Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4292results about "Carboxylic acid salt preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluorinated surfactants for making fluoropolymers

ActiveUS20070142541A1Easy to preparePrepared cost-effectivelyLiquid surface applicatorsTransportation and packagingEmulsion polymerizationFluoropolymer

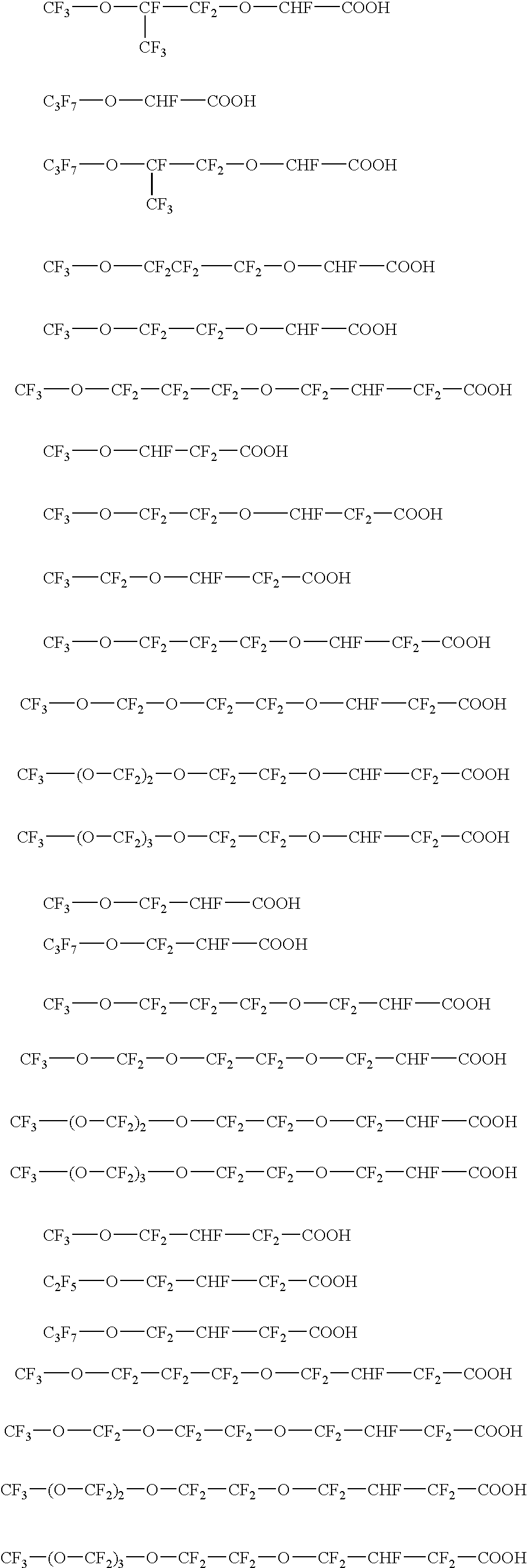

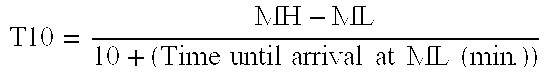

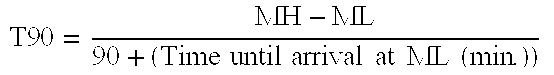

The invention provides a fluorinated surfactant having the general formula: [Rf—(O)t—CHF—(CF2)n—COO—]iXi+ (I) wherein Rf represents a partially or fully fluorinated aliphatic group optionally interrupted with one or more oxygen atoms, t is 0 or 1 and n is 0 or 1, Xi+ represents a cation having a valence i and i is 1, 2 or 3. The surfactant can be used in emulsion polymerization of fluoromonomers to prepare fluoropolymers.

Owner:3M INNOVATIVE PROPERTIES CO

Fluoroalkyl carboxylic acid derivative, method for producing fluorine-containing polymer, and aqueous dispersion of fluorine-containing polymer

ActiveUS20060281946A1Improve efficiencyImprove stabilityPreparation from carboxylic acid halideOrganic compound preparationHydrogen atomAcid derivative

This invention provides a novel compound which can be properly used as a surfactant, a method of producing a fluoropolymer, surfactant and a fluoropolymer aqueous dispersions using the novel compound. This invention is a fluoroalkylcarboxylic acid derivative which is represented by the general formula (i): Rf1(OCH2CF2CF2)n1OCX1X2CF2(Rf2)n2COOM (i) wherein Rf1 represents a straight or branched fluoroalkyl group containing 1 to 20 carbon atoms, which fluoroalkyl group may optionally contain 1 to 5 oxygen atoms in the principal chain thereof, Rf2 represents a straight or branched fluoroalkylene group containing 1 to 25 carbon atoms, said fluoroalkylene group may optionally contain 1 to 5 oxygen atoms in the principal chain thereof, n1 represents an integer of 0 to 3, n2 represents an integer of 0 or 1, X1 and X2 are the same or different and each represents hydrogen atom or fluorine atom, and M represents NH4 or a monovalent metal element.

Owner:DAIKIN IND LTD

Regulation of Mammalian Keratinous Tissue Using Skin and/or Hair Care Actives

Personal care compositions containing an active selected from the group consisting of phlorogine, phlorgine BG, deoxyArbutin, sucrose dilaurate, bakuchiol, pyrenoine, millet, arlatone dioic acid, cinnamic acid, ferulic acid, achromaxyl, methyl nicotinamide, oil soluble licorice extract, folic acid, undecylenic acid, zinc undecylenate, L-tryptophan, thiamine HCl, hexylresorcinol, lipidami red vine, dragosine, methyl gentisate, inositol, symdiol 68, laminaine, their salts, their derivatives, their precursors, and / or combinations thereof. Methods for regulating the condition of mammalian keratinous tissue by topically applying the personal care compositions are also provided.

Owner:THE PROCTER & GAMBLE COMPANY

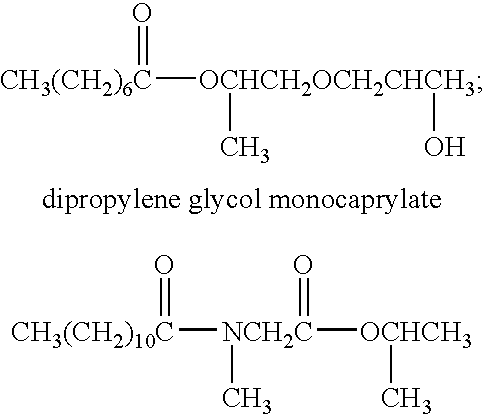

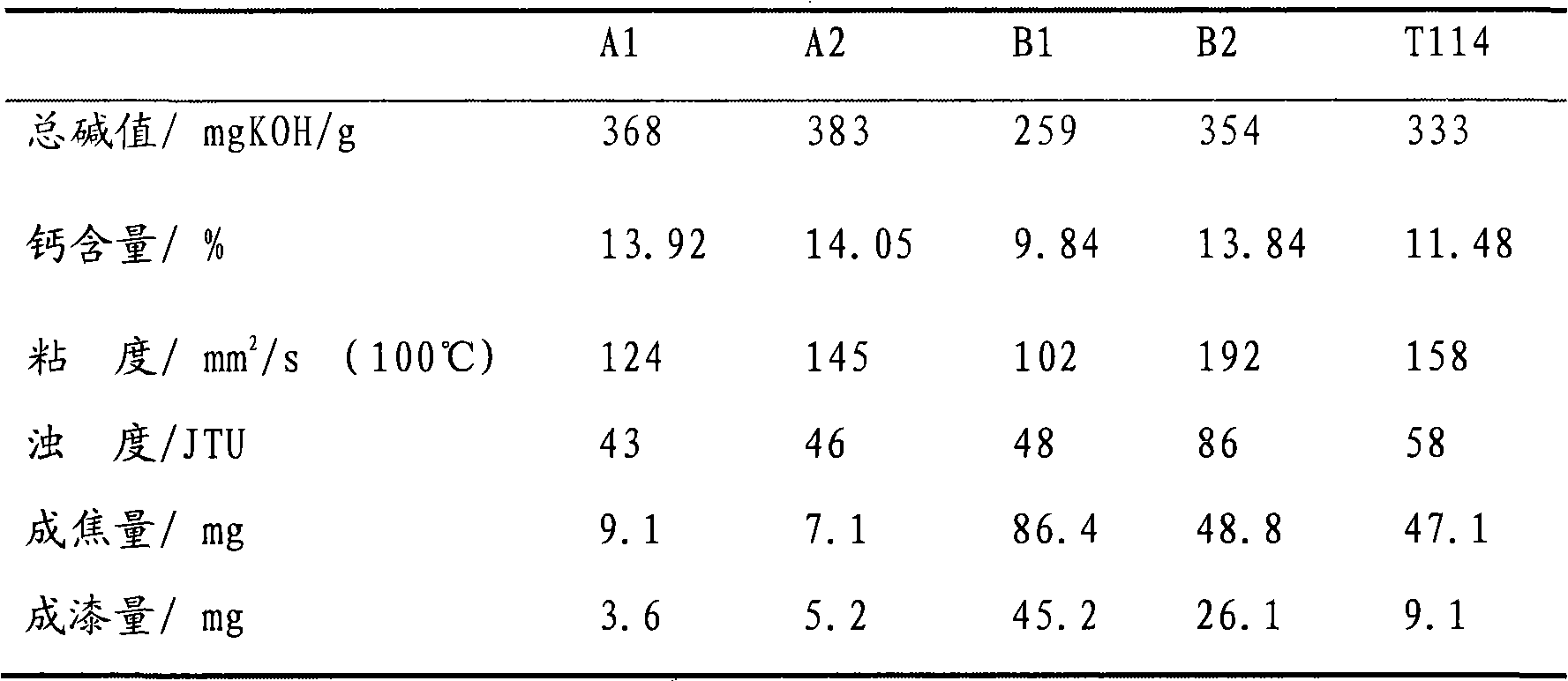

Preparation method for high-alkaline calcium naphthenate

ActiveCN101885677AAvoid aggregation and sedimentationHelps neutralize the reactionAdditivesCarboxylic acid salt preparationCalcium hydroxideAlkaline water

The invention relates to a preparation method for high-alkaline calcium naphthenate. In the method, calcium hydroxide and calcium oxide are taken as calcifying agents, pure water is replaced by alkaline aqueous solution, and a mode of multiple addition is adopted to prepare a calcium naphthenate product with the base number of more than or equal to 350 mgKOH / g. The product has the advantages of low viscosity and turbidity and better high temperature cleanliness.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method and applications of porous metal organic skeleton material

ActiveCN104370820AGood application effectEasy to operateOther chemical processesGroup 8/9/10/18 element organic compoundsMetal-organic frameworkSolvent

The invention relates to a preparation method of a porous metal organic skeleton material. The porous metal organic skeleton material comprises at least a metal ion and at least an organic compound that can be matched with the metal ion. The material can be prepared by dissolving metal compounds, organic ligand, and sustained-released alkali into a solvent and carrying out direct water (solvent) thermal synthesis at a certain temperature under a certain pressure so as to obtain the porous metal organic skeleton material. The operation of the provided preparation method is simple, the preparation method is suitable for massive industrial production and is suitable for the synthesis of porous metal organic skeleton membrane, and the provided porous metal organic skeleton material is used to absorb, separate, and store gas.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

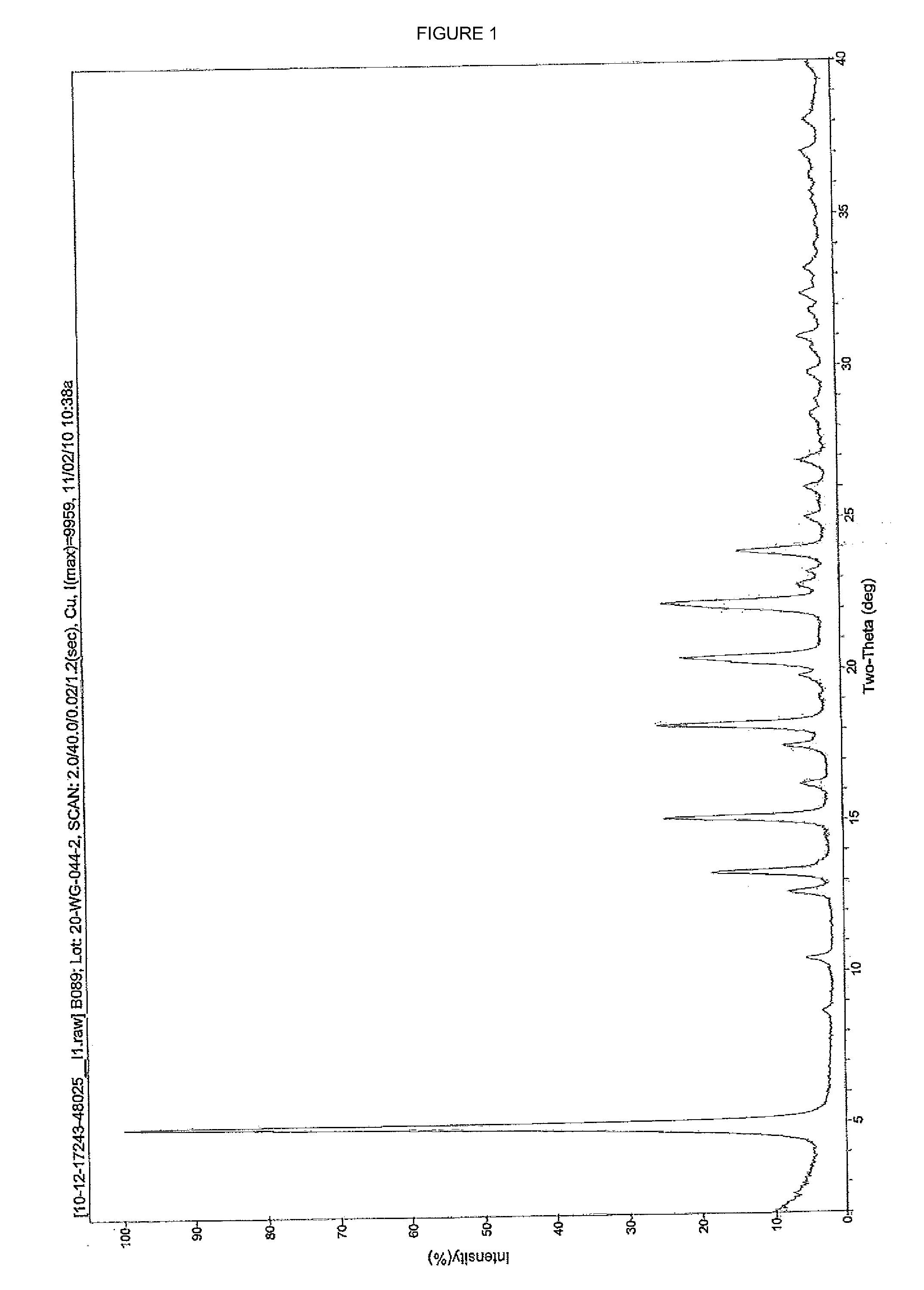

Pharmaceutical-grade ferric citrate

The present invention relates to pharmaceutical-grade ferric citrate. Pharmaceutical-grade ferric citrate contains a definite composition and a definite hydrate. The present invention also relates to a method using a solid—solid reaction to produce pharmaceutical-grade ferric citrate. The present invention also relates to a pharmaceutical composition comprising a therapeutically effective amount of pharmaceutical-grade ferric citrate and a food comprising pharmaceutical-grade ferric citrate.

