Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

256results about "Fructose production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

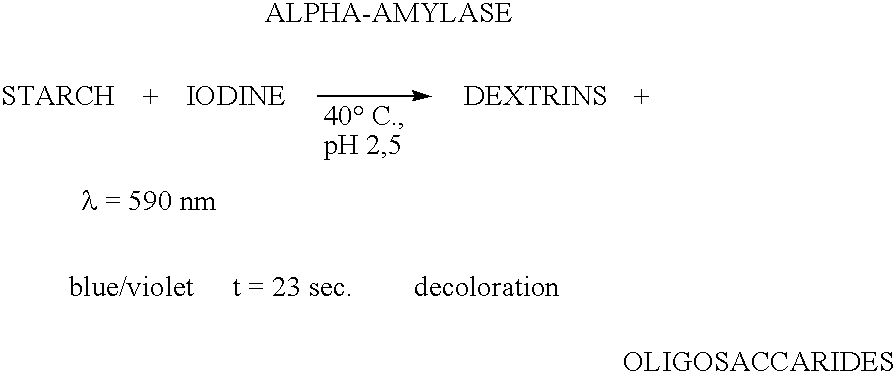

Enzymes for starch processing

InactiveUS20050054071A1Increased acid alpha-amylase activityImprove enzyme stabilitySugar derivativesBacteriaBiotechnologyCarbohydrate-binding protein

The present invention relates to a hybrid enzyme comprising carbohydrate-binding module amino acid sequence and a fungal alpha-amylase amino acid sequence and to a variant of a fungal wild type enzyme comprising a carbohydrate-binding module and an alpha-amylase catalytic module. The invention also relates to the use of the hybrid enzyme or the variant in starch liquefaction.

Owner:NOVOZYMES AS +1

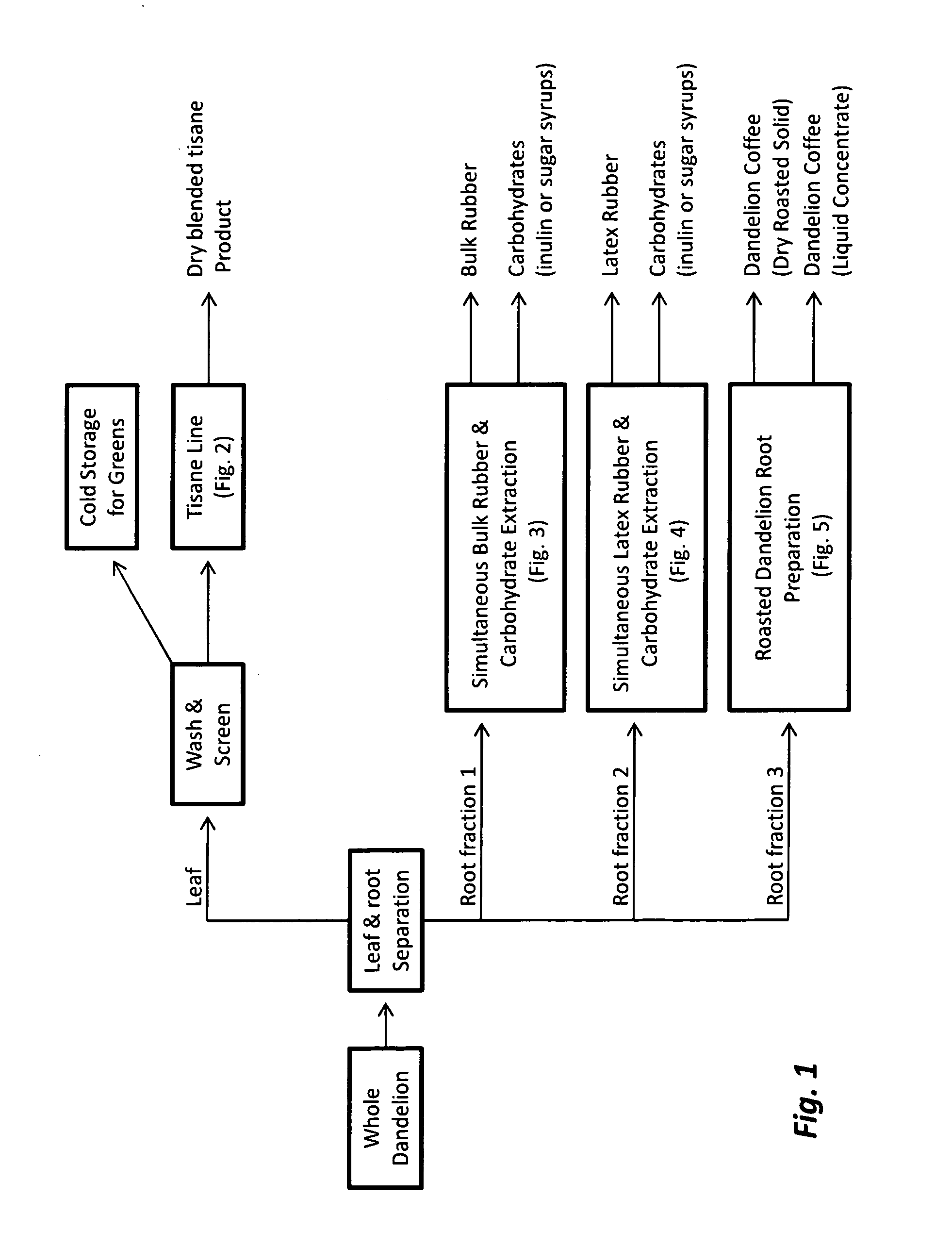

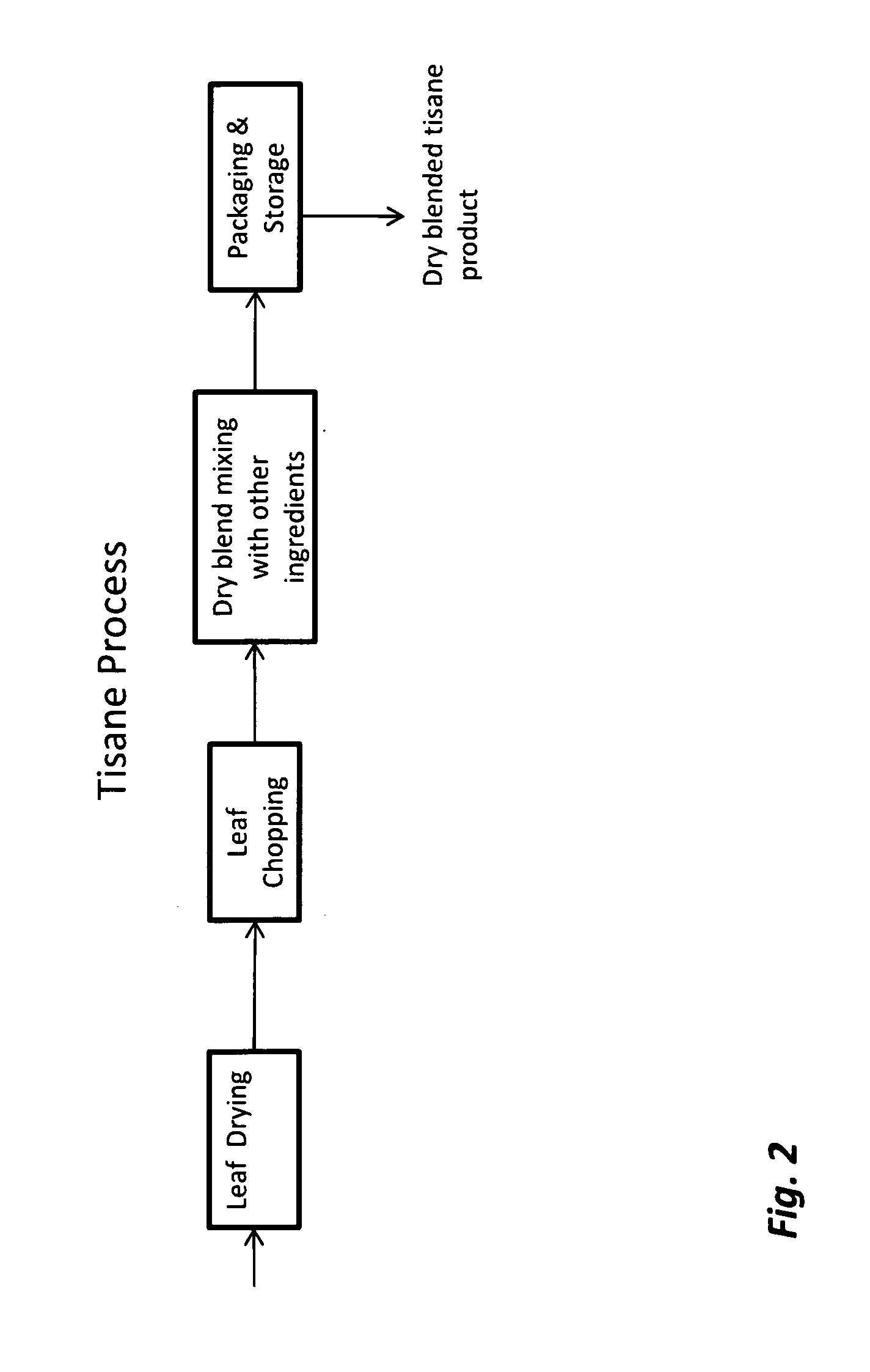

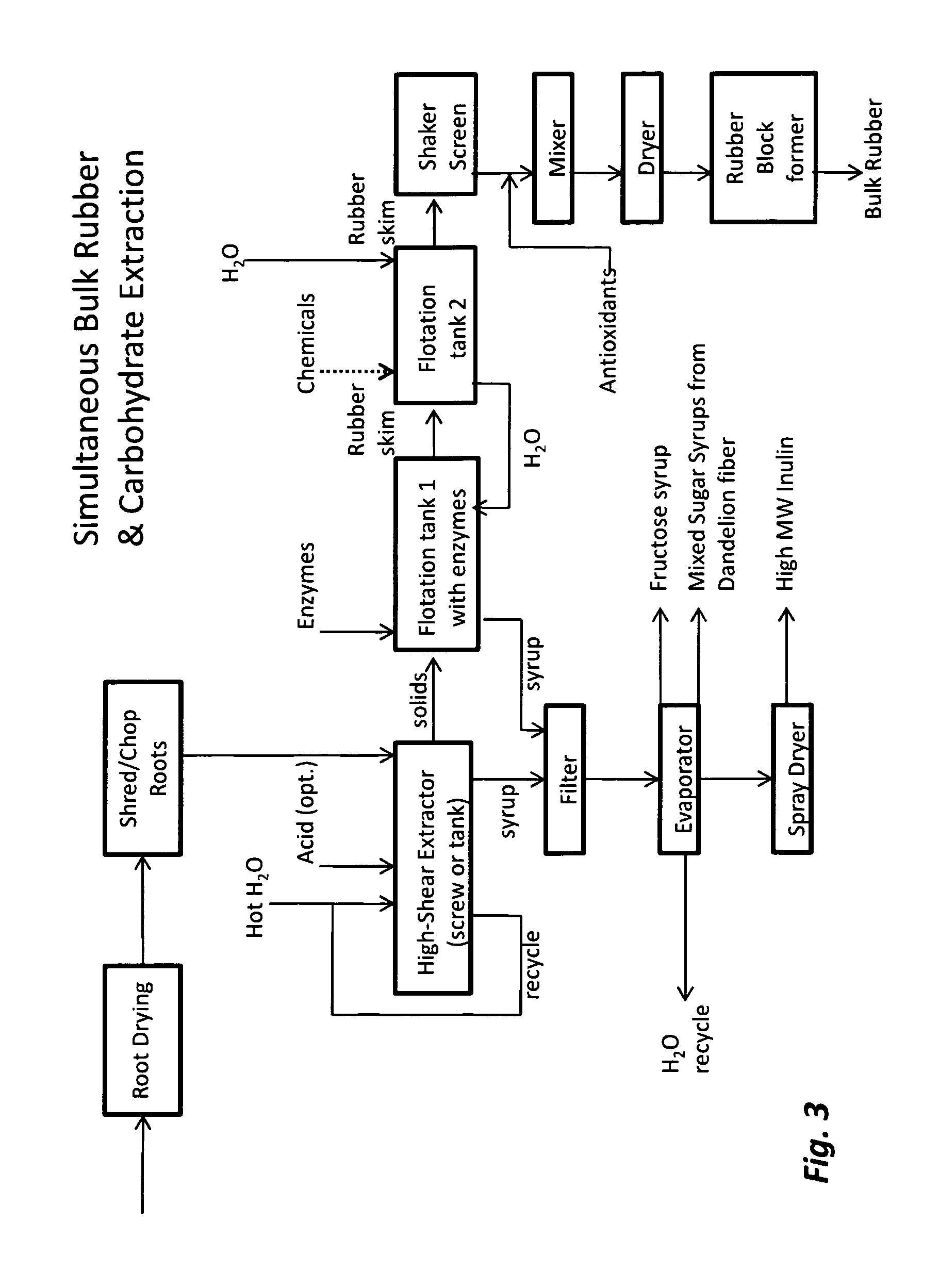

Dandelion processes, compositions and products

Dandelion processes, compositions and products are provided. One process is a method of preparing dandelion that utilizes a species of a Taraxacum genus, the process including the steps of extracting and recovering a rubber and a carbohydrate from a dandelion root substantially simultaneously. The process employs a dandelion species that is selected from the group consisting of: Taraxacum officianale, Taraxacum kok-saghyz, a rubber-bearing species of the genus Taraxacum, and a combination of two or more thereof. This Abstract is provided for the sole purpose of complying with the Abstract requirement rules that allow a reader to quickly ascertain the subject matter of the disclosure contained herein. This Abstract is submitted with the explicit understanding that it will not be used to interpret or to limit the scope or the meaning of the claims.

