Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

140 results about "Induction plasma technology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The 1960s were the incipient period of thermal plasma technology, spurred by the needs of aerospace programs. Among the various methods of thermal plasma generation, induction plasma (or inductively coupled plasma) takes up an important role.

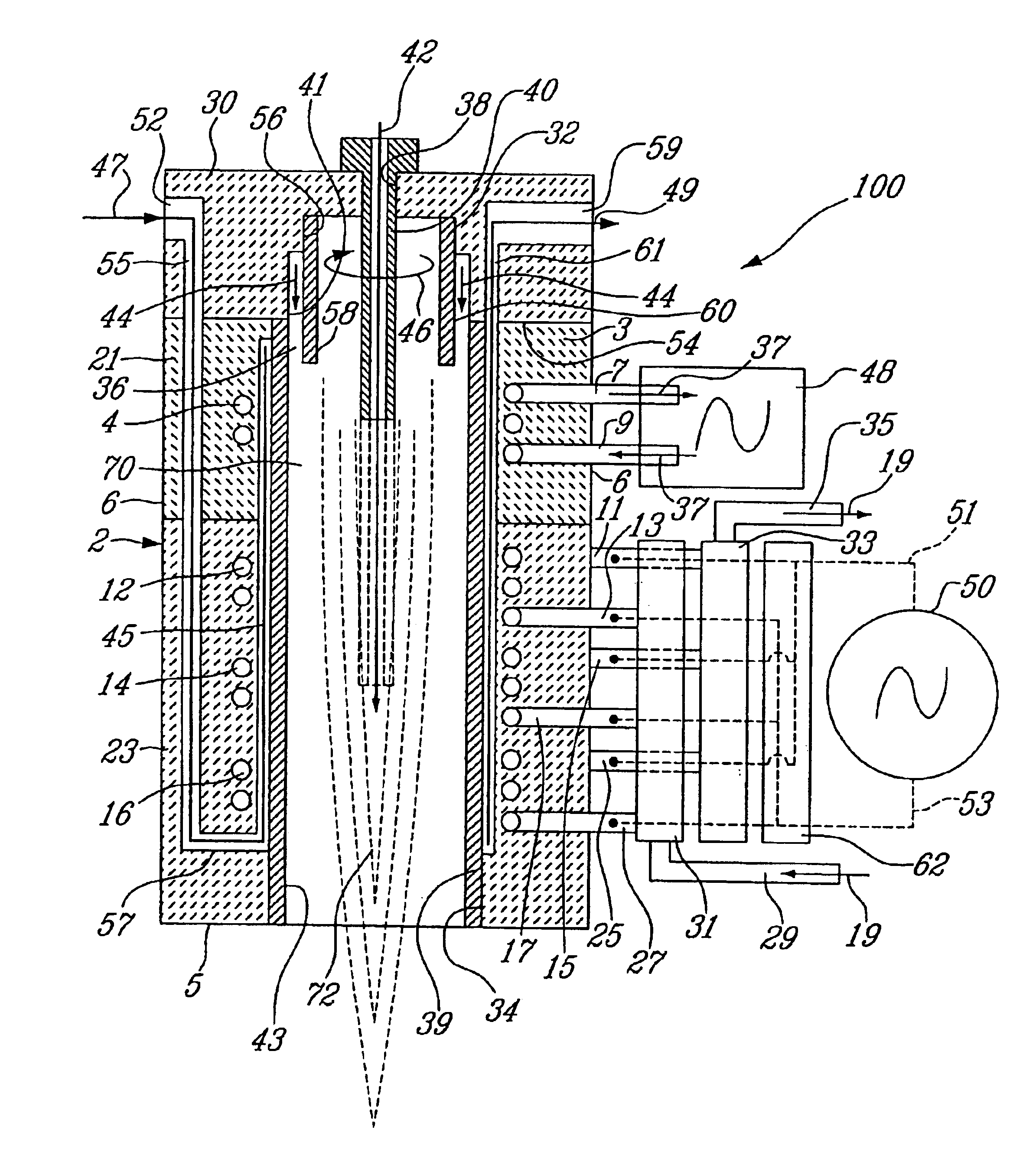

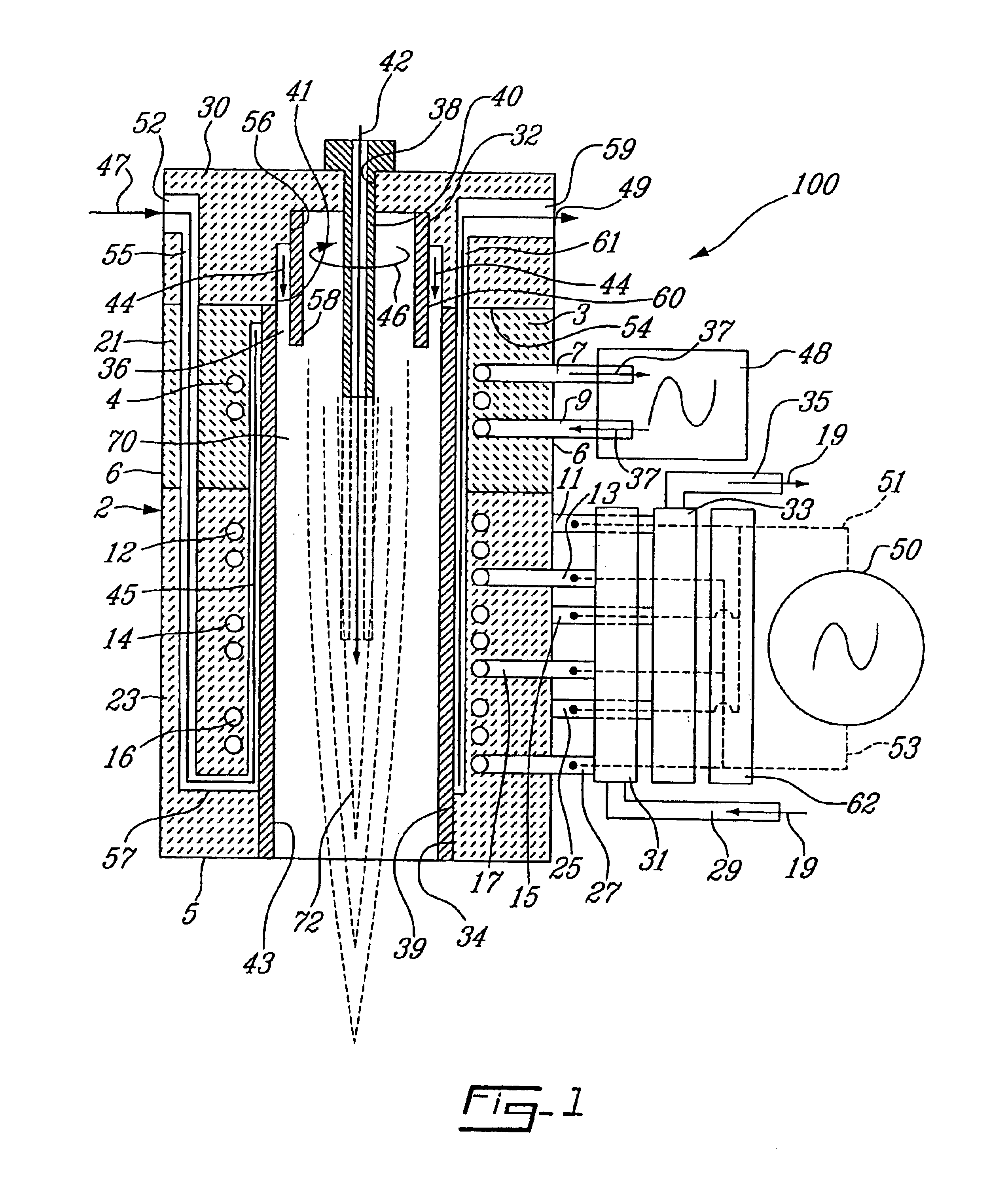

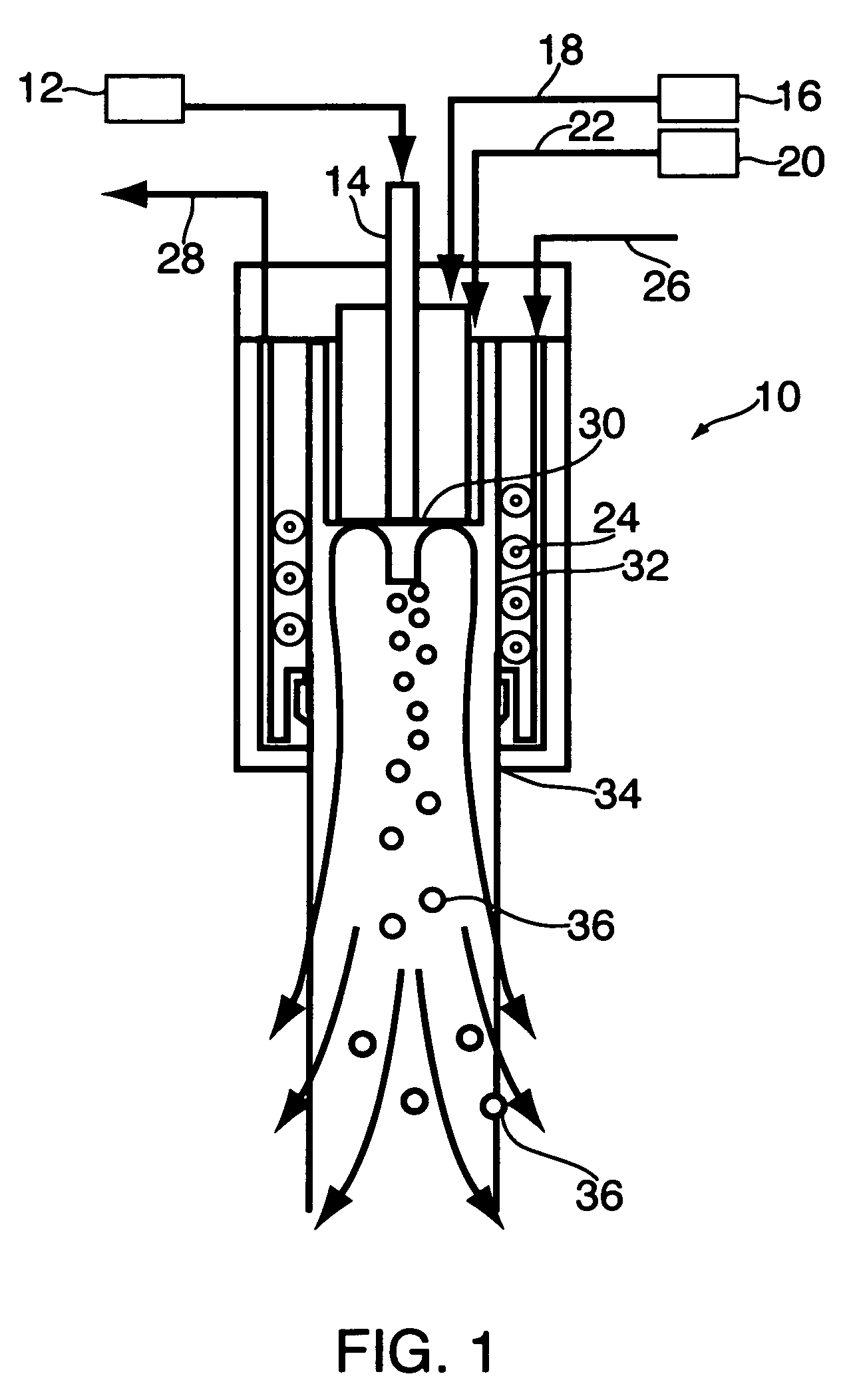

Multi-coil induction plasma torch for solid state power supply

InactiveUS6919527B2Efficient heatingImprove thermal conductivityElectric discharge tubesElectric arc lampsHigh frequency powerInduction plasma technology

Owner:TEKNA PLASMA SYST INC

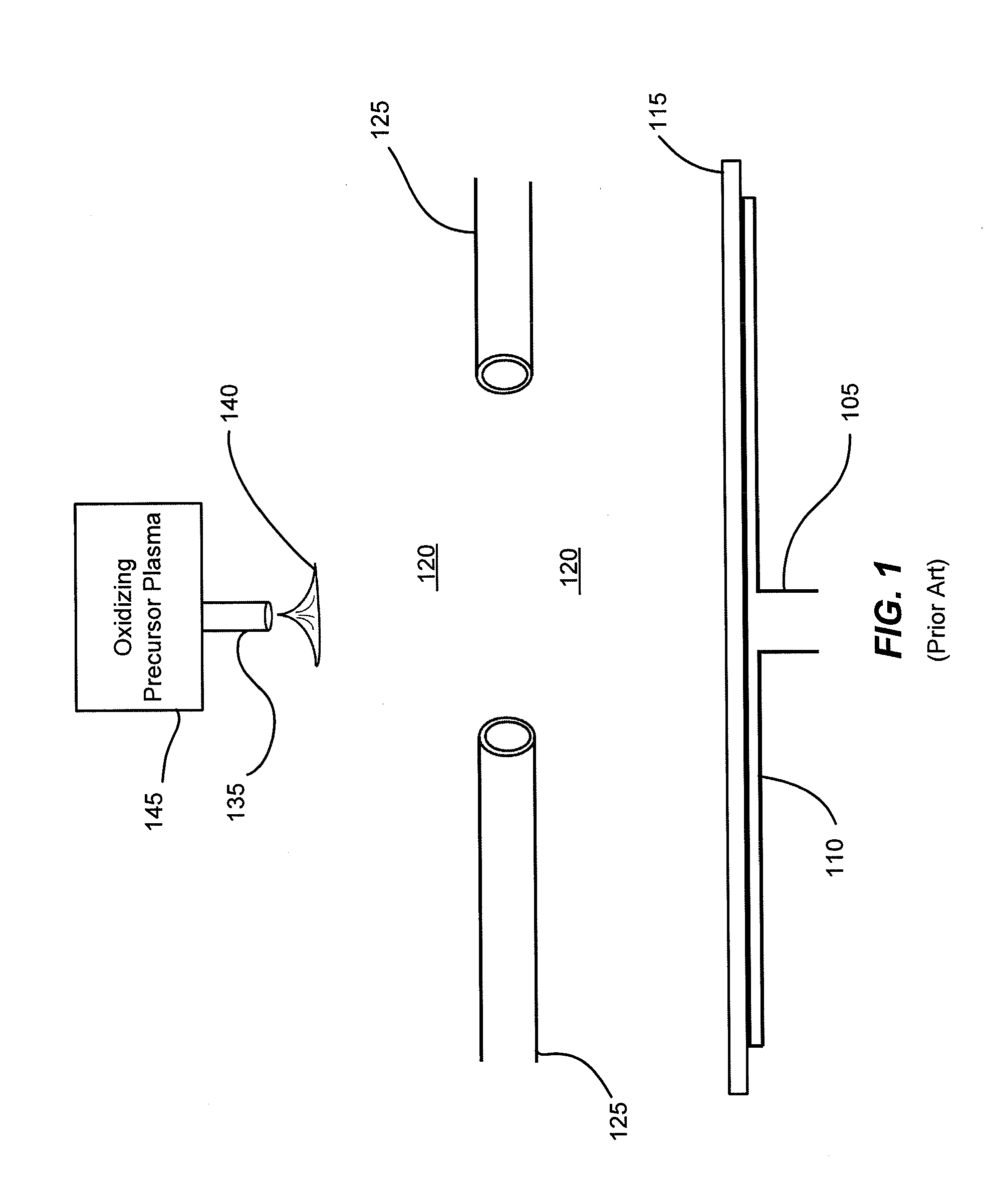

Inductive plasma sources for wafer processing and chamber cleaning

InactiveUS20130034666A1Electric discharge tubesChemical vapor deposition coatingInduction plasma technologyBiological activation

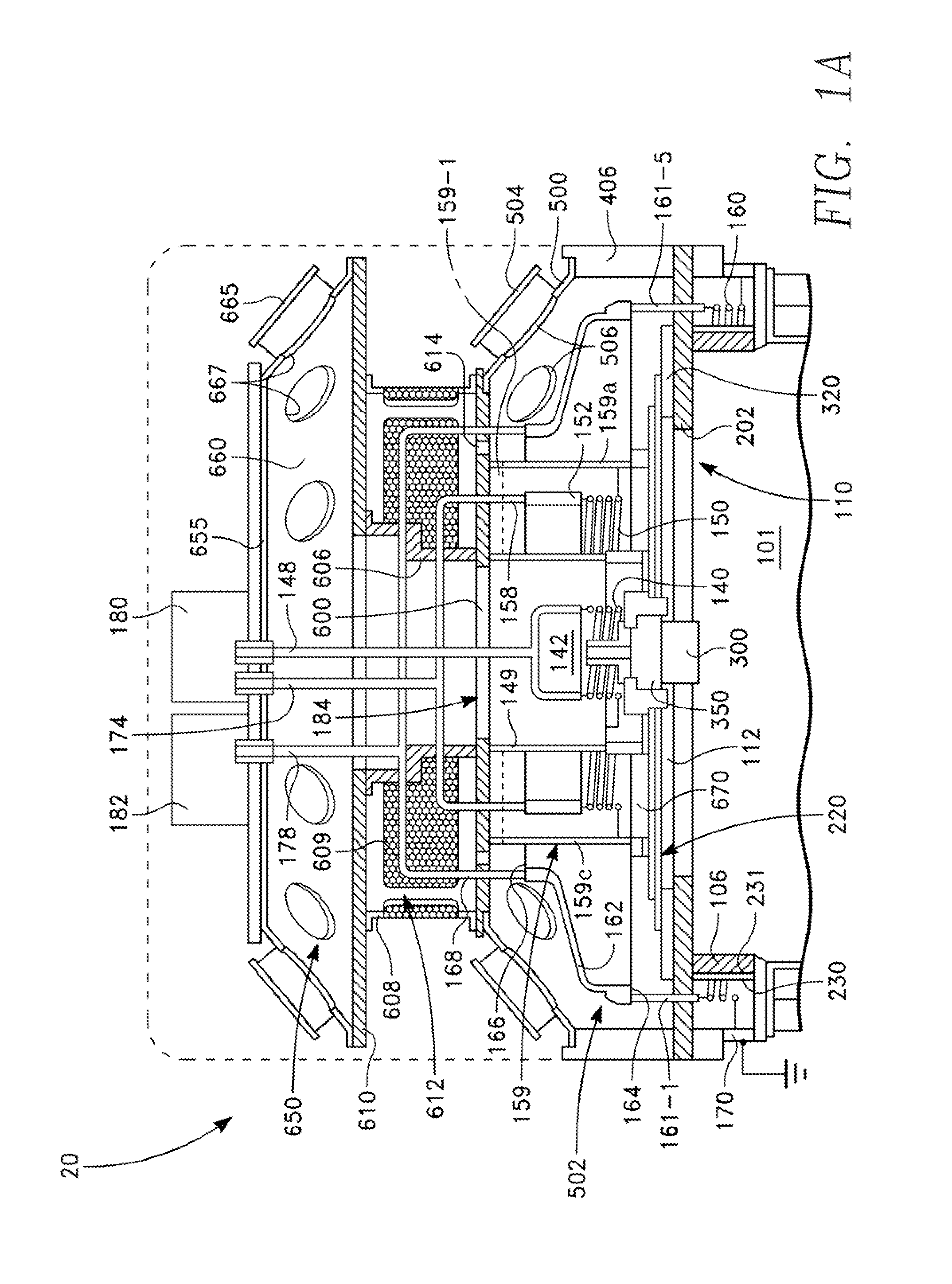

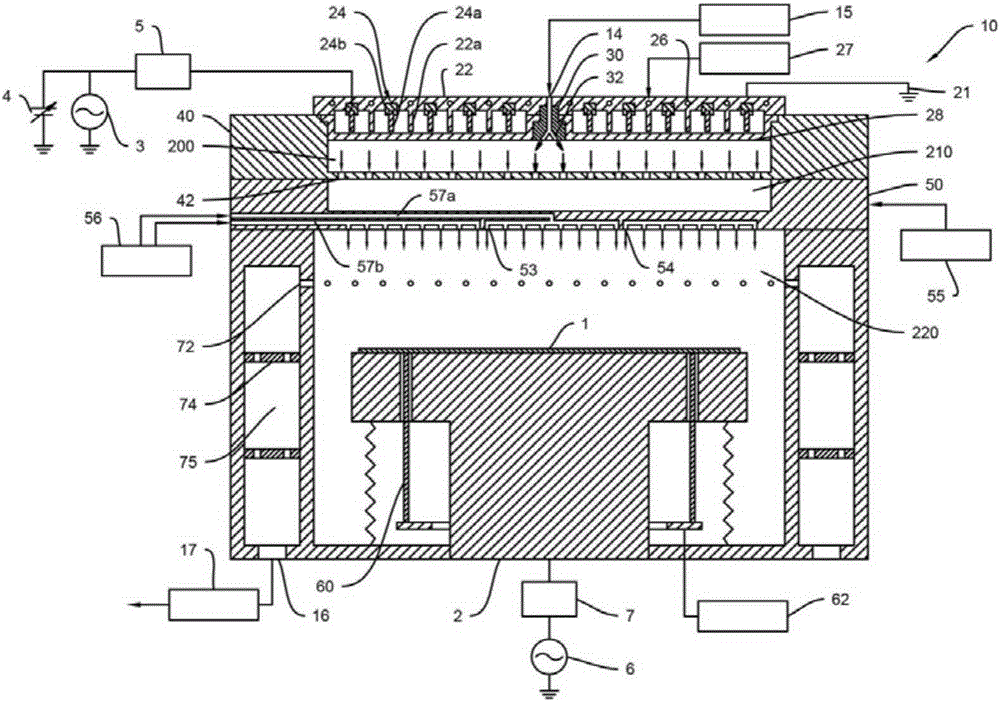

Methods and systems for depositing material on a substrate are described. One method may include providing a processing chamber partitioned into a first plasma region and a second plasma region. The method may further include delivering the substrate to the processing chamber, where the substrate may occupy a portion of the second plasma region. The method may additionally include forming a first plasma in the first plasma region, where the first plasma may not directly contact the substrate, and the first plasma may be formed by activation of at least one shaped radio frequency (“RF”) coil above the first plasma region. The method may moreover include depositing the material on the substrate to form a layer, where one or more reactants excited by the first plasma may be used in deposition of the material.

