Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1260 results about "Shape control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

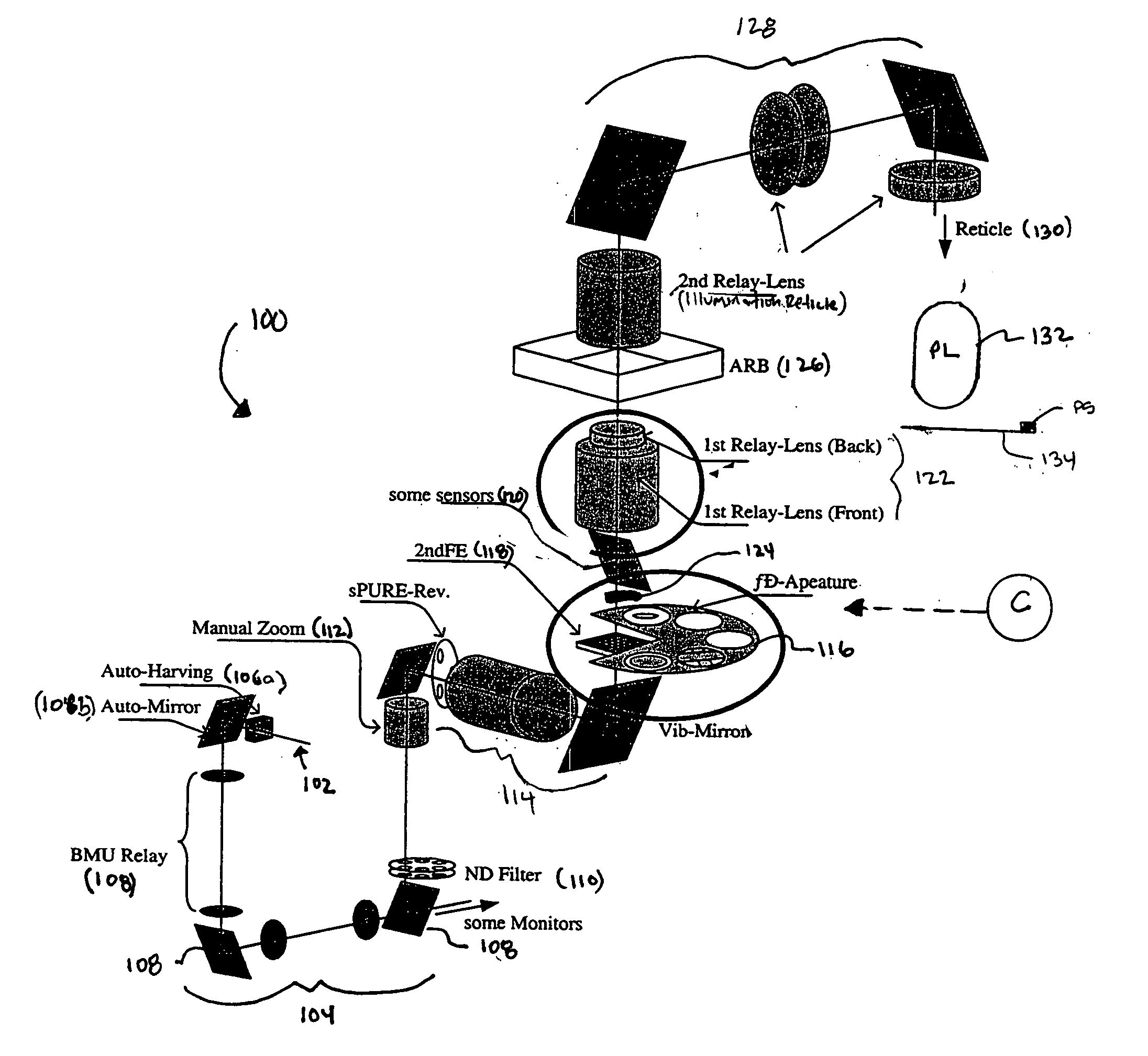

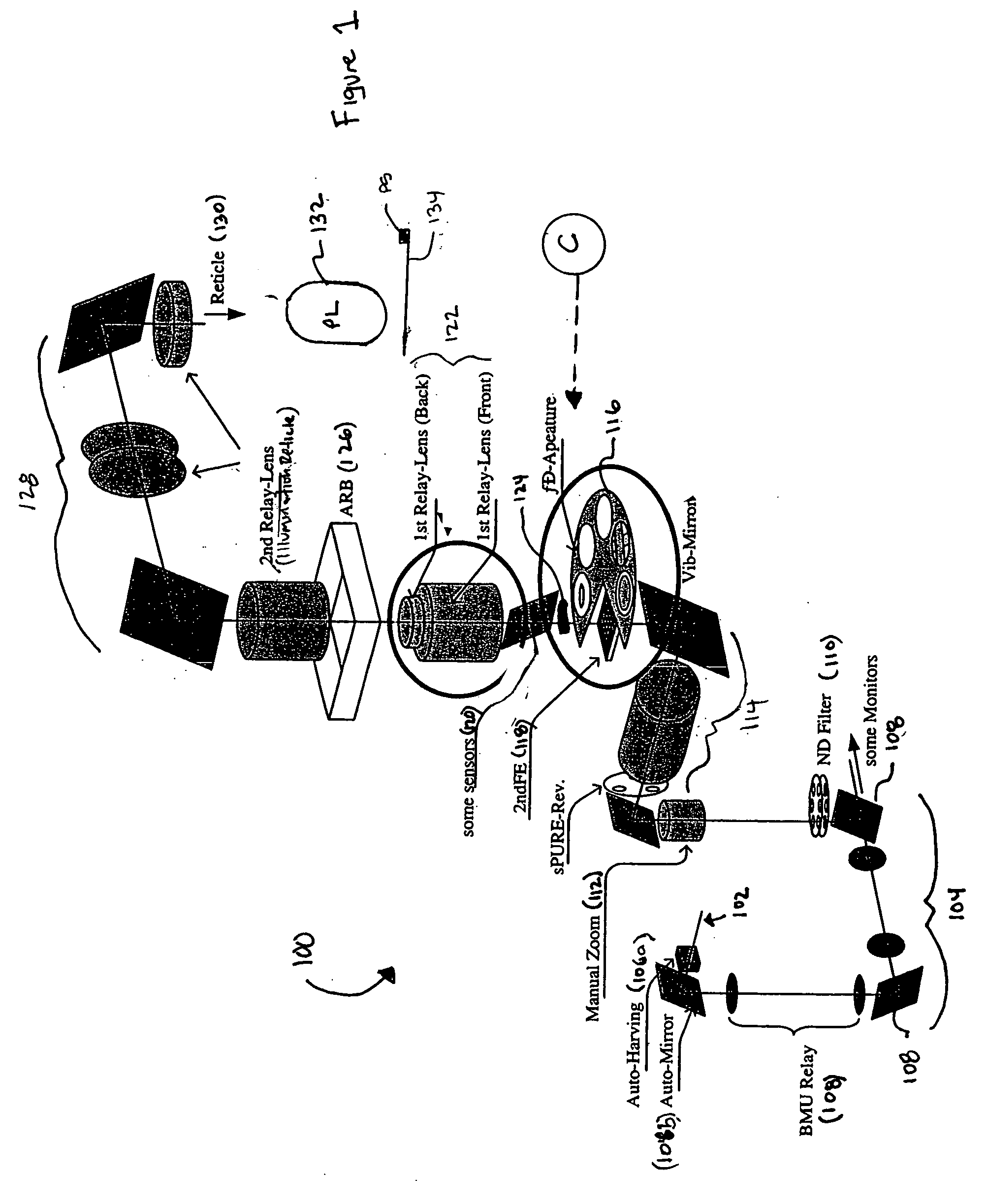

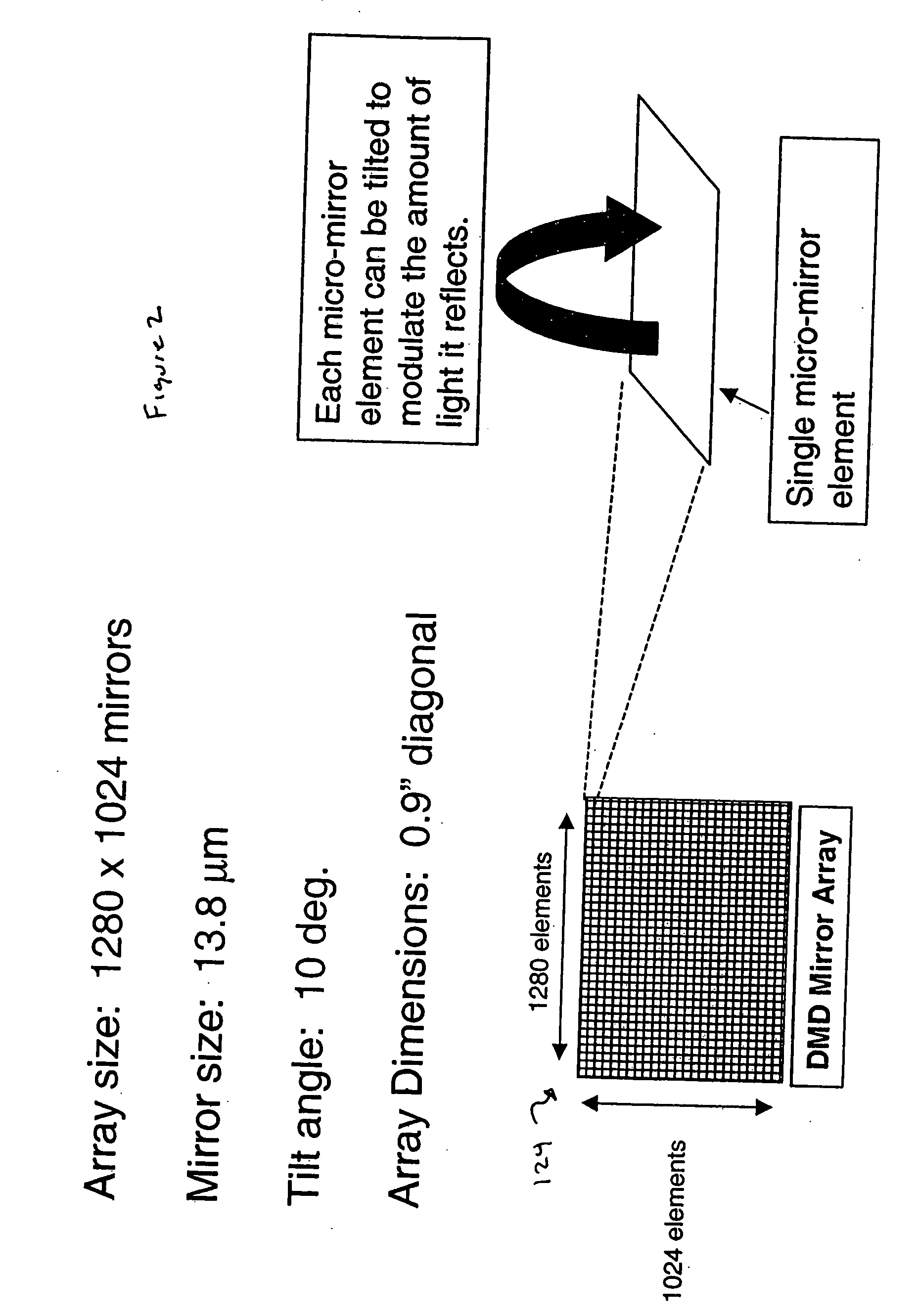

Dynamic illumination uniformity and shape control for lithography

InactiveUS20060087634A1Reducing illumination non-uniformityReduce illumination non-uniformityPhotomechanical apparatusPhotographic printingShape controlLight beam

A subsystem for an exposure apparatus has at least one array of tilting mirrors placed in either an image reticle plane or a conjugate image plane to provide dynamic control of an illumination beam through an exposure field. In the system, an optical subsystem and a plurality of mirrors directs light to a reticle and a sensor senses the illumination distribution of the light at a wafer stage. When the at least one array of tilting mirrors is placed in the image reticle plane, a control is used to interpolate data of the illumination distribution sensed by the sensor, and then control movement of at least one mirror of the array of mirrors based on the interpolated data.

Owner:NIKON PRECISION

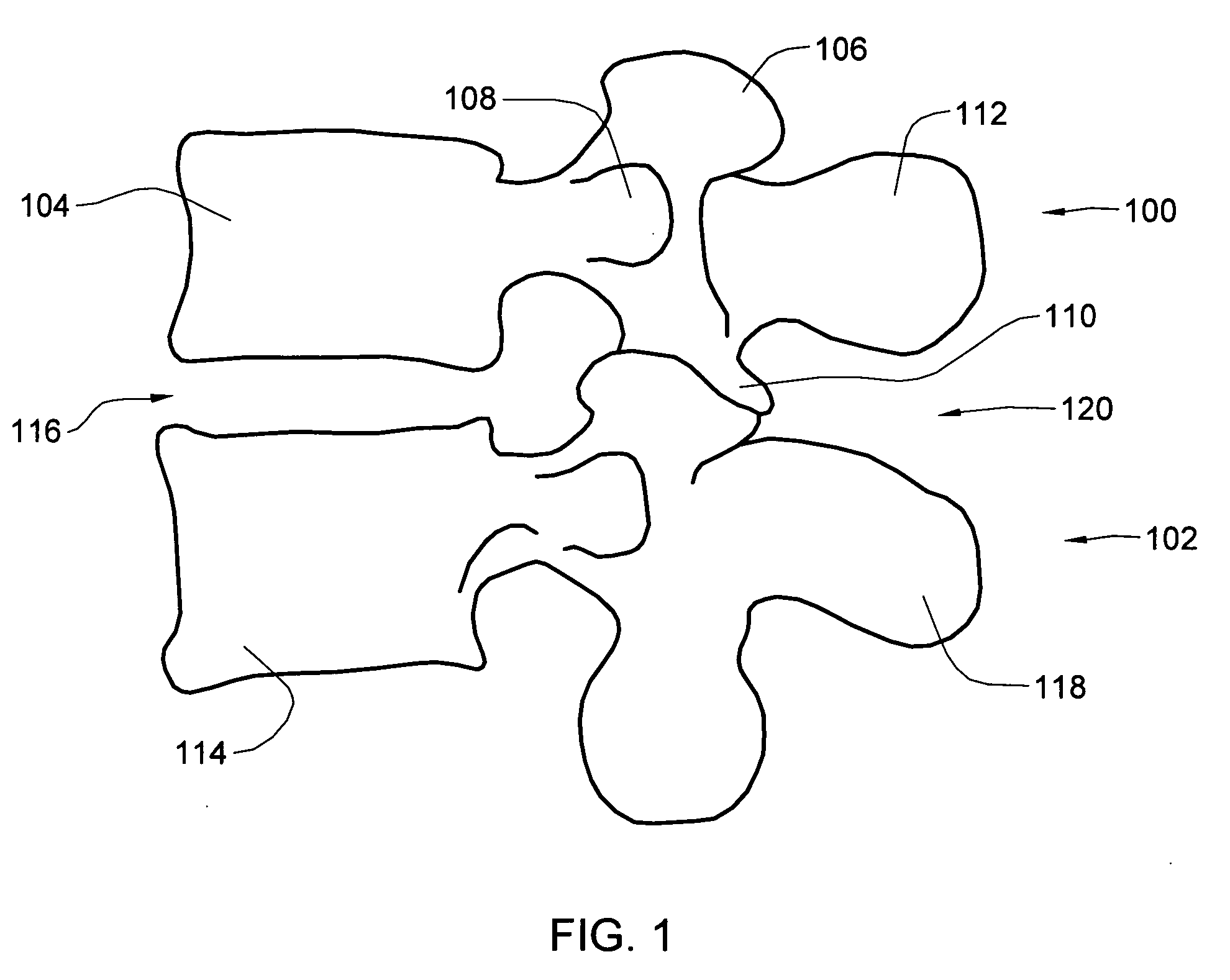

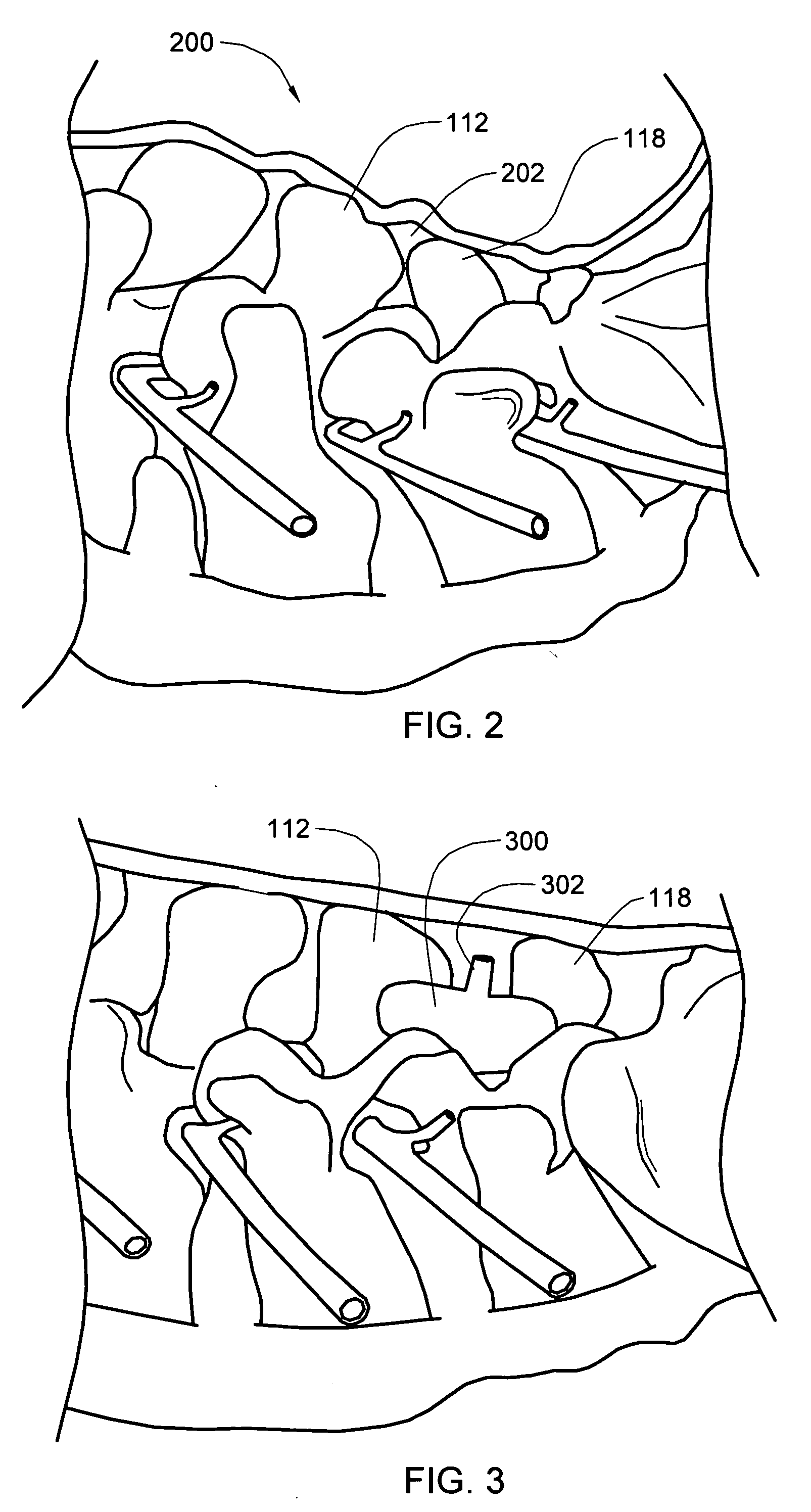

Surgical spacer with shape control

An interspinous spacer for placement between adjacent spinous processes includes a flexible, fillable container (e.g., a bag or balloon) for containing a material that is compressible during end use, for example, silicone after curing. The container is impermeable to the material it will be filled with. A structural mesh, for example, made of PET fabric and interwoven shape-memory alloy wire, provides structure for and containment of the container, as well as shape control. The material can be injected into the container through an optional conduit, for example, a one-way valve.

Owner:WARSAW ORTHOPEDIC INC

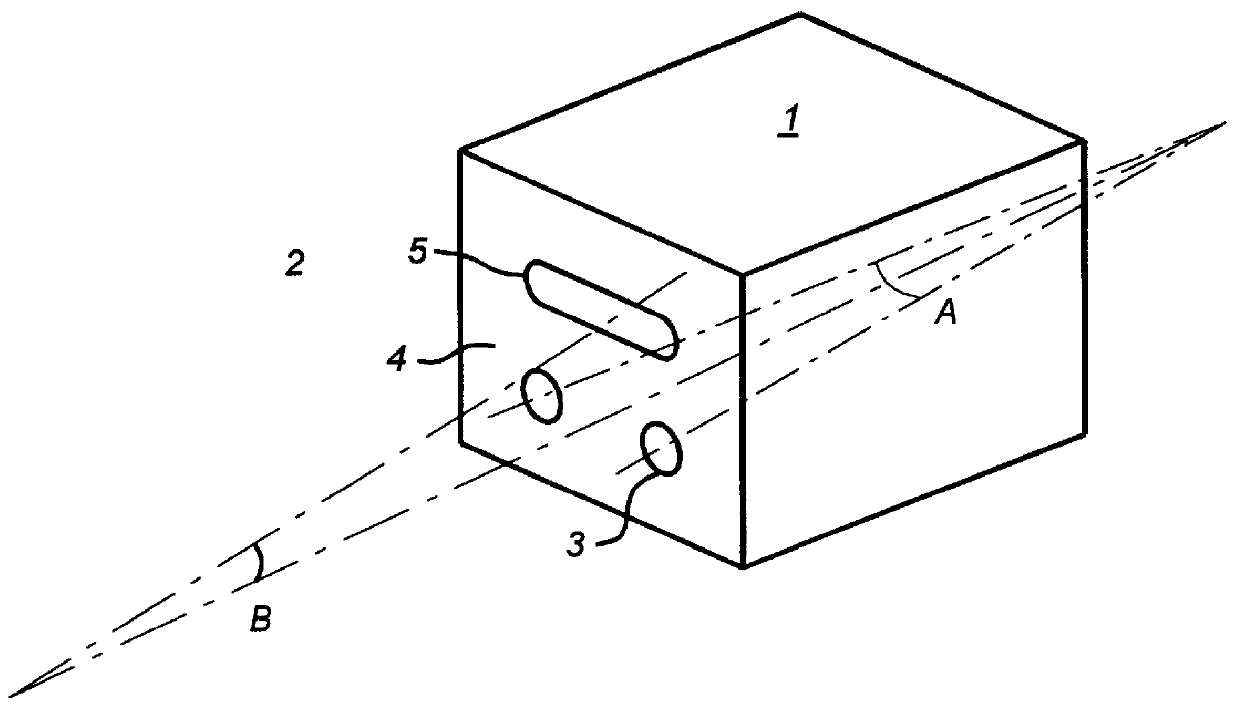

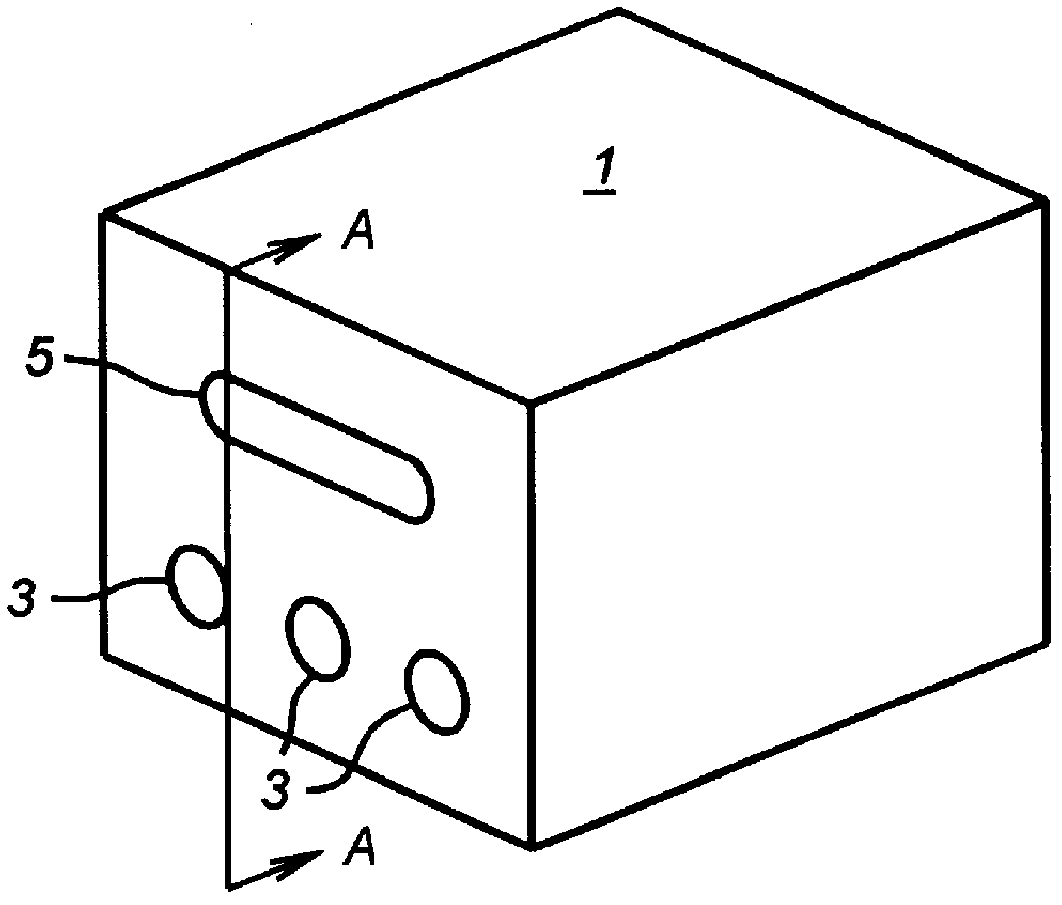

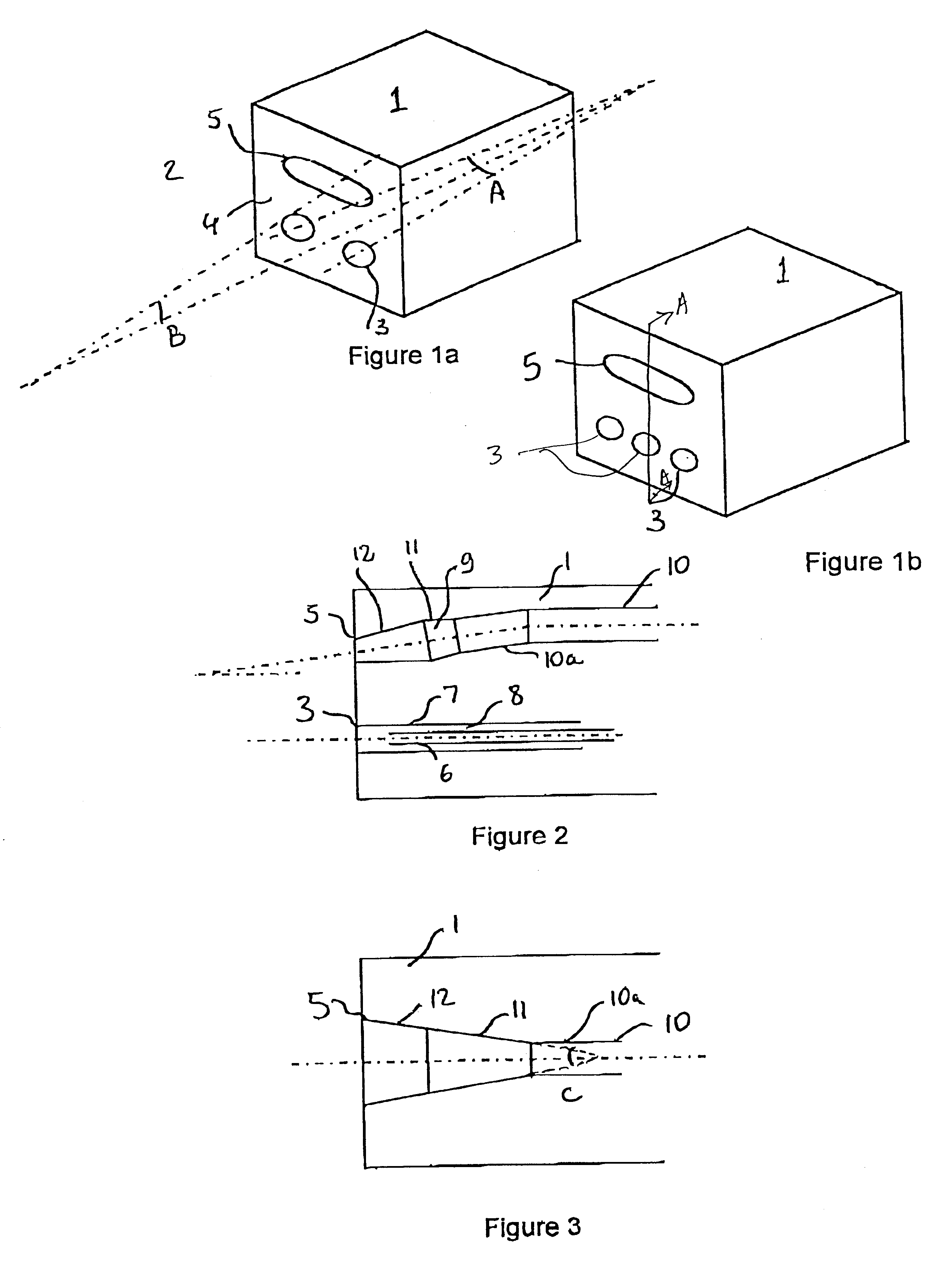

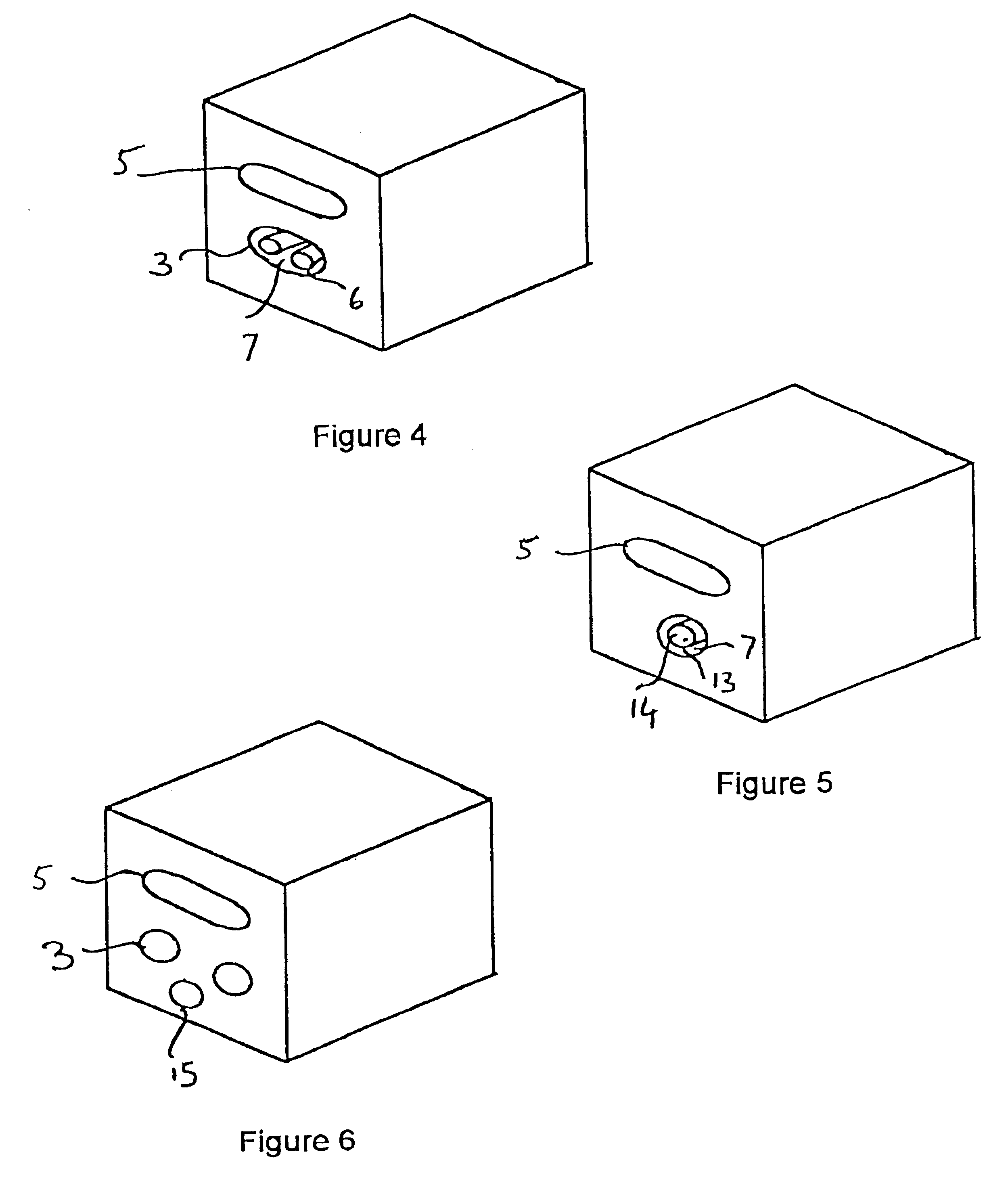

Combustion process and apparatus therefore containing separate injection of fuel and oxidant streams

InactiveUS6074197AReduce nitrogen oxide emissionsAvoid chemical reactionsCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorCombustion chamber

A burner assembly having improved flame length and shape control is presented, which includes in exemplary embodiments at least one fuel fluid inlet and at least one oxidant fluid inlet, means for transporting the fuel fluid from the fuel inlet to a plurality of fuel outlets, the fuel fluid leaving the fuel outlets in fuel streams that are injected into a combustion chamber, means for transporting the oxidant fluid from the oxidant inlets to at least one oxidant outlet, the oxidant fluid leaving the oxidant outlets in oxidant fluid streams that are injected into the combustion chamber, with the fuel and oxidant outlets being physically separated, and geometrically arranged in order to impart to the fuel fluid streams and the oxidant fluid streams angles and velocities that allow combustion of the fuel fluid with the oxidant in a stable, wide, and luminous flame. Alternatively, injectors may be used alone or with the refractory block to inject oxidant and fuel gases. The burner assembly affords improved control over flame size and shape and may be adjusted for use with a particular furnace as required.

Owner:AIR LIQUIDE AMERICA INC +1

Refractory block for use in a burner assembly

InactiveUS6068468ACombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorCombustion chamber

A burner assembly having improved flame length and shape control is presented, which includes in exemplary embodiments at least one fuel fluid inlet and at least one oxidant fluid inlet, means for transporting the fuel fluid from the fuel inlet to a plurality of fuel outlets-, the fuel fluid leaving the fuel outlets in fuel streams that are injected into a combustion chamber, means for transporting the oxidant fluid from the oxidant inlets to at least one oxidant outlet, the oxidant fluid leaving the oxidant outlets in oxidant fluid streams that are injected into the combustion chamber, with the fuel and oxidant outlets being physically separated, and geometrically arranged in order to impart to the fuel fluid streams and the oxidant fluid streams angles and velocities that allow combustion of the fuel fluid with the oxidant in a stable, wide, and luminous flame. Alternatively, injectors may be used alone or with the refractory block to inject oxidant and fuel gases. The burner assembly affords improved control over flame size and shape and may be adjusted for use with a particular furnace as required.

