Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

383 results about "Plasma flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

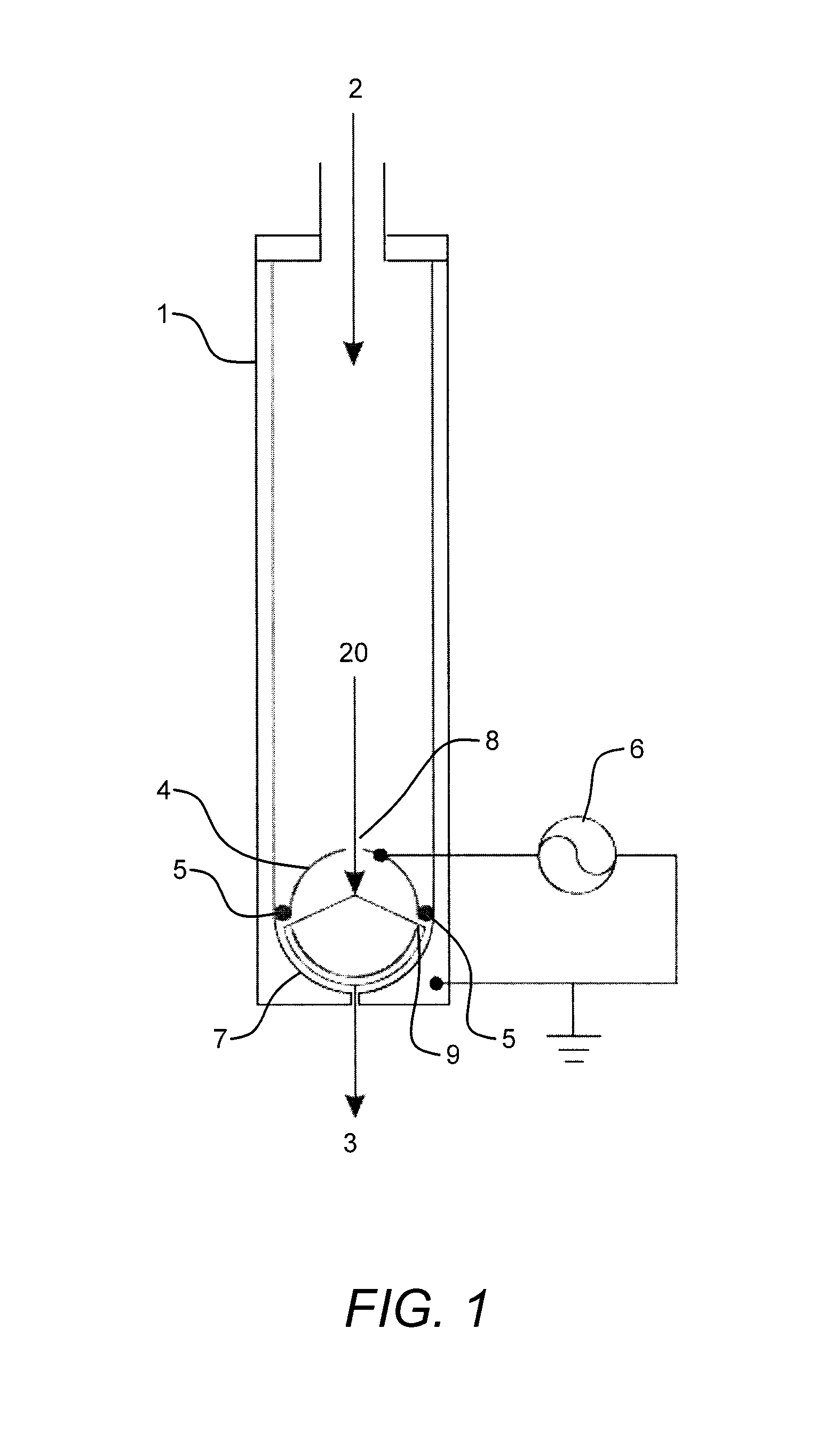

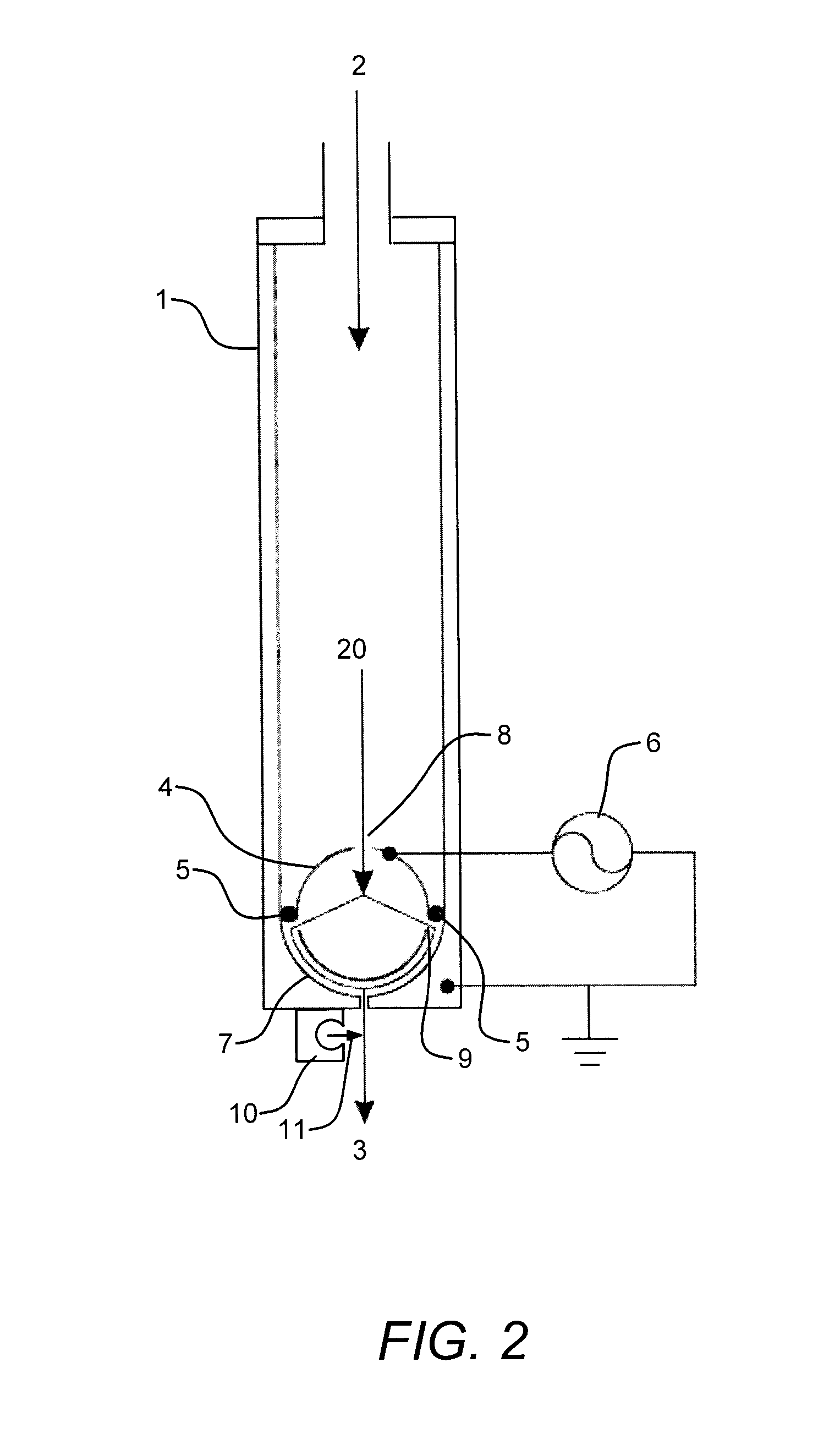

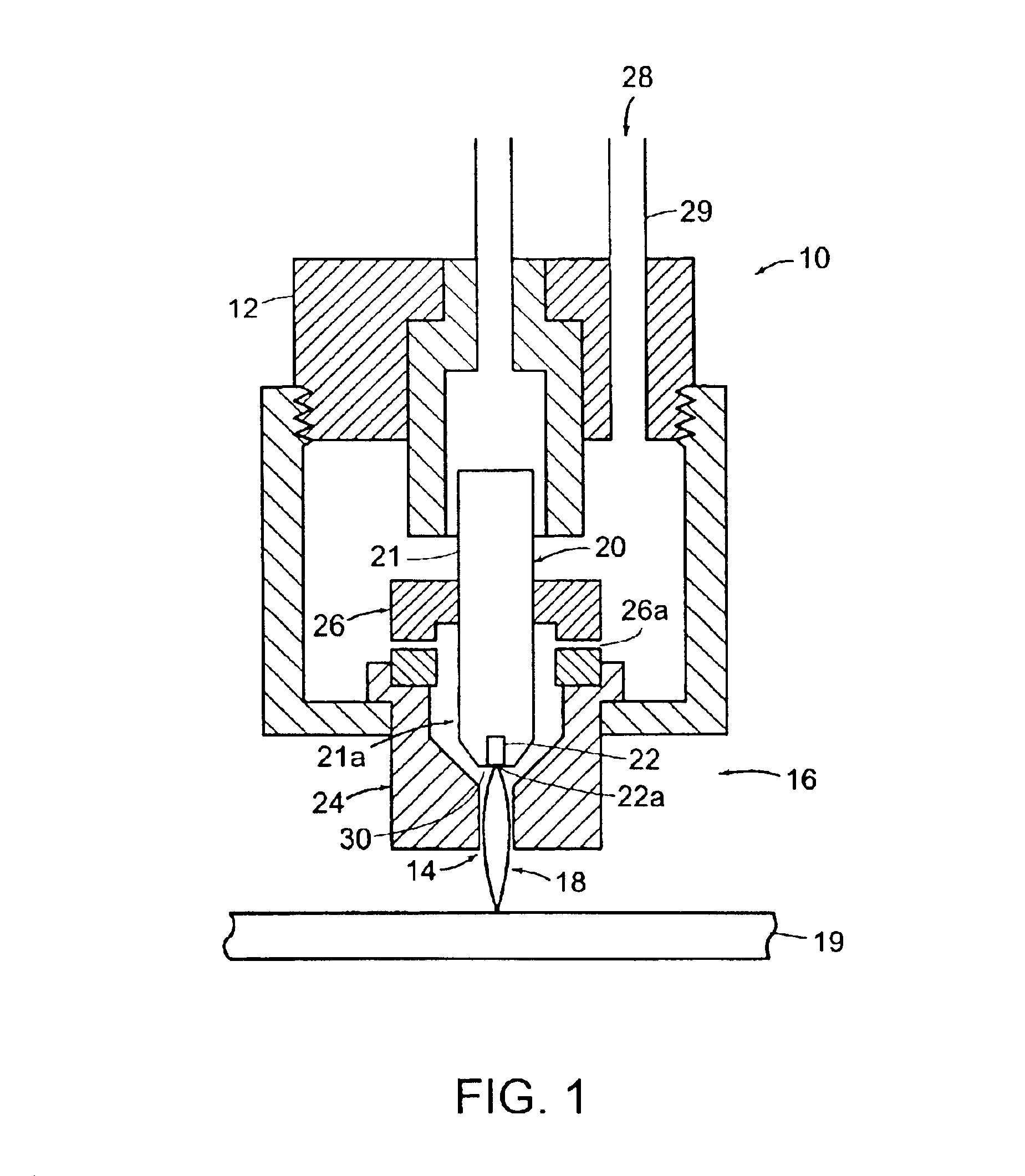

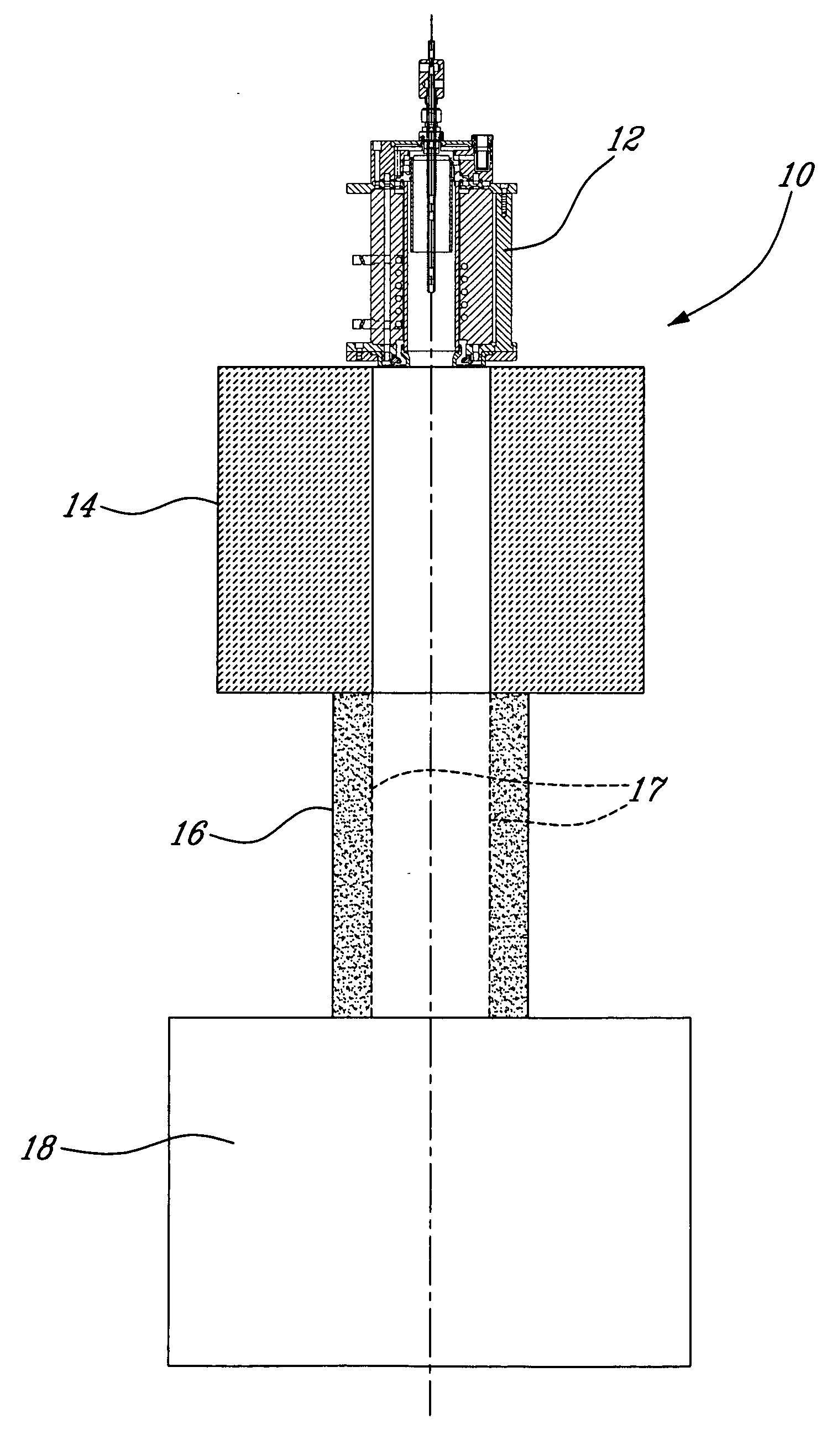

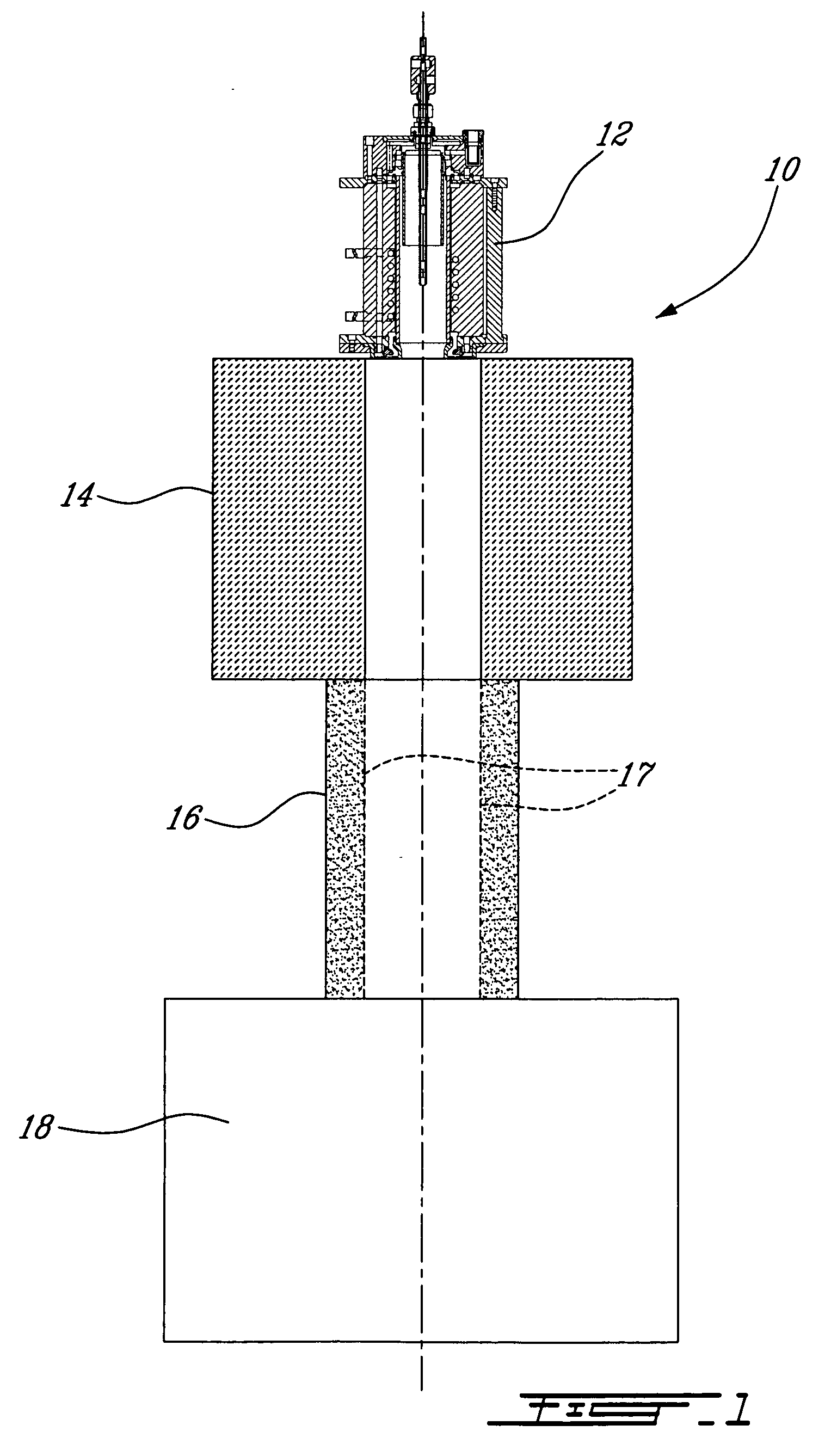

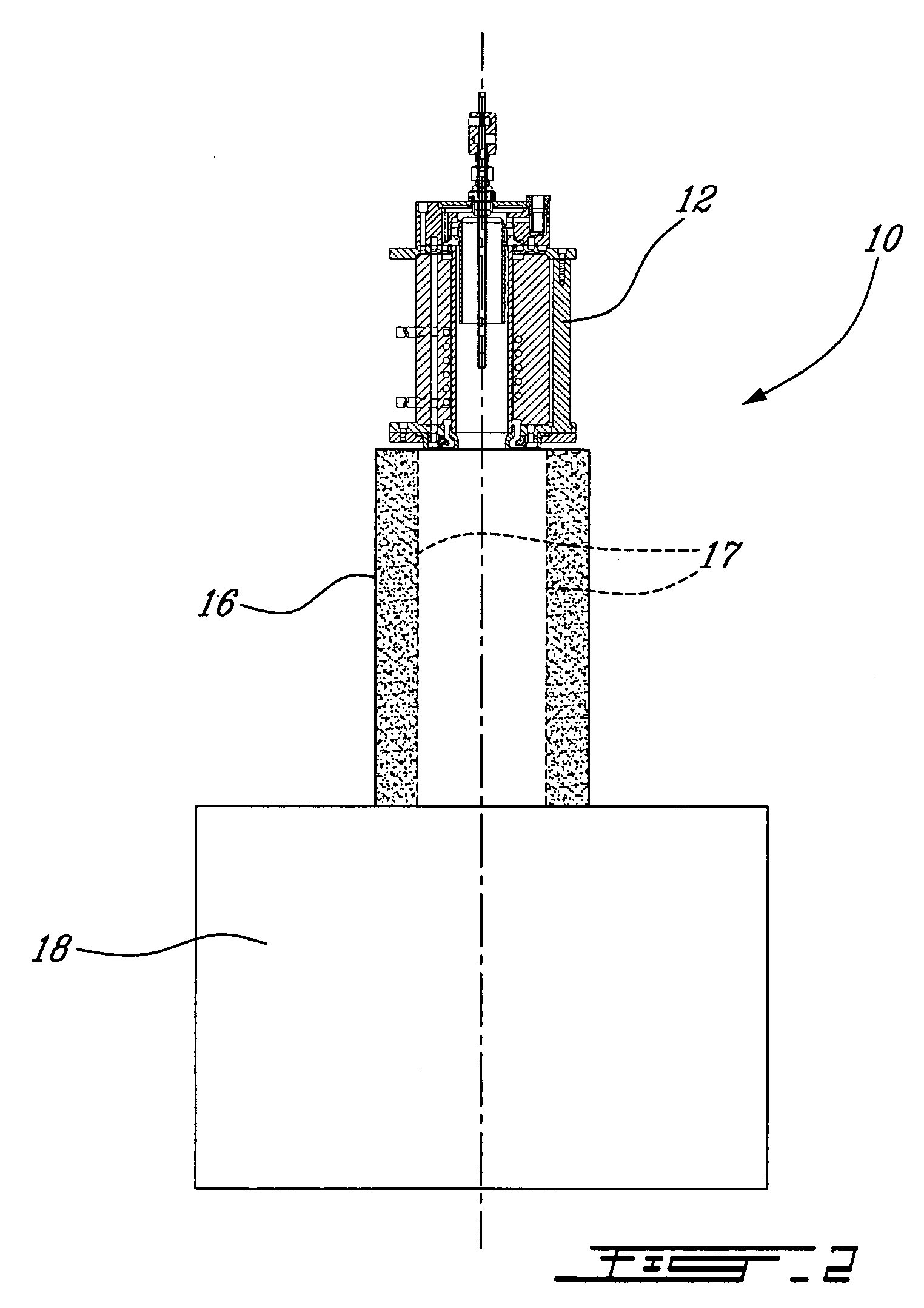

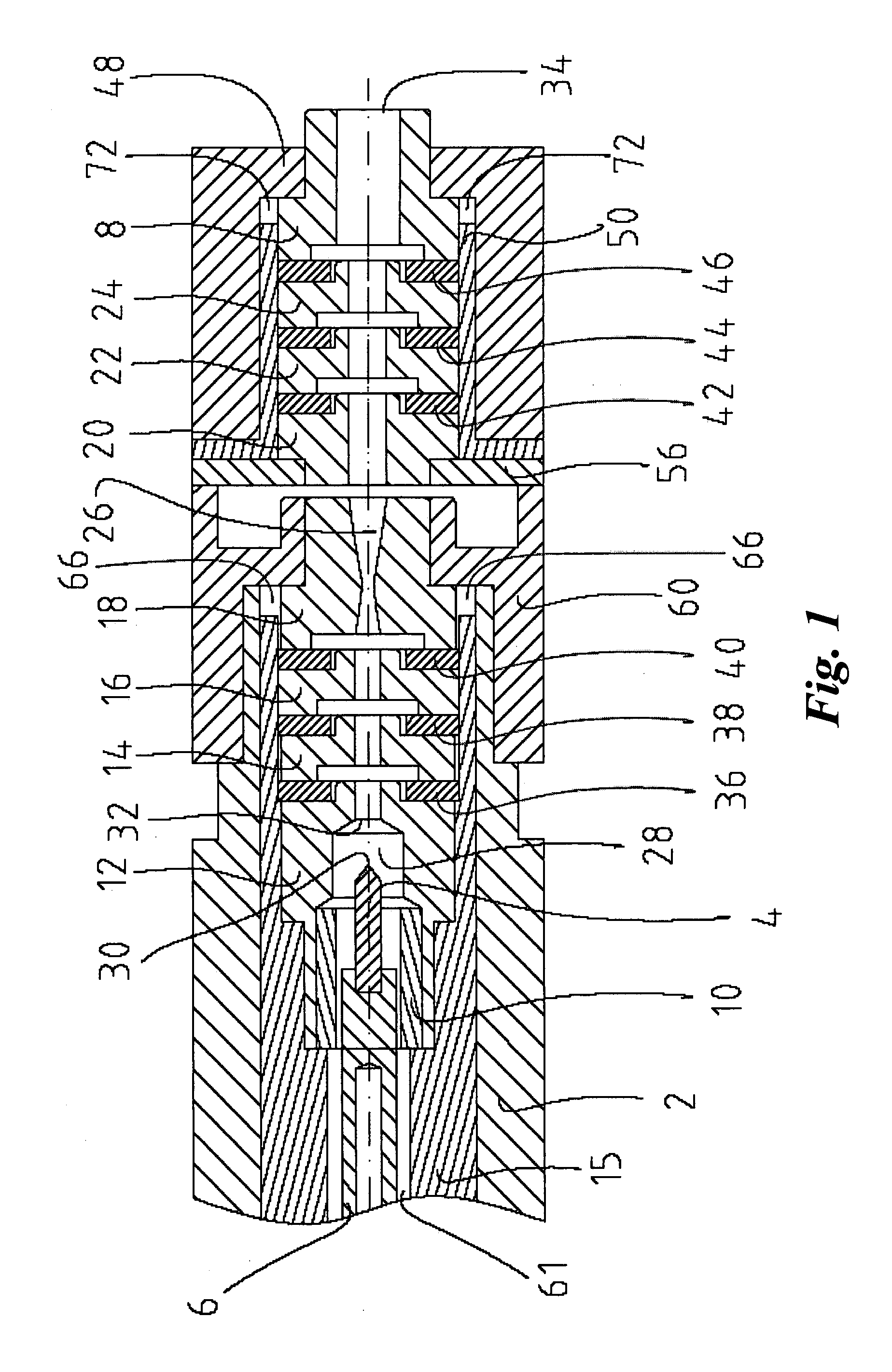

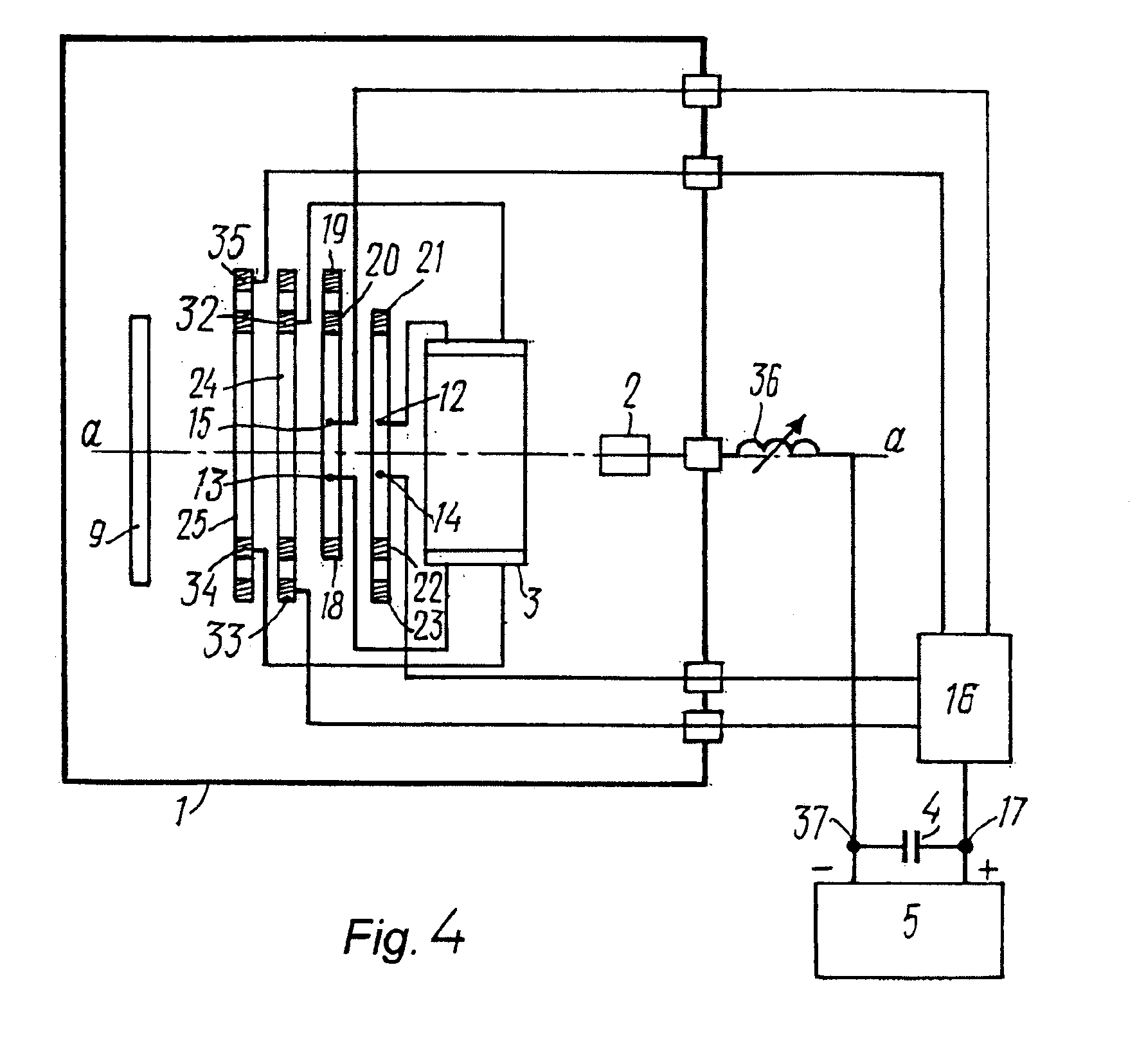

Low-temperature compatible wide-pressure-range plasma flow device

InactiveUS20020129902A1Electric discharge tubesSemiconductor/solid-state device manufacturingGas phaseReactive gas