Owner:APPLIED MATERIALS INC

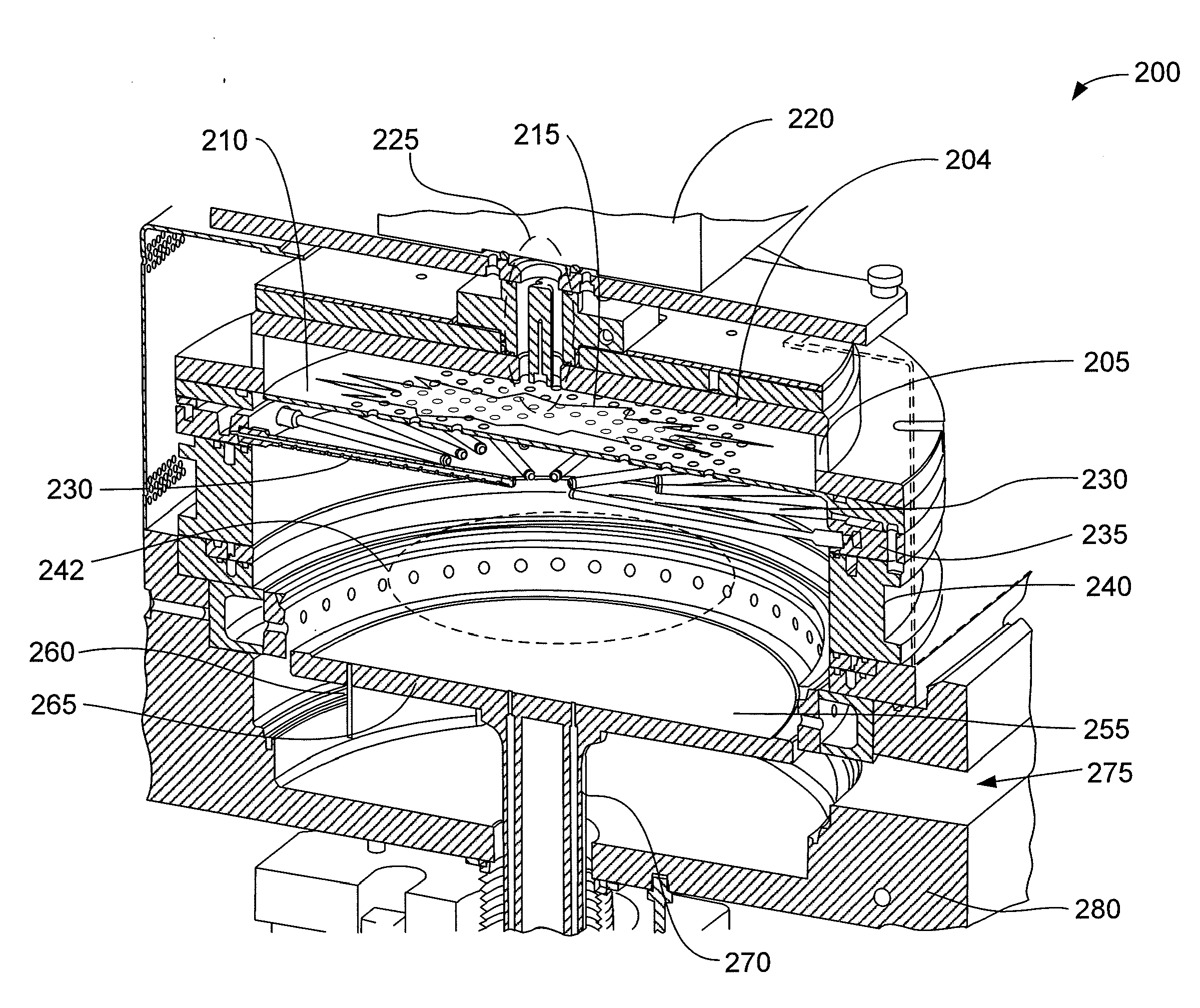

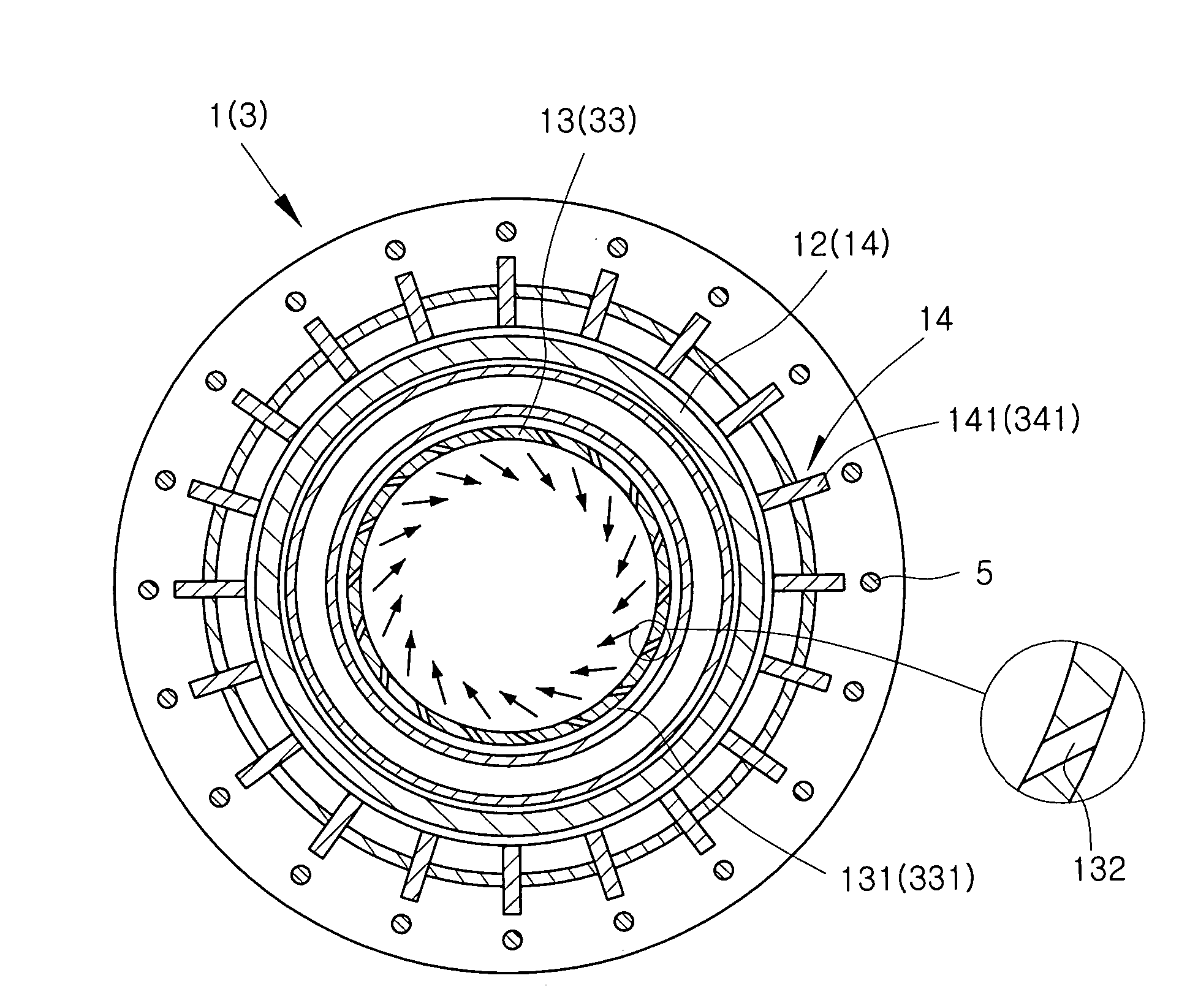

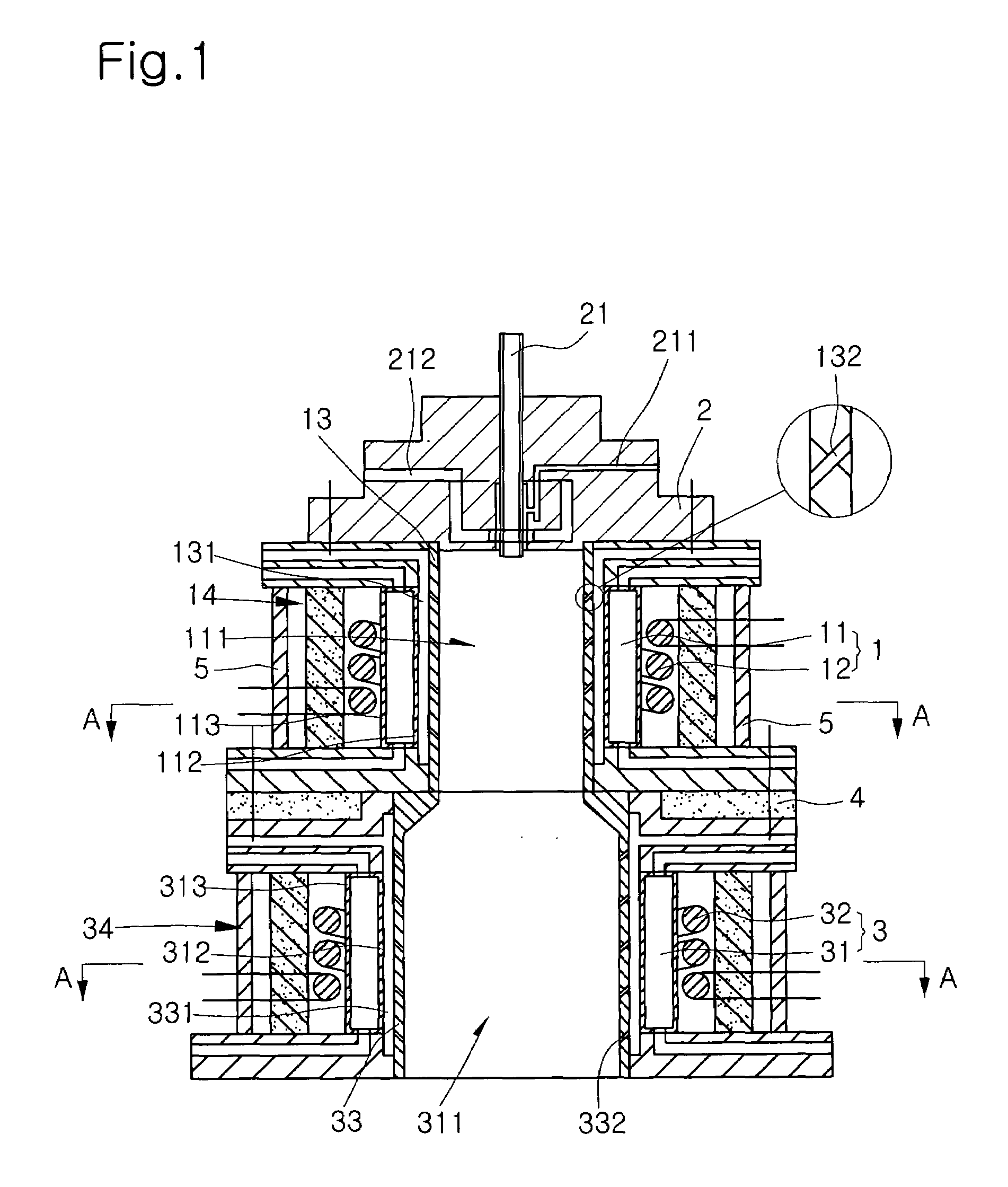

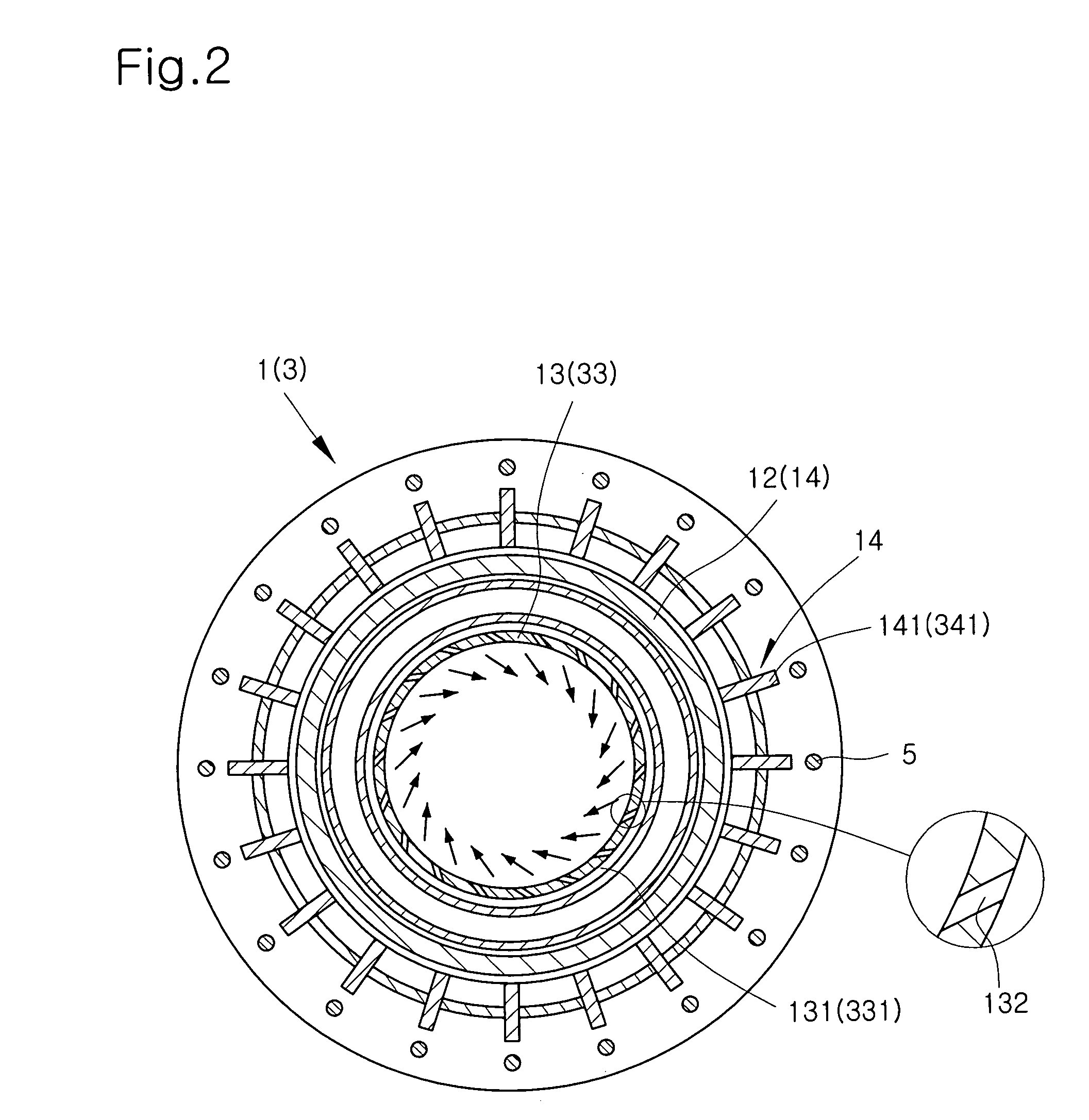

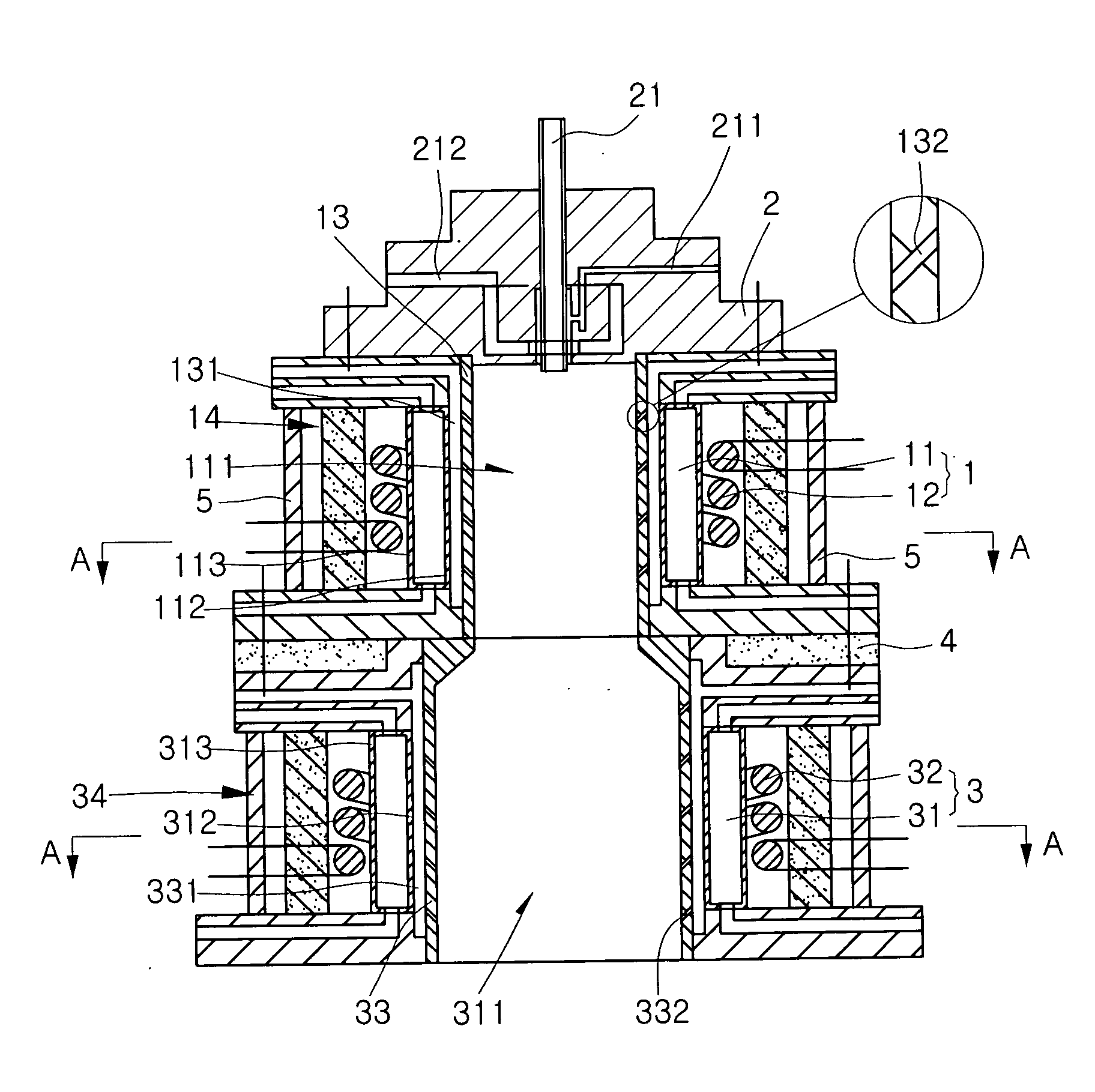

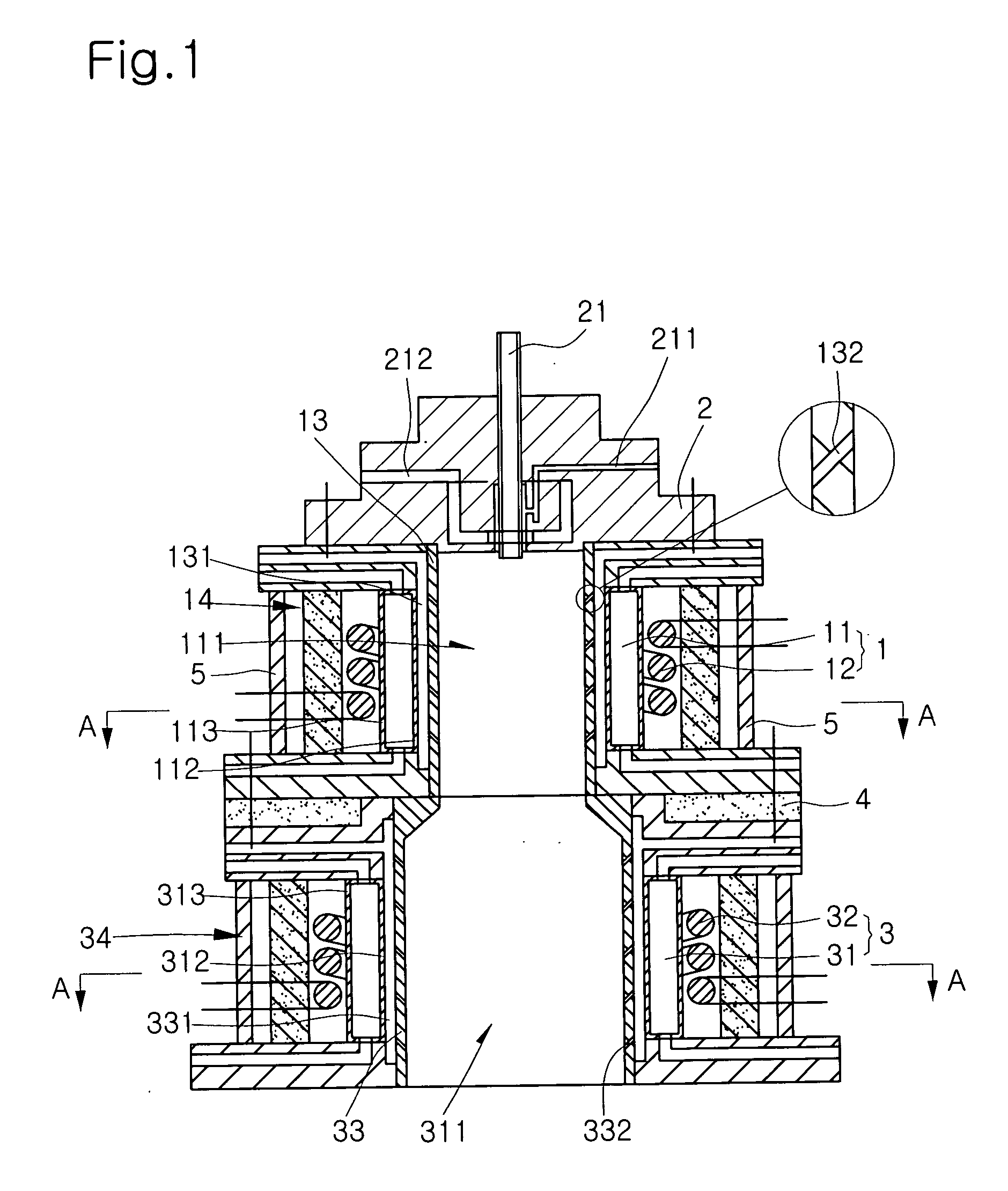

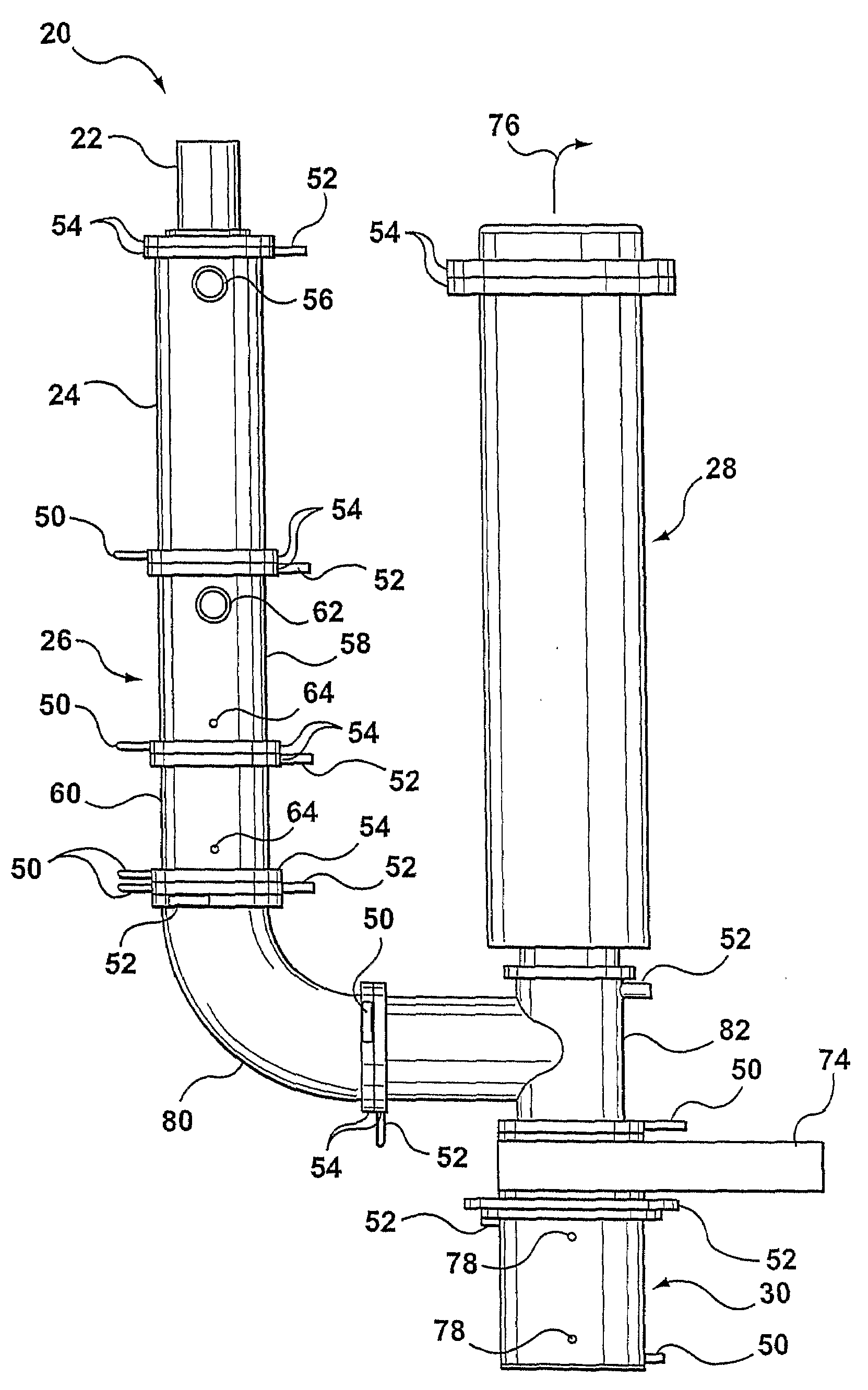

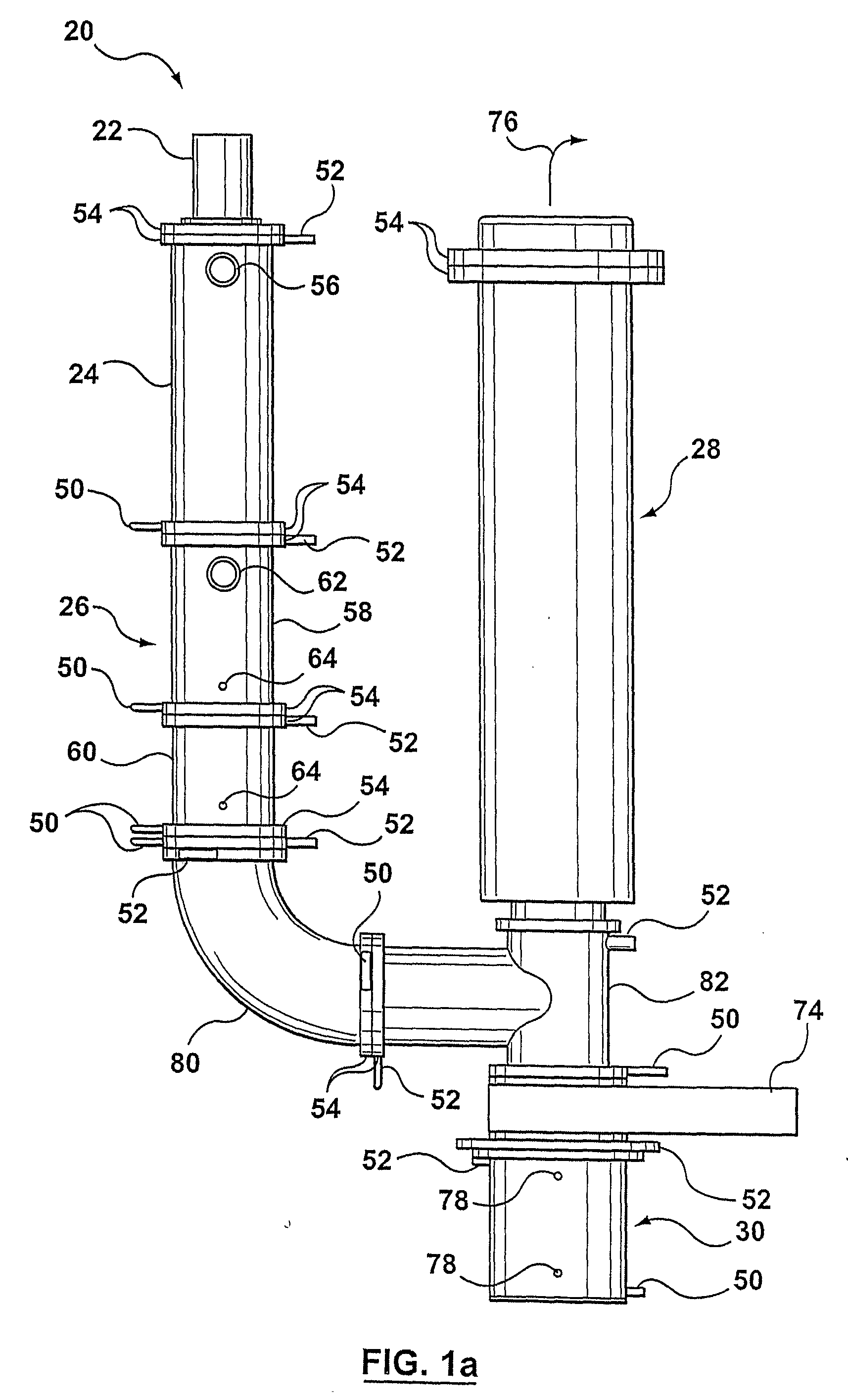

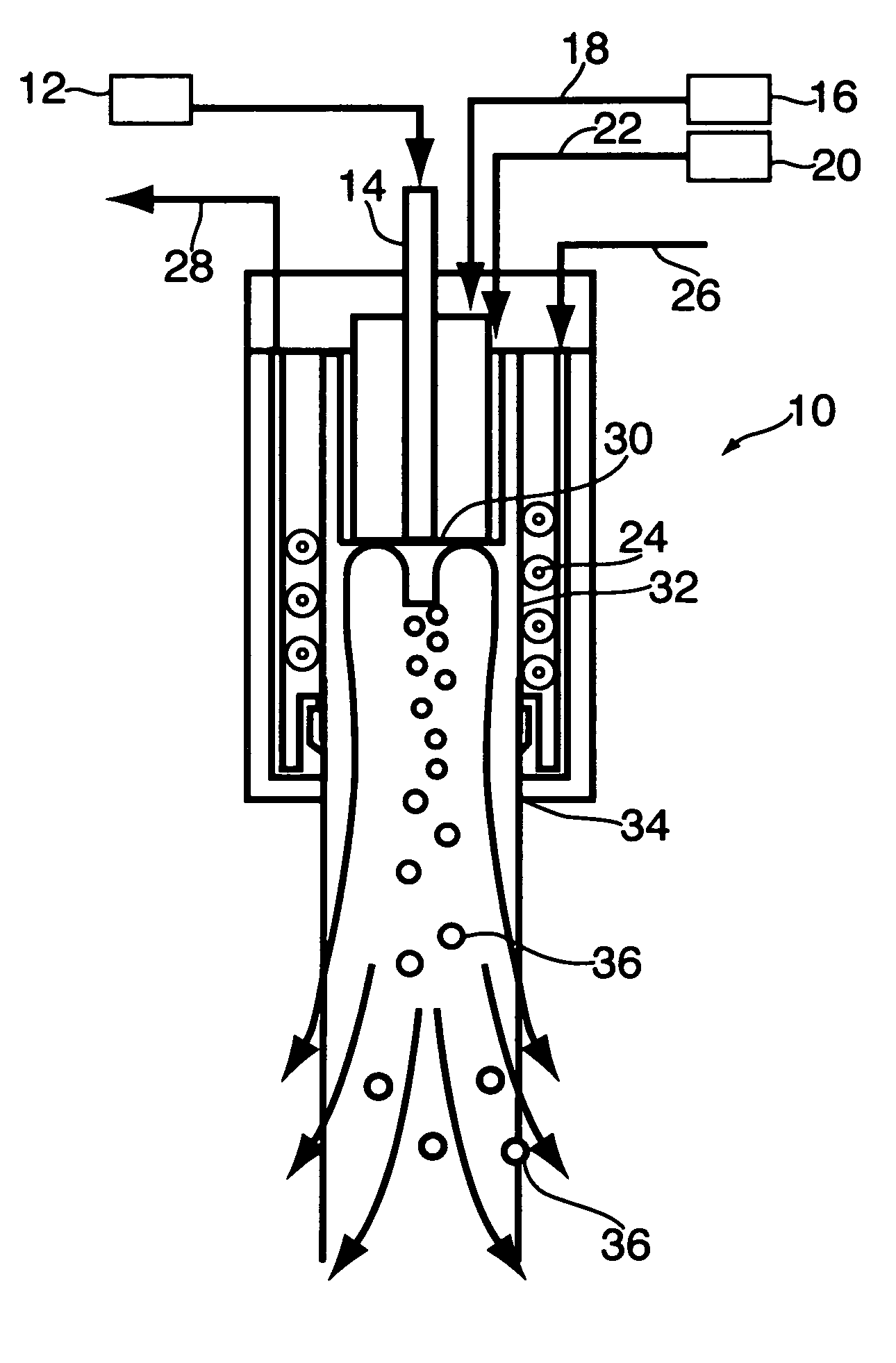

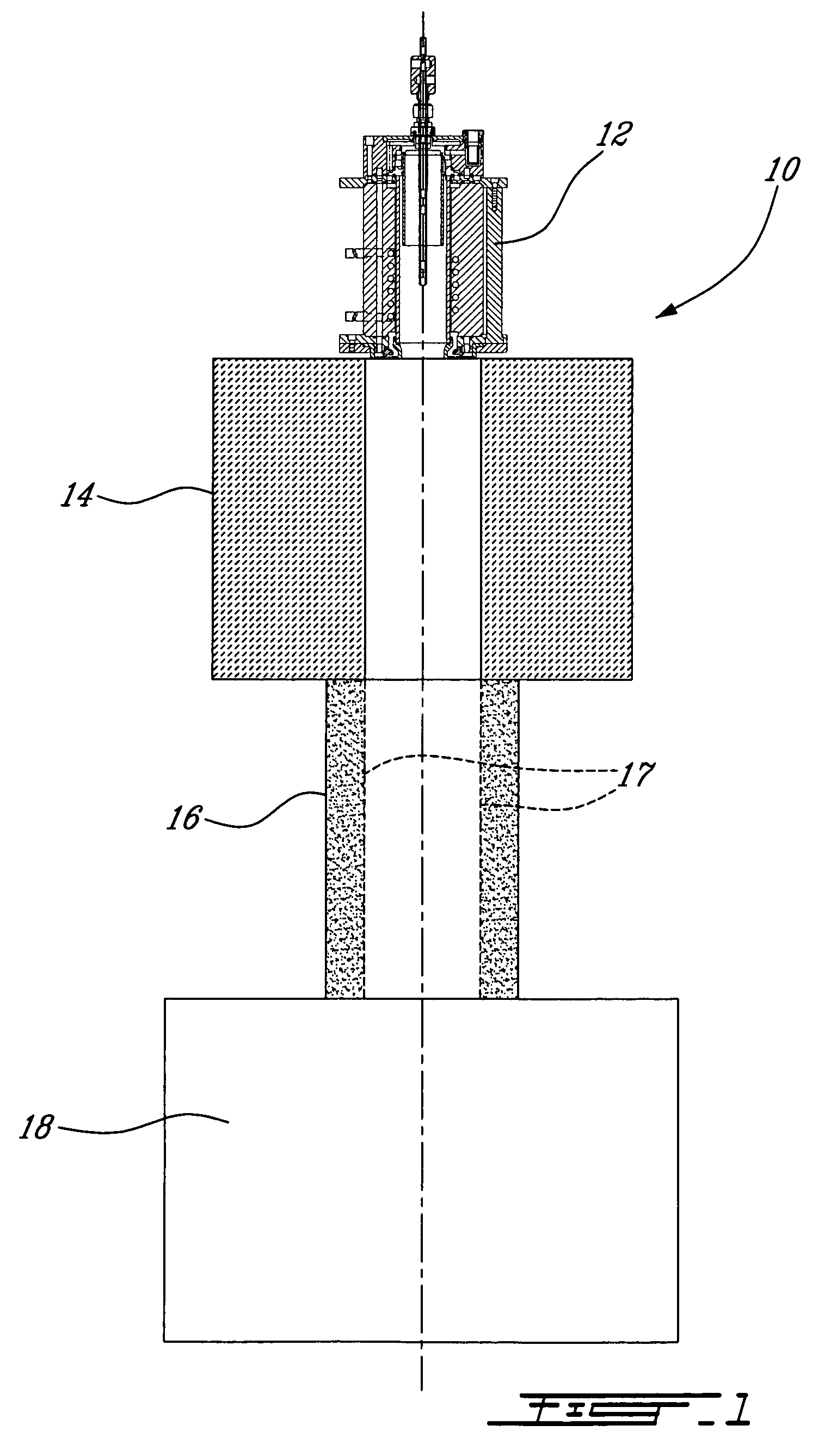

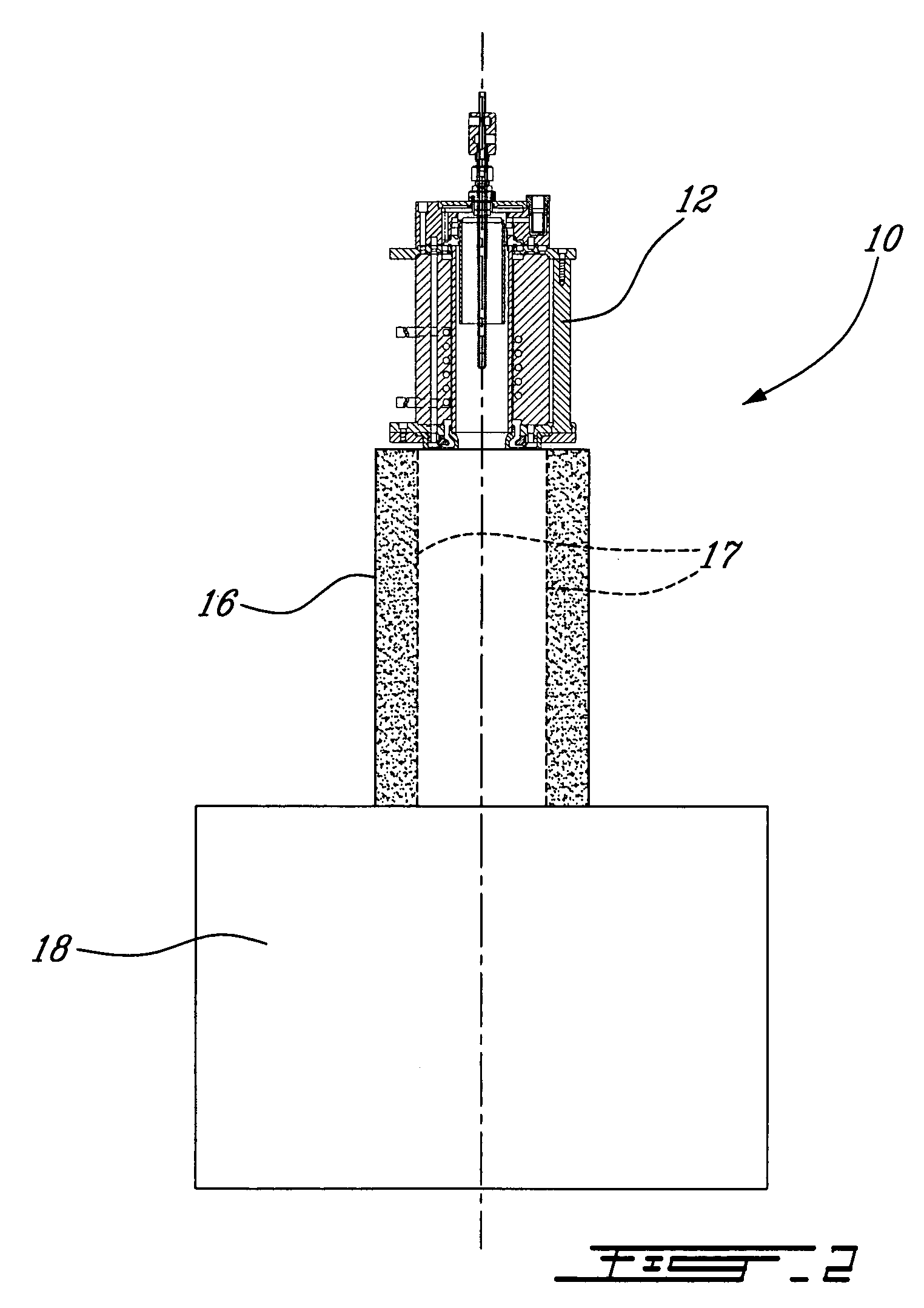

Inductively coupled plasma reactor for producing nano-powder

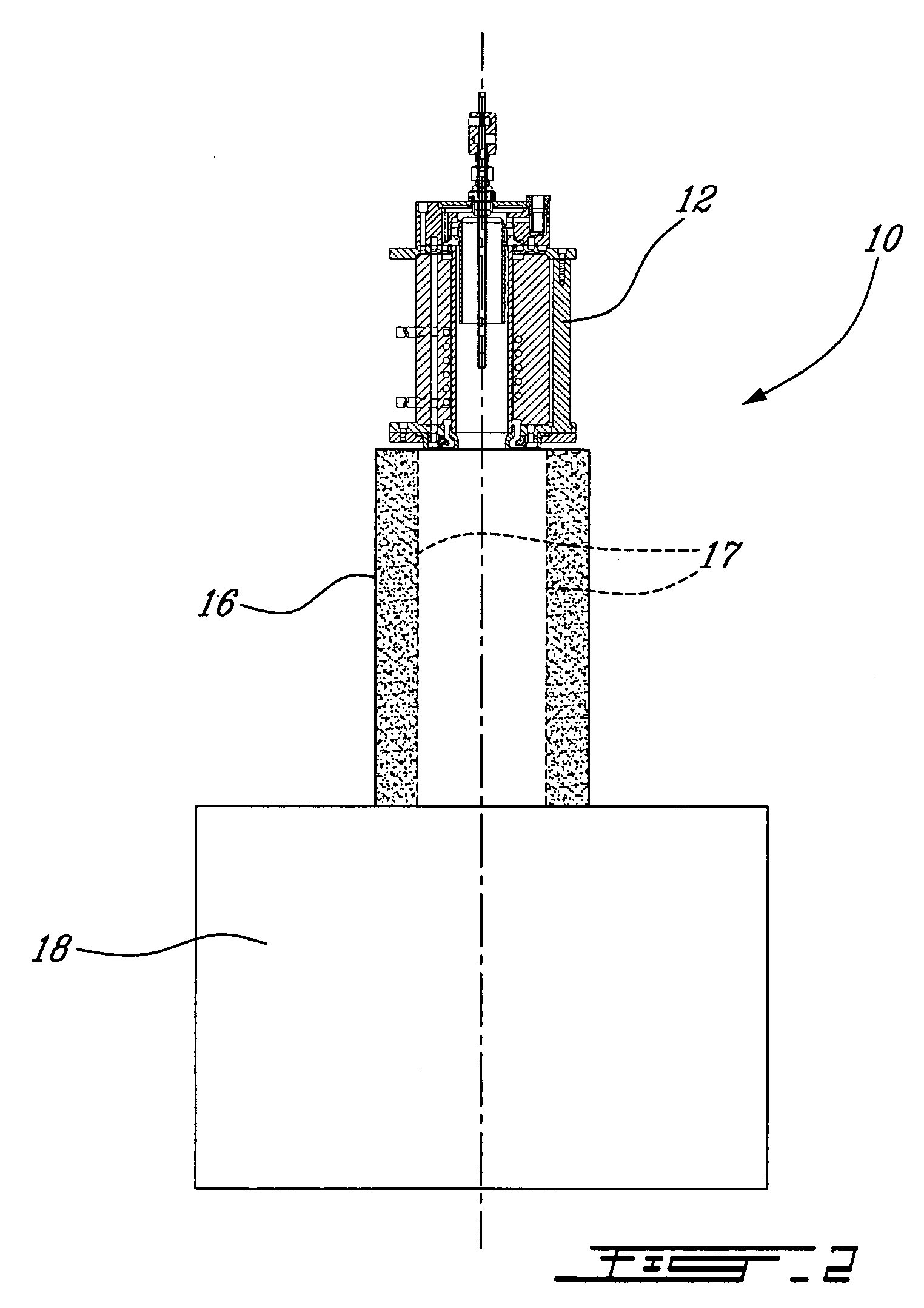

InactiveUS7323655B2Growth inhibitionGuaranteed to move normallyNanostructure manufactureElectric discharge tubesGas passingInduction plasma technology

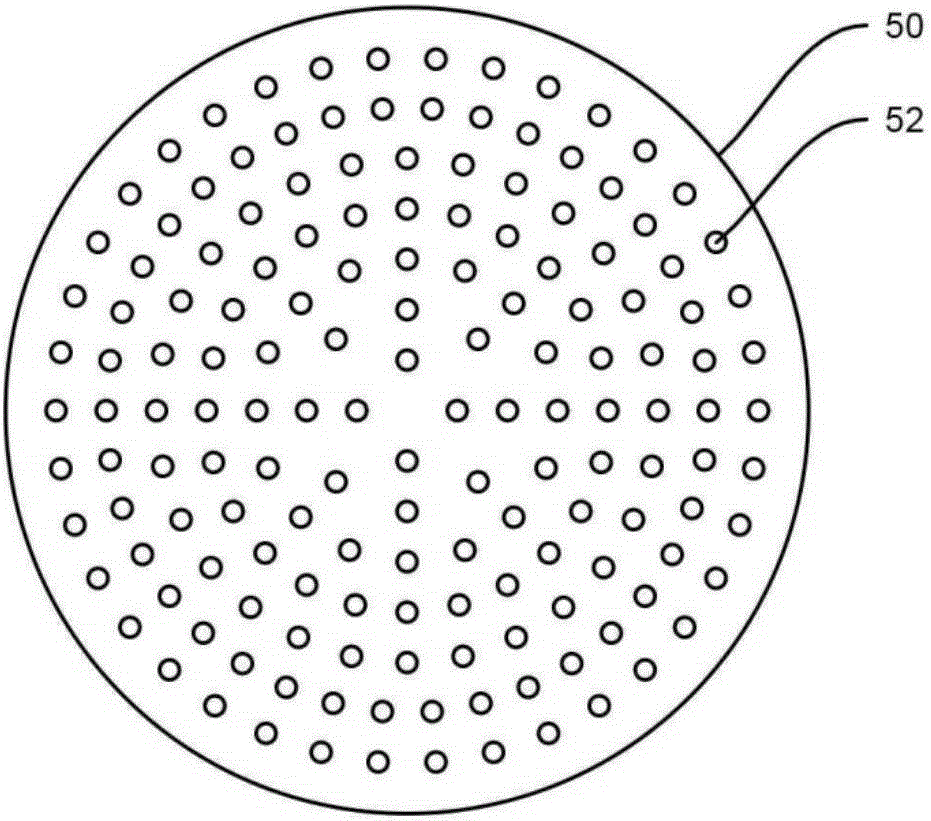

Disclosed herein is a high-frequency induction plasma reactor apparatus for producing nano-powder, which is configured to continuously manufacture nano-powder in large quantities using solid-phase powder as a starting raw material and to manufacture high-purity nano-powder by completely vaporizing the material powder. The high-frequency induction plasma reactor apparatus comprises an upper body and a cover. The upper body is provided with a reaction pipe receiving a reactor extending vertically inside thereof, a high-frequency coil surrounding the outer periphery of the reaction pipe and a ceramic inner wall provided inside the reaction pipe. The ceramic inner wall is formed with a plurality of gas passing bores and defines a gas movement passage with the inner side wall of the reaction pipe therebetween for allowing the inflow of argon gas from the outside into the reactor. The cover is mounted to the upper end of the reactor and adapted to seal the reactor. The cover is provided with a powder injection tube communicating with the reactor.

