Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

411 results about "Hexose" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

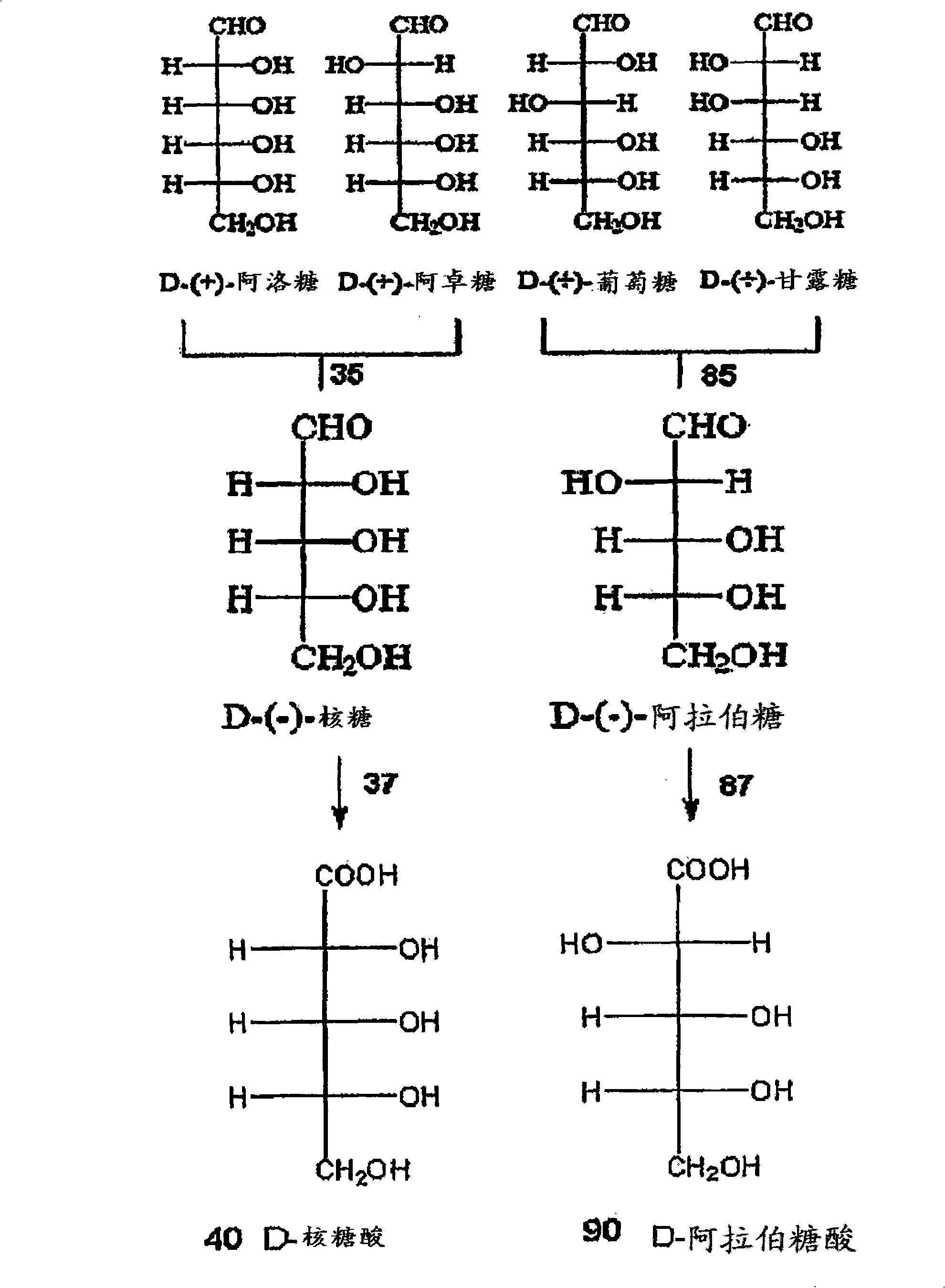

In bio-organic chemistry, a hexose is a monosaccharide with six carbon atoms, having the chemical formula C₆H₁₂O₆. Hexoses are classified by functional group, with aldohexoses having an aldehyde at position 1, and ketohexoses having a ketone at position 2.

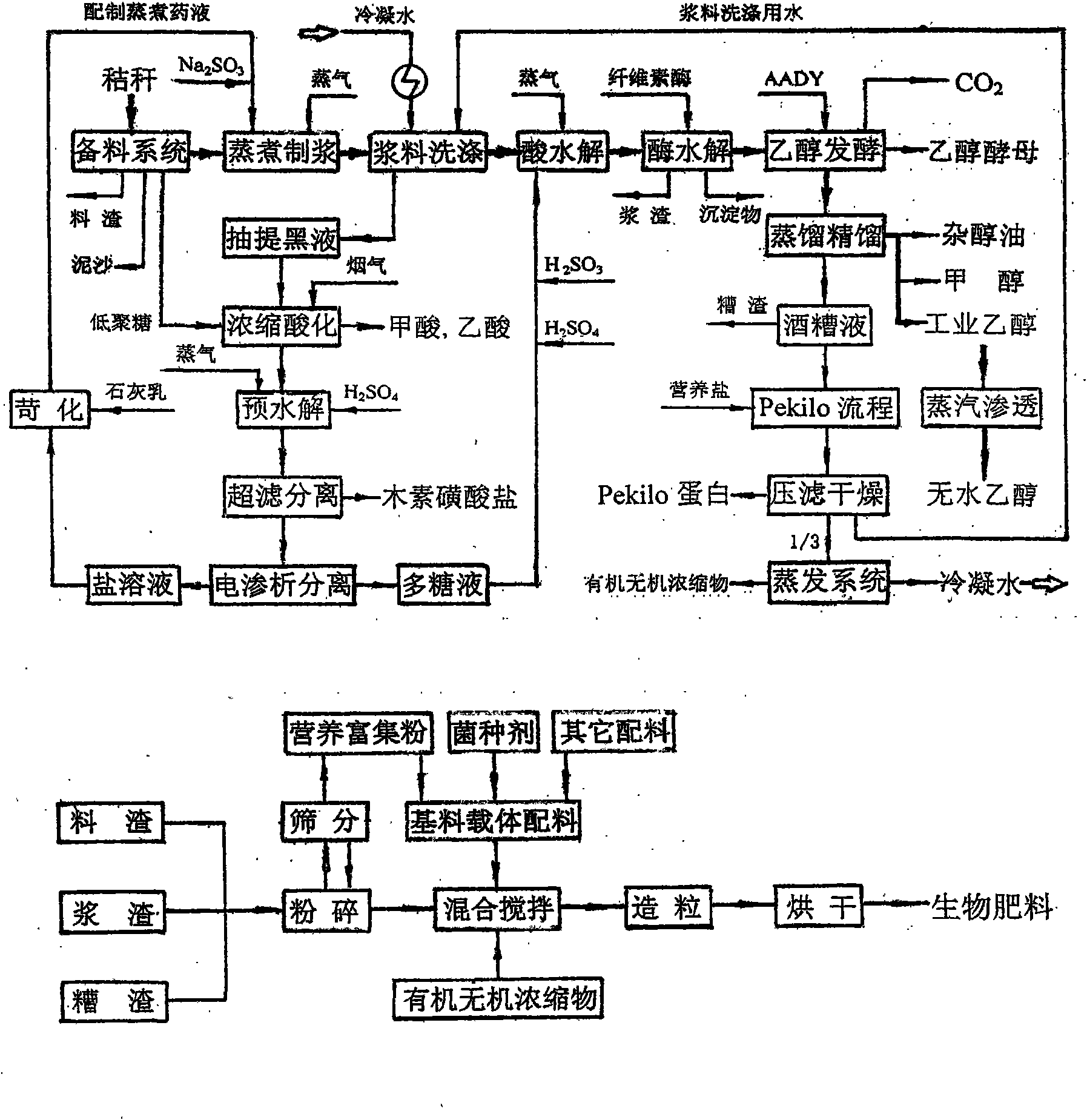

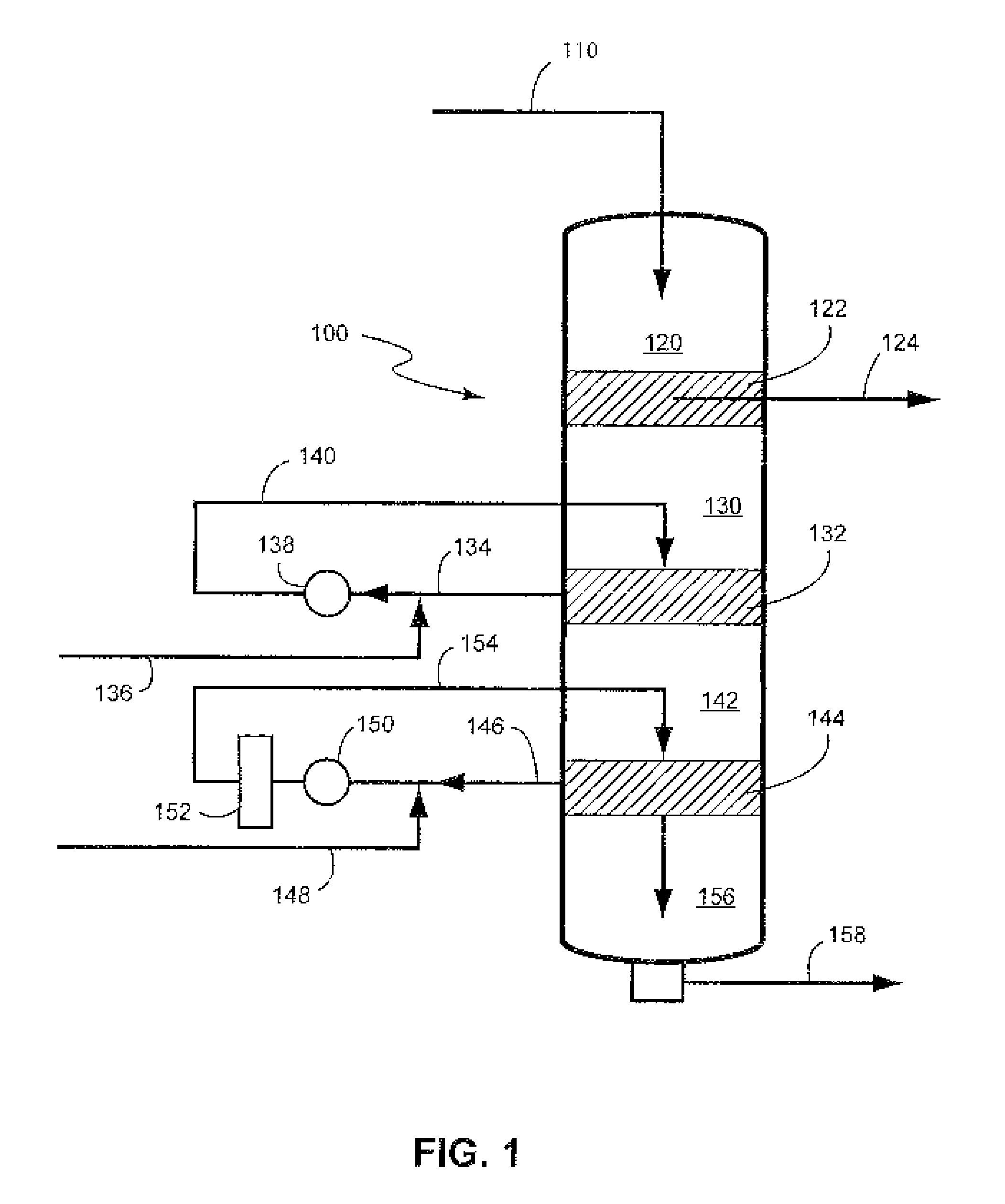

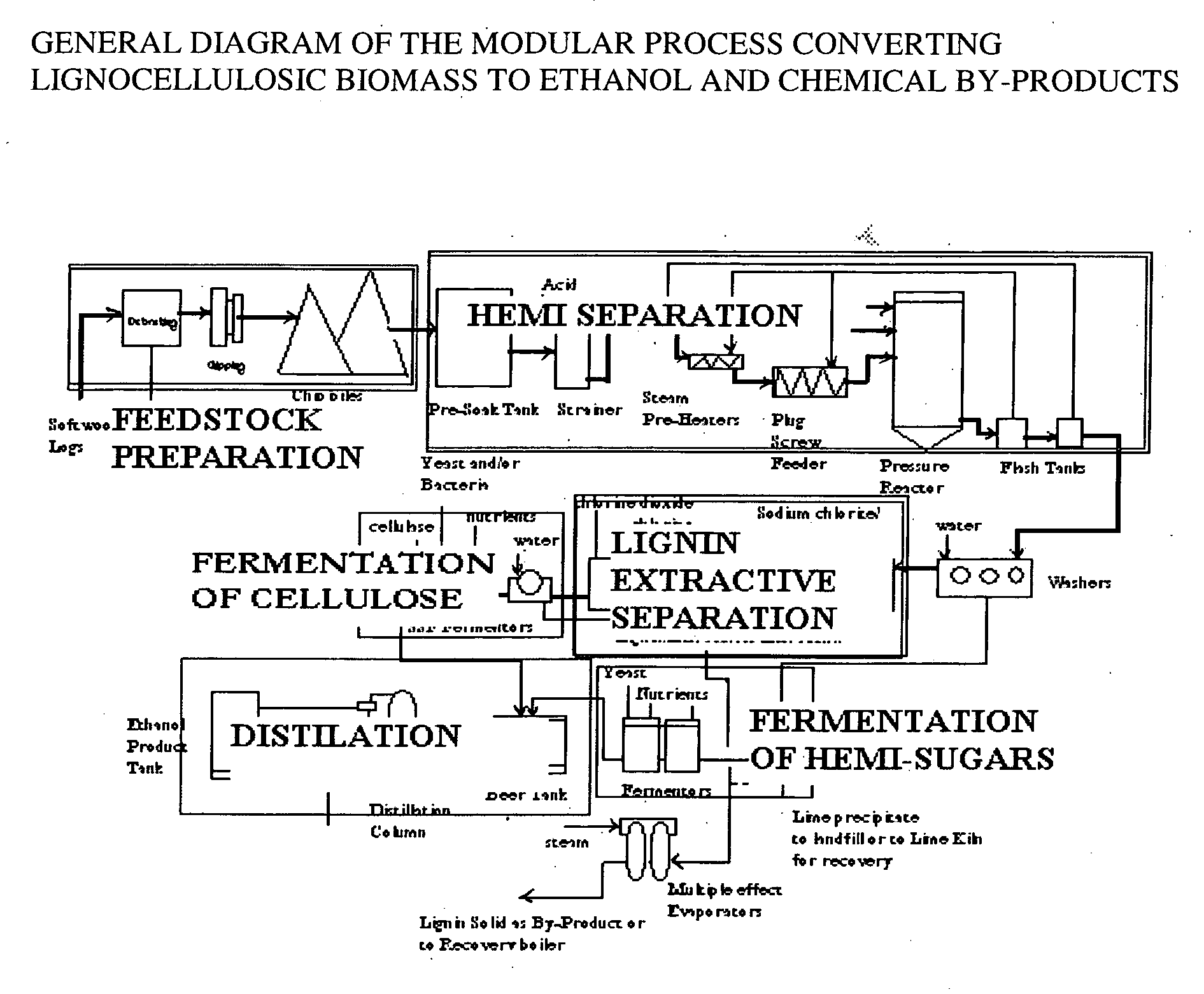

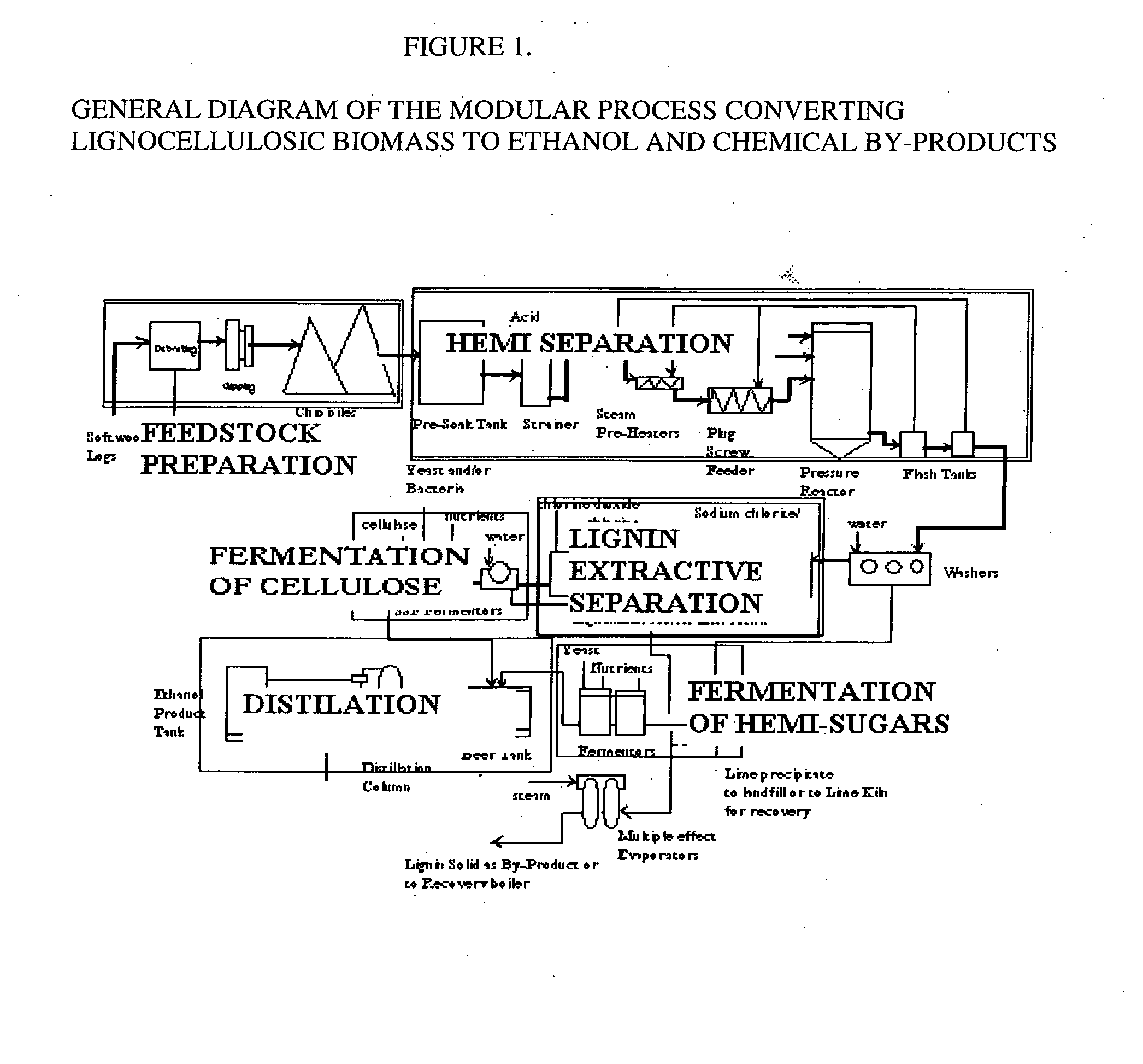

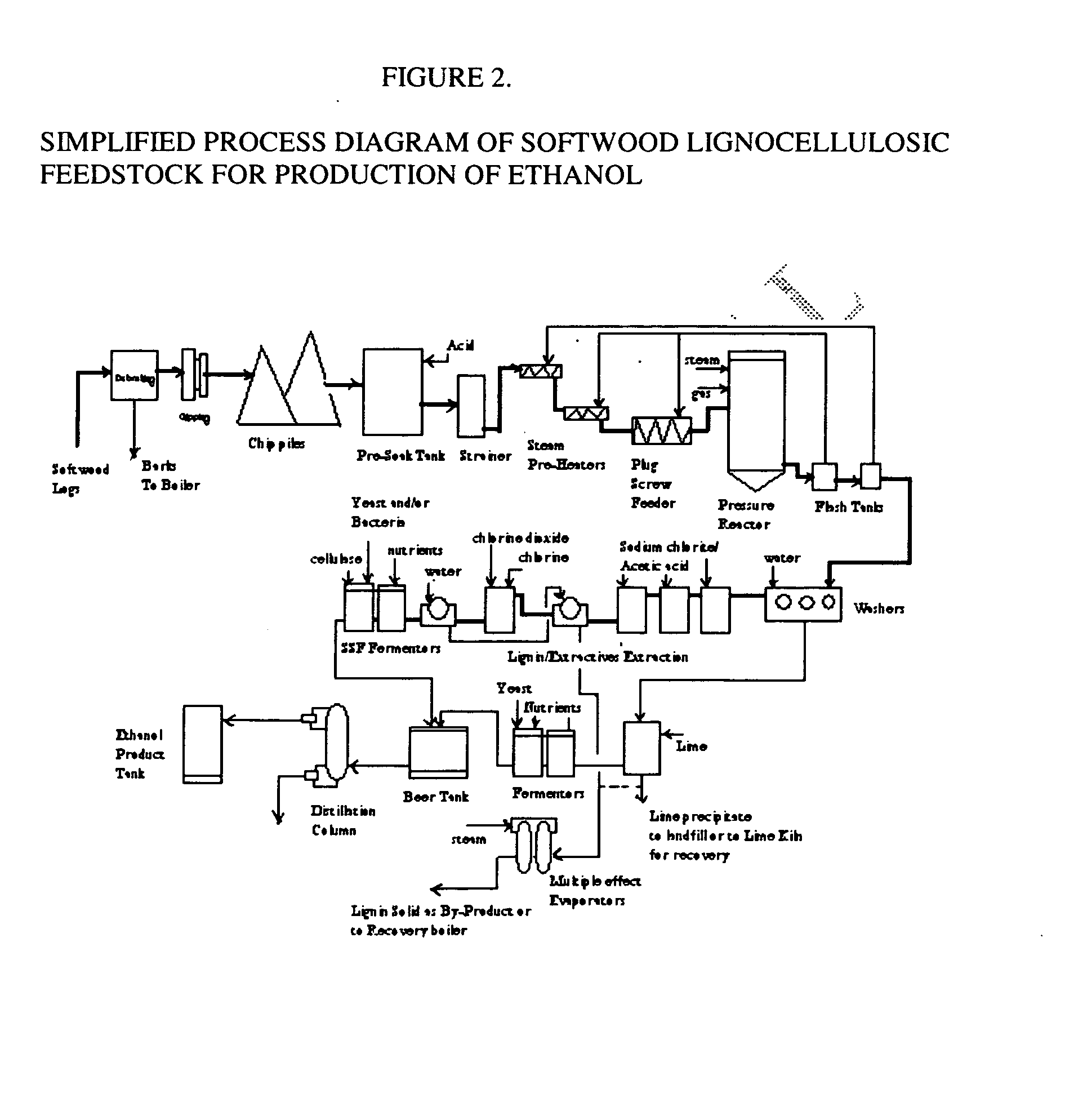

Integrated process for separation of lignocellulosic components to fermentable sugars for production of ethanol and chemicals

InactiveUS20080057555A1Robust and cost-effectiveImprove responseChemical industryBiofuelsChemical treatmentButanediol

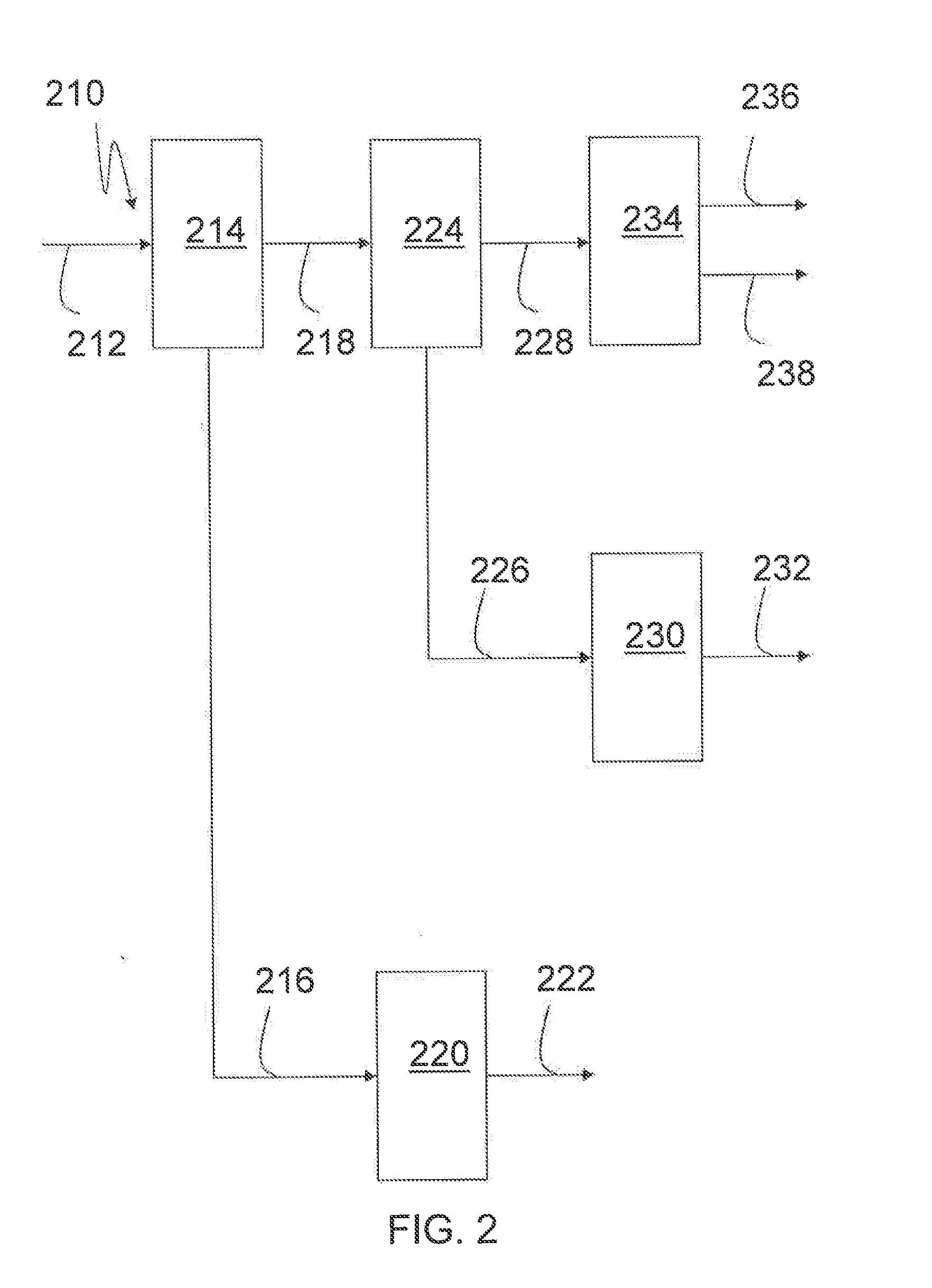

A continuous and modular process converts lignocellulosic materials for the production of ethanol principally and / or chemicals such as methanol, butanediol, propanediol, hydrocarbon fuel, etc. Renewable lignocellulosic biomass such as but not all inclusive hardwoods (gum, beech, oak, sweet gum, poplar, eucalyptus, etc.), soft woods (pines, firs, spruce, etc.), corn stovers, straws, grasses, recycled papers, waste products from pulp and paper mills, etc can be used as feedstock. The process is designed to be modular and the feed entry point can be selected to adapt to different biomass feedstock. Lignocellulosic biomass such as hardwood and softwood are subjected to chemical / pressure treatment stages using potent and selective chemicals such as sodium chlorite / acetic acid (anhydrous) and chlorine / chlorine dioxide to separate the main components—lignin, cellulose (glucose) and hemicelluloses (xylose, arabinose, galactose)—into three process streams. The separated carbohydrates are further subjected to washing, cleaning, neutralization, and / or mild hydrolysis and subsequently fermented to produce ethanol. Residual lignin and extractives remained with the cellulose are removed by chemical treatment steps to enhance the fermentations of cellulose. Pre-hydrolysate after neutralization to neutralize and remove toxic components such as acetic acid, furfural, phenolics, etc. containing (xylose, arabinose, galactose) and hexoses (glucose) can be either separately or together with the purified cellulosic fraction fermented to produce ethanol. Approximately 100 gallons of ethanol, suitable to be used as a fuel, can be produced from one dried ton of wood. Significant amount of lignin are separated as a by-product and can be converted to hydrocarbon fuel, surfactant, drilling aid, or can be incinerated for generation of power and steam.

