Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

74results about How to "Separation efficiency can be improved" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

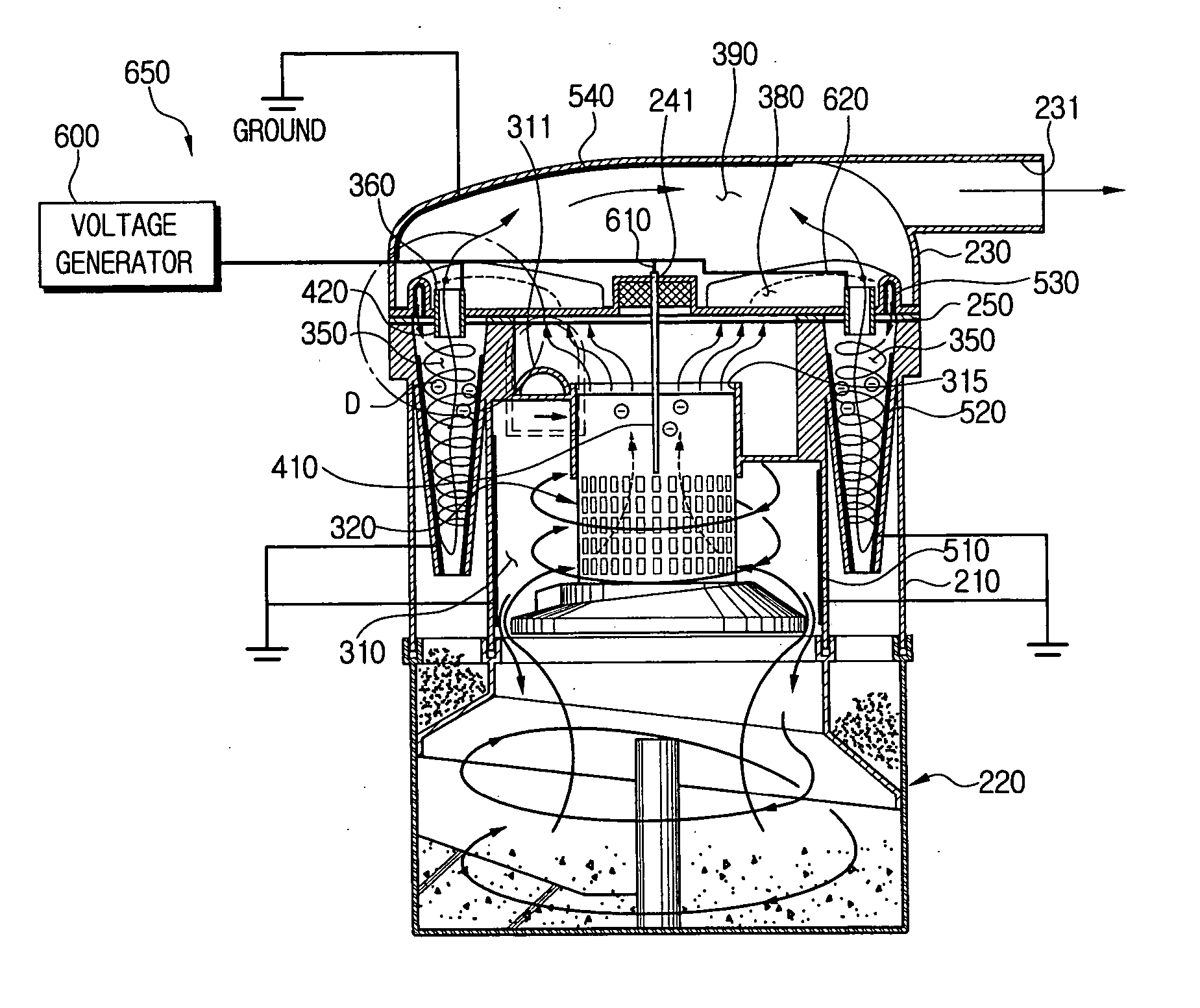

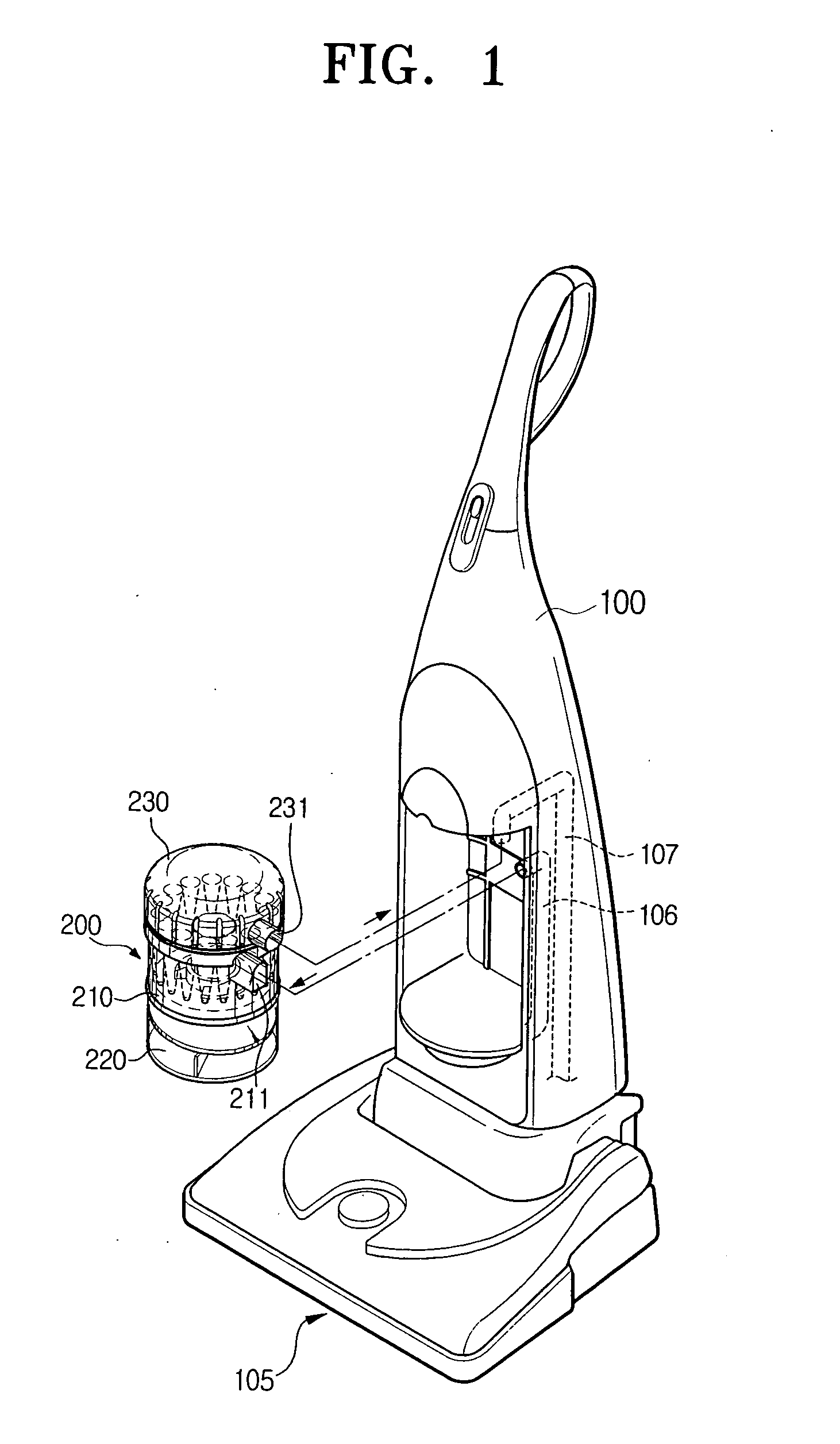

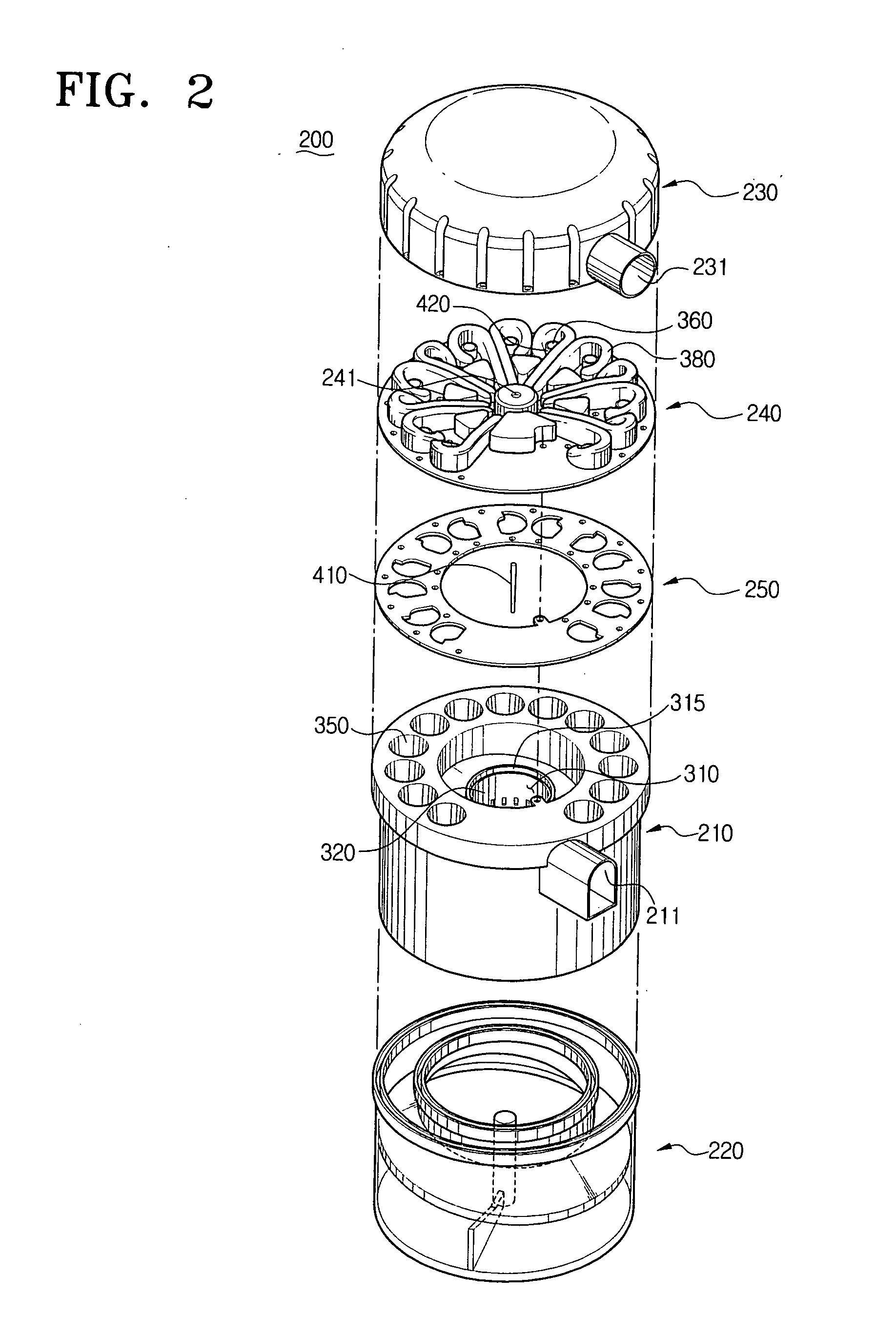

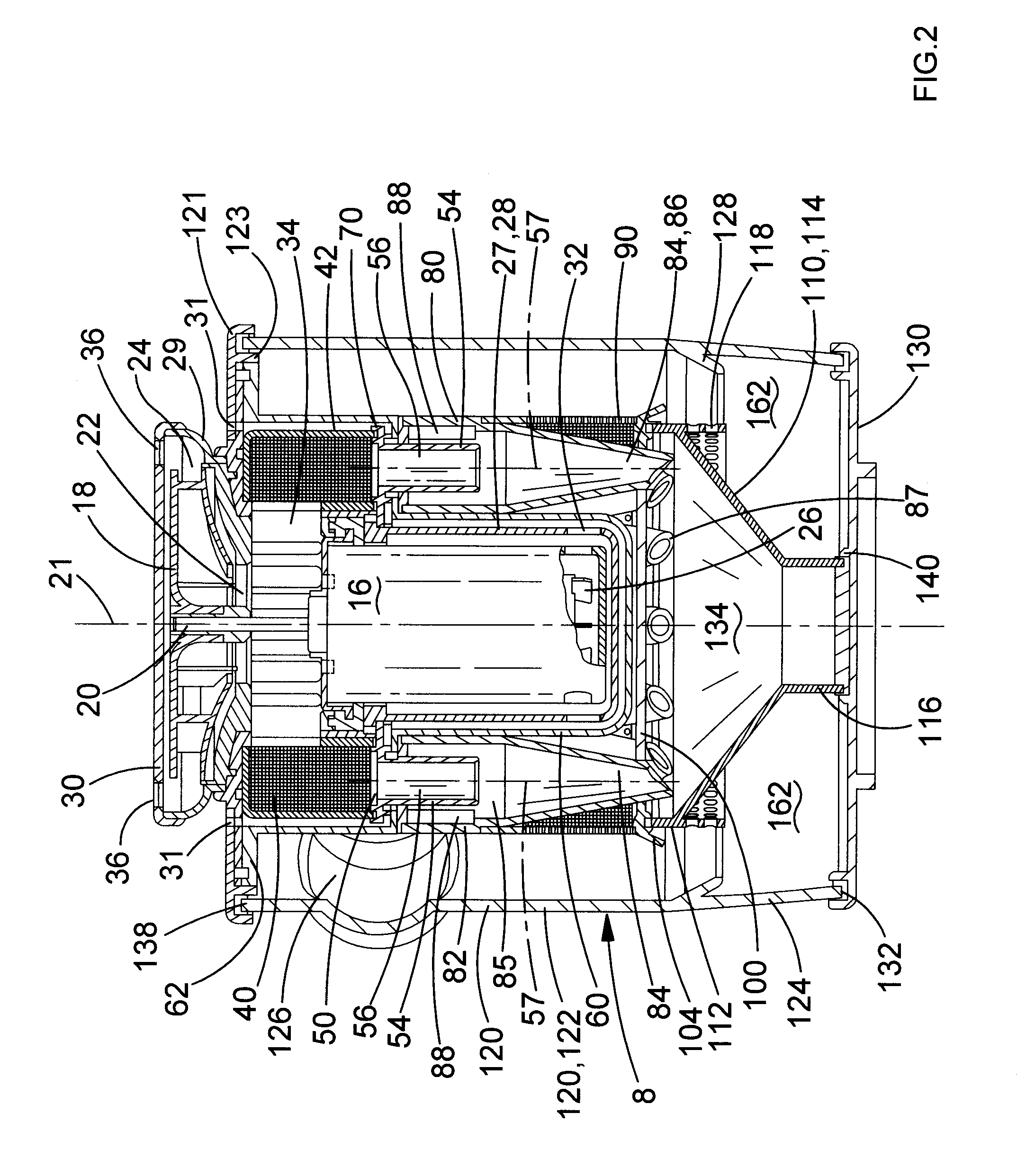

Cyclone dust collecting device for vacuum cleaner

InactiveUS20060278081A1Separation efficiency can be improvedIncreased durabilityCleaning filter meansSuction filtersCorona dischargeConductive materials

A cyclone dust collecting device using a corona discharge is provided. The cyclone dust collecting device includes a cyclone chamber rotating air drawn in from the outside to separate contaminants from the air, a discharge pipe guiding the air separated from the contaminants to the outside of the cyclone chamber and including a discharge electrode part with at least a part made of a conductive material and a power supply unit supplying a power to the discharge electrode part for the discharge electrode part to perform a corona discharge.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

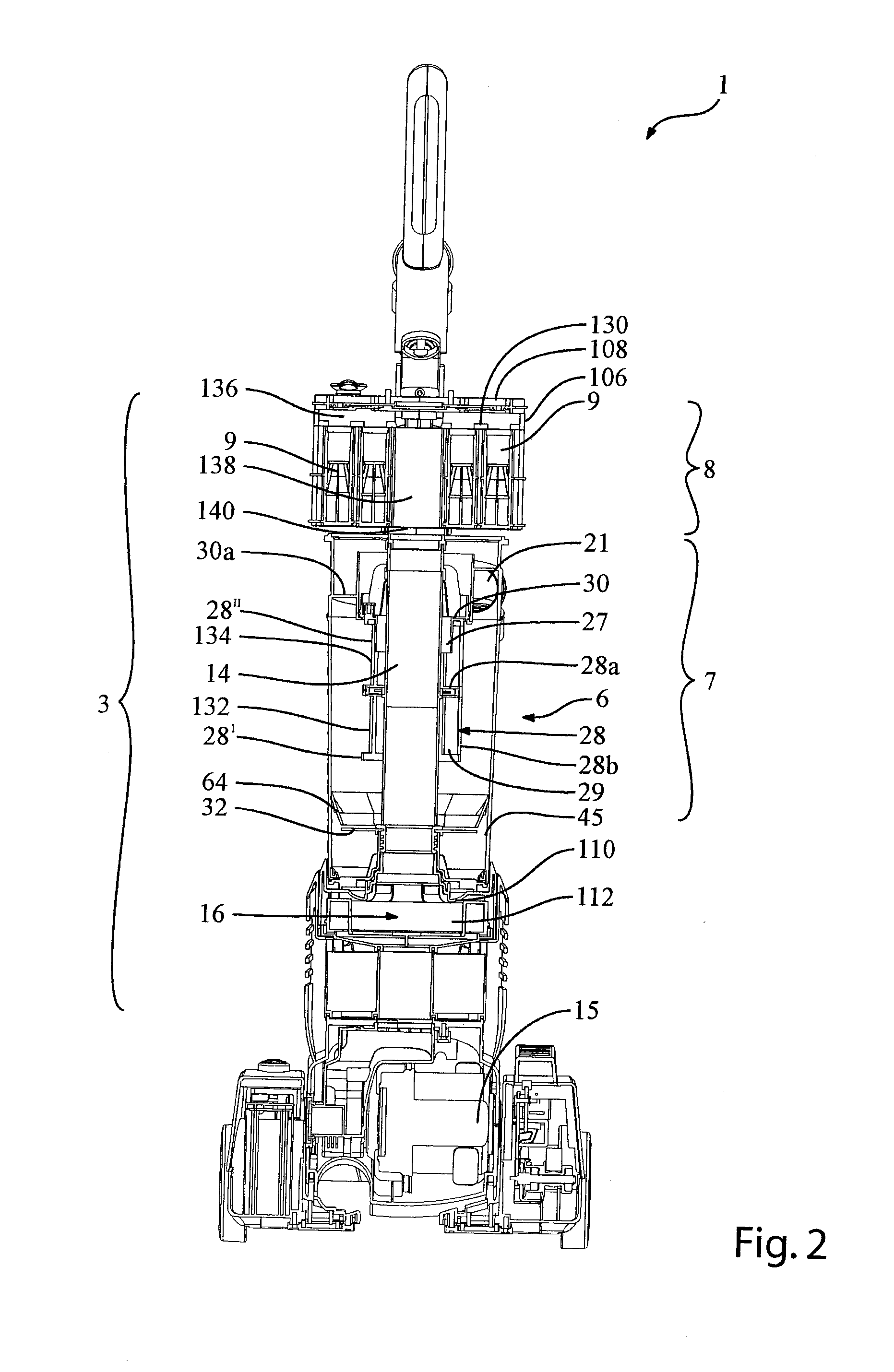

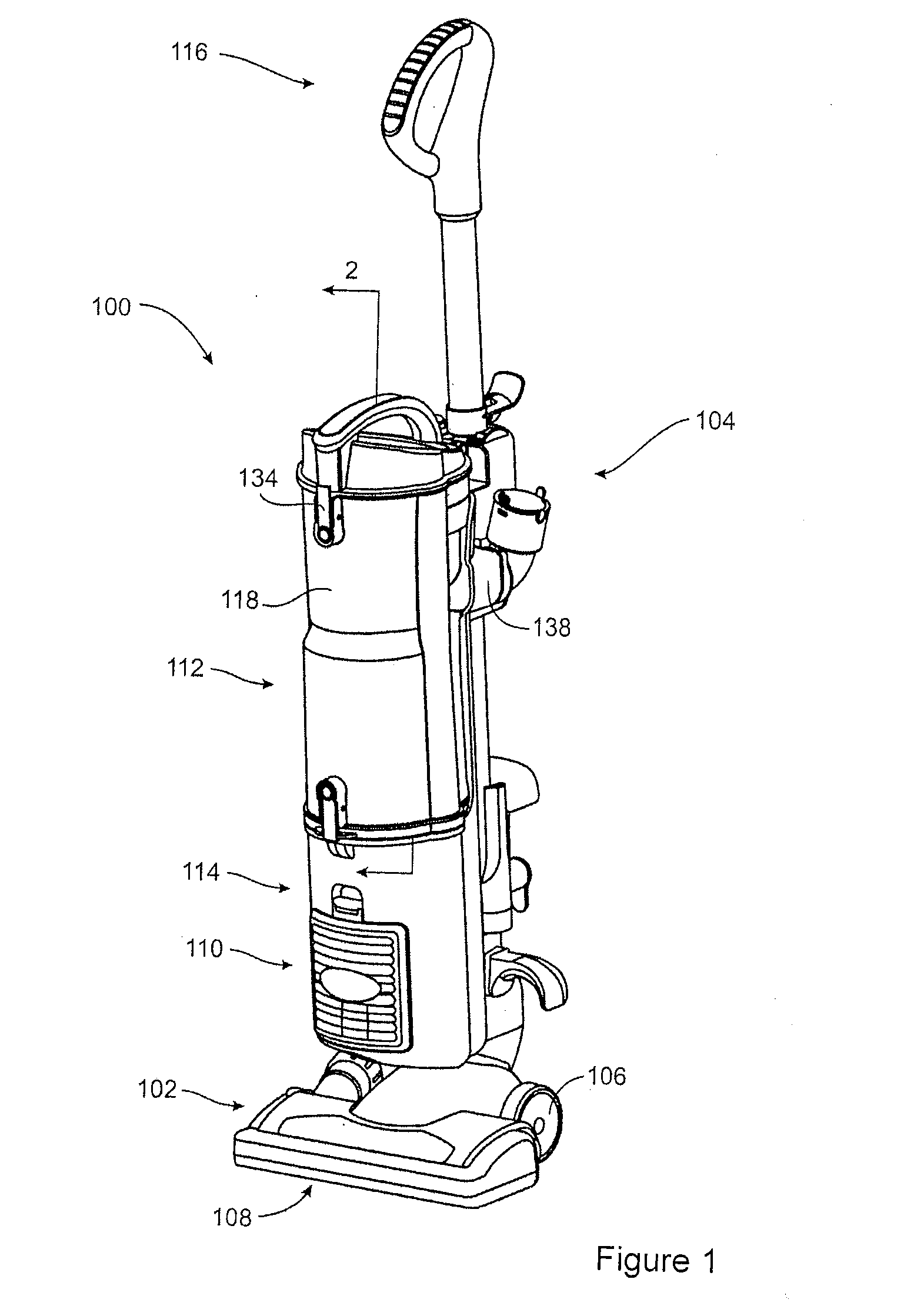

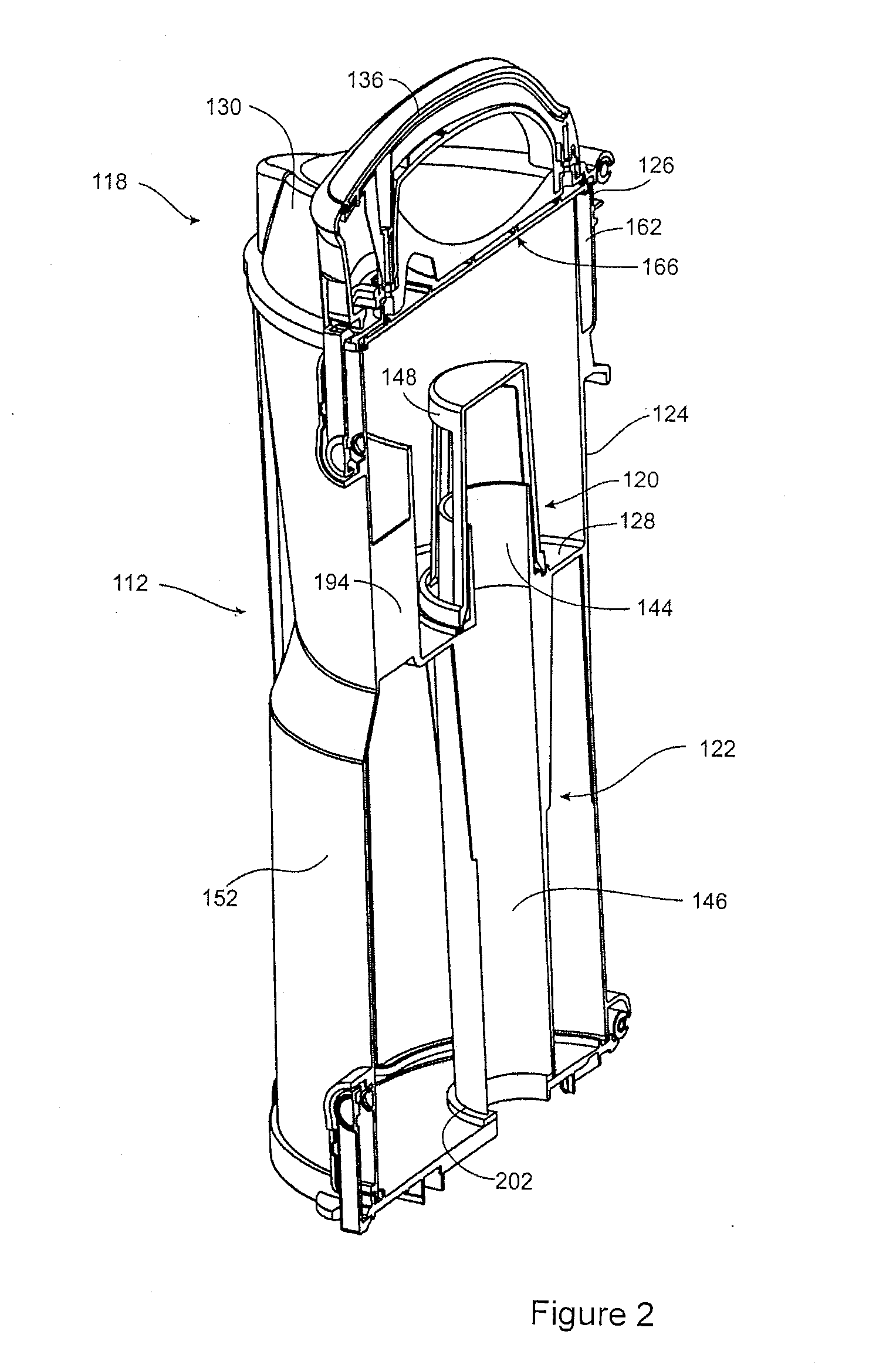

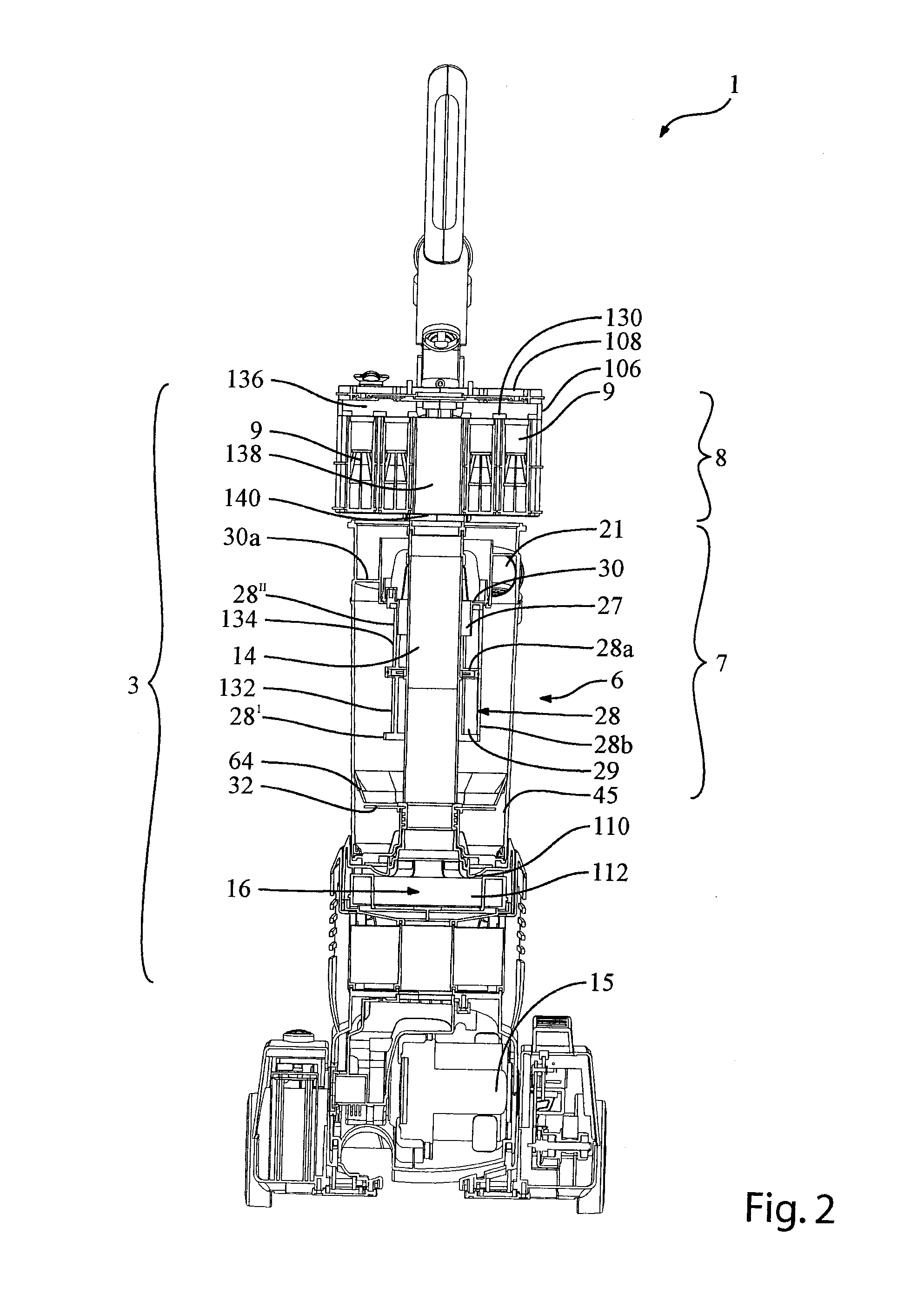

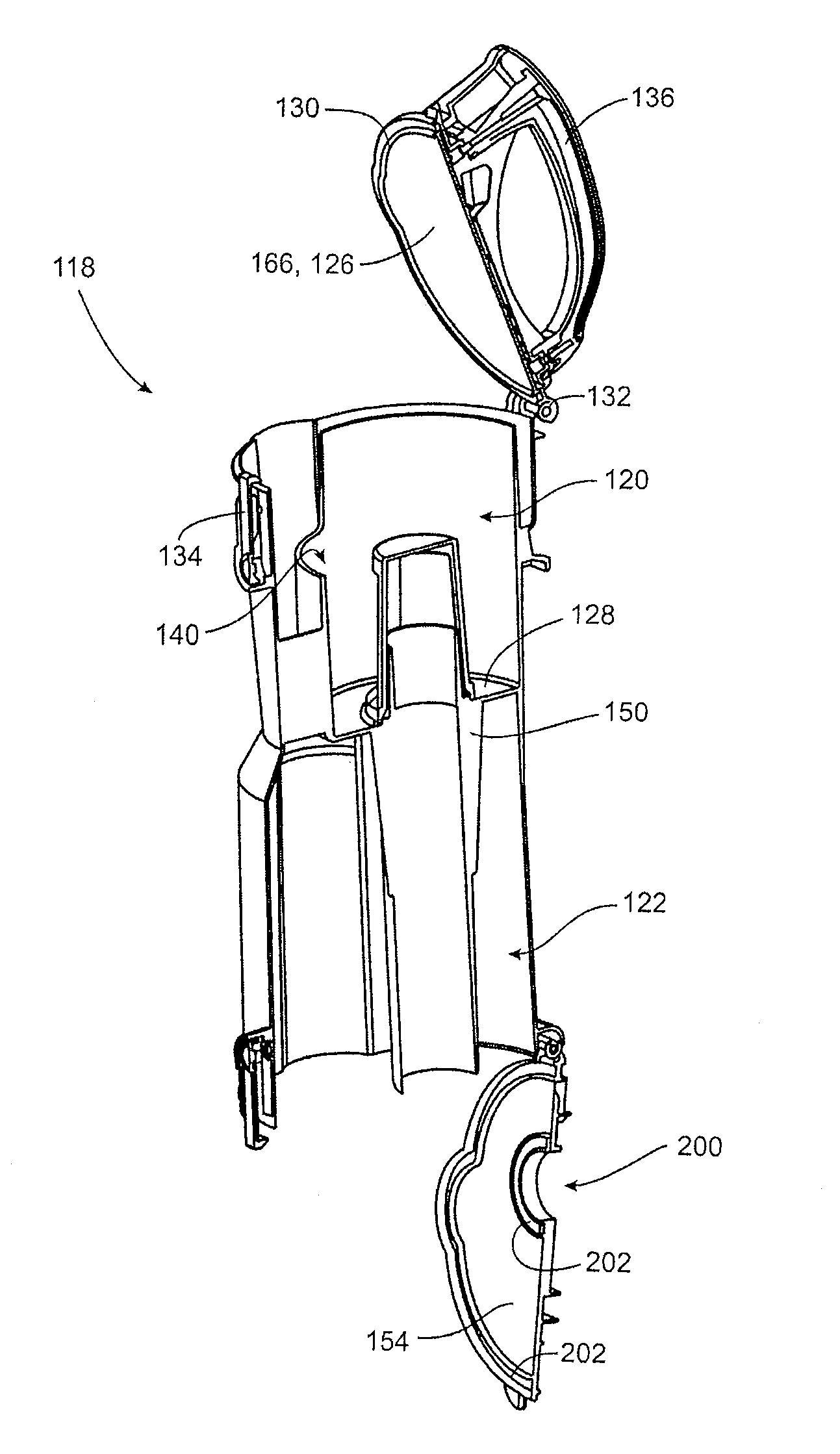

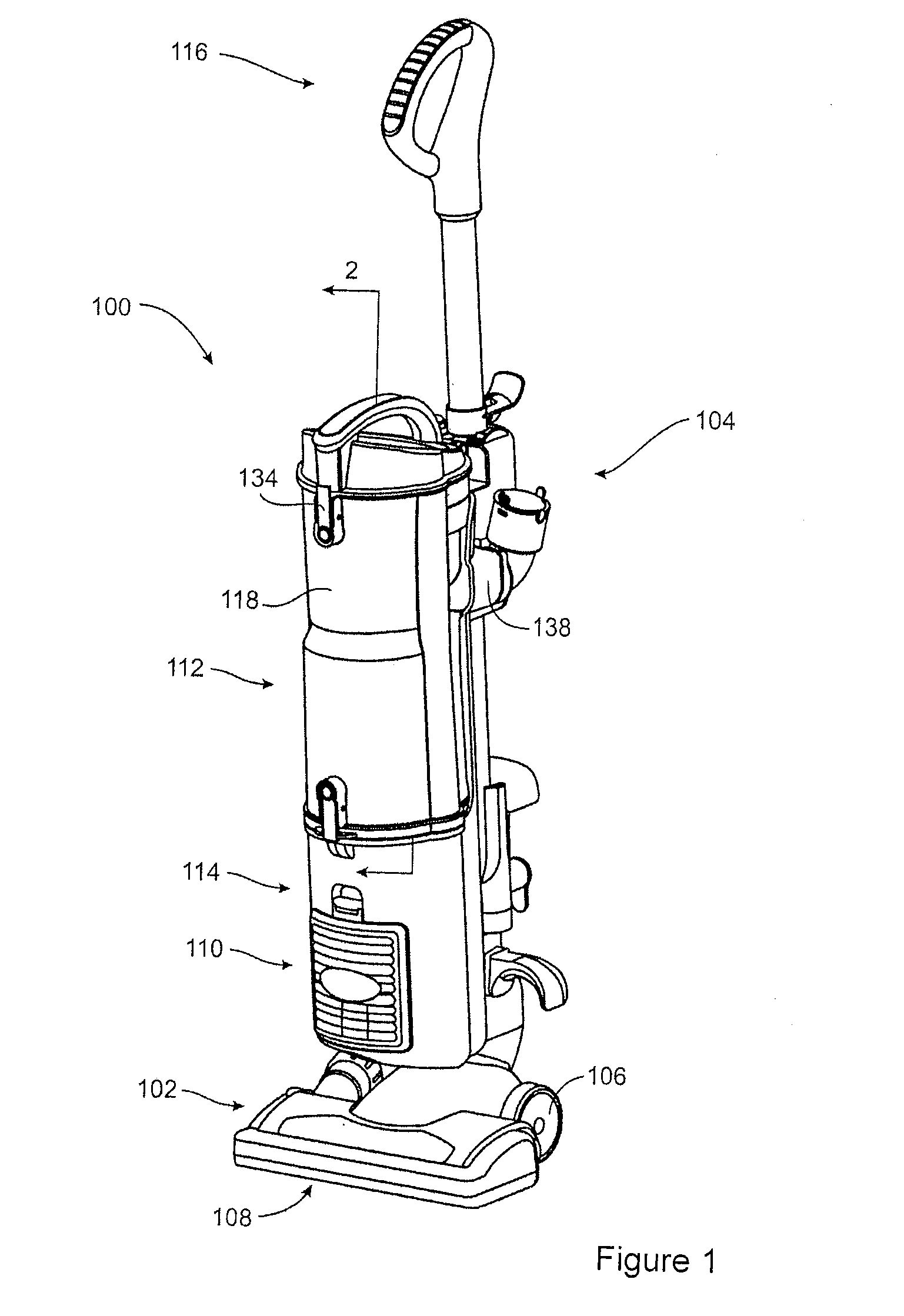

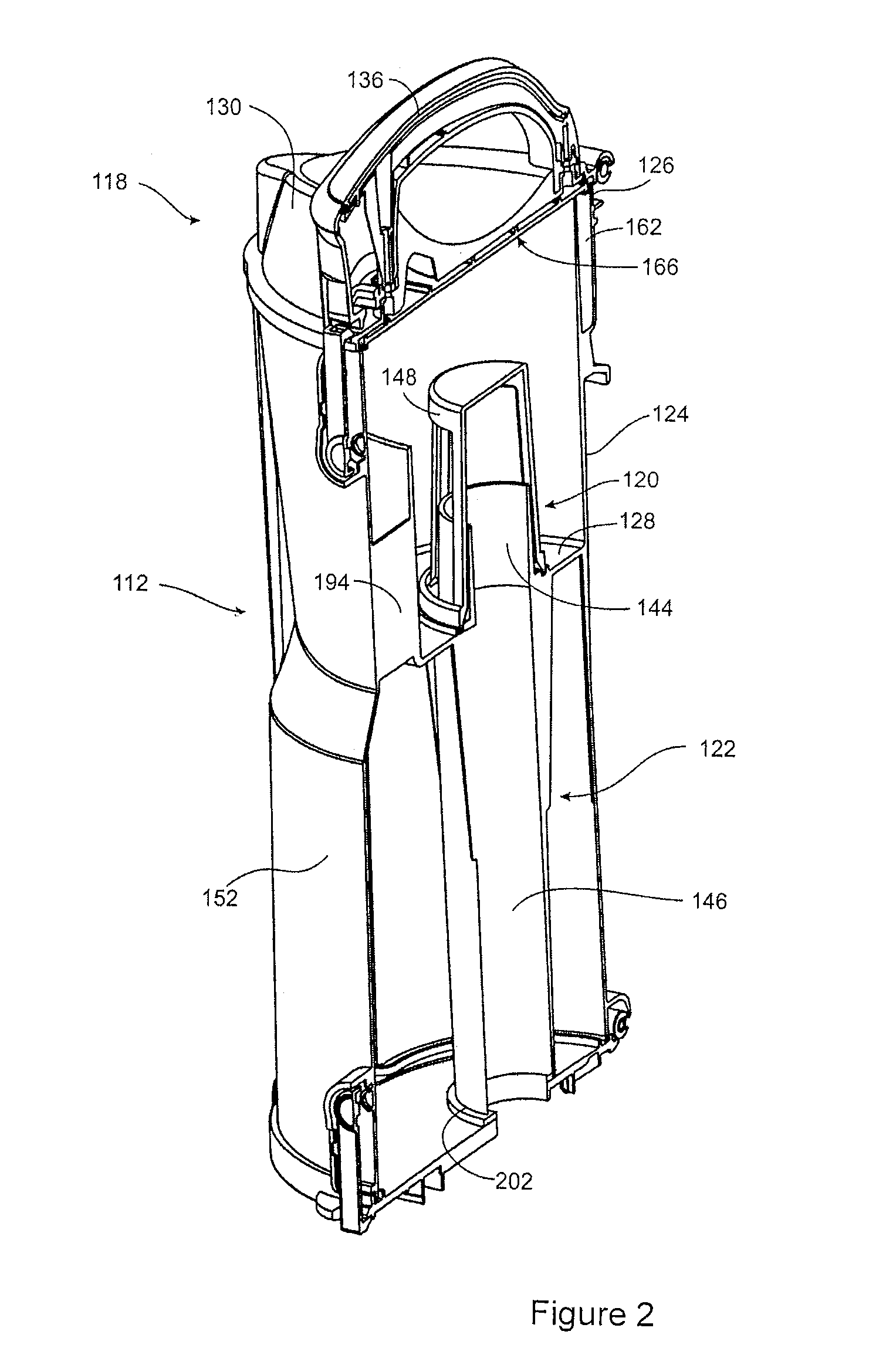

Vacuum cleaner with a moveable divider plate

ActiveUS20070209335A1Improve efficiencyGrowth inhibitionCombination devicesAuxillary pretreatmentSurface cleaningVacuum cleaner

A surface cleaning apparatus comprises a dirt inlet, a handle, a cyclone separator having an outer wall, a fluid inlet downstream from the dirt air inlet and a fluid outlet, a plate having a cyclone chamber surface and positioned to substantially divide the cyclone separator into a cyclone chamber and a dirt collection chamber, the plate being removably mounted in the cyclone separator, a passage extending between the cyclone chamber and the dirt collection chamber and a fluid flow motor.

