Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

12522 results about "Materials preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Materials preparation. Materials Preparation is one of the four tier 2 crafting skills in the Artisan branch. It allows to build simple constructions like a kiln or a furnace and to build wooden and plaster shacks as well as Sign on level 100. Level 30 of Artisan is required to learn this skill.

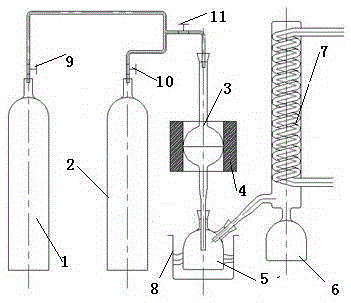

Method for preparing precursor for chemical vapor deposition of metallic rhenium

The invention discloses a method for preparing a precursor for chemical vapor deposition of metallic rhenium and belongs to the technical field of material preparation. According to the method, ReCl5 is made to react in an oxidizing atmosphere, efficient solid-liquid-gas separation is conducted on reactants and products with a sand core filter bulb so that reactants, reaction products and waste gas can be effectively separated, the reaction products ReOCl4 and ReO3Cl are gathered in a collection vessel heated by an oil bath pan at the same time, oxygen introduction is stopped after reaction ends, circulation of inert gases is maintained, a tube furnace is cooled, the oil bath pan is heated at the same time to enable ReO3Cl to volatilize to enter a rectification unit to be collected, ReOCl4 is purified, and then the high-purity precursor ReOCl4 for chemical vapor deposition of metallic rhenium is obtained. By the adoption of the method, reaction efficiency is high, ReOCl4 and ReO3Cl are separated through rectification, and the purity of the product ReOCl4 is improved.

Owner:海朴精密材料(苏州)有限责任公司

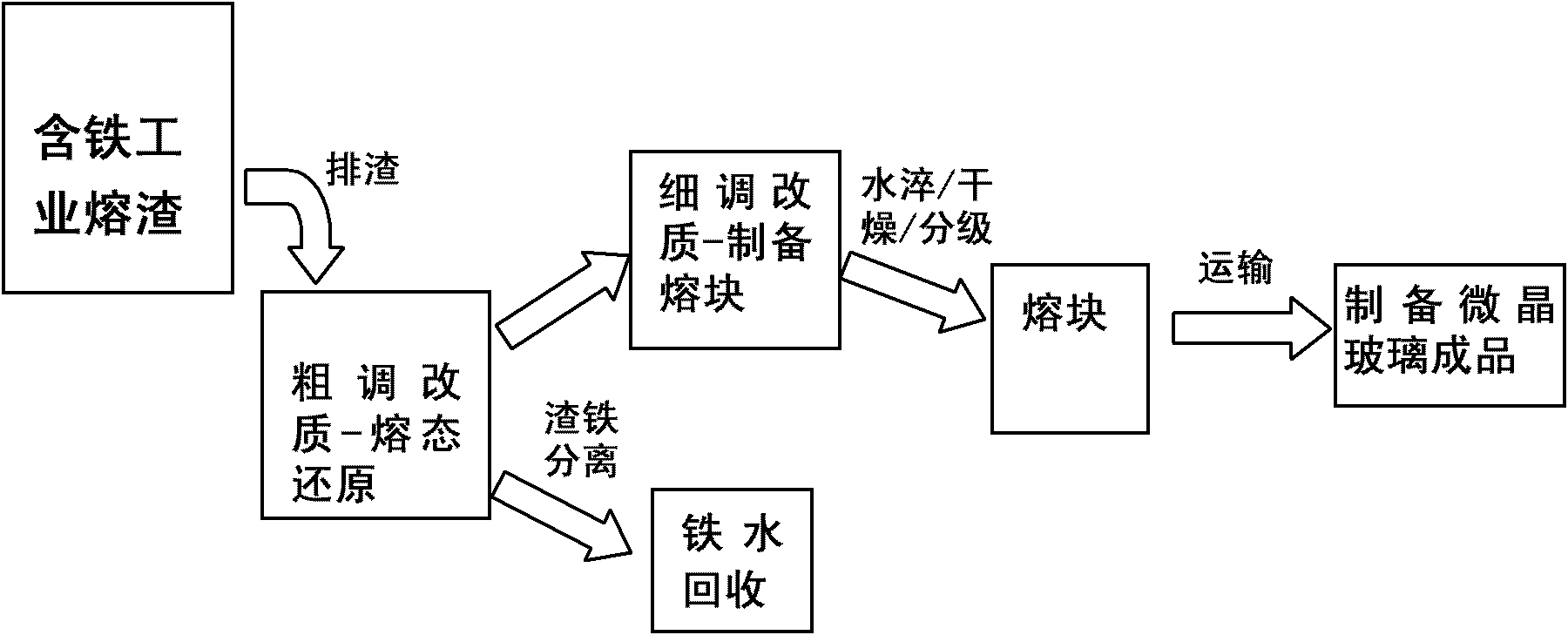

Method for recycling iron on line from iron-containing industrial slag and preparing glass ceramics frit

InactiveCN101914639AGuaranteed slag compositionRecycling and recovery technologiesProcess efficiency improvementMaterials preparationSlag

The invention relates to a method for recycling iron on line from iron-containing industrial slag and preparing a glass ceramics frit, belonging to the technical field of resource comprehensive utilization and material preparation and mainly comprising a two-step method process of iron-containing industrial slag online rough adjustment and modification for reducing iron and fine adjustment and modification for preparing the frit. The method comprises the steps of: discharging high-temperature iron-containing slag into a high-temperature furnace device, and simultaneously adding a reducing agent and a modifying agent to ensure that slag components are adjusted to reach the optimal component point in which iron oxide is reduced; after fully reacted, separating reduced molten iron from the slag, and recycling to obtain high-temperature molten iron; further adding a modifying agent and an adjusting agent into the slag remained after the separation to ensure that the slag components are adjusted to achieve the quality requirement of slag glass ceramics on the frit; and water-hardening, drying and grading the qualified slag to prepare the glass ceramics frit. The invention realizes multiple purposes that the heat of the slag is directly utilized and metal iron is recycled to prepare a high addition value product as well as solid wastes are massively utilized, and the like.

Owner:UNIV OF SCI & TECH BEIJING

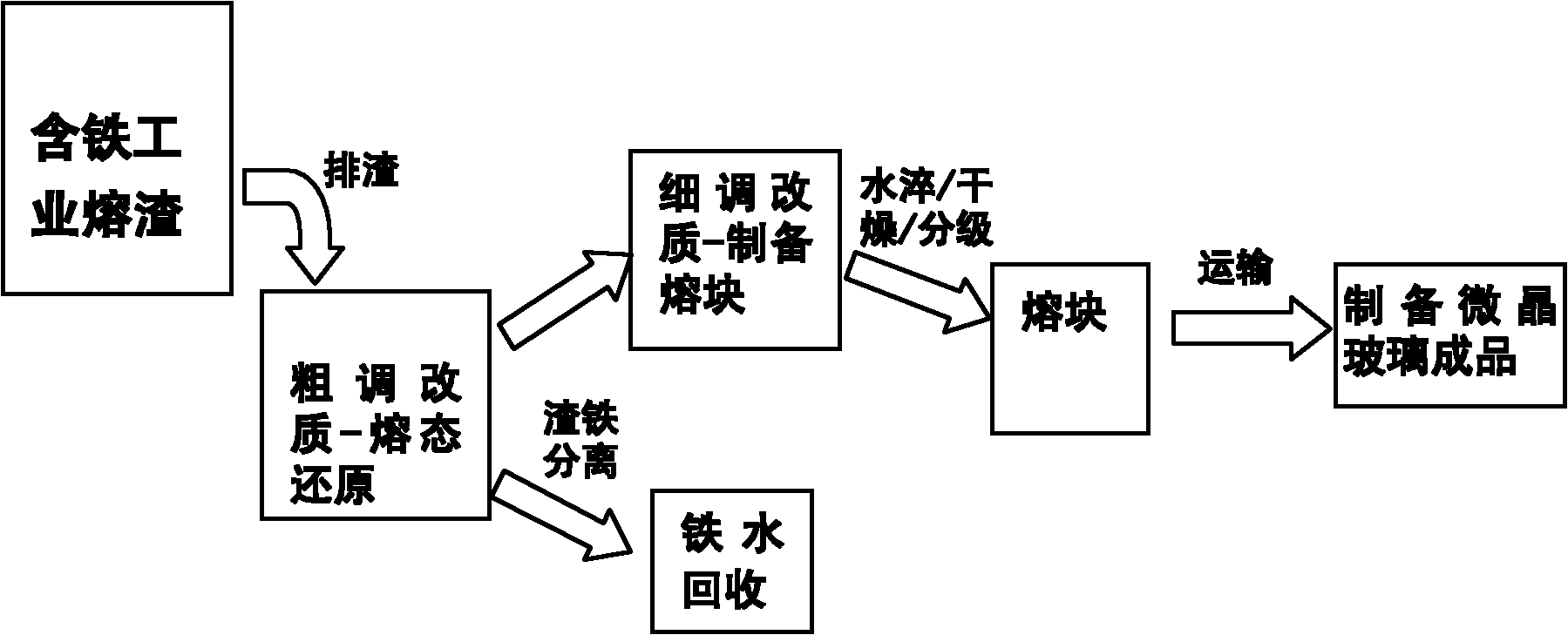

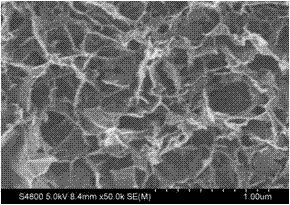

Graphene foam/polymer high-conductivity composite material preparation method and application thereof

ActiveCN102732037AImprove conductivityEasy to manufactureChemical vapor deposition coatingMaterials preparationGraphite

The invention relates to the graphene composite material field, and particularly to a graphene foam / polymer high-conductivity composite material, a preparation method and applications thereof. Steps of the method comprises as follows: providing a fully communicated three-dimension grapheme foam network and a precursor solution of a high-molecular polymer; mixing the graphene foam with the precursor solution of the high-molecular polymer to form a graphene foam / high-molecule polymer precursor mixture; and solidifying the precursor of the high-molecular polymer in the mixture to form a high-conductivity graphene foam composite material. The invention adopts the three-dimension graphene foam to form a fully- communicated graphite rapid transmission network by a seamless connection, which enables the graphene foam composite material to possess great conductivity and mechanical property and can be widely applied to the conductive composite materials and elasticity conductor field.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

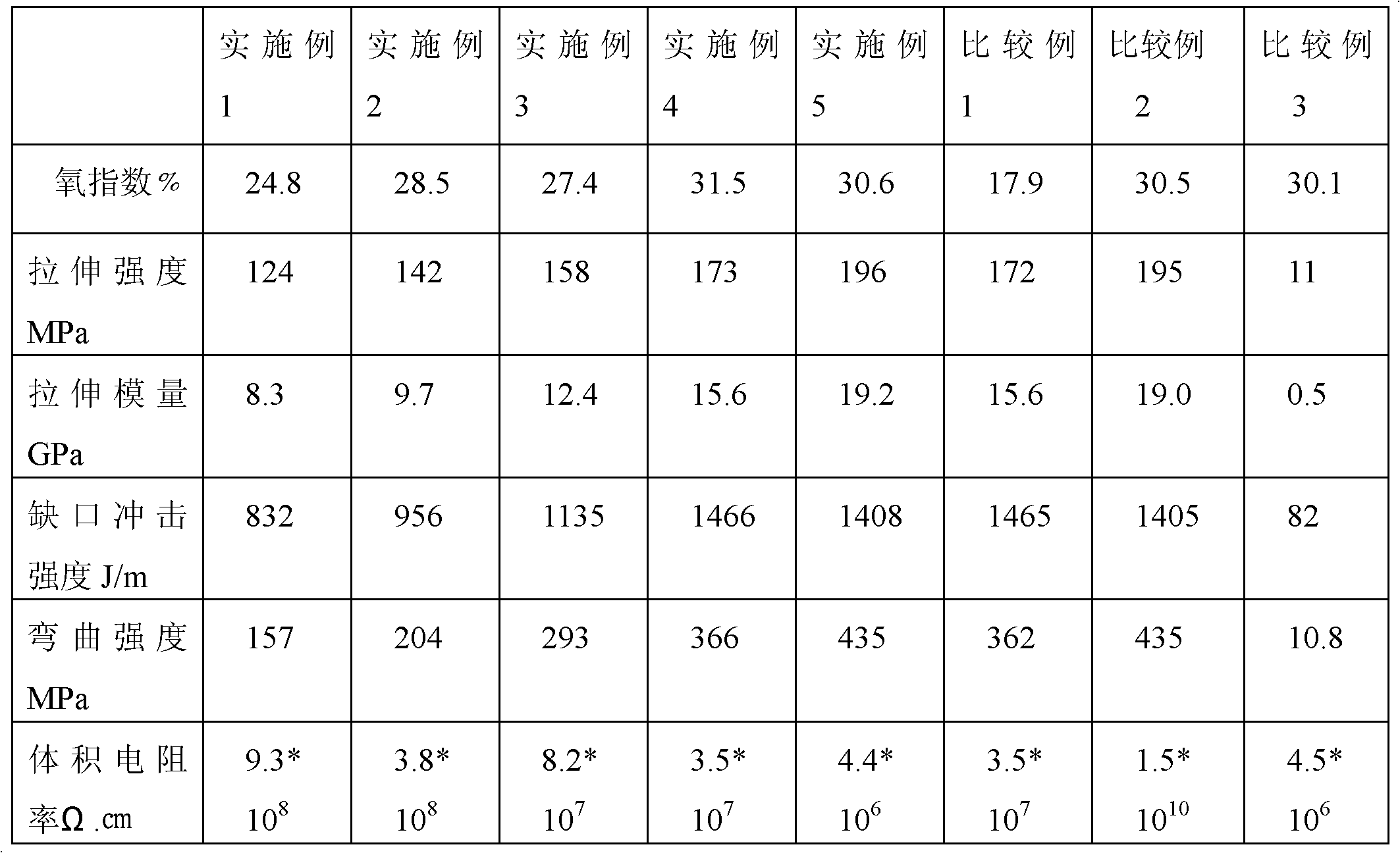

Flame-retardant antistatic high-strength thermoplastic composite material and its preparation method

The invention belongs to polymer modification technical field and processing technology field, and discloses a flame-retardant antistatic high-strength thermoplastic composite material and its preparation method. The material comprises (by weight share) 80-100 thermoplastic resin, 50-120 reinforcing fiber, 8-18 flame retardant, 0-5 flame retardant synergistic agent, 0.5-1.8 antistatic agent, 15-30 compatibilizer, 4-10 composite antioxidants, and 0-80 other additives. The invention also discloses the thermoplastic composite material preparation method. The inventive lame-retardant antistatic high-strength thermoplastic composite material has high tension and bending strength, high impact resistance property at low and high temperature, obvious antistatic property, high flame-retardant and fire proof performance. It can reach UL-94 V-O level standard.

Owner:杭州电力设备制造有限公司建德冠源成套电气制造分公司

Method for processing traditional Chinese herbs broken wall powder

ActiveCN101147746AFully dissolvedReduce dosageGranular deliveryPlant ingredientsMedicinal herbsMaterials preparation

The present invention relates to a processing method of Chinese medicinal material wall-broken powder. Said processing method includes the following steps: (1), medicinal material preparation: selecting material, slicing and drying to obtain cleaned medicinal material; (2), pulverization: using universal pulverizing machine to make wall-breaking pulverization of medicinal material so as to obtain crude powder with above 60 meshes; (3), wall-breaking pulverization: using wall-breaking pulverizing machine to make wall-breaking pulverization to obtain superfine powder body with above 300 meshes; (4), granulating: placing the above-mentioned superfine powder body into a mix-stirring machine, adding water or ethyl alcohol to make them into soft material, using granulating machine to make granulation to obtain wet granules and drying said wet granules; (5), finishing and screening; and (6), filling and packaging.