Owner:NPC CO LTD

Inductively coupled plasma reactor for producing nano-powder

InactiveUS20050258766A1Inhibit growthAvoid adsorptionNanostructure manufactureElectric discharge tubesGas passingInduction plasma technology

Disclosed herein is a high-frequency induction plasma reactor apparatus for producing nano-powder, which is configured to continuously manufacture nano-powder in large quantities using solid-phase powder as a starting raw material and to manufacture high-purity nano-powder by completely vaporizing the material powder. The high-frequency induction plasma reactor apparatus comprises an upper body and a cover. The upper body is provided with a reaction pipe receiving a reactor extending vertically inside thereof, a high-frequency coil surrounding the outer periphery of the reaction pipe and a ceramic inner wall provided inside the reaction pipe. The ceramic inner wall is formed with a plurality of gas passing bores and defines a gas movement passage with the inner side wall of the reaction pipe therebetween for allowing the inflow of argon gas from the outside into the reactor. The cover is mounted to the upper end of the reactor and adapted to seal the reactor. The cover is provided with a powder injection tube communicating with the reactor.

Owner:NPC CO LTD

Induction plasma reactor

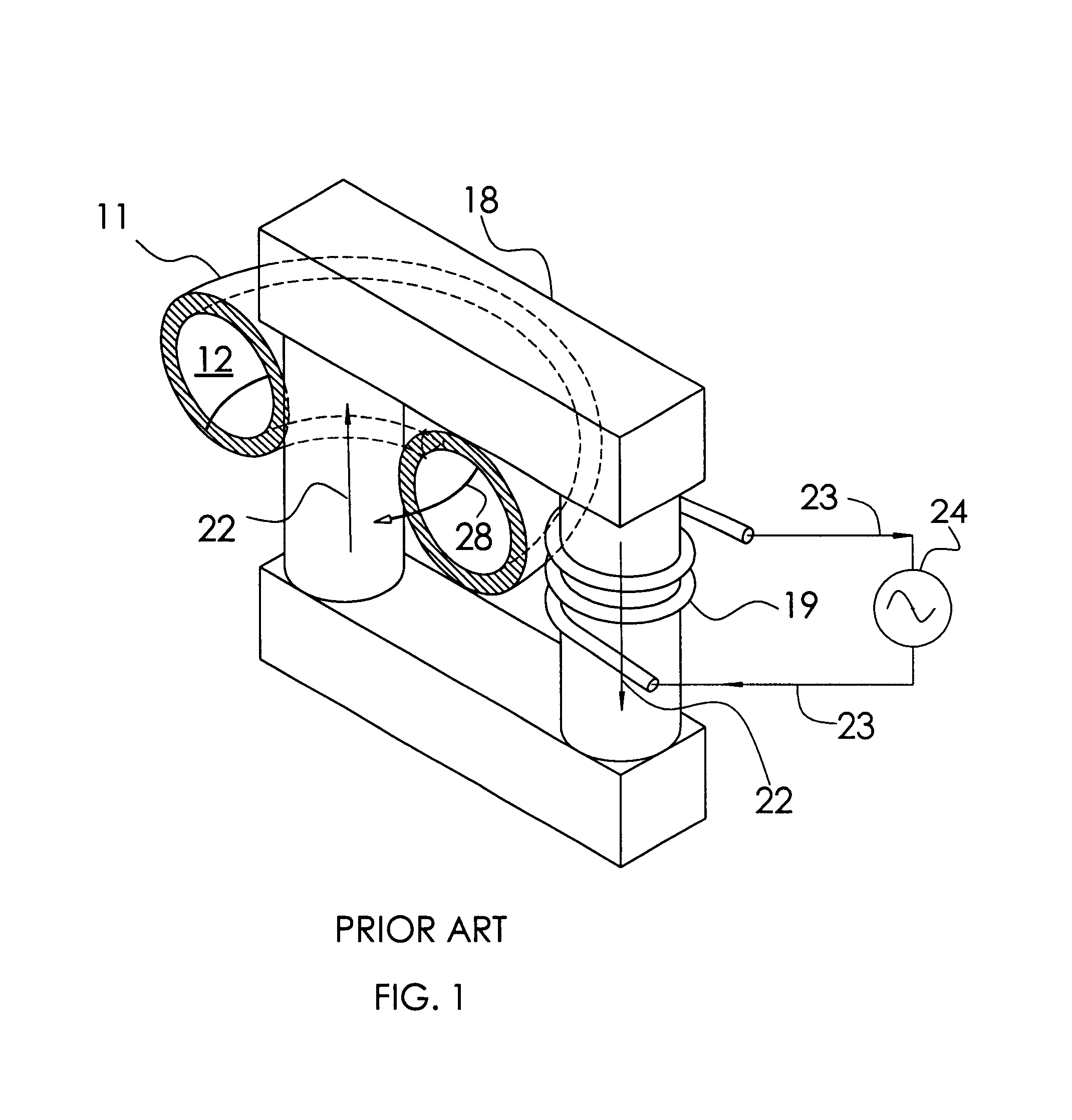

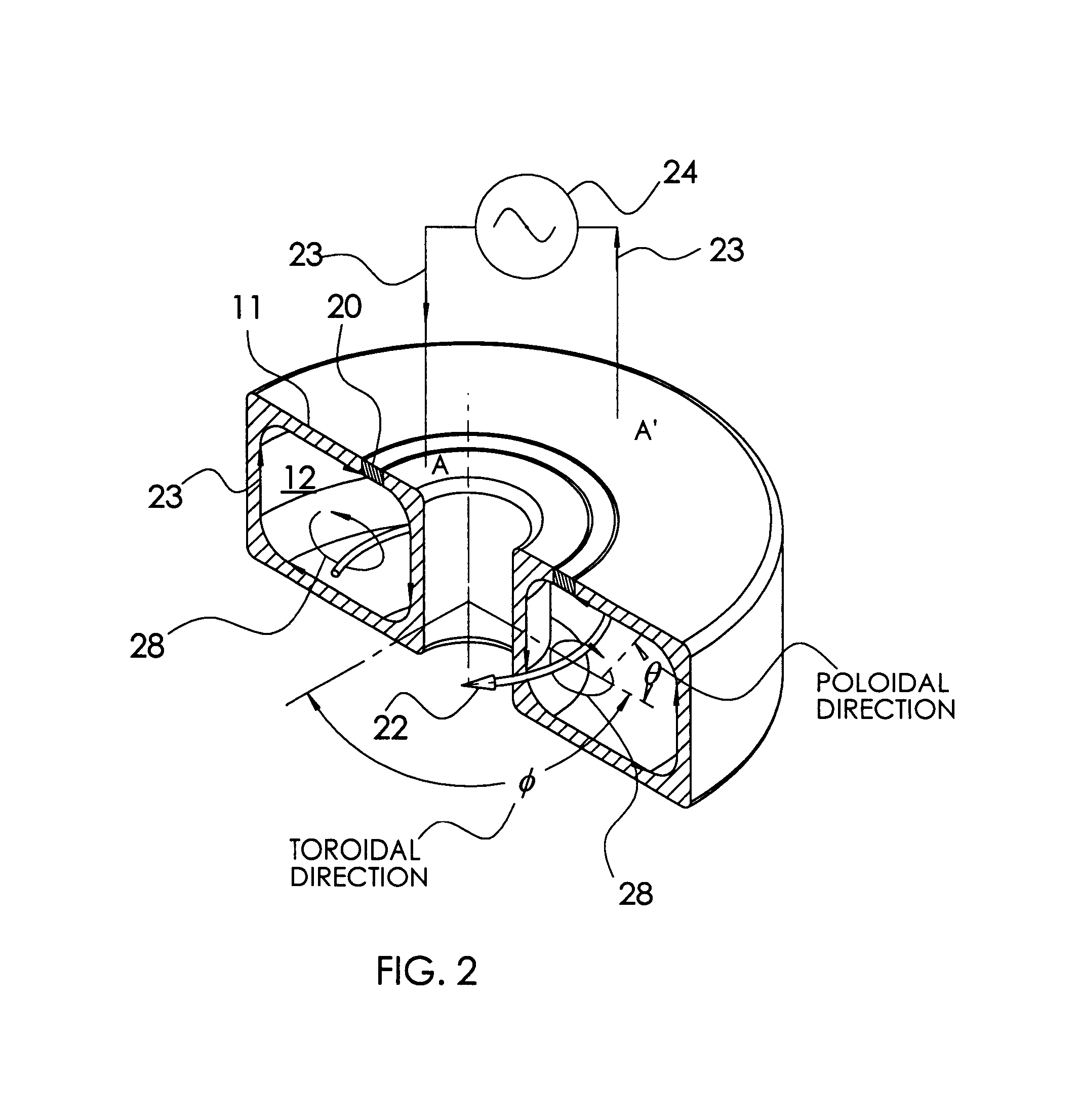

InactiveUS6855906B2Increase plasma densityImprove productivityCoil arrangementsSemiconductor/solid-state device manufacturingEffective powerElectricity

The invention is a plasma-generating device useful in a wide variety of industrial processes. The plasma is formed in a chamber having a toroidal topology, and is heated inductively. As with all inductive plasmas, a primary coil carries an applied AC current, which, in turn, generates a corresponding applied AC magnetic flux inside the plasma. This flux induces current to flow through the plasma in closed paths that encircle the flux, thereby heating and maintaining the plasma. In this invention, the applied AC current flows through the primary coil around substantially the short poloidal direction on the torus. Accordingly, the applied magnetic flux is caused to circulate through the plasma along the larger toroidal direction. Finally, the current induced within the plasma will flow in the poloidal direction, anti-parallel to the applied primary current. The plasma chamber wall is preferably made of metal such as aluminum and includes one or more electrical breaks that extend fully around the chamber wall in the toroidal direction. This prevents poloidal currents from being induced in the chamber wall, ensuring effective power transfer to the plasma. Elastomeric seals made from electrically insulating material seal the breaks.

Owner:BRAILOVE ADAM ALEXANDER

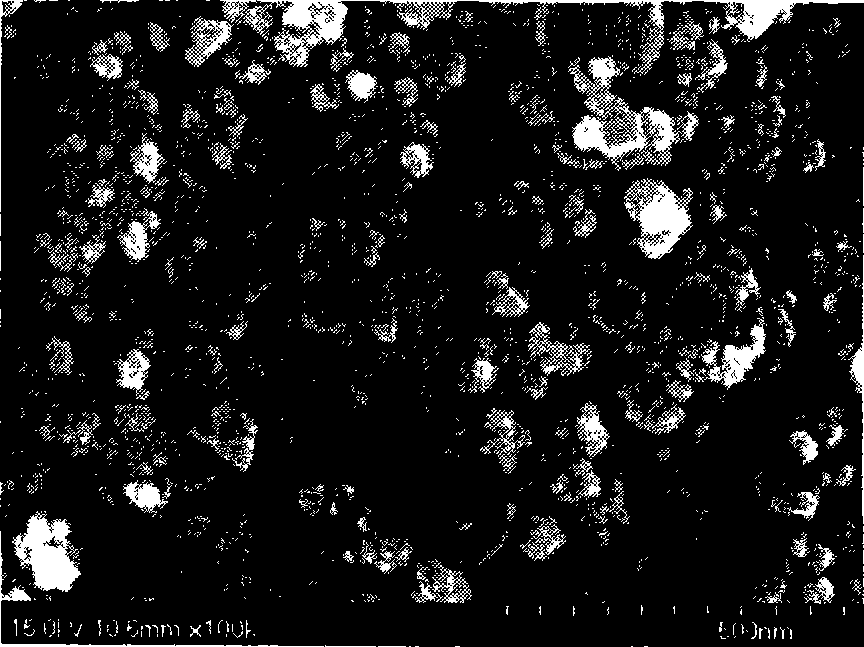

Induction plasma synthesis of nanopowders

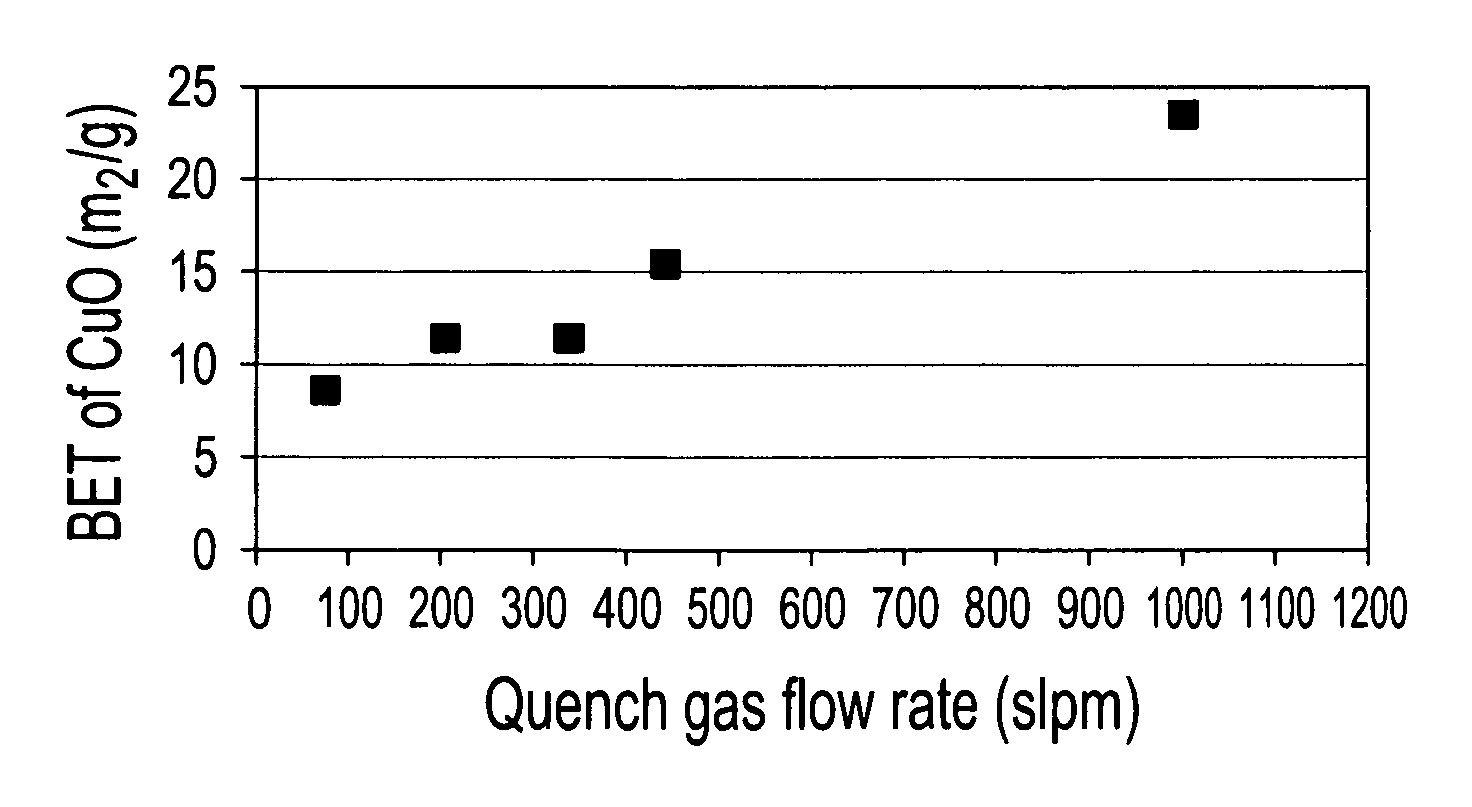

ActiveUS20070029291A1Tight controlEasy to controlMaterial nanotechnologyOxygen/ozone/oxide/hydroxideIodideInduction plasma technology

A process and apparatus for synthesizing a nanopowder is presented. In particular, a process for the synthesis of nanopowders of various materials such as metals, alloys, ceramics and composites by induction plasma technology, using organometallic compounds, chlorides, bromides, fluorides, iodides, nitrites, nitrates, oxalates and carbonates as precursors is disclosed. The process comprises feeding a reactant material into a plasma torch in which is generated a plasma flow having a temperature sufficiently high to yield a superheated vapour of the material; transporting said vapour by means of the plasma flow into a quenching zone; injecting a cold quench gas into the plasma flow in the quenching zone to form a renewable gaseous cold front; and forming a nanopowder at the interface between the renewable gaseous cold front and the plasma flow.

Owner:TEKNA PLASMA SYST INC

Inductive plasma source for plasma electric generation system

ActiveUS8031824B2Facilitates controlled fusionReduce eliminate anomalous transportElectric discharge tubesNuclear energy generationNuclear forcePlasma electron