Owner:OMACHRON INTPROP

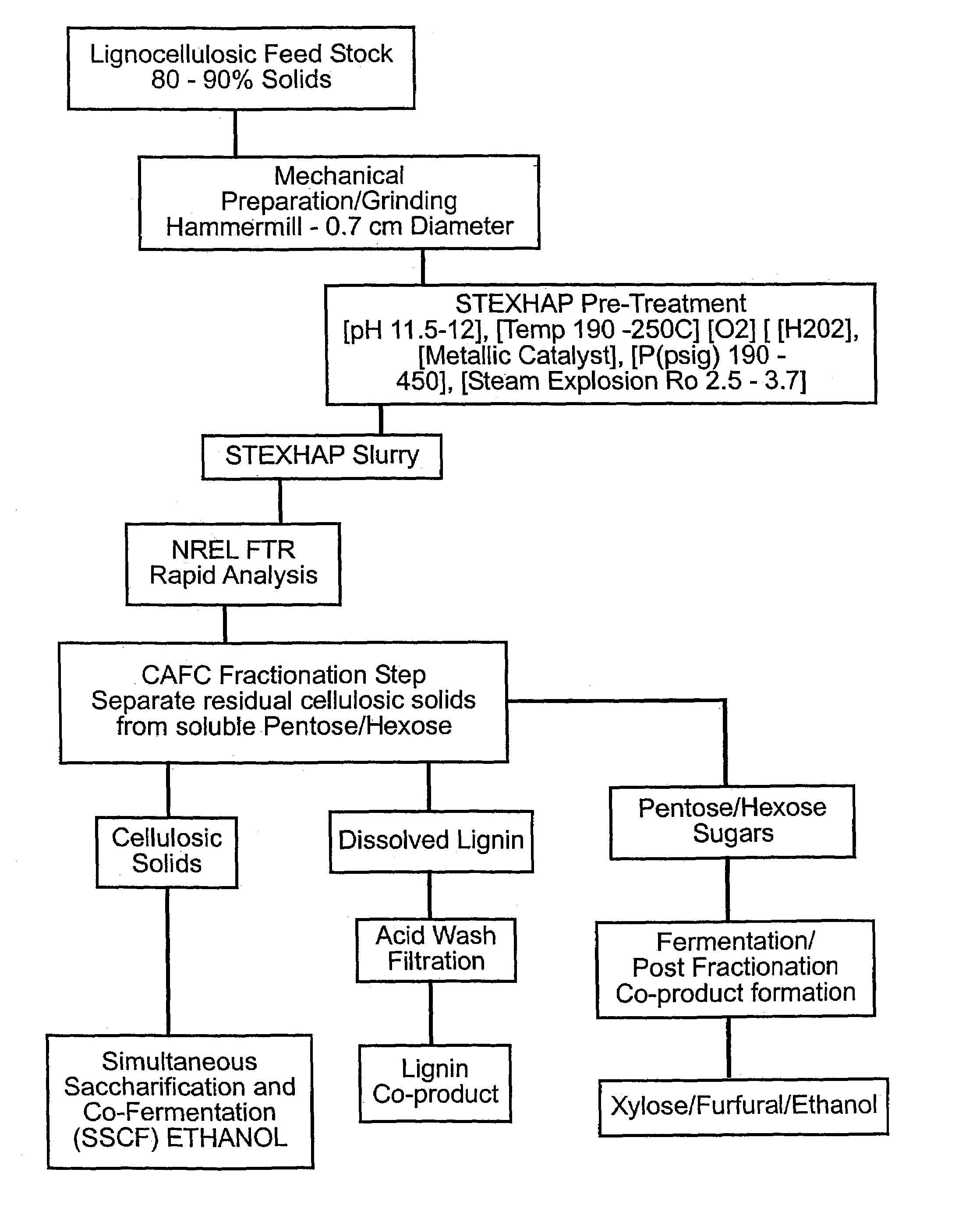

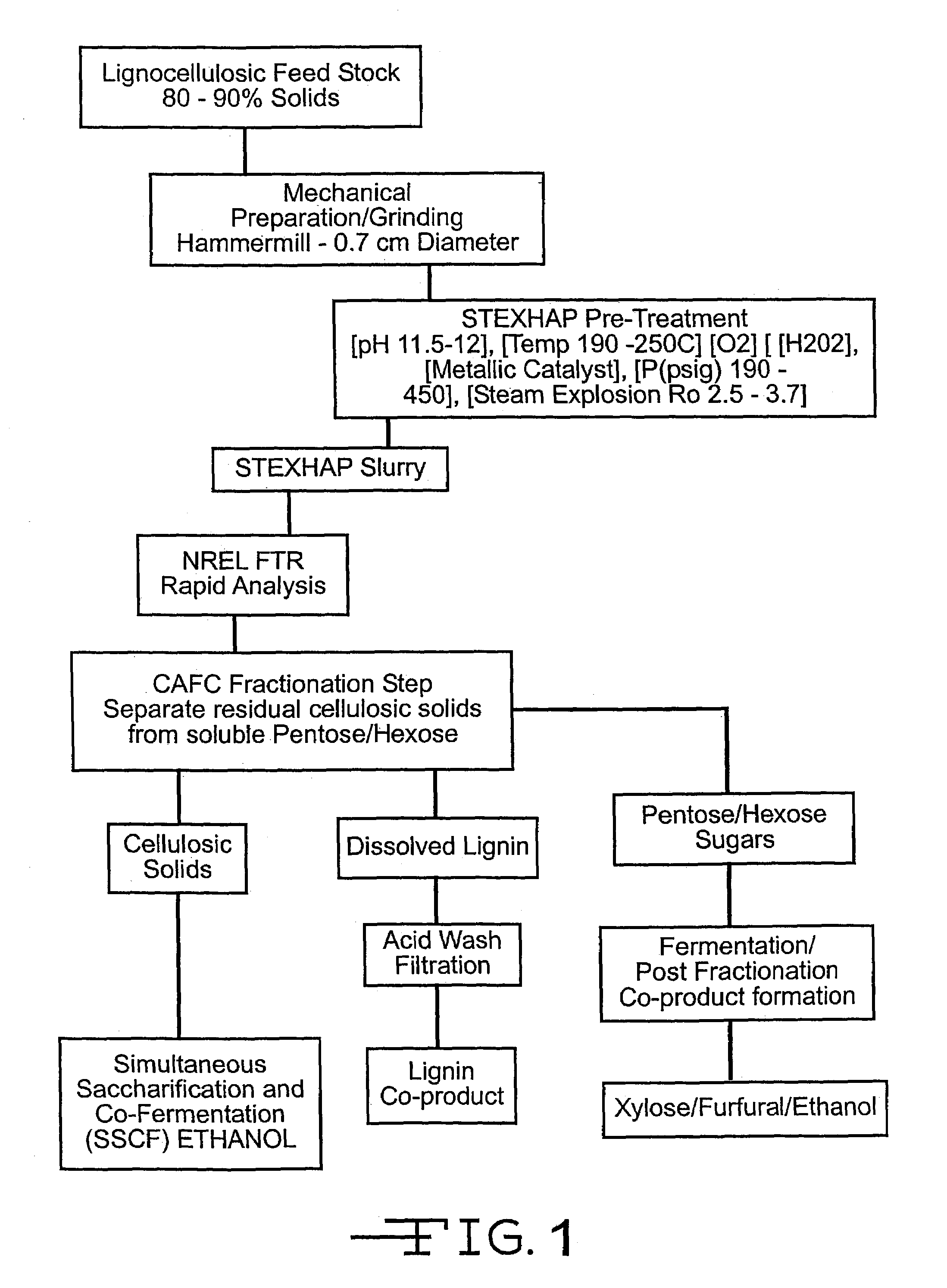

Process of treating lignocellulosic material to produce bio-ethanol

InactiveUS7189306B2Separation efficiency can be improvedEasy to separatePretreatment with water/steamPulp liquor regenerationSide productCo product

This invention relates to a process of treating a lignocellulosic material to produce bio-ethanol. The process includes the steps of: (a) exposing the lignocellulosic material to conditions including a pH not less than about 8, and steam at a first pressure, to produce a step (a) product; (b) explosively discharging the step (a) product to a second pressure less than the first pressure to produce a step (b) product; and (c) further processing the step (b) product to produce bio-ethanol and other co-products. In another embodiment, the invention relates to a conical auger fractionation column. The fractionation column includes a column body having an input and an output. A conical filter is positioned inside the column body, the filter having a larger diameter end directed toward the input and a smaller diameter end directed toward the output. A conical auger is positioned inside the conical filter, the conical auger having an outer diameter which is approximately the same as an inner diameter of the conical filter. The auger and filter are adapted to cooperate to separate cellulosic solids from a liquid stream in a process of producing bio-ethanol from a lignocellulosic material.

Owner:GERVAIS GIBSON W

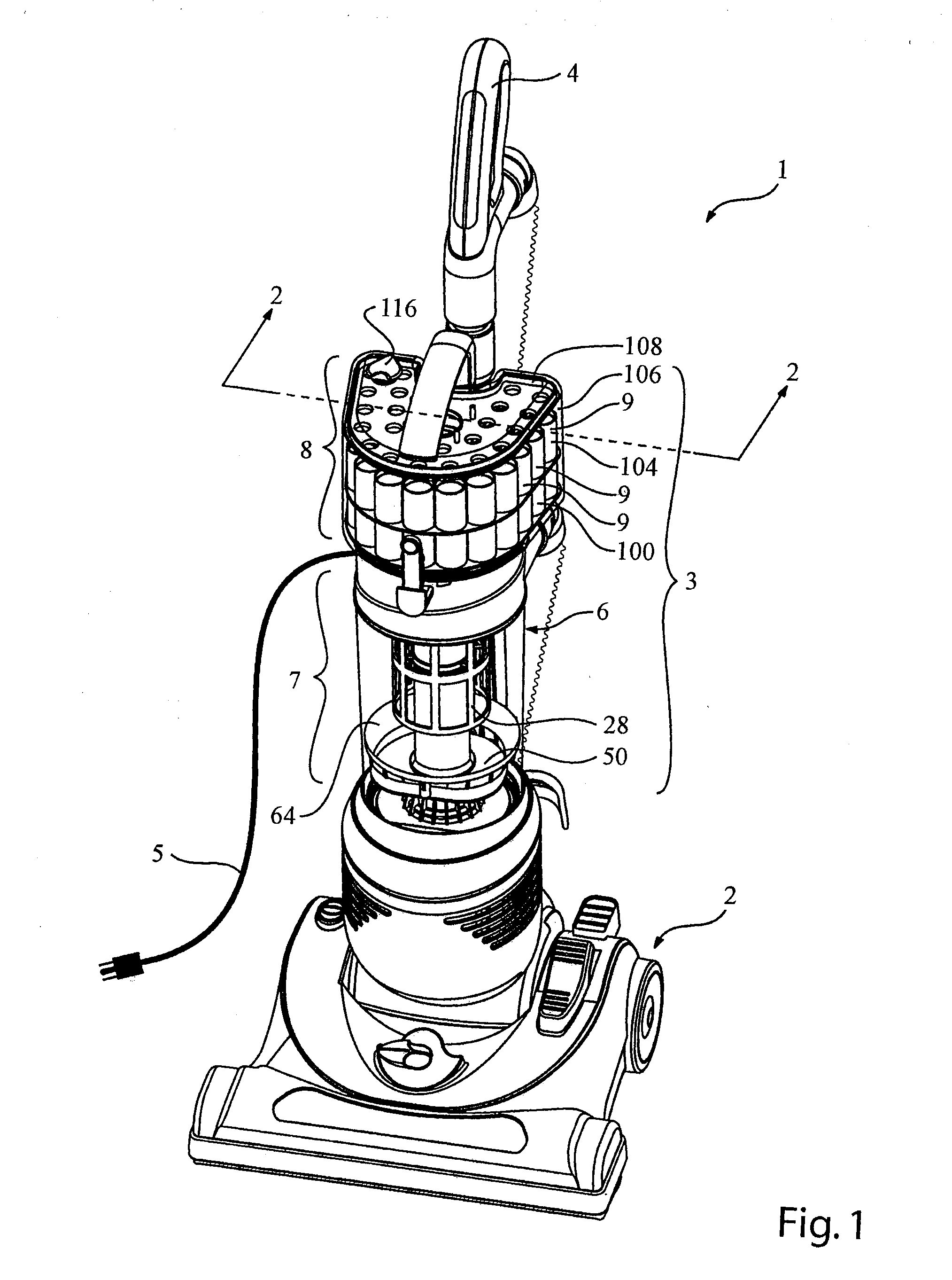

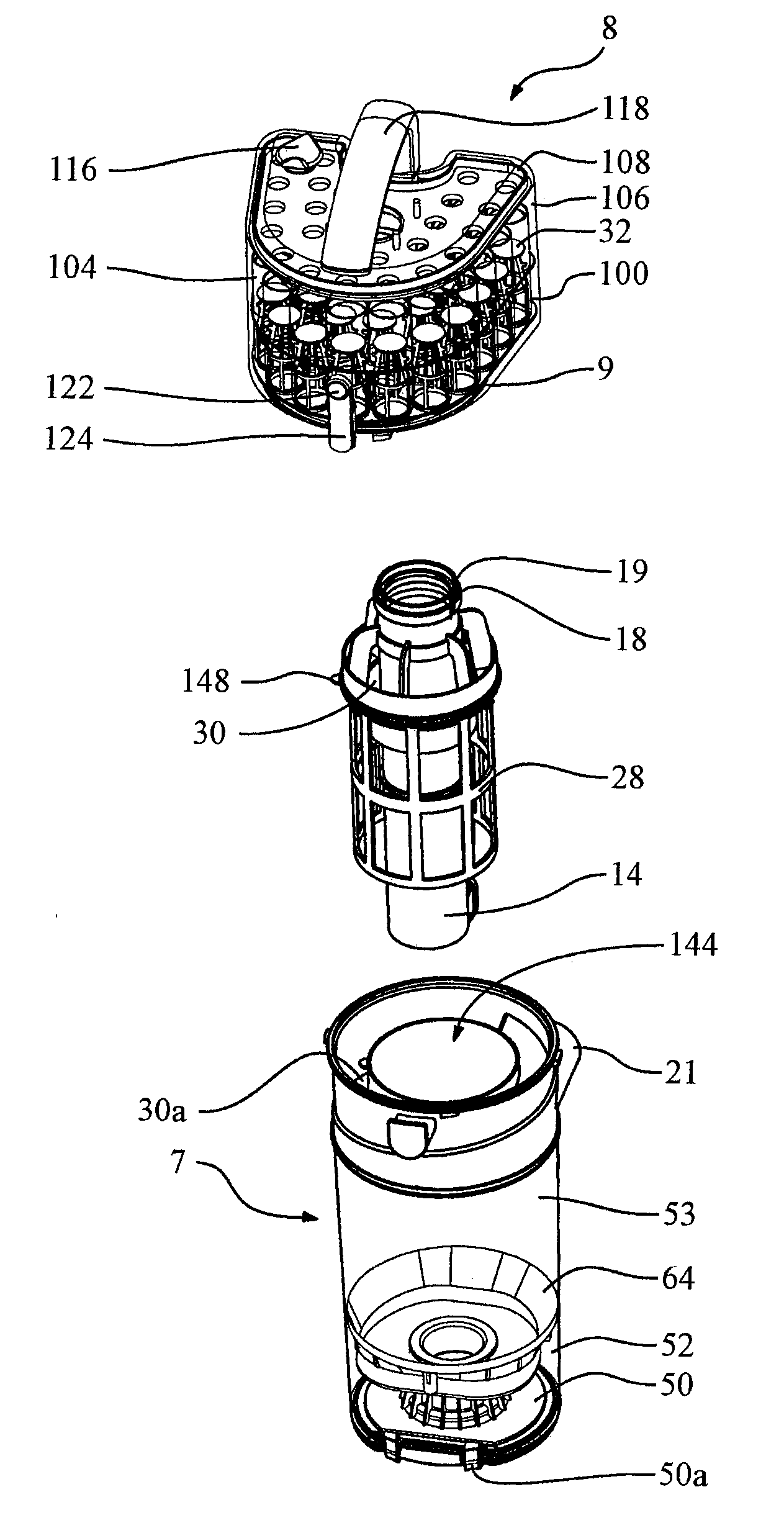

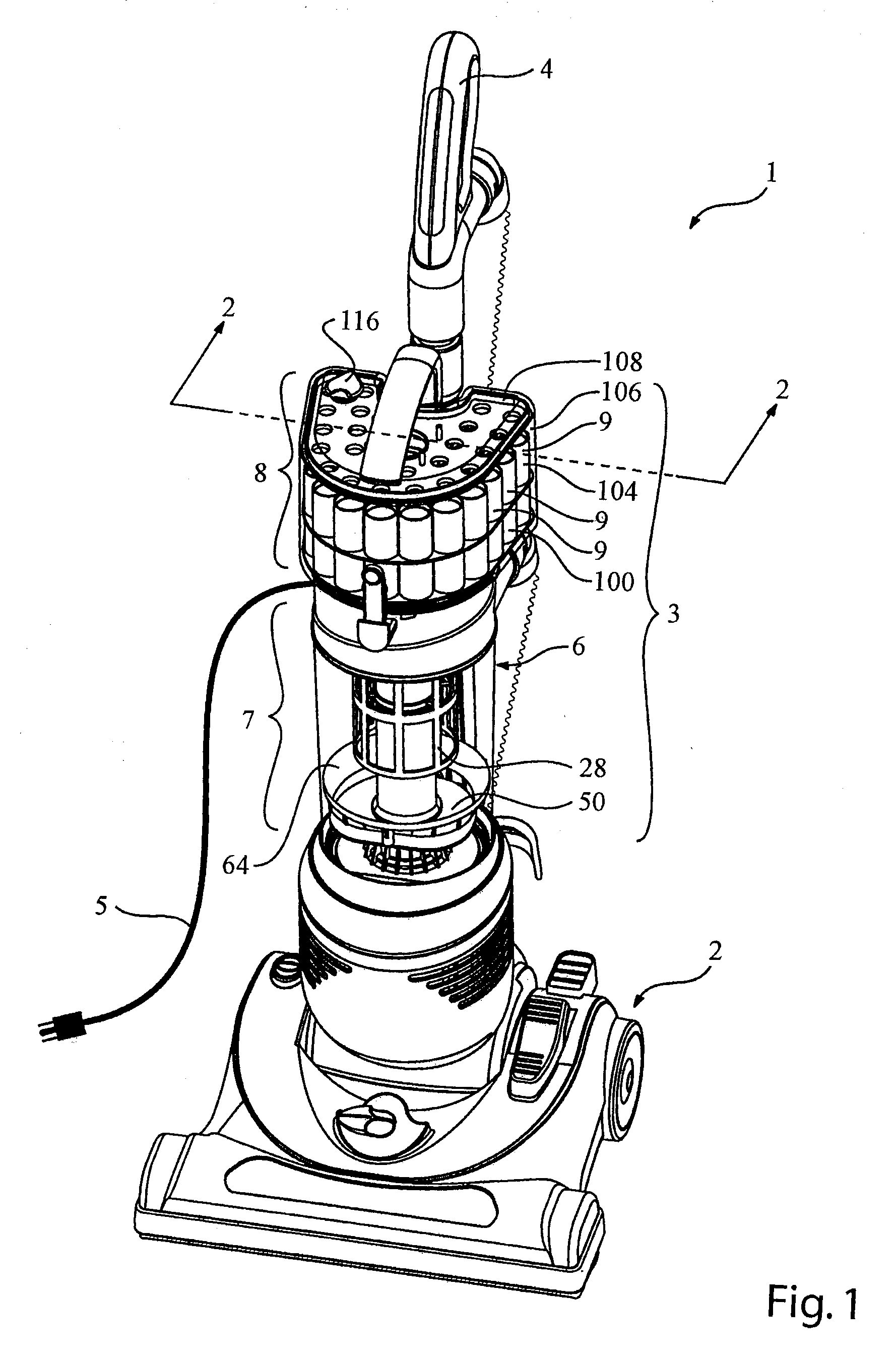

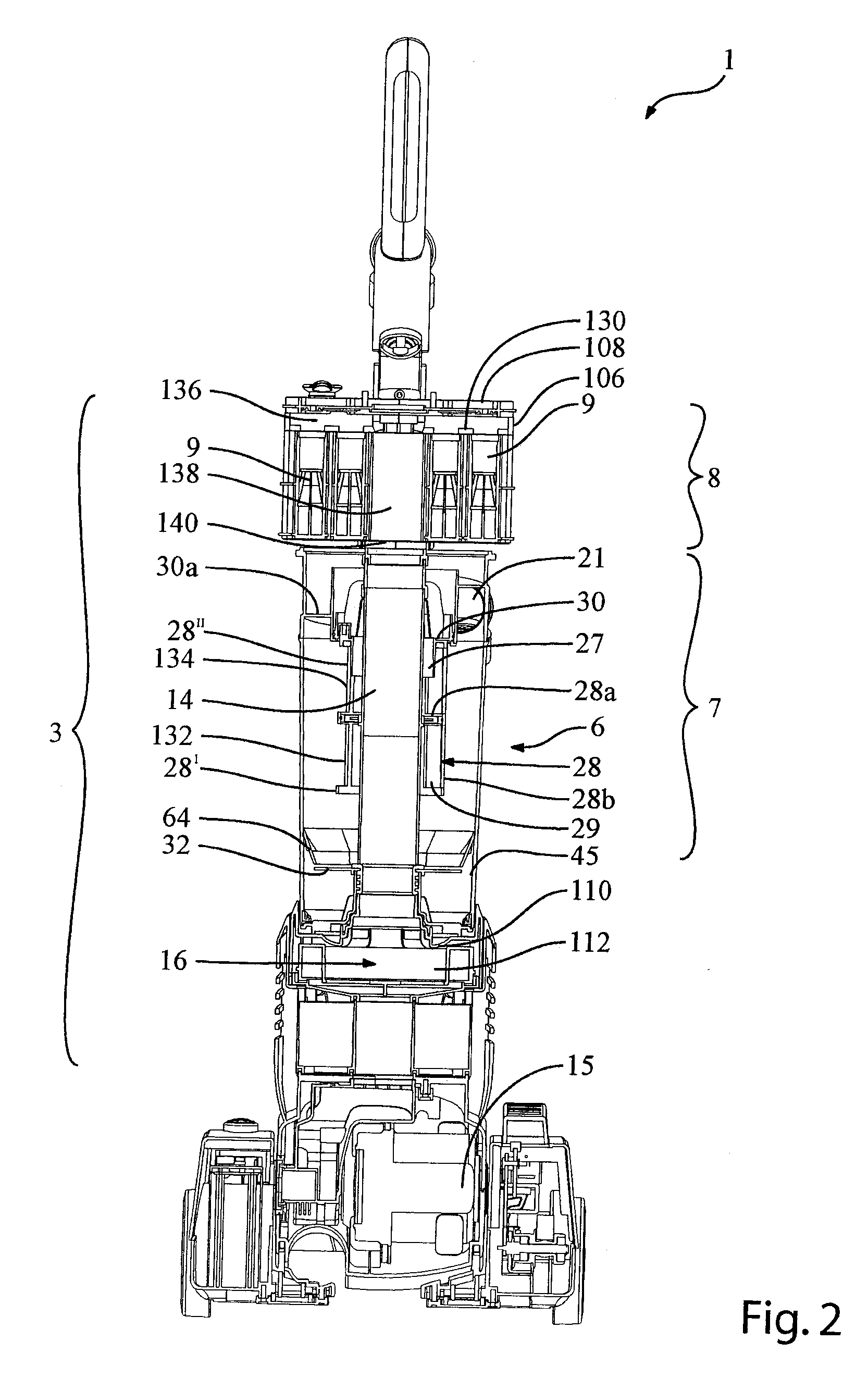

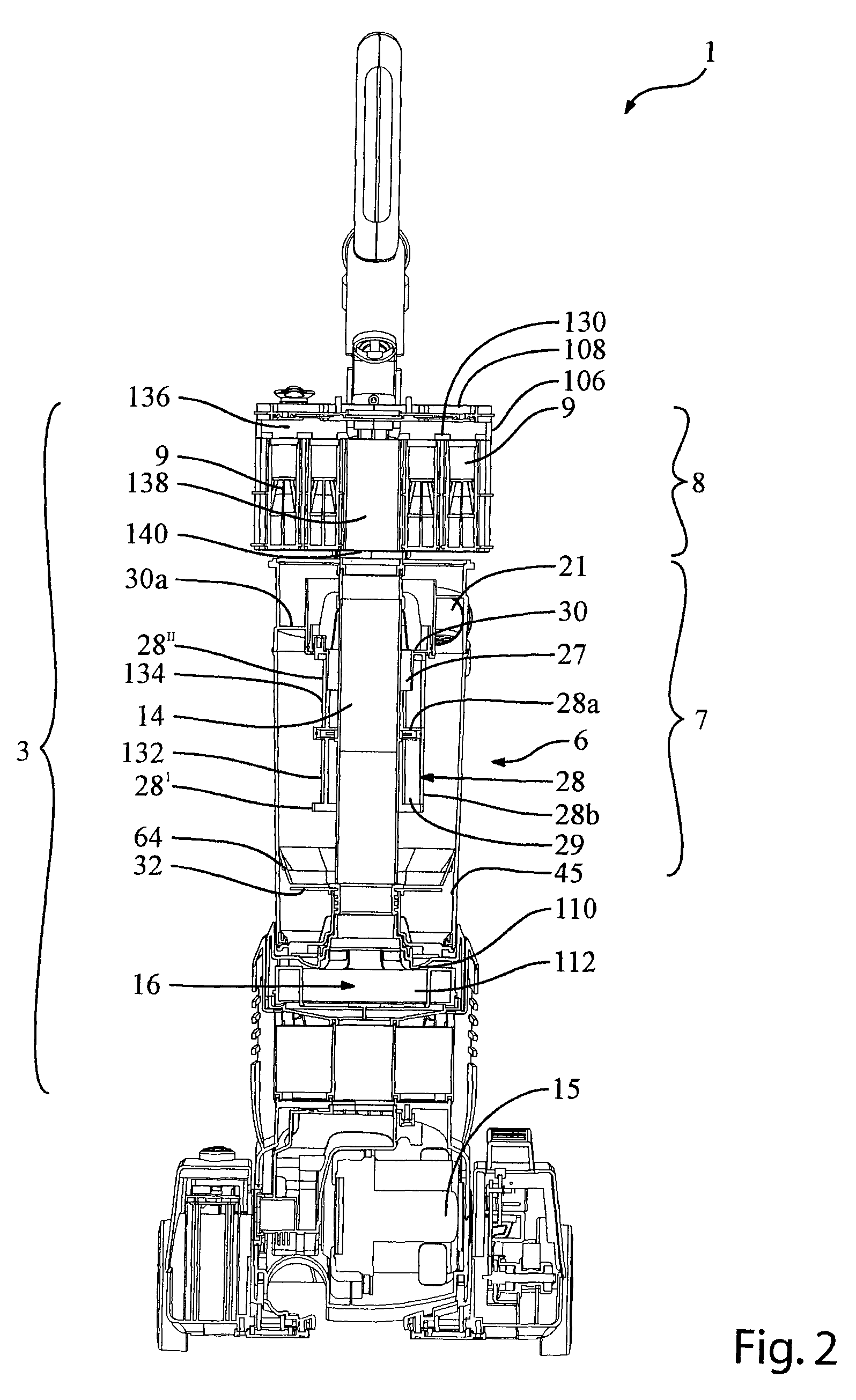

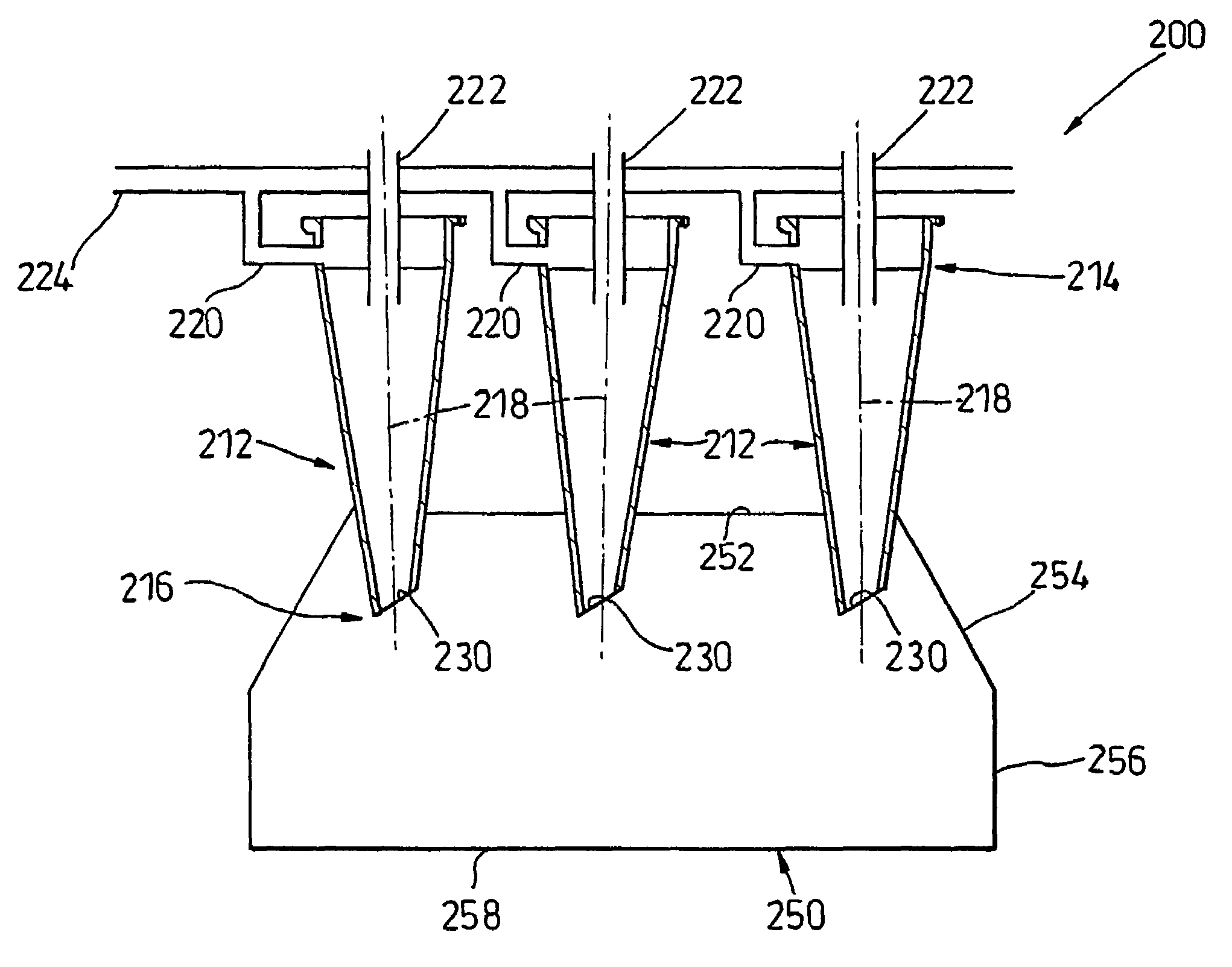

Vacuum cleaner with a plurality of cyclonic cleaning stages

InactiveUS20070209339A1Improve efficiencyAssist in removingCombination devicesAuxillary pretreatmentCycloneEngineering

A portable appliance comprises a dirt inlet, first and second cyclonic stages wherein each cyclonic stage comprises a plurality of cyclones in parallel and the second cyclonic stage is downstream from the first cyclonic stage and a fluid flow motor.

Owner:OMACHRON INTPROP

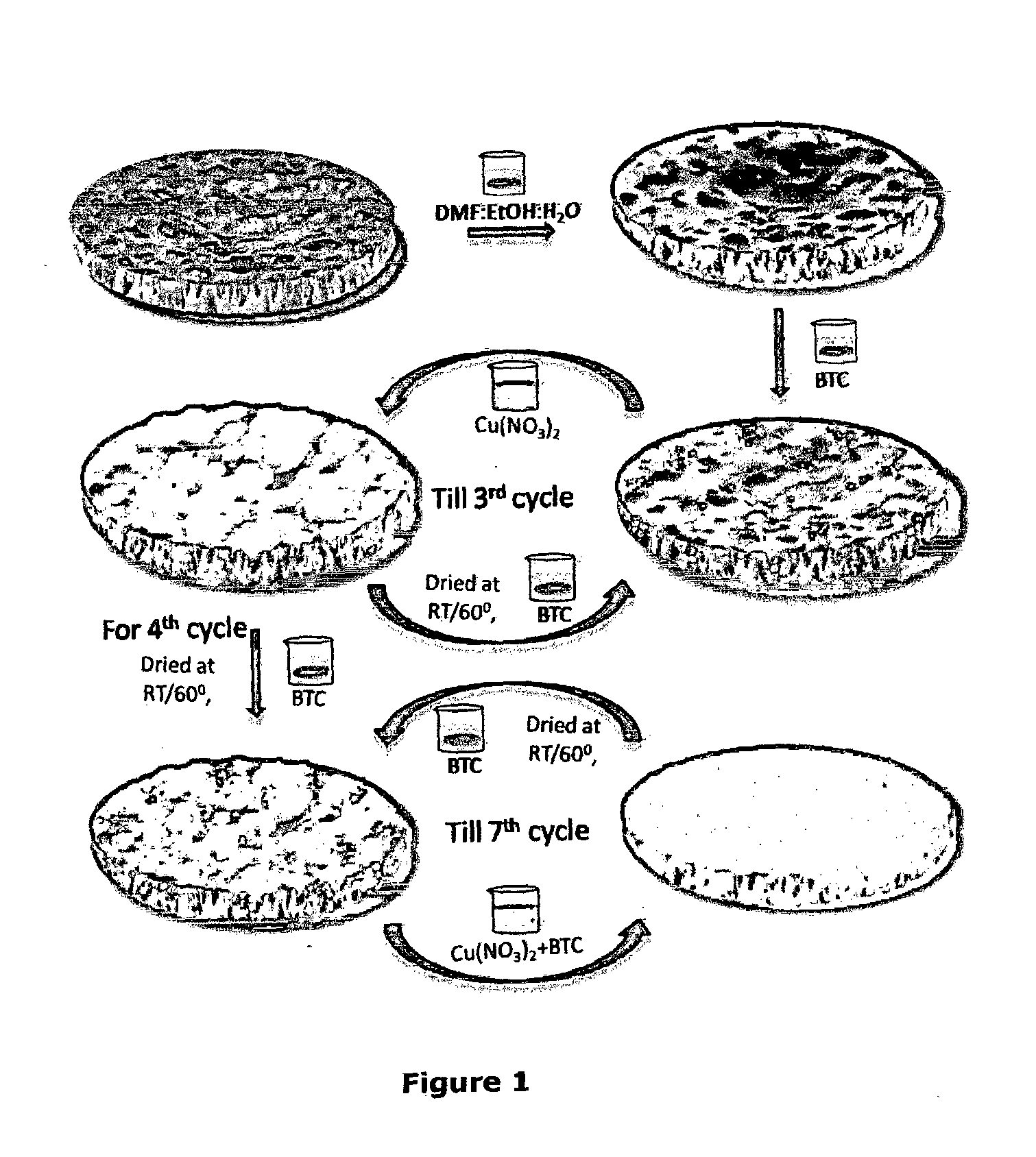

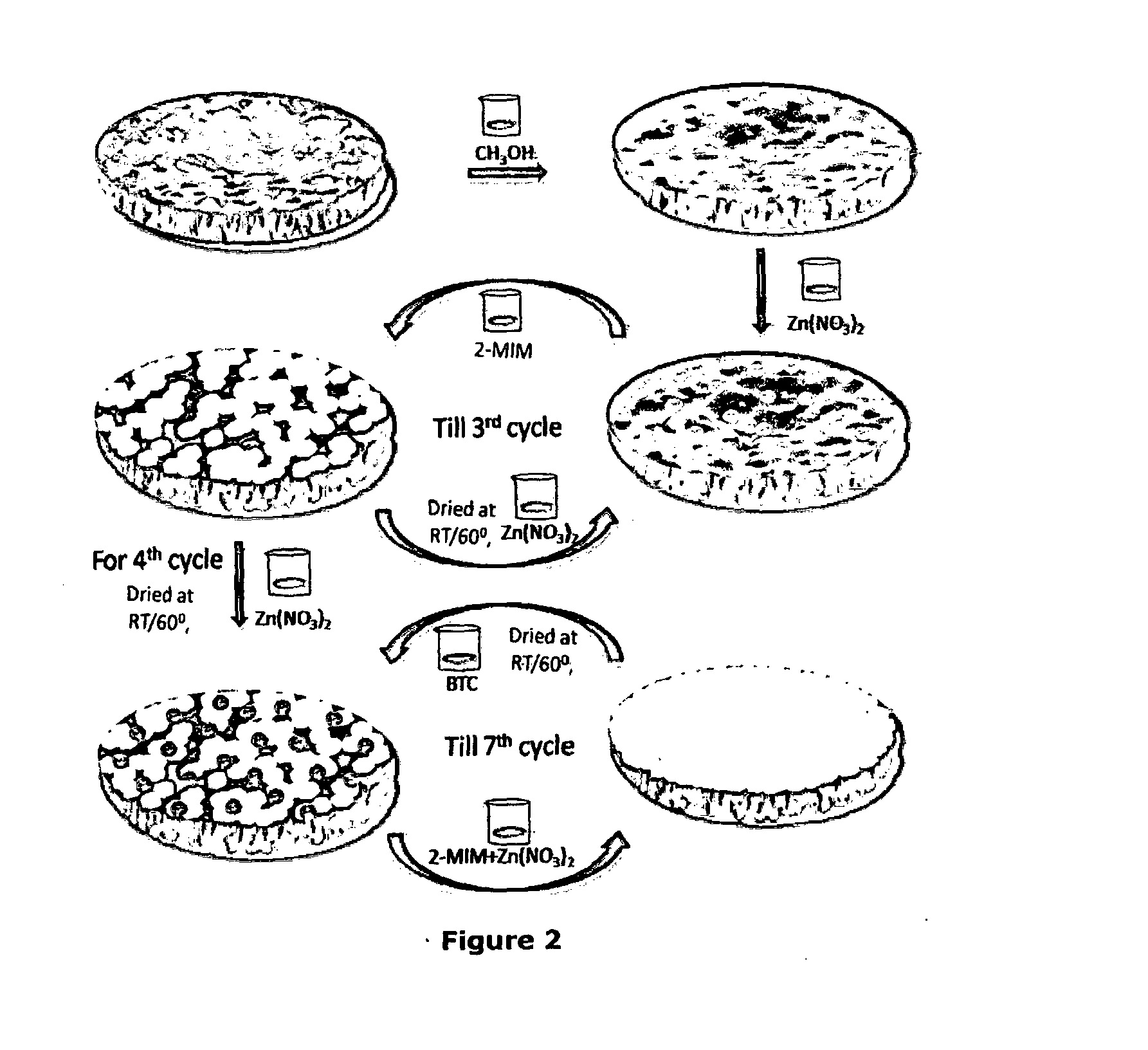

Process for the preparation of mofs-porous polymeric membrane composites

ActiveUS20150367294A1Separation efficiency can be improvedMembranesSemi-permeable membranesPolymer sciencePolymer composites

Disclosed herein is an in-situ process for the preparation of Metallic Organic Framework's (MOF's)—polymer composites at room temperature, without requirement of pre-seeding o MOF's or substrate modification. Further, the invention provides MOF-polymer composites membranes, wherein MOF forms a layer substantially covering the porosity of the membrane.

