Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63results about "Invert sugar production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

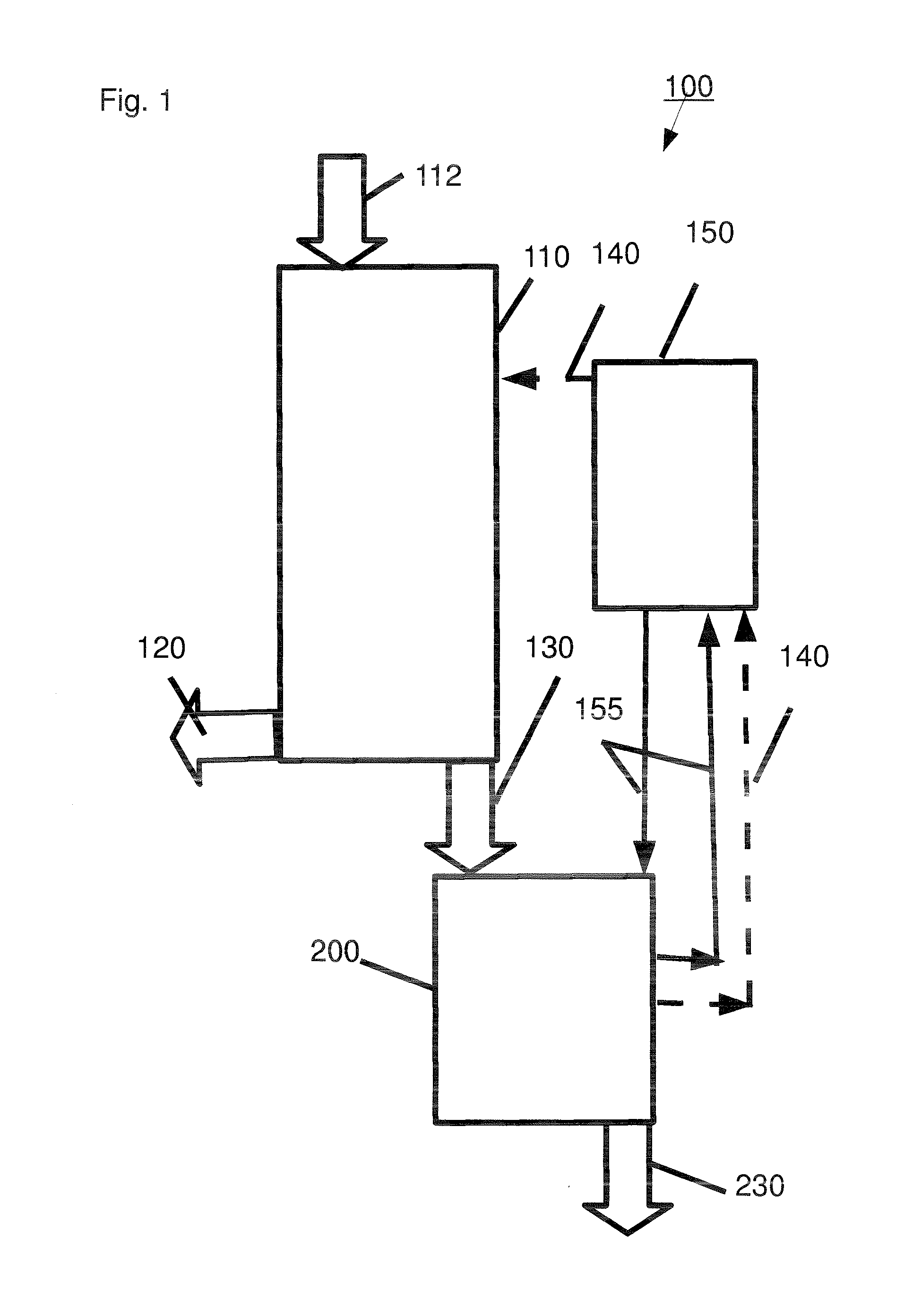

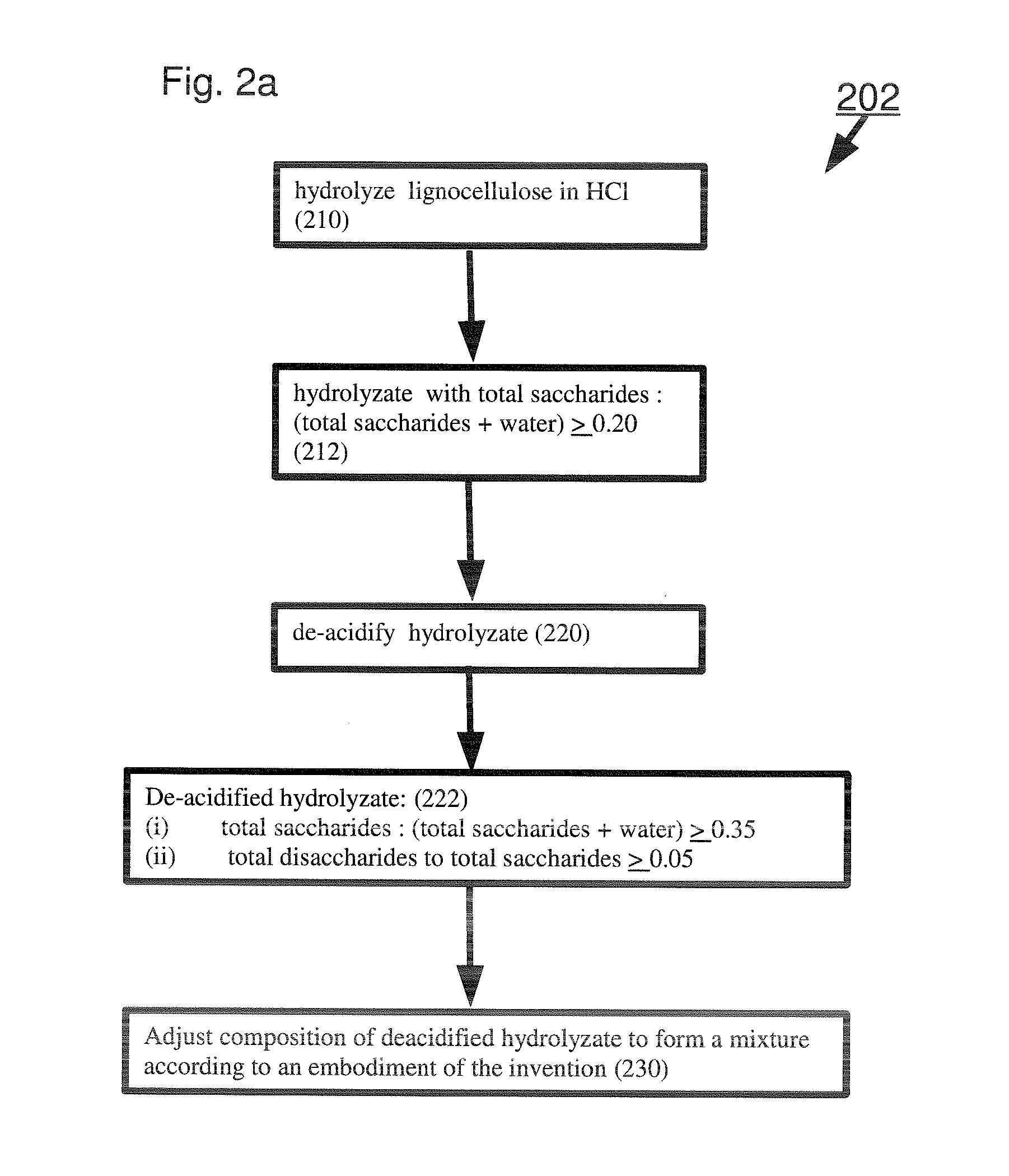

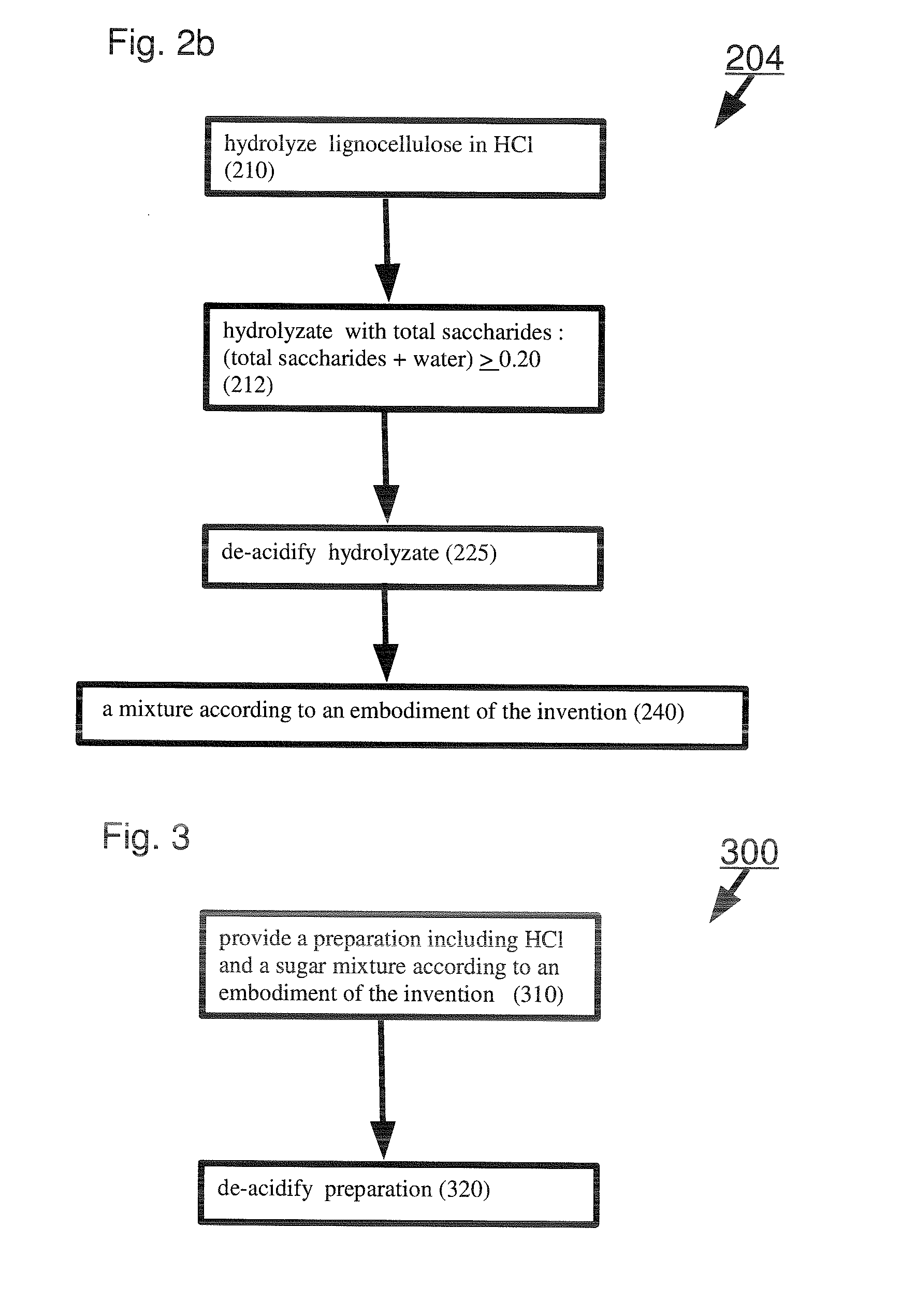

Sugar mixtures and methods for production and use thereof

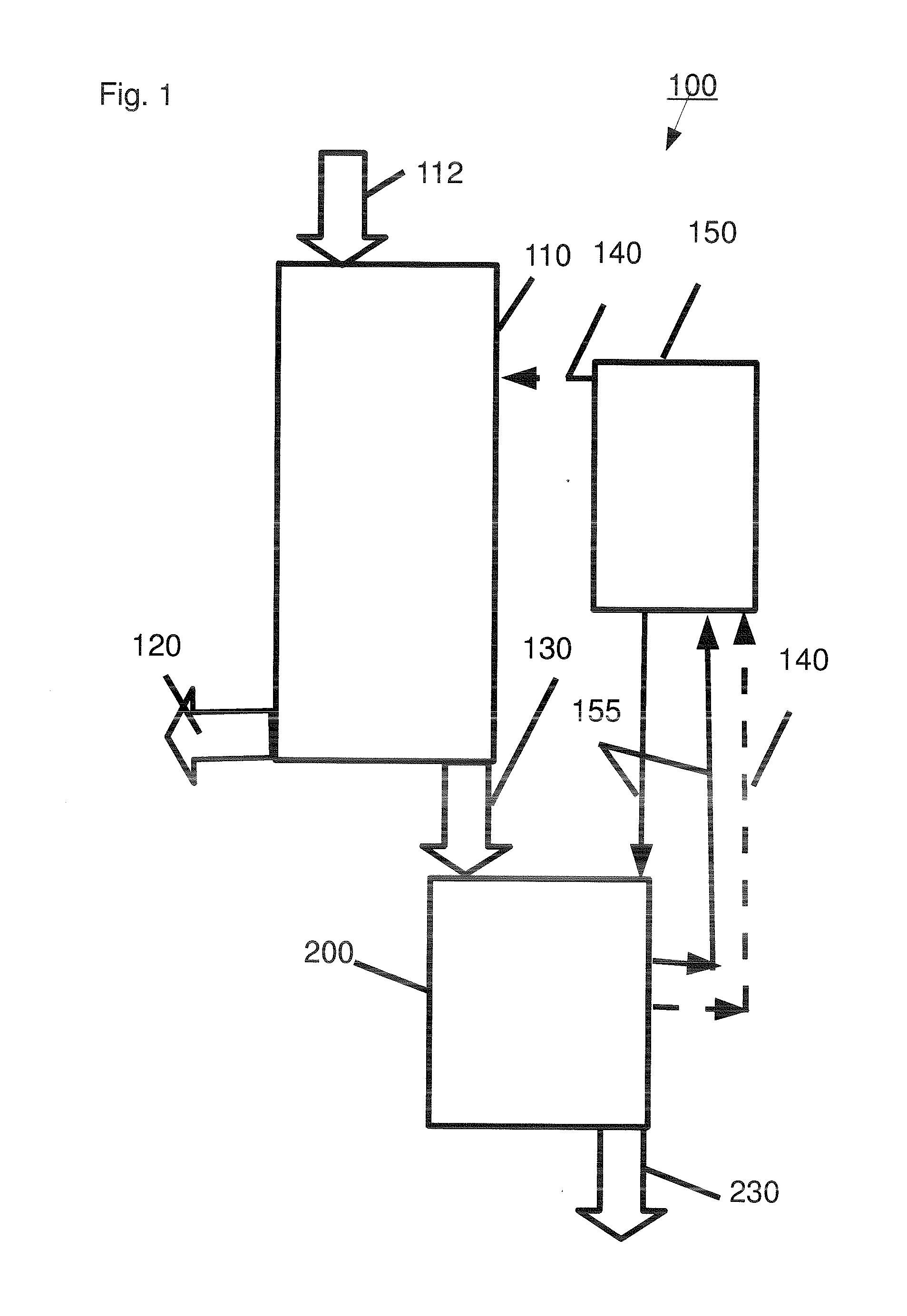

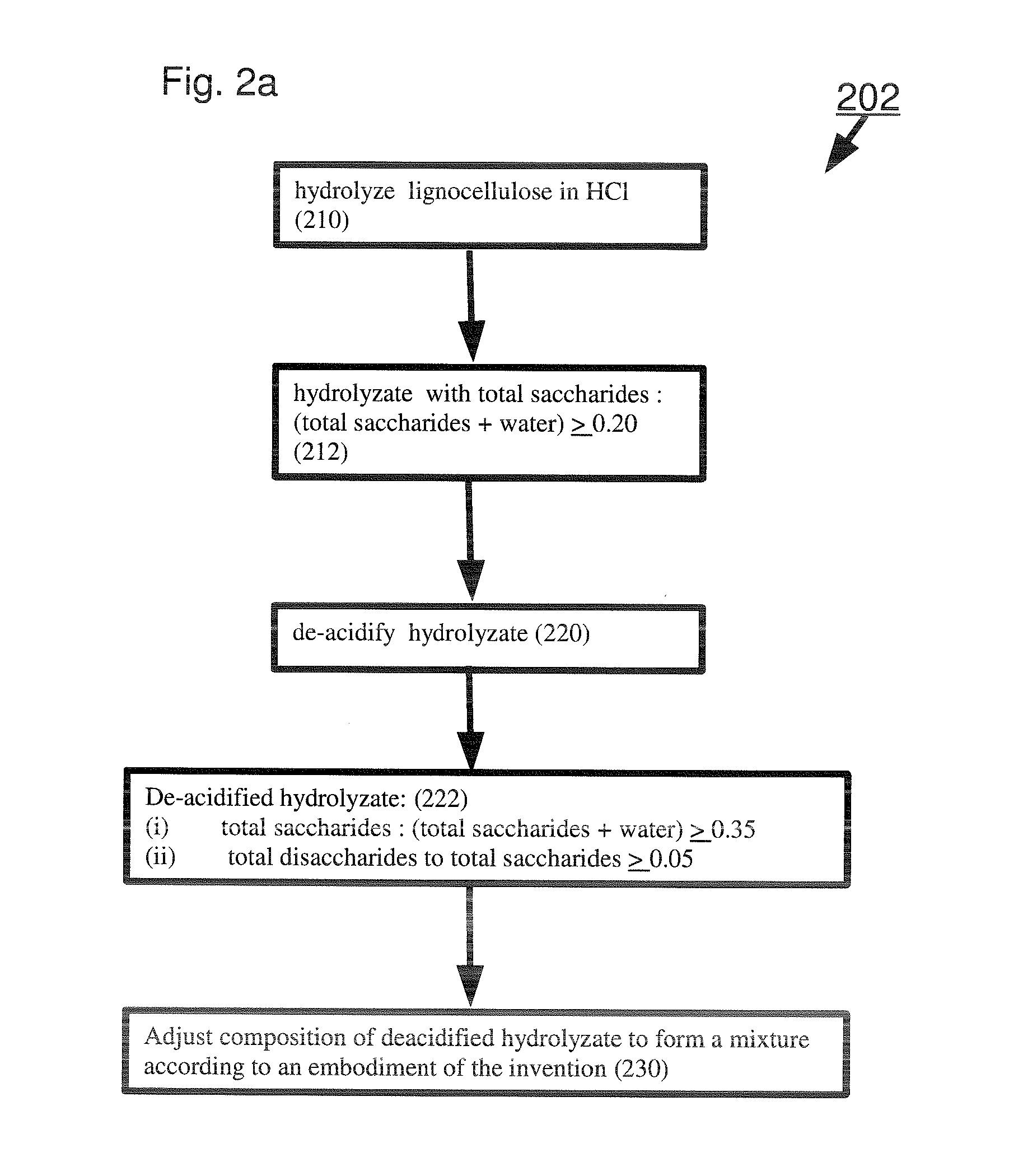

