Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1154results about "Cellulose treatment using microorganisms/enzymes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

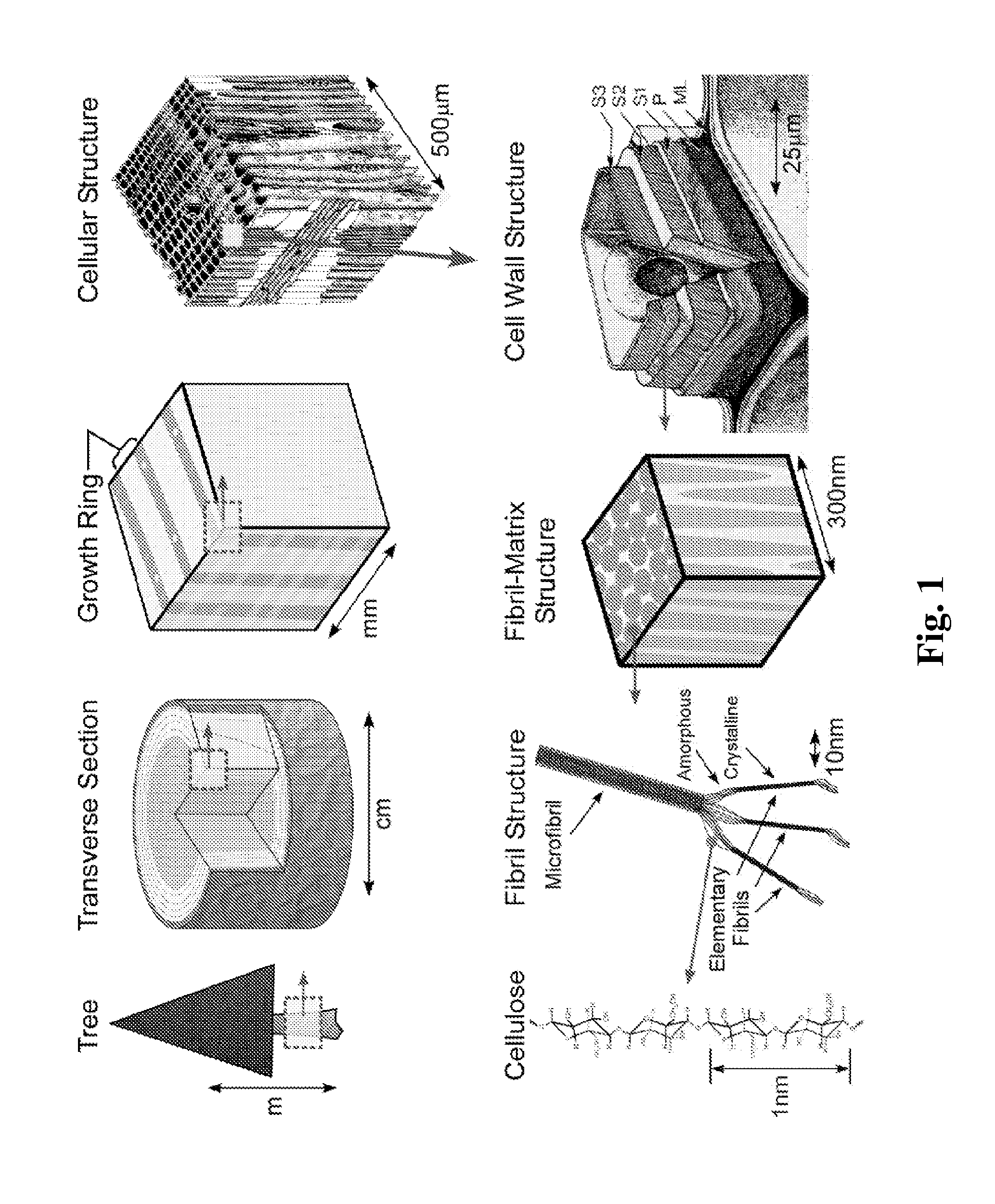

Method of producing and the use of microfibrillated paper

InactiveUS20100065236A1Non-fibrous pulp additionPulp properties modificationChemical structureEngineering

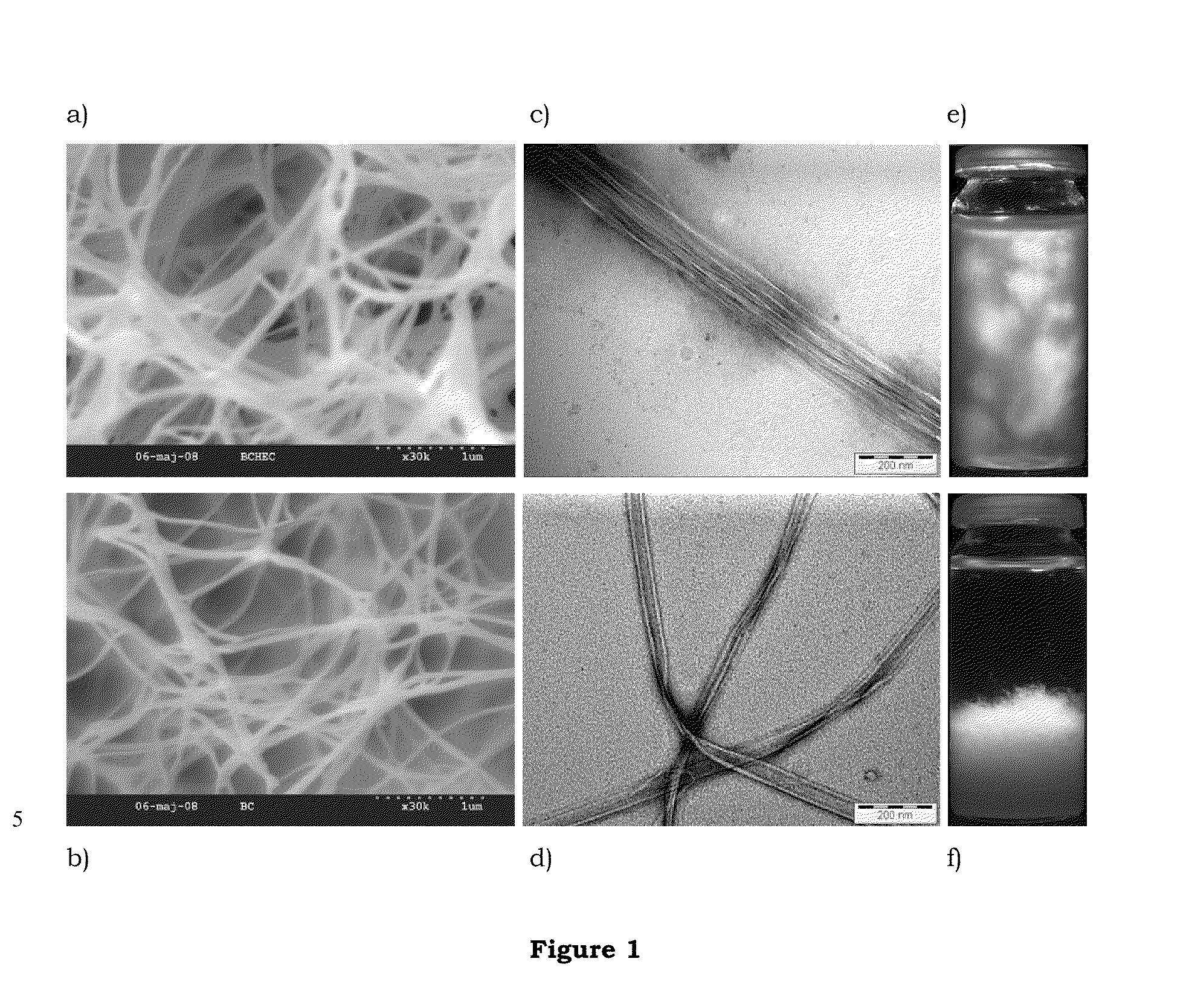

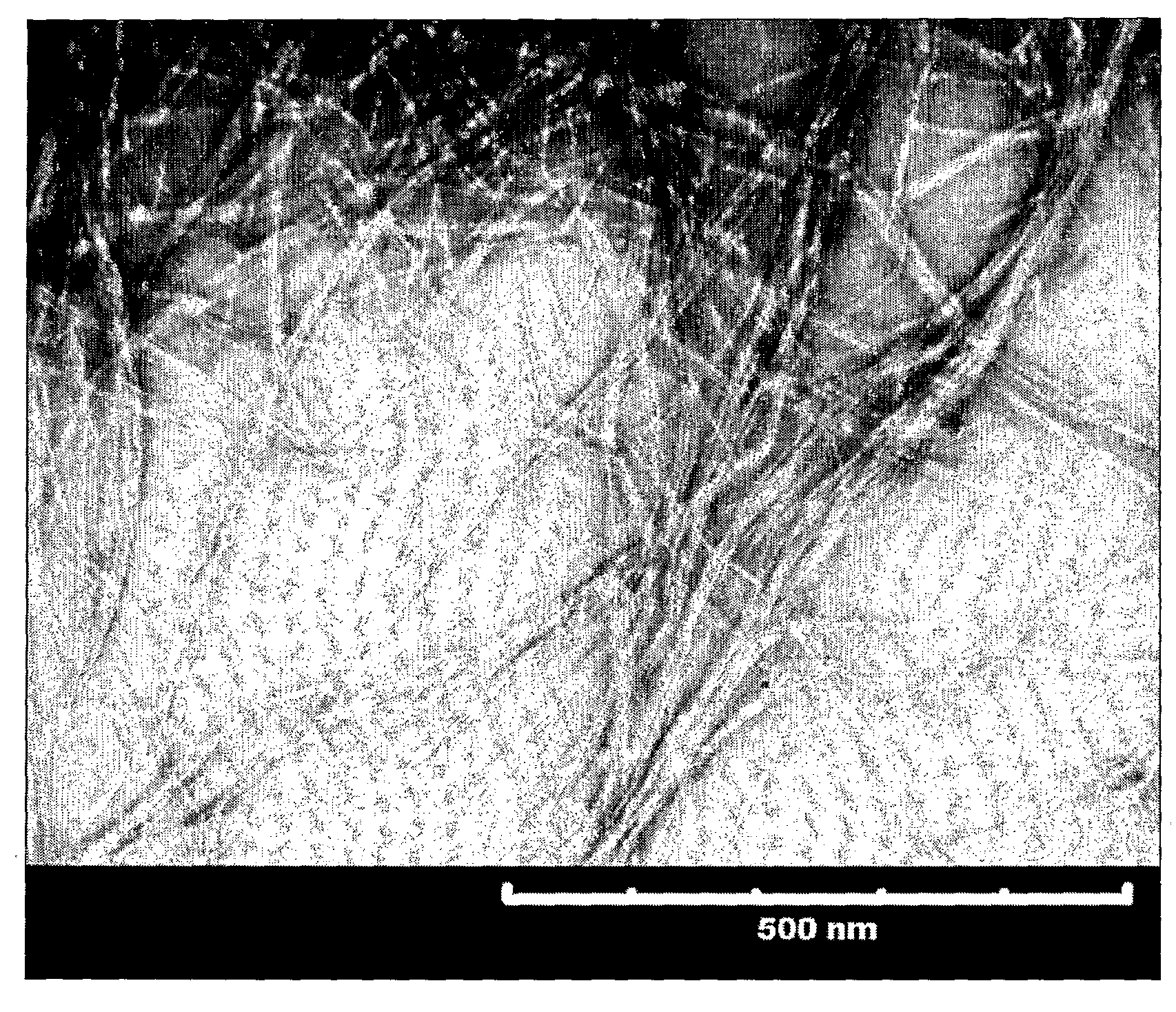

The present invention relates to a method of producing a cellulose based paper, the paper itself and the use thereof where the paper exhibits enhanced mechanical properties. The method involves providing a suspension of well dispersed modified cellulose at a low concentration. The properties and the chemical structure of the paper make it suitable for in vivo applications such as implant material.

Owner:SWETREE TECHOLOGIES AB

Method for the manufacture of microfibrillated cellulose

ActiveUS20090221812A1Reduce energy consumptionCellulose treatment using microorganisms/enzymesMultistage pulping processHemicelluloseEnzyme

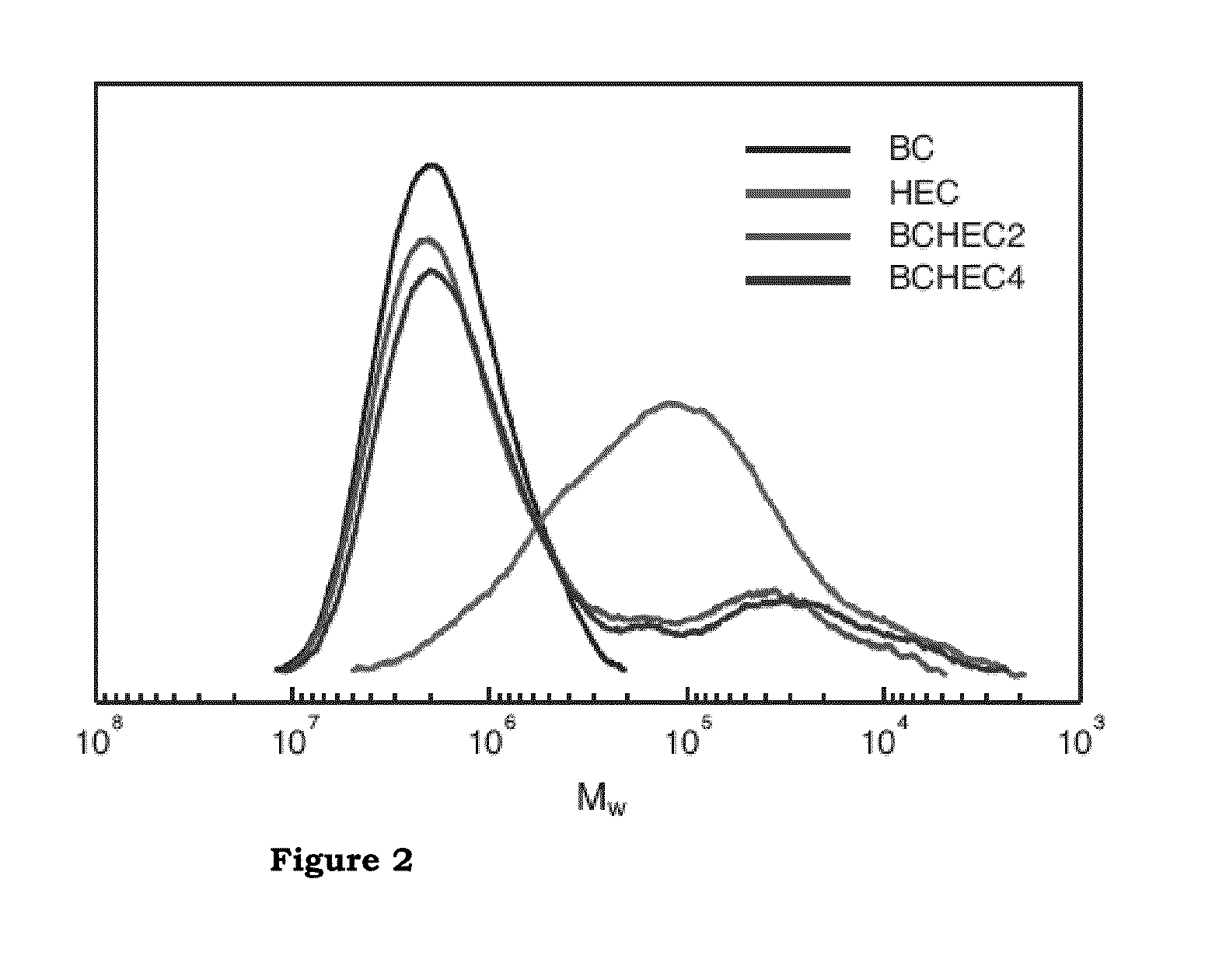

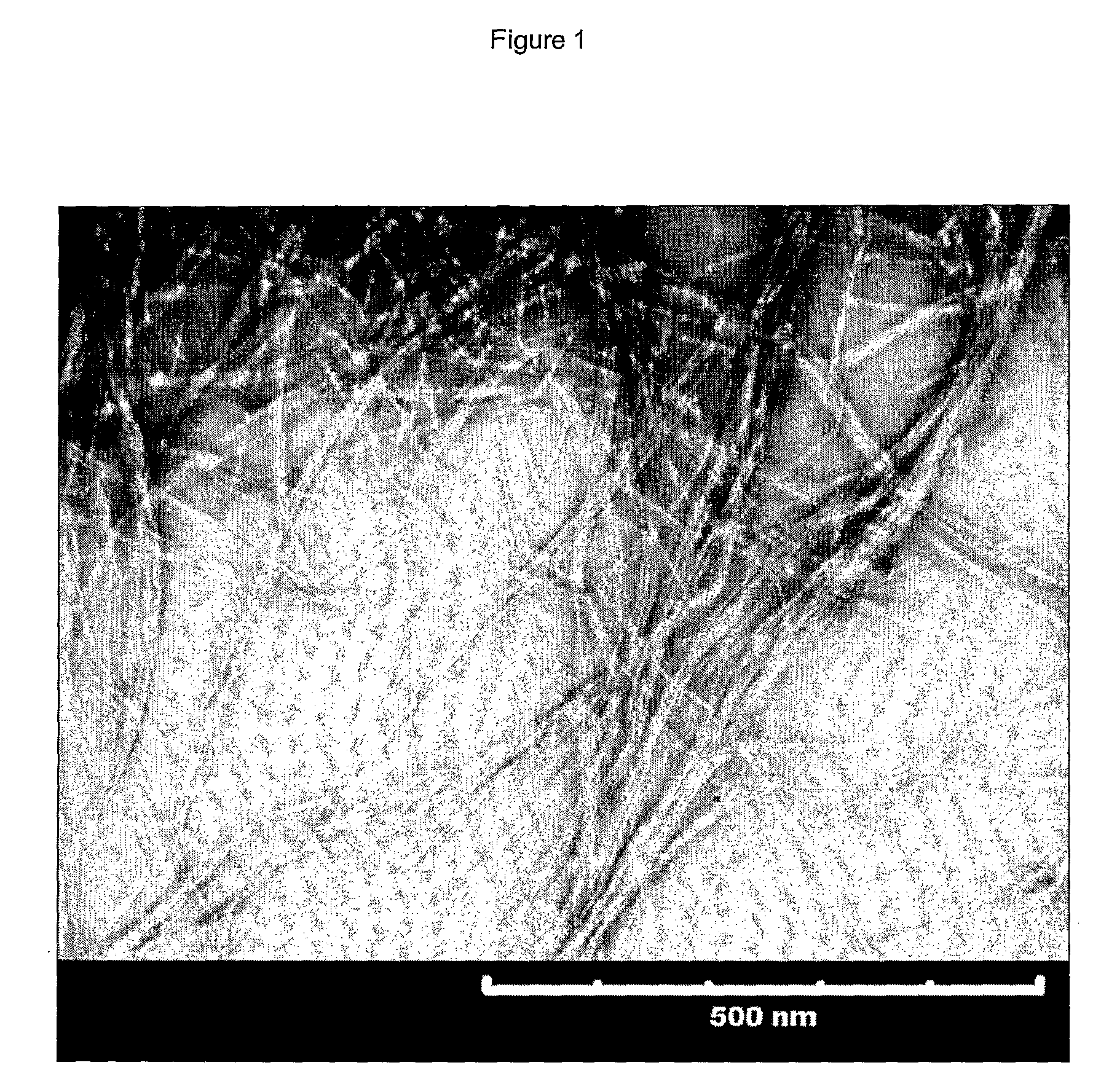

A method for treatment of chemical pulp for the manufacturing of microfibrillated cellulose includes the following steps: a) providing a hemicellulose containing pulp, b) refining the pulp in at least one step and treating the pulp with one or more wood degrading enzymes at a relatively low enzyme dosage, and c) homogenizing the pulp thus providing the microfibrillated cellulose. According to a second aspect of the invention a microfibrillated cellulose obtainable by the method according to the first aspect is provided. According to a third aspect of the invention, use of the microfibrillated cellulose according to the second aspect in food products, paper products, composite materials, coatings or in rheology modifiers (e.g. drilling muds) is provided.

Owner:STFI PACKFORSK AB

Product and processes from an integrated forest biorefinery

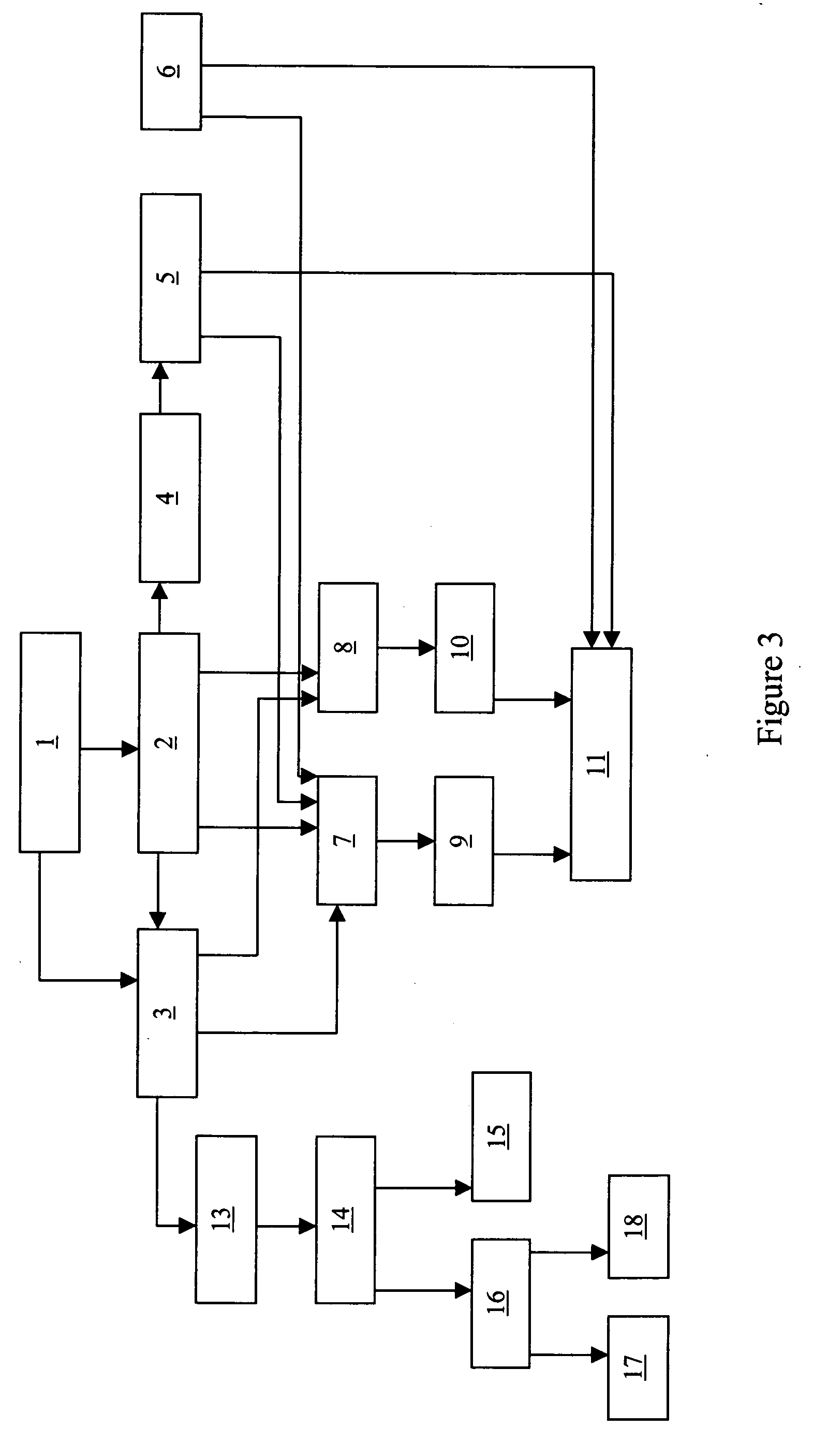

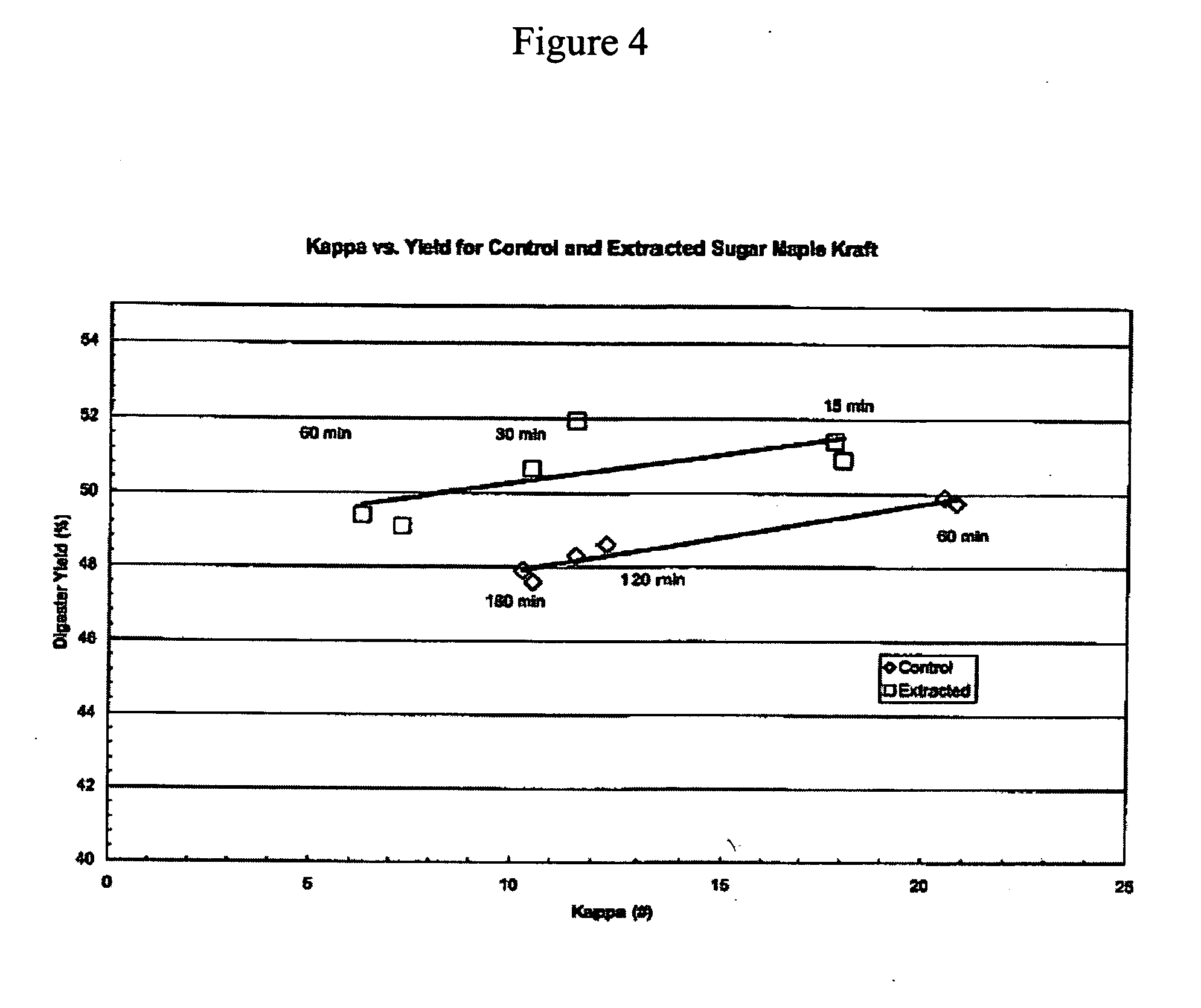

ActiveUS20070079944A1Easy to optimizePretreatment with water/steamPulping with acid salts/anhydridesPulp and paper industrySugar

An omnibus process of pulping and bleaching lignocellulosic materials in which a charge of a lignocellulosic material is biopulped and / or water extracted prior to pulping and bleaching. The lignocellulosic material may be mechanically pulped and bleached in the presence of an enzyme that breaks lignin-carbohydrate complexes. The aqueous extract in embodiments including a water extract step is separated into acetic acid and hemicellulose sugar aqueous solutions.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