Owner:PANION & BF BIOTECH INC

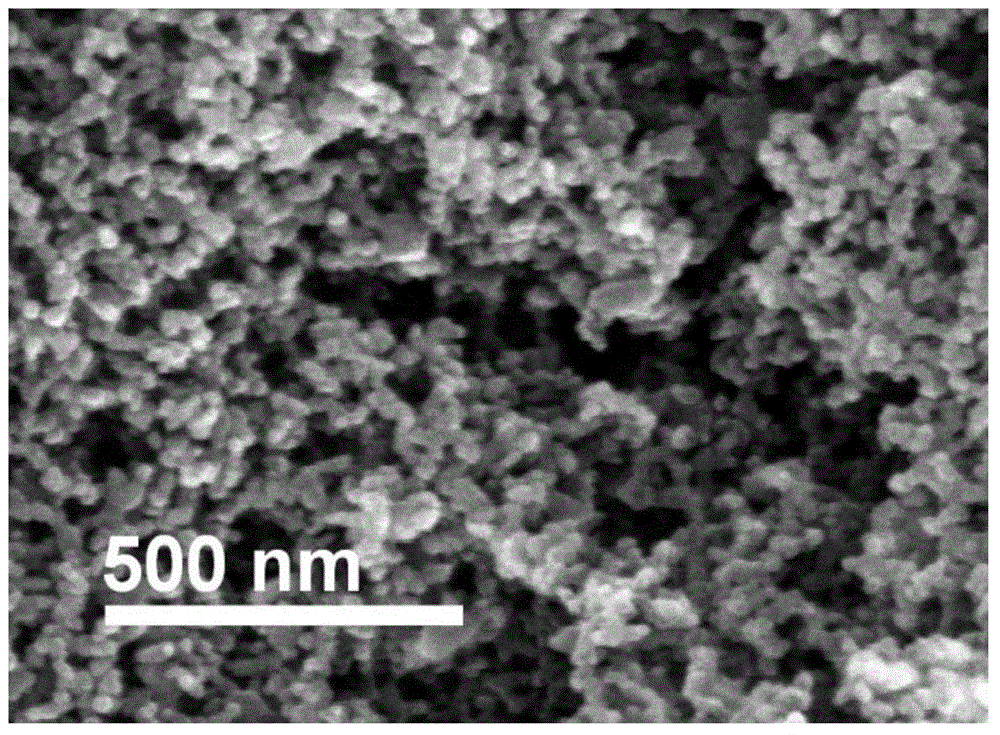

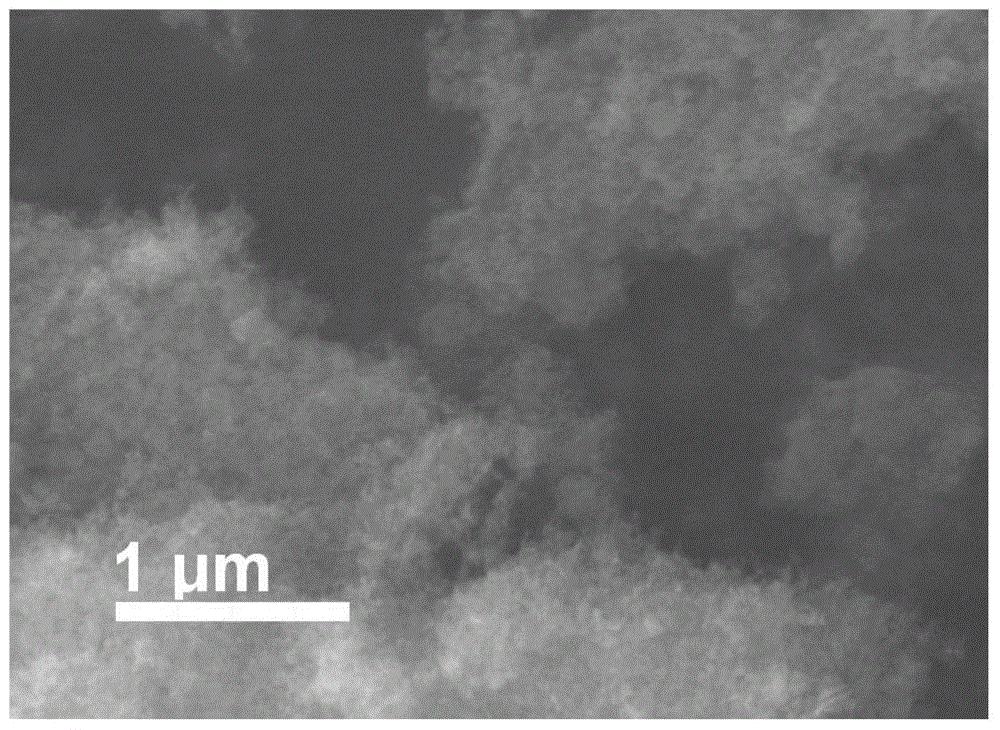

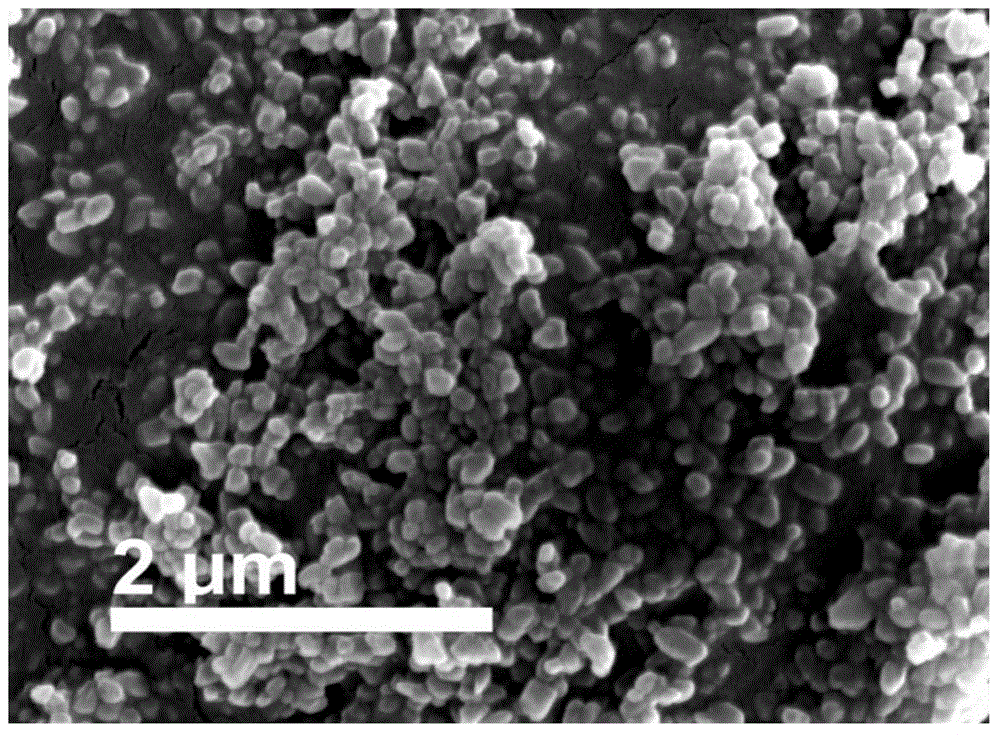

Preparation method and application of porous nano metal organic framework material

ActiveCN104892518AIncrease surface areaLarge hole volumeMaterial nanotechnologyOther chemical processesSulfurMetal-organic framework

The invention aims to provide a preparation method and application of a porous nano metal organic framework material, and is characterized in that the preparation method comprises the steps: adding a metal ion, an organic ligand, a surfactant and a nanocrystalline guide agent or a reagent forming the nanocrystalline guide agent into a growth medium, forming a framework structure through chemical complexation, crystallizing, filtering, washing, drying, and finally obtaining the porous nano metal organic framework material. The addition amount of the surfactant is 0-30% of the molar concentration of the metal ion; the metal ion is one or more of Cu<II>, Al<III>, Mg<II>, Fe<III>, Ni<II>, Co<II> and Zn<II>; the organic ligand has at least one atom independently selected from oxygen, sulfur and nitrogen and can be subjected to coordinated complexation to the metal ion through the atom. The method not only can effectively suppress the size of MOFs materials, but also easily improves size homogeneity and synthetic efficiency of the product.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Amido-containing ionic liquid used for absorbing acidic gases and preparation method and application thereof

ActiveCN101993378ASynthetic raw materials are cheap and easy to obtainLow costDispersed particle separationSulfonic acids salts preparationPressure reductionIonic liquid

The invention provides an amido-containing ionic liquid used for absorbing acidic gases and a preparation method and application thereof and in particular relates to a method for absorbing acidic gases of CO2, H2S, SO2 and the like by using an amido-containing ionic liquid. The amido-containing ionic liquid comprises one or more of primary amine, secondary amine and tertiary amine, wherein positive ions of the ionic liquid are derived from organic polyamines, negative ions of the ionic liquid are derived from inorganic acid or organic acid, and the ionic liquid is prepared by mixing the organic polyamines with the inorganic acid or organic acid and then carrying out neutralization reaction through acid and alkali. The ionic liquid has the advantages of low cost, simple preparation method,strong absorbing capability and short balance time, can be used for the enriching of acidic gases, the deacidification refining of acid-containing gases of natural gas, refinery gas, methane, coal gas, synthesis gas, coke-oven gas, pyrolysis gas, smoke, motor vehicle tail gas and the like and the purification of gases under a proper space and an operating environment; meanwhile, the ionic liquid absorbing the acidic gases can release the acidic gases through pressure reduction and temperature raise, thus the absorbing capability of the ionic liquid is restored and the multiple absorption property of the ionic liquid is better.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Overbased magnesium deposit control additive for residual fuel oils

An overbased magnesium composition deposit control additive for residual fuel oils and turbine fuels is an overbased magnesium sulfonate, carboxylate or phenate or mixtures thereof containing at least 14% and upwards to about 18% by weight of magnesium and containing a succinic anhydride and lower carboxylic acid co-promoter reaction product. The additive when added to fuel oils, such as residual fuel oils containing high asphaltenes, reduces, if not eliminates, magnesium / asphaltene deposits or sediment and the consequential plugging of filters. The additive also reduces, if not eliminates, vanadium caused corrosion in the turbine. The invention is also the process for preparing the overbased composition or deposit control additive, wherein the overbasing reaction incorporates the combination of a lower carboxylic acid, preferably acetic acid and a succinic anhydride, preferably dodecenyl succinic anhydride (DDSA), as the co-promoter.

Owner:CK WITCO

Environmental-friendly dust-free calcium-zinc composite heat stabilizer for PVC processing

ActiveCN101602863AAchieve individual synthesisAvoid it happening againCarboxylic acid salt preparationThermal stabilityZinc

The invention relates to an environmental-friendly dust-free calcium-zinc composite heat stabilizer for PVC processing, which comprises the following components: 20 to 80 percent of metallic soap of main stabilizer, 10 to 60 percent of auxiliary stabilizer and 5 to 30 percent of lubricant. The invention also provides a preparation method of the heat stabilizer. The environmental-friendly dust-free calcium-zinc composite heat stabilizer has the advantages of meeting the requirements for environmental protection, along with excellent thermal stability, low cost of production and use, high efficiency and innocuity.

Owner:九江天盛塑料助剂有限公司

Methods of making alkyl lactates and alkyl levulinates from saccharides

InactiveUS20150045576A1Organic compound preparationPreparation by carbon monoxide or formate reactionLevulinic acidAlcohol

Unique methods have been developed to convert saccharides into value-added products such as alkyl lactates, lactic acid, alkyl levulinates, levulinic acid, and optionally alkyl formate esters and / or hydroxymethylfurfural (HMF). Useful catalysts include Lewis acid catalysts and Brønsted acid catalysts including mineral acids, metal halides, immobilized heterogeneous catalysts functionalized with a Brønsted acid group or a Lewis acid group, or combinations thereof. The saccharides are contacted with the catalyst in the presence of various alcohols.

Owner:BATTELLE MEMORIAL INST

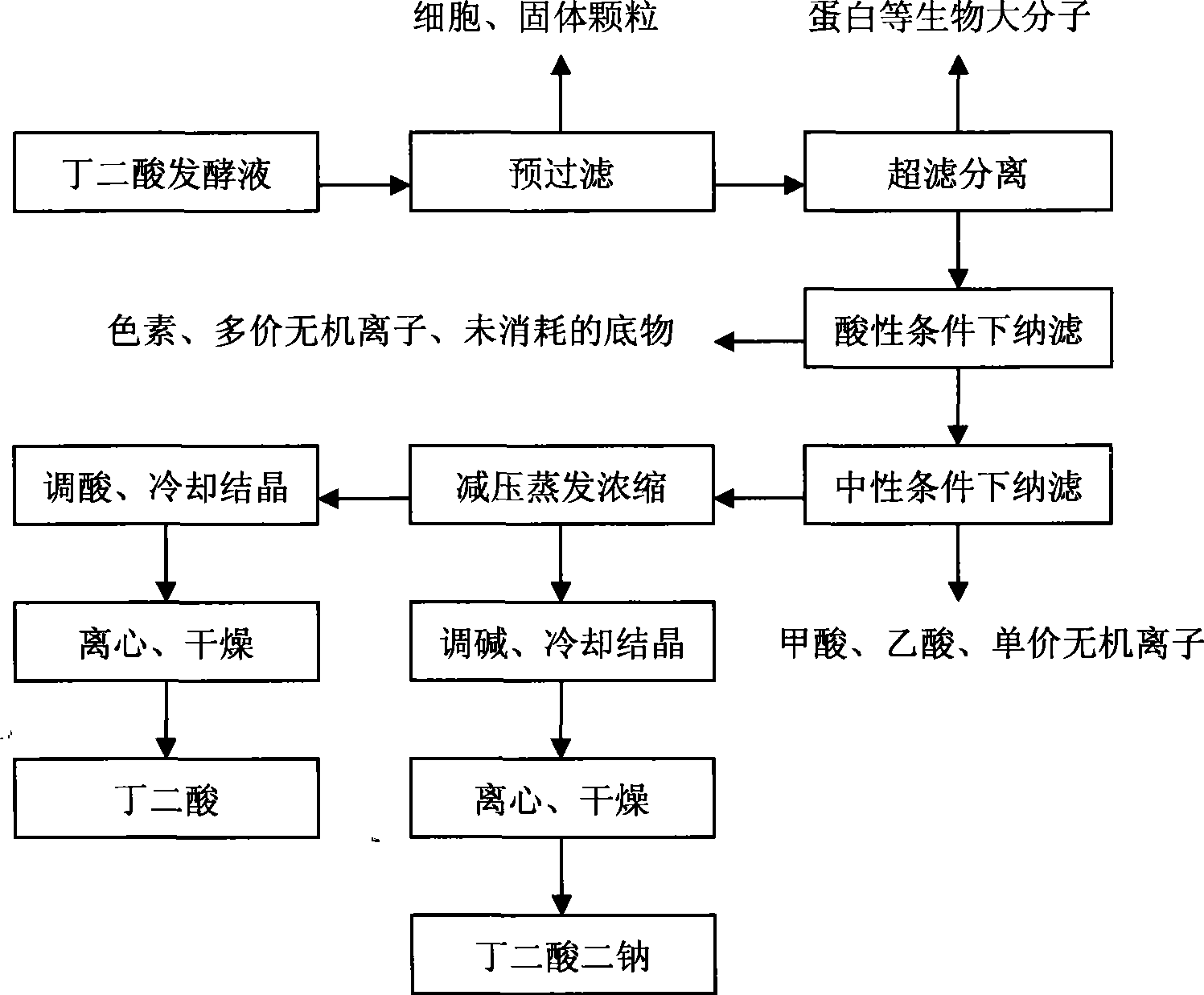

Method for separating and extracting amber acid from amber acid fermentation liquor by nanofiltration

InactiveCN101475464ALow costMild conditionsUltrafiltrationCarboxylic acid salt preparationFiltrationEvaporation

The invention discloses a method for separating and extracting butane diacid by nano-filtration from a butane diacid zymotic fluid. The method comprises the following steps that: the butane diacid zymotic fluid is subjected to prefiltration, and hyperfiltration under an acidity condition; an hyperfiltration permeate liquid is subjected to nano-filtration under an acidity condition, a nano-filtration permeate liquid is subjected to re-nano-filtration under a neutrality condition; a nano-filtration trapped fluid is subjected to reduced pressure evaporation concentration; and a concentrated solution is subjected to cooling crystallization under an alkalinity condition to prepare succinic acid disodium salt or under an acidity condition to prepare the butane diacid. The method does not use any organic solvent or active carbon in the processes of separation and extraction of the butane diacid or the succinic acid disodium salt, and completes decolorization, purification, desalinization, preconcentration and other processes of the butane diacid in the same nano-filtration separation device. The method has the advantages of mild condition, convenient operation, good selectivity, low cost of raw materials, high product quality, small pollution, and the like, can recover unconsumed substrate of the zymotic fluid, and has wide social and economic benefits.

