Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

446results about "Pulp liquor regeneration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

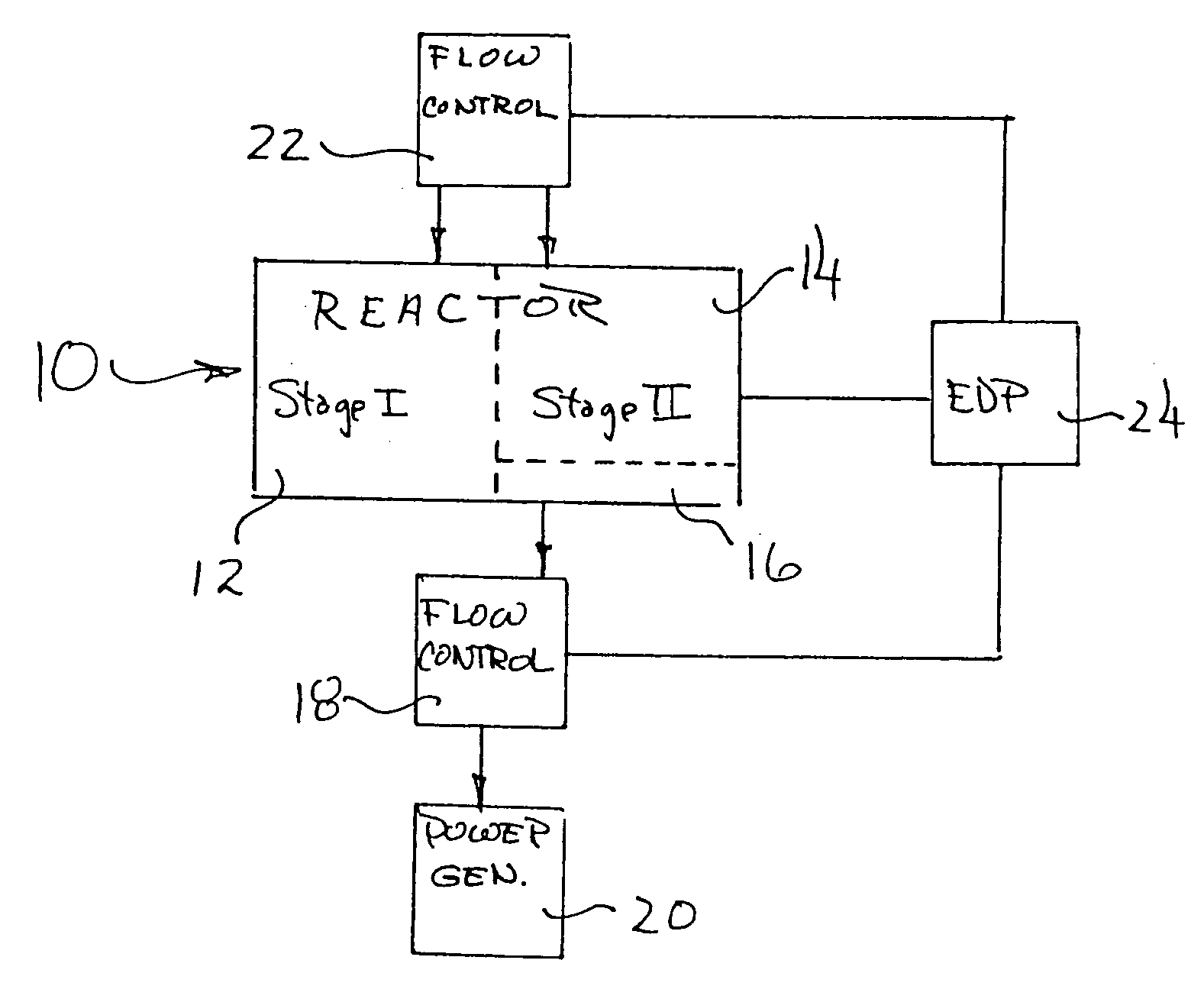

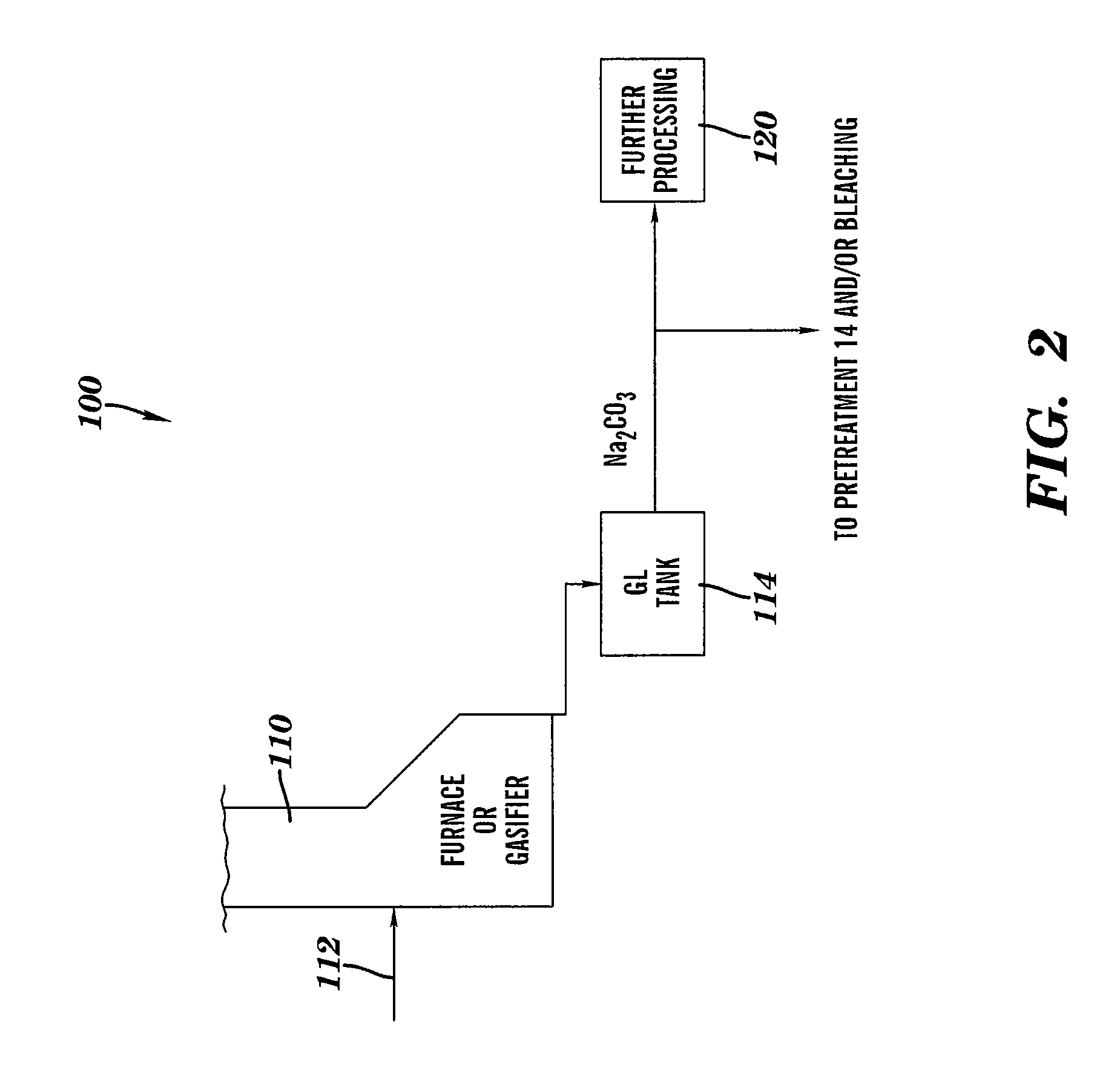

Catalytic Gasification Process with Recovery of Alkali Metal from Char

ActiveUS20090169448A1Quantity minimizationThermal non-catalytic crackingMuffle furnacesPhysical chemistryAlkali metal

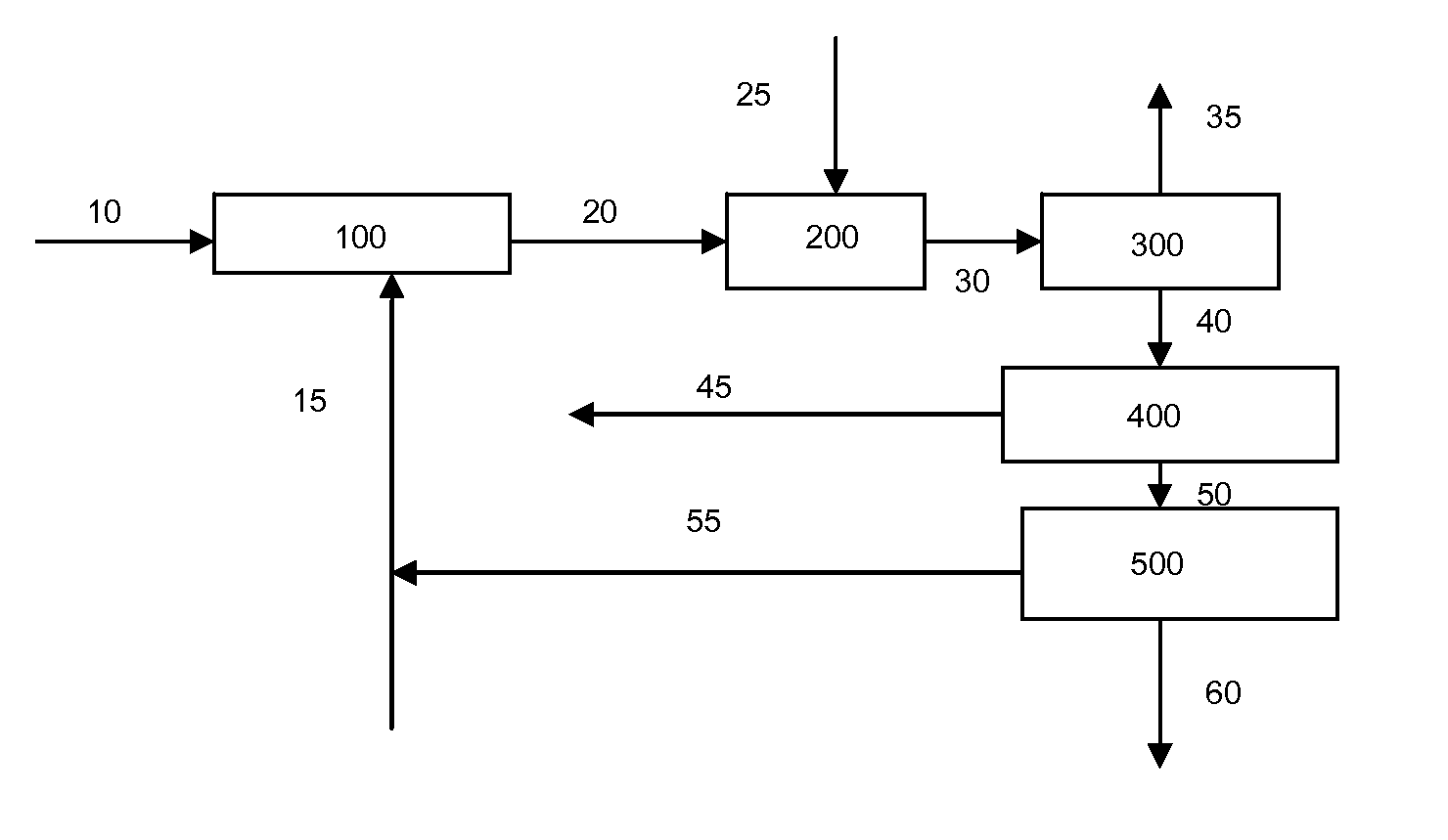

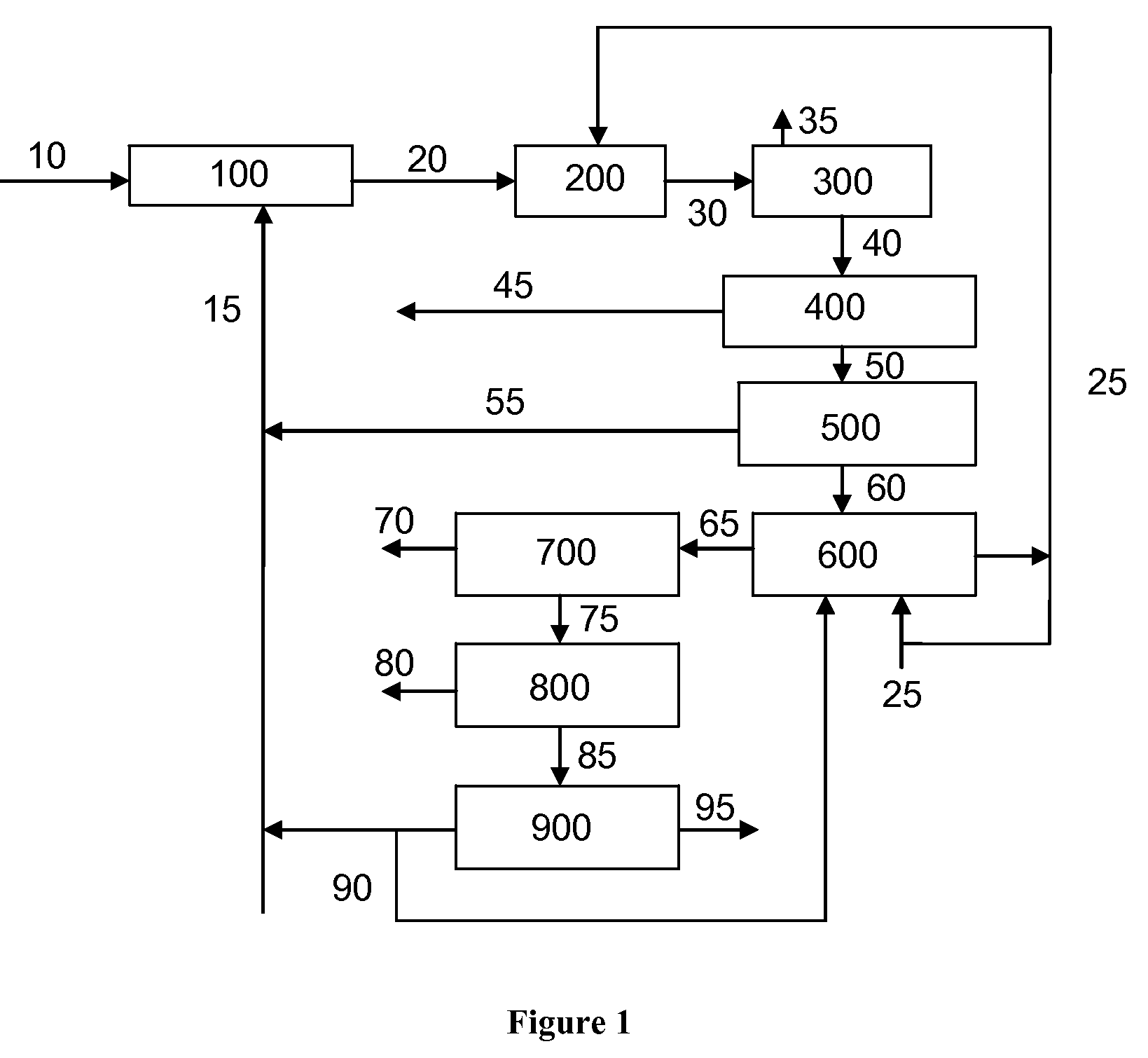

Processes are described for the extraction and recovery of alkali metal from the char that results from catalytic gasification of a carbonaceous material. Among other steps, the processes of the invention include a hydrothermal leaching step in which a slurry of insoluble particulate comprising insoluble alkali metal compounds is treated with carbon dioxide and steam at elevated temperatures and pressures to effect the conversion of insoluble alkali metal compounds to soluble alkali metal compounds. Further, processes are described for the catalytic gasification of a carbonaceous material where a substantial portion of alkali metal is extracted and recovered from the char that results from the catalytic gasification process.

Owner:SURE CHAMPION INVESTMENT LTD

Catalytic Gasification Process with Recovery of Alkali Metal from Char

ActiveUS20090169449A1Quantity minimizationThermal non-catalytic crackingMuffle furnacesParticulatesSlurry

Processes are described for the extraction and recovery of alkali metal from the char that results from catalytic gasification of a carbonaceous material. Among other steps, the processes of the invention include a hydrothermal leaching step in which a slurry of insoluble particulate comprising insoluble alkali metal compounds is treated with carbon dioxide and steam at elevated temperatures and pressures to effect the conversion of insoluble alkali metal compounds to soluble alkali metal compounds. Further, processes are described for the catalytic gasification of a carbonaceous material where a substantial portion of alkali metal is extracted and recovered from the char that results from the catalytic gasification process.

Owner:SURE CHAMPION INVESTMENT LTD

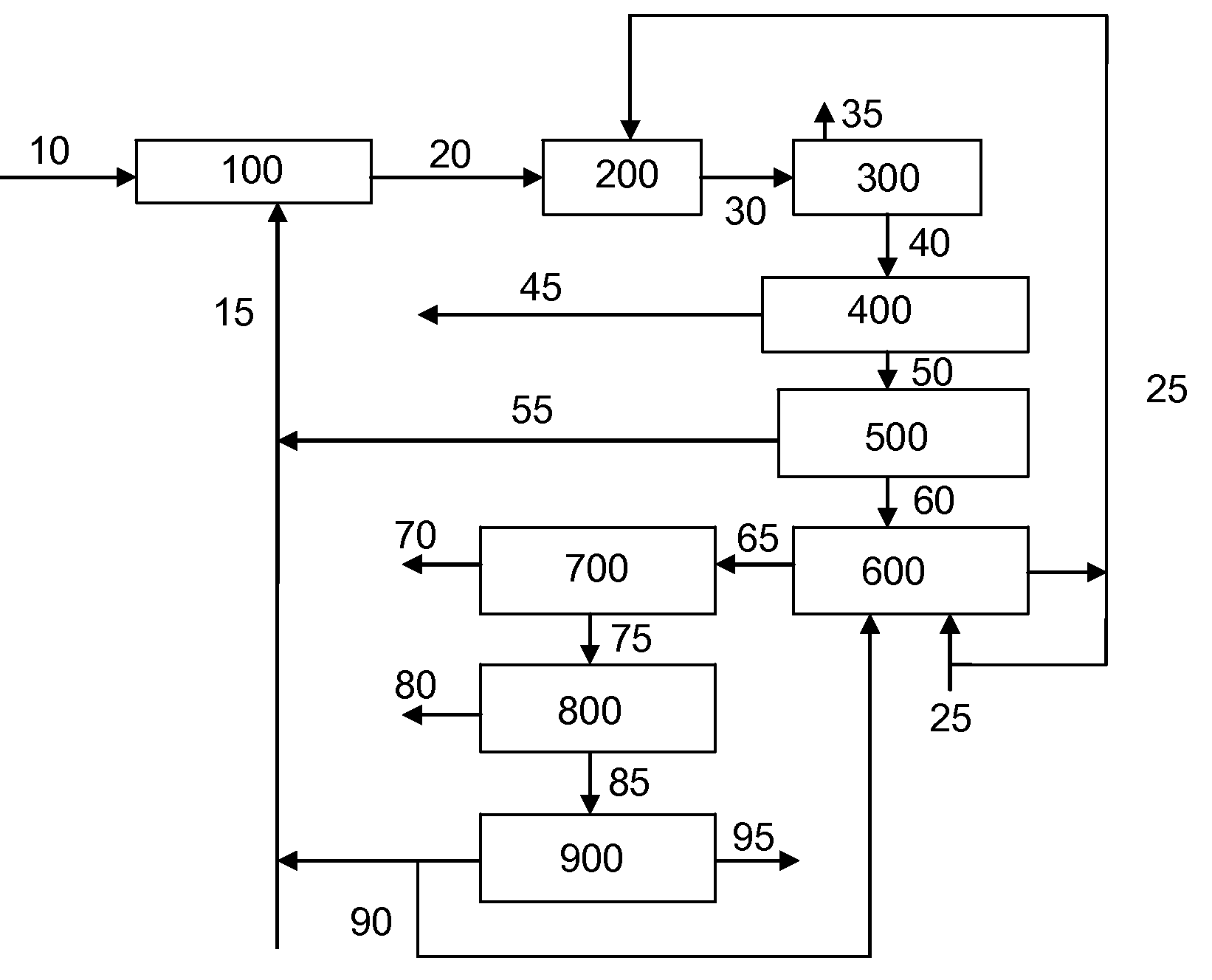

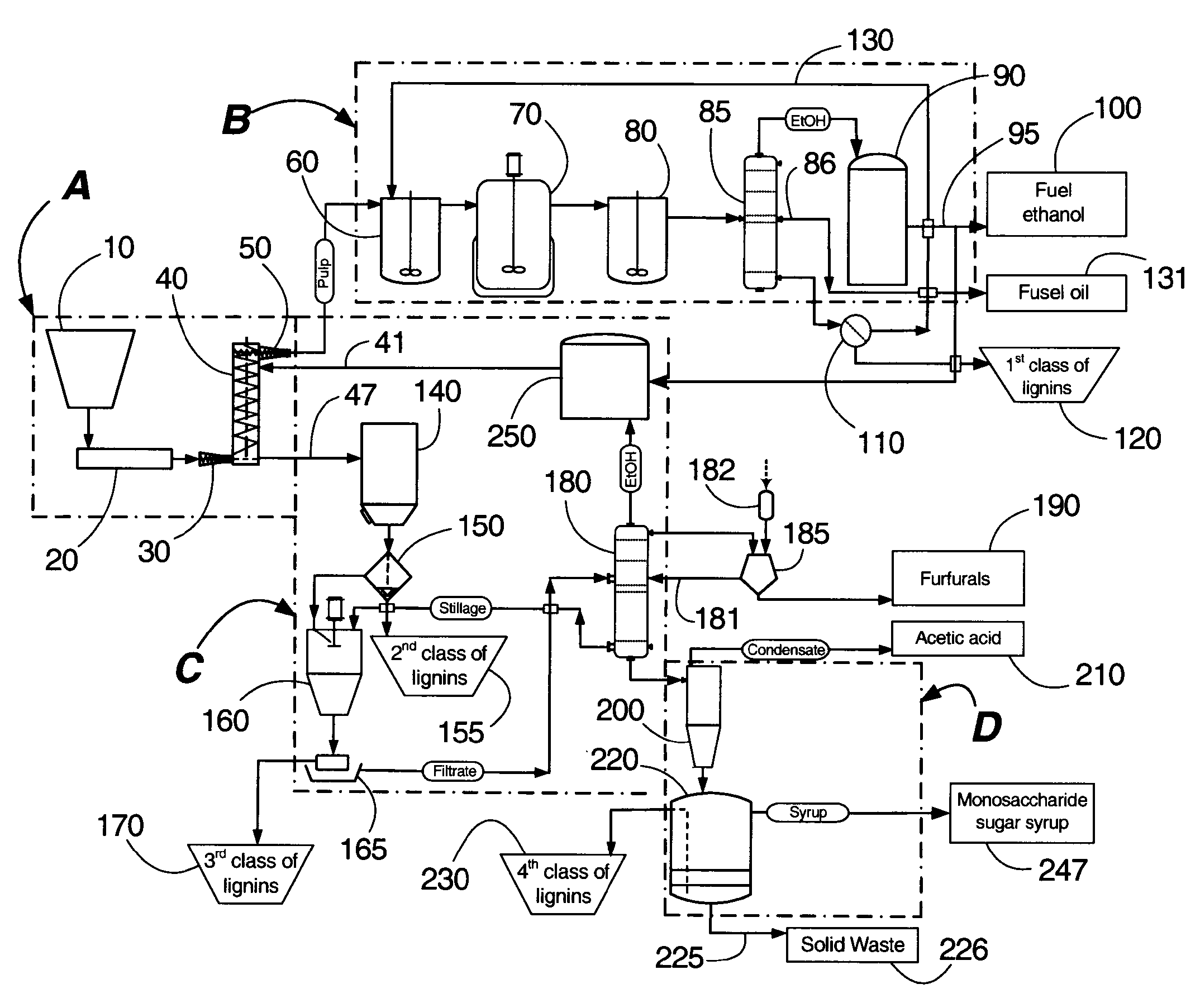

Continuous counter-current organosolv processing of lignocellulosic feedstocks

InactiveUS7465791B1Low viscosityNon-fibrous pulp additionBiological substance pretreatmentsFractionationOrganosolv