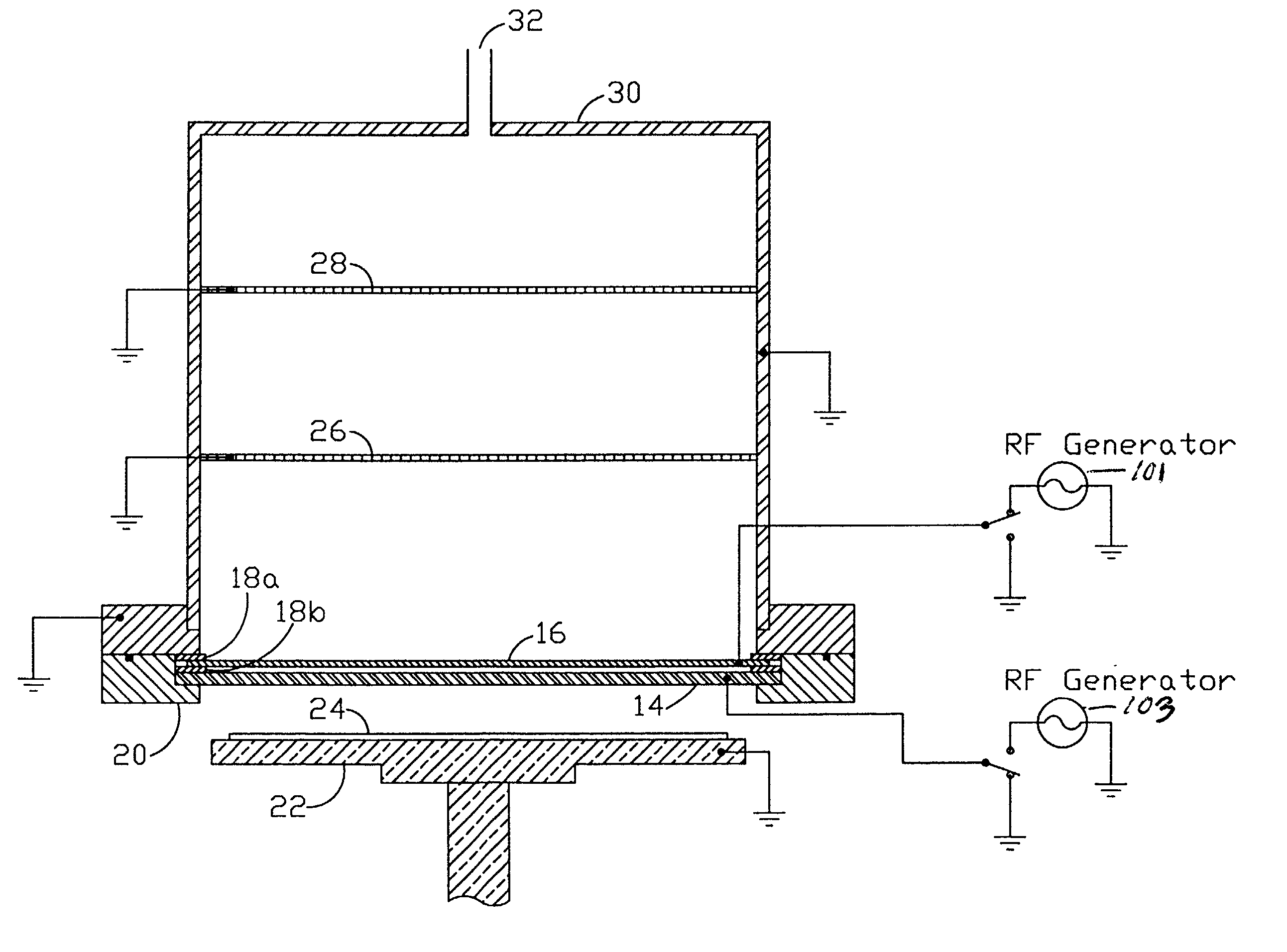

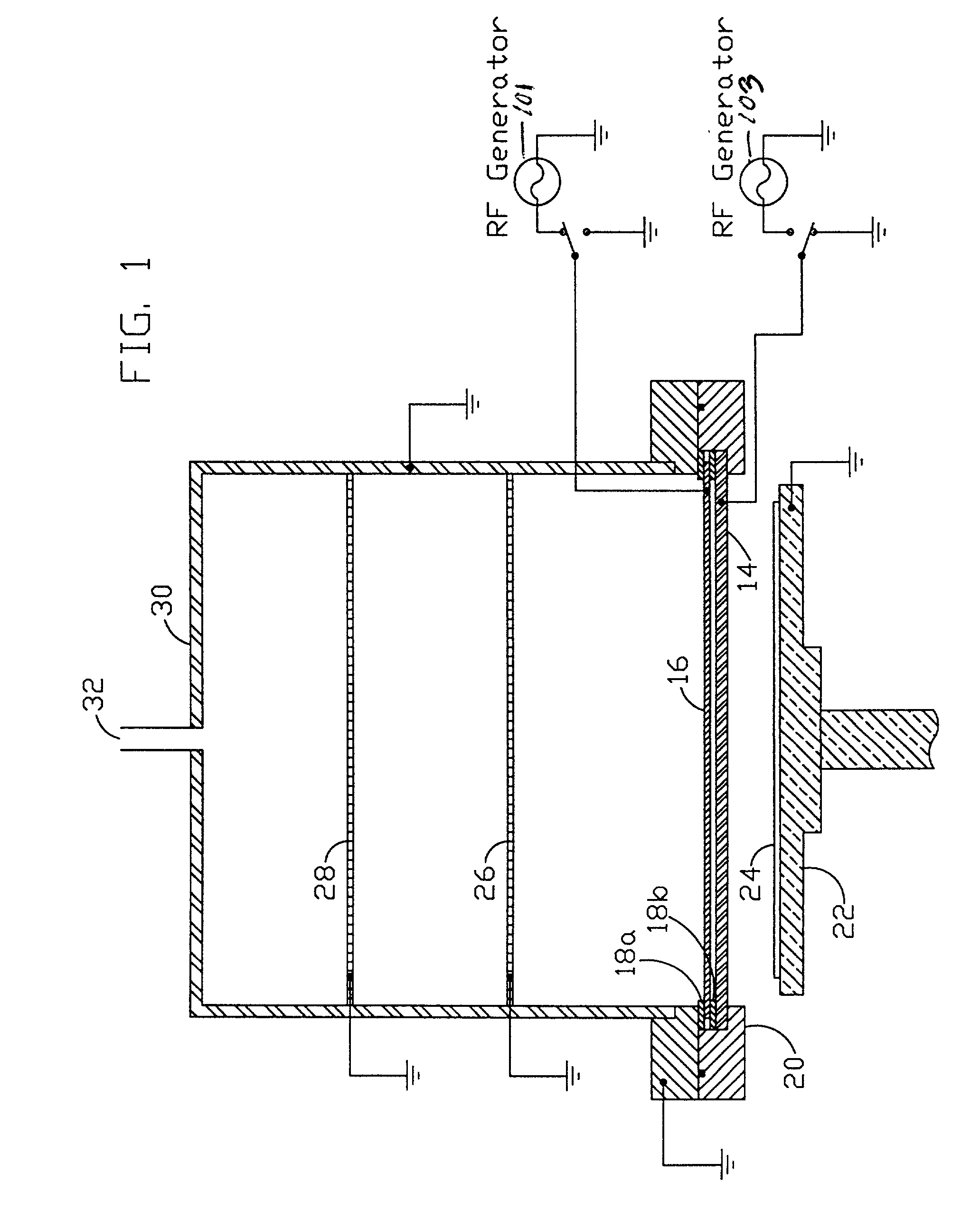

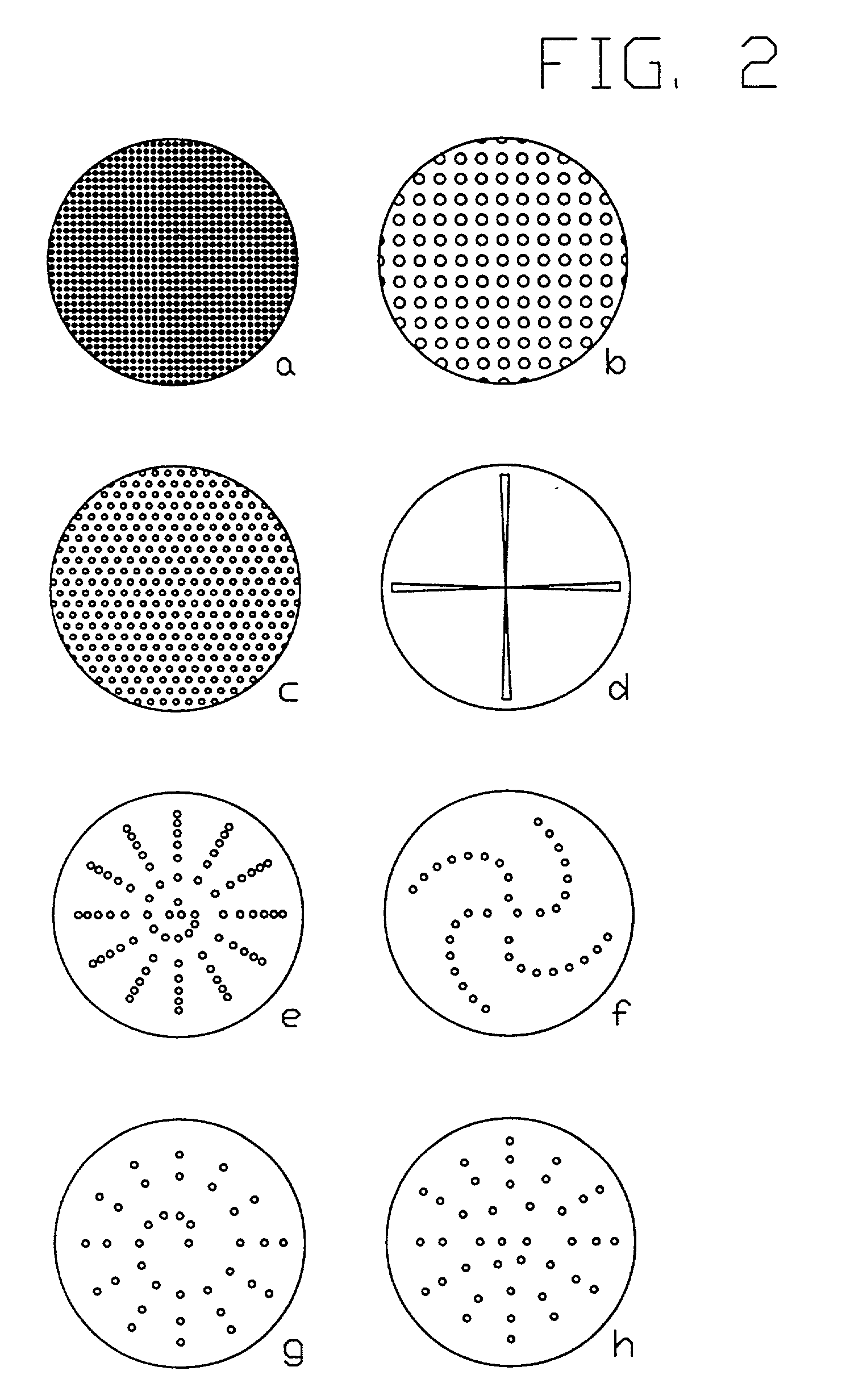

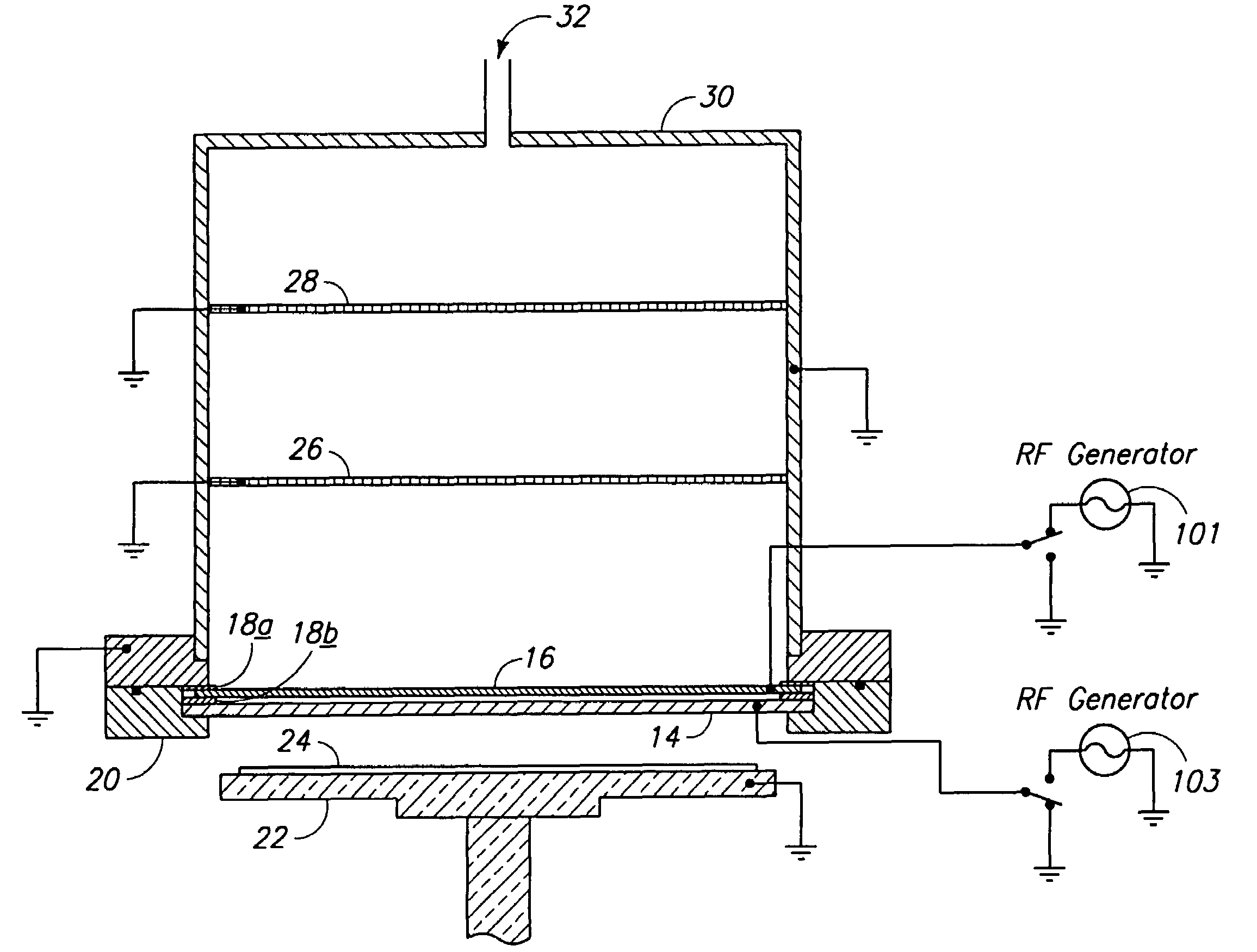

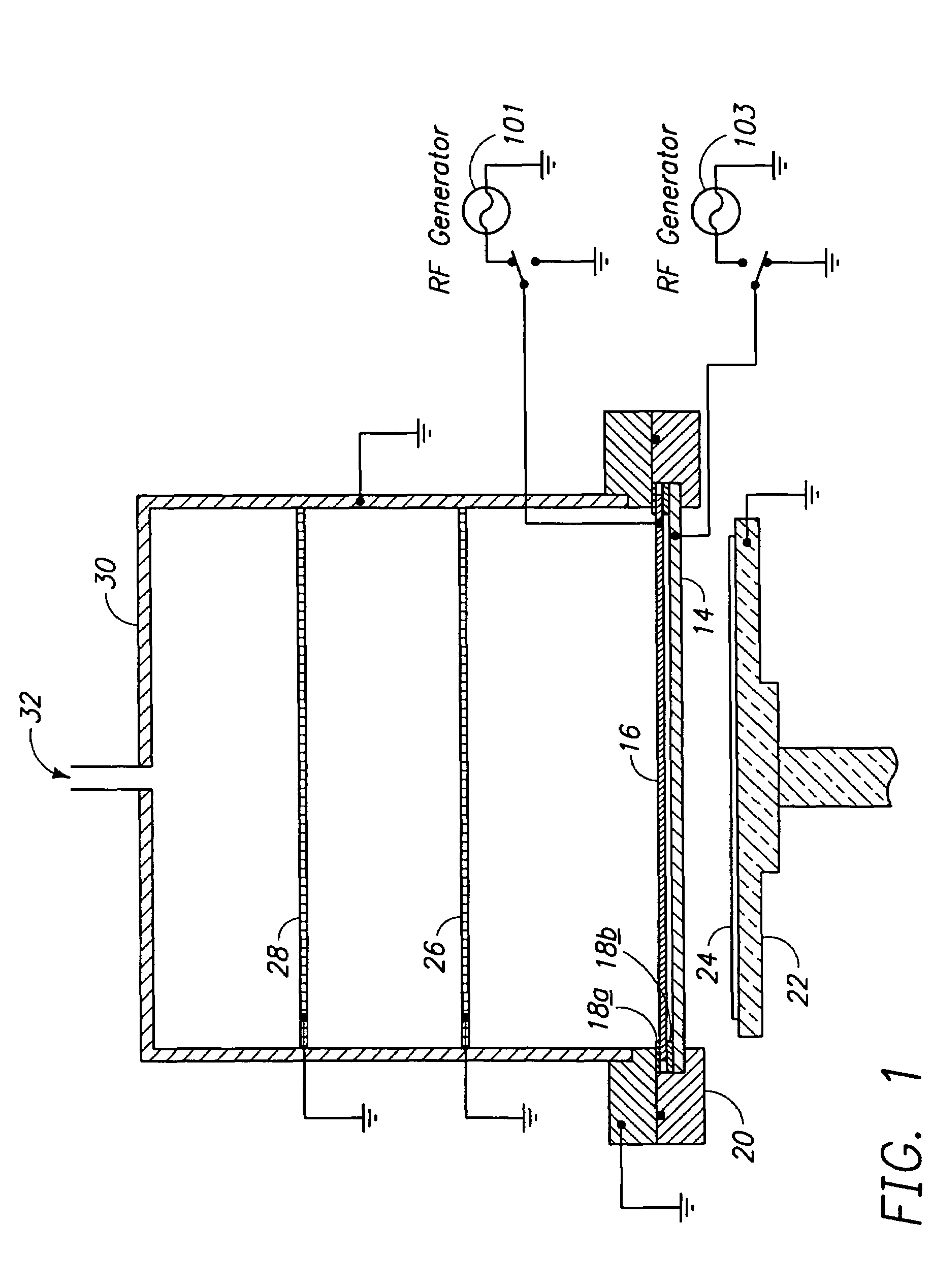

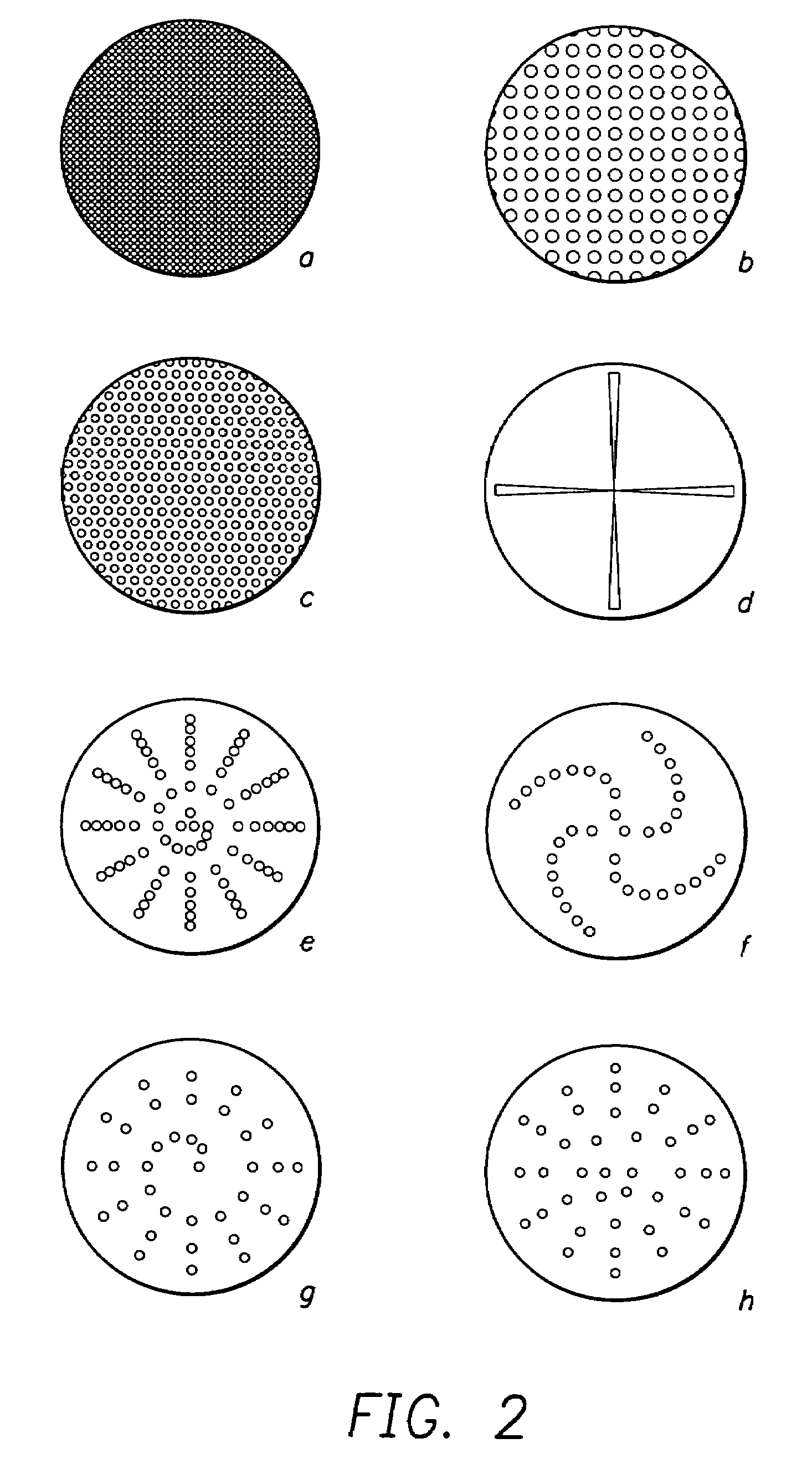

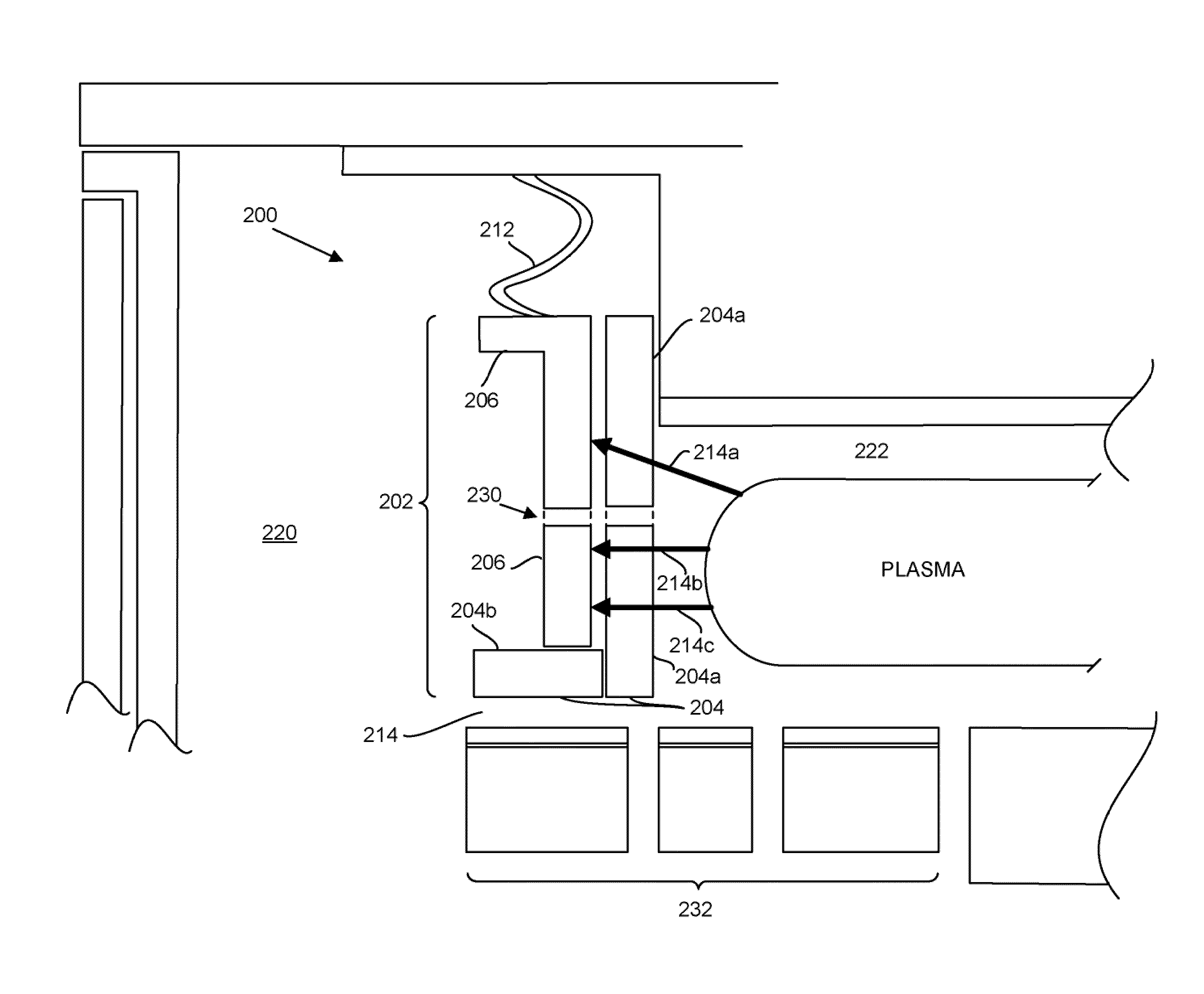

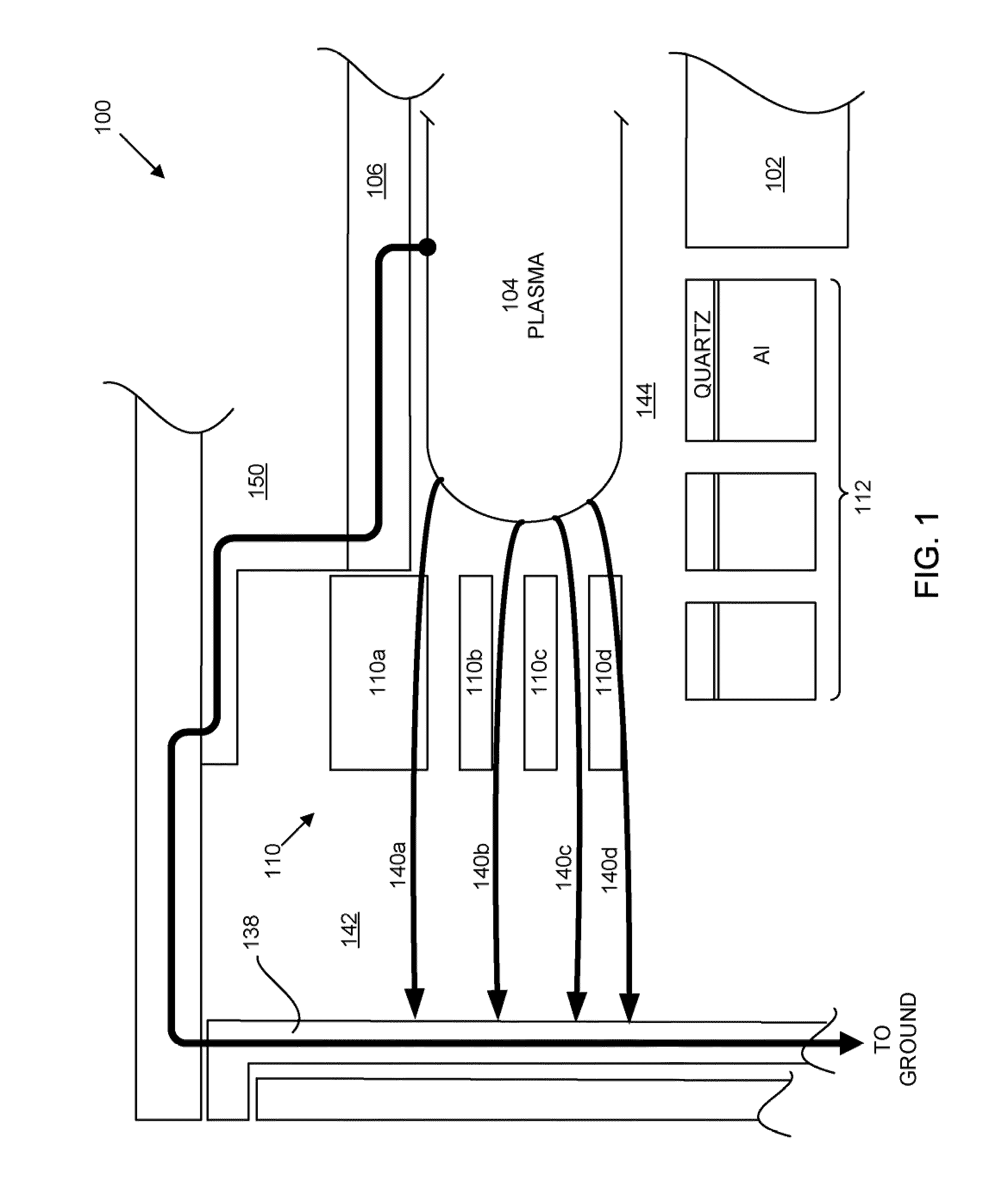

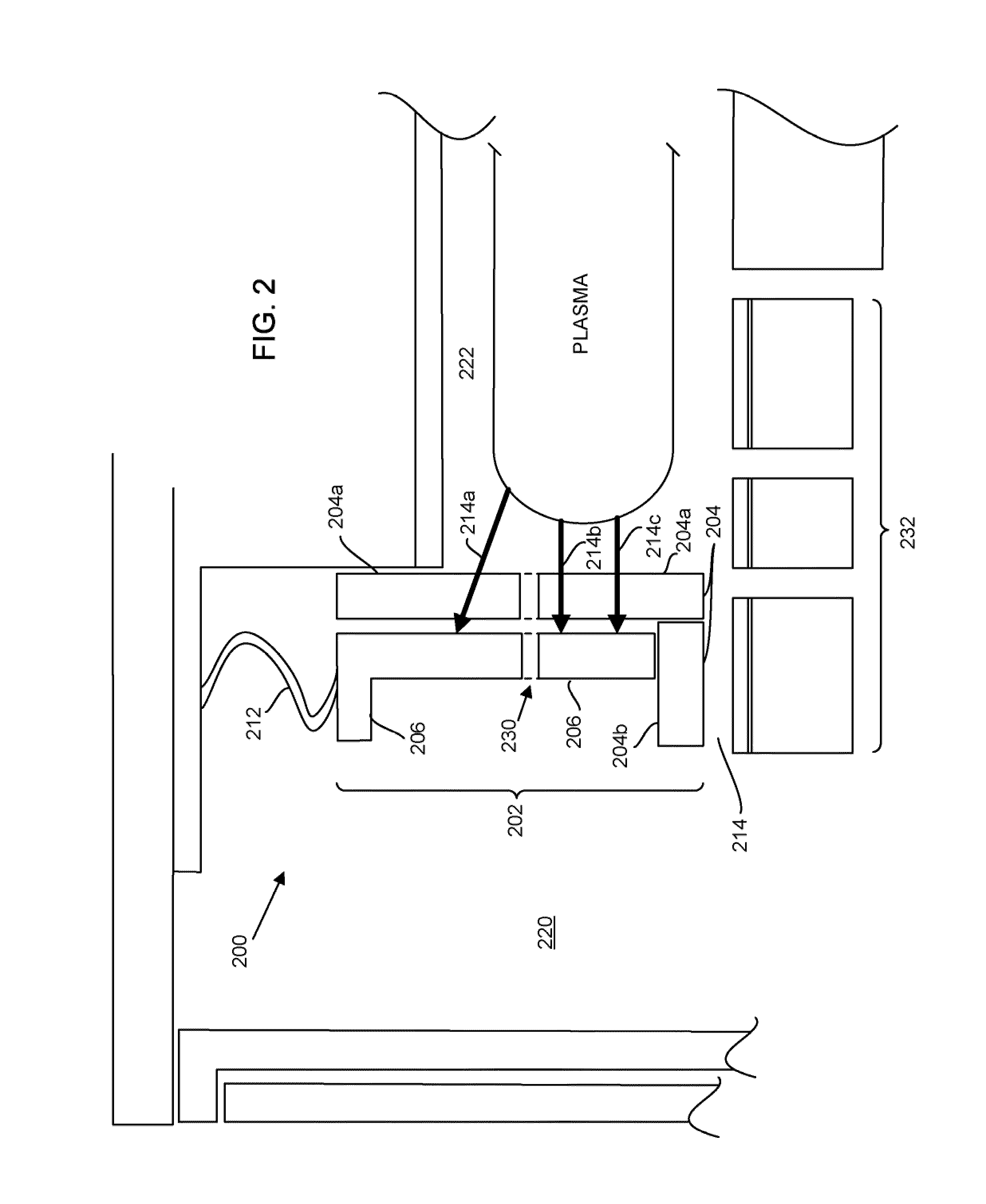

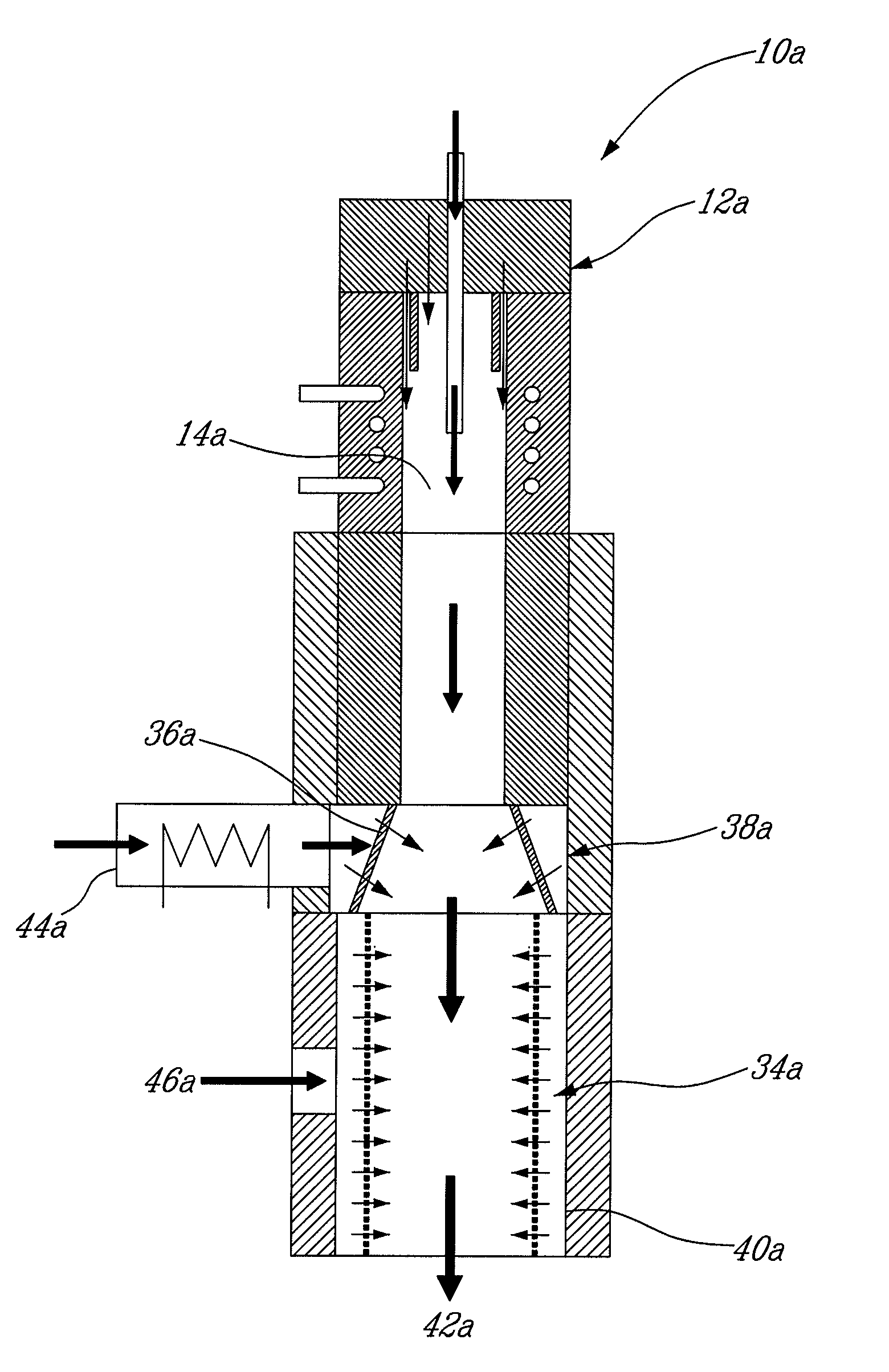

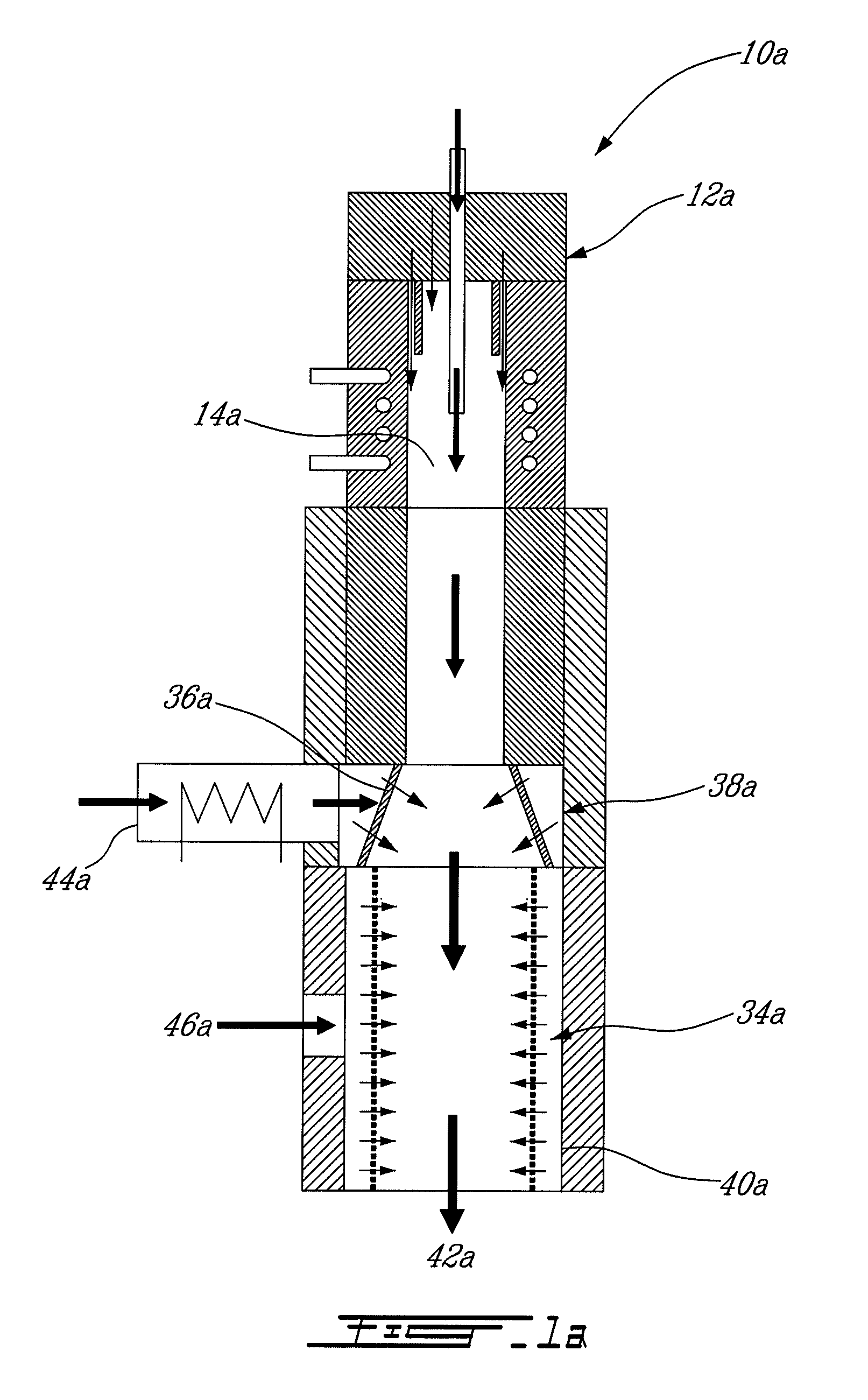

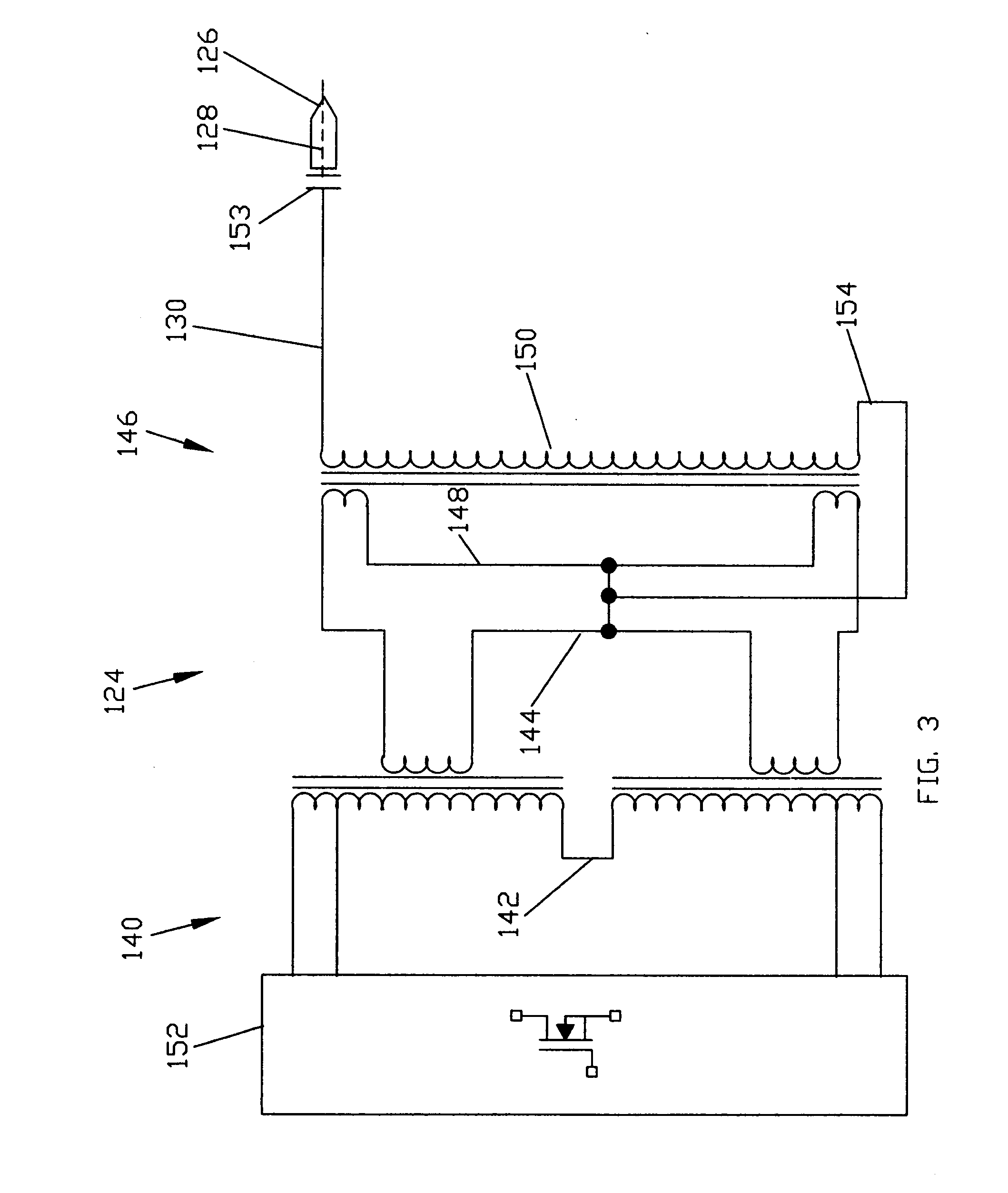

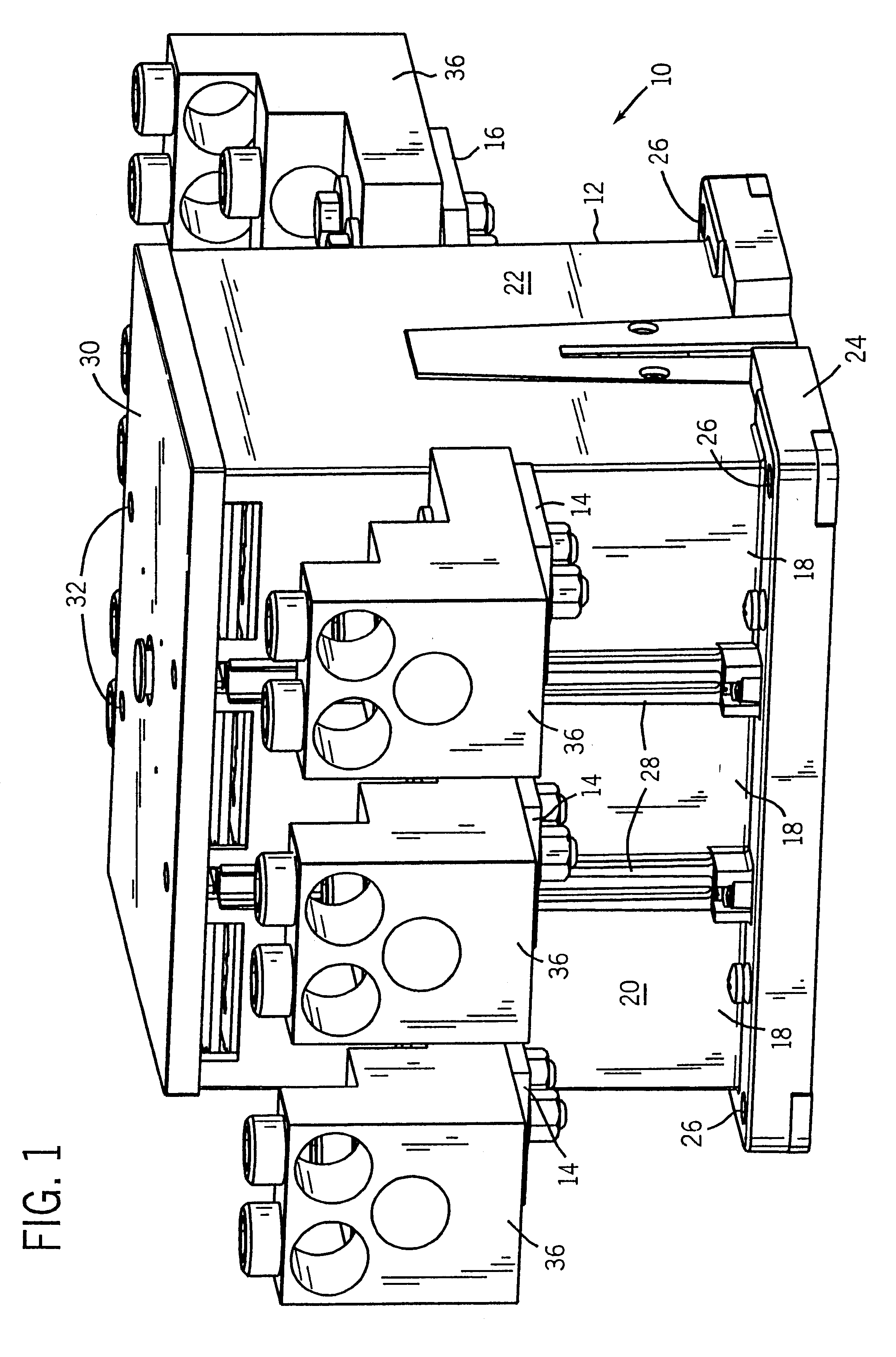

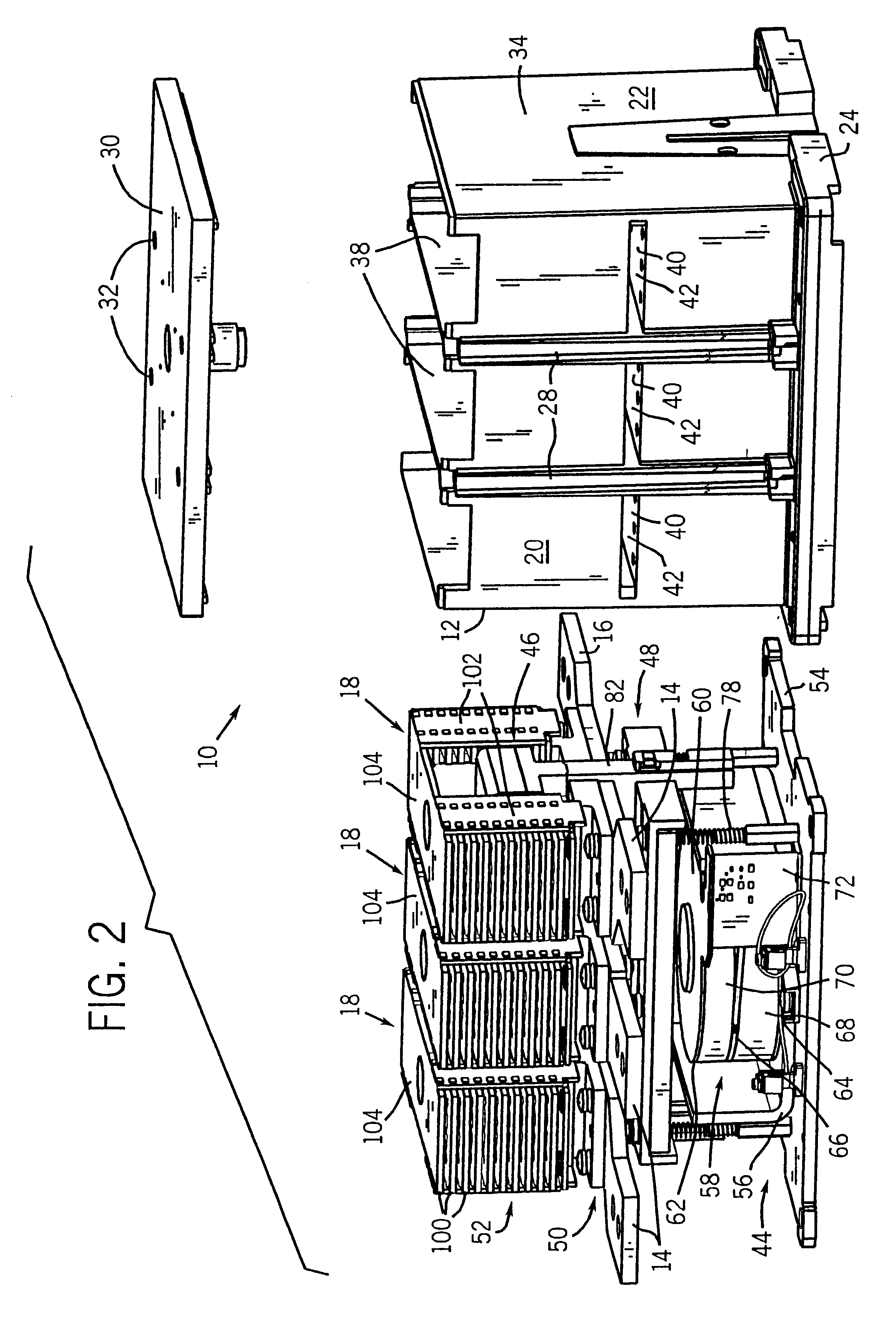

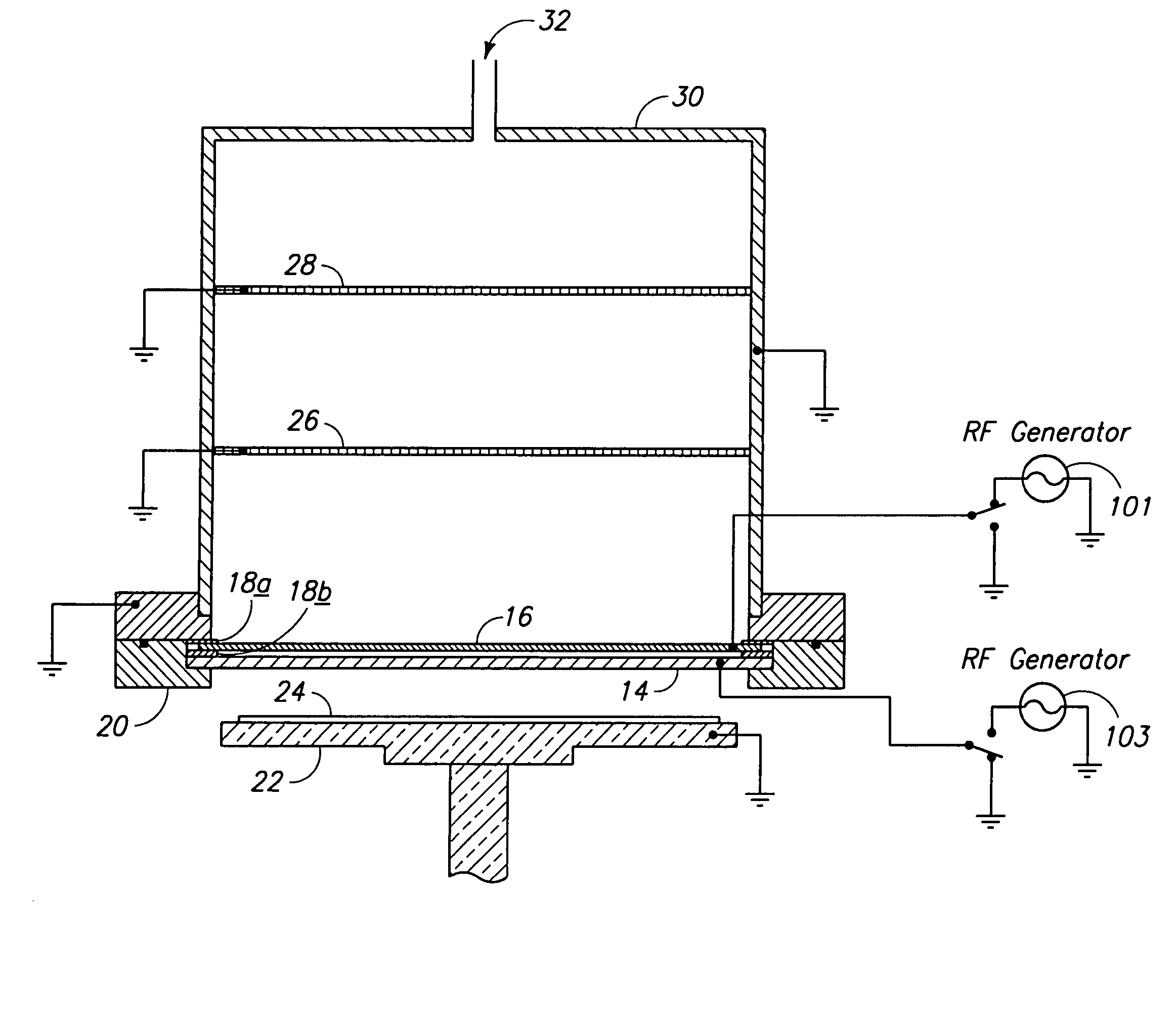

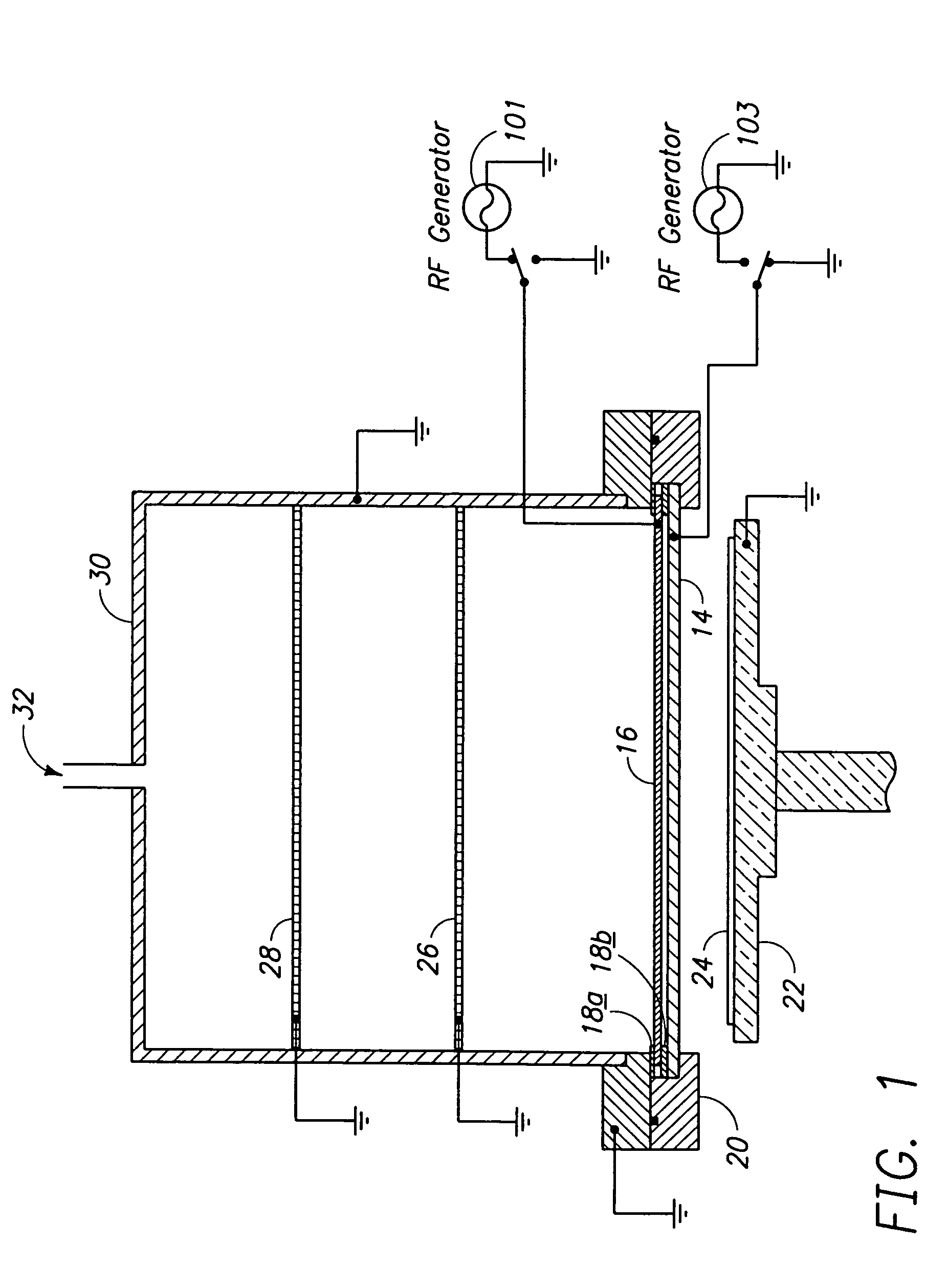

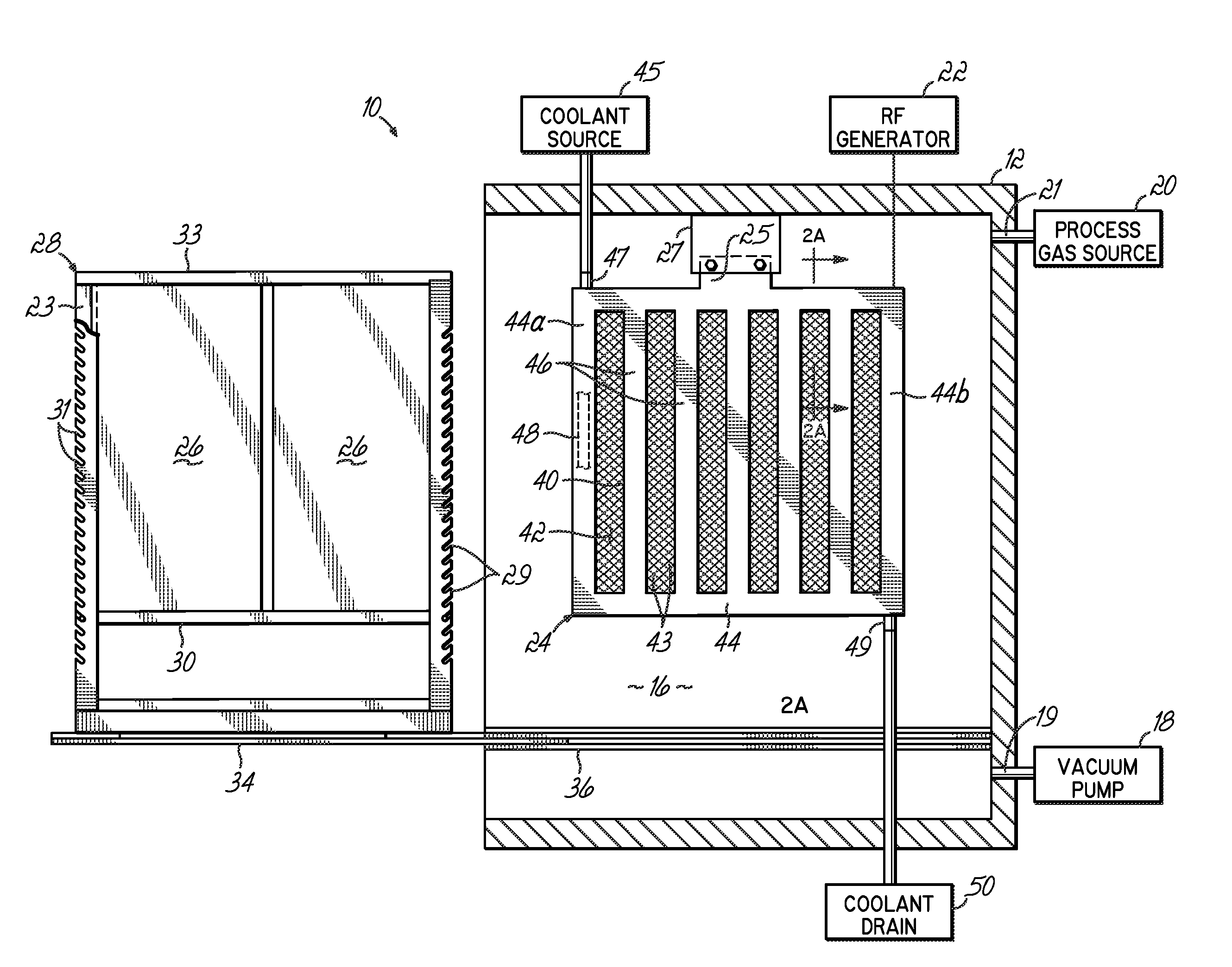

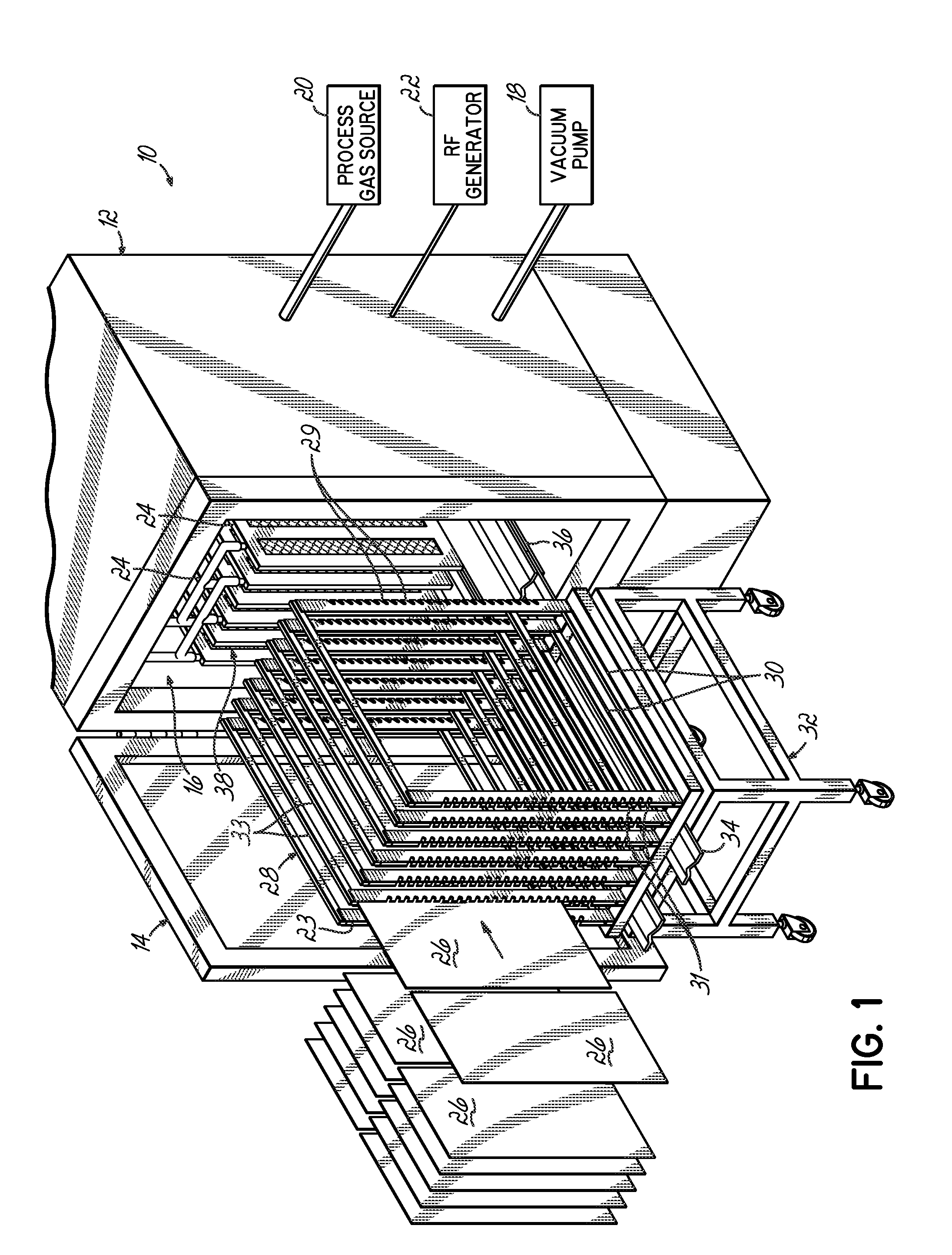

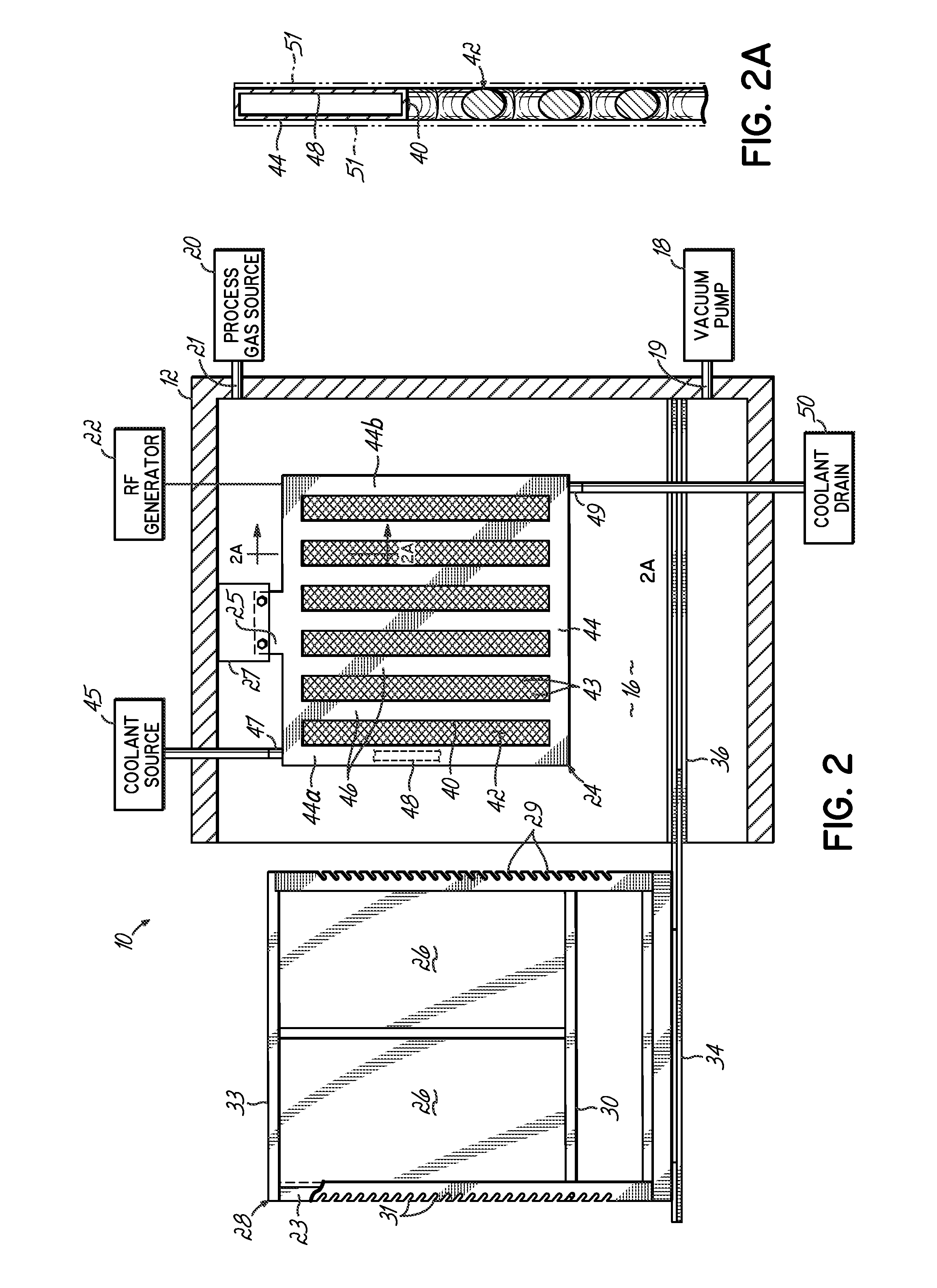

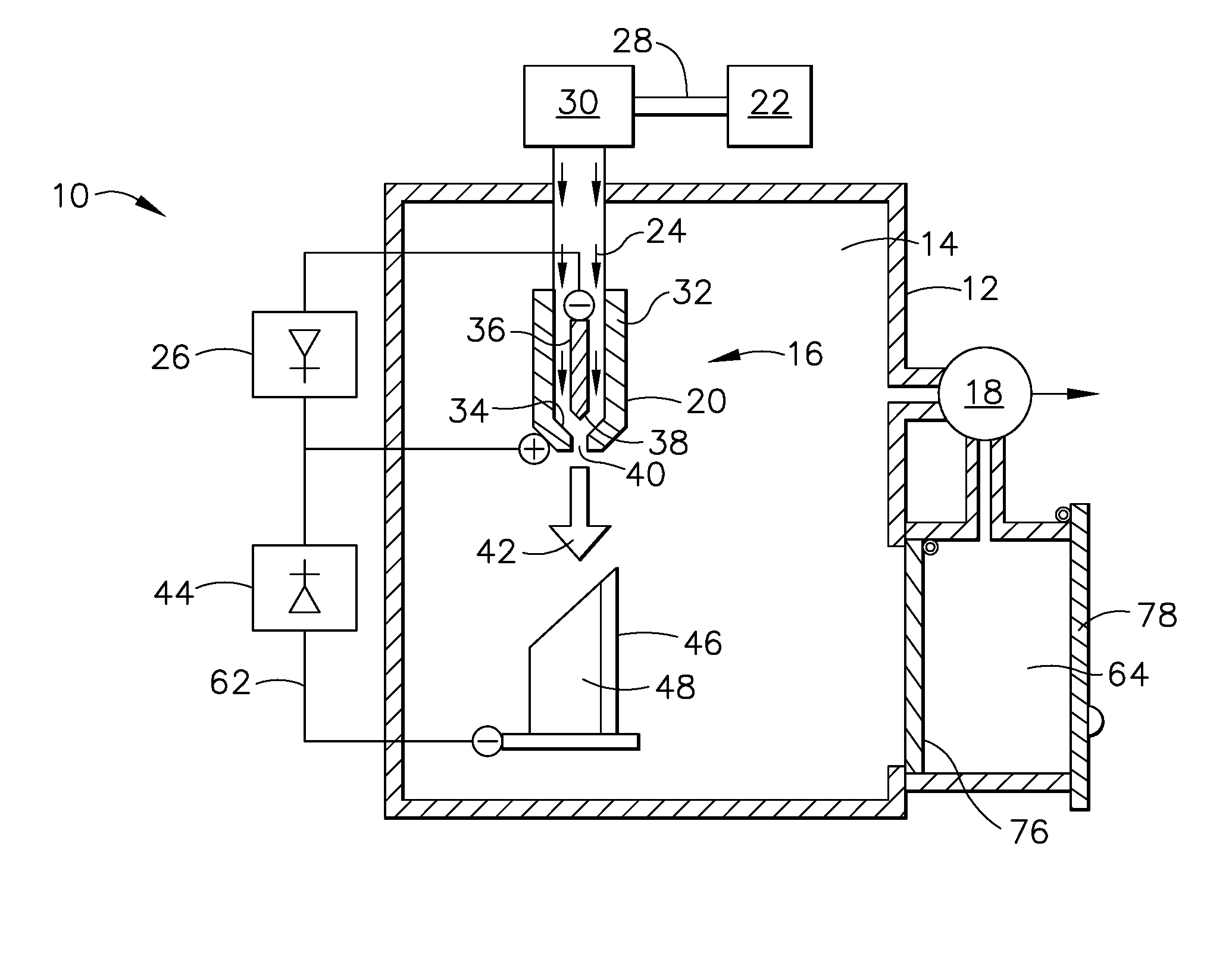

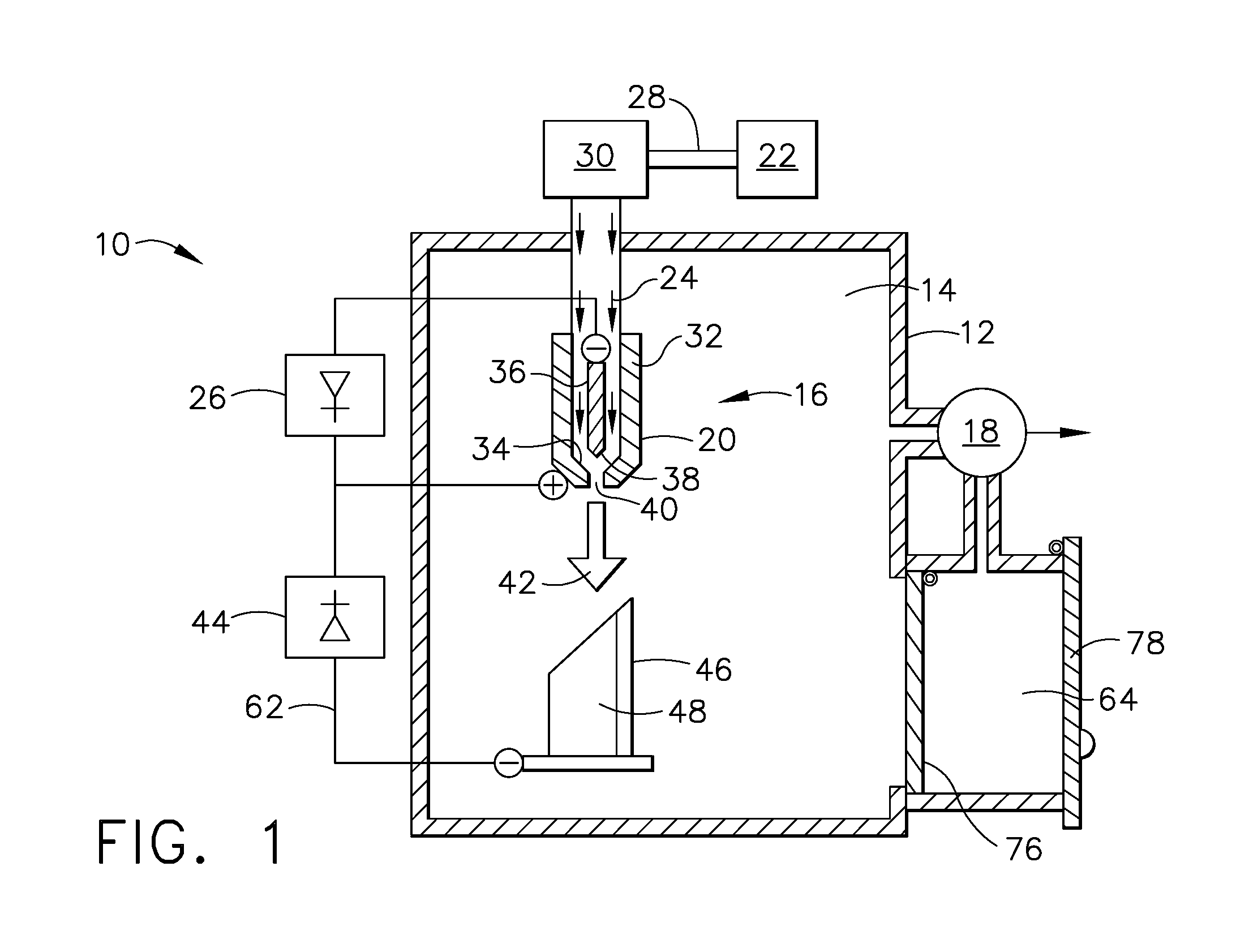

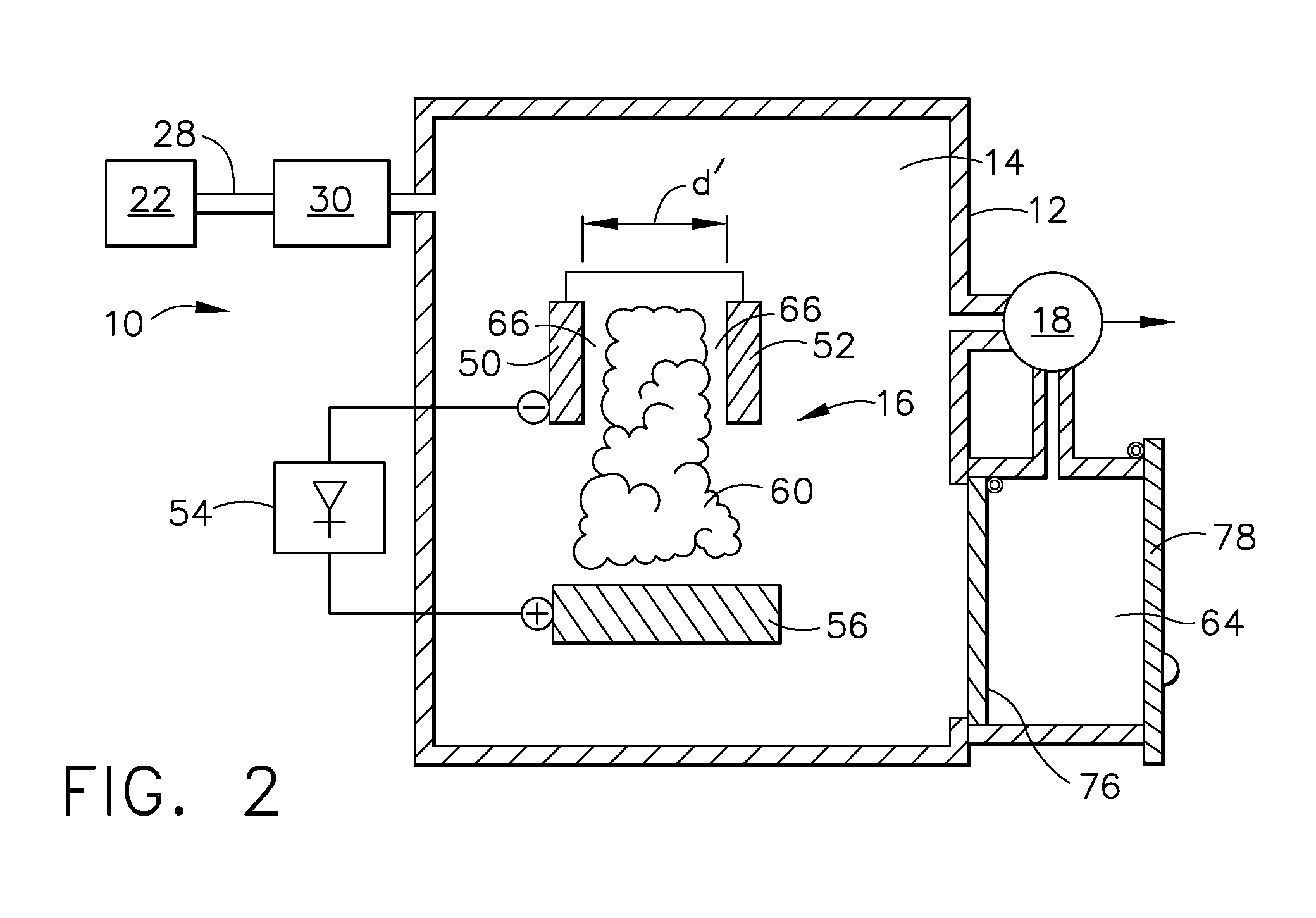

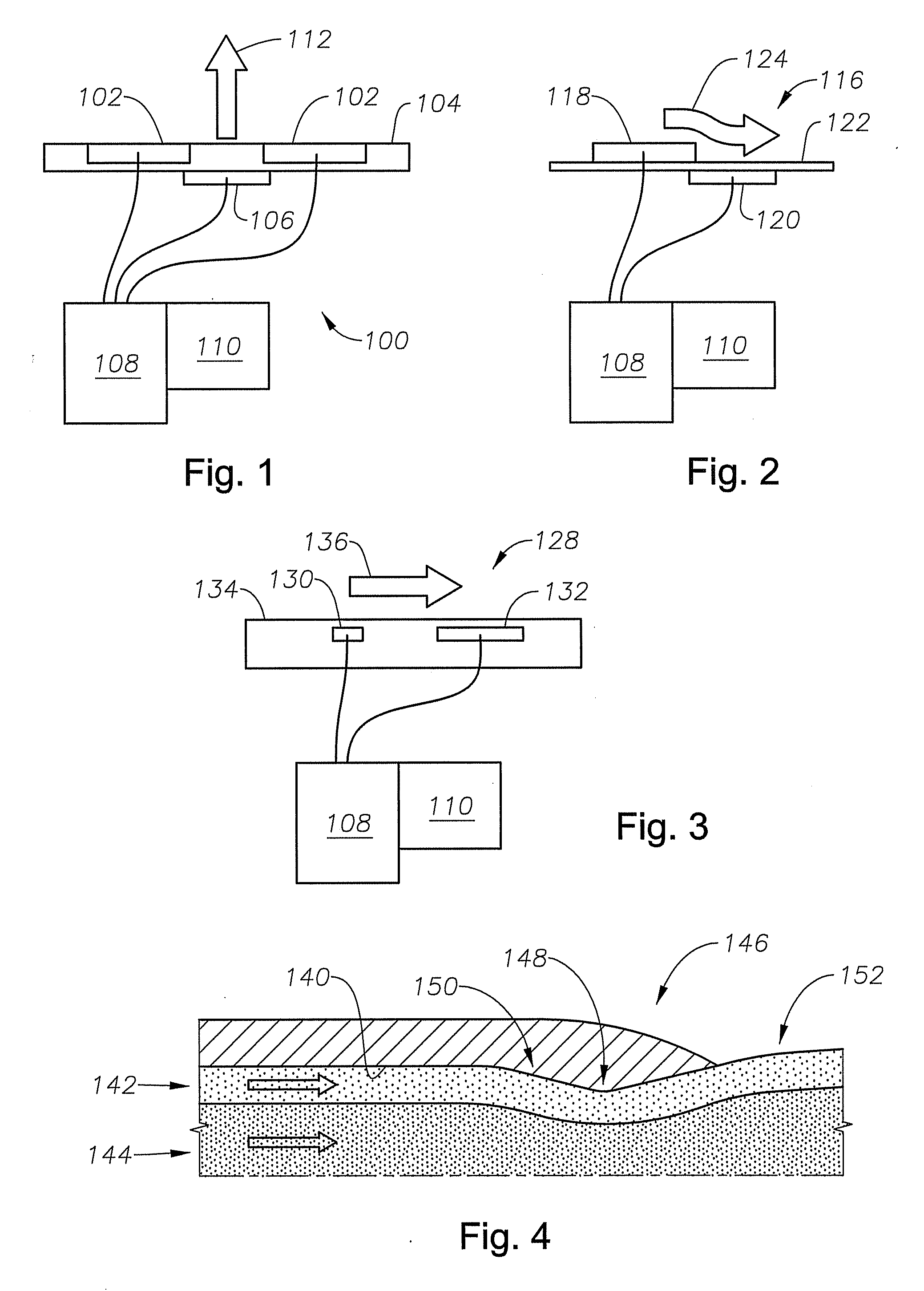

The invention is embodied in a plasma flow device or reactor having a housing that contains conductive electrodes with openings to allow gas to flow through or around them, where one or more of the electrodes are powered by an RF source and one or more are grounded, and a substrate or work piece is placed in the gas flow downstream of the electrodes, such that said substrate or work piece is substantially uniformly contacted across a large surface area with the reactive gases emanating therefrom. The invention is also embodied in a plasma flow device or reactor having a housing that contains conductive electrodes with openings to allow gas to flow through or around them, where one or more of the electrodes are powered by an RF source and one or more are grounded, and one of the grounded electrodes contains a means of mixing in other chemical precursors to combine with the plasma stream, and a substrate or work piece placed in the gas flow downstream of the electrodes, such that said substrate or work piece is contacted by the reactive gases emanating therefrom. In one embodiment, the plasma flow device removes organic materials from a substrate or work piece, and is a stripping or cleaning device. In another embodiment, the plasma flow device kills biological microorganisms on a substrate or work piece, and is a sterilization device. In another embodiment, the plasma flow device activates the surface of a substrate or work piece, and is a surface activation device. In another embodiment, the plasma flow device etches materials from a substrate or work piece, and is a plasma etcher. In another embodiment, the plasma flow device deposits thin films onto a substrate or work piece, and is a plasma-enhanced chemical vapor deposition device or reactor.