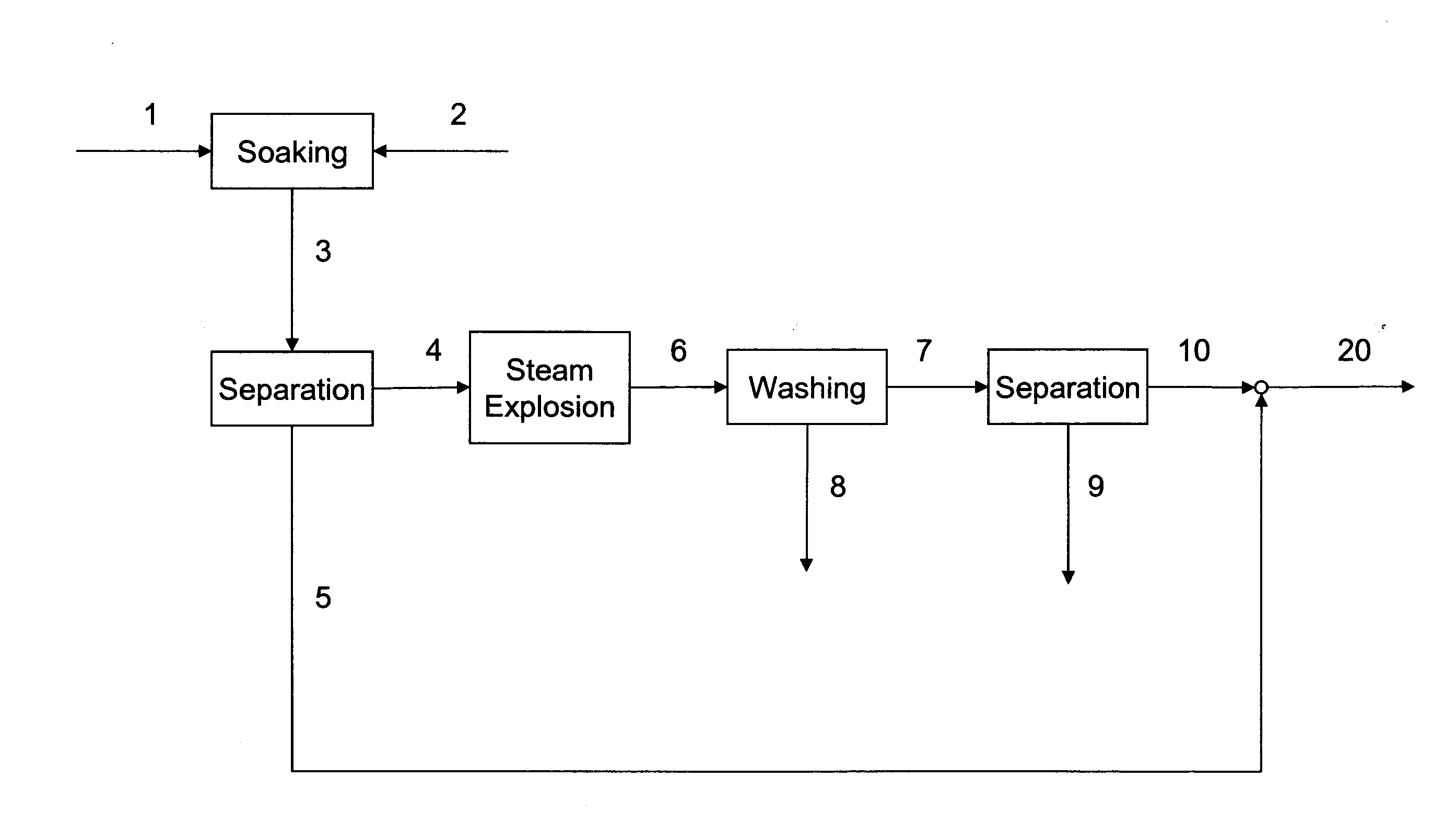

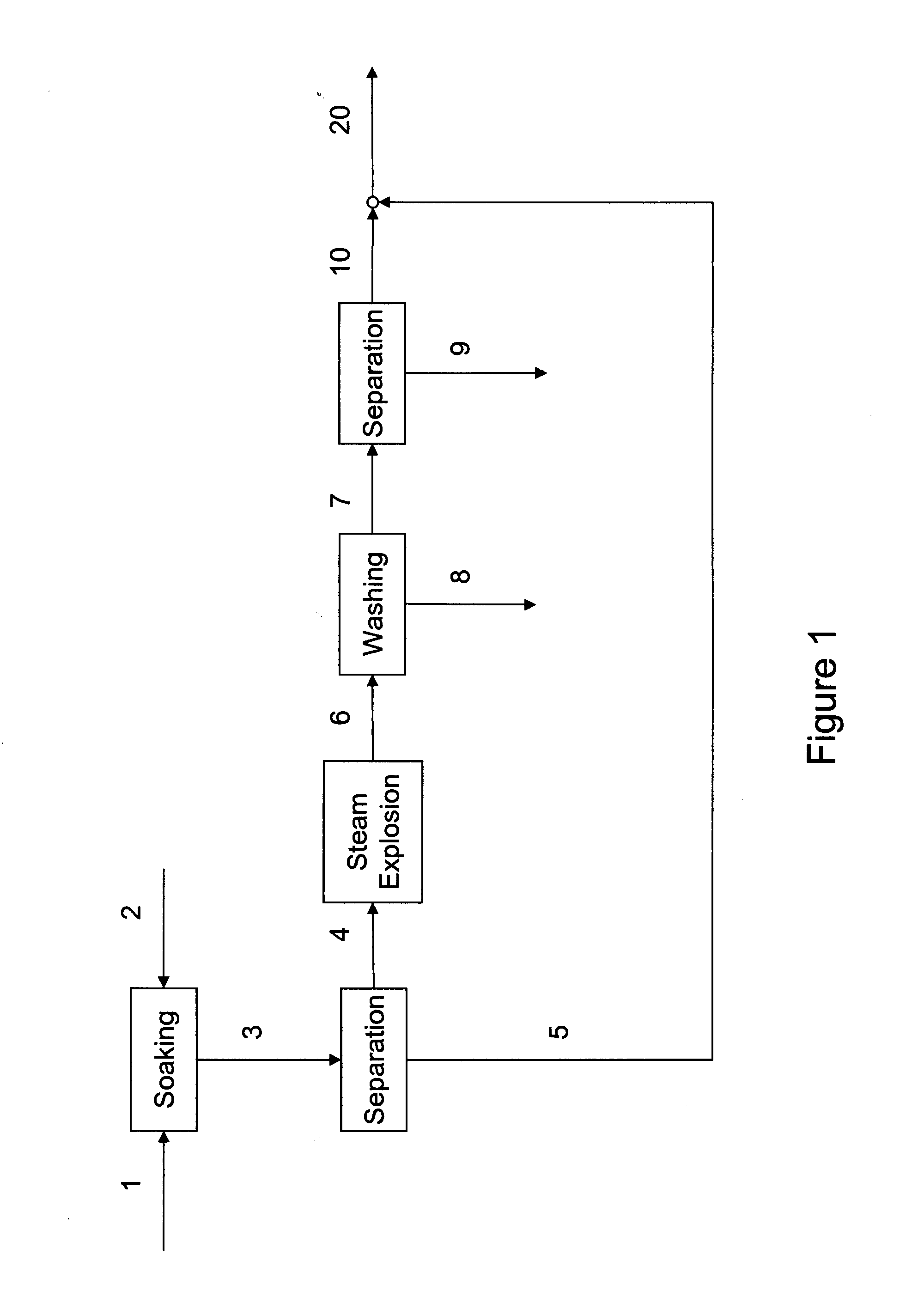

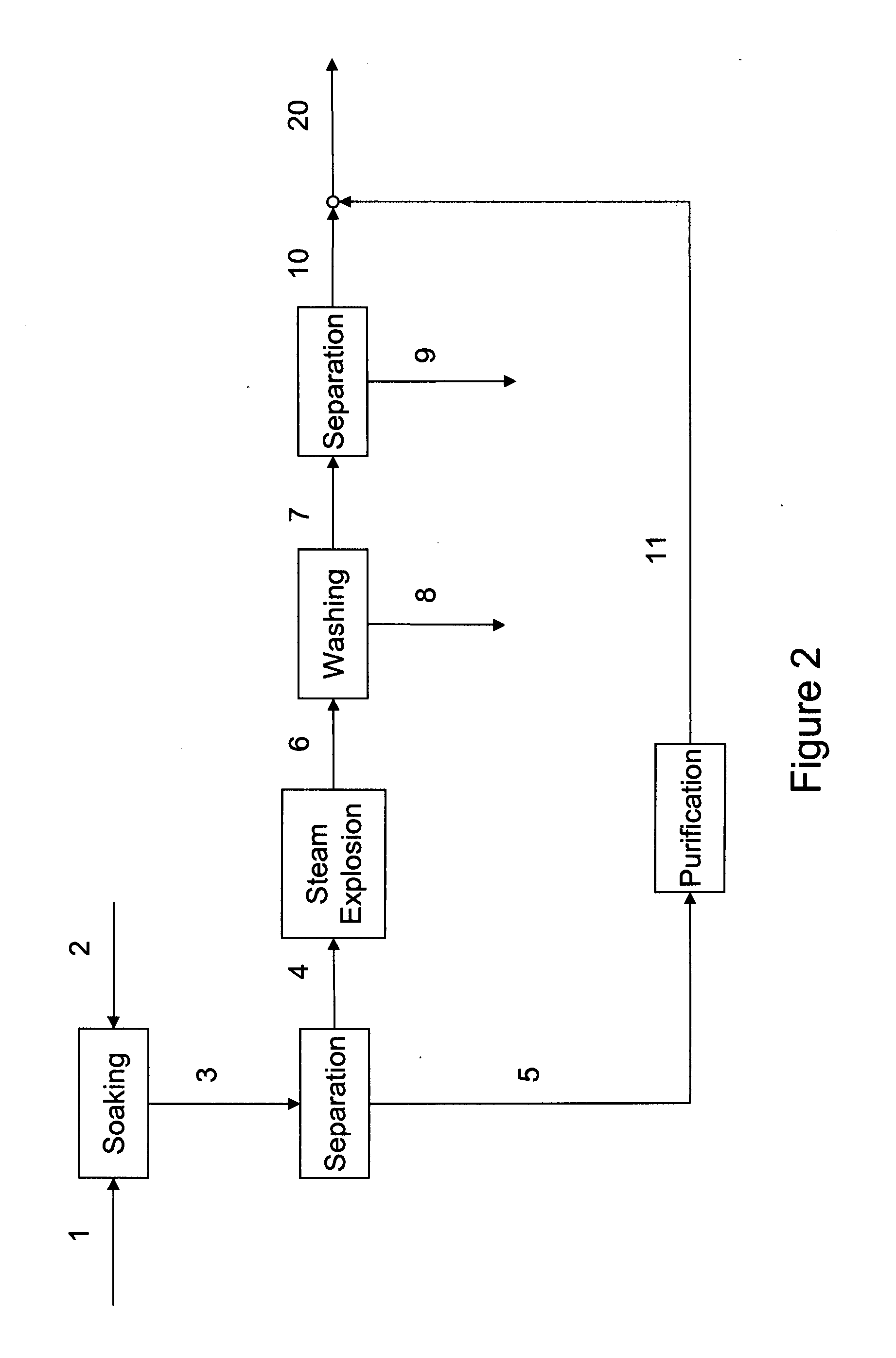

Detoxifying and Recylcing of Washing Solution Used In Pretreatment Of Lignocellulose-Containing Materials

ActiveUS20090056889A1Improve hydrolysis efficiencyImprove filtering effectWashing/displacing pulp-treating liquorsBiofuelsPre treatmentOrganic chemistry

The invention relates to a process of detoxifying pretreated lignocellulose-containing material comprising washing the pretreated lignocellulose-containing material in a washing solution and treating the used washing solution to remove an enzyme inhibitor and / or an inhibitor of a fermenting organism before recycling the used washing solution.

Owner:COFCO GROUP

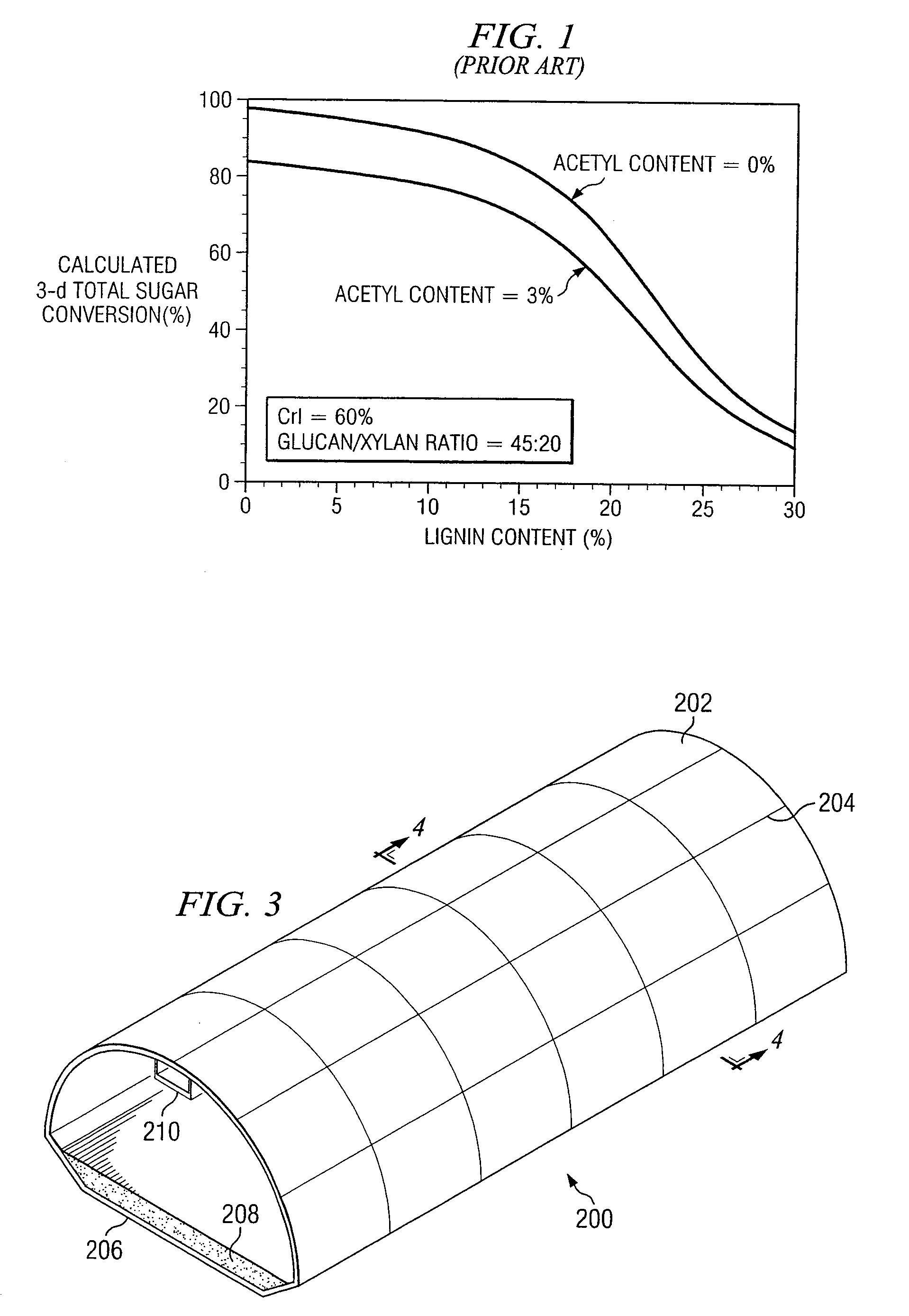

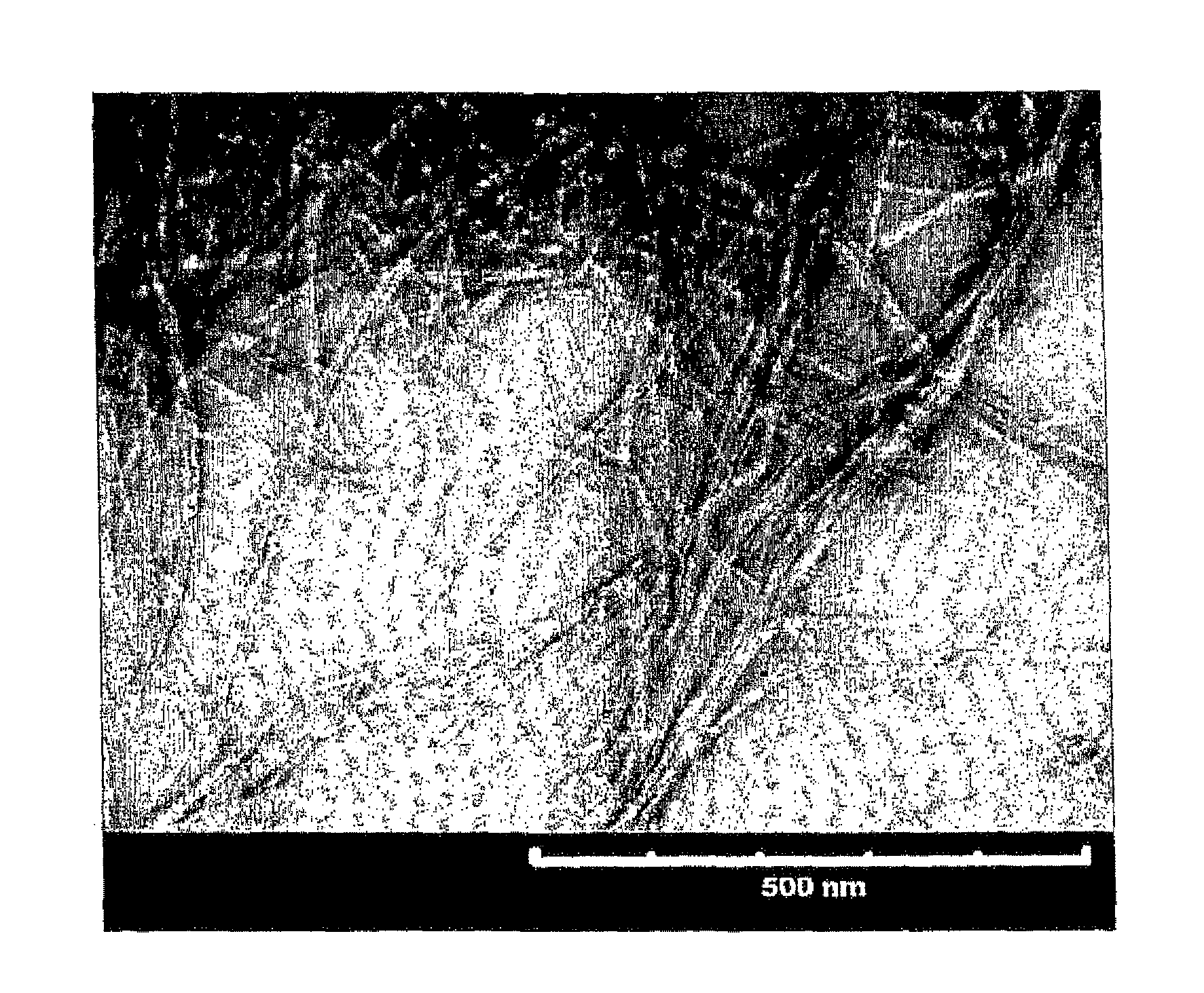

Processes and apparatus for producing nanocellulose, and compositions and products produced therefrom

