Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2137 results about "Roasting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Roasting is a process of heating of sulfide ore to a high temperature in presence of air. It is a step of the processing of certain ores. More specifically, roasting is a metallurgical process involving gas–solid reactions at elevated temperatures with the goal of purifying the metal component(s). Often before roasting, the ore has already been partially purified, e.g. by froth flotation. The concentrate is mixed with other materials to facilitate the process. The technology is useful but is also a serious source of air pollution.

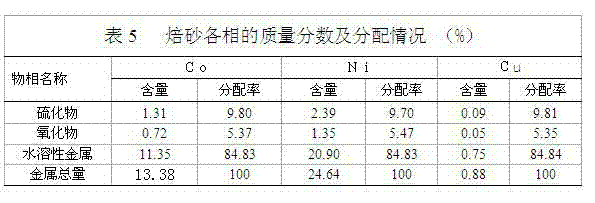

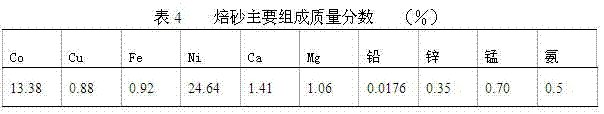

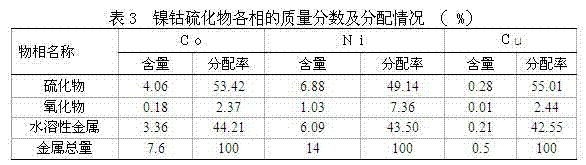

Treatment method of nickel-cobalt material

The invention provides a treatment method of a cobalt-containing material, belonging to the technical field of non-ferrous metal smelting. In the treatment method, through six steps such as peroxidation roasting, sulfuric acid leaching, N902 extraction of copper, chemical iron calcium magnesium removal, P204 extraction and impurity removal, P507 extraction and separation of nickel-cobalt, nickel,cobalt and copper in the nickel-cobalt material are extracted in high recovery, and impurities such as iron, zinc, manganese, calcium, magnesium and the like in the nickel-cobalt material are removed, thereby achieving nickel-cobalt-copper separation and resource comprehensive utilization. According to the treatment method provided by the invention, the process is simple and production cost is relatively low; the adaptability of the method on raw materials is strong and can be used for treating the nickel-cobalt material with complicated components and high copper-zinc-magnesium contents.

Owner:JINCHUAN GROUP LIMITED

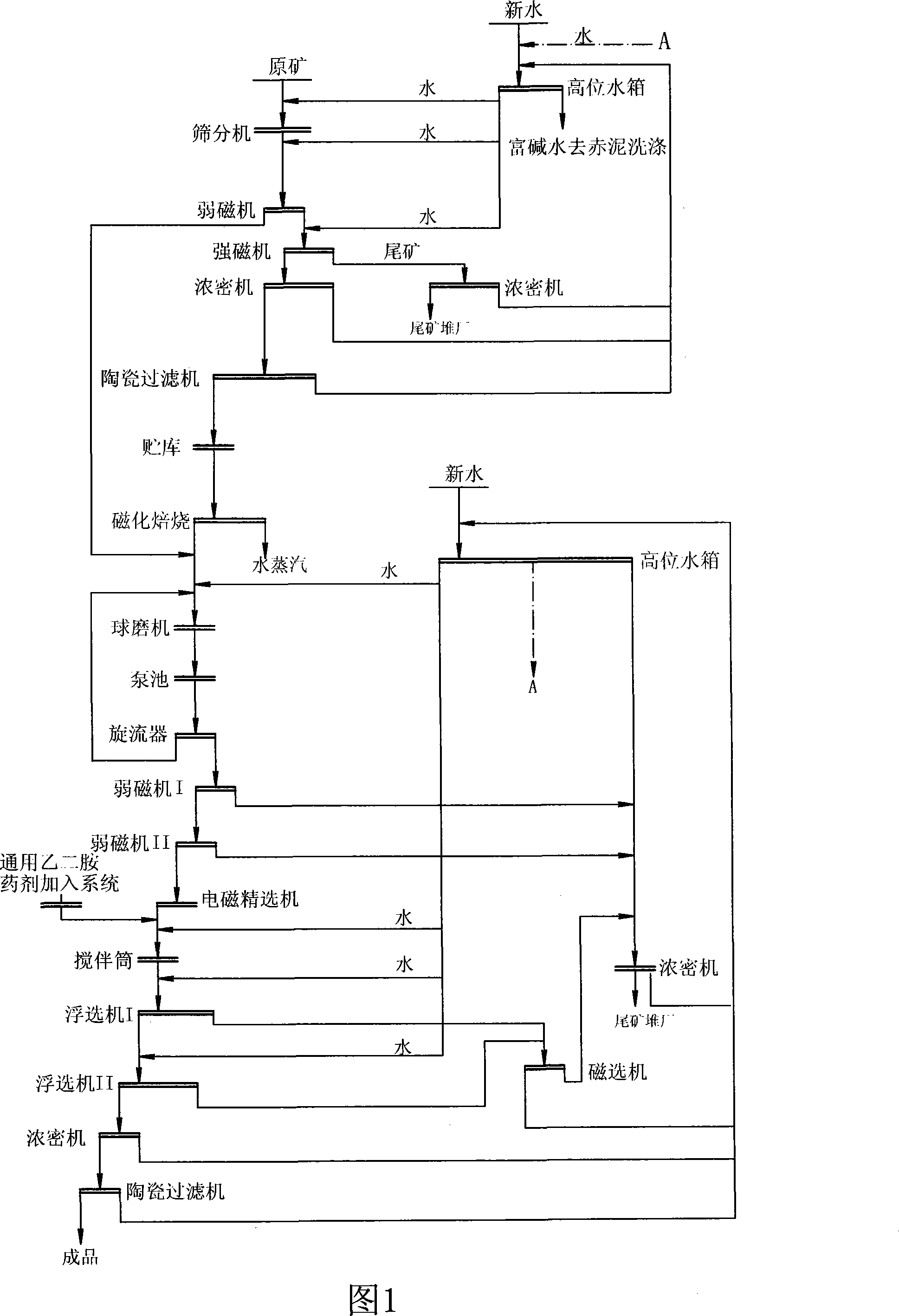

Method of refining iron ore from alkaline red mud and making gangue neutral

The invention relates to a method to select refined iron ore from alkaline red mud and neutralize mine tailings. The method consists of red mud pretreatment and technological process of preparing refined iron ore. The red mud pretreatment is that water is added into the red mud slurry discharged from aluminum factory; the red mud slurry is diluted to the solid concentration of 30 to 40 percent and then is screened and put into a low intensity magnetic separator for selecting ferromagnetic substance. The ferromagnetic substance is dehydrated and directly selected as the product. The remaining red mud is watered down to 30 percent solid concentration and put into a high intensity magnetic separator for magnetic separation and desliming. The obtained coarse ore is washed to a coarse ore settling tank or a thickener to be concentrated while the undercurrent is sent into a vacuum ceramic filter and a filter cake is roasted in a suspended magnetic roasting furnace. The roasted materials are crushed into a ball mill and then are milled. The water is overflown until 95 percent of the solid material granularities are less than 75m and then is treated by the third stage magnetic separation and the second flotation. The undercurrent is filtered by the ceramic filter, and then the refined iron ore with a purity of 58 to 65 percent is obtained. The refined iron ore is recycled from the red mud by the invention so as to fully employ aluminum ore, save resources and energy consumption and neutralize the whole red mud. The invention reduces environmental pollution and has good economic and social benefits.

Owner:SHENYANG XINBO IND TECH

Method for treating low-grade tungsten concentrate and tungsten slag

ActiveCN103614545AImprove resource utilization efficiencyAchieve selective separationMagnetic separationProcess efficiency improvementNiobiumSlag

The invention discloses a method for treating low-grade tungsten concentrate and tungsten slag. The method comprises the steps of mixing low-grade tungsten concentrate or tungsten slag and coal powder with a reduction roasting enhancer, and then performing reduction roasting; grinding the product obtained through the reduction roasting, then performing neutral leaching to obtain a tungstate solution and leaching residues, and performing magnetic separation on the leaching residues by adopting a magnetic field so as to obtain iron concentrate and valuable metal tailings; removing silicon from the valuable metal tailings by using dilute hydrochloric acid and leaching out manganese from the valuable metal tailings by using concentrated hydrochloric acid in sequence, and then leaching out tantalum and niobium by using hydrofluoric acid to prepare tantalum and niobium products. By adopting the method, valuable elements including tungsten, iron, copper, manganese, bismuth, cobalt, tantalum, niobium and the like which are difficult to extract in the low-grade tungsten concentrate and tungsten slag can be efficiently enriched, separated and recovered effectively, so that the resource comprehensive utilization of the valuable elements in the low-grade tungsten concentrate or tungsten slag is realized; moreover, the method is simple in equipment, short in flow, simple and convenient in operation, is economical and reliable, and is favorable for industrial production.

Owner:CENT SOUTH UNIV

Method for preparing complete methanation catalyst for hydrothermal chemical process

ActiveCN102029161AGood activity and stabilityGood hydrothermal stabilityHydrocarbon from carbon oxidesCatalyst activation/preparationChemical synthesisPtru catalyst

The invention provides a method for preparing a complete methanation catalyst for a hydrothermal chemical process. The catalyst comprises the following components: 10 to 75 percent of active nickel ingredient, 10 to 90 percent of high-temperature resistant carrier and 0.1 to 15 percent of rare-earth auxiliary agent, wherein the content is counted on the basis of metal oxide, and the percentage is weight percentage of the total weight of the active ingredient, the carrier and the auxiliary agent. The preparation method comprises the following steps of: (a) forming a catalyst precursor by using the hydrothermal chemical synthesis process; and (b) preparing the obtained catalyst precursor into the complete methanation catalyst by filtering, washing, drying, roasting, forming, re-roasting and reducing. The method is convenient for crystallization and precipitation of catalyst materials, and has simple process and good repeatability. The method provides guarantee for meeting the current increasing clean energy requirement, and has irreplaceable important effect on the enhancement of energy / resource safety at the same time.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for recycling vanadium and molybdenum from waste petroleum catalyst

InactiveCN105274344AReduce pollutionAchieve recyclingProcess efficiency improvementPtru catalystPorphyrin

The invention relates to a method for recycling vanadium and molybdenum from a waste petroleum catalyst, and belongs to the technical field of petrochemical industry. The method comprises air-burning and ball-removing, ball-milling, soda roasting-water leaching, aluminum removing, molybdenum precipitating and enriching molybdenum by ion exchange. The method specifically comprises the following steps: firstly, igniting sticky oil in the waste catalyst in air to burn carbon and oils in the waste catalyst; then, oxidizing the vanadium and nickel in the forms of porphyrin compounds in the waste catalyst into vanadium oxide and nickel oxide, converting most of the molybdenum into molybdenum oxide, wherein the waste catalyst subjected to air-burning and oil-removing is more beneficial for crushing, and the crushed waste catalyst and a certain proportion of sodium carbonate are mixed, and are roasted at a high temperature; leaching roasted materials by hot water, dissolving sodium salts of the vanadium and the molybdenum into water to obtain a solution, filtering the solution, introducing the filtered solution into a leaching solution, introducing a little aluminum into the leaching solution, regulating the pH value of the solution to remove aluminum; regulating the pH value of the solution to 8-9, adding ammonium chloride, precipitating and separating out the vanadium in the form of ammonium vanadate; and concentrating vanadium-precipitated solution by adopting an ion exchange process and enriching an ammonium molybdate solution.

Owner:刘楚玲

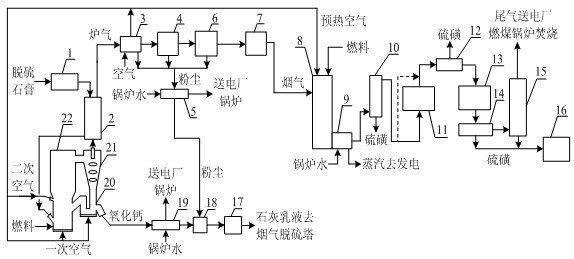

Method for preparing calcium oxide and sulfur by double-atmosphere fluidized roasting of desulfurated gypsum

InactiveCN102303883ASolve the use problemAbundant raw materialsEnergy inputSulfur preparation/purificationDust controlSulfur dioxide

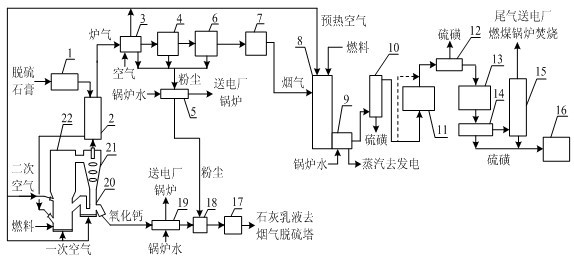

The invention provides a method for preparing calcium oxide and sulfur by double-atmosphere fluidized roasting of desulfurated gypsum, belonging to the technical fields of solid pollutant treatment and in environmental protection chemical production. The method comprises the following steps: drying and dehydrating aged desulfurated gypsum, and then entering a multi-stage suspension heat exchangerfor pre-heating; entering hot-state gypsum into a circulating fluidized bed decomposition furnace, and introducing primary and secondary air for decomposition; cooling discharged hot-state calcium oxide, wherein cooled hot-state calcium oxide is used as a desulfurizer for later use; entering discharged smoke containing sulfur dioxide into the multi-stage suspension heat exchanger; removing calcium oxide dust in cooled hot smoke through multi-stage dust removing equipment; and feeding the smoke without the dust into a high-temperature-resistant high-efficiency filter for further removing the dust, and feeding clean smoke into a sulfur recovery system; and preparing the sulfur product by the processes of hot reduction, catalytic reduction, Clause reaction and the like, and feeding Clause tail gas into a coal burning boiler in a power plant for combustion. The method has the advantages of good environmental protection benefits and strong economic benefits.