Owner:COUNCIL OF SCI & IND RES

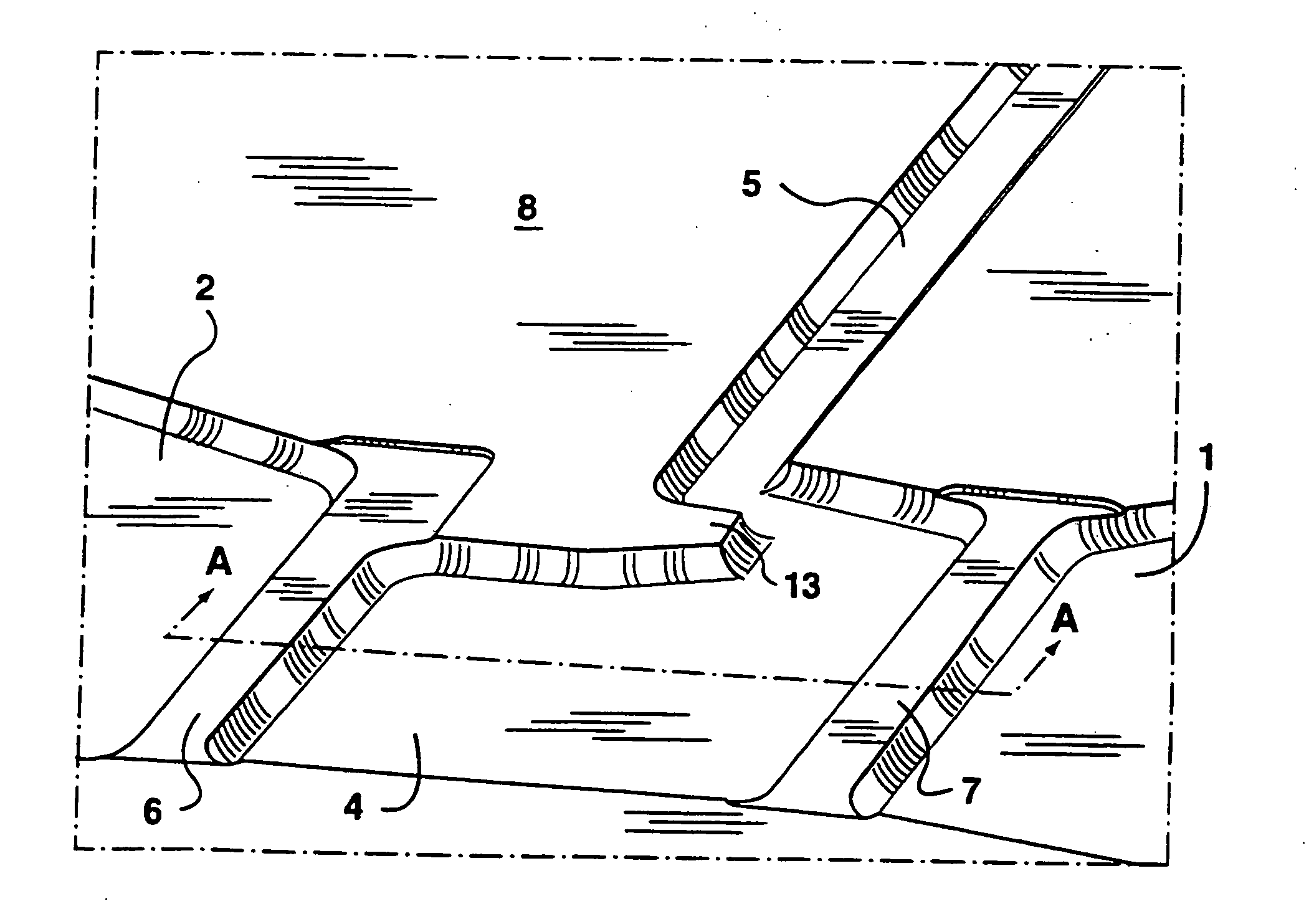

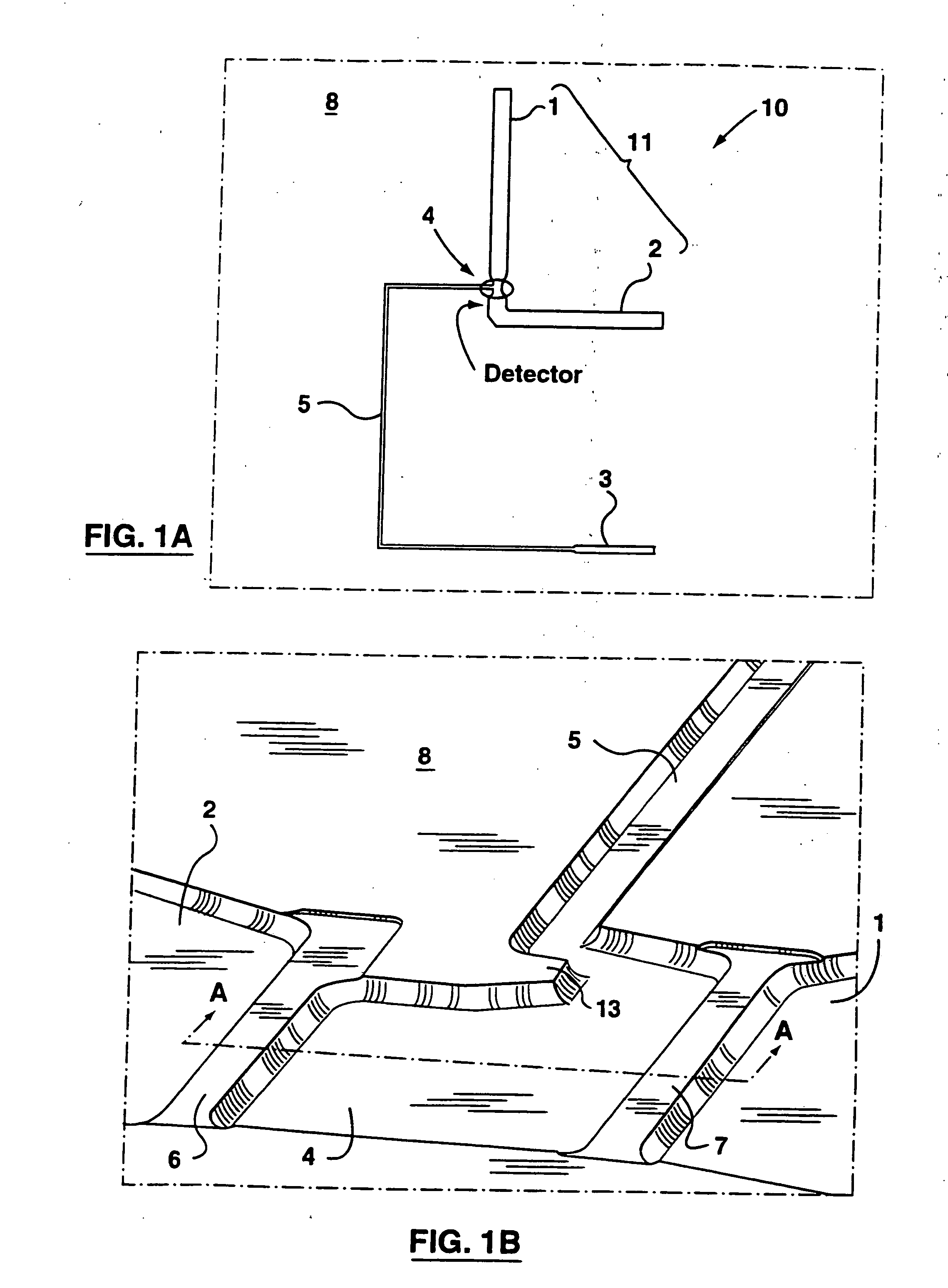

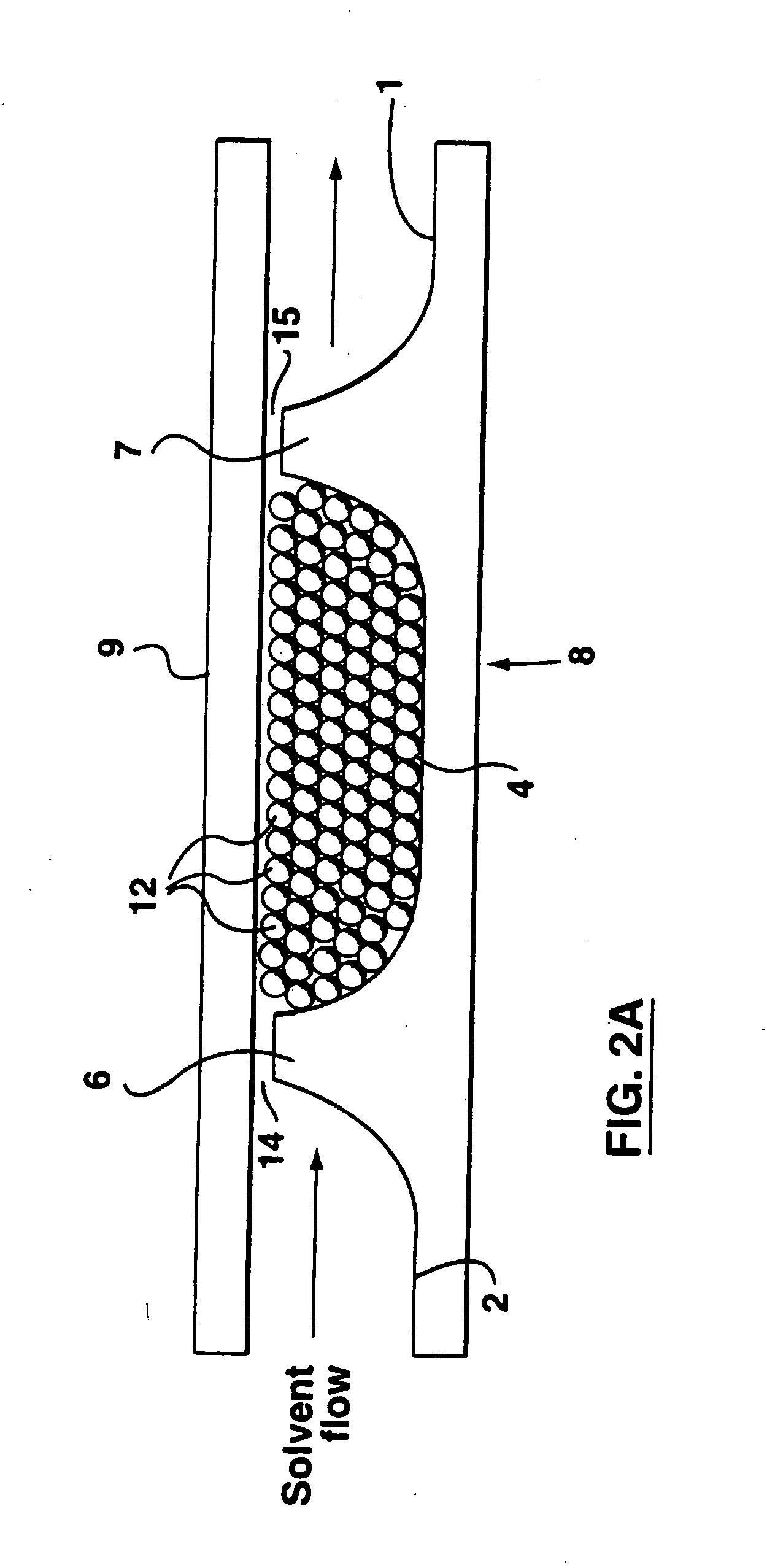

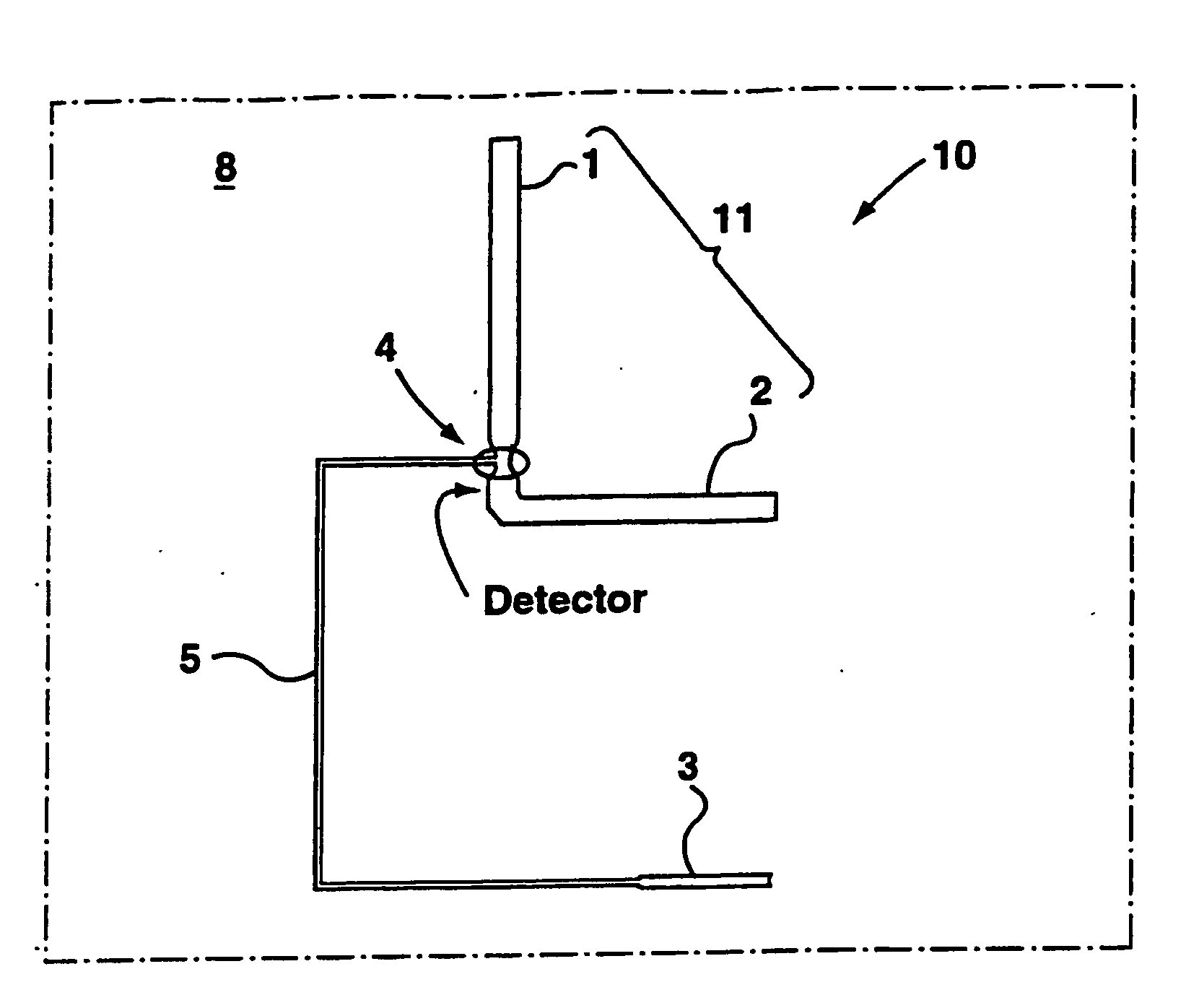

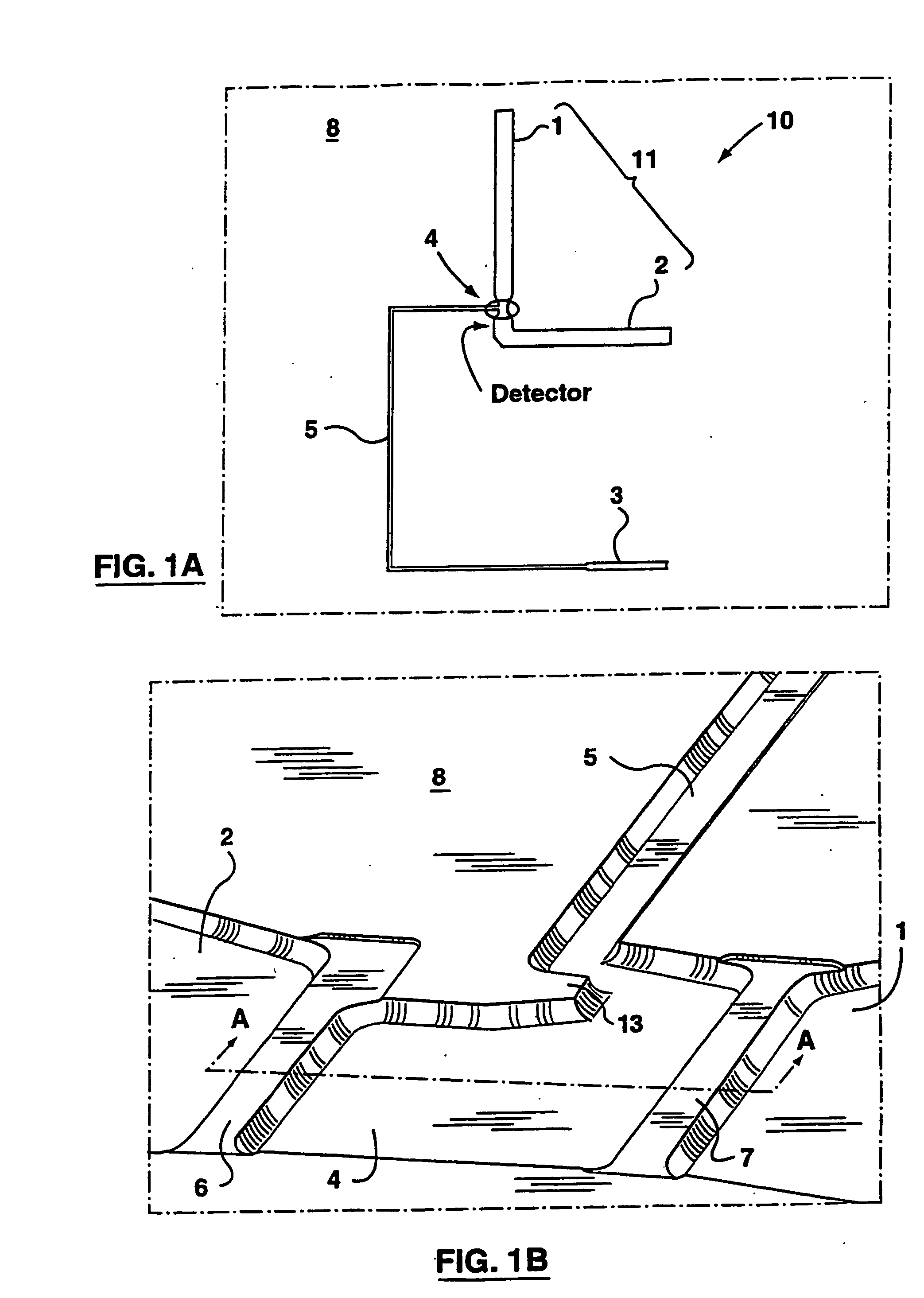

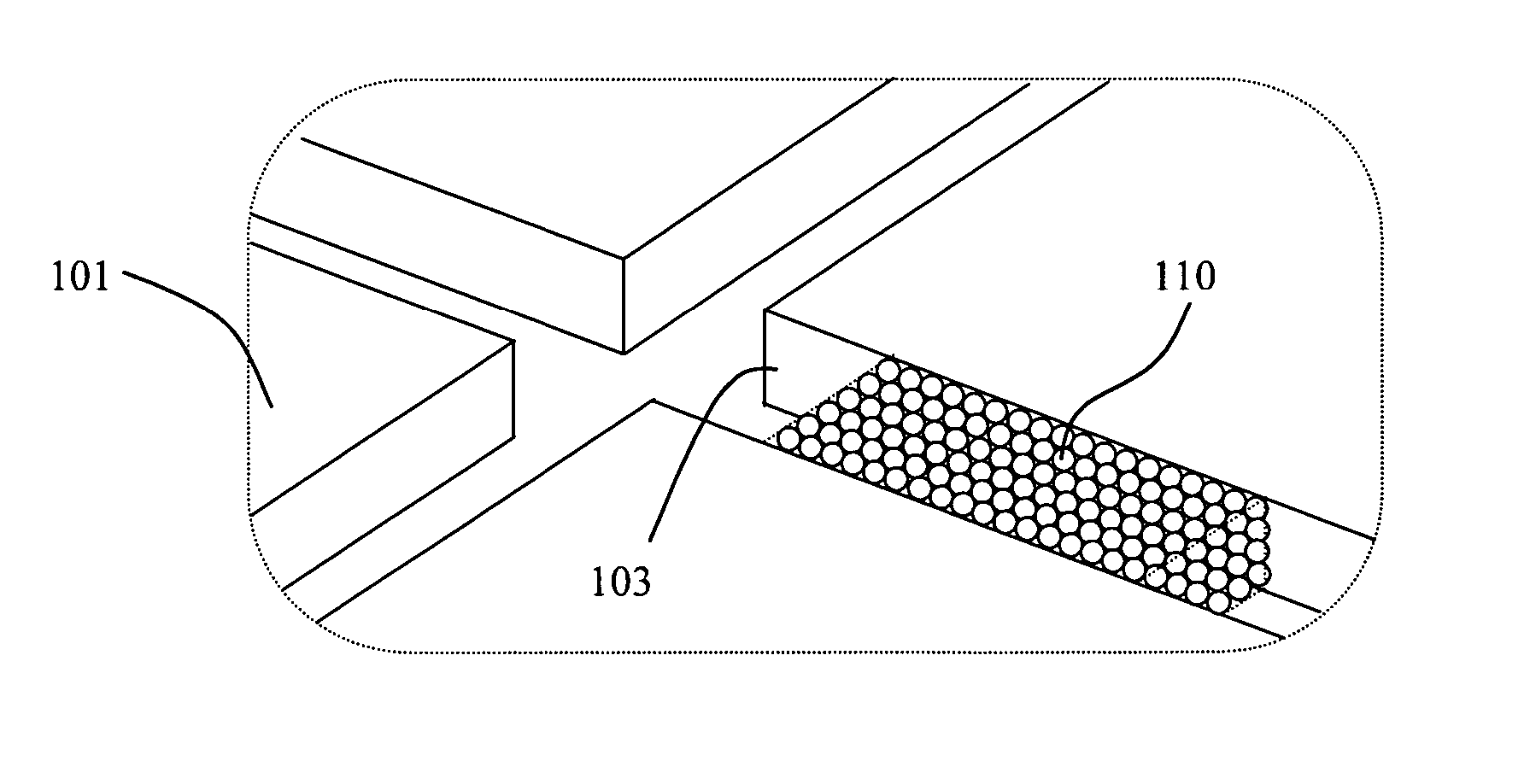

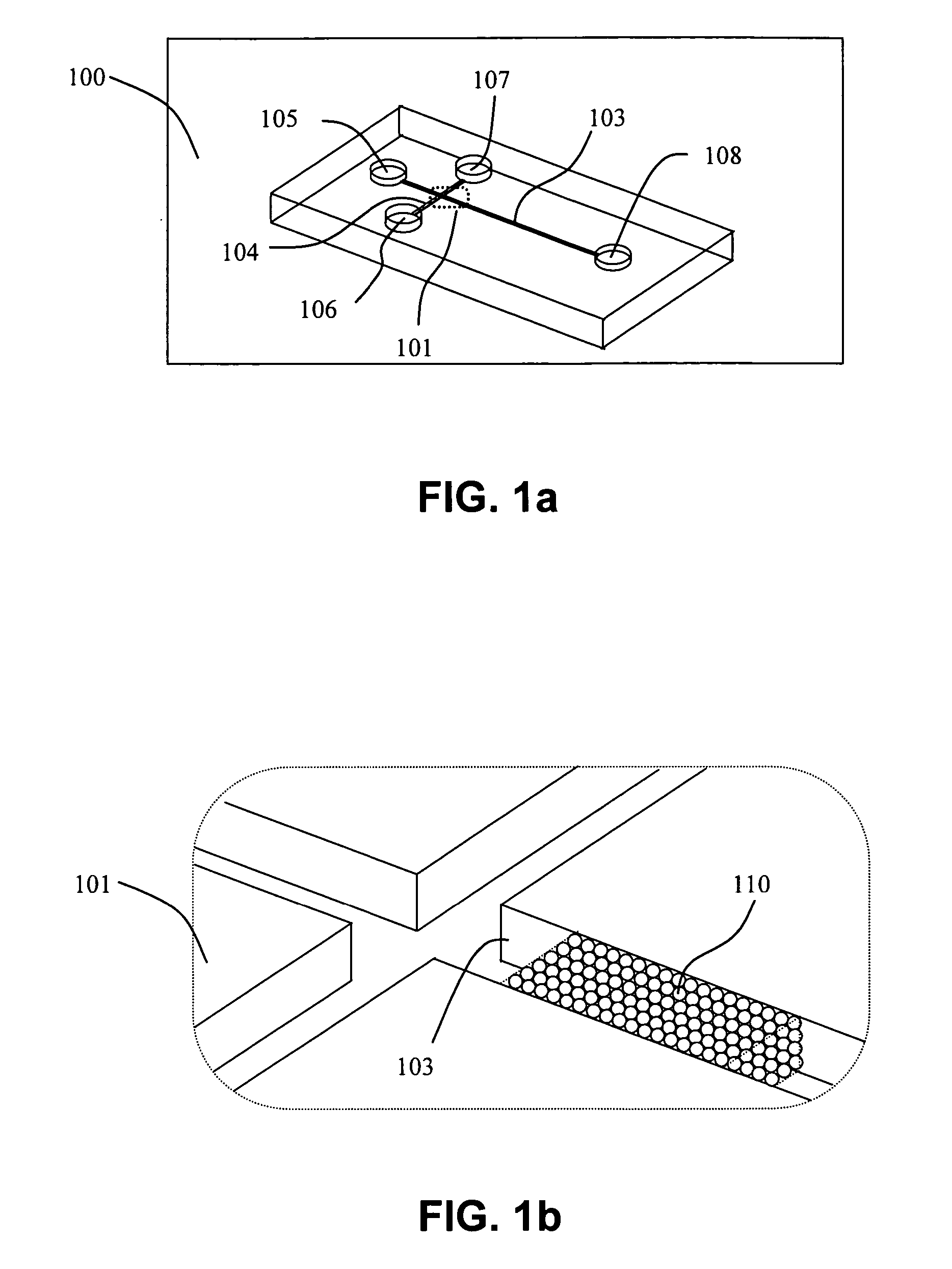

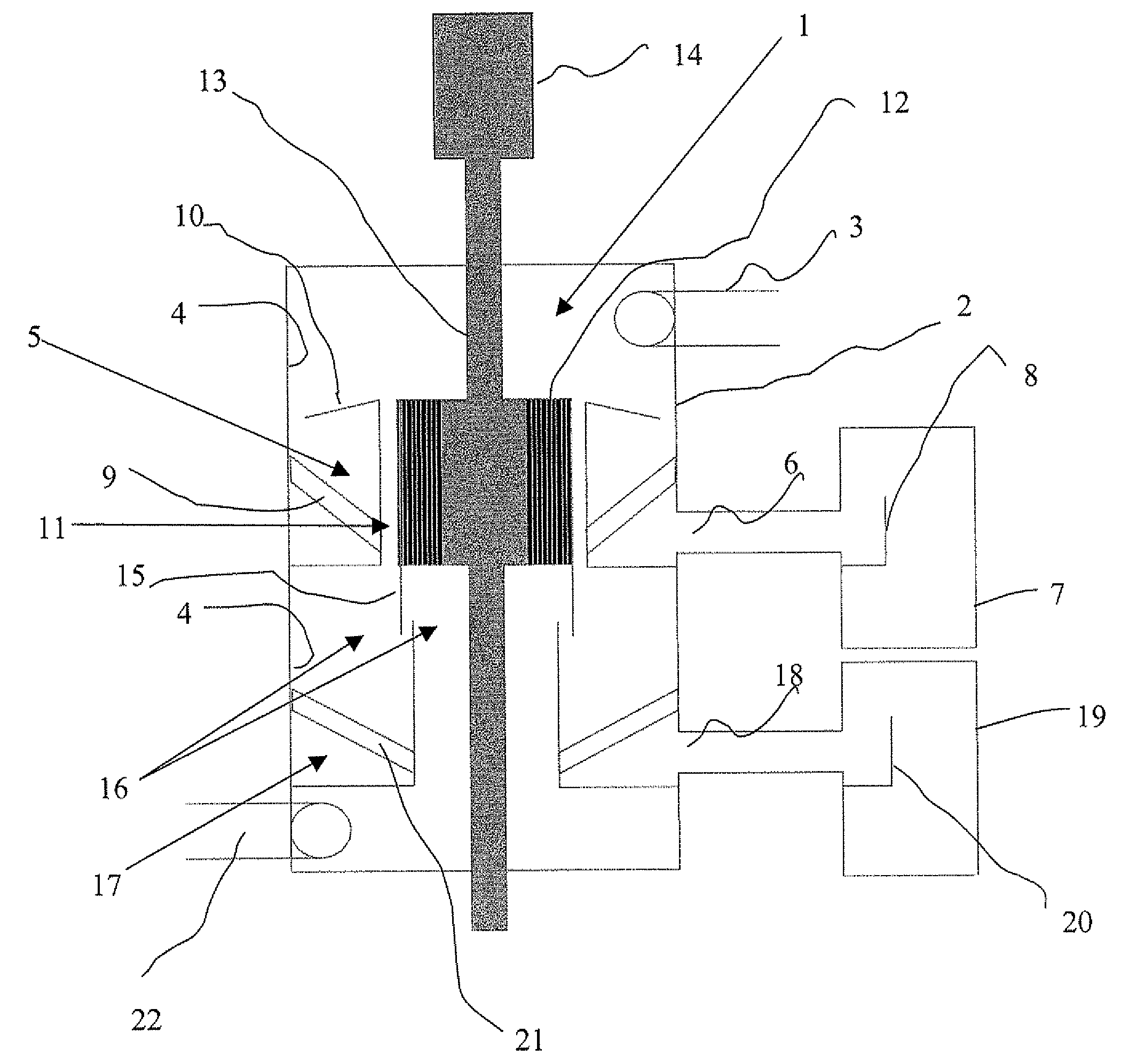

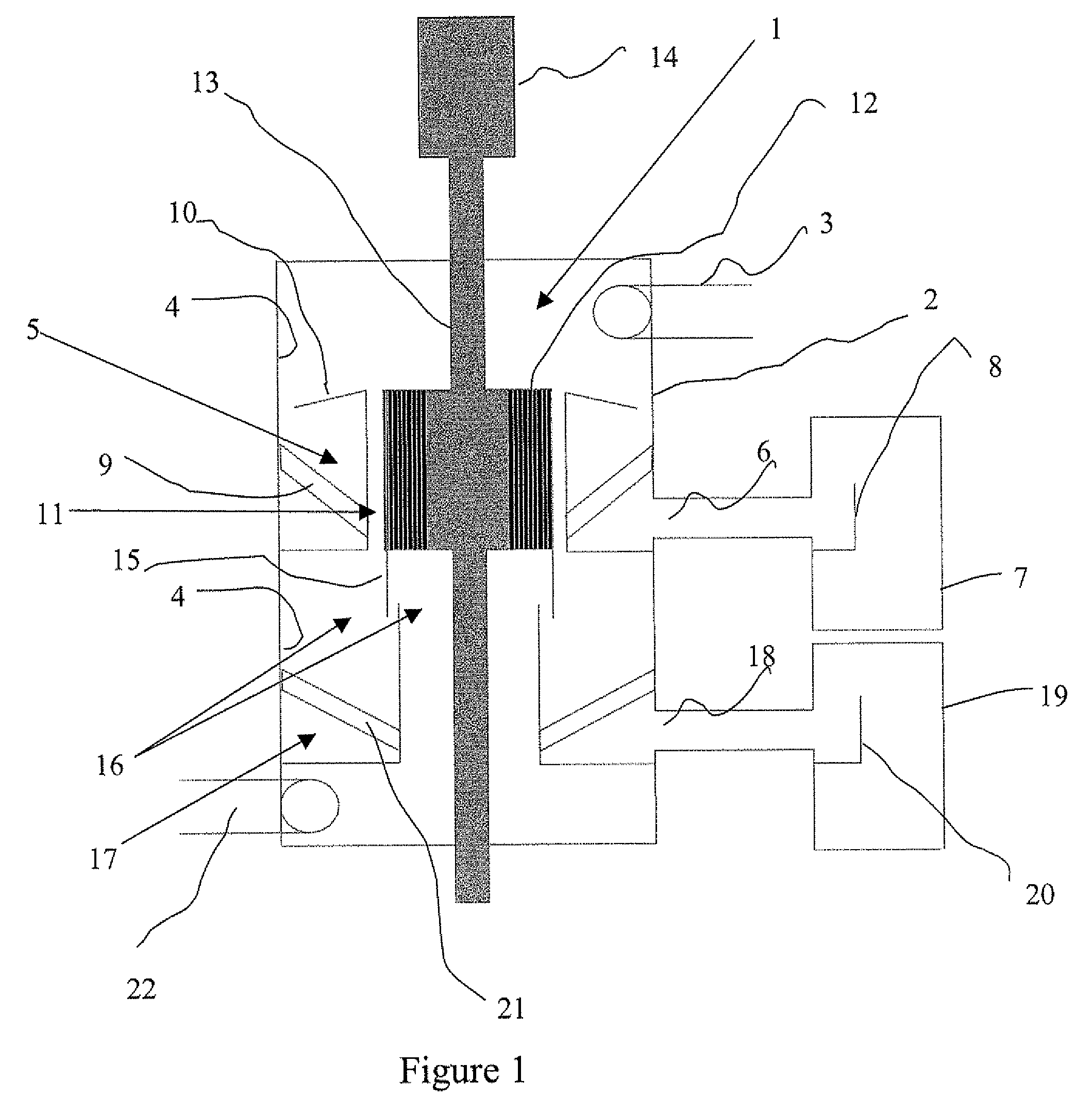

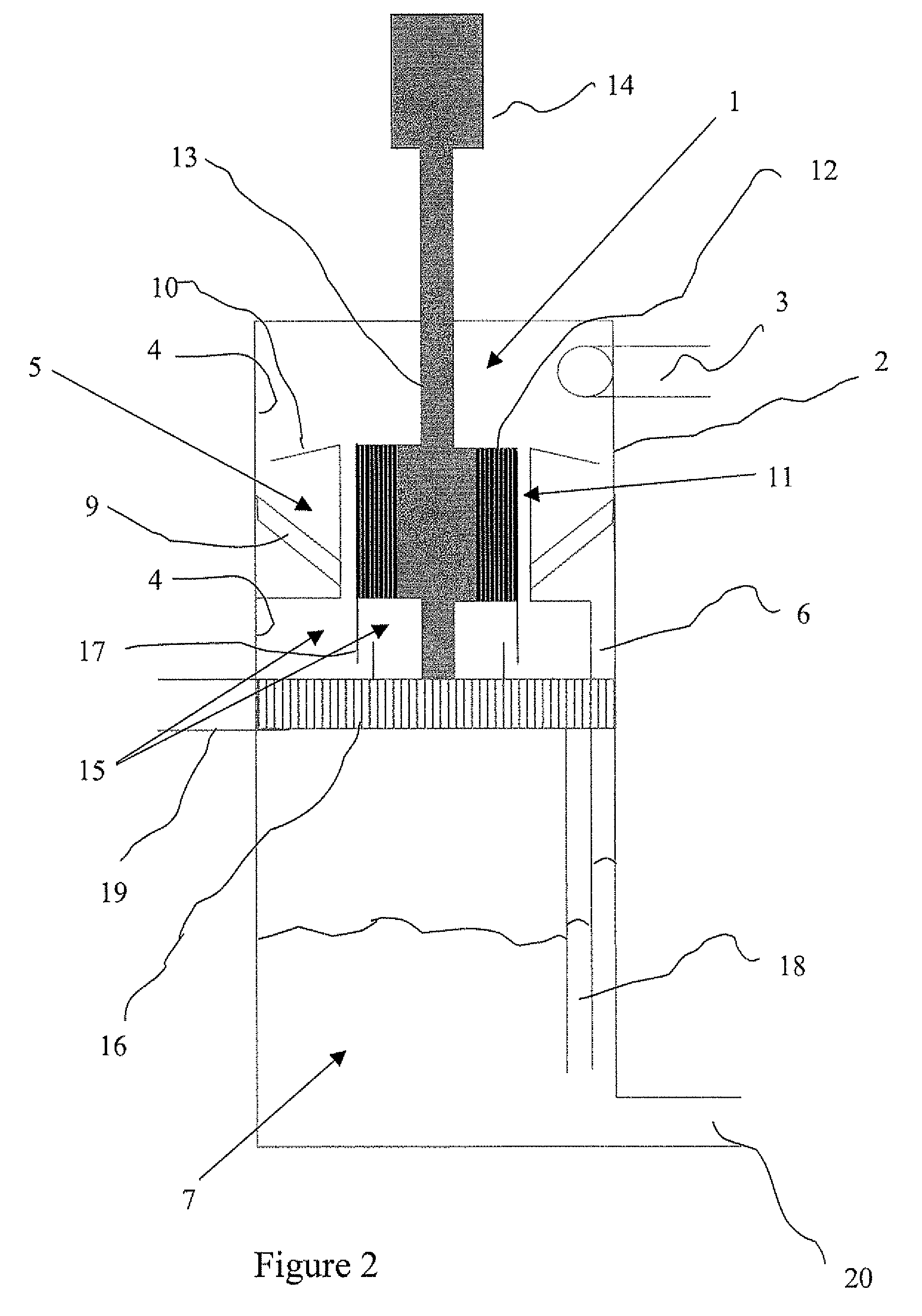

Apparatus and method for trapping bead based reagents within microfluidic analysis systems

InactiveUS20060027456A1Separation efficiency can be improvedAccelerated programBioreactor/fermenter combinationsBiological substance pretreatmentsElectricityCapillary electrochromatography

The present invention provides an on-chip packed reactor bed design that allows for an effective exchange of packing materials such as beads at a miniaturized level. The present invention extends the function of microfluidic analysis systems to new applications including on-chip solid phase extraction (SPE) and on-chip capillary electrochromatography (CEC). The design can be further extended to include integrated packed bed immuno- or enzyme reactors.

Owner:THE GOVERNORS OF THE UNIV OF ALBERTA

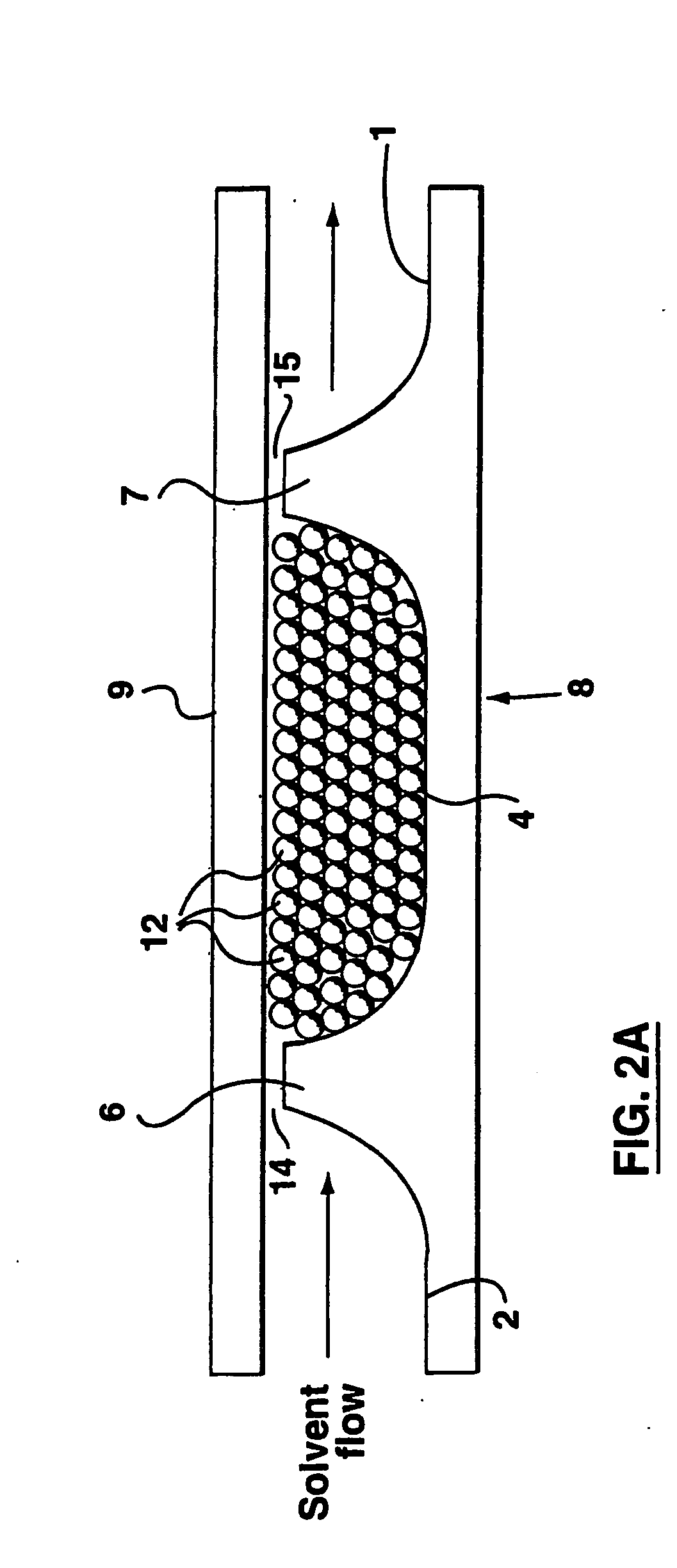

Apparatus and method for trapping bead based reagents within microfluidic analysis systems

InactiveUS20050224352A1Reduce lightSeparation efficiency can be improvedBioreactor/fermenter combinationsSludge treatmentElectricityCapillary electrochromatography

The present invention provides an on-chip packed reactor bed design that allows for an effective exchange of packing materials such as beads at a miniaturized level. The present invention extends the function of microfluidic analysis systems to new applications including on-chip solid phase extraction (SPE) and on-chip capillary electrochromatography (CEC). The design can be further extended to include integrated packed bed immuno- or enzyme reactors. The system comprises two weirs (6, 7) in a channel to trap packing material (12). The packing material might be introduced through a side channel to the chamber formed between the two weirs (6, 7). A plug is positioned in the side channel to close it.

