Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1484 results about "Jet engine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A jet engine is a type of reaction engine discharging a fast-moving jet that generates thrust by jet propulsion. This broad definition includes airbreathing jet engines (turbojets, turbofans, ramjets, and pulse jets). In general, jet engines are combustion engines.

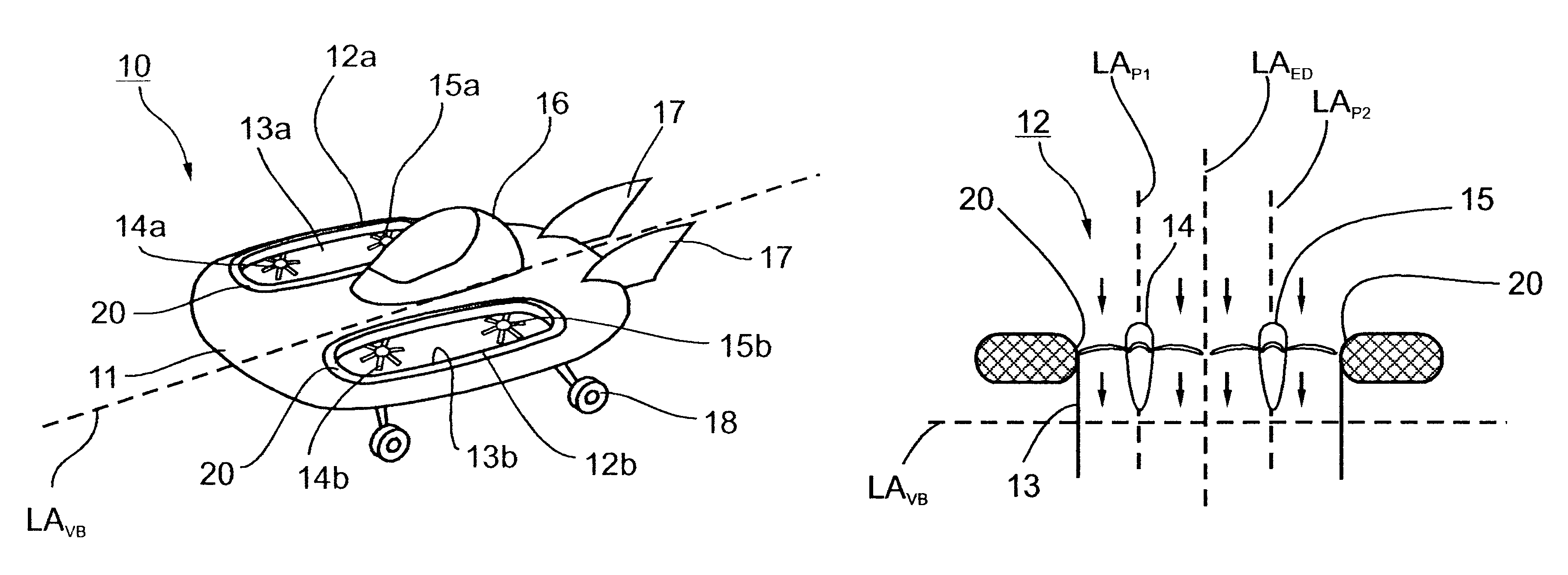

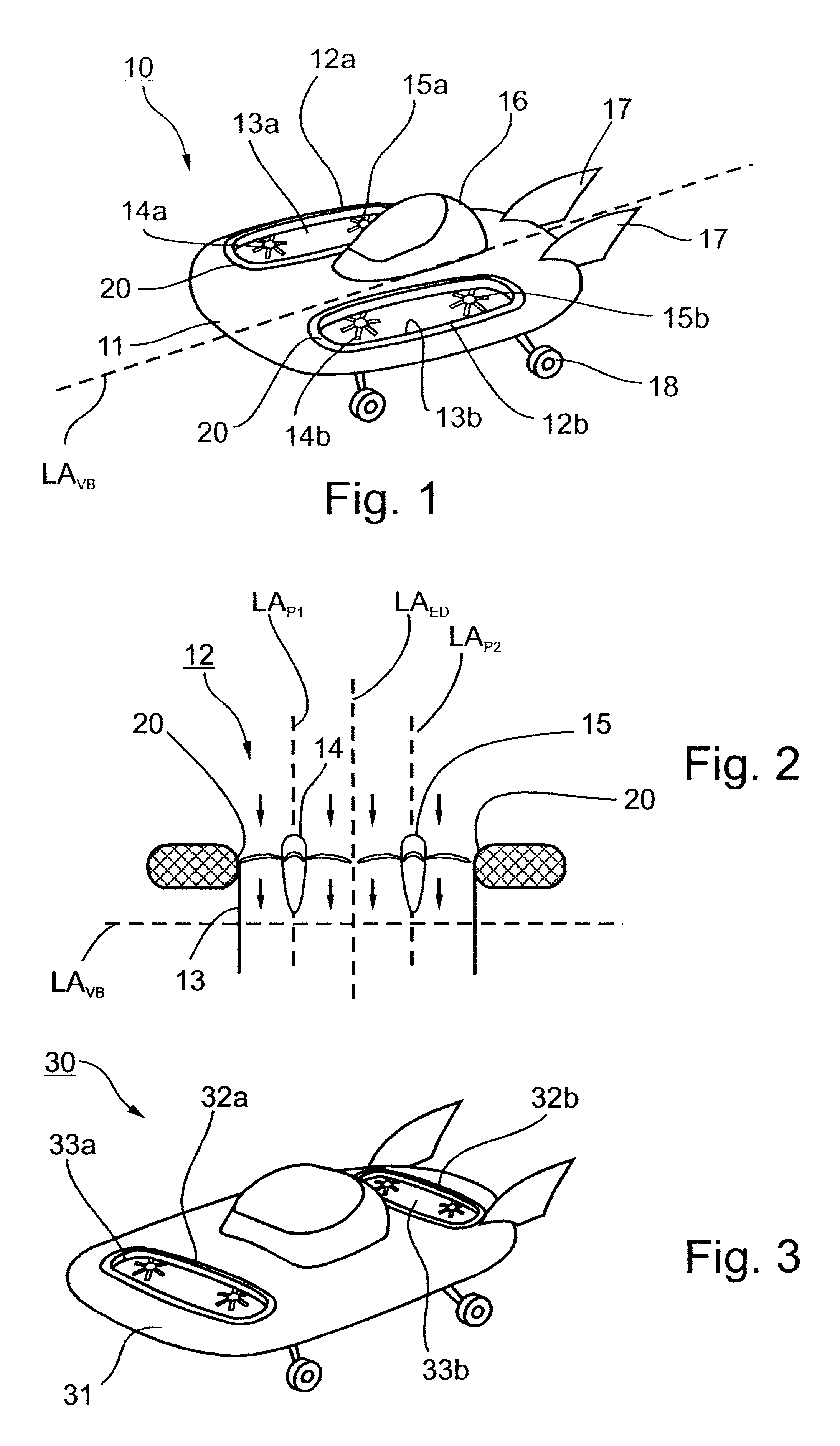

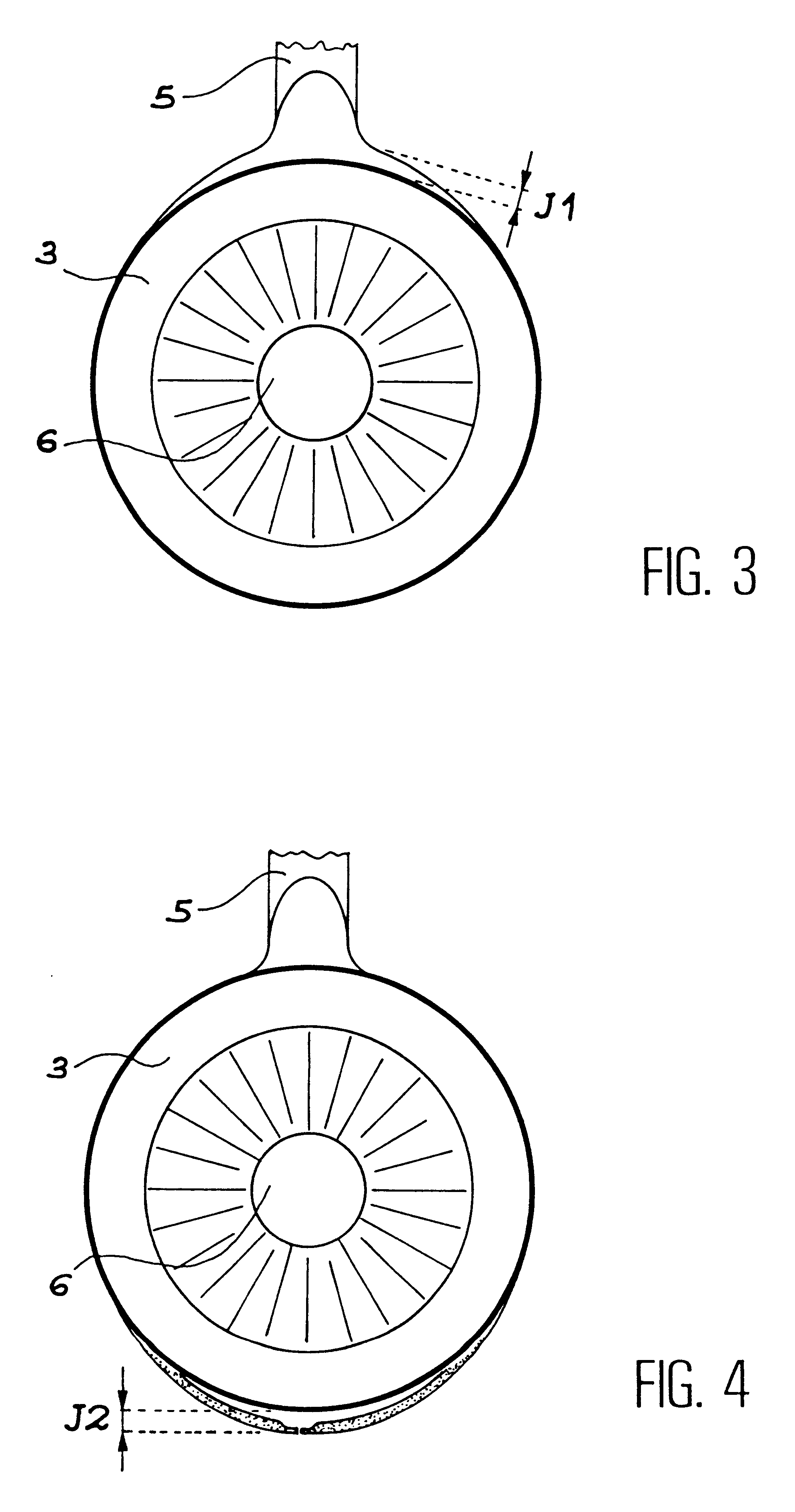

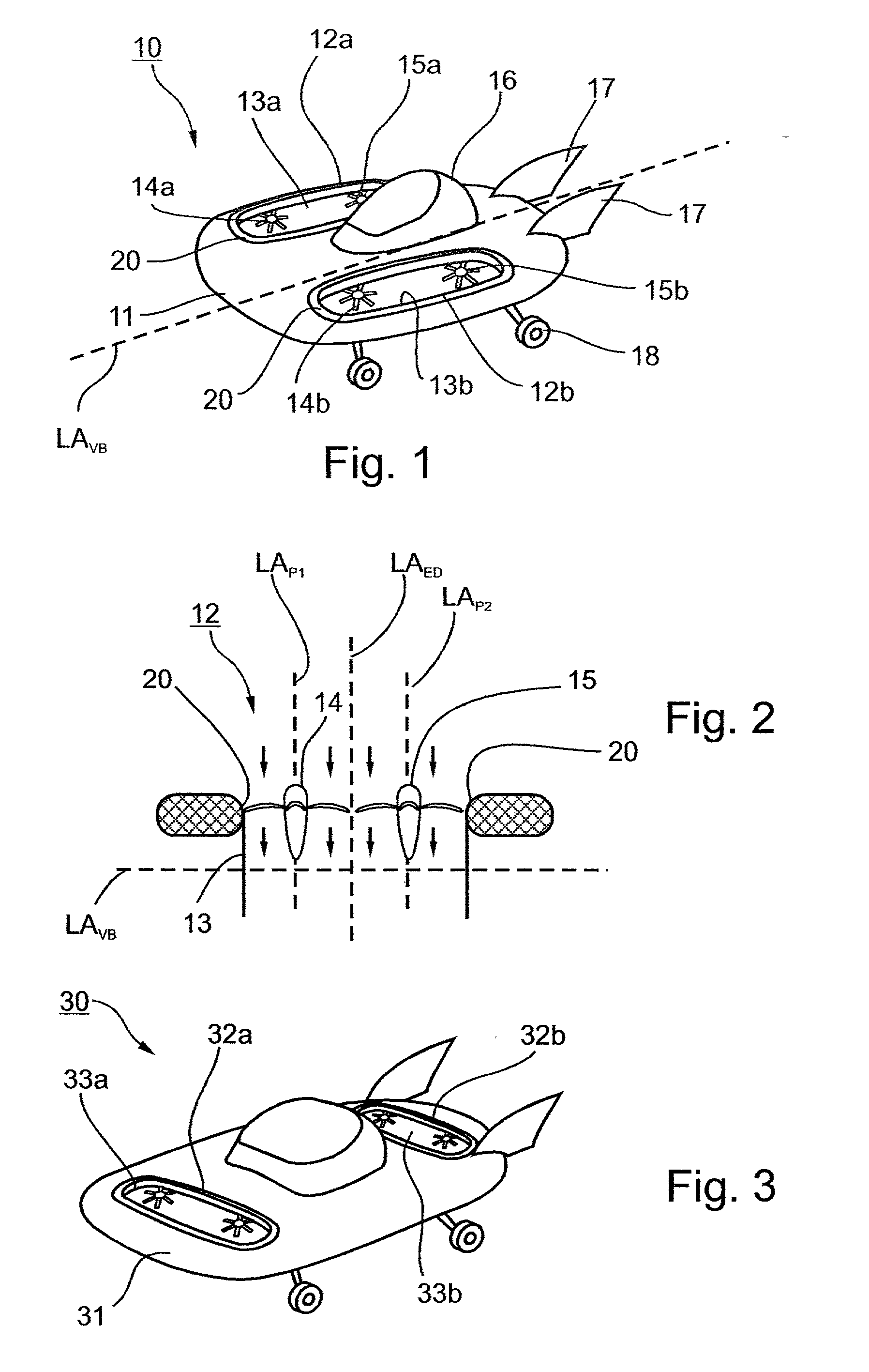

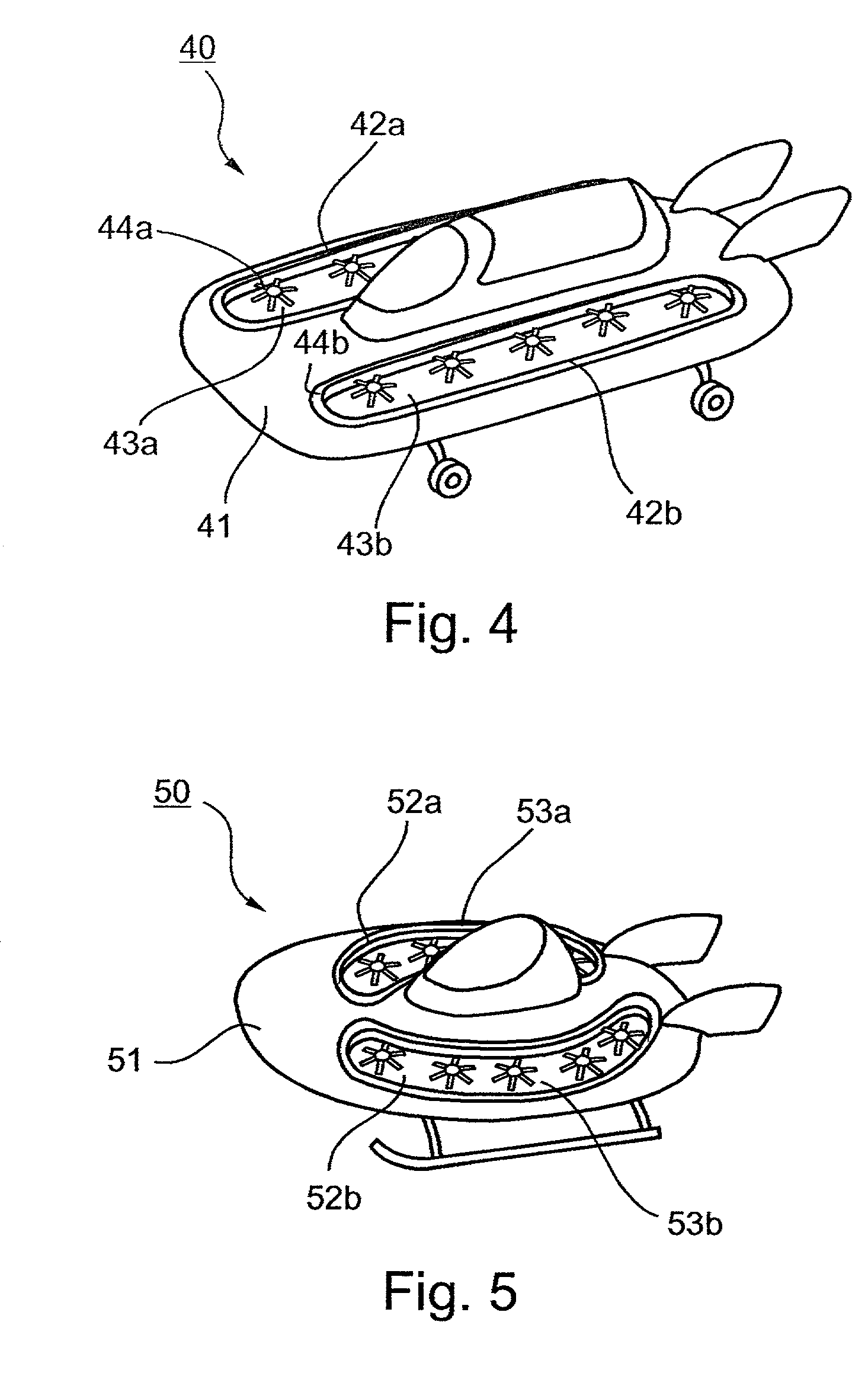

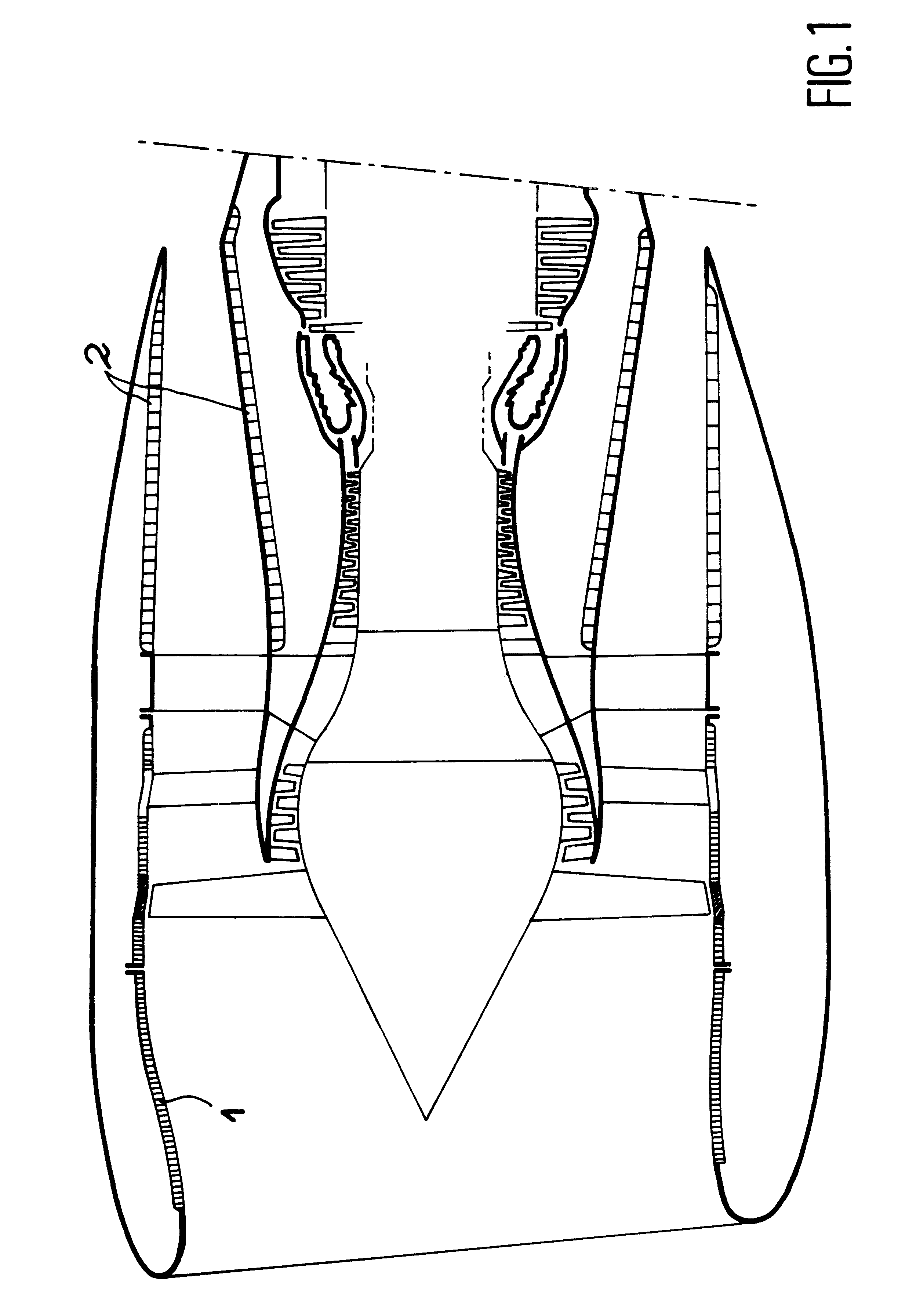

Ducted vehicles particularly useful as VTOL aircraft

InactiveUS6568630B2Easy entryEasy exitAircraft navigation controlFlying saucersJet aeroplaneJet engine

A VTOL aircraft (or other vehicle such as a sea vehicle) includes a pair of elongated ducts on opposite sides of the vehicle body, and a plurality of powered propellers (or other propulsion units such as jet engines) mounted within and enclosed by each of the elongated ducts, such as to produce an upward lift force to the vehicle. Each of the elongated ducts has a short transverse dimension slightly larger than the diameter of the blades of each propeller enclosed thereby, and a large transverse dimension slightly larger than the sum of the diameters of the blades of all the propellers enclosed thereby.

Owner:URBAN AERONAUTICS

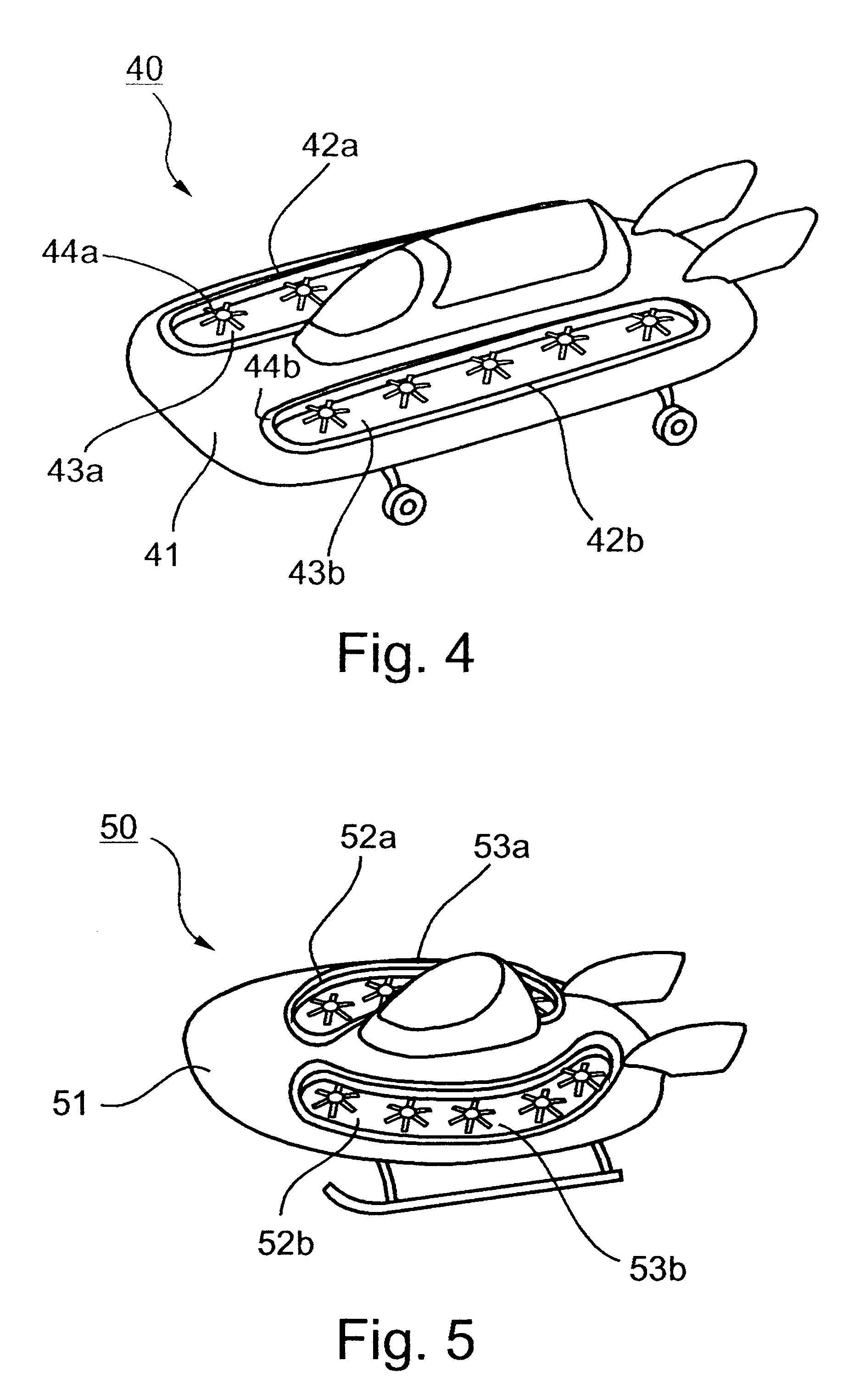

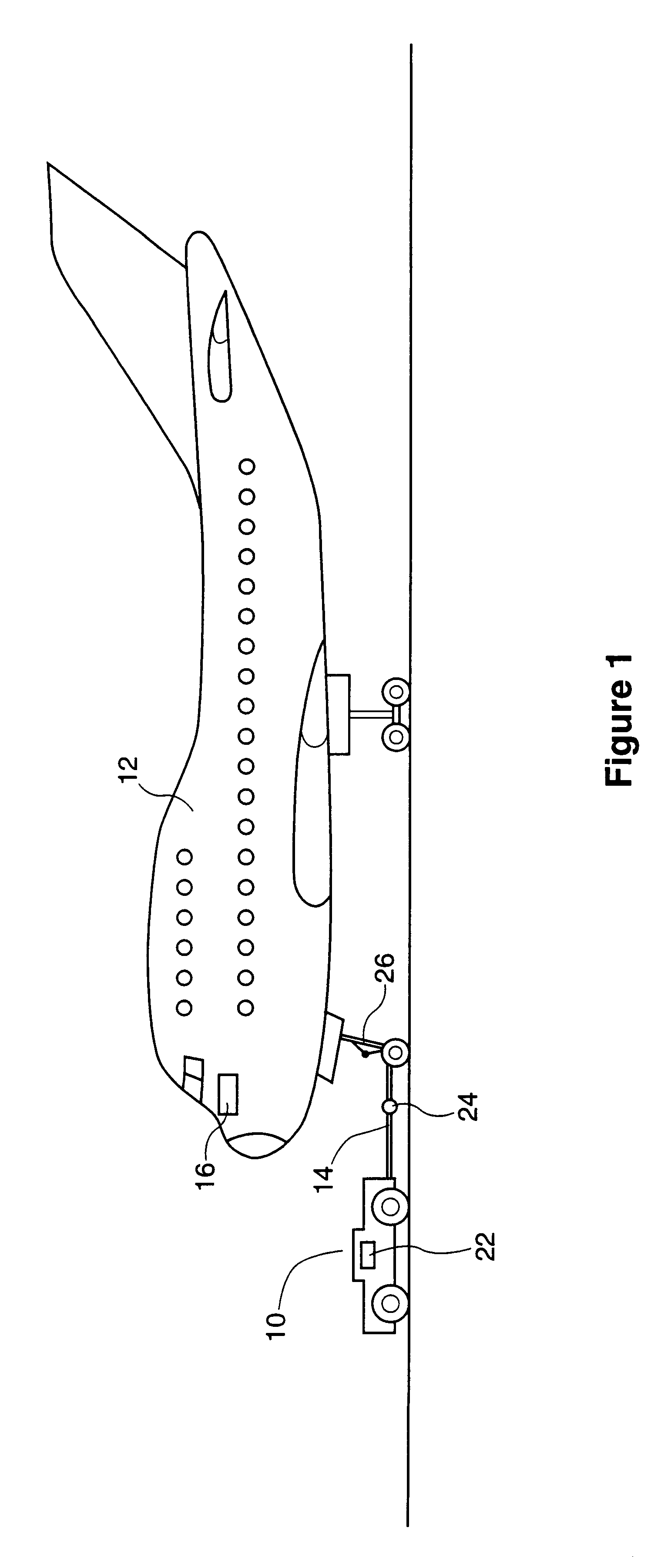

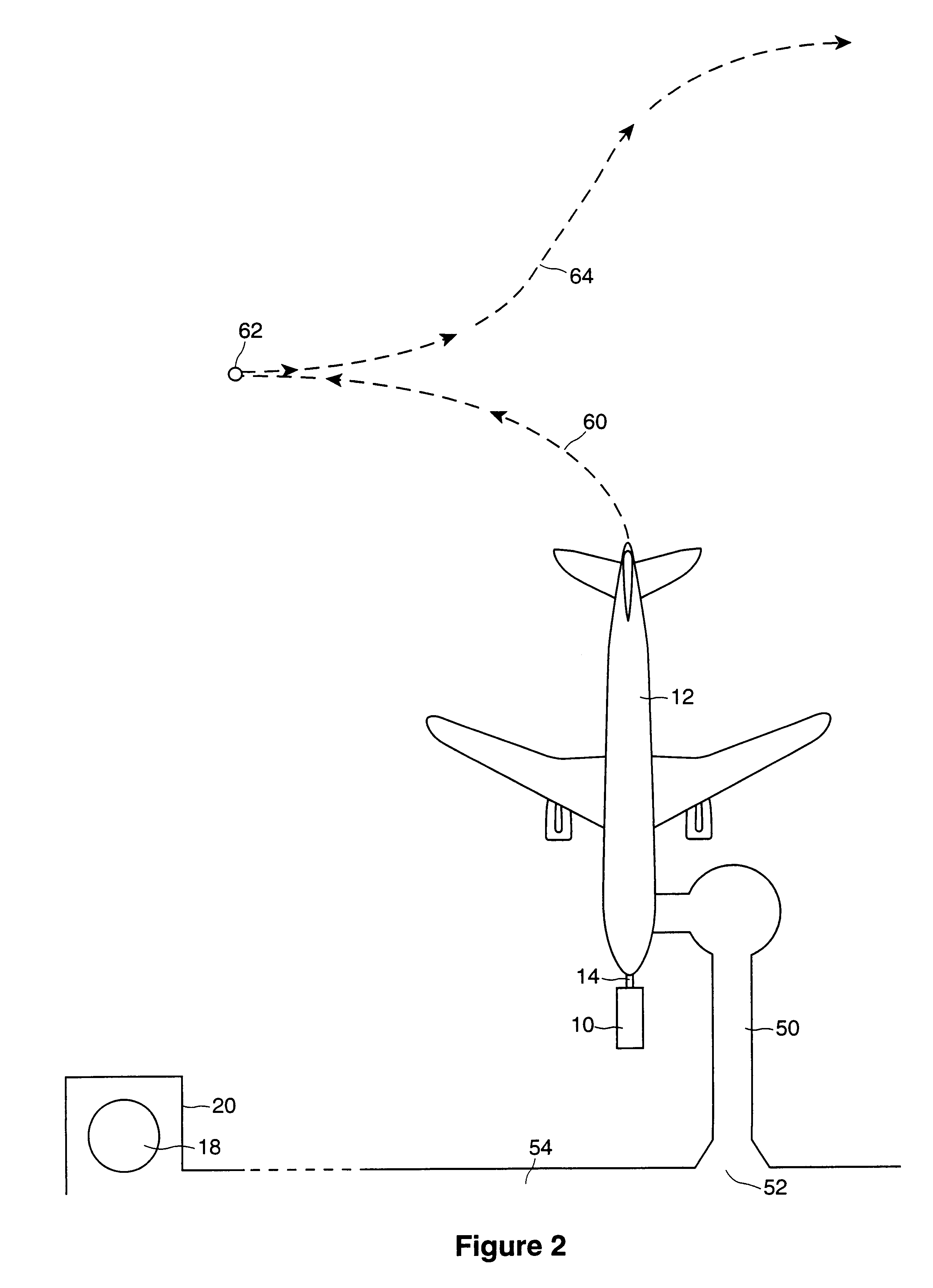

Automated aircraft towing vehicle system

InactiveUS6305484B1Extension of timeReduce idle timeEnergy efficient operational measuresAutomatic initiationsJet engineCoupling

An automated aircraft towing vehicle system for use with aircraft is provided. When coupled to an aircraft the towing tractor vehicle facilitates the movement of the aircraft without the requirement for use of the aircraft's jet engines. The towing vehicle system comprises a towing tractor vehicle having remotely controllable steering, braking, and acceleration. The remote system controller is located in the aircraft being towed such that the pilot of the aircraft being towed is capable of controlling the starting, stopping and steering of the towing tractor vehicle. The towing tractor vehicle further includes a remotely controllable de-coupling means. When the aircraft is towed to the desired location, the decoupling of the aircraft from the towing tractor vehicle is controllable by the remote system controller.

Owner:LEBLANC EDWARD L

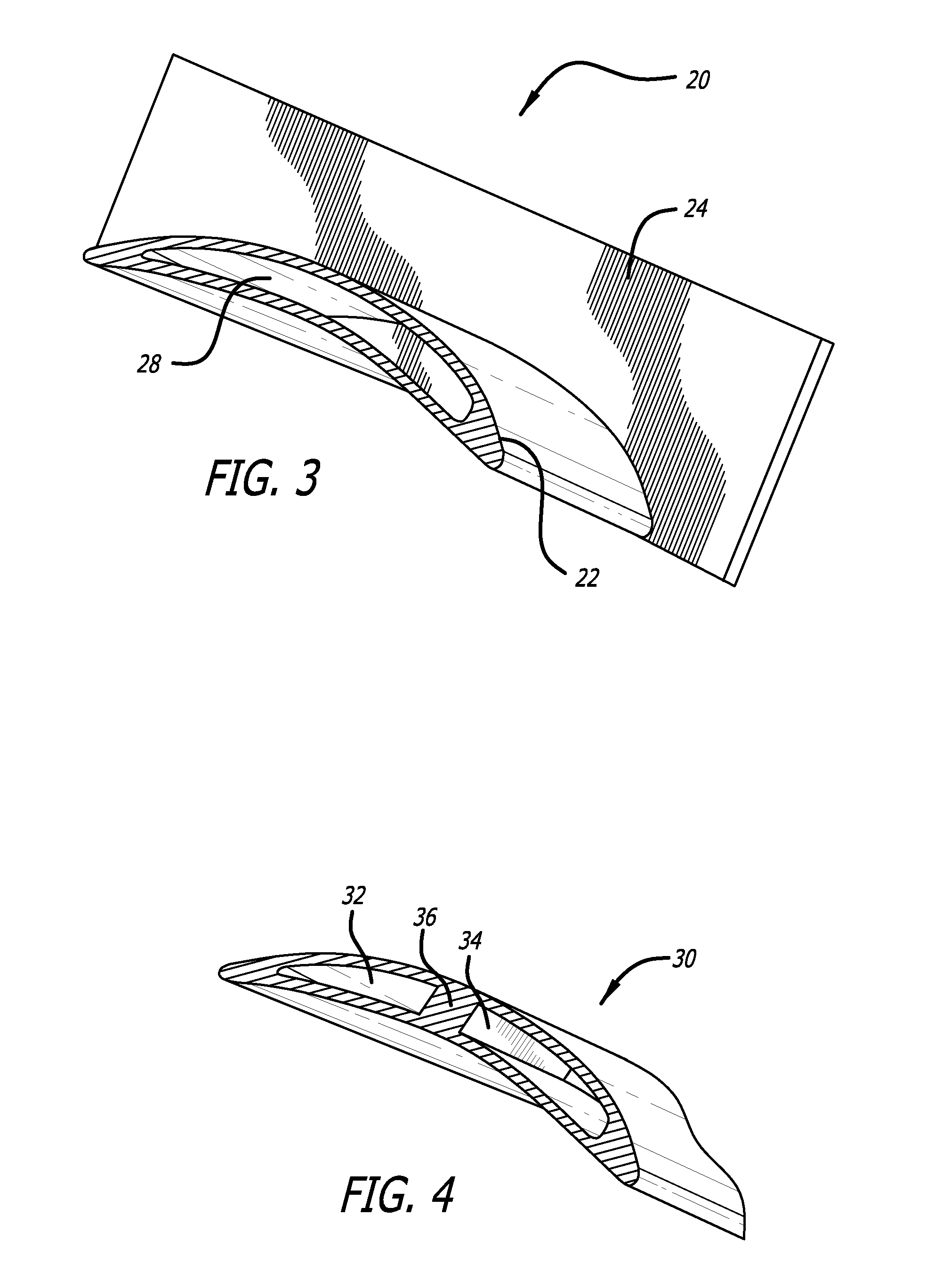

Turbomachine blade, in particular a fan blade, and its method of manufacture

The composite turbomachine blade of the present invention comprises a preform made of yarns or fibers woven in three dimensions and a binder maintaining the relative disposition between the yarns of the preform. Said preform is made up of warp yarns and of weft yarns, the direction of the warp yarns forming the longitudinal direction of the preform. In characteristic manner, said preform comprises at least a first portion made using a first weave forming the airfoil of the blade, and a second portion made using a second weave forming the root of the blade, and the first and second portions are united by a transition zone in which the first weave is progressively modified to end up with the second weave, thereby obtaining a reduction at least in the thickness of the blade between the second portion and the first portion. The invention is applicable to making a fan blade for a turbojet.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