Owner:RGT UNIV OF CALIFORNIA

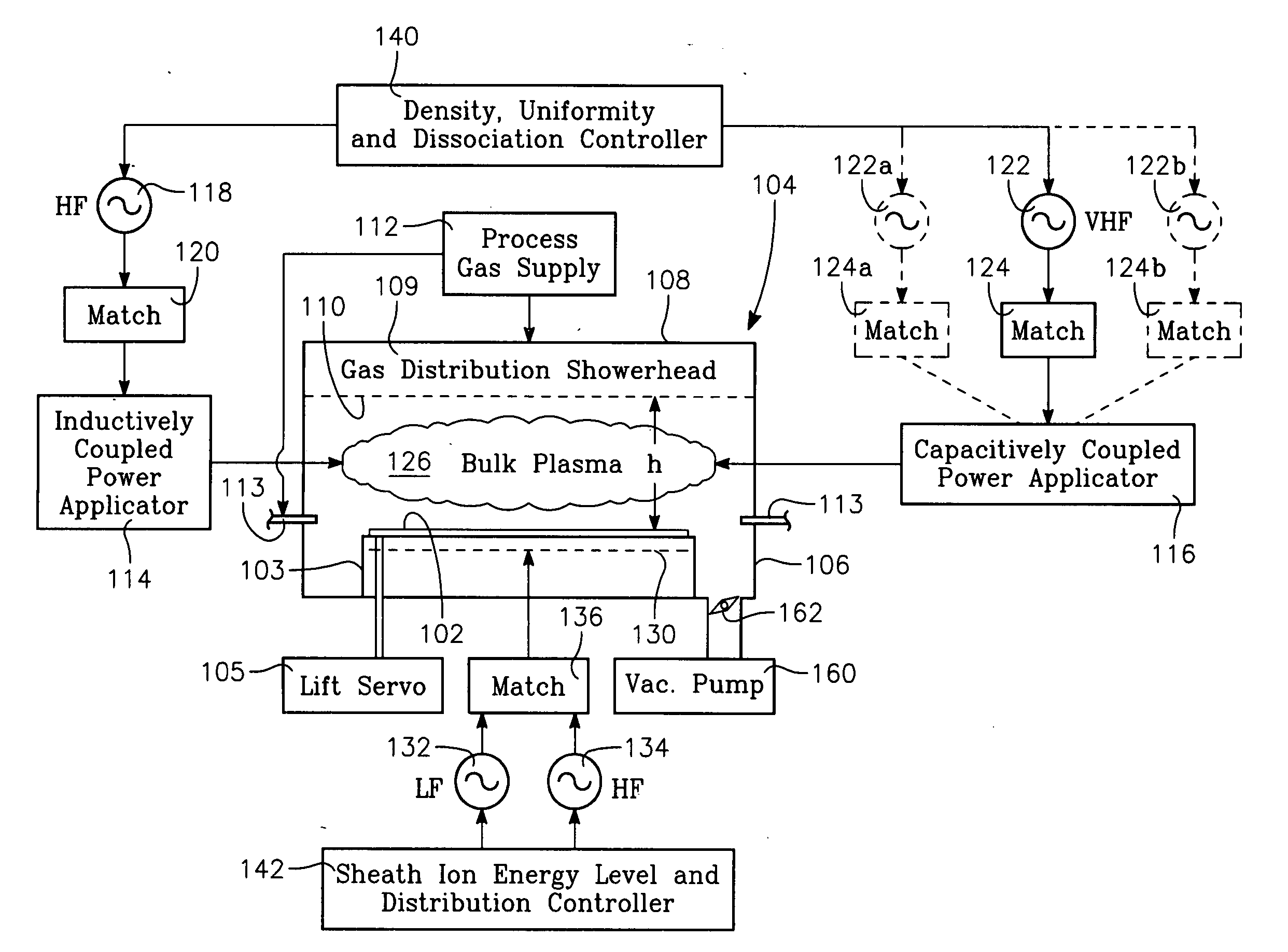

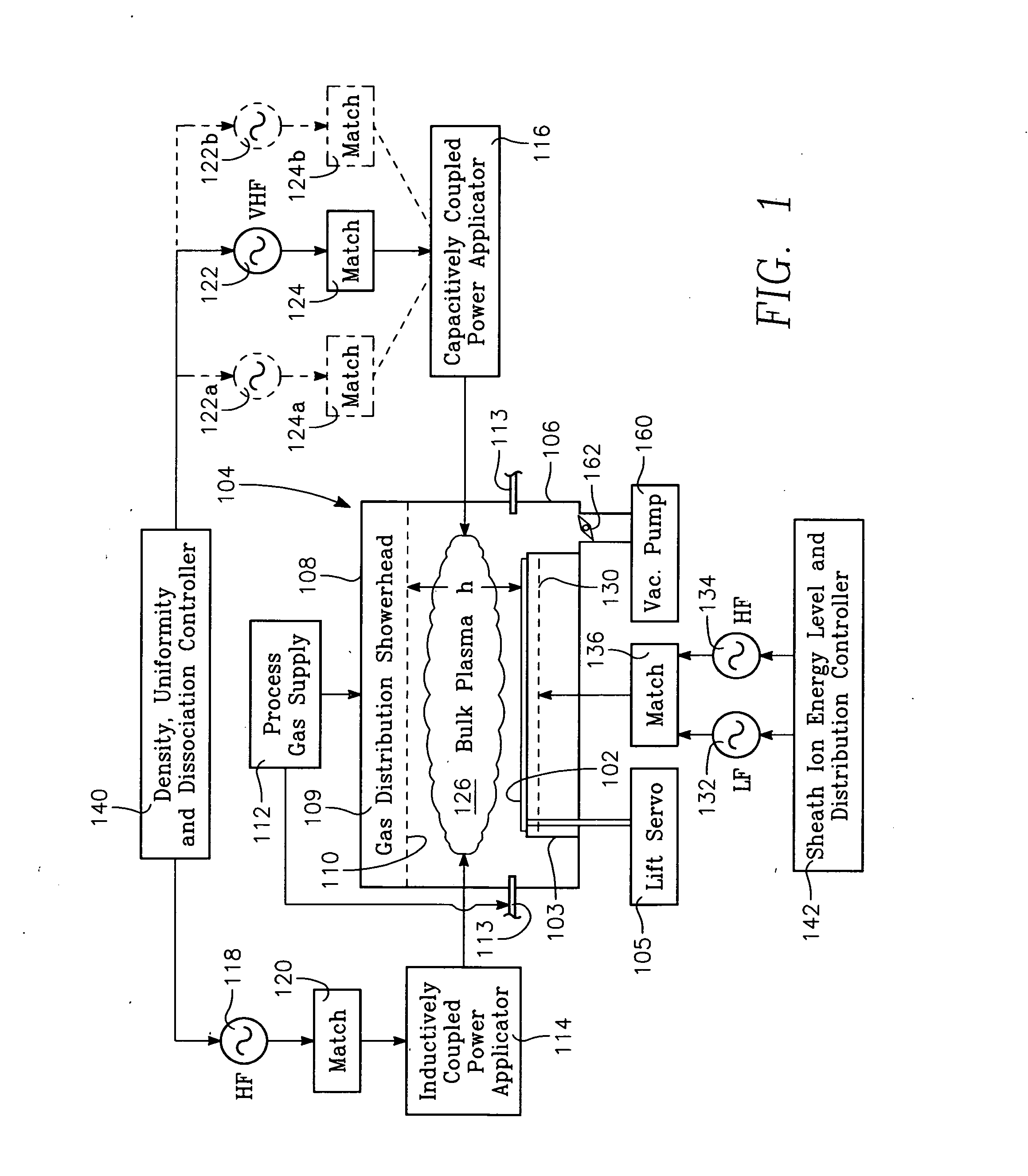

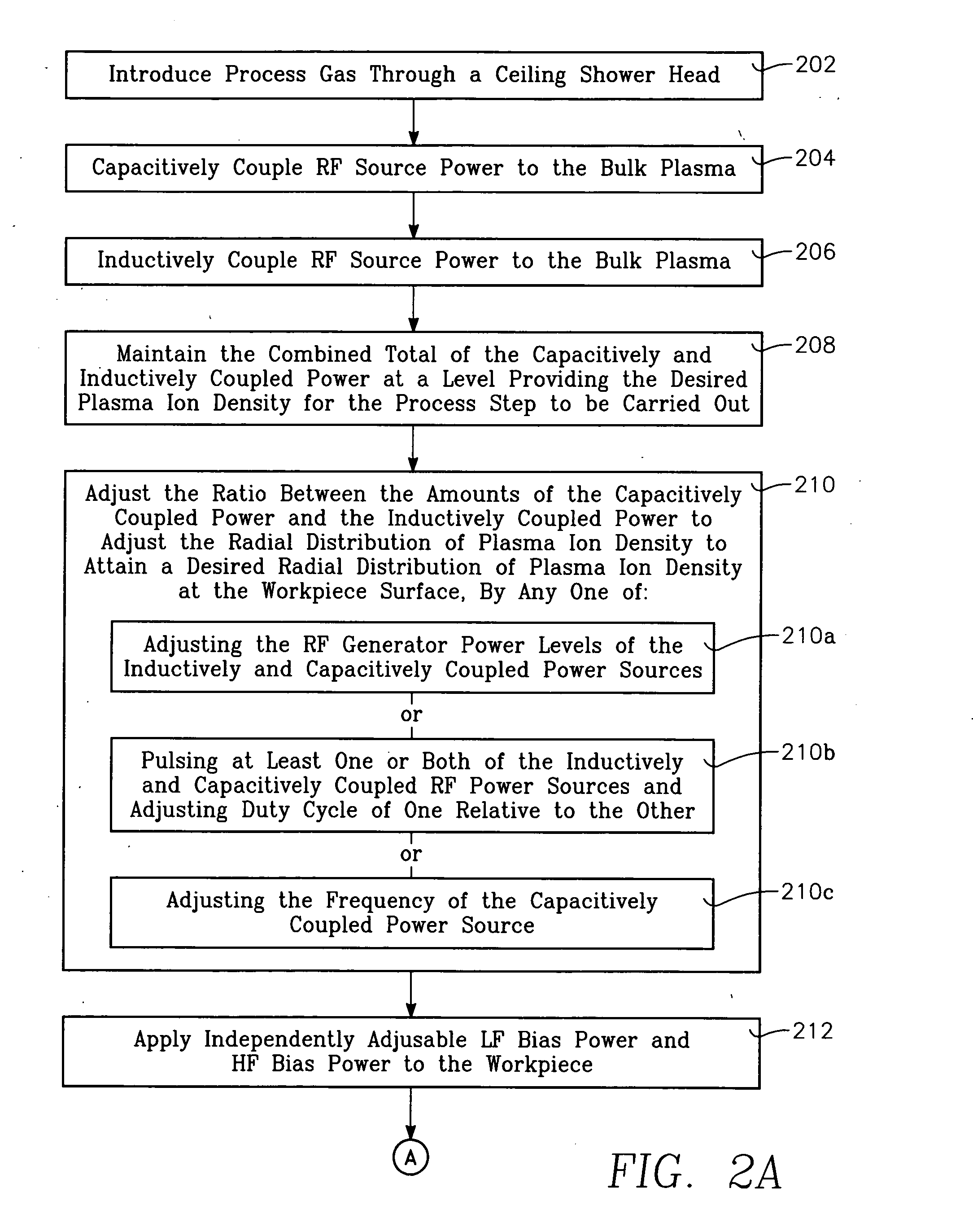

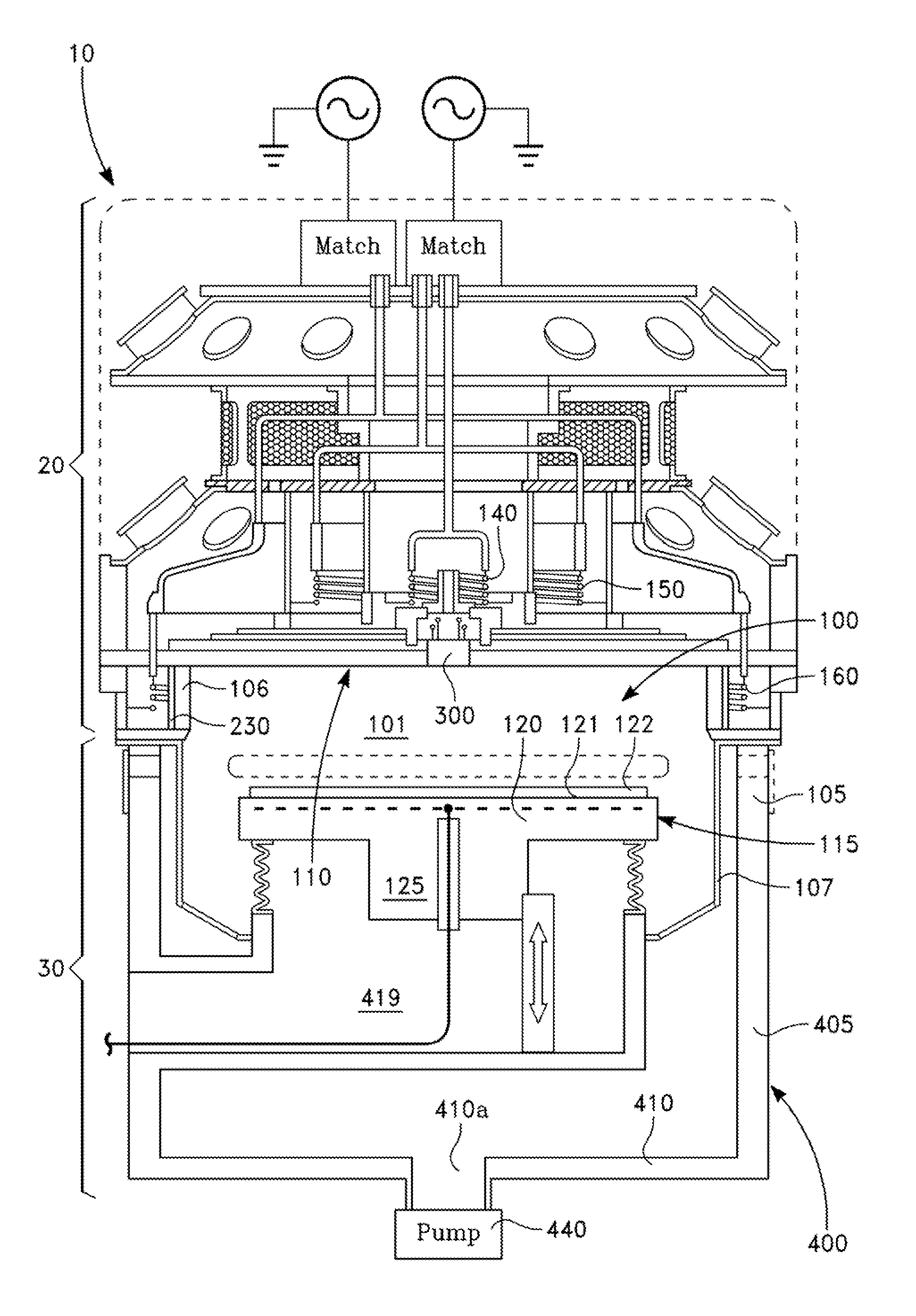

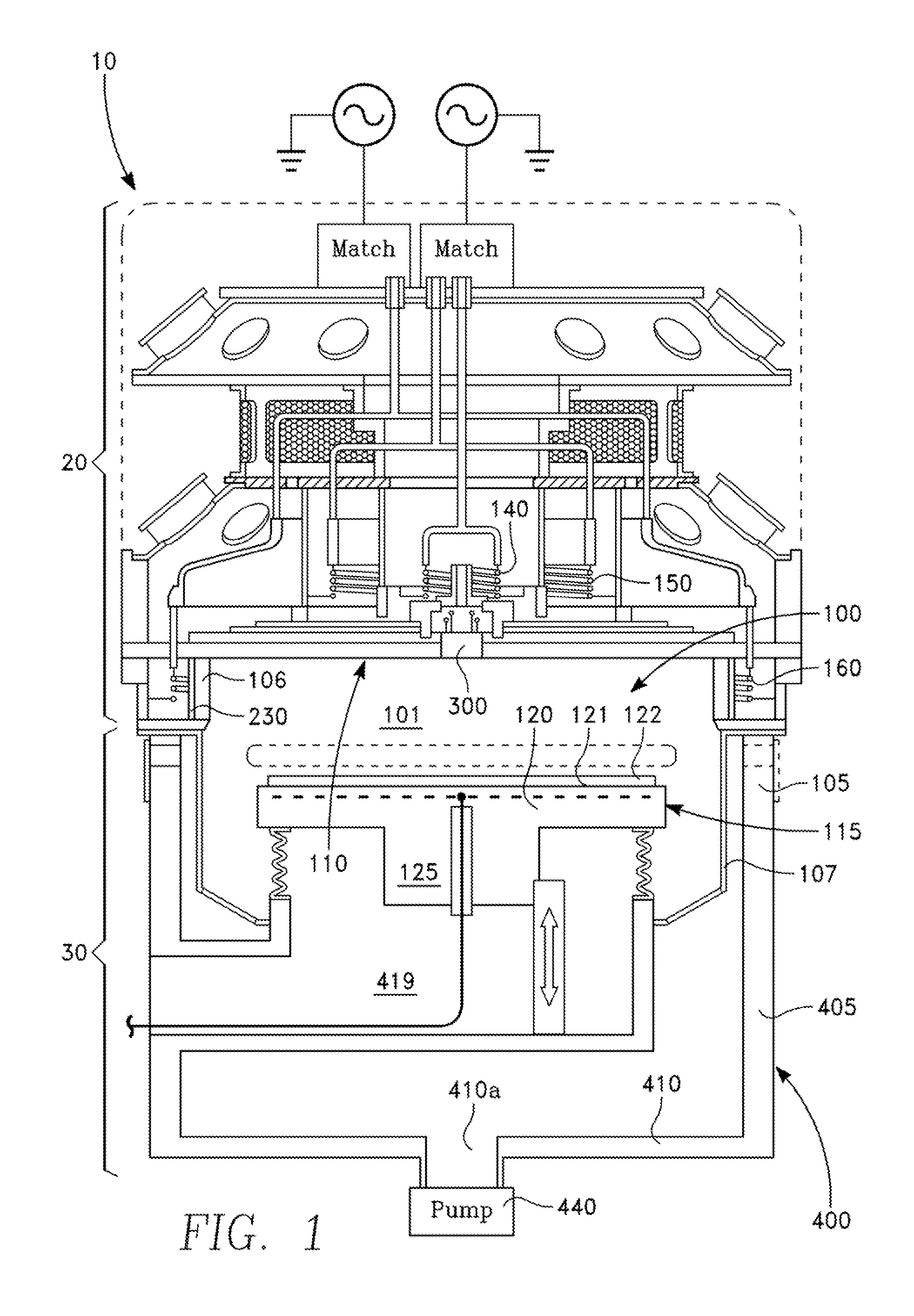

Plasma reactor apparatus with an inductive plasma source and a VHF capacitively coupled plasma source with variable frequency

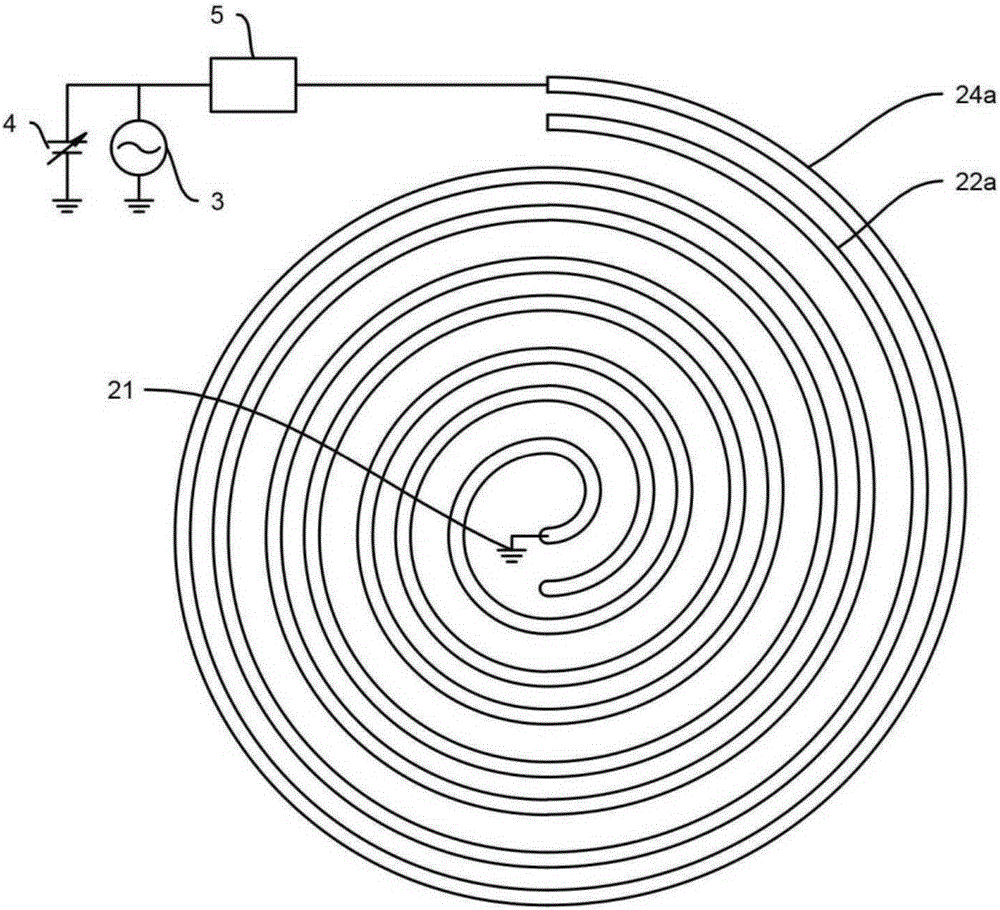

InactiveUS20070246162A1Increase ratingsIncrease ion densityElectric discharge tubesSemiconductor/solid-state device manufacturingCapacitanceNuclear engineering

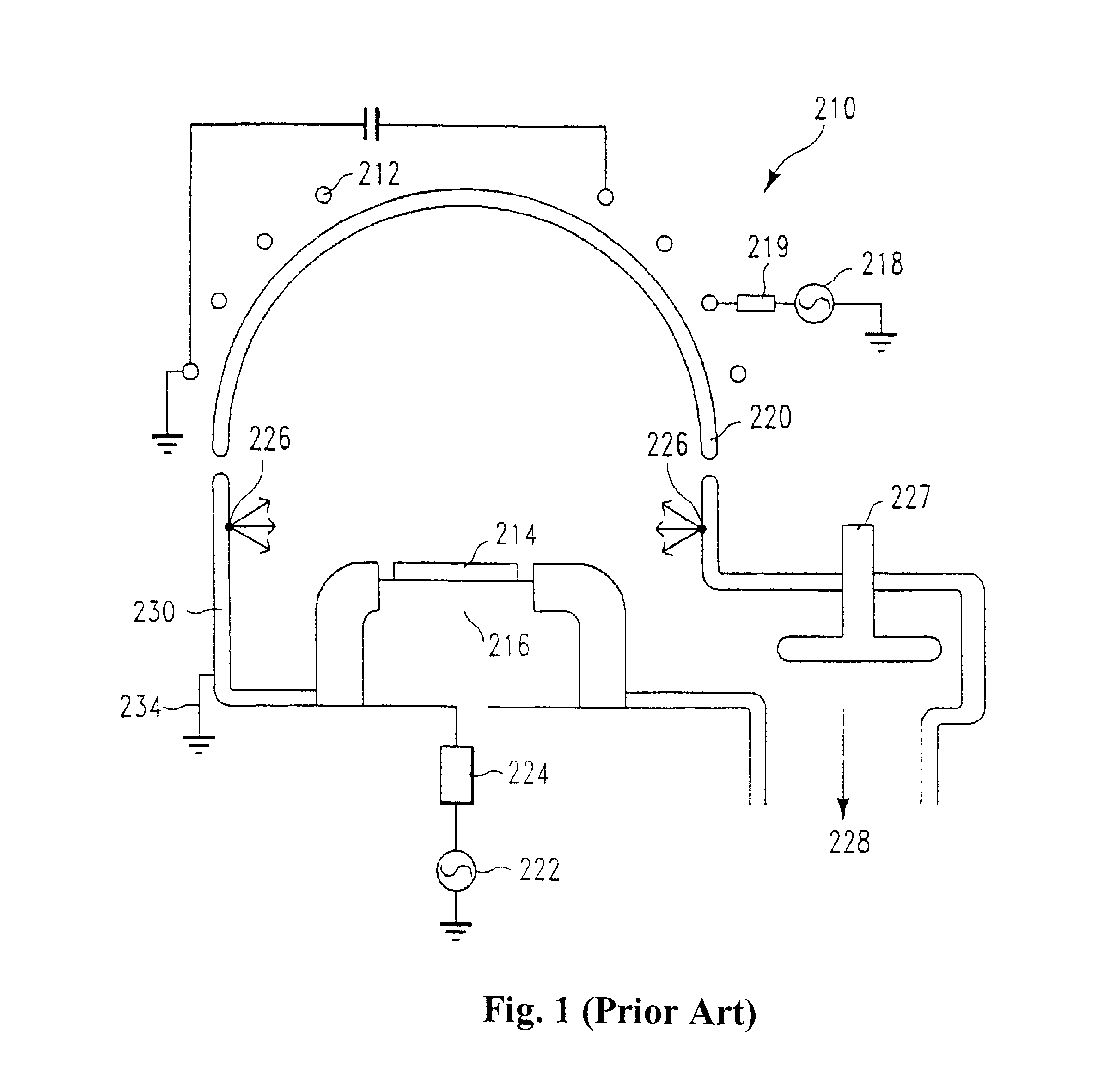

A plasma reactor for processing a workpiece includes a reactor chamber and a workpiece support within the chamber, the chamber having a ceiling facing the workpiece support, an inductively coupled plasma source power applicator overlying the ceiling, and an RF power generator coupled to the inductively coupled source power applicator, a capacitively coupled plasma source power applicator comprising a source power electrode at one of: (a) the ceiling (b) the workpiece support, and plural VHF power generators of different fixed frequencies coupled to the capacitively coupled source power applicator, and a controller for independently controlling the power output levels of the plural VHF generators so as to control an effective VHF frequency applied to the source power electrode. In a preferred embodiment, the reactor further includes a plasma bias power applicator including a bias power electrode in the workpiece support and one or more RF bias power generators of different frequencies coupled to the plasma bias power applicator.

