Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2591 results about "Reaction tube" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

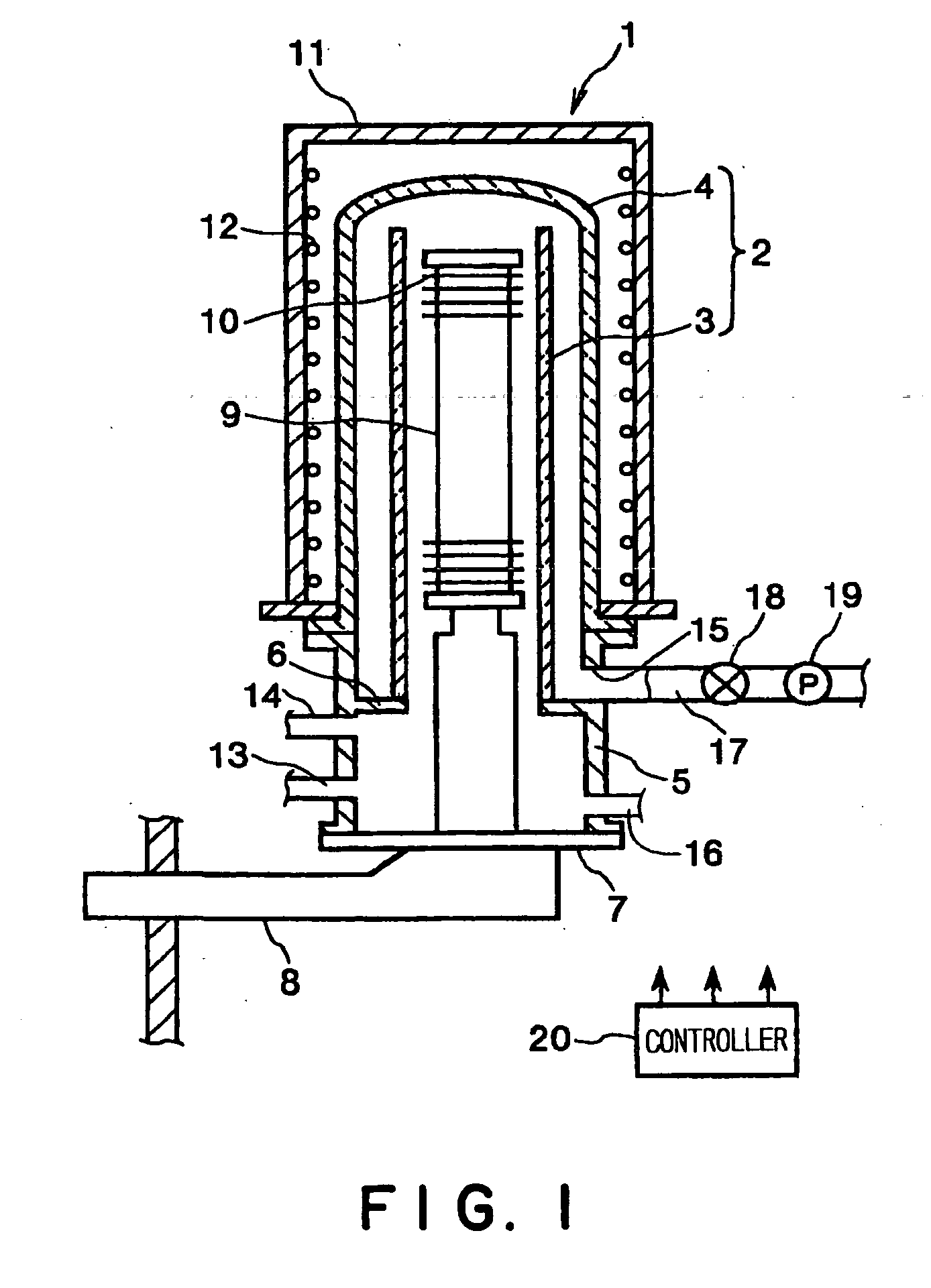

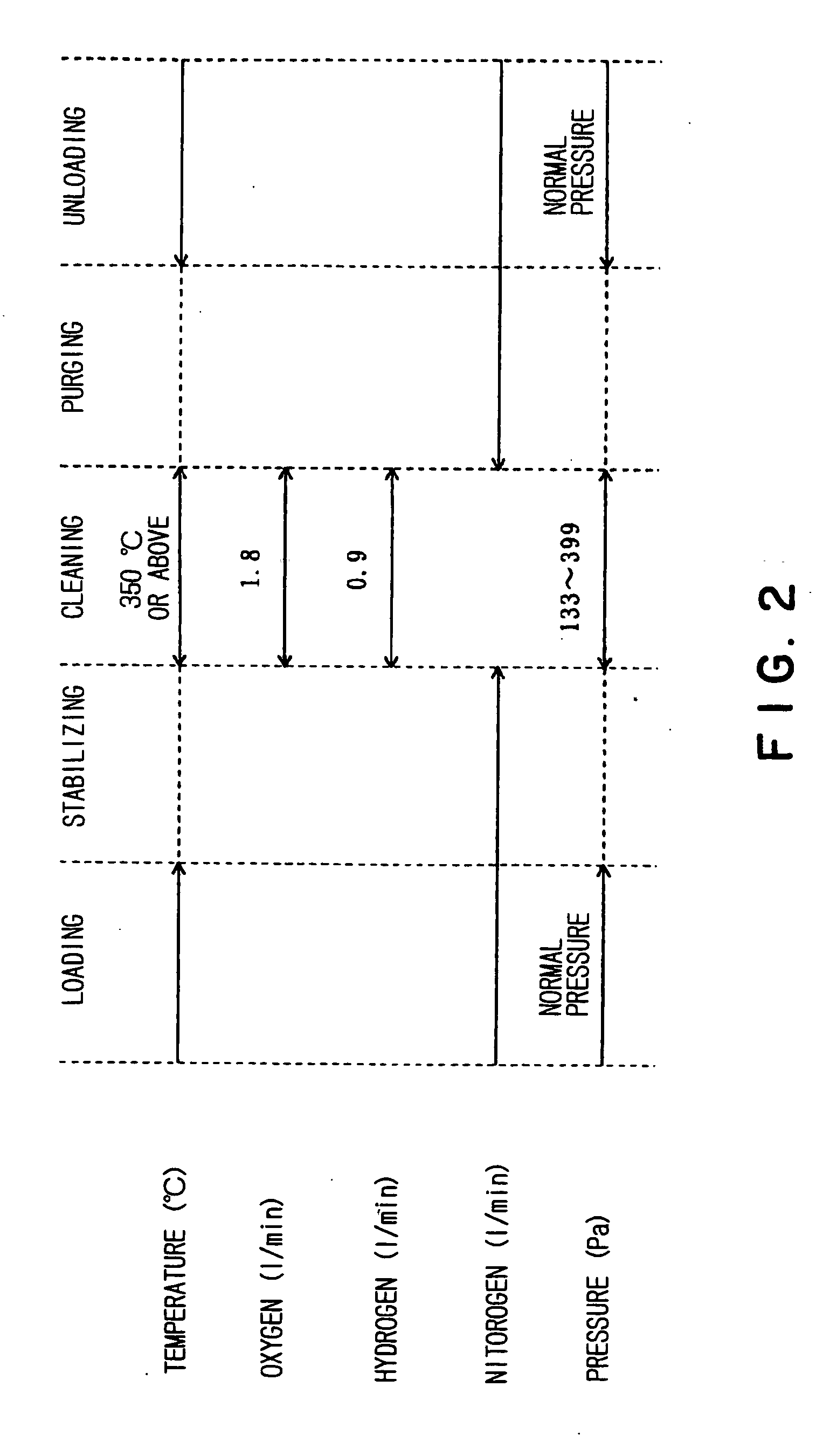

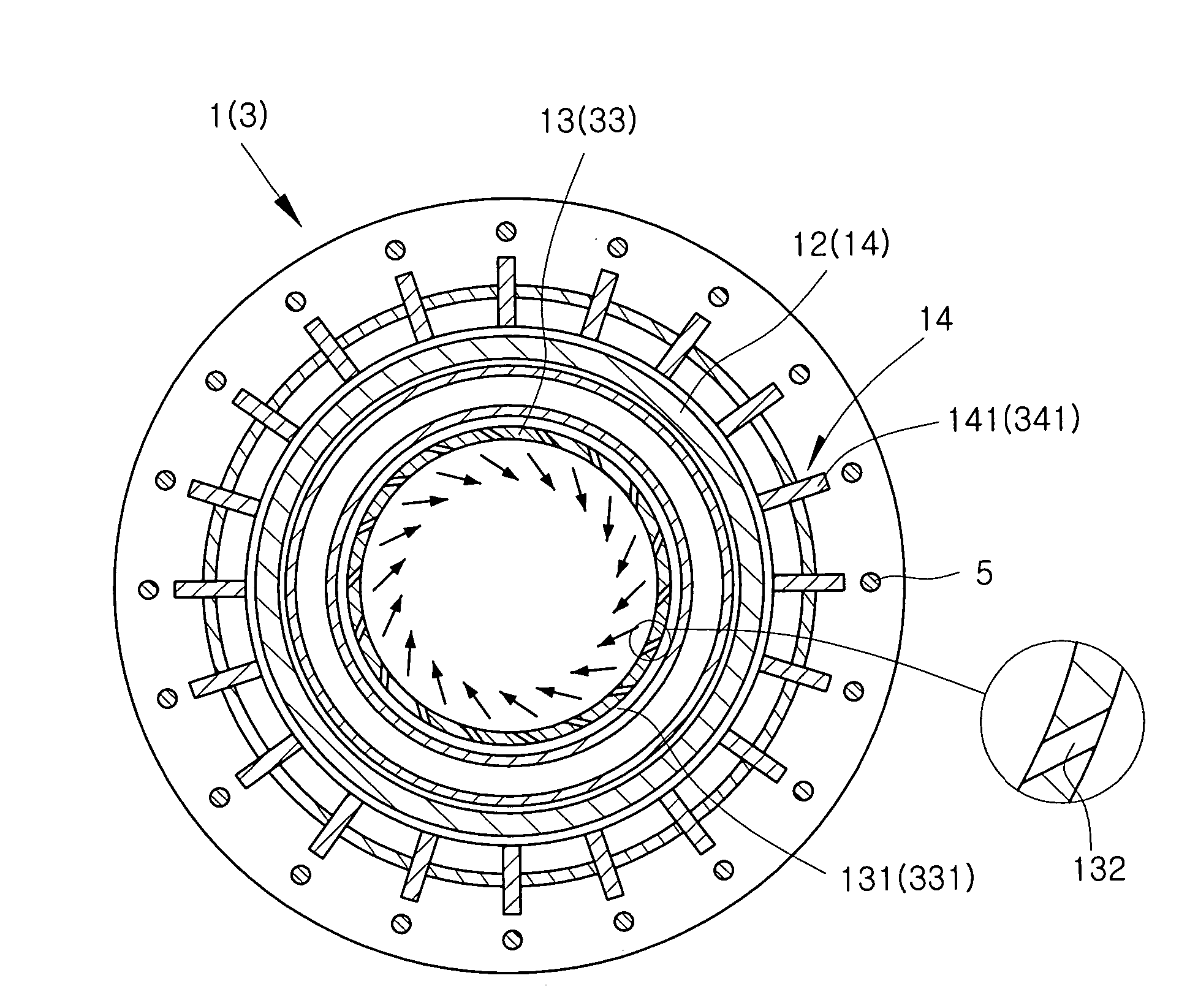

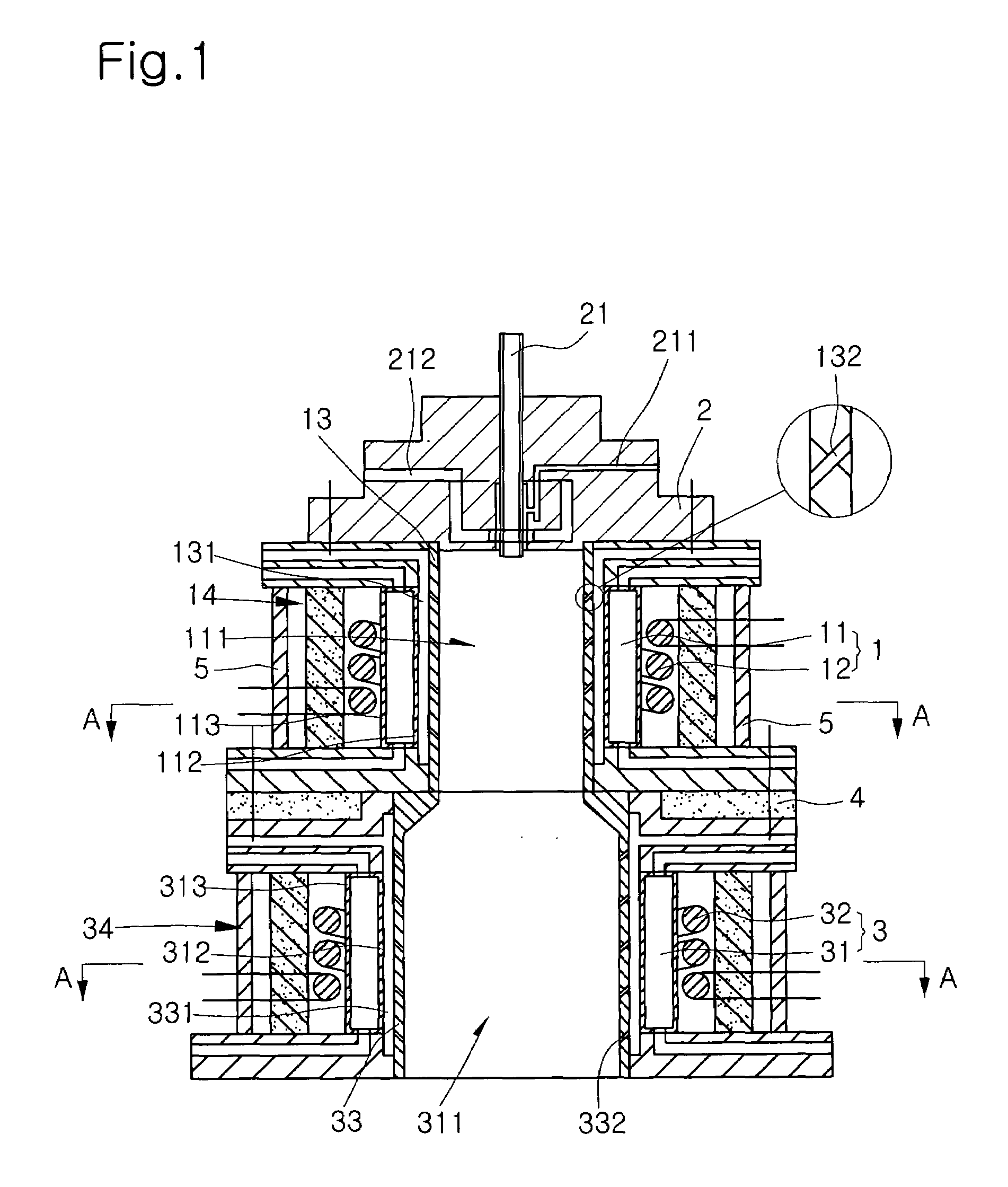

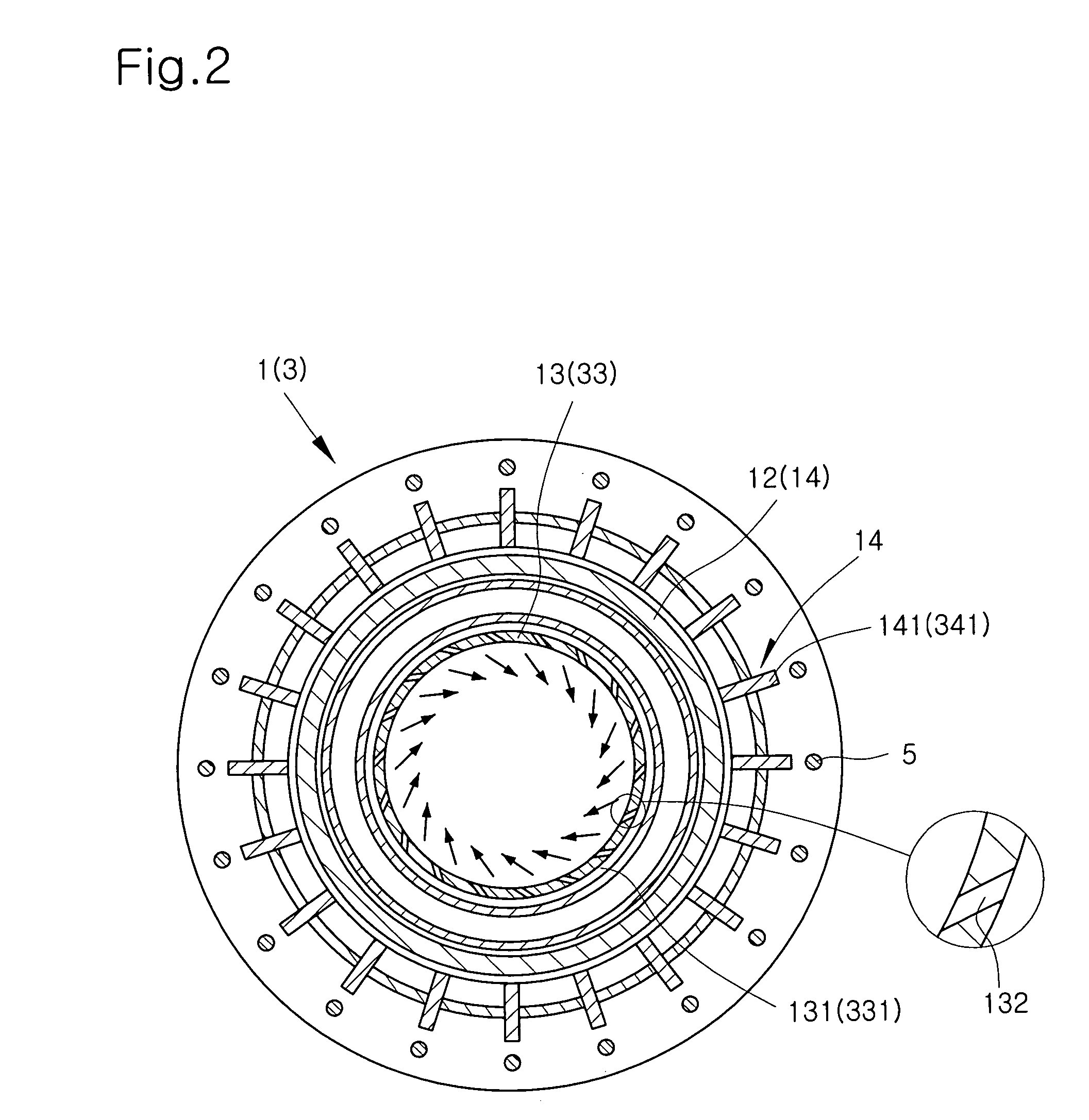

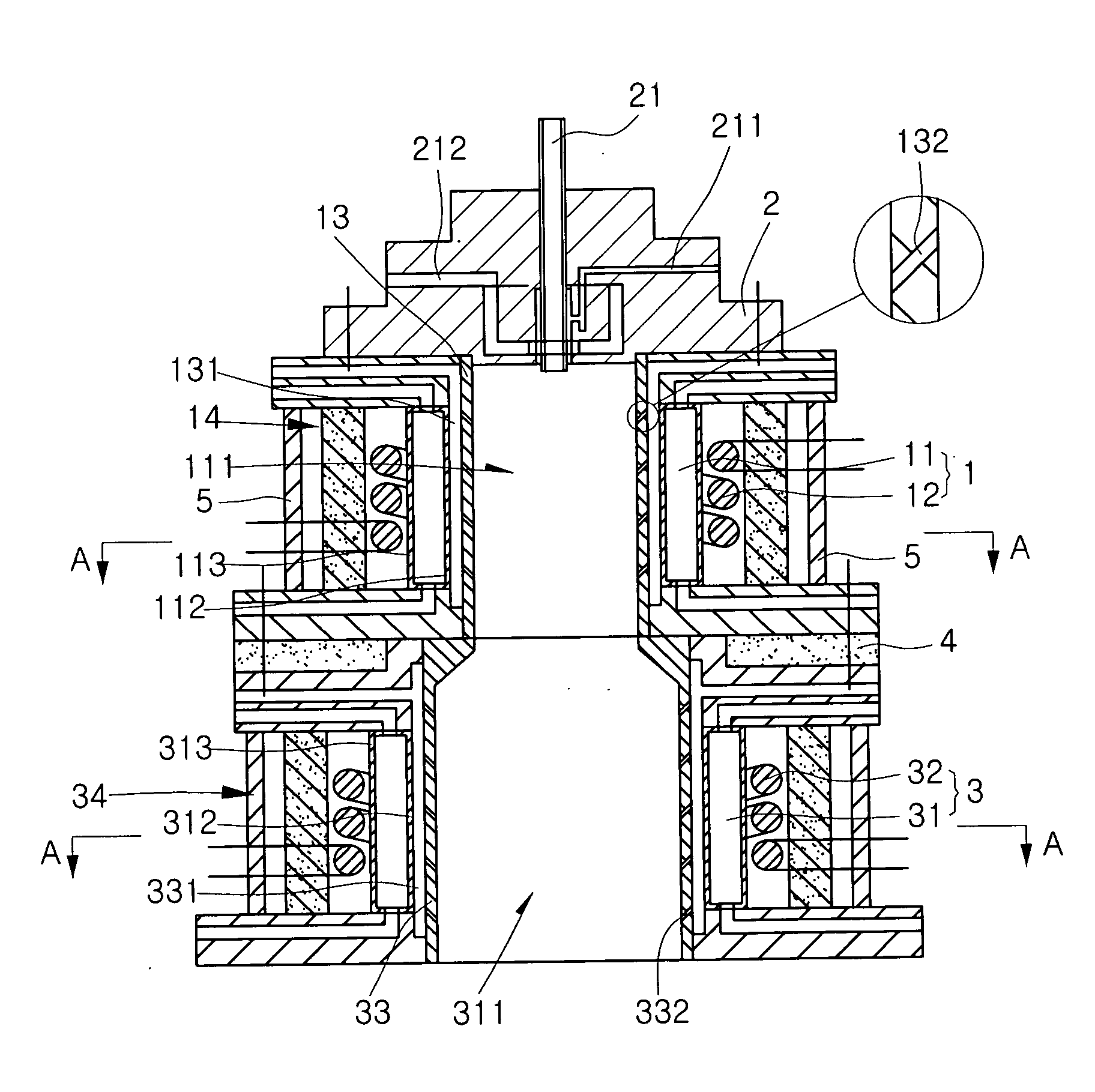

Method and apparatus for treating article to be treated

InactiveUS20040219793A1Efficient removalShort timeAfter-treatment detailsSemiconductor/solid-state device manufacturingCombustionHydrogen

A thermal treatment apparatus 1 includes a reaction tube 2 for containing wafers 10 contaminated with organic substances having a heater 12 capable of heating the reaction tube; a first gas supply pipe 13 for carrying oxygen gas into the reaction tube 2; and a second gas supply pipe 14 for carrying hydrogen gas into the reaction tube 2. Oxygen gas and hydrogen gas are supplied through the first gas supply pipe 13 and the second gas supply pipe 14, respectively, into the reaction tube 2, and the heater 12 heats the reaction tube 2 at a temperature capable of activating oxygen gas and hydrogen gas. A combustion reaction occurs in the reaction tube 2 and thereby the organic substances adhering to the wafers 10 are oxidized, decomposed and removed.

Owner:TOKYO ELECTRON LTD

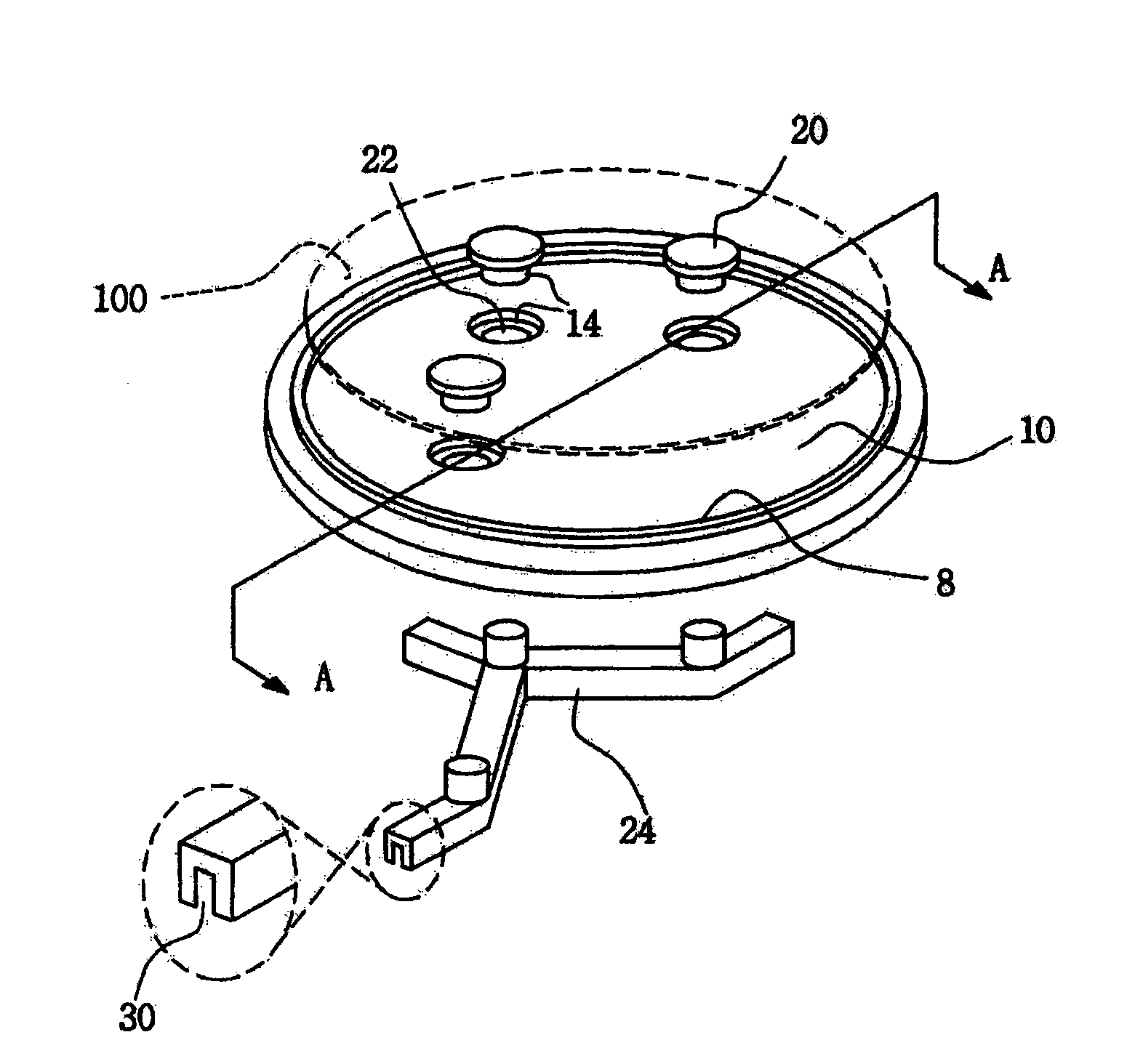

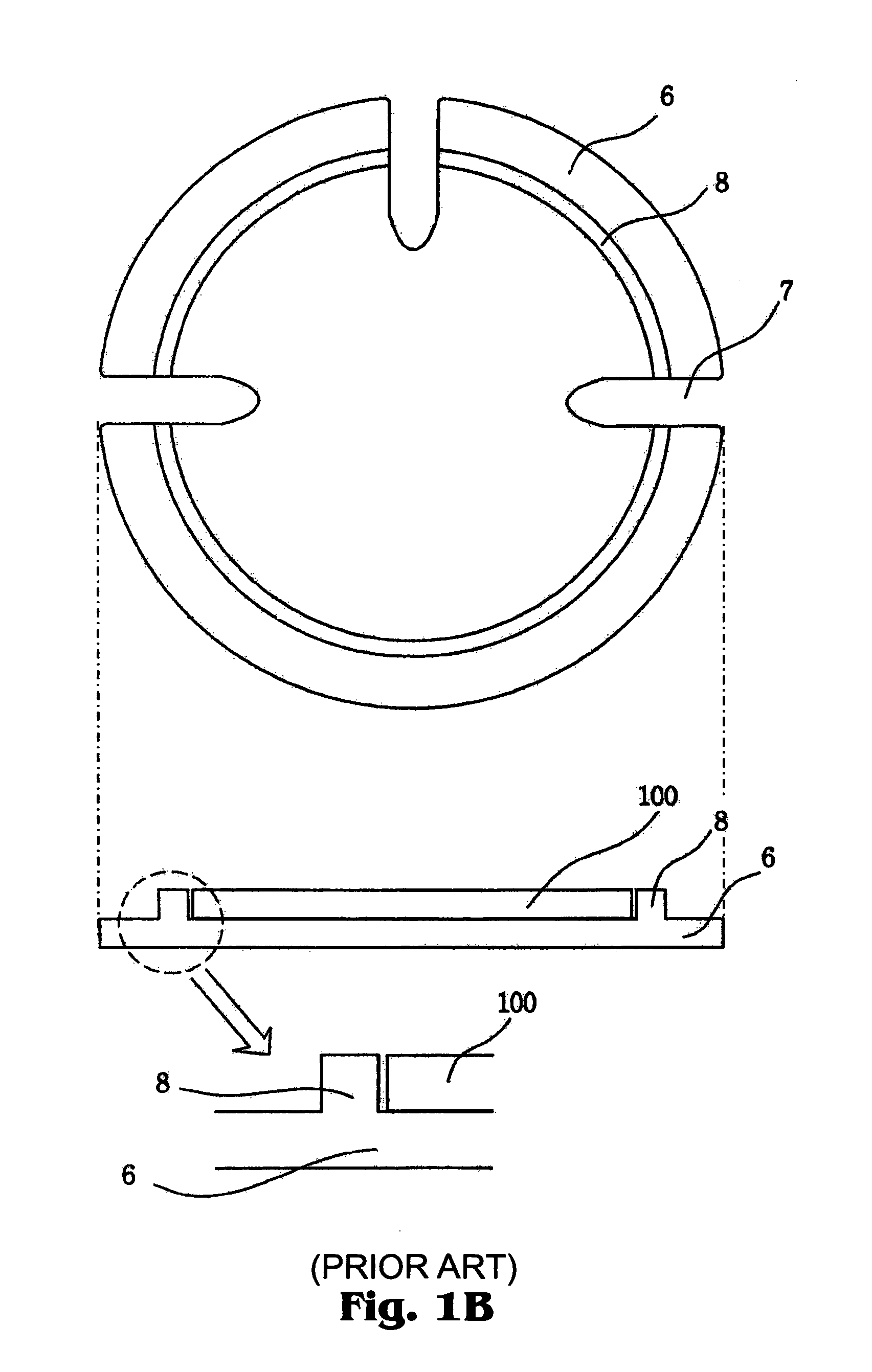

Semiconductor manufacturing system and wafer holder for semiconductor manufacturing system

InactiveUS7207763B2Improves yield and productivitySemiconductor/solid-state device manufacturingPlatesWaferingEngineering

A semiconductor manufacturing system and wafer holder for a semiconductor manufacturing system which prevents a semiconductor wafer from being exposed to a process reaction and which includes a reaction tube for providing a sealed process space and a dual boat and which prevents the backside deposition by the wafer holder. The wafer holder includes a holder body to hide the backside of the semiconductor wafer during a process in the reaction tube and a wafer lifter having a portion that can be disengaged from and coupled to the holder body so that a lower portion of the semiconductor wafer is supported by the dual boat and so that the semiconductor wafer can be lifted up from the wafer body when the semiconductor wafer is loaded and unloaded. A separation boundary between the holder body and the wafer lifter includes a gas inflow interception surface to hinder reaction gas from flowing through the separation boundary.