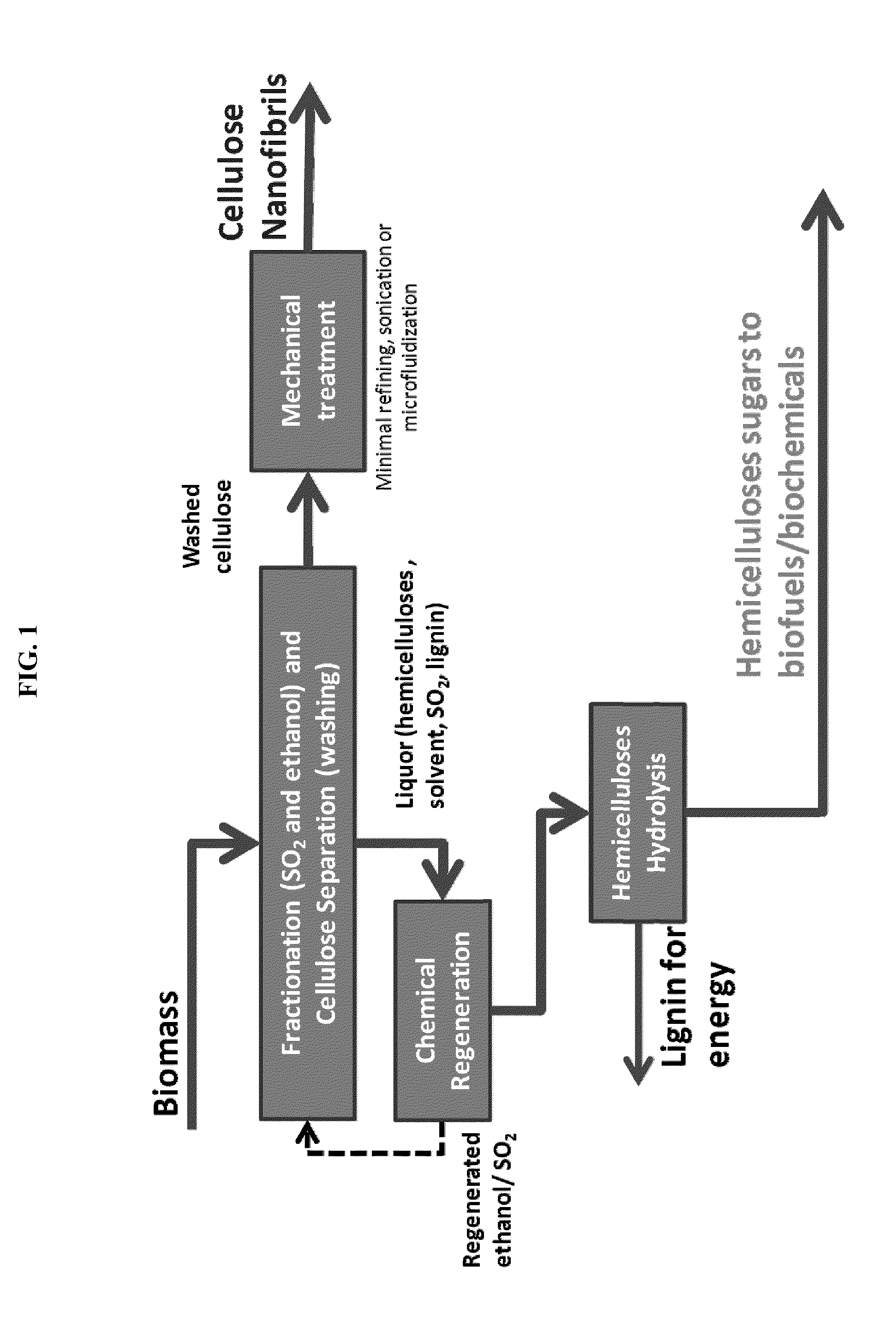

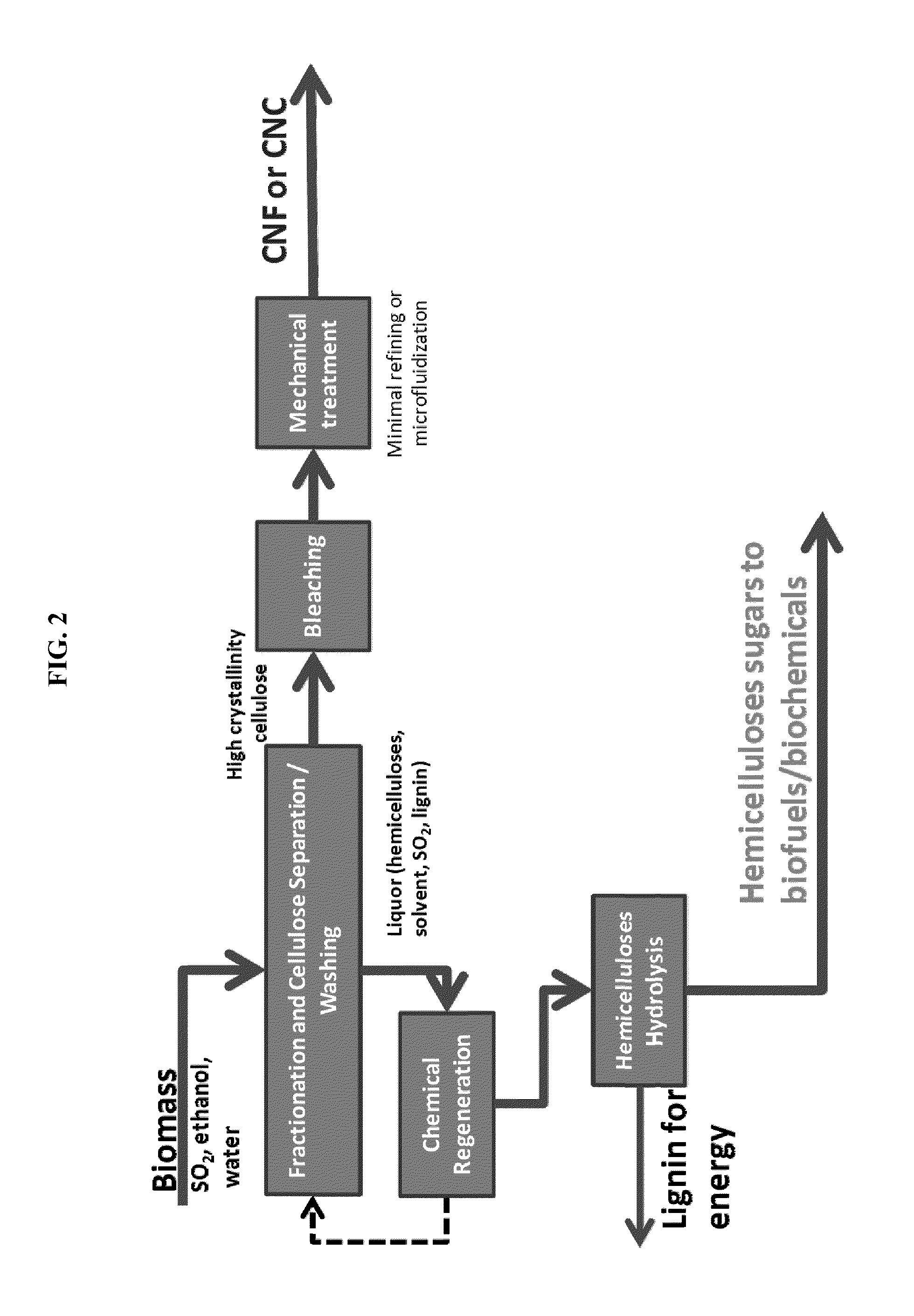

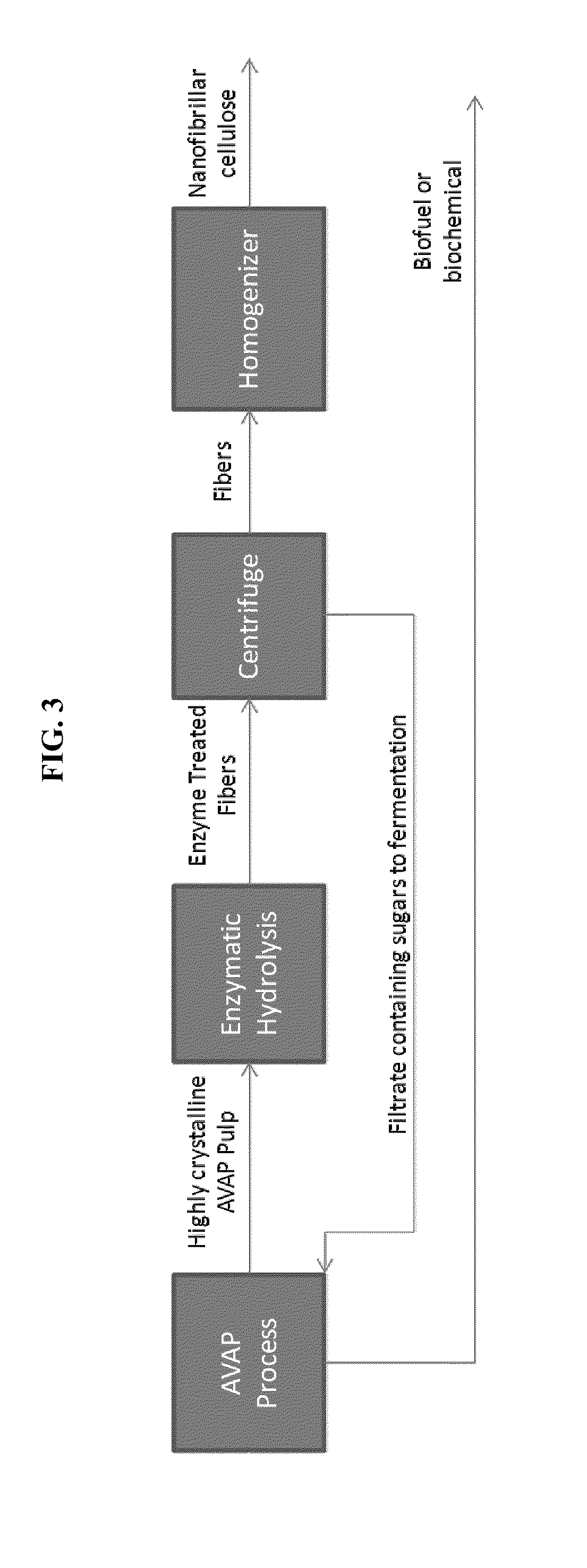

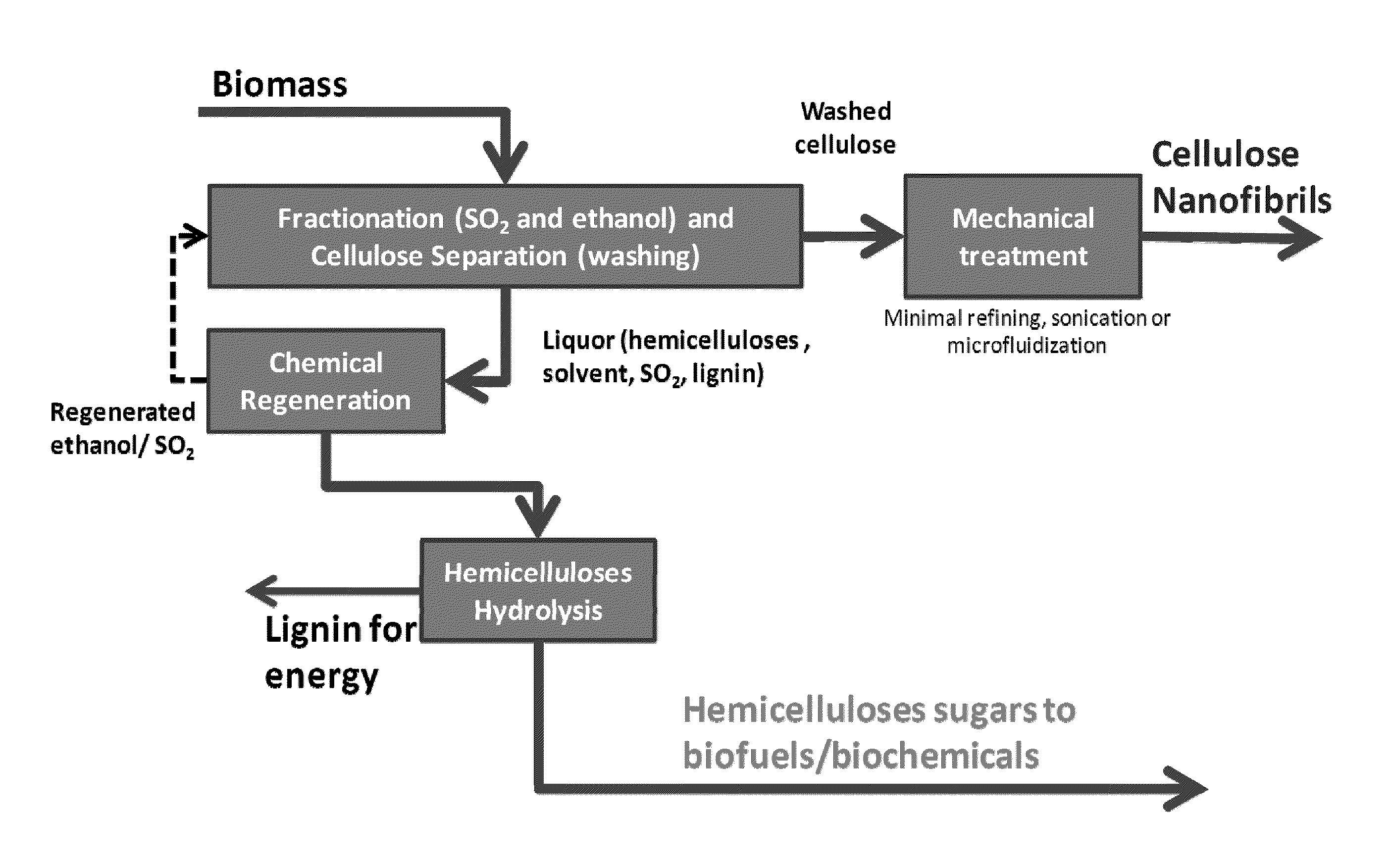

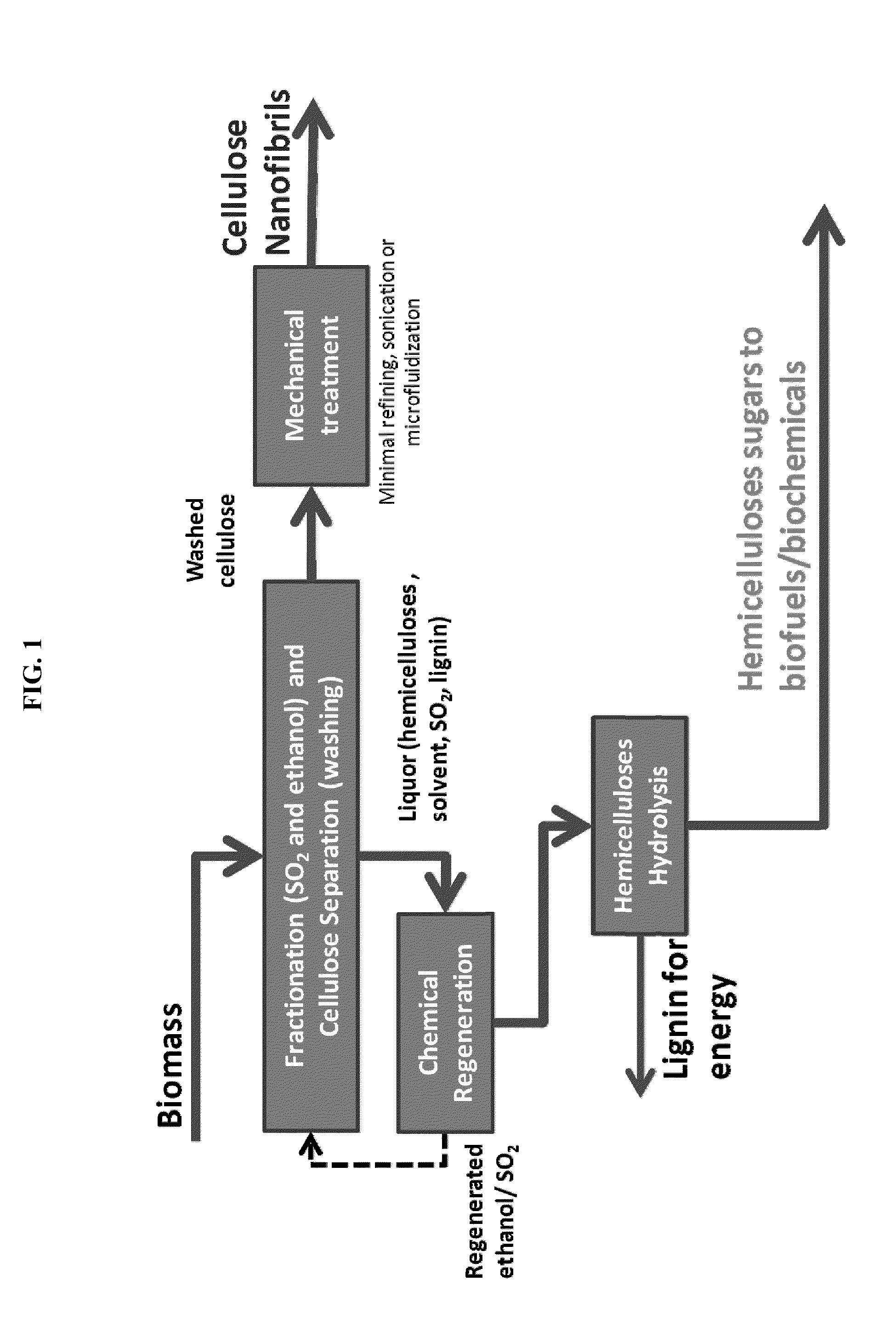

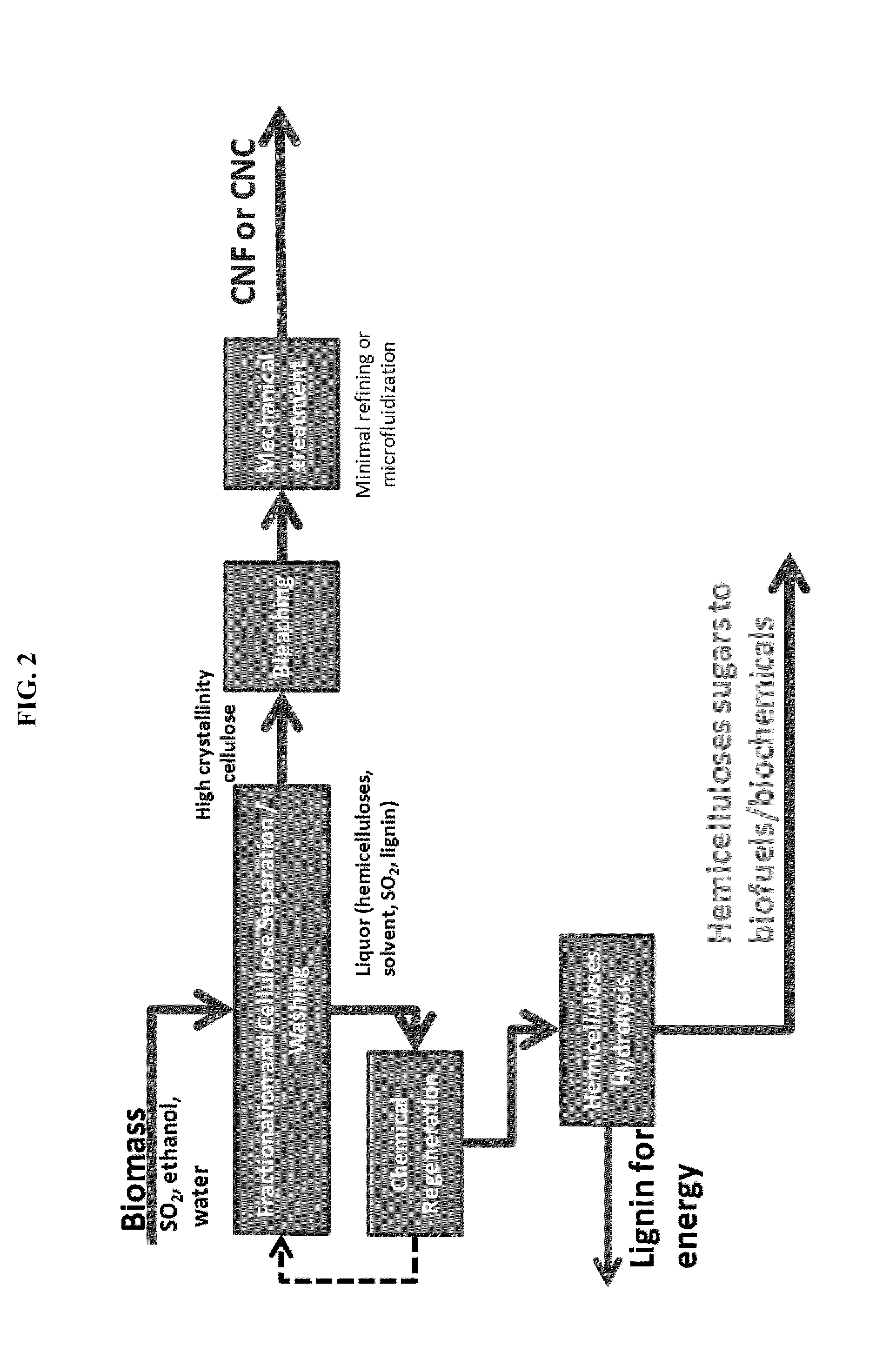

Processes disclosed are capable of converting biomass into high-crystallinity nanocellulose with surprisingly low mechanical energy input. In some variations, the process includes fractionating biomass with an acid (such as sulfur dioxide), a solvent (such as ethanol), and water, to generate cellulose-rich solids and a liquid containing hemicellulose and lignin; and mechanically treating the cellulose-rich solids to form nanofibrils and / or nanocrystals. The total mechanical energy may be less than 500 kilowatt-hours per ton. The crystallinity of the nanocellulose material may be 80% or higher, translating into good reinforcing properties for composites. The nanocellulose material may include nanofibrillated cellulose, nanocrystalline cellulose, or both. In some embodiments, the nanocellulose material is hydrophobic via deposition of some lignin onto the cellulose surface. Optionally, sugars derived from amorphous cellulose and hemicellulose may be separately fermented, such as to monomers for various polymers. These polymers may be combined with the nanocellulose to form completely renewable composites.

Owner:GRANBIO INTELLECTUAL PROPERTY HOLDINGS LLC

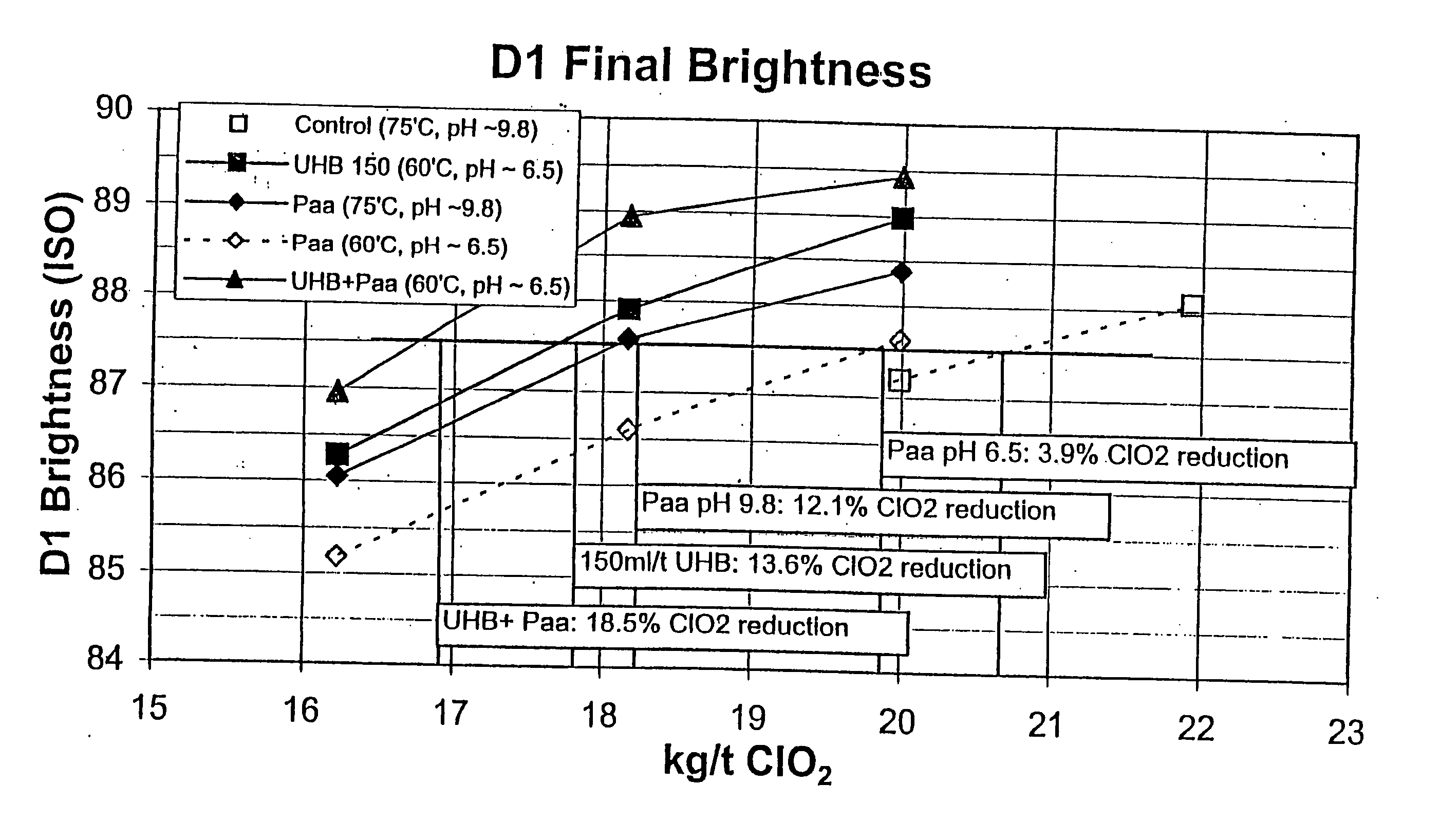

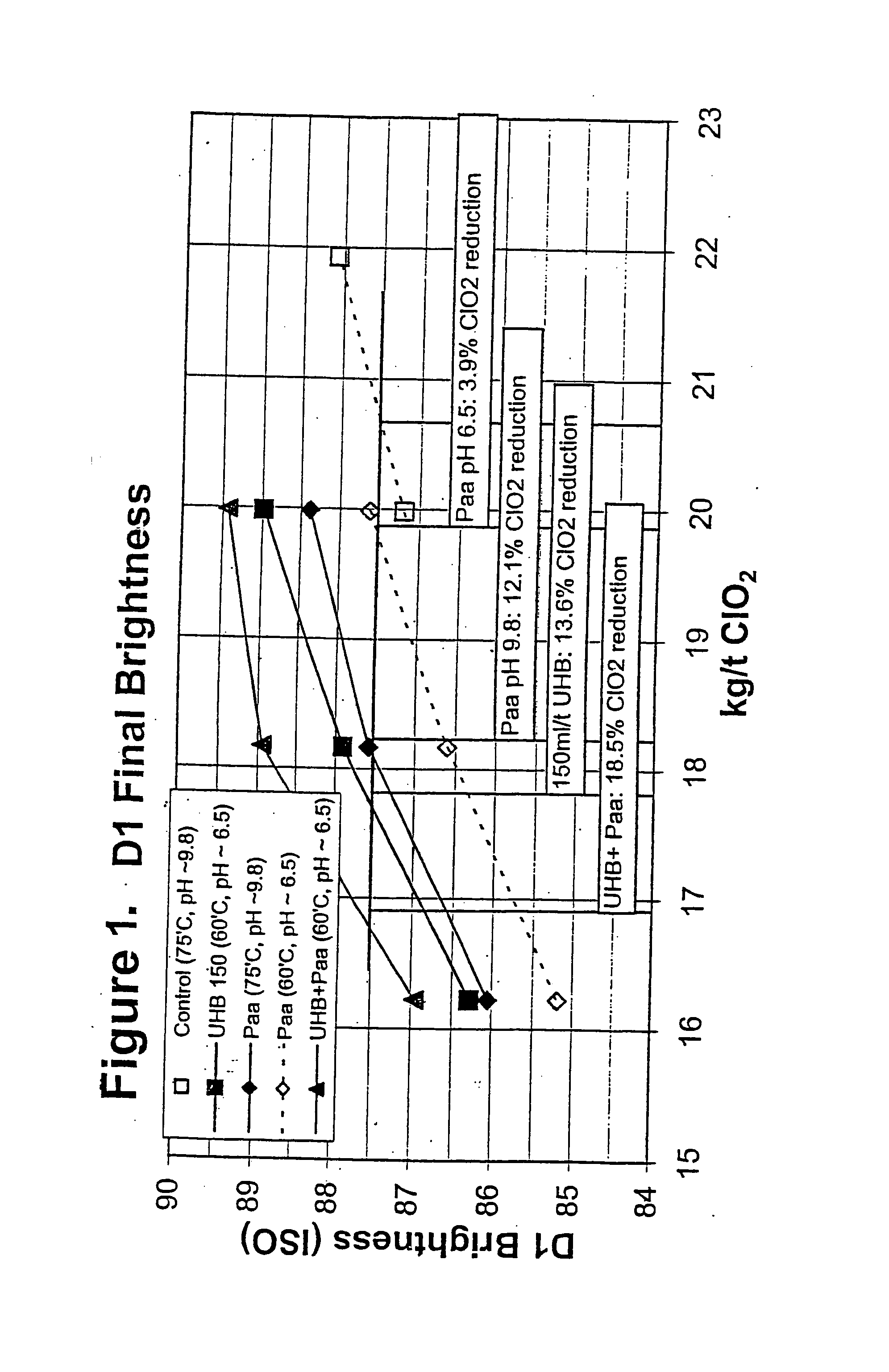

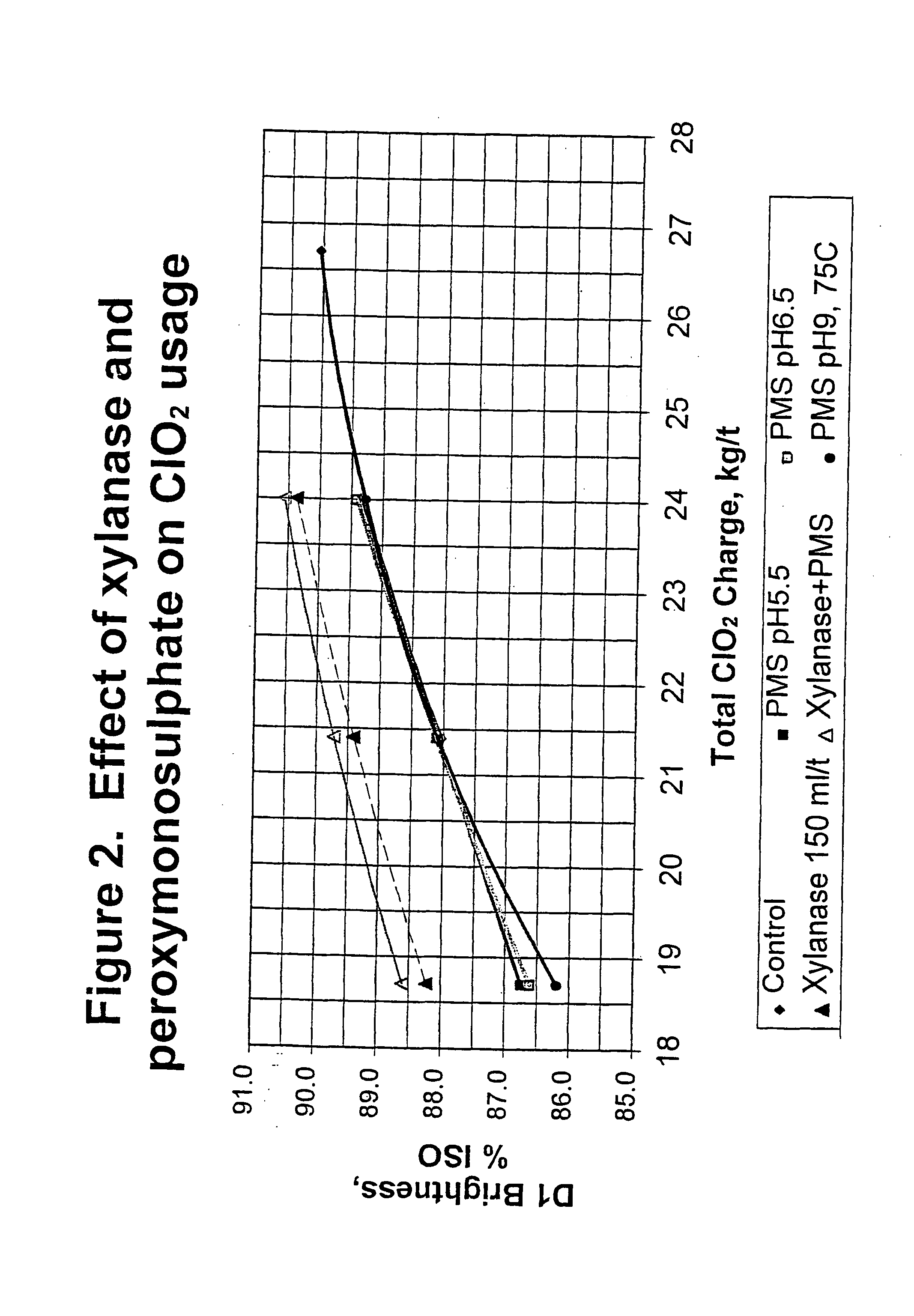

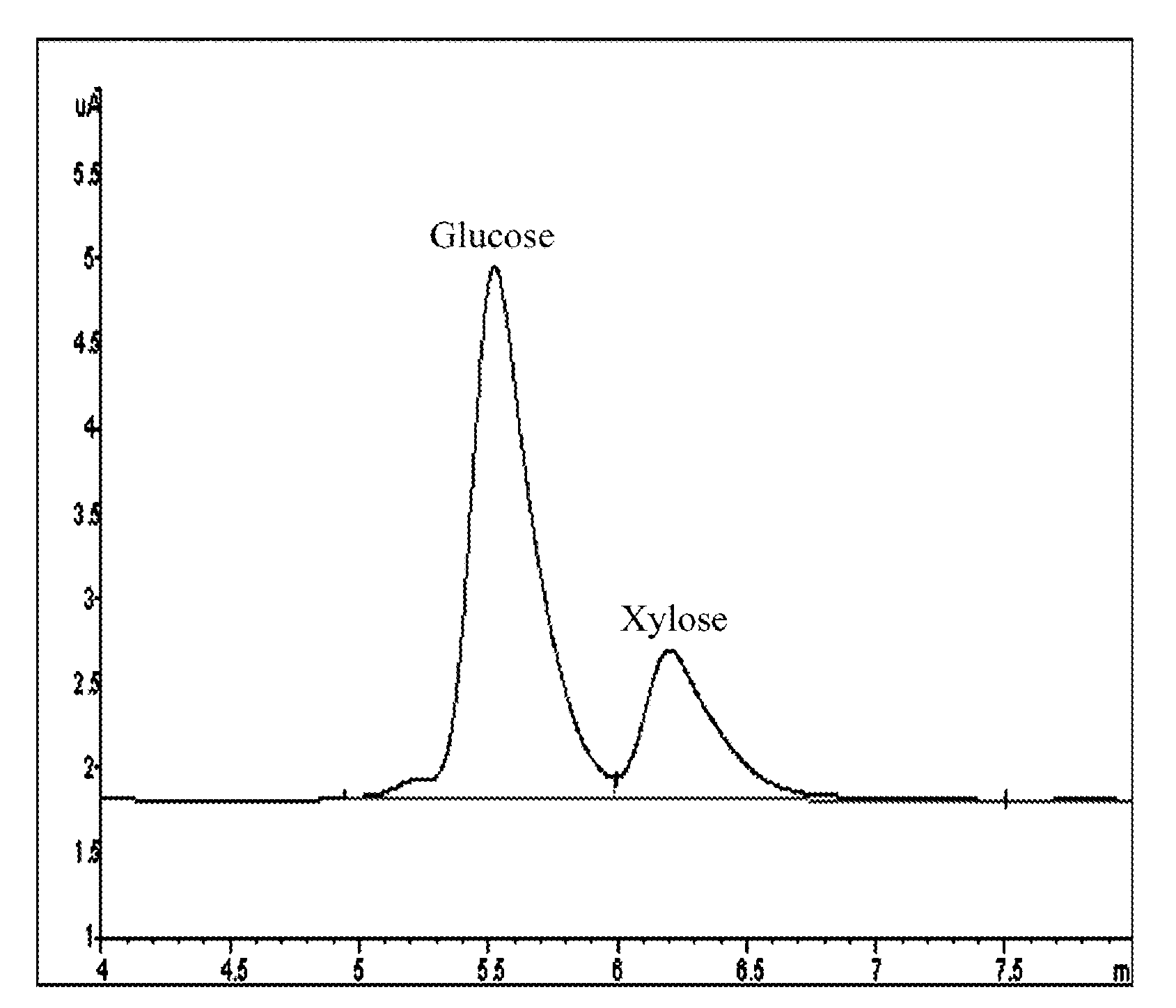

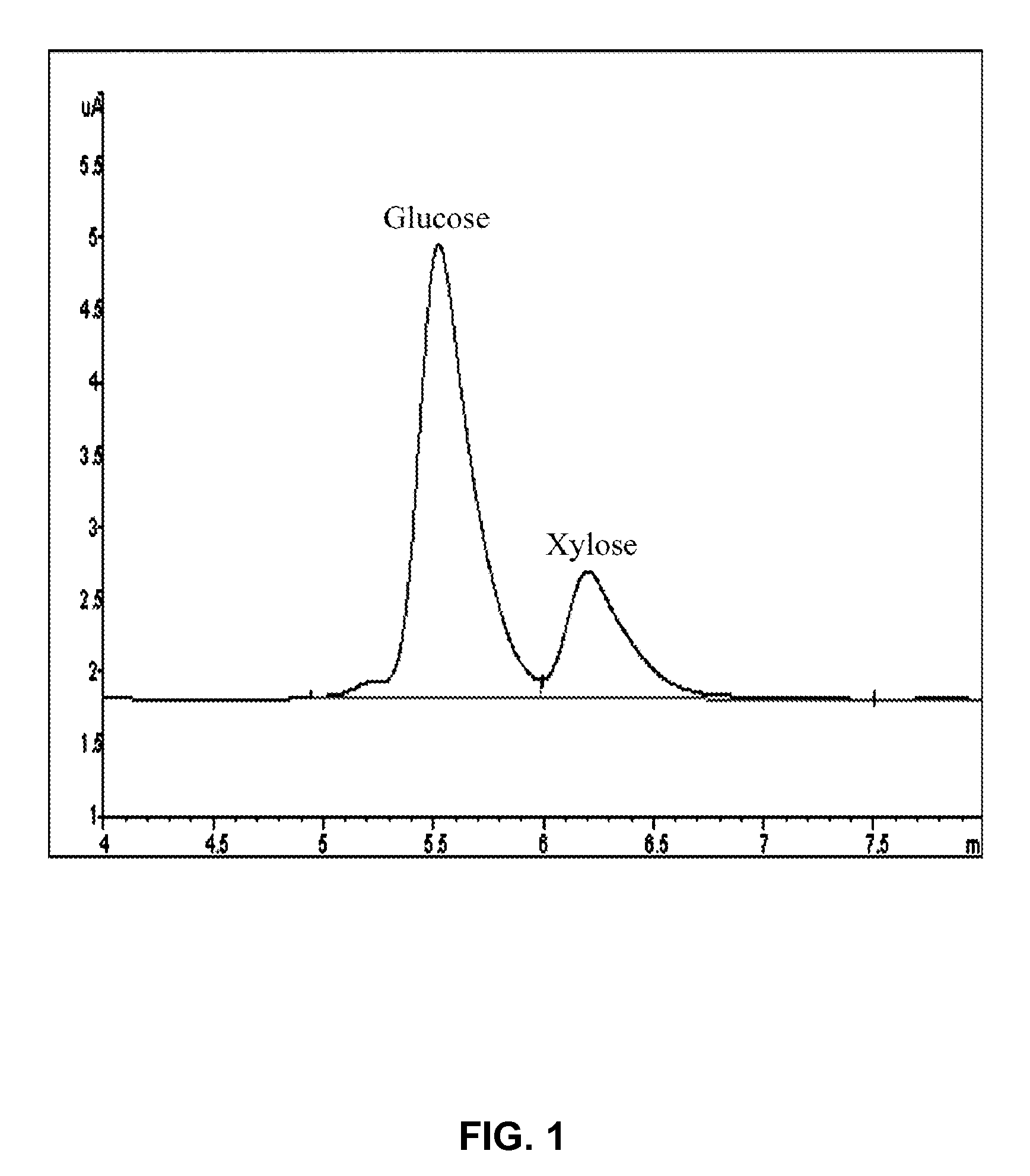

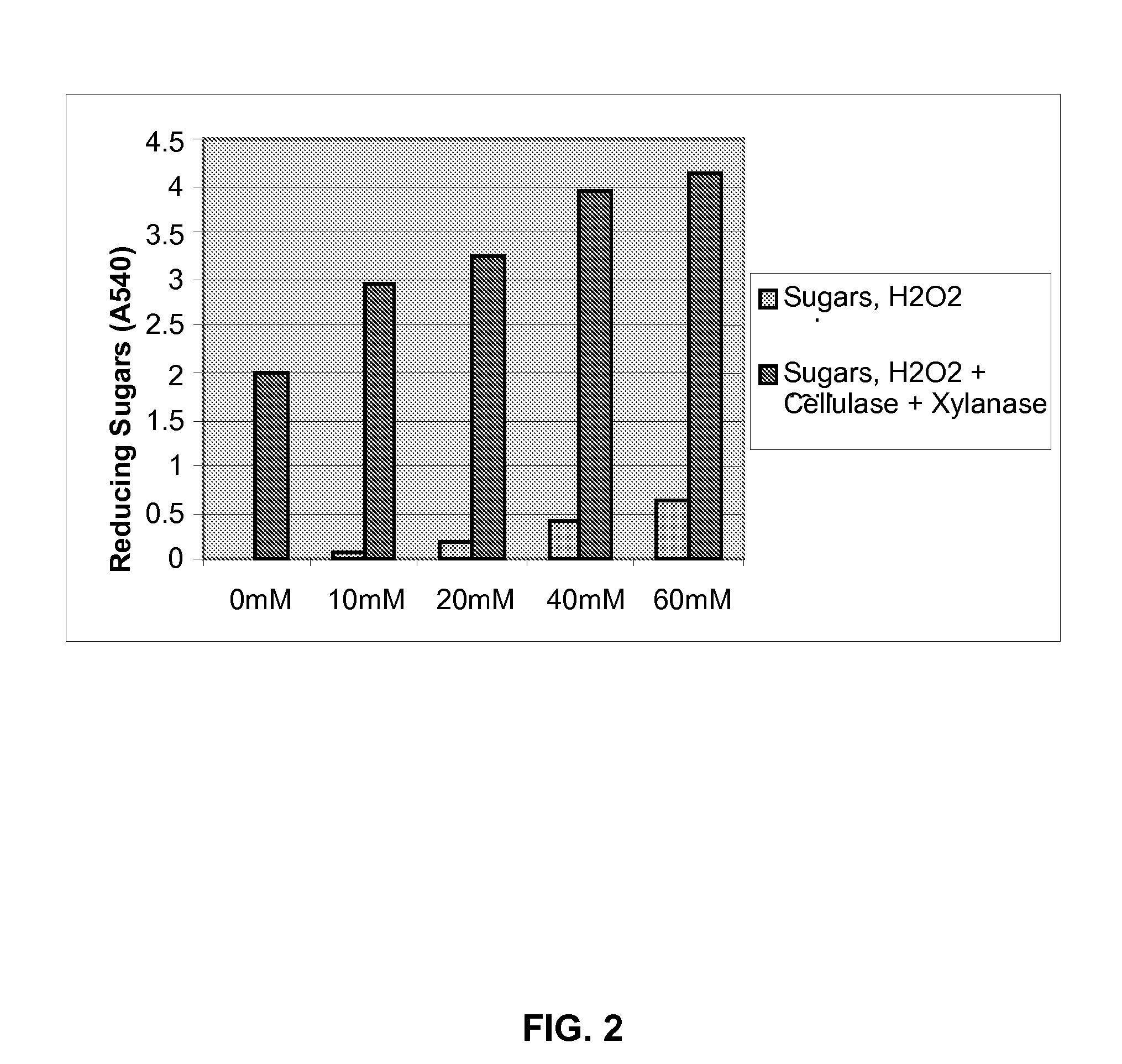

Bleaching stage using xylanase with hydrogen peroxide, peracids, or a combination thereof

InactiveUS20040112555A1Less-costly bleaching operationReduce usagePulp bleachingPulping with inorganic basesChlorine dioxideXylanase Y

The present invention discloses methods of bleaching chemical pulp that combine xylanase enzymes with hydrogen peroxide, peracids, or a mixture. The method comprises the steps of carrying out a chemical pulping operation, optionally followed by delignifying the pulp with oxygen, then combining xylanase enzymes with hydrogen peroxide, peracids, or a mixture to bleach the pulp. The method allows the mill to use both xylanase and peracids in a single bleaching tower to decrease the usage of chlorine dioxide and other bleaching chemicals. The pulp bleaching method of the present invention may be performed in a pulp mill as part of a complex pulp bleaching process.

