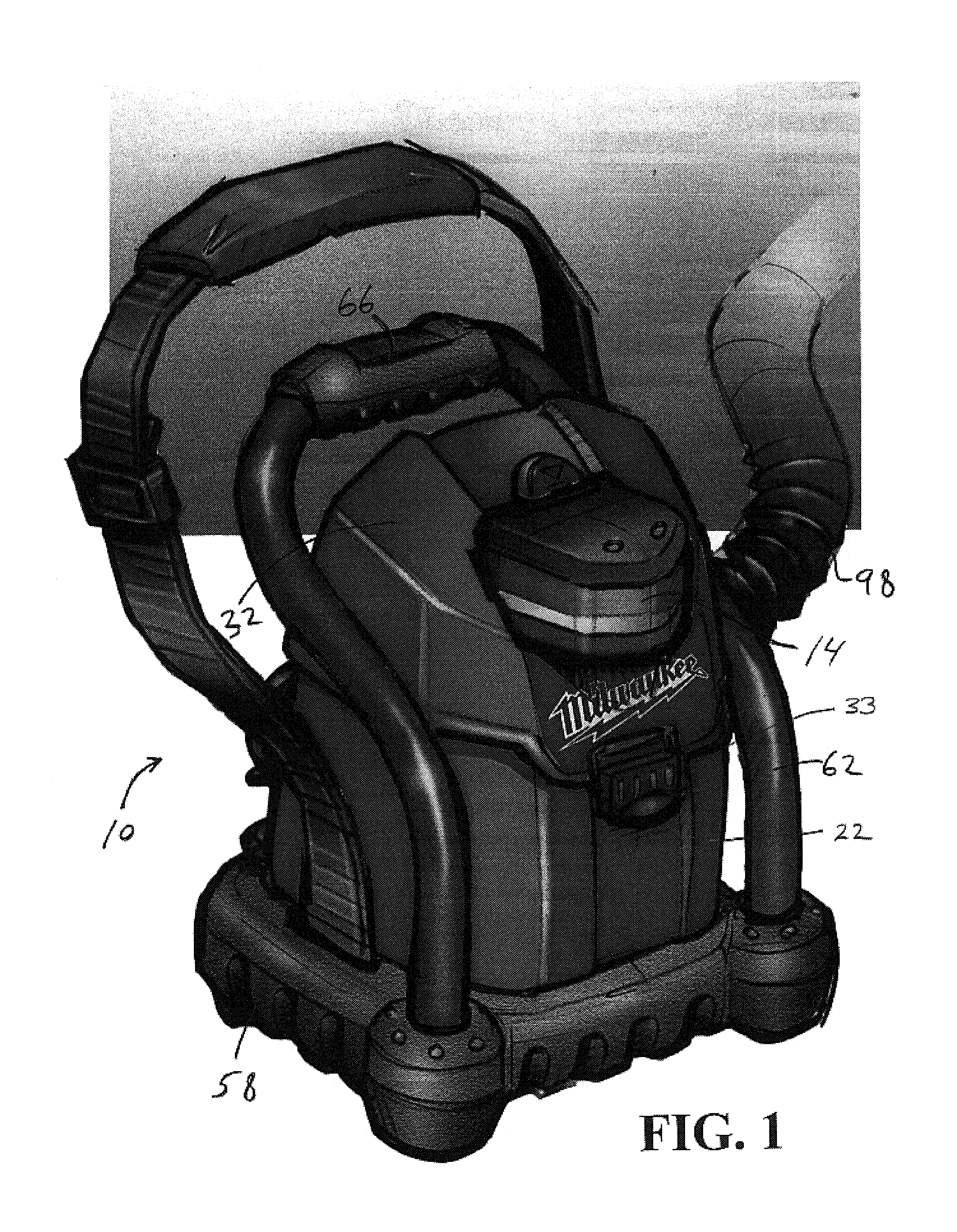

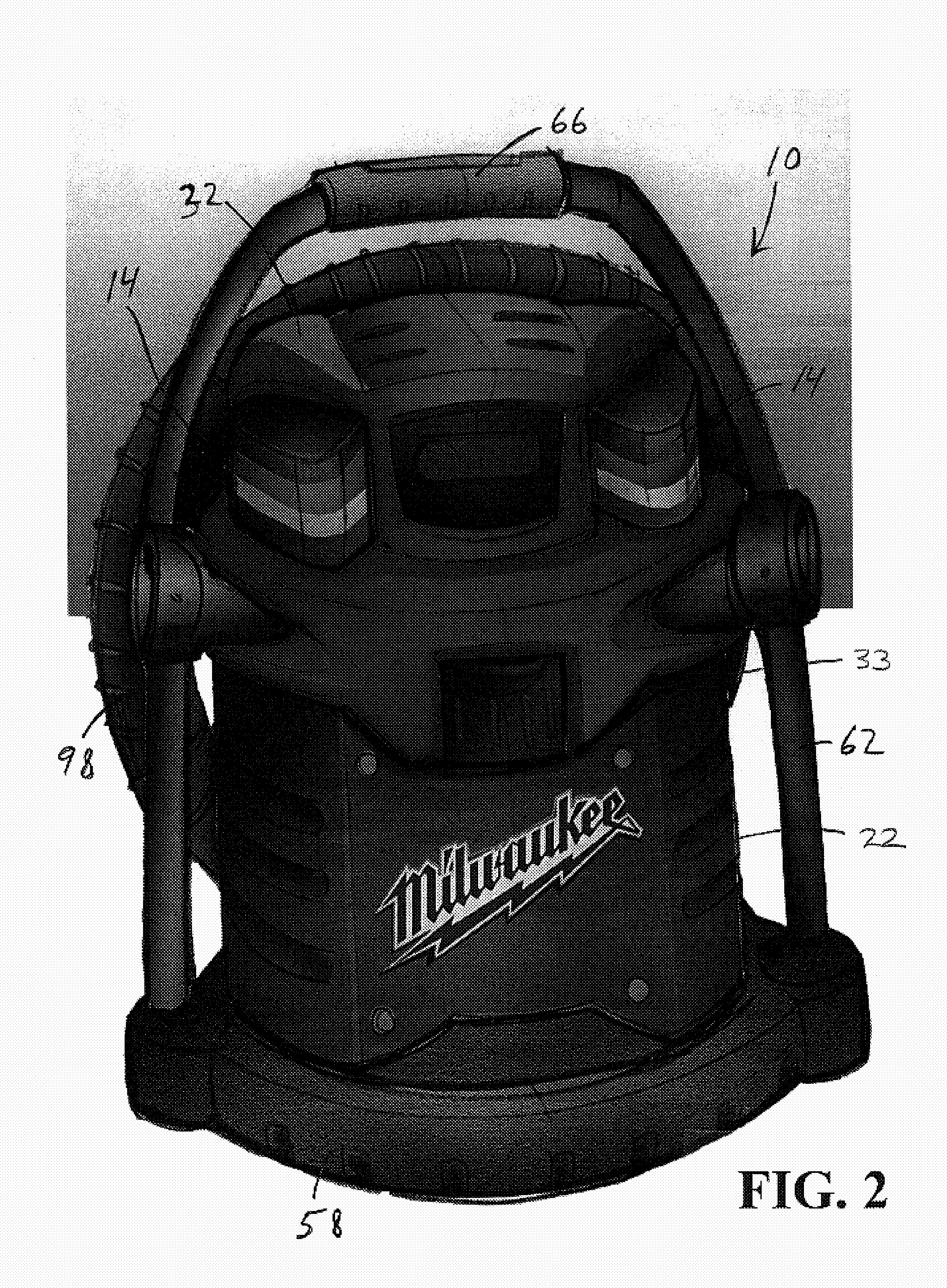

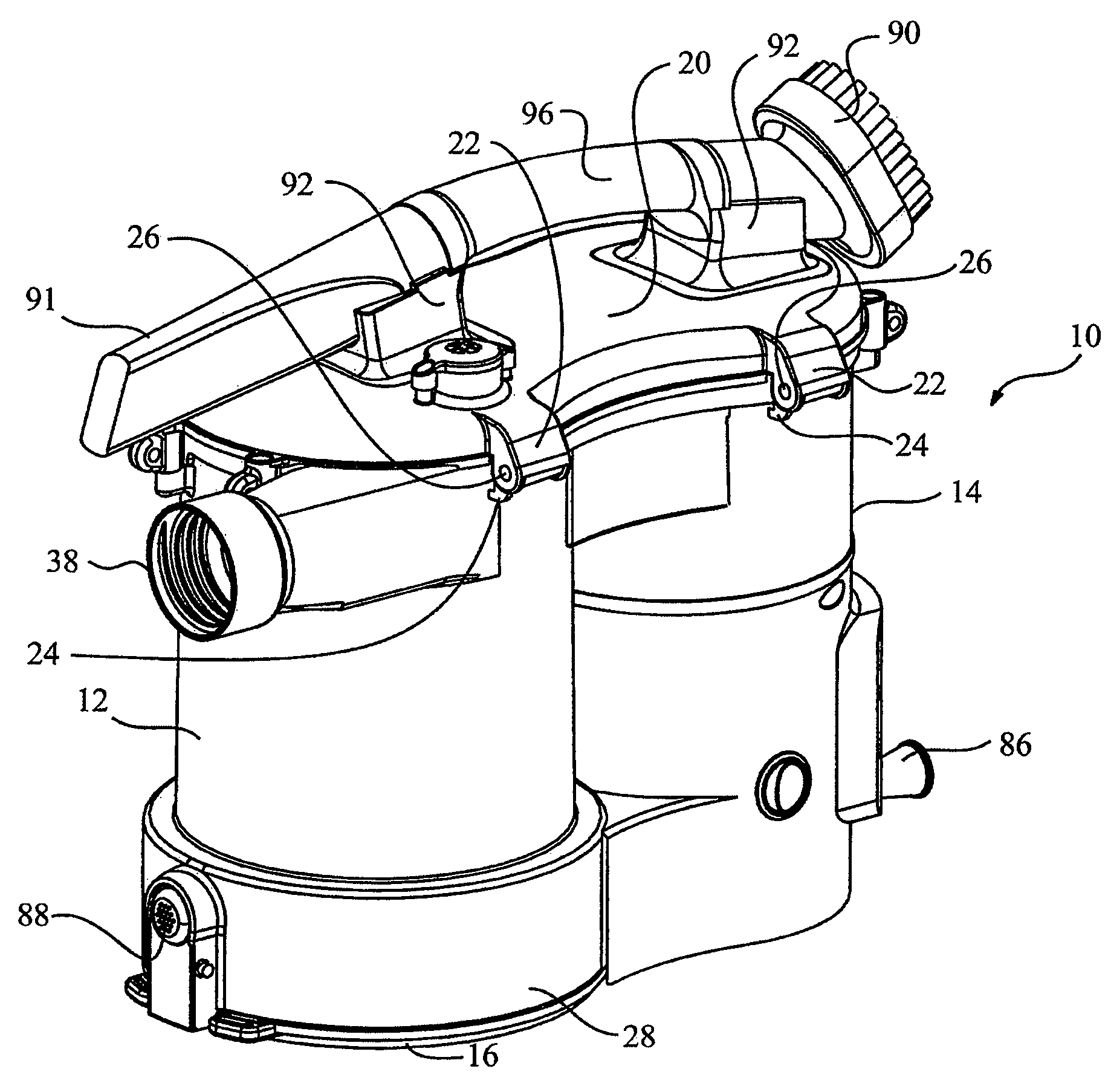

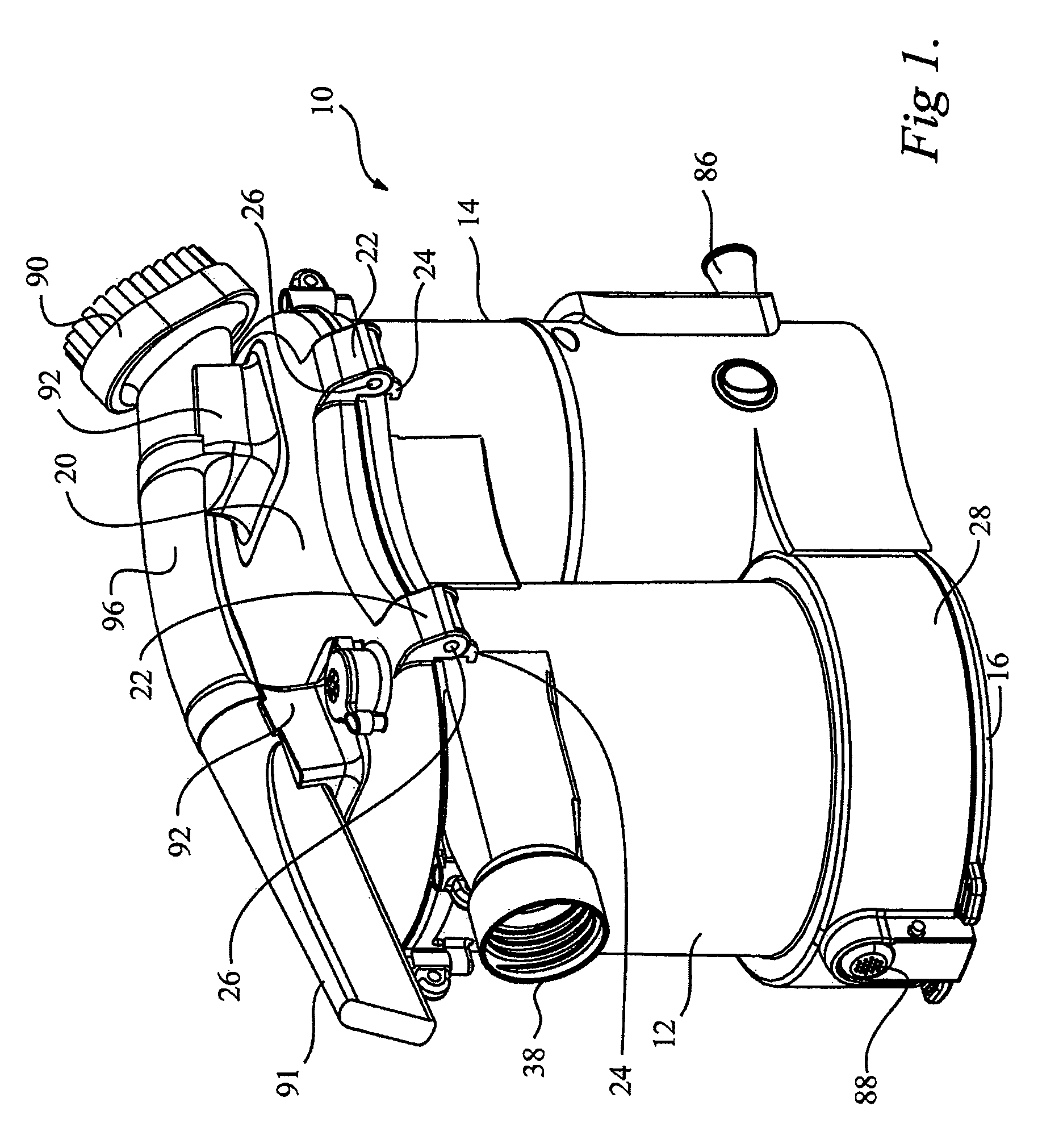

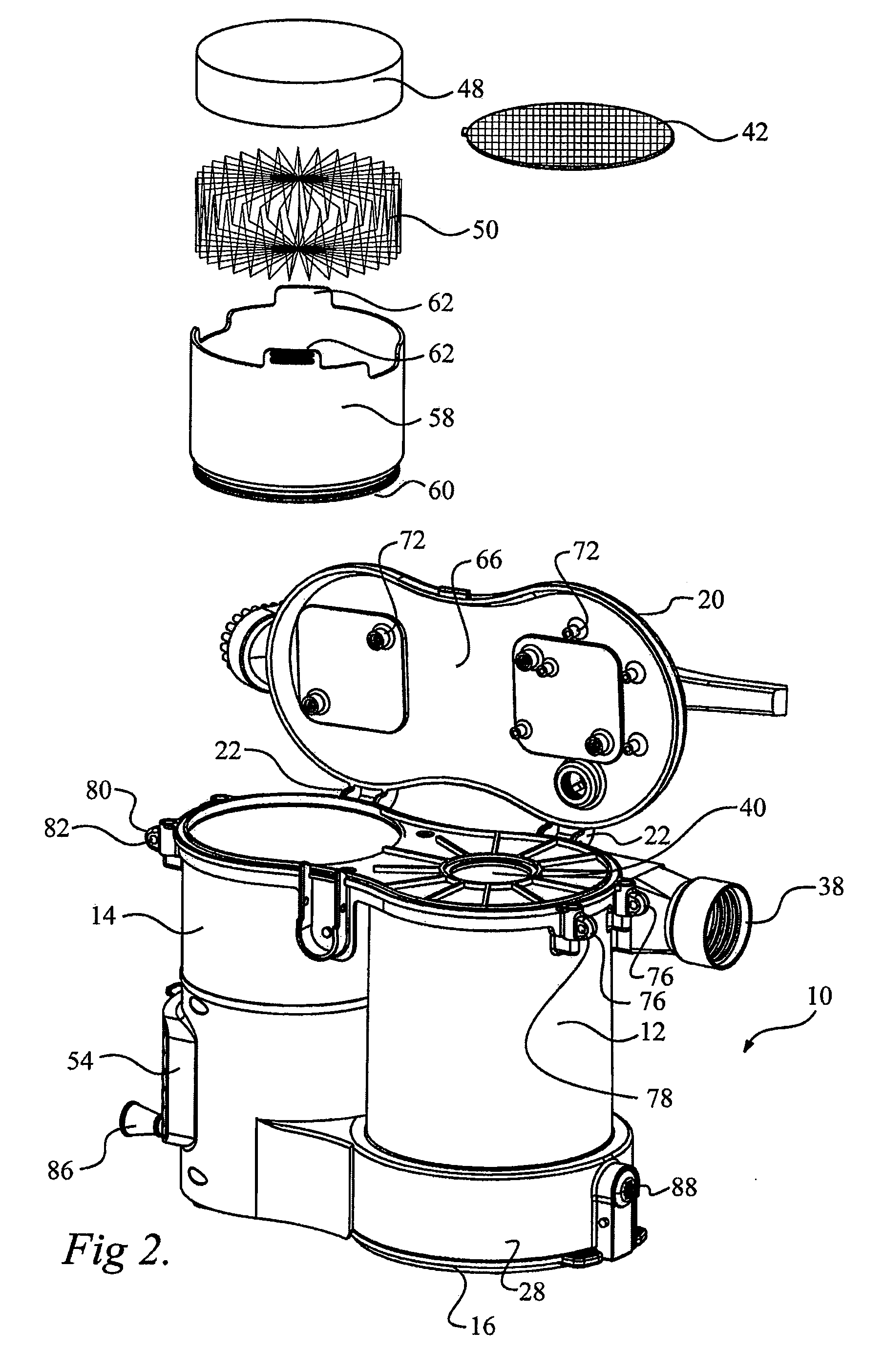

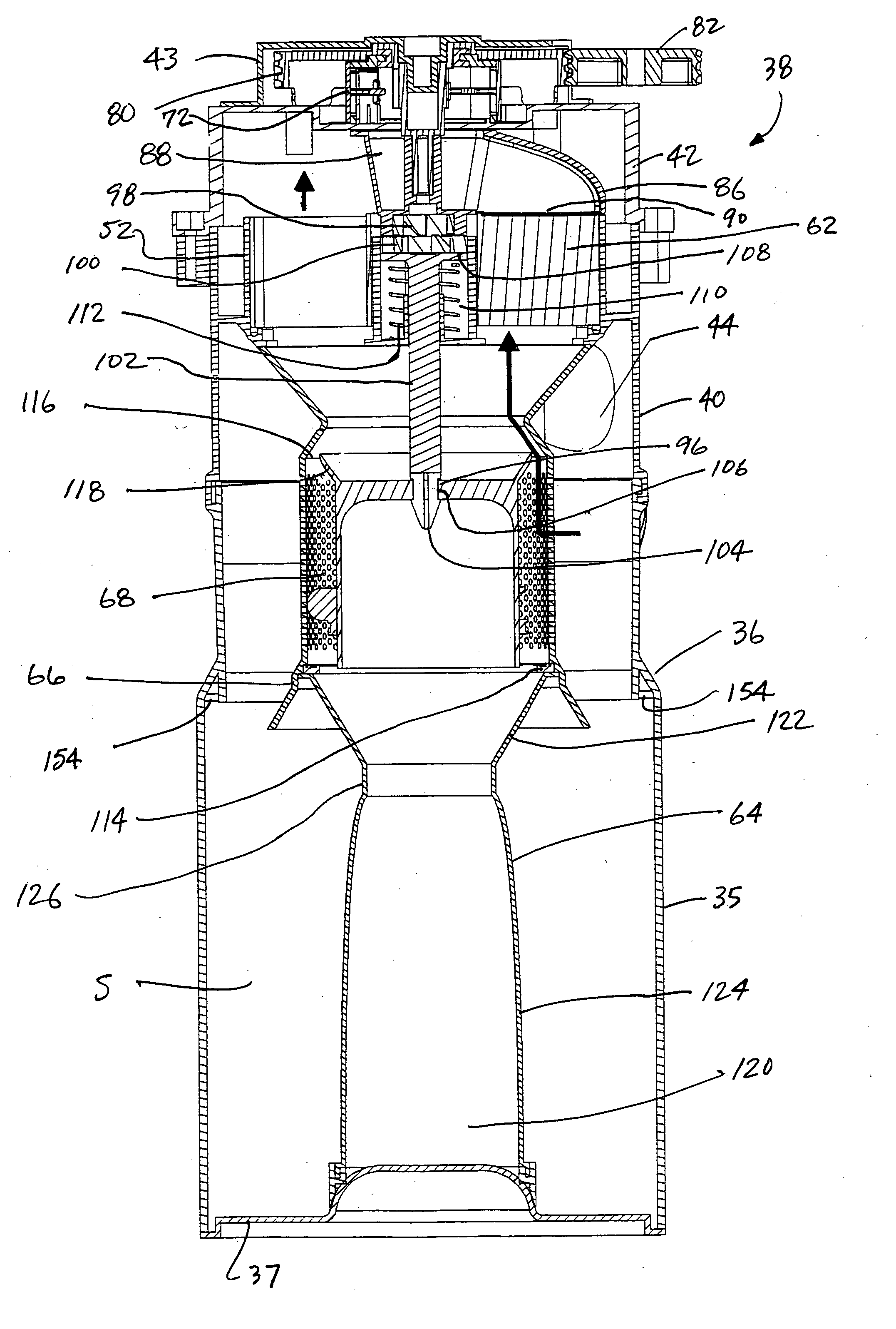

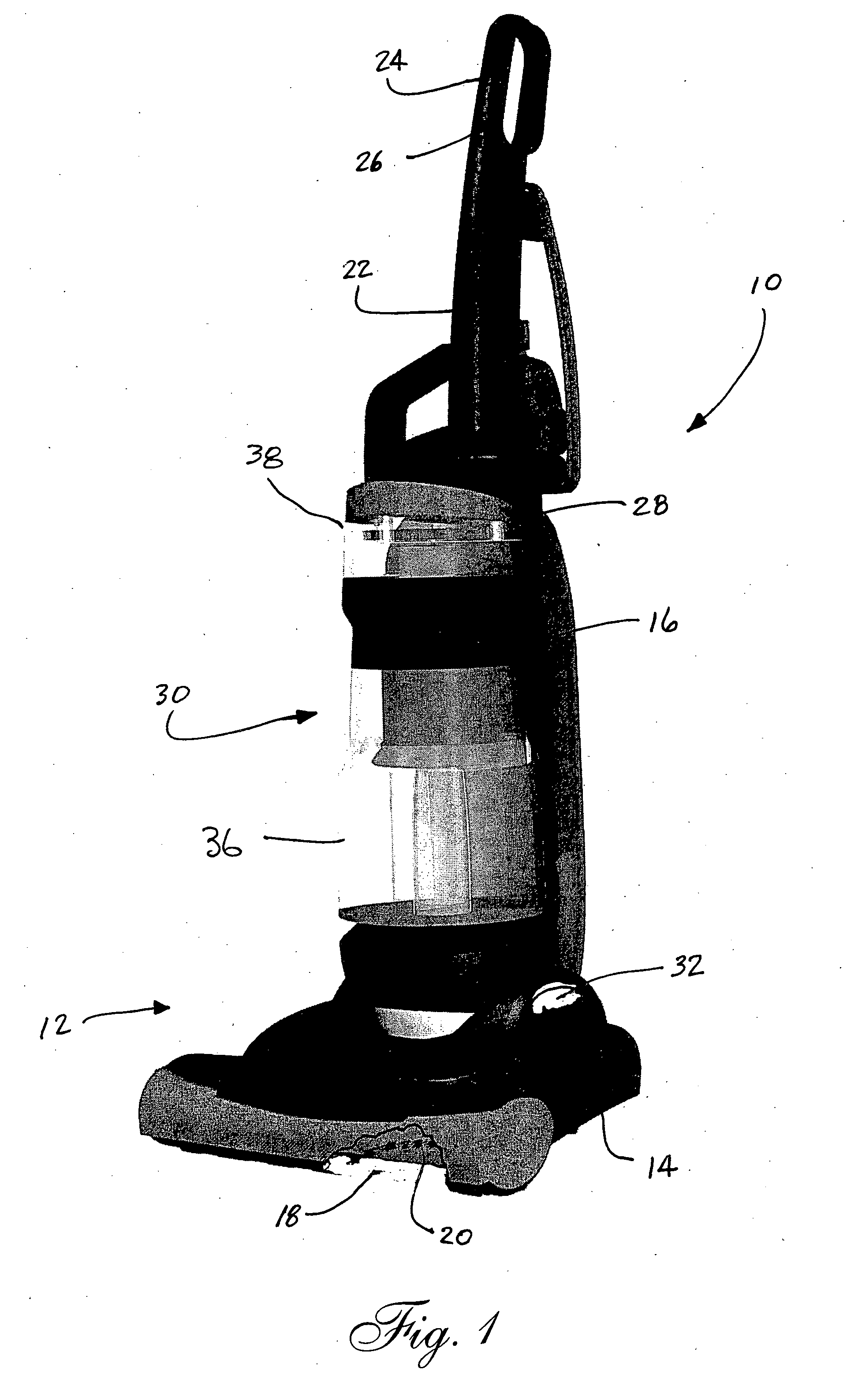

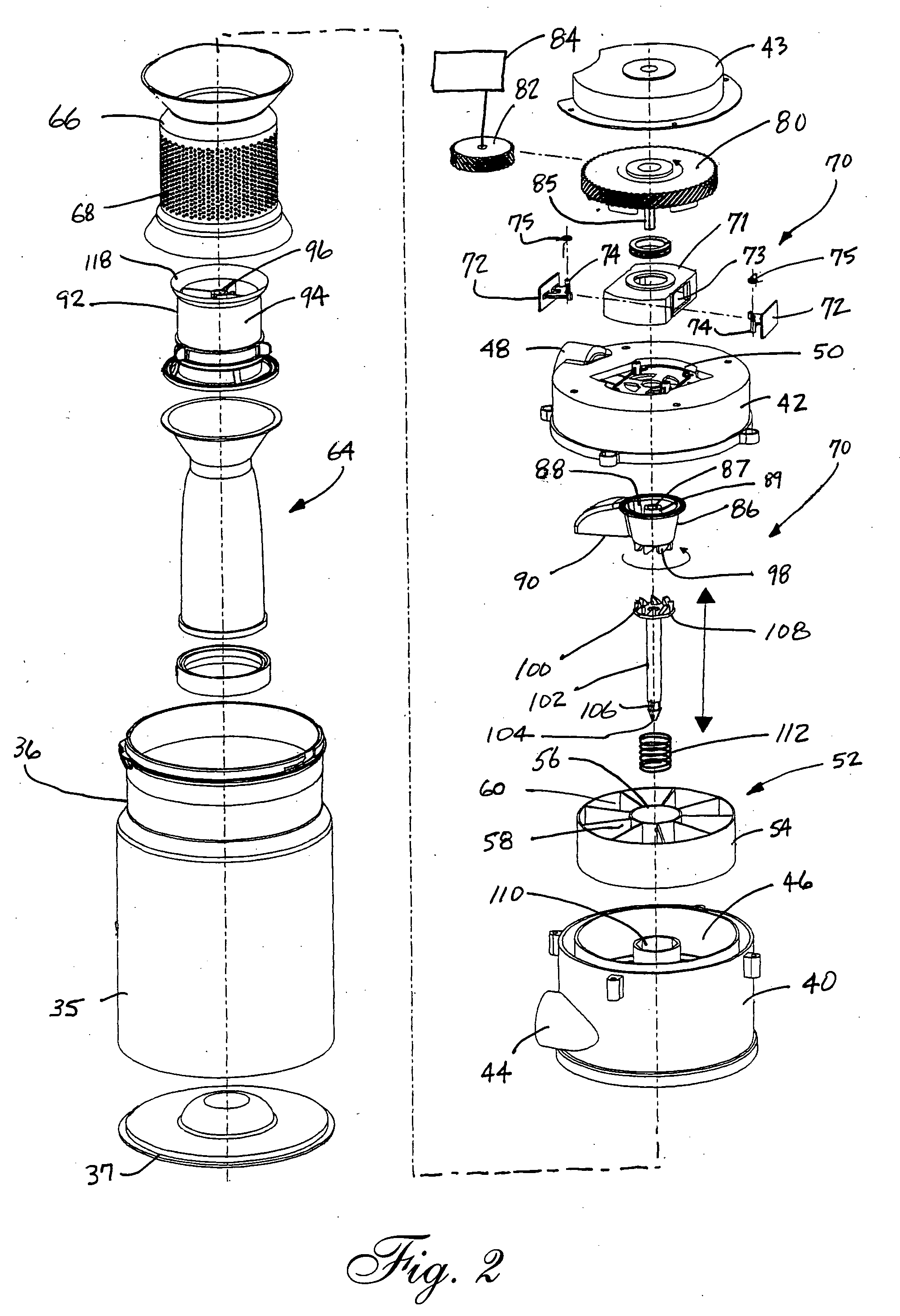

Air flow-producing device, such as a vacuum cleaner or a blower

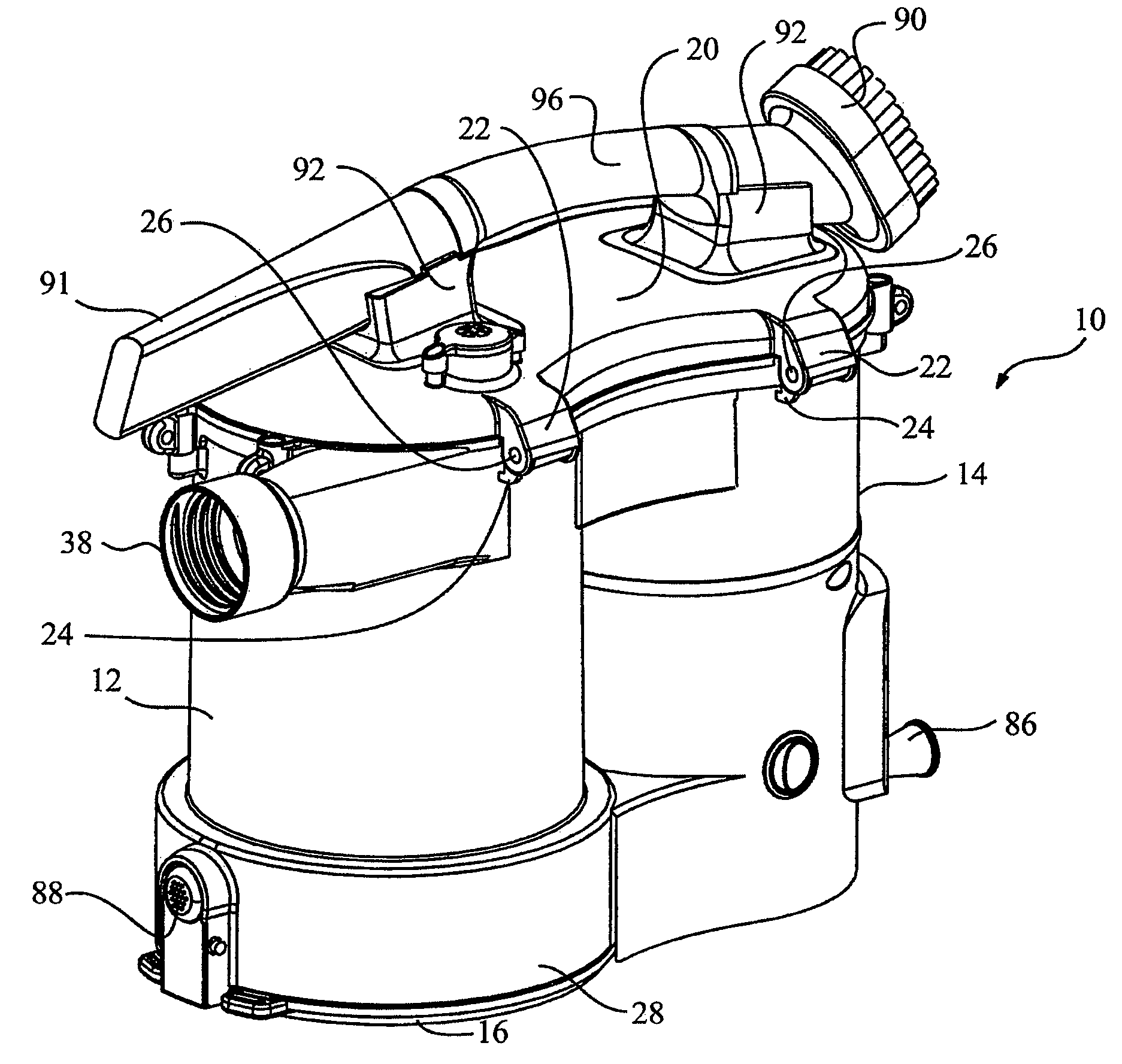

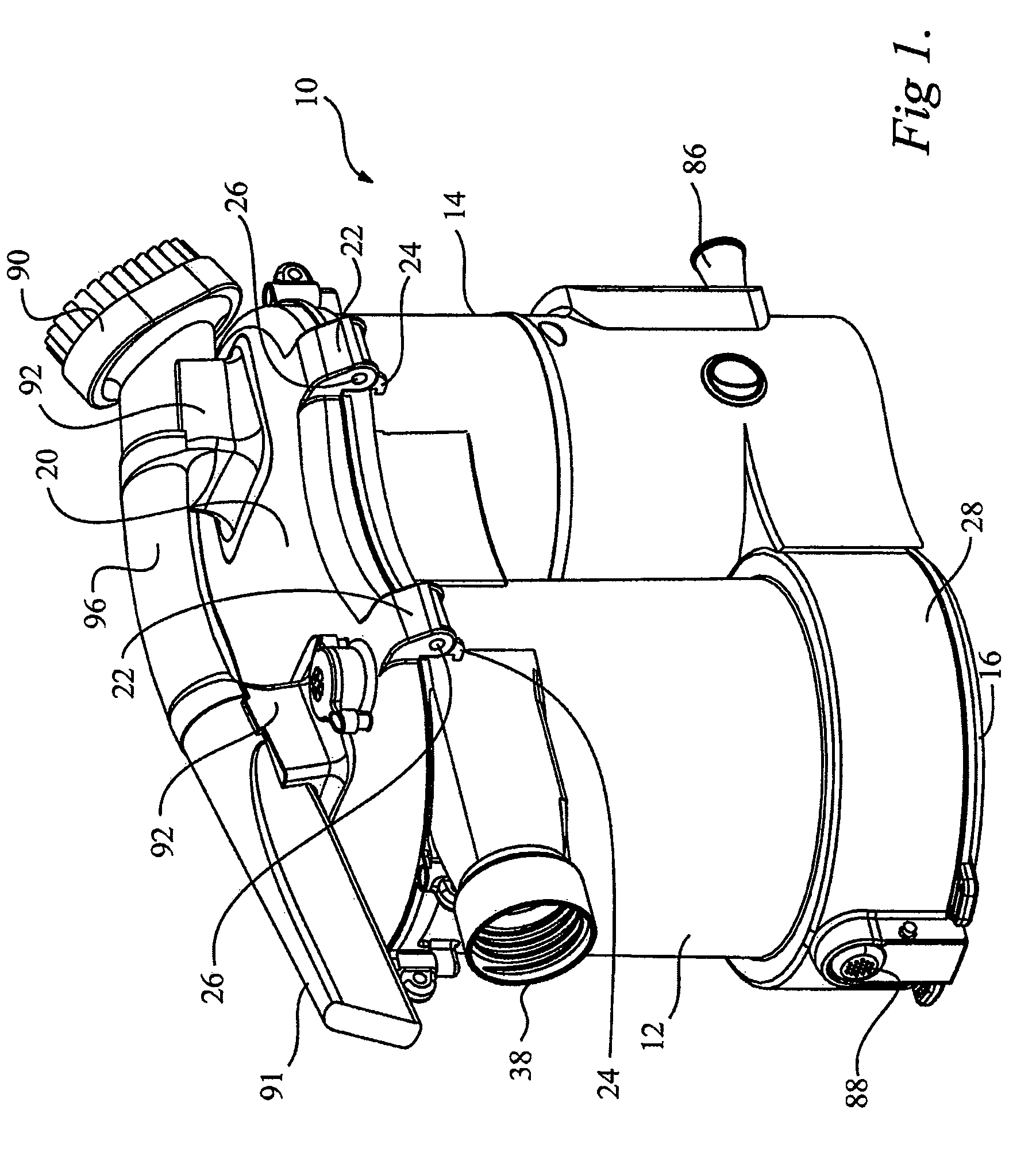

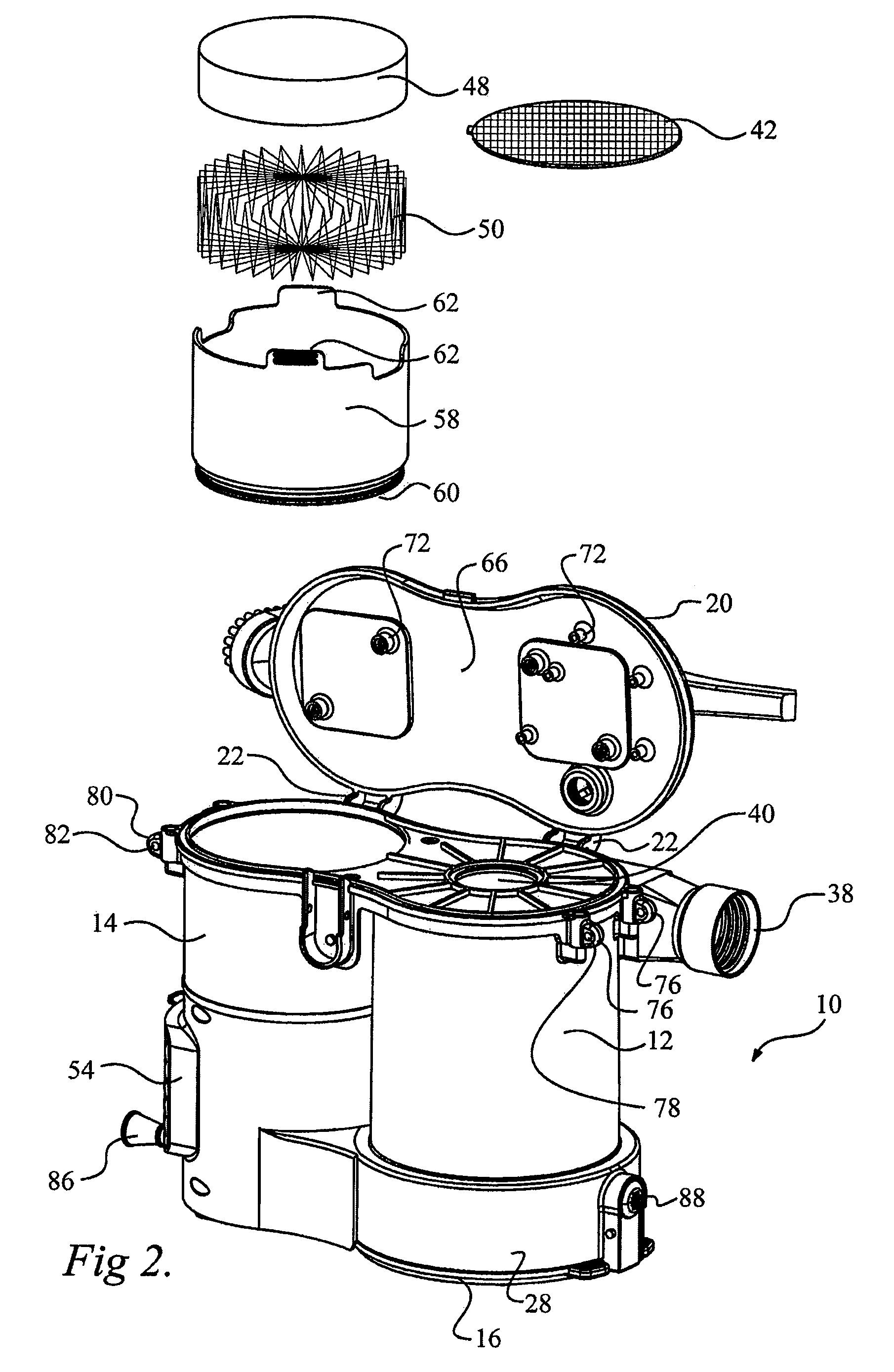

ActiveUS7712182B2Heavy-duty constructionAvoid contactCleaning filter meansSuction filtersElectricityElectrical battery