Owner:APPLIED MATERIALS INC

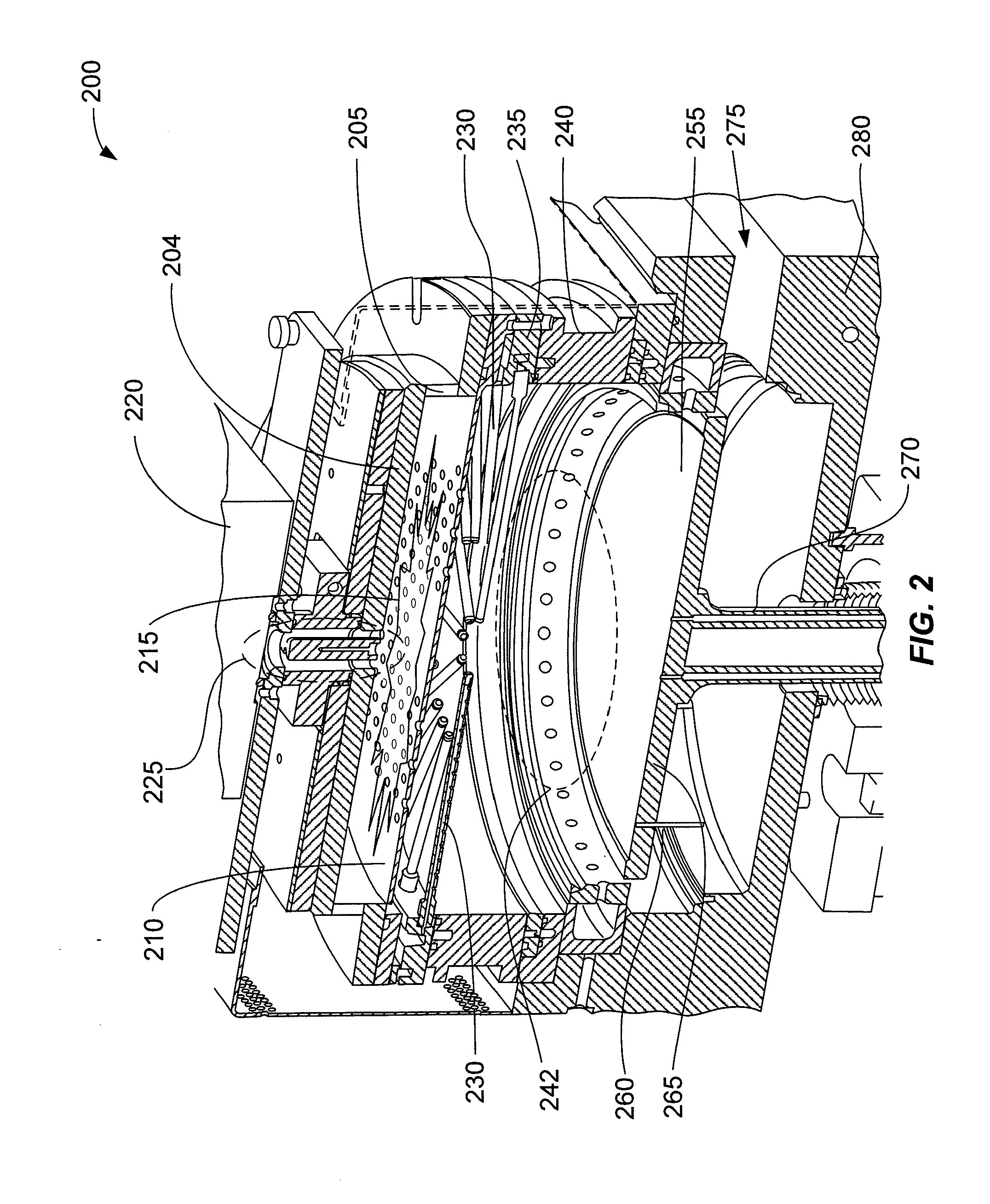

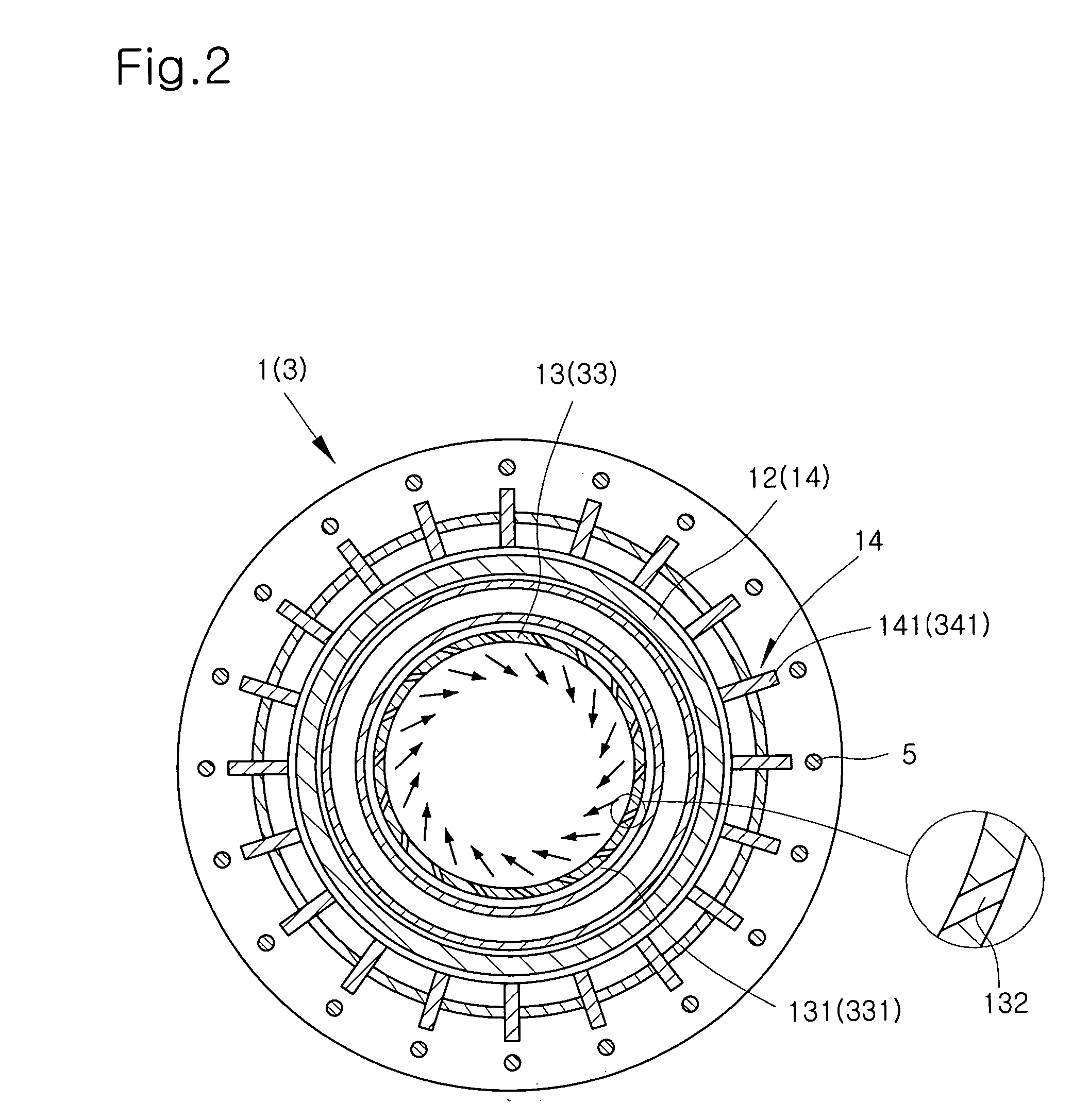

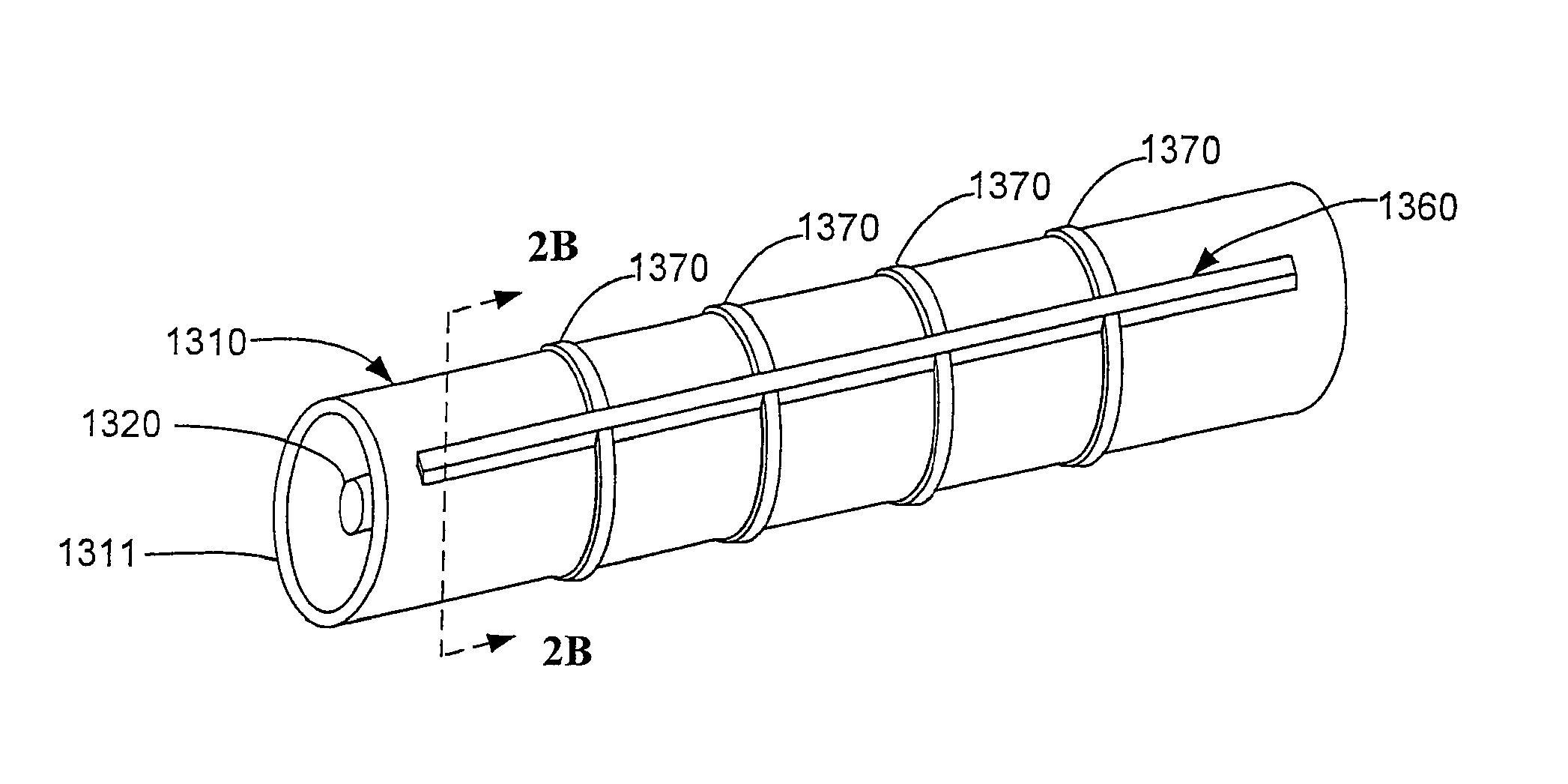

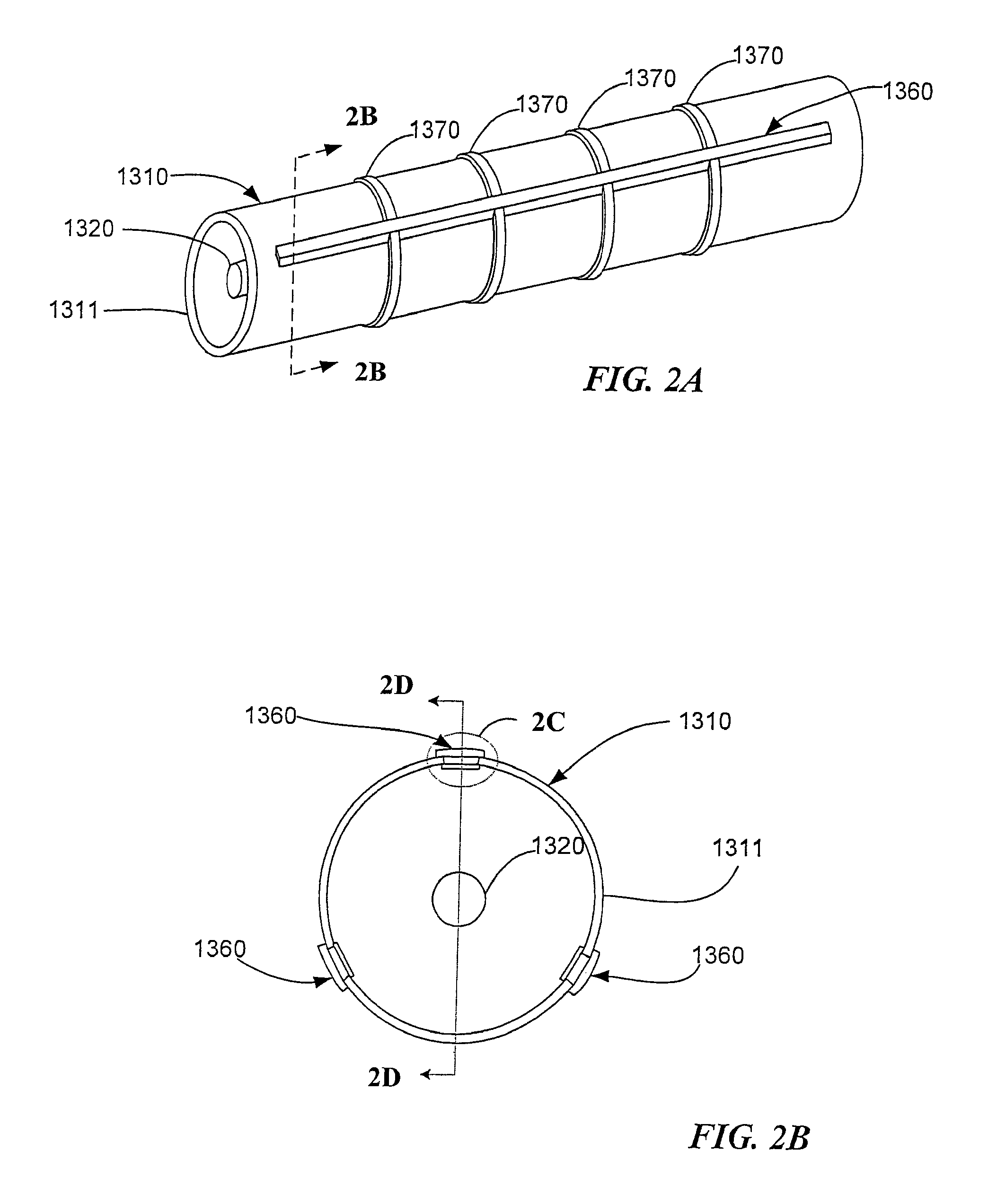

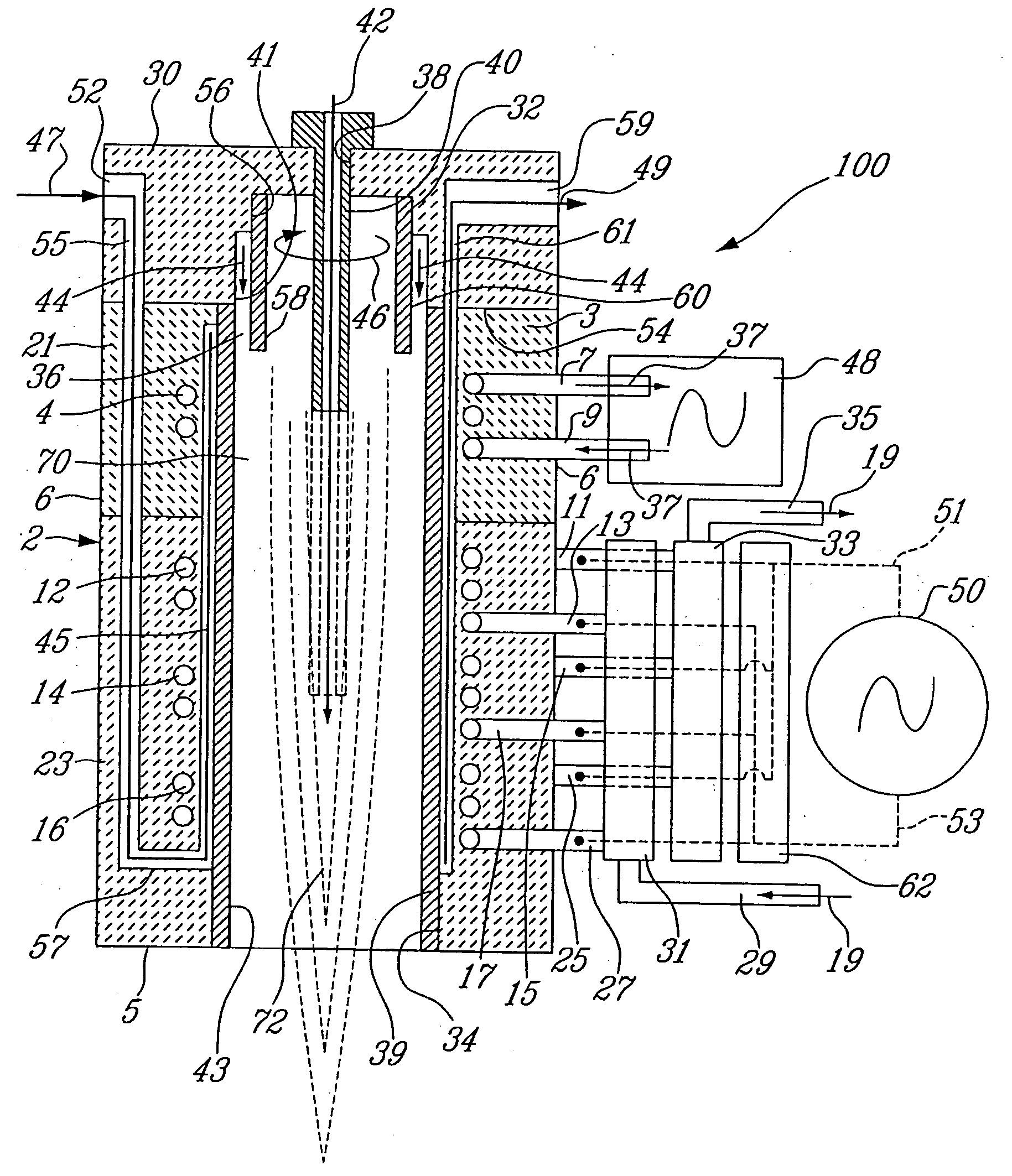

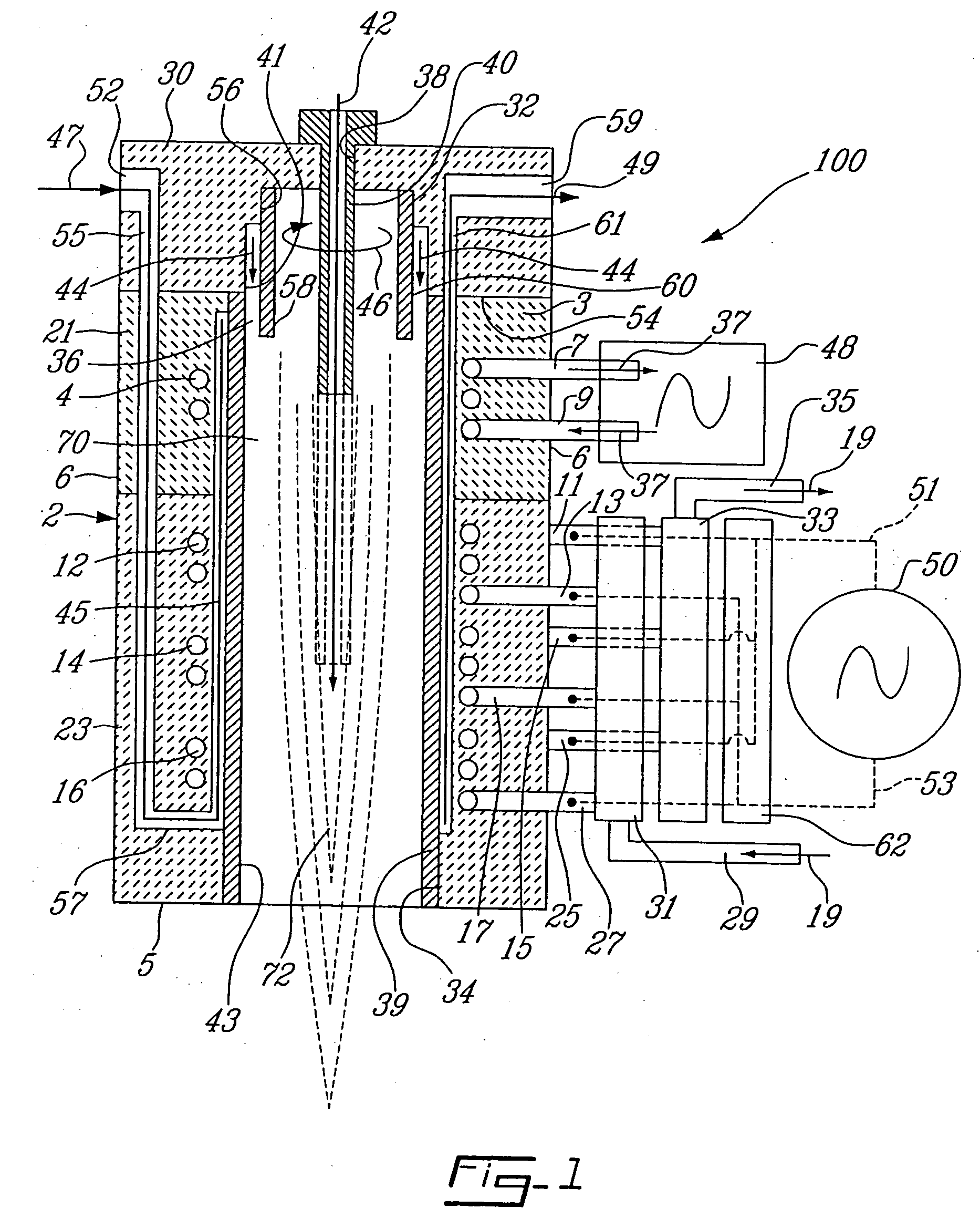

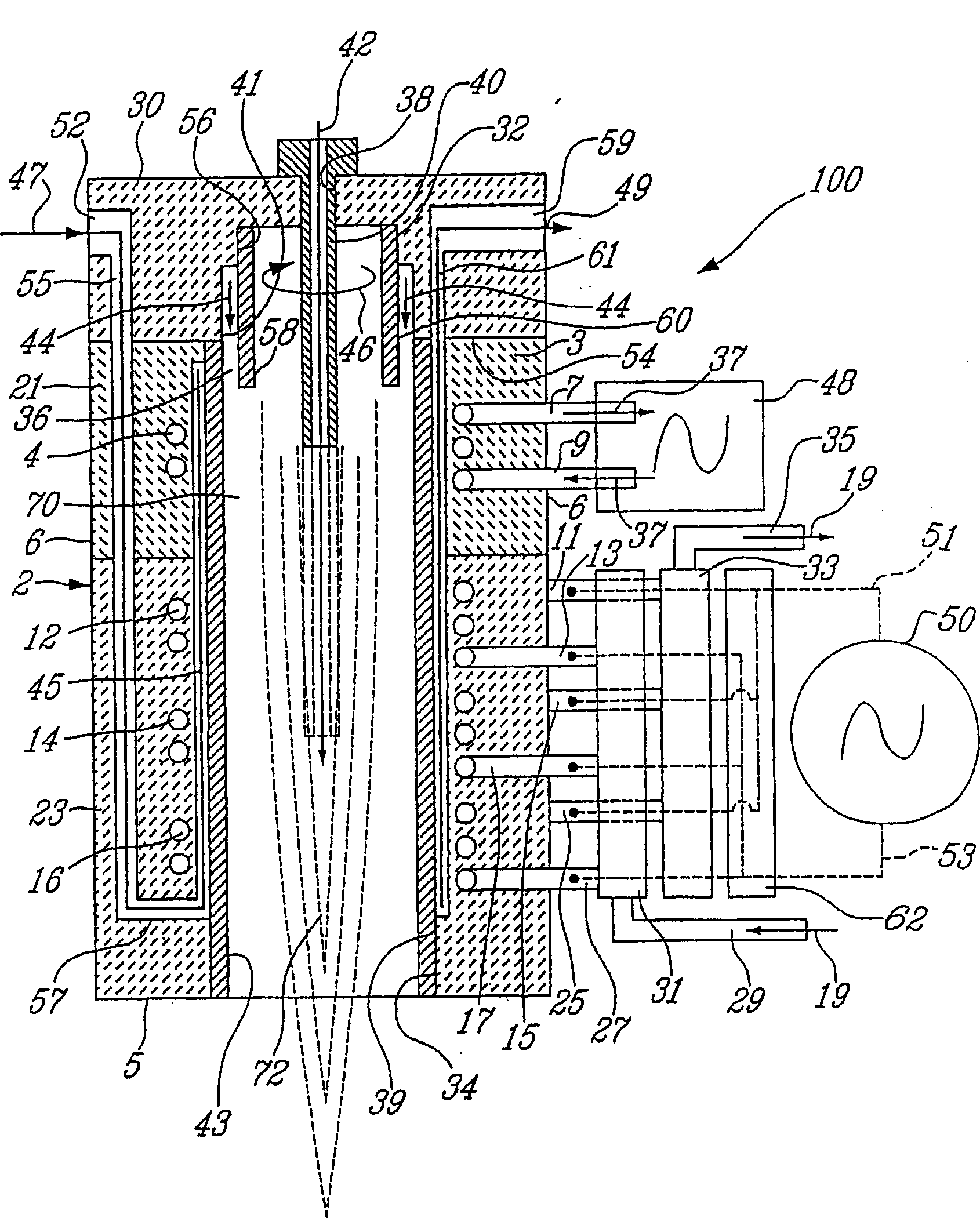

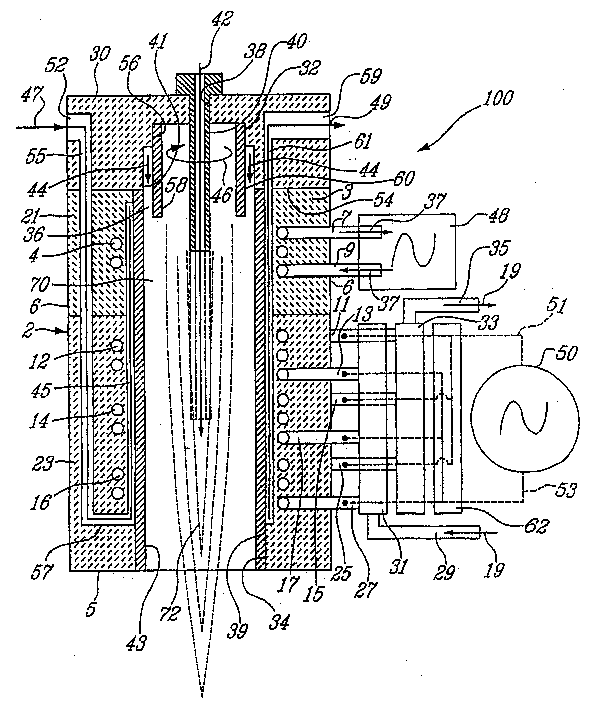

Multi-coil induction plasma torch for solid state power supply

InactiveUS20050017646A1Efficiently transfer heatImprove thermal conductivityElectric discharge tubesElectric arc lampsHigh frequency powerInduction plasma technology

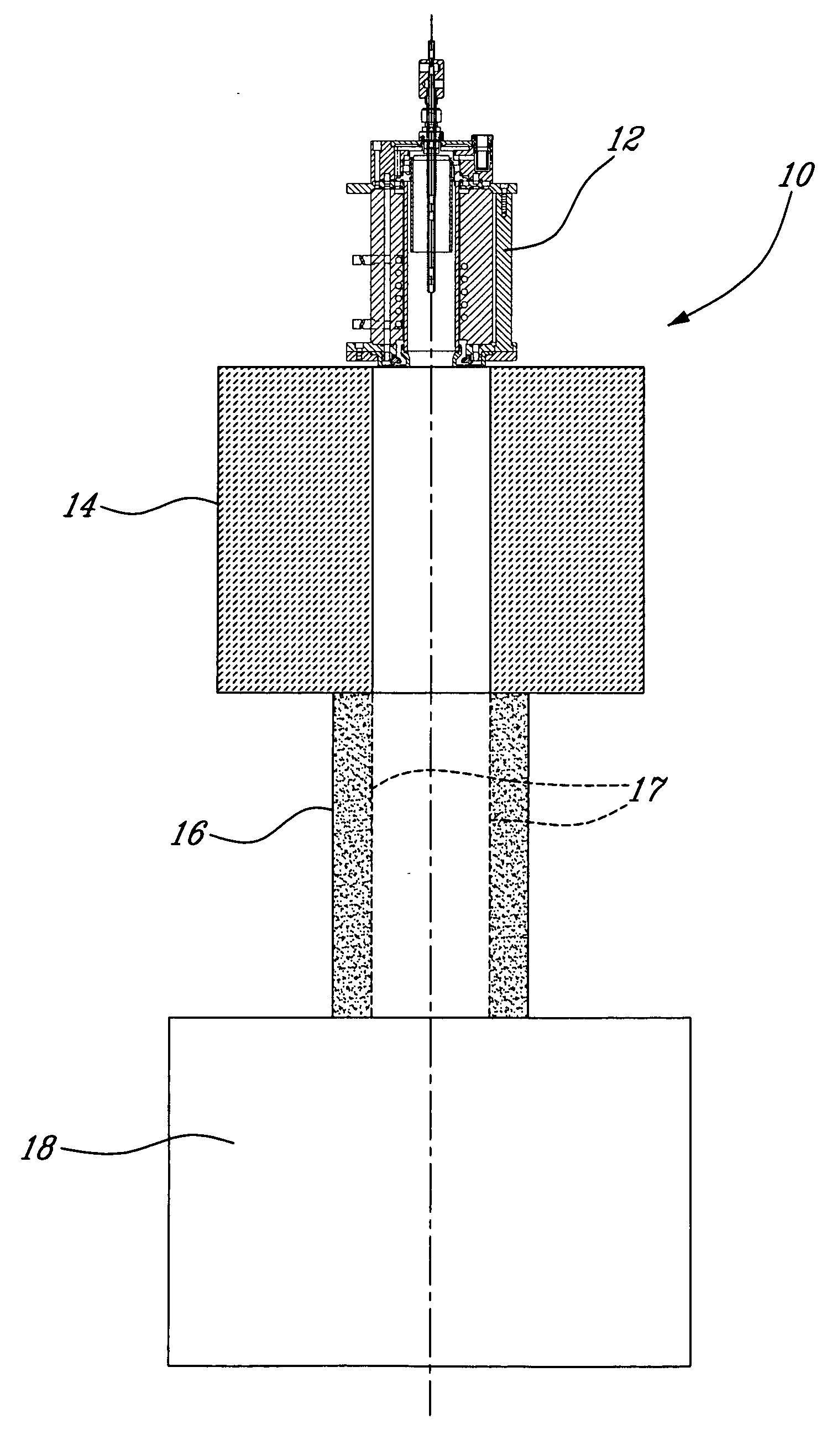

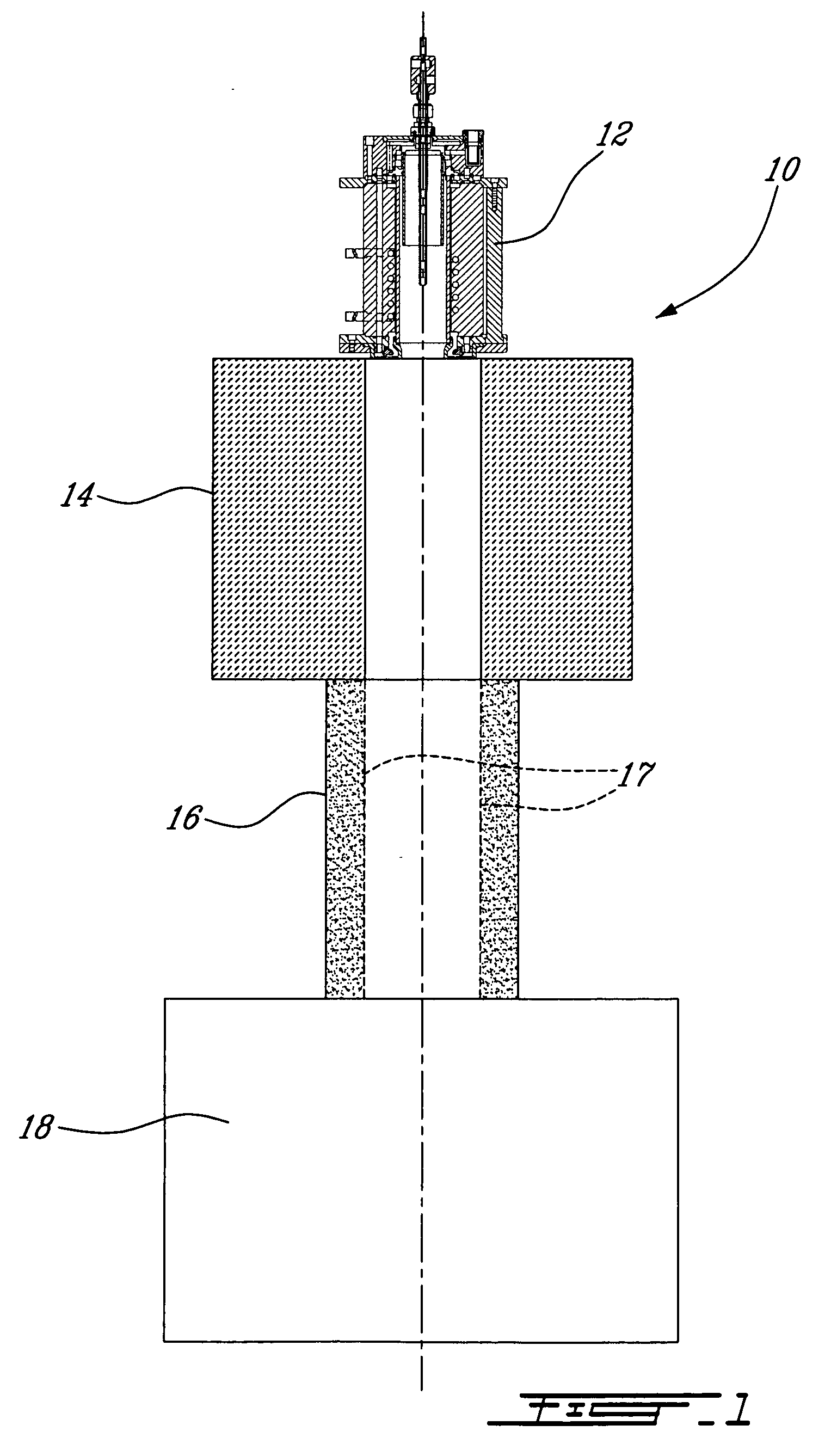

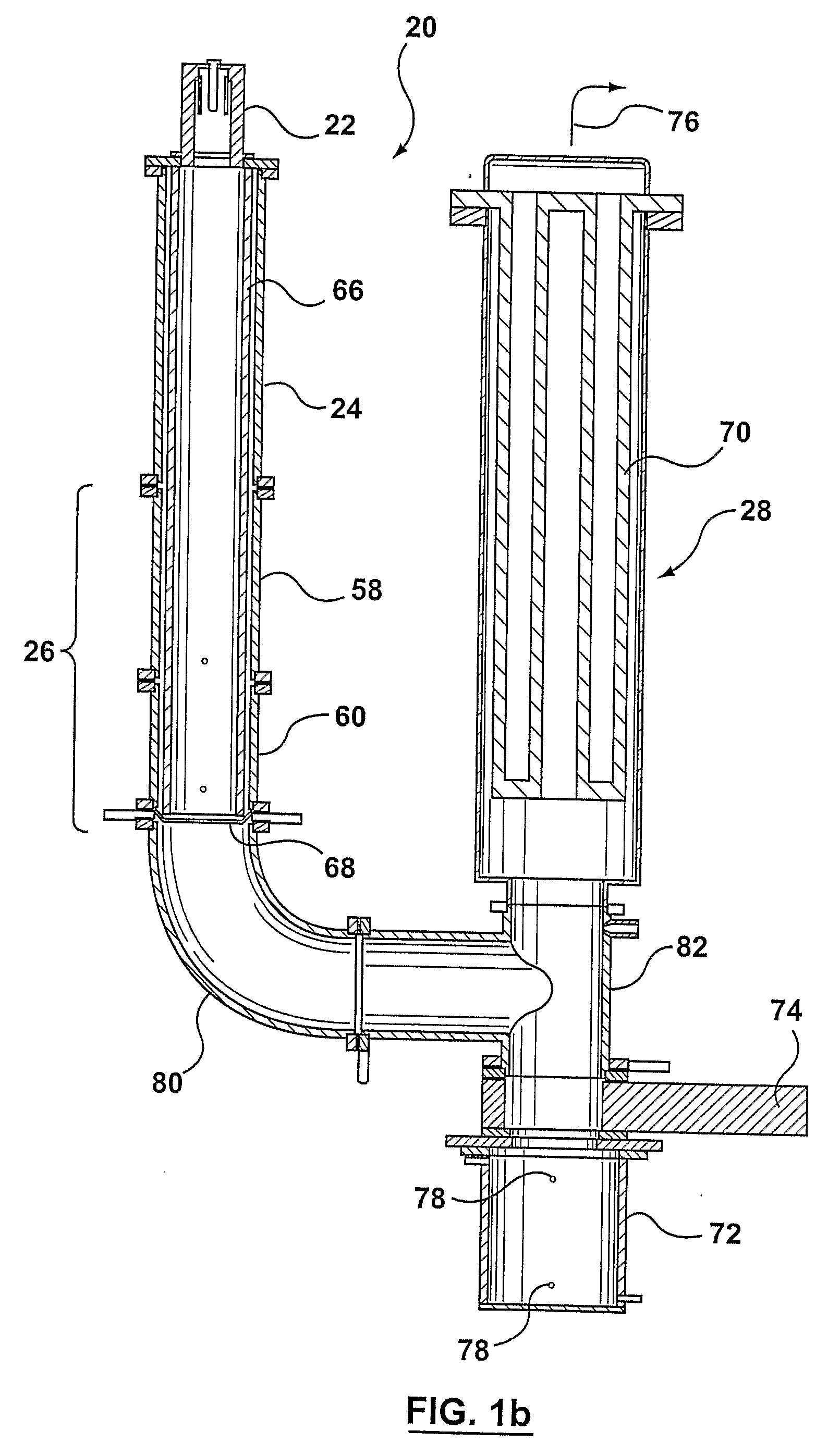

An induction plasma torch comprises a tubular torch body, a gas distributor head located at the proximal end of the torch body for supplying at least one gaseous substance into the chamber within the torch body, a higher frequency power supply connected to a first induction coil mounted coaxial to the tubular torch body, a lower frequency solid state power supply connected to a plurality of second induction coils mounted coaxial to the tubular torch body between the first induction coil and the distal end of this torch body. The first induction coil provides the inductive energy necessary to ignite the gaseous substance to form a plasma. The second induction coils provide the working energy necessary to operate the plasma torch. The second induction coils can be connected to the solid state power supply in series and / or in parallel to match the impedance of this solid state power supply.

Owner:TEKNA PLASMA SYST INC

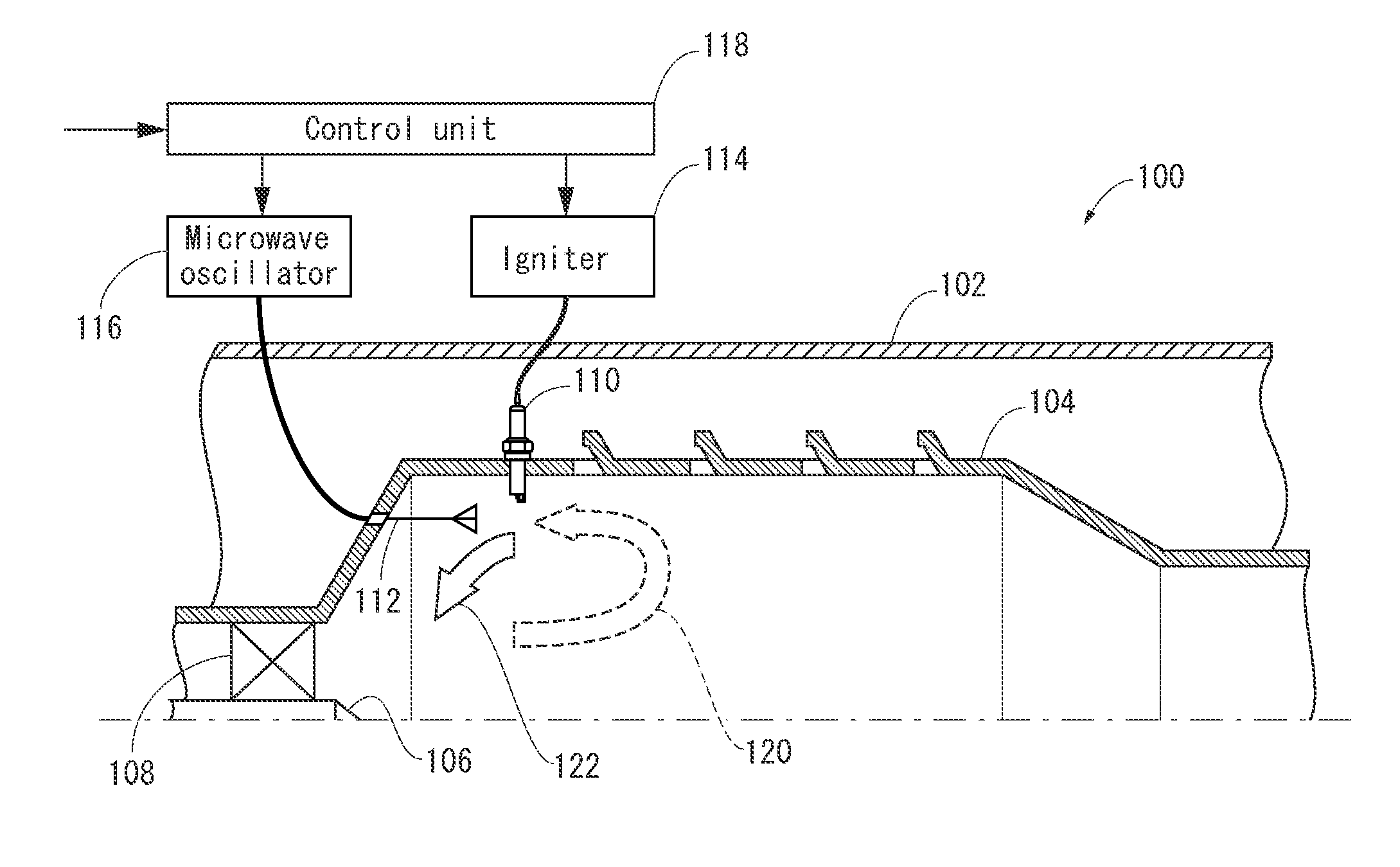

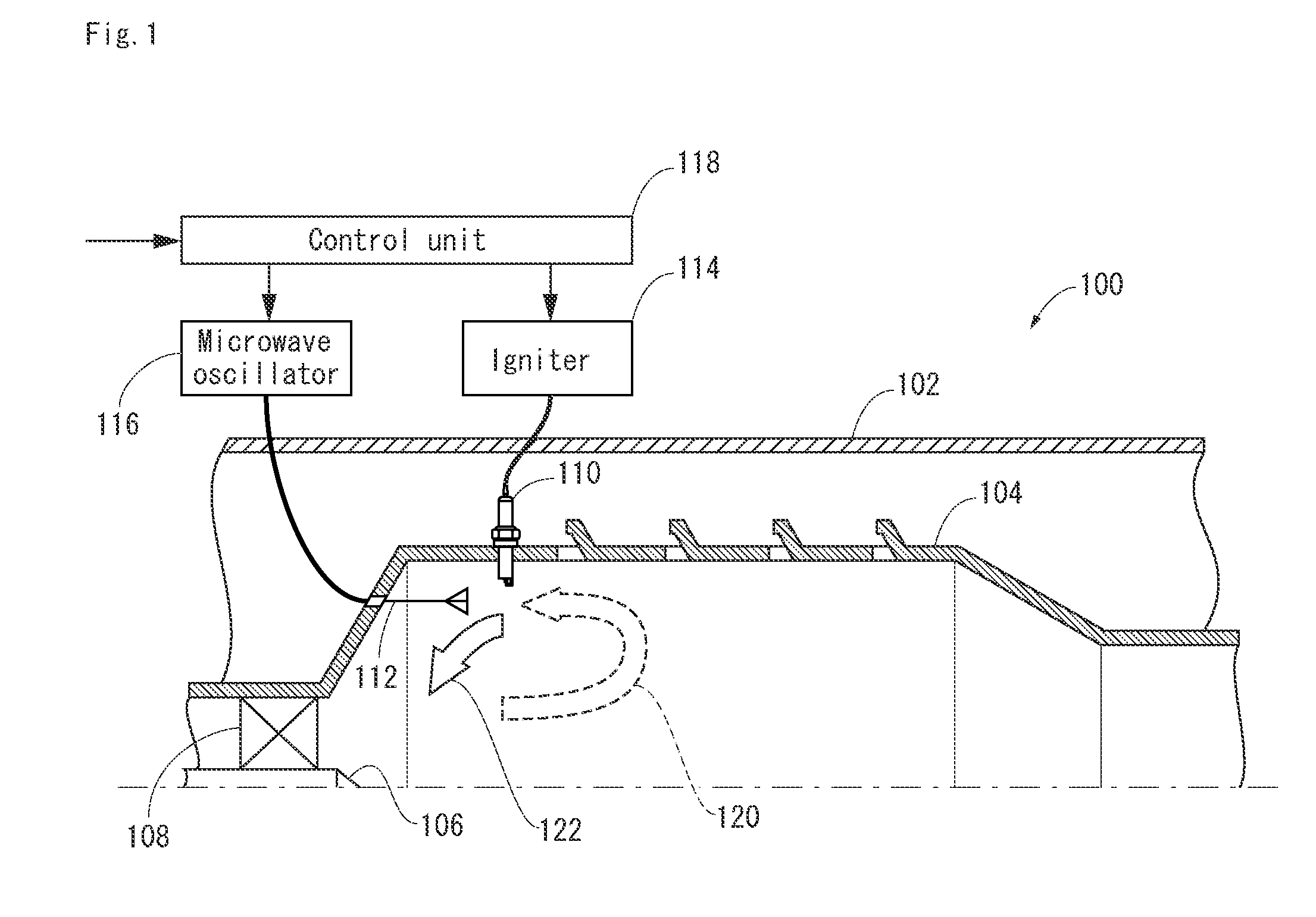

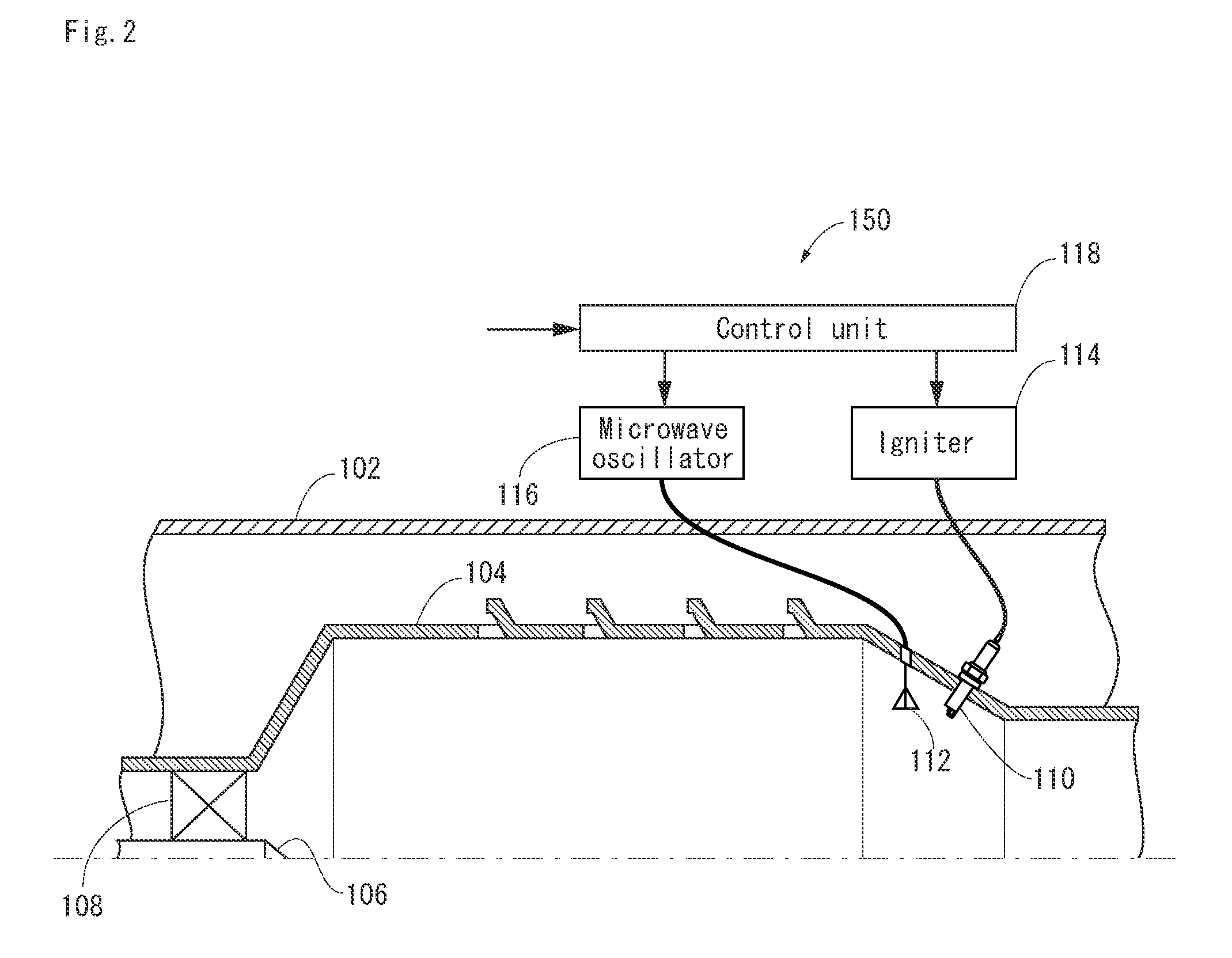

Ignition/ chemical reaction promotion/ flame holding device, speed-type internal combustion engine, and furnace

ActiveUS20100186368A1Easy to igniteEasy to spreadContinuous combustion chamberIncandescent ignitionWorking fluidChemical reaction

An ignition and chemical reaction accelerator and flame stabilizer and a high-performance speed-type internal combustion engine using this device are provided, whereby ignition and the spreading and holding of flames can be dramatically improved in a gas turbine, a ram machine, a rocket engine, or another speed-type internal combustion engine. An ignition and chemical reaction accelerator and flame stabilizer of a speed-type internal combustion engine comprises a spark plug (110) for preparing charged particles in a predetermined location in a combustor (104) of the speed-type internal combustion engine, and a microwave oscillator (116) and antenna (112) for inducing plasma with a working fluid in the combustor as a starter material by irradiating the charged particles and their surrounding vicinity with microwave pulses; wherein a region in which sufficient conditions for performing combustion are met is formed in the combustor by supplying an active chemical species produced from the working fluid by the effect of the plasma.