Owner:KULTEVAT

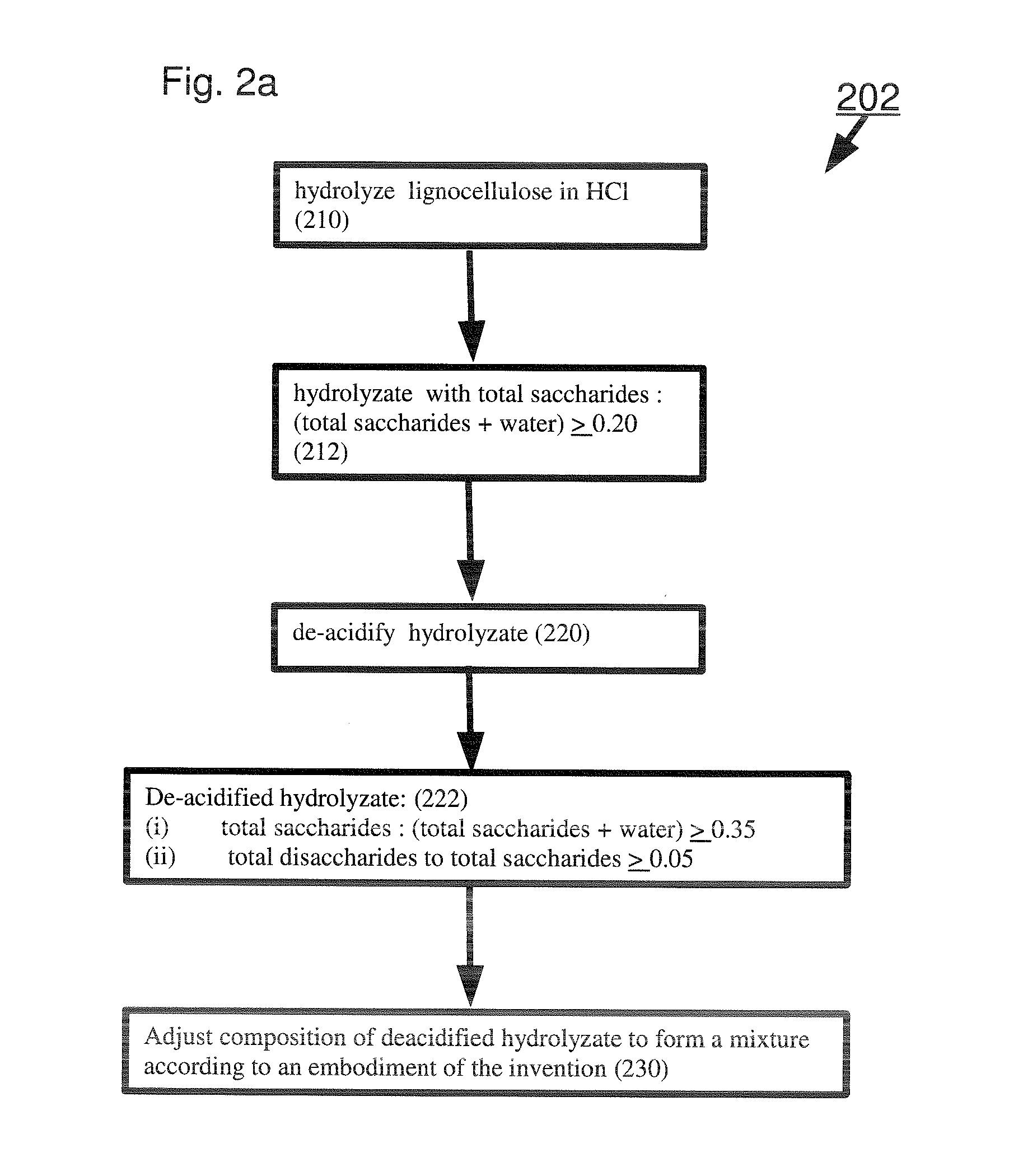

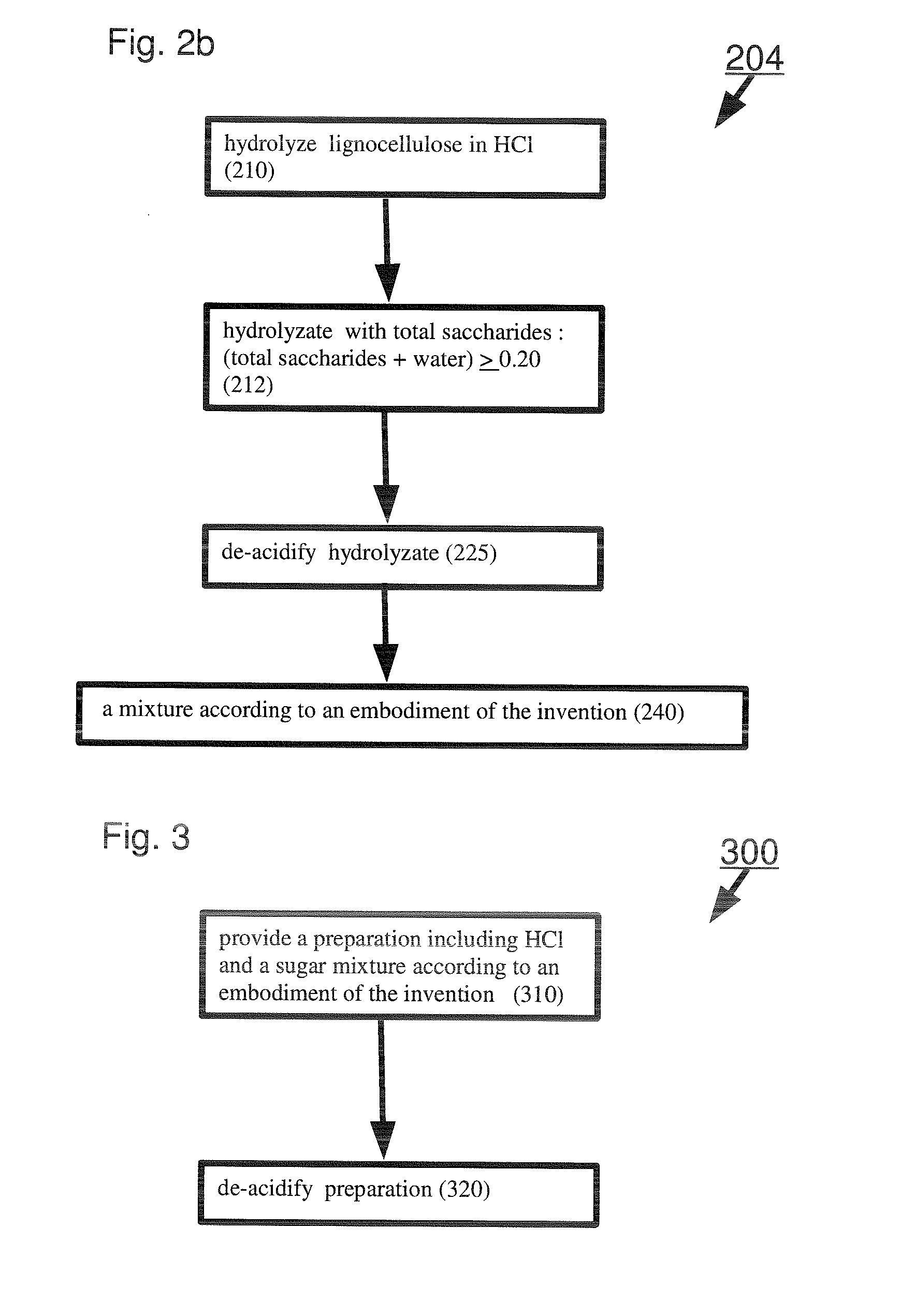

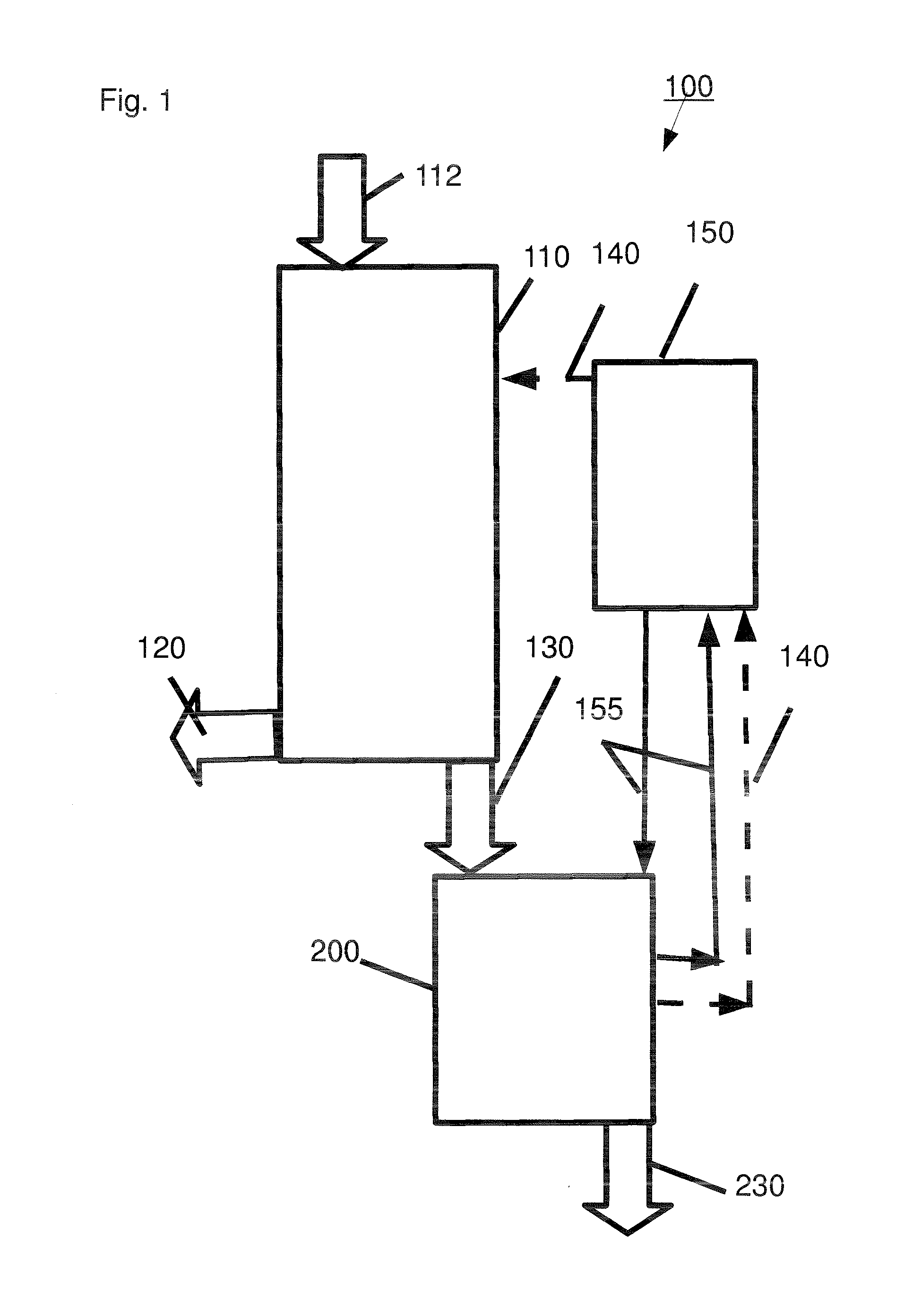

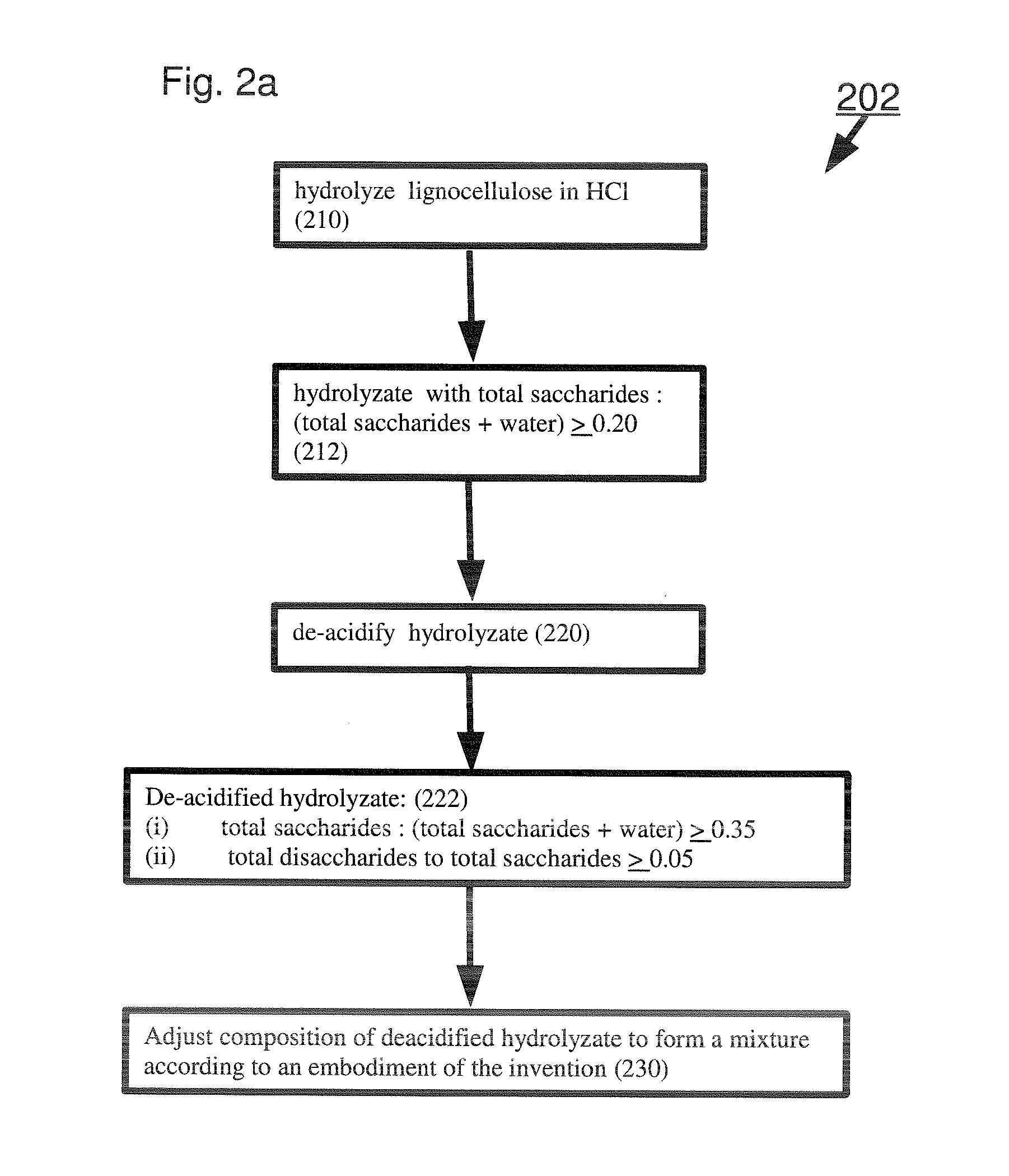

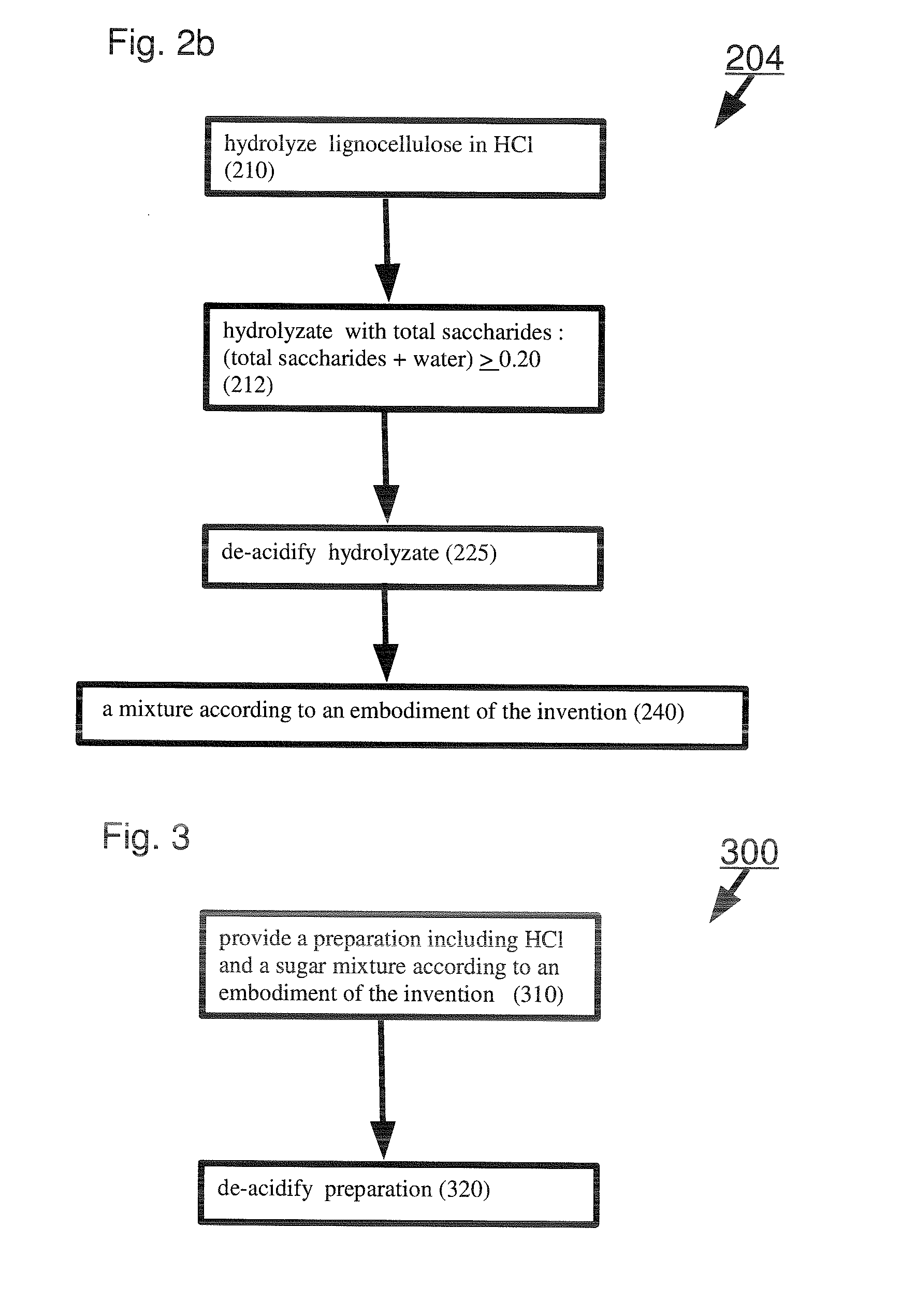

Sugar mixtures and methods for production and use thereof

A sugar mixture comprising: monosaccharides; oligosaccharides in a ratio ≧0.06 to total saccharides; disaccharides in a ratio to total saccharides ≧0.05; pentose in a ratio to total saccharides ≧0.05; at least one alpha-bonded di-glucose; and at least one beta-bonded di-glucose. Also disclosed are methods to make and / or use such mixtures.