Owner:MILWAUKEE ELECTRIC TOOL CORP

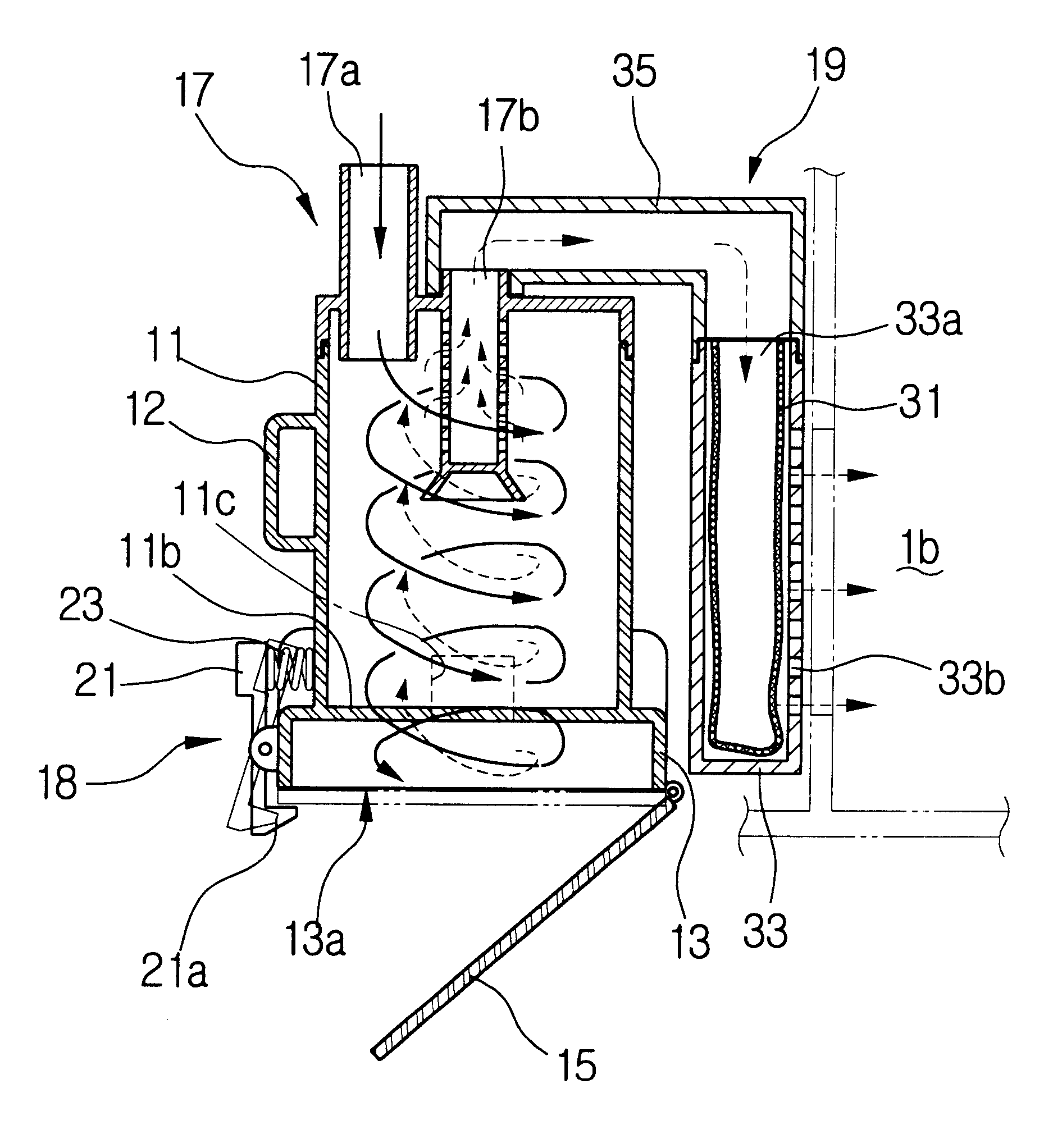

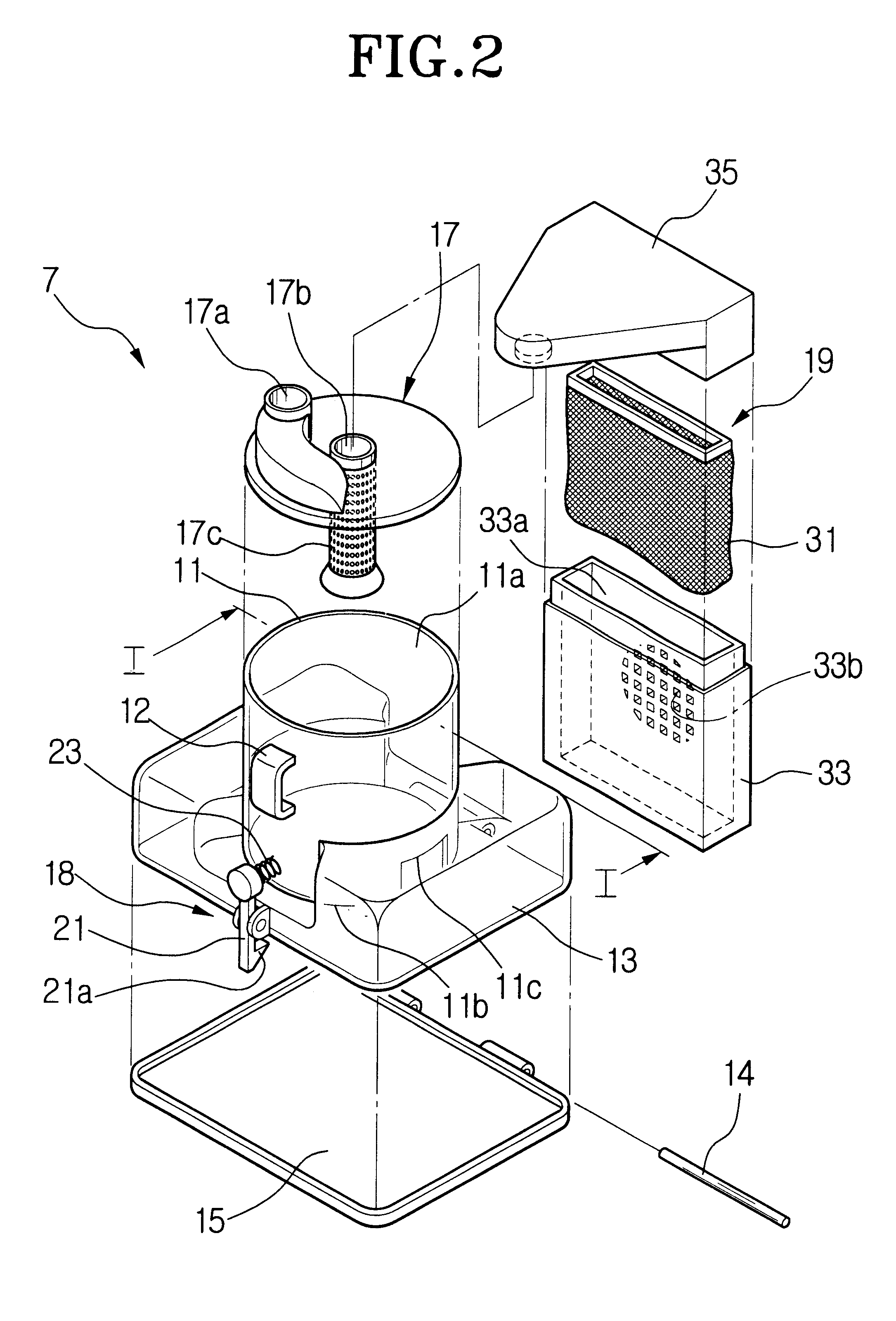

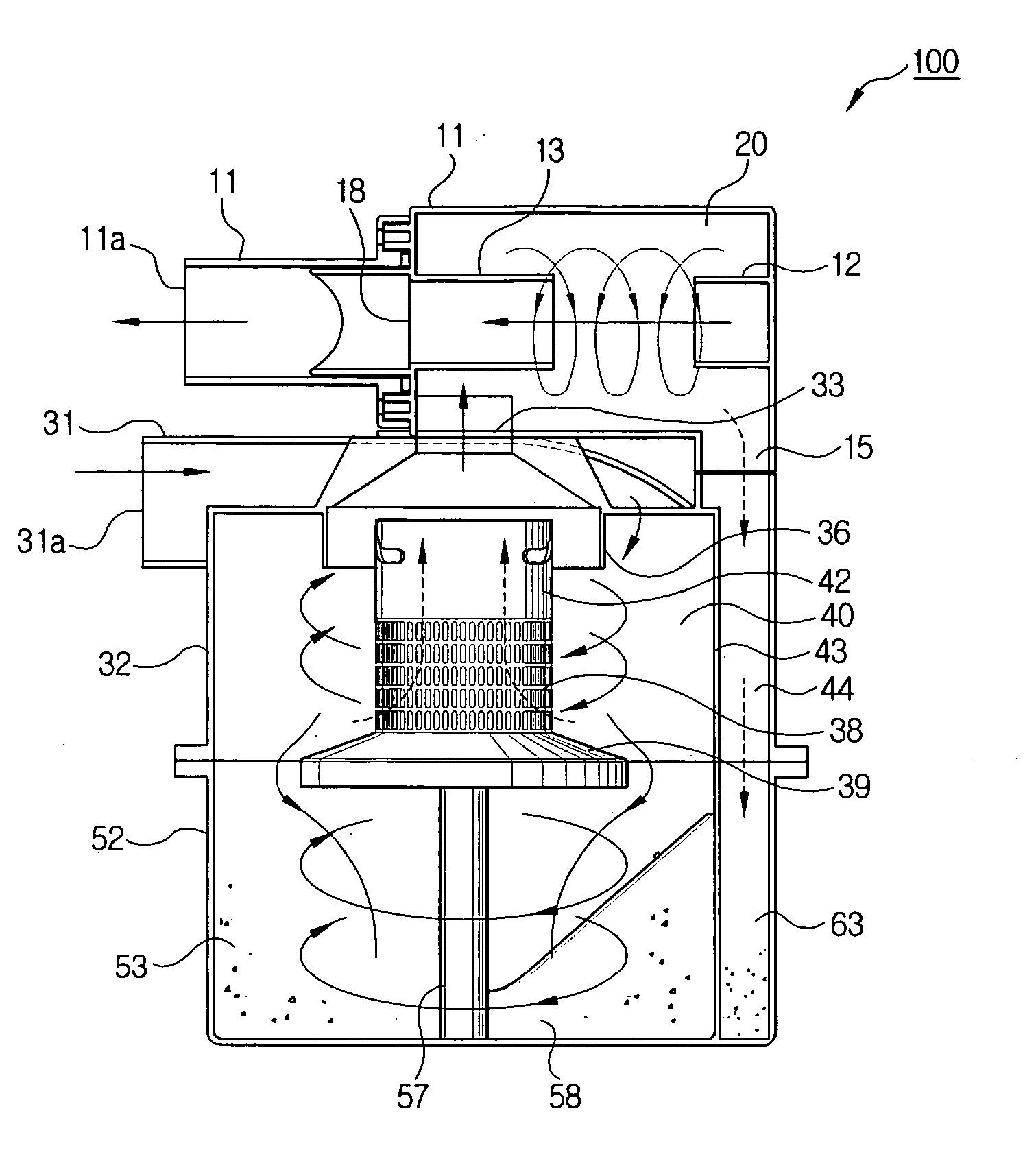

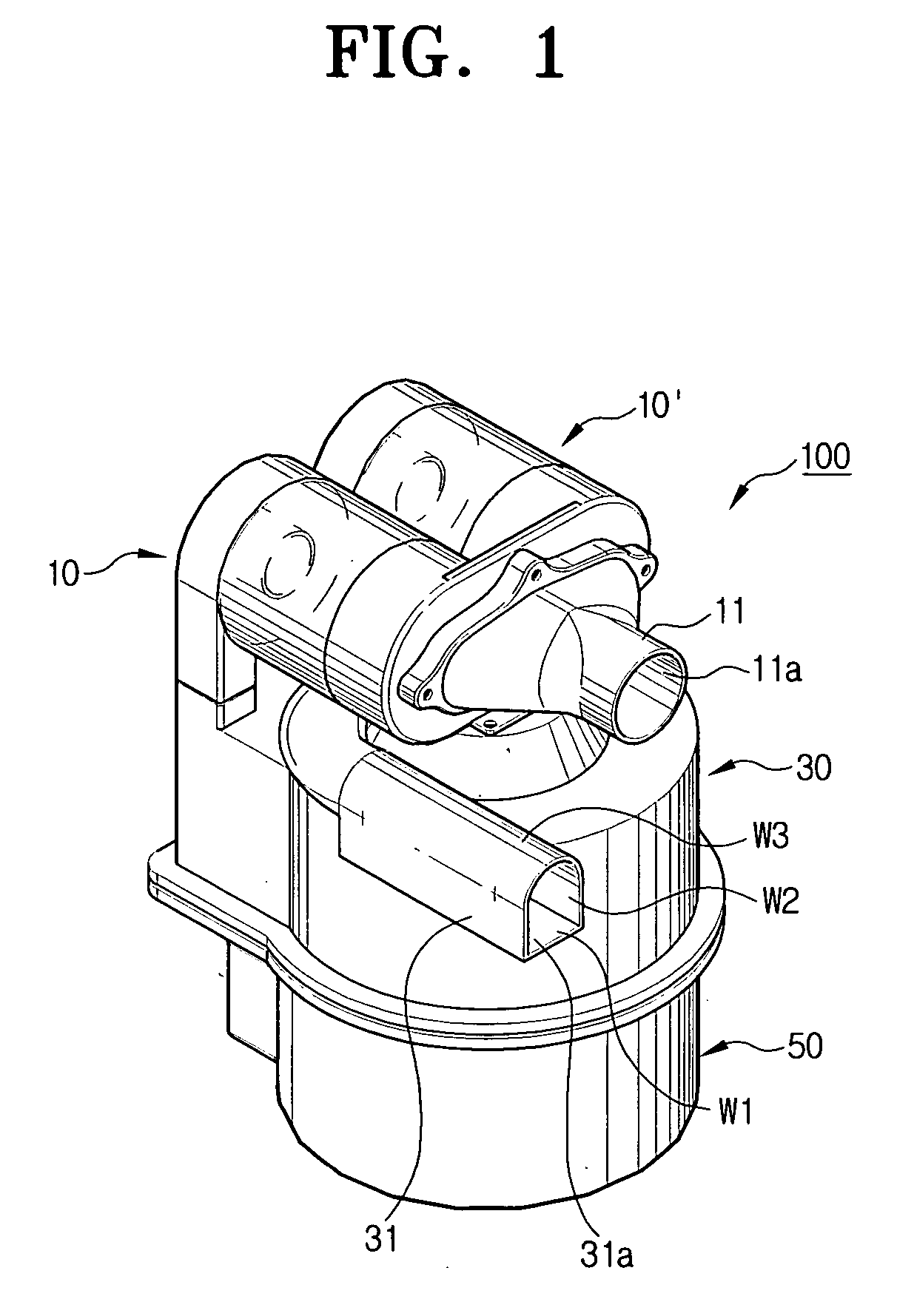

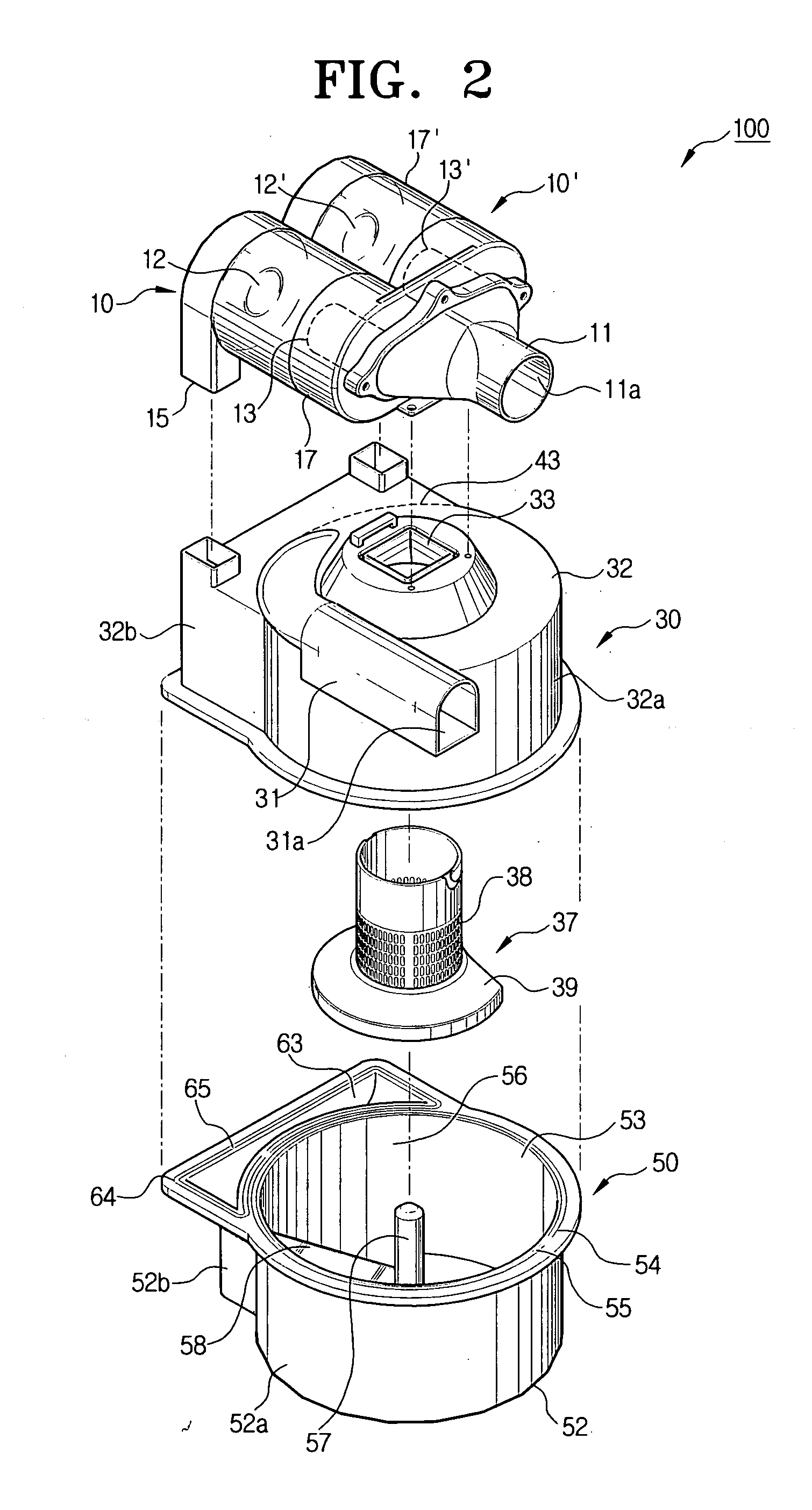

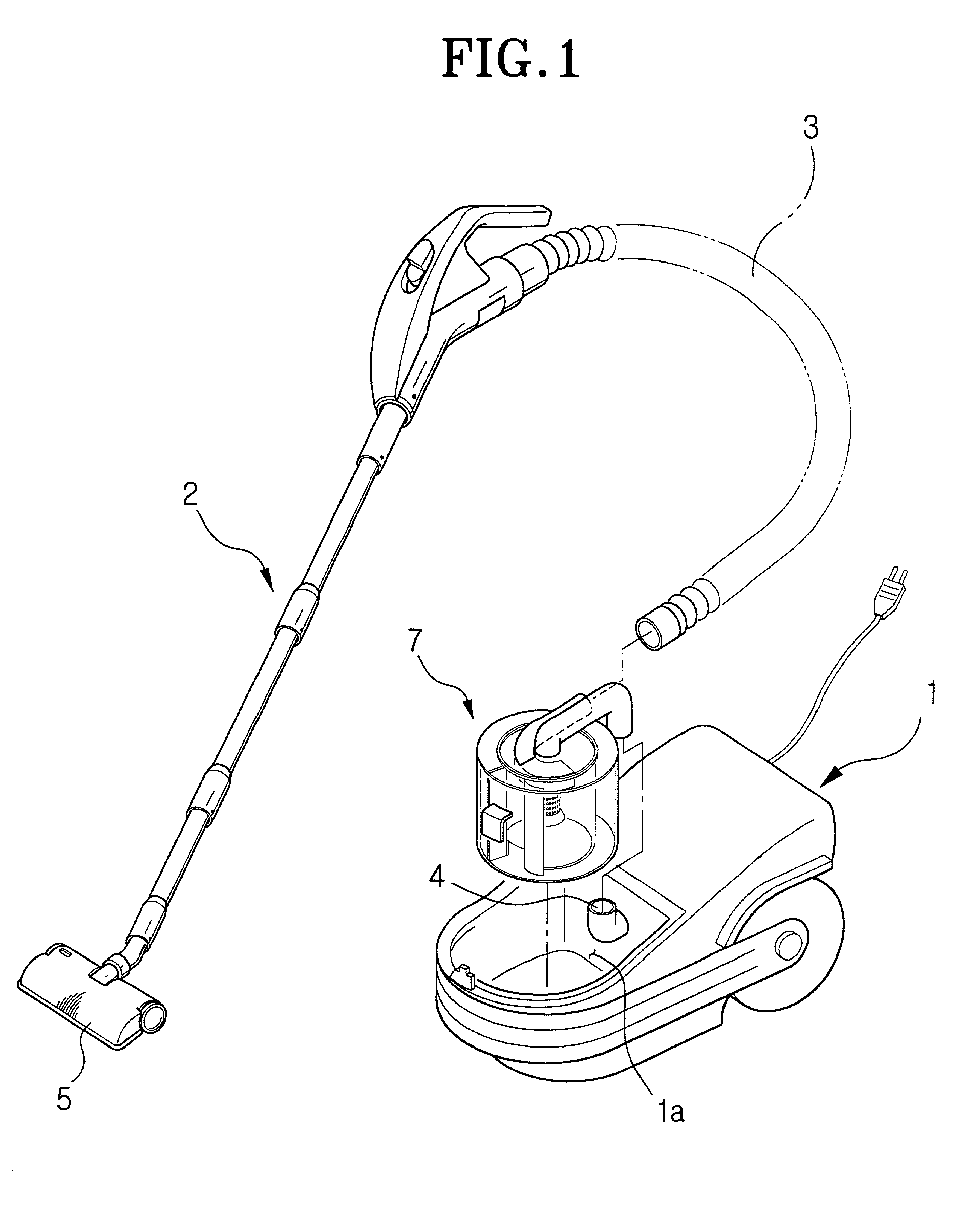

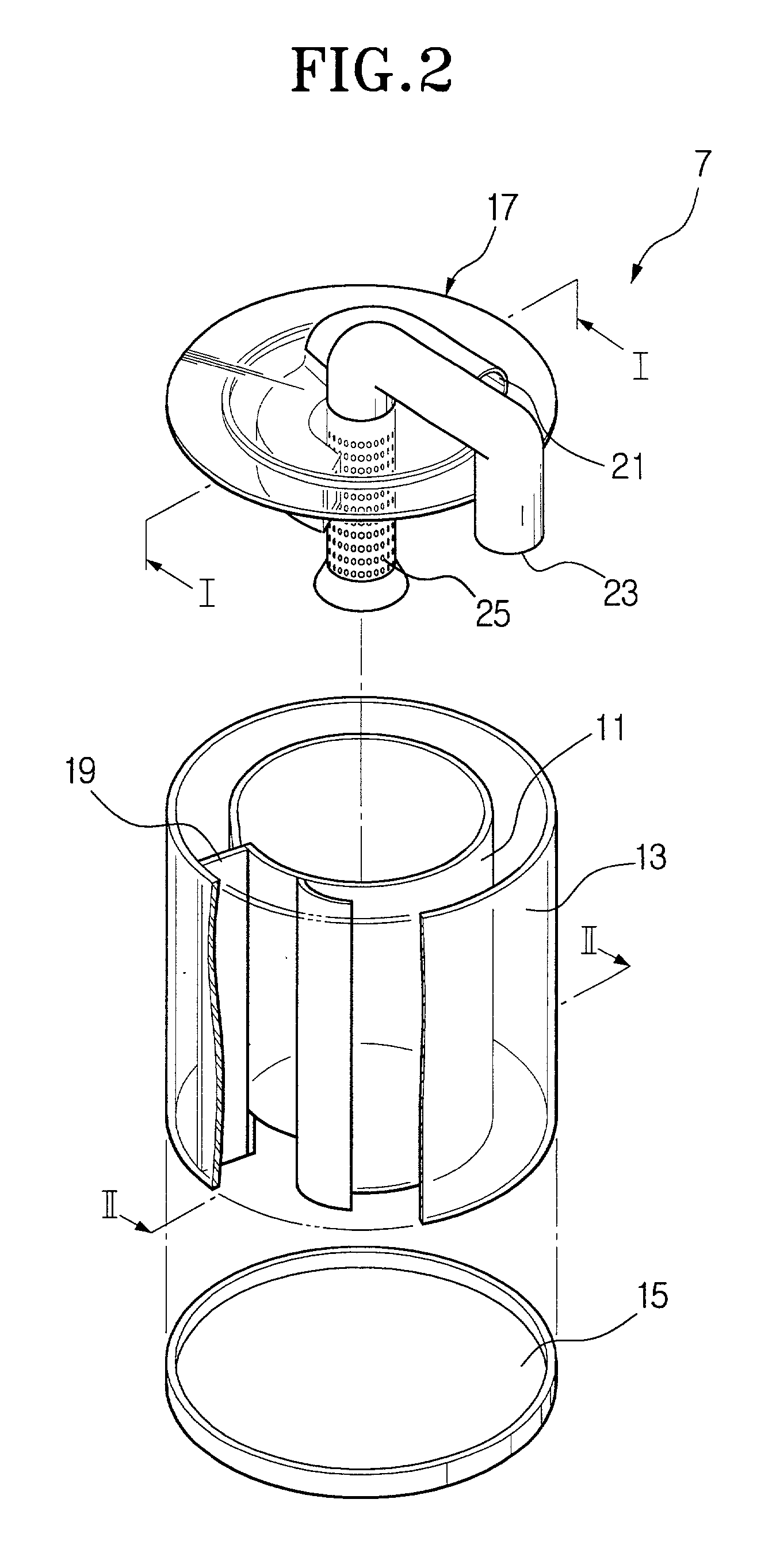

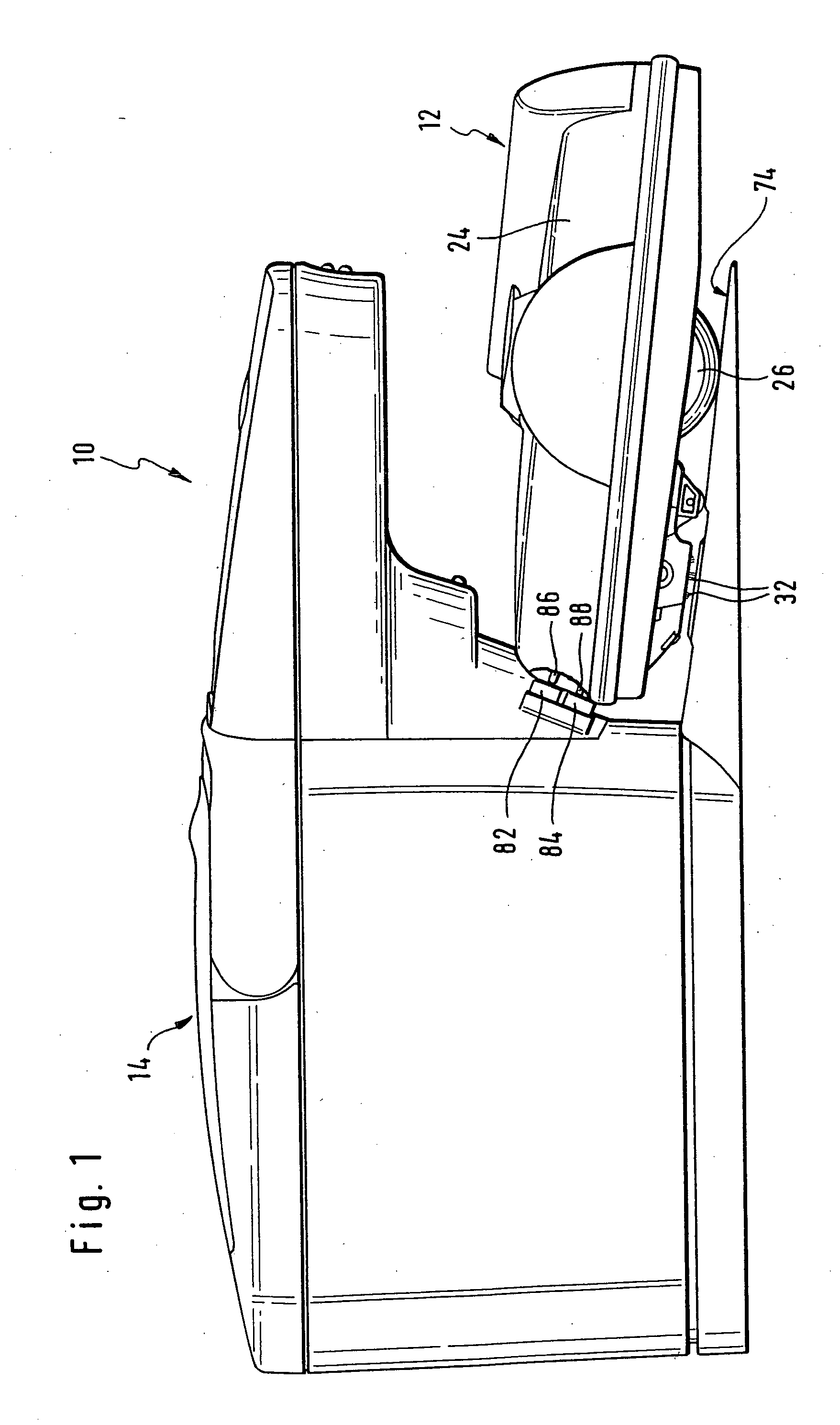

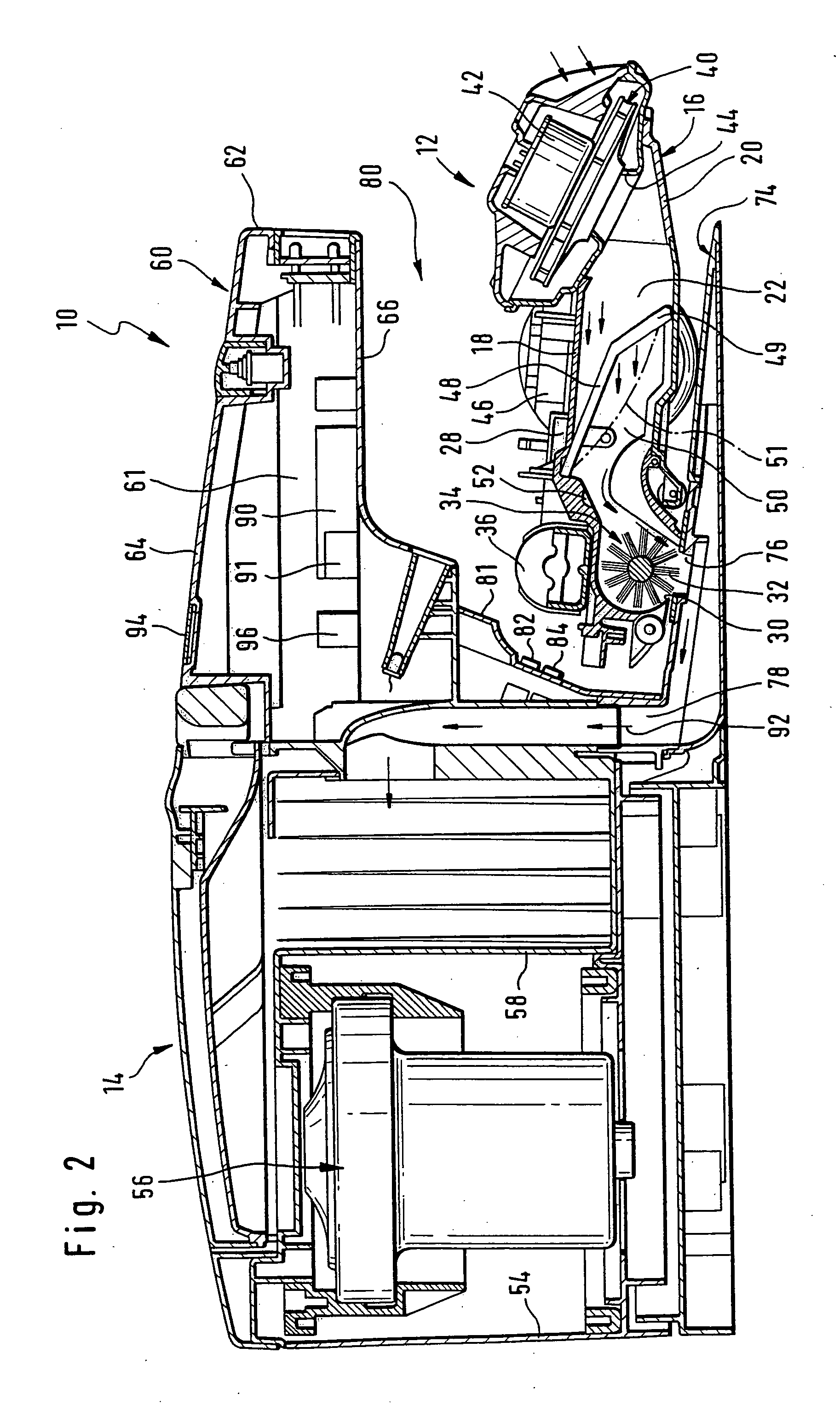

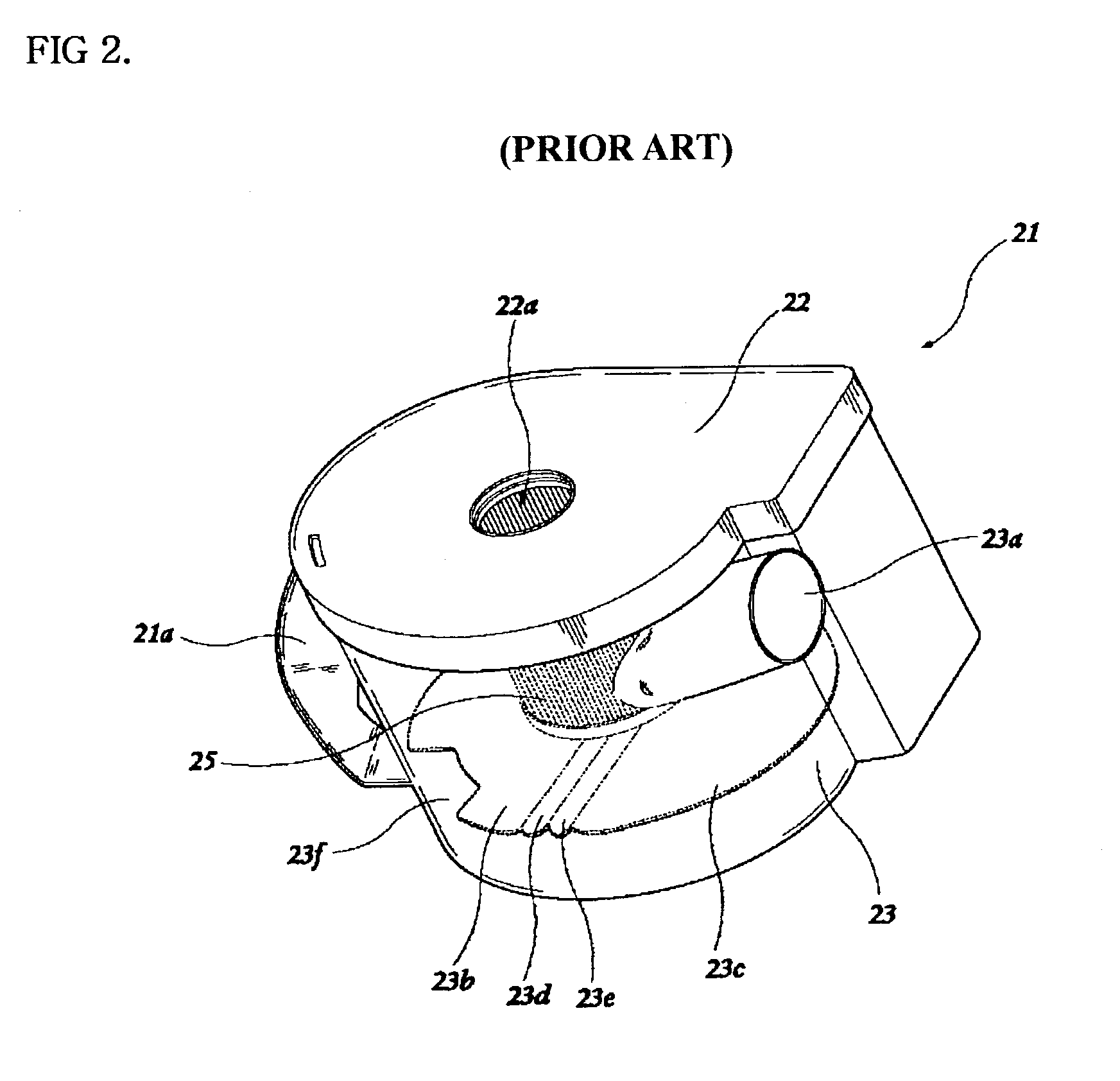

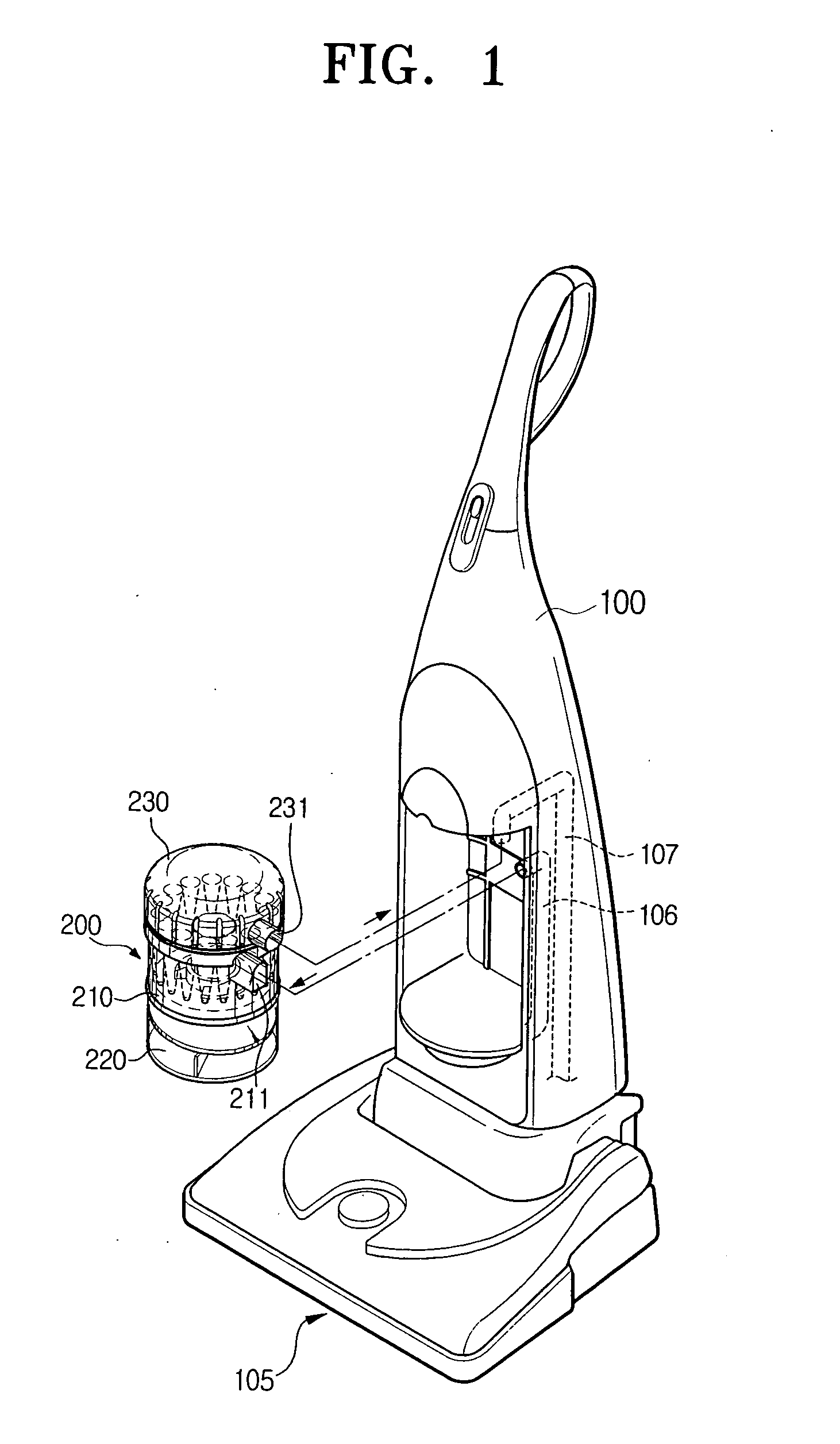

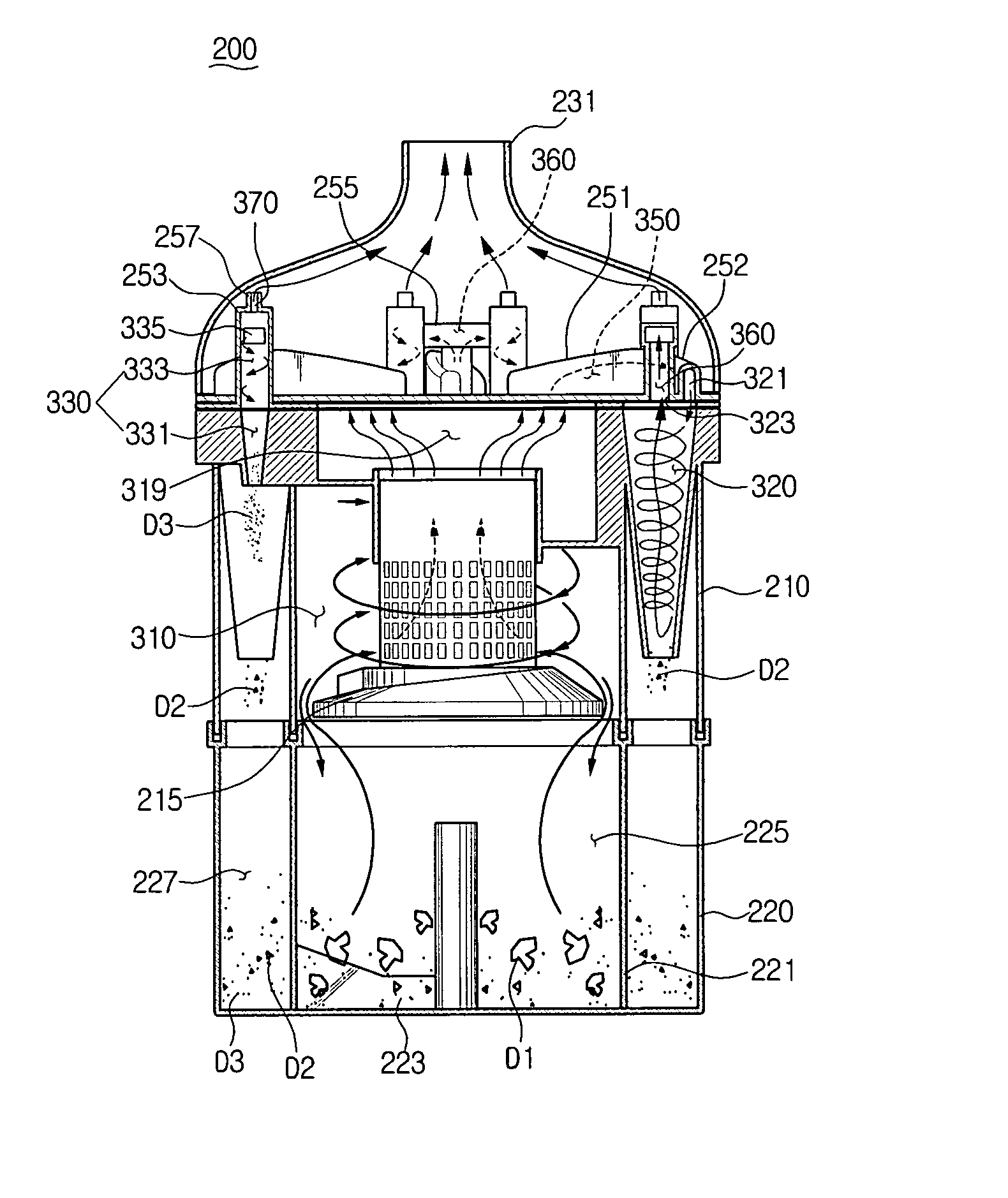

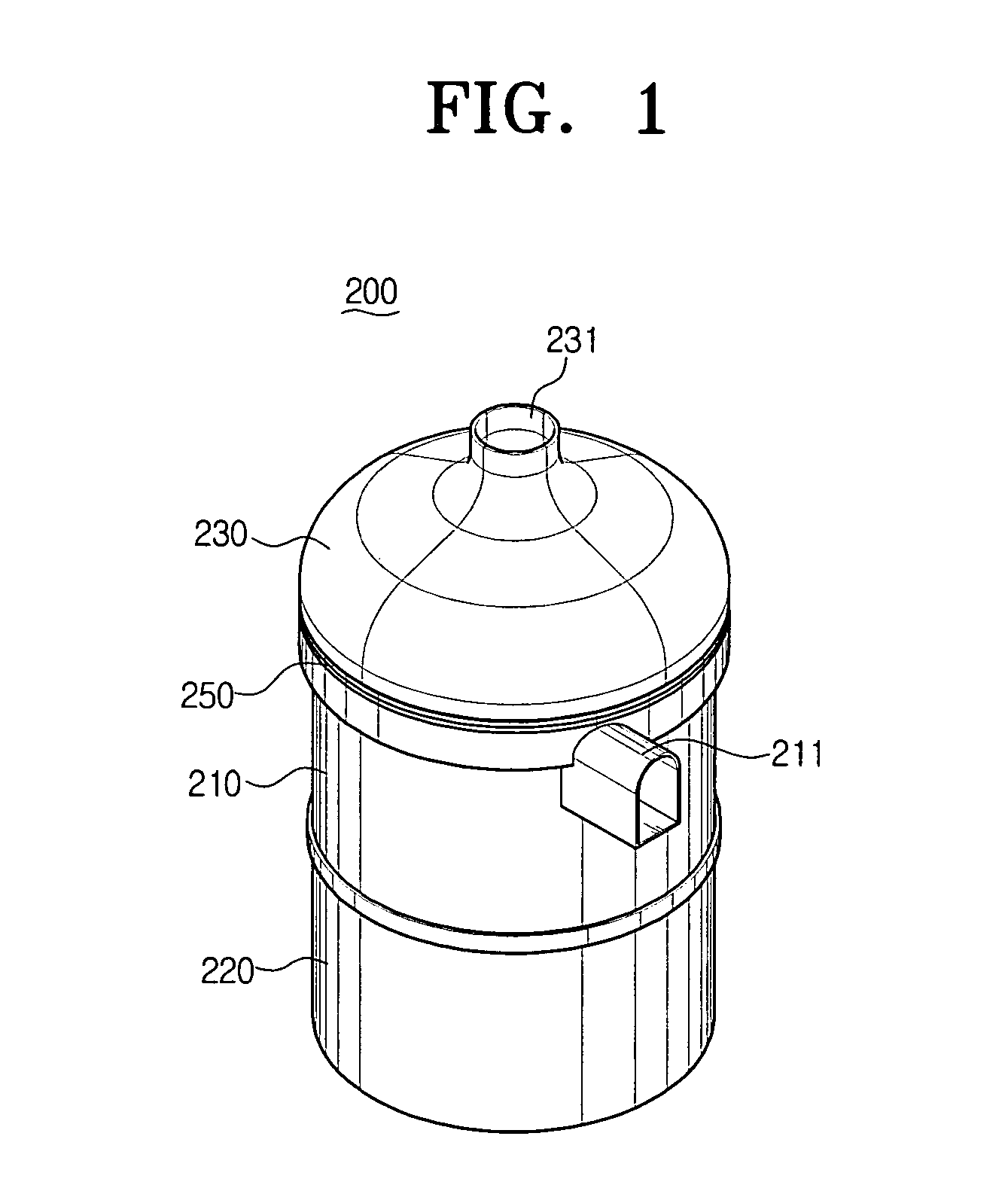

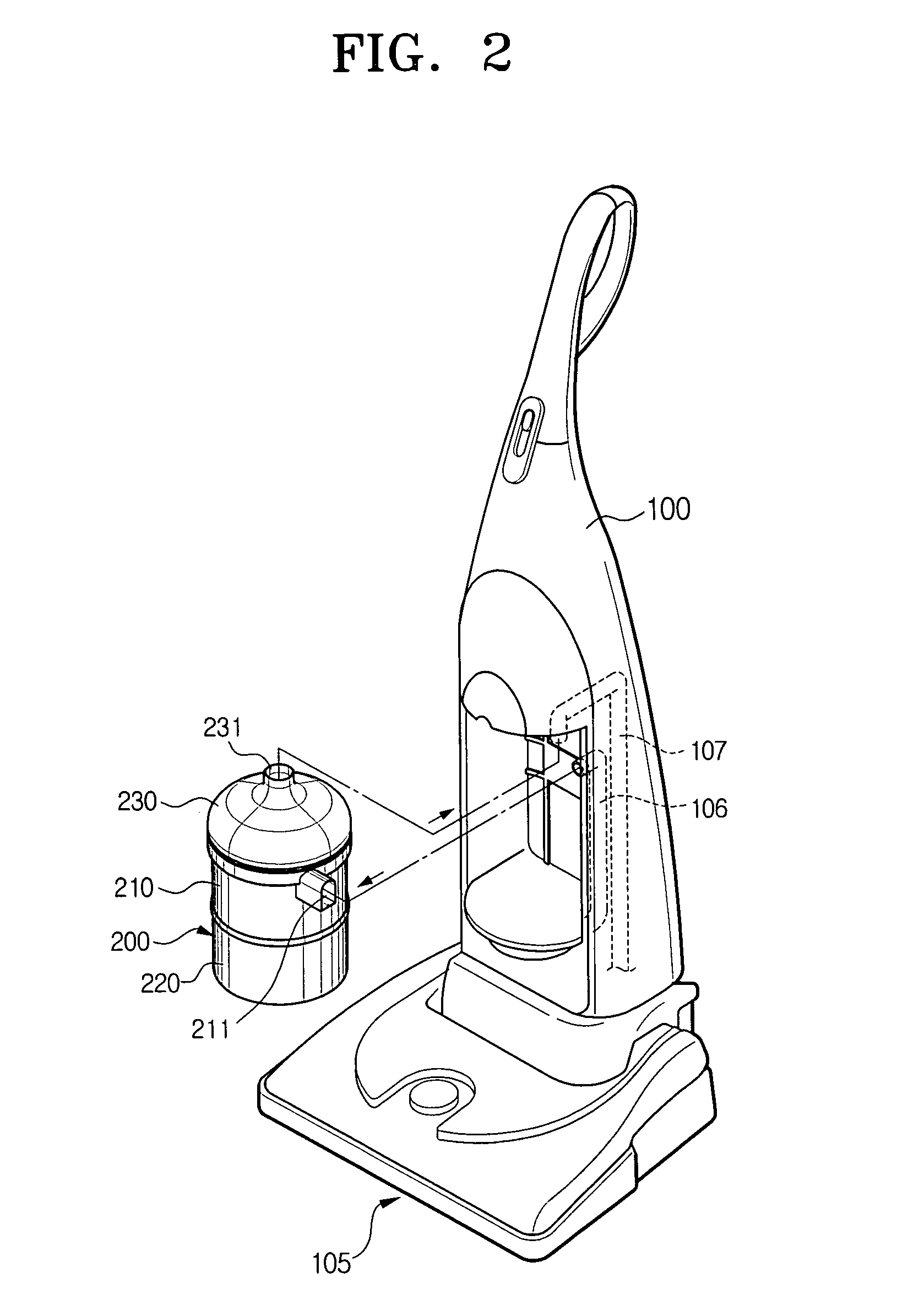

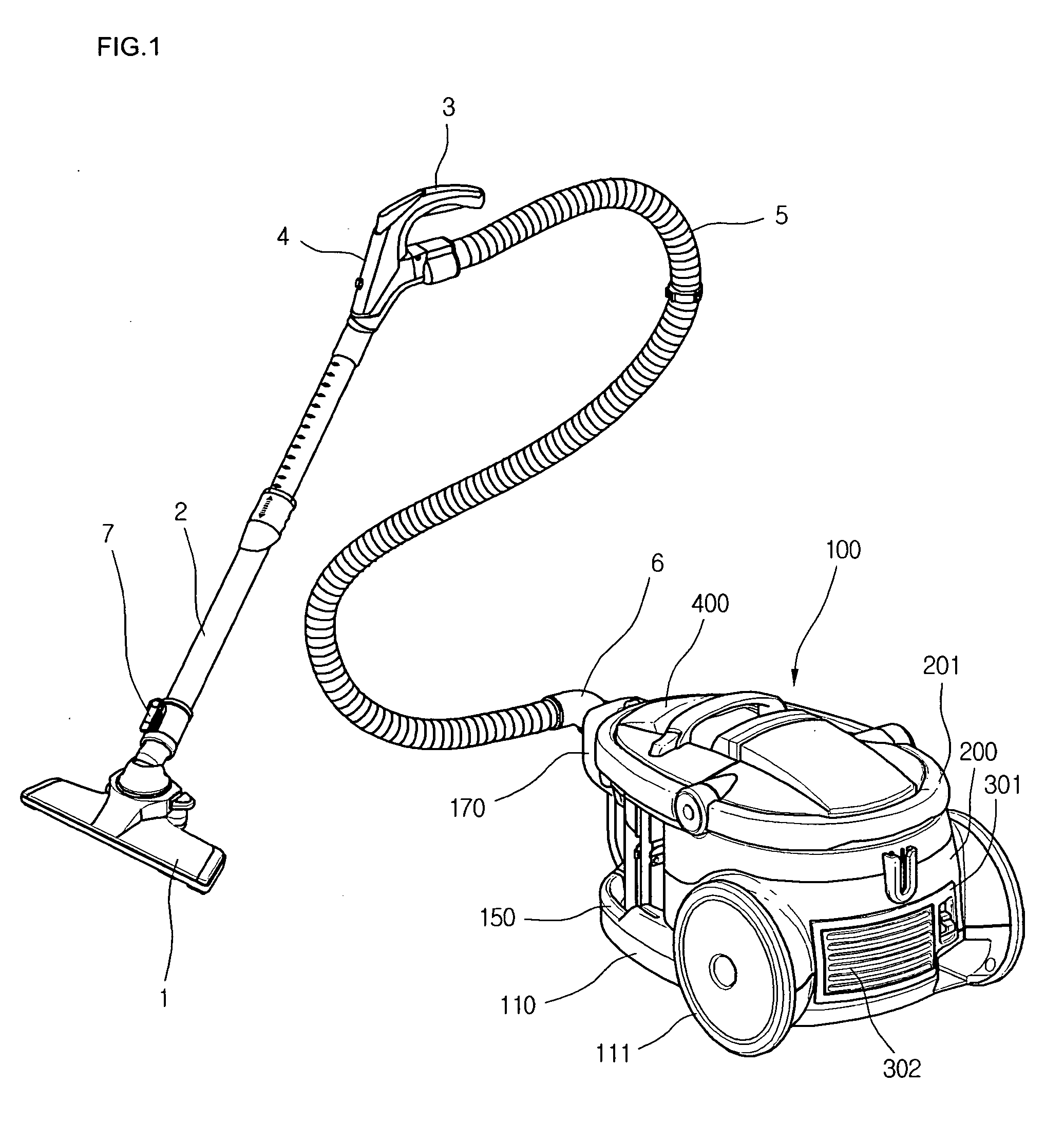

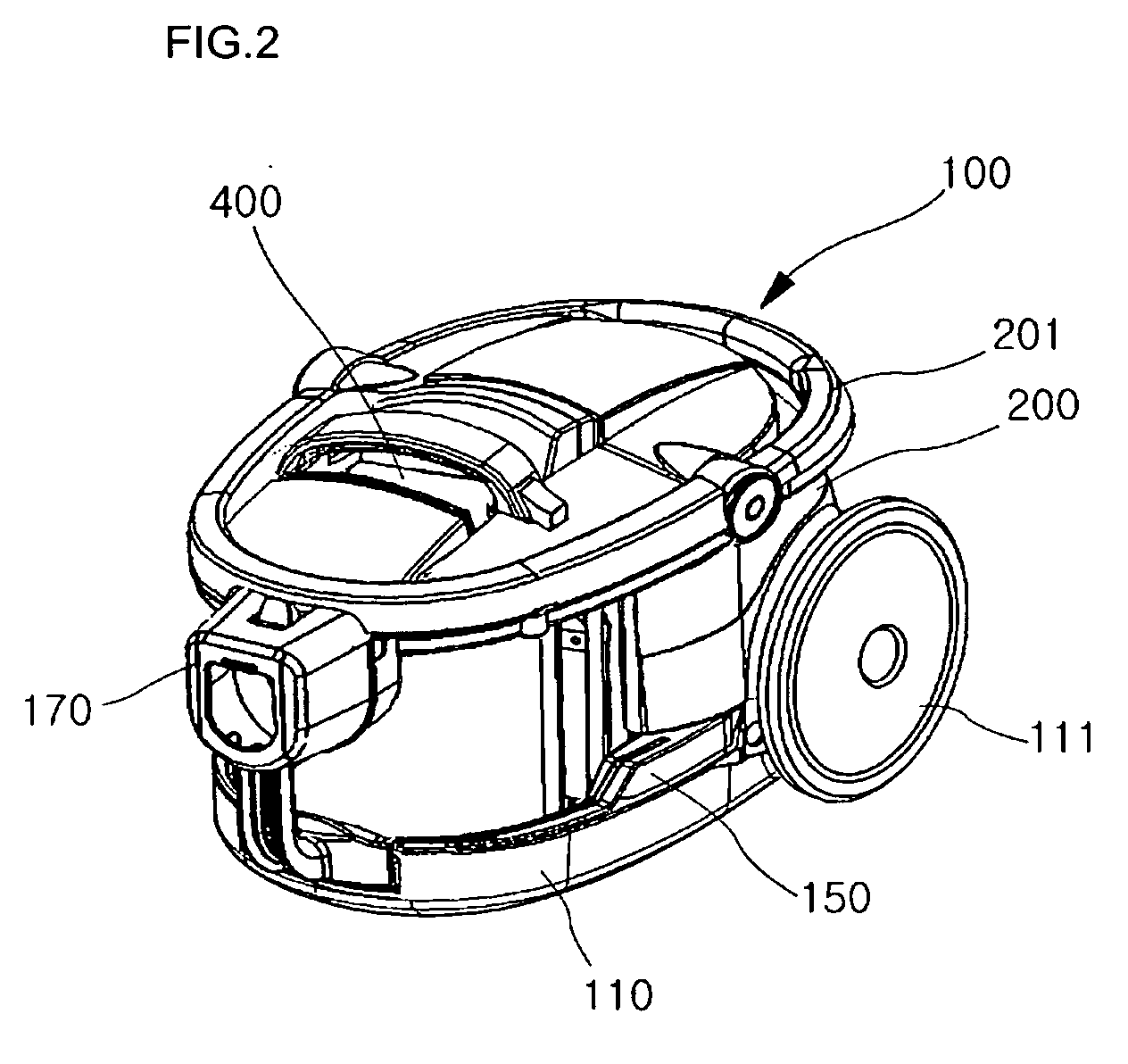

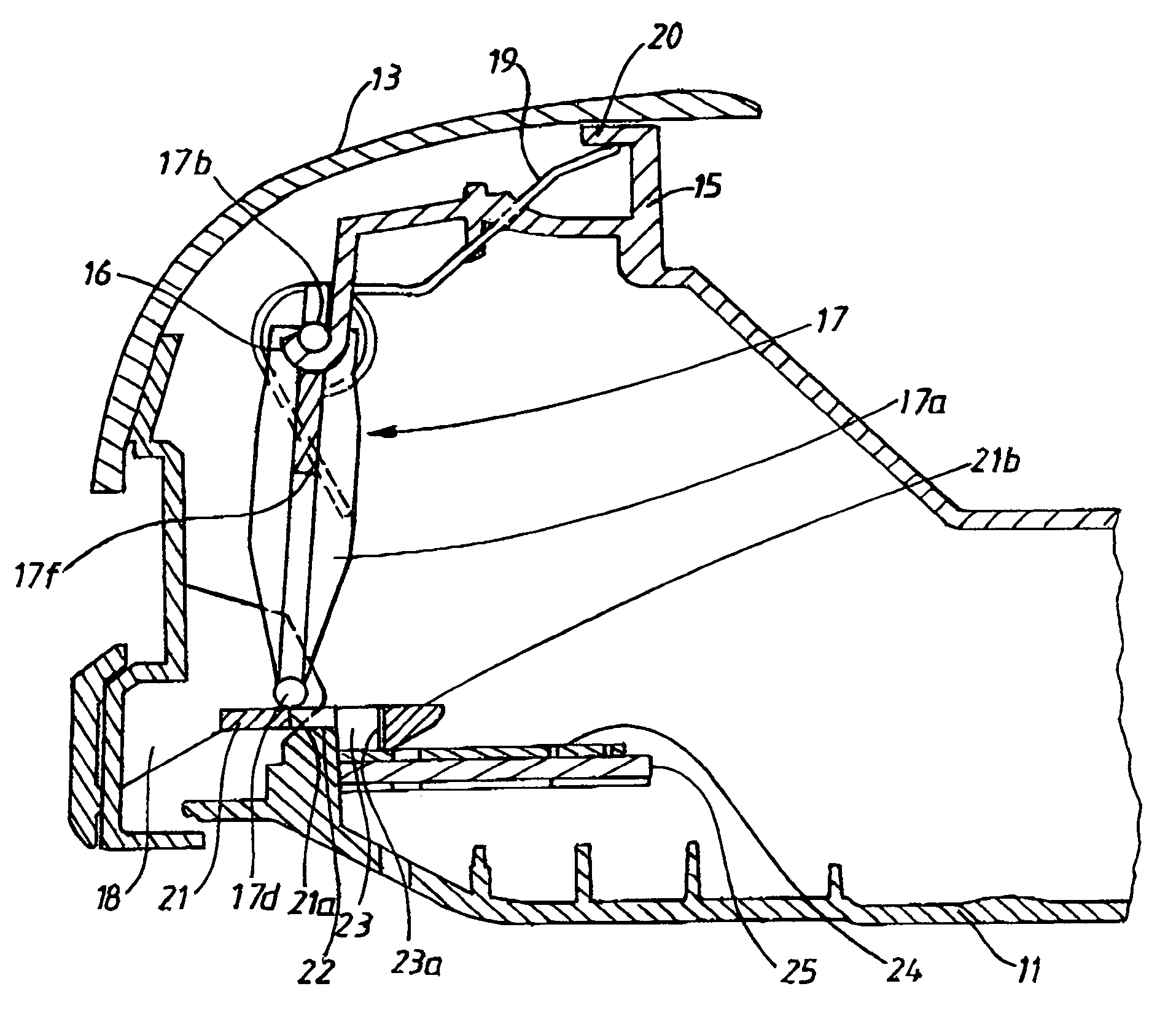

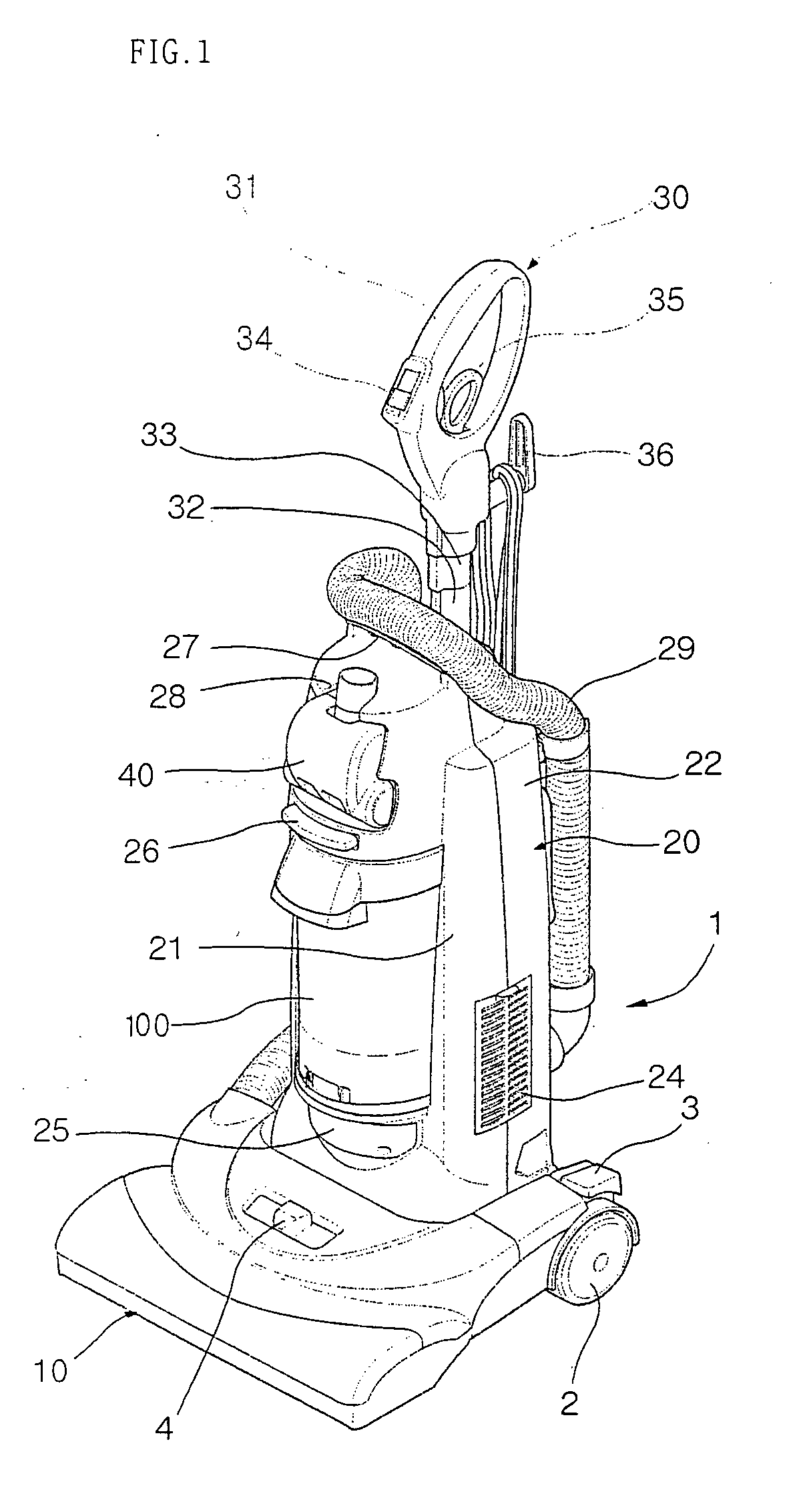

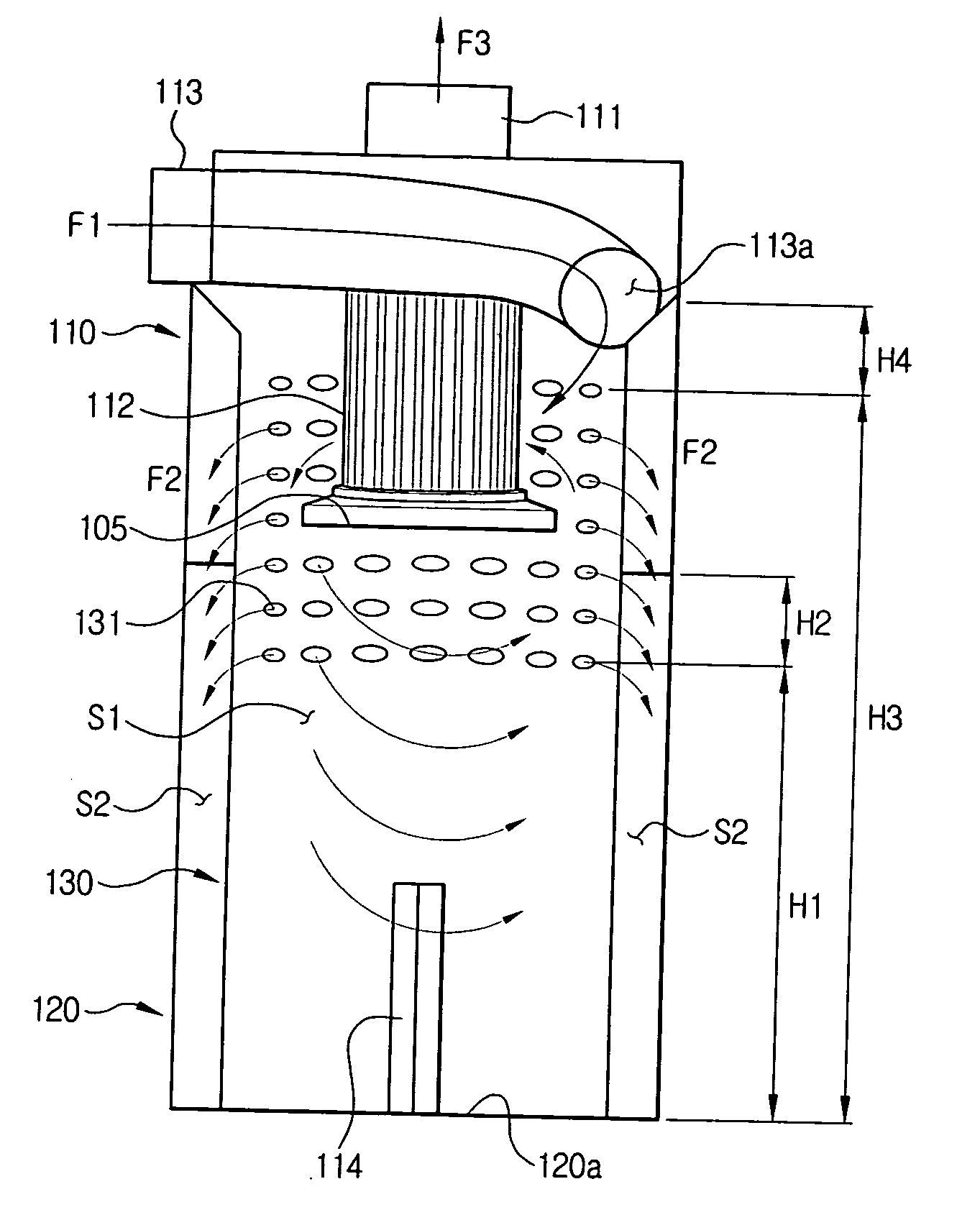

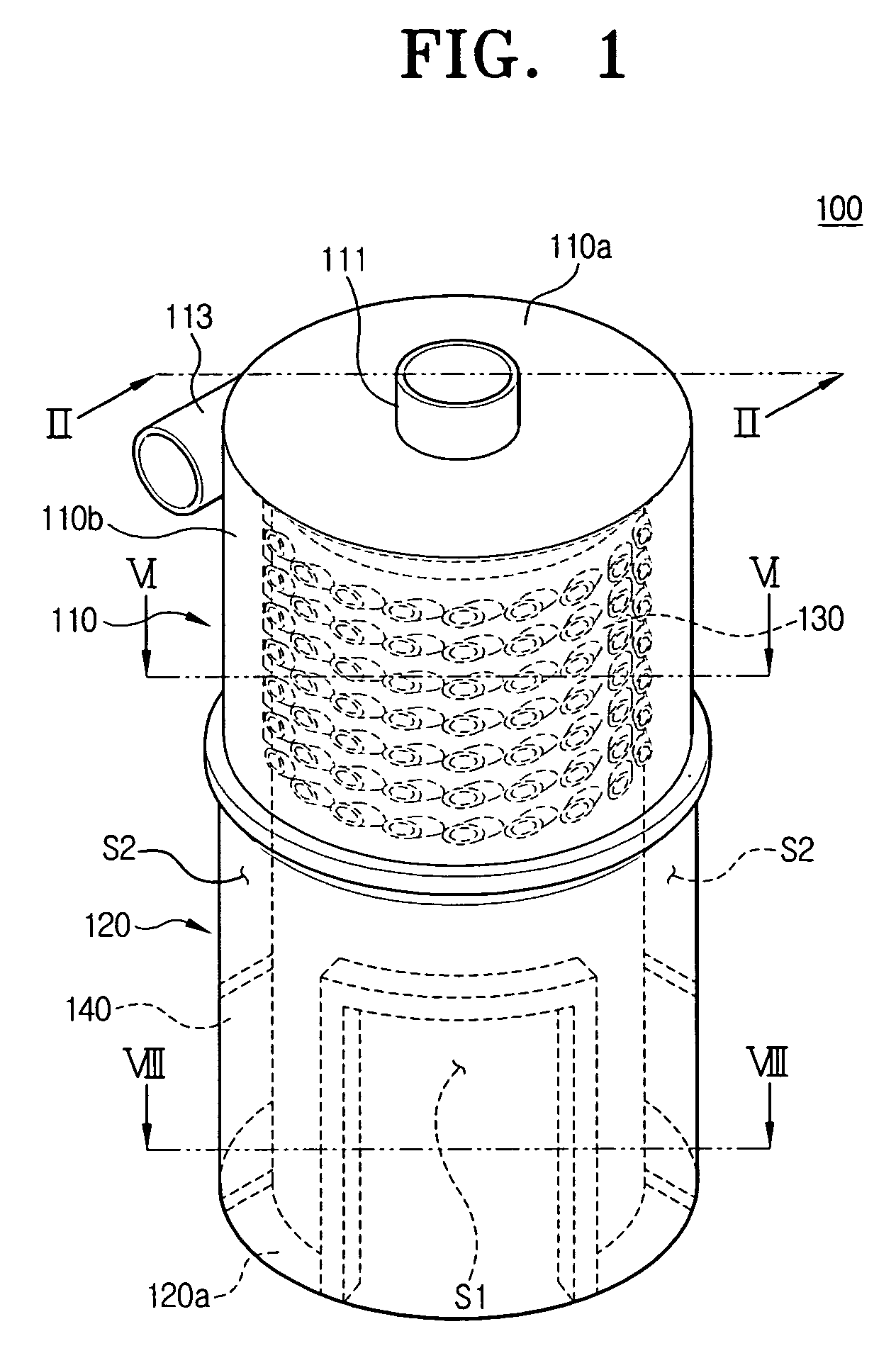

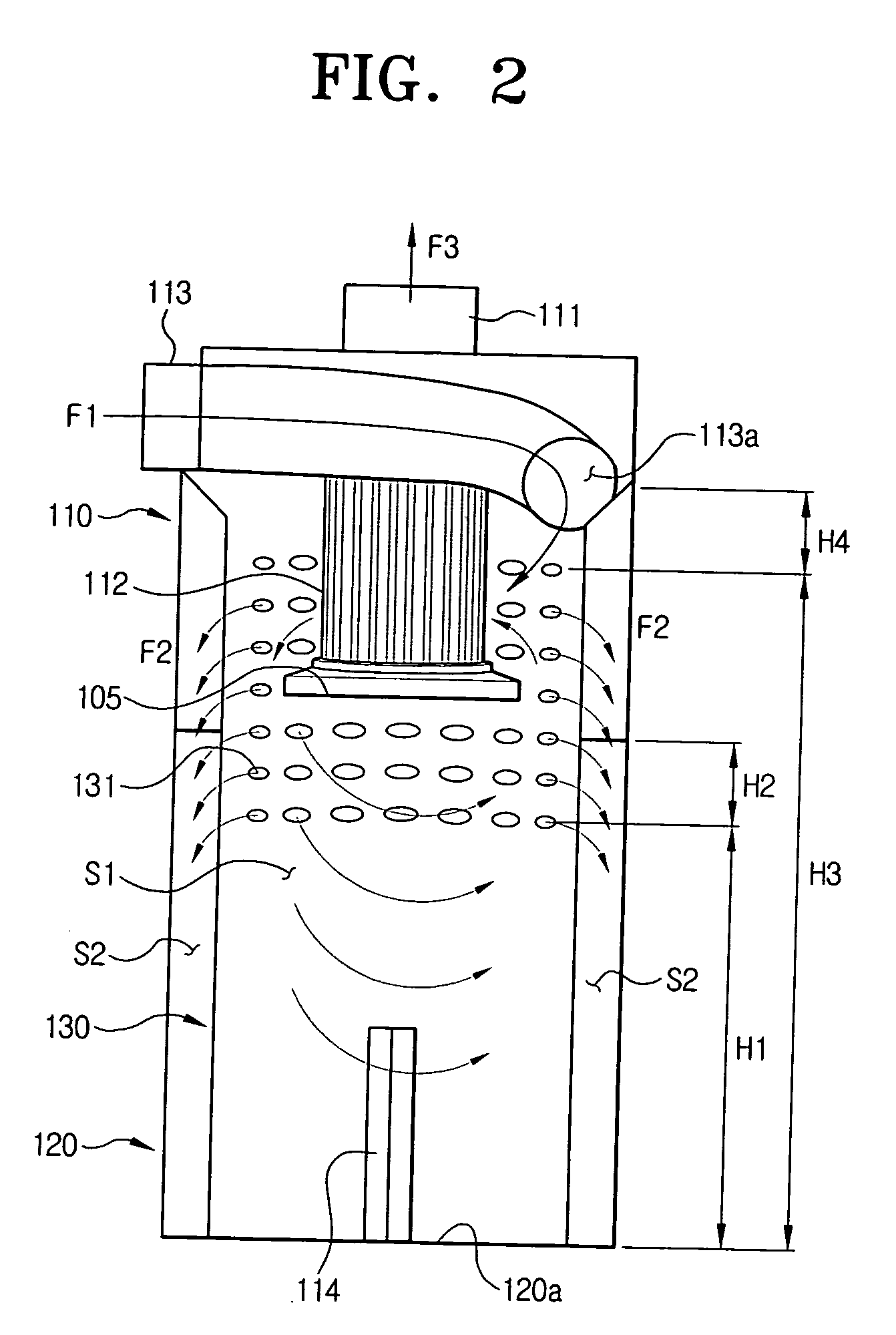

Vacuum cleaner having a cyclone type dust collecting apparatus

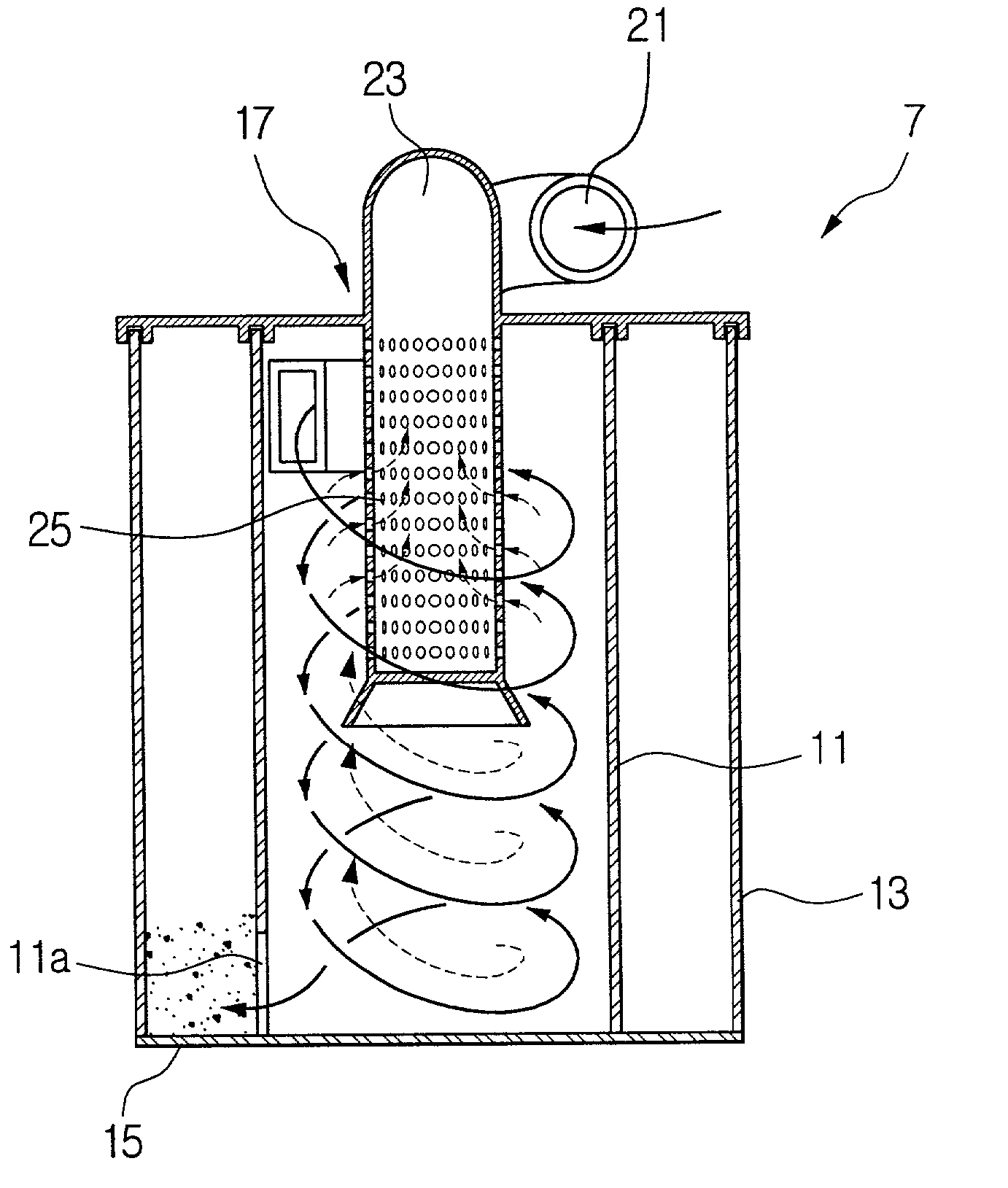

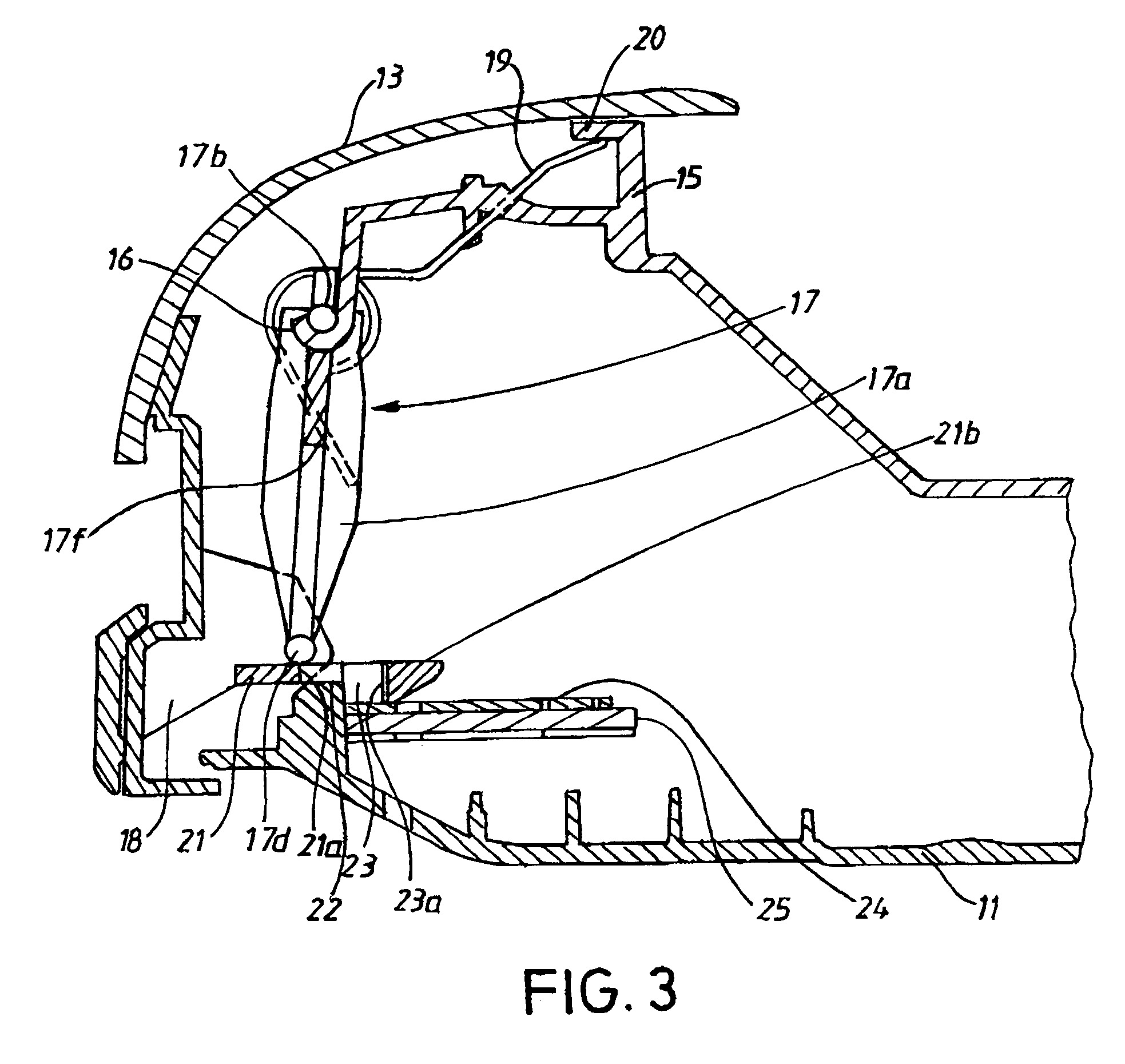

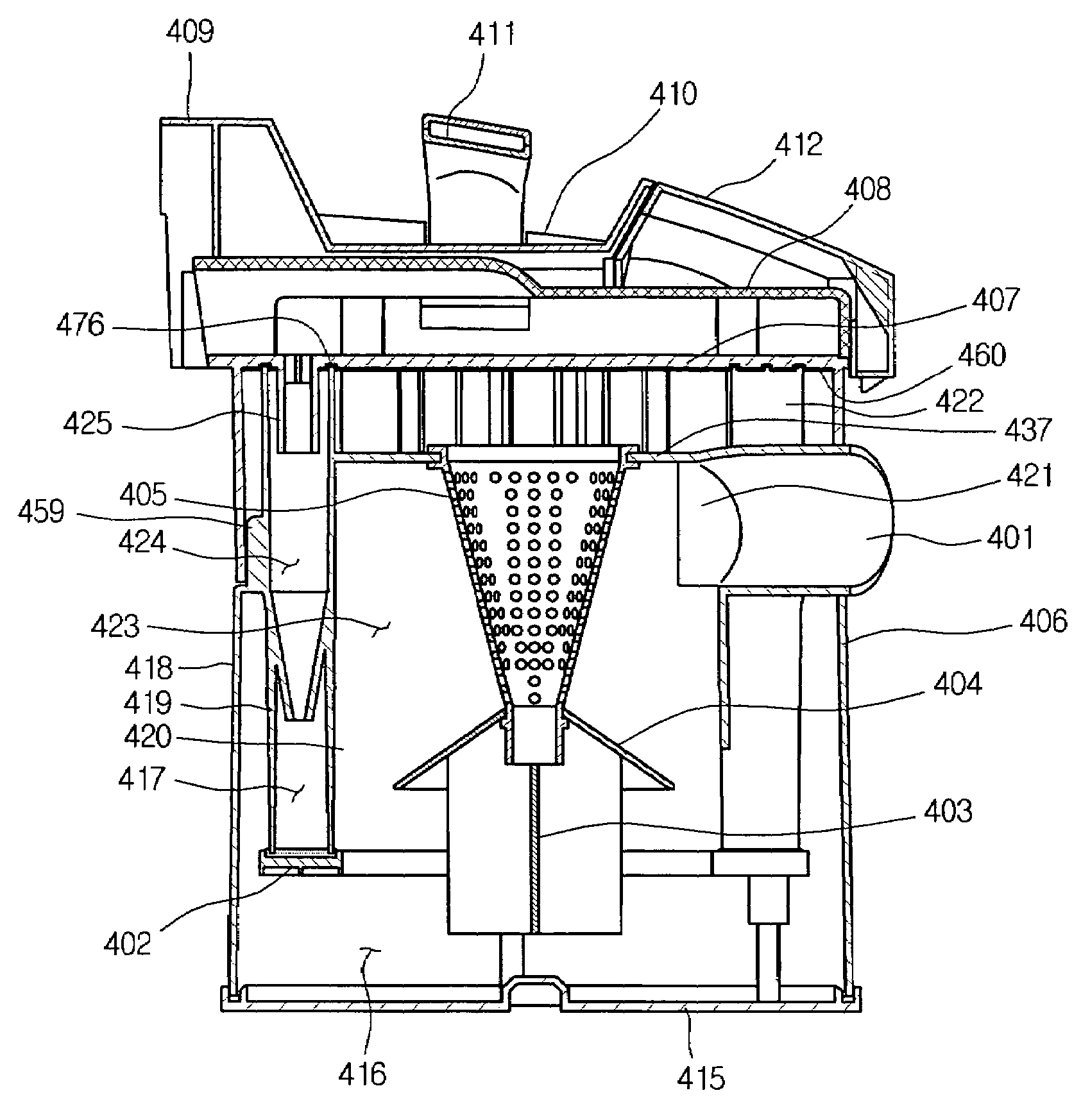

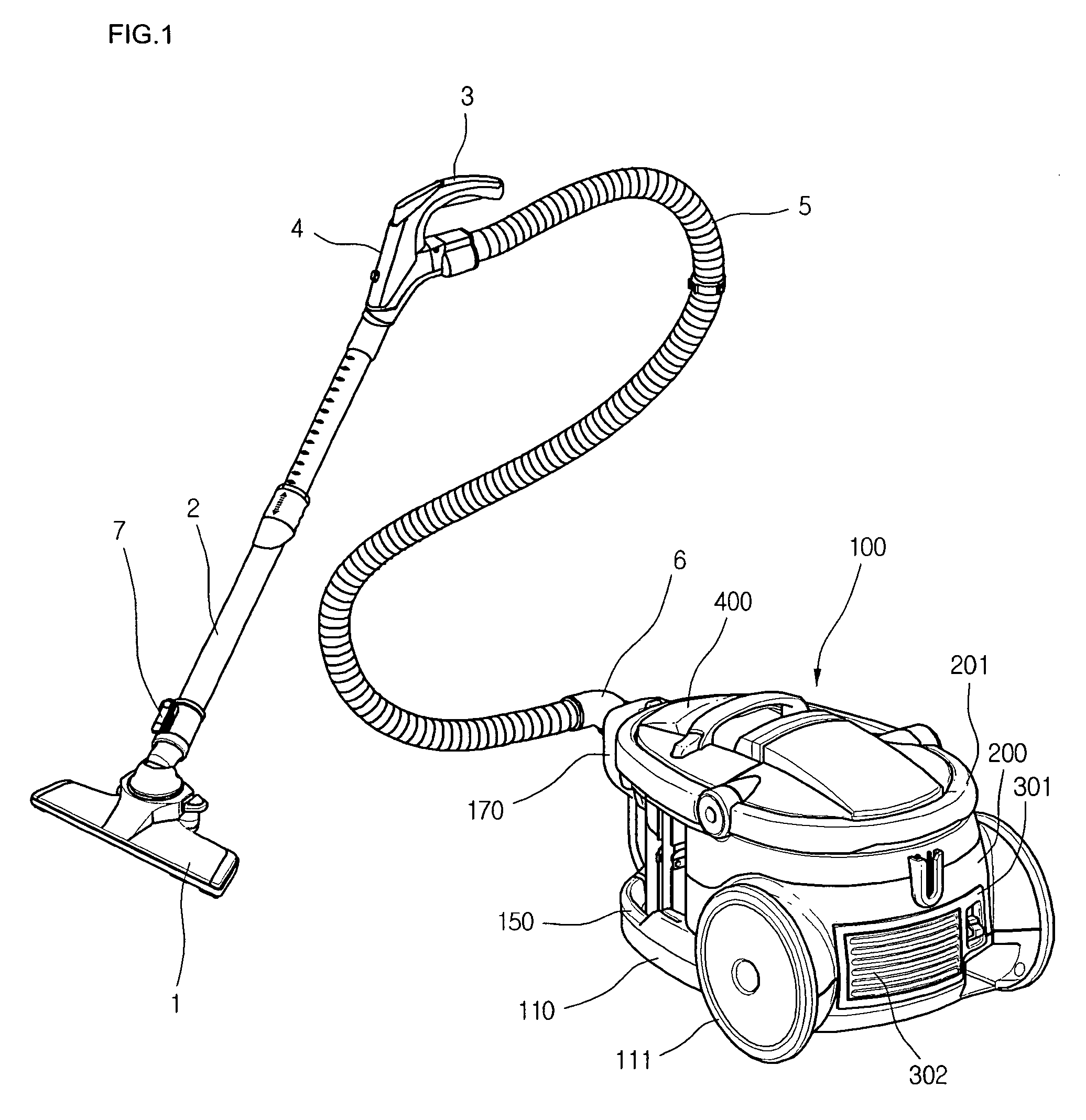

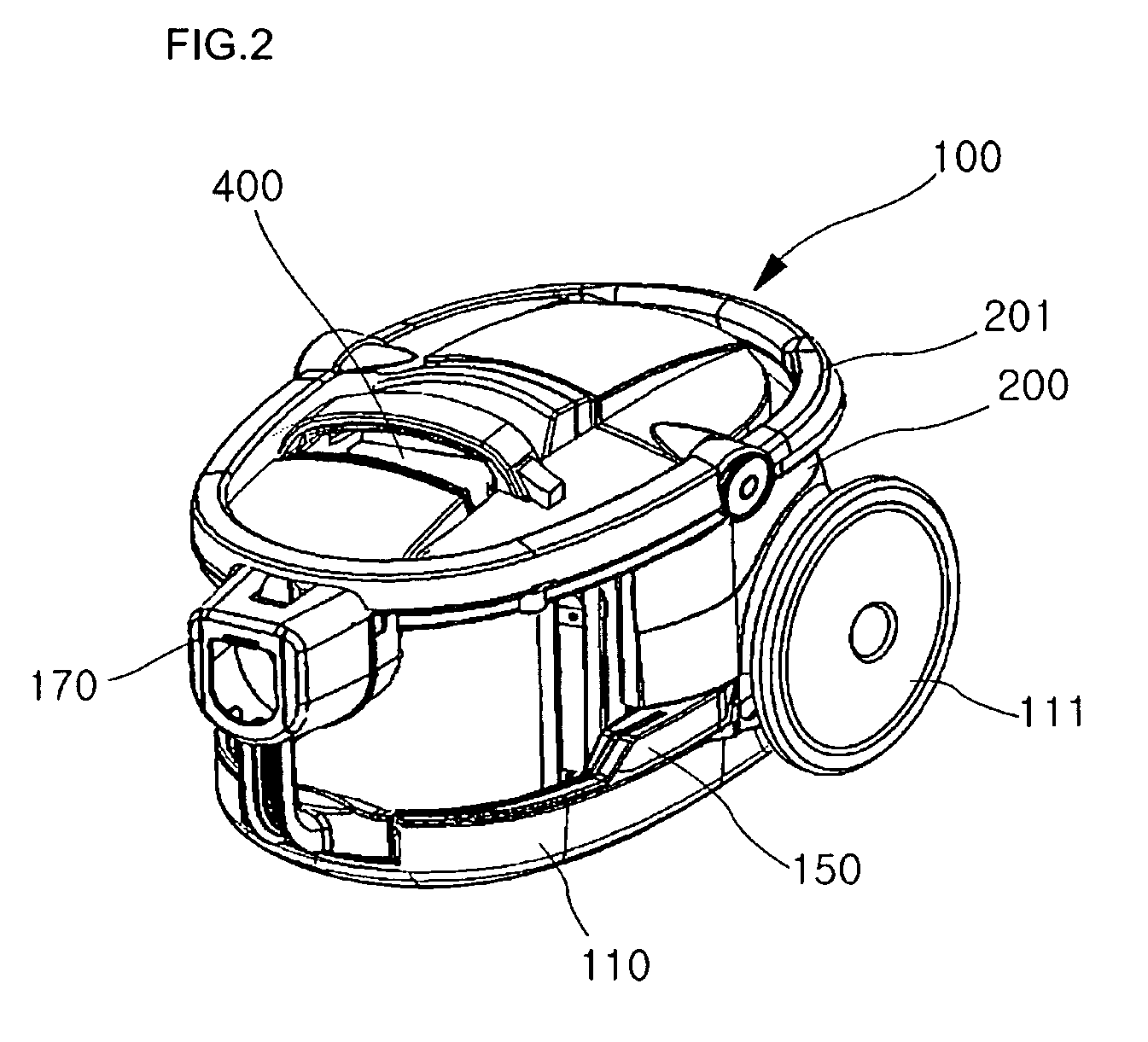