Owner:ZHONGSHAN ZHONGZHI PHARMA GRP +1

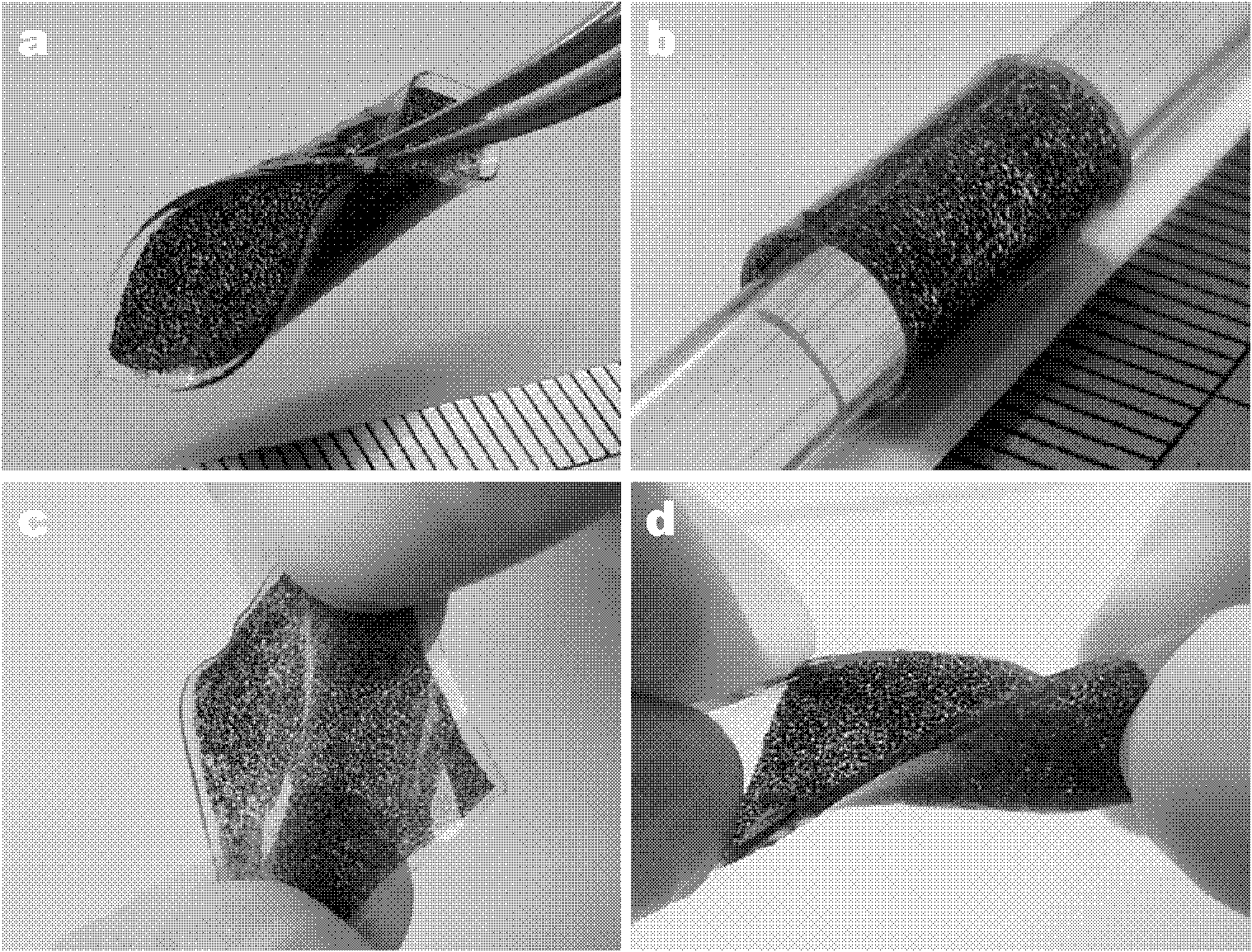

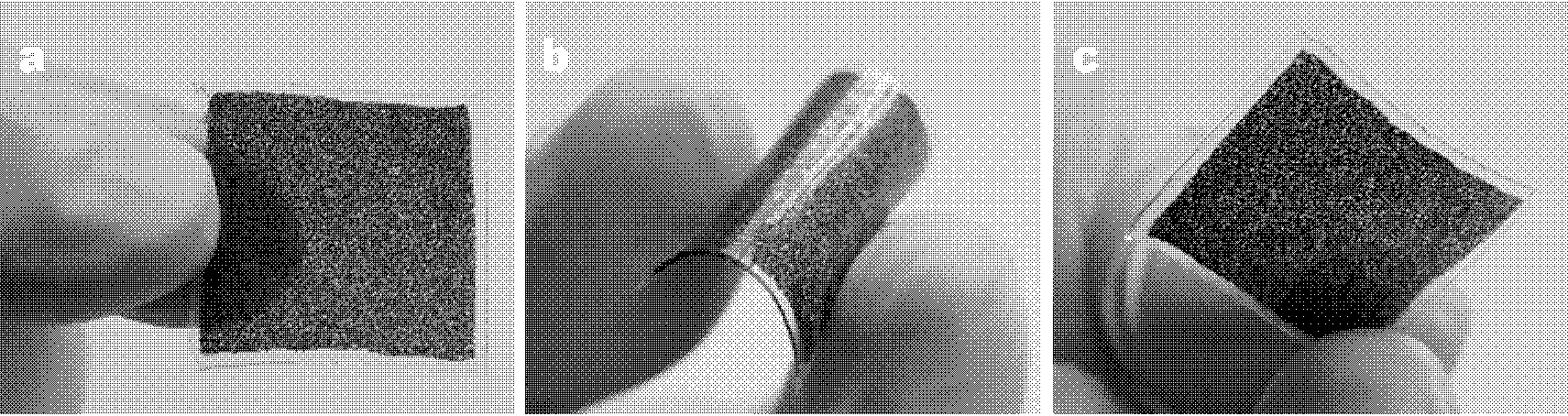

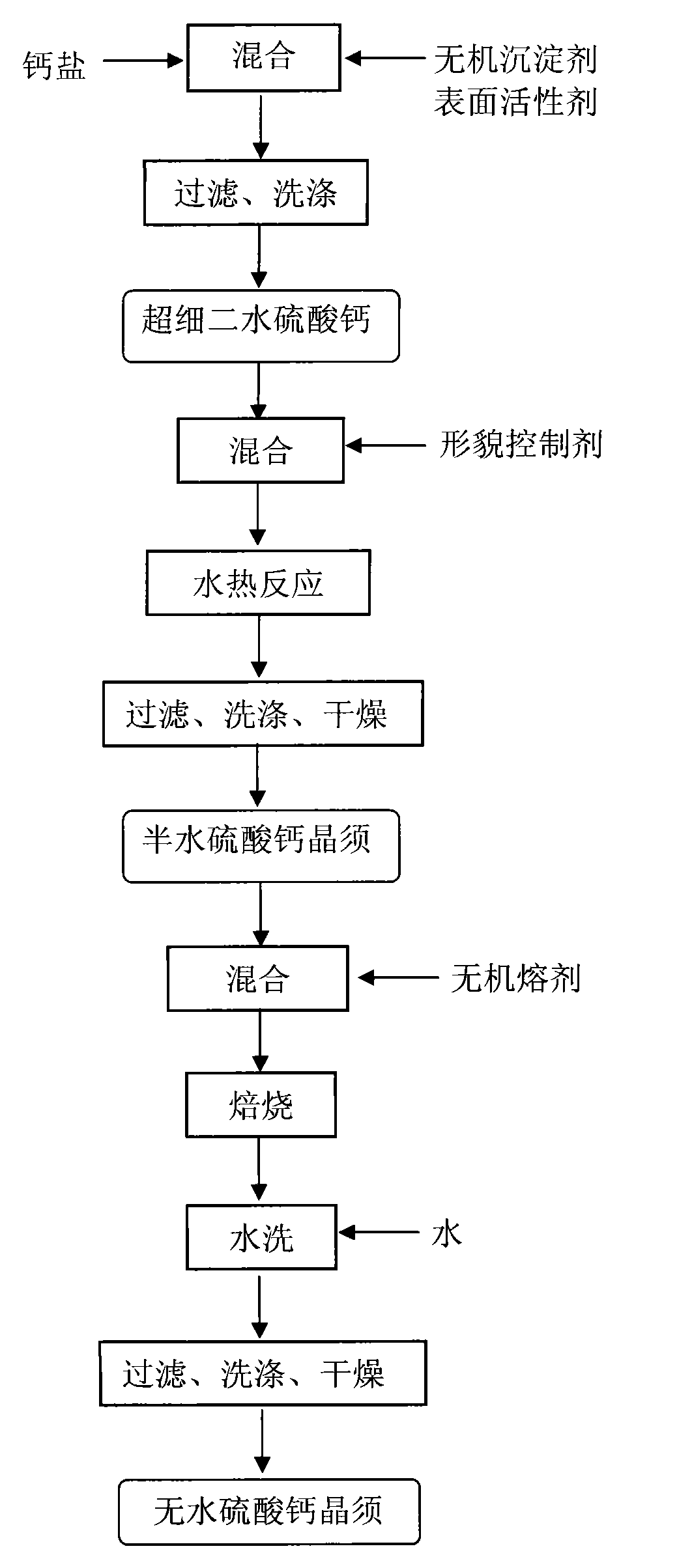

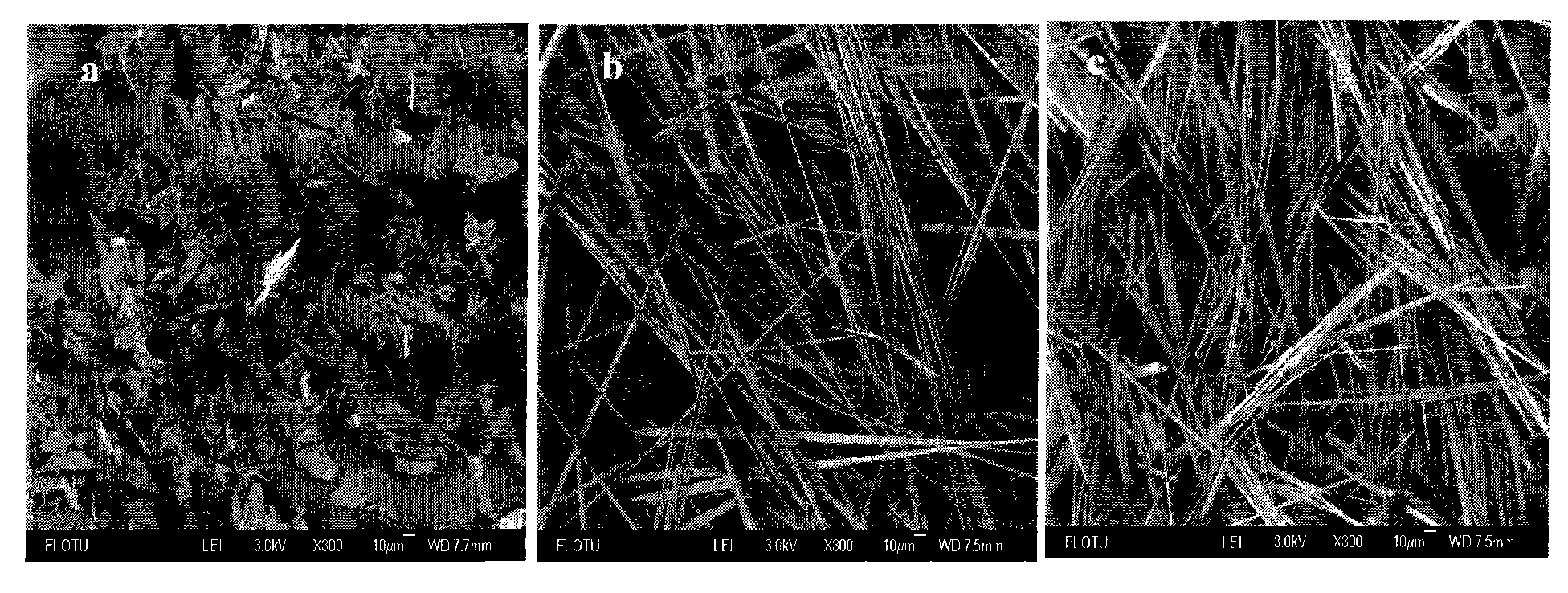

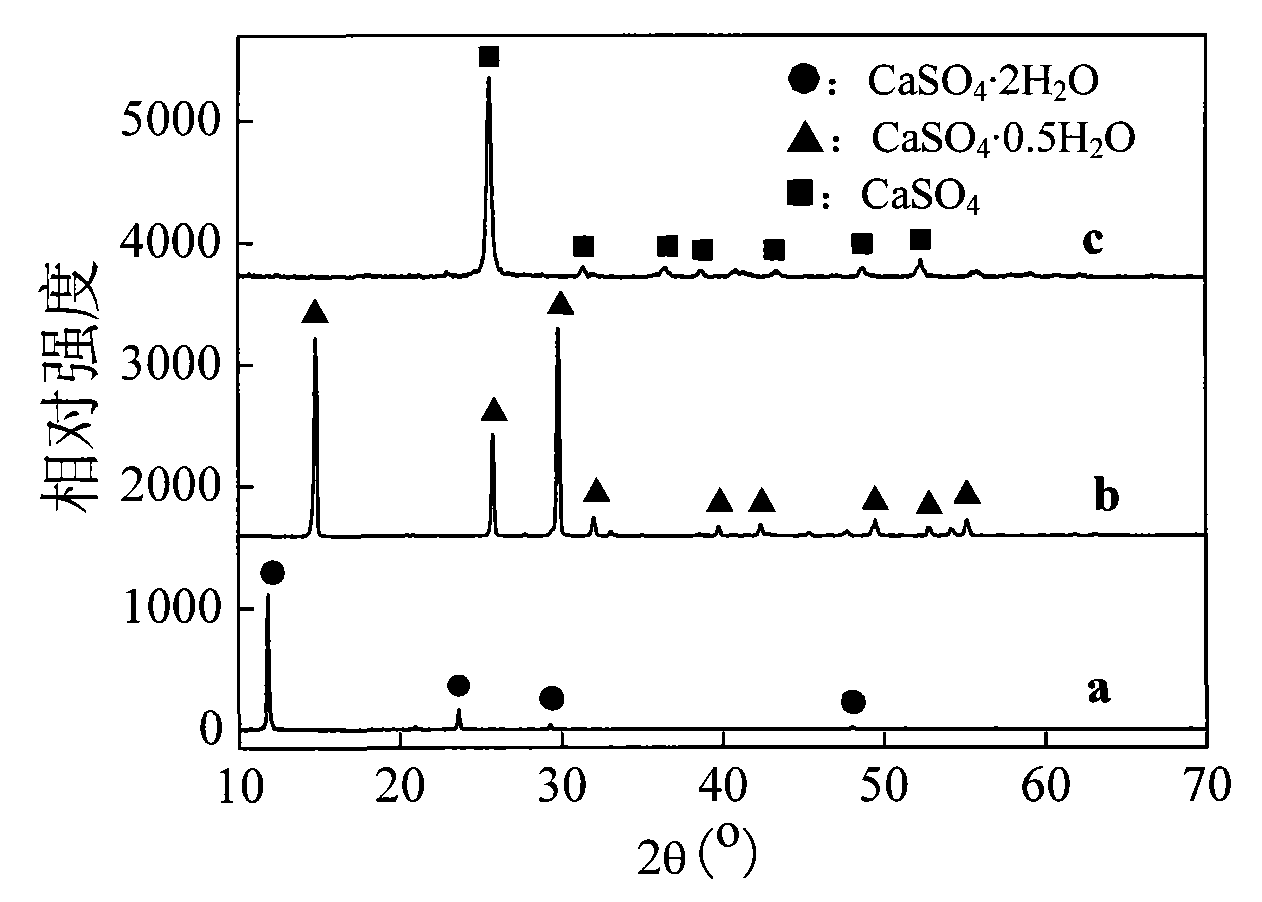

Preparation method of high length-diameter ratio anhydrous calcium sulfate whisker

ActiveCN101671848AHigh crystallinityMorphological rulesPolycrystalline material growthFrom normal temperature solutionsAnhydrous Calcium SulfatePapermaking

A preparation method of high length-diameter ratio anhydrous calcium sulfate whisker belongs to the technical field of inorganic chemical material preparation. The method takes inorganic calcium saltand inorganic precipitant as raw materials and surfactant as dispersant, and includes the following steps: first preparing superfine calcium sulphate dihydrate precursor with good dispersion at the temperature of 10-90 DEG C; then adding the precursor into water solution containing shape control agent to conduct hydrothermal reaction for 0.5-10h at the temperature of 100-250 DEG C, and obtaining calcium sulfate hemihydrate whisker; mixing the calcium sulfate hemihydrate whisker with inorganic solvent; and roasting the mixture for 0.5-6h at the temperature 200-800 DEG C to obtain anhydrous calcium sulfate whisker with the length of 20-2000mum, the diameter of 0.5-20mum, the length-diameter ratio of 40-1000 and the main content greater than 95wt% after washing and drying. The technology is simple, the cost is low and the added value of the product is high. The prepared calcium sulfate whisker has large length-diameter ratio and regular shape and can be used as reinforcing material to beapplied in industries such as plastics, rubber, ceramics, cement, papermaking and the like.

Owner:TSINGHUA UNIV

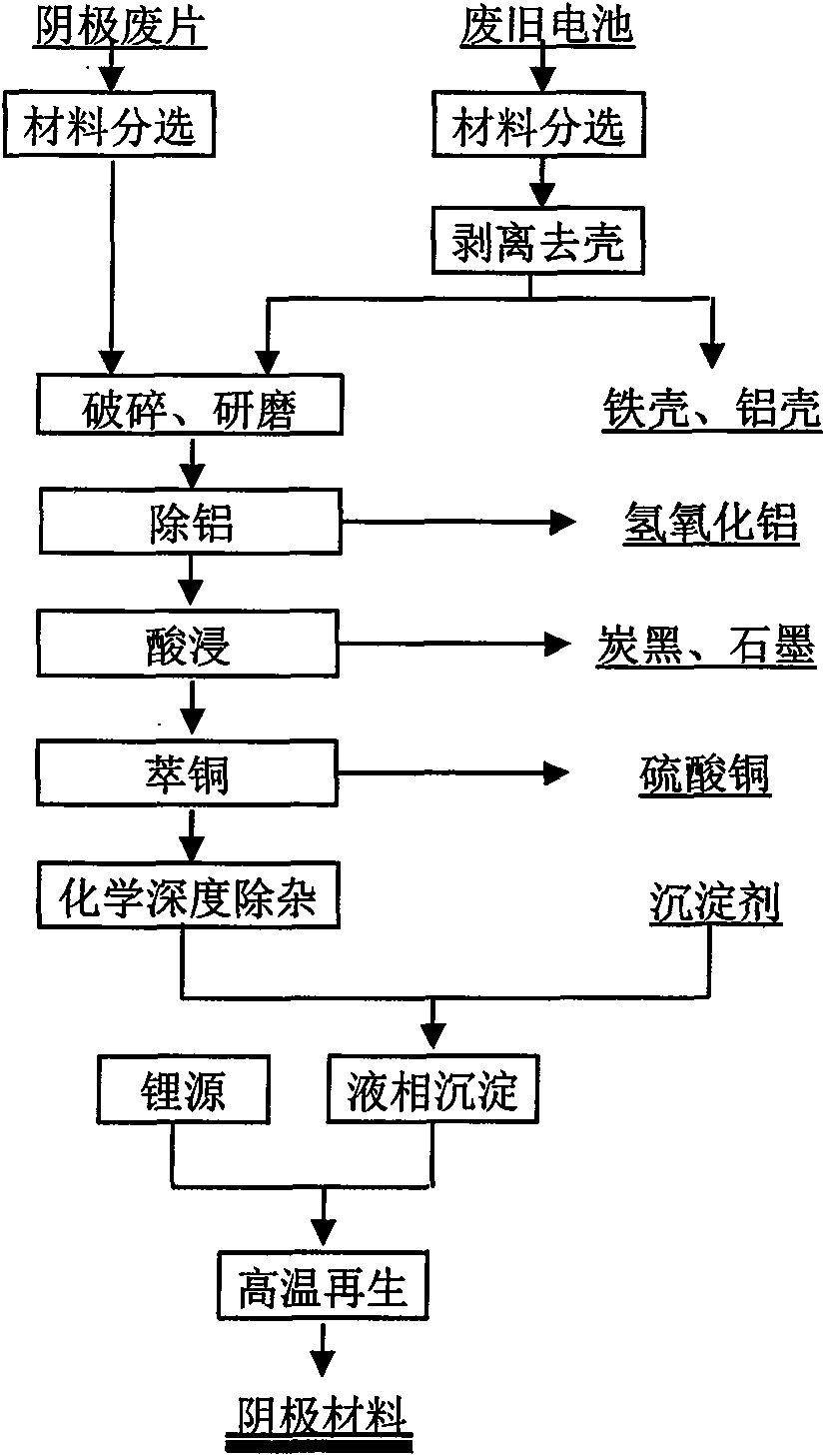

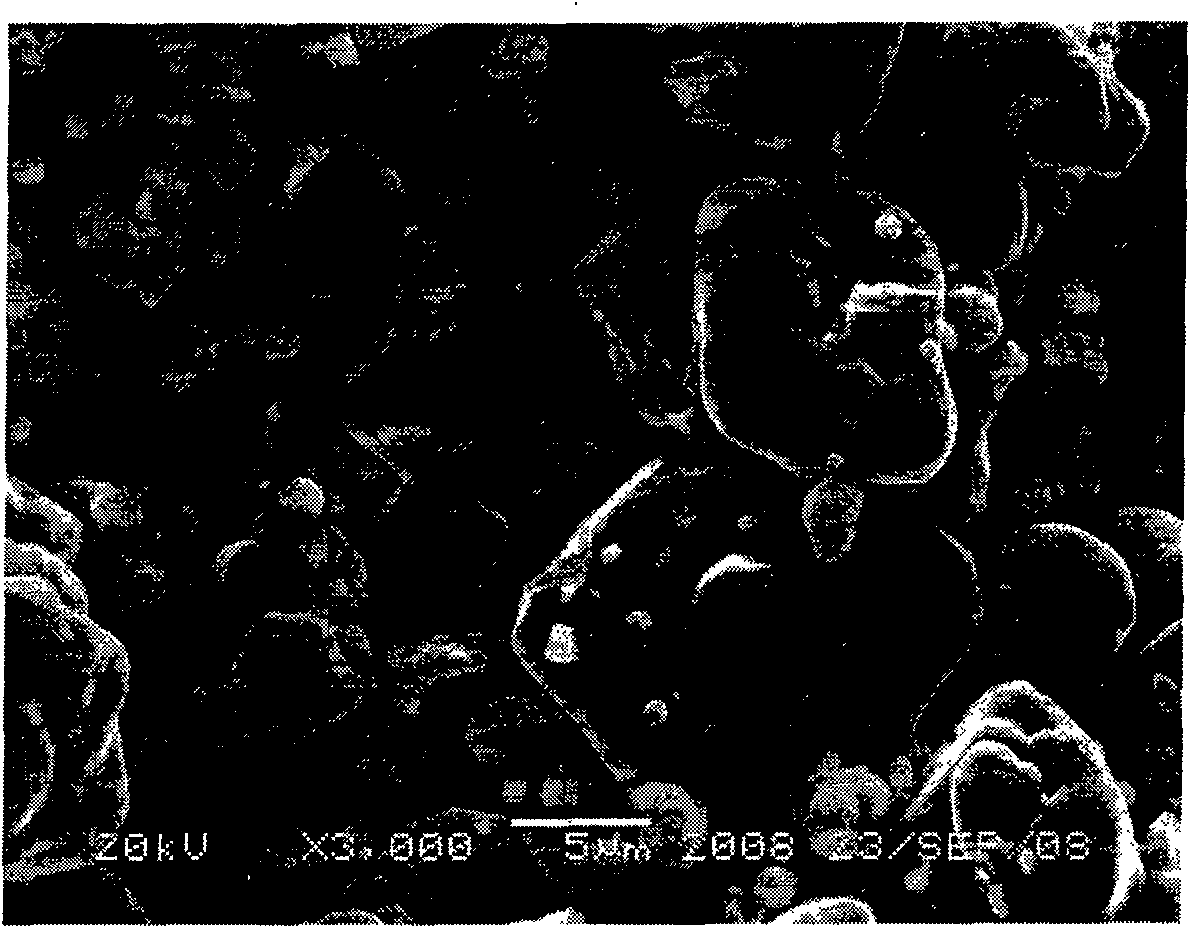

Method for recovering and recycling waste lithium ion battery cathode material

InactiveCN101555030AAchieve recyclingAchieve regenerationCobalt compoundsNickel compoundsEngineeringLithium-ion battery

The invention discloses a method for recovering and recycling waste lithium ion battery cathode material, belonging to the fields of lithium ion battery material preparation and recycling use of waste resources. The method has the technical proposal with the key points as follows: the recovered waste batteries are sorted, cathode waste material (after being sorted) which is stripped to remove the shell and generated in the production process of the lithium ion battery is directly crushed and ground, and then processed by the procedures such as aluminum removing, acid dipping, copper extracting, chemical purification and the like under different conditions, so that byproduct materials such as aluminum hydroxide, carbon black, graphite, copper sulphate and the like are generated; reaction products are added with precipitator with certain concentration for liquid-phase precipitation and then added with lithium source, so that cathode material can be generated in the high temperature environment. The technical proposal successfully realizes the valuable constituent recovery and cathode material regeneration of the waste lithium ion battery cathode material.