Owner:VIRIDA

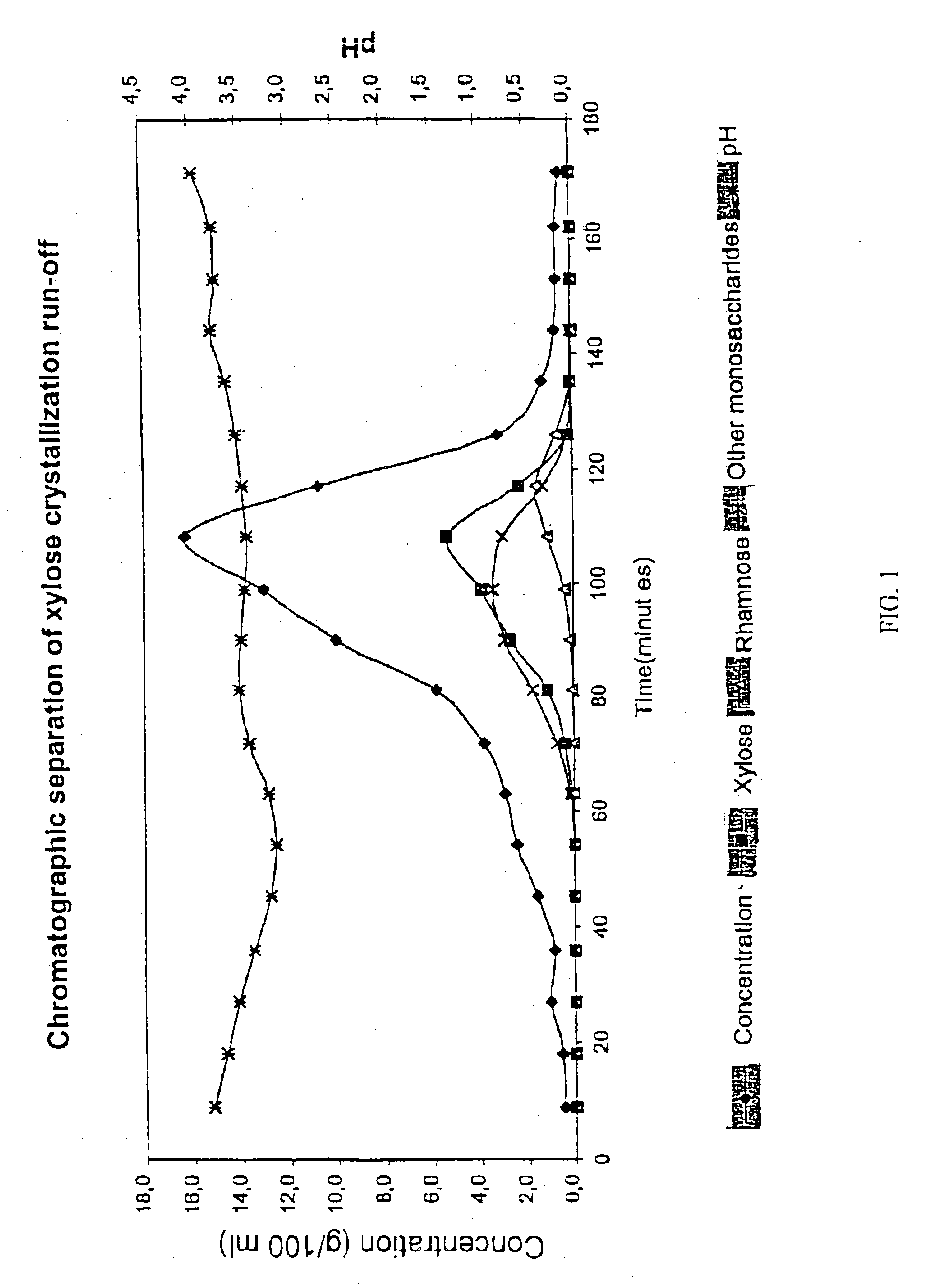

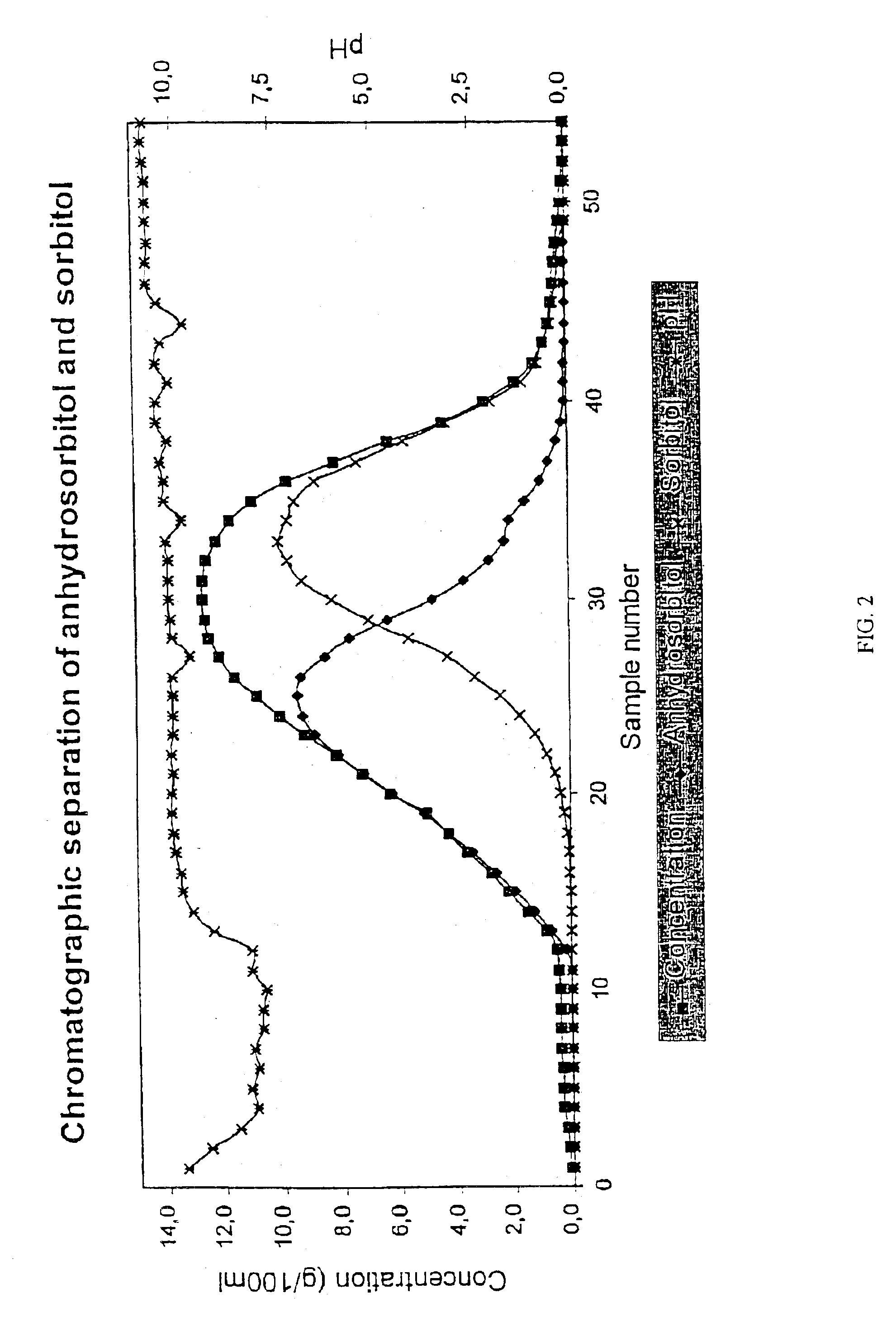

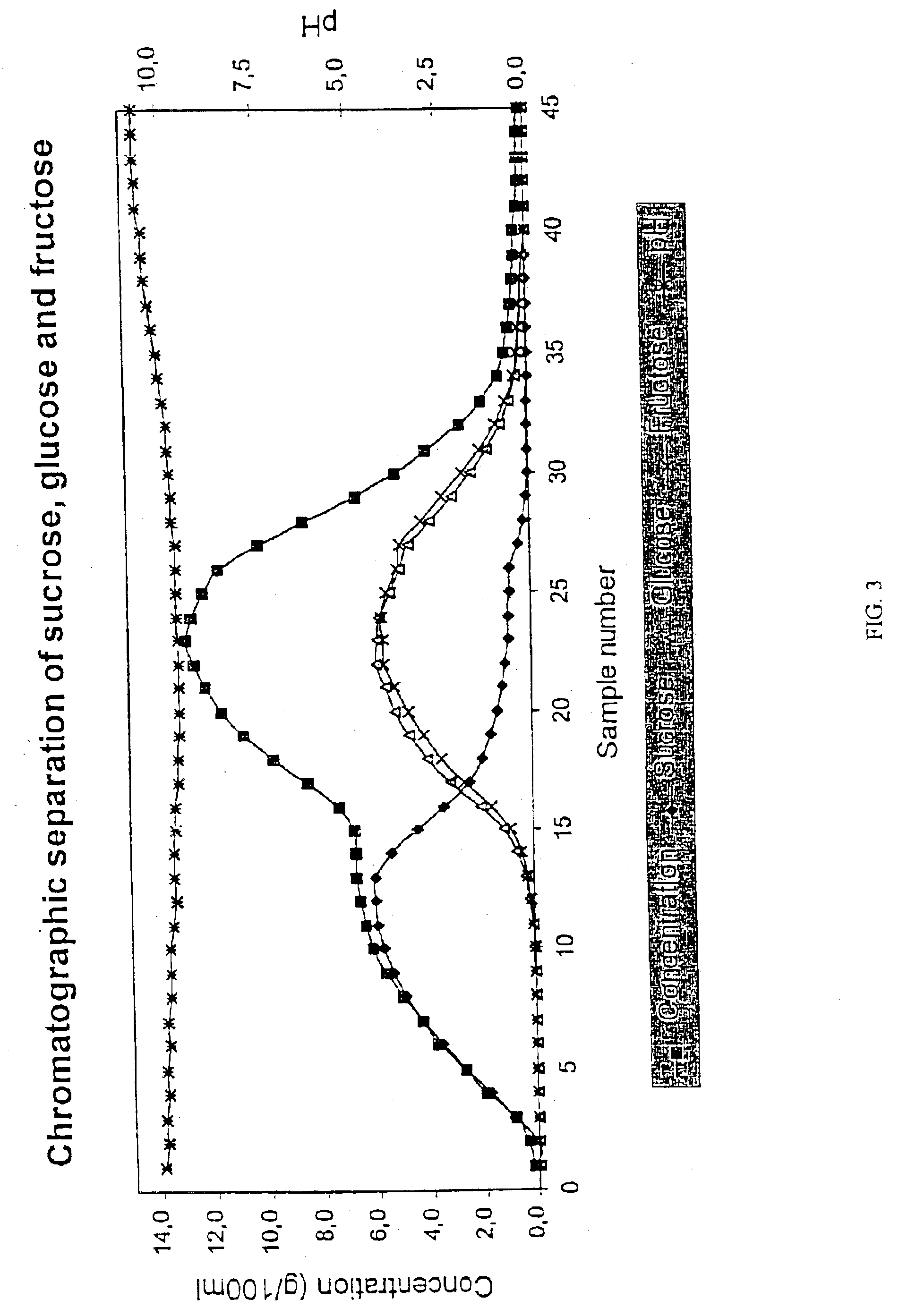

Use of a weakly acid cation exchange resin for chromatographic separation of carbohydrates

InactiveUS6924371B2High yieldEasy to separateChromatographic cation exchangersCation exchanger materialsChromatographic separationAlcohol sugars

The invention relates to the use of a weakly acid cation exchange resin for chromatographic separation of carbohydrates. In the invention the hydrophilic / hydrophobic interaction of carbohydrates, sugars and sugar alcohols with the weakly acid cation exchange resin is utilized. The weakly acid cation exchange resin is used for separation of hydrophobic saccharides, such as deoxy, methyl and anhydrosugars and anhydrosugaralcohols from more hydrophilic saccharides.

Owner:DANISCO SWEETENERS

Sugar mixtures and methods for production and use thereof

A sugar mixture comprising: monosaccharides; oligosaccharides in a ratio ≧0.06 to total saccharides; disaccharides in a ratio to total saccharides ≧0.05; pentose in a ratio to total saccharides ≧0.05; at least one alpha-bonded di-glucose; and at least one beta-bonded di-glucose. Also disclosed are methods to make and / or use such mixtures.

Owner:VIRIDA

Apparatus and method for hydrolysis of cellulosic material in a multi-step process to produce c5 and c6 sugars using a single vessel

InactiveUS20090308383A1Undesirable effectFructose productionSugar juice extraction using extracting agentsCelluloseSingle vessel

Owner:ANDRITZ INC

Sugar compositions

Owner:VIRIDA

Crystallization of sugars

The invention relates to removing crystallization inhibitors from a solution comprising one or more reducing sugars by nanofiltration, hydrolysis and / or chromatography. The reducing sugars are typically selected from fructose and xylose.

Owner:DANISCO SWEETENERS

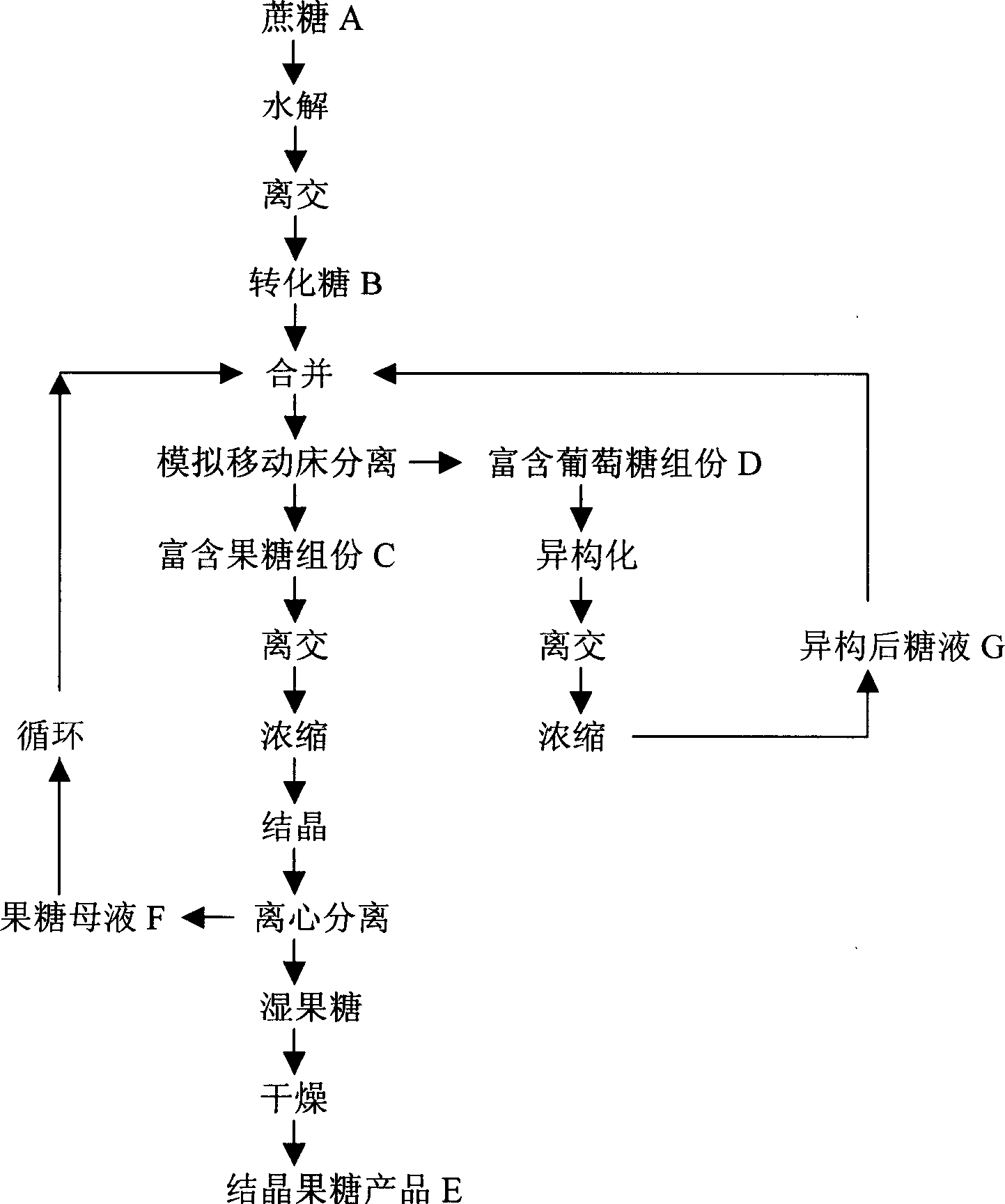

Method for co-producing crystalline fructose and fructose corn syrup by taking wheat as raw material, and preparation method of wheat starch

ActiveCN103146849ASolve constraintsExpand the field of sourcesFructose productionGlucose productionBiotechnologyGluten

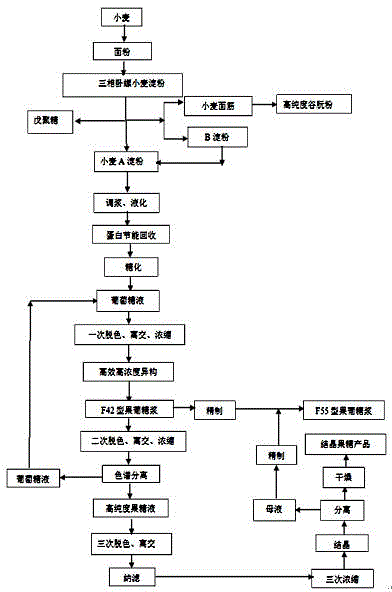

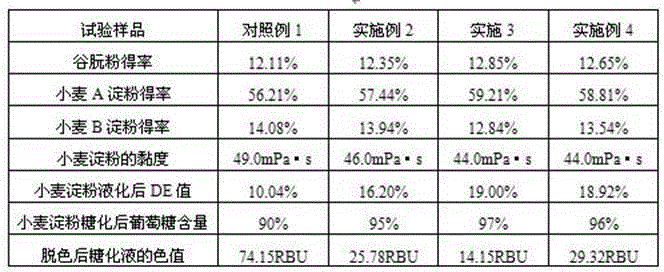

The invention discloses a process for co-producing crystalline fructose and F55 fructose corn syrup by taking wheat as a raw material and belongs to the technical field of starch sugar. The process comprises the following steps: grinding the wheat used as the raw material into powder, producing wheat starch by adopting a three-phase horizontal decanter production process, adding a compound enzymic preparation containing lipase into size mixing water to produce by-products such as wheat starch, vital gluten, pentosan and B starch, returning the B starch separated by a three-phase horizontal decanter to a starch finished product tank, subsequently mixing the B starch with A starch and performing a process of producing sugar; acquiring crystalline fructose by mixed wheat starch milk through processes of liquefying, recycling protein, saccharifying, efficiently isomerizing, separating chromatograph, concentrating, crystallizing and drying; and circularly crystallizing mother liquor for a certain number of times, and then compounding the mother liquor with F42 fructose corn syrup acquired by isomerizing to acquire an F55 fructose corn syrup product. By utilizing the preparation method, the problems of high material liquid viscosity, low product yield and poor quality caused by the process of producing starch by taking the wheat as the raw material and sugaring the wheat starch are solved, and the yield and purity of the product are effectively improved.

Owner:BAOLINGBAO BIOLOGY

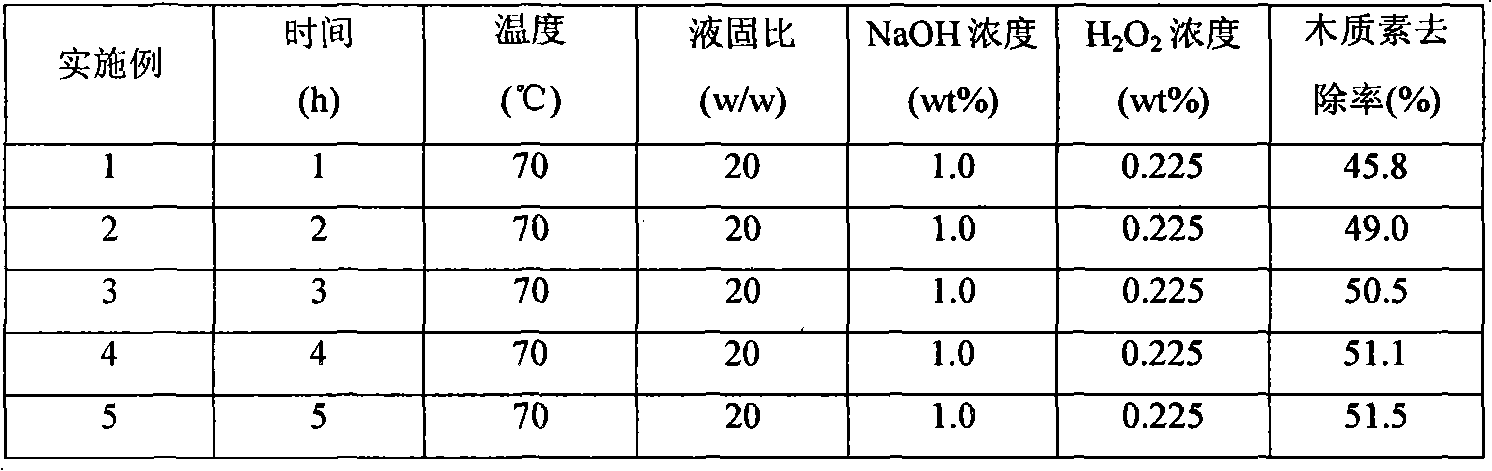

Method for pre-treating lignocellulose raw material and for preparing reducing sugar by conversion

InactiveCN102758028AImprove enzymatic hydrolysis efficiencyReduce manufacturing costFructose productionGlucose productionEthanol fuelSodium hydroxide

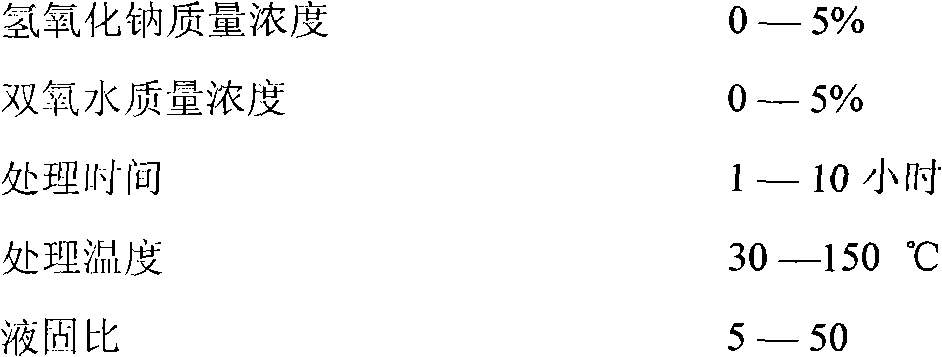

The invention relates to a method for pre-treating lignocellulose raw material and for preparing reducing sugar by conversion. With liquid-solid ratio of 5-50, lignocellulose is treated for 1-10h in a mixed solution of 0-5% of sodium hydroxide by mass and 0-5% of hydrogen peroxide by mass; solid residue obtained by treating is washed by using water, and is dried by baking; the obtained material is treated under a liquid-solid ratio of 5-50, an acid hydrolysis time of 10-120min, an acid hydrolysis temperature of 30-150min, and a sulfuric acid mass concentration of 0-10%, such that a solid residue is obtained; a pH value is regulated to 7; and the obtained material is dried by baking. With the treatment process, lignin can be effectively removed, and hemicellulose is hydrolyzed under a dilute acid condition, such that pentose is obtained. With further reactions, products with high added value can be obtained. With a sample treated with the process, ineffective adsorption upon cellulase is reduced, and a conversion rate of cellulose in preparing ethanol can reach 67%. Therefore, a production cost is relatively reduced.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