Owner:RGT UNIV OF CALIFORNIA

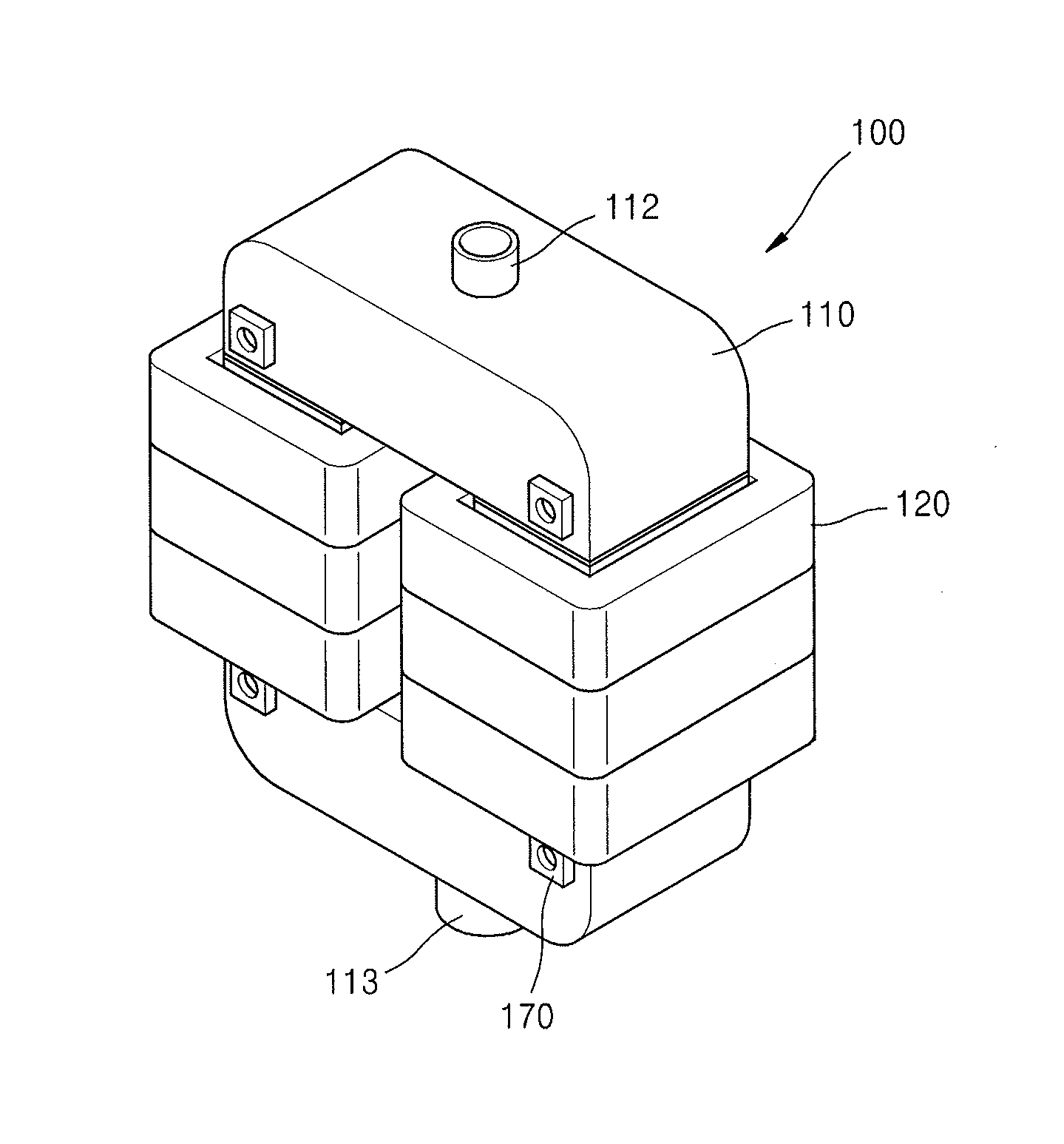

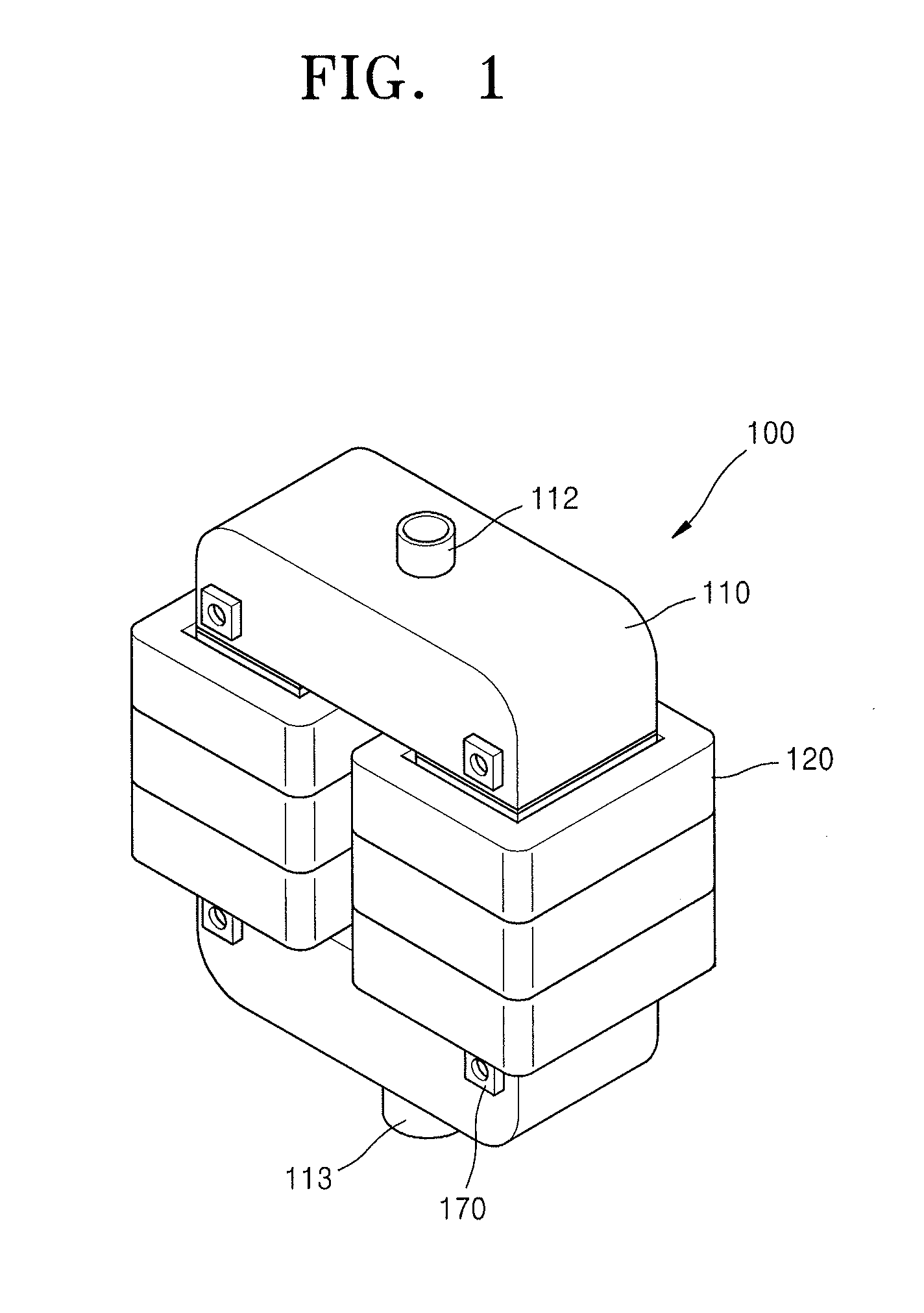

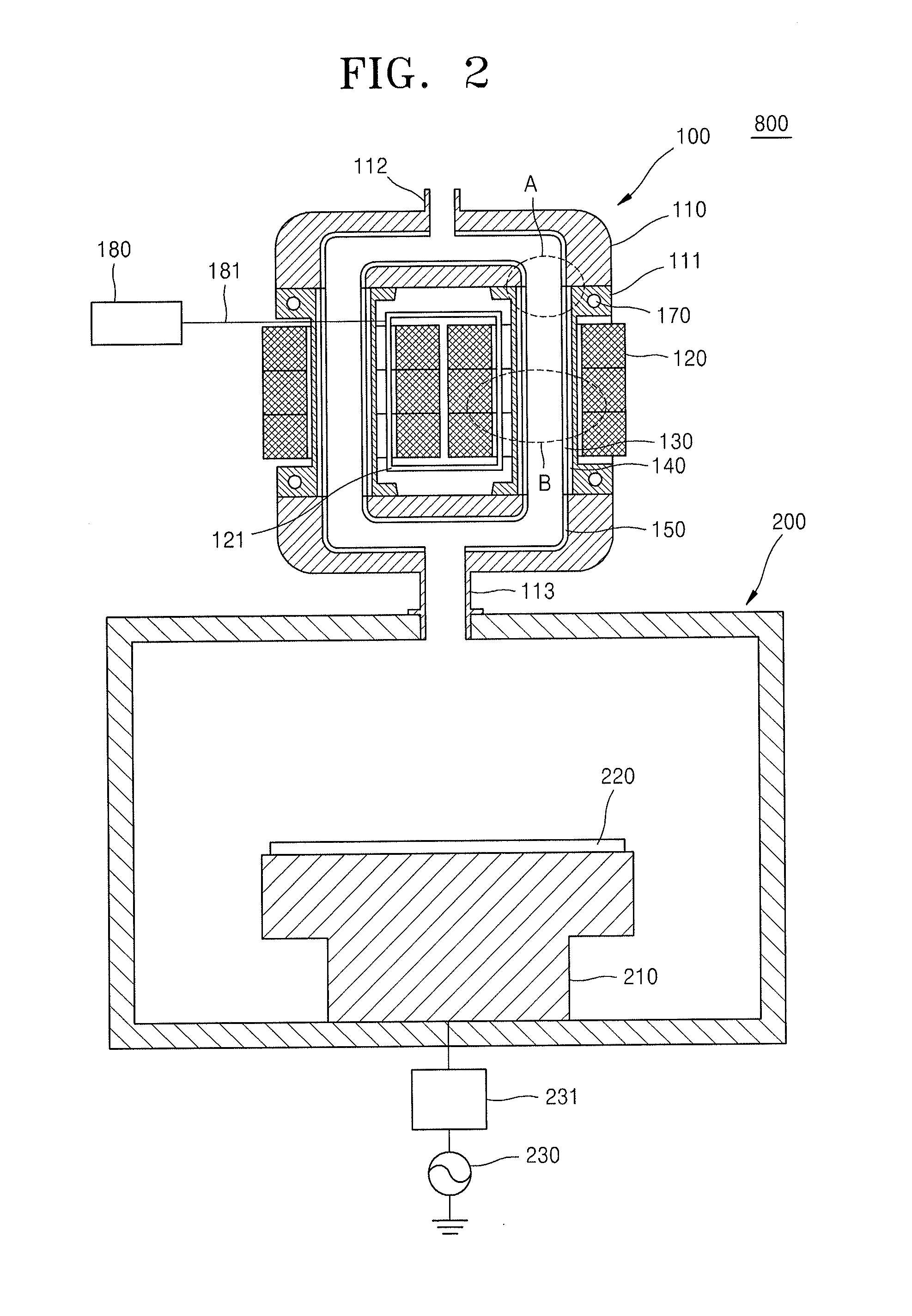

Remote plasma generator using ceramic

A remote plasma generator includes a body, a driver, and a protection tube. The body includes a gas injection port, a plasma exhaust port, and a plasma generation pipe through which discharge gas or plasma flow. The driver is coupled to the body and generates a magnetic field and plasma in the body. The protection tube is at an inner side of the plasma generation pipe to protect the plasma generation pipe from plasma.

Owner:SAMSUNG ELECTRONICS CO LTD +2

Method of processing a substrate

InactiveUS7329608B2Semiconductor/solid-state device detailsDispersed particle separationReactive gasGas phase

Owner:RGT UNIV OF CALIFORNIA

Plasma confinement structures in plasma processing systems

ActiveUS8540844B2Electric discharge tubesSemiconductor/solid-state device manufacturingPower flowEngineering

A movable plasma confinement structure configured for confining plasma in a plasma processing chamber during plasma processing of a substrate is provided. The movable plasma confinement structure includes a movable plasma-facing structure configured to surround the plasma. The movable plasma confinement structure also includes a movable electrically conductive structure disposed outside of the movable plasma-facing structure and configured to be deployed and retracted with the movable plasma-facing structure as a single unit to facilitate handling of the substrate. The movable electrically conductive structure is radio frequency (RF) grounded during the plasma processing. The movable plasma-facing structure is disposed between the plasma and the movable electrically conductive structure during the plasma processing such that RF current from the plasma flows to the movable electrically conductive structure through the movable plasma-facing structure during the plasma processing.

Owner:LAM RES CORP

Plasma synthesis of nanopowders

ActiveUS20070221635A1Improve scalabilityReduce the possibilityArc welding apparatusPlasma techniquePlasma flowQuenching

A process and apparatus for preparing a nanopowder are presented. The process comprises feeding a reactant material into a plasma reactor in which is generated a plasma flow having a temperature sufficiently high to vaporize the material; transporting the vapour by means of the plasma flow into a quenching zone; injecting a preheated quench gas into the plasma flow in the quenching zone to form a renewable gaseous condensation front; and forming a nanopowder at the interface between the renewable controlled temperature gaseous condensation front and the plasma flow.

Owner:TEKNA PLASMA SYST INC

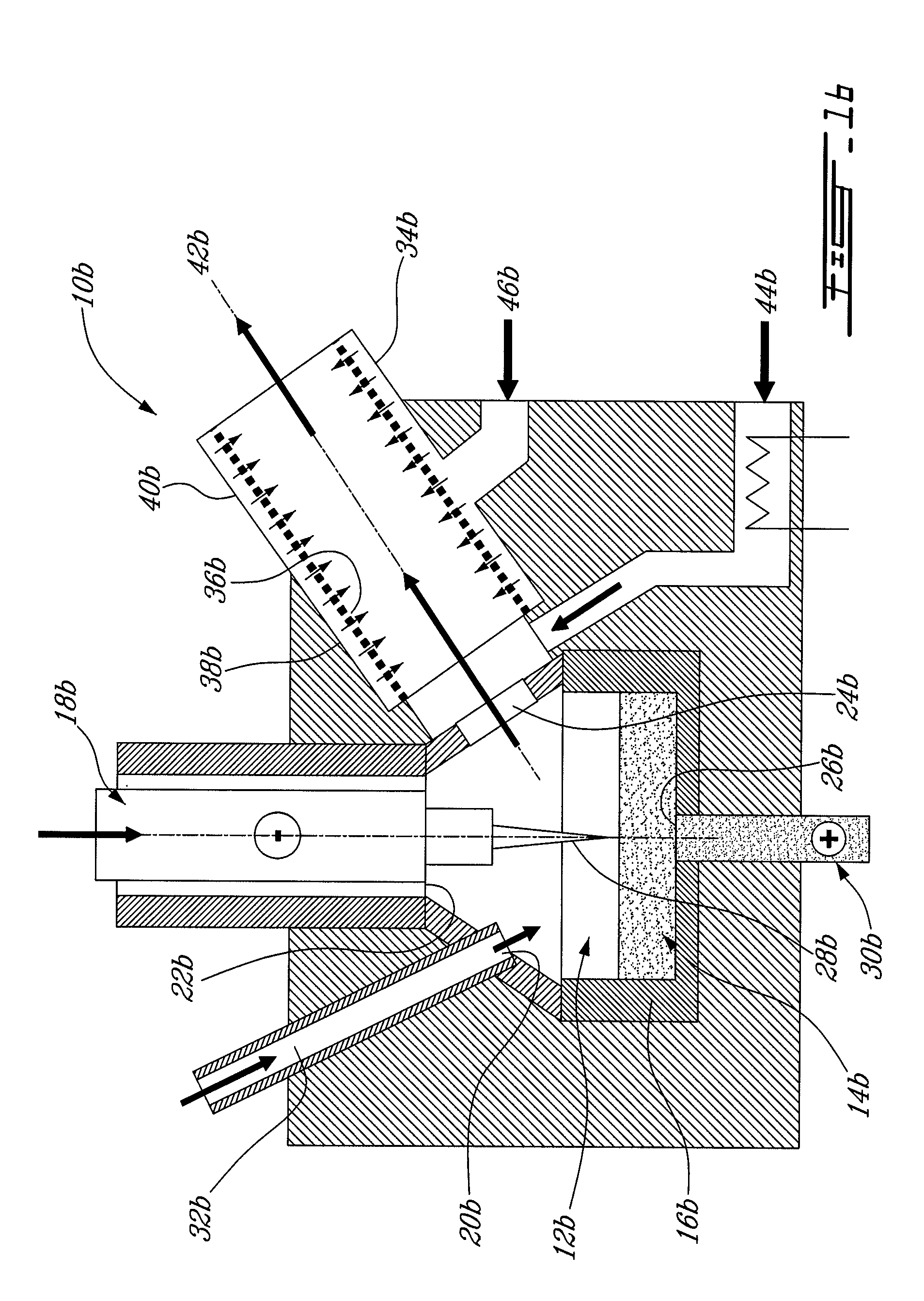

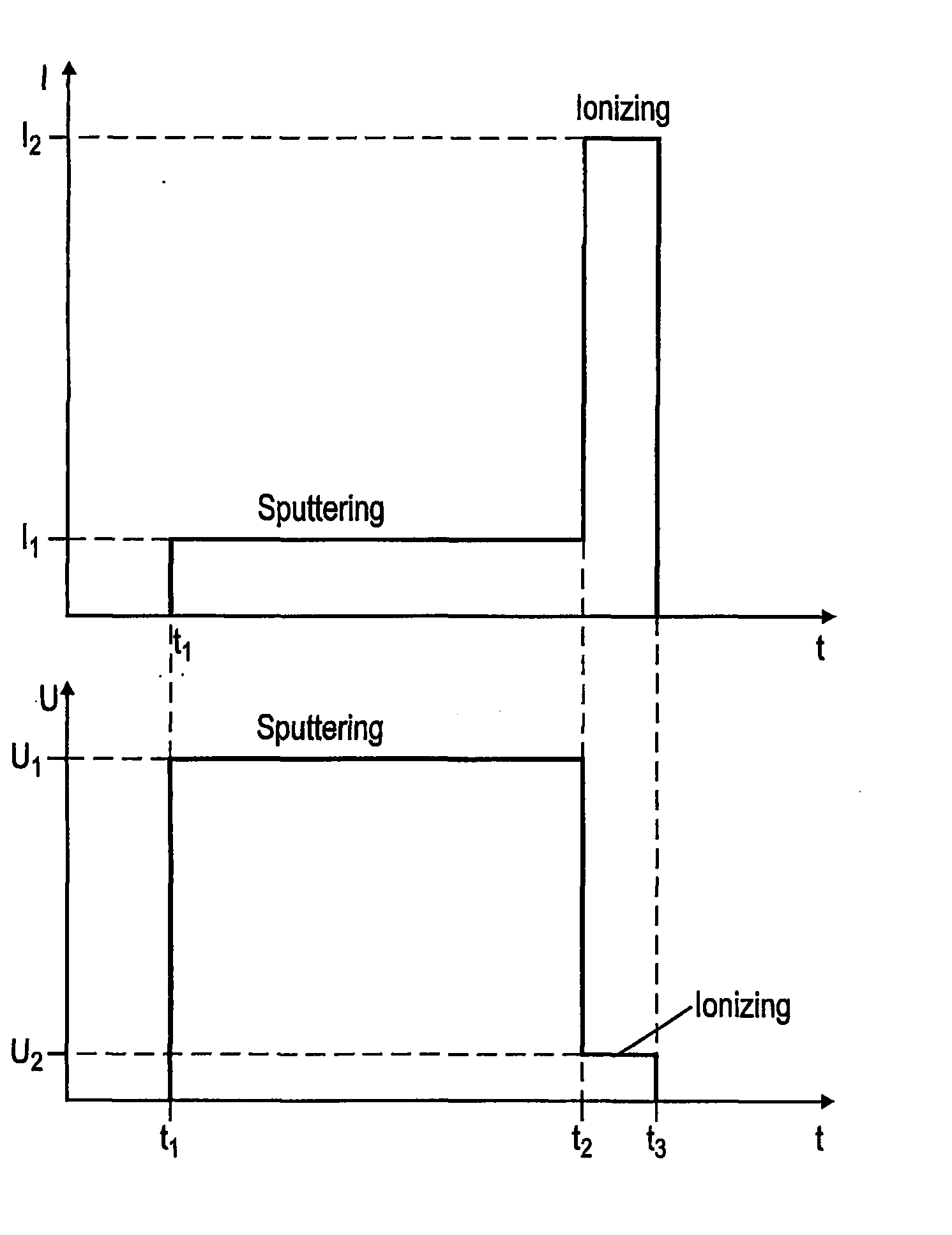

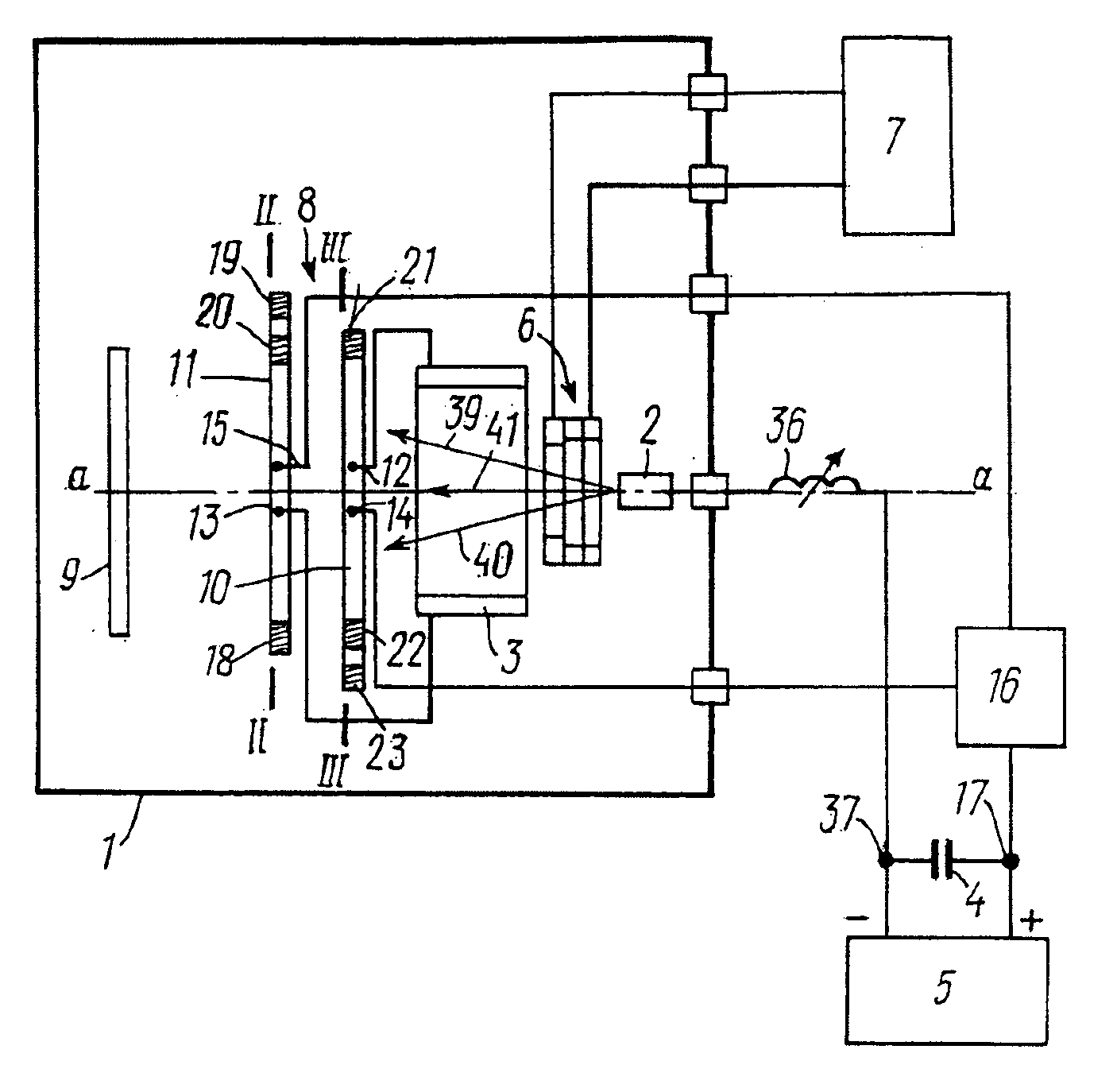

Method and apparatus for plasma generation

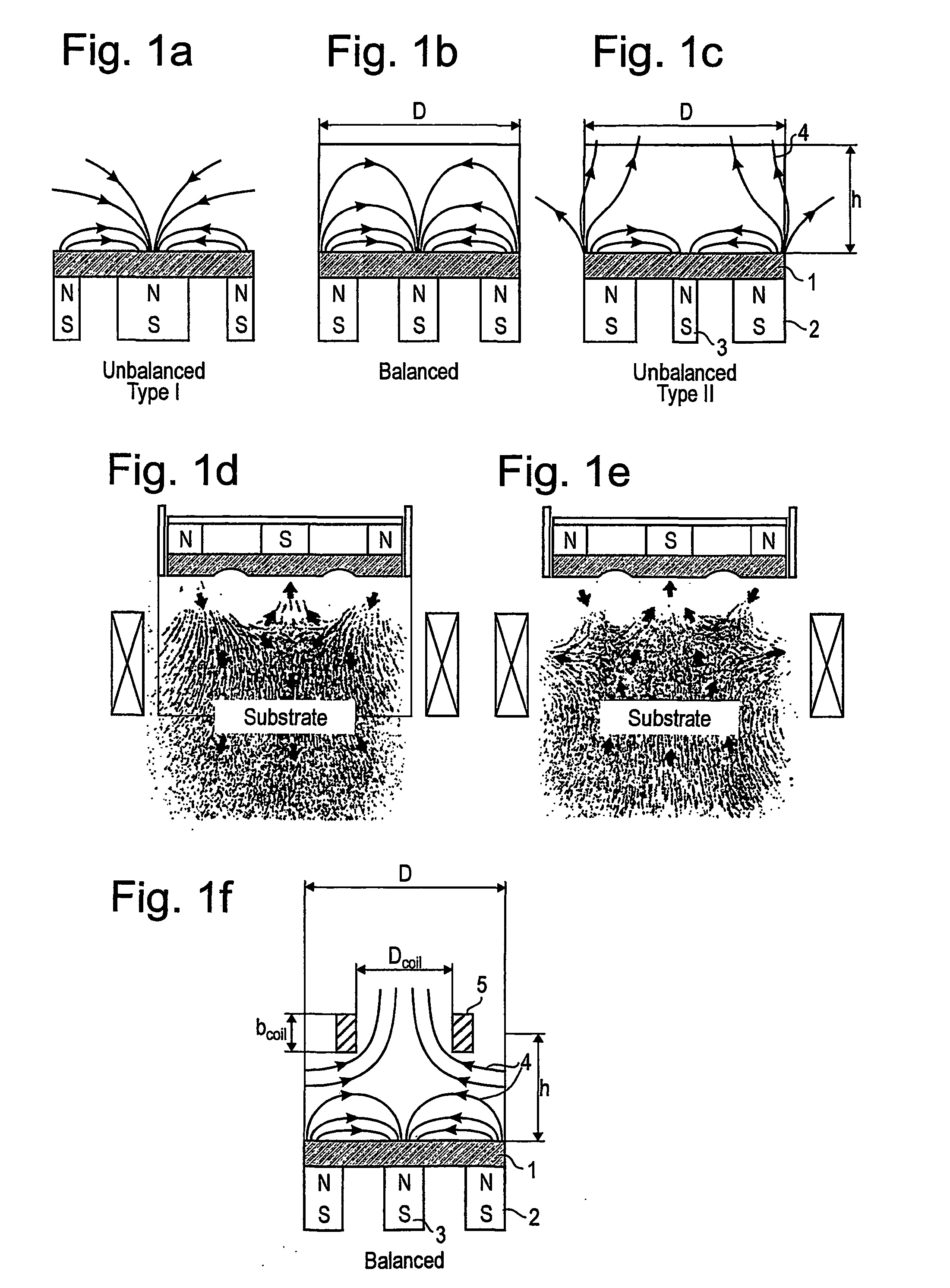

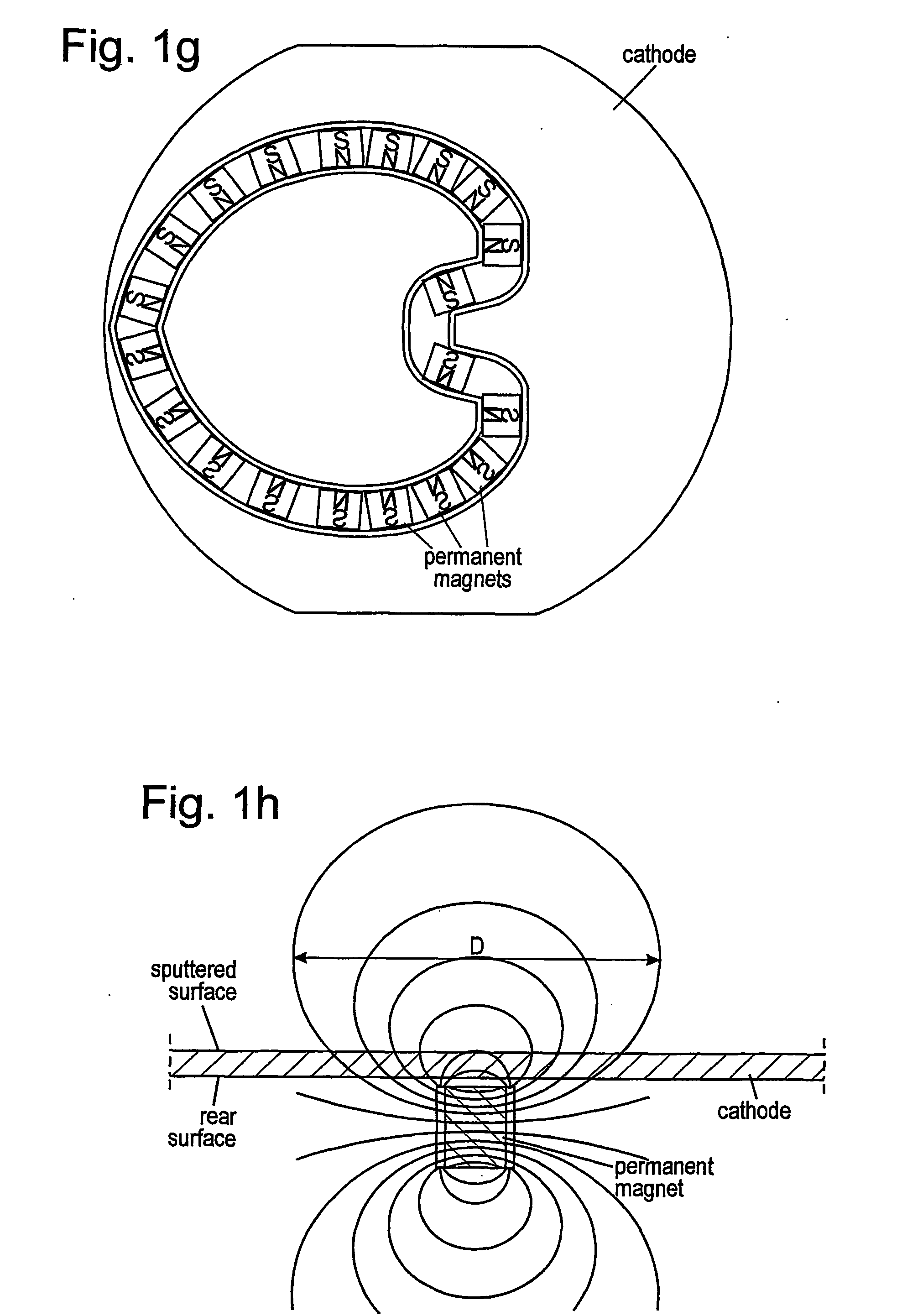

ActiveUS20050092596A1Improved plasma confinement propertyIncrease currentElectric discharge tubesVacuum evaporation coatingElectric dischargePlasma flow

In a simple method and device for producing plasma flows of a metal and / or a gas electric discharges are periodically produced between the anode and a metal magnetron sputtering cathode in crossed electric and magnetic fields in a chamber having a low pressure of a gas. The discharges are produced so that each discharge comprises a first period with a low electrical current passing between the anode and cathode for producing a metal vapor by magnetron sputtering, and a second period with a high electrical current passing between the anode and cathode for producing an ionization of gas and the produced metal vapor. Instead of the first period a constant current discharge can be used. Intensive gas or metal plasma flows can be produced without forming contracted arc discharges. The selfsputtering phenomenon can be used.

Owner:CEMECON +1

Plasma knife

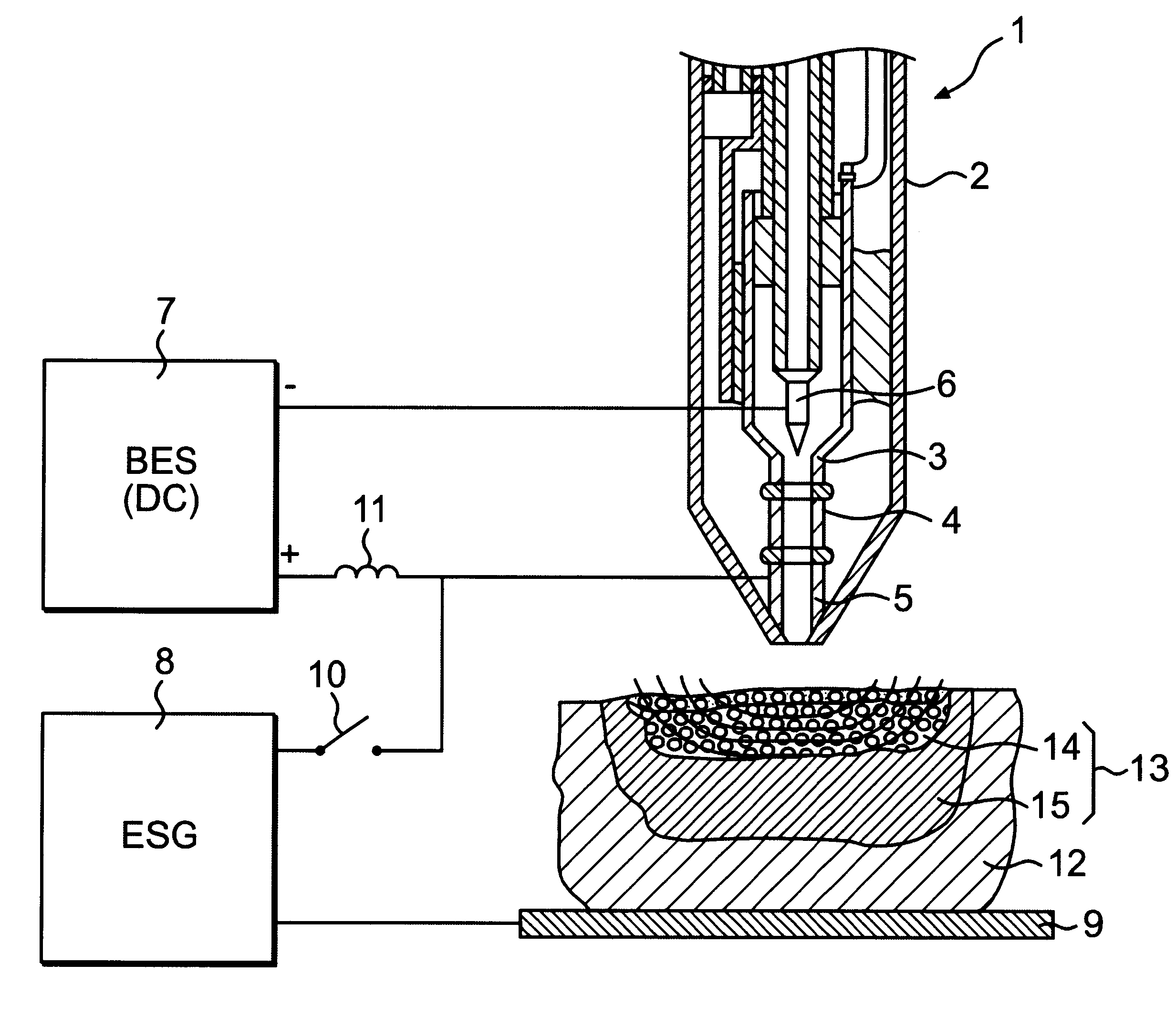

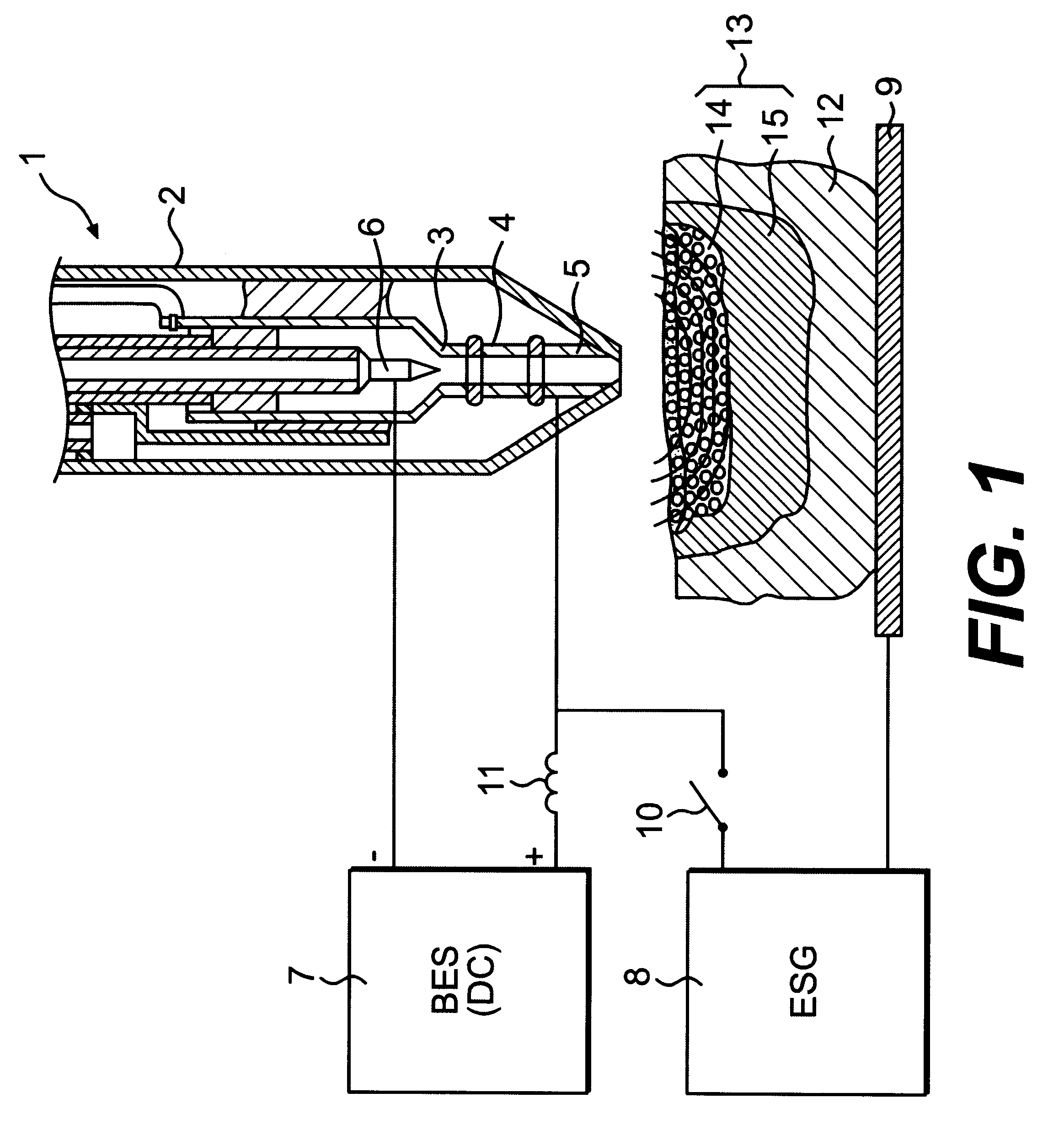

InactiveUS6443948B1Increasing the thicknessStop especially heavy bleedingsArc welding apparatusSurgical instruments for heatingPorous layerPlasma flow

A device for stopping a bleeding in living tissue in humans and animals by forming a necrotic layer in the tissue comprises a member for generating a dynamic plasma flow capable of wholly or partially penetrating an outer, porous layer of the necrotic layer. The device also has an electrosurgical generator arranged to transfer electric energy to the inner limit of the porous layer through a circuit that comprises the plasma flow and the tissue.