Owner:AIR LIQUIDE AMERICA INC +1

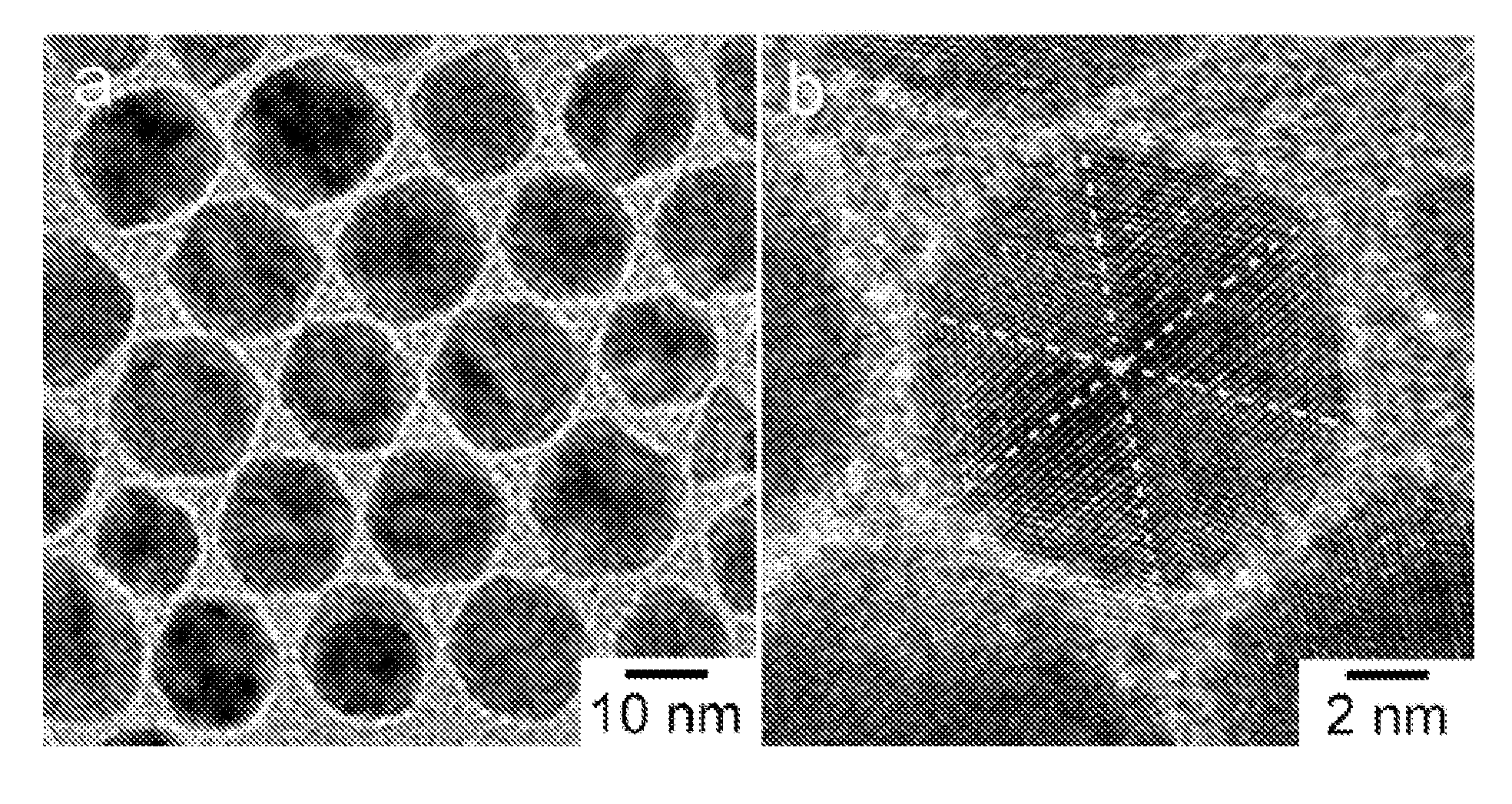

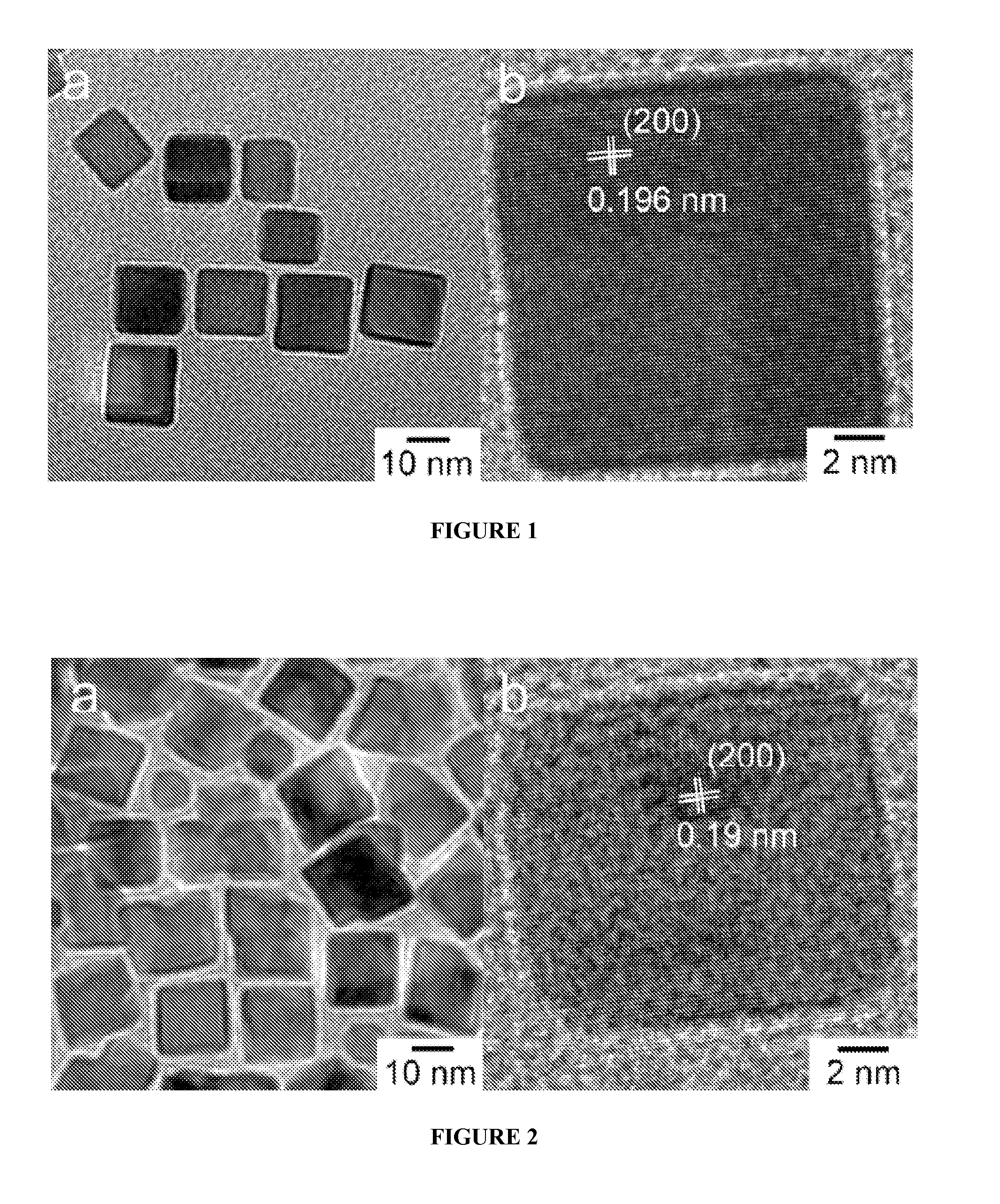

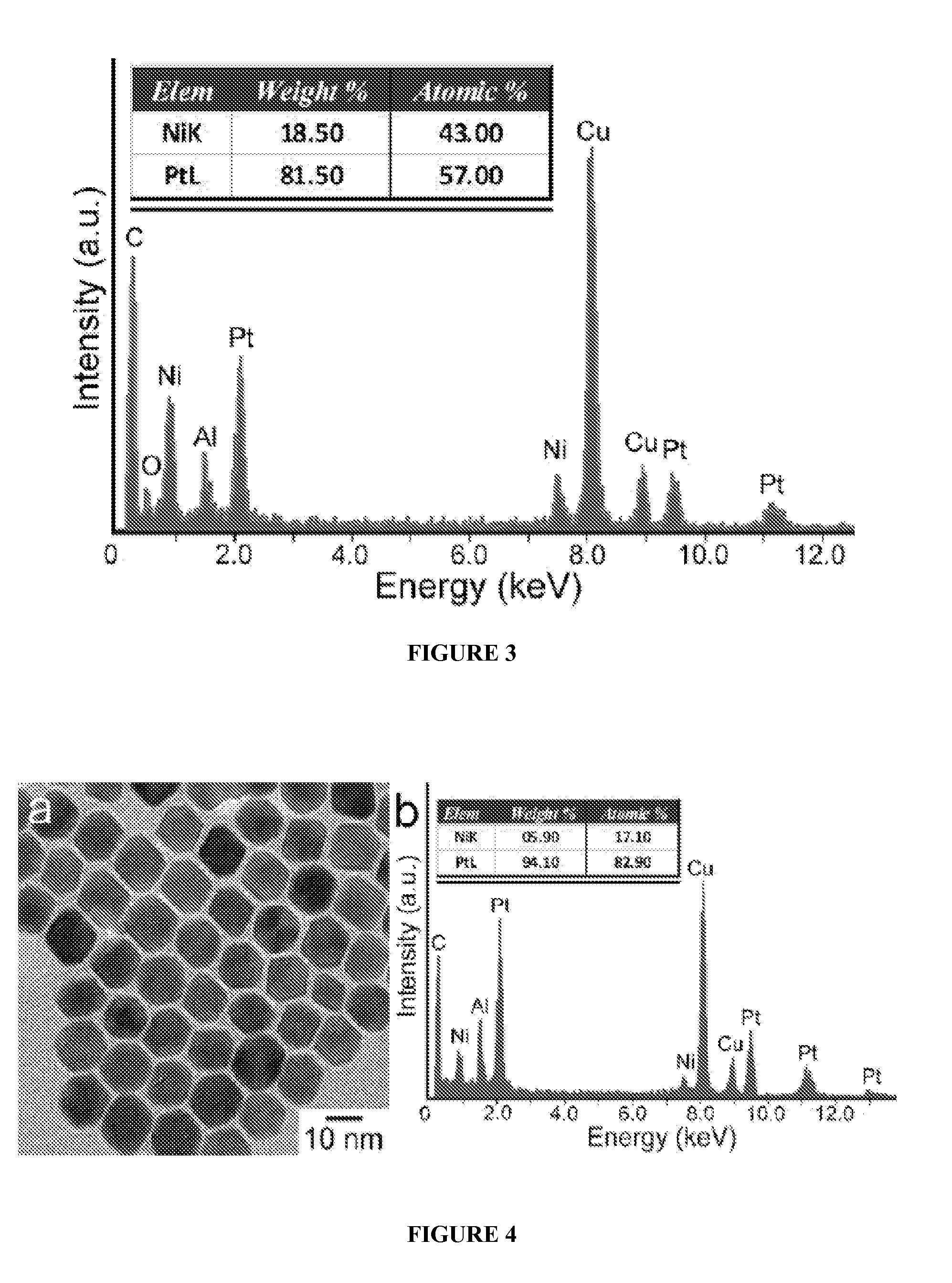

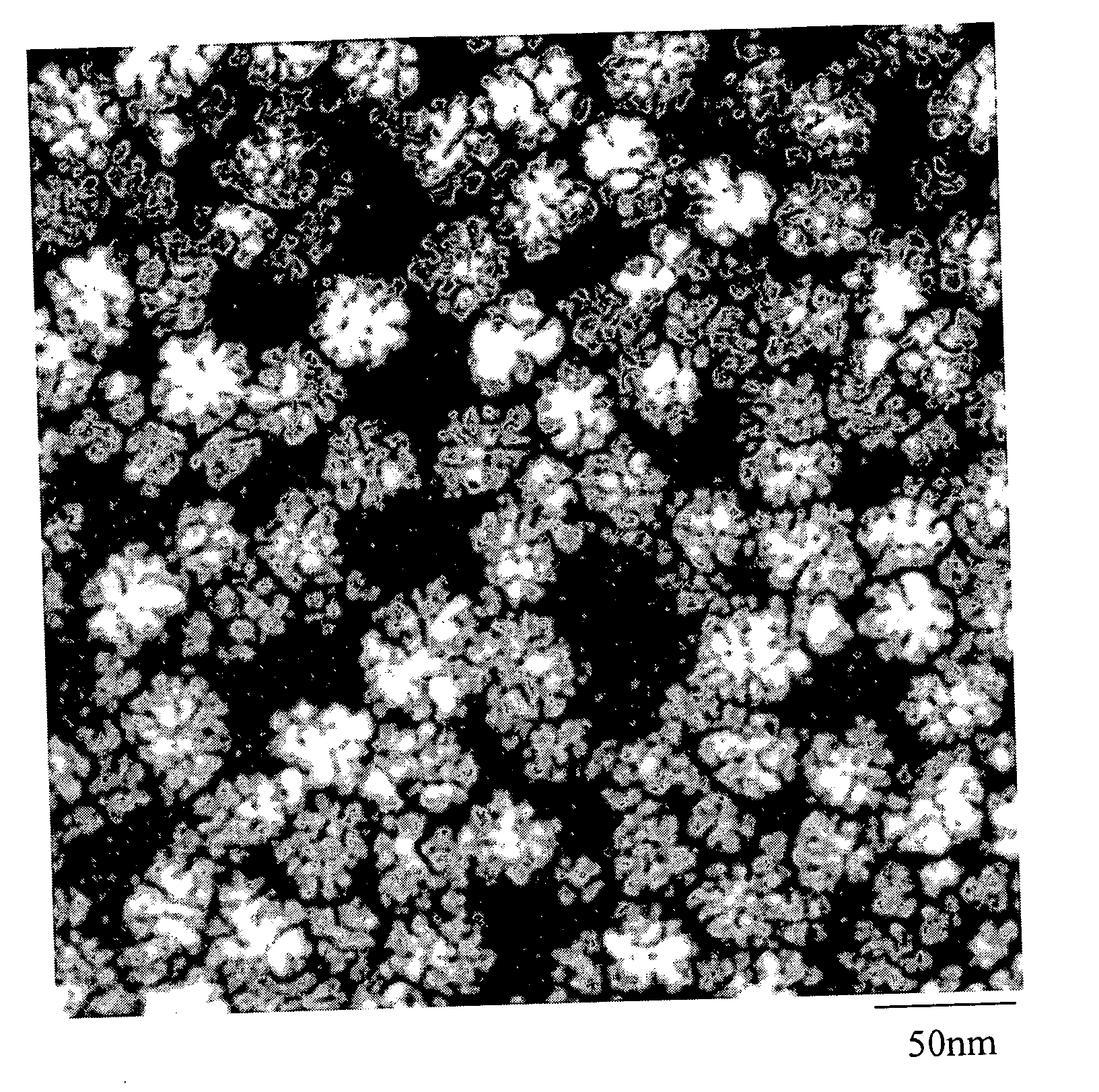

Synthesis of Nanoparticles Using Reducing Gases

Selective gas-reducing methods for making shape-defined metal-based nanoparticles. By avoiding the use of solid or liquid reducing reagents, the gas reducing reagent can be used to make shape well-defined metal- and metal alloy-based nanoparticles without producing contaminates in solution. Therefore, the post-synthesis process including surface treatment become simple or unnecessary. Weak capping reagents can be used for preventing nanoparticles from aggregation, which makes the further removing the capping reagents easier. The selective gas-reducing technique represents a new concept for shape control of nanoparticles, which is based on the concepts of tuning the reducing rate of the different facets. This technique can be used to produce morphology-controlled nanoparticles from nanometer- to submicron- to micron-sized scale. The Pt-based nanoparticles show improved catalytic properties (e.g., activity and durability).

Owner:UNIVERSITY OF ROCHESTER

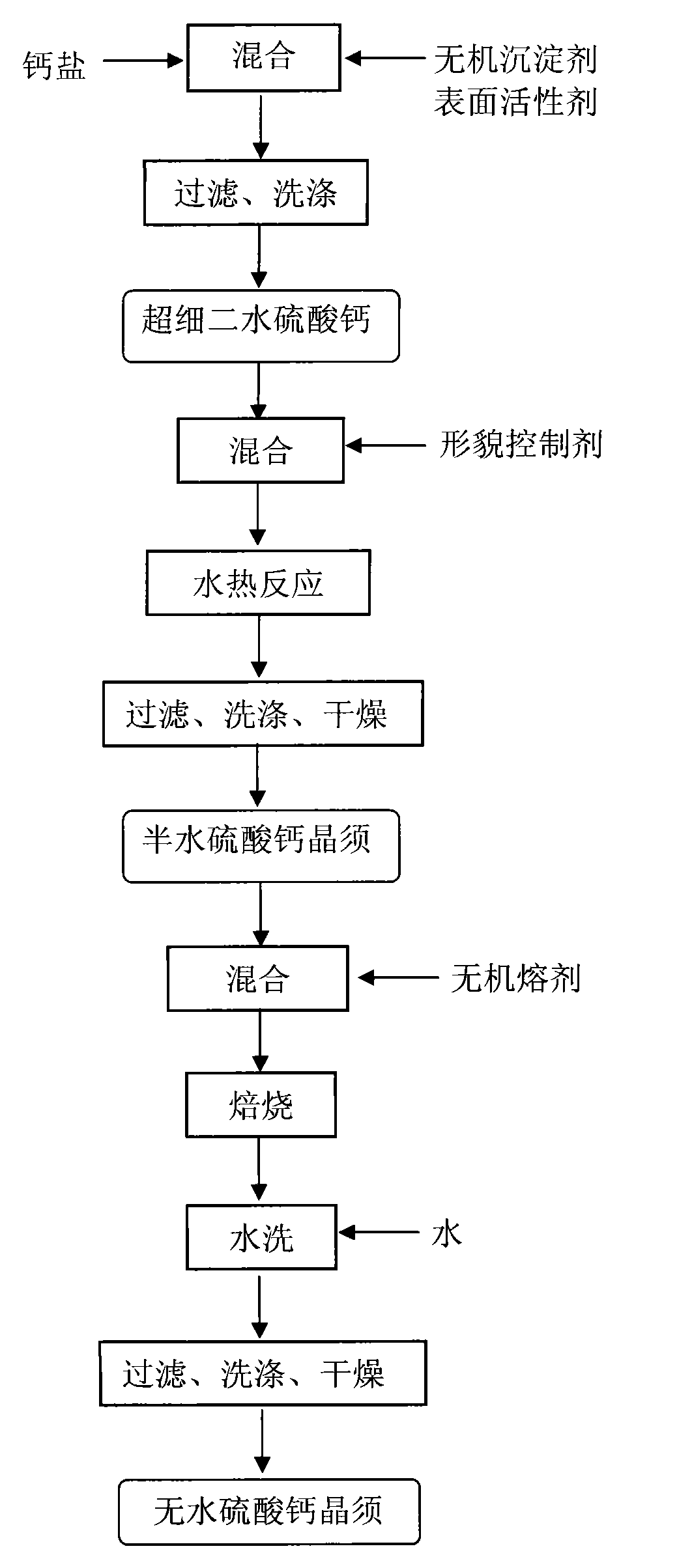

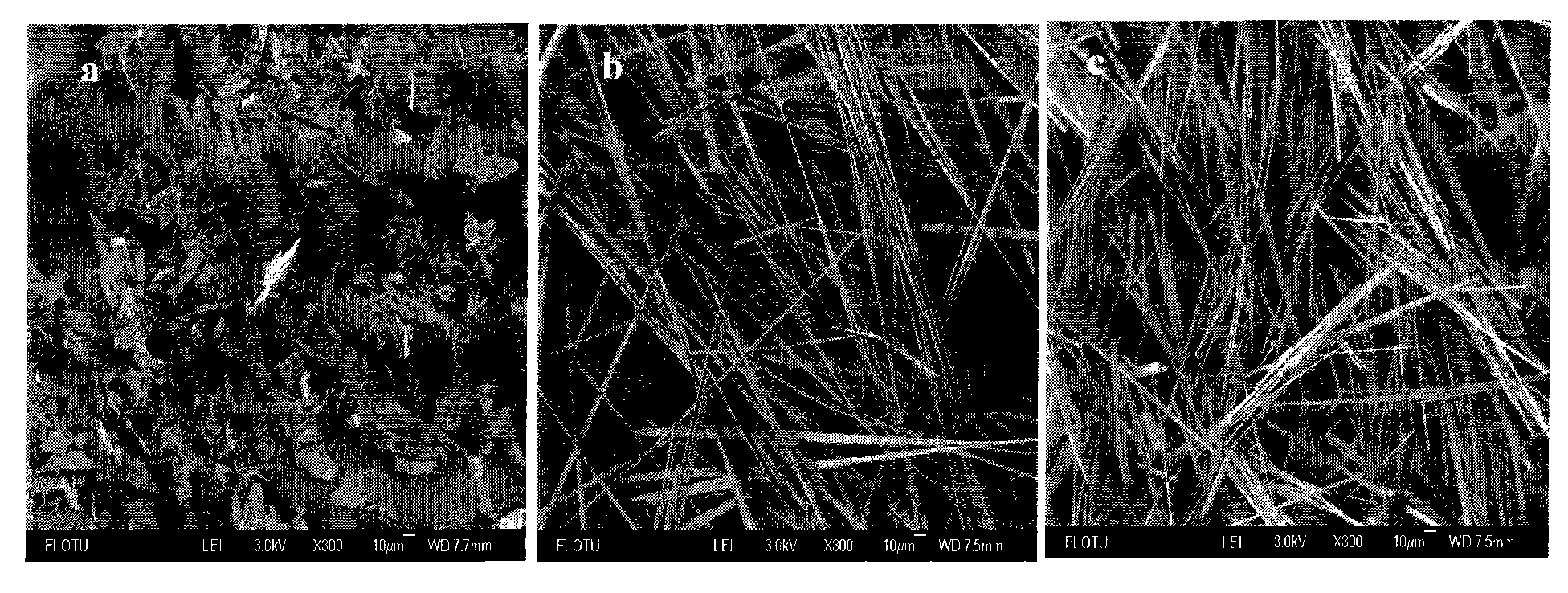

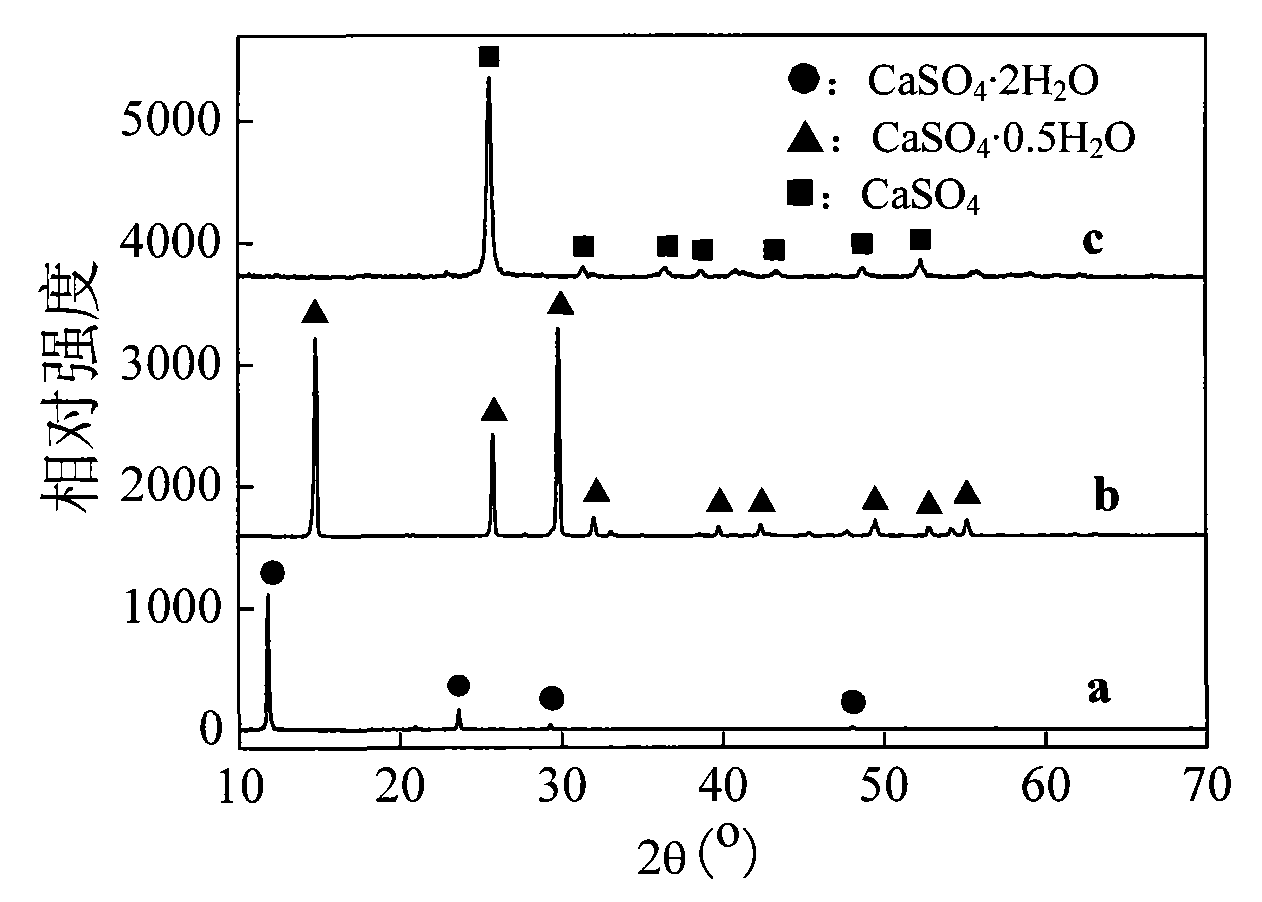

Preparation method of high length-diameter ratio anhydrous calcium sulfate whisker

ActiveCN101671848AHigh crystallinityMorphological rulesPolycrystalline material growthFrom normal temperature solutionsAnhydrous Calcium SulfatePapermaking

A preparation method of high length-diameter ratio anhydrous calcium sulfate whisker belongs to the technical field of inorganic chemical material preparation. The method takes inorganic calcium saltand inorganic precipitant as raw materials and surfactant as dispersant, and includes the following steps: first preparing superfine calcium sulphate dihydrate precursor with good dispersion at the temperature of 10-90 DEG C; then adding the precursor into water solution containing shape control agent to conduct hydrothermal reaction for 0.5-10h at the temperature of 100-250 DEG C, and obtaining calcium sulfate hemihydrate whisker; mixing the calcium sulfate hemihydrate whisker with inorganic solvent; and roasting the mixture for 0.5-6h at the temperature 200-800 DEG C to obtain anhydrous calcium sulfate whisker with the length of 20-2000mum, the diameter of 0.5-20mum, the length-diameter ratio of 40-1000 and the main content greater than 95wt% after washing and drying. The technology is simple, the cost is low and the added value of the product is high. The prepared calcium sulfate whisker has large length-diameter ratio and regular shape and can be used as reinforcing material to beapplied in industries such as plastics, rubber, ceramics, cement, papermaking and the like.

Owner:TSINGHUA UNIV

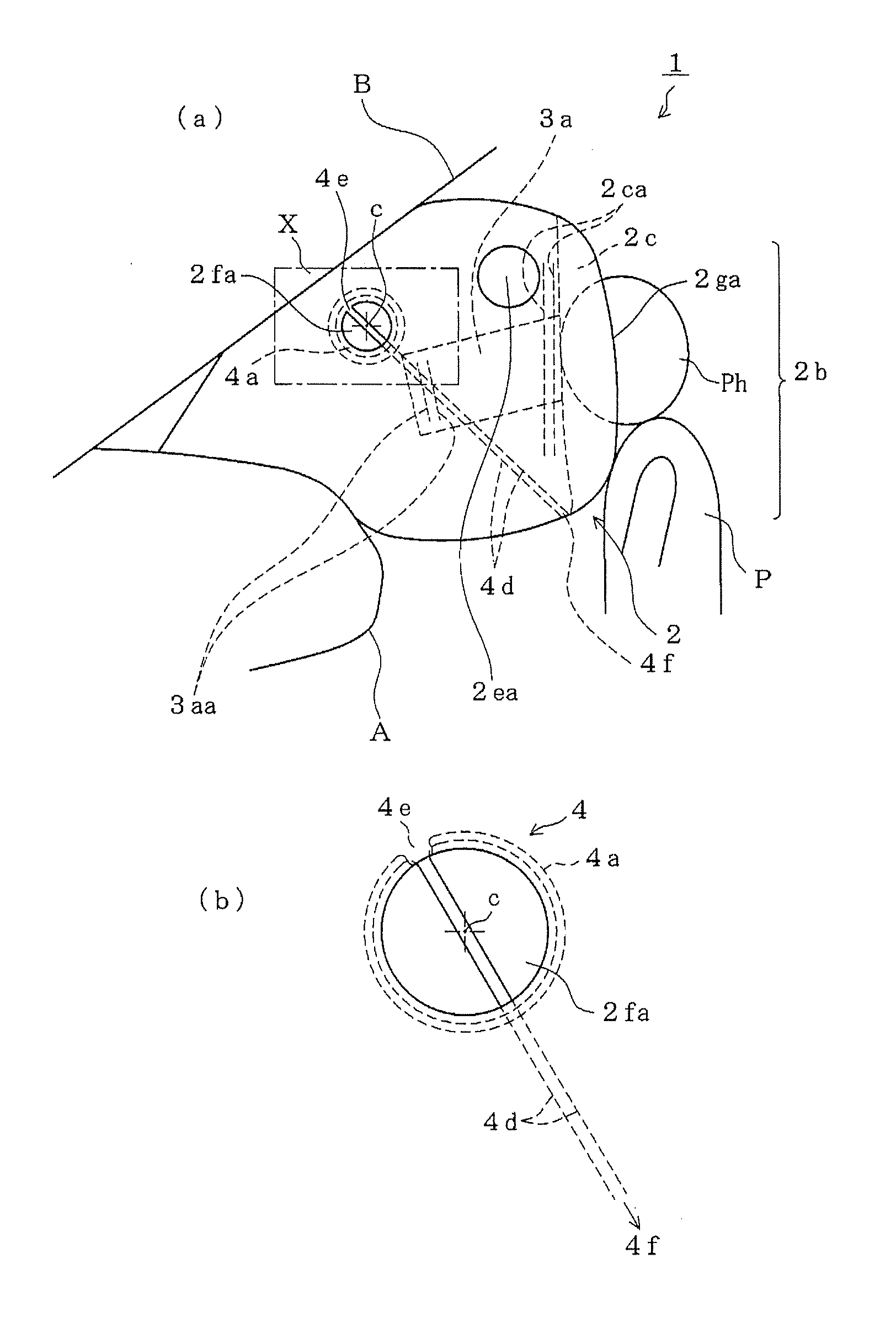

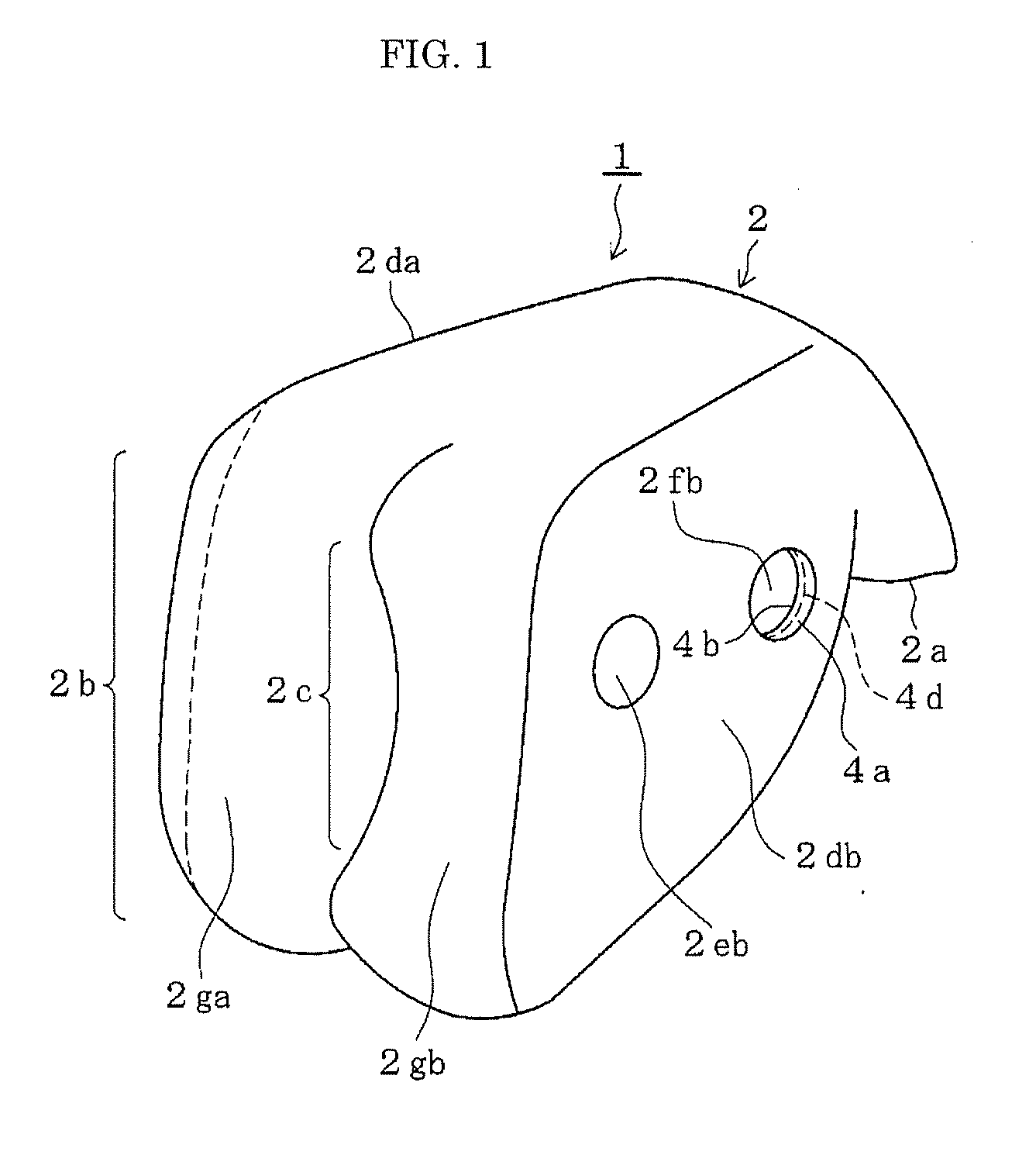

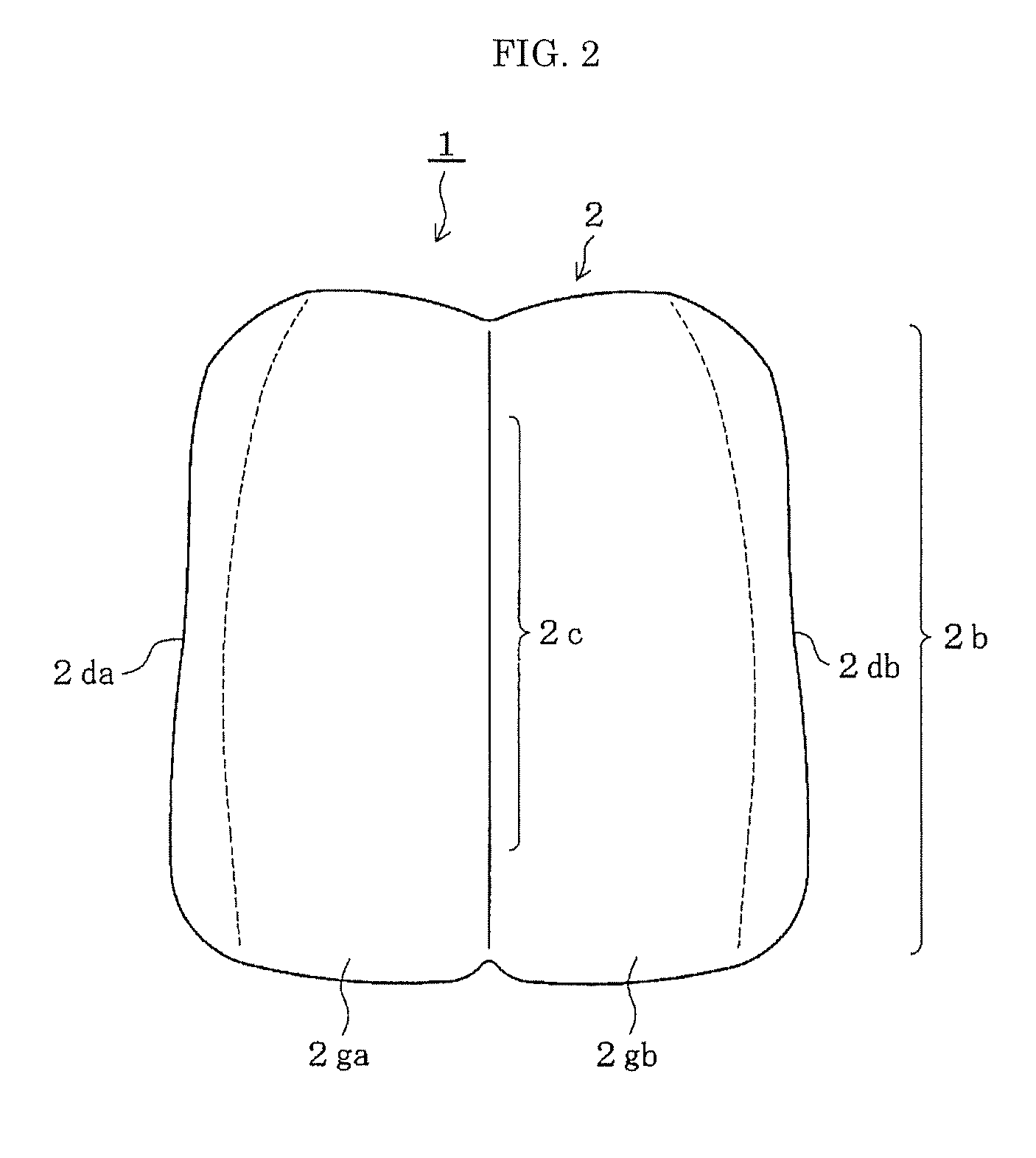

Airbag device

[PROBLEMS] To cushion impact acting on an occupant who is not in a regular position. [MEANS FOR SOLVING PROBLEMS] When an abnormality occurs, an airbag device (1) inflates and expands in front of an occupant and absorbs an impact from the front of a vehicle. An airbag (2) to which gas from an inflator is supplied in an abnormality is provided with a vertical recess (2c) facing the head (Ph) of the occupant (P). The recess (2c) is located at the center, in the right and left direction of the vehicle, of an occupant restriction surface (2b) formed at a position facing the occupant (P) sitting on the seat during inflation and expansion. At least one fixed vent (2ea, 2eb) and at least one variable vent (2fan, 2fb) are provided at each of opposite sidewalls (2da, 2db). The fixed vent (2ea, 2eb) has an invariant opening area, and the variable vents (2fan 2fb) has an opening area variable depending on the sitting position of the occupant (P) during expansion. The recess (2c) and the opposite sidewalls (2da, 2db) are coupled in the airbag (2) by shape control members (3a,3b). [EFFECT] Even an occupant of out of position or an occupant not wearing a seat belt can be received relatively flexibly, and trouble caused on the occupant by the airbag is reduced.