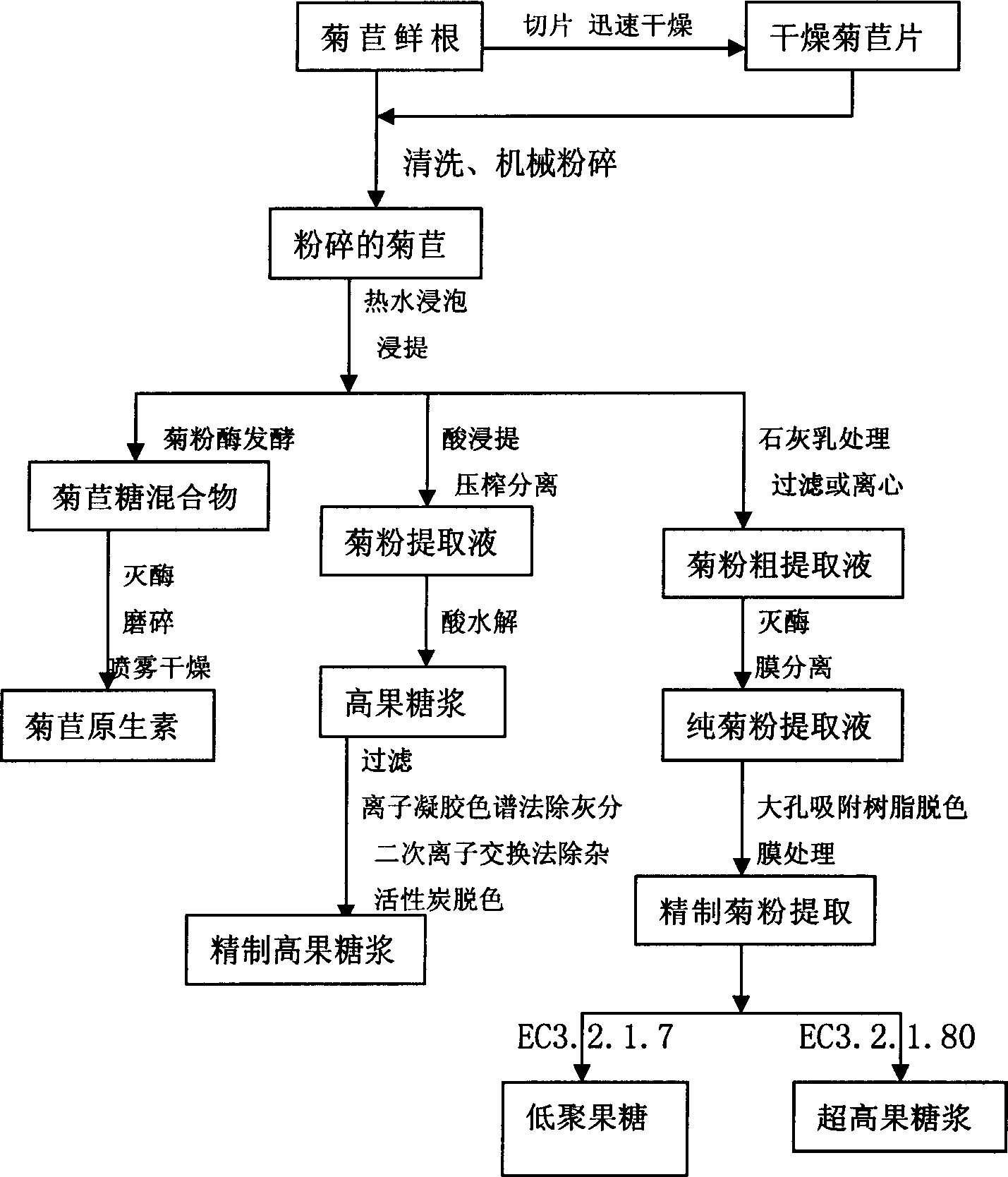

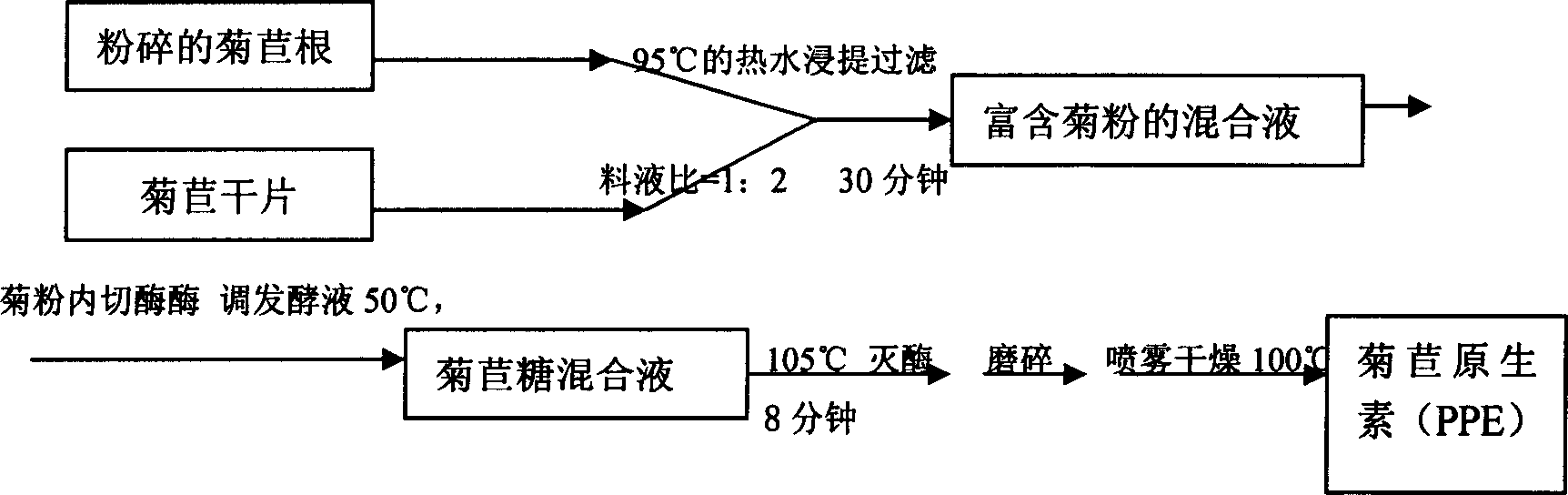

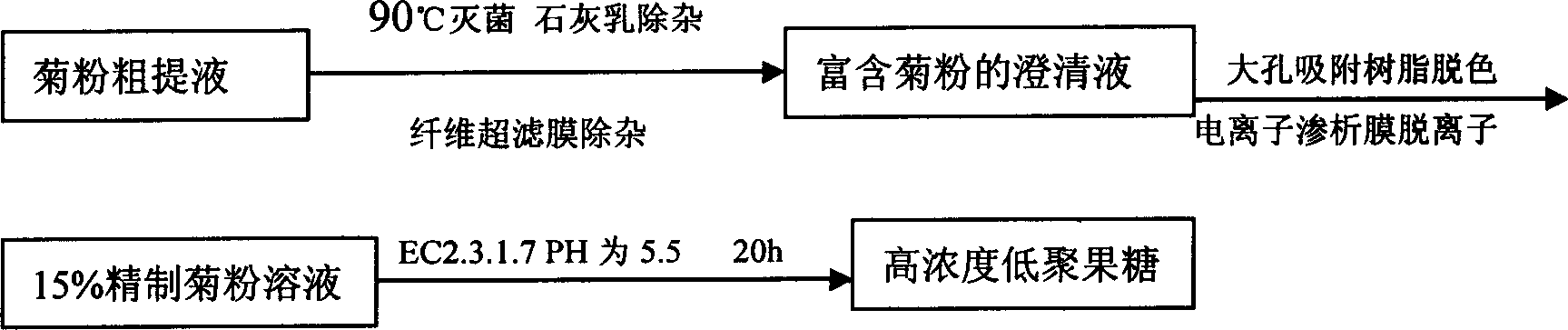

Technique for producing fruit sugar by using chicory to carry out hydrolysis

InactiveCN1661027AReduce manufacturing costImprove product qualityFructose productionFermentationFructoseCichorium

A process for preparing pectose from witloof by hydrolysis features that the acidolsis is used to prepare the high-pectose syrup, the inulase is used to prepare chicorose mixture (PPE), the inulin endonuclease is used to prepare oligopectose by fermenting, and the inulin exonuclease is used to prepare the ultrahigh-pectose syrup by fermentation.

Owner:NORTHWEST A & F UNIV

Sugar compositions

A sugar composition comprising at least 40% dissolved solids in an aqueous solution having a viscosity at least 10% lower than a 42 DE (Dextrose Equivalents) reference solution with a same dissolved solids concentration at a given temperature. Another sugar composition comprising at least 30% glucose relative to total sugars, at least 10% mannose relative to total sugars, at least 5% xylose relative to total sugars, and less than 0.25% ash. Another sugar composition comprising at least 30% glucose relative to total sugars at least 10% mannose relative to total sugars, at least 5% xylose relative to total sugars, and at least 2% total furfurals.

Owner:VIRDIA

Sugar compositions

Owner:VIRDIA

Method for preparing high-concentration fructose syrup

ActiveCN101709336ASimple production processGuaranteed appearanceFructose productionGlucose productionHigh concentrationStrong acids

The invention relates to a method for preparing high-concentration fructose syrup by hydrolyzing sucrose, which comprises the following steps: (1) decolorizing a high-concentration sucrose solution by using acid with dosage accounting for 0.1-1.0% of the high-concentration sucrose solution as the hydrolyst while adding 0.05-0.8% of powder active carbon, and carrying out the reaction at 50-80 DEG C for 15-75 minutes to obtain the high-concentration fructose syrup of which the concentration is more than or equal to 45%, wherein the degree of hydrolysis is more than or equal to 97%; (2) and removing acid radicals and a small amount of pigments in the fructose syrup by using weak-base anion-exchange resin, and removing cations by using a strong-acid cation exchange resin, thereby adjusting the pH value of the fructose syrup. Compared with the exisiting method, the method of the invention is simple and convenient. Through deep research into the hydrolysis conditions, the invention provides the hydrolysis conditions capable of ensuring the hydrolysis effect and reducing the production cost. In addition, the invention carries out the hydrolysis and the decoloring synchronously, thereby ensuring the appearance of the syrup and simplifying the production technology. Then, the acid radicals and the cations in the syrup are removed by using anion and cation exchange resins, thereby obtaining the qualified high-concentration fructose syrup.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

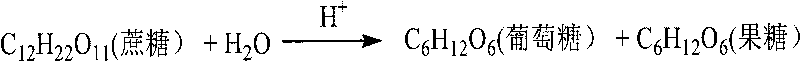

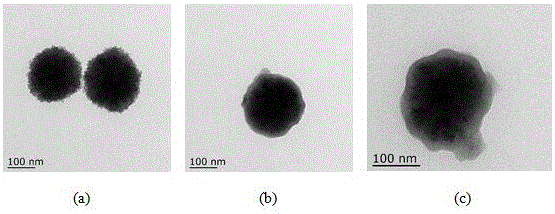

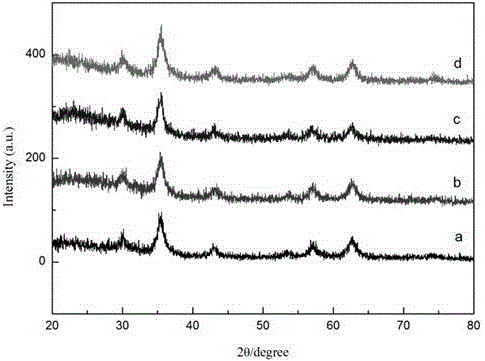

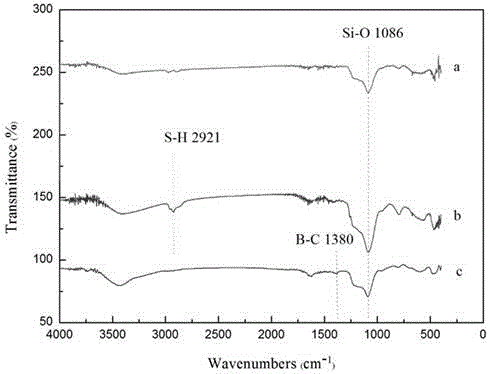

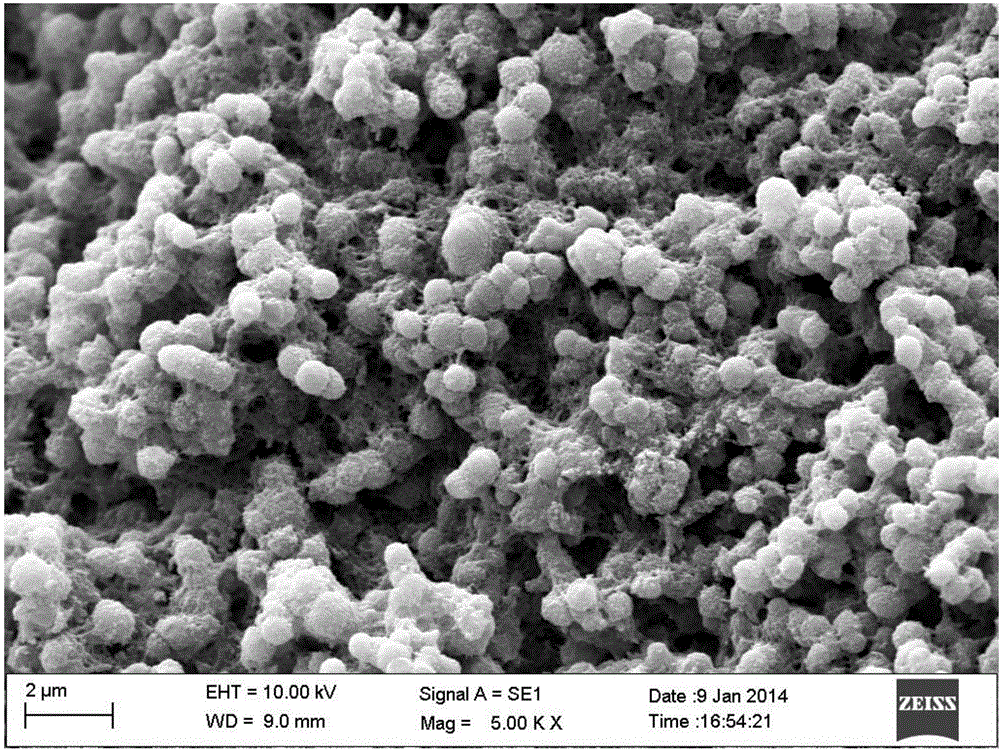

Phenylboronic acid modified magnetic nanoparticle, and preparation method and application thereof

ActiveCN106693909AGood core-shell morphologyThe synthesis steps are simpleOther chemical processesFructose productionWater bathsMicrosphere

The invention relates to a phenylboronic acid modified magnetic nanoparticle, and a preparation method and application of the phenylboronic acid modified magnetic nanoparticle, and belongs to the technical field of nano materials. Firstly, a magnetic silicon dioxide nanoparticle is prepared, a sulfydryl modified magnetic nanoparticle is prepared through a silanization reaction, the sulfydryl modified magnetic nanoparticle is then dissolved in ethyl alcohol, 4-vinyl phenylboronic acid and AIBN (azodiisobutyronitrile) are then added, the mixture is stirred and reacts in a water bath kettle, a product is magnetically separated, an obtained solid is washed through distilled water and ethyl alcohol and dried to obtain a final product of the phenylboronic acid modified magnetic nanoparticle; and the obtained material is used in enrichment and separation of fructose. The synthesized magnetic material has the advantages of excellent nuclear shell morphology, and can be rapidly separated in an externally applied magnetic field; the adsorption efficiency of fructose of a magnetic microsphere is 6 times that of glucose, the application effects of enrichment and separation of fructose are quite good, and meanwhile, the phenylboronic acid modified magnetic nanoparticle is excellent in repeatability.