Owner:CHINA PETROCHEMICAL CORP +1

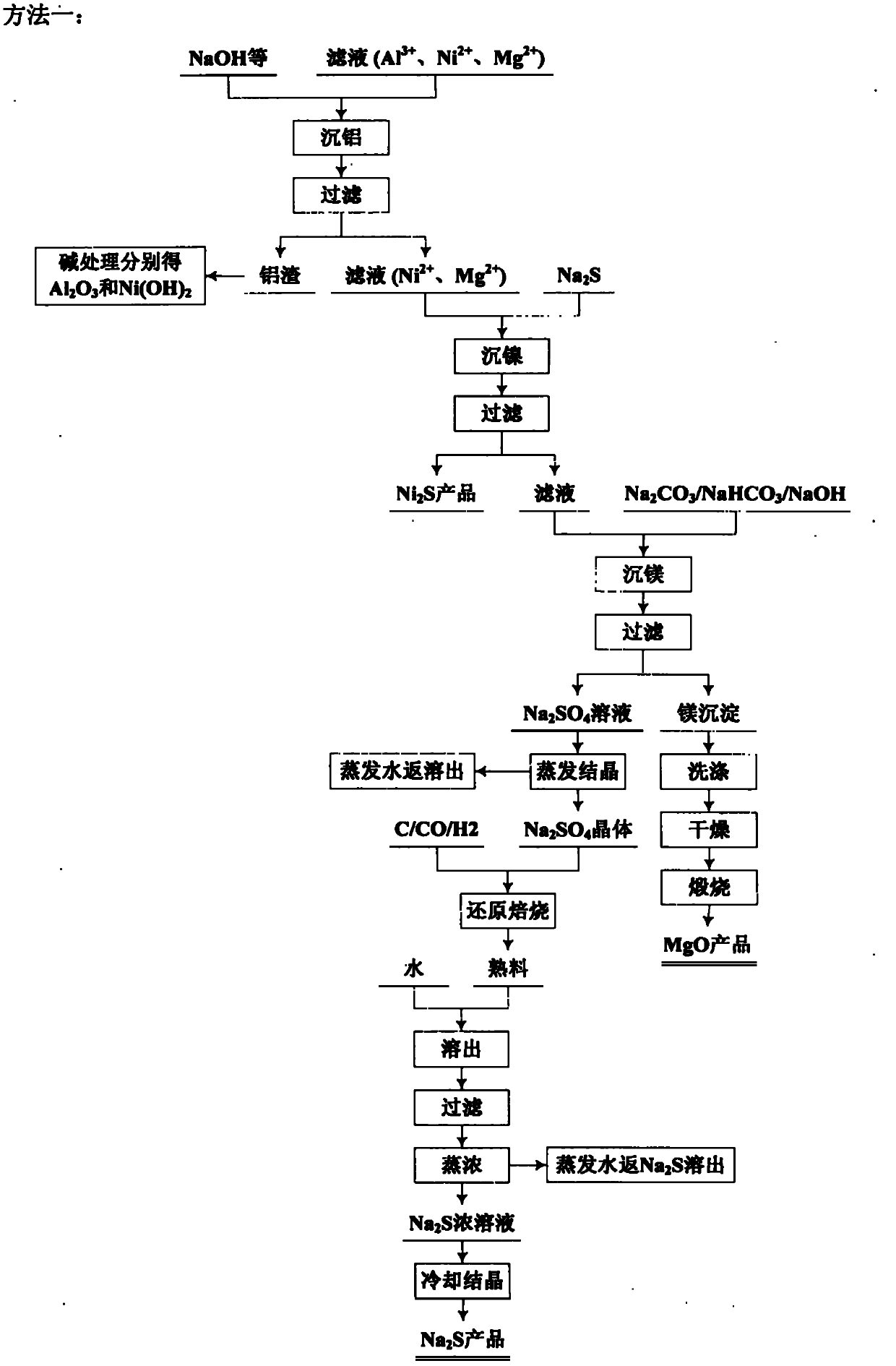

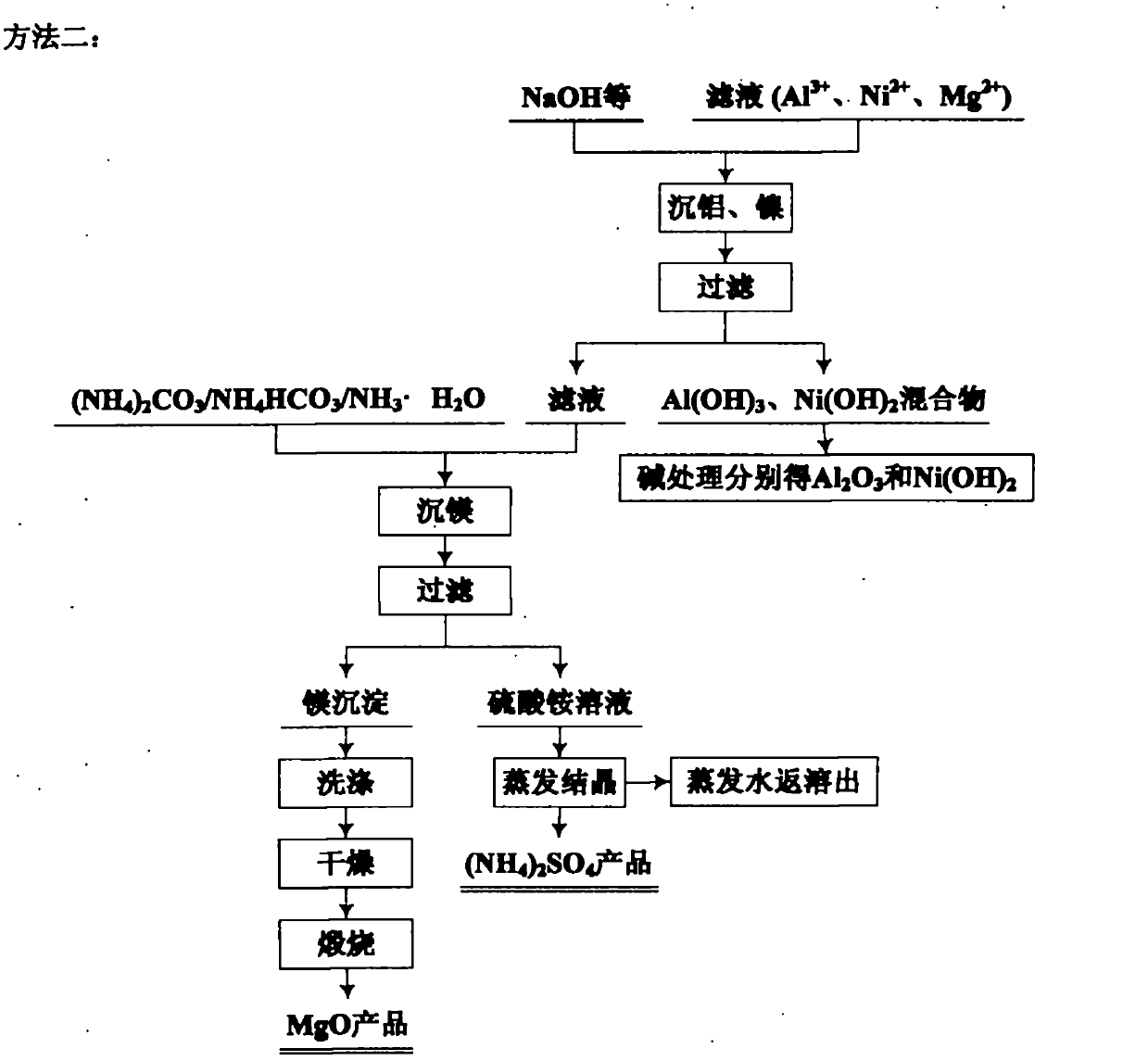

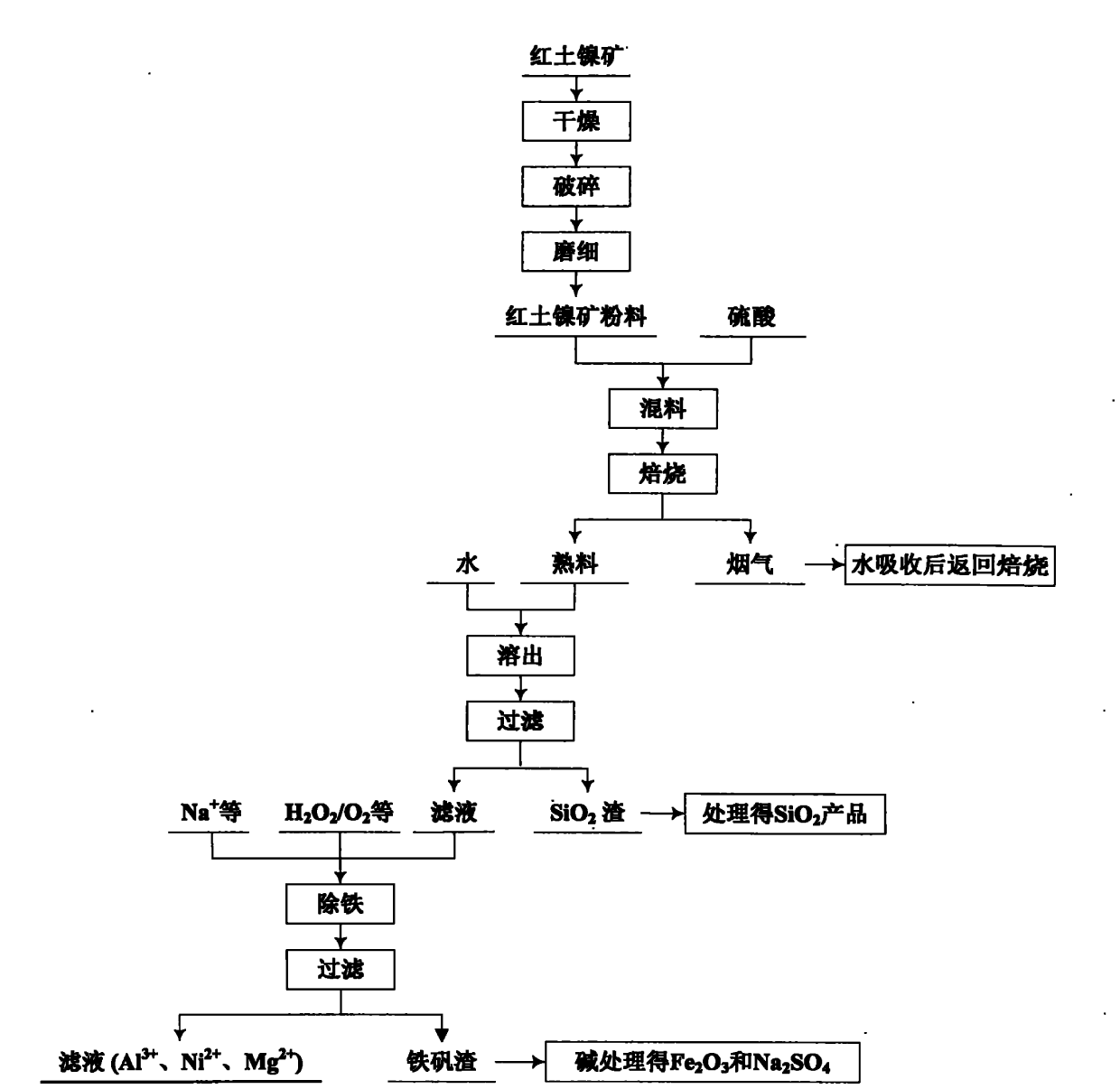

Comprehensive utilization method for laterite-nickel ore

The invention relates to an environmental-friendly comprehensive utilization method for a laterite-nickel ore, which comprises the following steps of: (1) grinding the laterite-nickel ore, mixing with sulfuric acid, roasting, dissolving out roasted clinker and filtering to obtain silicon dioxide and dissolution liquid; (2) deironing the dissolution liquid to obtain liquid No.2 and filter residue (iron compounds), wherein the liquid No.2 comprises aluminum, nickel and magnesium and can be treated by the step (3) or (4); (3) precipitating the aluminum in the liquid No.2 by using alkali, filtering, precipitating the nickel in filtrate by using sodium sulfide, filtering, precipitating the magnesium by using the alkali, and treating filter residue to obtain aluminum oxide, nickel hydroxide, nickel sulfide and magnesium oxide respectively; and (4) precipitating the aluminum and the nickel in the liquid No.2 by using the alkali, treating mixed slag containing the aluminum and the nickel by using the alkali to obtain aluminum hydroxide and nickel hydroxide products, and precipitating the magnesium in filtrate subjected to aluminum and nickel precipitation by using ammonia or ammonium saltto obtain a magnesium oxide product. The method is suitable for treating various laterite-nickel ores, three wastes (waste gas, waste water and waste residue) are not generated, and valuable components magnesium, nickel, iron, aluminum and silicon in the laterite-nickel ore are separated and extracted.