Owner:GUANGDONG BRUNP RECYCLING TECH

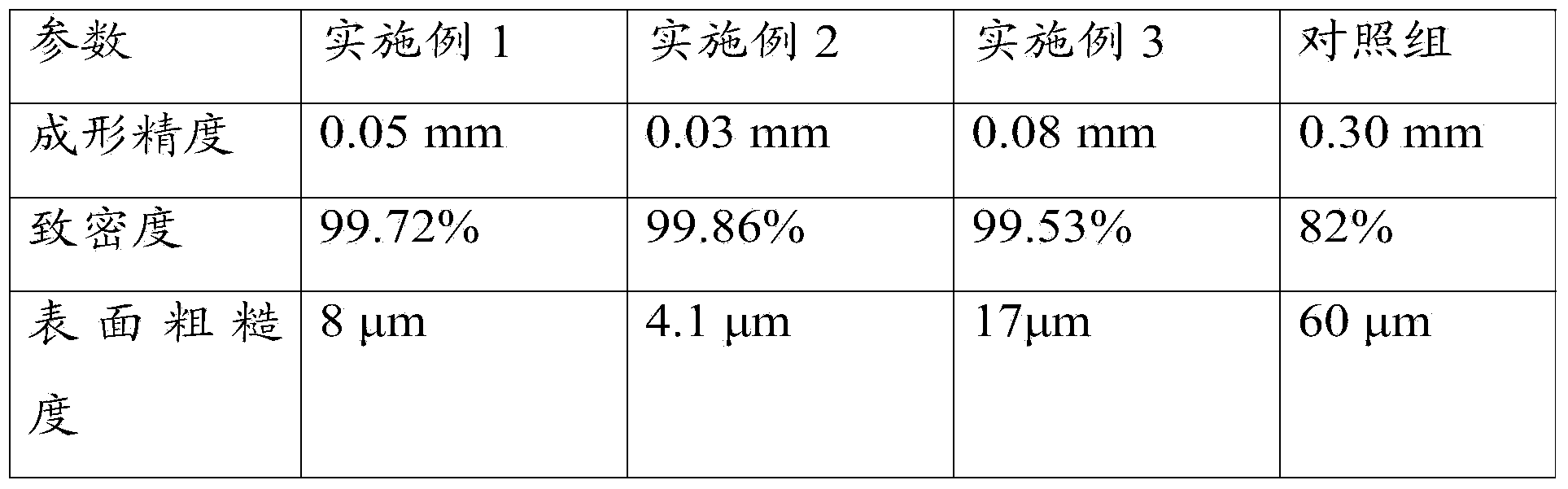

Method for producing titanium alloy artware by adopting selective laser melting

ActiveCN104259459AHigh precisionImprove forming qualityIncreasing energy efficiencySelective laser meltingSelective laser sintering

The invention relates to the field of material preparation, in particular to a method for producing titanium alloy artware by adopting selective laser melting. The method includes the steps: creating two-dimensional slicing data of a part structure to be produced and importing the two-dimensional slicing data into a metal powder laser melting system; setting processing technological parameters of the metal powder laser melting system; taking titanium alloy powder and spreading the titanium alloy powder on the metal powder laser melting system, and sequentially performing laser melting, powder sieving, heat treatment, wire cutting, cleaning, sand blasting, polishing and the like under the protection of inert gas to obtain the titanium alloy artware. According to the method, specific titanium alloy types and specification parameters are selected, and the processing technological parameters of the metal powder laser melting system are optimized for multiple times, so that the produced titanium alloy artware is high in precision, stable in shaping quality, small in distortion, excellent in mechanical property and good in surface smoothness through follow-up processing and has great artistic value.

Owner:飞而康快速制造科技有限责任公司

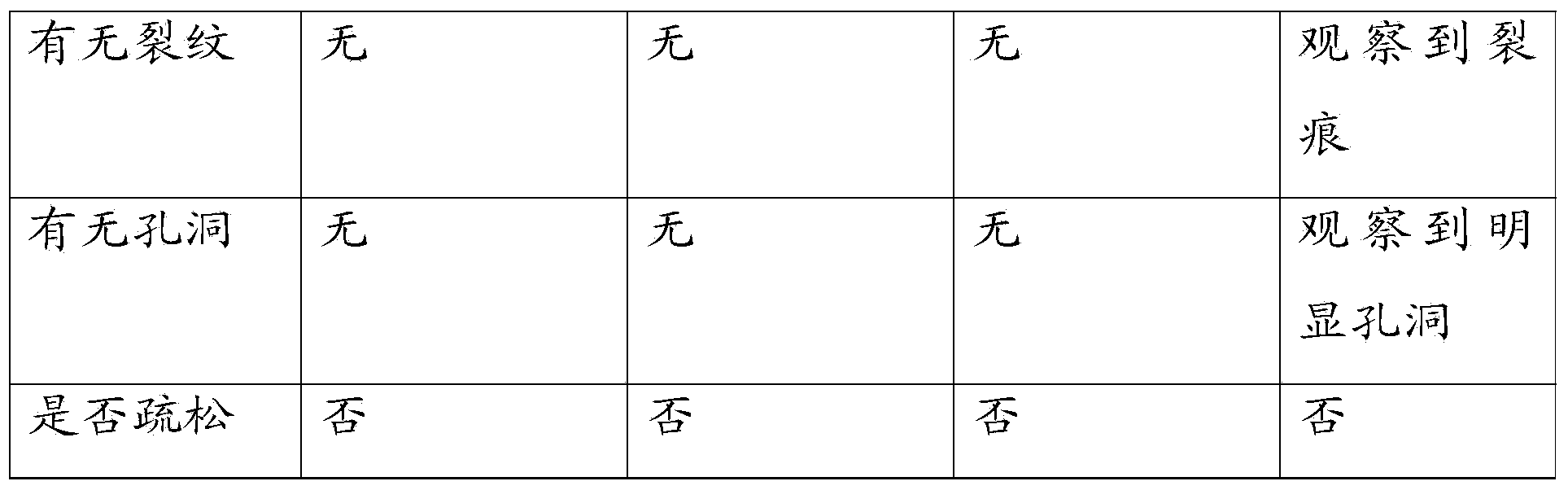

Ecological protection method for high steep side slope

The invention relates to an ecological protection method for a high steep side slope. The method mainly comprises the steps of slope surface treatment, concrete shotcrete and rock bolt support, vegetating hole arrangement, net spreading, spray material preparation, granule spray sowing, maintenance, management, and the like. In the method, guest soil materials such as humus loam rich in organic matters and clay are utilized to undergo a granule reaction after mixed with a granule agent at the moment of spray sowing so as to form a greening template which has the same high order granule structure as natural soil and strong erosion resistance and can suppress water and soil loss. After a diversified mature plant community which is in harmony with surrounding vegetation environment is formed, the slope surface can be protected, which can effectively resist diseases and insect pests and maintain the ecological balance. Post maintenance management and expenses can be saved. All used materials can be naturally degraded, have no pollution to the environment and can purify air and beautify the environment. Equipment of the method does not need to be hung on the slope surface for construction, and spray sowing operations are carried out only below the slope surface, thus the method has high construction speed and safety. The method is suitable for slope surfaces which are difficult to green, and the like, such as various high steep and unstable slope surfaces, bare slope surfaces having high greening expected values, and the like.