Owner:NGUYEN XUAN NGHINH

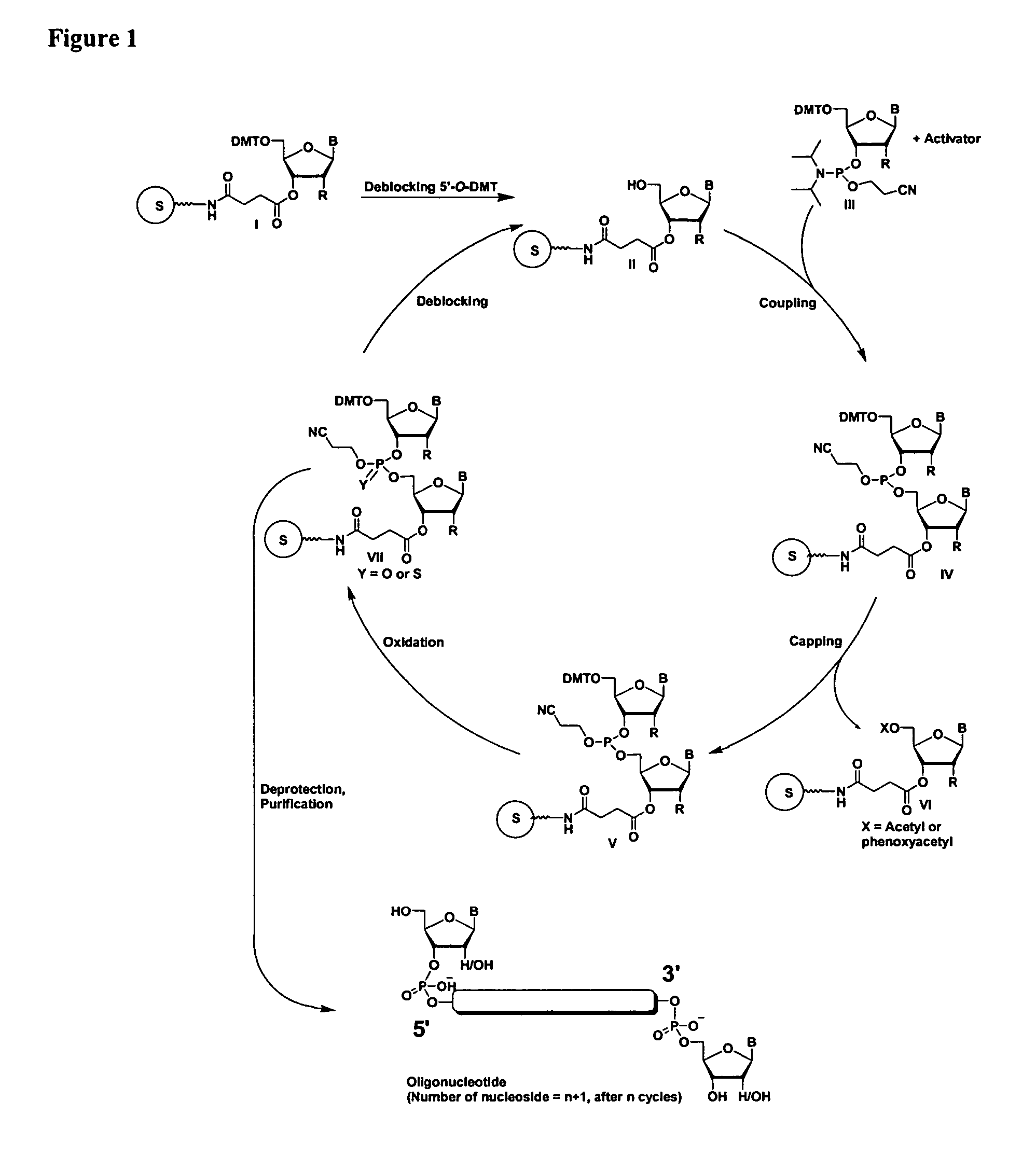

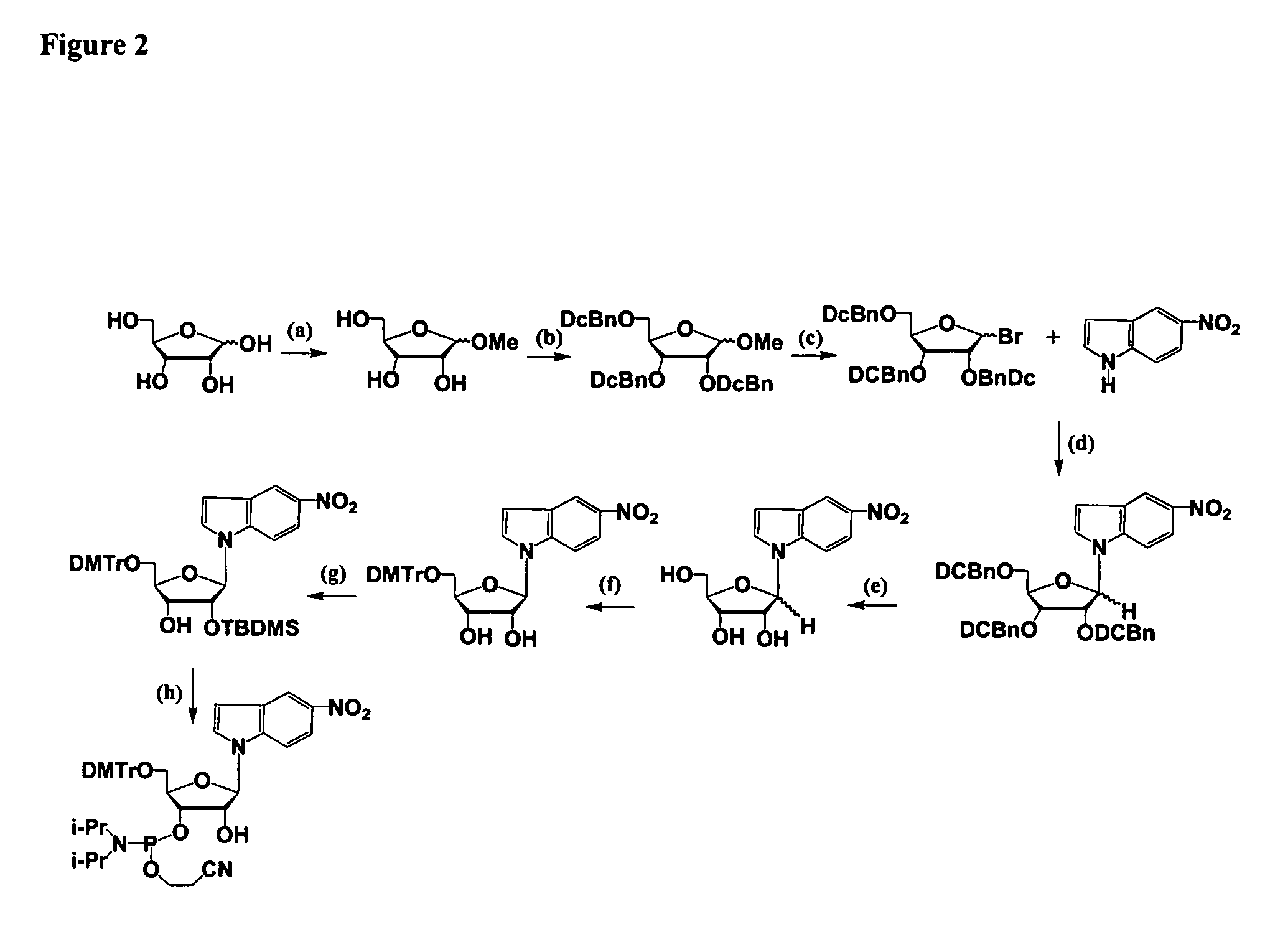

Oligonucleotides comprising a modified or non-natural nucleobase

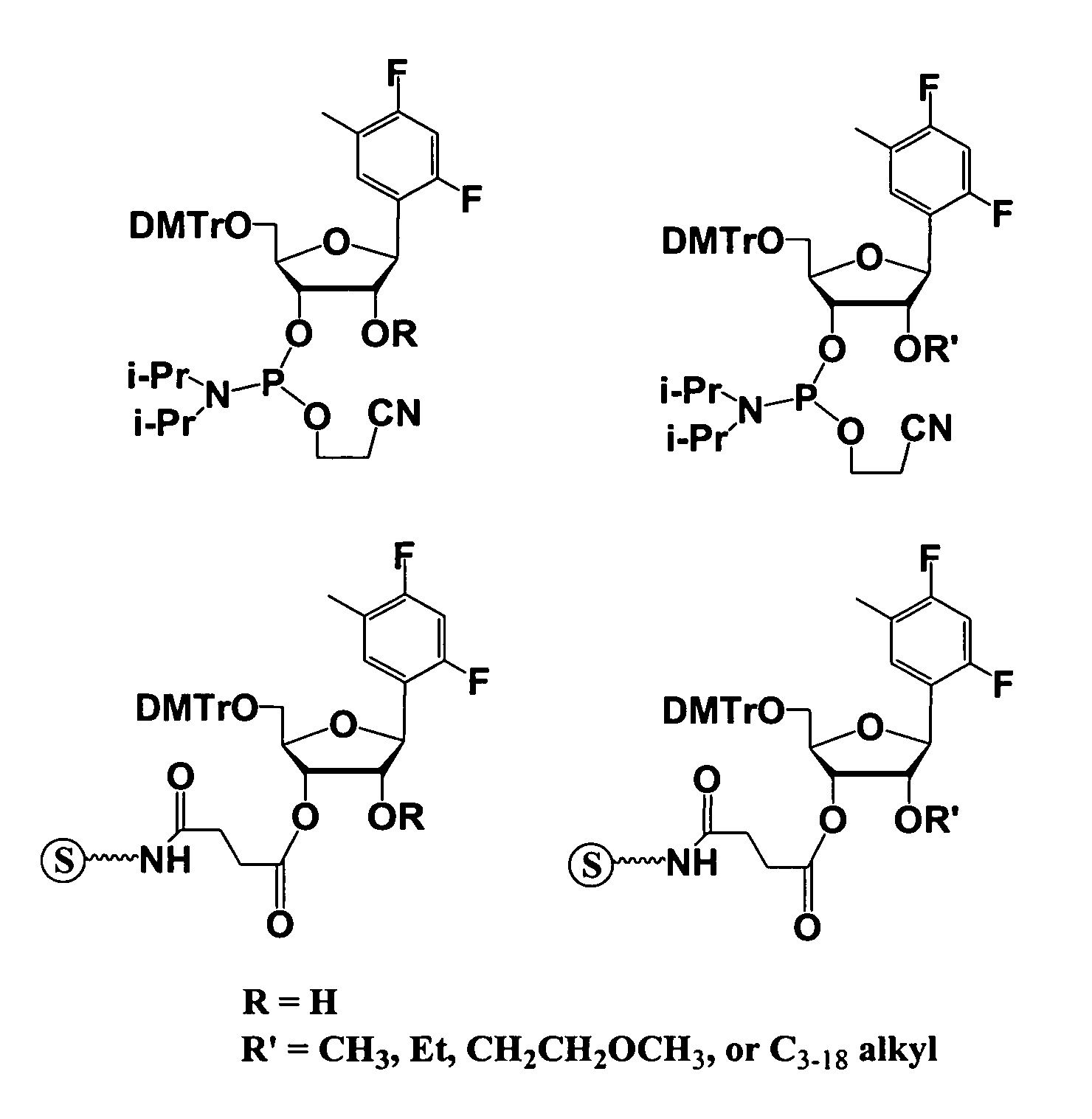

One aspect of the present invention relates to a double-stranded oligonucleotide comprising at least one non-natural nucleobase. In certain embodiments, the non-natural nucleobase is difluorotolyl, nitroindolyl, nitropyrrolyl, or nitroimidazolyl. In a preferred embodiment, the non-natural nucleobase is difluorotolyl. In certain embodiments, only one of the two oligonucleotide strands comprising the double-stranded oligonucleotide contains a non-natural nucleobase. In certain embodiments, both of the oligonucleotide strands comprising the double-stranded oligonucleotide independently contain a non-natural nucleobase. In certain embodiments, the oligonucleotide strands comprise at least one modified sugar moiety. Another aspect of the present invention relates to a single-stranded oligonucleotide comprising at least one non-natural nucleobase. In a preferred embodiment, the non-natural nucleobase is difluorotolyl. In certain embodiments, the ribose sugar moiety that occurs naturally in nucleosides is replaced with a hexose sugar, polycyclic heteroalkyl ring, or cyclohexenyl group. In certain embodiments, at least one phosphate linkage in the oligonucleotide has been replaced with a phosphorothioate linkage.

Owner:ALNYLAM PHARM INC

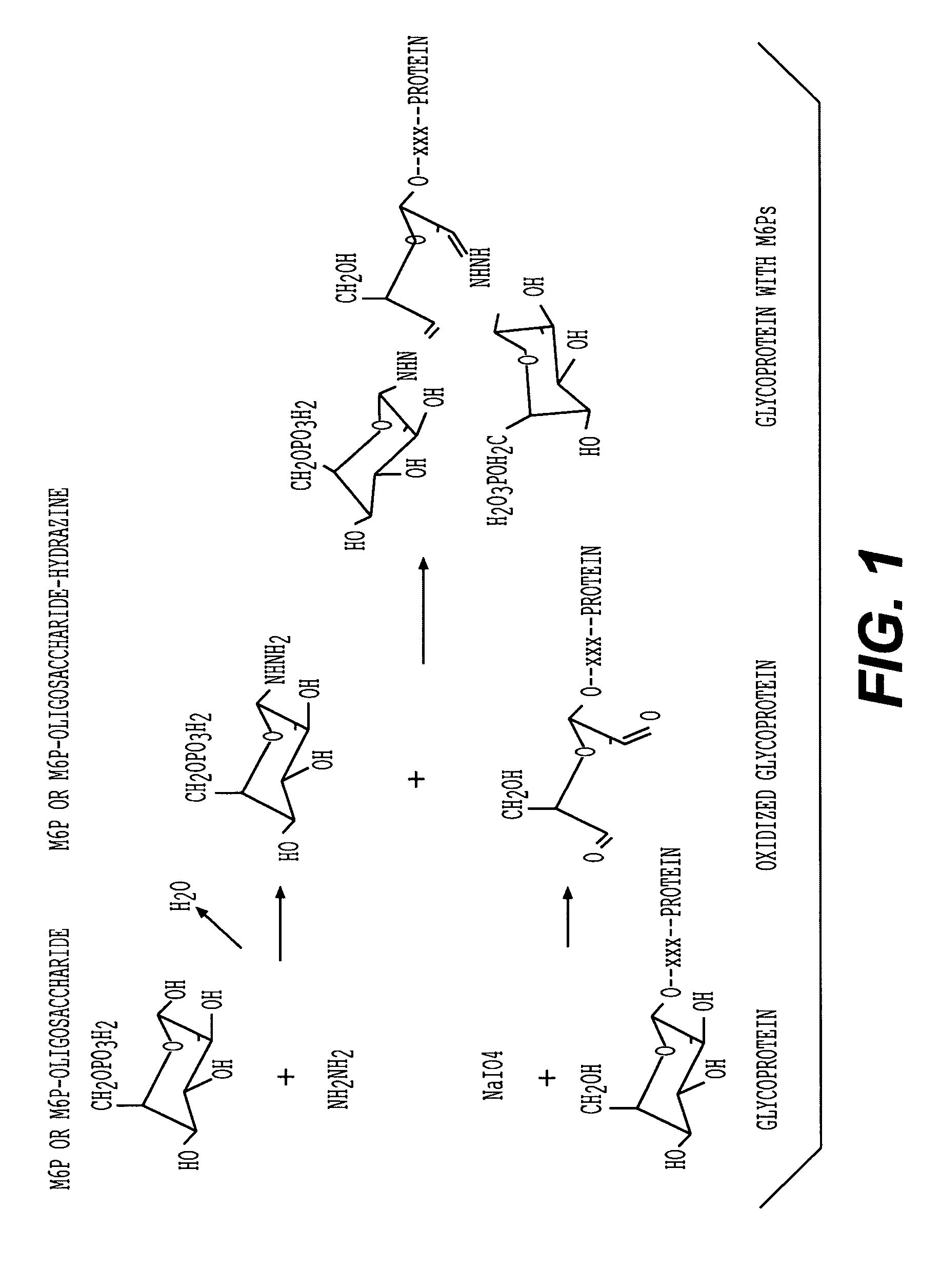

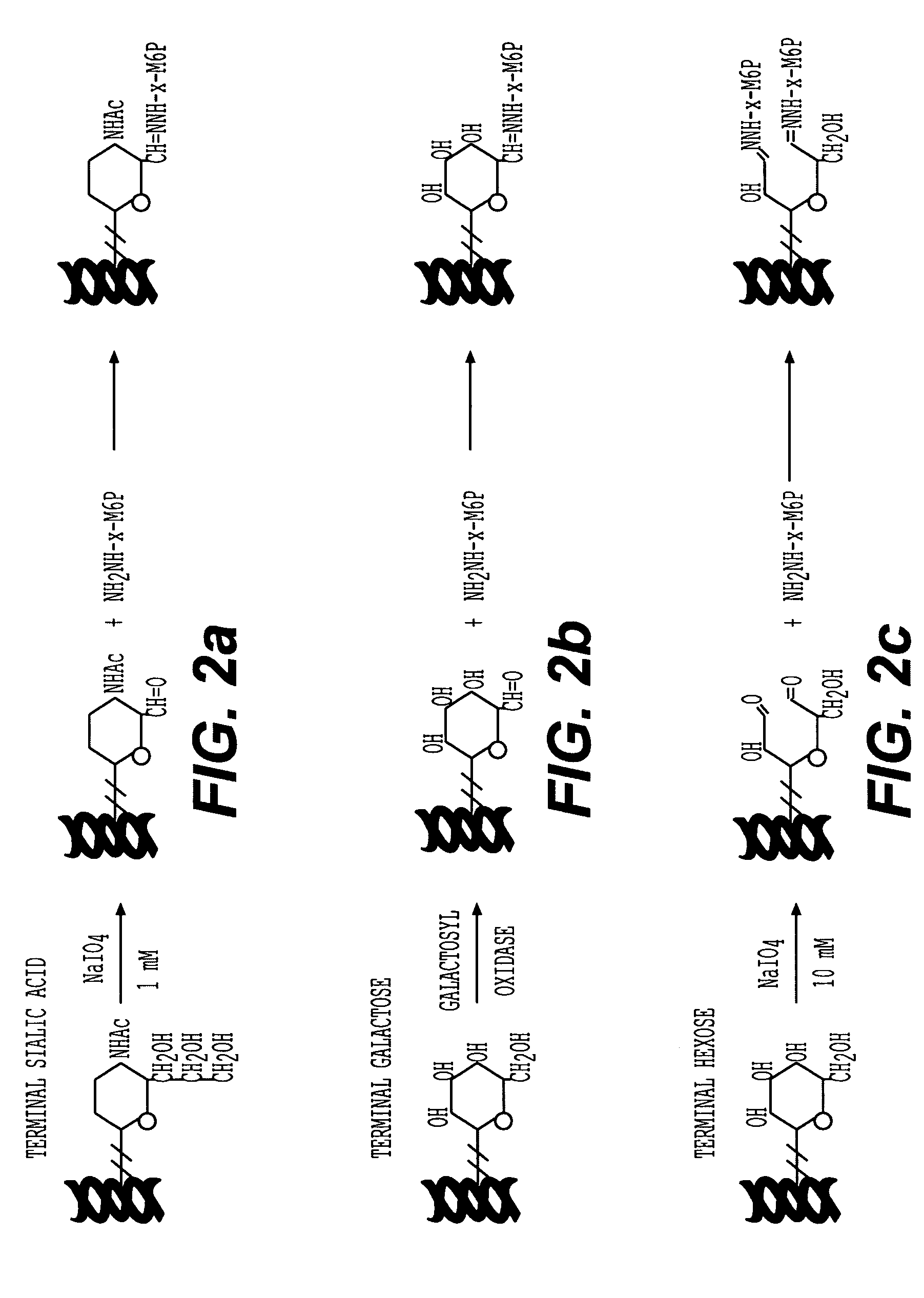

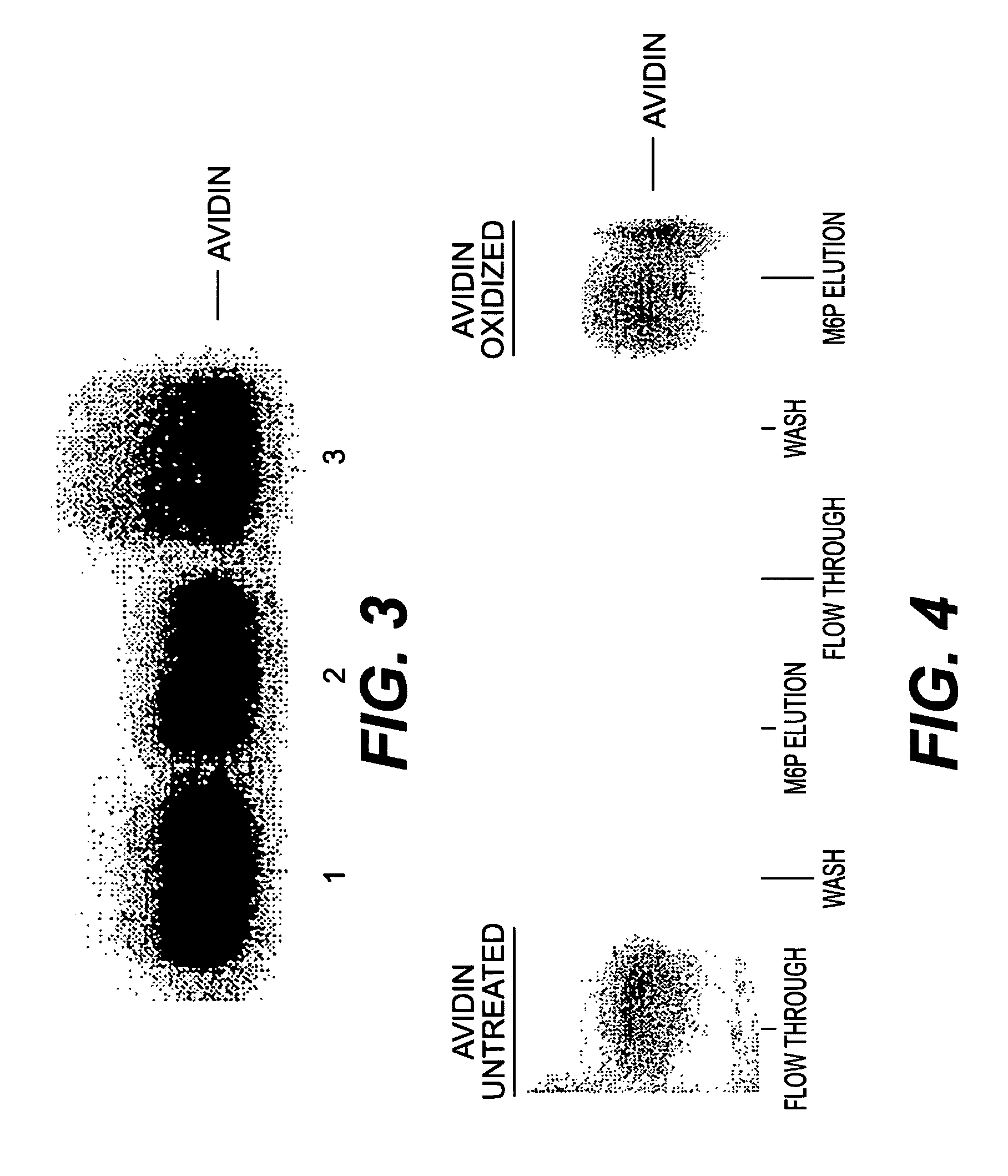

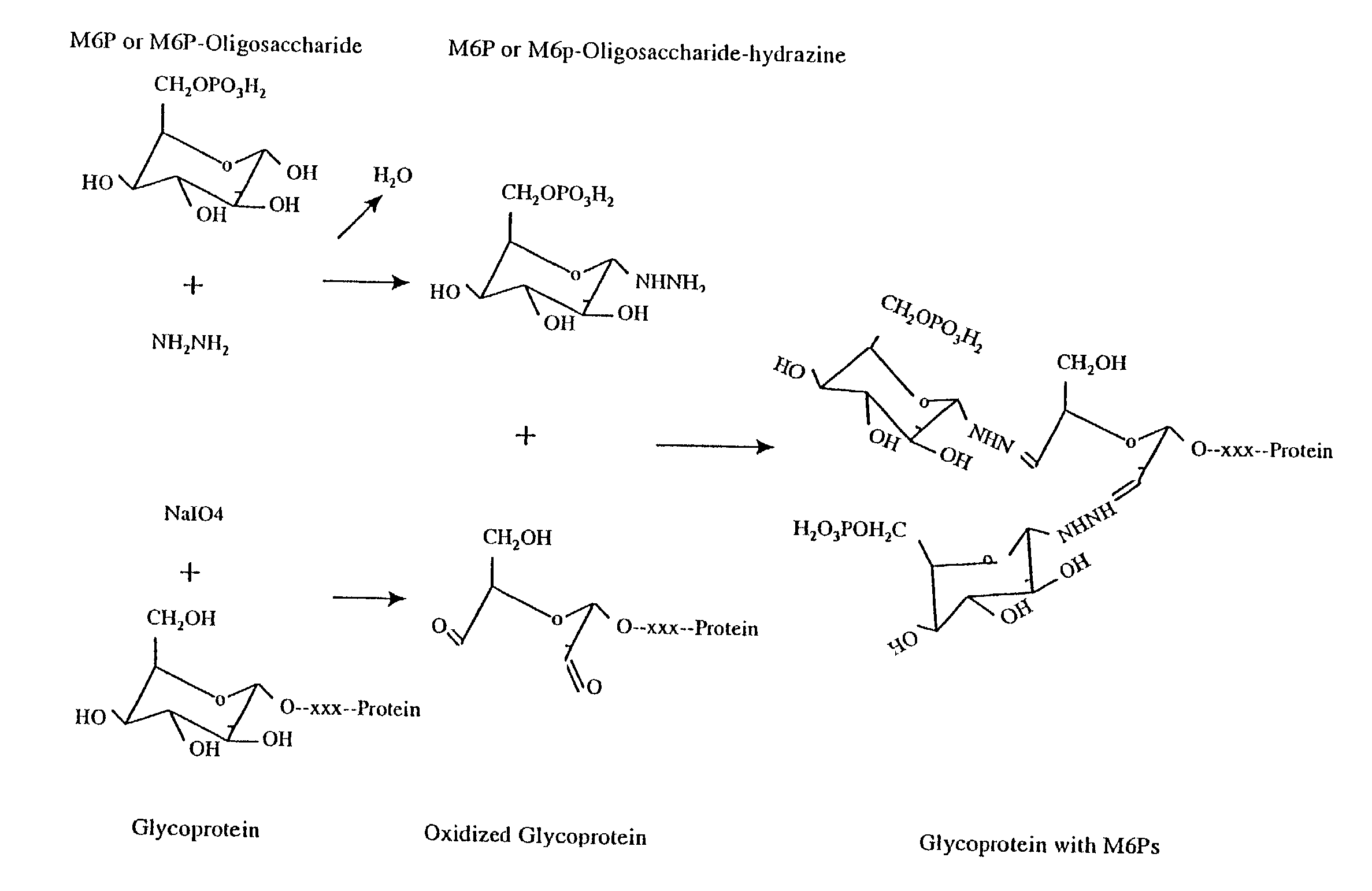

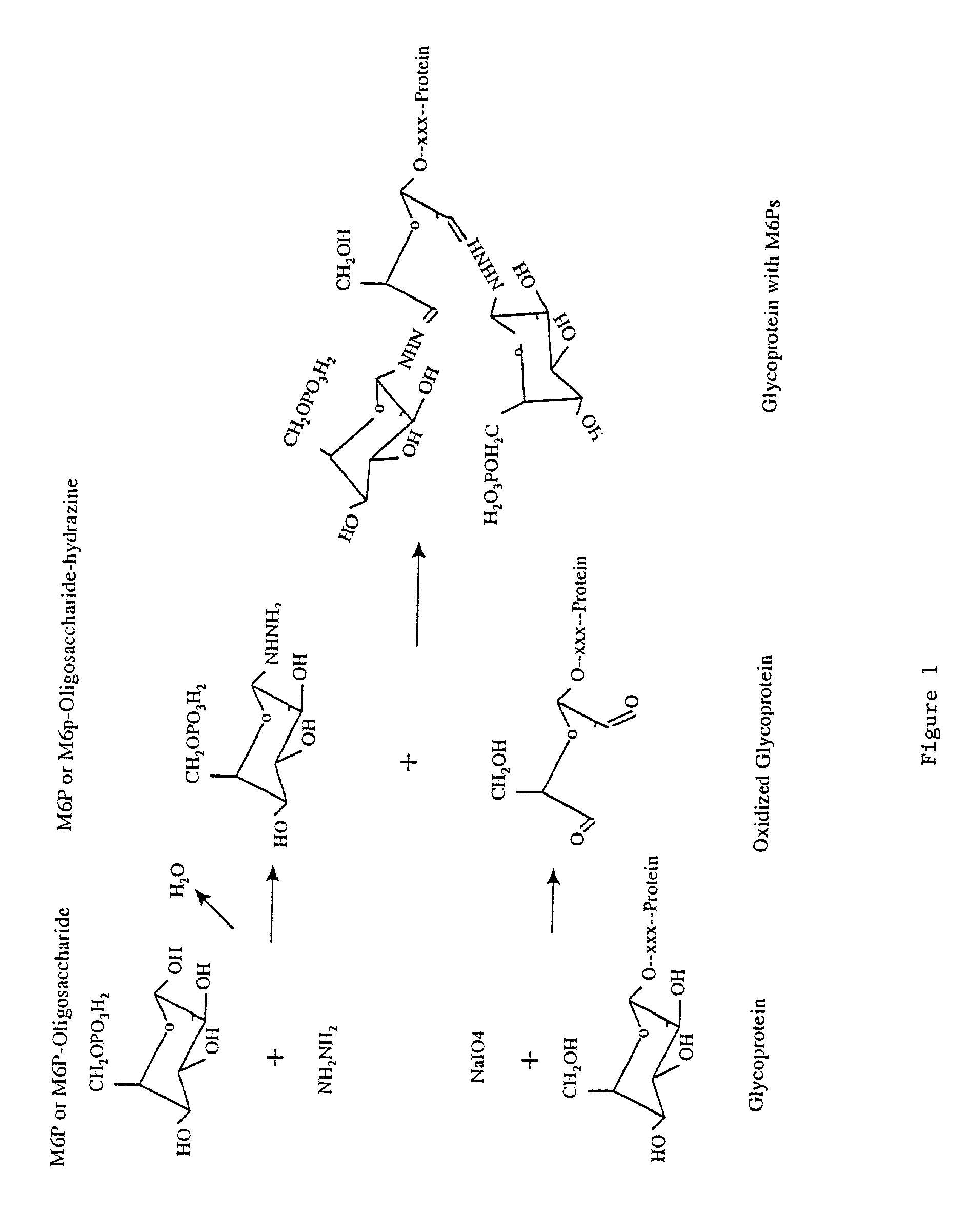

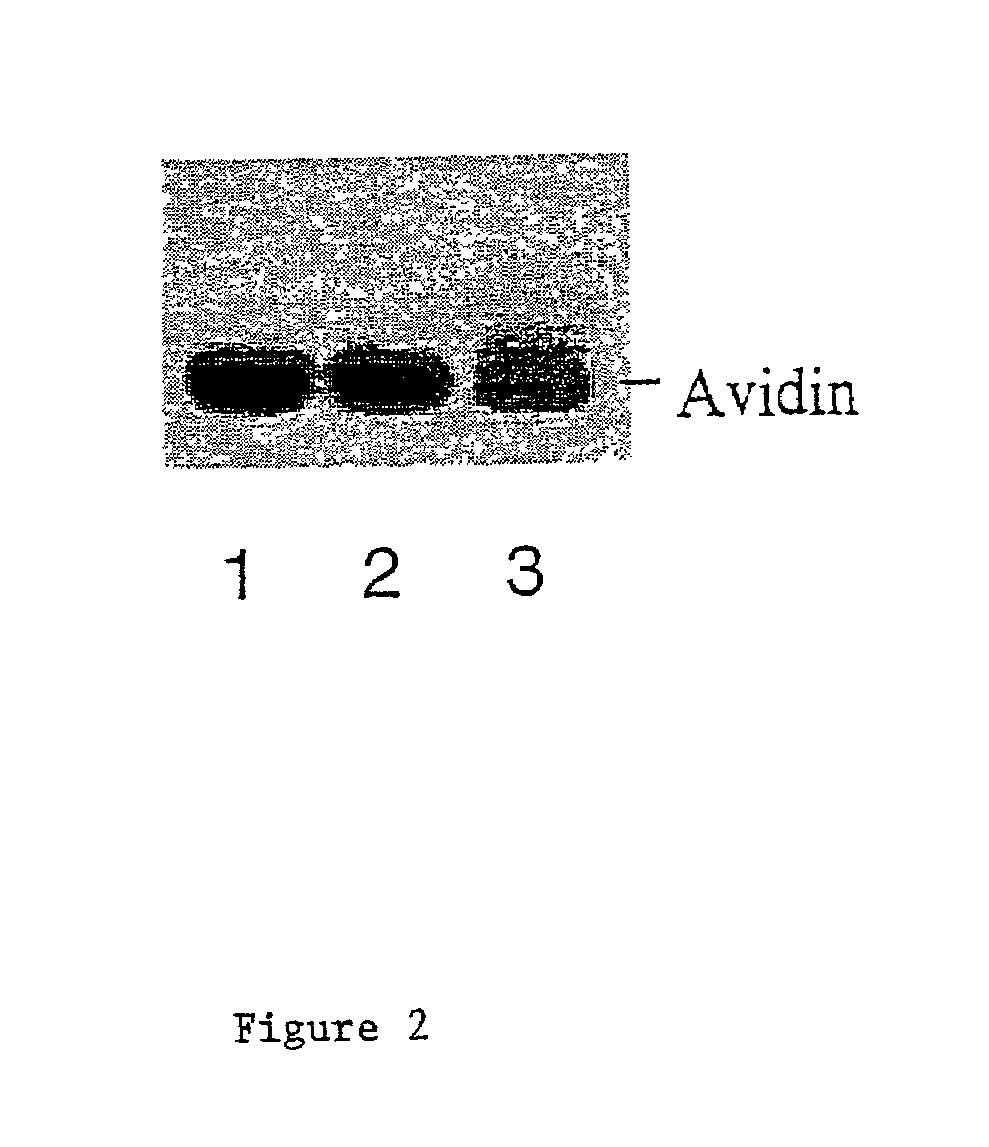

Methods for introducing mannose 6-phosphate and other oligosaccharides onto glycoproteins

InactiveUS7001994B2Well formedIncrease the cellular uptake of lysosomal enzymesHydrolasesPeptide/protein ingredientsPhosphorylationPhosphoric acid

Methods to introduce highly phosphorylated mannopyranosyl oligosaccharide derivatives containing mannose 6-phosphate (M6P), or other oligosaccharides bearing other terminal hexoses, to carbonyl groups on oxidized glycans of glycoproteins while retaining their biological activity are described. The methods are useful for modifying glycoproteins, including those produced by recombinant protein expression systems, to increase uptake by cell surface receptor-mediated mechanisms, thus improving their therapeutic efficacy in a variety of applications.