Owner:NANJING UNIV OF TECH

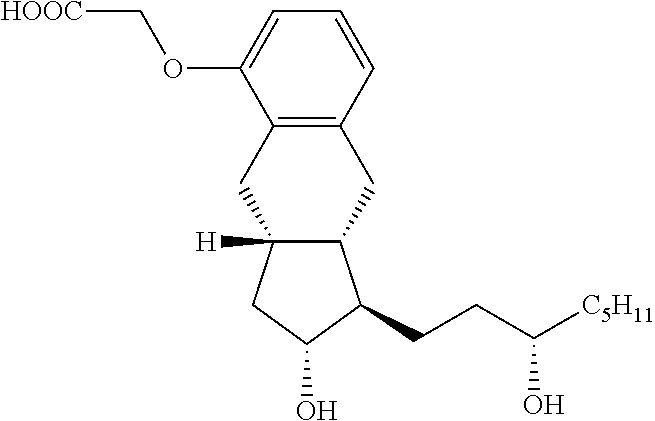

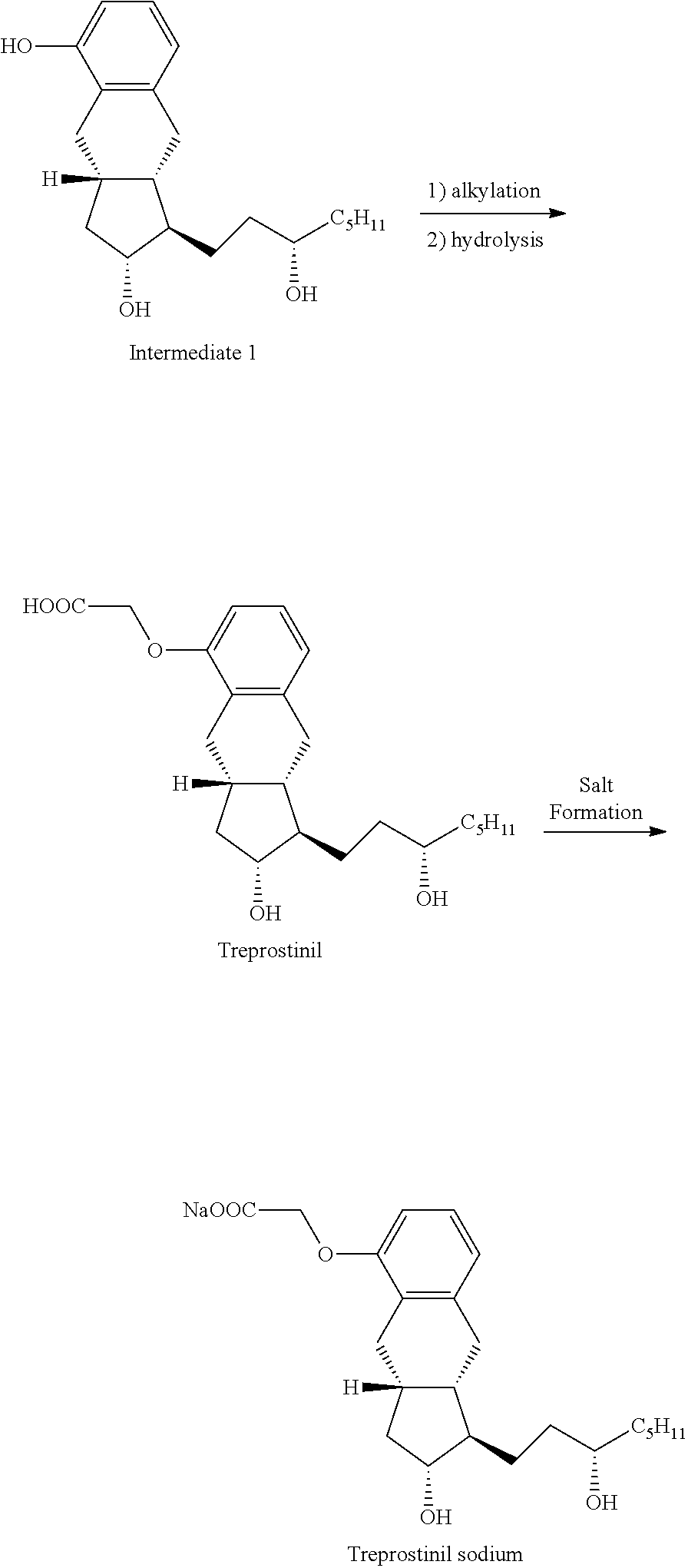

Process for treprostinil salt preparation

ActiveUS20140024856A1Organic compound preparationCarboxylic acid salt preparationOrganic solventAqueous solution

Disclosed is a process for preparing a treprostinil salt. The process involves the step of dissolving treprostinil in a water-miscible organic solvent to form a treprostinil solution. The treprostinil solution is reacted with an aqueous basic solution containing an alkali metal cation to form treprostinil salt. Allowing crystallization of the treprostinil salt to take place, and then collecting the treprostinil salt formed.

Owner:SANDOZ INC

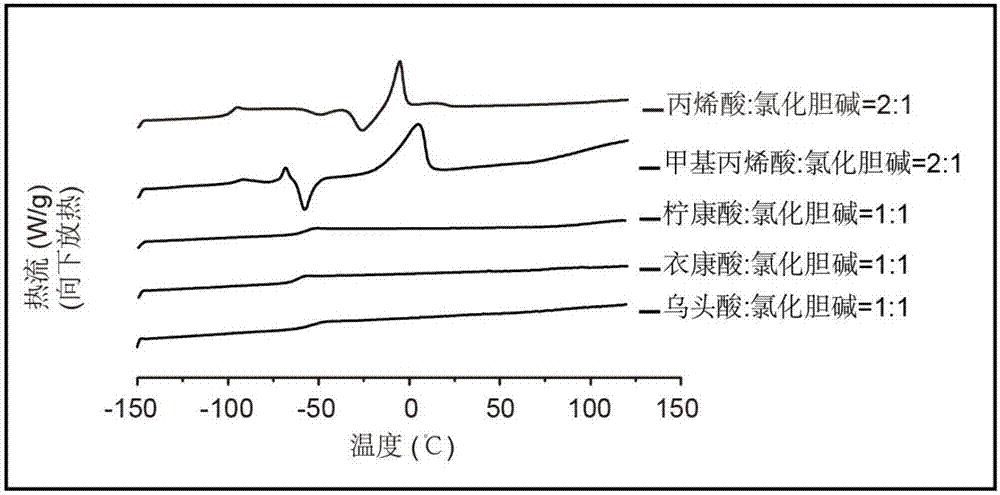

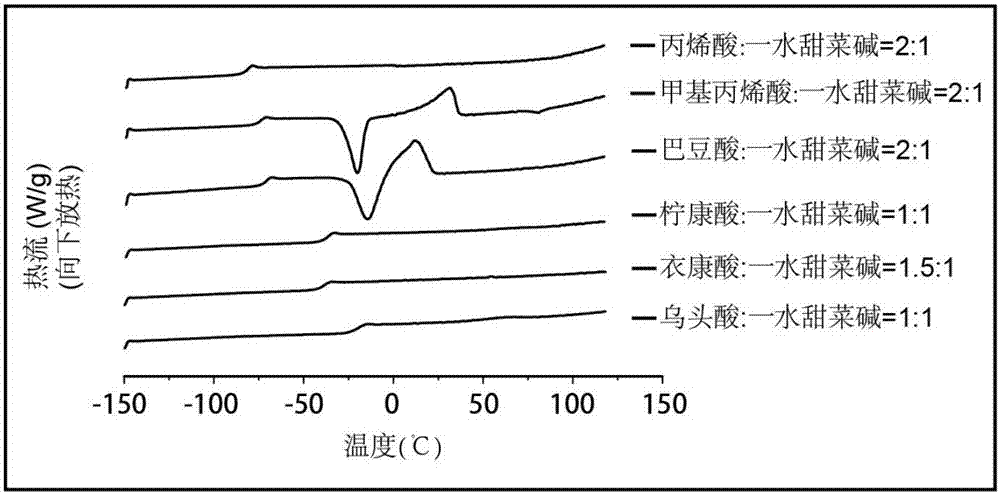

Polymerizable deep eutectic solvent

InactiveCN107417553AOrganic compound preparationGroup 5/15 element organic compoundsMacromolecular SubstancesDeep eutectic solvent

The invention discloses a polymerizable deep eutectic solvent. The polymerizable deep eutectic solvent is obtained by mixing a hydrogen bond acceptor and a hydrogen bond donor at 60 DEG C to 100 DEG C; the mol ratio of the hydrogen bond donor to the hydrogen bond acceptor is not less than 1 to 3. The polymerizable deep eutectic solvent disclosed by the invention can be subjected to polymerization reaction to prepare a macromolecular substance, and a new turn of technical innovation can be brought to the deep eutectic solvent; the knowledge of people that the deep eutectic solvent only has a dissolving effect in processes of preparing and purifying the compound and the like is changed, and an application field of the deep eutectic solvent is greatly expanded.

Owner:广州纽楷美新材料科技有限公司

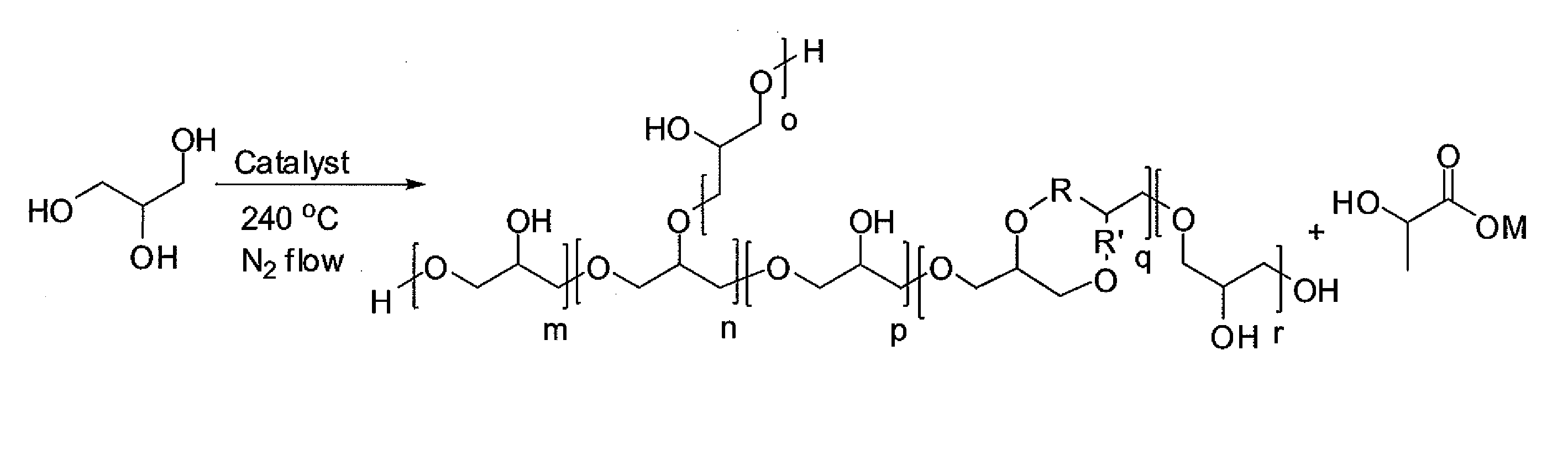

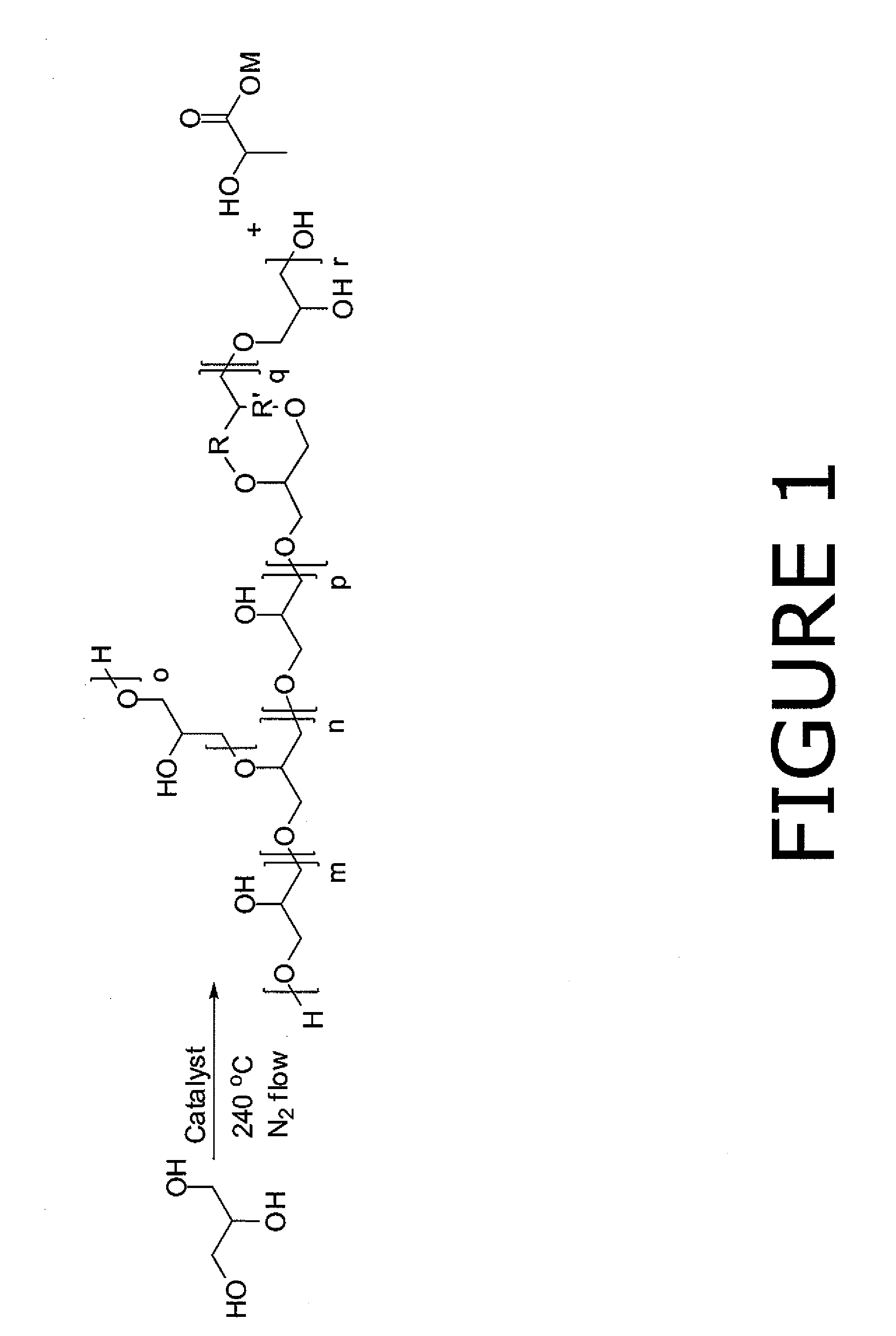

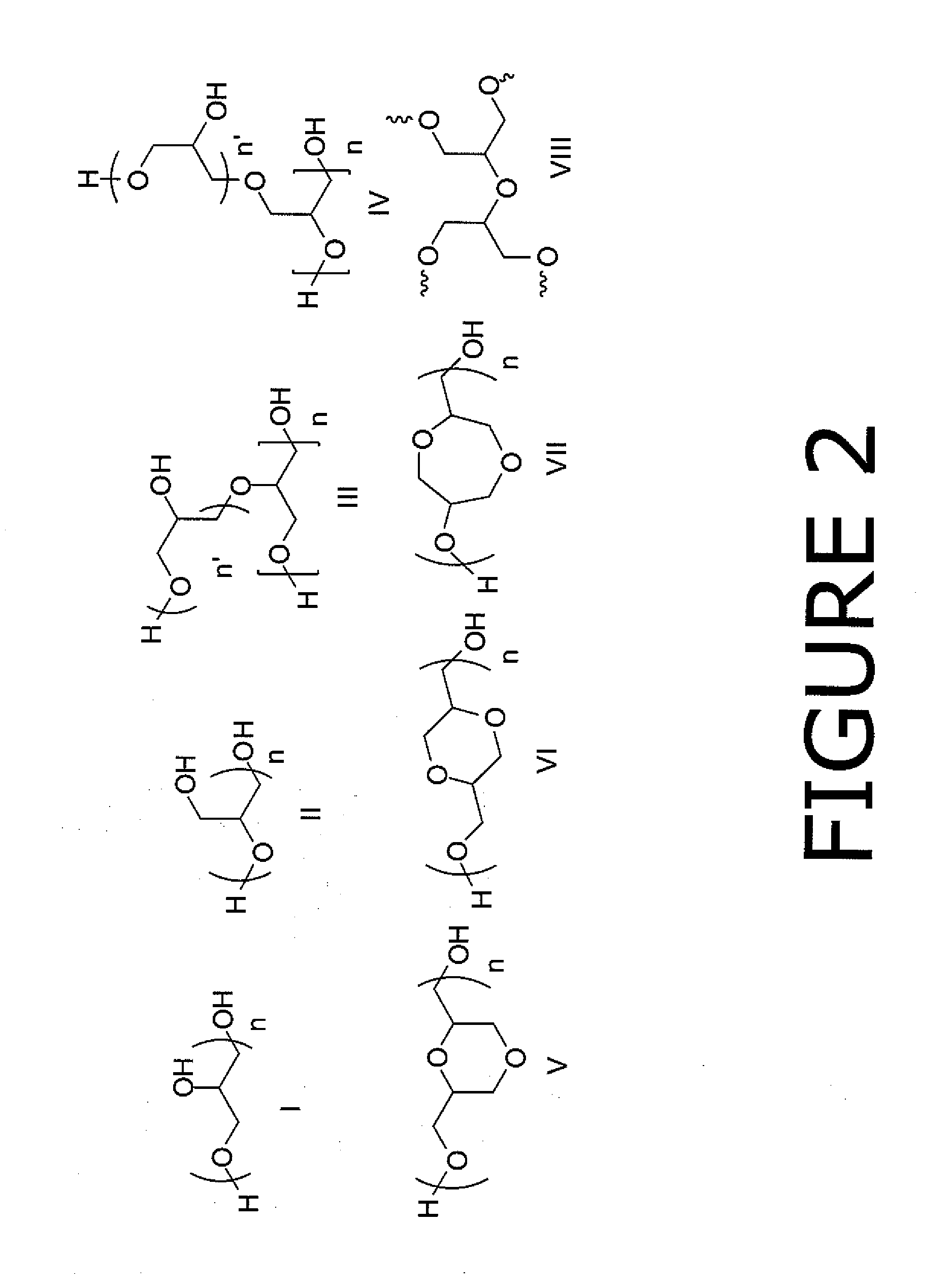

Production and composition of glycerol based polyols

ActiveUS20110092743A1Protection is in progressHigh proportionOrganic compound preparationCarboxylic acid salt preparationDistillationGlycerol

The invention provides a method of efficiently producing branched, cyclic glycerol-based polyols with a co-product as anti-biodegrading agent from inexpensive readily available glycerol monomer. The method involves polymerizing glycerol or glycerol with at least another monomer to multiple other monomers in the presence of particular amount of a strong base as the catalyst under a particular distillation environment. The polyol produced by the inventive method is beneficial of reducing scales in Bayer liquid for aluminum production process and improving brightness of coated paper substrates without greening effect.