Owner:TERASEMICON CO LTD

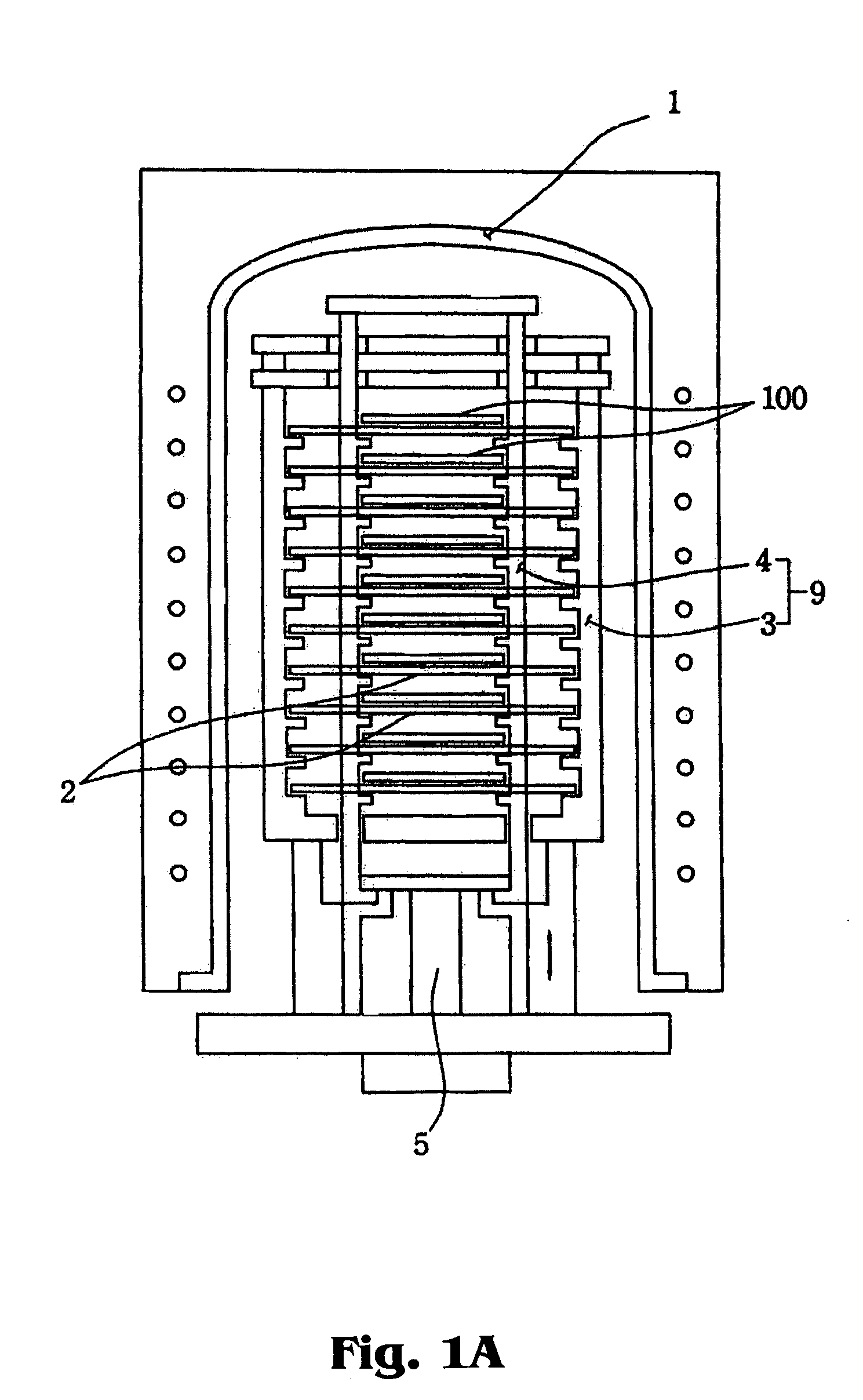

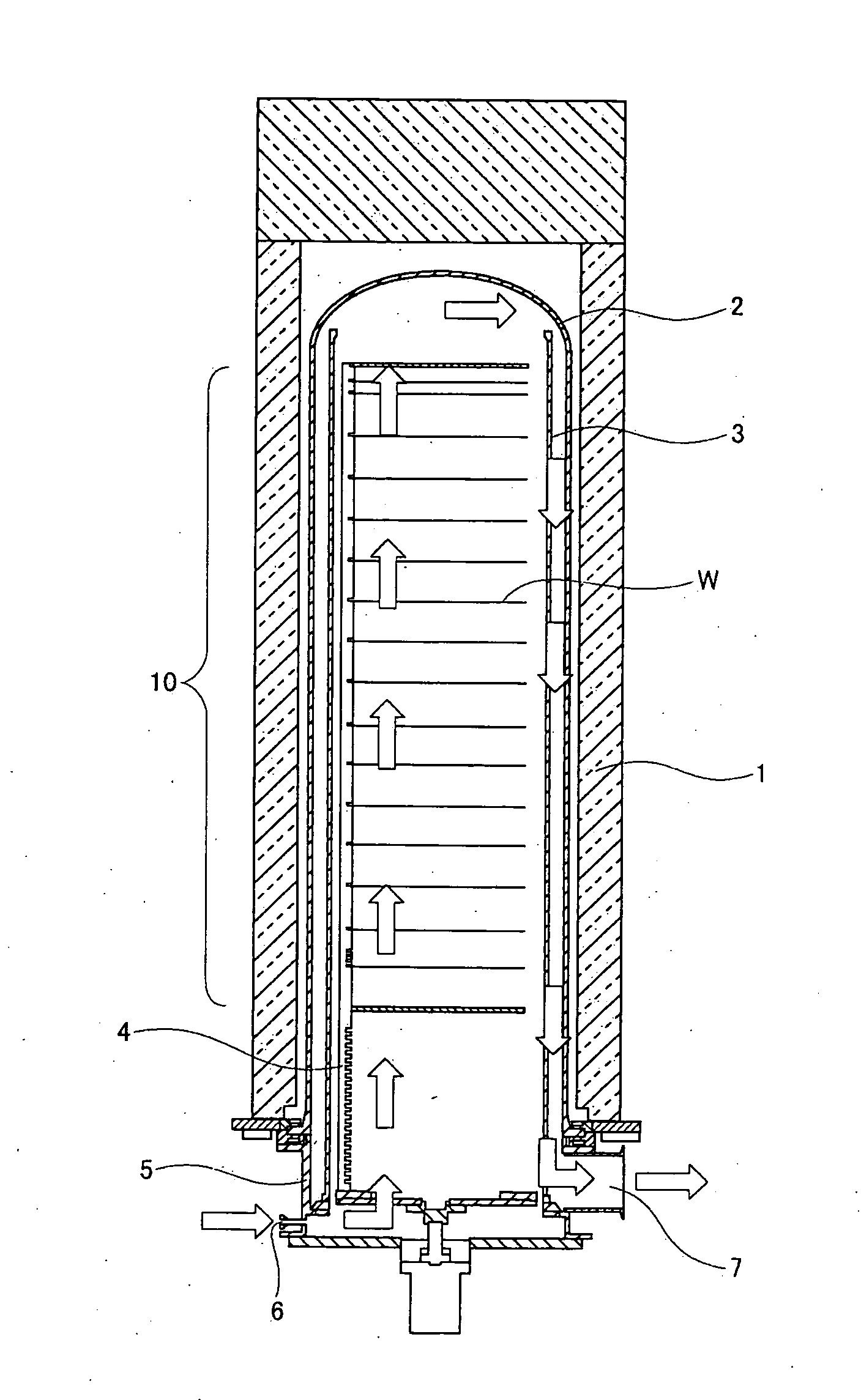

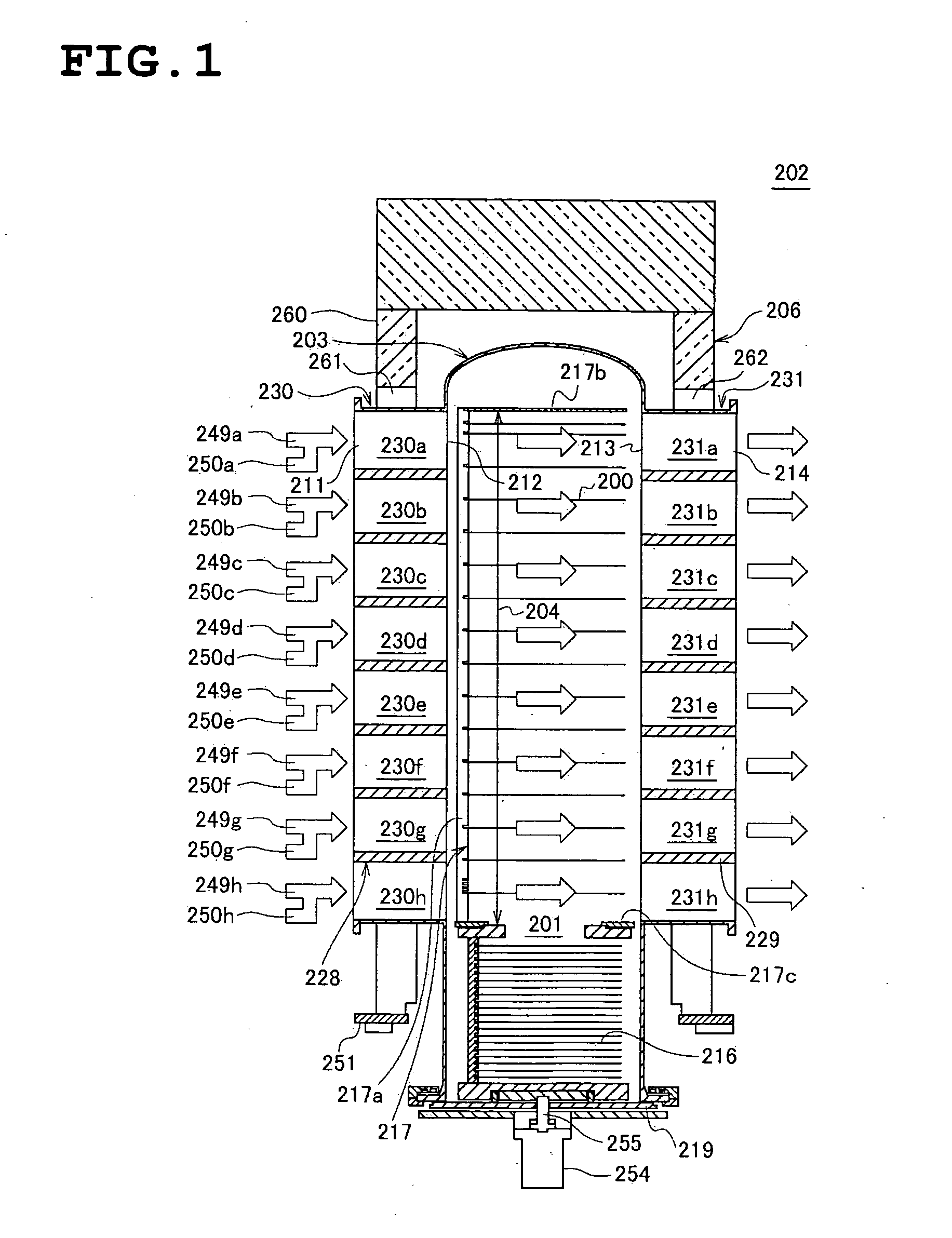

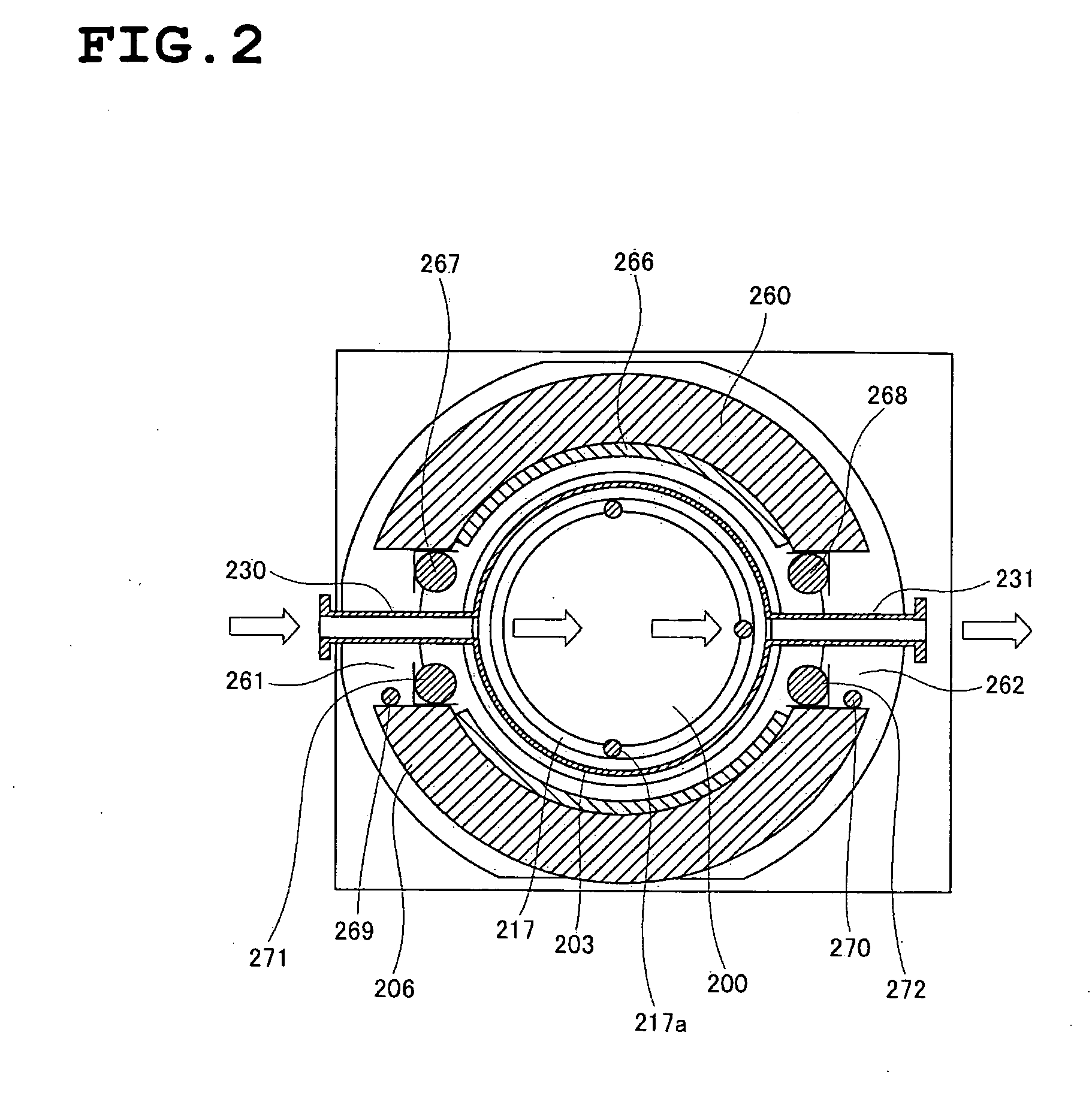

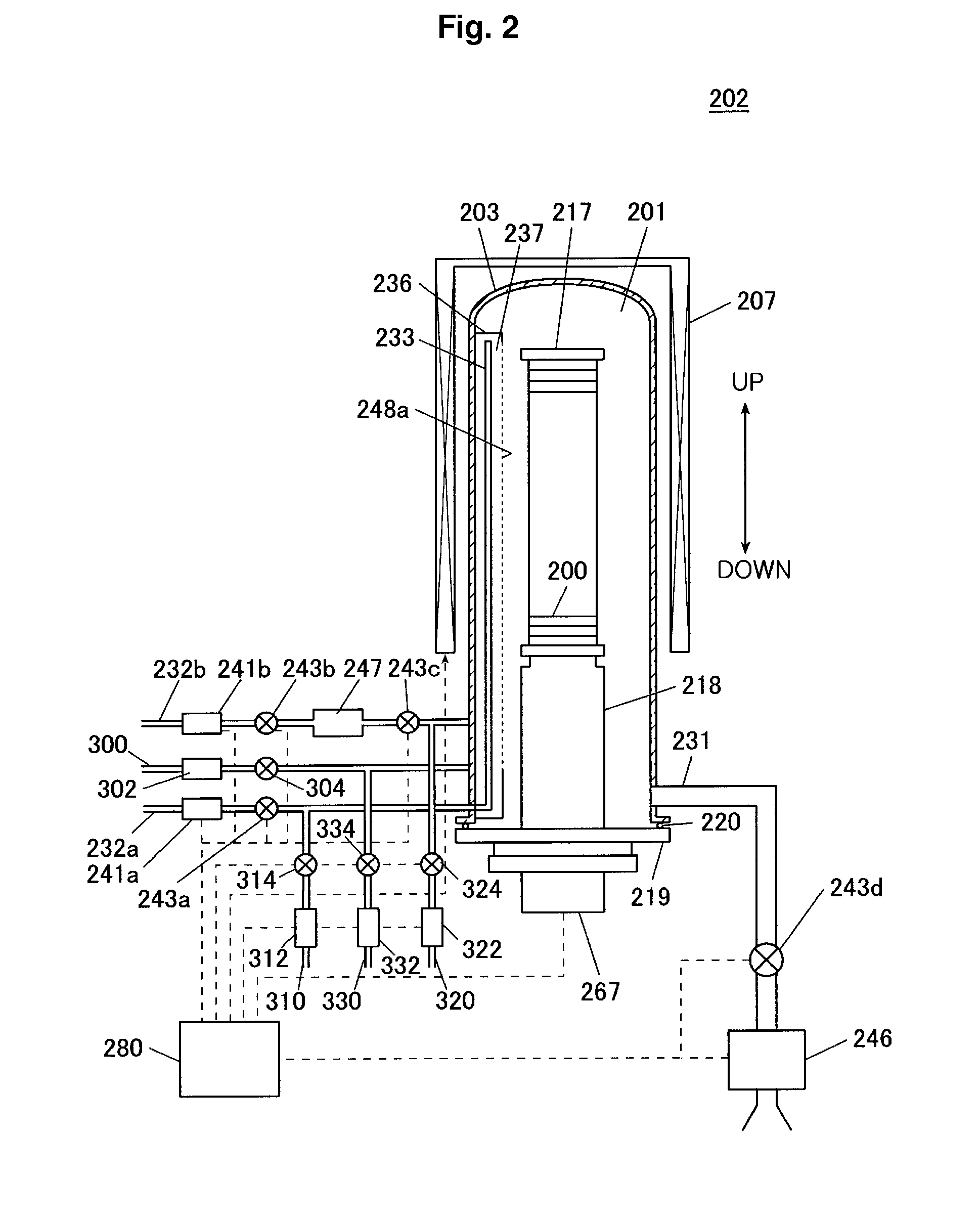

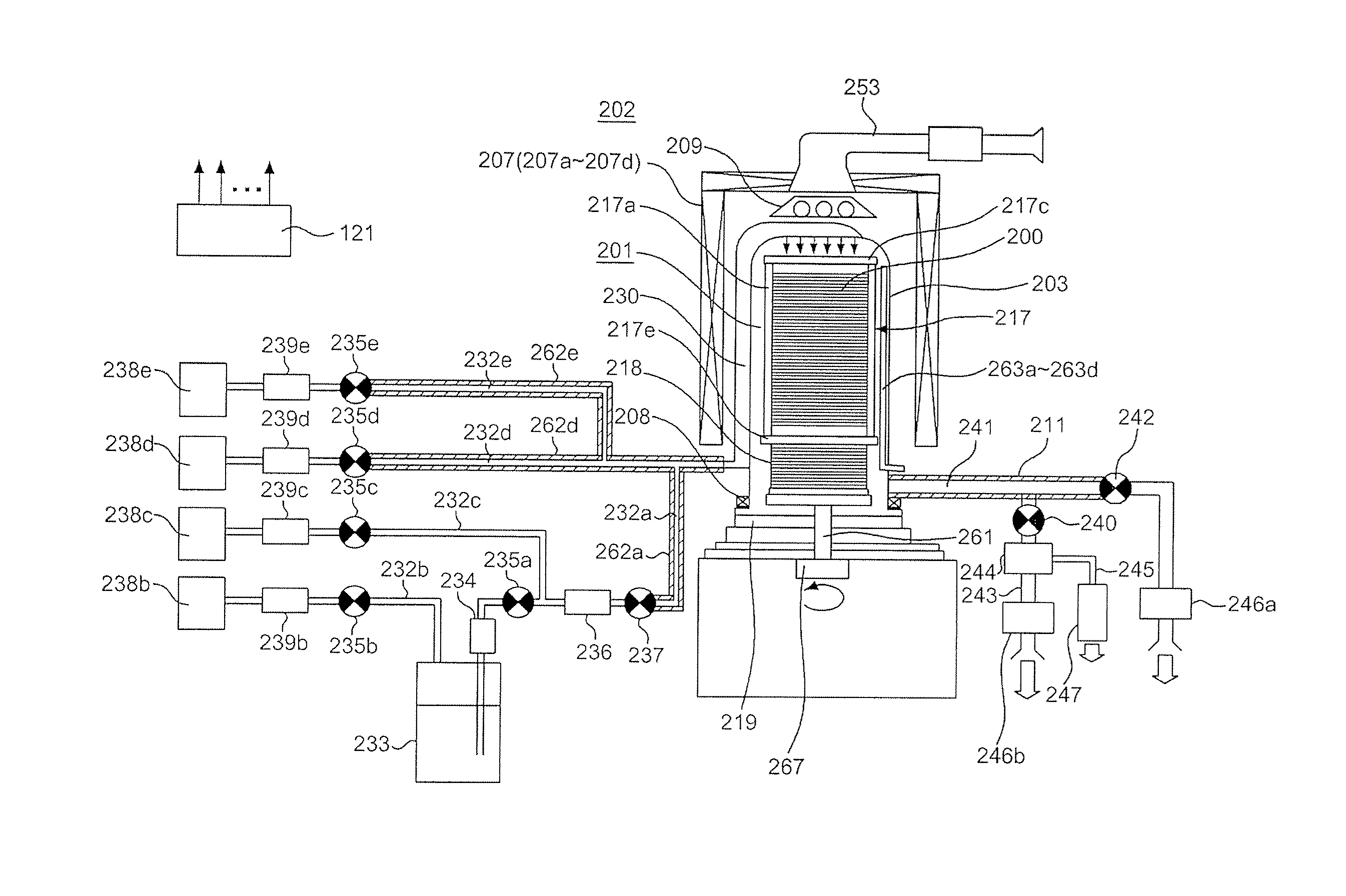

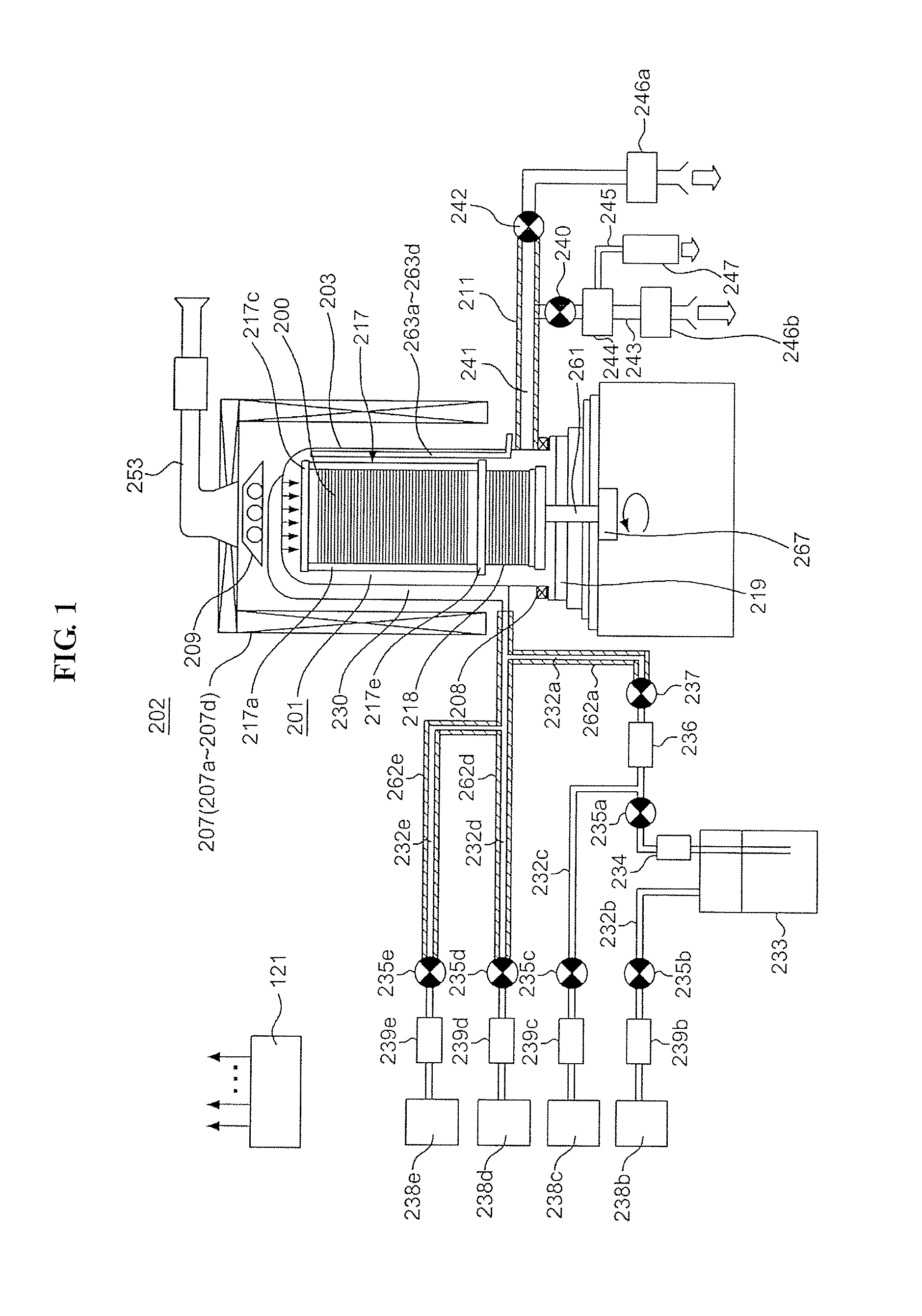

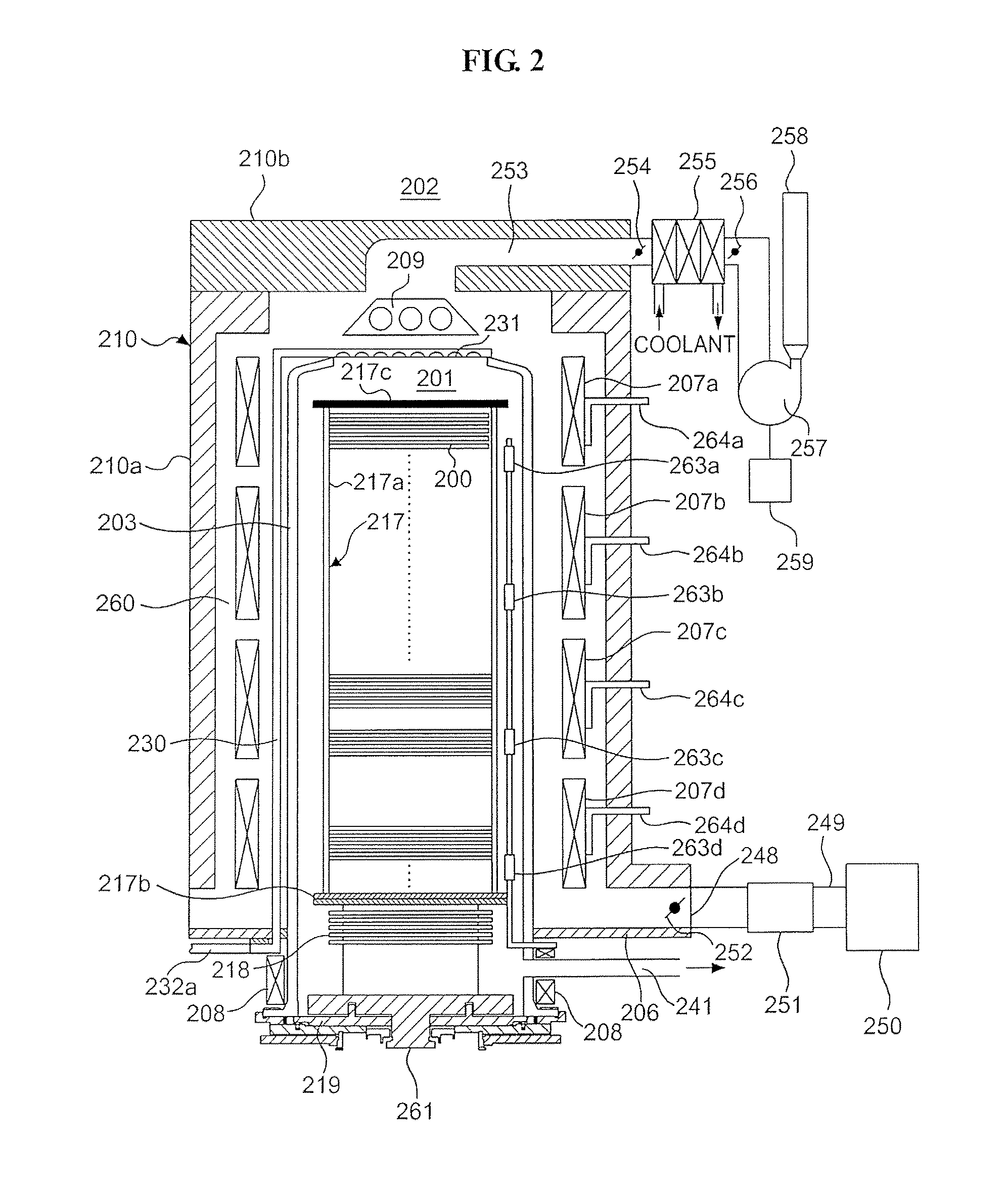

Substrate processing apparatus, method of manufacturing semiconductor device, and reaction vessel

InactiveUS20080173238A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingIn planeProduct gas

A substrate processing apparatus that affords improved uniformity to in-plane wafer and interwafer film thickness of a large number of wafers on which a film is simultaneously formed, having: a reaction tube having in an interior thereof a processing chamber in which a plurality of substrates disposed in a direction perpendicular to a substrate processing surface can be processed; and a heating device provided to surround an outer circumference of the reaction tube, a gas inlet tube being provided on a side face of the reaction tube in a region for processing a substrate inside the reaction tube, so as to reach at least an outside of the heating device; and a gas spouting port being disposed in this gas inlet tube in a slit form so as to straddle at least a plurality of the substrates in a direction perpendicular to the substrate processing surface, for spouting gas from the gas inlet tube into the processing chamber.

Owner:KOKUSA ELECTRIC CO LTD

Thermal processing furnace and liner for the same

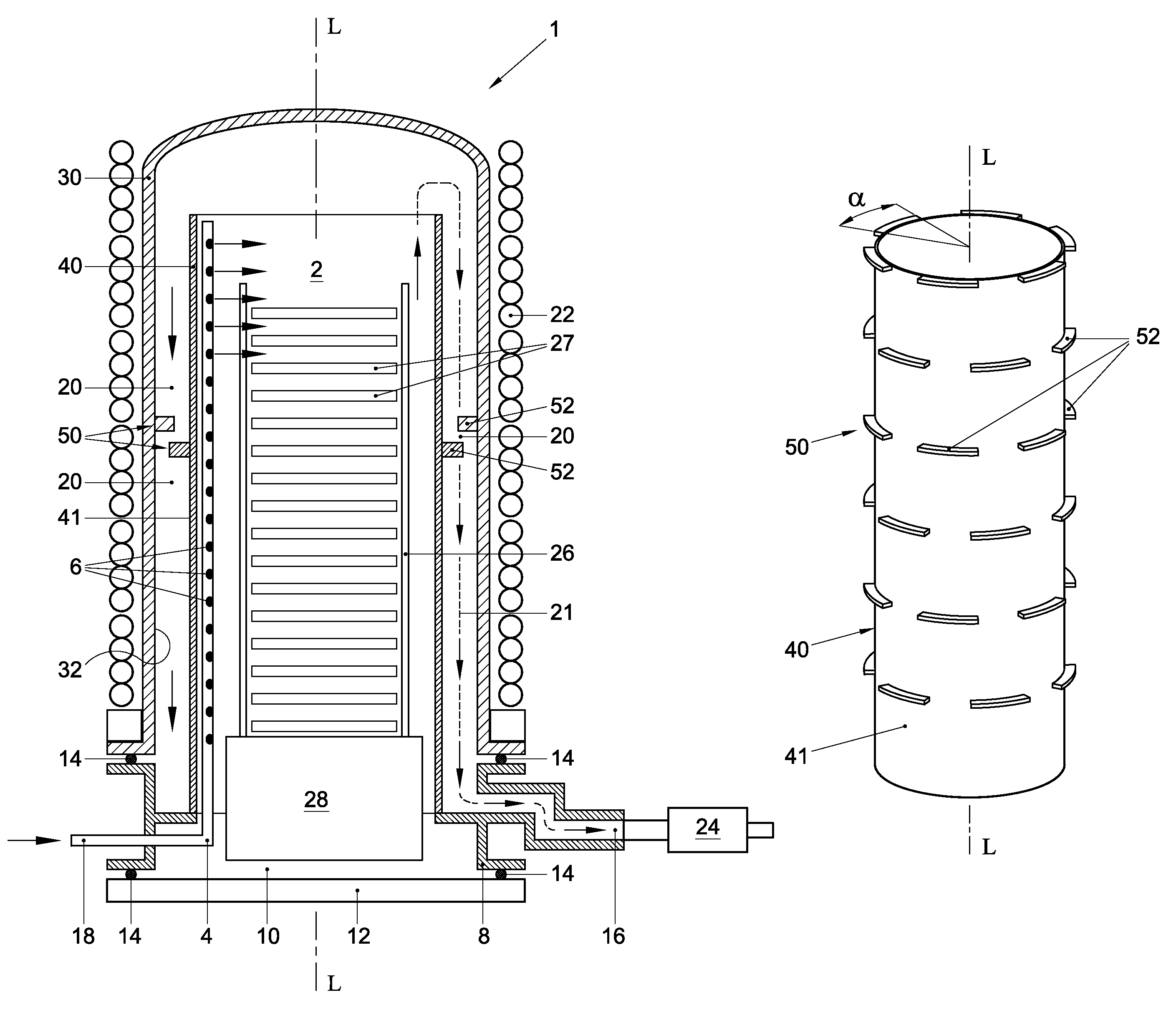

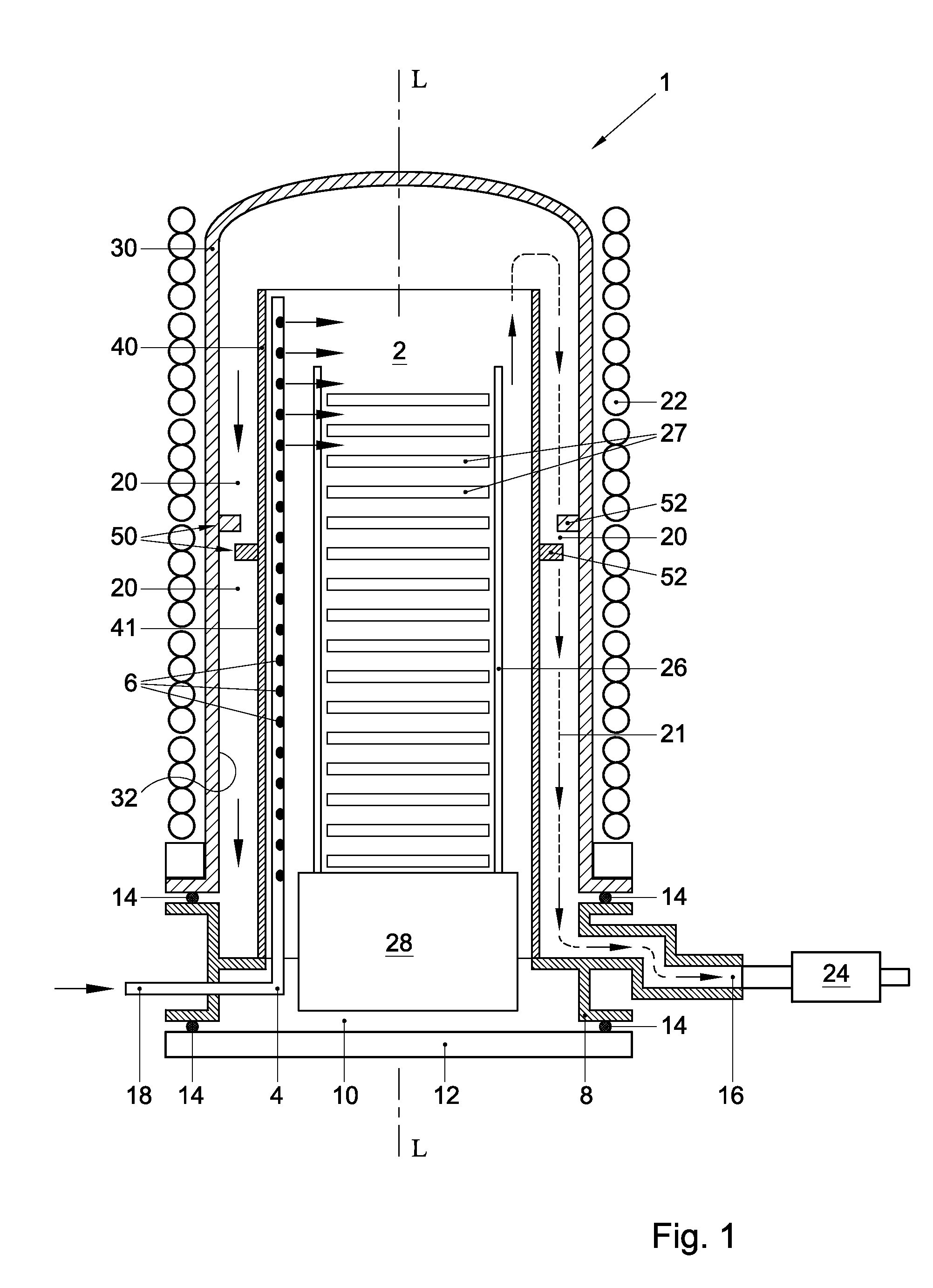

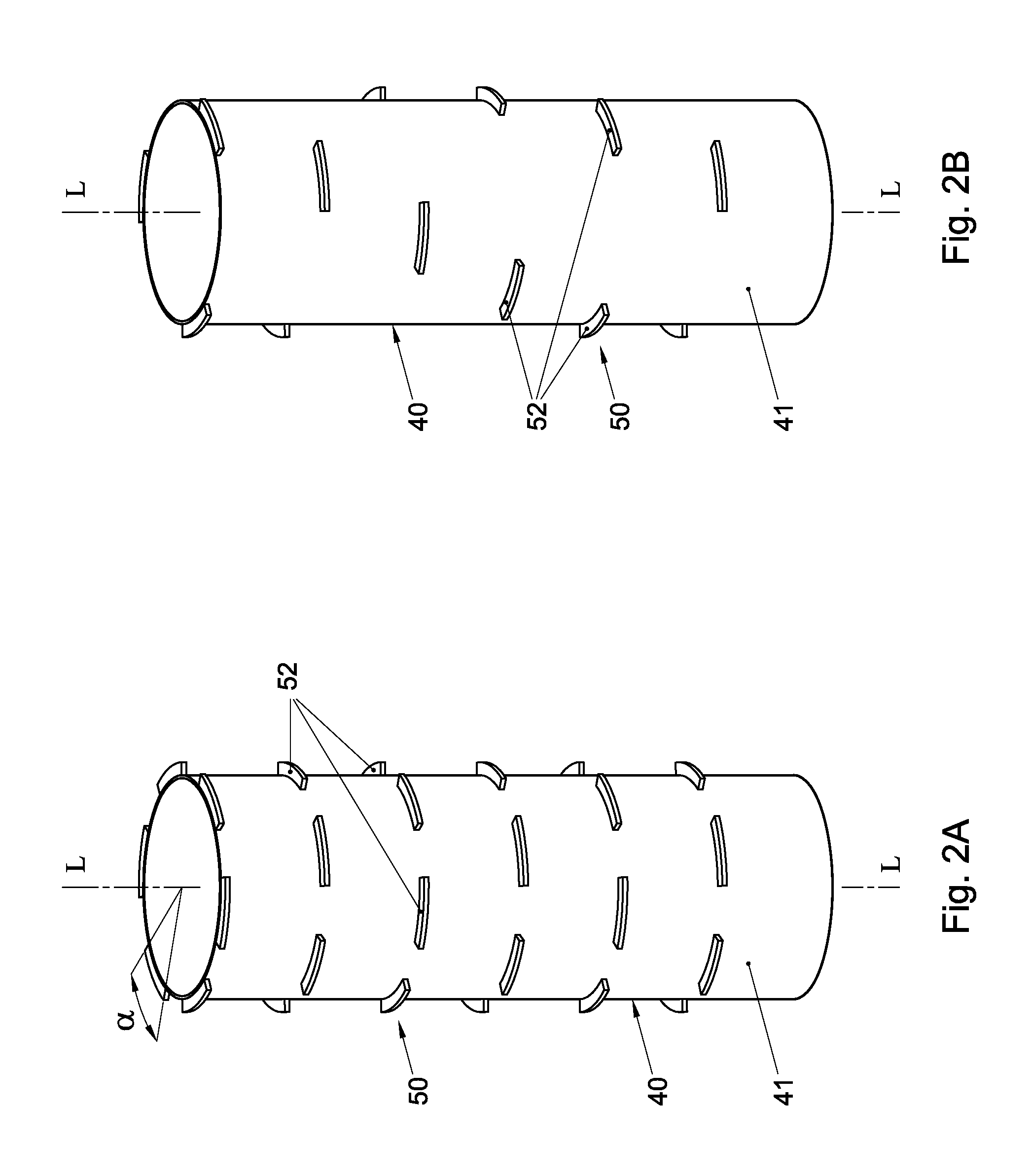

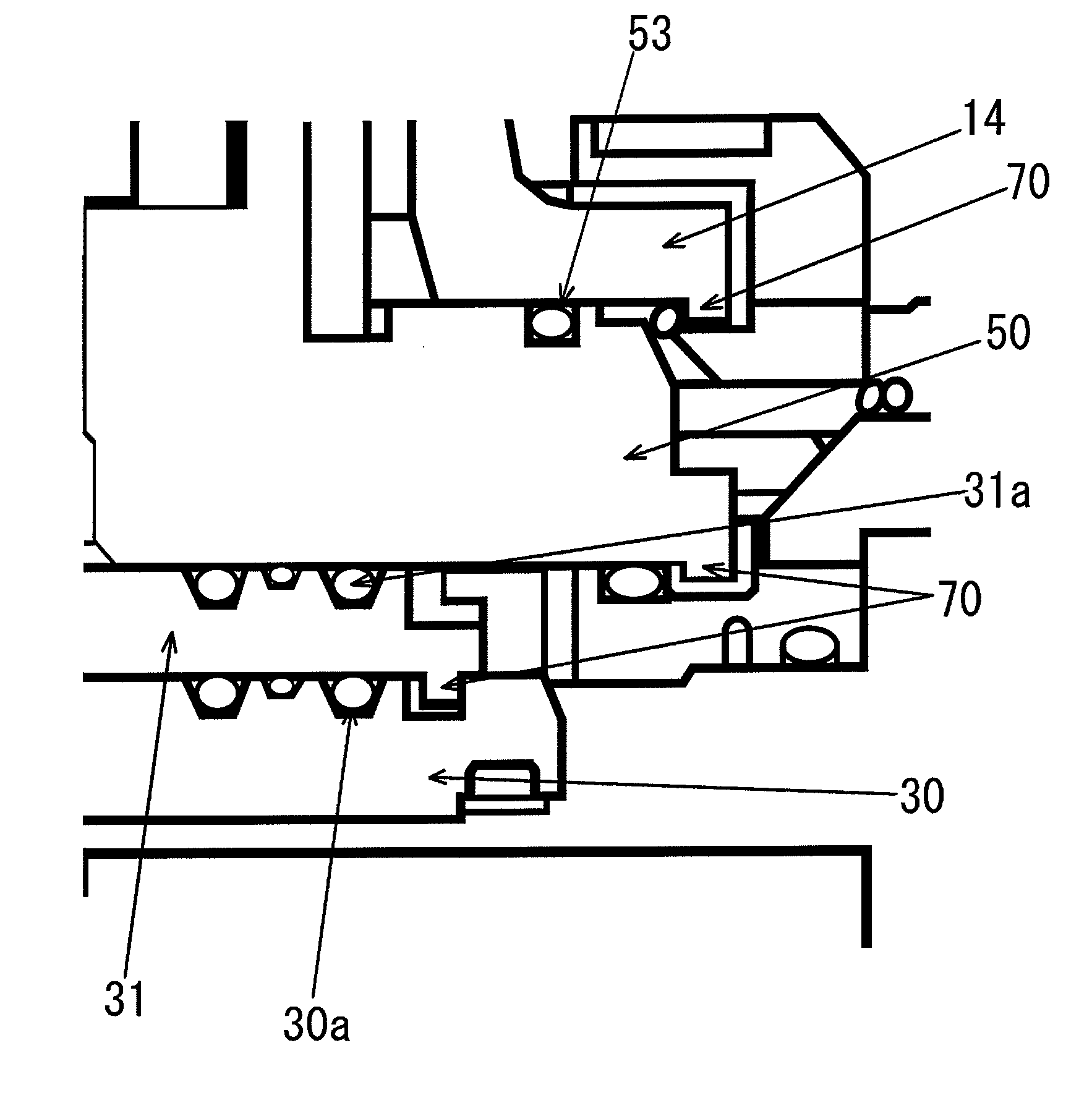

ActiveUS8398773B2Easy to transportMinimized in sizeDomestic stoves or rangesRotary drum furnacesEngineeringReaction tube

A thermal processing furnace, comprising:a generally bell jar-shaped outer reaction tube having a central axis; andan open-ended inner reaction tube for accommodating a wafer boat holding a plurality of substrates, which inner reaction tube is substantially coaxially disposed within the outer reaction tube, thereby defining a gas passage between an outer wall of the inner reaction tube and an inner wall of the outer reaction tube,wherein at least one of the outer wall of the inner reaction tube and the inner wall of the outer reaction tube is provided with a flow deflector that protrudes radially from the respective wall into the gas passage.