Owner:GENZYME CORP

Production of chemicals from lignocellulose, biomass or sugars

InactiveUS20050250192A1High yieldLow costBacteriaUnicellular algaeBiological bodyCompound (substance)

The subject invention relates to newly isolated organisms from nature that produce L(+)-lactic acid high yield from hexose and pentose sugars found in biomass. Organisms and processes or methods for the production of lactic acid and other industrially important chemicals from cellulose and hemicellulose are also provided.

Owner:UNIV OF FLORIDA

Production of chemicals from lignocellulose, biomass or sugars

Owner:UNIV OF FLORIDA RES FOUNDATION INC

Cryopreservation of human red blood cells

InactiveUS20060127375A1Lower Level RequirementsAvoid hemolysisBiocideDead animal preservationFreeze thawingPhosphorylation

A red blood cell storage composition includes a composition of red blood cells and biochemistry altering reagents, the biochemistry altering reagents being present at a concentration so as to reduce the percent hemolysis of the red blood cells during the freeze-thaw cycle below that of the percent hemolysis of the red blood cells in the absence the biochemistry altering reagents. The red blood cell storage composition preferably includes reagents selected from: modifiers of glycolytic / metabolic components, modifiers of antioxidant potential, effectors of intracellular ionic distribution, modifiers of membrane fluidity, modifiers of cytoskeletal structure, effectors of the cyclooxygenase second messenger pathway, effectors of the lipoxygenase second messenger pathway, effectors of the hexose monophosphate second messenger pathway, effectors of the phosphorylation second messenger pathway, modifiers of specific messenger molecules, and combinations thereof.

Owner:LIFECELL

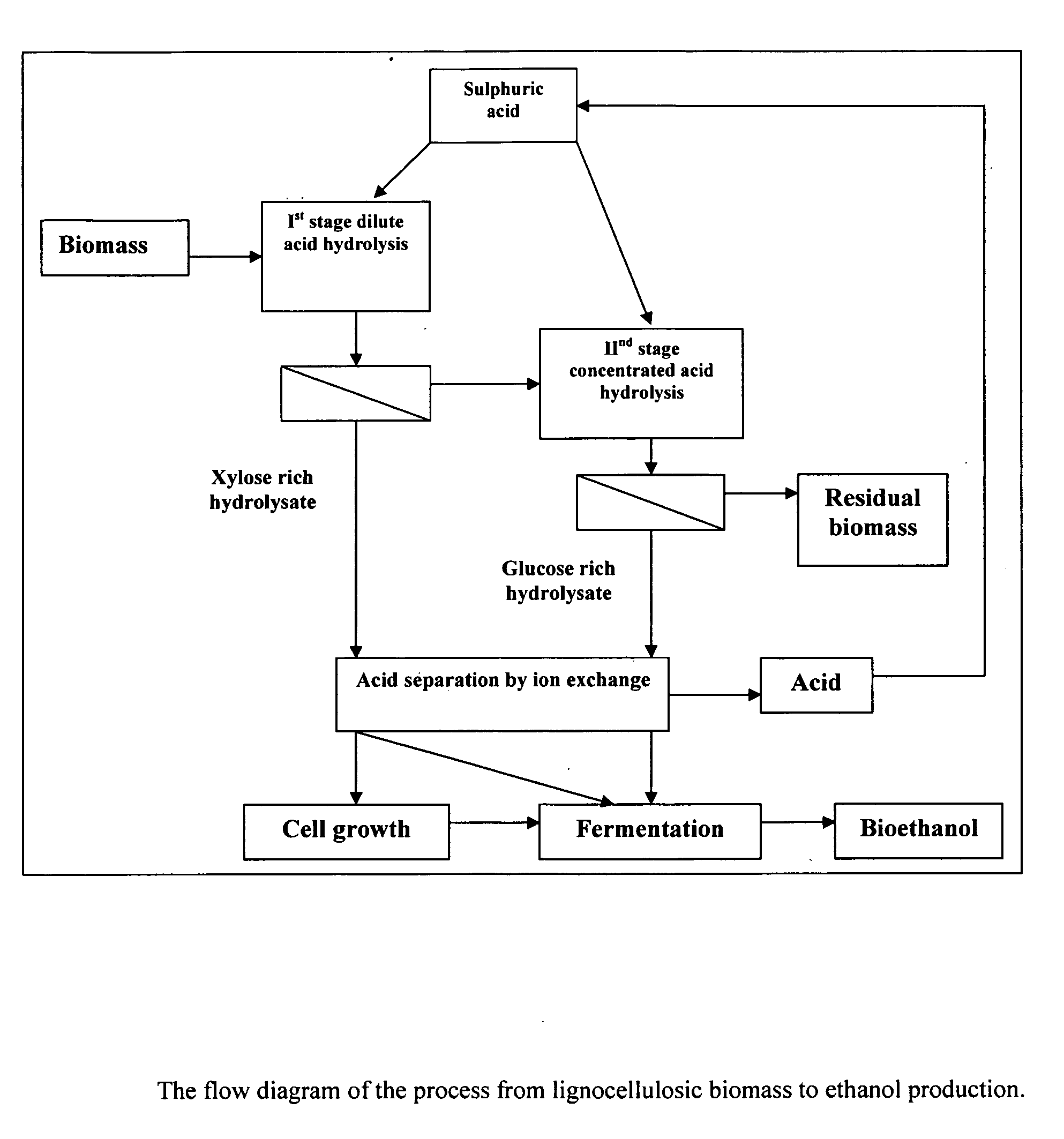

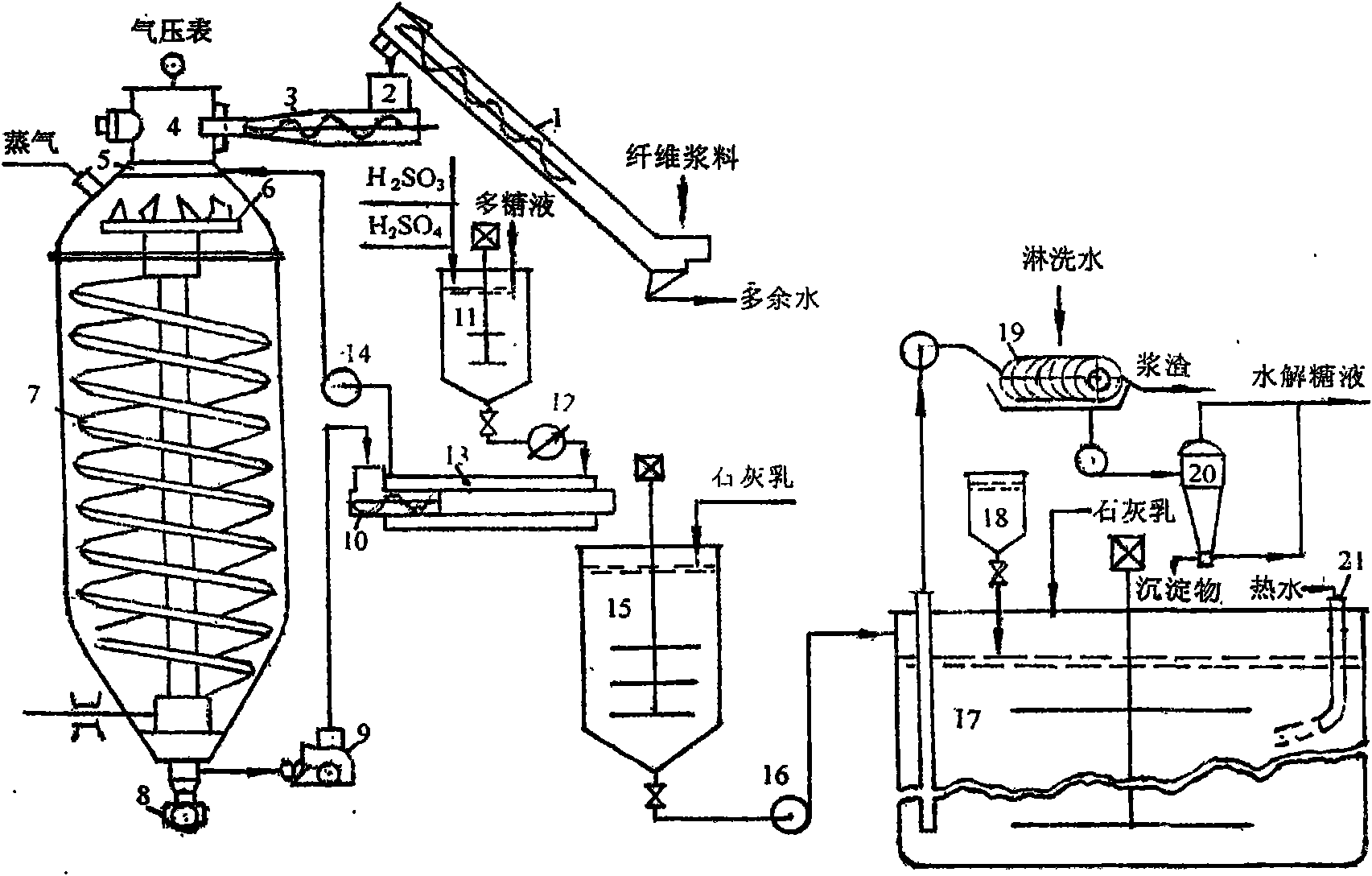

Concentrated sulfuric acid hydrolysis of lignocellulosics

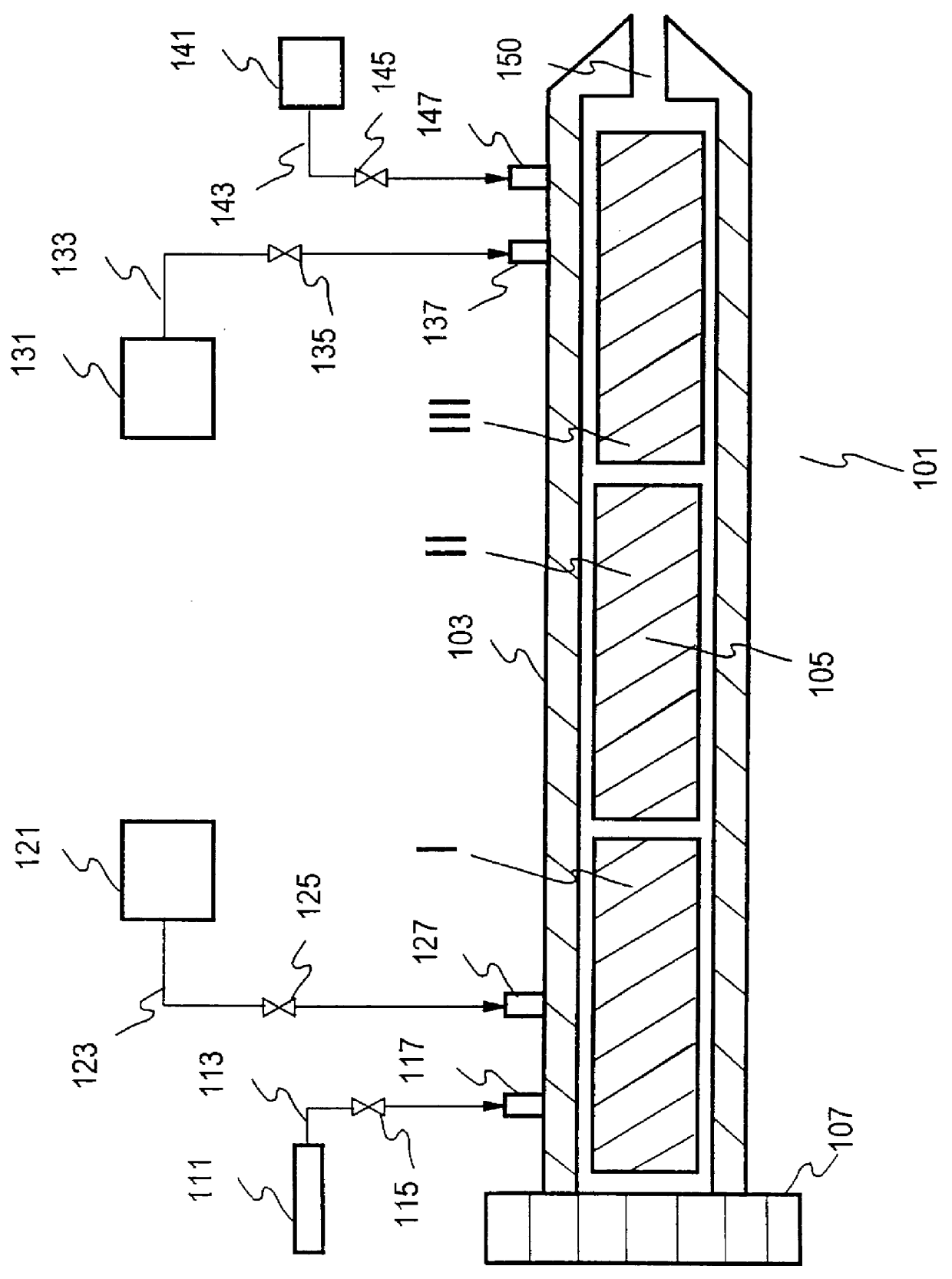

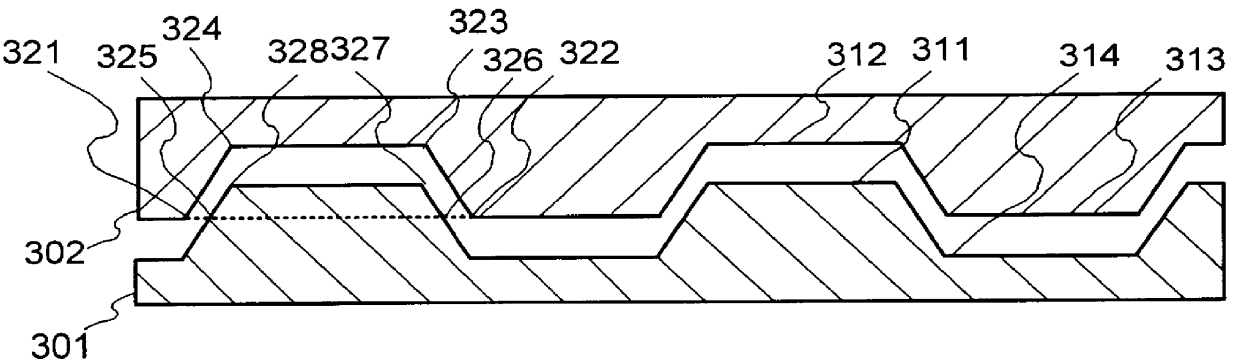

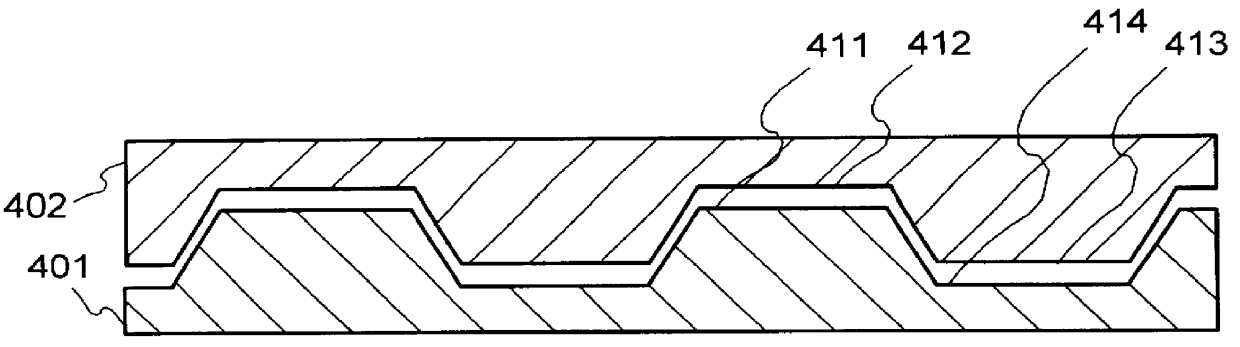

InactiveUS6063204AMinimize and preclude potential backflowEliminate requirementsPressurized chemical processOther chemical processesUnit operationFermentable sugar

A process, system, and apparatus for effectively and economically producing fermentable sugars from cellulosic feedstocks is described. The economic viability of using wood and / or agricultural waste, containing large fractions of cellulose and hemicellulose is highly dependent on the method used for hydrolysis. Underlying the gist of this invention are newly discovered methods, means, and techniques by which both the pentosans and hexosans comprising the hemicellulose fraction of the selected feedstock and the hexosans comprising the cellulose fraction of the selected feedstock can be quickly and efficiently converted in a single pass through a single device to fermentable sugars containing minimal quantities of degradation products known to inhibit fermentation. Successful operation of this new hydrolysis process employing a new reactor design can produce fermentable sugars at rates and efficiencies previously thought unattainable by reducing the number of processing steps, pieces of equipment, and unit operation previously used.