Owner:AUTOLIV DEV AB

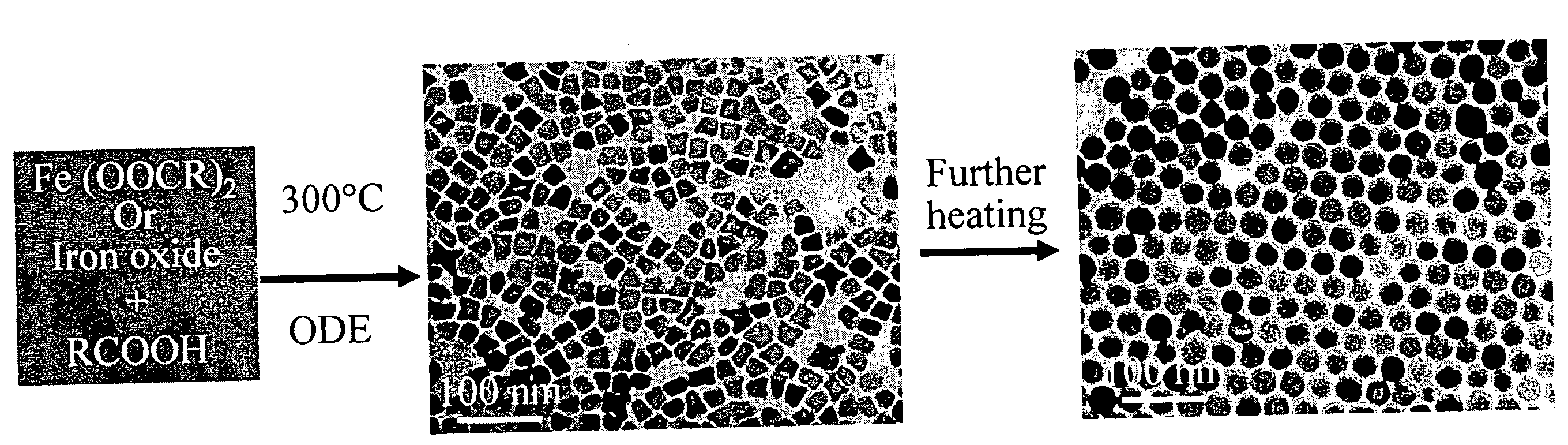

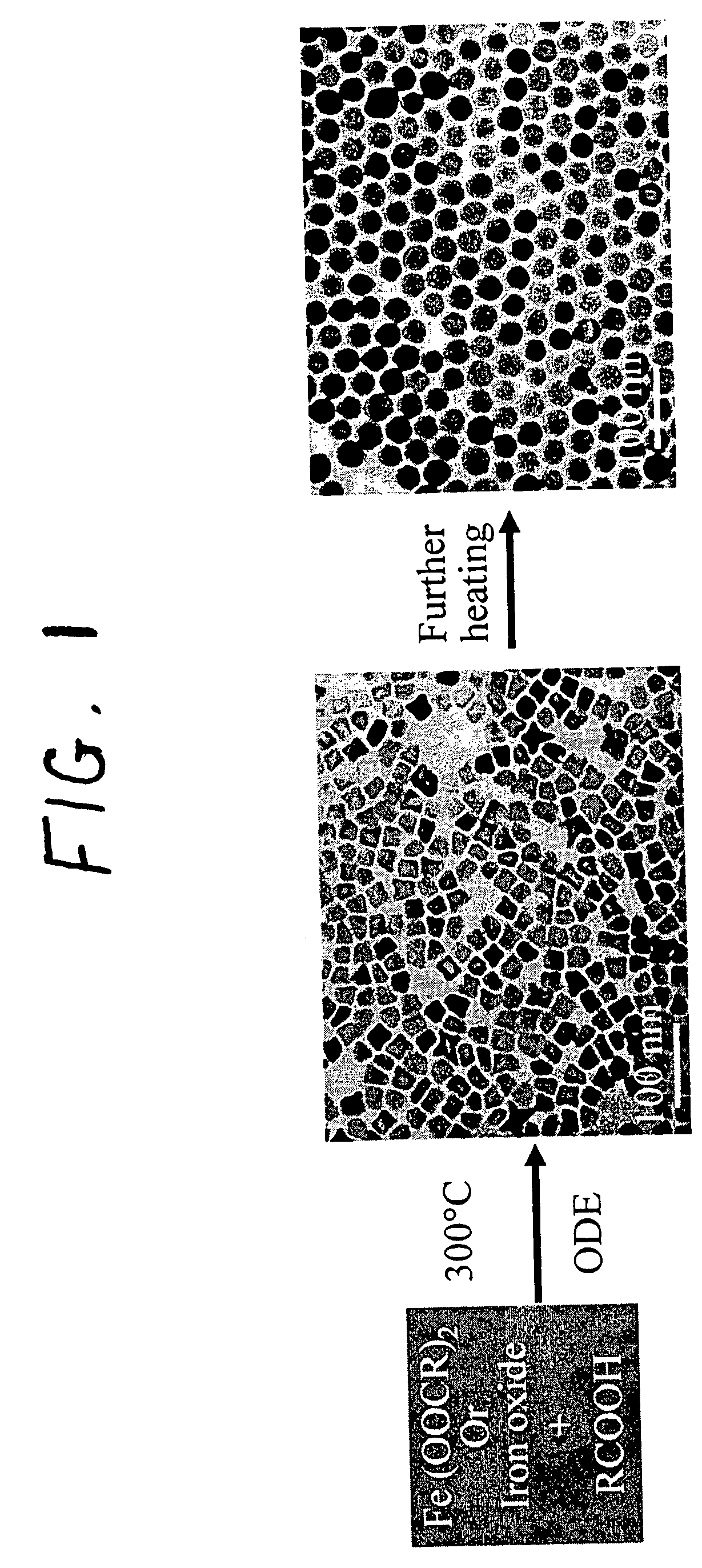

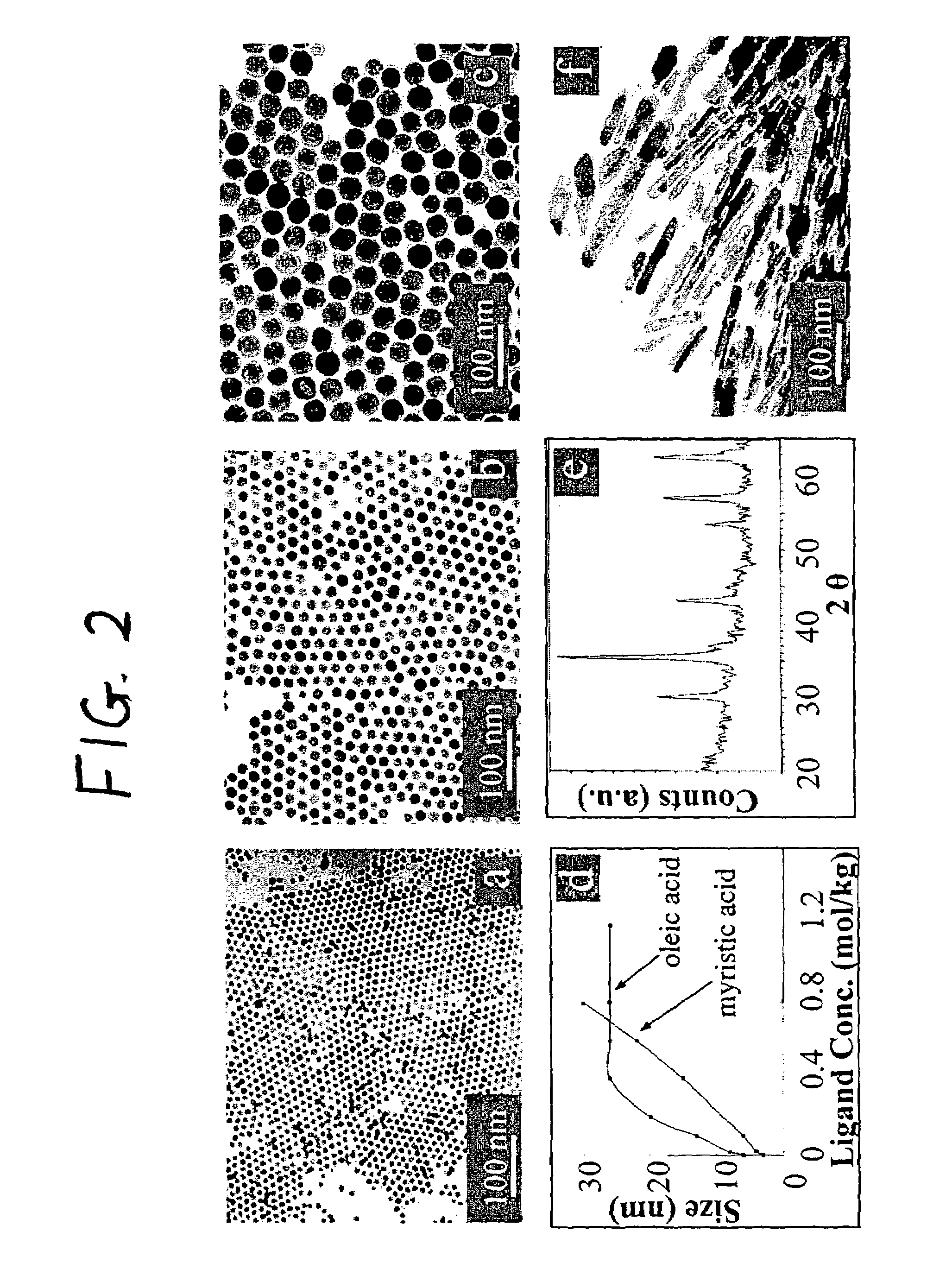

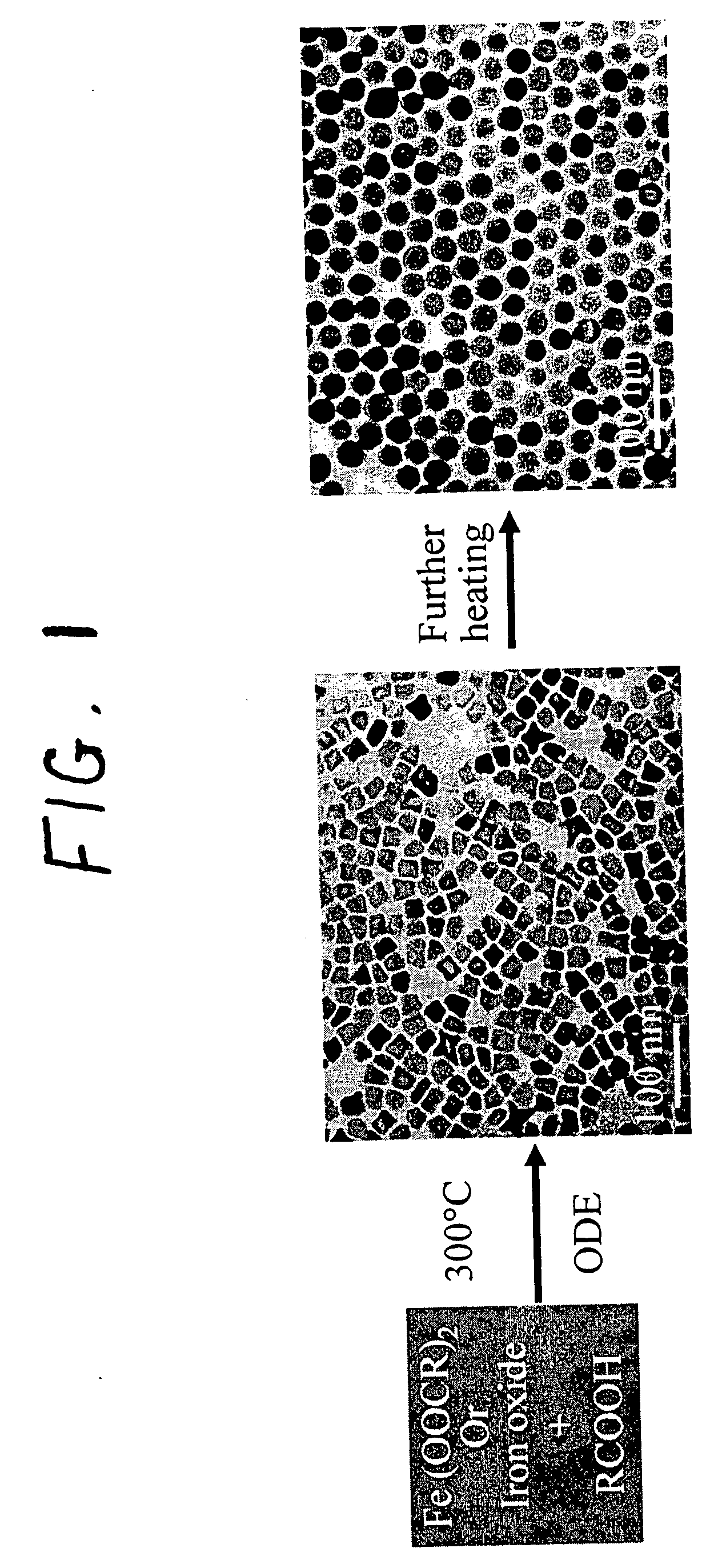

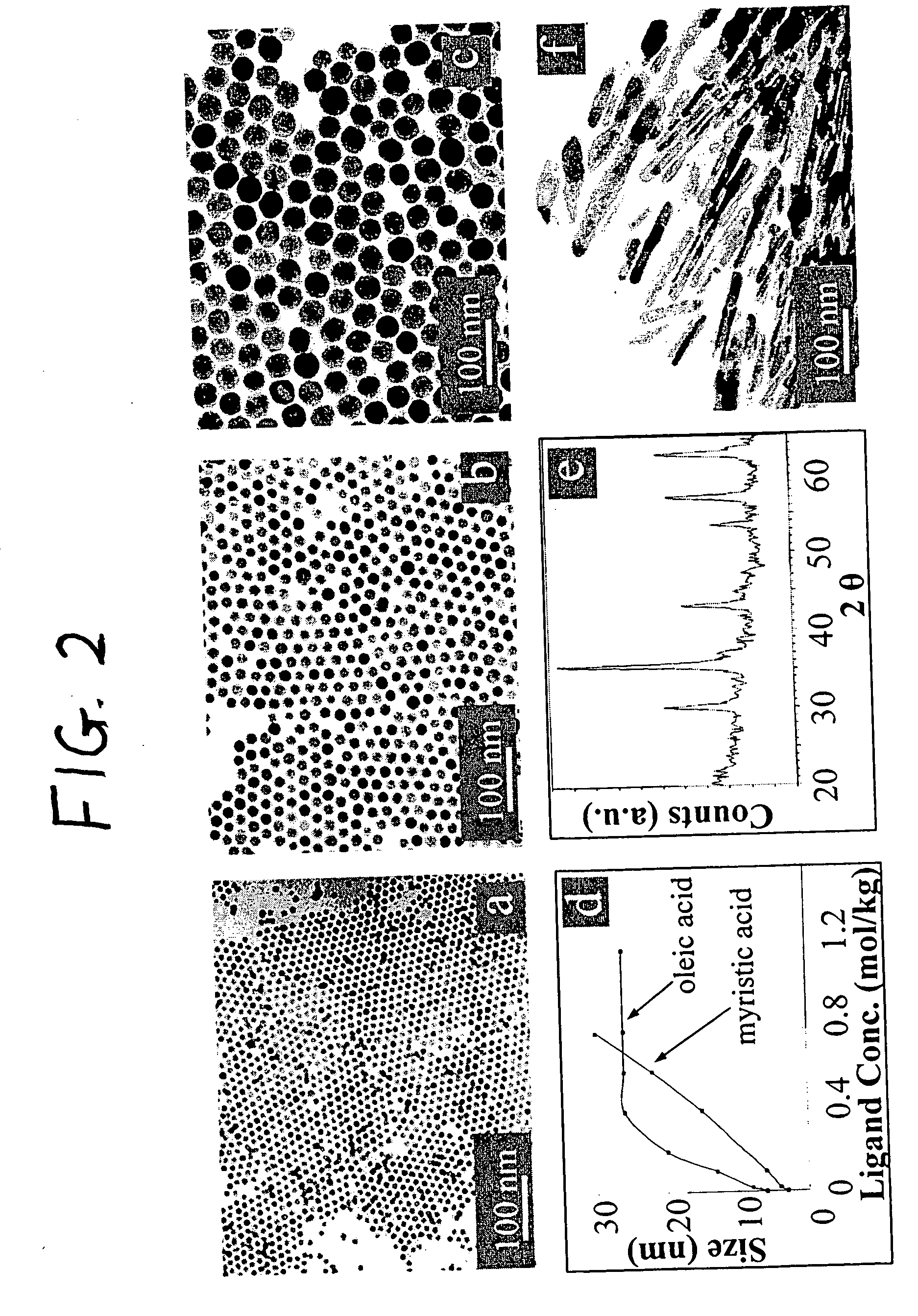

Synthetic control of metal oxide nanocrystal sizes and shapes

A general, reproducible, and simple synthetic method that employs readily available chemicals permits control of the size, shape, and size distribution of metal oxide nanocrystals. The synthesis entails reacting a metal fatty acid salt, the corresponding fatty acid, and a hydrocarbon solvent, with the reaction product being pyrolyzed to the metal oxide. Nearly monodisperse oxide nanocrystals of Fe3O4, Cr2O3, MnO, Co3O4, NiO, ZnO, SnO2, and In2O3, in a large size range (3-50 nm), are described. Size and shape control of the nanocrystals is achieved by varying the reactivity and concentration of the precursors.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS

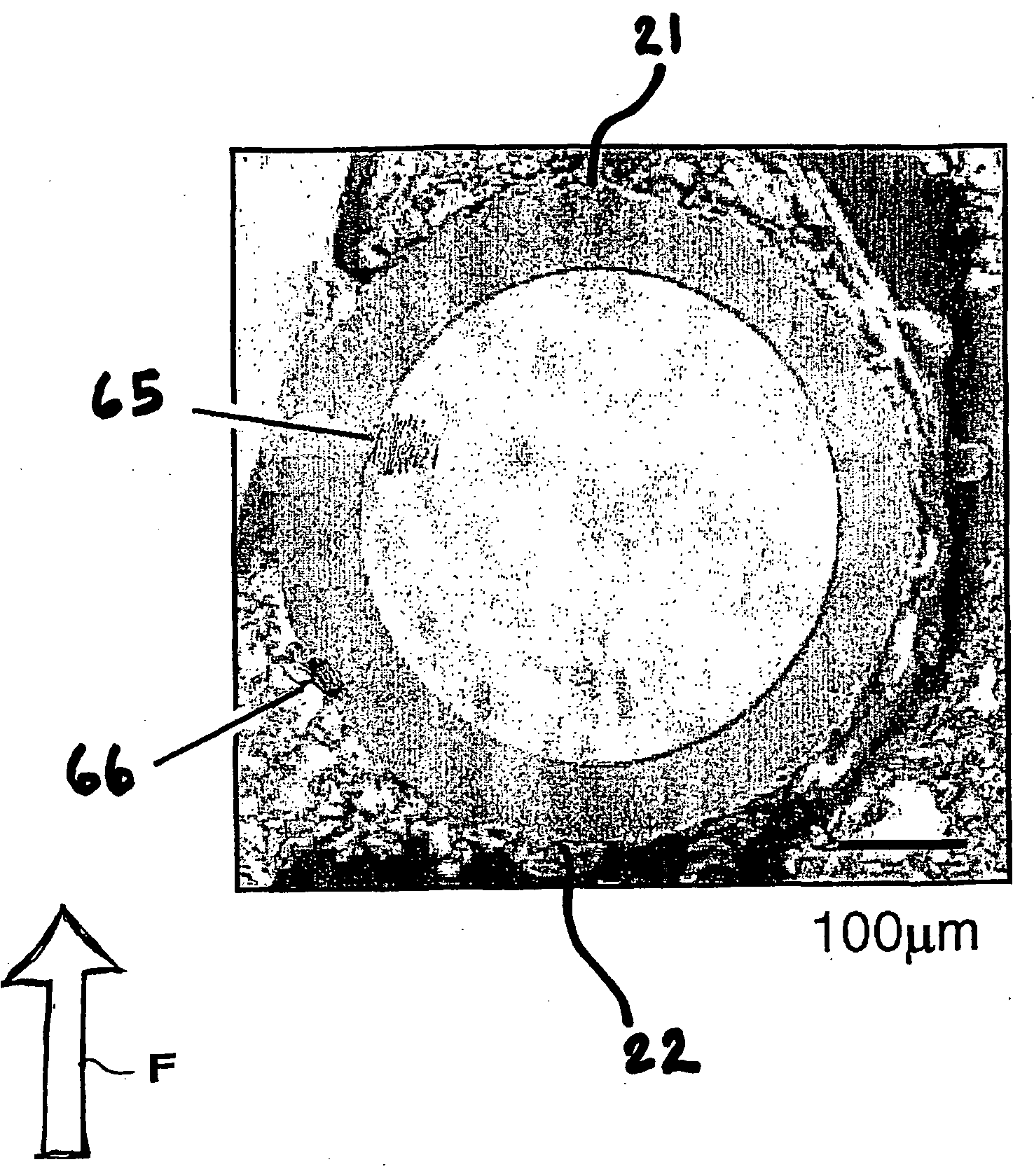

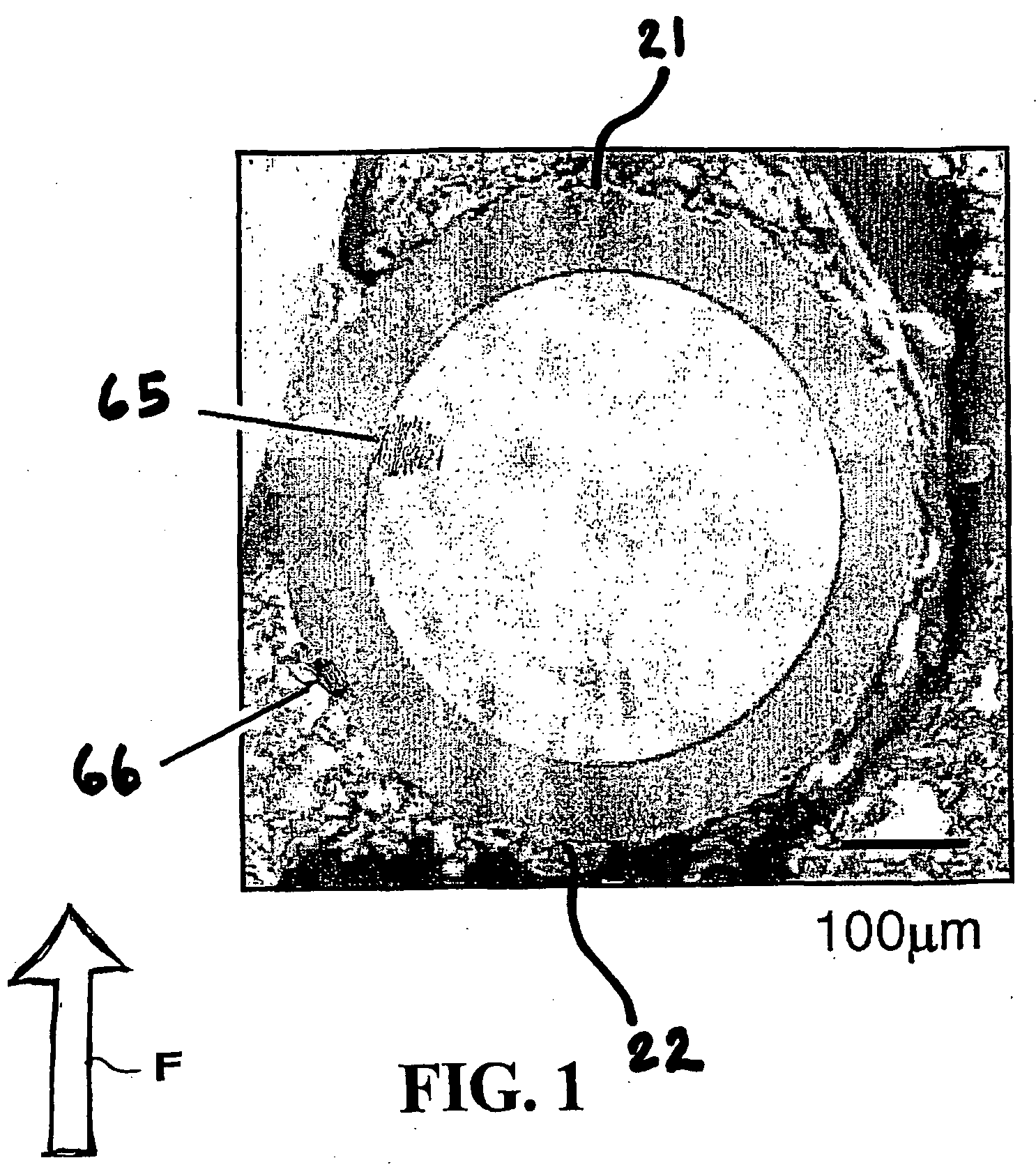

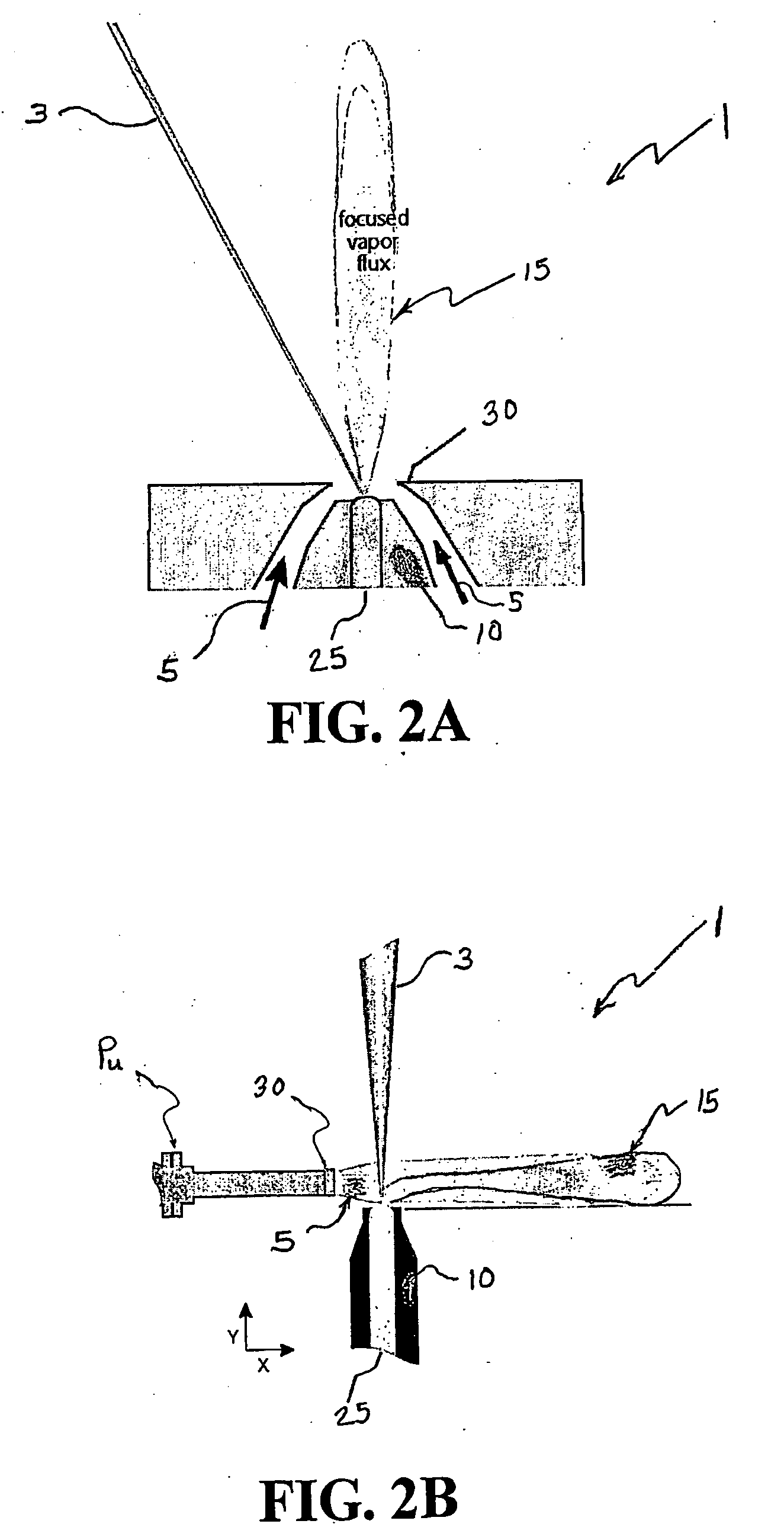

Apparatus and method for applying coatings onto the interior surfaces of components and related structures produced therefrom

ActiveUS20090017217A1Limited effectivenessWide rangeMolten spray coatingElectric discharge heatingEngineeringVacuum chamber

Provided is a methodology and system for applying coatings onto the interior surfaces of components. The approach comprises a vapor creation device (for example an electron beam or laser that evaporates a single or multiplicity of solid or liquid sources), a vacuum chamber having a moderate gas pressure (between about 10−4 to about 103 Torr) and a inert gas jet having controlled velocity and flow fields of gas jet. The gas jet is created by a rarefied, inert gas supersonic expansion through a nozzle. By controlling the carrier gas flow into a region upstream of the nozzle an upstream pressure is achieved (i.e. the gas pressure prior to its entrance into the processing chamber through the nozzle). The carrier gas flow and chamber pumping rate control the downstream (or chamber) pressure (i.e., downstream of the nozzle). The ratio of the upstream to downstream pressure along with the size and shape of the nozzle opening controls the speed of the gas entering the chamber. The carrier gas molecular weight (compared to that of the vapor) and the carrier gas speed controls its effectiveness in redirecting the vapor atoms via binary collisions towards the substrate. The speed and flux of the atoms entering the chamber, the nozzle parameters, and the operating chamber pressure can all vary leading to a wide range of accessible processing conditions. Vapor created from a source is transported into the interior regions of a component using binary collisions between the vapor and gas jet atoms. Under certain process conditions these collisions enable the vapor atoms to scatter onto the interior surfaces of the component and deposit.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