Owner:ECOLAB USA INC

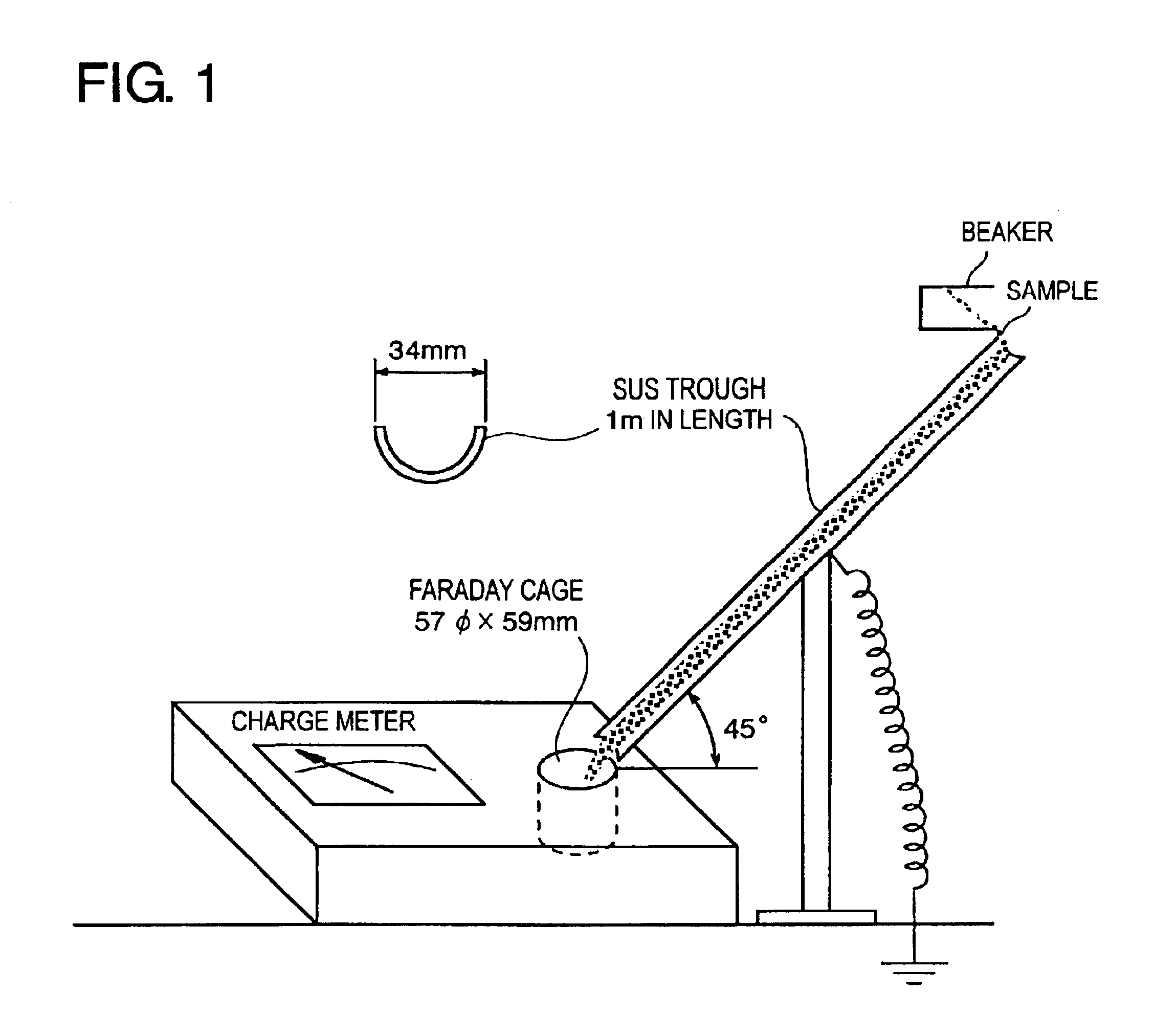

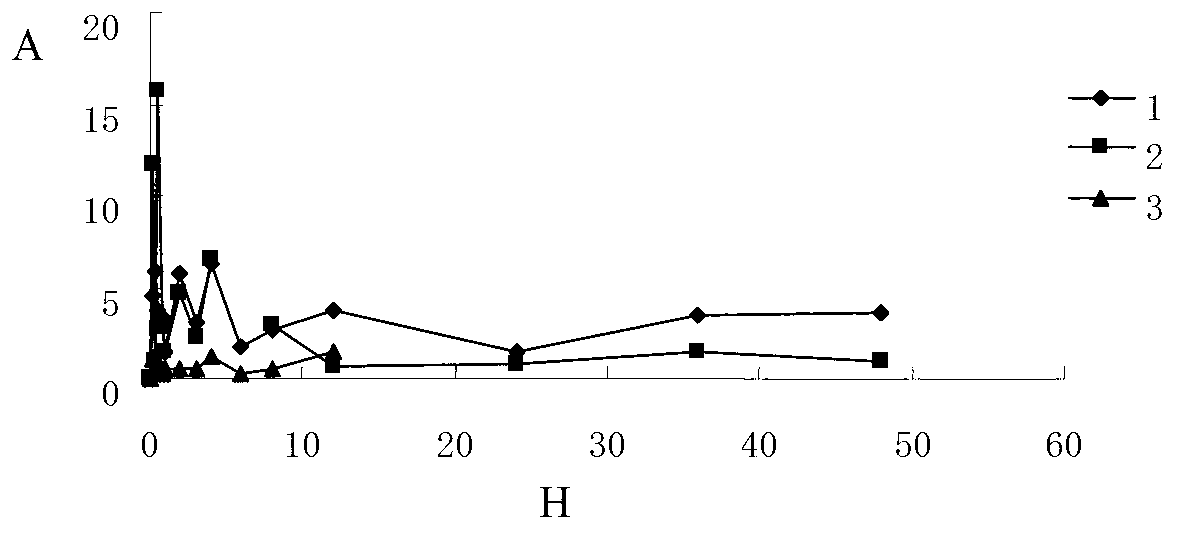

Zinc acrylate particle composition, method for production thereof, and golf ball using the composition

InactiveUS6956128B2Difficult to scatterEasy to handleOrganic compound preparationConductive materialPolymer scienceActive agent

A zinc acrylate particle composition which is substantially fine and, even when kneaded with a rubber composition, is capable of being uniformly dispersed and kneaded in a state very rarely inducing fast adhesion or agglomeration, a method for the production thereof, and a golf ball using the composition are provided. The zinc acrylate particle composition contemplated by this invention comprises zinc acrylate satisfying the conditions that the proportion accounted for by the zinc acrylate particles measuring not less than 300 μm in particle size as determined by the dry type method be not more than 20% by mass of all the particles, that the median of particle sizes as determined by the dry type method be in the range of 10-300 μm, and that the ratio of the median (A) of particle sizes as determined by the dry type method to the median (B) of particle sizes as determined by the wet type method exceed 2, and an anionic surfactant.

Owner:BRIDGESTONE SPORTS +2

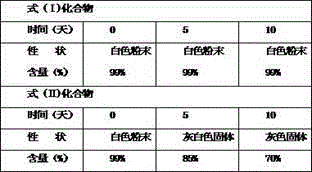

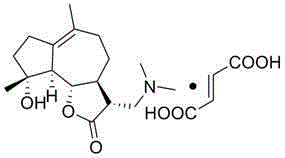

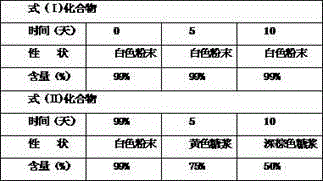

Dimethylamino sphaelactone fumarate and use thereof

InactiveCN104876899AReduce humidityImprove stabilityOrganic active ingredientsCarboxylic acid salt preparationMedicinal chemistryPharmacology

Owner:ACCENDATECH

Preparation method and application of gum rosin acid copper

InactiveCN101935275ASimple methodMethod environmentally friendlyBiocideFungicidesFilter paperSolvent

The invention discloses a preparation method and application of gum rosin acid copper. The method for preparing the gum rosin acid copper comprises the following steeps: evenly mixing copper salt with alkali liquor; mixing the obtained mixture into a uniform suspension; then slowly dropping the uniform suspension into a solution consisting of rosin and solvent, wherein in the dropping process, the color of the solution is gradually changed from blue to green, and the exothermic phenomenon is produced, then timely cooling is carried out in time, and the dropping process is completed within 20 to 40 minutes; after the dropping process is completed, raising the temperature of the obtained solution to 70 to 90 DEG C, and then carrying out atmospheric dehydration reaction on the obtained solution by using a water separator (100L); and after the dehydration reaction is completed, filtering the obtained object by using standard filter papers so as to obtain a gum rosin acid copper solution of which the concentration is 20 to 50 percent, then analyzing and detecting the content of the obtained product. The application of the gum rosin acid copper is as follows: the gum rosin acid copper prepared in the invention is used together with medicaments for preventing crop diseases and pests. The invention solves the problems that the existing method for preparing the gum rosin acid copper is complicated, hard to implement and not environmental-friendly, and the application scope of the current gum rosin acid copper is narrow.