Owner:NORTHEASTERN UNIV

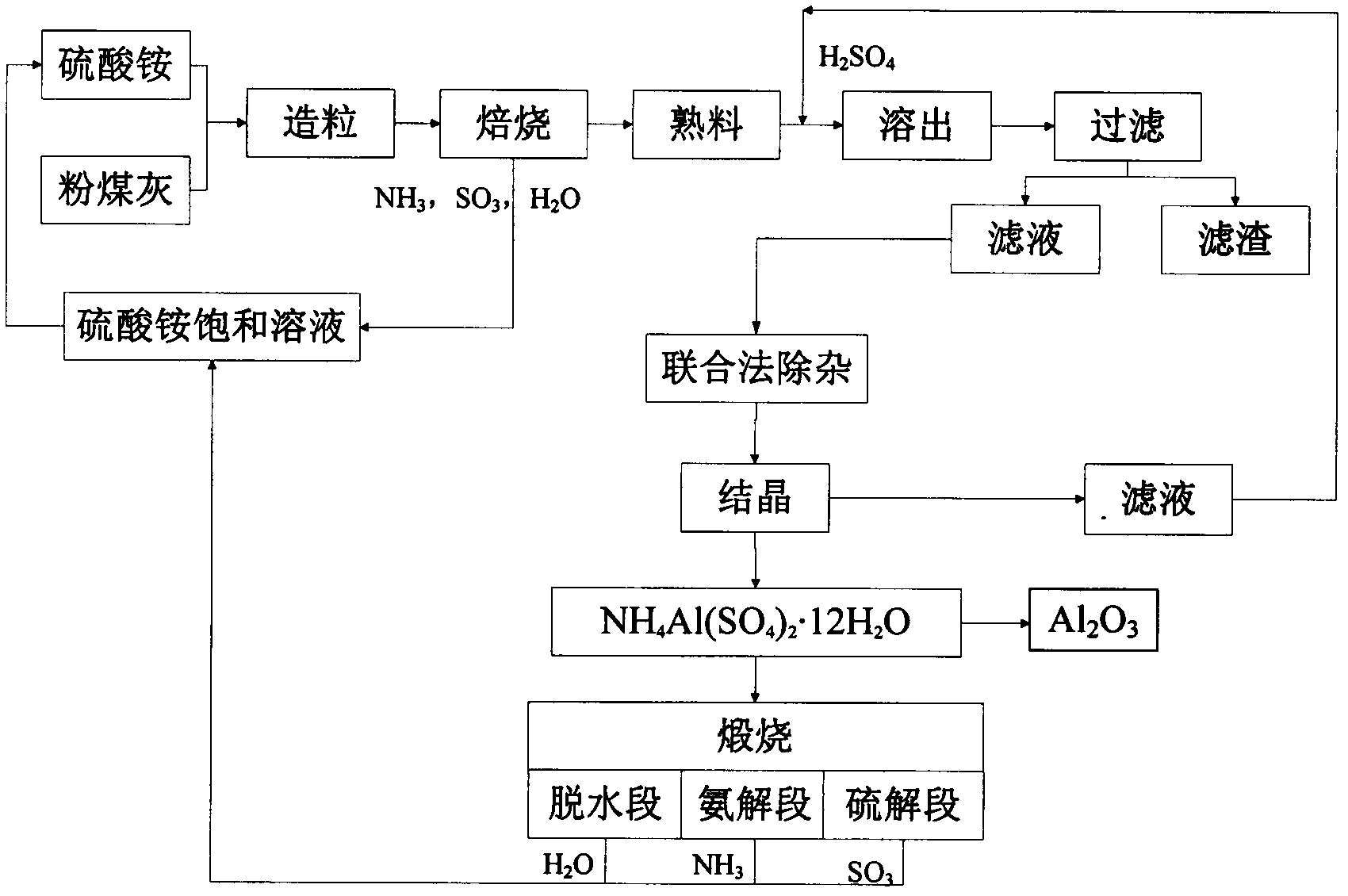

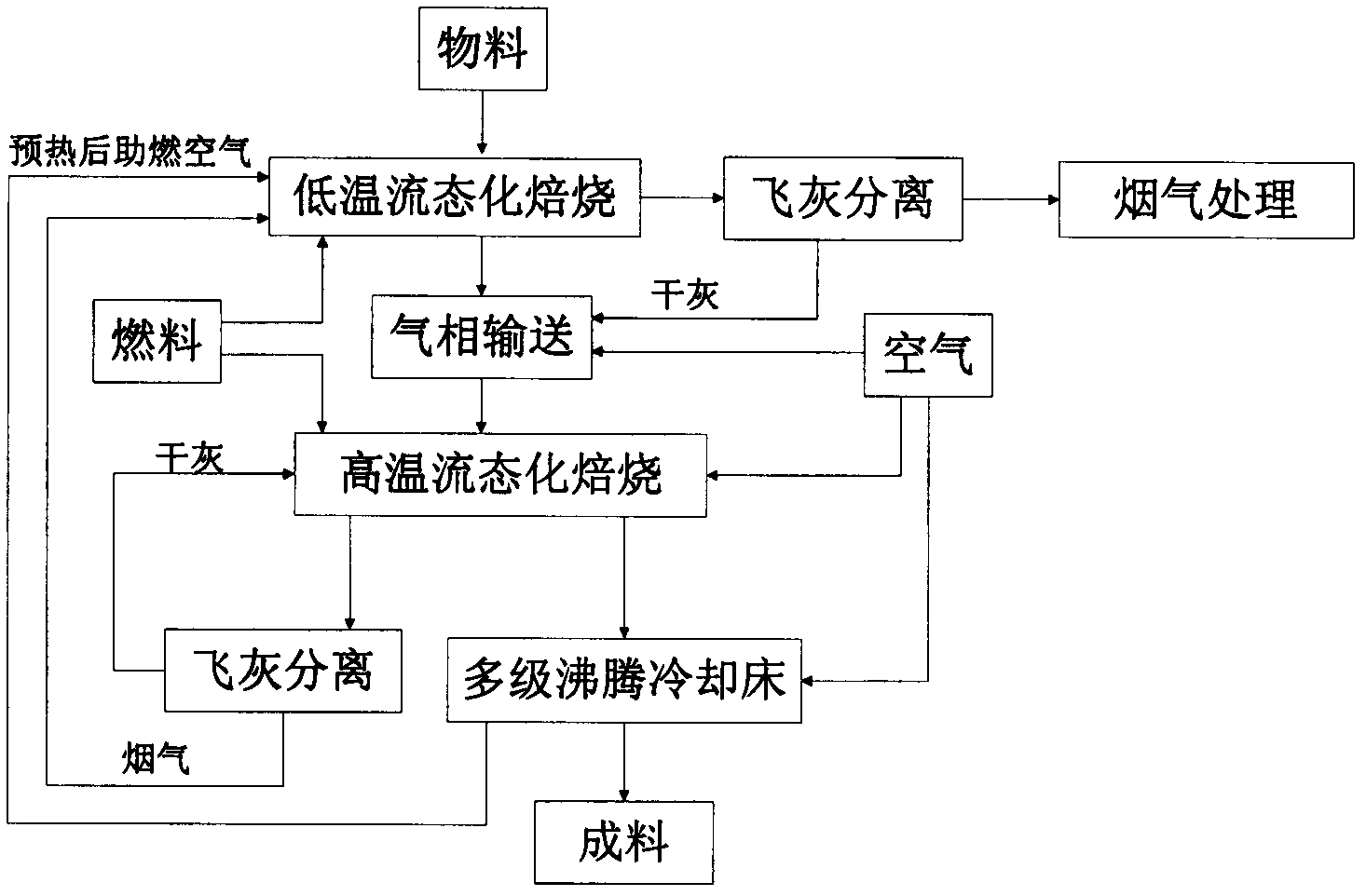

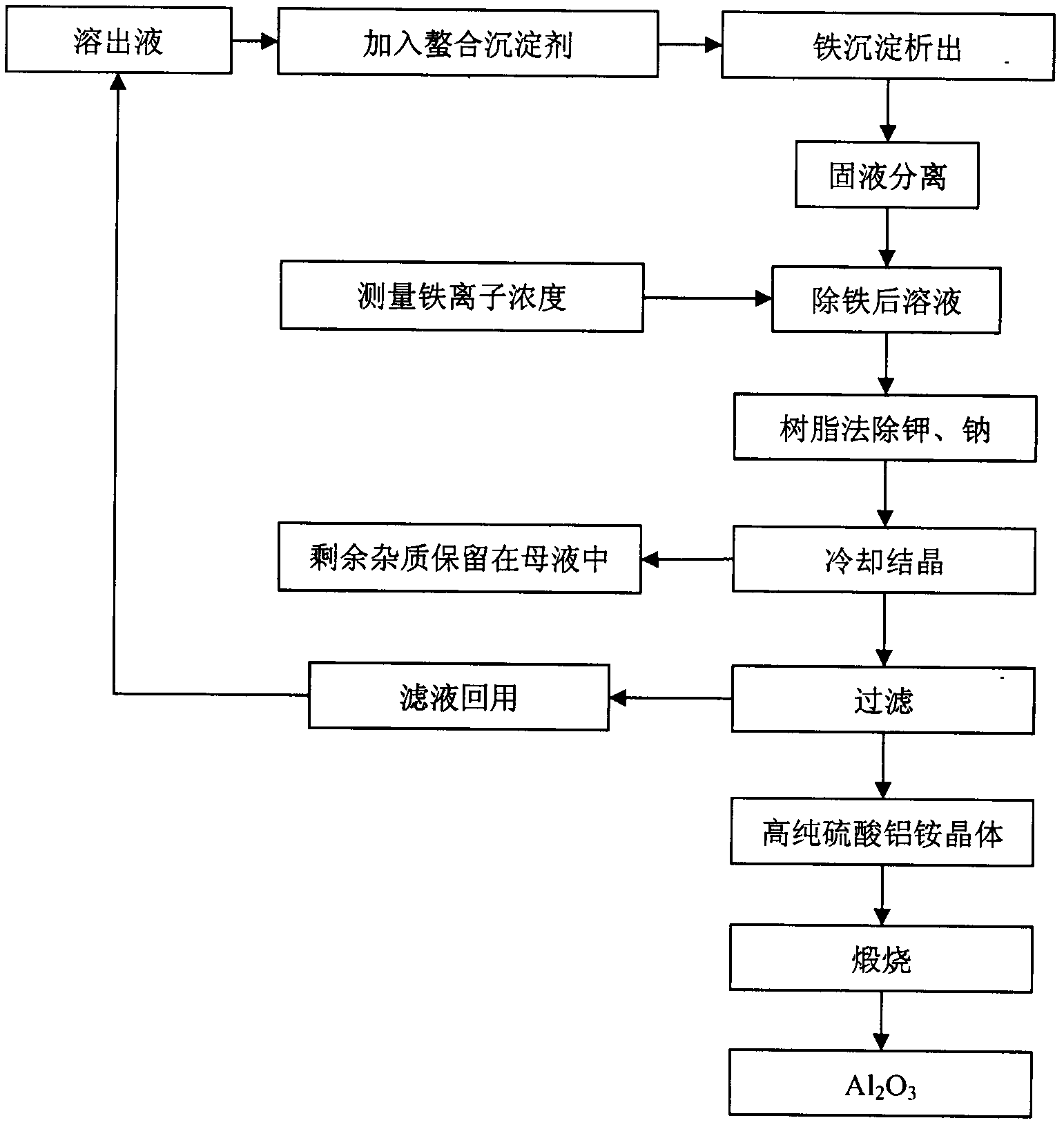

Method for extracting aluminum oxide from fly ash based on ammonium sulfate activation process

The invention relates to a method for extracting aluminum oxide from fly ash based on an ammonium sulfate activation process. By adopting roasting of the fly ash and ammonium sulfate, combined impurity removal and a two-section fluidized roasting system, the problem of high corrosion of equipment in the background technology is solved; a process chain of a main flow is shortened; through the roasting system, the roasting process is low in energy consumption, economic and low in cost by using methods such as two-section cyclic fluidized roasting and dense phase transportation; and the technical problem of material melting, wall sticking, caking or ring forming is solved.

Owner:CHINA SHENHUA ENERGY CO LTD +2

Ultra-deep absorption desulfurizer for light oil and application thereof

InactiveCN101940908AGood dispersionEfficient removalOther chemical processesHydrocarbon oils refiningNaphthaAdhesive

The invention relates to an ultra-deep absorption desulfurizer for light oil and an application thereof. The desulfurizer comprises 10.0-80.0% of zinc oxide, 5.0-75.0% of VIII metal oxide, 1.0-50.0% of adsorption assistant, 1.0-10.0% of pore-expanding agent and 10.0-35.0% of adhesive. The method for making the desulfurizer comprises the following steps: uniformly mixing, pressing to obtain sheets or squeezing to obtain strips, drying and roasting. The absorption desulfurizer does not use noble metals, thereby having the advantage of low price; the invention adopts mixed roasting technique, thereby having the advantages of simple preparation method and easy operation; the desulfurizer has the advantages of high desulfurization activity and favorable regeneration effect, and can be used for processing low-sulfur light oil; the content of sulfides in the processed light oil can be reduced to below 0.5 ppm; and the desulfurizer is suitable to be used in the low-temperature fine desulfurization process of naphtha, gasoline, diesel, aviation kerosene and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

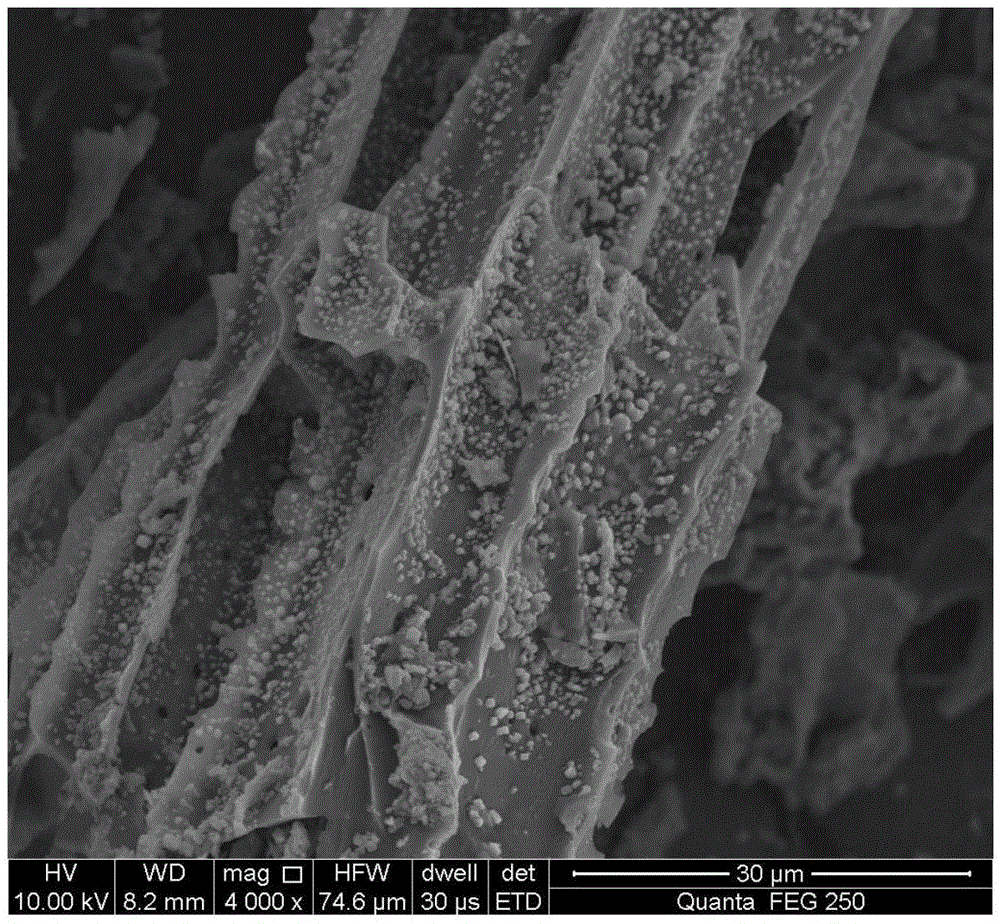

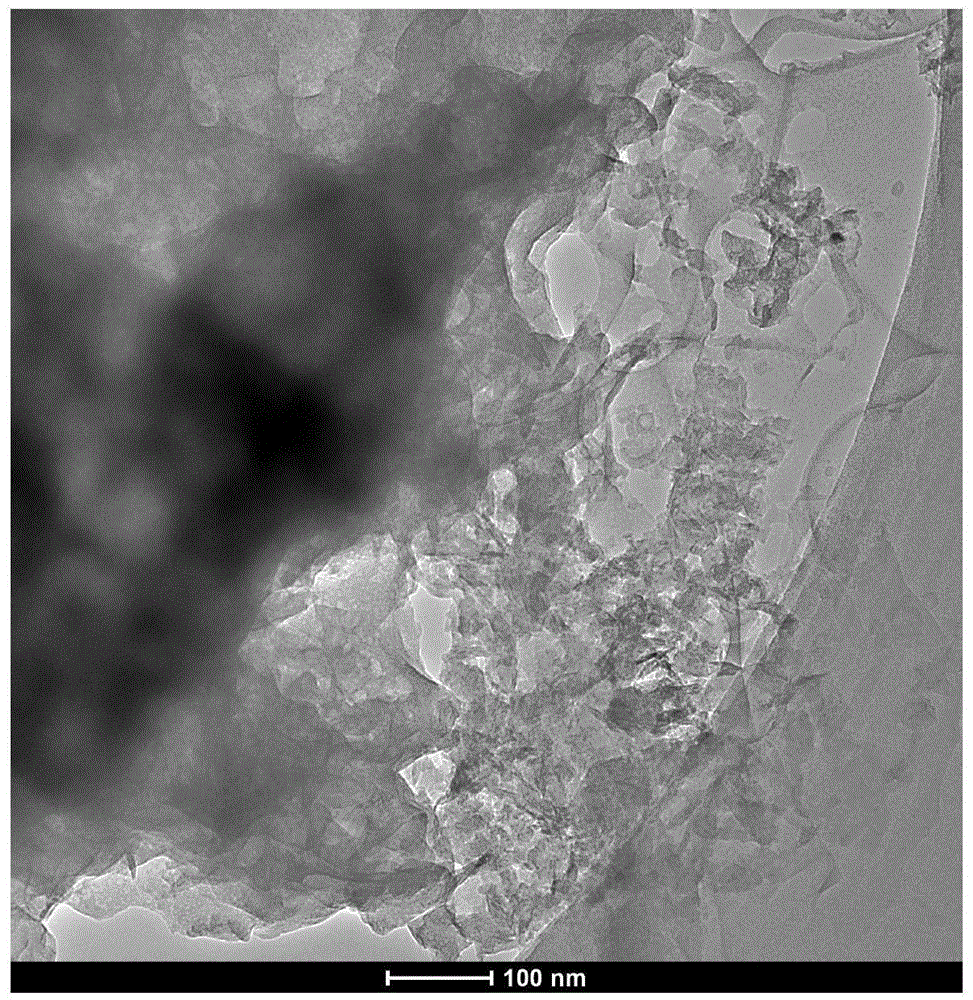

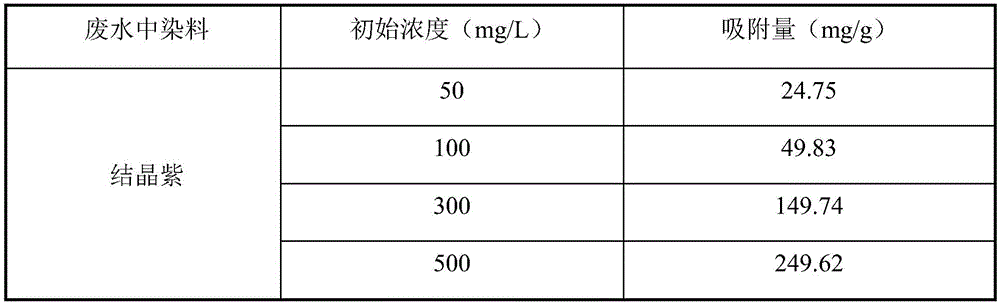

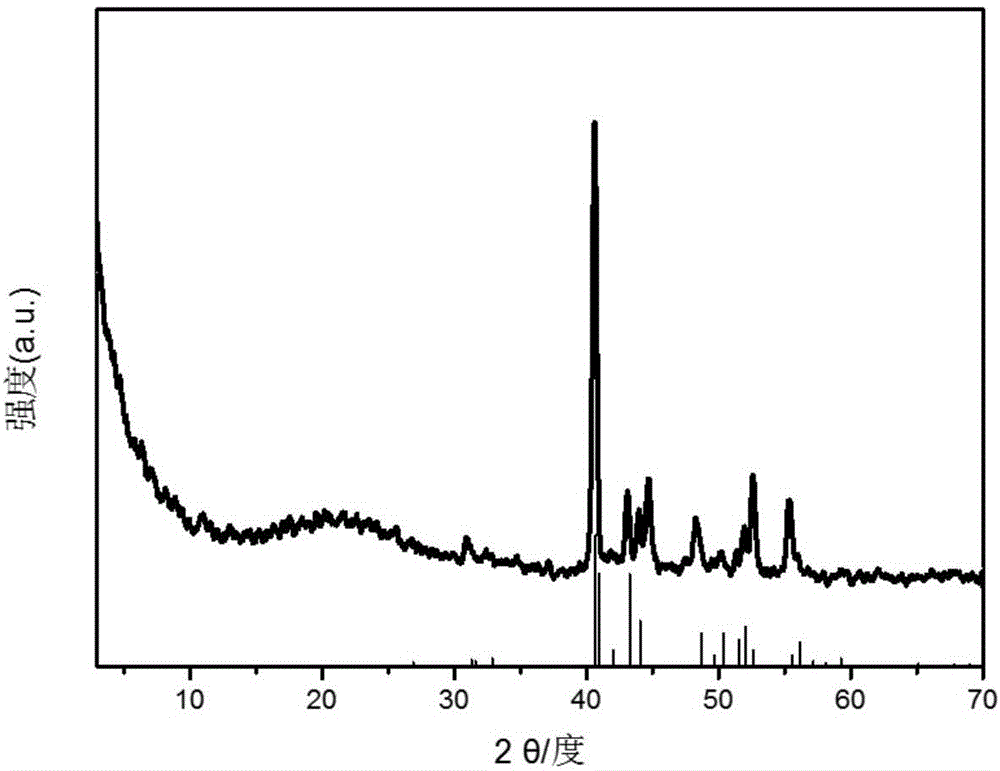

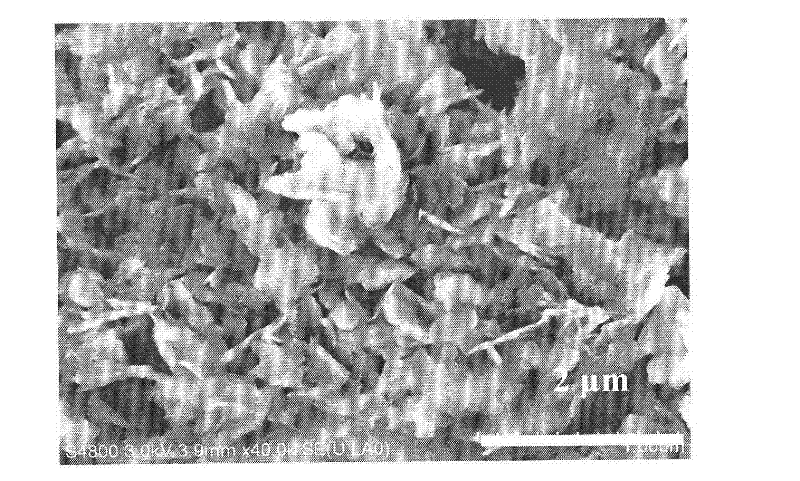

Mg/Al hydrotalcite modified charcoal composite material and preparation method and application thereof