Owner:I LAB INC

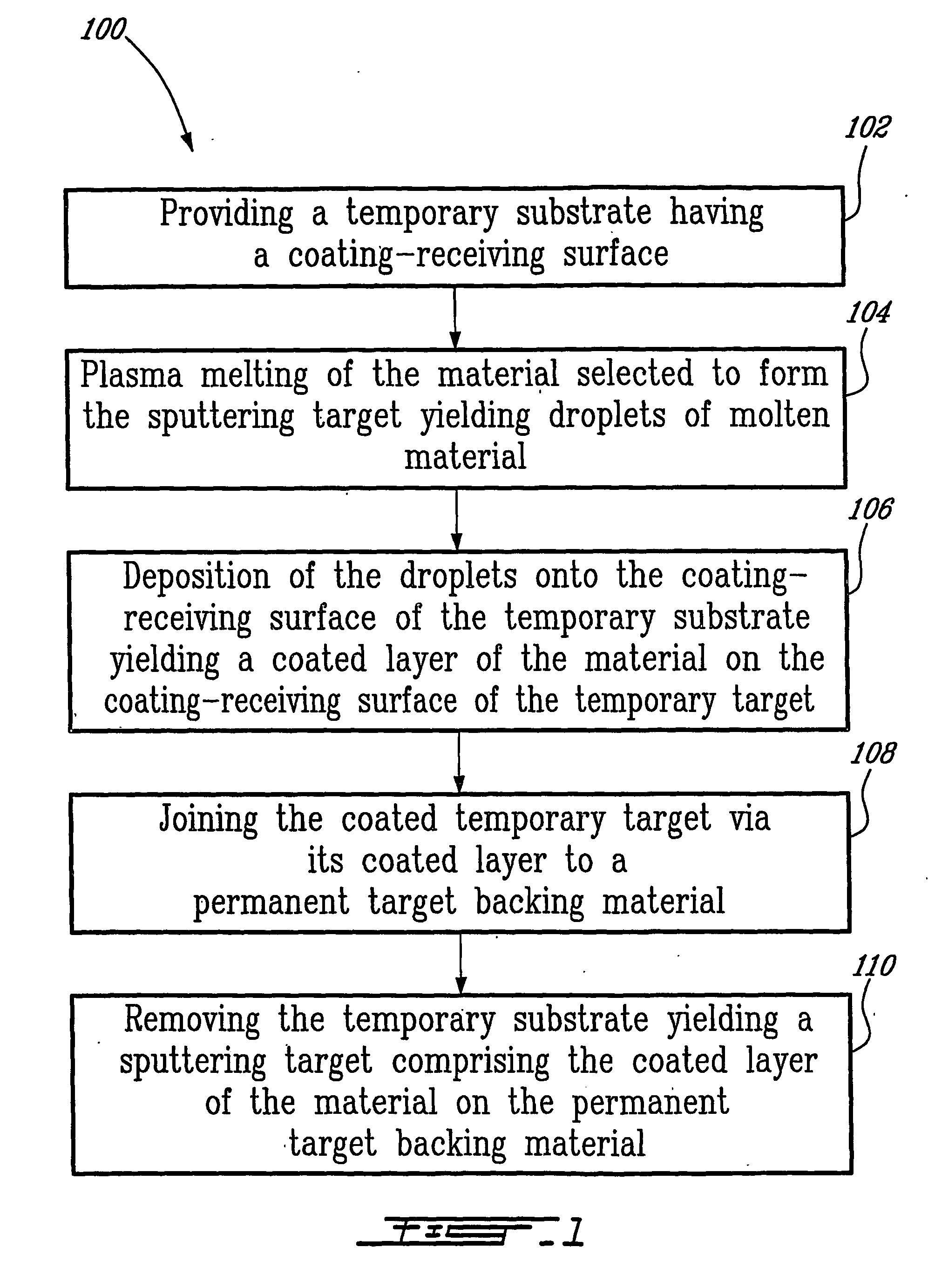

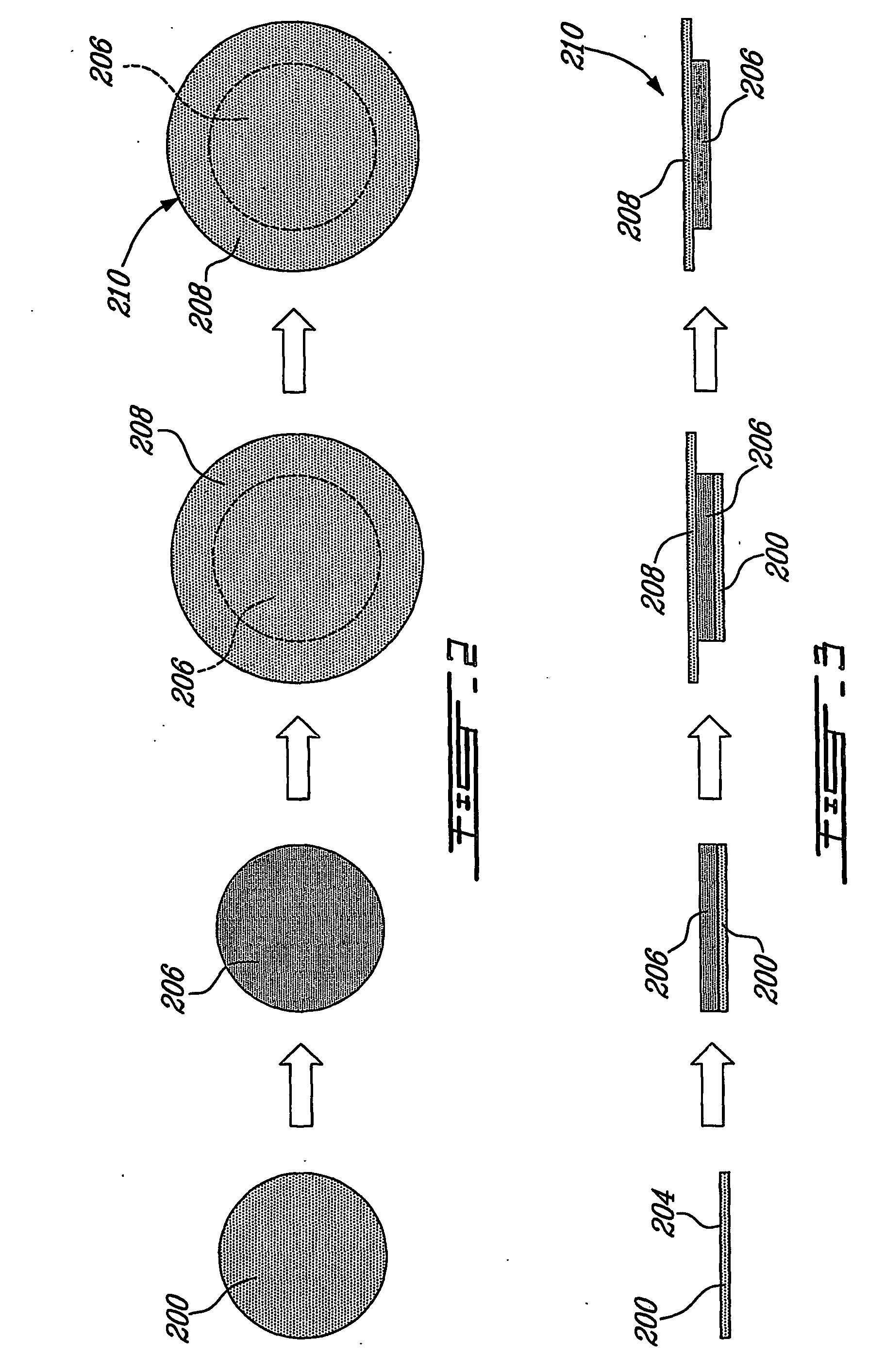

Process and apparatus for the manufacture of a sputtering target

A process for the manufacture of sputtering target comprises the steps of i) providing a substrate; ii) plasma melting of a material selected to form the sputtering target, yielding droplets of molten material; and iii) deposition of the droplets onto the substrate, yielding a sputtering target comprised of the coated layer of the material on the substrate. In some application, it might be preferable that the substrate be a temporary substrate and iv) to join the coated temporary target via its coated layer to a permanent target backing material; and v) to remove the temporary substrate, yielding a sputtering target comprised of the coated layer of the material on the permanent target backing material. The plasma deposition step is carried out at atmospheric pressure or under soft vacuum conditions using, for example, d.c. plasma spraying, d.c. transferred arc deposition or induction plasma spraying. The process is simple and does not require subsequent operation on the resulting target.

Owner:TEKNA PLASMA SYST INC

Method and Apparatus for the Continuous Production and Functionalization of Single-Walled Carbon Nanotubes Using a High Frequency Plasma Torch

An integrated method and apparatus to continuously produce purified Single Wall Carbon Nanotubes (SWNT) from a continuous supply of solid carbon powder fed to an induction plasma torch. The apparatus includes a reactor body disposed to maintain laminar flow of gases with the torch body and coupled to a quenching body where temperature and residence time is controlled. Conveniently, functionalization may take place in the quenching body. The torch is operated with an argon carrier gas, an argon stabilizing gas and a helium sheath gas. Solid carbon reactants are preferably mixed with at least two metal catalysts containing nickel and cobalt with additional metal oxides of yttrium and cerium being desirable.

Owner:LA SOC DE COMMLISATION DES PROD DE LA RECH APPLIOUEE SOCPRA - SCI & GENIE S E C +1

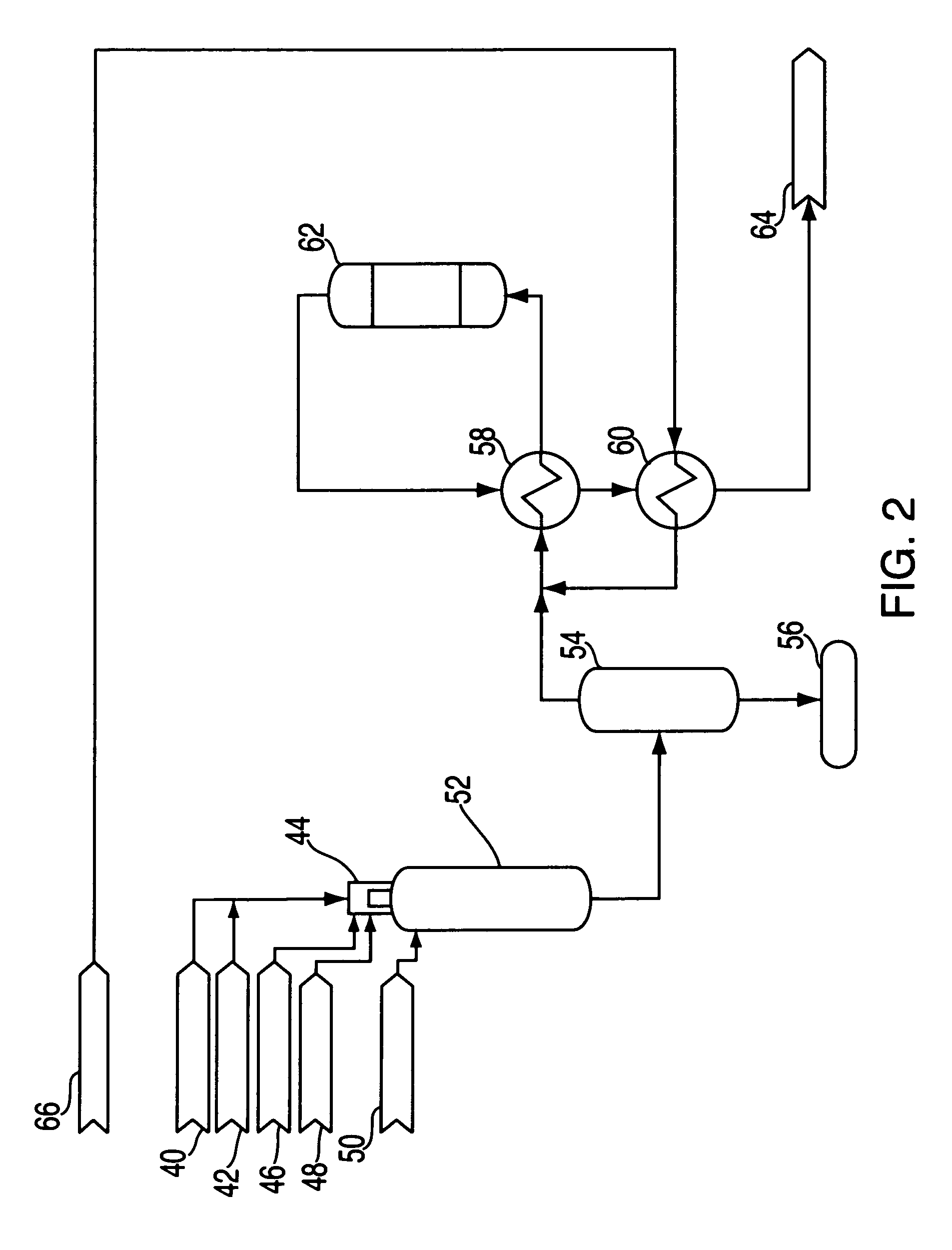

RF plasma system for medical waste treatment

ActiveUS20080247904A1Toxic gas generationReduce Medical WasteSolid waste disposalLavatory sanitoryNuclear engineeringInduction plasma technology

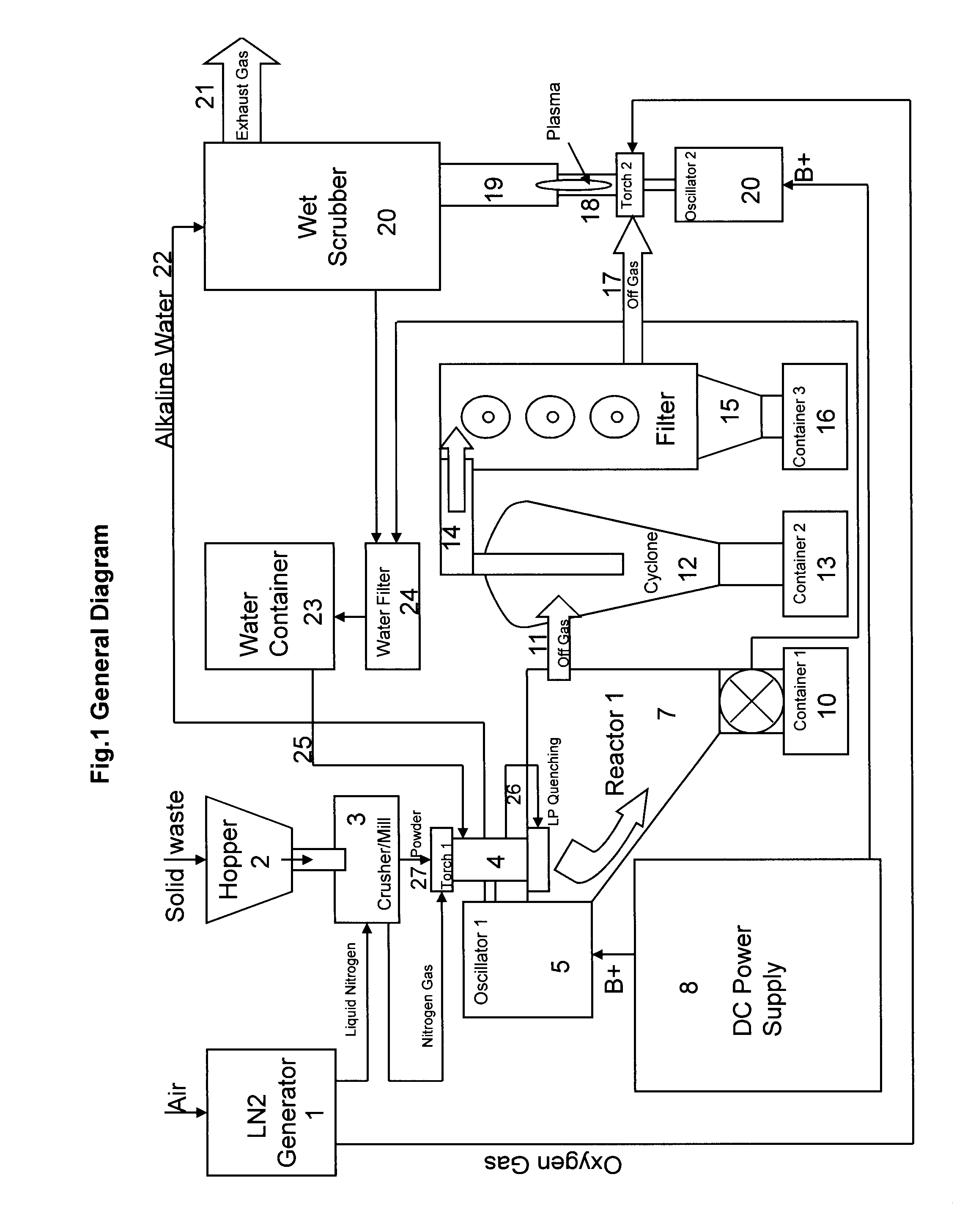

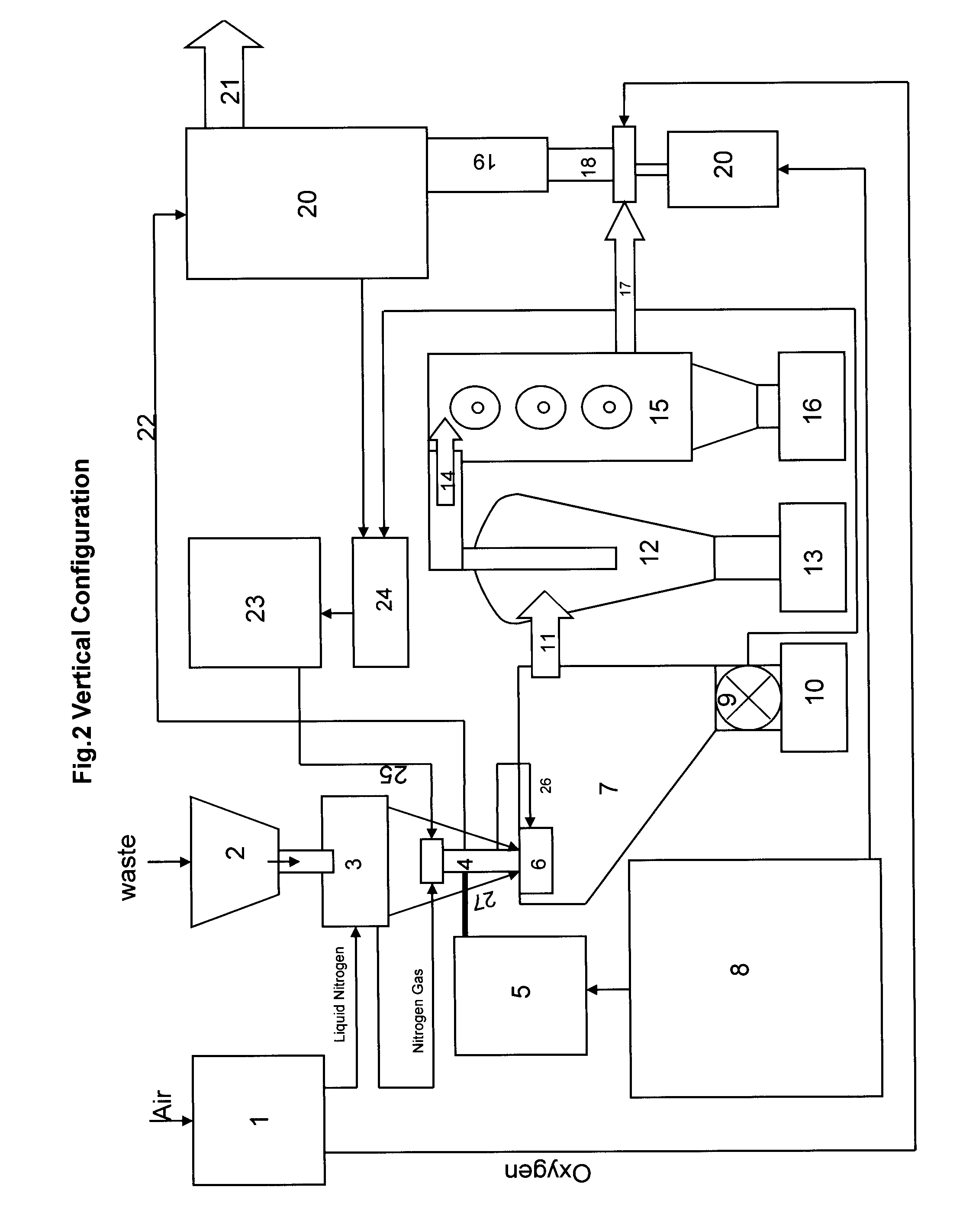

A system and method are provided for the thermal and non-thermal (oxidation) plasma treatment of medical waste using an electrode-less induction (thermal) and capacitive (non-thermal) plasma torches. The medical waste is pre-treated by liquid nitrogen, crushed and pulverized by LN2 crusher / pulverizer, and conveyed to the nitrogen / water thermal plasma reactor, which converts the powdered medical waste into carbon black and generated gas (resulting from the thermal step) is directed to the Oxygen non-thermal plasma reactor for post-treatment. The system is equipped with an emission control unit, dual frequency pulse RF power supply, and Liquid Nitrogen Generator. The off gas from LN2 crusher (nitrogen) is used for the induction plasma torch and off gas from LN2 generator (oxygen) is used as a plasma gas for the Non-thermal plasma torch.

Owner:PASKALOV GEORGE

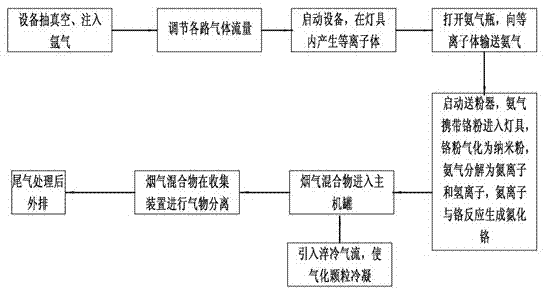

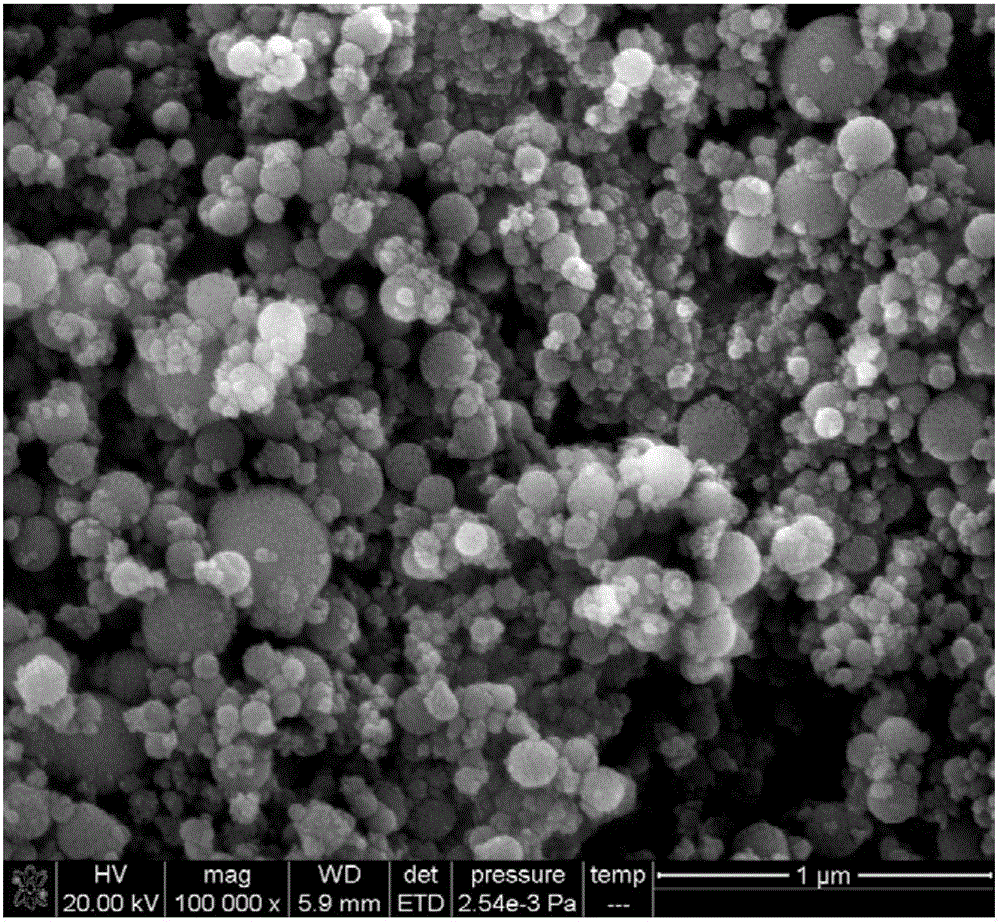

Preparation method of chromium nitride nanometer powder

ActiveCN106927436ANo electrode contaminationGuaranteed purityNitrogen-metal/silicon/boron binary compoundsGranularityInduction plasma technology

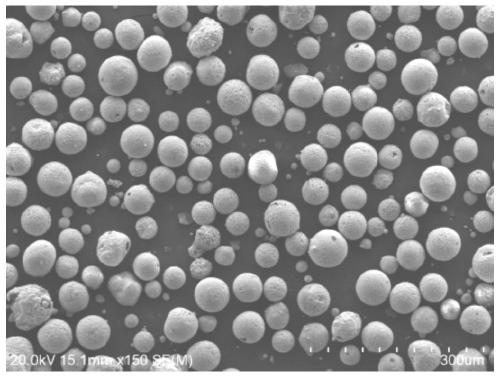

The invention discloses a preparation method of chromium nitride nanometer powders. The method utilizes the high temperature and etching effects produced by high-frequency induction plasma to realize a chemical vapor synthesis and obtain chromium nitride superfine powders. The method comprises the steps of vacuumizing the whole equipment, producing hyperthermal plasma, adjusting the flux of ammonia gas, congealing solid nanometer powders, collecting congealed chromium nitride nanometer powders, packaging and the like. By the means of using the preparation method, chromium nitride nanometer powders with an average grain diameter of 40nm are obtained, wherein the size distribution of the chromium nitride nanometer powders is pretty narrow and the shape of the powders is spherical. The preparation method has the advantages of simple processing steps, a rapid burning rate, high reaction temperature, ease for controlling in the reaction process, no pollution and the like.

Owner:陕西安康三航纳米科技股份有限公司

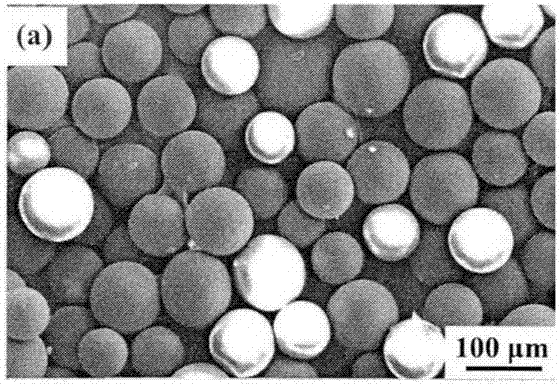

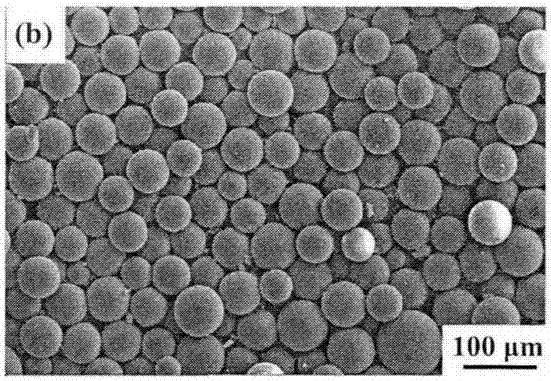

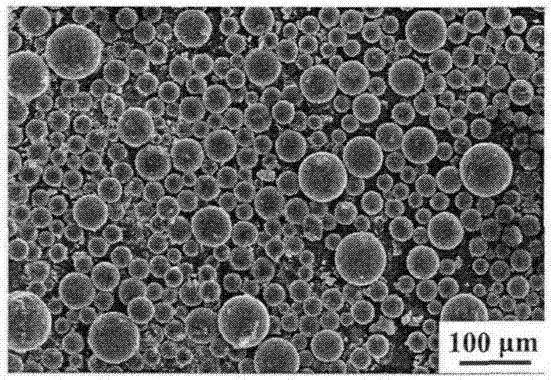

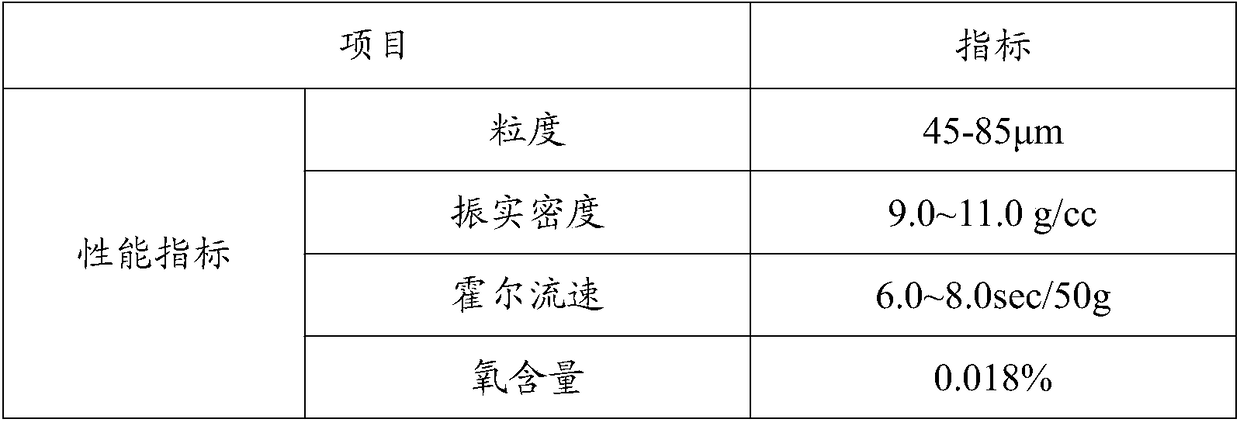

Preparing method and application of high purity and density spherical titanium zirconium alloy powder

ActiveCN107363262AHigh purityLow costTransportation and packagingMetal-working apparatusTitanium zirconiumInduction plasma technology

The invention relates to a preparing method and application of high purity and density spherical titanium zirconium alloy powder, and belongs to the technical field of alloy powder material preparation. The preparing method comprises the following steps that titanium sponge and zirconium sponge are used as raw materials, and titanium zirconium alloy ingots are prepared by using a vacuum induction melting technology; uniform vacuum annealing treatment is conducted on the titanium zirconium alloy ingots, and the ingots of uniform elements are obtained; the titanium zirconium alloy ingots are crushed into particles, hydrotreating is conducted, and hydrogen absorption titanium zirconium alloy powder is obtained; the hydrogen absorption titanium zirconium alloy powder is ball-milled under atmosphere protecting, and the hydrogen absorption titanium zirconium alloy powder of small particle sizes and irregular forms is obtained; the hydrogen absorption titanium zirconium alloy powder of irregular forms are sent to an inductive plasma torch, and the hydrogen absorption titanium zirconium alloy powder quickly absorbs heat, is dissolved and dehydrogenized; and in the dehydrogenizing process, the hydrogen absorption titanium zirconium alloy powder is split and shattered and then fused and nodulized under the high temperature, and finally, the high purity and density spherical titanium zirconium alloy powder is obtained by cooling. The titanium zirconium alloy powder prepared through the method has the advantages of being high in purity, small in particle size, good in uniformity, high in degree of sphericity and good in flowability.

Owner:云航时代(重庆)科技有限公司

Earlier stage treatment process of raw material powder for preparing induction plasma capacitor level nano tantalum powder

InactiveCN101439403AImprove liquidityImprove particle size distributionInduction plasma technologyGas flux

The invention relates to a pre-treatment technology of raw material powder used for preparing induction plasma capacitor grade nanometer tantalum powder. The technology comprises the steps as follows: a. tantalum powder with the granularity of 2-10micrometer which is prepared by sodium thermal reduction is used raw material; b. spheroidizing treatment is carried out on the raw material tantalum powder by an induction plasma powder synthesizing system, the technological parameters of the spheroidizing treatment are as follows: medium gas flux is 30 standard liter / min; sheath gas flux is 80-120 standard liter / min of argon and 0-10 standard liter / min of hydrogen; reaction chamber pressure is 50-120Kpa; plasma power is 30-60KW; powder feed rate is 2-15kg / h; cooling gas flux is 300-800 standard liter / min; the relative position of a powder feeder is arranged at the middle part of a plasma area; powder feeding gas flux is 8-20 standard liter / min; c. filtering treatment is that vibration filter is carried out by a 160-220 mesh screen mesh on a screen grader; d. air current grading treatment is that grading treatment is carried out on a cyclone separator, the technological parameters of the g rading treatment are as follows: power feed rate is 2-5kg / h, and the grading gas flux is 300-600 standard liter / min. The invention can carry out the continuous preparation of capacitor grade nanometer and submicron tantalum powder and ensures that the raw material is spherical by spheroidizing, filtering and grading treatment, and the powder with the granularity controlled within 2-5 micrometer takes more than 90 percent of the whole powder; and the invention improves the granularity distribution state, overcomes the aggregation and improves the collection efficiency of the tantalum powder, the utilization rate of energy and material and the electrical property.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

Method producing metal nanopowders by decompositon of metal carbonyl using an induction plasma torch

InactiveUS7967891B2Increase flexibilityImprove toleranceMaterial nanotechnologyTransportation and packagingMetallurgyInduction plasma technology

Owner:TEKNA PLASMA SYST INC

Symmetrical inductively coupled plasma source with symmetrical flow chamber

InactiveUS20140020835A1Electric discharge tubesGas-gas reaction as plasma stateInduction plasma technologyEngineering

A plasma reactor has an overhead multiple coil inductive plasma source with symmetric RF feeds and a symmetrical chamber exhaust with plural struts through the exhaust region providing access to a confined workplace support. A grid may be included for masking spatial effects of the struts from the processing region.