Owner:FARINA GEORGE E

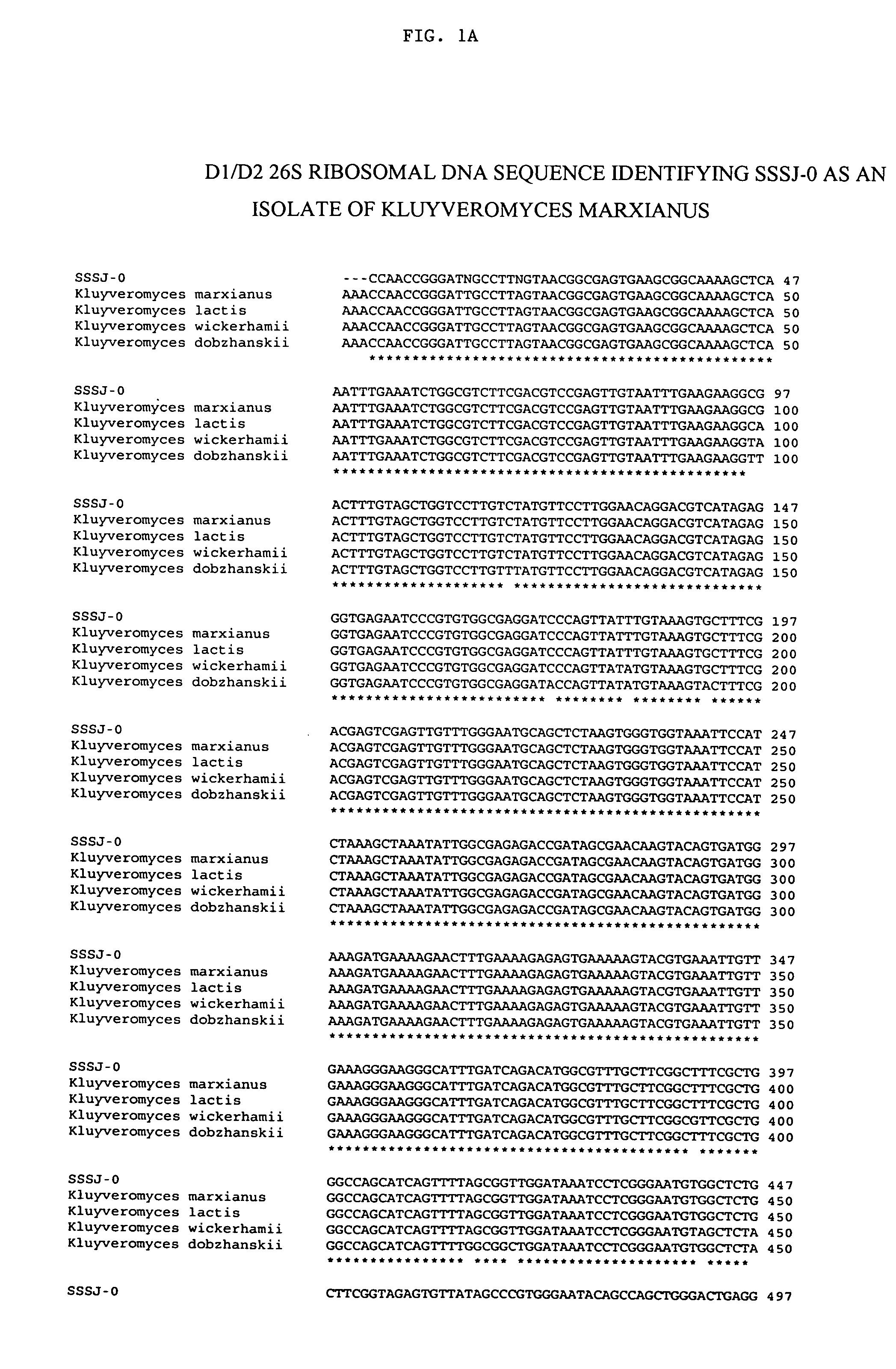

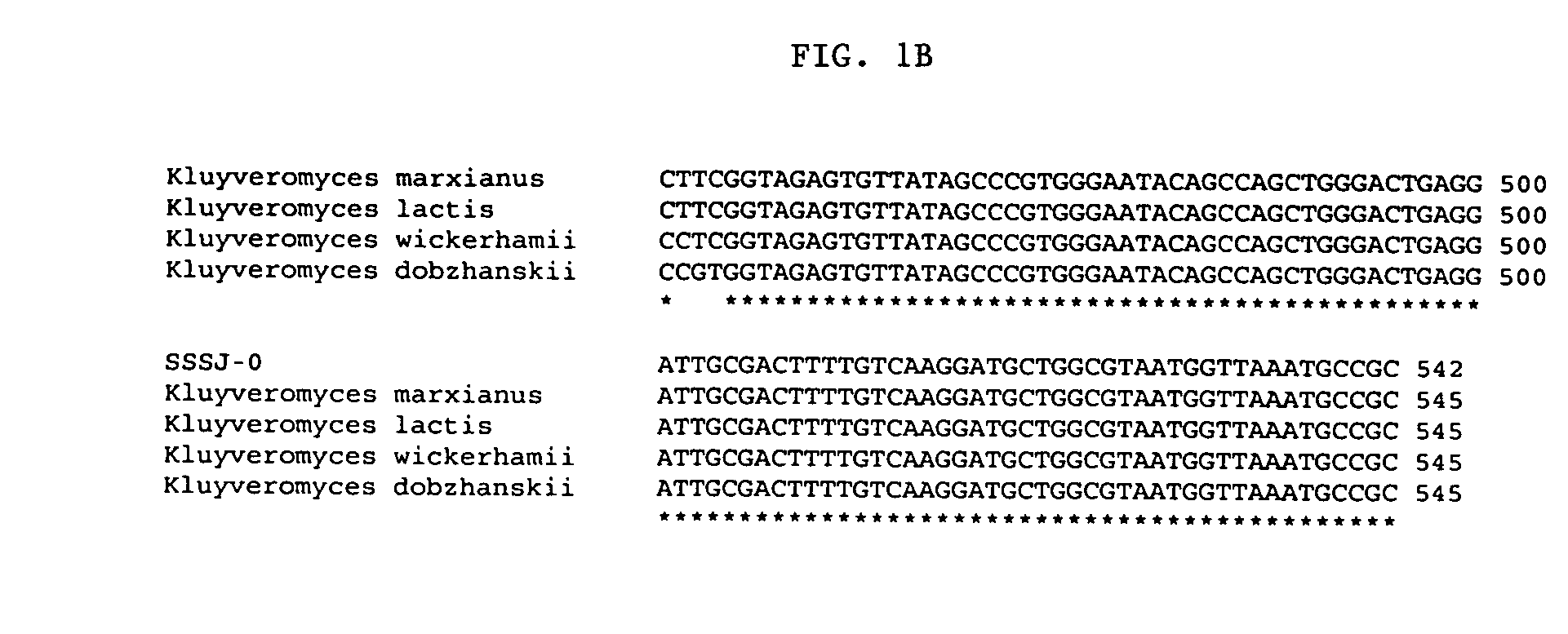

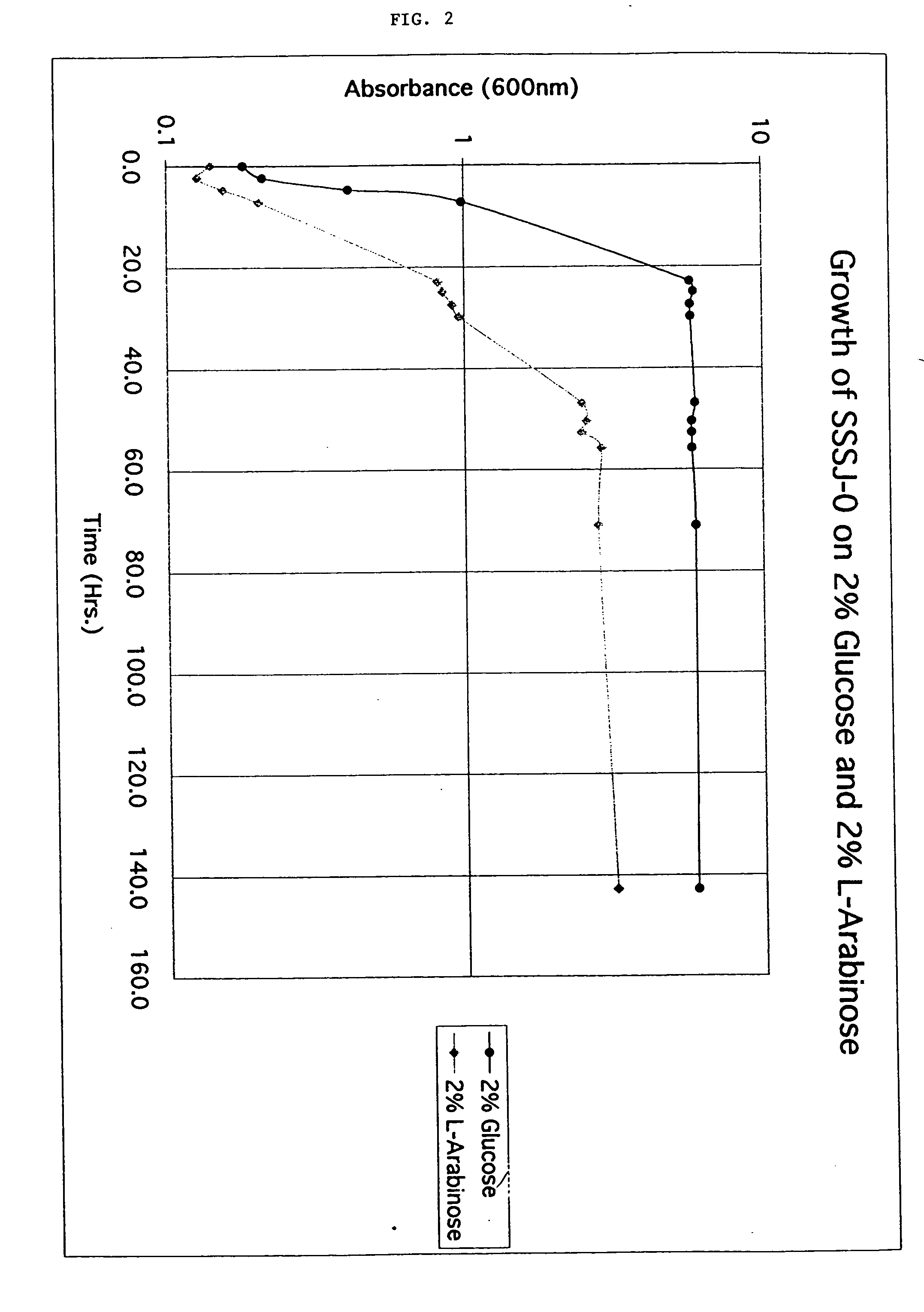

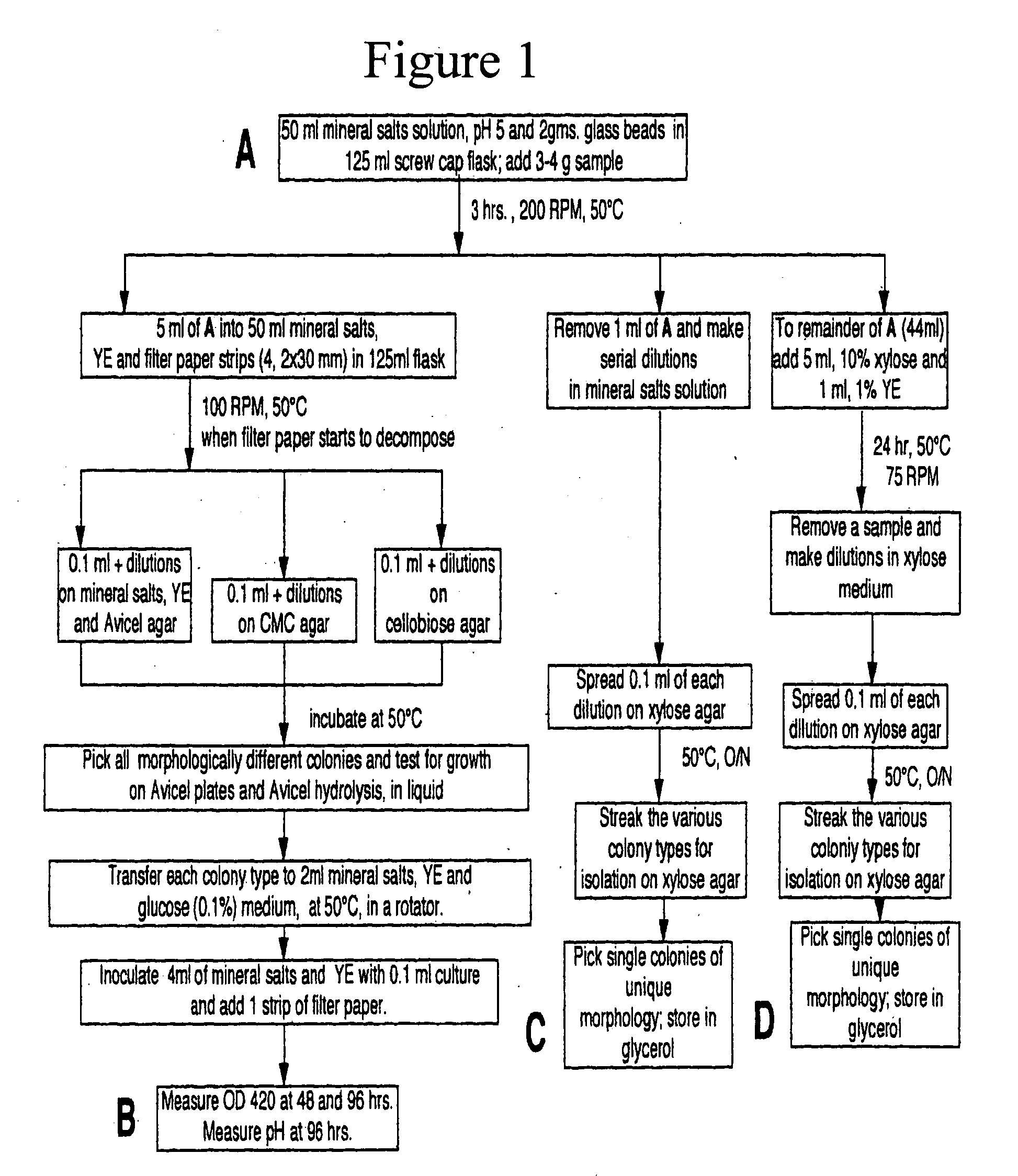

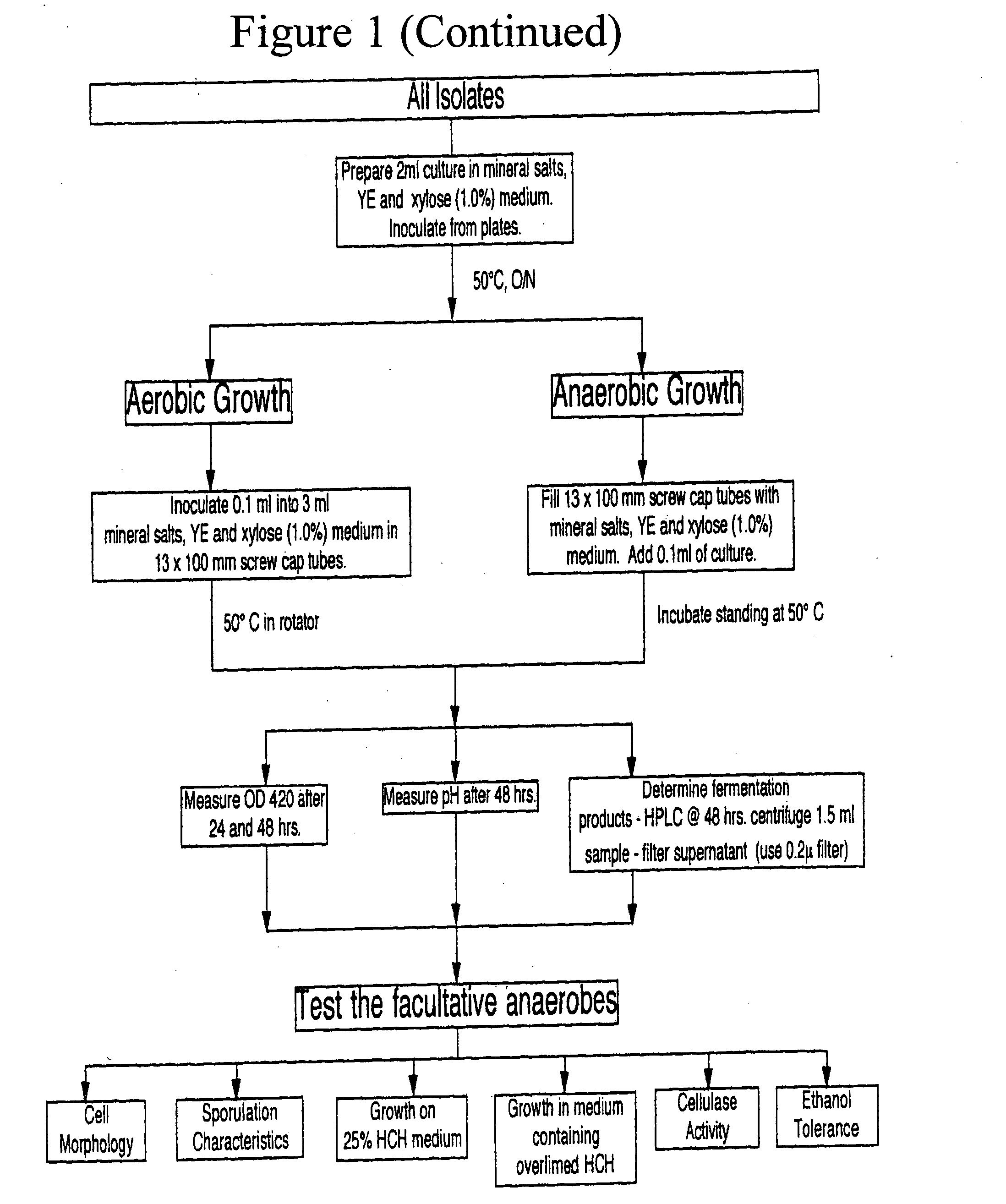

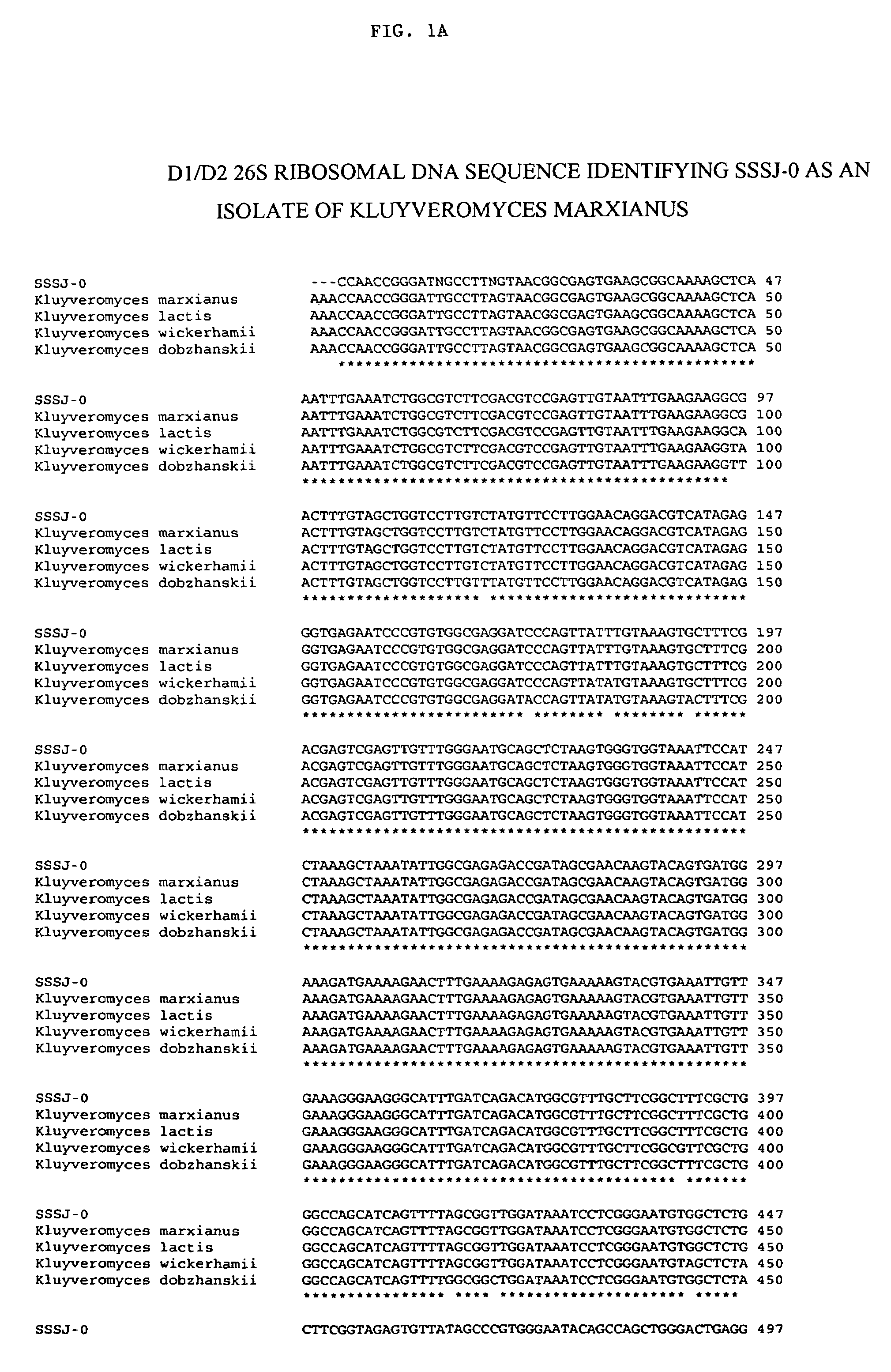

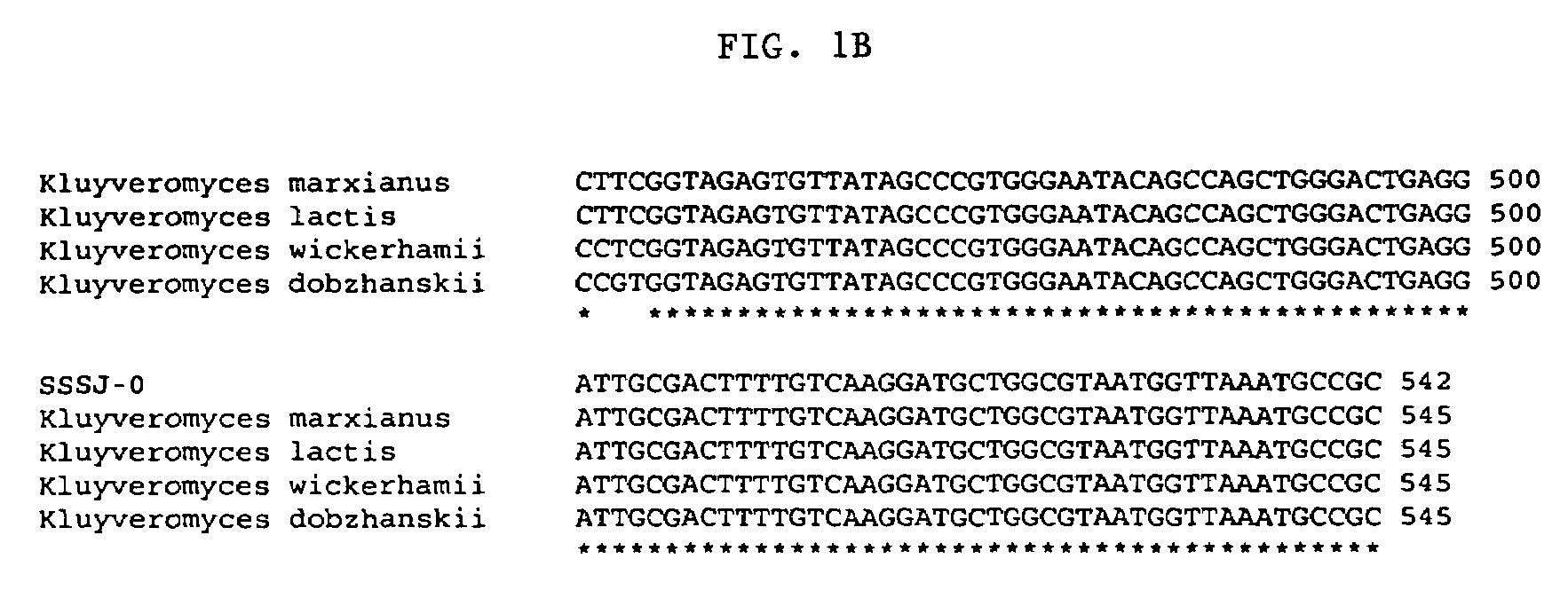

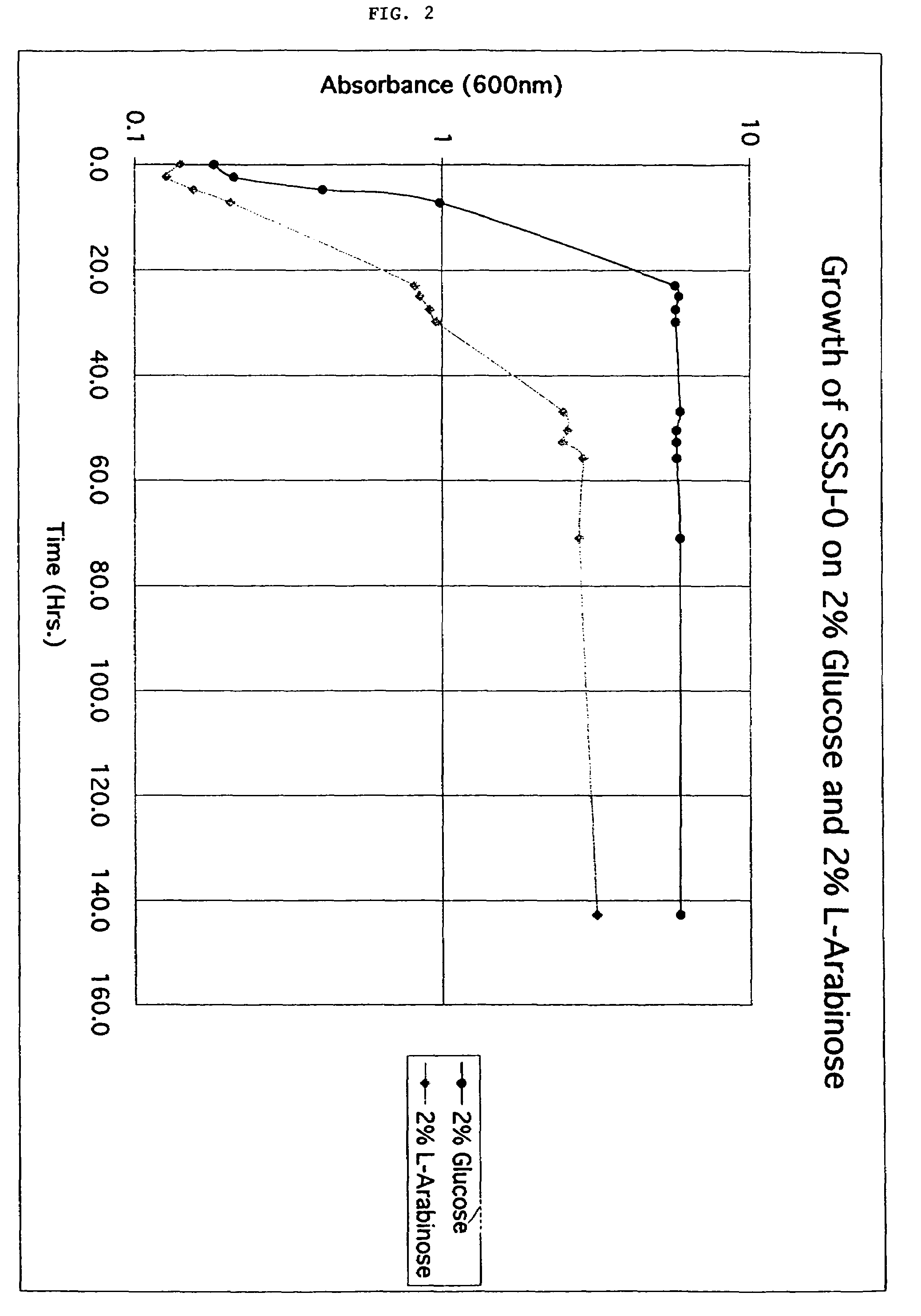

Kluyveromyces strains metabolizing cellulosic and hemicellulosic materials

This invention relates to the use of microorganisms for the generation of ethanol from lignocellulosic waste materials. Yeast strains of the genus Kluyveromyces which have the capability to ferment cellulose, hexose sugars to ethanol are provided. Also provided are methods for converting cellulose, hexoses, or mixed hydrolysates of hexoses to ethanol by fermentation with Kluyveromyces strains. The invention also provides methods to isolate yeast strains which metabolize cellulose, pentoses, or hemicelluloses from waste materials.

Owner:NEW TECH HLDG

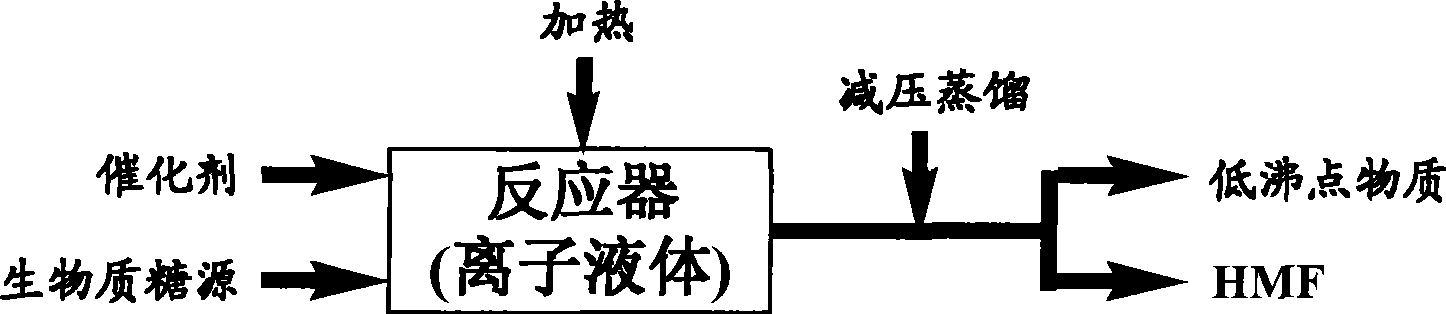

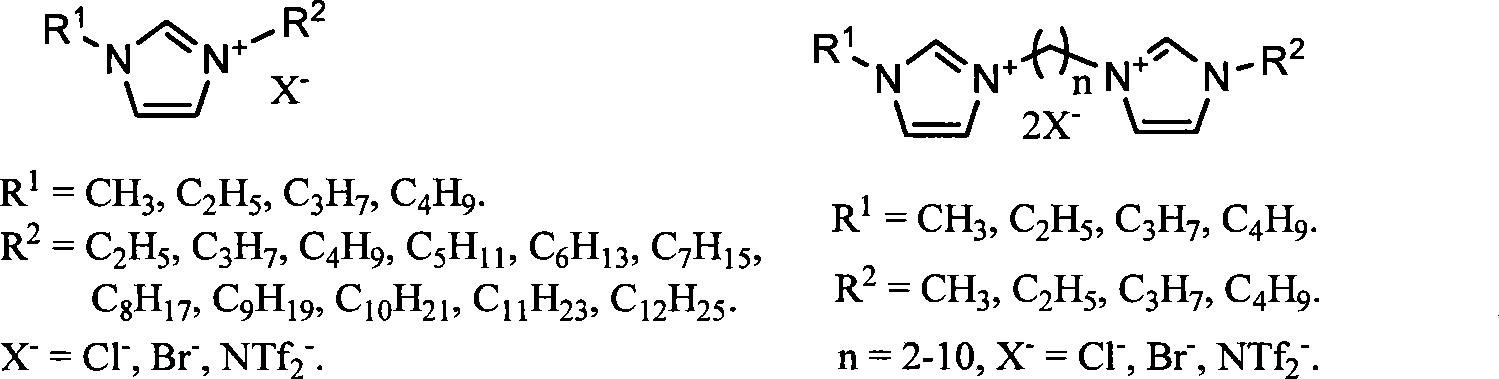

Method for preparing 5-hydroxymethyl-furfural

InactiveCN101386611ALow costCorrosion resistance requirements are not highOrganic chemistryAlternative fuelsSolvent

The invention relates to a method for transforming biomass sugar source into 5-hydroxymethyl-furfural, in particular to a method for preparing the 5-hydroxymethyl-furfural. The method comprises the following steps: using ionic liquid as a solvent, hexose or hexose source biomass as raw material substrates, and 0.5 to 50 percent (relative to the mass of the biomass sugar source) of acidic ionic liquid, inorganic acid or organic acid as a catalyst, and performing the reaction of materials for 1.5 minutes to 23 hours at normal pressure and at a temperature of between 80 DEG C and 100 DEG C to efficiently generate HMF. The method has the advantages of high HMF selectivity, less acid consumption, moderate operating conditions, fast reaction, reusable ionic liquid, simple process, environment protection and the like, and opens up a new approach for preparing commodity chemicals and replacing fuels starting from renewable biological resources.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing 5-hydroxymethyl-furfural

InactiveCN101456850ALow costCorrosion resistance requirements are not highOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsAlternative fuelsSolvent

The invention relates to a method for preparing 5-hydroxymethylfurfural (HMF) by transforming a biomass saccharine source. The method comprises the following concrete steps: using an ionic liquid as a solvent, hexose or hexose source biomass as a raw material substrate, and acid as a catalyst, heating the mixture to react for 5 minutes to 20 hours at normal pressure, and then depressurizing and distilling the mixture under the condition that an operation temperature is not higher than 180 DEG C to obtain the HMF after the reaction is ended; and after the distilled remainder is cooled, directly adding the remainder into the biomass saccharine source, and repeating the processes of reaction and separation to obtain the HMF, so as to realize recycling of an ionic liquid catalyst system and semi-continuous preparation of the HMF. By using the method, once through yield of the HMF reaches as high as 94 percent. The method has the advantages of high selectivity, low acid consumption, mild condition, quick reaction, reusability of the ionic liquid, low cost, simple process, environmental protection, semi-continuous production and the like, and provides new technology for industrialized production of the HMF by transforming the biomass saccharine source, so as to develop a new path for preparing common chemicals in a large scale by using biomass resources and replacing fuels.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

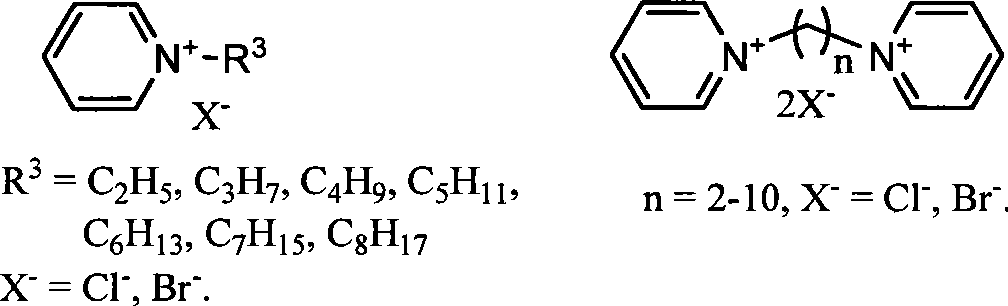

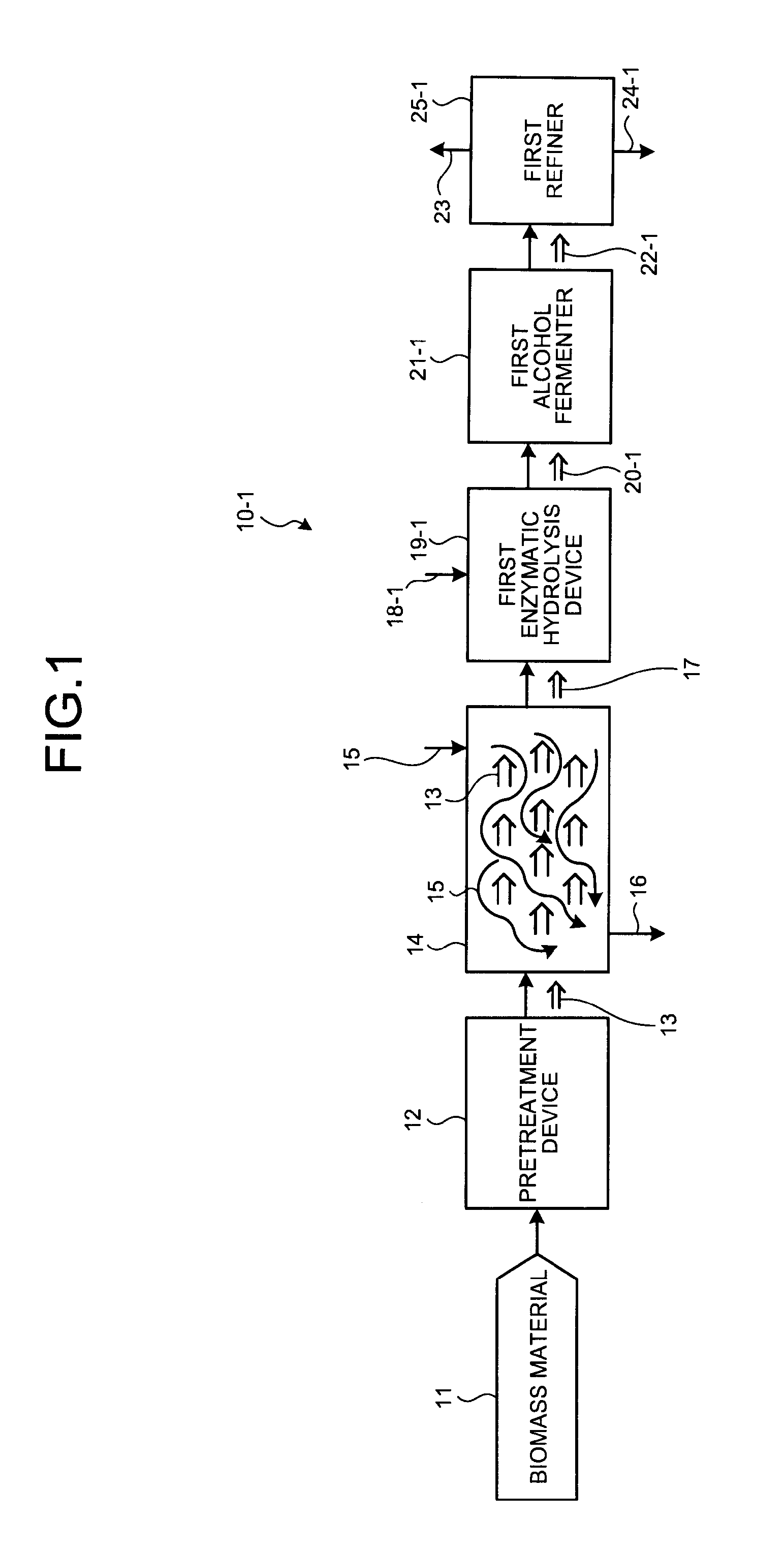

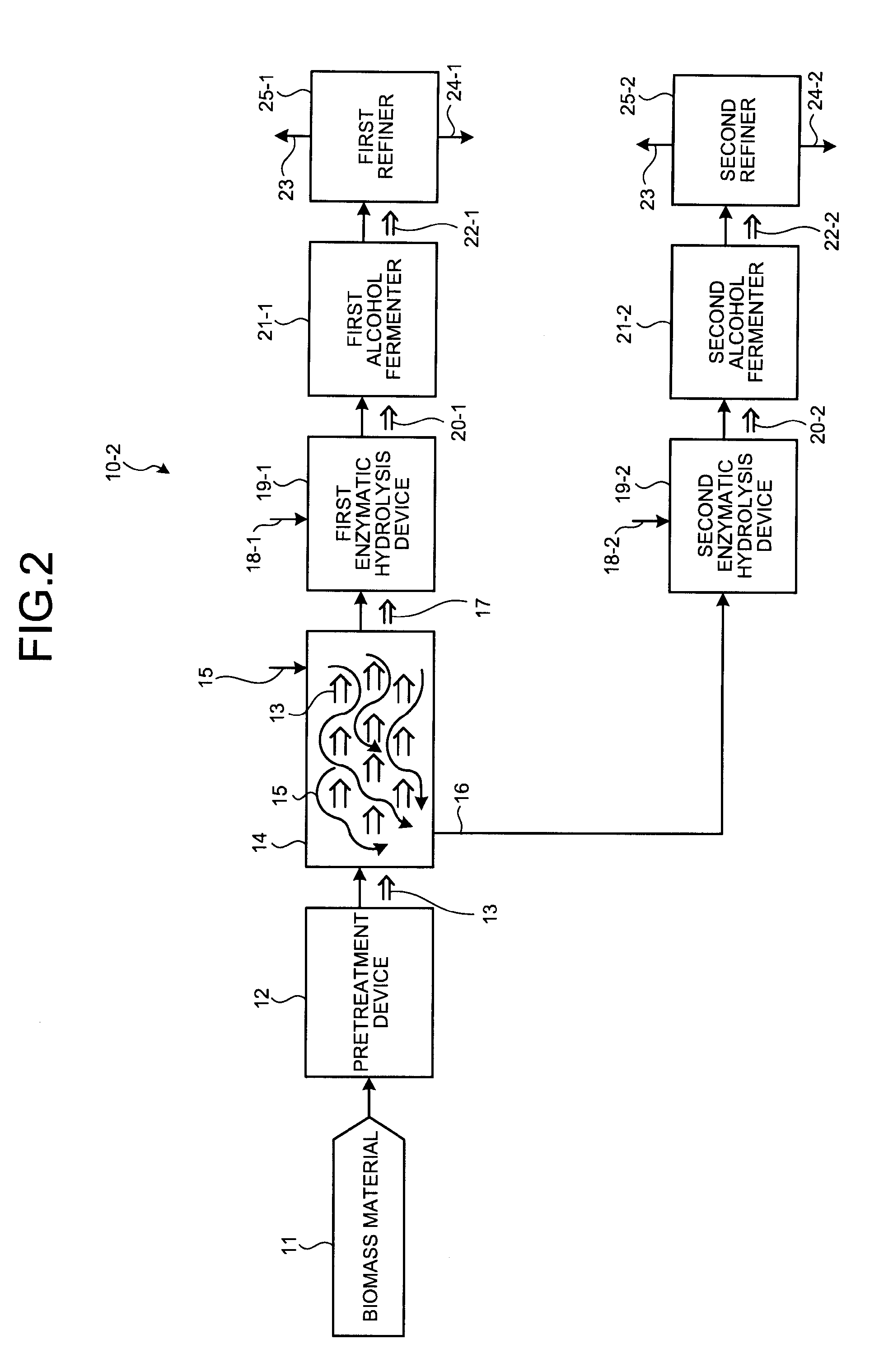

Organic material production system using biomass material and method

ActiveUS20110003348A1Efficiently saccharifyingEfficient productionBioreactor/fermenter combinationsBiological substance pretreatmentsDecompositionChemistry