Owner:烟台博瑞特生物科技有限公司

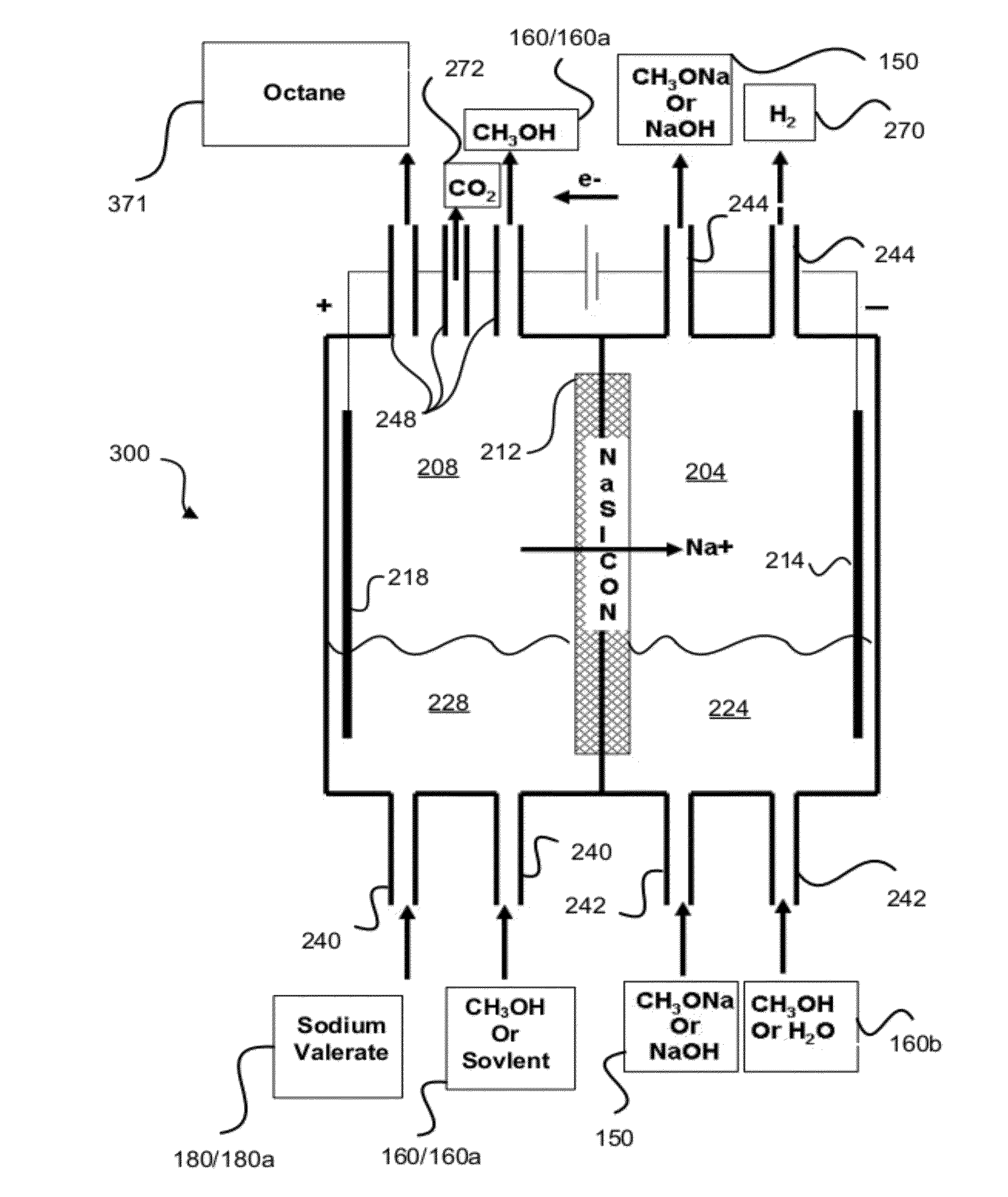

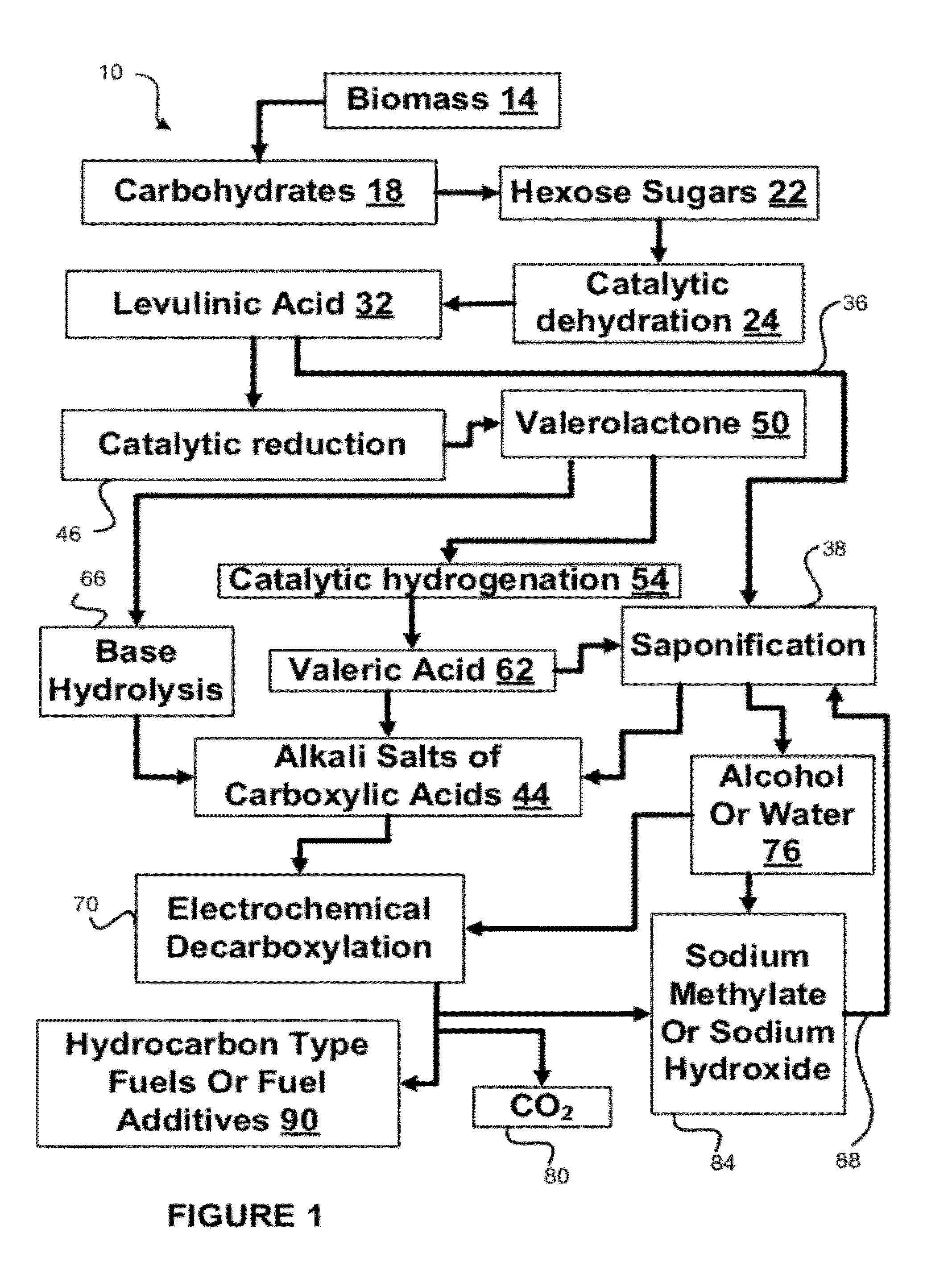

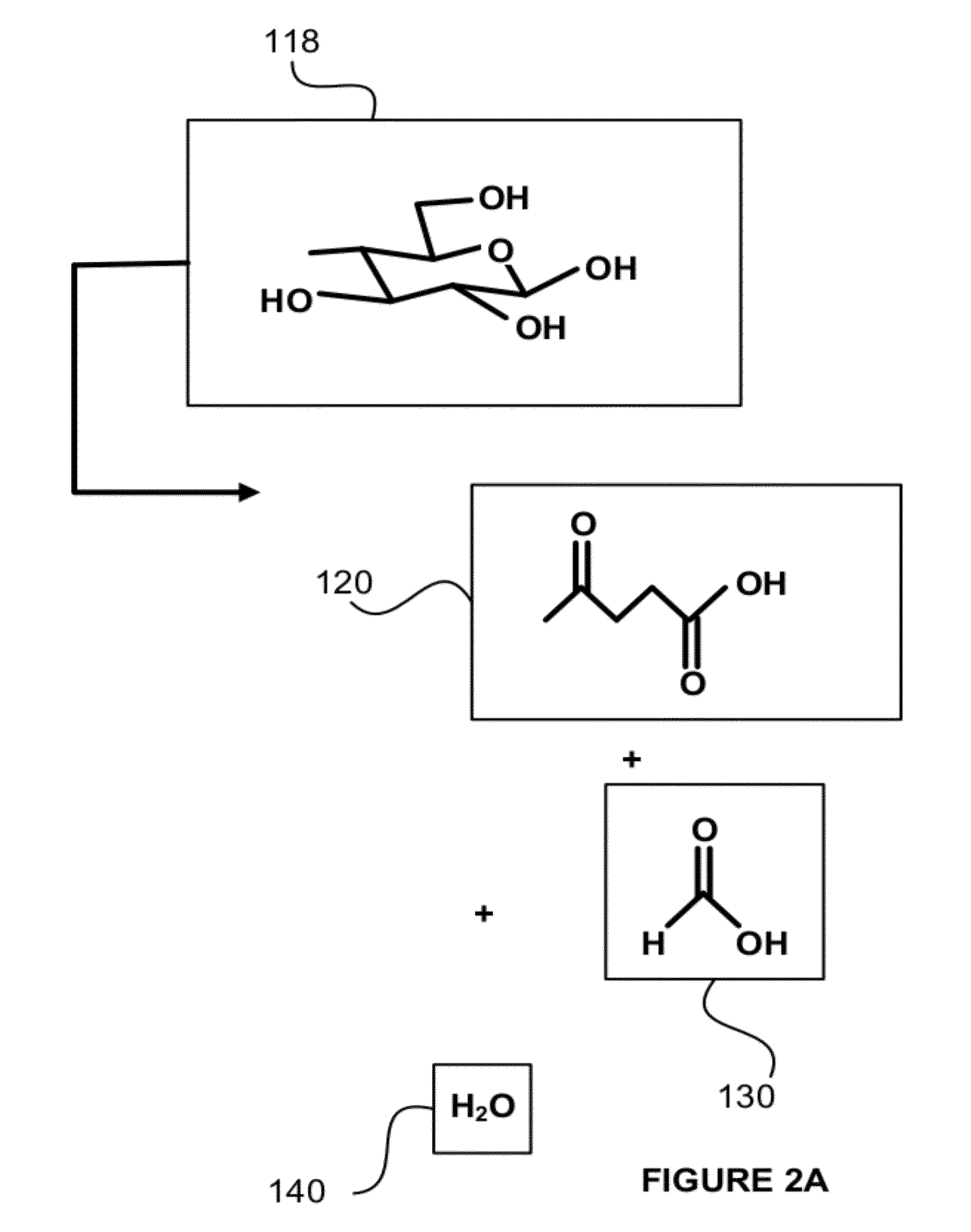

Production of fuel from chemicals derived from biomass

Hydrocarbons may be formed from six carbon sugars. This process involves obtaining a quantity of a hexose sugar. The hexose sugar may be derived from biomass. The hexose sugar is reacted to form an alkali metal levulinate, an alkali metal valerate, an alkali metal 5-hydroxy pentanoate, or an alkali metal 5-alkoxy pentanoate. An anolyte is then prepared for use in a electrolytic cell. The anolyte contains the alkali metal levulinate, the alkali metal valerate, the alkali metal 5-hydroxy pentanoate, or the alkali metal 5-alkoxy pentanoate. The anolyte is then decarboxylated. This decarboxylating operates to decarboxylate the alkali metal levulinate, the alkali metal valerate, the alkali metal 5-hydroxy pentanoate, or the alkali metal 5-alkoxy pentanoate to form radicals, wherein the radicals react to form a hydrocarbon fuel compound.

Owner:ENLIGHTEN INNOVATIONS INC

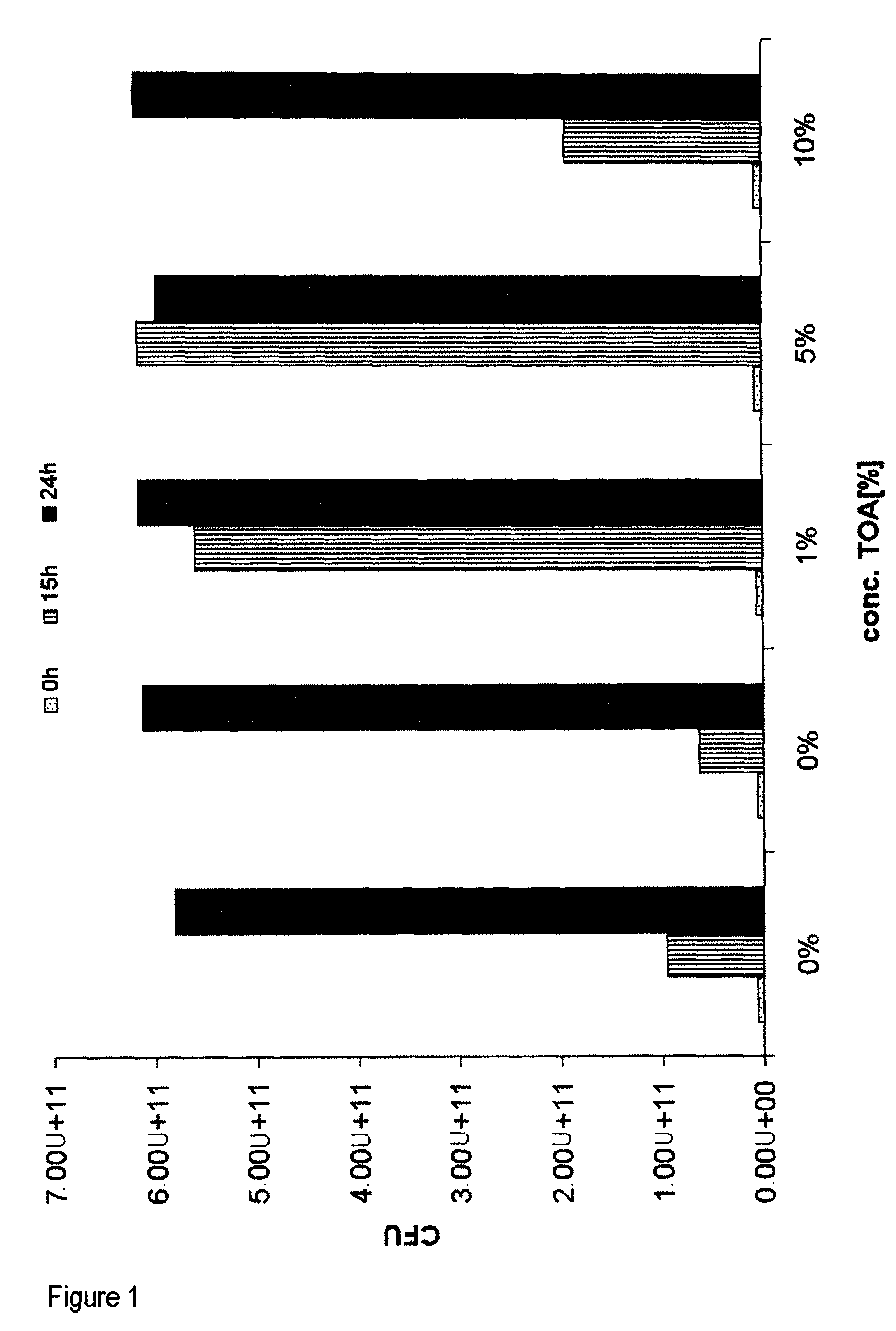

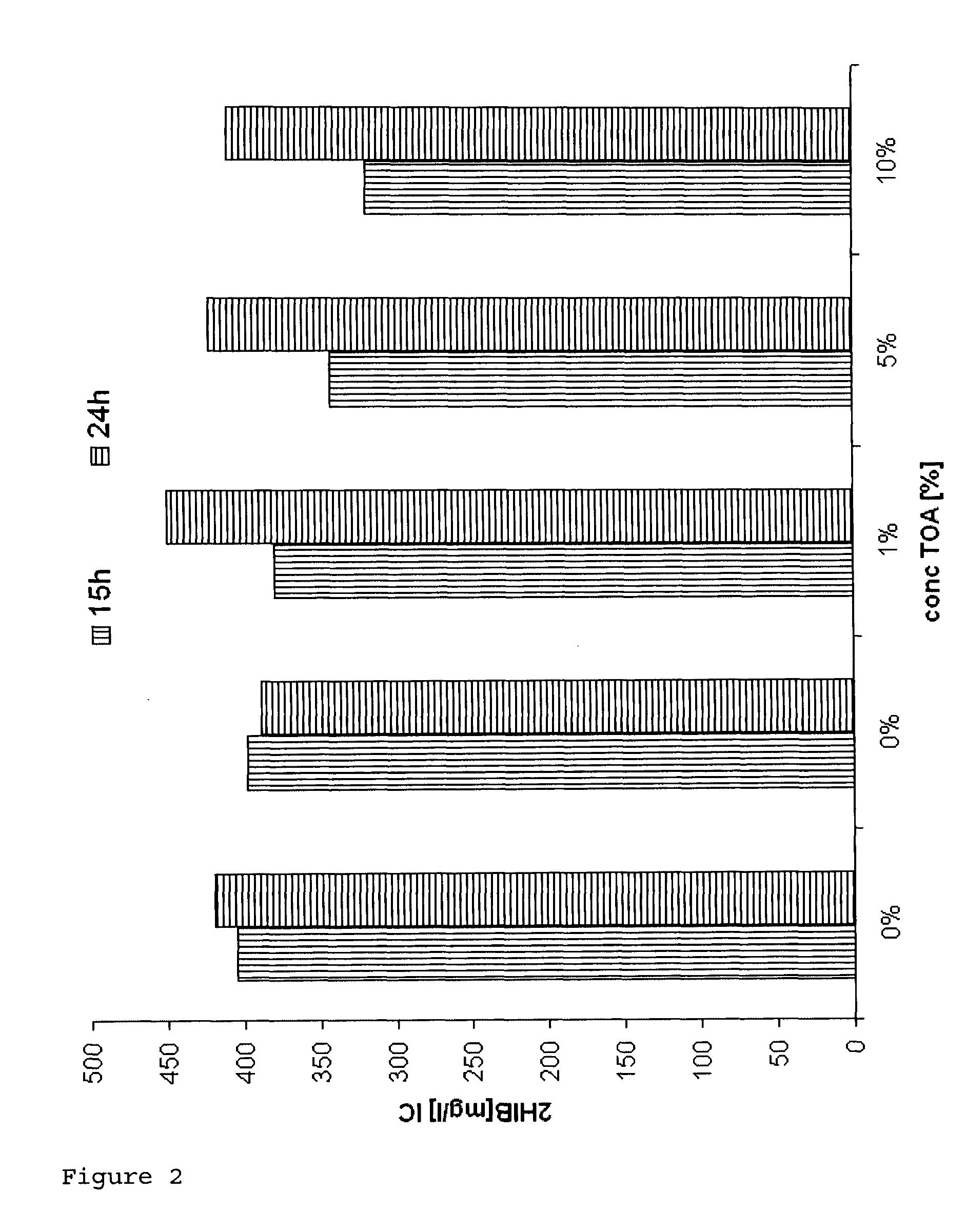

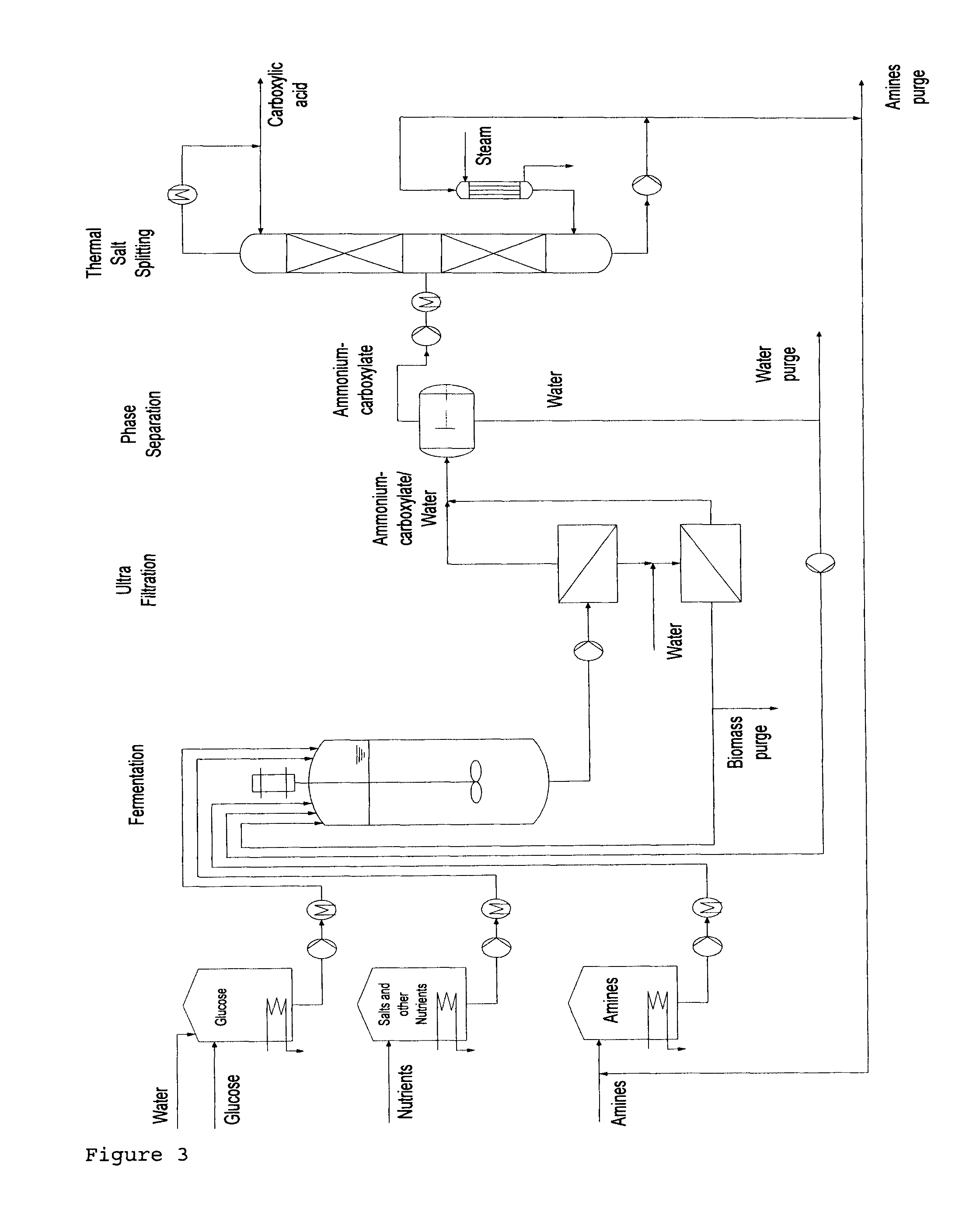

Method for the production of free carboxylic acids

InactiveUS8703451B2Substance reductionLow viscosityPreparation from carboxylic acid saltsOrganic compound preparationBiological cellWater insoluble