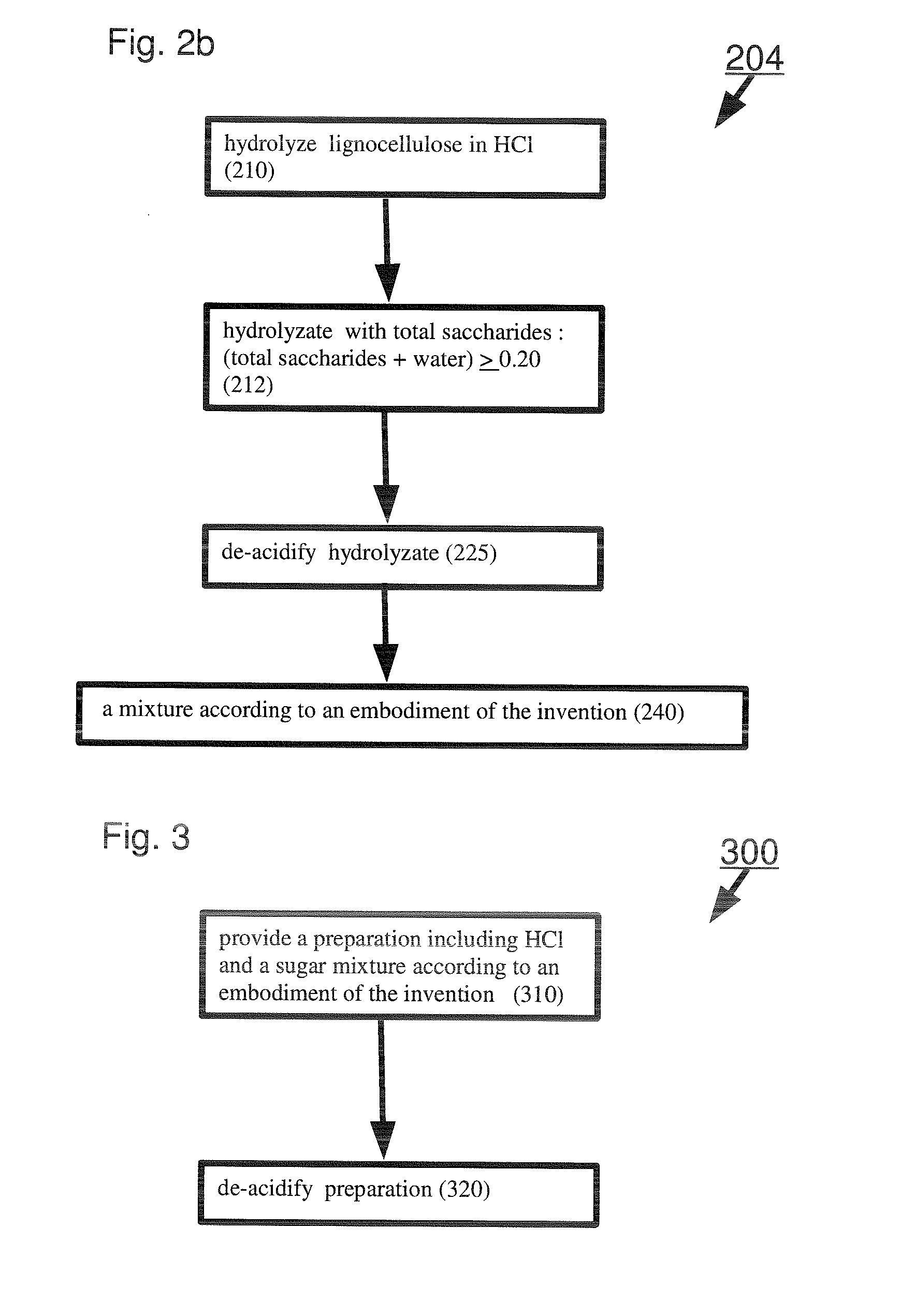

A sugar mixture comprising: monosaccharides; oligosaccharides in a ratio ≧0.06 to total saccharides; disaccharides in a ratio to total saccharides ≧0.05; pentose in a ratio to total saccharides ≧0.05; at least one alpha-bonded di-glucose; and at least one beta-bonded di-glucose. Also disclosed are methods to make and / or use such mixtures.