Owner:NIKVAL INT +1

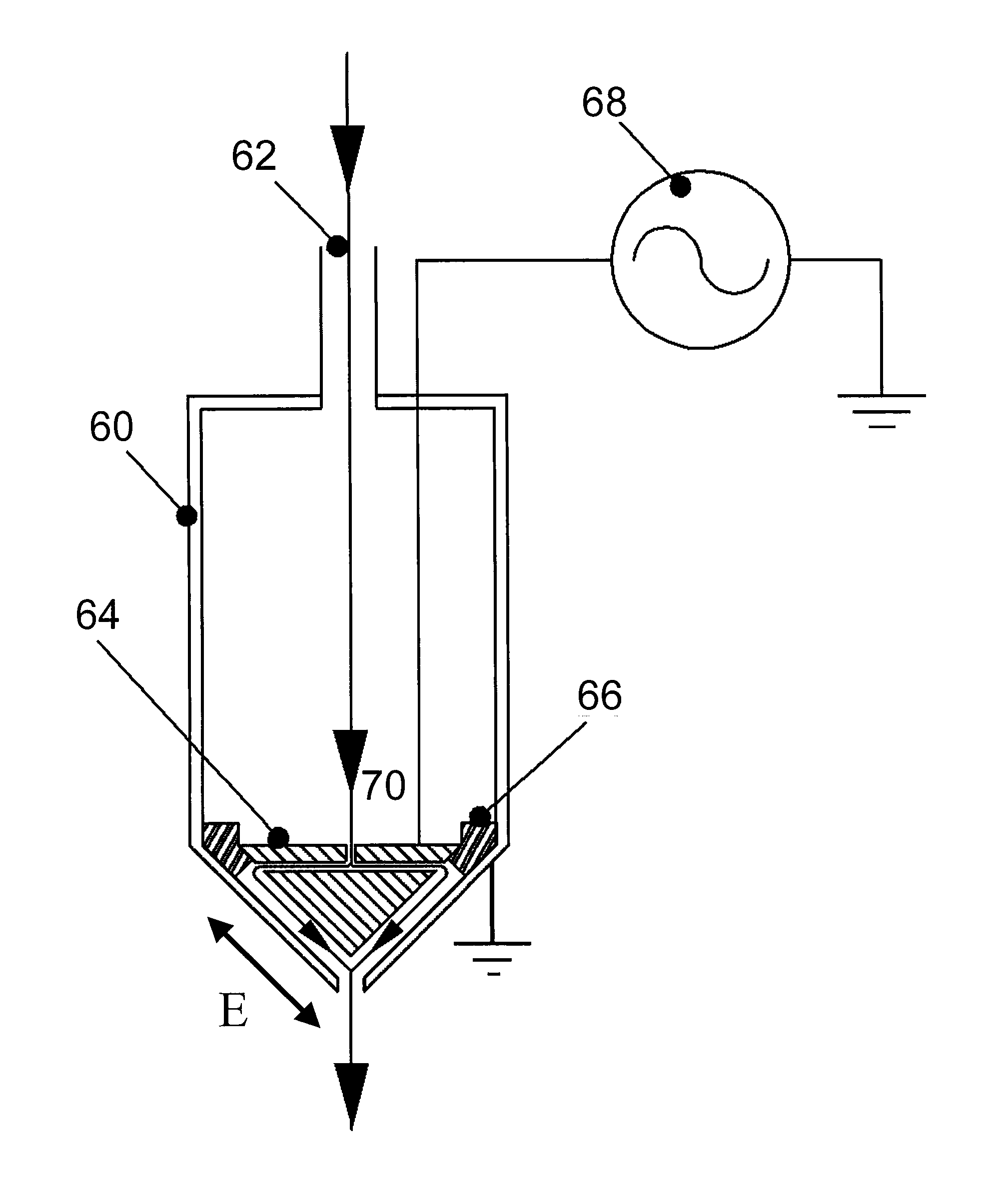

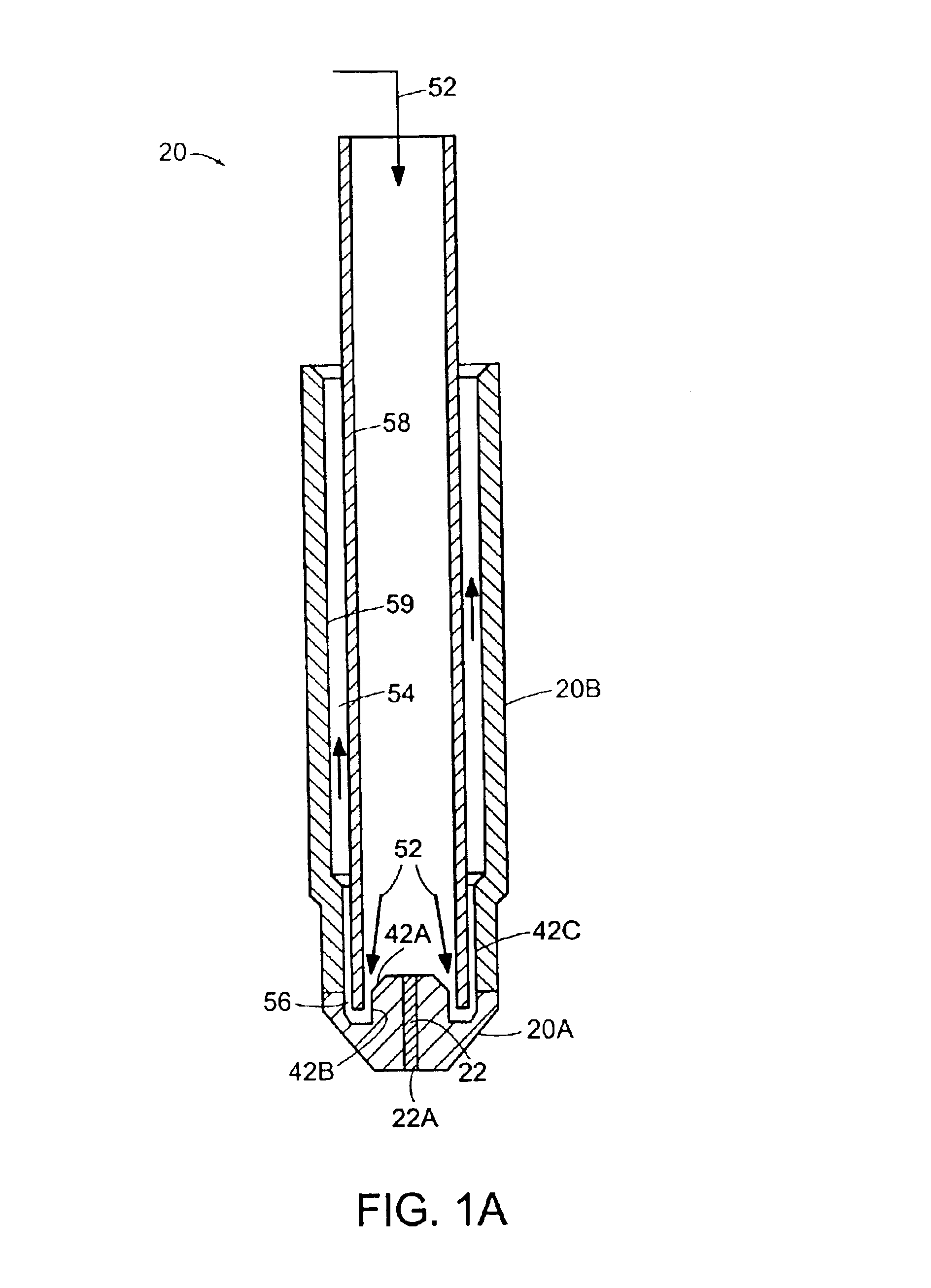

Low-temperature, converging, reactive gas source and method of use

ActiveUS8328982B1Electric discharge tubesSemiconductor/solid-state device manufacturingEtchingReactive gas

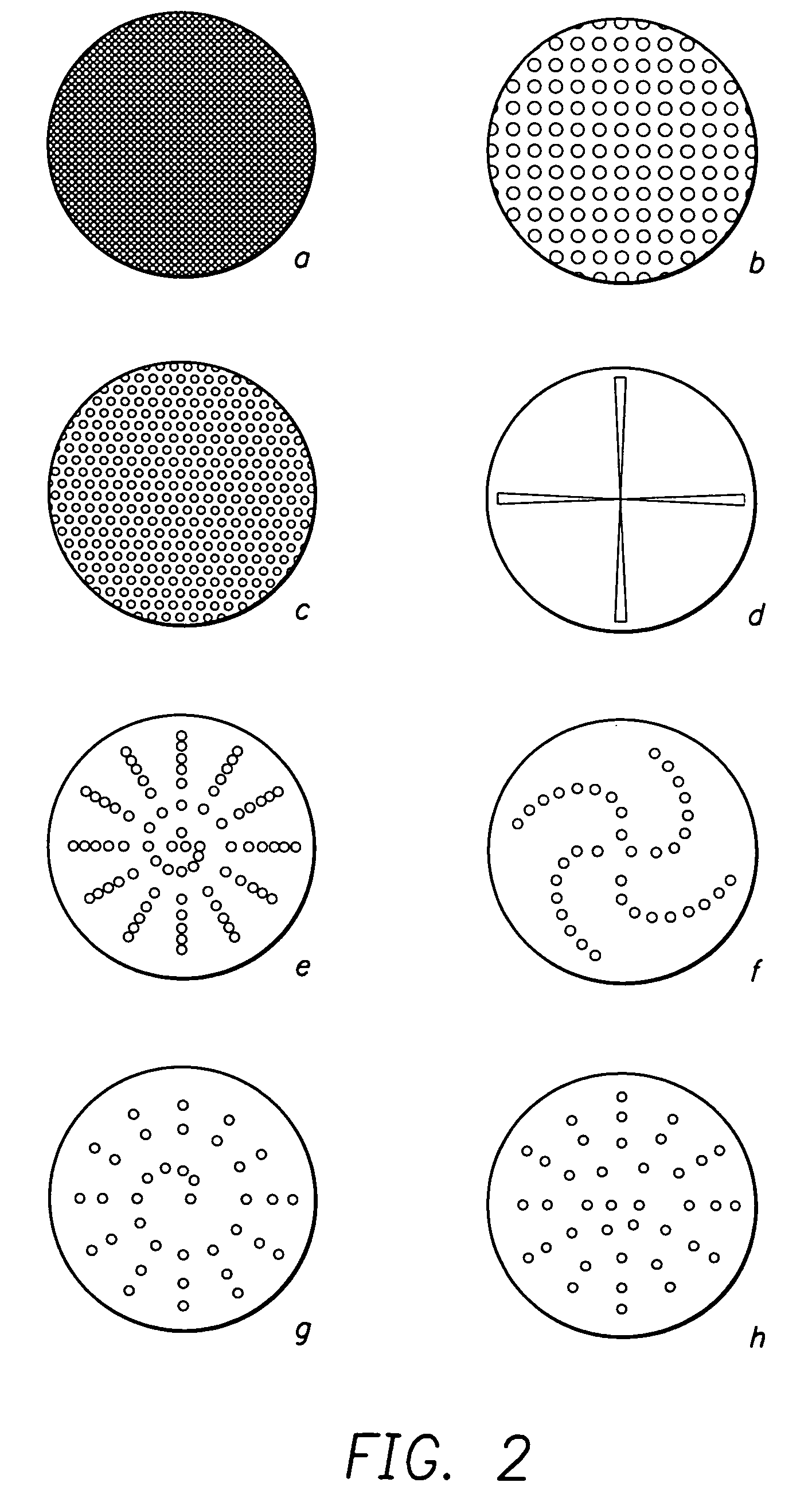

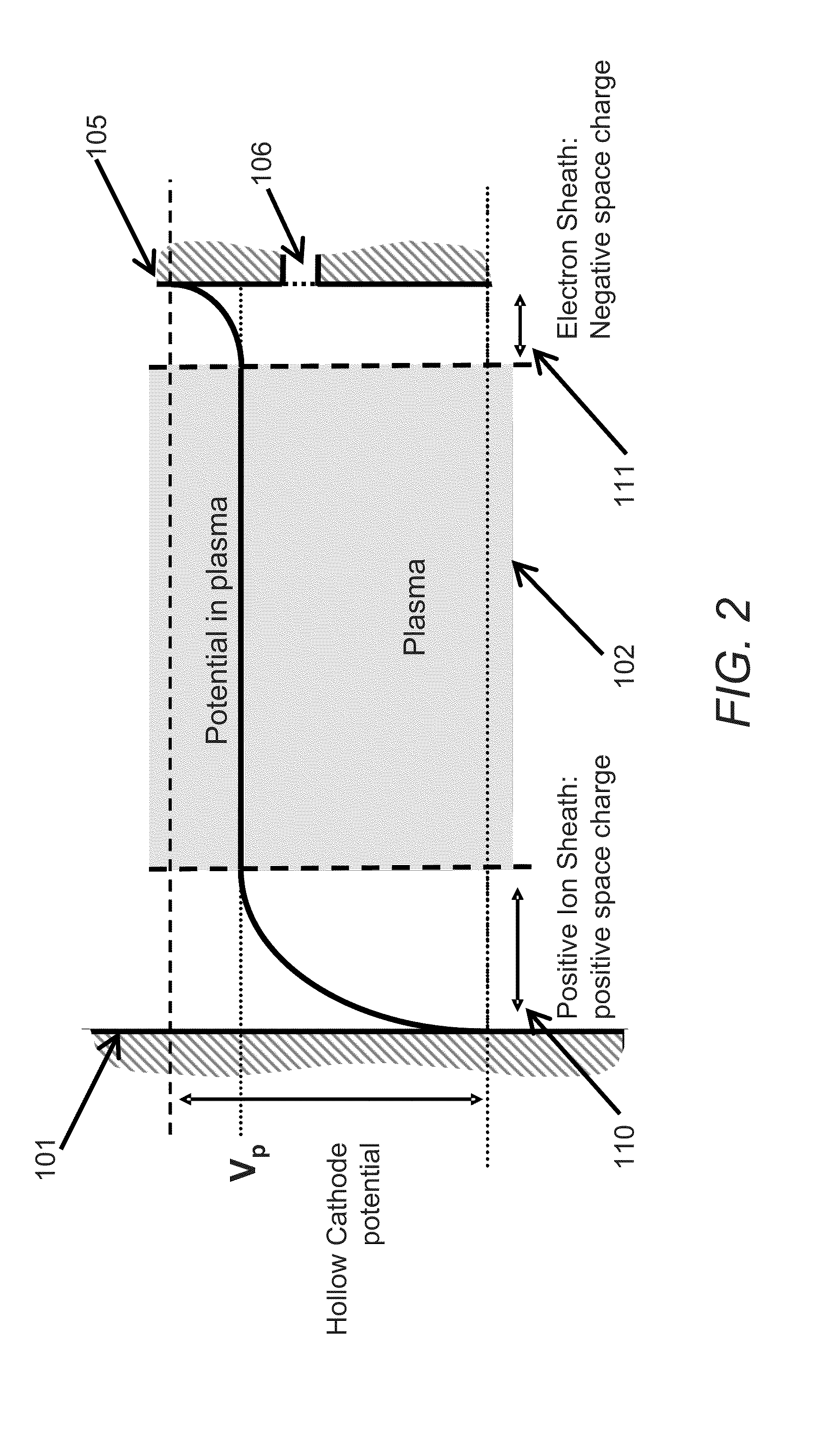

Devices and methods for generating a low-temperature, atmospheric pressure plasma are disclosed. A plasma device may include a first electrode having an inlet for a gas, a second electrode having an outlet for the gas and disposed proximate to the first electrode to form a substantially uniform gap therebetween. The gas flows along the substantially uniform gap and from a plurality of different directions to converge and flow through the outlet. High frequency electrical power is applied between the first electrode and the second electrode to generate a plasma within the gas flow emerging at the outlet. Precursor chemicals are added to the plasma flow at the outlet. Various electrode designs may be implemented and various applications involving surface treatment of materials with the low-temperature atmospheric plasma, including surface activation, cleaning, sterilization, etching and deposition of thin films are disclosed.

Owner:SURFX TECH

Composite electrode for a plasma arc torch

InactiveUS6841754B2Improve heat transfer performanceImprove thermal conductivityElectric discharge heatingArc welding apparatusMetallic materialsCopper electrode

A plasma arc torch that includes a torch body having a nozzle mounted relative to a composite electrode in the body to define a plasma chamber. The torch body includes a plasma flow path for directing a plasma gas to the plasma chamber in which a plasma arc is formed. The nozzle includes a hollow, body portion and a substantially solid, head portion defining an exit orifice. The composite electrode can be made of a metallic material (e.g., silver) with high thermal conductivity in the forward portion electrode body adjacent the emitting surface, and the aft portion of the electrode body is made of a second low cost, metallic material with good thermal and electrical conductivity. This composite electrode configuration produces an electrode with reduced electrode wear or pitting comparable to a silver electrode, for a price comparable to that of a copper electrode.

Owner:HYPERTHERM INC

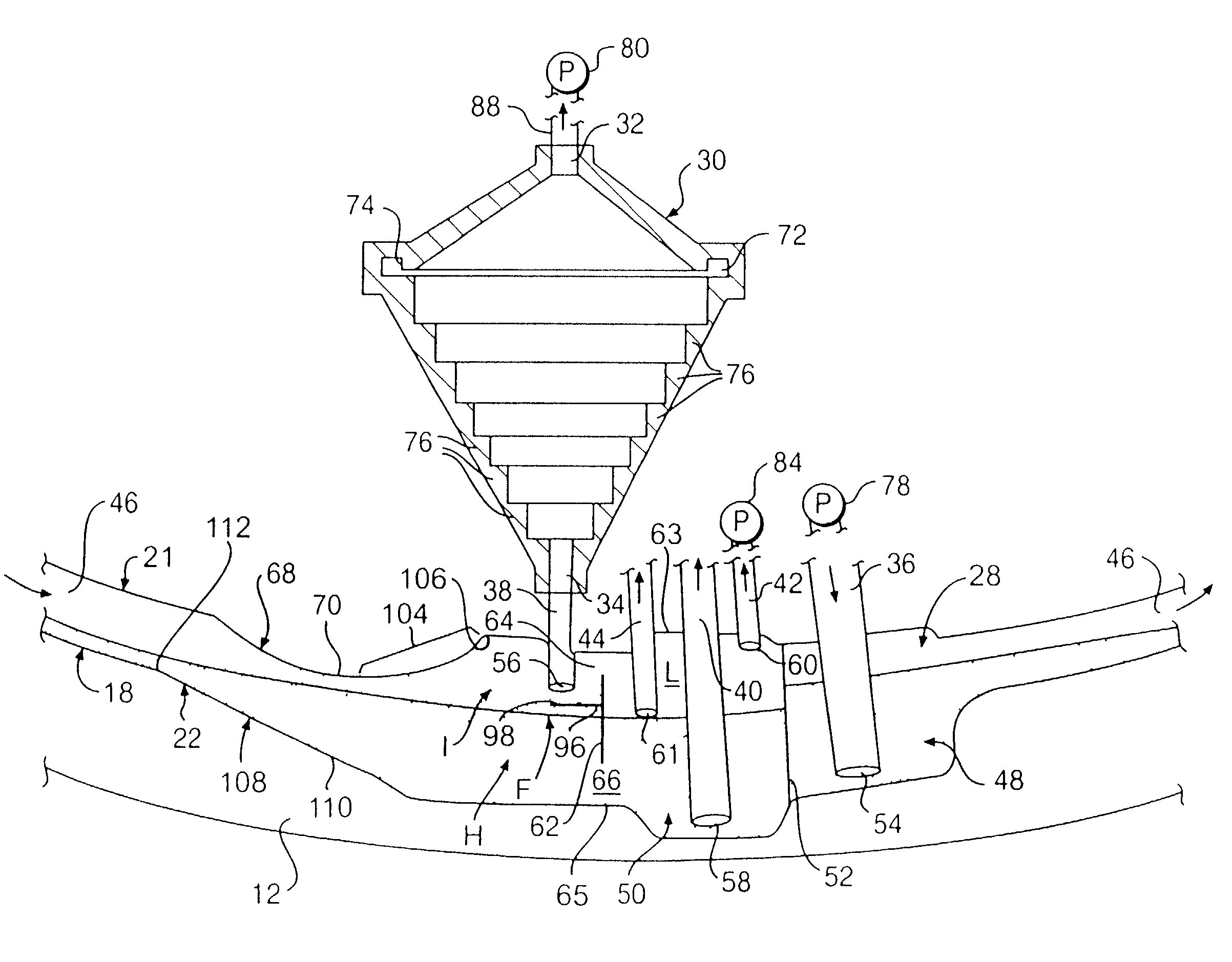

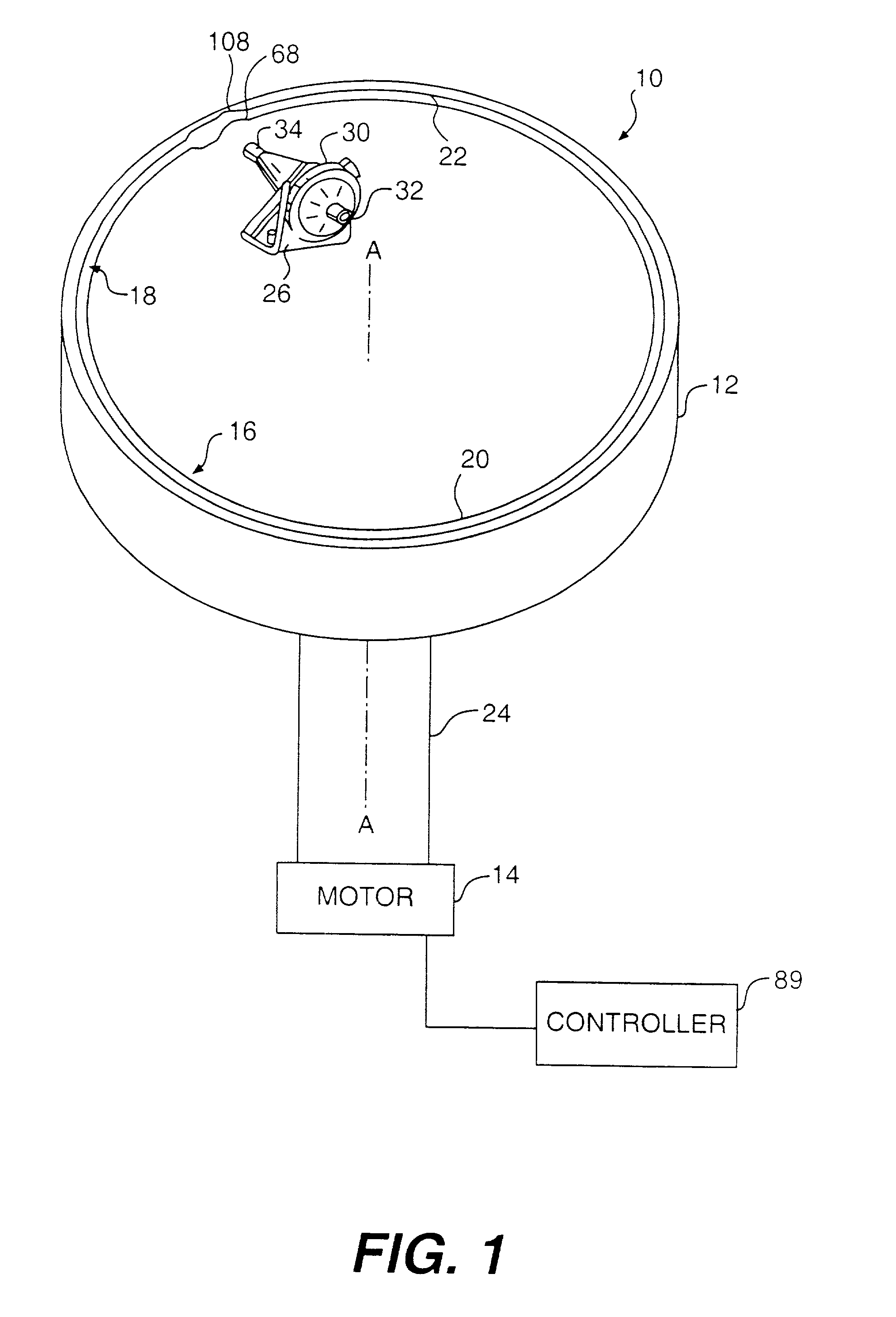

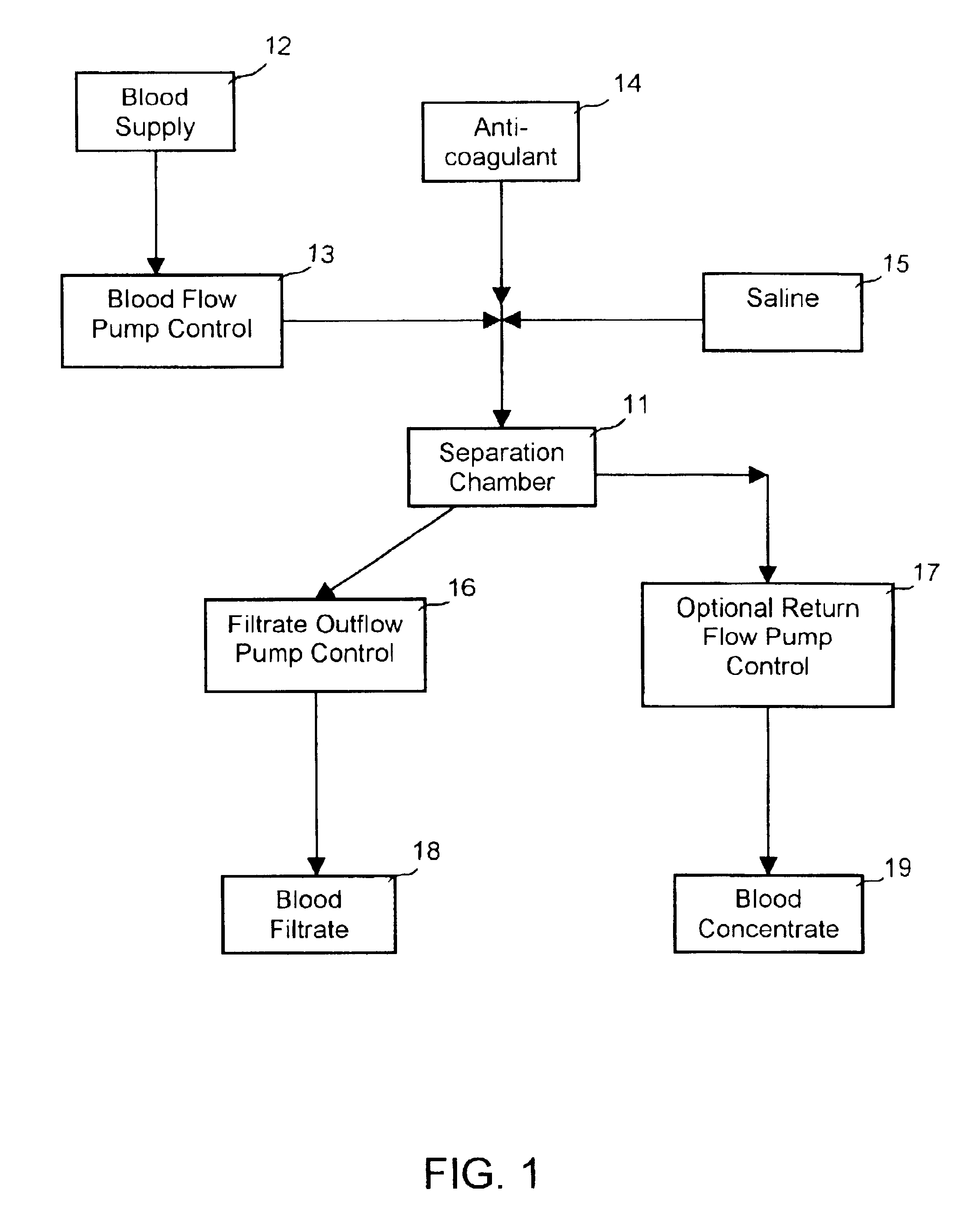

Centrifugal separation apparatus and method for separating fluid components

InactiveUS7029430B2Reduce cakingReduces platelet clumpingOther blood circulation devicesWithdrawing sample devicesHigh densityRed blood cell

An apparatus and method are provided for separating components of a fluid or particles. A separation vessel having a barrier dam is provided to initially separate an intermediate density components of a fluid, and a fluid chamber is provided to further separate these intermediate density components by forming an elutriative field or saturated fluidized particle bed. The separation vessel includes a shield for limiting flow into the fluid chamber of relatively high density substances, such as red blood cells. The separation vessel also includes a trap dam with a smooth, gradually sloped downstream section for reducing mixing of substances. Structure is also provided for adding additional plasma to platelets and plasma flowing from the fluid chamber. The system reduces clumping of platelets by limiting contact between the platelets and walls of the separation vessel.

Owner:TERUMO BCT

Induction plasma synthesis of nanopowders

ActiveUS20070029291A1Tight controlEasy to controlMaterial nanotechnologyOxygen/ozone/oxide/hydroxideIodideInduction plasma technology

A process and apparatus for synthesizing a nanopowder is presented. In particular, a process for the synthesis of nanopowders of various materials such as metals, alloys, ceramics and composites by induction plasma technology, using organometallic compounds, chlorides, bromides, fluorides, iodides, nitrites, nitrates, oxalates and carbonates as precursors is disclosed. The process comprises feeding a reactant material into a plasma torch in which is generated a plasma flow having a temperature sufficiently high to yield a superheated vapour of the material; transporting said vapour by means of the plasma flow into a quenching zone; injecting a cold quench gas into the plasma flow in the quenching zone to form a renewable gaseous cold front; and forming a nanopowder at the interface between the renewable gaseous cold front and the plasma flow.

Owner:TEKNA PLASMA SYST INC

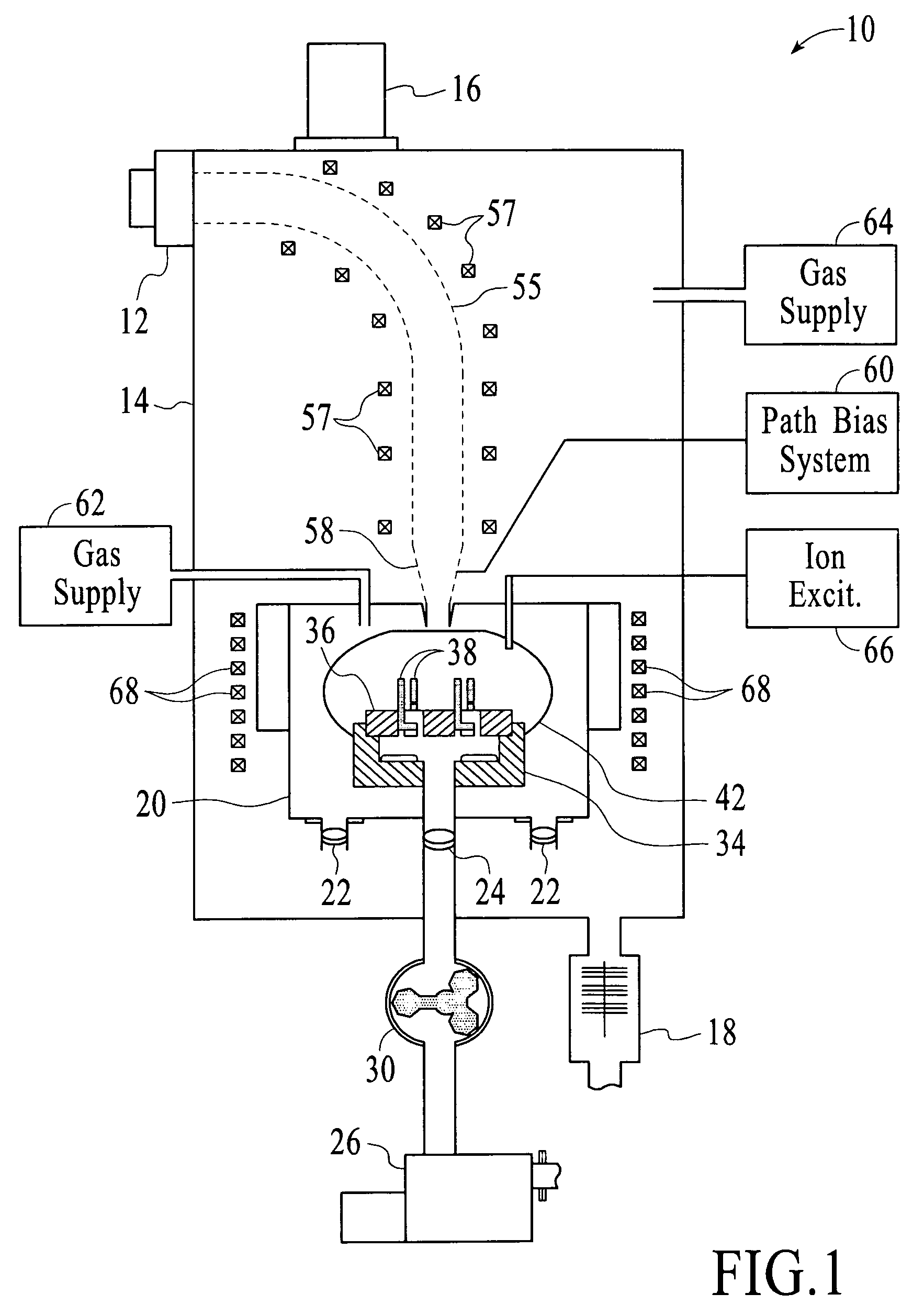

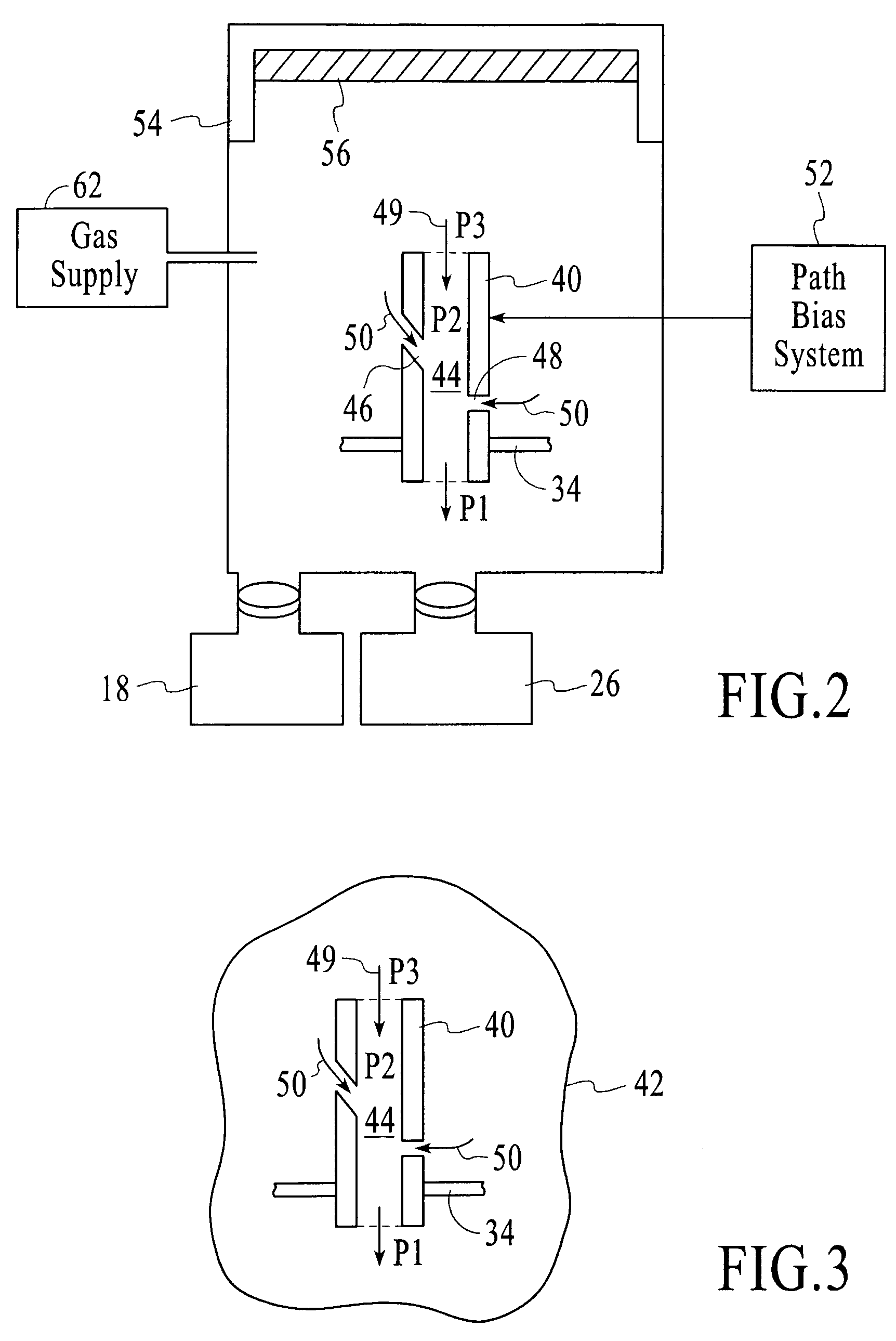

Apparatus for directing plasma flow to coat internal passageways

InactiveUS7444955B2Improve integrityLess expensiveCellsElectric discharge tubesSupporting systemHardness

An apparatus for coating surfaces of a workpiece is configured to establish a pressure gradient within internal passageways through the workpiece, so that the coating within the internal passageways exhibits intended characteristics, such as those relating to smoothness or hardness. The coating apparatus may include any or all of a number of cooperative systems, including a plasma generation system, a manipulable workpiece support system, an ionization excitation system configured to increase ionization within or around the workpiece, a biasing system for applying a selected voltage pattern to the workpiece, and a two-chamber system that enables the plasma generation to take place at a first selected pressure and the deposition to occur at a second selected pressure.

Owner:SUB ONE TECH

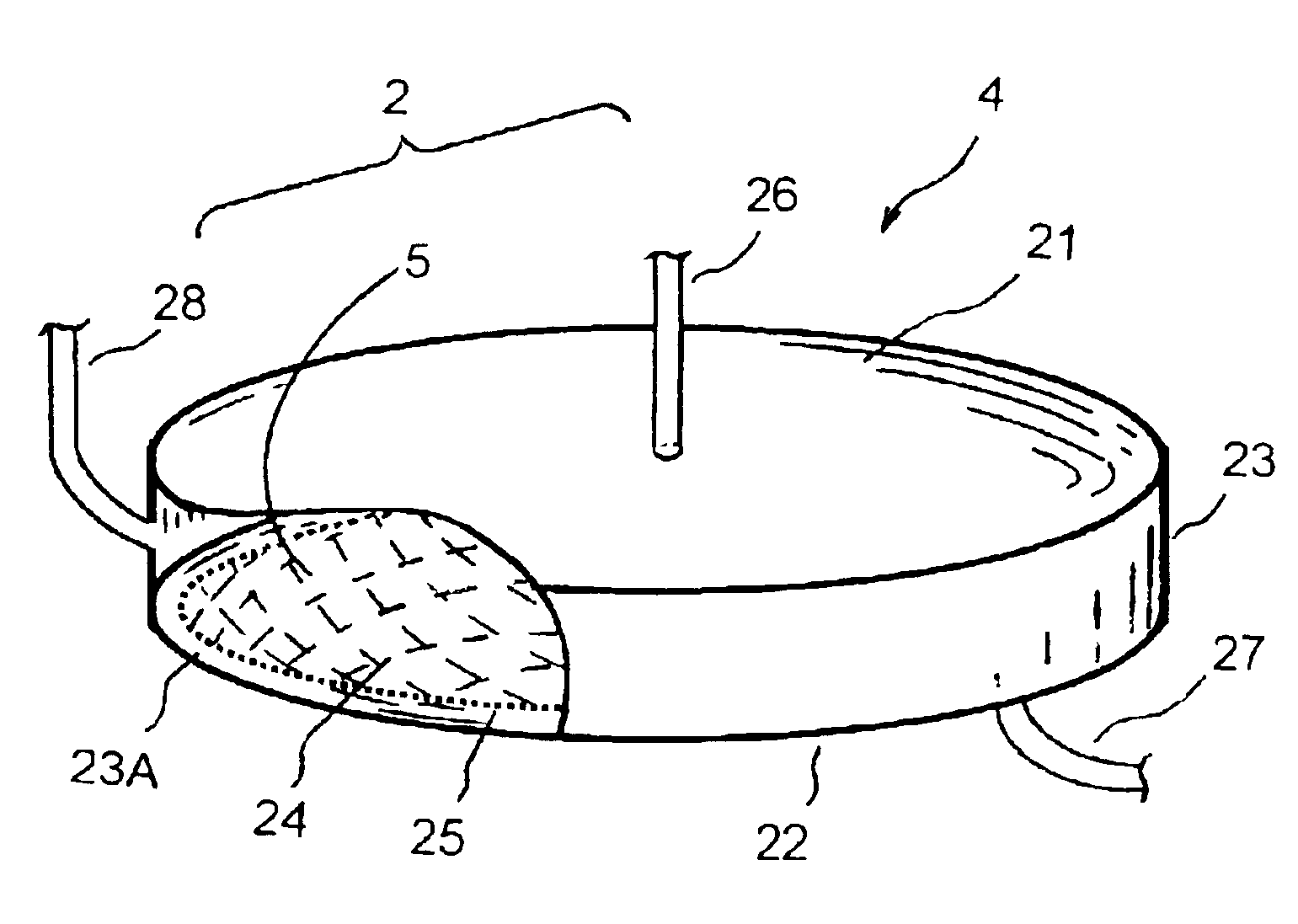

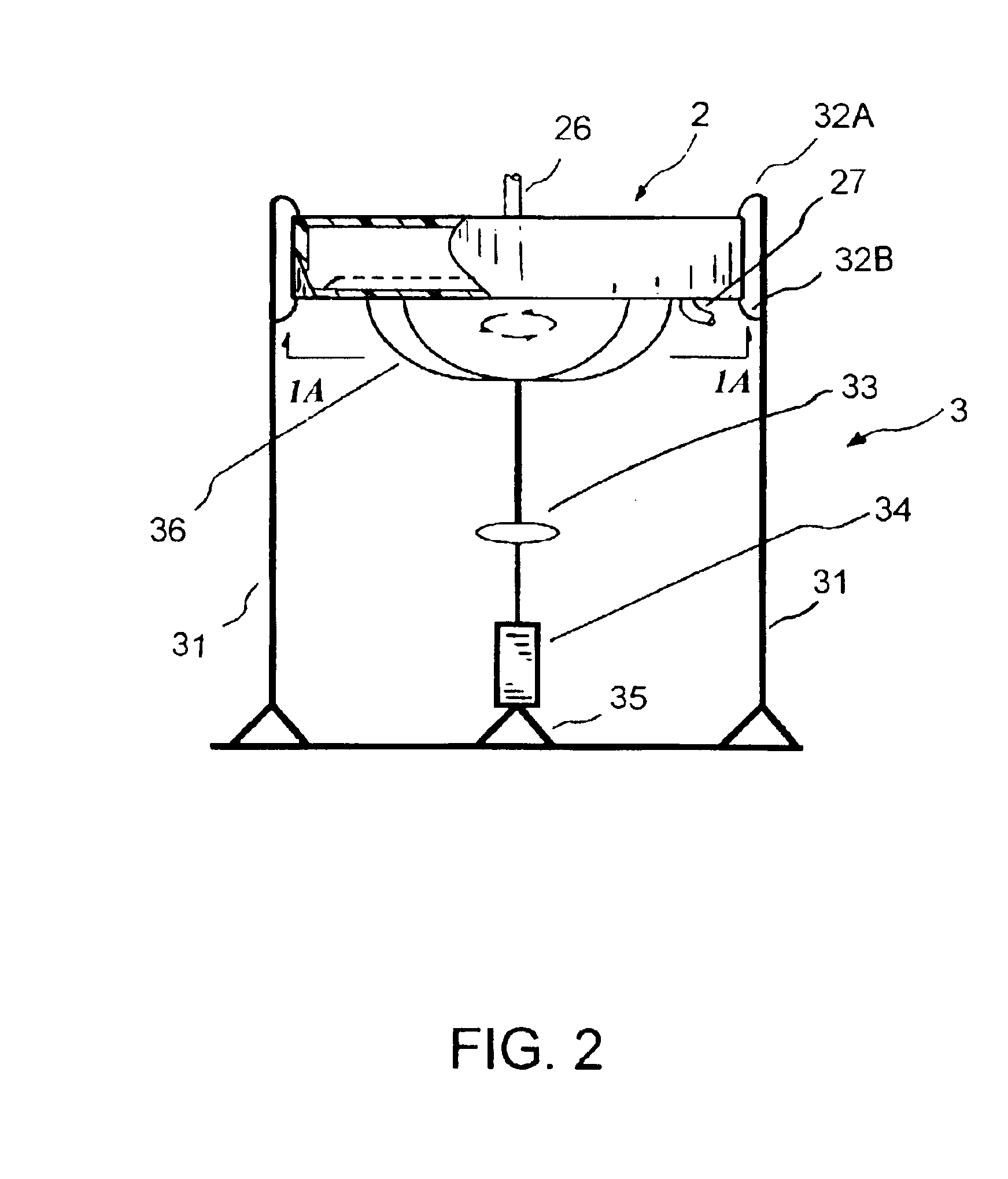

Apparatus for enhanced plasmapheresis and methods thereof

InactiveUS6960178B2Easy to separateEnhanced continuous plasmapheresisWater/sewage treatment by centrifugal separationSemi-permeable membranesRed blood cellPlasma flow

An apparatus and methods for enhanced plasmapheresis comprising a filter membrane under an orbital motion or movement that has optimal local shear forces and maximum plasma flow output. The methods for biological separation and therapies comprise platelet collection, viral particle removal, cell washing and processing for stem cell selection, bone marrow purging, red blood cell collection, auto-transfusion, auto-immune disease treatment, selective macro-molecule removal, toxin removal, LDL removal, extracorporeal plasma delipidation, and the like.