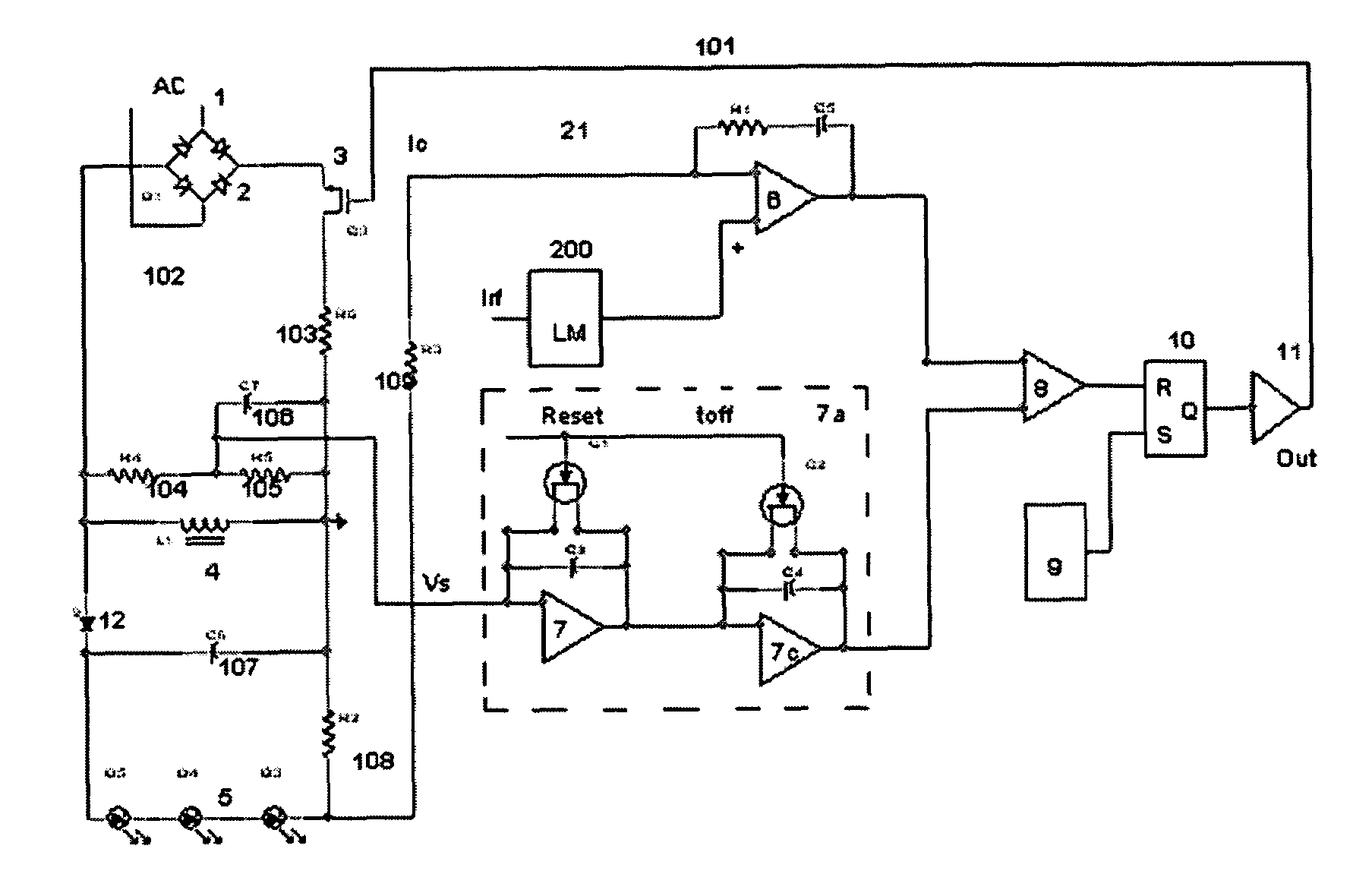

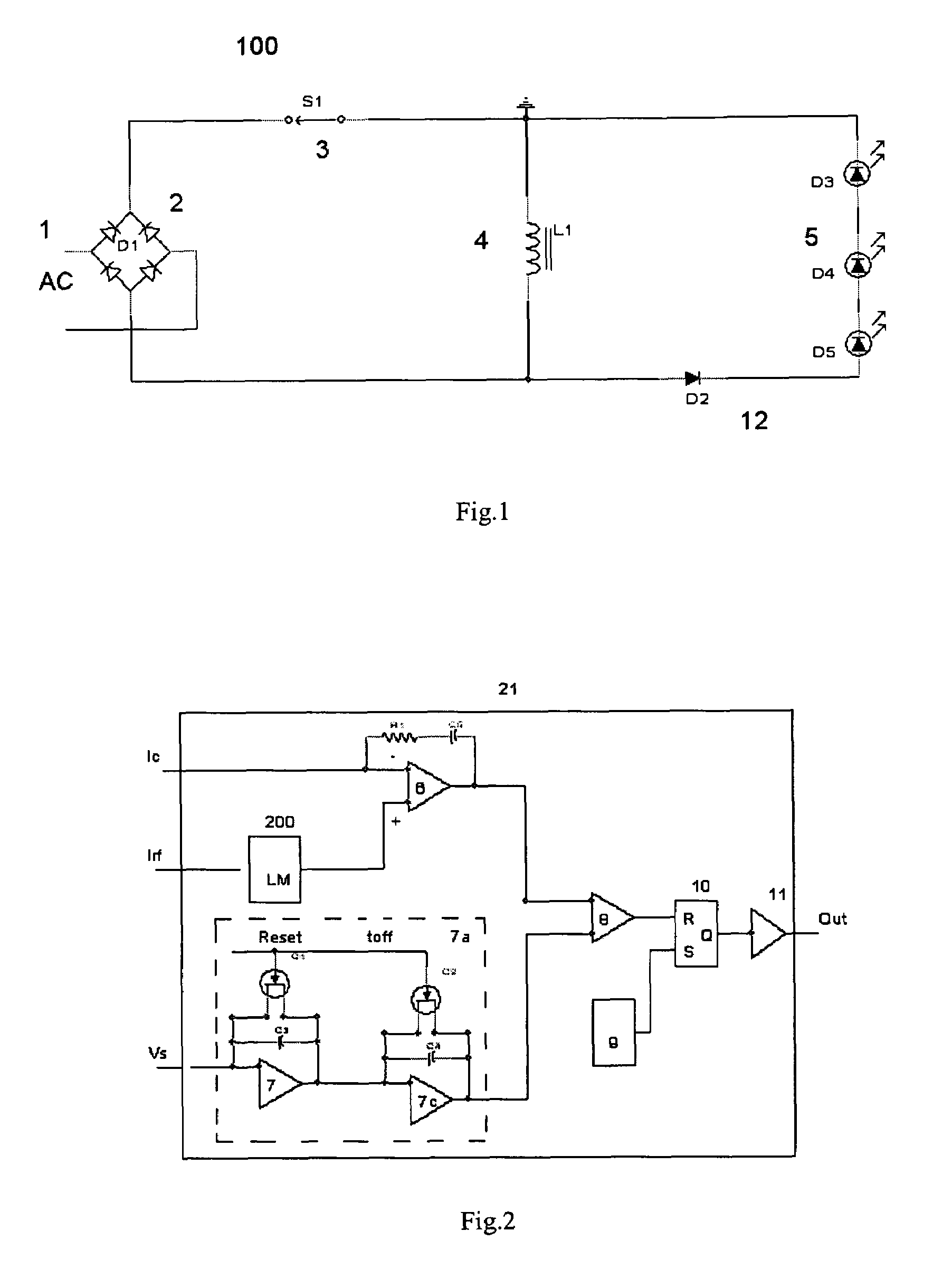

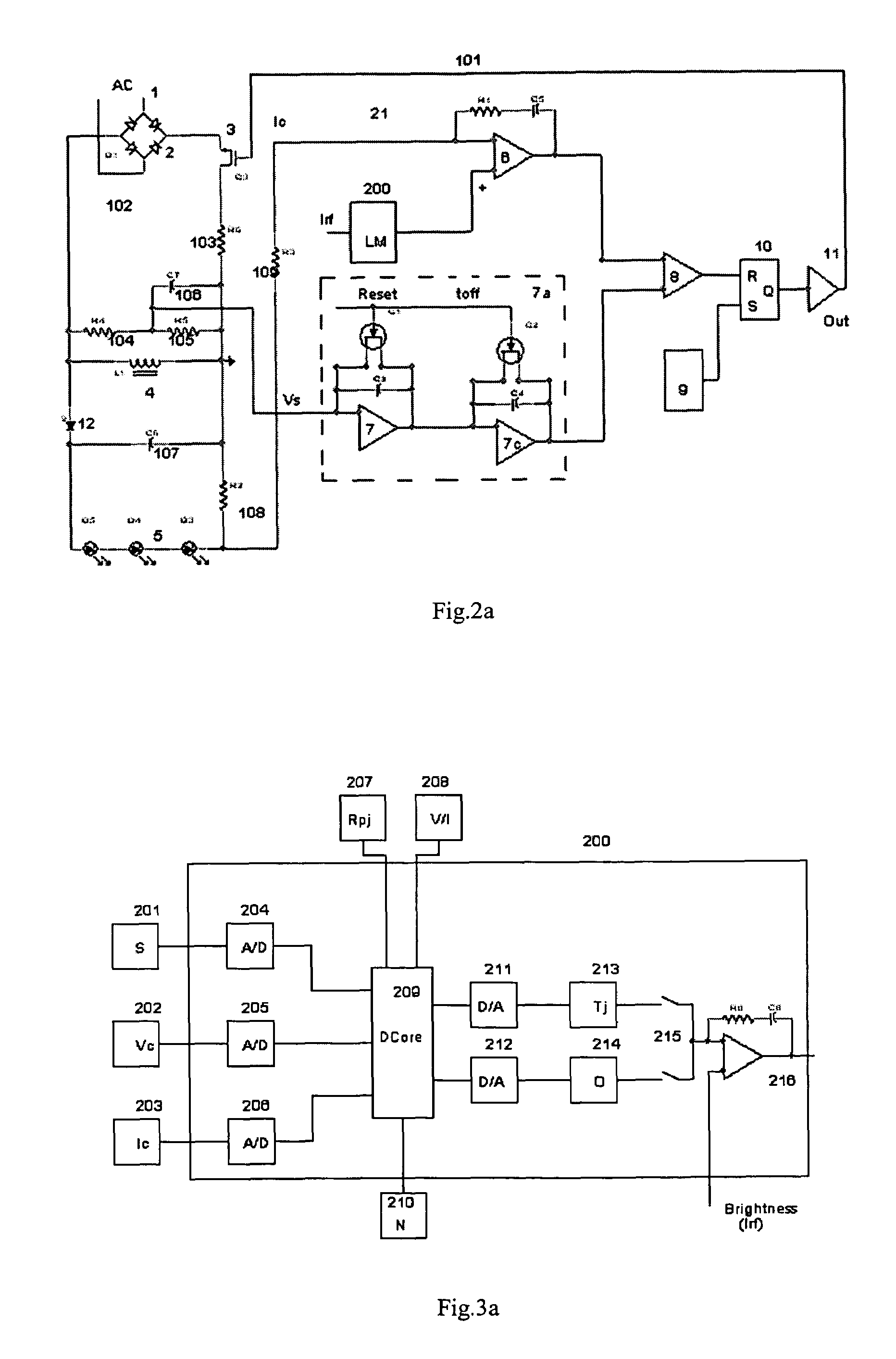

Off line LED driver with integrated synthesized digital optical feedback

ActiveUS7598685B1Quality improvementImprove power factorElectrical apparatusElectroluminescent light sourcesEngineeringAc current

The present invention creates an LED driver in which all feedback signals are derived from a power stage media, and presents an isolated off-line LED driver with an accurate primary side controller only to power one or more LEDs. The present invention further provides an effective off-line LED driver comprising AC current shape controller with a minimum number of components. The present invention further provides a high quality luminous system based on LED drivers with the integrated synthesized optical feedback to compensate for imperfections of the LEDs as sources of light.

Owner:CHEMTRON RES

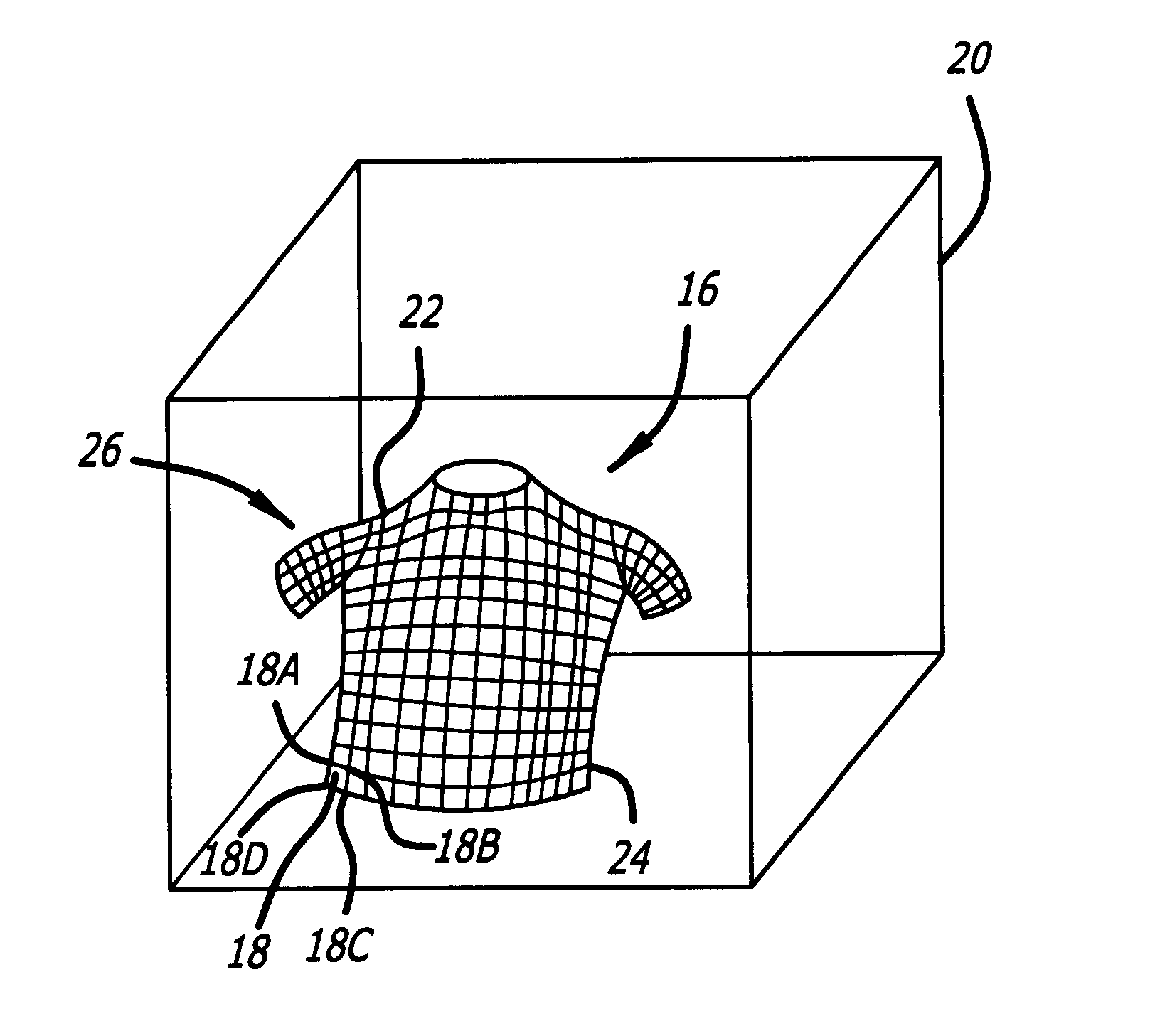

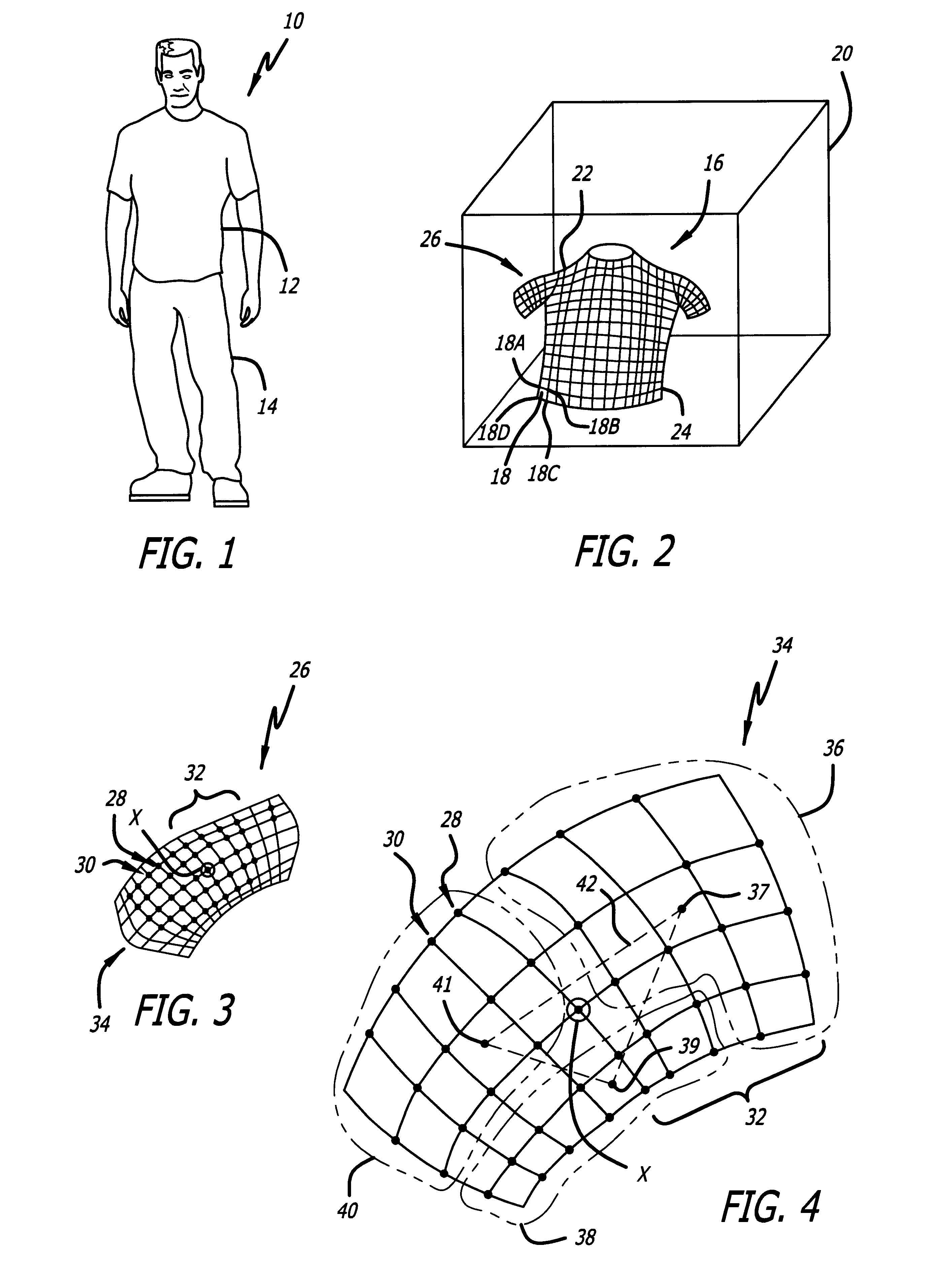

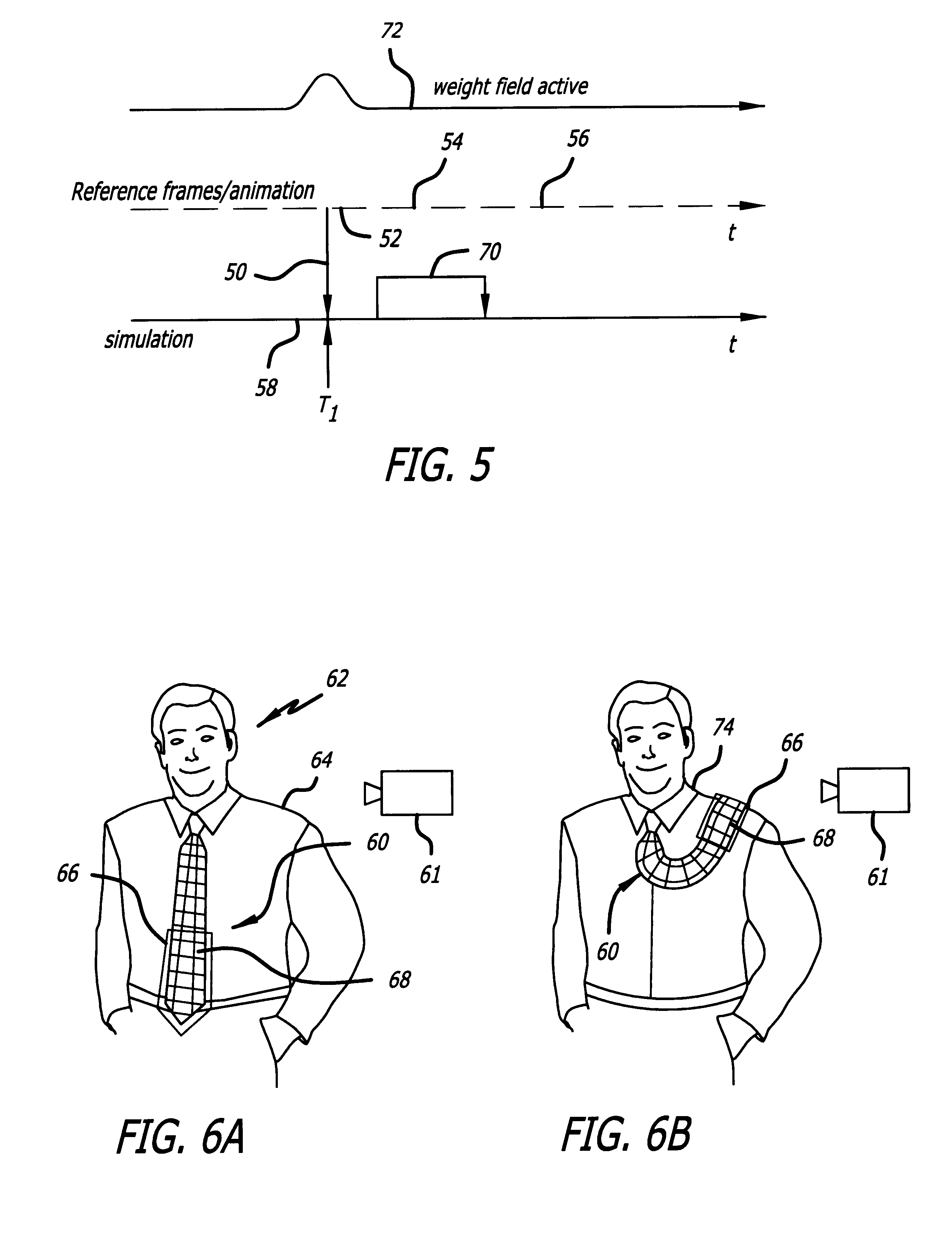

Position and shape control for cloth and soft body animation

InactiveUS6909431B1Objectionable movementObjectionable popAnimationImage generationAnimationSoft body

Animation controls according to the present invention introduce a predictable level of control for animation without the need for iterating the simulation. Controls include shape controls that permit the effect of the simulation to be overridden for cloth and soft body materials. The effect of shape tacks are to control the local shape of objects such as cloth and soft body materials, the shape may be weighted and time varying. Shape tacking is relative to the reference coordinate system of the object being shaped. Position tacks provide control in absolute space and permit accurate placement of an object to be animated overriding the control of the simulation.

Owner:LUCASFILM ENTERTAINMENT

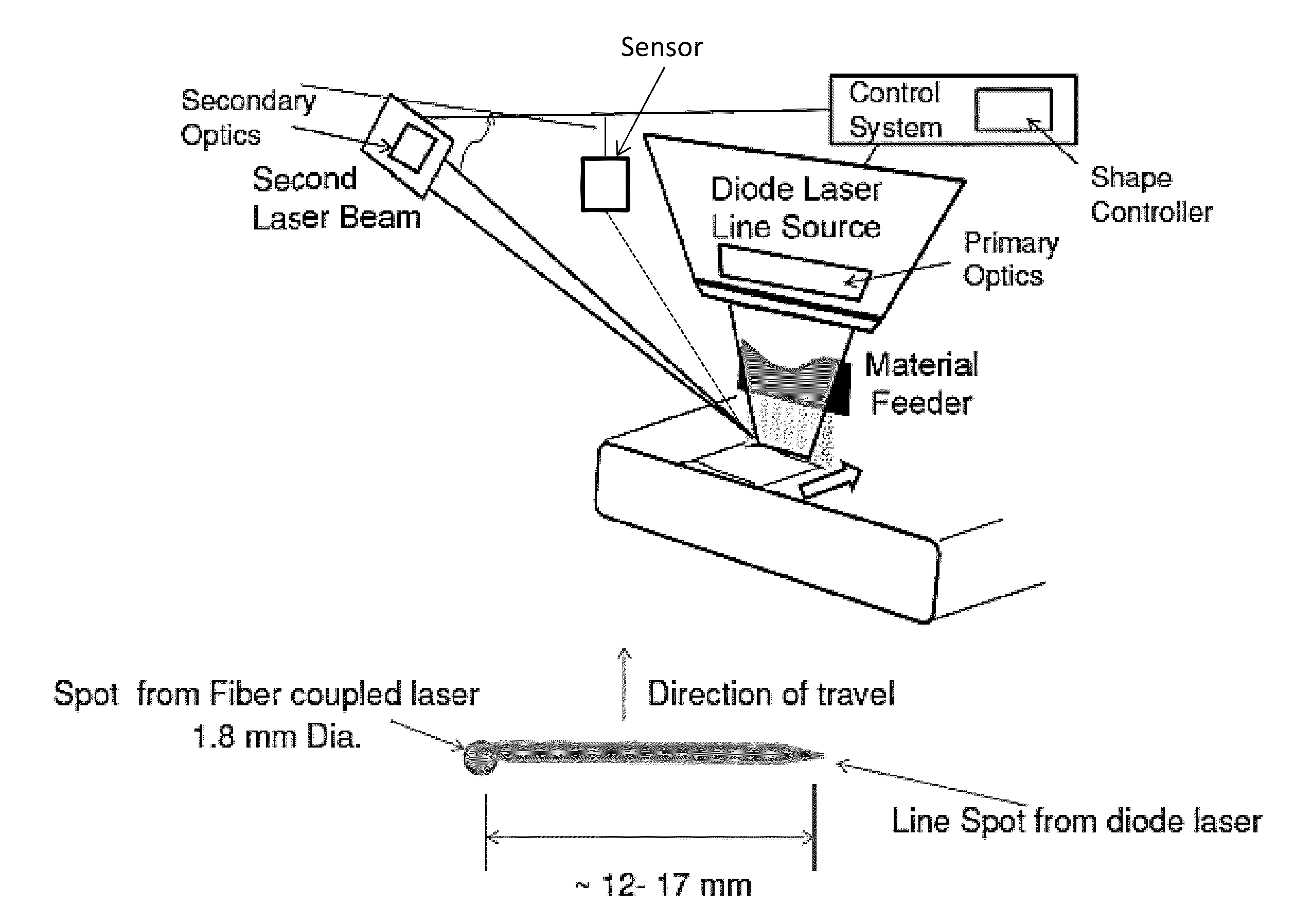

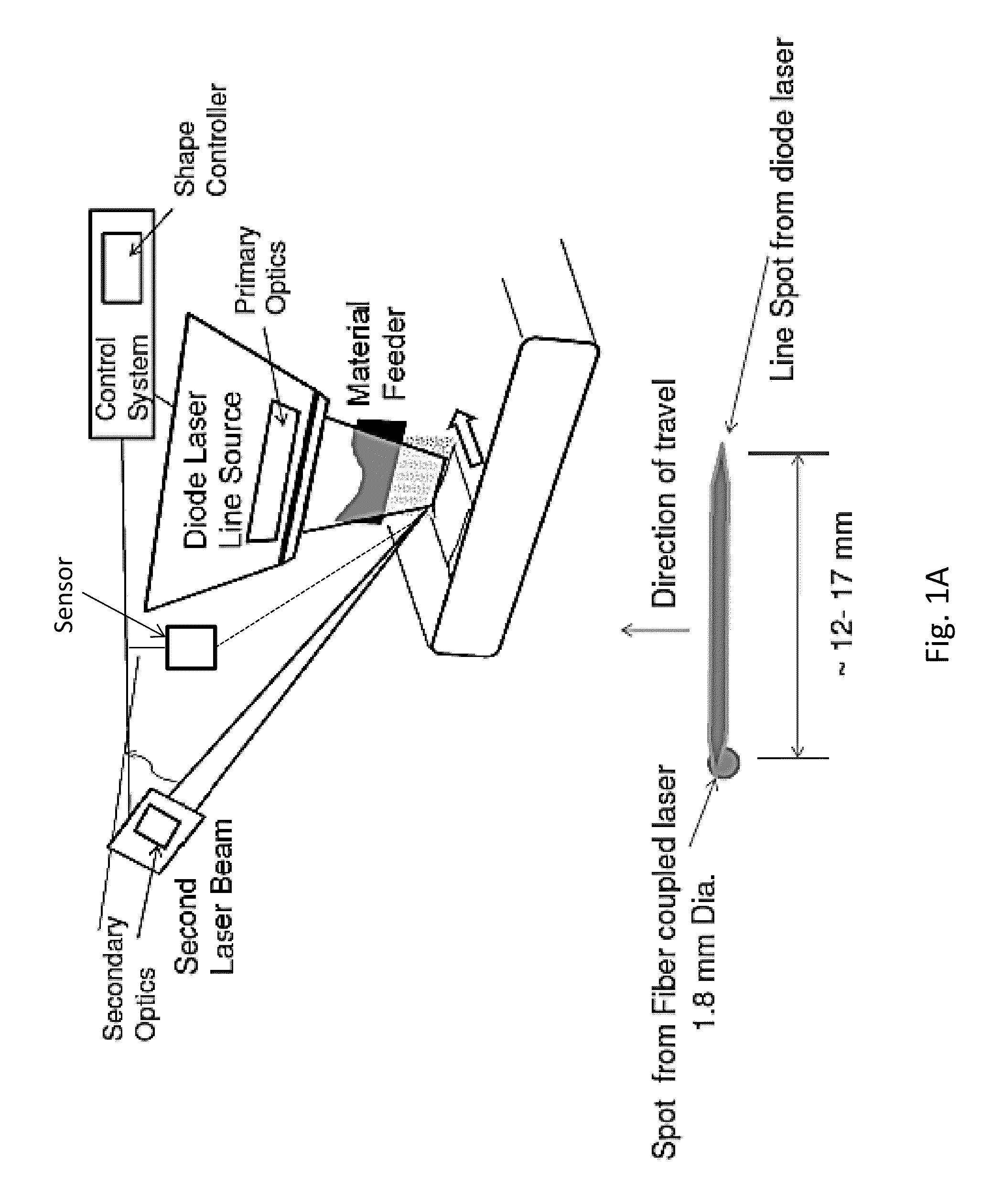

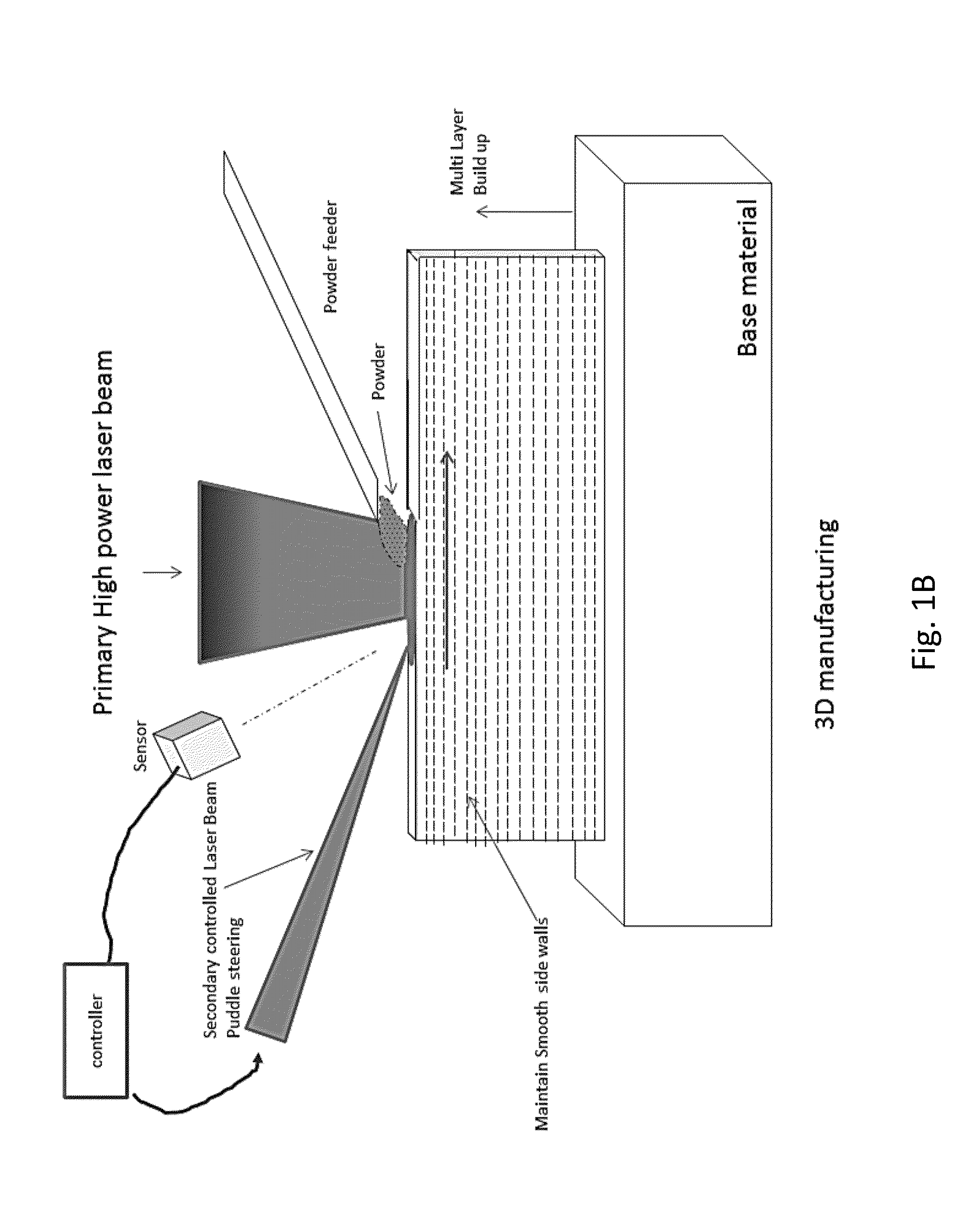

Puddle forming and shaping with primary and secondary lasers

A material processing system for a base material is provided. The system includes a feeder having a distal end proximate to a surface location of the base material. The feeder supplies a deposit material to the surface location. The deposit material has a width having a first side and a second side. A first laser is directed to the deposit material at the surface location. The first laser is directed across the width from the first side to the second side. A second laser is directed to a desired location within the width. A control system drives the process of cladding the deposit material. The control system includes a shape controller to control the movement of the secondary laser along the deposit material based on feedback from a sensor.

Owner:TITANOVA

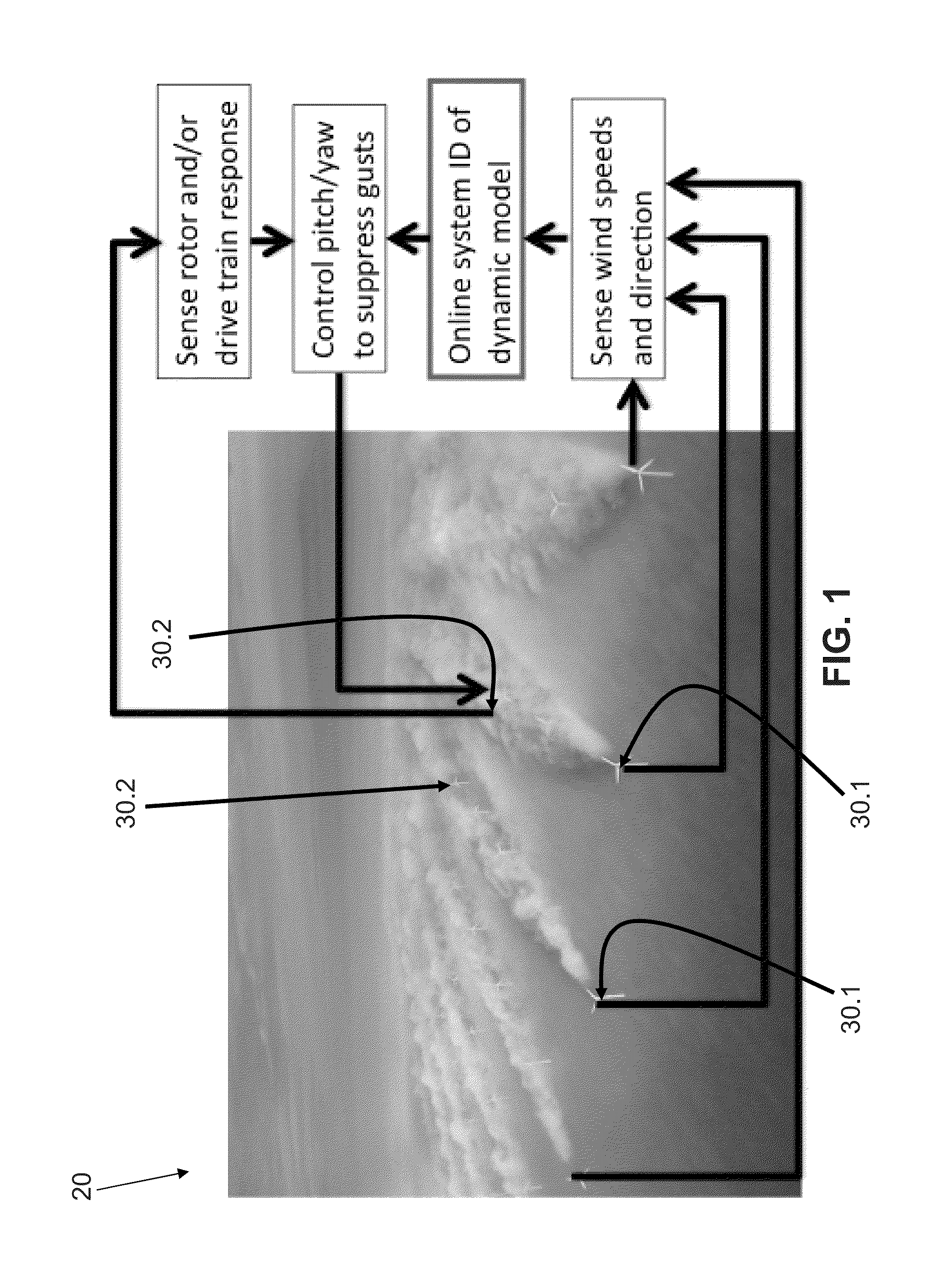

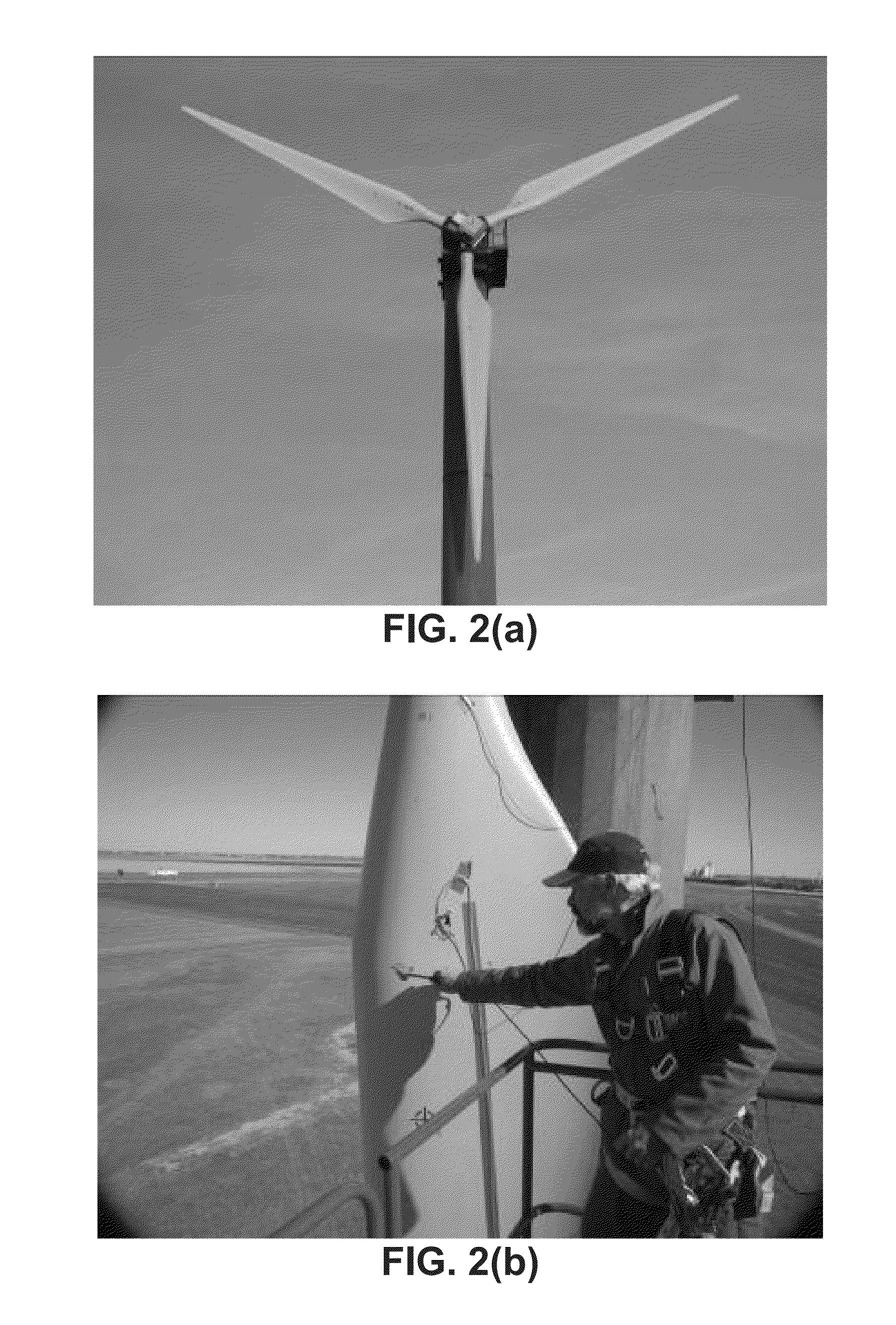

Load shape control of wind turbines

Methods and apparatus for control and monitoring of wind turbines. Various embodiments pertain to the operational analysis of vibratory modes of the blades of the wind turbine. This real time analysis of blade modal response can be used as feedback in a control system to change the yaw angle of the hub and nacelle to capture higher power from the wind stream, change the pitch on one or more blades to reduce uneven blade loading, to identify damage to a blade, and further to identify the accumulation of ice on a blade.