Owner:IOGEN BIO PRODUCKTS CORP

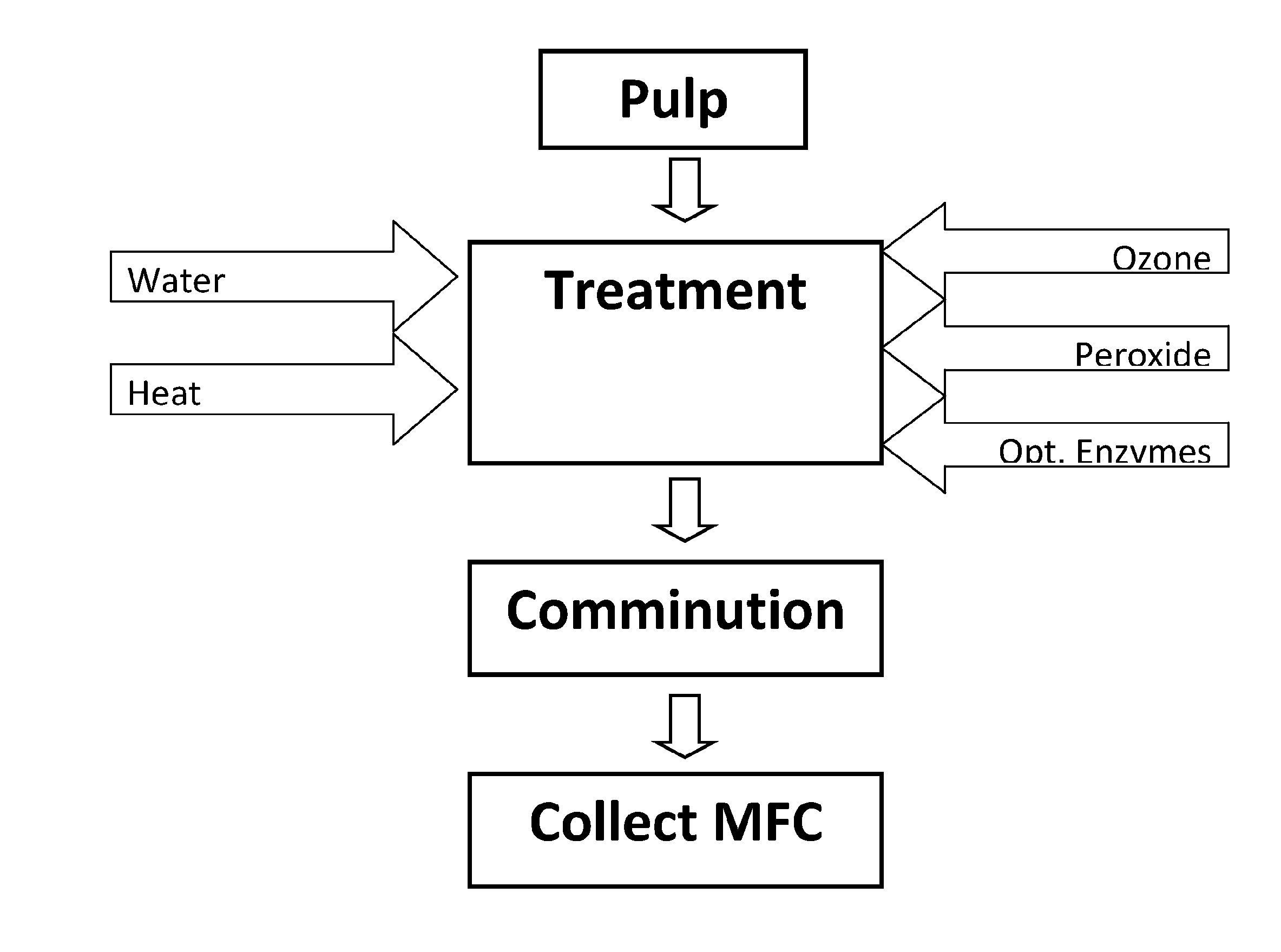

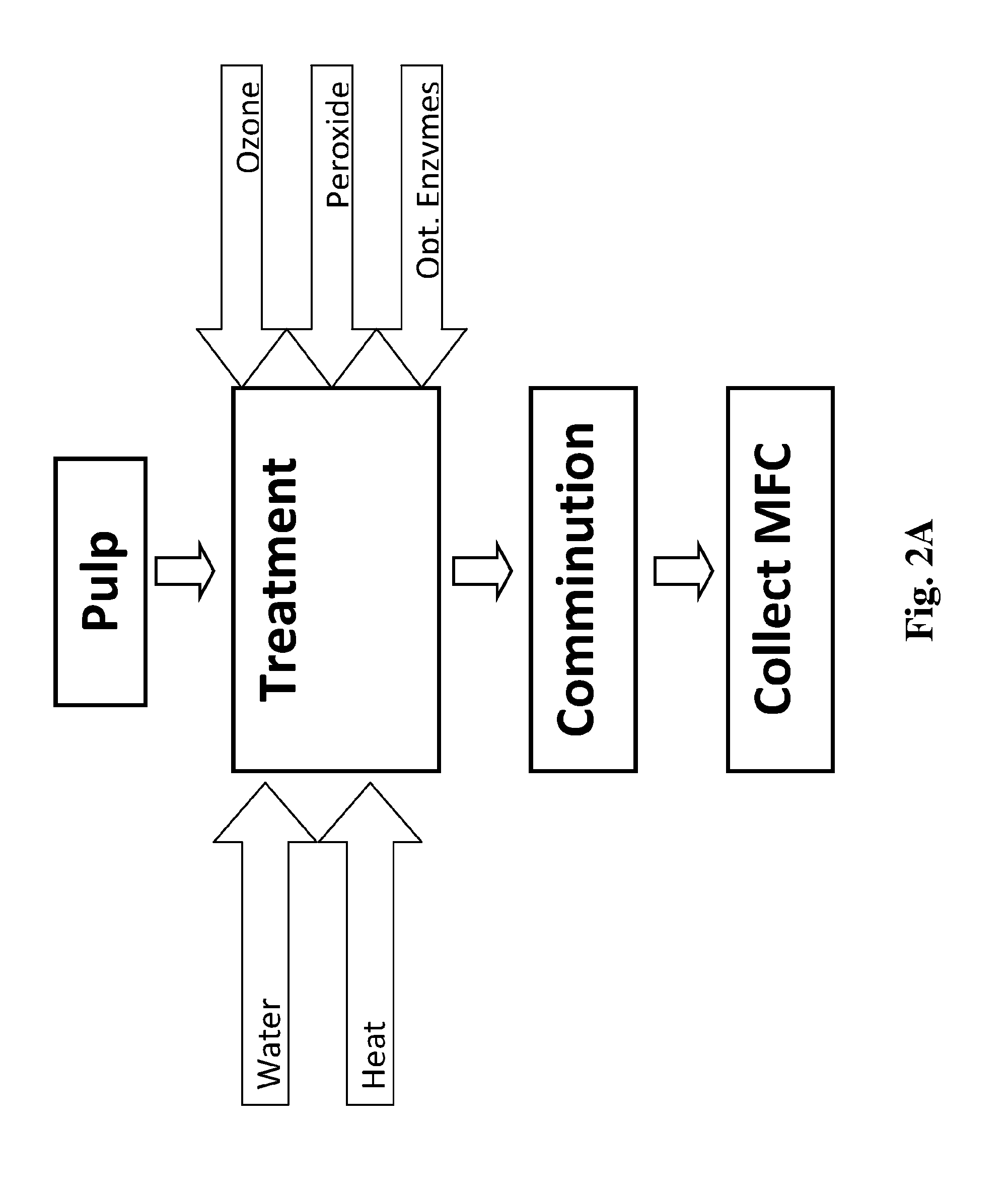

Energy Efficient Process for Preparing Nanocellulose Fibers

ActiveUS20150167243A1Improve efficiencyWeaken energySpecial paperPaper after-treatmentDepolymerizationNanofiber

A scalable, energy efficient process for preparing cellulose nanofibers is disclosed. The process employs a depolymerizing treatment with one or both of: (a) a relatively high charge of ozone under conditions that promote the formation of free radicals to chemically depolymerize the cellulose fiber cell wall and interfiber bonds; or (b) a cellulase enzyme. Depolymerization may be estimated by pulp viscosity changes. The depolymerizing treatment is followed by or concurrent with mechanical comminution of the treated fibers, the comminution being done in any of several mechanical comminuting devices, the amount of energy savings varying depending on the type of comminuting system and the treatment conditions. Comminution may be carried out to any of several endpoint measures such as fiber length, % fines or slurry viscosity.

Owner:UNIVERSITY OF MAINE

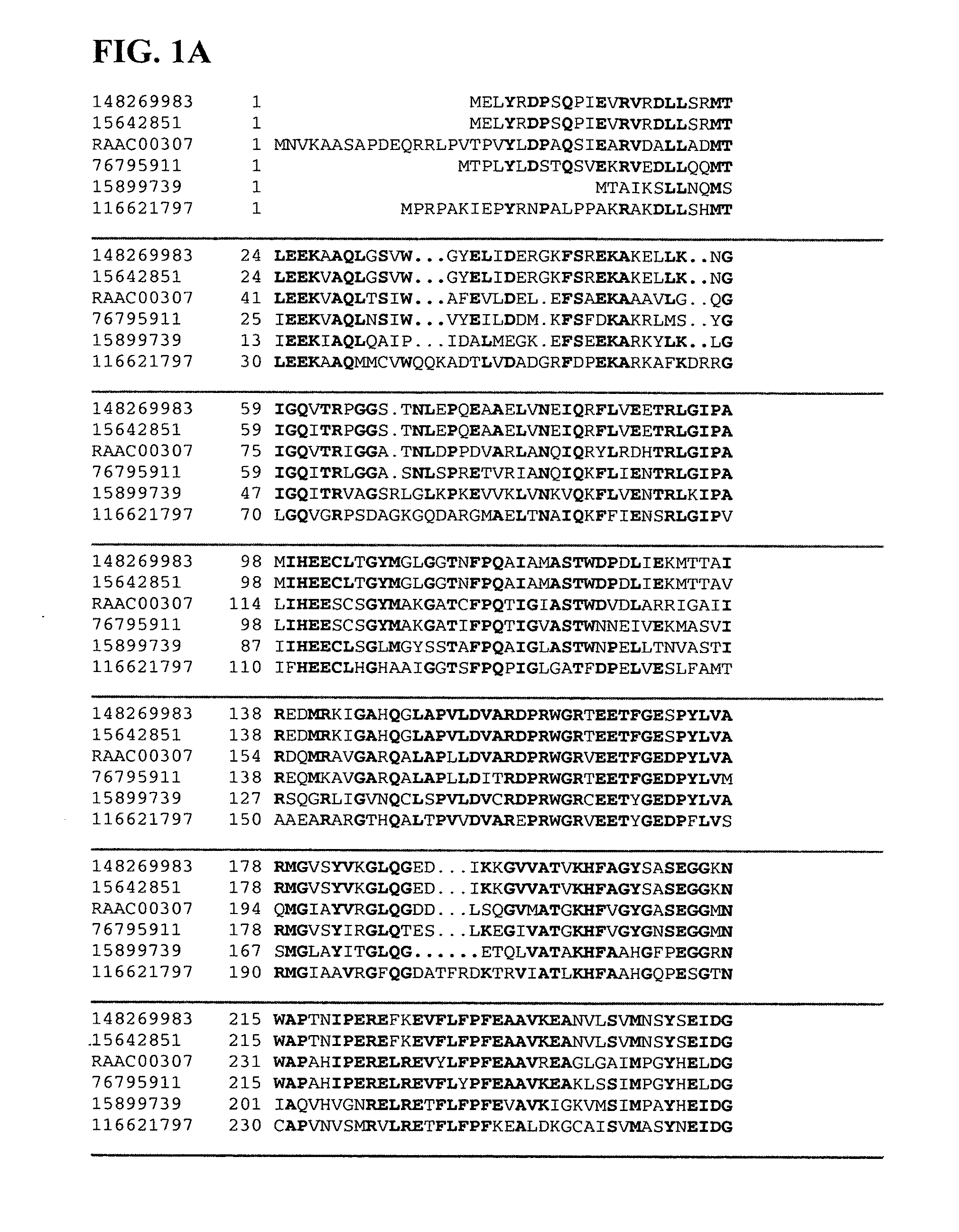

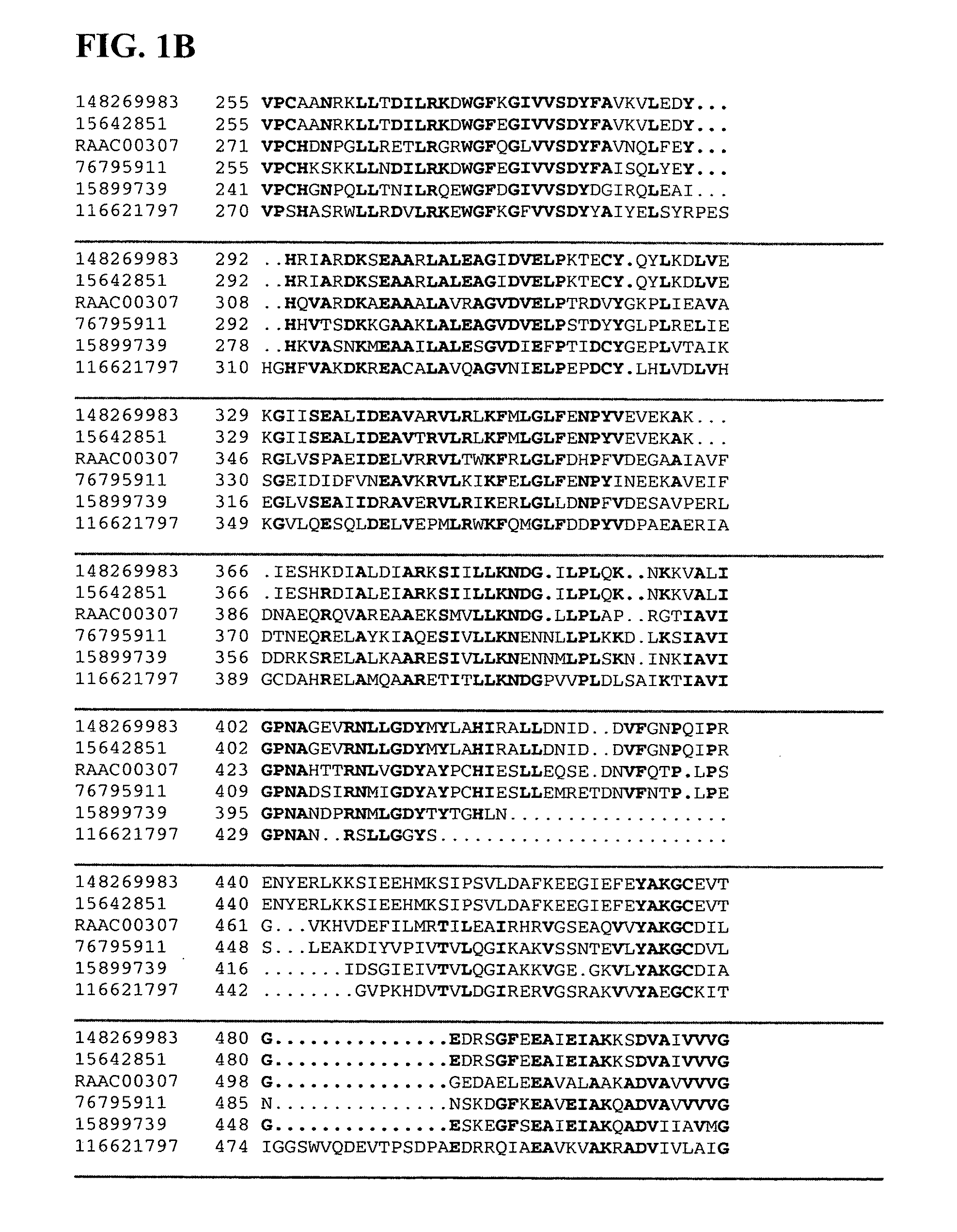

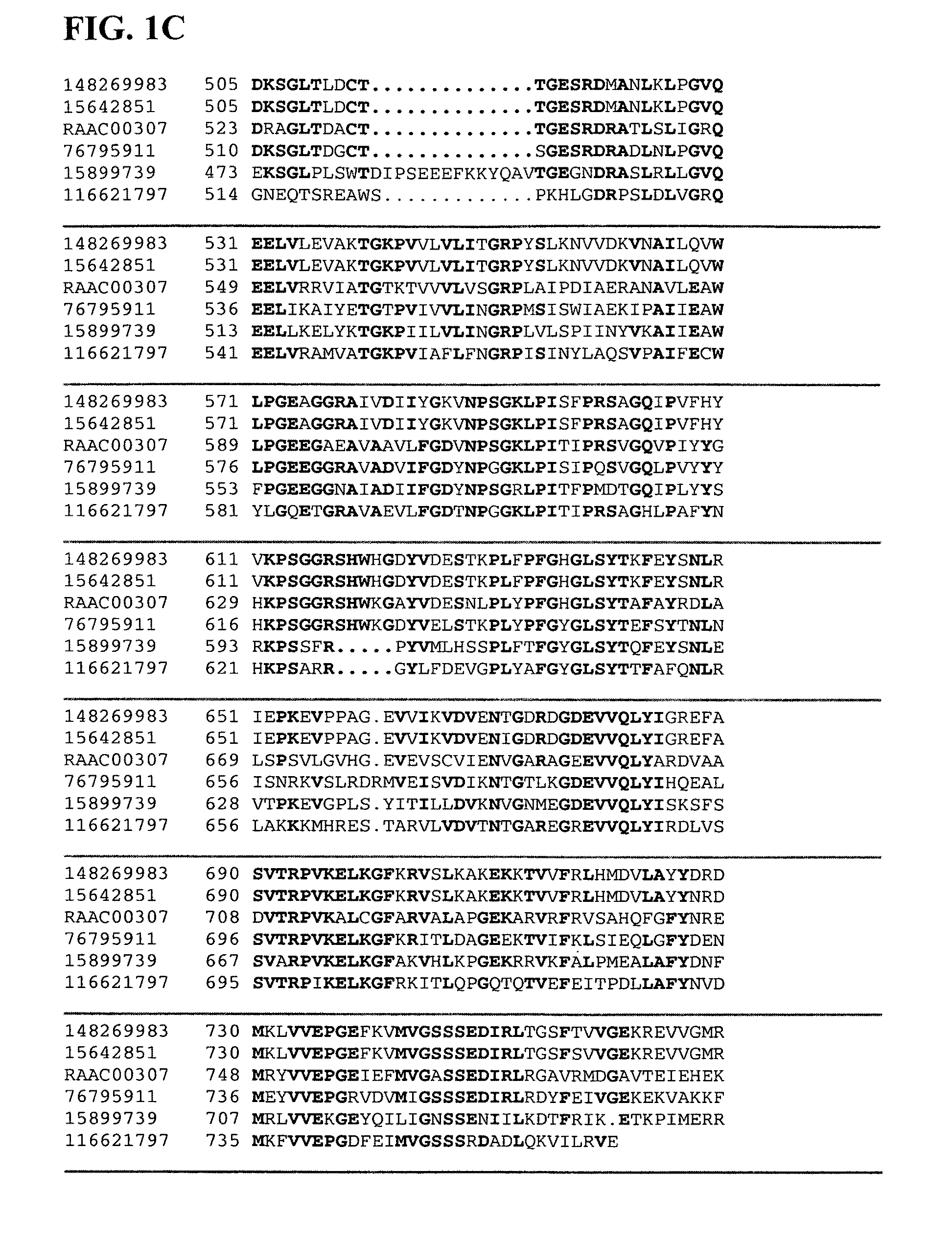

Xylanases, nucleic acids encoding them and methods for making and using them

InactiveUS20060003433A1Low viscosityIncrease profitBacteriaAntibody mimetics/scaffoldsXylanase YIncrease ph

The invention relates to xylanases and to polynucleotides encoding the xylanases. In addition, methods of designing new xylanases and methods of use thereof are also provided. The xylanases have increased activity and stability at increased pH and temperature.

Owner:BP CORP NORTH AMERICA INC

Material for odor control

The present invention is directed to materials containing an enzyme inhibitor, including treated fibers, nonwovens, functional particles and processes for making these materials. These materials are useful in reducing or delaying onset of odor generation from various waste materials including human and animal elimination products.

Owner:BUCKEYE TECH INC

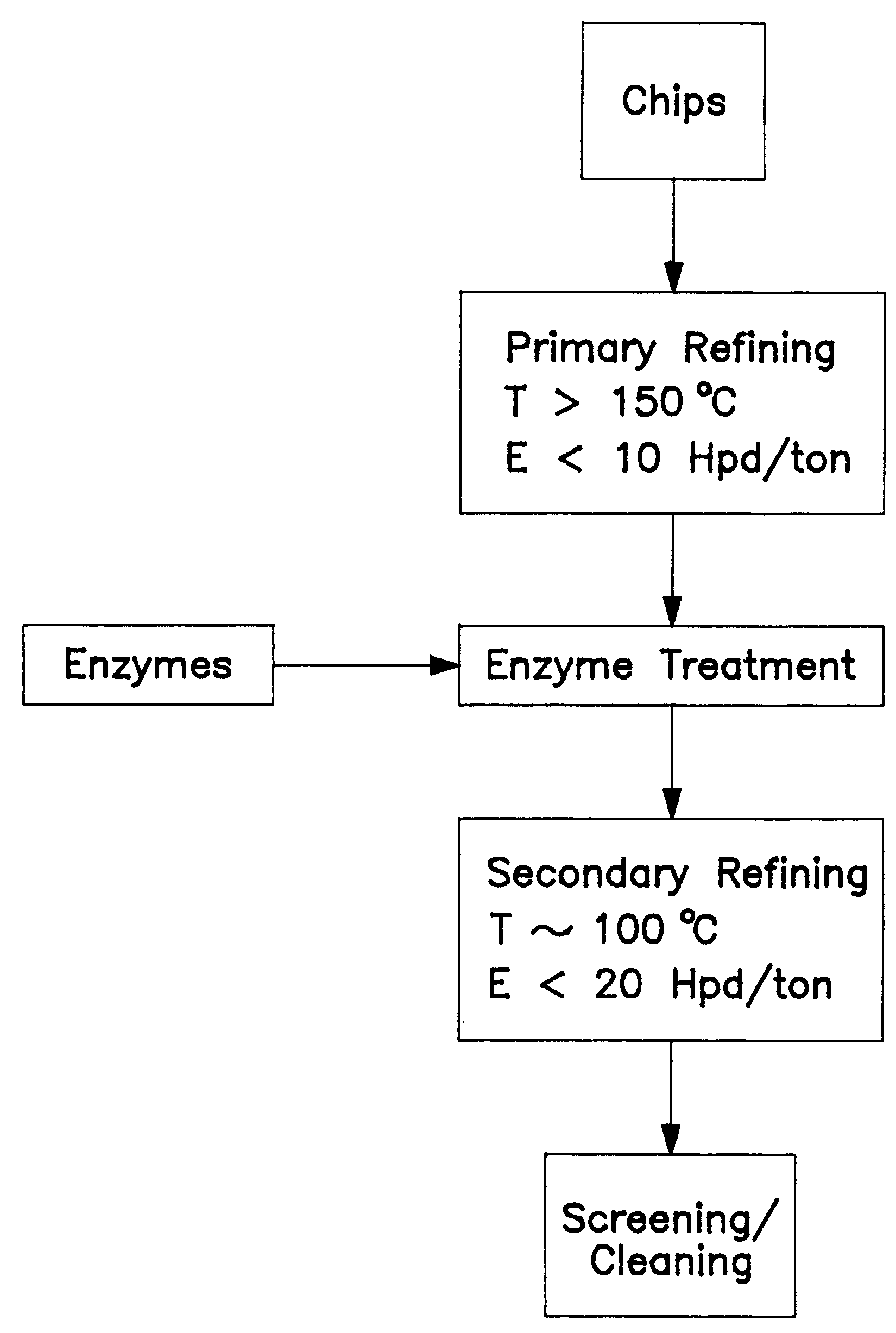

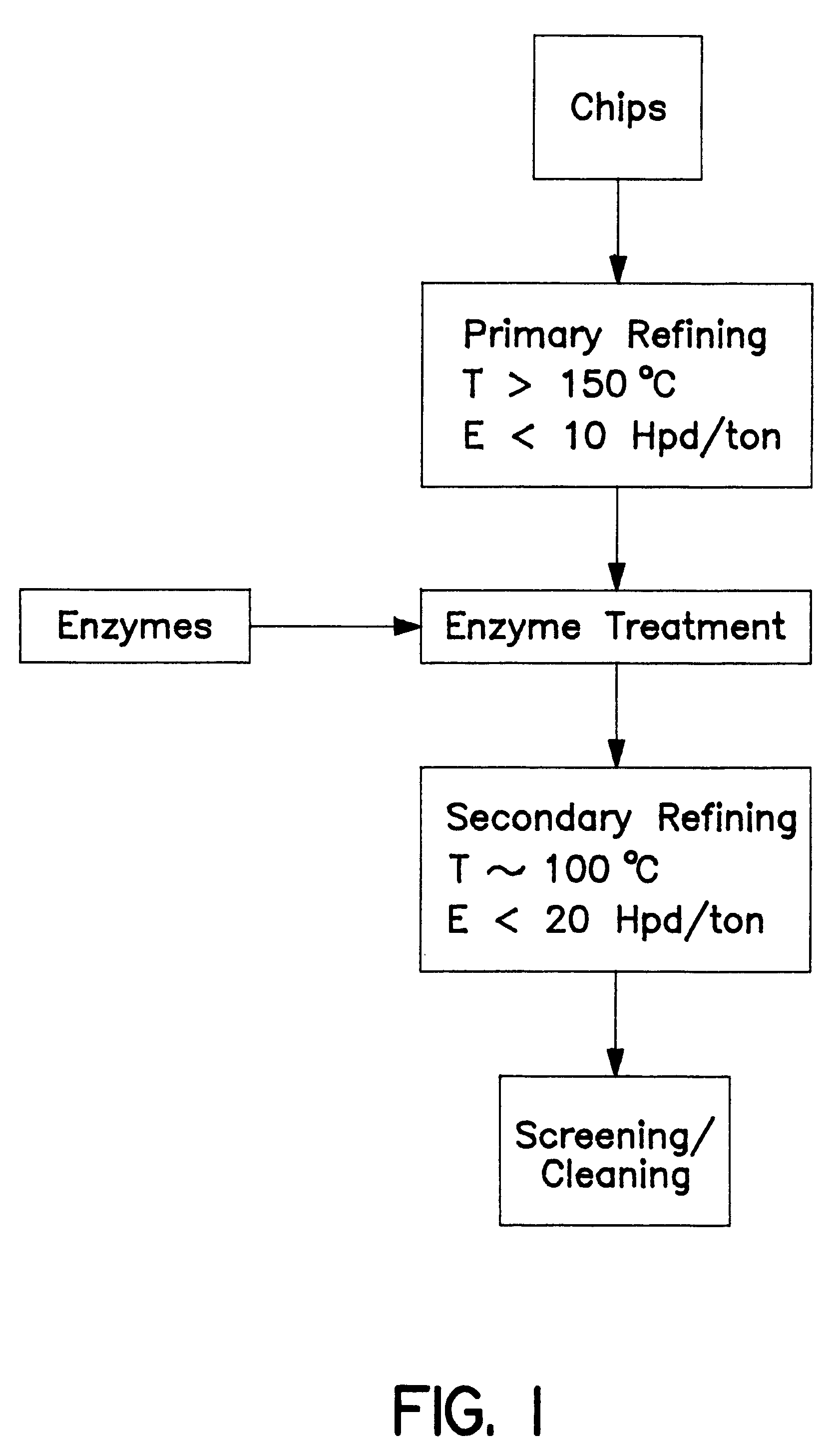

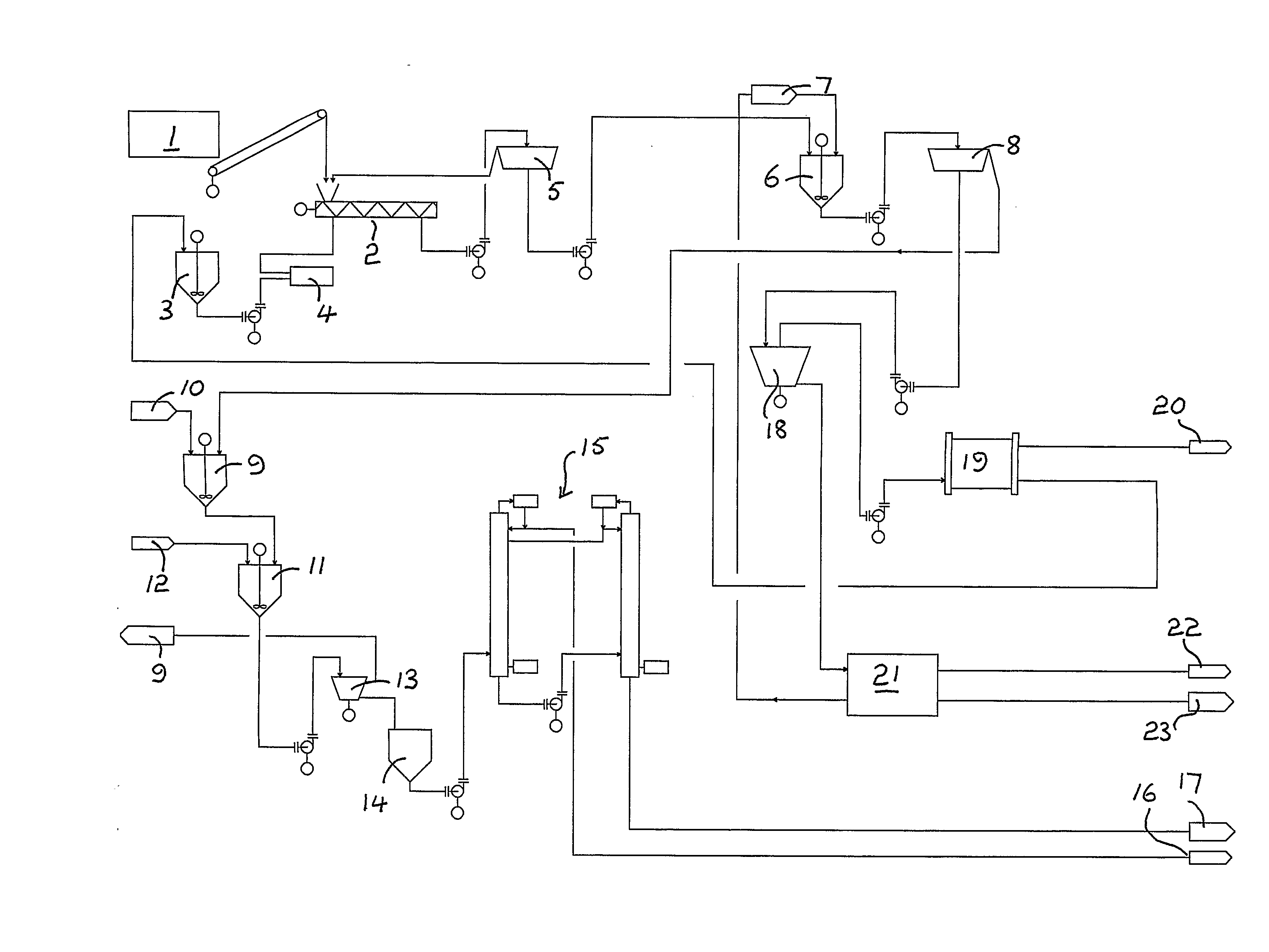

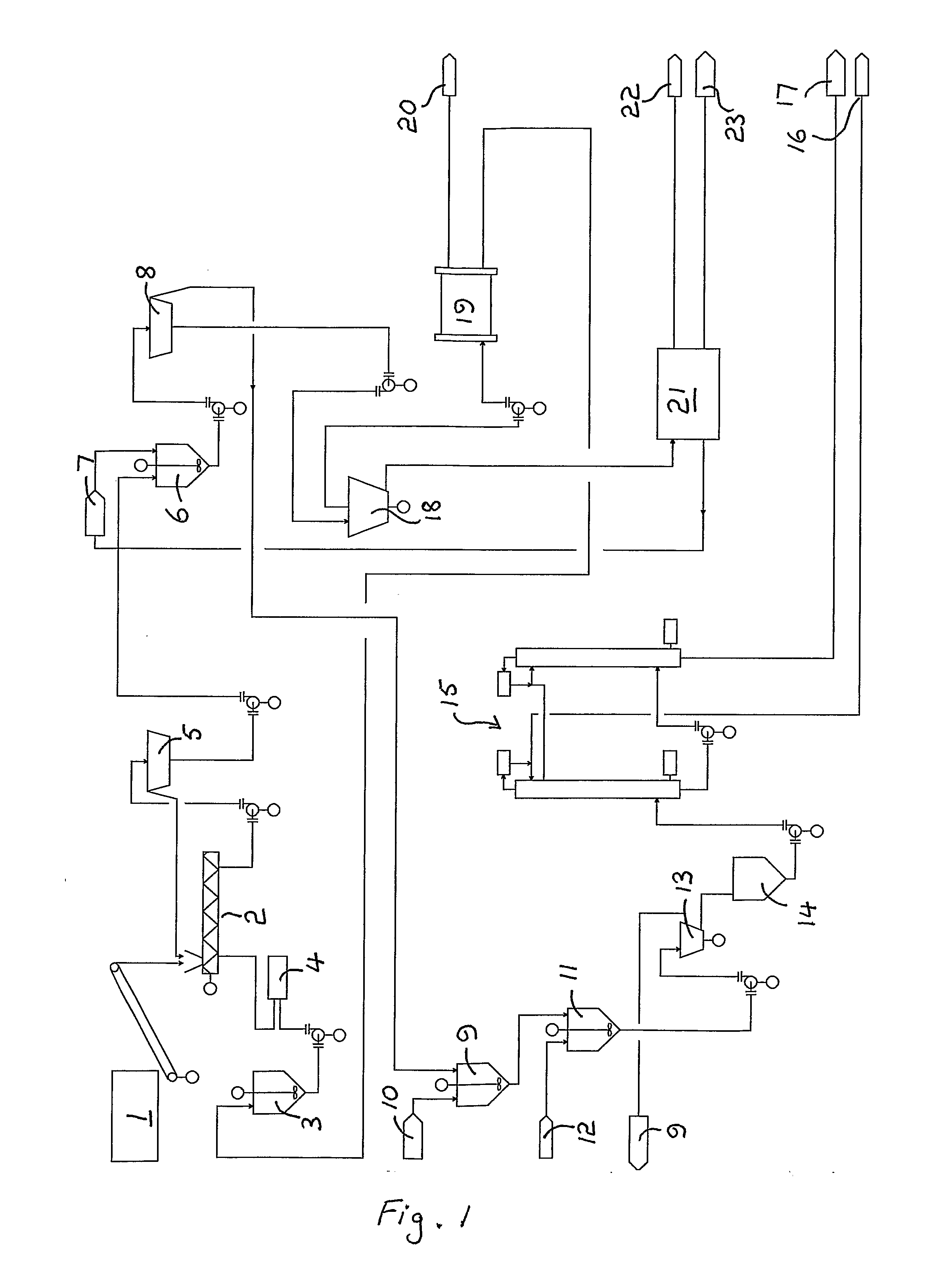

Low energy thermomechanical pulping process using an enzyme treatment between refining zones

InactiveUS6267841B1Pulping with acid salts/anhydridesPulping with inorganic basesPulp and paper industryEnzyme

A low energy thermomechanical pulping process which employs an enzyme treatment stage between two low energy thermomechanical stages.