Owner:THE GOVERNORS OF THE UNIV OF ALBERTA

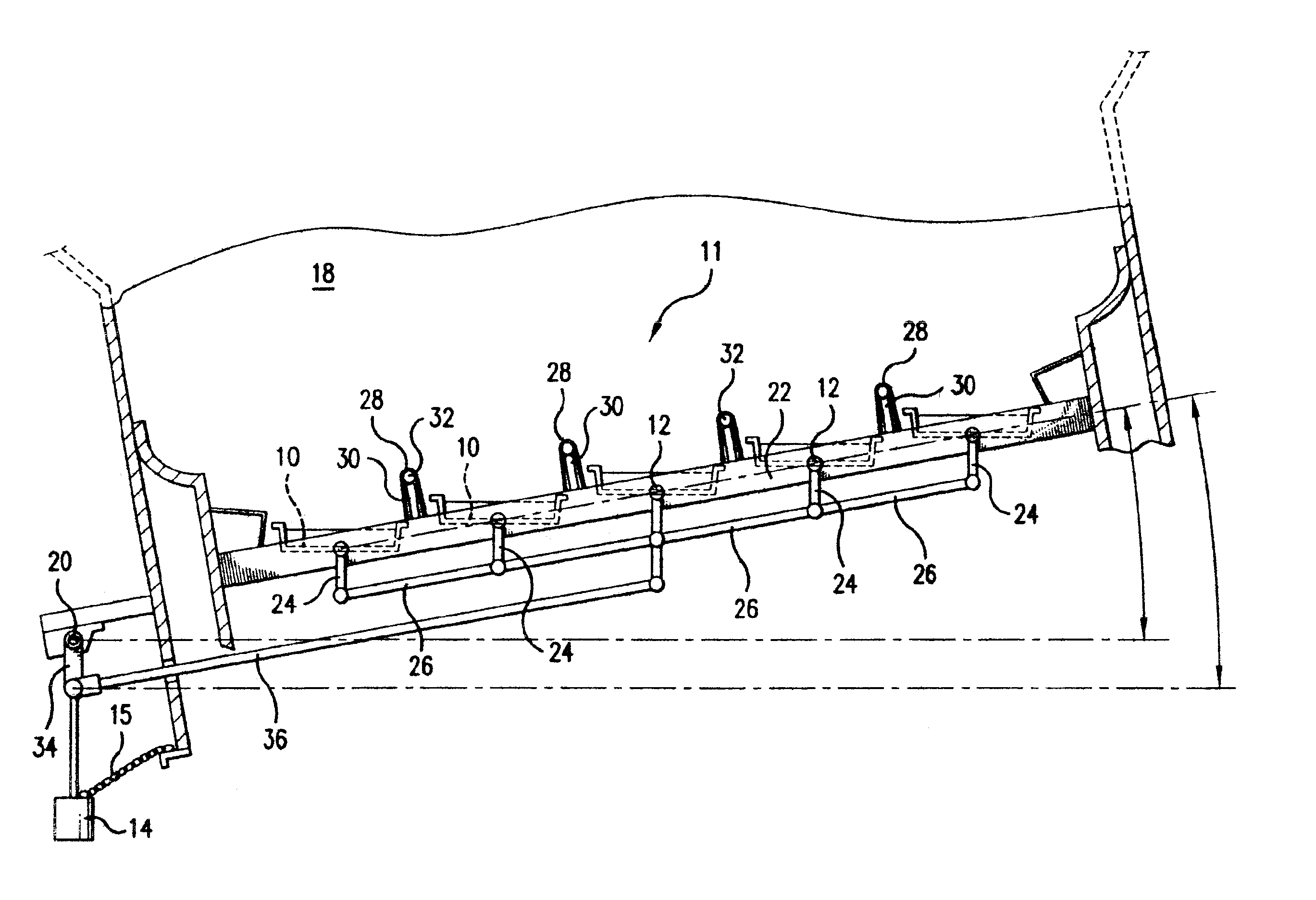

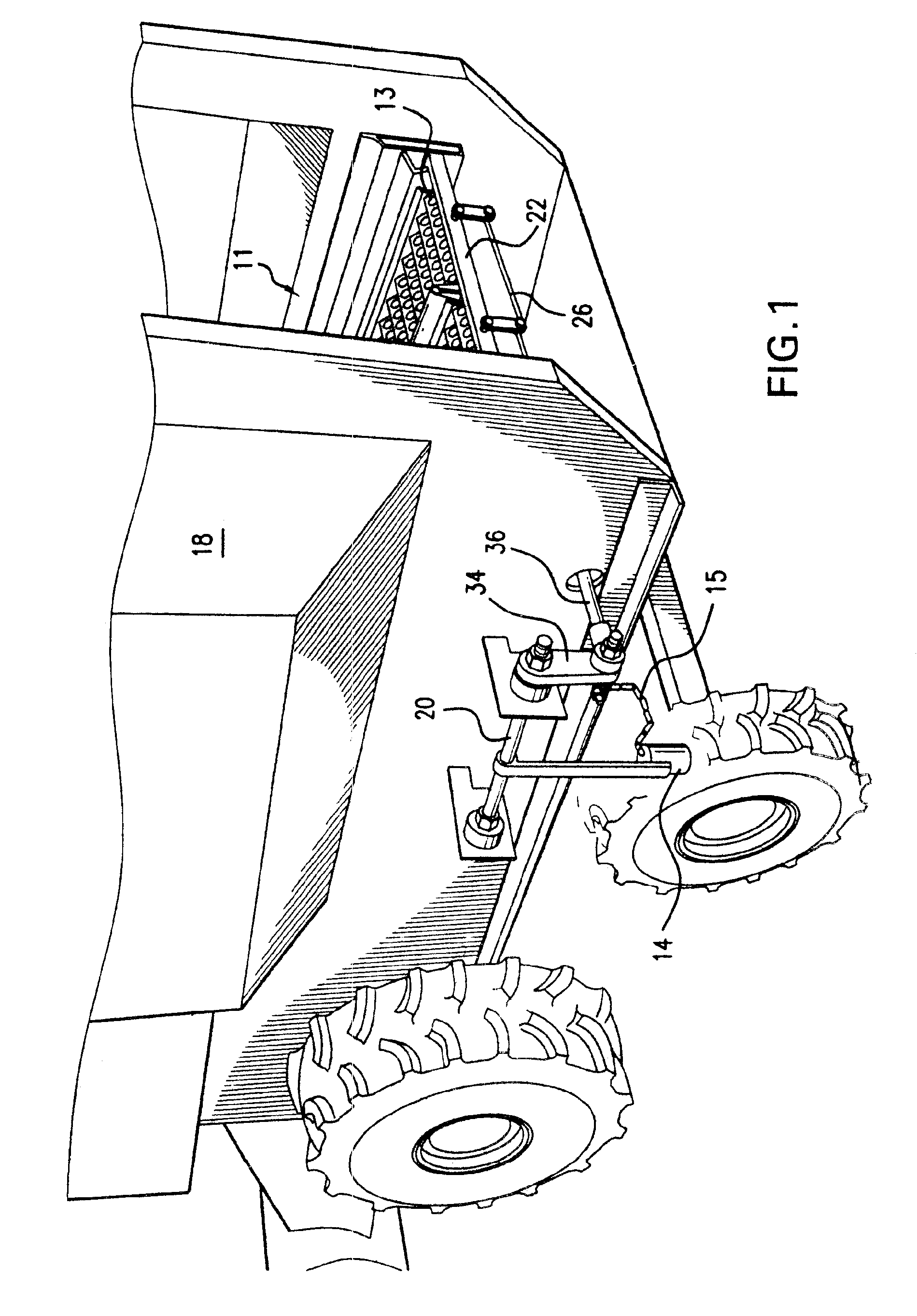

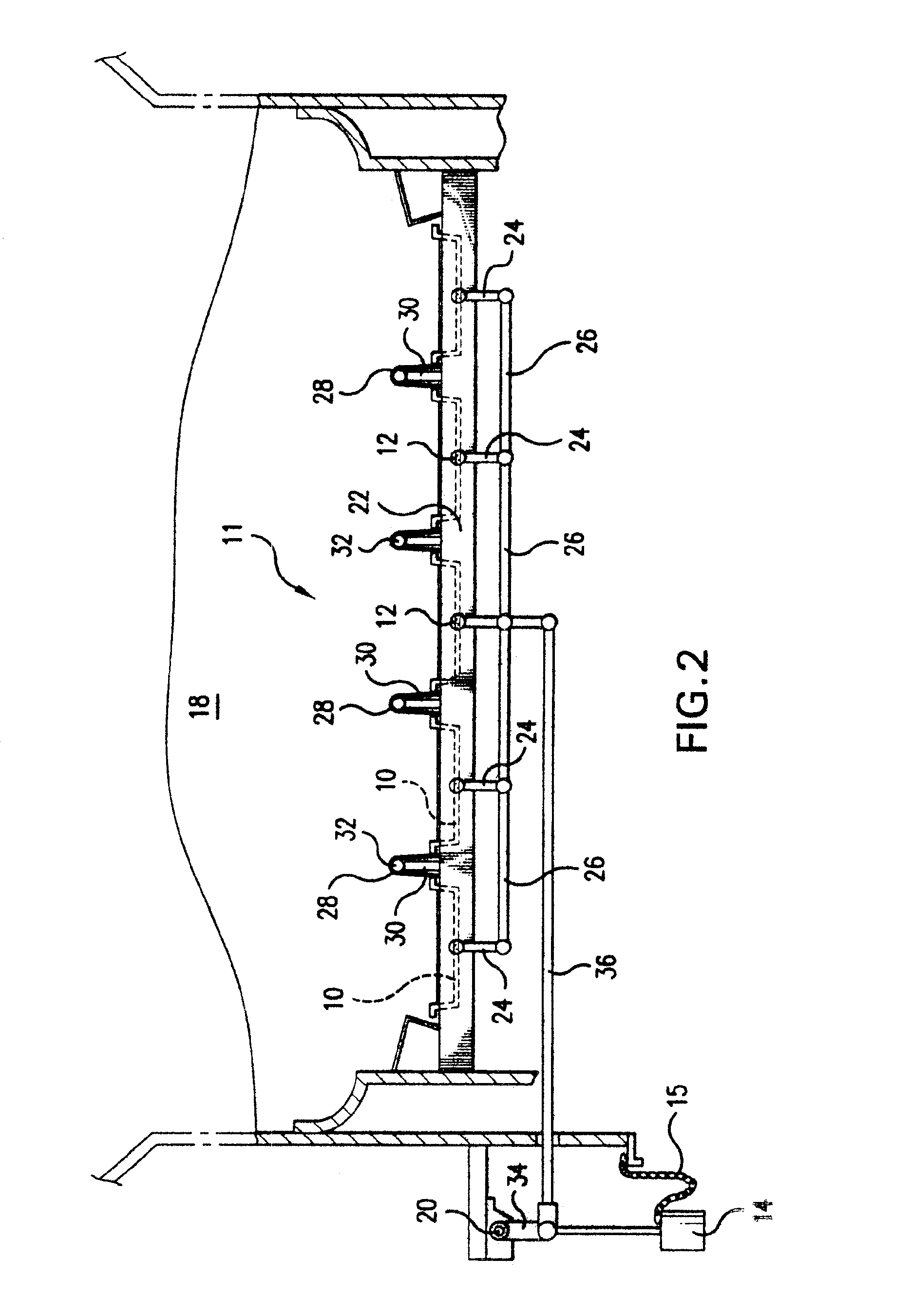

Floating combine sieve assembly

InactiveUS6843719B1Improve efficiencySeparation efficiency can be improvedSievingScreeningEngineeringCombine harvester

A sieve assembly for separating grain from chaff inside of a combine. The sieve assembly comprises a plurality of longitudinal sieve planks that pivot on their longitudinal axis. A hanging weighted member combined with the sieve planks regulates the angle of the sieve planks relative to the combine. As the combine becomes laterally inclined on a hillside, the weighted member changes its angular position relative to the combine. In doing so, the weighted member causes the sieve planks to pivot on their longitudinal axis so that the sieve planks remain level relative to the horizon. Dividers extend between each sieve plank.

Owner:SACQUITNE DAVID

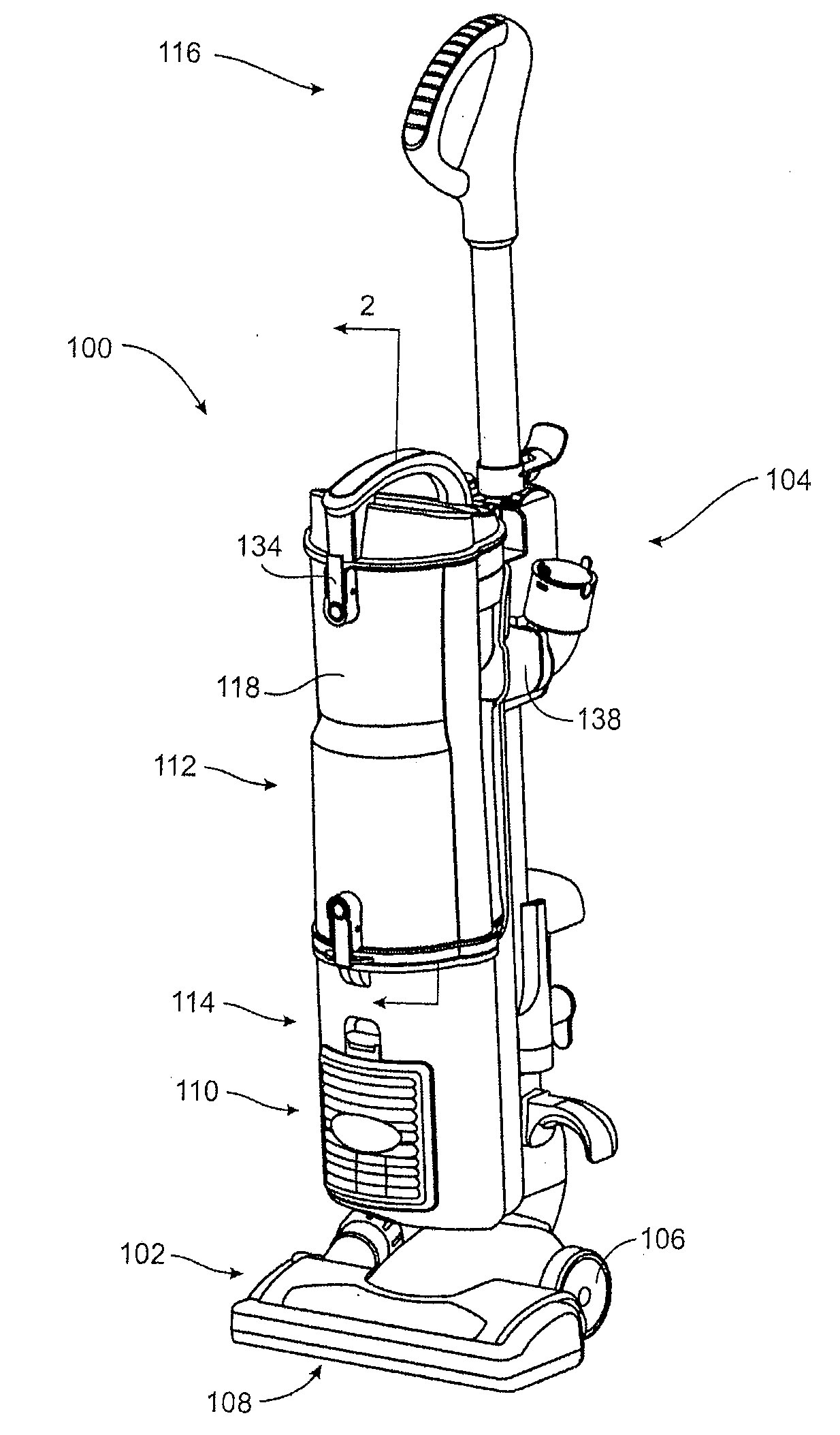

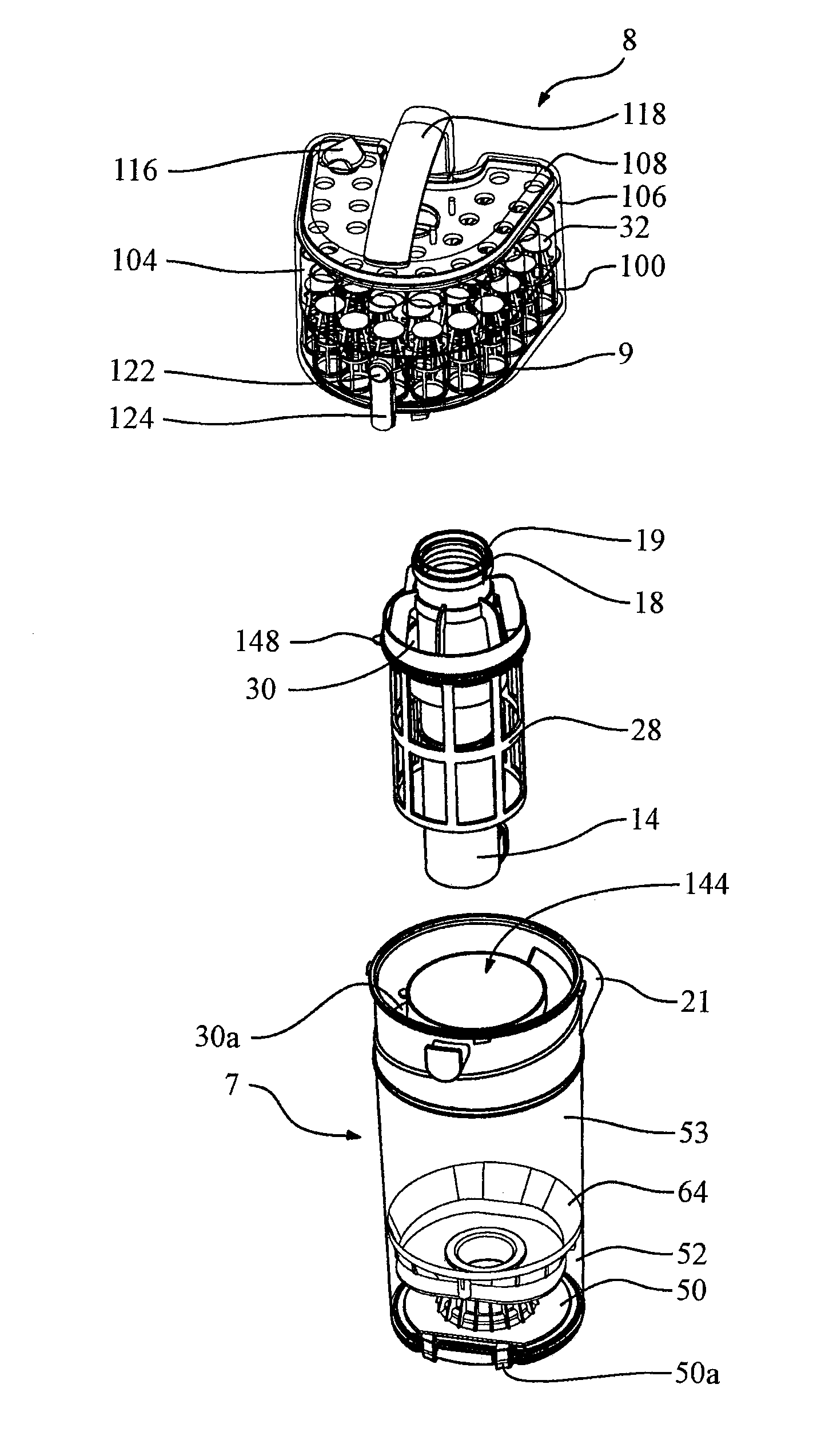

Surface cleaning apparatus

ActiveUS20130227813A1Separation efficiency can be improvedReduce amountCleaning filter meansCombination devicesSurface cleaningWaste management

A surface cleaning apparatus comprises an air flow passage extending from a dirty air inlet to a clean air outlet and a suction motor. The surface cleaning apparatus may also comprise a cyclone chamber provided in the air flow passage. The cyclone chamber may comprise a cyclone air inlet, a cyclone air outlet and a dirt outlet. The surface cleaning apparatus may comprise a dirt collection chamber having a dirt inlet, a dirt collection chamber first end, an opposed dirt collection chamber second end and a longitudinally extending sidewall. Various design improvements are provided.

Owner:OMACHRON INTPROP

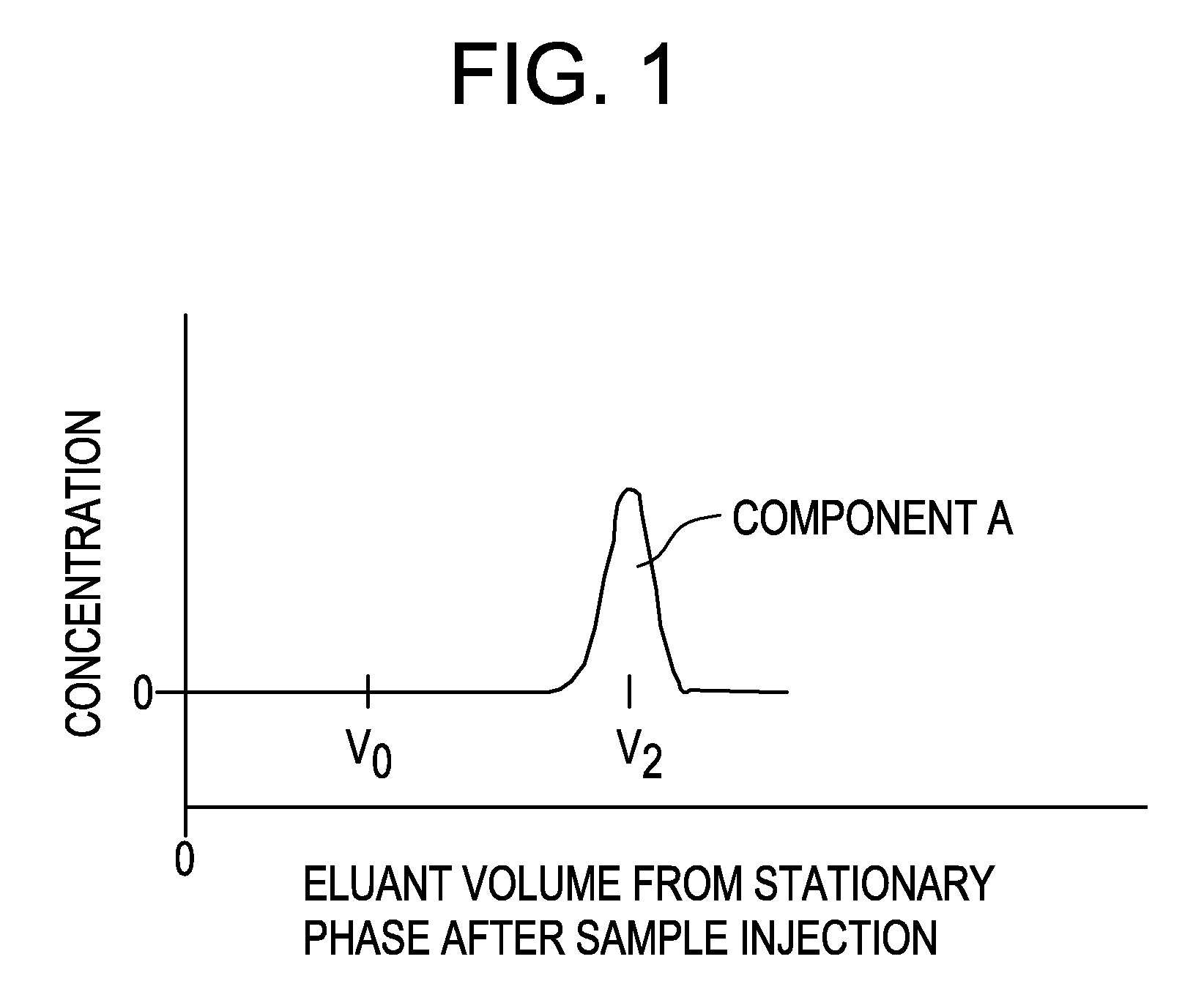

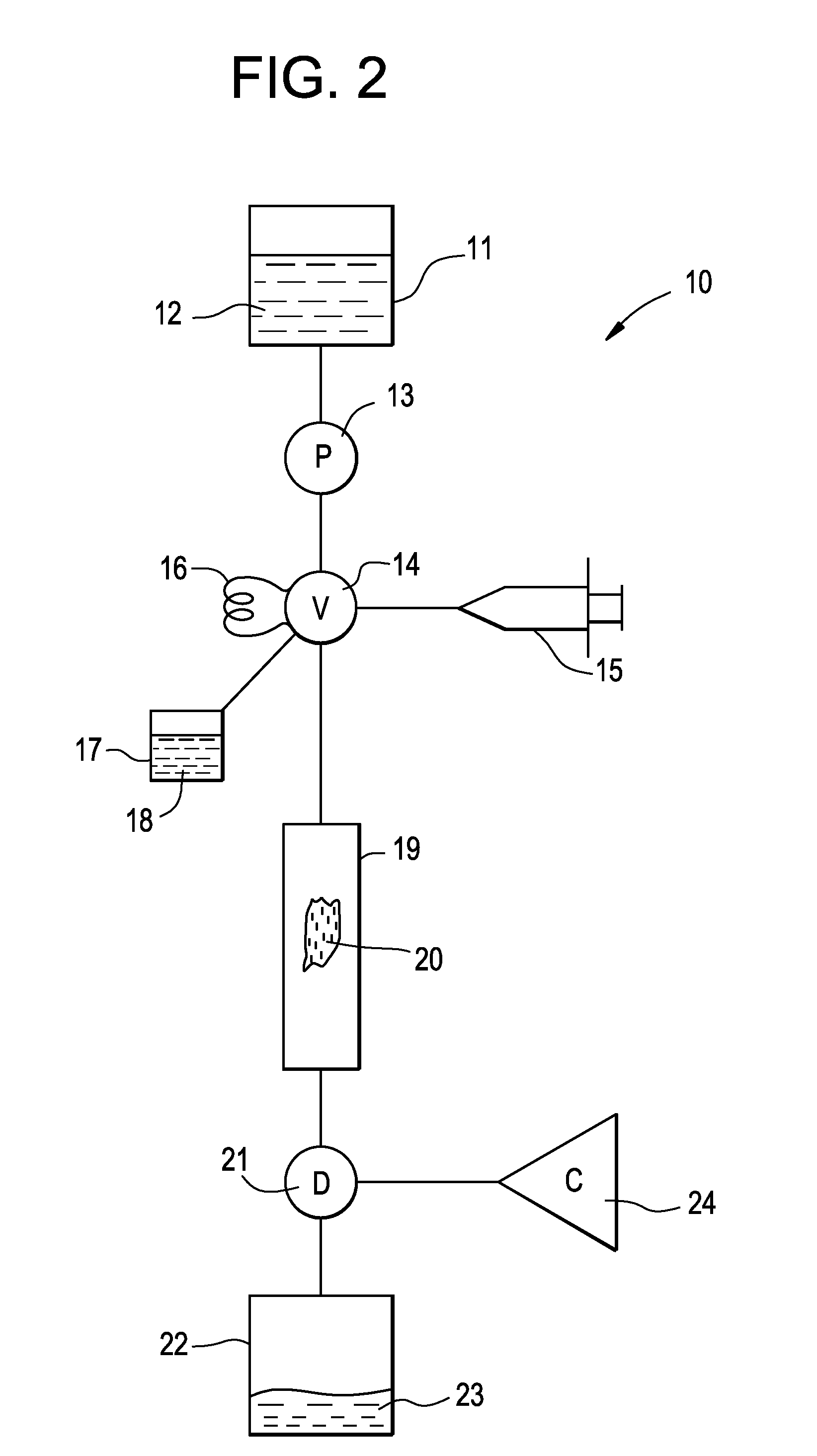

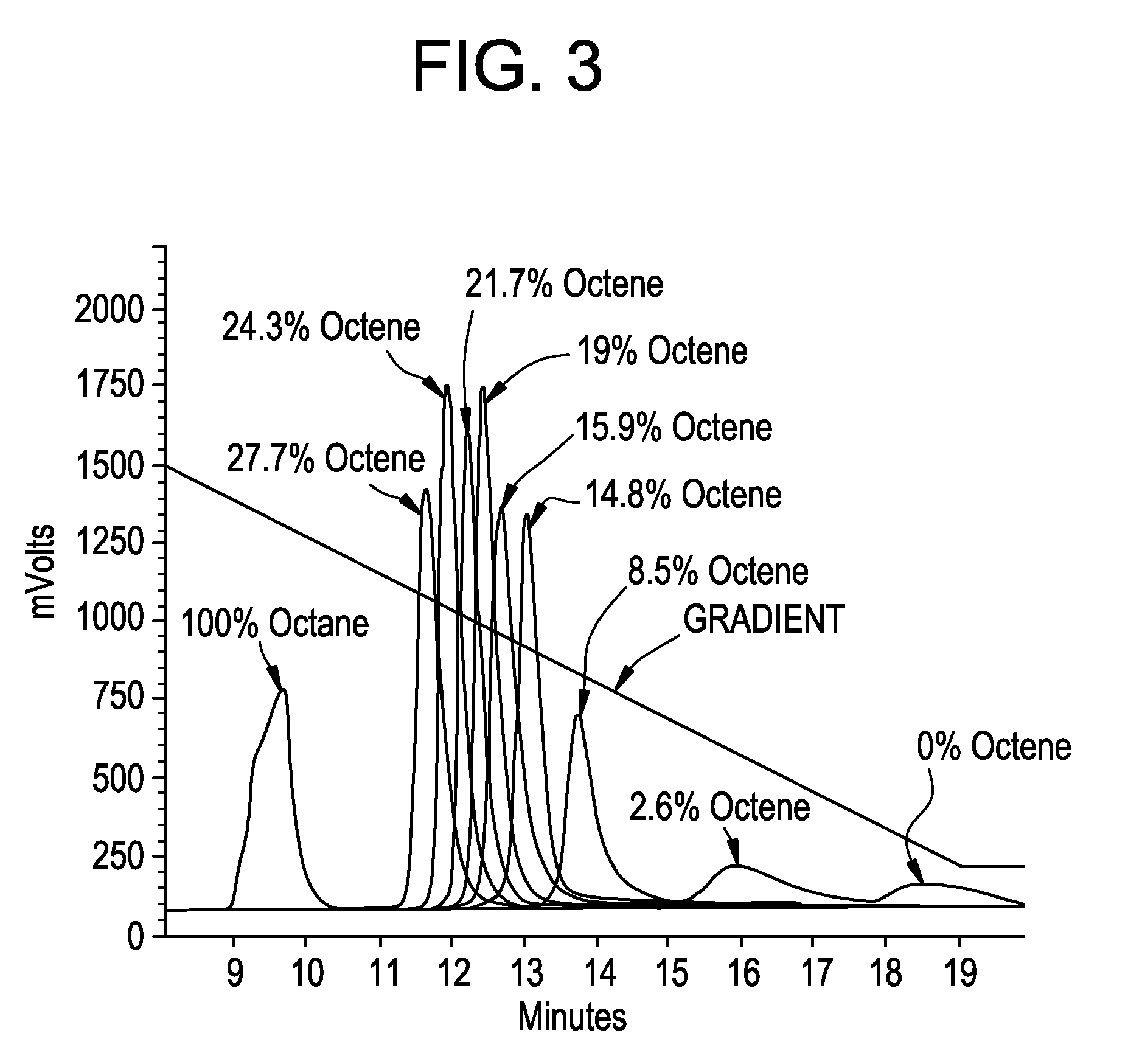

Chromotography of polyolefin polymers

ActiveUS8076147B2Separation efficiency can be improvedIon-exchange process apparatusComponent separationStationary phasePolymer science

A method and apparatus for chromatography of a polyolefin polymer by flowing a solution of the polyolefin polymer through liquid flowing through a graphitic carbon liquid chromatography stationary phase. The method can be used to determine the monomer to comonomer ratio of a polyolefin copolymer such as a copolymer of ethylene and 1-octene or a copolymer of propylene and ethylene.