Owner:ASM INTERNATIONAL

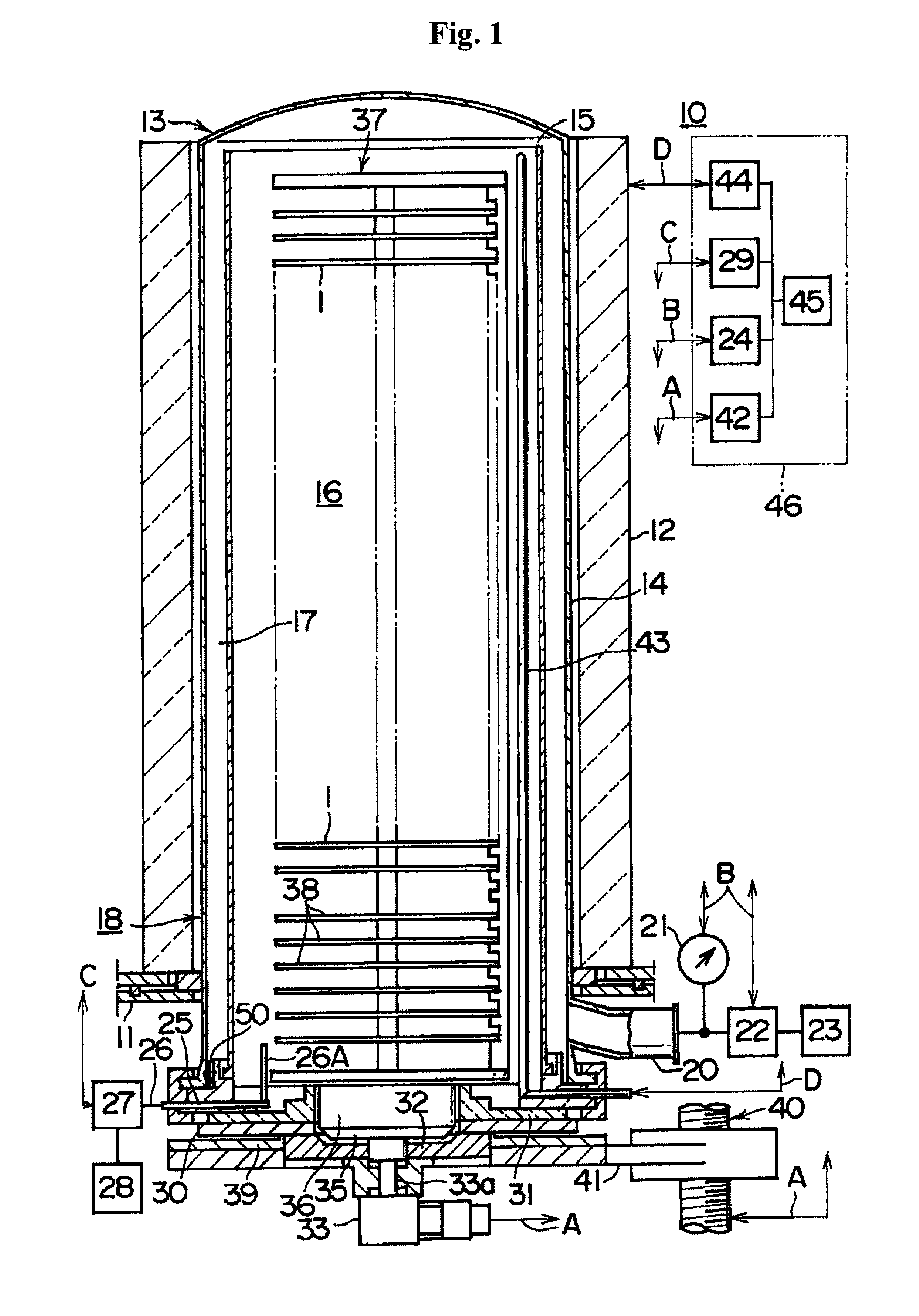

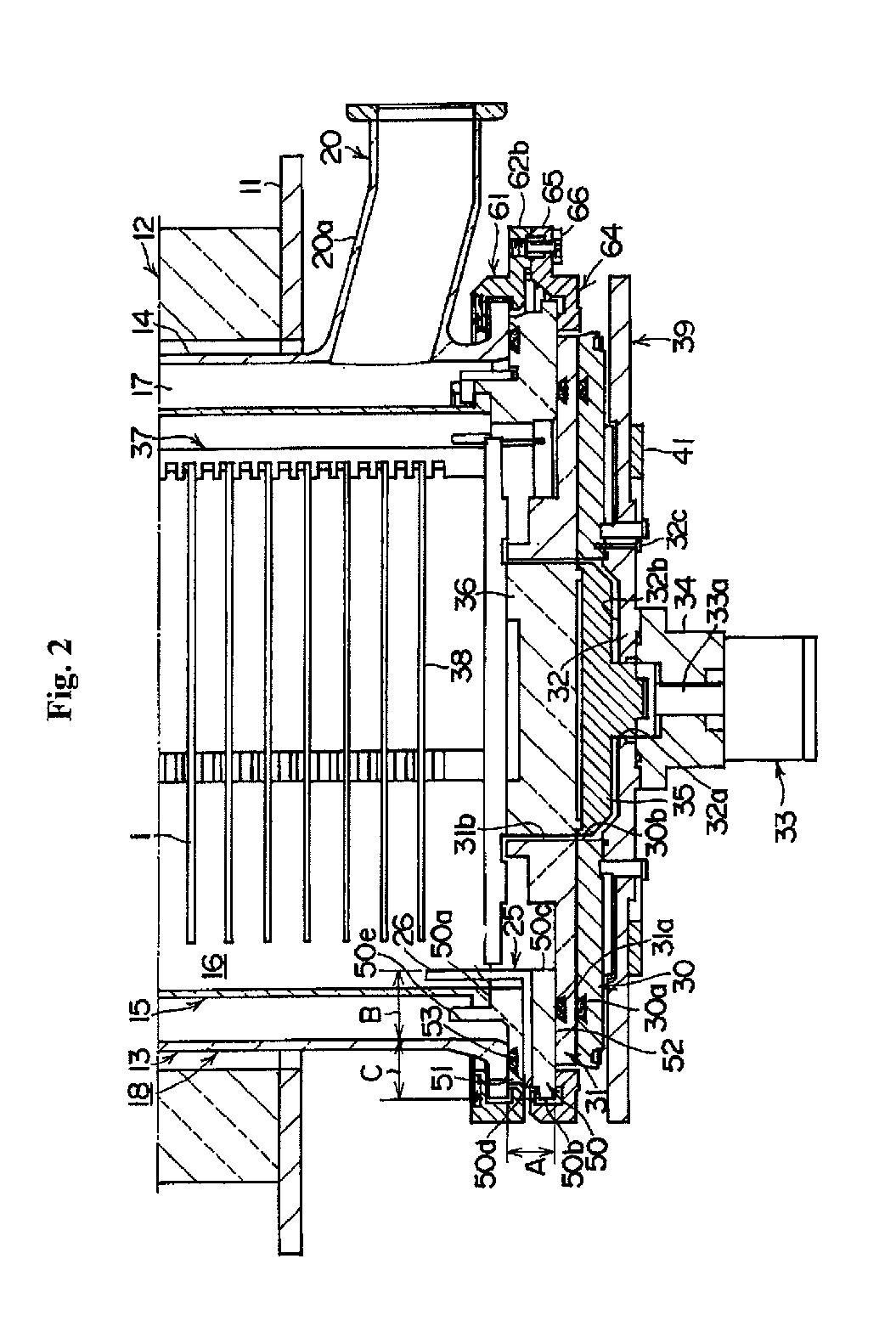

Substrate processing apparatus

ActiveUS8529701B2Damages of breakageDamages of partSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringMechanical engineering

A substrate processing apparatus includes a reaction tube, the reaction tub including an inner tube made of quartz and an outer tube made of quartz; a manifold made of quartz disposed under the outer tube, a top surface of the manifold being in air-tight contact with a bottom surface of the outer tube via a sealing member; a seal cap cover made of quartz disposed under the manifold, a top surface of the seal cap cover being in air-tight contact with a bottom surface of the manifold via a sealing member; a seal cap covered by the seal cap cover, a top surface of the seal cap being in air-tight contact with a bottom surface of the seal cap cover via a sealing member; and at least one protrusion disposed at the bottom surface of one of the outer tube, the manifold, the seal cap cover, and combinations thereof.

Owner:KOKUSA ELECTRIC CO LTD

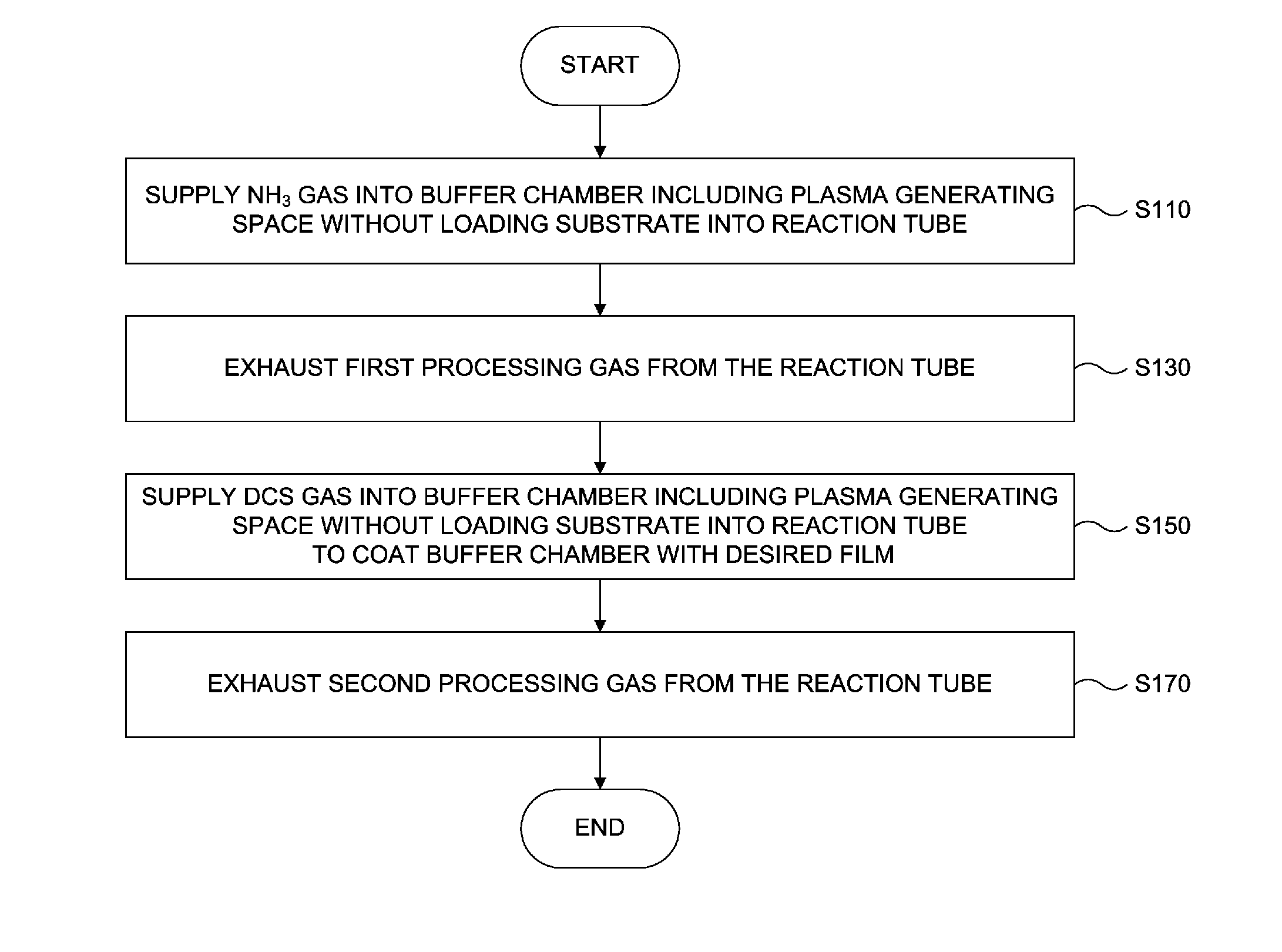

Coating method for coating reaction tube prior to film forming process

InactiveUS20120122319A1Prevent and restrainElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringContamination

Contamination of a substrate can be prevented or suppressed. A substrate processing apparatus includes a reaction tube having an inner space divided by a barrier wall into a film forming space and a plasma generating space. When a desired film is formed on a substrate placed inside the reaction tube, first and second processing gases are supplied to the reaction tube through nozzles. On the other hand, when a part of the reaction tube constituting the plasma generating space is coated with a film, second and third processing gases are supplied to the plasma generating space through the nozzle.

Owner:SHIMIZU HIRONOBU

Reaction tube structure and substrate processing apparatus

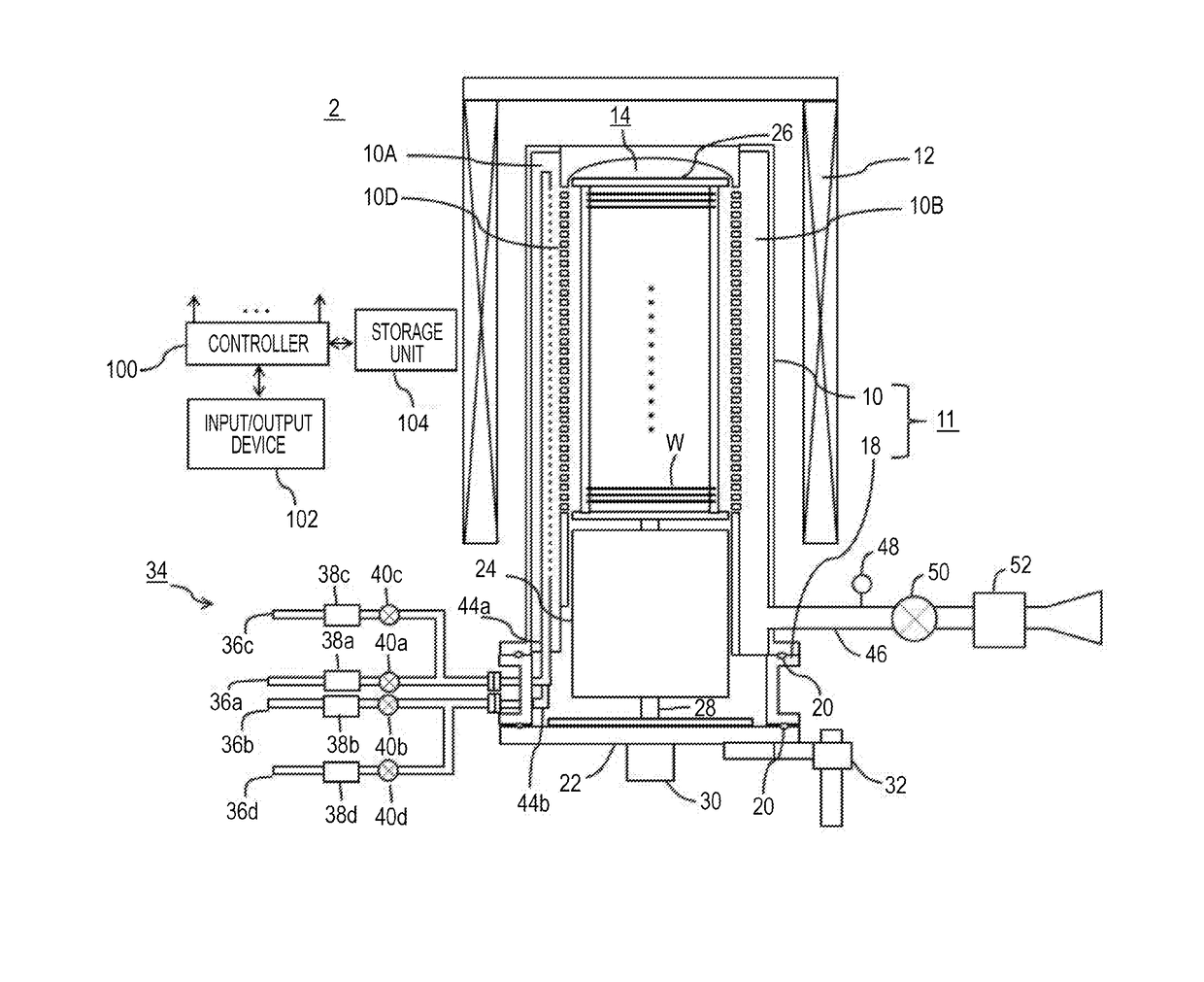

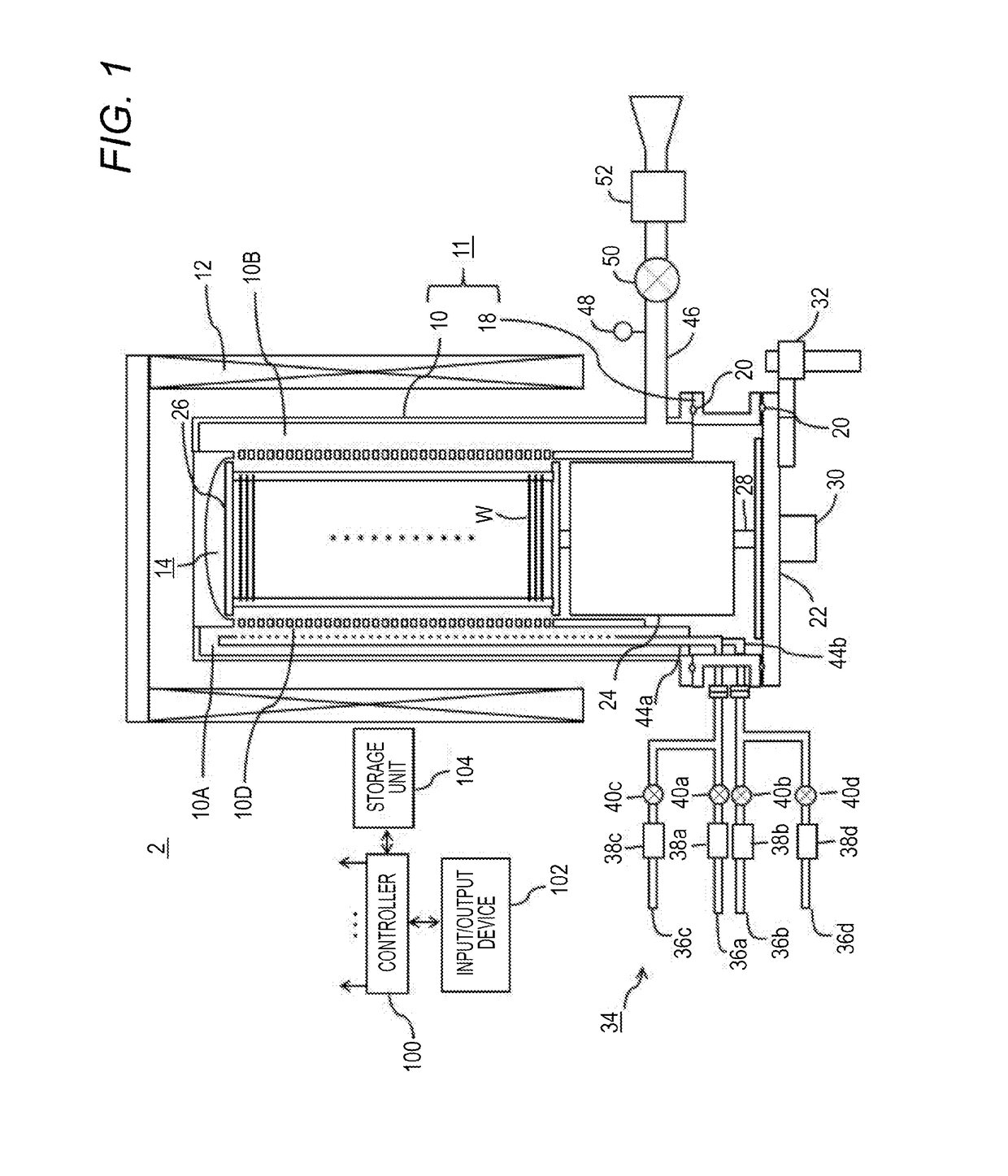

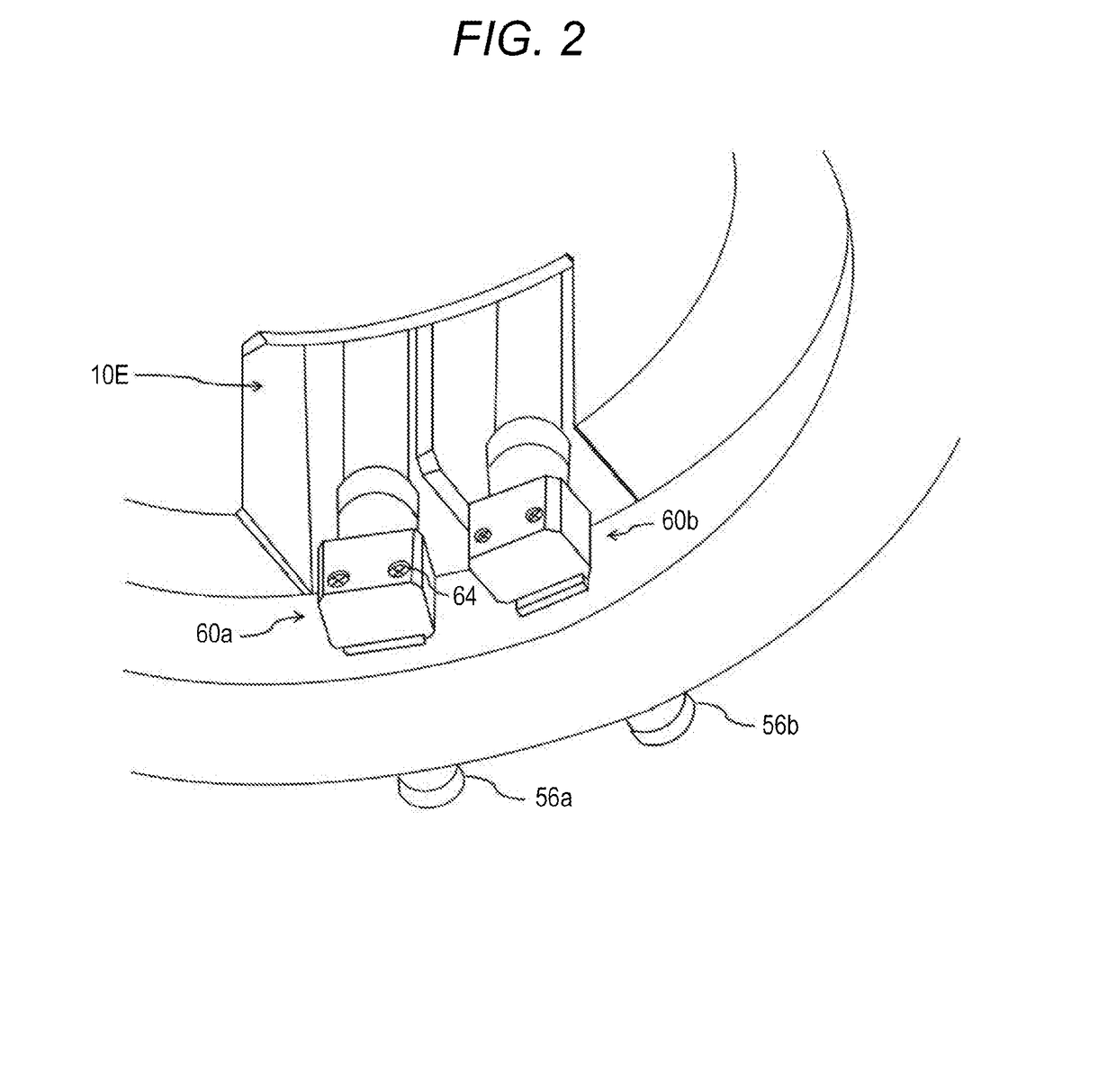

ActiveUS20180142353A1Speed up the flowSemiconductor/solid-state device manufacturingChemical vapor deposition coatingProcess engineeringGas supply

A substrate processing apparatus includes a reaction tube defining a substrate processing chamber; a gas inlet provided at a lower portion of the reaction tube to supply a process gas; a first buffer unit for temporarily retaining the process gas, the first buffer unit at a first side of an inner surface of the reaction tube and includes a plurality of gas supply holes; and a gas outlet provided at a second side of the inner surface of the reaction tube opposite to the first side, to exhaust the process gas from the process chamber. The gas supply holes are provided from an upper end portion of the first buffer unit to a lower end portion of the first buffer unit, and the process gas is supplied through the plurality of gas supply holes into the process chamber, passes through the process chamber, and exhausted through the gas outlet.

Owner:KOKUSA ELECTRIC CO LTD

Substrate processing apparatus, nozzle base, and manufacturing method for semiconductor device

ActiveUS20180087152A1Low costImprove maintainabilitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingDevice materialEngineering

Provided is a processing container formed of a reaction tube and a manifold that supports the reaction tube from below, and adapted to process a substrate inside, a nozzle adapted to supply a processing gas to the substrate, and a connecting portion adapted to erect the nozzle inside the processing container. The connecting portion includes (1) a fixing portion formed of a cylindrical portion inserted into an introduction portion provided at the manifold, and a flange plate formed at an end portion of the cylindrical portion, and (2) a detachable portion formed of an elbow engaged with the flange plate, and an installation portion in which the nozzle is installed.

Owner:KOKUSA ELECTRIC CO LTD

Substrate processing apparatus

ActiveUS20090116936A1Prevent slippingProcess safety and stabilityConveyorsSemiconductor/solid-state device manufacturingMechanical engineeringMaterials science

Provided is a substrate processing apparatus. The substrate processing apparatus includes a reaction tube, a substrate holder, a gas nozzle, a heating unit, a temperature detector, and an exhaust unit. The reaction tube accommodates and processes substrates. The substrate holder holds substrates stacked at predetermined intervals in the reaction tube. The gas nozzle is installed along a stacked direction of the substrates. The heating unit heats the substrates. The temperature detector is installed along the stacked direction of the substrates. The exhaust unit exhausts an inside atmosphere of the reaction tube. Each of the gas nozzle and the temperature detector includes first and second parts and is supported by a narrow tube supporting member including first and second supporting parts. The first supporting part makes contact with the first part. The second supporting part is parallel with the second part and supports the second part.

Owner:KOKUSA ELECTRIC CO LTD

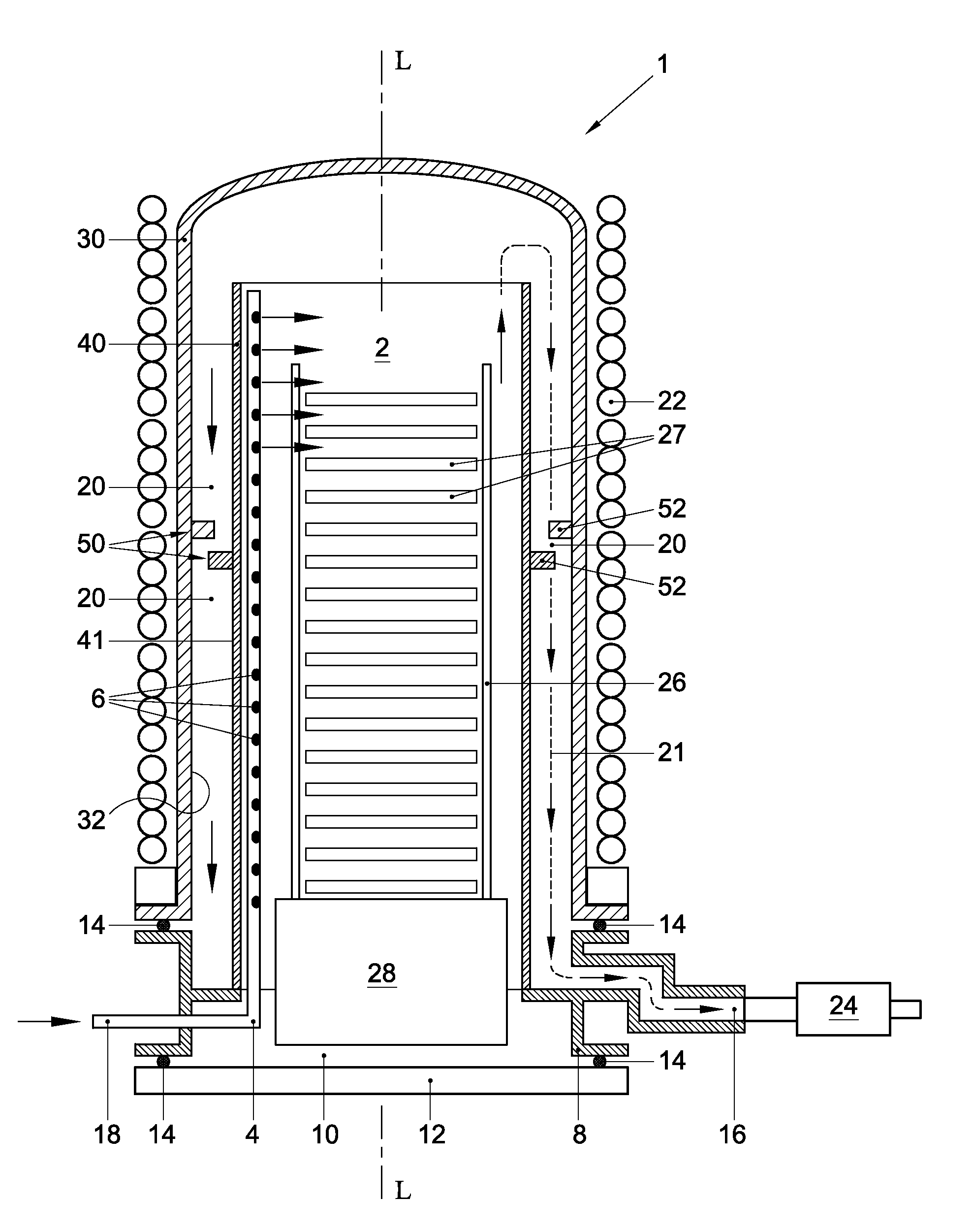

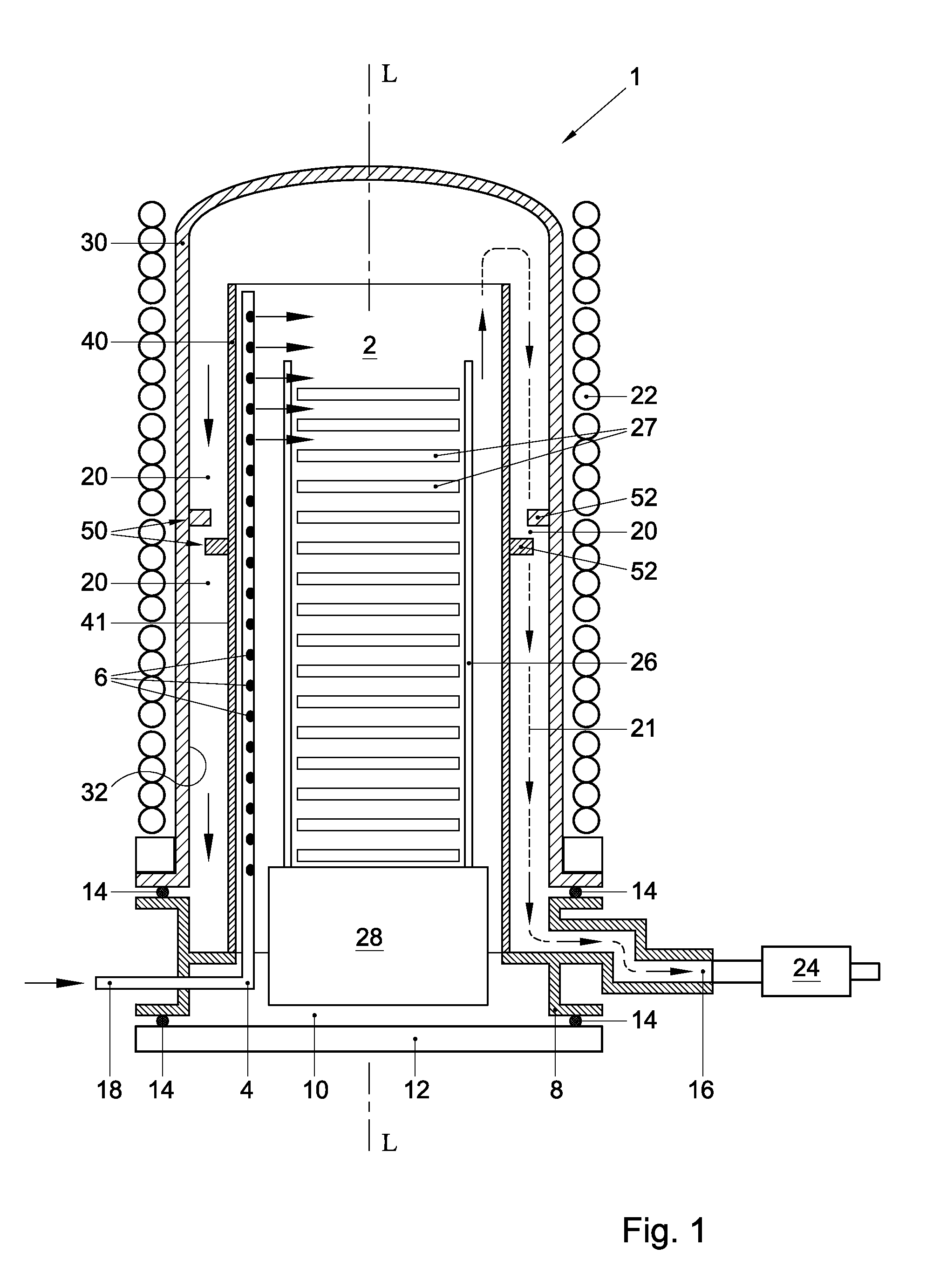

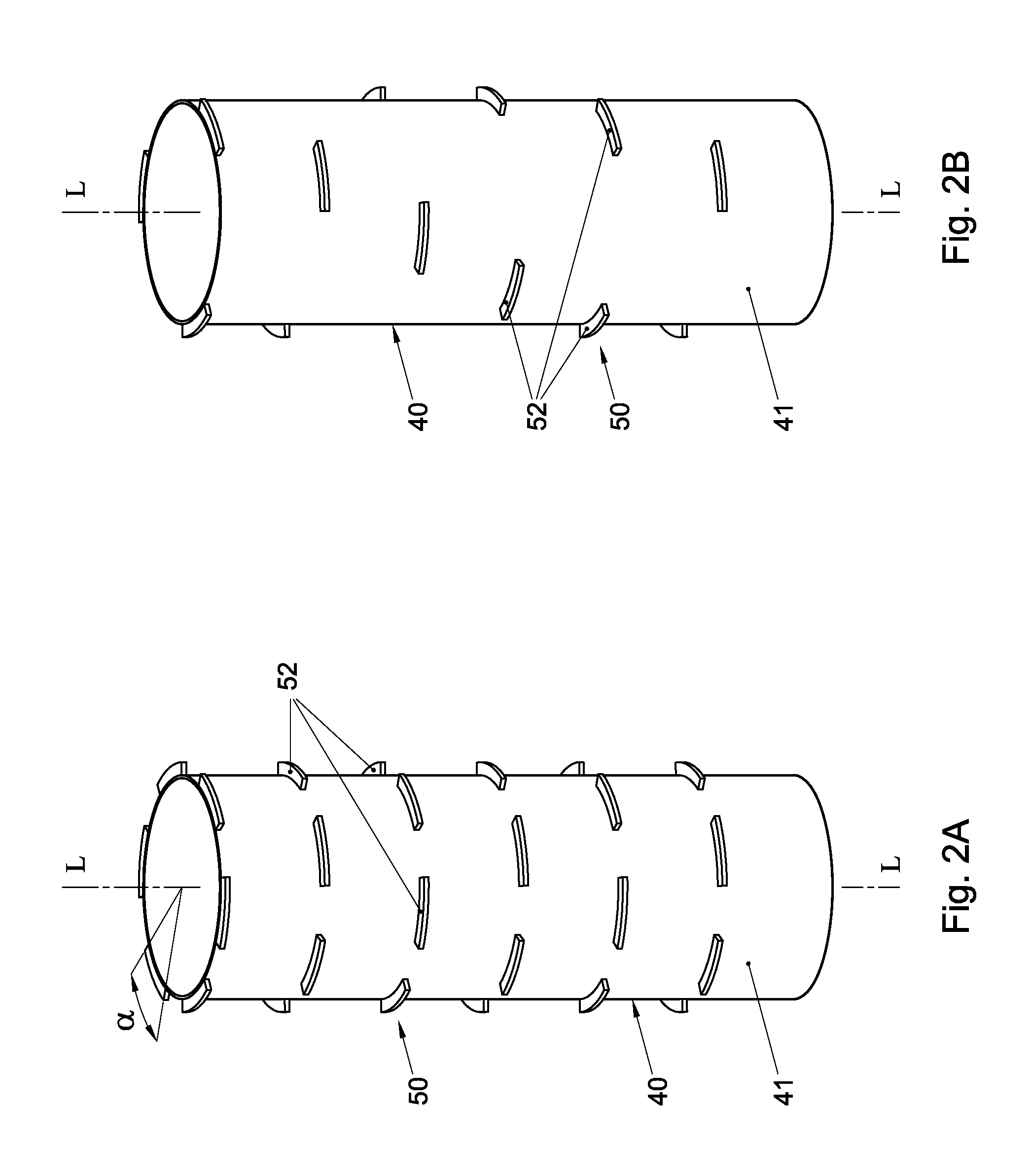

Thermal processing furnace and liner for the same

ActiveUS20120186573A1Easy to transportReduce decreaseDomestic stoves or rangesRotary drum furnacesEngineeringBell jar

A thermal processing furnace, comprising:a generally bell jar-shaped outer reaction tube having a central axis; andan open-ended inner reaction tube for accommodating a wafer boat holding a plurality of substrates, which inner reaction tube is substantially coaxially disposed within the outer reaction tube, thereby defining a gas passage between an outer wall of the inner reaction tube and an inner wall of the outer reaction tube,wherein at least one of the outer wall of the inner reaction tube and the inner wall of the outer reaction tube is provided with a flow deflector that protrudes radially from the respective wall into the gas passage.