Owner:PURDUE RES FOUND INC

Combustion process and apparatus therefore containing separate injection of fuel and oxidant streams

InactiveUS6331107B1Reduce nitrogen oxide emissionsAvoid chemical reactionsCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorCombustion chamber

A burner assembly having improved flame length and shape control is presented, which includes in exemplary embodiments at least one fuel fluid inlet and at least one oxidant fluid inlet, means for transporting the fuel fluid from the fuel inlet to a plurality of fuel outlets, the fuel fluid leaving the fuel outlets in fuel streams that are injected into a combustion chamber, means for transporting the oxidant fluid from the oxidant inlets to at least one oxidant outlet, the oxidant fluid leaving the oxidant outlets in oxidant fluid streams that are injected into the combustion chamber, with the fuel and oxidant outlets being physically separated, and geometrically arranged in order to impart to the fuel fluid streams and the oxidant fluid streams angles and velocities that allow combustion of the fuel fluid with the oxidant in a stable, wide, and luminous flame. Alternatively, injectors may be used alone or with the refractory block to inject oxidant and fuel gases. The burner assembly affords improved control over flame size and shape and may be adjusted for use with a particular furnace as required.

Owner:AIR LIQUIDE AMERICA INC

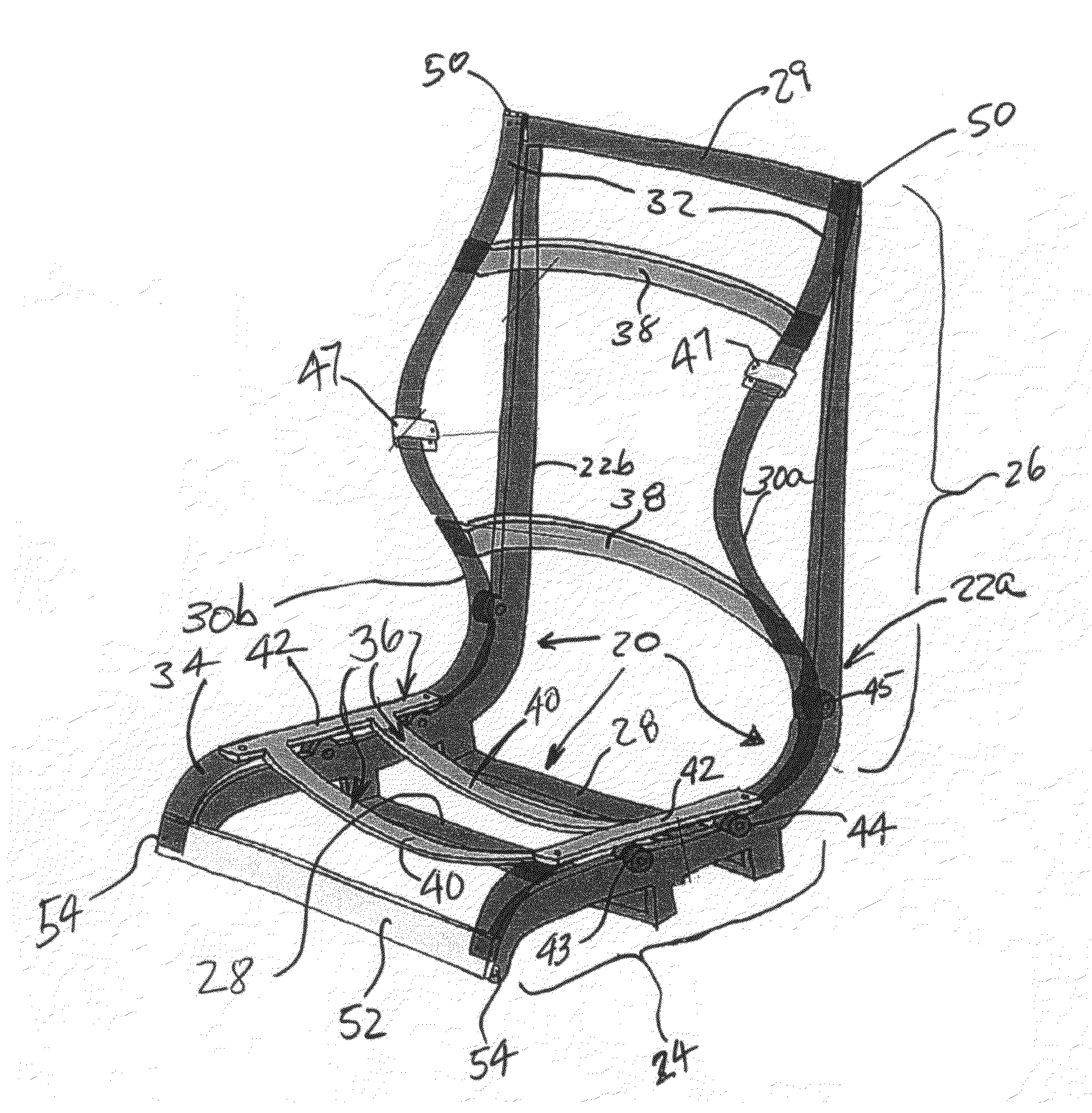

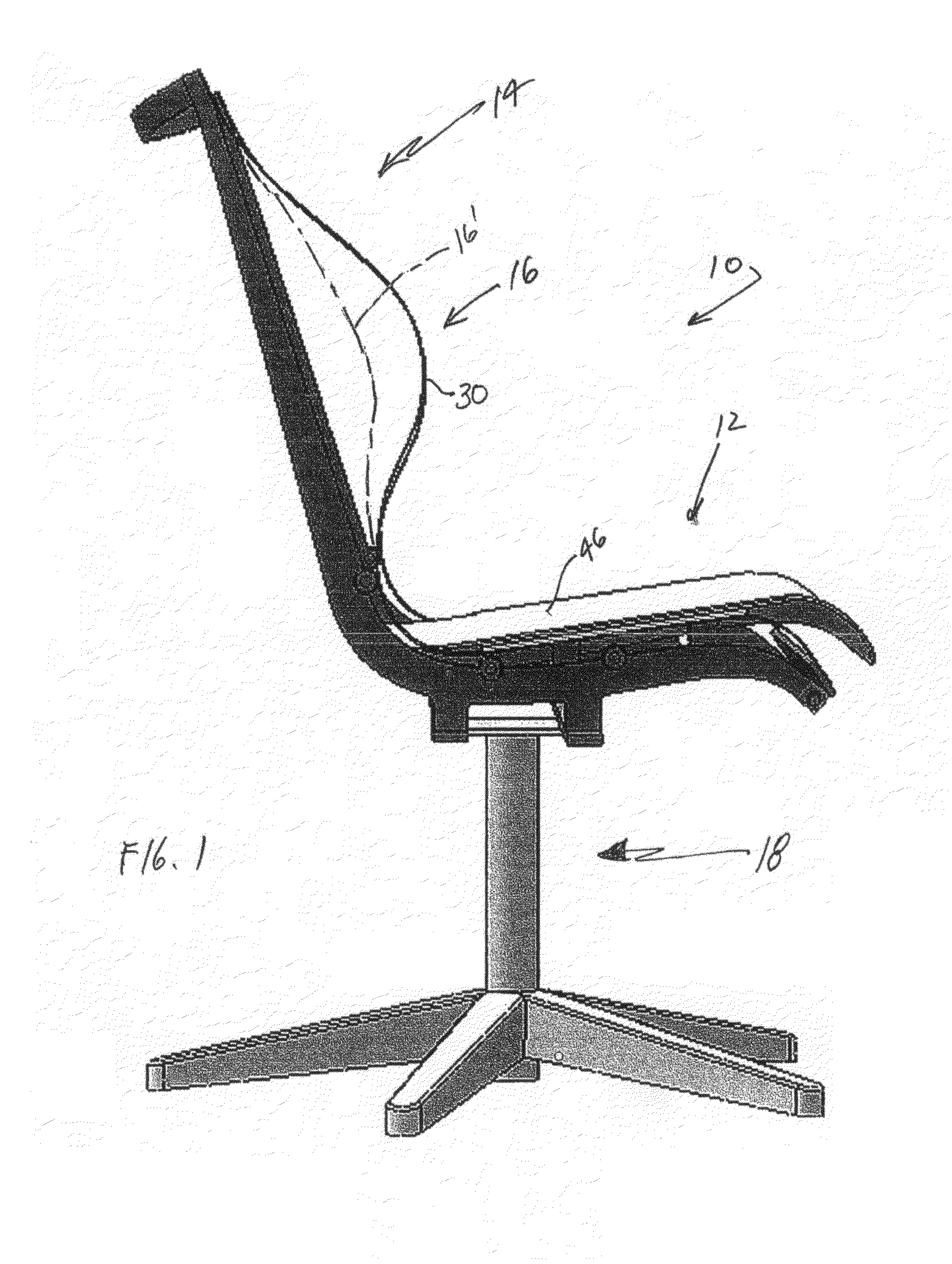

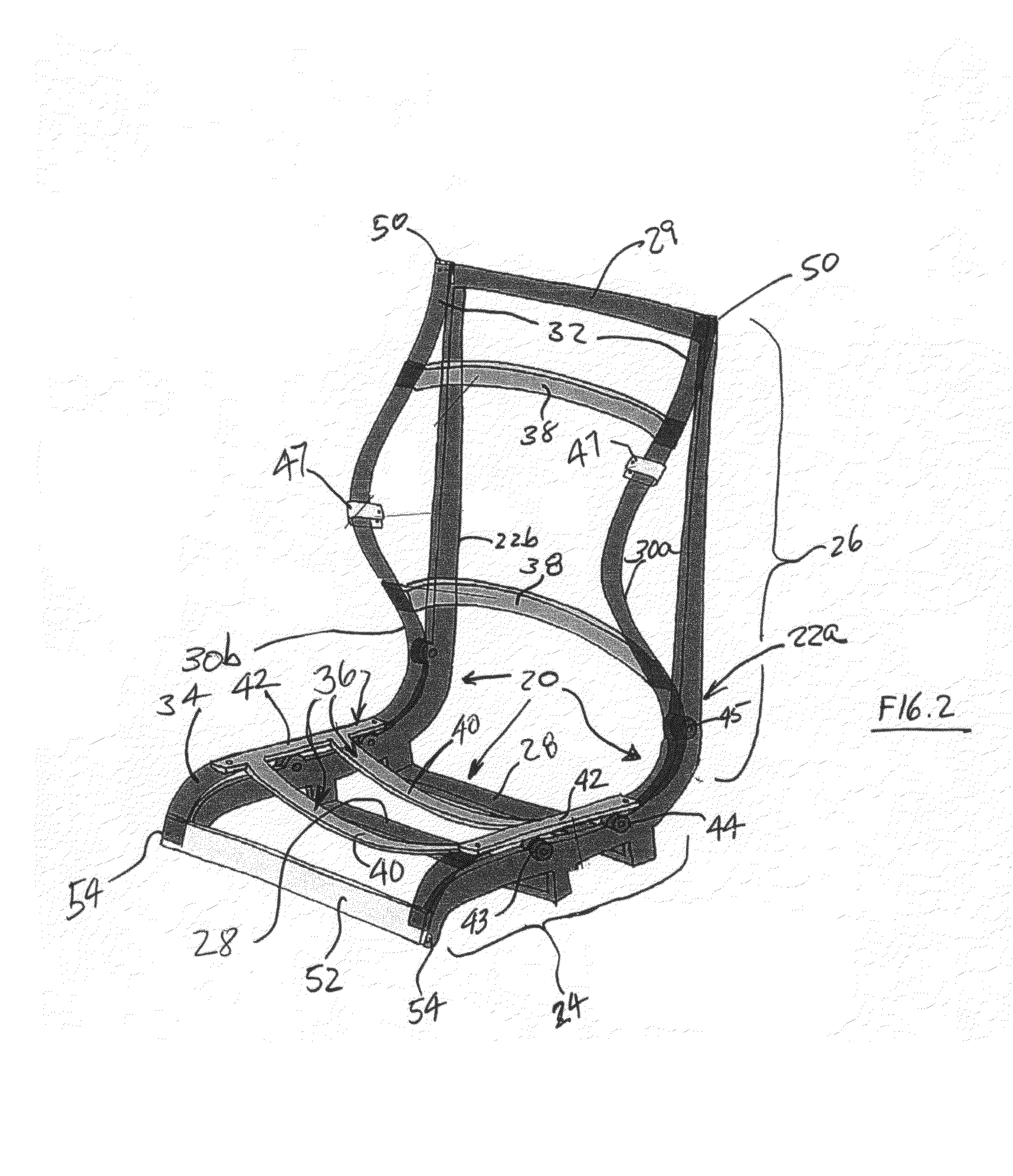

Ergonomic adjustable chair

A chair mechanism for an ergonomically adjustable, reclinable chair includes a frame and profile bands mounted to the frame. The profile bands are flexible and are configured to define a forwardly projecting lumbar region, the degree of forward projection of the lumbar region being variable in response to the position and movement of the chair seat. A flexible back support surface is carried by and spans the region between the profile bands. The shape and contour of the back surface is controlled by the shape of the profile bands. The chair mechanism enables the user to shift easily between upright and reclining positions without requiring the use of heavy springs or complex linkages.

Owner:GOETZ MARK W +1

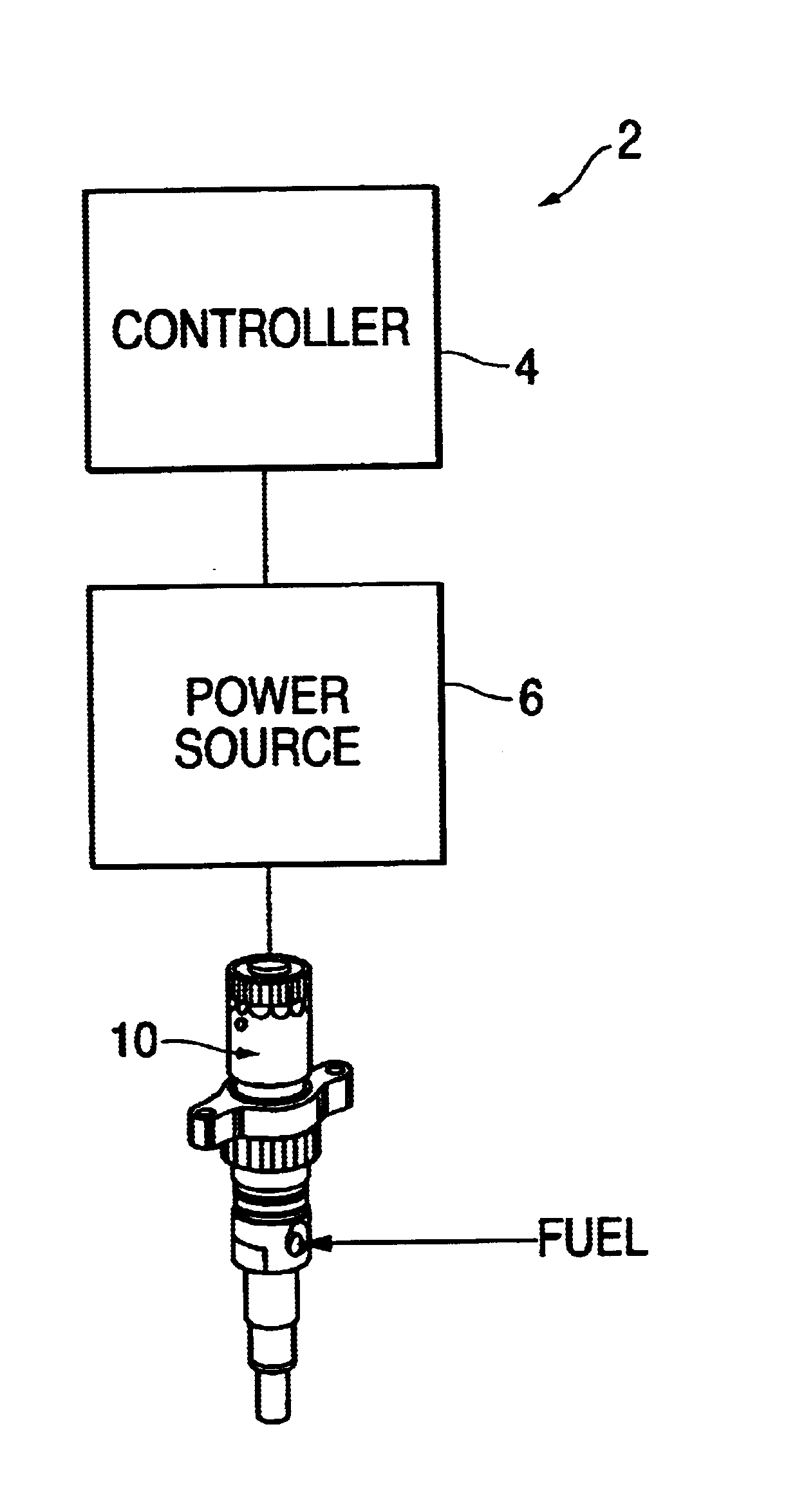

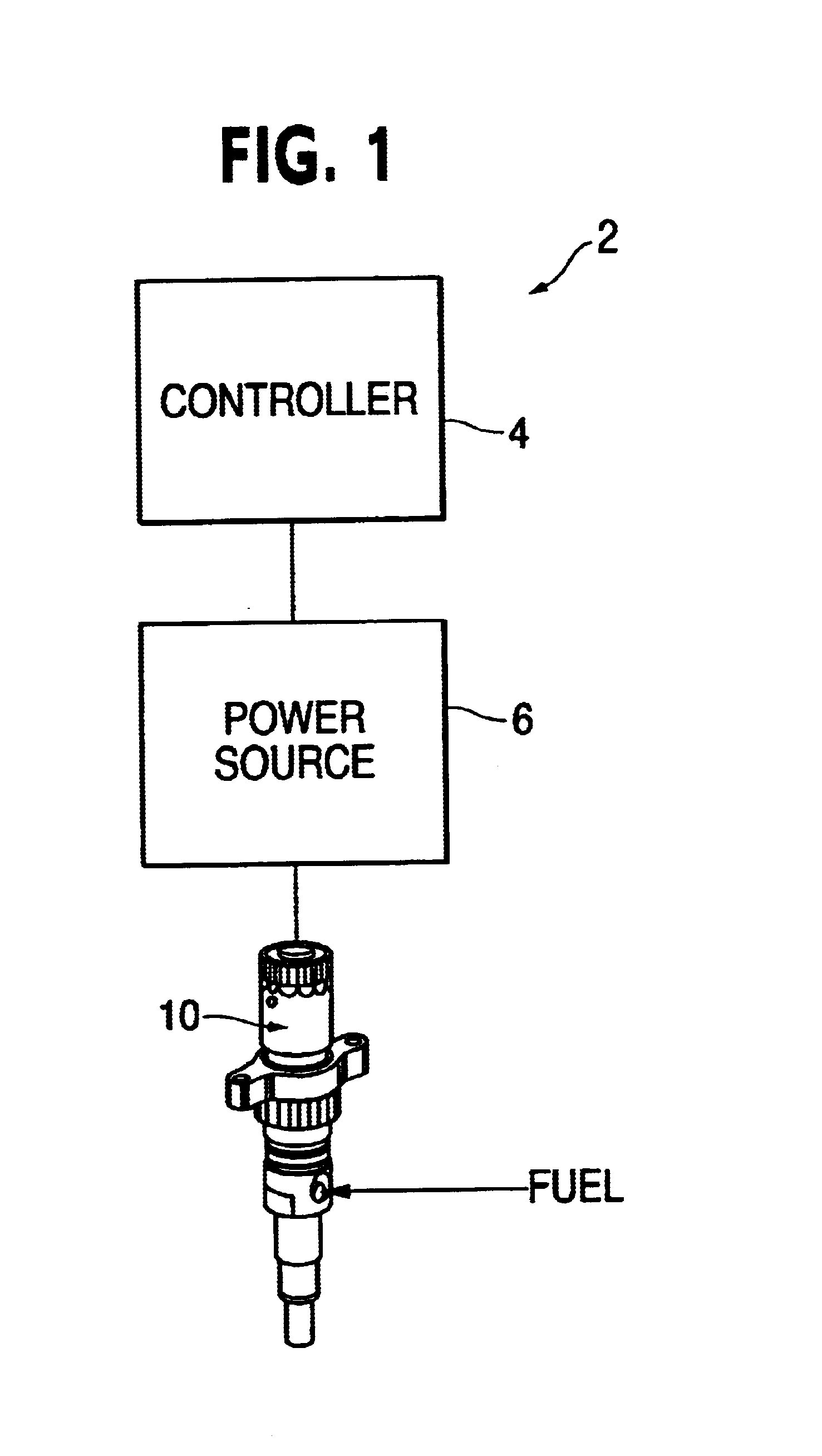

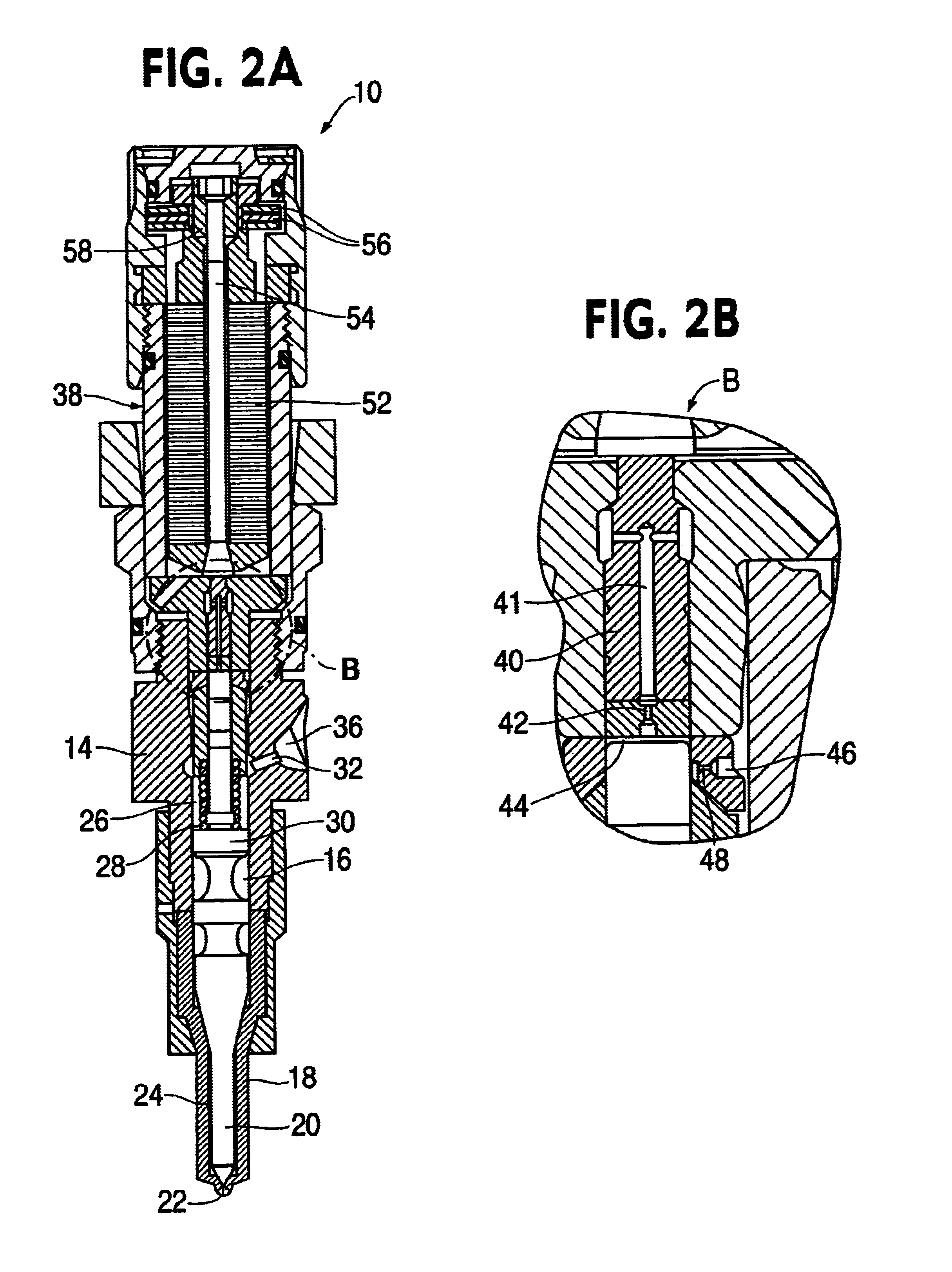

Piezoelectric fuel injection system with rate shape control and method of controlling same

ActiveUS6912998B1Reduce exhaust emissionsImprove fuel economyElectrical controlPiezoelectric/electrostriction/magnetostriction machinesElectricityNuclear engineering

A piezoelectric fuel injection system and a method of controlling same, the system including a piezoelectric fuel injector having a piezoelectric element, a power source adapted to provide power to the piezoelectric element to actuate the piezoelectric fuel injector, and a controller adapted to cyclically modulate power provide to the piezoelectric element by the power source during at least a portion of the injection event. The controller cyclically modulates the power between a predetermined first voltage and a predetermined second voltage that is less than the first voltage to control the rate of fuel injected by the piezoelectric fuel injector during the portion of the injection.

Owner:CUMMINS INC

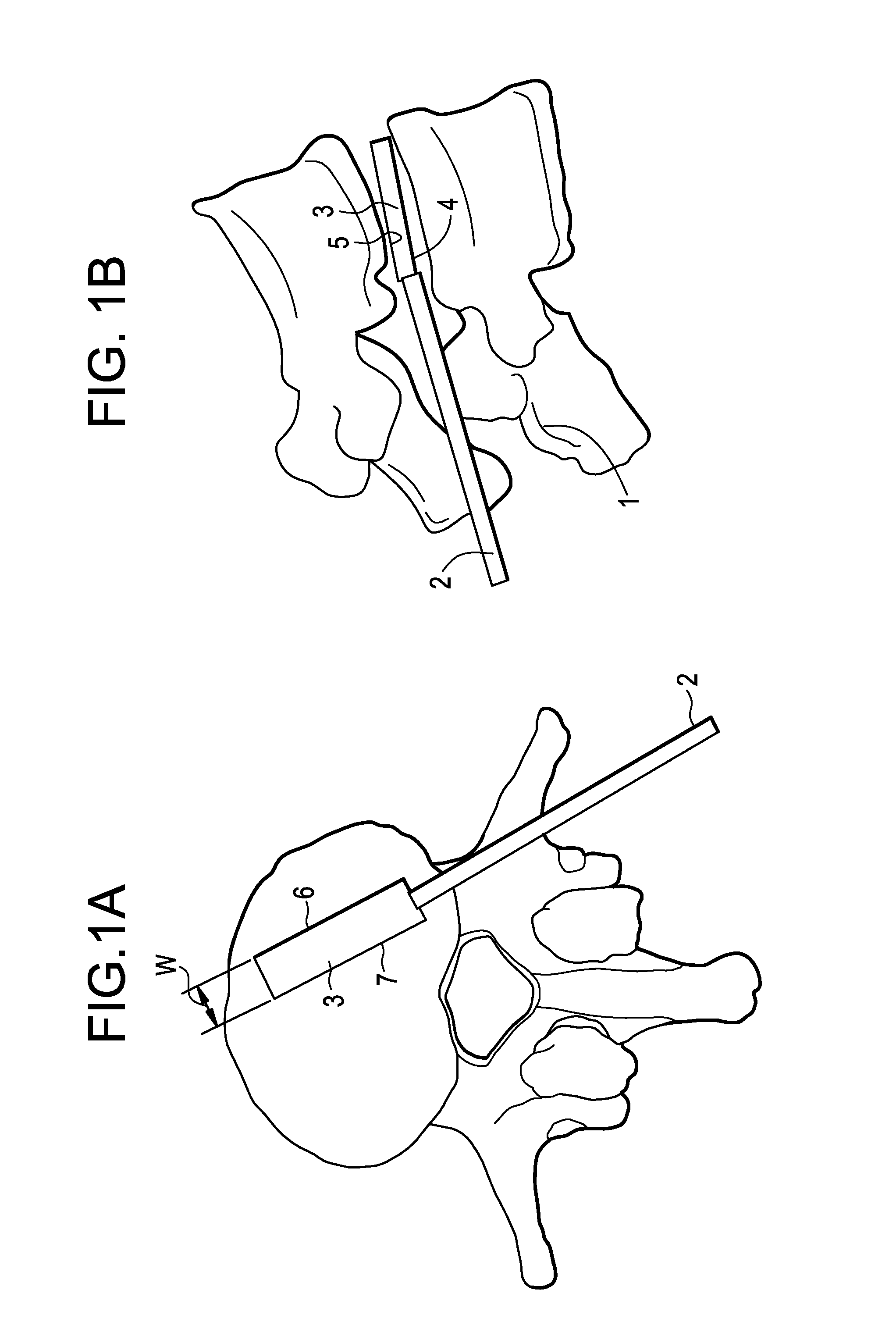

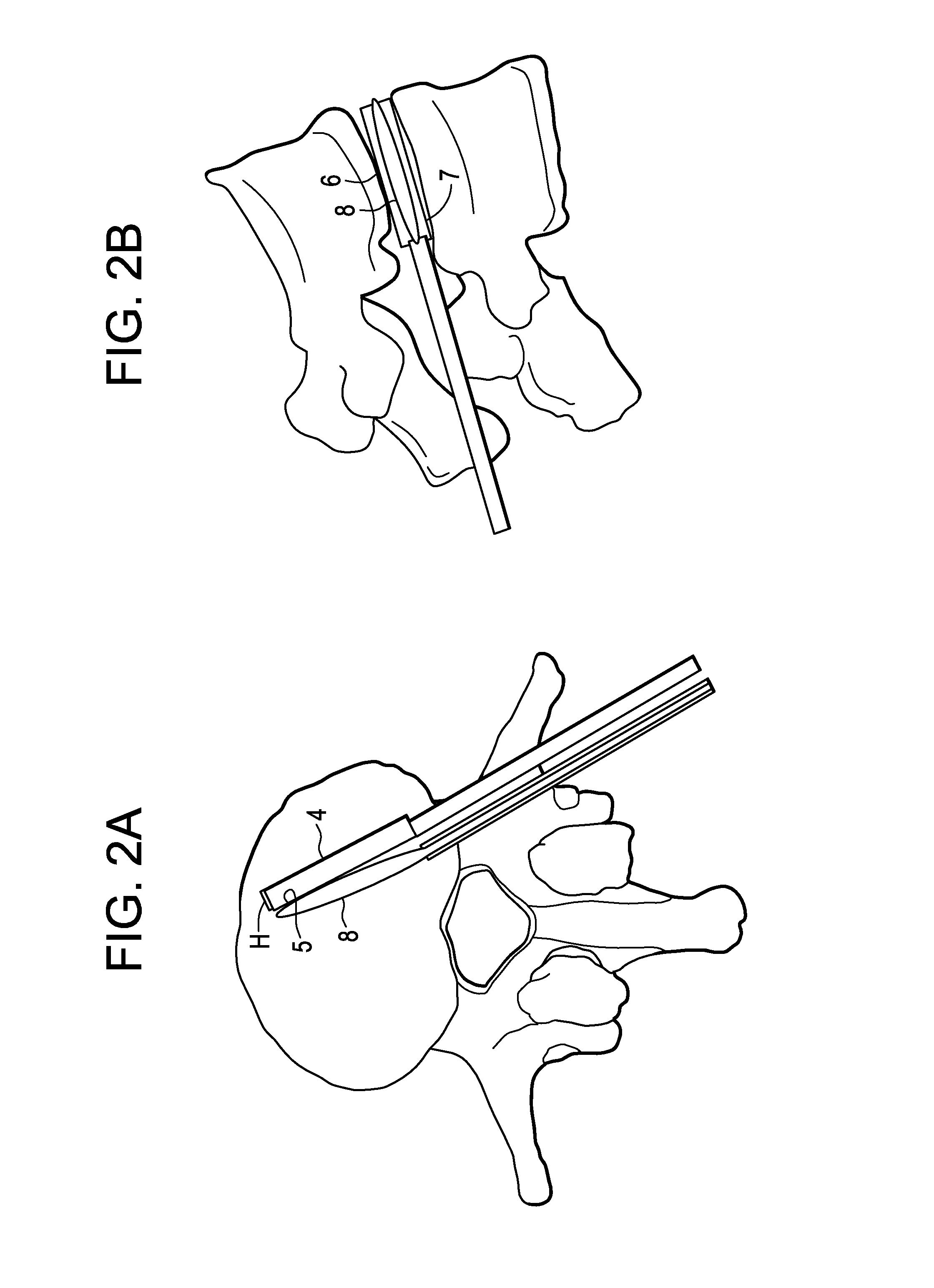

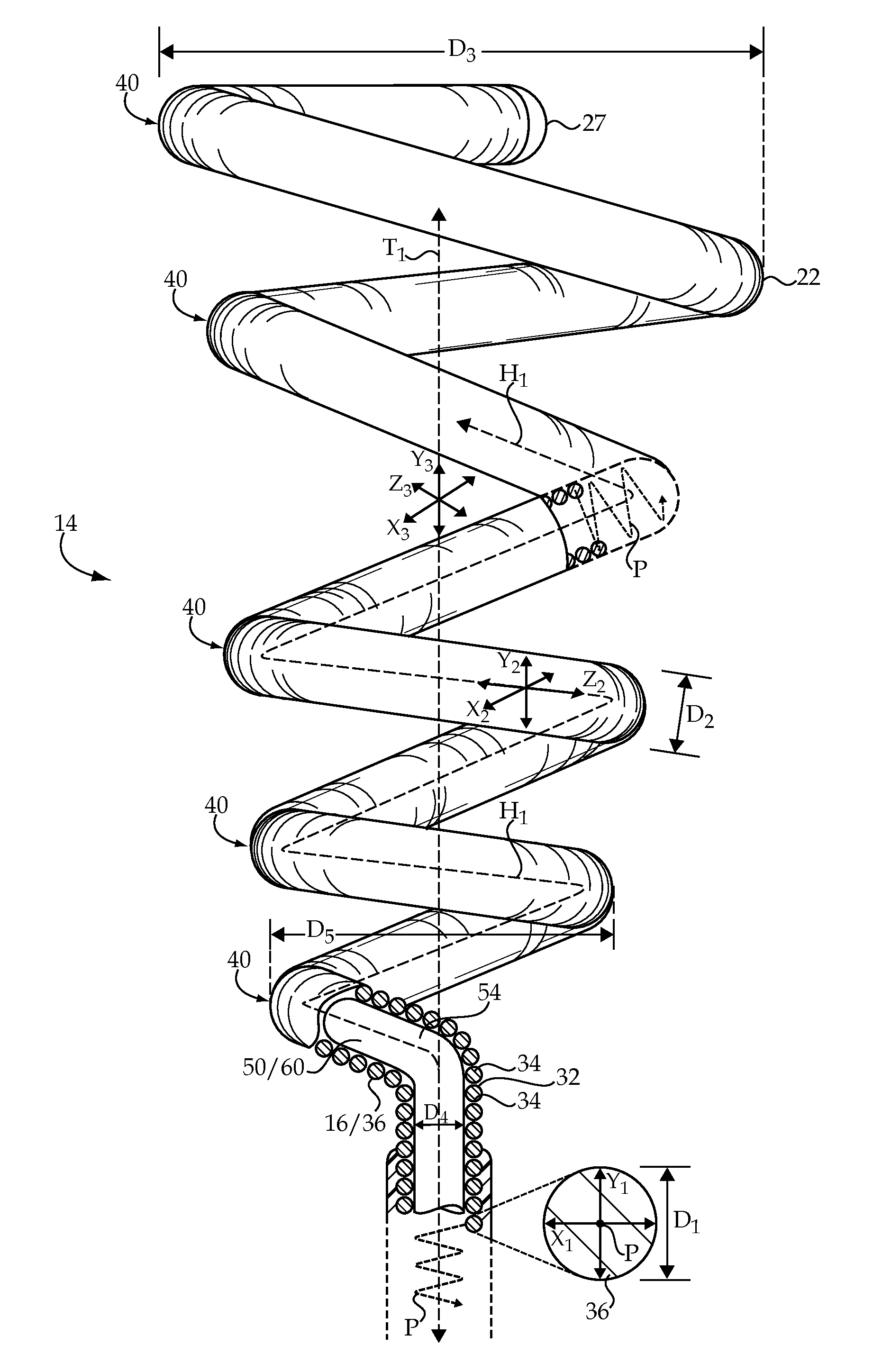

Balloon With Shape Control For Spinal Procedures

InactiveUS20090088789A1Limit radial expansionRegain even more disc heightBalloon catheterDilatorsDividing attentionSurgery spine

In intervertebral operative spinal procedures, using separate or pre-attached spreader blocks to control the directional growth of a distracting balloon.