Owner:THE DOW CHEM CO

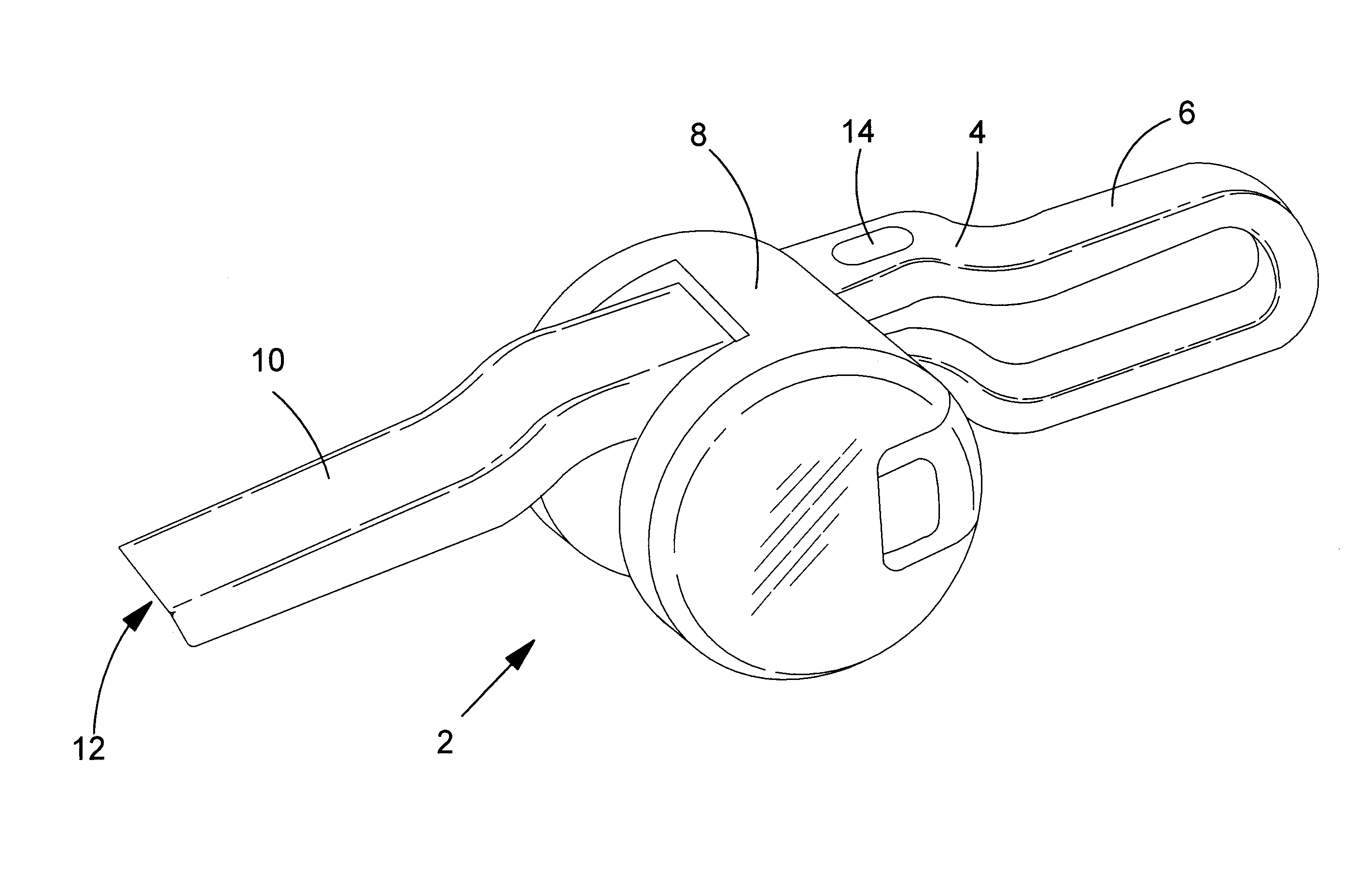

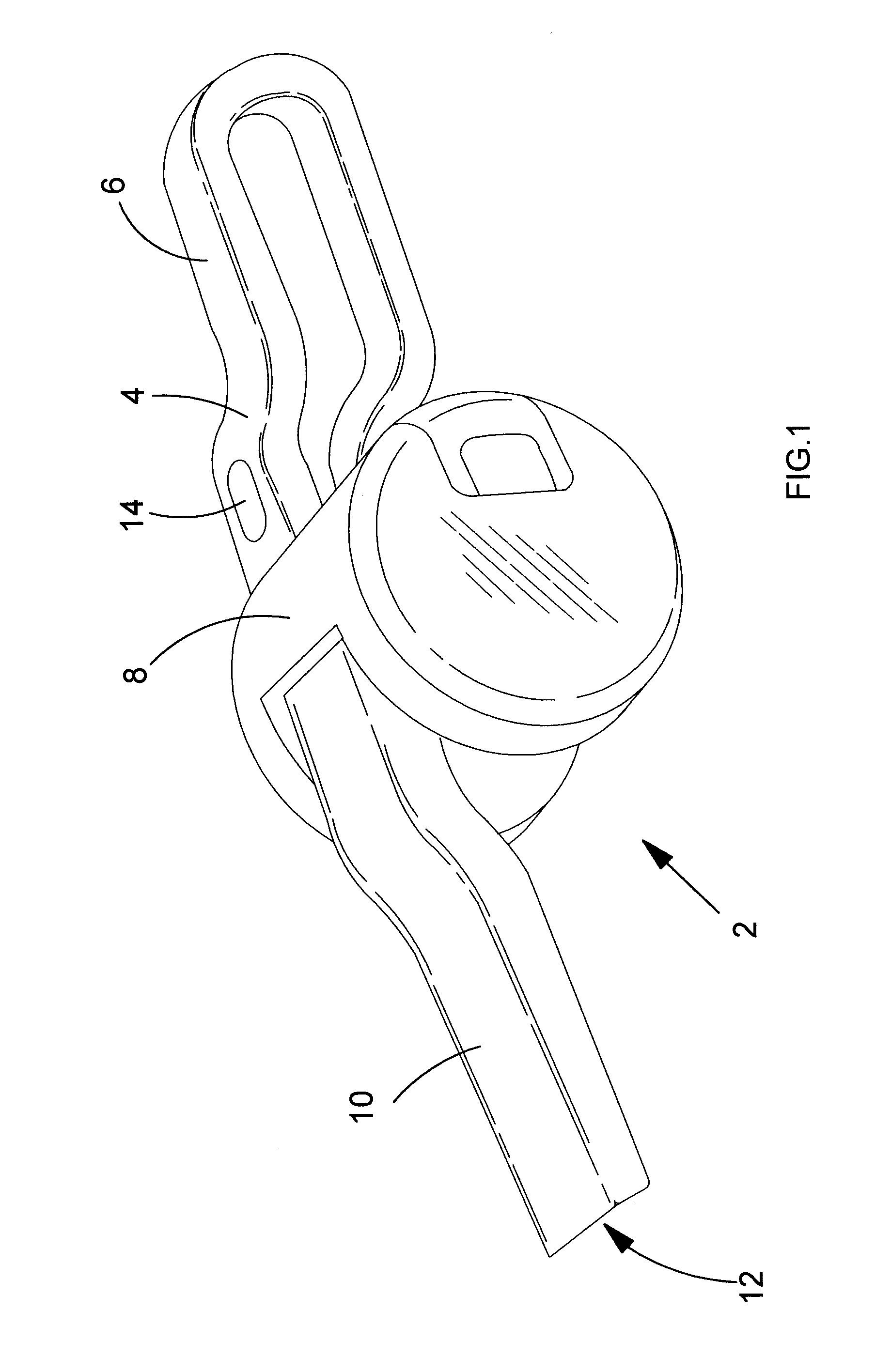

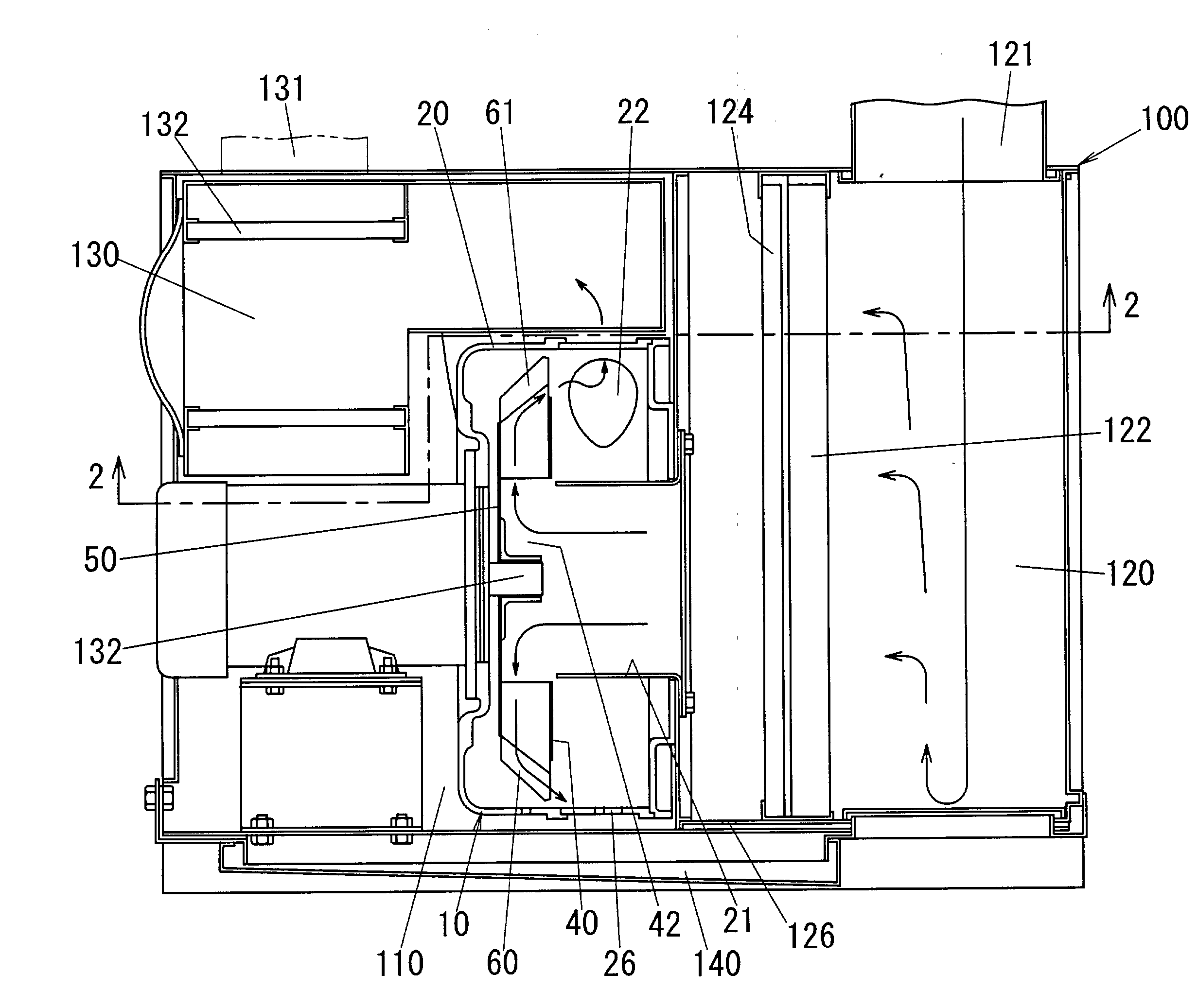

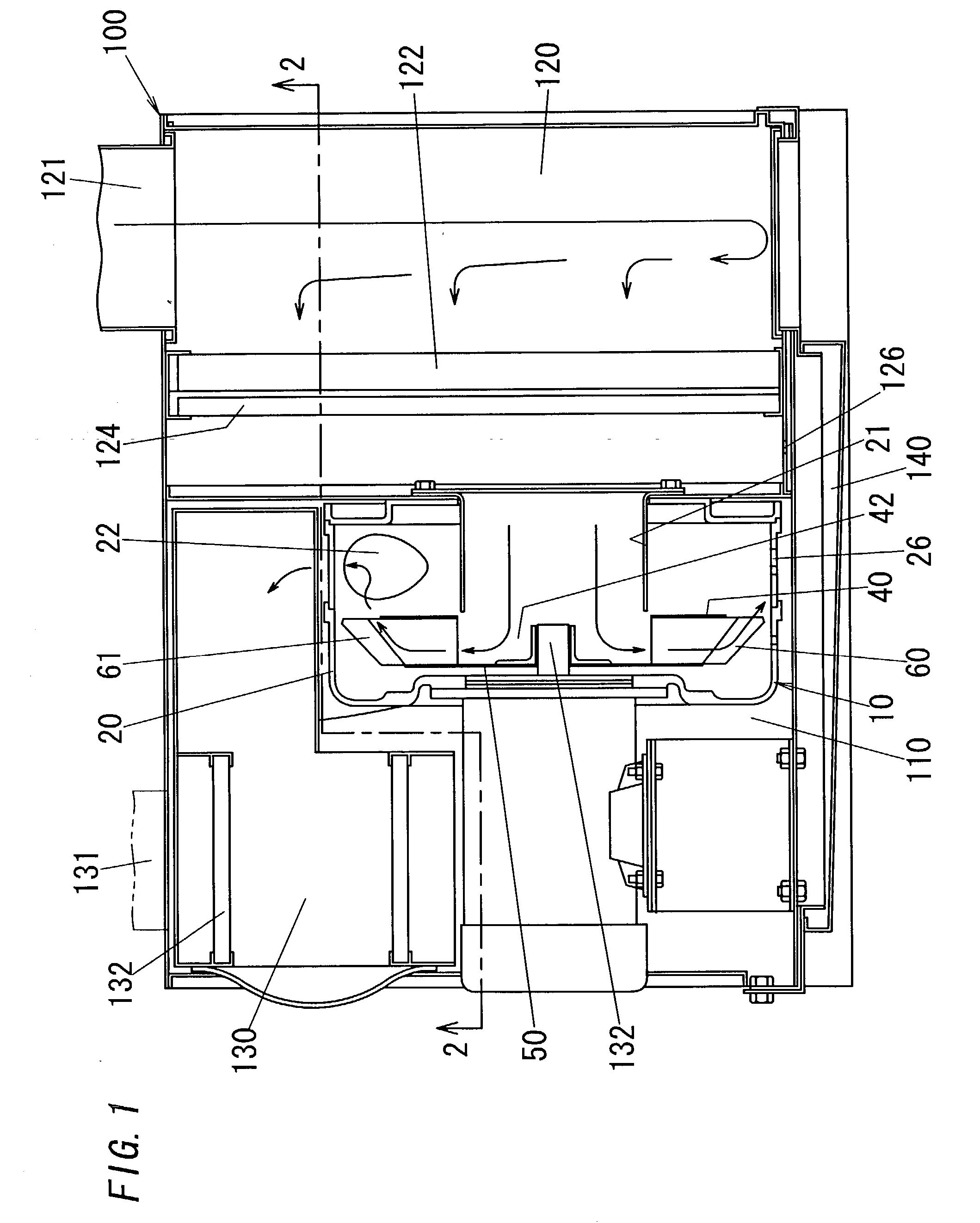

Battery-powered vacuum cleaner

ActiveUS20130091657A1Separation efficiency can be improvedLess spaceCleaning filter meansSuction filtersAirflowEngineering

A vacuum cleaner comprising: a motor coupled to a fan for generating air flow; a body with a handle; a dirty air duct with a dirty air inlet; a battery pack housing at least one rechargeable cell for powering the motor; and a dirt separating means located in a path of the air flow generated by the fan, wherein the dirt separating means comprises: a hollow substantially cylindrical dirt container with a longitudinal central axis; and an air inlet port to the dirt container, wherein the air inlet port is in communication with the dirty air duct and wherein the battery pack has a curvilinear or annular cross-sectional profile transverse to the central axis and a curvilinear inner wall embracing the dirt container.

Owner:BLACK & DECKER INC

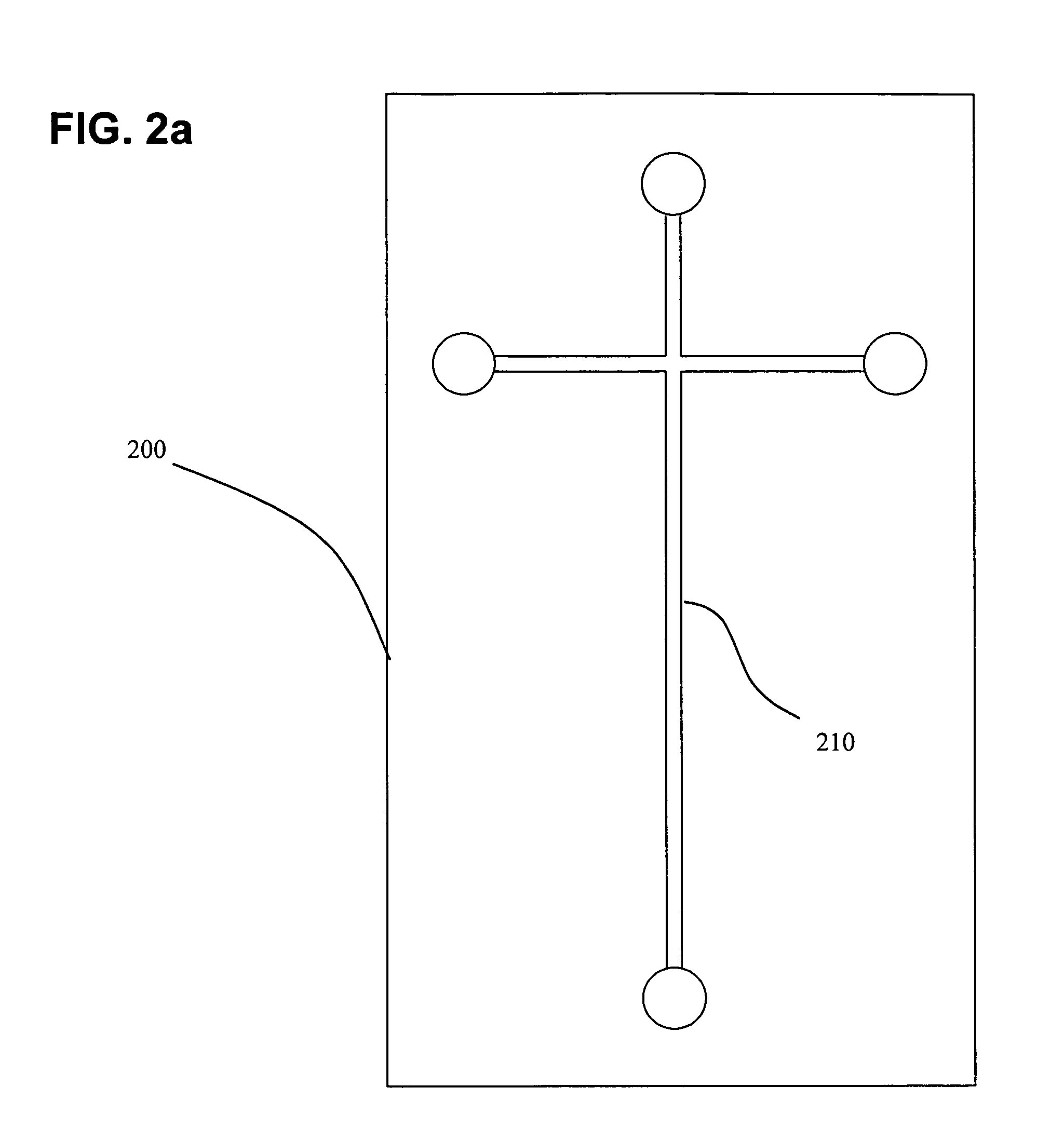

Fully packed capillary electrophoretic separation microchips with self-assembled silica colloidal particles in microchannels and their preparation methods

InactiveUS20060147344A1Rapid and improved separationEnhanced interactionComponent separationMaterial analysis by electric/magnetic meansCapillary electrophoresisElectrophoresis

A novel CEC column preparation method for various forms of CEC separation using selectively or fully packed microchannels with self-assembled silica colloidal particles is disclosed. The method relies on the three dimensional uniform silica colloidal packing through selective regions or whole channels resulting in uniform EOF and reproducibility. The fully packed capillary electrophoretic separation microchip is inherently suited for a handheld system since it exploits uniquely fully packed separation channels to achieve better separation efficiency and stability. The fully packed capillary electrophoretic separation microchip can be easily fabricated using low-cost, rapid manufacturing techniques, and can provide high performance for CEC separation with various chromatographic stationary support packing, functionalized surface of packed beads. The fully packed microchannels with self-assembled silica colloidal particles can be applied for preparation of a built-in submicron filter. Embodiments of the present invention address a significant challenge in the development of disposable CEC microchips, specifically, providing a reliable solution for preparation of the CEC separation column in a device that may be immediately applied for a variety of CEC applications.

Owner:UNIVERSITY OF CINCINNATI

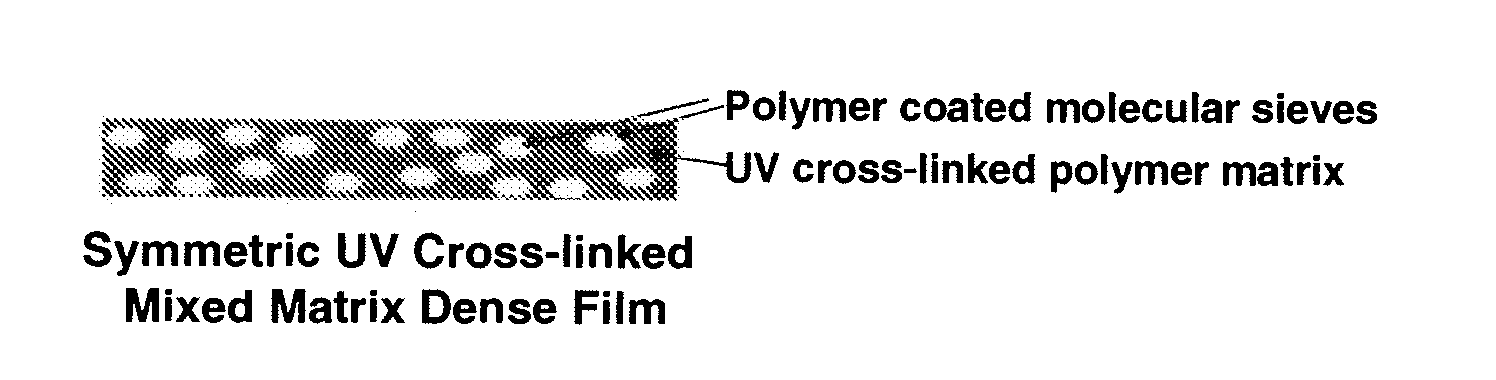

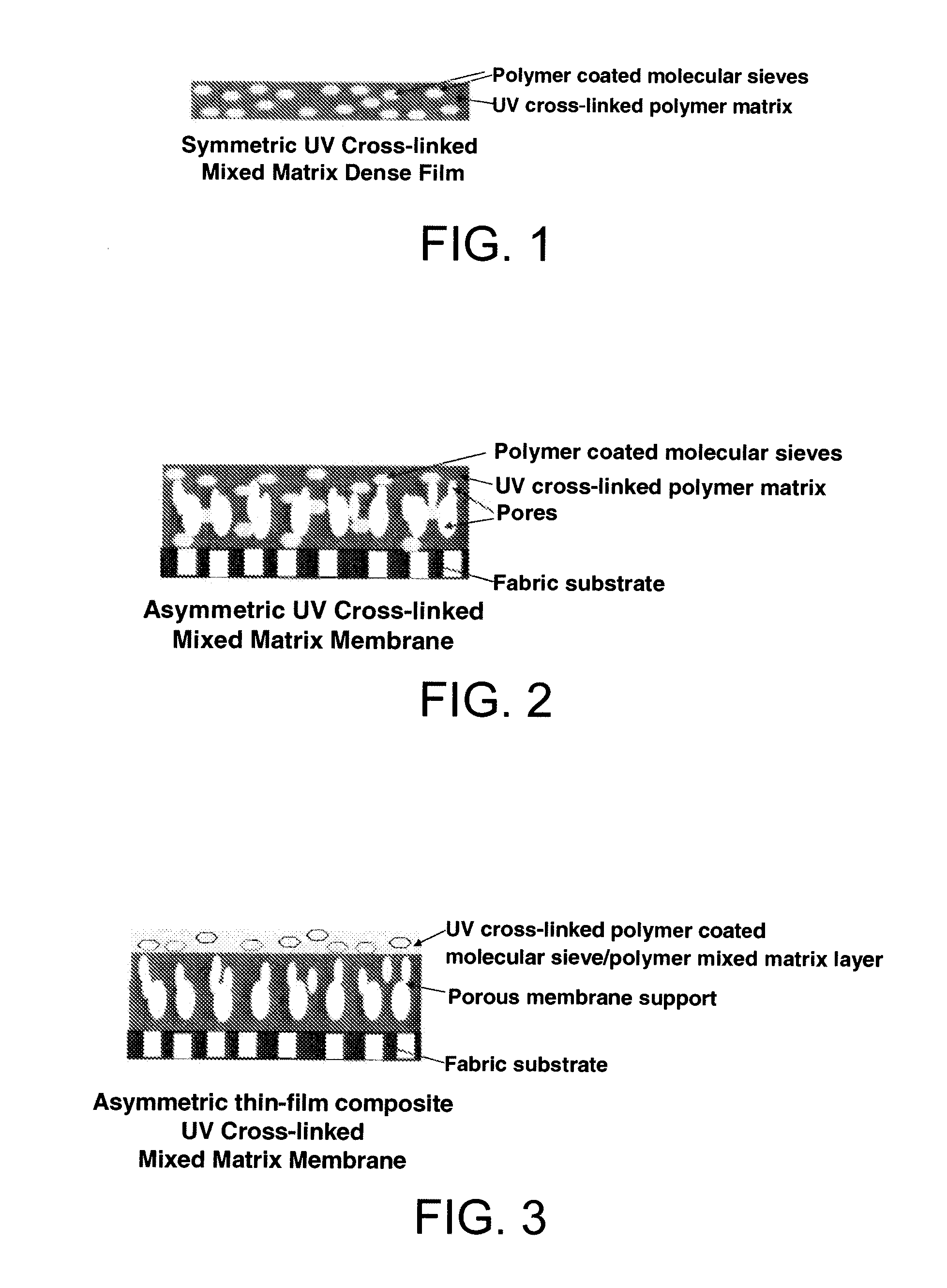

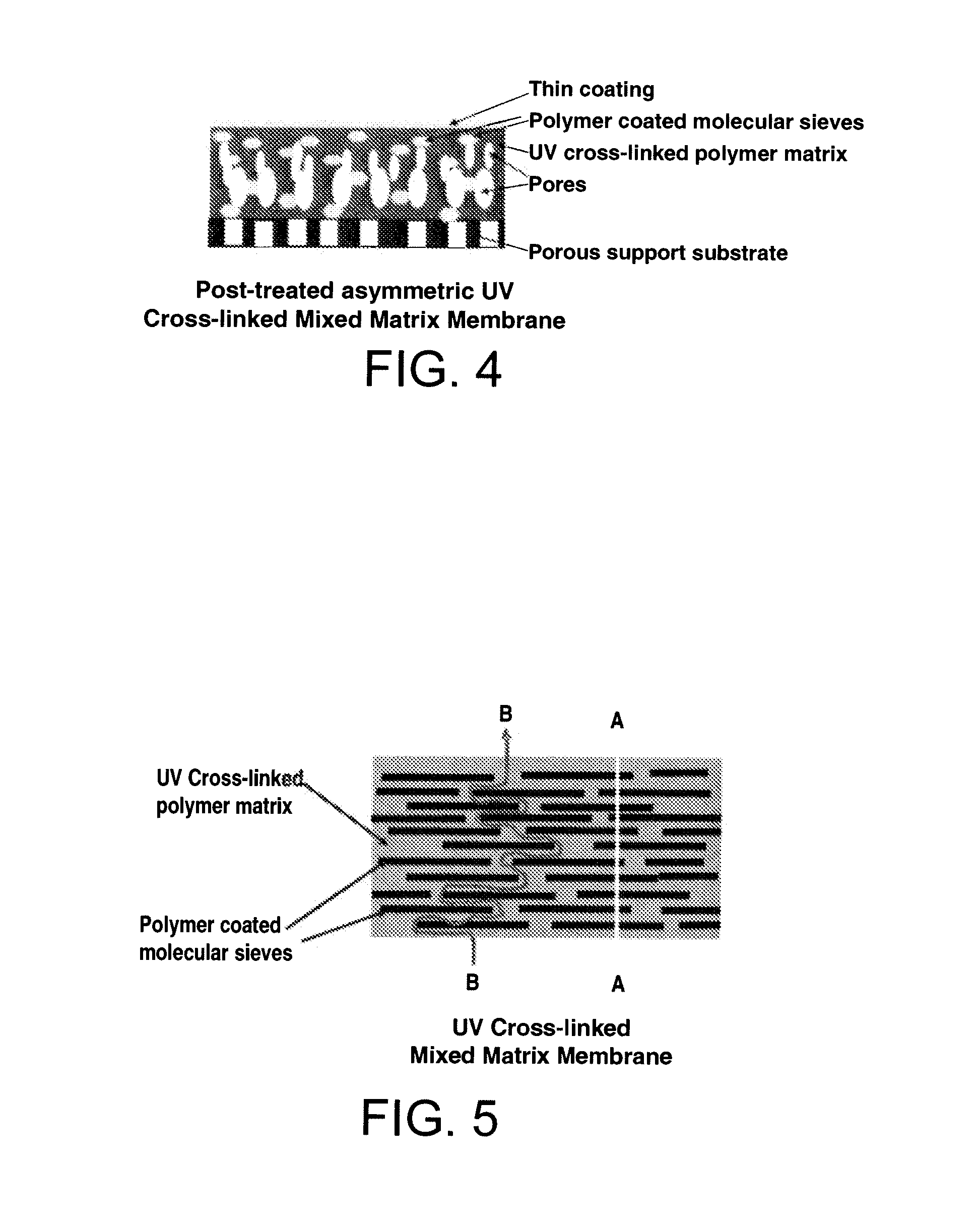

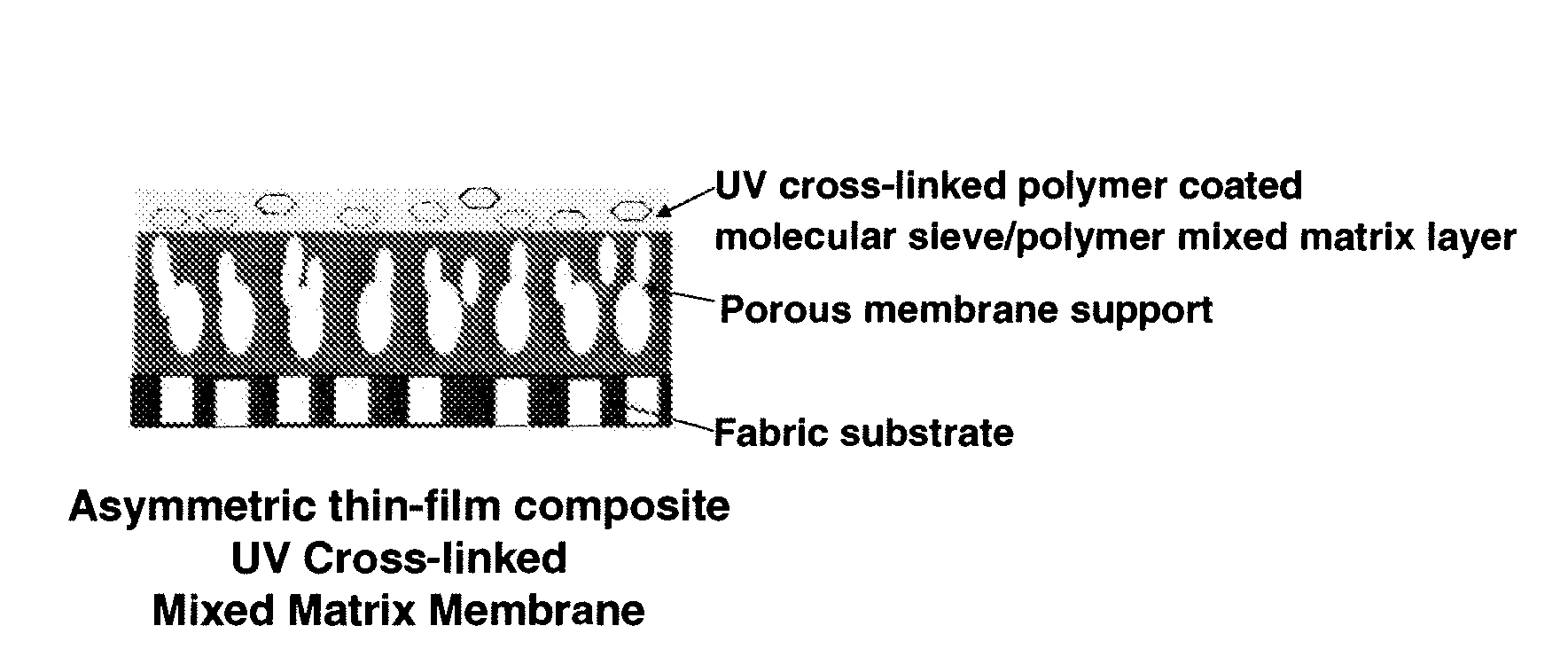

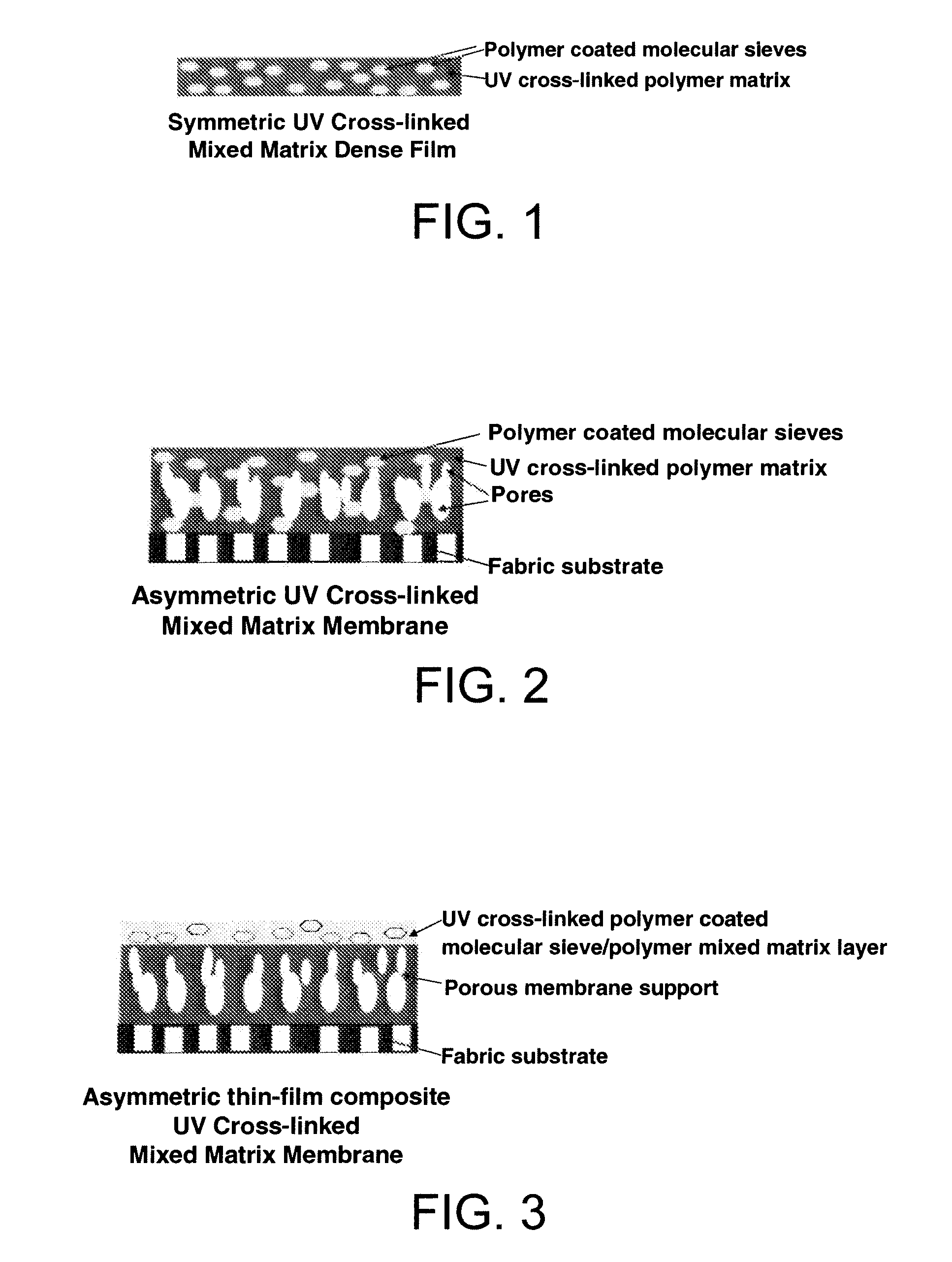

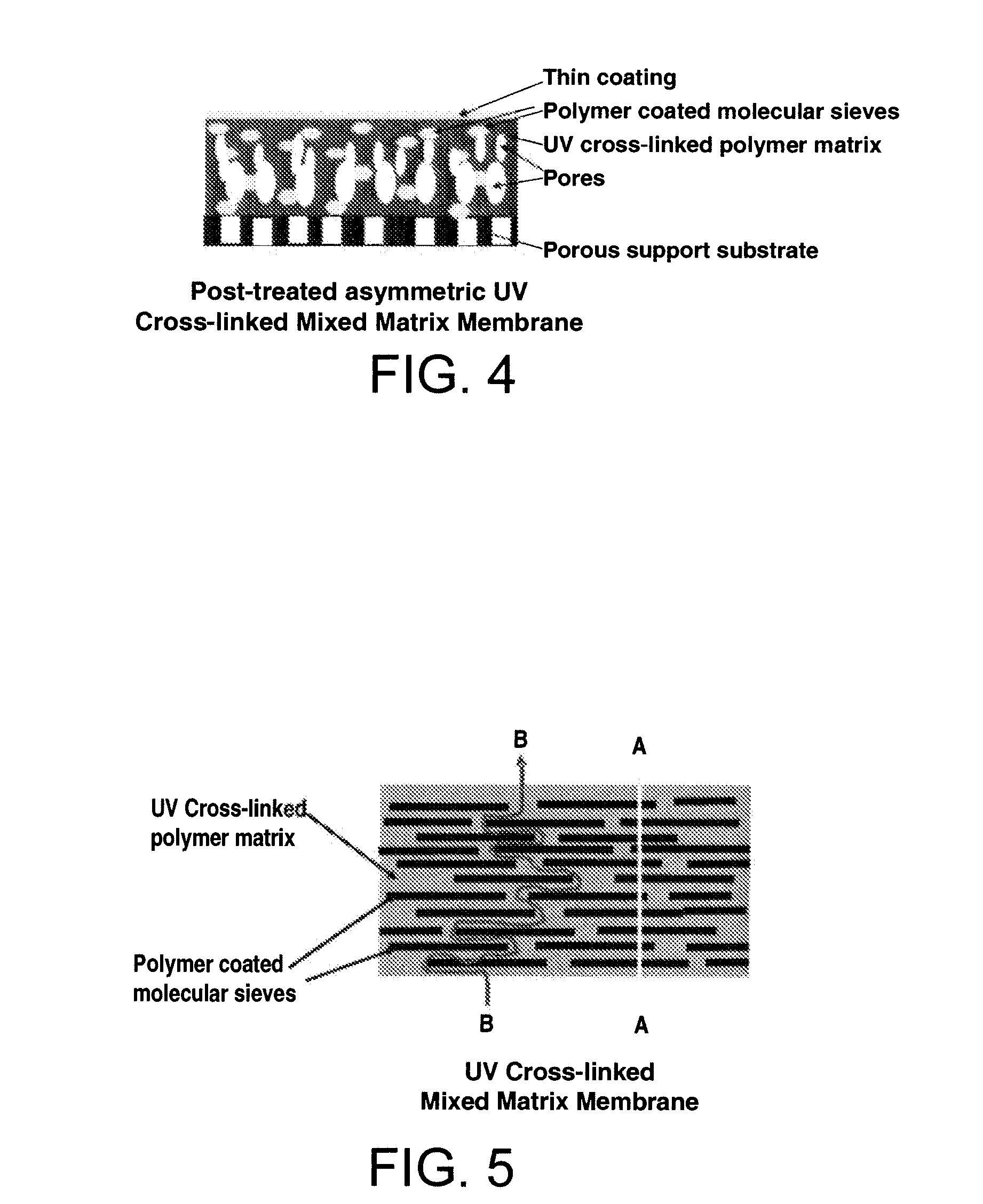

UV cross-linked polymer functionalized molecular sieve/polymer mixed matrix membranes

InactiveUS20080296527A1Separation efficiency can be improvedEasy to separateMembranesSemi-permeable membranesCross-linkPliability

The present invention discloses high performance UV cross-linked polymer functionalized molecular sieve / polymer mixed matrix membranes (MMMs) with either no macrovoids or voids of less than several angstroms at the interface of the polymer matrix and the molecular sieves. These UV cross-linked MMMs were prepared by incorporating polyethersulfone (PES) functionalized molecular sieves such as AlPO-14 and UZM-25 small pore microporous molecular sieves into a continuous UV cross-linkable polyimide polymer matrix followed by UV cross-linking. The UV cross-linked MMMs in the form of symmetric dense film, asymmetric flat sheet membrane, or asymmetric hollow fiber membranes have good flexibility, high mechanical strength, and exhibit significantly enhanced selectivity and permeability over polymer membranes made from corresponding continuous polyimide polymer matrices for carbon dioxide / methane and hydrogen / methane separations. The MMMs of the present invention are suitable for a variety of liquid, gas, and vapor separations.

Owner:UOP LLC

Vacuum cleaner with a divider

ActiveUS20070209340A1Increase efficiencyPrevent growthCombination devicesLiquid degasificationAirflowEngineering

An indoor vacuum cleaner comprises a dirty air inlet, a handle, a cyclone separator having an outer wall, a fluid inlet downstream from the dirty air inlet and a fluid outlet, a plate having a cyclone chamber surface and positioned to substantially divide the cyclone separator into a cyclone chamber and a dirt collection chamber, each of the cyclone chamber and the dirt collection chamber having an outer wall, the outer wall of each of the cyclone chamber and the dirt collection chamber having an outer perimeter, the dirt collection chamber having a cyclone chamber end spaced from a dirt collection floor, a passage extending between the cyclone chamber and the dirt collection chamber, the passage configured such that separated dirt travels at least outwardly as the dirt travels through the passage and, an air flow motor.

Owner:OMACHRON INTPROP

Vacuum cleaner with an illuminated interior

InactiveUS7722709B2Improve efficiencyAssist in removingCombination devicesAuxillary pretreatmentSurface cleaningEngineering

A surface cleaning apparatus having an outer surface and comprises a dirt inlet, a handle, a cyclone separator having a cyclone separator interior and an outer wall having an inner surface, the cyclone separator comprising a cyclone chamber and a dirt collection chamber, the dirt collection chamber and the cyclone chamber each having an outer wall, the surface cleaning apparatus is constructed such that the cyclone separator interior is visible from a position exterior to the surface cleaning apparatus, an illumination member positioned to provide illumination to at least a portion of the cyclone separator interior, and a fluid flow motor.

Owner:OMACHRON INTPROP

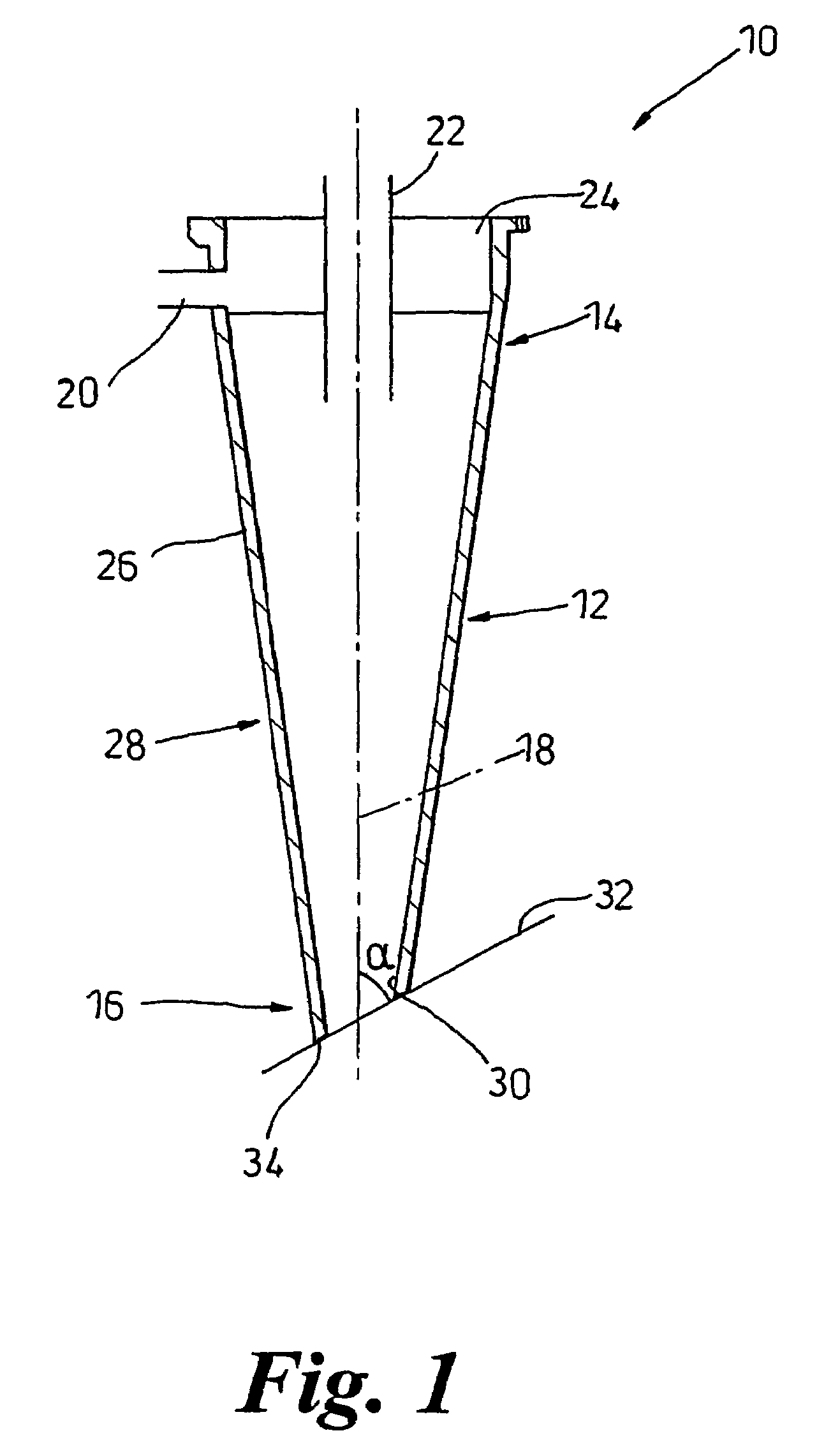

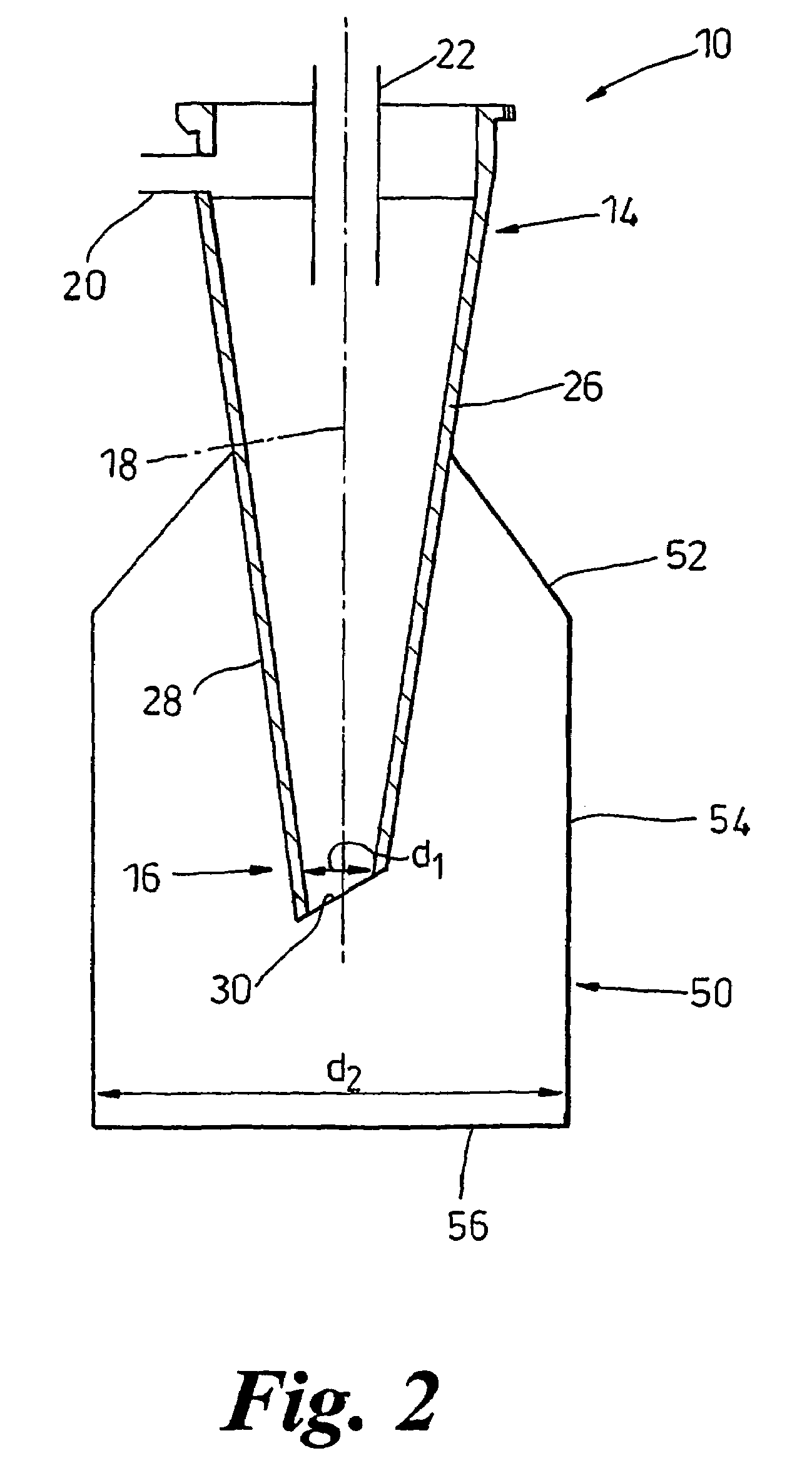

Cyclonic separating apparatus

ActiveUS7291190B2Reduce riskAvoid cloggingSuction filtersReversed direction vortexCycloneCyclonic separation

A cyclonic separating apparatus includes at least one cyclone having a first end, a second end a longitudinal axis. An inlet is located at the first end for introducing a fluid flow into the cyclone, and a cone opening is located at the second end. At least part of the cone opening lies in a plane inclined at an angle to the longitudinal axis

Owner:DYSON TECH LTD

Vacuum cleaner with an illuminated interior

InactiveUS20070209519A1Improve efficiencyAssist in removingCombination devicesLiquid degasificationSurface cleaningEngineering

A surface cleaning apparatus having an outer surface and comprises a dirt inlet, a handle, a cyclone separator having a cyclone separator interior and an outer wall having an inner surface, the cyclone separator comprising a cyclone chamber and a dirt collection chamber, the dirt collection chamber and the cyclone chamber each having an outer wall, the surface cleaning apparatus is constructed such that the cyclone separator interior is visible from a position exterior to the surface cleaning apparatus, an illumination member positioned to provide illumination to at least a portion of the cyclone separator interior, and a fluid flow motor.