Owner:VIRIDA

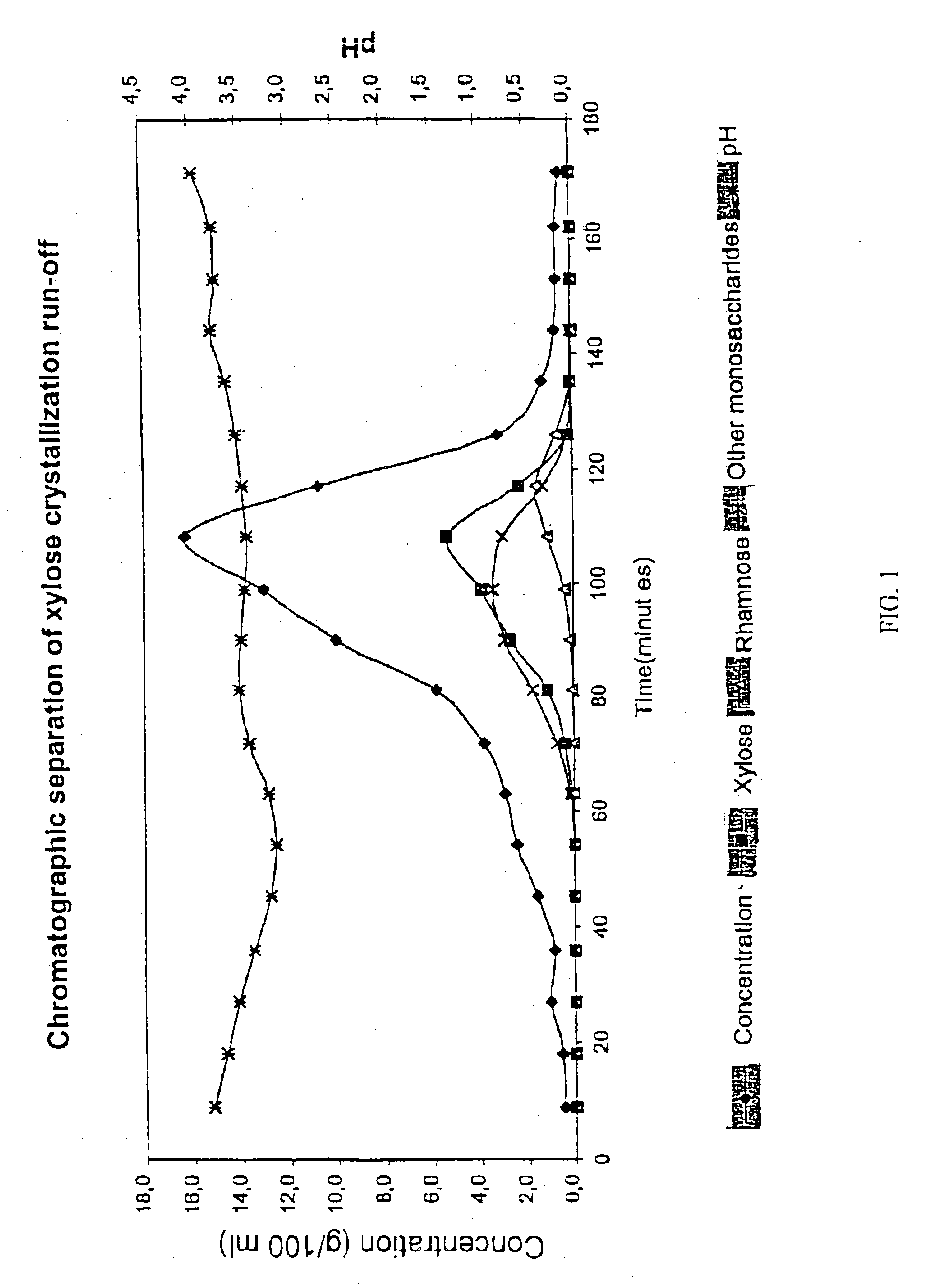

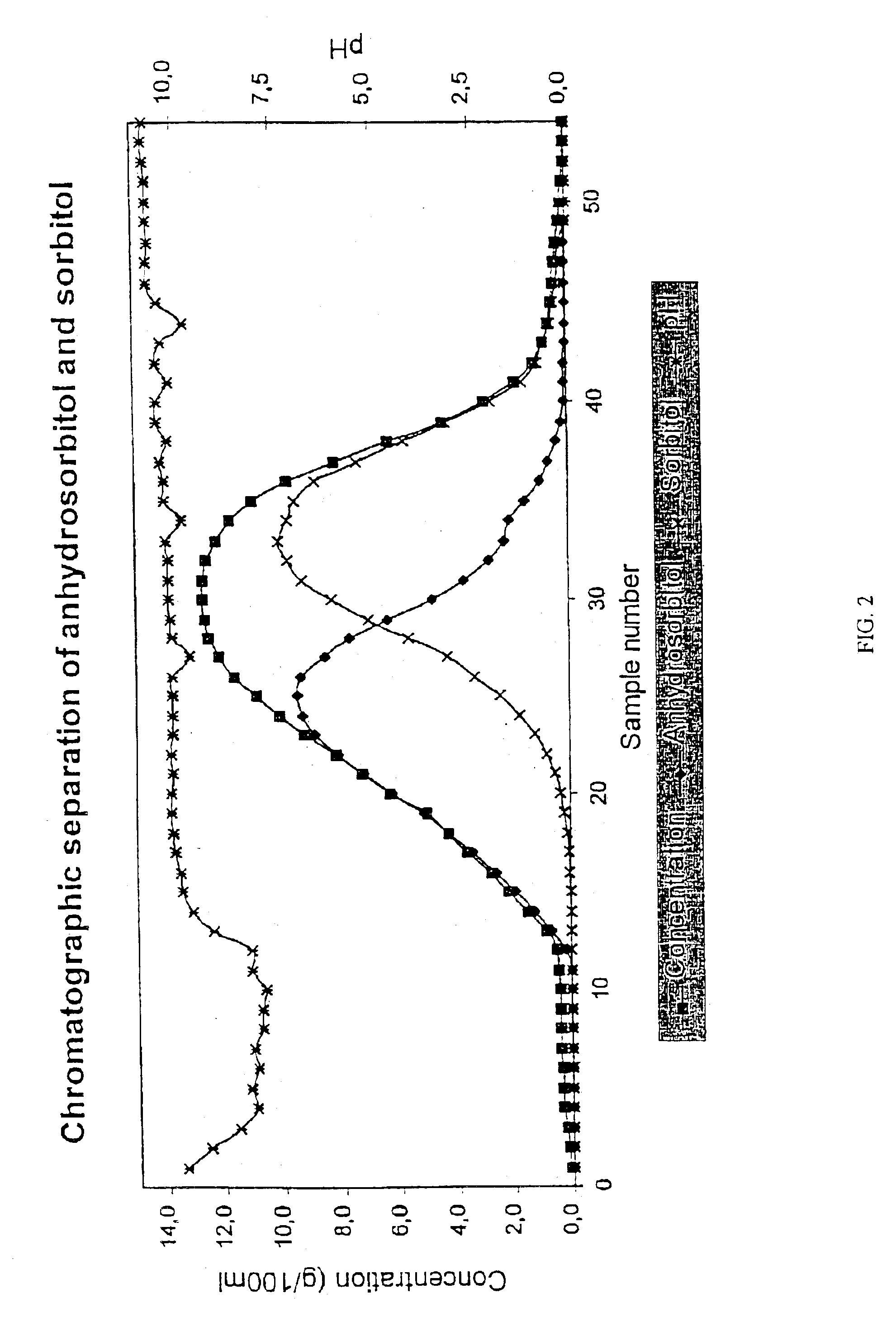

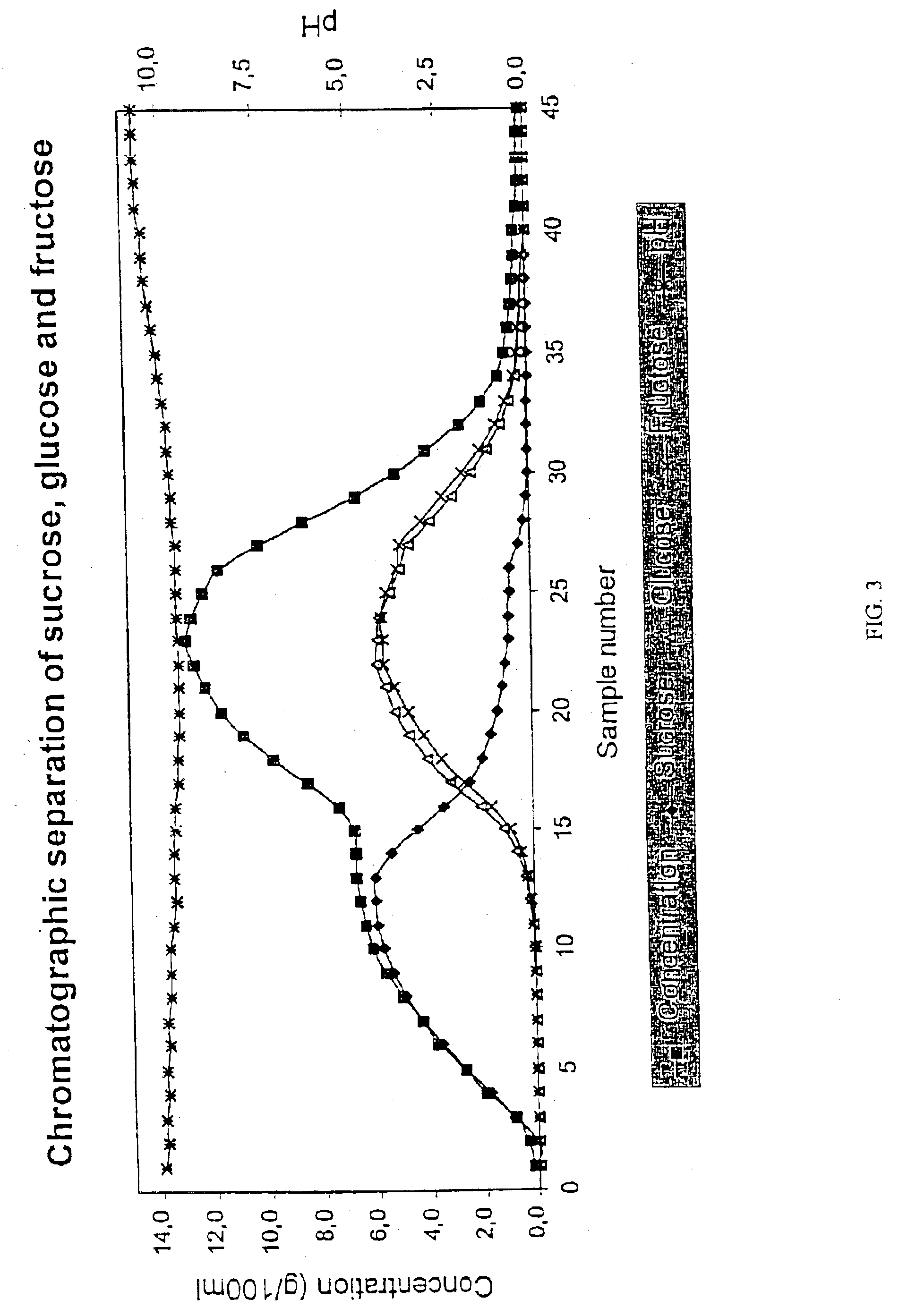

Use of a weakly acid cation exchange resin for chromatographic separation of carbohydrates

InactiveUS6924371B2High yieldEasy to separateChromatographic cation exchangersCation exchanger materialsChromatographic separationAlcohol sugars

The invention relates to the use of a weakly acid cation exchange resin for chromatographic separation of carbohydrates. In the invention the hydrophilic / hydrophobic interaction of carbohydrates, sugars and sugar alcohols with the weakly acid cation exchange resin is utilized. The weakly acid cation exchange resin is used for separation of hydrophobic saccharides, such as deoxy, methyl and anhydrosugars and anhydrosugaralcohols from more hydrophilic saccharides.

Owner:DANISCO SWEETENERS

Sugar mixtures and methods for production and use thereof

A sugar mixture comprising: monosaccharides; oligosaccharides in a ratio ≧0.06 to total saccharides; disaccharides in a ratio to total saccharides ≧0.05; pentose in a ratio to total saccharides ≧0.05; at least one alpha-bonded di-glucose; and at least one beta-bonded di-glucose. Also disclosed are methods to make and / or use such mixtures.

Owner:VIRIDA

Crystalline glucose producing process based on whole membrane method

ActiveCN1810994AImprove qualityNo pollution in the processInvert sugar productionGlucose productionUltrafiltration

Owner:SANDA FILM SCI & TECH XIAMEN

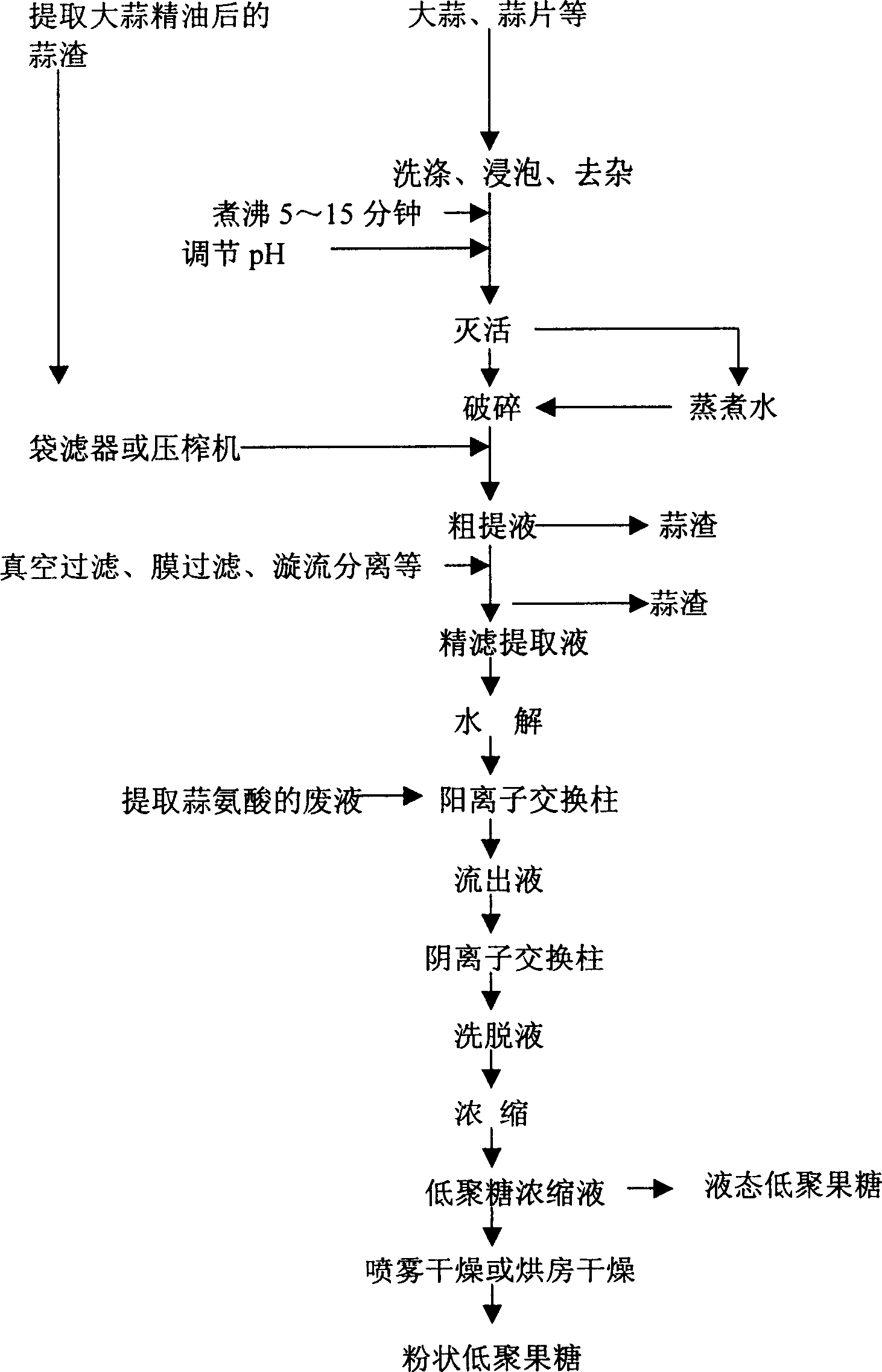

Process for producing oligofructose of garlic

The invention discloses a garlic low poly fruit sugar manufacturing method. It includes the following steps: processing various garlic materials to gain garlic polysaccharide coarse extracting solution; fine processing to gain transparent refine garlic polysaccharide extracting solution; hydrolyzing with 1.0-2.5 pH value to make reducing value reach 10-35%; then gaining the garlic low poly fruit sugar solution with 3-10 polymerization degree. The product can be helpful to delay garlic material overstock, exploit medicine or health food used garlic low poly fruit sugar as material, and greatly increase addition value of the garlic further processed product.

Owner:JINAN UNIVERSITY

Crystal fructose production process by corn starch

ActiveCN1876845AReduce energy consumptionOvercome the defect of difficult crystallizationInvert sugar productionChromatographic separationFructose