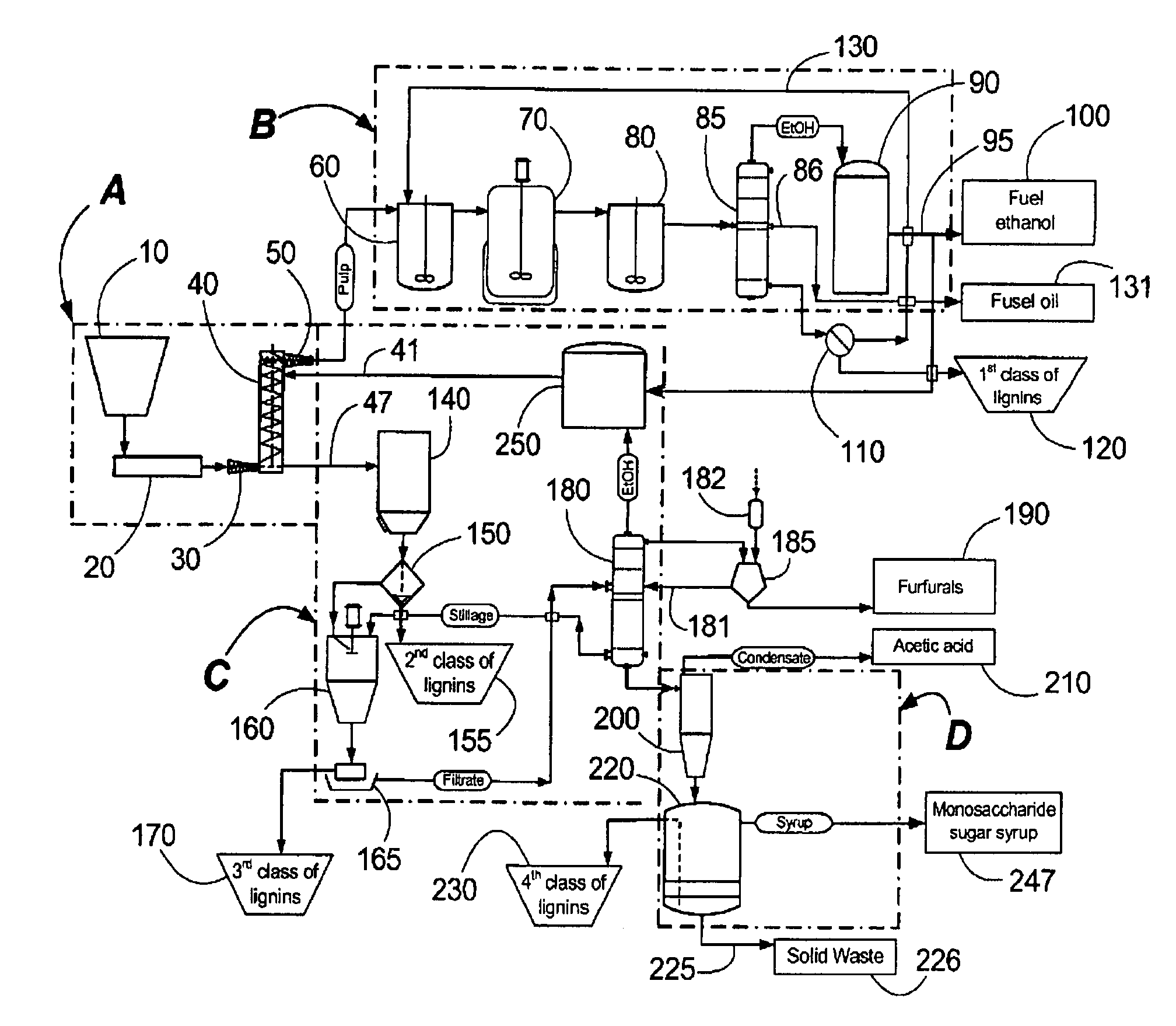

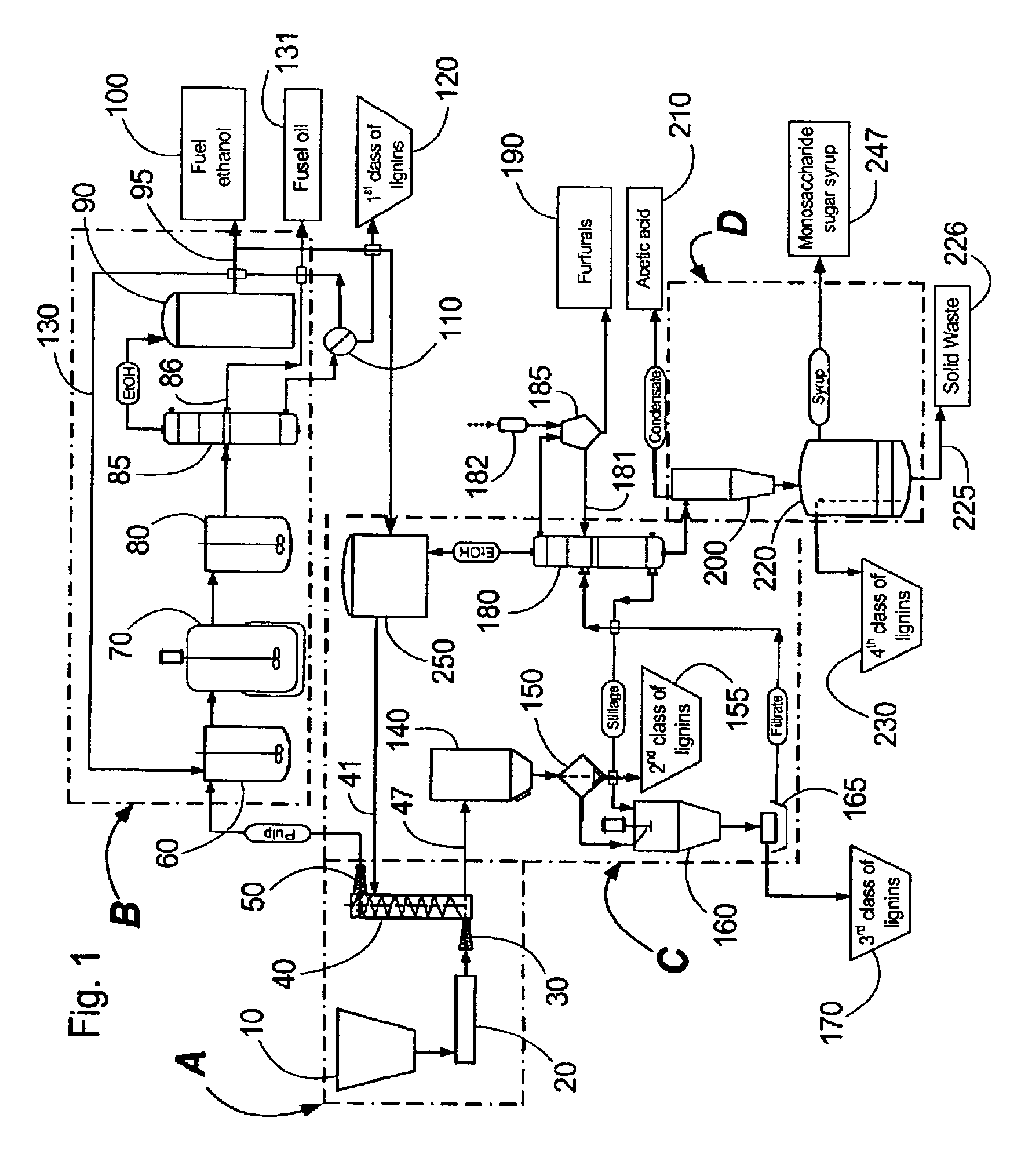

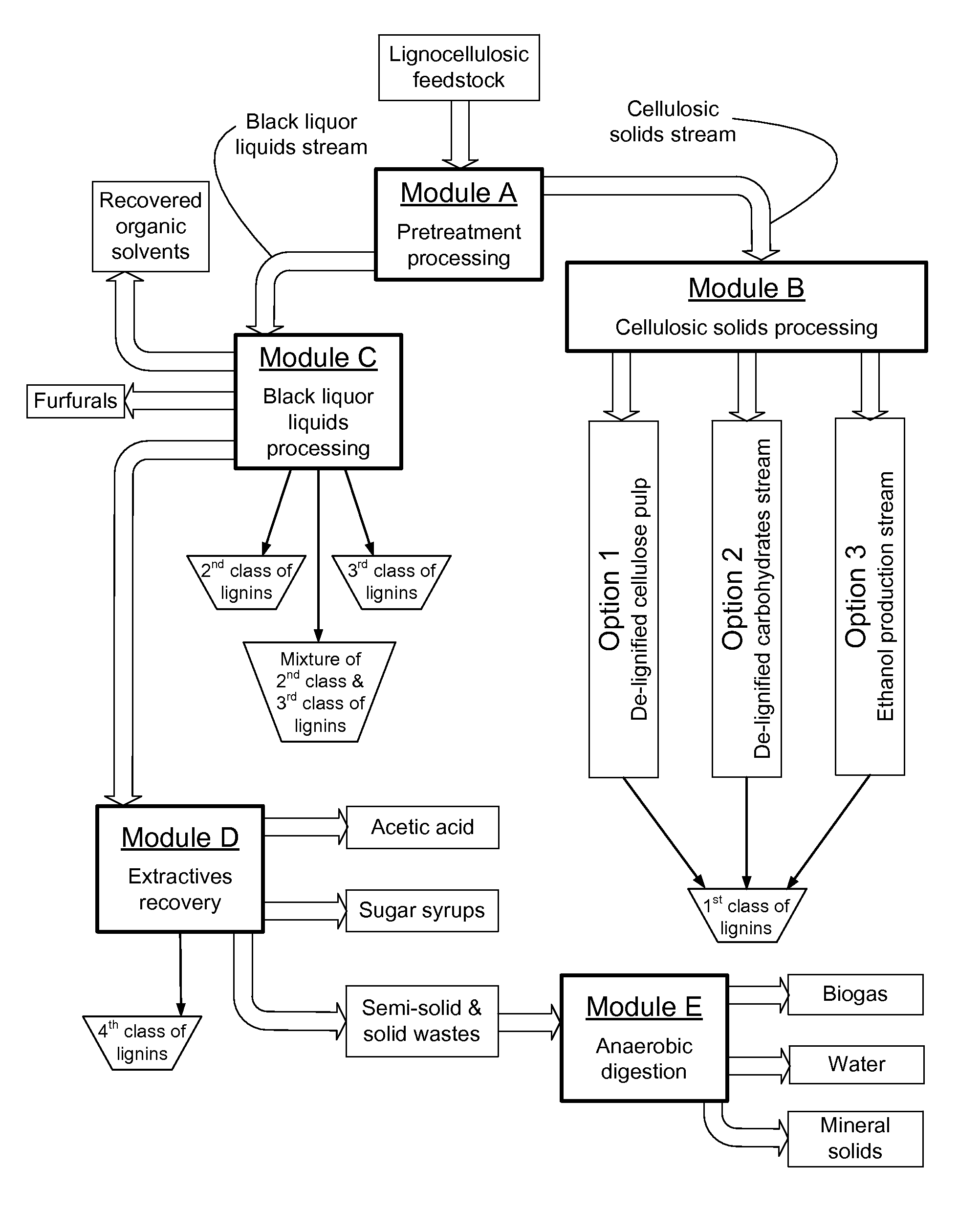

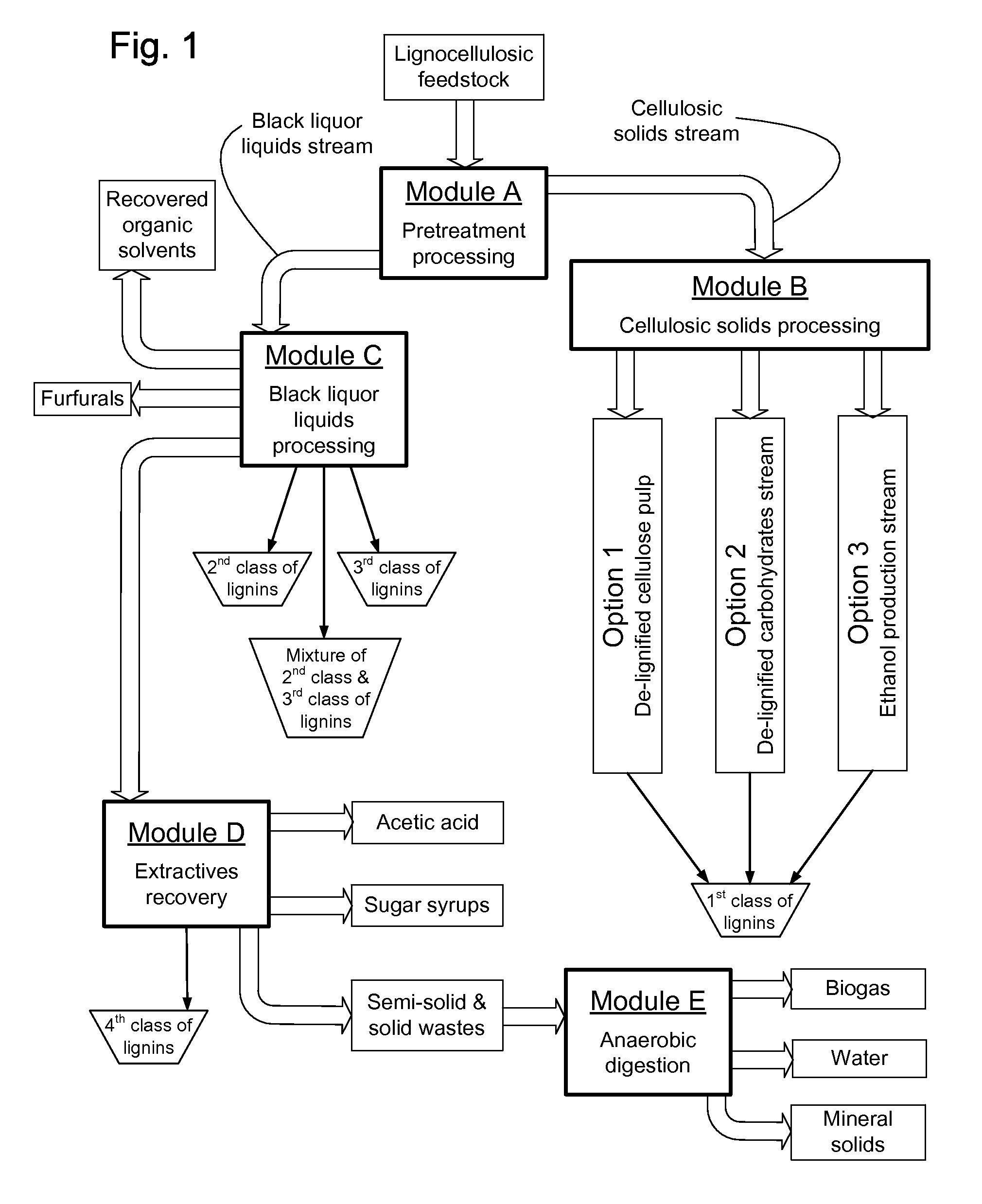

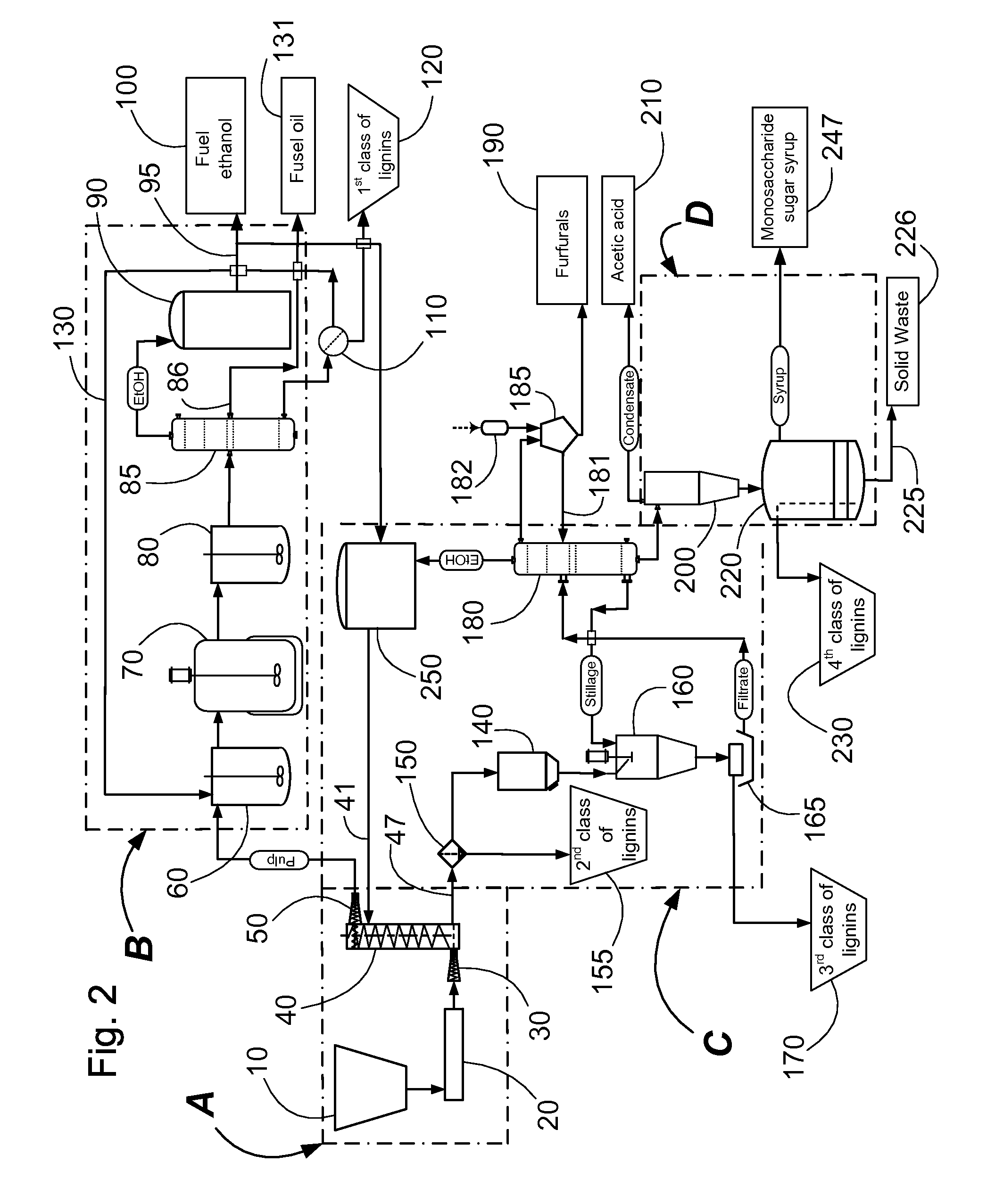

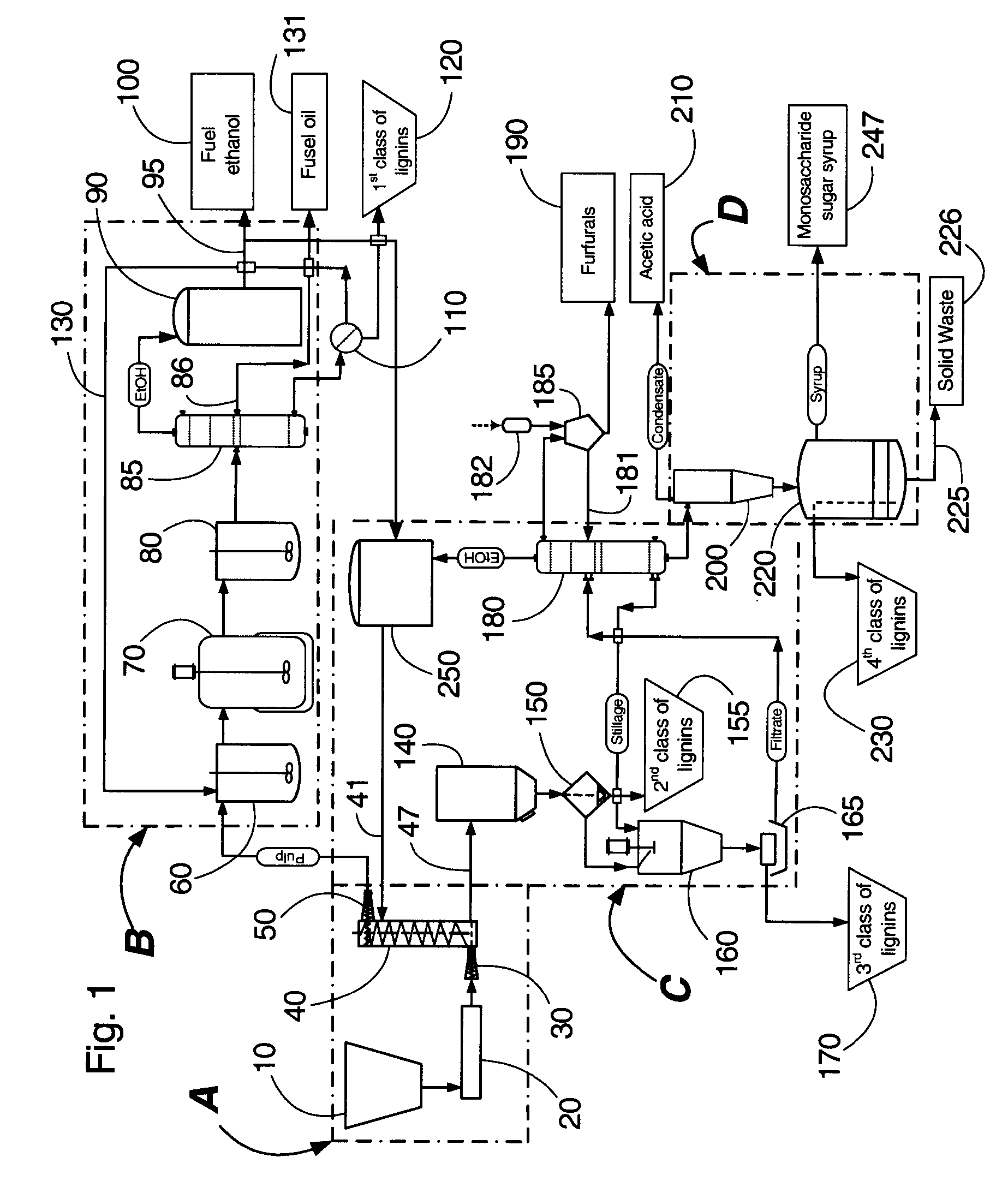

A modular process for organosolv fractionation of lignocellulosic feedstocks into component parts and further processing of said component parts into at least fuel-grade ethanol and four classes of lignin derivatives. The modular process comprises a first processing module configured for physico-chemically digesting lignocellulosic feedstocks with an organic solvent thereby producing a cellulosic solids fraction and a liquid fraction, a second processing module configured for producing at least a fuel-grade ethanol and a first class of novel lignin derivatives from the cellulosic solids fraction, a third processing module configured for separating a second class and a third class of lignin derivatives from the liquid fraction and further processing the liquid fraction to produce a distillate and a stillage, a fourth processing module configured for separating a fourth class of lignin derivatives from the stillage and further processing the stillage to produce a sugar syrup.

Owner:SUZANO CANADA INC

Catalytic gasification process with recovery of alkali metal from char

ActiveUS7897126B2Quantity minimizationThermal non-catalytic crackingMuffle furnacesParticulatesSlurry

Processes are described for the extraction and recovery of alkali metal from the char that results from catalytic gasification of a carbonaceous material. Among other steps, the processes of the invention include a hydrothermal leaching step in which a slurry of insoluble particulate comprising insoluble alkali metal compounds is treated with carbon dioxide and steam at elevated temperatures and pressures to effect the conversion of insoluble alkali metal compounds to soluble alkali metal compounds. Further, processes are described for the catalytic gasification of a carbonaceous material where a substantial portion of alkali metal is extracted and recovered from the char that results from the catalytic gasification process.