Owner:OMACHRON INTPROP

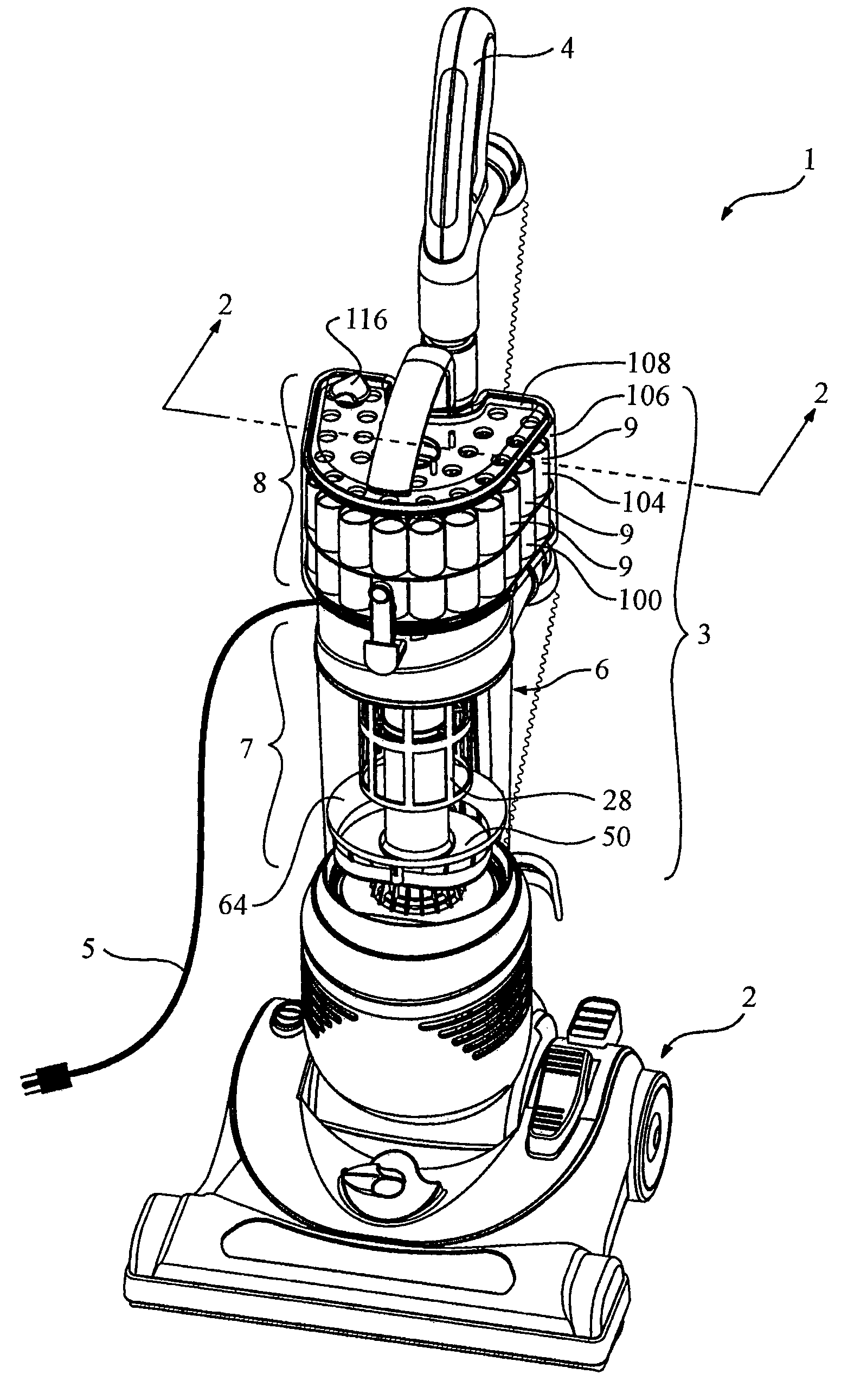

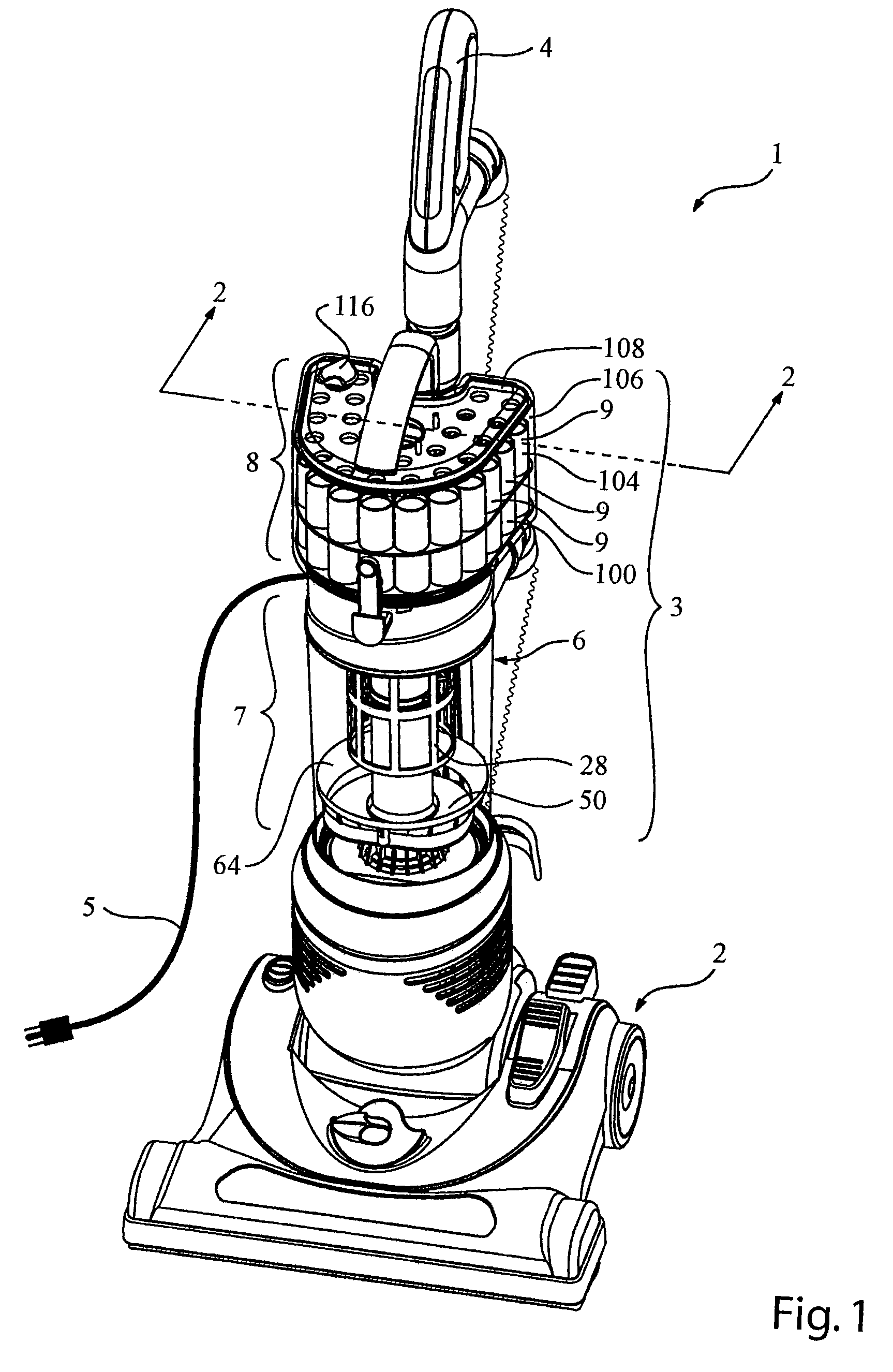

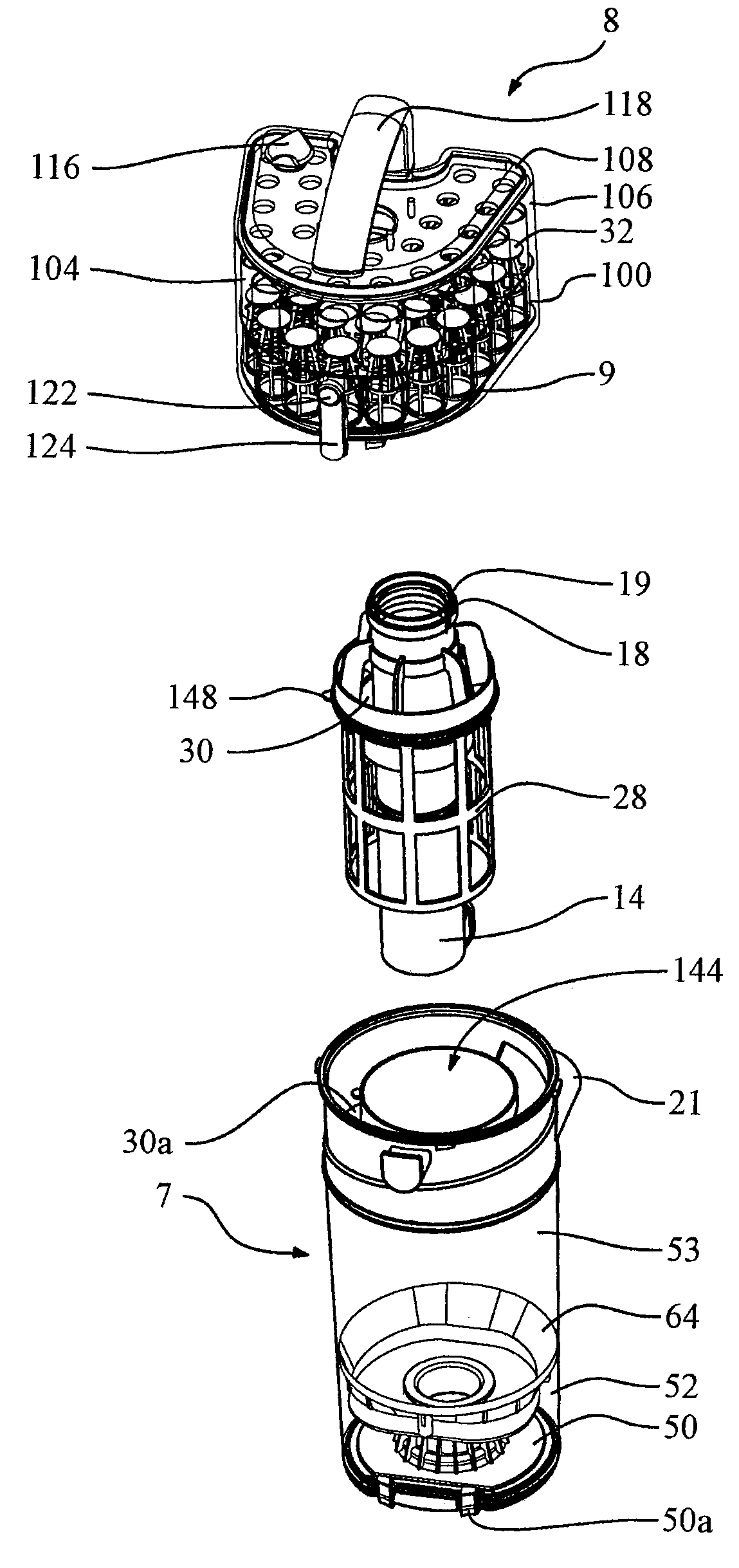

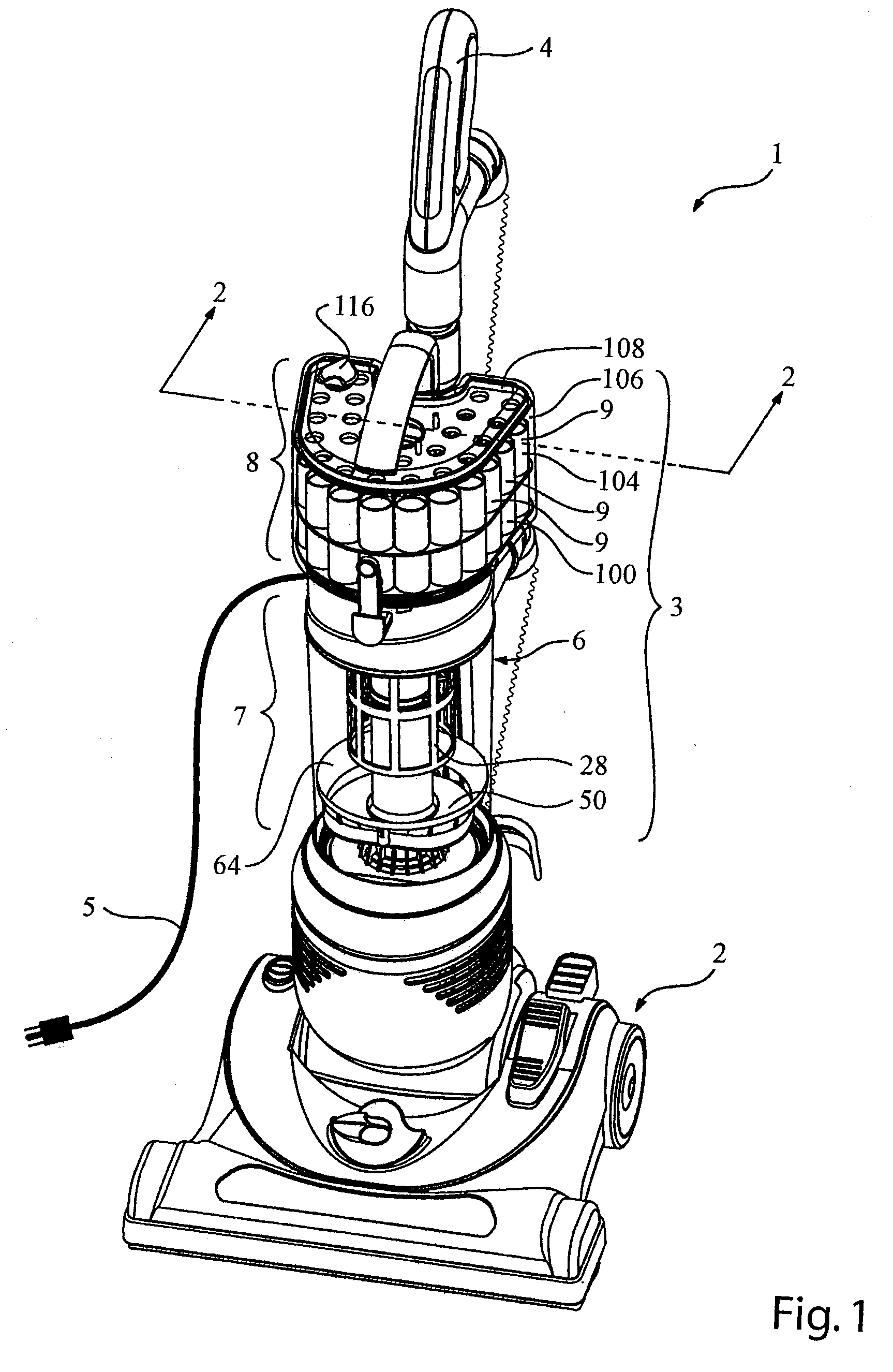

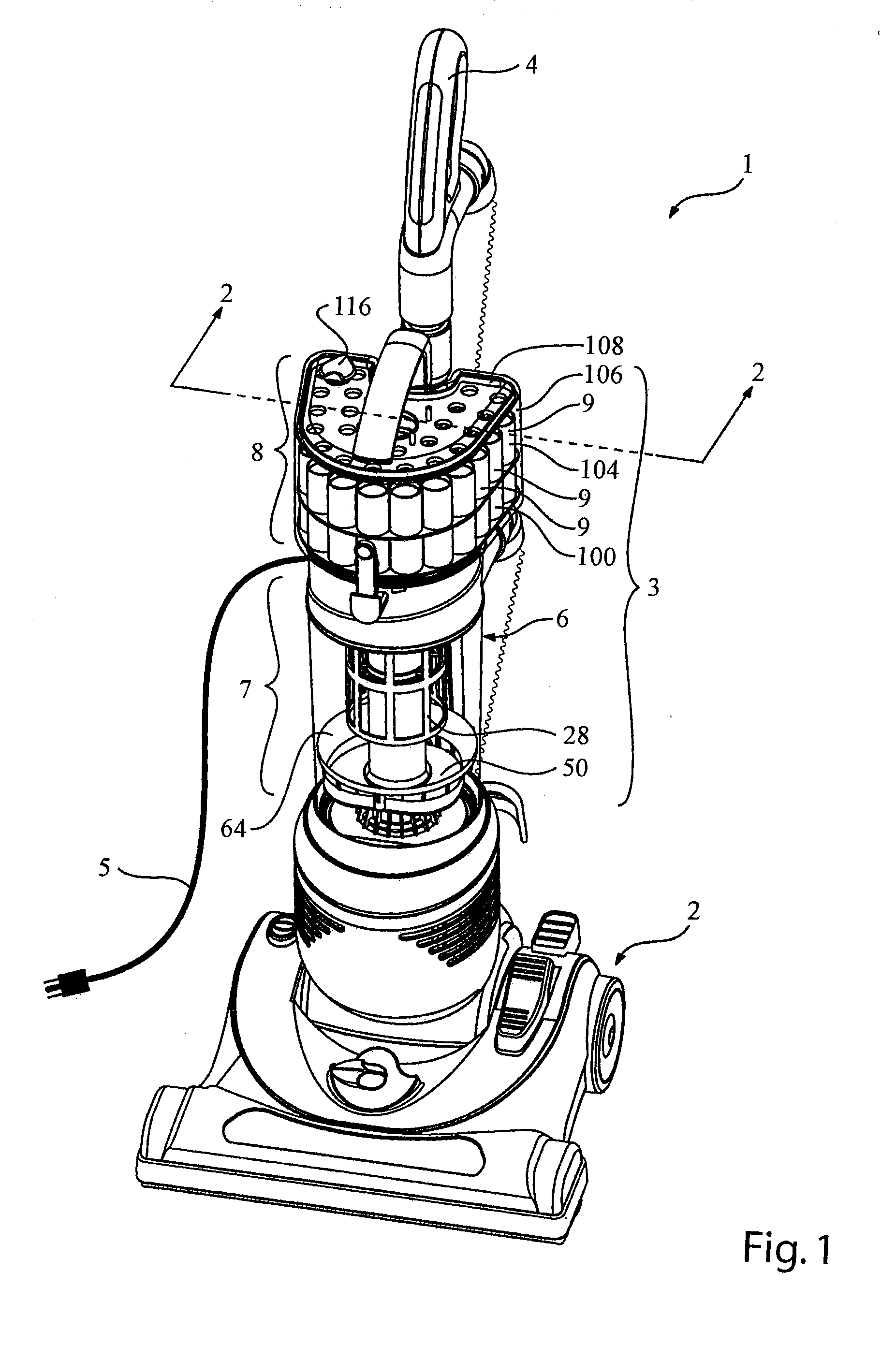

Vacuum cleaner with a removable cyclone array

InactiveUS20070209338A1Improve efficiencyGrowth inhibitionCombination devicesAuxillary pretreatmentCycloneSurface cleaning

A surface cleaning apparatus comprises a dirt inlet, a handle, at least a first cleaning stage comprising a plurality of cyclones in parallel and a plurality of dirt collection chambers that are emptied concurrently wherein the plurality of cyclones and the plurality of dirt collection chambers are removable as a unit from the surface cleaning apparatus, and an air flow motor.

Owner:OMACHRON INTPROP

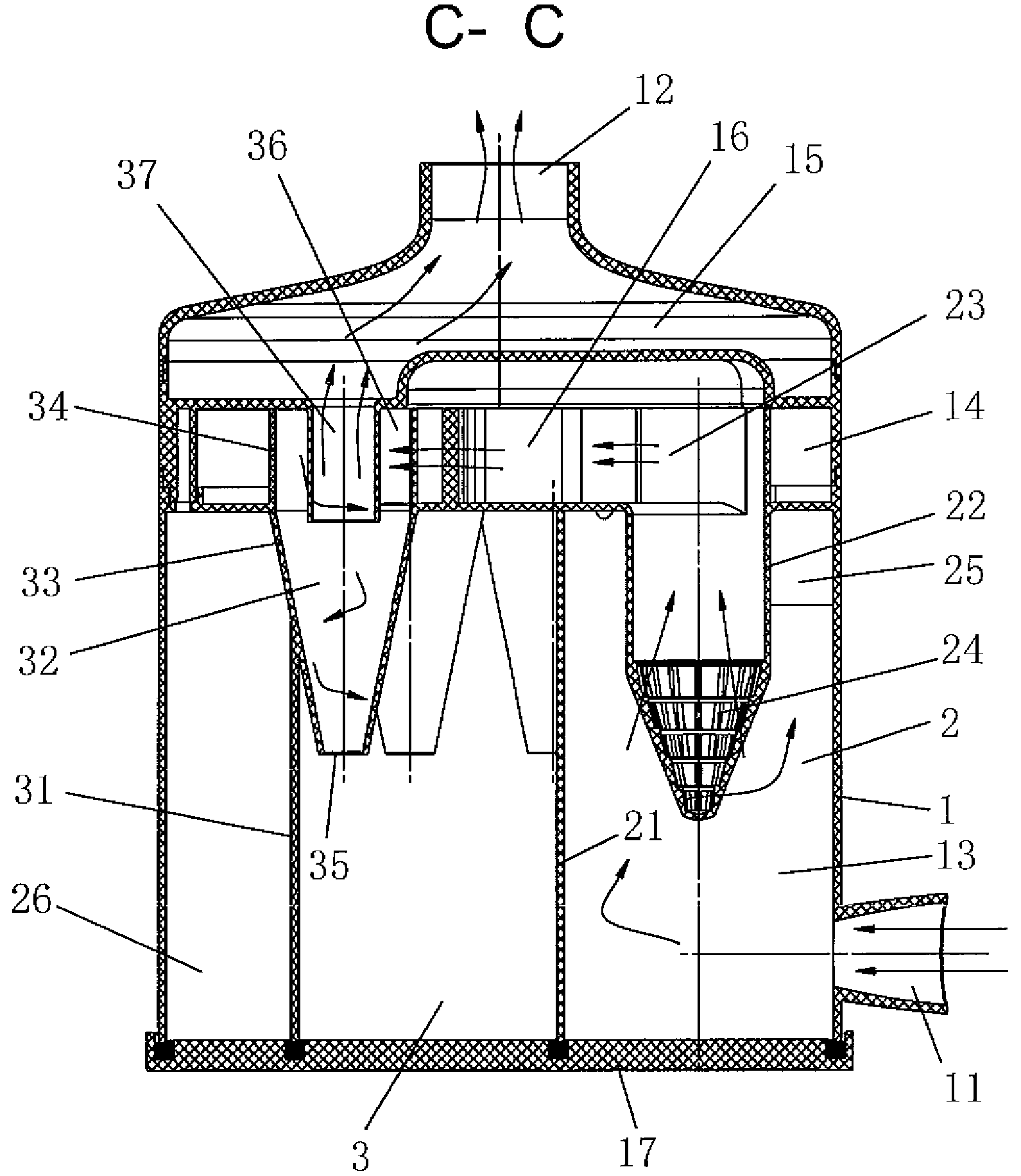

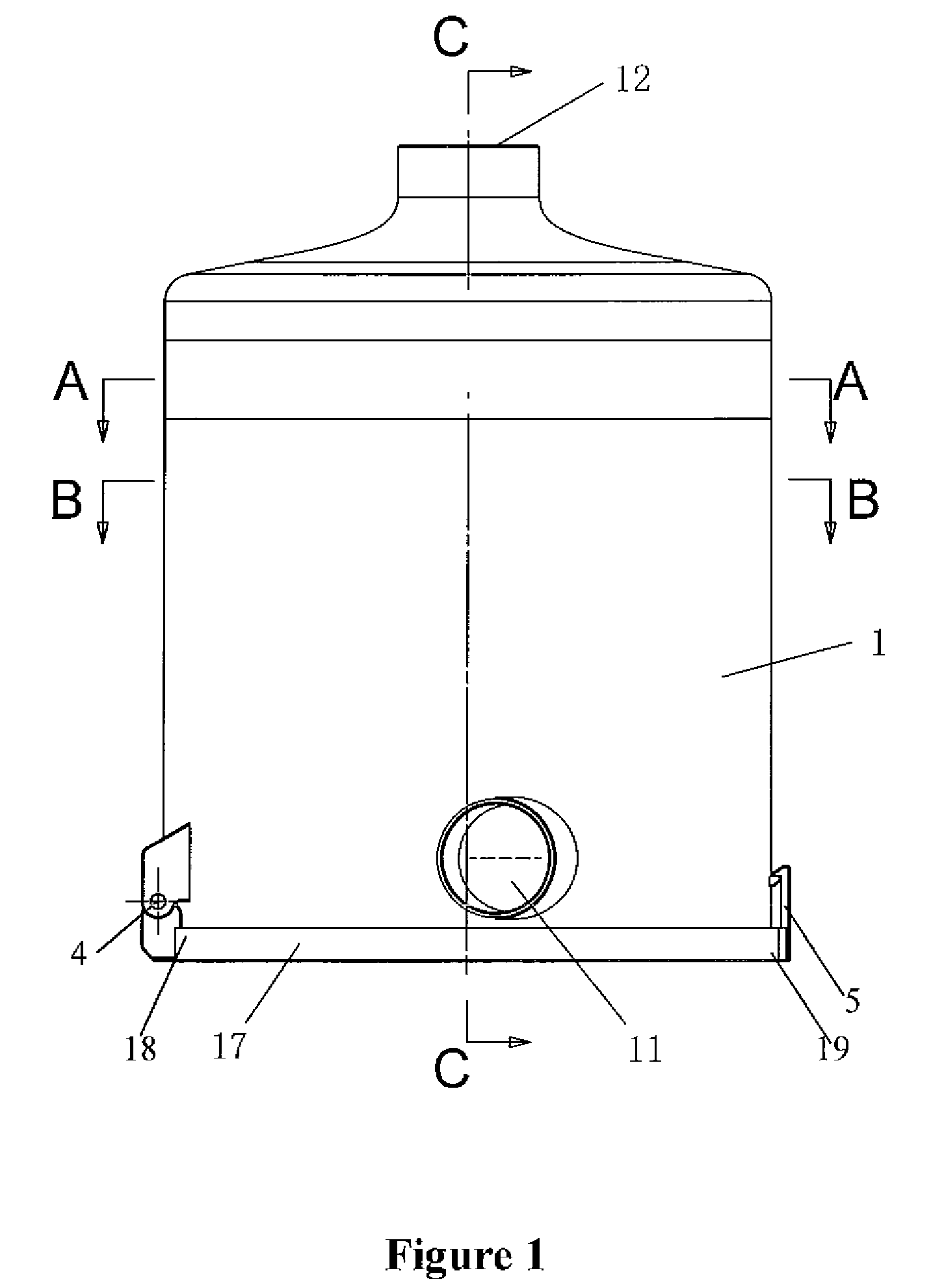

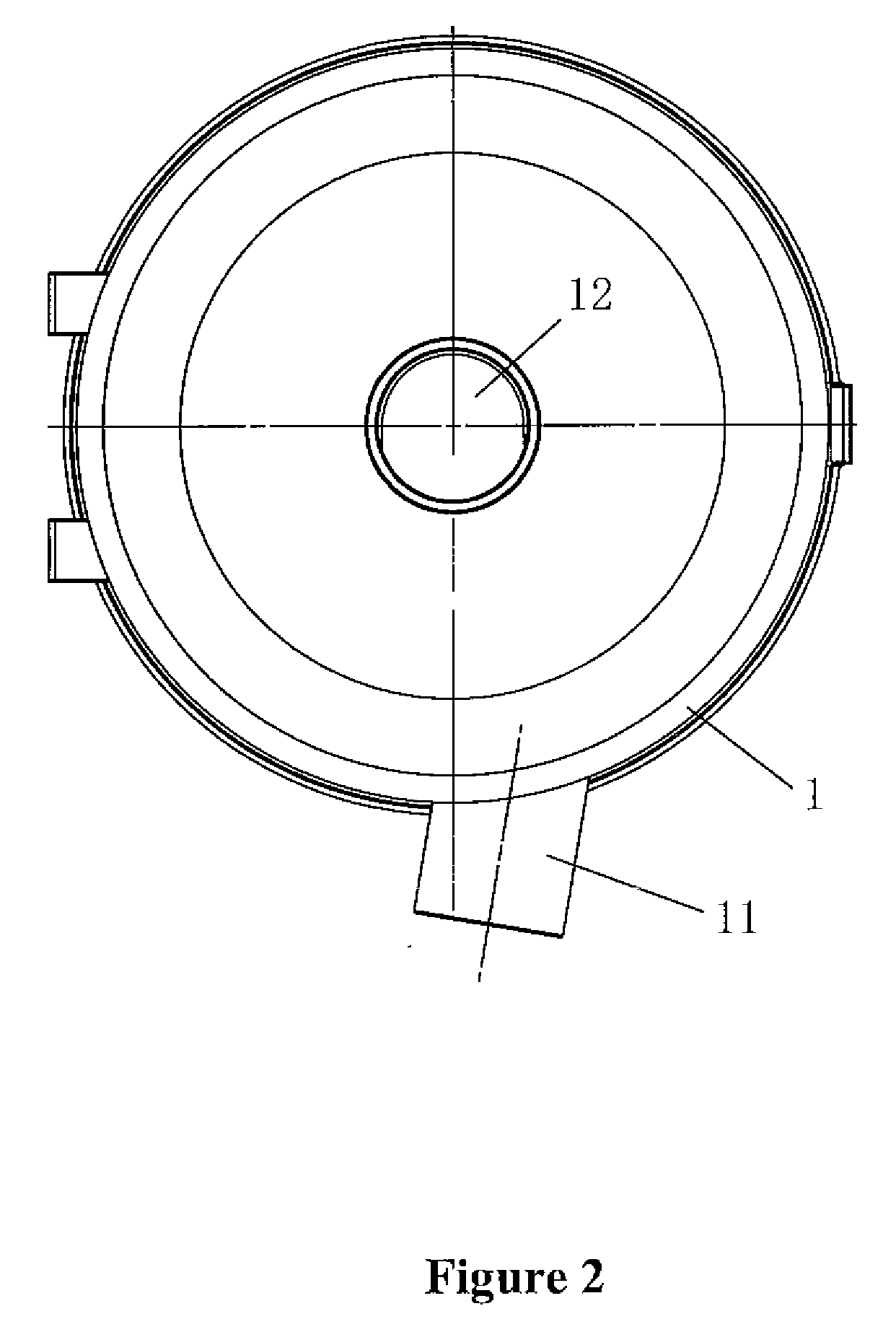

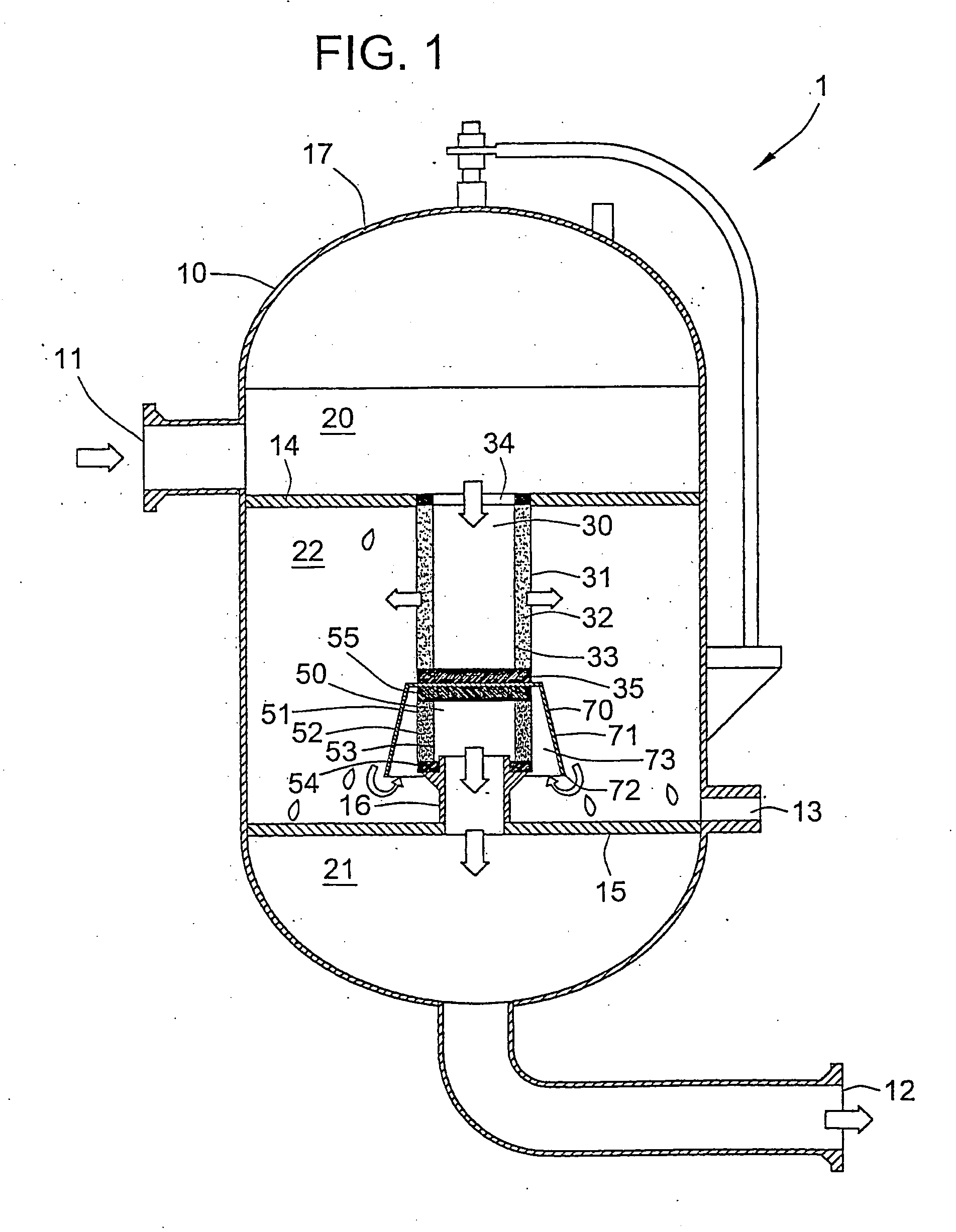

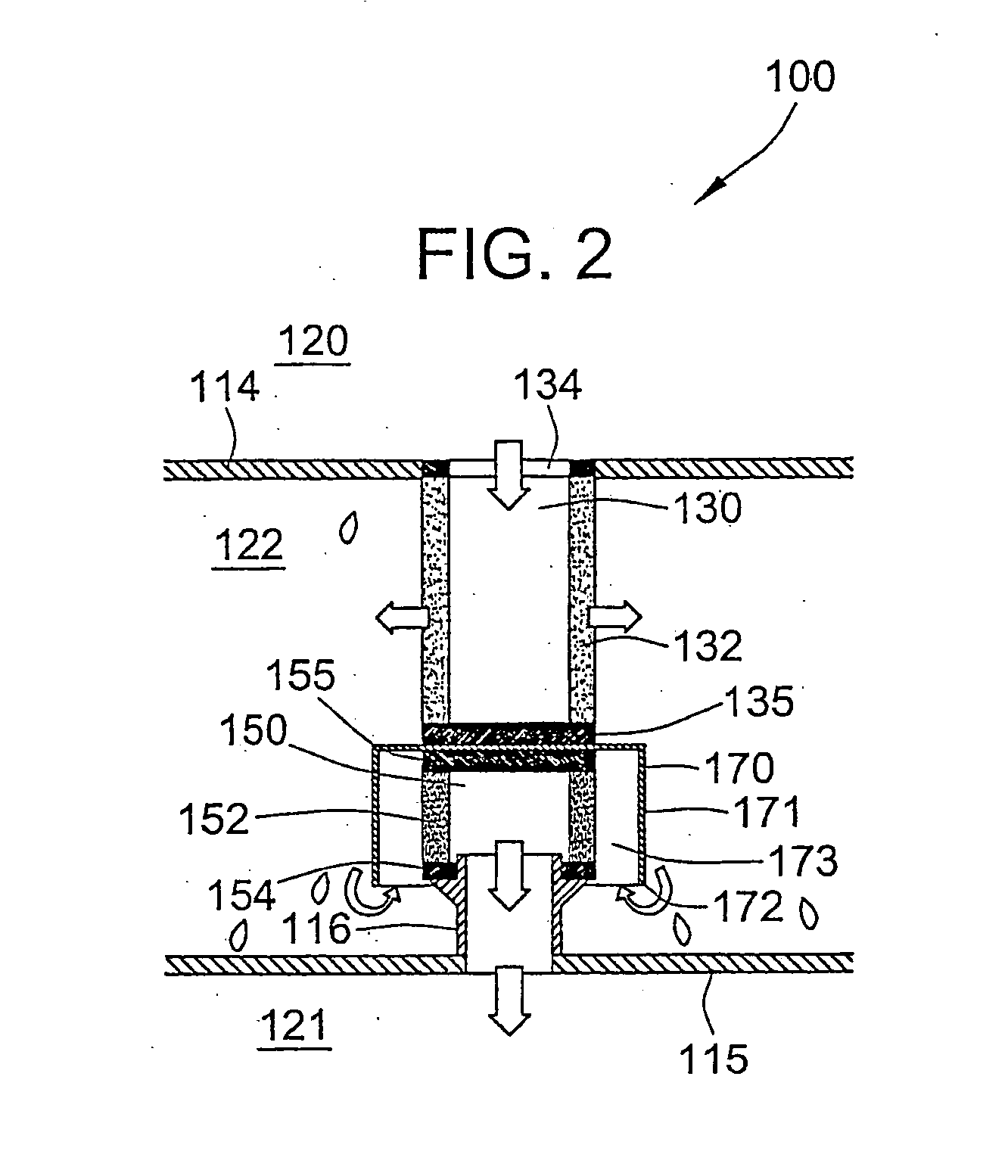

Cyclonic separation device for vacuum cleaner

InactiveUS20100089014A1Separation efficiency can be improvedLower the volumeCombination devicesReversed direction vortexCyclonic separationVacuum cleaner

It is provided in the present invention with a cyclonic separation device for vacuum cleaner comprising a external barrel having a main wind inlet and a main wind outlet; a primary separator and a secondary separator in communication with each other both of which are located in the external barrel, and the primary separator is connected to the main wind inlet when the secondary separator is connected to the main wind outlet. Both filter and cyclonic separators are integrated in present invention: cyclonic filter device works as the primary separator and cyclonic separation device works as the secondary separator; which increases separation efficiency and reduces the volume of whole machine.