ActiveCN105597678AWide variety of sourcesLow priceOther chemical processesWater contaminantsWastewaterHydrotalcite

The invention relates to an Mg / Al hydrotalcite modified charcoal composite material and a preparation method and application thereof. According to the composite material, charcoal is used as a substrate, and roasted Mg / Al hydrotalcite is loaded on the surface of the substrate. The preparation method comprises the specific steps that biomass powder is soaked with an Mg / Al water solution at first, then, a composite of Mg / Al hydrotalcite and biomass is prepared, and finally the composite of Mg / Al hydrotalcite and biomass is pyrolyzed through a tubular atmosphere furnace in N2 atmosphere to obtain the product. In the preparation process of the Mg / Al hydrotalcite modified charcoal composite material, biomass pyrolysis and hydrotalcite roasting are carried out in one heat treatment process, the preparation cost is reduced, and the preparation time is shortened. The structure of the roasted Mg / Al hydrotalcite can be partially recovered to be hydrotalcite of an orderly stratified structure after the roasted Mg / Al hydrotalcite makes contact with the water. The Mg / Al hydrotalcite modified charcoal composite material has the good adsorption effect on dye in waste water.

Owner:湖南飞博环保科技有限公司

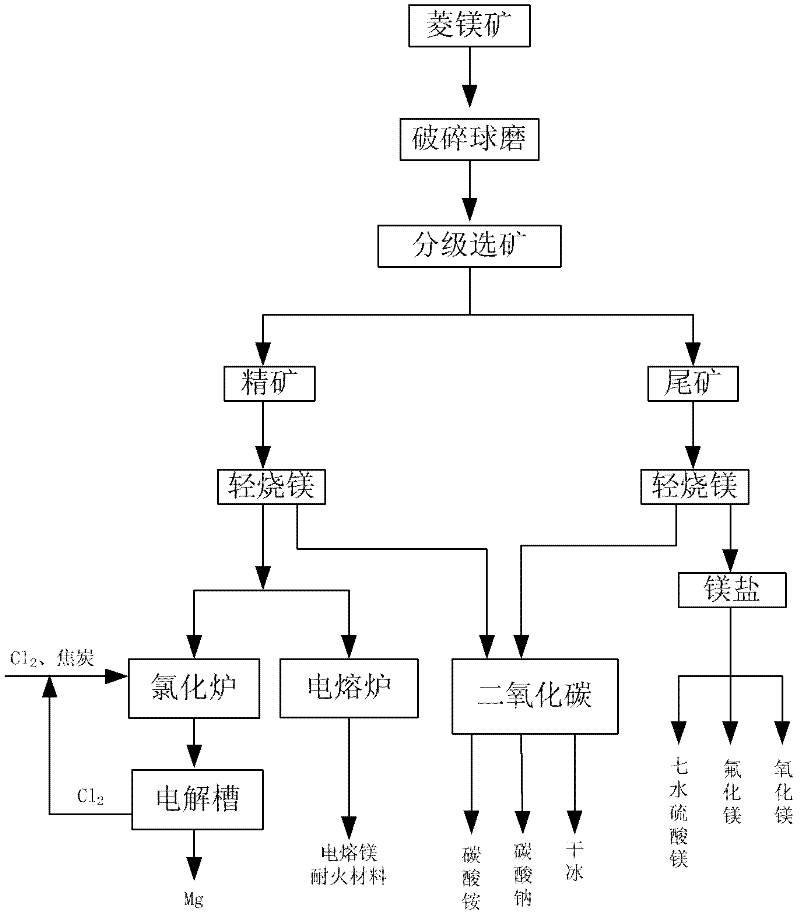

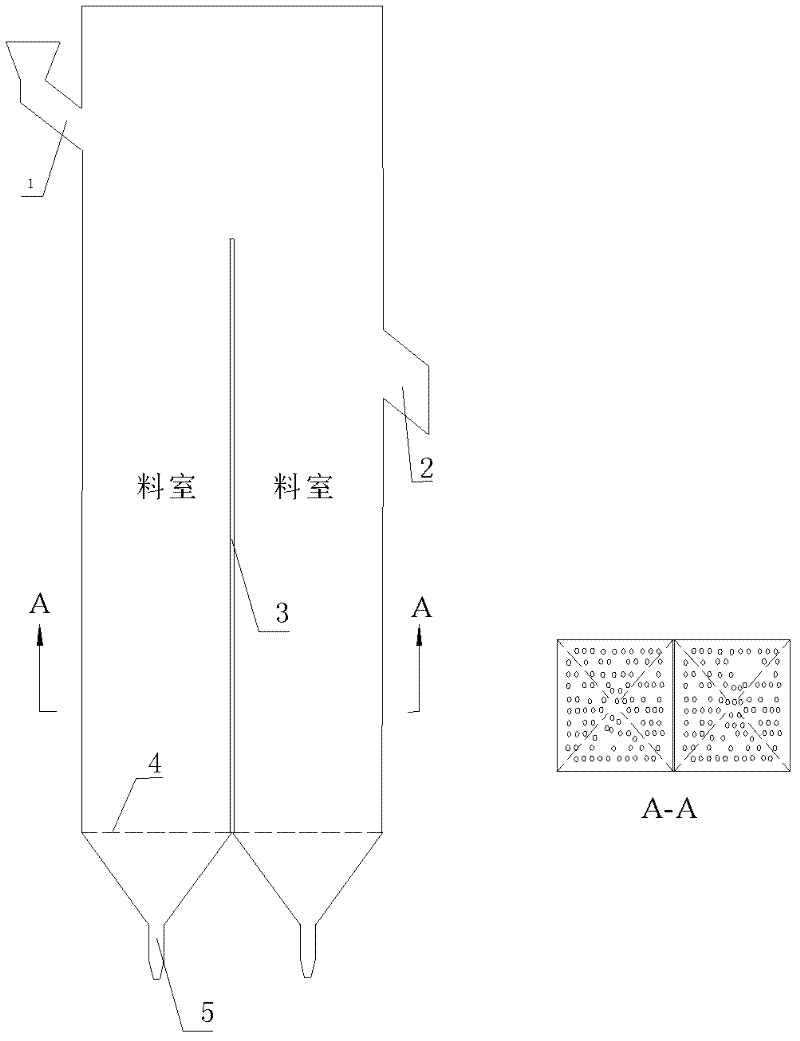

Integrated utilization method of low grade magnesite

InactiveCN102515213ASave raw materialsSimple processCarbon compoundsAmmonium carbonates/bicarbonatesElectrolysisMagnesium salt

The invention belongs to the fields of integrated utilization technology of magnesite and environmental protection, and relates to an integrated utilization method of low grade magnesite. The method comprises steps of: magnesite fragmentation; ore grinding; ore dressing; ore dressing product calcining; conversion of calcined useful components into magnesium salt to prepare high purity magnesium oxide or direct electrolysis of the calcined useful components into magnesium metal or preparation of refractory material; and recovery utilization of gas generated by calcination. The invention comprehensively utilizes useful ingredients in the magnesite, realizes zero discharge of magnesite mine tailing, increases utilization rate of low grade magnesite and efficiently utilizes ore resource; and especially, fluidized roasting by a horizontal fluidized bed saves energy consumption and maximize economic benefit.

Owner:UNIV OF SCI & TECH BEIJING

Stone powder sludge sintering brick and method for making the same

InactiveCN101081732AHigh strengthImprove performanceCeramic materials productionClaywaresAdobeAdhesive

The present invention discloses one kind of stone powder sludge sintering brick and its production process. The stone powder sludge sintering brick is produced with stone powder sludge from stone material producing process as main material, sludge from river, lake or sea, building waste clay or clay as adhesive, slag, coal slack, fly ash or coal as inner material, and through crushing, stirring, forming adobe, drying, roasting and other steps. The present invention has the features of waste utilization, environment friendship, saving in soil, low power consumption, high compression strength, etc. It may be used in replacing sintered clay brick.

Owner:林建国

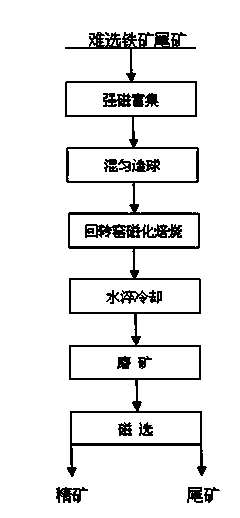

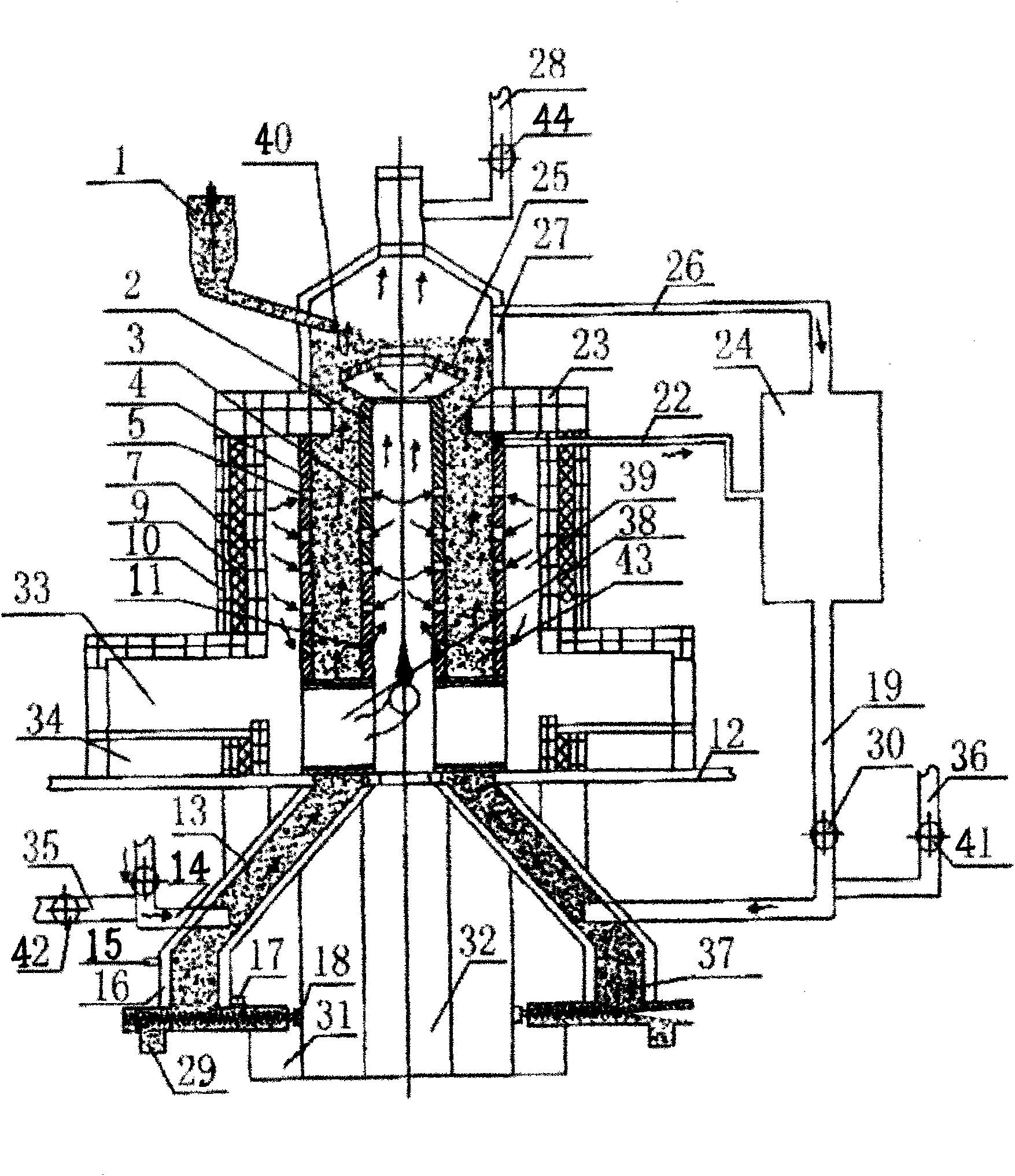

Difficult-separation iron ore tailing pelletizing rotary kiln magnetic roasting treatment technology

The invention provides a difficult-separation iron ore tailing pelletizing rotary kiln magnetic roasting treatment technology. The technology mainly comprises the following technological steps: 1, carrying out magnetic separation enrichment of iron ore tailing by a strongly-magnetic magnet separator having a field intensity of 0.6-1.2T; 2, uniformly mixing an obtained enriched tailing with coal dust and a binder according to a ratio of 100:0.5-2:1-3, drying, carrying out damp milling treatment, and pelletizing; 3, drying pellets obtained in step 2; 4, carrying out the magnetic roasting of dried pellets by adopting a rotary kiln; 5, cooling the magnetically-roasted pellets in a water quenching mode; 6, milling the cooled pellets; and 7, carrying out magnetic separation of ground ore powder to obtain iron ore concentrate. The technology allows the iron ore concentrate having a TF2 grade of about 56% can be obtained, increases the metal recovery rate to above 75% from original 65-70%, improves the resource utilization rate and reduces the environmental pollution.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