Owner:河南国网宝泉抽水蓄能有限公司

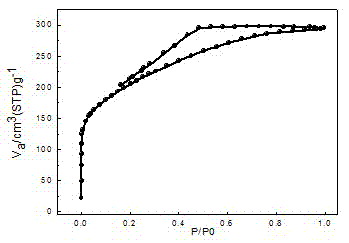

Nitrogen-doped porous carbon material, preparation method and use thereof

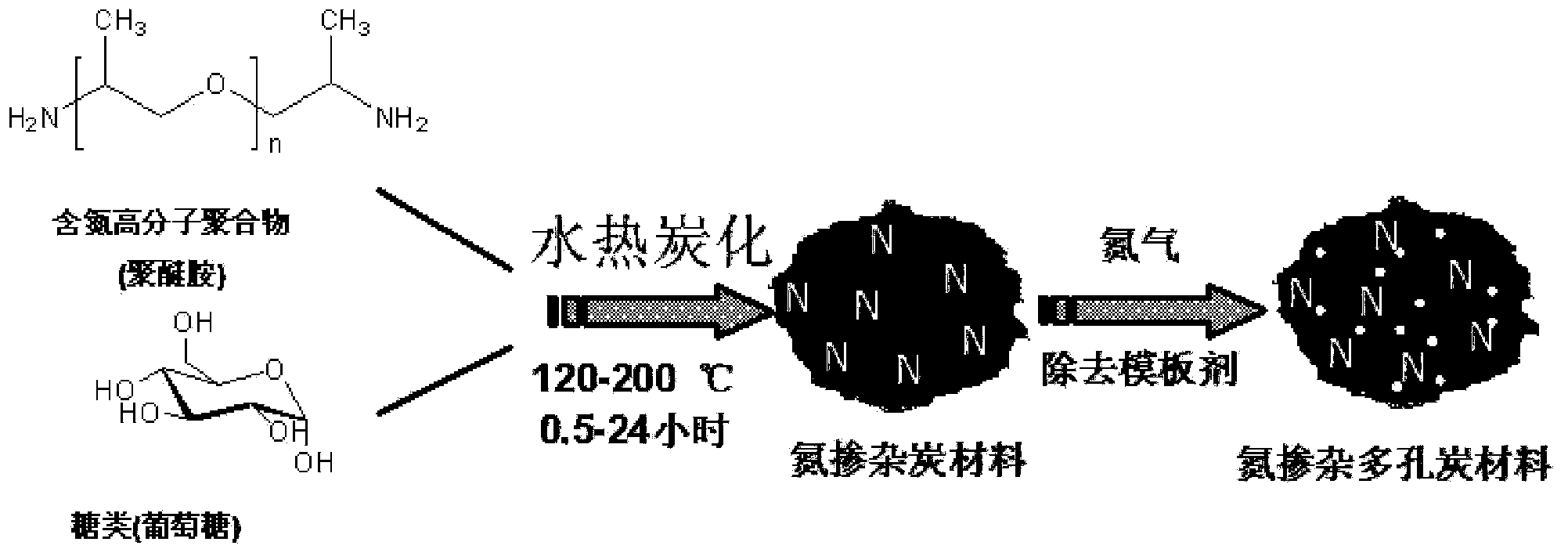

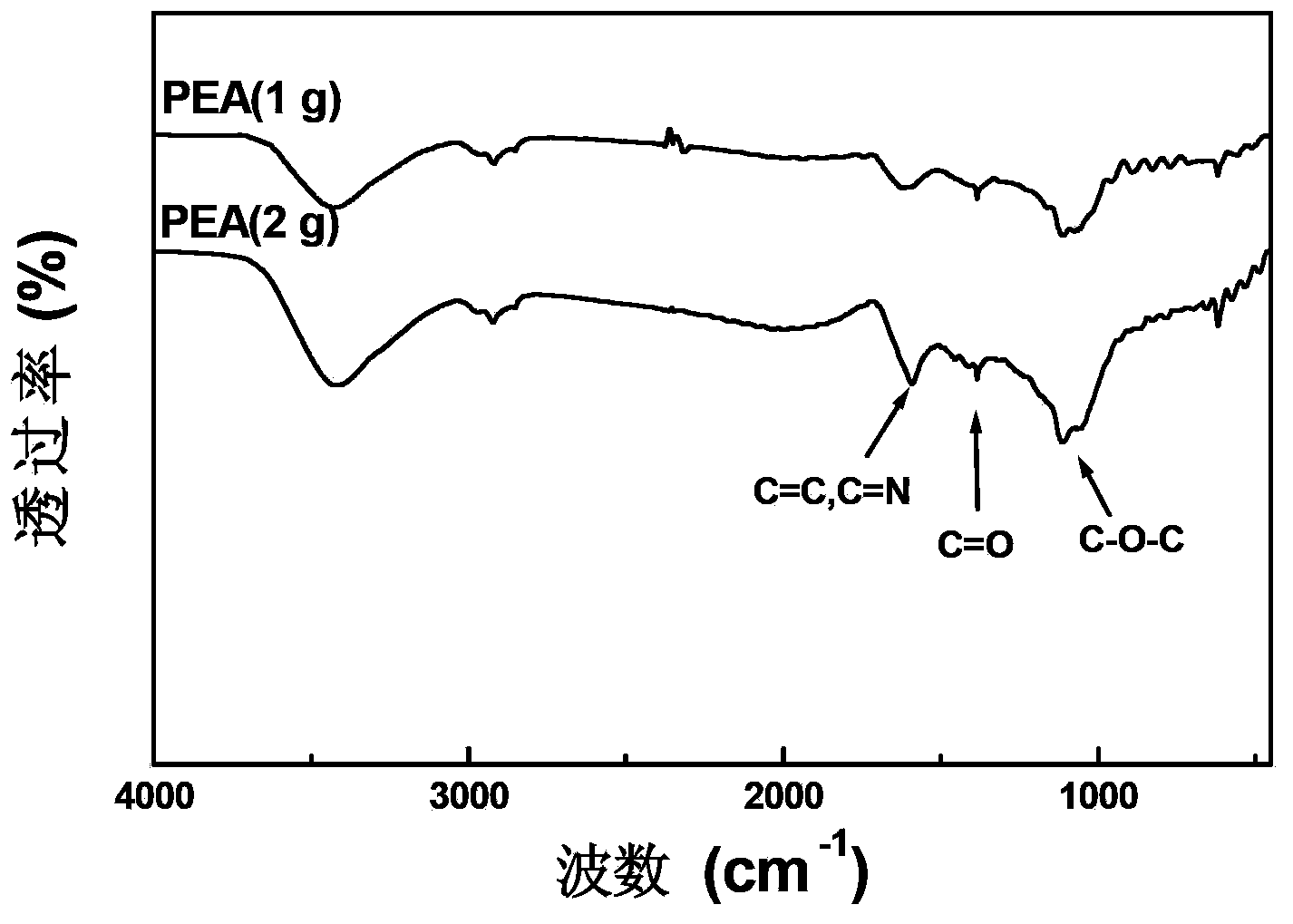

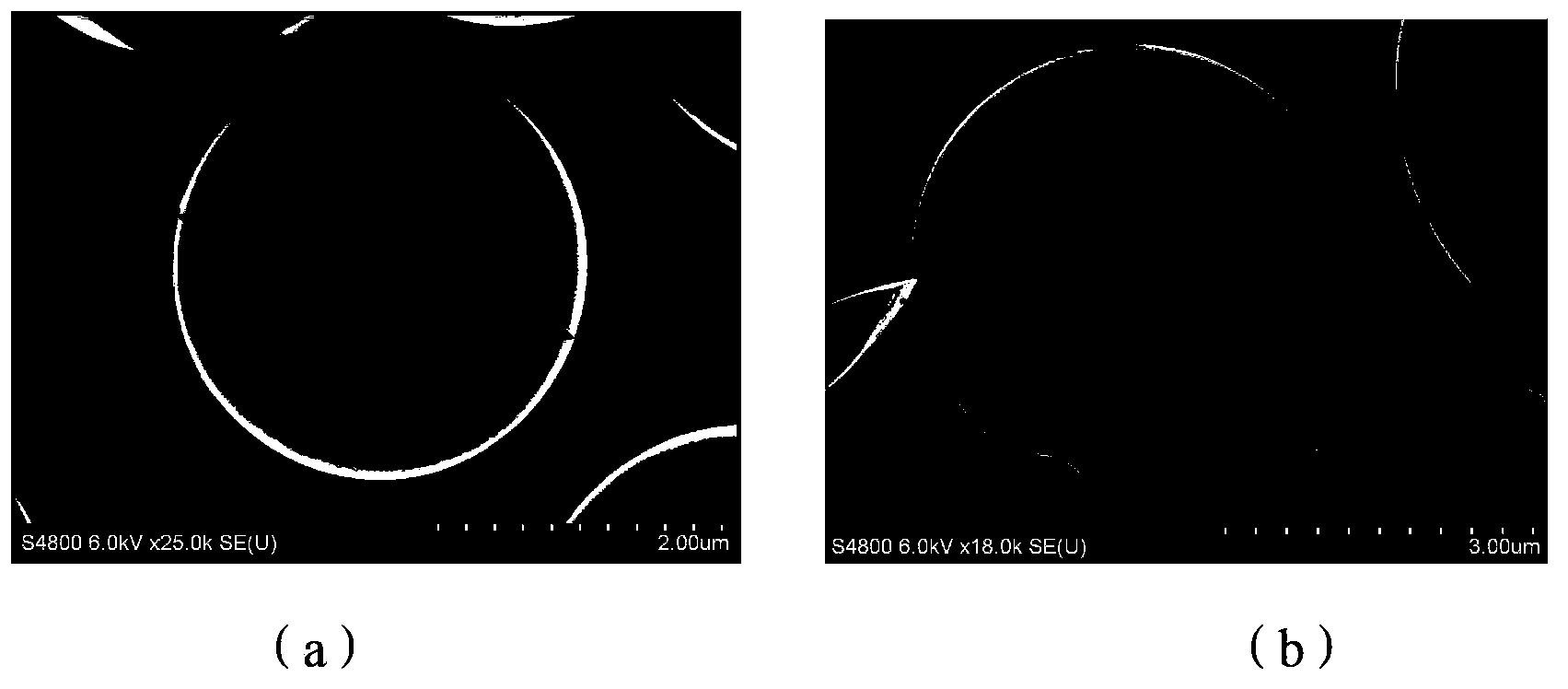

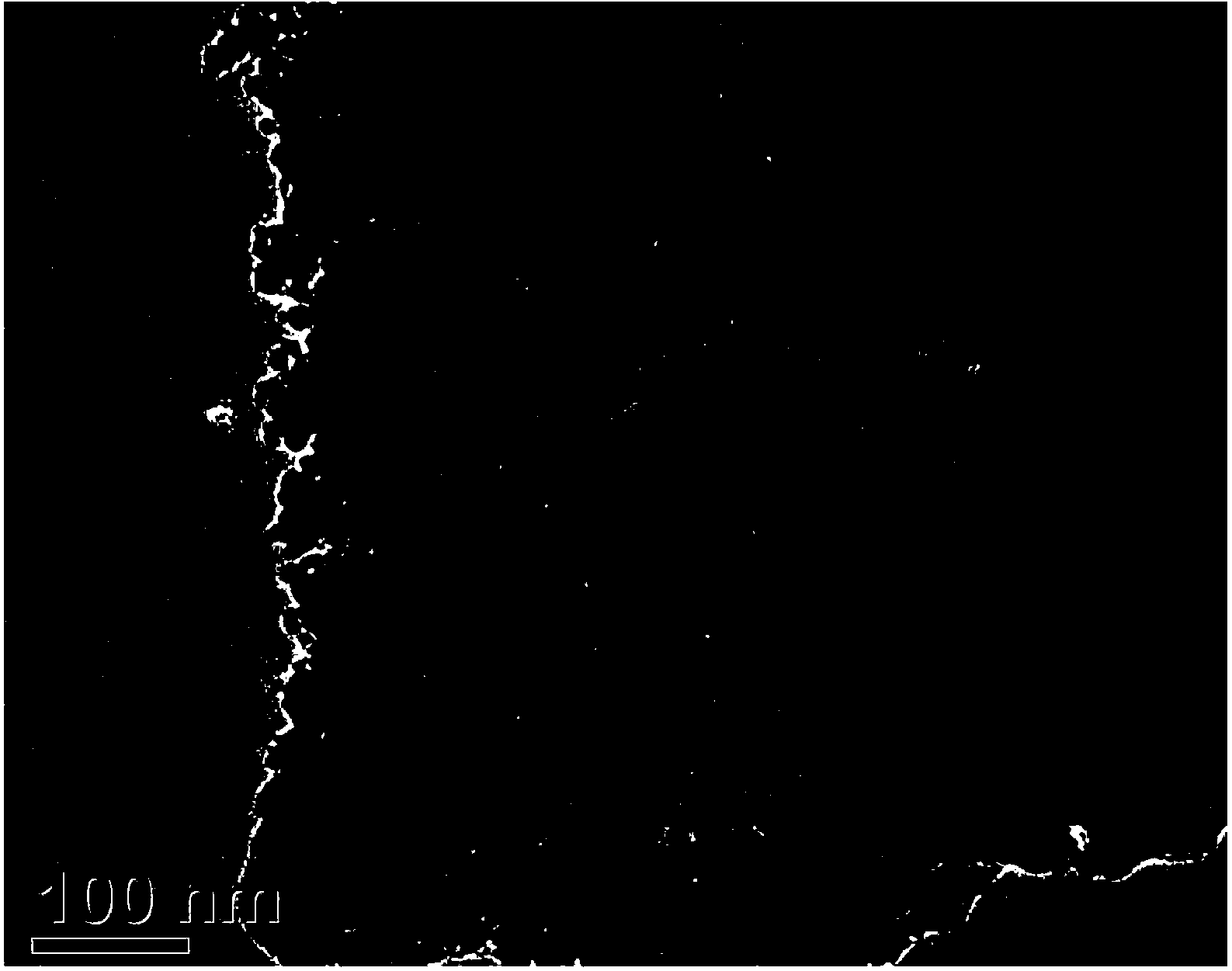

ActiveCN103406096AHigh nitrogen dopingLarge specific surface areaOther chemical processesDispersed particle separationMaterials preparationPorous carbon

The present invention discloses a nitrogen-doped porous carbon material preparation method, which comprises: adopting nitrogen-containing macromolecule as a template agent and a nitrogen source, adopting a biomass derivative as a carbon source, carrying out a hydrothermal carbonization reaction under a hydrothermal condition, and removing the template agent to obtain the nitrogen-doped porous carbon material. The present invention further provides a class of nitrogen-doped porous carbon materials prepared by using the method. The material obtained through the preparation method has characteristics of high nitrogen content and relatively high specific surface area. Experiment results show that the nitrogen-doped porous carbon materials provide excellent absorption performances for hydrogen and carbon dioxide. In addition, due to presence of the nitrogen-containing group, the porous material of the present invention can be expected to be used for catalysis, gas storage, molecule separation, clean energy carriers, super capacitors and other fields.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

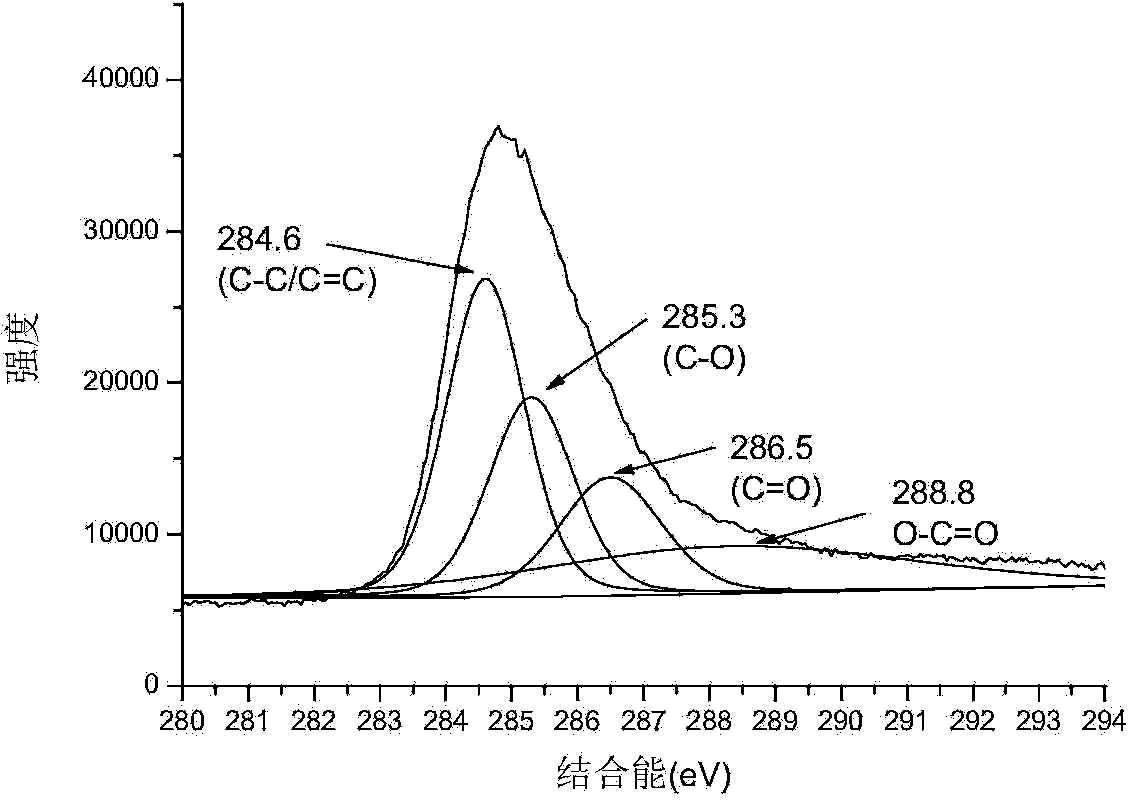

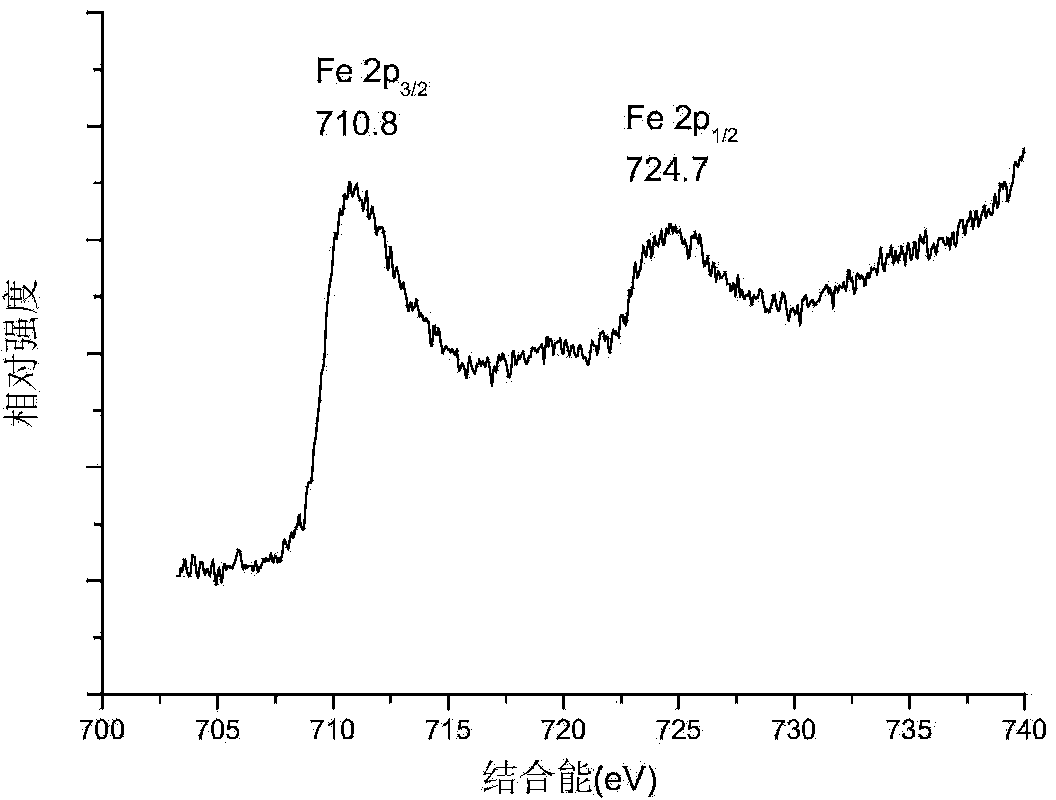

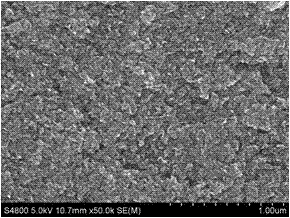

Polyaniline/oxidized graphene/ferriferrous oxide absorbing material and preparation method

InactiveCN104163919AStrong dielectric loss performanceHigh surface energyMaterials preparationTernary complex

The invention belongs to the field of electromagnetic wave absorbing material preparation and relates to a polyaniline / oxidized graphene / ferriferrous oxide composite material and its preparation method. The preparation method comprises the following steps: (1) preparing graphite oxide; (2) preparing ferriferrous oxide nanoparticles; (3) preparing a polyaniline / oxidized graphene / ferriferrous oxide ternary complex; and (4) weighing the polyaniline / oxidized graphene / ferriferrous oxide ternary complex and paraffin, and uniformly mixing to obtain the polyaniline / oxidized graphene / ferriferrous oxide absorbing material. The material provided by the invention has characteristics of low cost, simple preparation technology, strong electromagnetic wave absorbing capability, wide absorption band, low density and the like, has good electromagnetic property, and has important application value in the field of microwave absorption and electromagnetic shielding.

Owner:UNIV OF SCI & TECH BEIJING

High-density high-rigidity graphene porous carbon material as well as preparation method and applications thereof

ActiveCN102730680AHigh densityHigh hardnessCell electrodesGrapheneMaterials preparationGel preparation

The invention discloses a high-density high-rigidity graphene porous carbon material as well as a preparation method and applications thereof. The method comprises the following steps: 1. original colloidal sol preparation: adding graphene-based component or a mixture of graphene-based component and auxiliary components into a solvent for dispersion to obtain the original colloidal for preparing the graphene porous carbon material; 2. graphene-based gel preparation: placing the original colloidal sol prepared in the step 1 into a reaction container, reacting for 0.1-100 hours at the temperature of 20-500 DEG C to obtain the graphene-based gel; and 3. high-density high-rigidity graphene porous carbon material preparation: drying the graphene-based gel at the temperature of 0-200 DEG C, increasing temperature to 100-3600 DEG C at anoxic atmosphere for conducting thermal treatment for 0.1-100 hours, or / and reacting for 0.1-50 hours at the temperature of 200-2000 DEG C by adopting an activation reaction method. Compared with the prior art, the prepared graphene-based material has the advantages of high density, high rigidity, abundant pores, large specific surface area and stable pore structure.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Preparation method of transition element doped iron lithium phosphate powder

InactiveCN1785799AIncrease capacityImprove capacity cycling performancePhosphorus compoundsMaterials preparationLithium iron phosphate

The present invention discloses a preparation method of transition element Mn, Co and Ni doped iron lithium phosphate powder body, belonging to the field of electrochemical power supply material preparation technology. Its molecular formula is Li1-x TRxFePO4, and its preparation method includes the following steps: weighting lithium salt, ferrous salt, phosphate and adulterant according to mole ratio, mixing them, drying, low-temperature prebaking and high-temperature secondary calcining so as to obtain the invented product which can be used as positive electrode material of lithium ion cell.

Owner:TSINGHUA UNIV

Method for preparing carbon/carbon composite material antioxidation coating layer

InactiveCN101565328AIncreased anti-oxidation timeStress reliefCarbon compositesMaterials preparation

The invention discloses a method for preparing a carbon / carbon composite material antioxidation coating layer. The processed C / C composite material packet is buried in powder lot and put in a graphite crucible and processed for 1 to 3 hours at a temperature of between 1,800 and 2,200 DEG C; MoSi2 powder is sprayed on the surface of the C / C composite material with a SiC transition layer through supersonic plasma spraying equipment; the C / C composite material prepared with the SiC / MoSi2 coating layer is put to a high-temperature furnace and is subjected to heat treatment for 2 to 6 hours at a temperature of between 1,200 and 1,400 DEG C to remove the residual heat stress in the MoSi2 coating layer. The SiC transition coating layer prepared by an embedding method relieves thermal expansion coefficients of a C / C composite material matrix and the MoSi2 coating layer of the outer layer; and subsequently, a C / C composite material preparation piece is subjected to heat treatment to remove the stress of the coating layer so that the antioxidation time of the C / C composite material in static air at a temperature of more than 1,650 DEG C is improved from 200 to 300 to 400 hours compared with the prior art.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

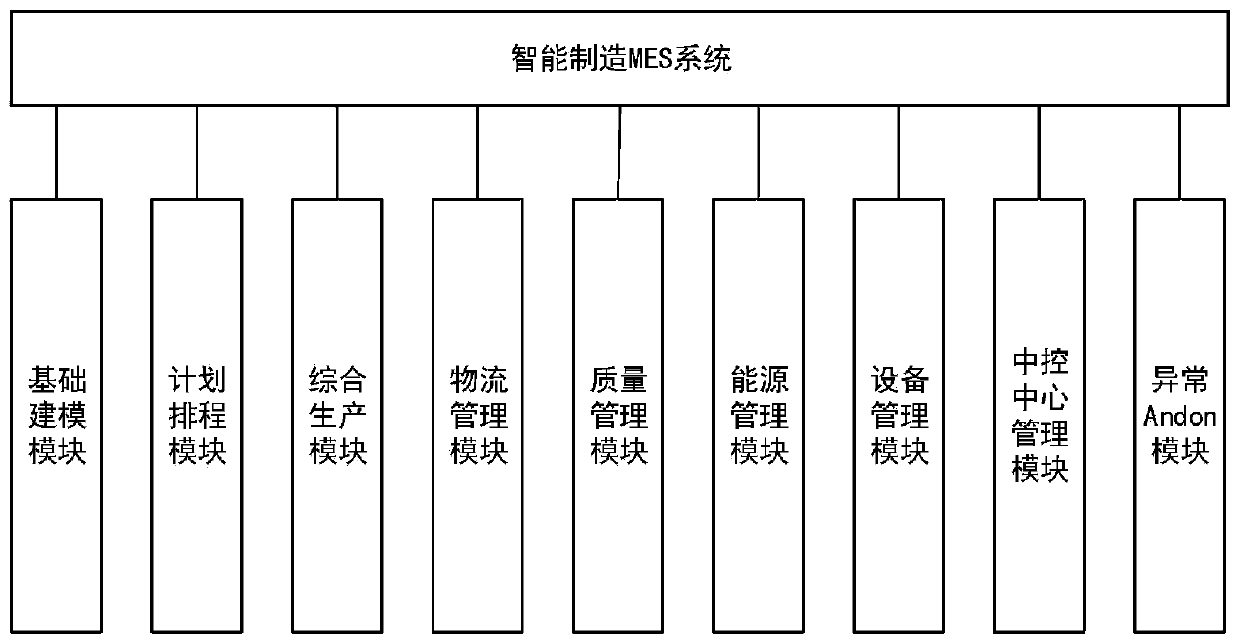

intelligent manufacturing MES system

InactiveCN110580026AIntelligent manufacturing whole process monitoringRealize the whole process monitoringEnergy industryTechnology managementMaterials preparationLogistics management

The invention discloses an intelligent manufacturing MES system which comprises a basic modeling module, a plan scheduling module, a comprehensive production module, a logistics management module, a quality management module, an energy management module, an equipment management module, a central control center management module and an abnormal Andon module. The basic modeling module is used for completing establishment of factory layout, establishment of product information and establishment of external resources. The plan scheduling module is used for establishing a production order, carryingout material preparation and distribution for a warehouse, work order scheduling, production execution, inspection, packaging and production warehousing. The comprehensive production module is used for managing a generated full-service process. The logistics management module is used for managing a production material taking management process and a production warehouse-in management process; andthe quality management module is used for carrying out inspection object maintenance on a purchasing department, a workshop department and a sales department. The invention provides a perfect intelligent manufacturing MES system, thereby realizing intelligent manufacturing full-process monitoring.

Owner:工业云制造(四川)创新中心有限公司

Nitrogen-doped porous carbon and preparation method thereof

ActiveCN103265008AWide range of choicesEasy to operateCarbon preparation/purificationPorous carbonCarbonization

The invention relates to a preparation method of nitrogen-doped porous carbon, and in particular relates to a method for preparing doped porous carbon by taking a heavy organism as a carbon source, belonging to the technical field of carbon material preparation. The method comprises the following steps of: firstly, conducting a reaction between a nitrogen source and formaldehyde to generate a prepolymer; then, mixing the prepolymer with a template and the carbon source, and reacting at certain temperature; and finally, curing and carbonizing a crosslinking product to obtain nitrogen-doped porous carbon. The method provided by the invention can obtain nitrogen-doped porous carbon with different pore structures and nitrogen contents through multiple ways such as control on the nitrogen source type, temperature control, control on the mass ratio of a carbon source to a nitrogen source, control on the dosage of a template agent and the like. By adopting a chemical polymerization blending carbonization method, the method effectively controls the loss of nitrogen in a thermal treatment process and improves the utilization rate of the nitrogen source; the selection range of the raw material is wide; and the method is easy to operate and easily realizes large-scale preparation while providing a new way for efficiently utilizing heavy organic matters.