A process for the preparation of free carboxylic acids including: A) preparation of carboxylic acid by a biological cell located in an aqueous medium with addition of an amine of formula (I)where R1, R2 and R3, independently of one another, are identical or different, branched or unbranched, optionally substituted hydrocarbon radicals or H; B) for cases where the added amine A) is water-soluble, addition of a water-insoluble amine of formula (I), where, in A) or B), a multiphase system is obtained and the corresponding ammonium carboxylate is formed from the water-insoluble amine and the carboxylic acid; C) removal of the water-insoluble phase; and D) heating of the water-insoluble phase with release of free carboxylic acid.

Owner:EVONIK ROEHM GMBH

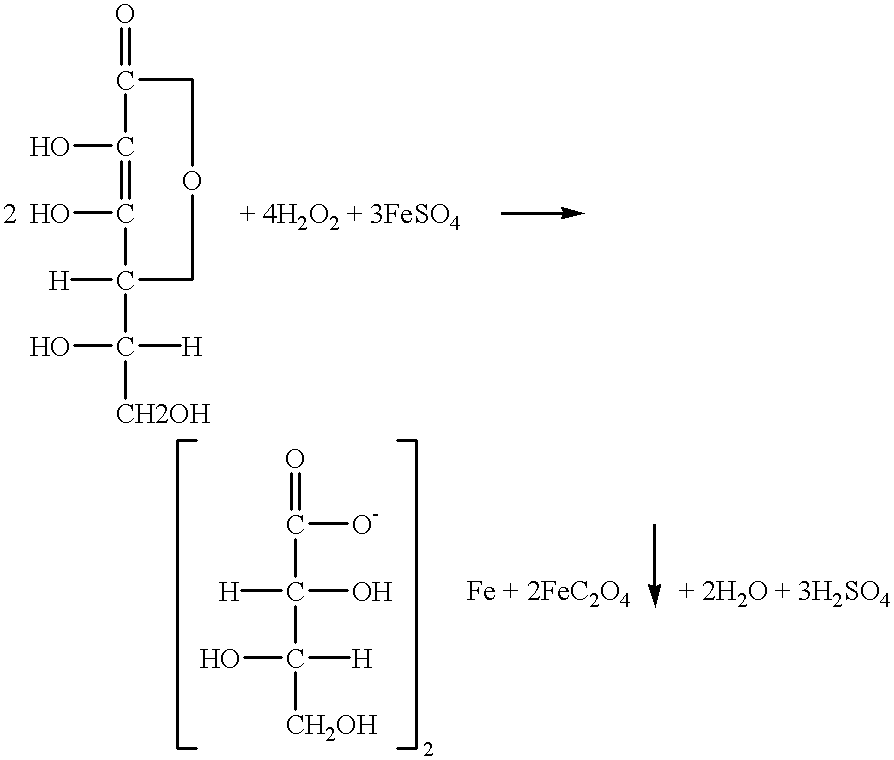

Deironing method for vanadium-bearing stone coal lixivium

ActiveCN105695738AReduce loss rateReduce the impact of vanadium enrichmentOrganic compound preparationCarboxylic acid salt preparationPregnant leach solutionIron powder

The invention relates to a deironing method for vanadium-bearing stone coal lixivium. According to the technical scheme, the deironing method comprises the steps that vanadium-bearing stone coal is firstly subjected to crushing, roasting and ore grinding to obtain vanadium-bearing stone coal roasted ore, the vanadium-bearing stone coal roasted ore and water are stirred to obtain vanadium-bearing stone coal ore pulp, then a leaching agent is added, heating and stirring are carried out, and solid-liquid separation is carried out to obtain the vanadium-bearing stone coal lixivium and leaching residues; reduced iron powder is added into the vanadium-bearing stone coal lixivium, and the adding amount of the reduced iron power is 2-4 times the stoichiometric number of the chemical reaction for reducing Fe3+ in the vanadium-bearing stone coal lixivium into Fe2+; heating and stirring are carried out, the pH value is adjusted to range from 1.5 to 5, heating and stirring are carried out, solid-liquid separation is carried out, and deironed lixivium and a filter cake are obtained; and the deironed lixivium is used for the vanadium enrichment technology, and a ferrous oxalate dehydrate byproduct is obtained after the filter cake is dried. Vanadium and iron in the vanadium-bearing stone coal lixivium can be effectively separated, the iron in the vanadium-bearing stone coal lixivium can be recycled, the vanadium loss rate in the deironing process is low, the iron content of the deironed lixivium is low, and the influence of the iron on the subsequent vanadium enrichment technology is reduced.

Owner:WUHAN UNIV OF SCI & TECH

Production of potassium formate

InactiveUS6849764B2Eliminate needOther chemical processesPotassium organic compoundsPotassium hydroxidePotassium formate

This invention relates to a process for the continuous production of potassium formate by the reaction of formaldehyde present in the reactor outlet gas in formaldehyde production plants with an aqueous solution of potassium hydroxide, wherein the formaldehyde is in gaseous monomeric form, the formaldehyde being fed to the reaction column at a temperature of 100° C. and above. By this invention, a straightforward method of potassium formate production and removal of excess reactant(s) are realized very efficiently. Pure potassium formate solution at any strength is produced. The strength of the product solution depends on where it will be used. Potassium Formate solution is used mainly as deicer, drilling mud, and / or in the production of flaked or granular Potassium Formate by appropriate methods. The flaked and granular Potassium Formate in turn is used in the fields mentioned above and also as an additive to animal feed.

Owner:MKS MARMARA ENTEGRA KIMYA SAN A S

Method for preparing modified micro granules

InactiveCN102139197AImprove targetingExcellent secondary particle sizeCalcium/strontium/barium carbonatesPigmenting treatmentBoiling pointAqueous solution

The invention discloses a method for preparing modified micro granules. Co-precipitation reaction is performed in aqueous solution and between the freezing point and the boiling point of reaction mother solution to generate the micro granules or mixed sediment of micro granule precursor and inorganic sediment. The problems of contradiction between granule micronization and surface modification and difficult separation of the micro granules and the reaction mother solution in the conventional method for preparing the modified micro granules are solved, and the brand-new industrialized production method for modified micro, submicron or nano granules is provided.

Owner:张颖

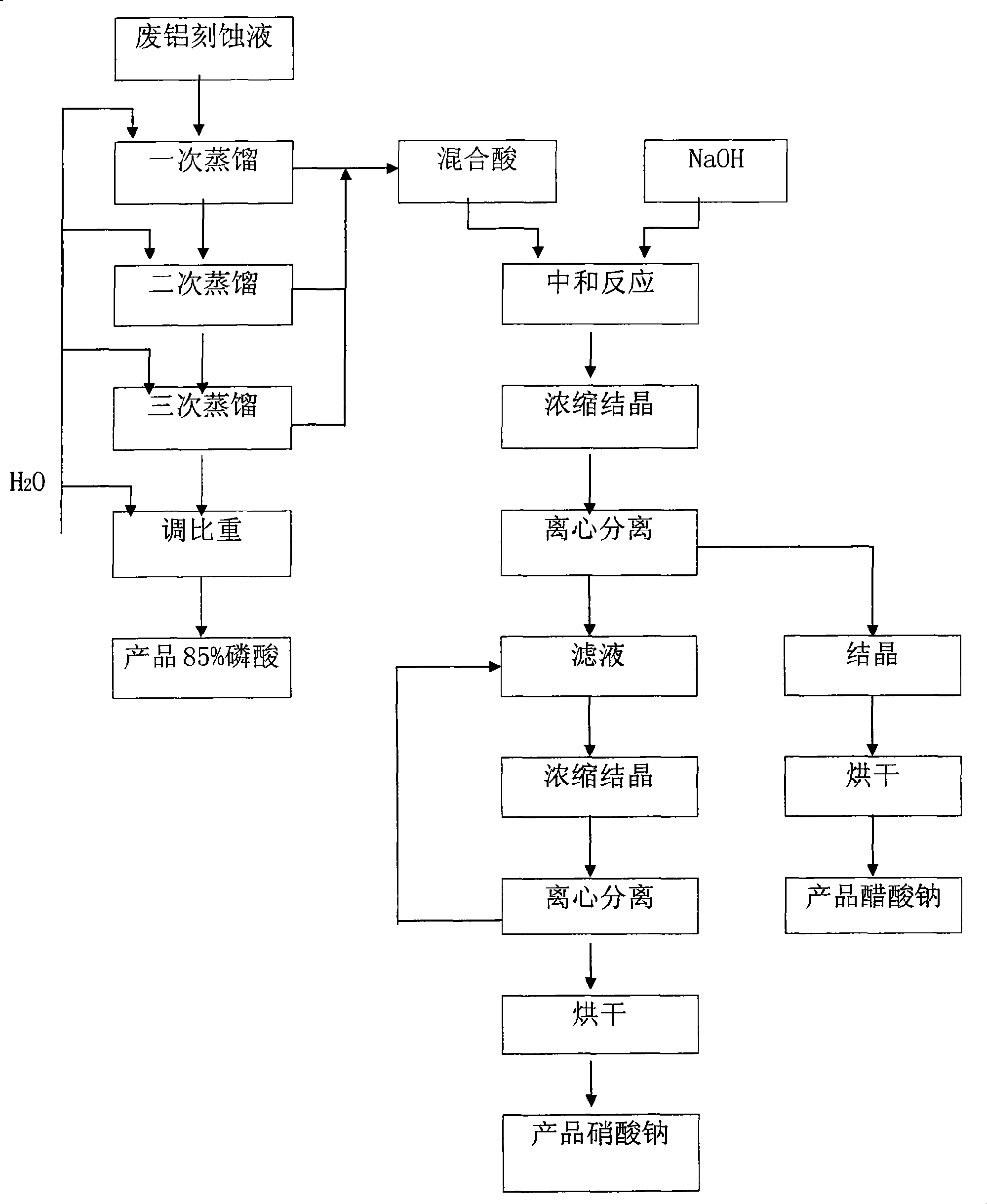

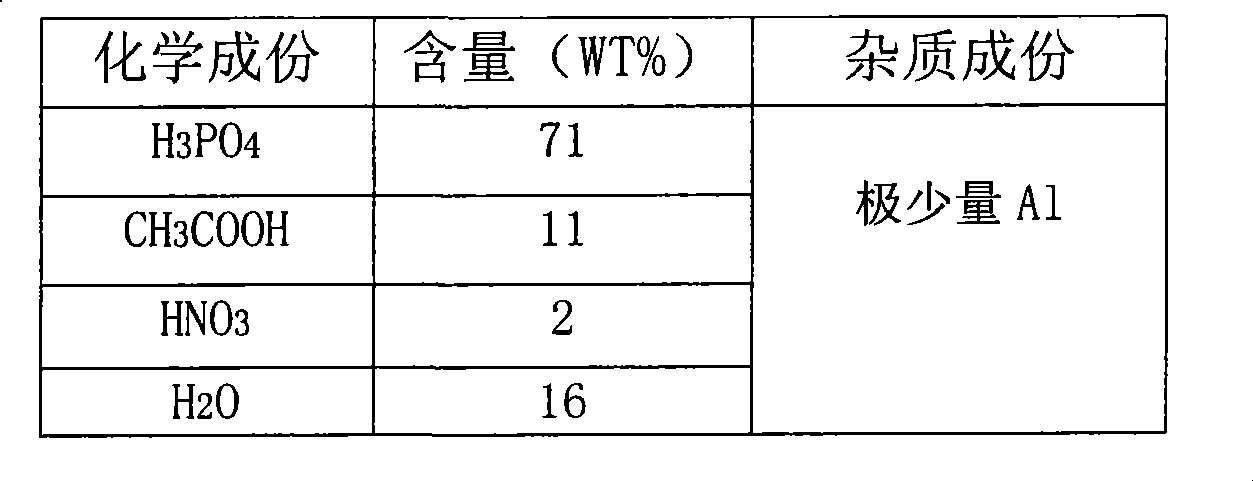

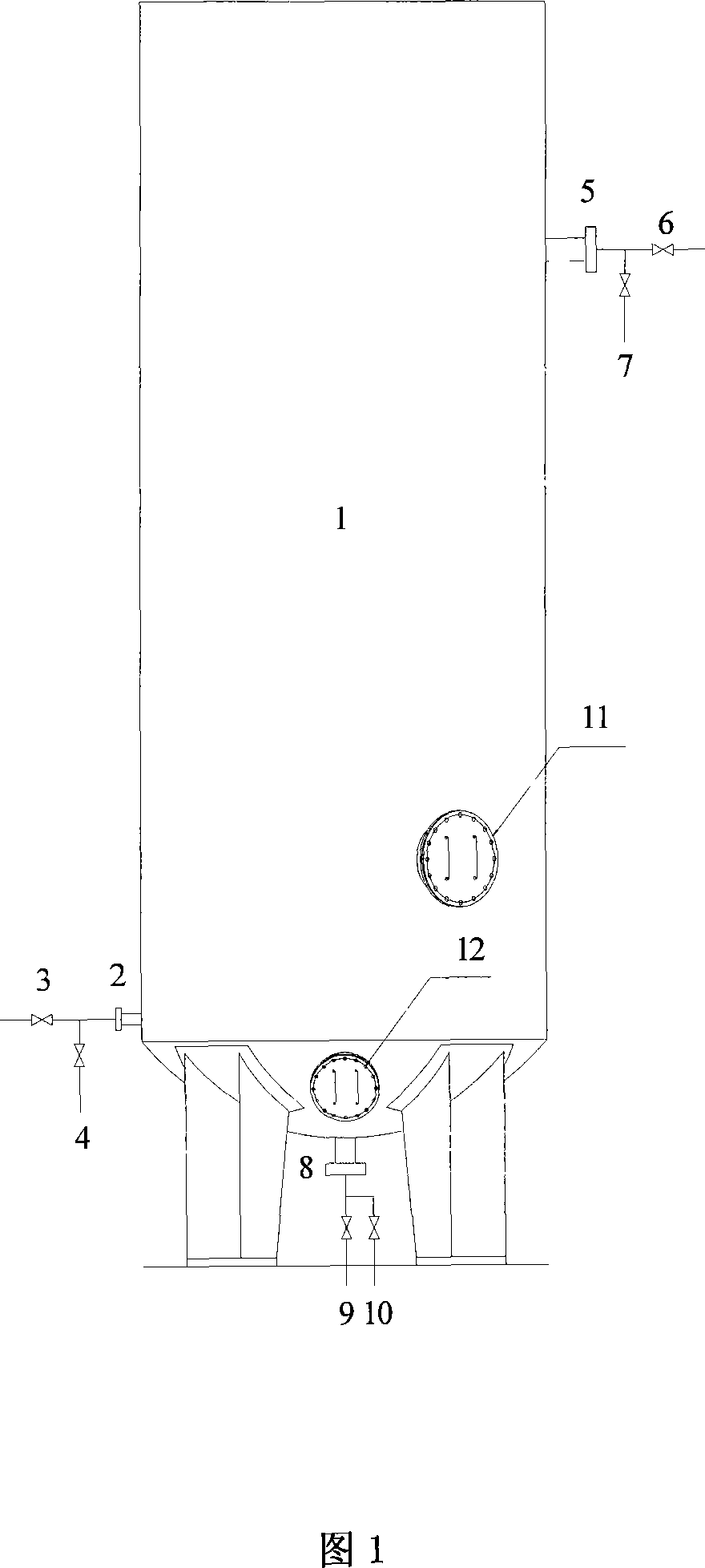

Comprehensive utilization process for waste aluminum etching solution

ActiveCN101439849AIncrease production capacityExtend your lifeAlkali metal nitrate preparationCarboxylic acid salt preparationPhosphorous acidSodium acetate

The invention relates to a comprehensive utilization process for a waste aluminum etching solution. The process utilizes the characteristic that the boiling point and the volatility of phosphorous acid are greatly different from those of nitric acid and acetic acid to separate the phosphorous acid from the nitric acid and the acetic acid by adopting a distillation method, then filters the phosphorous acid after the distillation separation to remove mechanical impurities, and then adds distilled water to adjust the specific gravity to obtain 85 percent industrial phosphorous acid; a mixed acid of the nitric acid and the acetic acid obtained by the distillation is placed into a stainless steel reaction kettle, sodium hydroxide is added into the mixed acid to react under the stirring, then a purified reaction liquid is concentrated, crystallized, and separated to obtain a filtrate and crystals; and the crystals are dried to obtain a product, namely sodium acetate, and then the filtrate is concentrated, crystallized, separated, and dried to obtain a product, namely sodium nitrate. The process can recover and utilize a mixed acid waste liquid containing a plurality of acids, and obtain a plurality of novel chemical raw materials from the mixed acid waste liquid.