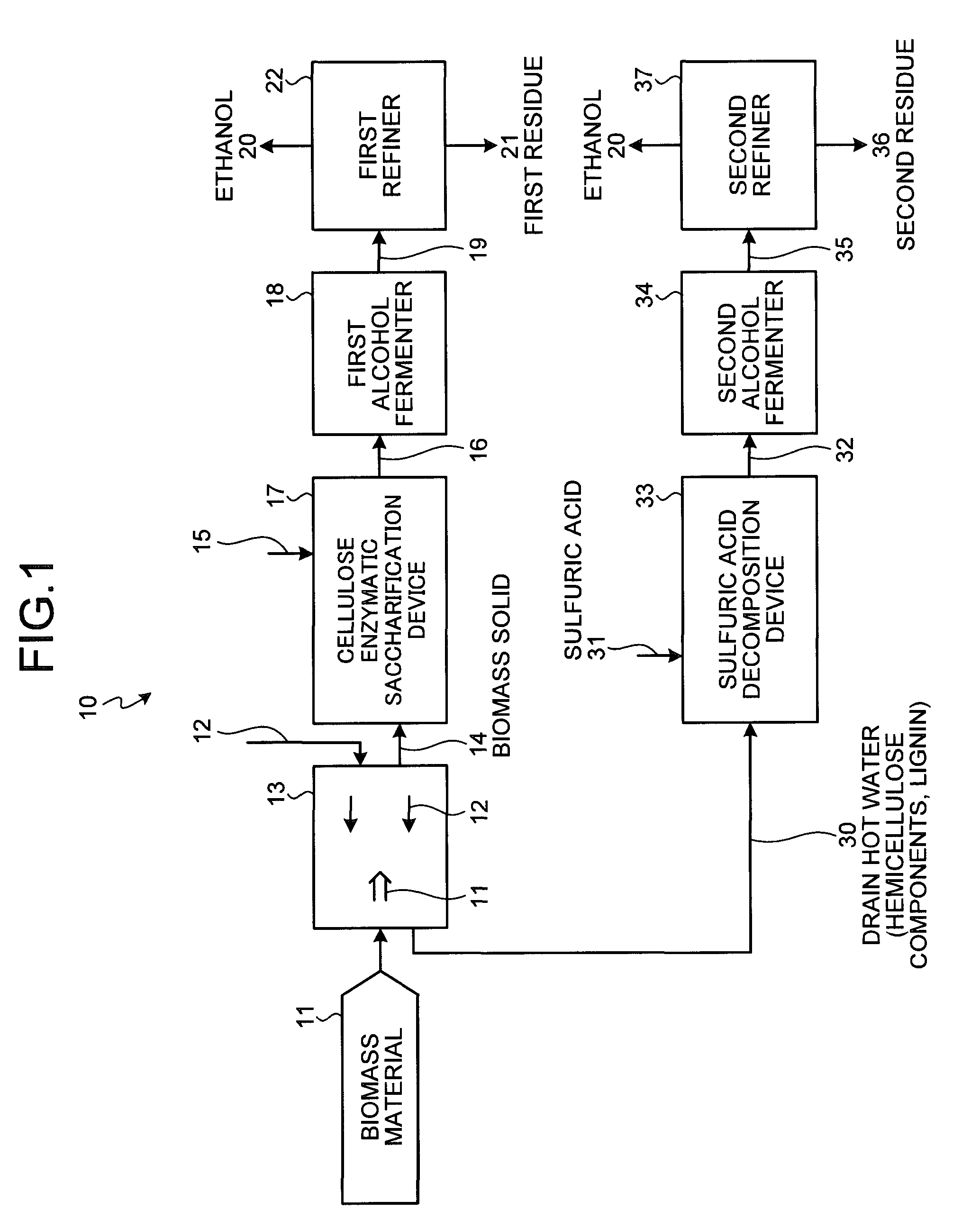

An organic material production system includes: a pretreatment device (12) that pulverizes a biomass material (11); a hydrothermal decomposition apparatus (14) that hydrothermally decomposes a pulverized biomass (13) by causing it to countercurrently contact with hot compressed water (15), elutes lignin components and hemicellulose components into the hot compressed water (15), and separates the lignin components and the hemicellulose components from a biomass solid residue; a first enzymatic hydrolysis device (19-1) that treats cellulose in a biomass solid residue (17), discharged from the hydrothermal decomposition apparatus, with an enzyme (18) to enzymatically hydrolyze it to a sugar solution containing hexose; a fermenter (21) that produces ethanol by fermentation using a sugar solution (20) obtained by the first enzymatic hydrolysis device (19-1); and a refiner 25 that refines an alcohol fermentation liquid (22), so as to separate it into ethanol (23) and a residue (24).

Owner:MITSUBISHI HITACHI POWER SYSTEMS ENVIRONMENTAL SOLUTIONS LTD +2

Process, Plant, and Biofuel For Integrated Biofuel Production

InactiveUS20110126448A1Bioreactor/fermenter combinationsBiological substance pretreatmentsCelluloseBiodiesel

This invention relates to a process, a plant, and a biofuel for integrated biofuel production, such as with biogasoline, biodiesel, and / or sugar product. The integrated process includes the step of removing hexose from a feedstock to form a lignocellulosic material. The process also includes the step of converting the hexose to a biogasoline and / or a biodiesel material, and the step of depolymerizing lignocellulosic material to form pentose and a residue. The process also includes the step of converting the pentose to a biogasoline and / or a biodiesel material.

Owner:BP BIOFUELS UK

Organic material production system using biomass material and method

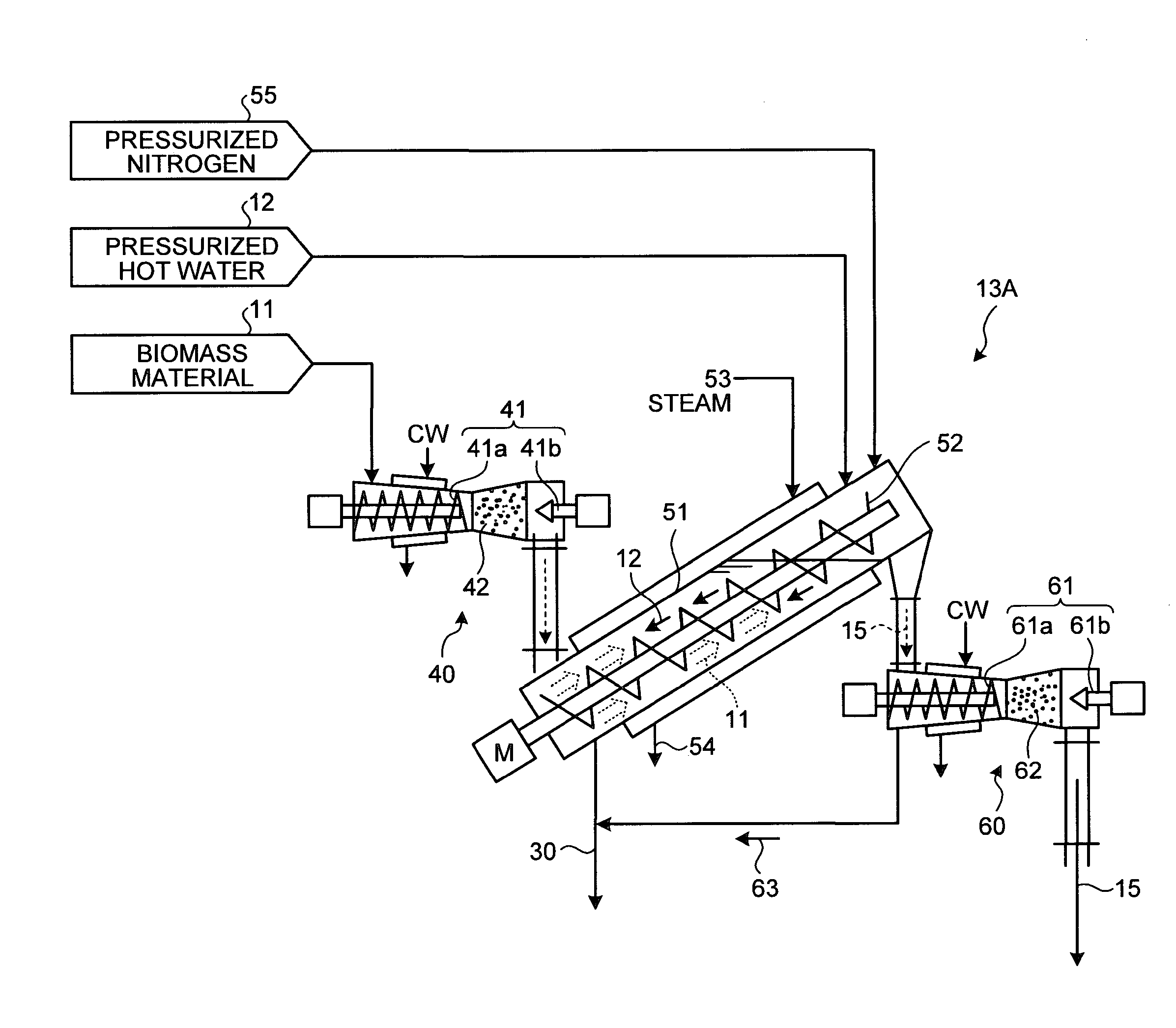

ActiveUS20110124057A1Efficiently saccharifyingImprove efficiencyPretreatment with water/steamBioreactor/fermenter combinationsAlcoholDecomposition

An organic material production system using biomass material includes: a hydrothermal decomposition apparatus (13) that causes the biomass material (11) and hot compressed water (12) to countercurrently contact with each other and undergo hydrothermal decomposition, and that transfers a lignin component and a hemicellulose component into the hot compressed water, so as to separate the lignin component and the hemicellulose component from a biomass solid residue; a cellulose enzymatic saccharification device (17) that treats, with an enzyme, cellulose in the biomass solid residue, so as to enzymatically saccharify the cellulose to a first sugar solution containing hexose; an alcohol fermenter (18) that produces alcohols by fermentation using the obtained first sugar solution; a sulfuric acid decomposition device (33) that decomposes, with sulfuric acid, the hemicellulose component in hot water (30) discharged from the hydrothermal decomposition apparatus, which contains the eluted lignin component and the eluted hemicellulose component, so as to decompose the hemicellulose component to a second sugar solution containing pentose; and a second alcohol fermenter (34) that produces, using the second sugar solution containing pentose, alcohols by fermentation.

Owner:MITSUBISHI HITACHI POWER SYSTEMS ENVIRONMENTAL SOLUTIONS LTD

Oligonucleotides comprising a modified or non-natural nucleobase

Owner:ALNYLAM PHARMA INC

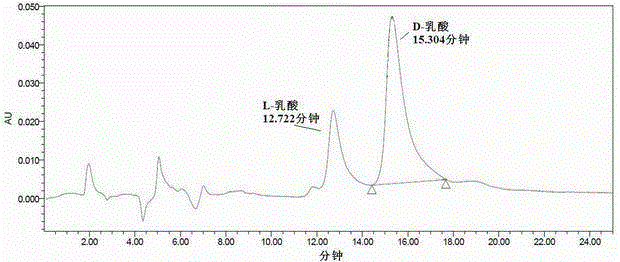

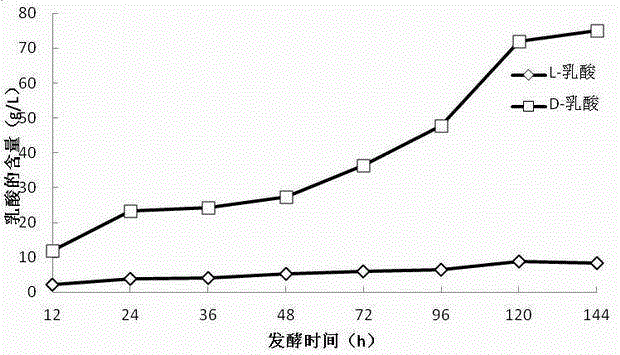

Lactobacillus and method for producing D-lactic acid by fermenting using lactobacillus

ActiveCN102978134AGood nutritional needsBacteriaMicroorganism based processesLactobacillusMicrobiology

The invention discloses lactobacillus and a method for producing D-lactic acid by fermenting using the lactobacillus. A strain for the lactobacillus is lactobacillus (Lactobacillussp.) DMDL9010, and preservation number is CGMCC No.5172. The method comprises the following steps of: firstly, carrying out three-time activation culture on the strain; and then, fermenting for 108-144 hours at the temperature of 20 DEG C-35 DEG C to obtain D-lactic acid which is high in optical purity. According to the lactobacillus DMDL9010, D-lactic acid can be produced by fermenting pentose and hexose, and D-lactic acid is stable and high in yield, and the yield is 65-85g / L; produced D-lactic acid is high in optical purity which reaches 80-90%; the raw material adopted in the fermentation is wide in source and low in cost, and the fermenting cycle of the strain is just 108-144 hours; and D-lactic acid is produced by using the method, thus cost is saved, production efficiency is improved. The method disclosed by the invention has an important industrial application value.

Owner:SOUTH CHINA UNIV OF TECH

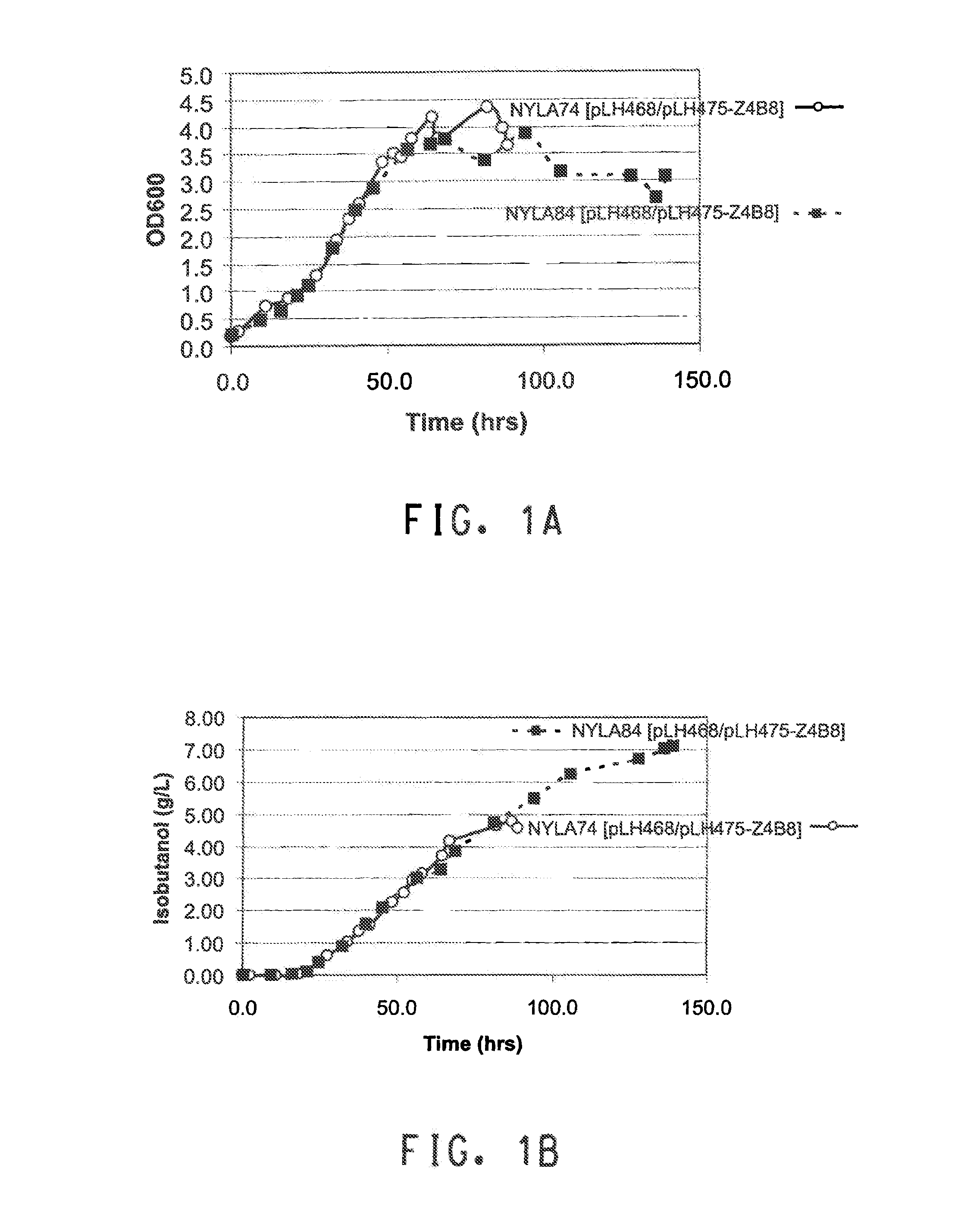

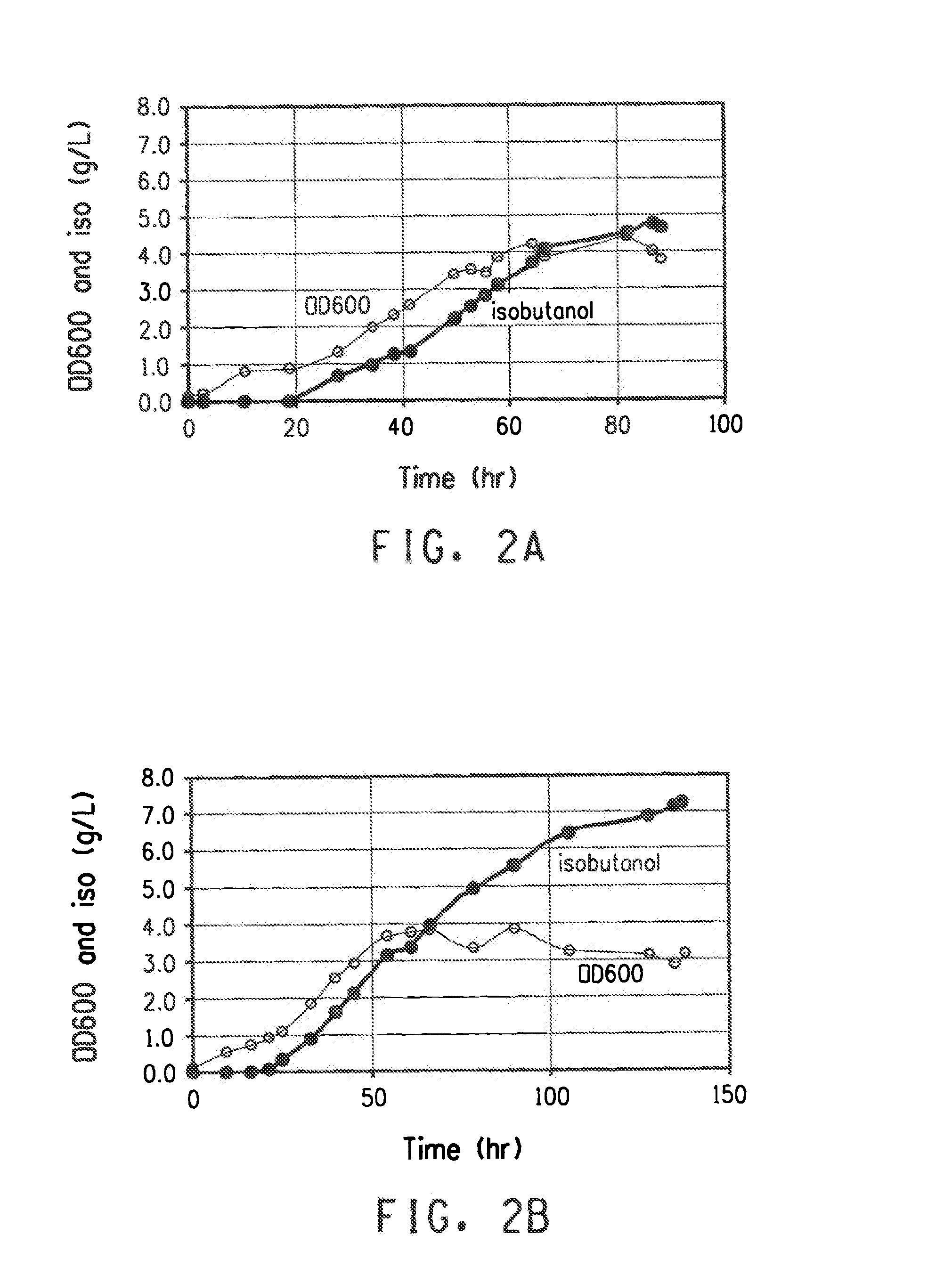

Expression of Hexose Kinase in Recombinant Host Cells

InactiveUS20140141479A1Increased glucose consumption rateAltered glucose repressionFungiBiofuelsHeterologousKinase activity