Owner:DALIAN UNIV OF TECH

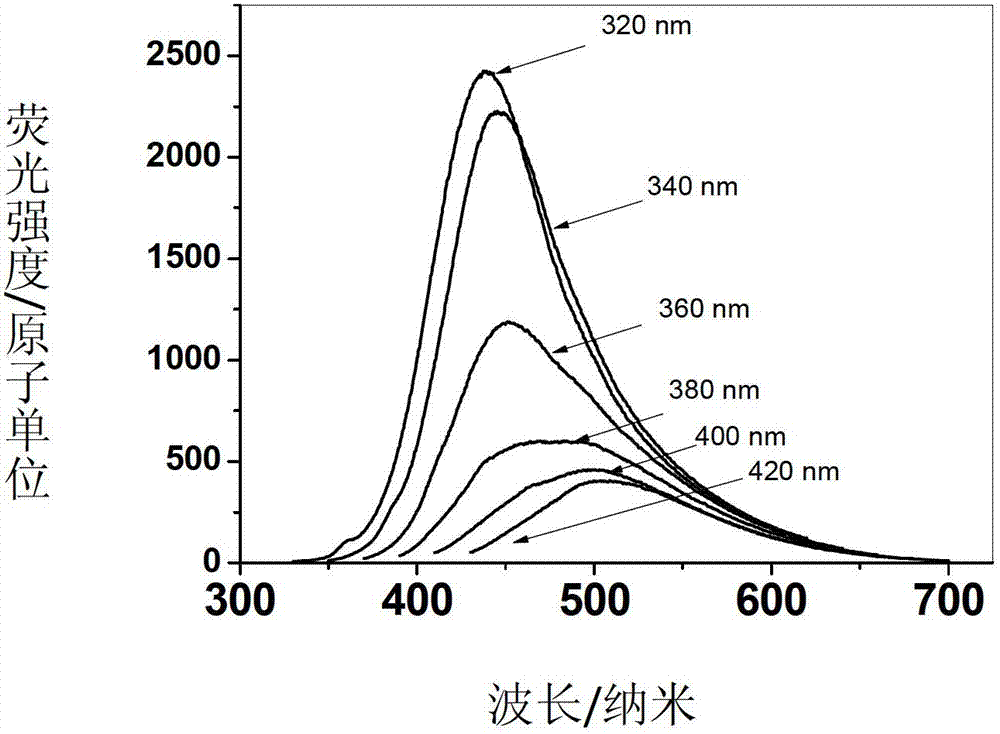

Method for preparing graphene quantum dots

ActiveCN102807209AHigh puritySmall particle sizeMaterial nanotechnologyGrapheneSolubilityFluorescence

The invention discloses a method for preparing graphene quantum dots, which belongs to the technical field of nano-material preparation. The method for preparing grapheme quantum dots comprises the following steps: firstly, utilizing graphite oxide to prepare graphene slices, and dissolving 50mg of graphene slices, 0-30mL of concentrated sulfuric acid, 10-40mL of concentrated nitric acid and the balance of de-ionized water for supplementing to 40mL into a dispersing system with 40mL; filtrating the abovementioned dispersing system, dispersing the solid into the de-ionized water again, adjusting the pH value to 8 with a sodium hydroxide solution, processing for 3 min in a microwave reaction kettle, naturally cooling, filtering with a filter membrane, collecting filtrate and dialyzing the filtrate in a dialysis bag for three days; and drying the dialyzed products to obtain the graphene quantum dots. The method provided by the invention is convenient in synthetic process and high in efficiency, and the obtained graphene quantum dots are high in purity, small in particle size, and strong in fluorescent property, and has monodispersity and water solubility, so that the graphene quantum dots are good in application prospect in the aspects of bioluminescent marks and solar cells.

Owner:TSINGHUA UNIV

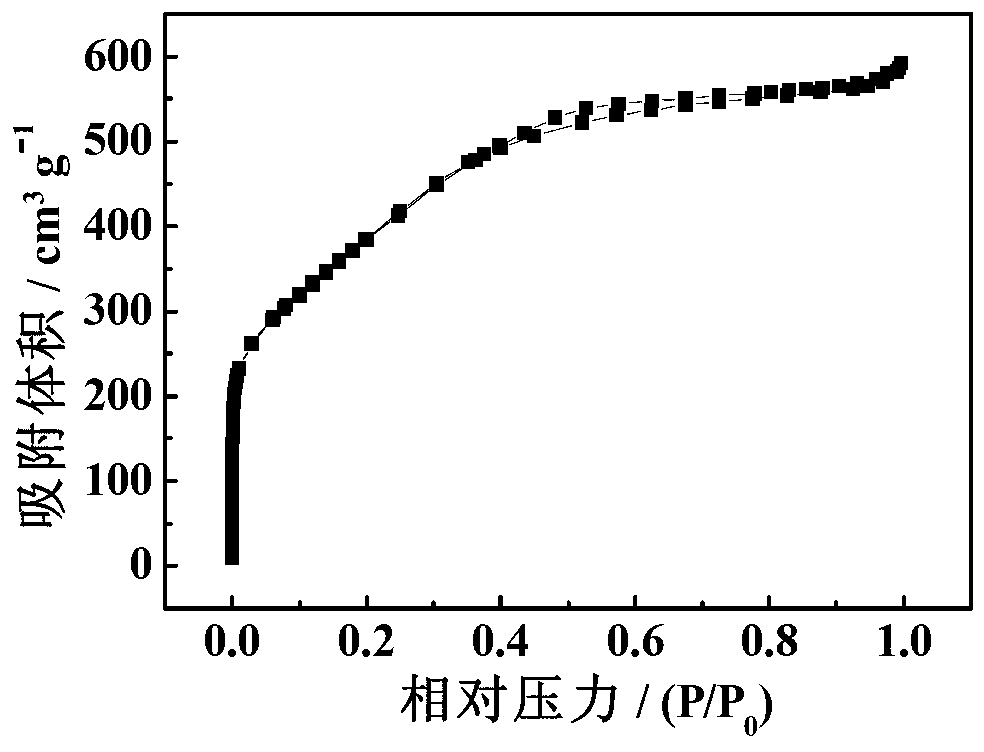

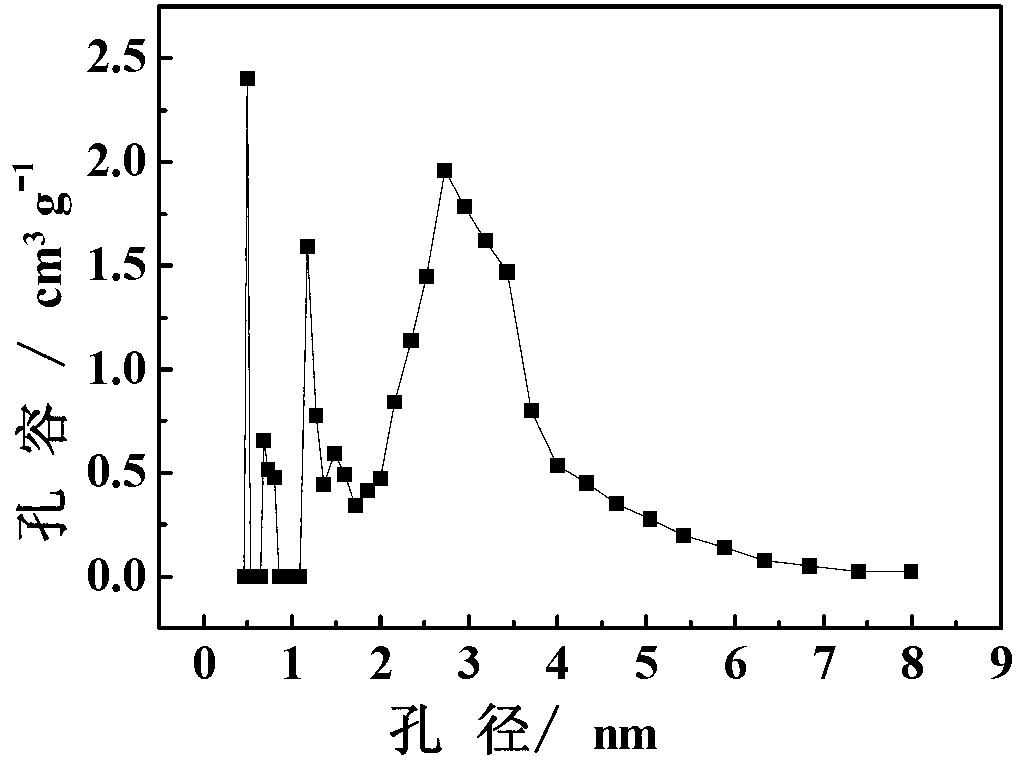

Preparation method for mesopore-micropore core-shell composite molecular sieve catalyst

ActiveCN101890363AMaintain microporosityHigh and adjustable microporosityMolecular sieve catalystsSilicon oxideSolution phase

The invention belongs to the technical field of material preparation and oil chemical engineering, and in particular discloses a preparation method for a mesopore-micropore core-shell composite molecular sieve catalyst. Zeolite particles are dispersed in organic solvent / water mixed solution which contains cationic surfactant and alkali under the action of ultrasound, and then silicon or silicon-aluminum species are introduced into the mixed solution to obtain a mesopore-micropore core-shell composite molecular sieve by solution phase self-assembly and a sol-gel process, wherein micropore zeolite serves as a core, and mesopore silicon oxide or aluminum-containing mesopore silicon oxide serves as a shell layer. The obtained composite molecular sieve has a retained zeolite micropore framework and an ordered two-dimensional hexagonal mesopore structure, a mesopore path is vertical with the surface of the zeolite particles, the path has high openness, the thickness of the mesopore shell layer is adjustable, and after the mesopore shell is packed, the mesopore-micropore can maintain high un-obstruction. The method has the advantages of simple operation, low raw material cost, low equipment requirement and the like.

Owner:上海介孔谷新材料发展有限公司

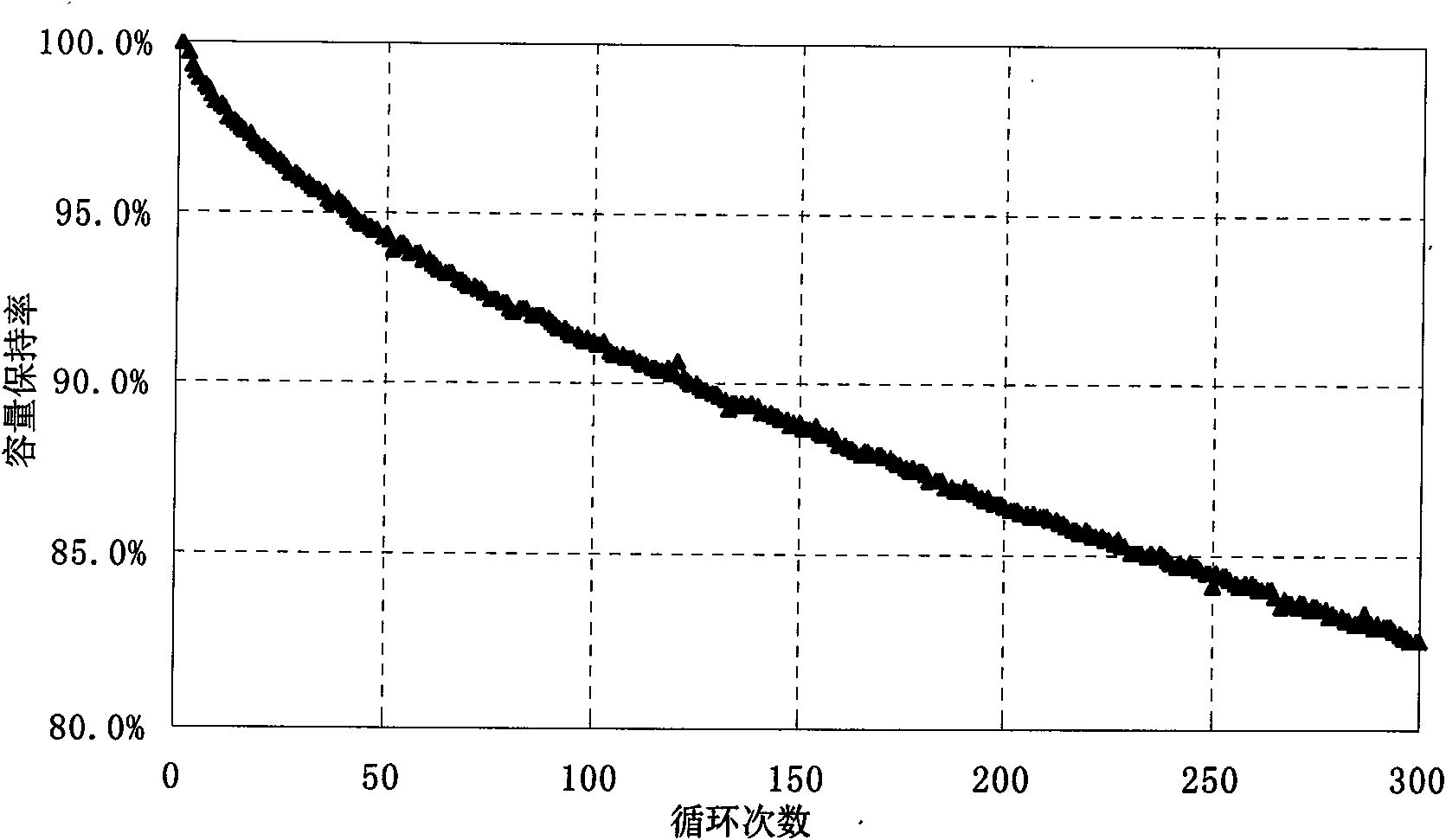

Silicon-carbon composite negative pole material preparation method and lithium ion battery

ActiveCN106257716AEvenly dispersedAvoid direct contactNegative electrodesSecondary cellsCarbon compositesElectric capacity

The invention relates to a silicon-carbon composite negative pole material preparation method and a lithium ion battery. The preparation method comprises putting nanometer silicon and graphite micro-powder into a ball mill, carrying out ball milling uniform dispersion in an organic solvent environment, carrying out vacuum drying, putting the dried mixture and asphalt into a cone-type mixer, carrying out coarse mixing, putting the mixed powder subjected to coarse mixing into a mechanical fusion machine, carrying out mechanical fusion, carrying out heat treatment in an inert gas protective atmosphere and carrying out cooling to obtain the silicon-carbon composite negative pole material. The preparation method carries out asphalt softening coating on nanometer silicon so that silicon particle and electrolyte direct contact is avoided, a capacity reduction rate is delayed, a lithium ion diffusion path is shortened, an electrode material electron conduction loss is avoided, and first charge-discharge efficiency, a charge-discharge electric capacity and cycle performances are improved. Before coating, nanometer silicon is dispersed through graphite micro-powder so that it is avoided that in asphalt coating, nanometer silicon aggregation causes local capacity excess and nanometer silicon is uniformly dispersed.