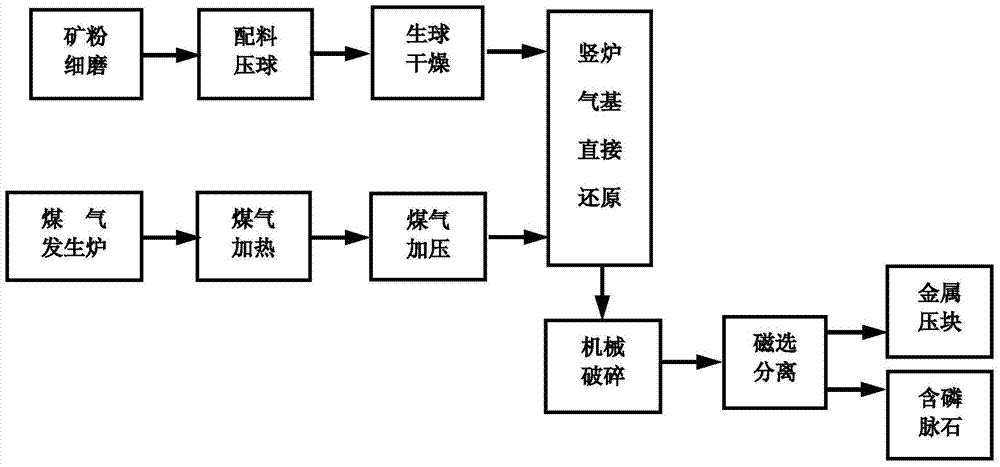

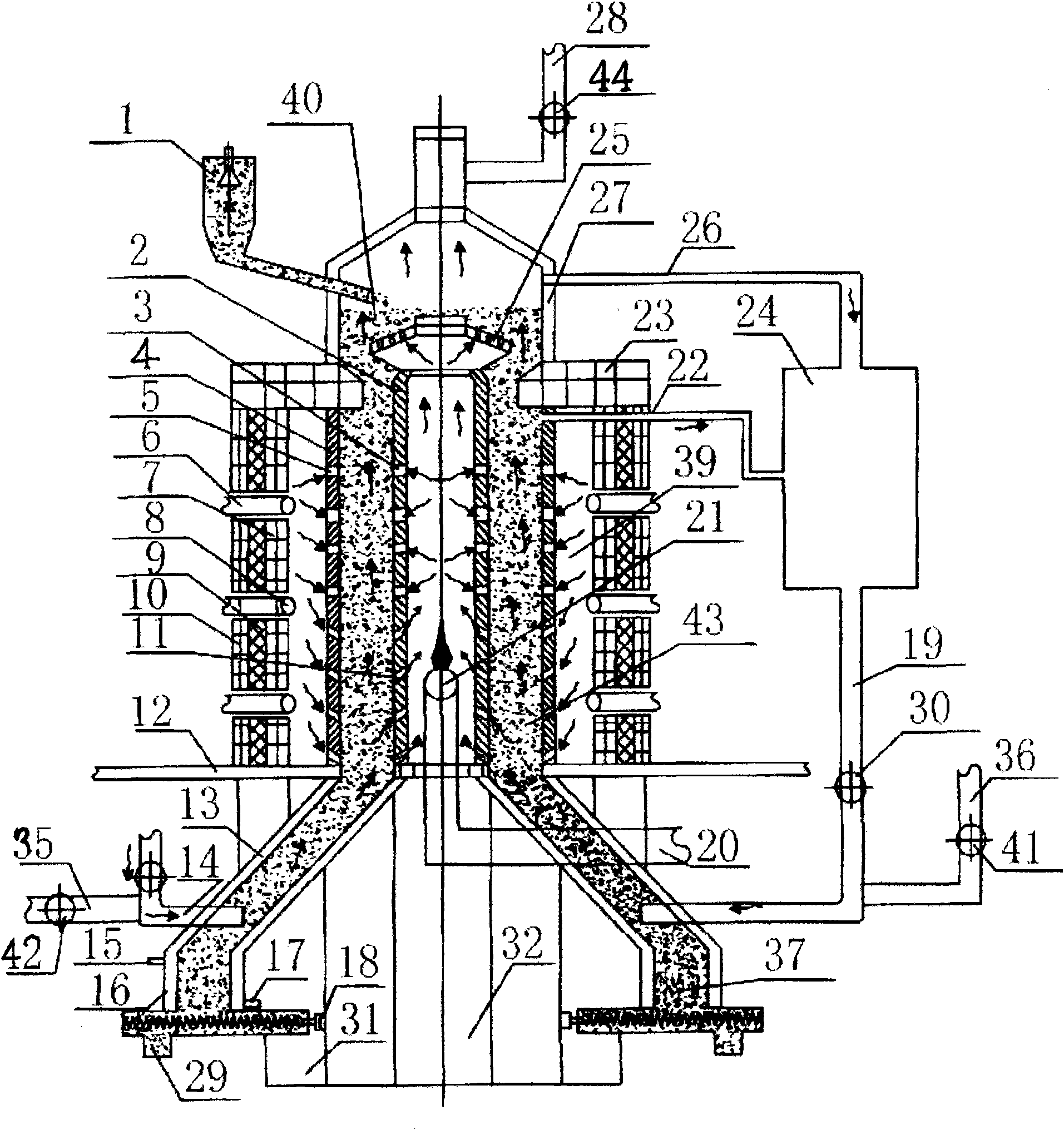

Method for preventing pellets from high temperature reduction bonding in high phosphorus oolitic hematite treatment shaft furnace

ActiveCN103667687ARelieve stickingGood for magnetic separationShaft furnaceDecreased energyShaft furnace

The invention discloses a method for preventing pellets from high temperature reduction bonding in a high phosphorus oolitic hematite treatment shaft furnace, belonging to the technical field of direct-reduction ironmaking. High phosphorus oolitic hematite powder, pulverized coal, a dephosphorization agent and a bonding agent are mixed together according to a proper ratio, the mixture is milled and pressed into balls so as to prepare cold bound pellets, and the bound pellets are dried or maintained and are further conveyed into a direct-reduction shaft furnace; in the direct-reduction shaft furnace, the pellets are subjected to hot coal gas roasting, gas-based prereduction, coal-based direct reduction and cooling process from top to bottom, temperature range of gas-based prereduction and coal-based direct reduction for the bound pellets is 850-1200 DEG C, and standing time in the shaft furnace is 1-5 hours; the reduction gas comprises H2 and CO in a ratio of 1.2-4; the reduced pellets are sealed and cooled, at the outlet of a cooling section, temperature of the bound pellets is controlled to be 100-200 DEG C, and the bound pellets are further smashed, magnetically separated and briquetted, wherein TFe in the obtained iron product is not less than 88%, and phosphorus content is less than 0.3%. The method has the advantages of decreasing energy consumption of reduction process of the shaft furnace.

Owner:韩其平

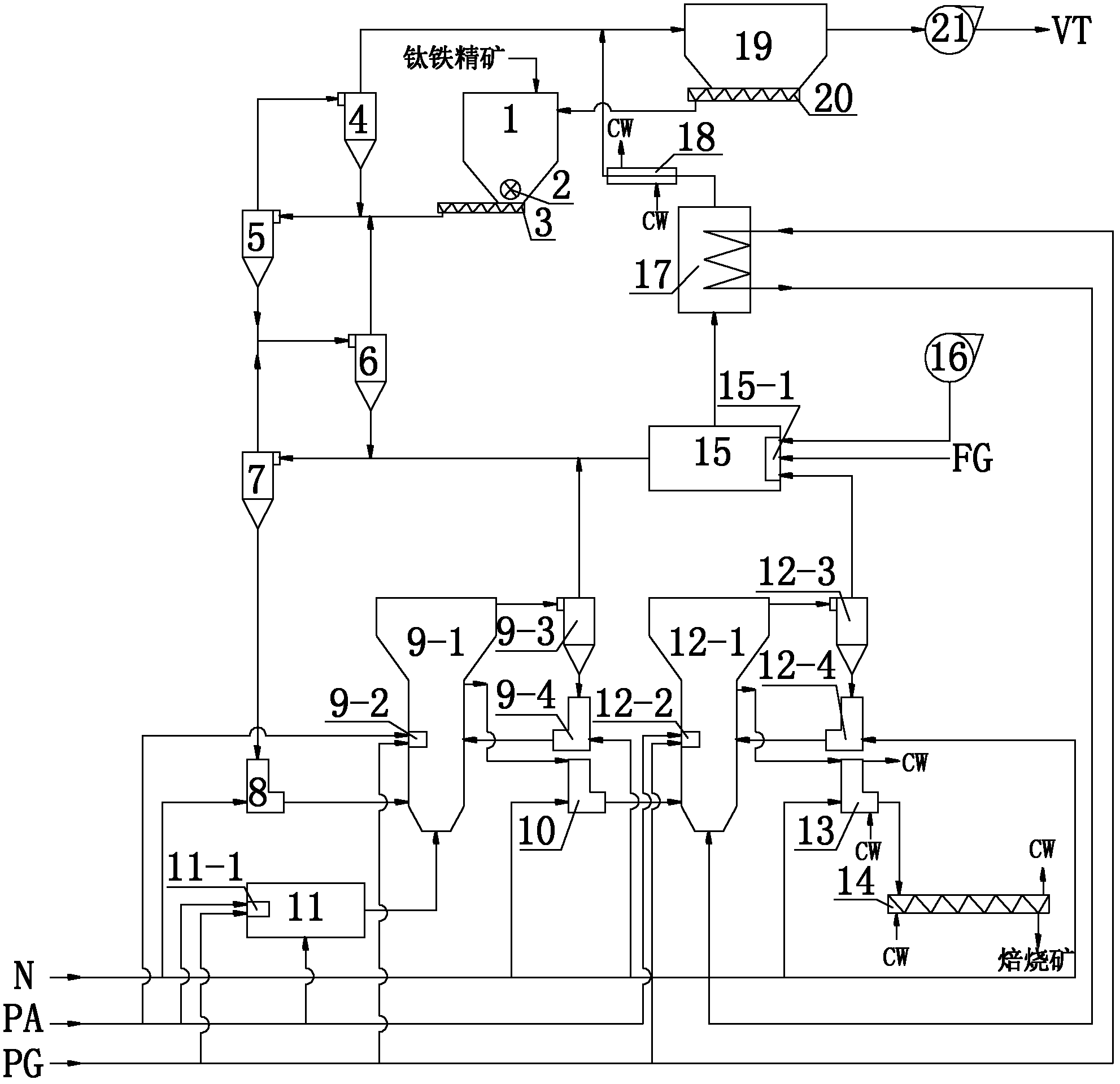

System for fluidized oxidizing/reducing roasting modification of titaniferous iron concentrate and roasting process

The invention discloses a system for fluidized oxidizing / reducing roasting modification of titaniferous iron concentrate and a roasting process. A fluidized bed oxidation reactor is adopted for the oxidizing roasting of titaniferous iron concentrate powder, and fluidized air is preheated by a hot blast heater and mineral powder is preheated by a multistage cyclone preheater so as to provide heat for oxidizing roasting; the oxidized mineral powder enters the fluidized bed reduction reactor for reducing roasting, and heat is provided for the reducing roasting through heating coal gas by a coal gas preheater; and latent heat of unreacted reducing gas in roasting tail gas of the reduction reactor is firstly released through combustion in a combustion chamber, one path of hot flue gas after the combustion is mixed with the tail gas of the oxidation reactor and then enters the multistage cyclone preheater to exchange heat with the cold titaniferous iron concentrate powder, heat is recycled while the titaniferous iron concentrate is preheated, and the other path of hot flue gas is used for preheating cold coal gas to warm the fluidized coal gas entering a reducing furnace so as to strengthen a reducing condition. The system has the advantages of high oxidizing / reducing efficiency, high heat utilization efficiency in a roasting process and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Deironing method for vanadium-bearing stone coal lixivium

ActiveCN105695738AReduce loss rateReduce the impact of vanadium enrichmentOrganic compound preparationCarboxylic acid salt preparationPregnant leach solutionIron powder

The invention relates to a deironing method for vanadium-bearing stone coal lixivium. According to the technical scheme, the deironing method comprises the steps that vanadium-bearing stone coal is firstly subjected to crushing, roasting and ore grinding to obtain vanadium-bearing stone coal roasted ore, the vanadium-bearing stone coal roasted ore and water are stirred to obtain vanadium-bearing stone coal ore pulp, then a leaching agent is added, heating and stirring are carried out, and solid-liquid separation is carried out to obtain the vanadium-bearing stone coal lixivium and leaching residues; reduced iron powder is added into the vanadium-bearing stone coal lixivium, and the adding amount of the reduced iron power is 2-4 times the stoichiometric number of the chemical reaction for reducing Fe3+ in the vanadium-bearing stone coal lixivium into Fe2+; heating and stirring are carried out, the pH value is adjusted to range from 1.5 to 5, heating and stirring are carried out, solid-liquid separation is carried out, and deironed lixivium and a filter cake are obtained; and the deironed lixivium is used for the vanadium enrichment technology, and a ferrous oxalate dehydrate byproduct is obtained after the filter cake is dried. Vanadium and iron in the vanadium-bearing stone coal lixivium can be effectively separated, the iron in the vanadium-bearing stone coal lixivium can be recycled, the vanadium loss rate in the deironing process is low, the iron content of the deironed lixivium is low, and the influence of the iron on the subsequent vanadium enrichment technology is reduced.

Owner:WUHAN UNIV OF SCI & TECH

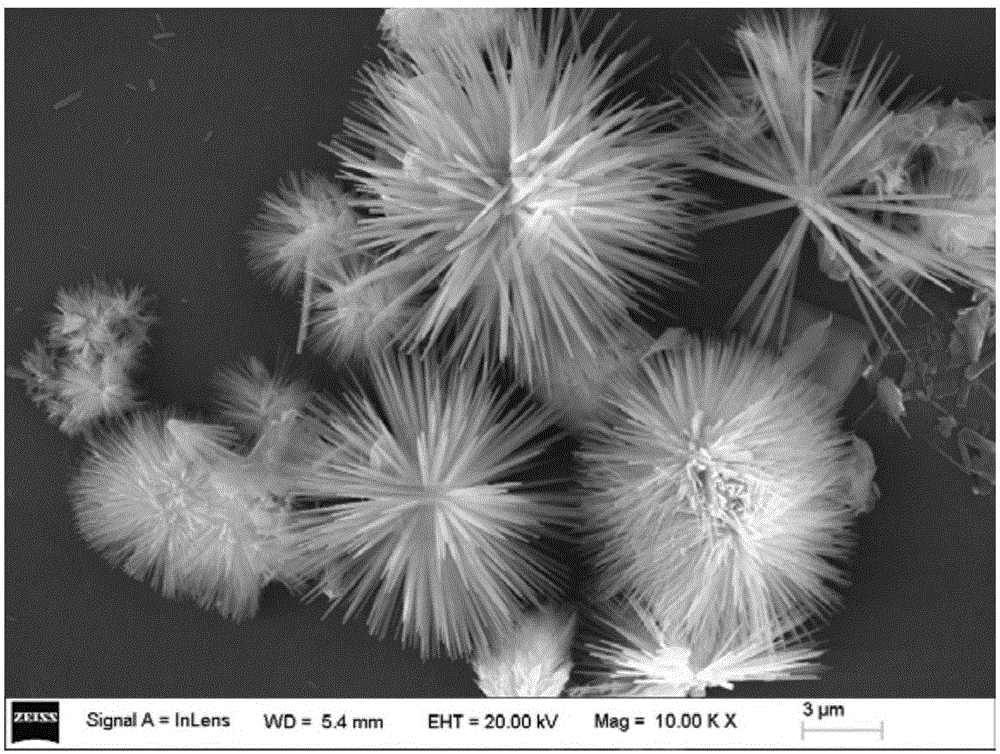

Preparation method of carbon-coated transition metal phosphide composite material and application of carbon-coated transition metal phosphide composite material to oxygen evolution reaction

ActiveCN106552654AImprove performanceLow onset potentialPhysical/chemical process catalystsElectrodesVolumetric Mass DensityOxygen

The invention provides a preparation method of a carbon-coated transition metal phosphide composite material and application of the carbon-coated transition metal phosphide composite material to the oxygen evolution reaction. Firstly, a pointed transition metal hydroxide precursor containing anion intercalations of a phosphorus source and a carbon source between layers is prepared through synthesis, and then the podiform carbon-coated transition metal phosphide composite material is obtained through high-temperature roasting. The composite material is applied to the positive pole reaction-oxygen evolution reaction of electrolysis of water, can effectively improve the performance of a catalyst, namely lowering the take-off potential and improving catalytic activity, and is long in service life and good in stability. Meanwhile, raw materials of the composite material are low in cost and have abundant reserves, the preparation method is simple, and environment friendliness is achieved. Under the alkaline condition of 0.1-1 M KOH, the overpotential required by the electric current density of 10 mA / cm<2> is 280-340 mV, and the Tafel slope is 60-80 mV / dec; and under the constant voltage of 1.65 V, the circulation time is as long as 1-24 hours or longer.