Owner:ASM INTERNATIONAL

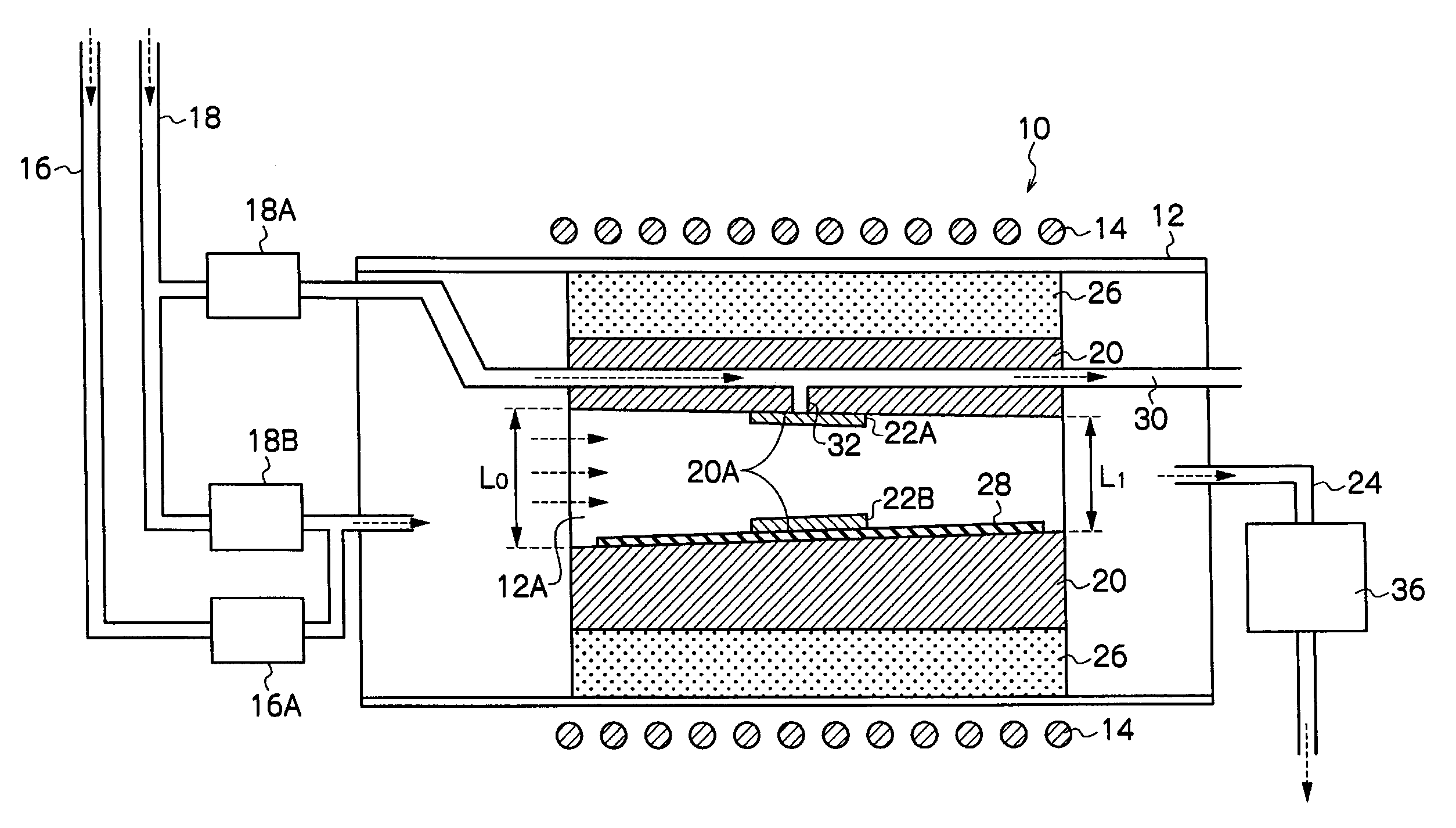

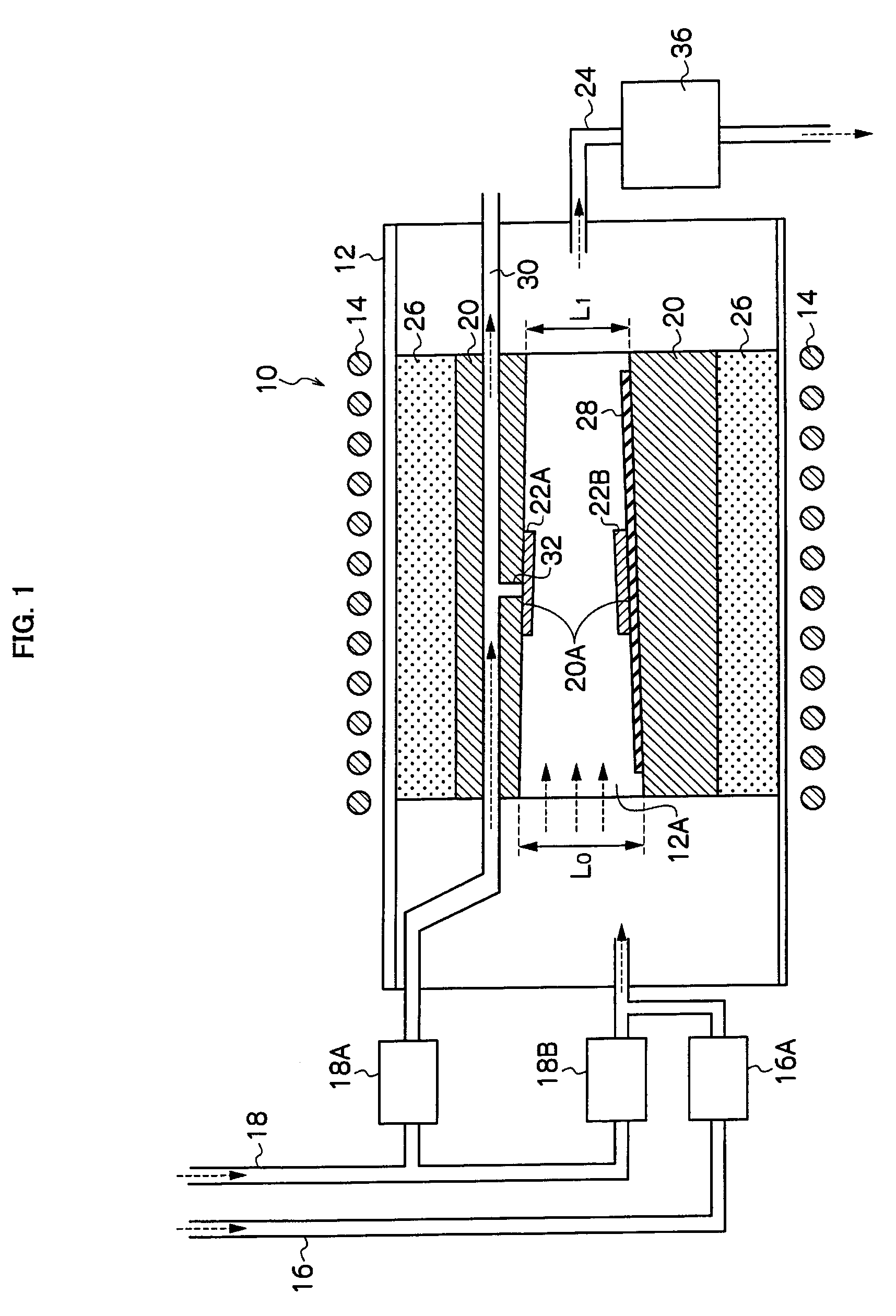

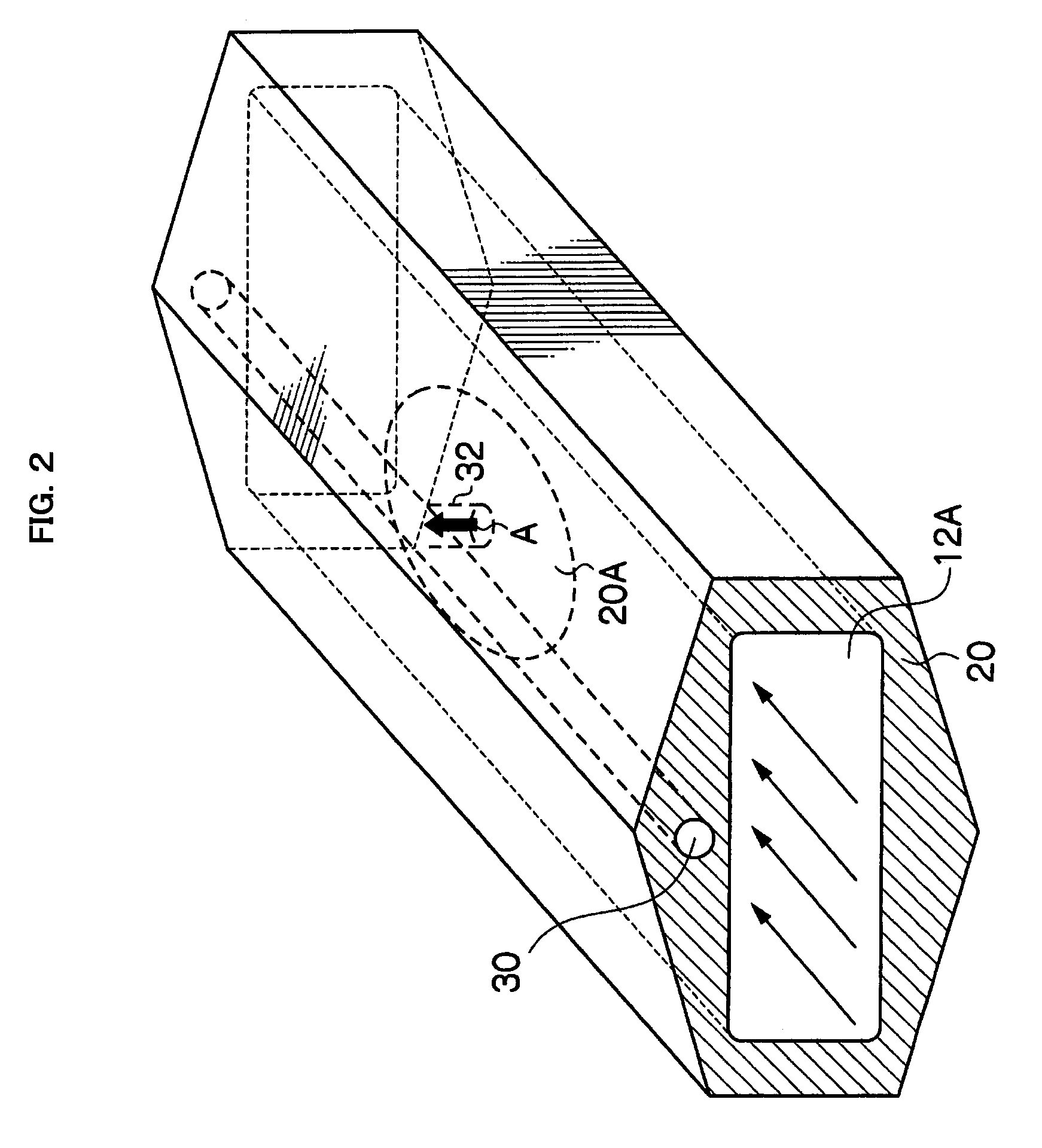

Apparatus for manufacturing semiconductor thin film

InactiveUS20090229519A1Improve in-plane evennessPolycrystalline material growthSemiconductor/solid-state device manufacturingIn planeSusceptor

The present invention provides an apparatus for manufacturing a semiconductor thin film that is capable of manufacturing an even thin film with substantially no adhesion of impurities, and is capable of improving in-plane evenness of a grown thin film. The invention is an apparatus for manufacturing a semiconductor thin film includes a reaction tube 12, a susceptor 20 disposed in the reaction tube 12, and a negative pressure generator, the negative pressure generator applying a negative pressure to a substrate 22A placed on the susceptor 20 to hold the substrate, and the substrate 22A is placed so that an angle of a normal line to a crystal growth face of the substrate 22A to a vertical downward direction is less than 180°.

Owner:TOYOTA JIDOSHA KK

Substrate treatment apparatus

ActiveUS20160195331A1Improve sealingIncrease productivityMuffle furnacesSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

Provided is a substrate processing apparatus. The substrate processing apparatus includes a chamber body having a passage, through which substrates are transferred, in one side thereof, the chamber body having opened upper and lower portions, an inner reaction tube disposed above the chamber body to provide a process space in which a process with respect to the substrates is performed, the inner reaction tube having an opened lower portion, a substrate holder disposed in the opened lower portion of the chamber to move between a stacking position at which the substrates transferred through the passage are vertically stacked and a process position at which the substrate holder ascends toward the process space to perform the process with respect to the stacked substrates, a blocking plate connected to a lower portion of the substrate holder to ascend or descend together with the substrate holder, the blocking plate closing the opened lower portion of the inner reaction tube at the process position, a connection cylinder vertically disposed on a lower portion of the blocking plate to ascend or descend together with the blocking plate, and a blocking member connected between the opened lower portion of the chamber body and the connection cylinder to isolate the opened lower portion of the chamber body from the outside.

Owner:EUGENE TECH CO LTD

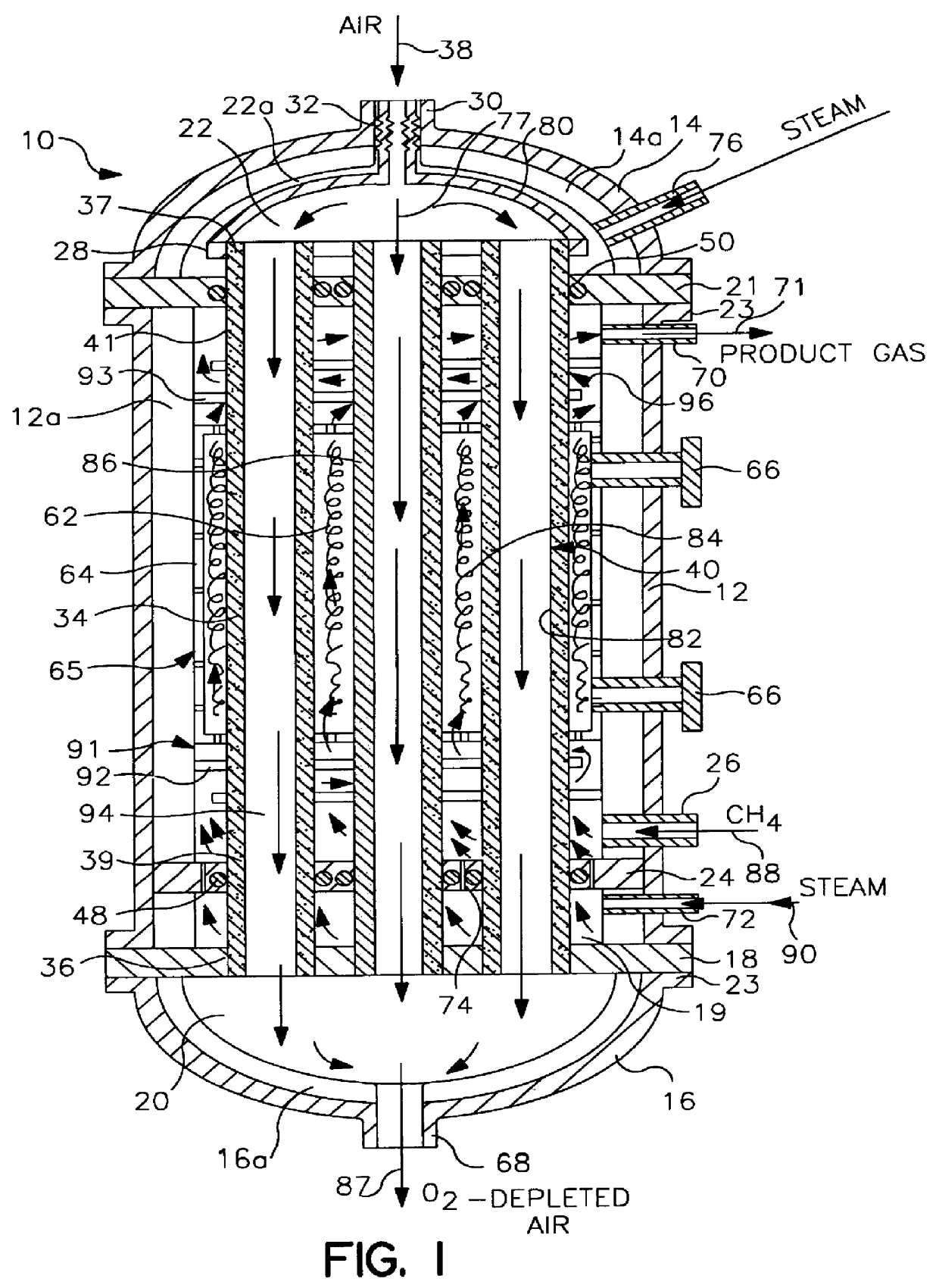

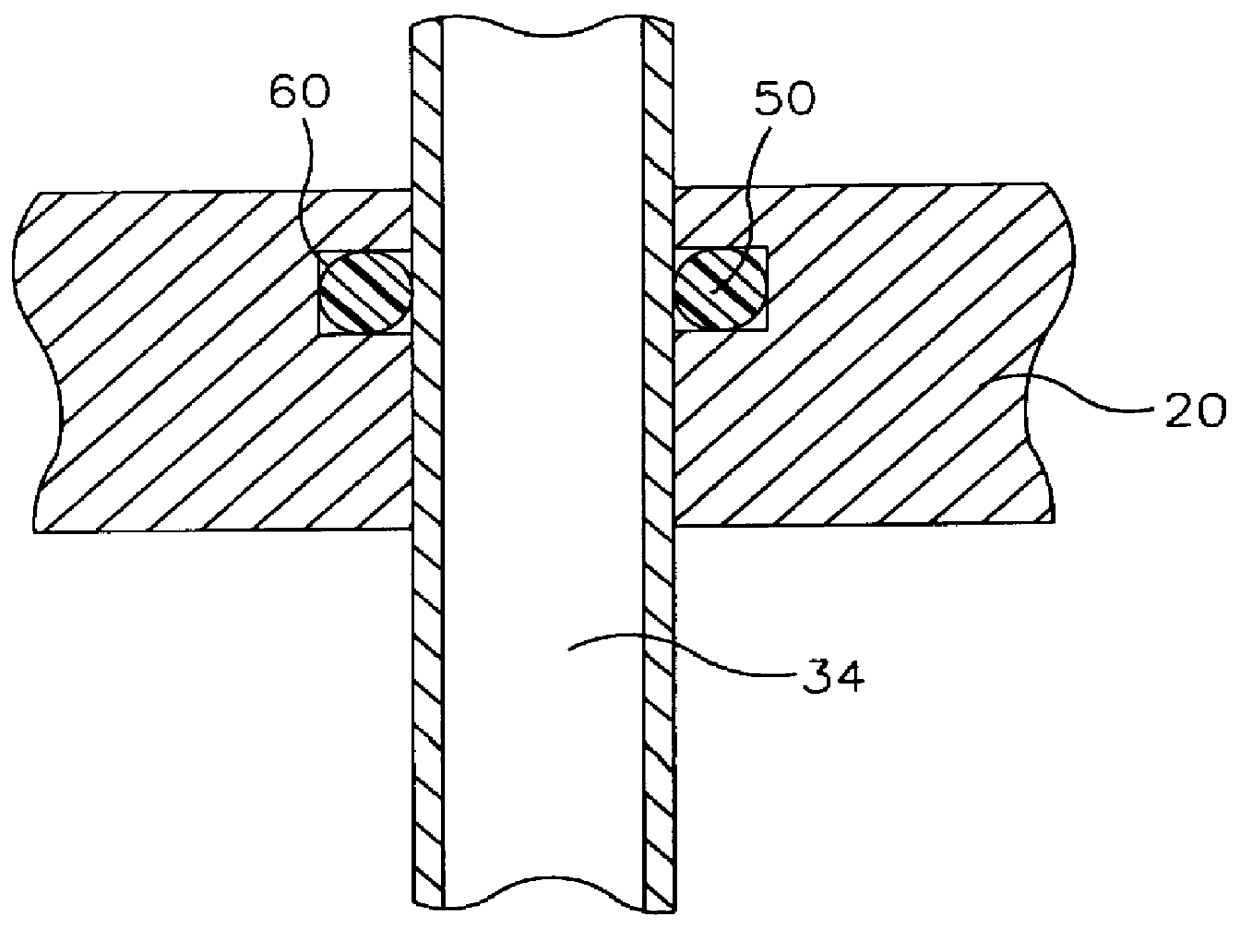

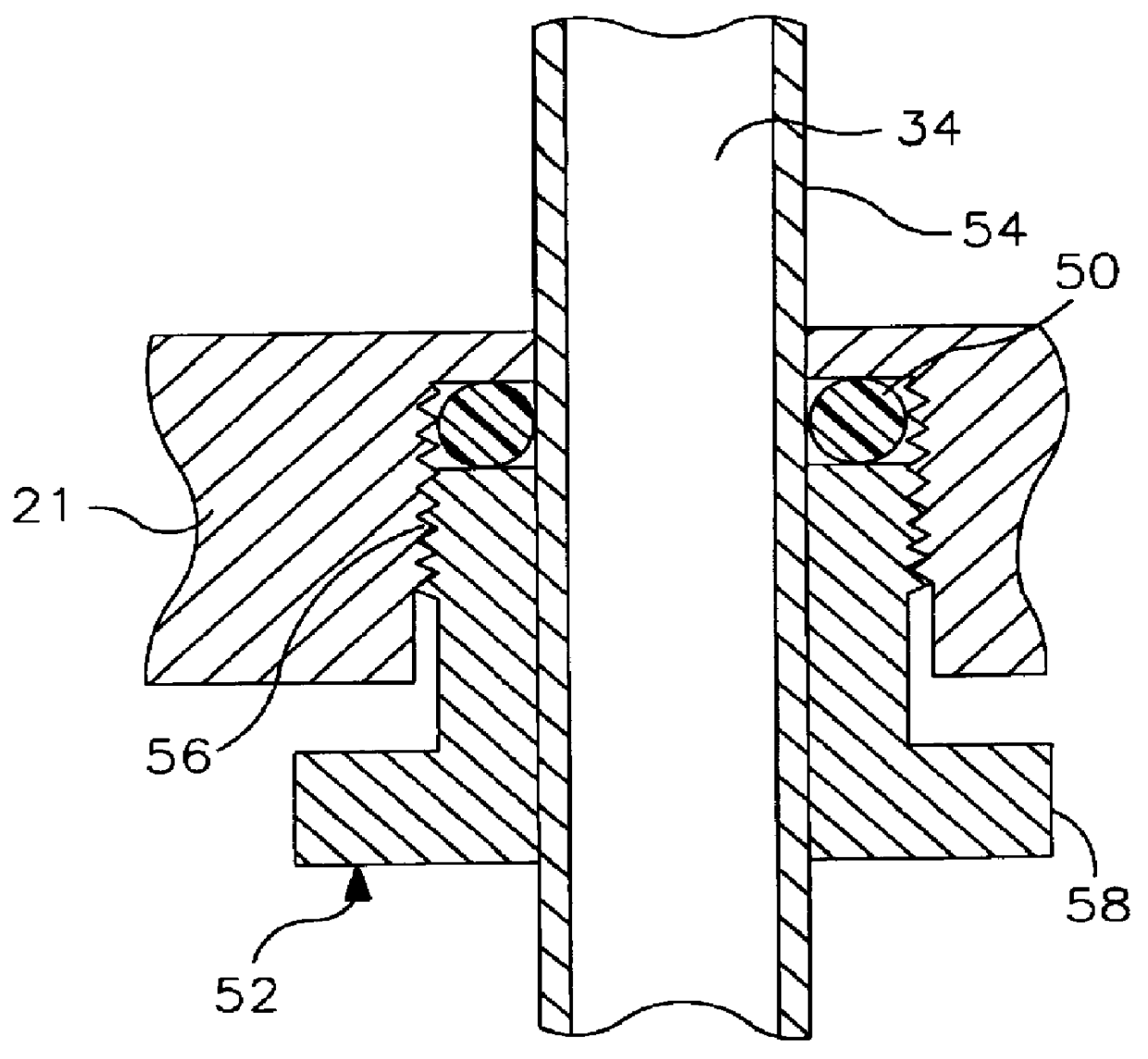

Tube and shell reactor with oxygen selective ion transport ceramic reaction tubes

InactiveUS6139810AIncrease oxygen fluxDecreasing anode side partial oxygen pressureIsotope separationHydrogen/synthetic gas productionPtru catalystElectrical conductor

A reactor comprising: a hollow shell defining a hermetic enclosure; a plurality of tube sheets disposed within said hermetic enclosure, a first one of said plurality of tube sheets defining a first chamber; at least one reaction tube each having a first end and an opposing second end, said first end being fixedly attached and substantially hermetically sealed to one end of said plurality of tube sheets and opening into said first chamber, the second end being axially unrestrained; each of said reaction tubes is comprised of an oxygen selective ion transport membrane with an anode side wherein said oxygen selective ion transport membrane is formed from a mixed conductor metal oxide that is effective for the transport of elemental oxygen at elevated temperatures and at least a portion of said first and second heat transfer sections are formed of metal; each of said reaction tubes includes first and second heat transfer sections and a reaction section, said reaction section disposed between said first and second heat transfer sections; a reforming catalyst disposed about said anode side of said oxygen selective ion transport membrane; a first process gas inlet; a second process gas inlet; and, a plurality of outlets.