Owner:浙江超恒动力科技有限公司

Corestone manufacture method

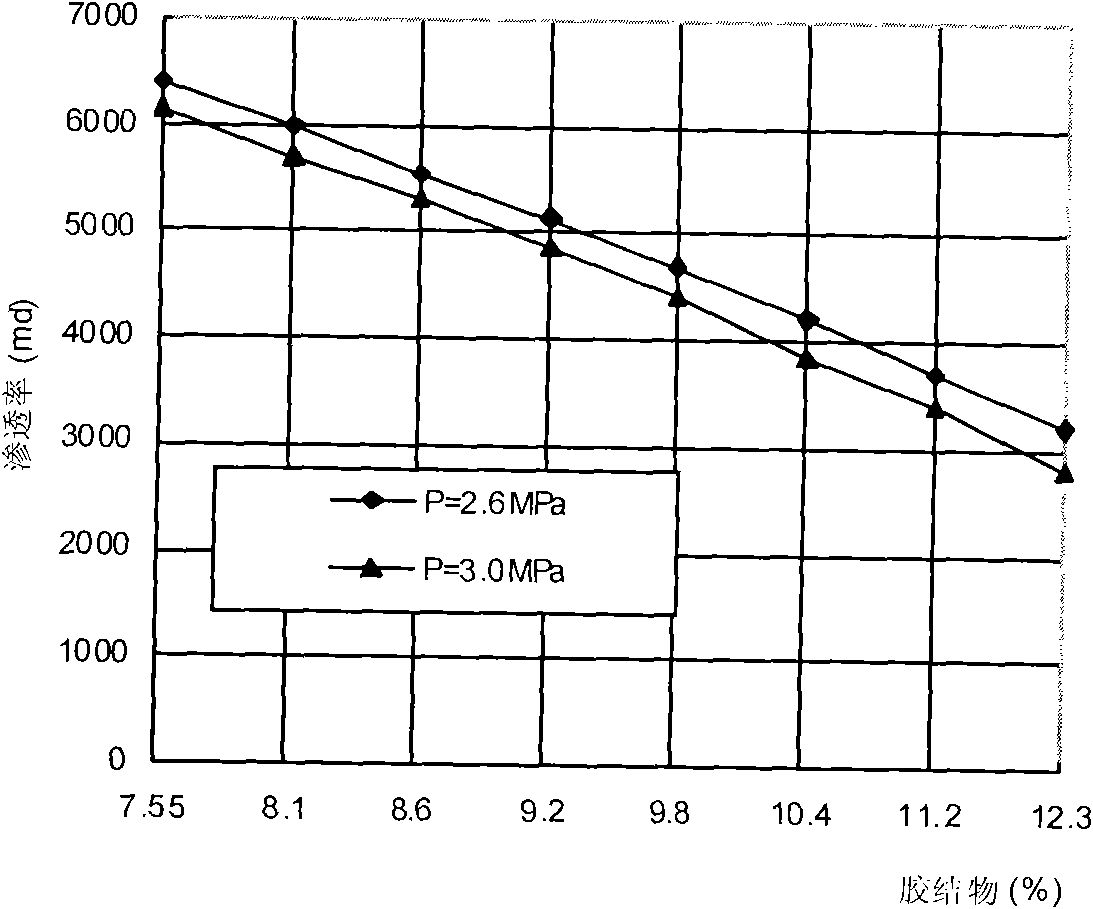

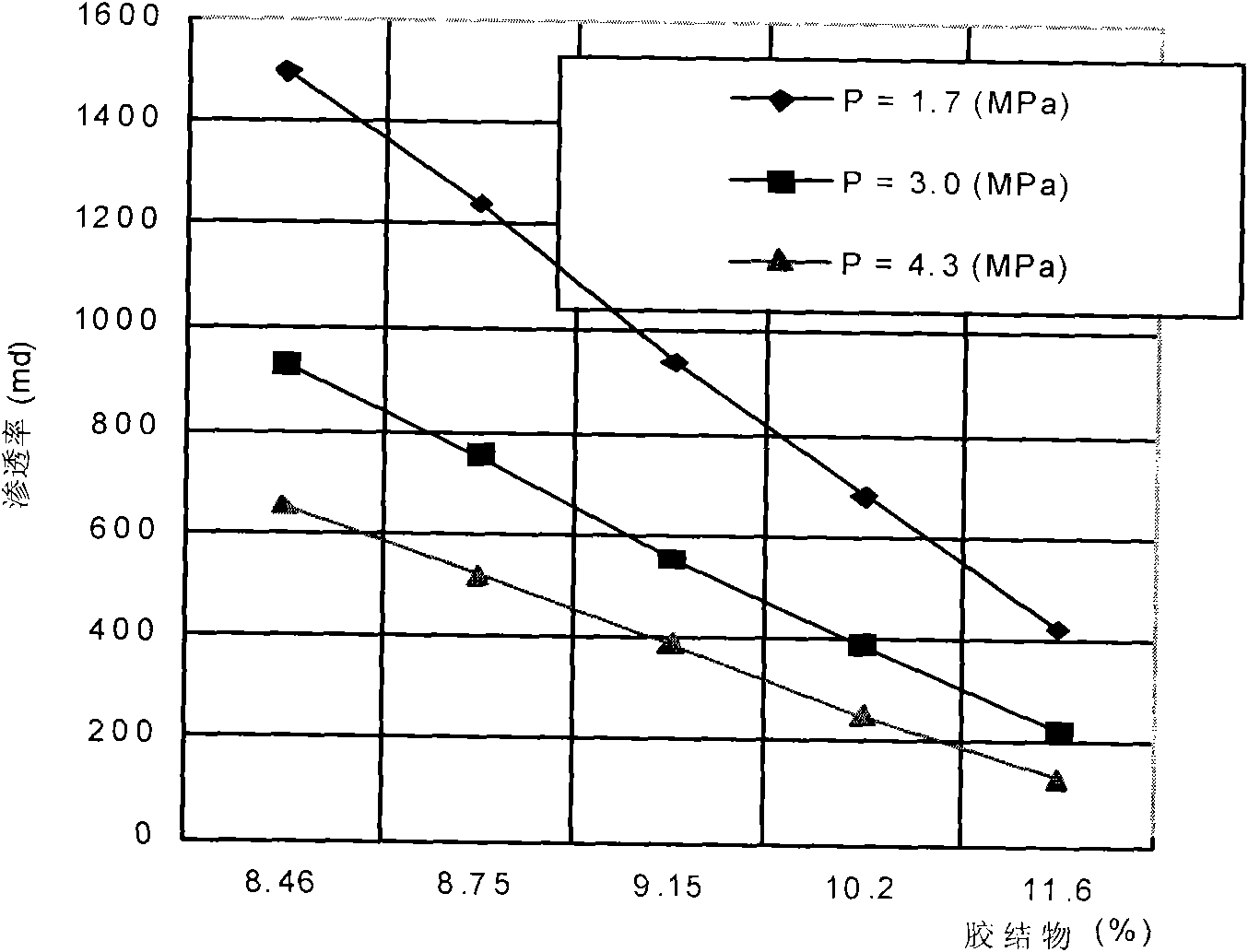

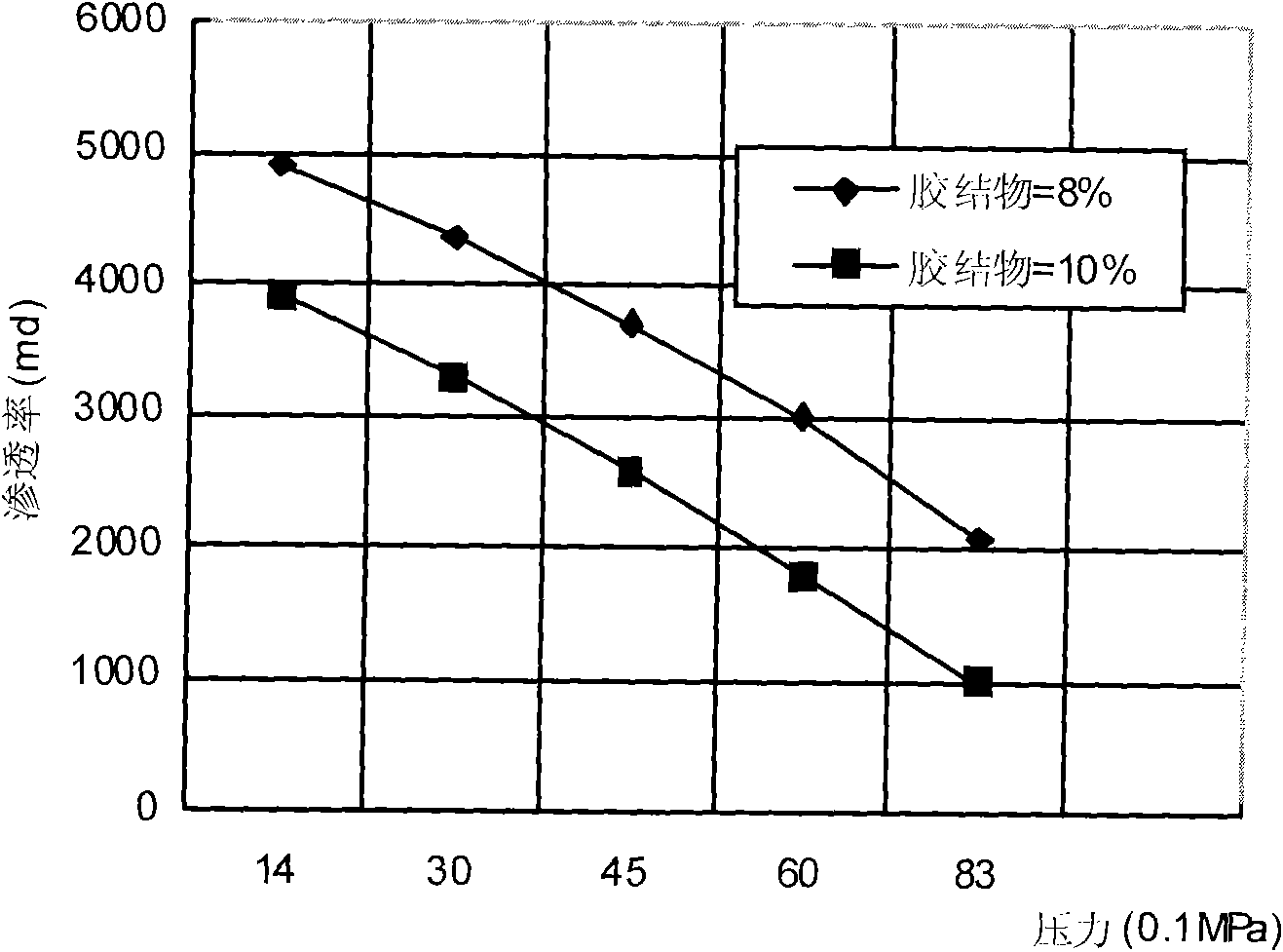

InactiveCN101798921ASimulation is accurateDrawn preciselyBorehole/well accessoriesMaterials preparationPhysical model

The invention relates to a corestone manufacture method, which comprises the following steps: (1) mold manufacture; (2) material preparation; (3) sand mixing; (4) molding; (5) pressurization; (6) electrode wire and pressure measuring pipe pre-burying in the corestone; (7) heating; (8) electrode lengthening wire welding; and (9) sealing. Compared with a physical model used at present, the invention has the advantages that indoor oil displacement experiments can be carried out under the condition of high pressure, the in-site production conditions can be simulated more accurately, oil-water distribution charts inside the model can be drawn more accurately, the oil-containing saturation change inside the corestone can be tracked in time, and the invention provides the scientific basis for the establishment of the development scheme.

Owner:DAQING OILFIELD CO LTD

Preparation method of rare earth doped iron lithium phosphate powder

InactiveCN1785800AIncrease capacityHigh crystallinityPhosphorus compoundsRare-earth elementMaterials preparation

The present invention discloses a preparation method of rare earth doped iron lithium phosphate powder body, belonging to the field of electrochemical power supply material preparation technology. Its molecular formula is Li1-xRExFePO4, and its preparation method includes the following steps: mixing lithium salt, ferrous salt, phosphate and adulterant according to a certain mole ratio, drying, low-temperature prebaking and high-temperature secondary calcining so as to obtain the invented product which can be used as positive electrode material of secondary lithium ion cell and power energy source cell. Said invention uses lanthanide series rare earth element compound as adulterant.

Owner:TSINGHUA UNIV

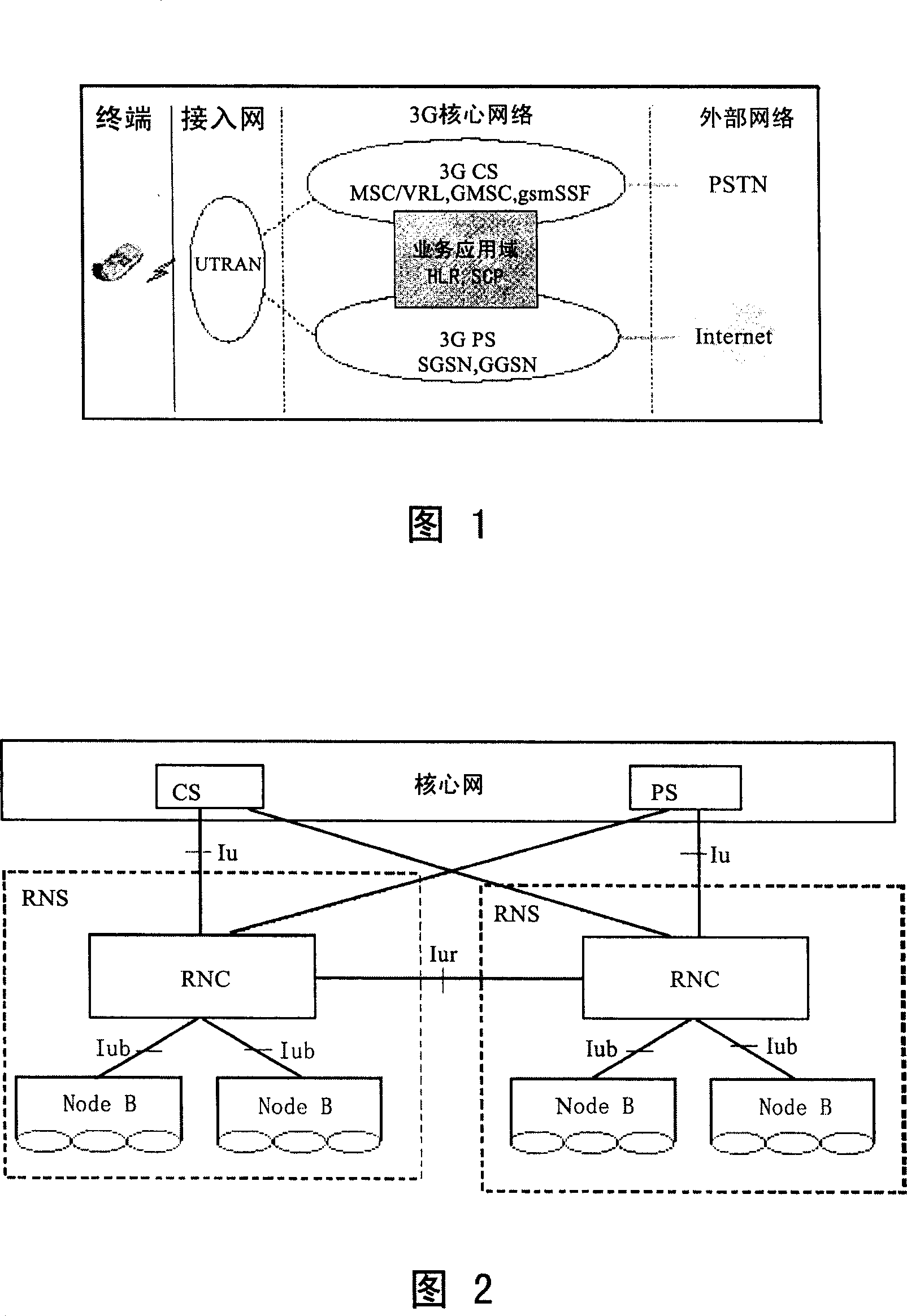

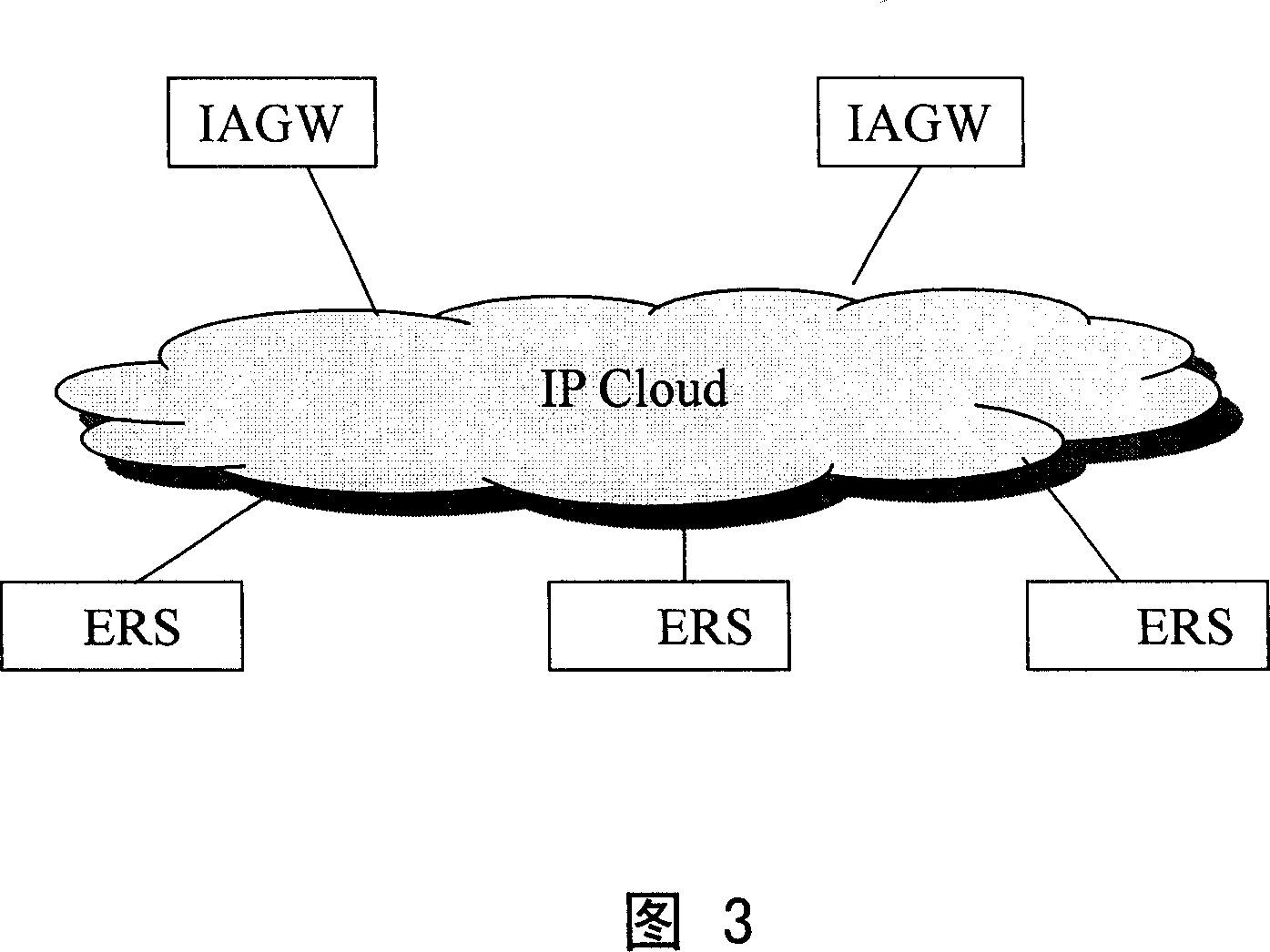

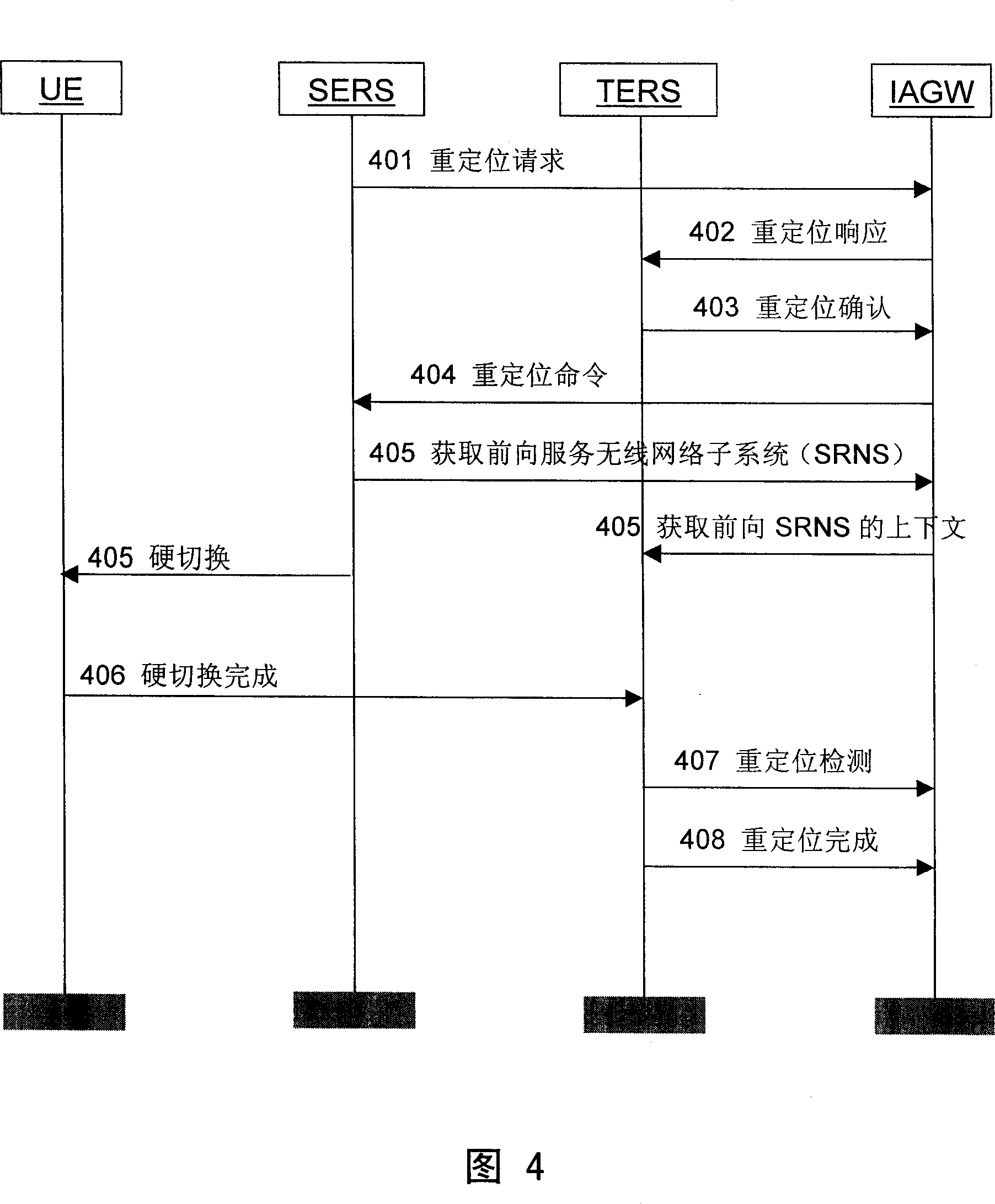

A method for switching among cells

ActiveCN1997204ANot lostIntegrity guaranteedNetwork traffic/resource managementRadio/inductive link selection arrangementsMaterials preparationInformation transmission

This invention discloses one method to realize area switching, which comprises the following steps: setting control panel and user panel agreement in base station and network gate; after receiving message, network gate processes buffer on sent data for materials preparation by aim base station; aim base station preserves materials to establish new user interface and establishing materials to fulfill UE area switching and the gate execution path and sending the data to aim station for information transmission between aim base station and UE.