The invention for the technology of using cornstarch to product crystallization diabetin relates to the field of carbohydrate manufacturing technique. This technique, using corn as material, through the procedures of compression, isomerization chromatographic fractionation, evaporation and crystallization and so on, by controlling the parameters in the steps of crystallization and so on, does not only resolve the defect of the high difficulty of diabetin crystallization, but also reduce the energy consumption of specific product.

Owner:SHANDONG XIWANG SUGAR

Process for the production of invert liquid sugar

InactiveUS6916381B2Reduce amountFew stepsPurification by oxidation/reductionPurification using adsorption agentsFruit juiceSugar

A process for the production of liquid sugar by forming a sugar solution of water and natural sugar containing juice, adjusting the pH of a sugar solution to the range of from 1.0 to 2.0 to obtain an inverted juice, filtering the inverted juice, decolorizing the inverted juice to obtain sugar syrup, demineralizing the sugar syrup, evaporating the demineralized sugar syrup, and cooling the sugar syrup to form the liquid sugar.

Owner:GRANGUILLHOME ENRIQUE R CARDENAS +2

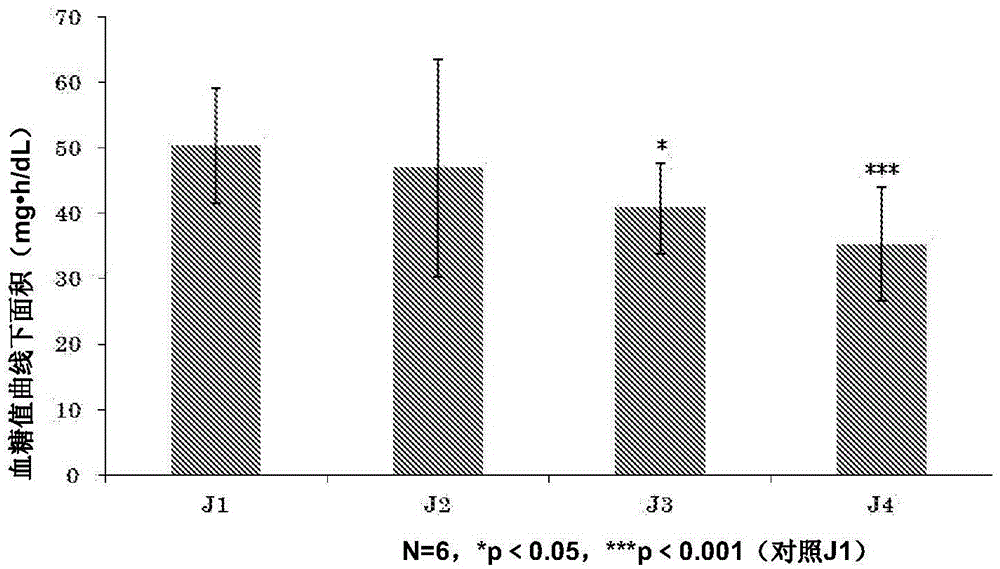

Sweetener composition, method for manufacturing same and use thereof

InactiveCN105163603ALow costIncrease sweetnessOrganic active ingredientsCosmetic preparationsDiseaseRare sugar

The present invention provides a novel sweetener, which is free from a risk of diseases caused by the intake of isomerized sugars and overcomes problems encountered in the course of producing a rare sugar-containing syrup or disadvantages in taste, a method for manufacturing the same, and a use thereof. A method for manufacturing a sweetener composition, said method comprising: treating sucrose with an acid and / or an enzyme under specific conditions to thereby efficiently decompose sucrose into glucose and fructose; and then isomerizing the obtained mixture using an alkali and / or an enzyme under specific conditions in such a manner as to allow the resultant isomerized product to contain D-psicose mainly as a rare sugar so that the product comprises, at a specific composition ratio, sucrose, D-glucose, D-fructose and rare sugar(s) at least containing D-psicose, or the product comprises, at a specific composition ratio, D-glucose, D-fructose and rare sugar(s) at least containing D-psicose.