Owner:BUTAMAXTM ADVANCED BIOFUELS

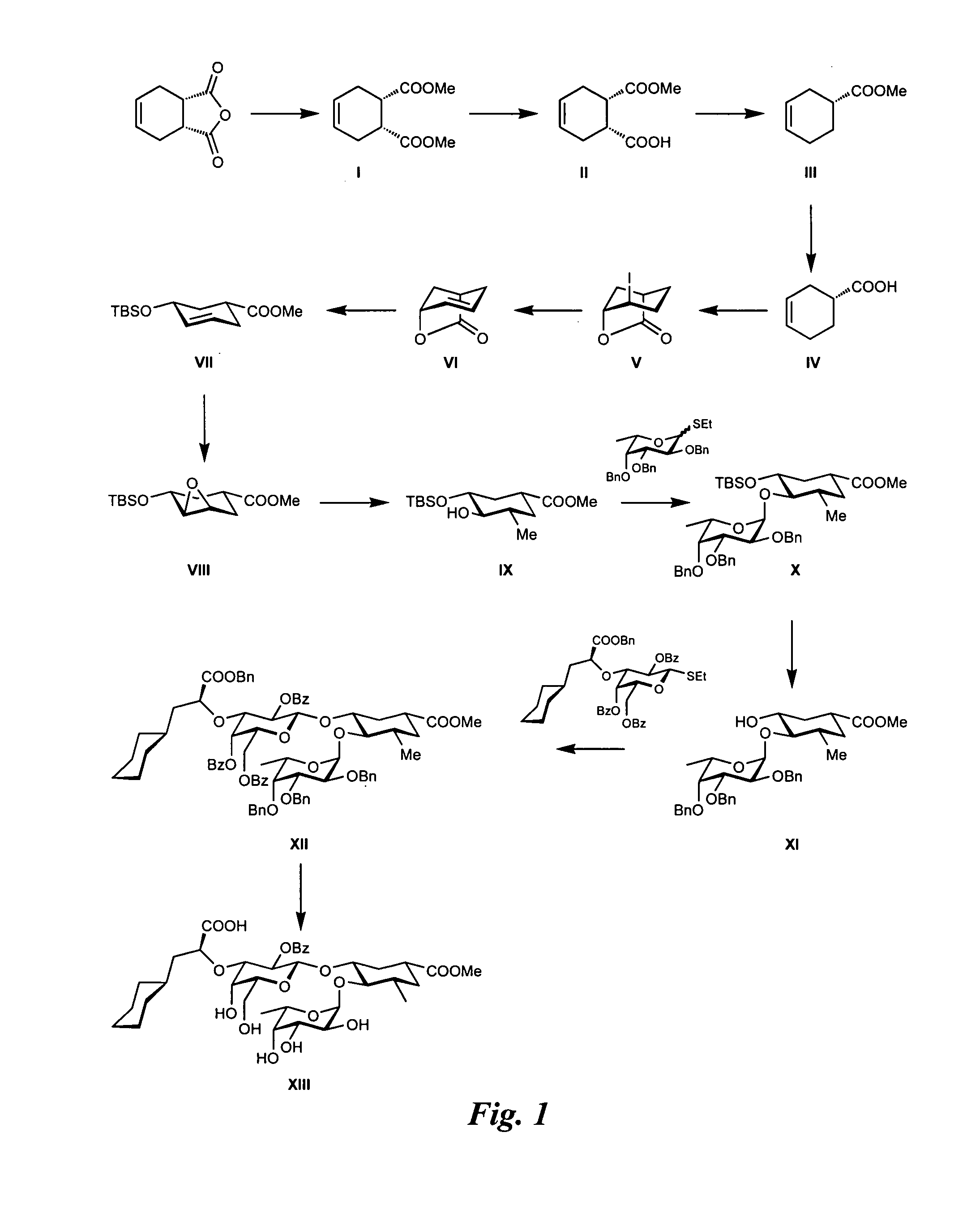

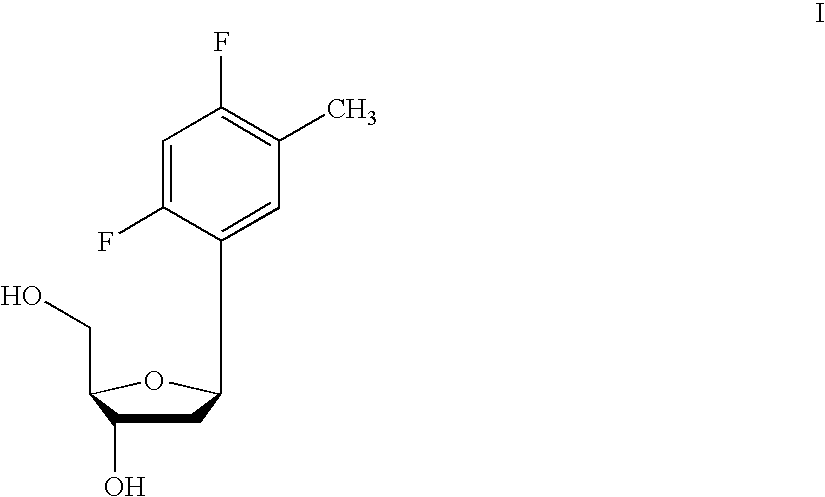

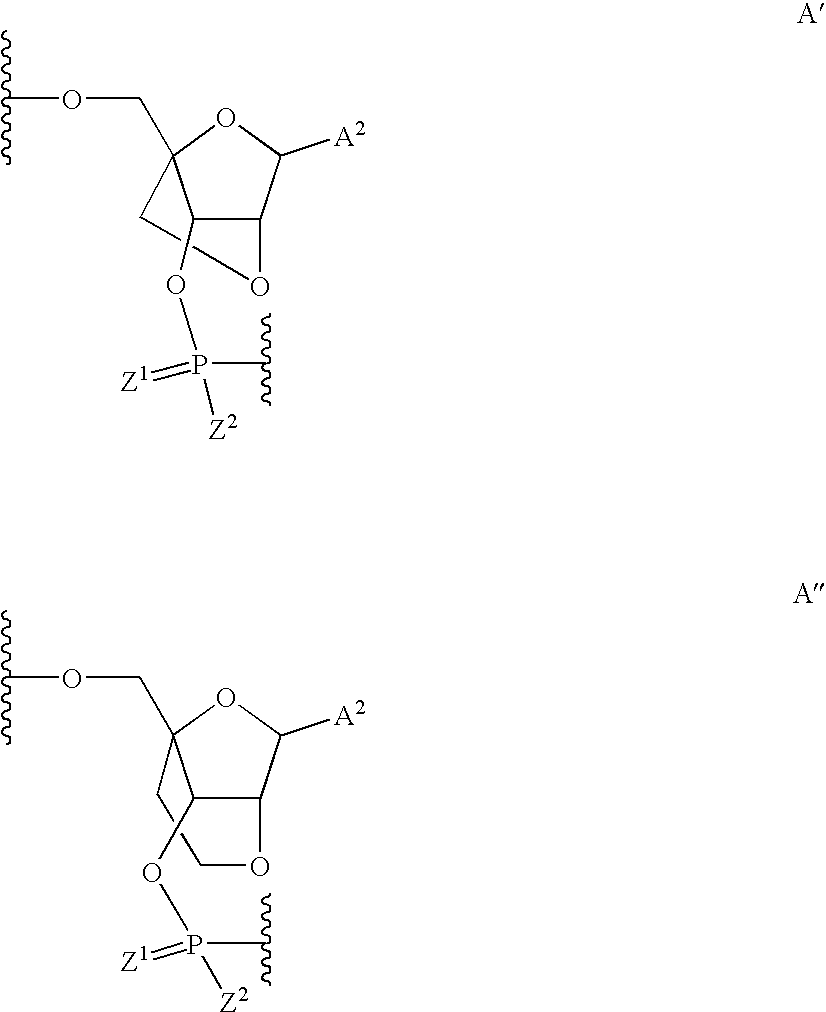

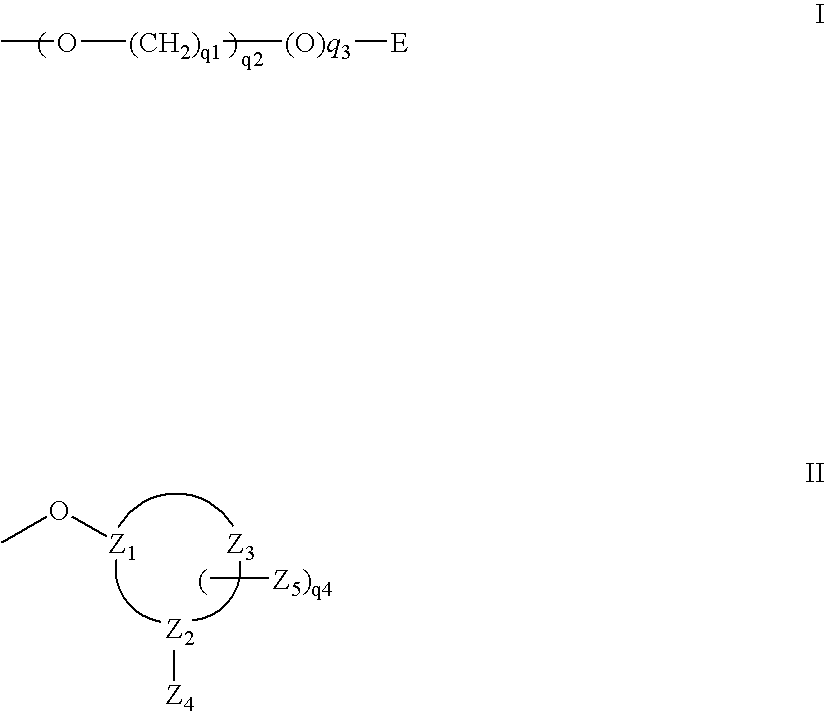

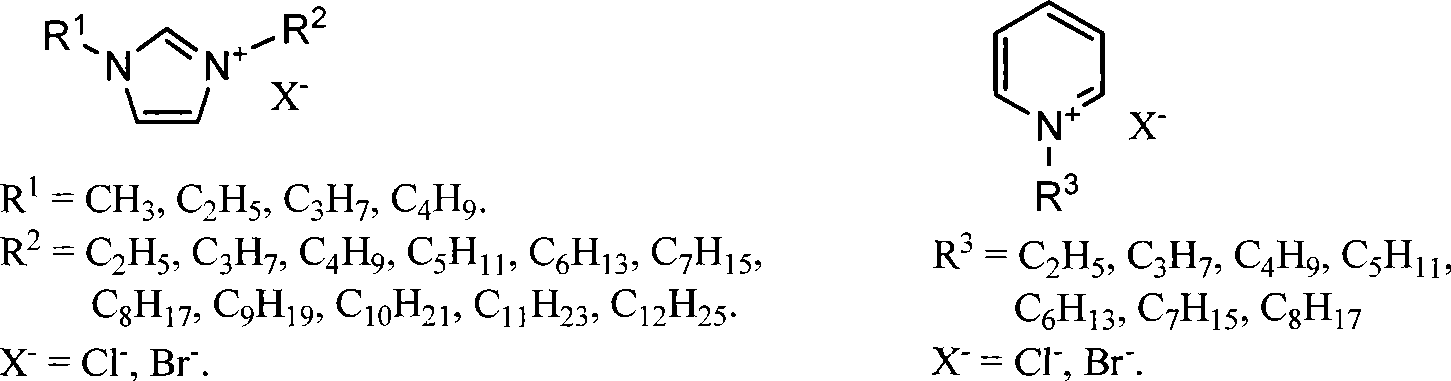

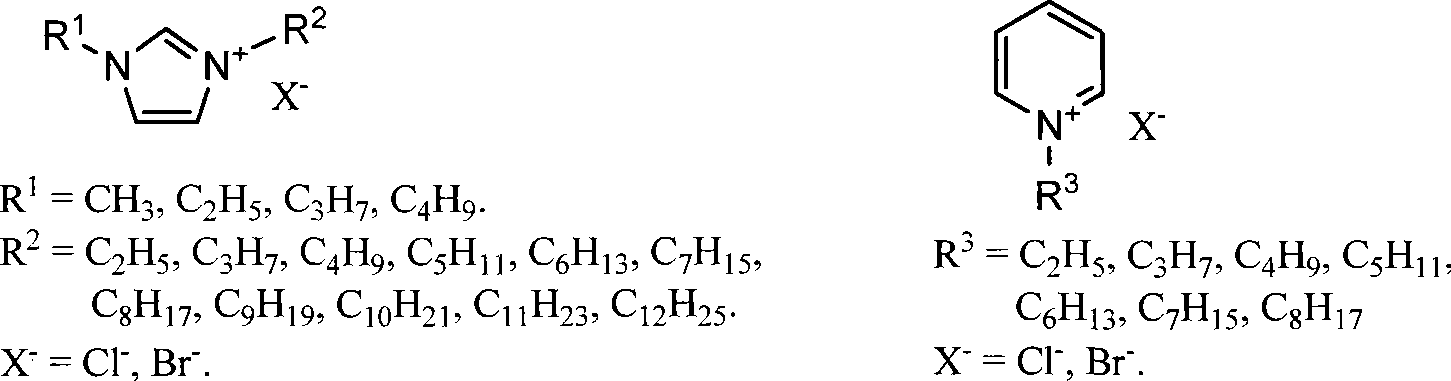

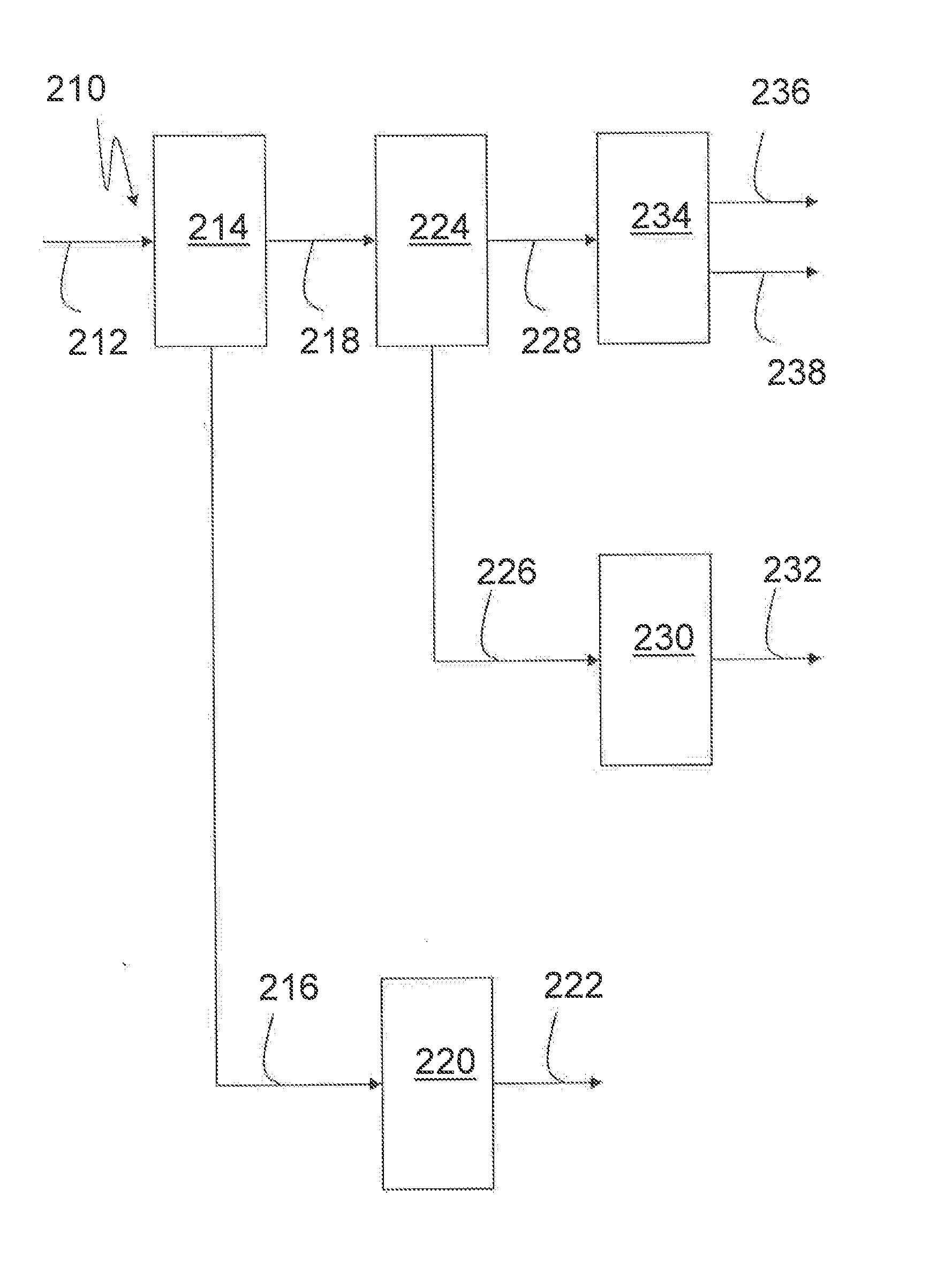

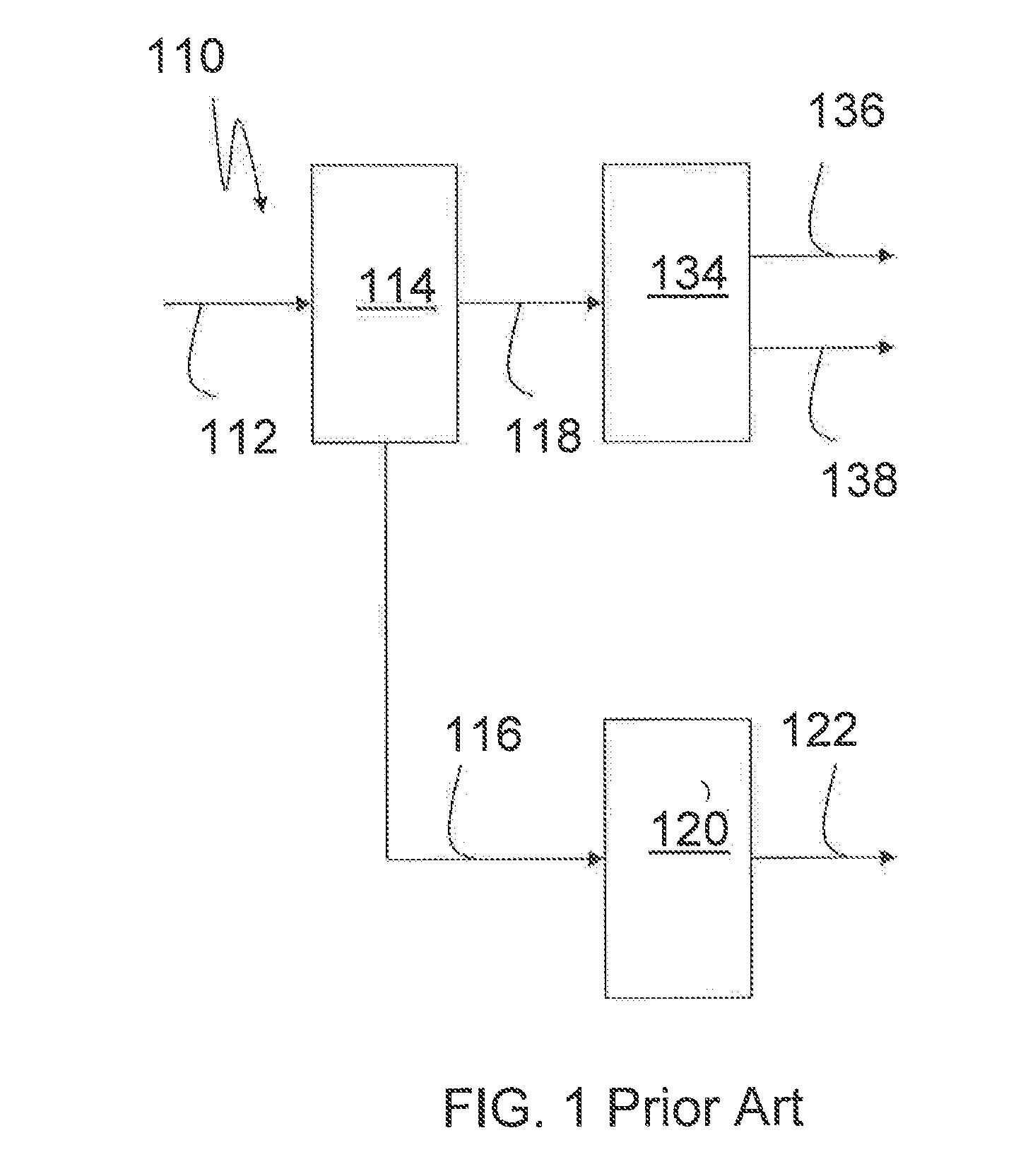

Substituted 3-azabicyclo[3.1.0]hexanes as ketohexokinase inhibitors

Provided herein are substituted 3-azabicyclo[3.1.0]hexanes as ketohexokinase inhibitors, processes to make said compounds, and methods comprising administering said compounds to a mammal in need thereof.

Owner:PFIZER INC

Catalyst for synthesizing 5-hydroxymethylfurfural by hexose dehydration and method for synthesizing 5-hydroxymethylfurfural

InactiveCN101811066AEnables a clean synthesis processHigh selectivityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsSolventHydroxymethylfurfural

The invention discloses a catalyst for synthesizing 5-hydroxymethylfurfural by hexose dehydration and a method for synthesizing the 5-hydroxymethylfurfural by using the catalyst. The catalyst consists of iron halide and ammonium halide, and the molar ratio of the iron halide to the ammonium halide is 0.1 to 10. The synthesizing method comprises the following steps: dissolving a reaction substrate into a solvent, adding the catalyst consisting of the iron halide and the ammonium halide into the solution, reacting the solution for 0.5 hour at the temperature of between 0 and 200 DEG C, distilling and condensing the solution, performing extraction, distilling the concentrate under reduced pressure, drying the distillate and collecting a product. The catalyst of the invention overcomes the defects that the catalyst in the prior art has large toxicity and the catalytic reaction needs a large amount of organic solvent and additive. The catalyst totally shows the characteristic of a homogeneous catalyst in the reaction process, and has high catalytic activity and high selectivity; and the using amount of the catalyst can be optimized to trace so as to facilitate the separation and purification of the reaction product. The catalyst has the advantages of simple reaction system, environment friendliness, low toxicity, low production cost and easy post treatment.

Owner:TIANJIN UNIV

Kluyveromyces strains metabolizing cellulosic and hemicellulosic materials

This invention relates to the use of microorganisms for the generation of ethanol from lignocellulosic waste materials. Yeast strains of the genus Kluyveromyces which have the capability to ferment cellulose, hexose sugars to ethanol are provided. Also provided are methods for converting cellulose, hexoses, or mixed hydrolysates of hexoses to ethanol by fermentation with Kluyveromyces strains. The invention also provides methods to isolate yeast strains which metabolize cellulose, pentoses, or hemicelluloses from waste materials.

Owner:NEW TECH HLDG

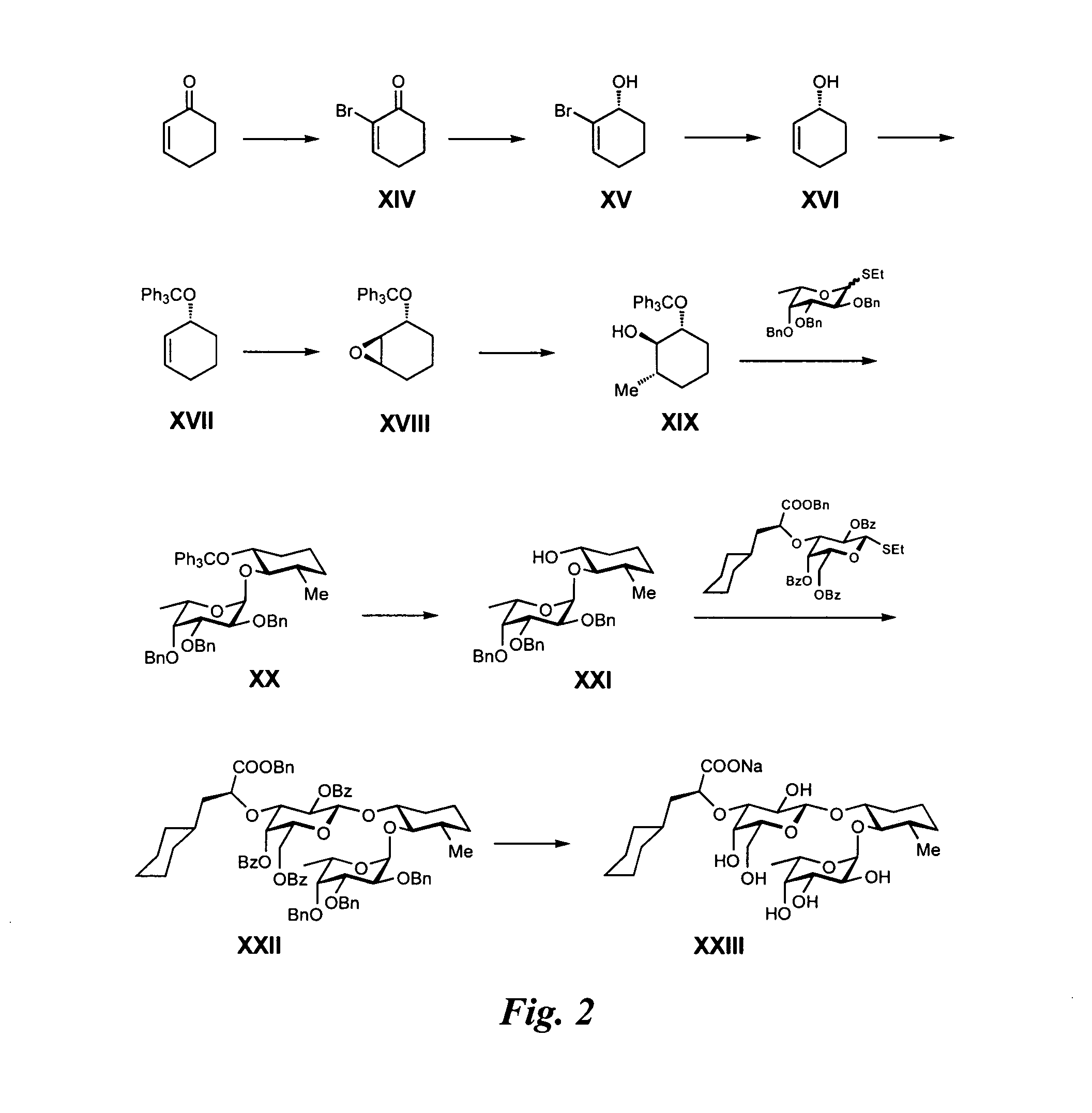

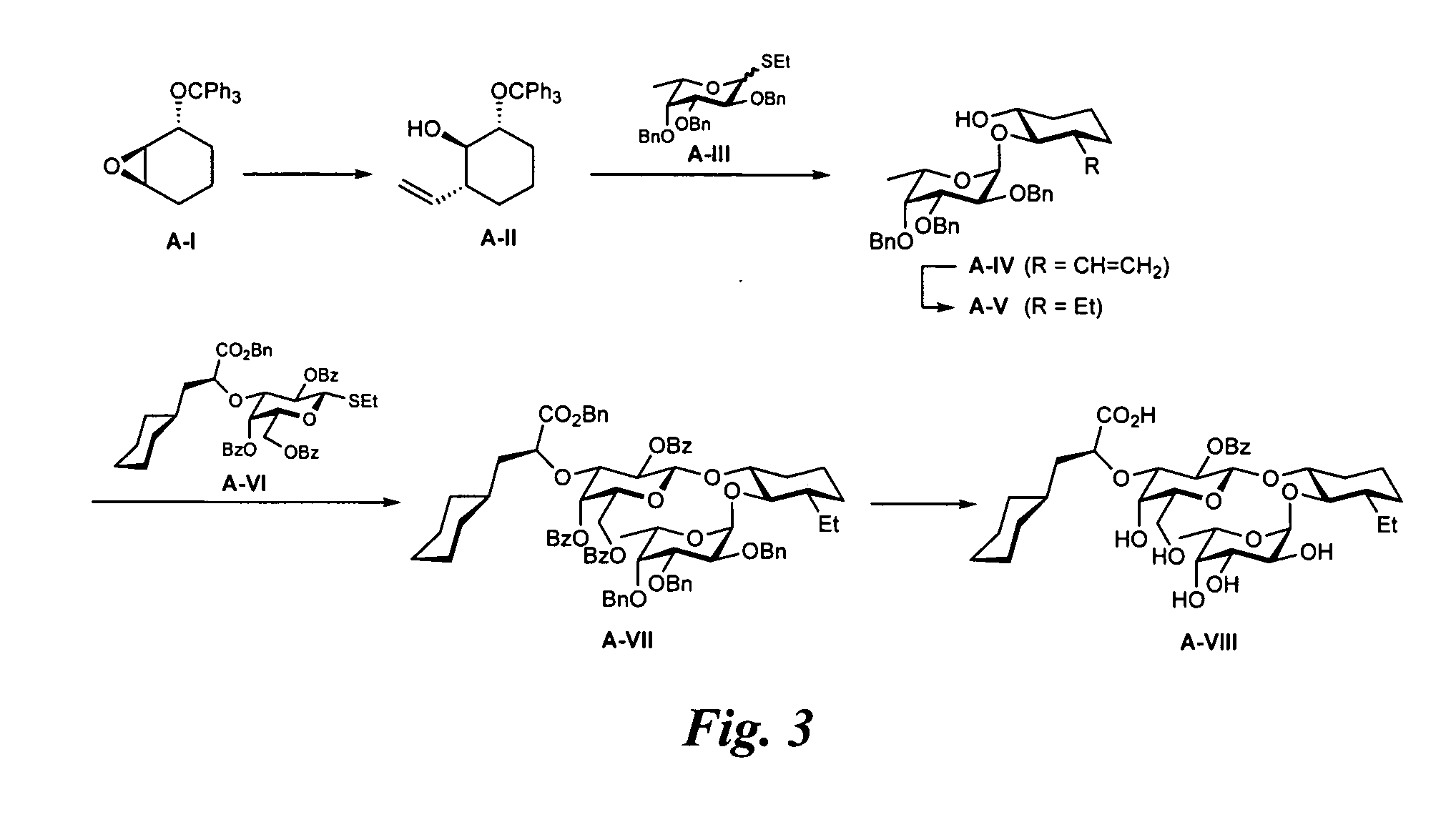

Methods of use of glycomimetics with replacements for hexoses and n-acetyl hexosamines

ActiveUS20080200406A1Effective treatmentAntibacterial agentsBiocideGlycomimeticEndothelial dysfunction

Owner:GLYCOMIMETICS

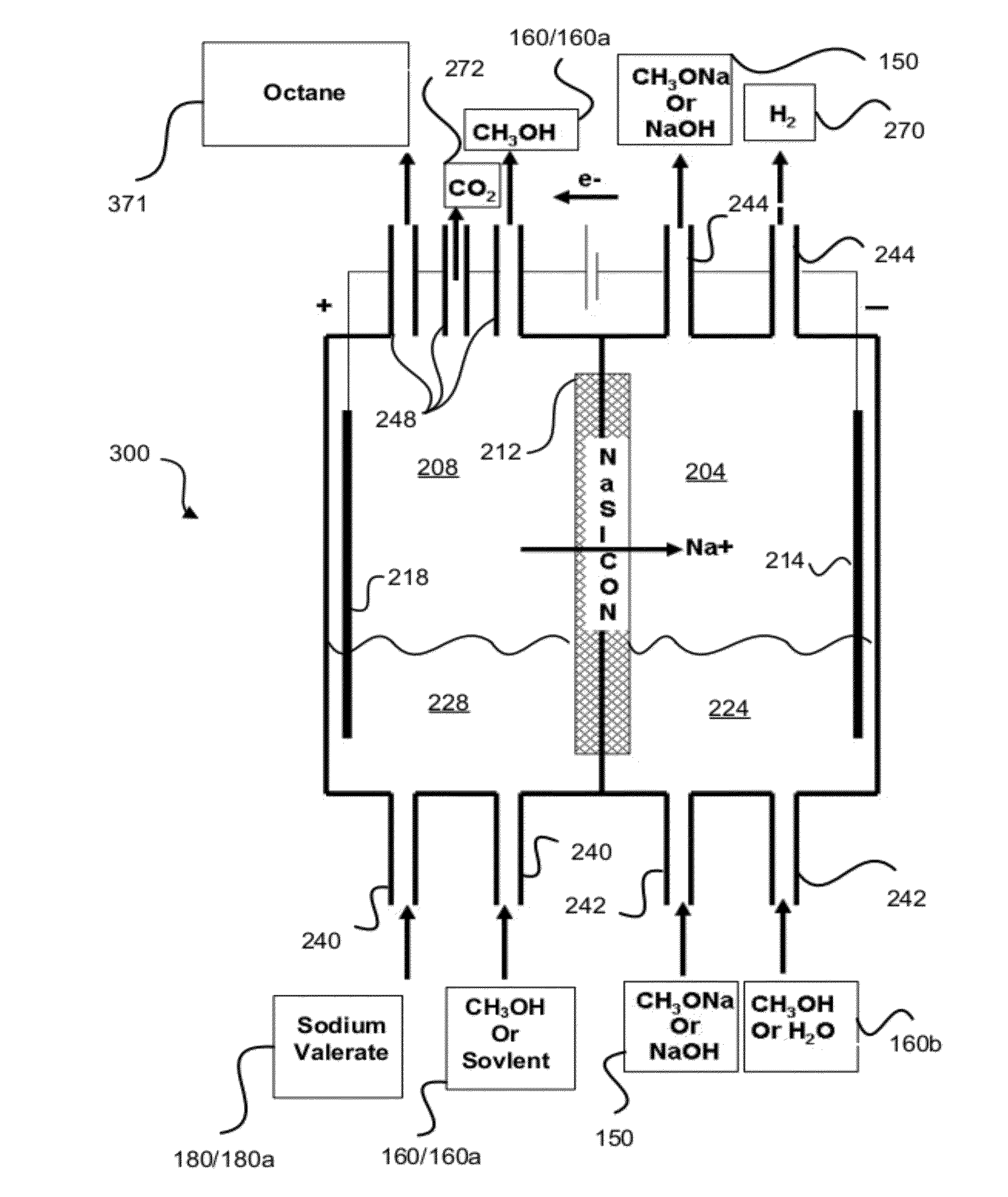

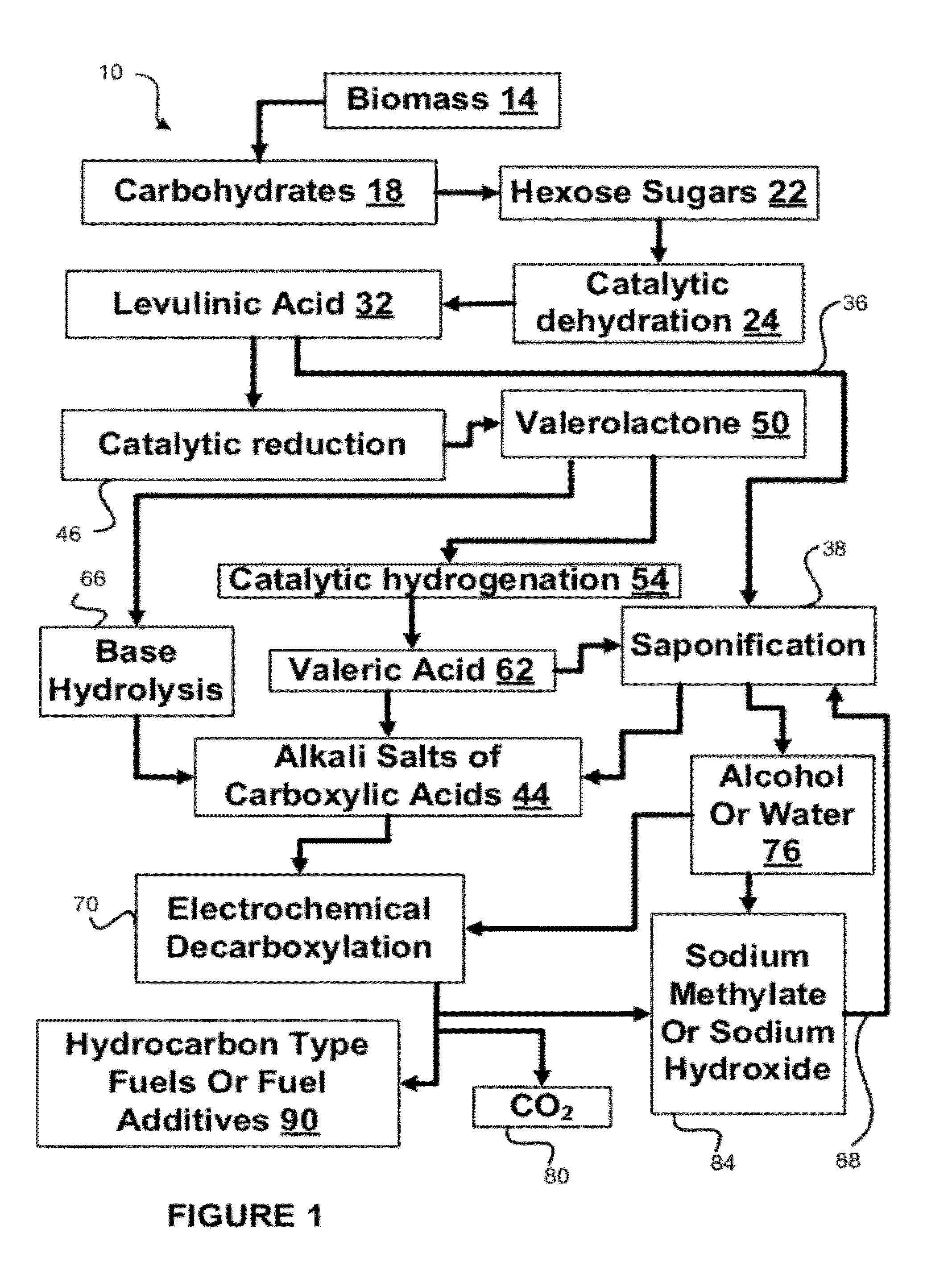

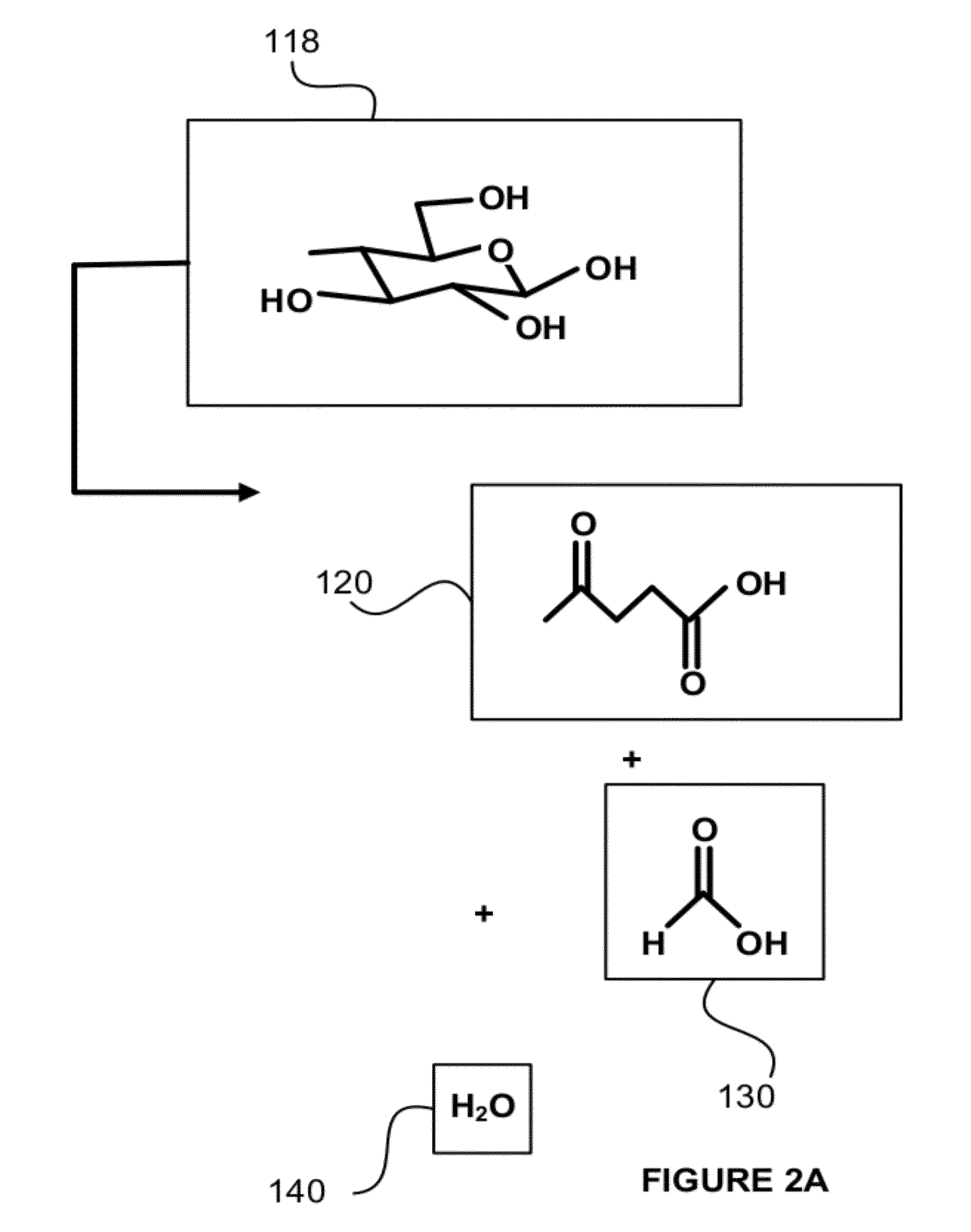

Production of fuel from chemicals derived from biomass

Hydrocarbons may be formed from six carbon sugars. This process involves obtaining a quantity of a hexose sugar. The hexose sugar may be derived from biomass. The hexose sugar is reacted to form an alkali metal levulinate, an alkali metal valerate, an alkali metal 5-hydroxy pentanoate, or an alkali metal 5-alkoxy pentanoate. An anolyte is then prepared for use in a electrolytic cell. The anolyte contains the alkali metal levulinate, the alkali metal valerate, the alkali metal 5-hydroxy pentanoate, or the alkali metal 5-alkoxy pentanoate. The anolyte is then decarboxylated. This decarboxylating operates to decarboxylate the alkali metal levulinate, the alkali metal valerate, the alkali metal 5-hydroxy pentanoate, or the alkali metal 5-alkoxy pentanoate to form radicals, wherein the radicals react to form a hydrocarbon fuel compound.