Owner:SURE CHAMPION INVESTMENT LTD

Continuous counter-current organosolv processing of lignocellulosic feedstocks

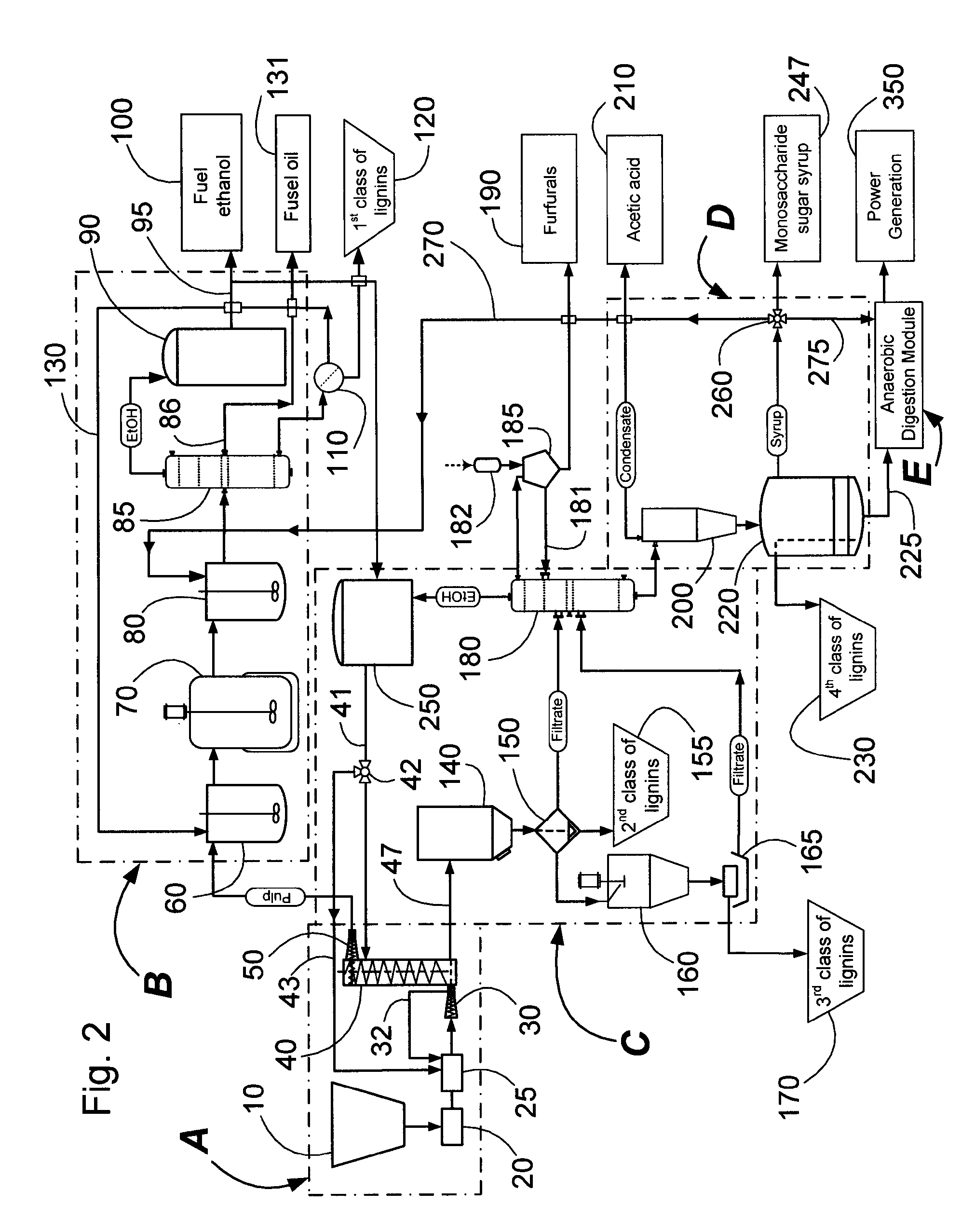

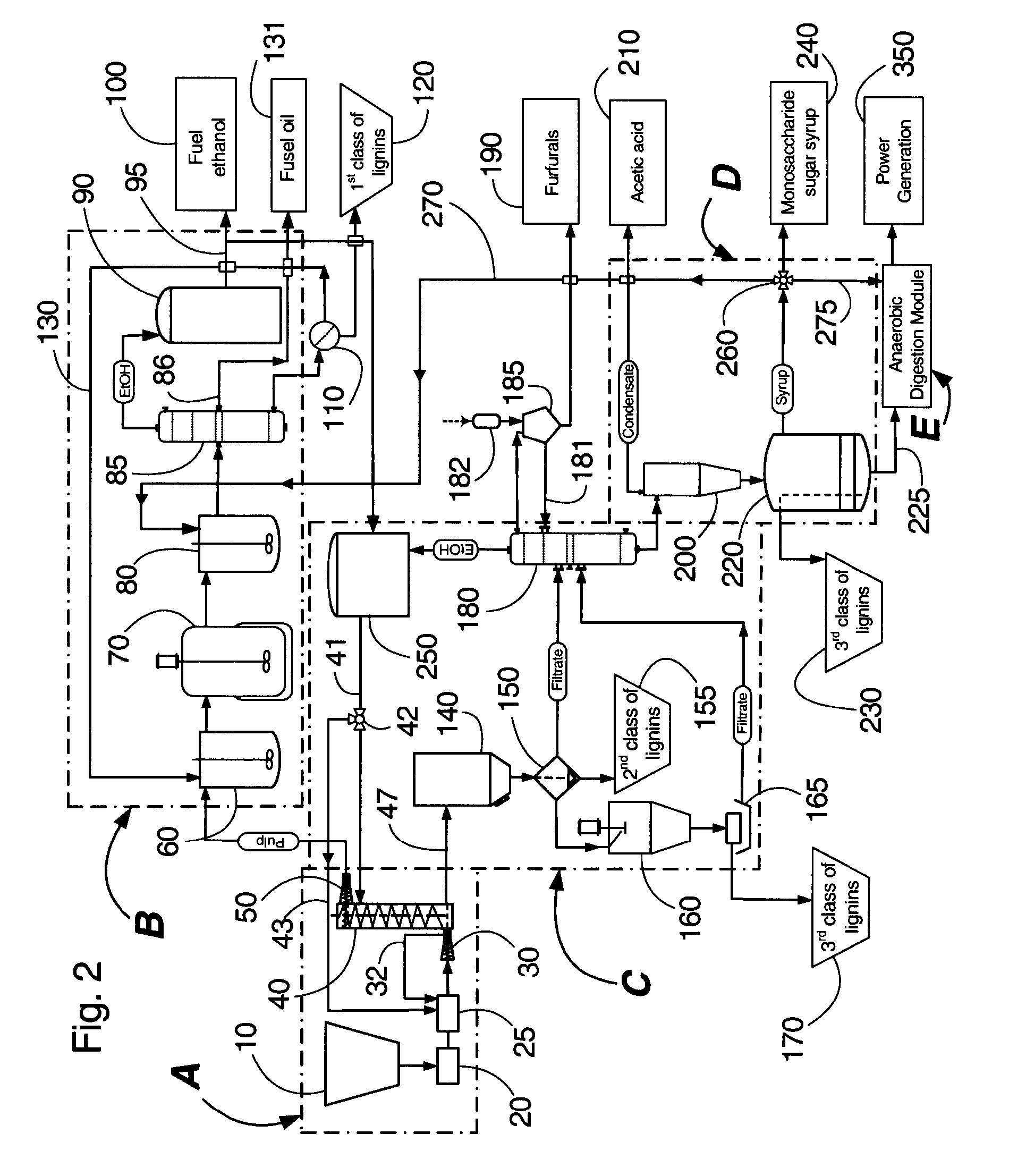

A modular process for organosolv fractionation of lignocellulosic feedstocks into component parts and further processing of said component parts into one or more of a de-lignified cellulose stream, a sugar stream, small-chain alcohol streams and four structurally distinct classes of lignin derivatives. The modular process comprises a first processing module configured for digesting lignocellulosic feedstocks with an organic solvent thereby producing a cellulosic solids fraction and a liquid fraction, a second processing module configured for recovering small-chain alcohols and optionally a first class of lignin derivatives from the cellulosic solids fraction, a third processing module configured for recovering from the liquid fraction at least one of a second class and a third class of lignin derivatives or mixtures thereof, and waste stream comprising a fourth class of lignin derivatives. The fourth processing module may optionally recover the fourth class of lignin derivatives.

Owner:SUZANO CANADA INC

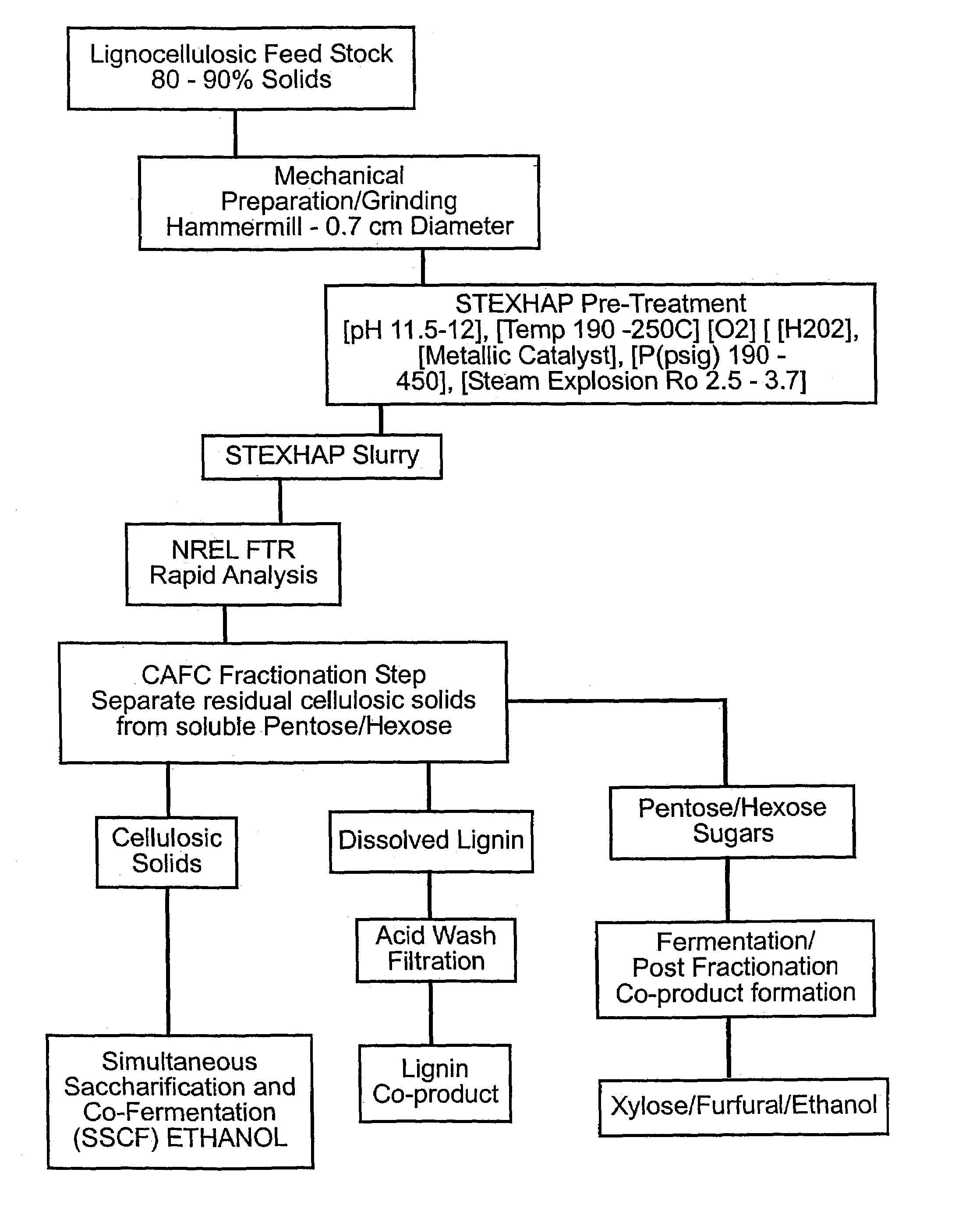

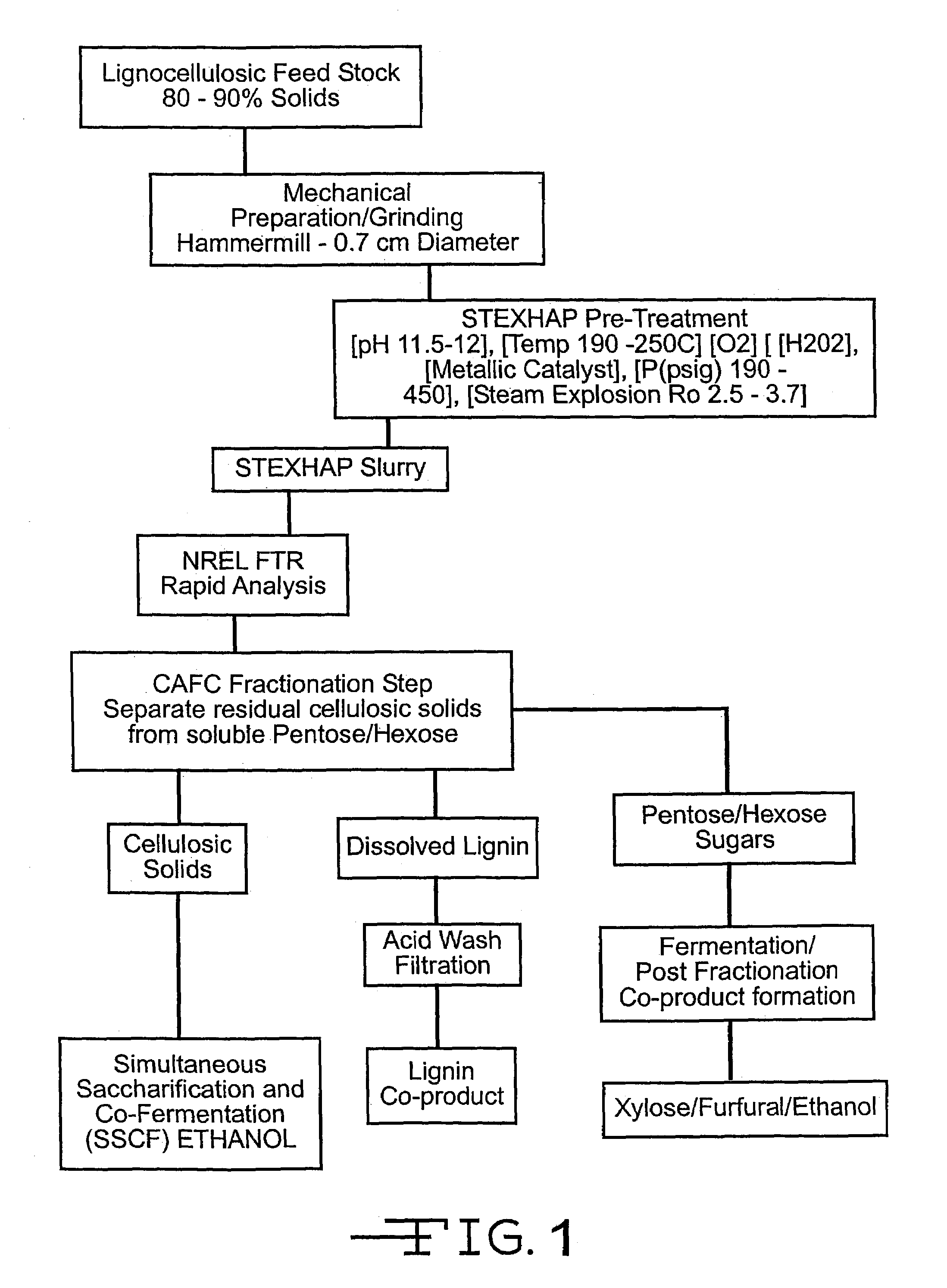

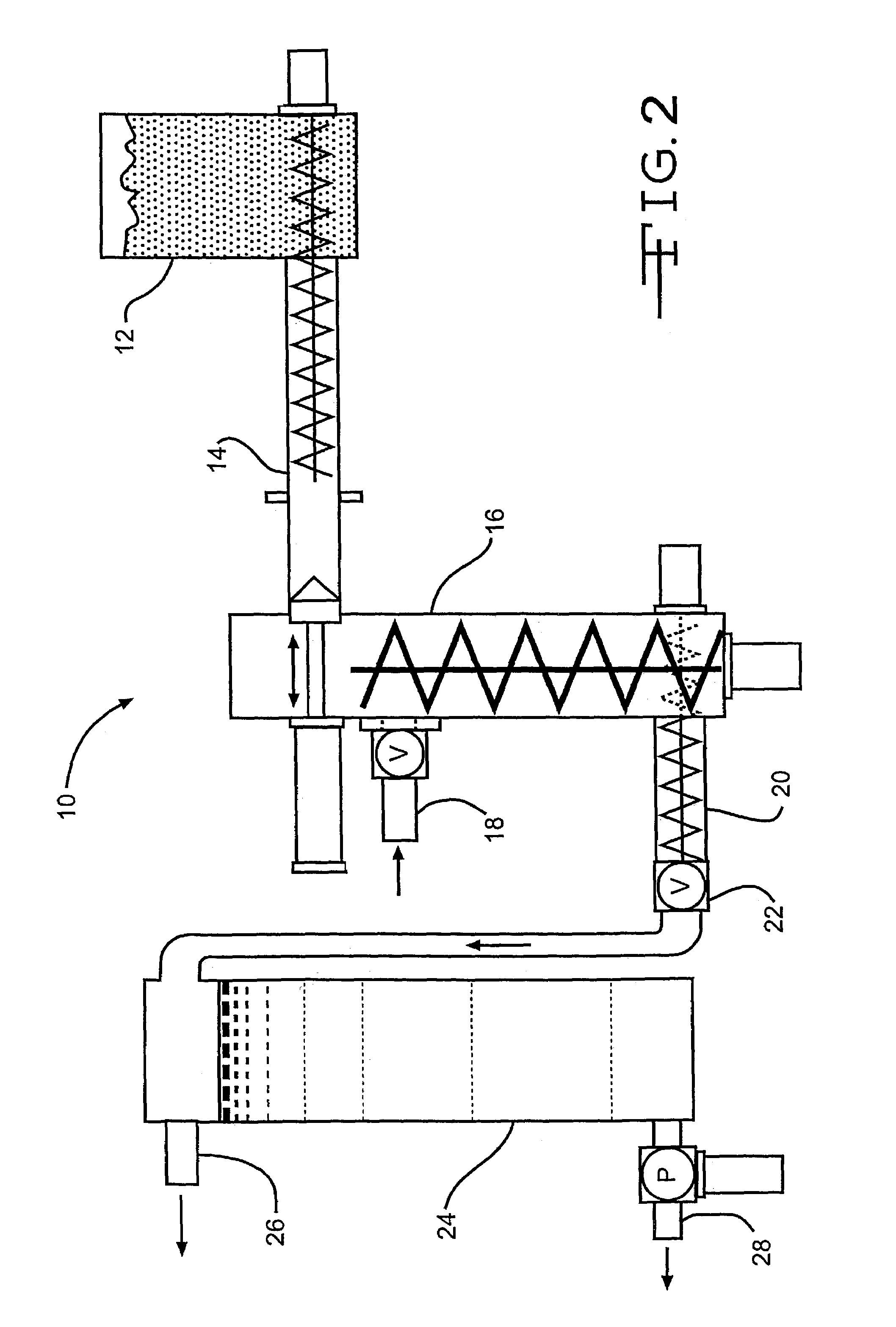

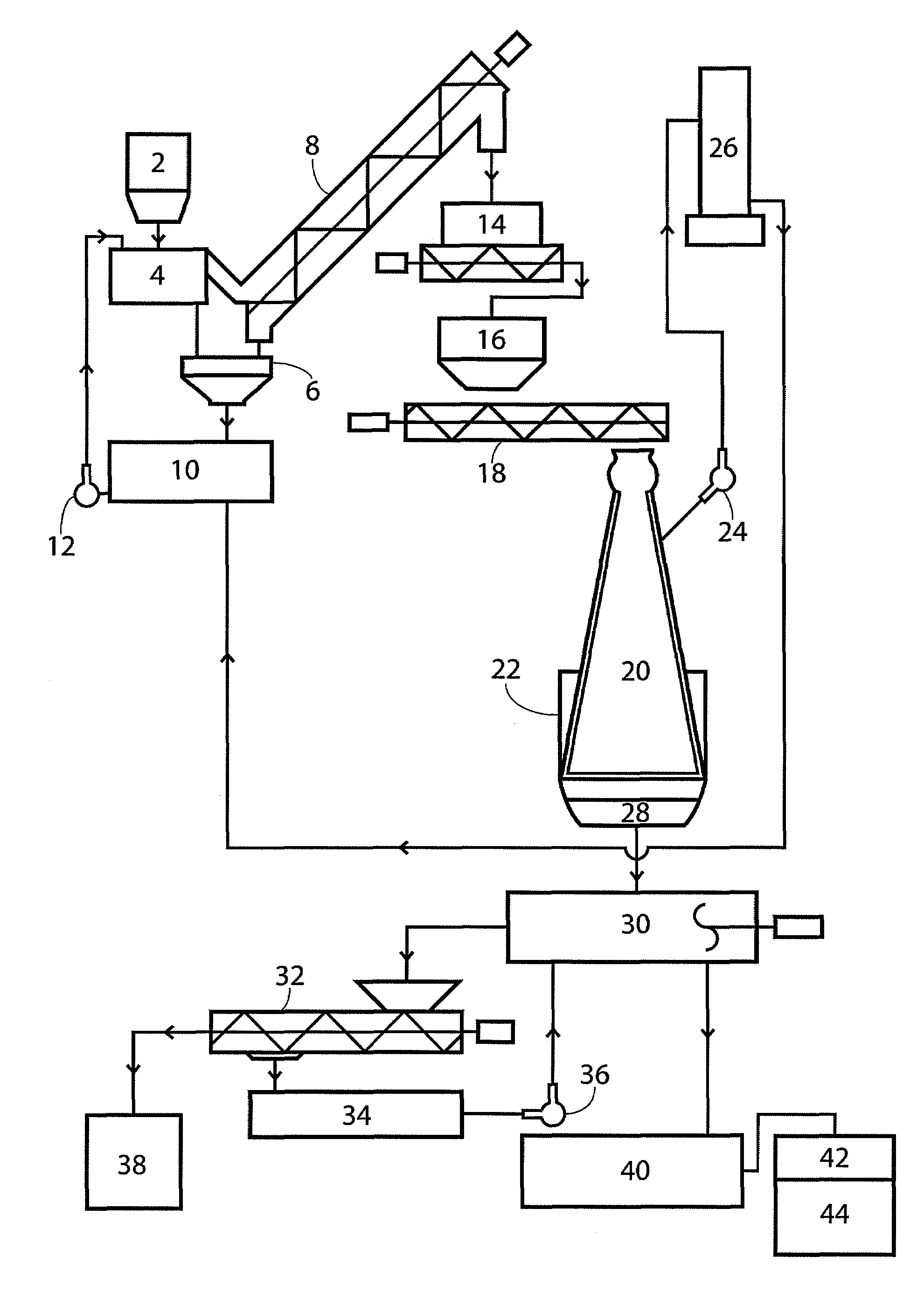

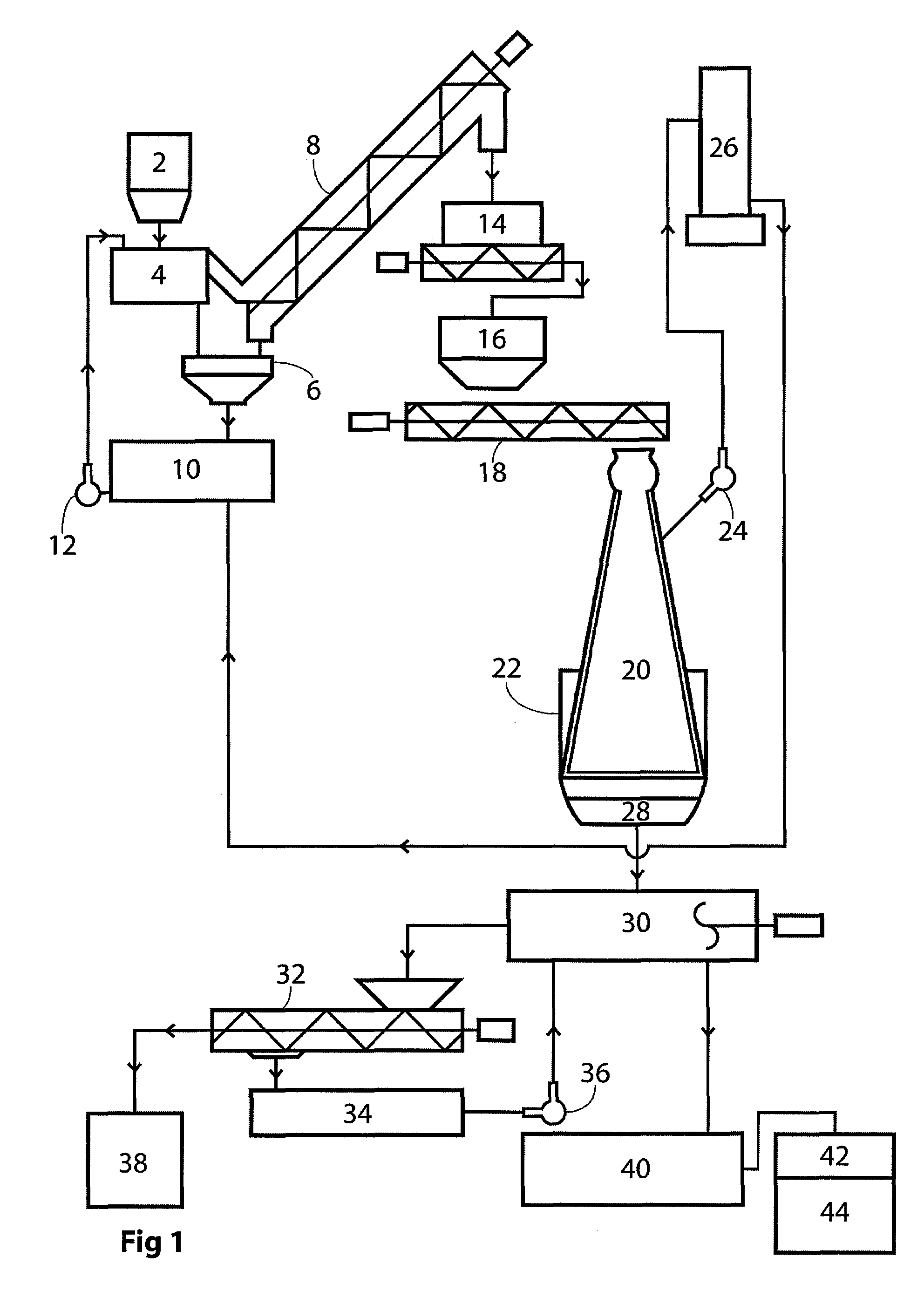

Process of treating lignocellulosic material to produce bio-ethanol

InactiveUS7189306B2Separation efficiency can be improvedEasy to separatePretreatment with water/steamPulp liquor regenerationSide productCo product

This invention relates to a process of treating a lignocellulosic material to produce bio-ethanol. The process includes the steps of: (a) exposing the lignocellulosic material to conditions including a pH not less than about 8, and steam at a first pressure, to produce a step (a) product; (b) explosively discharging the step (a) product to a second pressure less than the first pressure to produce a step (b) product; and (c) further processing the step (b) product to produce bio-ethanol and other co-products. In another embodiment, the invention relates to a conical auger fractionation column. The fractionation column includes a column body having an input and an output. A conical filter is positioned inside the column body, the filter having a larger diameter end directed toward the input and a smaller diameter end directed toward the output. A conical auger is positioned inside the conical filter, the conical auger having an outer diameter which is approximately the same as an inner diameter of the conical filter. The auger and filter are adapted to cooperate to separate cellulosic solids from a liquid stream in a process of producing bio-ethanol from a lignocellulosic material.