Owner:MATSUTANI CHEM INDS CO LTD

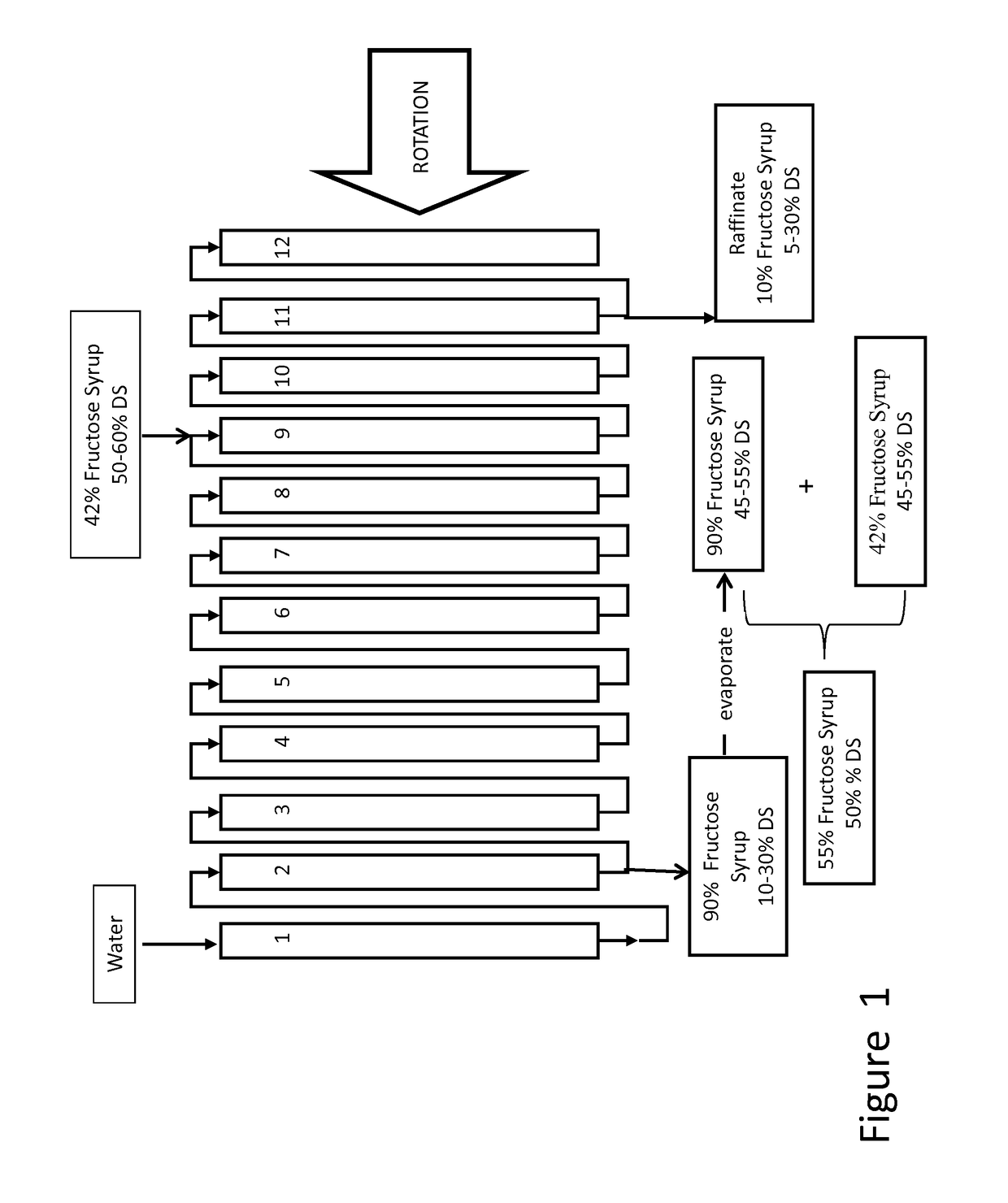

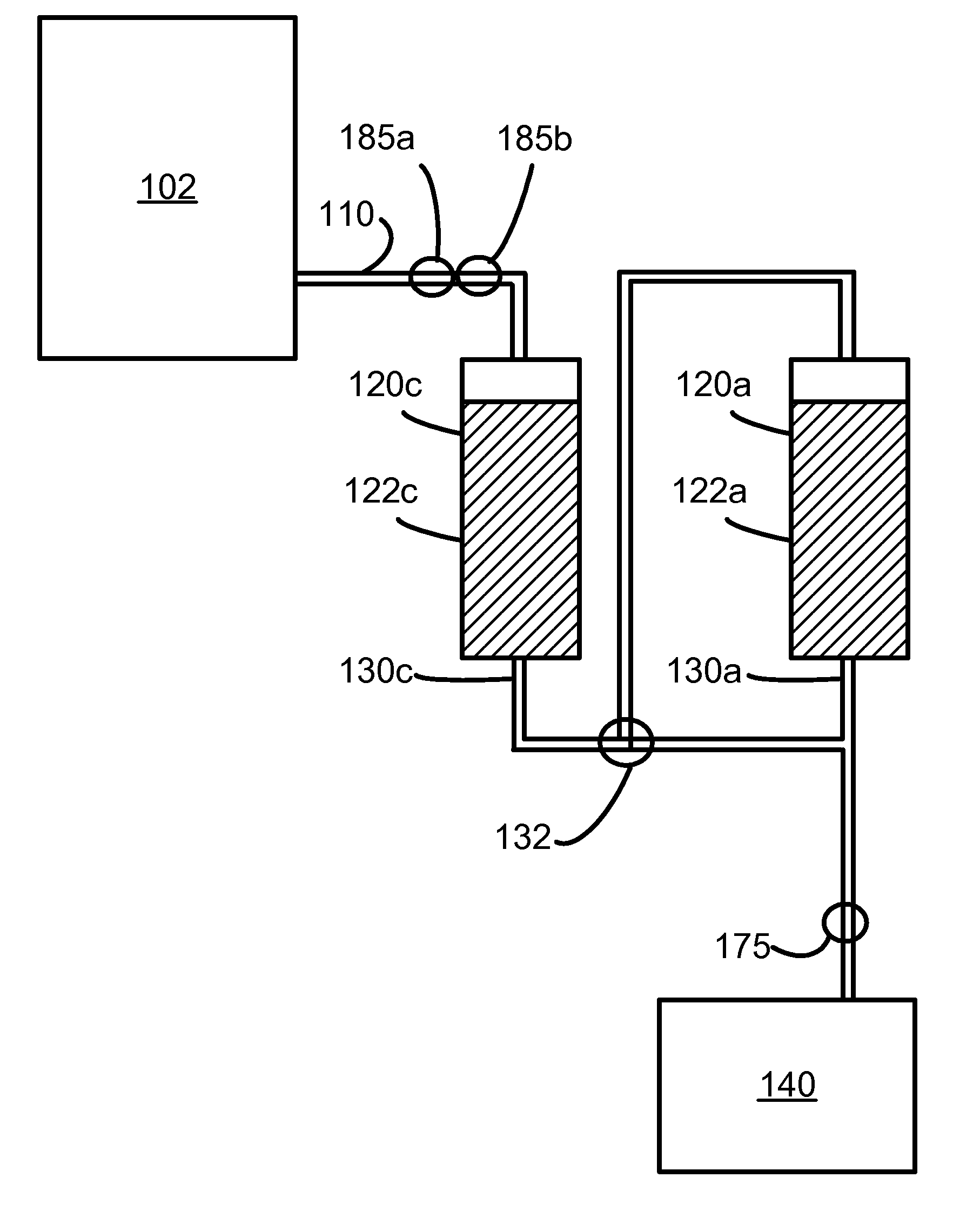

Method for adjusting the composition of chromatography products

ActiveUS20170304745A1Lower fructose proportionCost optimizationChromatographic cation exchangersCation exchanger materialsHigh-fructose corn syrupSimulated moving bed

Described herein is a method of adjusting the composition of a chromatography product to achieve a target enriched proportion of a desired component from an input feed having a lower proportion of the desired component using simulated moving bed (“SMB”) chromatography wherein the eluent for the SMB apparatus may comprise the very input feed being enriched. The method is exemplified by enriching a high fructose corn syrup from a 42% fructose syrup to a 55% fructose syrup without substantially reducing the dissolved solids concentration of the 55% syrup relative to the input 42% syrup. The 42% syrup is also used as the eluent for the SMB apparatus and may be reconstituted from the raffinate stream by passing the raffinate stream over a glucose isomerase column alone or in combination with a dextrose feed. The method reduces water usage and saves energy by minimizing the need for evaporation to obtain a 55% fructose syrup with a high dissolved solids content.