Owner:JIANGSU UNIV

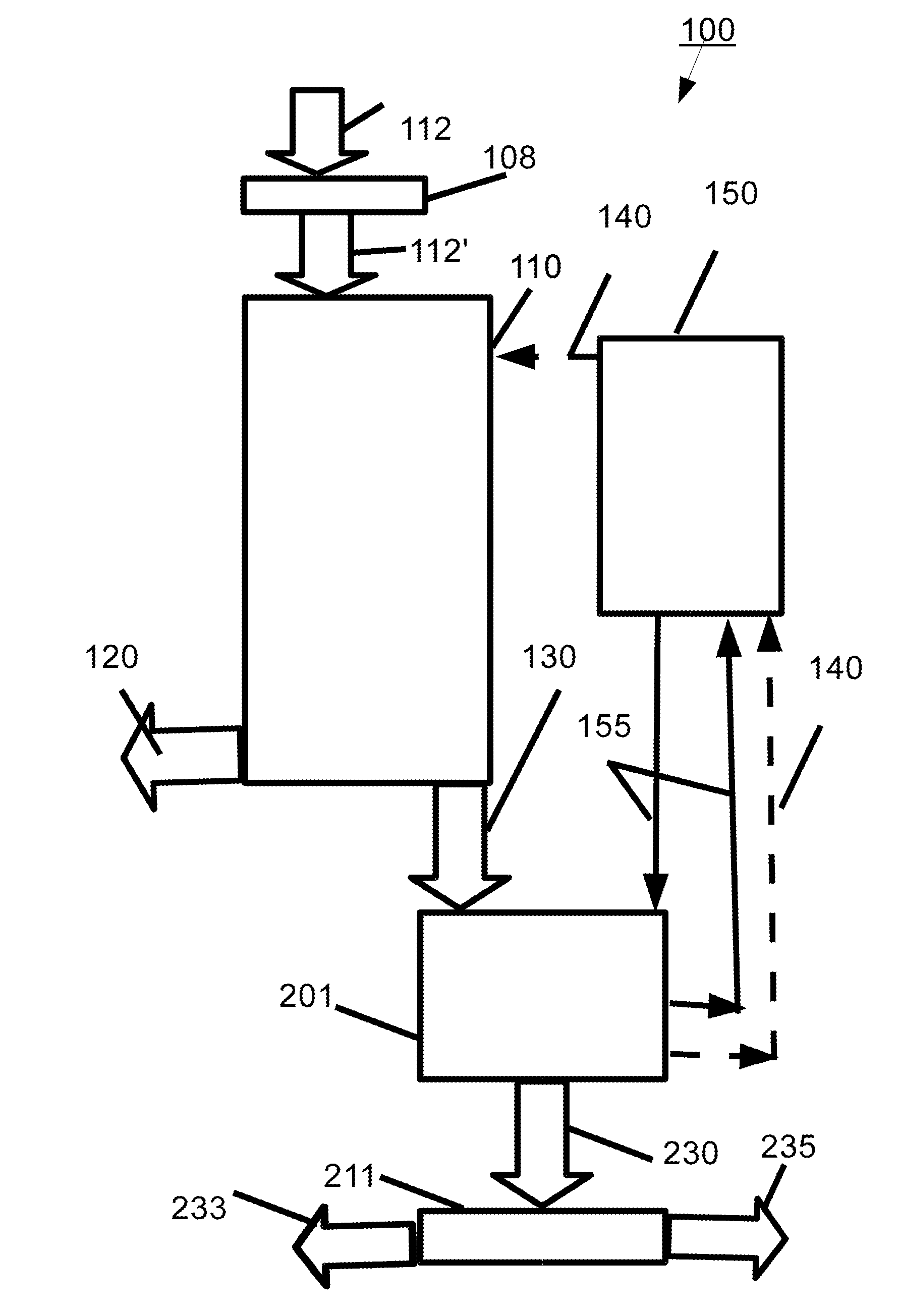

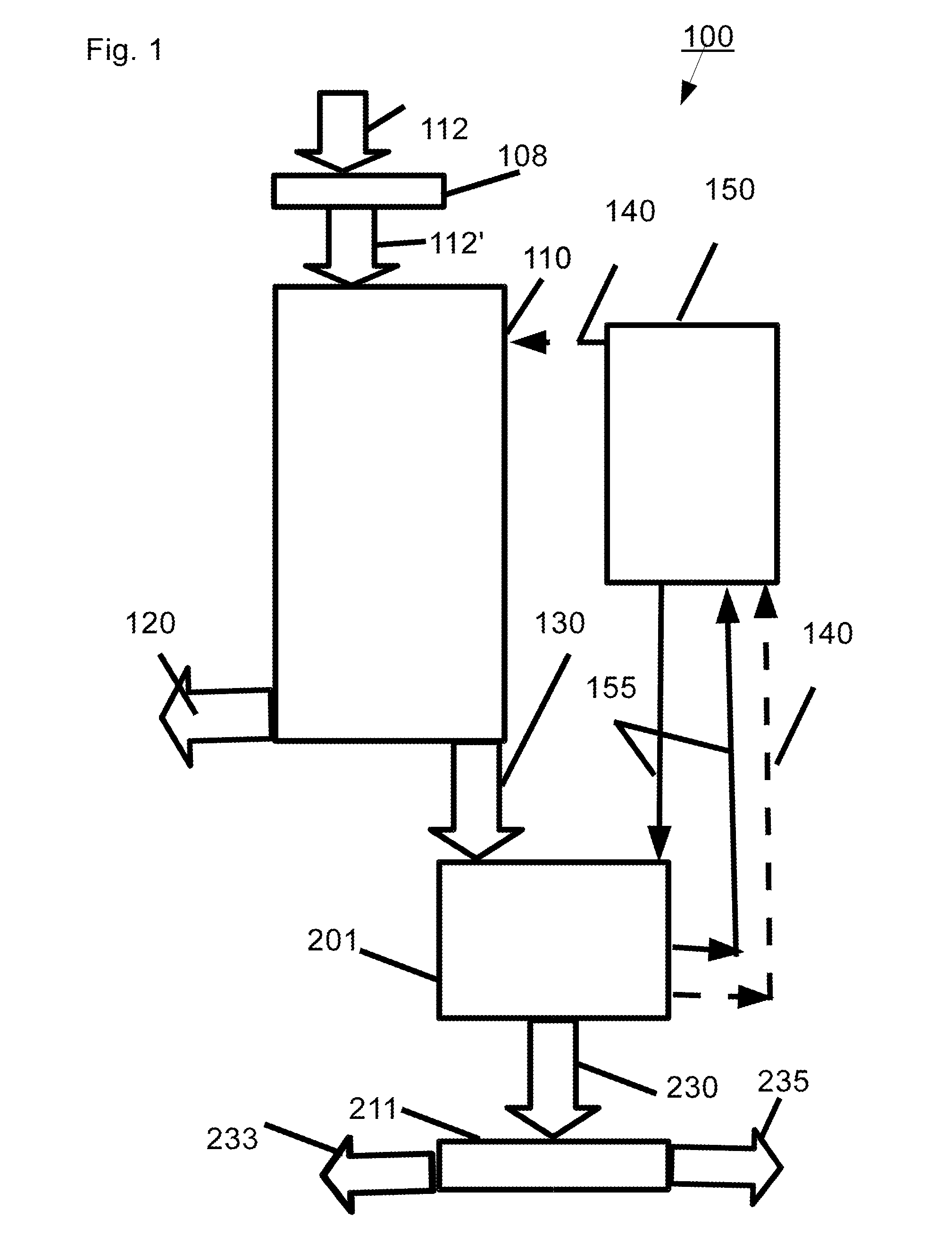

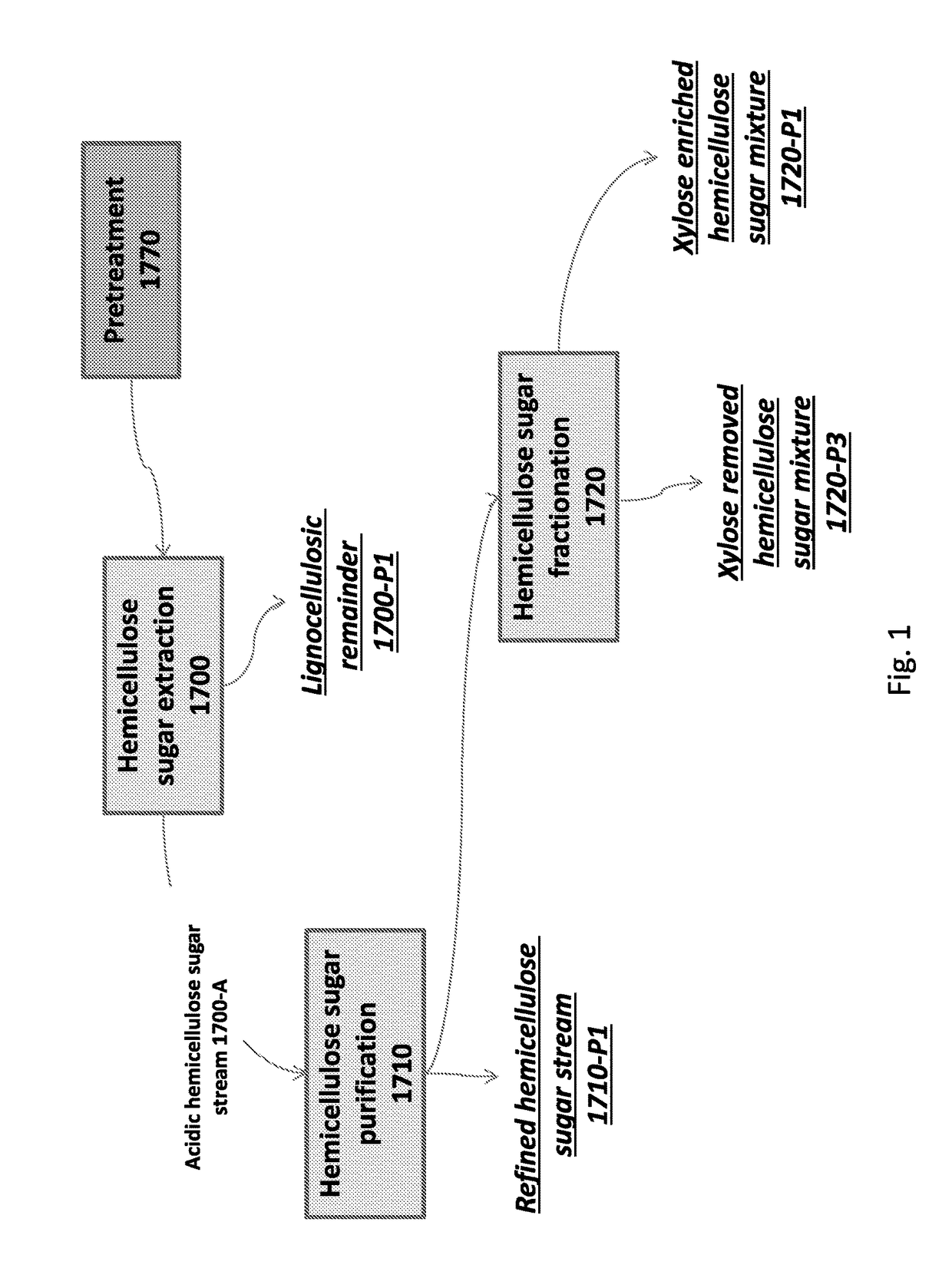

Methods for treating lignocellulosic materials

The present invention relates to methods of processing lignocellulosic material to obtain hemicellulose sugars, cellulose sugars, lignin, cellulose and other high-value products. Also provided are hemicellulose sugars, cellulose sugars, lignin, cellulose, and other high-value products.

Owner:VIRDIA

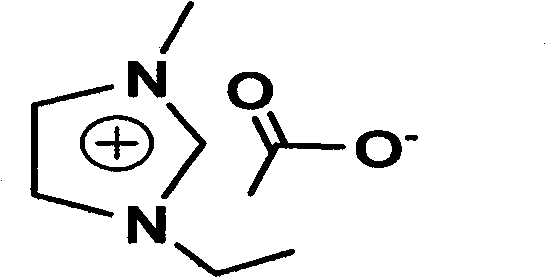

Application of ionic liquid to preparation of reducing sugar by cellulose hydrolysis

InactiveCN102071266ALow viscosityEasy to operateFructose productionGlucose productionCelluloseIon exchange

The invention relates to dissolution of straws and hydrolysis of celluloses, in particular to a method for preparing reducing sugar by dissolving the straws and hydrolyzing the celluloses in ionic liquid. The method comprises the following steps of: adding 1-ethyl-3-methylimidazole acetate serving as a straw solvent into Fe3+-containing aqueous solution and reacting in the presence of acidic ionic liquid serving as a catalyst under normal pressure at the temperature of between 110 and 140 DEG C for 0.5 to 5 hours; quenching with cold water; neutralizing with alkali liquor to prepare cellulose hydrolyzate; and measuring reducing sugar content by a 3,5-dinitrosalicylic acid method, wherein the reducing sugar in the hydrolyzate and the ionic liquid can be separated by an ion exchange method and the ionic liquid can be repeatedly used. Experiment results show that the reducing sugar yield is up to 93 percent to the maximum extent. Compared with the conventional straw cellulose hydrolysis method, the method has the advantages of solving the problems of complicated pretreatment, low hydrolysis activity, high corrosion to equipment, high cellulose solvent viscosity, inconvenience of operation and the like and providing a new approach for full utilization of the straws.

Owner:JIANGNAN UNIV

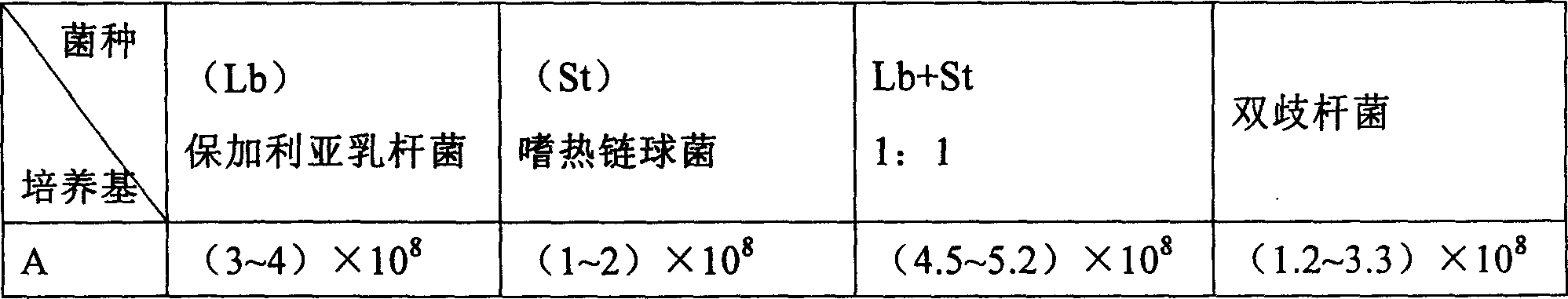

Multi-health-bateria compound nutrient freezed powder capsule and its making method

InactiveCN1579232AAvoid destructionPromote peristalsisMilk preparationCapsule deliveryBifidobacteriumGram

The invention relates to healthy keeping food, which concretely is a nutrition food based on milk product. According to the design project in the invention, the content of the fungus is not less than 1Xten to power 9 per gram in the frozen dry power capsule, in the alive fungus: Bulgaria fungus: 20-35%; heat indulged streptococcus: 20-35%; bifidobacterium 30-45%; the unit is weight percentage; the invention can make the milk product into capsule, thus it is convenient to be transmitted, carried, reserved and eaten.

Owner:HANLANG CARRE OUT GROUP WUXI

Method for degrading lignocellulose to generate reducing sugar

InactiveCN103409566ALow costIncrease reaction rateFructose productionGlucose productionCelluloseCatalyst degradation

The invention discloses a method for degrading lignocellulose to generate reducing sugar, and in particular relates to the method for degrading lignocellulose to generate reducing sugar by using H2O2 as a catalyst and using metal ion as a catalyst promoter. The method comprises the following steps: adopting an ionic liquid as a solvent, commercially available hydrogen peroxide with the mass fraction of 30% as a catalyst and metal ion as a catalyst promoter; and dissolving and degrading lignocellulose materials to generate water-soluble reducing sugar, wherein the ionic liquid can be recycled. The method for degrading lignocellulose to generate reducing sugar has the characteristics of being simple and convenient to operate, gentle in condition, environment-friendly, low in cost, less in byproducts, high in reducing sugar yield and the like. The method for degrading lignocellulose to generate reducing sugar can be used for treating various lignocellulose materials; and when the lignocellulose materials are treated by adopting the method, the conversion rate of the lignocellulose materials is bigger than 80%, the reducing sugar yield is bigger than 65%, and the recovery rate of the ionic liquid is bigger than 95%.

Owner:CHONGQING UNIV

Method for preparing reducing sugar by hydrolyzing biomass with super-critical/sub-critical water in two steps

InactiveCN101886143AEfficient extractionIncrease profitFructose productionGlucose productionReducing sugarChemistry

The invention discloses a method for preparing a reducing sugar by hydrolyzing a biomass with super-critical / sub-critical water in two steps, which belongs to the technical field of new energy. The method is characterized in that the high-yield reducing sugar is prepared by hydrolyzing the biomass with the super-critical / sub-critical water through a two-step method, namely a low-temperature section and a high-temperature section. The hydrolysis reaction is performed under the following conditions that: the temperature is 180 to 230 DEG C; the reaction time is 0 to 60 minutes; and the solid-to-liquid ratio is 1:100-1:20. The method of the invention has the advantages that: under two-step method hydrolysis condition of the super-critical / sub-critical water, hemicelluloses in the biomass arereclaimed; the yield of the biologically hydrolyzed reducing sugar is obviously improved; according to different raw materials, the highest total yield of the reducing sugar can reach 40 to 60 percent; and the recovery rate of the raw material and the reducing sugar is over 70 percent.

Owner:DALIAN UNIV OF TECH

Crystallization of sugars

The invention relates to removing crystallization inhibitors from a solution comprising one or more reducing sugars by nanofiltration, hydrolysis and / or chromatography. The reducing sugars are typically selected from fructose and xylose.