Owner:INT PAPER CO

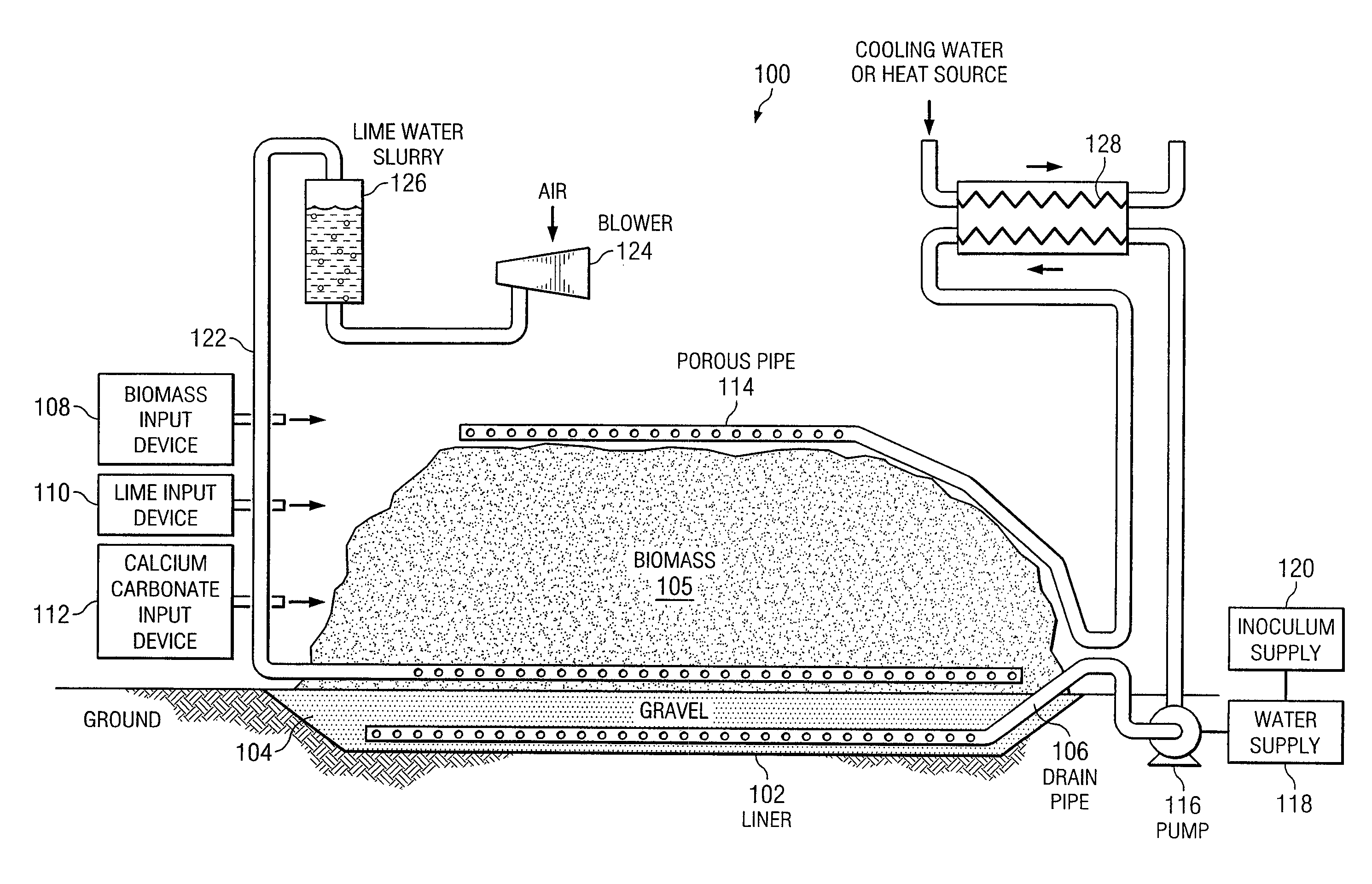

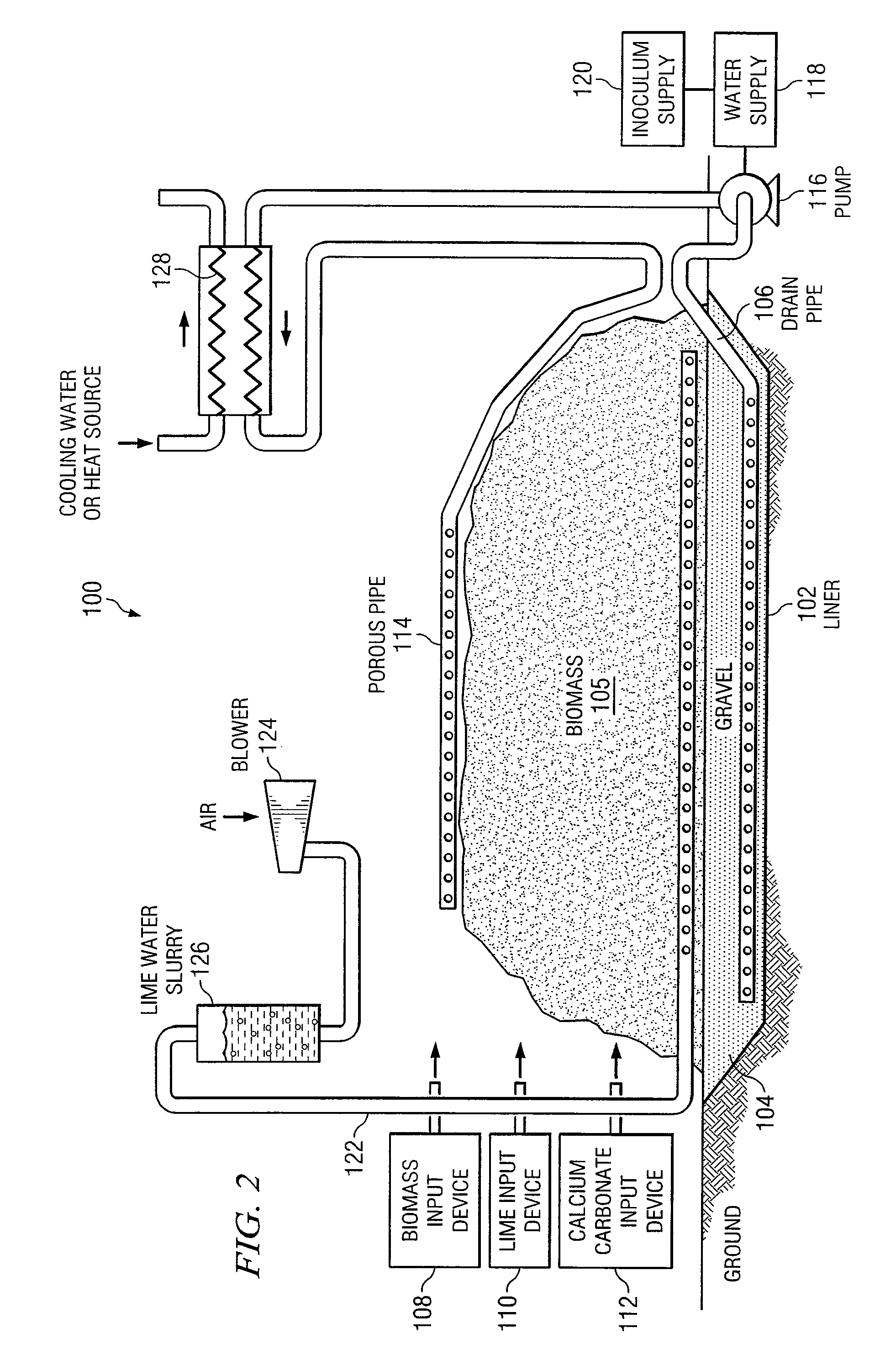

Methods and Systems for Pretreatment and Processing of Biomass

InactiveUS20080121359A1Increasing enzyme digestibilityLow lignin contentBio-organic fraction processingProductsEnzymatic digestionCellulose

According to one embodiment of the invention, a system for processing biomass includes a water-impermeable bottom liner, a gravel layer supported by the bottom liner, a drain pipe disposed within the gravel layer, a biomass input device operable to deliver biomass over the gravel layer to form a biomass pile, a lime input device operable to deliver lime to the biomass for pretreating the biomass, a distribution pipe elevated above the gravel layer, and a pump operable to circulate water through the biomass pile by delivering water to the distribution pipe and receiving water from the drain pipe after it has traveled through the biomass pile.According to another embodiment, a method for biomass pretreatment with alkali, conducted at ambient pressure for approximately 4-16 weeks at temperatures ranging from approximately 25° C. to 95° C. Biomass may be lignocellulosic biomass and may be rendered suitable for enzymatic digestion or pulp production.

Owner:TEXAS A&M UNIVERSITY

Thermal and acid tolerant beta xylosidases, arabinofuranosidases, genes encoding, related organisms, and methods

ActiveUS20100311110A1Decreasing proteolysisAllow stabilizationSugar derivativesMicrobiological testing/measurementXylanNucleic acid sequencing

Isolated and / or purified polypeptides and nucleic acid sequences encoding polypeptides from Alicyclobacillus acidocaldarius and variations thereof are provided. Further provided are methods of at least partially degrading xylotriose, xylobiose, and / or arabinofuranose-substituted xylan using isolated and / or purified polypeptides and nucleic acid sequences encoding polypeptides from Alicyclobacillus acidocaldarius and variations thereof.

Owner:BATTELLE ENERGY ALLIANCE LLC

Biomass pretreatment process

Owner:CHEMTEX ITAL +1

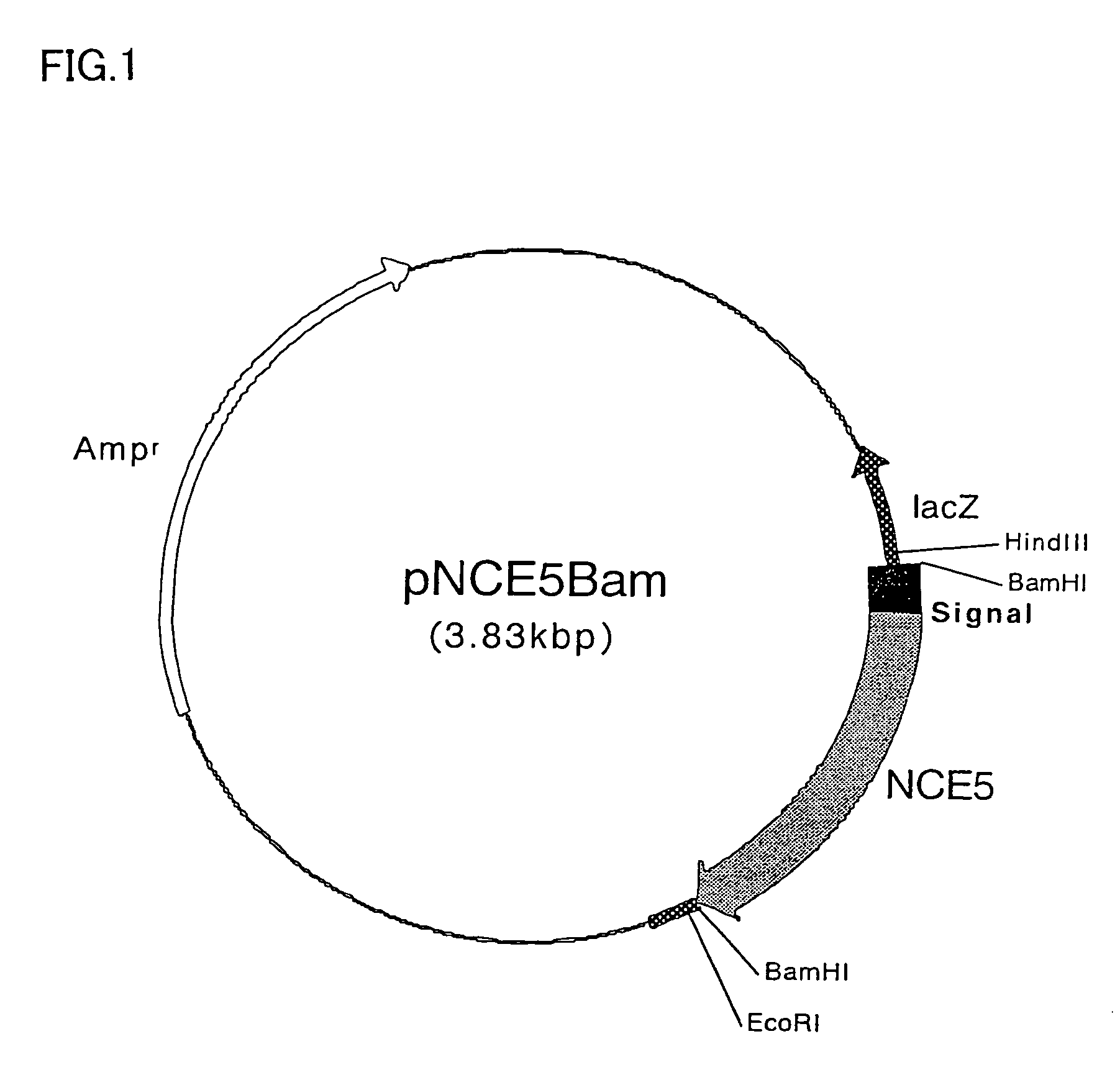

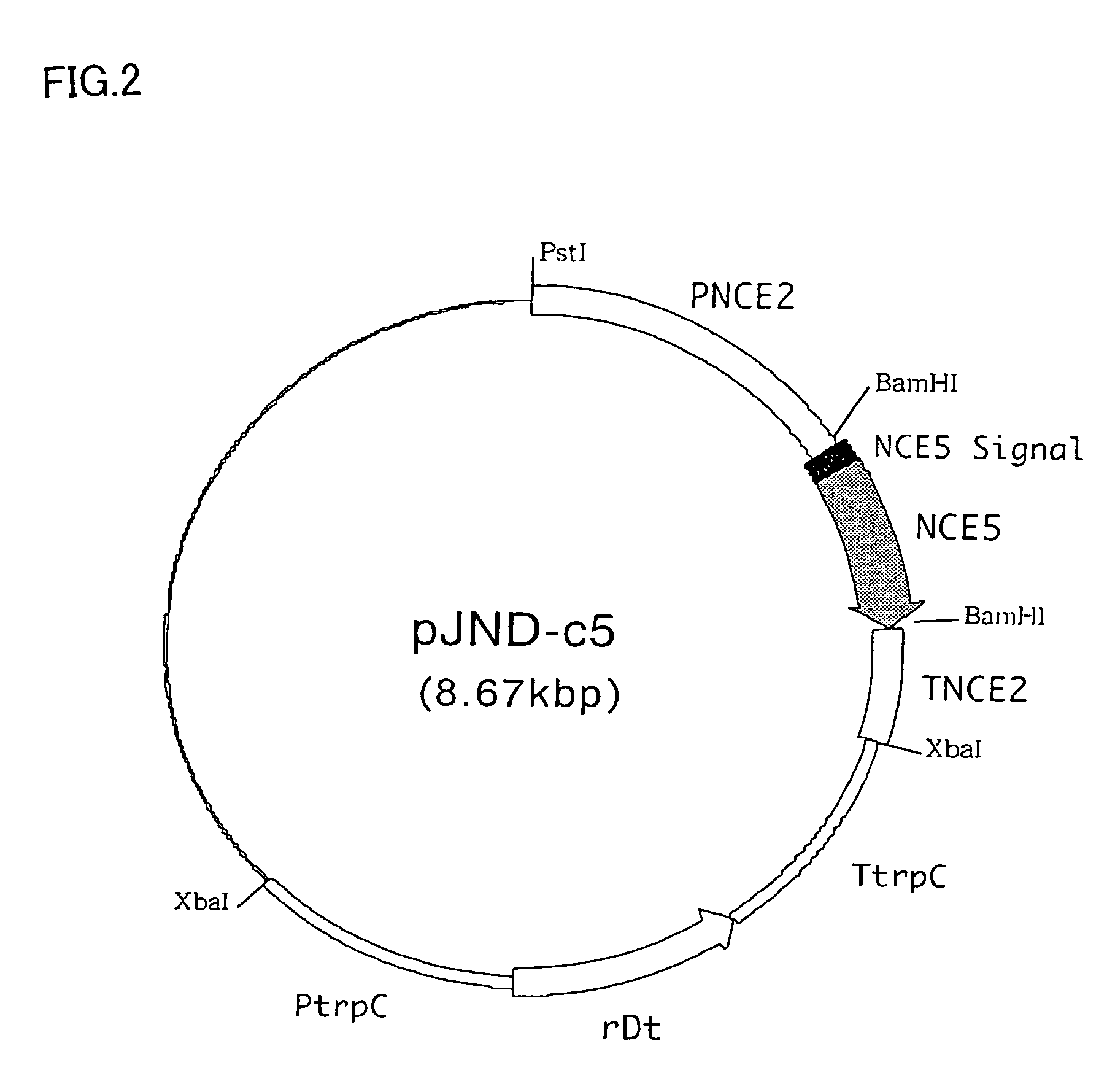

Endoglucanase enzyme NCE5 and cellulase preparations containing the same

InactiveUS7138263B2Efficient and inexpensive treatmentLow degreeFungiOrganic detergent compounding agentsBiotechnologyCellulase

There is provided an endoglucanase enzyme, which is useful for reducing fuzz of regenerated cellulose-containing fabrics, improving the touch and appearance, color clarification, localized variation in color, reducing stiffness and using it as components of a detergent, as well as deinking waste paper and improving freeness of paper pulp. A cDNA coding for the endoglucanase enzyme NCE5 was cloned and its DNA sequence and amino acid sequence derived from it were determined.

Owner:MEIJI SEIKA KAISHA LTD

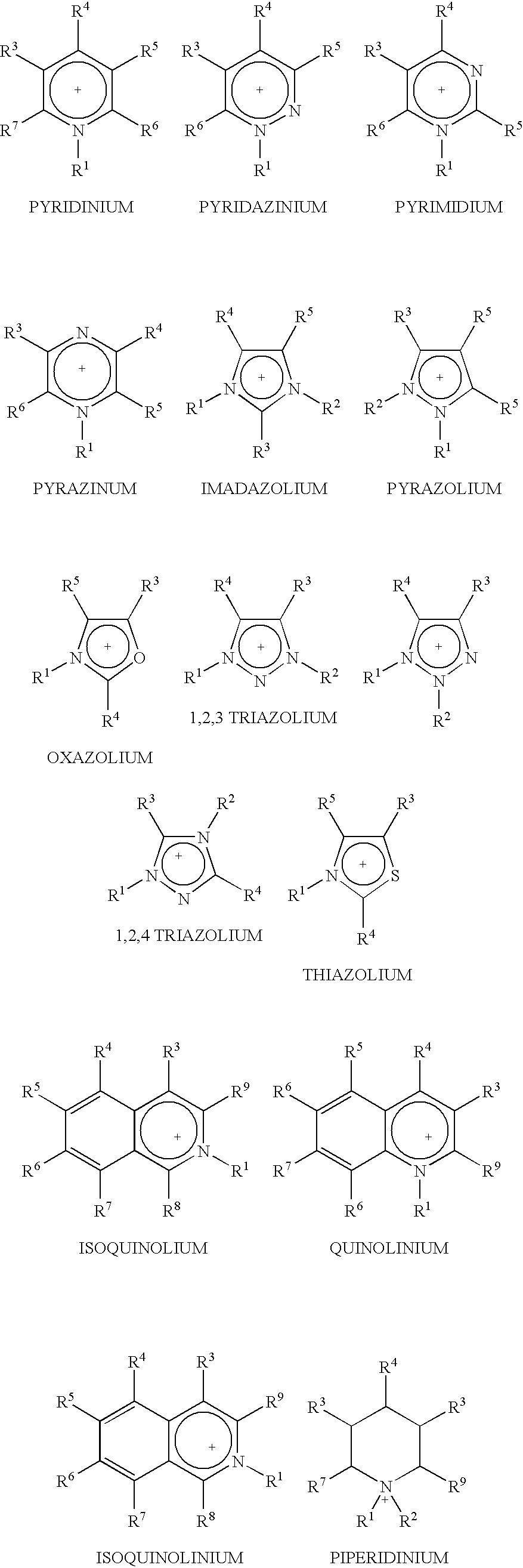

Fractionation of a lignocellulosic material

InactiveUS20100196967A1Lower Level RequirementsImprove permeabilityBiofuelsLignin derivativesCelluloseNon solvent

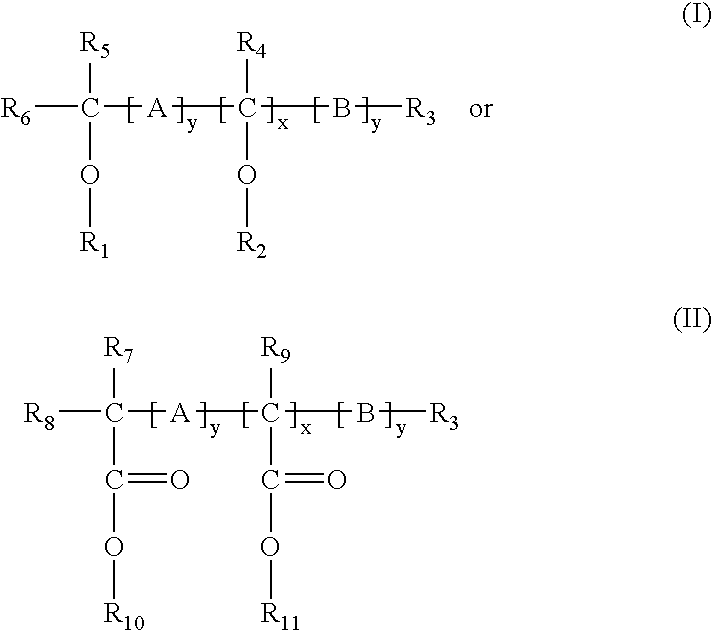

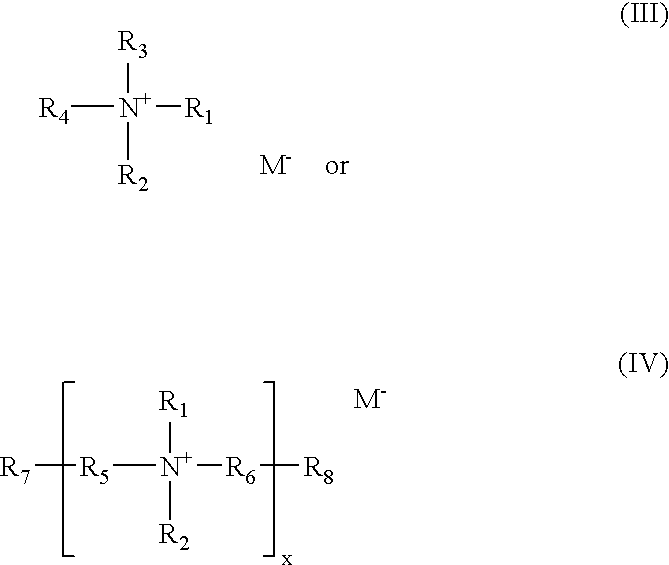

A method for fractionating a lignocellulosic material, the method comprising; contacting (2) the lignocellulosic material with an ionic liquid (3) and dissolving the lignocellulosic material therein, providing a second liquid (7) which is immiscible with the ionic liquid and is also a non-solvent for cellulose, adding the second liquid to the ionic liquid so as to form a biphasic system (6) which comprises an ionic liquid phase essentially free of lignocellulose and a second liquid phase comprising lignin in solution and cellulose as a precipitate, separating the two phases and recovering (8) the precipitated cellulose from the separated second liquid phase.

Owner:QUEENSLAND UNIVERSITY OF TECH

Use of 1,3-selective lipases for pitch control in pulp and paper processes

InactiveUS20100269989A1Reduce the amount requiredReduce concentrationNon-fibrous pulp additionFats/resins/pitch/waxes removal in pulpMonoglycerideSorbent

Formulations for pitch control, and methods of making and using thereof, are described herein. The formulations contains one or more 1,3-selective lipases. 1,3-selective lipases catalyze the hydrolysis of the terminal ester groups in triglycerides leaving the internal ester group intact. The enzyme formulations can contain one or more additives, such as dispersants, metal ions, absorbents, adsorbents, cationic polymers, and combinations thereof. The enzyme formulation is typically applied as a solution to the pulp stock. The enzyme formulations can be applied at any of one or more various points during the pulping and paper manufacturing processes. The use of selective lipase(s) decreases the total concentration of fatty acids in the system, and catalyzes the formation of monoglycerides, which are more effective at dispersing fatty acids than glycerol, the product of non-selective lipases, thereby improving pulp and paper machine runnability and pulp and paper quality.