Owner:ARCHER DANIELS MIDLAND CO

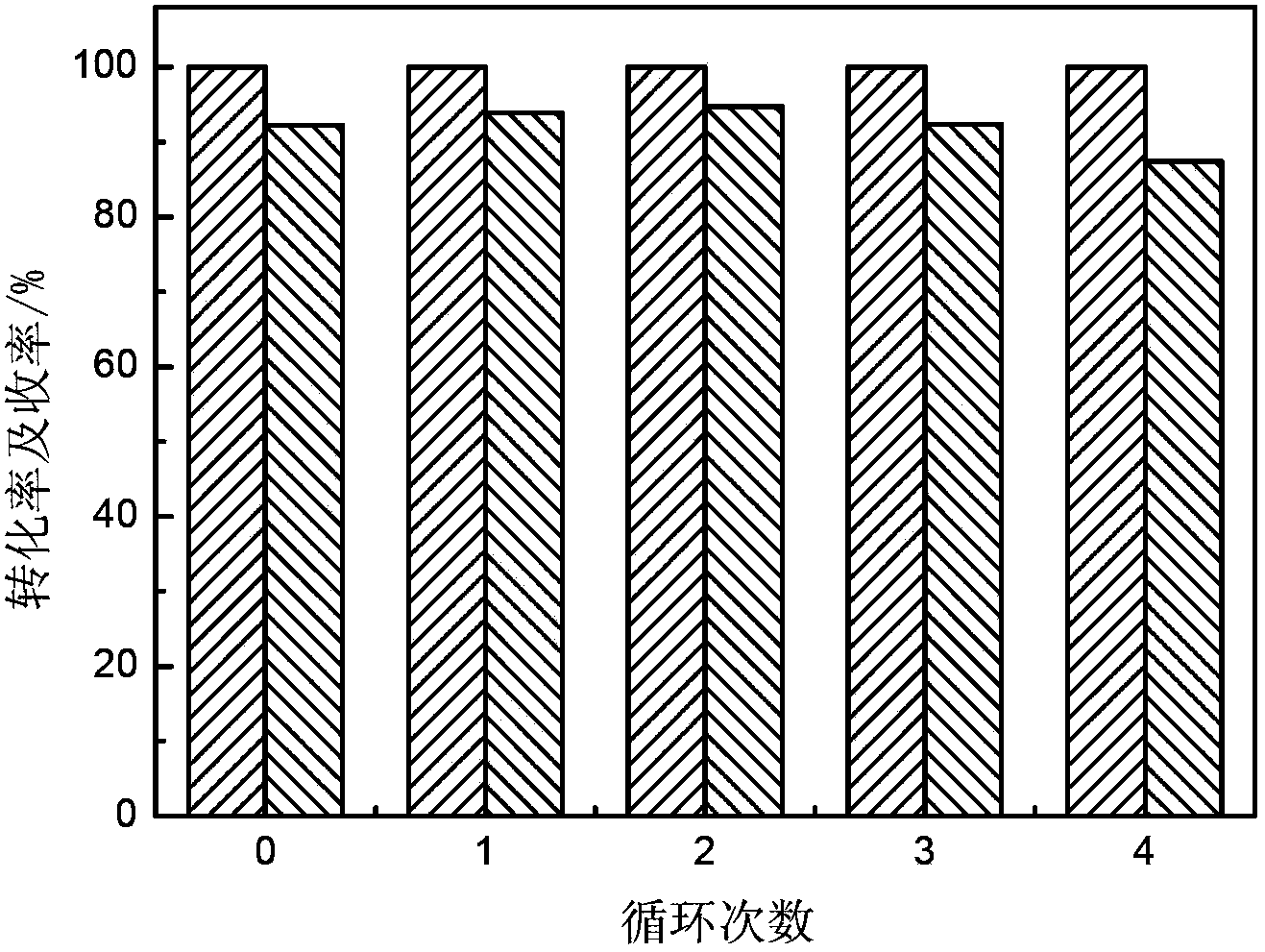

Method and catalyst for hydrolyzing saccharide compounds

InactiveCN103509886ARich sourcesMild reaction conditionsOrganic-compounds/hydrides/coordination-complexes catalystsInvert sugar productionHydrolysisChemistry

The invention relates to a method and catalyst for hydrolyzing saccharide compounds. An acidic material with densely distributed strong / weak-acidity groups is used in the process of hydrolyzing the saccharide compounds into monosaccharides, thereby solving the problems of lower monosaccharide yield and overhigh catalyst cost. By adopting the catalyst provided by the invention, the hydrolysis conversion rate of the saccharides can reach 90% above, and the oligosaccharide hydrolysate selectivity can reach 90% above. The catalyst is easy for separation and can be recycled, and has the characteristics of wide application range for saccharide compounds and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

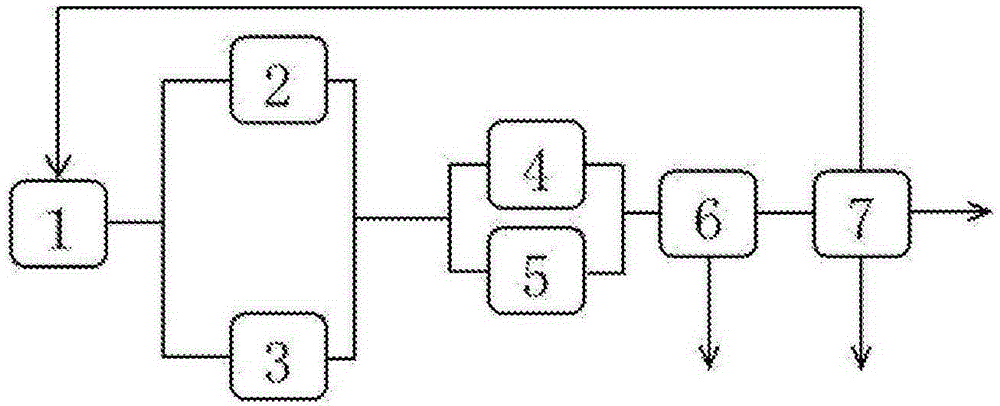

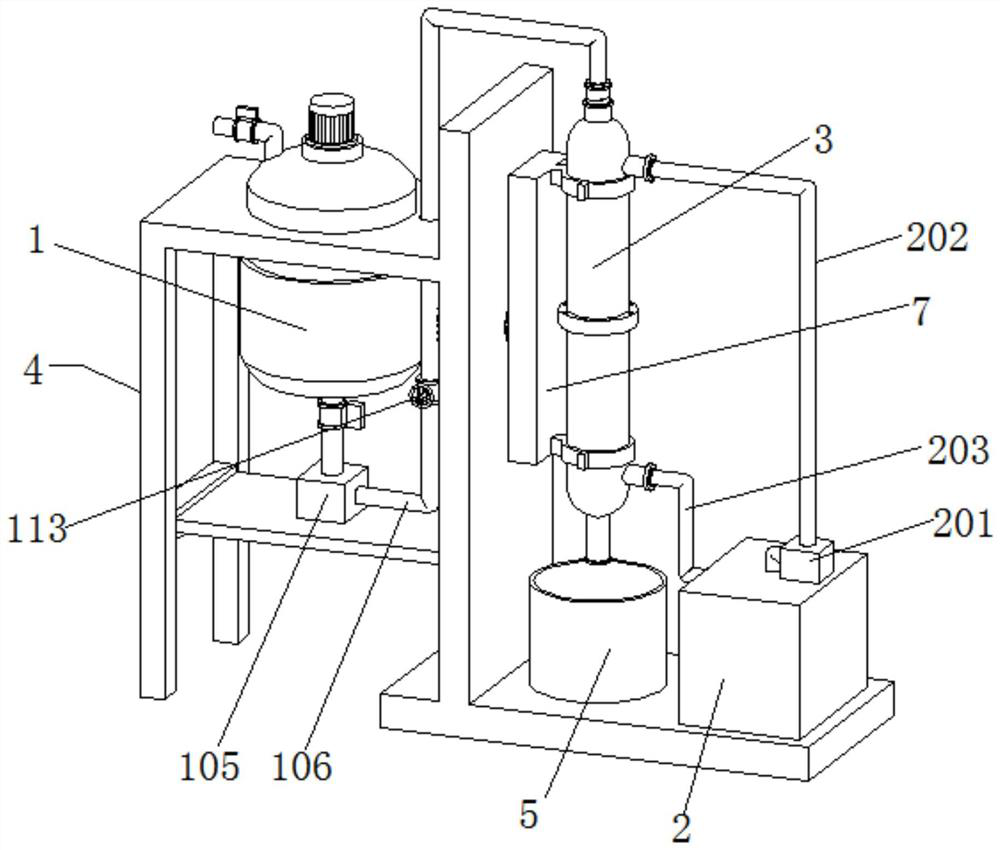

Production of invert syrup from sugarcane juice using immobilized invertase

ActiveCN1914329AReduce contentExtend your lifePurification using ion-exchange materialsPurification by physical meansSaccharumFiltration

This invention is directed to a novel process in which raw sugarcane juice is first refined through a number of steps and then bioenzymatically converted into refined invert syrup or glucose-fructose concentrated solution using a reactor packed with immobilized invertase. The refining steps preferably include a first filtration (particle filtration or microfiltration) followed by a second filtration (microfiltration or ultrafiltration) and then at least one pass through a column packed with an anionic exchange resin. The refined sugarcane juice can be optionally concentrated and / or pasteurized before passing through a reactor packed with immobilized invertase to convert sucrose to glucose - fructose.

Owner:MONTERREY POLYTECHNIC INST

Method for preparing medicinal waterless crystallized fructose by taking sugarcane as raw material

PendingCN105331751AIncrease fructose contentIncreased spawn chanceFructose productionInvert sugar productionBiotechnologyHigh-fructose corn syrup

A method for preparing medicinal waterless crystallized fructose by taking sugarcane as raw material is disclosed. The technological process of the method comprises the following steps: performing cane juice squeezing concentration, preparing high fructose corn syrup, refining high fructose corn syrup, separating refined high fructose corn syrup, crystallizing fructose and recovering a glucose solution. In the method, the equipment and technological parameters of all procedures are comprehensively optimizes and reasonable matched, the method is suitable for industrialized production demand, equipment investment and production cost are substantially reduced, the once yield of the industrialized produced crystallized fructose product is up to 50%, the technology content of fructose production is improved, and the situation that fructose market severely depends on imported high-quality medicinal fructose and technology equipment thereof is solved.

Owner:姜蓉生

Production of invert syrup from sugarcane juice using immobilized invertase

ActiveUS20050084939A1Large scaleSugar derivativesPurification using ion-exchange materialsFiltrationMicrofiltration

This invention is directed to a novel process in which raw sugarcane juice is first refined through a number of steps and then bioenzymatically converted into refined invert syrup or glucose-fructose concentrated solution using a reactor packed with immobilized invertase. The refining steps preferably include a first filtration (particle filtration or microfiltration) followed by a second filtration (microfiltration or ultrafiltration) and then at least one pass through a column packed with an anionic exchange resin. The refined sugarcane juice can be optionally concentrated and / or pasteurized before passing through a reactor packed with immobilized invertase to convert sucrose to glucose - fructose.

Owner:INST TECHNOLOGICO & DE ESTUDIOS SUPERIORES DE MONTERREY

Process for the preparation of monoethylene glycol

The invention provides a process for the preparation of monoethylene glycol from sucrose comprising the steps of: i) hydrolysing sucrose to form a reaction product stream comprising glucose and fructose; ii) separating the reaction product stream comprising glucose and fructose into a fructose or fructose derivative rich stream and a glucose rich stream; and iii) contacting the glucose rich stream with hydrogen in a reactor in the presence of a solvent and a catalyst system with catalytic hydrogenation abilities to produce a product stream comprising monoethylene glycol.