A vacuum cleaner includes a cleaner body, a suction brush, through which air and contaminants are drawn in, and a cyclone type dust collecting device. The cleaner body has a motor driving chamber and a dust collecting chamber in communication with the motor driving chamber. The cyclone type dust collecting device is mounted in the dust collecting chamber and separates by centrifugal force the contaminants from the air. The cyclone type dust collecting device includes a hollow cylindrical cyclone body having an open top, a closed bottom, and a contaminant outlet. The open top allows air and contaminants into the cyclone body, where the contaminants are separated from the air by centrifugation. The contaminants are then discharged from the cyclone body through the contaminant outlet. The cyclone type dust collecting device further includes a contaminant receptacle for collecting the contaminants discharged through the contaminant outlet, a base member hingedly connected to the contaminant receptacle, and a cover for covering the top of the cyclone body. The cover has an air inlet passage, through which air and contaminants drawn in through the suction brush enter into the cyclone body, an air outlet passage, through which the air is discharged from the cyclone body, and a contaminant separating grill. The grill extends downward from the air outlet passage into the cyclone body and has a plurality of fine holes.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

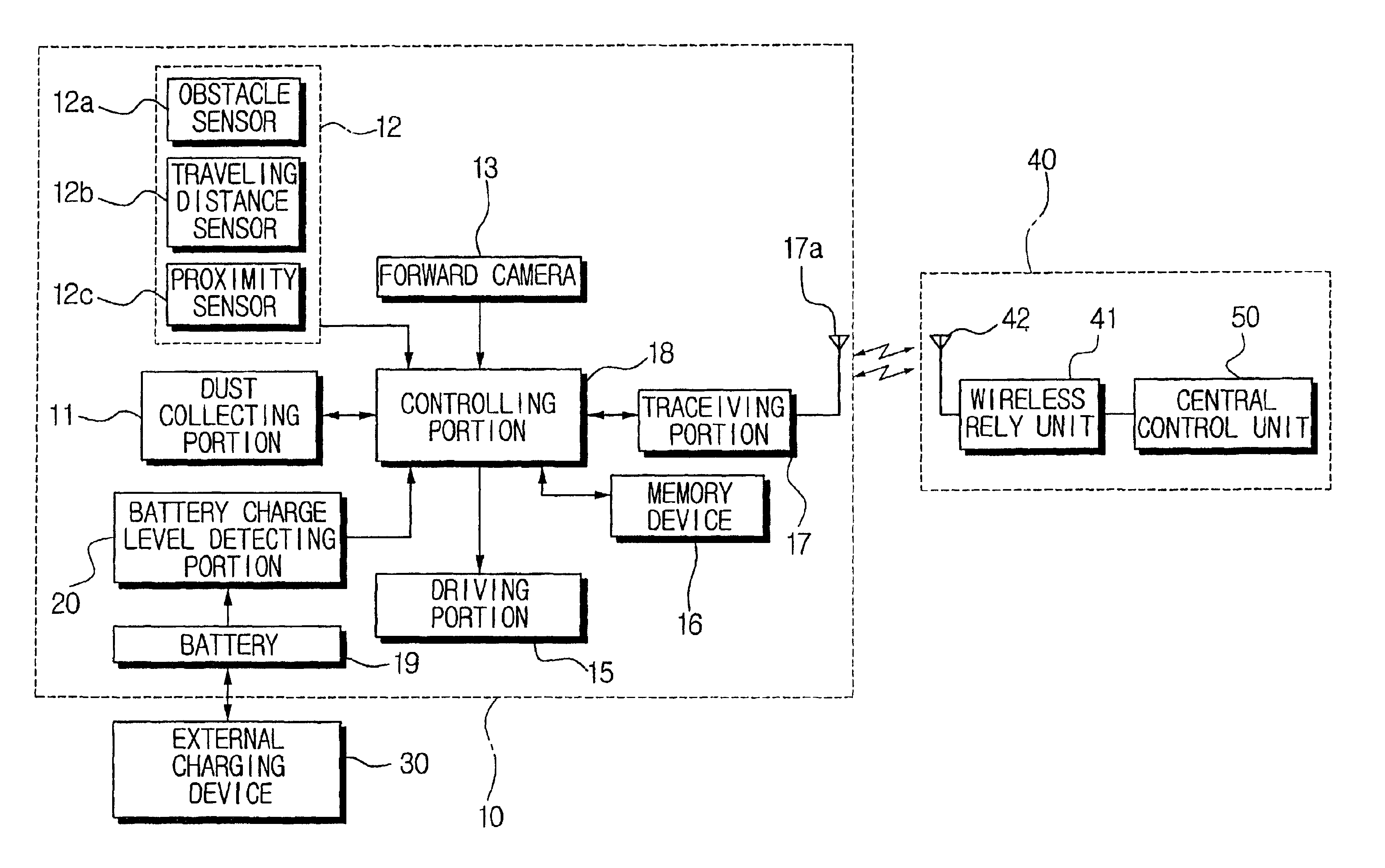

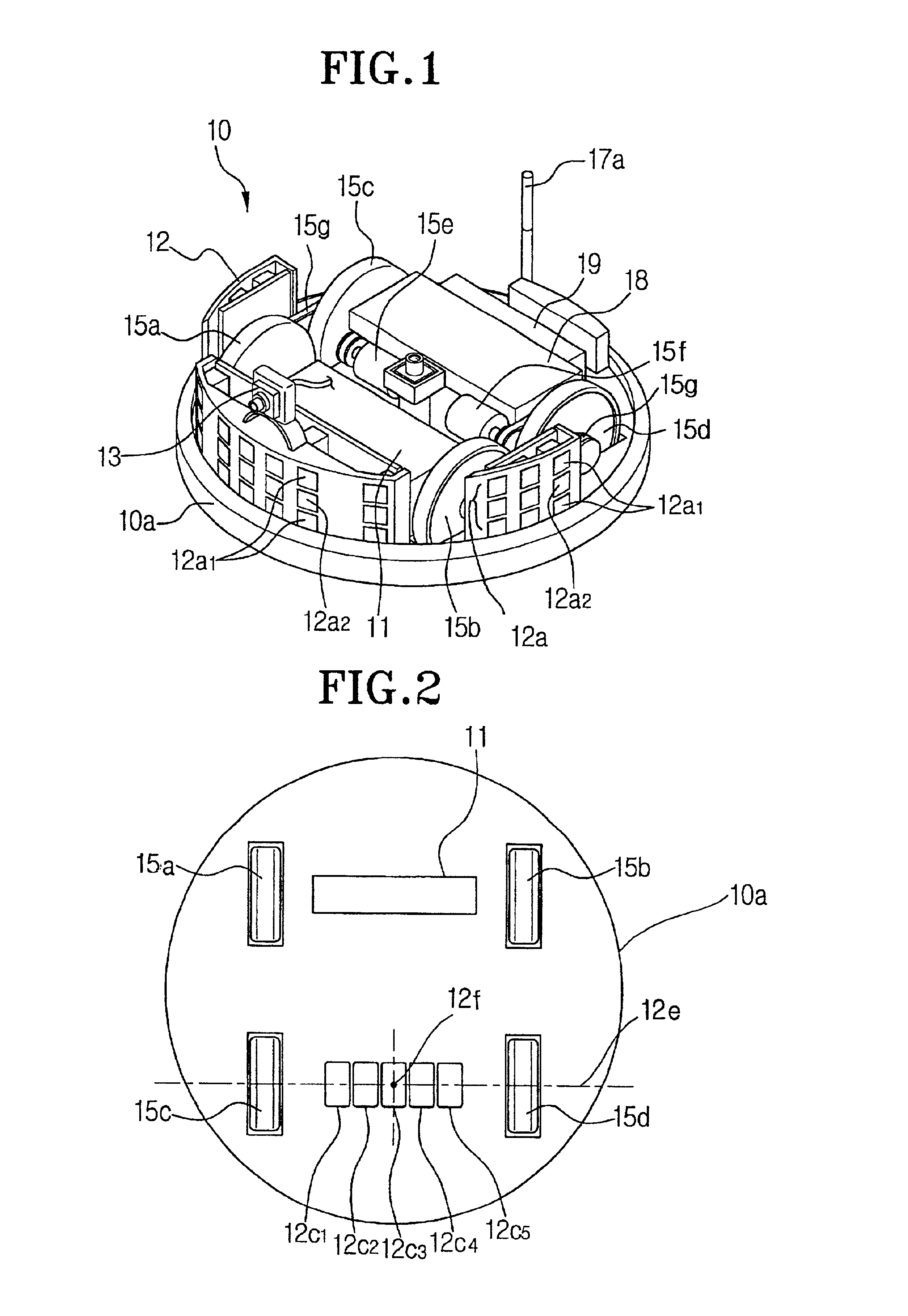

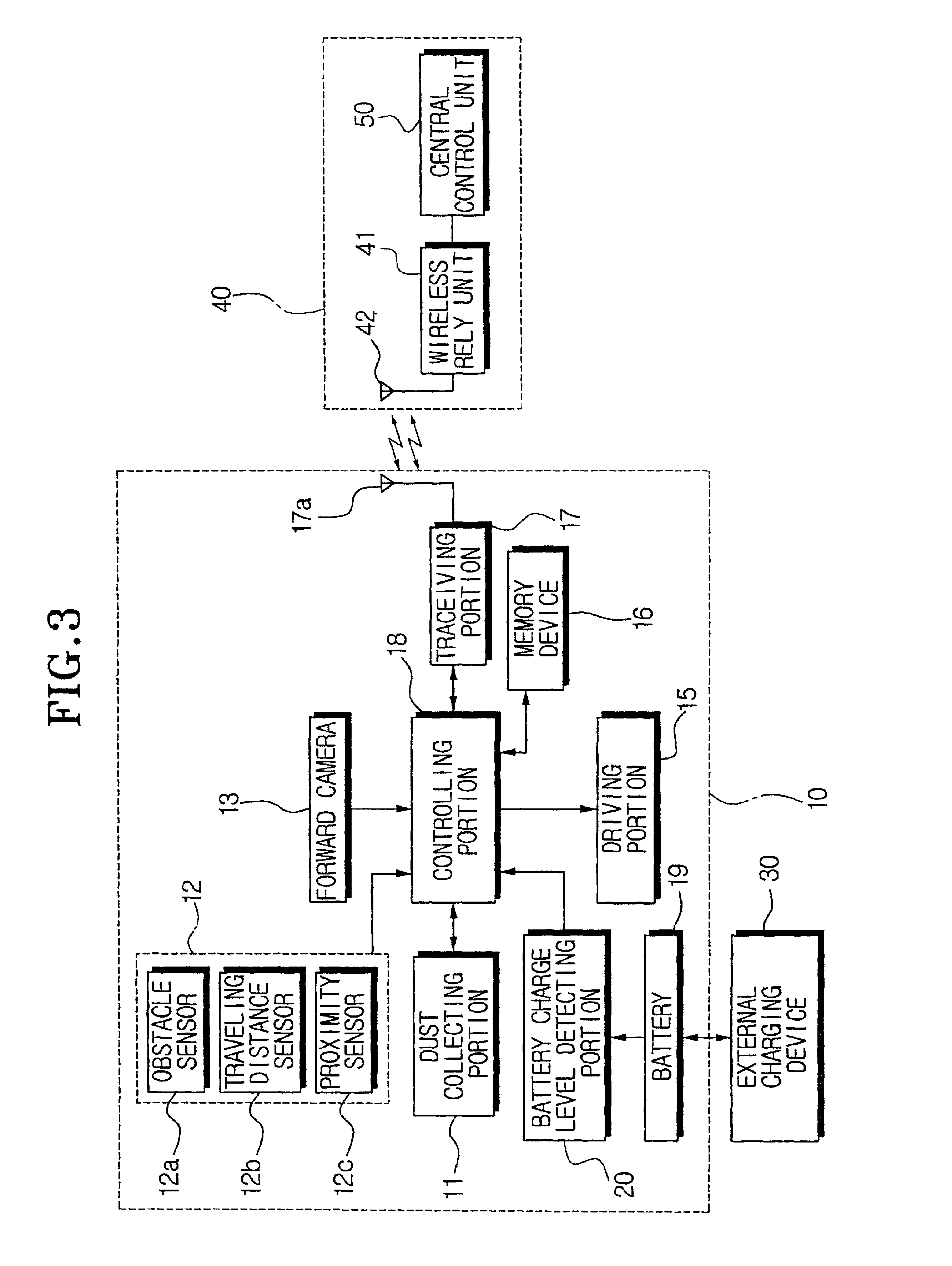

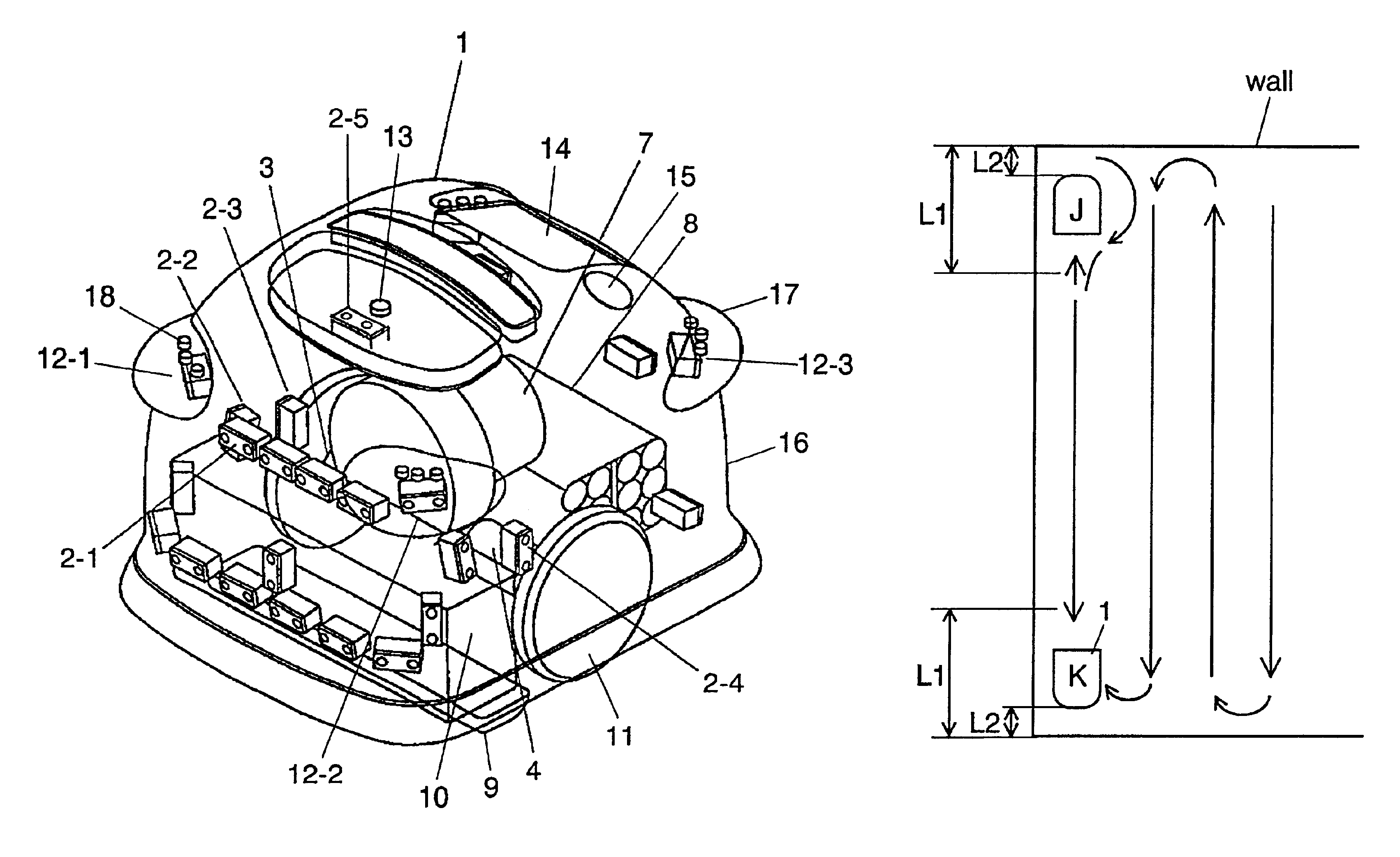

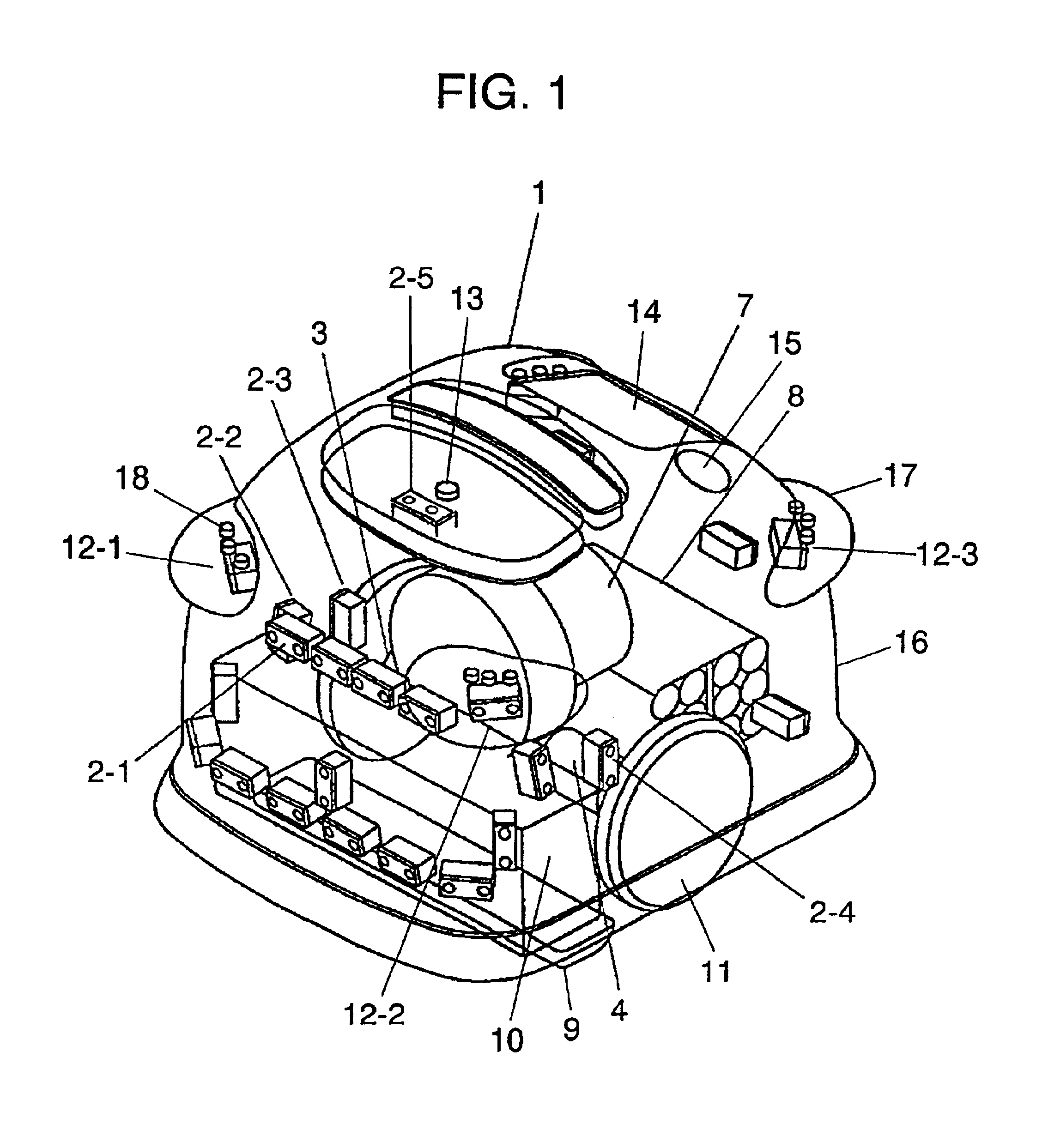

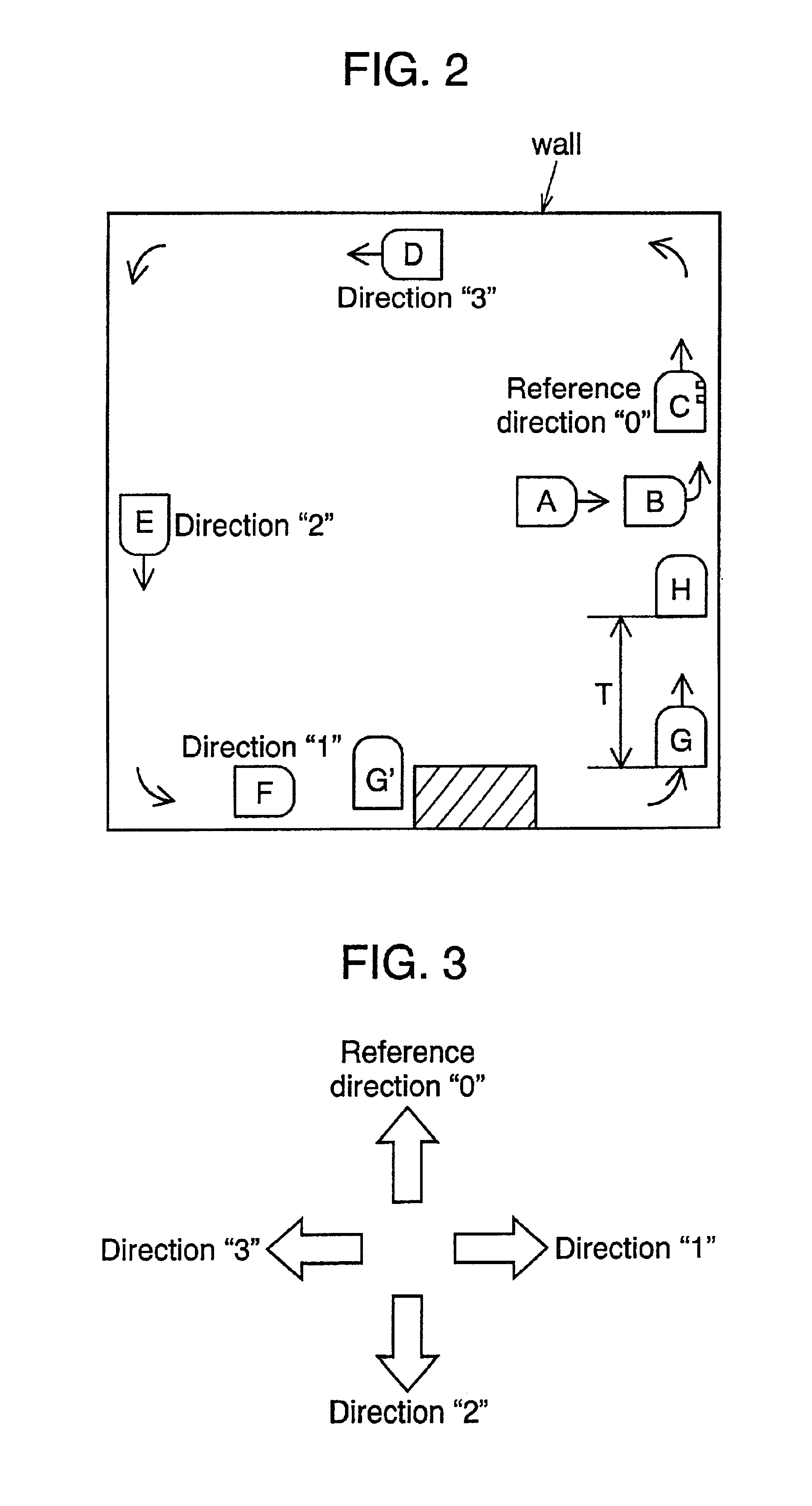

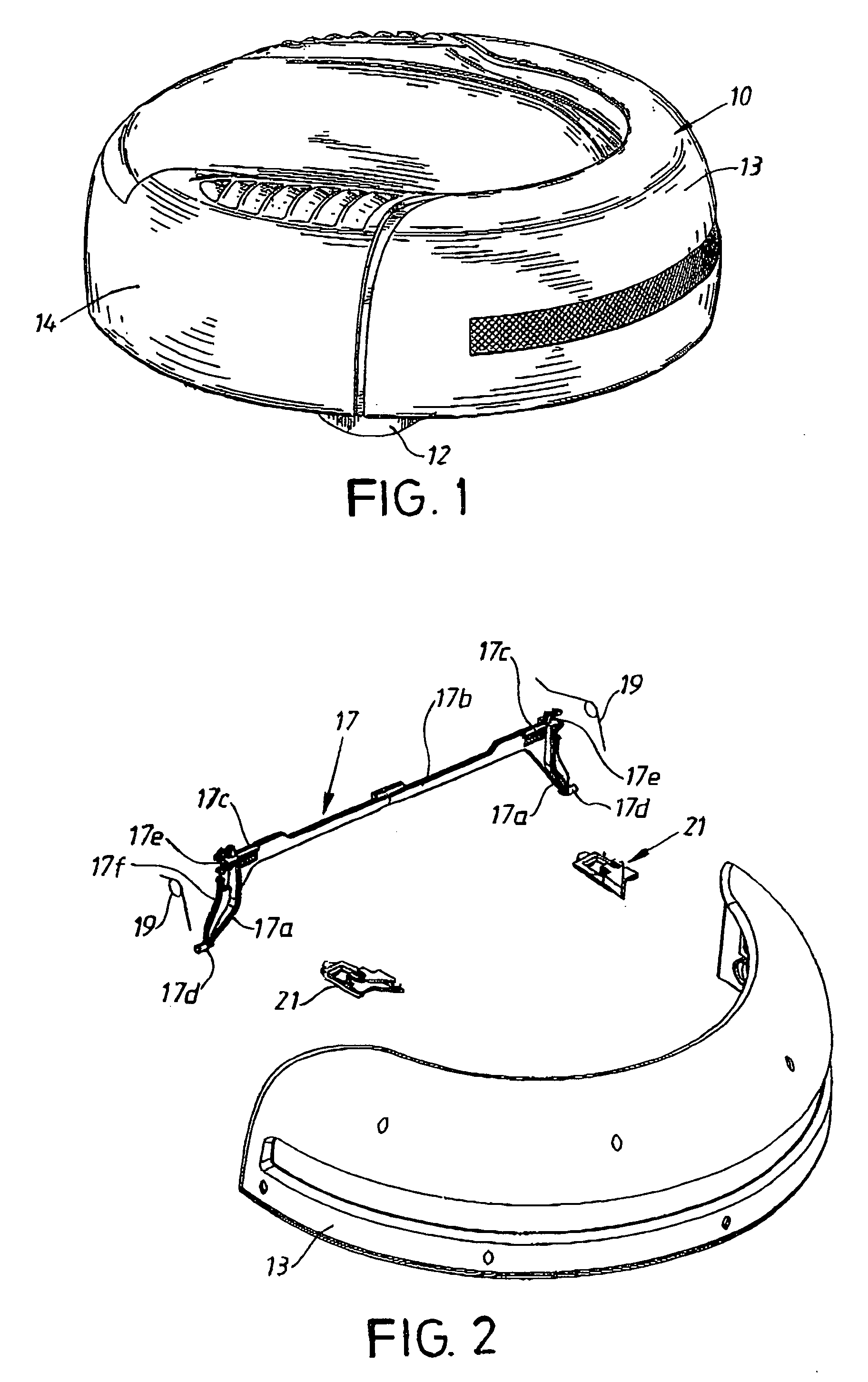

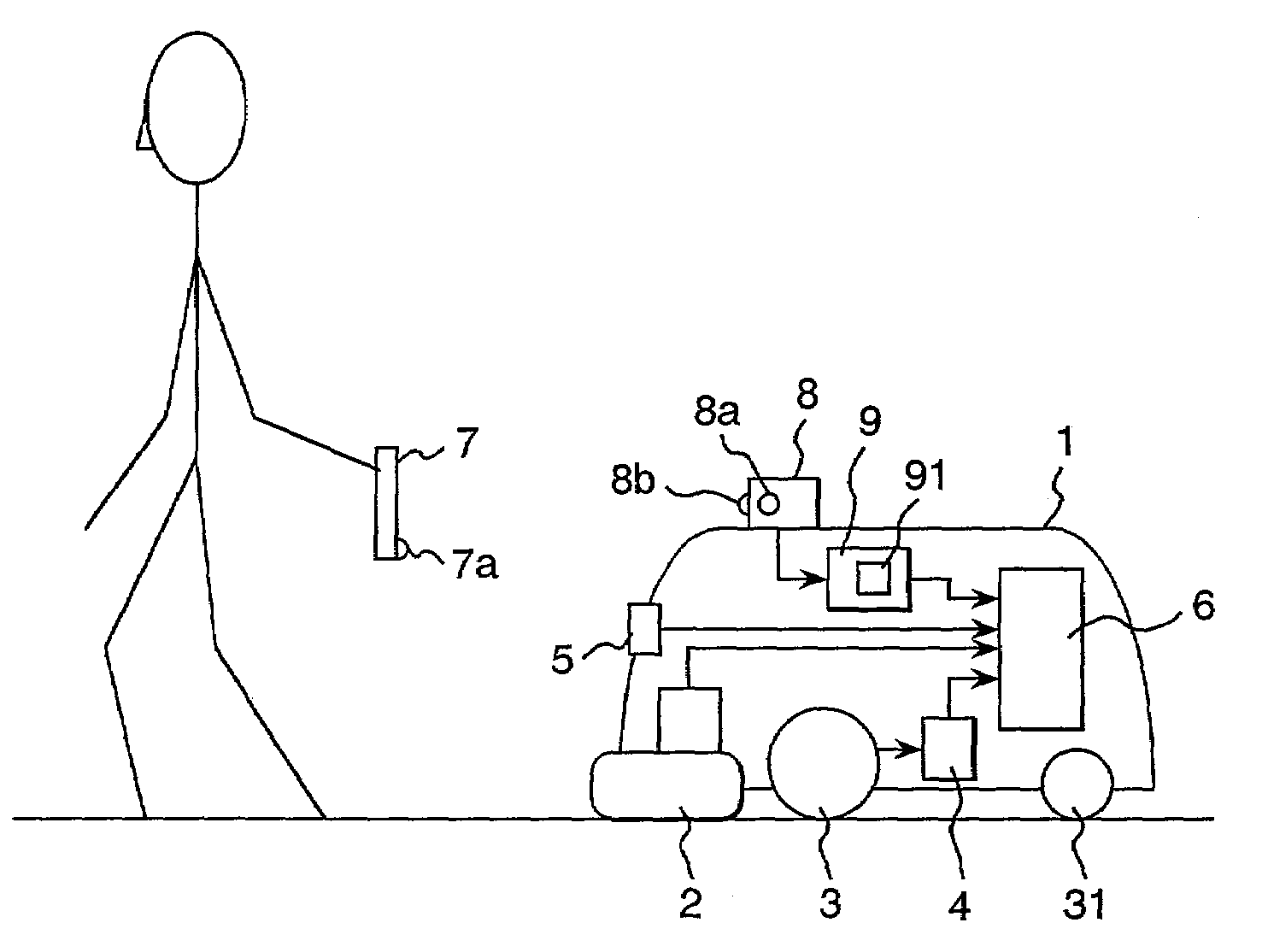

Robot cleaner, system thereof and method for controlling same

InactiveUS6841963B2Accurate identificationReduce the burden onAutomatic obstacle detectionTravelling automatic controlControl theoryPeripheral

A robot cleaner, a system thereof, and a method for controlling the same. The robot cleaner system includes a robot cleaner that performs a cleaning operation while communicating wirelessly with an external device. The robot cleaner has a plurality of proximity switches arranged in a row on a lower portion of the cleaner body. A guiding plate is disposed in the floor of the work area, the guiding plate having metal lines formed in a predetermined pattern, the metal lines being detectible by the proximity switches. Since the recognition of the location and the determination of traveling trajectory of the cleaner within a work area becomes easier, performance of the robot cleaner is enhanced, while a burden of having to process algorithms is lessened.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