Owner:DANISCO SWEETENERS

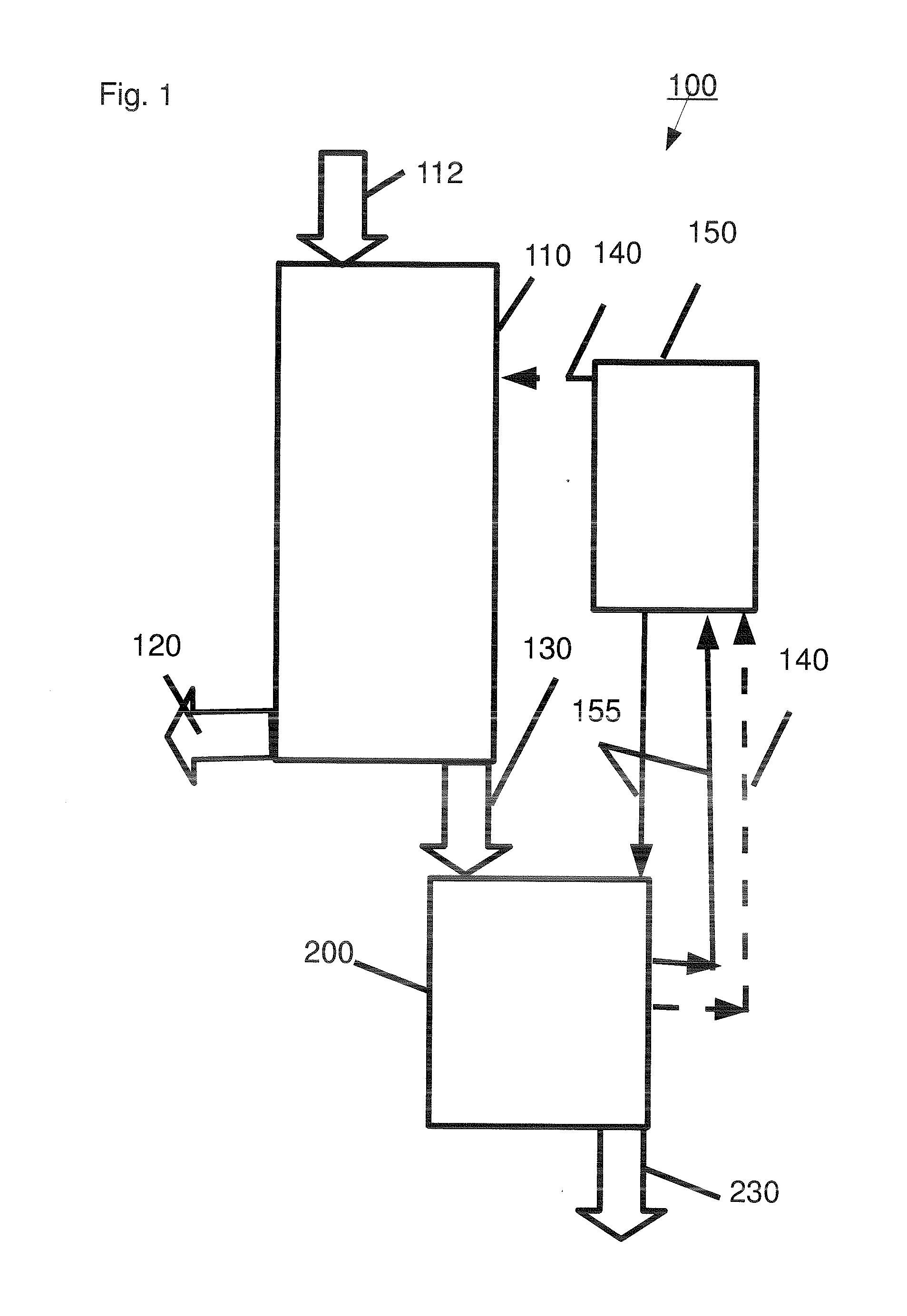

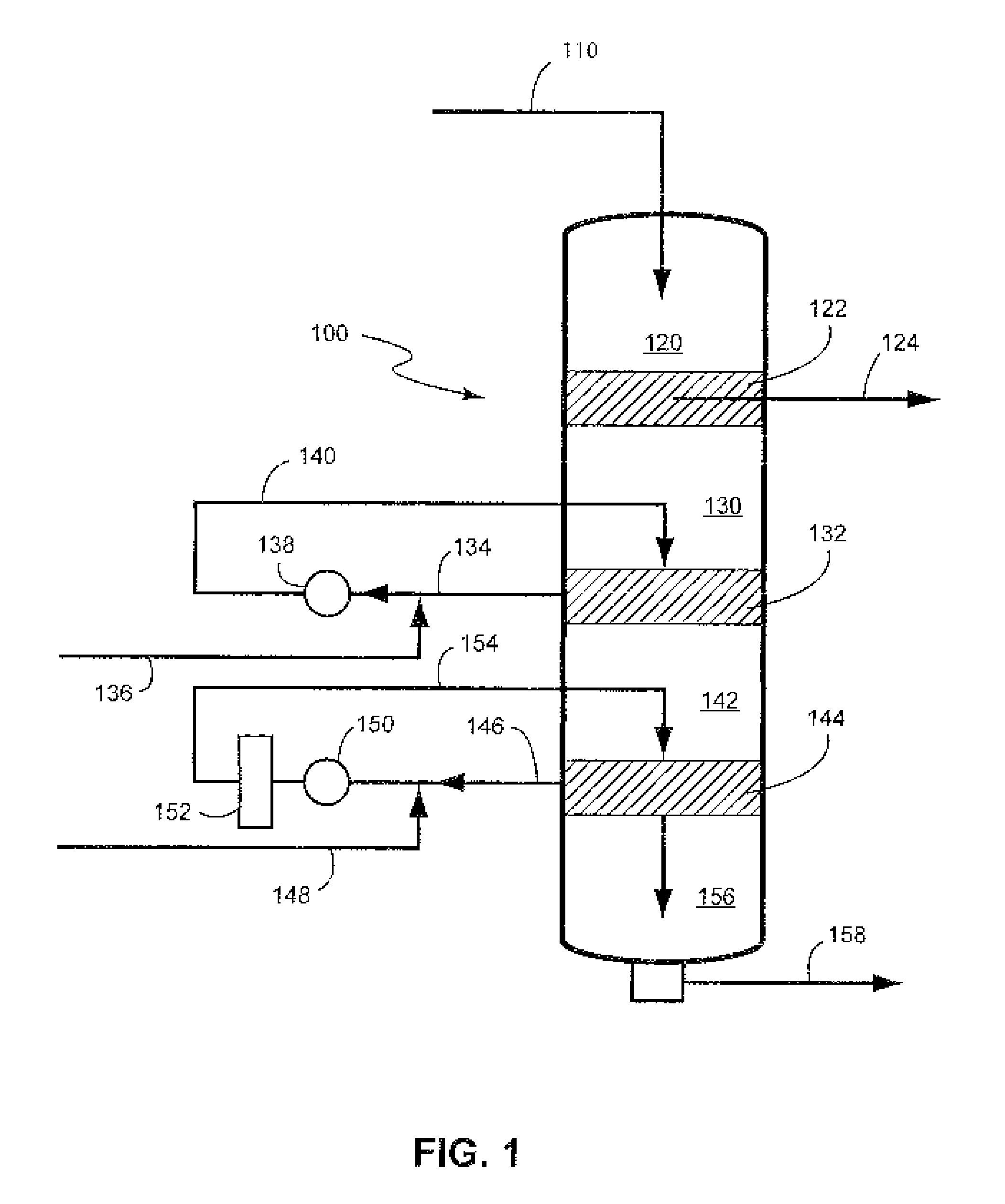

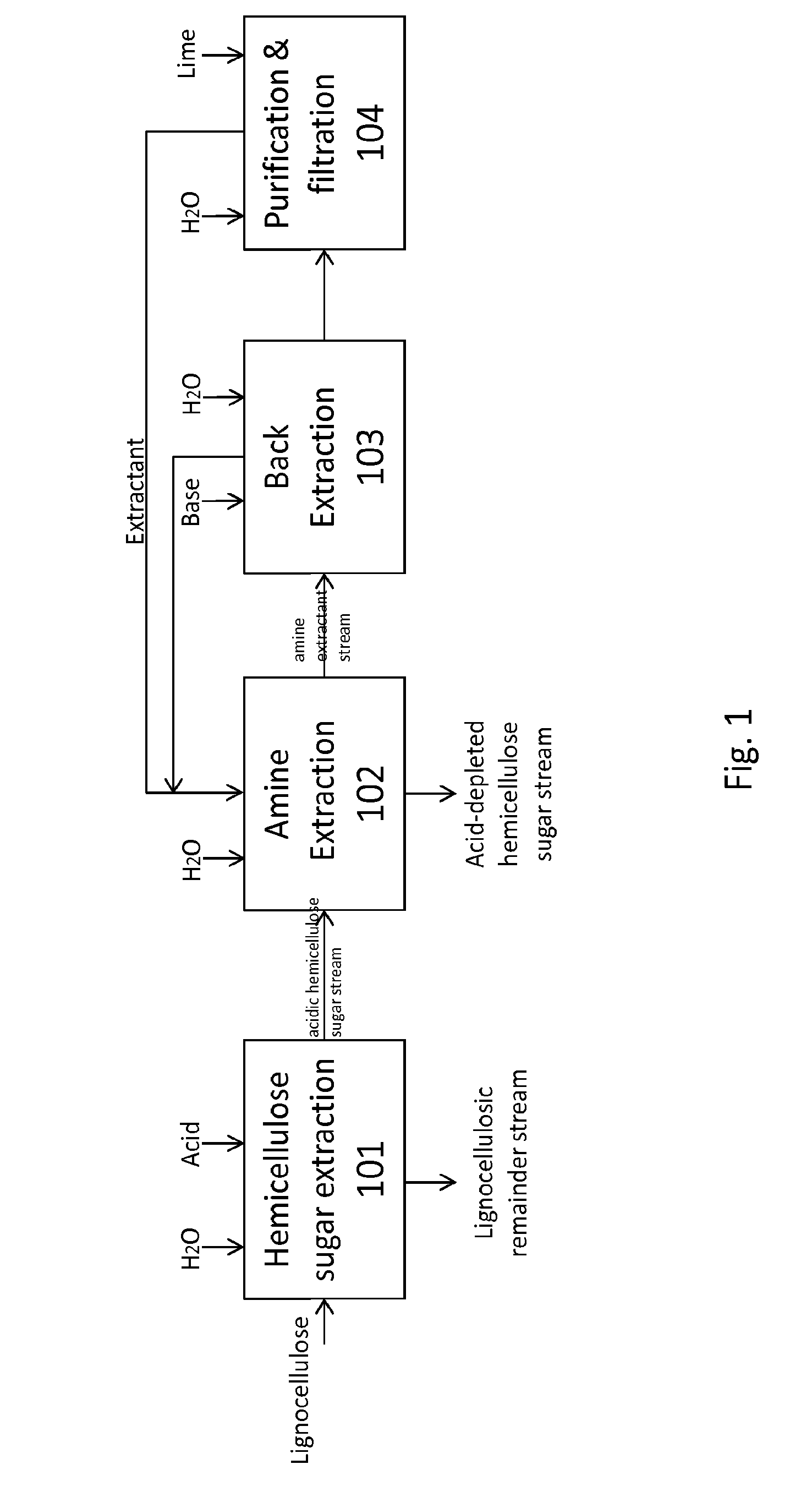

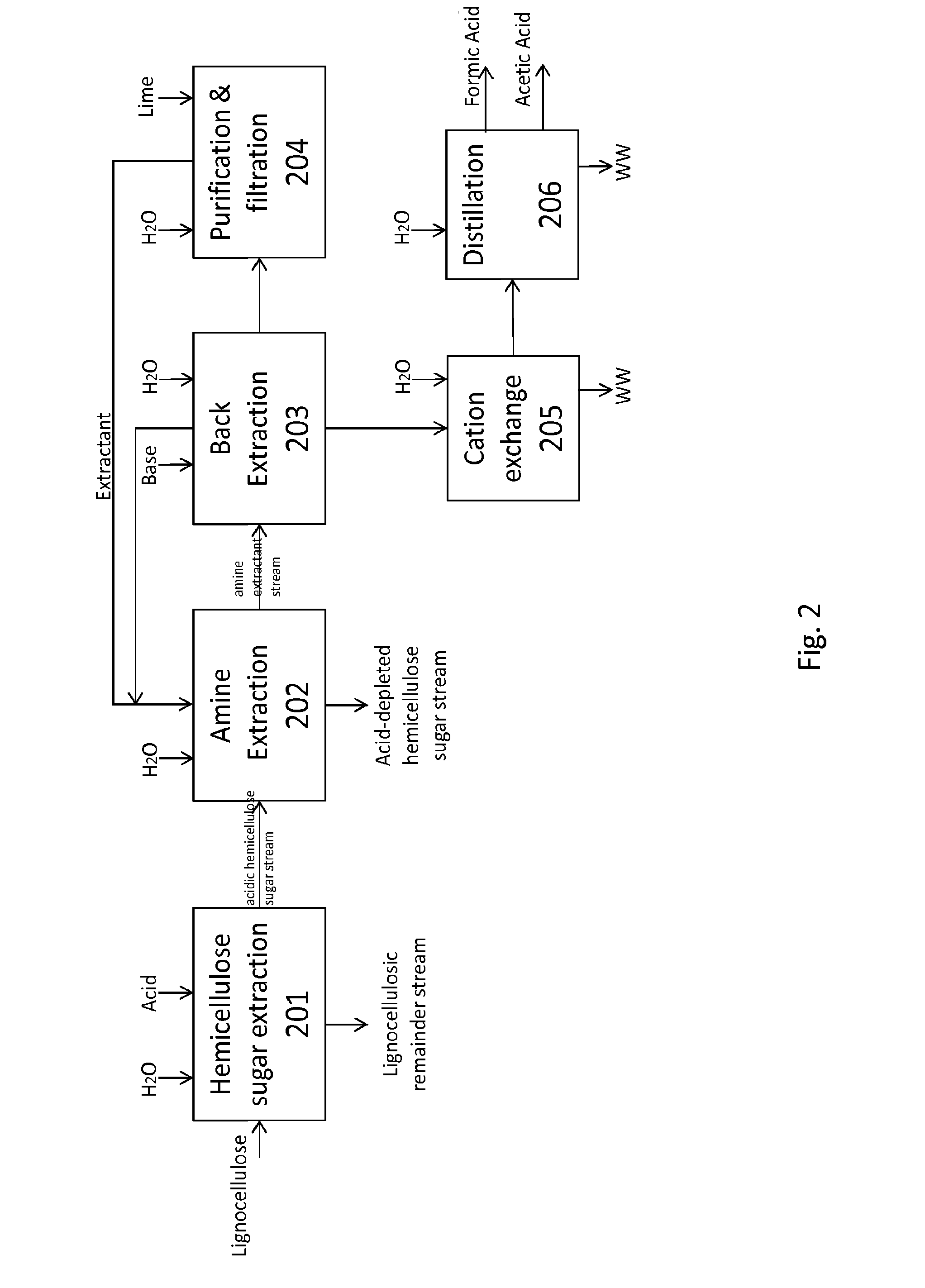

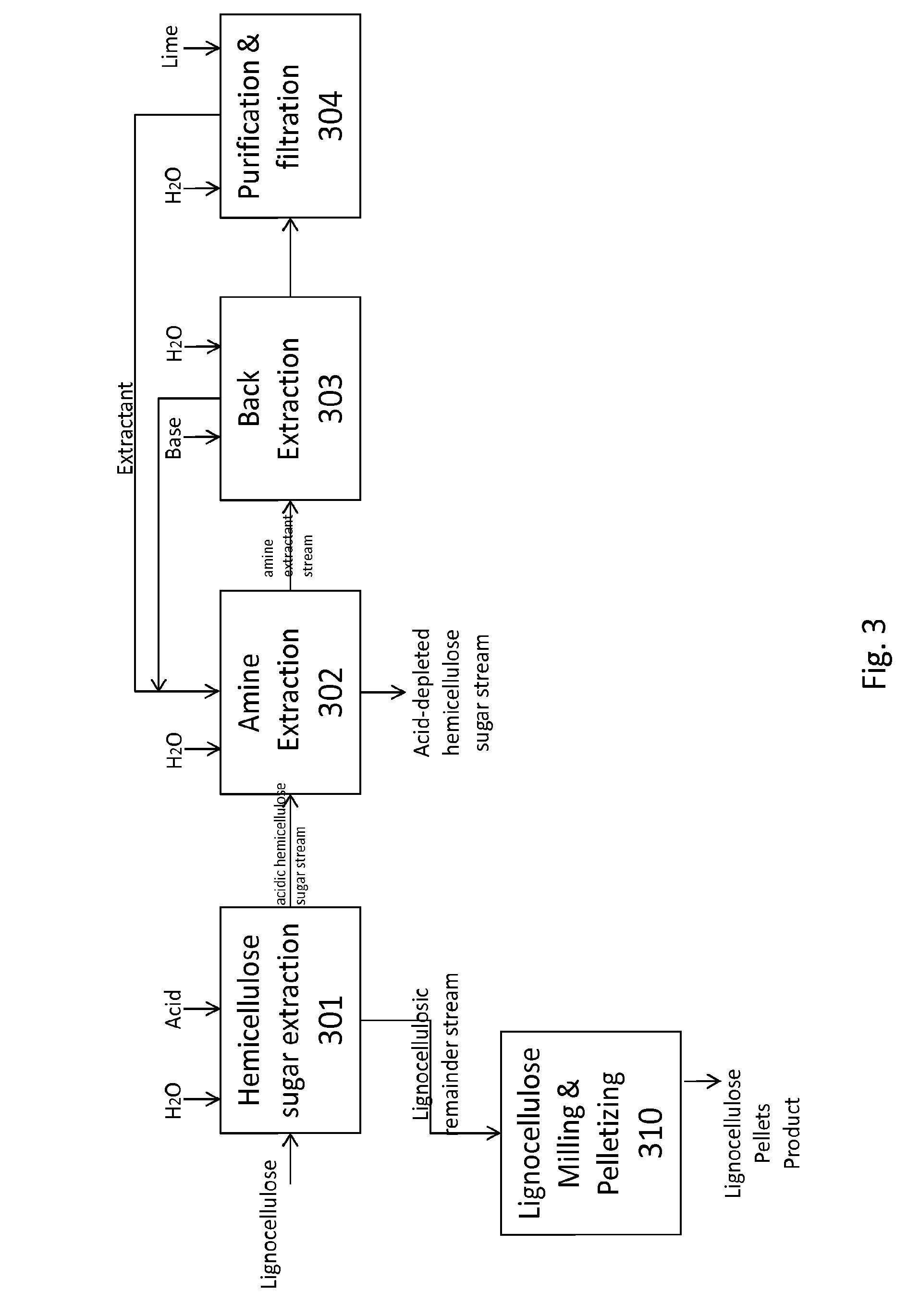

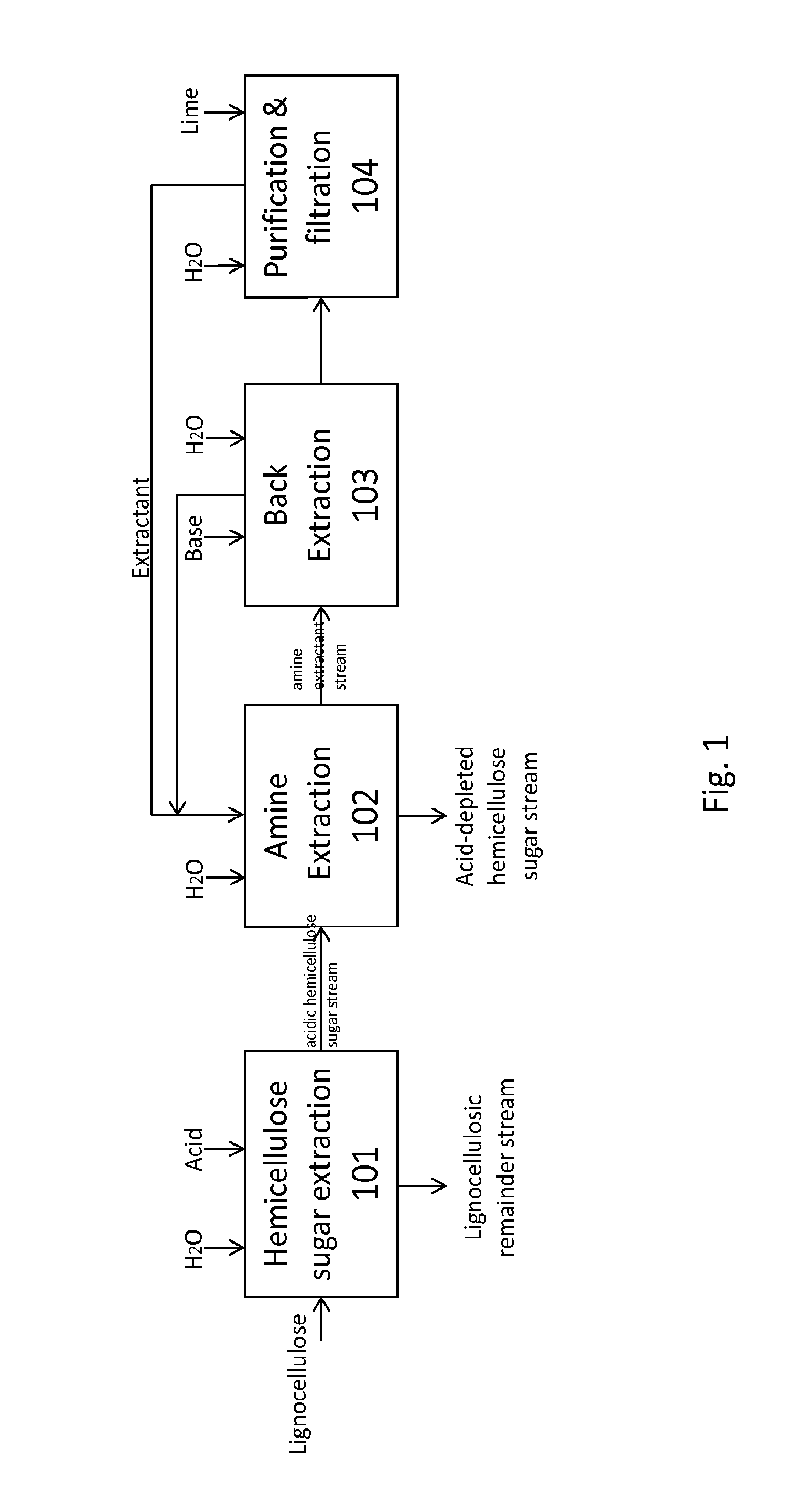

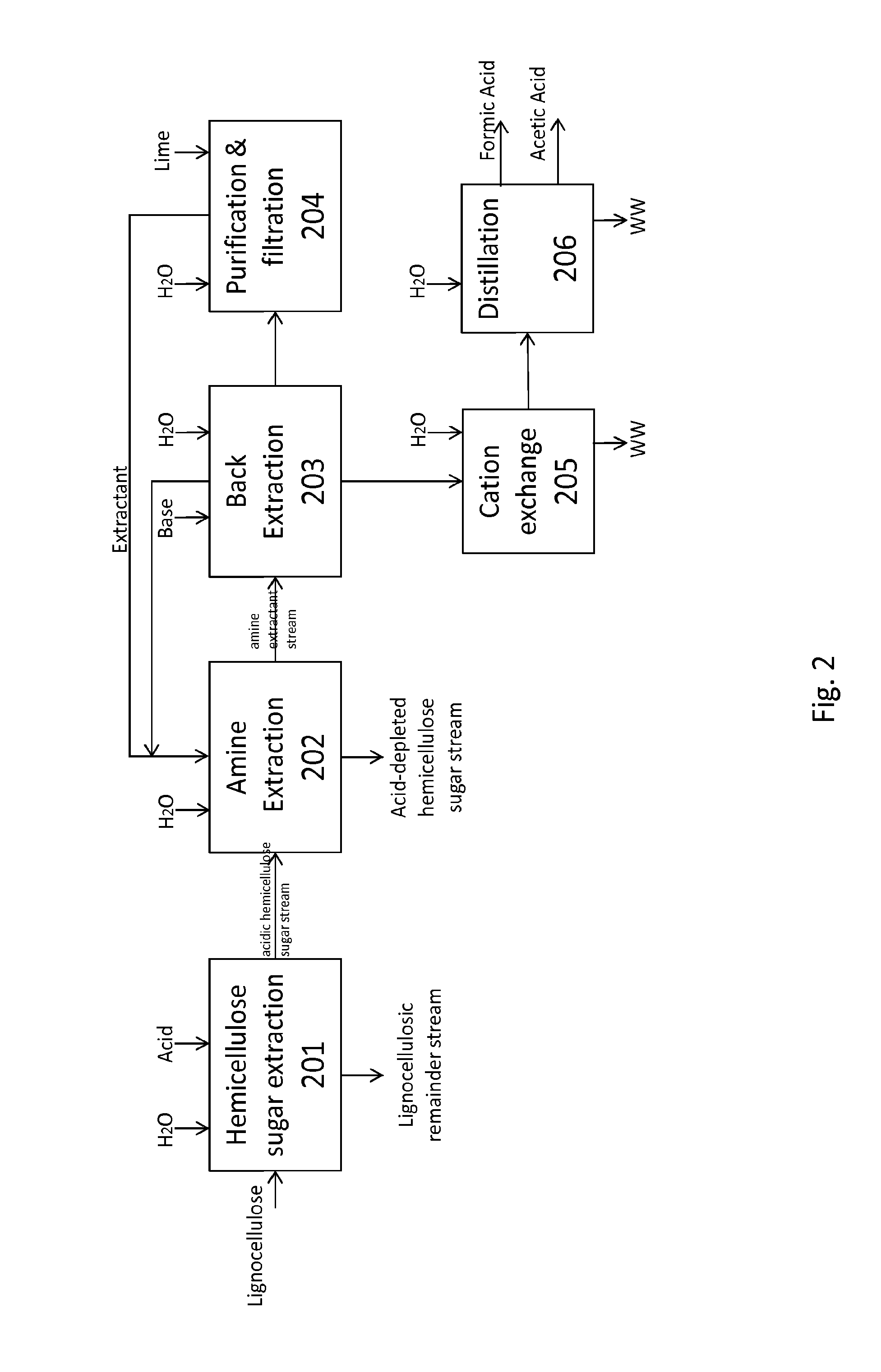

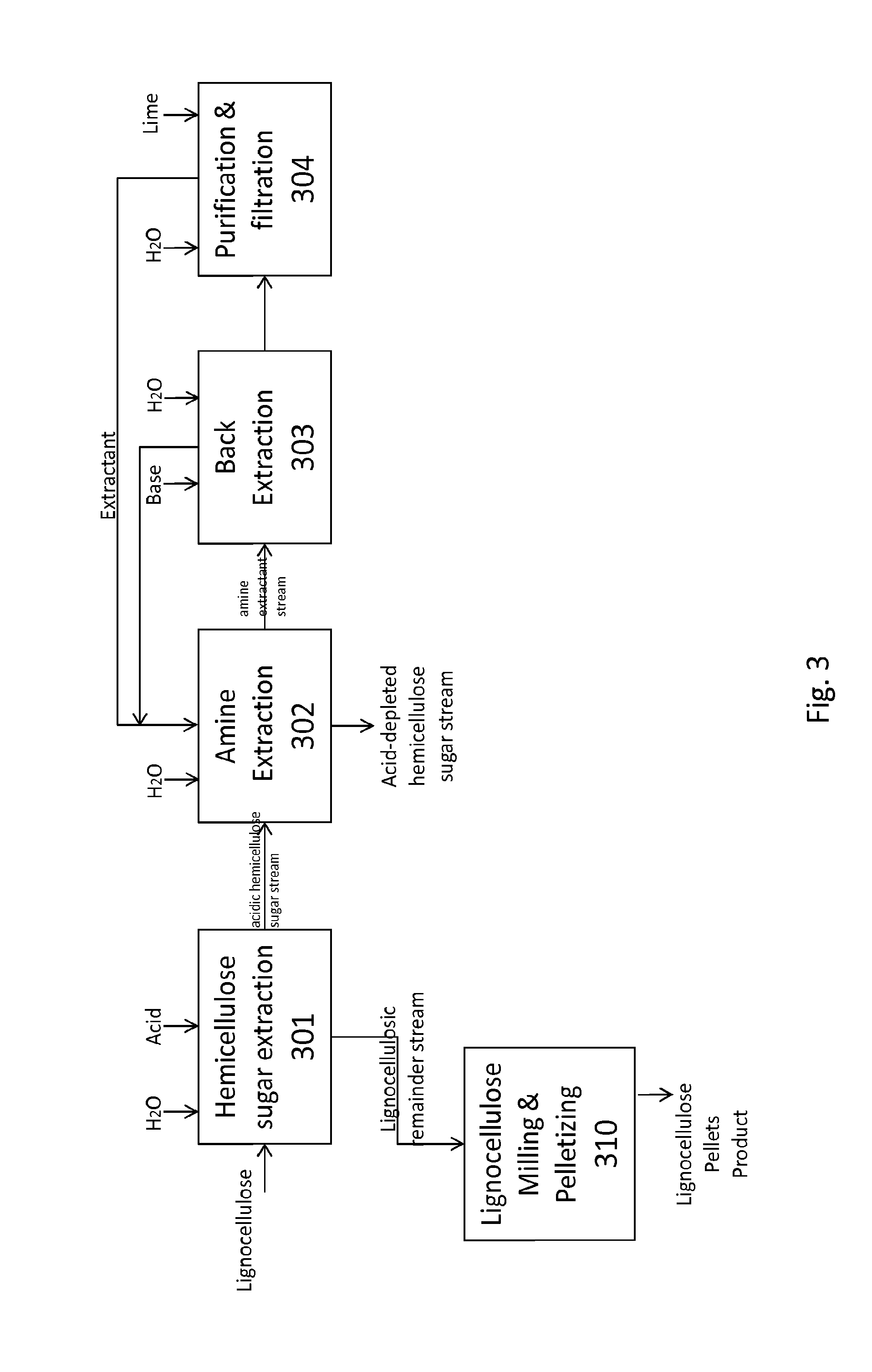

Methods for treating lignocellulosic materials

ActiveUS20150136121A1Increase acid concentrationChromatographic cation exchangersPurification using adsorption agentsSugarHemicellulose

The present invention relates to methods of processing lignocellulosic material to obtain hemicellulose sugars, cellulose sugars, lignin, cellulose and other high-value products. Also provided are hemicellulose sugars, cellulose sugars, lignin, cellulose, and other high-value products.

Owner:VIRDIA

Method for hydrolyzing chitin and chitosan

The invention relates to a method for hydrolyzing chitin and chitosan, in particular to a method for jointly hydrolyzing chitin and chitosan through a physical method and a chemical method. The method for hydrolyzing chitin and chitosan comprises the following steps that: the chitin or chitosan is taken as a raw material, binary mixed ionic liquid is taken as a solvent for the chitin or chitosan,acid functionalized ionic liquid is taken as a catalyst for hydrolysis, a water and strong polar co-solvent is added, and hydrolysis reaction is performed under the microwave reaction condition; and the obtained product is analyzed through ion chromatography, gel permeation chromatography and infrared, and the content of total reducing sugar is measured by an Imoto method. The method for hydrolyzing chitin and chitosan has the advantages of high efficiency, environmental friendliness, and high yield.

Owner:苏州九一高科无纺设备有限公司

High yield crystallized diabetin production process

The invention uses sucrose or white sugar as material to treat and separate and prepare crystal fruit sugar with high yield more than 80% for given sucrose quantity. Wherein, it relates to hydrolysis, simulated moving bed adsorption and separation, isomerization, condensation, crystallization, centrifugal separation and drying.

Owner:南宁市化工研究设计院

Preparation method of biochar-based solid acid and application of biochar-based solid acid to cellulose hydrolysis reaction

InactiveCN106111188AWide variety of sourcesIncrease productionOrganic-compounds/hydrides/coordination-complexes catalystsFructose productionAir atmosphereCellulose