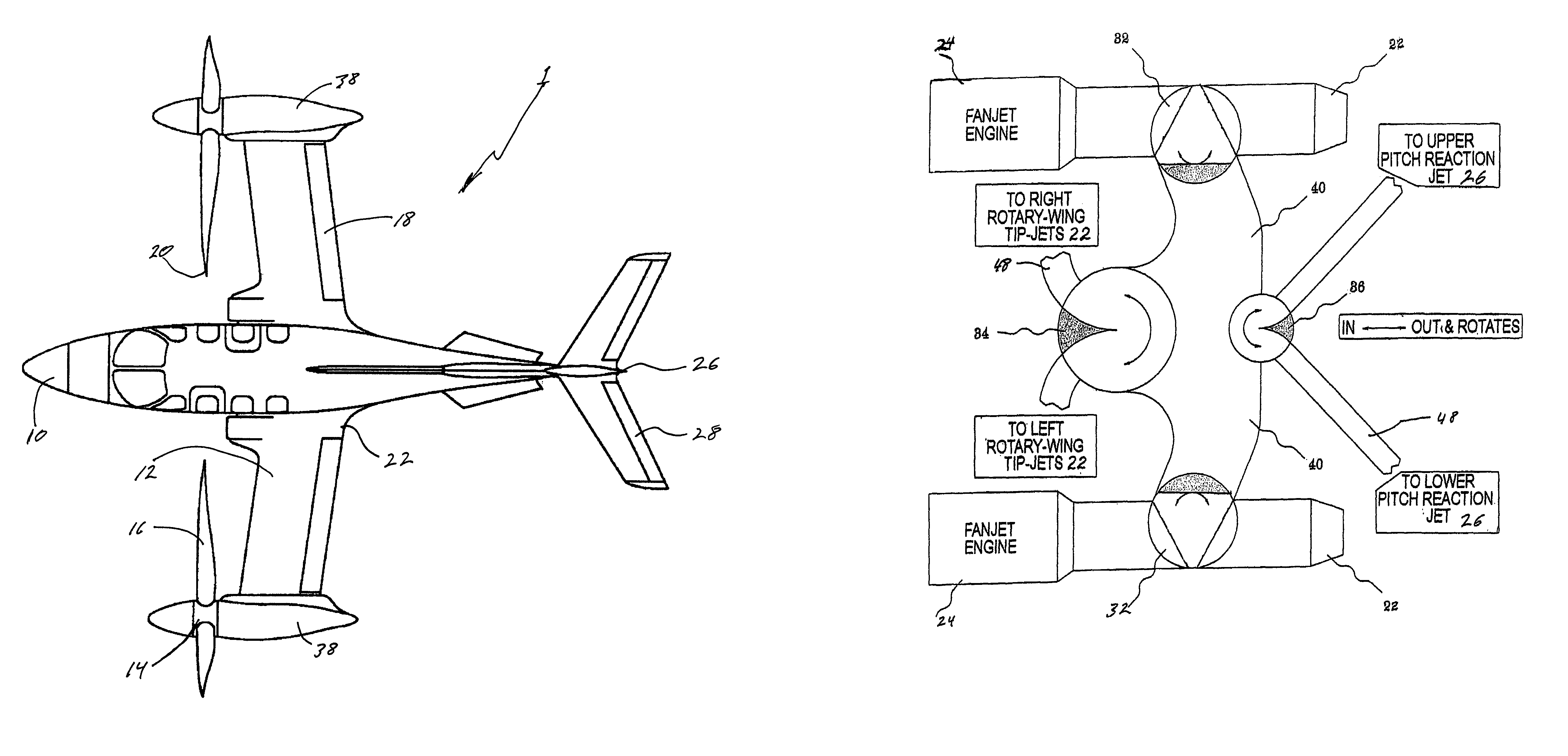

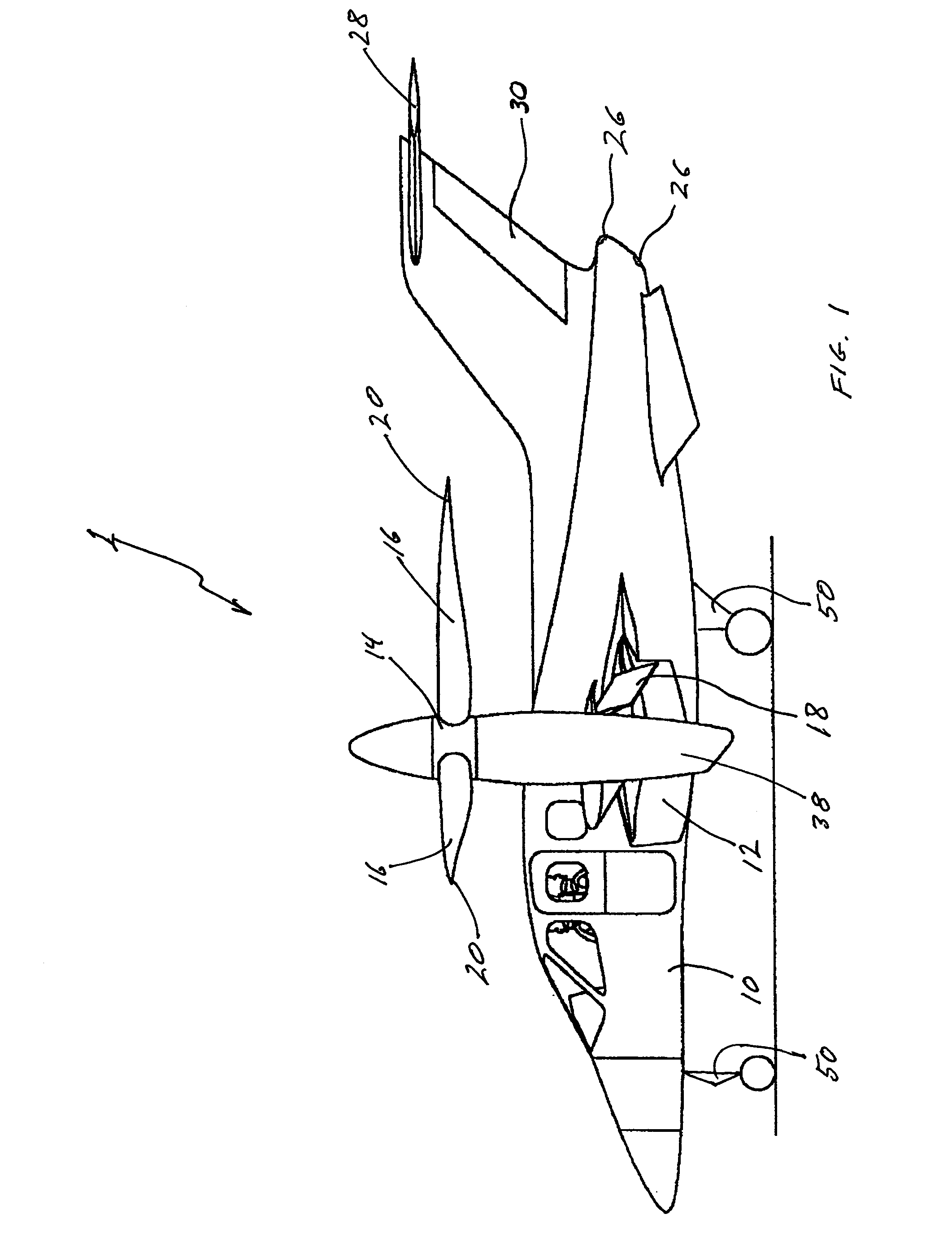

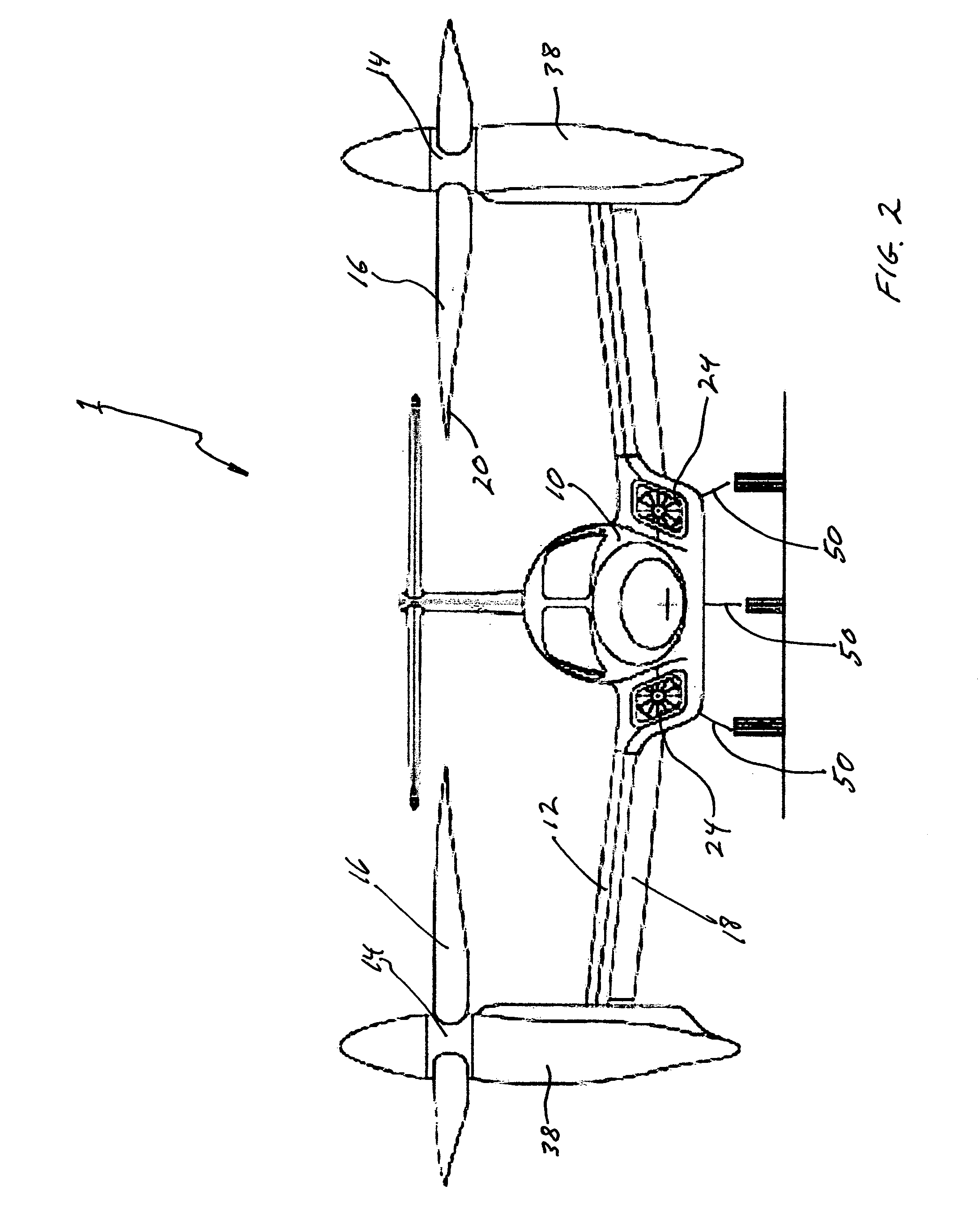

Gas-powered tip-jet-driven tilt-rotor compound VTOL aircraft

ActiveUS7147182B1Easily take over powering of both rotorLarge thrust augmentation ratioPropellersPump componentsJet engineControl power

A tilt-rotor compound VTOL aircraft has a multiple-flow thrust generator(s) comprising a gas-powered tip-jet driven rotor(s) having a thrust-augmentation ratio of at least two; that tilts about the aircraft's pitch axis wherein the rotor's plane of rotation is substantially horizontal for VTOL operations and the rotor's plane of rotation is substantially vertical forward flight operations. A relatively small fixed-wing sustains the aircraft during forward flight. Compressed exhaust gas from the fan-jet engine(s) is ducted to a manifold having valves which control power to the multiple-flow thrust generator(s) and to the jet exhaust nozzle(s) as supplemental thrust for forward propulsion and yaw control. The manifold also serves to distribute compressed gas to the dead engine side of the aircraft in the event of a dead engine emergency, and to reaction jets for attitude control during VTOL operations. Thus this tilt-rotor aircraft is more efficient, faster, immensely lighter, less complex and less expensive to purchase and maintain than its shaft-driven counterparts.

Owner:FLANIGAN KENNETH WARREN

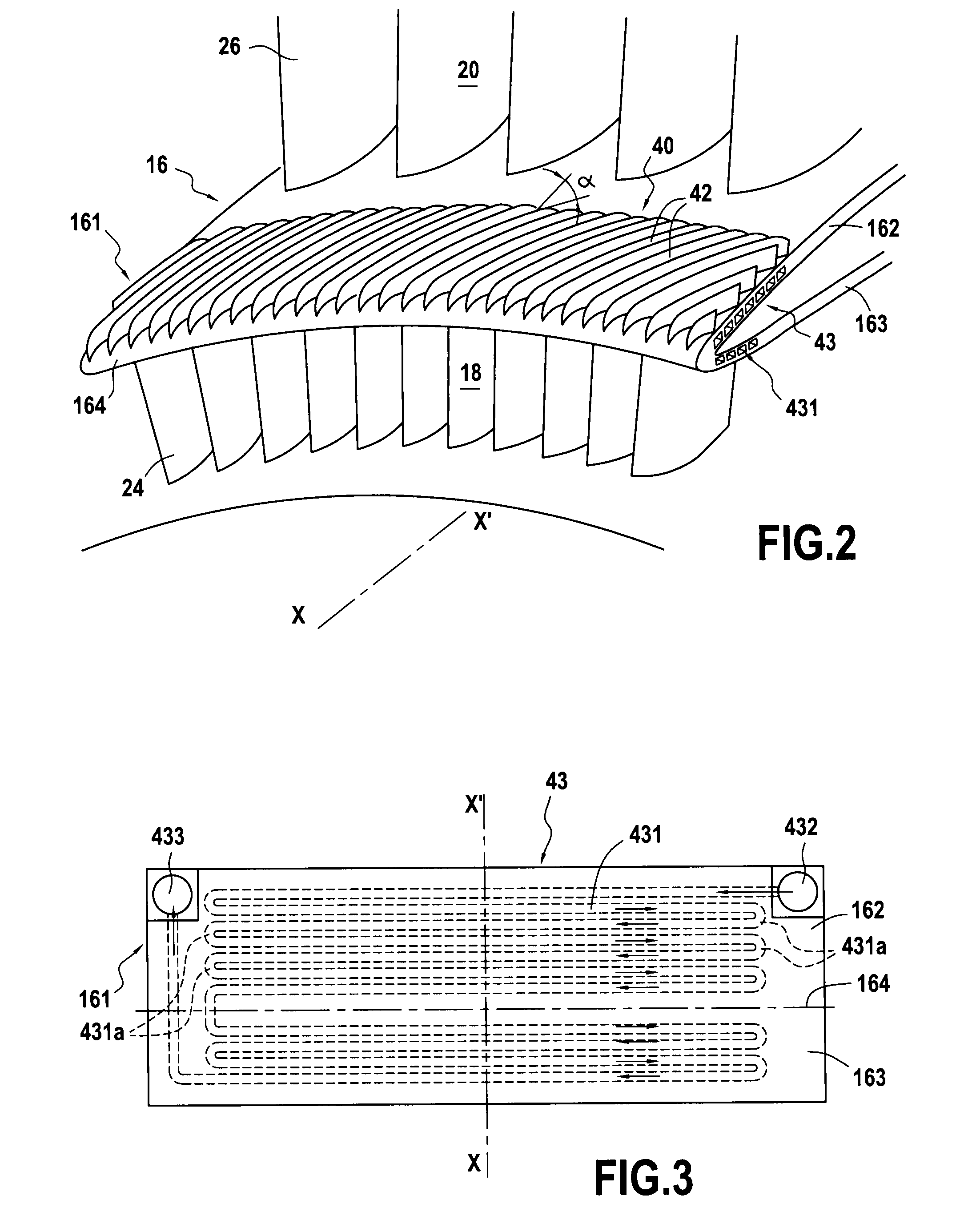

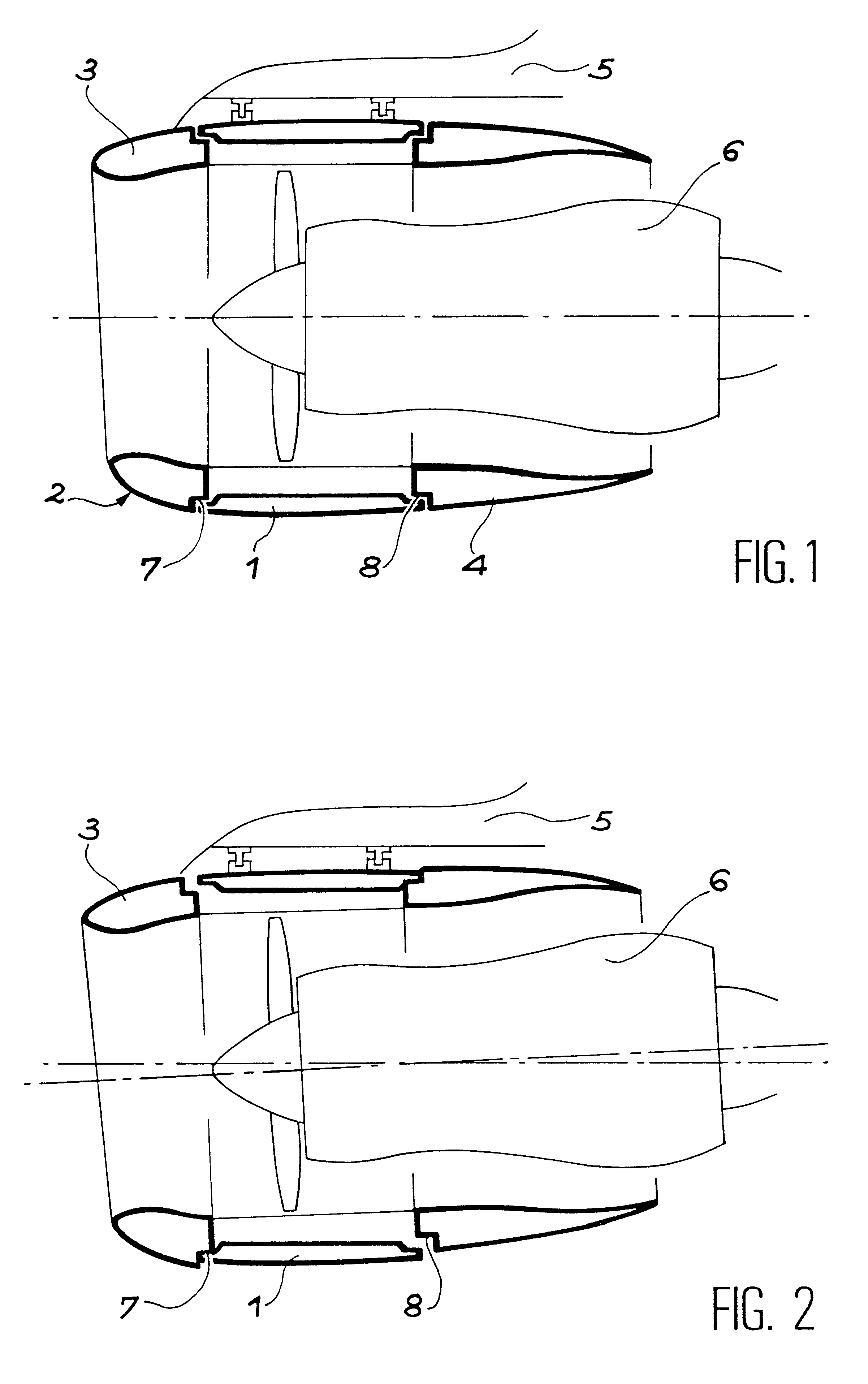

Air-oil heat exchanger placed at the location of the air separator nose of a turbojet, and a turbojet including such an air-oil heat exchanger

InactiveUS20090165995A1Prevent freezingWithout significantly disturbing the air streamExhaust apparatusTurbine/propulsion engine coolingLeading edgeJet engine

The invention relates to an air-oil heat exchanger located at the inner shroud of the secondary duct of a turbojet. In characteristic manner, it comprises an oil circuit placed inside the separator nose and fins placed outside the top wall of the separator nose, between the leading edge of the separator nose and the outlet guide vanes.

Owner:TECHSPACE AERO

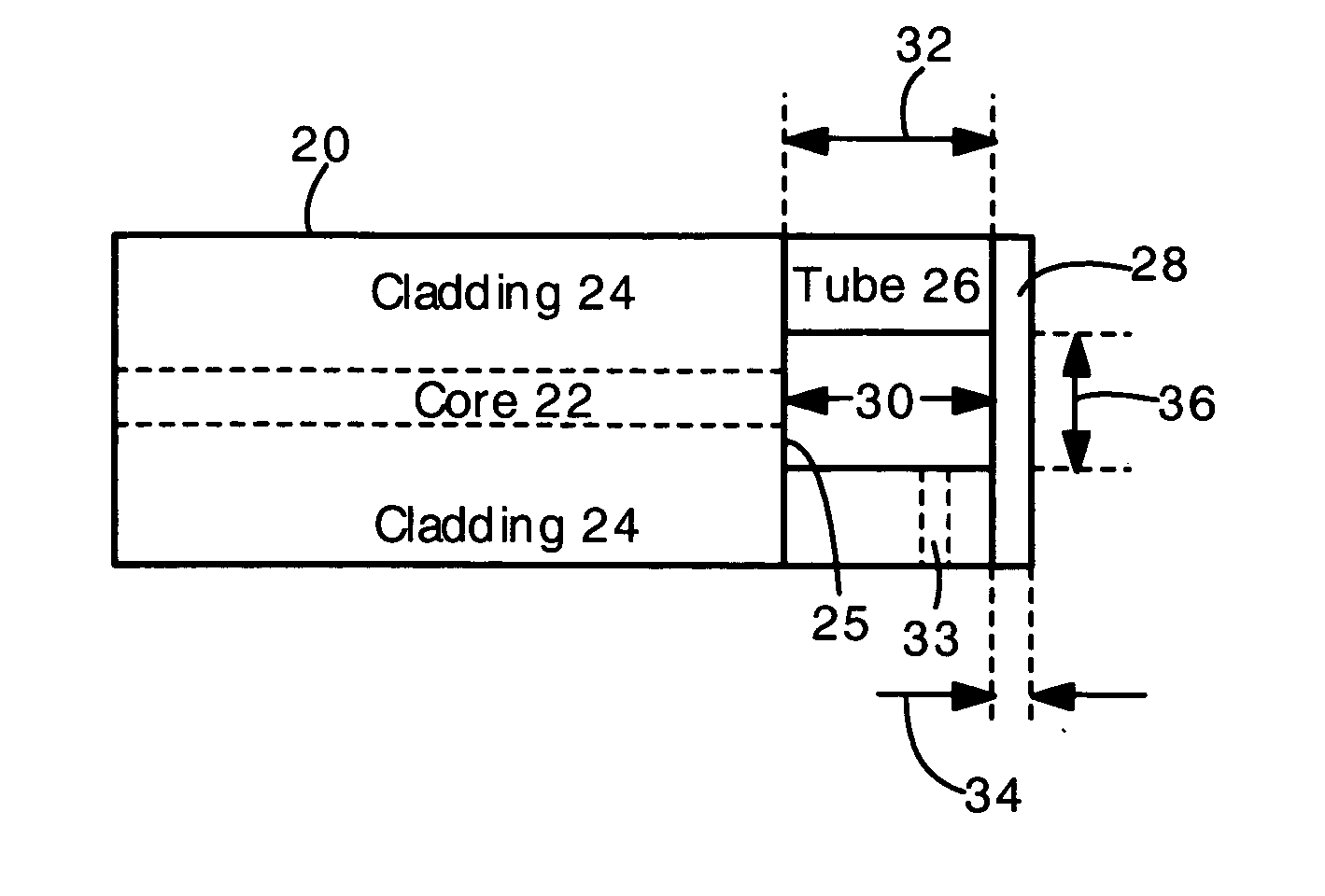

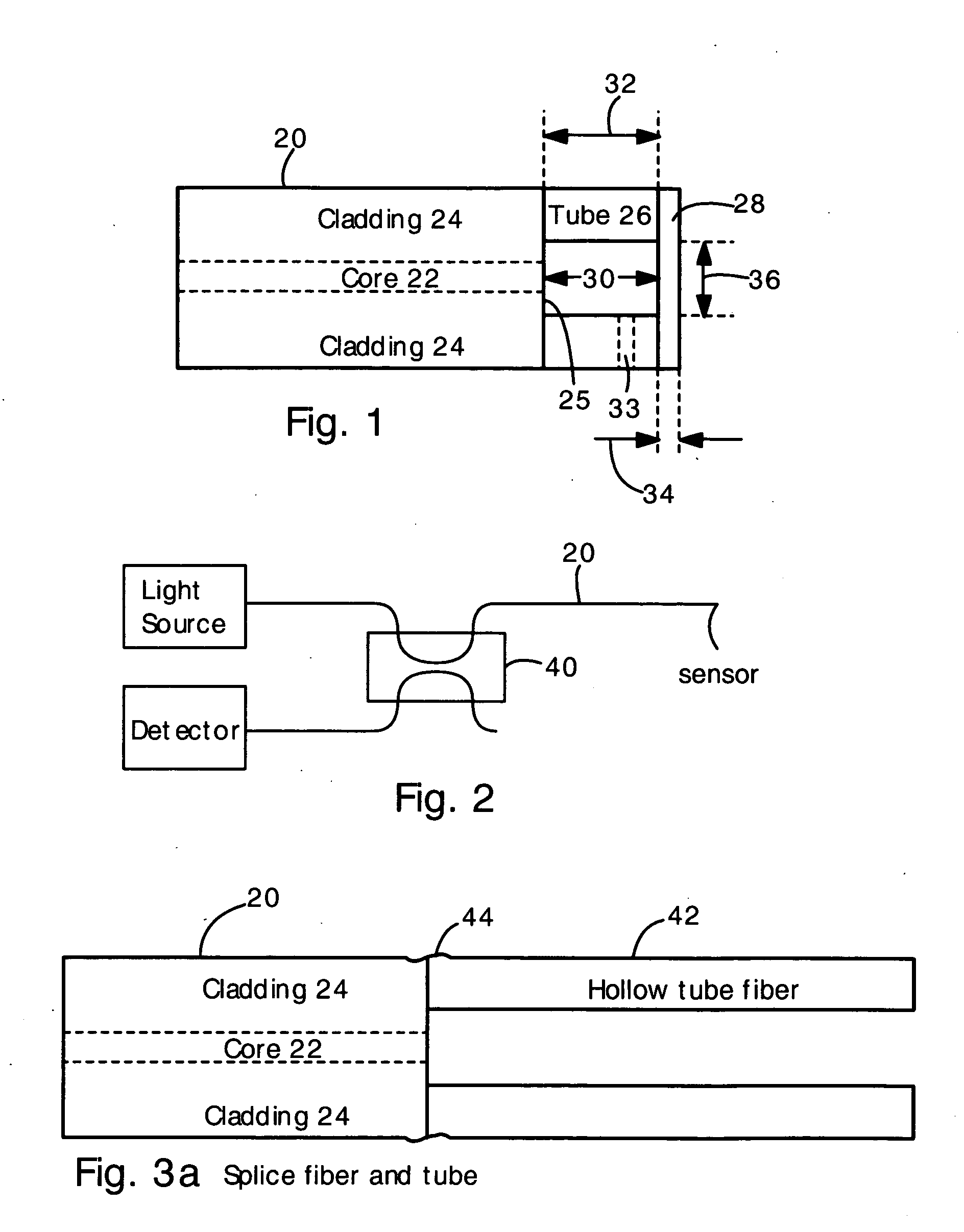

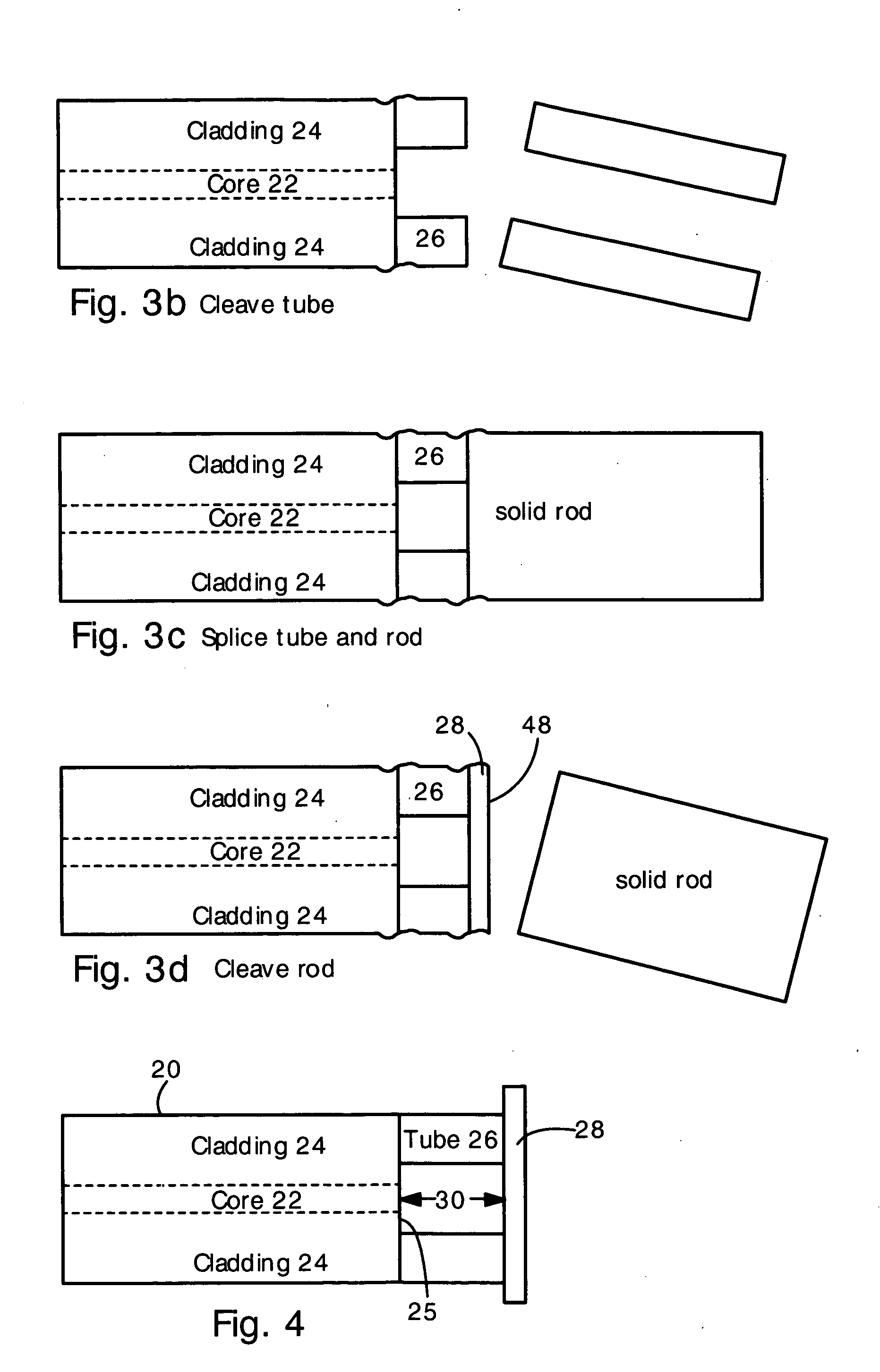

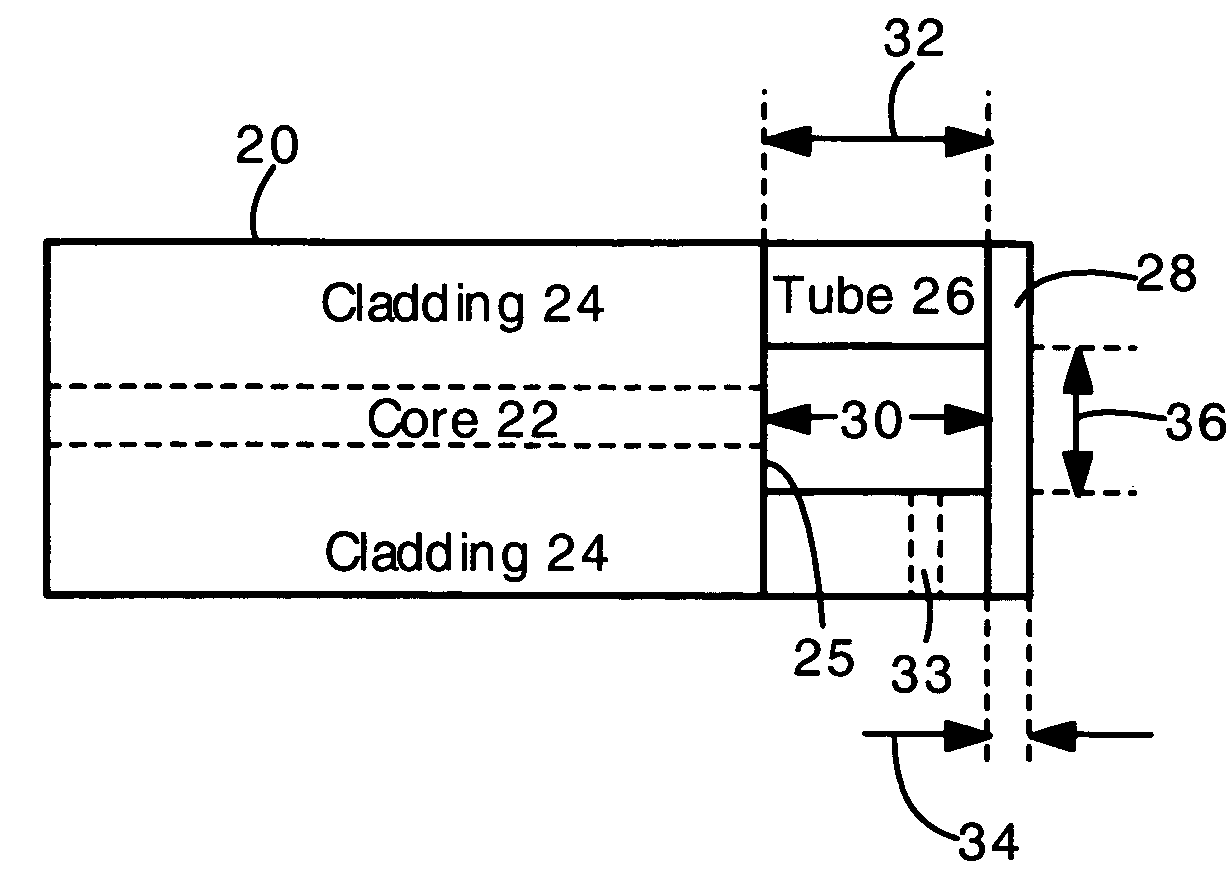

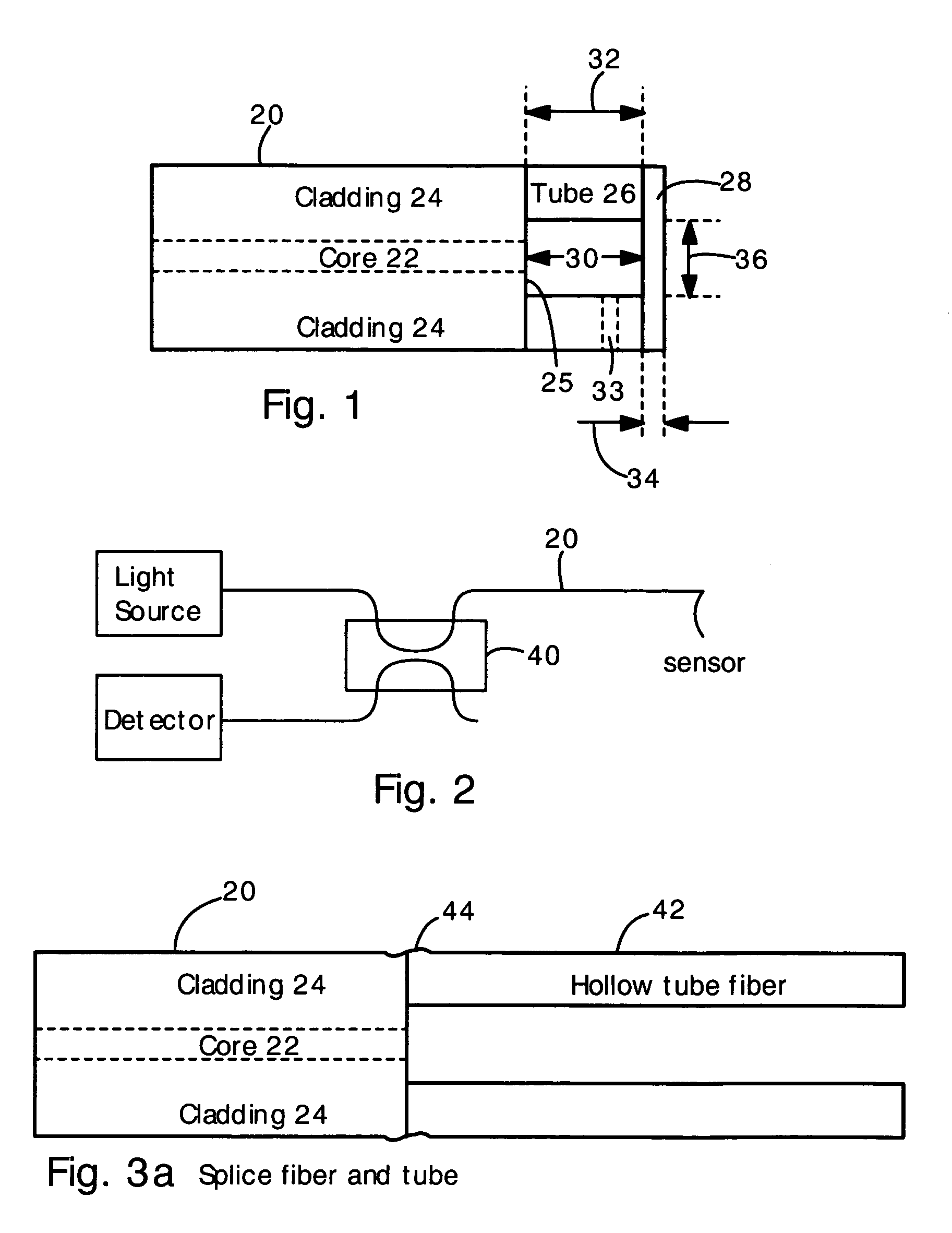

Optical fiber pressure and acceleration sensor fabricated on a fiber endface

InactiveUS20050062979A1Subsonic/sonic/ultrasonic wave measurementFluid pressure measurement by electric/magnetic elementsJet engineClassical mechanics

A fiber optic sensor has a hollow tube bonded to the endface of an optical fiber, and a diaphragm bonded to the hollow tube. The fiber endface and diaphragm comprise an etalon cavity. The length of the etalon cavity changes when applied pressure or acceleration flexes the diaphragm. The entire structure can be made of fused silica. The fiber, tube, and diaphragm can be bonded with a fusion splice. The present sensor is particularly well suited for measuring pressure or acceleration in high temperature, high pressure and corrosive environments (e.g., oil well downholes and jet engines). The present sensors are also suitable for use in biological and medical applications.