Owner:GERVAIS GIBSON W

Catalytic gasification process with recovery of alkali metal from char

ActiveUS7901644B2Quantity minimizationThermal non-catalytic crackingMuffle furnacesParticulatesSlurry

Processes are described for the extraction and recovery of alkali metal from the char that results from catalytic gasification of a carbonaceous material. Among other steps, the processes of the invention include a hydrothermal leaching step in which a slurry of insoluble particulate comprising insoluble alkali metal compounds is treated with carbon dioxide and steam at elevated temperatures and pressures to effect the conversion of insoluble alkali metal compounds to soluble alkali metal compounds. Further, processes are described for the catalytic gasification of a carbonaceous material where a substantial portion of alkali metal is extracted and recovered from the char that results from the catalytic gasification process.

Owner:SURE CHAMPION INVESTMENT LTD

Conversion of Lignocellulosic Biomass to Chemicals and Fuels

InactiveUS20080312346A1Pulp liquor regenerationOther chemical processesCelluloseLignocellulosic biomass

A method for preparing biomass for slurry processing. The method includes solubilizing the solid material into either a dissolved state or a suspended solid in a liquid phase, and treating the liquid phase to produce chemicals and fuels.

Owner:UOP LLC +1

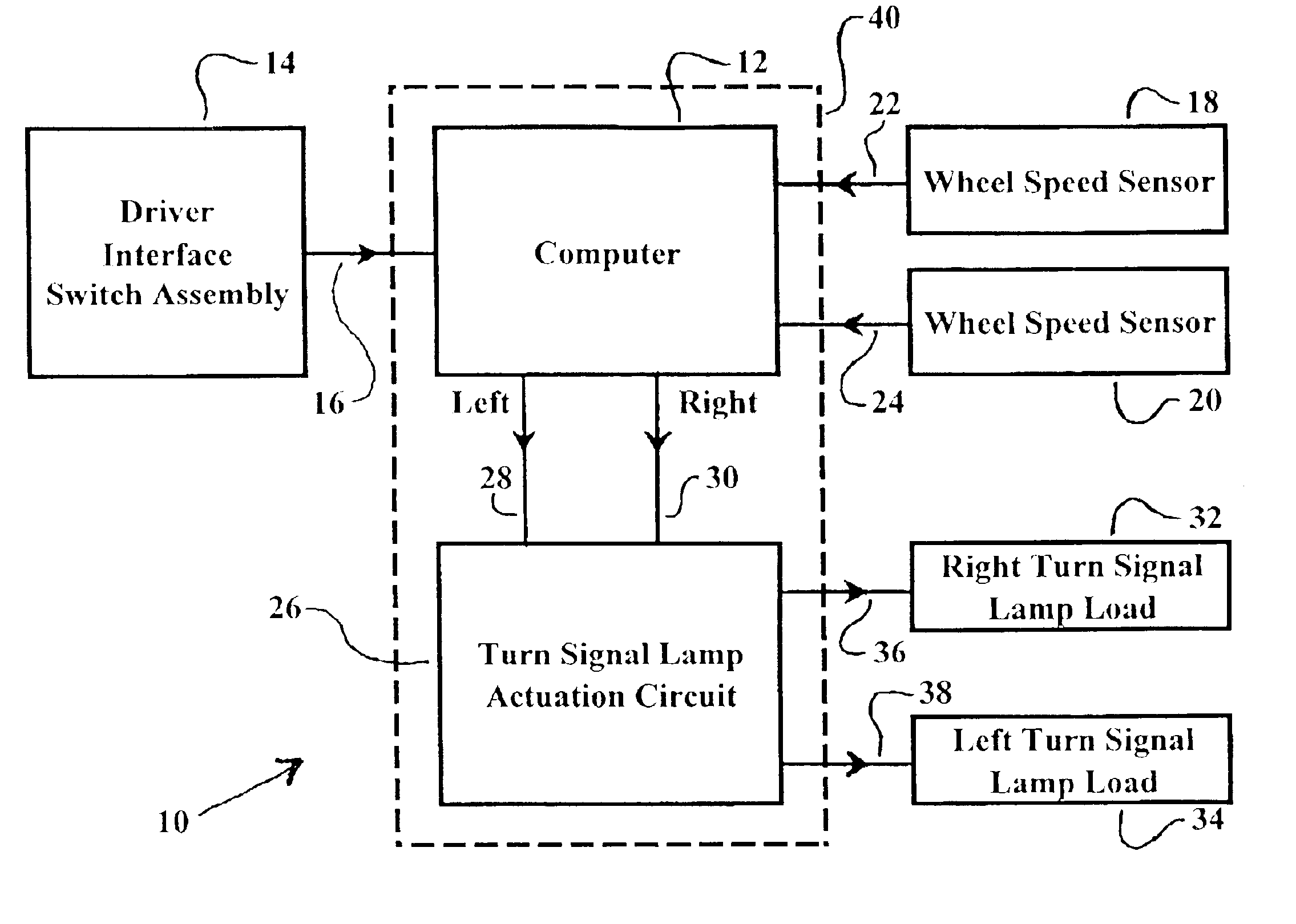

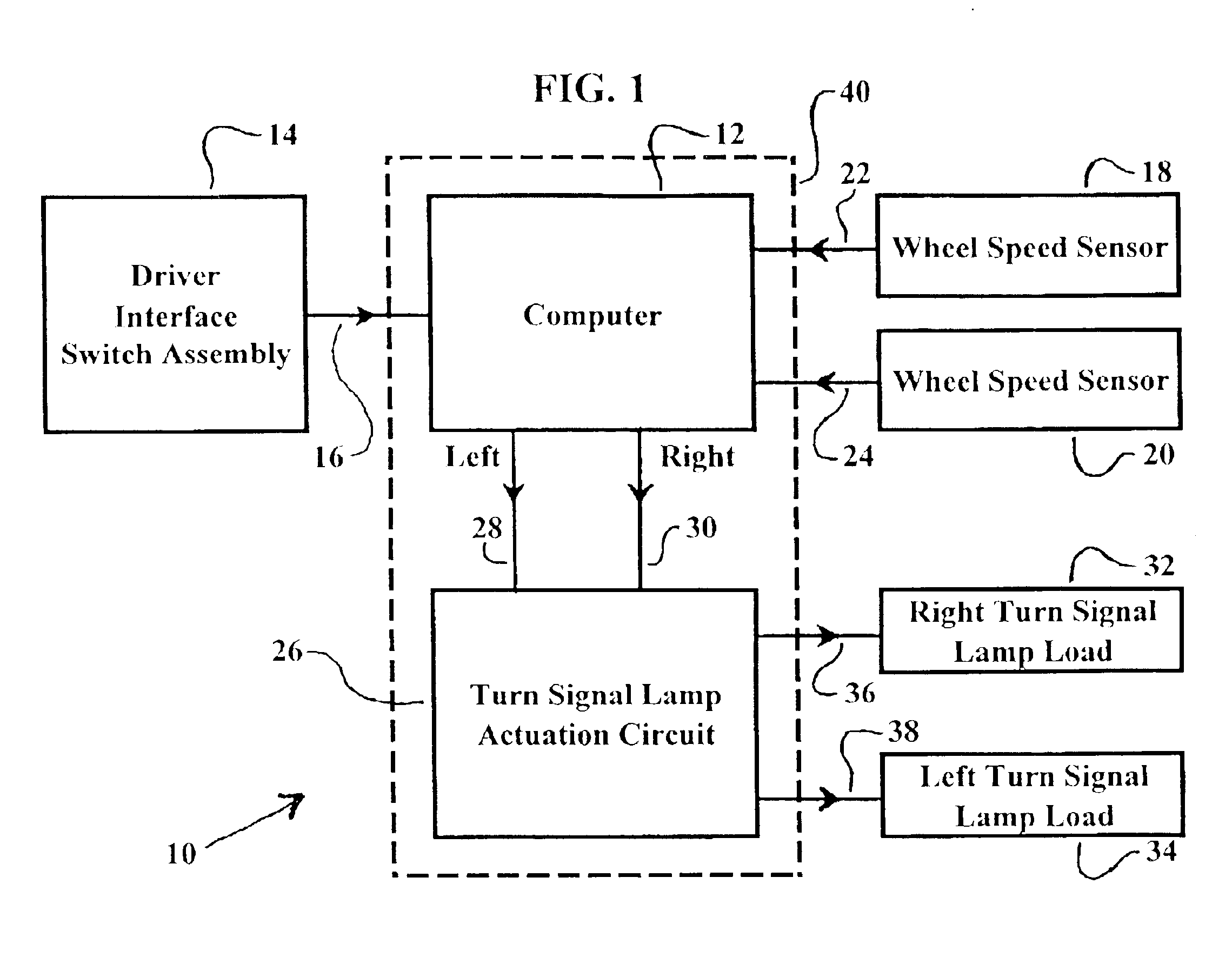

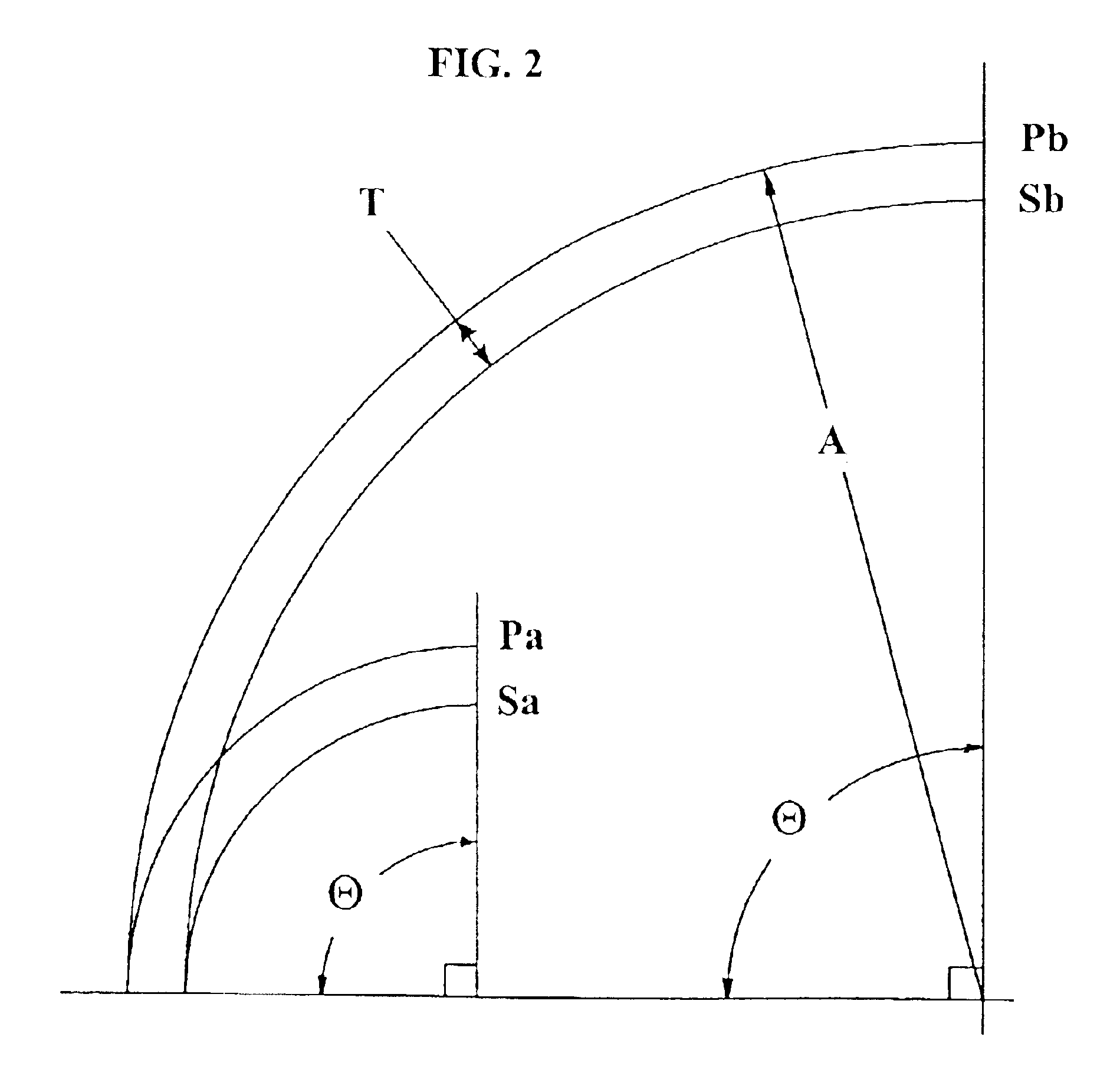

Electronic intelligent turn signal control system

InactiveUS6876300B2Low costSmall sizeSteering initiationsDigital data processing detailsDriver/operatorWheel speed sensor

An intelligent turn signal control system for turning on and off left and right turn signals in a vehicle includes a computer, such as an antilock braking system computer, with programmed software operably disposed on a vehicle, a driver interface switch assembly as input to the computer. Two or more wheel speed sensors transmit differential wheel movement data as input to the computer, a circuit drives turn signal indicator lamps from conditionally computed output data from the computer to turn on and off turn signals in a situation-appropriate manner. Upon turn signal indication intent data input from the driver, extensive travel and turn data is computed, including yaw rotation and steering system position to turn off or cancel the turn signal at the appropriate point.

Owner:PONZIANI RICHARD L

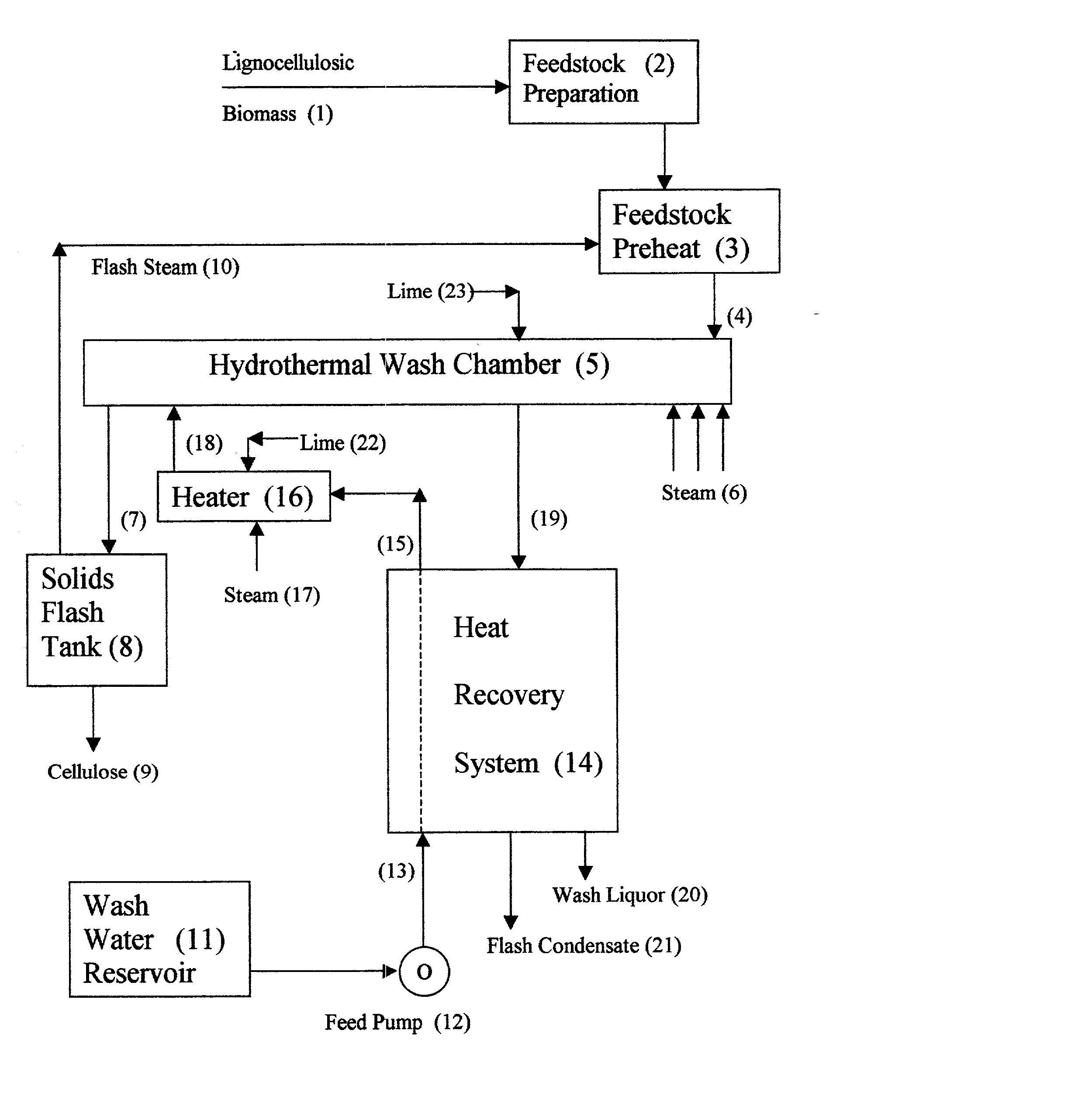

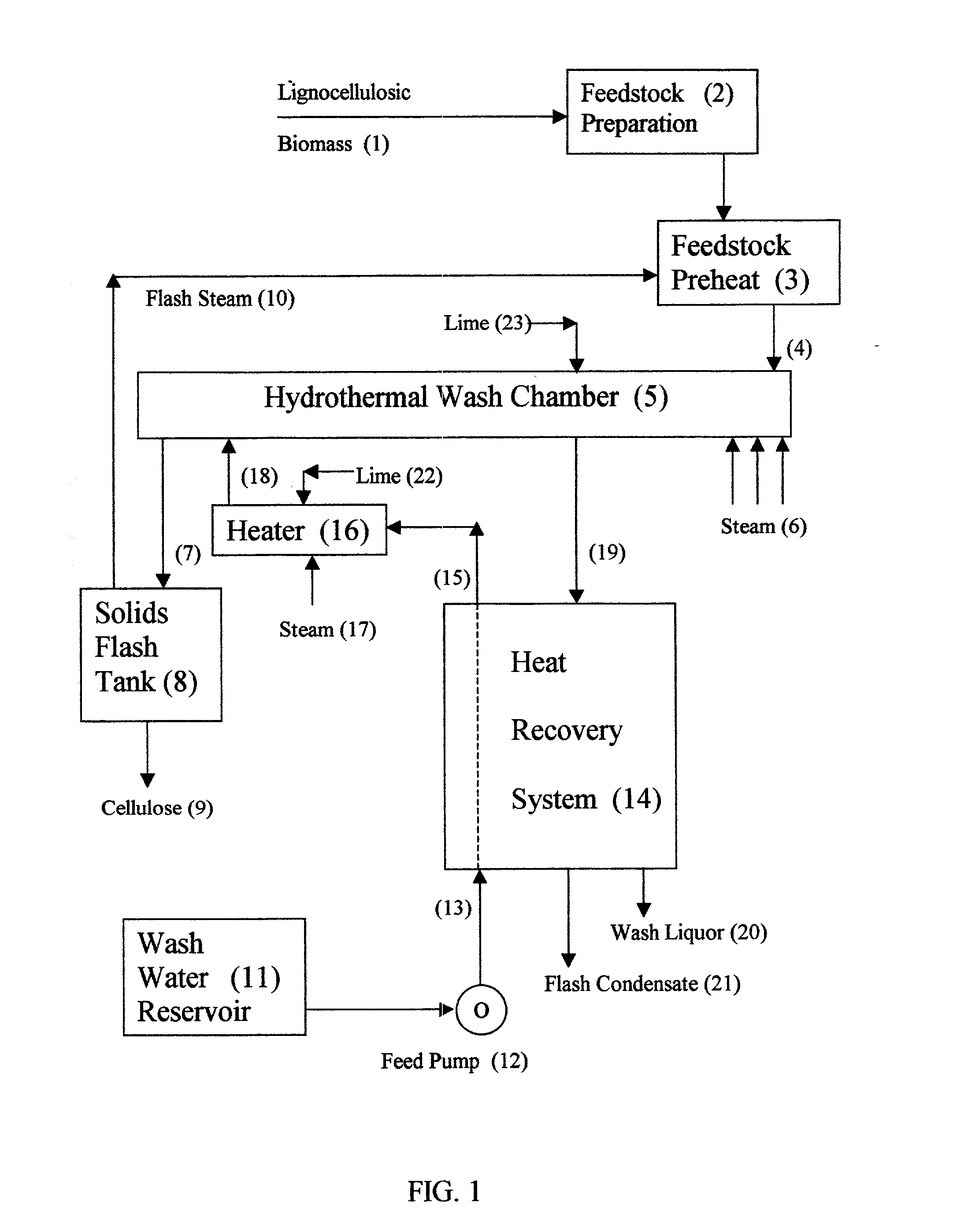

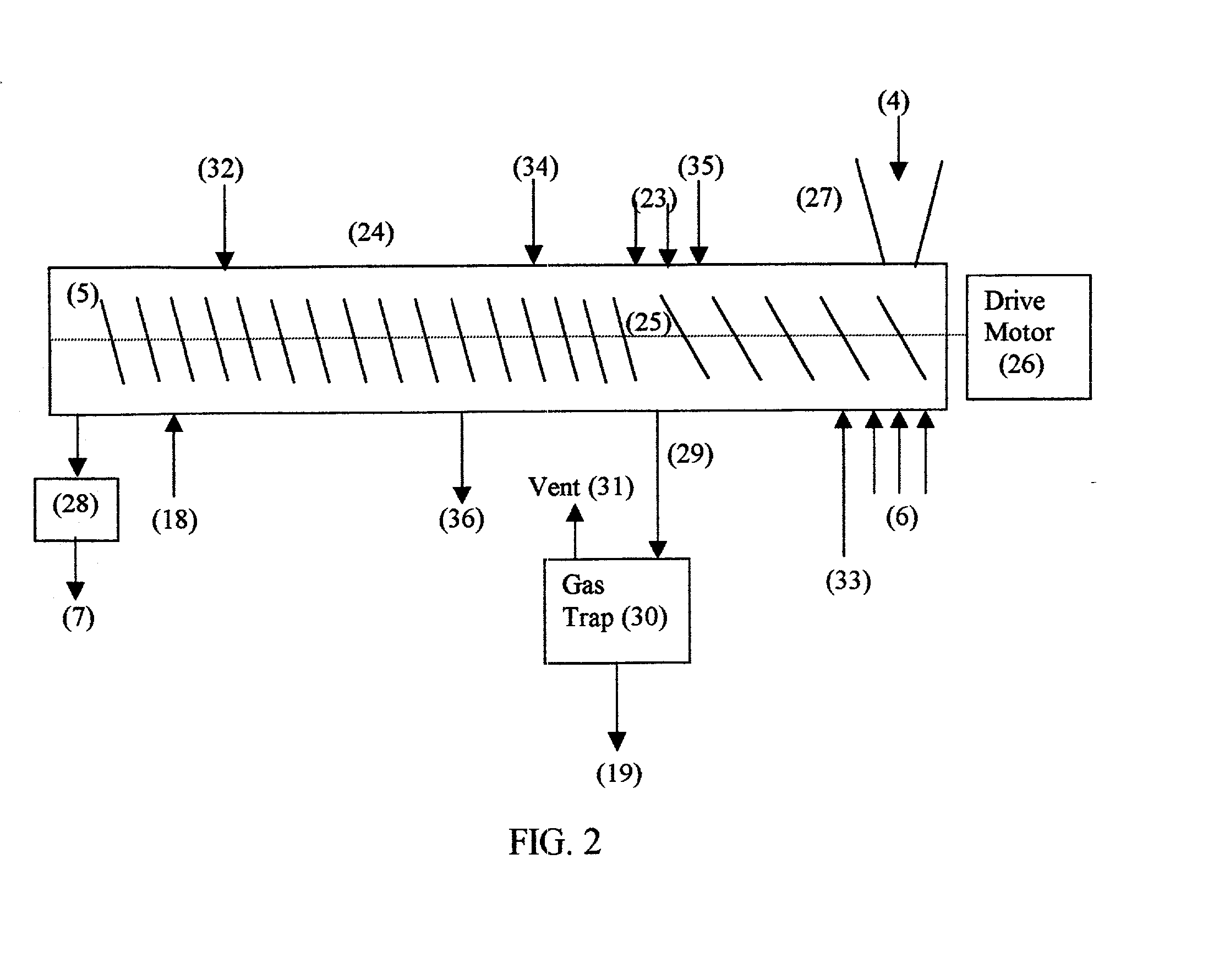

Cellulose production from lignocellulosic biomass

InactiveUS20020148575A1Low costHigh yieldPretreatment with water/steamPulp liquor regenerationEnergy recoveryCellulose fiber