Owner:STANDARD OIL CO +1

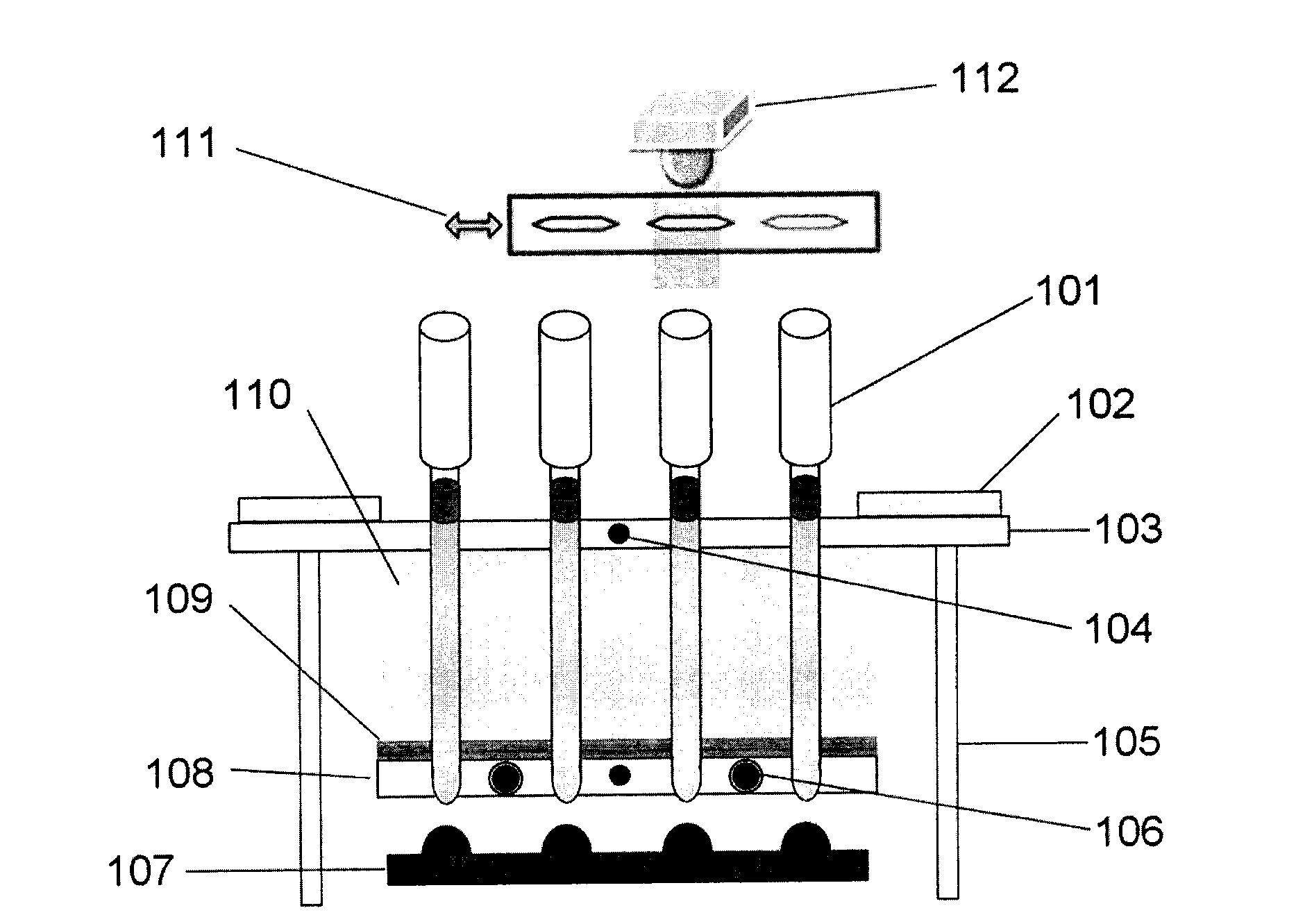

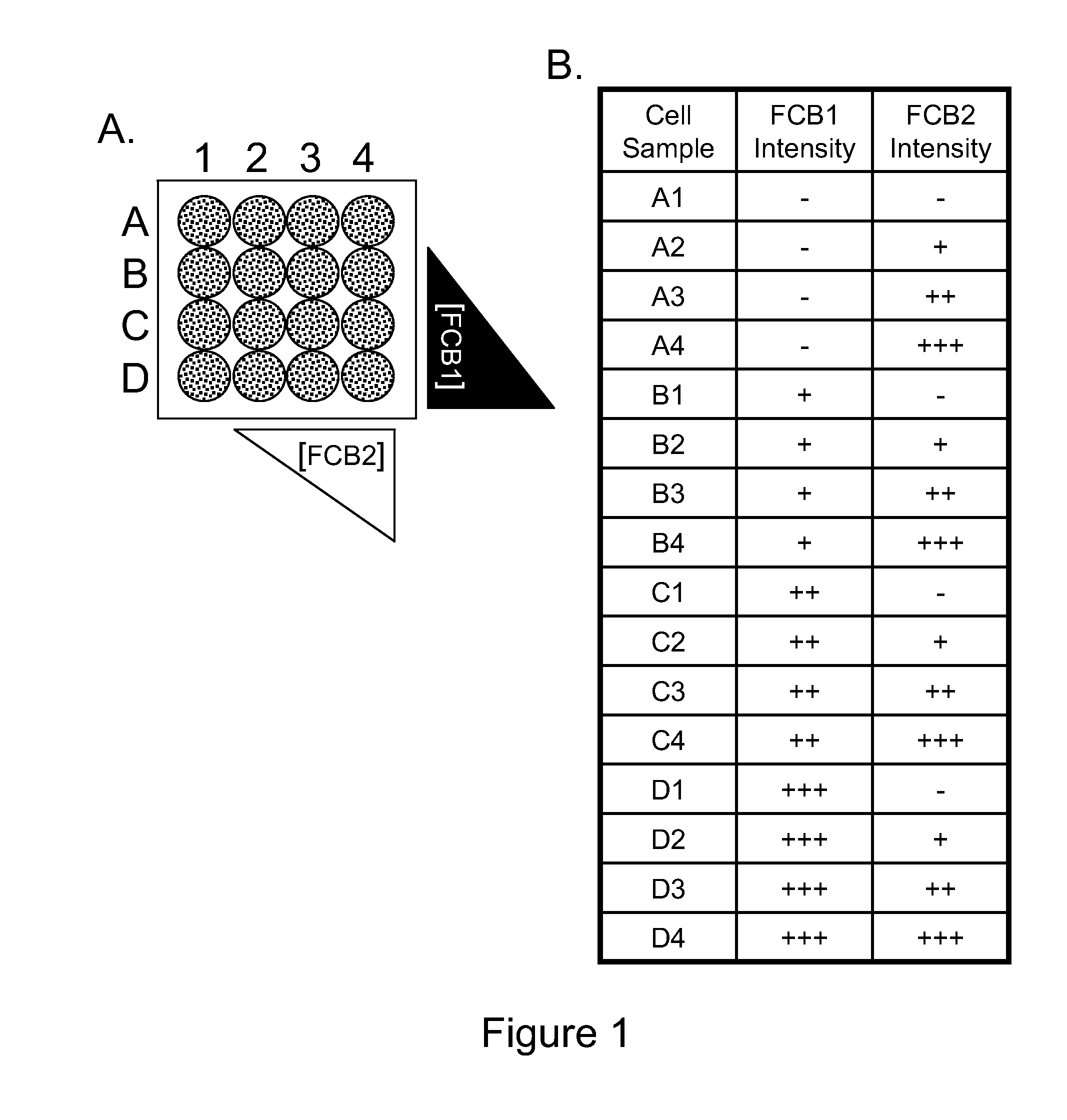

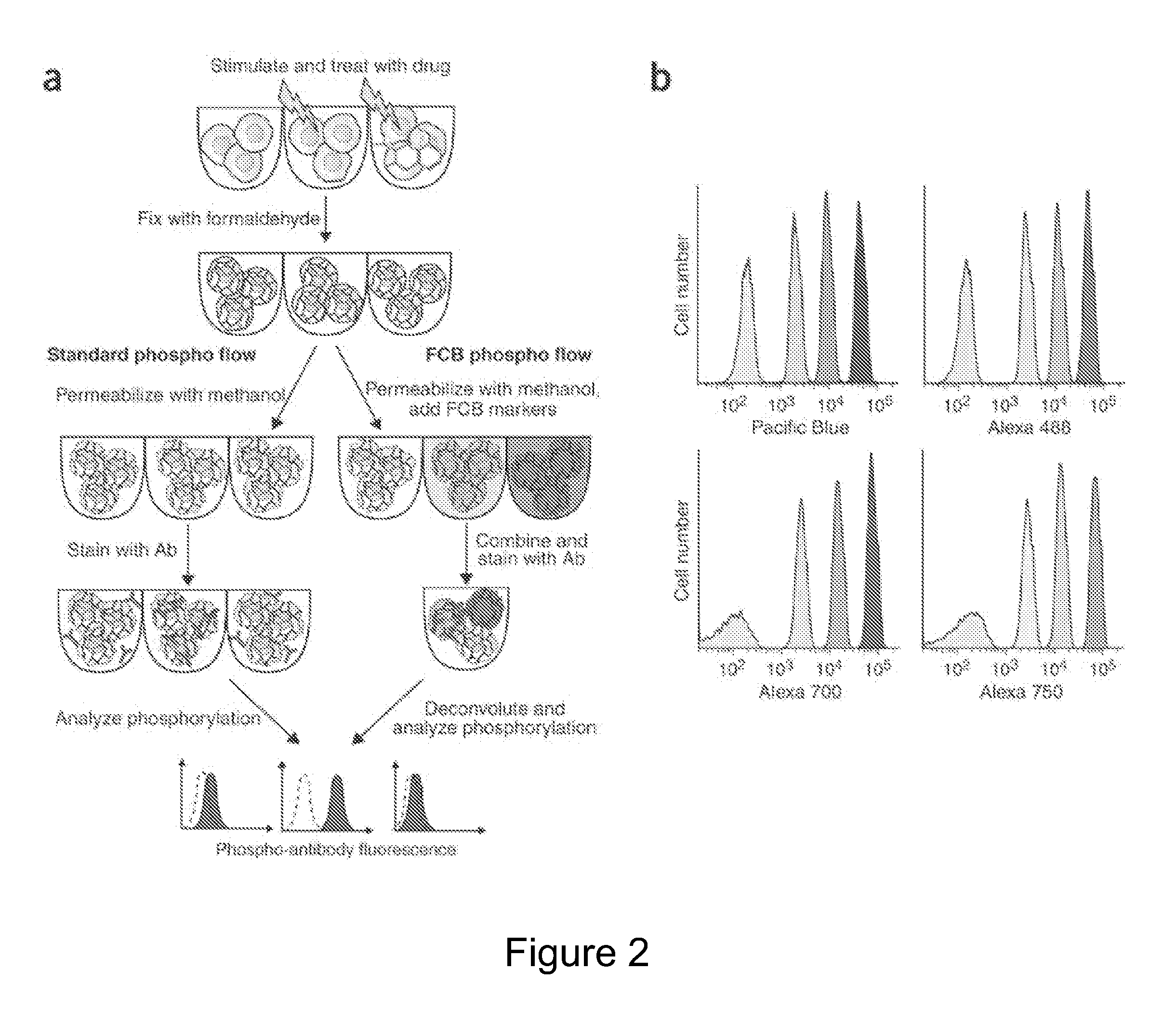

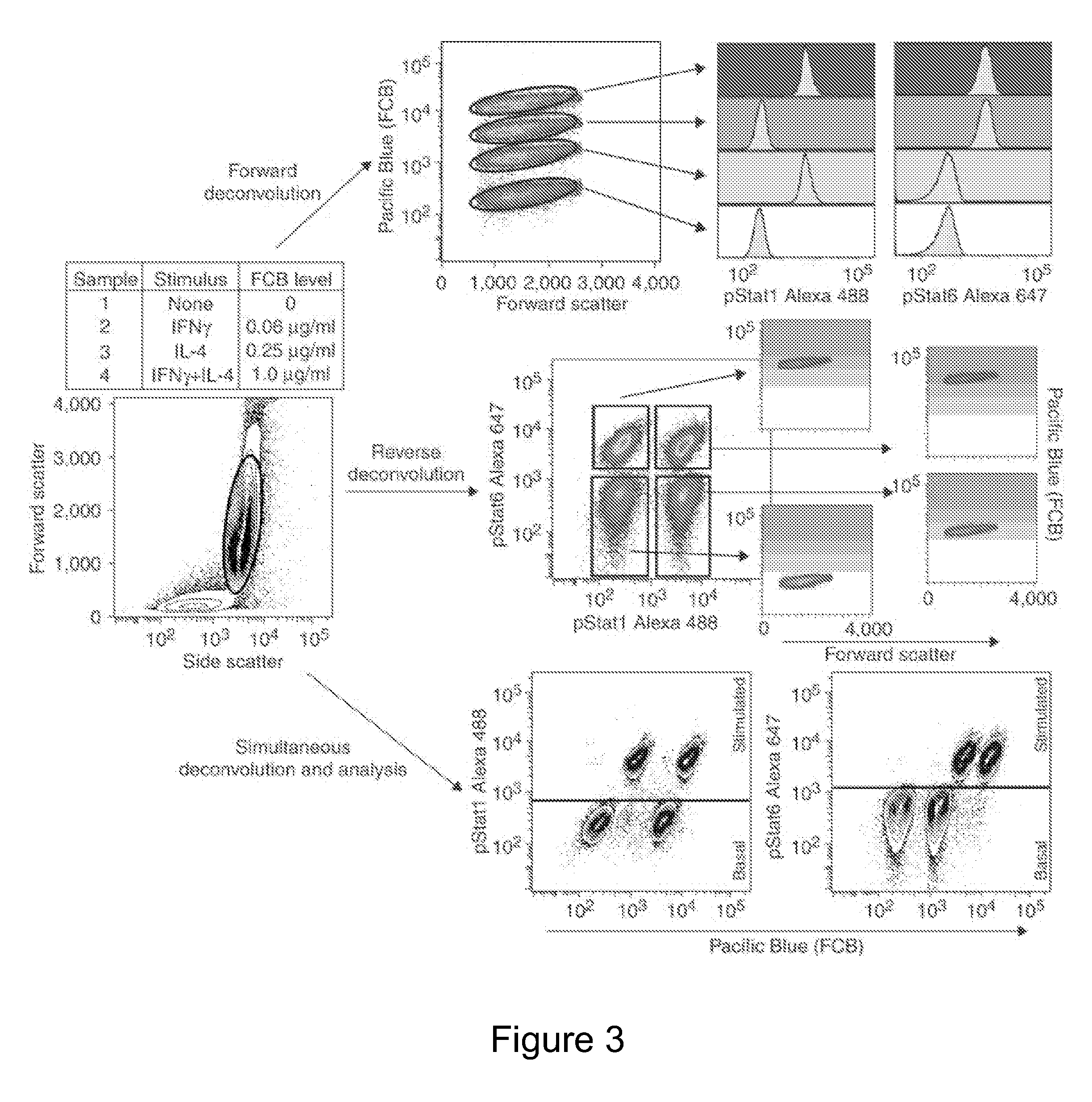

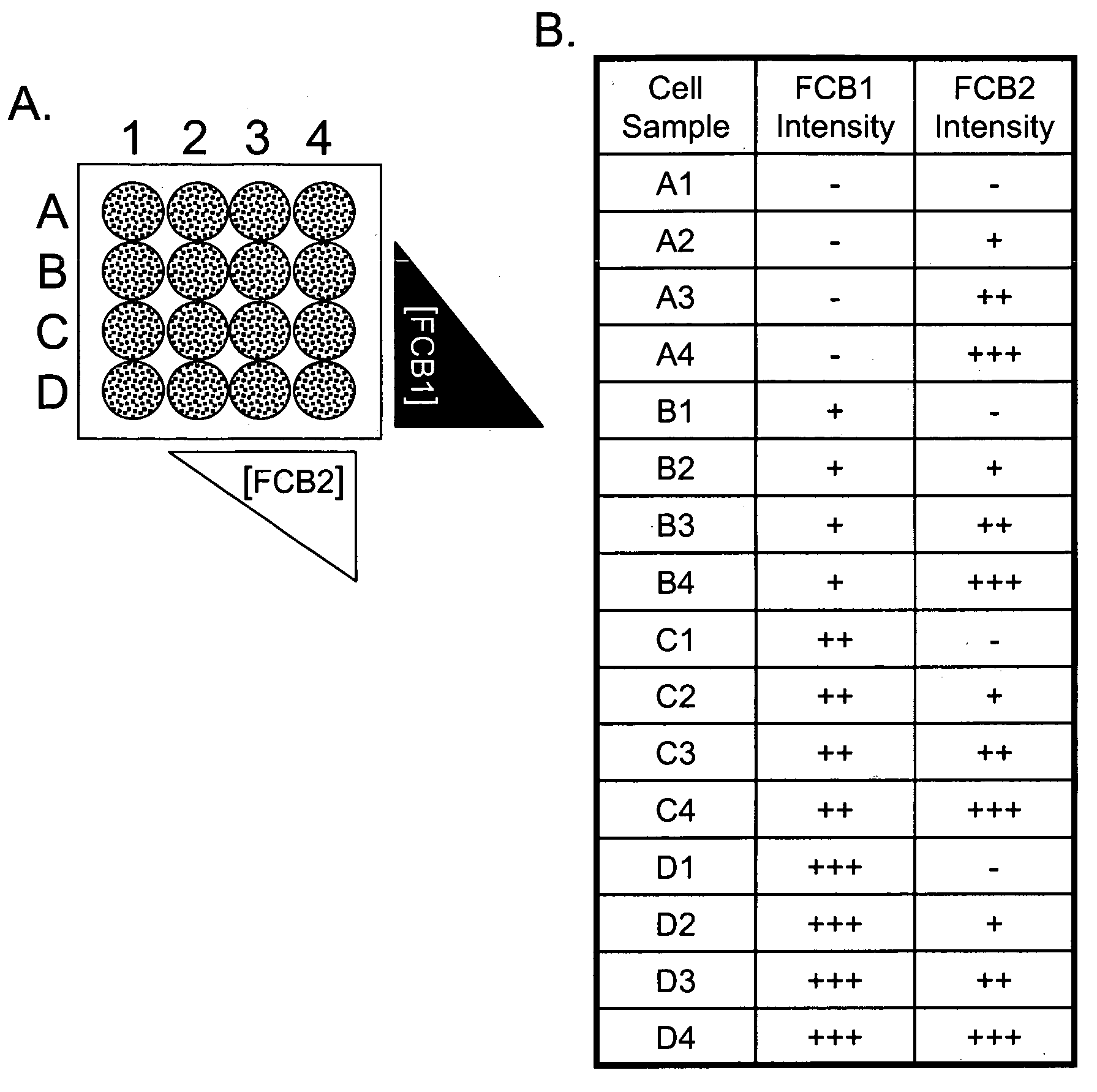

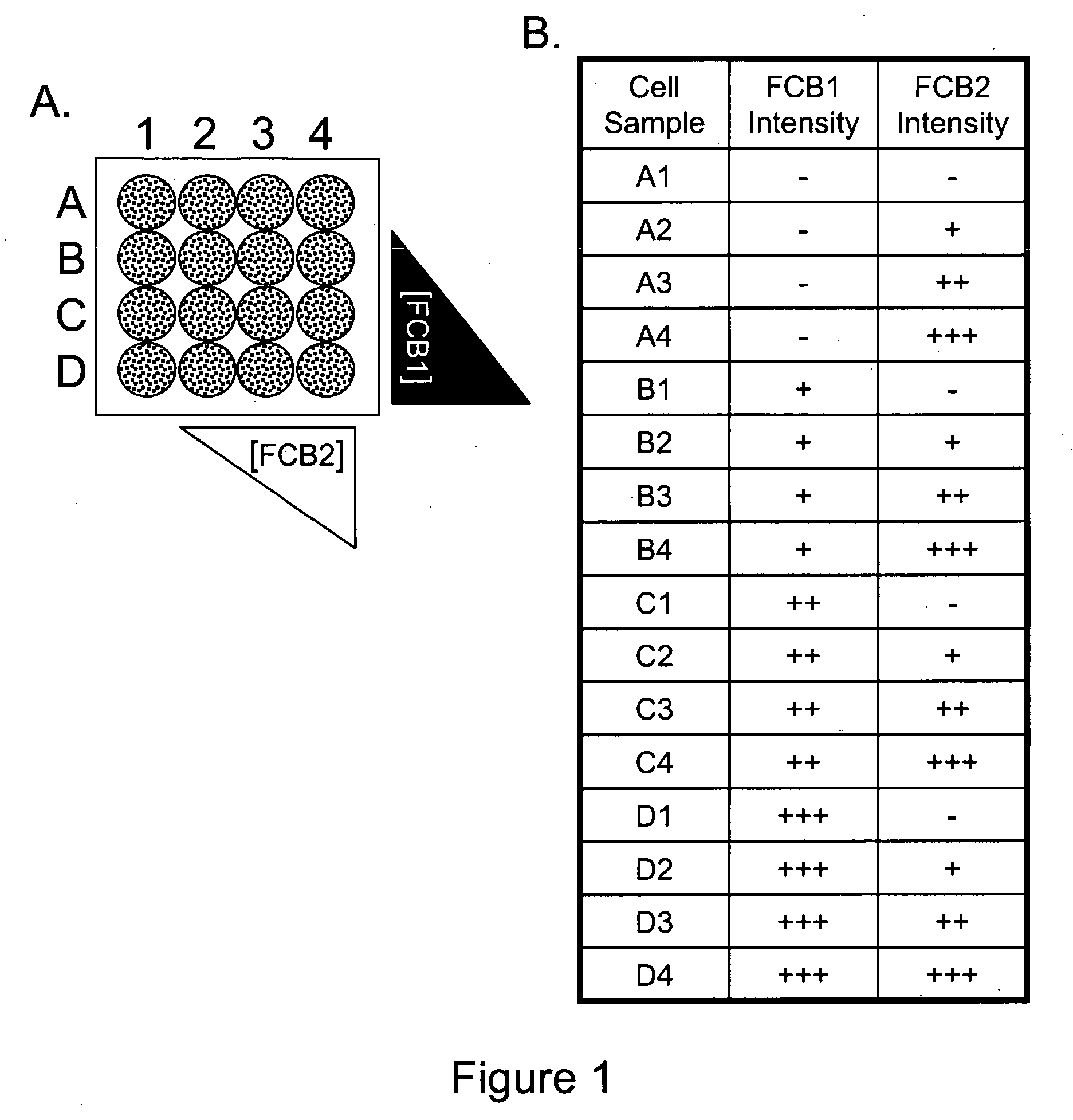

Multiplex Cellular Assays Using Detectable Cell Barcodes

InactiveUS20110263457A1Improve throughputReduce consumptionOrganic chemistryMicrobiological testing/measurementMultiplexingAnalyte

We describe herein a cell-based multiplexing technique called detectable cell barcoding (DCB). In DCB, each individual sample is labeled with a different DCB signature that distinguishes each sample by one or both of detected intensity or type of detection characteristic. The samples are then combined and analyzed for a detectable characteristic of interest (e.g., presence of an analyte). By employing multiple distinct DCB labels at varying concentrations, one can perform multiplex analyses on up to hundreds or thousands (or more) of cell samples in a single reaction tube. DCB reduces reagent consumption by factors of 100-fold or more, significantly reduces data acquisition times and allows for stringent control sample analysis.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

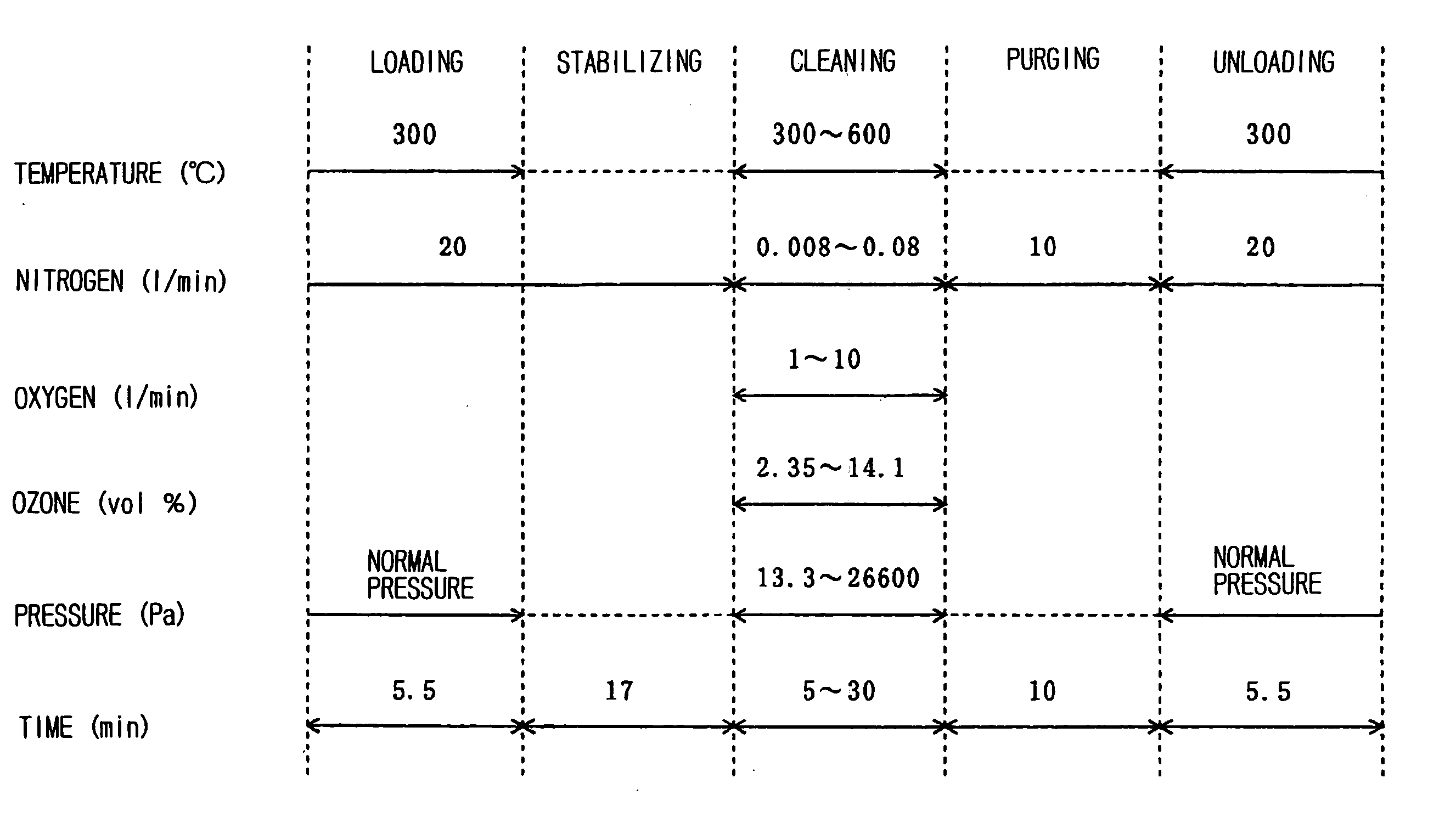

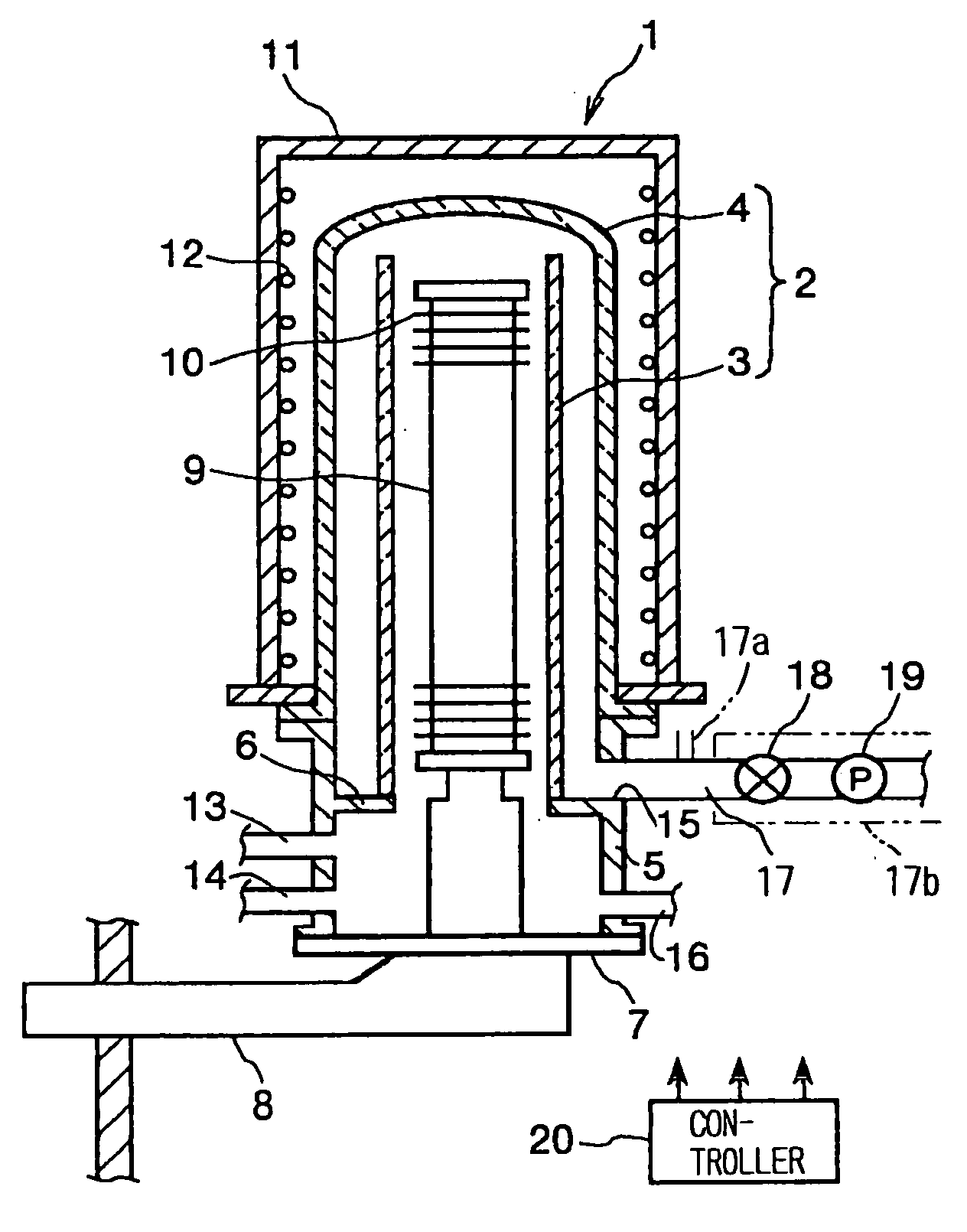

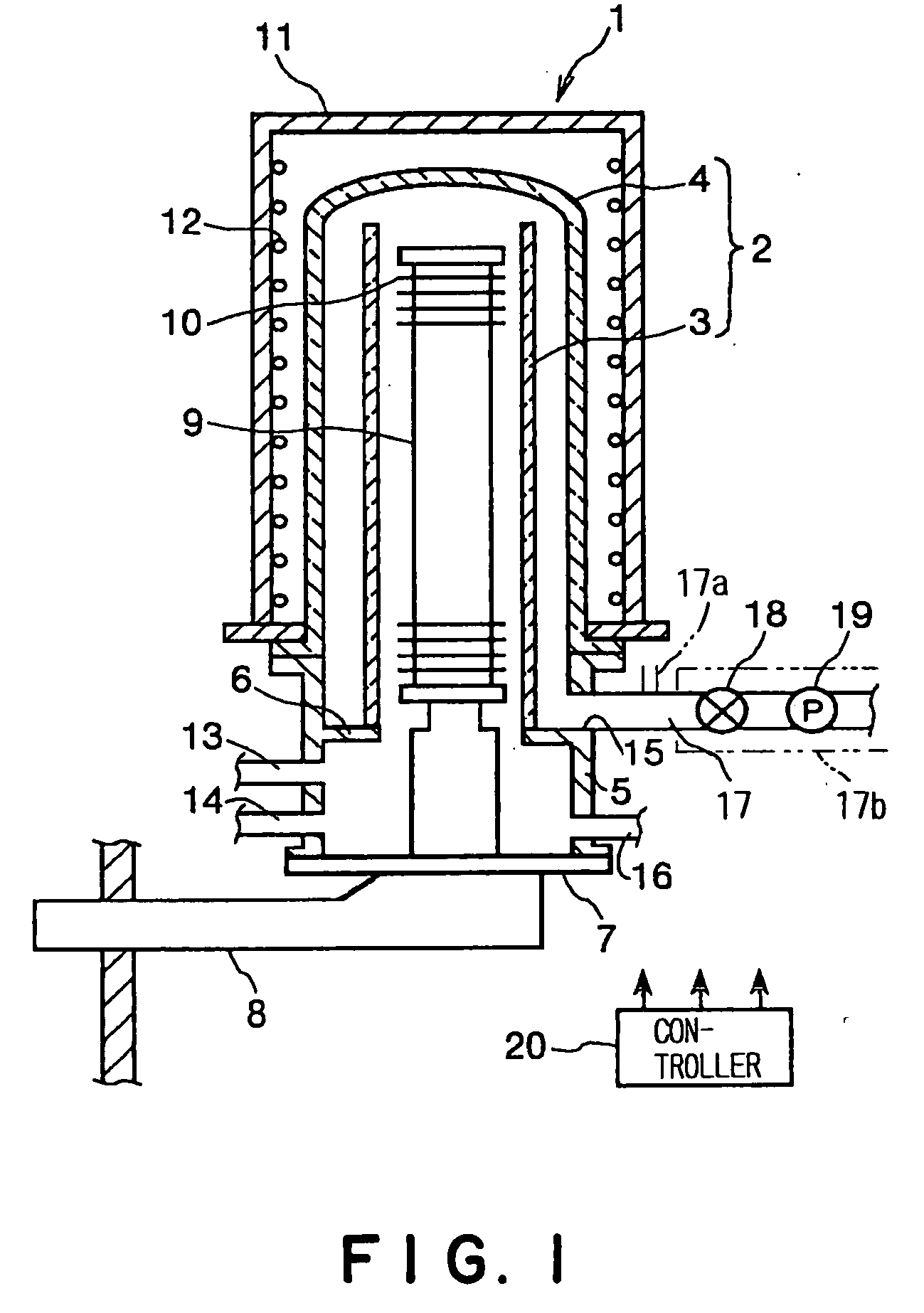

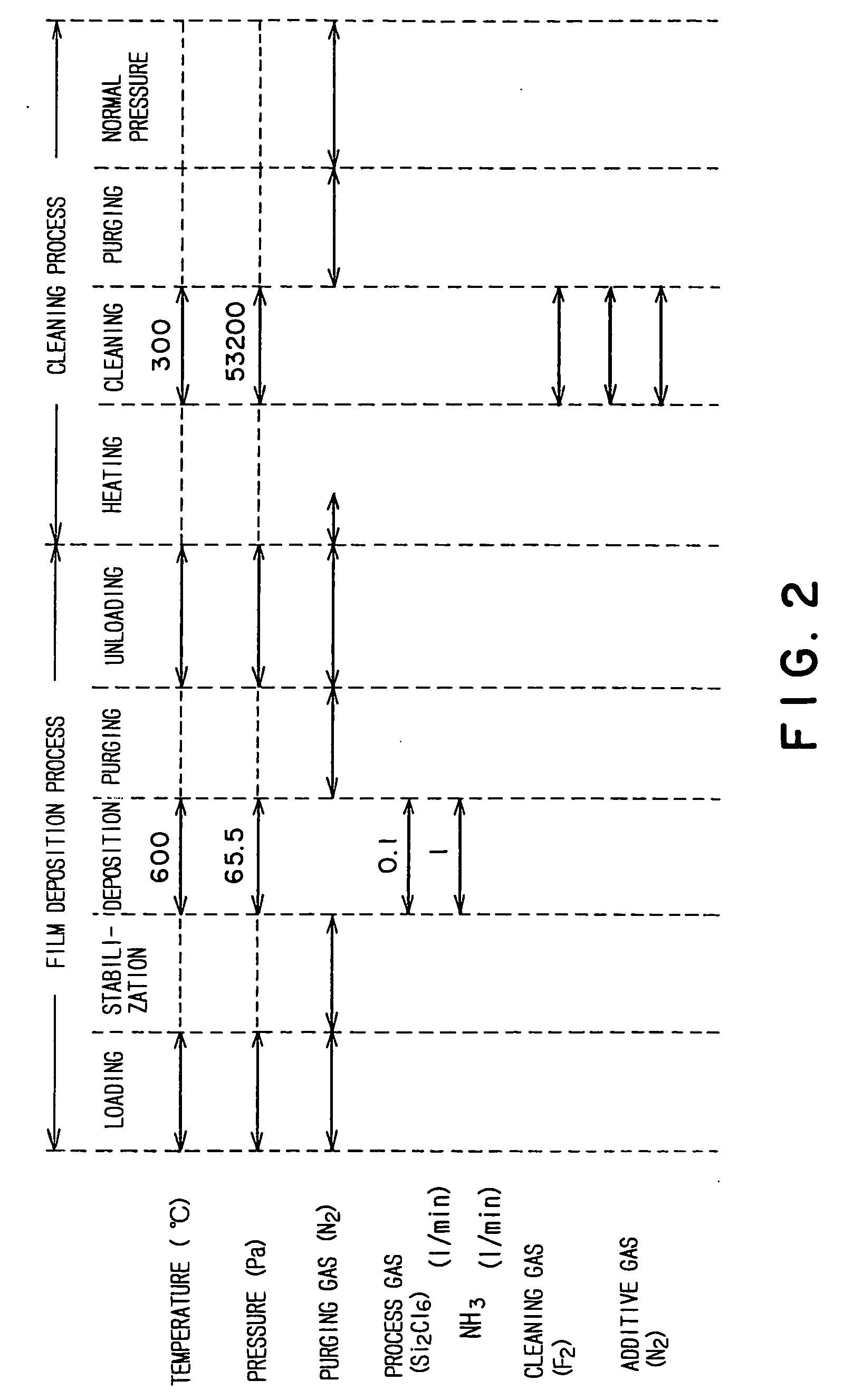

Thin film forming apparatus cleaning method

InactiveUS20050090123A1Inhibit deteriorationIncrease etch rateDrying solid materials without heatSemiconductor/solid-state device manufacturingCleaning methodsNitrogen gas

A cleaning process for cleaning a thermal processing apparatus includes: a heating step of heating an interior of a reaction tube at 300° C., and a cleaning step of removing deposits deposited in the thermal processing apparatus. In the cleaning step, a cleaning gas containing fluorine gas, chlorine gas and nitrogen gas is supplied into the interior of the reaction tube heated at 300° C. to remove silicon nitride so to clean an interior of the thermal processing apparatus.

Owner:TOKYO ELECTRON LTD

Multiplex cellular assays using detectable cell barcodes

ActiveUS20080241820A1Reduces regent consumptionImprove throughputMicrobiological testing/measurementBiological testingMultiplexingAnalyte

We describe herein a cell-based multiplexing technique called detectable cell barcoding (DCB). In DCB, each individual sample is labeled with a different DCB signature that distinguishes each sample by one or both of detected intensity or type of detection characteristic. The samples are then combined and analyzed for a detectable characteristic of interest (e.g., presence of an analyte). By employing multiple distinct DCB labels at varying concentrations, one can perform multiplex analyses on up to hundreds or thousands (or more) of cell samples in a single reaction tube. DCB reduces reagent consumption by factors of 100-fold or more, significantly reduces data acquisition times and allows for stringent control sample analysis.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

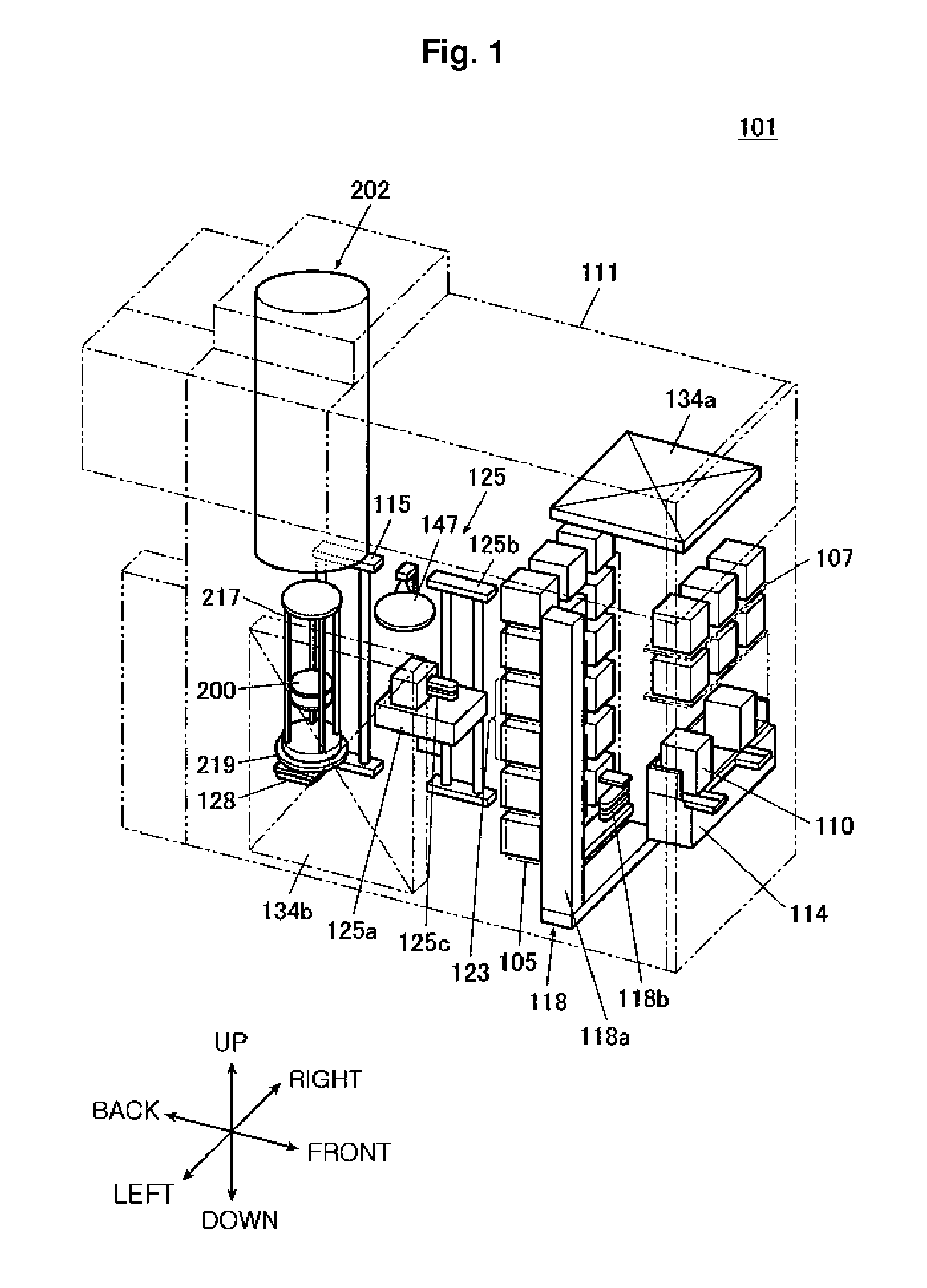

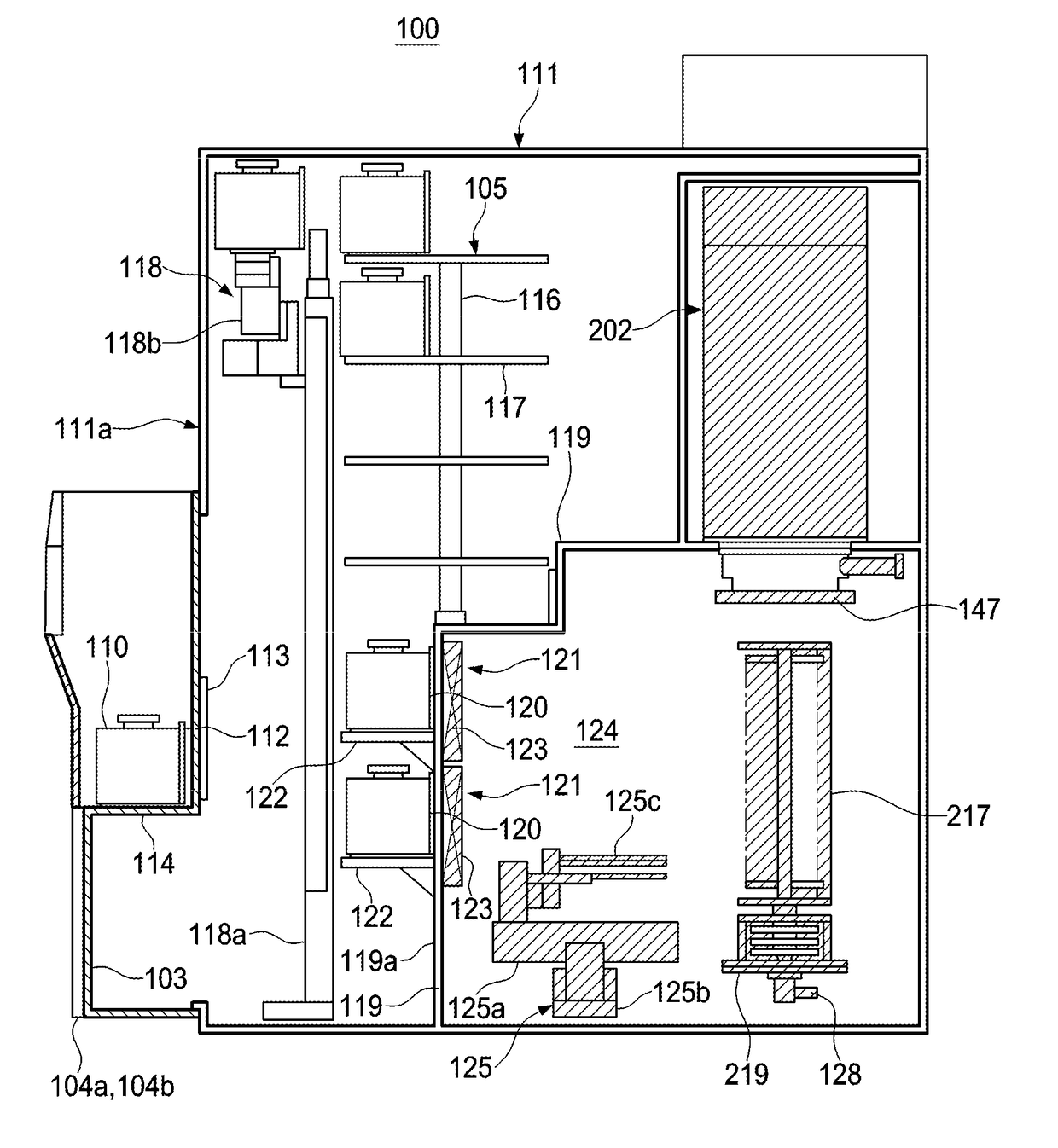

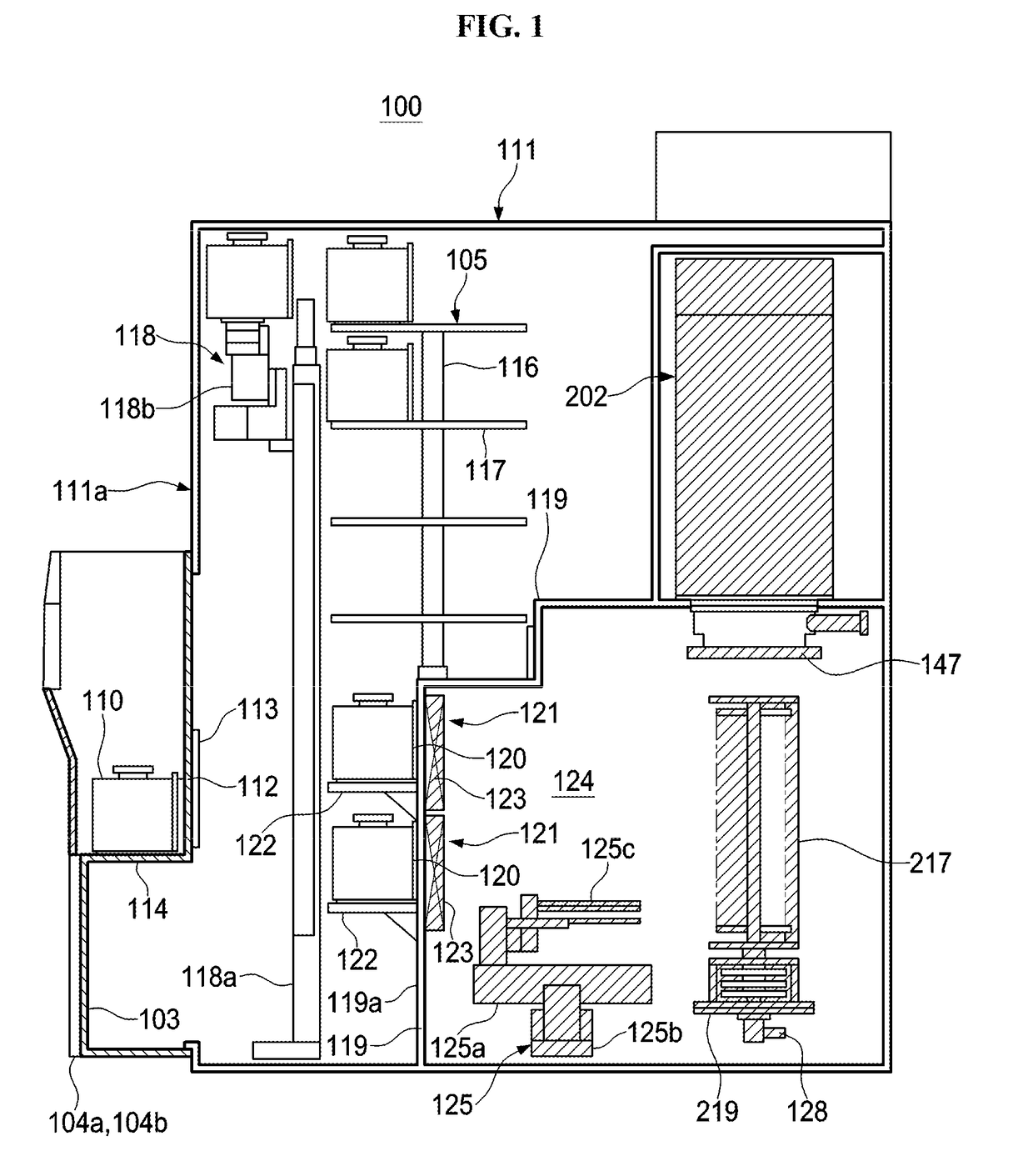

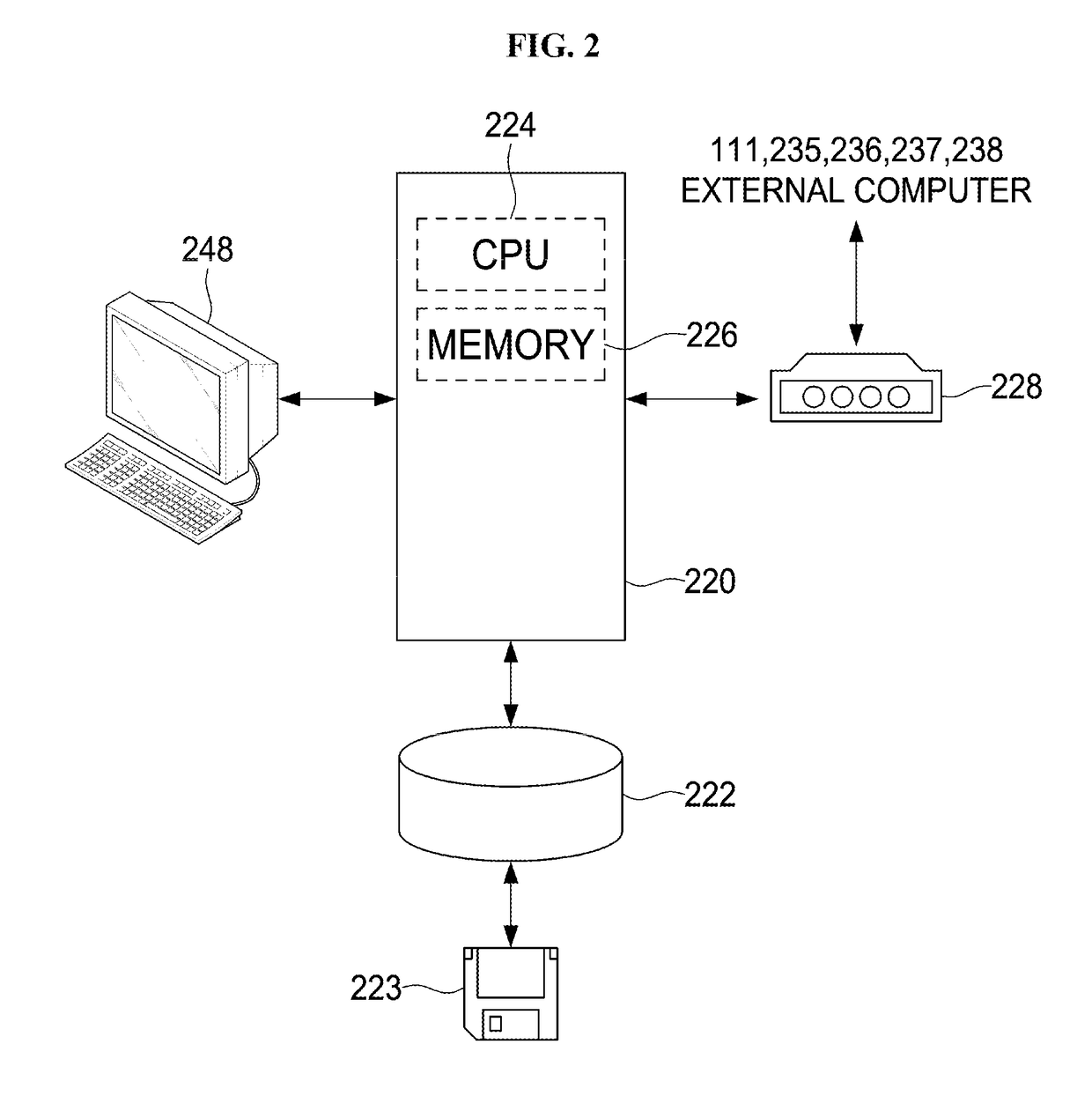

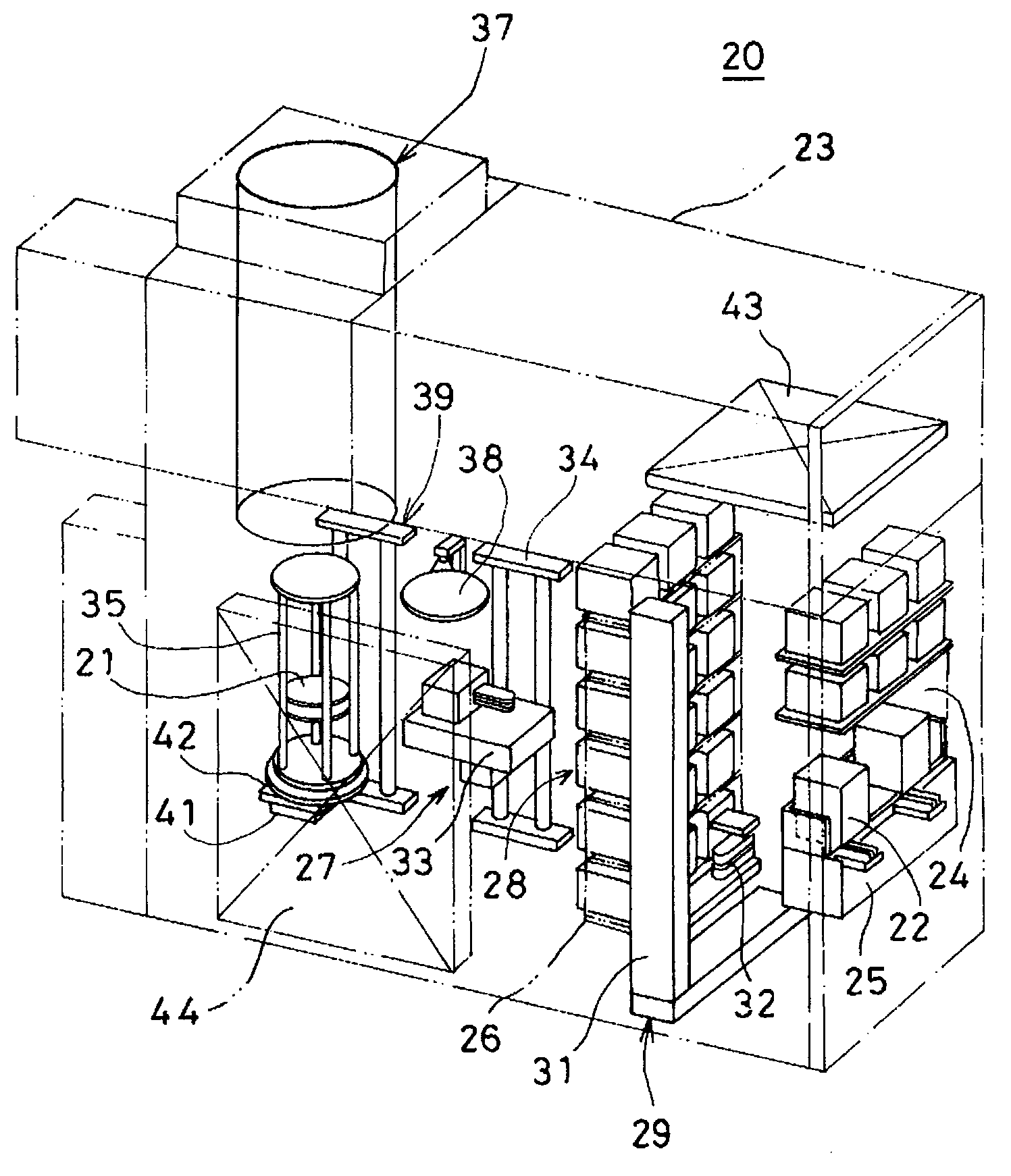

Substrate processing apparatus and its maintenance method, substrate transfer method and program

InactiveUS20130247937A1Semiconductor/solid-state device manufacturingCleaning processes and apparatusProcess engineeringIndustrial engineering

There is provided a substrate processing apparatus, including at least: a substrate holder that holds a substrate; a processing furnace including a reaction tube in which the substrate holder is loaded, and is configured to apply a specific processing to the substrate held by the substrate holder in a state that the substrate holder is loaded in the reaction tube; an operation part configured to select a maintenance recipe for the reaction tube used for substrate processing, and a maintenance recipe for both of the reaction tube and the substrate holder loaded in the reaction tube; and a control part configured to execute the maintenance recipe selected by the operation part, when a maintenance timing of the reaction tube and / or the substrate holder arrives.