Owner:VIRGINIA TECH INTPROP INC

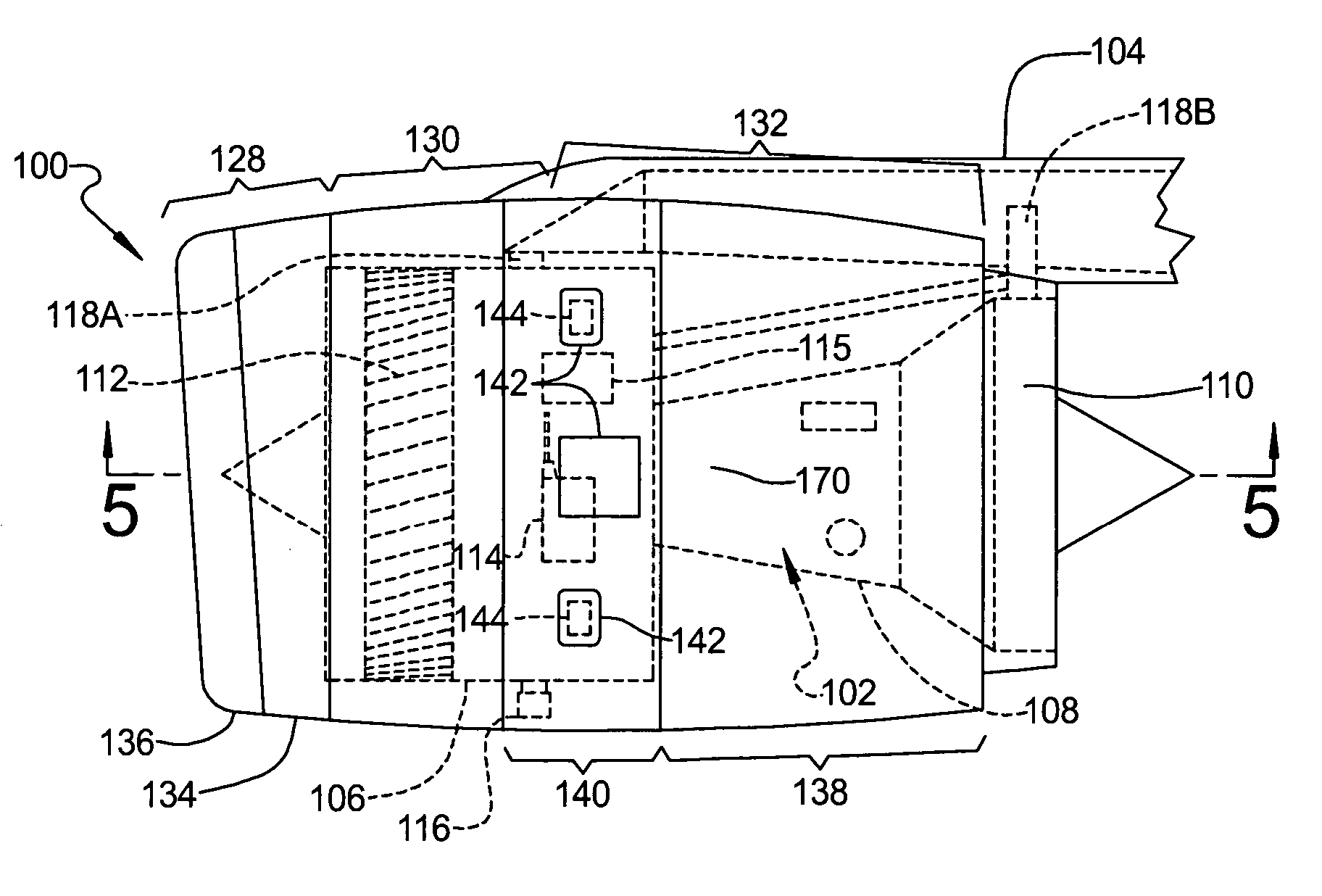

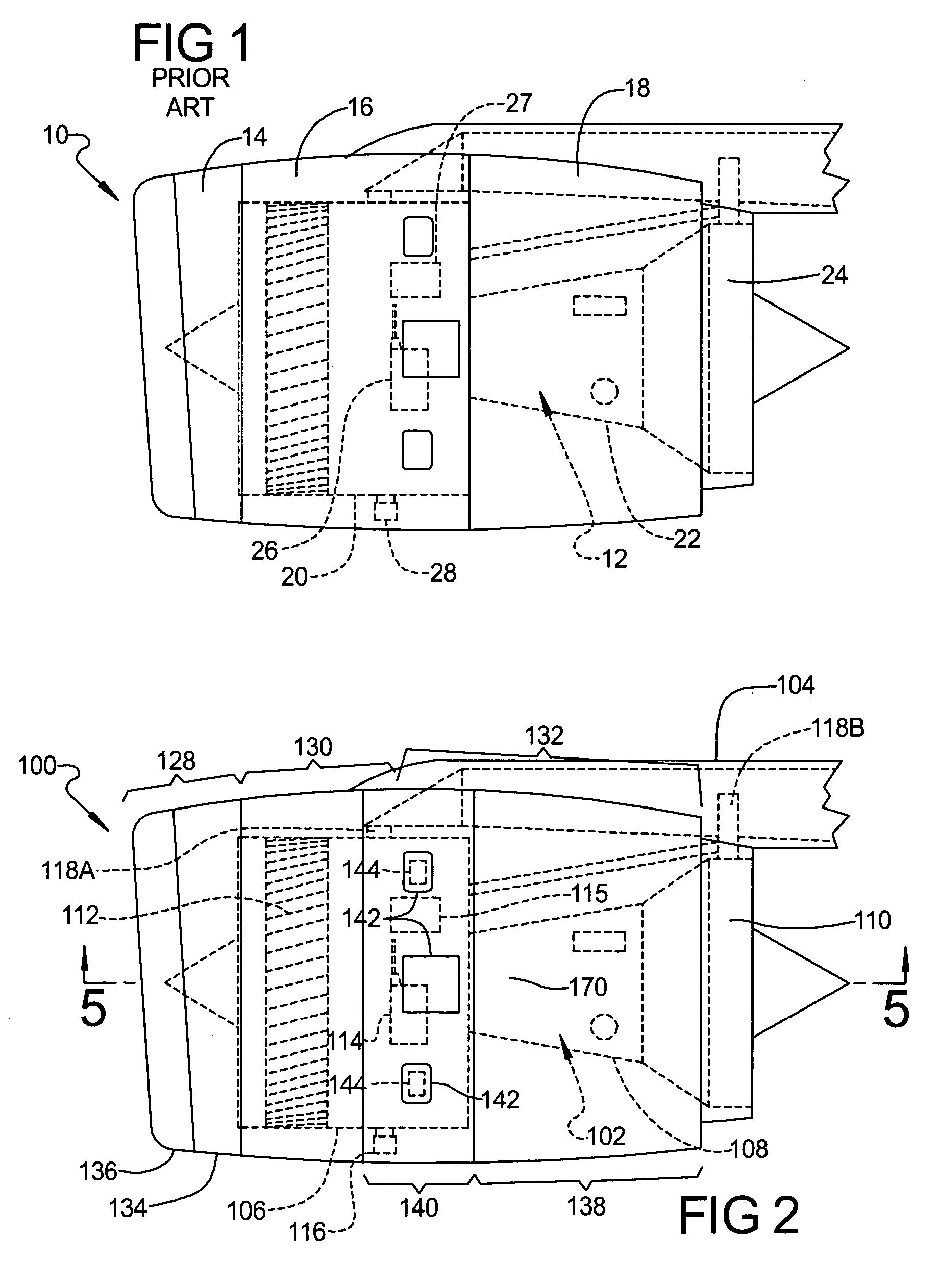

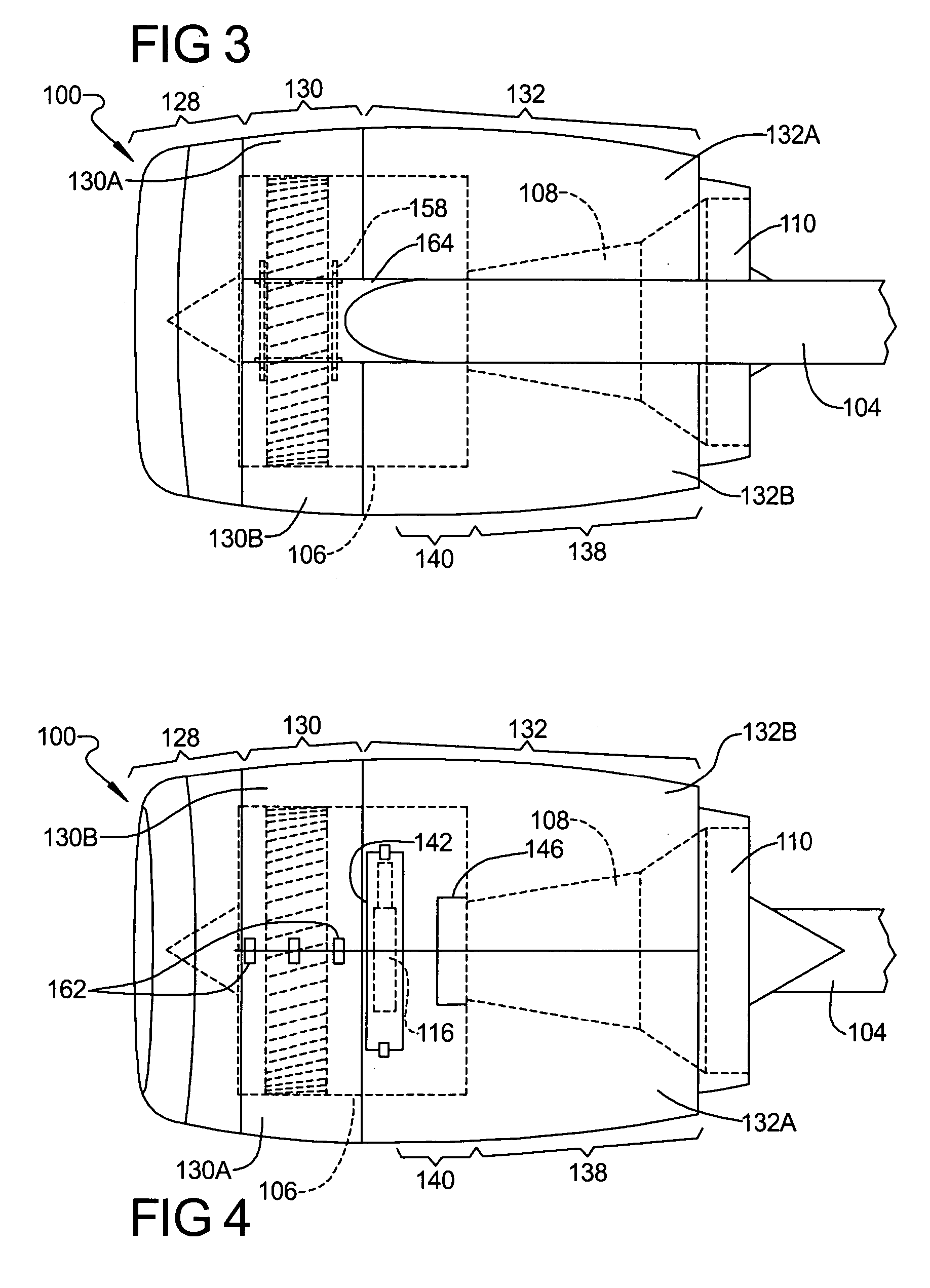

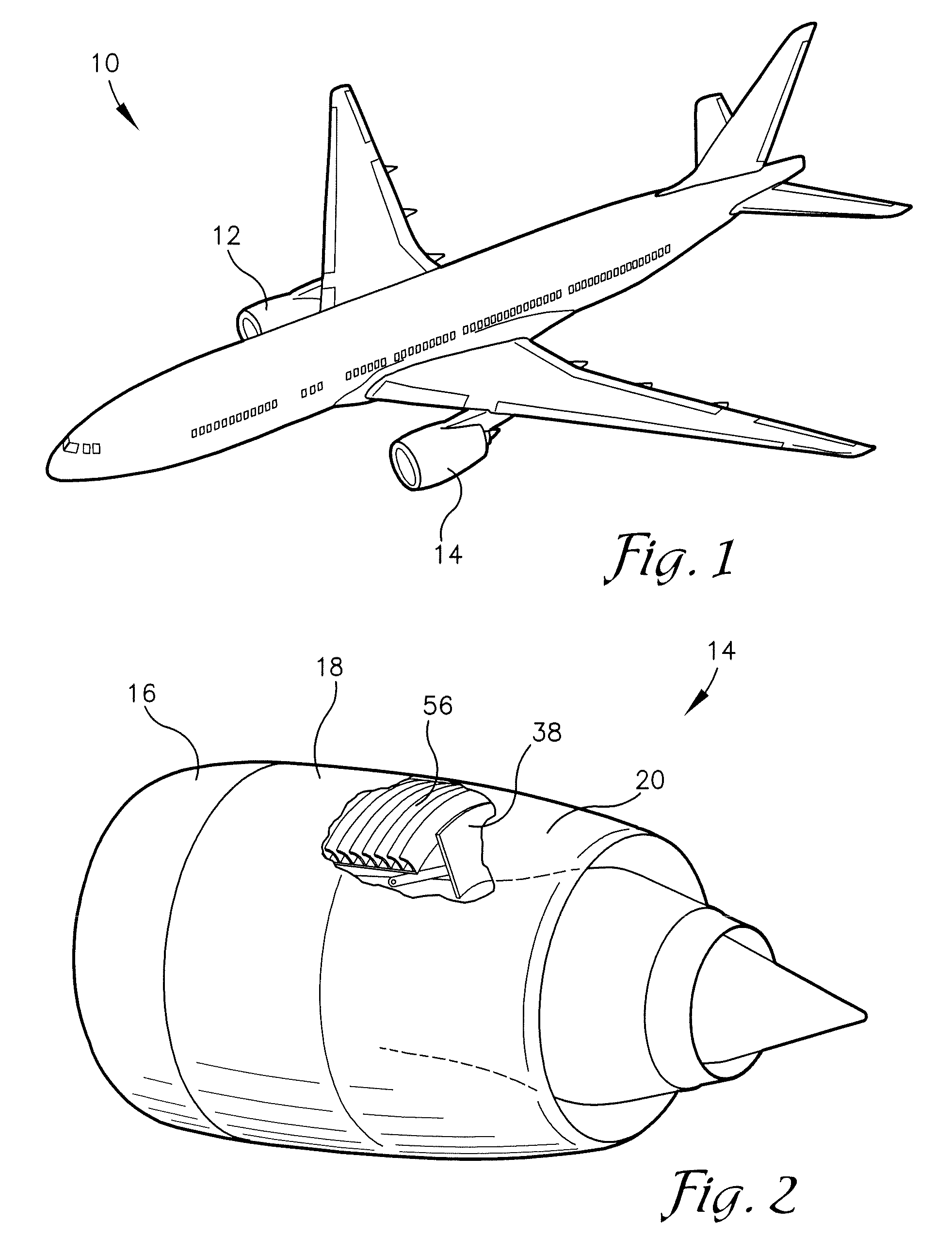

Fan cowl door elimination

InactiveUS20060145001A1Improve fuel efficiencyReduce weightPower plant exhaust arrangementsPower plant inspection panelsNacelleJet engine

A nacelle for housing an aircraft jet engine. The jet engine has a fan case and a portion disposed downstream of the fan case relative to a direction of airflow through the jet engine. The nacelle comprises an inlet for receiving airflow, a fan cowl panel for covering a forward portion of the fan case, and a thrust reverser having a longitudinal length sufficient to cover the downstream portion of the jet engine in addition to a rearward portion of the fan case. Opening the thrust reverser enables access to an entire area formed by the downstream portion as well as the rearward portion of the fan case.

Owner:THE BOEING CO

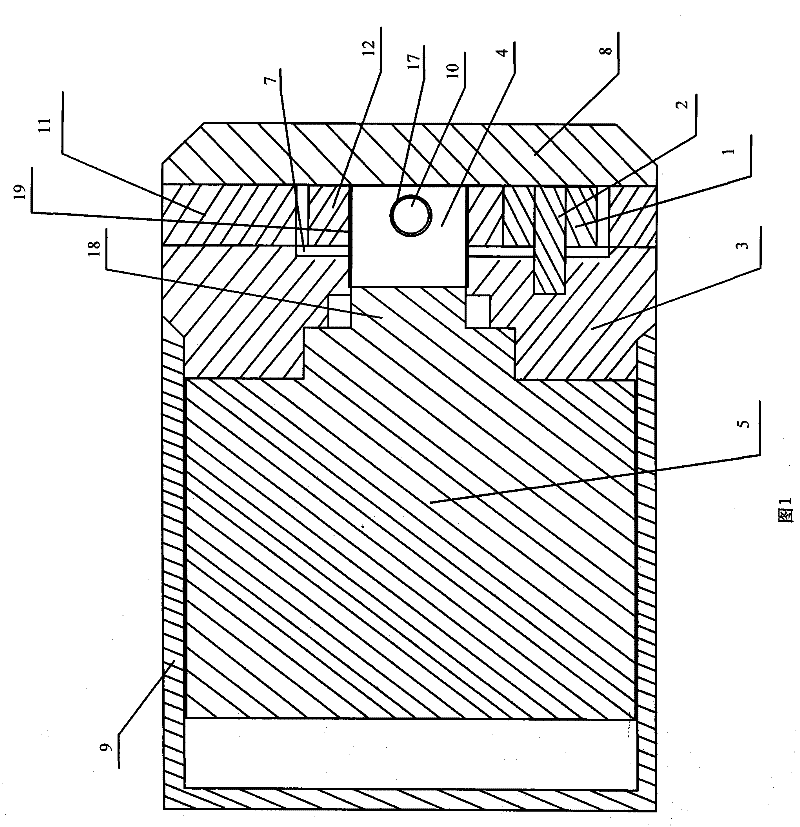

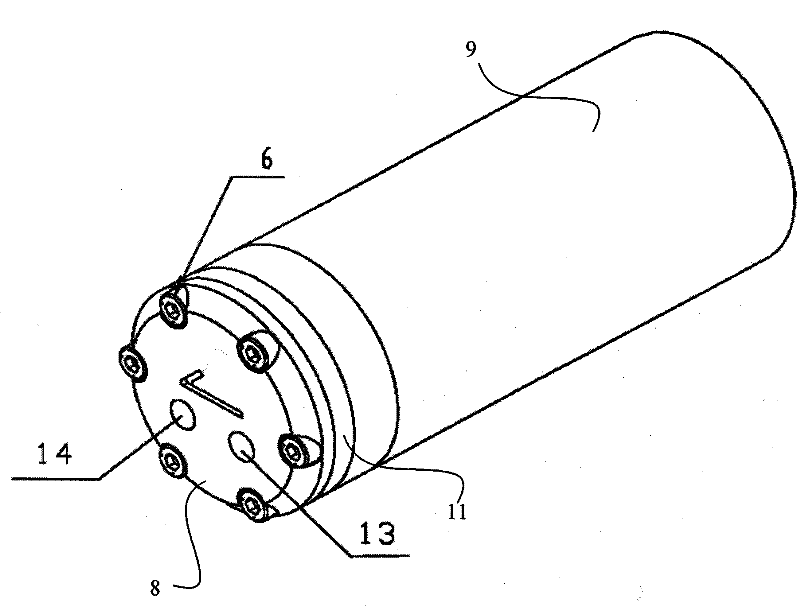

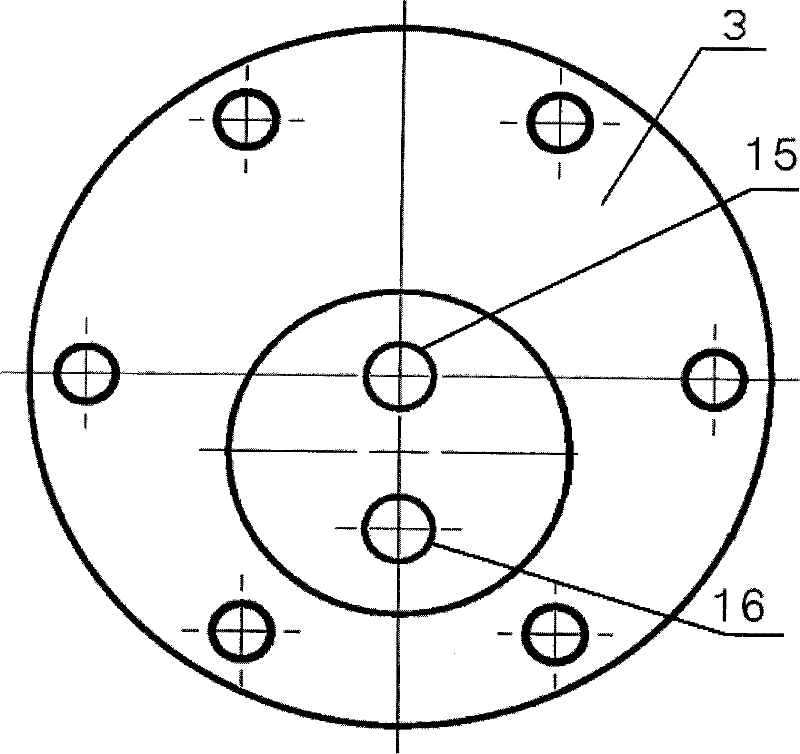

Gear pump for micro-miniature turbojet engine

ActiveCN101403382BReduce weightReduce leakageRotary piston pumpsRotary piston liquid enginesMicrocontrollerJet engine

The invention discloses a gear pump used for a microminiature turbo-jet engine, comprising a direct current motor, a pump body, an upper pump cover, a lower pump cover, a shell, a pair of driving and driven gears which are meshed and a driving shaft and a driven shaft. The driving gear is arranged on the driving shaft; the driven gear is arranged on the driven shaft and is aligned and meshed withthe driving gear; the lower pump cover is fixed on the direct current motor, the upper pump cover is connected to the lower pump cover and the plane of the pump body is pressed tightly and sealed so as to lead the structure to be simple; the shell is sleeved at the outside of the lower pump cover; the driving gear and the driving shaft adopt a method of combining clearance fit and a transmission pin to eliminate the installation error of an output shaft of the direct current motor; and an antifriction material is embedded at the positions on the lower pump cover and the upper pump cover corresponding to the driving gear and the driven gear so as to increase the reliability and durability of the gear pump. Most parts of the gear pump adopt aluminium alloy so as to reduce the weight furthest. The gear pump can control the rotating speed of the direct current motor by pulse-width modulation of a single-chip microcontroller and control the flow rate of the gear pump precisely.

Owner:北京领动国创科技有限公司

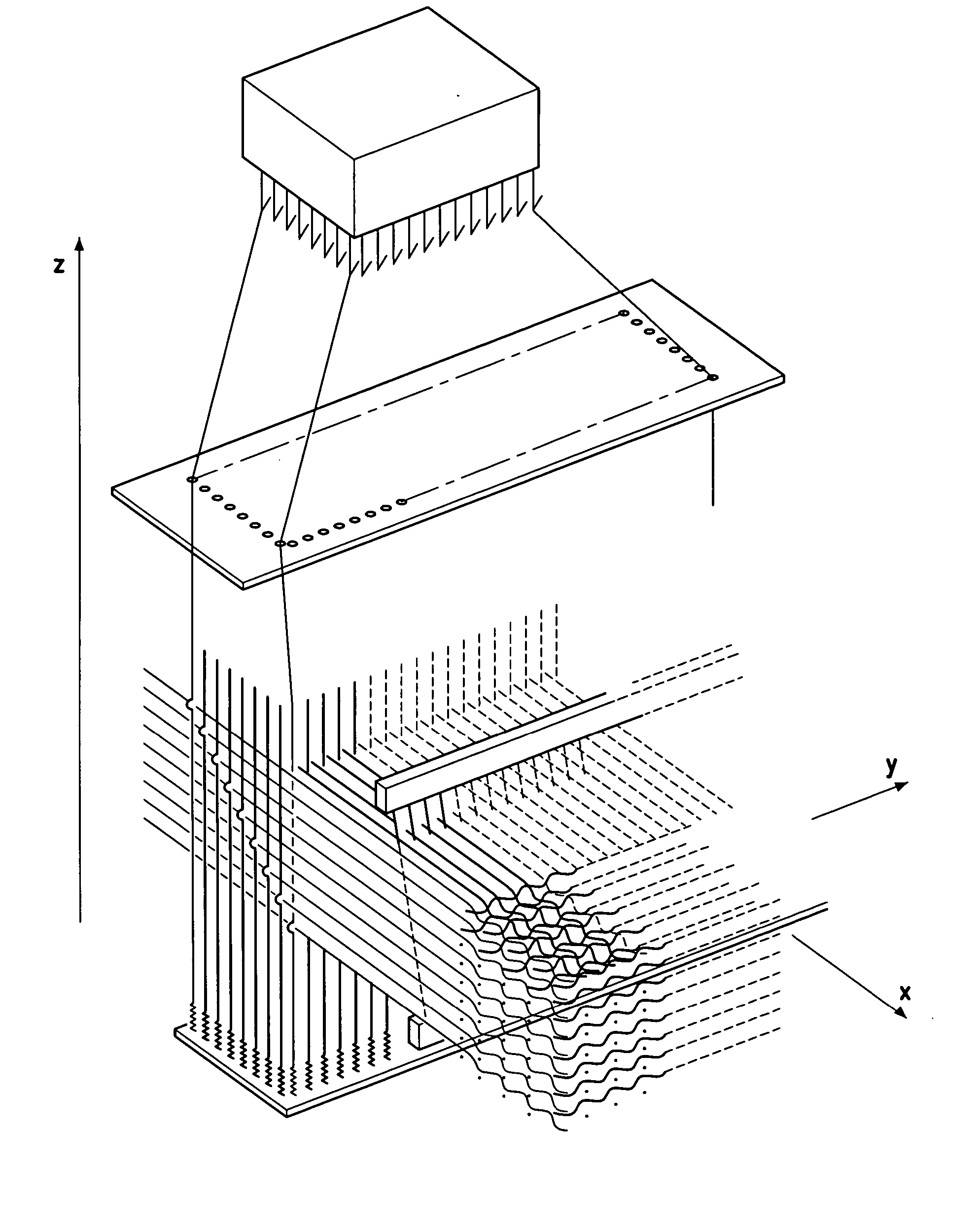

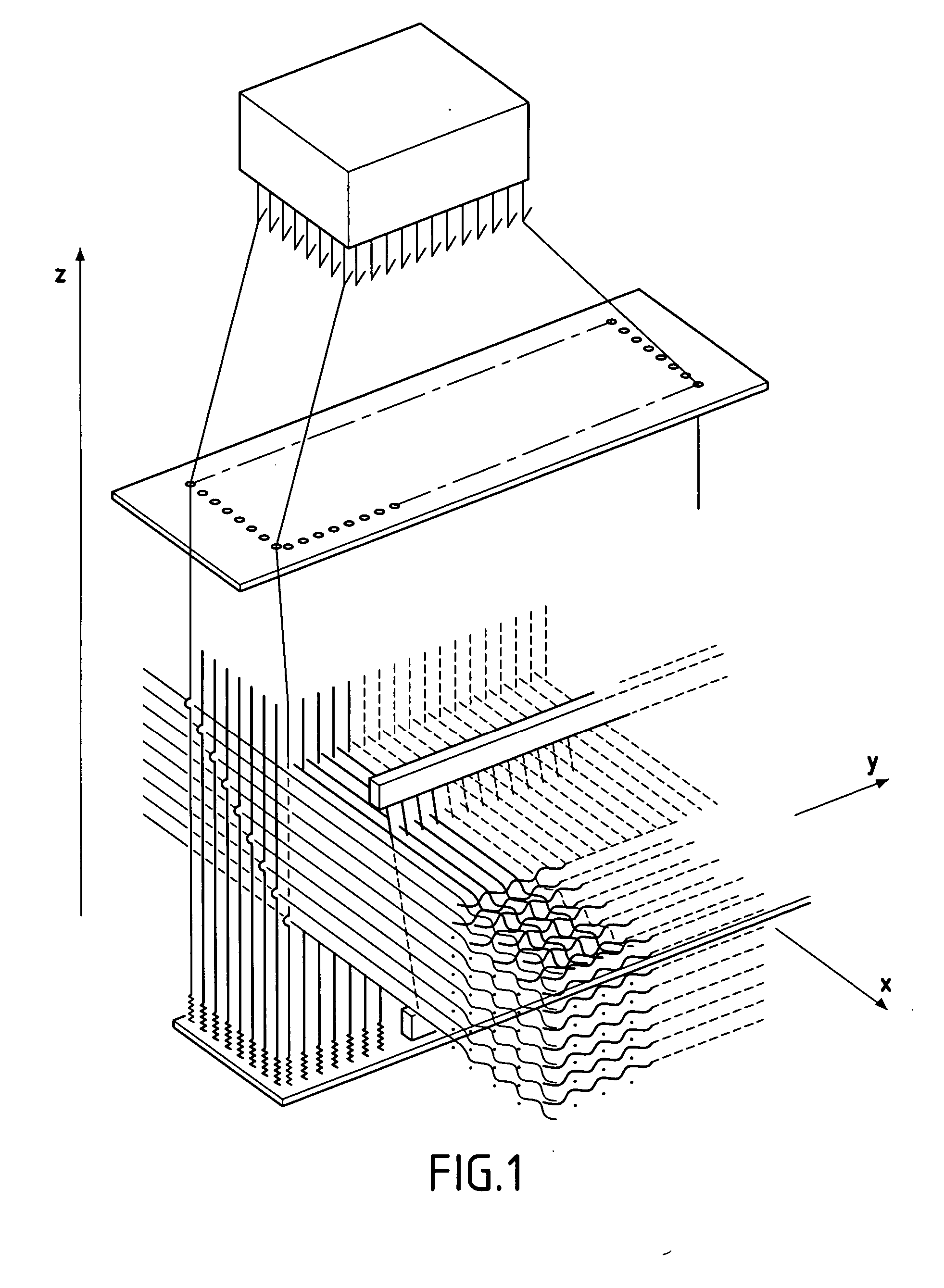

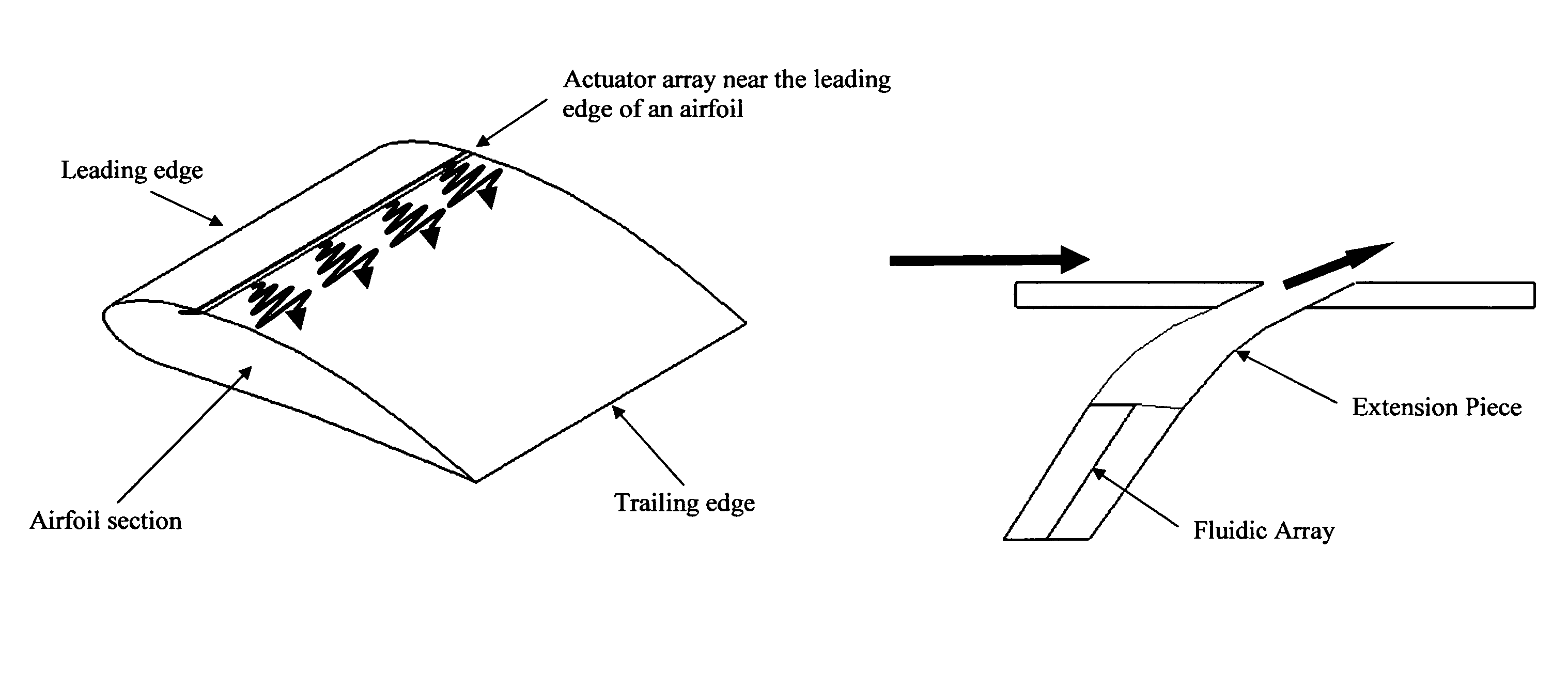

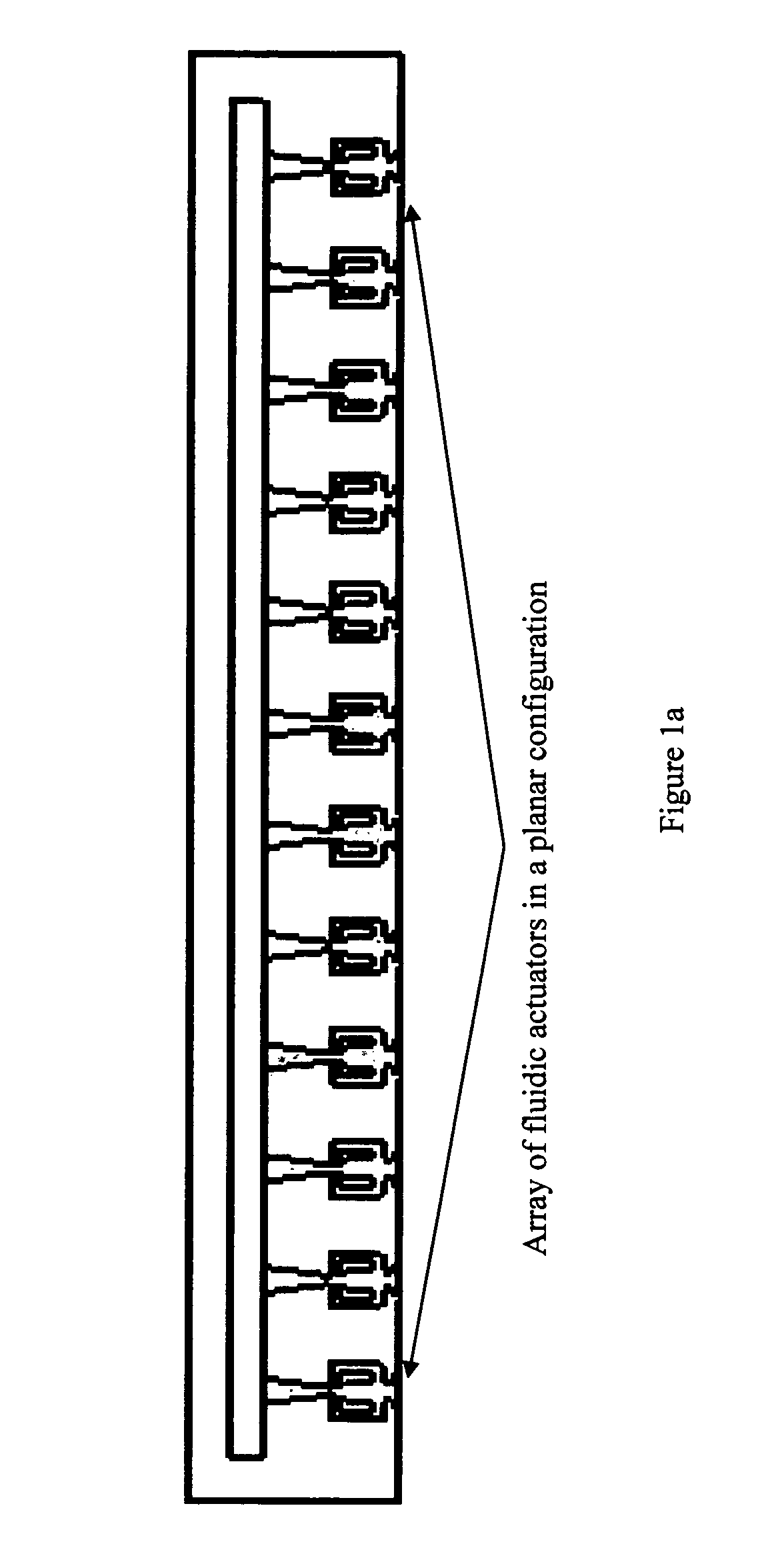

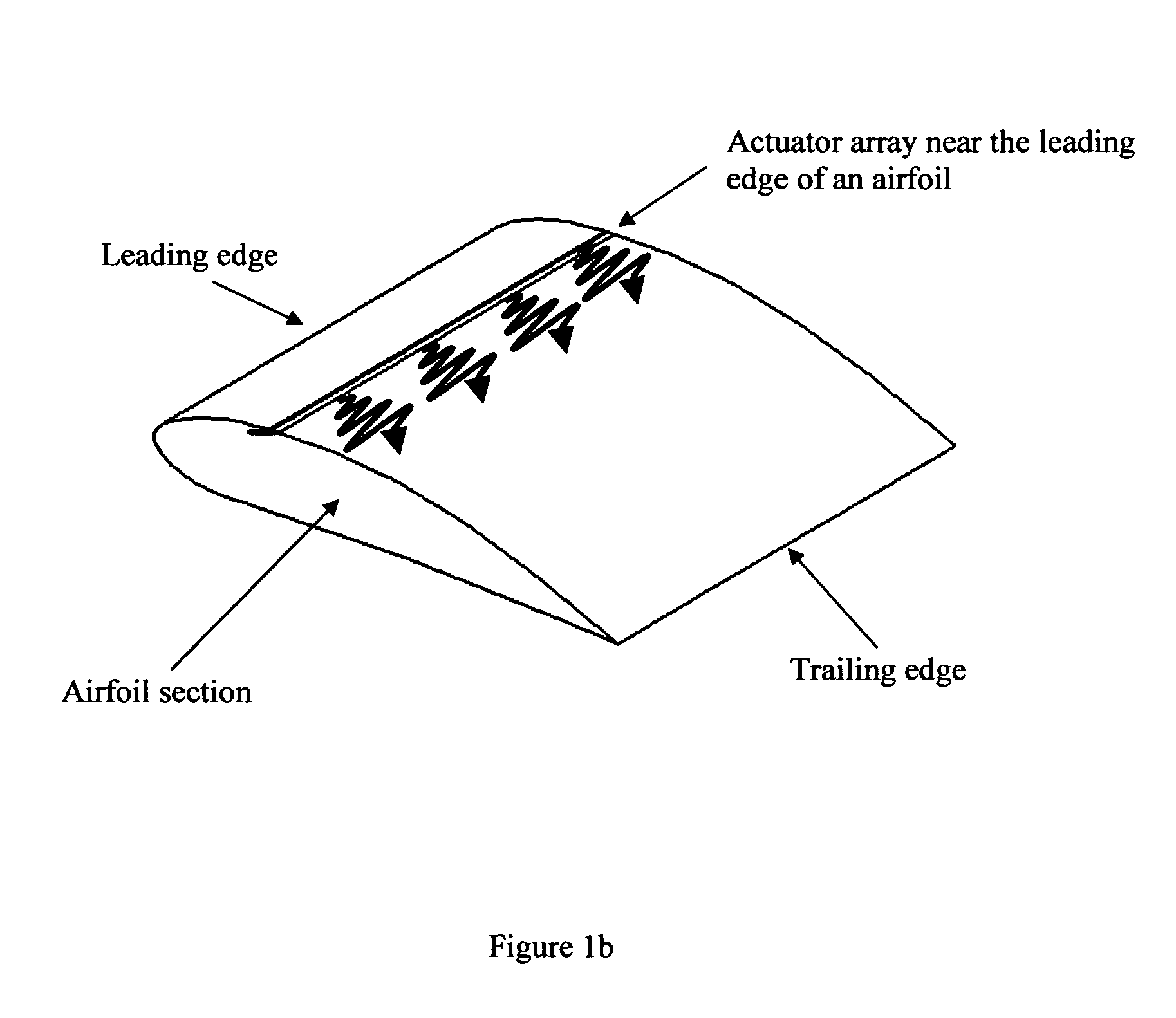

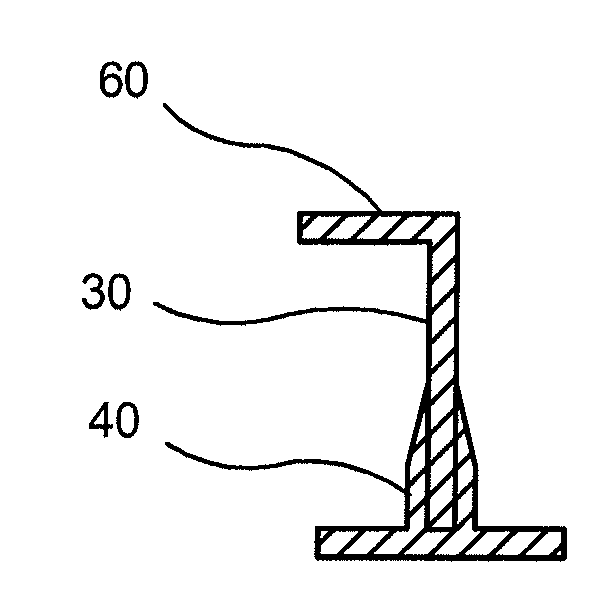

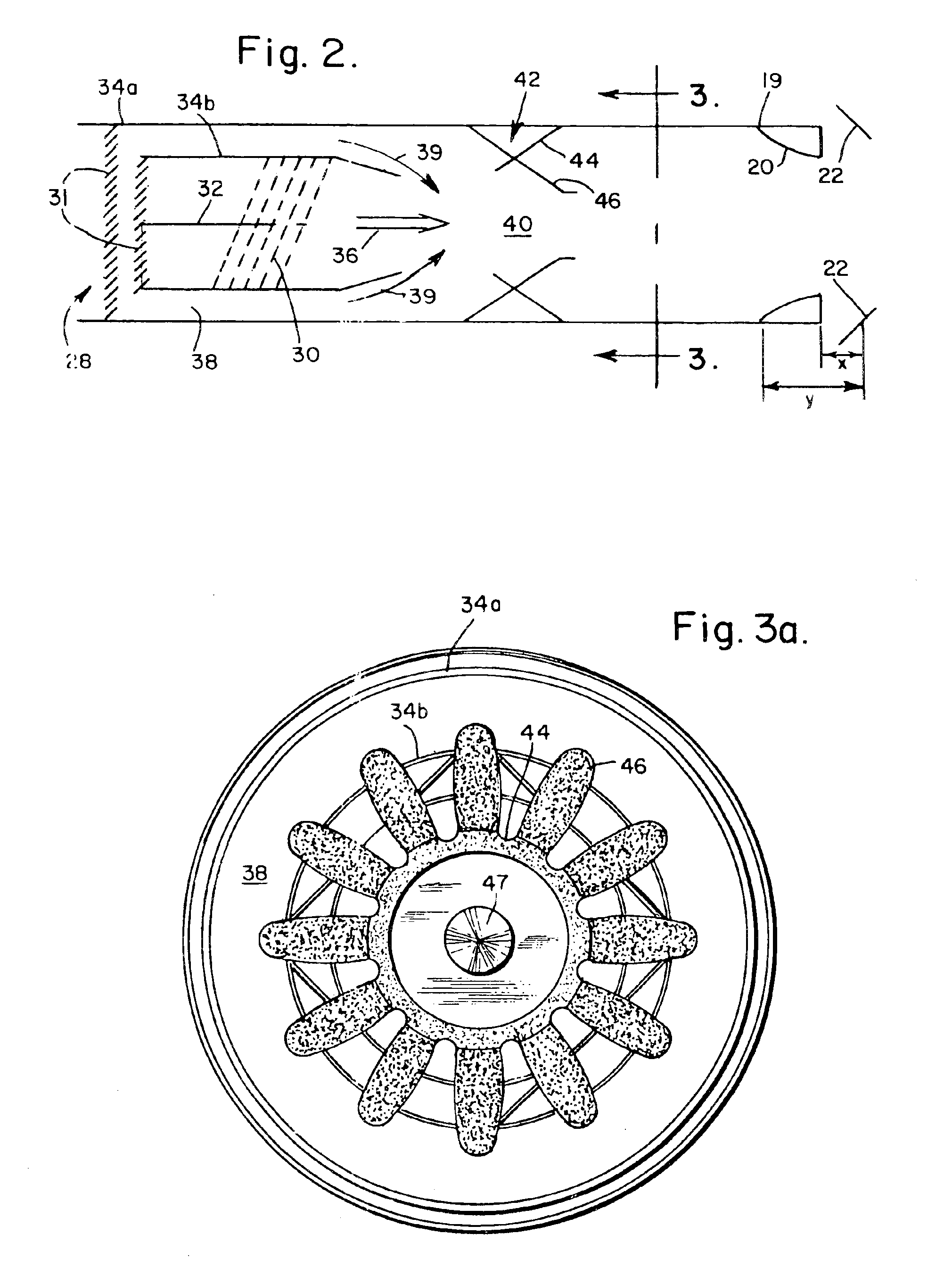

Method and apparatus for aerodynamic flow control using compact high-frequency fluidic actuator arrays

ActiveUS8382043B1Even air distributionAvoid separationBoundary layer controlsWingsJet engineEngineering

The present invention is directed to the manufacture of and the use of an aerodynamic flow control device having a compact array of a plurality of fluidic actuators in planar, curved, circular and annular configurations. The compact array of fluidic actuators of the invention may be designed to produce oscillating or pulsed jets at the exit ports with frequencies in the range of 1-22 kHz. They may be integrally manufactured along with the wing sections, flaps, tail and rudder of airplane, the inlet or exit geometries of a jet engine. When supplied with a source of fluid such as air, these arrays of actuators produce a set of fluid jets of random phase of high velocity and influence the main stream of air over the subject surface. The beneficial effects of modifying flow using the present invention include increased lift, reduced drag, improved performance and noise reduction in jet engines.