Owner:孟庆深

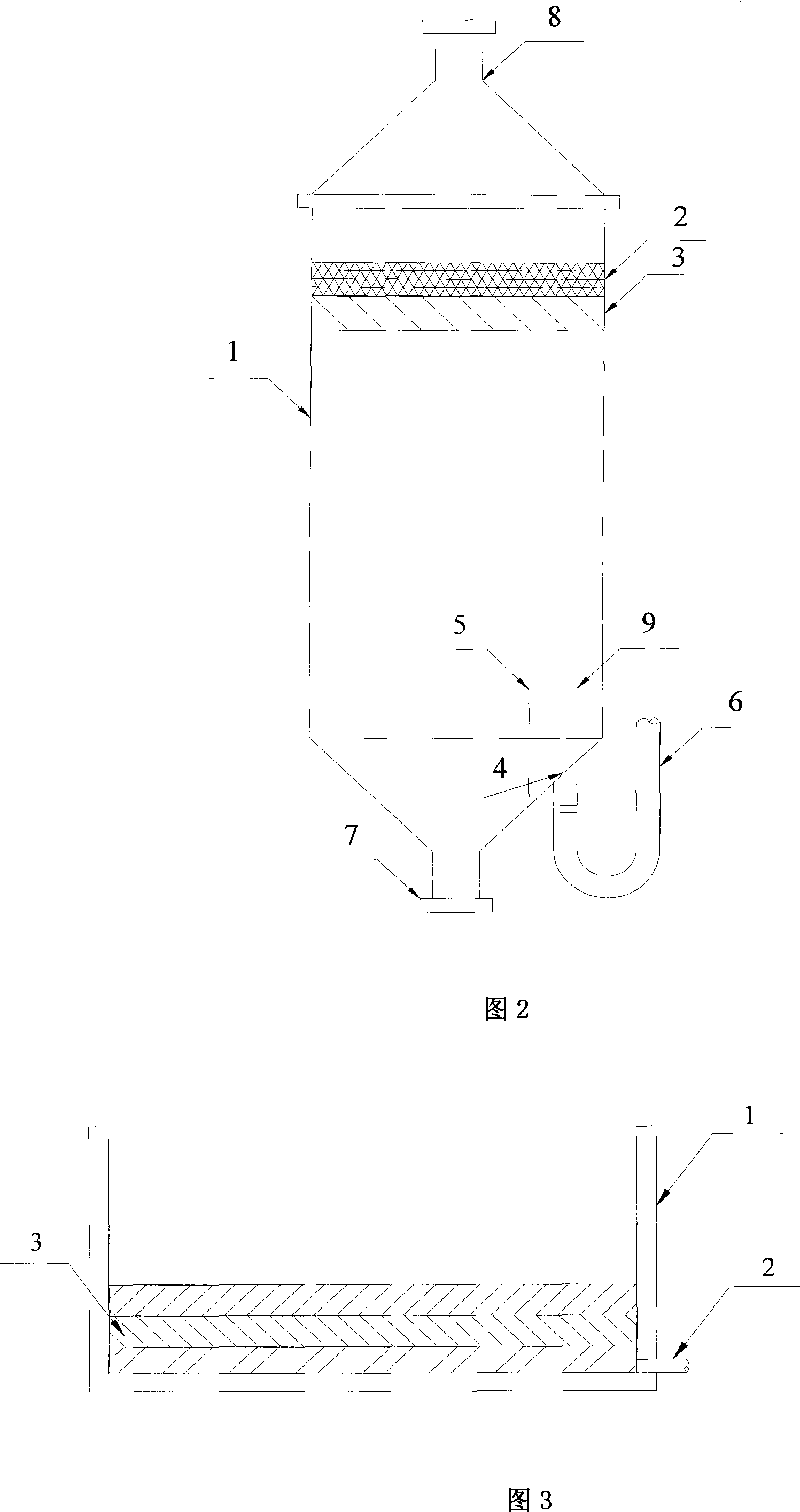

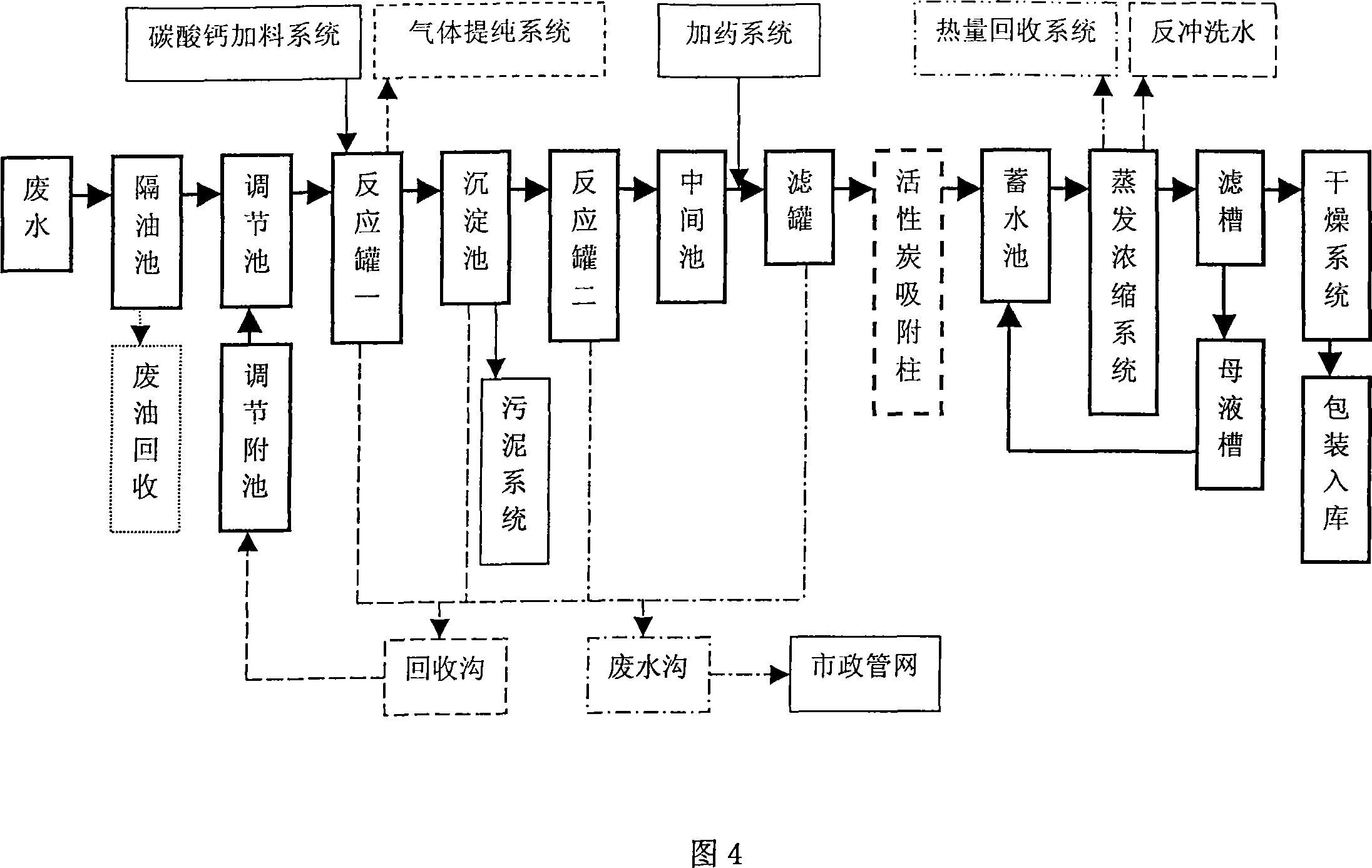

Epoxy ester wastewater recycling treatment method

ActiveCN101200423AAdapt to needsSufficient hydraulic retention timeFatty/oily/floating substances removal devicesCarbon compoundsEpoxyIndustrial effluent

The present invention discloses a method for recycling and processing epoxy-ester sewage, relating to a technical method that resources are reclaimed from industrial wastewater to produce chemical products. The technical proposal of the invention is: formic acid sewage generated during the process of epoxy-ester production is treated by oil separating, and then formic acid solution is achieved by reaction with calcium carbonate; and the formic acid solution is further neutralized with calcium carbonate for a plurality of times after sedimentation; coagulant and precipitator are added into the solution to further remove heavy metal and solid impurities, and then is filtered, decolored, evaporated and dried to achieve formic acid powder. The process is applicable to the production of fodder-grade, industrial-grade and other grades of formic acids; besides, the process is characterized in less investment and high yield; and in addition, byproducts such as waste gas and waste water can be reclaimed for reuse. As a result, the reduction of waste water is realized and economic efficiency is improved.