Owner:ENZYMATIC DEINKING TECH LLC

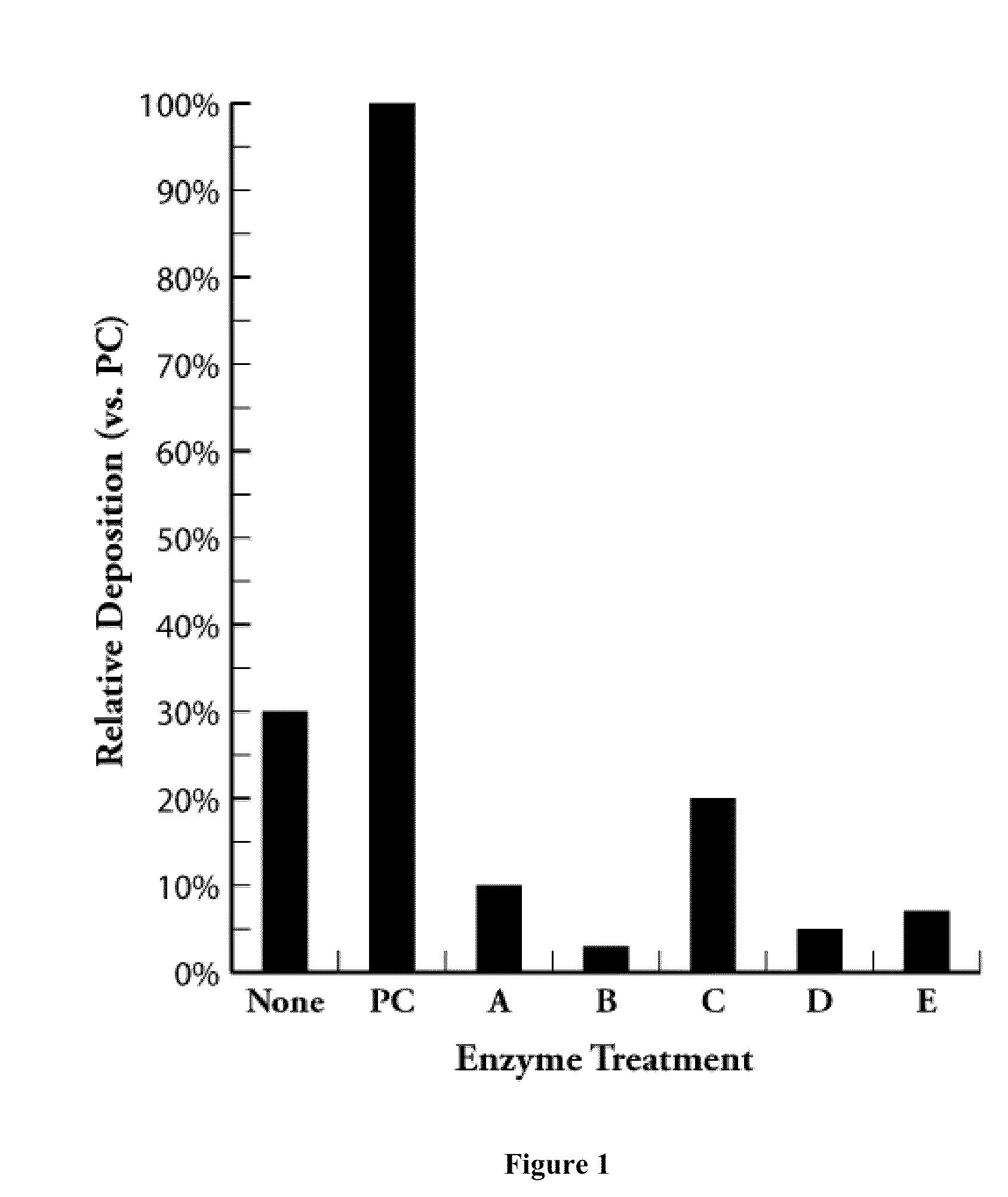

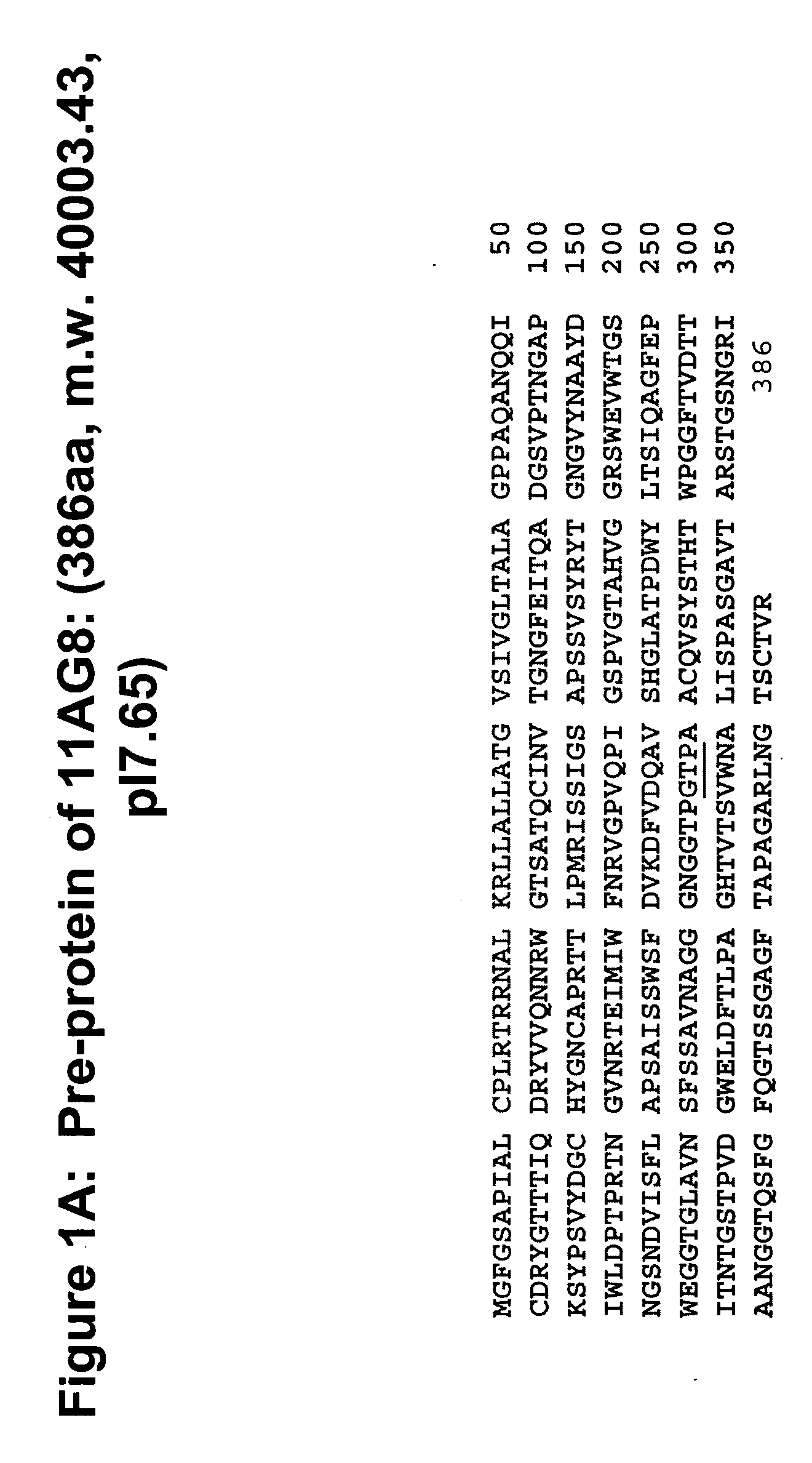

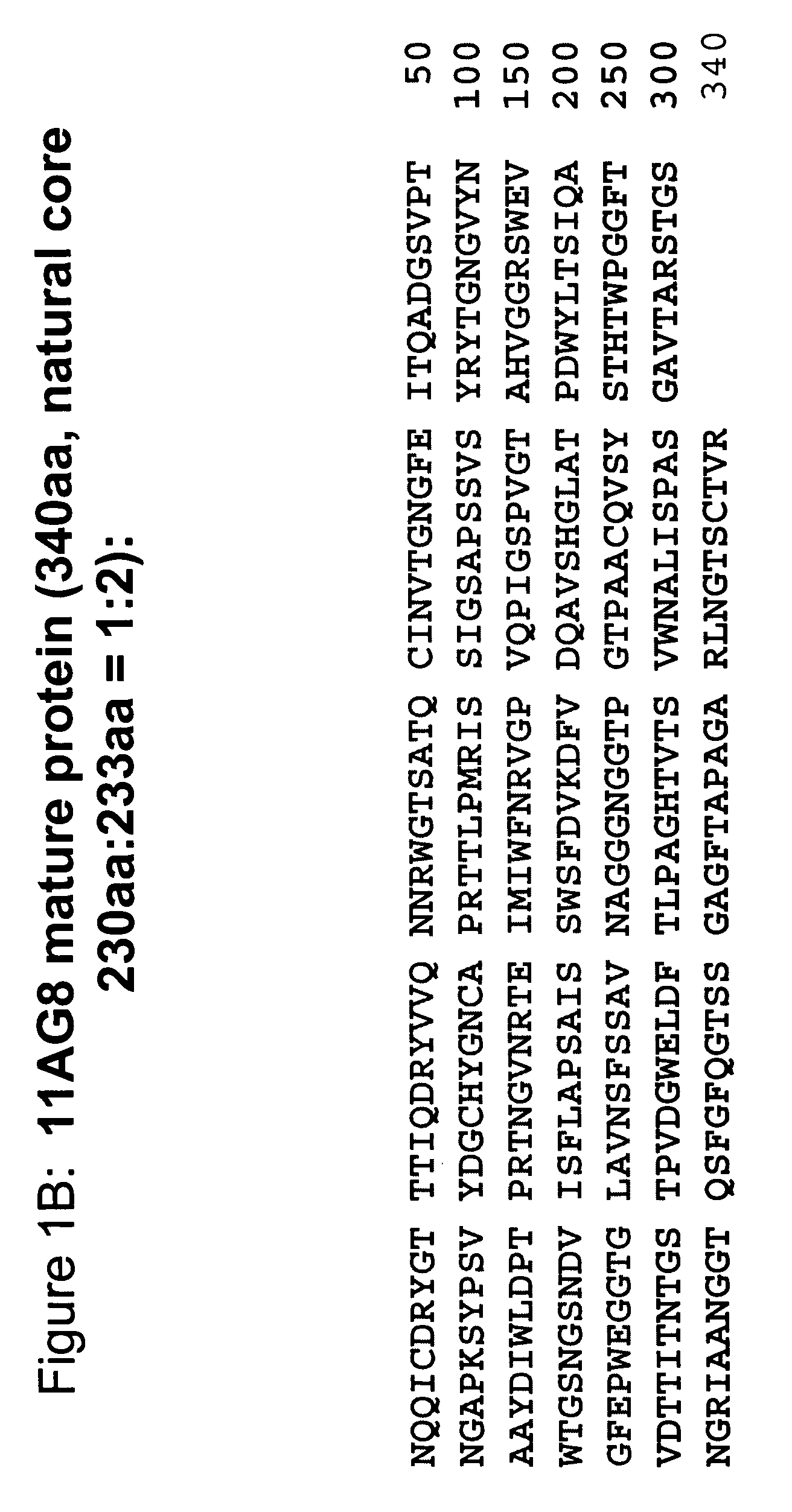

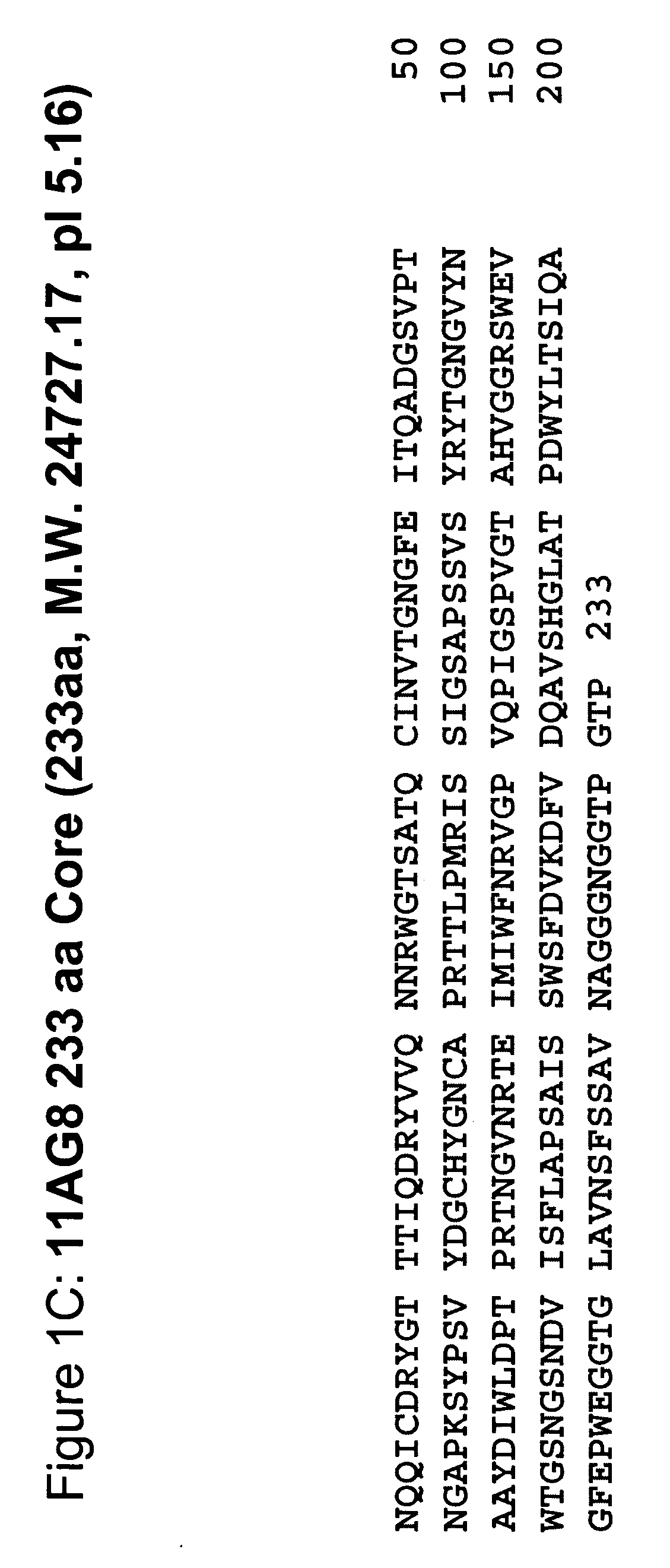

Neutral cellulase catalytic core and method of producing same

InactiveUS20060154843A1Reduce redepositionEasy to wearBacteriaFermentationHigh level expressionCellulose breakdown

The present invention relates to the cloning and high level expression of novel cellulase proteins or derivatives thereof in the in a host cell. Further aspects of the present invention relate to transformants that express the novel cellulases, and expression vectors comprising the DNA gene fragments or variants thereof that code for the novel cellulases derived from Actinomycete using genetic engineering techniques. The present invention is also directed to novel cellulase compositions and methods of use therefore in industrial processes. In particular, the present invention is related to treating textiles with a novel cellulase derived from Actinomycete spp. The present invention also relates to the use of cellulase derived from Actinomycete spp. to enhance the digestibility of animal feed, in detergents, in the treatment of pulp and paper and in the production of starch and treatment of by-products thereof.

Owner:GENENCOR INT INC

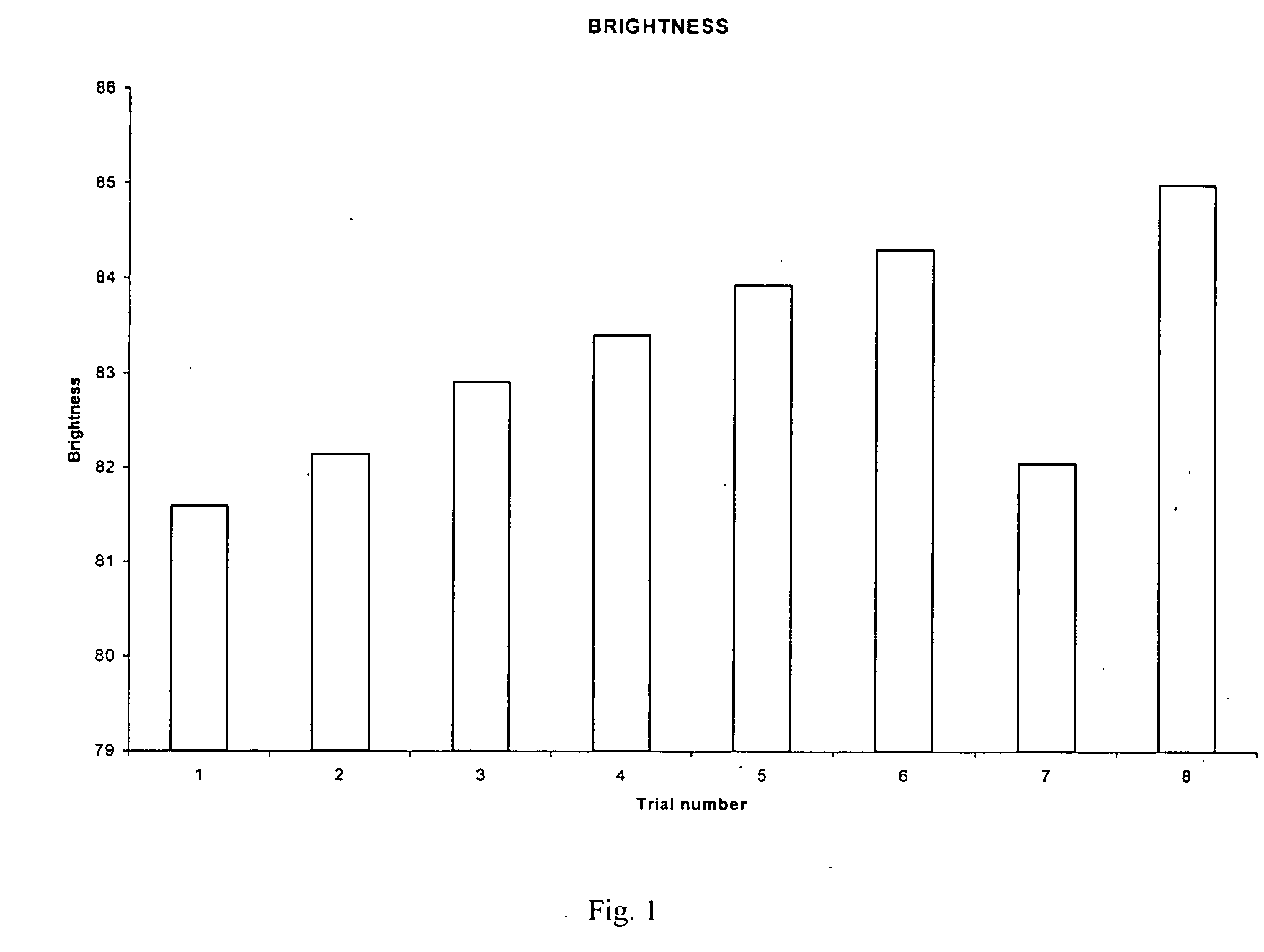

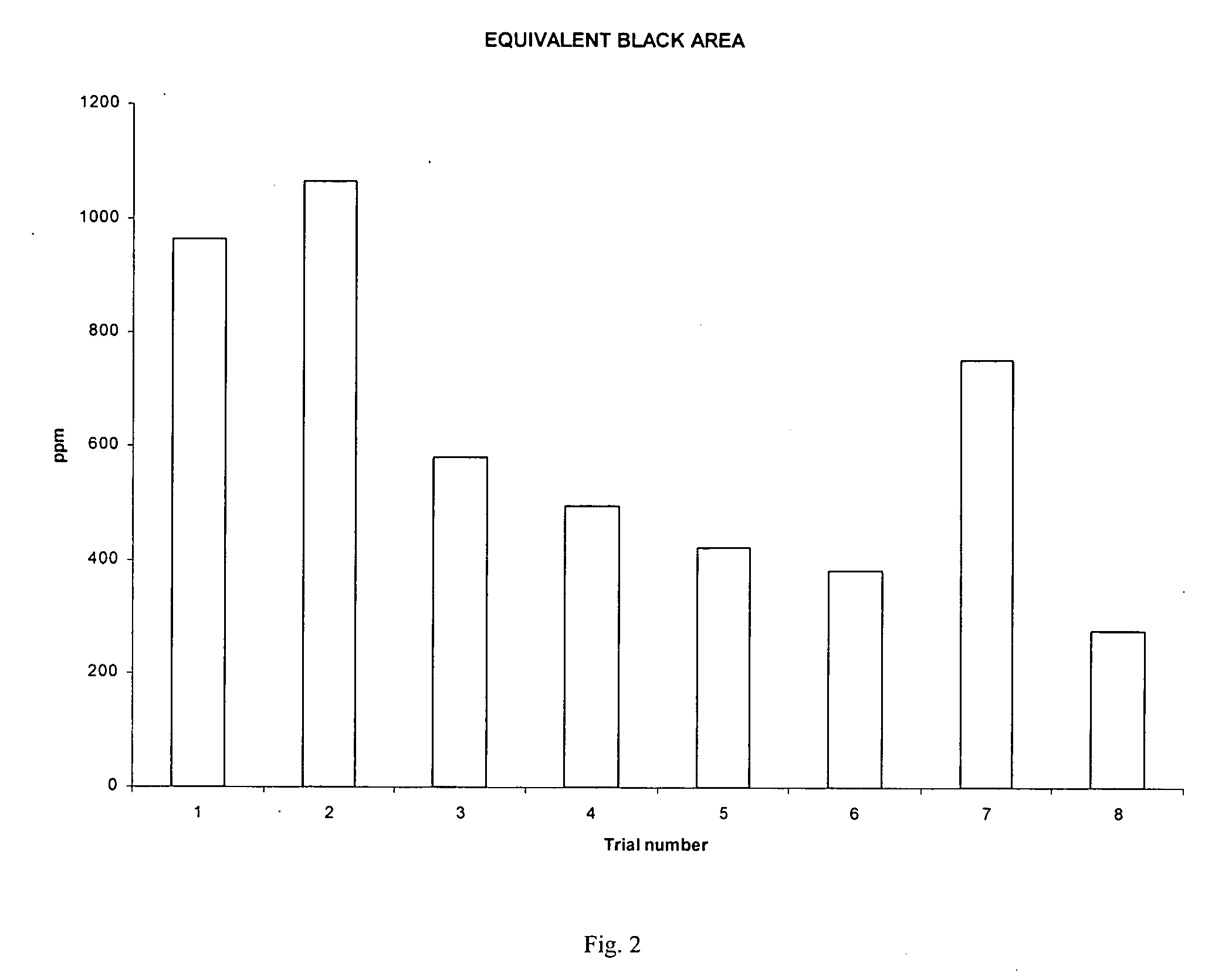

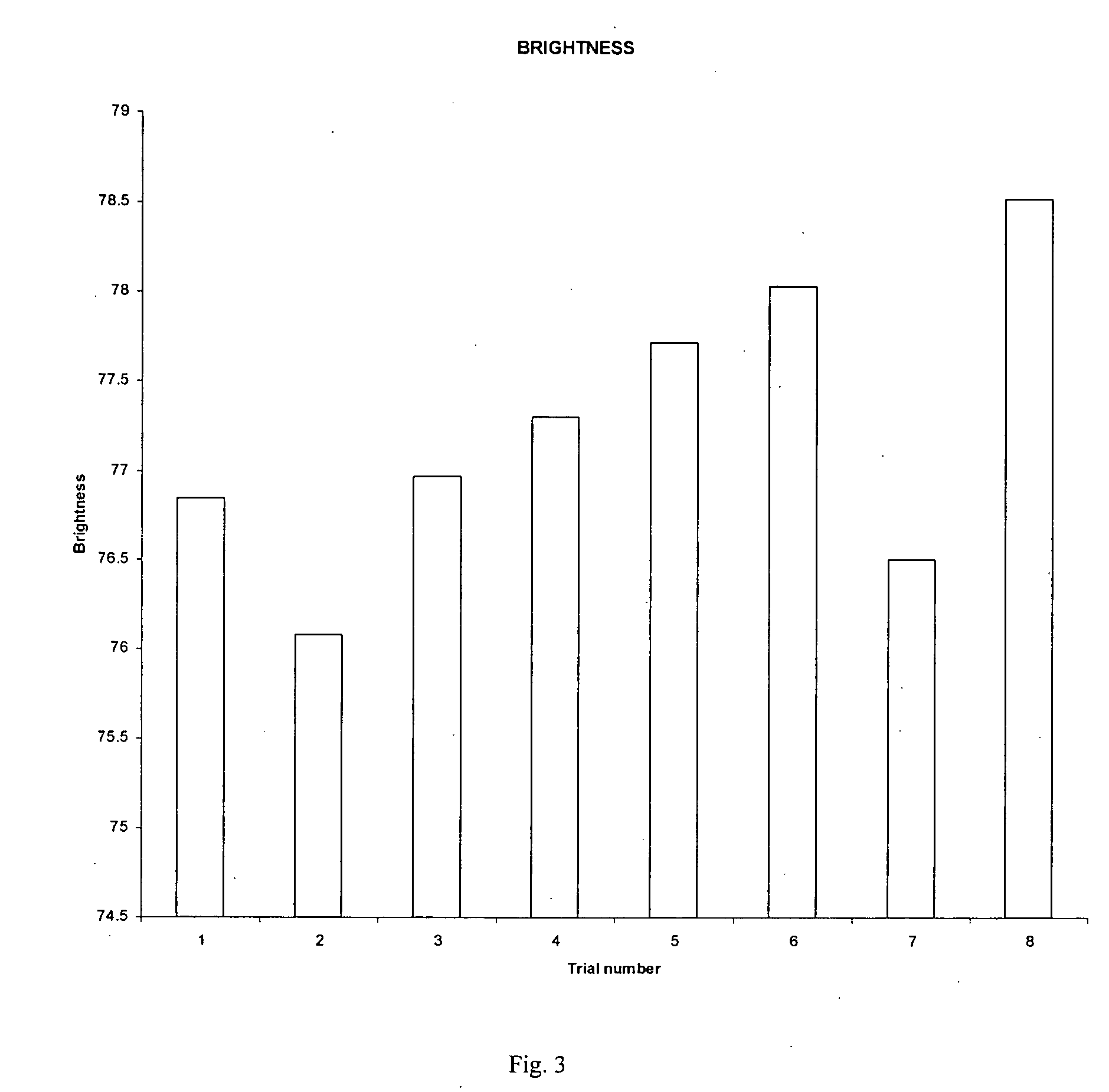

Method for enzymatic deinking of waste papers, the waste papers so treated and the treating composition

ActiveUS20060102299A1Prolonged actionIncrease brightnessPaper recyclingCellulose treatment using microorganisms/enzymesDeinkingPaper sheet

The present invention relates to a deinking composition and a method of deinking wastepaper by using a mixture of enzymes that act on constituents of all three waste paper components involved in ink retention on final pulp. The first component represents substrates located on the surface and in the internal waste paper structure. The second component represents substrates located in the interface between paper and ink, usually formed by coatings or size-press (starch containing or not) applied layers. The third component represents substrates located in the ink and / or toner compounds. This method provides improved performance in relation to conventional methods, or current deinking with enzymes, which acts on a limited number of substrates involved in ink retention on final pulp.

Owner:TRI TEX

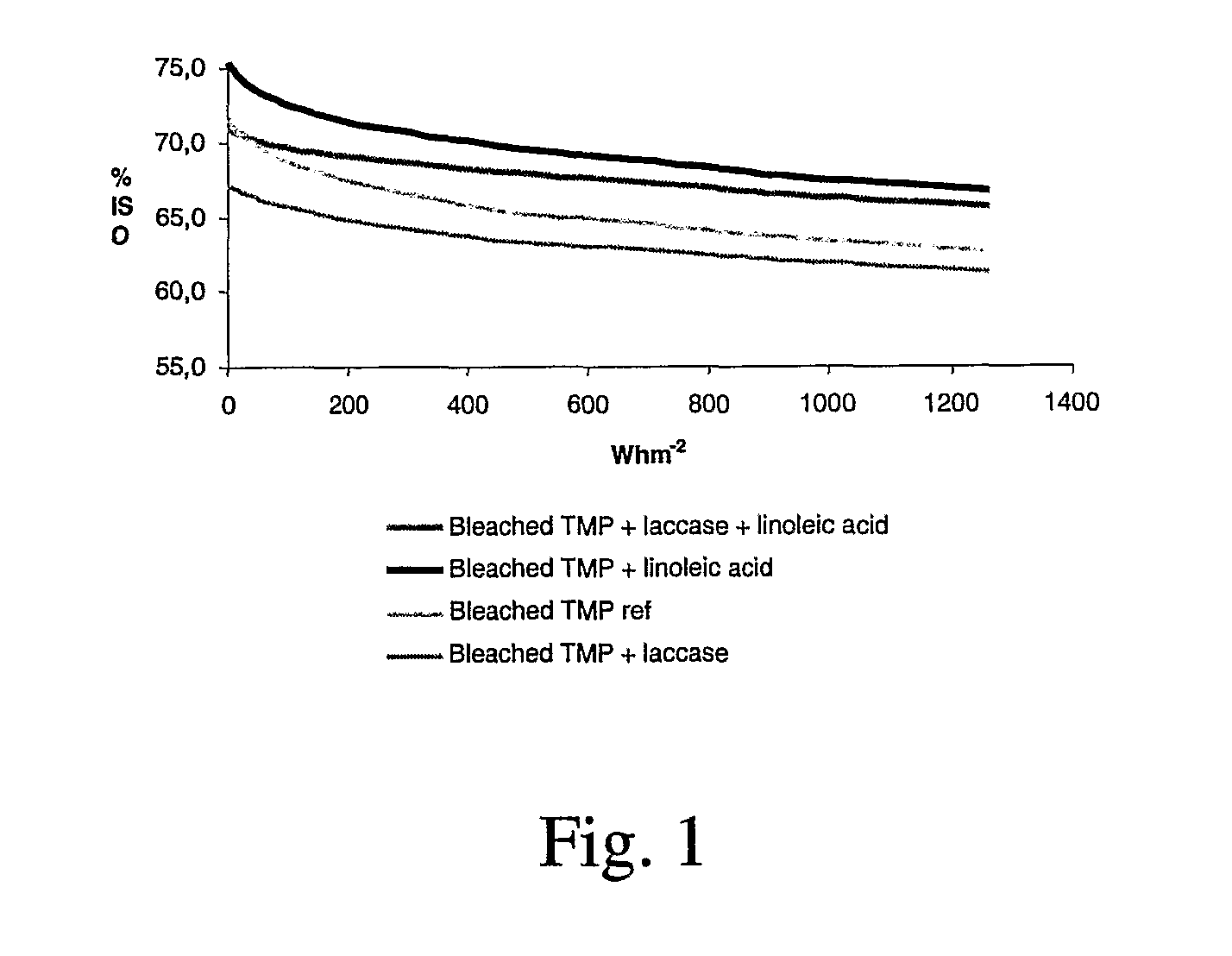

Method for reducing brightness reversion of mechanical pulps and high-yield chemical pulps

InactiveUS20070163735A1Improved brightness reversionImprove the immunityAgeing prevention agents additionSpecial paperCelluloseFiber