Owner:DEPUY SYNTHES PROD INC

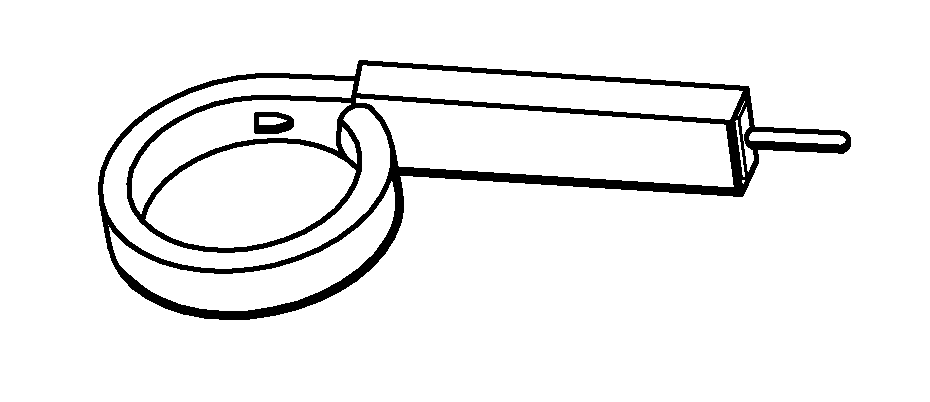

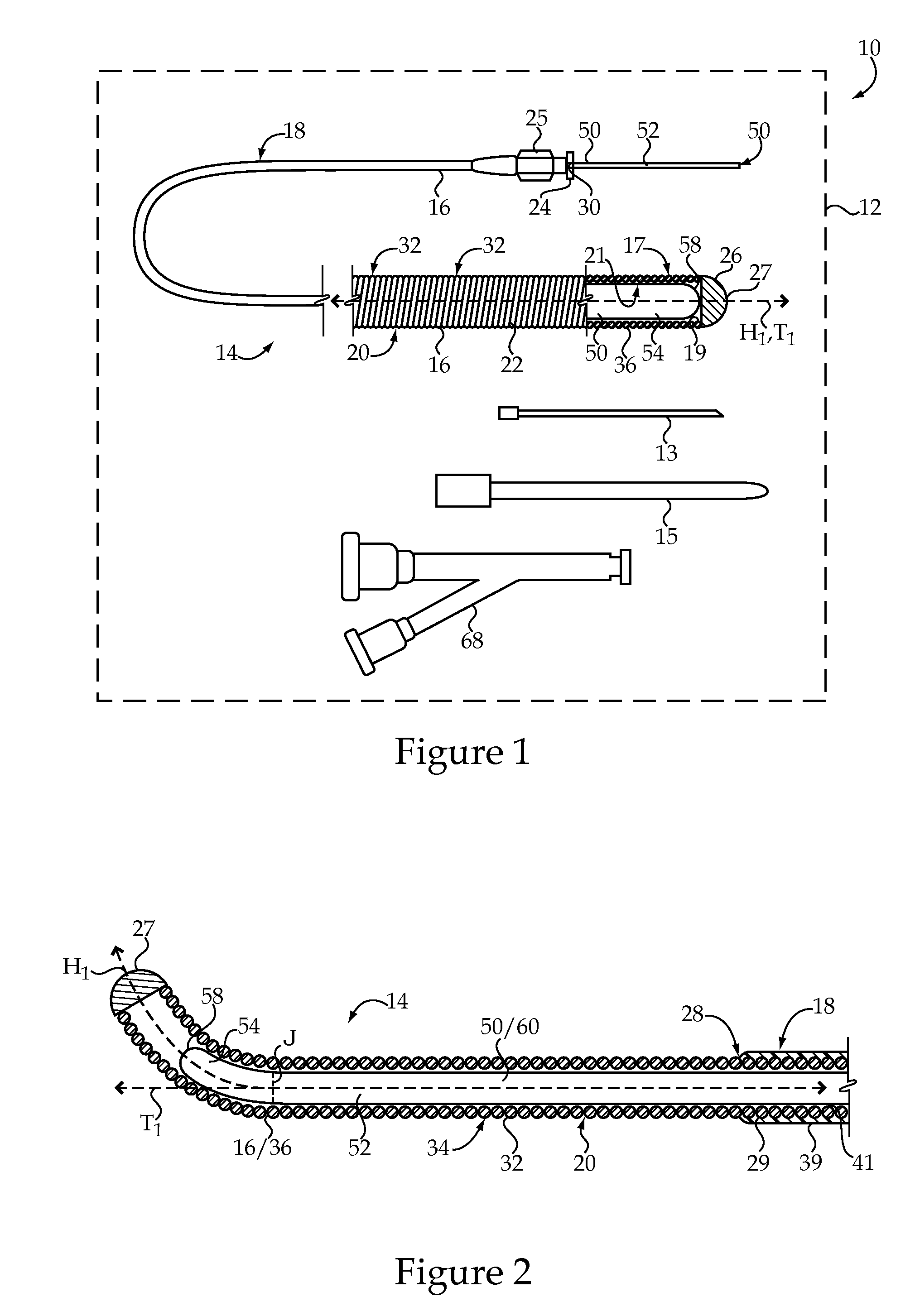

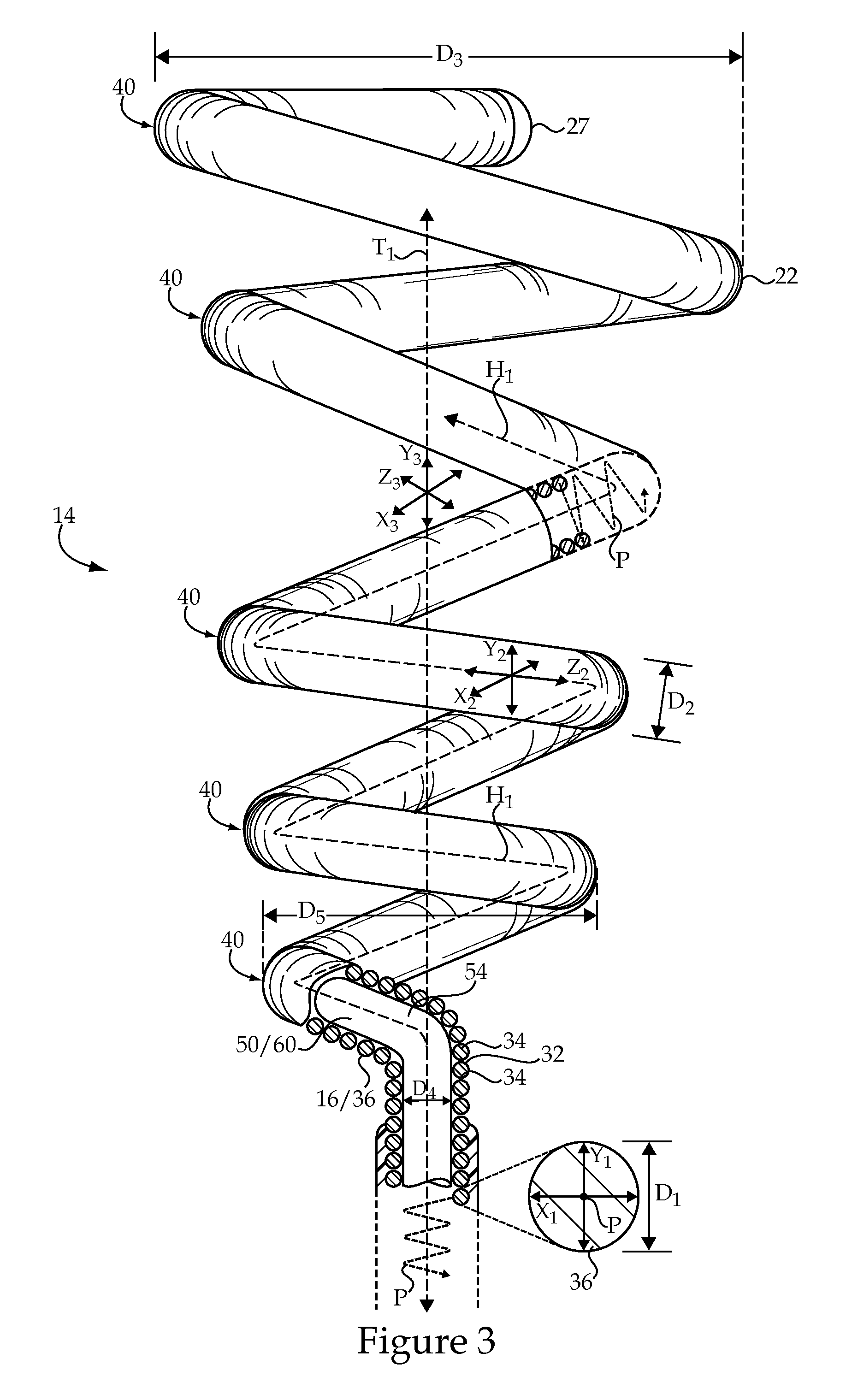

Treatment Fluid Delivery Method, And Turbulator For Promoting Uptake Of A Treatment Agent

ActiveUS20110276024A1Well mixedConvenient treatmentSurgeryMedical devicesBody fluidBiomedical engineering

A turbulator for promoting mixing of fluids passing through a body lumen includes an elongate flow perturbing component and an elongate shape controlling component freely slidable within the flow perturbing component. The turbulator is adjustable from a low profile, lumen access configuration to a deployed configuration via sliding the shape controlling component within the flow perturbing component. Adjusting the turbulator within a body lumen of a patient induces turbulence within a flow of fluid passing through the body lumen to increase mixing of a treatment fluid with the body fluid by way of the induced turbulence.

Owner:COOK MEDICAL TECH LLC

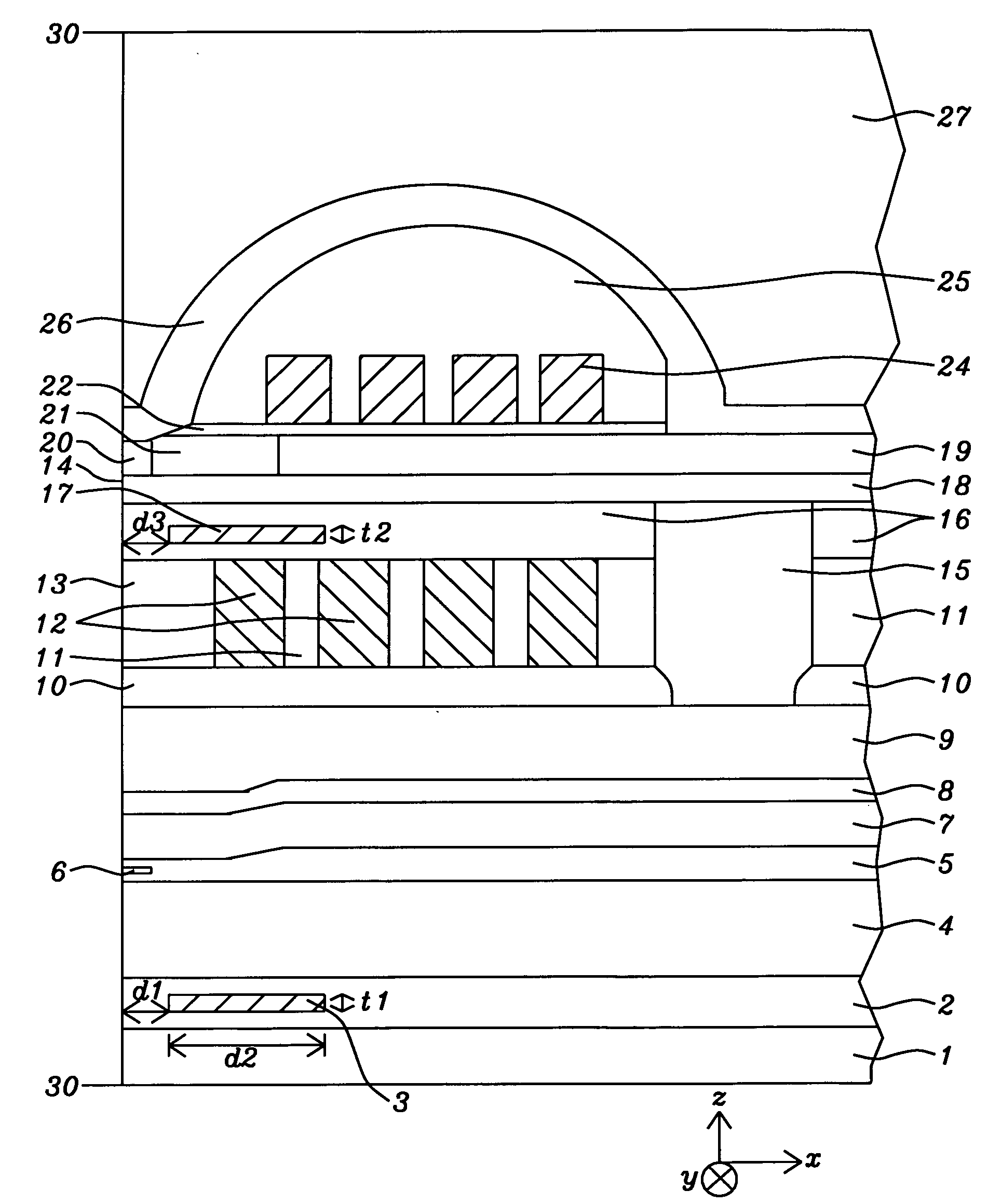

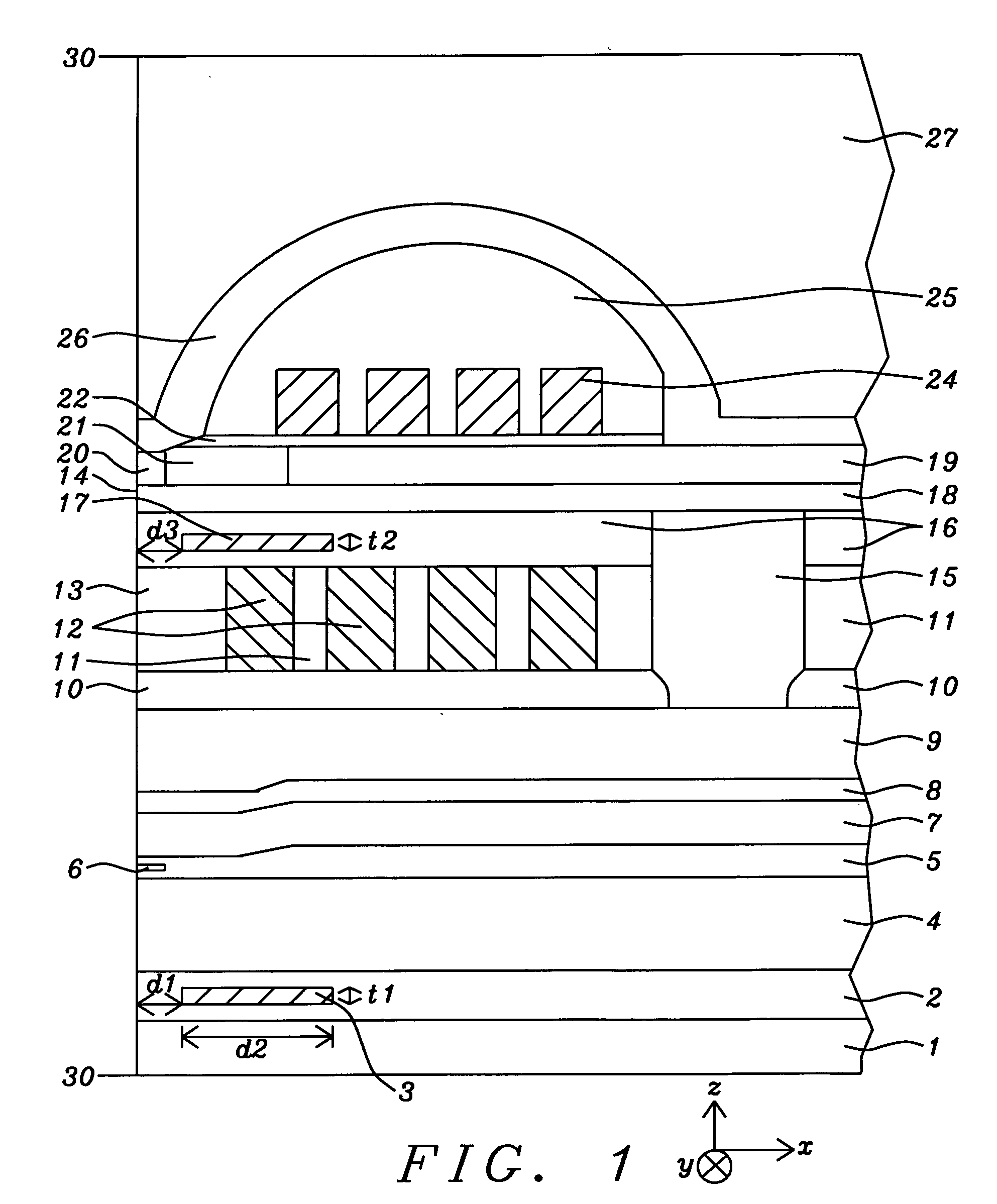

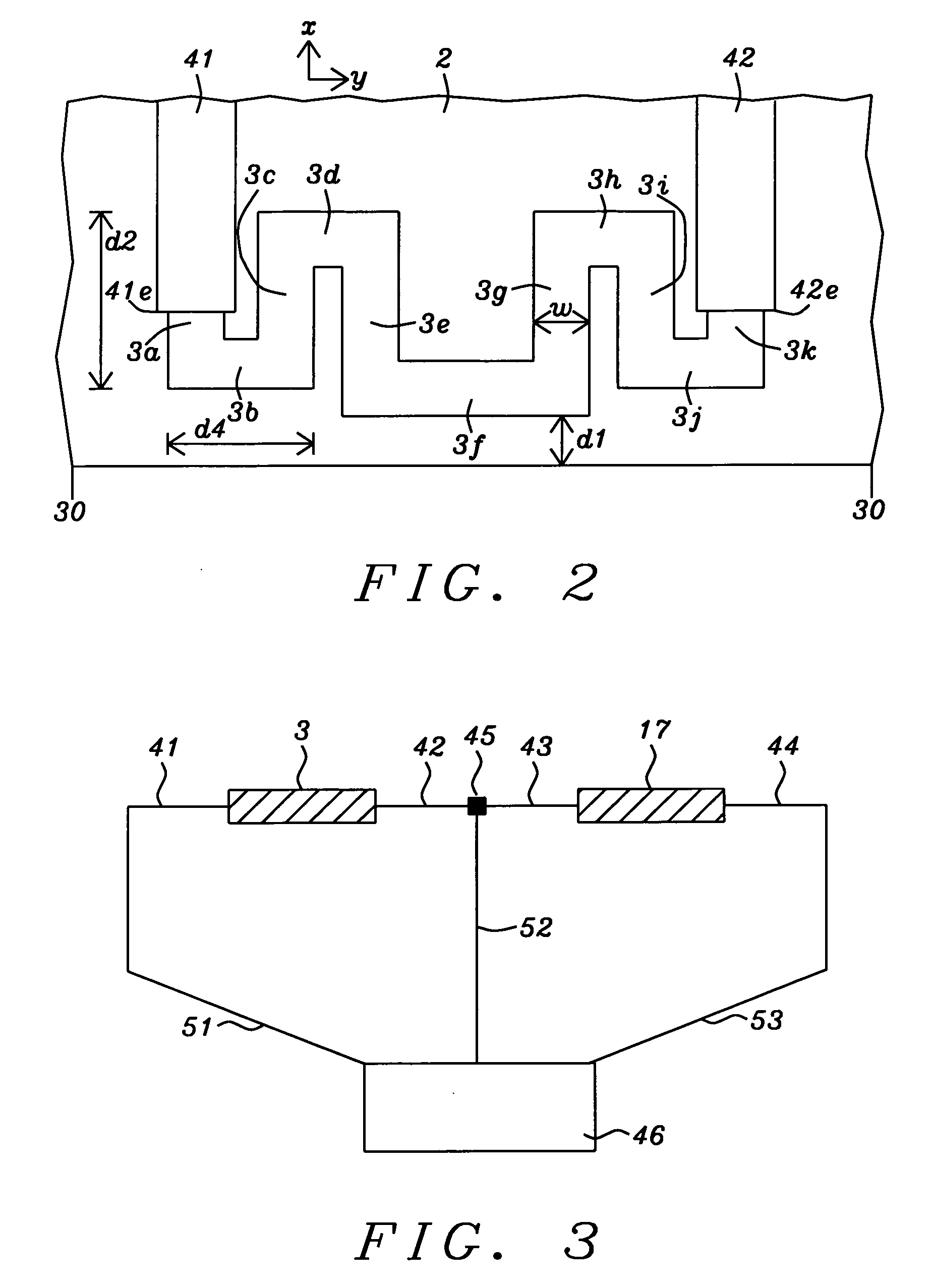

Vertically stacked DFH heater design for protrusion shape control

ActiveUS20090251828A1Fast timeReduce power consumptionNanomagnetismDisposition/mounting of recording headsElectric forceInsulation layer

A vertically stacked DFH design in a read / write head is disclosed that allows independent control of write gap protrusion and read gap protrusion. A first heater is formed in an insulation layer proximate to a sensor in a read head. A second heater is formed in a second insulation layer proximate to the write pole tip in a main pole layer. The two heaters are connected in series or in parallel through leads to a power source that activates the heaters. In one embodiment, the heaters have a fixed resistance ratio. Preferably, there are two drivers in the power source so that a first power can be applied to the first heater and a second power can be applied to the second heater to enable an adjustment of reader protrusion / writer protrusion or gamma ratio. Fast reader and writer actuation is achieved and low power consumption is realized.

Owner:HEADWAY TECH INC

Synthetic control of metal oxide nanocrystal sizes and shapes

A general, reproducible, and simple synthetic method that employs readily available chemicals permits control of the size, shape, and size distribution of metal oxide nanocrystals. The synthesis entails reacting a metal fatty acid salt, the corresponding fatty acid, and a hydrocarbon solvent, with the reaction product being pyrolyzed to the metal oxide. Nearly monodisperse oxide nanocrystals of Fe3O4, Cr2O3, MnO, Co3O4, NiO, ZnO, SnO2, and In2O3, in a large size range (3-50 nm), are described. Size and shape control of the nanocrystals is achieved by varying the reactivity and concentration of the precursors.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS

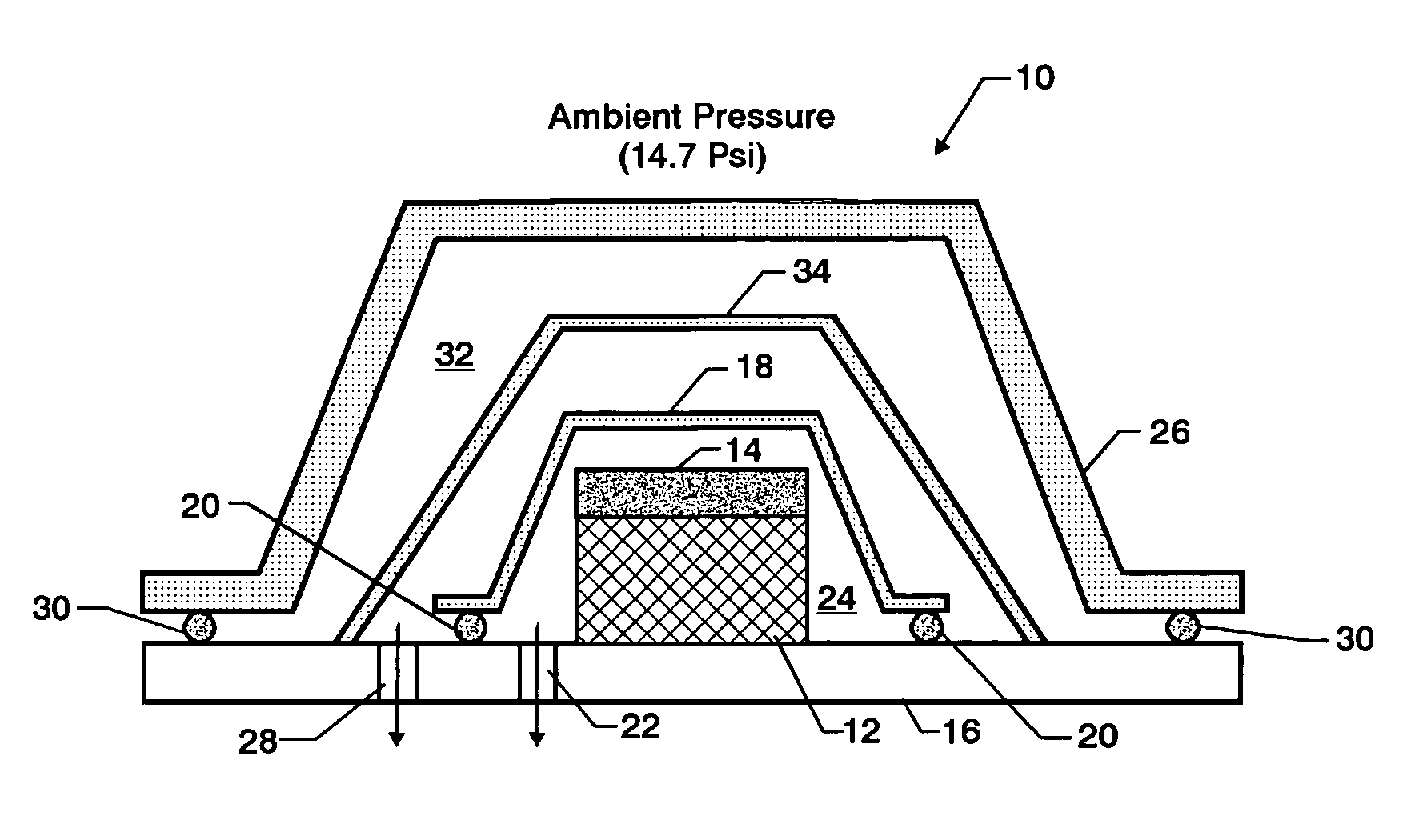

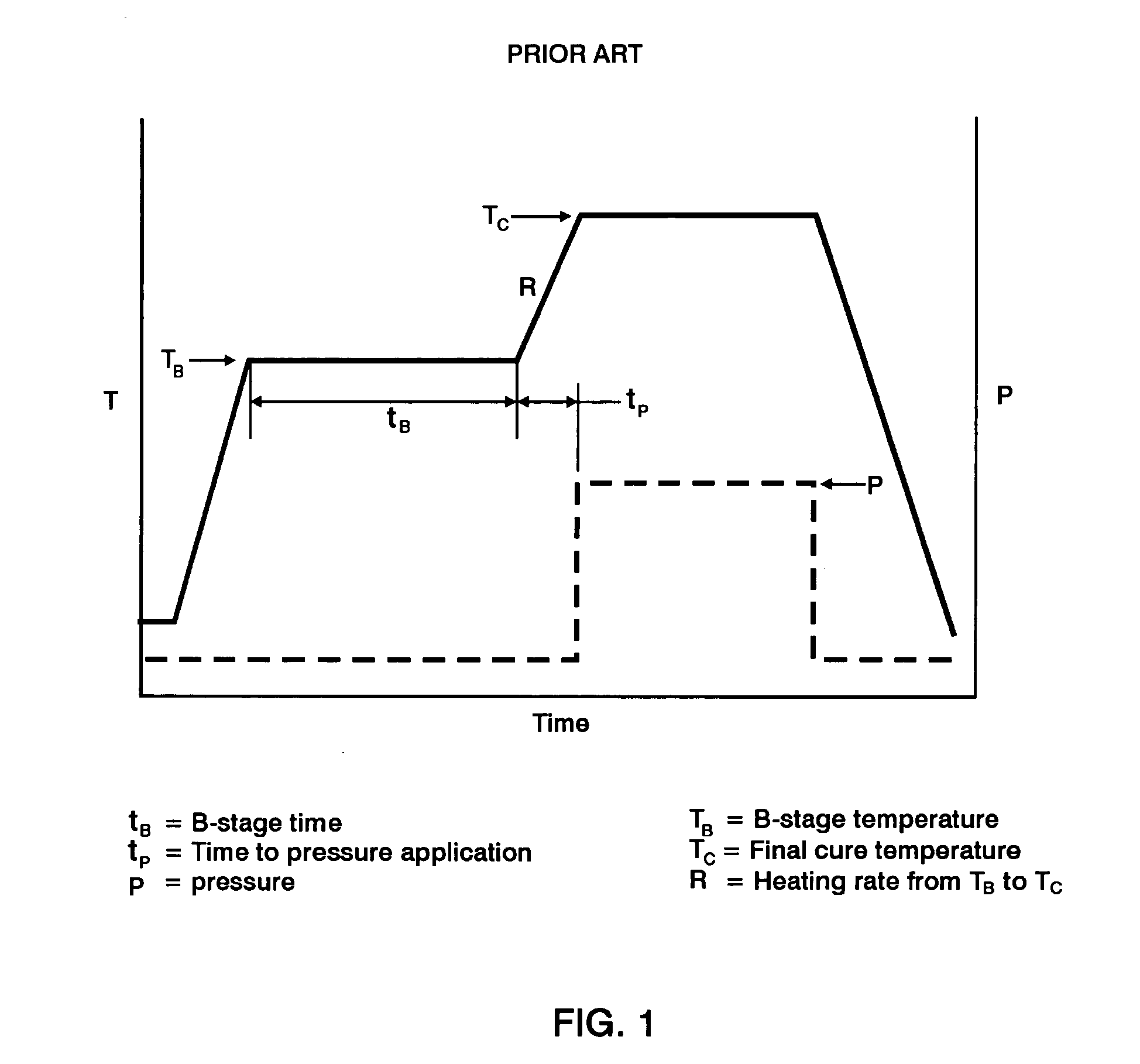

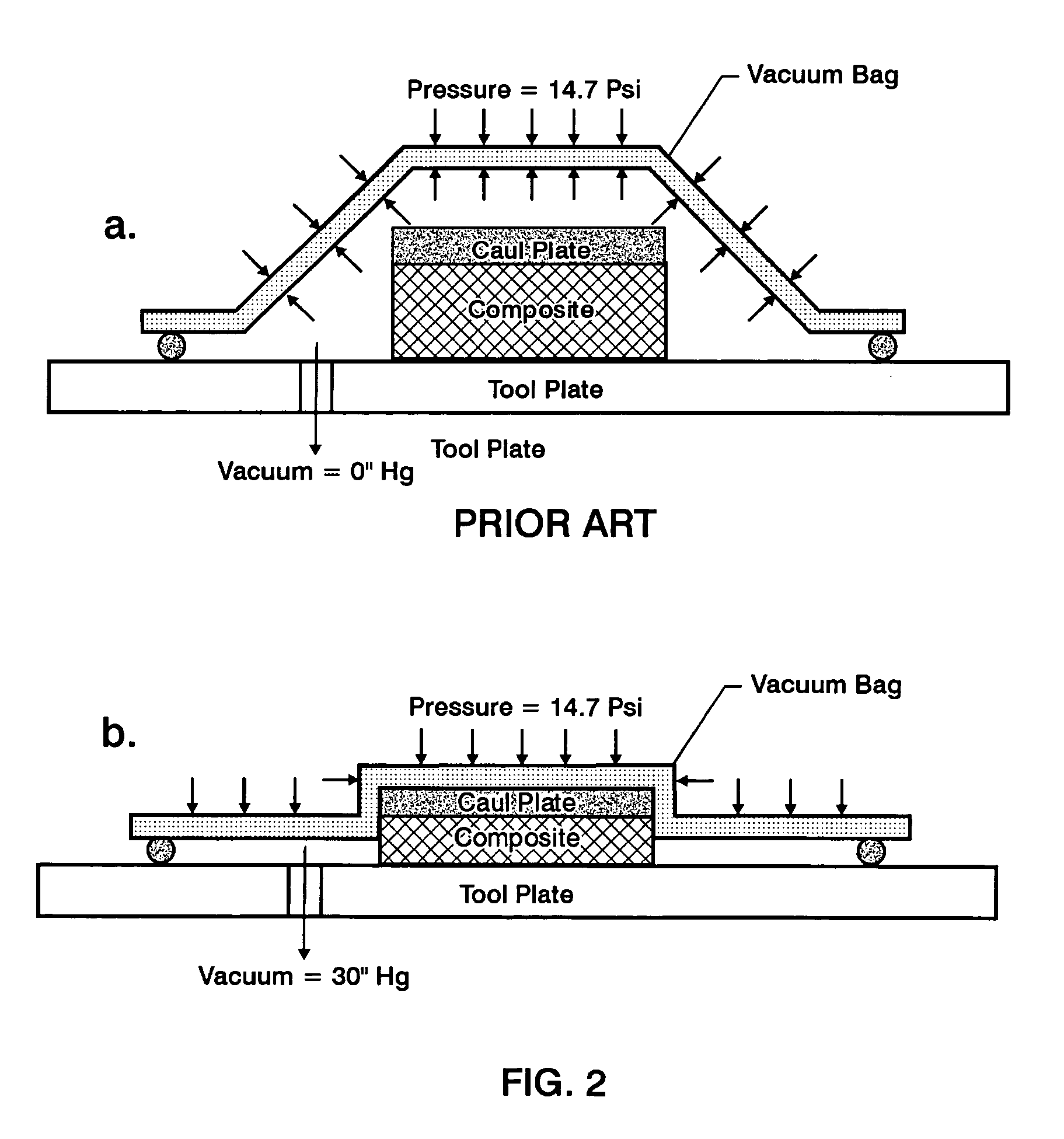

Double vacuum bag process for resin matrix composite manufacturing

InactiveUS7186367B2Improve performanceImprove propertiesLaminationLamination apparatusRelative pressureResin matrix

A double vacuum bag molding assembly with improved void management and laminate net shape control which provides a double vacuum environment for use in fabricating composites from prepregs containing air and / or volatiles such as reactive resin matrix composites or composites from solvent containing prepregs with non-reactive resins matrices. By using two vacuum environments during the curing process, a vacuum can be drawn during a B-stage of a two-step cycle without placing the composite under significant relative pressure. During the final cure stage, a significant pressure can be applied by releasing the vacuum in one of the two environments. Inner and outer bags are useful for creating the two vacuum environments with a perforated tool intermediate the two. The composite is placed intermediate a tool plate and a caul plate in the first environment with the inner bag and tool plate defining the first environment. The second environment is characterized by the outer bag which is placed over the inner bag and the tool plate.