Owner:RAGHU SURYA

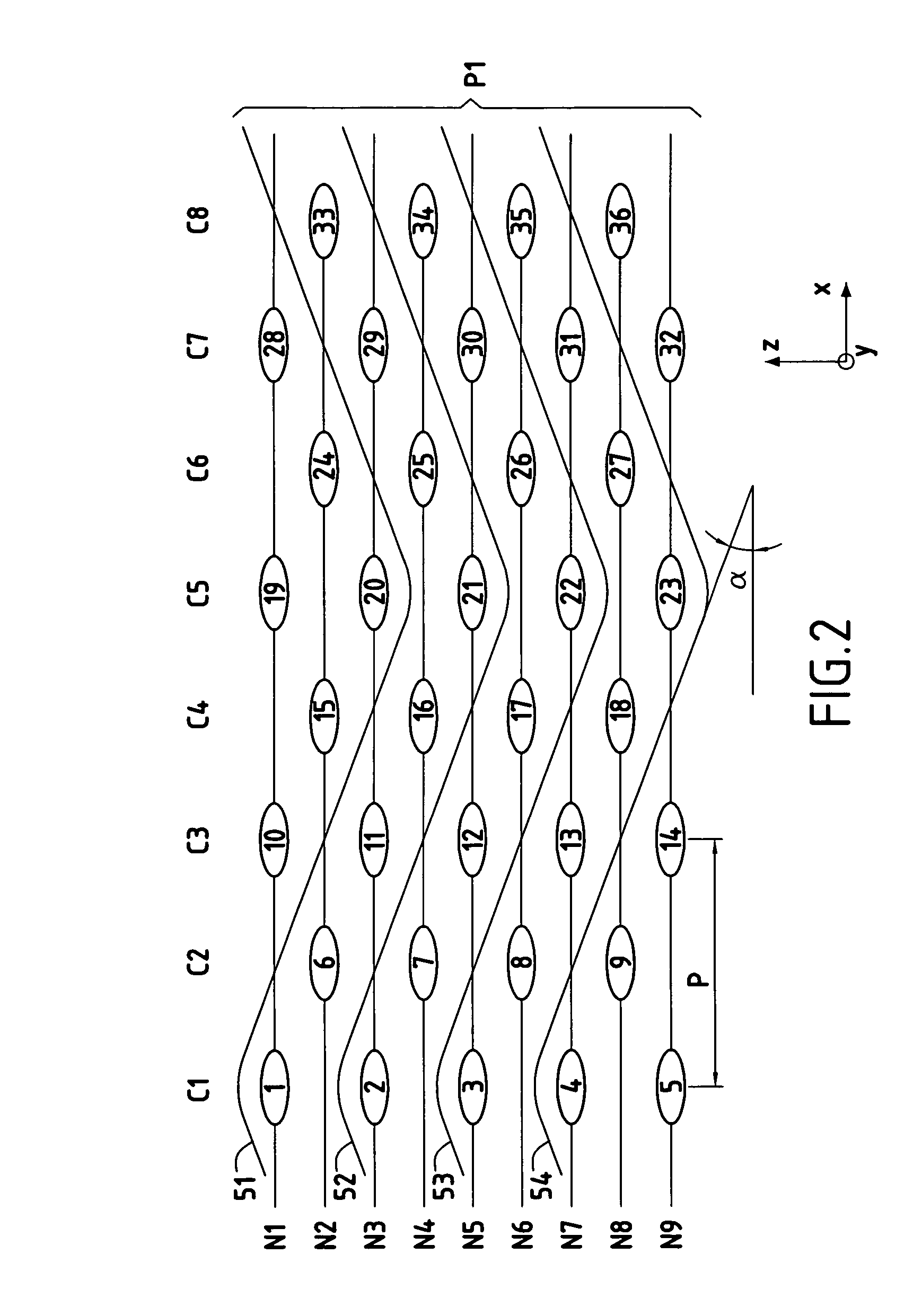

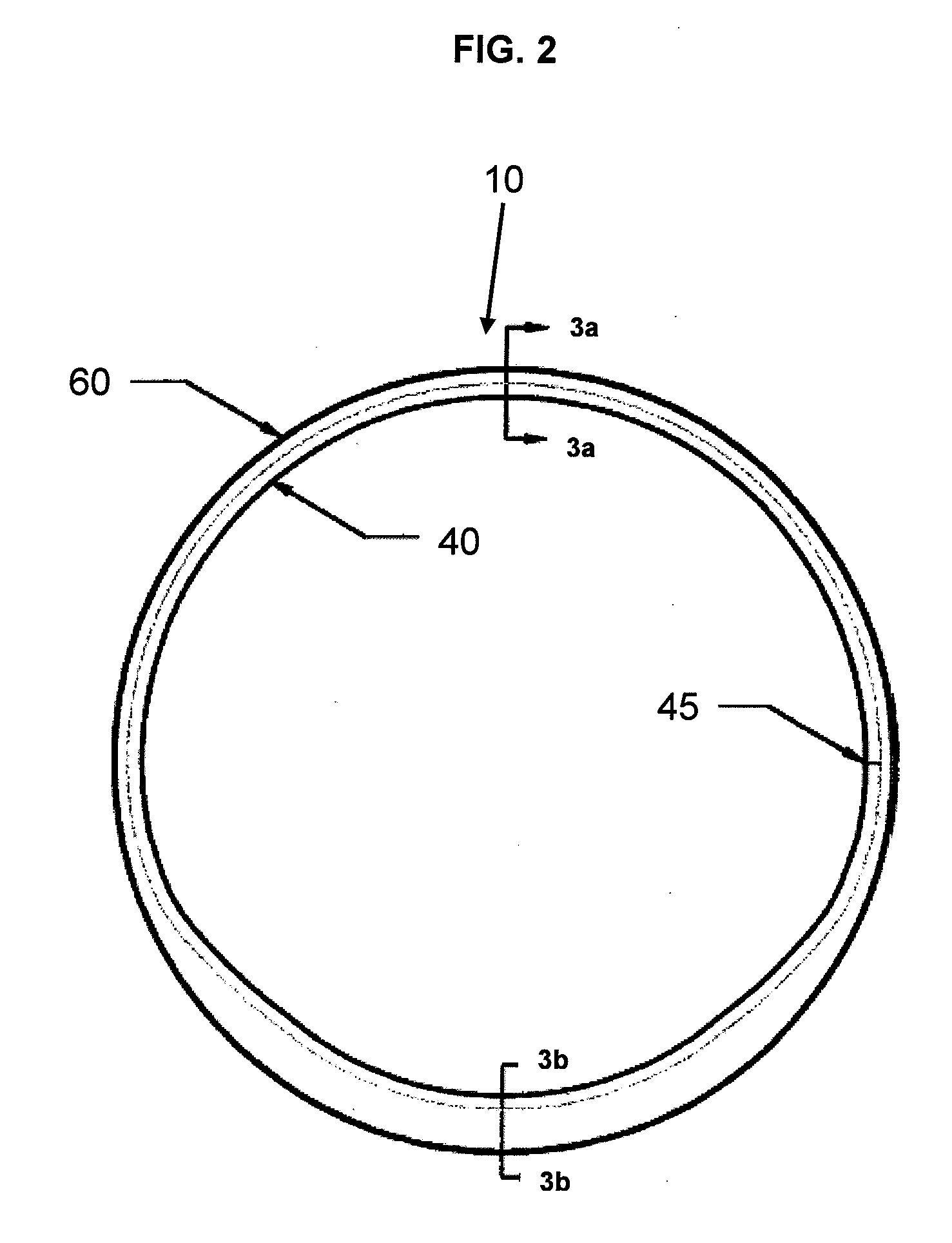

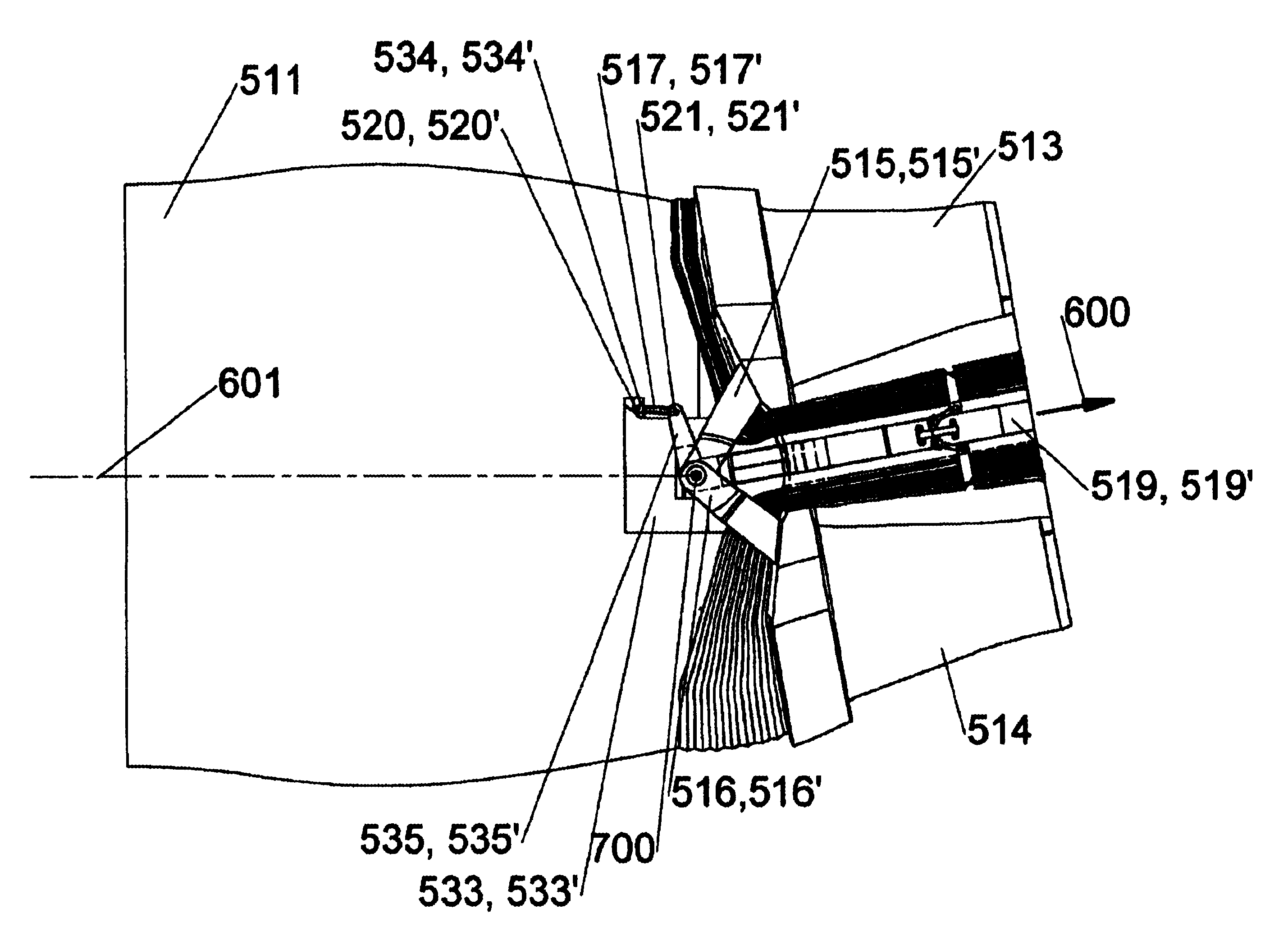

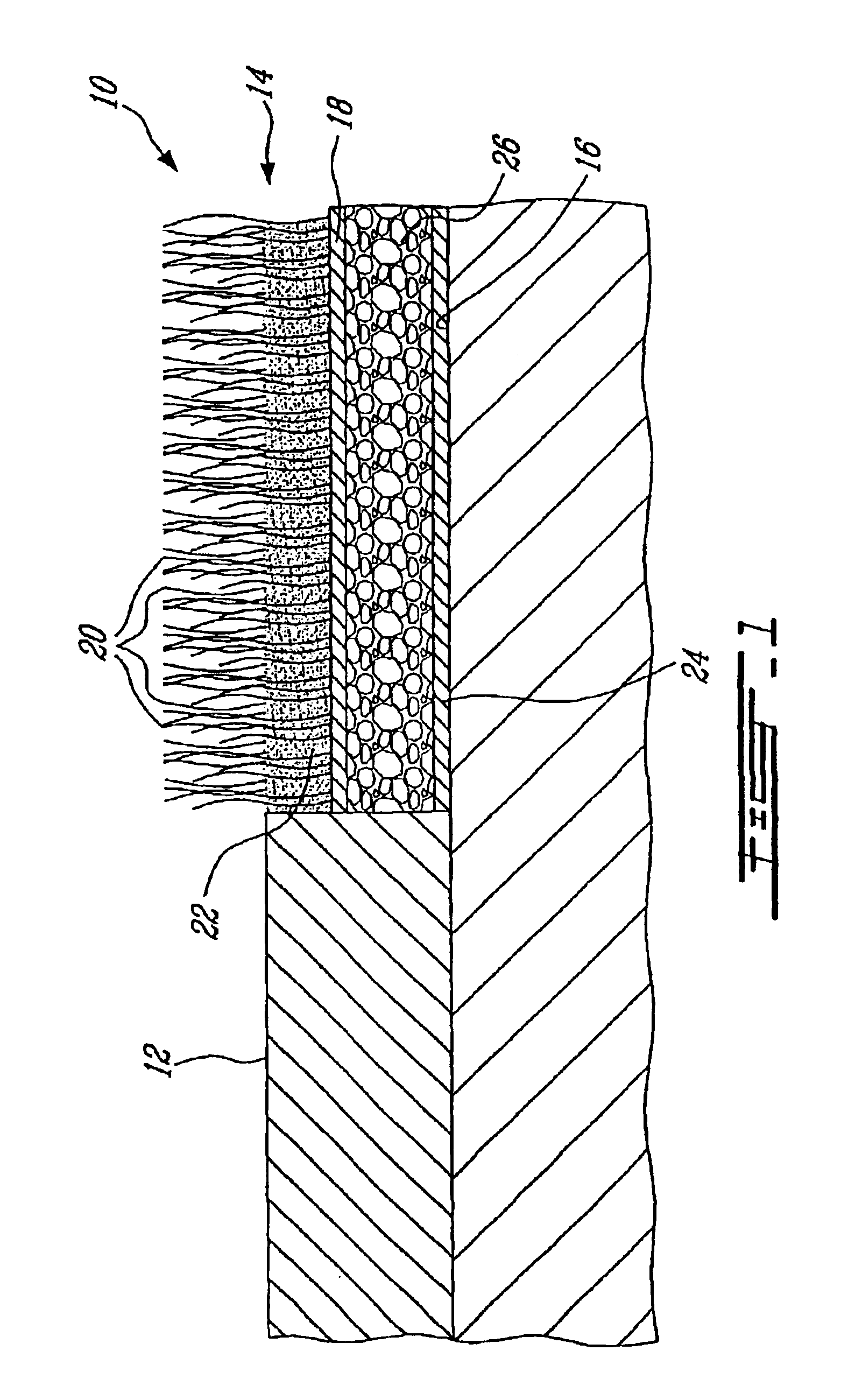

Multidirectionally Reinforced Shape Woven Preforms for Composite Structures

ActiveUS20090202763A1High strengthReadily conformsLoomsPedestrian/occupant safety arrangementFiberNacelle

The present invention relates to multidirectionally reinforced fiber preforms that conform easily to complex curvatures, such as, composite turbine fan cases, jet engine containment rings, aircraft fuselage frames, aircraft window frames, and flanged rings for attaching nacelles to aircraft engines. The present invention provides multidirectionally reinforced shape woven preforms with improved strength for composite structures that are axisymmetric as well as non-axisymmetric in nature. The invention is a preform used to reinforce a composite structure which includes a contour woven fabric portion, bi-axially braided, tri-axially braided or bias fabric portion, and / or a polar woven fabric portion, and a method of making thereof. The preform may optionally include a three-dimensionally woven portion. The combination of different forms of fabrics allows the preform to be produced without cutting and darting of the individual plies. Eliminating these cuts and darts improves the strength and performance of the resulting structure.

Owner:ALBANY ENGINEERED COMPOSITES

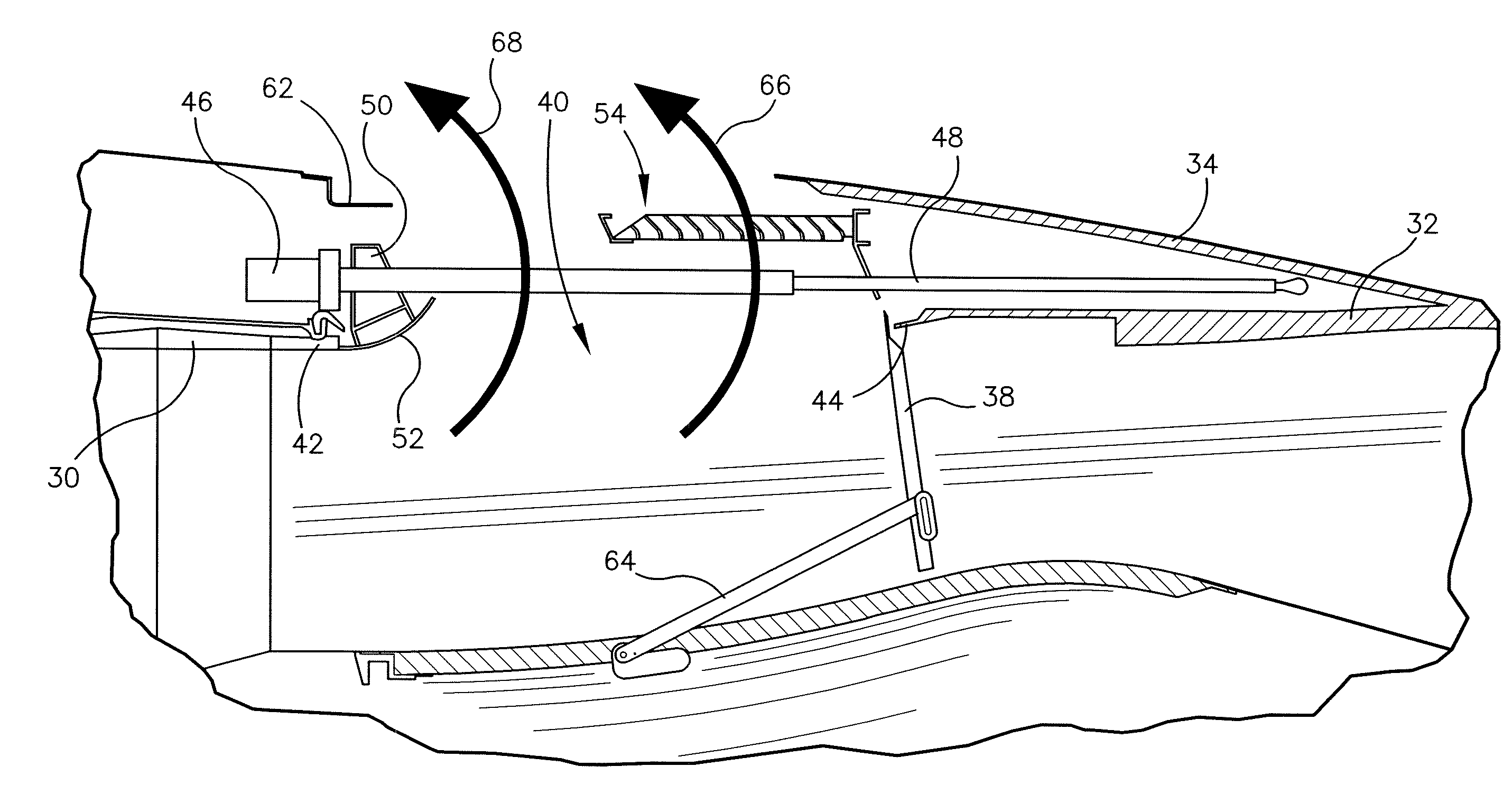

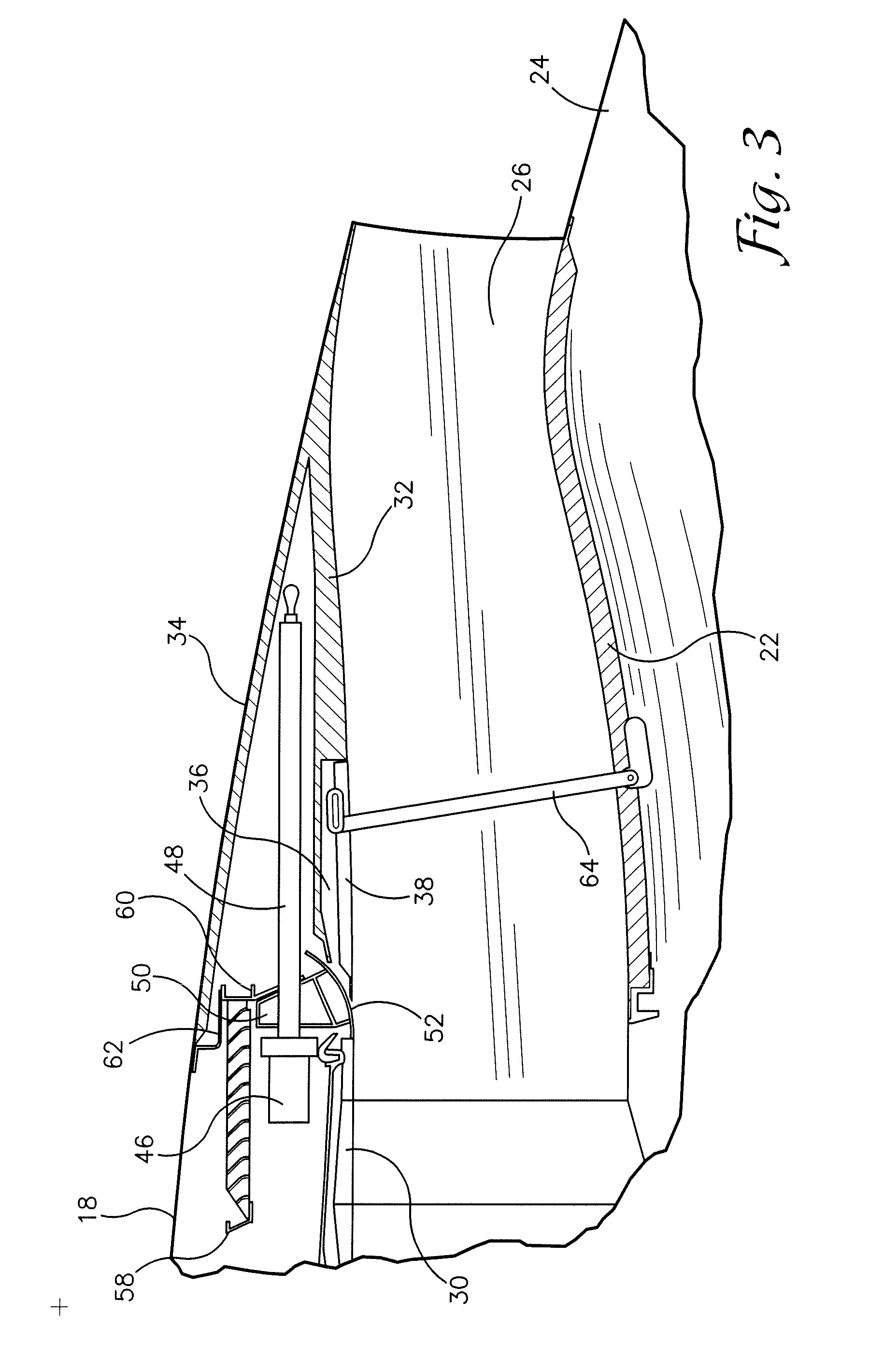

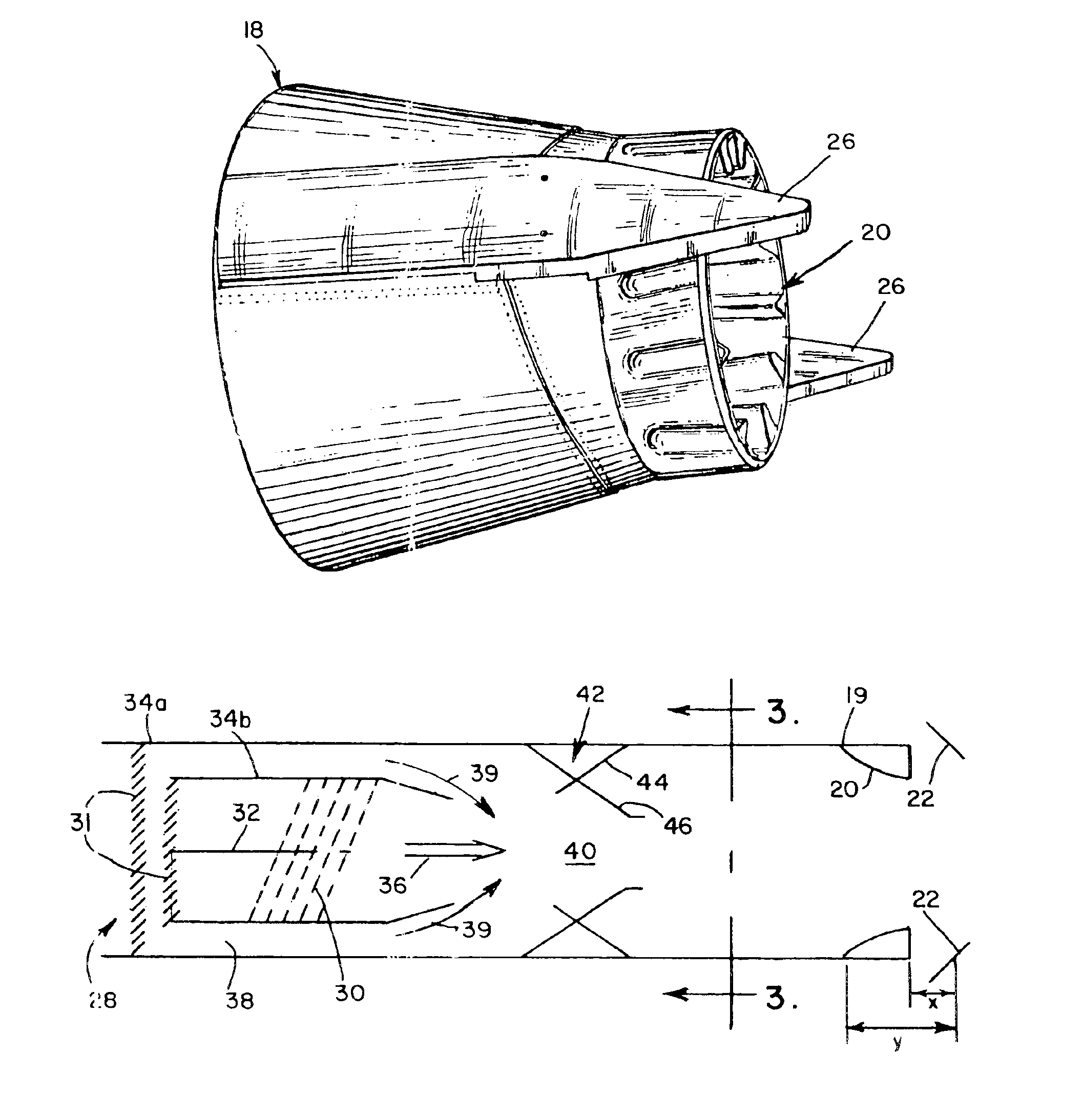

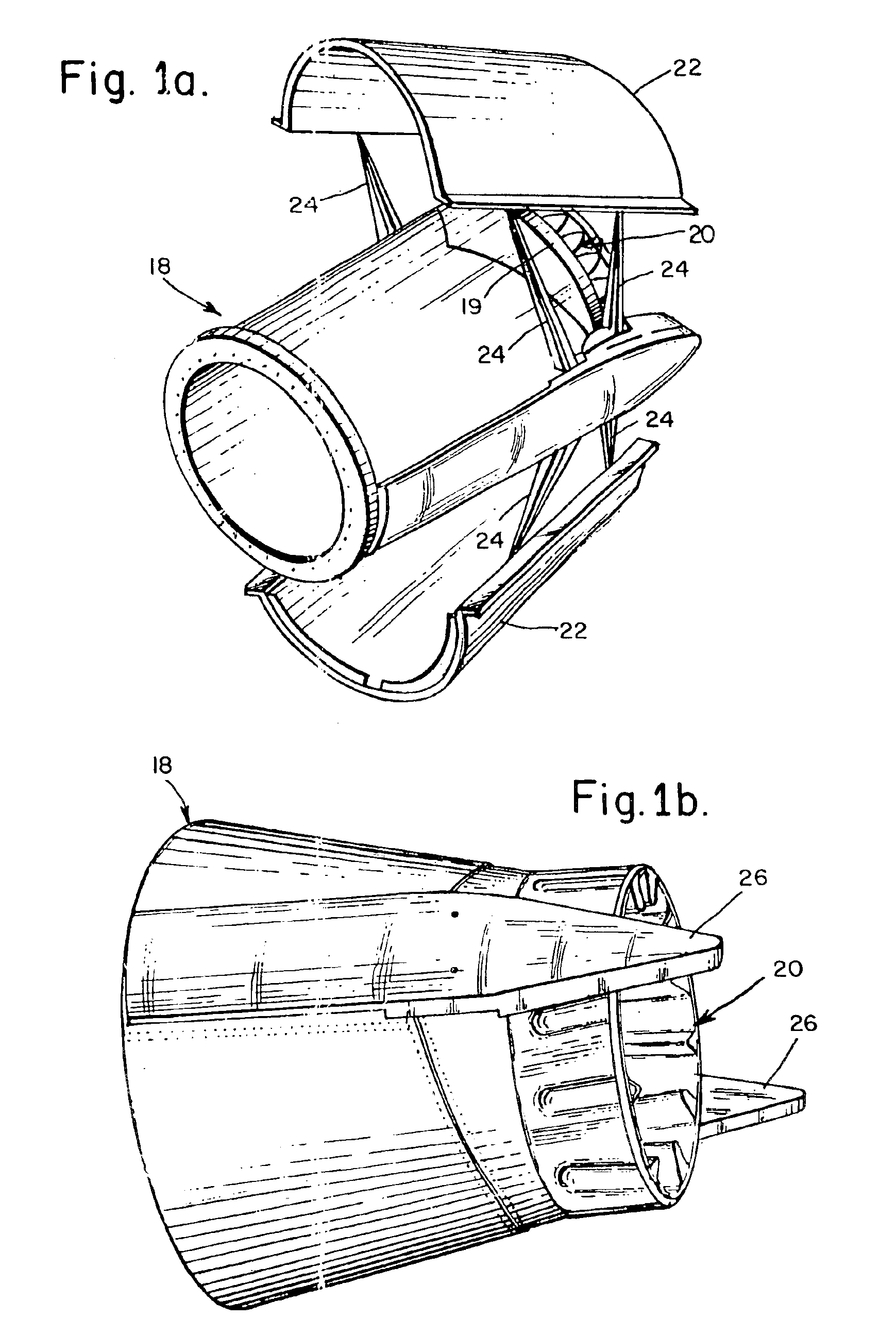

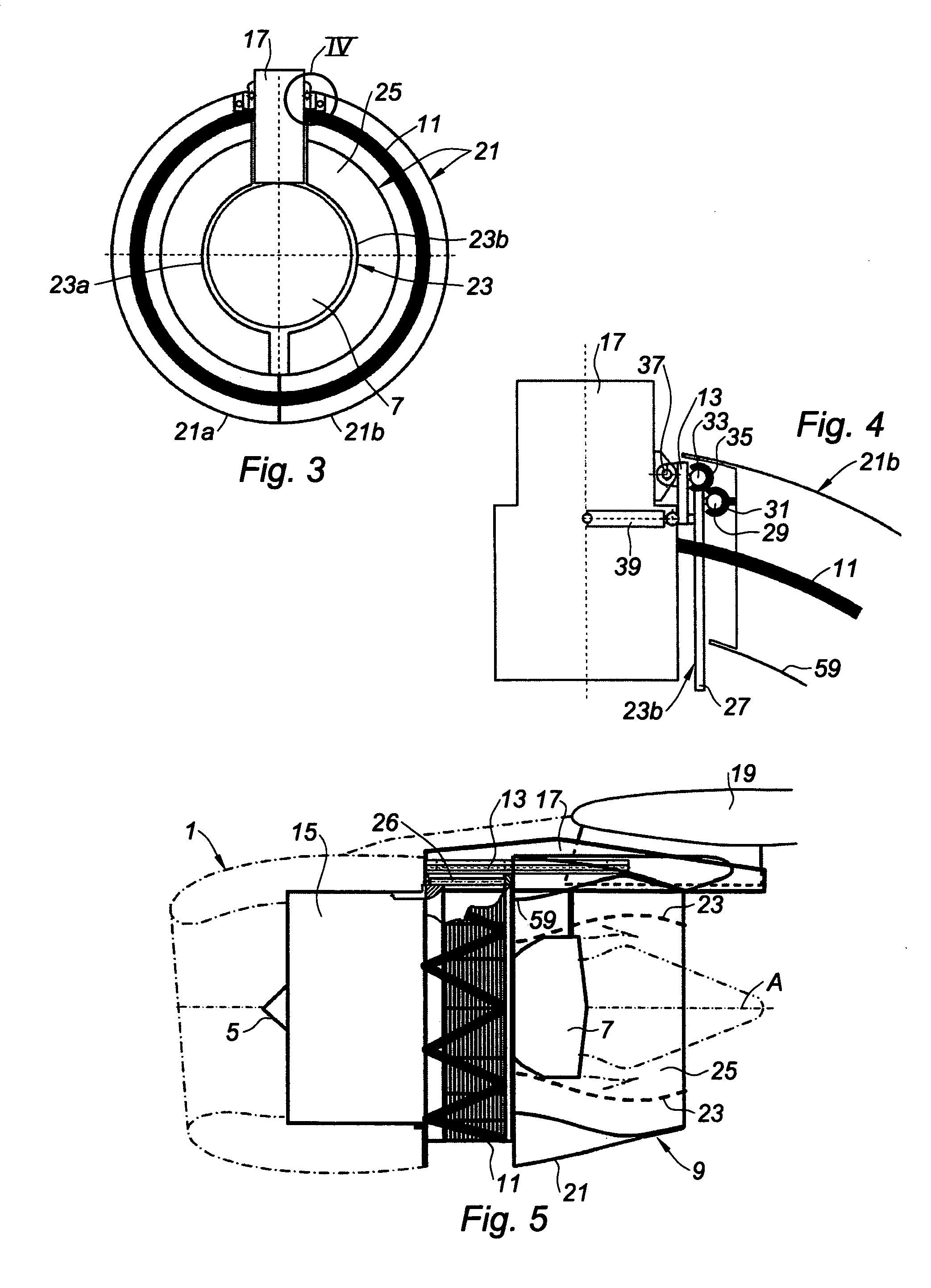

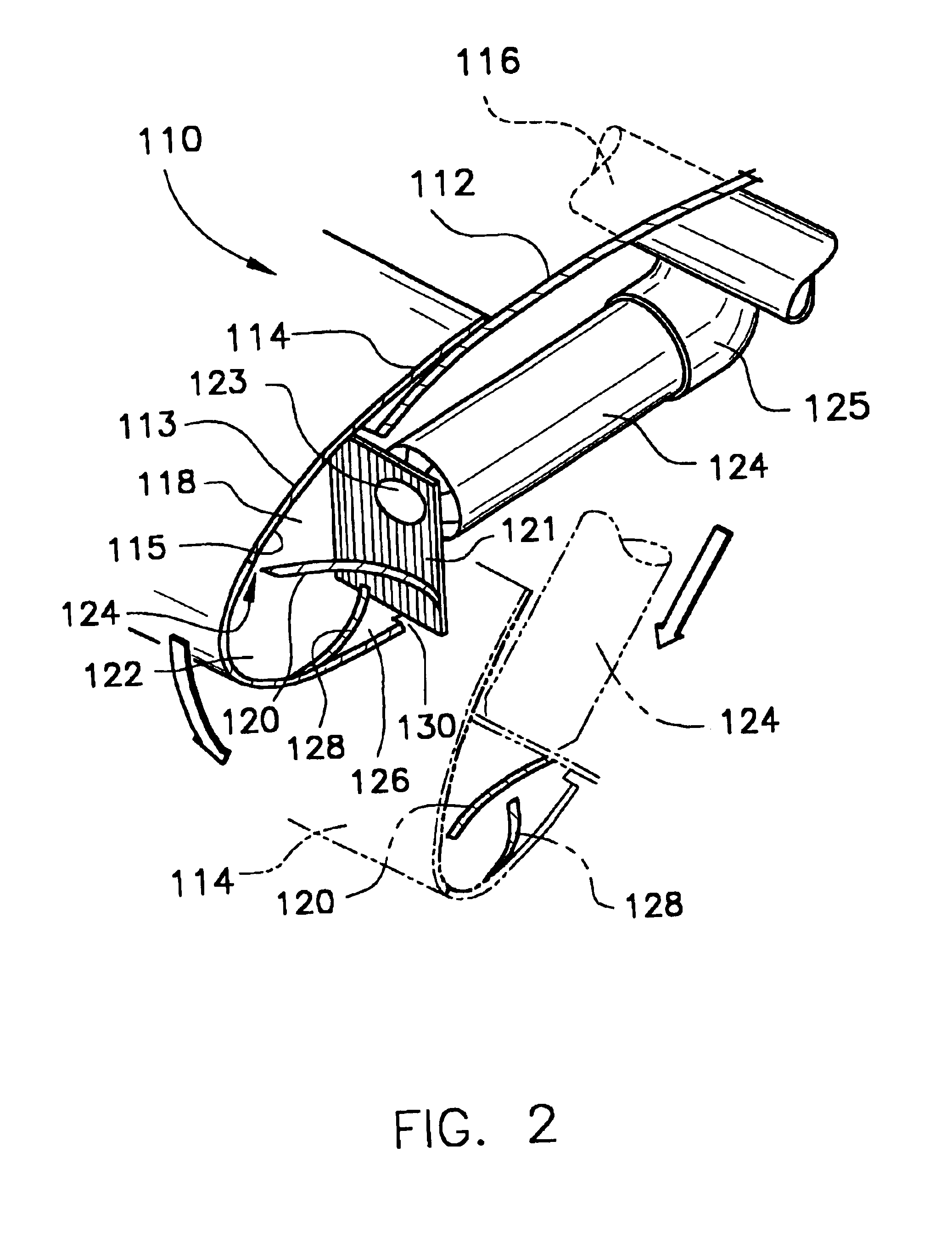

Partial cascade thrust reverser

ActiveUS20090151320A1Small sizeReduce weightSpraying apparatusEfficient propulsion technologiesJet engineThrust reversal

A thrust reverser for a jet engine comprises a translating wall section moveable between a stowed position and a deployed position. The translating wall section is adjacent an annular fan duct wall or other fixed portion of the jet engine when in the stowed position and is separated from the annular fan duct wall when in the deployed position, thereby creating an aperture through which a fluid stream passes. A fluid flow reverser element directs the fluid stream in a direction generally forward relative to the jet engine when the translating wall section is in the deployed position. The fluid flow reverser element extends only partially into the fluid stream such that only a first portion of fluid of the fluid stream engages the fluid flow reverser element. A second portion of the fluid stream is entrained in the first portion and is thereby directed forward relative to the jet engine.