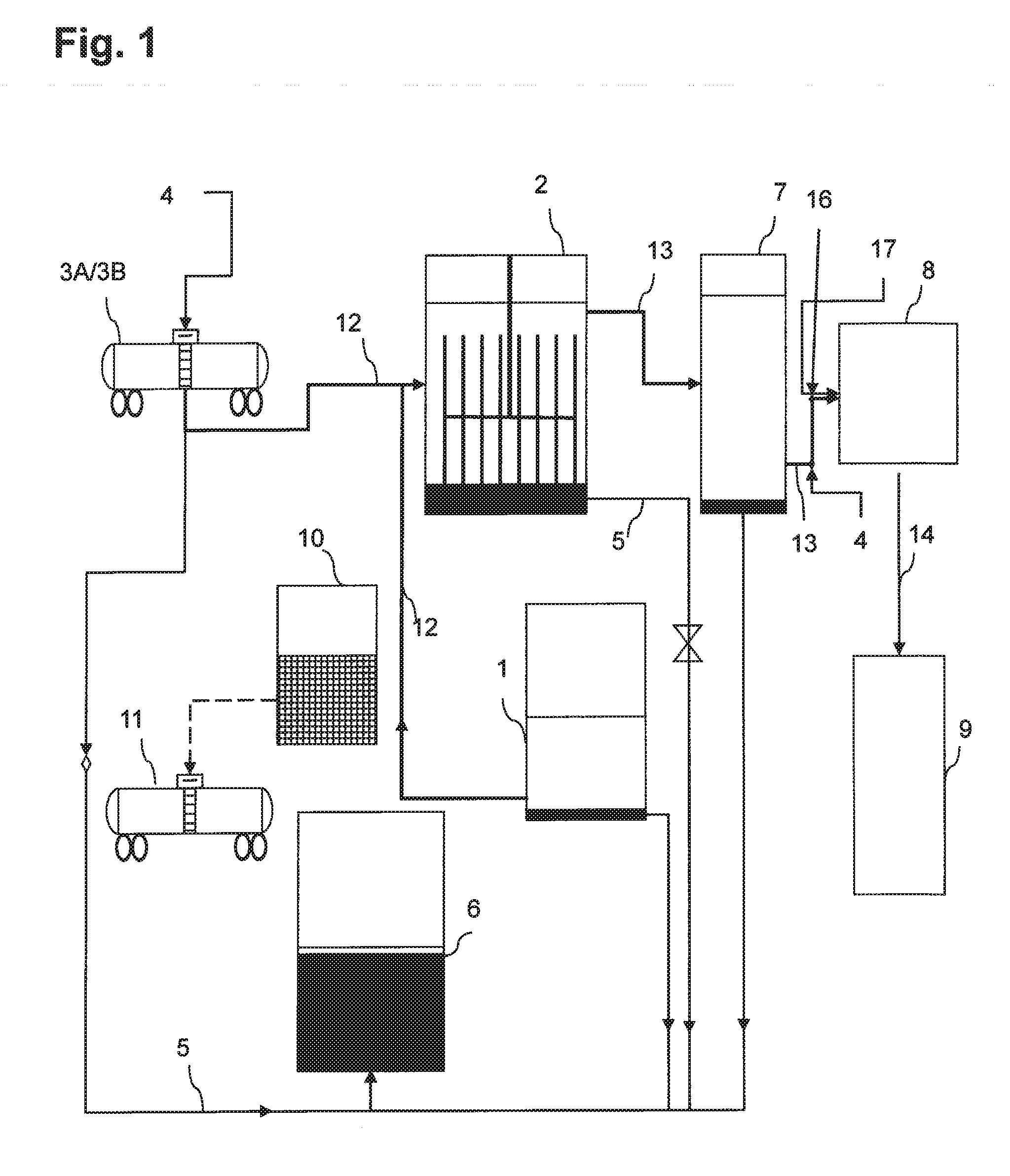

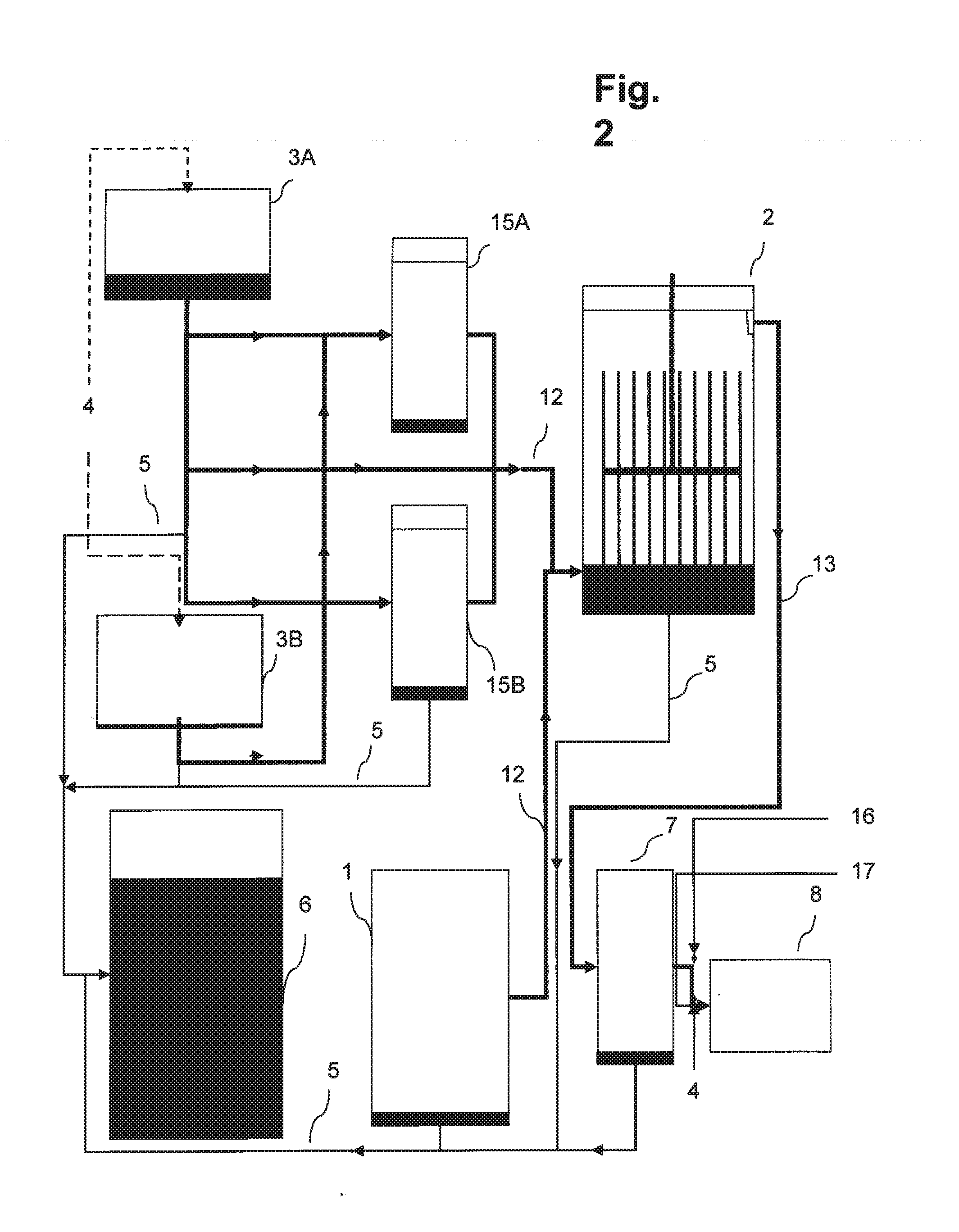

A multi-function process is described for the separation of cellulose fibers from the other constituents of lignocellulosic biomass such as found in trees, grasses, agricultural waste, and waste paper with application in the preparation of feedstocks for use in the manufacture of paper, plastics, ethanol, and other chemicals. This process minimizes waste disposal problems since it uses only steam, water, and oxygen at elevated temperature in the range of 180° C. to 240° C. for 1 to 10 minutes plus a small amount of chemical reagents to maintain pH in the range 8 to 13. An energy recuperation function is important to the economic viability of the process.

Owner:PUREVISION TECH

Continuous counter-current organosolv processing of lignocellulosic feedstocks

InactiveUS20080295980A1Facilitate and enhance of fermentation and efficiencyFacilitate and enhance rateNon-fibrous pulp additionBiological substance pretreatmentsFractionationOrganosolv

A modular process for organosolv fractionation of lignocellulosic feedstocks into component parts and further processing of said component parts into at least fuel-grade ethanol and four classes of lignin derivatives. The modular process comprises a first processing module configured for physico-chemically digesting lignocellulosic feedstocks with an organic solvent thereby producing a cellulosic solids fraction and a liquid fraction, a second processing module configured for producing at least a fuel-grade ethanol and a first class of novel lignin derivatives from the cellulosic solids fraction, a third processing module configured for separating a second class and a third class of lignin derivatives from the liquid fraction and further processing the liquid fraction to produce a distillate and a stillage, a fourth processing module configured for separating a fourth class of lignin derivatives from the stillage and further processing the stillage to produce a sugar syrup.

Owner:LIGNOL INNOVATIONS

Separation of Lignin From Hydrolyzate

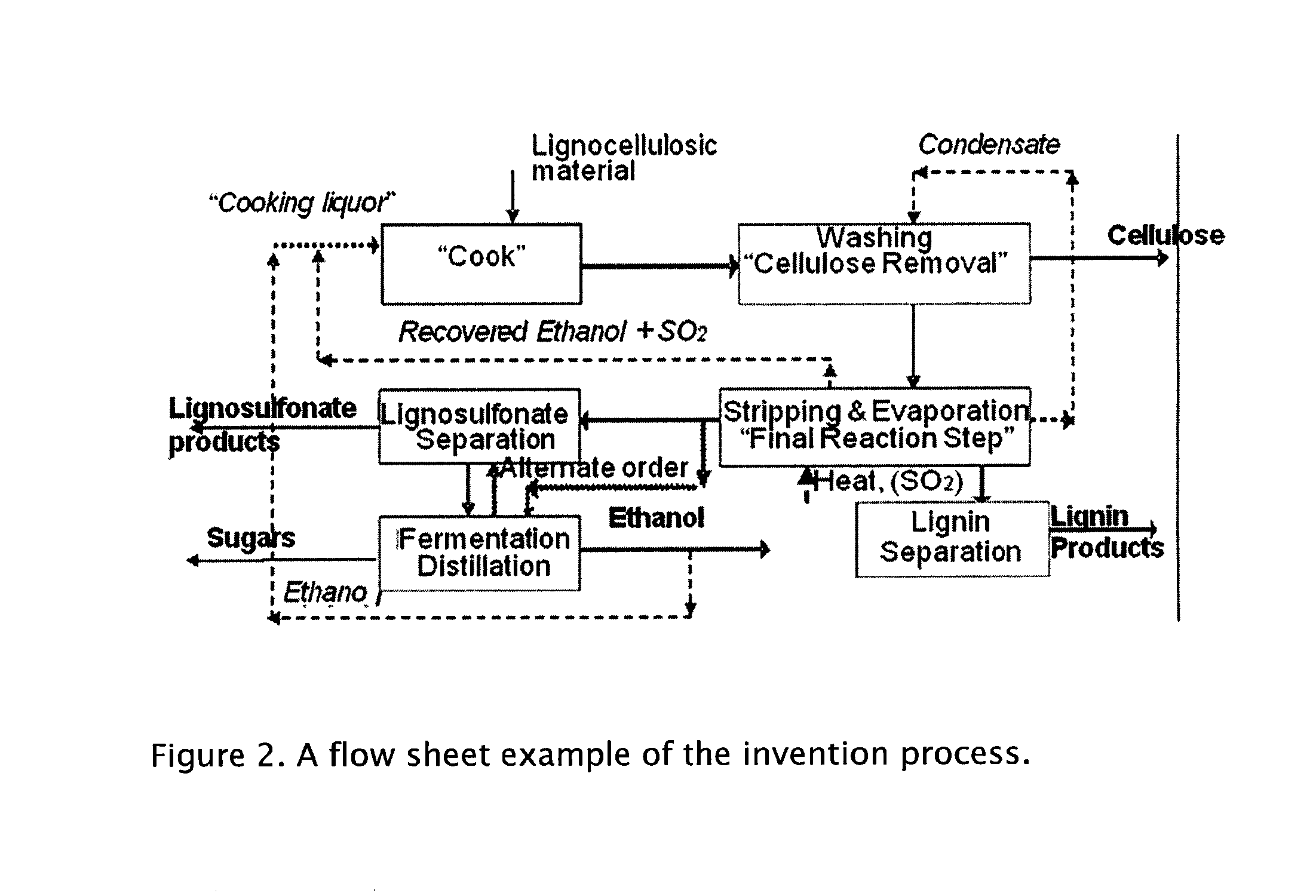

ActiveUS20110165643A1Pulp liquor regenerationPulping with acid salts/anhydridesWater insolubleLignosulfonates

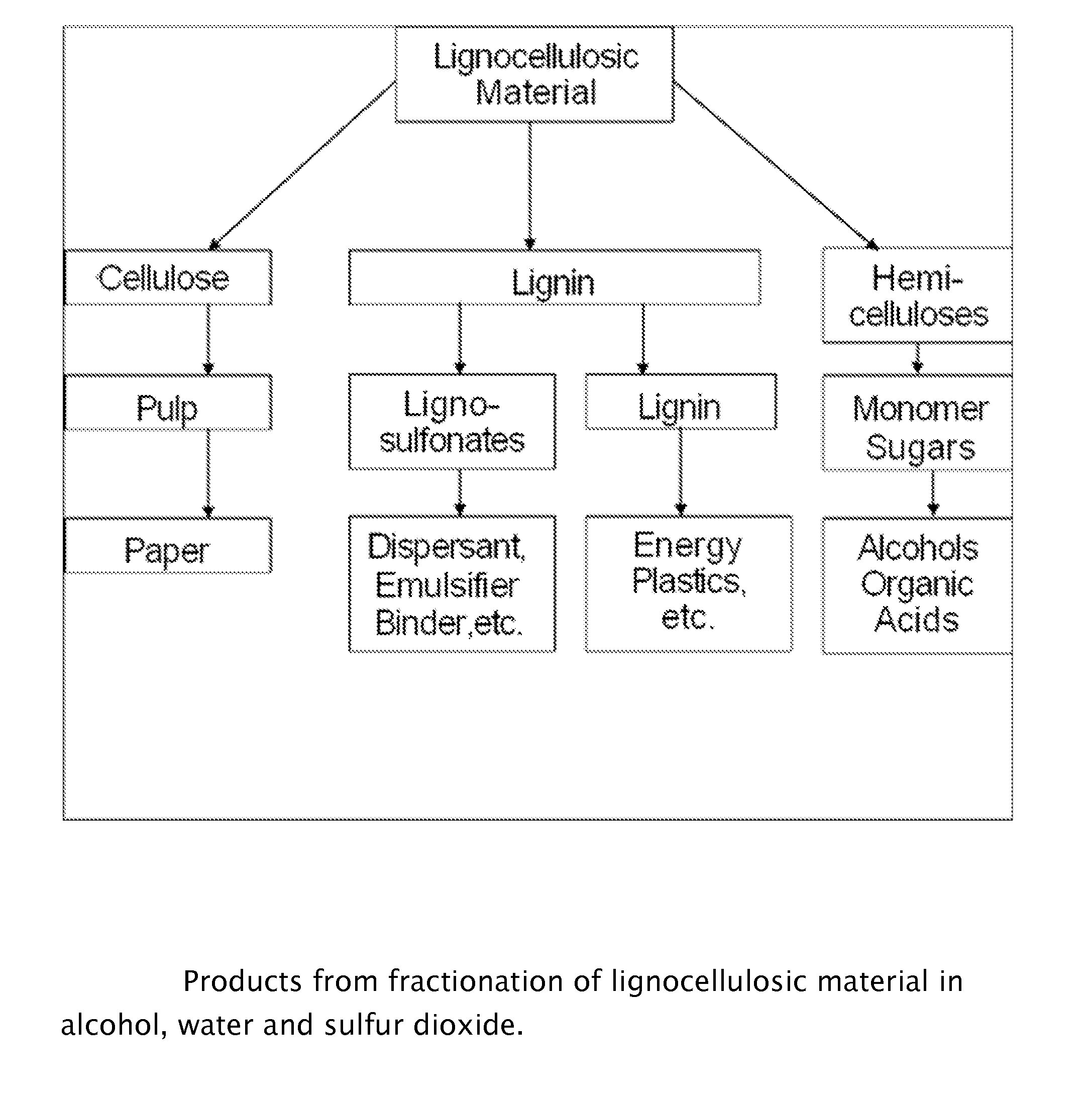

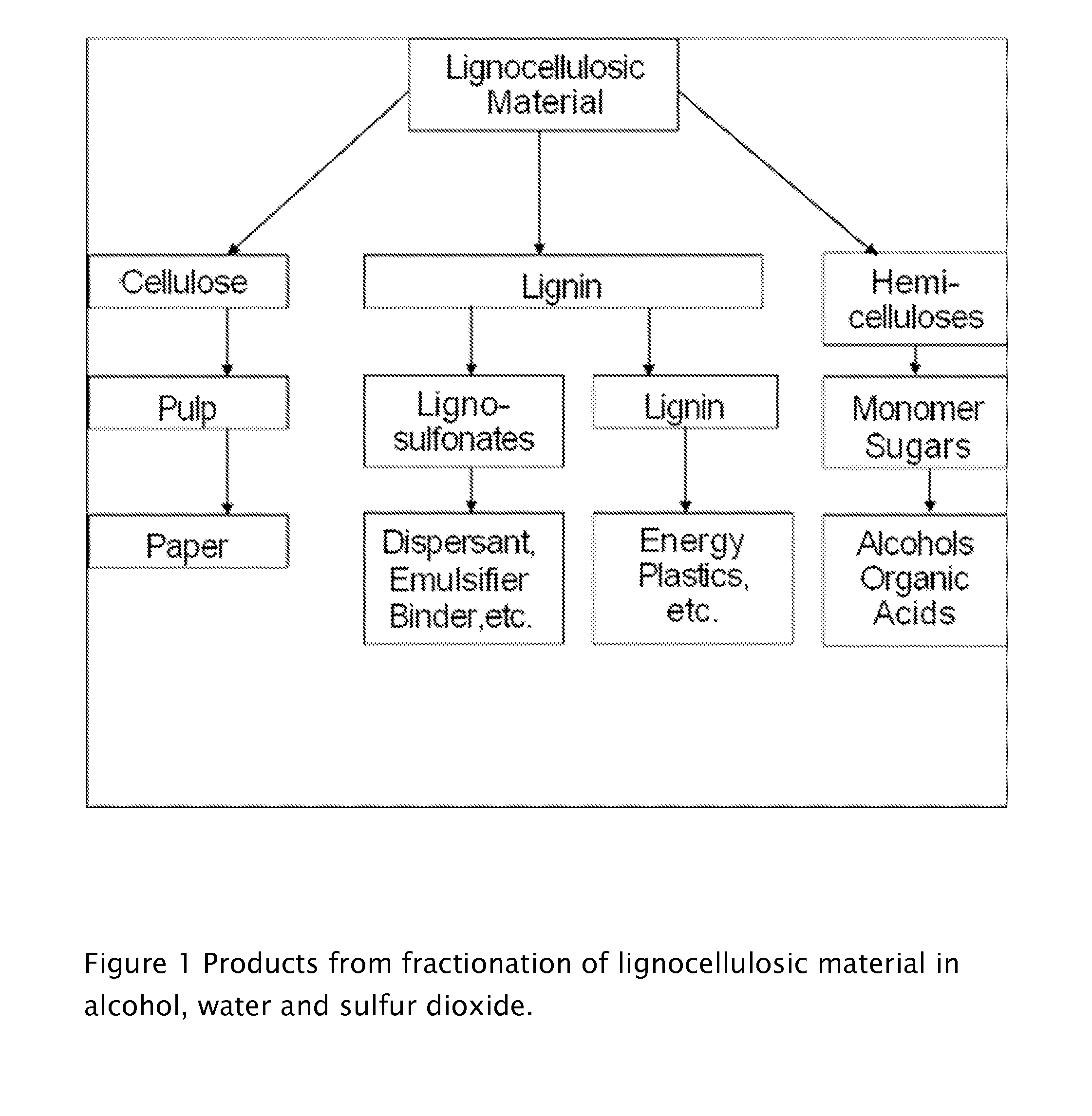

A method for the production water insoluble reactive lignin having low sulfur content and lignosulfonates from lignocellulosic material in a batch or continuous process. Lignocellulosic material is fractionated to produce water insoluble native lignin and lignosulfonates in various ratios, while preserving the cellulose and hydrolyzed hemicelluloses using water, ethanol and sulfur dioxide.