Owner:NASA

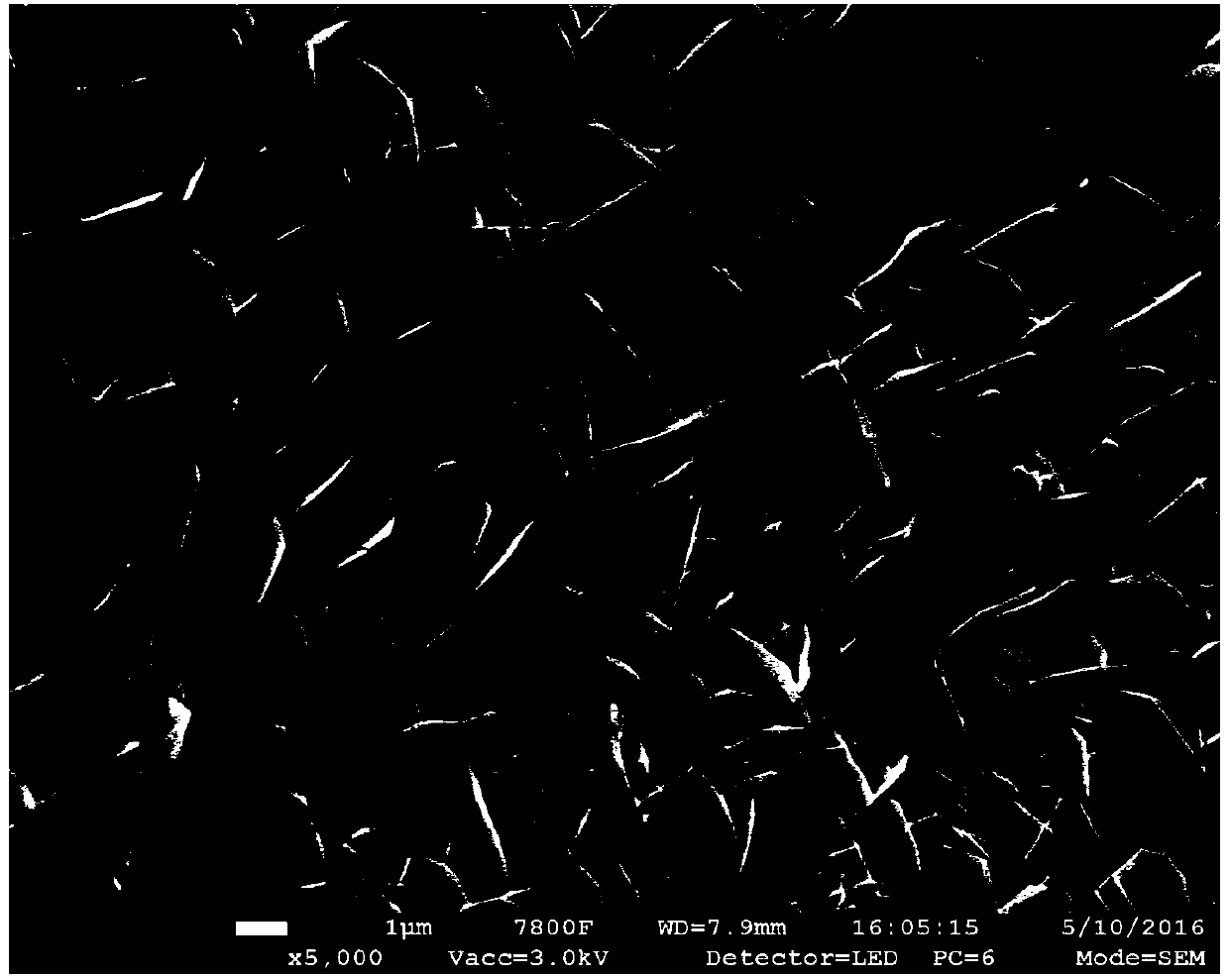

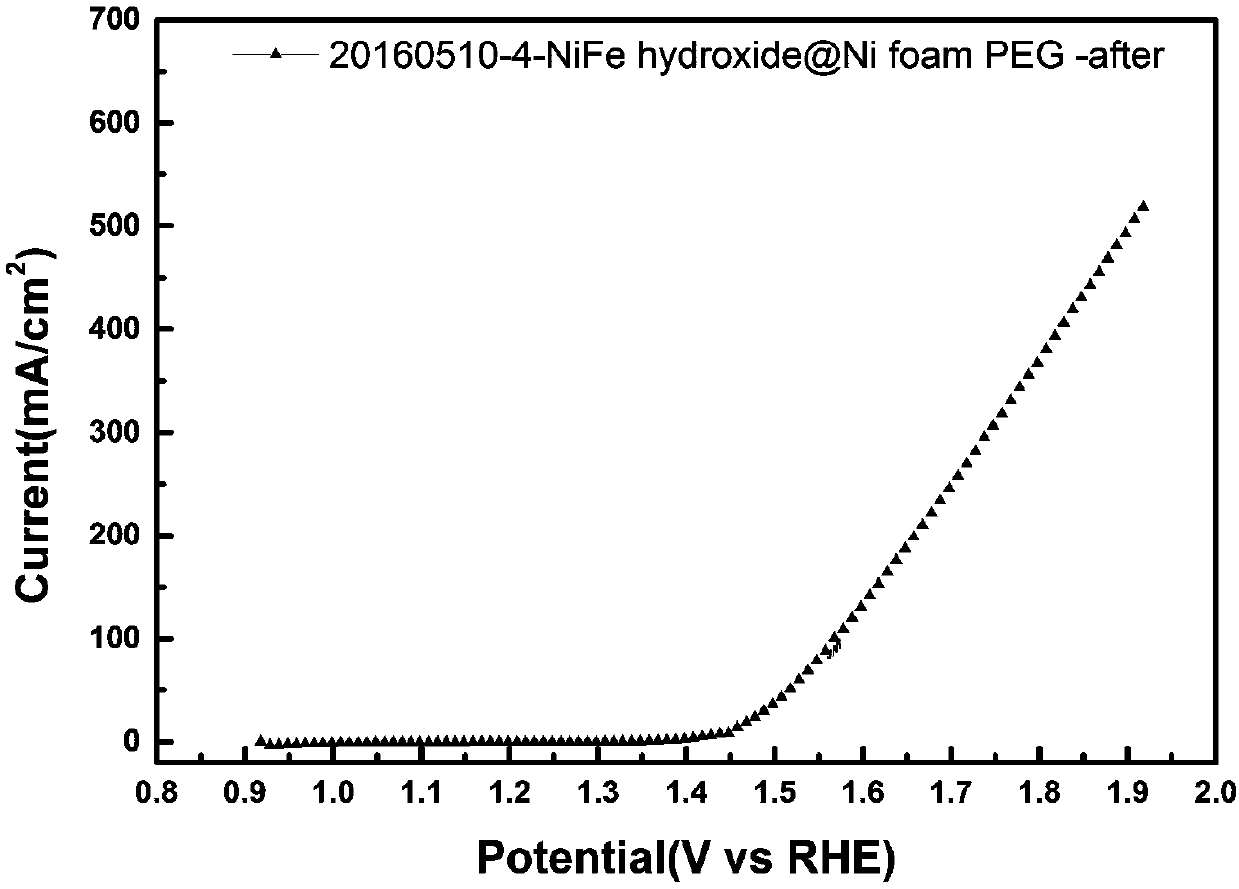

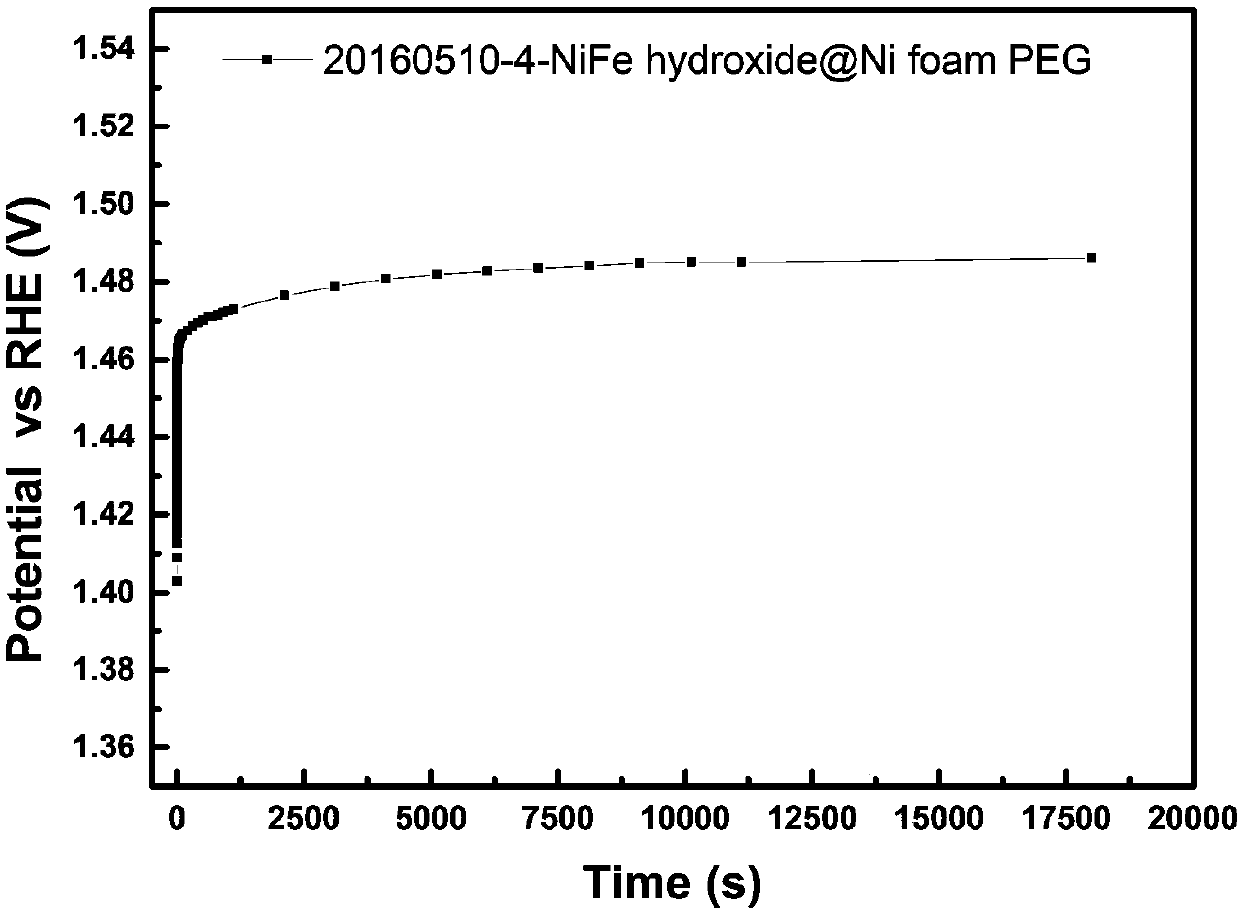

Hydroxyl oxidize iron-nickel-iron hydrotalcite integrated oxygen evolution electrode and preparation method and application thereof

InactiveCN107620087AHigh catalytic activityImprove catalytic stabilityMetal/metal-oxides/metal-hydroxide catalystsElectrodesElectrolysisExternal bias

The invention relates to a hydroxyl oxidize iron-nickel-iron hydrotalcite integrated oxygen evolution electrode applicable to alkaline mediums and a preparation method and application thereof. The electrode is applicable to the oxygen evolution reaction in the water-electrolytic hydrogen making process under catalytic alkaline conditions. The hydroxyl oxidize iron-nickel-iron hydrotalcite integrated oxygen evolution electrode and the preparation method and application thereof have the advantages as follows: the nickel-iron hydroxide integrated electrode is shape-controlled, the preparation process is simple and under mild conditions, and the electrode can be used for a water electrolytic tank for hydrogen production from water splitting under external bias potentials; the prepared hydroxyloxidize iron-nickel-iron hydrotalcite integrated oxygen evolution electrode further has a better performance when being used in an alkaline solid polymer electrolyte (AEM) water electrolytic tank; and besides, an extensive utilization value in achieved in regenerative fuel cells (RFC), photoelectro-catalytic devices and electrolytic hydrogen generators.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

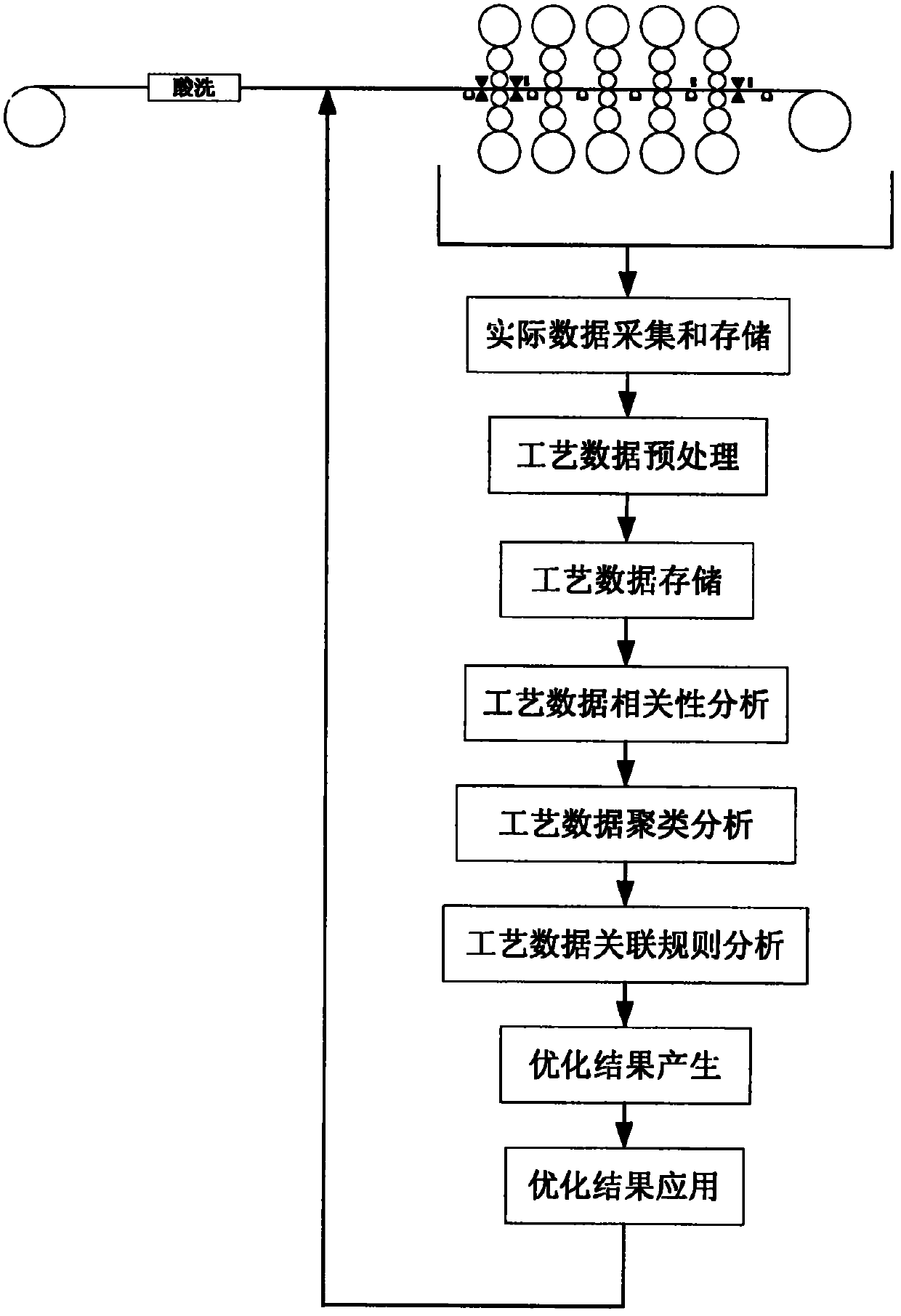

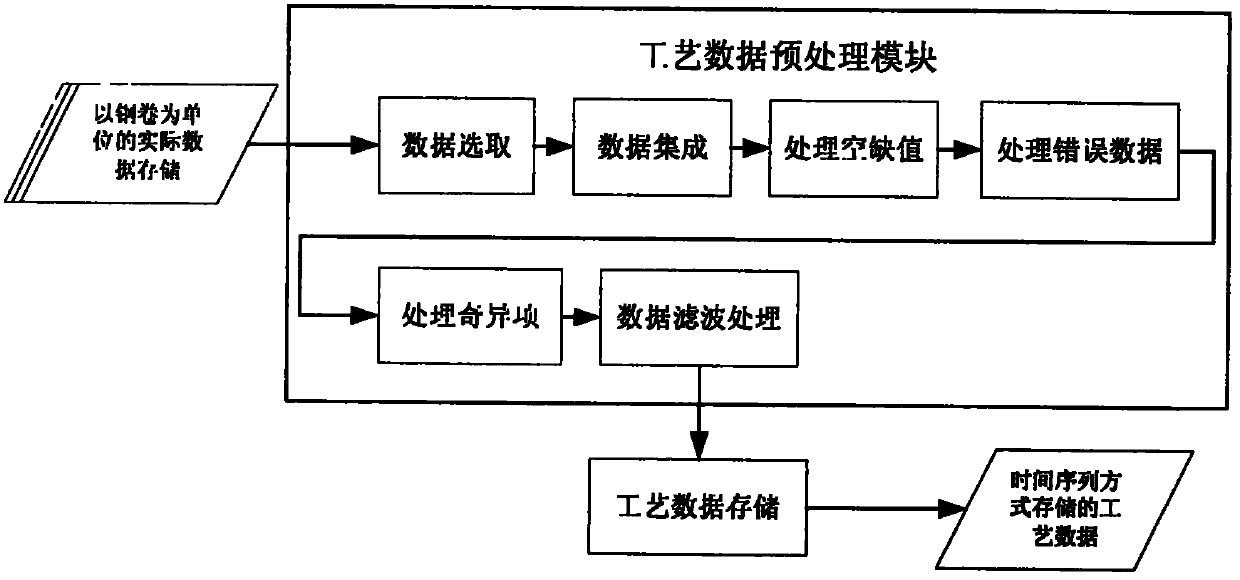

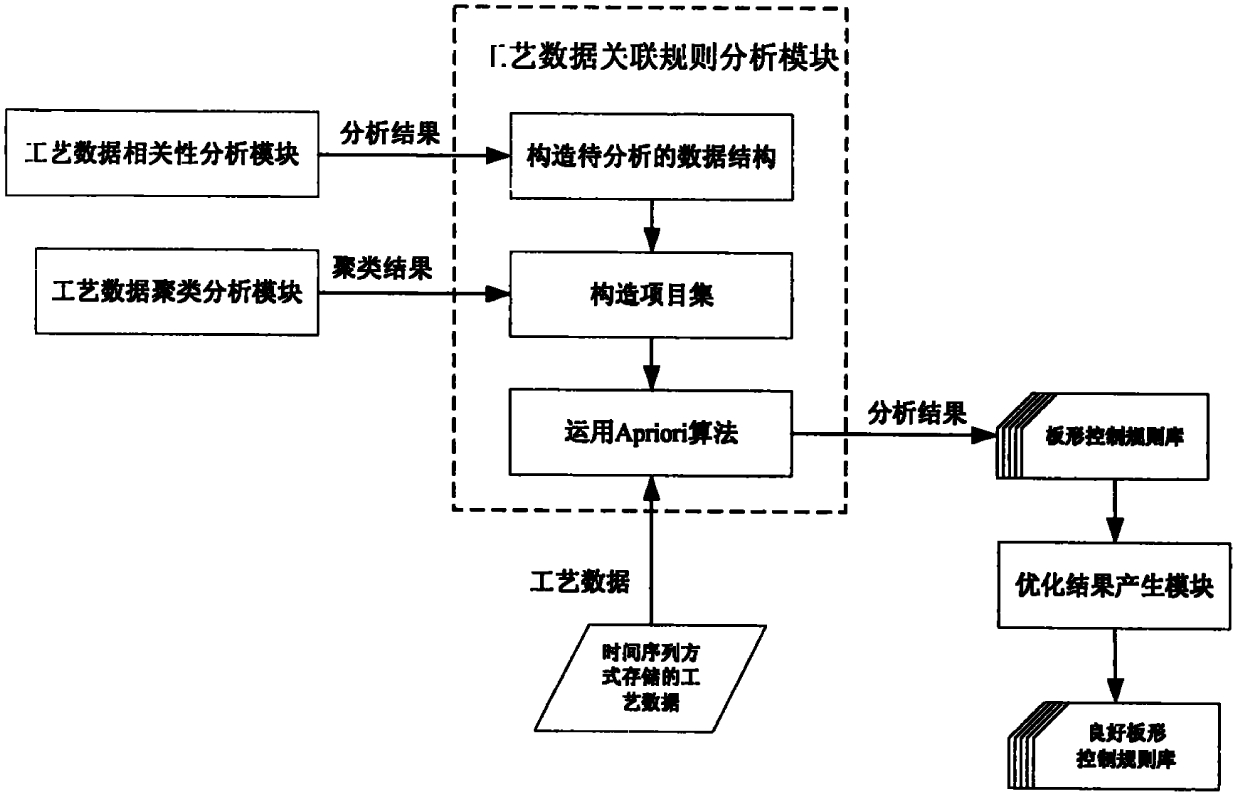

Data mining-based plate shape control key process parameter optimization system

ActiveCN102069094AImprove pass rateImprove the rate of successProfile control deviceAutomatic controlData acquisition

The invention relates to a data mining-based plate shape control key process parameter optimization system, and belongs to the technical field of automatic control of cold continuous rolling plate shape. The data mining method is adopted for acquiring key process parameter optimization settings which can meet the good cold continuous rolling plate shape. The system is characterized by comprising the following functional modules: an actual data acquisition and storage module, a process data pre-processing module, a process data storage module, a process data correlation analysis module, a process data clustering analysis module, a process data association rule analysis module, an optimization result generating module and an optimization result application module. The system has the advantage that the good plate shape can be obtained by applying the plate shape control system. The method avoids endless theoretical research on plate shape control and fully utilizes actual plate shape control process data containing successful operation experience of field operators, and the plate shape process parameter settings which can obtain the good plate shape are acquired by data mining, so the plate shape qualification rate and the finished product rate of cold continuous rolled strip steel are improved.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH

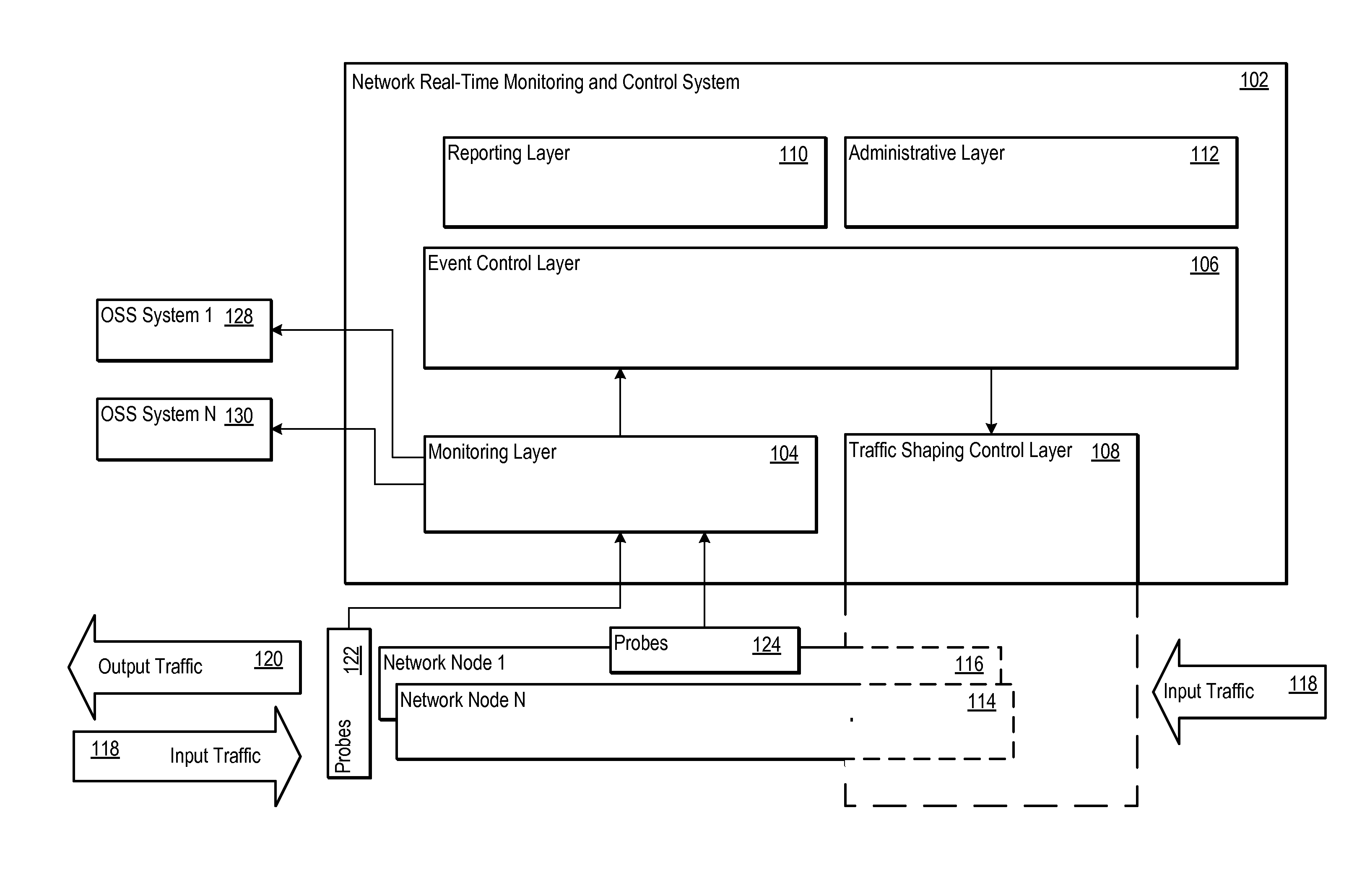

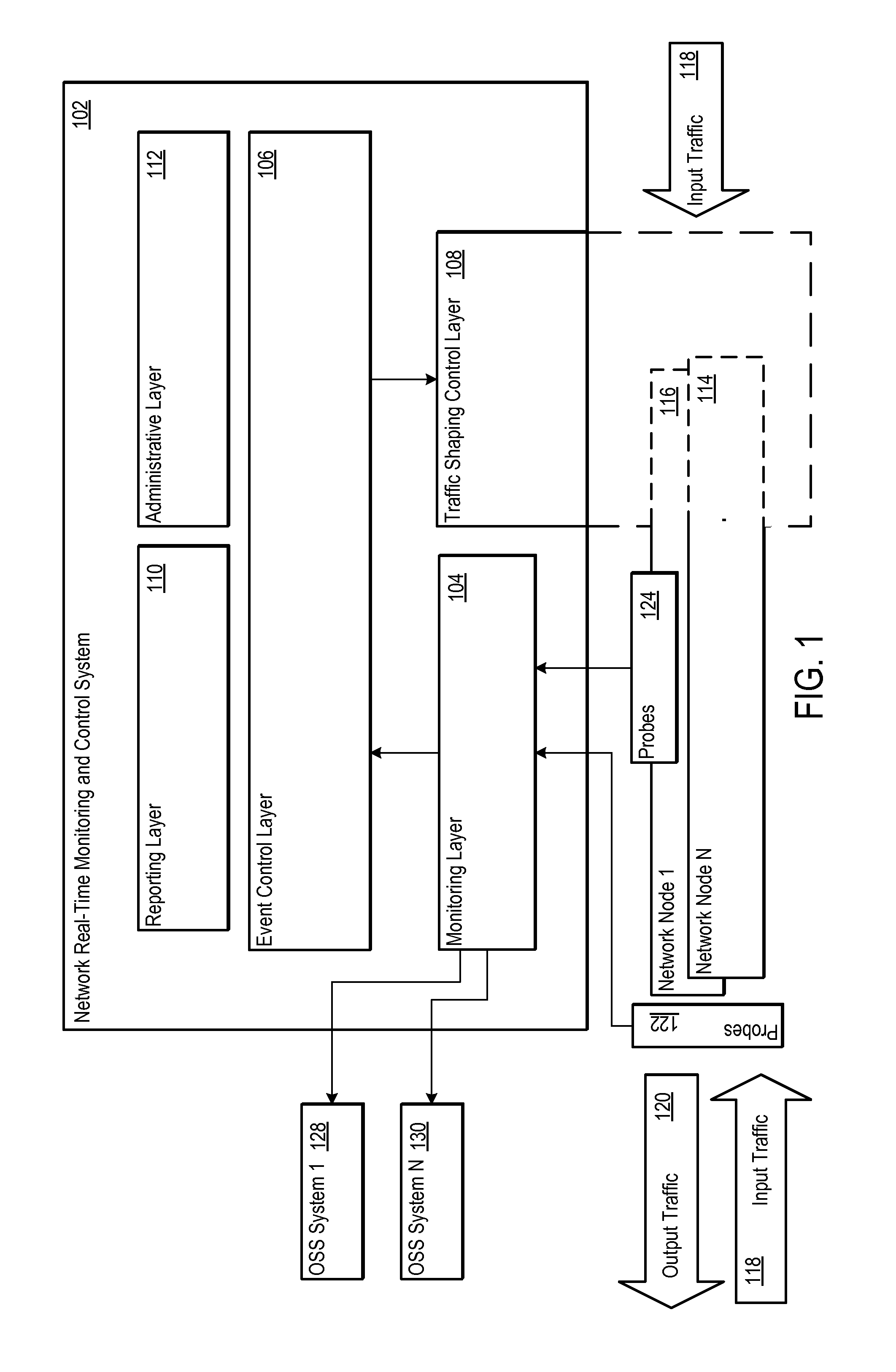

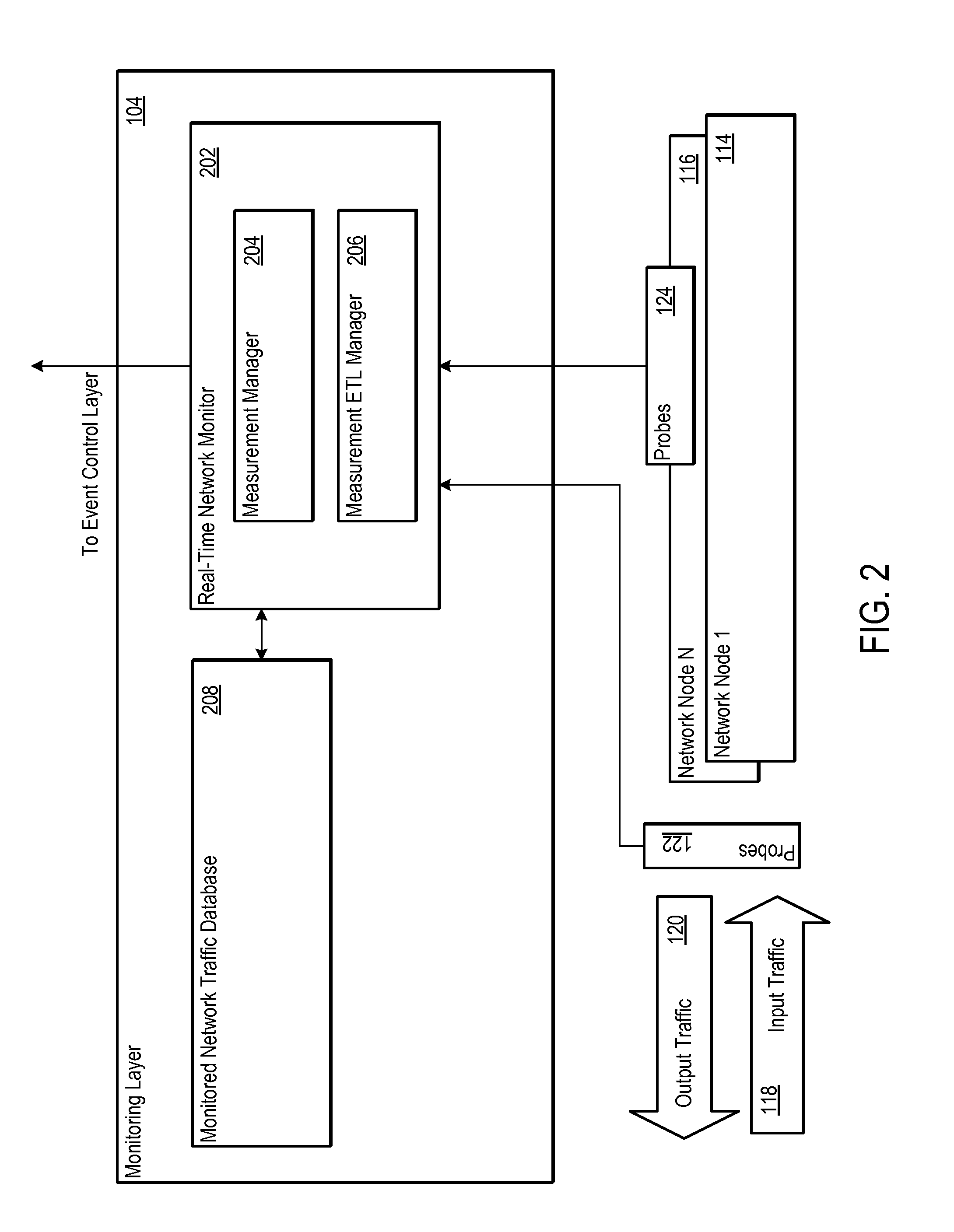

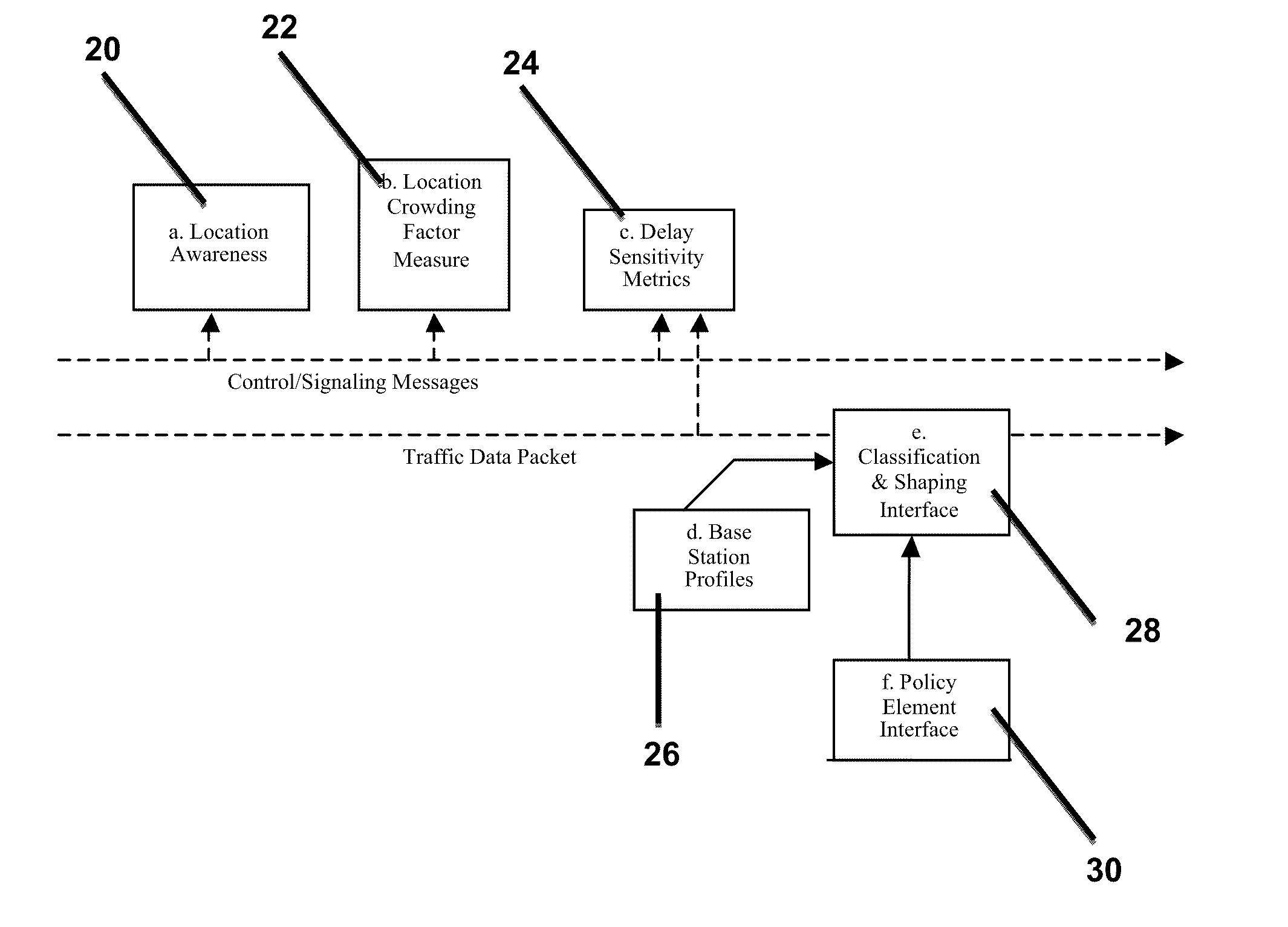

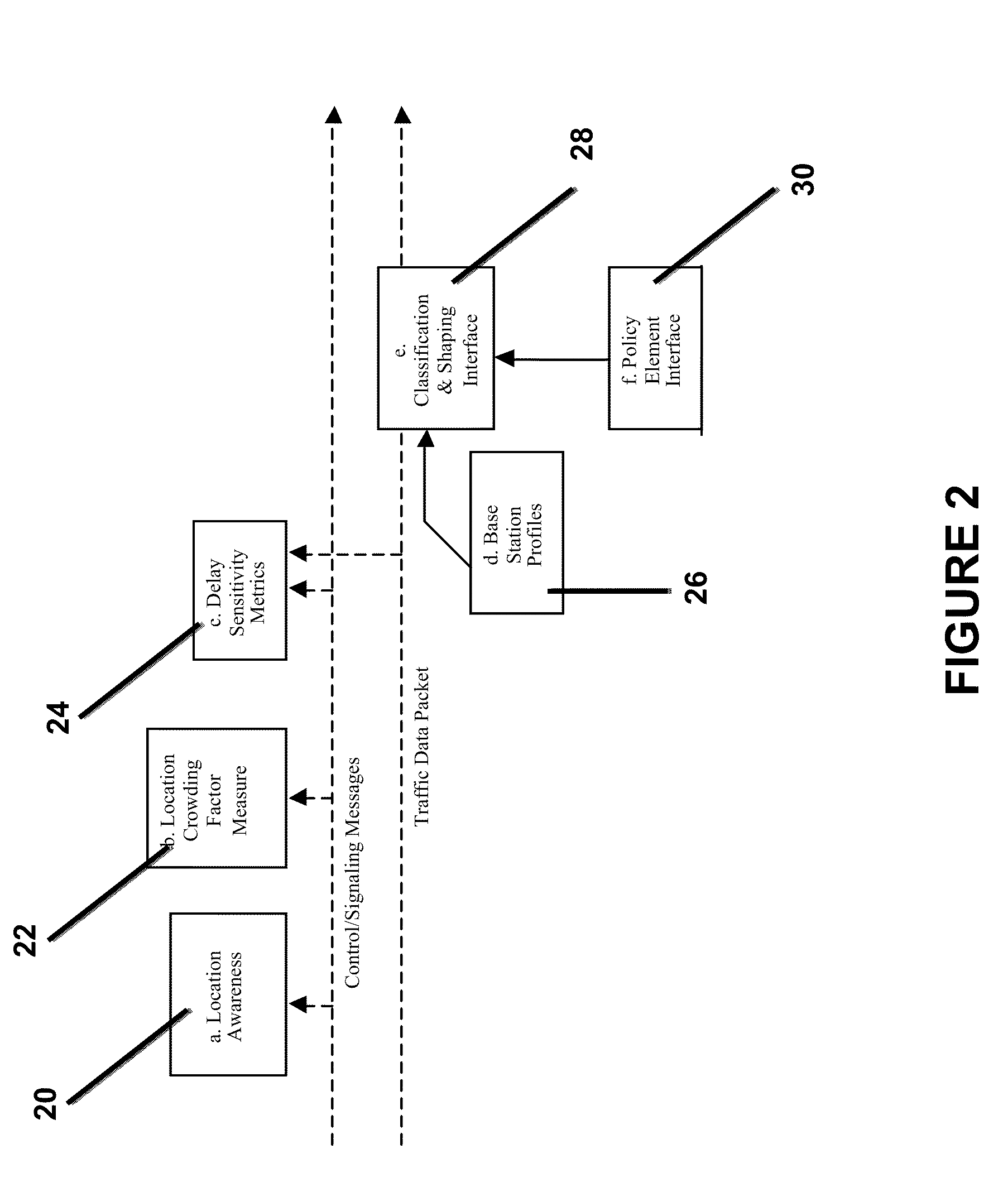

Network real time monitoring and control system

A network real-time monitoring and control system includes several layers of components for generating a network traffic shaping control that is used to shaping network traffic flows for one or more network nodes. The layers of the network real-time monitoring and control system include a monitoring layer, an event control layer, a traffic shaping control layer, a reporting layer, and an administrative layer. The monitoring obtains network traffic indicator measurements and network node operational indicator measurements. The event control layer uses the indicator measurements to generate a network event identifier, and generates a request for a network traffic shaping control based on a correlation of the network event identifier with a network node status identifier. The request for the network traffic shaping control is communicated to the traffic shaping control layer to generate a network traffic shaping control.