Owner:SPIRIT AEROSYSTEMS

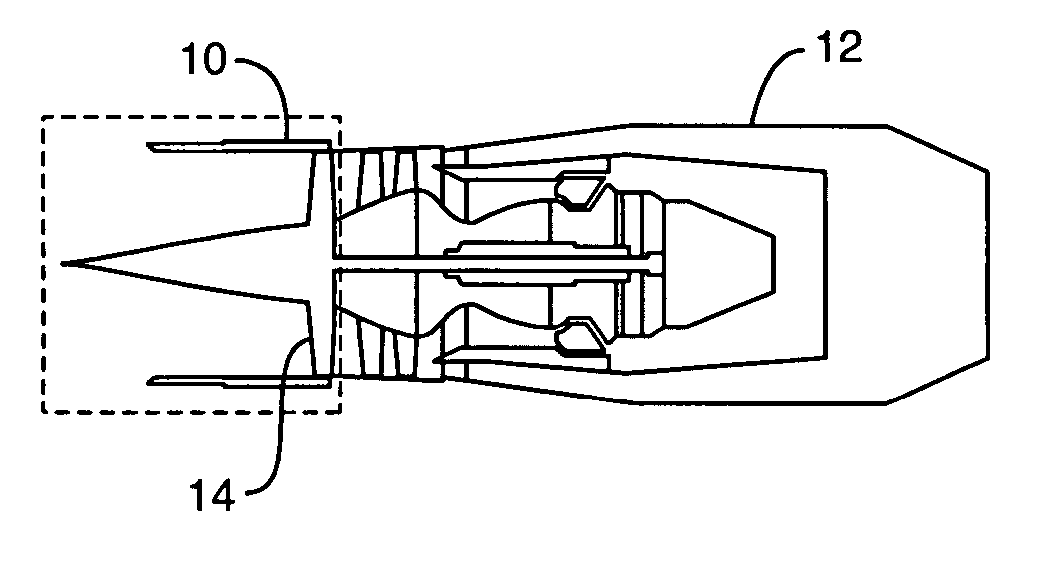

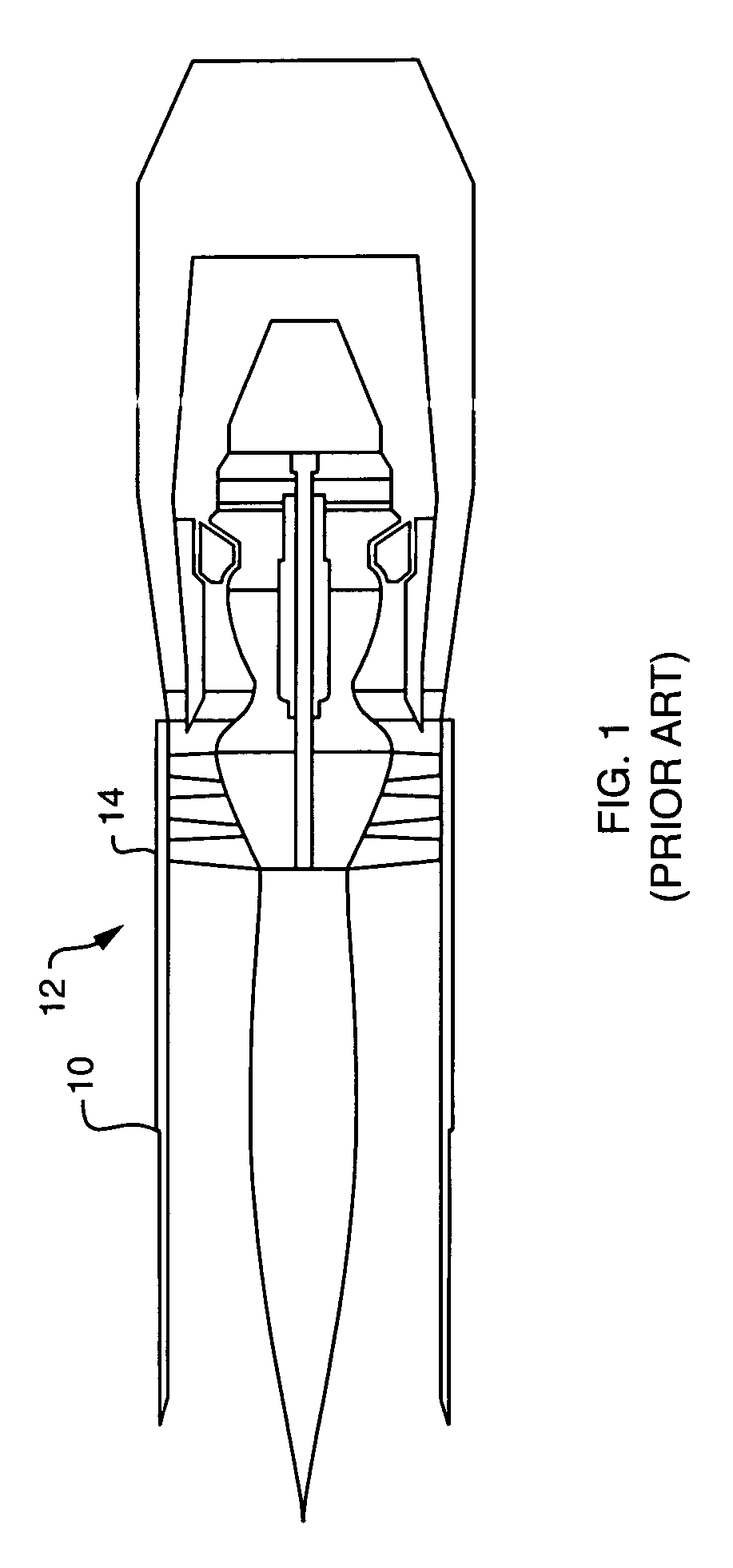

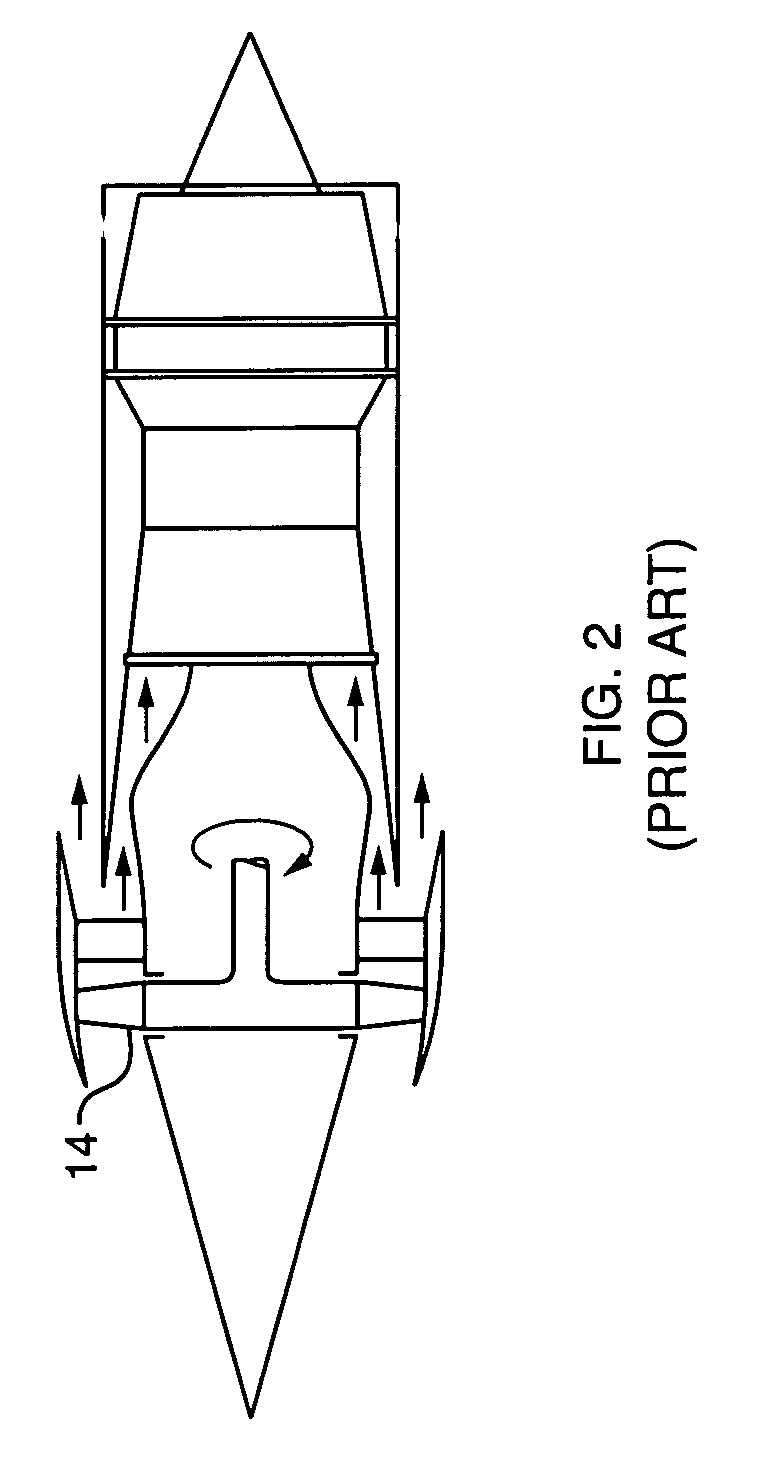

Jet engine inlet-fan system and design method

InactiveUS20060179818A1Improve performanceIncrease pressureSupersonic fluid pumpsEfficient propulsion technologiesJet engineDesign methods

A supersonic aircraft engine axial fan that includes a rotating blade row having blades that receive a supersonic entry flow in the absolute frame and decelerate the flow to a lower supersonic or subsonic velocity exit flow while adding work to the flow to increase stagnation pressure. It is preferred that the lower velocity be subsonic. When the fan is combined with a suitably designed inlet, the propulsion system is compact and lighter in weight than conventional engines for supersonic aircraft.

Owner:MASSACHUSETTS INST OF TECH

Optical fiber pressure and acceleration sensor fabricated on a fiber endface

InactiveUS7054011B2Subsonic/sonic/ultrasonic wave measurementFluid pressure measurement by electric/magnetic elementsJet engineClassical mechanics

A fiber optic sensor has a hollow tube bonded to the endface of an optical fiber, and a diaphragm bonded to the hollow tube. The fiber endface and diaphragm comprise an etalon cavity. The length of the etalon cavity changes when applied pressure or acceleration flexes the diaphragm. The entire structure can be made of fused silica. The fiber, tube, and diaphragm can be bonded with a fusion splice. The present sensor is particularly well suited for measuring pressure or acceleration in high temperature, high pressure and corrosive environments (e.g., oil well downholes and jet engines). The present sensors are also suitable for use in biological and medical applications.

Owner:VIRGINIA TECH INTPROP INC

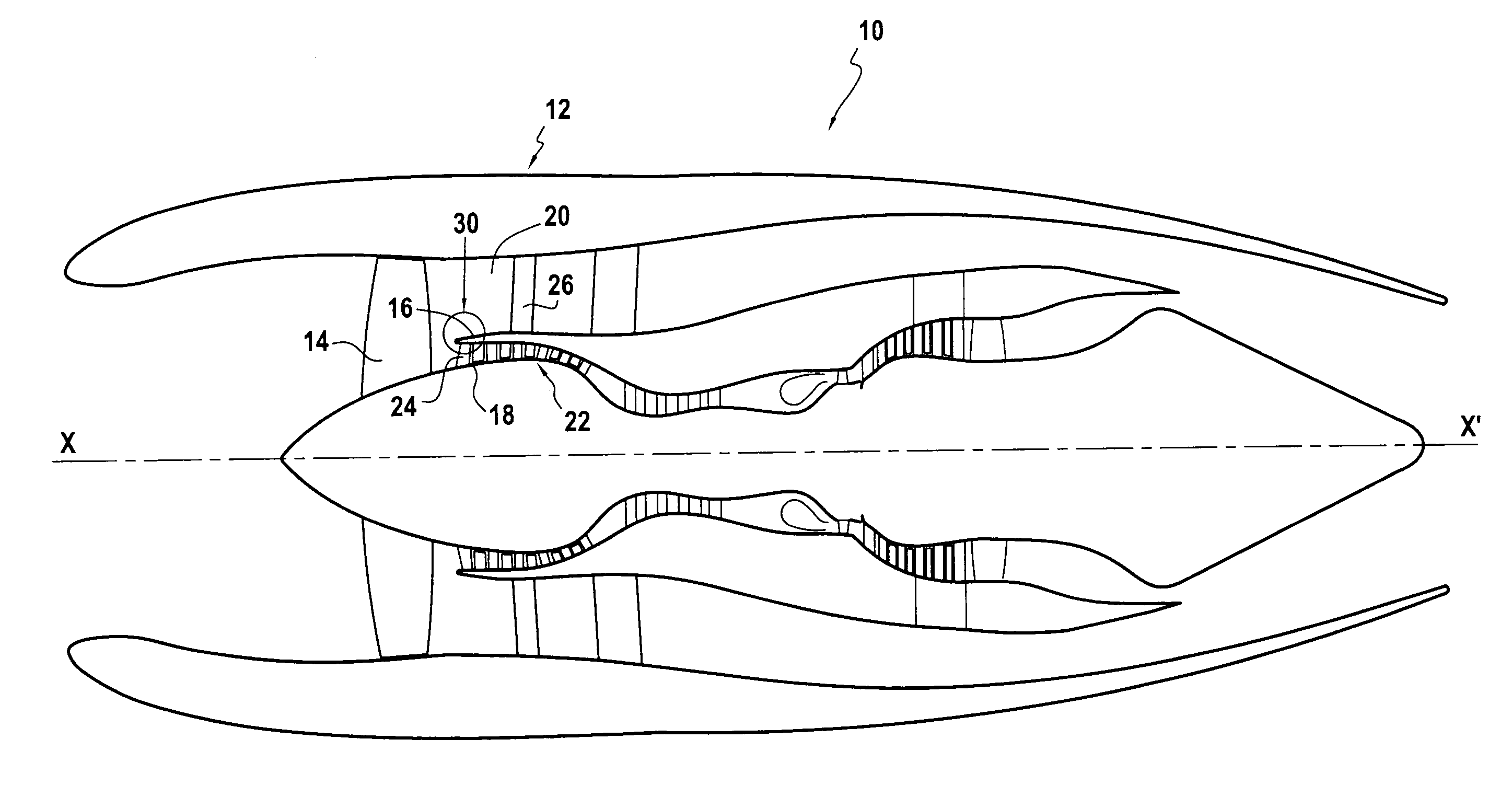

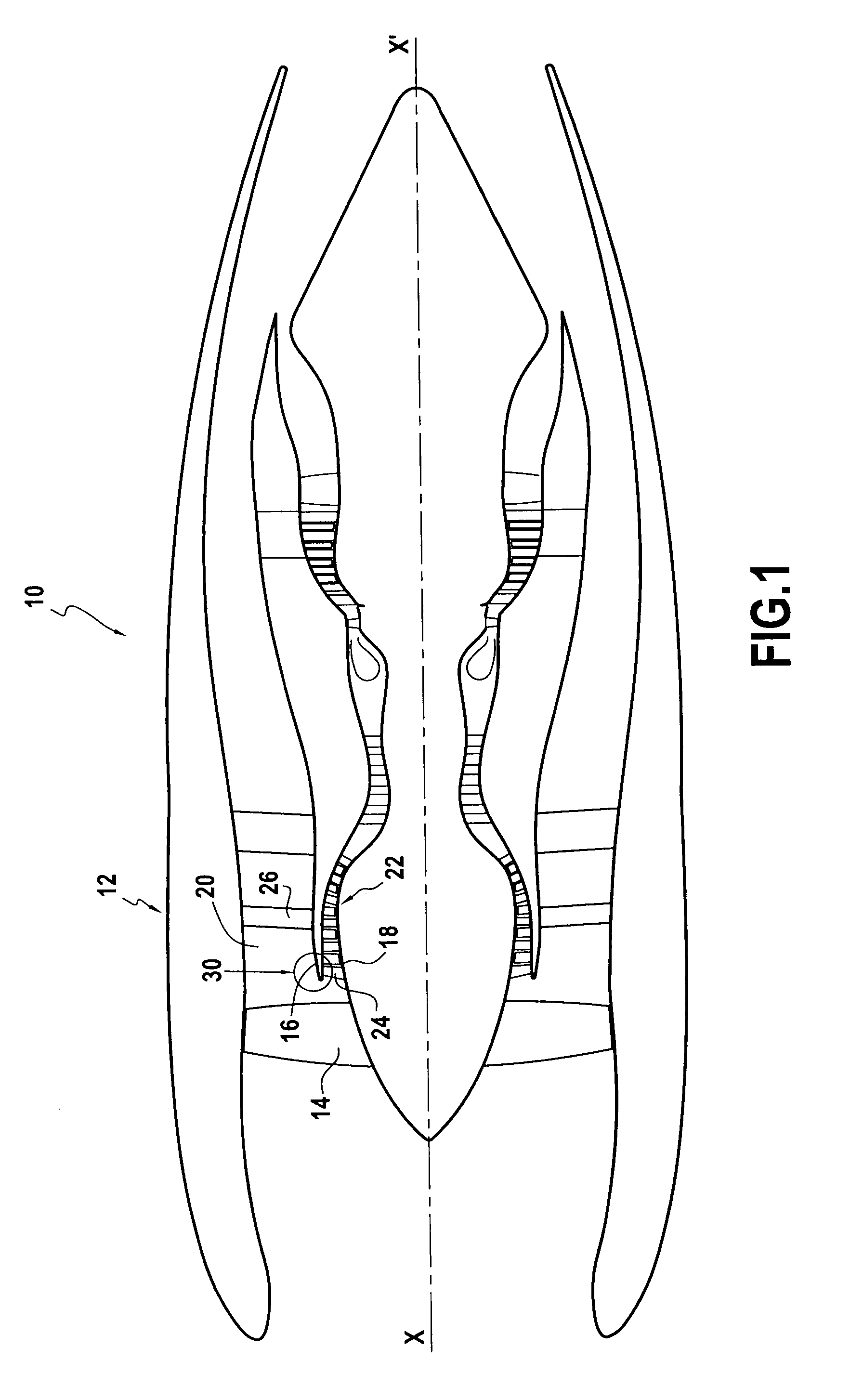

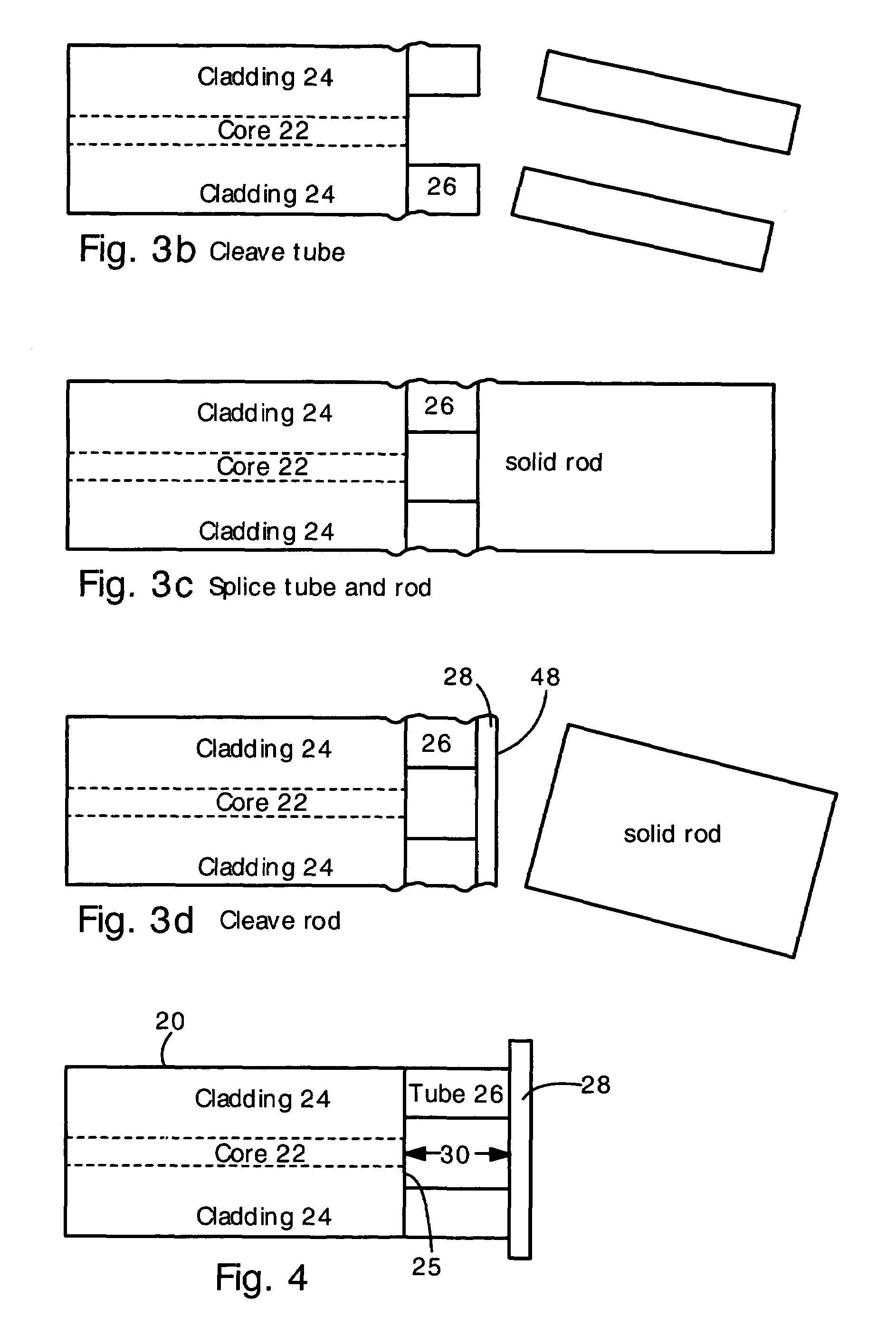

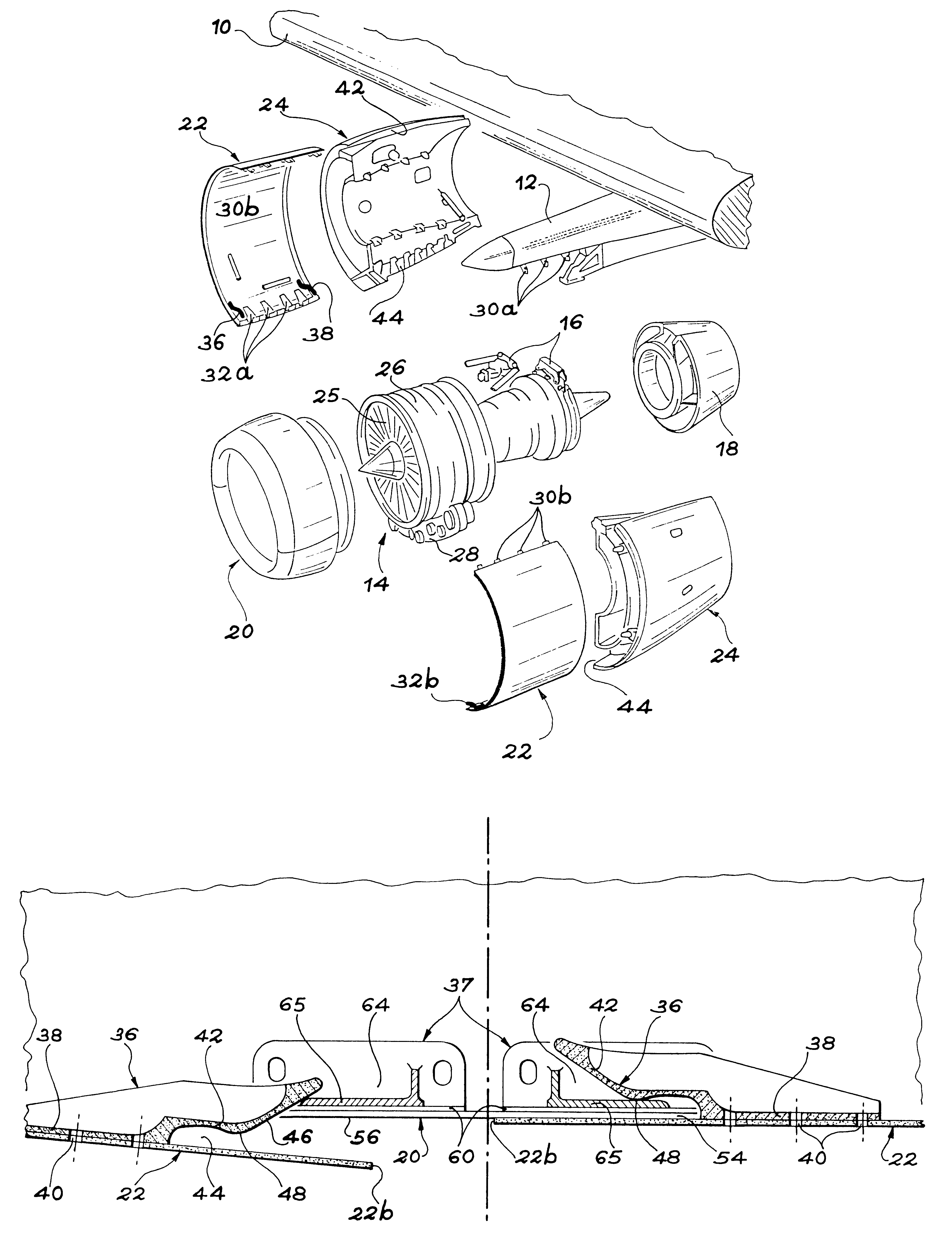

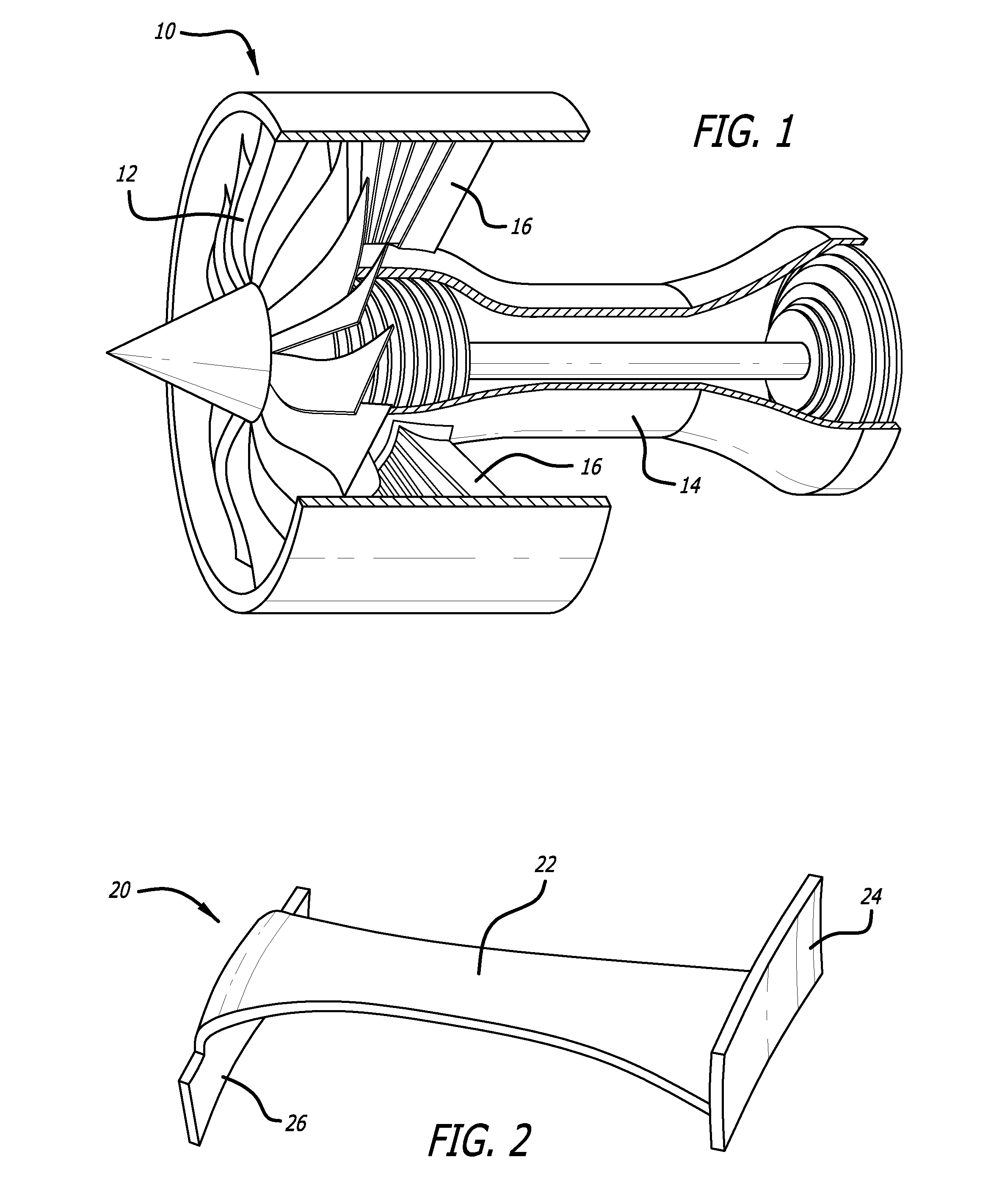

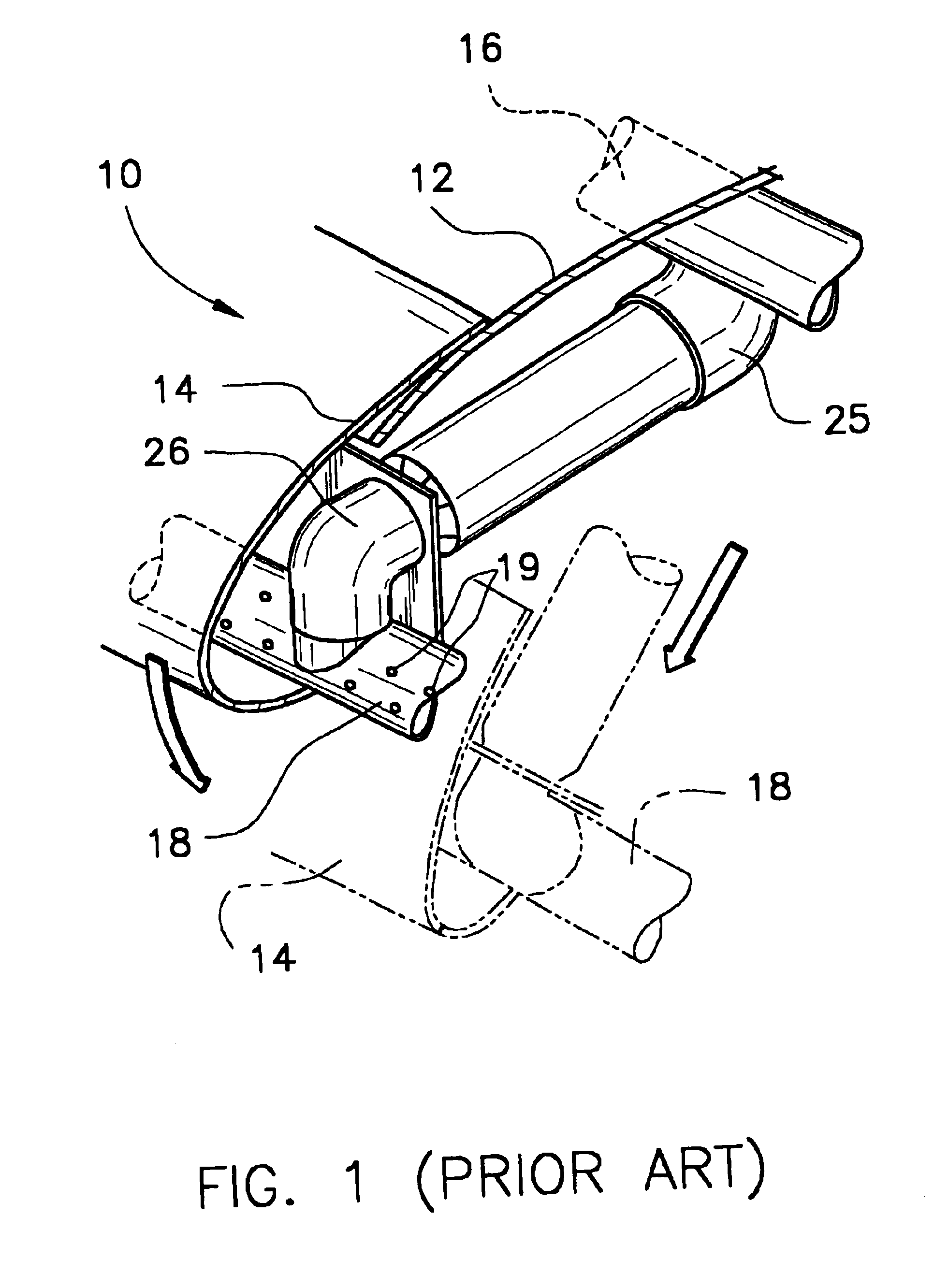

Aircraft propulsion unit fan cowls equipped with maintaining and positioning safety elements

In an aircraft propulsion system, such as a jet engine, the fan cowls (22) are articulated to the support strut or pylon (12) by which the centre or core engine (14) is connected to a wing element (10). The cowls (22) are kept closed by hooked locks (32a, 32b), which connect their lower edges. To eliminate any risk of accidental opening, guide devices (36, 38) are placed between the lower edges of the cowls (22) and structures (20; 24, 26) connected to the centre engine (14), at least at the front of the cowls. The front structure (20) opposes any axial and radial displacement of the cowls.

Owner:SOC NATIONALE INDUSTRIELLE AEROSPATIALE SA

Ducted vehicles particularly useful as VTOL aircraft

InactiveUS20030038213A1Improve efficiencyEasy entryAircraft navigation controlFlying saucersJet enginePropeller

A VTOL aircraft (or other vehicle such as a sea vehicle) includes a pair of elongated ducts on opposite sides of the vehicle body, and a plurality of powered propellers (or other propulsion units such as jet engines) mounted within and enclosed by each of the elongated ducts, such as to produce an upward lift force to the vehicle. Each of the elongated ducts has a short transverse dimension slightly larger than the diameter of the blades of each propeller enclosed thereby, and a large transverse dimension slightly larger than the sum of the diameters of the blades of all the propellers enclosed thereby.

Owner:URBAN AERONAUTICS

Jet nozzle mixer

InactiveUS6854260B2Reduce noiseAvoid problemsAircraft navigation controlCosmonautic vehiclesJet engineThrust efficiency

An external jet nozzle mixer (20) includes identically formed lobes (48), equal in number those of the internal mixer (42). External mixer (20) works with internal mixer (42), further to mix the engine internal bypass flow with the internal jet engine core flow, to level the disparate exhaust flow velocities, to reduce the peak velocities from the jet engine core and increase the lower bypass velocities of the engine internal bypass flow, and thereby to reduce noise. The internal lobe contours act as lifting flutes, causing mixing of the primary hot and cold flows before exiting the nozzle. The external lobe contours act as venturi chutes, accelerating the cooler ambient air secondary flow. The lobes thus act collectively as an injector to force the cooler ambient secondary flow into the previously mixed primary flow as it exits the nozzle. Also obtained is an increased thrust efficiency and a consequently decreased fuel consumption and engine emissions.

Owner:COMTRAN LTD

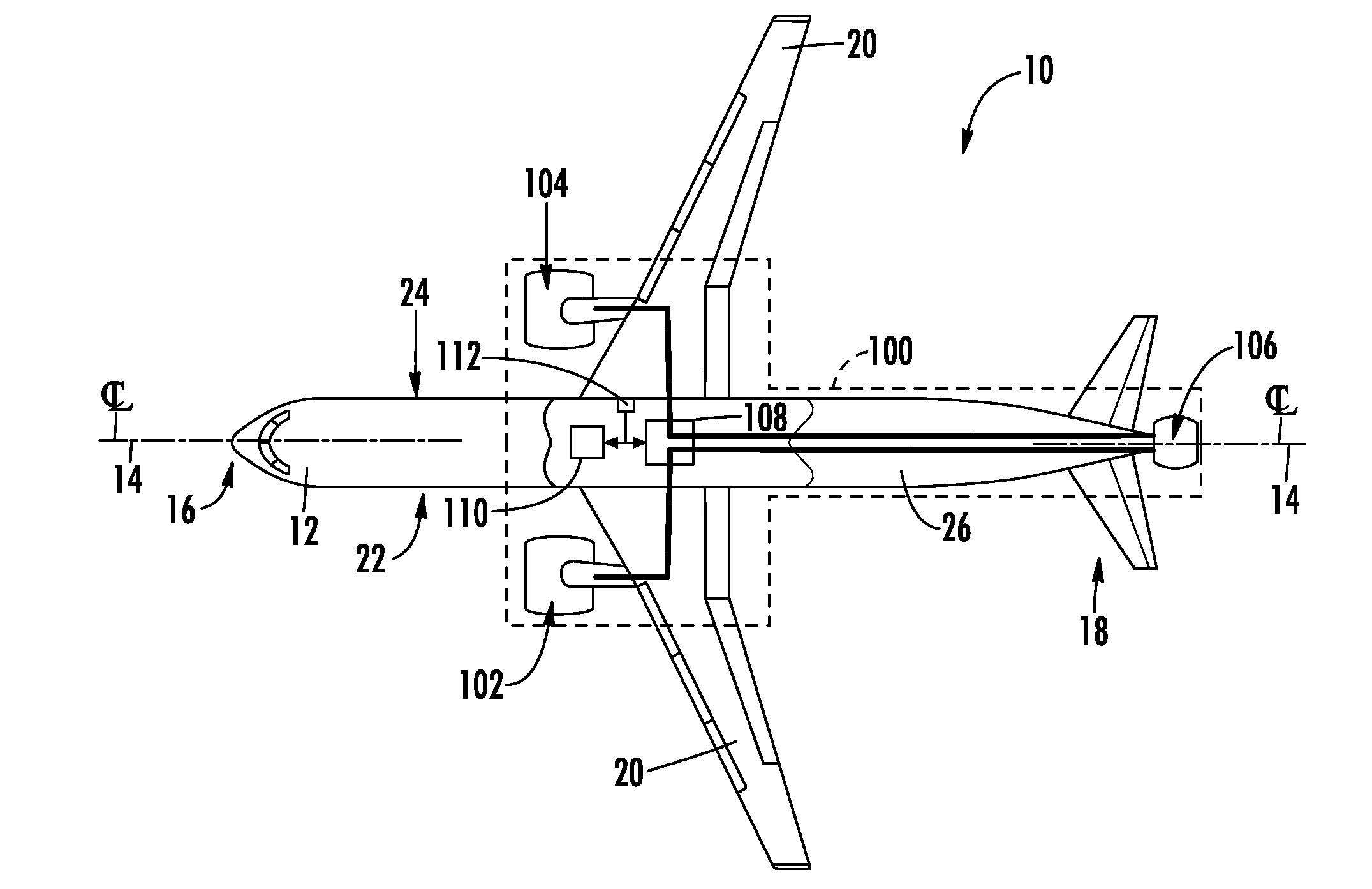

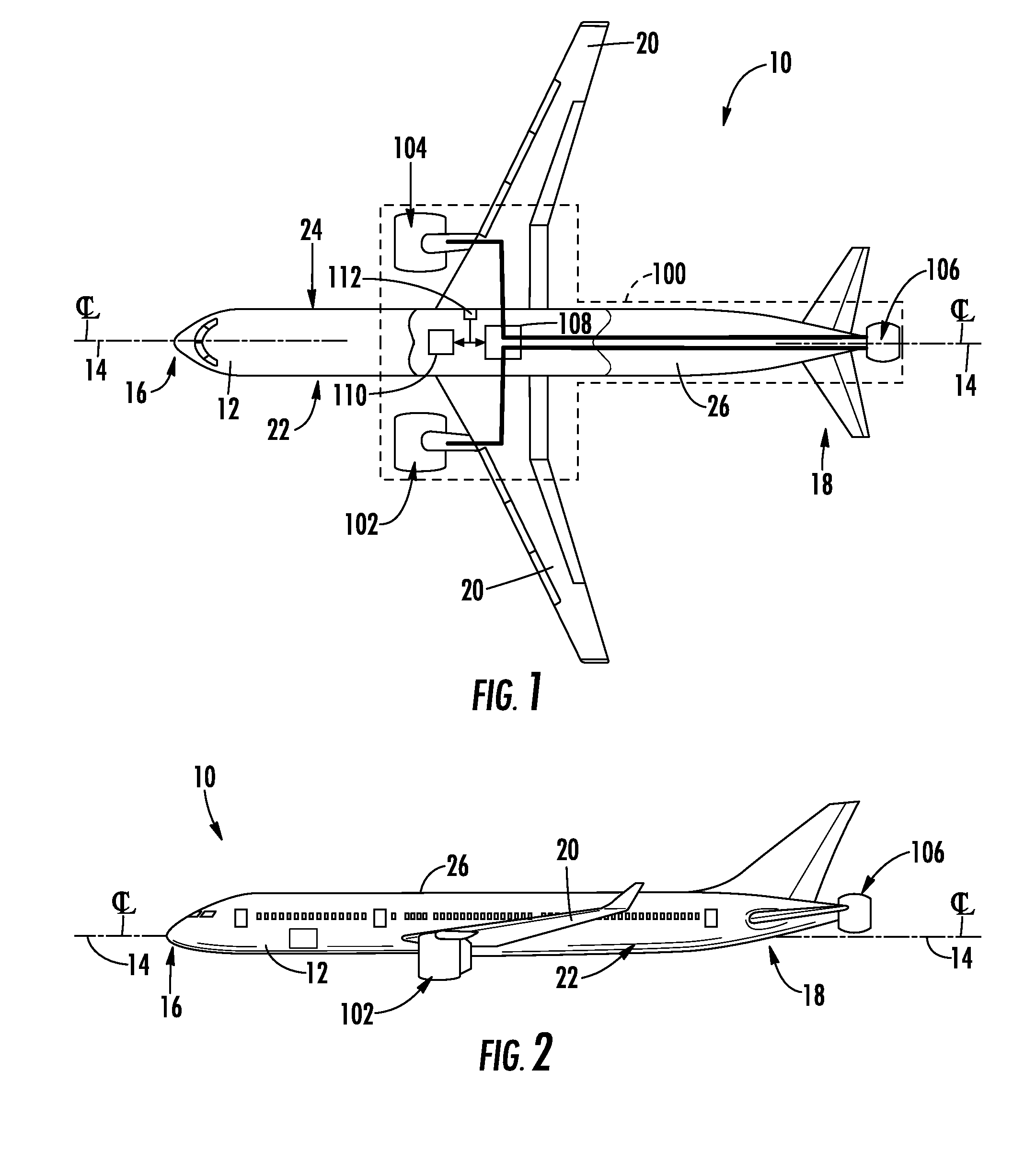

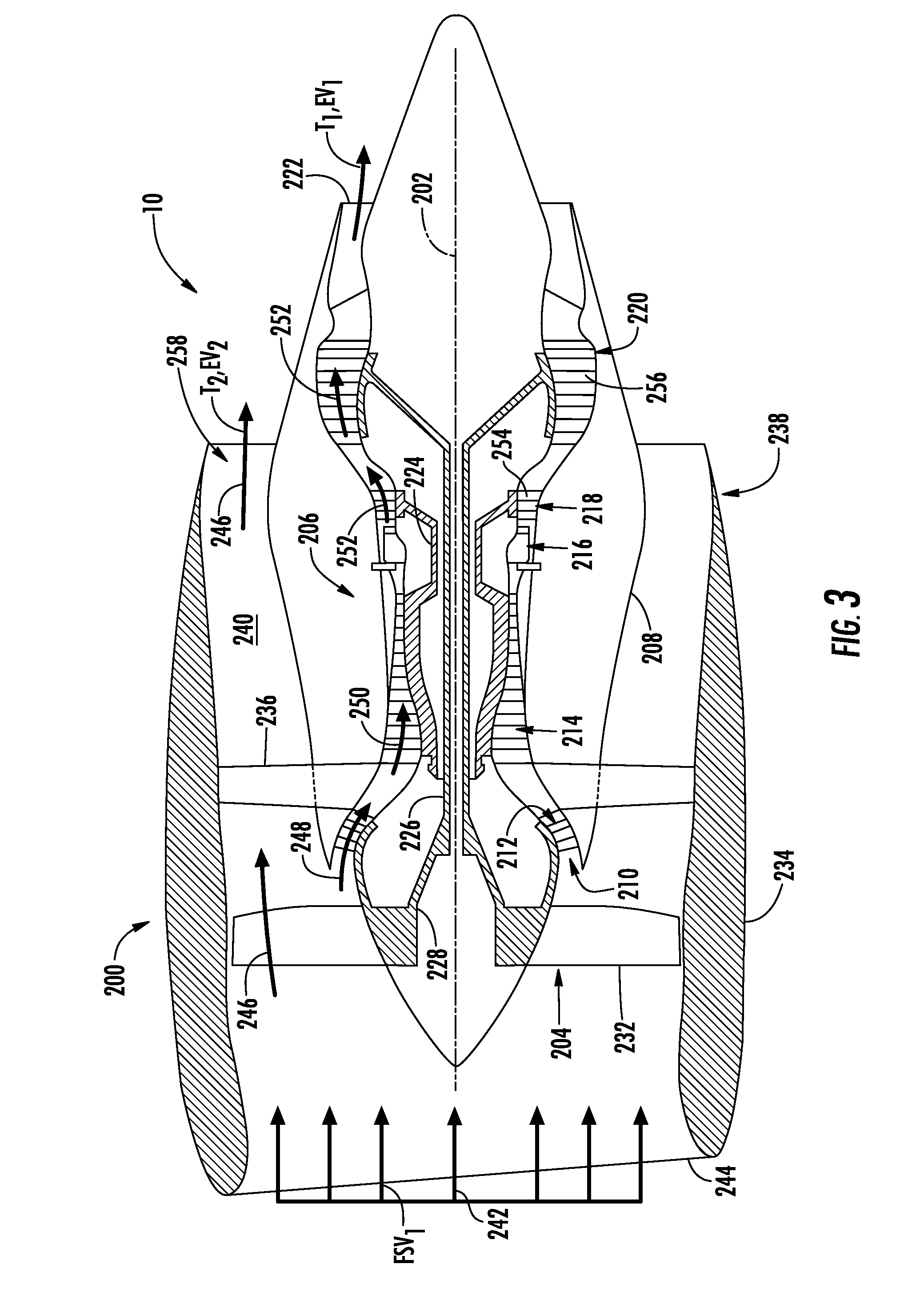

Gas-electric propulsion system for an aircraft

In one aspect the present subject matter is directed to a gas-electric propulsion system for an aircraft. The system may include a turbofan jet engine, an electric powered boundary layer ingestion fan that is coupled to a fuselage portion of the aircraft aft of the turbofan jet engine, and an electric generator that is electronically coupled to the turbofan jet engine and to the boundary layer ingestion fan. The electric generator converts rotational energy from the turbofan jet engine to electrical energy and provides at least a portion of the electrical energy to the boundary layer ingestion fan. In another aspect of the present subject matter, a method for propelling an aircraft via the gas-electric propulsion system is disclosed.