Owner:APPLIED MATERIALS INC

High resist-selectivity etch for silicon trench etch applications

InactiveUS6653237B2Easy to controlChamber deposits are reducedSemiconductor/solid-state device manufacturingResistInduction plasma technology

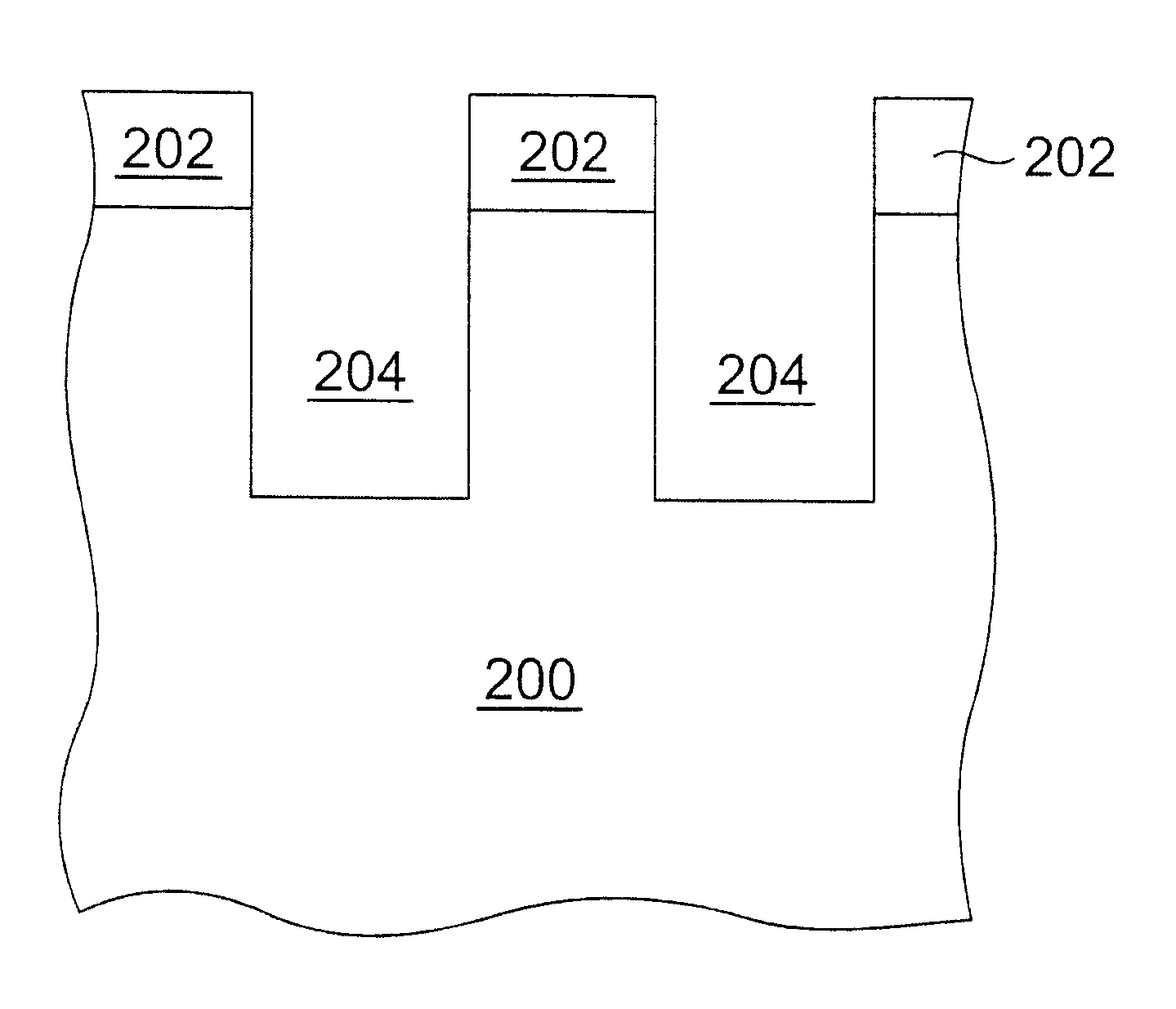

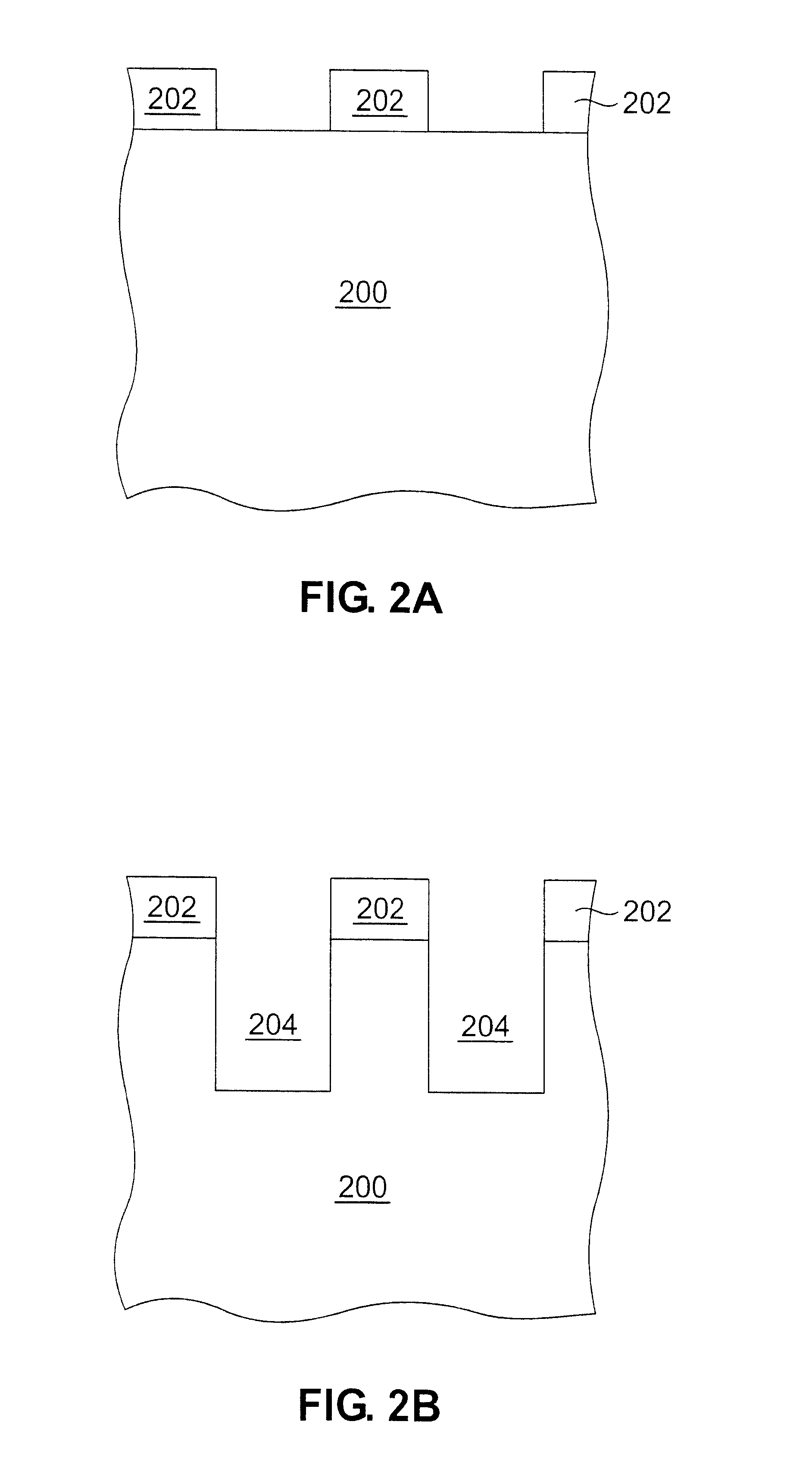

Processes for forming trenches within silicon substrates are described. According to an embodiment of the invention, a masked substrate is initially provided that comprises (a) a silicon substrate and (b) a patterned resist layer over the silicon substrate. The patterned resist layer has one or more apertures formed therein. Subsequently, a trench is formed in the substrate through the apertures in the resist layer by an inductive plasma-etching step, which is conducted using plasma source gases that comprise SF6, at least one fluorocarbon gas, and N2. If desired, Cl2 can also be provided in addition to the above source gases. The process of the present invention produces chamber deposits in low amounts, while providing high etching rates, high silicon:resist selectivities, and good trench sidewall profile control.

Owner:APPLIED MATERIALS INC

Plasma treating apparatus for vapor phase etching and cleaning

ActiveCN106098548ANo damageImprove the selection ratioElectric discharge tubesSemiconductor/solid-state device manufacturingEtchingInduction plasma technology

Disclosed herein is a plasma treating apparatus for vapor phase etching and cleaning. The plasma treating apparatus for vapor phase etching and cleaning includes: a reactor body treating a substrate to be treated; a direct plasma generation region in the reactor body into which process gas is introduced to directly induce plasma; a plasma inducing assembly inducing the plasma to the direct plasma generation region; a substrate treatment region in the reactor body in which the plasma introduced from the direct plasma generation region and vaporized gas introduced from the outside of the reactor body are mixed with each other to form reactive species and the substrate to be treated is treated by the reactive species; and a dual gas distributing baffle provided between the direct plasma generation region and the substrate treatment region to distribute the plasma to the substrate treatment region and distribute the vaporized gas to a center region and a peripheral region of the substrate treatment region.

Owner:俣愿技术 +1

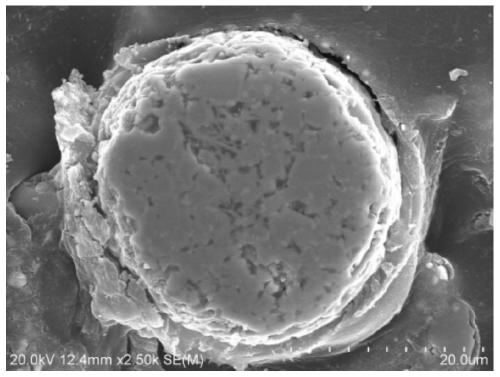

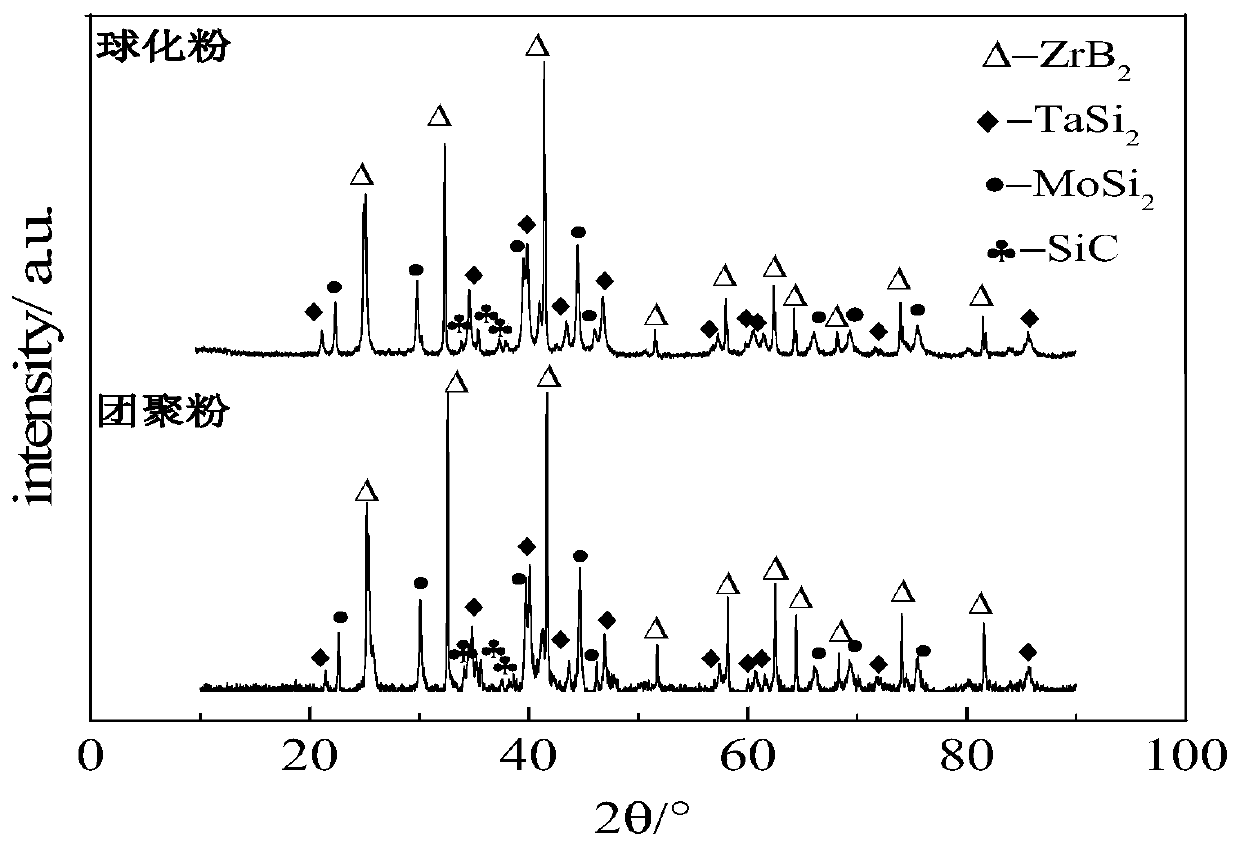

Preparation method of multi-component-doping modified zirconium diboride-silicon carbide coating

ActiveCN110396003AImprove densification performanceImprove high temperature resistanceZirconium hydrideInduction plasma technology

The invention relates to a preparation method of a multi-component-doping modified zirconium diboride-silicon carbide coating, and belongs to the technical field of composite powder and coating preparation. The method comprises the following steps: preparing ZrB2-SiC agglomerated powder doped with MoSi2 and TaSi2 through spray granulation and induction plasma spheroidization, and forming a coatingon a substrate by adopting an atmospheric plasma spraying process. By doping MoSi2 and TaSi2 at the same time, firstly, the two components serve as low-melting-point phases to fill pores and cracks in the powder, so that the compactness of the coating is improved; secondly, the two components serve as high-emissivity components to effectively radiate out heat in the coating, so that the high-temperature resistance of the coating is improved. The coating has good temperature resistance, infrared radiation performance, oxidation resistance, scouring resistance and thermal shock resistance. Thecoating can bear 300s oxyacetylene ablation examination at the surface temperature of 2000 DEG C and breaks through the technical bottleneck of 1800 DEG C.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

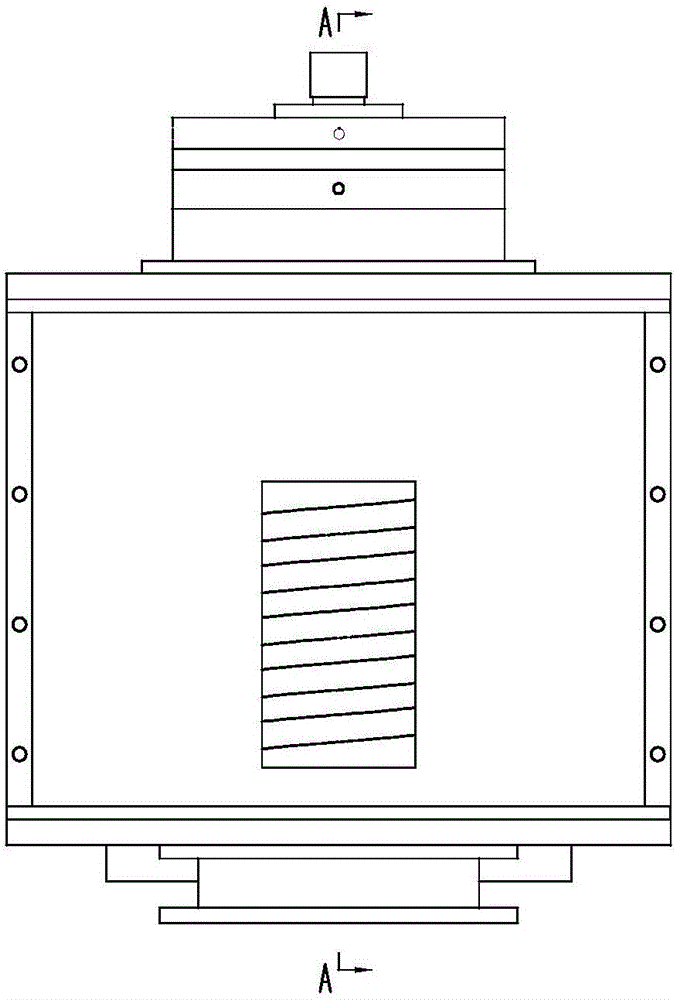

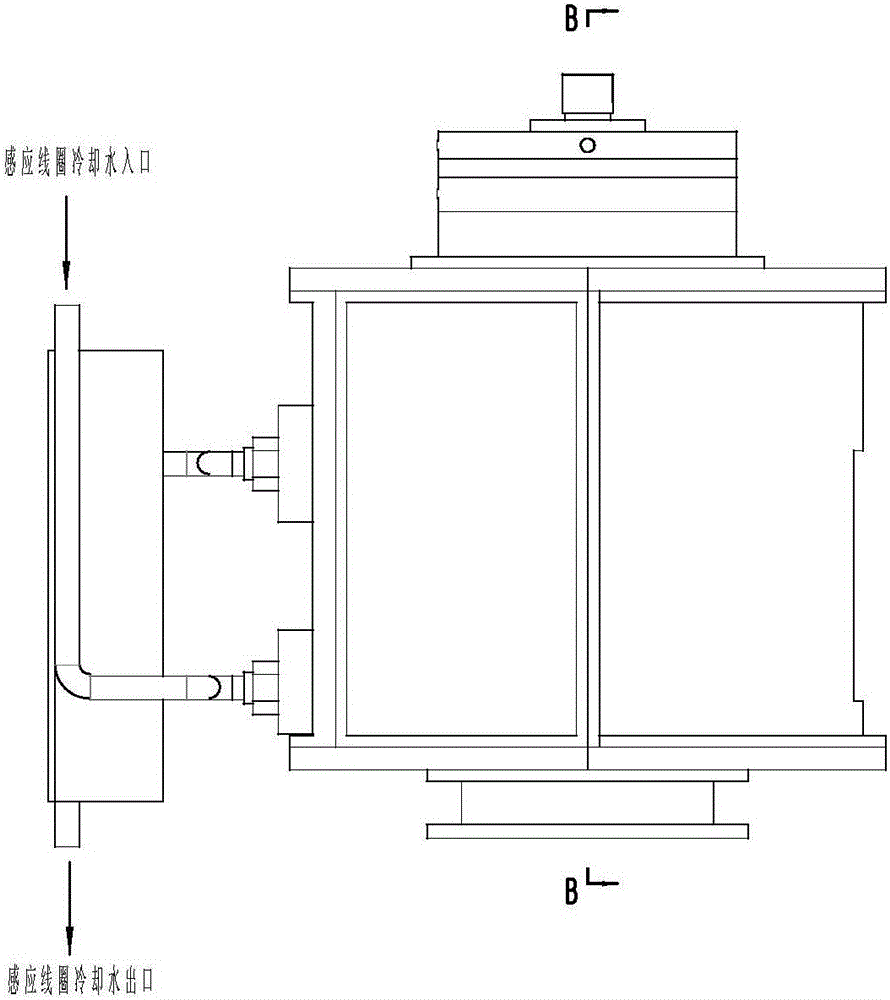

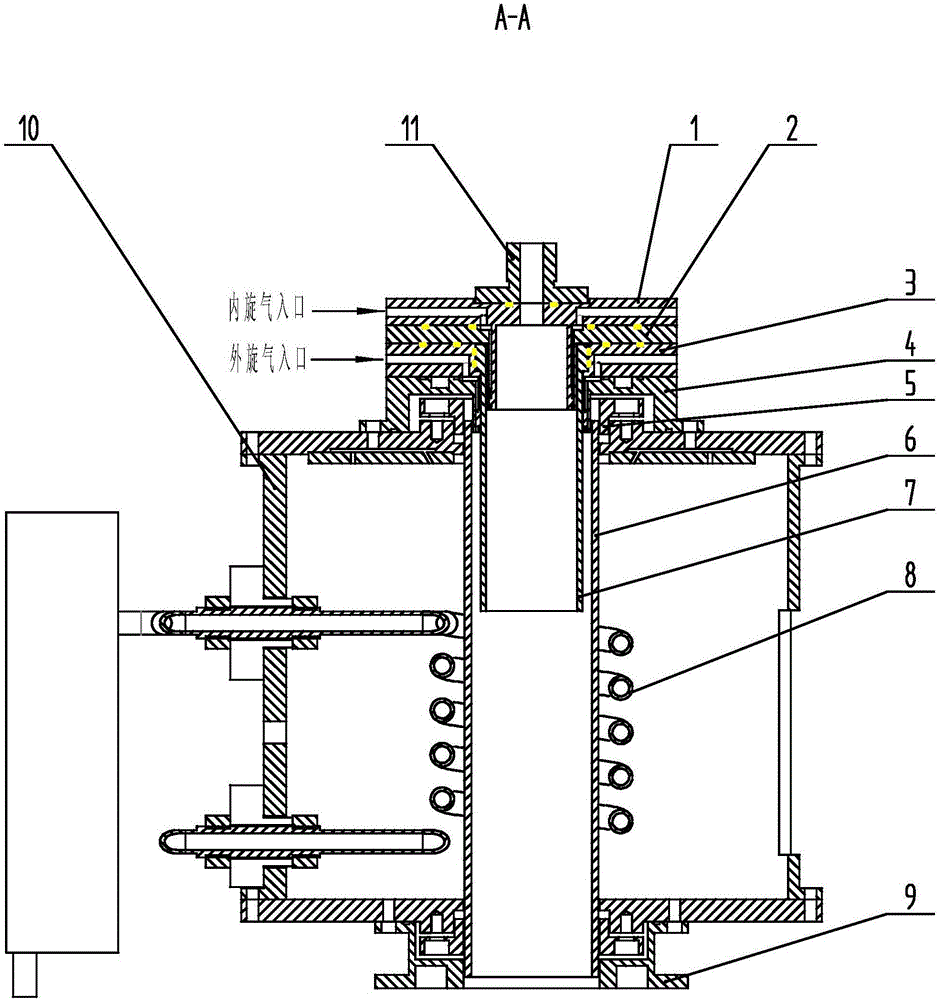

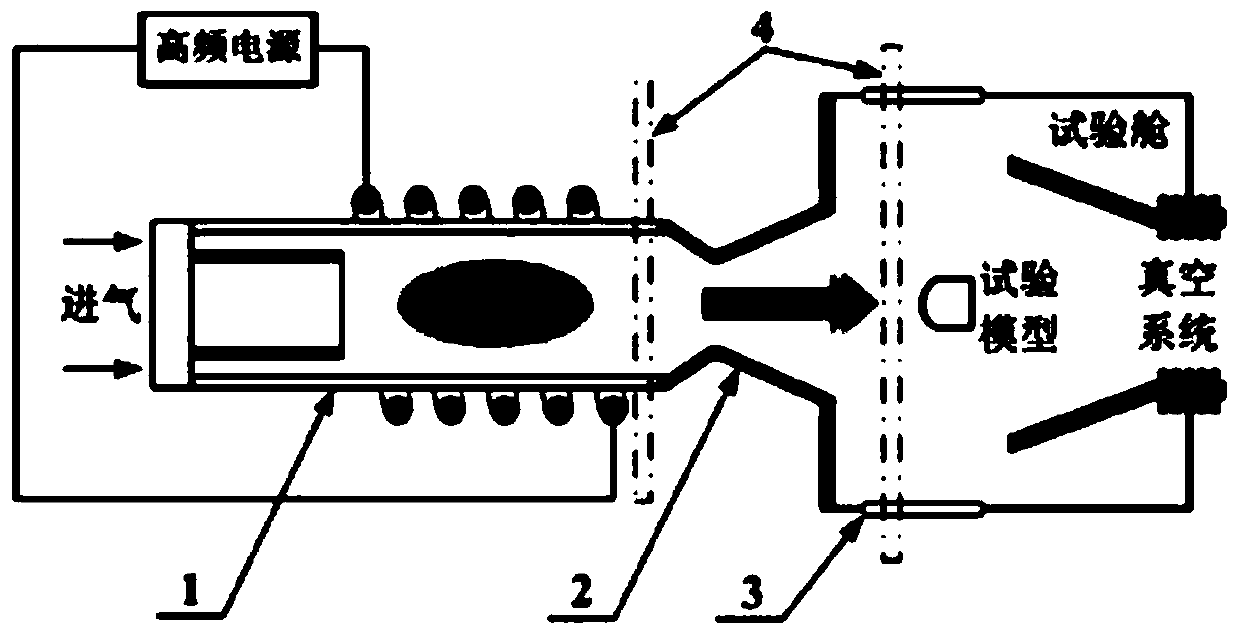

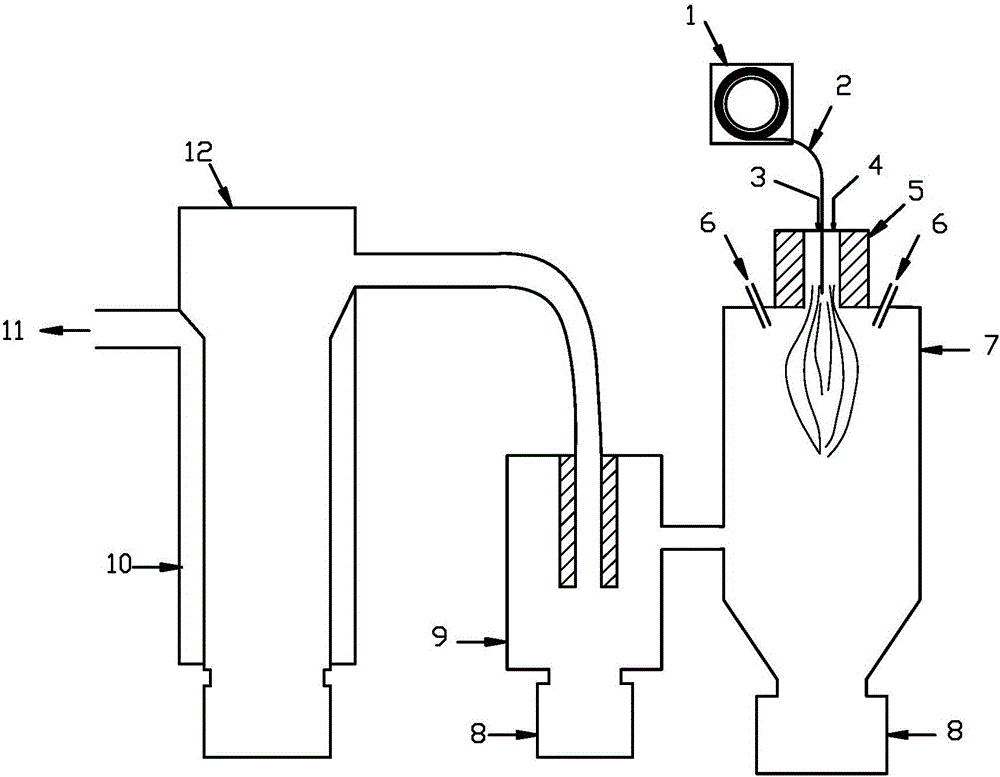

High frequency induction plasma heating wind tunnel

ActiveCN106679924AFulfil requirementsGuaranteed rotational strengthAerodynamic testingPlasma techniqueDeep space explorationPlasma generator

A high frequency induction plasma heating wind tunnel is used for a nonequilibrium thermal environment and deep space exploration research. The heating wind tunnel comprises a plasma generator, a jet pipe, a test segment, a diffusion segment, a cooler, a vacuum set and an assisting system. Working gas is heated by the plasma generator, acts on a model of the test segment under the effect of the jet pipe, and is discharged outside via the vacuum set by being pressurized by the diffusion segment and cooled by the cooling segment. The high frequency induction plasma heating wind tunnel is a ground simulation apparatus that can provide a chemically pure, high temperature and high speed air flow environment, and can meet requirements of gas components for deep space exploration research.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

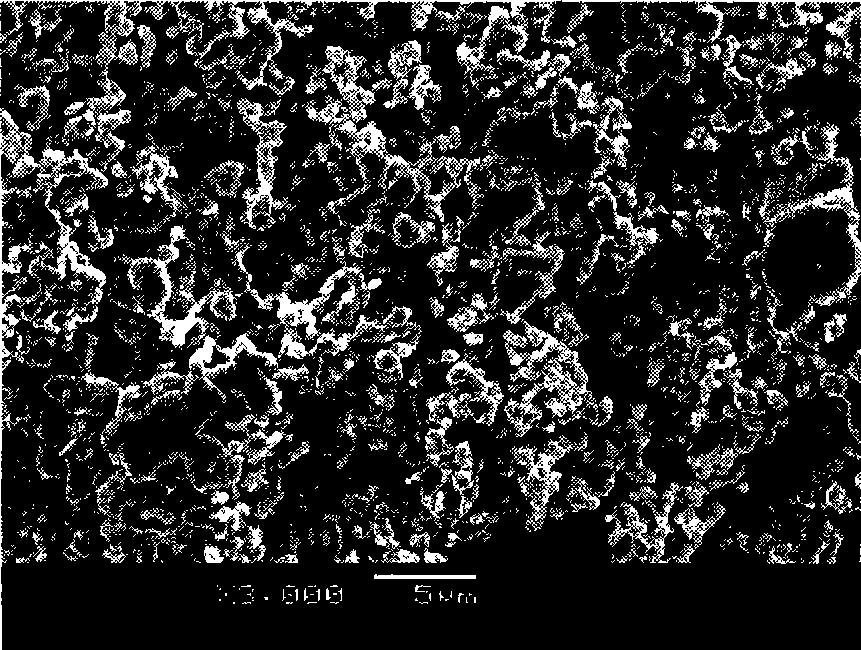

Method for preparing nanometer silicon powder

ActiveCN106185947AHigh purityLarge specific surface areaNanotechnologySilicon compoundsInduction plasma technologyPlasma generator

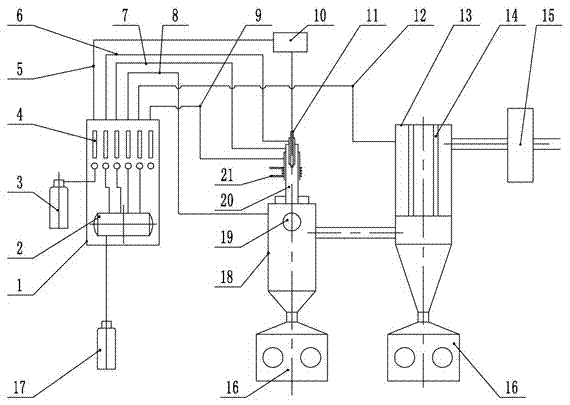

The invention discloses a method for preparing nanometer silicon powder. The nanometer silicon powder is made of coarse silicon powder. Inert gas is used as carrier gas. The method includes carrying the coarse silicon powder by the carrier gas, allowing the coarse silicon powder to penetrate plasmas generated by a high-frequency plasma generator and feeding the coarse silicon powder into a reaction chamber; quickly gasifying the coarse silicon powder in high-temperature plasma regions in the reaction chamber to generate silicon atom steam cloud; forming tiny silicon particles by the generated silicon atom steam cloud under the effects of cooling gas flow when the silicon atom steam cloud flows through cooling regions; driving the silicon particles by gas flow to flow into a cyclone classification chamber; detaining the classified coarse silicon particles in the cyclone classification chamber; carrying the fine silicon particles into a gas-solid separation chamber by the aid of the gas flow; ultimately depositing the fine silicon particles on a filter of the gas-solid separation chamber; collecting the silicon particles on the filter to obtain the nanometer silicon powder. The method has the advantages that the induction plasmas are used as heat sources, accordingly, electrode pollution can be prevented in preparation procedures, the nanometer silicon powder prepared by the aid of the method is high in purity, and the particles are in spherical or approximately spherical morphology, have large specific surface areas and are high in surface activity and good in flowability and dispersibility.

Owner:CHINA NONFERROUS METAL (GUILIN) GEOLOGY & MINING CO LTD

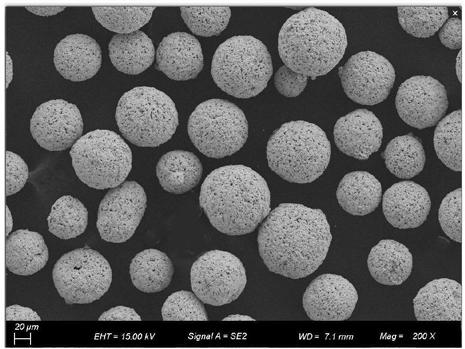

3D printing special alloy powder and preparing method thereof

InactiveCN108941596AImprove liquidityReduce porosityAdditive manufacturing apparatusTransportation and packagingPorosityInduction plasma technology

The invention provides a preparing method of 3D printing special alloy powder. The preparing method comprises the following steps that tungsten carbide powder, cobalt powder, chromium powder, aluminite powder and titanium powder are mixed to be subjected to ball milling, and mixed metal powder is obtained; and the mixed metal powder is subjected to induction plasma spheroidization treatment, and the 3D printing special alloy powder is obtained. According to the preparing method, high temperature of plasmas is used as a heat source to melt and evaporate raw material powder, the spheroidizationprocess of the irregular raw material powder can be achieved, and the physical and chemical characteristics of the powder can be effectively improved and are mainly showed in improving the liquidity of the alloy powder, reducing the powder porosity, improving the powder density, reducing powder brittleness, improving particle surface smoothness, improving powder purity and accurately controlling the oxygen content. According to the embodiment, the 3D printing special alloy powder prepared through the method has the high powder density, good liquidity and the accurate oxygen content.