Owner:CHANGZHOU SHINRI HOUSEHOLD APPLIANCE MFG

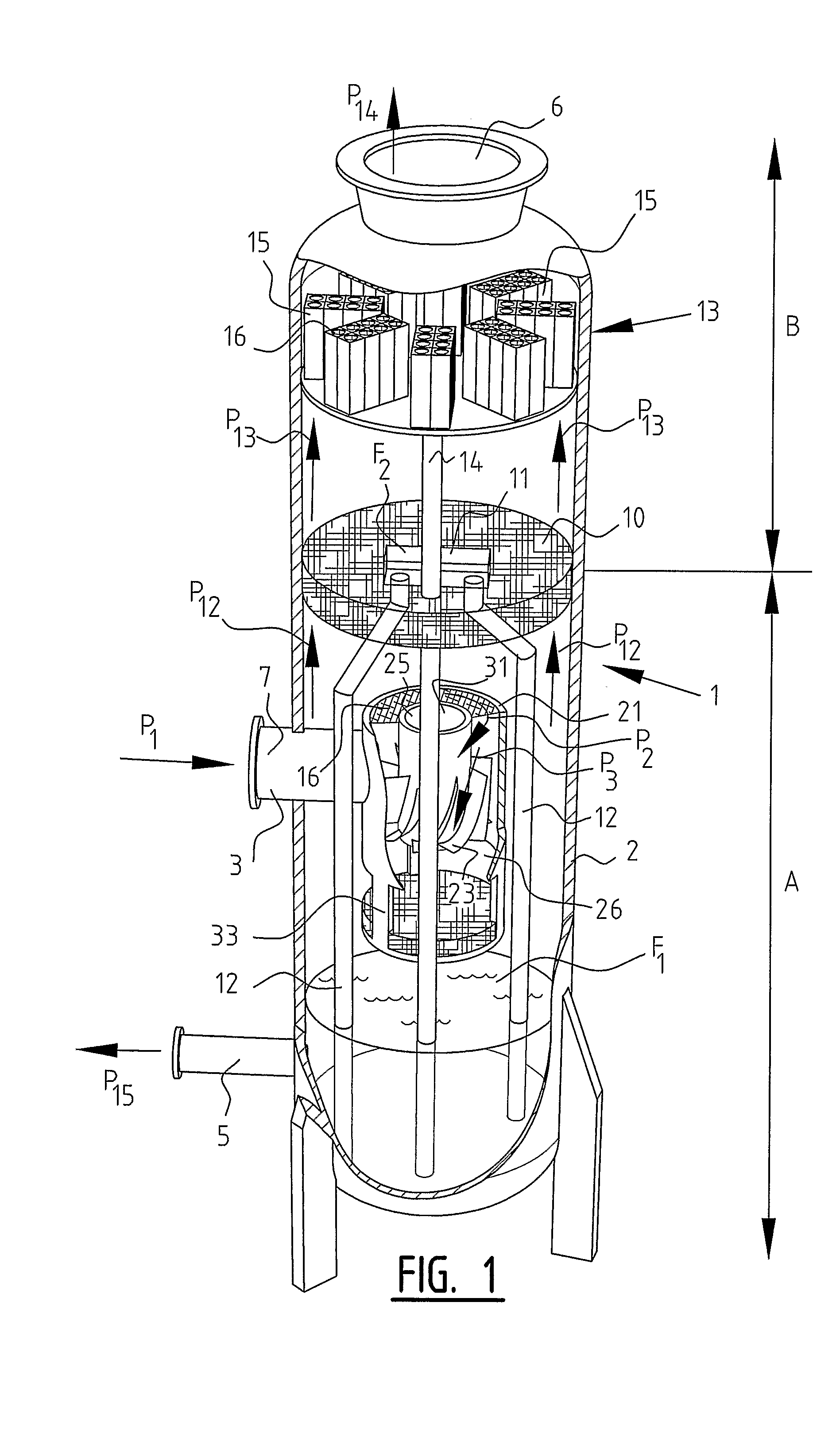

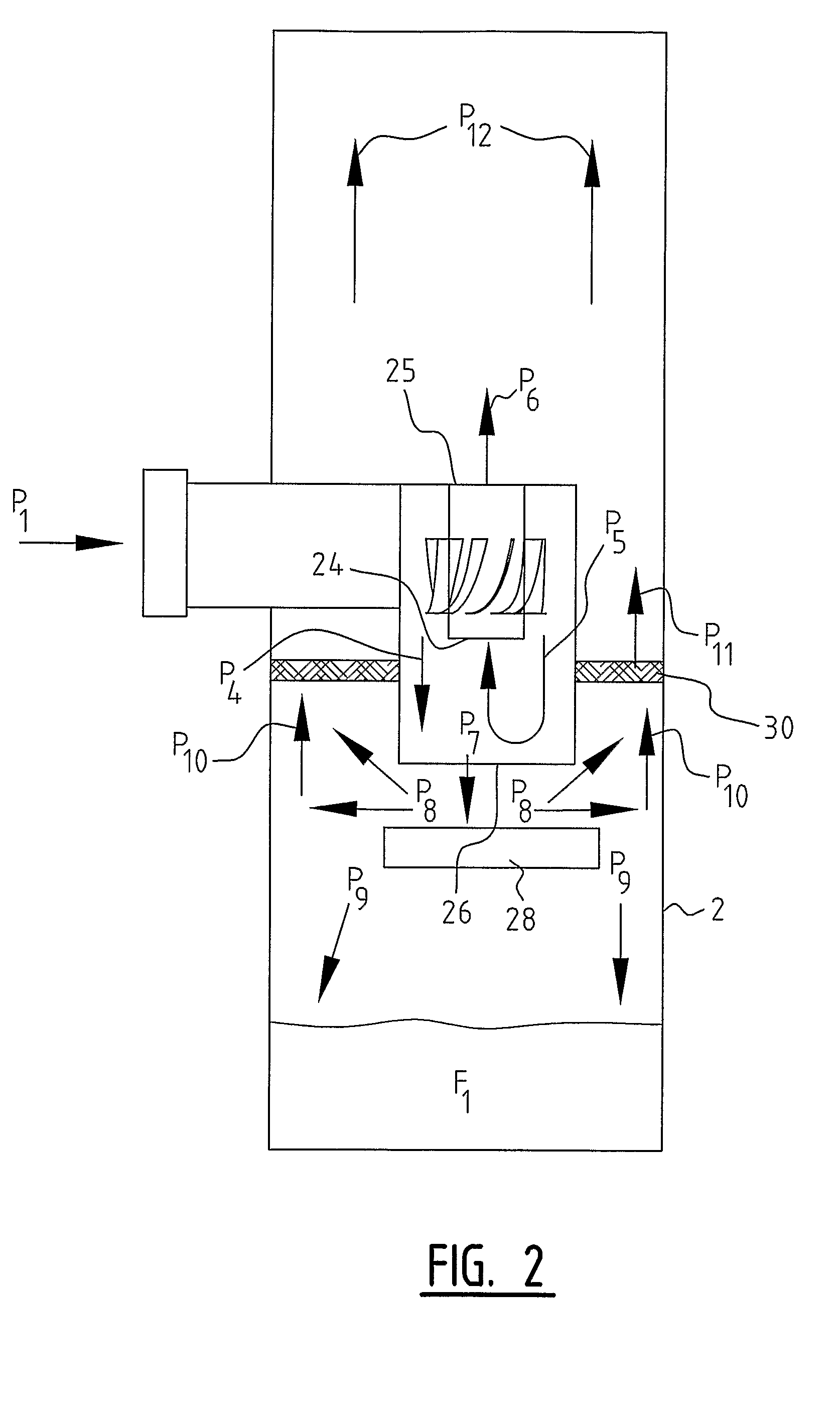

System and inlet device for separating a mixture

ActiveUS7833298B2Separation efficiency can be improvedEasy to separateCombination devicesAuxillary pretreatmentProduct gasEngineering

Owner:FMC TECH CV

UV cross-linked polymer functionalized molecular sieve/polymer mixed matrix membranes

InactiveUS20080295691A1Separation efficiency can be improvedEasy to separateSemi-permeable membranesMembranesCross-linkPliability

The present invention discloses methods of separating gases using high performance UV cross-linked polymer functionalized molecular sieve / polymer mixed matrix membranes (MMMs) with either no macrovoids or voids of less than several angstroms at the interface of the polymer matrix and the molecular sieves. These UV cross-linked MMMs were prepared by incorporating polyethersulfone (PES) functionalized molecular sieves such as AIPO-14 and UZM-25 small pore microporous molecular sieves into a continuous UV cross-linkable polyimide polymer matrix followed by UV cross-linking. The UV cross-linked MMMs in the form of symmetric dense film, asymmetric flat sheet membrane, or asymmetric hollow fiber membranes have good flexibility, high mechanical strength, and exhibit significantly enhanced selectivity and permeability over polymer membranes made from corresponding continuous polyimide polymer matrices for carbon dioxide / methane and hydrogen / methane separations. The MMMs of the present invention are suitable for a variety of liquid, gas, and vapor separations.

Owner:UOP LLC

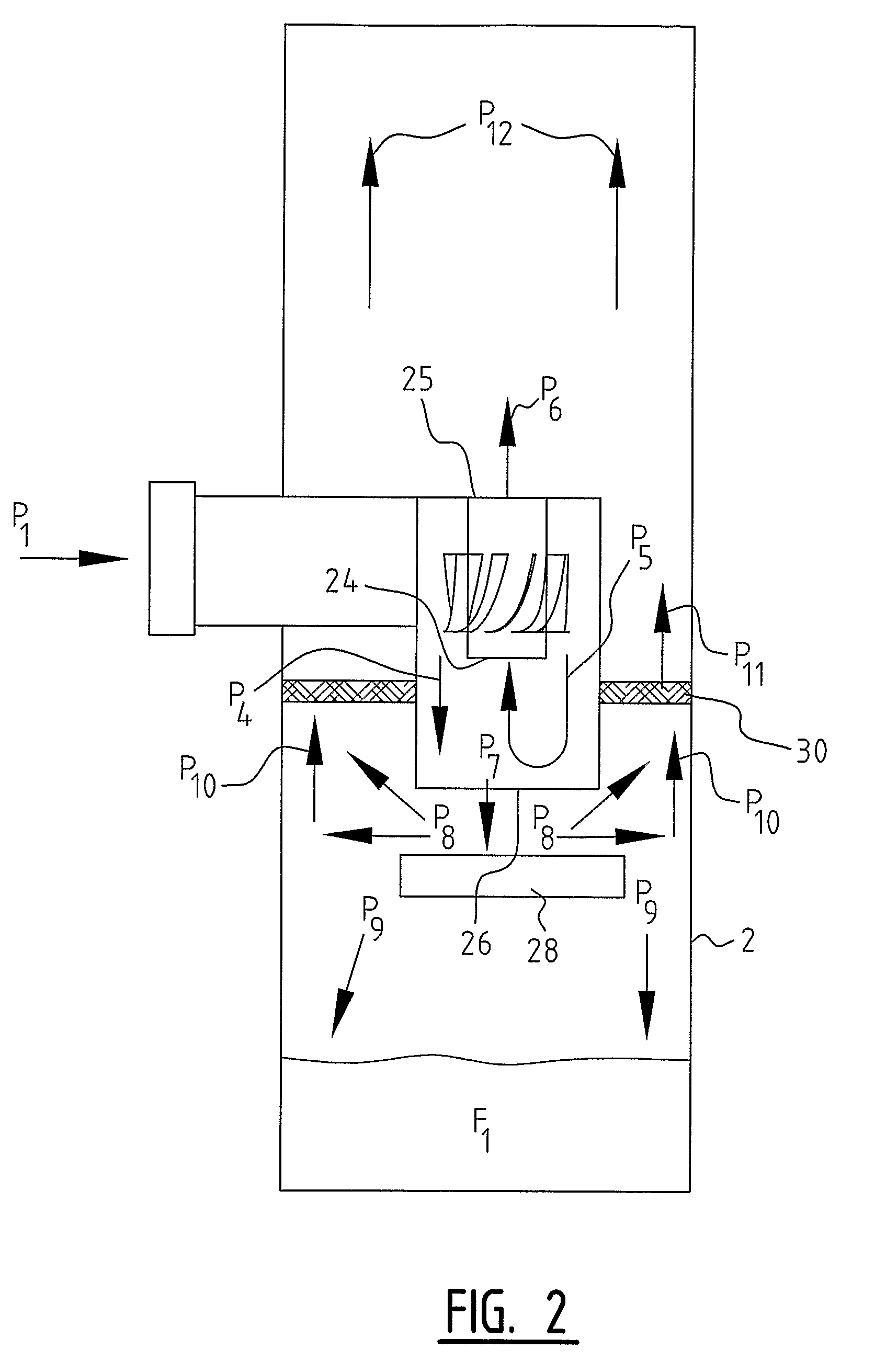

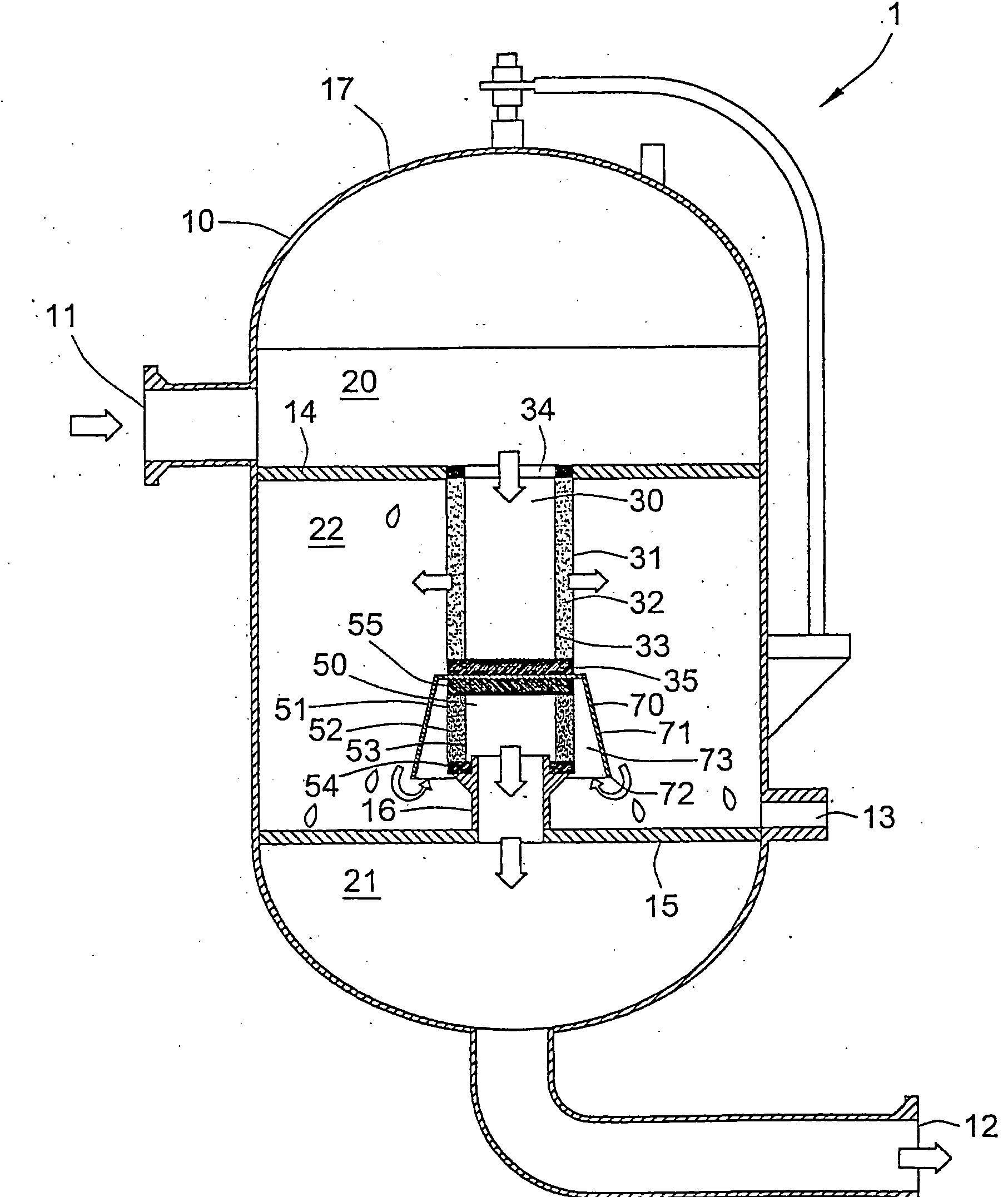

System and inlet device for separating a mixture

ActiveUS20090196806A1Improve result of separationGood resultCombination devicesAuxillary pretreatmentProduct gasEngineering

The invention relates to a system for separating a mixture of gas and liquid into a heavy fraction and a light fraction, the system comprising: —a separation vessel having a vessel inlet for the supply of the mixture to be separated, an upper vessel outlet for the discharge of the light fraction and a lower vessel outlet for the discharge of the heavy fraction; —at least one inlet device for pretreatment of the incoming mixture, the inlet device, comprising a casing having a liquid outlet for the discharge of a first mixture part mainly containing liquid to a lower compartment of the separation vessel; and at least one demister element arranged at a position below the liquid outlet for separating liquid from the gas in the first mixture part flowing from the liquid output.

Owner:FMC TECH CV

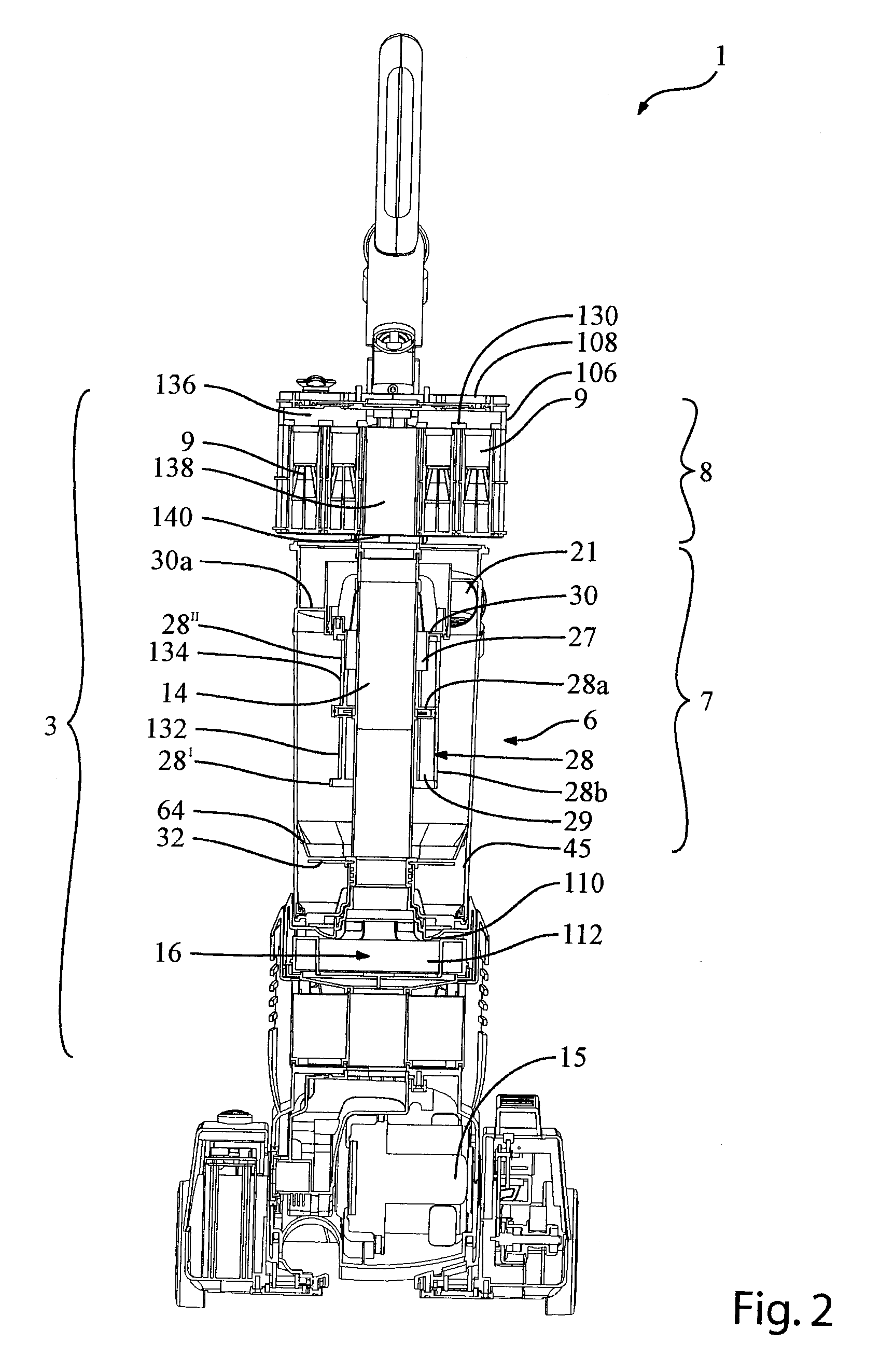

Surface cleaning apparatus

ActiveUS8997309B2Separation efficiency can be improvedReduce the amount requiredCleaning filter meansCombination devicesDesign improvementSurface cleaning

A surface cleaning apparatus comprises an air flow passage extending from a dirty air inlet to a clean air outlet and a suction motor. The surface cleaning apparatus may also comprise a cyclone chamber provided in the air flow passage. The cyclone chamber may comprise a cyclone air inlet, a cyclone air outlet and a dirt outlet. The surface cleaning apparatus may comprise a dirt collection chamber having a dirt inlet, a dirt collection chamber first end, an opposed dirt collection chamber second end and a longitudinally extending sidewall. Various design improvements are provided.

Owner:OMACHRON INTPROP

Coalescing and separation arrangements systems and methods for liquid mixtures

InactiveUS20050178718A1Separation efficiency can be improvedReduce the amount requiredLiquid suspension thickening by filtrationSettling tanks feed/dischargeChromatographyCoalescer

Coalescing and / or separating arrangements for separating a discontinuous phase liquid from a continuous phase liquid may comprise two or more of a coalescer (30), a separator (50) and a flow director (70).