Owner:KOKUSA ELECTRIC CO LTD

Ammonothermal process for bulk synthesis and growth of cubic GaN

InactiveUS20030209191A1Easy to transportQuality improvementPolycrystalline material growthFrom chemically reactive gasesLanthanideSingle crystal

A method of growing single-crystals of a cubic (zinc blende) form of gallium nitride, the method comprising the steps of: placing into a reaction tube or acid resistant vessel a gallium source, anhydrous ammonia, an acid mineralizer and a metal halide salt selected from the group consisting of alkali metal halides, copper halides, tin halides, lanthanide halides and combinations thereof; closing said reaction tube or vessel; heating said reaction tube; cooling said reaction tube or vessel; and collecting single-crystals of cubic (zinc blende) form of GaN; wherein said reaction tube or vessel has a temperature gradient with a hot zone of at least 250° C., wherein said reaction tube or vessel has a temperature gradient with a cool zone of at least 150° C., and wherein said acid mineralizer has a sufficient concentration to permit chemical transport of GaN in said reaction tube or vessel from said hot zone to said cool zone due to said temperature gradient within said reaction tube or vessel.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

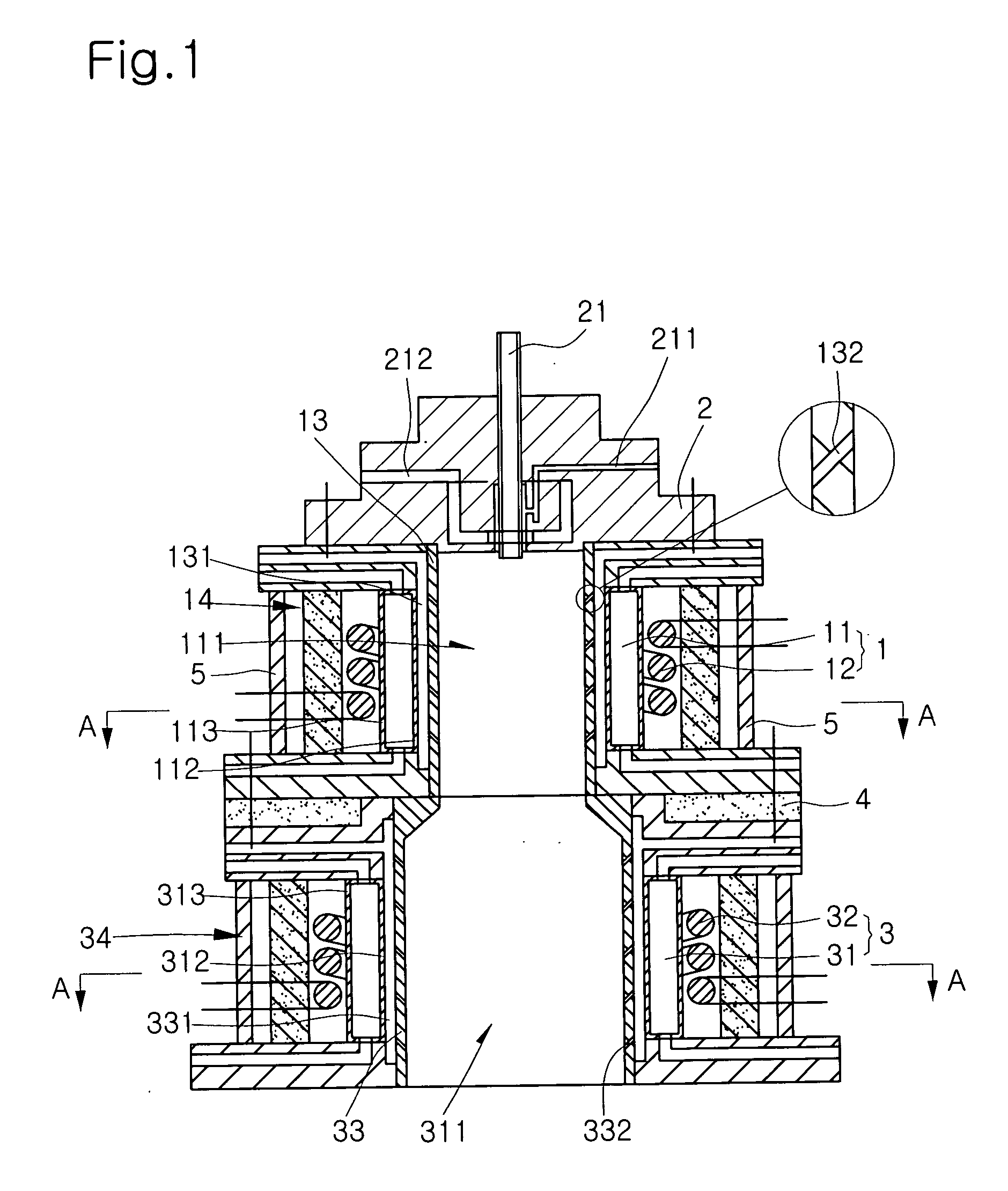

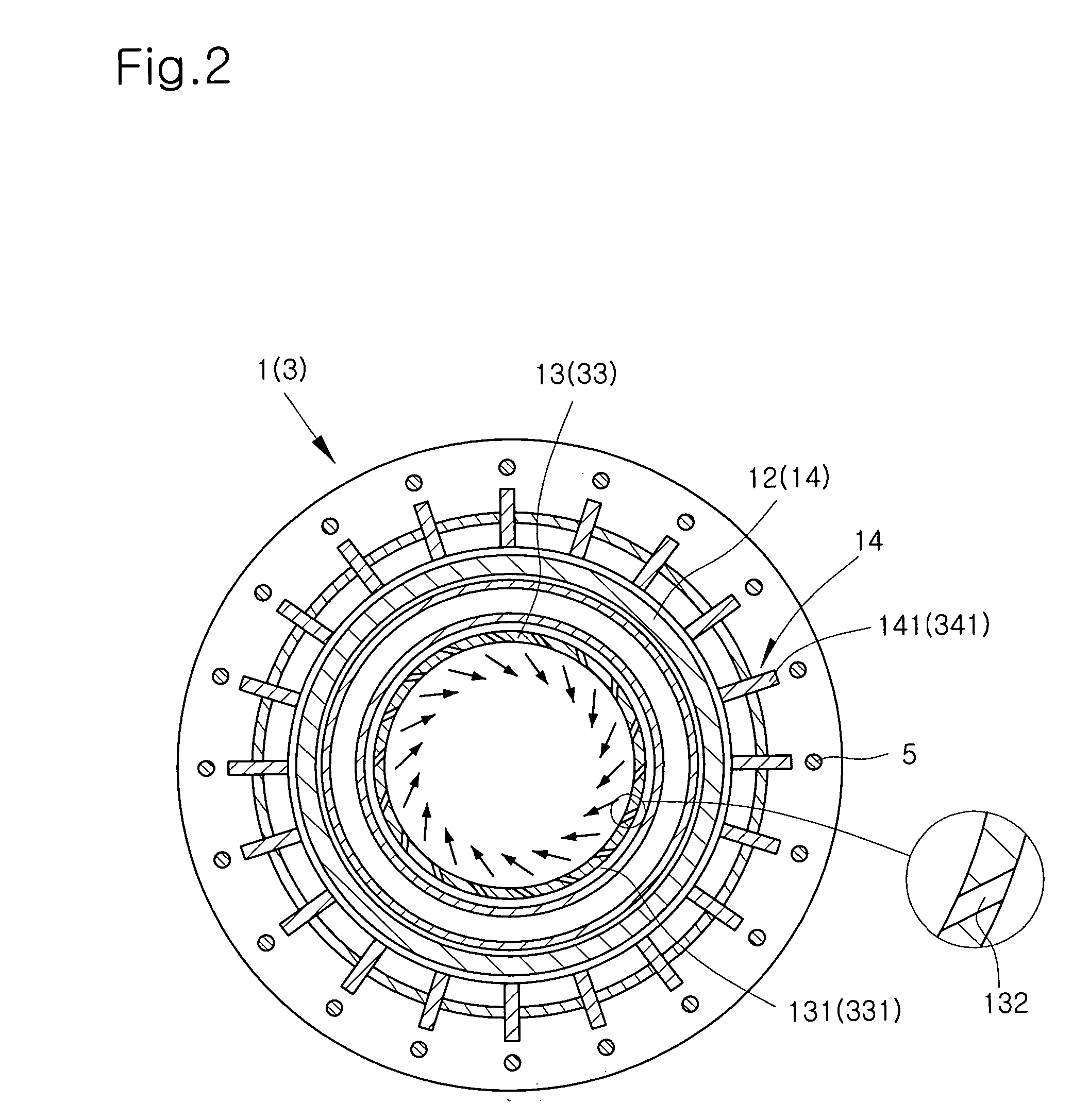

Inductively coupled plasma reactor for producing nano-powder

InactiveUS7323655B2Growth inhibitionGuaranteed to move normallyNanostructure manufactureElectric discharge tubesGas passingInduction plasma technology

Disclosed herein is a high-frequency induction plasma reactor apparatus for producing nano-powder, which is configured to continuously manufacture nano-powder in large quantities using solid-phase powder as a starting raw material and to manufacture high-purity nano-powder by completely vaporizing the material powder. The high-frequency induction plasma reactor apparatus comprises an upper body and a cover. The upper body is provided with a reaction pipe receiving a reactor extending vertically inside thereof, a high-frequency coil surrounding the outer periphery of the reaction pipe and a ceramic inner wall provided inside the reaction pipe. The ceramic inner wall is formed with a plurality of gas passing bores and defines a gas movement passage with the inner side wall of the reaction pipe therebetween for allowing the inflow of argon gas from the outside into the reactor. The cover is mounted to the upper end of the reactor and adapted to seal the reactor. The cover is provided with a powder injection tube communicating with the reactor.

Owner:NPC CO LTD

Inductively coupled plasma reactor for producing nano-powder

InactiveUS20050258766A1Inhibit growthAvoid adsorptionNanostructure manufactureElectric discharge tubesGas passingInduction plasma technology

Disclosed herein is a high-frequency induction plasma reactor apparatus for producing nano-powder, which is configured to continuously manufacture nano-powder in large quantities using solid-phase powder as a starting raw material and to manufacture high-purity nano-powder by completely vaporizing the material powder. The high-frequency induction plasma reactor apparatus comprises an upper body and a cover. The upper body is provided with a reaction pipe receiving a reactor extending vertically inside thereof, a high-frequency coil surrounding the outer periphery of the reaction pipe and a ceramic inner wall provided inside the reaction pipe. The ceramic inner wall is formed with a plurality of gas passing bores and defines a gas movement passage with the inner side wall of the reaction pipe therebetween for allowing the inflow of argon gas from the outside into the reactor. The cover is mounted to the upper end of the reactor and adapted to seal the reactor. The cover is provided with a powder injection tube communicating with the reactor.

Owner:NPC CO LTD

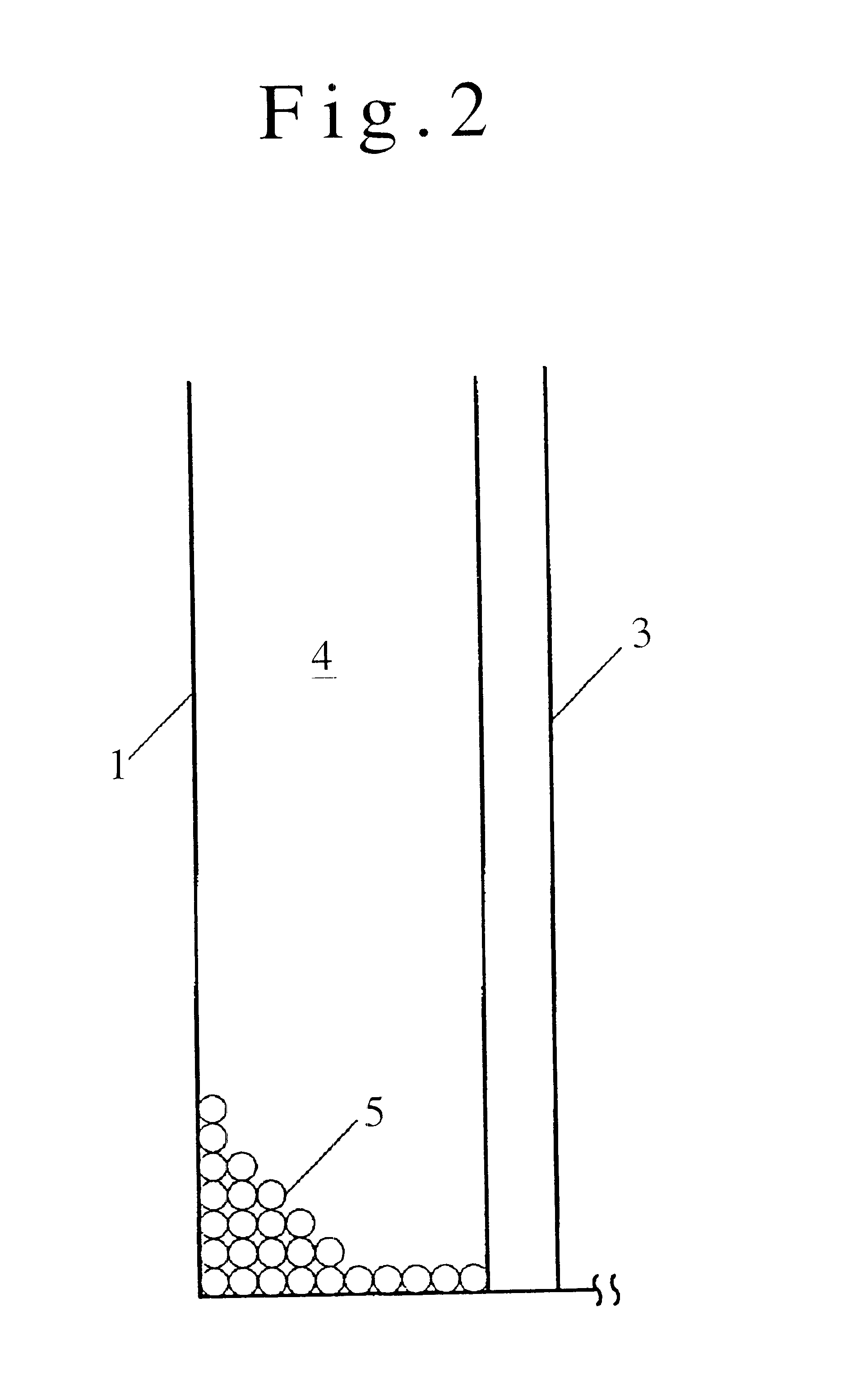

Method for packing catalyst and device therefor

InactiveUS6467513B1Maintaining the falling distance of the catalyst within a certain rangeSolid materialLiquid materialReaction tubeChemical engineering

In a reactor in which reaction tube(s), cooling tubes, heating tubes or combinations thereof are provided, a method for packing a catalyst comprising a step of packing the catalyst in the space formed between the inner wall of the reactor and the outer walls of the tubes by passing the catalyst through a flexible tube provided in the inside of the reactor and having a means to absorb the impact to the catalyst and thereby feeding the catalyst along the inner wall of the reactor with the falling distance of the catalyst maintained within a certain range and a step of fluidizing the catalyst thus-packed in said space, and a device for effecting the method.

Owner:TOYO ENG CORP

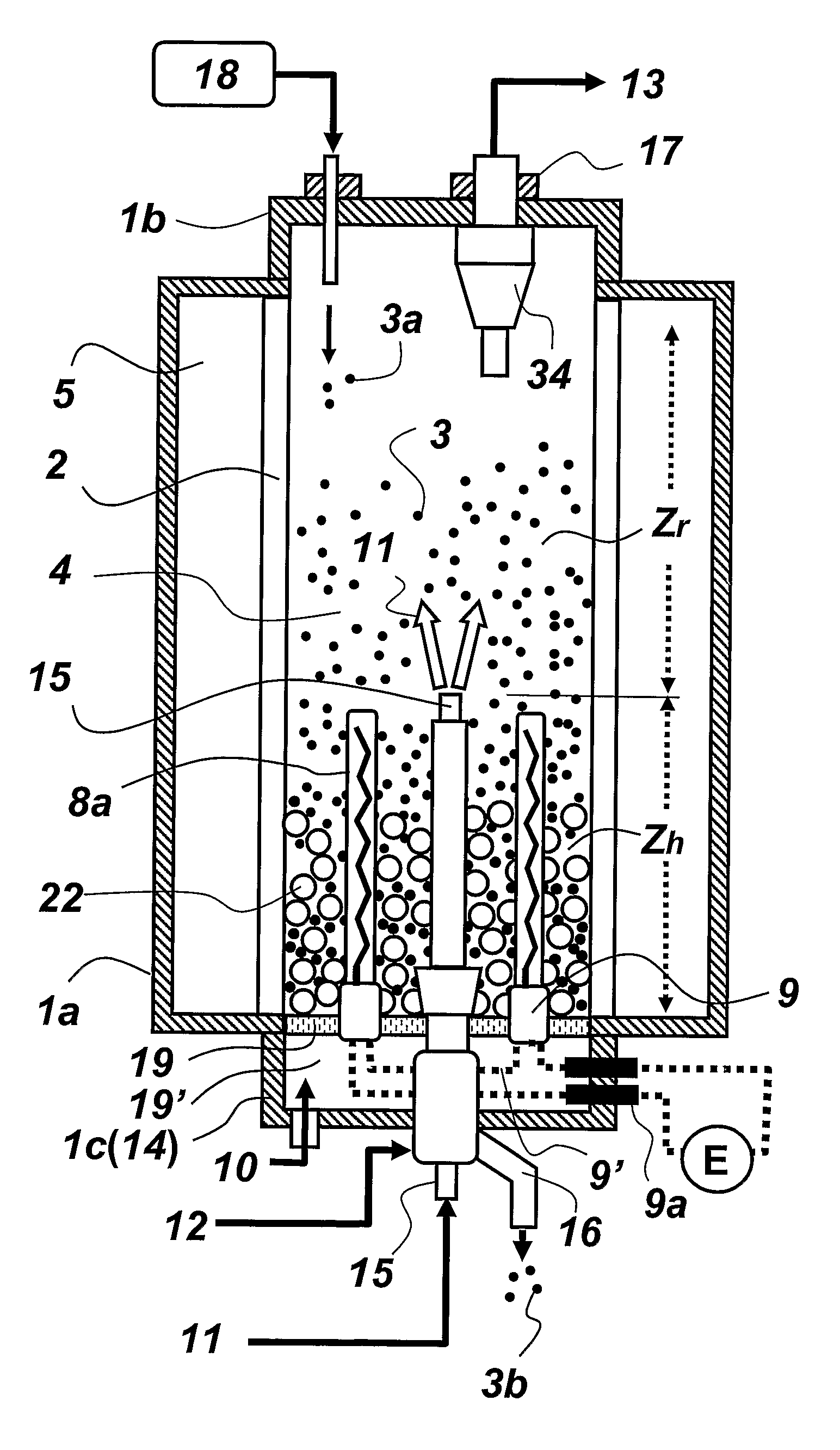

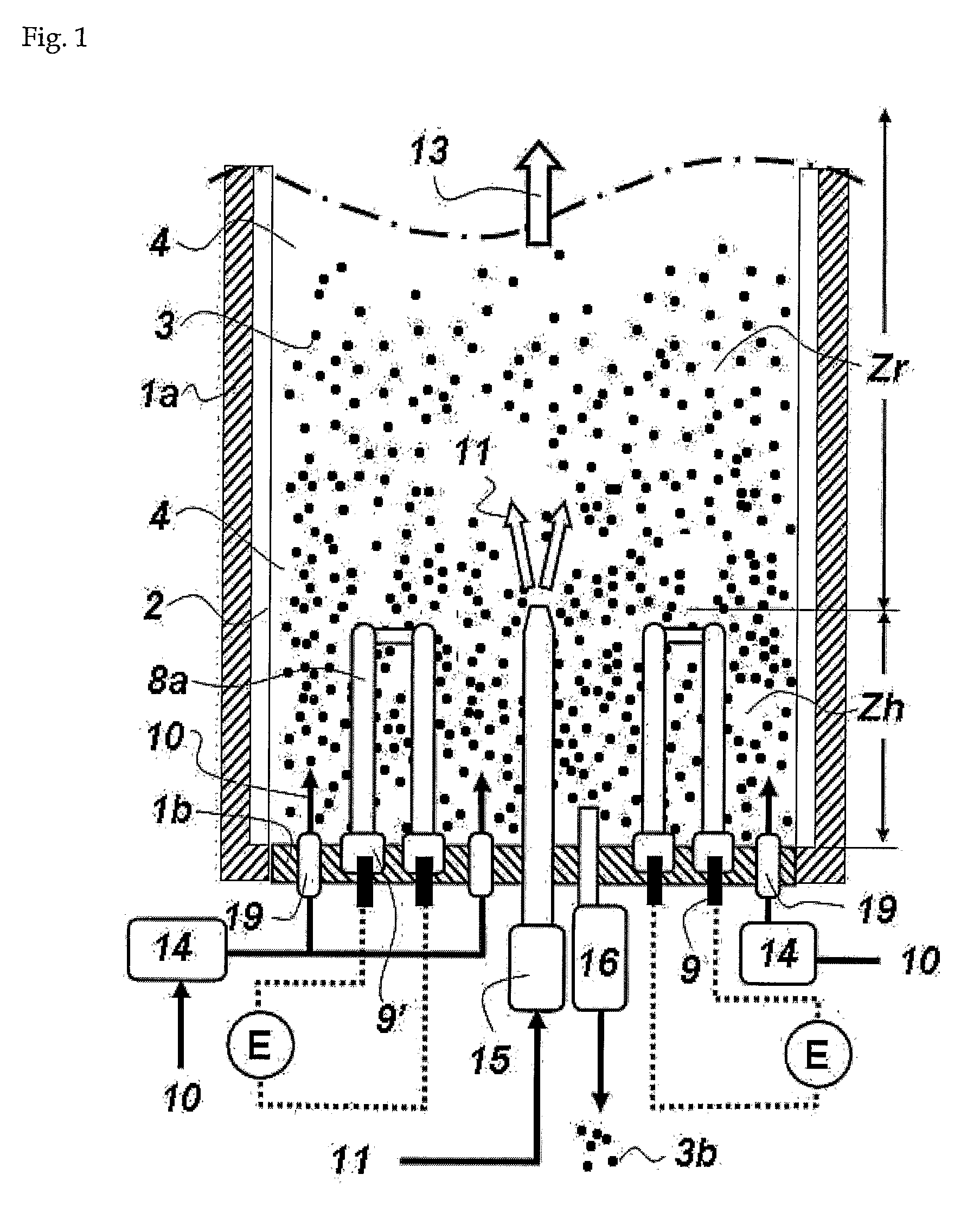

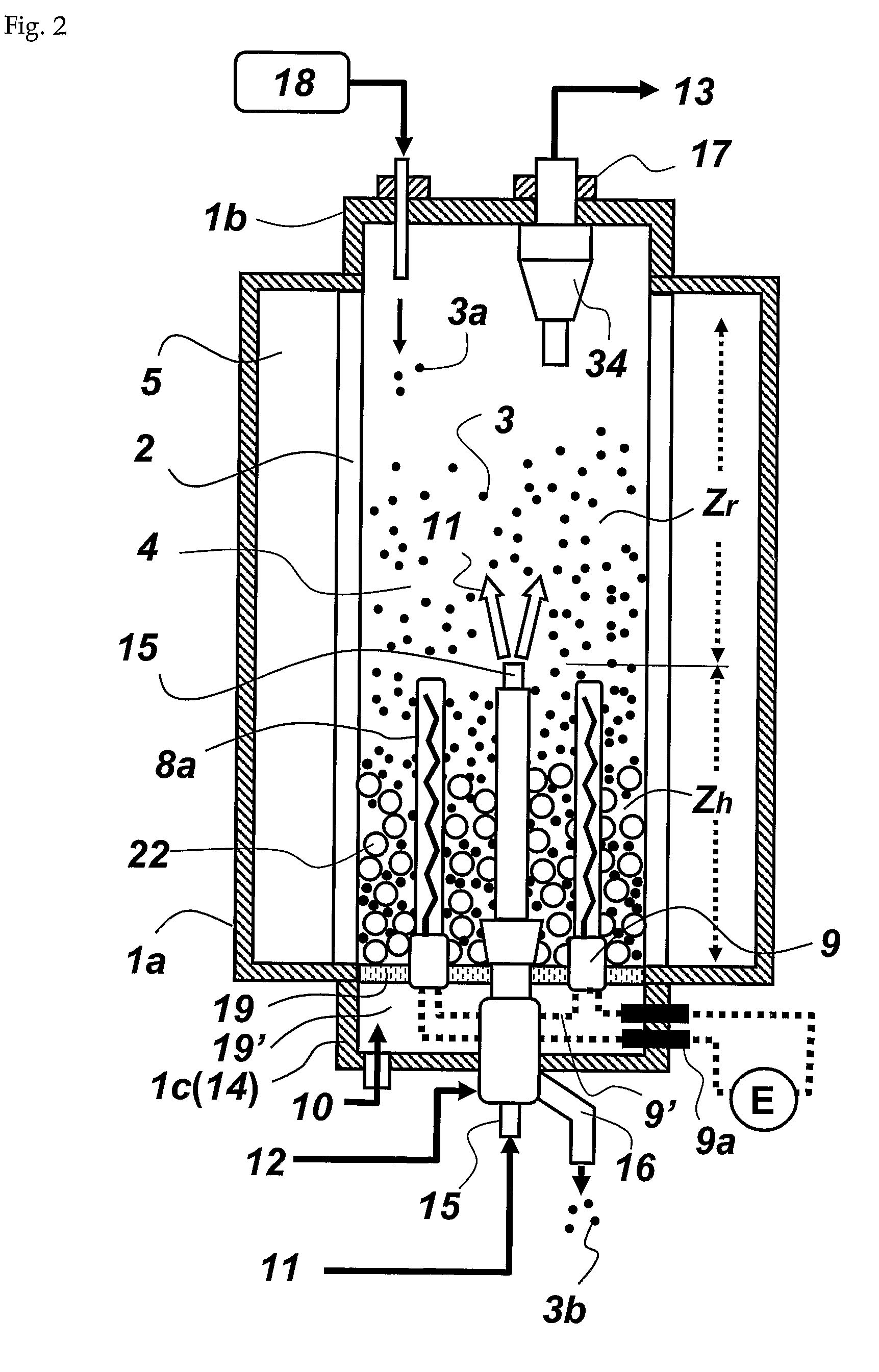

Method and Apparatus for Preparation of Granular Polysilicon

InactiveUS20090047204A1Reduce stepsPolycrystalline material growthSiliconProduction rateElectrical resistance and conductance

A process for preparing granular polysilicon using a fluidized bed reactor is disclosed. The upper and lower spaces of the bed are defined as a reaction zone and a heating zone, respectively, with the height of the reaction gas outlet being selected as the reference height. The invention maximizes the reactor productivity by sufficiently providing the heat required and stably maintaining the reaction temperature in the reaction zone, without impairing the mechanical stability of the fluidized bed reactor. This is achieved through electrical resistance heating in the heating zone where an internal heater is installed in a space in between the reaction gas supplying means and the inner wall of the reactor tube, thereby heating the fluidizing gas and the silicon particles in the heating zone. The heat generated in the heating zone is transferred to the reaction zone by supplying the fluidizing gas at such a rate that the silicon particles can be intermixed between the reaction zone and the heating zone in a continuous, fluidized state.