Owner:KEMIRA OY

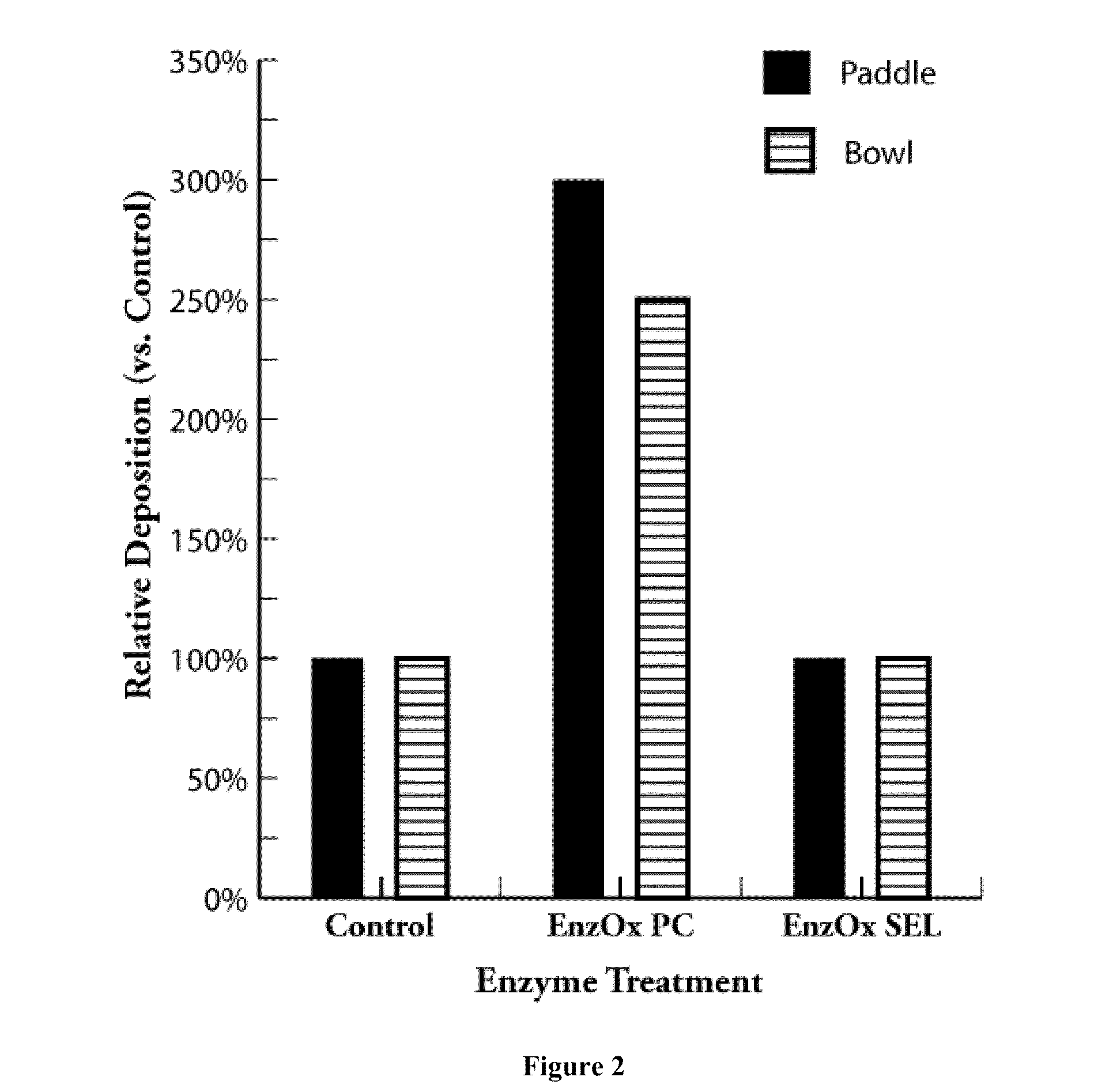

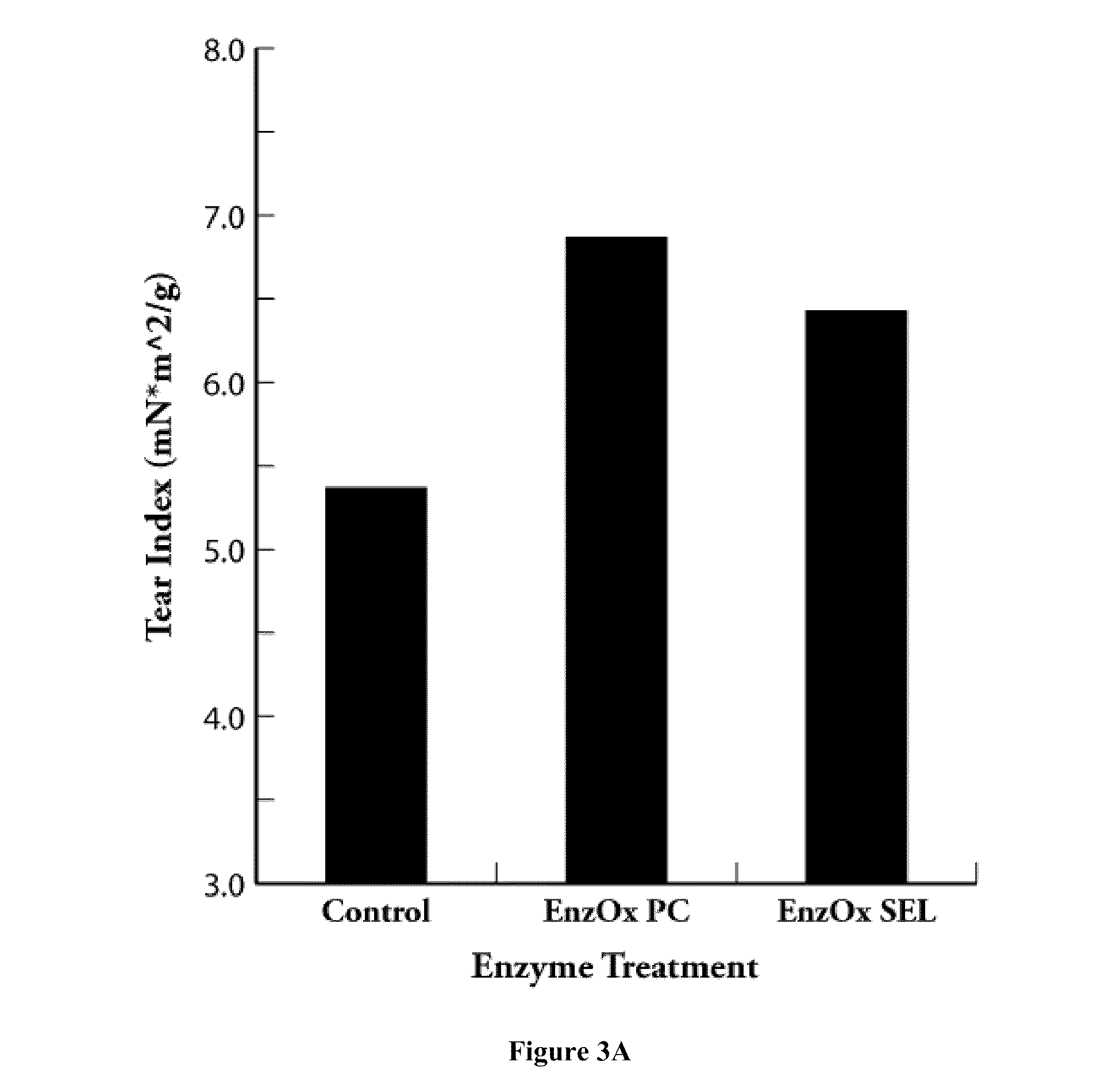

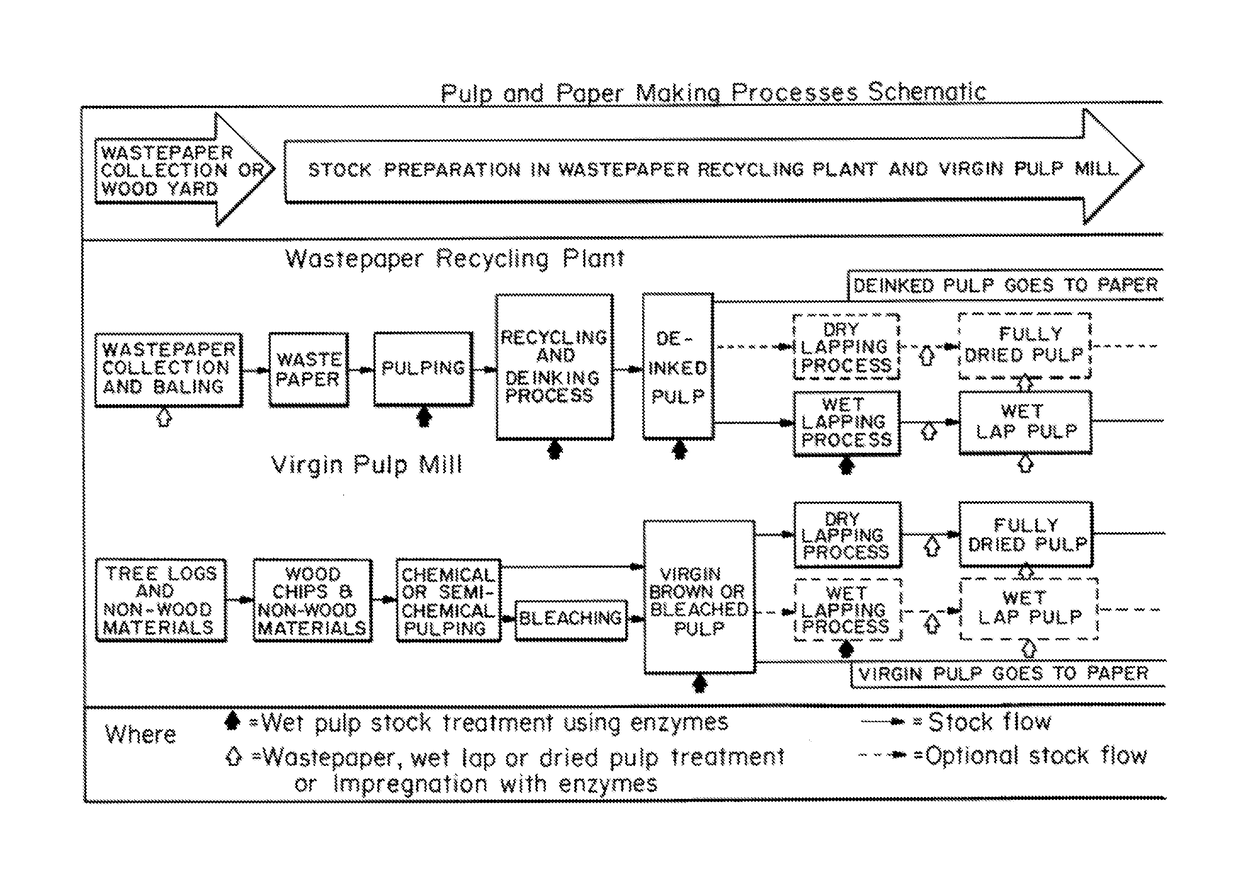

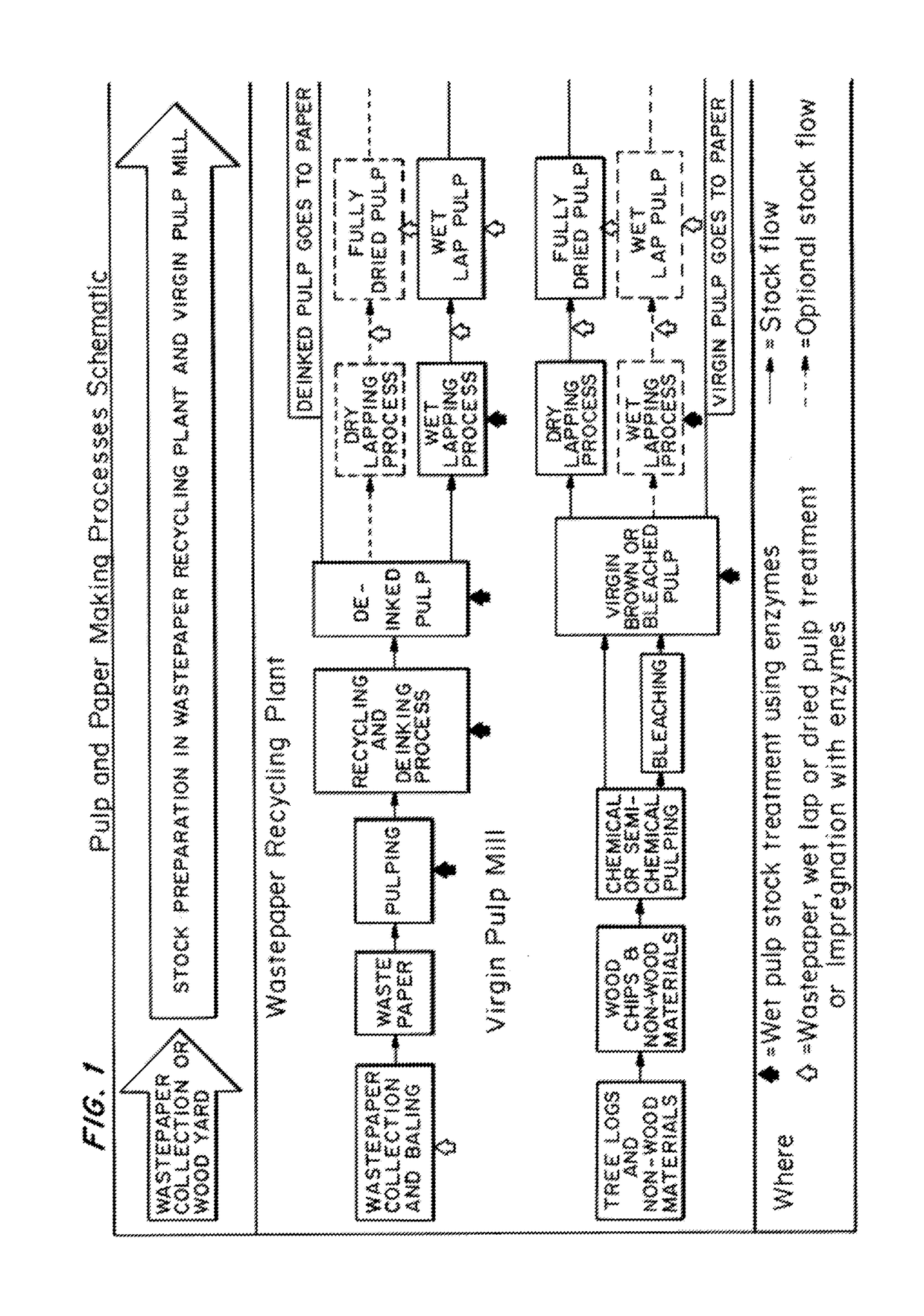

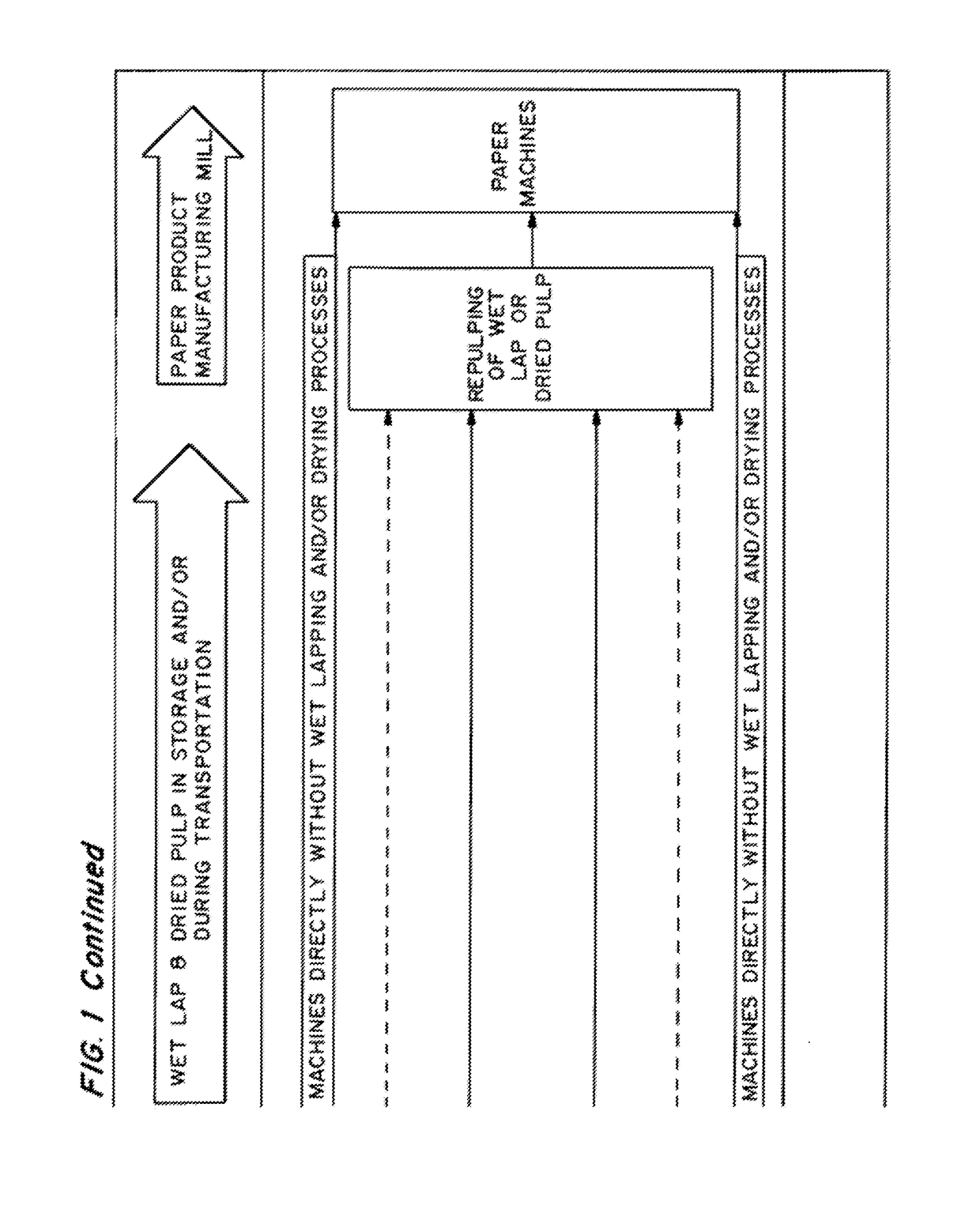

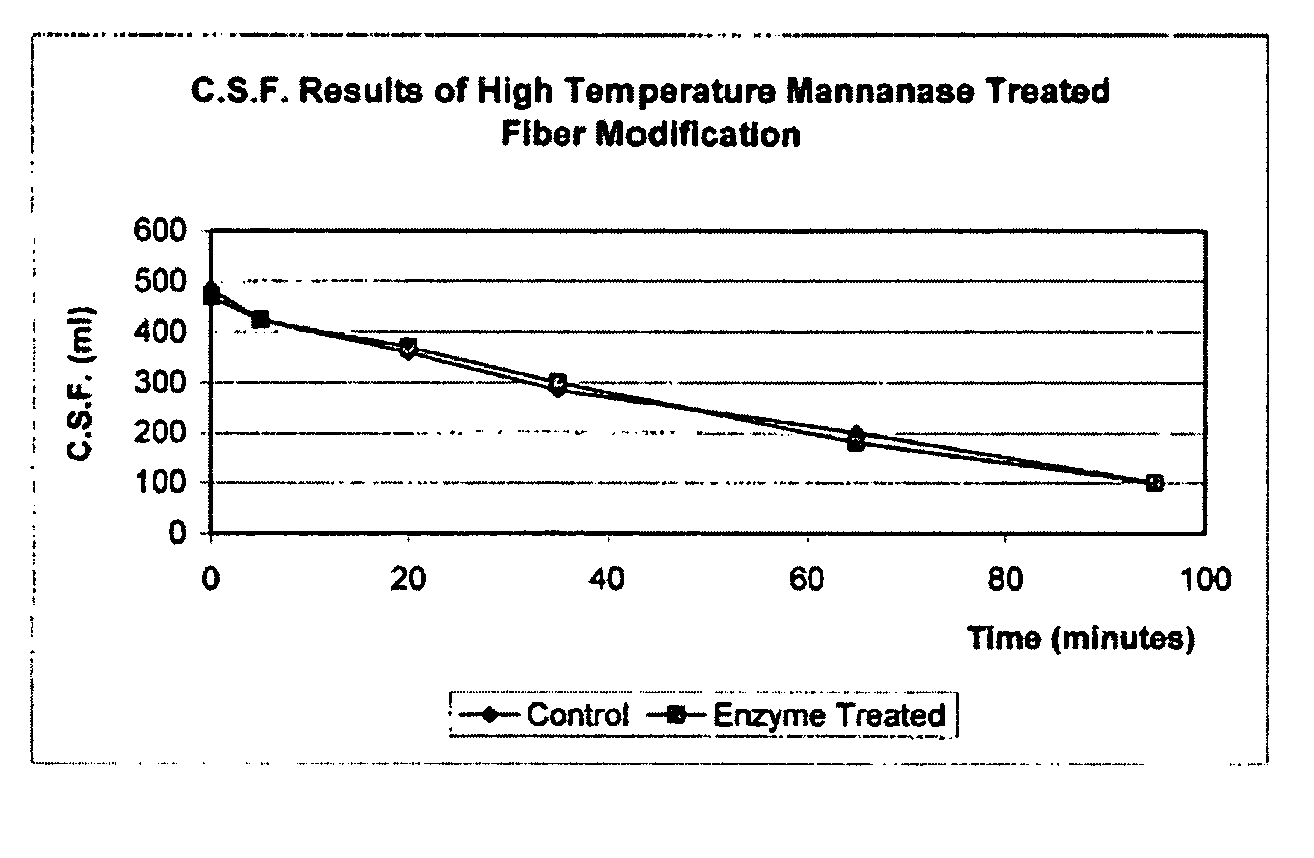

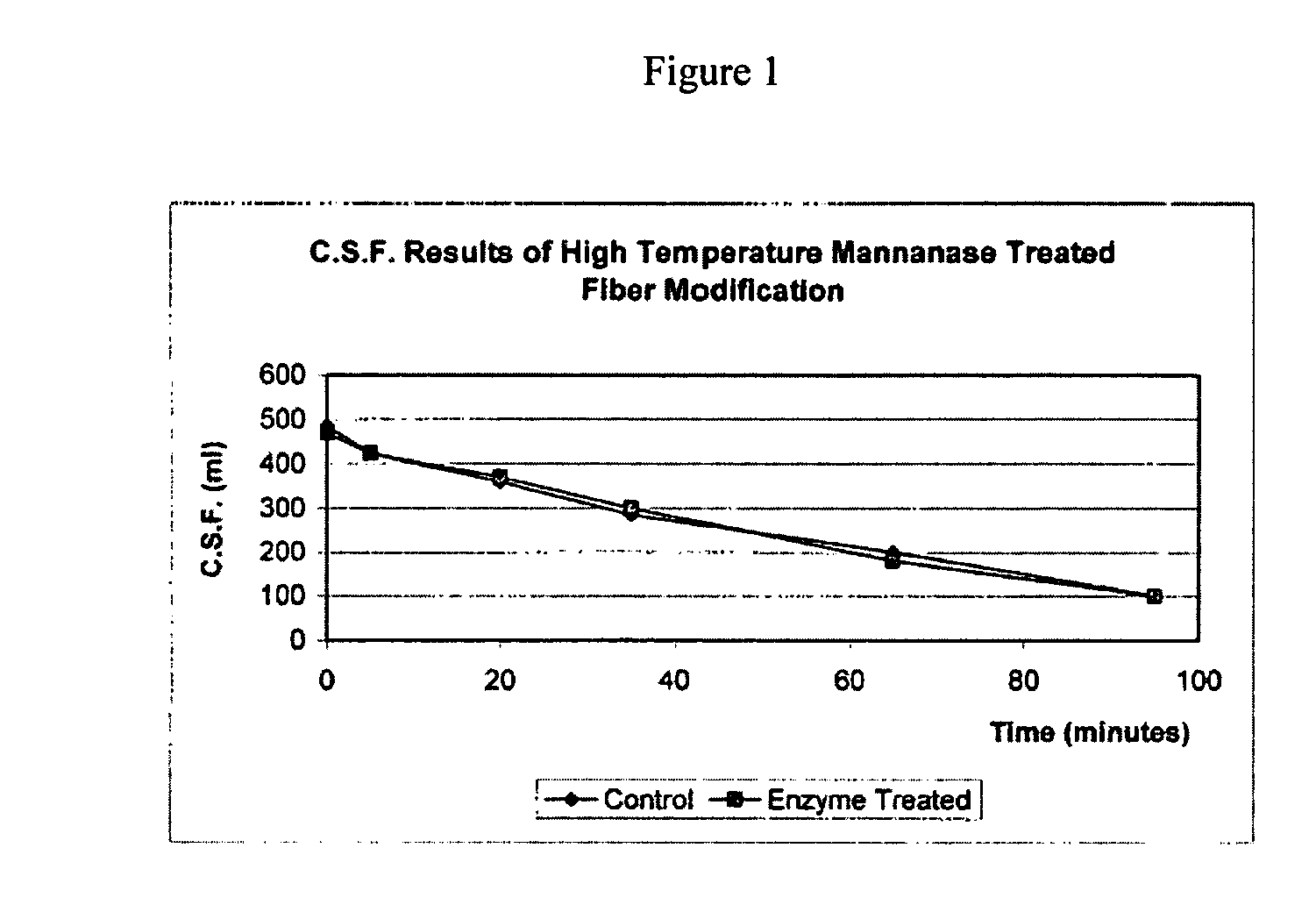

Enzymatic pre-treatment of market pulp to improve fiber drainage and physical properties

ActiveUS20170328006A1Increasing pulp drainage and strength propertyQuality improvementMicroorganism/enzyme additionPaper recyclingFiberPulp and paper industry

Owner:ENZYMATIC DEINKING TECH LLC

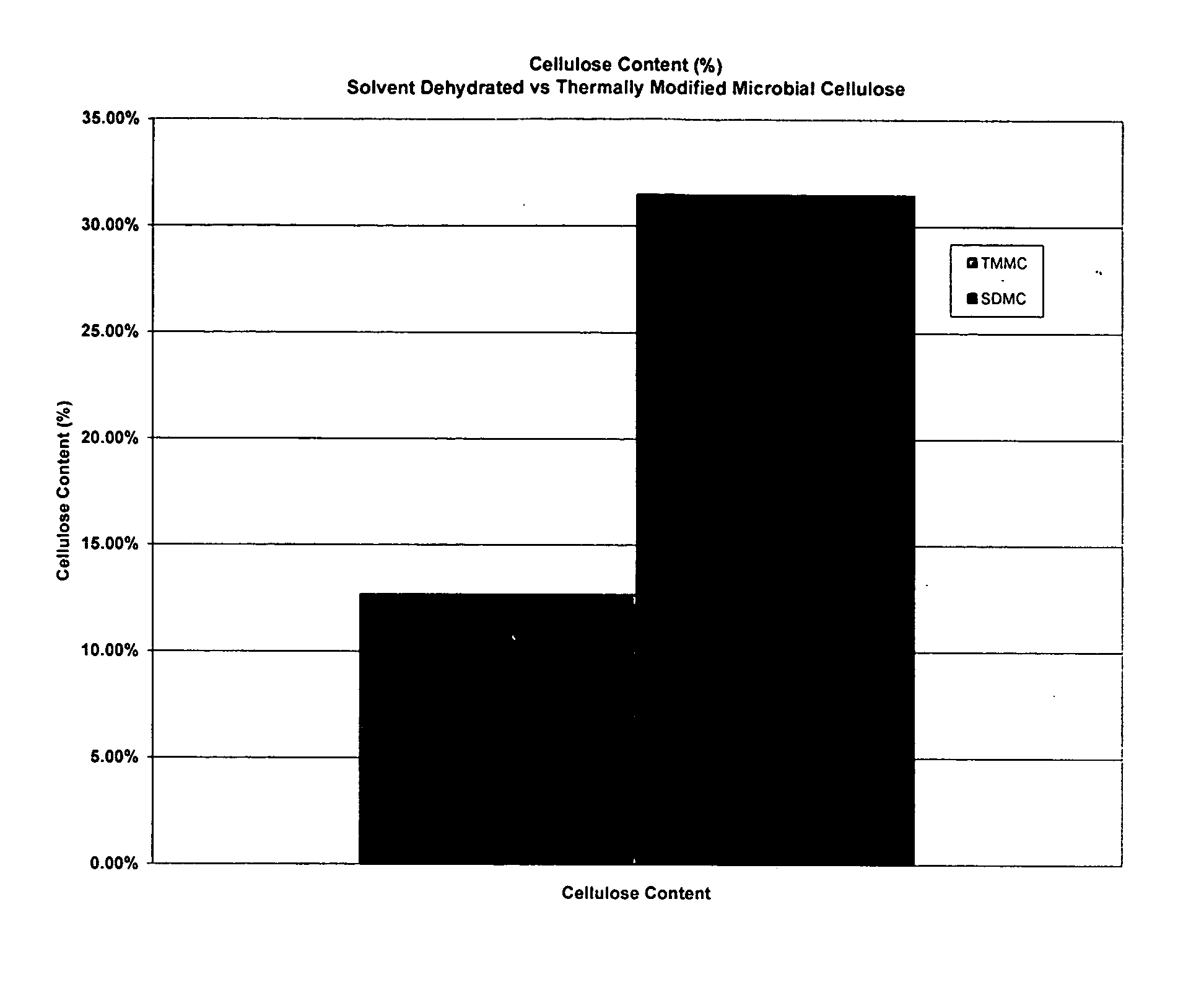

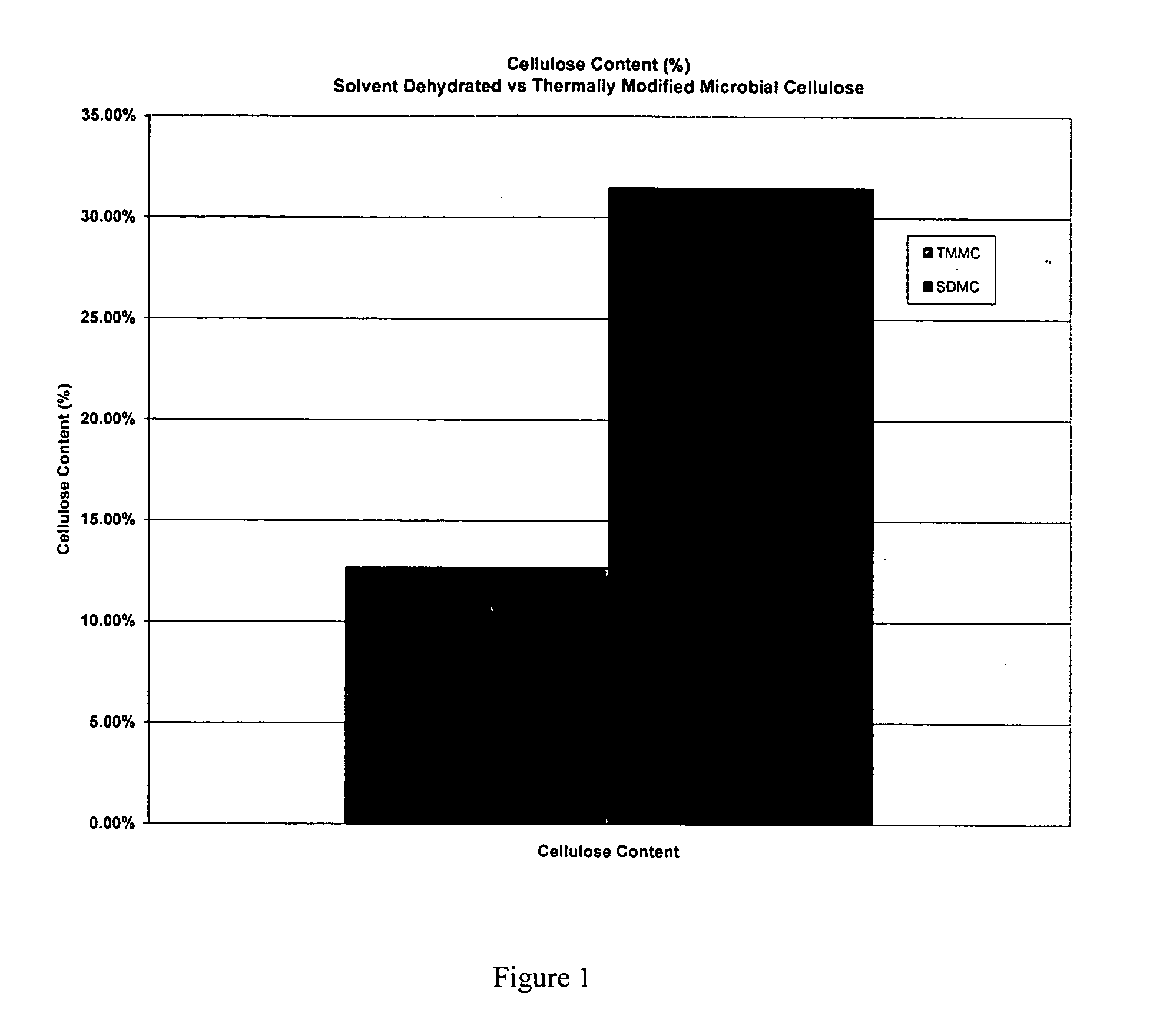

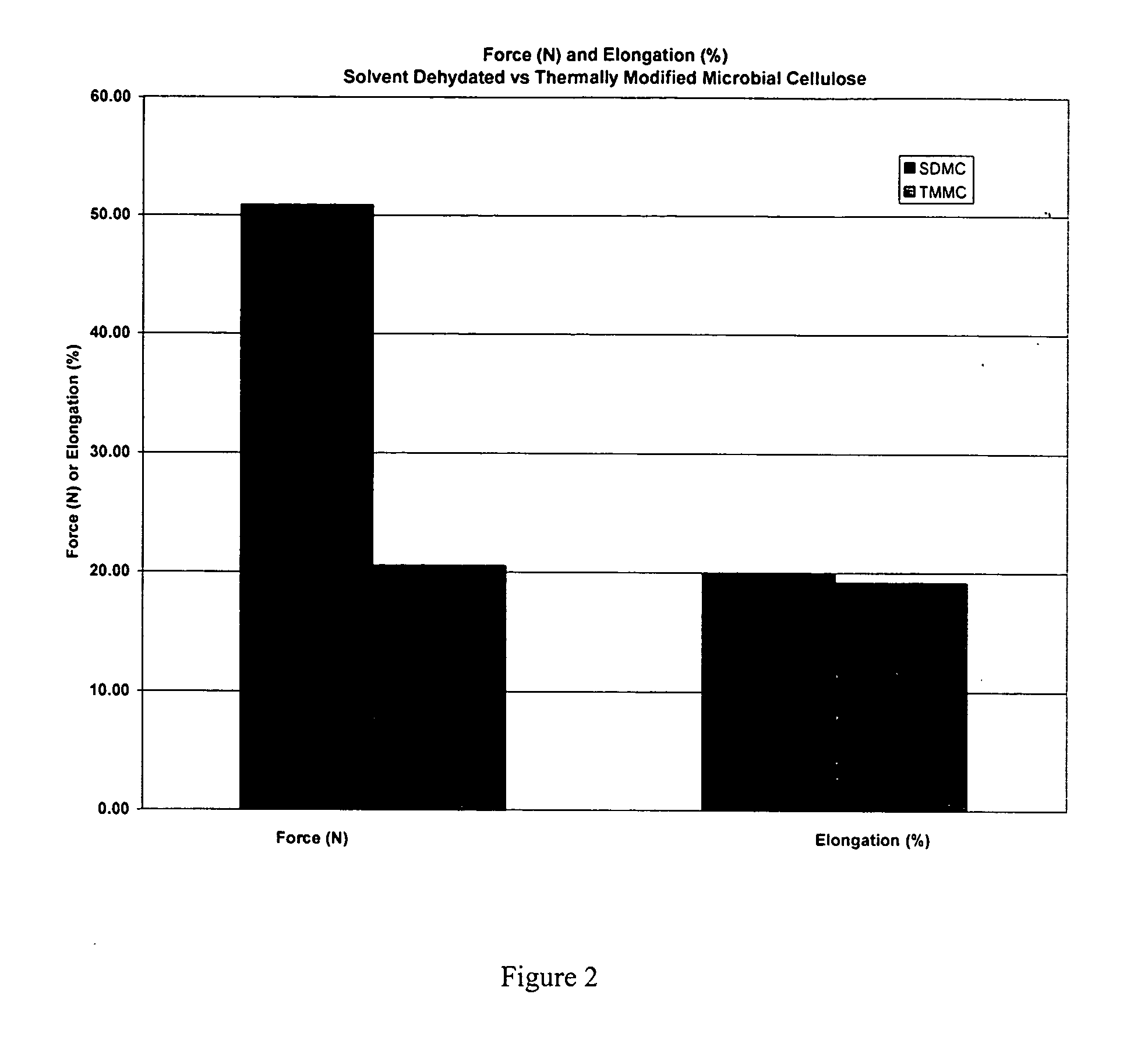

Thermally modified microbial-derived cellulose for in vivo implantation

ActiveUS20050042250A1Desirable mechanical propertyReadily apparentBiocideOrganic active ingredientsCelluloseMicroorganism

A thermally modified microbial-derived cellulose material is described for use as an implantable material in general surgery, plastic surgery and neurosurgery.