Owner:GRANBIO INTELLECTUAL PROPERTY HOLDINGS LLC

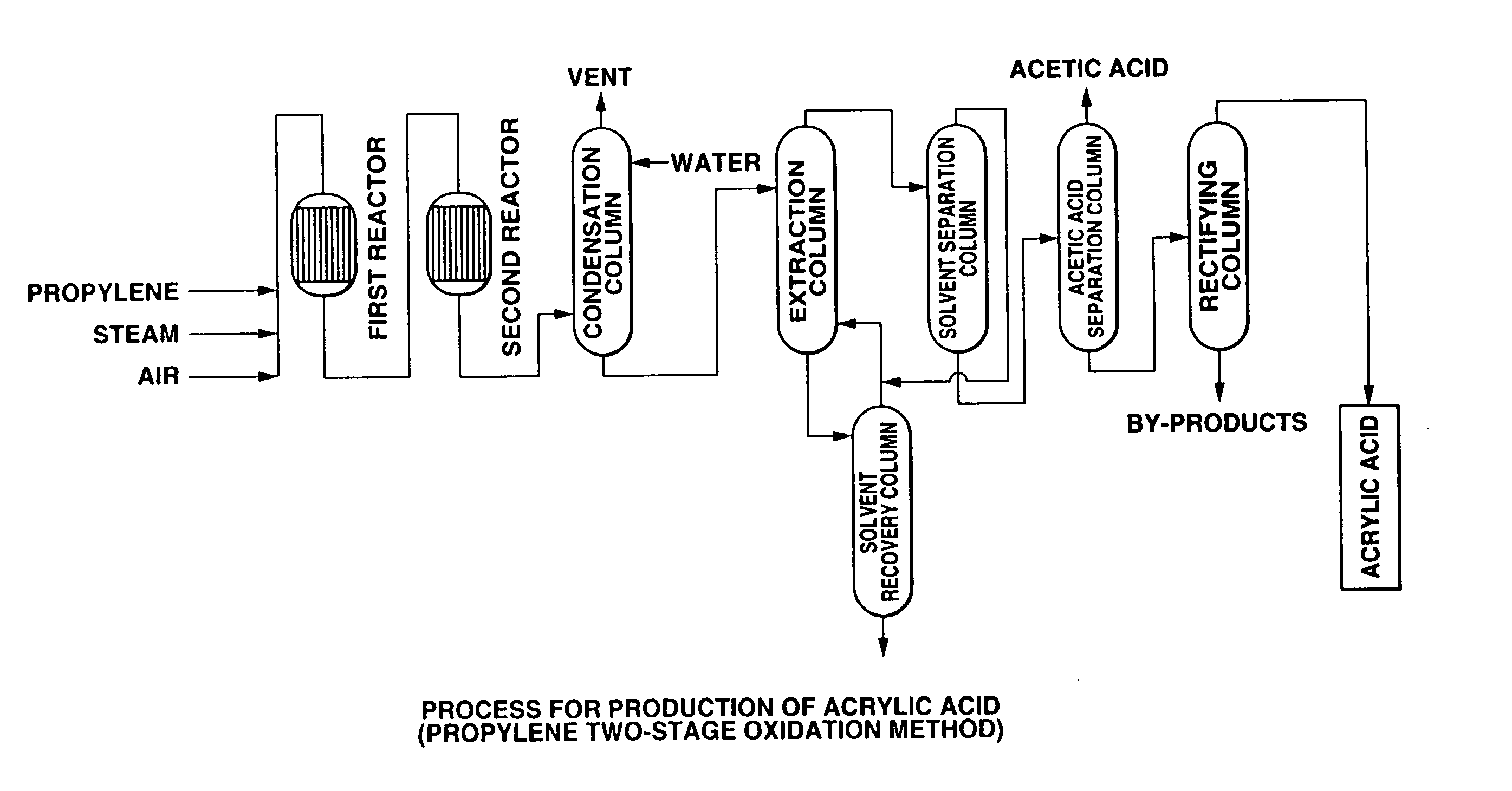

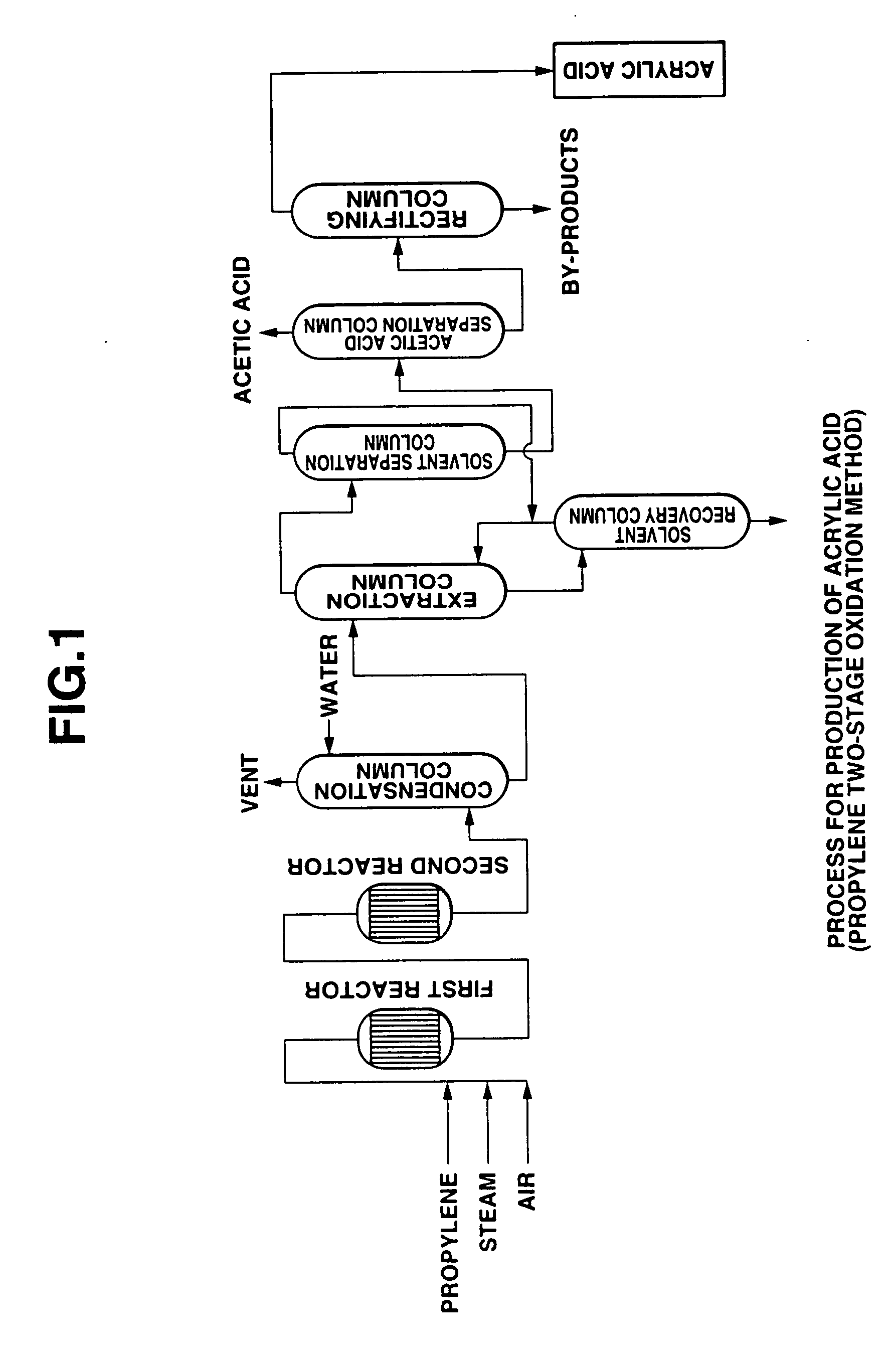

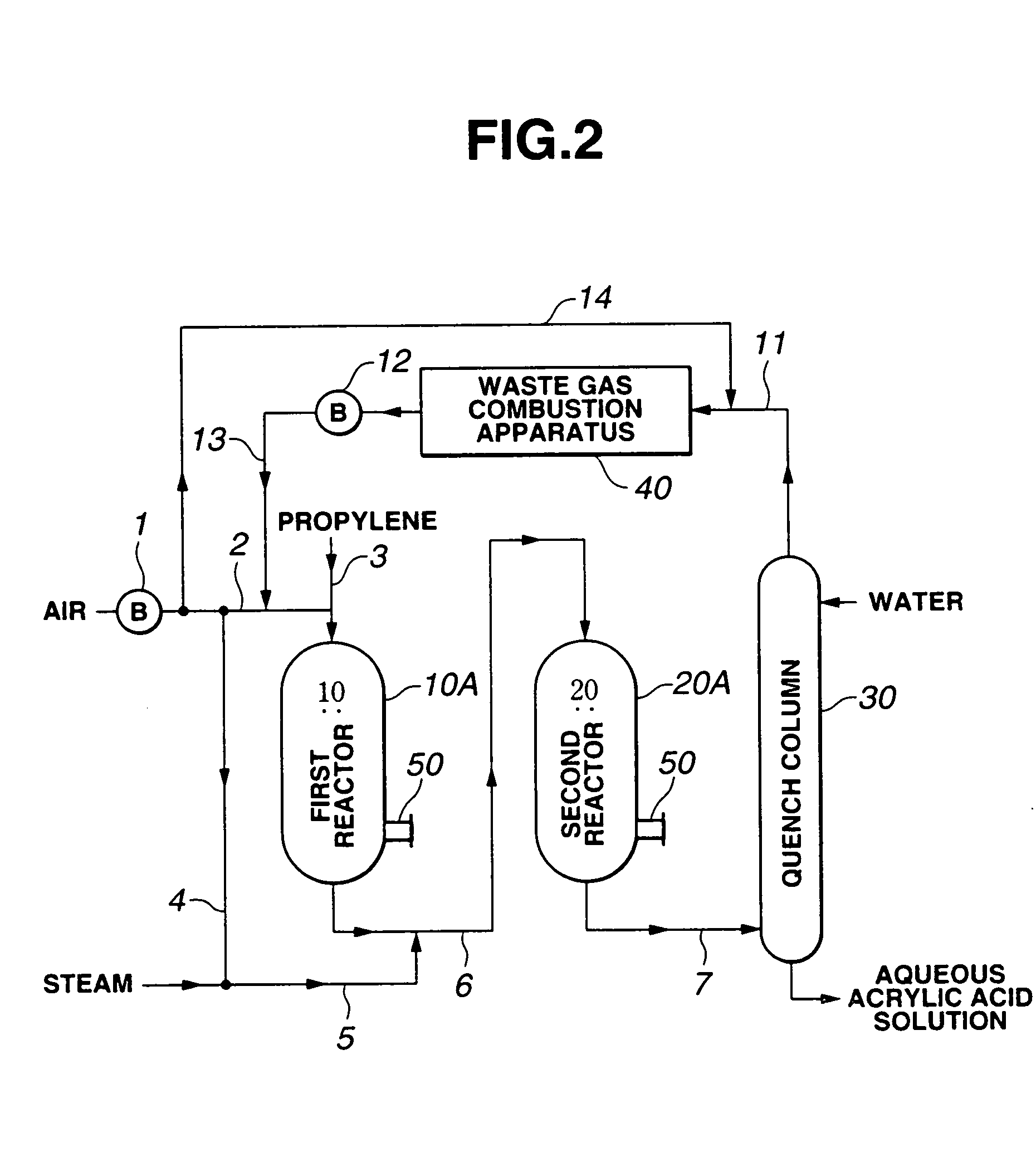

Oxidation reactor, process for producing (meth) acrylic acids, and method for analyzing easily-polymerizable compounds

ActiveUS20050143602A1Prevent auto-oxidationAvoid accumulationDisinfectionFeed devicesDouble tubeMeth-

An oxidation reactor includes a reactor body, a manhole nozzle projecting from the reactor body, and a partition plate separating an inside of the manhole nozzle and an inside of the reactor body from each other. In an oxidation reactor including the reactor body and a nozzle projecting from the reactor body, there is provided a means for feeding an inert gas into the nozzle. In a process for producing (meth)acrylic acids by subjecting propane, propylene or isobutylene to catalytic gas-phase oxidation reaction in an oxidation reactor for producing (meth)acrolein or (meth)acrylic acid, the above oxidation reactor is used as the oxidation reactor. In a method for analyzing an easily-polymerizable compound by introducing a gas containing the easily-polymerizable compound into an analyzing apparatus through a sampling tube, a double tube is used as the sampling tube, and a heating medium is fed into an outer tube of the double tube. According to these methods, the oxidation reaction can be stably conducted, and the reaction product gas can be prevented from being condensed and polymerized in the sampling tube, so that an on-line analysis can be performed at a high accuracy for a long period of time.

Owner:MITSUBISHI CHEM CORP

Method for comprehensive utilization of grass type stalk

ActiveCN101451315AHigh in Fulvic AcidSmall molecular weightPulp liquor regenerationDigestersCelluloseBlack liquor

The invention relates to a comprehensive utilization method for grass straws. Firstly, cellulose in the straws is utilized to pulp to serve as a raw material of paper pulp; during the pulping, lignin is dissolved in a stewing liquor to become a main constituent of a solid in a black liquor; the lignin is fully refined through the stewing and has easy degradation, and crops are easy to absorb, so the black liquor becomes a good organic fertilizer; at the same time, a fulvic acid with considerable quantity can be formed under conditions of high temperature and high pressure during the pulping, so the black liquor can be prepared into a high-quality fulvic acid fertilizer; the aim of comprehensive utilization of the grass straws is achieved through the steps, and the good economic benefit can be obtained thanks to the fact that the paper pulp and the fulvic acid fertilizer are expensive.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

Method of producing a pulp from cellulosic material using formic acid and hydrogen peroxide

InactiveUS6183597B1Facilitate lignin breakdownIncrease brightnessPulp liquor regenerationPulping with organic compoundsCardboardCellulose

A process for producing a pulp from cellulose-containing material, wherein the material is reacted with formic acid as the solvent, and cooked at approximately the boiling temperature of the solvent, whereby return condensation is used. Annual plants, deciduous or coniferous wood can be used as the cellulose-containing material. In one variant of the process, the cellulose-containing material is only slightly warmed, whereby backflow cooling is used, and then a precisely predetermined quantity of hydrogen peroxide is slowly added to the liquid at a constant rate. This process variant can be repeated at a lower cooking temperature. The pulp thus obtained is preferably utilized in the production of cellulose, and in particular in the production of paper or cardboard. It is proposed that the lignin, which is isolated from the cellulose-containing material, have further applications, whereby such lignin is, after the pulp has been separated from the solvent, itself precipitated out in water. The lignin thus obtained can be used as a new building material, as a filler material or as an output substance to be used in the manufacture of aromatic products.

Owner:NATURAL PULPING

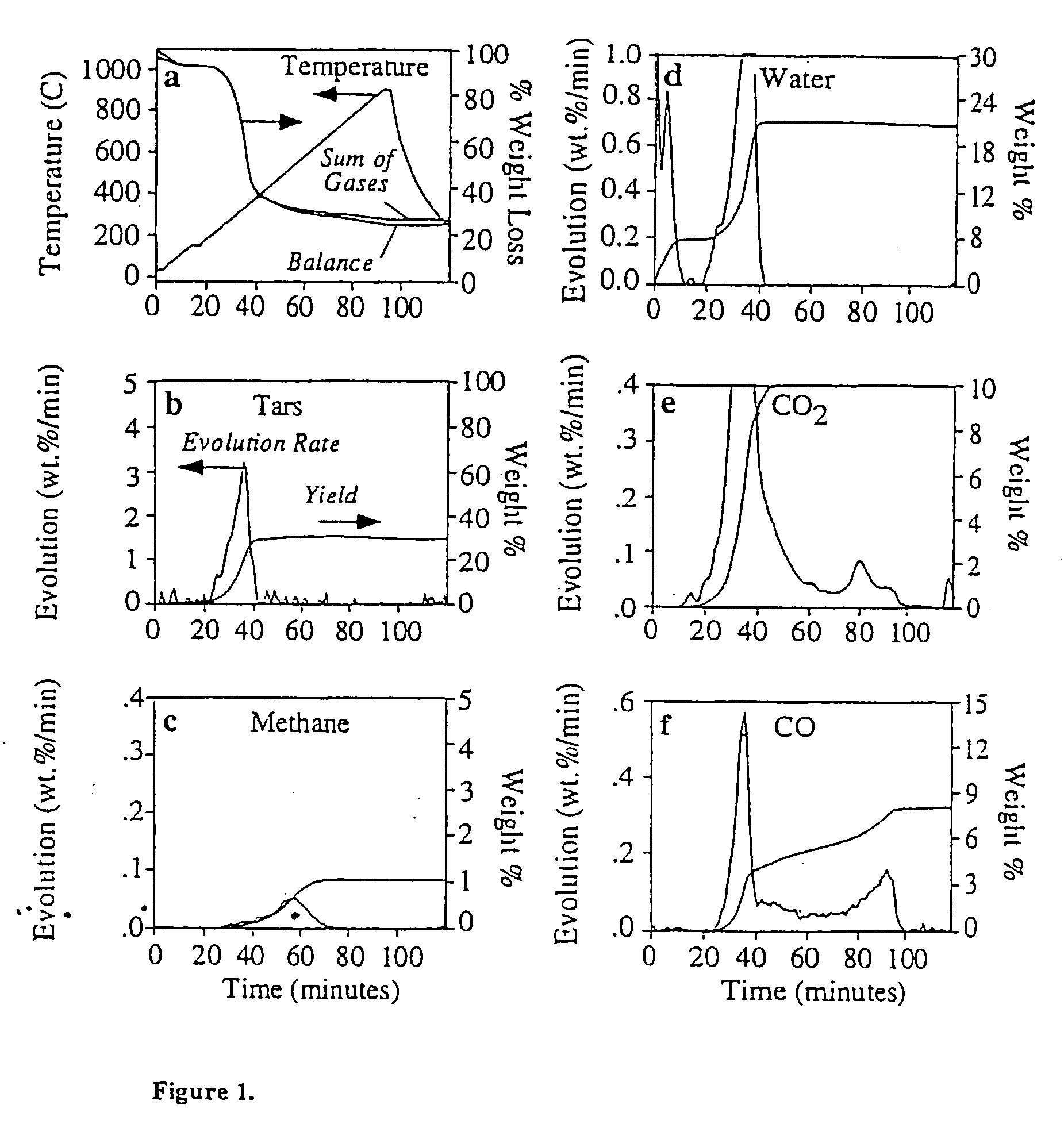

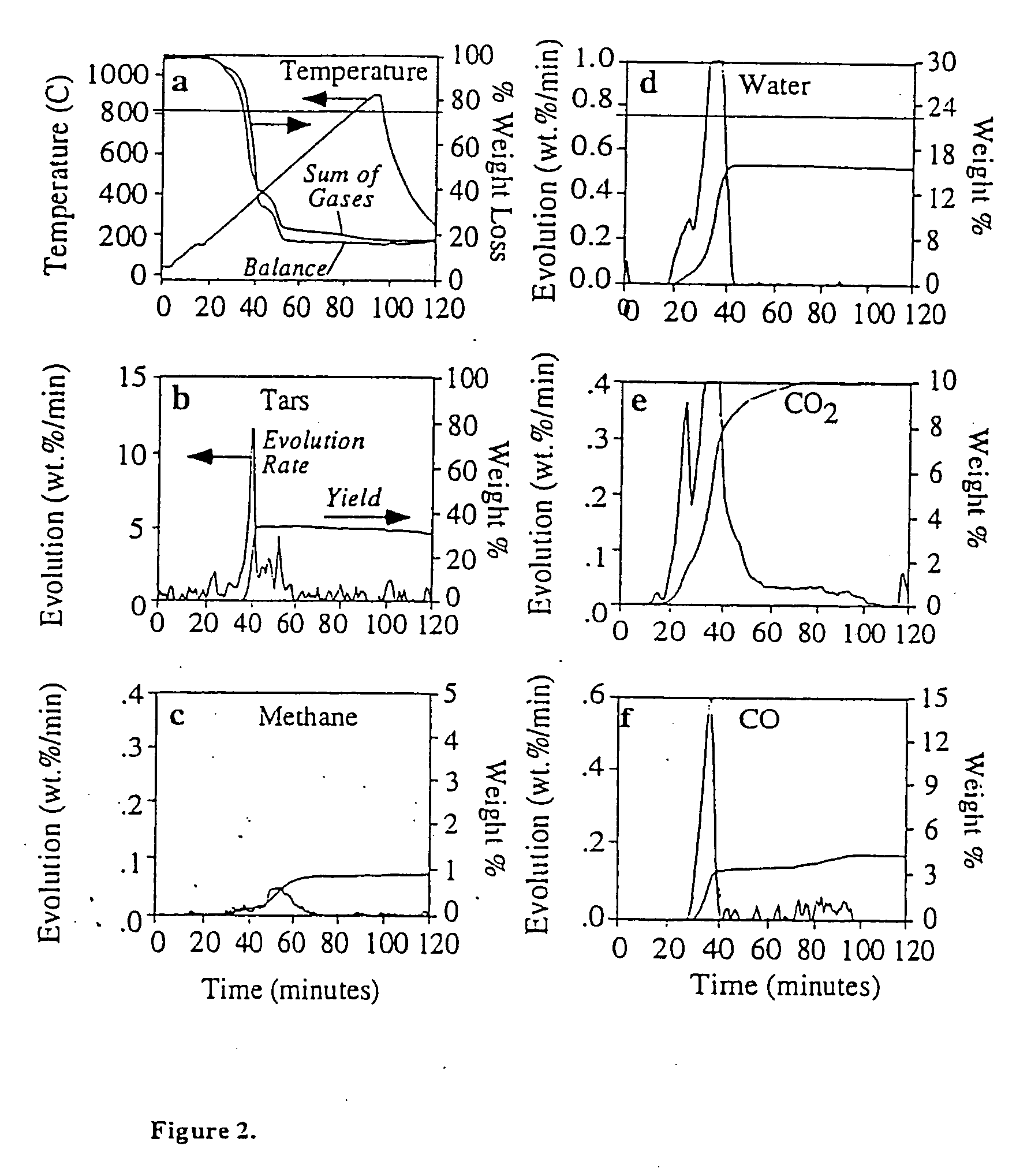

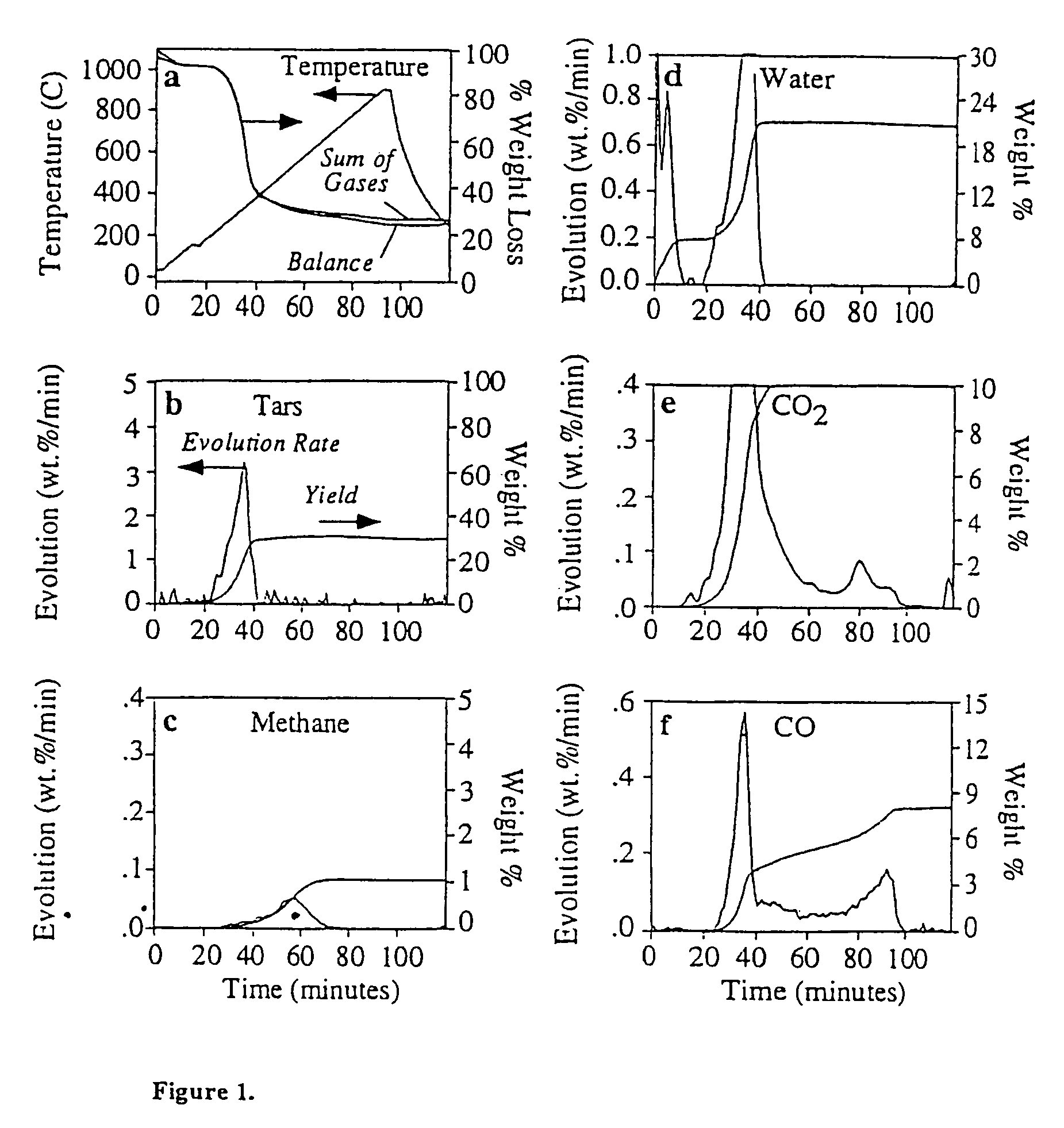

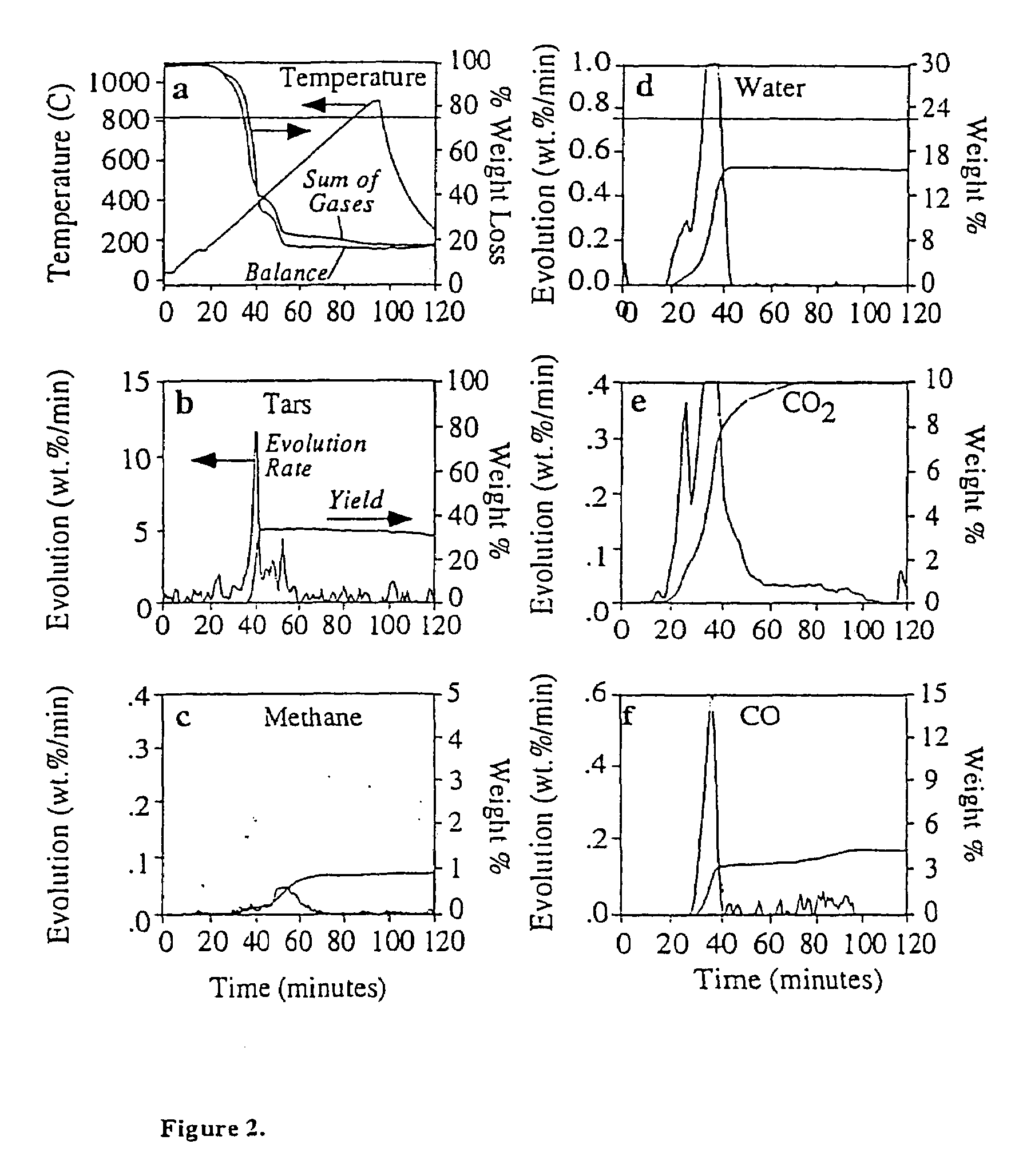

Pyrolysis process for producing fuel gas

Solid waste resource recovery in space is effected by pyrolysis processing, to produce light gases as the main products (CH4, H2, CO2, CO, H2O, NH3) and a reactive carbon-rich char as the main byproduct. Significant amounts of liquid products are formed under less severe pyrolysis conditions, and are cracked almost completely to gases as the temperature is raised. A primary pyrolysis model for the composite mixture is based on an existing model for whole biomass materials, and an artificial neural network models the changes in gas composition with the severity of pyrolysis conditions.

Owner:ADVANCED FUEL RES INC

Processing and recovering process of chemical fiber pulp cellulose alkali pressed liquor

The invention provides a processing and recovering process of a chemical fiber pulp cellulose alkali pressed liquor. The processing and recovering process mainly comprises the steps of primary film separating, secondary film separating, hemi-cellulose separating-out, ternary film separating, hemi-cellulose recovering, and the like. The invention provides a process for recovering the hemi-cellulose and alkali from the alkali pressed liquor. Compared with the prior art of recovering the alkali by using a nano-filtration system, the process provided by the invention has the advantages that the alkali recovering rate is higher and can reach 95% under the precondition that the concentration of the alkali is unchanged. Meanwhile, the recovering of the hemi-cellulose in the pressed liquor is realized, the obtained hemi-cellulose can be used as xylose producing raw material or directly used as a dispersing agent. In addition, the service life of the films can be prolonged.