Owner:BEIJING UNIV OF CHEM TECH

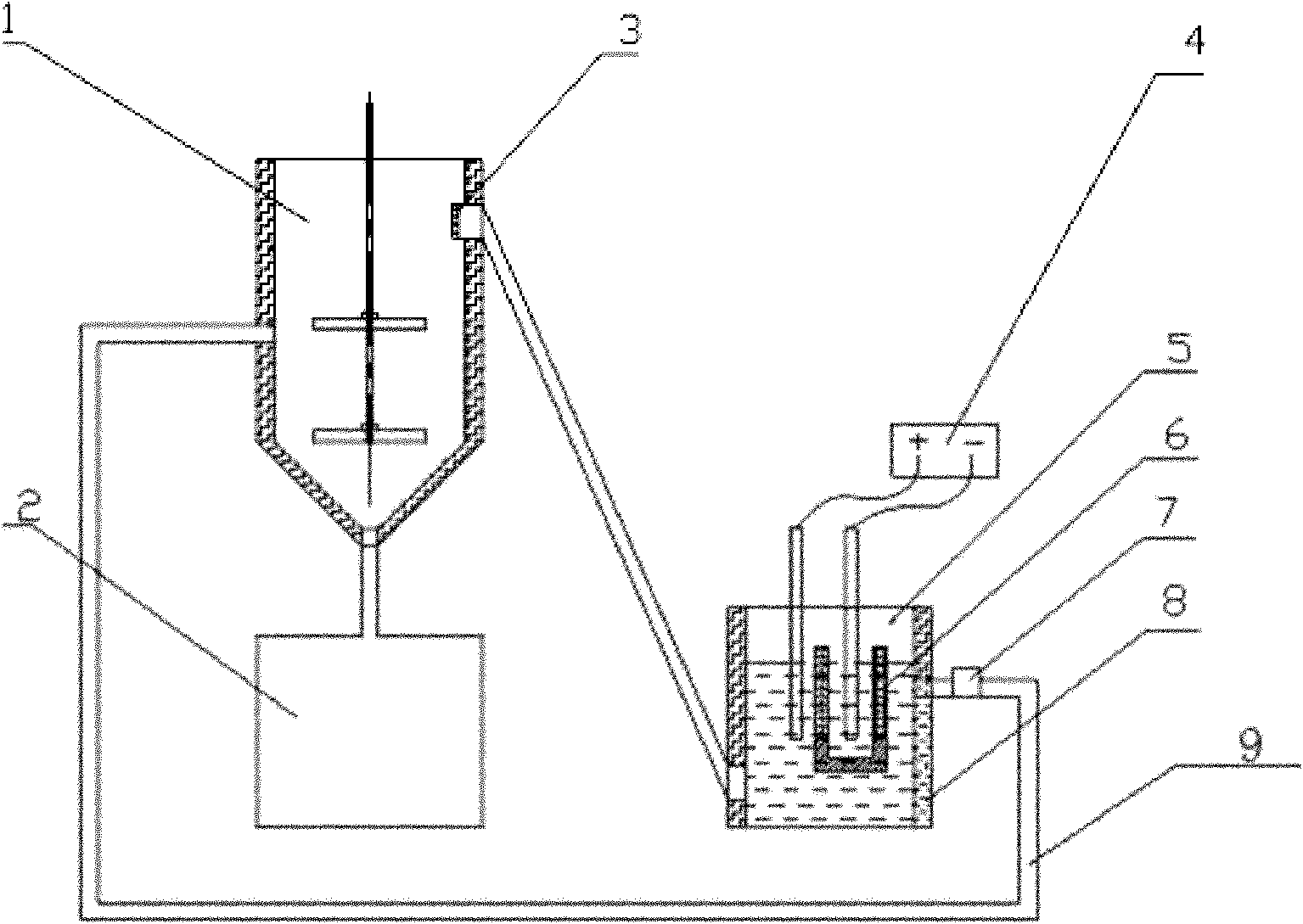

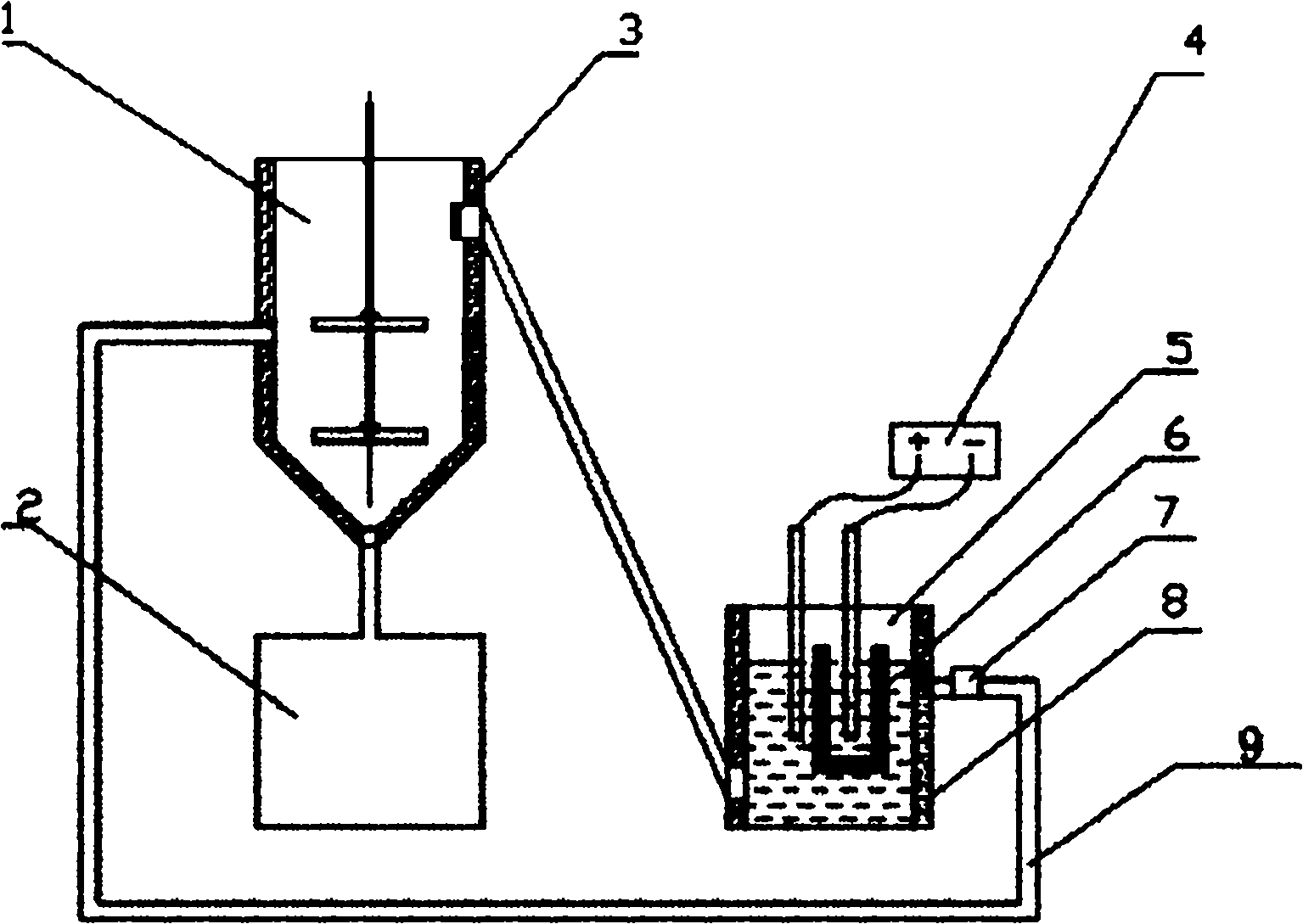

Method and device for recovering metallic lead from lead plaster of waste lead-acid storage battery

ActiveCN102031380AHigh concentrationConcentration unchangedPhotography auxillary processesProcess efficiency improvementLead dioxideSlag

The invention belongs to recovery treatment on lead plaster of a waste lead-acid storage battery. The method comprises the following steps of: mixing the lead plaster of the waste lead-acid storage battery with waste sulfuric acid in the waste lead-acid storage battery according to the design requirement and roasting; adding roasting sand in a stirring kettle; adding tap water to a water level line of the device and stirring the roasting sand; adding a proper amount of calcium acetate, acetic acid and nitric acid; starting a solution circulating system pump, leaching out the roasting sand and maintaining the concentration of lead acetate to be saturated; adding a proper amount of bone glue and beta-naphthol, electrolyzing immersion liquid, recovering the metallic lead at the cathode and recovering lead dioxide at the anode; press filtering residues to obtain lead-off slag and filtrate; and adding calcium carbonate in the filtrate and recycling. The device mainly comprises a leaching part, a press filtration part, a circulating part and an electrolysis part, and concretely includes eight key components of the stirring kettle, a press filter, an overflow port, an electrolysis direct current power supply, an electrolytic cell, a cathode titanium basket, a corrosion resistant pump and a heating element.

Owner:北京绿色引领环保科技研究院有限公司

Nano carbon material modified copper base catalyst and its preparing method

InactiveCN1586718AHigh activityHigh hydrogen selectivityHydrogenMetal/metal-oxides/metal-hydroxide catalystsHydrogen selectivityWater vapor

The present invention belongs to the field of chemical technology, and especially one kind of copper base catalyst with nanometer carbon material as co-catalyst for vapor reformation of methanol to prepare hydrogen and its preparation process. The catalyst is prepared through the process including the steps of: compounding 0.1 M solution of Cu / Zn / Al nitrate; compounding 0.1 M solution of sodium carbonate, dropping the 0.1 M solution of Cu / Zn / Al nitrate and 0.1 M solution of sodium carbonate in the same rate into reactor with nanometer carbon material for co-precipitation under strong stirring and 60 deg.c to obtain carbonate coprecipitate containing nanometer carbon material; washing, drying, roasting, etc. The prepared catalyst has unique porous structure of great specific surface area, high low temperature activity and high hydrogen selectivity, and may be used in preparing reformed product with hydrogen content up to 75 % and CO content lower than 0.1 %.

Owner:FUDAN UNIV

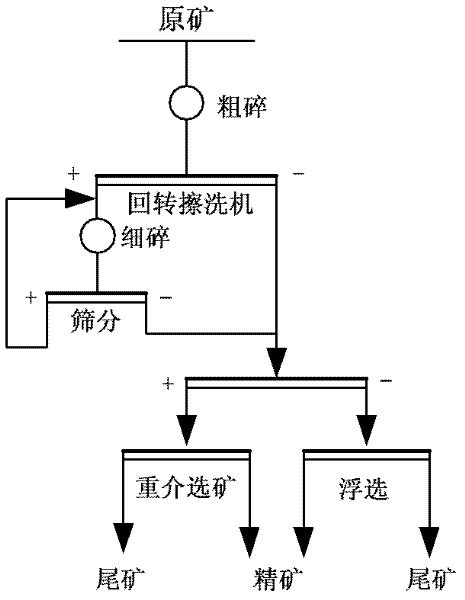

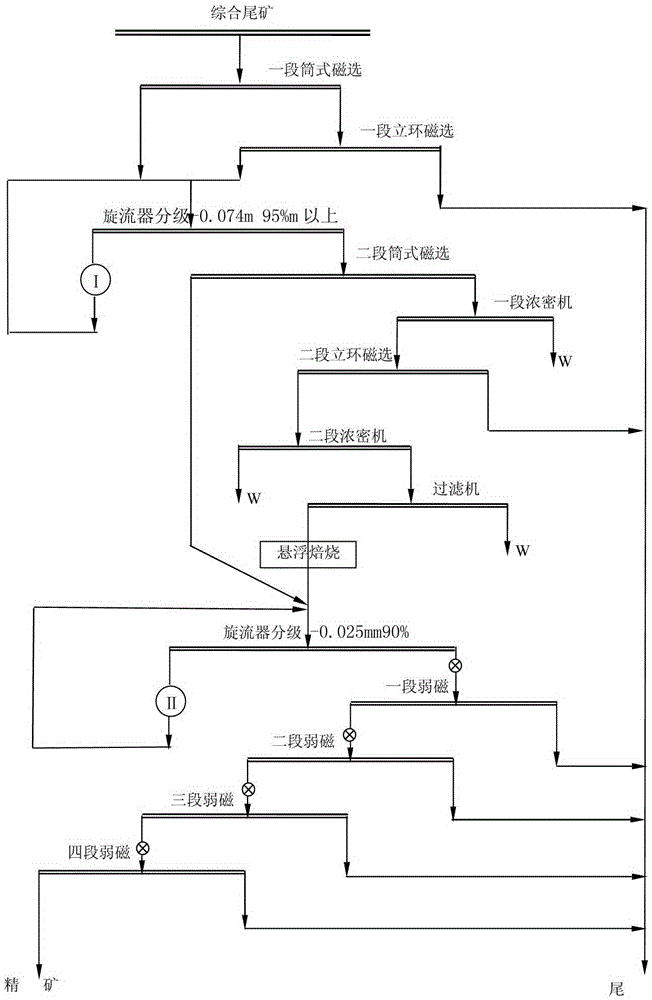

Tailing recovery process adopting preconcentration-roasting-regrinding and magnetic separation method

ActiveCN105233976AEfficient recyclingReduce the processing volume of subsequent grinding and sorting operationsMagnetic separationProcess efficiency improvementMagnetic separatorReducing atmosphere

The invention relates to a tailing recovery process adopting a preconcentration-roasting-regrinding and magnetic separation method. The tailing recovery process is characterized by comprising the following steps: concentrate extraction and tailing discarding are carried out by virtue of a preconcentration process which sequentially comprises first-section drum magnetic separation, first-section vertical ring magnetic separation, ore grinding, second-section drum magnetic separation and second-section vertical ring magnetic separation, so that a rough concentrate grade is increased, and a subsequent operation treatment amount is reduced; suspension roasting is adopted, so that a rotational-flow suspension state of rough concentrate materials in a suspension magnetization roasting furnace under the conditions of a high temperature of 500 DEG C and a reducing atmosphere can be ensured, and micro-and fine-grained hematite, siderite and limonite in the rough concentrate materials are converted to magnetic iron minerals; and meanwhile, multi-section continuous fine separation is carried out by virtue of a regrinding and fourth-section low-intensity magnetic separation machine, thus the good indexes of a concentrate grade of more than 65% and a metal recovery rate of 48-55% are obtained.

Owner:ANSTEEL GRP MINING CO LTD

Method for processing copper anode slime in total wet manner

ActiveCN102965501ABig investmentHigh separation recovery rateProcess efficiency improvementElemental selenium/telluriumRaffinateTin

The invention discloses a method for processing copper anode slime in a total wet manner, relating to a total wet production process for recycling rare and precious metals from the copper anode slime in nonferrous metallurgy. The method comprises the steps of pressurizing the copper anode slime by a chloride medium at a high temperature and leaching to directly separate out valuable metals such as copper, stibium, bismuth, tellurium, and tin; and recycling tellurium, stibium, tin, bismuth, copper and the like from a pressurized lixivium in stages. The method is further characterized in that a selective extraction method is adopted to separate gold in a gold selenium chloride solution and the selenium is recycled from a gold raffinate. According to the method, the sulfating roasting with serious pollution and huge investment is avoided, but the sulfating roasting is carried out firstly for the copper anode slime in the conventional wet method or (pyrometallurgical process); the separation recovery rate of the metals is high, but the separation effect of tellurium, stibium, tin and bismuth in the conventional process is far from ideal; by adopting the method, the leaching problems of above metals can be solved in a single process and above metals can be recycled respectively from the lixivium; the recovery rate of the metals is 90-99% respectively; the copper separation and the tellurium separation can be simplified; and the operation flow is optimized in a better manner.