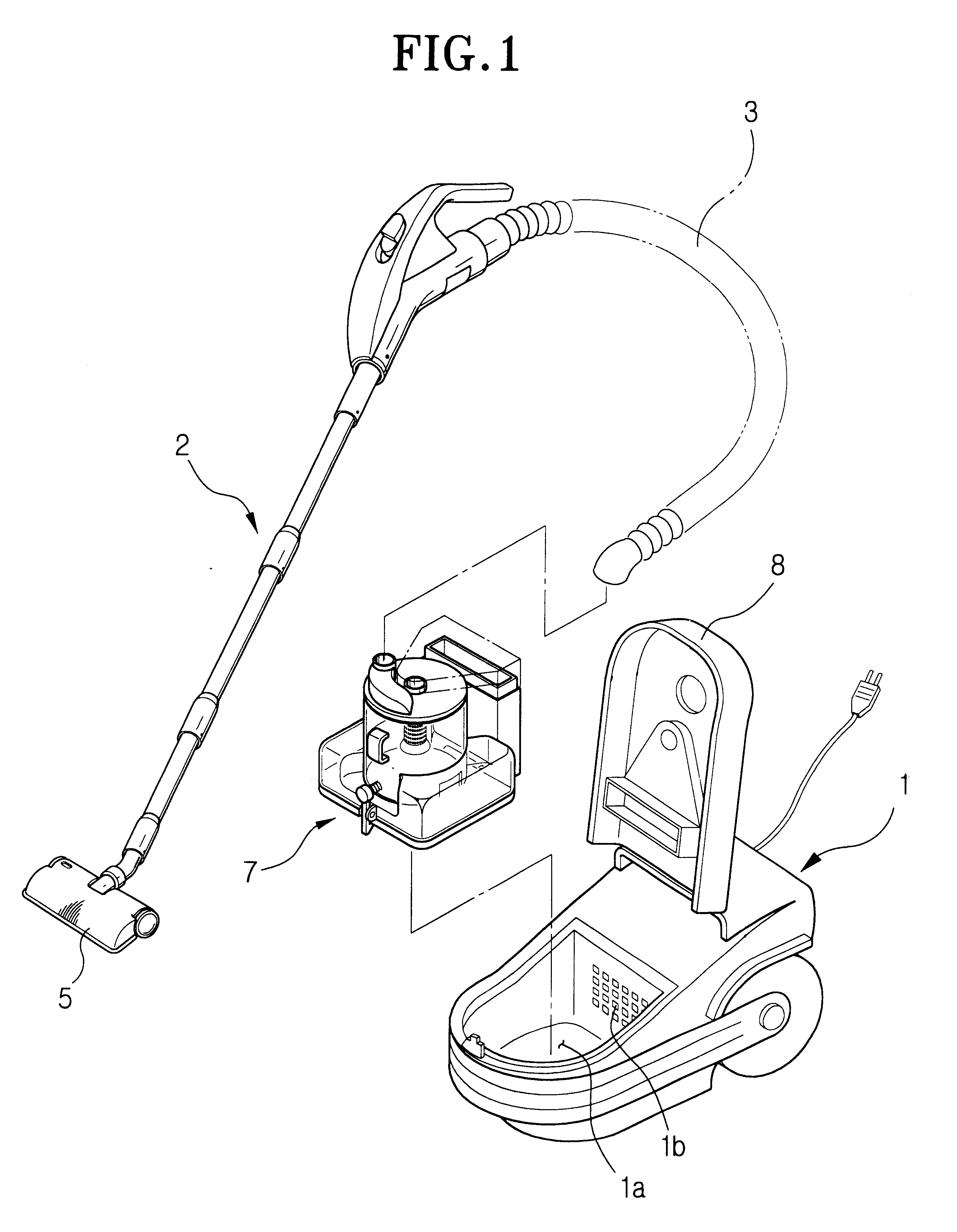

Air Flow Losses in a Vacuum Cleaners

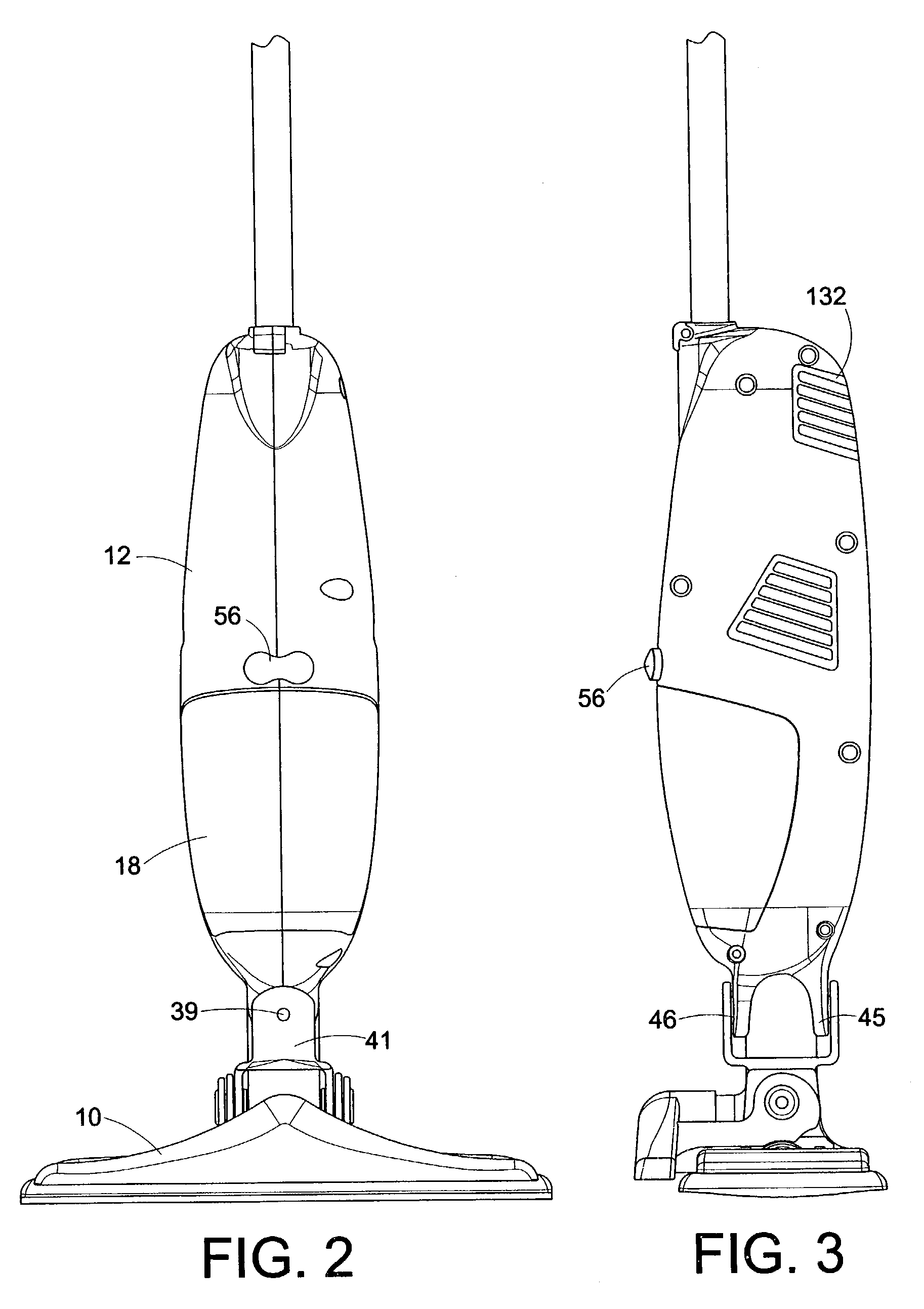

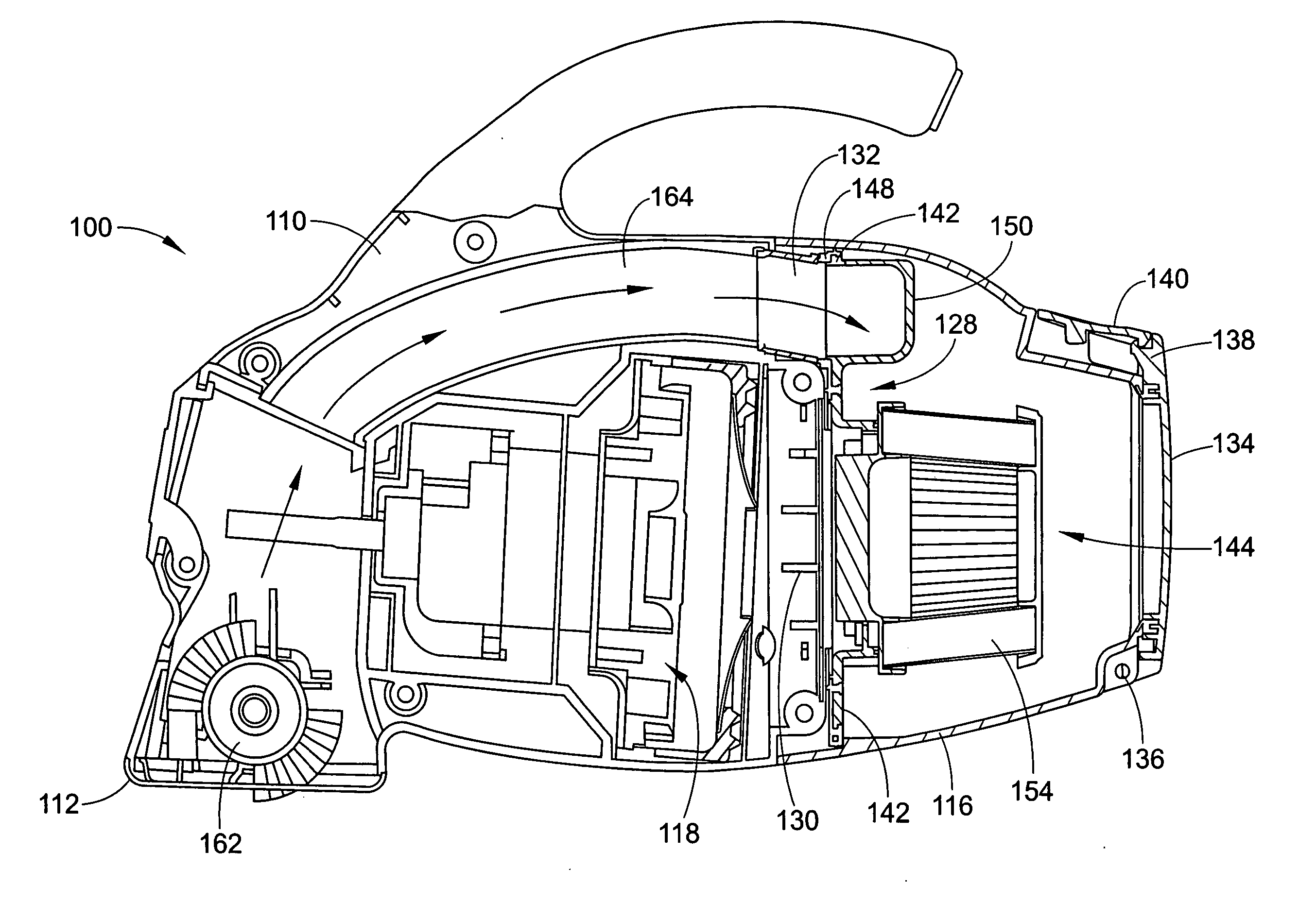

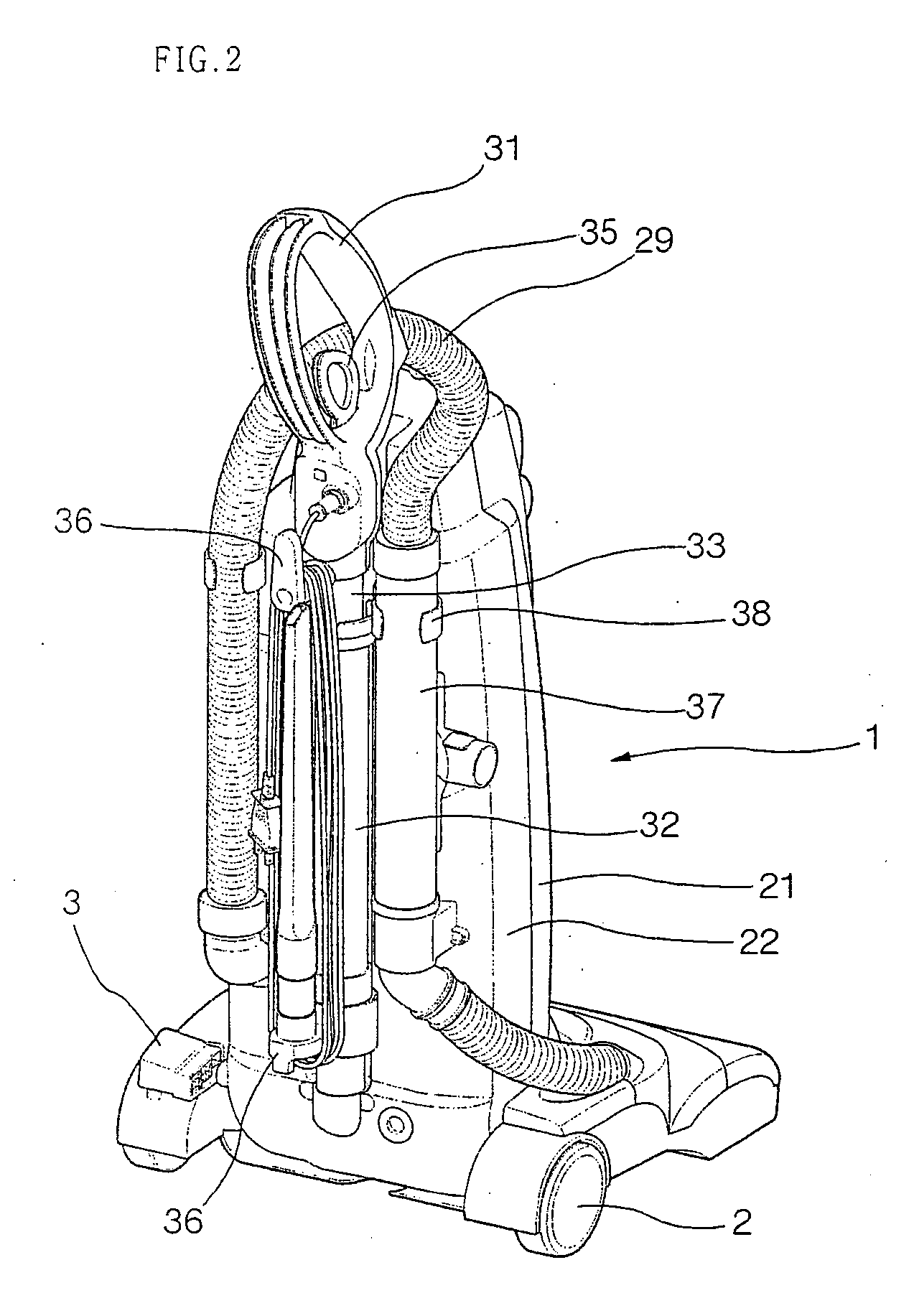

A vacuum cleaner having a handle with a handle air passage, a base attached to a first end of the handle by an articulating joint and having a base inlet positioned to face a surface to be cleaned, a base air passage extending from the base inlet and past the articulated joint by a flexible hose and to the handle air passage, a dirt collection assembly associated with the handle and in fluid communication with the handle air passage, a fan associated with the handle and in fluid communication with the handle air passage, and a motor associated with the handle and adapted to drive the fan to thereby generate an airflow through the base inlet, flexible hose, handle air passage, and dirt collection assembly. The flexible hose has a generally rectangular cross-section along a substantial portion thereof.

Owner:AB ELECTROLUX

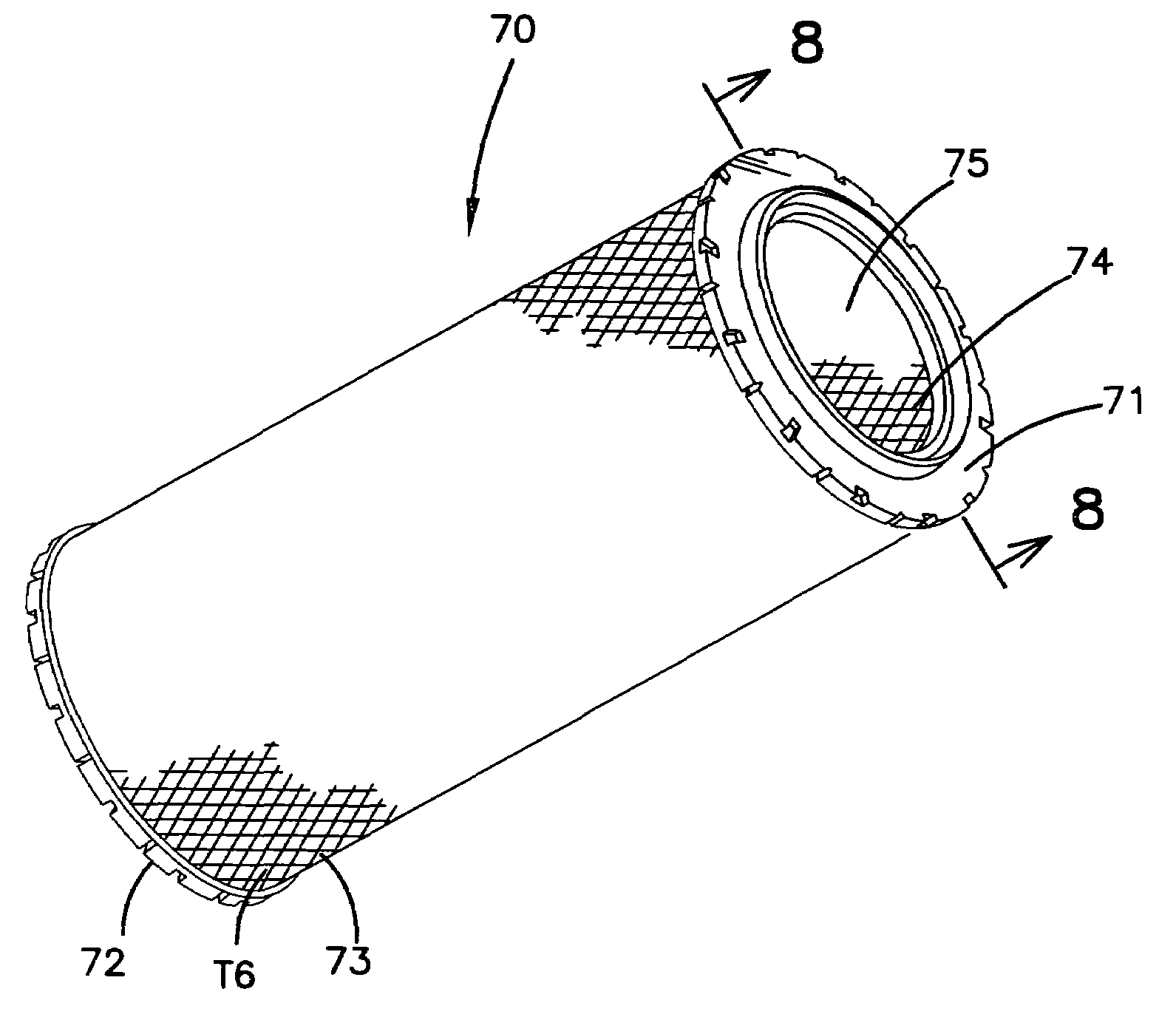

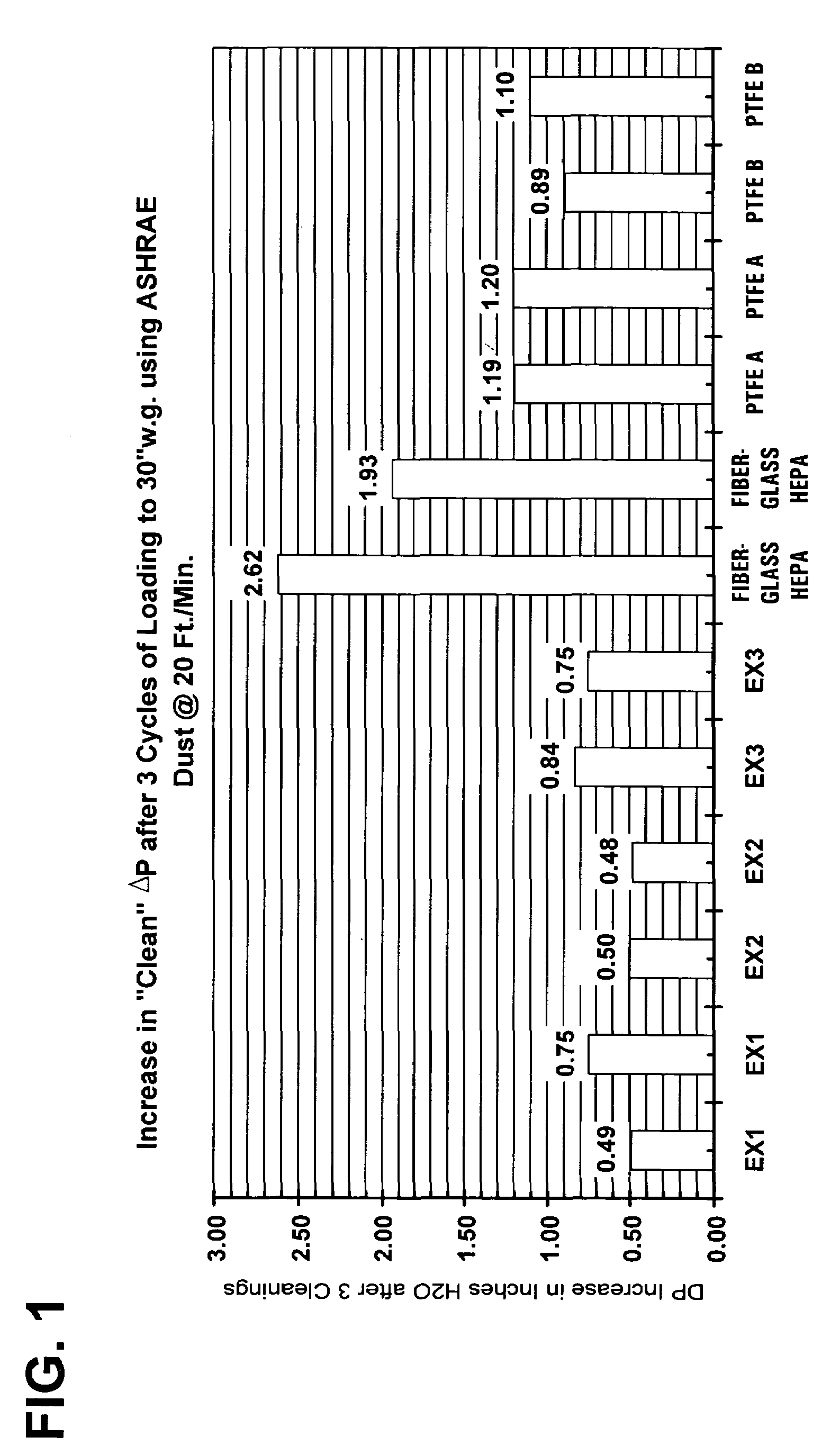

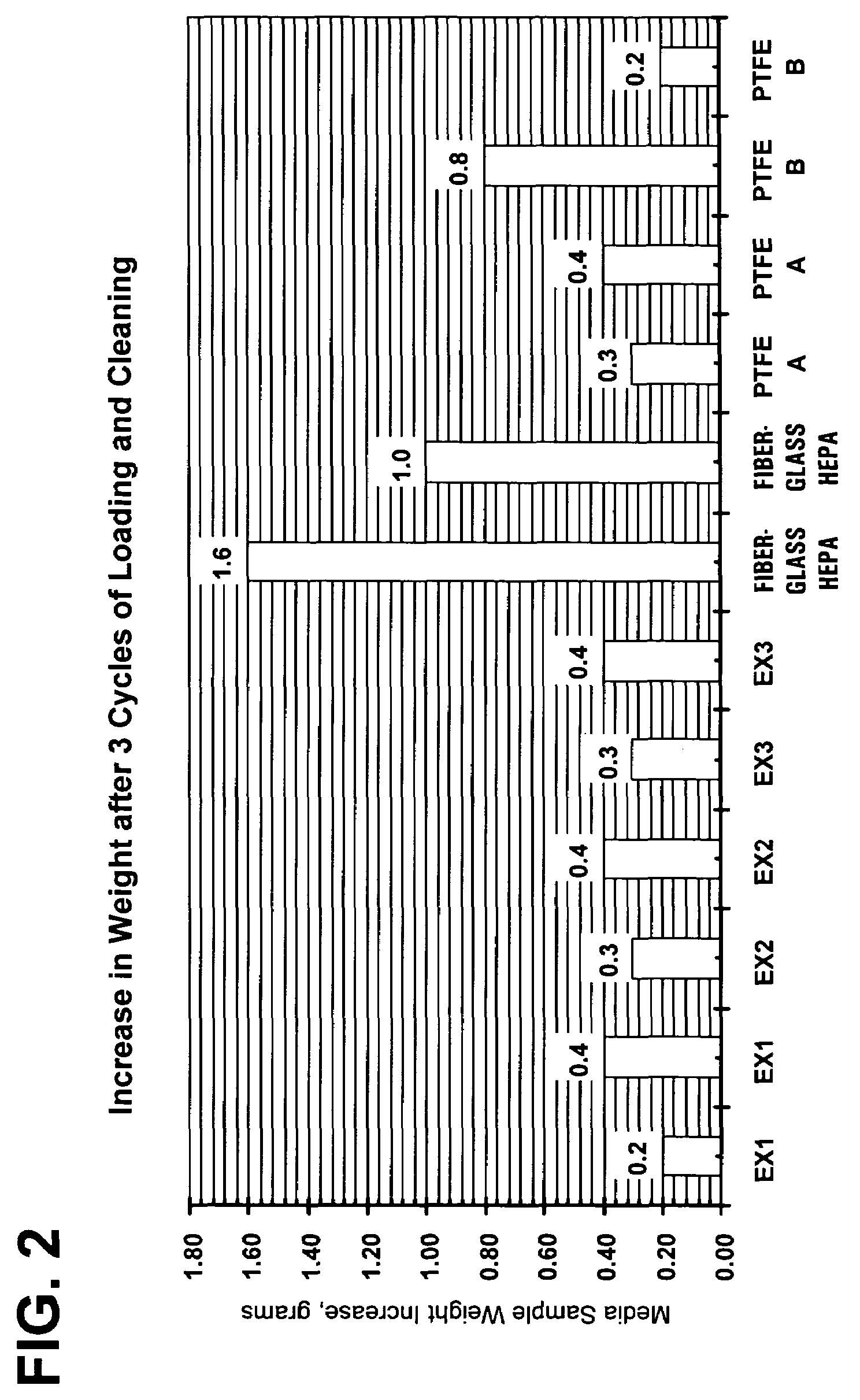

Cleanable high efficiency filter media structure and applications for use

ActiveUS7008465B2Improve filtering effectHigh particle captureCombination devicesAuxillary pretreatmentParticulatesFiber

An improved cartridge, typically in cylindrical or panel form that can be used in a dry or wet / dry vacuum cleaner. The cartridge is cleanable using a stream of service water, or by rapping on a solid object, or by using a compressed gas stream, but can provide exceptional filtering properties even for submicron particulate in the household or industrial environment. The cartridge has a combination of nanofiber filtration layer on a substrate. The nanofiber and substrate are engineered to obtain a maximum efficiency at reasonable pressure drop and permeability. The improved cartridge constitutes at least a substrate material and at least a layer including a non-woven, fine fiber separation layer.

Owner:DONALDSON CO INC

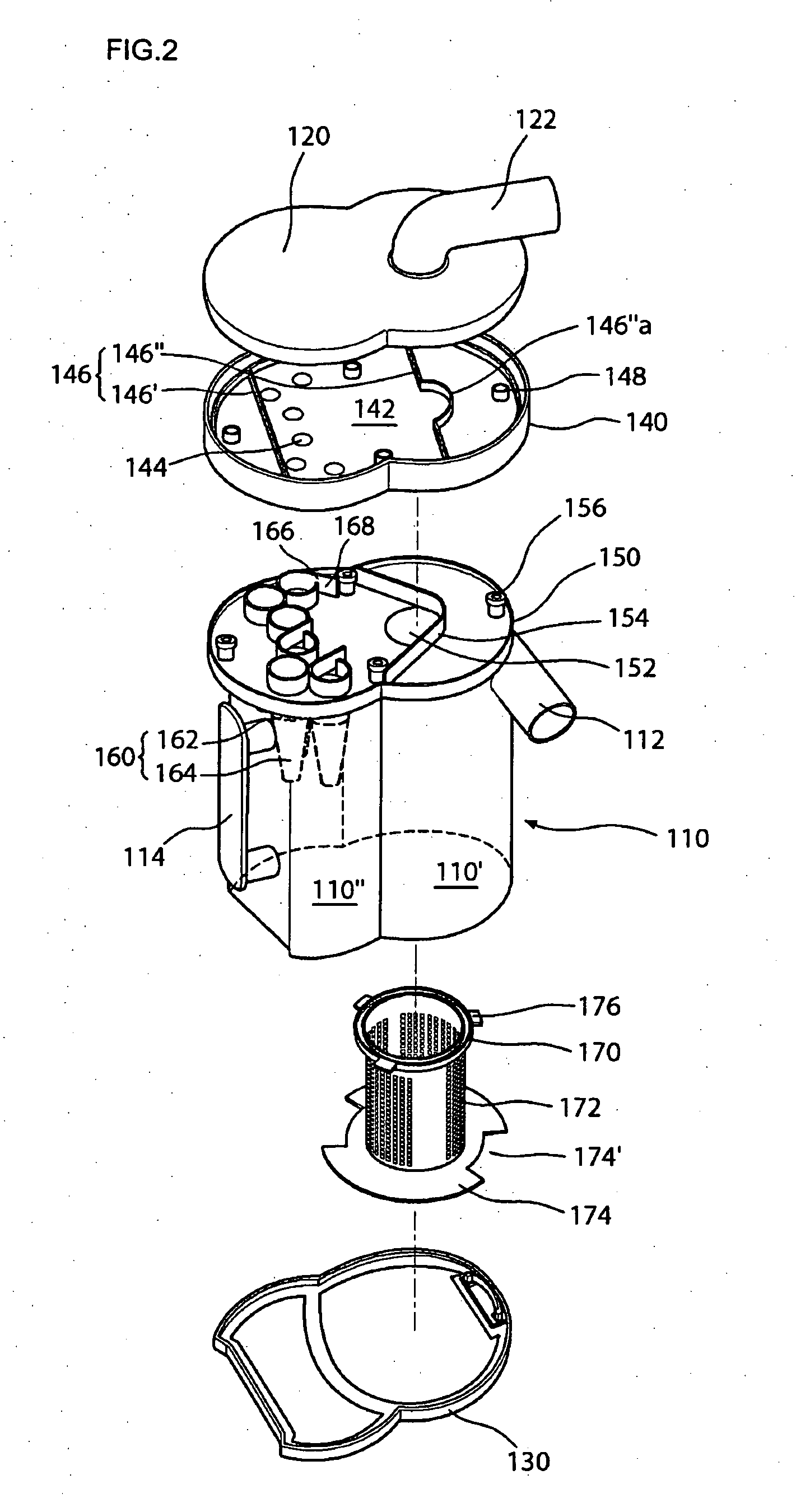

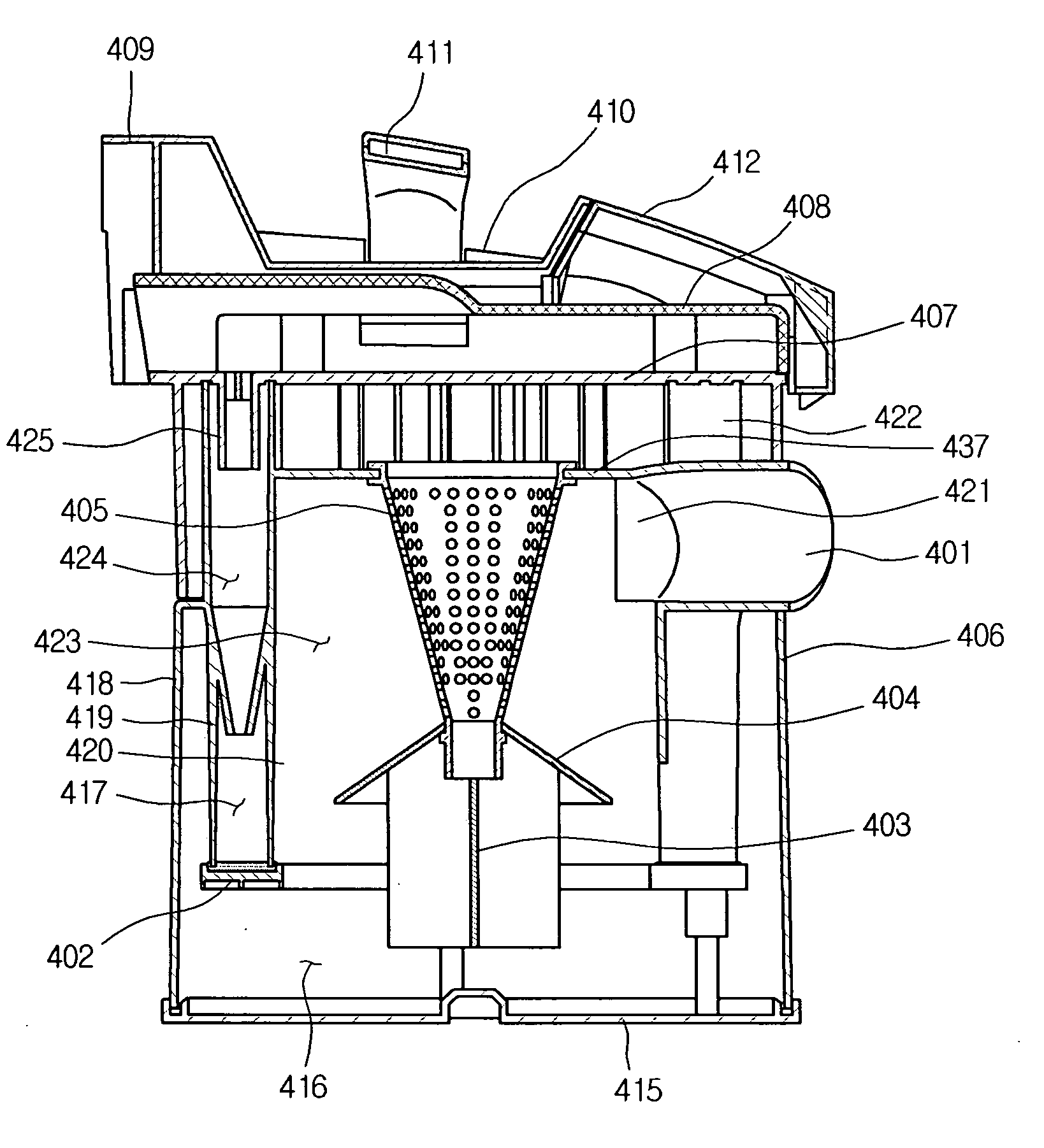

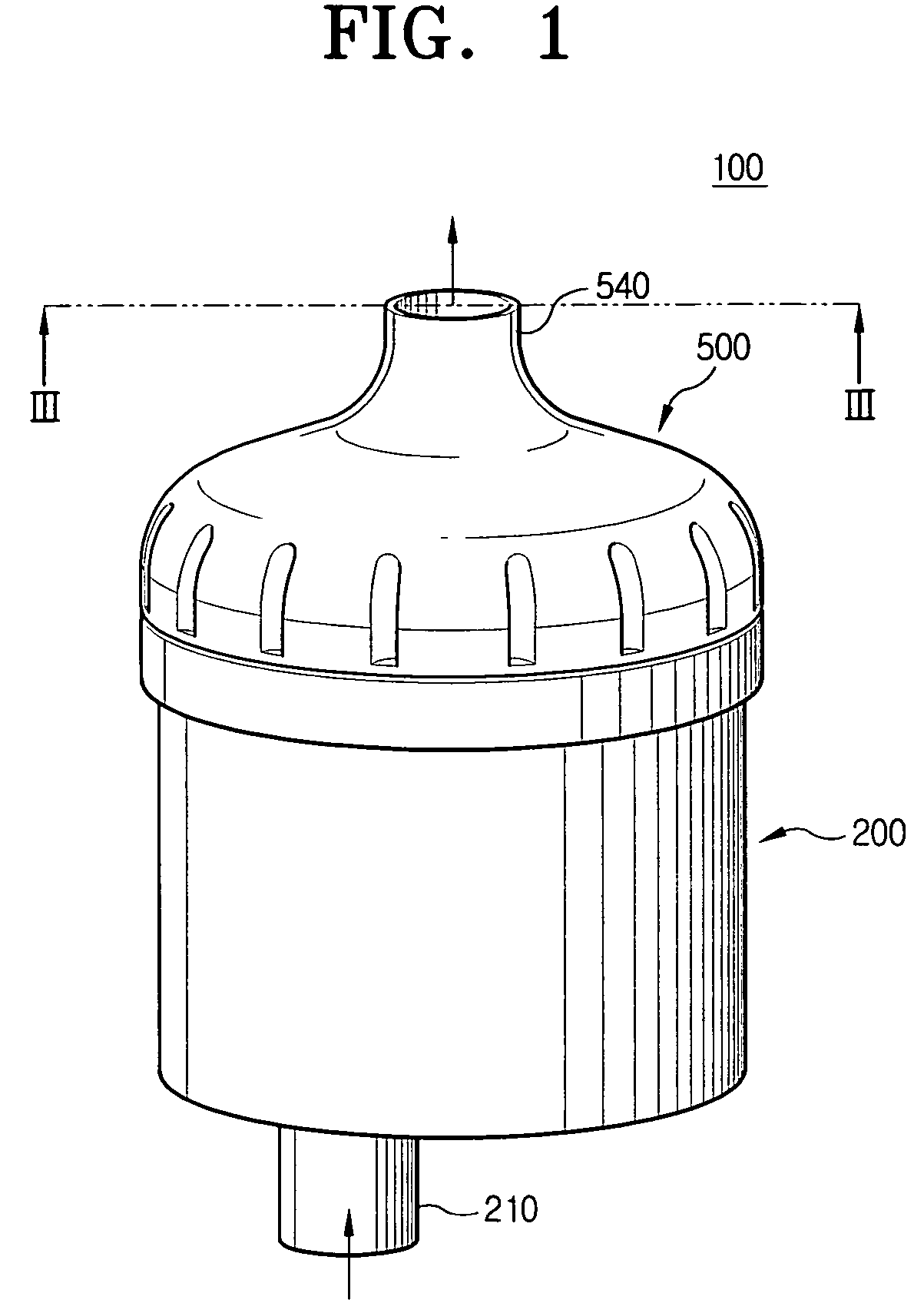

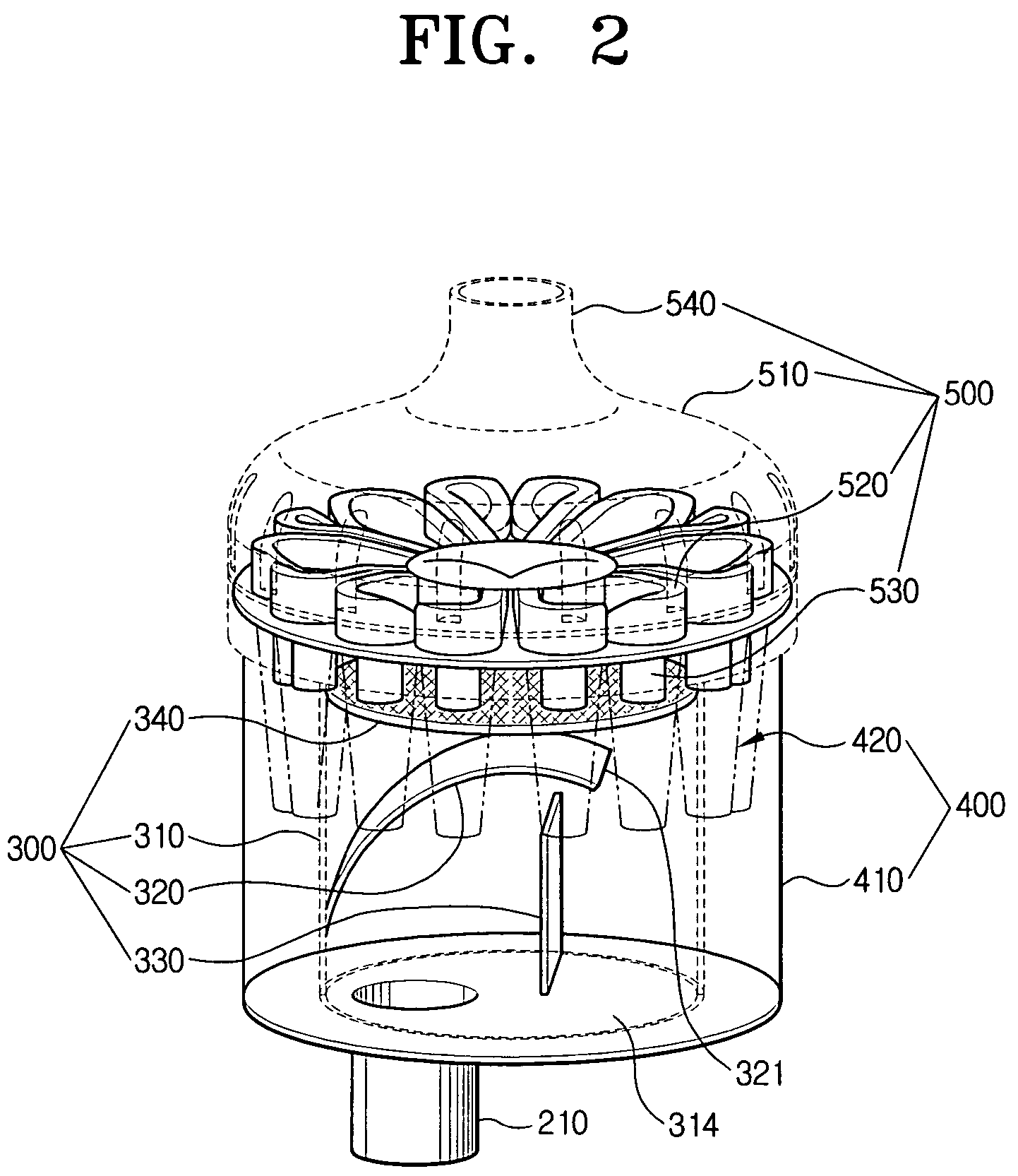

Multi cyclone vessel dust collecting apparatus for vacuum cleaner

A multi cyclone vessel dust collecting apparatus comprises a first cyclone vessel for centrifugally separating contaminants from drawn in air; a plurality of a second cyclone vessels configured on the first cyclone vessel; and a contaminant collecting unit attached to a bottom portion of the first cyclone vessel. Each of a plurality of the second cyclone vessels are parallel to each other. The center axis line of air rotation movement of the second cyclone vessel is substantially perpendicular to that of the first cyclone vessel. The contaminants collecting unit comprises a body which can be used as a handle.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