Owner:HUAWEI TECH CO LTD

Preparation method of colored zirconia ceramics

The invention discloses a preparation method of colored zirconia ceramics, which belongs to the field of doped ceramic material preparation. The method comprises the following steps that: stabilizer and colorant are added into the suspension of zirconia powder by the mixture ratio of 850 to 980 parts of zirconia powder, 10 to 50 parts of stabilizer and 10 to 120 parts of colorant; by controlling the pH value of the solution or using various precipitant, the stabilizer and the colorant are precipitated on the surface of the zirconia powder; the solution is filtered and dried; the obtained powder is ground, screened, formed, degreased and sintered to obtain the colored zirconia ceramics. In nano-scale, the preparation method realizes the homogeneous compounding of the stabilizer, the colorant and the nano zirconia powder, can greatly reduce the volatilization of the colorant in the high-temperature sintering phase of the zirconia ceramics, has uniform sample color and good repeatability, and the colored zirconia ceramics prepared by the method can be widely applied to arts and crafts decoration, clocks and watches, mobile phone cases, jewelry and other fields.

Owner:TSINGHUA UNIV

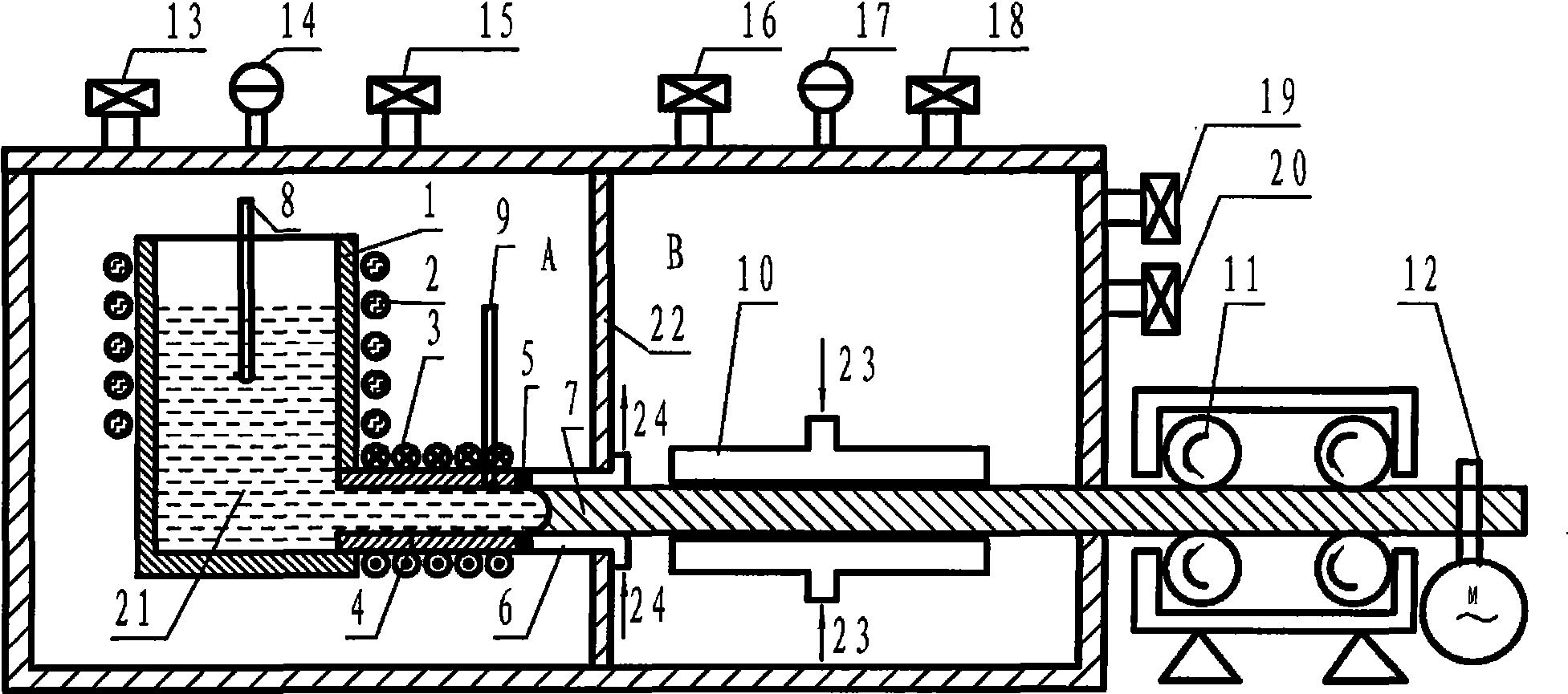

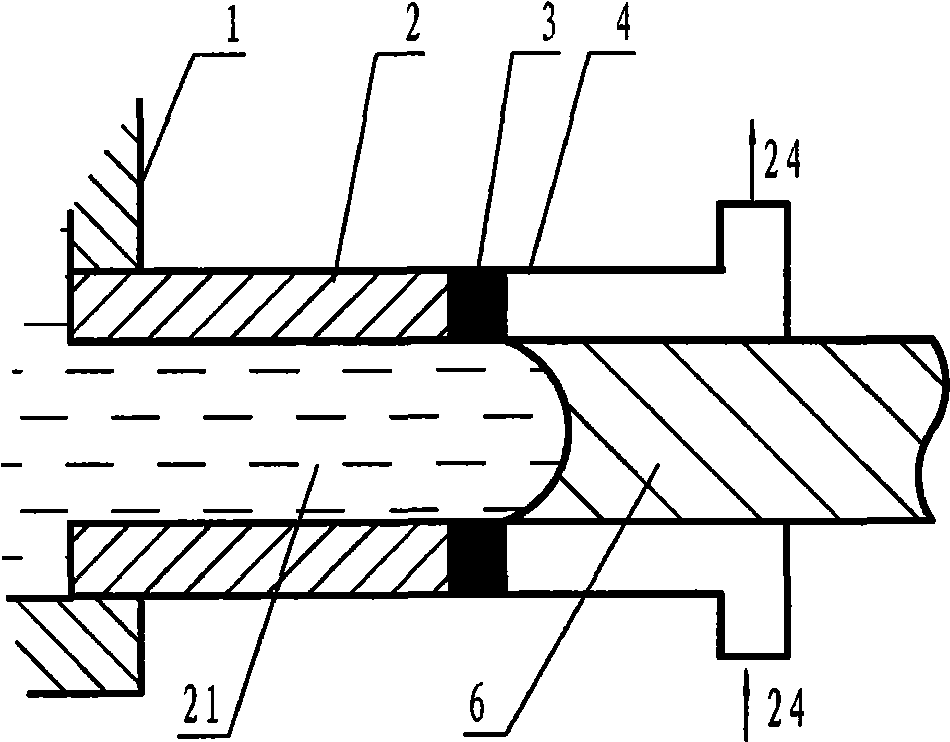

Device and method for continuous block metal glass shaping

InactiveCN101543885ASolve the vacuum problemIncrease cooling intensityMetallic materialsPressure difference

The invention relates to a device and method for continuous block metal glass shaping, belonging to the technical field of metal material preparation. A heat insulating ring is arranged between a graphite casting mould and a water cooling copper mould which are arranged in a first vacuum chamber, an air cooler is arranged in a second vacuum chamber, and a traction rod enters the graphite casting mould and horizontally moves by a traction device. The method uses the graphite casting mould and the water cooling copper mould for primary main cooling and the air cooling mode for secondary auxiliary cooling, and the two vacuum chambers have a certain air-pressure difference. The device and the method have a high cooling speed, satisfy the requirements of the amorphous phase change of the block metal glass material. The shaping pressure of a metal melting body can be easily controlled, and the good shaping performance of the metal melting body is ensured by adjusting the pressure in the vacuum chambers. The metal passes through the graphite casting mould in a liquid state and is solidified in the water cooling copper mould, and the casting graphite casting mould has long service. The composite casting mould and the traction device have exchangeability to be convenient for realizing the continuous shaping of rod wires, boards, pipes and abnormal-shaped materials of different section sizes.

Owner:江苏苏州洲盛非晶科技有限公司

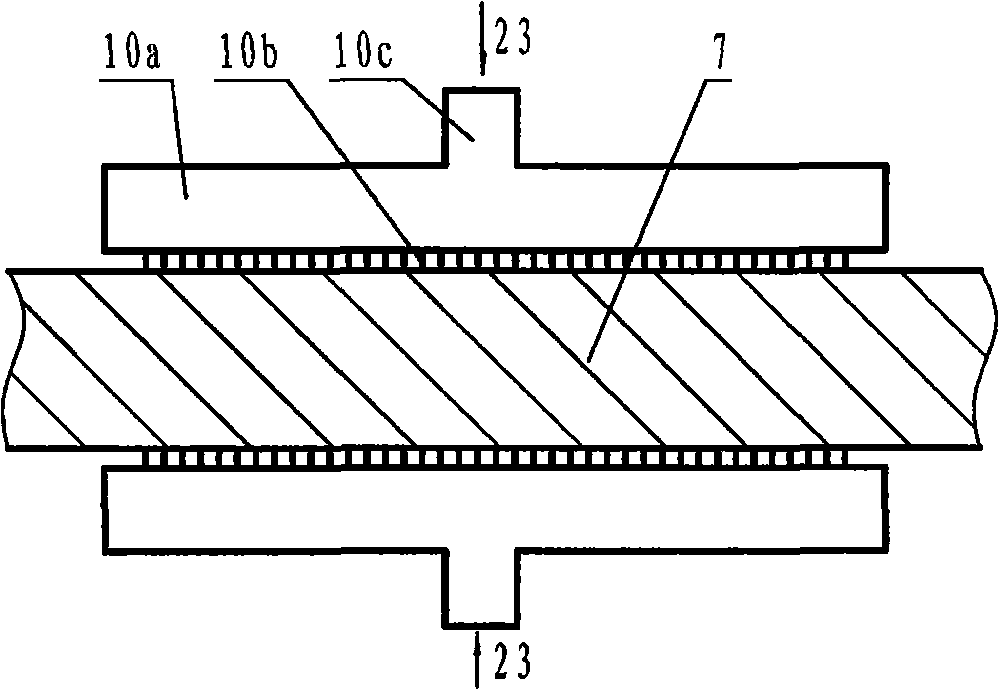

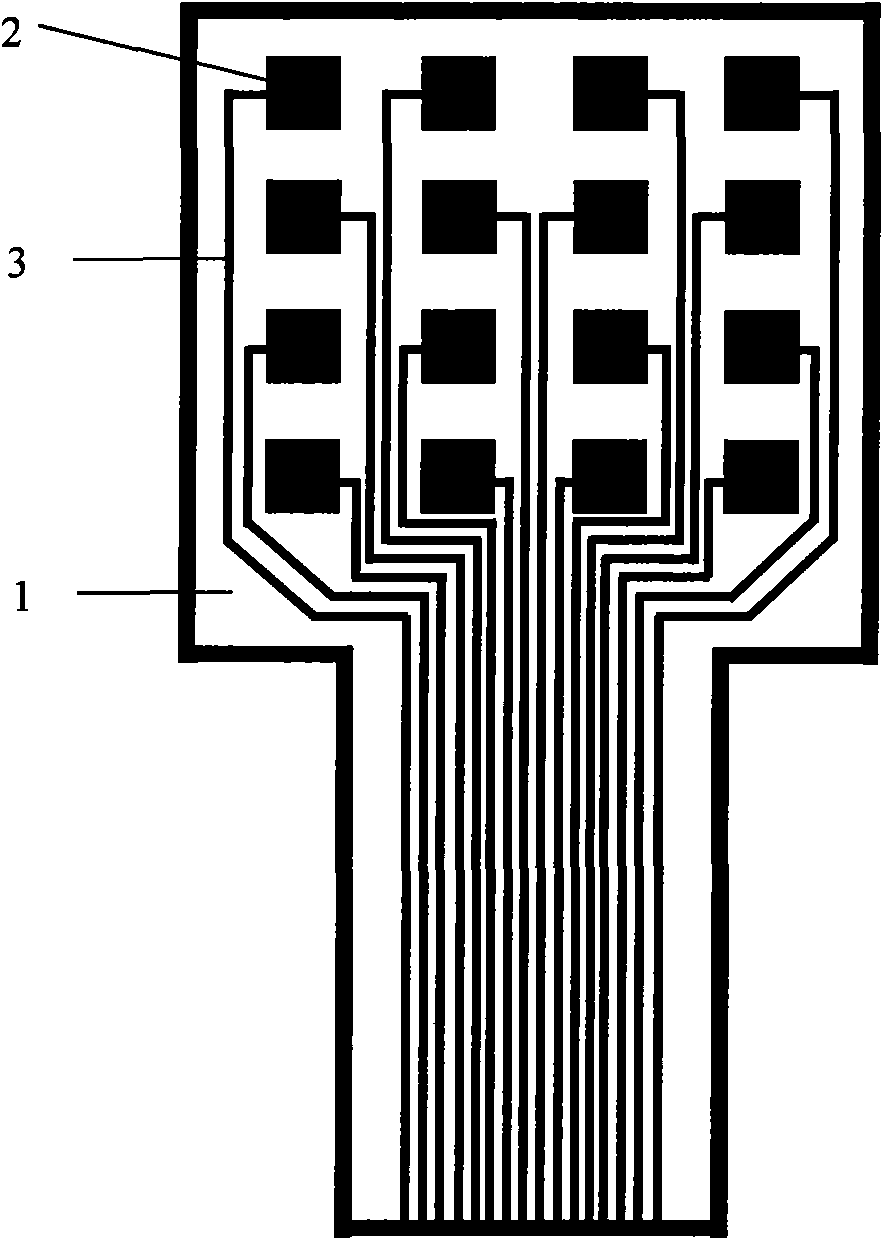

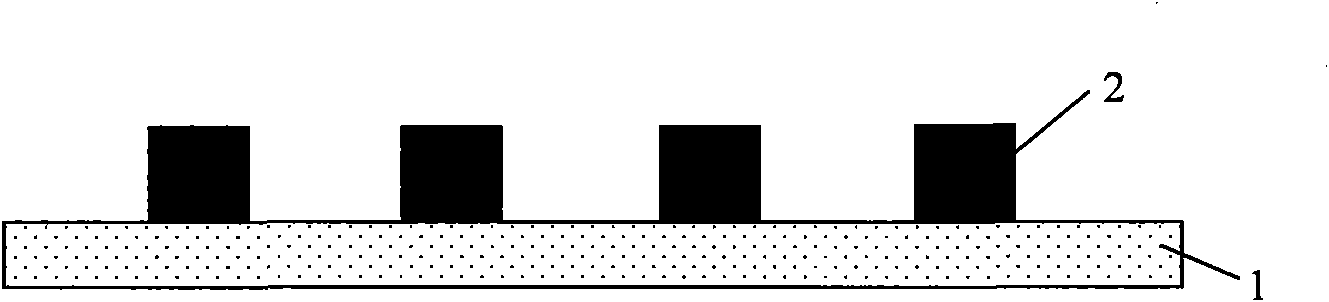

Development method of flexible pressure-sensitive element based on carbon nano-tube filled high polymer composite material

InactiveCN101885463ALarge aspect ratioHigh sensitivityDecorative surface effectsChemical vapor deposition coatingCarbon nanotubeCopper foil

The invention relates to a development method of a flexible pressure-sensitive element based on a carbon nano-tube filled high polymer composite material, which belongs to the technical field of sensors. The method comprises the following steps of: 1. pressure-sensitive material preparation: dispersing carbon nano-tubes into polydimethylsiloxane by utilizing ultrasonic vibration and mechanical stirring methods, and preparing a thin and flexible pressure-sensitive material by using tetraethoxysilane as a crosslinking agent and dibutyltin dilaurate as a catalyst with a spin coating method; 2. pressure-sensitive element packaging, wherein a two-stage sandwich structure is adopted, the first-stage sandwich structure comprises two layers of packaging films and the pressure-sensitive material positioned in the middle; and in the second-stage sandwich structure, each layer of packaging film comprises two layers of polyimide films as well as a copper foil electrode and a lead which are embedded in the two layers of polyimide films. The pressure-sensitive element developed by the invention has good flexibility, high precision, thin thickness, simple process and low cost and is applicable to the fields of pressure monitoring of structures between narrow curved surface layers in the fields of military industry and civil use and artificial electronic skin development and the like.