Owner:JIANGXI COPPER

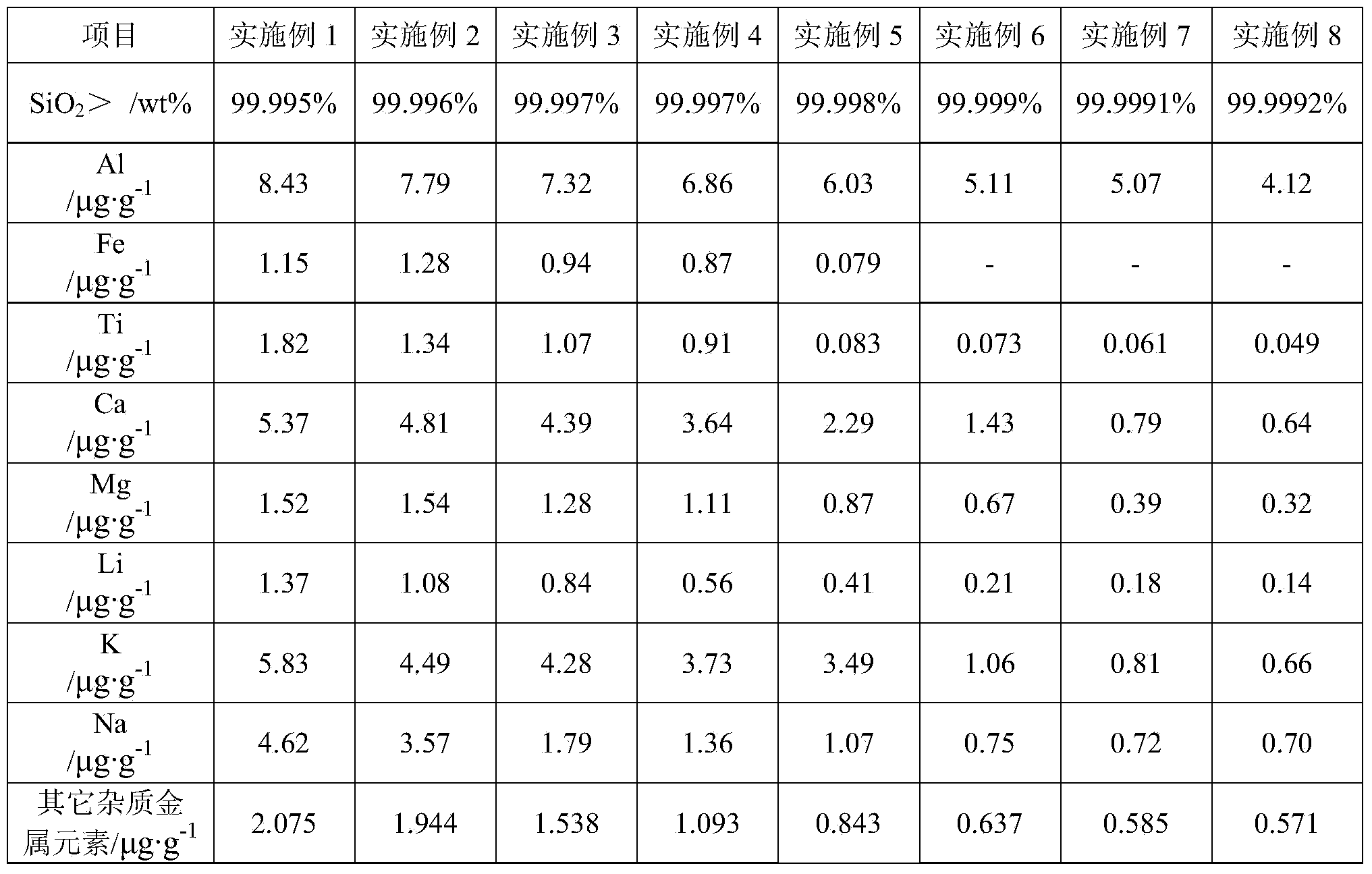

Method for preparing ultralow-metallic-element ultrahigh-purity quartz through mixed acid hot-pressing leaching reaction

ActiveCN103539133AReduce mineral contentIncreased contact surface areaSilicaPurification methodsChemical reaction

The invention relates to a method for preparing ultralow-metallic-element ultrahigh-purity quartz through mixed acid hot-pressing leaching reaction. The method is characterized by comprising the following steps of crushing and classifying; performing magnetic separation; performing three-section preferential reverse flotation; performing roasting and water quenching; performing hot-pressing leaching, namely putting a product of roasting and water quenching in a reaction kettle, and performing hot-pressing acid leaching reaction in a mixed acid system while stirring, wherein the reaction temperature is 120-400 DEG C, the reaction pressure is 0.5-15.0MPa, the reaction time is 0.5-8h, and the mixed acid system for the hot-pressing leaching chemical reaction is a mixed solution of HF, HNO3 and HCl; after hot-pressing acid leaching, filtering and washing the product until the product is neutral, and drying to obtain the ultralow-metallic-element ultrahigh-purity quartz. The purification method is simple in process and easy to operate; the ultralow-metallic-element ultrahigh-purity quartz of which the SiO2 content reaches 99.995wt%, preferably 99.999wt%, can be prepared by the method.

Owner:陕西合兴硅砂有限公司

Attapulgite lay base composite adsorbent for ammonia adsorption refrigeration and its preparing and use

InactiveCN1899683AImprove performanceImprove adsorption capacityBoiler absorbersOther chemical processesMetal chlorideAdhesive

The present invention relates to adsorbent for ammonia refrigeration, is especially one kind of attapulgite clay base composite adsorbent for ammonia refrigeration and its preparation and application, and belongs to the field of new chemical functional material preparing technology. The composite adsorbent for ammonia refrigeration is prepared through mixing alkali earth chloride, attapulgite clay, pore expanding agent and adhesive in certain proportion, forming in a pelletizing machine, stoving and roasting. The composite adsorbent has the advantages of stable performance, high adsorption stability, etc.

Owner:NANJING UNIV OF TECH

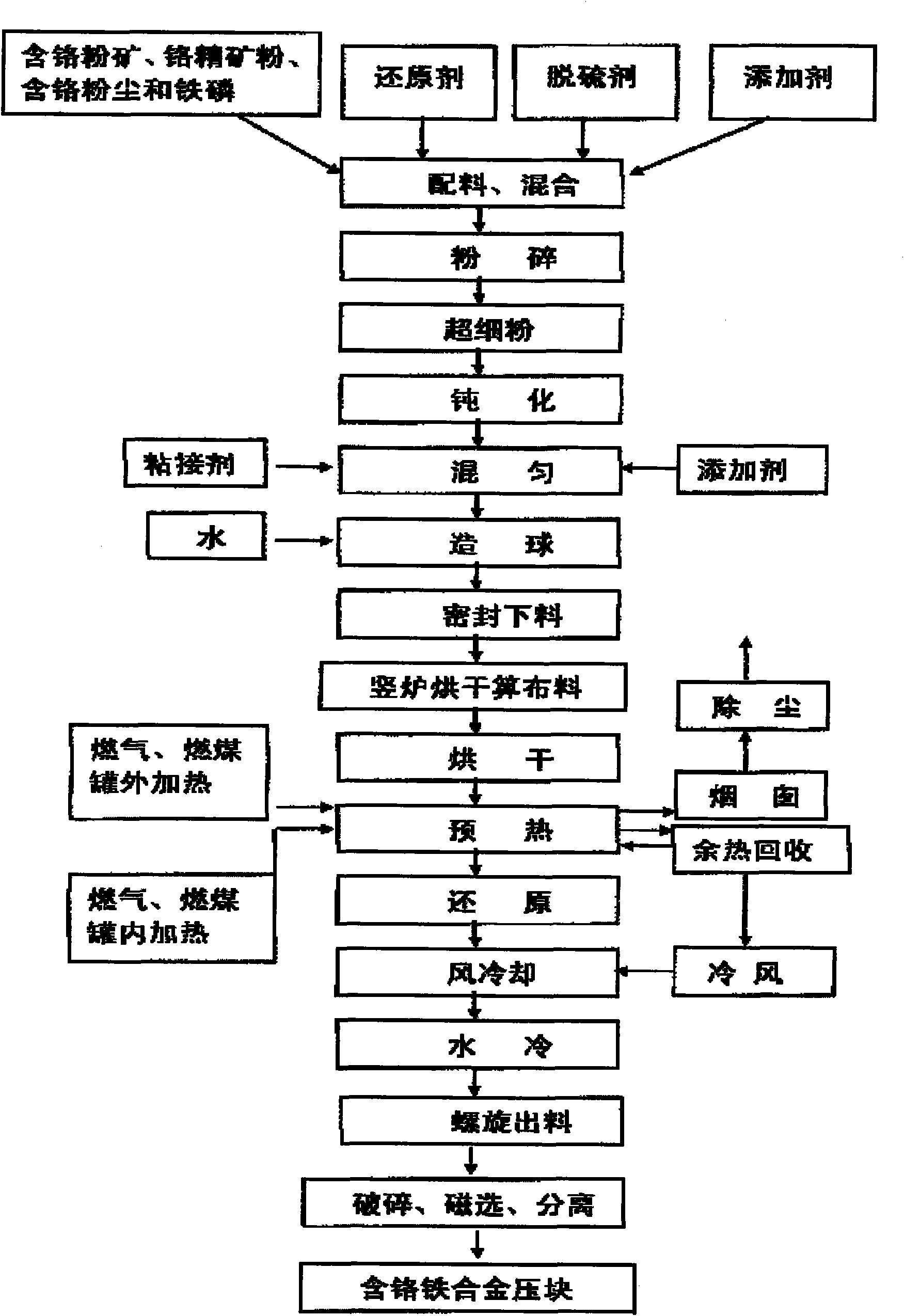

Process and device for preparing chromium iron by using chromium ore powder

InactiveCN101538630AHigh recovery rateGuaranteed uniformityProcess efficiency improvementShaft furnaceResource consumptionSolvent

The invention relates to a process and a device for preparing chromium iron by using chromium ore powder, which belongs to metallurgical industry steel-making raw material. The process comprises the following steps: mixing chromium iron containing raw materials with reducing agent, solvent and catalyst to prepare ultra fine powder, mixing to make pelletizing materials, sending the pelletizing materials into a reducing furnace, drying and roasting, and obtaining chromium irons after the reduction reaction. The reducing device is connected with an upper furnace above a furnace base, a lower furnace body is connected to the downside of the furnace base, the upper end of the upper furnace body is connected with an upper furnace mantle, a drying bed grate is positioned at the upper end in the upper furnace body, a purifying device is connected with the upper furnace body and the lower furnace body through pipelines, and a residual heat circulating device is connected with the lower furnace body. The invention has the advantages that: firstly, the reduction temperature is low, the reduction speed is high, the energy consumption is reduced, the production cost is lowered, the production efficiency is high, and the uniformity of the quality is ensured; secondly, the device is simple with less investment, the degree of mechanization is high, the procedure is simple, the yield is large, the mass production can be performed; thirdly, the waste of raw materials is reduced, the environment pollution is lowered; fourthly, the cost is low because the chromium ore powder and chromium-containing waste are adopted as raw materials; and fifthly, the waste resource can be recycled so as to save the resource consumption.

Owner:丁家伟

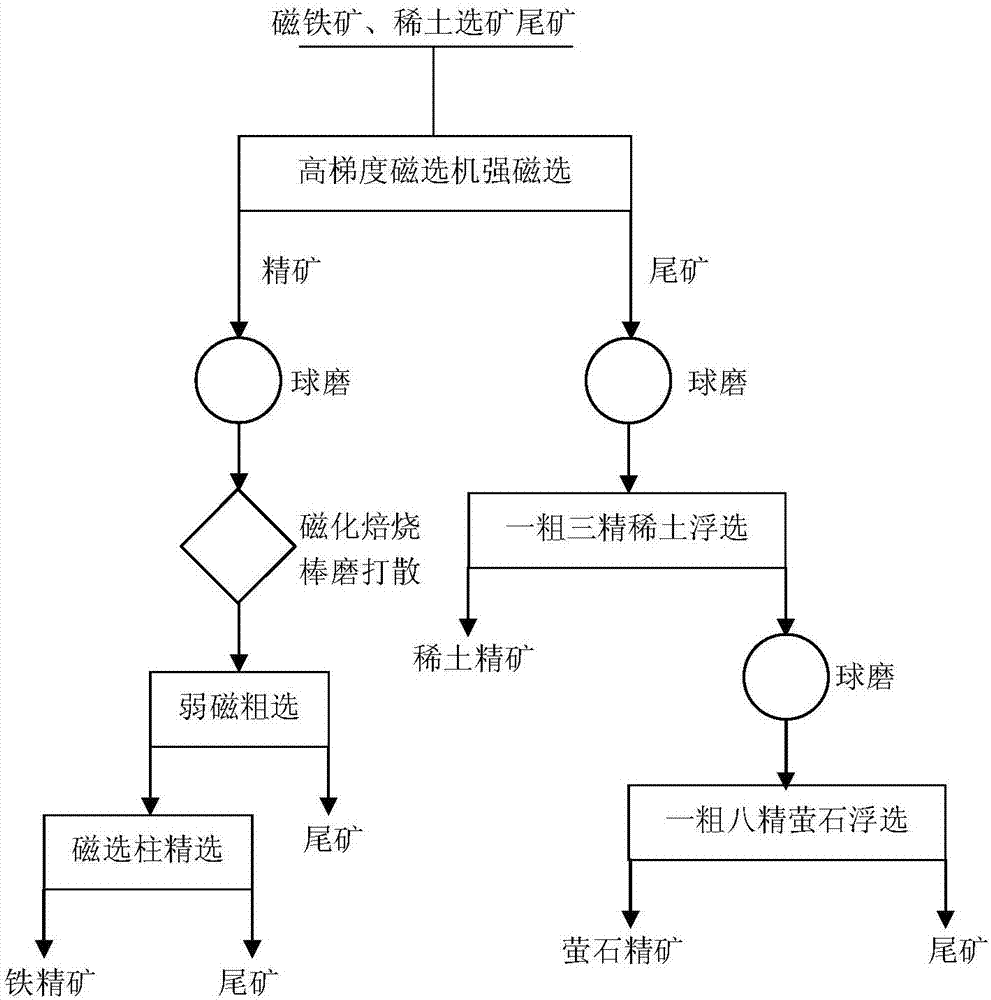

Mineral processing method for comprehensively recovering weak magnetic iron, rare earth and fluorite

InactiveCN107282288ARealize comprehensive utilizationHigh gradient magnetic separationFlotationMagnetic separatorSodium silicate

The invention discloses a mineral processing method for comprehensively recovering weak magnetic iron, rare earth and fluorite. The mineral processing method comprises the following steps: by taking tailings as a raw material, adopting high intensity magnetic separation by a high gradient magnetic separator, ore grinding, magnetic roasting, low intensity magnetic separation by a cylinder magnetic separator and selection by a magnetic separation column to obtain final iron concentrates with a TFe grade being 60-62 percent; adopting ore grinding on the tailings subjected to high intensity magnetic separation by taking o-hydroxy naphthalene hydroxamic acid as a collector and water glass as an inhibitor, and carrying out flotation with one rough floatation and three concentrating to obtain rare earth concentrates with an REO grade being 48-52 percent; and adopting ore grinding on rare earth flotation tailings by taking sodium oleate as a collector and acidified sodium silicate as an inhibitor, and carrying out flotation with one rough floatation and eight concentrating to obtain fluorite concentrates with a CaF2 grade being 92-94 percent. By adopting a technology provided by the invention, iron, rare earth and fluorite concentrates which can be directly sold can be obtained, comprehensive utilization of useful resources in the tailings is realized, and the mineral processing method has important economic value and environmental significance.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