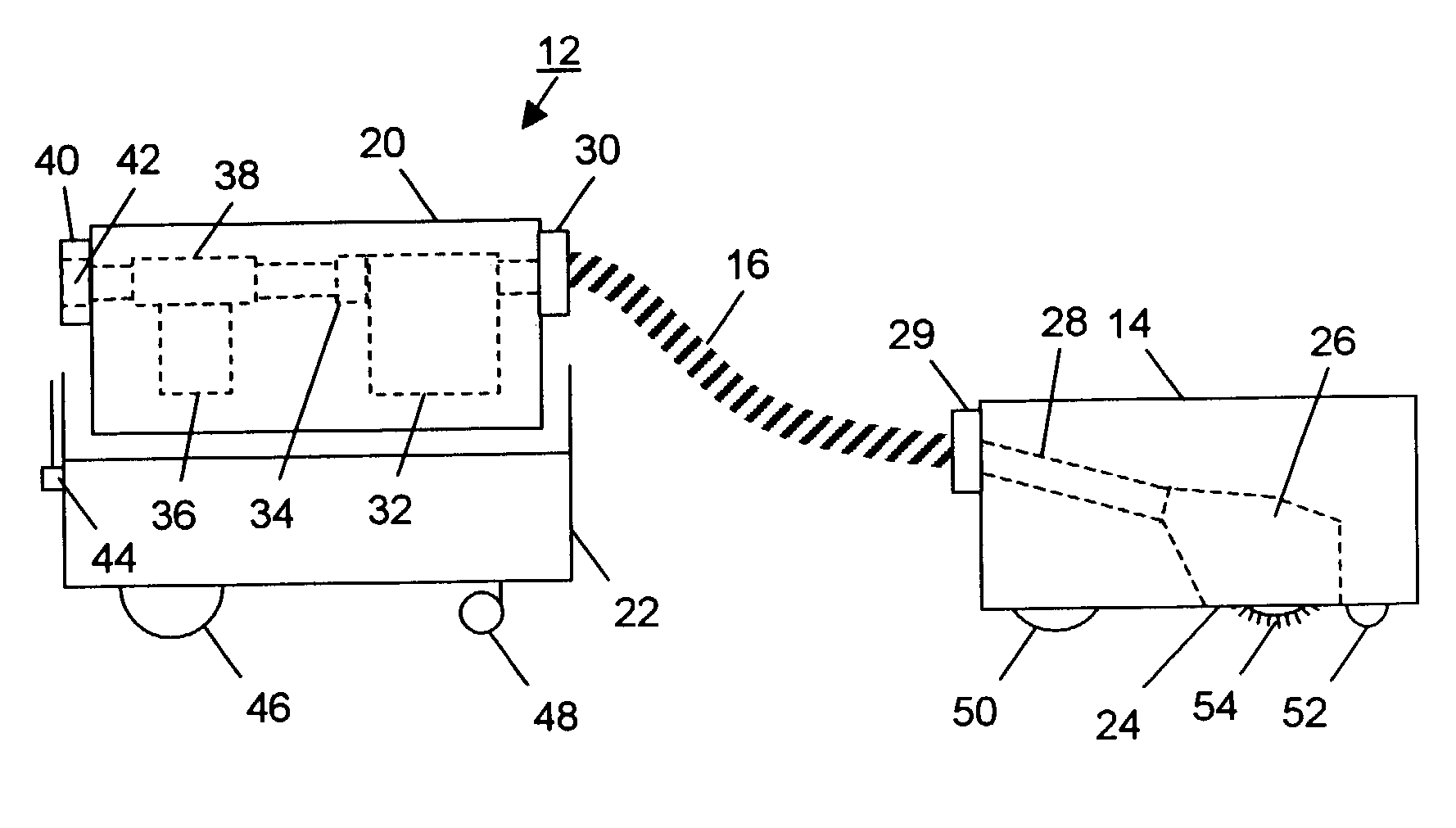

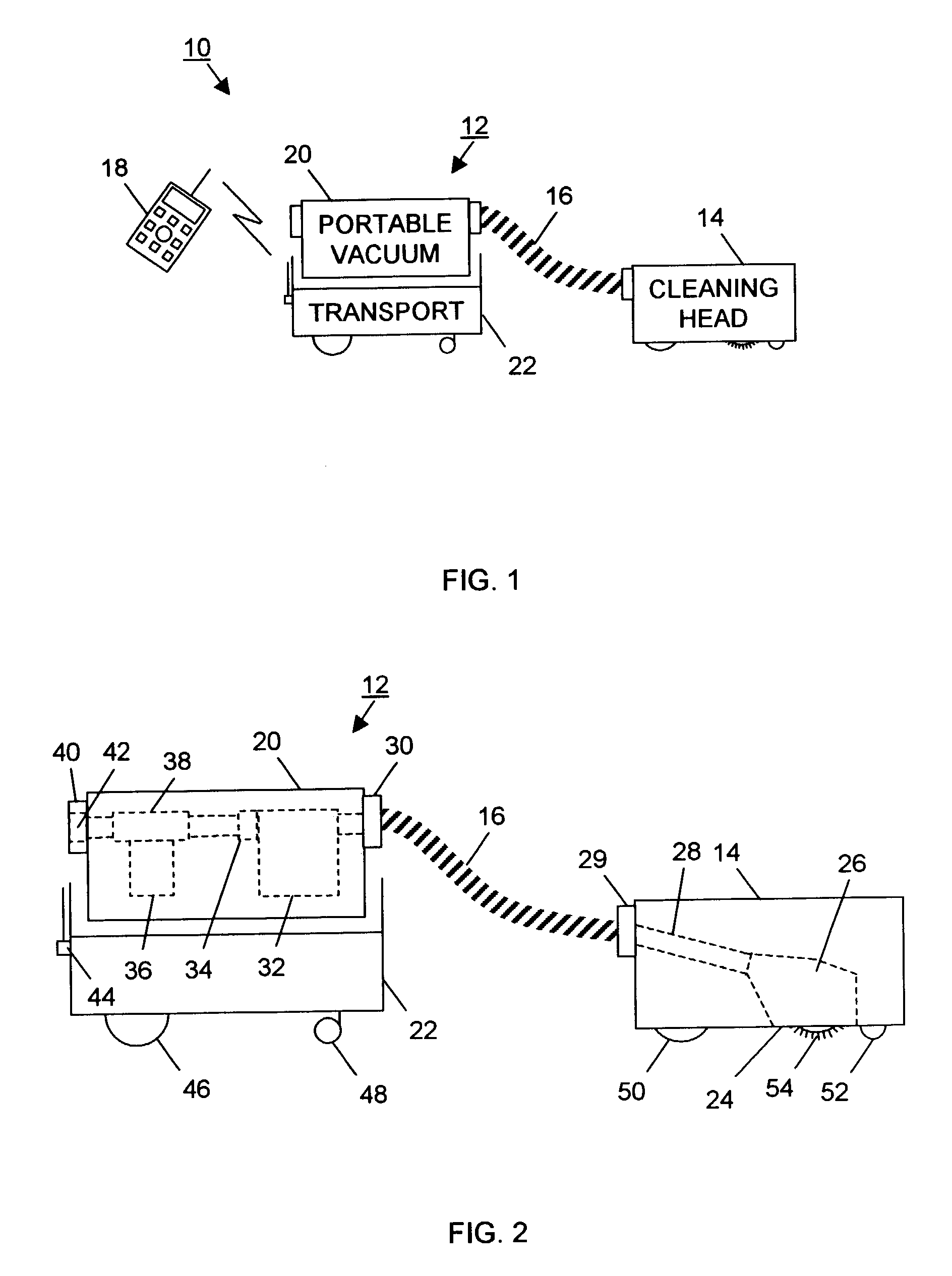

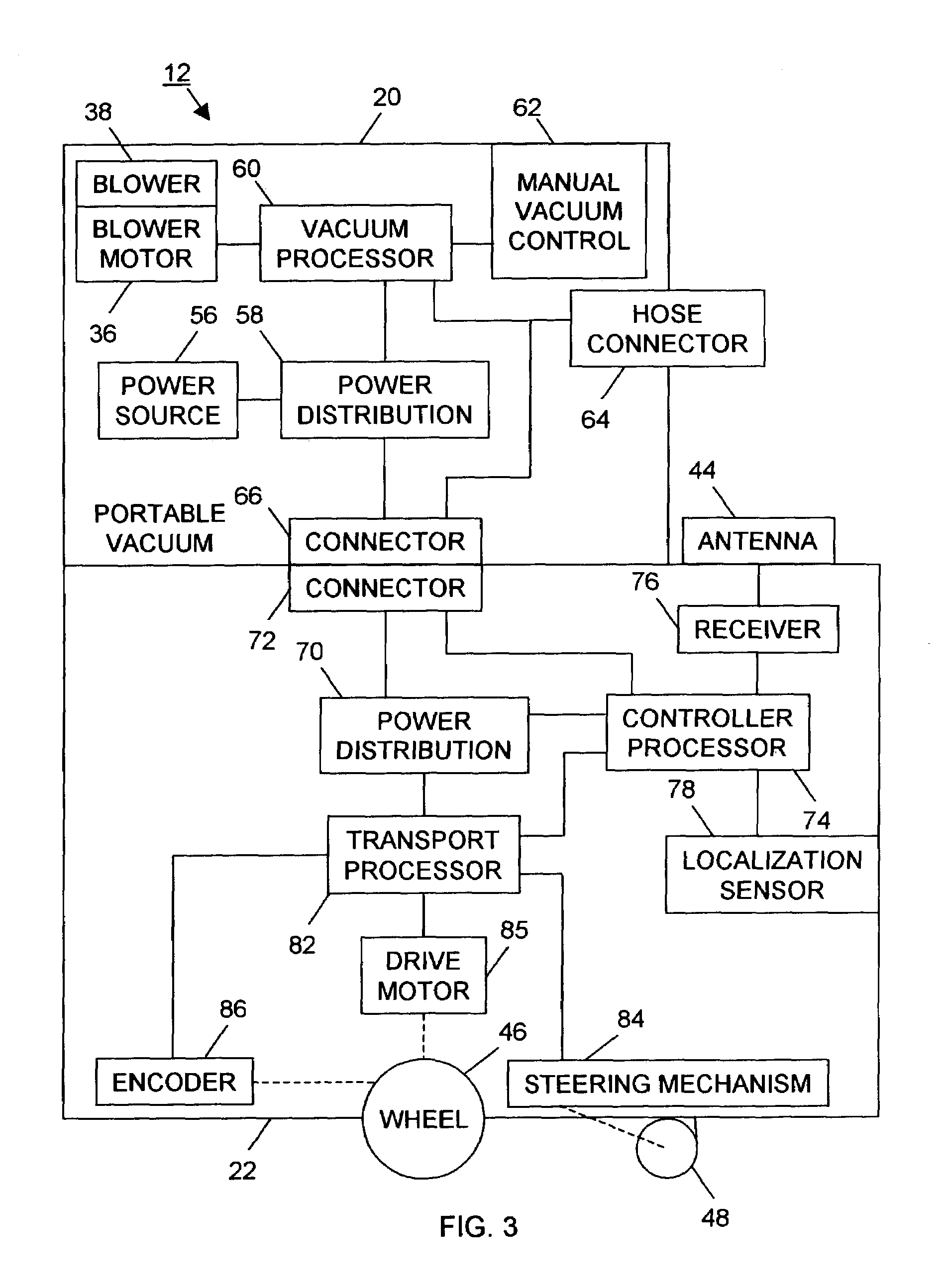

Robotic vacuum with removable portable vacuum and semi-automated environment mapping

ActiveUS7113847B2Programme-controlled manipulatorAutomatic obstacle detectionRemote controlRobotic arm

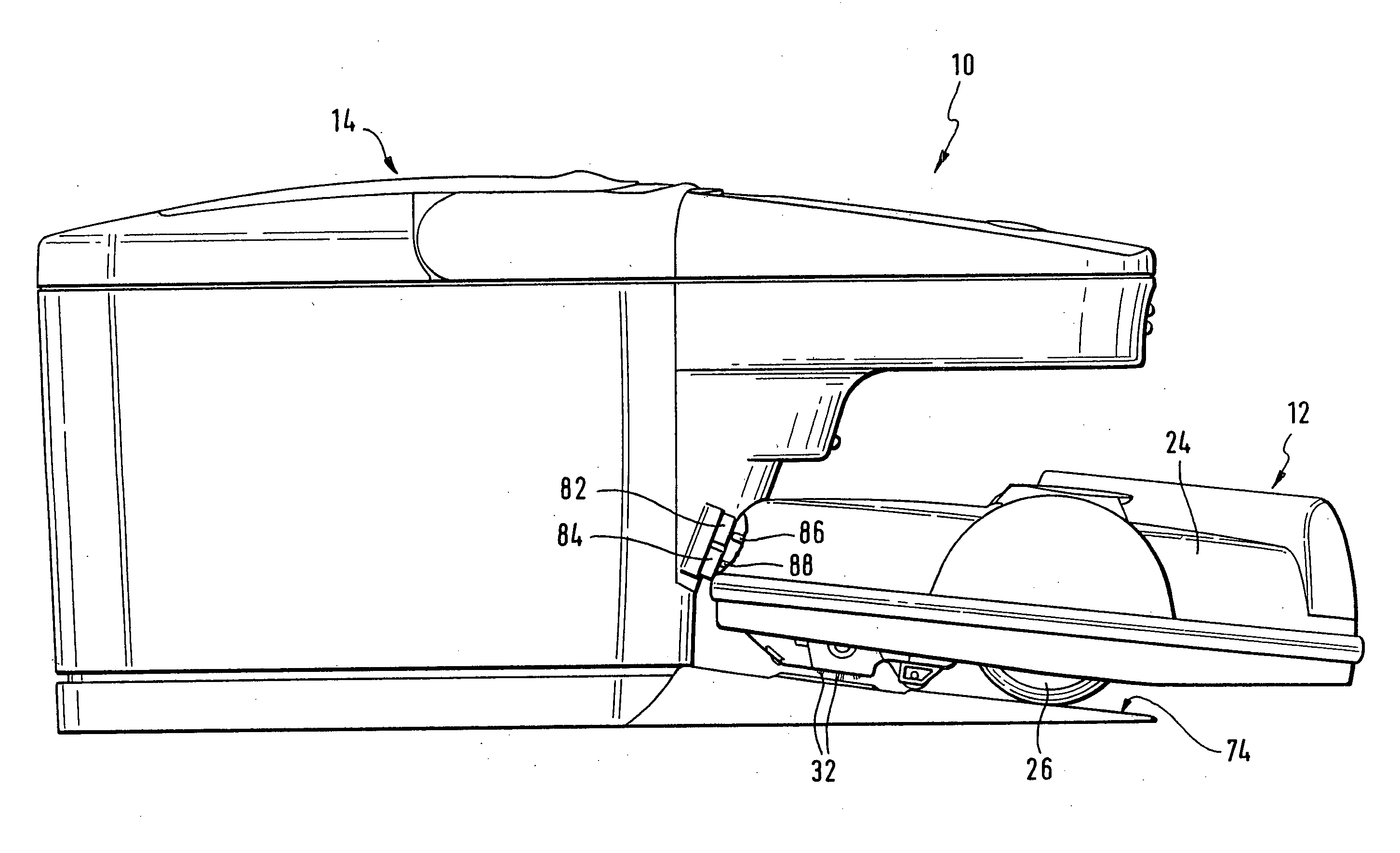

A robotic vacuum cleaner (10) with a self-propelled controller (12) with a vacuum source (36, 38) and a dirt receptacle (32), a self-propelled cleaning head (14) with a suction inlet (24), and an interconnecting hose (16) is provided. The controller and cleaning head cooperatively traverse a surface area in tandem when the interconnecting hose is connected between the cleaning head and the controller. In one embodiment, the controller includes a power source (56) making the robotic vacuum autonomous. In another embodiment, the controller includes a power cord dispense / retract assembly (168) to provide access to utility power. In another aspect, the controller includes a portable vacuum (20) that is removed for manual operations. In still another aspect, a method of semi-automated environment mapping for a self-propelled robotic vacuum is provided. With respect to the method, the robotic vacuum also includes a remote control (18).

Owner:ROYAL APPLIANCE MFG

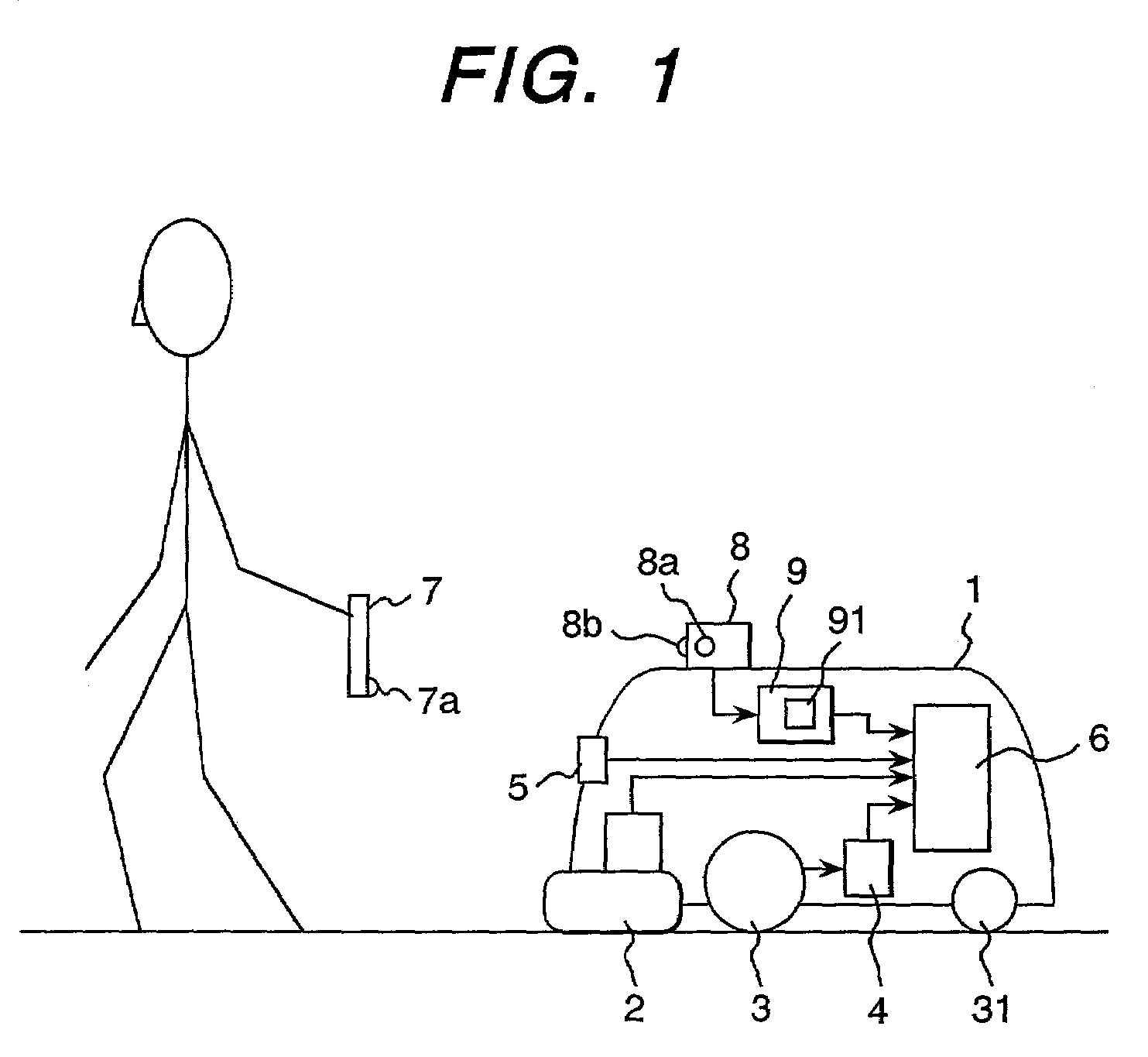

Self-moving cleaner

InactiveUS6901624B2Automatic obstacle detectionTravelling automatic controlDrive motorElectric power

A self-moving cleaner has a main body and comprises an intake opening for suctioning dust, an electric blower for generating airflow to suction dust, a dust receiver for collecting the dust suctioned by the electric blower, rollers driven by drive motors, a power source for supplying electric power to the electric blower and the drive motors, and sensors for optically detecting a distance to an obstacle. An enclosure surrounds the main body, the electric blower, the dust receiver, the power source, and the sensors, wherein the enclosure is transparent or semi-transparent, and the sensors transmit and receive light through the enclosure.

Owner:PANASONIC CORP

Autonomous vacuum cleaner

InactiveUS20050166354A1Accurate materialsHigh resolutionAutomatic obstacle detectionTravelling automatic controlCMOSLine sensor

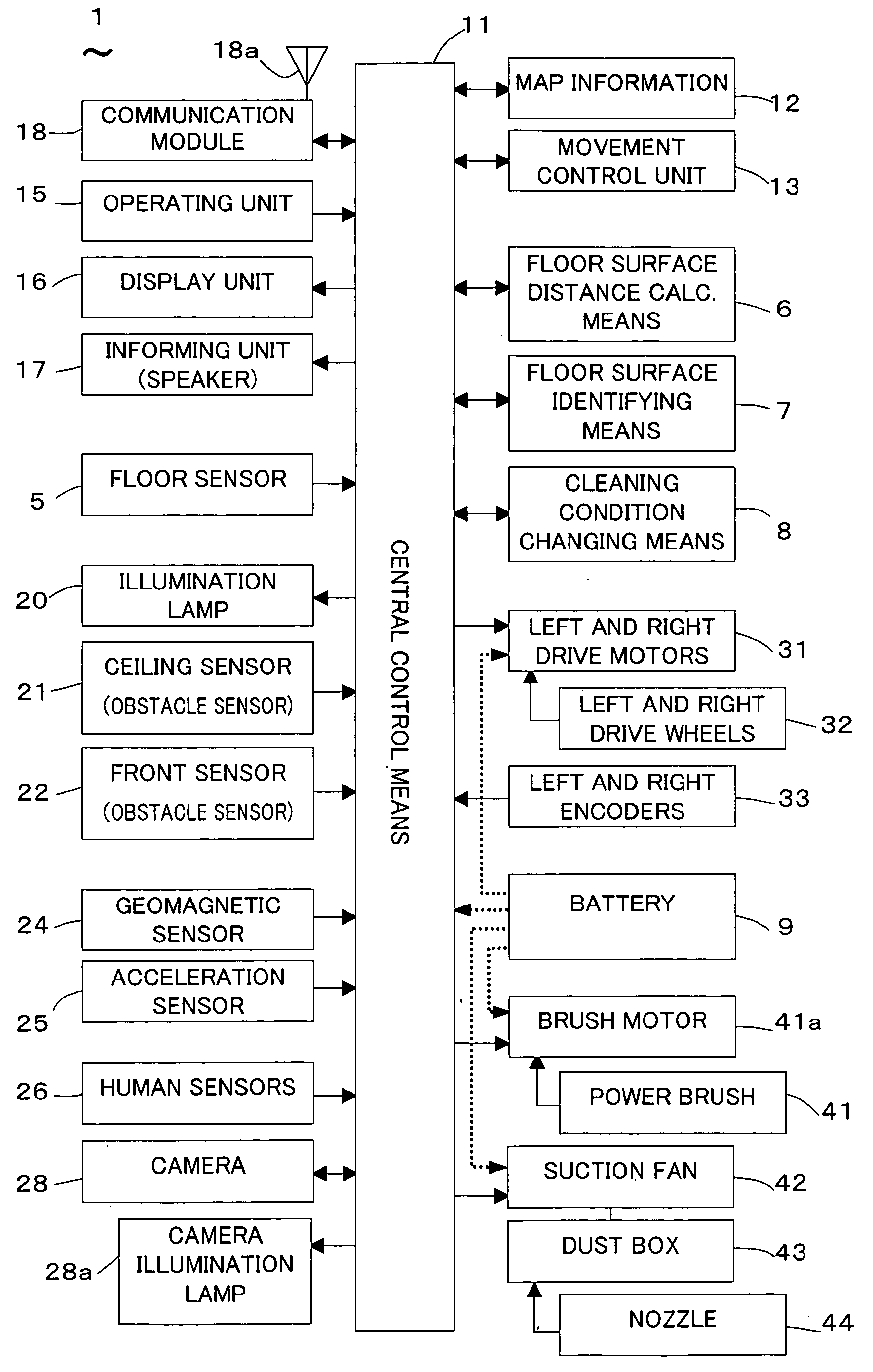

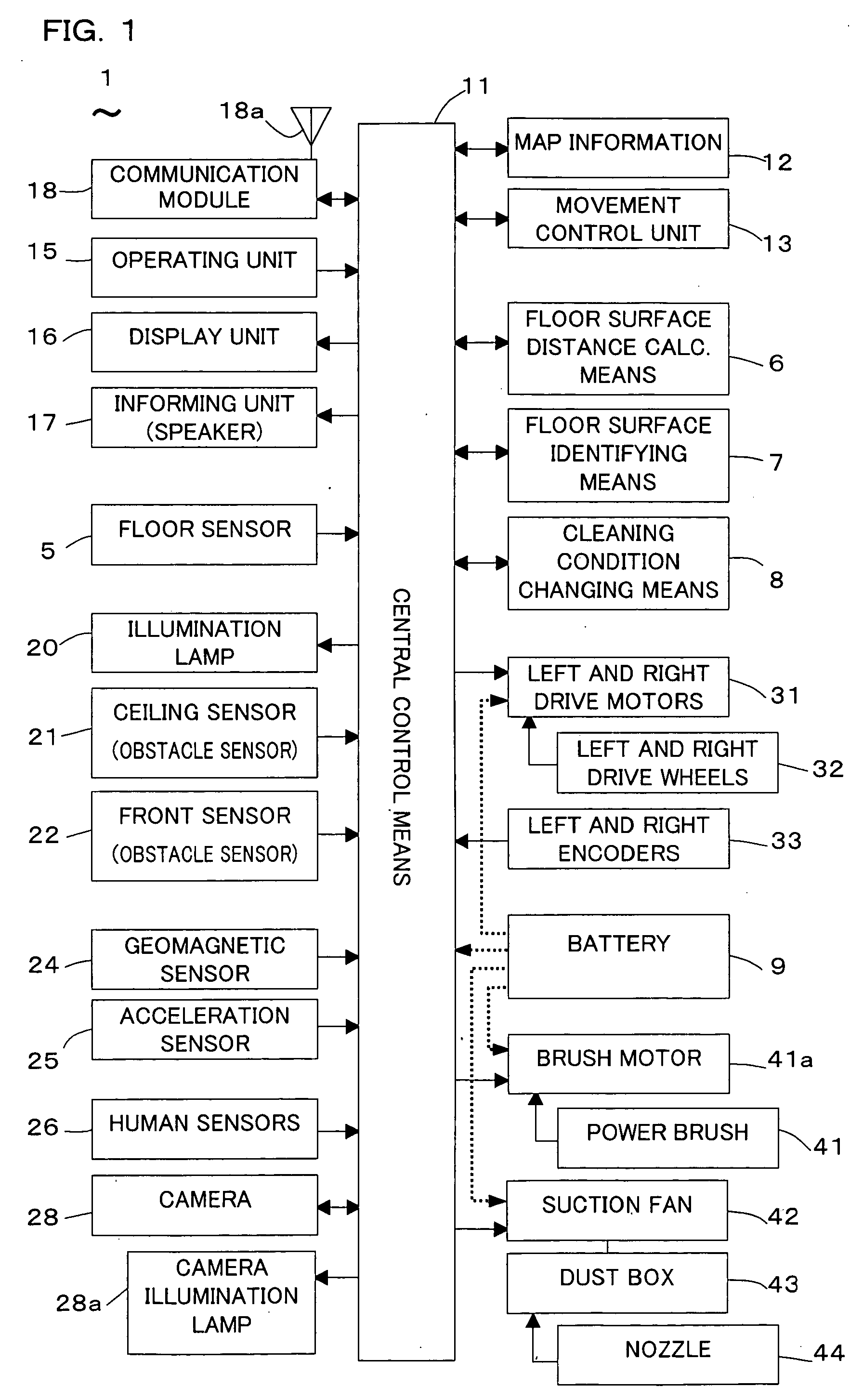

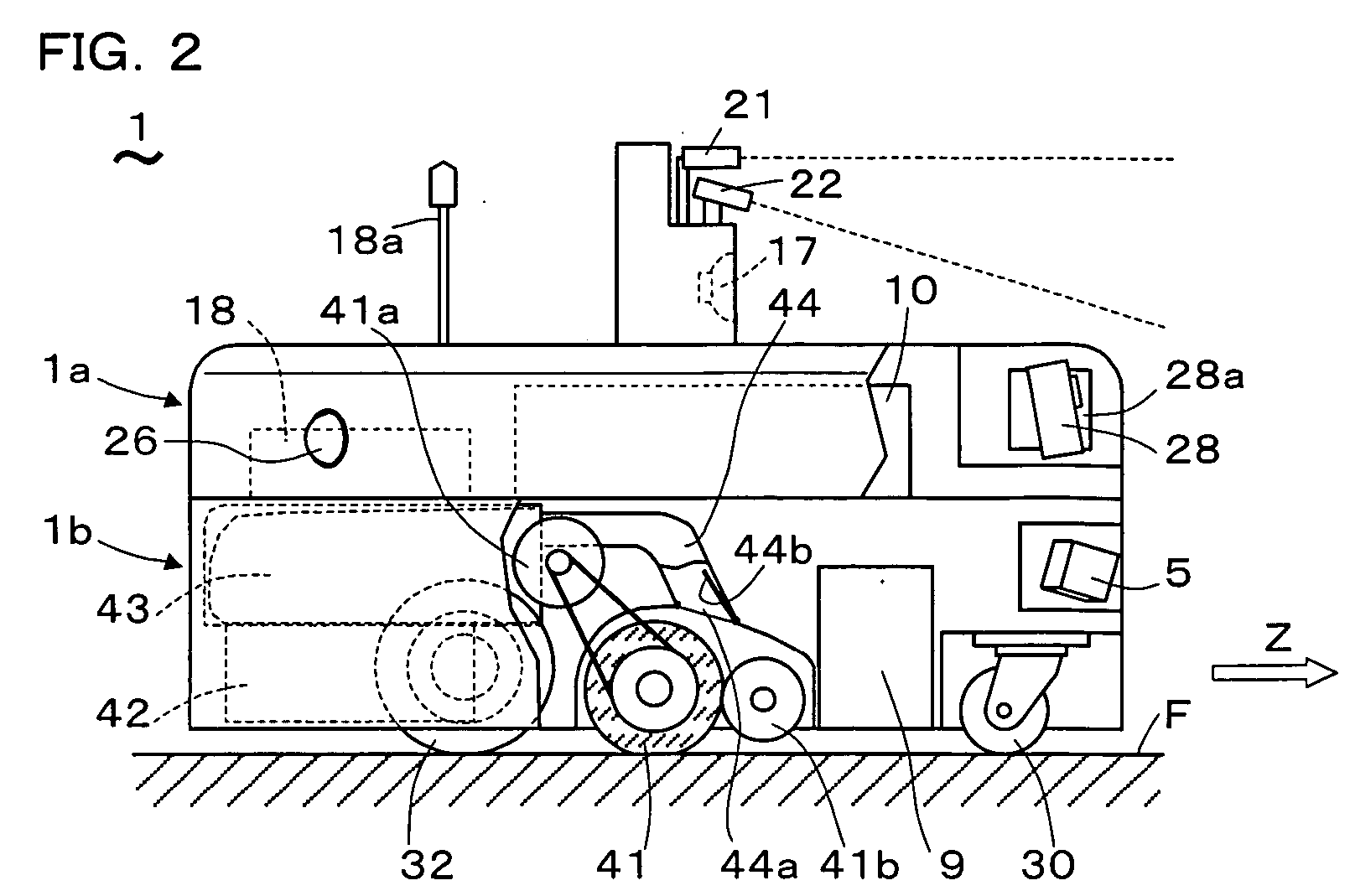

An autonomous vacuum cleaner comprises: obstacle detection sensors; moving means; a cleaning means including a power brush, a suction fan and a nozzle for sucking up dust on a floor surface; floor surface sensors each comprising a passive-type CMOS line sensor to receive light from the floor surface for detecting floor surface conditions. It performs cleaning while autonomously moving. Based on received light signals of the floor surface sensors, distance distributions to floor surface areas within the viewing angle of each sensor are derived. Detection of a step on the floor surface and identification of the material of the floor surface (polished floorboard, tatami or carpet) are performed by analyzing spatial frequency in the distance distribution. Based on the identification, cleaning conditions including at least the moving speed, the dust suction force of the suction fan or the brushing strength of the power brush are changed. With simple structure using one same floor sensor, this autonomous vacuum cleaner can detect a step on a floor surface and can more accurately identify the material of the floor surface, thereby enabling meticulous cleaning.

Owner:FUNAI ELECTRIC CO LTD

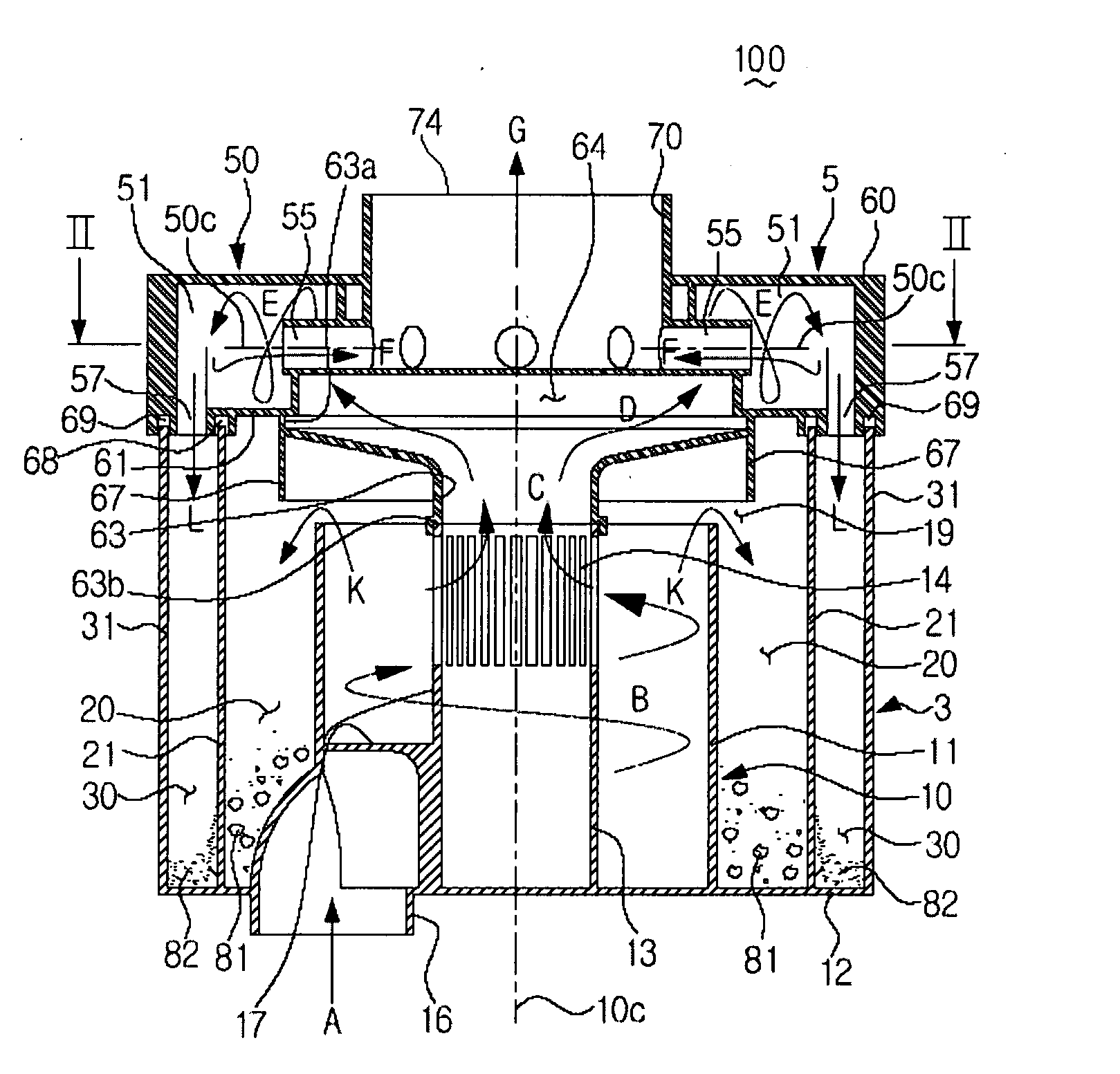

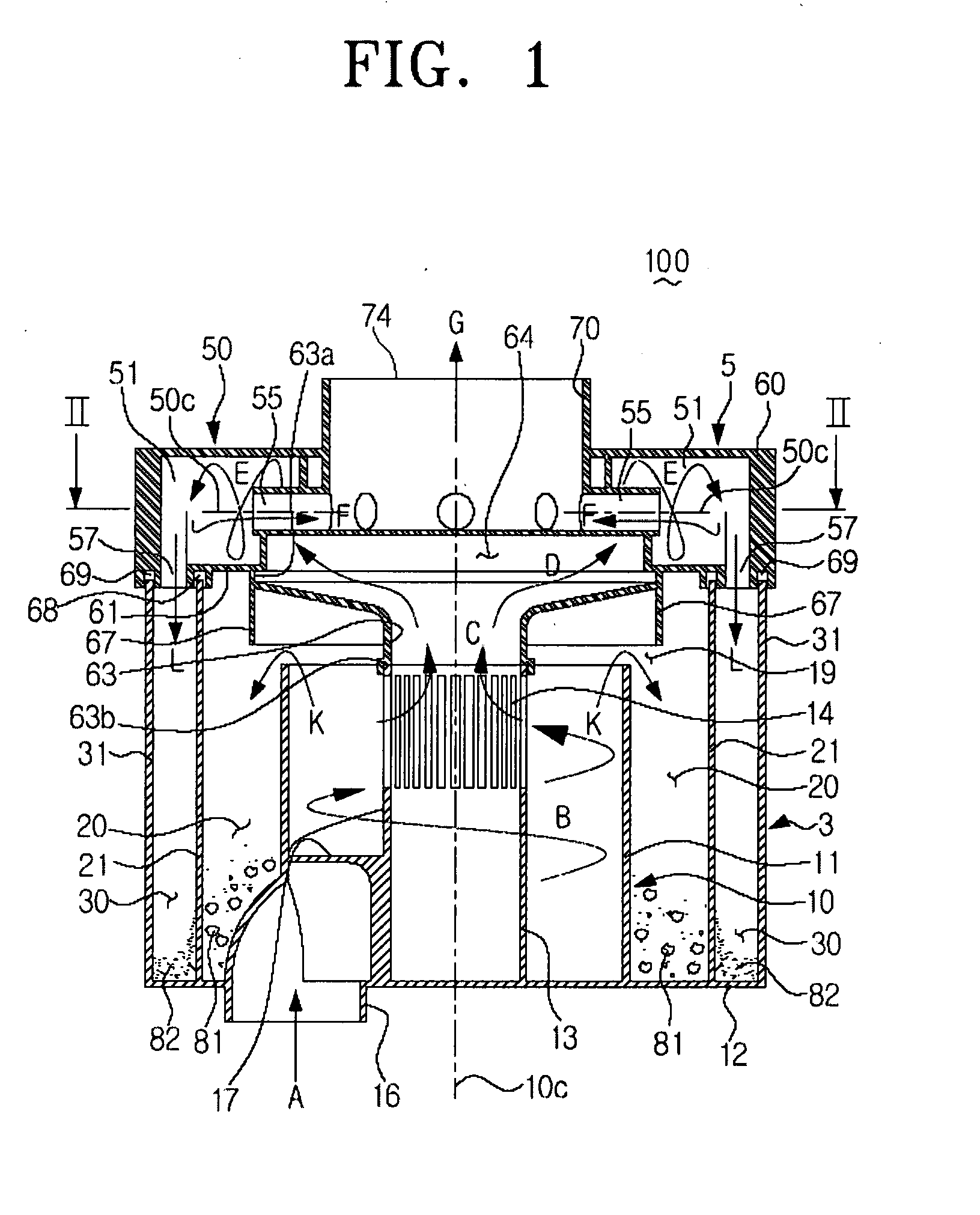

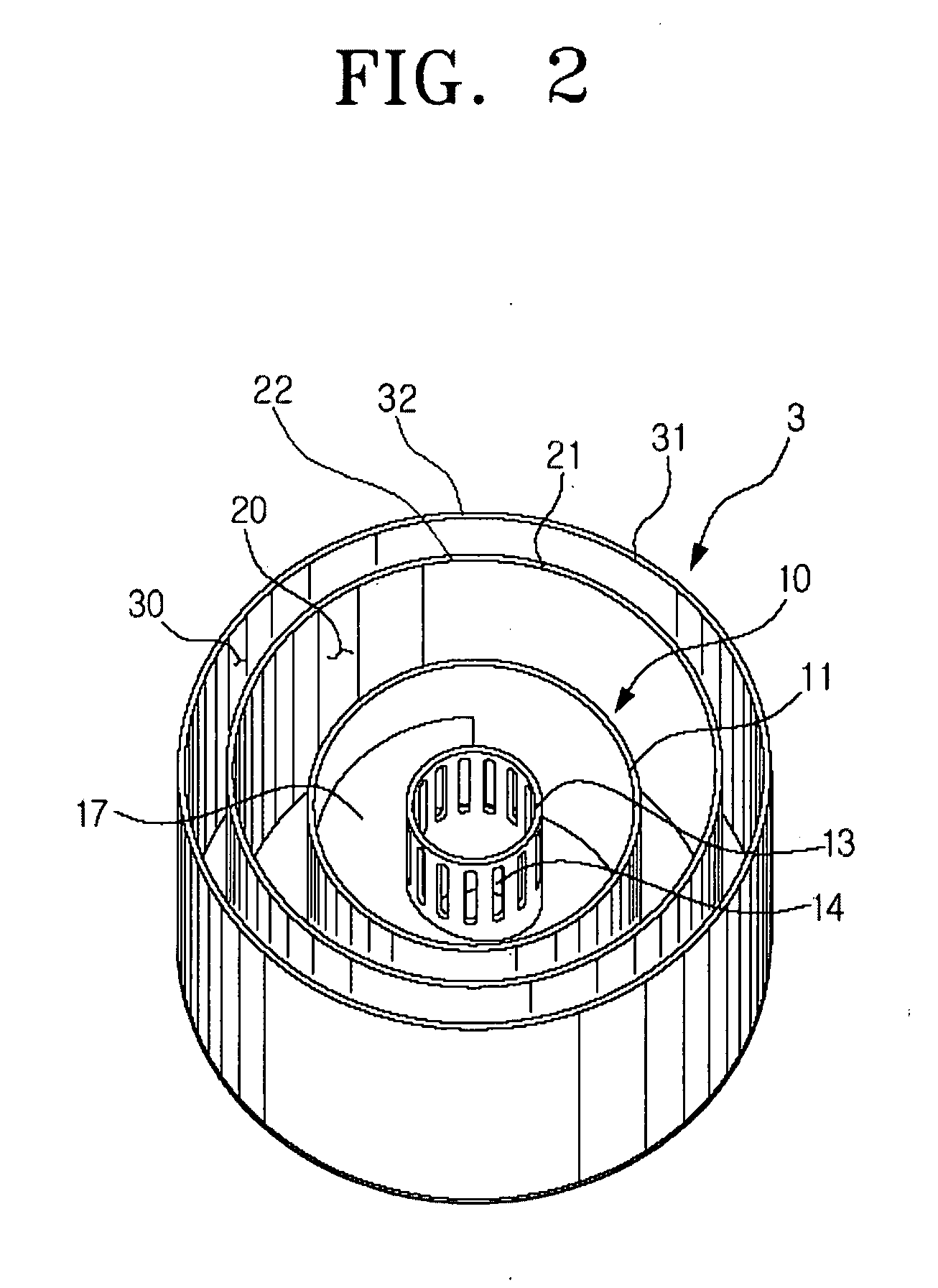

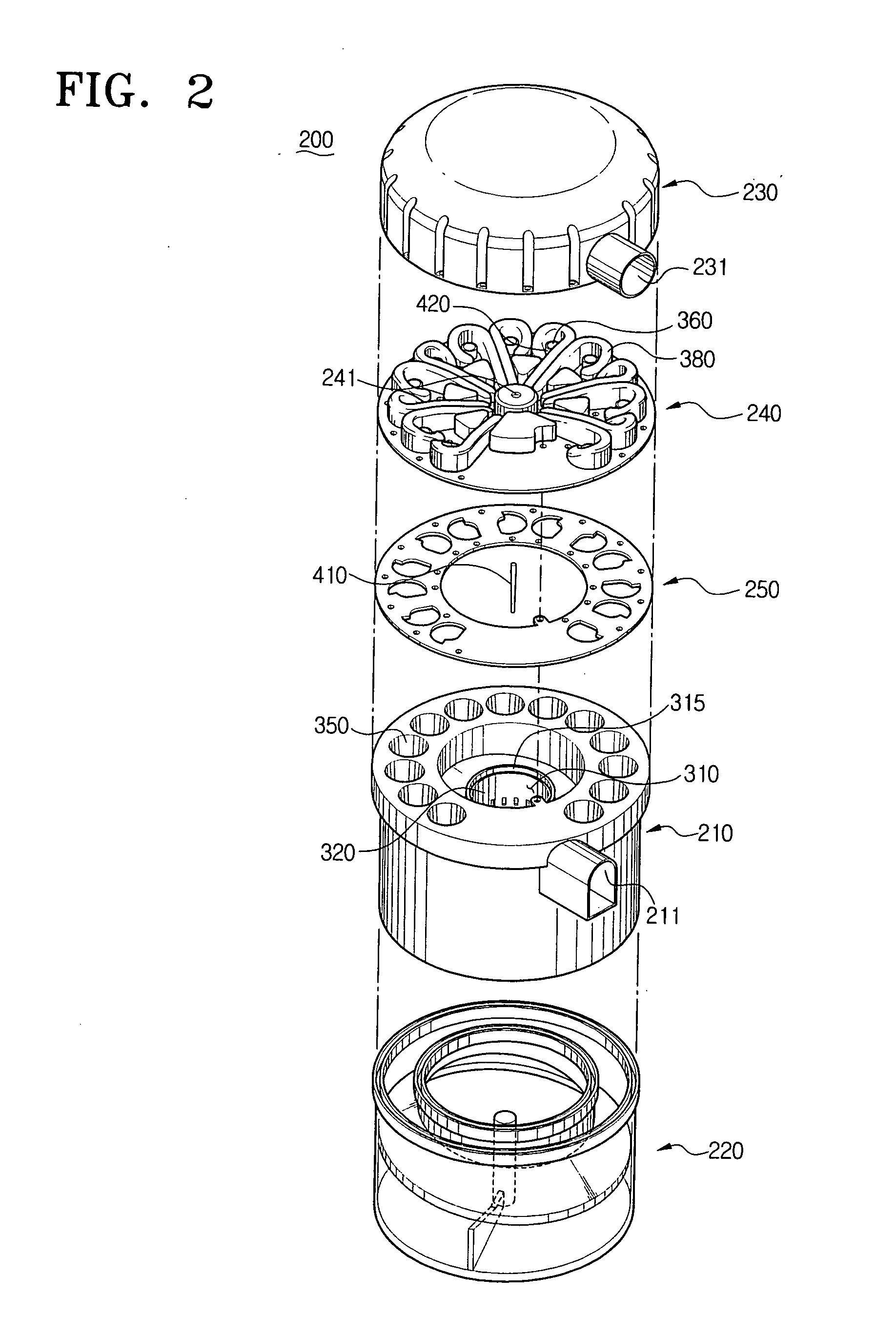

Cyclone type dust collecting apparatus for a vacuum cleaner

A cyclone type dust collecting apparatus for a vacuum cleaner includes a cyclone body having a cylindrical shape, open upper and lower ends and a contaminant outlet. Air and contaminants are drawn into the cyclone body through one open end of the cyclone body. The contaminants are separated from the air by centrifugal force and are discharged through the contaminant outlet, which is located proximate the other open end of the cyclone body. The apparatus further includes a contaminant receptacle for collecting the contaminants that have been discharged from the cyclone body. The contaminant receptacle has open upper and lower ends and surrounds the cyclone body. A base member is connected to and closes the lower end of the cyclone body and the contaminant receptacle, and a cover is removably connected to the upper end of the cyclone body and the contaminant receptacle. The cover includes an air inlet and an air outlet, both of which communicate with the cyclone body. The cover further includes a contaminant separating grill that has a plurality of fine holes. The grill extends downward from the air outlet and into the cyclone body. The apparatus further includes a partition that is disposed between the cyclone body and the contaminant receptacle for restricting the movement of the contaminants in the contaminant receptacle.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