Owner:XEPMED INC (US)

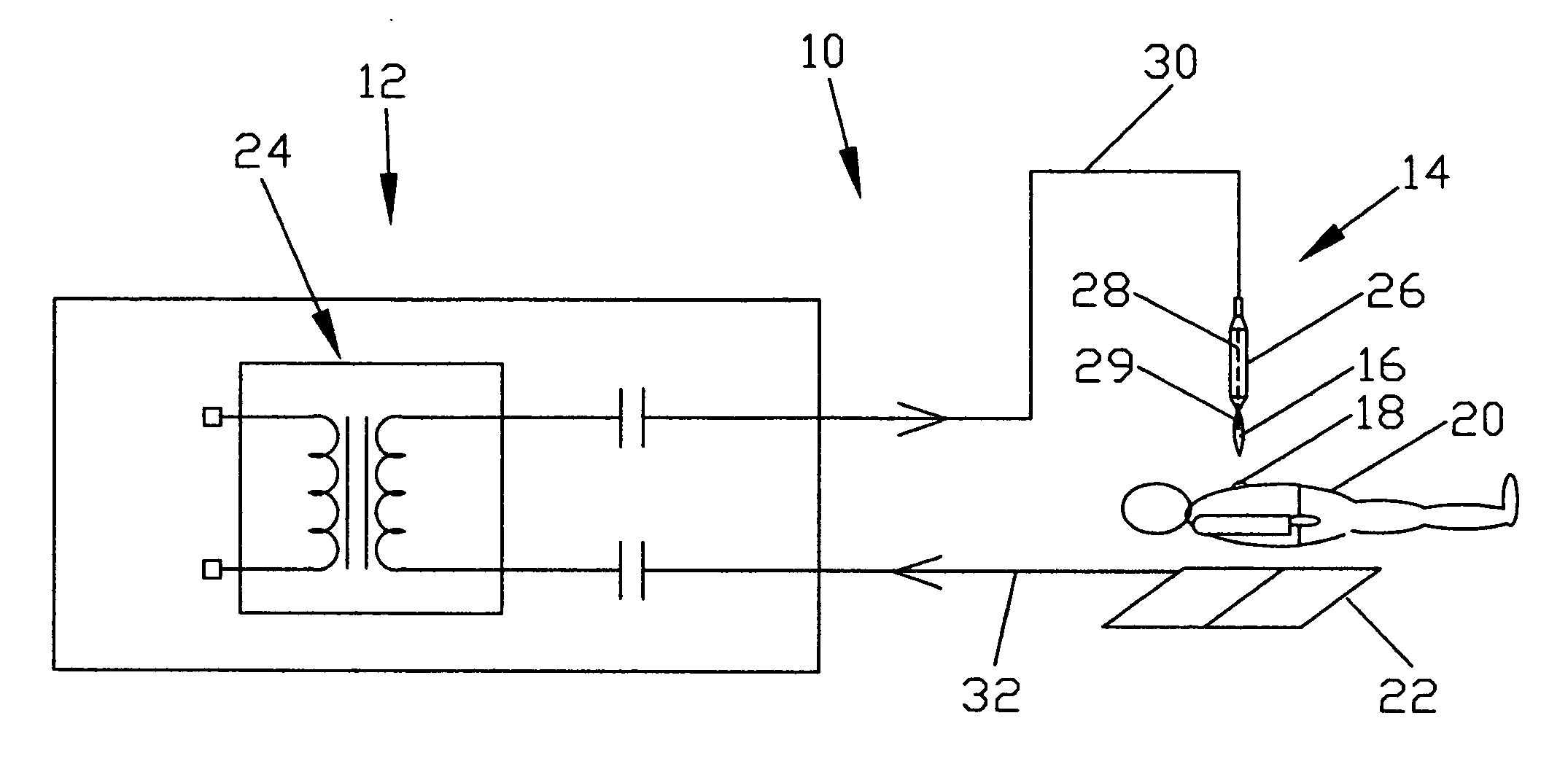

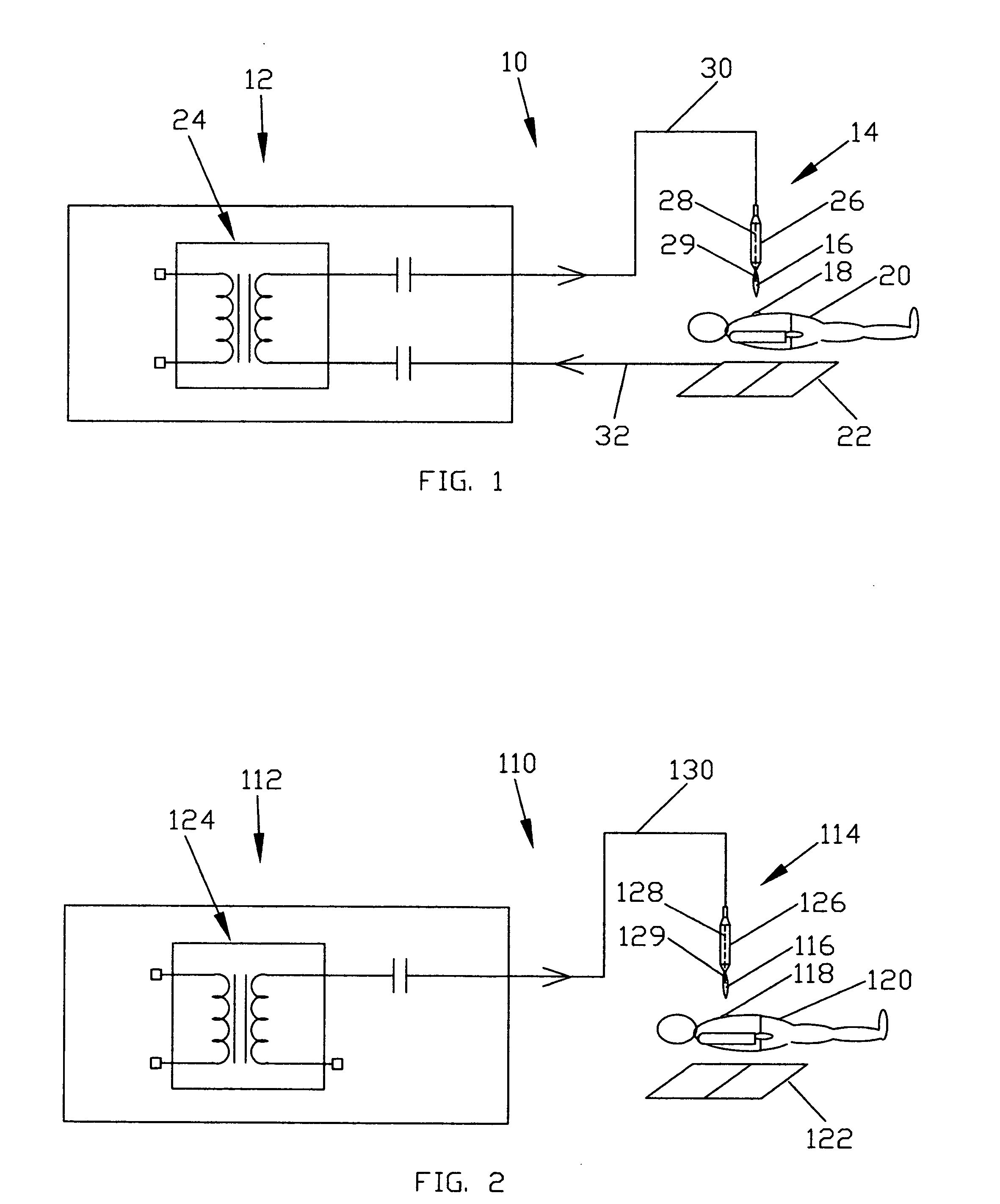

Electrosurgical device to generate a plasma stream

ActiveUS20080108985A1Enhance flow-assisted removalControl areaSurgical instruments for heatingSurgical instruments for aspiration of substancesNoble gasPlasma generator

An electrosurgical device to generate a plasma stream and method to perform endoscopic or laparoscopic surgery within a patient's body comprising an electrosurgical generator coupled to a electrical power source to supply power to the electrosurgical device and a plasma generator including an electrode operatively coupled to the electrosurgical generator to receive electrical energy therefrom and concentrically disposed within an inner noble gas conduit to form a plasma channel coupled to a noble gas source to feed noble gas to the inner noble gas conduit and an outer electronegative gas conduit disposed in surrounding coaxial relation relative to the inner noble gas conduit to cooperatively form an electronegative gas channel therebetween coupled to a gas source to feed electronegative gas to the electronegative gas channel or an outer aspiration conduit disposed in surrounding coaxial relation relative to the inner noble gas conduit to cooperatively form an aspiration channel therebetween coupled to a negative pressure source such that the electrode heats the noble gas to at least partially ionize the noble gas to generate the plasma stream to be directed to the surgical site to perform the surgical procedure while the electronegative gas sustains the plasma stream at the surgical site and dilutes the noble gas adjacent the surgical site or the negative pressure source removes fluid and solid debris from the surgical site respectively.

Owner:BOVIE MEDICAL CORPORATION

Interchangeable plasma nozzle interface

ActiveUS7759599B2Increase flexibilityEasy to usePlasma welding apparatusWelding/cutting media/materialsSpray nozzleElectrical connection

The present invention provides a standard interface for providing mechanical location, mechanical orientation, electrical connections, and water chamber seals for the exchange of a variety of plasma forming nozzles each associated with a specific plasma plume characteristic. The flexibility of the nozzle attachment is improved over prior designs by providing a standard exterior nozzle configuration and nozzle clamping assembly on the plasma gun so that multiple nozzles configurations (giving different plasma flow properties) can easily be used with the same devices. The joining of the nozzle to the receptacle forms a channel for cooling liquid to flow from the plasma gun through the nozzle to a return path in the plasma gun and creates an electrical contact between the plasma gun and the nozzle.

Owner:SULZER METCO (US) INC

Electric contactor housing

InactiveUS6417749B1Prevent and reduce potential for exchange of gasElectric switchesElectromagnetic relay detailsThree-phaseEngineering

A unitary housing structure is provided for an electrical switching device such as a three-phase contactor. The housing includes internal partitions for separating an operator section from contact sections, and for isolating phase sections from one another. The partitions are contiguous with one another and with side walls of the housing, inhibiting plasma flow within the housing cavities. The housing is made of a thermoplastic material which is molded as a single piece. The thermoplastic may be partially protected from plasma and arcs by shields within the phase sections, such as splitter plate supports.

Owner:ALLEN-BRADLEY CO LLC

Method of processing a substrate

InactiveUS20050093458A1Electric discharge tubesSemiconductor/solid-state device detailsReactive gasGas phase

The invention is embodied in a plasma flow device or reactor having a housing that contains conductive electrodes with openings to allow gas to flow through or around them, where one or more of the electrodes are powered by an RF source and one or more are grounded, and a substrate or work piece is placed in the gas flow downstream of the electrodes, such that said substrate or work piece is substantially uniformly contacted across a large surface area with the reactive gases emanating therefrom The invention is also embodied in a plasma flow device or reactor having a housing that contains conductive electrodes with openings to allow gas to flow through or around them, where one or more of the electrodes are powered by an RF source and one or more are grounded, and one of the grounded electrodes contains a means of mixing in other chemical precursors to combine with the plasma stream, and a substrate or work piece placed in the gas flow downstream of the electrodes, such that said substrate or work piece is contacted by the reactive gases emanating therefrom. In one embodiment, the plasma flow device removes organic materials from a substrate or work piece, and is a stripping or cleaning device. In another embodiment, the plasma flow device kills biological microorganisms on a substrate or work piece, and is a sterilization device. In another embodiment, the plasma flow device activates the surface of a substrate or work piece, and is a surface activation device. In another embodiment, the plasma flow device etches materials from a substrate or work piece, and is a plasma etcher. In another embodiment, the plasma flow device deposits thin films onto a substrate or work piece, and is a plasma-enhanced chemical vapor deposition device or reactor.