Owner:GENERAL ELECTRIC CO

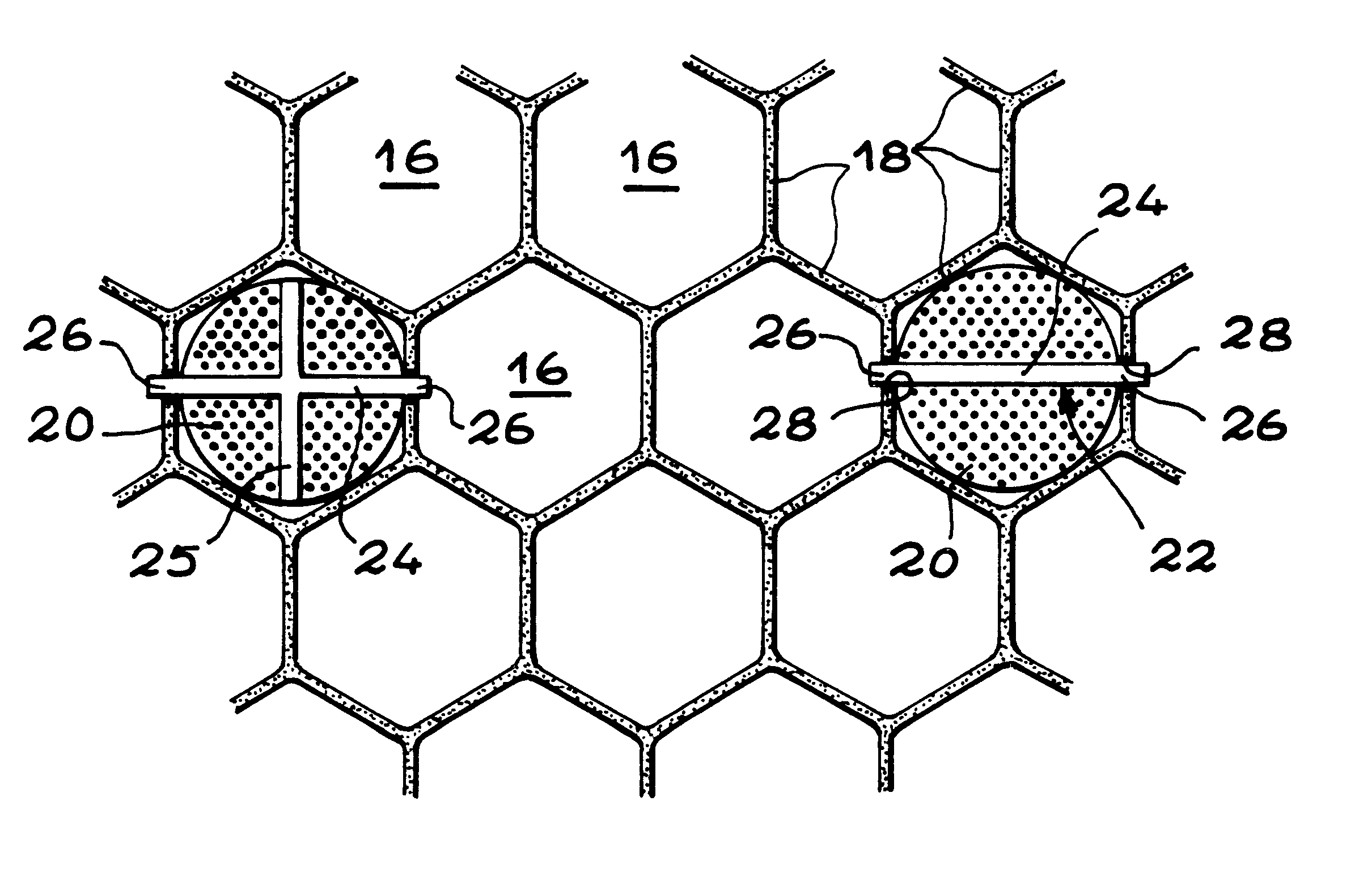

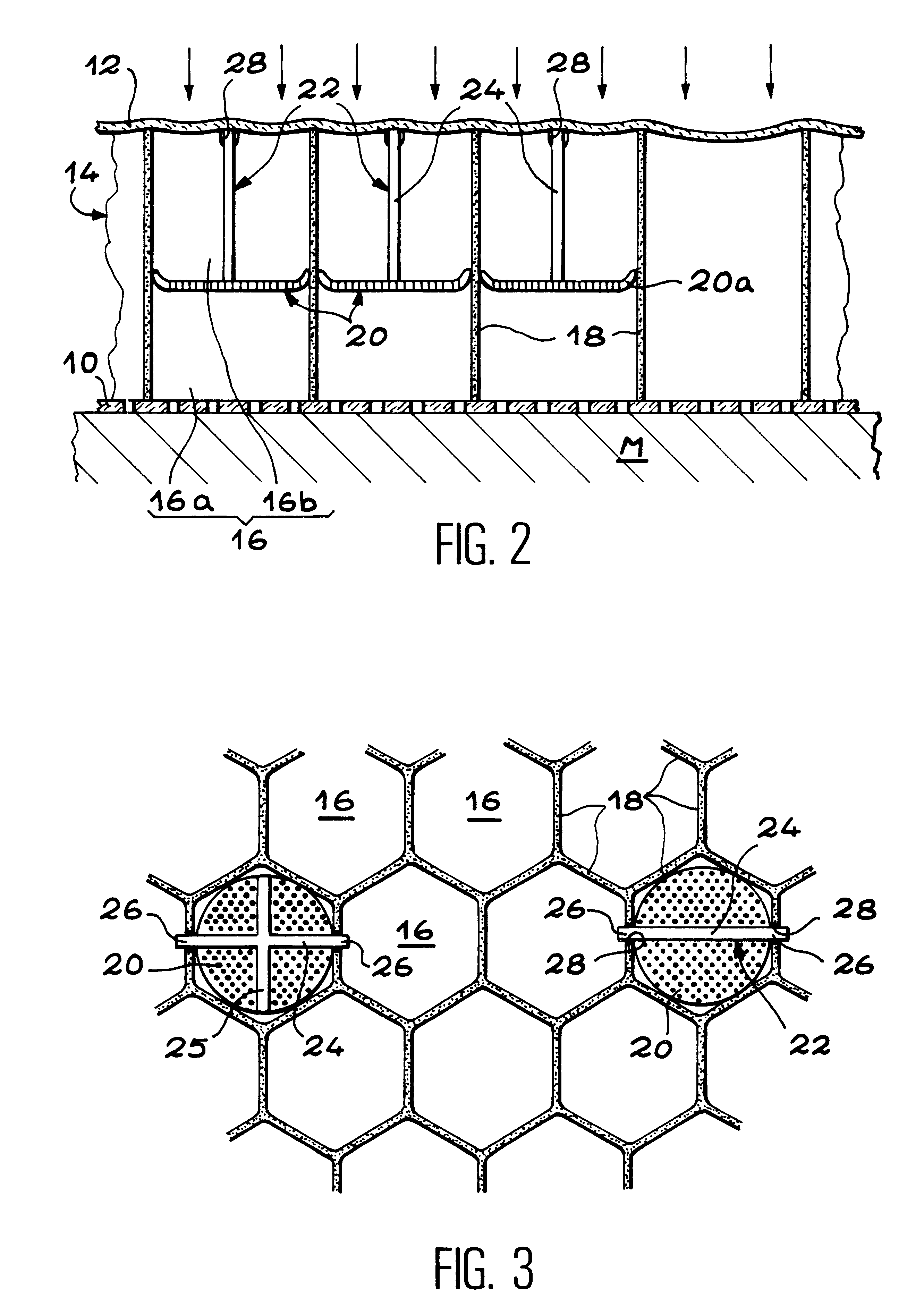

Noise reduction sandwich panel, notably for aircraft turbojet engine

InactiveUS6536556B2Improve suppression propertiesEasy to installCeilingsLayered productsRelative displacementJet engine

Noise reduction sandwich panel, notably for an aircraft turbojet engine.In order to produce a noise reduction sandwich panel having a structure with two degrees of freedom, inserted separative components (20) are placed into the hexagonal cells (16) of the unique waffle core of the panel. More specifically, the separative components (20) have an substantially circular external peripheral edge, which allows them to be easily assembled, in spite of the deformations of the walls (18) of the cells (16) due to manufacturing tolerances and to the optional forming of the waffle core. Advantageously, several separative components (20) are supported by a same positioning unit (22), which then allows relative displacement between the separative components.

Owner:AIRBUS OPERATIONS (SAS)

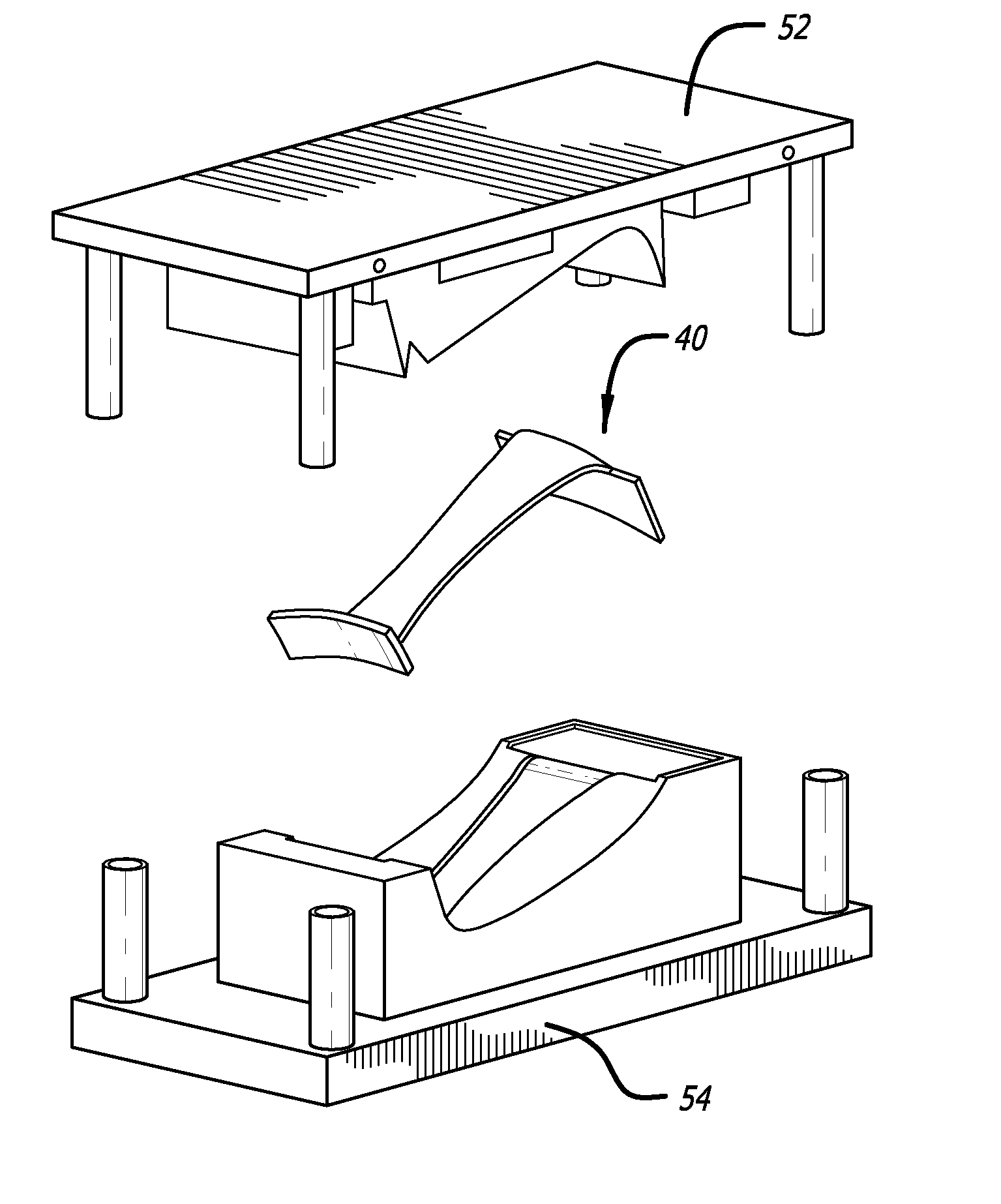

High pressure molding of composite parts

ActiveUS20130101406A1Avoid distortionReduce weightPump componentsReaction enginesJet engineShell molding

Composite pre-forms are molded at high pressure to form composite parts that can be used in place of metal-based high performance parts, such as the outlet guide vanes found in turbofan jet engines. The composite pre-forms include two different fiber orientations that are co-molded in a resin matrix at high pressures to provide composite outlet guide vanes and other high performance parts. Chambers within the composite part are optionally formed during molding of the pre-form at high pressures.

Owner:HEXCEL

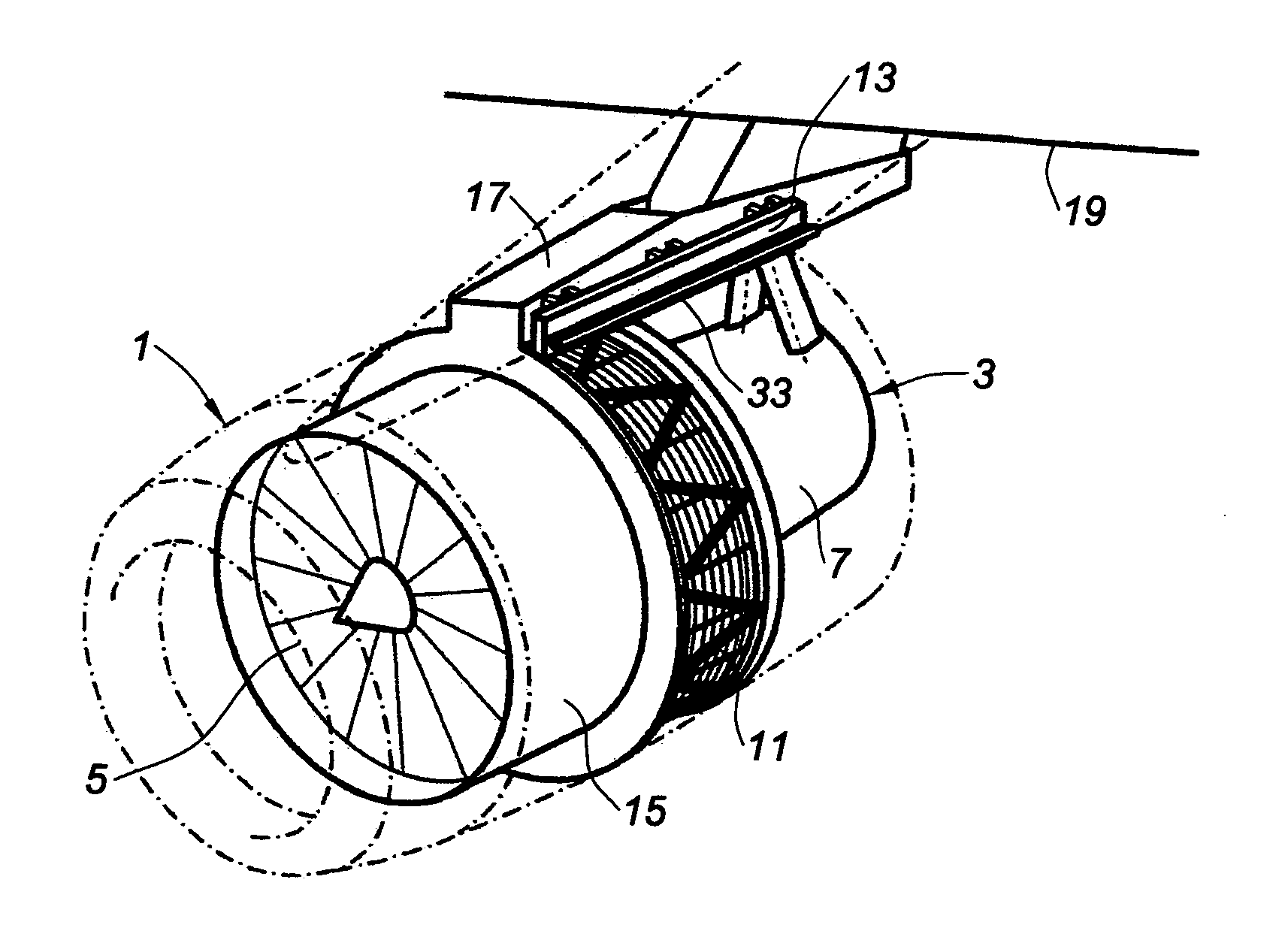

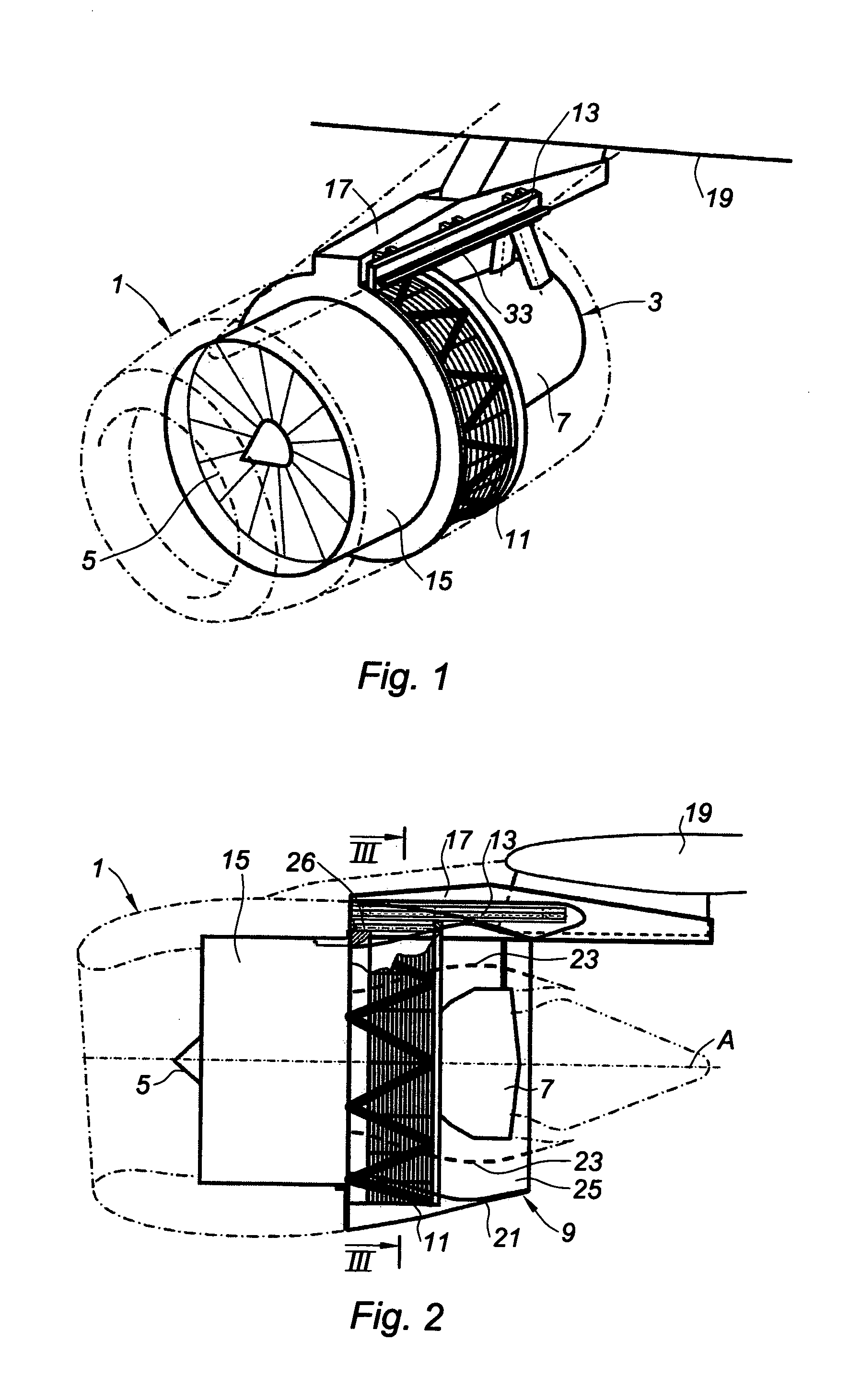

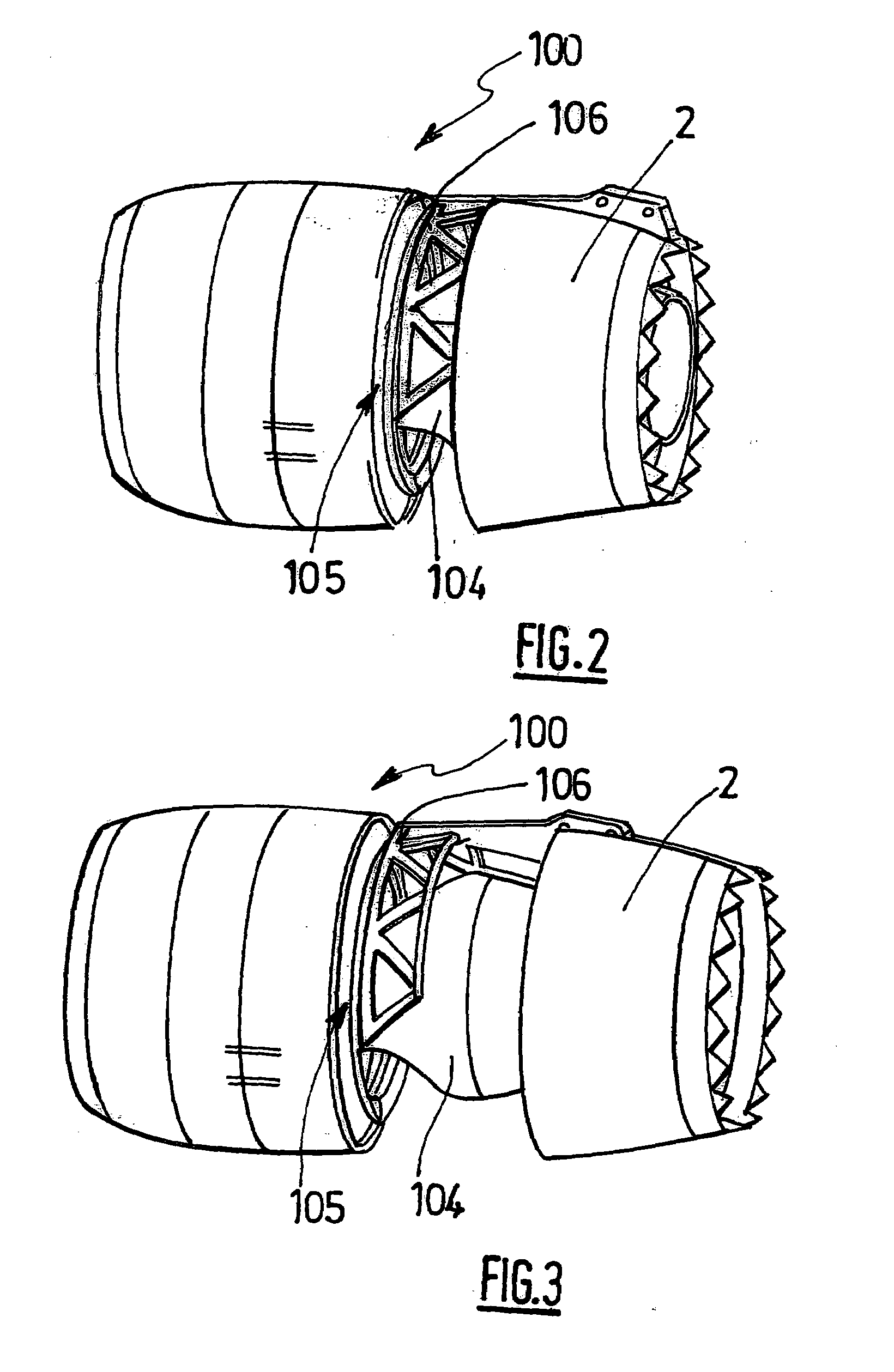

Thrust reverser for a jet engine

The invention relates to a thrust reverser (9) for an aircraft nacelle (1), including: a front frame (11), a cowl (21) which can move between an operating position and an intermediate maintenance position downstream of the front frame (11), means (26) for moving the cowl (21) between closed and open positions, and an inner structure (23) which can move between an operating position and an intermediate maintenance position downstream of the front frame (11). In addition, the cowl (21) comprises two half-cowls (21a, 21b) and the inner structure (23) comprises two structure halves (23a, 23b), whereby said half-cowls (21a, 21b) and said inner structure halves (23a, 23b) can open outward when the cowl (21) and the inner structure (23) are in the intermediate maintenance position.

Owner:SAFRAN NACELLES

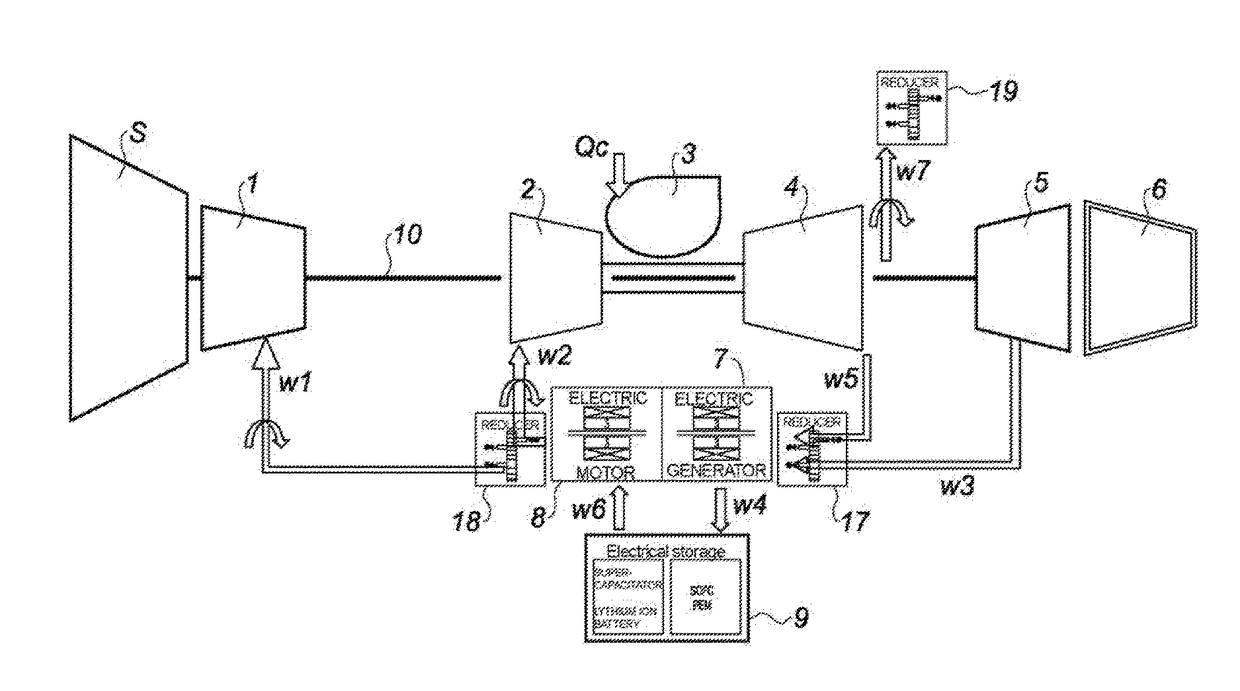

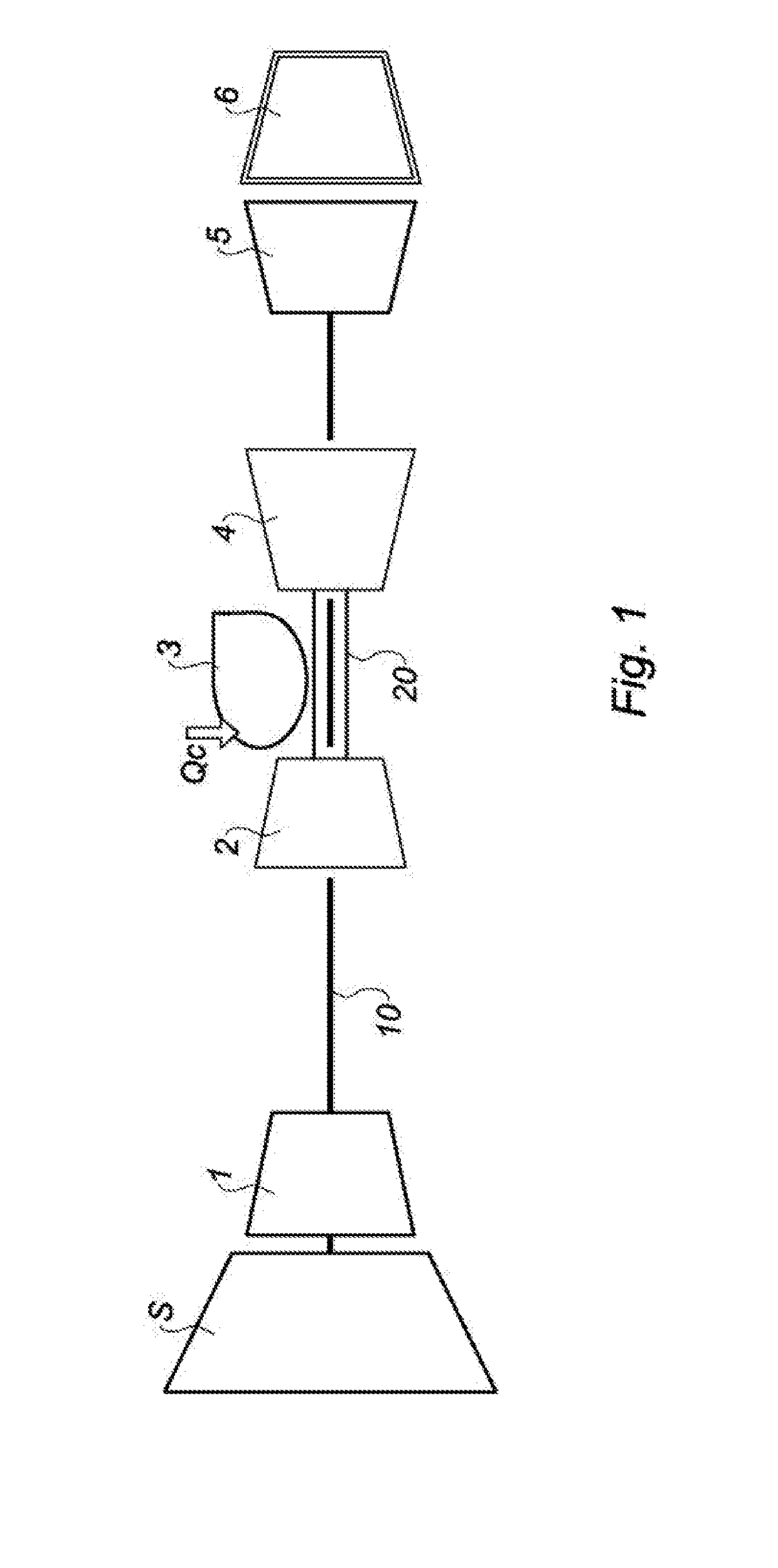

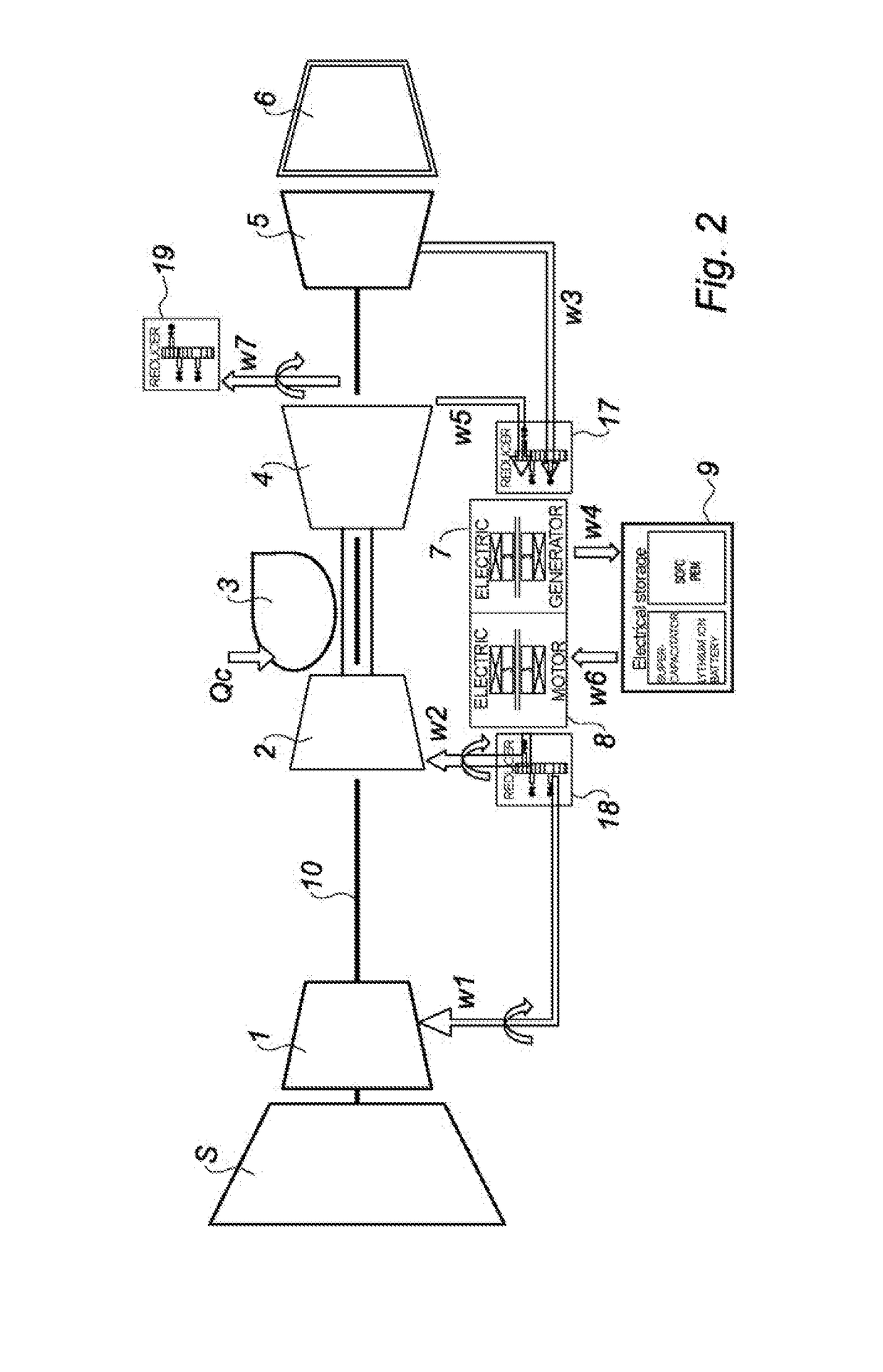

Hybridisation of the compressors of a turbojet

PendingUS20170226934A1Optimising surge marginReduce constraintsEfficient propulsion technologiesGas turbine plantsCombustion chamberJet engine

twin-flow, double body turbojet includes a fan that is positioned upstream from a gas generator and delimits primary and secondary flows. The gas generator is traversed by the primary flow and includes a low-pressure compressor, a high-pressure compressor, a combustion chamber, a high-pressure turbine and a low-pressure turbine. The low-pressure turbine is linked to the low-pressure compressor by a low-pressure rotating shaft, and the high-pressure turbine is linked to the high-pressure compressor by a high-pressure rotating shaft. The turbojet has an electric motor for injecting mechanical power into at least one of the rotating shafts. The turbojet also has a device for removing power from at least one of the rotating shafts and transforming the excess power into electrical energy. An electric storage means is positioned between the device for removing power and the electric motor.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