Owner:SHANGHAI KAIXIN ISOLATION TECH CO LTD

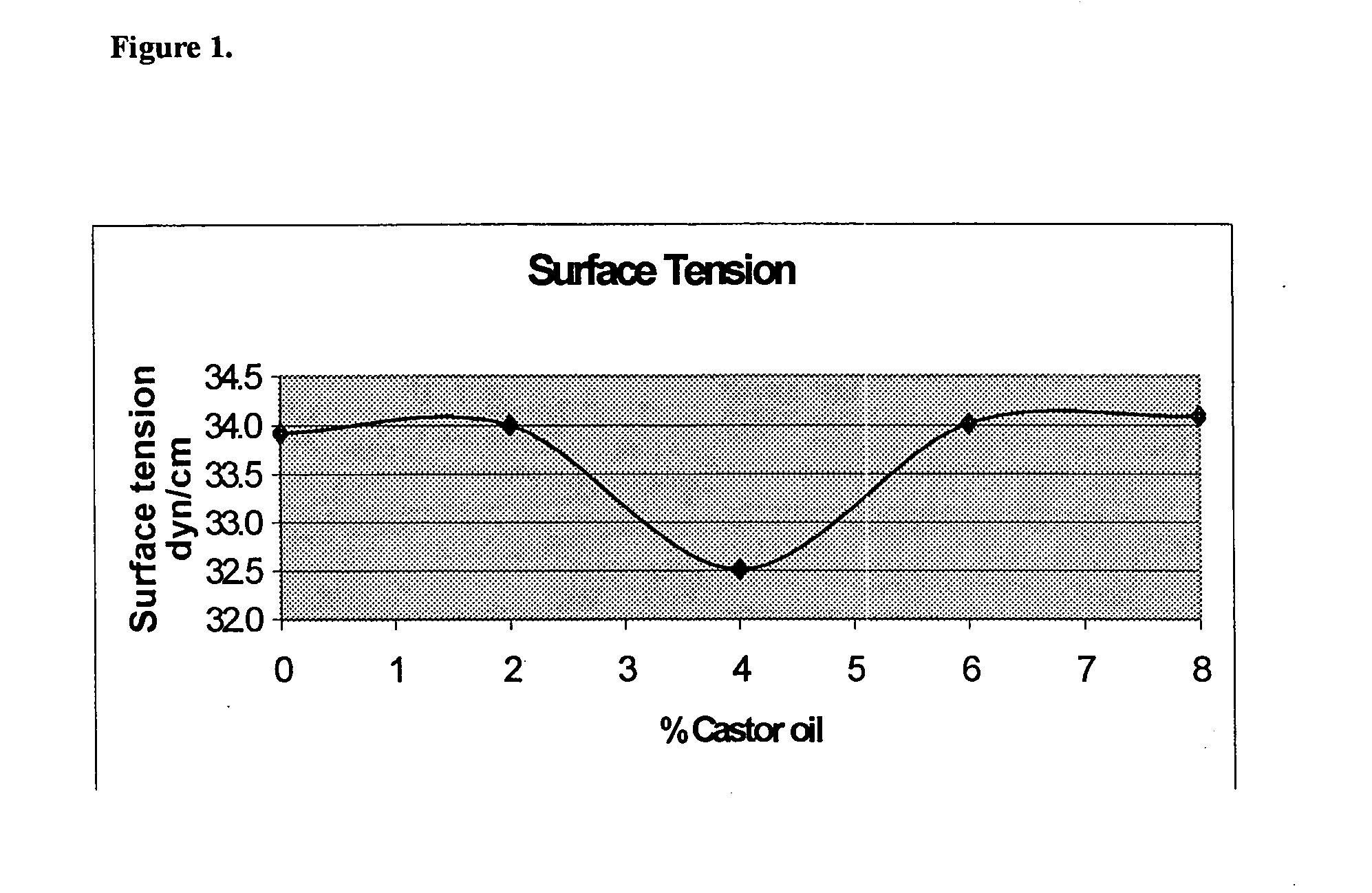

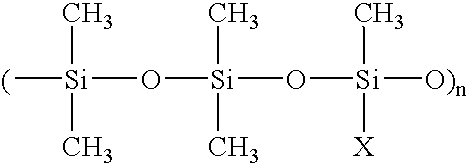

Defoamer emulsion compositions for pulp mill applications

InactiveUS20060128816A1Reduce usageLow costNatural cellulose pulp/paperDefoamers additionPulp millHydrophobic silica

An oil-in-water emulsion useful as a defoamer for pulp and paper mill applications is described. The defoamer has an oil blend (of a triglyceride oil or a mixture of triglyceride oils and silicone), a stabilizing agent (to make the oil blend stable in the emulsion), hydrophobic silica particles, surfactants, dispersants, and other components. The emulsion is usable directly at low concentrations to control foam.

Owner:SOLENIS TECH CAYMAN

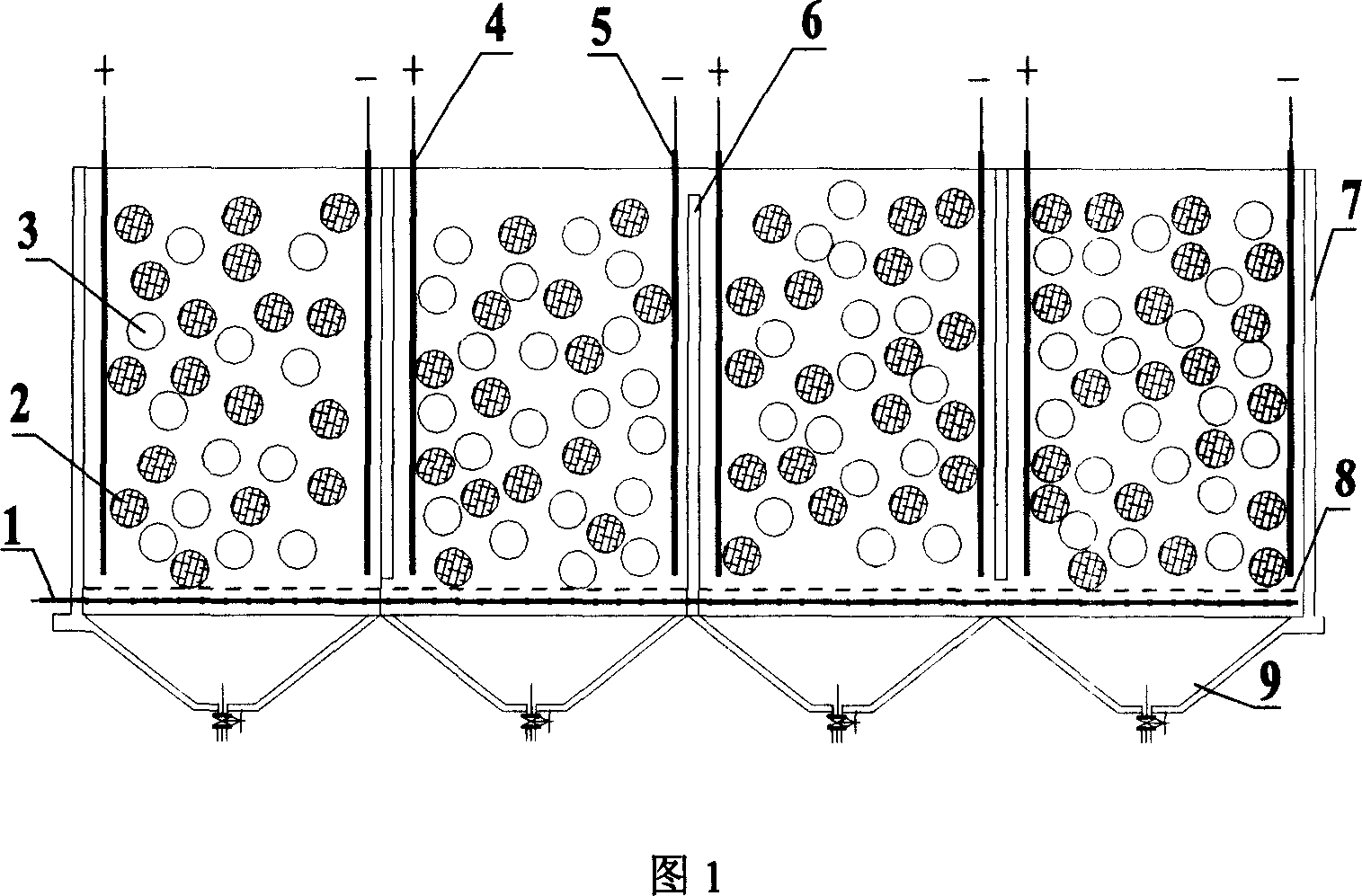

Composite electrolytic bath and method for electrolyzing and decoloring pulp-making effluent

InactiveCN101028944ALow cost of decolorization treatmentLow pricePulp liquor regenerationWater/sewage treatmentLiquid wasteElectrolysis

A composite electrolyzer for the electrolytic decoloring of chemico-mechanical pulping sewage is composed of multiple unit electrolyzers formed by dividing the composite electrolyzer by bulkheads and containing the plate anode, plate cathode and filler layer consisting of electric conductive particles and inertial particles, a supporting air distributing plate, aerating tube and sludge bath. Its electrolytic decoloring method for the chemico-mechanical pulping sewage includes such steps as flitering by oblique net, regulating pH=3-3.5, depositing, filtering and decoloring in said composite electrolyzer.

Owner:SOUTH CHINA UNIV OF TECH

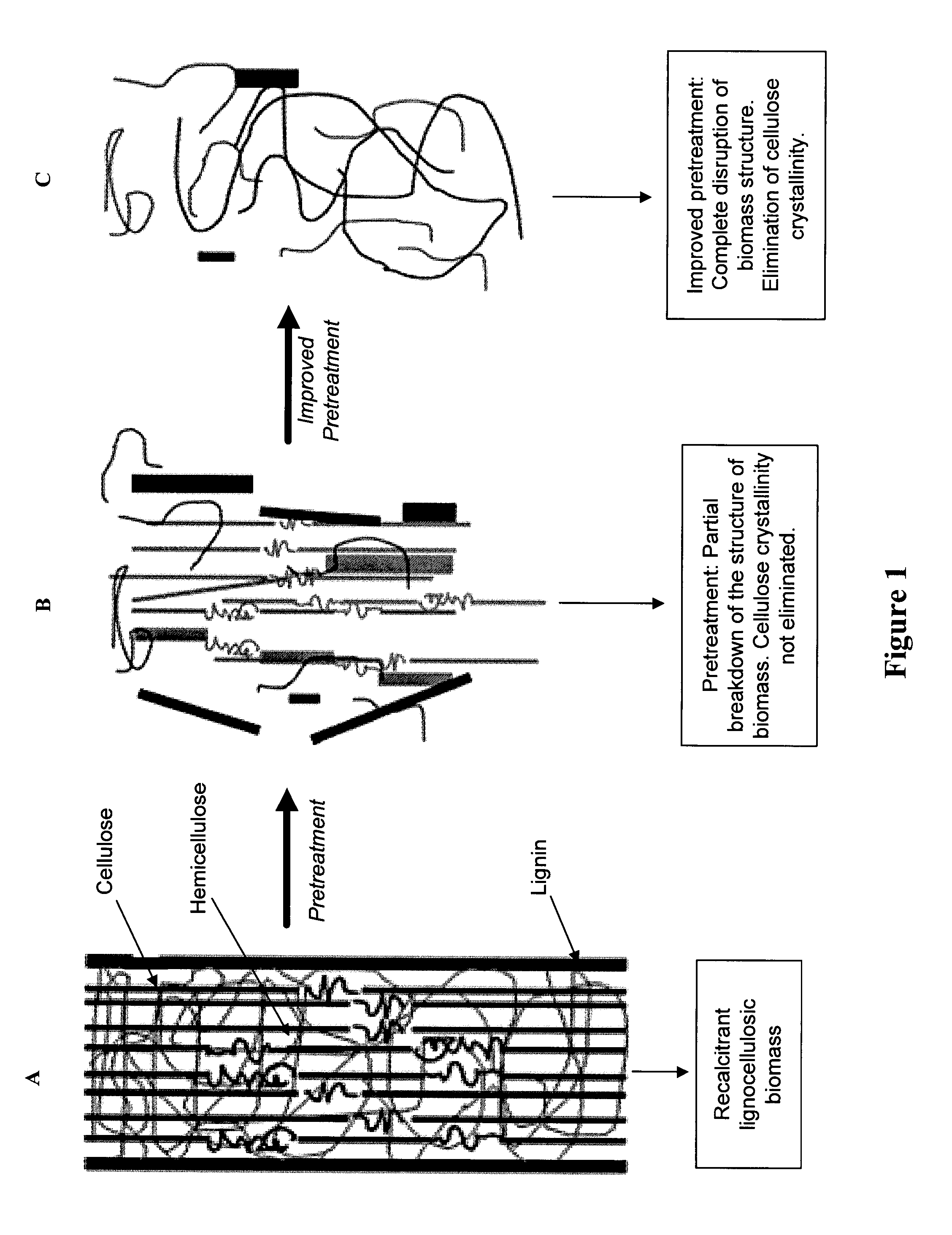

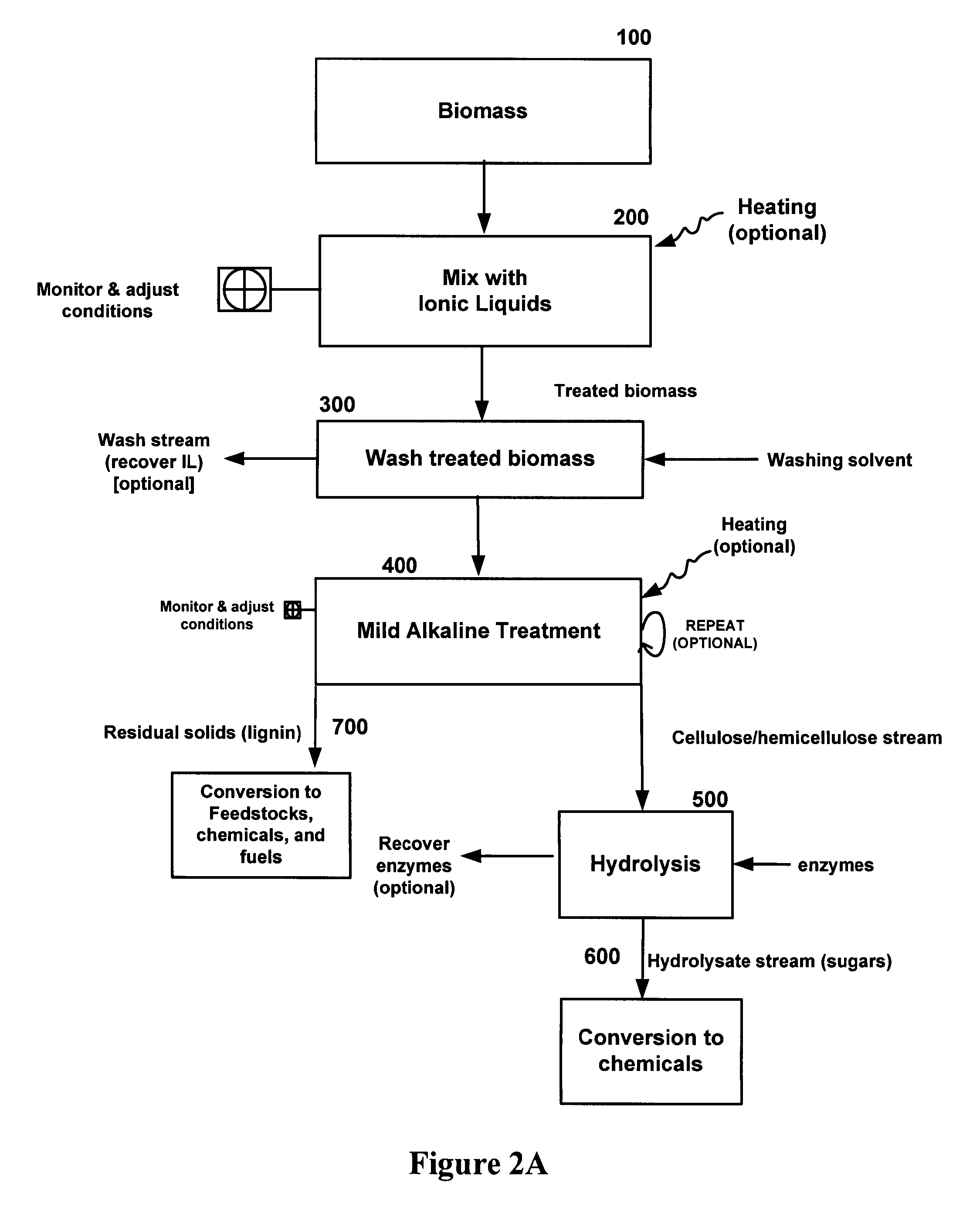

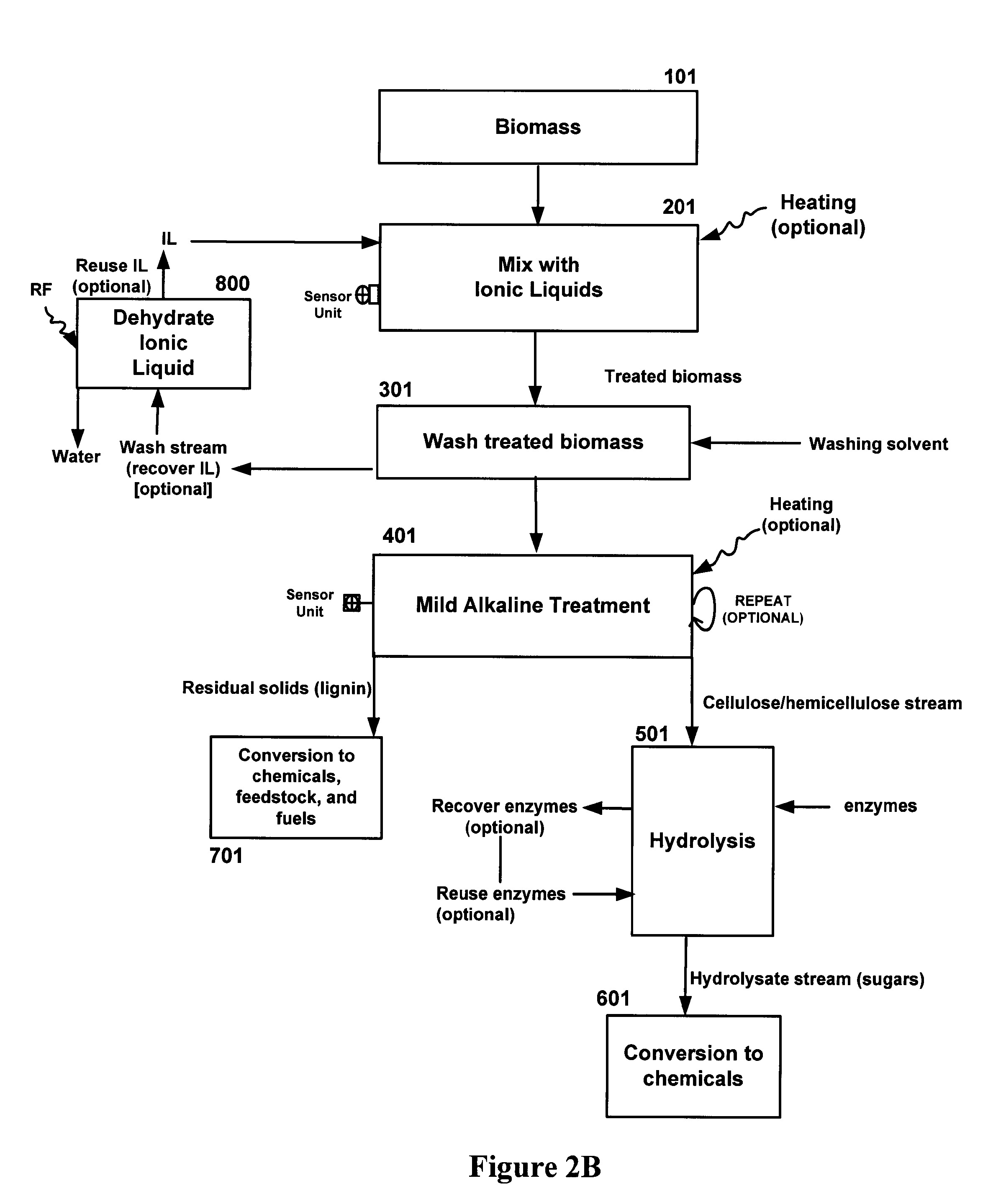

Pretreatment and fractionation of lignocellulosic biomass

InactiveUS20140273104A1Pulp liquor regenerationPretreatment with alkaline reacting compoundsCelluloseFractionation

Method and apparatus for enhanced production of sugars and lignin via fractionation of lignocellulosic biomass through sequential ionic liquid pretreatment and mild alkaline treatment. The resulting biomass is easily fractionated and amenable to efficient and rapid hydrolysis and catalytic conversion to valuable products with high recovery of the enzymes used in the hydrolysis.

Owner:SUGANIT SYSTEMS INC

Catalytic reactor process for the production of commercial grade pulp, native lignin and unicellular protein

ActiveUS7396434B2Pulp liquor regenerationWashing/displacing pulp-treating liquorsCelluloseChemical solution

A continuous and batch system to produce cellulose, native lignin and unicellular protein from any form of vegetation in a closed process. The biomass is mixed in the impregnate solution of nitric acid and / or ammonium hydroxide and water. After a period of time at room temperature and atmospheric pressure the chemical solution is recycled. The biomass is moved to the reactor and heated. Evaporated impregnate is recovered via absorption tower and recycled back to chemical solution. The biomass is moved to an alkaline solution, then cooled to separate pulp from black liquor. The black liquor is pumped to a separation tank and is treated to precipitate lignin. The solution is filtered to separate sweet liquor and lignin. The lignin is dried and the sweet liquor is fermented to produce unicellular protein.

Owner:PURE LIGNIN ENVIRONMENTAL TECH

Production method for high-grey-specification and high-thickness grey board

ActiveCN106087522AImprove adsorption capacityIncreasing the thicknessPulp liquor regenerationCellulose treatment using microorganisms/enzymesCardboardPapermaking

The invention relates to a production method for a high-grey-specification and high-thickness grey board. The production method comprises the steps of sizing agent preparation, sizing agent mixing and papermaking, wherein in sizing agent preparation, an OCC sizing agent, an ONP sizing agent, a sawdust sizing agent and a recovery sizing agent are prepared, and Hasun saccharomyces microorganisms and an adhesion agent are added into the sawdust sizing agent; in sizing agent mixing, the ONP sizing agent is used for making a grey board face layer, and the OCC sizing agent, the sawdust sizing agent mixture and the recovery sizing agent are mixed according to proportions to form a grey board liner, a grey board core layer and a grey board bottom layer; in papermaking, the sizing agents are dewatered through a net part to be shaped, the face layer, the liner, the core layer and the bottom layer are composited, a pressing part is used for squeezing and dewatering, a drying part is used for carrying out drying, and then paper is made. Microbial culture is carried out on the sawdust sizing agent, the surface chemical performance and the pore structure of the sawdust sizing agent are modified, and the thickness, the tightness and the deflection of the grey board are effectively improved. Low-concentration tailings at the tail section of an OCC line are recycled, the benefits of environmental protection are remarkable, and the production cost is effectively reduced.

Owner:LIANSHENG PAPER IND LONGHAI

Urea sulfate and urea hydrochloride in paper and pulp processing

InactiveUS7029553B1Regulate securityLess process equipmentNon-fibrous pulp additionNatural cellulose pulp/paperFlocculationSulfate

The present invention relates to the use of urea sulfate or urea hydrochloride, or both, in process streams in the paper and pulping industries to control pH, to bring about flocculation or precipitation of various materials, and to replace all or part of the sulfuric acid, hydrochloric acid, and / or papermaking alum used in the paper and pulping industries.