Owner:DEPUY SYNTHES PROD INC +1

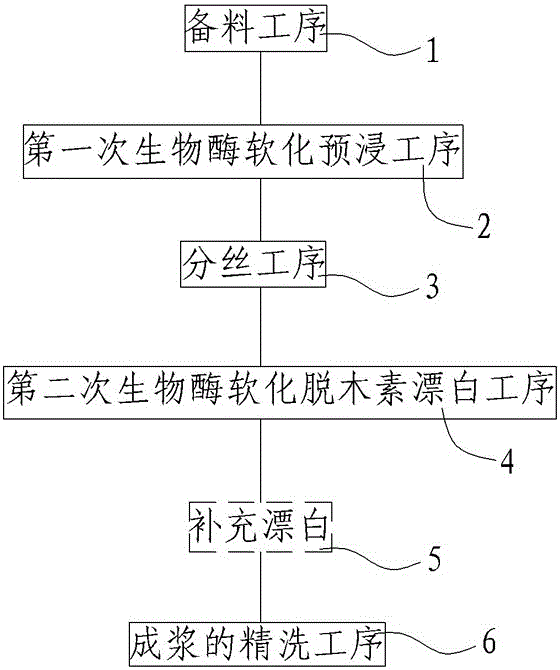

Pulp making technology through performing biological enzyme softening lignin removal twice combined with mechanical method

ActiveCN105780568ASimple methodStrong targetingPulp bleachingCellulose treatment using microorganisms/enzymesMaterials preparationBlack liquor

The invention provides a pulp making technology through performing biological enzyme softening lignin removal twice combined with a mechanical method. The pulp making technology comprises the following steps: step 1) material preparation; step 2) biological enzyme softening preimpregnation for the first time; step 3) mechanical pulp making and thread separation; step 4) biological enzyme softening lignin removal and bleaching for the second time; step 5) fine purification of made pulp. According to the pulp making technology disclosed by the invention, a composite permeating softener and a composite biological enzyme preparation are used for performing the preimpregnation working procedure and the bleaching working procedure, and a new pulp making technology through biological enzyme softening lignin removal twice combined with the mechanical method is obtained. According to the pulp making technology disclosed by the invention, the conventional alkaline pulp making technology, the conventional mechanical pulp making technology and the biological pulp making technology which is in the process of exploration are changed, so that the defects of conventional pulp making technologies are overcome, the method is simple and effective, the pertinence is high, the maneuverability is high, high-temperature cooking is not needed in the lignin degradation process, hazardous substances such as caustic soda are not added, and black liquor is not produced.

Owner:上海锴晨实业有限公司

Xylanase treatment of chemical pulp

InactiveUS20050150619A1Reduce usageHigh strengthPulp bleachingPulping with organic solventsChlorine dioxidePulp mill

The present invention discloses methods of bleaching chemical pulp that use xylanase enzymes after chemical bleaching. The method comprises the steps of carrying out a chlorine dioxide stage to produce a partially bleached pulp, treating the partially bleached pulp with a xylanase enzyme, optionally in the presence of oxygen and hydrogen peroxide, in a mild extraction stage, then bleaching the pulp with a second chlorine dioxide stage. The method allows the mill to decrease the usage of sodium hydroxide or other alkali, while decreasing the use of chlorine dioxide, and possibly improving the yield and strength of the pulp, while maintaining a similar level of bleached brightness of the pulp. The pulp bleaching method of the present invention may be performed in a pulp mill as part of a complex pulp bleaching process.

Owner:NOVOZYMES AS

Processes and apparatus for producing nanocellulose, and compositions and products produced therefrom

Processes disclosed are capable of converting biomass into high-crystallinity nanocellulose with surprisingly low mechanical energy input. In some variations, the process includes fractionating biomass with an acid (such as sulfur dioxide), a solvent (such as ethanol), and water, to generate cellulose-rich solids and a liquid containing hemicellulose and lignin; and mechanically treating the cellulose-rich solids to form nanofibrils and / or nanocrystals. The total mechanical energy may be less than 500 kilowatt-hours per ton. The crystallinity of the nanocellulose material may be 80% or higher, translating into good reinforcing properties for composites. The nanocellulose material may include nanofibrillated cellulose, nanocrystalline cellulose, or both. In some embodiments, the nanocellulose material is hydrophobic via deposition of some lignin onto the cellulose surface. Optionally, sugars derived from amorphous cellulose and hemicellulose may be separately fermented, such as to monomers for various polymers. These polymers may be combined with the nanocellulose to form completely renewable composites.

Owner:API INTELLECTUAL PROPERTY HOLDINGS LLC

Composition comprising microfibrillated cellulose and a process for the production of a composition

ActiveUS20130047893A1Easy to moveIncrease dry contentPigmenting treatmentCoatings with pigmentsCellulose fiberViscosity

The present invention relates to a composition comprising microfibrillated cellulose, mono-, di- or oligo-saccharides and a pigment in order to achieve a composition with improved rheological properties such as a low viscosity even at high dry content. The present invention further relates to process for the production of said composition. The microfibrillated cellulose is produced by at least partly enzymatic treatment of cellulosic fibers such that even mono-, di- or oligo-saccharide is formed.

Owner:STORA ENSO OYJ

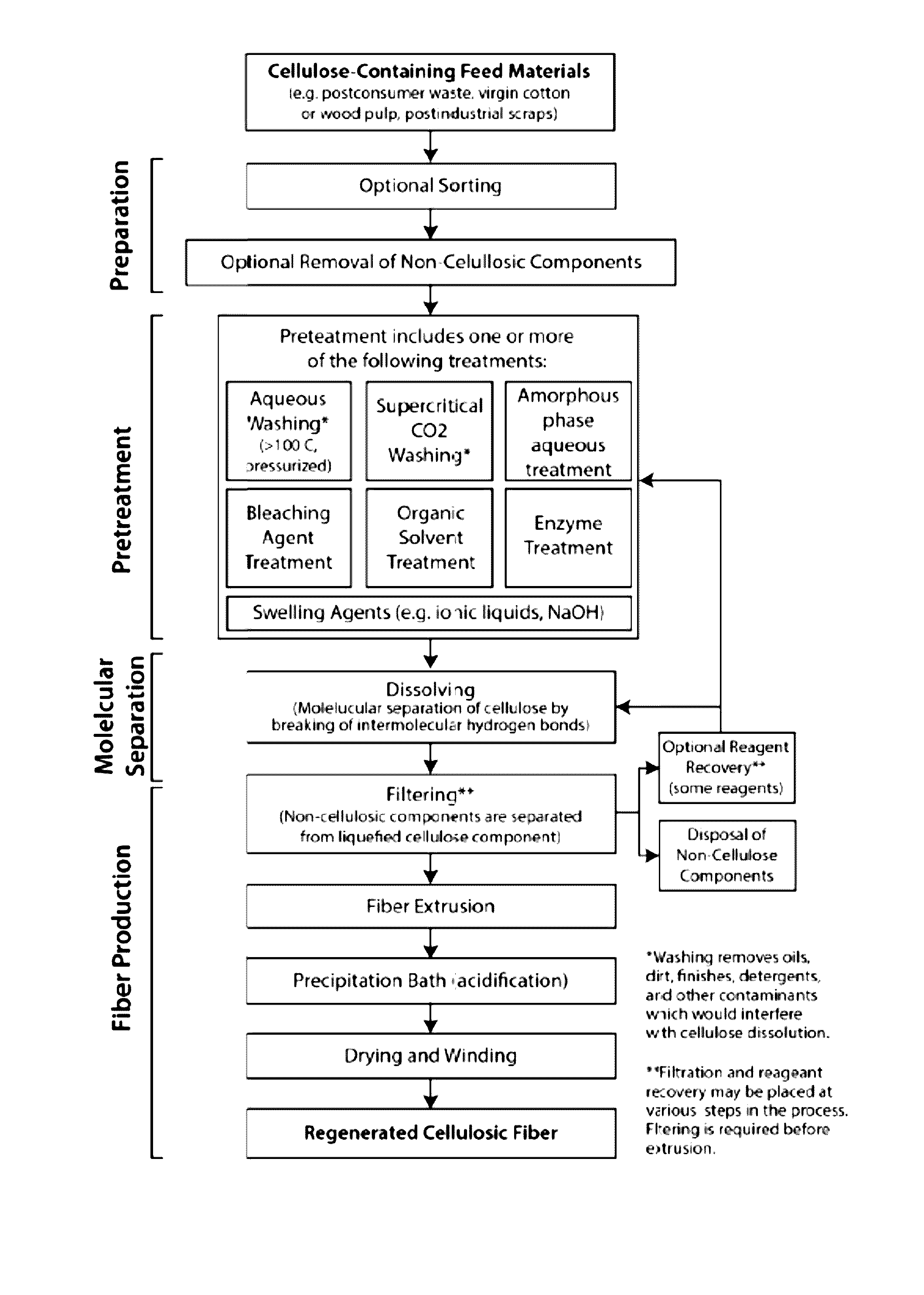

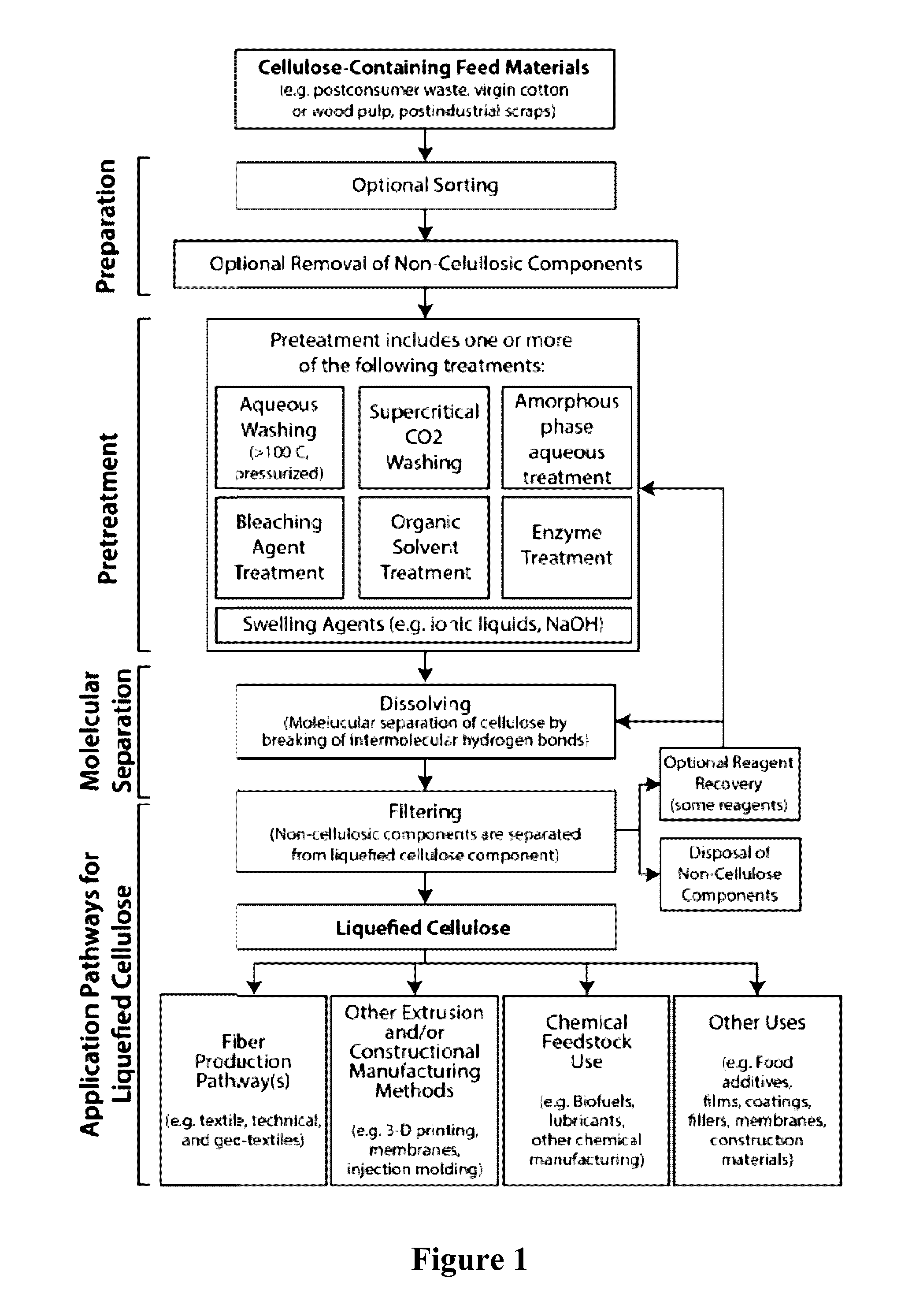

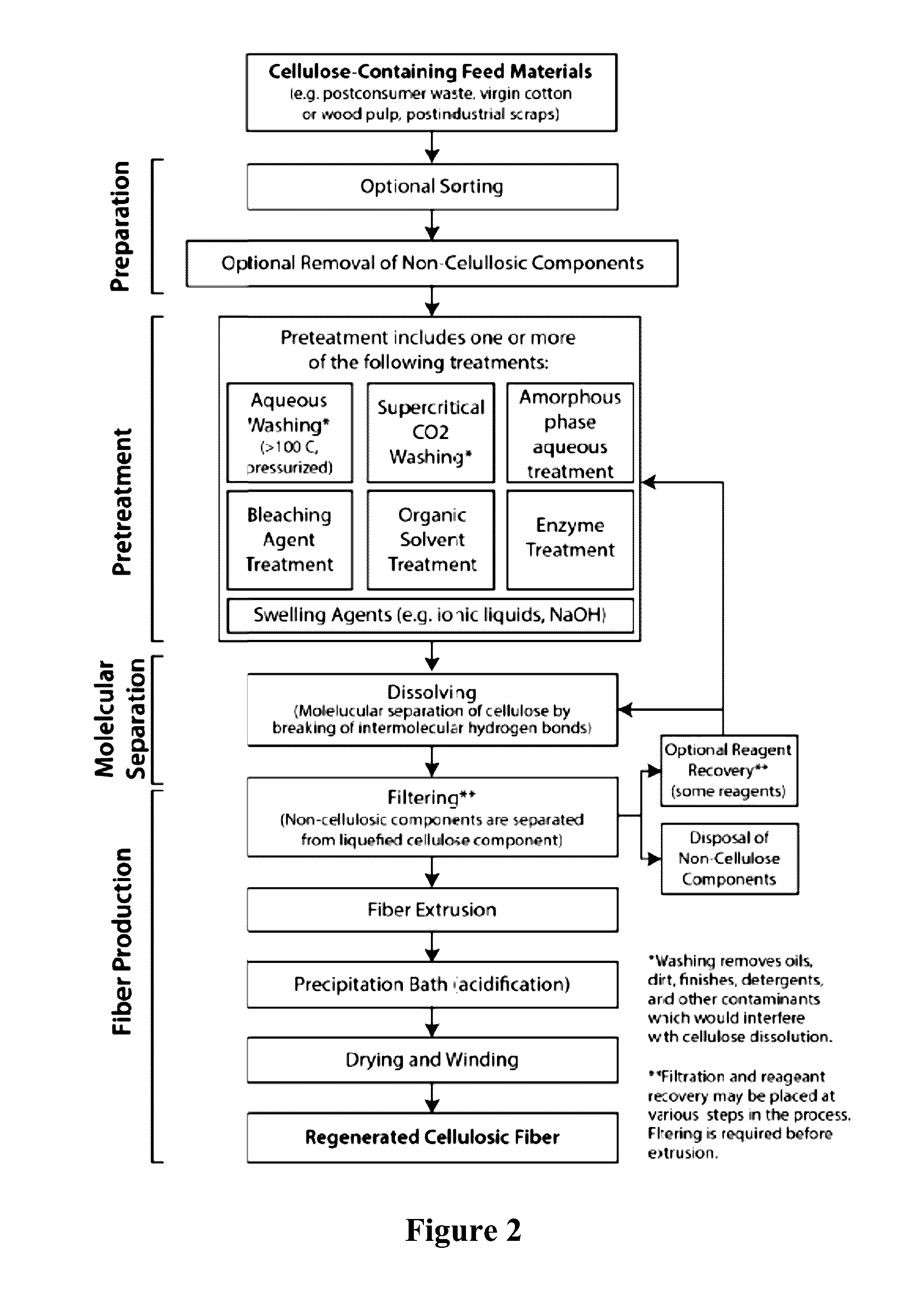

Methods and systems for processing cellulose-containing materials and isolating cellulose molecules; methods for regenerating cellulosic fibers

InactiveUS20160369456A1Reduce environmental impactPretreatment with water/steamPulp properties modificationPost-consumer wastePre treatment

Methods and systems of the present invention use cellulose-containing materials, which may include post-consumer waste garments, scrap fabric and / or various biomass materials as a raw feed material to produce isolated cellulose molecules having desirable properties that can be used in the textile and apparel industries, and in other industries. A multi-stage process is provided, in which cellulose-containing feed material is subjected to one or more pretreatment stages, followed by a pulping treatment, to isolate cellulose molecules. The isolated cellulose molecules may be used in a variety of downstream applications. In one application, isolated cellulose molecules are extruded to provide regenerated cellulose fibers having desirable (and selectable) properties that are usable in various industrial applications, including textile production.

Owner:EVRNU SPC

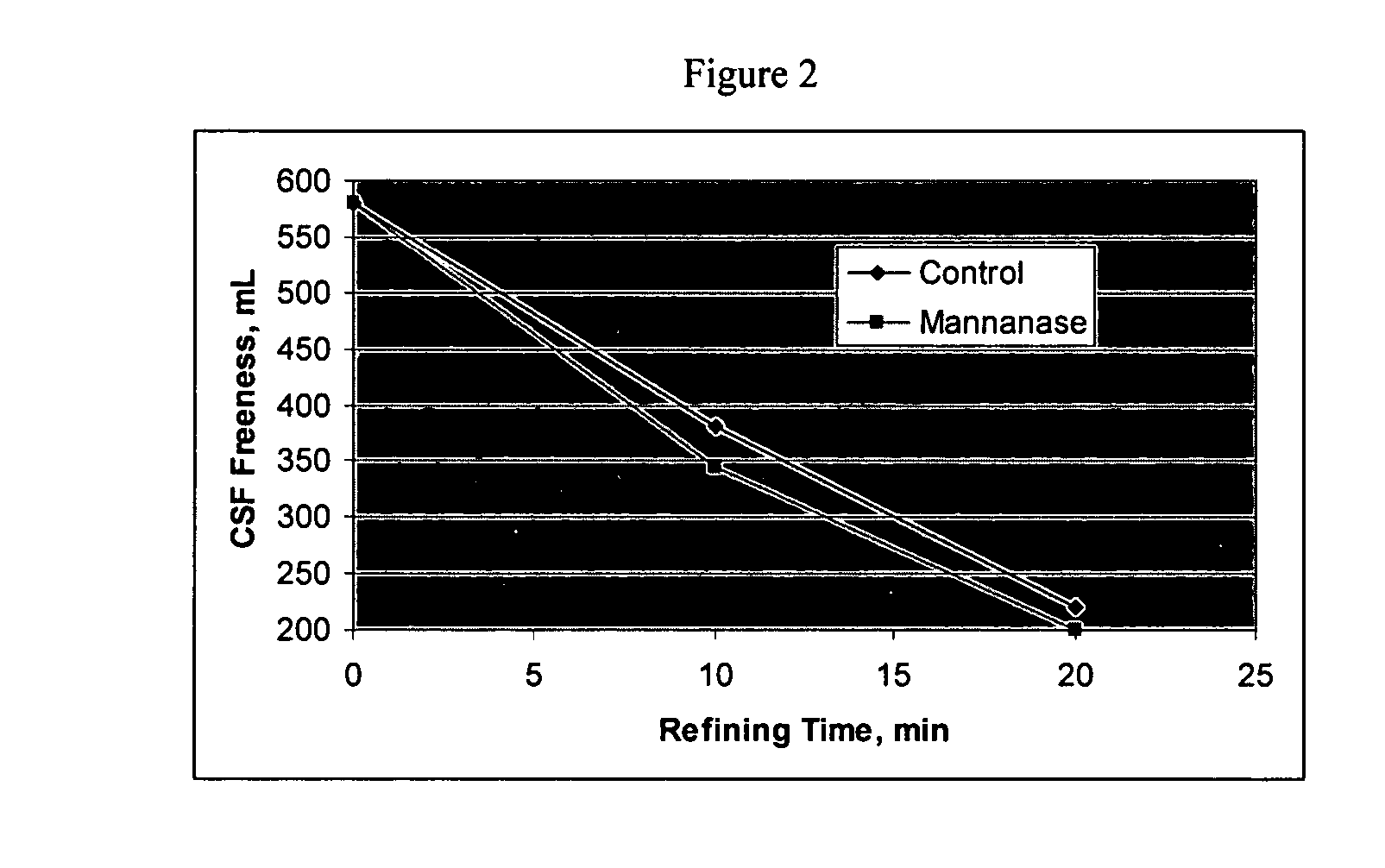

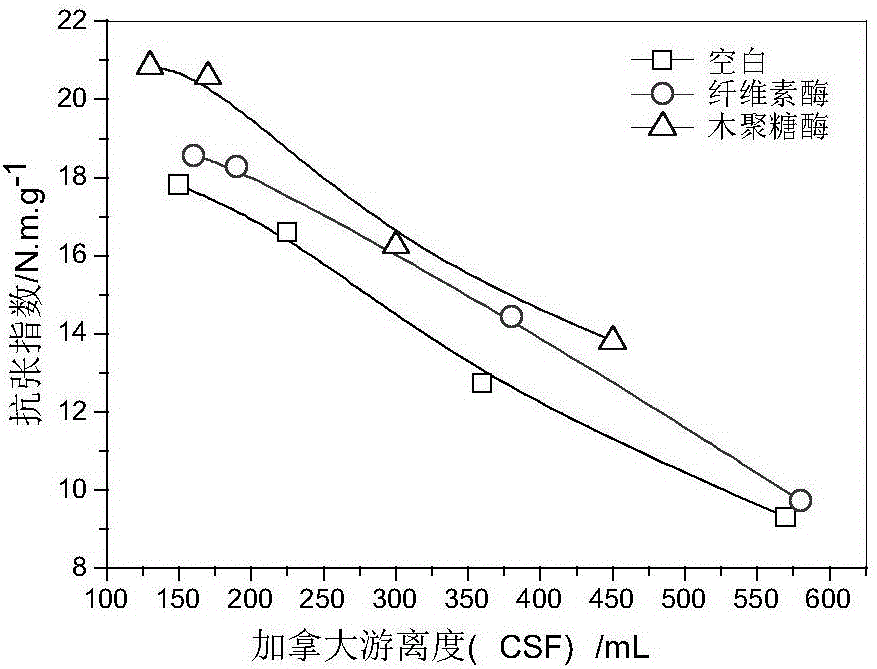

Use of hemicellulase composition in mechanical pulp production

InactiveUS20050000666A1High strengthLess energyFibrous raw materialsPulp beating/refining methodsPulp and paper industryHemicellulose

Owner:BUCKMAN LAB INT INC

Method for the manufacture of microfibrillated cellulose

ActiveUS8546558B2Cellulose treatment using microorganisms/enzymesMultistage pulping processHemicelluloseEnzyme

A method of treating chemical pulp for the manufacture of microfibrillated cellulose includes the following steps: a) providing a hemicellulose containing pulp, b) refining the pulp in at least one step and treating the pulp with one or more wood degrading enzymes at a relatively low enzyme dosage, and c) homogenizing the pulp thus providing the microfibrillated cellulose. A microfibrillated cellulose obtainable by the method is also provided. The microfibrillated cellulose can be used in food products, paper products, composite materials, coatings or in rheology modifiers (e.g. drilling muds).

Owner:STFI PACKFORSK AB

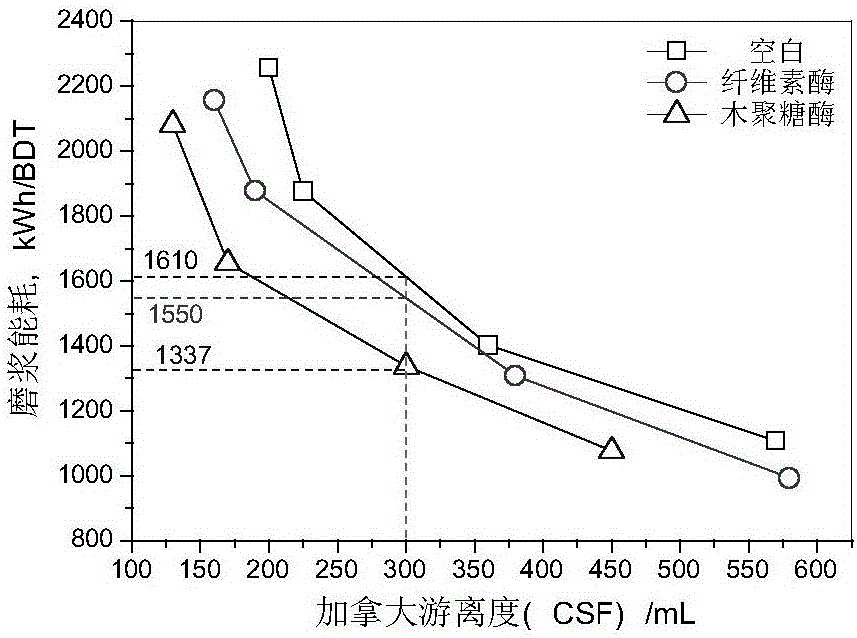

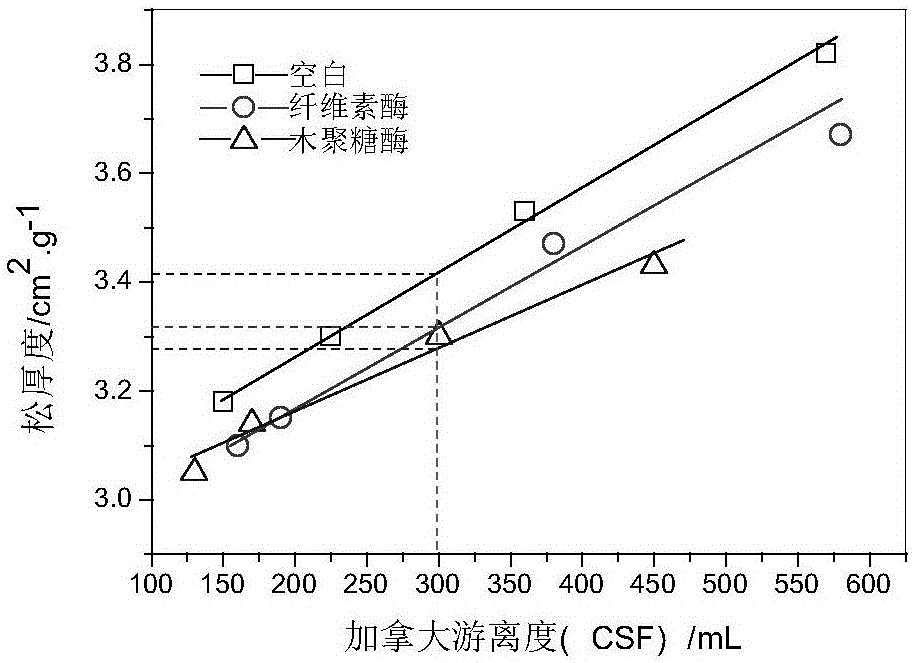

Bamboo chemimechanical pulp bioenzyme pretreatment method

ActiveCN106381741AReduce physical strengthHigh whitenessFibrous raw materialsCellulose treatment using microorganisms/enzymesPretreatment methodPre treatment

The invention discloses a bamboo chemimechanical pulp bioenzyme pretreatment method. The bamboo chemimechanical pulp bioenzyme pretreatment method comprises the following steps: feeding bamboo pieces into a steaming cabin for normal-pressure pre-steaming after screening the bamboo pieces, and then carrying out first-stage screw extrusion; adding bioenzyme in an extruded material for pretreatment, then carrying out high-temperature deactivation, washing and dewatering, then carrying out first-stage and second-stage chemical pre-impregnating in sequence, then carrying out first-stage high-consistency normal-pressure pulp grinding by using a high-consistency disc refiner of which rho is 300, and completing bleaching reaction by enabling pulp to stay in a high-consistency reaction cabin for about 50 to 60 minutes; then carrying out follow-up pulp grinding by using a disc refiner, preparing pulp samples in different Canadian freeness degrees by controlling and inputting different pulp grinding energy consumptions, respectively recording the pulp grinding energy consumption needed for preparing each pulp sample, and using the different pulp samples for paper pulp performance testing after respectively carrying out latent elimination, acidification, washing, screening and dewatering concentration. According to the bamboo chemimechanical pulp bioenzyme pretreatment method disclosed by the invention, by carrying out pretreatment on bamboo bioenzyme, compared with a traditional PRC (Preconditioning Refiner Chemical)-APMP (Alkaline Peroxide Mechanical Pulping) technology, the difference in respects of pulp grinding energy consumption and pulp performance can be observed, and a reference technology is provided for preparing chemimechanical pulp by using bamboos as raw materials.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Methods to enhance the activity of lignocellulose-degrading enzymes

Methods for hydrolyzing lignocellulose are provided, comprising contacting the lignocellulose with at least one chemical treatment. Methods for pretreating a lignocellulosic material comprising contacting the material with at least one chemical are also provided. Methods for liberating a substance such as an enzyme, a pharmaceutical, or a nutraceutical from plant material are also provided. These methods are more efficient, more economical, and less toxic than current methods.

Owner:ATHENIX

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com