Owner:KOREA RES INST OF CHEM TECH

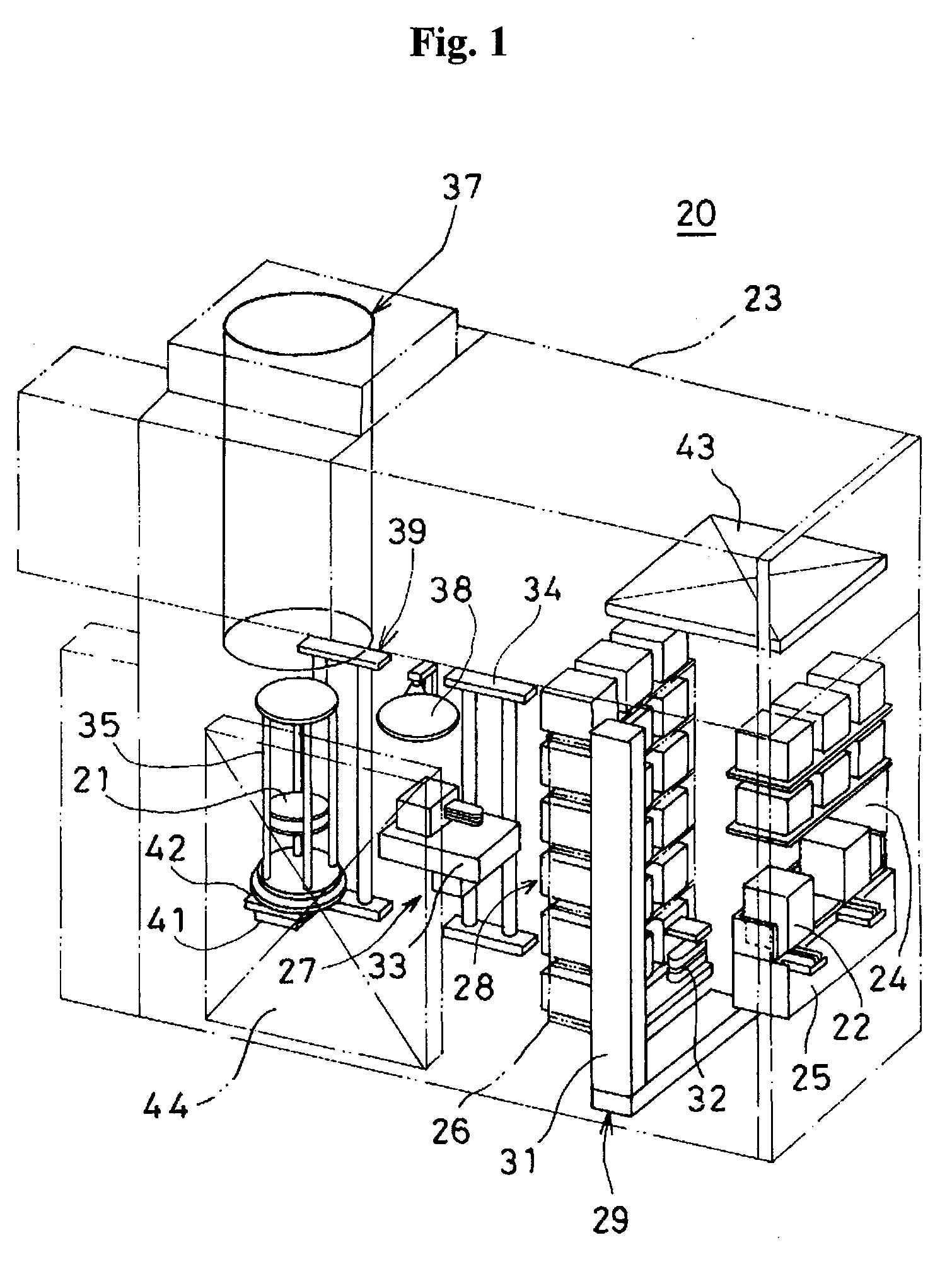

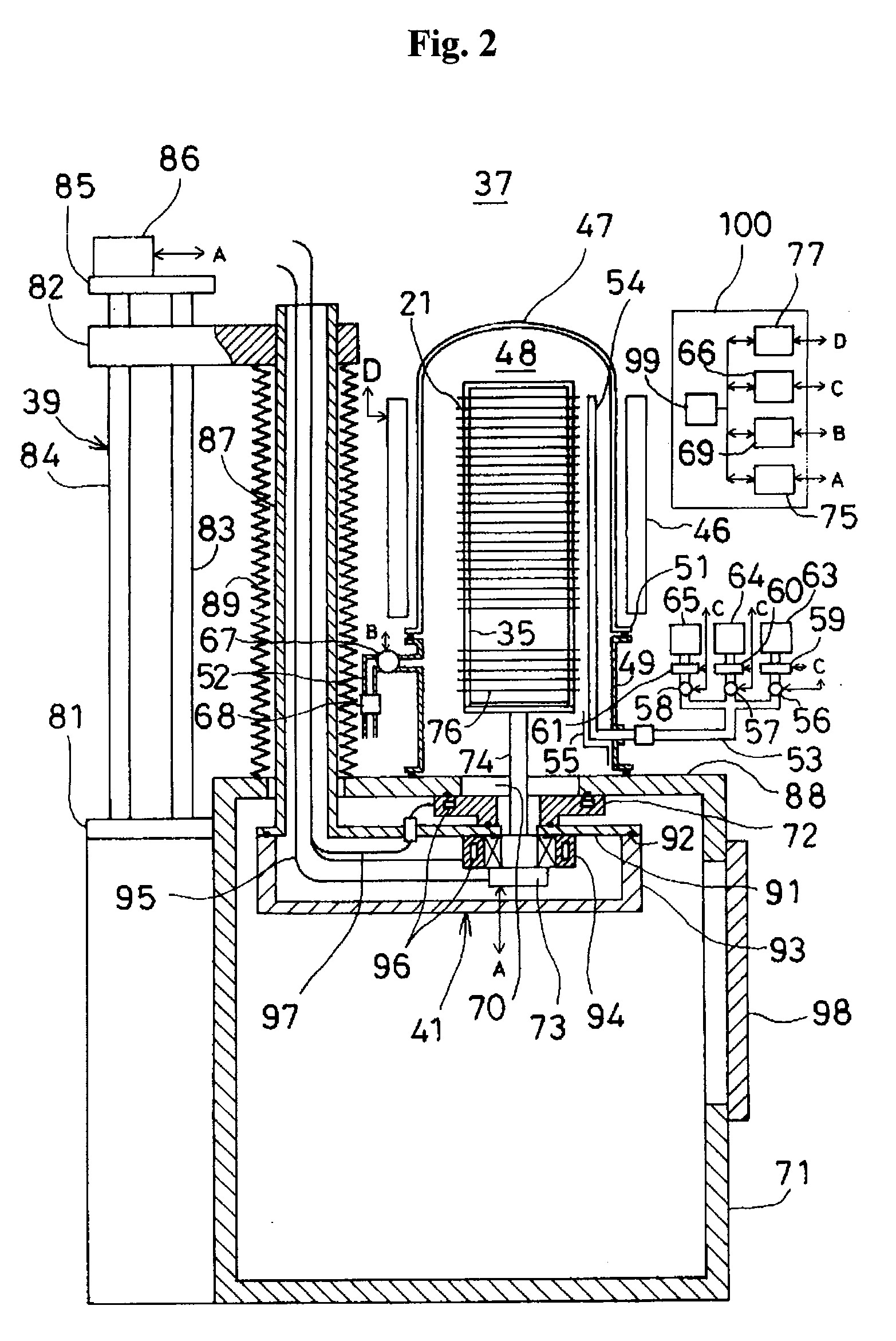

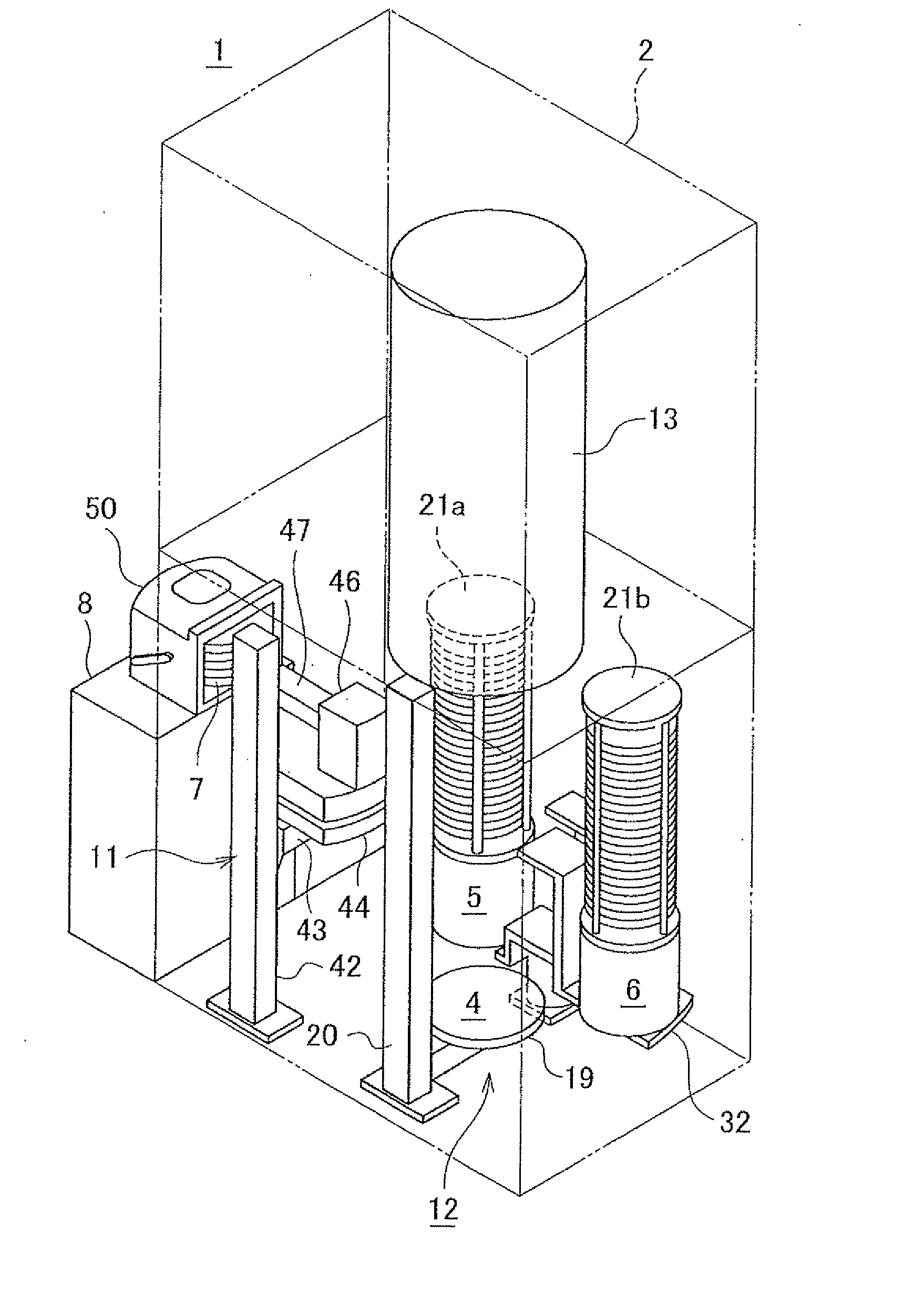

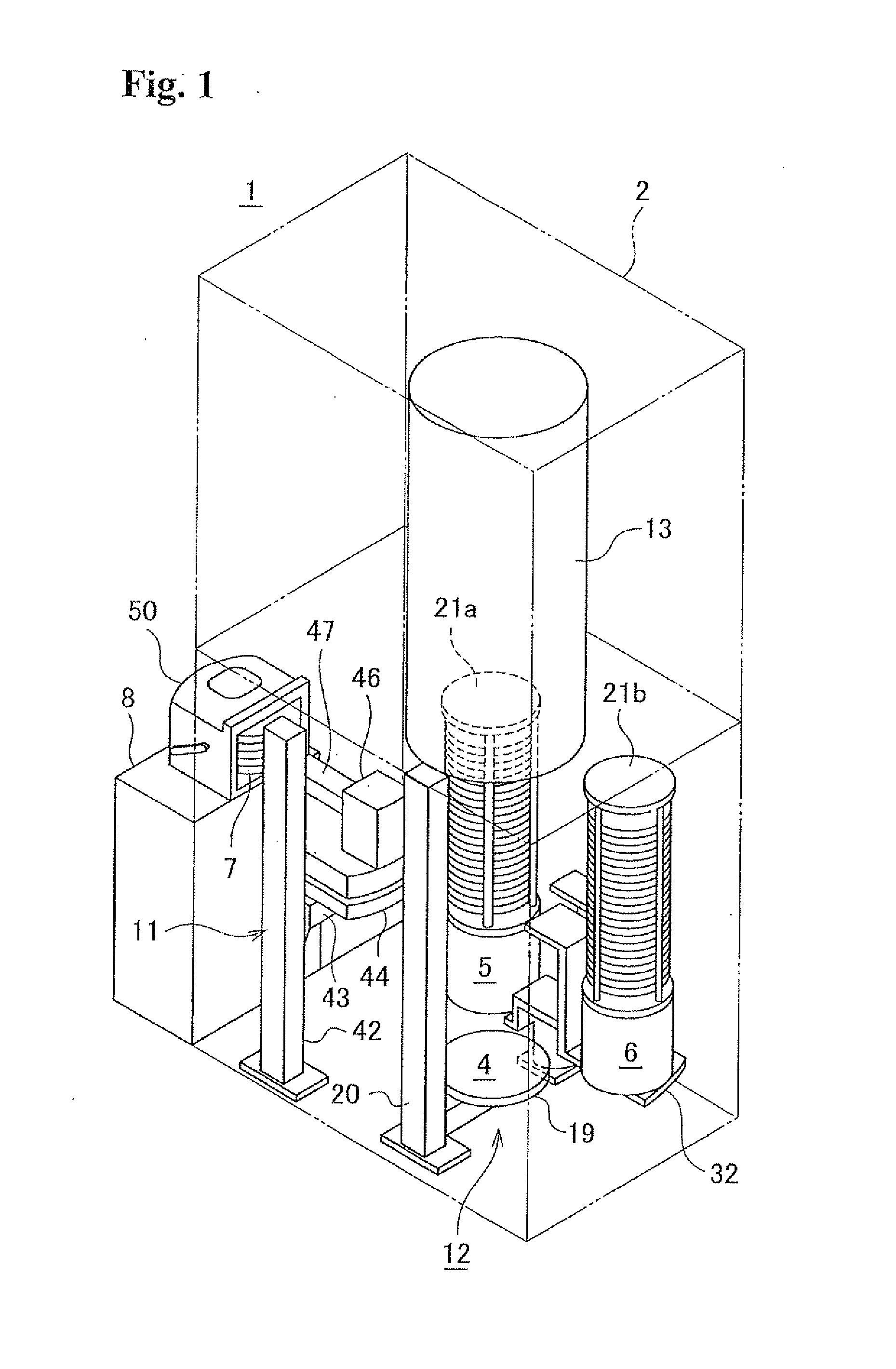

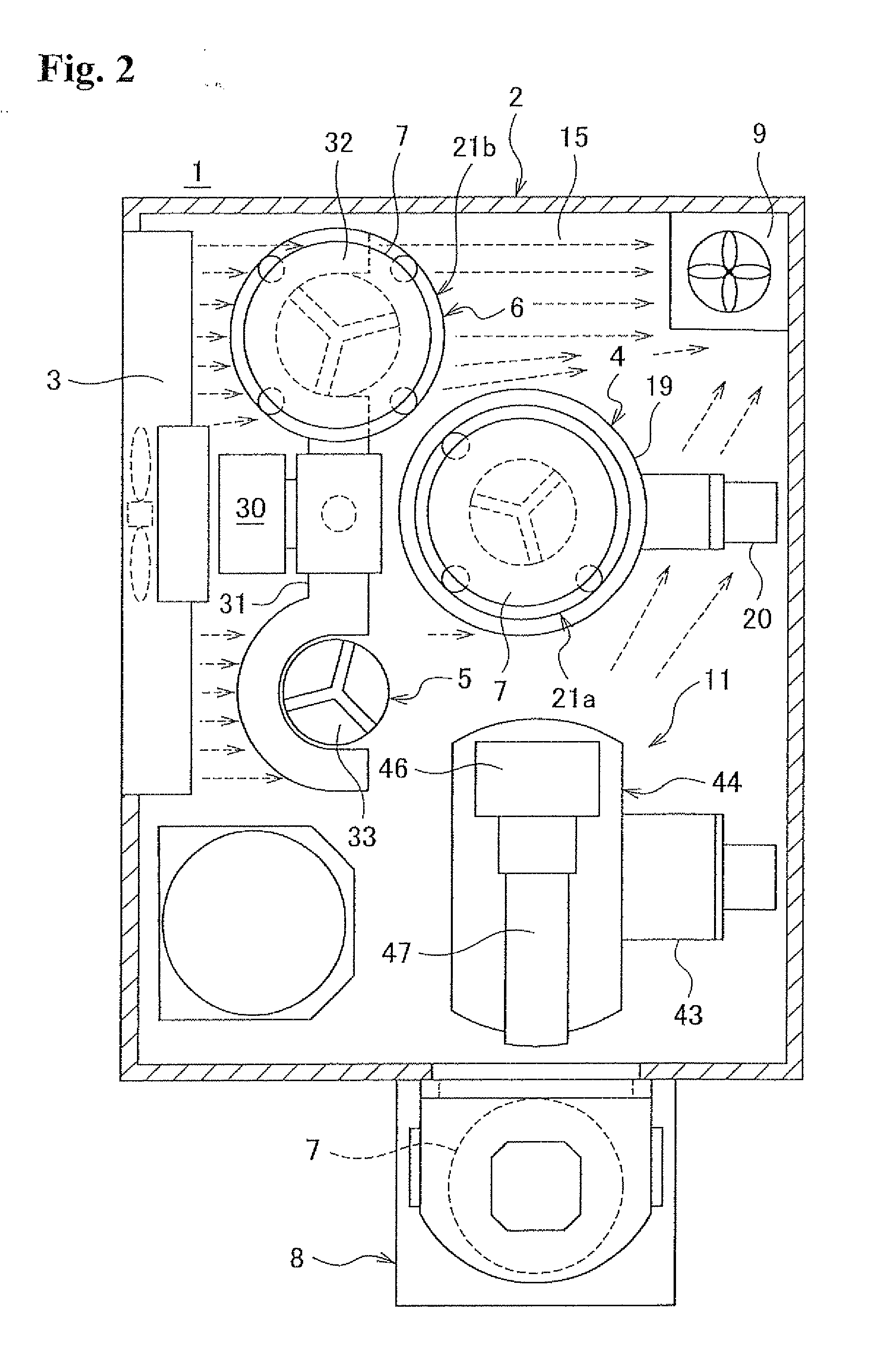

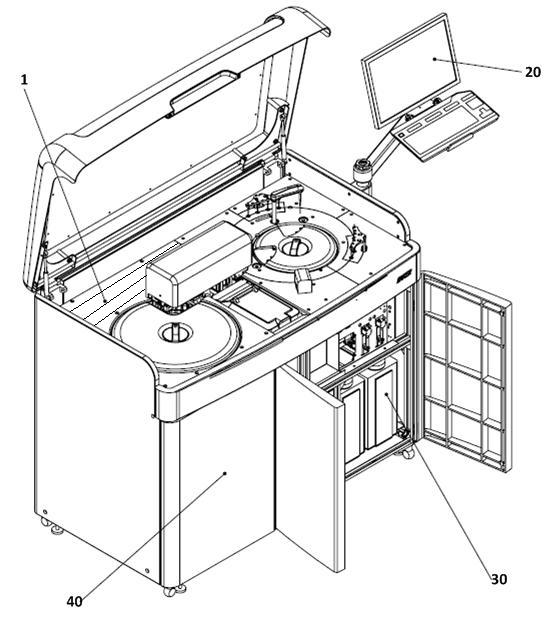

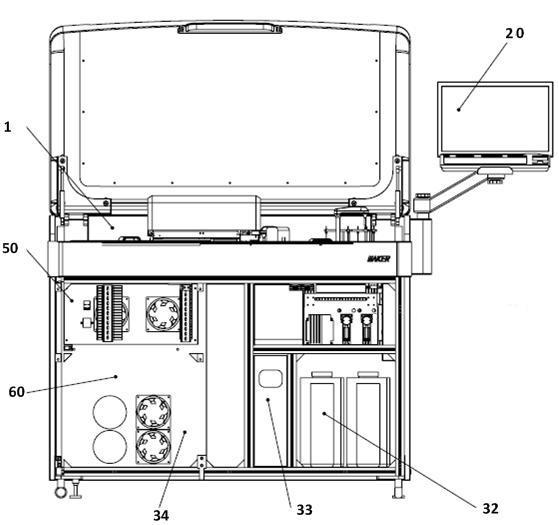

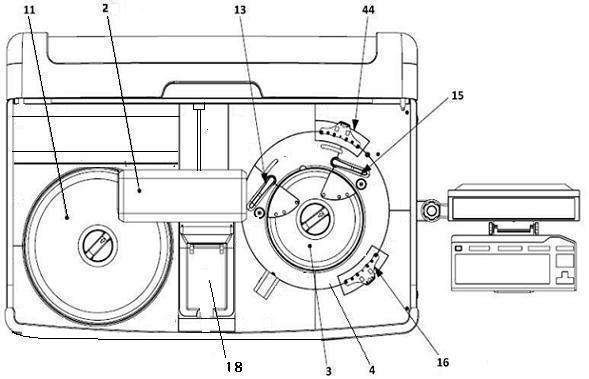

Full-automatic chemoluminescence immunoassay analyzer

ActiveCN102419375AReduce the impactHigh sensitivityChemiluminescene/bioluminescenceBiological testingSystem integrationEngineering

The invention discloses a full-automatic chemoluminescence immunoassay analyzer. The analyzer is mainly composed of a working main body and a control computer connected with the working main body; a storage cabin and a control box are arranged under the working main body. The analyzer can be used for implementing the full-automatic operation of the immunoreaction process comprising reaction tube loading, sample automatic injection, reagent automatic injection, reaction solution incubation reaction, reaction solution automatic cleaning, reaction result detection and analysis; the full-automatic operation reduces the influence of human factors on the experiment, thereby improving the sensitivity. Each component of the invention is ingenious in design, the mutual cooperation of components isconvenient for the system integration so as to realize the automation; and based on the full-automatic chemoluminescence immunoassay analyzer, more devices with automatic function can be developed.

Owner:SICHUAN MACCURA BIOTECH CO LTD

Immobilizing and processing specimens on matrix materials for the identification of nucleic acid sequences

InactiveUS6103192AMicrobiological testing/measurementMaterial analysis by optical meansBiological unitOrganism

The invention is a method and device for collecting and processing a biological specimen for the analyses of nucleic acids. A device comprises a matrix to which cells and viruses adhere and a handle to manipulate the matrix. The devices are used to collect, dry, transport, store and process small amounts of blood or other tissue. The matrix of the device is transferred to a reaction tube and amplifying reagents added to it. Nucleic acid sequences and relative quantities are detected and analyzed from the same specimen. The relative amounts of amplified nucleic acid from one or more particular RNA sequences are compared to one another and to the amount of amplified nucleic acid from DNA sequences serving as an internal control for the number of biological units per specimen. The relative amounts of amplified viral sequences from suspected viruses in the biological specimen and from recombinant viral particles serving as a viral quantitation standard enable estimation of viral burden in a given quantity of specimen.

Owner:GENETEC

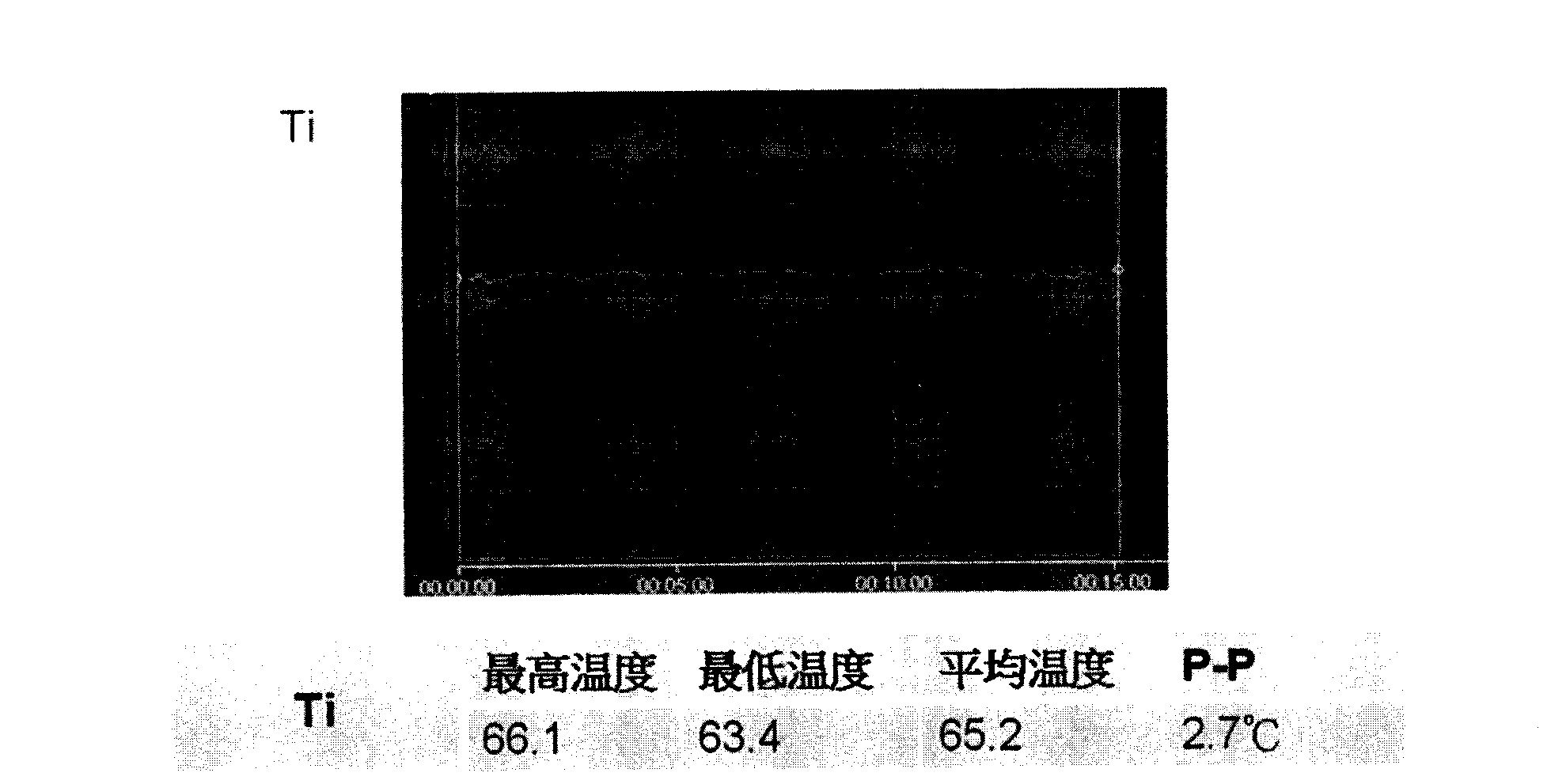

Detection method and device of coke reactivity and post-reaction heat-treatability

ActiveCN101825548AAppear thermal characterizationWeighing by removing componentThermometers using electric/magnetic elementsHearthEngineering

The invention discloses a detection method and device of the reactivity and post-reaction heat-treatability of coke and the method and device are used to detect the gasifying starting temperature, reactivity and post-reaction heat-treatability of coke. The detection method adopts an electric furnace as a heating furnace and uses an electronic balance for to weight. The reactivity detection method is performed on the condition of first heating and second keeping temperature constant, the electronic balance is used to measure the mass loss of a coke sample; and when the coke weight-loss ratio equals a specified value, the measurement weight-loss ratio (time) minus one is used as the reactivity index; the detection method of the post-reaction heat-treatability of coke is that when the coke weight-loss ratio equals the specified value, coke is continuously heated under the protection of inert gas, and the coke weight-loss ratio is used as the post-reaction heat-treatability index during the detection period of heat treatment. The detection device comprises the electronic balance, a reaction tube support, a reaction tube, the heating furnace and a heating furnace elevating mechanism. The method and device of the invention can provide 1500-1600 DEG C of detection temperature and the coke thermal characterization in the bosh (before an air port) and the hearth can be displayed.

Owner:山西今日太工煤焦技术研究有限公司

Substrate processing apparatus, method of manufacturing semiconductor device and furnace lid

InactiveUS20160076149A1Heat is not easyReduce the temperatureFurnace componentsSemiconductor/solid-state device manufacturingPower semiconductor deviceProcess engineering

By suppressing a re-liquefaction of a processing gas in a reaction tube, the processing gas is maintained in a gaseous state. There is provided a substrate processing apparatus that includes a reaction tube, a supply unit, an exhaust unit, a first heating unit configured to heat a substrate in the reaction tube, a second heating unit configured to heat a downstream portion of a reactant in gaseous state flowing in the reaction tube from the supply unit toward the exhaust unit, and a furnace lid, wherein the furnace lid includes a heat absorbing unit facing a lower surface of a lower end portion of the reaction tube and being heated by the second heating unit, the heat absorbing unit having an outer perimeter surface disposed outer than an inner circumference surface of the lower end portion.