Owner:NORTHEASTERN UNIV

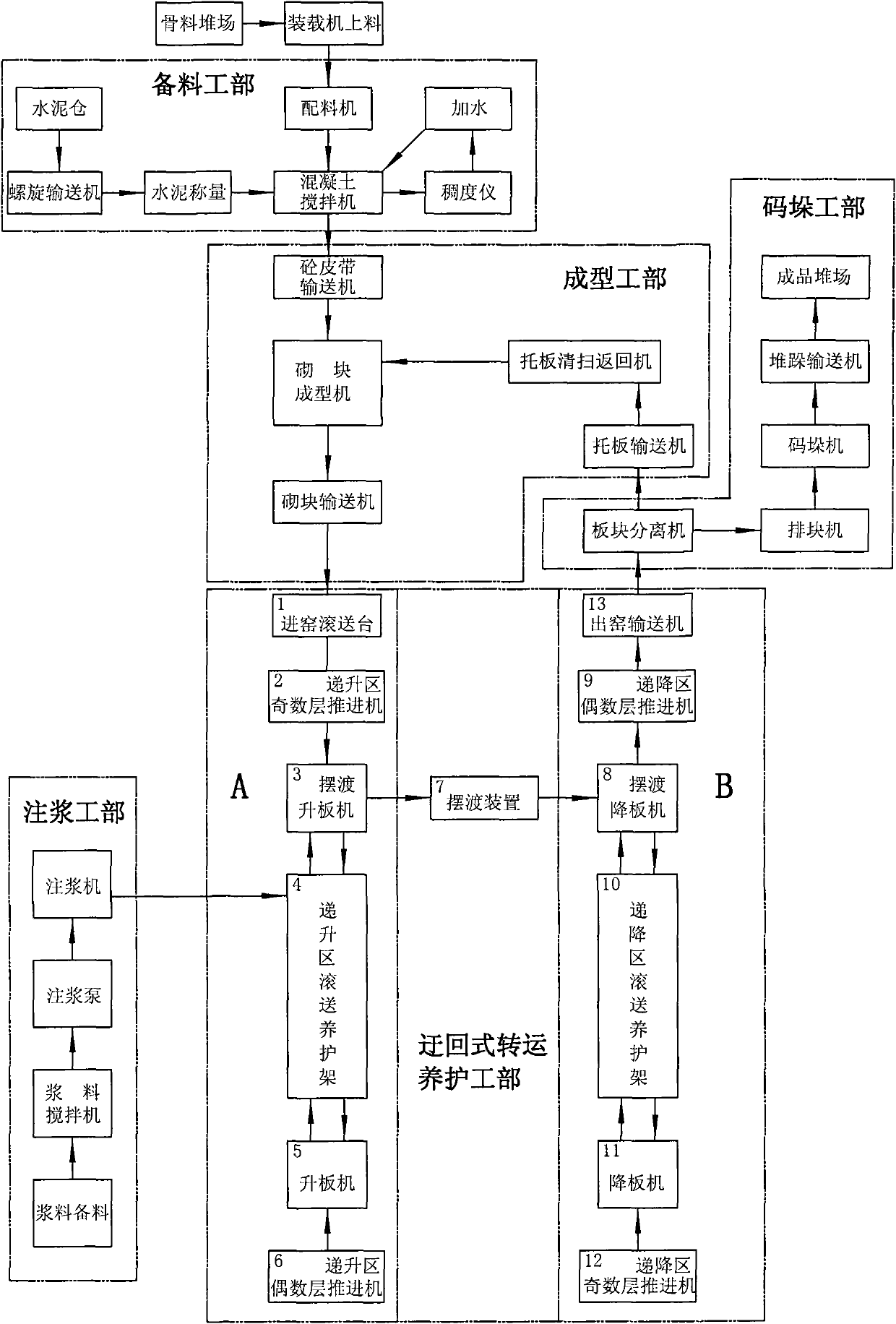

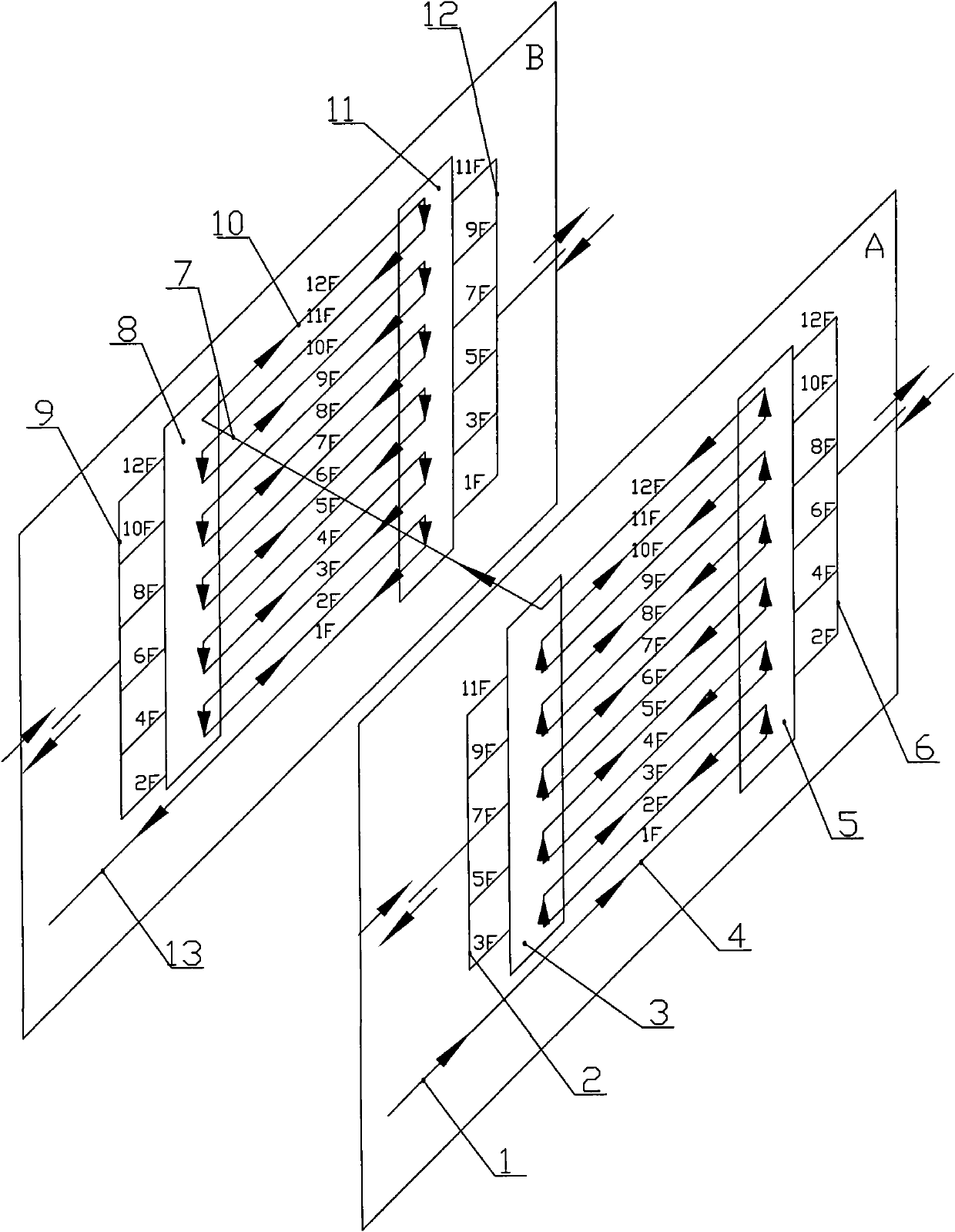

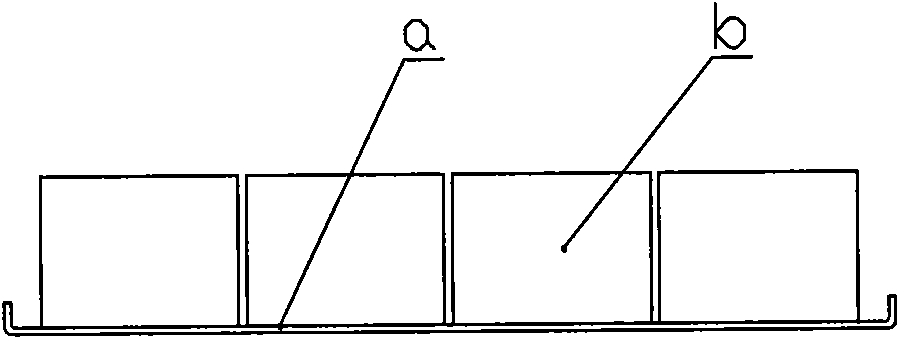

Production method of concrete grouting compound heat-insulating building block

InactiveCN101767365AAvoid manual operationIncrease productivityCeramic shaping plantsProduction lineMaterials preparation

The invention discloses a production method of a concrete grouting compound heat-insulating building block, which belongs to the field of building material machines and comprises a material preparation part, a forming part, a roundabout type transfer curing part, a grouting part and a stacking part, wherein the material preparation part is used for evenly stirring raw materials of building blocks and conveying the stirred raw materials to the forming part; the forming part is used for forming hollow building blocks by a building block forming machine and placing the hollow building blocks on a support plate; the hollow building blocks enter the roundabout type transfer curing part and are cured while being transferred; in the process of transferring and curing, the grouting part is used for grouting the hollow building blocks, so that the hollow building blocks become heat-insulating building blocks; and the cured compound heat-insulating building blocks are stacked into piles by the stacking part. By using the method, the transferring and the curing are combined into a whole, the curing is carried out in the process of the transferring, the transferring is carried out in the process of curing, any idle stroke does not exist and the production efficiency is greatly improved. In addition, in the curing process, the hollow building blocks can be grouted, so that the filling of a heat-insulating material can be finished in the production line and the manual operation can be avoided.

Owner:扬州威奥重工机械有限公司 +1

Preparation method and application of macropore-mesoporous silicon dioxide hollow micro-sphere

InactiveCN101214965AImprove connectivityGood slow releaseOrganic active ingredientsSilicaMaterials preparationEmulsion

Disclosed are a preparation method and application of macroporous-mesoporous silicon dioxide hollow microsphere, which relate to the field of inorganic materials preparation and pesticide application. The process of materials preparation includes adding templates P123 in aqueous phase, after generating steady oil-water-oil dual emulsion, adding silica source tetraethyl ortho-silicate TEOS, producing hydrolysis under the effect of precipitant, generating silicon dioxide hollow microsphere, after filtering and drying, the product of the invention can be produced via calcining in 550 DEG C for 6 hours. The silicon dioxide hollow microsphere of the invention has macroporous structure and mesoporous structure. Through the mesoporous structure of the microsphere wall, realizing the communication between the hollow inside of the microshere and the outside. The invention also relates to the application in area of release carrier of the materials as avermectin drugs, the prepared release controlling agent has perfect long-acting slow release performance.

Owner:BEIJING UNIV OF CHEM TECH

Method for synthesizing LiFePO4/C material based on chemical gas phase sediment auxiliary solid phase method

InactiveCN101237039AControl chemical compositionSmall particle sizeElectrode manufacturing processesChemical vapor deposition coatingGas phasePhosphate

The invention relates to a method for synthesizing LiFePO4 / C material by chemical vapor deposition supporting the solid phase reaction method, namely, the method for preparing carbon coating lithium iron battery anode material, belonging to the Li-ion battery material preparation art technical field. The characteristics of the method for synthesizing LiFePO4 / C materials by solid phase and auxiliary chemical vapor deposition are that auxiliary chemical vapor deposition supporting the solid phase reaction method is adopted to synthesize the carbon coating phosphate lithium iron, namely, the LiFePO4 / C material. In the method for synthesizing LiFePO4 / C material by chemical vapor deposition supporting the solid phase reaction method, a precursor comprising raw materials of lithium, iron and phosphor is adopted to prepare the carbon coating phosphate lithium iron after being blended, grinded by a globe mill, treated by preheating and calcined as well as vapor deposition. The method for synthesizing LiFePO4 / C material by chemical vapor deposition supporting the solid phase reaction method has the advantages that the chemical composition, carbon contents and grain size of LiFePO4 can be controlled effectively; the Li-ion battery anode material prepared has sound conductive performance and can improve the charge-discharge rate and cycling performance of the material.

Owner:SHANGHAI CHIYUAN NEW MATERIAL TECH

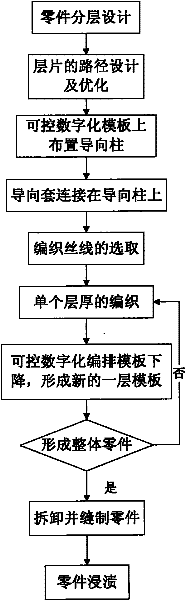

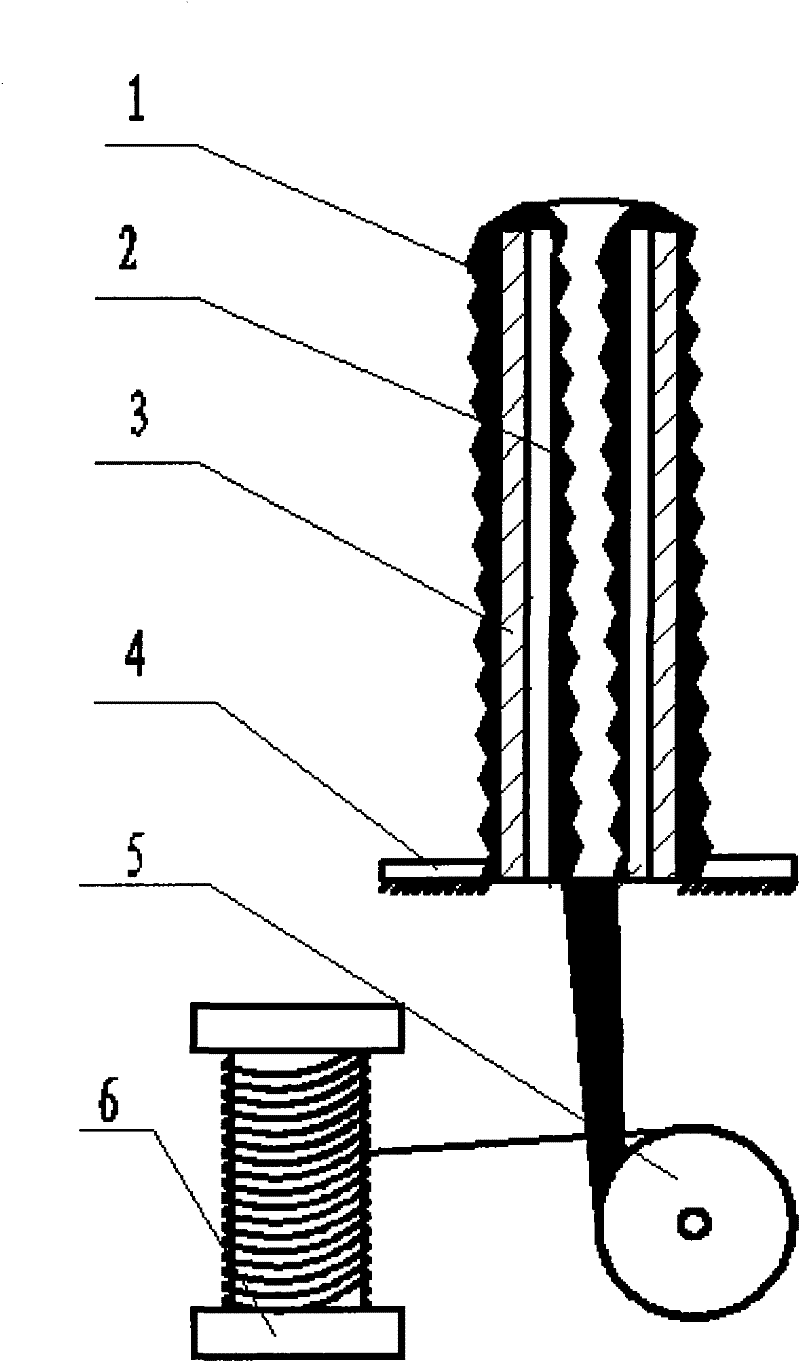

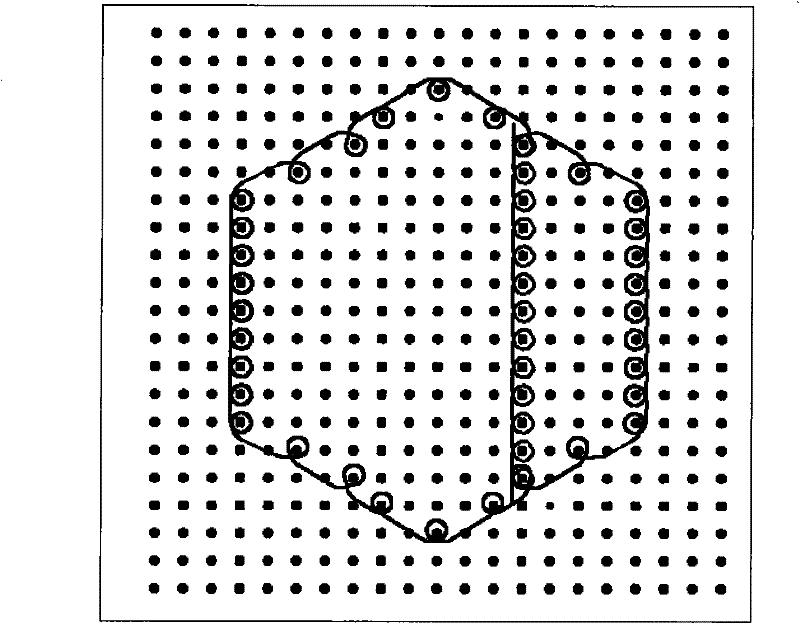

Three-dimensional weaving forming method for composite material

ActiveCN102192396ARealize 3D WeavingAchieve preparationAdditive manufacturing apparatusLoomsMaterials preparationEngineering

The invention discloses a three-dimensional weaving forming method for a composite material, and belongs to the cross field of weaving and manufacturing. The method comprises the following steps of: performing layered design according to the characteristics of a part structure, and optimizing a weaving path; arranging weaving guide posts on a controllable digital arrangement template at intervals according to certain rules; after a guide sleeve passes through the hollow guide posts along the Z direction and is turned outwards, fixing the guide sleeve on the controllable digital template; selecting a silk material for weaving the layer; after the weaving of one layer is finished, lowering the controllable digital arrangement template, and driving the guide sleeve to expose for a distance to form a new layer of arrangement template; weaving layer by layer till the weaving of the whole part is finished; detaching and sewing the part; and soaking the part into resin to form a composite material part. According to the method, the quick prototyping technology and the weaving technology are organically combined to realize three-dimensional weaving of the complex functional part; and meanwhile, composite material preparation and part formation are integrated, so that manufacture of the complex functional part is realized.

Owner:BEIJING NAT INNOVATION INST OF LIGHTWEIGHT LTD

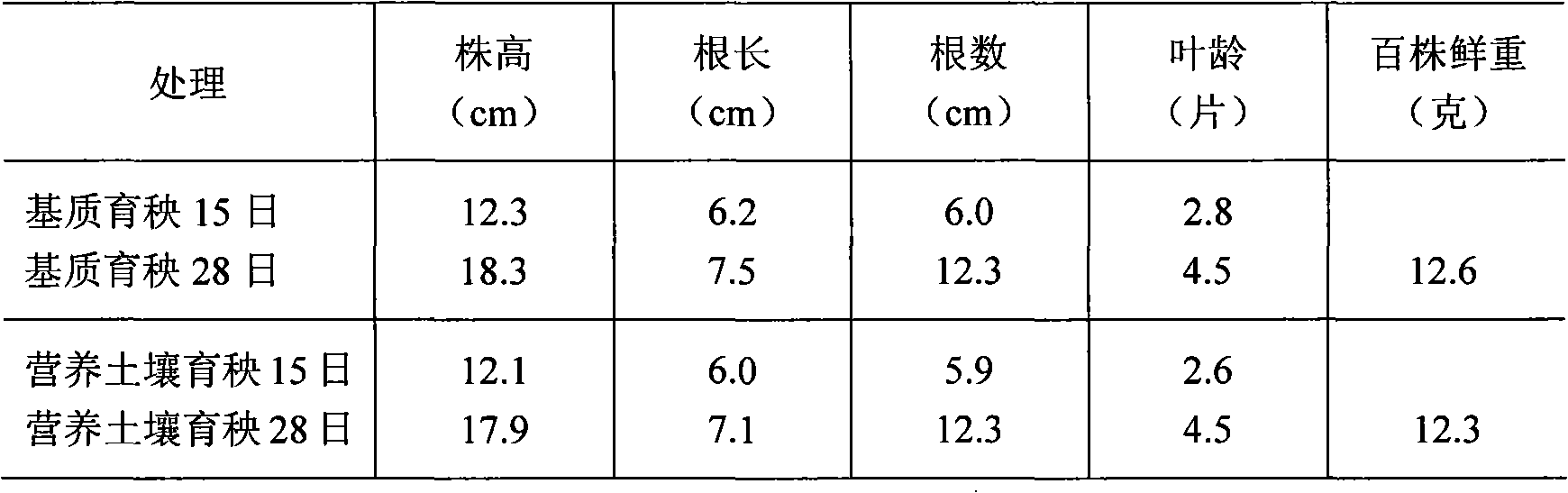

Straw matrix and production method thereof

InactiveCN102010259AFully absorbedIncrease vitalityBio-organic fraction processingOrganic fertiliser preparationSlagFarmyard manure

The invention relates to a rice seedling raising matrix and a production method thereof, and belongs to a seedling raising matrix and a production method thereof. The matrix is prepared by the following formula and method that: the formula comprises 50 to 70 percent of crushed corn stalk of 40 to 60 meshes, 10 to 30 percent of crushed rice straw of 40 to 60 meshes, 5 to 15 percent of farmyard manure of 40 to 60 meshes and 5 to 15 percent of industrial slag powder of 40 to 60 meshes; and the method comprises material preparation, raw material crushing, fermentation, mixing, drying and stirring. The method for producing the seedling raising matrix by using the raw materials such as straws, farmyard manure, slag and the like thoroughly solves the problems of vegetation destroy caused by taking soil for raising seedlings and difficult soil taking, reduces the production processes of taking soil, sieving soil, regulating acid, stirring fertilizers, stirring drugs and the like, and lightens the labor intensity of rice farmers. The method can be applied in rice seedling raising and vegetable and flower seedling raising production, and is a new effective path for making full use of straw resources and realizing energy conservation, emission reduction and agricultural circular economy.

Owner:前郭县百禾农业开发有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com