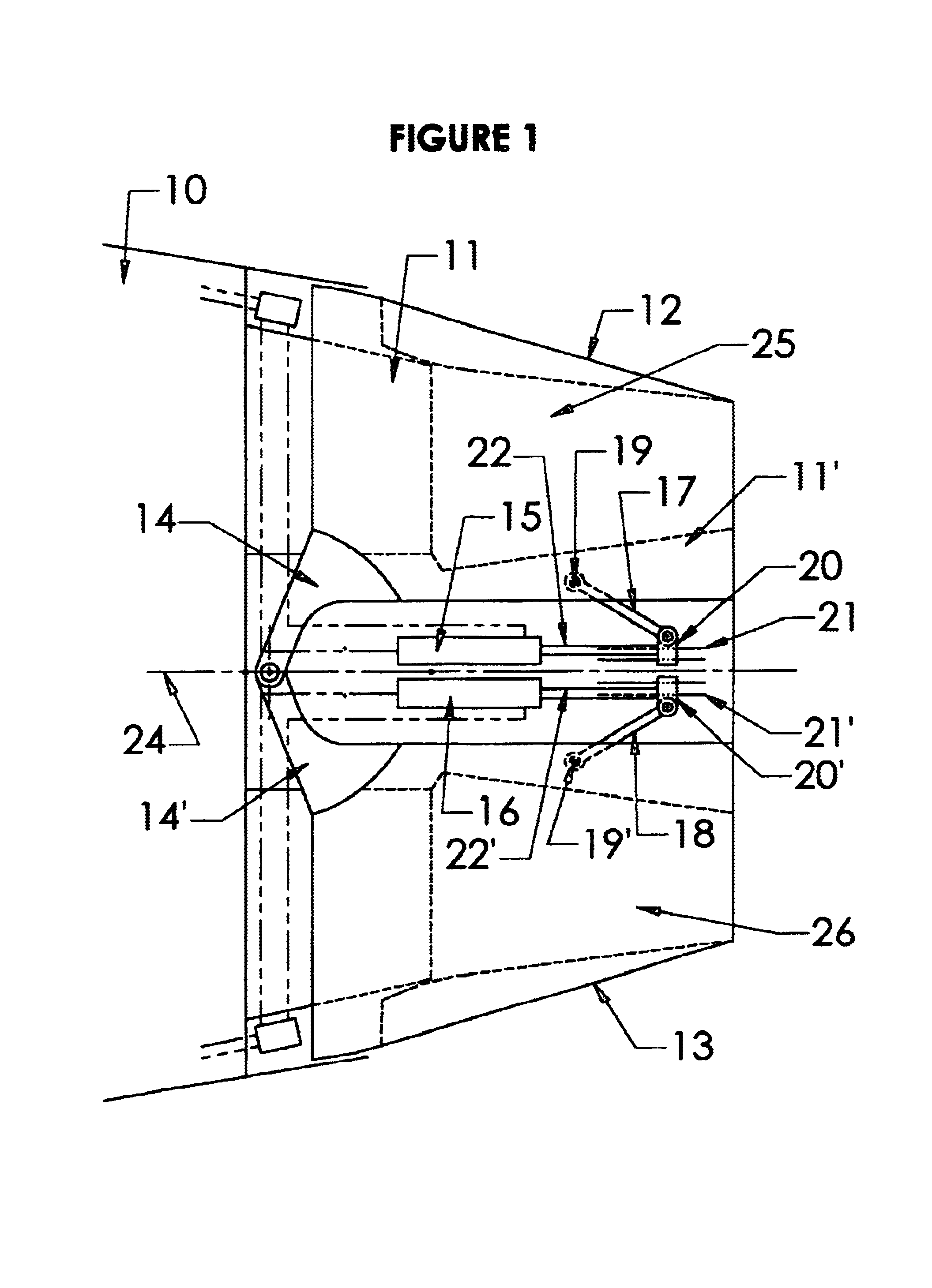

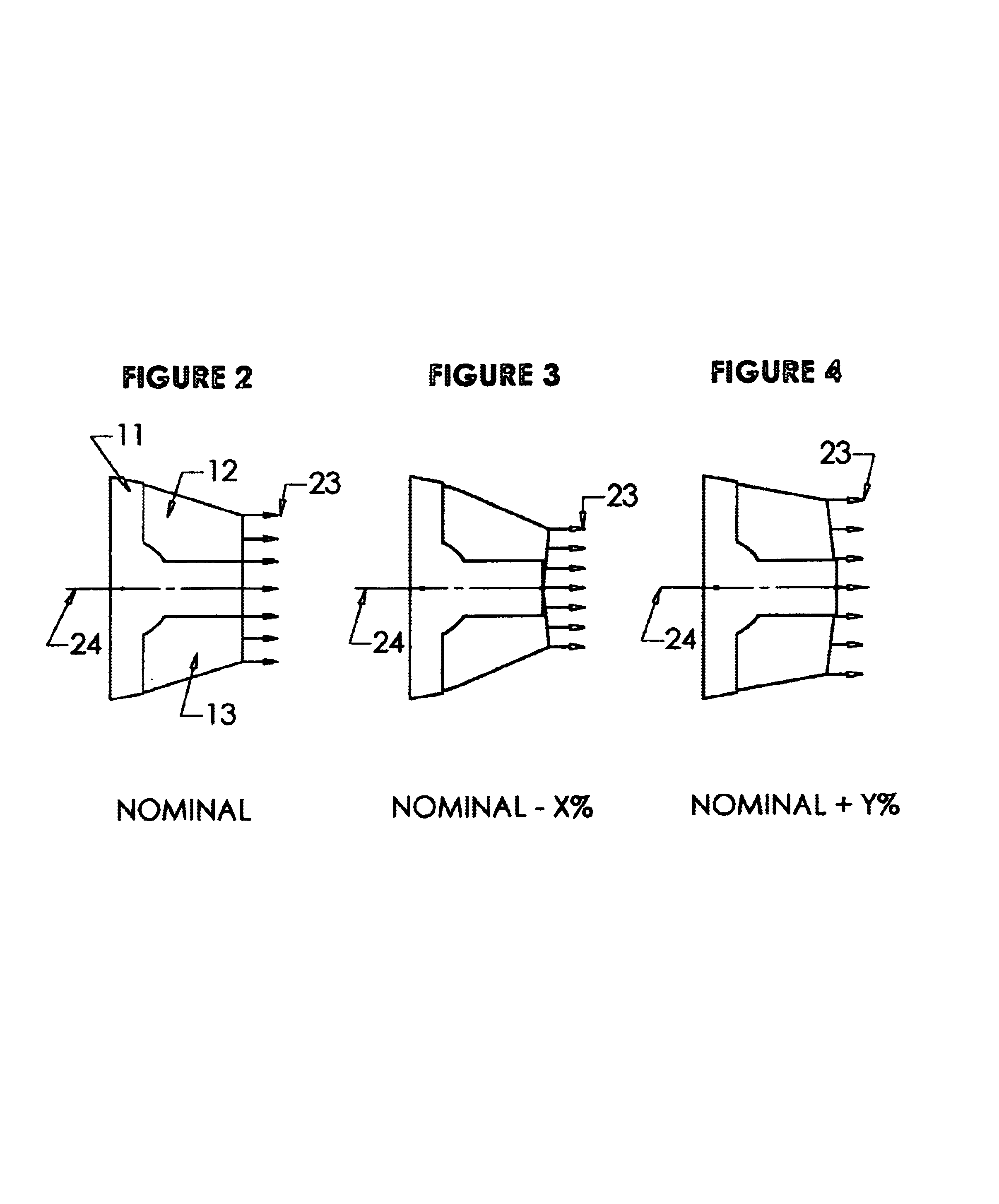

Thrust vectoring and variable exhaust area for jet engine nozzle

InactiveUS6938408B2Increased longitudinal stabilitySlow down the landing speedAircraft navigation controlSpraying apparatusJet engineThrust vectoring

A jet engine nozzle having a pair of pivoting extension arms and a pair of pivoting shells connected to a jet pipe is provided. The first extension arm is pivotally connected to the jet pipe at a first location, while the second extension arm is pivotally connected to the jet pipe at a second location. Each shell is pivotally connected at both the first and second locations. An axis of rotation associated with the first location is coaxial to an axis of rotation associated with the second location. Independent actuation means are provided to rotate the extension arms and the shells, thereby enabling adjustment of the thrust-vector angle or the exhaust area of the nozzle.

Owner:PROPULSION VECTORING

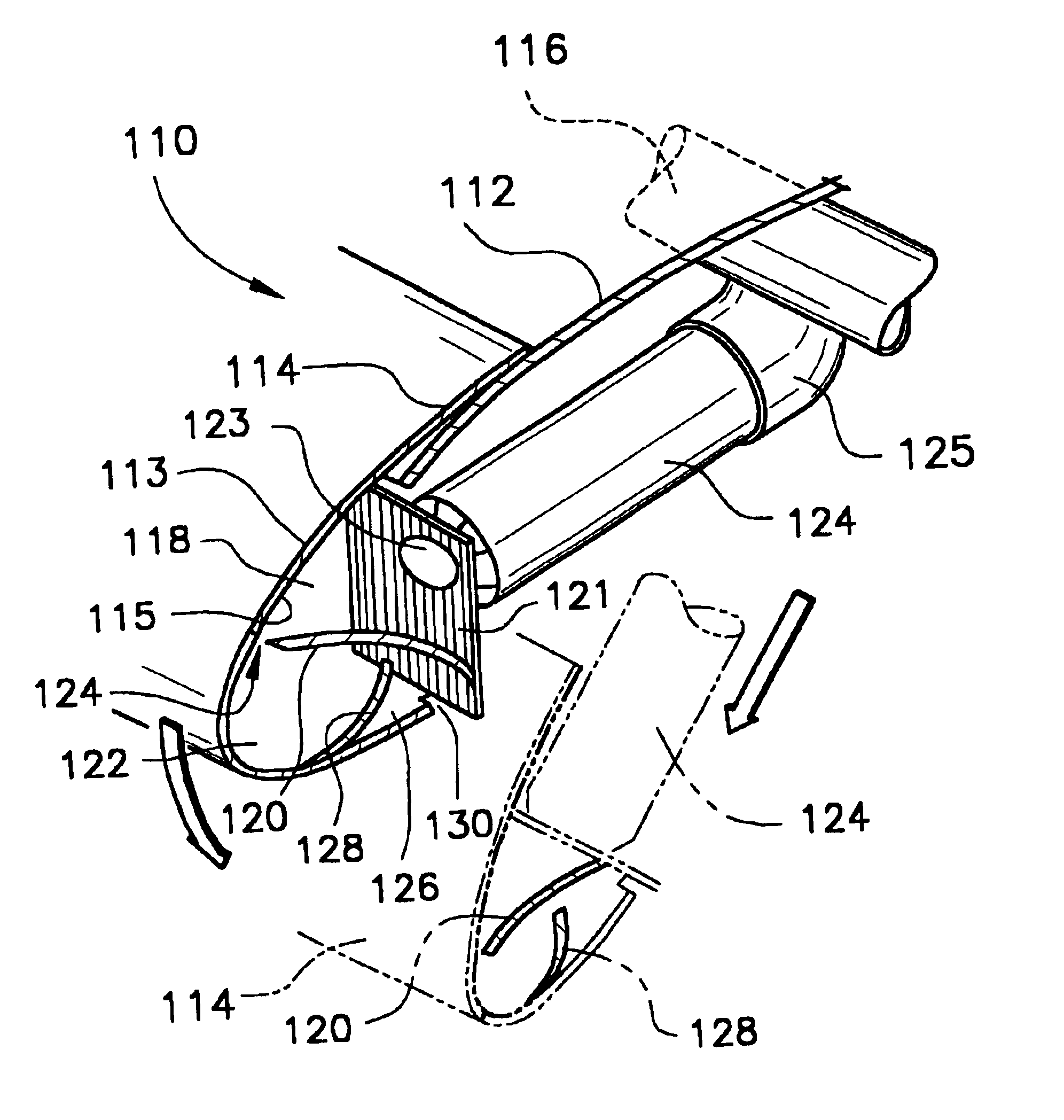

Airfoil anti-icing assembly and method

InactiveUS6702233B1De-icing equipmentsHot gas positive displacement engine plantsJet engineEngineering

An anti-icing assembly for an airfoil such as an aircraft wing or slat comprises: (a) an airfoil having an exterior surface and interior wall defining an interior cavity, and bottom, middle and side portions all adjacent to the interior cavity; (b) an inlet plenum integral to the airfoil, wherein the inlet plenum comprises (i) an inlet baffle capable of directing hot gases into the airfoil interior cavity and (ii) a throat section interfacing the inlet plenum and airfoil interior cavity; and (c) an outlet plenum integral to the airfoil, wherein the outlet plenum comprises an outlet baffle capable of directing hot gases from the airfoil interior cavity. The airfoil anti-icing method of this invention comprises providing hot gases such as jet engine bleed air to the airfoil assembly of this invention, swirling the hot gases within the airfoil interior cavity, and discharging the hot gases from the airfoil interior cavity through the airfoil outlet end. The system of this invention comprises a source of hot gases, typically jet engine bleed air, and the airfoil assembly of this invention.

Owner:ROHR INC

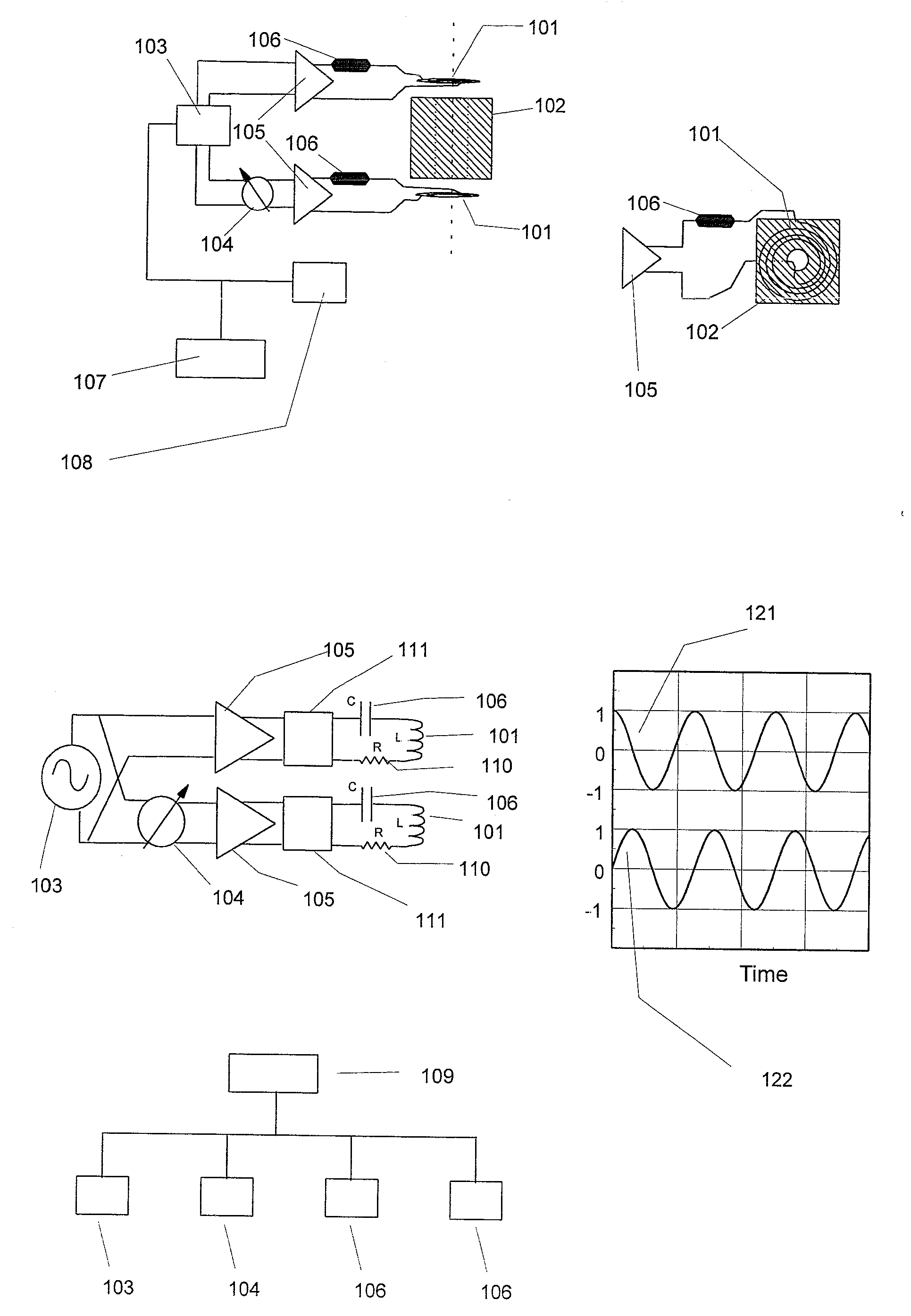

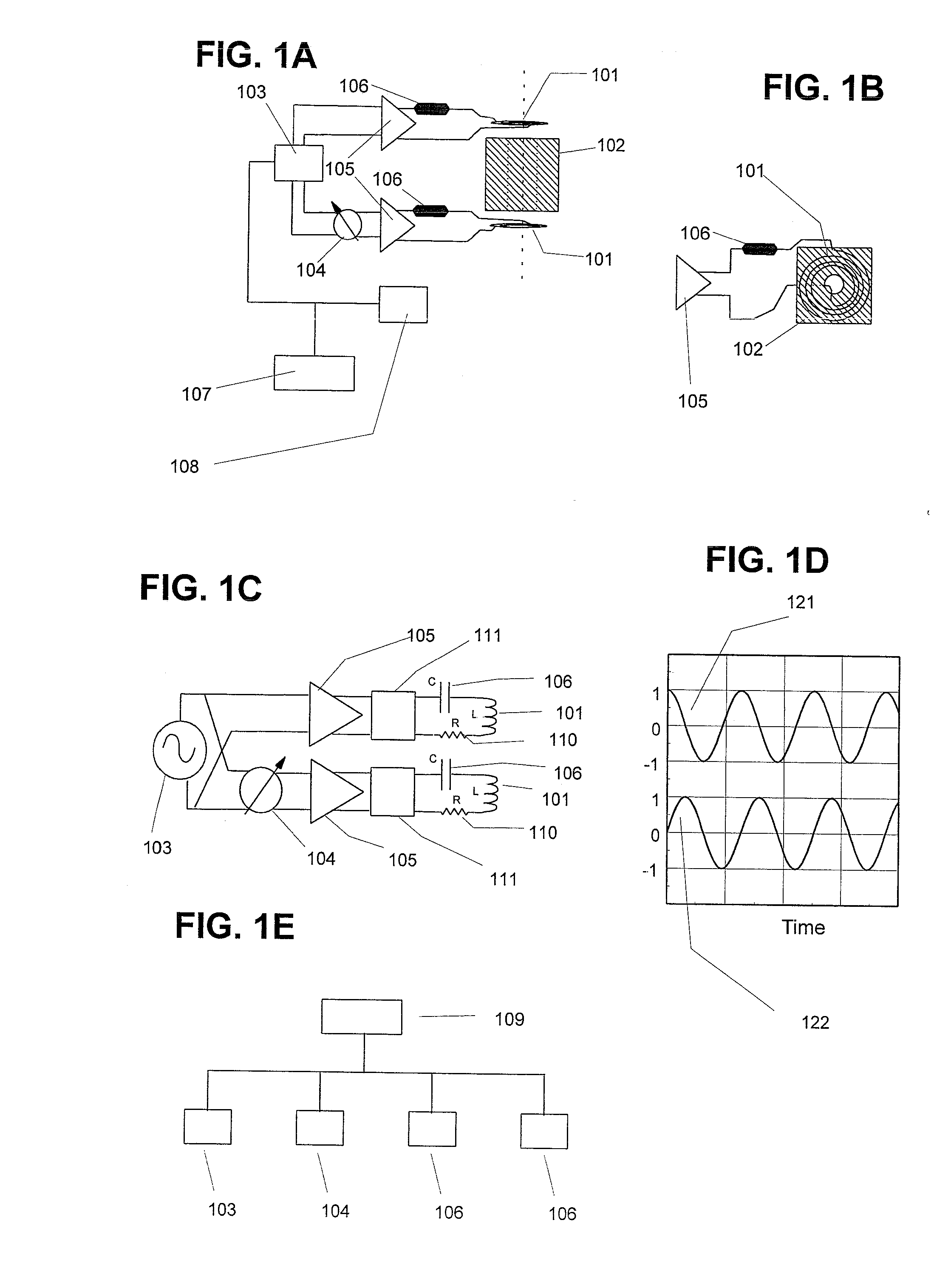

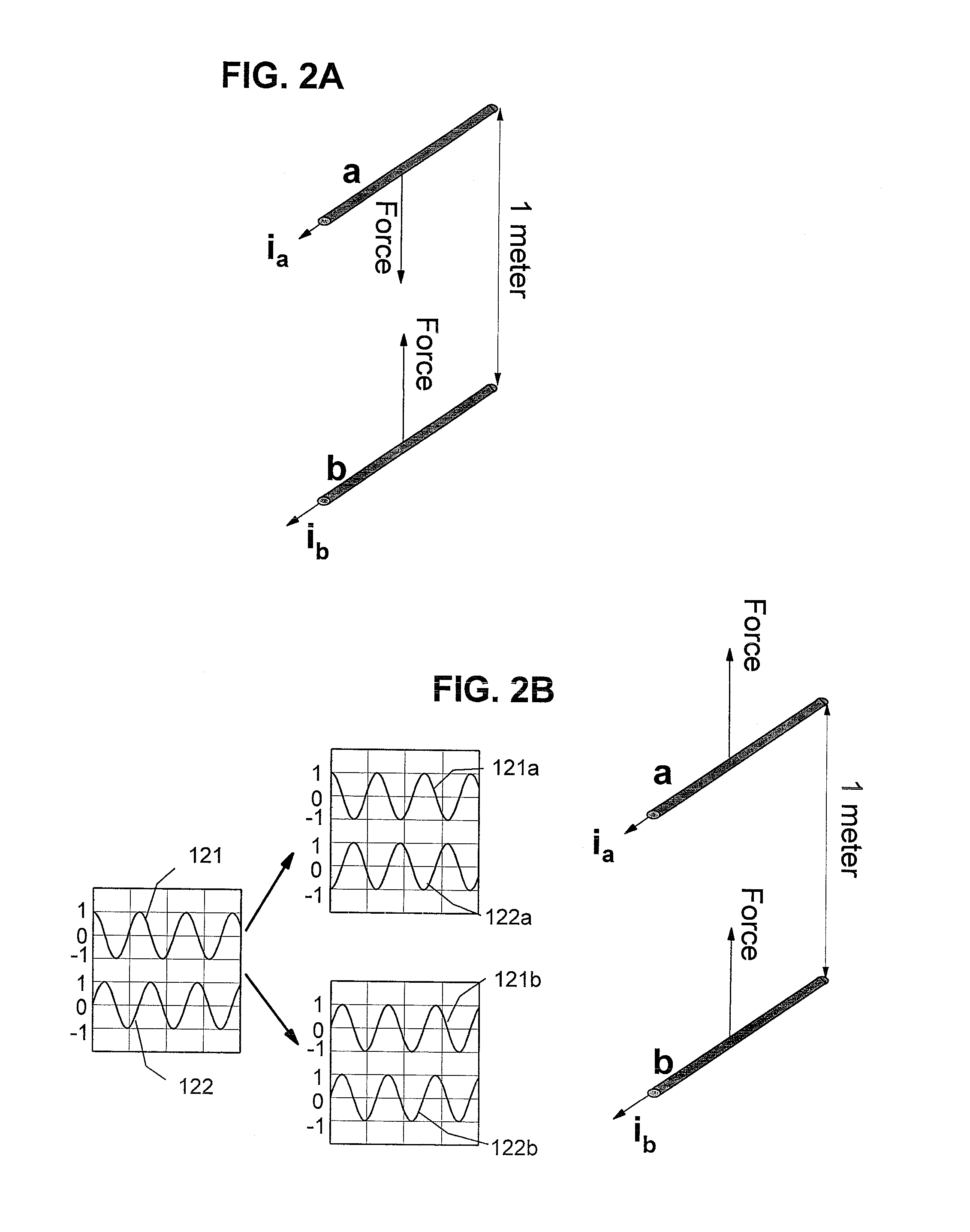

Efficient RF Electromagnetic Propulsion System With Communications Capability

ActiveUS20100326042A1Reduce lossesImprove efficiencyMachines/enginesUsing plasmaDielectricElectromagnetic field

An electronic propulsion engine that creates a propulsive force or thrust using electromagnetic forces or electrostatic forces, with an effect that is similar to the thrust of a jet or rocket engine. Forces are generated using electromagnets or capacitor plates that are separated by dielectric spacer cores and are operated with two modulated currents. The two modulated currents are synchronized, but with a relative phase such that the forces on the two magnets or capacitor plates are not balanced. Included are techniques to reduce circuit impedance and control electric-magnetic field dispersion, such as tuned LCR circuits, dielectric core materials between the magnets or capacitor plates, and RF superconductors result in high propulsion efficiencies. The system operates at RF frequencies and can also be used as a communication device.

Owner:MCLEAN JOHN P +1

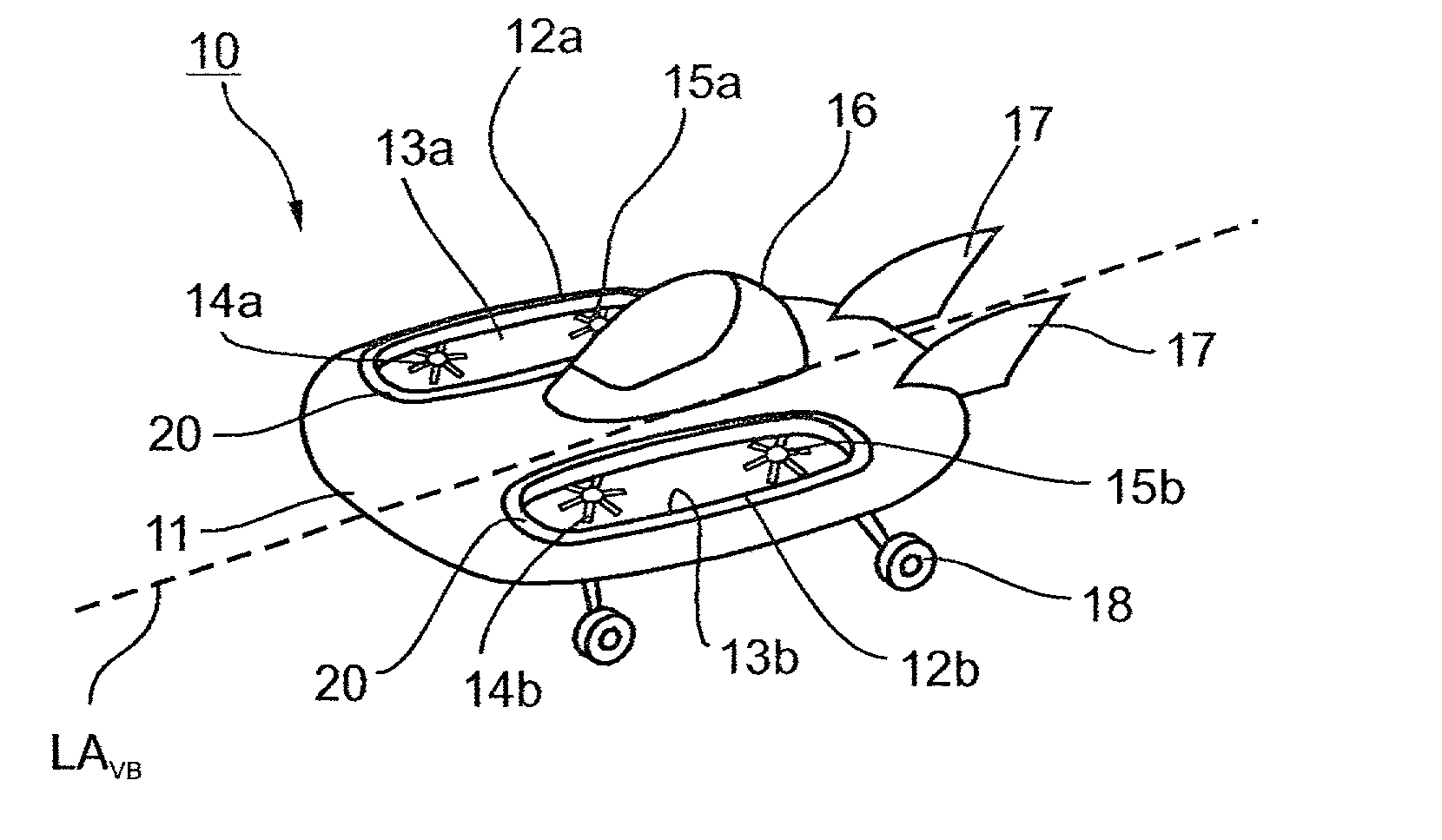

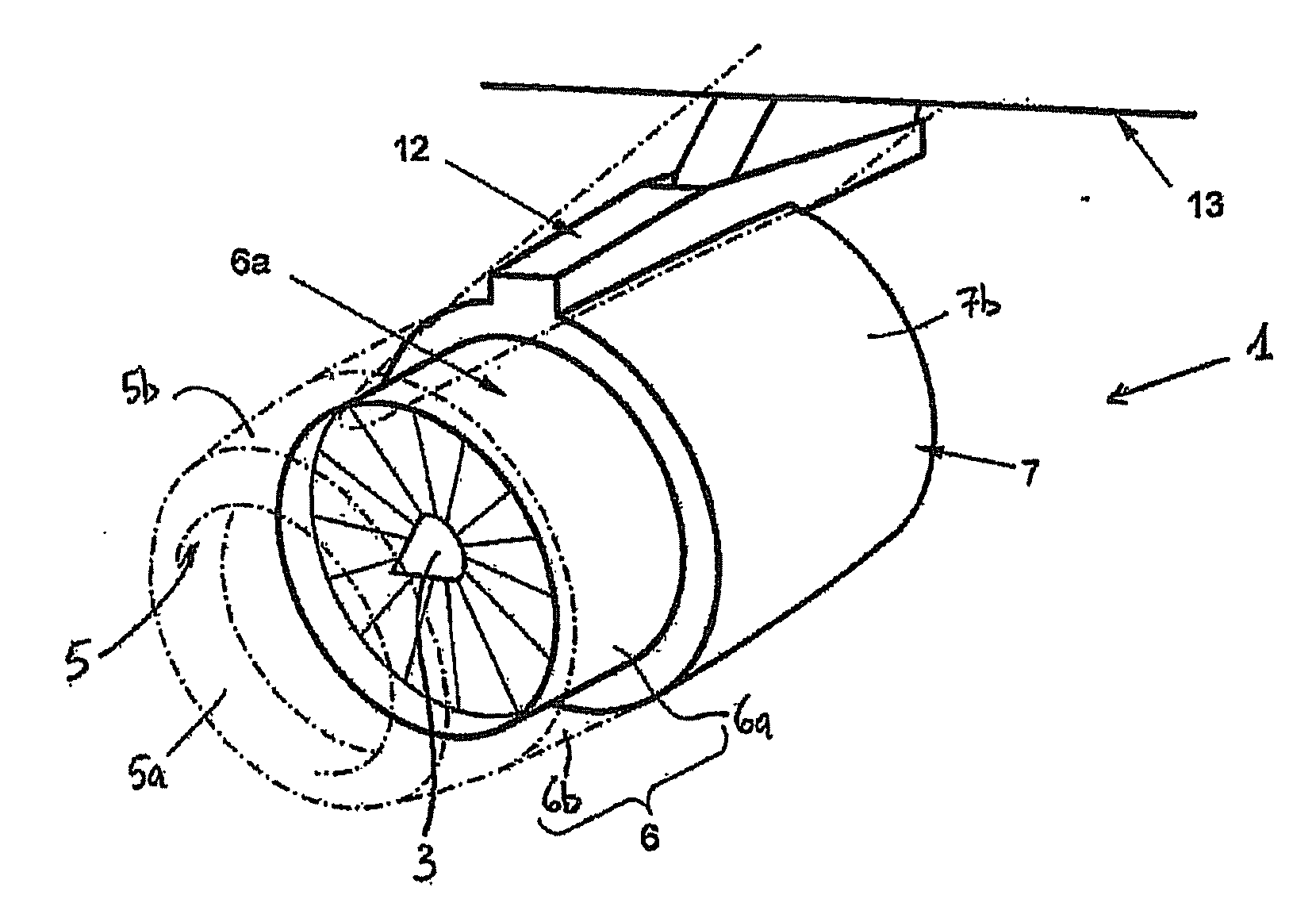

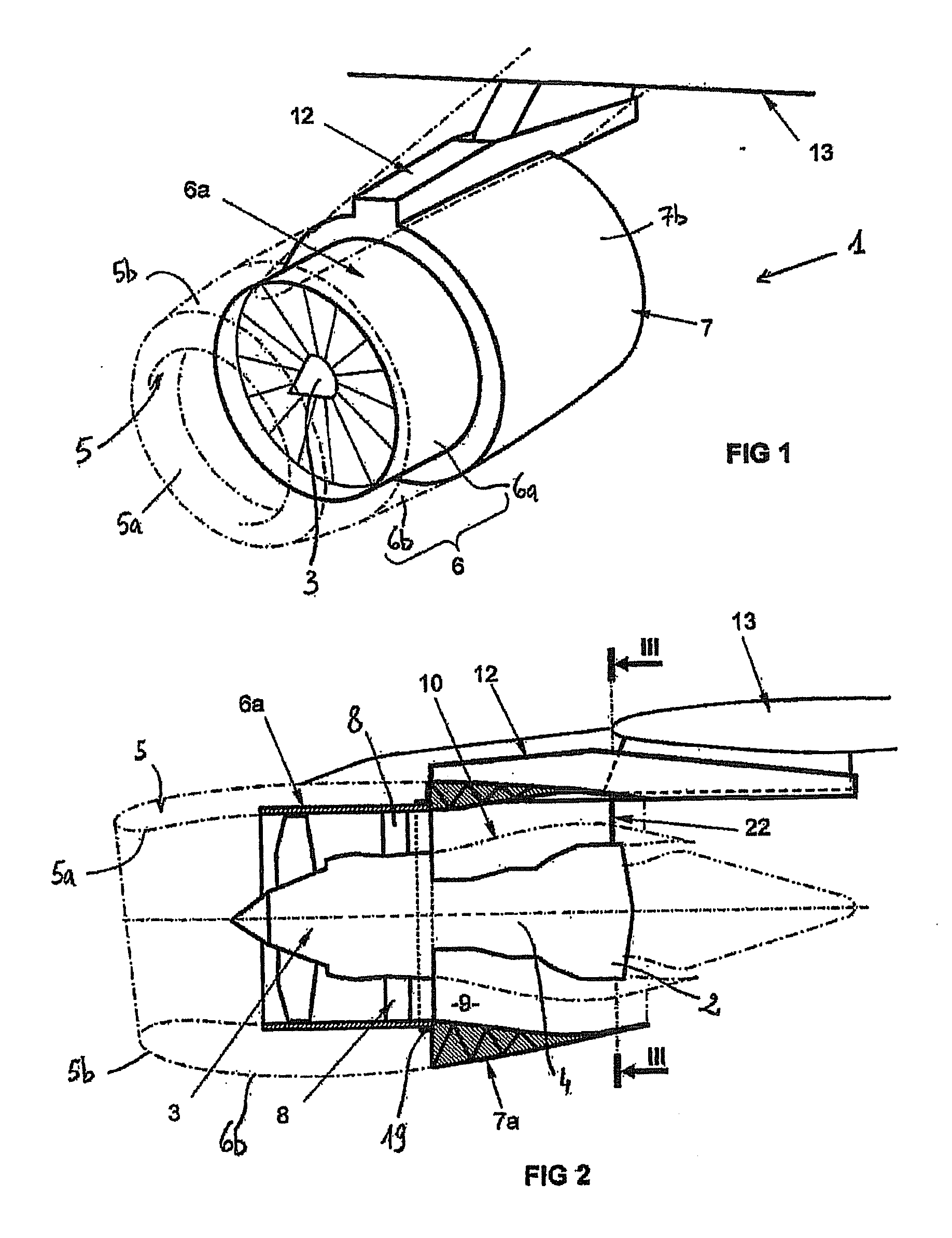

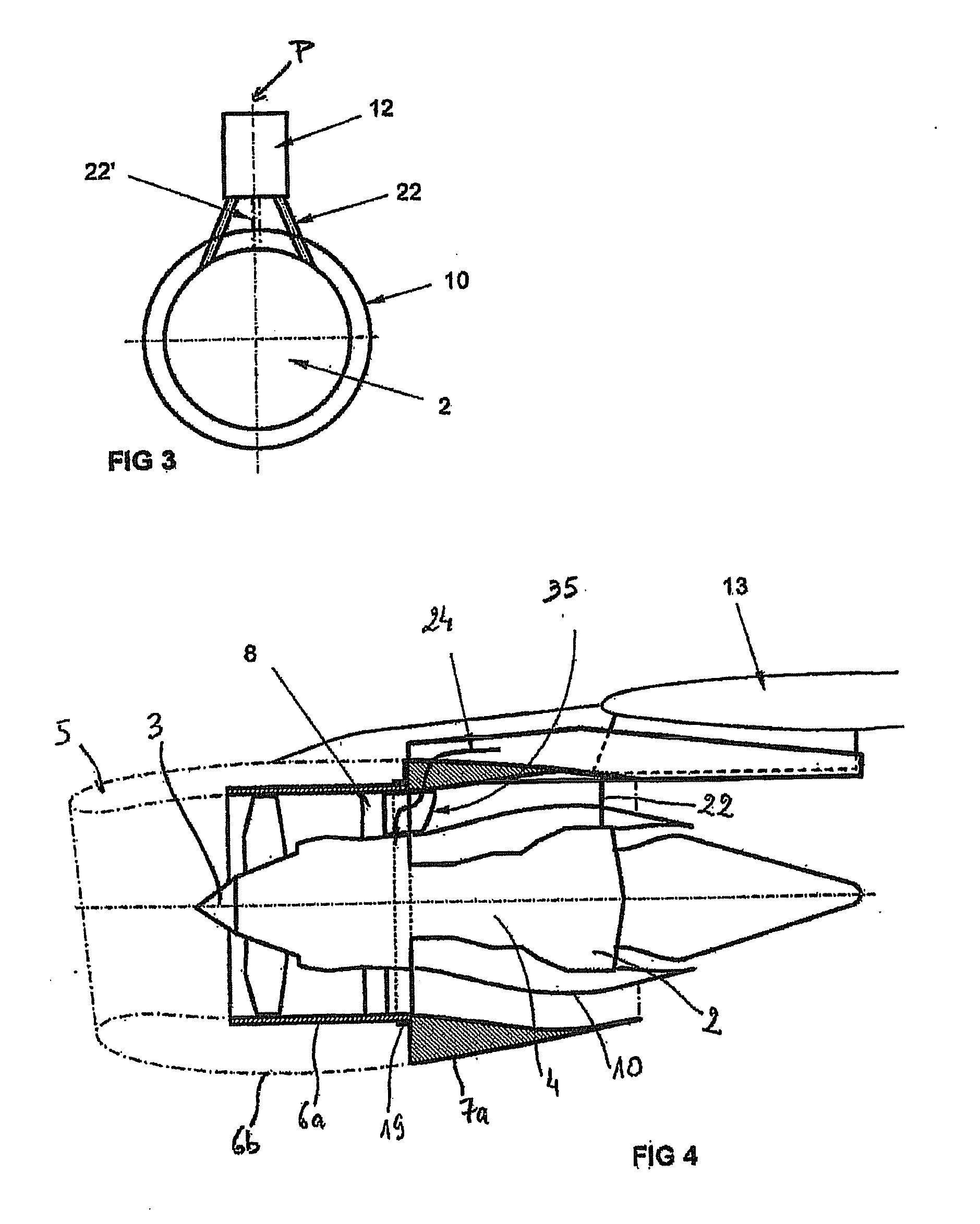

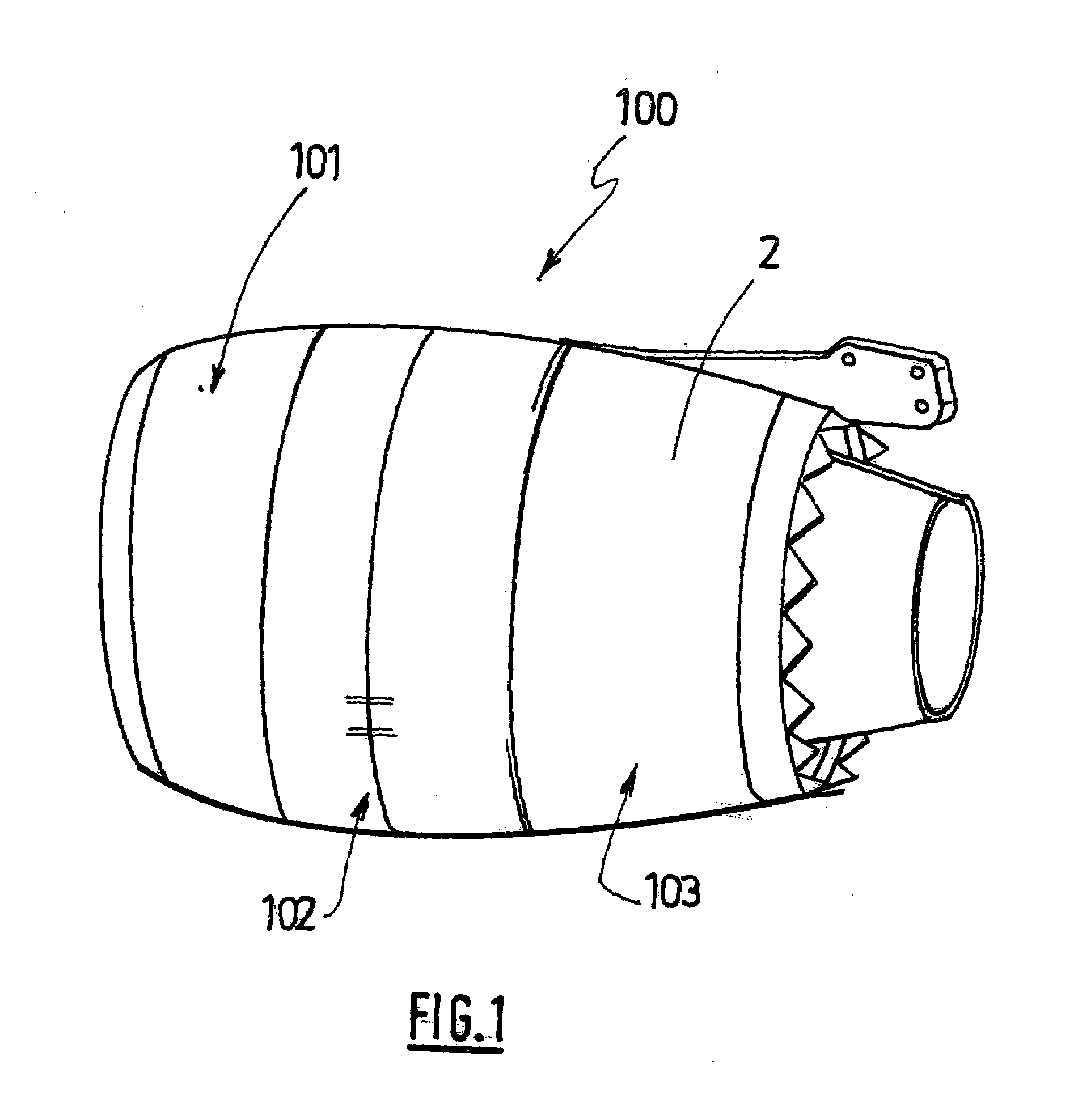

Bypass turbojet engine nacelle

InactiveUS20100040466A1Avoid disadvantagesImprove performancePower plant arrangements/mountingGas turbine plantsNacelleJet engine

The nacelle (1) comprises an air intake (5) upstream of the turbojet engine (2), a middle section (6) an internal casing (6a) of which is intended to surround a fan (3) of the turbojet engine (2), and a downstream section (7) comprising an external structure (7a)which is rigidly connected to a downstream part of the casing (6a) of the fan (3) so as to support the turbojet engine (2) and has means of attachment to a strut (12) intended to be connected to a fixed structure (13) of an aeroplane.