Owner:ENLIGHTEN INNOVATIONS INC

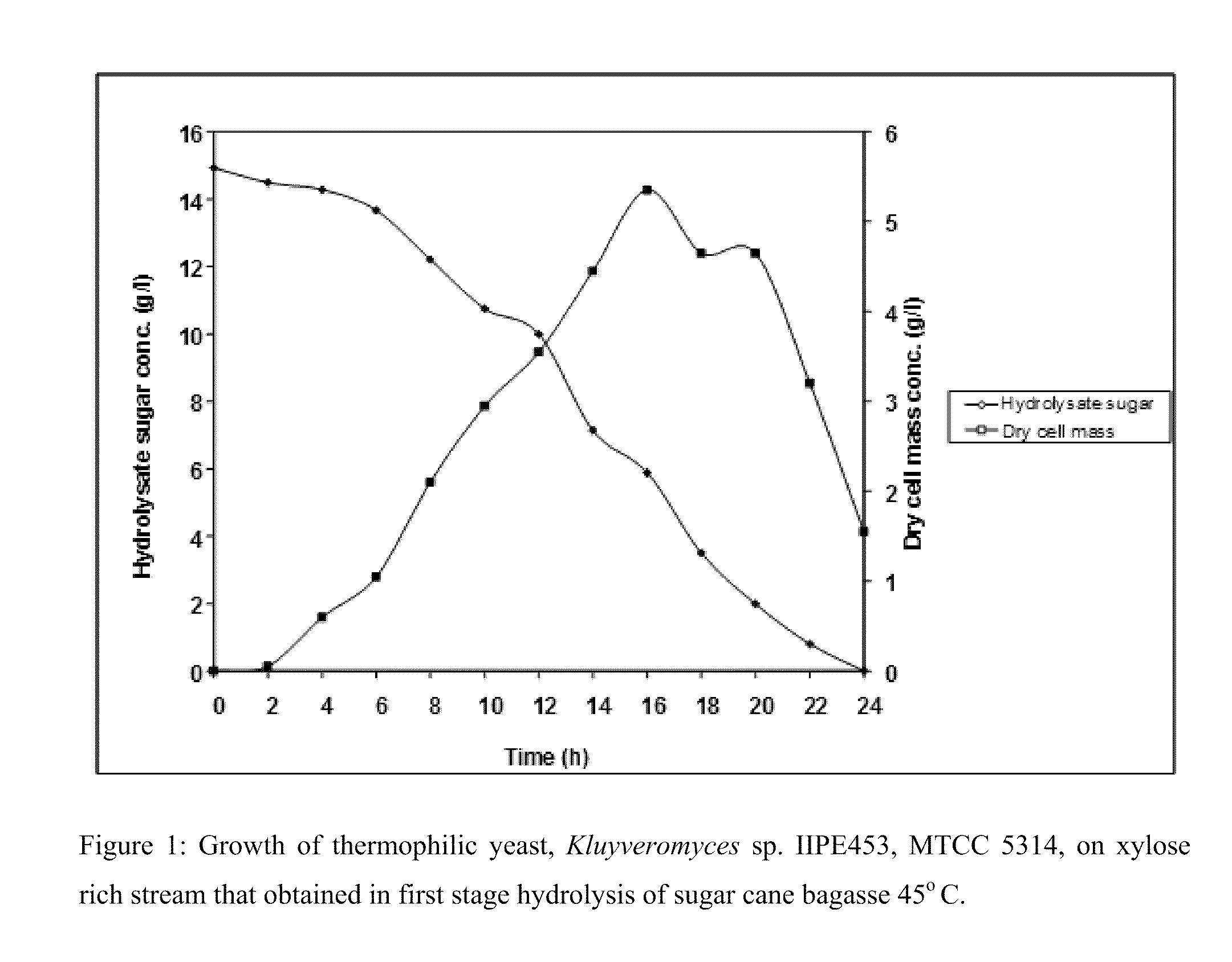

Novel strain and a novel process for ethanol production from lignocellulosic biomass at high temperature

The present invention relates to a novel thermophilic ethanol producing yeast strain, a microorganism, Kluyveromyces sp. IIPE453 MTCC 5314, classified as yeast, which exhibits growth and sugar fermentation at higher temperature range between 37° C. to 55° C. The novel yeast strain is capable of utilizing wide range of mono and di-saccharide sugars belongs to hexose and pentose carbohydrate family individually or in a mixture that obtained from hydrolysis of lignocellulosic biomass, such as sugarcane bagasse or starch based biomass such as cassava, potato, corn etc. for its growth and produce ethanol by fermentation process at temperature range 40° C. to 55° C. It also relates to a novel process for the preparation of ethanol by Kluyveromyces species IIPE453. Thus application of thermophilic yeast strain Kluyveromyces sp. IIPE453 MTCC 5314 has wide scope for industrial production of bioethanol from low cost renewable biomass as alternate feedstock to molasses.

Owner:COUNCIL OF SCI & IND RES

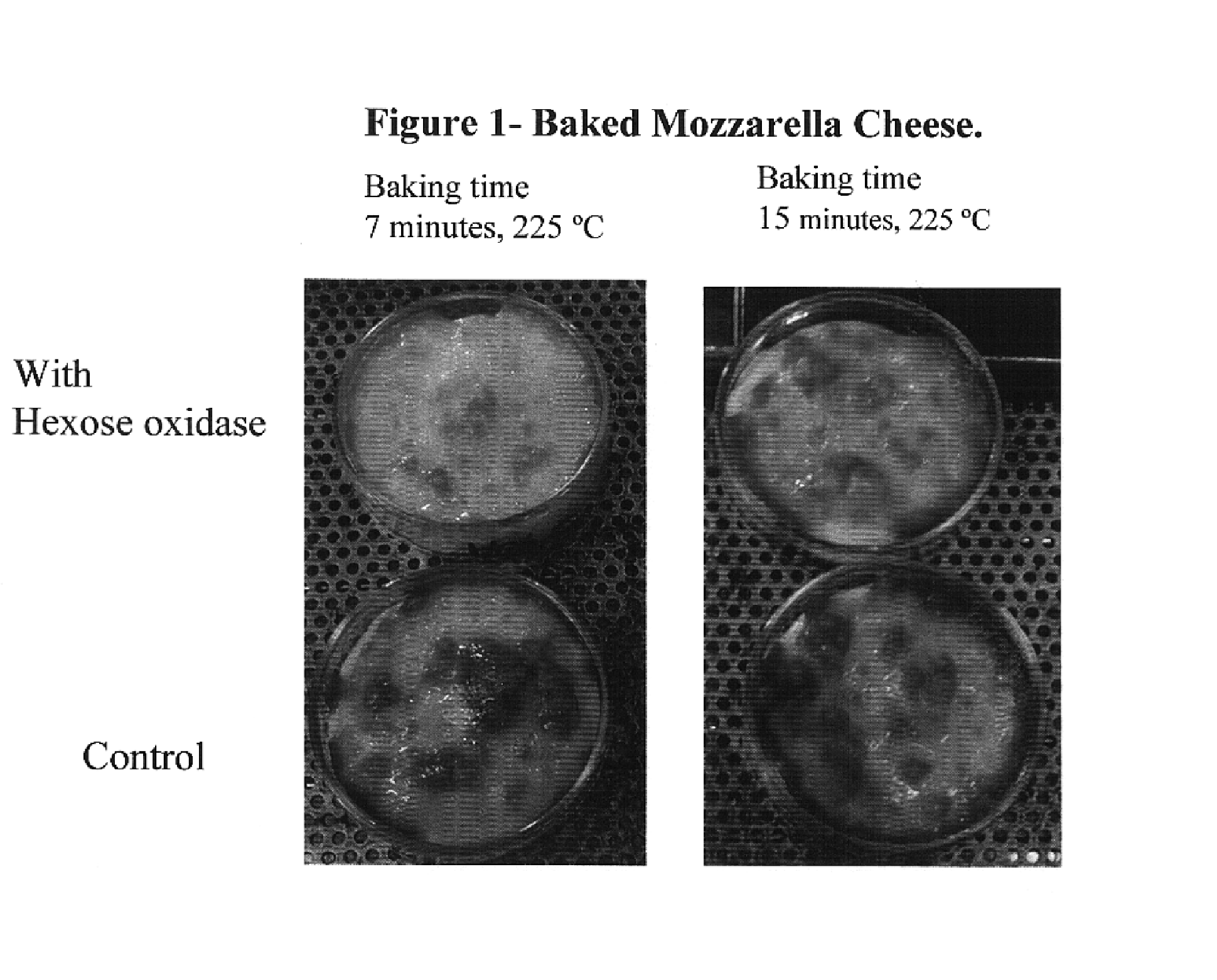

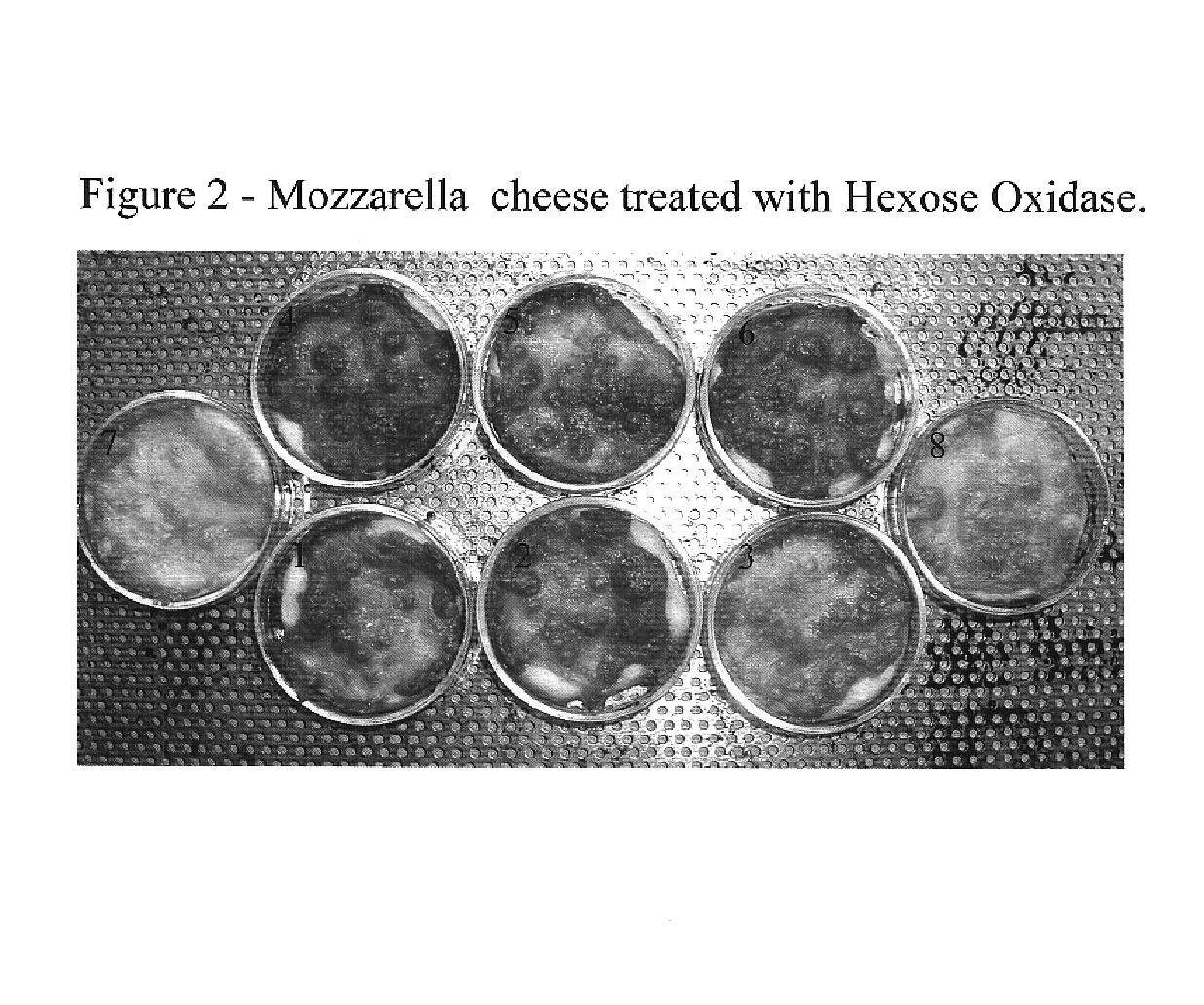

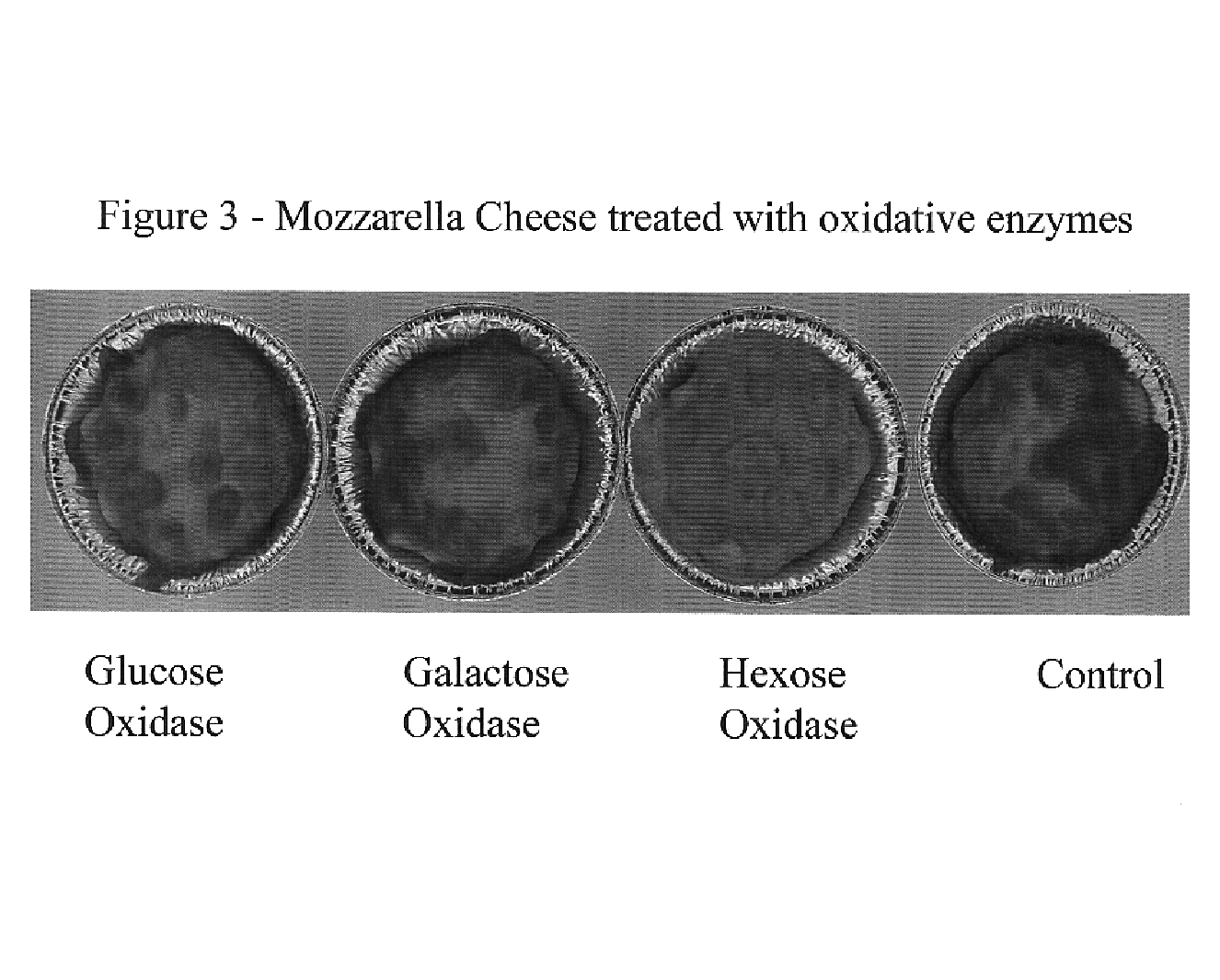

Method of reducing or preventing Maillard reactions in potato with hexose oxidase

InactiveUS6872412B2Avoid the Maillard reactionEliminating the reducing sugarMilk preparationTea extractionMaillard reactionOxidative enzyme

There is provided a process for the prevention and / or reduction of Maillard reaction in a foodstuff containing (i) a protein, a peptide or an amino acid and (ii) a reducing sugar, the process comprising contacting the foodstuff with an enzyme capable of oxidising a reducing group of the sugar.