Owner:PALL CORP

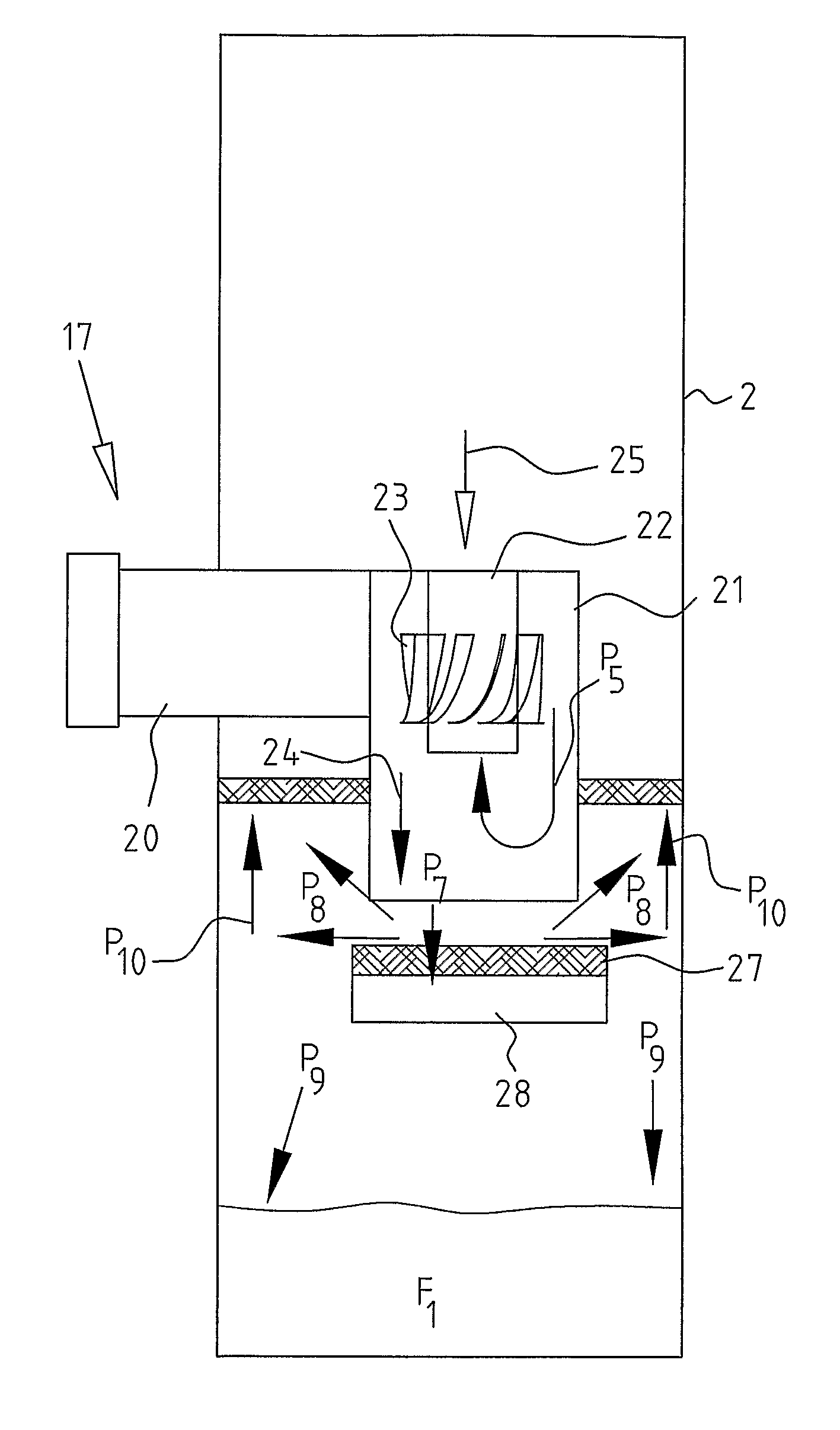

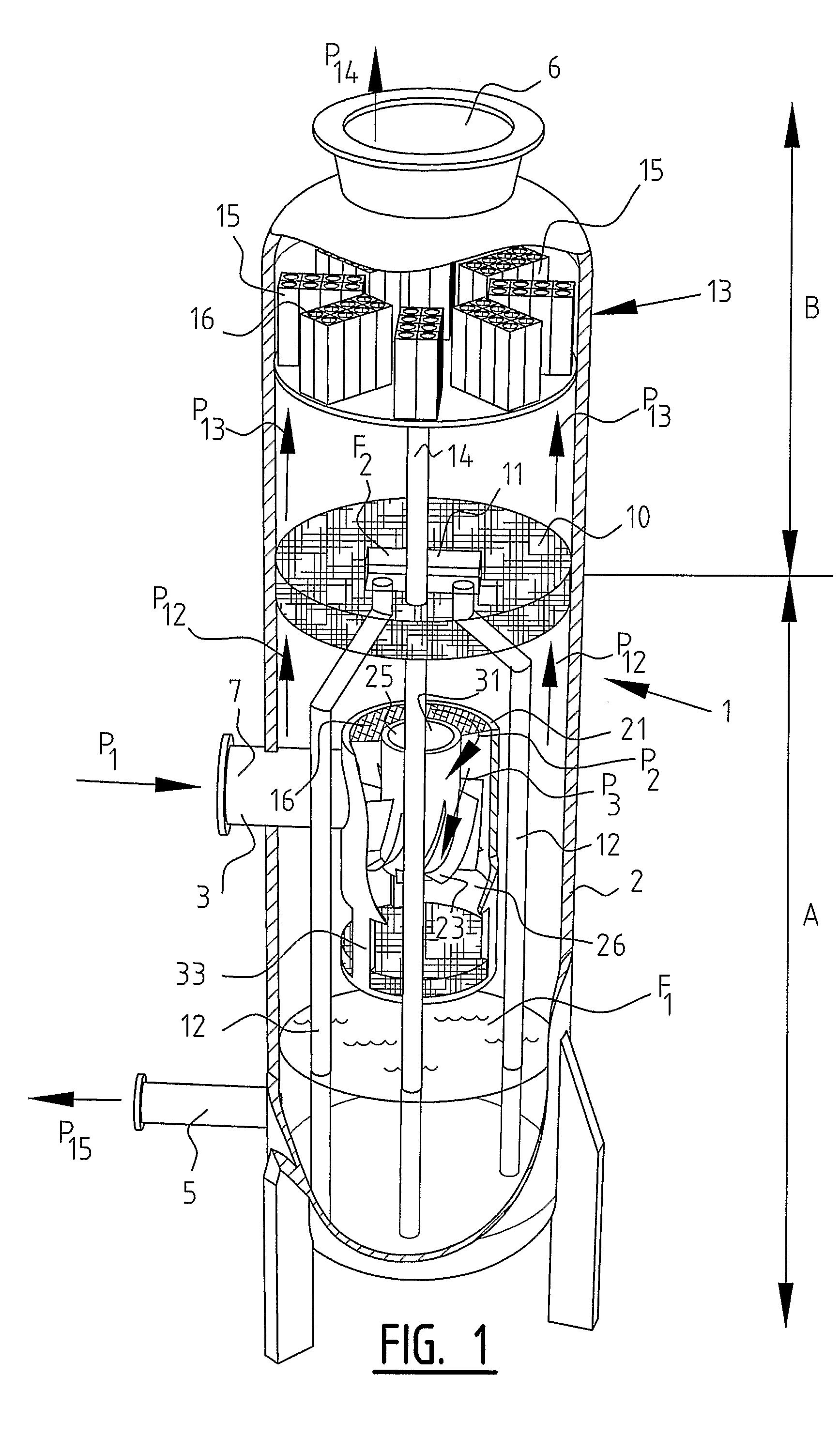

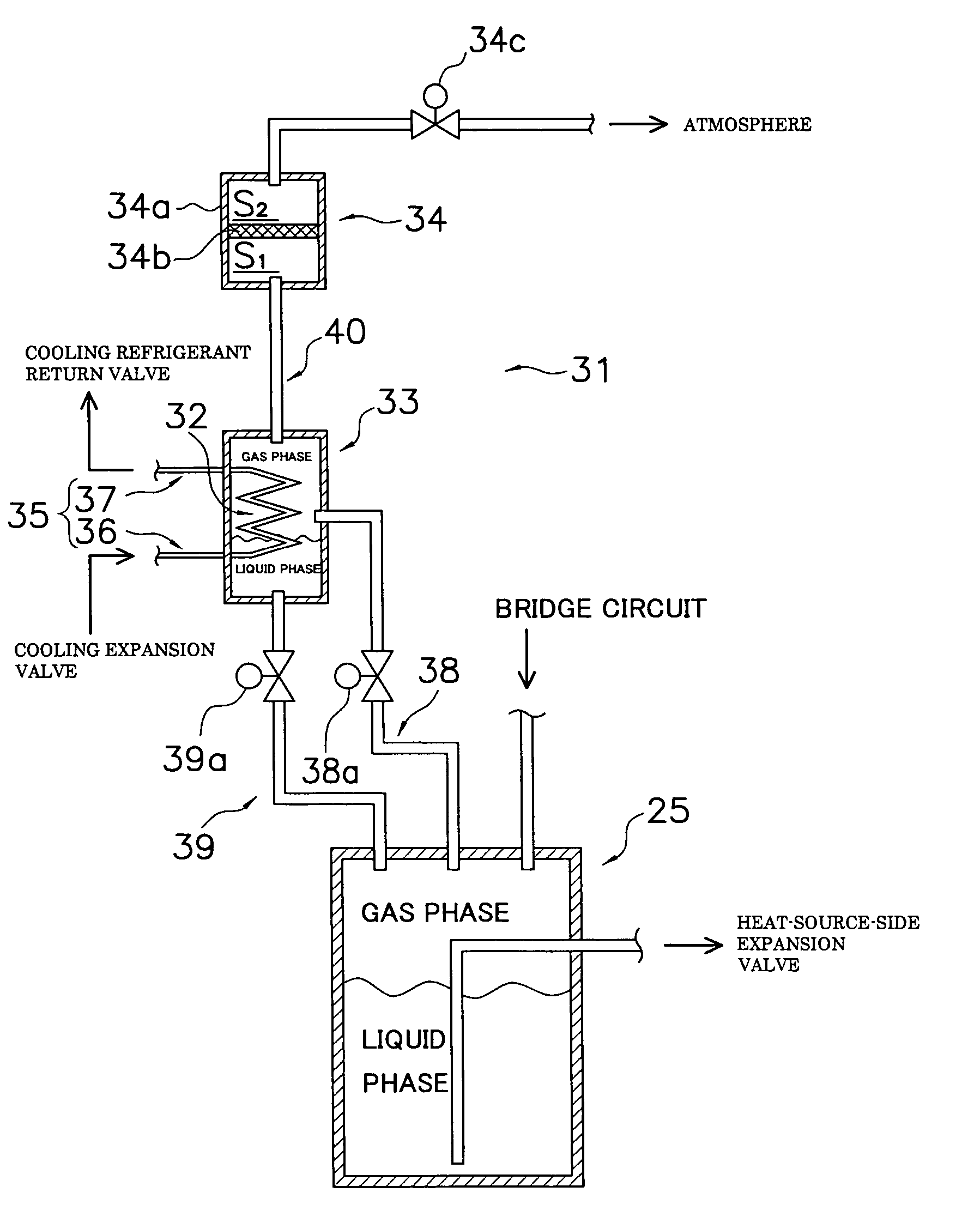

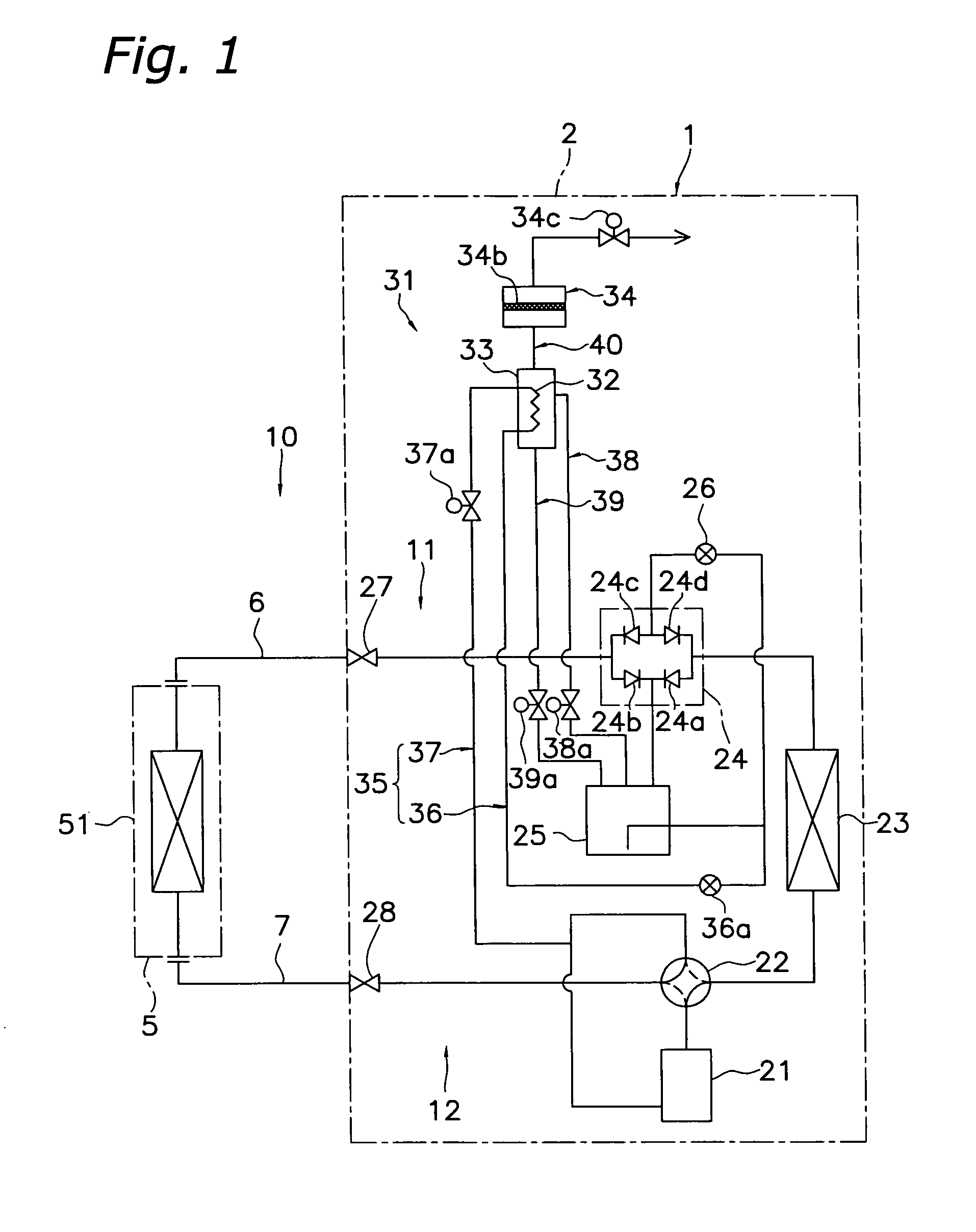

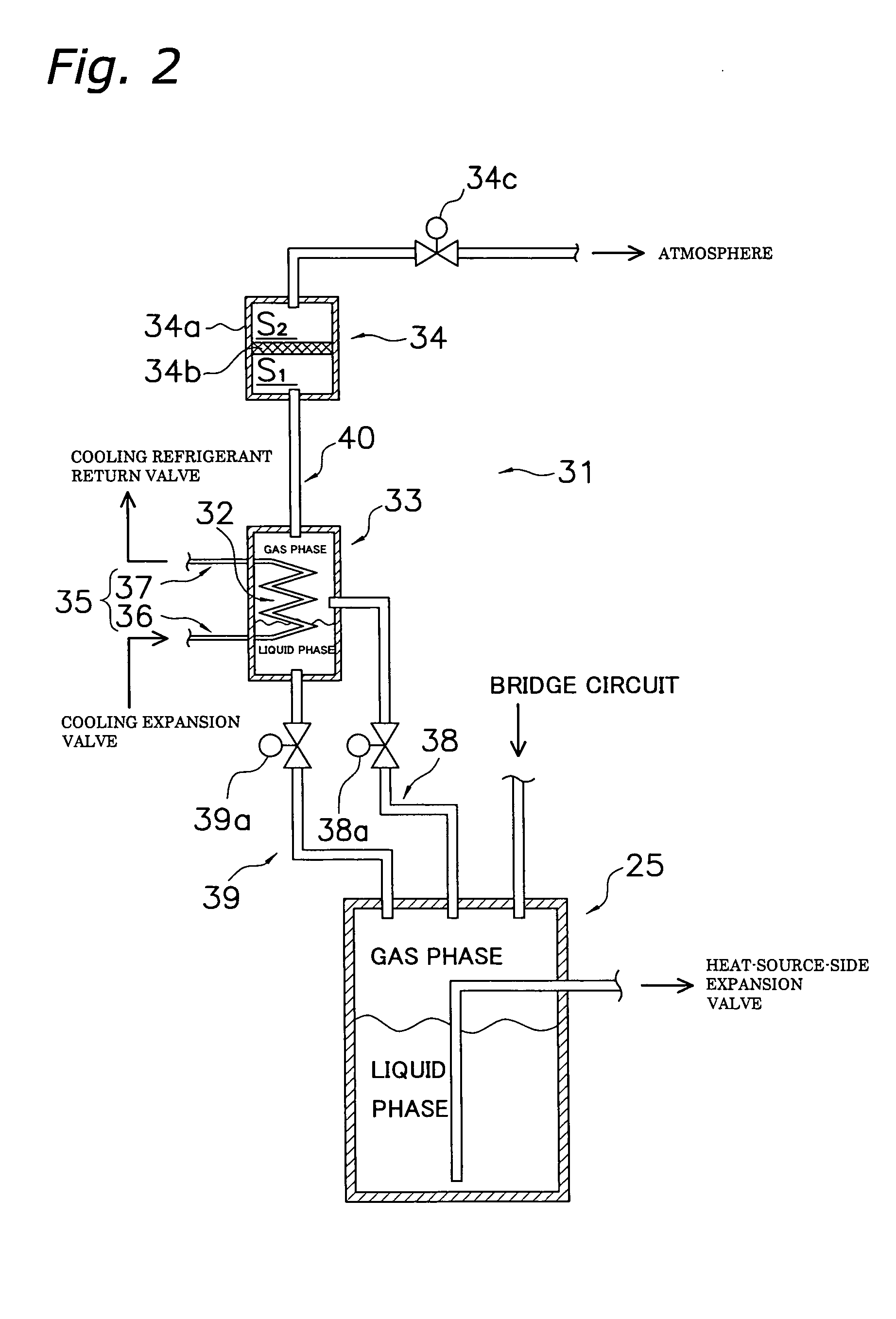

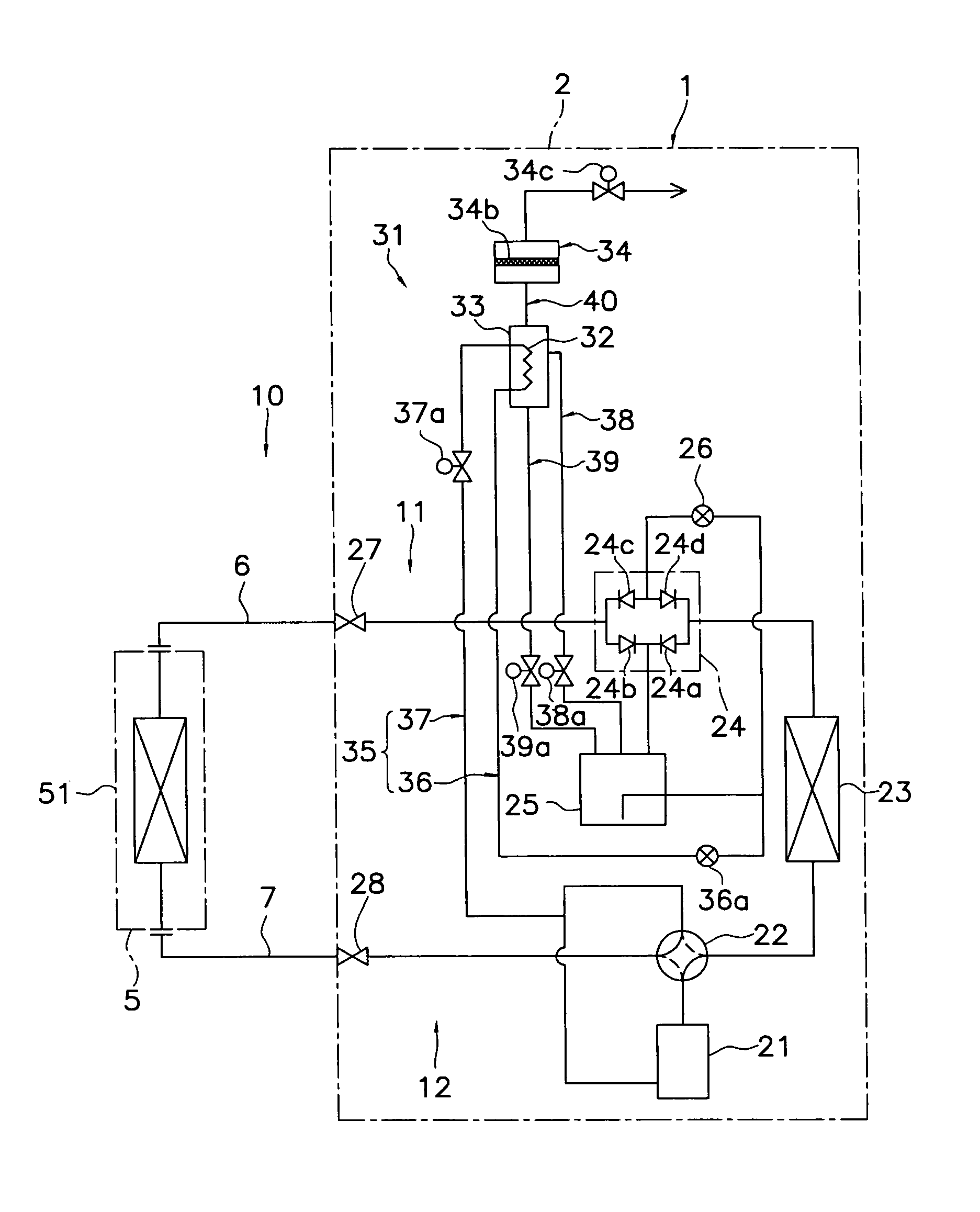

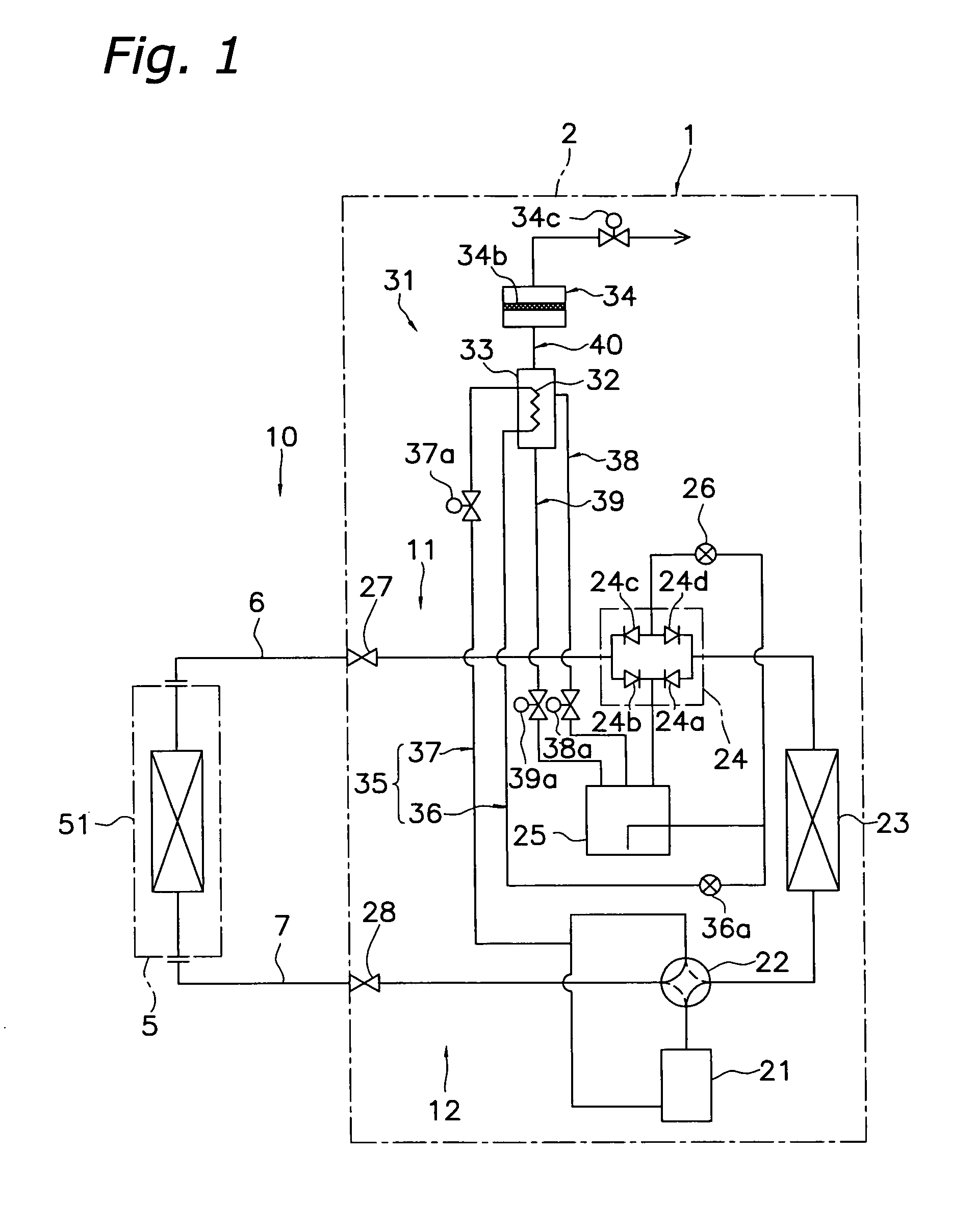

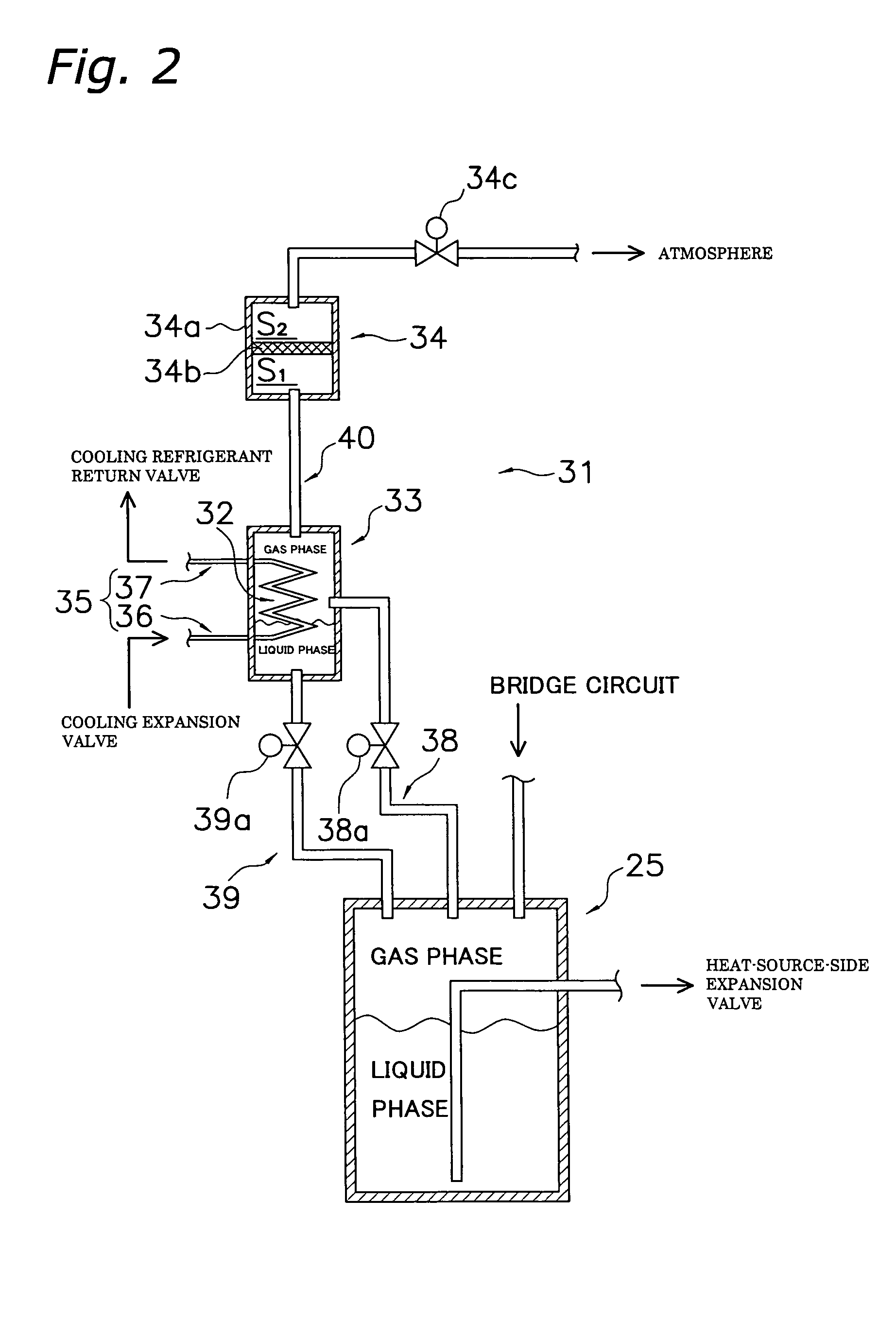

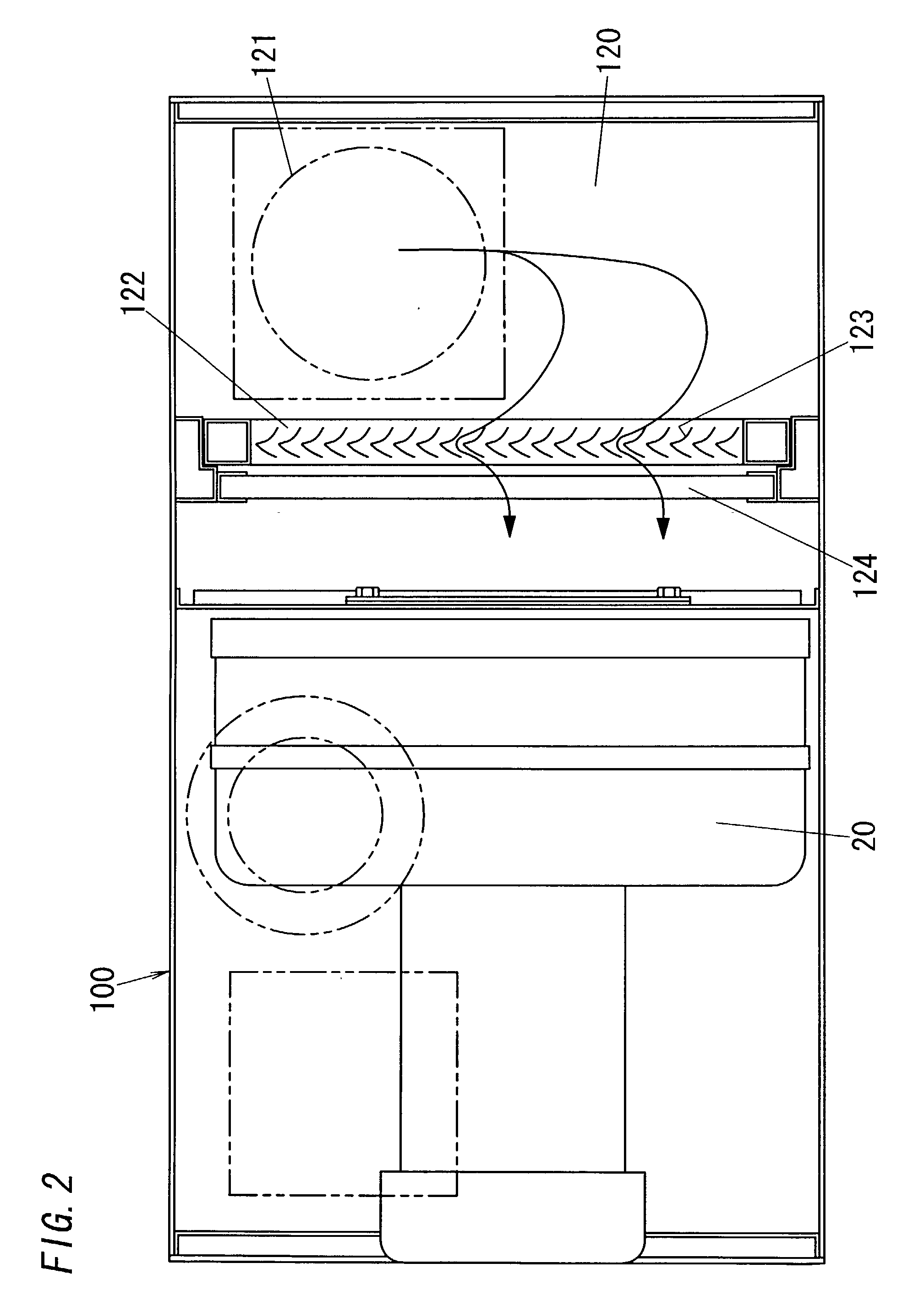

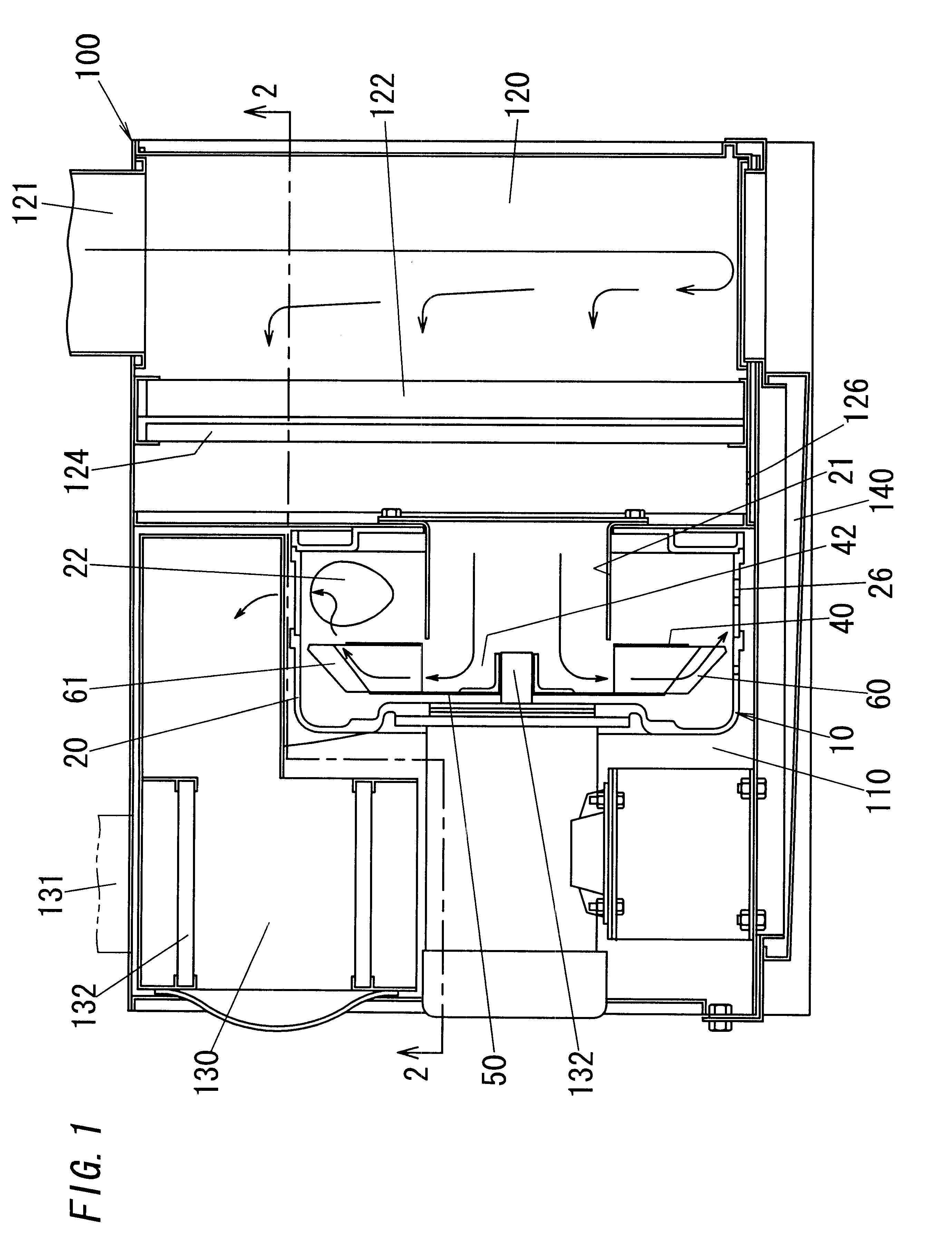

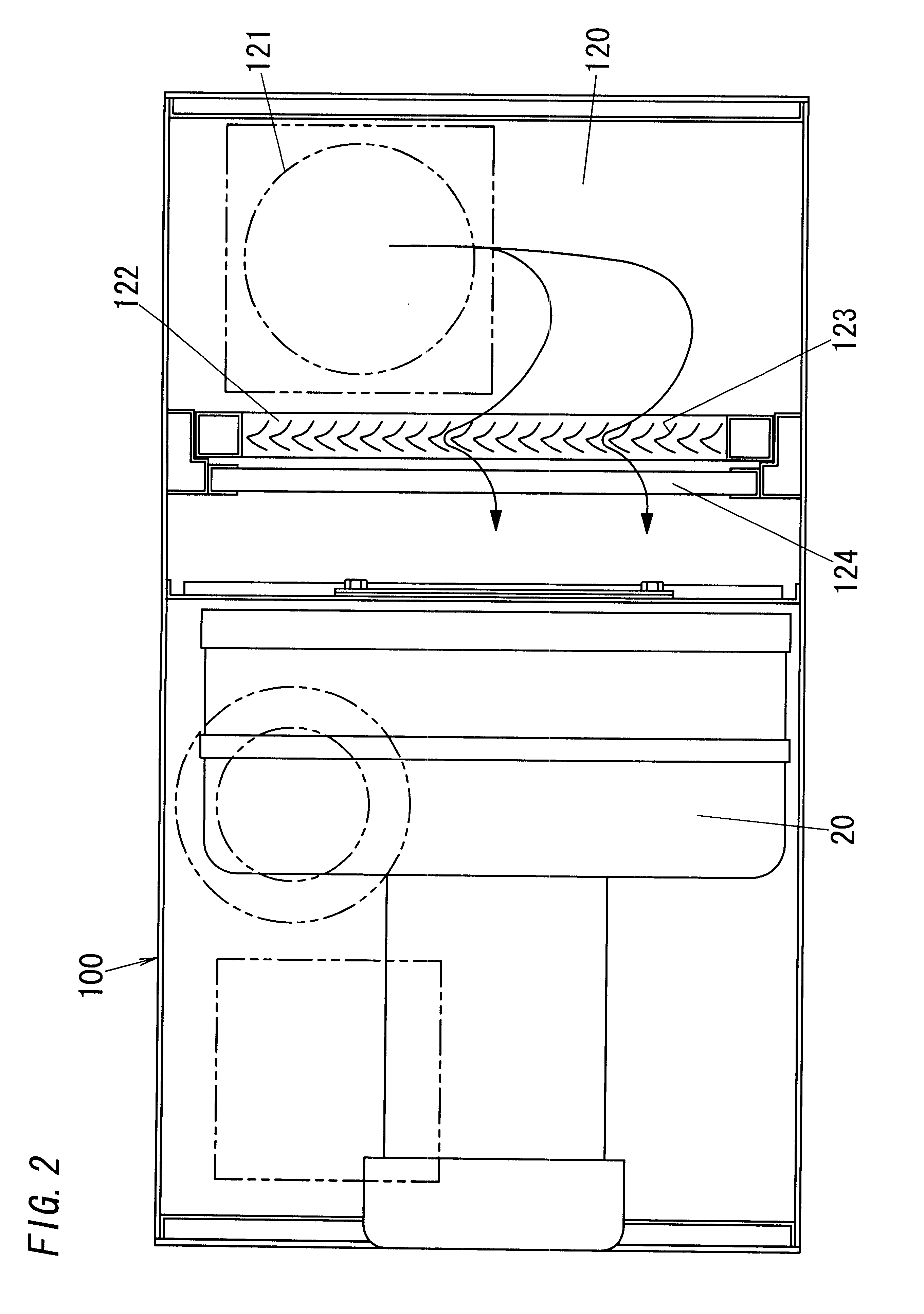

Method for installing refrigeration device, and refrigeration device

InactiveUS20070113581A1Reduce numberSimplify structureCompression machines with non-reversible cycleFluid circulation arrangementRefrigerantChiller

The separation efficiency of non-condensable gas in the separation membrane is enhanced in a refrigeration device provided with a configuration whereby non-condensable gas remaining in the refrigerant connection pipes at the time of on-site installation can be separated and removed from a state of mixture with the refrigerant in the refrigerant circuit using a separation membrane. An air conditioning device 1 comprises a heat source unit (2) and a utilization unit (5) connected via a refrigerant connection pipe (6, 7) to form a refrigerant circuit (10), and has a cooler (32), a secondary receiver (33), and a separation membrane device (34). The cooler (32) cools at least a portion of the refrigerant that flows through the liquid-side refrigerant circuit (11) as the compressor (21) is operated and the refrigerant in the refrigerant circuit (10) is recirculated. The secondary receiver (33) separates the refrigerant cooled by the cooler (32) into a liquid refrigerant and a gas refrigerant that includes non-condensable gas. The separation membrane device (34) has a separation membrane (34b) for separating the non-condensable gas from the gas refrigerant obtained by gas-liquid separation, and discharges the non-condensable gas thus separated to the outside of the refrigerant circuit (10).

Owner:DAIKIN IND LTD

Separation device for removing liquid from a mixture comprising a gas and liquid

InactiveUS8790447B2Separation efficiency can be improvedCombination devicesLiquid degasificationEngineeringCOMPONENT II

A separation device for removing at least part of a liquid from a mixture which comprises a gas and the liquid in the form of droplets, comprises:a) a housing comprising first, second and third separation sections for separating liquid from the mixture, wherein the second section is arranged below the first section and above the third section, the respective sections are in communication with each other, and the second section comprises a rotating coalescer element;b) tangentially arranged means to introduce the mixture into the first section;c) means to remove liquid from the first section;d) means to remove liquid from the third section; ande) means to remove a gaseous stream, lean in liquid, from the third section.A separation process for removing at least part of a liquid from a mixture comprising the liquid in the form of droplets using the separation device.

Owner:SHELL OIL CO

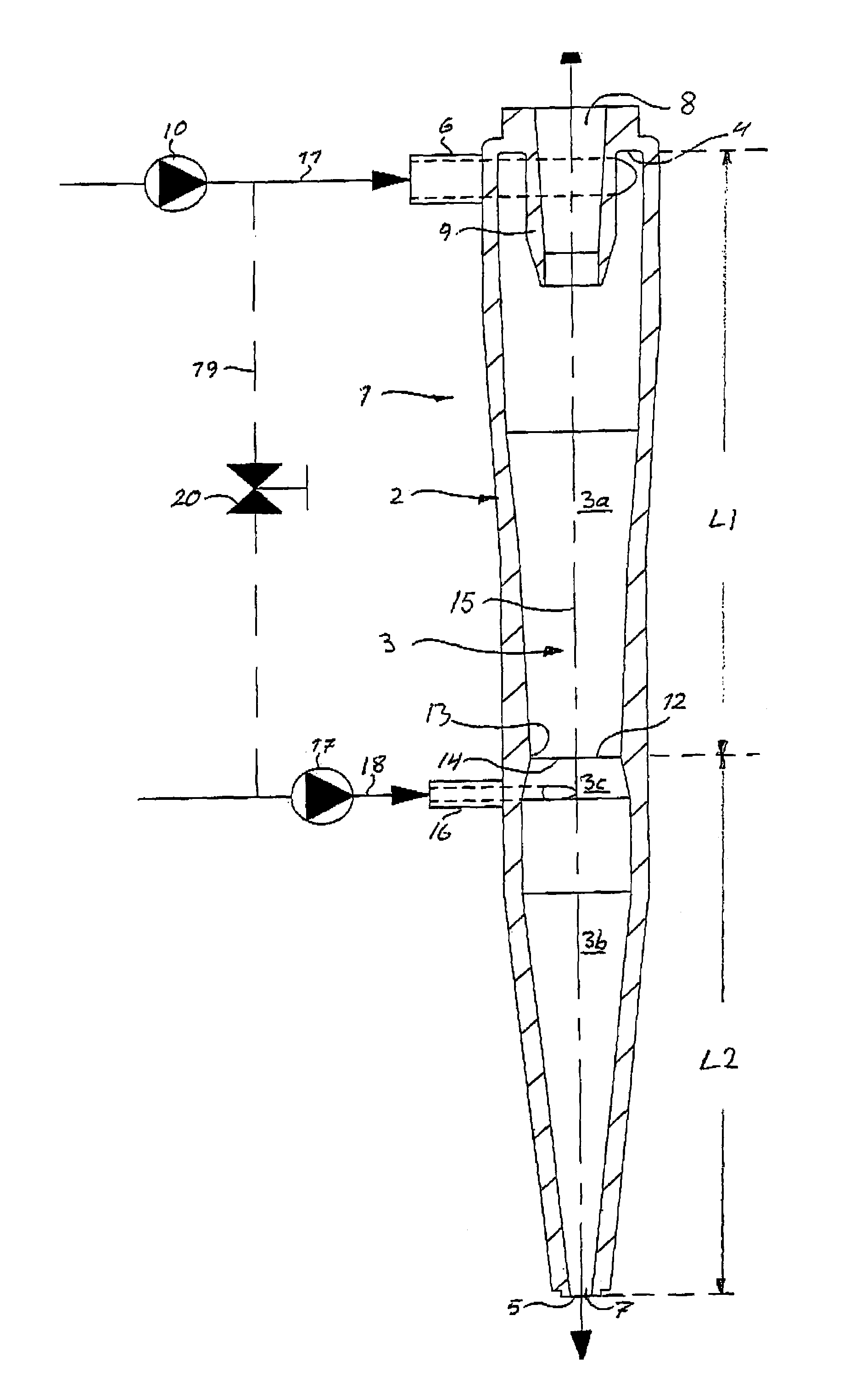

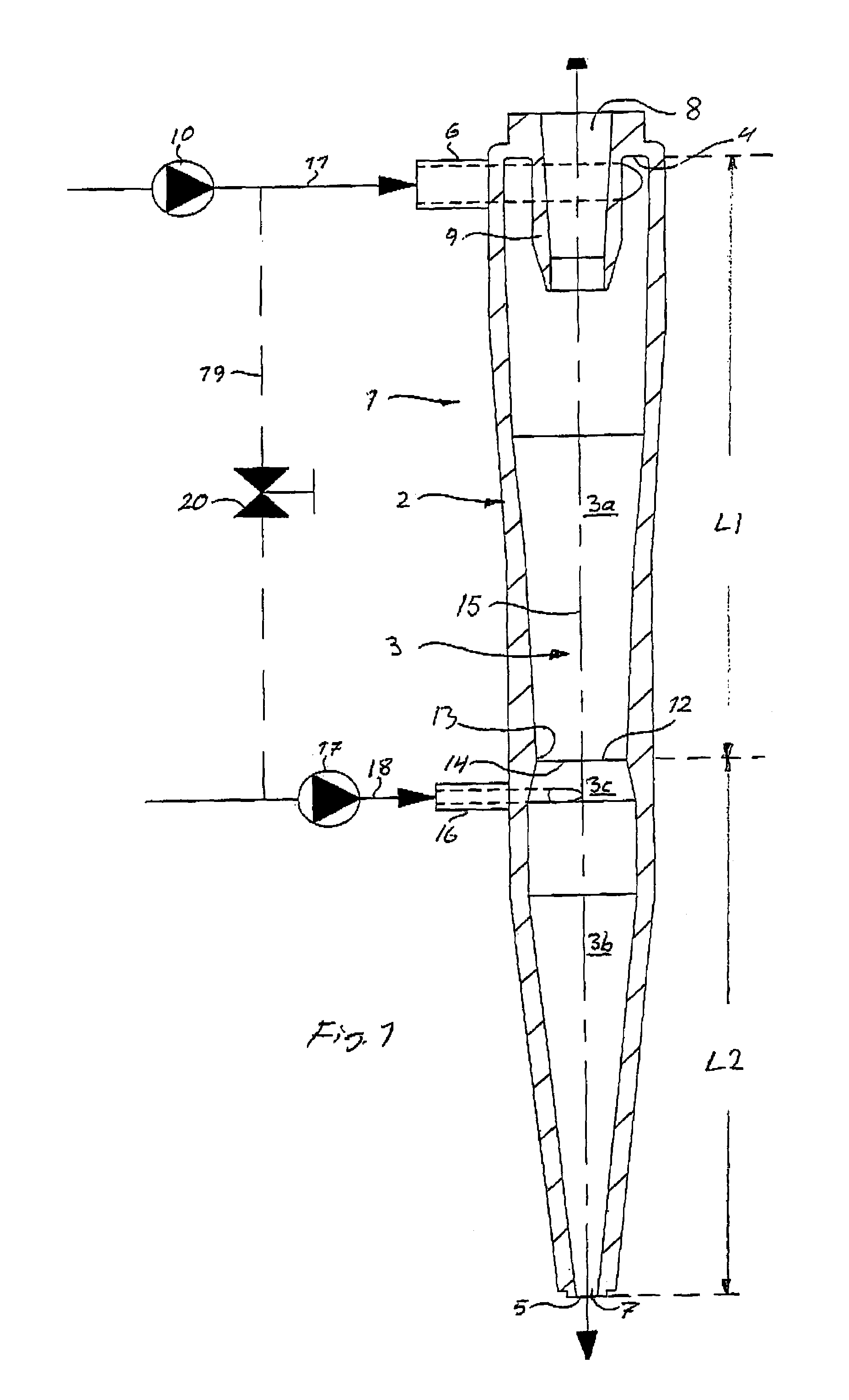

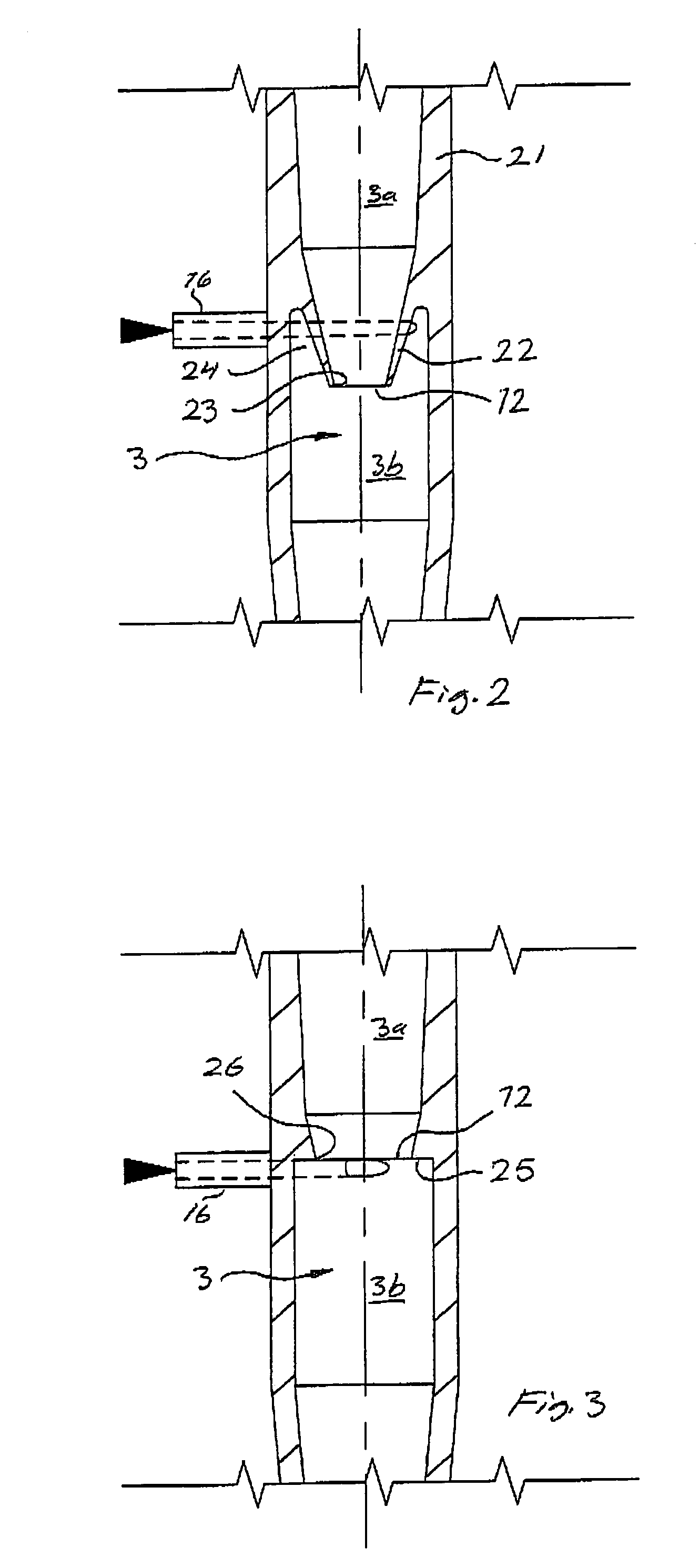

Separation of fibre pulp suspensions containing relatively heavy contaminants

ActiveUS7404492B2Increase in production capacityReduce energy consumptionReversed direction vortexSingle direction vortexFiberCell separation

A hydrocyclone unit for separating a fibre pulp suspension containing relatively heavy contaminants has an elongate tapering separation chamber, an inlet member that feeds the suspension tangentially into the separation chamber at a base end, so as to form a vortex in the separation chamber, a reject fraction outlet at the apex end of the separation chamber for discharging a reject fraction containing heavy contaminants, and a central accept fraction outlet at the base end for discharging a central fraction containing fibres. A fluid injection member is adapted to inject a fluid tangentially into the separation chamber at a distance from the apex end which is at least 40% of the length of the separation chamber, such that the injected fluid increases the rotational speed of a portion of the vortex in the chamber to increase the separation efficiency with respect to fibres existing in the vortex portion.

Owner:GLV FINANCE HUNGARY KFT +1

Method for installing refrigeration device, and refrigeration device

InactiveUS7357002B2Separation efficiency can be improvedCompression machines with non-reversible cycleFluid circulation arrangementEngineeringAir conditioning

Owner:DAIKIN IND LTD

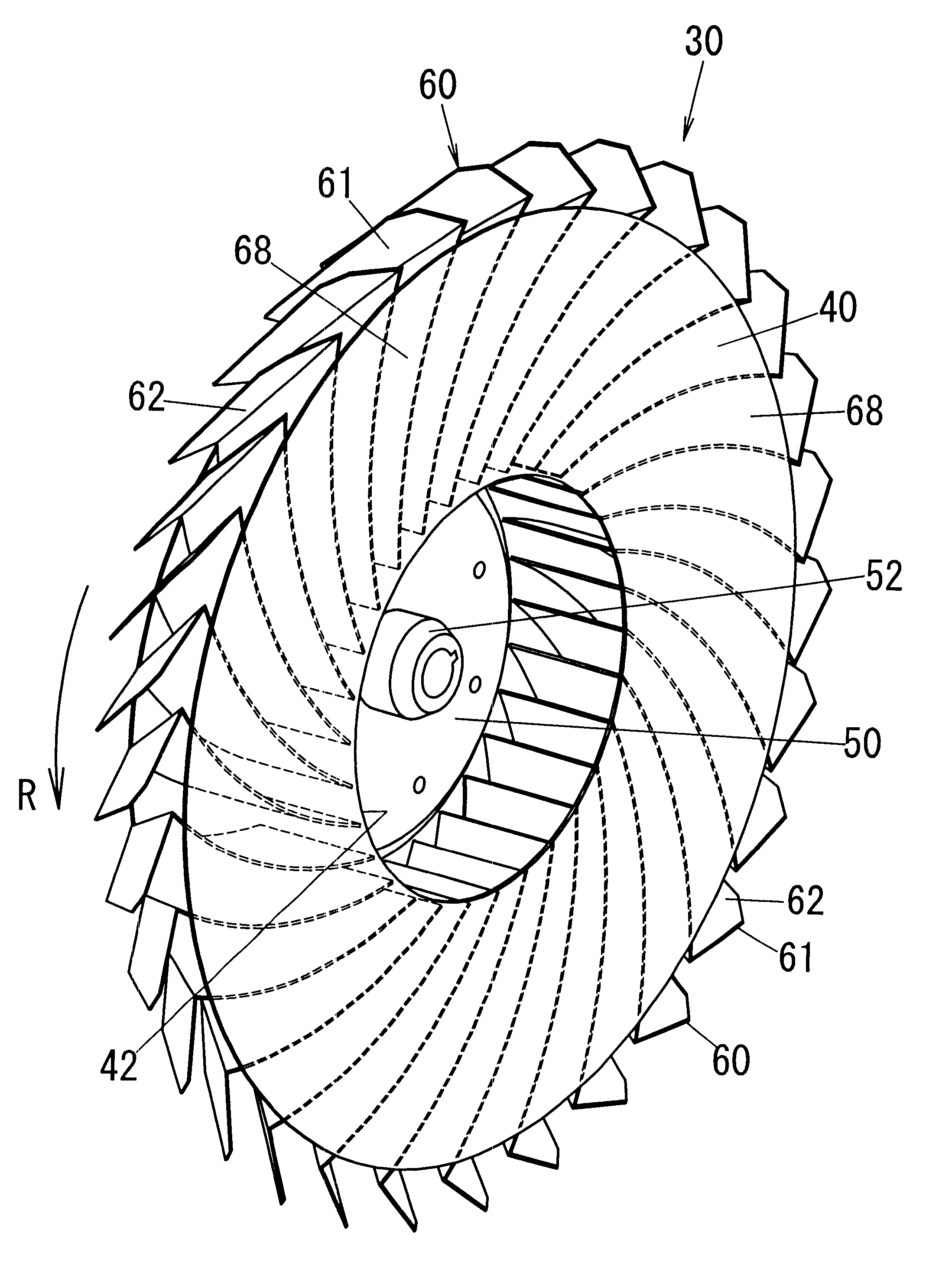

Oil mist eliminator

InactiveUS20030000185A1Separating the oil mist successfully and efficientlySeparation efficiency can be improvedCombination devicesPropellersImpellerForced-air

An oil mist eliminator includes an impeller rotating about its axis in one direction within a casing having an inlet and an outlet. The impeller includes a plurality of circumferentially spaced blades held between front and rear discs. The front disc has a center opening for introducing an oil-contaminated air. Each blade is composed of an inner fin extending in a radial direction and an outer fin bent from the inner fin for deflecting the air proceeding between the adjacent inner fins in a forward direction, thereby creating a forced air flow for introducing the air axially from the front opening, guiding it radially between the discs, and venting it axially forwardly in a front-in and front-out fashion. Thus, even a portion of the air being guided immediately along the rear disc can be successfully deflected for collision against the outer fins without fail, maximizing oil separation efficiency.

Owner:KURAKO

Oil mist eliminator

InactiveUS6648936B2Separating the oil mist successfully and efficientlySeparation efficiency can be improvedCombination devicesLiquid degasificationImpellerForced-air

An oil mist eliminator includes an impeller rotating about its axis in one direction within a casing having an inlet and an outlet. The impeller includes a plurality of circumferentially spaced blades held between front and rear discs. The front disc has a center opening for introducing an oil-contaminated air. Each blade is composed of an inner fin extending in a radial direction and an outer fin bent from the inner fin for deflecting the air proceeding between the adjacent inner fins in a forward direction, thereby creating a forced air flow for introducing the air axially from the front opening, guiding it radially between the discs, and venting it axially forwardly in a front-in and front-out fashion. Thus, even a portion of the air being guided immediately along the rear disc can be successfully deflected for collision against the outer fins without fail, maximizing oil separation efficiency.

Owner:KURAKO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com