Owner:ZHEJIANG UNIV +1

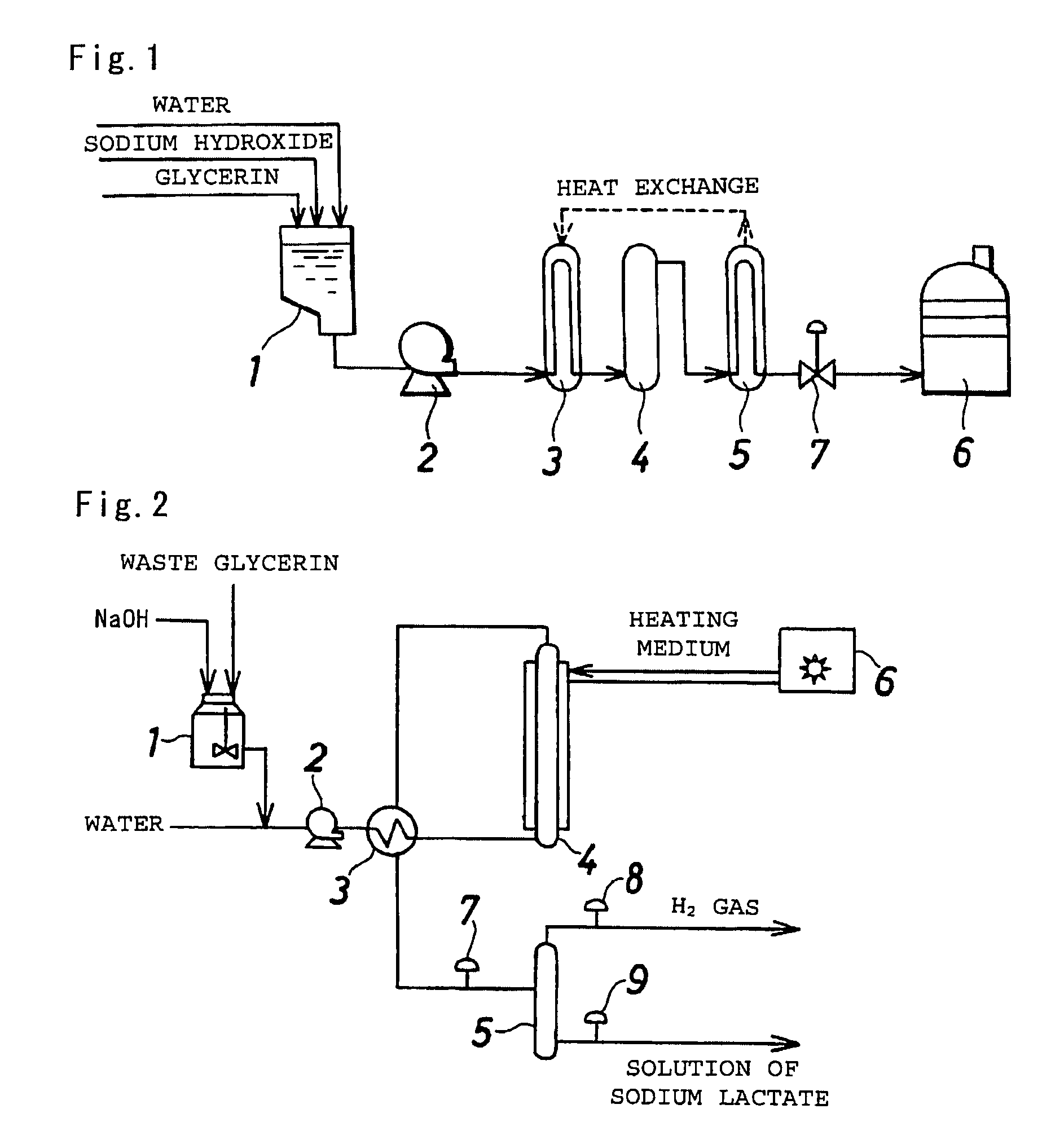

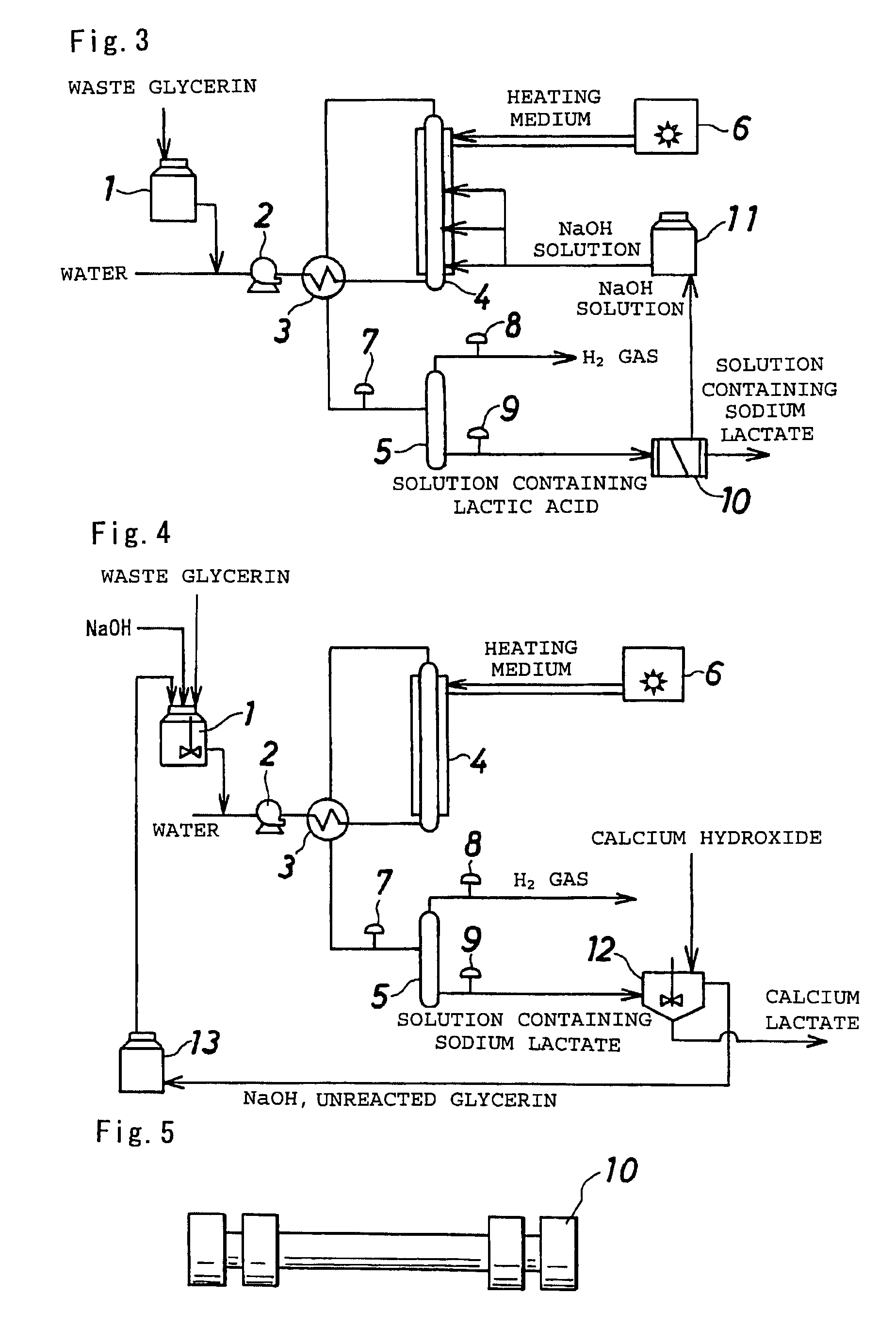

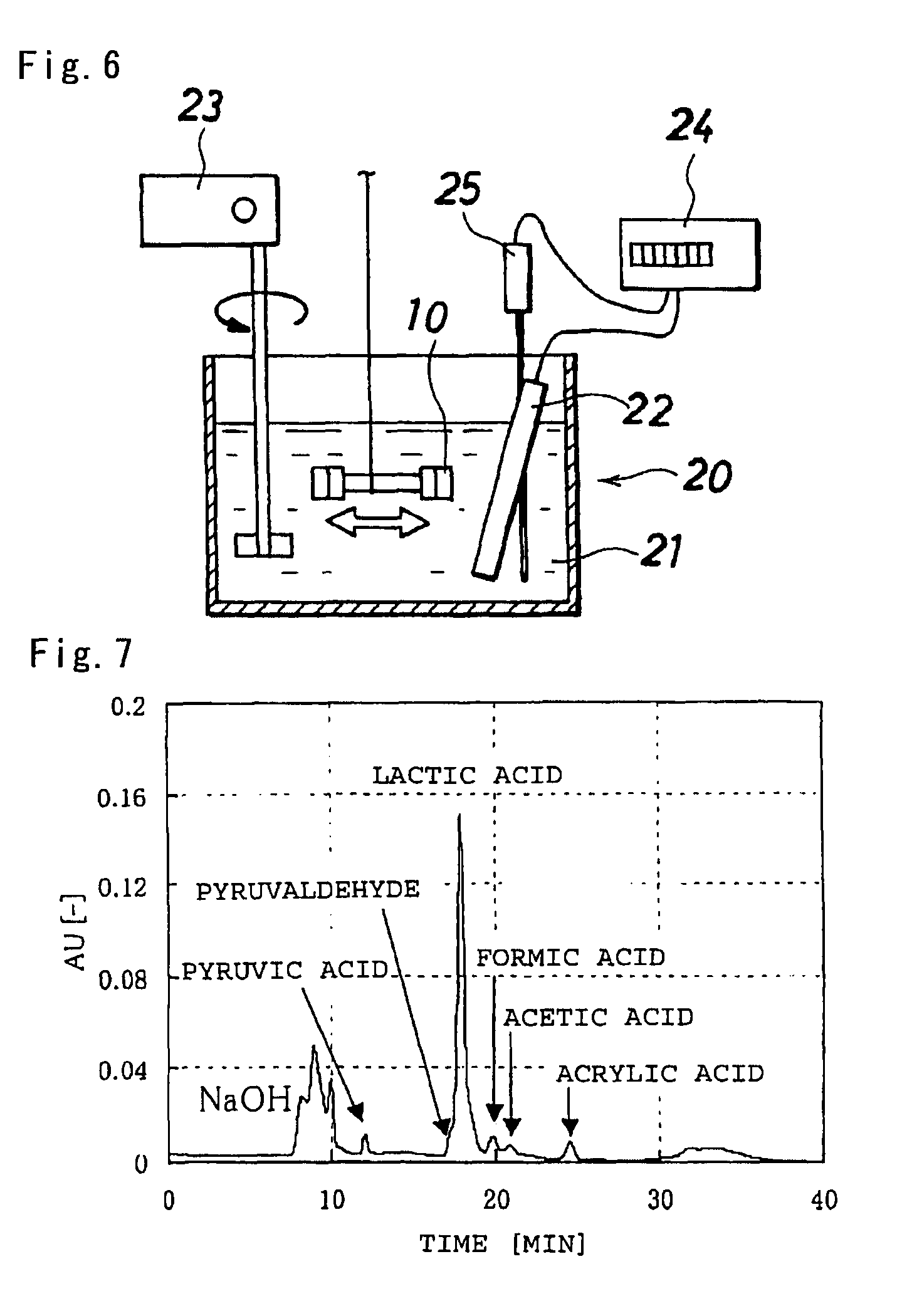

Process for production of lactic acid and equipment for the production

InactiveUS7829740B2Easy to useIncrease conversion ratePreparation from carboxylic acid saltsFatty acid esterificationChemical synthesisAlcohol

A process for producing lactic acid according to the invention is characterized in that glycerin is subjected to a hydrothermal reaction under an alkaline condition at a temperature in the range of 150 to 400° C. and under pressure equal to or more than the saturated vapor pressure at the temperature. The glycerin produced from plant fats, animal fats or the like or pure product synthesized chemically or a discharge containing glycerin generated at the production of diesel fuel oil from fats, in which the fats are subjected to a transesterification with alcohol in the presence of an alkali catalyst in order to obtain fatty acid ester is preferably used as a starting material.

Owner:ENOMOTO HEIJI +2

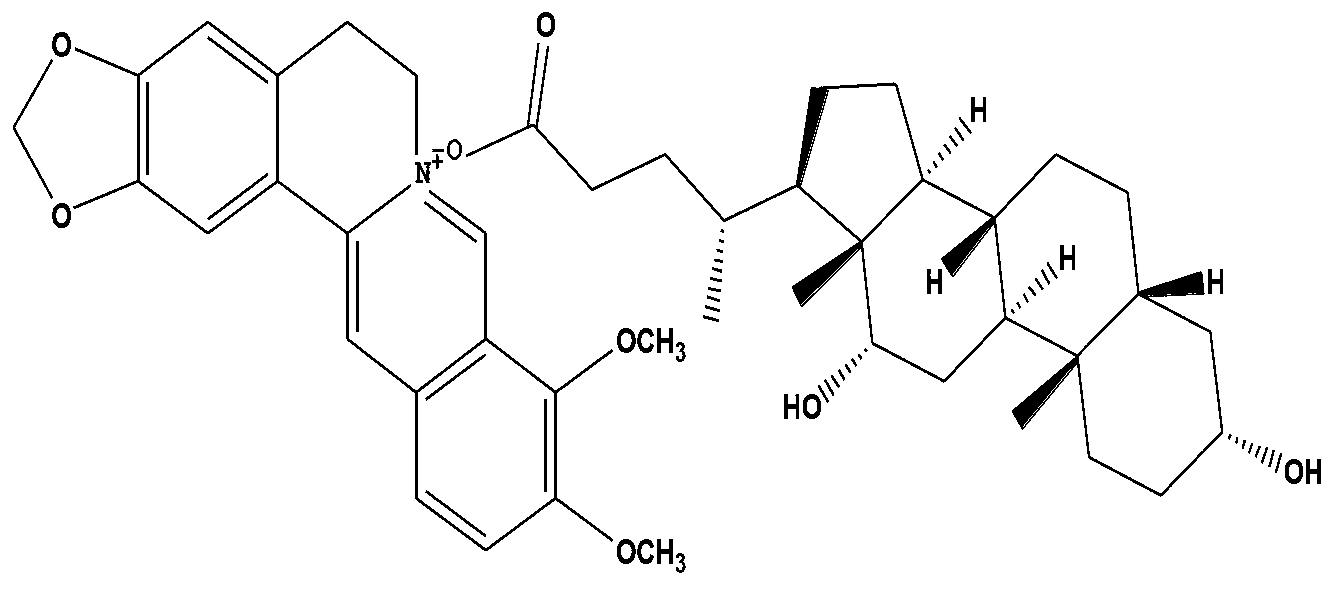

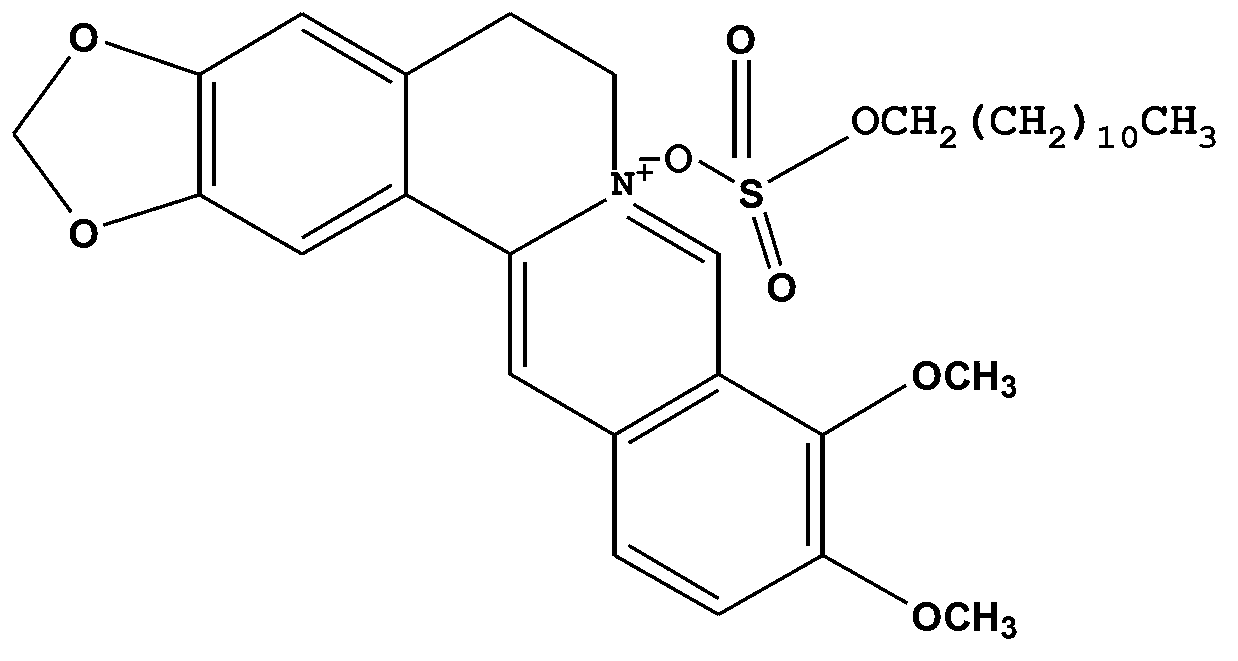

Berberine electrostatic composite and preparation method of berberine electrostatic composite

ActiveCN102702190AIncrease biofilm permeabilityImprove oral bioavailabilitySteroidsCarboxylic acid salt preparationChemical synthesisFatty acid

The invention discloses a berberine electrostatic composite and a preparation method of the berberine electrostatic composite, which are applied to medical and health industries. The berberine electrostatic composite is prepared from anionic surfactant and berberine or berberine salt by compositing; the molar ratio of the anionic surfactant to the berberine or berberine salt is 1 to 0.5-10; the molar ratio of anion to the berberine salt is 1 to 1; the anionic surfactant is one or more of alkyl sulfate or alkyl sulfonate or fatty acid salt; the alkyl sulfate is one or more of sodium cholesteryl sulfate, lauryl sodium sulfate and deoxysodium cholate; the alkyl sulfonate is one or more of sodium heptanesulfonate and sodium dodecyl sulfate; the fatty acid salt is one or more of sodium caprate and sodium enanthate, and the berberine and berberine salt are obtained by chemical synthesis or by extracting traditional Chinese medicine. The berberine is prepared into the berberine electrostatic composite to increase the biological membrane penetrating ability of the berberine and improve the oral bioavailability of the berberine, and the berberine electrostatic composite plays a significant treatment role on important chronic metabolic disorder diseases such as diabetes mellitus, complication of the diabetes mellitus, hyperlipidemia and the like.

Owner:NORTHEAST PHARMA GRP

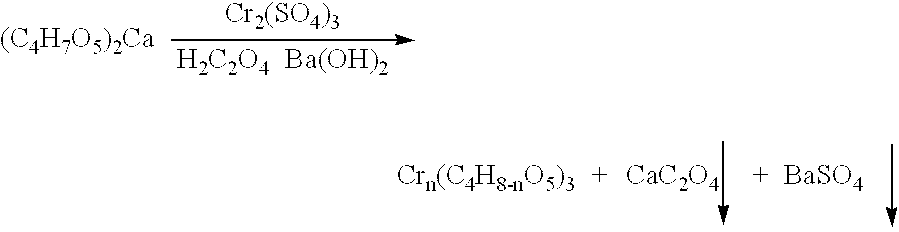

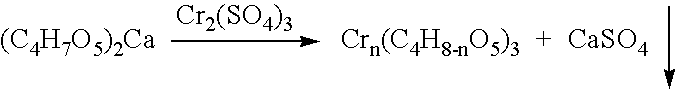

Chromium L-threonate, process for preparation of the same and their use

InactiveUS6548687B1Content of may changeHeavy metal active ingredientsBiocideDiabetic patientPharmacology

This invention involves a new kind of compound-the chromate L-threonate which molecular formula is Crn(C4H8-nO5)3 (n=1, 2 or 3). The chromate L-thronate can be applied to a high performance supplement of chromium(III) as well as effective hypoglycemic treatment for those diabetes patients and health care.

Owner:JUNENG INDUSTRY CO LTD

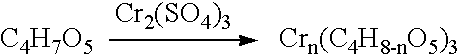

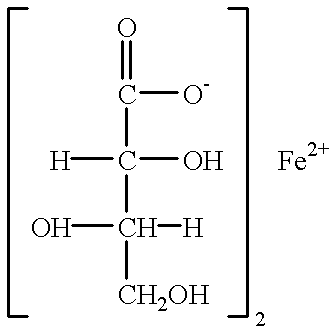

L-threonate ferrous, as well as pharmaceutical composition and use for improving and treating human anemia thereof

InactiveUS6313170B1High absorption rateImprove absorption rateHeavy metal active ingredientsBiocideBlood loss anemiaPhysiology

A compound of ferrous L-threonate with structure (I), its compostions and methods useful for iron supplementation for mammals, particularly for human body to improve and treat nutritional iron-deficiency anemia, blood loss anemia and hemolytic anemia.

Owner:JUNENG INDUSTRY CO LTD

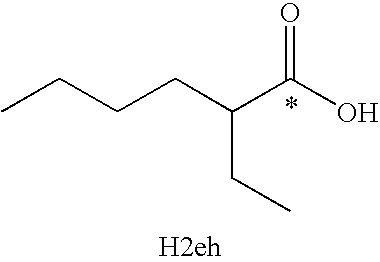

Ionic liquids

InactiveUS20070129568A1Sufficient solubilityReduce volatilityGroup 5/15 element organic compoundsTransportation and packagingPhosphoniumChemical reaction

Low melting point organic liquid compounds with high boiling points are prepared by a preferred process having the J+xQy(R—COO−)x-y where x is 1 to 8, preferably 1-3, y is 0 to x−1, where R—COO− is an anion selected from the group consisting of 2-ethyl hexanoate, pivalate, neodecanoate, and mixtures thereof, Q is another anion or mixture of other anions, and J+x is a cation selected from cations of Groups IA, IIA, IB, IIB, IIIB, IVB, VB, VIB, VIIB, VIII and lanthanide metals, cations selected from cations of B, Si, Ge, As, Sb, Te and Po metalloids, an ammonium cation derived from ammonia or an organic amine, an organic phosphonium cation, and mixtures thereof the organic liquid compounds being substantially free of volatile organic compounds. These compounds, as liquids, are useful as low volatile organic solvents, e.g., solvents in which a variety of chemical reactions may be carried out.

Owner:NGIMAT CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com