Owner:PEACH STATE LABS +1

Pyrolysis process for producing fuel gas

Owner:ADVANCED FUEL RES INC

Grass type unbleached paper products and production method thereof

Provided is an unbleached paper product made from grass type pulp, the unbleached paper product has a brightness of 35-60% ISO, the grass type pulp is unbleached. The unbleached paper product includes an unbleached toilet paper, an unbleached hand towel, an unbleached wiping paper, an unbleached duplicating paper, an unbleached meal container, an unbleached food wrapping paper and an unbleached printing paper. The paper products have a high intensity and have no detection of dioxin and absorbable organic halides in the harmful substance detection test.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

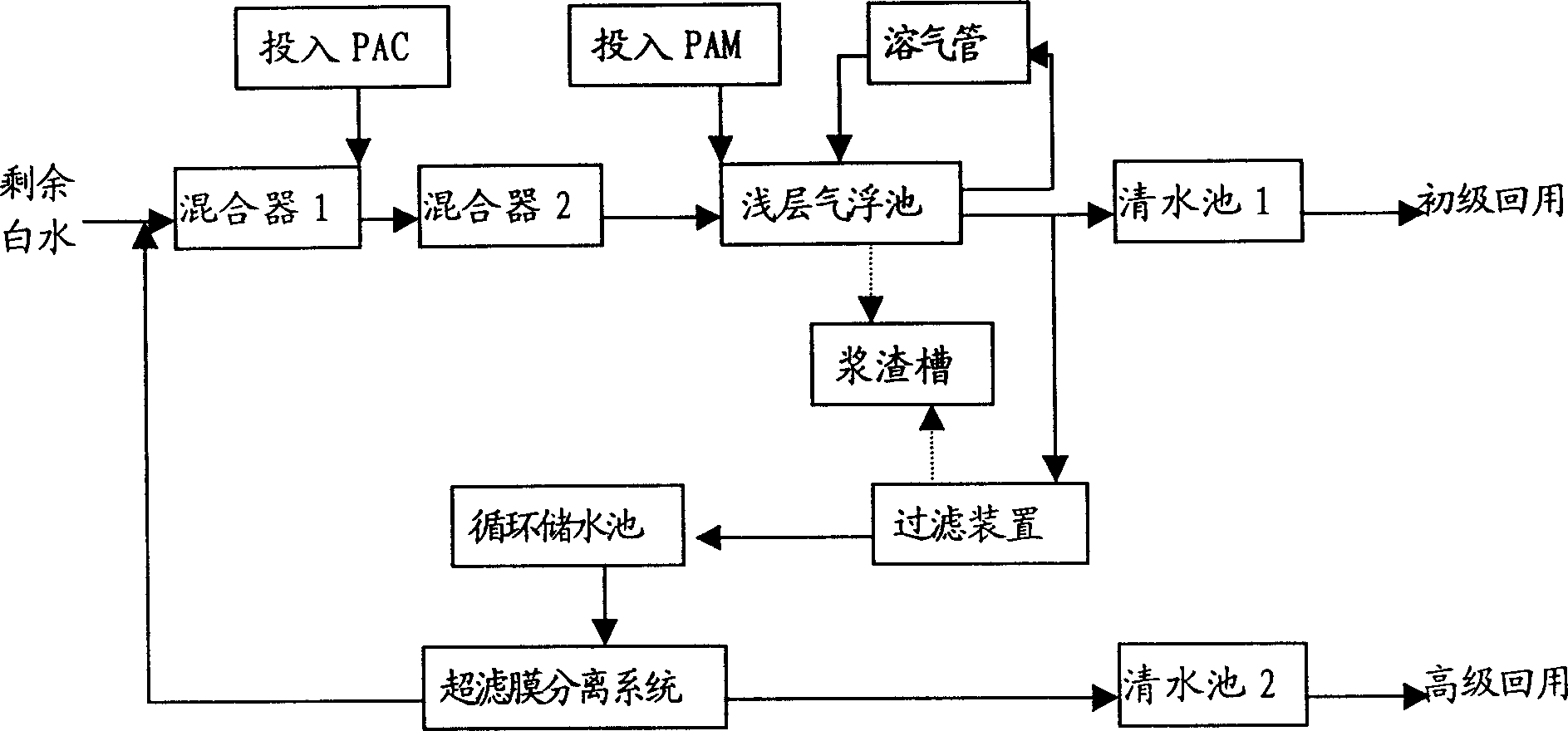

Processing mthod of white water from paper making

ActiveCN1766227AReduce turbidityMeet the requirements of advanced circulating waterPulp liquor regenerationMultistage water/sewage treatmentAluminium chlorohydrateUltrafiltration

The invention relates to a treatment method for paper-making white water, which comprises: treating residual white water with superficial air-float technique and with polyaluminium chloride and strong-cation polyacrylamide as flocculant and coagulant by special proportion to make SS of out water about 10mg / L and turbidity not larger than 15NTU and become primary recycling water, ultrafiltrating to remove all SS with turbidity not larger than 1NTU, and obtaining super recycling water. This invention can realize zero-discharge of paper-making white water in deed.

Owner:BAODING BANKNOTE PAPER CO LTD +1

Clean high-valued utilization method for straw resources

InactiveCN101787656AHigh yieldEasy to separatePulp liquor regenerationSewage/sludge fertilisersEvaporationPotassium

The invention provides a paper pulp and fertilizer co-production technique, which aims at the present statuses of generally low utilization value of straw resources and serious environmental pollution caused by papermaking black liquor in China. In the technique, KOH and 1,3-propane diamine are used as the main stewing components to prepare pulp from various straws. The 1,3-propane diamine is beneficial to removing lignin and enhancing the product yield. High value-added paper products are obtained, and meanwhile, black liquor contains kalium, nitrogen and humic acid, thereby being a good nutrient source for organic fertilizers. Acid is added to the black liquor to neutralize, thereby obtaining a humic acid liquid fertilizer; and nitrogen, phosphorus, kalium and chelated microelements are added to obtain a liquid compound fertilizer. The pulverized straw scraps leftover materials can be directly used for adsorbing the black liquor, and are subjected to evaporation and granulation to prepare a solid organic fertilizer. The whole paper pulp and fertilizer co-production system does not discharge waste, thus the invention can thoroughly eliminate the pollution caused by the papermaking black liquor and realize the clean high-valued utilization of the straw resources.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for producing crude tall oil by soap washing with calcium carbonate removal

ActiveUS20120123087A1Avoid confusionAvoid accumulationFatty oils/acids recovery from wastePulp liquor regenerationBlack liquorFiltration

A method for producing crude tall oil from black liquor soap while removing calcium carbonate and lignates is disclosed. Black liquor soap is first combined with an alkaline ash medium having a lower concentration of lignates and inorganic solids than the black liquor soap, to form washed tall oil soap, fortified brine, lignates, and calcium carbonate. The washed tall oil soap is then separated from the fortified brine, lignates, and calcium carbonate, by centrifugation, decantation, filtration, settling, or a combination of these techniques. Acidification of the washed tall oil soap gives crude tall oil and a spent acid mixture. The crude tall oil is separated from the spent acid. The spent acid is made alkaline, and at least a portion of it is returned for use as alkaline wash medium. The method avoids accumulation of calcium sulfate in acidulation units.

Owner:KRATON CHEM LLC

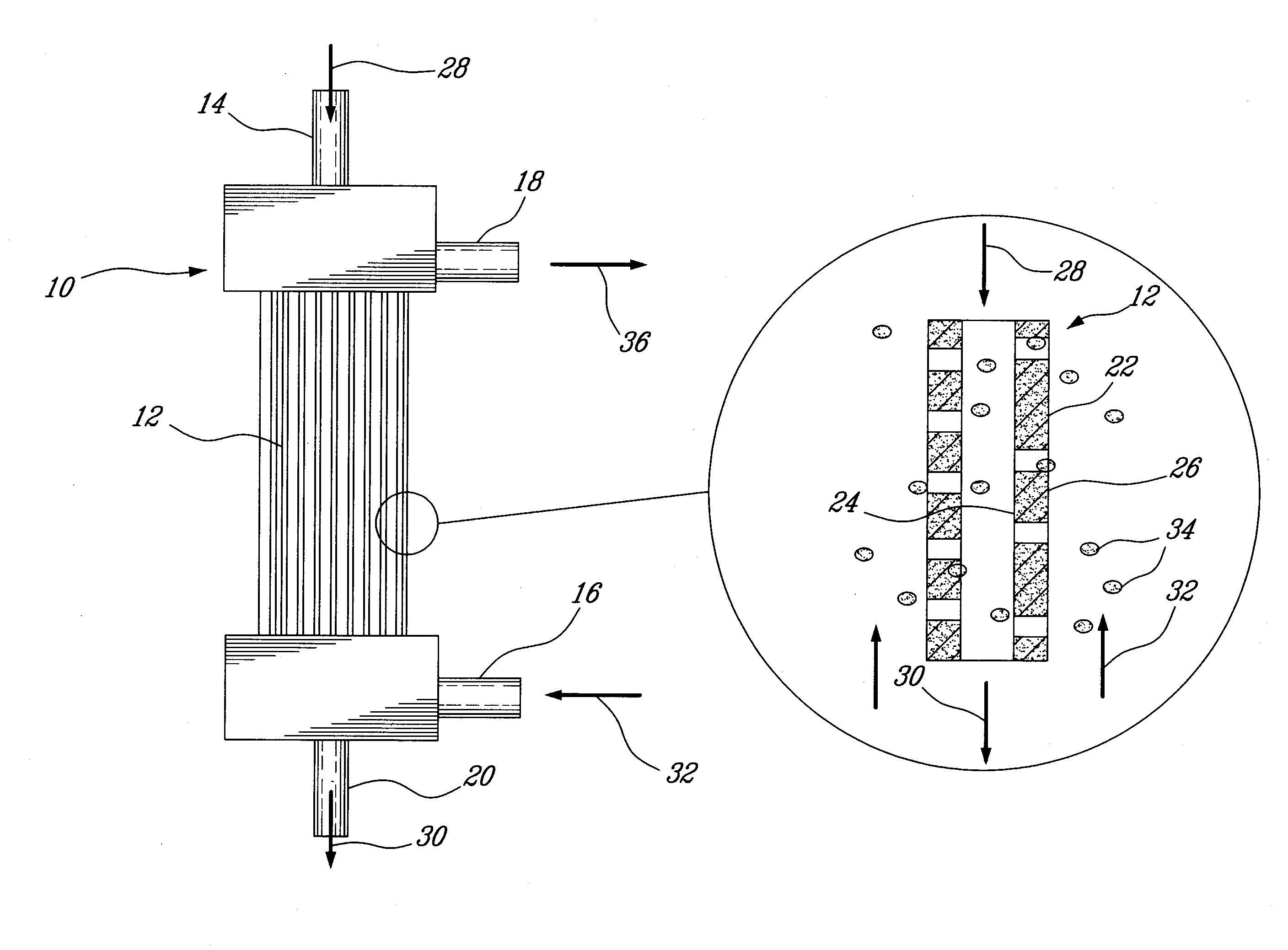

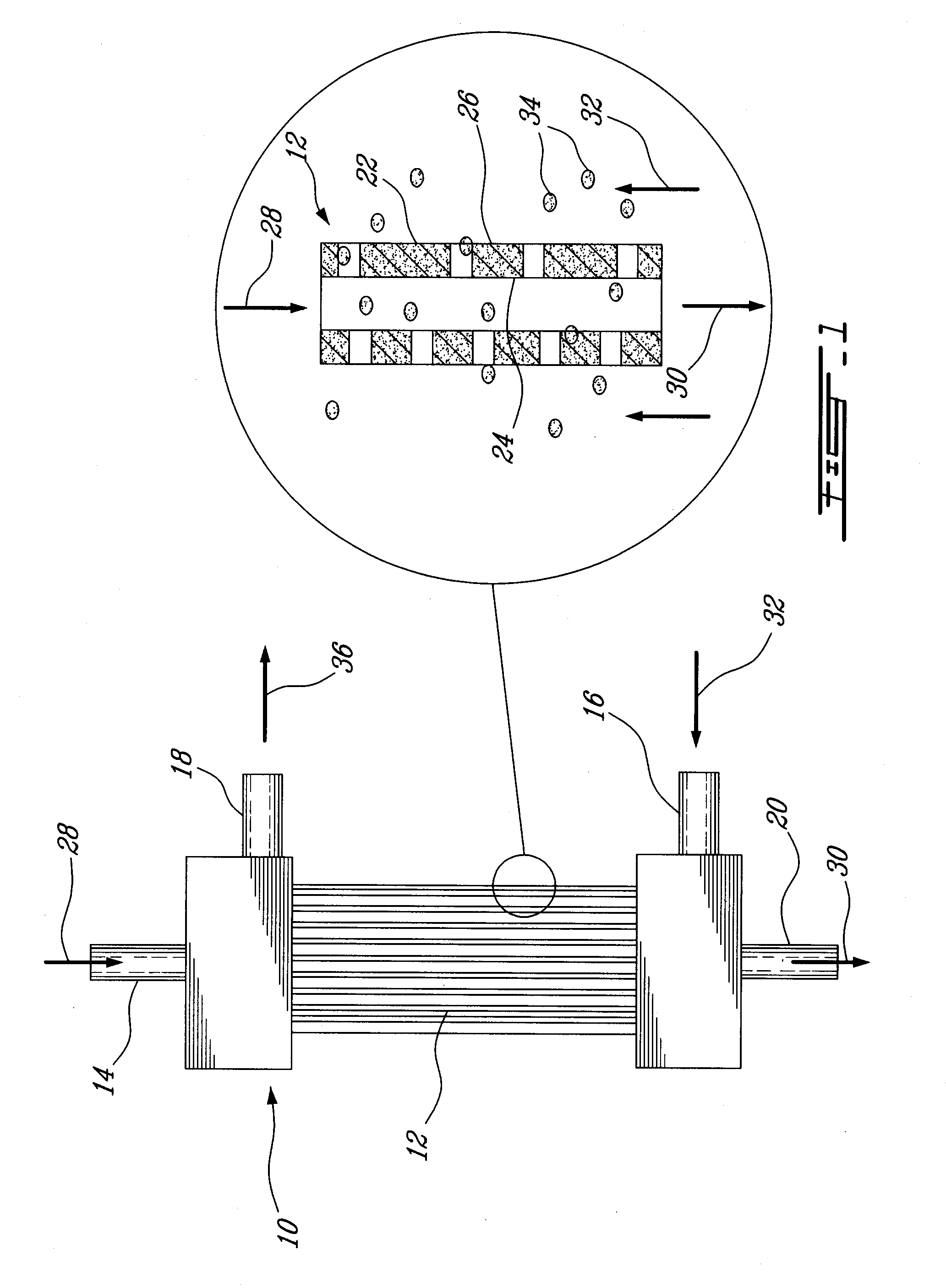

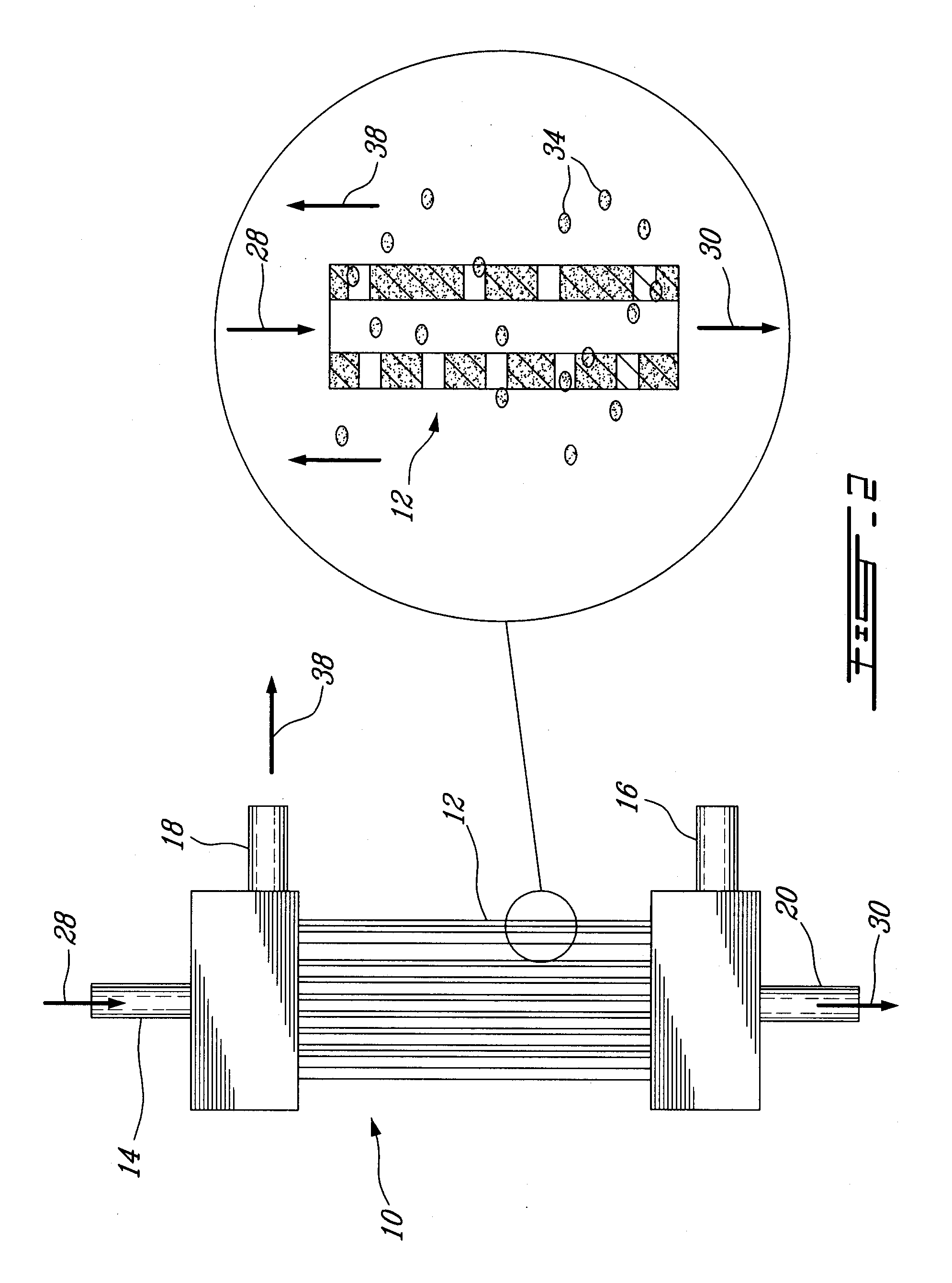

Process for treating pulp mill condenstates using a hollow fiber contactor

A method and apparatus for the treatment of pulp mill condensates is described. A hollow fiber contactor, incorporating a hydrophobic membrane, was used to remove several undesirable compounds from pulp mill condensates. For example, TRS compounds and SO2 were efficiently stripped from kraft and sulphite mill evaporator condensates, respectively. Methanol was also removed from kraft mill condensates but at a lower efficiency than TRS. Furthermore, other undesirable compounds found in condensates of pulp mills that contribute to the BOD and COD loading to effluent treatment systems were also removed. These contactors are cost effective since air, vacuum or a suitable solvent or scrubbing solution can be used as the stripping medium to drive off through the membrane several undesirable compounds from the feed solution. The undesirable compounds removed can thus be burned in the recovery boiler, lime kiln or a dedicated boiler.

Owner:FPINNOVATIONS INC

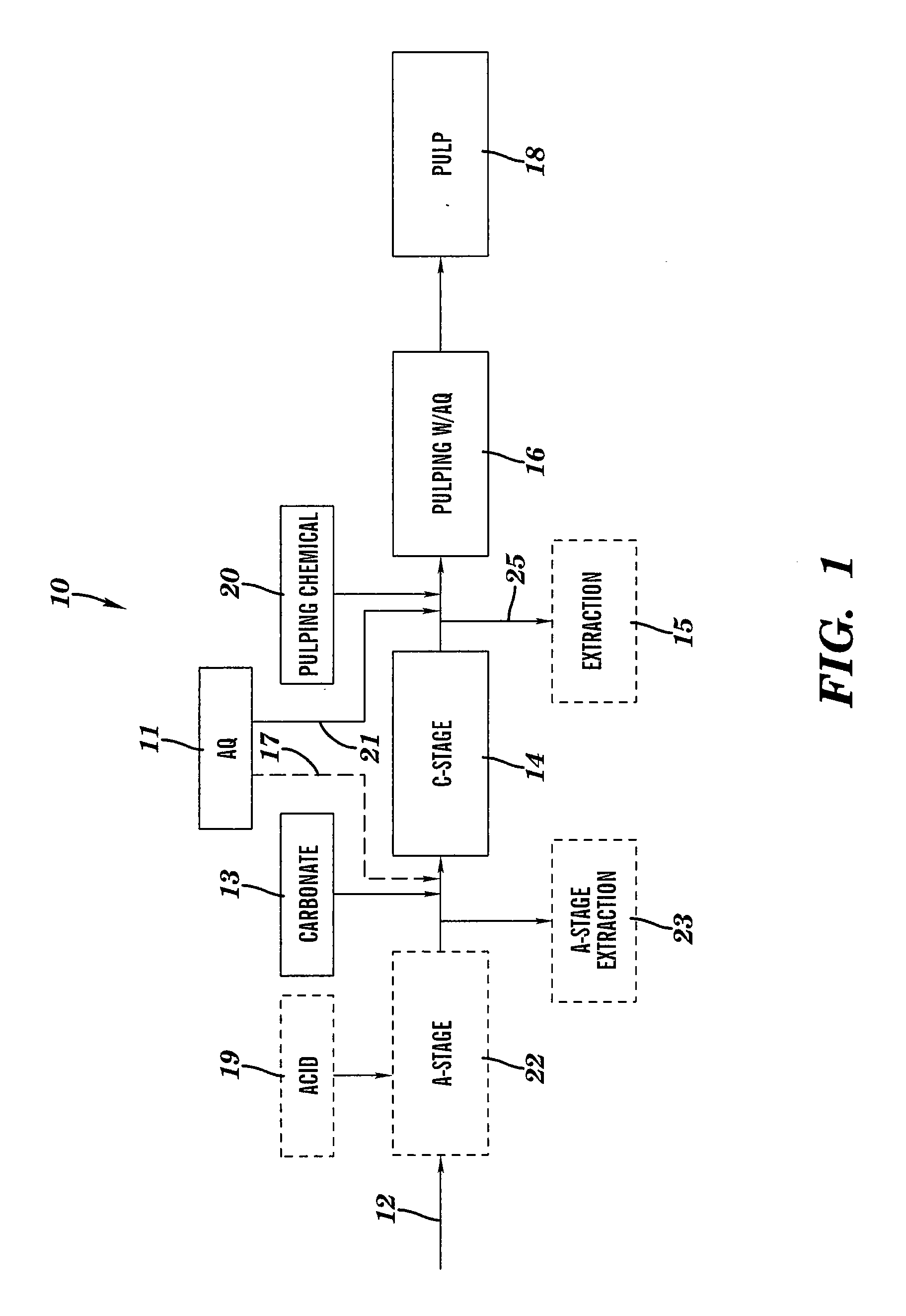

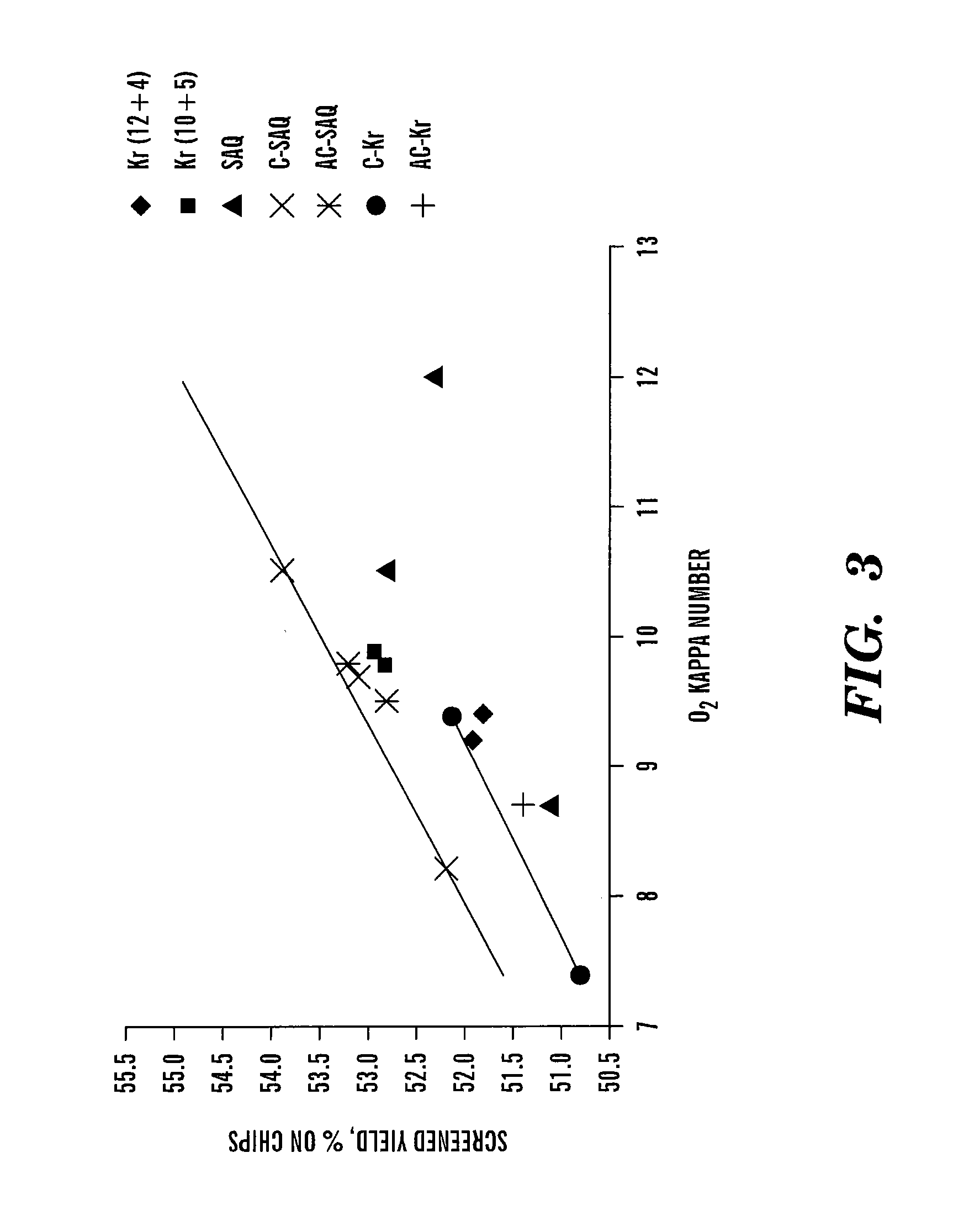

Methods for carbonate pretreatment and pulping of cellulosic material

InactiveUS20070284068A1Pulp liquor regenerationPretreatment with acid reacting compoundsFiberCarbonate

A method of pretreating comminuted fibrous material with sodium carbonate and then cooking the pretreated material in the presence of anthraquinone (AQ) is provided. The resulting pulp produced has a higher yield, enhanced strength, and better bleachability compared to pulp produced by prior art methods. AQ may also be introduced to the carbonate pretreatment stage. The method may further include an acid pretreatment providing further enhanced properties to the pulp produced.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com