Owner:KOKUSA ELECTRIC CO LTD

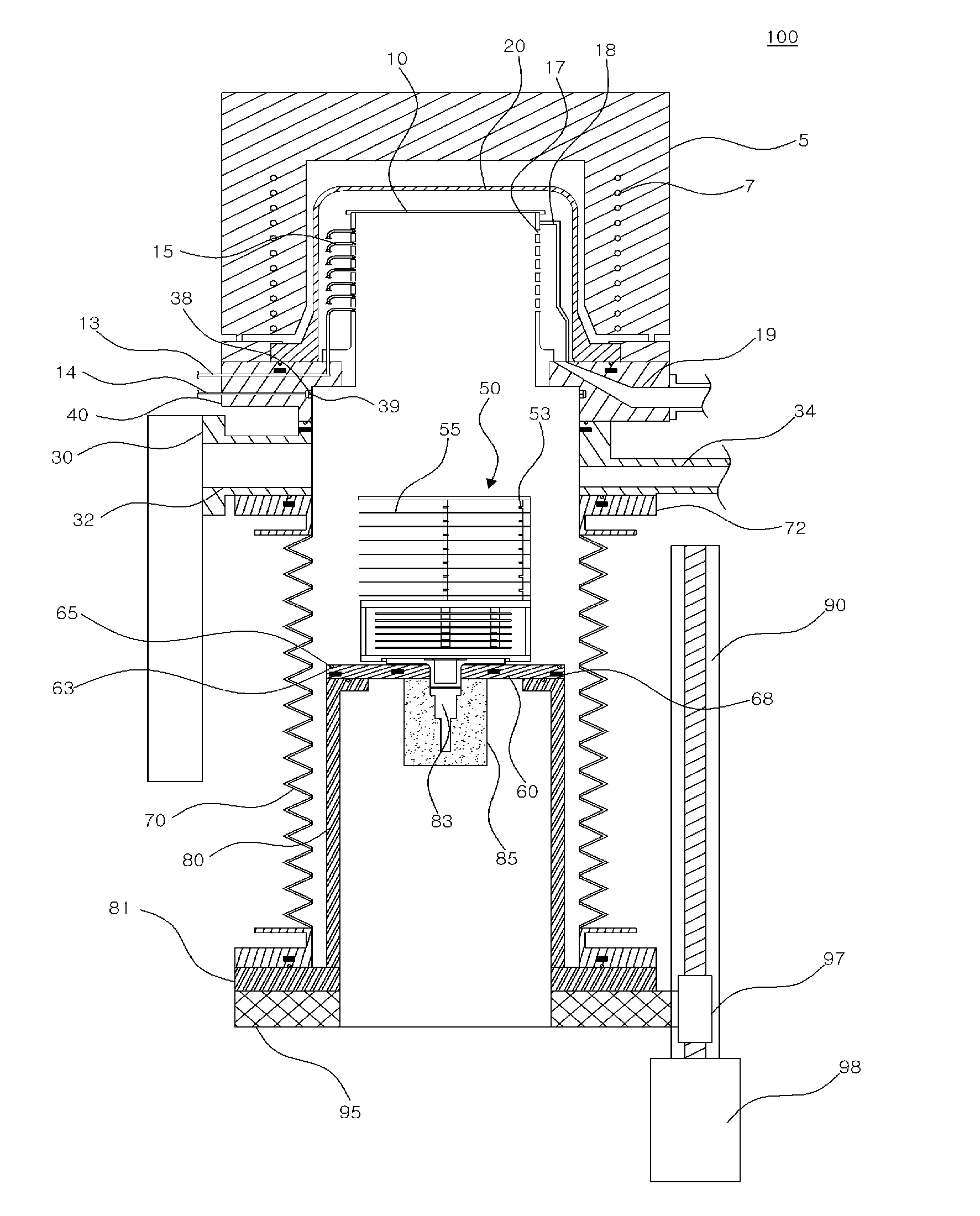

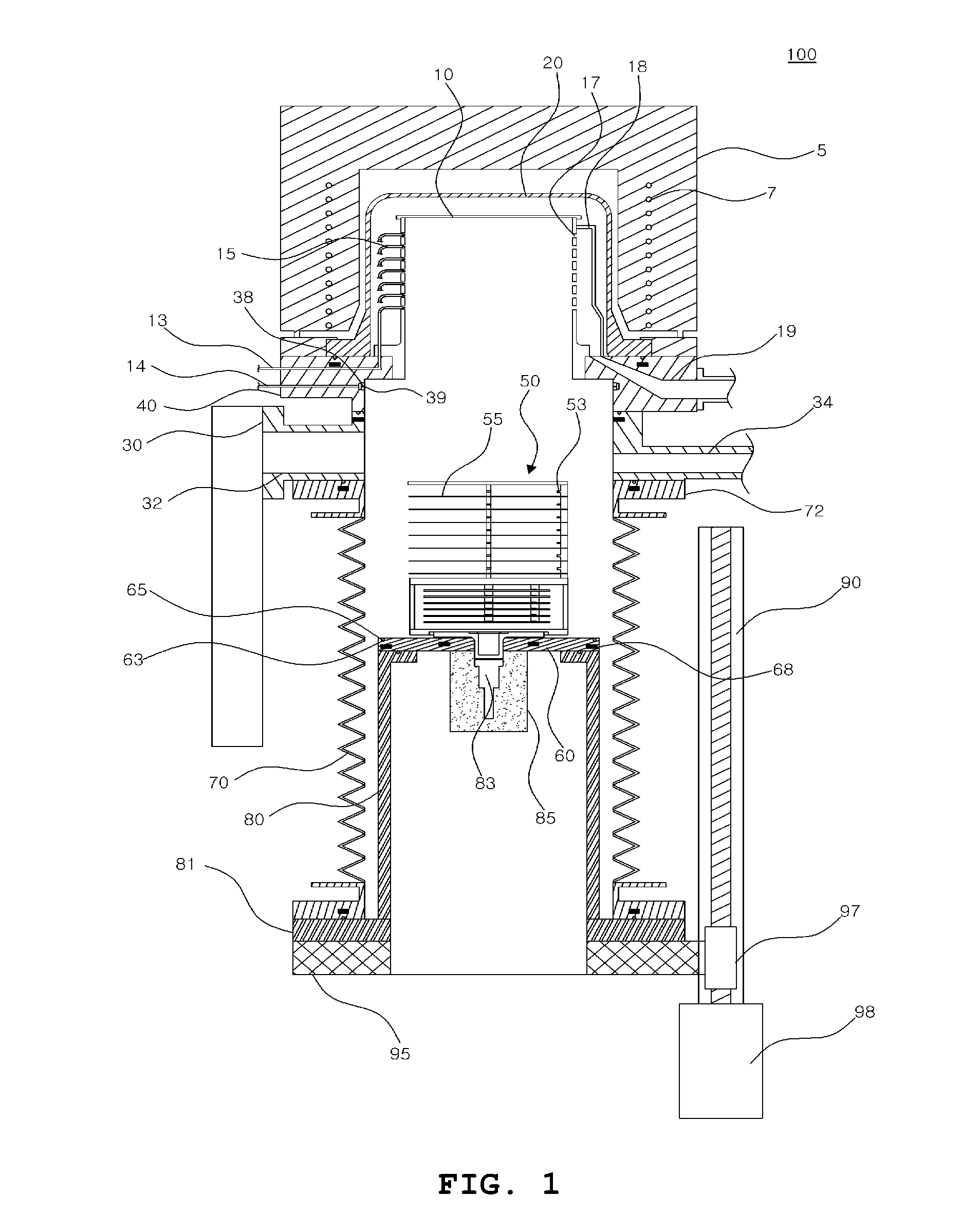

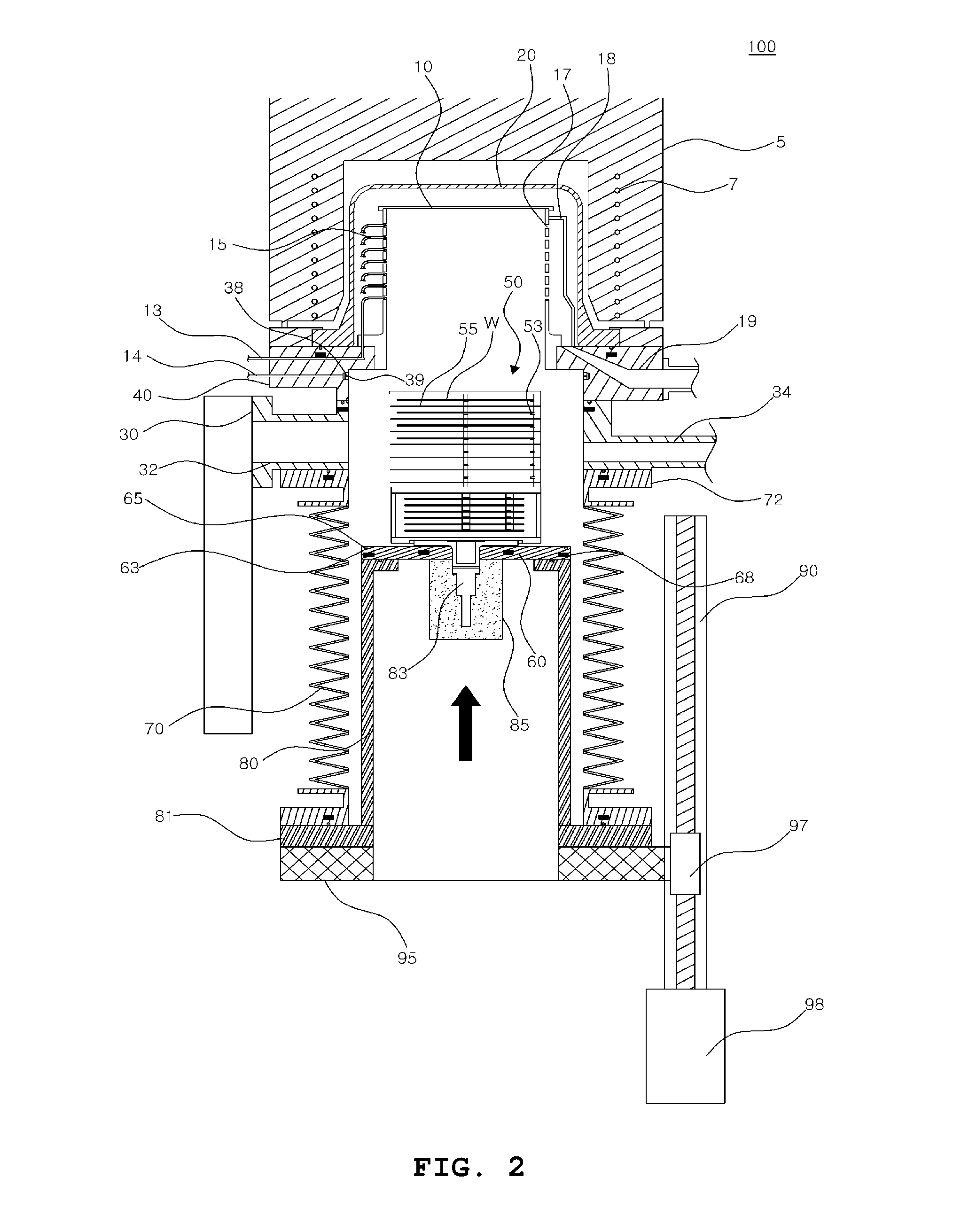

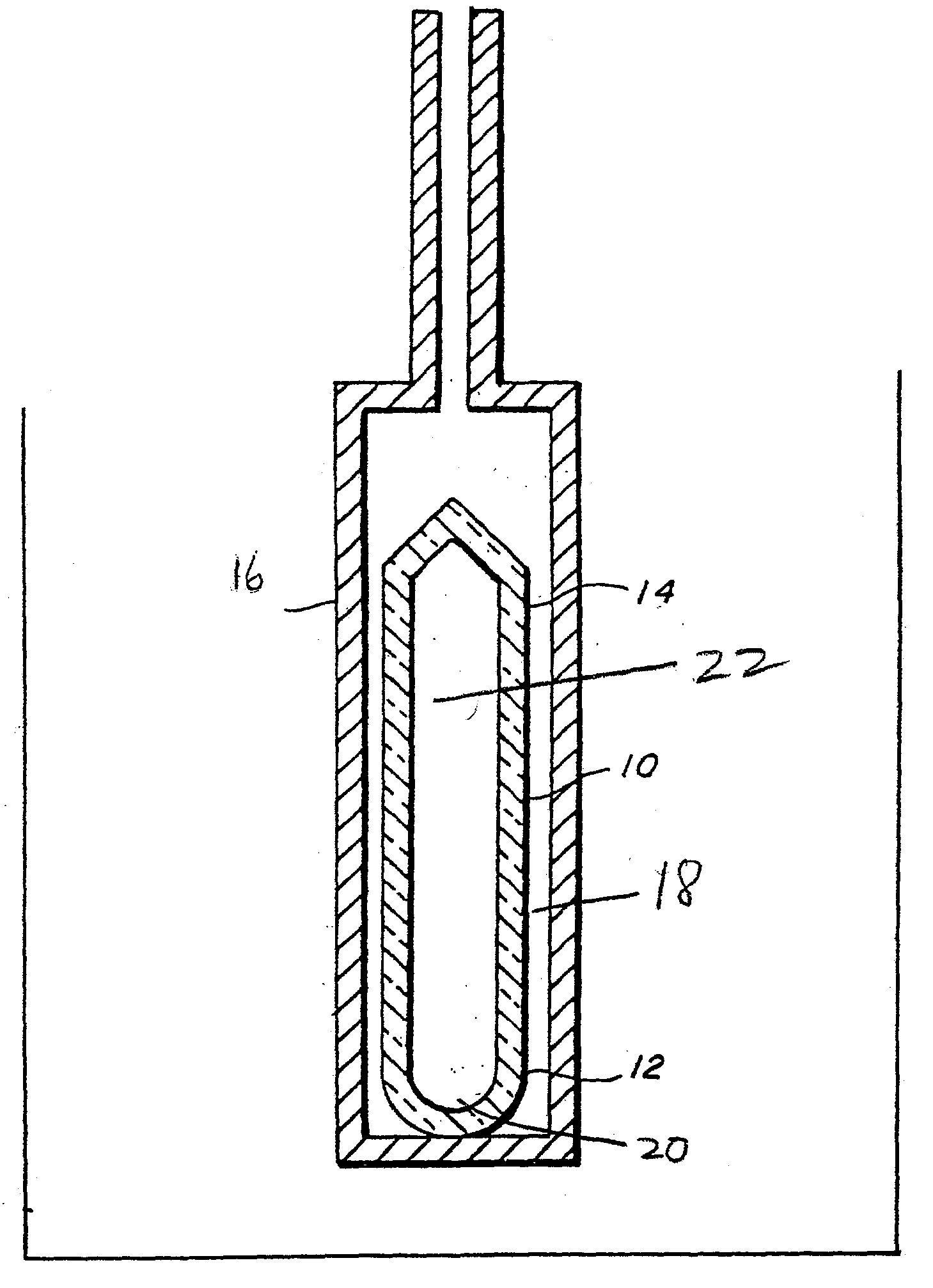

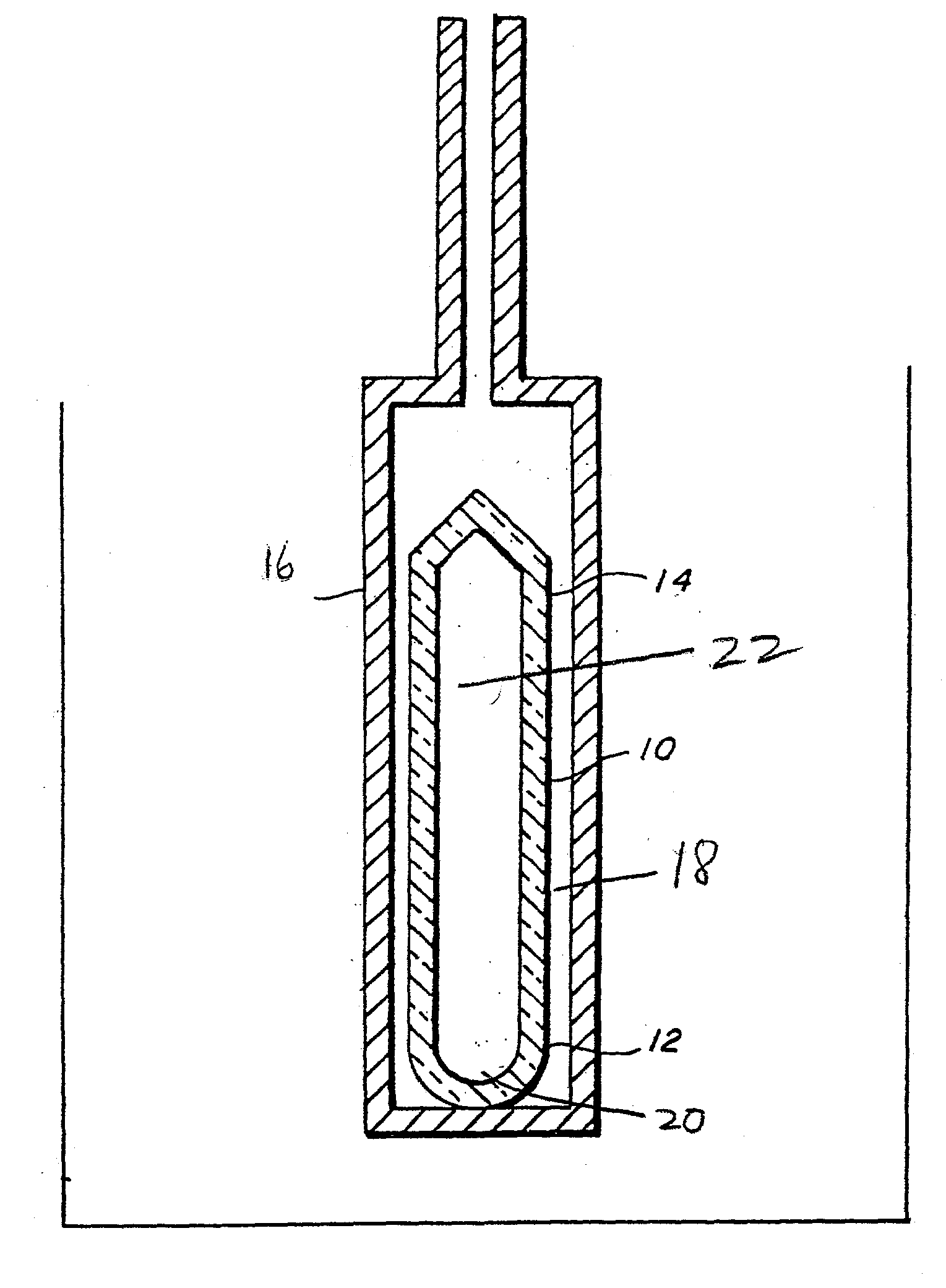

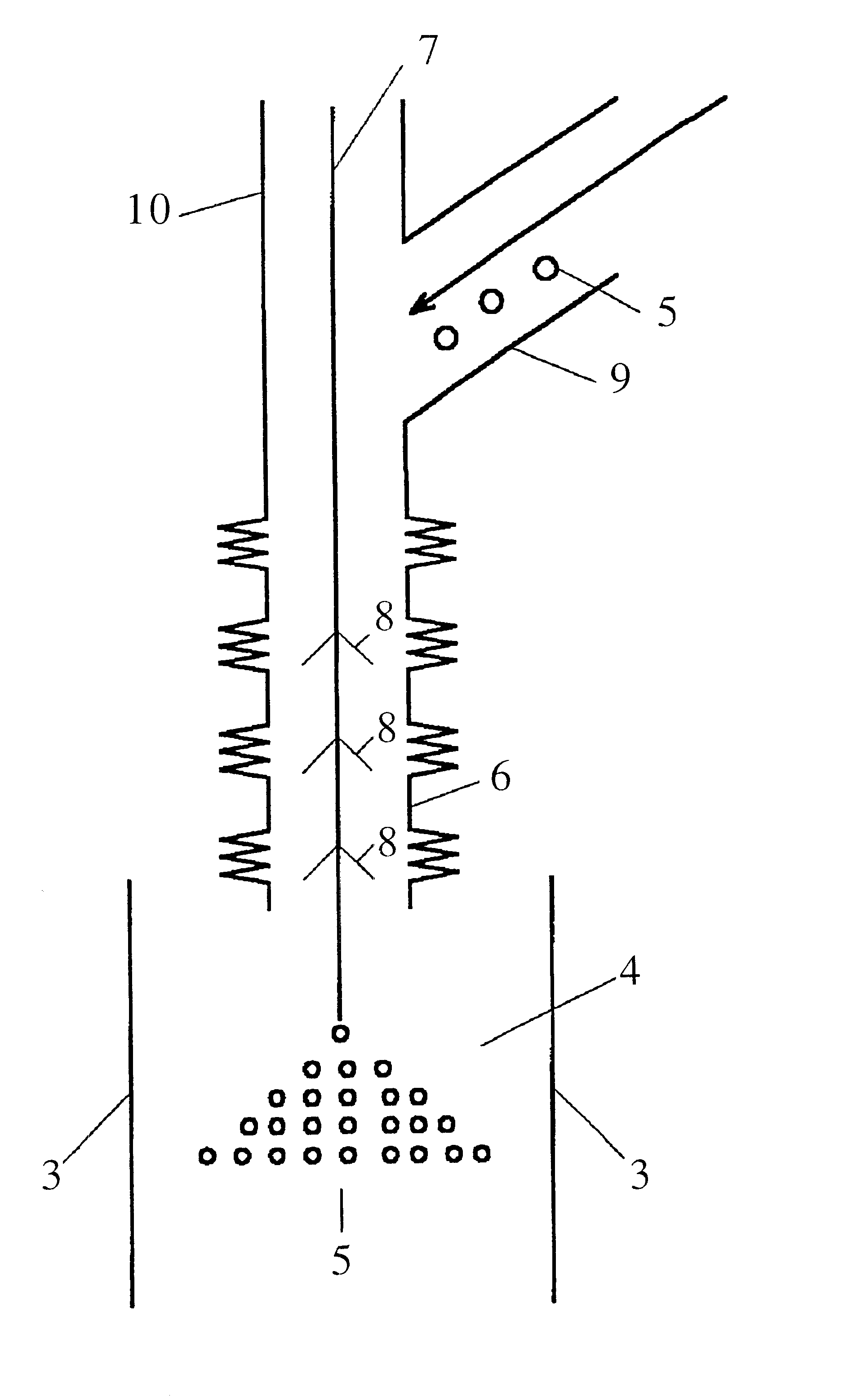

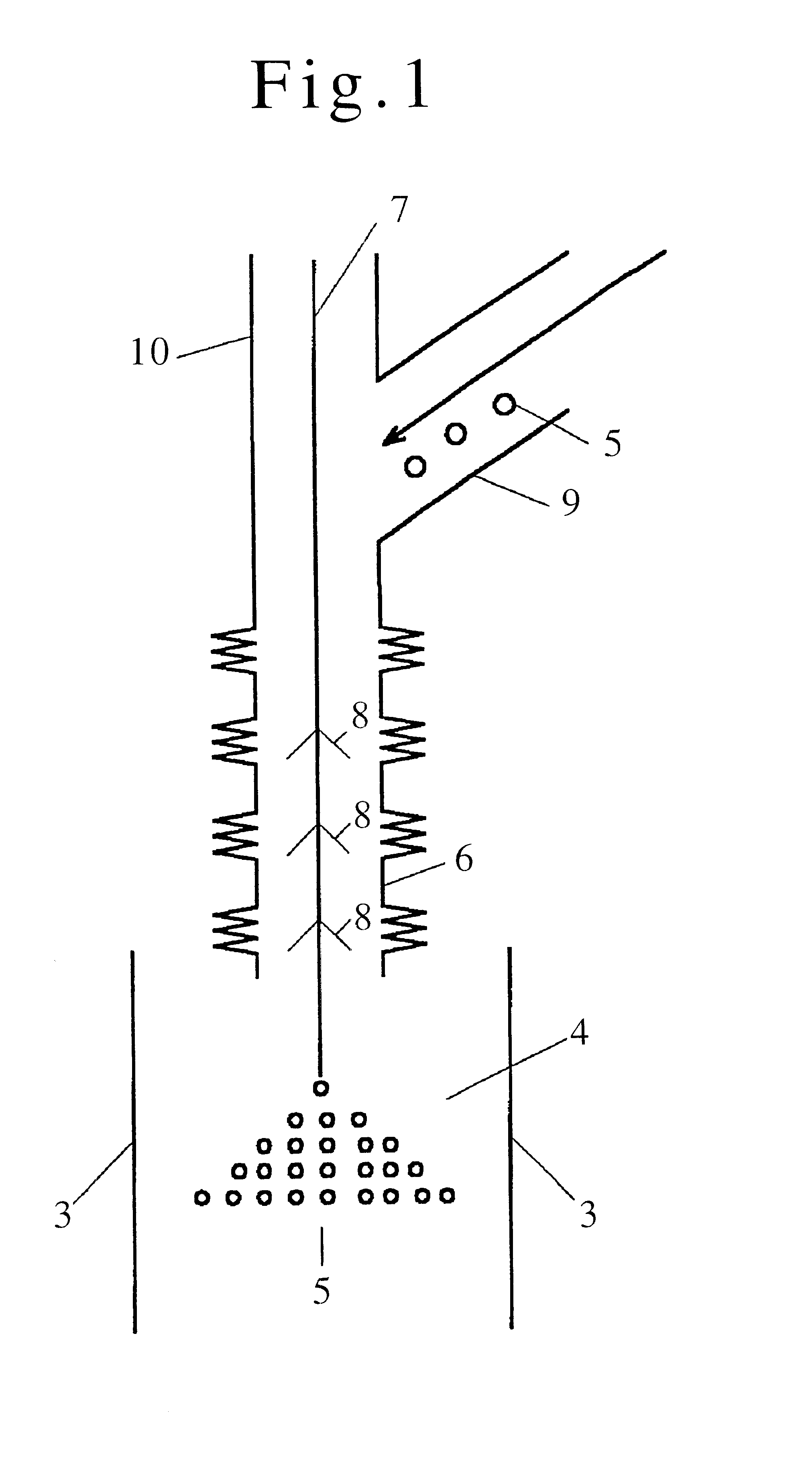

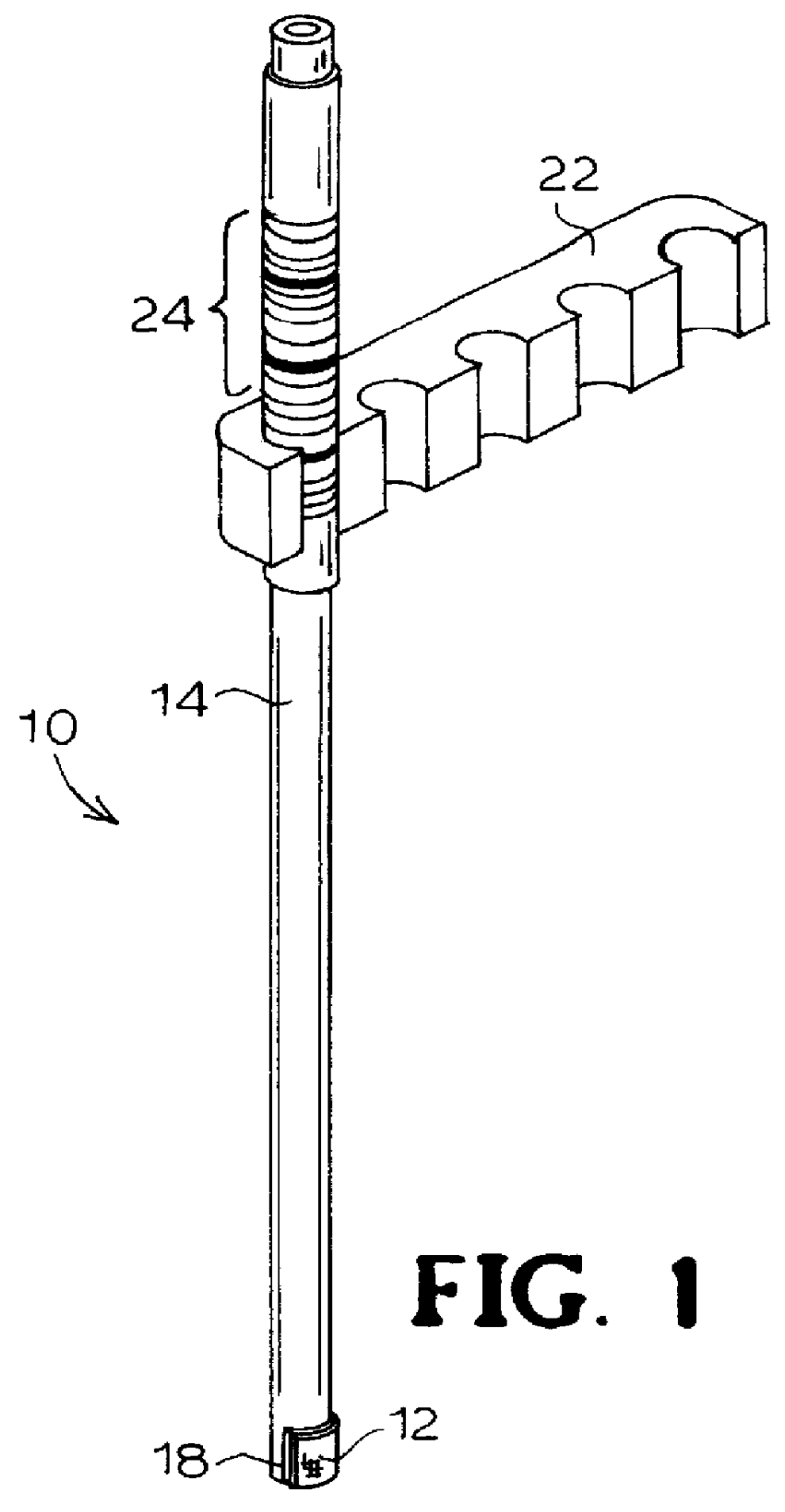

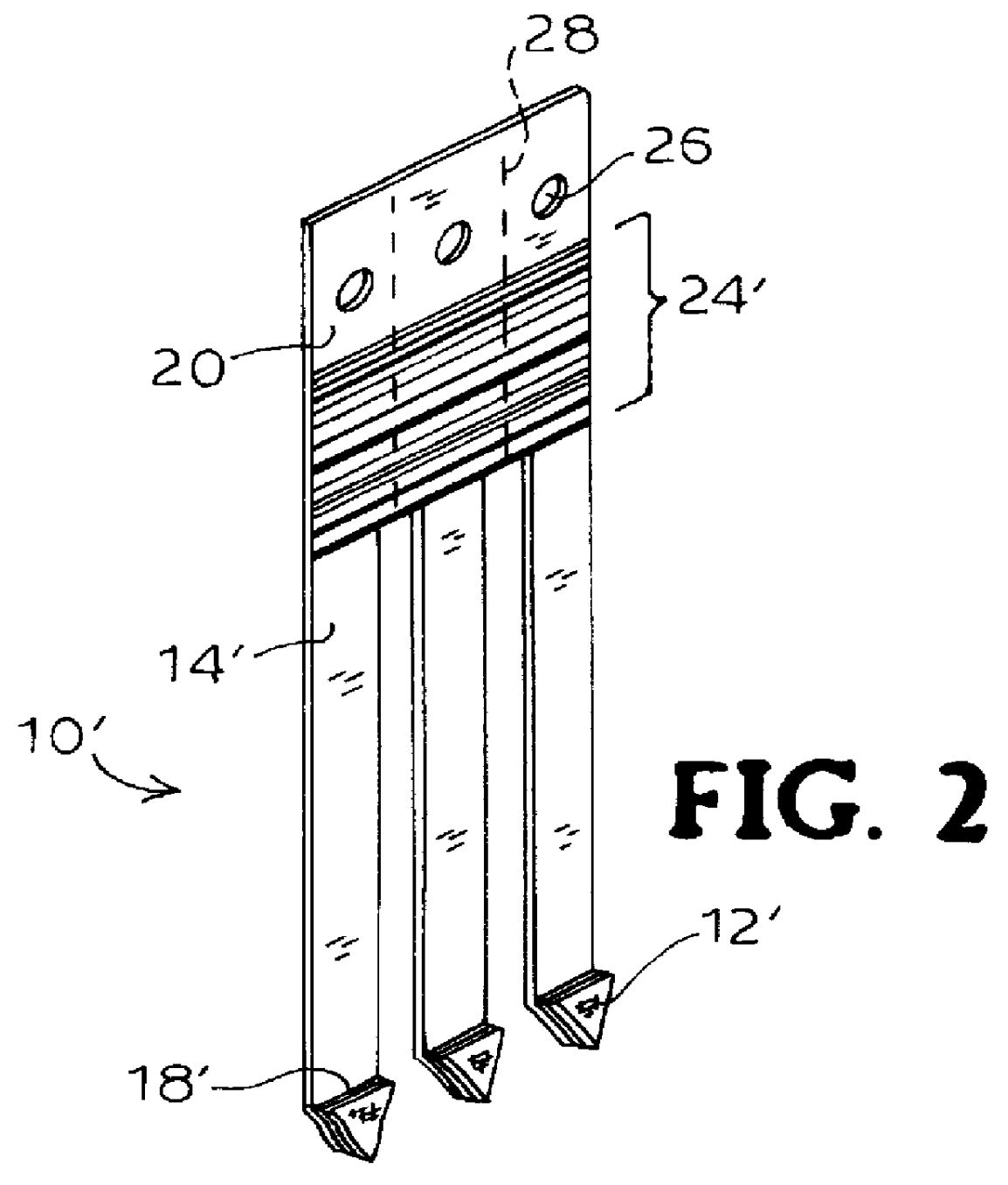

Formation of [2,2]paracyclophane and related compounds and methods for the formation of polymers from cyclophanes

ActiveUS8633289B2Increase in costLimited utilityOrganic compound preparationHydrocarbons from unsaturated hydrocarbon additionReaction intermediateReactive intermediate

An improved process and method for the formation of stable intermediate cyclophanes. Embodiments describe a general method for the production of substituted and unsubstituted cyclophanes. The components include a pyrolysis reaction tube that may be electrically heated into which a flowing stream of nitrous oxide with xylene vapor in an optional inert carrier gas at atmospheric pressure. The exit gas is condensed resulting in the deposition of [2,2′]paracyclophane. Additionally a process and method whereby the reactive intermediates of the reaction described above can be directly deposited and polymerized at atmospheric pressures or thereabout is disclosed.

Owner:CARVER SCI INC

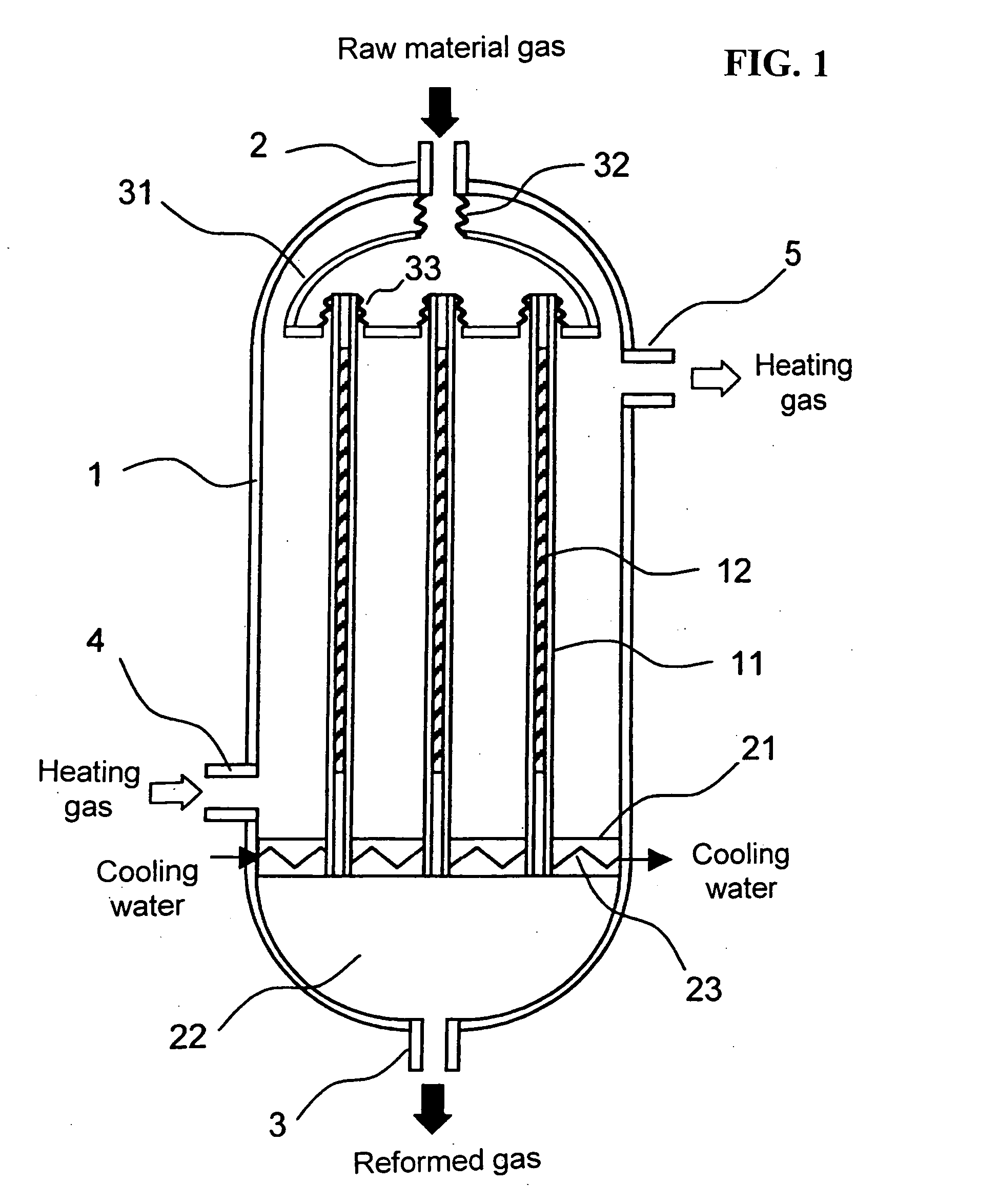

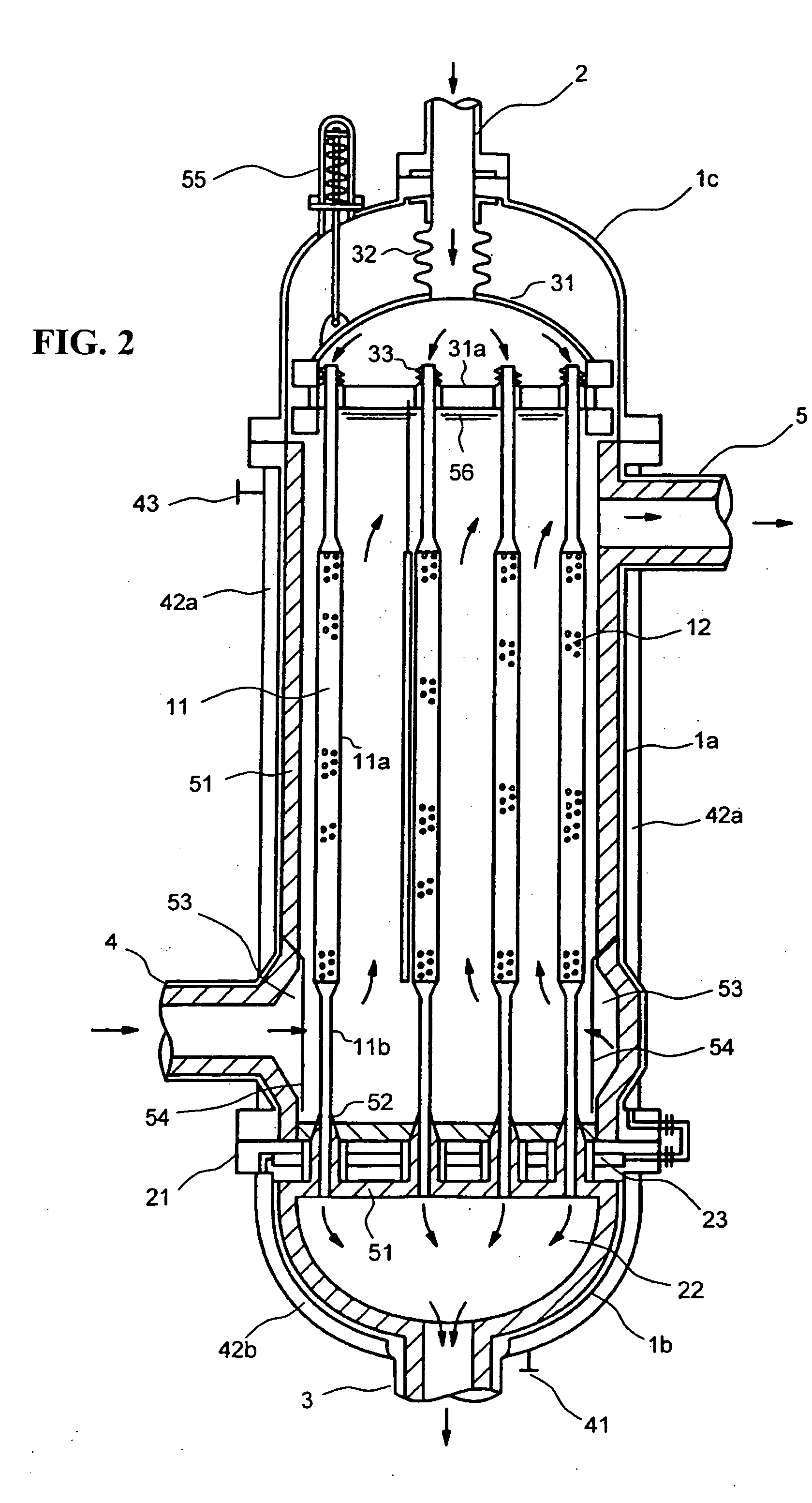

Reformer

InactiveUS20050287053A1Avoid it happening againDecreasing methane conversion efficiency and heat transfer efficiencyHydrogenPhysical/chemical process catalystsSyngasProcess engineering

A device to reform a raw material gas into a synthesis gas rich in hydrogen and carbon monoxide is disclosed. The device includes a vessel, a floating head, a plurality of reaction tubes, inlets and outlets for raw material and heating gases, and a cooled fixed tube plate.

Owner:TOYO ENG CORP

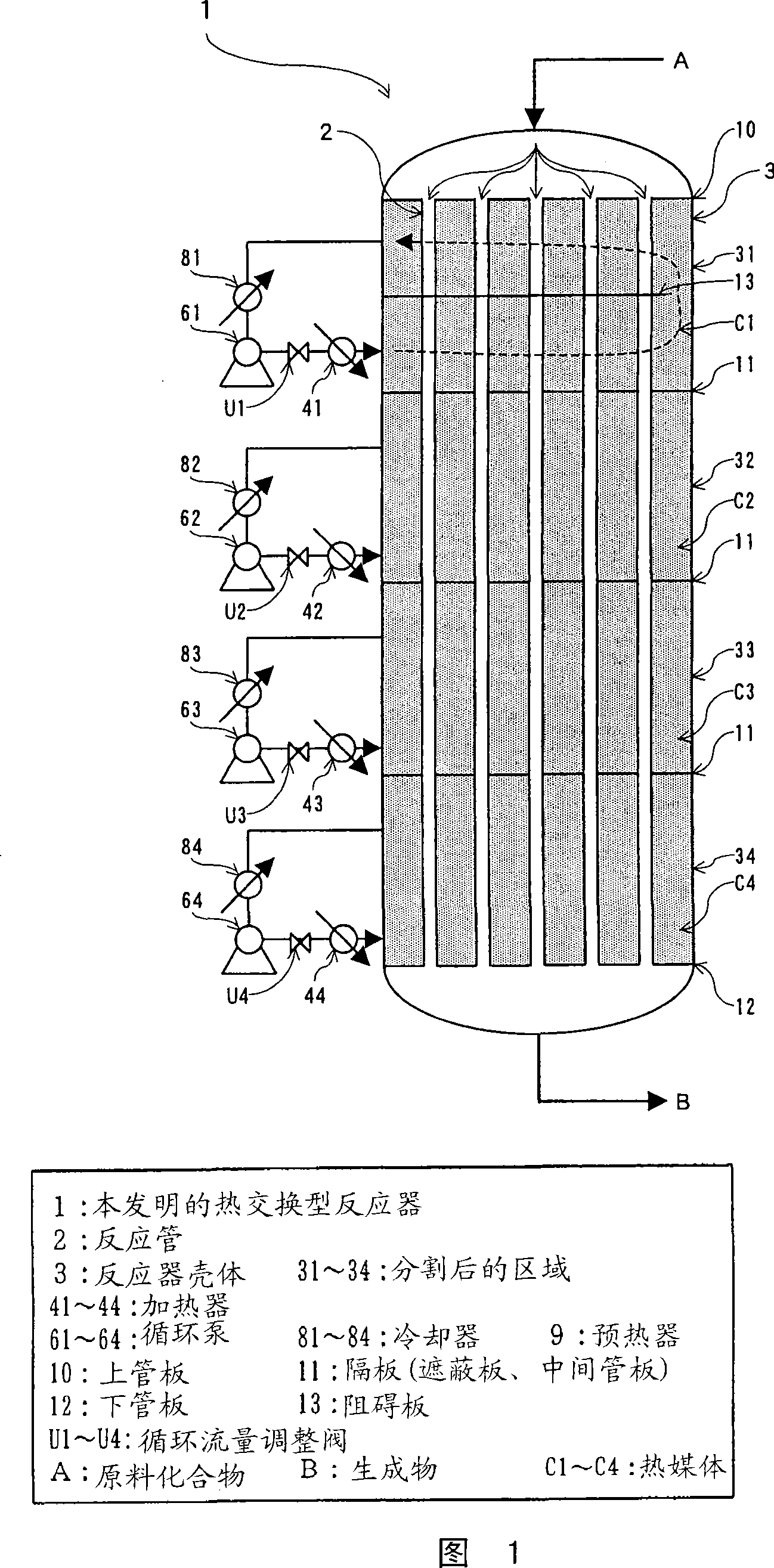

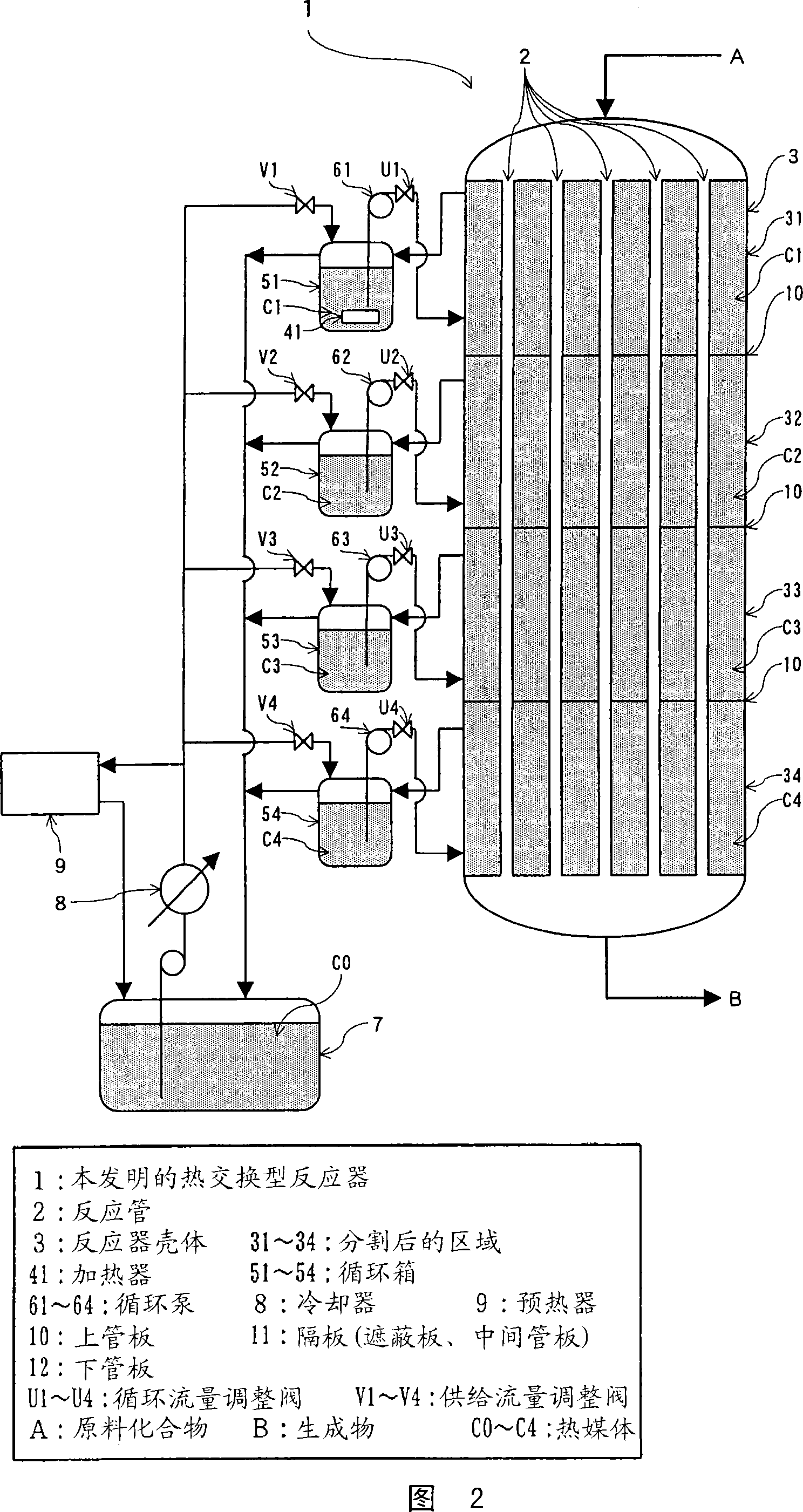

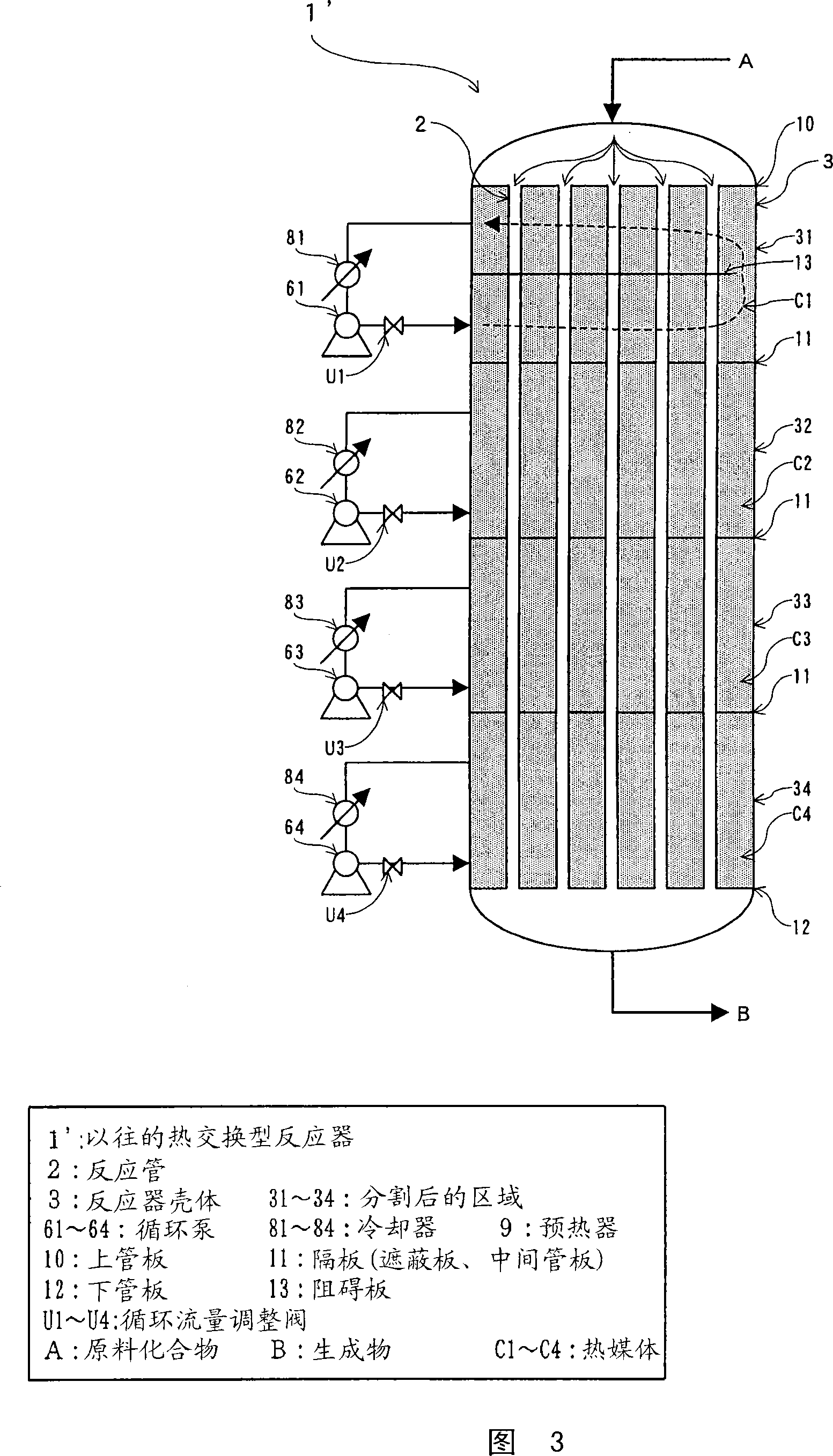

Heat exchange type reactor

ActiveCN1988950AReaction Yield ReducedGas-gas reaction processesChemical/physical/physico-chemical stationary reactorsExothermic reactionReaction tube

Owner:SUMITOMO CHEM CO LTD

Method and device for carrying out polymerase chain reaction under constant-temperature heat source

InactiveCN103173434ASimple preparation processLow costBioreactor/fermenter combinationsBiological substance pretreatmentsFluorescencePhysical chemistry

The invention provides a method and device for carrying out polymerase chain reaction under a constant-temperature heat source, and specifically relates to a method for providing heat to or taking away heat from a specific area of a reaction test tube based on a Rayleigh-Benard theory to build a temperature gradient from bottom to top of reagents in the reaction tube, spontaneously carrying out convection under the condition that the reaction reagents are unevenly heated, and carrying out corresponding PCR (Polymerase Chain Reaction) amplification when the reaction reagents flow through different temperature areas. The invention also discloses a device for carrying out the reaction of the method and in-time fluorescence detection.

Owner:XIAMEN INNOVAX BIOTECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Formation of [2,2]paracyclophane and related compounds and methods for the formation of polymers from cyclophanes Formation of [2,2]paracyclophane and related compounds and methods for the formation of polymers from cyclophanes](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/4eb334cd-5ed6-4078-97fe-269a42ccd686/US08633289-20140121-D00000.png)

![Formation of [2,2]paracyclophane and related compounds and methods for the formation of polymers from cyclophanes Formation of [2,2]paracyclophane and related compounds and methods for the formation of polymers from cyclophanes](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/4eb334cd-5ed6-4078-97fe-269a42ccd686/US08633289-20140121-D00001.png)

![Formation of [2,2]paracyclophane and related compounds and methods for the formation of polymers from cyclophanes Formation of [2,2]paracyclophane and related compounds and methods for the formation of polymers from cyclophanes](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/4eb334cd-5ed6-4078-97fe-269a42ccd686/US08633289-20140121-D00002.png)