Owner:SHELL USA INC

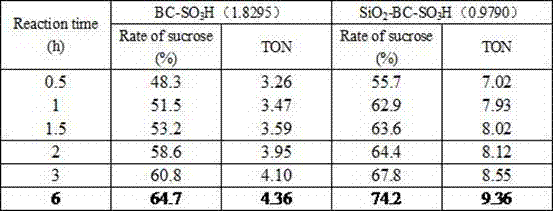

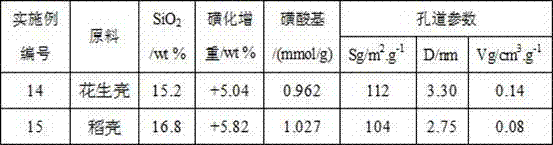

Preparation method of silica gel column supported meso-porous biochar solid sulfonic acid

ActiveCN106914258AHigh yieldHigh sulfonic acid contentPhysical/chemical process catalystsInvert sugar productionFiberSucrose

The invention provides a preparation method of silica gel column supported meso-porous biochar solid sulfonic acid (SiO2-BC-SO3H) from wood fiber biomass, and a method using the silica gel column supported meso-porous biochar solid sulfonic acid to catalyze sucrose hydrolysis for preparing glucose. The preparation method of the SiO2-BC-SO3H comprises the following steps: biomass heat carbonization or concentrated sulfuric acid dehydration carbonization, boiling water swelling, acidic silica sol intercalation, heating (350 DEG C) dehydration in nitrogen, and concentrated sulfuric acid sulfonation. The silica gel content of the SiO2-BC-SO3H prepared through the steps is about 15 wt%, the sulfonic group density is 0.9 mmol / g or above, and the SiO2-BC-SO3H has an interlayer meso-porous structure. The SiO2-BC-SO3H has better catalysis activity and better reusability than non-porous biochar solid sulfonic acid in the catalysis of the sucrose hydrolysis reaction.

Owner:岳阳湘茂医药化工有限公司

Production of invert syrup from sugarcane juice using immobilized invertase

ActiveUS7435564B2Large scalePurification using ion-exchange materialsPurification by physical meansBiotechnologyFructose

This invention is directed to a novel process in which raw sugarcane juice is first refined through a number of steps and then bioenzymatically converted into refined invert syrup or glucose-fructose concentrated solution using a reactor packed with immobilized invertase. The refining steps preferably include a first filtration (particle filtration or microfiltration) followed by a second filtration (microfiltration or ultrafiltration) and then at least one pass through a column packed with an anionic exchange resin. The refined sugarcane juice can be optionally concentrated and / or pasteurized before passing through a reactor packed with immobilized invertase to convert sucrose to glucose-fructose.

Owner:INST TECHNOLOGICO & DE ESTUDIOS SUPERIORES DE MONTERREY

Process for the preparation of monoethylene glycol

Owner:SHELL USA INC

Preparation process of liquid sugar

InactiveCN106480234AReduce wasteAvoid the reverse reactionSugar productsSucrose extraction by chemical meansAcid hydrolysisCitric acid

The invention discloses a preparation process of liquid sugar. The preparation process comprises the following steps of (1) raw material preparation and treatment; (2) temperature rise concentration; (3) acid addition; (4) heat insulation conversion; (5) alkali addition for conversion stopping; (6) temperature reduction. Compared with the prior art, the preparation process of liquid sugar aims at an integral utilization technology of sugar production byproducts, uses a method of a weak acid hydrolysis method, and has the advantages that the reaction is mild; the content of reducing sugar can be conveniently controlled; the operation is simple and convenient; in addition, the generated syrup cannot easily precipitate; the state is stable; citric acid belongs to food grade additives, and the remained additives cannot be harm to the body.

Owner:南京甘汁园股份有限公司

Method for preparing industrial fructose with isomeric glucose by adopting chemical catalysis method

ActiveCN109369734AAvoid ineffective degradationHigh selectivitySugar derivativesFructose productionIsomerizationSubstrate concentration

The invention discloses a method for preparing industrial fructose with isomeric glucose by adopting a chemical catalysis method. The method comprises the following steps that 1, a glucose water solution is prepared, borax and sodium hydroxide are sequentially added into the glucose water solution, then magnesium-based solid base is added, and reaction is performed in the inert atmosphere; 2, reaction is completed, a solid base catalyst is recovered through solid-liquid separation, liquid is fed into an electroosmosis system, and glucose and a fructose complex are separated to obtain a fructose borate complex solution; 3, the fructose borate complex solution flows through boron specific resin to remove the borax and the sodium hydroxide, and a pure fructose product is obtained. By combining homogeneous-phase base catalysis and non-homogeneous-phase base catalysis, the method is suitable for higher substrate concentration, also improves the isomerization rate and fructose selectivity, utilizes the difference of the fructose complex and glucose to achieve their simple and efficient separation, provides possibility for large-scale development of fuel and chemicals based on an industrial fructose platform and has a good application prospect.

Owner:HUAIYIN TEACHERS COLLEGE

Method for preparing syrup used for sweety

The invention discloses a preparation method of syrup for candies, pertaining to the production field of syrup, and is characterized in that a two enzymes (heat-resistant Alpha-amylase, composite liquefied enzyme) method is adopted and enzyme types, time of adding enzyme and enzyme dosage are controlled so as to prepare the syrup used for candies production. Compared with the prior art, the syrup for candies produced by the preparation method of the invention is characterized by excellent and stable performance, conformance to requirements of the candies production and can be widely applied to the production of various candies and chocolates, thus having good value of popularization and application.

Owner:BAOLINGBAO BIOLOGY

Method for producing mannitol and sorbitol through waste fructooligosaccharide liquid

ActiveCN103508848AMaximize recoveryIncrease added valueSugar derivativesOrganic compound preparationSucroseFructooligosaccharide

The invention relates to the technical field of the sugar industry, in particular to a method for producing mannitol and sorbitol through waste fructooligosaccharide liquid. The method comprises the following steps: after pretreating the waste production liquid, firstly, hydrolyzing the waste production liquid to hydrolyze sucrose in the waste production liquid into the invert sugar of 1 / 2 fructose and glucose; secondly, epimerizing glucose as a raw material so as to convert the glucose into mannose; finally, performing hydroconversion to obtain the mannitol, and converting the fructose and the glucose in the mixed liquid into the sorbitol and the mannitol under the action of hydrogenation, thus realizing the maximum recovery of the product. The method is simple in process steps, and adopts the waste production liquid as a raw material, so that the production cost is greatly reduced, the added value of a byproduct is improved, the environment is protected, and the production yield is improved. Therefore, the method is suitable for wide popularization and application.

Owner:SHANDONG BAILONG CHUANGYUAN BIO TECH

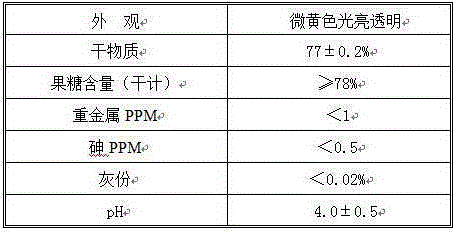

Method for preparing medicinal invert sugar by sugar hydrolysis

The invention relates to a method for preparing medicinal invert sugar by sugar hydrolysis, which belongs to the technical field of preparation technology of medicaments and solves the problem that the invert sugar directly prepared by the sugar hydrolysis in the prior art cannot meet the medicinal standard. The method for preparing aqueous solution of medicinal invert sugar by directly hydrolyzing the sugar comprises the following steps of: adding 35 percent solution of concentrated hydrochloric acid into water for injection to adjust the pH value to a proper value; controlling a proper internal temperature and adding a proper amount of medicinal sugar to react for a certain time; and adding the injection water at the temperature of between 5 and 10 DEG C to rapidly reduce the temperature so as to obtain the aqueous solution of the medicinal invert sugar. The aqueous solution of the medicinal invert sugar prepared by the method can be used for preparing medicinal invert sugar injection and medicinal invert sugar electrolyte injection.

Owner:HAISCO PHARMA GRP INC

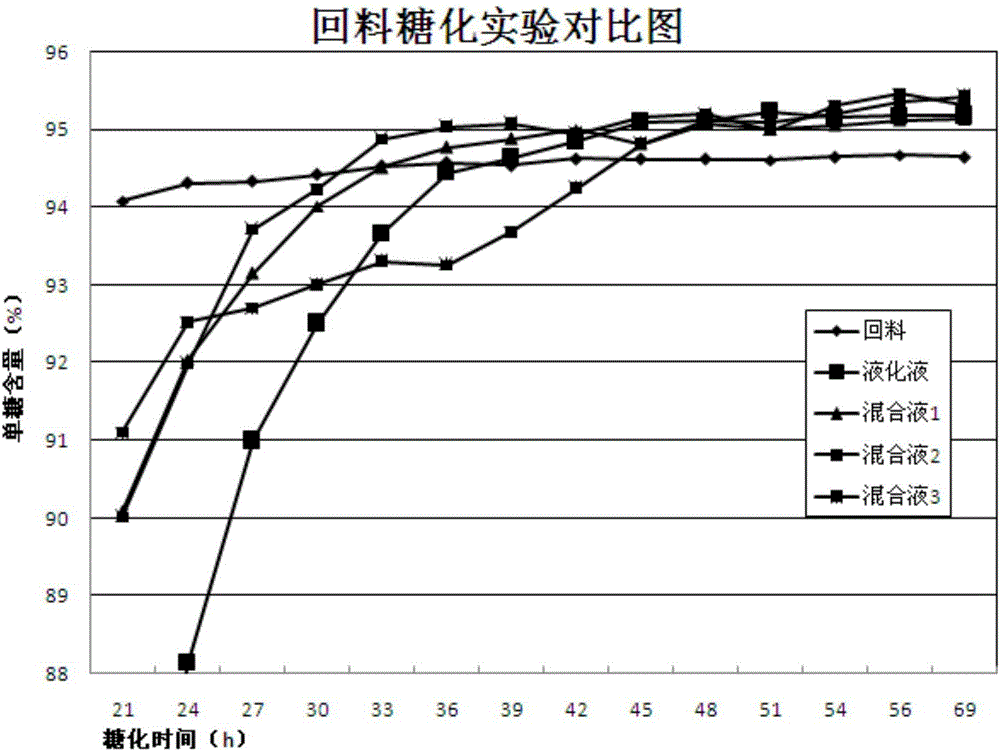

Preparation method of high fructose corn syrup

InactiveCN105907817AEasy to handleEfficient use ofFermentationInvert sugar productionChromatographic separationIsomerization

The invention relates to a preparation method of high fructose corn syrup. The preparation method comprises 1, taking starch as a raw material and orderly carrying out slurry mixing, liquefaction, saccharification, enzyme deactivation, coarse filtration, first ion exchange, first decolorizing filtration, first condensation, isomerization, second ion exchange, second decolorizing filtration and second condensation to obtain a high fructose corn syrup semi-finished product, 2, orderly carrying out chromatographic separation, third ionic exchange, third decolorizing filtration and third condensation on the high fructose corn syrup semi-finished product to obtain a high fructose corn syrup finished product, blending the returned material produced through chromatographic separation and a liquefied liquid to obtain a mixed liquefied liquid, putting the mixed liquefied liquid into a saccharification section, carrying out saccharification and orderly carrying out later processes to obtain a high fructose corn syrup finished product. The preparation method can effectively treat a returned material of a chromatographic separation section, improve returned material tank use efficiency, effectively utilize the returned material in production without influence on product quality, saves raw materials and reduces an enterprise cost.