Owner:DUPONT NUTRITION BIOSCIENCES APS

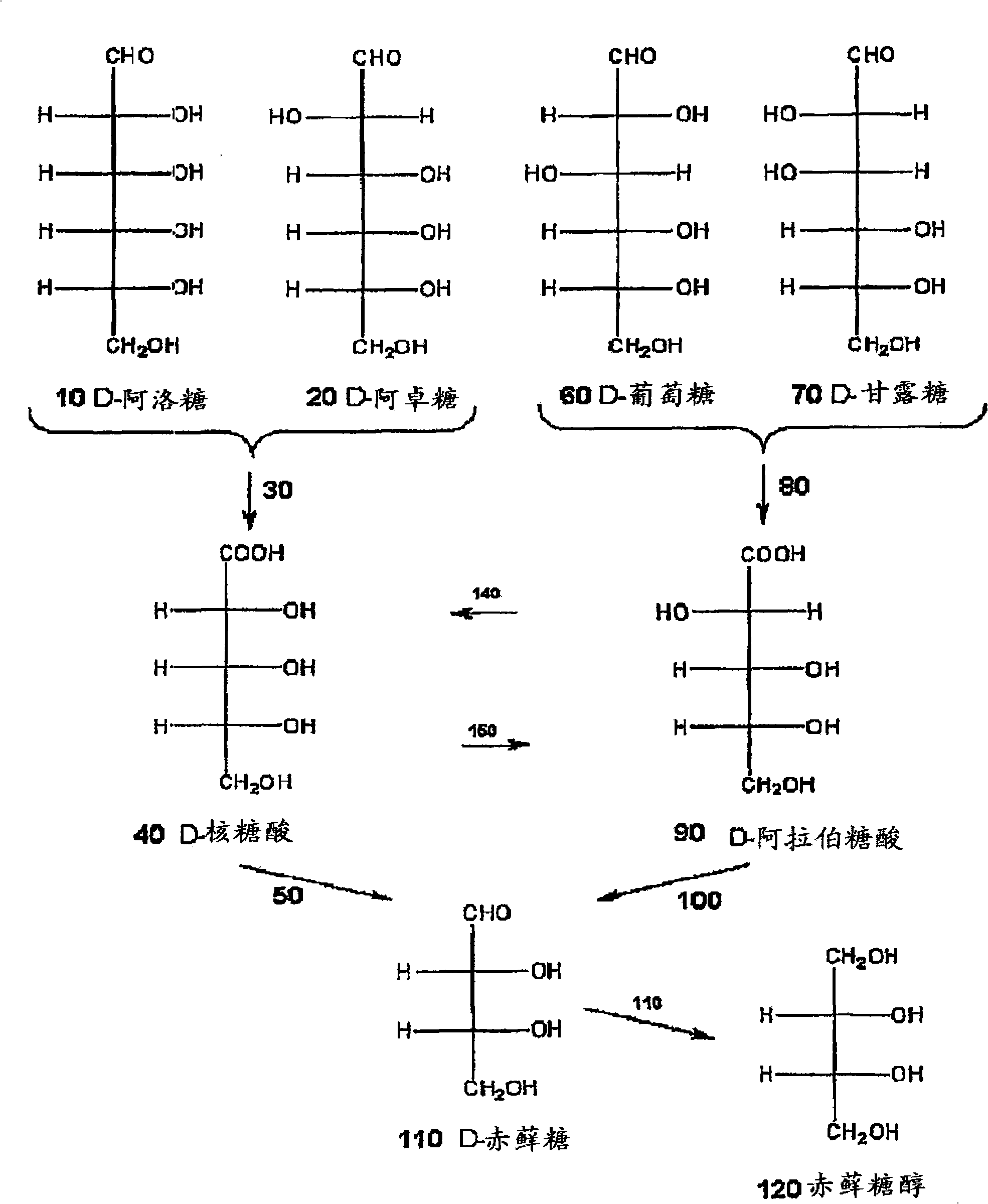

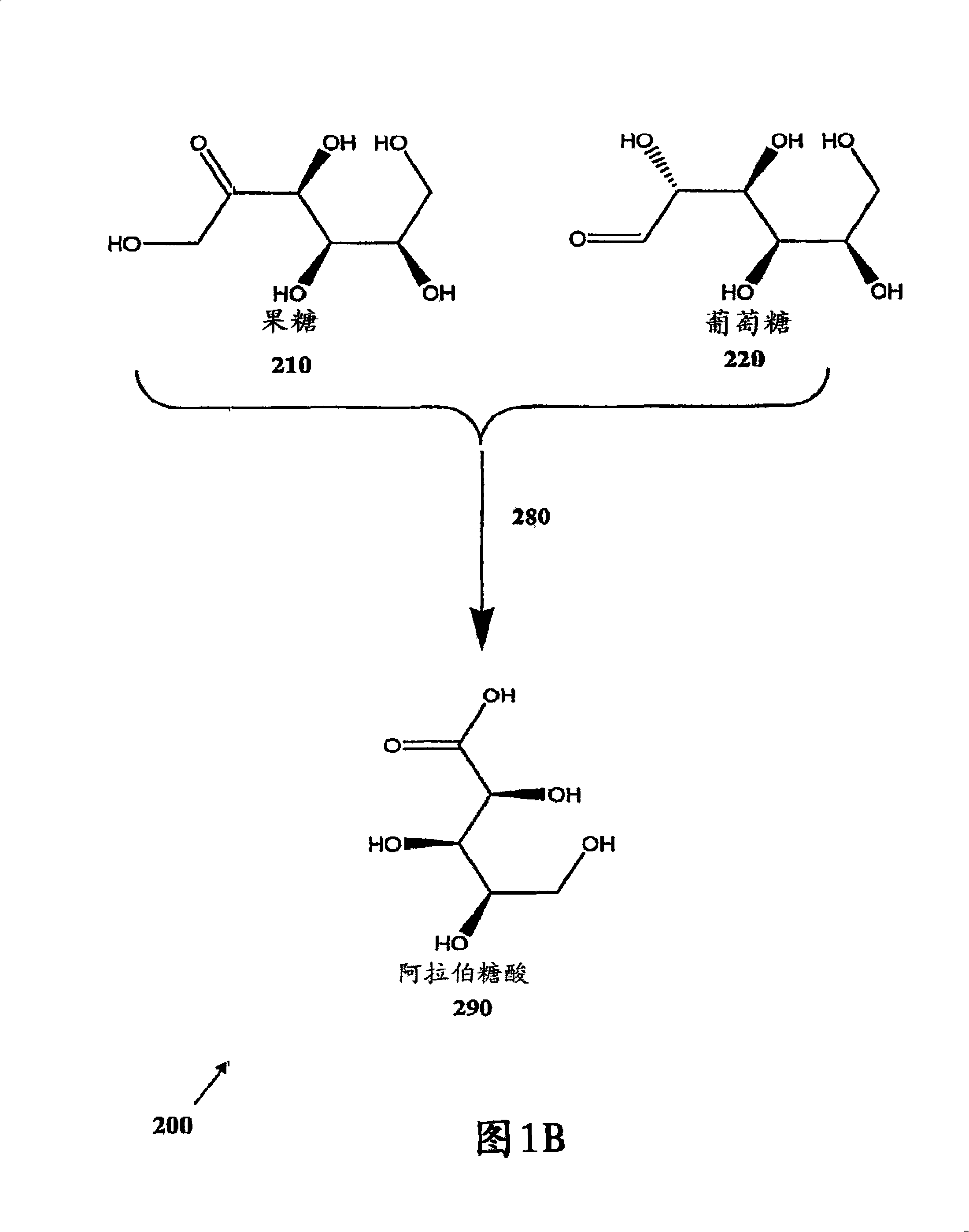

Methods for the electrolytic production of erythrose or erythritol

Owner:DFI USA LLC

Fermentation Process, Starter Culture and Growth Medium

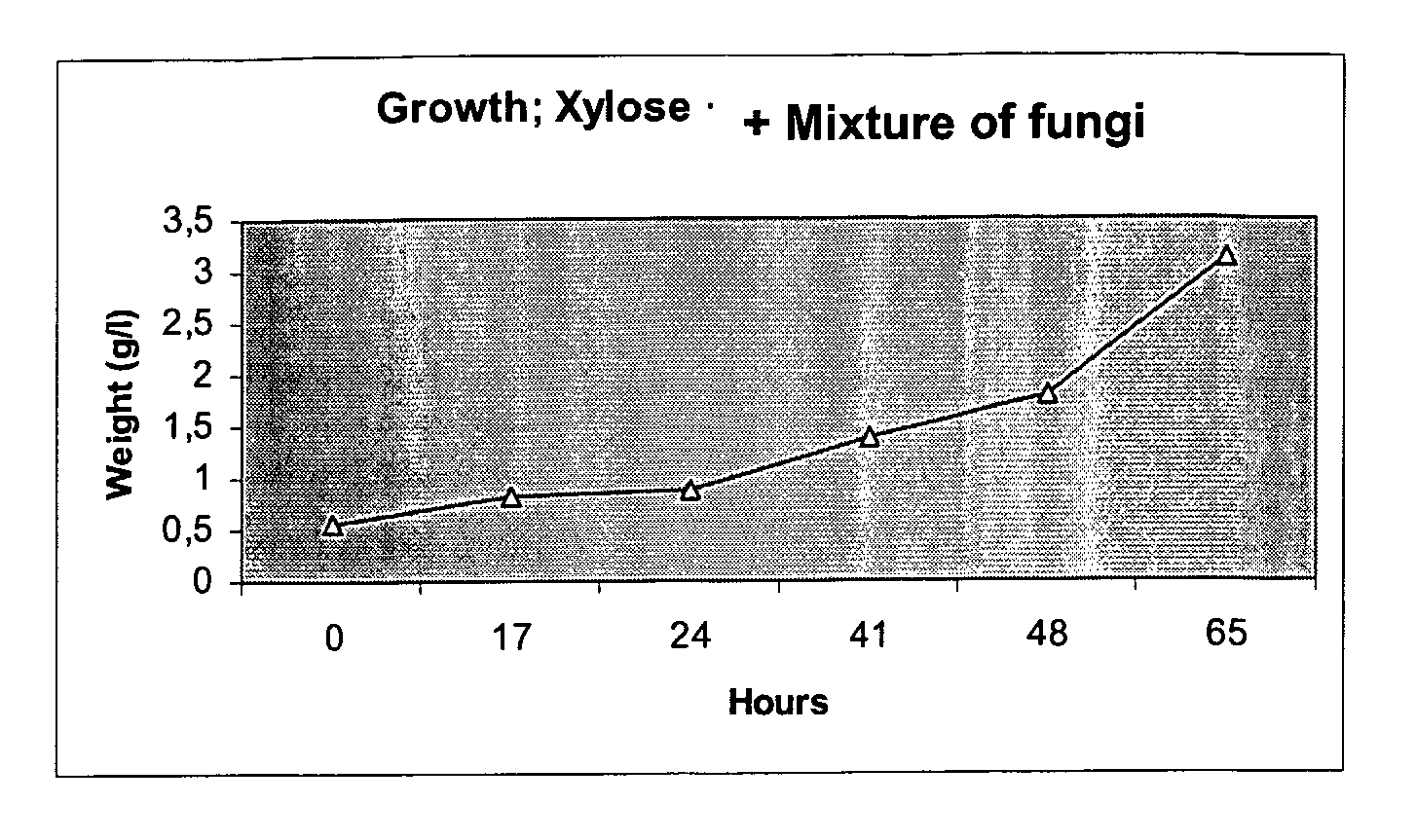

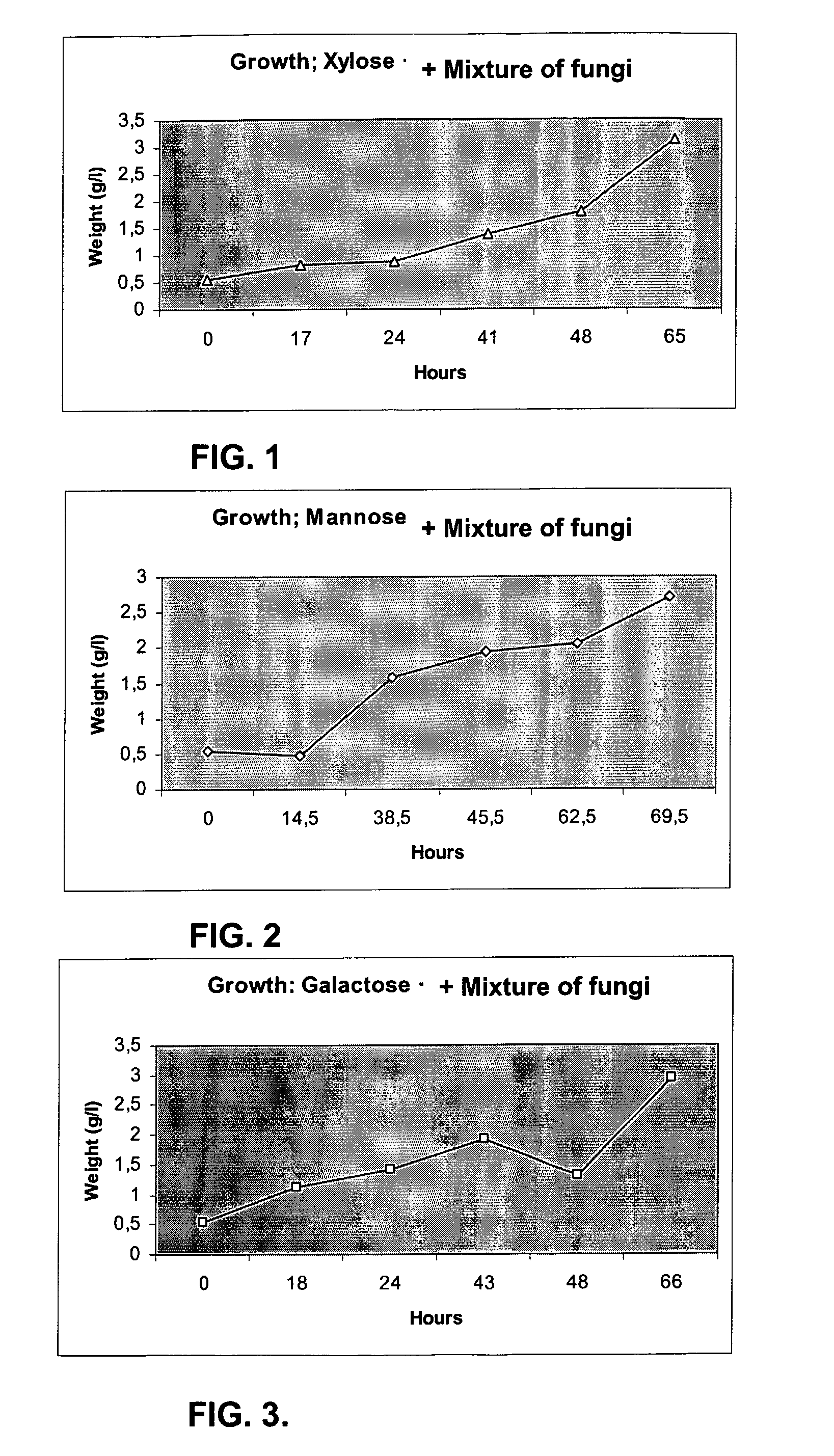

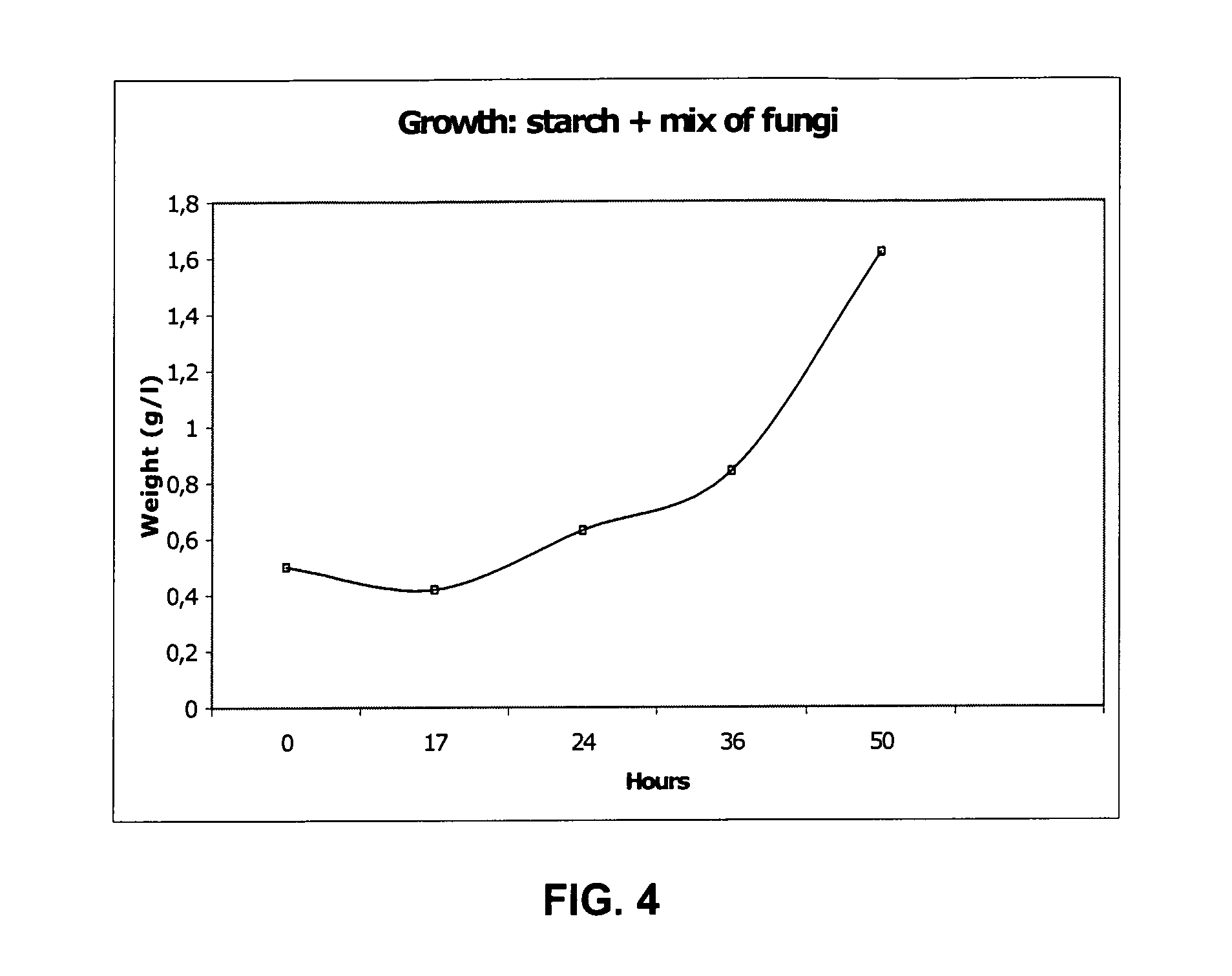

InactiveUS20070231869A1High economicHigh environmental interestFungiBiofuelsMicroorganismCell culture media

Ethanol production from biomass can be rendered more effective by the use of at least one fungus or a mix of fungi capable of fermenting pentose compounds, or both pentose as well as hexose compounds. Preferably said at least one fungus is a fungus belonging to the species Chalara sp., optionally used in combination with a second fungus belonging to the species Trametes sp. Preferably said fungus or fungi is / are used in combination with other fermenting microorganisms, such as a yeast, e.g. Saccaromyces cerevisiae.

Owner:SWETREE TECHOLOGIES AB

Methods for introducing mannose-6-phosphate and other oligosaccharides onto glycoproteins and its application thereof

InactiveUS7723296B2Increase the cellular uptake of lysosomal enzymesEnhanced uptake formNervous disorderSaccharide peptide ingredientsPhosphorylationPhosphoric acid

Methods to introduce highly phosphorylated mannopyranosyl oligosaccharide derivatives containing mannose-6-phosphate (M6P), or other oligosaccharides bearing other terminal hexoses, to carbonyl groups on oxidized glycans of glycoproteins while retaining their biological activity are described. The methods are useful for modifying glycoproteins, including those produced by recombinant protein expression systems, to increase uptake by cell surface receptor-mediated mechanisms, thus improving their therapeutic efficacy in a variety of applications.

Owner:GENZYME CORP

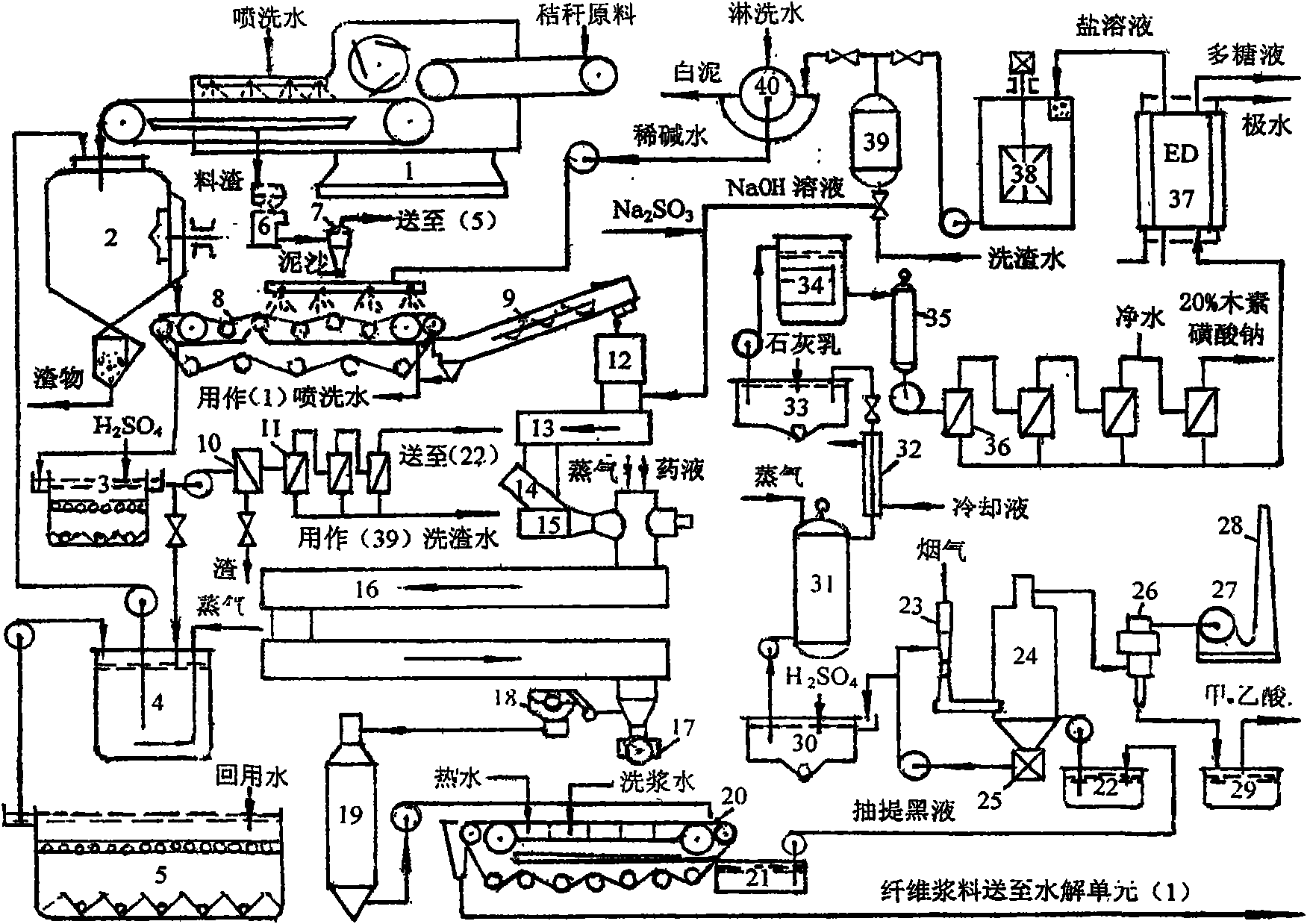

Ethanol-guiding straw bio-refining full-sealing integration system

InactiveCN101555495AImprove productivityStrong profitabilityBy-product recoveryFungiFiberLiquid waste

The invention relates to a fiber biomass refining technology, in particular to an ethanol-guiding straw bio-refining full-sealing integration system. Based on the clean pulping of the straw, a chemical and biological combined method is used for totally hydrolyzing amylose separated from a cellulose and a hemicellulose separated into pulps and braised waste liquid to prepare a hexose and a pentose;and the hexose and the pentose are converted into series of chemical and biological products which taking ethanol as dominant product. As a firstly separated and subsequently disposed straw bio-refin ing integration system, the cellulose and the hemicellulose in the straw raw material are utilized effectively; furthermore, 20-25% of the lignin in the raw material and the material slag, slurry slag, trough slag and ashes (mineral matter) produced in the production process are totally converted into the product with high additional values, thus realizing the environment objects of full sealing and zero draining and controlling the production cost (apportionment cost after the straw biomass is totally utilized) of the fuel ethanol within 1800-2000RMB / t.

Owner:徐守才

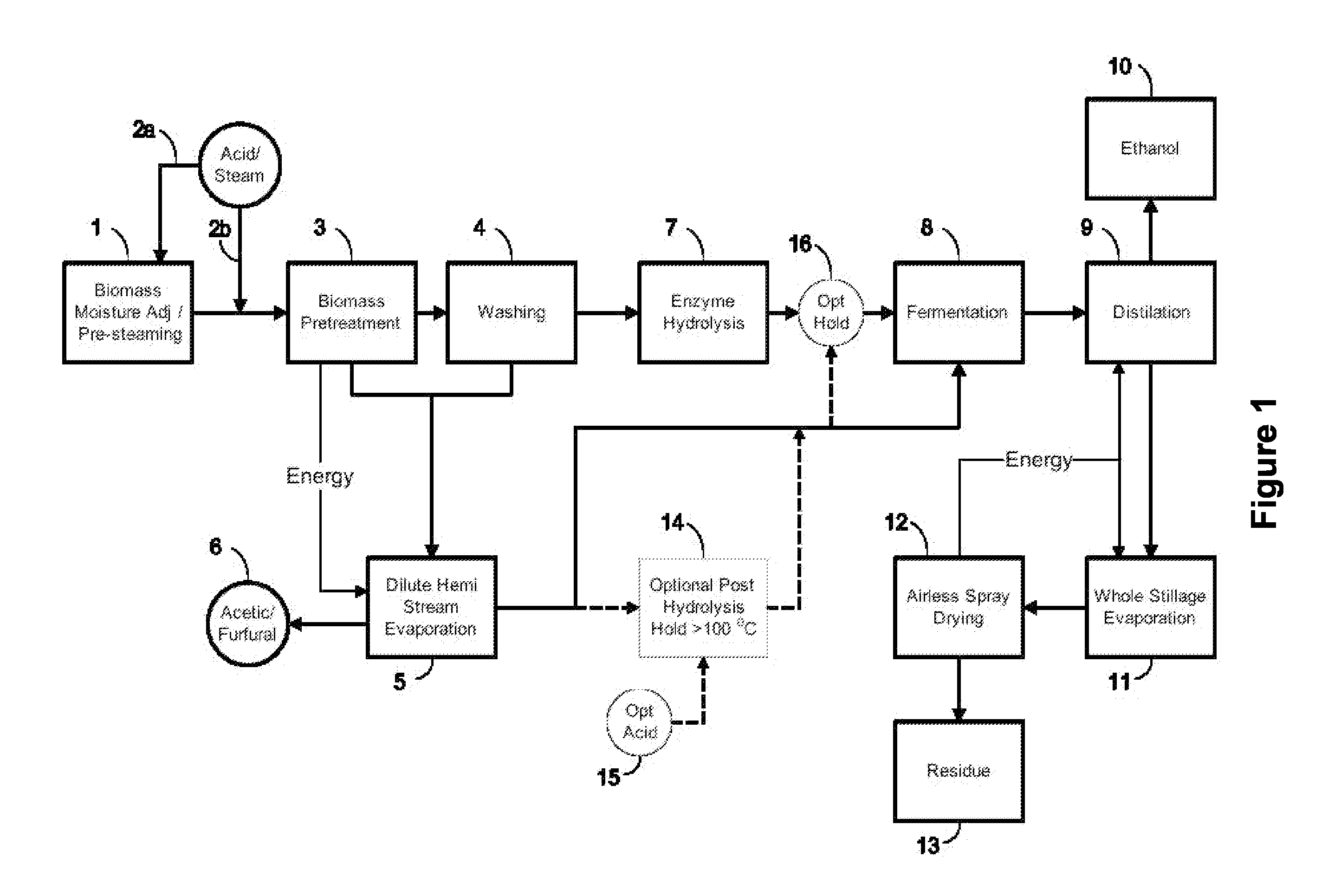

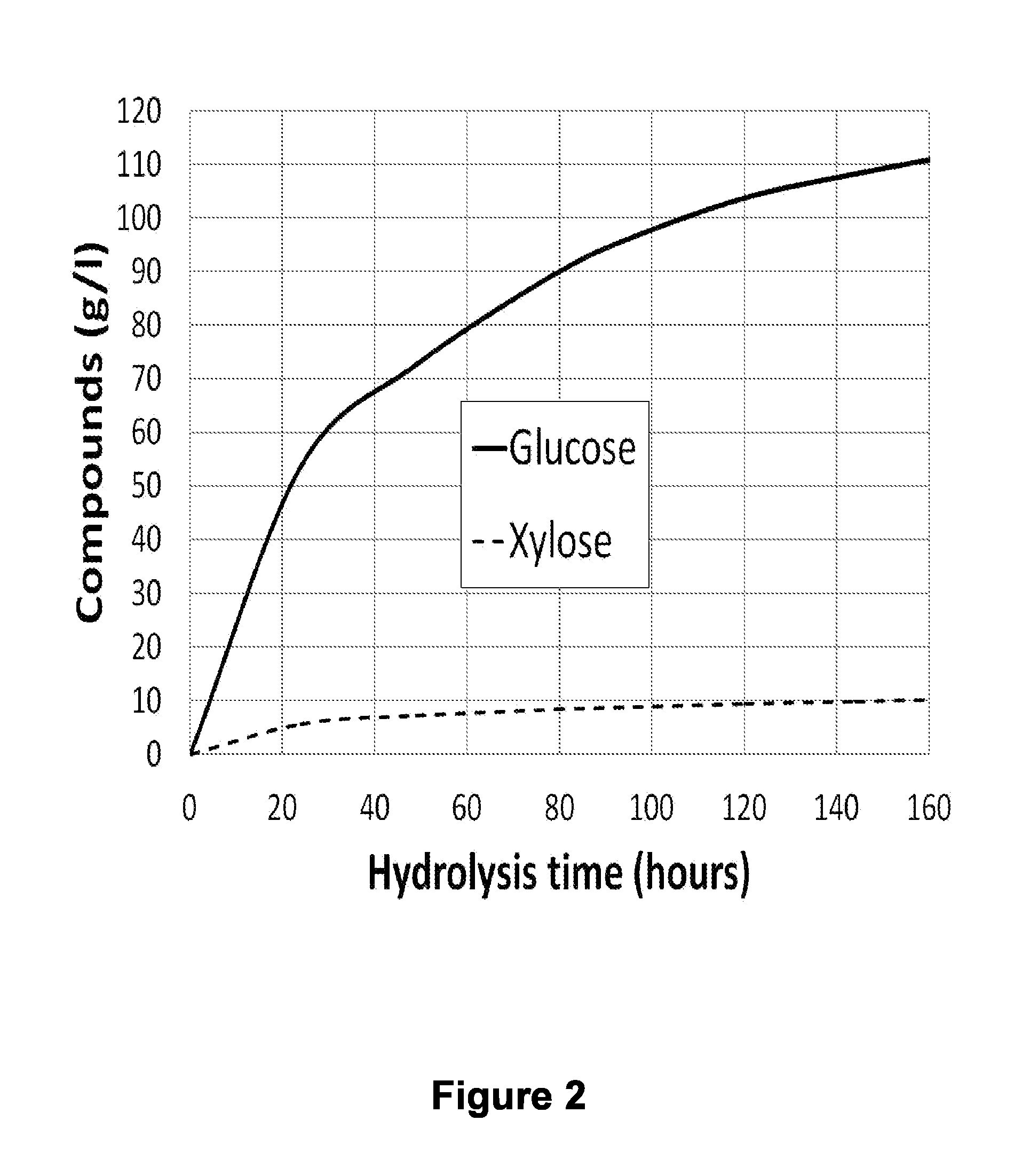

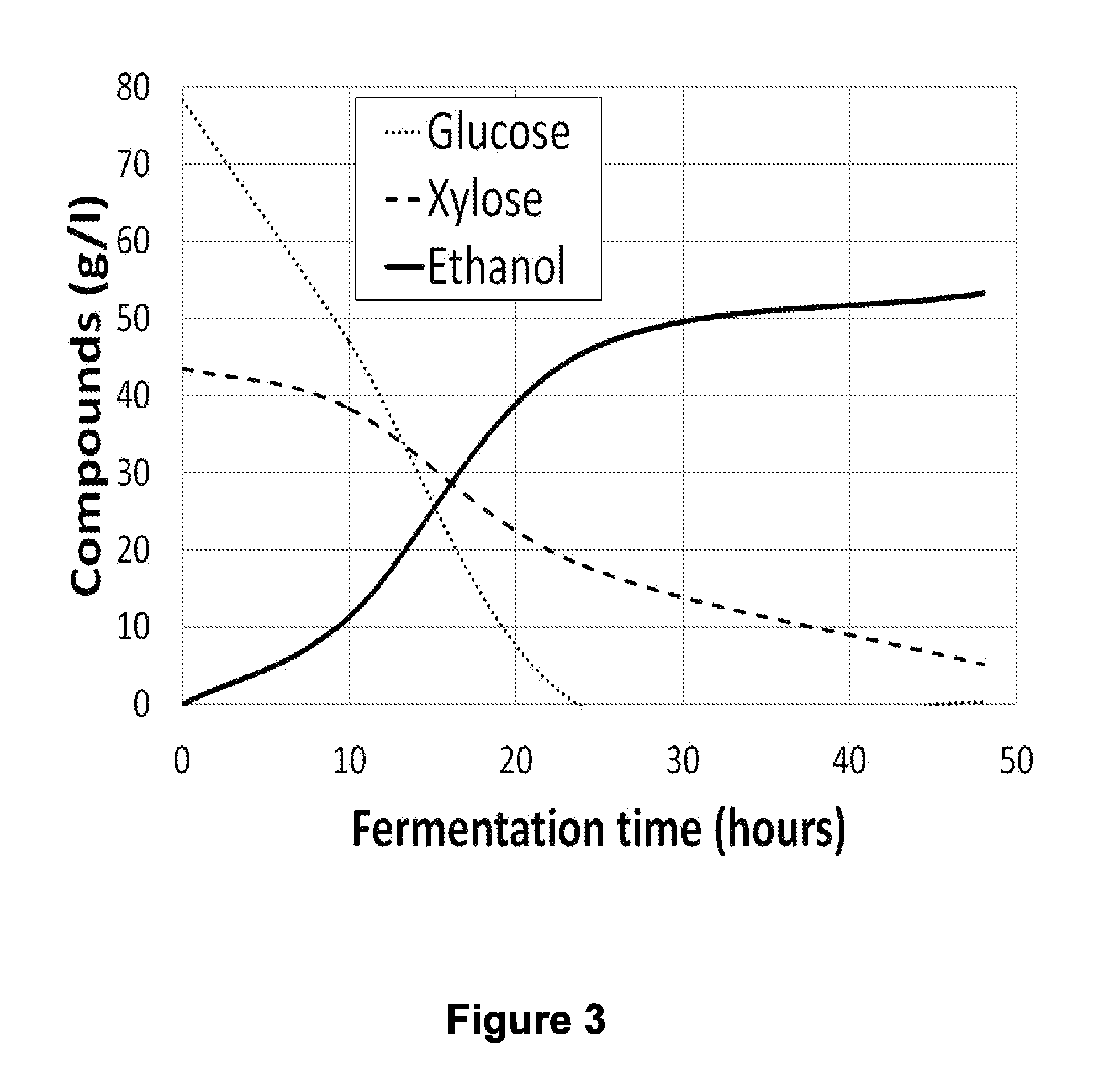

Continuous process for the production of ethanol from lignocellulosic biomass

A continuous process for the recovery of ethanol from hemicellulose and cellulose from lignocellulosic biomass. Yield of fermentable sugars can be maximized by continuous operation of the pre-treatment system and careful selection of pretreatment conditions including the addition of only small amounts of dilute mineral acid and low pressure. With this approach, the xylose component that is mainly present in its unfermentable oligomeric form in known pre-hydrolysis Kraft processes can be recovered more efficiently and as a monomer that can be fermented by xylose fermenting yeasts and bacteria. Due to the use of only dilute acids, there is a very low loss of glucose and xylose hence very low production of toxic chemicals (e.g. HMF, furfural) in the pretreatment step. The resulting overall fermentation efficiency of both hexose and pentose sugars is 90% of the theoretical maximum.

Owner:GREENFIELD SPECIALTY ALCOHOLS

Apparatus and method for hydrolysis of cellulosic material in a multi-step process to produce c5 and c6 sugars using a single vessel

InactiveUS20090308383A1Undesirable effectFructose productionSugar juice extraction using extracting agentsCelluloseSingle vessel

Owner:ANDRITZ INC

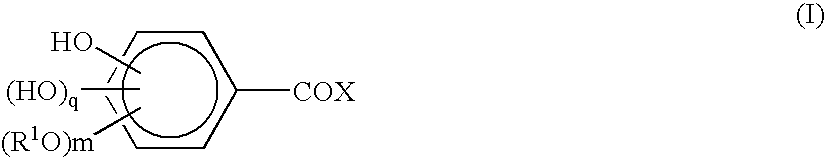

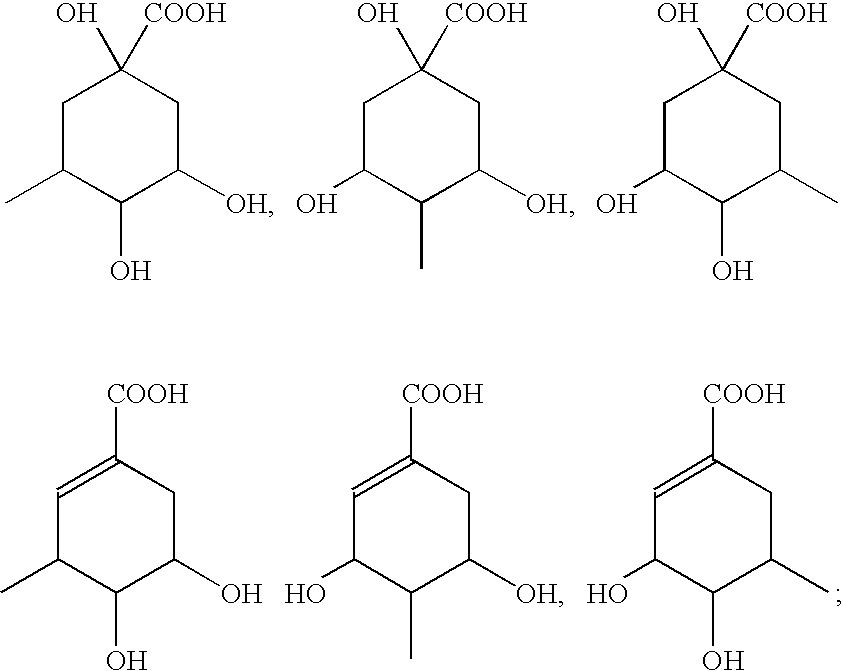

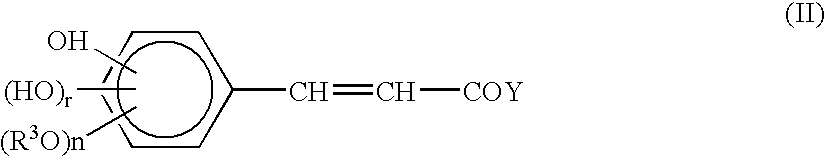

Photoprotector and/or photoimmunoprotector compositions of the skin and their uses

InactiveUS20070025933A1Prevent and minimise damaging effectPrevent and minimise reactionCosmetic preparationsBiocideBenzoic acidPhototherapy unit

The composition comprises of a component A selected from a hydroxylated derivative of benzoic acid or of cinamic acid, their esters, amides or salts, a glycoside of a hexose, and their mixtures; and a component B selected from quinic acid, shikimic acid, their alkaline metal or alkaline earth salts, their methyl esters, and mixtures of the same. This composition is suitable for protecting the skin against ultraviolet radiation coming from the sun or artificial sources, such as those used in phototherapy units and in sun tanning rooms. For application in the field of dermatology and nutrition, and, in particular, in the photoprotection of the skin and mucosa, photo-ageing and photocarcinogenesis, including protection of the immune system associated with the skin.

Owner:IND FARM CANTABRIA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Substituted 3-azabicyclo[3.1.0]hexanes as ketohexokinase inhibitors Substituted 3-azabicyclo[3.1.0]hexanes as ketohexokinase inhibitors](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/03cc0bdf-652d-44ee-bece-135e2ceb7d7a/US20170183328A1-20170629-D00000.png)

![Substituted 3-azabicyclo[3.1.0]hexanes as ketohexokinase inhibitors Substituted 3-azabicyclo[3.1.0]hexanes as ketohexokinase inhibitors](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/03cc0bdf-652d-44ee-bece-135e2ceb7d7a/US20170183328A1-20170629-D00001.png)

![Substituted 3-azabicyclo[3.1.0]hexanes as ketohexokinase inhibitors Substituted 3-azabicyclo[3.1.0]hexanes as ketohexokinase inhibitors](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/03cc0bdf-652d-44ee-bece-135e2ceb7d7a/US20170183328A1-20170629-D00002.png)