Owner:ACCENTURE GLOBAL SERVICES LTD

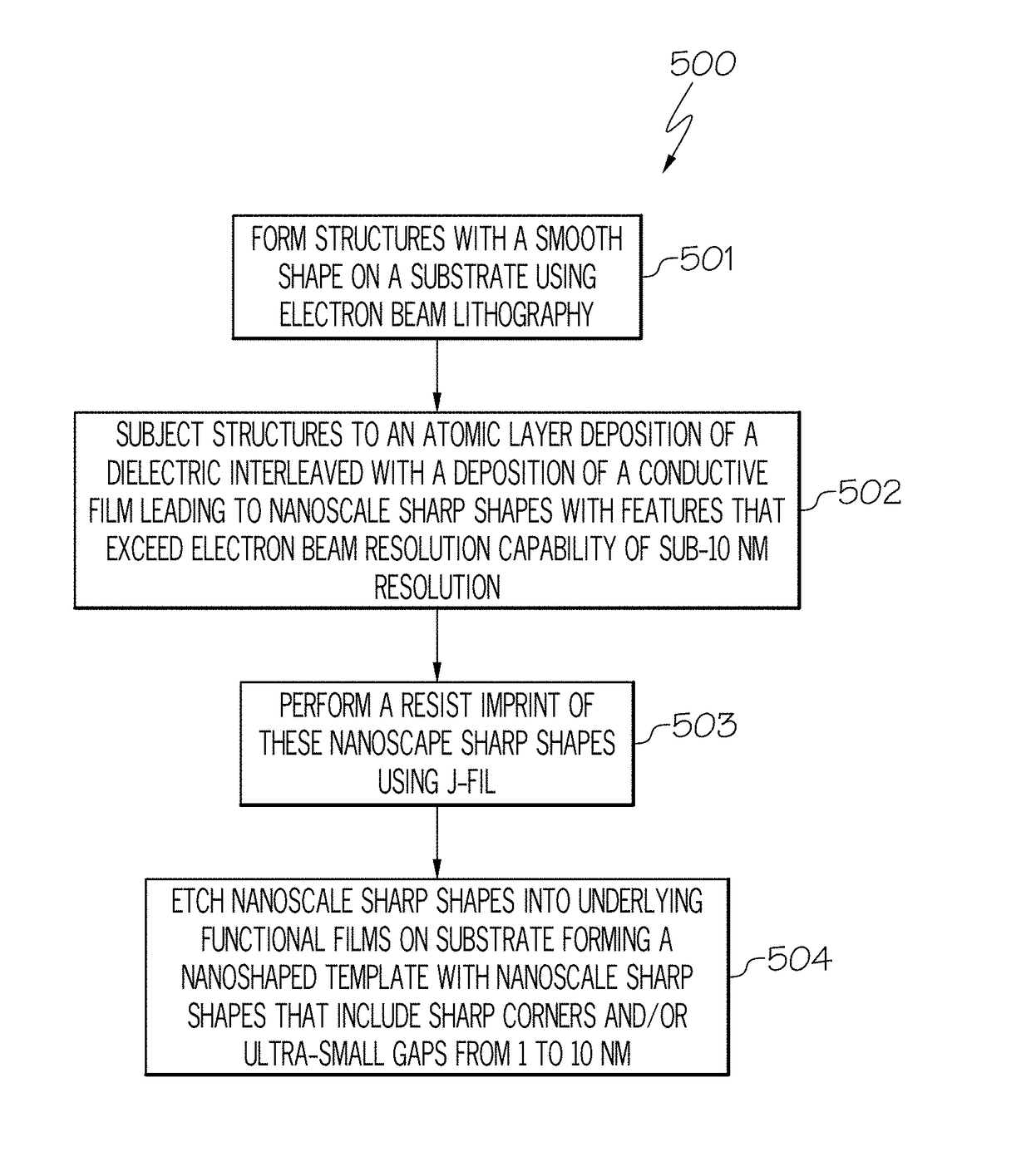

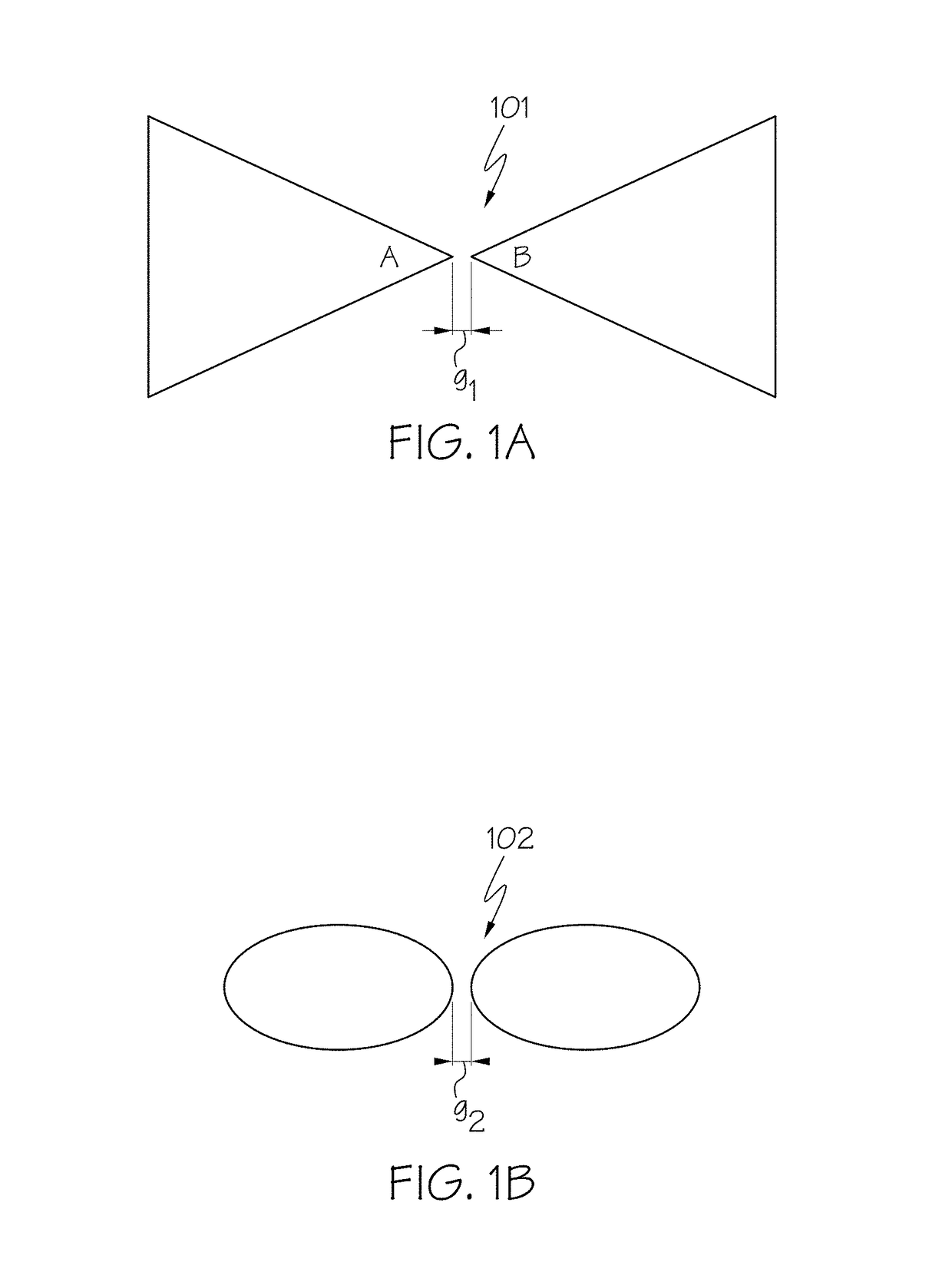

Nanoshape patterning techniques that allow high-speed and low-cost fabrication of nanoshape structures

A method for template fabrication of ultra-precise nanoscale shapes. Structures with a smooth shape (e.g., circular cross-section pillars) are formed on a substrate using electron beam lithography. The structures are subject to an atomic layer deposition of a dielectric interleaved with a deposition of a conductive film leading to nanoscale sharp shapes with features that exceed electron beam resolution capability of sub-10 nm resolution. A resist imprint of the nanoscale sharp shapes is performed using J-FIL. The nanoscale sharp shapes are etched into underlying functional films on the substrate forming a nansohaped template with nanoscale sharp shapes that include sharp corners and / or ultra-small gaps. In this manner, sharp shapes can be retained at the nanoscale level. Furthermore, in this manner, imprint based shape control for novel shapes beyond elementary nanoscale structures, such as dots and lines, can occur at the nanoscale level.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Radio access network load and condition aware traffic shaping control

ActiveUS20110170412A1Lower performance requirementsUsedError preventionAccounting/billing servicesDifferentiated servicesFrequency spectrum

Fine grained RAN aware traffic prioritization in spectrum constrained modern wireless networks which support differentiated service plans uses cell load metrics supplied to a Fine grained Traffic flow Prioritization Engine (FTPE) with and without the assistance from a client side collection module, Peer Agent (PA), at the mobile. Knowledge about a mobile's subscription plan is derived from a Subscription Profiles Repository (SPR). Dynamic control on traffic prioritization is applied through operator policy control engines, Policy and Charging Rules Function (PCRF) module. The FTPE works with flexible flow aggregation rules to simplify and scale prioritizing, blocking, and deferring decisions. The FPTE may apply Deep Packet Inspection (DPI) techniques to identify application flows, and uses hierarchical queue disciplines to achieve the necessary flow control. The FPTE may also instead use an adjunct DPI to perform the flow identifications.

Owner:VENTURI WIRELESS +1

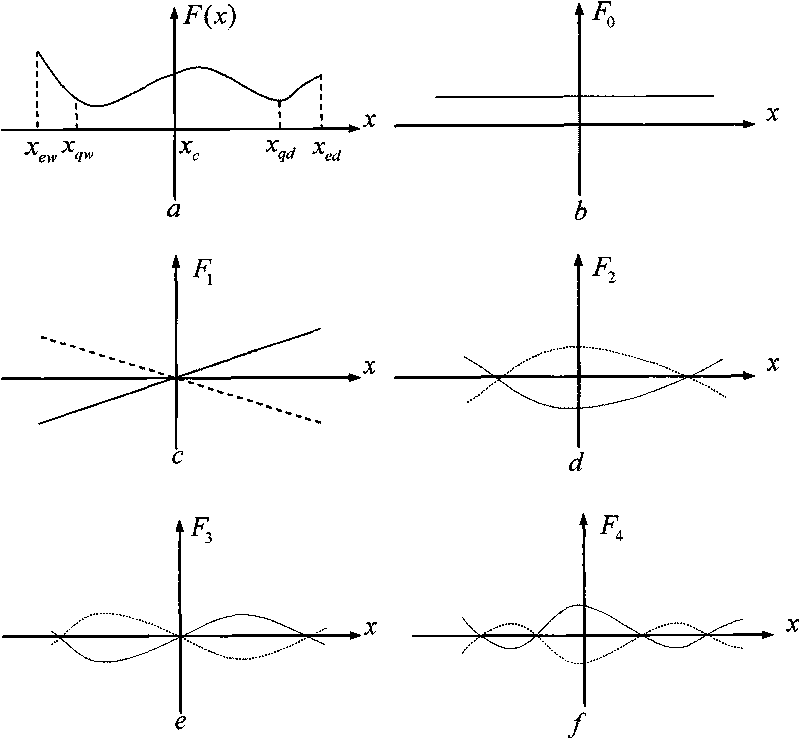

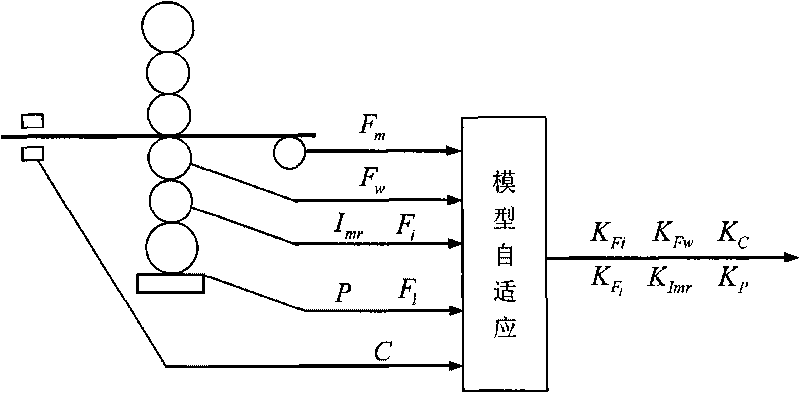

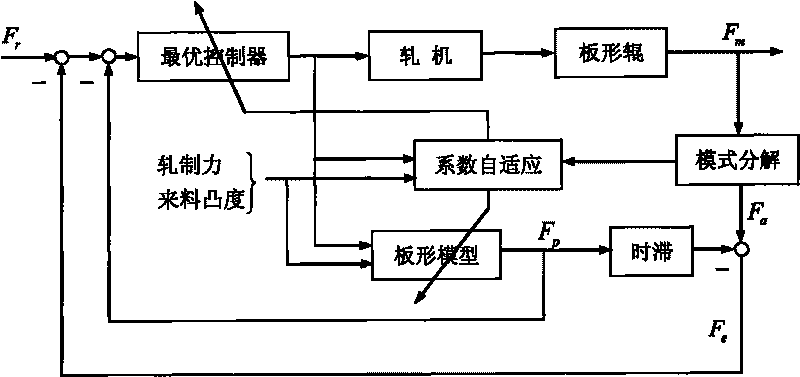

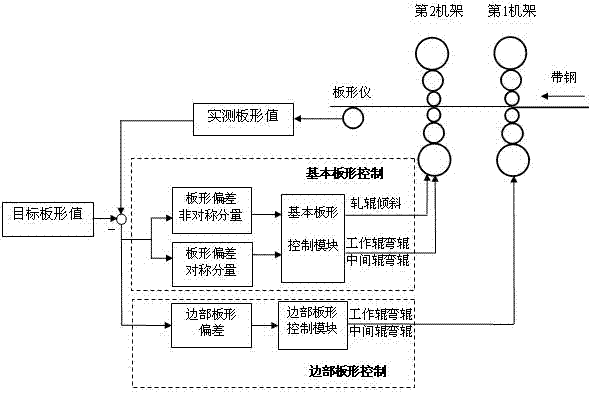

Model self-adapting sheet shape prediction and control method

ActiveCN101758084AEnsure consistencyHigh yieldProfile control deviceAdaptive controlTransmission time delayFeedback controller

The invention relates to a sheet shape control method for strip rolling. A model self-adapting sheet shape prediction and control method comprises the following steps: a sheet shape decomposition method and a sheet shape control model are given, and the input signals of the sheet shape control model include a rolling force and a crown of incoming material; then a sheet shape model which includes executing mechanism characteristics is obtained according to history sheet shape actual output data, the model is dynamically corrected according to real-time rolling parameters and corresponding actual sheet shape values, a correction model is used for accurately predicting the sheet shape and determining the optimal control quantity, and a feedback path, which removes transmission time-delay of strip steel between a frame and a measuring system, is established, thus carrying out regulation of a feedback controller in real time and ensuring rapid and dynamical sheet shape control. As the sheet shape control model is corrected in real time according to actual data, constantly changing actual conditions of the sheet shape model of a rolling mill are satisfied, thus predicting the sheet shape more accurately to increase the control accuracy of the sheet shape.

Owner:BAOSHAN IRON & STEEL CO LTD

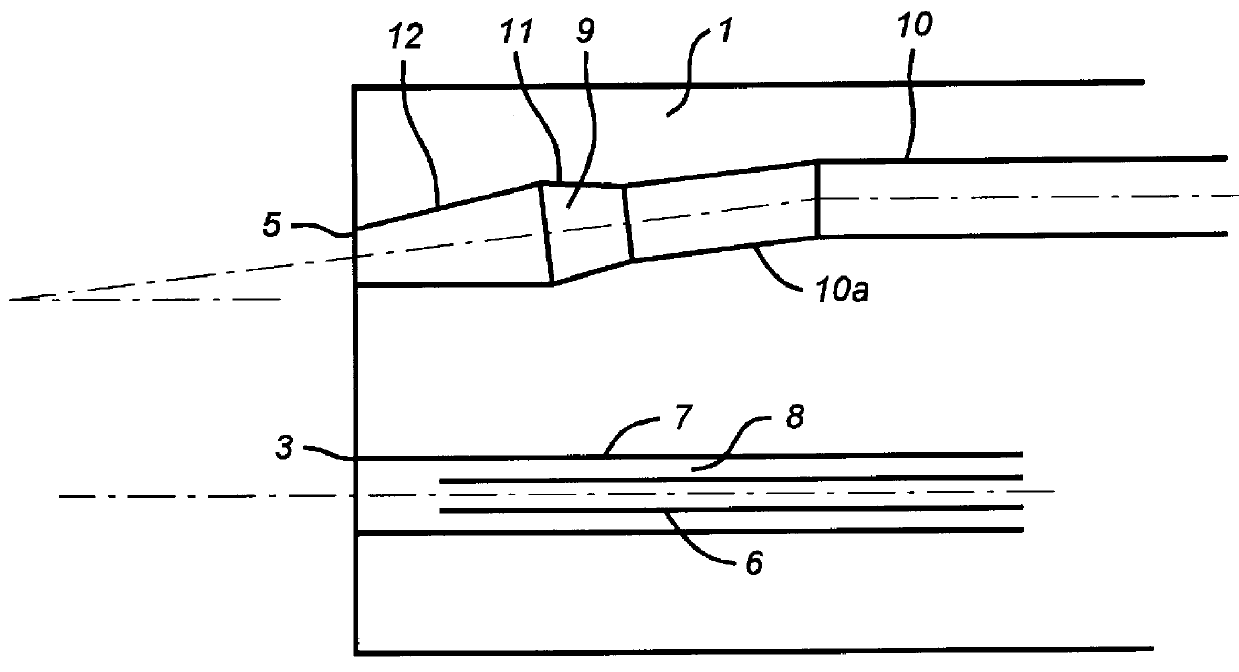

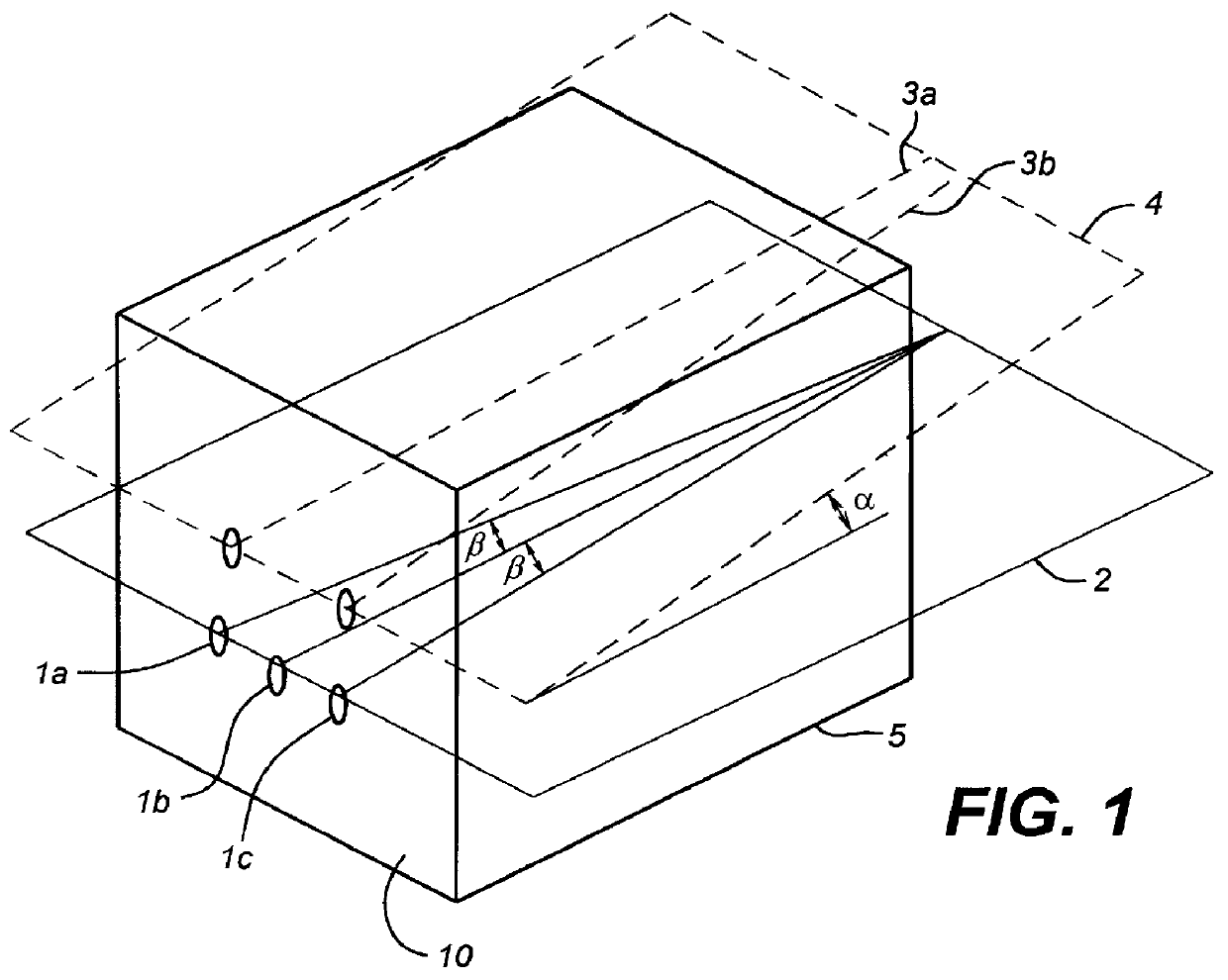

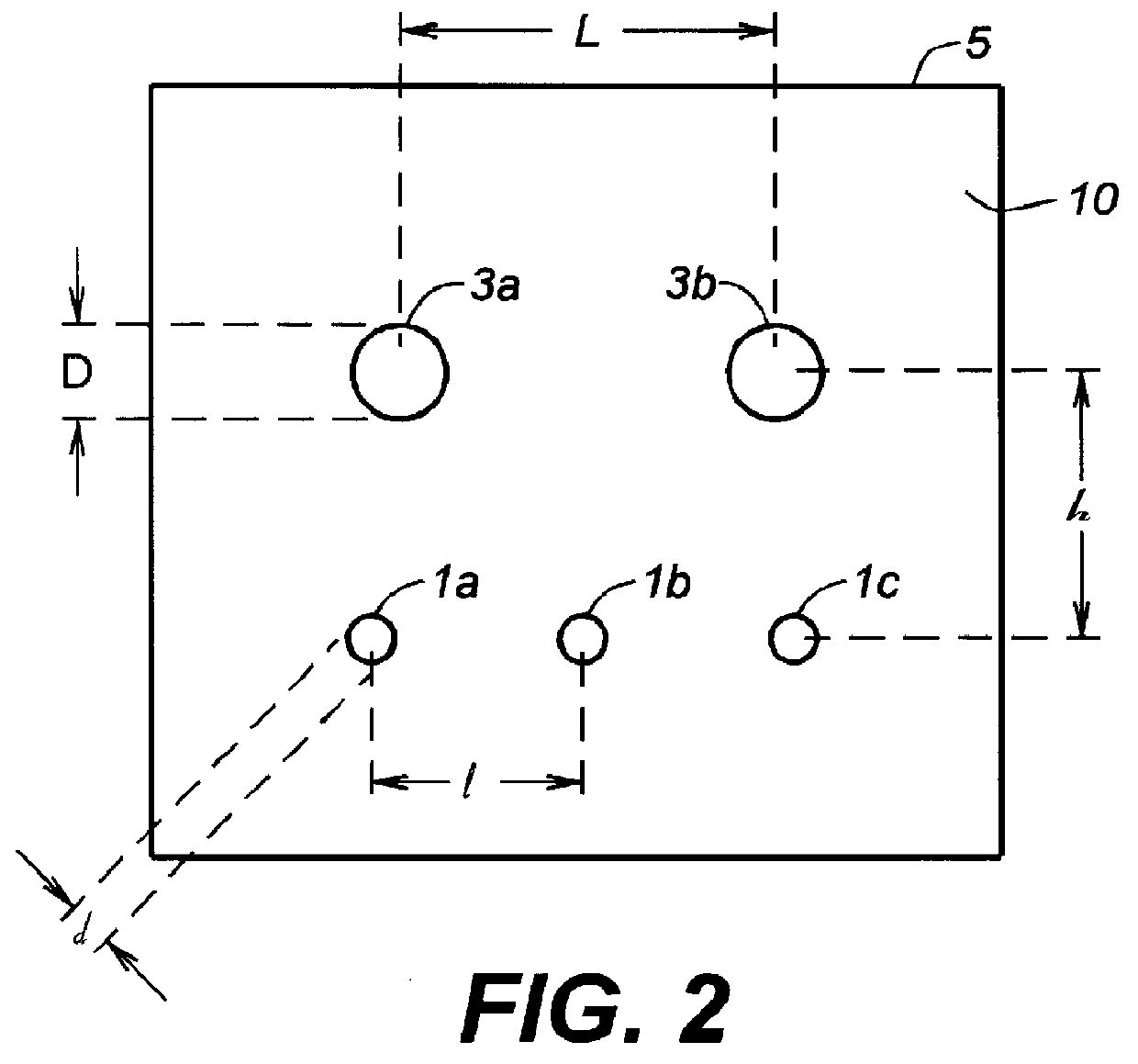

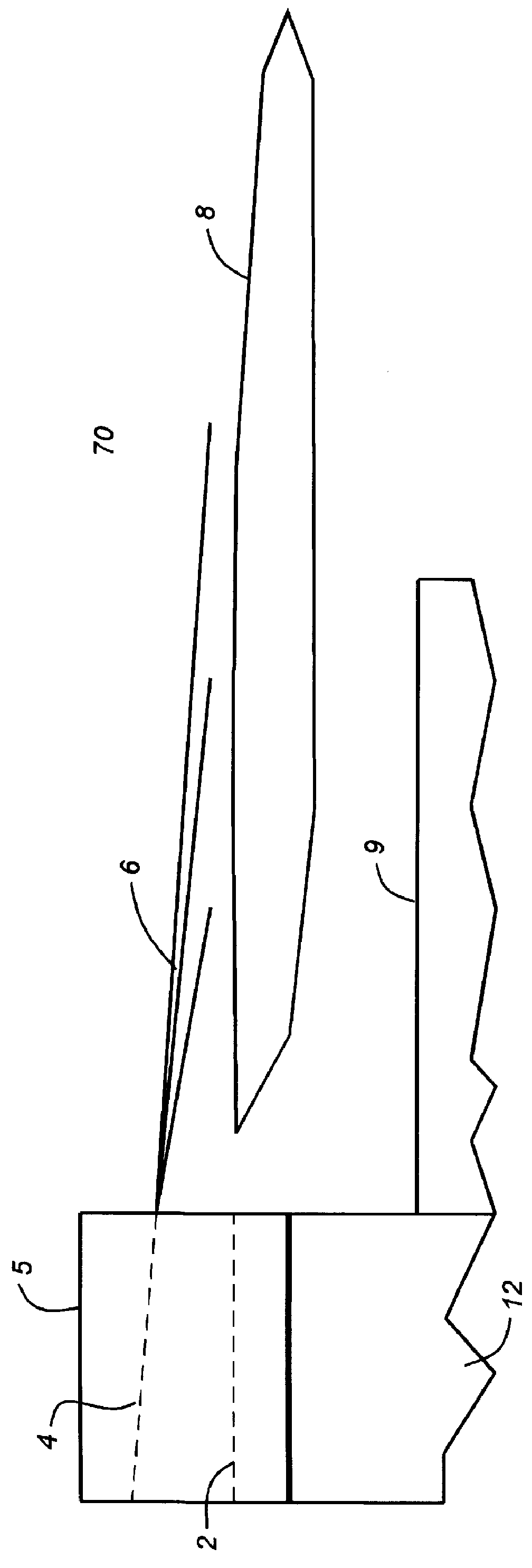

Variable camber continuous aerodynamic control surfaces and methods for active wing shaping control

ActiveUS9227721B1Improve various performance metricNo additional benefitAircraft controlWing shapesLeading edgeControl signal

An aerodynamic control apparatus for an air vehicle improves various aerodynamic performance metrics by employing multiple spanwise flap segments that jointly form a continuous or a piecewise continuous trailing edge to minimize drag induced by lift or vortices. At least one of the multiple spanwise flap segments includes a variable camber flap subsystem having multiple chordwise flap segments that may be independently actuated. Some embodiments also employ a continuous leading edge slat system that includes multiple spanwise slat segments, each of which has one or more chordwise slat segment. A method and an apparatus for implementing active control of a wing shape are also described and include the determination of desired lift distribution to determine the improved aerodynamic deflection of the wings. Flap deflections are determined and control signals are generated to actively control the wing shape to approximate the desired deflection.

Owner:NASA

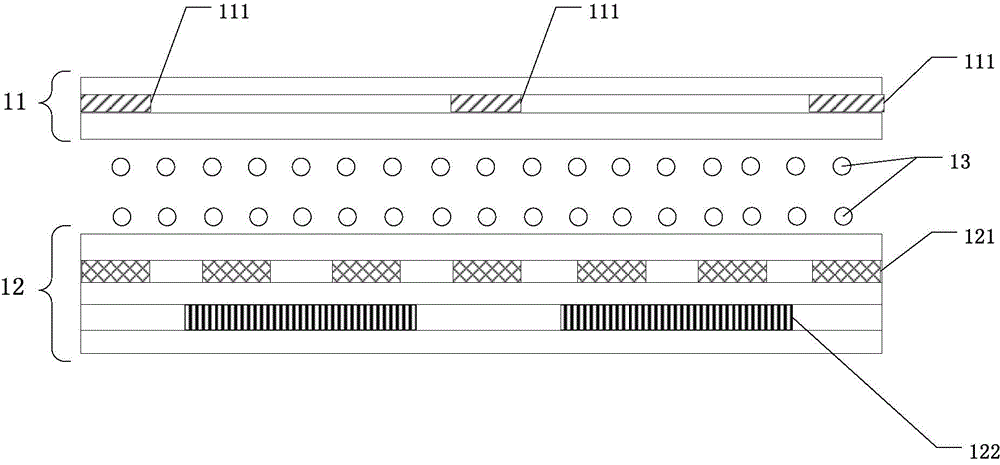

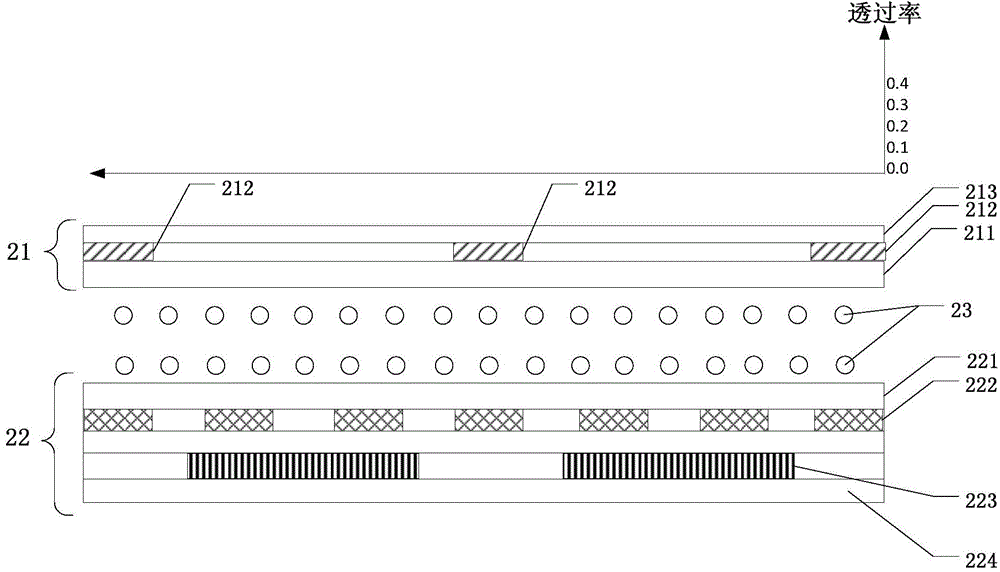

Display panel, display device and view angle control method of display panel

ActiveCN104865757ANo need to increase thicknessRealize controllable adjustmentNon-linear opticsLiquid-crystal displayDisplay device

The invention discloses a display panel, a display device and a view angle control method of the display panel. The display panel comprises an array substrate, a color film substrate and a liquid crystal layer, wherein the array substrate and the color film substrate are arranged oppositely, and the liquid crystal layer is located between the array substrate and the color film substrate. A plurality of strip-shaped control electrodes are arranged at one side, adjacent to the liquid crystal layer, of the color film substrate. A common electrode and a pixel electrode are arranged on the array substrate. Orthographic projections, on the array substrate, of the strip-shaped control electrodes are located in an orthographic projection, on the array substrate, of the common electrode or the pixel electrode. The strip-shaped control electrodes are used for exerting bias voltage to adjust the view angle of the display panel. The display device comprises a drive chip and the display panel. The drive chip is used for displaying drive. The controllable adjustment of the view angle of the display panel can be achieved by means of the display panel and the display device.

Owner:KUSN INFOVISION OPTOELECTRONICS

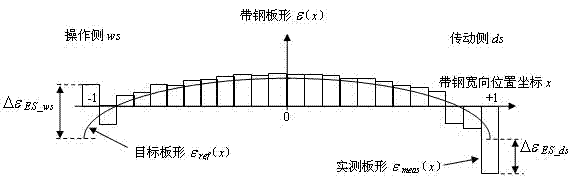

Control method of edge portion strip shape of cold rolling strip steel

The invention relates to a rolling method of cold rolling strip steel, in particular to a control method of edge portion strip shape of thin strip steel rolled by a cold continuous rolling mill or a two-stand temper mill. In a strip shape feedback control system centered on a last stand and on the basis of fundamental strip shape control function of major control for conventional edge waves and center waves, the method identifies the state of the edge portion strip shape of the strip steel based on the difference between the actual measured strip shape of strip steel edge portion together with the adjacent areas at the exit of last stand and an objective strip shape, and adjusts the corresponding strip shape executive mechanisms of the last stand and the rest stands according to the state of the edge portion strip shape to realize effective control for the edge portion strip shape of the strip steel, such as small edge waves and small side waves, thereby further improving the quality of the strip steel after cold rolling or temper rolling.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com