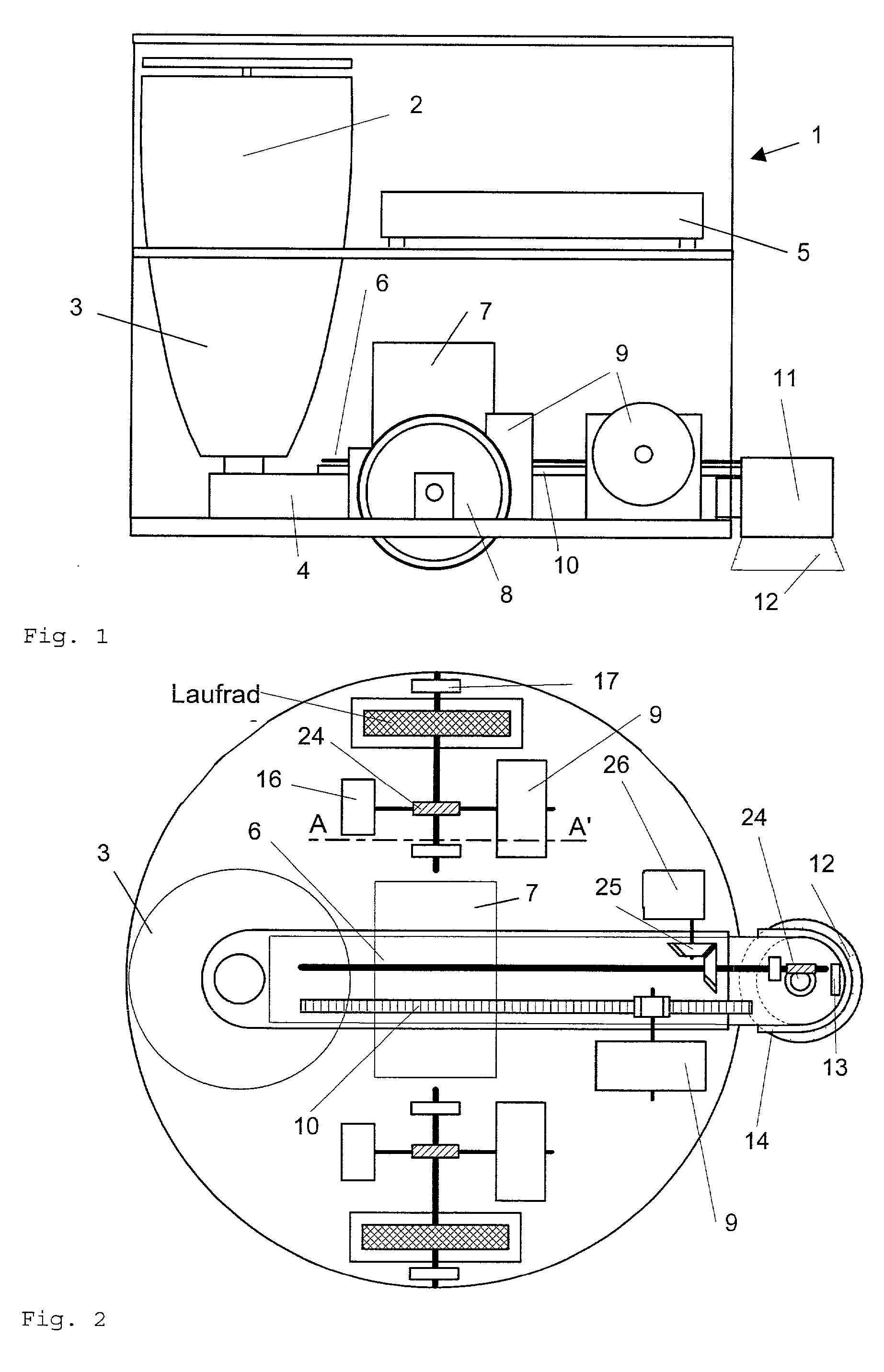

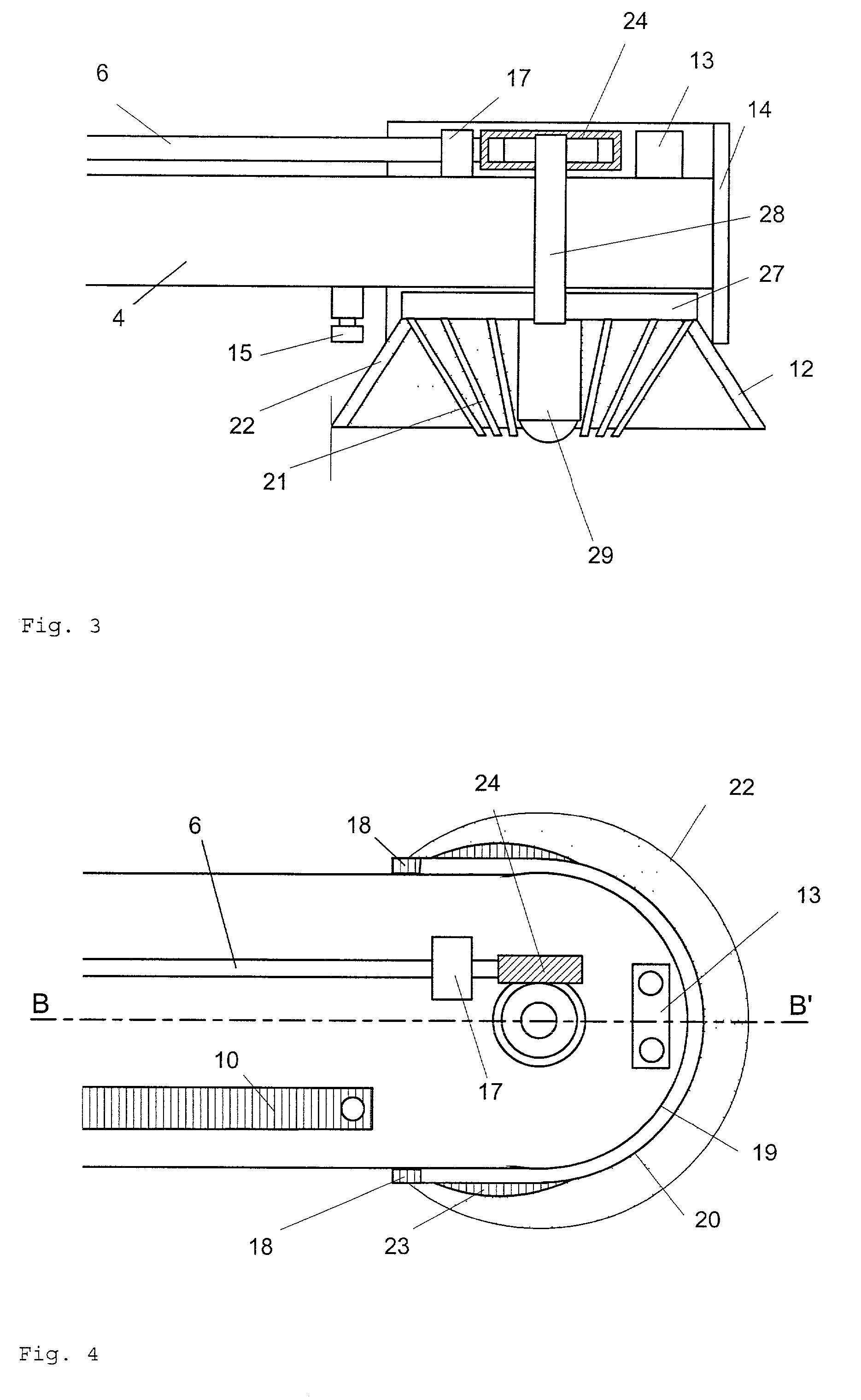

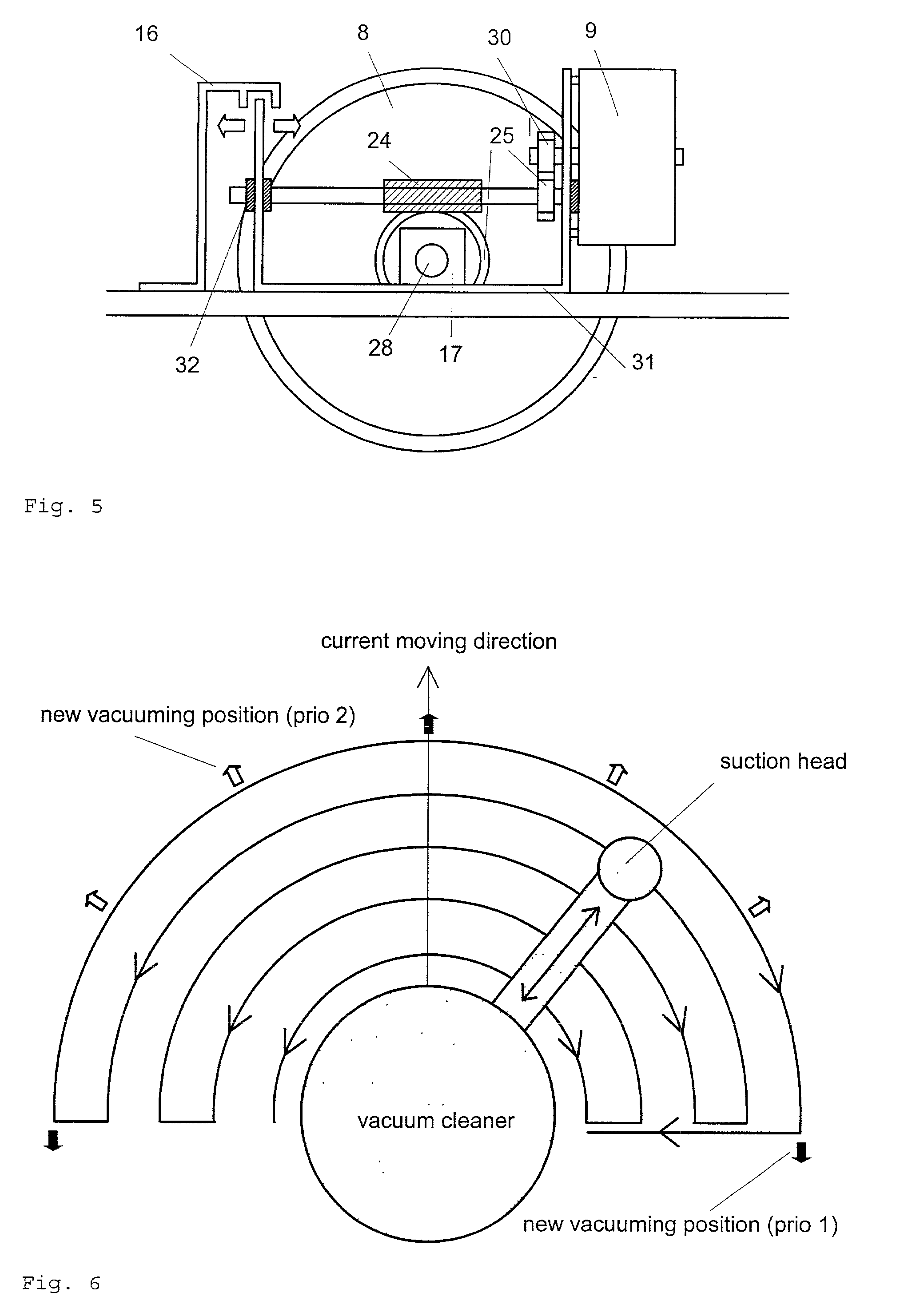

Service robot for the automatic suction of dust from floor surfaces

InactiveUS20010004719A1Automatic obstacle detectionTravelling automatic controlData fieldEngineering

The present invention is used for the complete and fully automatic examination of floor surfaces of all kind as well as for a particularly efficient suction of dust therefrom since the lower areas, the edges and the recessed can be detected. In each case, the robot is controlled so as to explore the adjacent area and to detect the potential obstacles using special sensors before storing them in a data field. The displacement towards a new location is then carried out using the stored data until the whole accessible surface has been covered. One of the main constituent members of the robot consists of an extensible arm that rests on the robot and on which contact and range sensors are arranged. When the robot is used as an automatic vacuum cleaner, an air flow is forced into the robot arm and the -cleaning effect can further be enhanced by providing one or more Circular rotary brushes at the front end of the arm. This invention can essentially be used for domestic or industrial Cleaning purposed with a view to replace traditional vacuum cleaners.

Owner:TECHN FACHHOCHSCHULE BERLIN

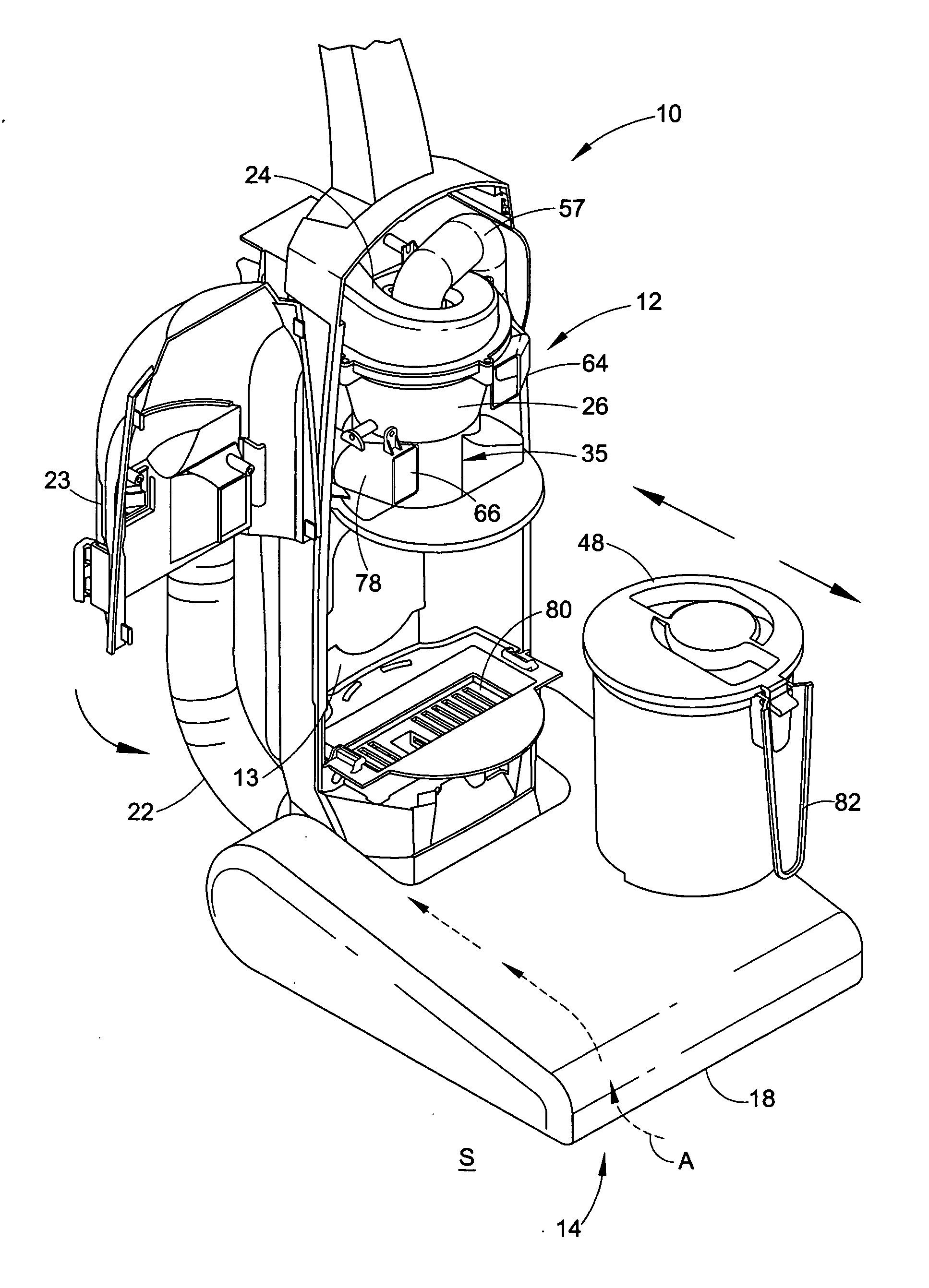

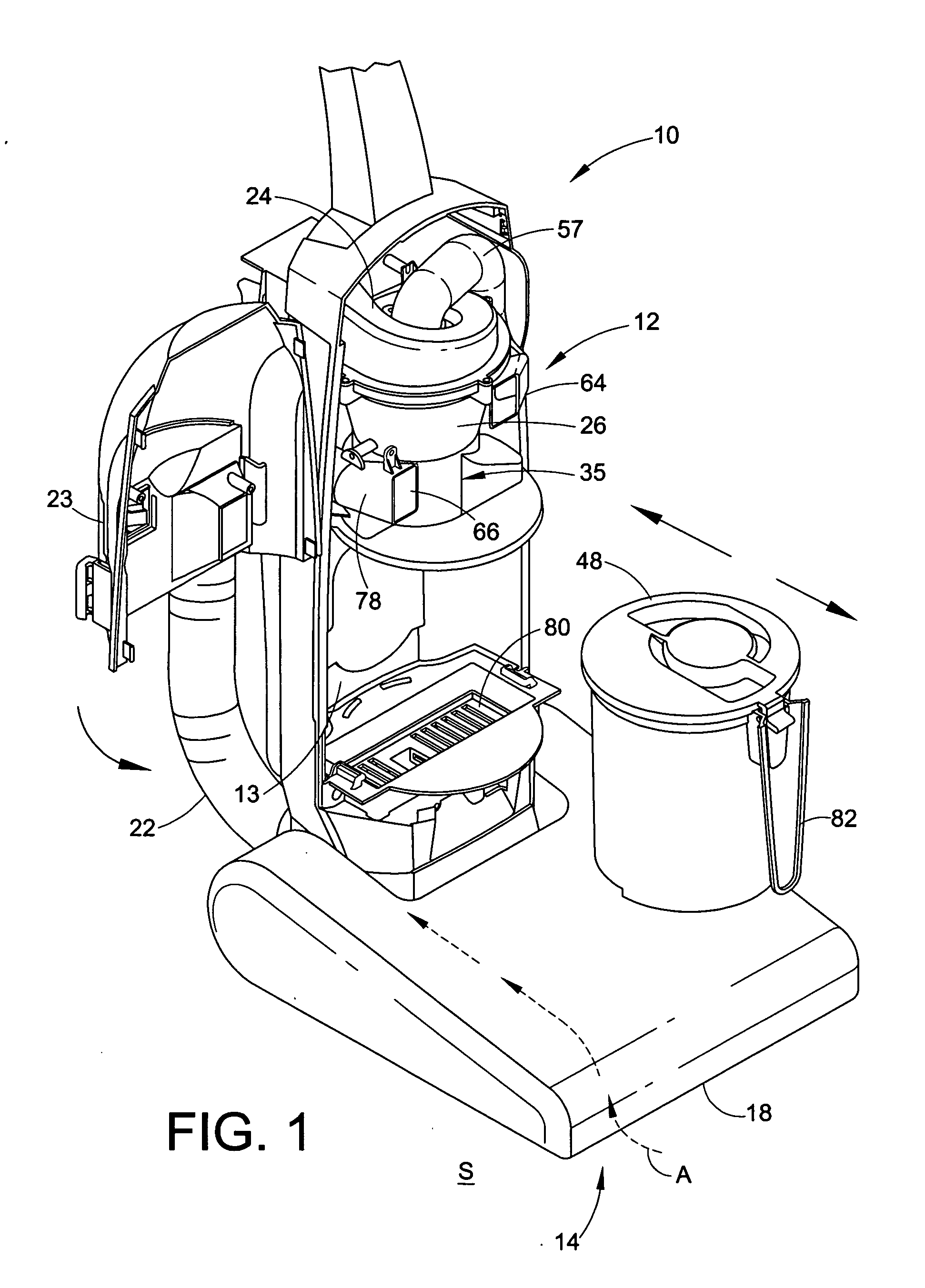

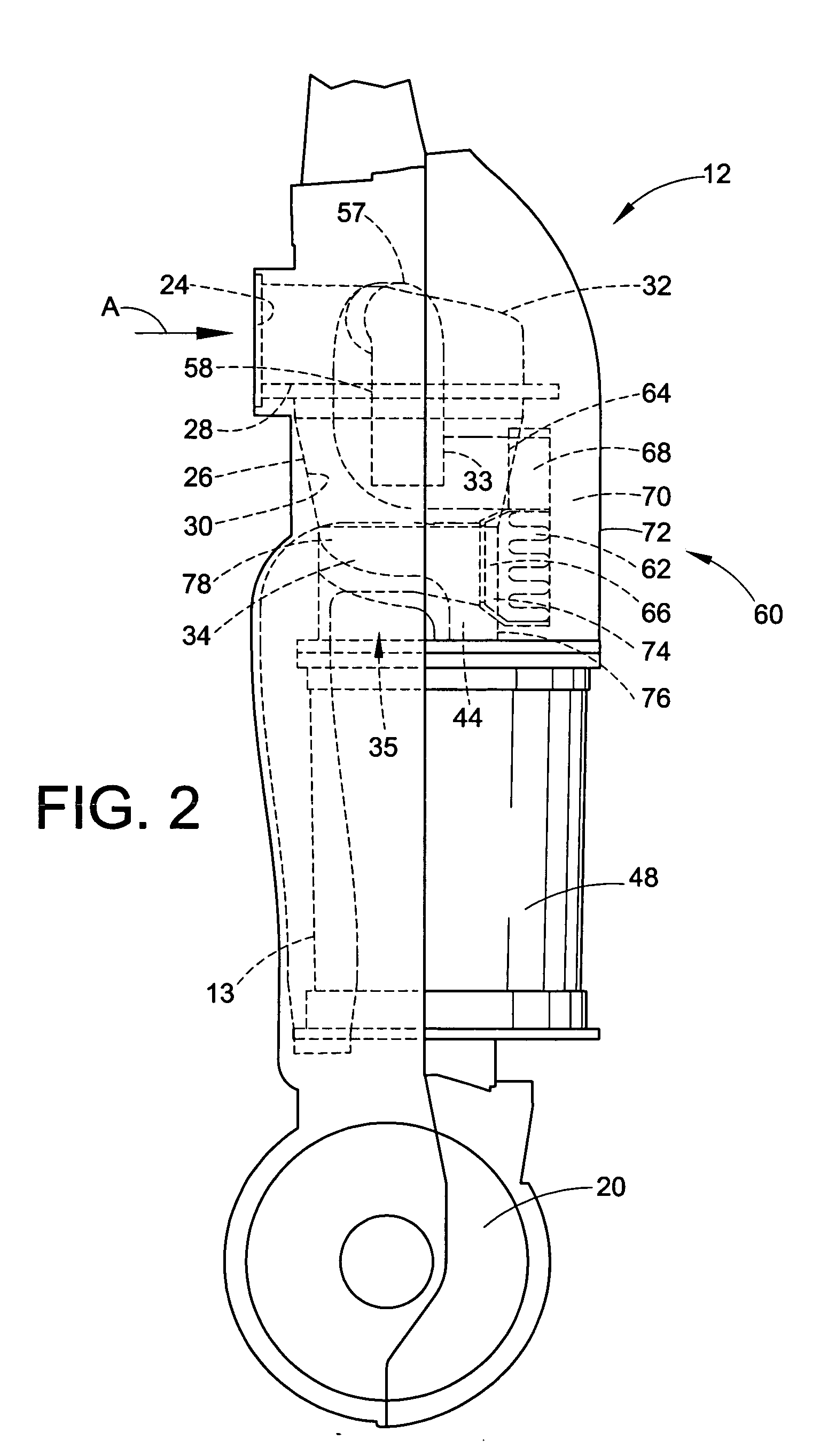

Cyclonic vacuum cleaner

InactiveUS20050138763A1Improve efficiencyEasy to emptyCleaning filter meansCombination devicesCycloneVacuum cleaner

A cyclonic vacuum cleaner includes a body portion, a nozzle portion and a dirt cup which is removable from the body portion. The dirt cup collects dirt and other debris separated by a cyclone and a cyclone slinger portion in the body portion. A main filter may be housed in a transparent filter door downstream of the cyclone. The dirt cup may be inserted into and sealingly held within the body portion by using a rotational camming structure.

Owner:MIDEA AMERICA CORP

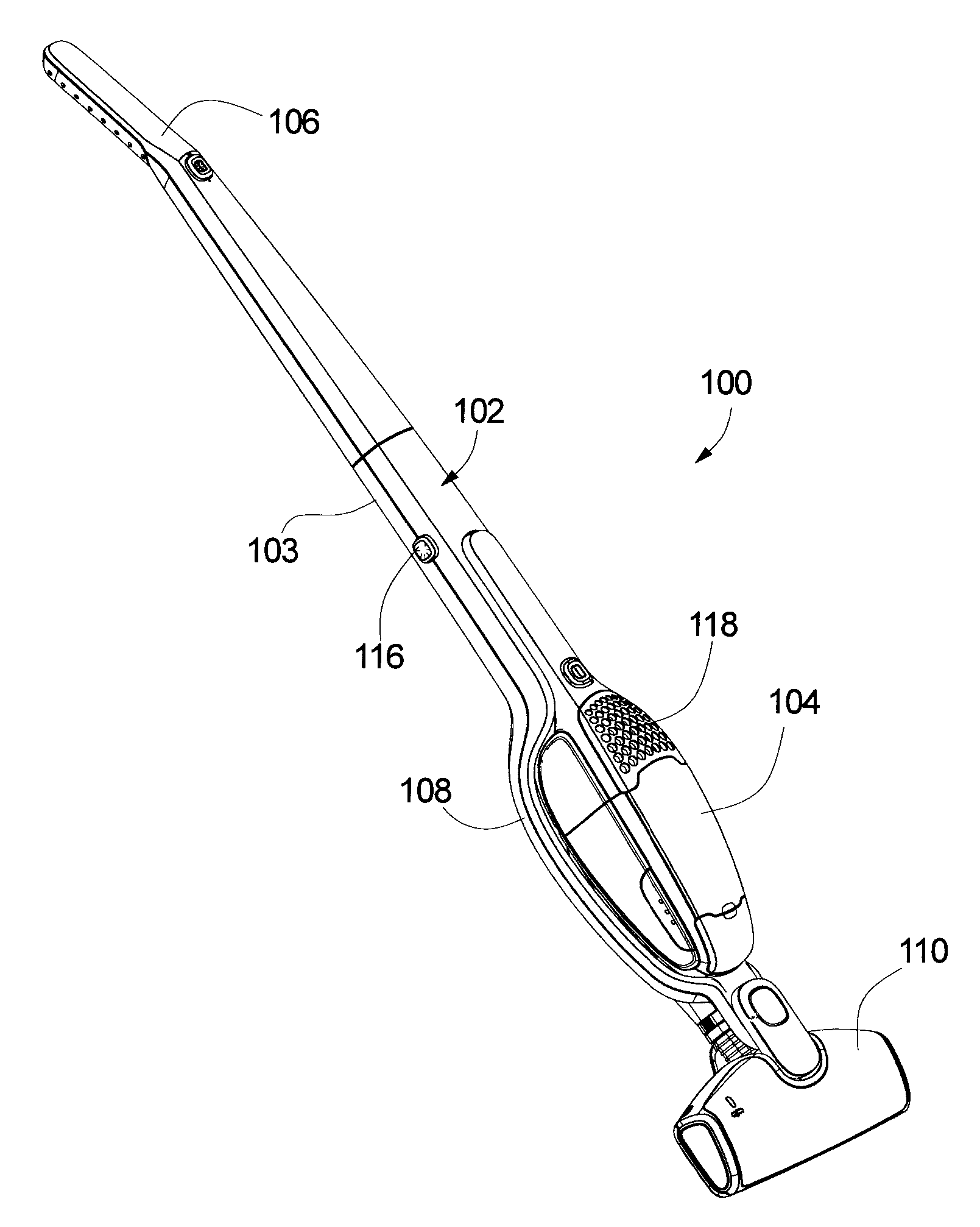

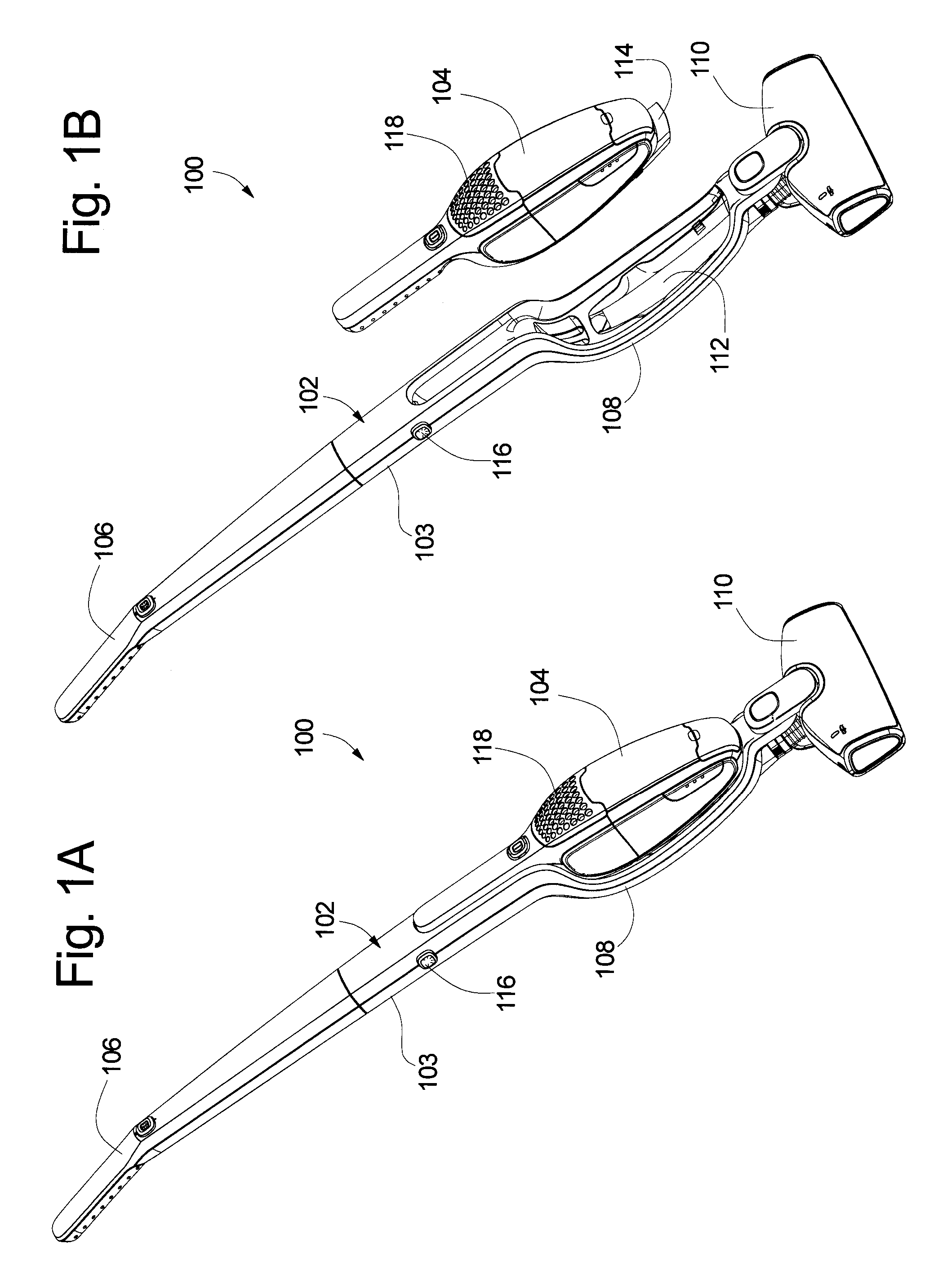

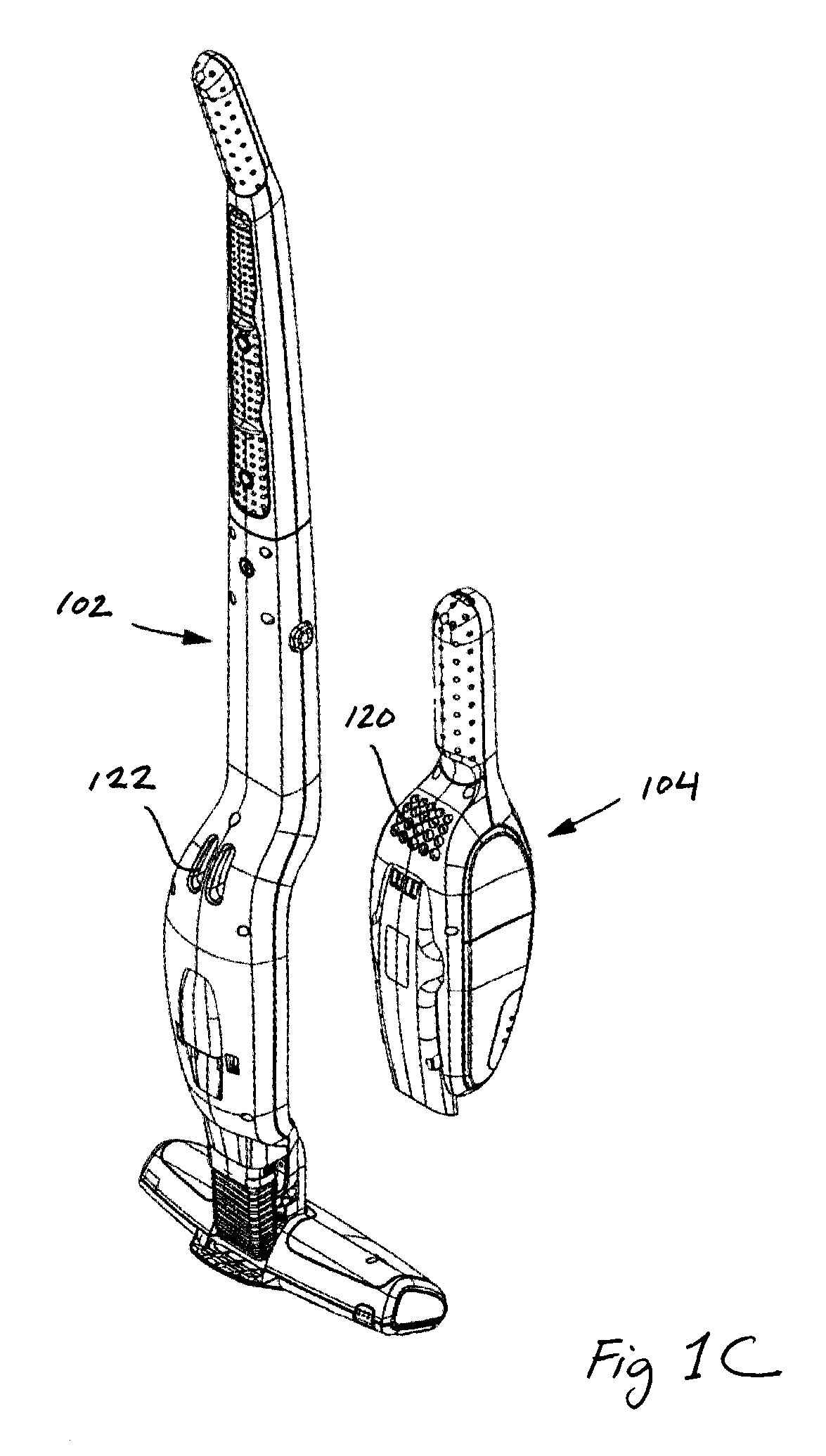

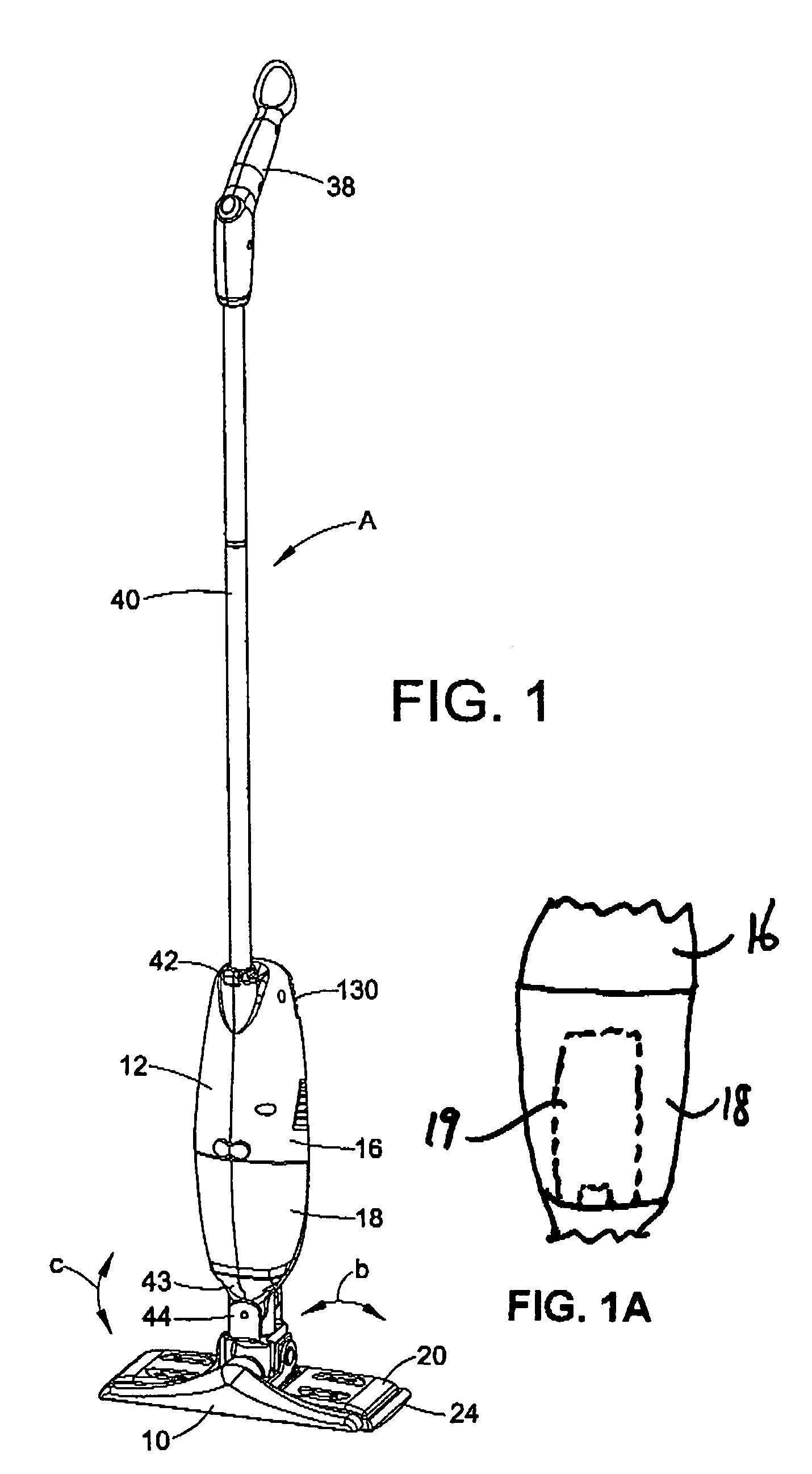

Surface cleaning apparatus

ActiveUS8146201B2Increasing overall height and linear extentMore compactCleaning filter meansBowling gamesSurface cleaningFiltration

A vacuum cleaner comprises adjacent housings, which contain the filtration and suction fan motor assembly of the vacuum cleaner.

Owner:OMACHRON INTPROP

Method for operating a floor cleaning system, and floor cleaning system for use of the method

InactiveUS20050150519A1Reduce noiseReduce cleaningSuction filtersLighting and heating apparatusEngineeringMechanical engineering

The invention relates to a method for operating a floor cleaning system having a central suction station with which there is associated a self-propelled and self-steering suction appliance, dirt being picked up from a floor surface that is to be cleaned by means of the suction appliance and being transferred into a dirt collection vessel of the suction appliance, and the suction station having a suction unit, and the dirt collection vessel being sucked out by means of the suction unit. To refine the method in such a manner that the levels of noise produced by the floor cleaning system can be reduced, it is proposed, according to the invention, that the suction unit is optionally operated with a maximum suction power or a reduced suction power. The invention also proposes a floor cleaning system for carrying out the method.

Owner:ALFRED KARCHER GMBH & CO KG

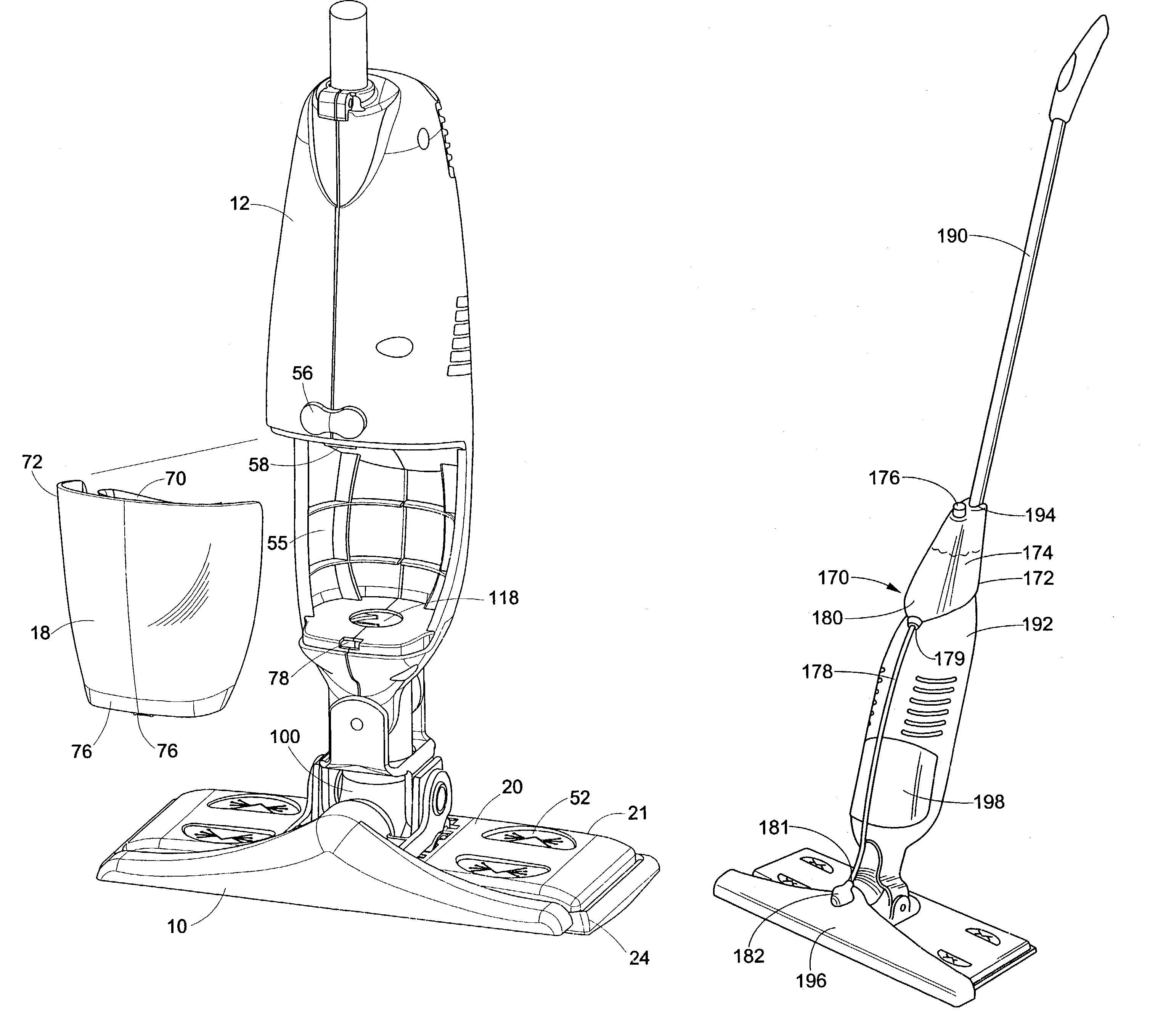

Vacuum cleaner with cleaning pad

A vacuum cleaner has a suction nozzle, a housing connected to the suction nozzle and a suction fan and motor assembly mounted to the housing. A dirt collecting receptacle is mounted to the housing and is in communication with the suction nozzle and suction fan and motor assembly. A support plate is pivotally mounted to the housing and selectively holds a cleaning sheet for collecting dust and debris from a surface to be cleaned.