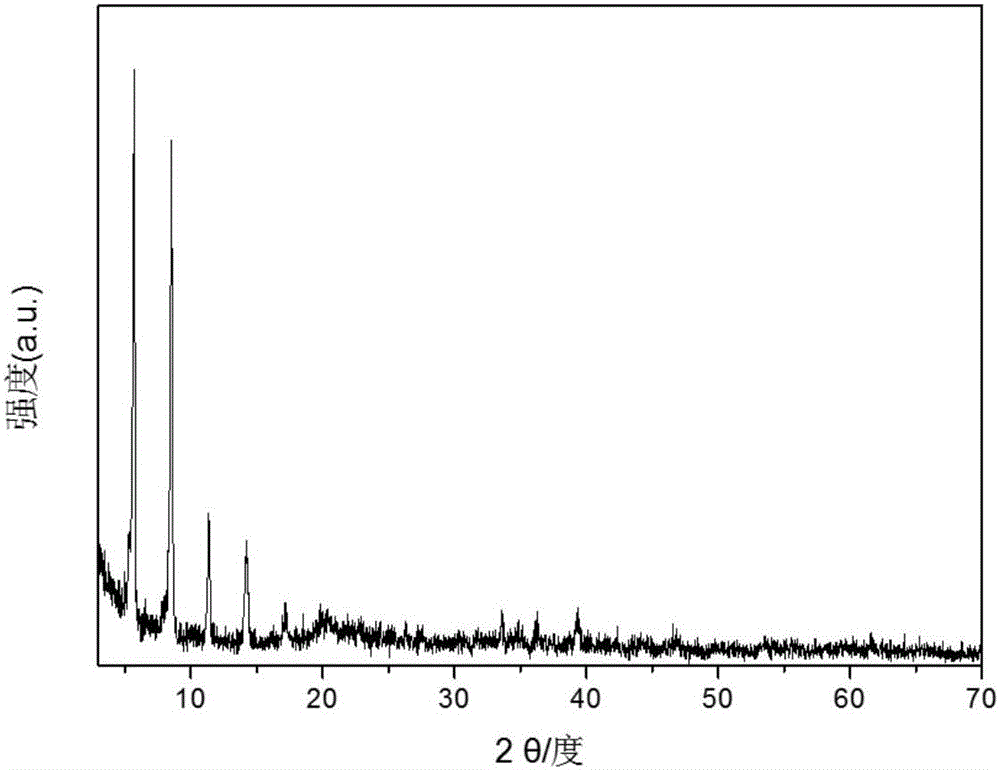

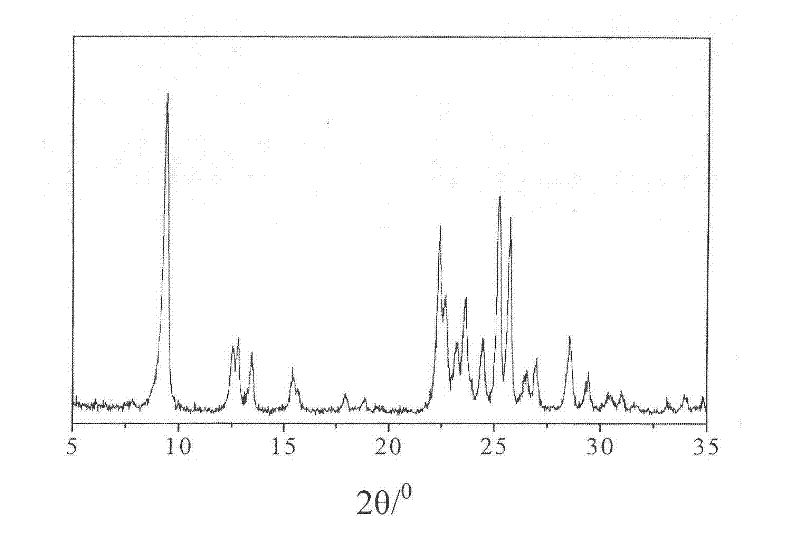

Synthesis method of ferrierite (FER) zeolite molecular sieve and obtained FER zeolite molecular sieve

InactiveCN102530979ALow costReduce manufacturing costFerrierite aluminosilicate zeoliteIsopropylaminePollution

The invention discloses a synthesis method of a ferrierite (FER) zeolite molecular sieve and the obtained FER zeolite molecular sieve. The synthesis method comprises the following steps: (1) adding an alkali source, an aluminum source, a silicon source and a template agent into water in turn to obtain a raw material mixture, wherein the template agent contains isopropylamine and an organic template agent which is used for synthesizing the FER zeolite molecular sieve through the existing hydrothermal crystallization method; (2) performing hydrothermal crystallization on the raw material mixture; and (3) filtering the hydrothermal crystallization product, washing, drying and roasting. By adopting the method, the FER zeolite molecular sieve with high silica-alumina ratio and pure phase can be synthesized and the cost of the template agent can be significantly reduced; and the method has the advantages of short production flow and low pollution, and is especially beneficial to industrial production and application.

Owner:SHANGHAI SHANSHAN TECH CO LTD

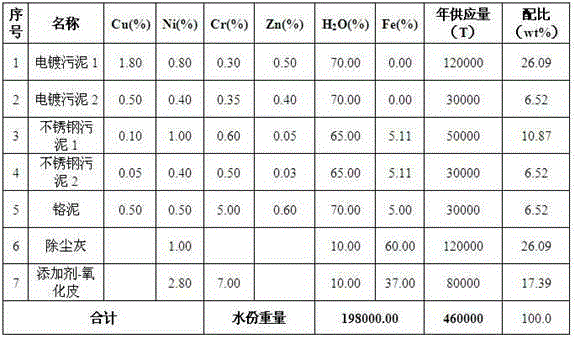

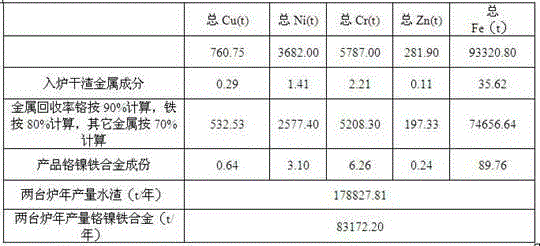

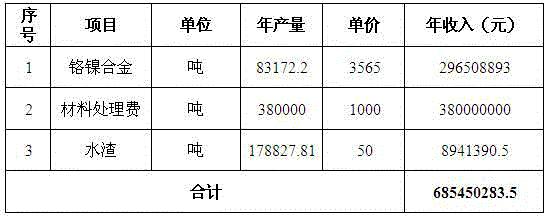

Heavy metal sludge recycling and comprehensive utilization method

InactiveCN104561525AAvoid secondary pollutionSave resourcesProcess efficiency improvementSludgeDust control

The invention belongs to the field of reutilization of heavy metal sludge, and particularly relates to a heavy metal sludge recycling and comprehensive utilization method. The method comprises the following steps: mixing stainless steel sludge, electroplating sludge, chromium sludge, dedusting ash generated in the chromium-nickel-iron alloy production process, and additive scales, predrying, carrying out reduction roasting, smelting to obtain a chromium-nickel-iron alloy, and using the byproduct smelting slag in preparing the cement additive. The dedusting ash and smelting slag generated in the whole technical process can be recycled, and thus, the method does not generate secondary pollution, maximally saves the resources and energy, lowers the production cost, and has obvious economic benefits.

Owner:FUJIAN NONNON RENEWABLE RESOURCES TECH

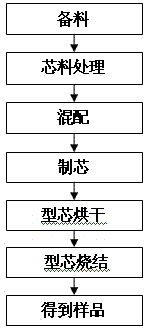

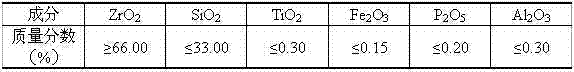

Water-soluble ceramic core and preparation method thereof

The invention relates to a ceramic core, in particular to a water-soluble ceramic core and a preparation method thereof, which can be used in investment casting of a casting with a complex cavity structure or a hollow casting with casting temperature of not greater than 900 DEG C. The water-soluble ceramic core is obtained by specifically taking fused corundum powder, zircon sand and sodium chloride particles as main body materials and NaCl solution and polyethylene glycol as adhesives through a specific mixing process by using low-temperature drying and a high-temperature roasting process. According to the water-soluble ceramic core, not only is the strength of the core guaranteed, but also the core has good moldability; and the water-soluble ceramic core has the advantages of convenience and quickness in operation (the core is only required to be washed with clear water and can be easily removed in a short time), no pollution, no need of special equipment, no damage to the casting and the like.

Owner:JIANGSU UNIV

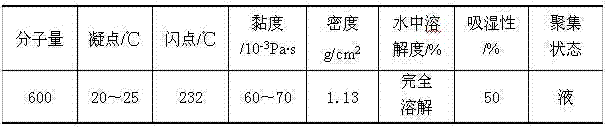

Production technology of large-specification extraordinary isotropic graphite material

A production technology of a large-specification extraordinary isotropic graphite material comprises the following steps: preparing coke powder with the average particle size of 6-20mum through utilizing airflow crushing, carrying out kneading, rolling and extrusion molding on the coke powder, rapidly charring, carrying out secondary kneading and rolling after charring, pre-molding the material subjected to the secondary kneading and rolling, and carrying out sequent processes of isopressing molding, dipping, roasting, graphitization and the like on pre-molded green body to prepare isopressed graphite; and carrying out cold molding and pressure holding stripping, and roasting and dipping many times to prepare the extraordinary isotropic graphite material. The extraordinary isotropic graphite material prepared through the method of the invention has the advantages of high mechanical strength, low porosity and excellent surface processing characteristic.

Owner:HUNAN CHANGYU NEW CARBON MATERIALS

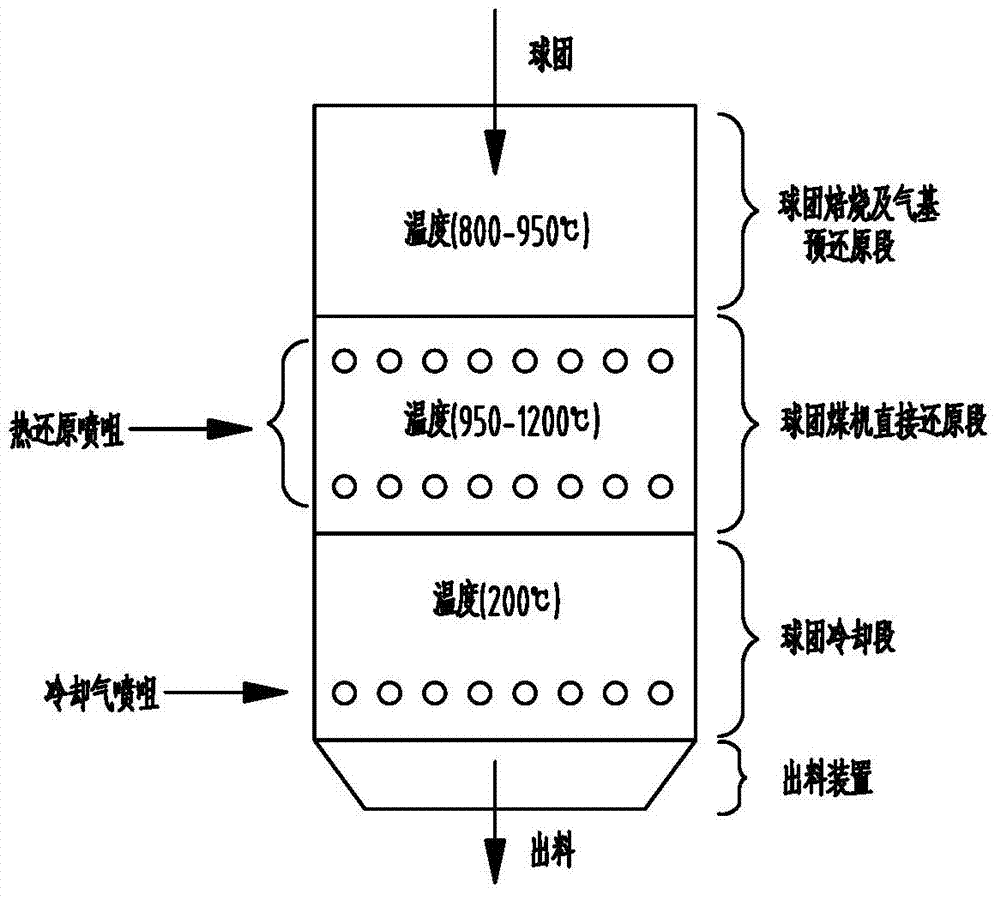

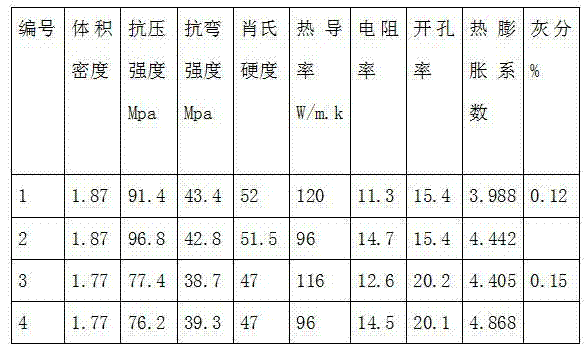

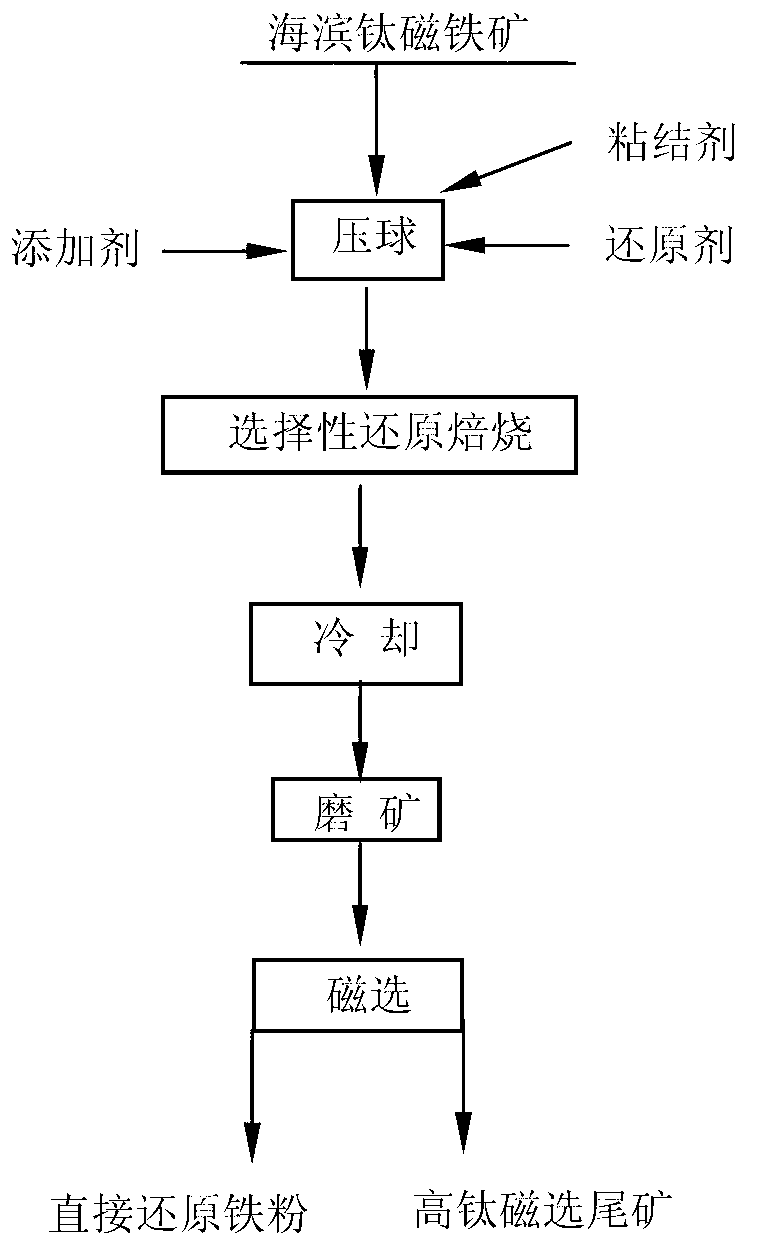

A process of separating iron and titanium in seaside titanomagnetite via direct reduction roasting by using coal

The invention provides a process of separating iron and titanium in seaside titanomagnetite via direct reduction roasting by using coal. According to the process, seaside titanomagnetite is employed as a raw material, a reducing agent, a binder, and an additive are added for briquetting, and then a selective direct reduction roasting - magnetic separation method is employed for respectively recovering iron and titanium. The process of the invention is simpler compared with other methods, wherein cost-effective coal is directly used as the reducing agent, additives added in the process is a mixture of sodium carbonate and sodium borate, and by adding the reducing agent and the additive, and controlling roasting temperature and time, selective reduction of iron and separation of iron and titanium can be achieved, ensuring the grade and recovery rate of direct reduced iron while reducing the titanium content in the direct reduced iron. The finally obtained direct reduction iron powder has a grade above 93%, the recovery rate of iron is generally greater than 85%, the titanium dioxide content is less than 0.5%, while the titanium dioxide content in obtained high titanium magnetic separation tailings is higher than 20%, and the recovery rate of titanium is greater than 90%.

Owner:UNIV OF SCI & TECH BEIJING +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com