A preparation method of biochar-based solid acid and an application of the biochar-based solid acid to a cellulose hydrolysis reaction belong to the technical field of biomass resource utilization. The preparation method of biochar-based solid acid comprises the following steps: in the normal pressure and temperature and in an air atmosphere, adding organic strong acid in a biomass ionic liquid solution drop by drop, performing a synchronous carbonization and nucleophilic substitution reaction, performing alternative washing with water and acetone, and performing drying to obtain the biochar-based solid acid. The raw biomass is cheap in price and available in resources; the ionic liquid solution is taken as a solvent; and sub-micron carbon sphere carriers high in specific surface area, abundant in surface functional groups and high in acid site capacity are obtained through ionothermal carbonization. Synthesis of the biochar-based solid acid catalyst is conducted in normal pressure and in an air atmosphere and is low in requirements to reaction equipment and simple and easy in operation, and the catalyst in high in yield. The biochar-based solid acid is used for cellulose hydrolysis, is mild in reaction condition and high in yield of reduction sugar and glucose, and can be reused.

Owner:DALIAN UNIV OF TECH

Preparation method of crystalline fructose

ActiveCN101638695AIncrease profitHigh purityFructose productionChromatographic separationSeparation technology

The invention relates to a preparation method of crystalline fructose, which sequentially comprises the following steps: carrying out chromatography separation on fructose-glucose syrup, carrying oution exchange and nanofiltration operation on the obtained fructose liquid, then respectively carrying out concentration through a double-effect plate type evaporator and a scraper evaporator, mixing the concentrated fructose liquid with ethanol and finally carrying out crystallization, centrifugal separation and drying, thereby obtaining the crystalline fructose. The prepration method of the crystalline fructose adopts the nanofiltration separation technology, removes impurities which affect the crystallization and the quality of a finished product before the crystallization, improves the product quality and the crystallization yield, combines the high-efficient plate type evaporator with the scraper evaporator, reduces the evaporation temperature of the fructose and the residence time inthe evaporators and effectively prevents the thermal decomposition and the complex reaction of the fructose. Compared with the prior art, the crystalline fructose produced by the method has the advantages of high purity of the fructose, uniform crystalline particles, good color and luster, high crystallization rate and low unit cost.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