Owner:ROYAL APPLIANCE MFG

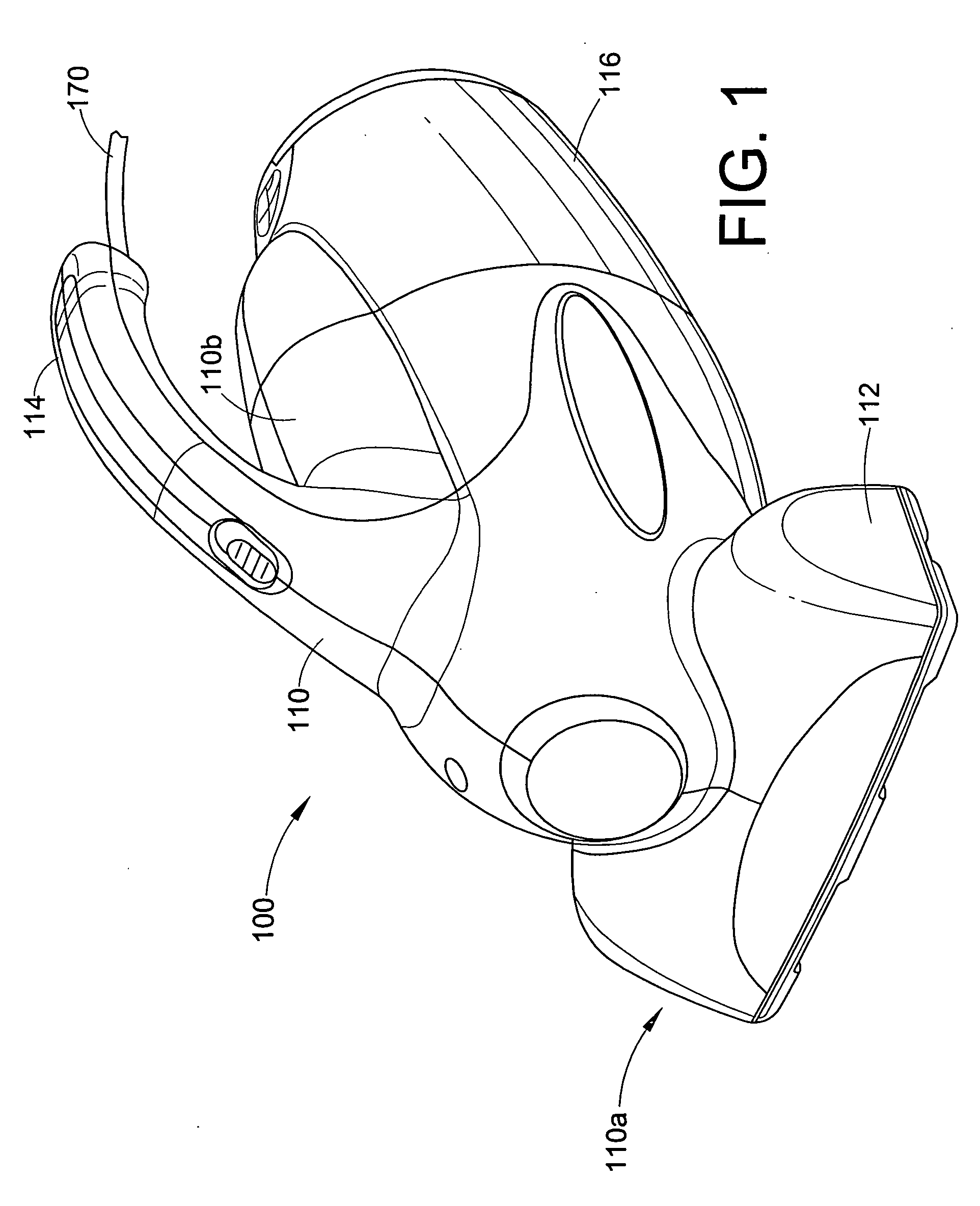

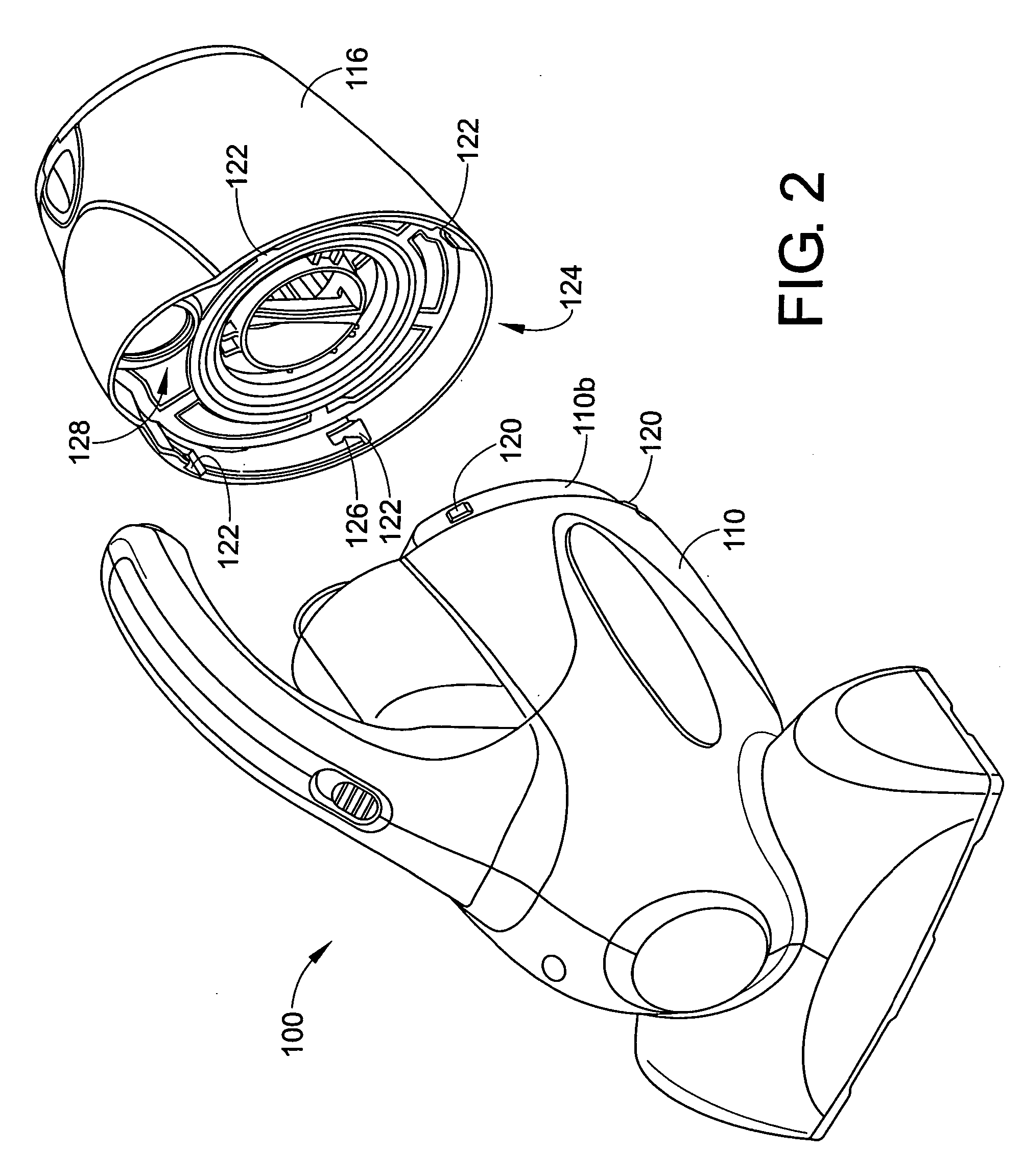

Vacuum cleaner with cyclonic separating dirt cup and dirt cup door

The present invention relates to a vacuum cleaner. In one embodiment, a hand-held vacuum cleaner includes a housing having a first end and a second end, a suction nozzle located at the first end of the housing, and a suction fan and motor assembly located in the housing. A brushroll may be disposed within the suction nozzle. The hand-held vacuum cleaner further includes a dirt cup including an inlet, an outlet, a cyclonic flow chamber, a filter assembly, and a dirt cup door. The dirt cup is rotatably detachable from the housing. At least one nub cooperates with the at least one slot in the dirt cup to rotatably secure the dirt cup to the second end of the housing. In addition, the filter assembly includes at twist on filter cartridge.

Owner:ROYAL APPLIANCE MFG

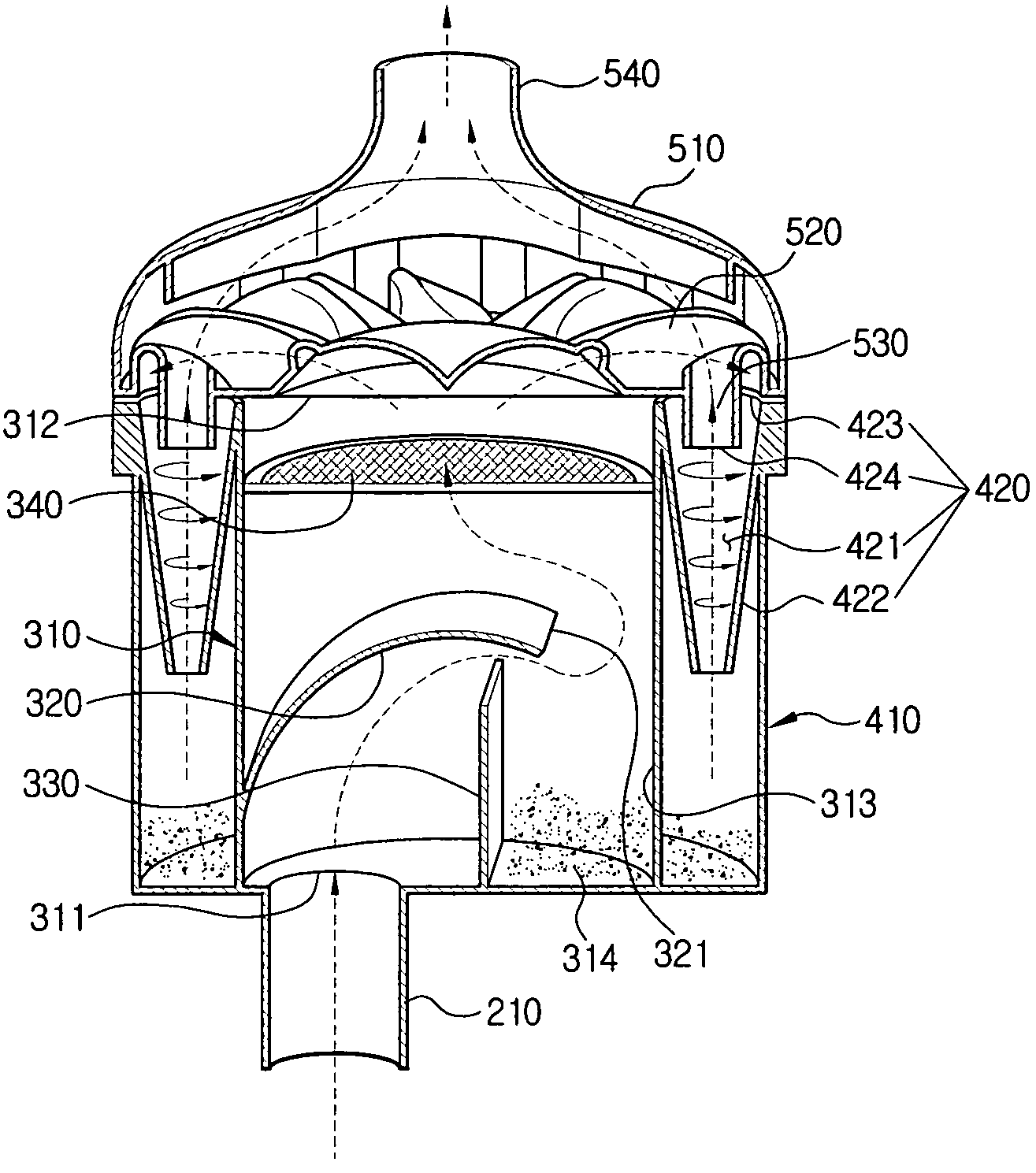

Cyclone separating apparatus for vacuum cleaner

InactiveUS20080190080A1High contaminant separating efficiencyProblem and drawbackCleaning filter meansCombination devicesCycloneCyclonic separation

A cyclone separating apparatus for a vacuum cleaner includes a first cyclone with an air entrance disposed on a lower portion of the first cyclone and an air exit disposed at an upper portion of the first cyclone; a first contaminants chamber substantially enclosing the first cyclone to collect contaminants discharged from the first cyclone; a plurality of second cyclones above the first cyclone, the plurality of second cyclones being substantially perpendicular to a center axis of the first cyclone; and a second contaminants chamber disposed outside the first contaminants chamber to collect contaminants discharged from the plurality of second cyclones.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

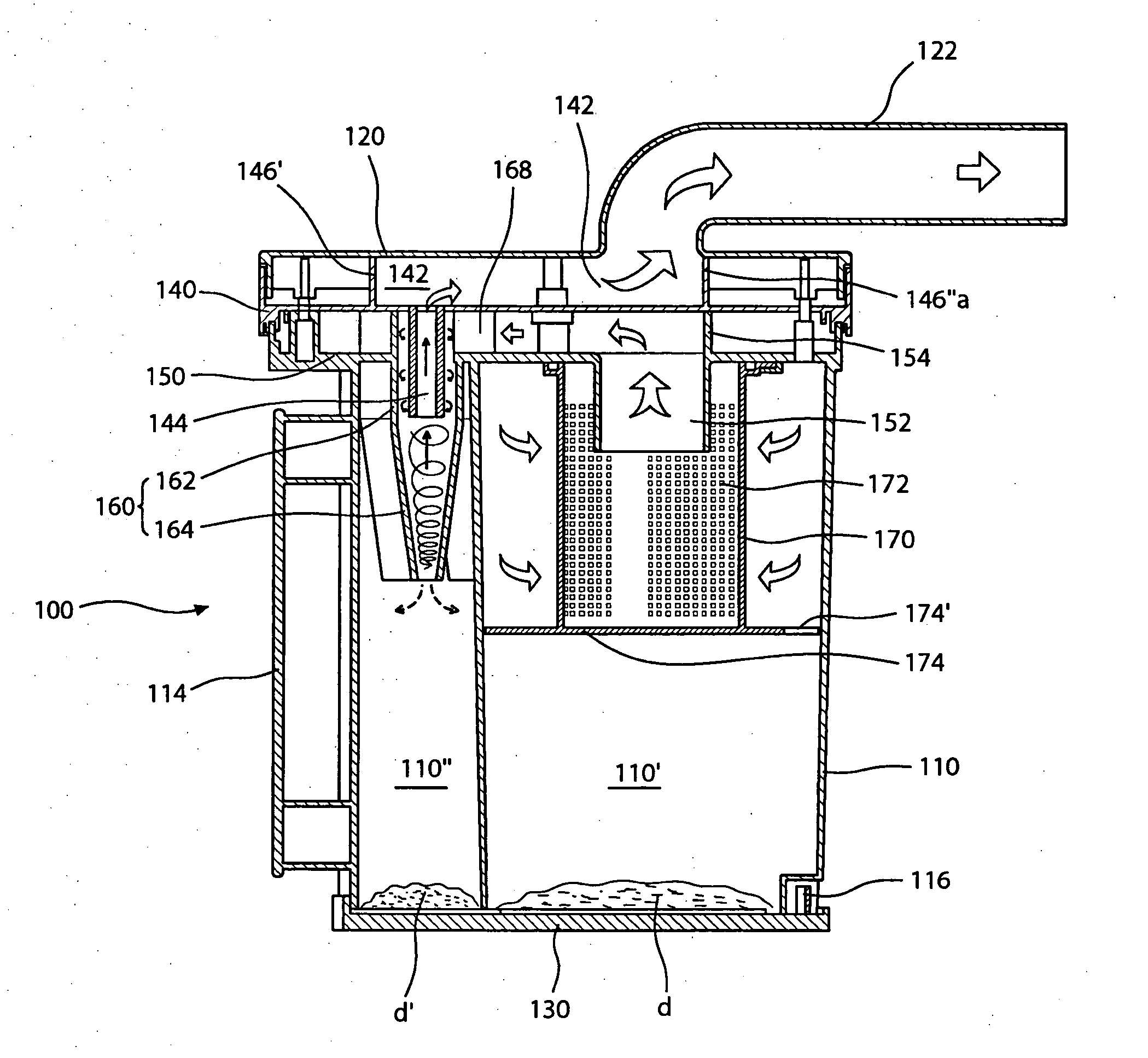

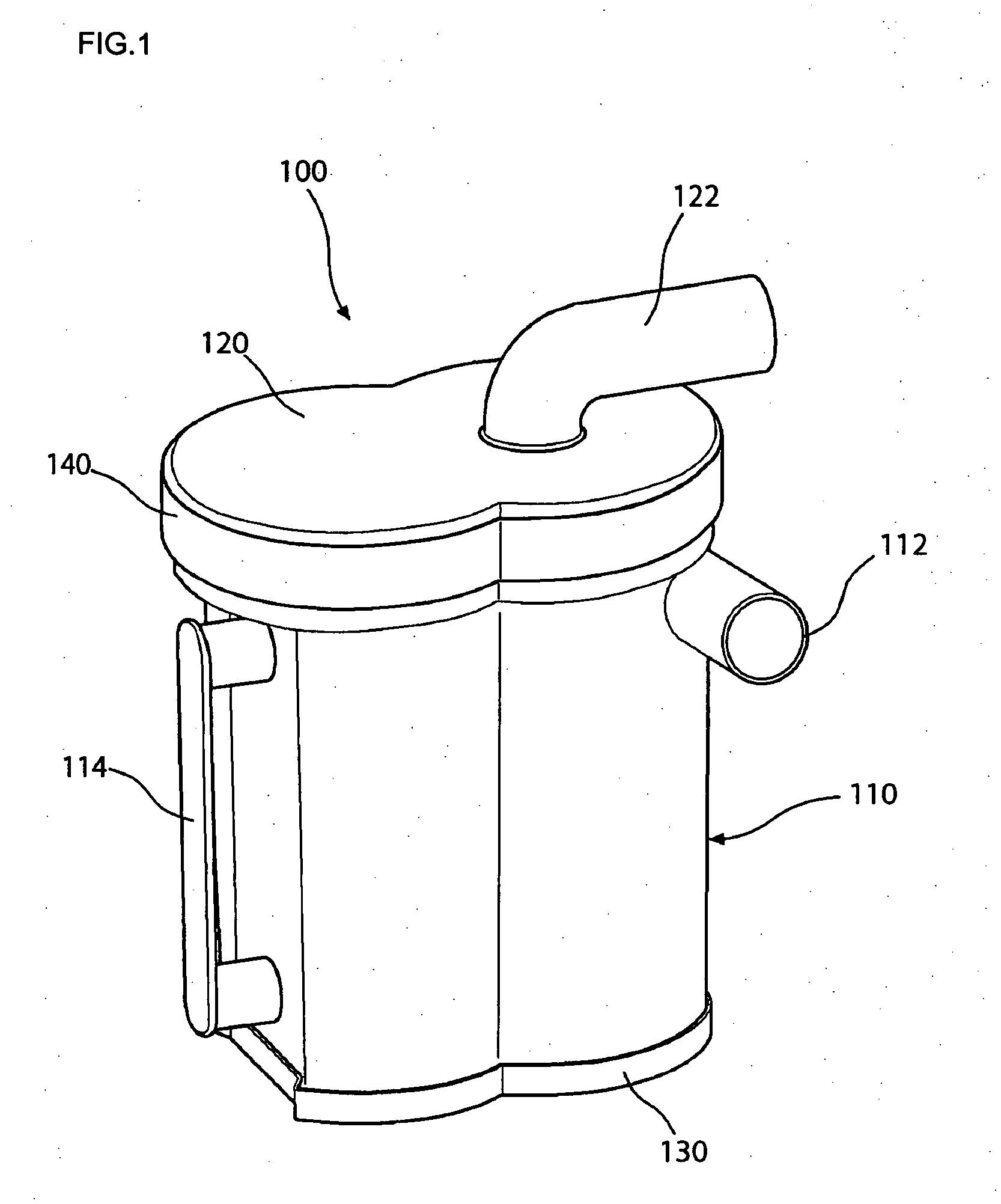

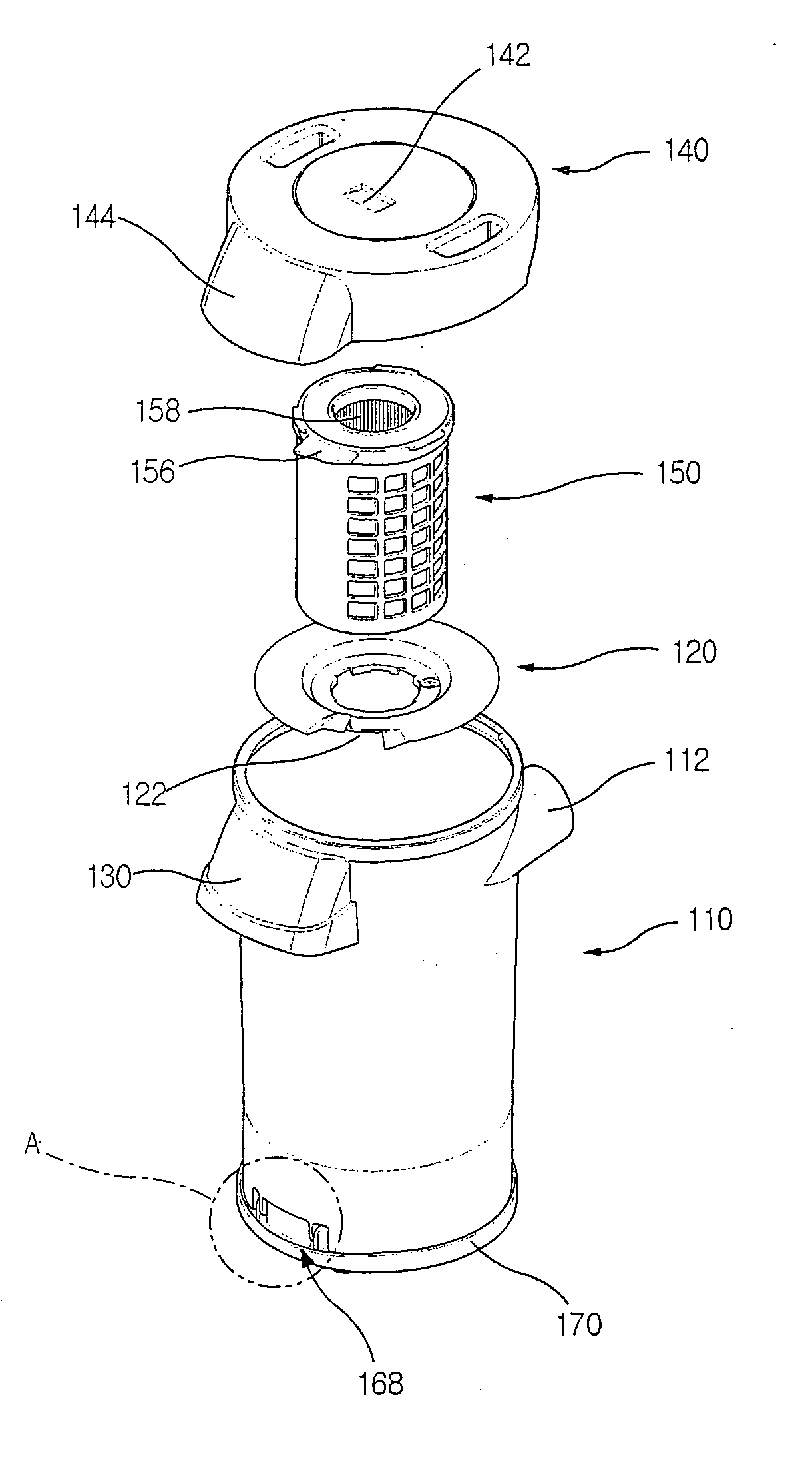

Dust and dirt collecting unit for vacuum cleaner

InactiveUS7160346B2Preventing mesh clogging of filterCleaning filter meansCombination devicesForeign matterEngineering

The present invention relates to a dust and dirt collecting unit for a vacuum cleaner capable of simultaneously performing a primary cyclonic dust collection and a secondary filter dust collection. According to the present invention, there is provided a dust and dirt collecting unit for a vacuum cleaner, which is mounted to one side of a main body of the vacuum cleaner to filter sucked air containing foreign substances. The dust and dirt collecting unit of the present invention comprises a dust casing which has an inlet formed in a direction tangential thereto for introducing the air containing the foreign substances thereinto and of which a top portion is open; a cover which is used to open and close the top portion of the dust casing and is provided at the center thereof with an outlet for discharging air from which the foreign substances have been filtered out; a filter assembly which is installed at a bottom surface of the cover corresponding to the outlet and includes a cylindrical filter of which the interior communicates with the outlet; a protective cylindrical body which is formed to wrap around an outer periphery of the filter assembly and installed below the cover so that the interior thereof can communicate with the exterior thereof through a plurality of vent holes formed at a lower portion thereof; and a separating plate which is coupled with the bottom of the filter assembly and extends radially to be spaced apart from an inner circumferential surface of the dust casing by a predetermined gap.

Owner:LG ELECTRONICS INC

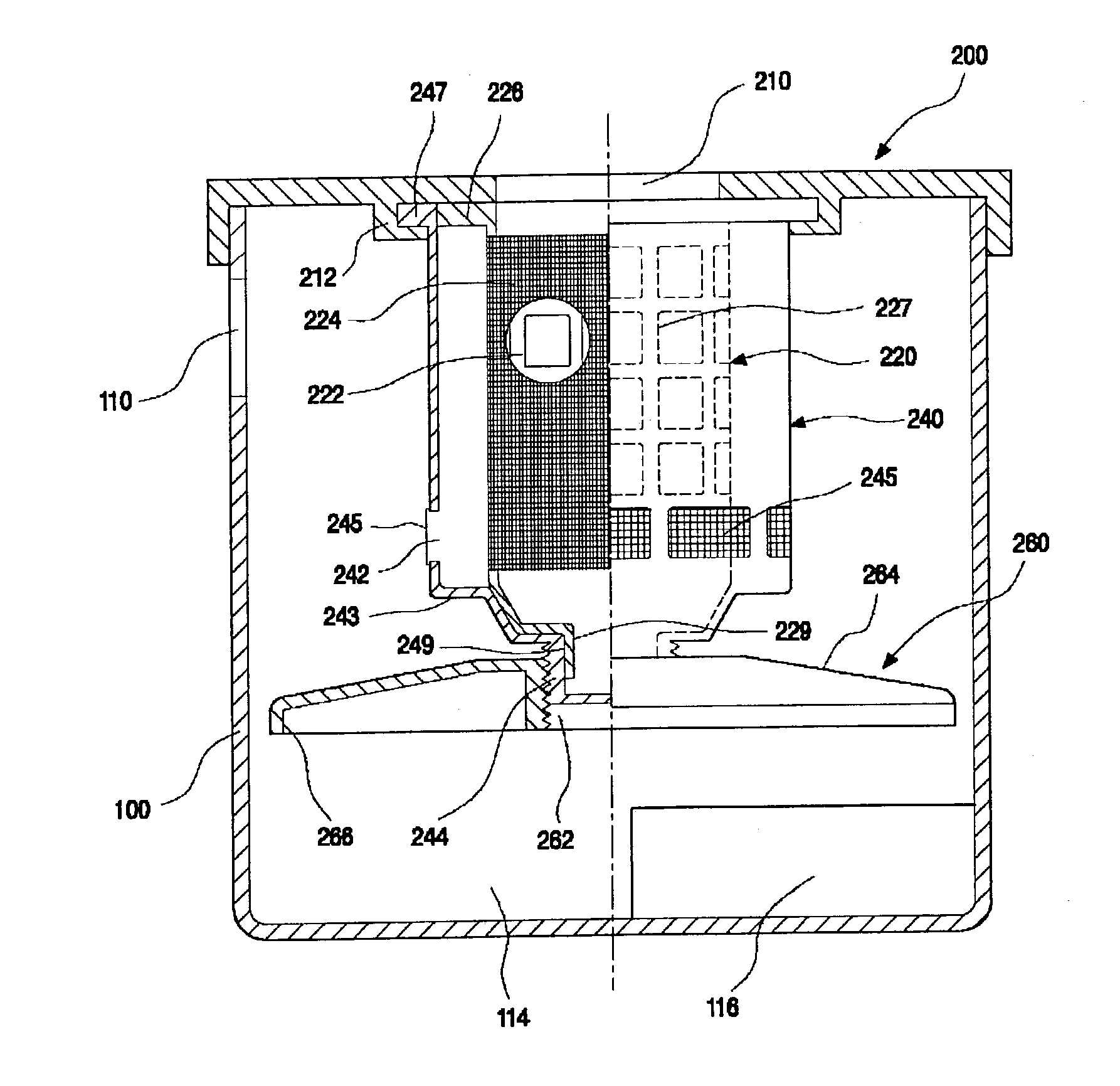

Dust collection assembly of vacuum cleaner

InactiveUS20060137304A1Improve dust removal efficiencyEasy constructionCombination devicesSuction filtersCycloneForeign matter

A dust collection assembly of a vacuum cleaner is provided. The dust collection assembly includes a dust collecting box, a filter, a flow guide unit, an exhaust guider, and an upper cover. The dust collecting box and the flow guide unit are integrally formed in a single body. The dust collecting box includes a first and second dust collecting spaces for collecting foreign objects. The filter is disposed in the inside of the dust collecting space to primarily filter foreign objects during operation of a cyclone. The flow guide unit guides airflow and has small cyclones integrally formed therein, for secondarily filtering the foreign objects in air. The exhaust guider guides airflow and has a plurality of discharge holes through which air filtered by the small cyclone flows. The upper cover is disposed on the upper side of the exhaust guider.

Owner:LG ELECTRONICS INC

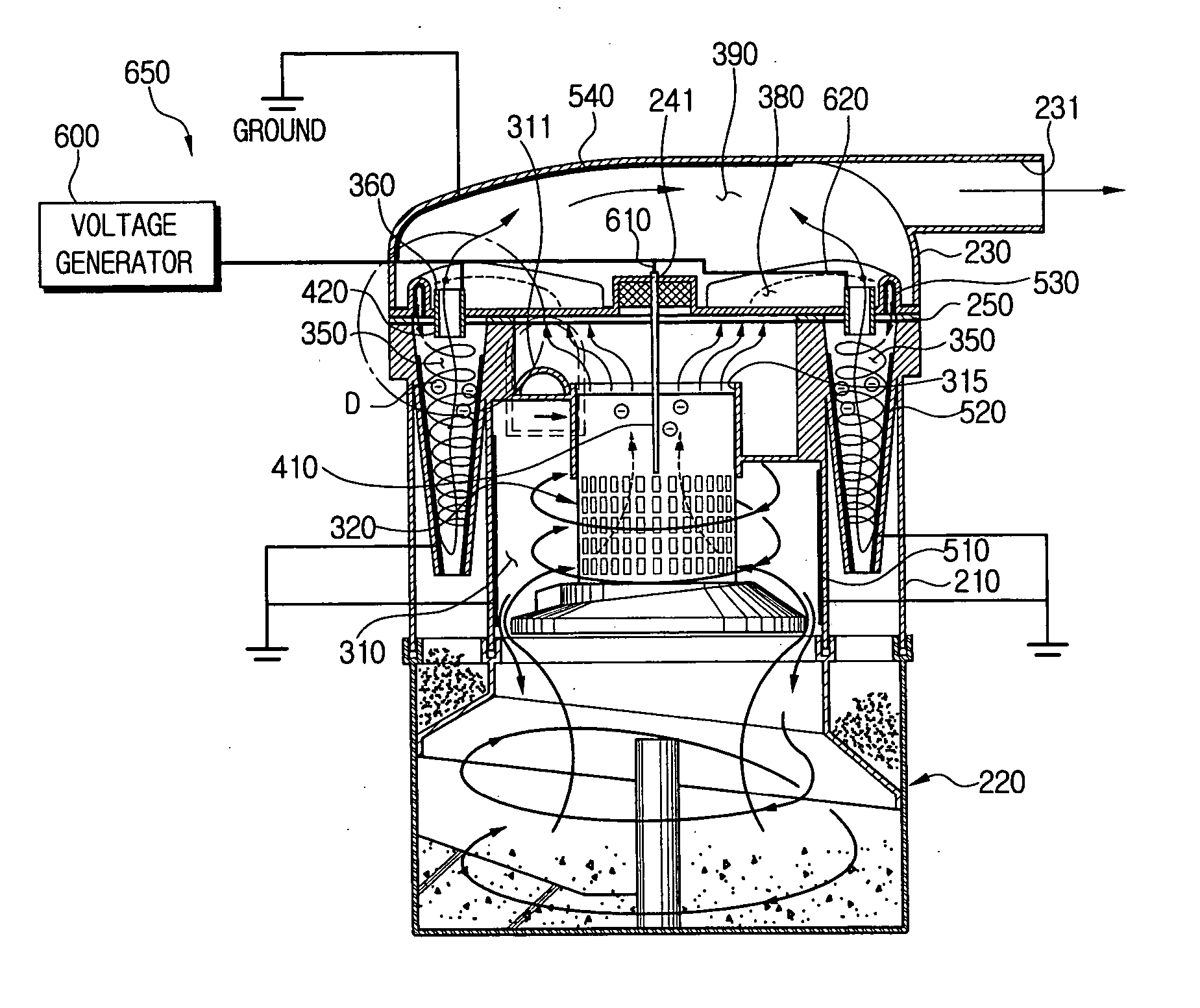

Cyclone dust collecting device for vacuum cleaner

InactiveUS20060278081A1Separation efficiency can be improvedIncreased durabilityCleaning filter meansSuction filtersCorona dischargeConductive materials

A cyclone dust collecting device using a corona discharge is provided. The cyclone dust collecting device includes a cyclone chamber rotating air drawn in from the outside to separate contaminants from the air, a discharge pipe guiding the air separated from the contaminants to the outside of the cyclone chamber and including a discharge electrode part with at least a part made of a conductive material and a power supply unit supplying a power to the discharge electrode part for the discharge electrode part to perform a corona discharge.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Cyclone dust separating apparatus for vacuum cleaner and vacuum cleaner having the same

ActiveUS20060230724A1Improved contaminant separation efficiencySmall sizeSuction filtersReversed direction vortexCycloneEngineering

A cyclone dust separating apparatus has a first cyclone chamber for separating particles from the externally-drawn fluid by centrifugal force, one or more second cyclone chambers for separating particles from the fluid discharged from the first cyclone chamber by centrifugal force, and one or more third cyclone chambers for separating particles from the fluid discharged from the second cyclone chambers, and causing the fluid to be discharged out via a discharge passage. The second and the third cyclone chambers are arranged in radial relation with respect to the first cyclone chamber, and thus, surround the first cyclone chamber. Therefore, the cyclone dust separating apparatus provides multi-stage centrifugal cleaning process and improved cleaning efficiency, while remaining compact-sized.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Dust collection unit and vacuum cleaner with the same

ActiveUS20060137309A1Improve foreign object removal efficiencyEasy to disassembleCombination devicesAuxillary pretreatmentForeign matterForeign object

A dust collection unit for a vacuum cleaner includes a first filtering chamber filtering foreign objects using a cyclone airflow, a separation plate defining a top surface of the first filtering chamber, a filter having a diameter that is reduced as it goes downward in response to airflow rate variation in the first filtering chamber, and a blocking member provided under the filter to prevent the foreign objects filtered in the first filtering chamber from flying.

Owner:LG ELECTRONICS INC

Obstacle sensing system for an autonomous cleaning apparatus

An obstacle-sensing system for carriers, particularly autonomous carriers such as robot vacuum cleaners, enables the carriers to disengage themselves from any obstacle or obstruction with which they come into physical contact and proceed past the obstacle or obstruction. The obstacle-sensing system is established by constructing a carrier to have front and rear sections which, normally, are in a neutral relationship with respect to one another but which move relative to one another when the front section physically engages an obstacle or obstruction. The relative movement activates a guidance and control system that maneuvers the carrier around the obstacle or obstruction.

Owner:AB ELECTROLUX

Surface cleaning apparatus

ActiveUS20080134460A1Increasing heightIncreasing linear extentCleaning filter meansBowling gamesSurface cleaningFiltration

A vacuum cleaner comprises adjacent housings, which contain the filtration and suction fan motor assembly of the vacuum cleaner.

Owner:OMACHRON INTPROP

Vacuum cleaner with dirt collection vessel having a stepped sidewall

A vacuum cleaner is provided including a nozzle assembly with a suction inlet and a canister assembly. A suction generator and dirt collection vessel ate carried on one of the nozzle assembly and canister assembly. The dirt collection vessel includes a base wall, a stepped sidewall and a dirt collection chamber. The stepped sidewall has a first cylindrical section with a circumference C1, and a second cylindrical section with a circumference C2 where C1, C1>C2. In addition the stepped sidewall includes a step connecting the first and second cylindrical sections where the step and first cylindrical section define an included angle A1≦90°.

Owner:PANASONIC OF NORTH AMERICA

Multi dust-collecting apparatus

InactiveUS7547338B2Improve efficiencyConstant forceCombination devicesAuxillary pretreatmentCycloneEngineering

A multi dust-collecting apparatus for a vacuum cleaner is provided. The apparatus includes a dust-collecting unit having an air guide member to separate dirt particles from drawn-in air by using a gravity and an inertia and a filter member to remove dirt particles from the discharged air. The apparatus also includes a plurality of cyclones to swirl the air discharged from the dust-collecting unit and separate minute dirt particles from the air by using a centrifugal force.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Vacuum cleaner and dust collection unit thereof

ActiveUS20060037172A1Improve suction efficiencyImprove convenienceCleaning filter meansSuction filtersCouplingVacuum cleaner

Provided is a dust collection unit of a vacuum cleaner, including a dust collection container and a coupling portion formed at a concaved inside of the dust collection container, for allowing a lower cover to be selectively coupled to the dust collection container. The dust collection unit is firmly supported against an external impact, thereby enhancing the reliability of the vacuum cleaner and preventing the vacuum cleaner from being damaged.

Owner:LG ELECTRONICS INC

Dust collection unit for vacuum cleaner

InactiveUS7485164B2Easy to assembleImproved in strength and enduranceCombination devicesDispersed particle filtrationVacuum cleanerWaste management

A dust collection unit for a vacuum cleaner includes a collection body having a plurality of filtering chambers different from each in a volume and a plurality of storing chambers storing foreign objects filtered in the filtering chambers, a bottom seal member defining a bottom of the collection body, and an exhaust member guiding airflow in the filtering chambers. The exhaust member contacts tops of the filtering chambers as well as an outer circumference of the collection body.

Owner:LG ELECTRONICS INC

Cyclonic separating apparatus for vacuum cleaner which is capable of separately collecting water from dust

InactiveUS20060162298A1Easy to separatePreventing dispersion and subsequent backflowCombination devicesAuxillary pretreatmentInterior spaceCyclonic separation

A cyclonic separating apparatus for a vacuum cleaner that can separately collect dust and water. The cyclonic separating apparatus includes: a cyclone body having an air inlet passage and an air discharge passage; a dust receptacle connected to a lower end of the cyclone body; and a screen dividing the cyclone body and interior space of the dust receptacle into a first chamber and a second chamber, the screen having a plurality of passing holes, wherein drawn air rotates in the first chamber and water separated from the air moves to the second chamber through the passing holes.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

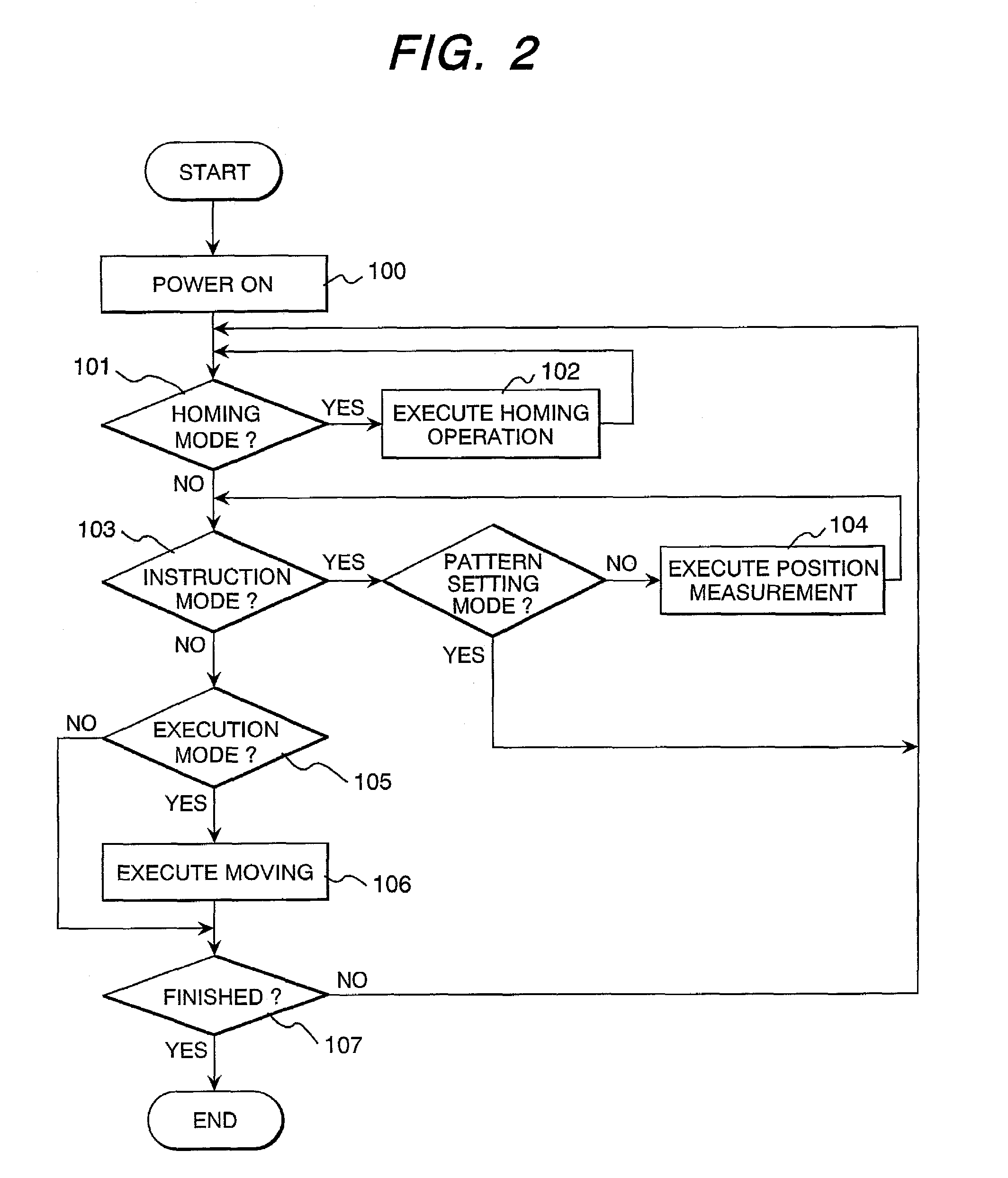

Self-running vacuum cleaner

InactiveUS6968592B2Applied load reductionReduce loadAutomatic obstacle detectionElectric signal transmission systemsOperation modeEngineering

A self-running vacuum cleaner comprises a homing mode of following a back of a user with receiving a signal from a light emitting means or a transmitting means of a position indicator means held by the user, an instruction operation mode, in which the user instructs a cleaning area to the self-running vacuum cleaner, and an execution mode for cleaning up the cleaning area instructed. When the self-running vacuum cleaner operates under the homing mode or the instruction mode, a signal from the light-emitting means or the transmitting means is received by a receiver means attached on a periphery portion of a measuring means, which is provided in an upper portion of the vacuum cleaner. Comparing the signals from the two (2) receiver means in strength thereof determines the distance and the direction from the position indicated by the light-emitting means or the transmitting means up to the vacuum cleaner.

Owner:HITACHI LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com