Owner:湖南伊澍制造股份有限公司

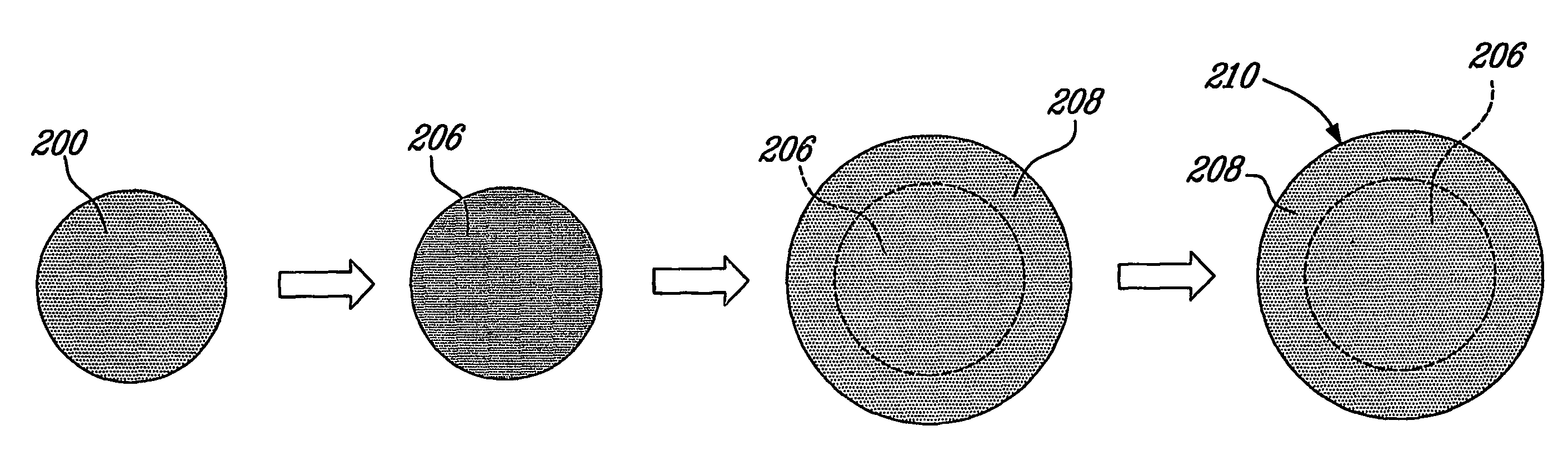

Induction plasma synthesis of nanopowders

ActiveUS8013269B2Easy to controlTight controlMaterial nanotechnologyOxygen/ozone/oxide/hydroxideIodideInduction plasma technology

A process and apparatus for synthesizing a nanopowder is presented. In particular, a process for the synthesis of nanopowders of various materials such as metals, alloys, ceramics and composites by induction plasma technology, using organometallic compounds, chlorides, bromides, fluorides, iodides, nitrites, nitrates, oxalates and carbonates as precursors is disclosed. The process comprises feeding a reactant material into a plasma torch in which is generated a plasma flow having a temperature sufficiently high to yield a superheated vapor of the material; transporting said vapor by means of the plasma flow into a quenching zone; injecting a cold quench gas into the plasma flow in the quenching zone to form a renewable gaseous cold front; and forming a nanopowder at the interface between the renewable gaseous cold front and the plasma flow.

Owner:TEKNA PLASMA SYST INC

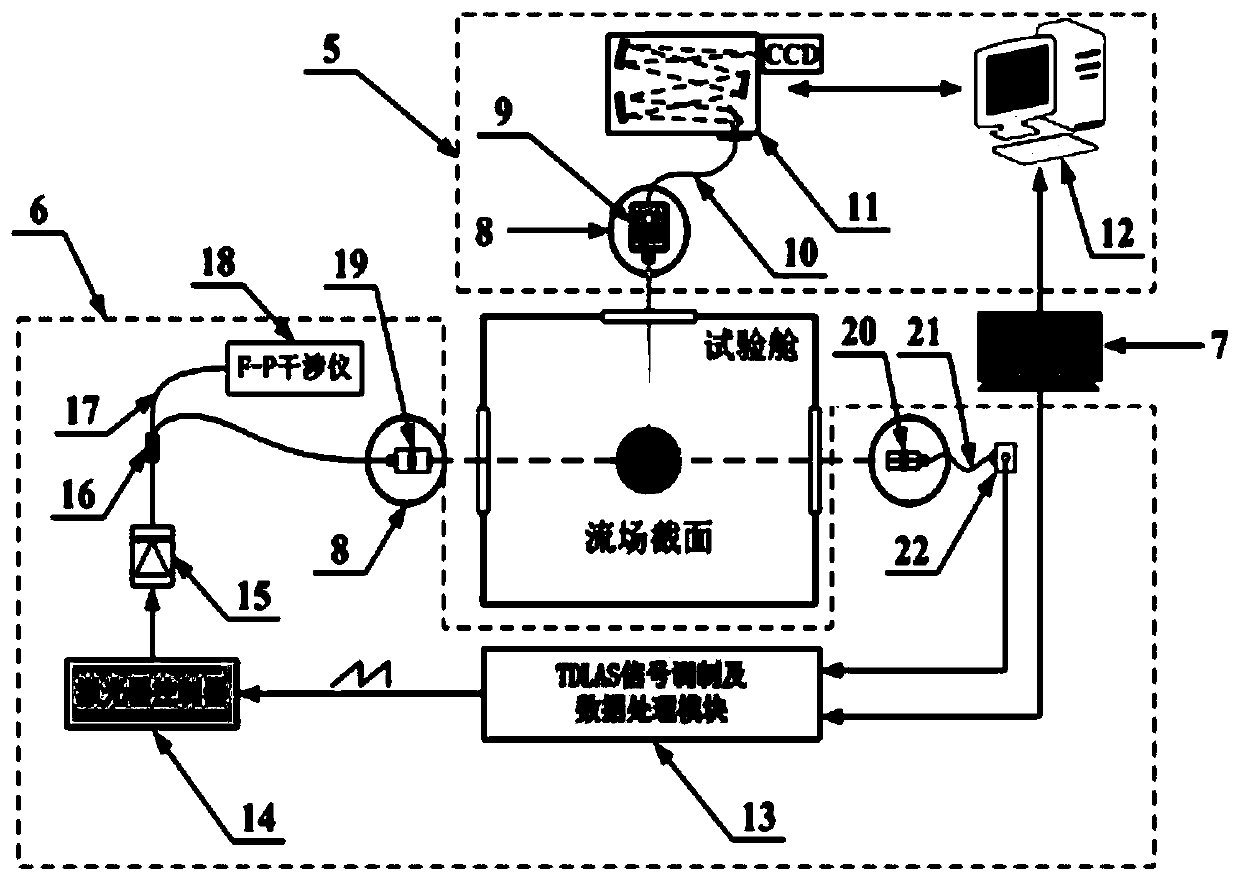

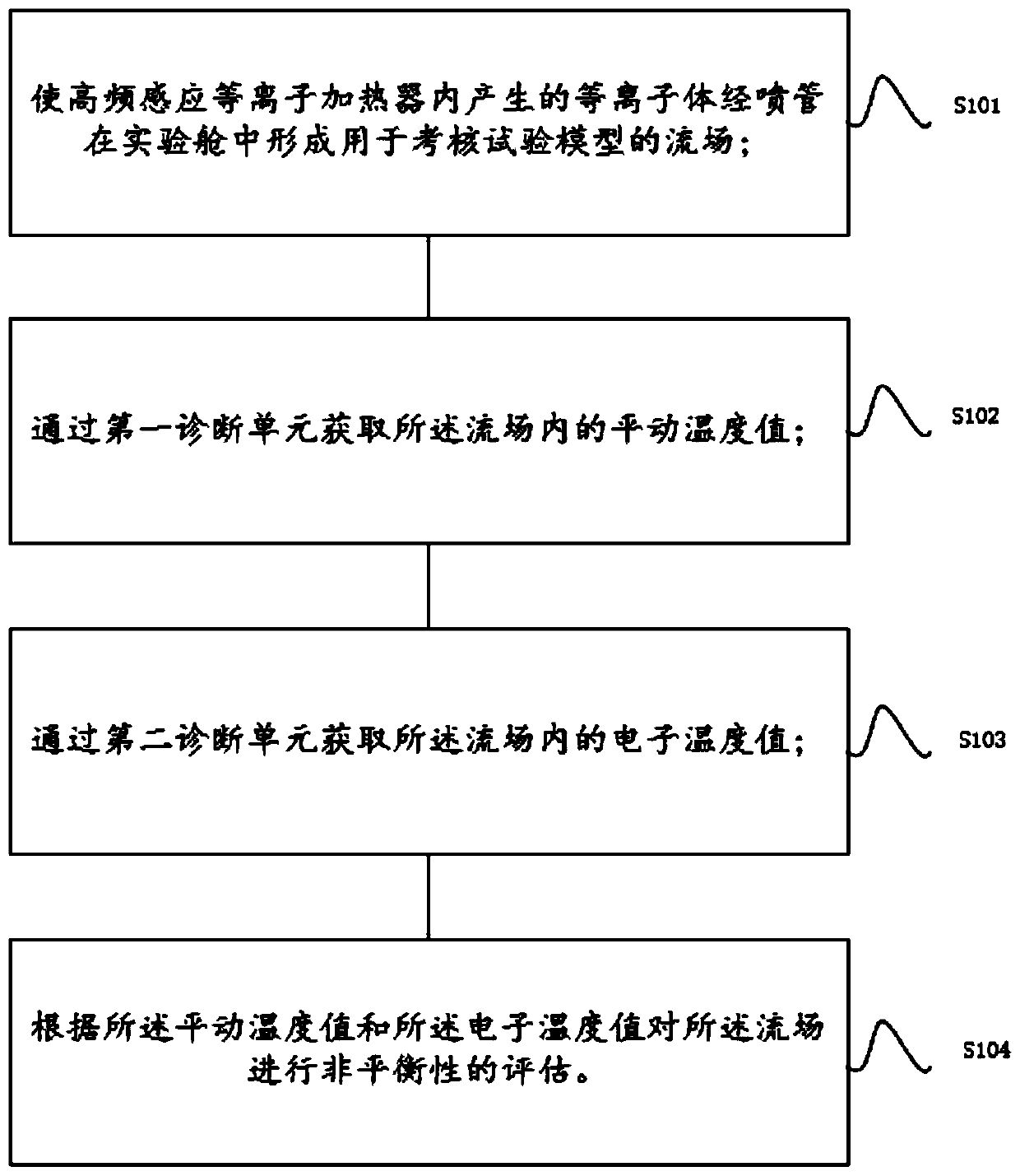

High-frequency induction wind tunnel flow field non-equilibrium diagnosis system and method

ActiveCN110095248ARealize synchronized measurementsRealize quantitative evaluationAerodynamic testingElectronic temperatureInduction plasma technology

The embodiment of the invention relates to a high-frequency induction wind tunnel flow field non-equilibrium diagnosis system. The system comprises a test device, a first diagnosis unit and a second diagnosis unit. A collimator of the first diagnosis unit emits a laser signal, and the laser signal passes through a flow field of the test device and then is transmitted by the test device, and the transmitted laser signal is received by a receiver of the first diagnosis unit so as to obtain a translational temperature in the flow field. The second diagnosis unit collects radiation luminescence inthe flow field to obtain an electronic temperature in the flow field in the test device. The system also comprises a signal trigger unit for controlling the first diagnosis unit and the second diagnosis unit. Therefore, synchronous measurement of the electronic temperature and the translational temperature in a high-frequency induction plasma heater and the high-temperature flow field after passing through a spray pipe can be realized, and quantitative evaluation of a non-equilibrium characteristic of a high-frequency induction plasma heating wind tunnel flow field can be further realized.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

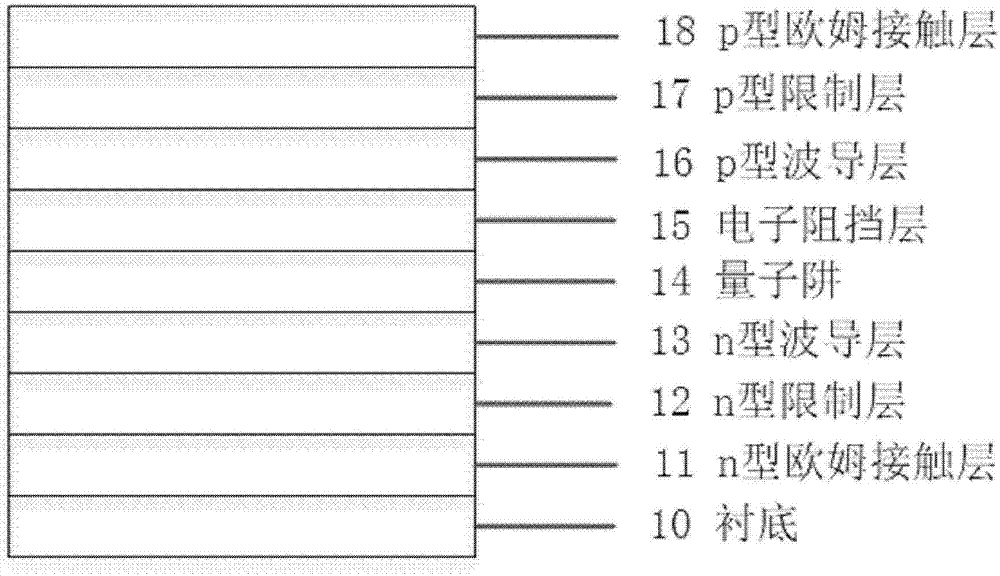

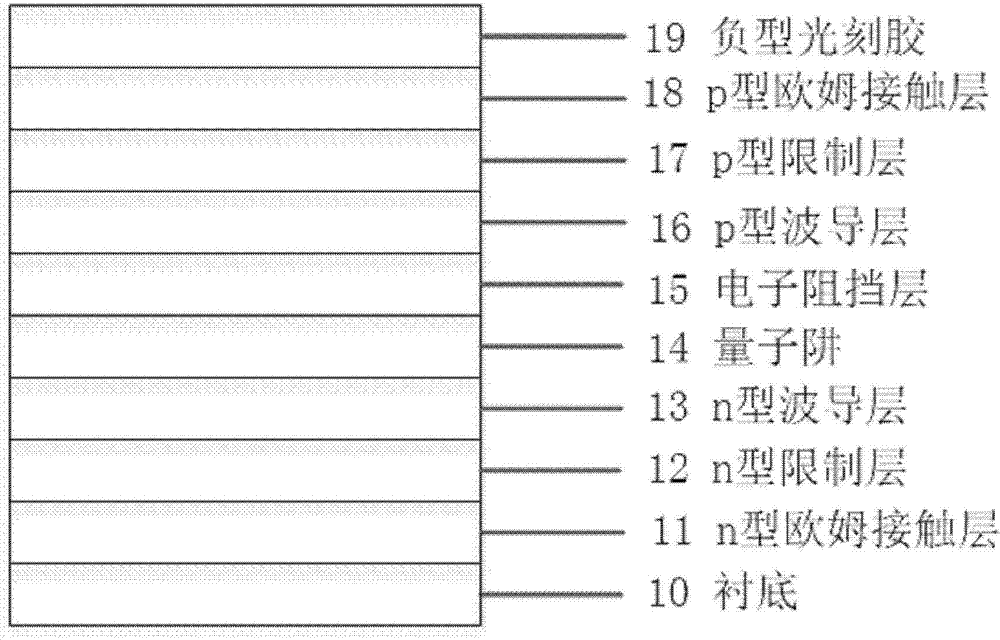

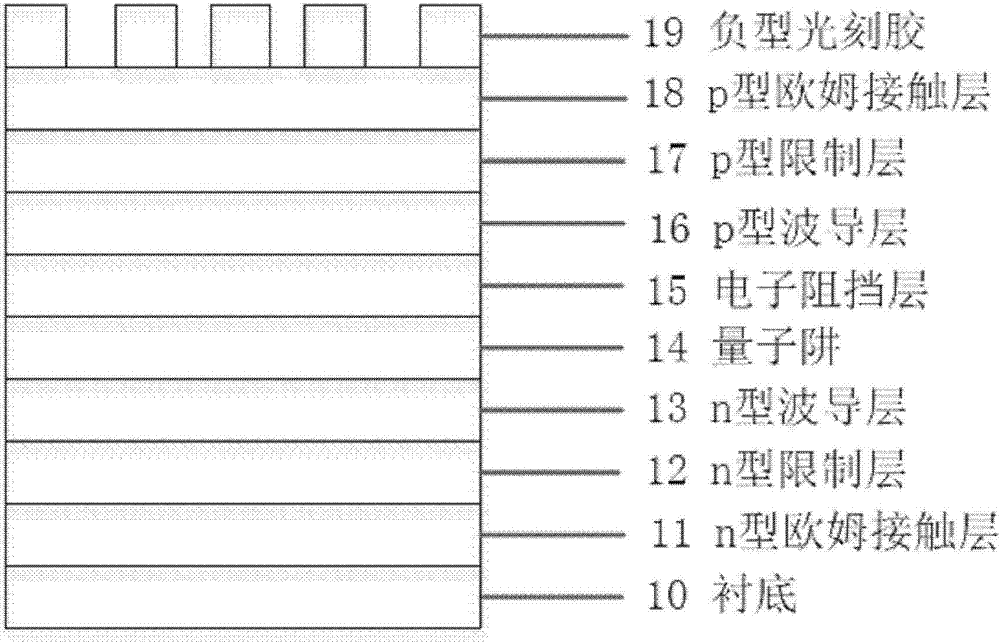

Fabrication method of gallium nitride laser cavity surface

ActiveCN103701037AEliminate damageRepair damageLaser detailsSemiconductor lasersInduction plasma technologyGallium nitride

The invention discloses a fabrication method of a gallium nitride laser cavity surface, which comprises the steps of epitaxially growing a gallium nitride laser structure on a substrate, obtaining an epitaxial wafer, coating an ohmic contact layer of the epitaxial wafer with photoresist, applying an photoetching plate for standard photoetching, evaporating metal on the epitaxial wafer, fabricating a metal mask on an epitaxial layer, etching to an n-type optical confinement layer of a laser, corroding and etching to form a side wall of the cavity surface, and removing the metal mask on the surface of the epitaxial layer, wherein the gallium nitride laser structure comprises an n-type ohmic contact layer, an n-type confinement layer, an n-type waveguide layer, a quantum well, an electronic barrier layer, a p-type waveguide layer, a p-type confinement layer and a p-type ohmic contact layer sequentially from one side of the substrate. According to the method, the cavity surface with the level and smooth surface is obtained by an induction plasma etching and alkaline solution corrosion method, so that the damage to the cavity surface caused by an ion bombardment effect after a dry corrosion technology is eliminated, the damage of plasma to the cavity surface is repaired, and the emissivity of the cavity surface is improved.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Multi-coil induction plasma torch for solid state power supply

InactiveCN1572127AAnalysis by thermal excitationPlasma welding apparatusPlasma torchInduction plasma technology

An induction plasma torch comprises a tubular torch body, a gas distributor head located at the proximal end of the torch body for supplying at least one gaseous substance into the chamber within the torch body, a higher frequency power supply connected to a first induction coil mounted coaxial to the tubular torch body, a lower frequency solid state power supply connected to a plurality of second induction coils mounted coaxial to the tubular torch body between the first induction coil and the distal end of this torch body. The first induction coil provides the inductive energy necessary to ignite the gaseous substance to form a plasma. The second induction coils provide the working energy necessary to operate the plasma torch. The second induction coils can be connected to the solid state power supply in series and / or in parallel to match the impedance of this solid state power supply.

Owner:泰克纳等子系统公司

Preparation method for spherical titanium or titanium alloy powder

ActiveCN106216702APrevent purityLower oxygen levelsTransportation and packagingMetal-working apparatusInduction plasma technologyTitanium nitride

The invention discloses a preparation method for spherical titanium or titanium alloy powder. The preparation method is characterized in that a titanium wire or a titanium alloy wire is taken as a raw material, and induction plasmas are taken as a heat source for preparing the spherical titanium or titanium alloy powder. According to the preparation method disclosed by the invention, the threadlike titanium wire or the titanium alloy wire is taken as the raw material, so that the problems such as low purity and relatively high oxygen content caused by a powdered raw material are avoided from the source; the titanium or titanium alloy powder is prepared by taking the induction plasmas as the heat source; and the prepared spherical titanium or titanium alloy powder has the advantages of being high in purity, high in degree of sphericity, good in mobility, low in oxygen content, narrow in grain size distribution and the like; the prepared titanium or titanium alloy powder has an average grain size which is adjustable between 10 [mu]m to 100 [mu]m; and the whole preparation process is free of electrode pollution.

Owner:CHINA NONFERROUS METAL (GUILIN) GEOLOGY & MINING CO LTD

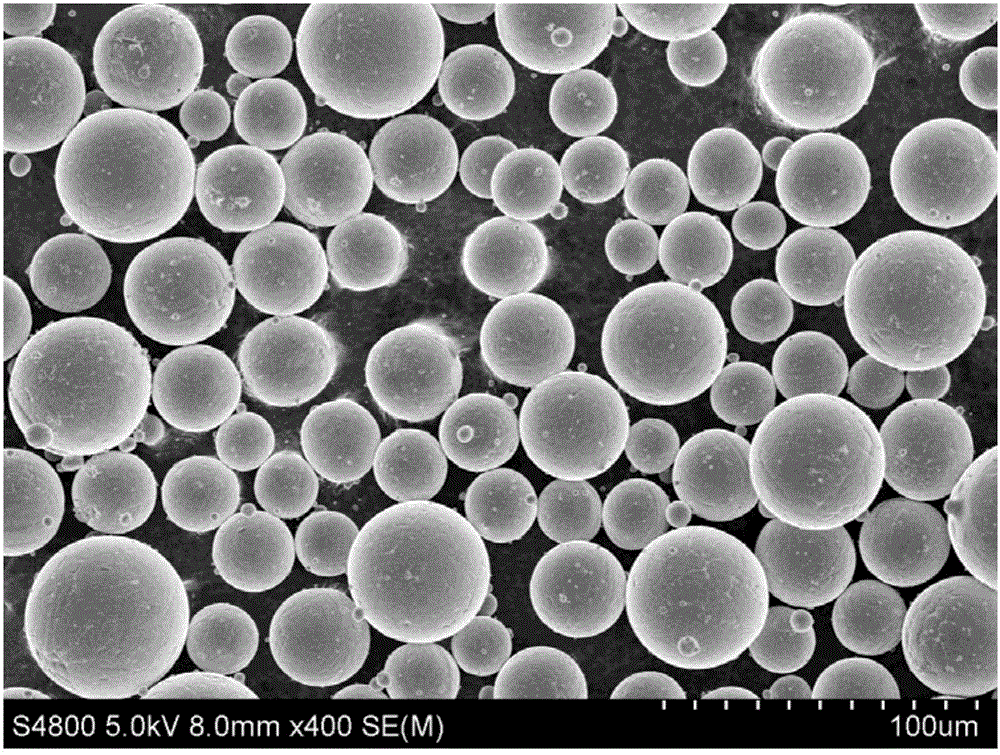

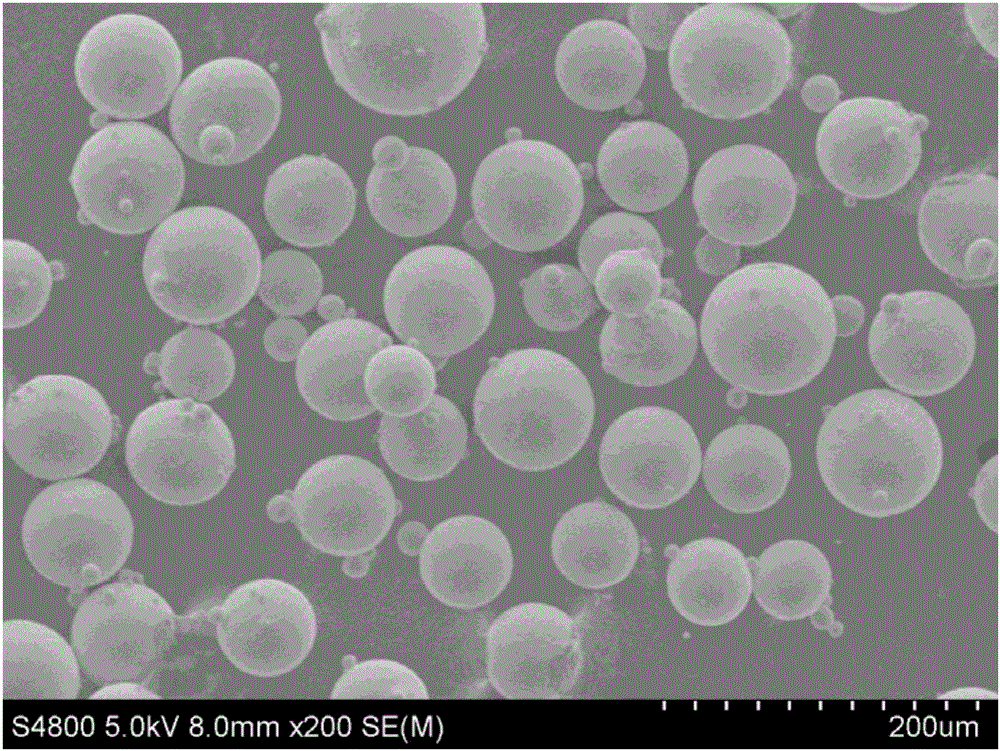

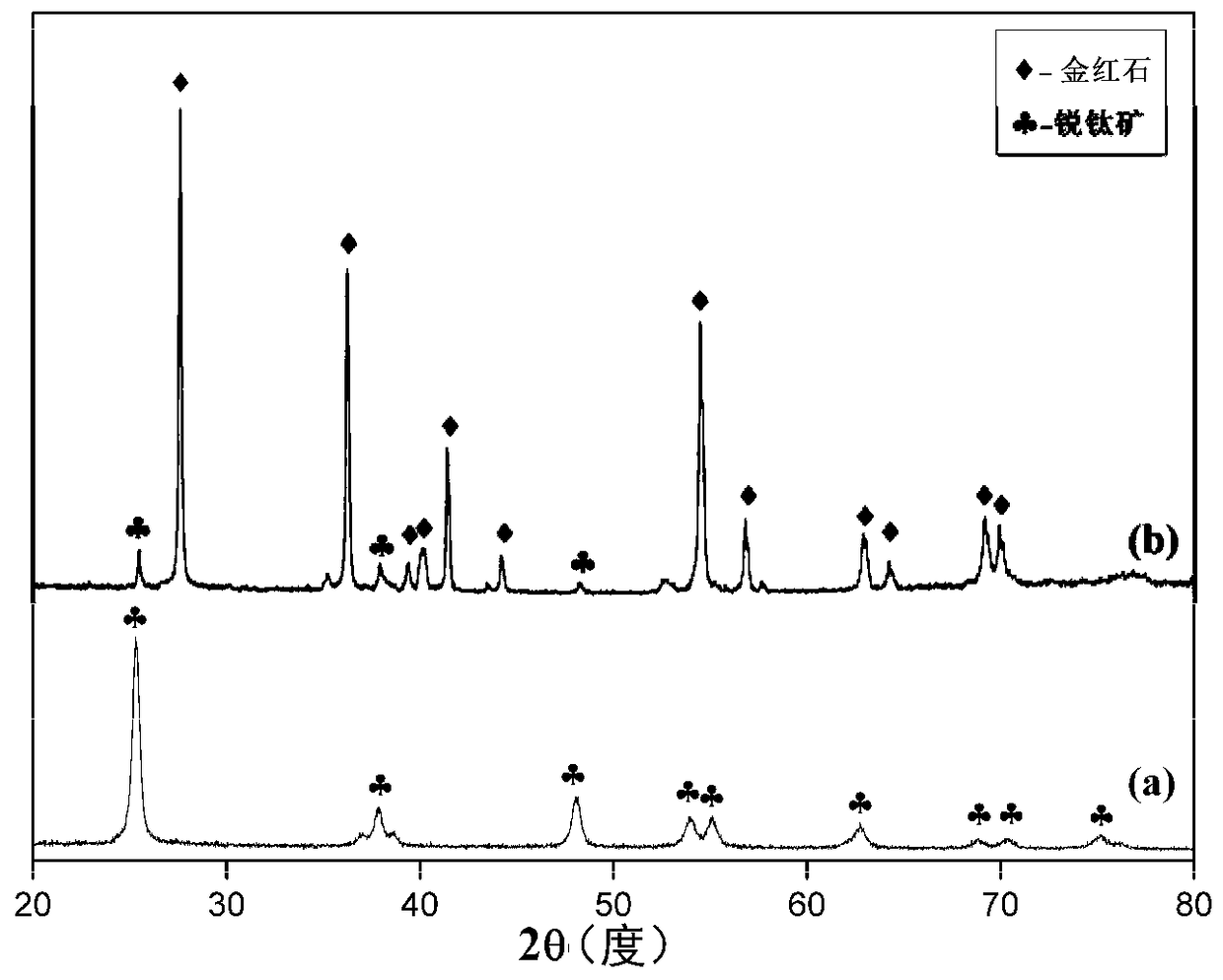

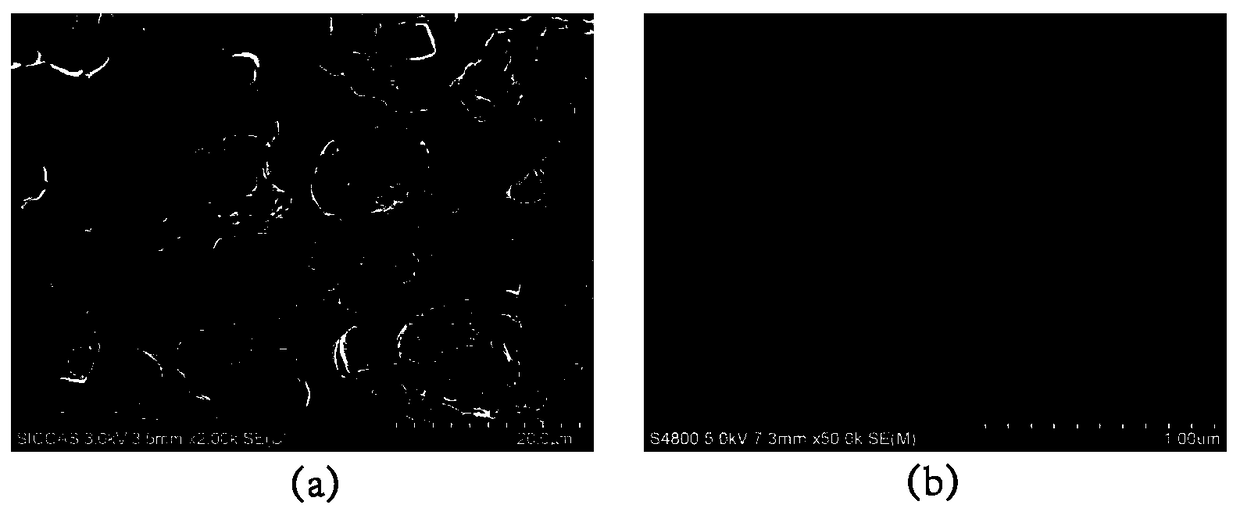

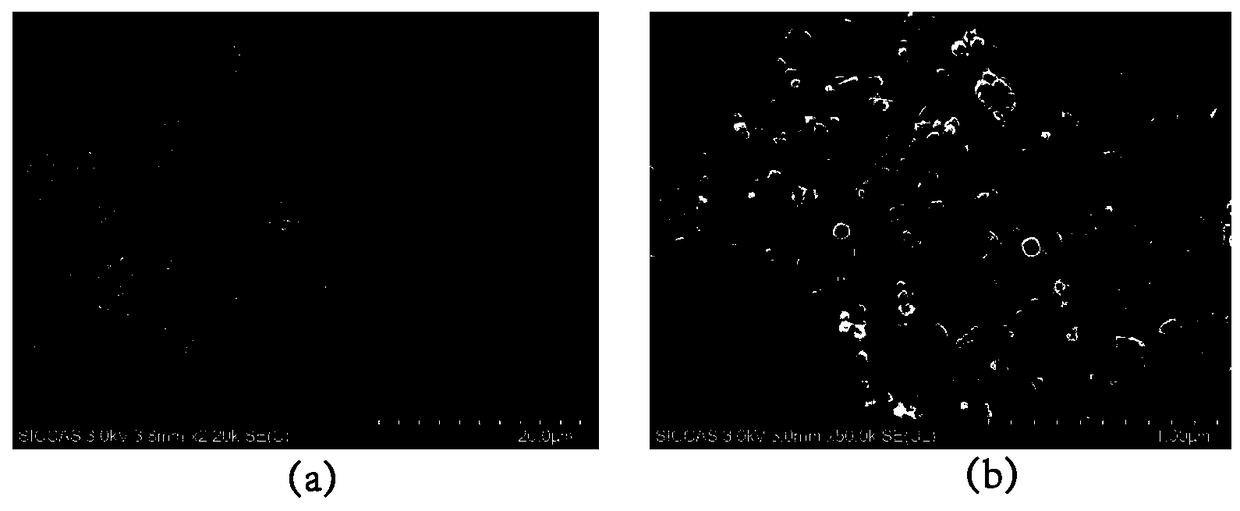

Micrometer/nanometer multi-level structure titanium dioxide coating with excellent biocompatibility, and preparation method thereof

ActiveCN108588626AGood osteogenic propertiesEasy to operateMolten spray coatingPharmaceutical delivery mechanismLevel structureMicrometer

The invention relates to a micrometer / nanometer multi-level structure titanium dioxide coating with excellent biocompatibility, and a preparation method thereof, wherein the micrometer / nanometer multi-level structure titanium dioxide coating is obtained by depositing a nanometer-TiO2-powder-containing spraying liquid on the surface of a substrate through a vacuum induction plasma spraying technology. According to the present invention, the preparation method has advantages of simple operation, high efficiency, low pollution, good repeatability and the like, and is suitable for large-scale production.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com