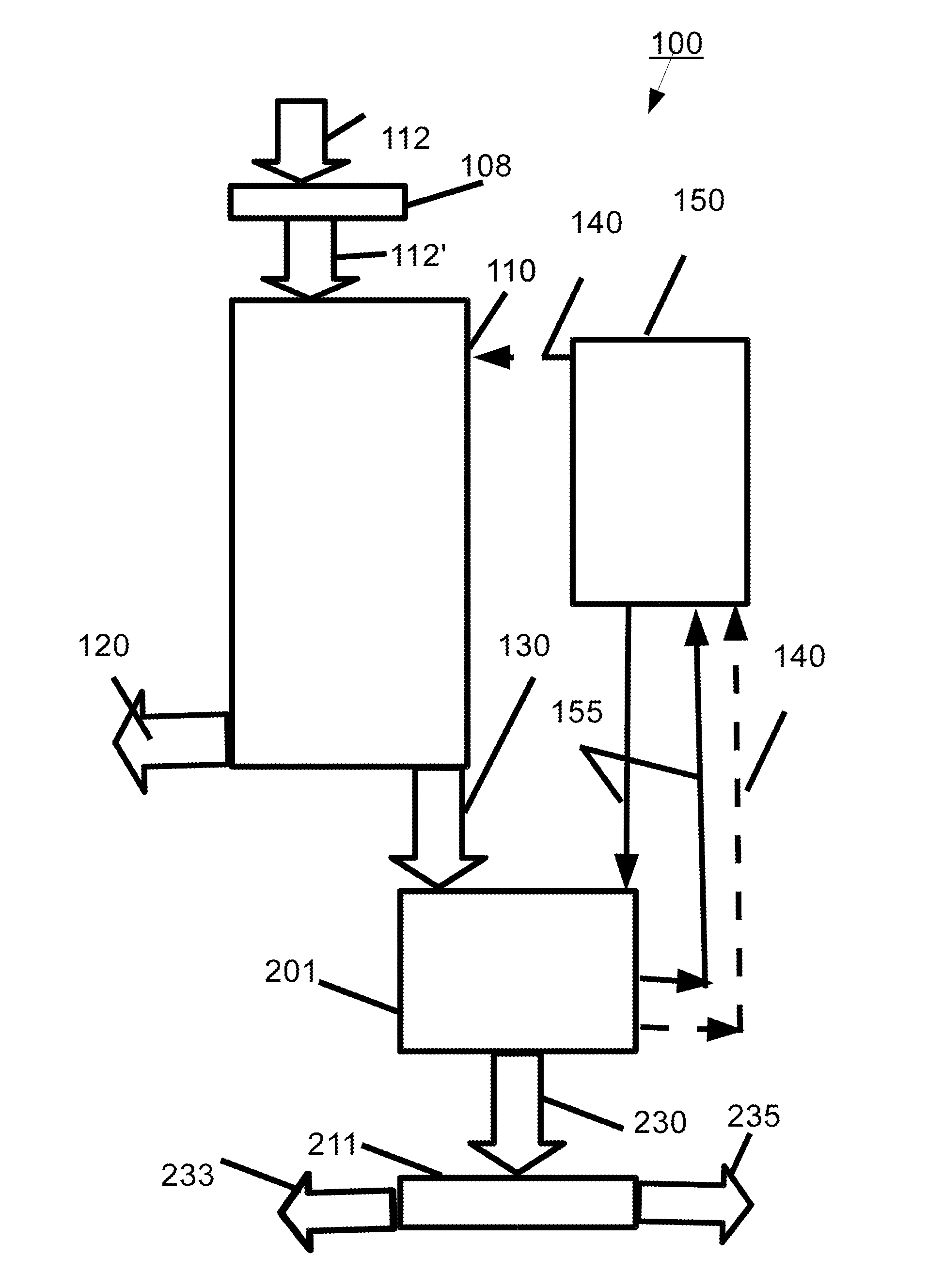

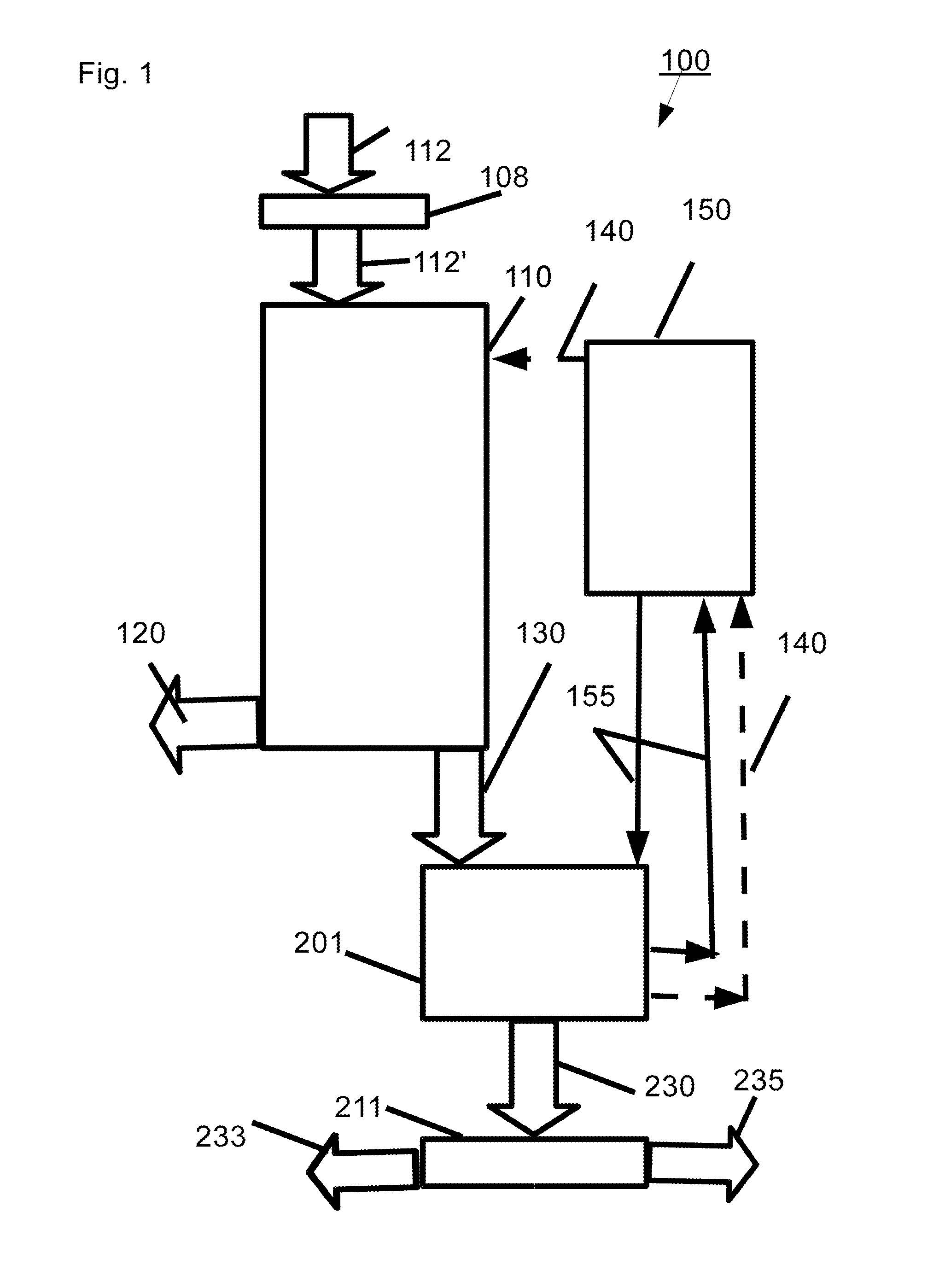

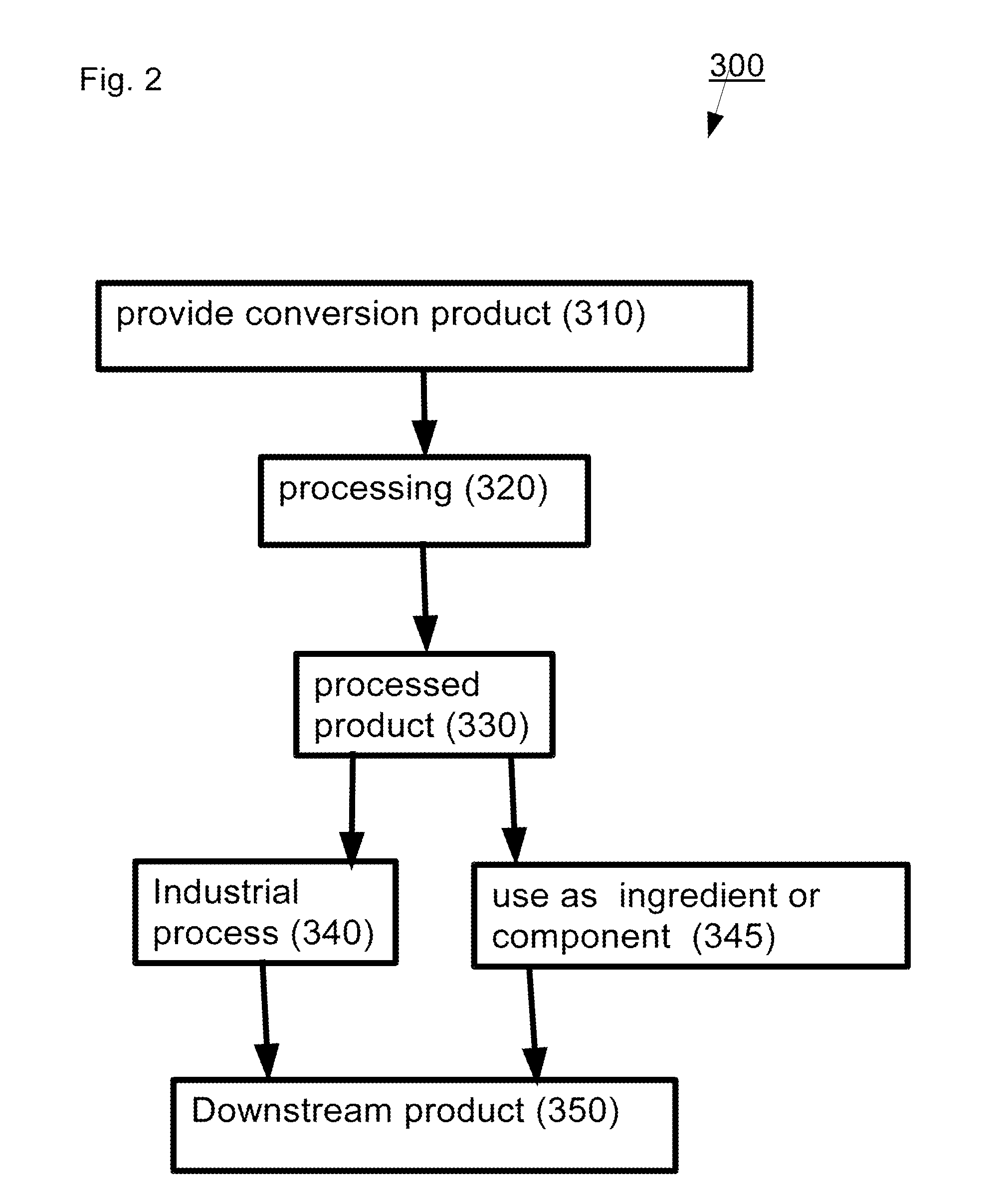

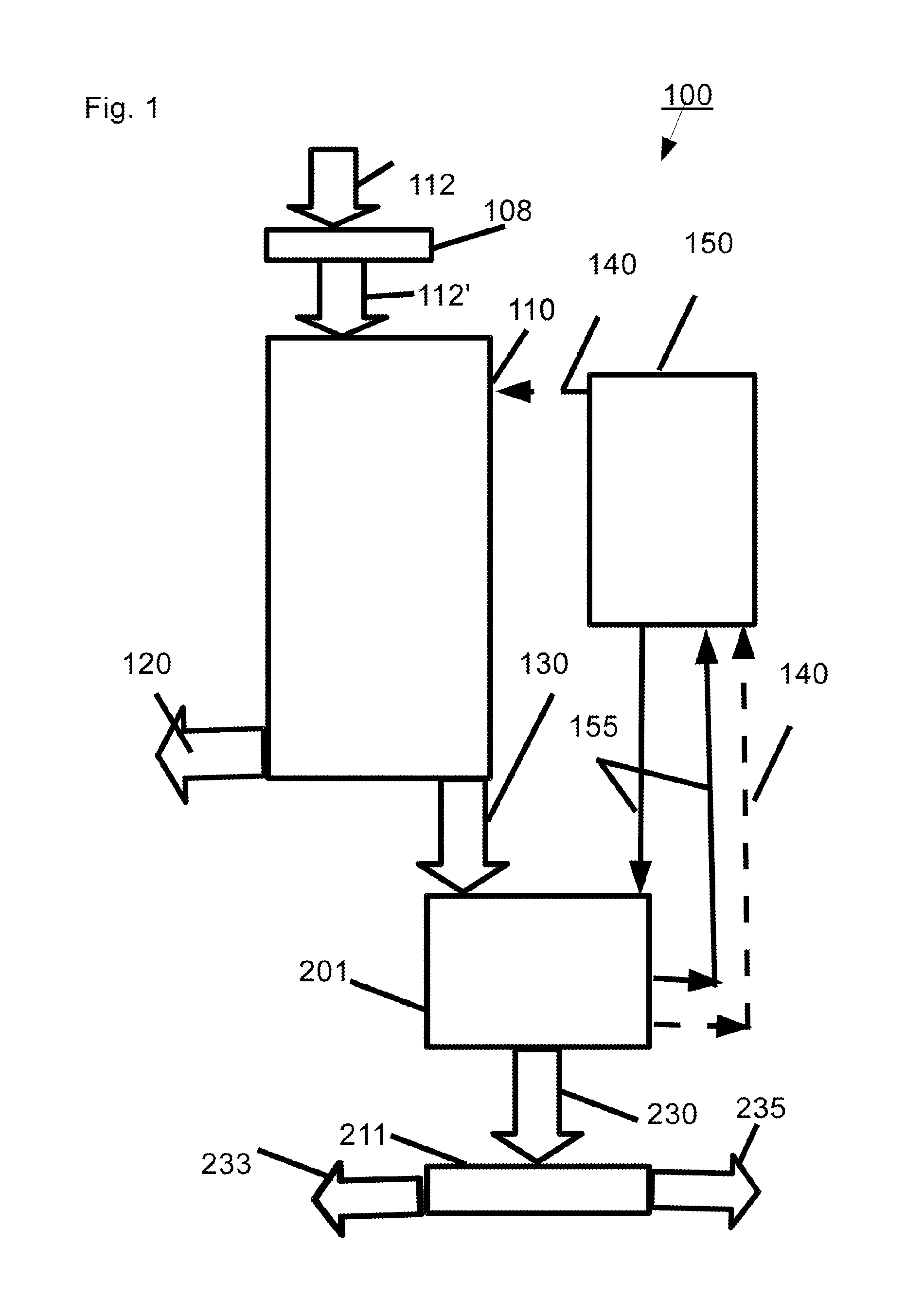

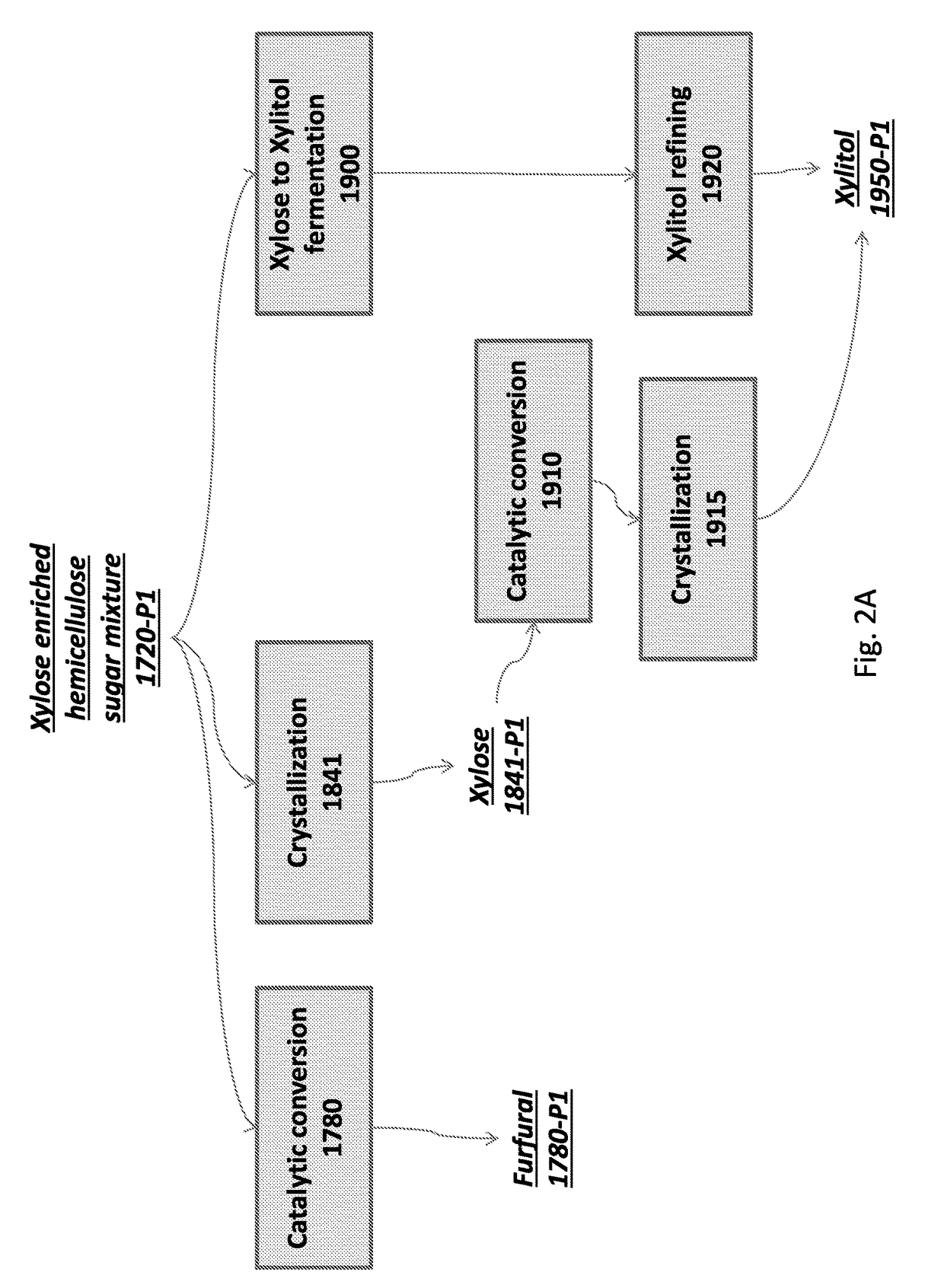

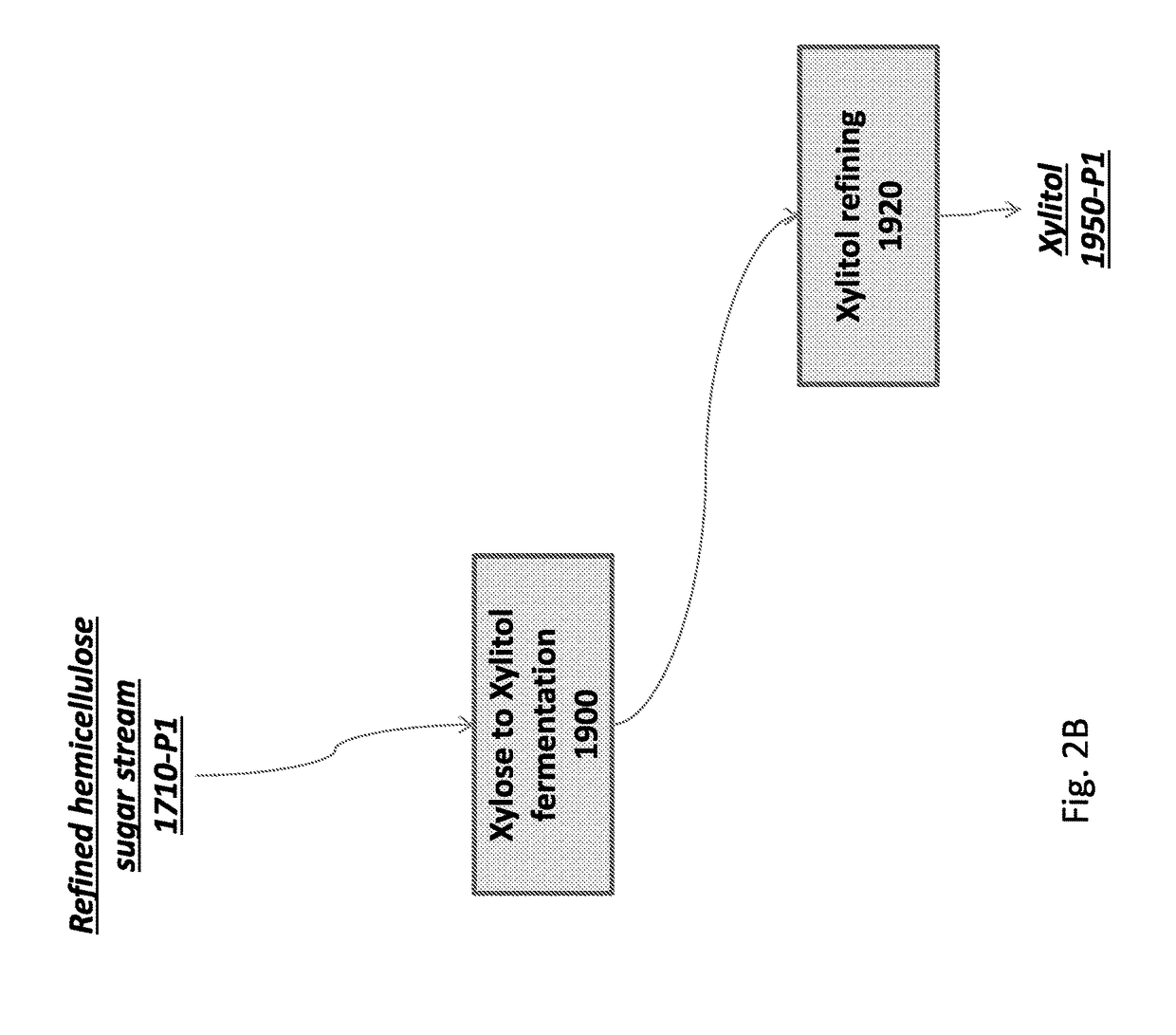

Methods for extracting and converting hemicellulose sugars

ActiveUS20170369957A1Efficient and cost-effective productionXylose productionFructose productionSugarHemicellulose

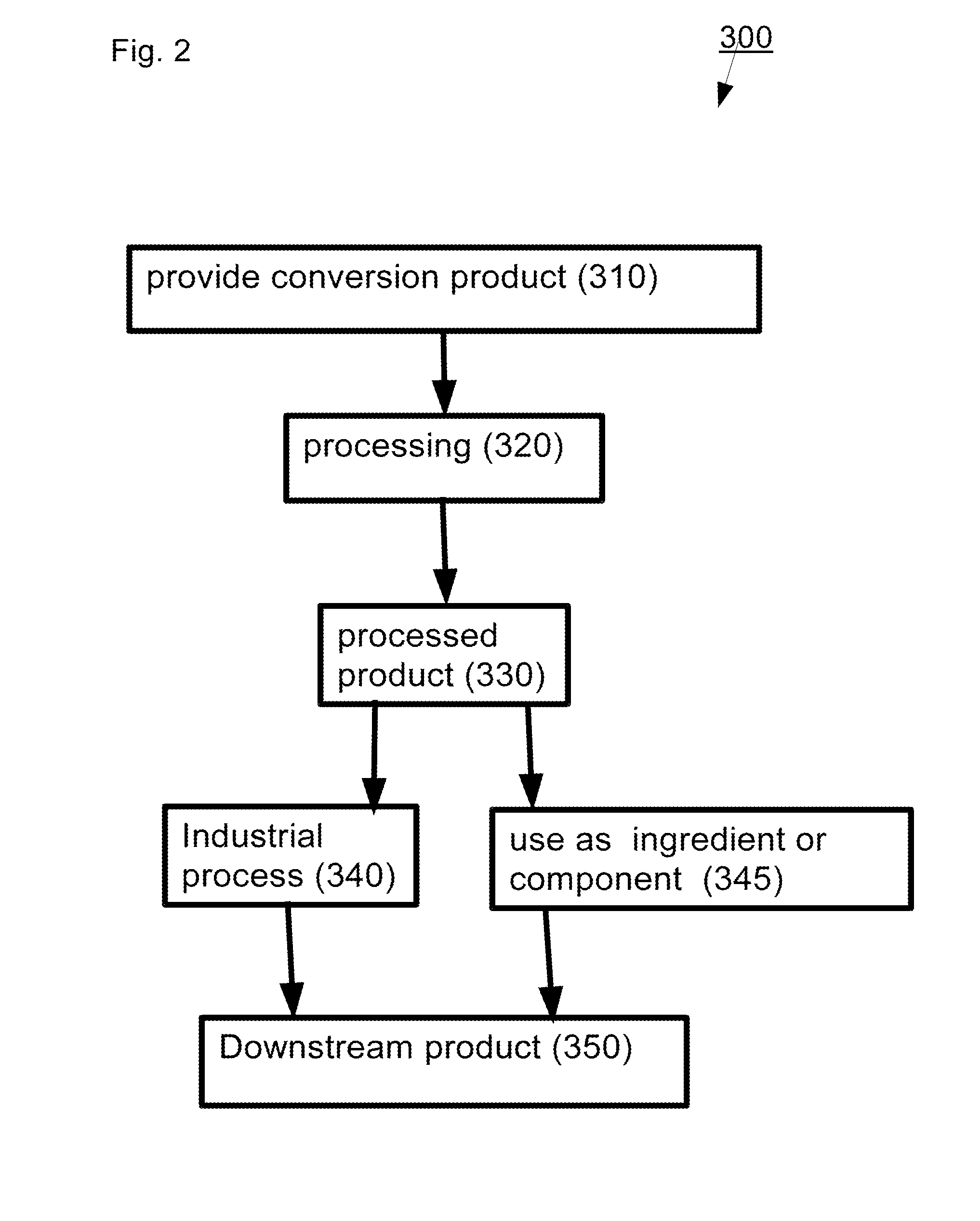

The present disclosure relates to systems, methods, and processes for the production of sugars and conversion products from biomass.

Owner:VIRDIA

Method for hydrolyzing cellulose-containing plant waste by taking AlCl3 as catalyst in near-critical water

InactiveCN101805807ARealize resource utilizationEasy to industrializeOrganic compound preparationFructose productionLiquid wasteCellulose

The invention relates to a method for hydrolyzing a cellulose-containing plant waste by taking AlCl3 as a catalyst in near-critical water, which comprises the following steps: crushing the cellulose-containing plant waste serving as a raw material until the obtained powder is 50 to 200 meshes; and mixing the powder, AlCl3 serving as the catalyst and pure water and feeding the mixture into a near-critical water kettle to perform an reaction, wherein the reaction conditions include a mass ratio of the liquid material of 1-50:200, a reaction temperature of 200 to 300 DEG C, a reaction pressure of 1.8 to 5.0MPa, a reaction time of 1 to 10 minutes and an adding amount of the catalyst of 0.5 to 2.0mmol / l. Compared with the traditional acid hydrolysis, the method using the near-critical water and a metal salt serving as the catalyst to hydrolyze farming and forestry waste is environment friendly, does not generate pollutants, such as waste gas, protects environment, can effectively realize resource recycling of the farming and forestry waste and recycles waste materials.

Owner:SHANGHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com