Owner:RGT UNIV OF CALIFORNIA

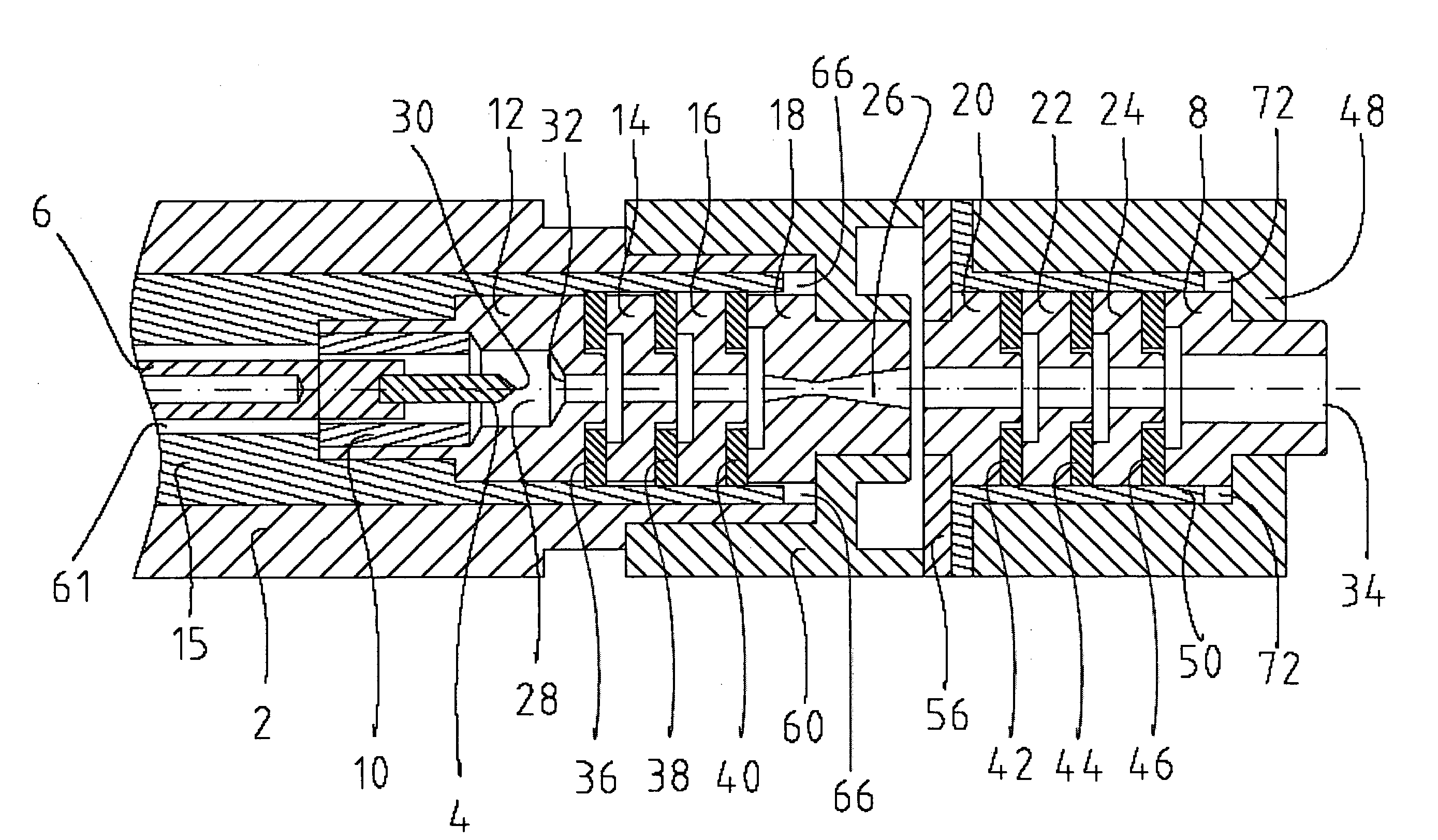

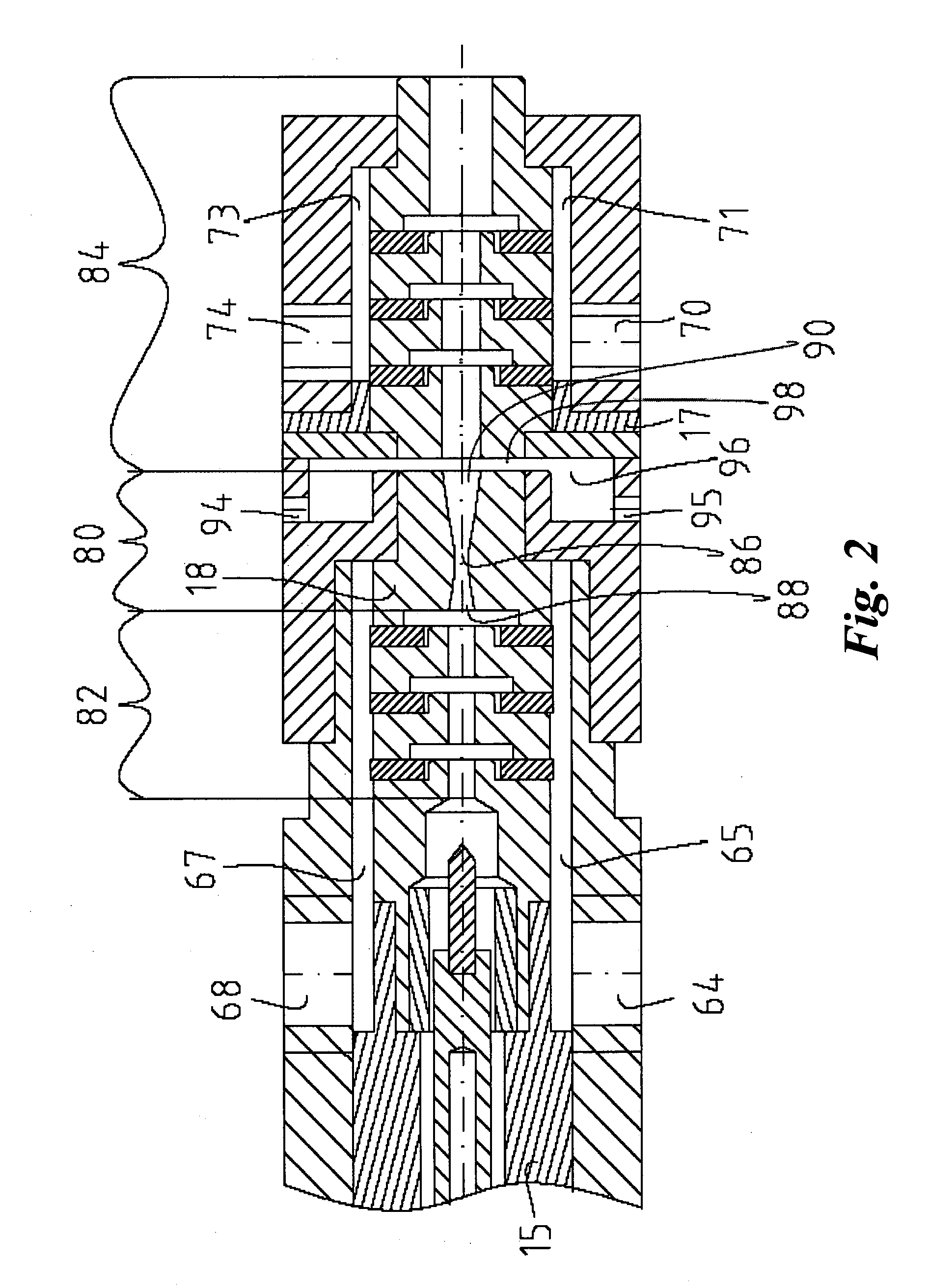

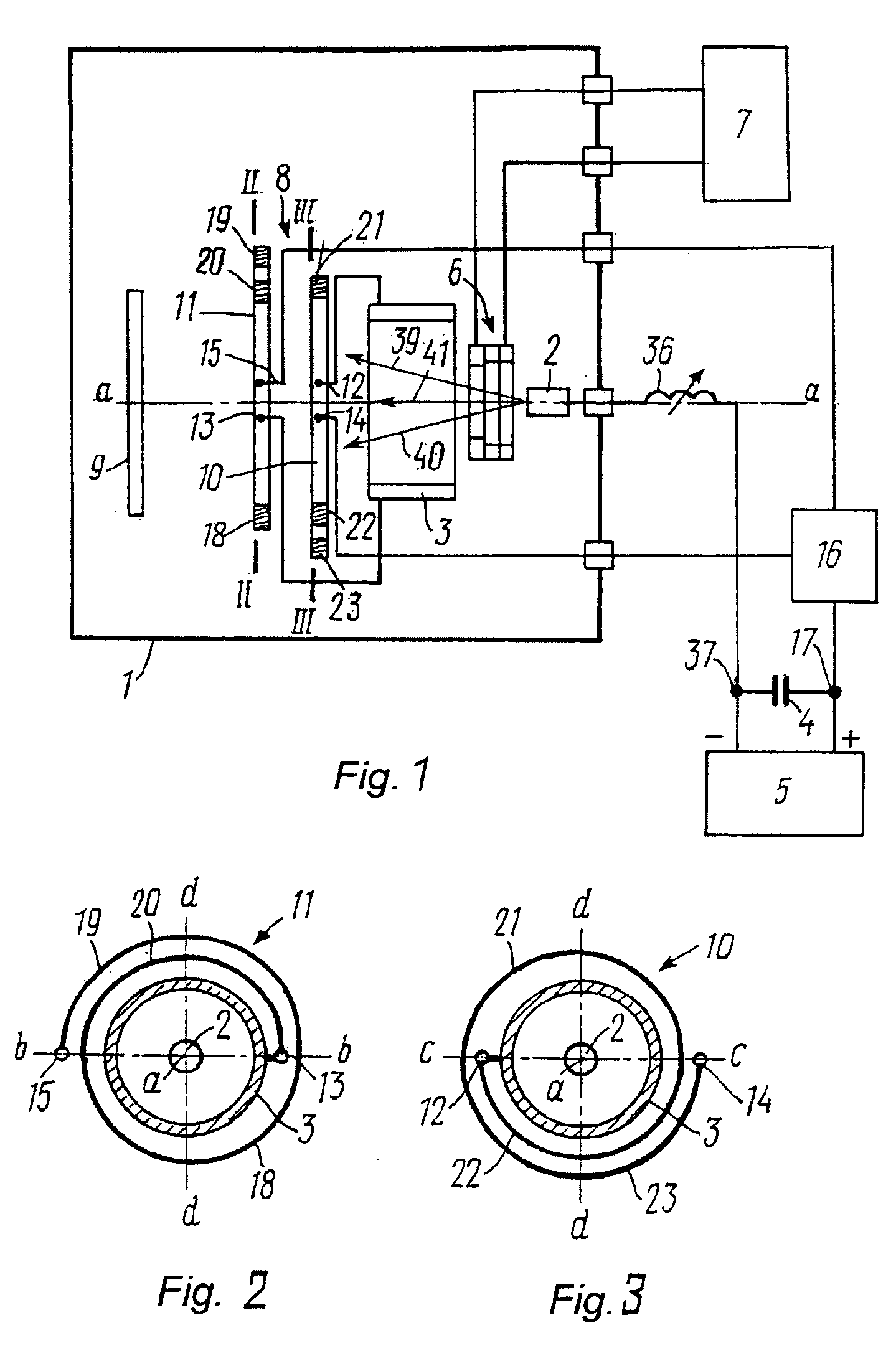

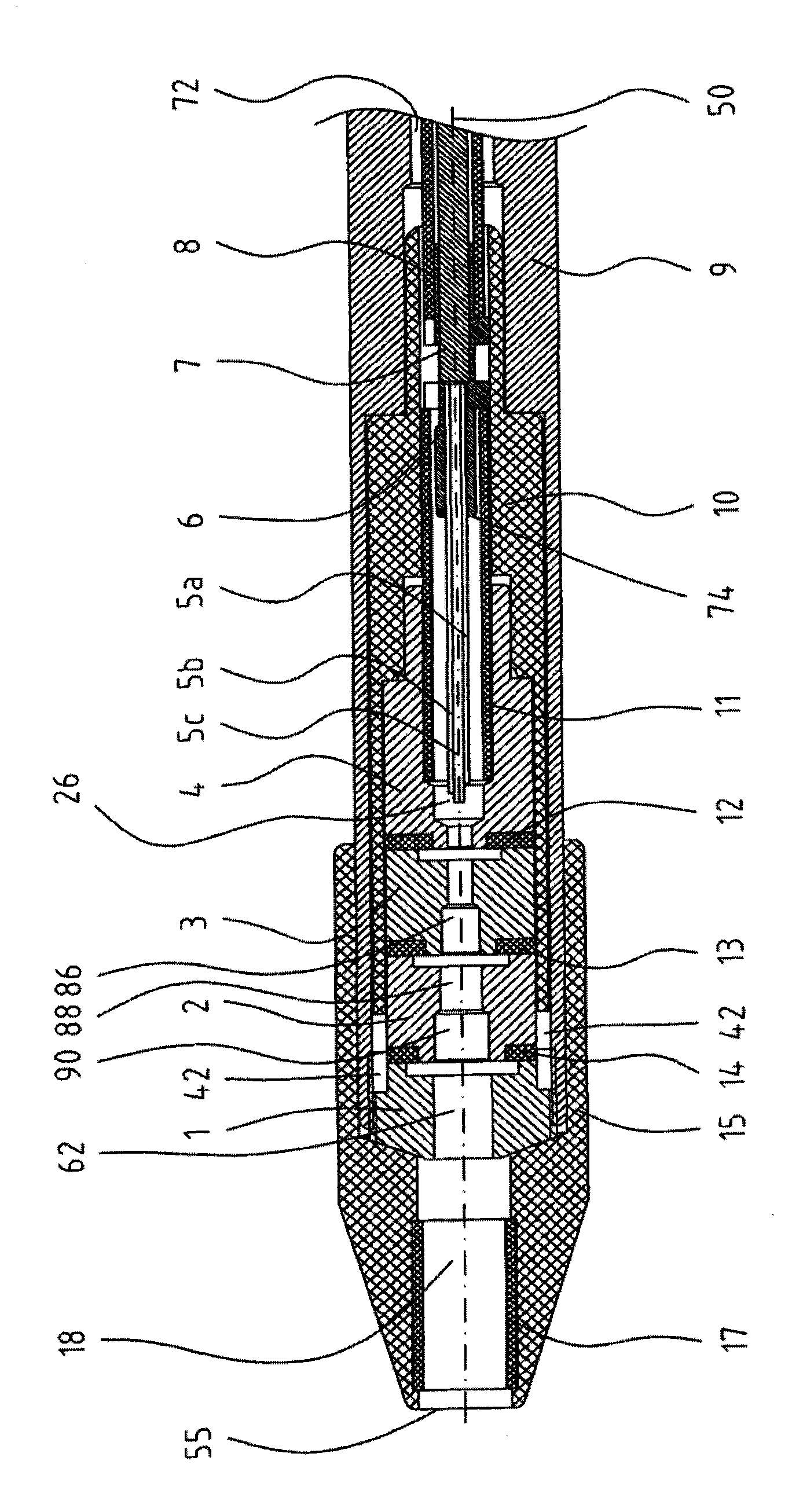

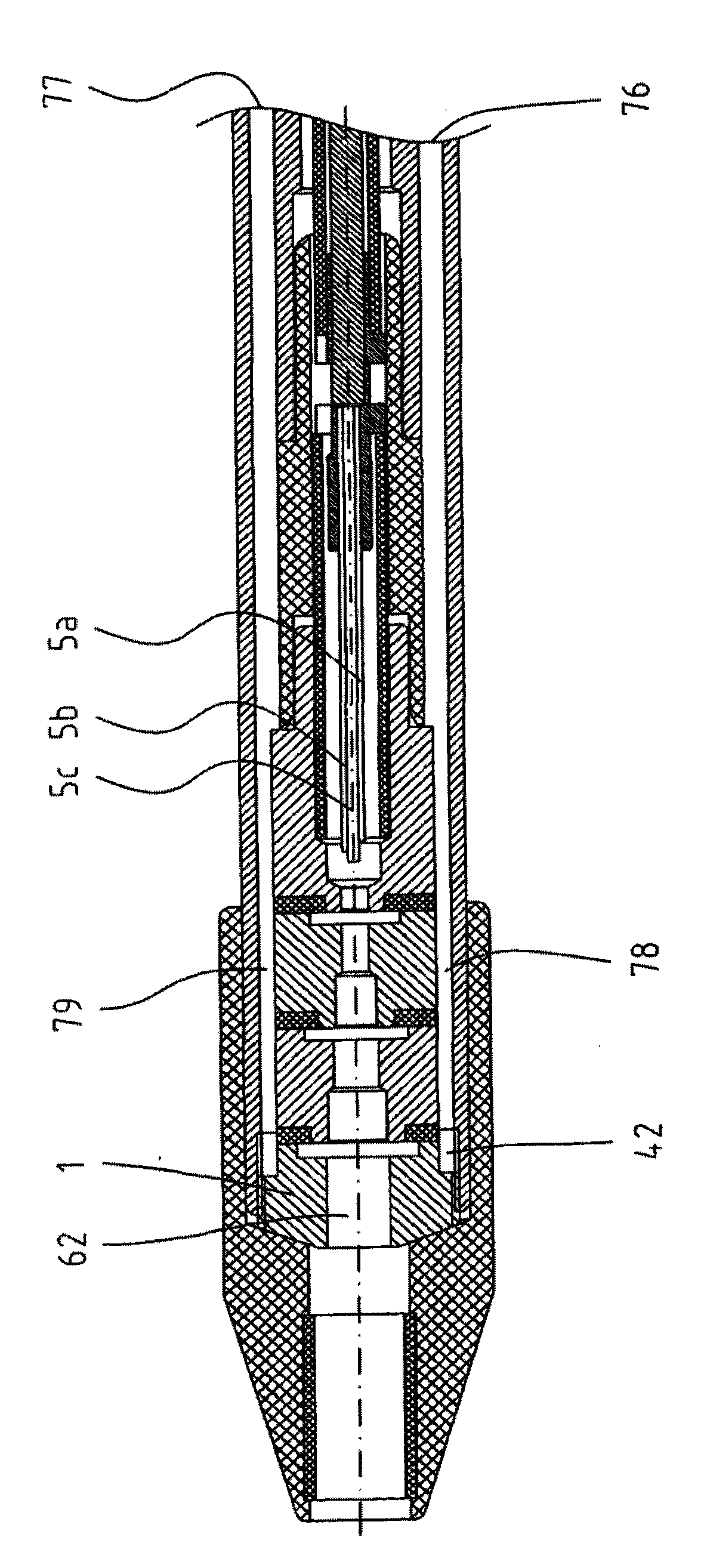

Plasma-spraying device

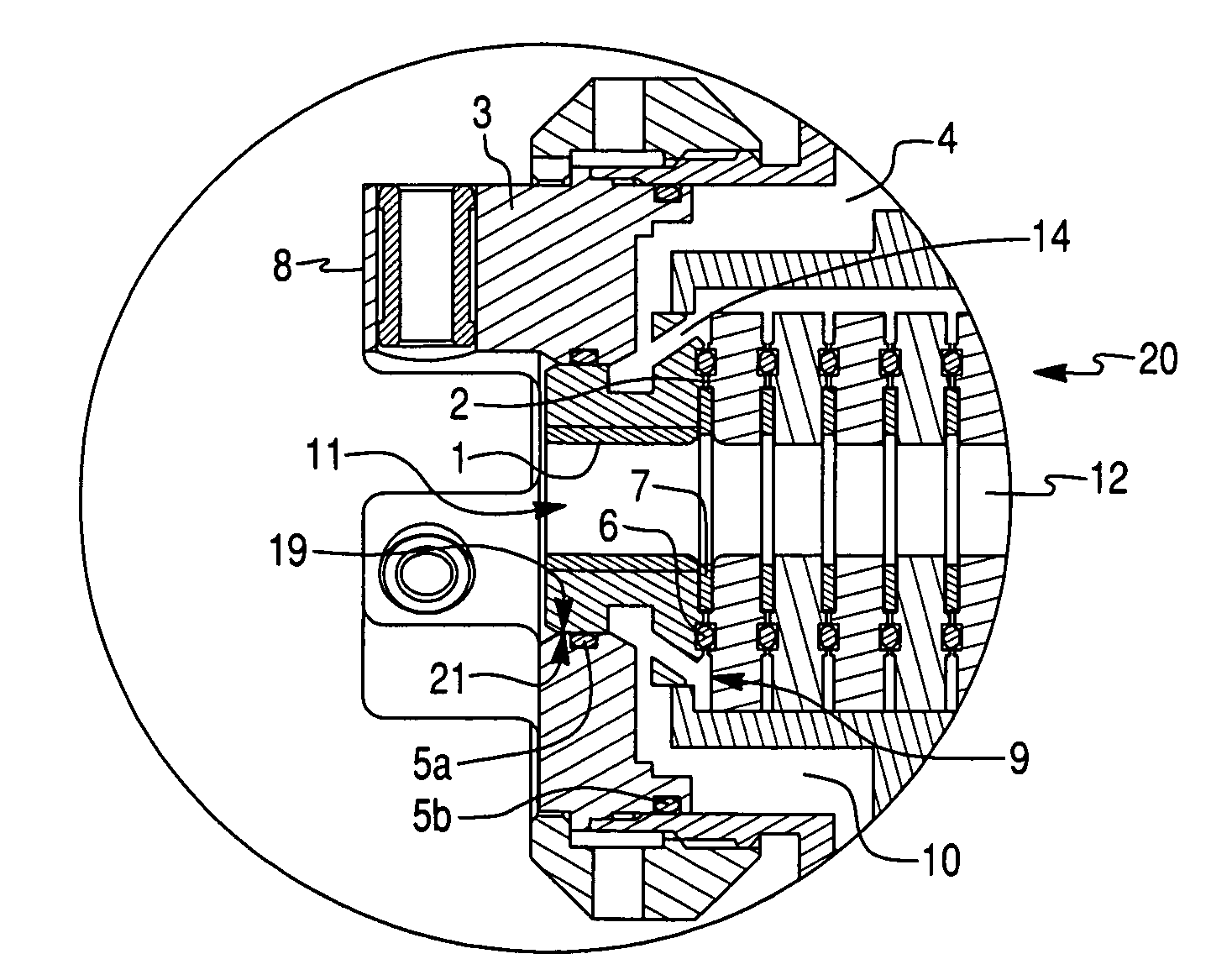

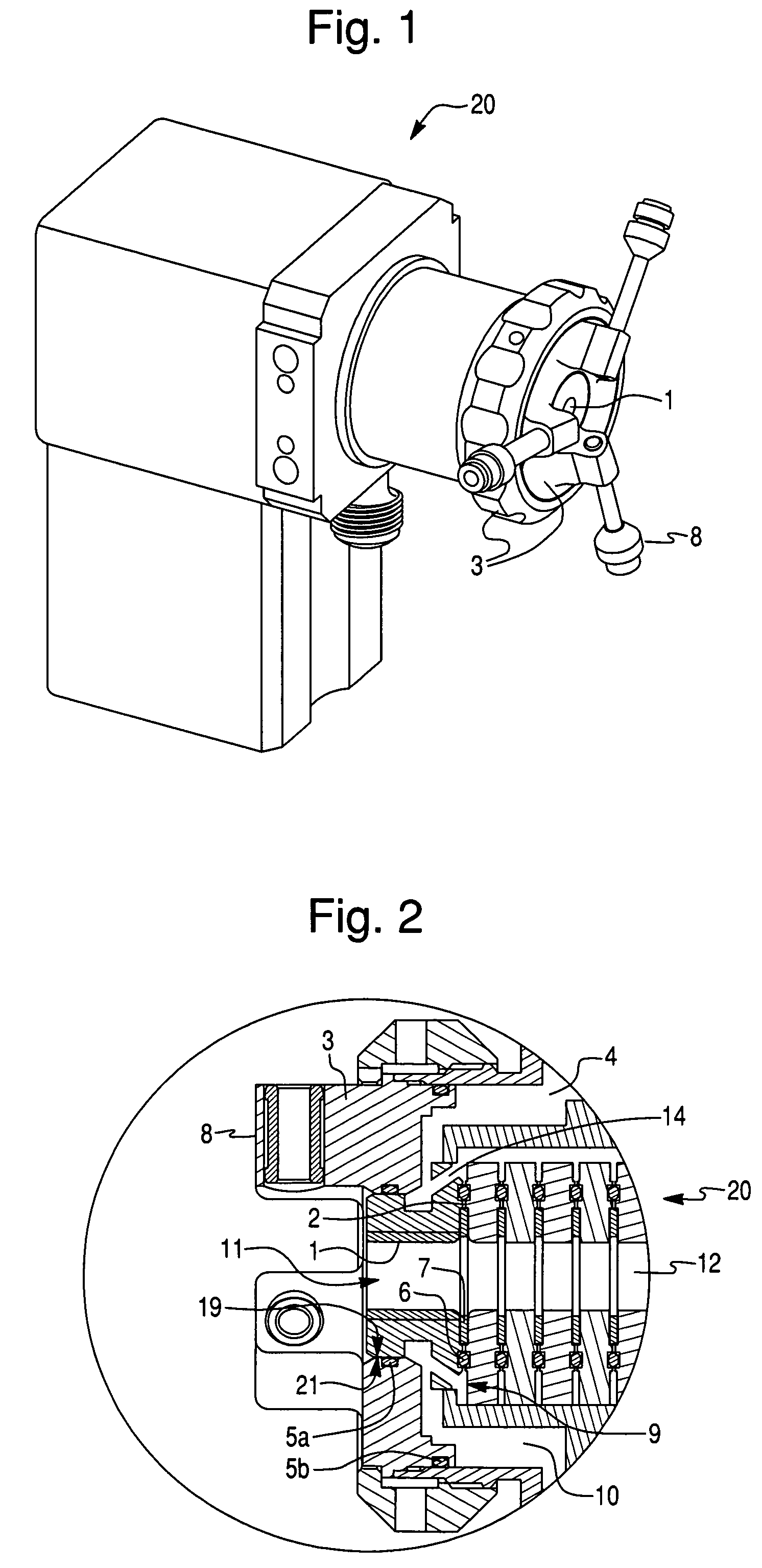

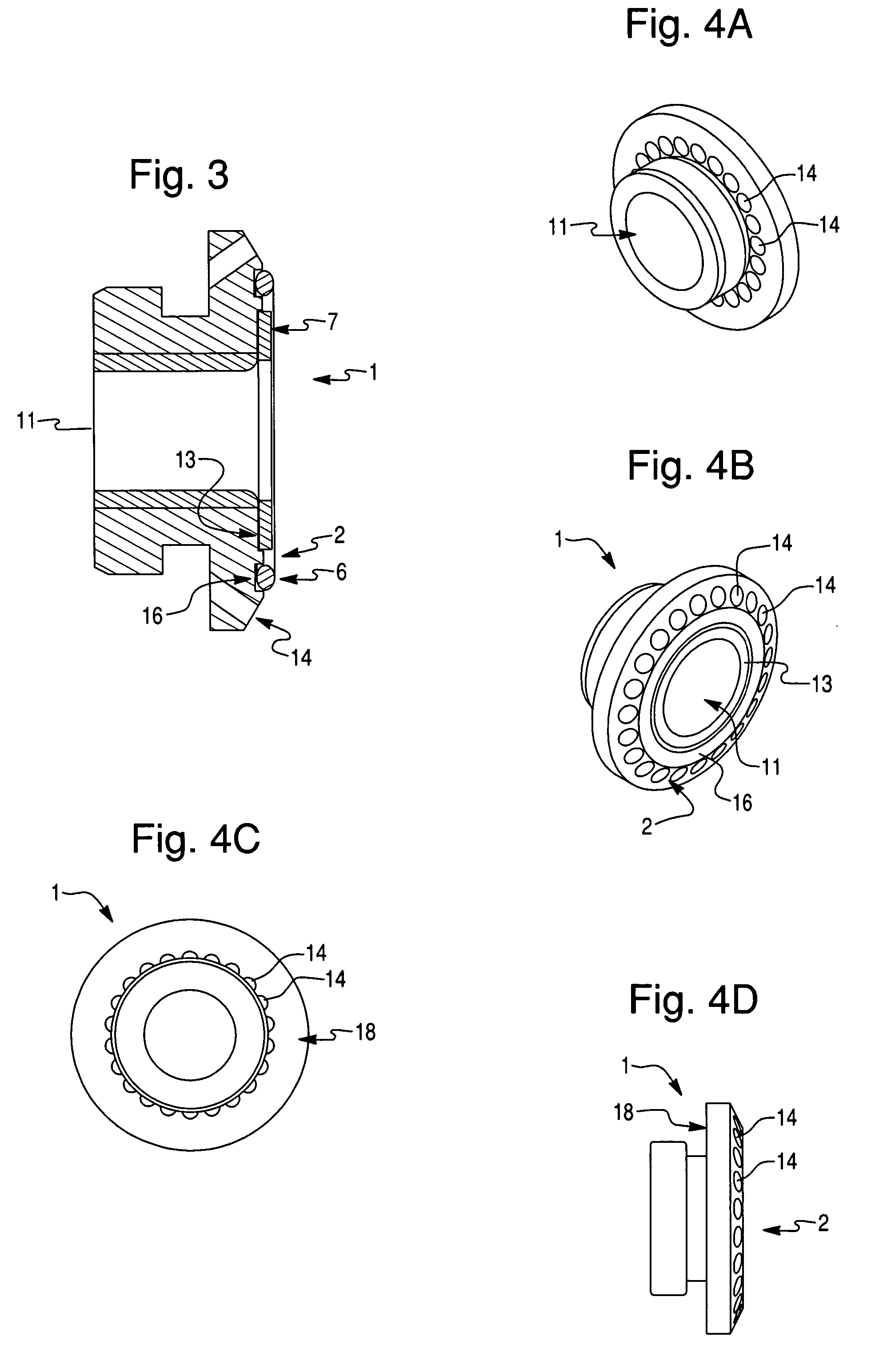

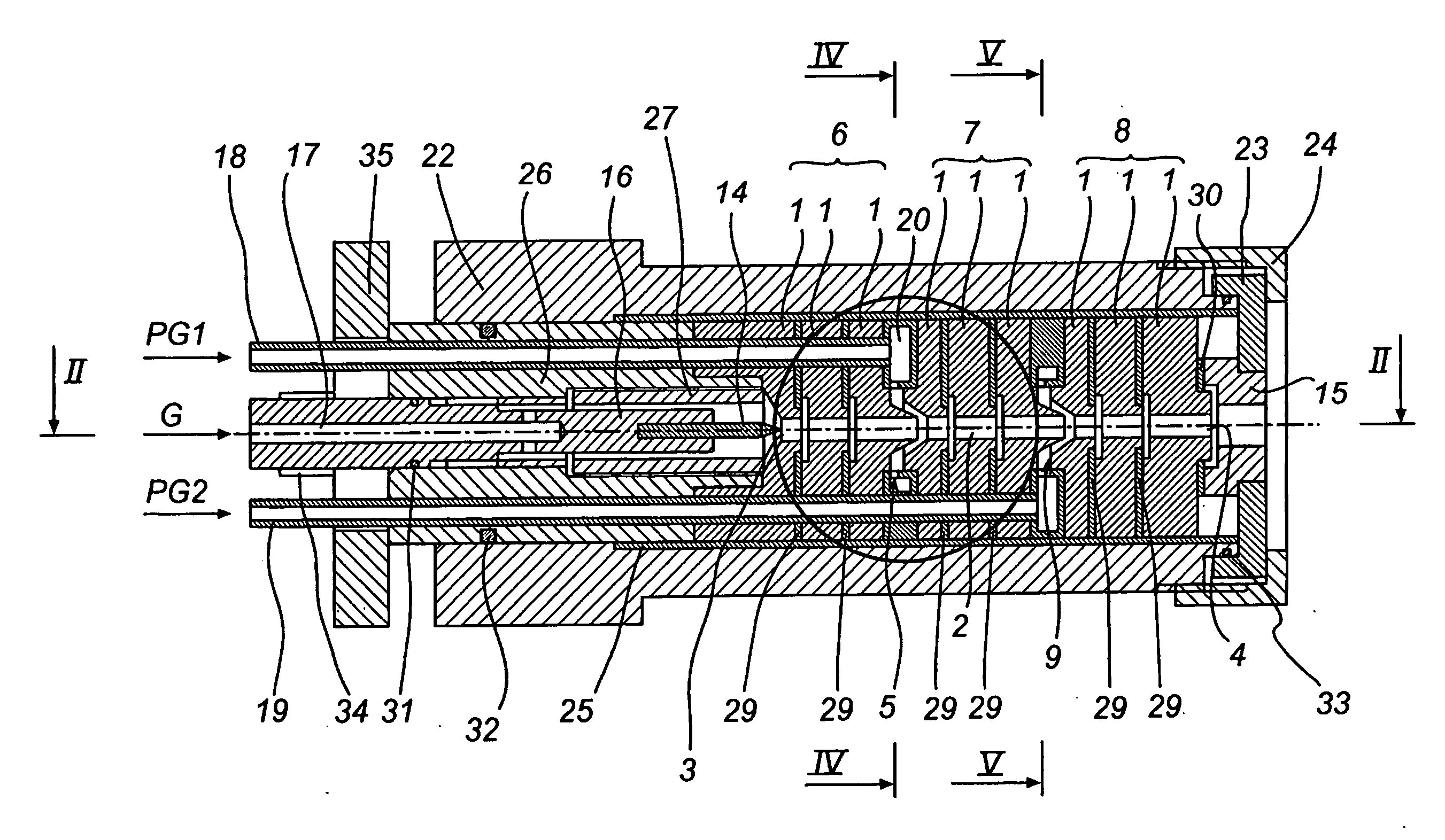

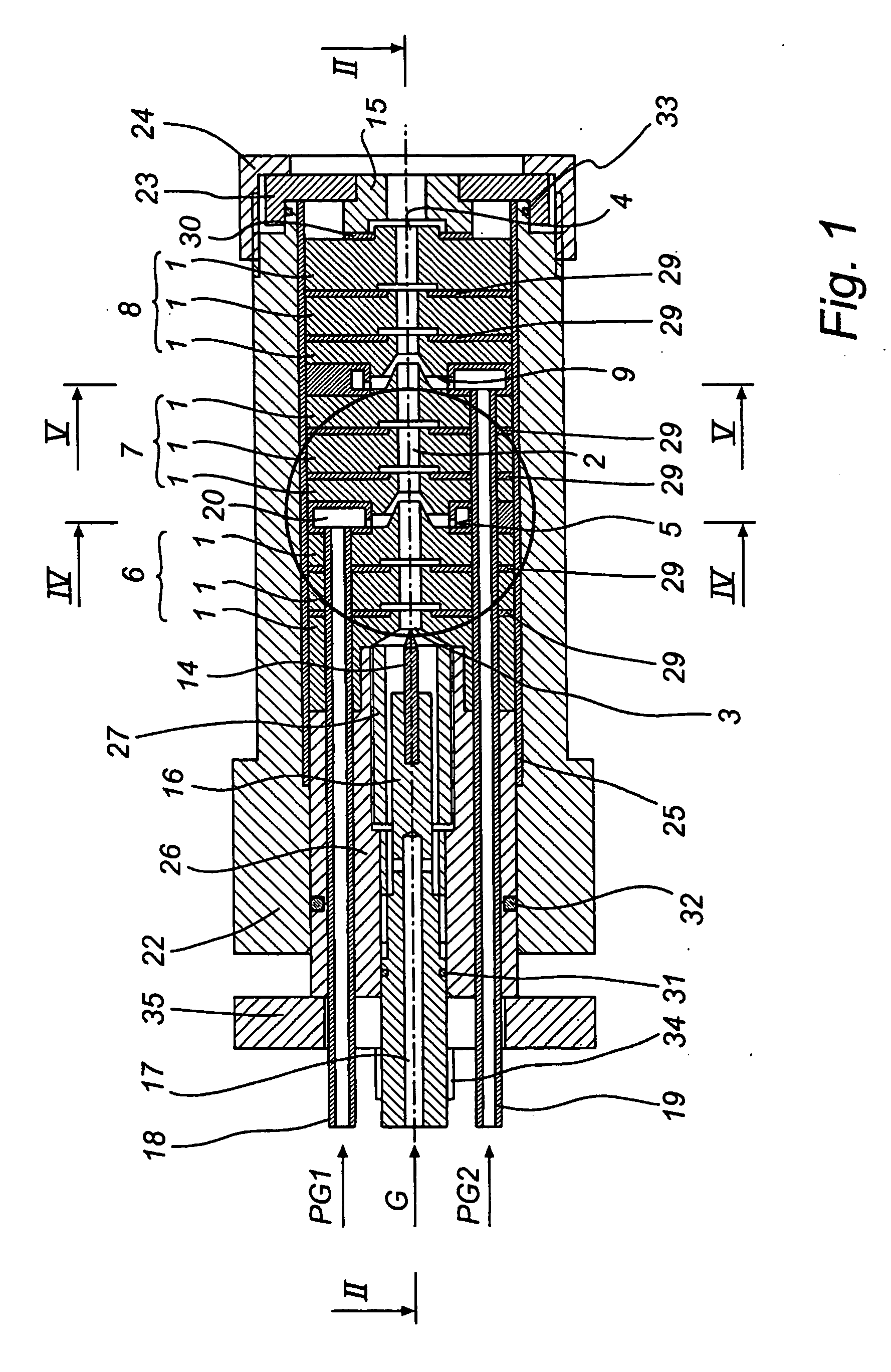

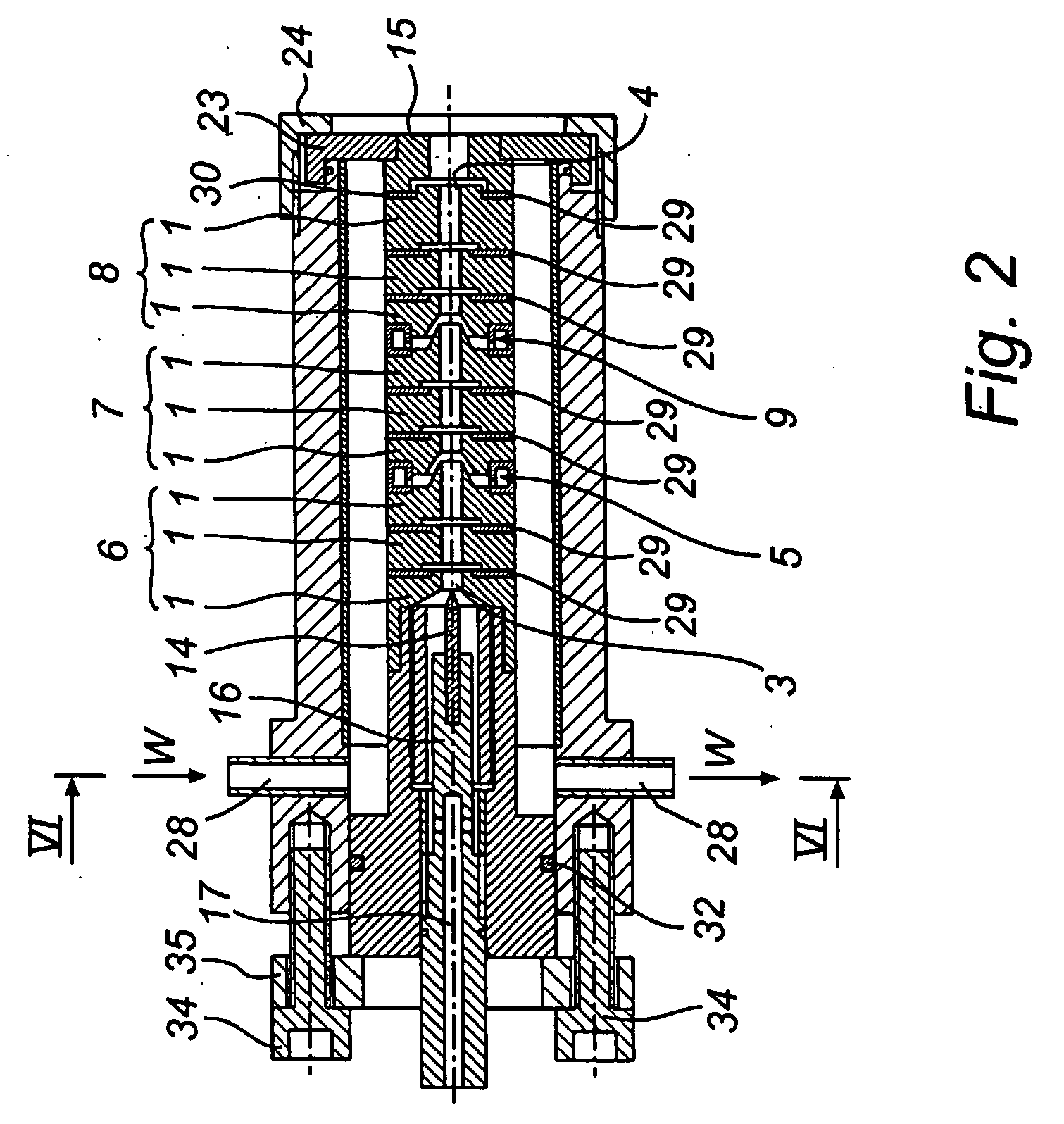

InactiveUS20060091116A1Satisfactory controlImprove homogeneityMolten spray coatingArc welding apparatusEngineeringPlasma channel

The invention relates to a plasma-spraying device for spraying a powdered material, comprising electrodes (1), which form a plasma channel (2) having an inlet end (3) and an outlet end (4), and a means (5) for supplying said powdered material to said plasma channel (2). The powder supply means (5) is arranged between a first section (6) of said electrodes (1) located upstream of the means (5) and a second section (7) of said electrodes (1) located downstream of the means (5), as seen in the direction of plasma flow of the plasma channel (2).

Owner:PLASMA SURGICAL INVESTMENTS

Plasma processing system and plasma treatment process

InactiveUS20060163201A1Electric discharge tubesDecorative surface effectsPolymer substrateEngineering

A plasma treatment system for treating multiple substrates with a plasma. The treatment chamber of the plasma treatment system includes at least one pair of electrodes, typically vertically oriented, between which a substrate is positioned for plasma treatment. Each electrode includes a perforated panel that permits horizontal process gas and plasma flow, which improves plasma uniformity. A process recipe is defined that is effective for removing thin polymer areas, such as flash or chad, attached to and projecting from a polymer substrate.

Owner:NORDSON CORP

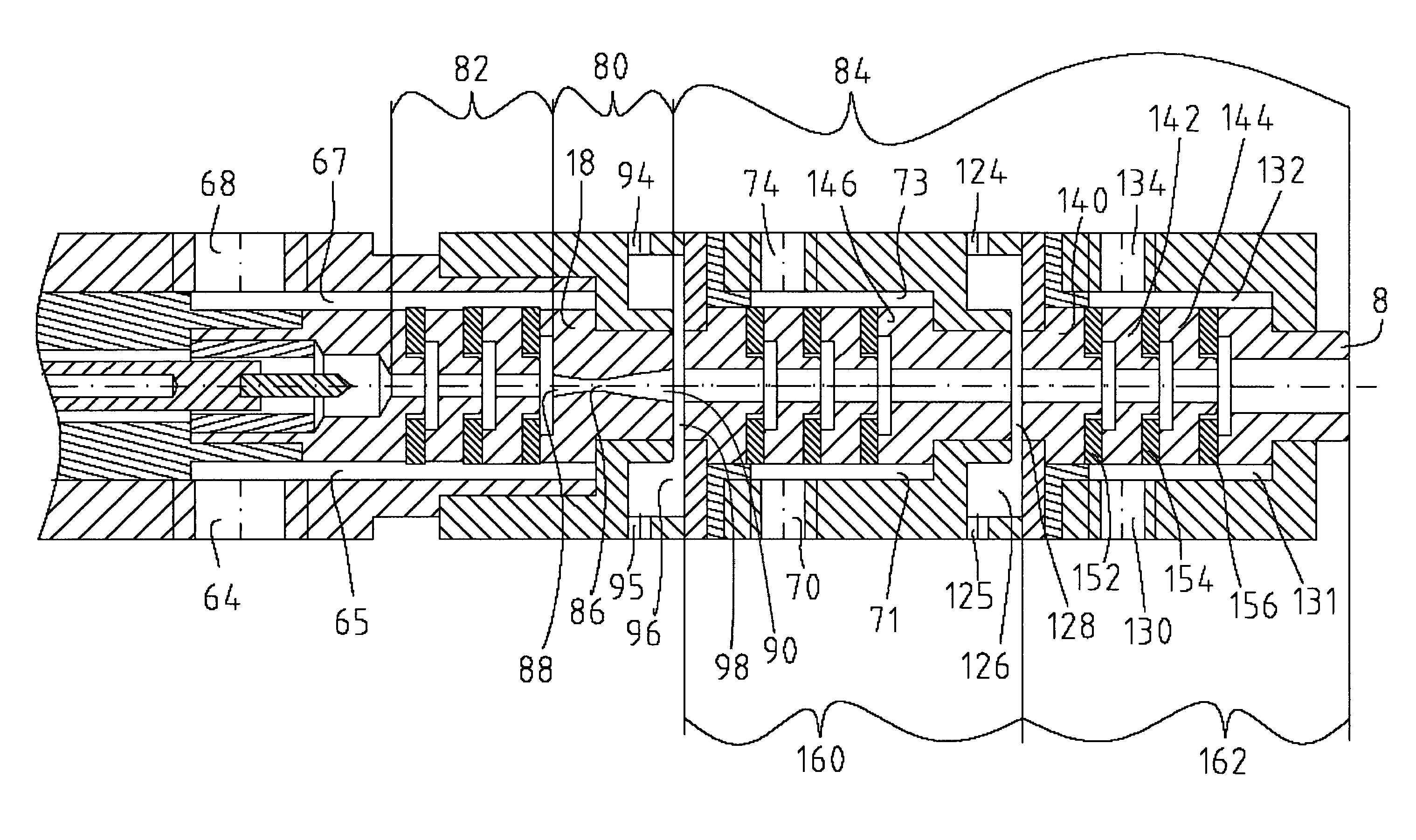

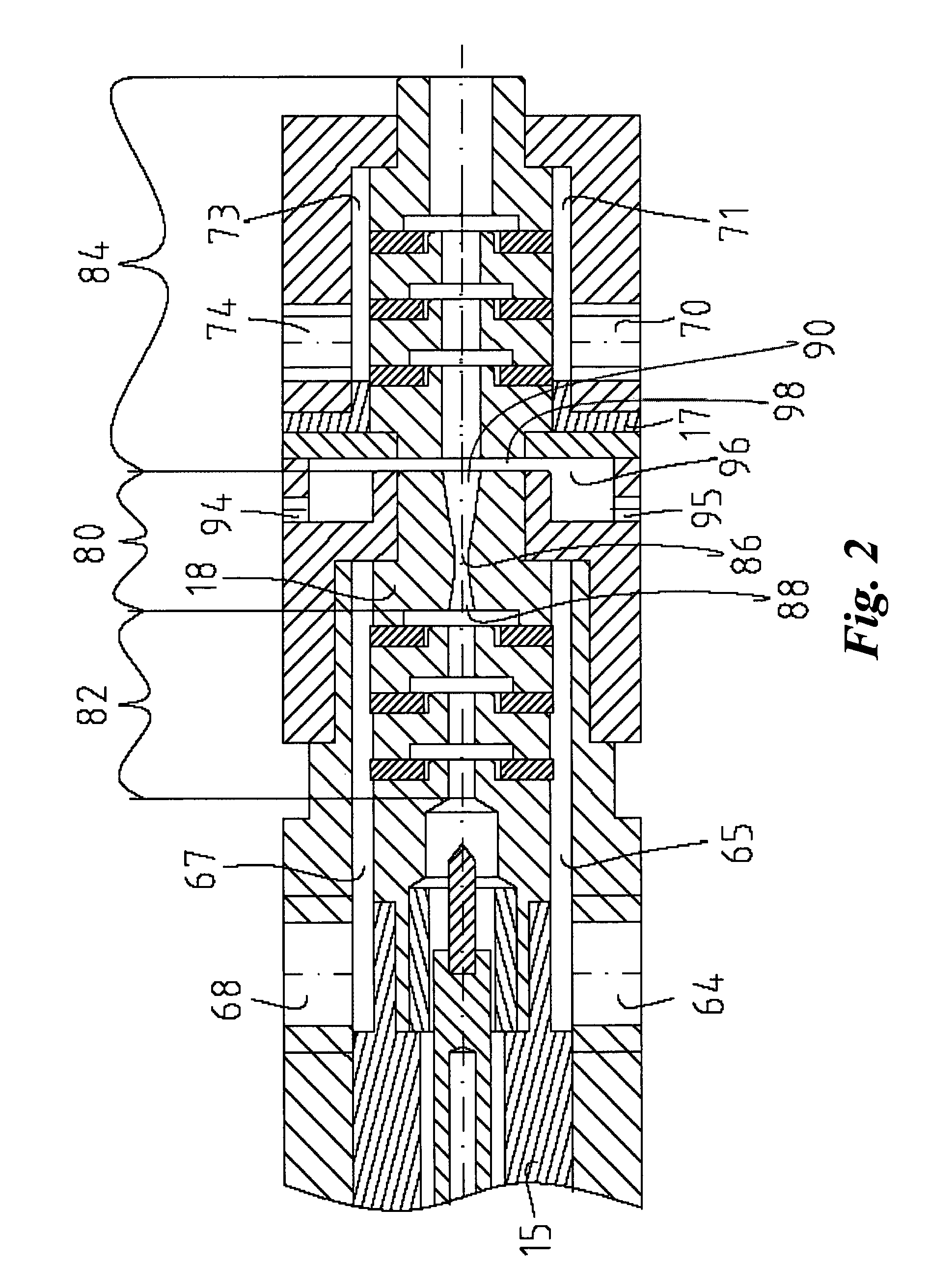

Plasma spraying device and method

ActiveUS20080185366A1High level of homogeneityAvoid insufficient heatingMolten spray coatingEfficient propulsion technologiesHigh pressurePlasma channel

A device and a method for plasma spraying are disclosed. The device comprises, a cathode, an anode, a plasma channel formed by the anode and intermediate electrodes, and one or more flowable material injectors. The plasma channel has a throttling portion that divides the plasma channel into a high pressure portion near the cathode formed by at least one intermediate electrode and a low pressure portion near the anode. During operation, a plasma generating gas is heated by the arc maintained between the cathode and the anode, forming plasma. When the plasma passes through the throttling portion, its speed increases to a supersonic speed, and at the same time its static pressure drops. Flowable materials are injected in the plasma flow in the low pressure portion. The particles in the flowable materials are heated by the plasma and the resultant heated particles and plasma are output from the outlet of the plasma channel.

Owner:PLASMA SURGICAL INVESTMENTS

Pulsed carbon plasma apparatus

InactiveUS6855237B2High degreeImprove life performanceCellsElectric discharge tubesDiamond-like carbonMachine parts

The present invention provides a pulsed carbon plasma apparatus to produce a diamond-like carbon coating over an extended object, the coating having a high degree of thickness uniformity achieved by scanning the plasma flow over the surface of the object. The pulsed carbon plasma apparatus of the invention comprises a carbon plasma flow scanning device having at least one pair of deflecting coils, where the deflecting coils have, in the scanning plane, a different number of turns on opposite sides. The object may be made of metal, ceramic, glass or plastic. The coatings may be used to improve life and operating performance of tools and machine parts, and as decorative coatings.

Owner:INT TECH EXCHANGE

Plasma spraying device and method

ActiveUS7928338B2High level of homogeneityAvoid insufficient heatingMolten spray coatingEfficient propulsion technologiesHigh pressurePlasma channel

A device and a method for plasma spraying are disclosed. The device comprises, a cathode, an anode, a plasma channel formed by the anode and intermediate electrodes, and one or more flowable material injectors. The plasma channel has a throttling portion that divides the plasma channel into a high pressure portion near the cathode formed by at least one intermediate electrode and a low pressure portion near the anode. During operation, a plasma generating gas is heated by the arc maintained between the cathode and the anode, forming plasma. When the plasma passes through the throttling portion, its speed increases to a supersonic speed, and at the same time its static pressure drops. Flowable materials are injected in the plasma flow in the low pressure portion. The particles in the flowable materials are heated by the plasma and the resultant heated particles and plasma are output from the outlet of the plasma channel.

Owner:PLASMA SURGICAL INC

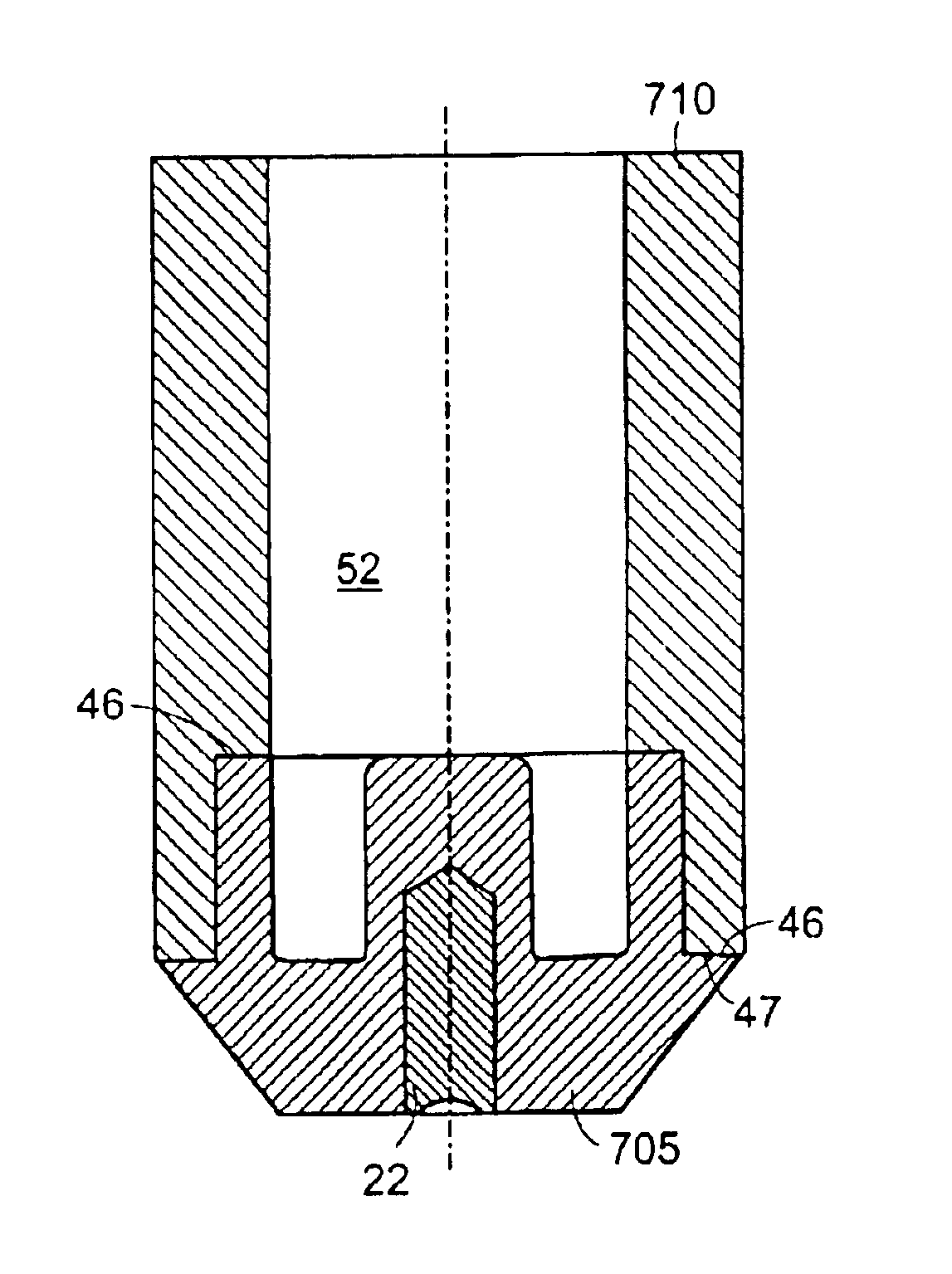

Pulsed plasma device and method for generating pulsed plasma

A device and a method for generating a truly pulsed plasma flow are disclosed. The device includes a cathode assembly comprising a cathode and a cathode holder, an anode, and two or more intermediate electrodes, the anode and the intermediate electrodes forming a plasma channel expanding toward the anode. The intermediate electrode closest to the cathode may form a plasma chamber around the cathode tip. An extension nozzle forming an extension channel having a tubular insulator along at least a portion of its interior surface is affixed to the anode end of the device. During operation, a voltage is applied between the cathode and the anode and a current is passed through the cathode, the plasma, and the anode. The voltage and current profiles are selected to cause the rapid development of a plasma flow with required characteristics. A substantially uniform temperature and power density distribution of the plasma pulse is achieved in the extension nozzle. Additionally, ozone may be generated in the extension nozzle during the generation of the plasma pulse.

Owner:PLASMA SURGICAL INVESTMENTS

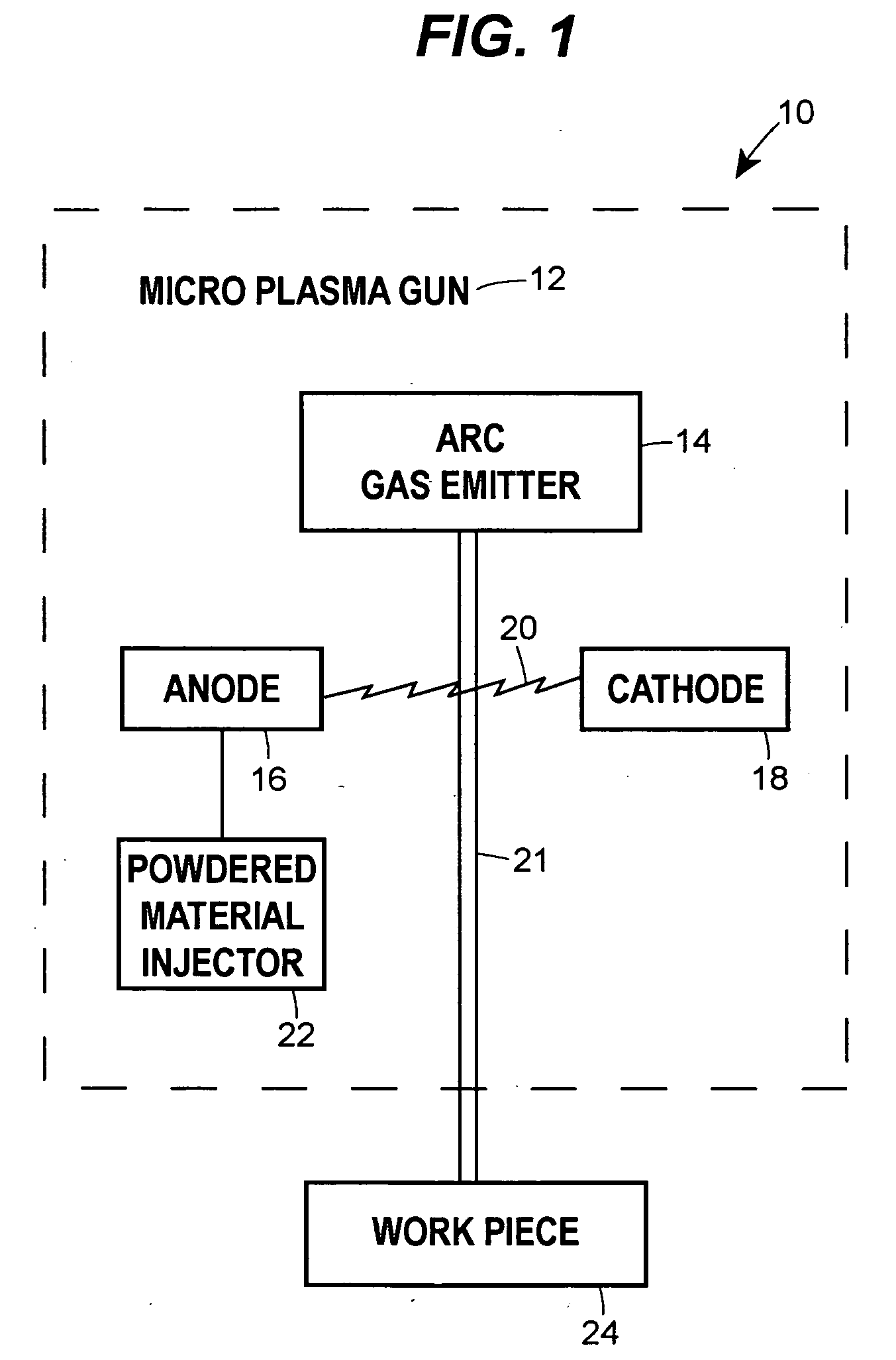

Plasma spray apparatus

A microplasma spray coating apparatus includes a microplasma apparatus with an anode, cathode, and an arc generator for generating an electric arc between the anode and cathode. An arc gas emitter injects inert gas through the electric arc. The electric arc is operable for ionizing the gas to create a plasma gas stream. A powder injector nozzle extends through the anode and injects powdered material into the plasma stream for transfer to the workpiece.

Owner:UNITED TECH CORP

Apparatus and method for reducing metal oxides on superalloy articles

InactiveUS20050035085A1Good effectEfficient removalEngine manufactureDecorative surface effectsSuperalloyPlasma flow

A method of removing a metal oxide from an alloy surface of an article, such as a superalloy turbine blade for a gas turbine engine, by contacting the alloy surface within the vacuum environment of a vacuum chamber with a reductive plasma for a time sufficient to reduce the metal oxide. Typically, the reductive plasma stream is provided by a plasma torch that electrically charges a stream of hydrogen gas, most typically mixed with a much greater portion of an inert gas such as 95% argon, to generate an active plasma stream of H3+ ions. Typically, a biasing circuit is made between the plasma torch and the alloy article to direct the plasma stream to the alloy surface.

Owner:GENERAL ELECTRIC CO

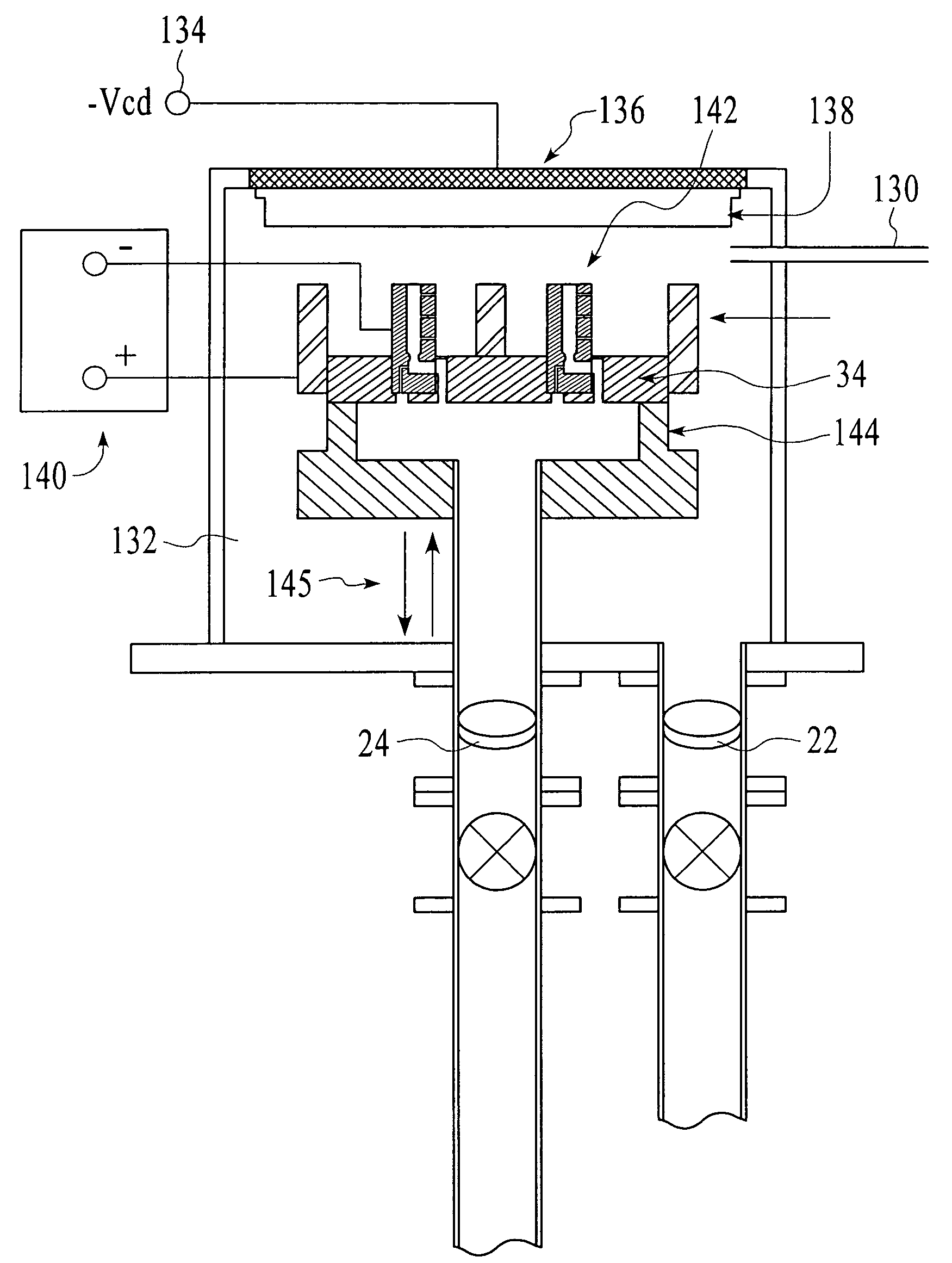

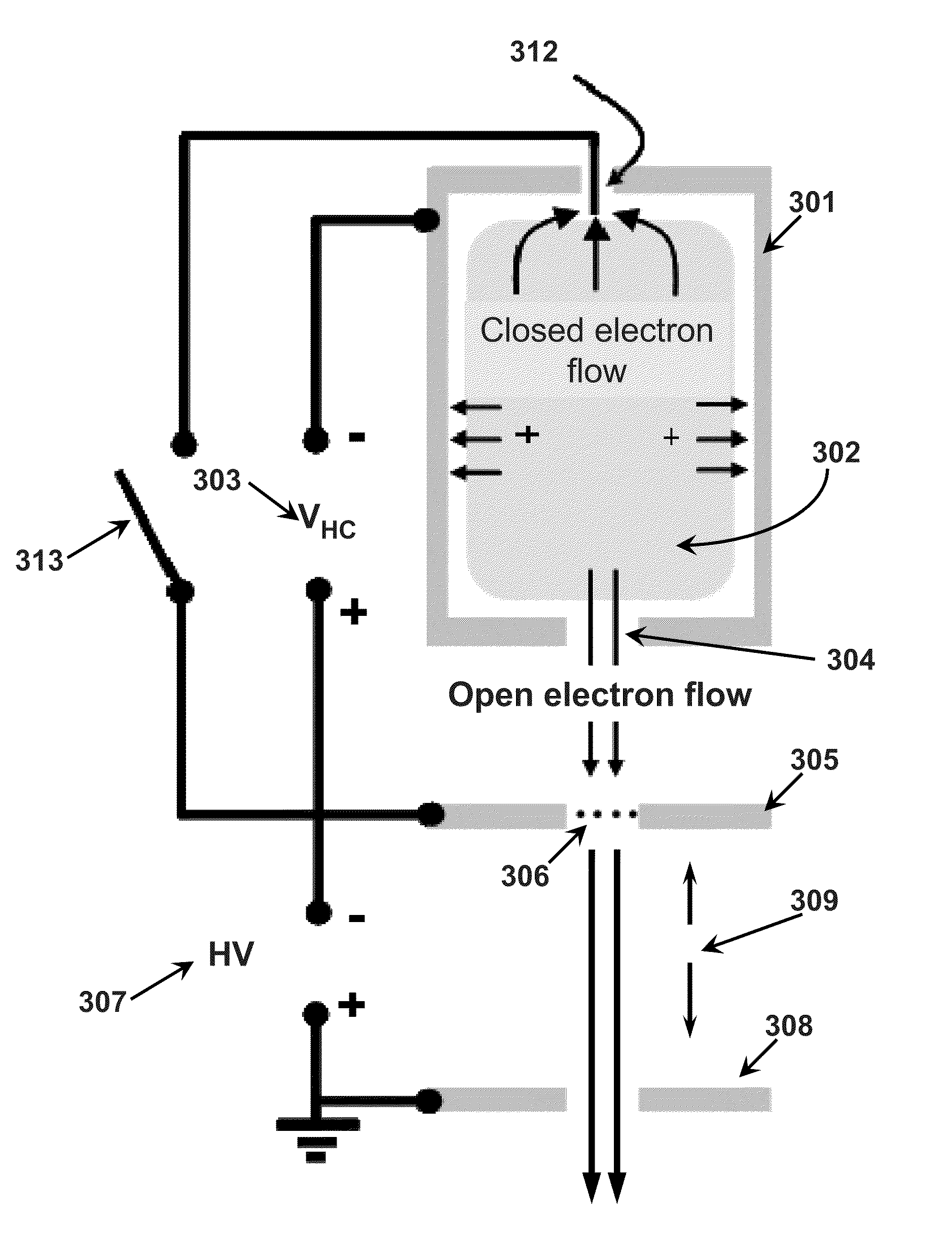

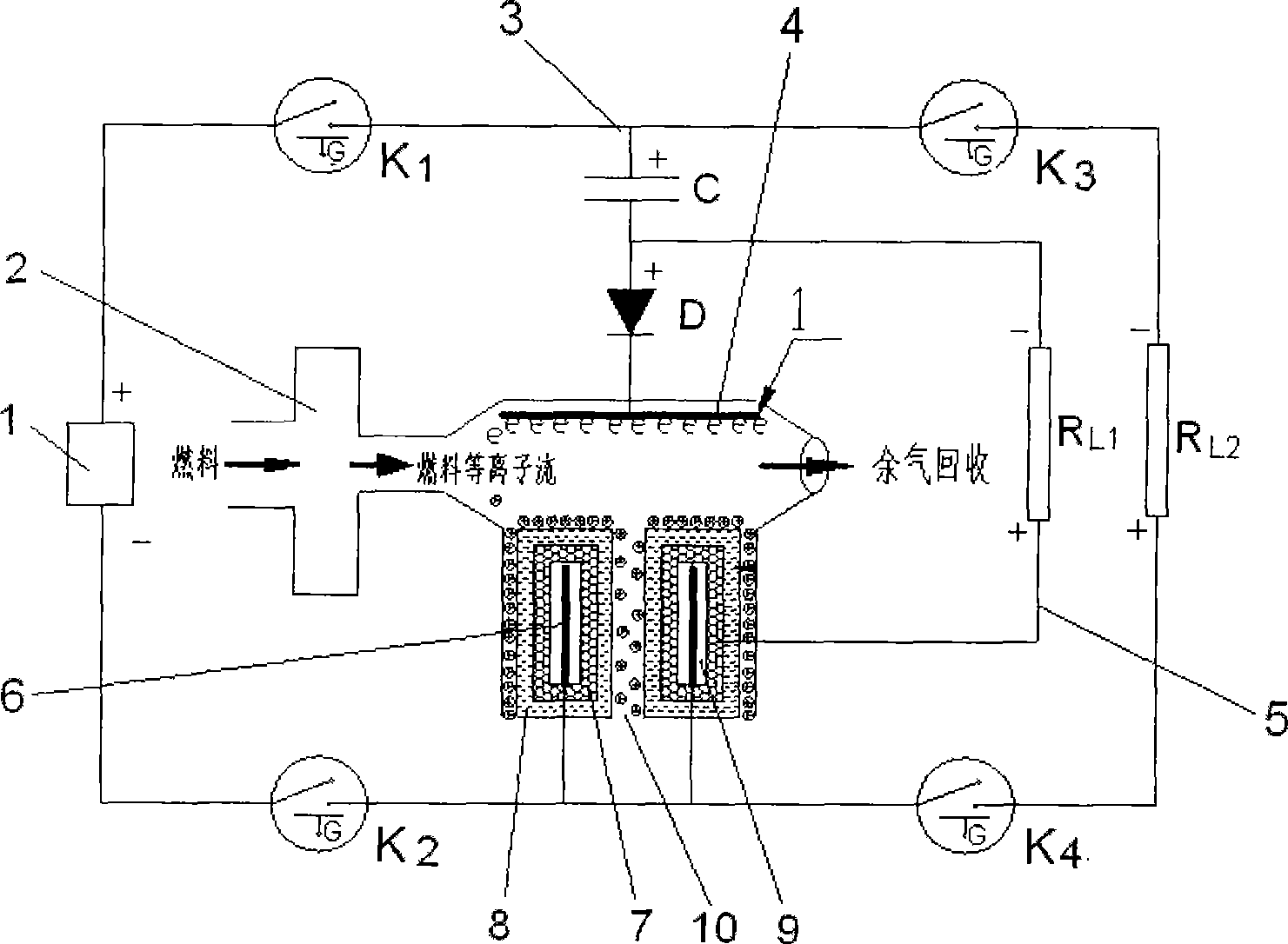

Apparatus and Method for Regulating the Output of a Plasma Electron Beam Source

ActiveUS20110080093A1Turn easilyEasy to controlElectric arc lampsDischarge tube/lamp detailsPlasma electronBeam source