Owner:KUNSHAN PINQING BIOTECH CO LTD

Method for producing reducing sugar with agricultural wastes hydrothermal degradation

InactiveCN101492479ARealize processingSave resourcesDisaccharidesMonosaccharidesSolventAgricultural waste

The invention pertains to the technical field of transforming organic wastes into resources and hydro-thermal reaction, in particular to a method of hydro-thermally degrading agricultural wastes to produce reducing sugar. The invention directly utilizes eco-agricultural wastes as the raw materials and de-ionized water as the solvent and hydro-thermally degrades the agricultural wastes to produce reducing sugar within the temperature range from 250 to 400 DEG C and under the condition of certain reaction time in a special hydro-thermal reaction system. In addition, the invention achieves the control of reducing sugar yield by changing the temperature and the time and adding the additives.

Owner:TONGJI UNIV

Method for preparing dedicated molecular sieve used for separating levulose from glucose by simulating moving bed

InactiveCN101444718AHigh separation factorStrong acid resistanceOther chemical processesInvert sugar productionSorbentAdhesive

A method for preparing a dedicated molecular sieve which can separate levulose from glucose by simulating a moving bed adopts the manufacturing technique of formation first and then exchange, and comprises the following steps: mixing a Y type molecular sieve with an adhesive to produce a seedball which is then subjected to formation; adding an acidproof adhesive during the process of formation; polishing after formation and meanwhile adding a surface coating; parching; baking; carrying out ion exchange or direct impregnation; and subjecting sorbent after undergoing ion exchange or direct impregnation to after-baking in order to obtain sorbent with good absorption property and excellent acid resistance. The substance produced by utilizing the invention is a molecular sieve which can be easily involved in ion exchange, has the advantages of high separation coefficient, excellent acid resistance, good stability, cheapness and long service life, and is used for separating levulose from glucose by simulating the moving bed. As the molecular sieve is stable in all indexes and can achieve the separation effects as required, the molecular sieve can replace resin.

Owner:LUOYANG TIANPING MOLECULAR SIEVE

Chromatographic separation filler applied to fructo-oligosaccharide, preparation process and chromatographic separation device

InactiveCN112973806AReduce manufacturing costLow production costFructose productionCation exchangersChromatographic separationFructose

The invention relates to the technical field of separation of fructo-oligosaccharide, and particularly discloses a chromatographic separation filler applied to fructo-oligosaccharide, a preparation process and a chromatographic separation device. The filler comprises the following components in parts by weight: cation exchange resin 2 and table salt. The preparation process of the chromatographic separation filler comprises the following steps: taking 20-26 parts of cation exchange resin, soaking the cation exchange resin in a hydrochloric acid aqueous solution, taking out the cation exchange resin, and performing washing with clear water until the cation exchange resin is neutral; putting the cleaned cation exchange resin into a high-speed centrifugal machine to be dewatered and dried, sieving dried cation exchange resin particles, and removing the sieved cation exchange resin particles; and uniformly mixing 2-5 parts of table salt with the cation exchange resin particles obtained in the step 2. The whole chromatographic separation filler applied to the fructo-oligosaccharide has an excellent separation effect on monosaccharide and disaccharide in the fructo-oligosaccharide, the production cost of the whole separation filler is low, the preparation method is simple, and the technical problem of chromatographic separation of fructo-oligosaccharide in China at present is effectively solved.

Owner:珠海高新区维得力生物工程有限公司

Sucrose inversion process

InactiveUS8092609B2Efficient and readily controllable inversionPurification using ion-exchange materialsSucrose extraction by chemical meansSucrose solutionAqueous solution

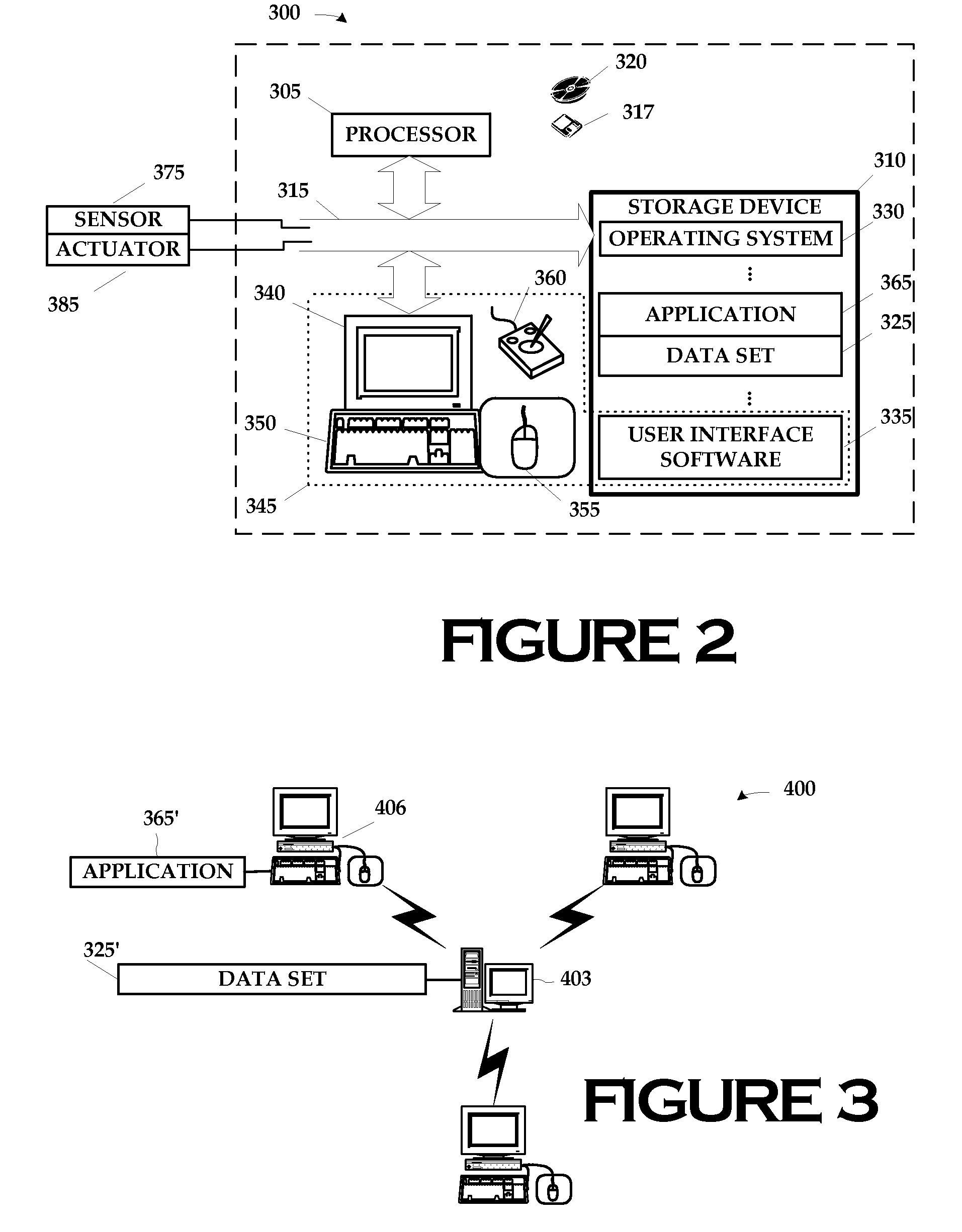

We disclose a method of inverting sucrose, including (i) determining an initial solids concentration of an aqueous sucrose solution (solidsi), an initial bed volume (BVi) of a sucrose inversion resin system, a minimum target inversion percentage (invert %min), a maximum target inversion percentage (invert %max), a target maximum hydroxymethylfuran (HMF) concentration (HMFmax), a minimum target pH (pHmin), or a maximum target pH (pHmax); (ii) contacting the sucrose inversion resin system with the aqueous sucrose solution under conditions of aqueous solution flow rate in BVi / hr (ratep) and aqueous solution temperature in ° C. (temperaturep) to produce an inverted sucrose solution having an inversion percentage (invert %product), an HMF concentration (HMFproduct), and a pH (pHproduct); (iii) observing an instantaneous inversion percentage (invert %inst), an instantaneous HMF concentration (HMFinst), or an instantaneous pH (pHinst) of the inverted sucrose solution; and, if invert %inst<invert %min, invert %inst>invert %max, HMFinst>HMFmax, pHinst<pHmin, or pHinst>pHmax; (iv) changing at least one of the aqueous solution flow rate or the aqueous solution temperature such that invert %min≦invert %product≦invert %max, HMFproduct≦HMFmax, or pHmin≦pHproduct≦pHmax. We also disclose a computing apparatus capable of use in performing a method of inverting sucrose.

Owner:EURO SUGAR HLDG S A R L

Method for preparing invert sugar by microwave reaction and special equipment thereof

ActiveCN101649357ARadiation intensity optimizationRealize continuous productionInvert sugar productionSucroseMicrowave power

The invention relates to a method for preparing invert sugar by microwave reaction and special equipment thereof. The invention is characterized in that the method directly obtains invert sugar by thefollowing steps: adding a catalyzer to a sugar solution and then reacting under microwave irradiation in a flowing way to obtain the invert sugar. The method has the actual conditions: adopting a glass, plastic or stainless steel coiled tube as a microwave irradiation reaction tube for the solution to pass, wherein the tube diameter is 2-6cm, the wall thickness of the single tube is 3-8mm, the tube length is 80-150m, the microwave power is 1000-3000W, and the flow speed of the solution when passing the microwave irradiation reaction tube is controlled between 0.2 and 0.8m / s. Compared with theprior art, the invention has the advantages that the flow speed of the sugar solution in the reaction tube is controlled by adding a set of reaction tubes in a microwave reactor, so that the sugar solution can receive sufficient microwave irradiation in the reaction tube and can be quickly converted, thereby realizing the continuous production of the sugar solution. Moreover, the product conversion rate exceeds 95%, the product purity is high, and byproducts are few.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Method of producing a sugar product from fruit

A method of producing a sugar -product from fruit, the method including the steps of : a) providing a fruit juice containing glucose and fructose; b) demineralizing and decolouring the fruit juice to obtain a clarified, demineralized fruit juice; c) concentrating the clarified, demineralized fruit juice to obtain a concentrated clarified, demineralized fruit juice; and d) separating the concentrated demineralized, clarified fruit juice by chromatography to obtain at least a glucose-enriched fraction and at least a fructose-enriched fraction,- the method including, after step d), a step e) of filtering the glucose-enriched fraction and fructose- enriched fraction on a carbon filter; and steps d) and e) being performed at a temperature of 50-70°C.

Owner:NATURALIA INGREDIENTS

Hydrolysis method of saccharide compound

InactiveCN108950090ALow costHigh activityPhysical/chemical process catalystsInvert sugar productionHydrolysisPolysaccharide

The invention discloses a hydrolysis method of a saccharide compound. Under the action of a solid catalyst, the saccharide compound is hydrolyzed to generate a monosaccharide; the solid catalyst is attapulgite clay; the natural attapulgite clay is subjected to heating treatment under certain temperature, and the acidity of the catalyst is regulated and controlled through different protonic acid under different temperature; then polysaccharide is catalytically hydrolyzed into the monosaccharide; and the hydrolysis method has the characteristics of moderate reaction conditions, low price of allcatalysts, environment friendliness, simple technology, easiness for separating the catalysts, capability of being repeatedly used and the like.

Owner:JIANGSU UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com