An apparatus and method for controlling electron flow within a plasma to produce a controlled electron beam is provided. A plasma is formed between a cathode and an acceleration anode. A control anode is connected to the plasma and to the acceleration anode via a switch. If the switch is open, the ions from the plasma flow to the cathode and plasma electrons flow to the acceleration anode. With the acceleration anode suitably transparent and negatively biased with a DC high voltage source, the electrons flowing from the plasma are accelerated to form an electron beam. If the switch is closed, the ions still flow to the cathode but the electrons flow to the control anode rather than the acceleration anode. Consequently, the electron beam is turned off, but the plasma is unaffected. By controlling the opening and closing of the switch, a controlled pulsed electron beam can be generated.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

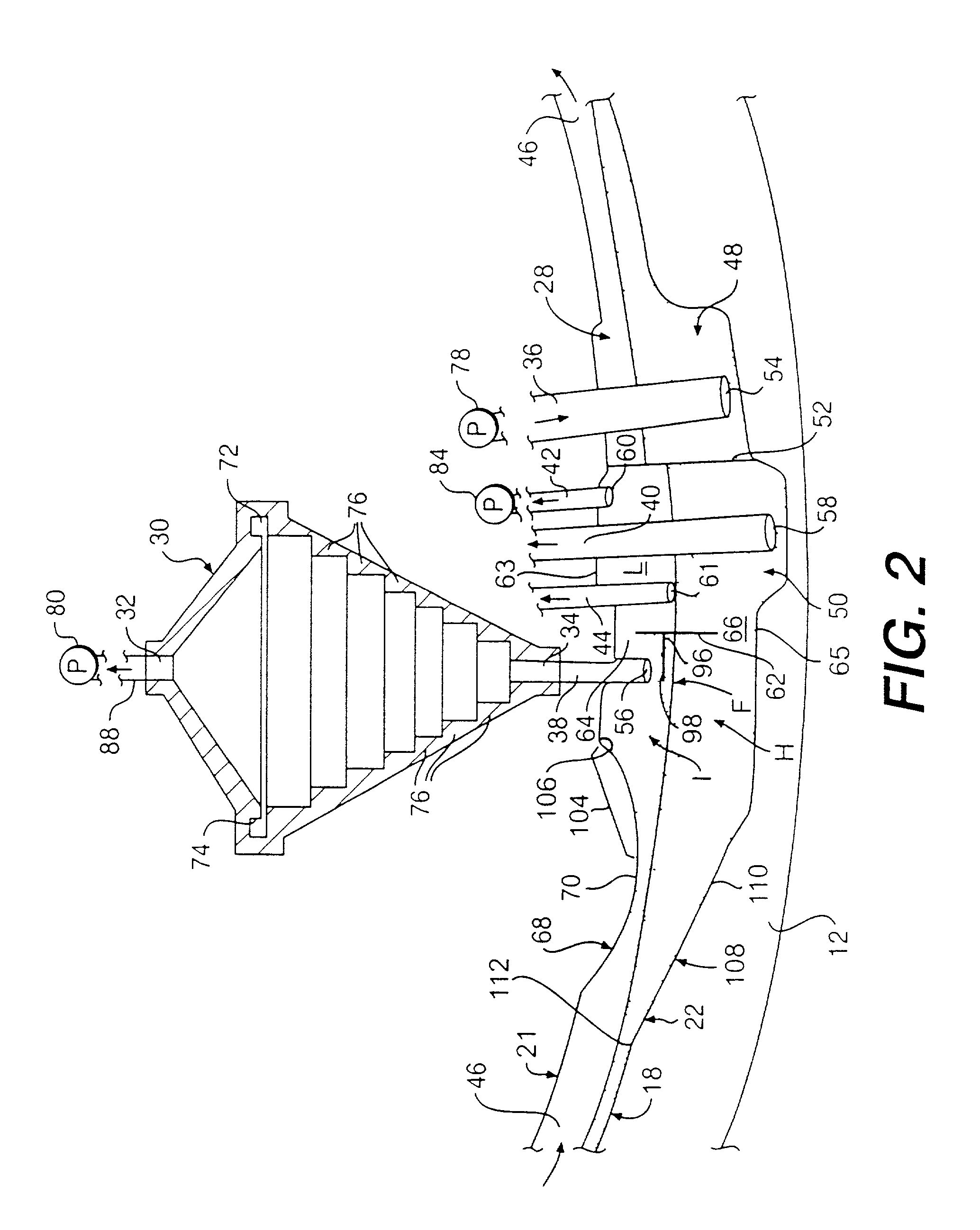

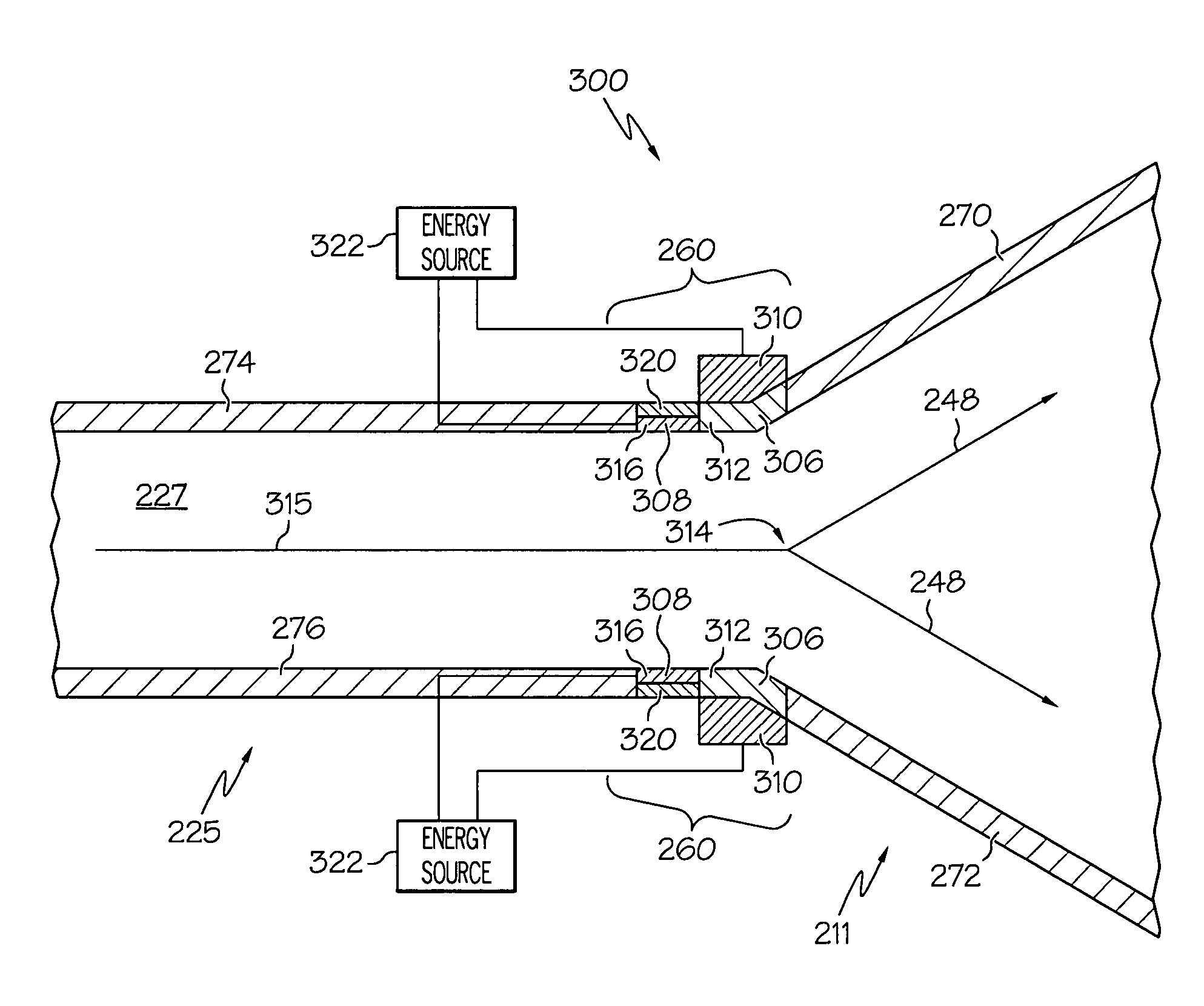

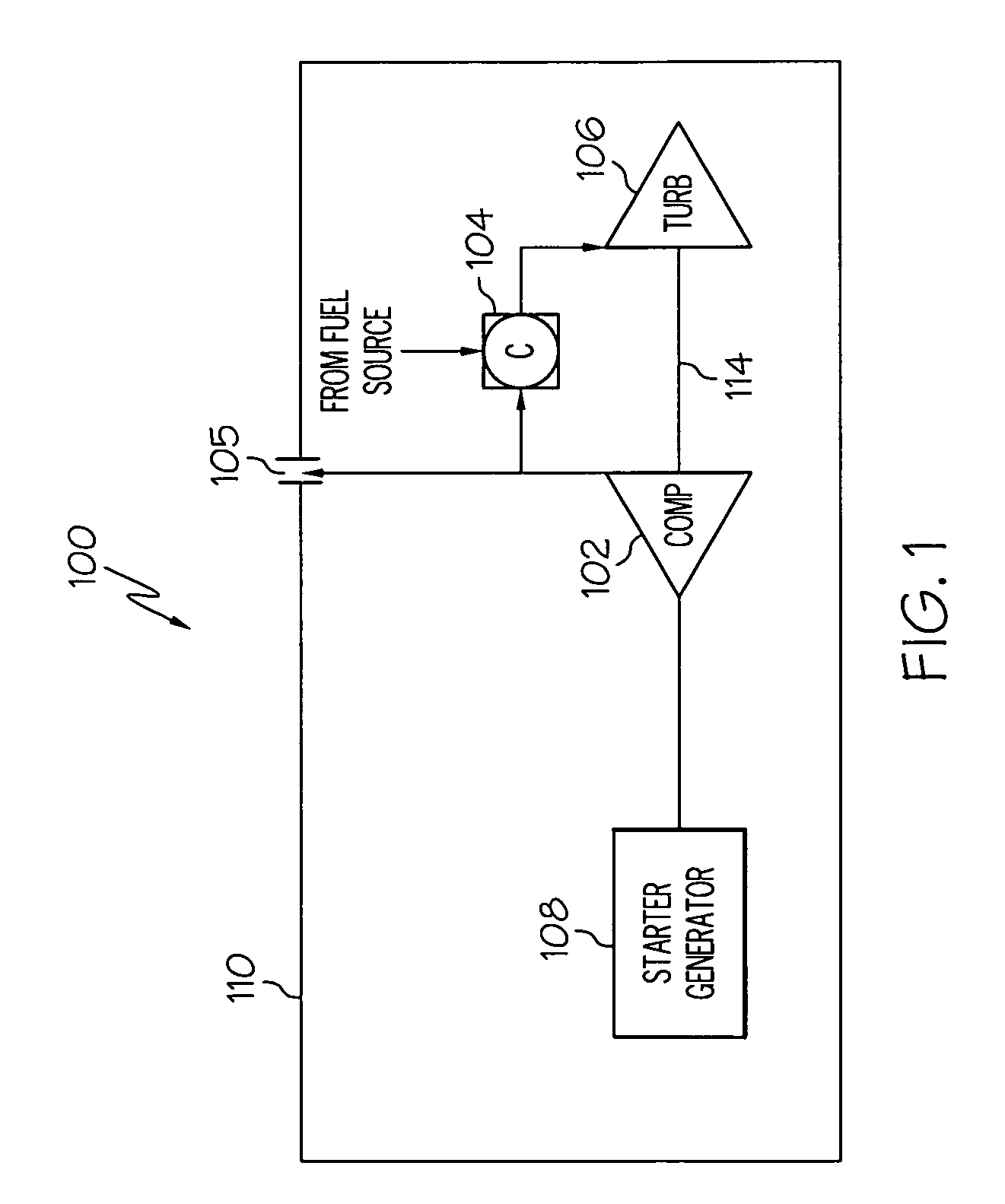

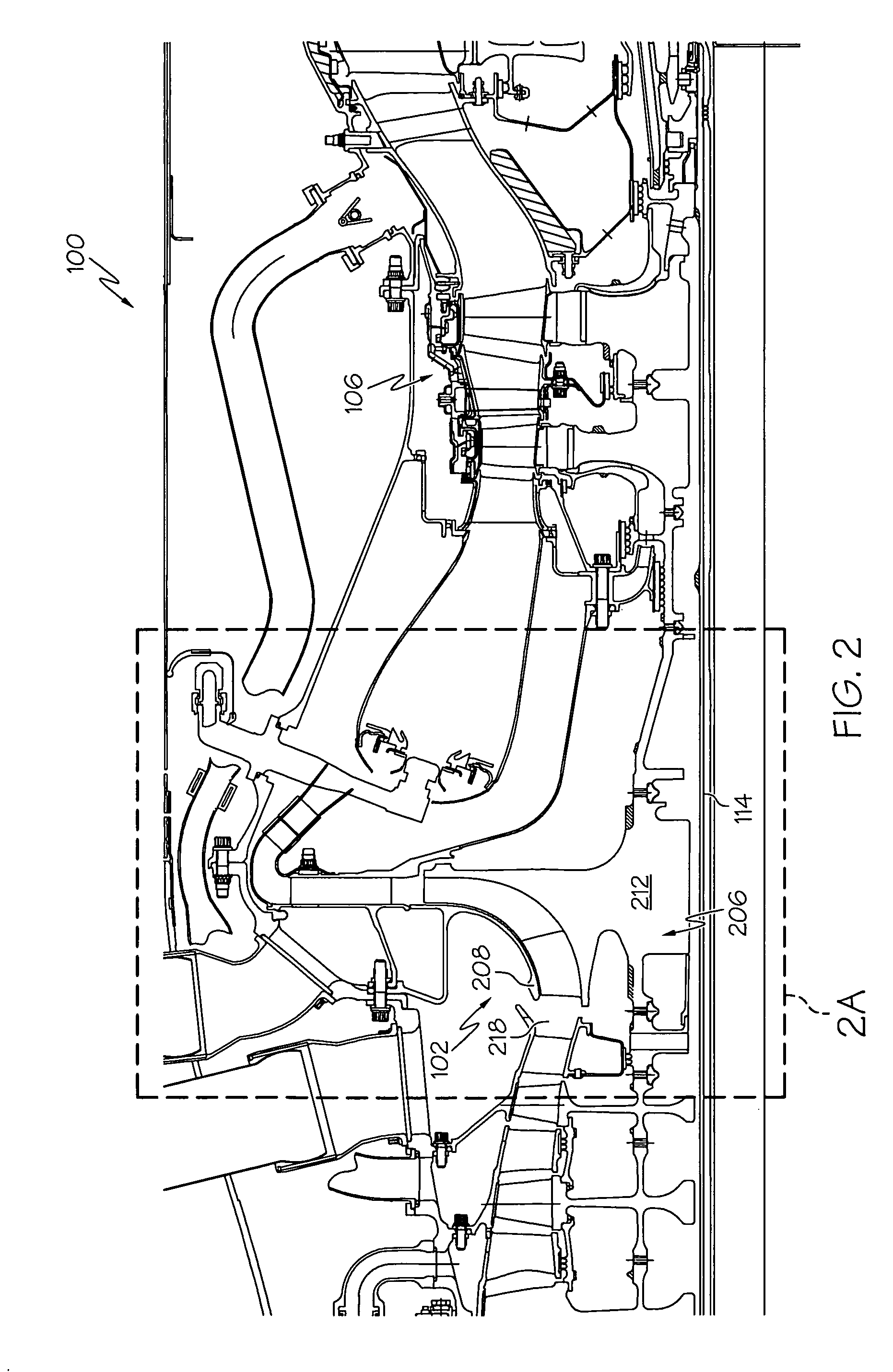

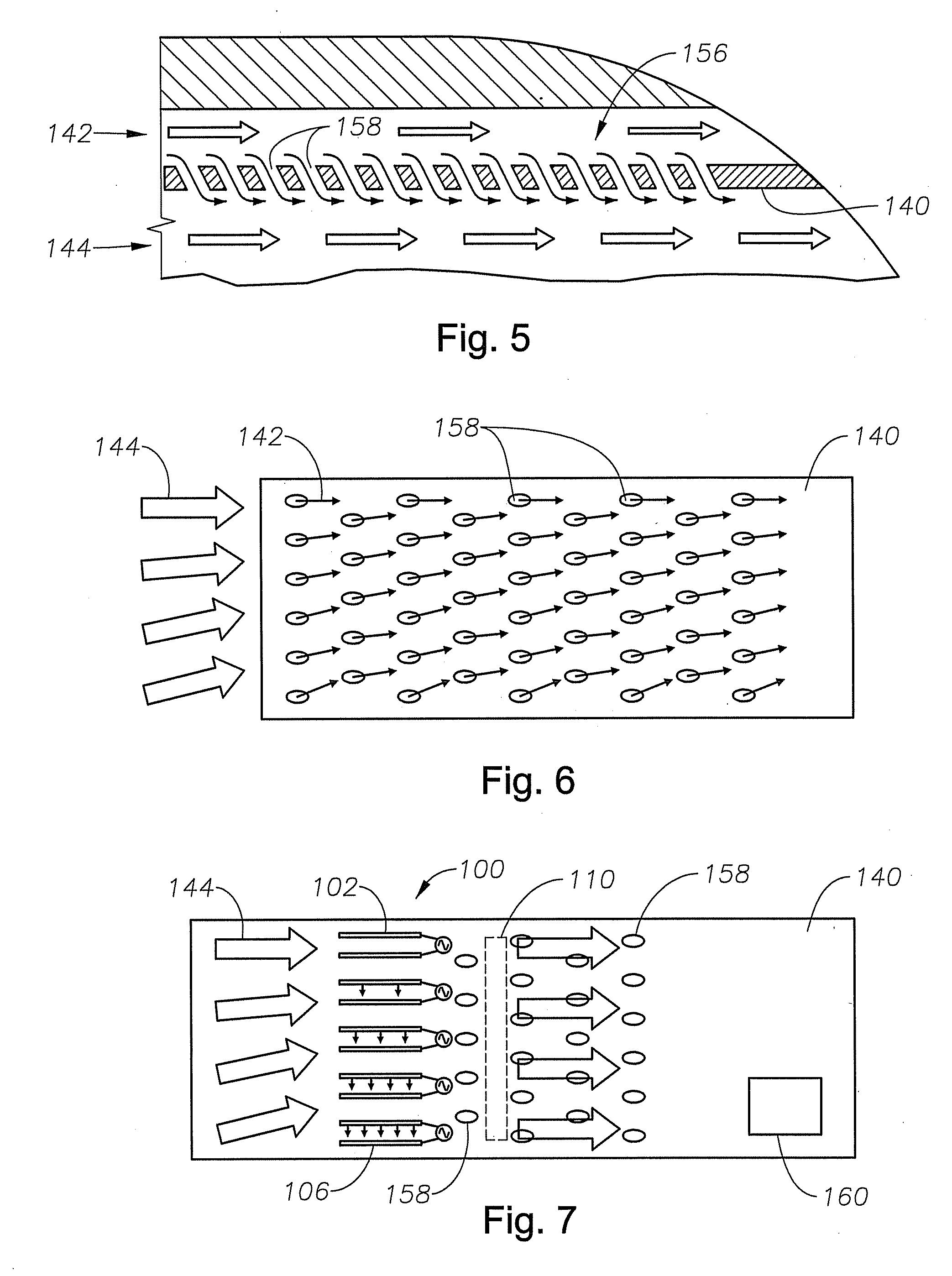

Plasma flow controlled diffuser system

A diffuser system for a compressor for a gas turbine engine includes a diffuser and a plasma actuator. The diffuser comprises a first wall and a second wall. The first and second walls form a diffuser flow passage therebetween. The plasma actuator is disposed at least partially proximate the second wall. The plasma actuator is adapted to generate an electric field to ionize a portion of air flowing through the flow passage.

Owner:HONEYWELL INT INC

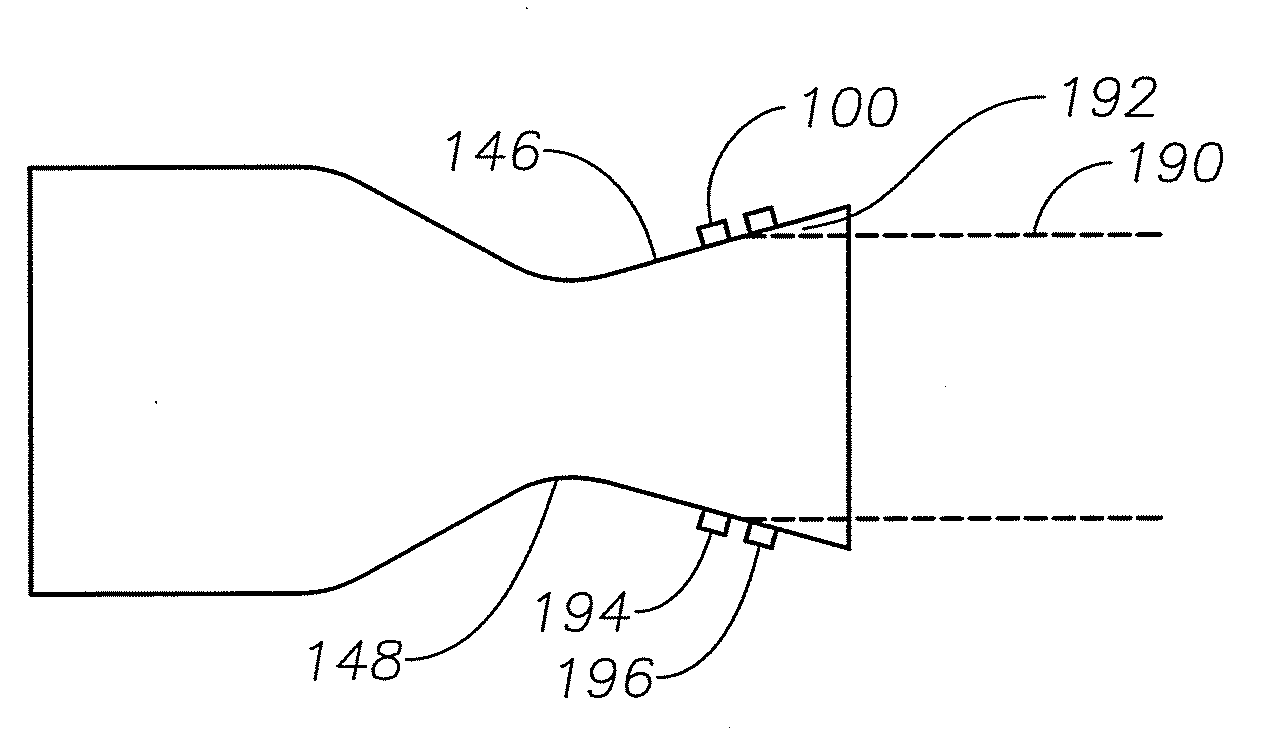

Nozzle plasma flow control utilizing dielectric barrier discharge plasma actuators

InactiveUS20110048025A1Reduce gradientReduce wall temperatureAircraft navigation controlGas-filled discharge tubesJet enginePlasma actuator

Dielectric barrier discharge plasma actuators are used to manipulate exhaust flow within and behind a jet engine nozzle. The dielectric barrier discharge plasma actuators may be used to direct cooling airflow near the surface of the nozzle to reduce heating of the nozzle, create thrust vectoring, and reduce noise associated with the exhaust flow exiting the nozzle.

Owner:LOCKHEED MARTIN CORP

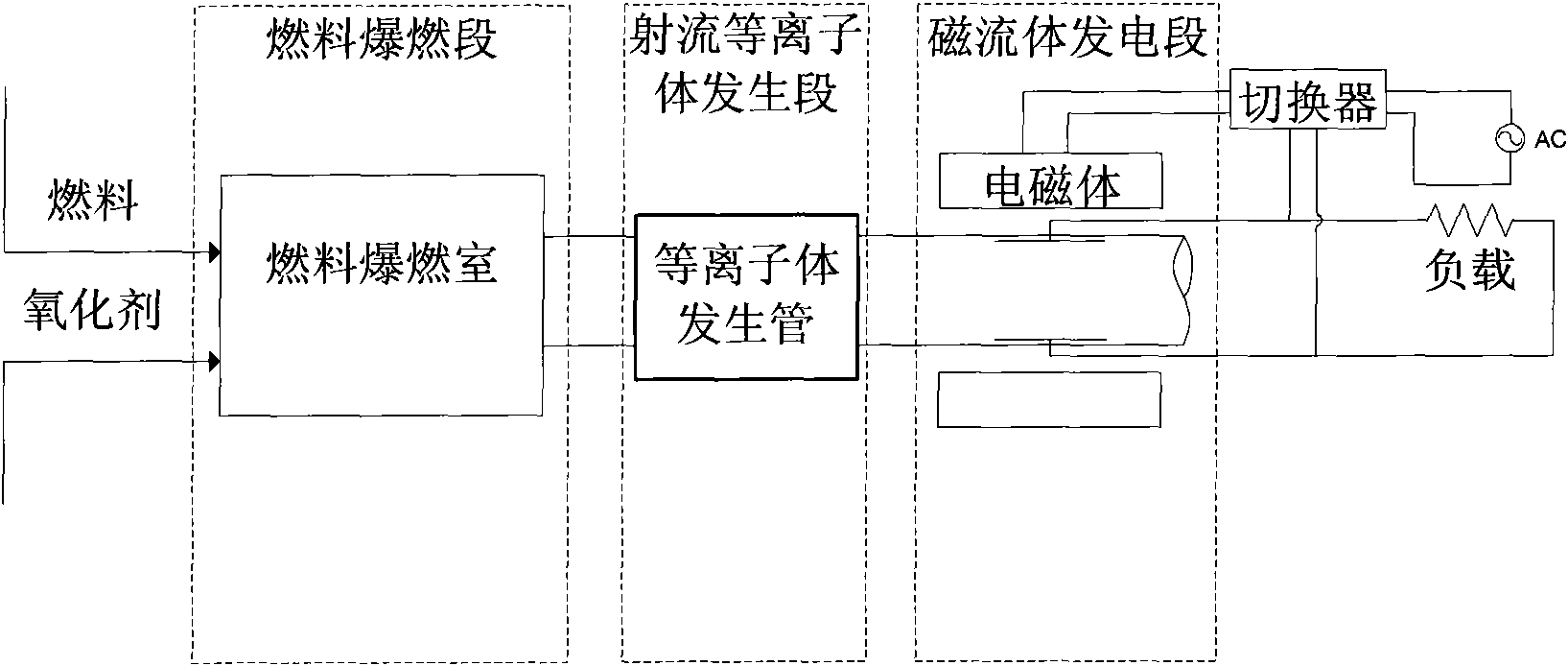

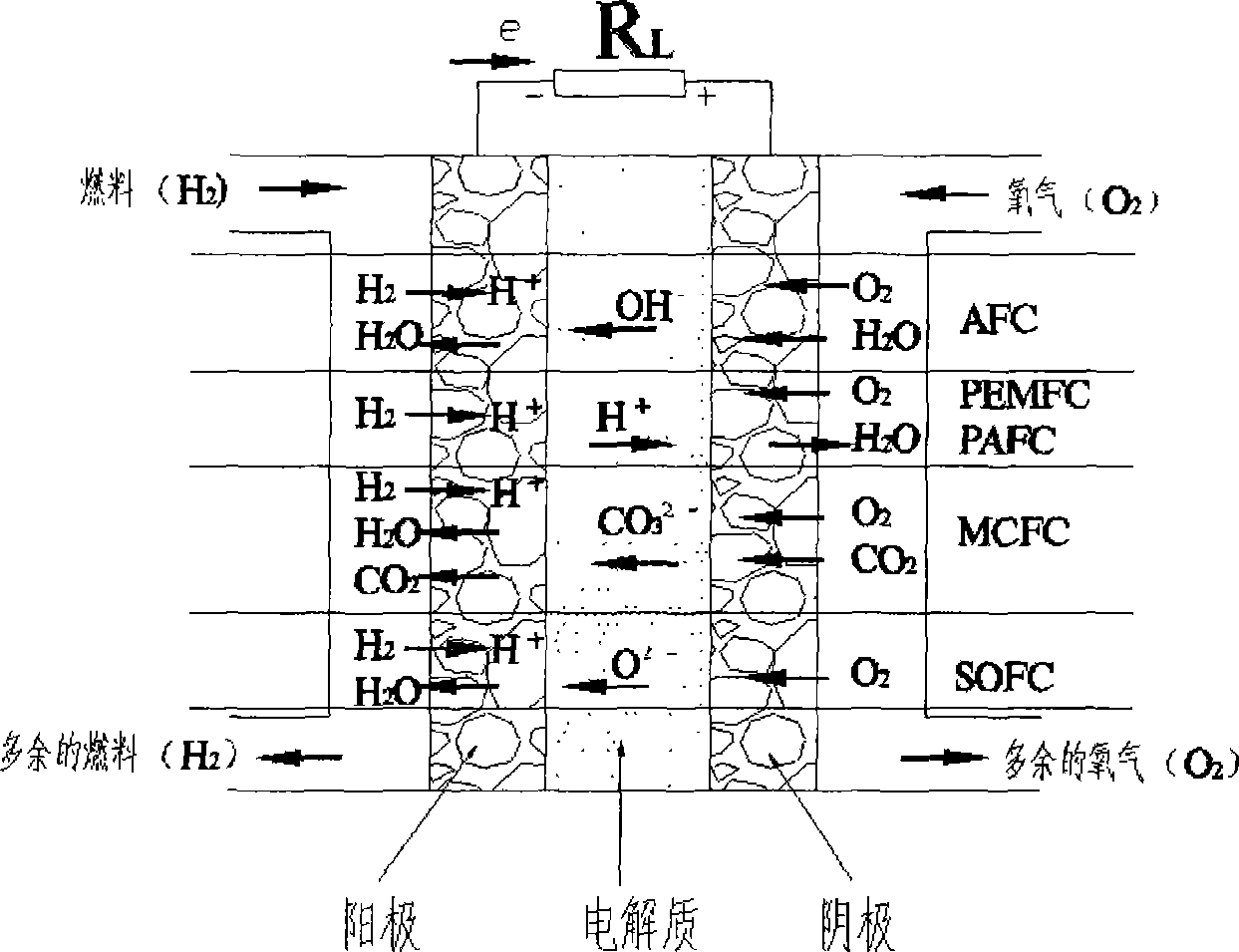

Deflagration-non-equilibrium plasma magnetohydrodynamics power generating method and device

InactiveCN101572476ALow ionization energy consumptionReduce energy consumptionDynamo-electric machinesPlasma techniqueChemical reactionEquivalent weight

The invention provides a deflagration-non-equilibrium plasma magnetohydrodynamics power generating method and a device used by the method, which can generate a low-temperature non-equilibrium plasma flow which flows through magnetic fields to form a magnetic fluid power generating system. The method comprises the following steps: 1, deflagrating fuel, wherein an oxidant and the fuel are mixed in a ratio of 1.05 to 1.5 times of chemical reaction equivalent weight, and the mixture enters a fuel deflagration chamber for continuous deflagration so as to form high-pressure gas of which the pressure is between 0.5 and 2 MPa; 2, generating the jet plasma, wherein the high-pressure gas obtained in the first step enters a plasma generating pipe of which the voltage is between 5 and 50 kV and the frequency is between 10 kHz and 1 MHz at a speed of between 20 and 200 m / s so as to generate the non-equilibrium jet plasma which has the characteristics of the magnetic fluid and of which the conductivity is between 10 and 20 S / m and the temperature is between 1,000 and 1,200 K; and 3, generating power by the magnetic fluid, wherein the non-equilibrium jet plasma enters the magnetic fields of a normal conducting electromagnet of which the magnetic induction is between 0.5 and 2.5 T at a speed of between 20 and 200 m / s, and moves to generate electromotive force.

Owner:SOUTHEAST UNIV

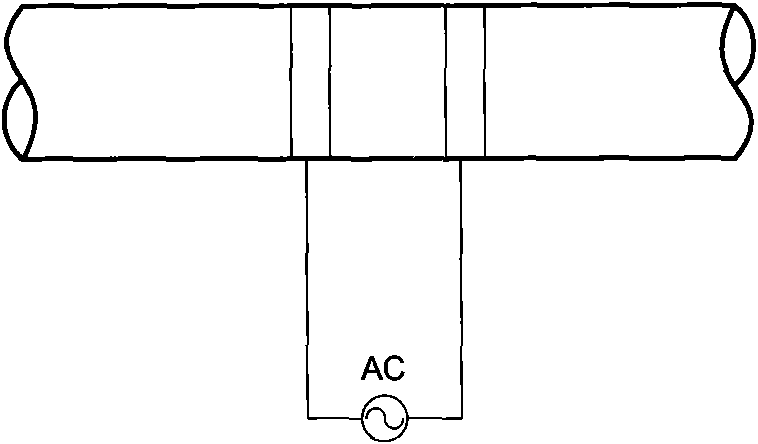

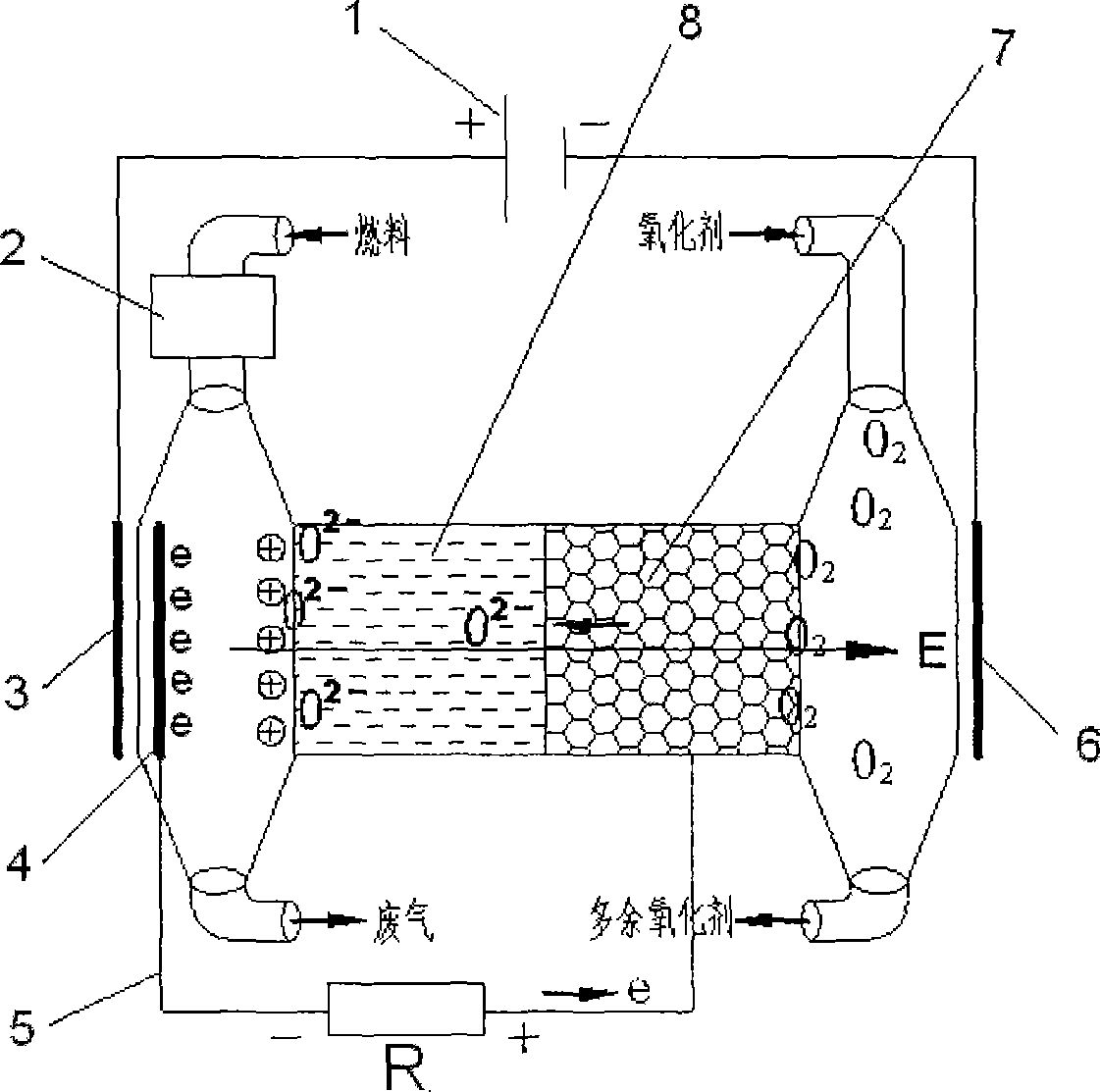

Plasma body fuel cell

InactiveCN101453028AStart fastIncrease powerFinal product manufactureFuel cell auxillariesPlasma jetElectrolysis

The invention provides a plasma fuel cell. An additional ion separation field with field direction which is vertical to running direction is arranged on a plasma flow operating path after a plasma jet generation unit; and corresponding collection structures are arranged on moving directions of separated cation and anion, wherein an electron collection structure is connected with an electric energy output circuit of an electron transfer circuit which is used for moving collected electrons out of the separation field; the electrons are transferred to a porous electrode structure which is on anion collecting side, is communicated with an oxygen introducing structure, and is isolated from the anions by a solid oxide electrolysis isolation structure; oxygen anions reduced by the electrons are combined with cations collected via isolation through the solid oxide electrolysis isolation structure to release converted electric energy to the outside. The cell can break electrostatic balance with feasibility, has a simple structure, can use various fuel gases and effectively recover fuel residual gas, does not need a noble metal catalyst or a biopolar plate so as to reduce the cost, and has the advantages of fast starting, large power and good loading adaptability.

Owner:肖远科 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com