Owner:AIRCELLE

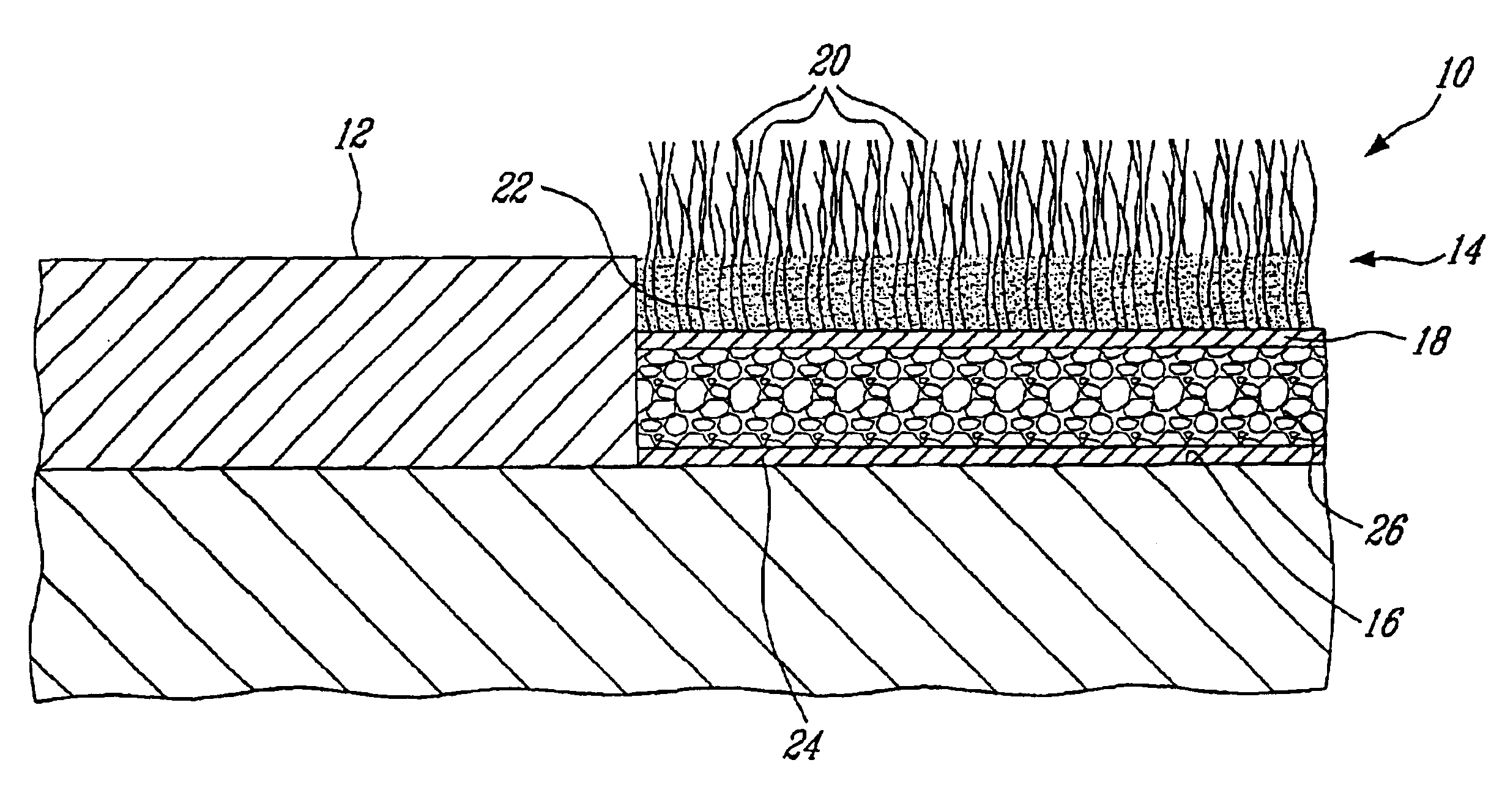

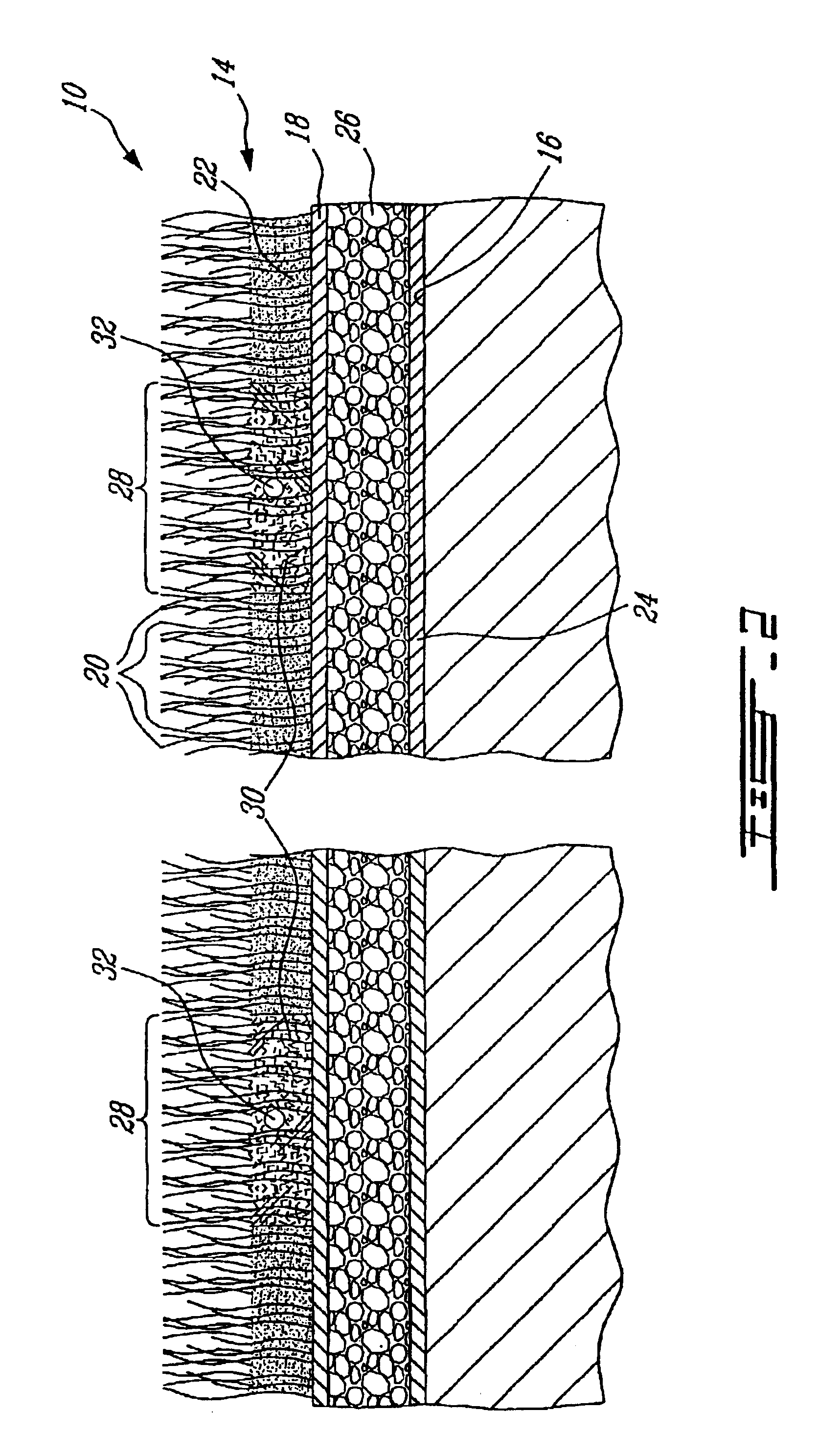

Artificial grass for landscaping

InactiveUS6946181B2Eliminating birds from an airfieldEasy maintenanceTraffic signalsGlass/slag layered productsJet engineLandscaping

An artificial grass surface (10) suited for bordering a runway (12) of an airfield in order to reduce the presence of birds in the airfield. The artificial grass surface (10) includes a pile fabric (14) having a plurality of pile elements (20) extending from a backing mat (18) and resembling grass. A water barrier (24) is provided for preventing water from percolating to the compacted soil surface. An infilled particulate material (22) is dispersed among the pile elements (20). A stabilizer is provided to resist dislodgment of the infilled particulate material (22) at the edges of the runways by the thrust of jet engines and to keep the particulate material (22) in the pile elements (20) when the edges of the runways are vacuumed to remove silt.

Owner:FIELDTURF TARKETT

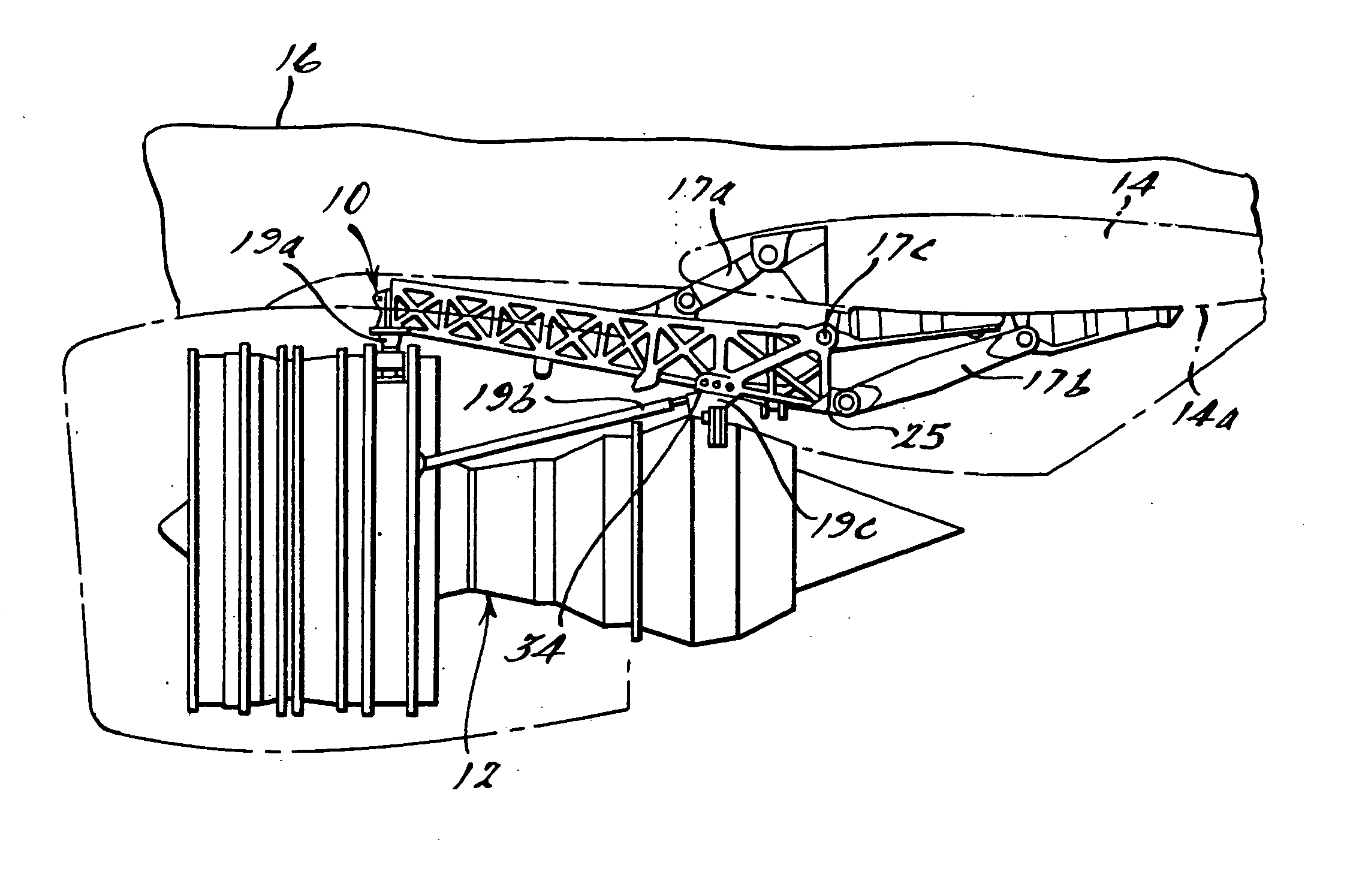

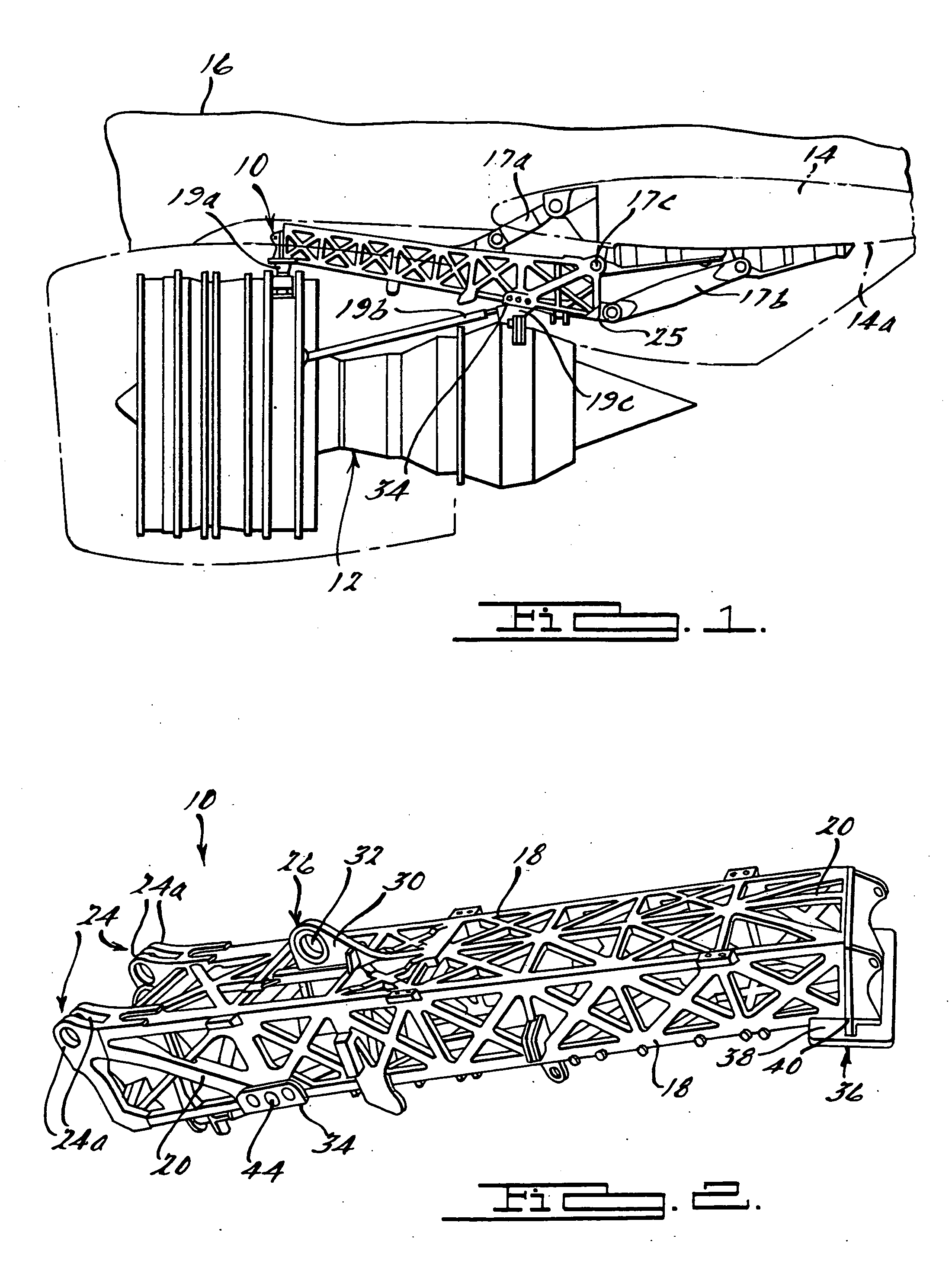

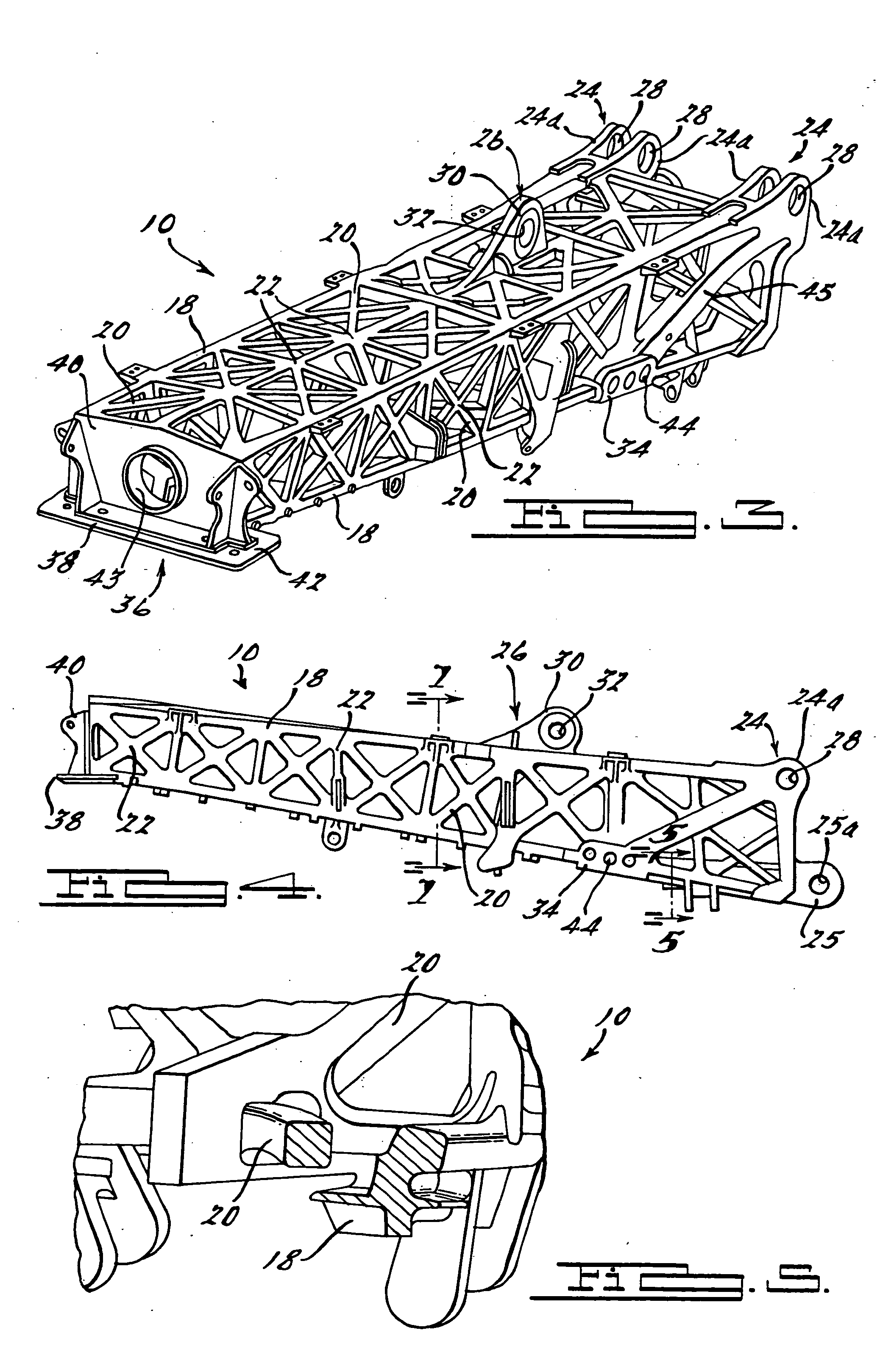

Cast unitized primary truss structure and method

ActiveUS20050274485A1Produced cost-effectivelyWeight morePower plant constructionFoundry mouldsJet engineFlight vehicle

A truss structure well suited for use as an engine strut on a commercial aircraft. The truss structure is cast as a single piece integrally formed component from a titanium alloy or another suitably lightweight, structurally strong material. The truss structure includes a plurality of integrally formed attachment structures which enable the truss structure to be secured to an element of an aircraft such as a wing. A plurality of attachment areas for an element such as an engine is also formed that allows the element (e.g. jet engine) to be secured to the truss structure. The truss structure includes a plurality of elongated rails and truss elements that are arranged to provide redundant load paths to ensure that a failure of any one truss element or elongated rail will not result in a failure of the overall truss structure to support whatever load is required.

Owner:THE BOEING CO

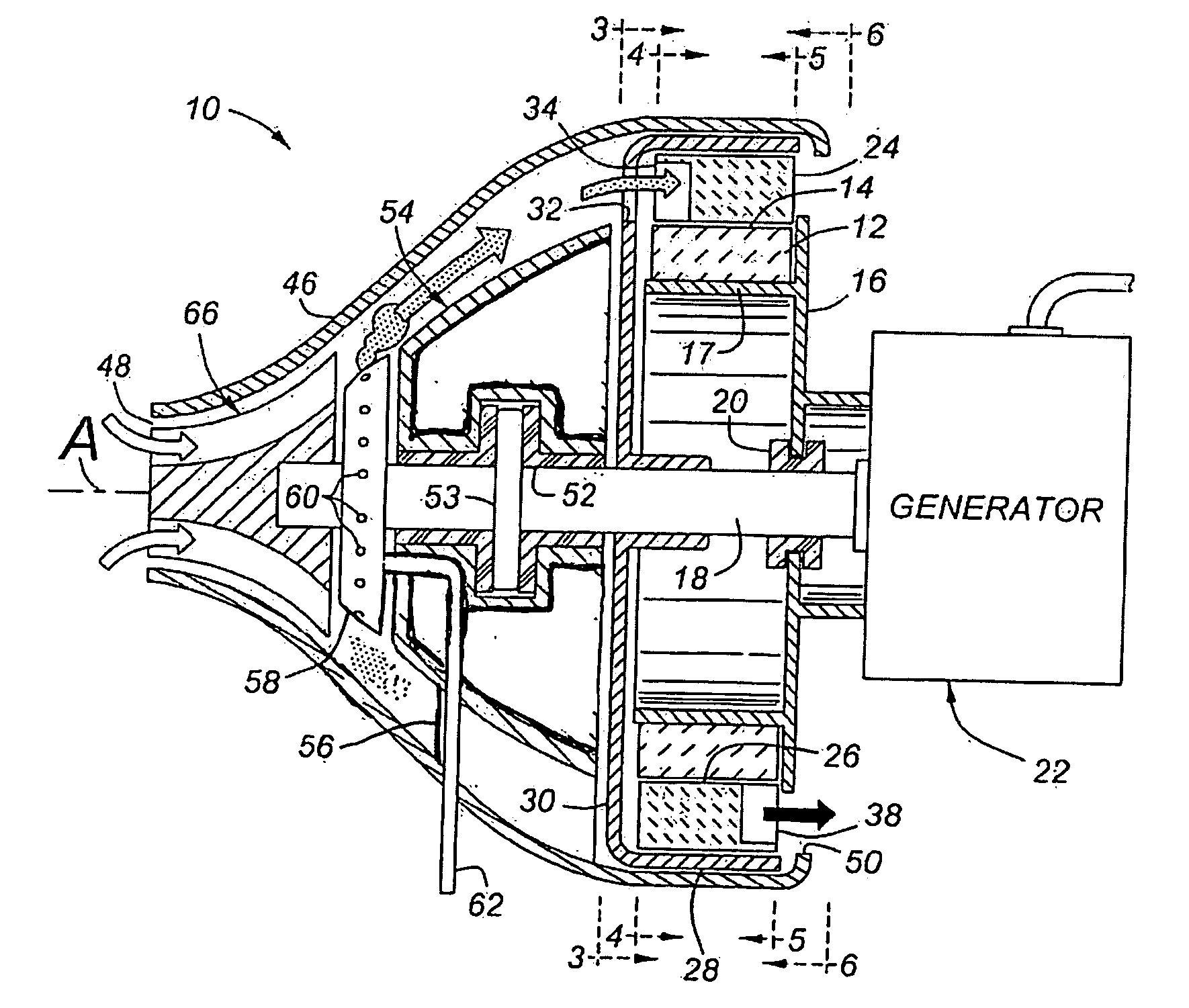

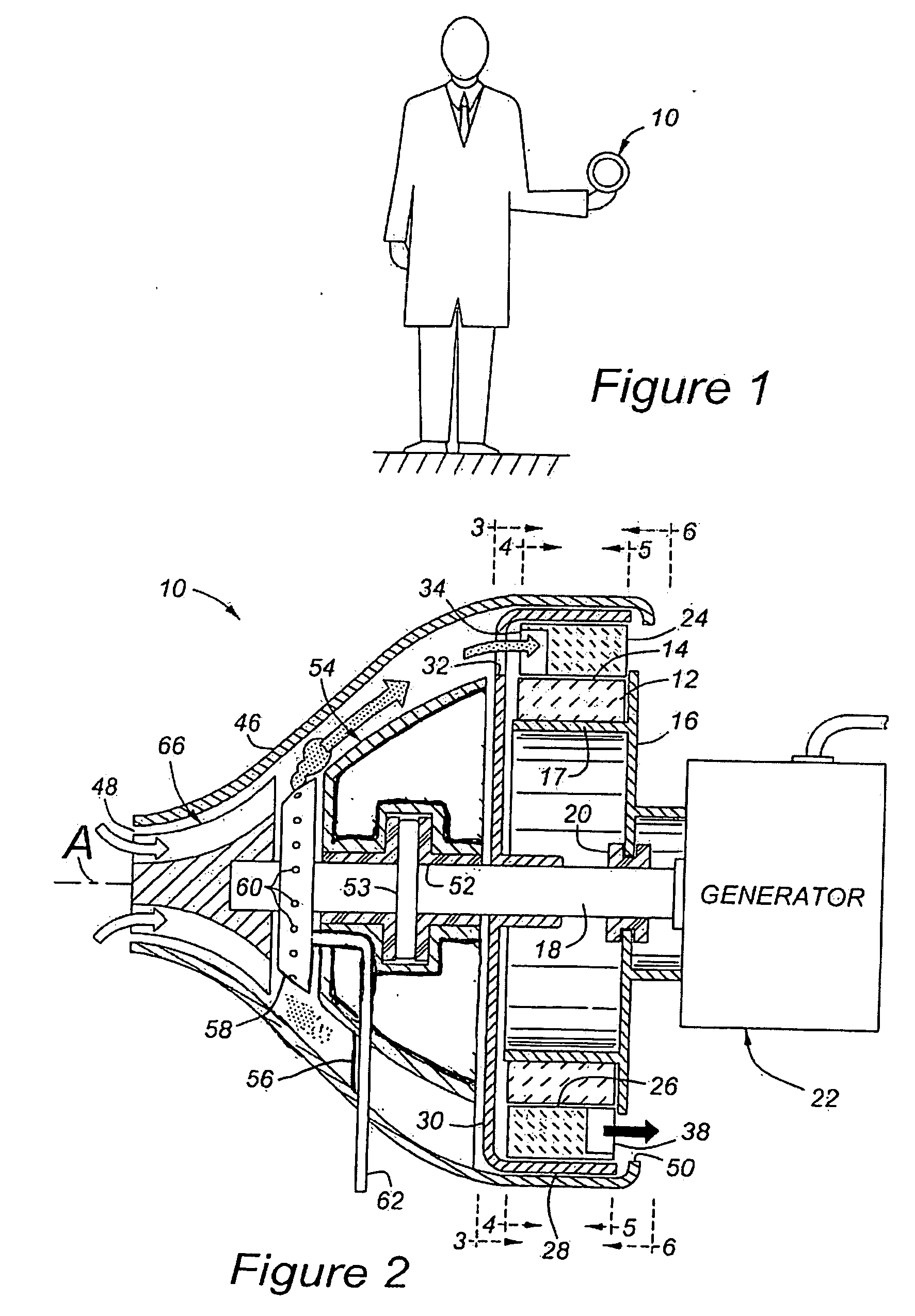

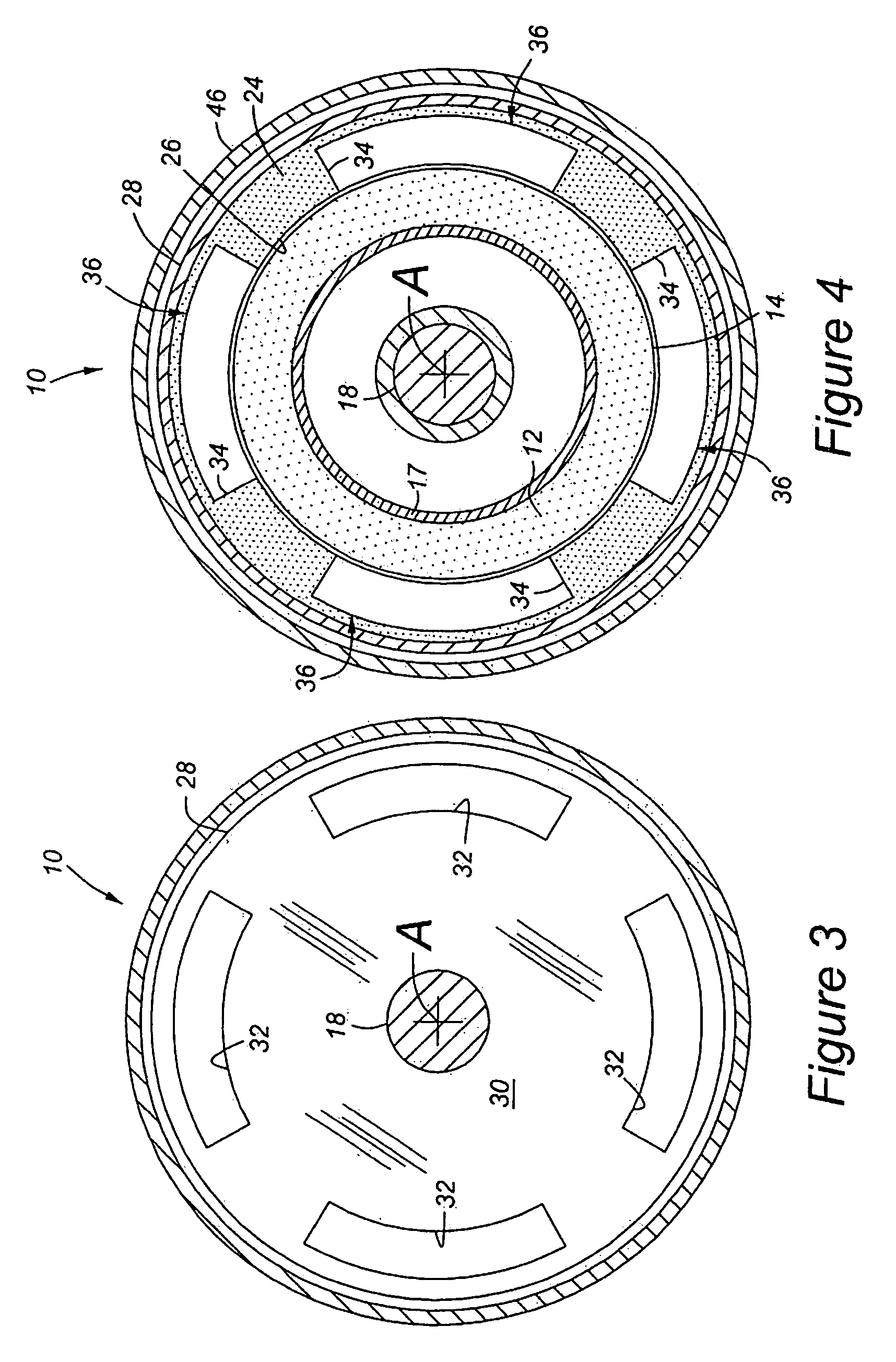

Rotary ramjet turbo-generator

ActiveUS20070056290A1MiniaturizationHigh thermal efficiencyEngine manufactureEfficient propulsion technologiesBrayton cycleElectricity

A Brayton-cycle rotary ramjet engine (10) operated within the confines of a helically elongated pass-through duct formed between a preferably stationary radially outward surface (14) and an outer rotating flow channel (36). The flow channel (36) is contoured between its inlet (34) and outlet (38) to include a supersonic diffuser (40), a combustor (42) and an expansion nozzle (44). Gaseous fuel, or liquid fuel atomized by a fuel slinger (58) within a housing (46), or solid fuel in the form of fine particulates, is inter-mixed with an oxidizer prior to being directed to the flow channel inlets (34). The air and fuel are combusted in the flow channels (36) and exhausted through the rear of the housing (46). A generator (22) can be coupled to a power shaft (18) to convert net shaft power into electricity. Preferably, the rotor (24) and stator (12) are fabricated from a ceramic or other high-temperature material so that combustor exit temperatures (T3) can be operated at highly efficient levels.

Owner:RGT UNIV OF MICHIGAN

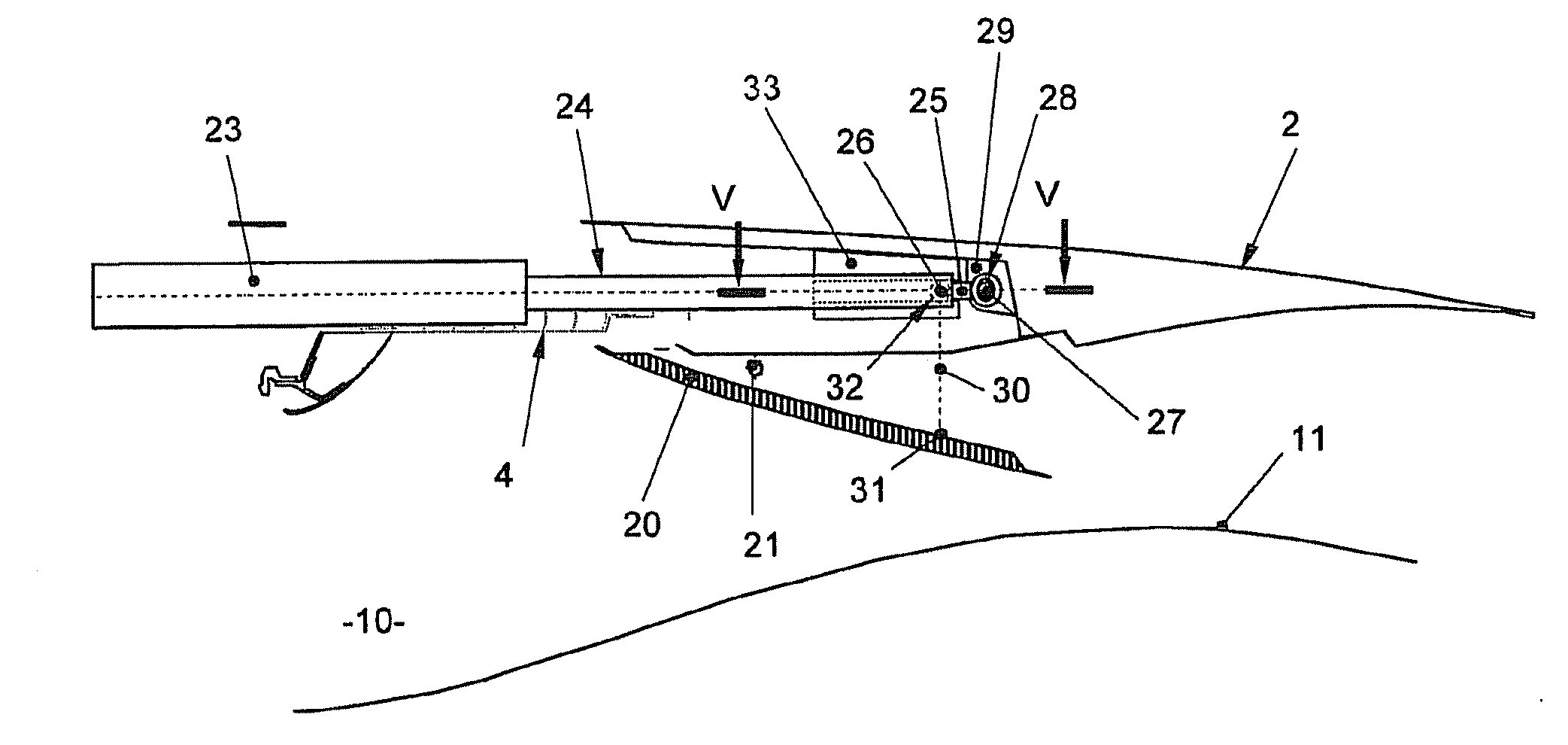

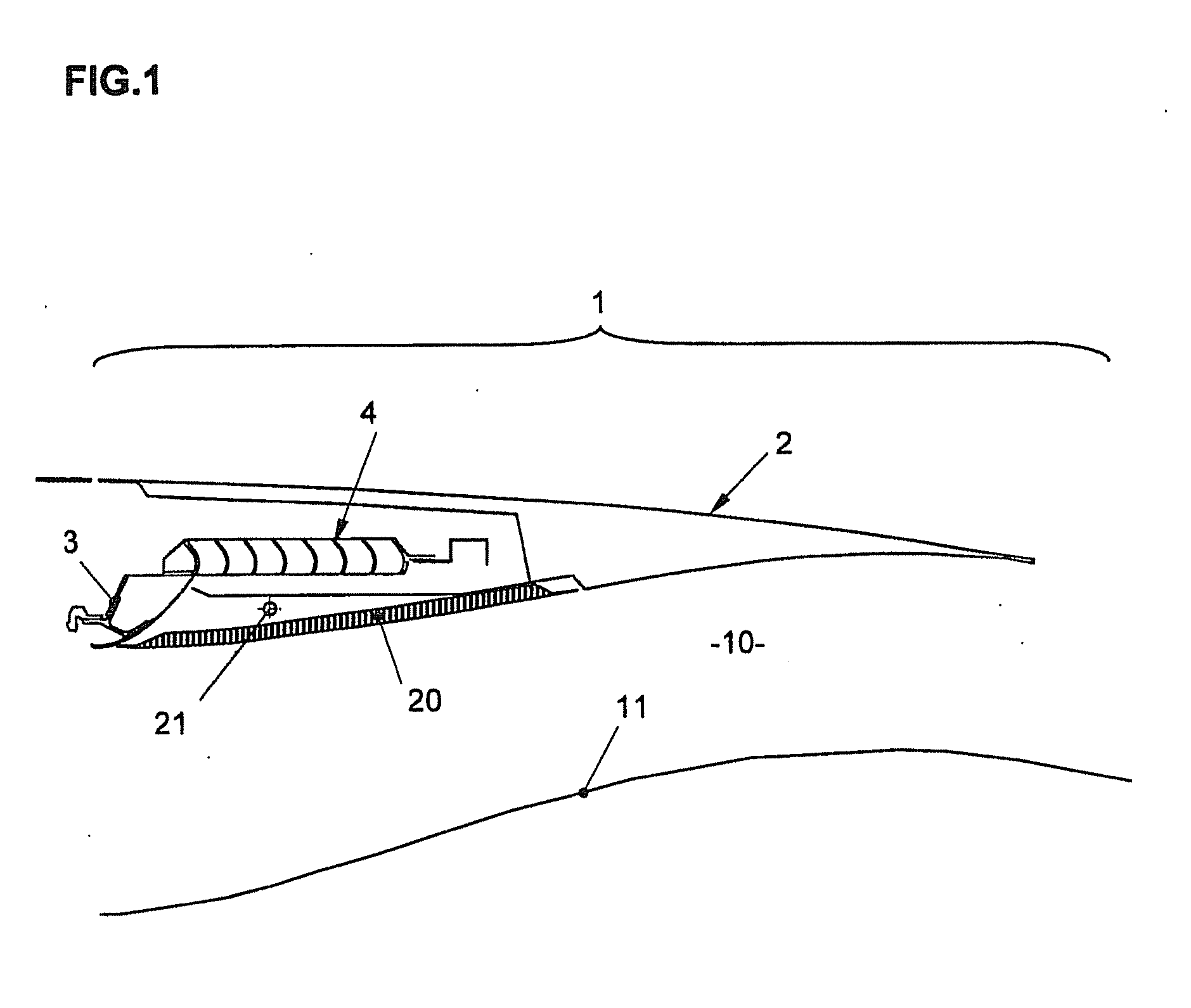

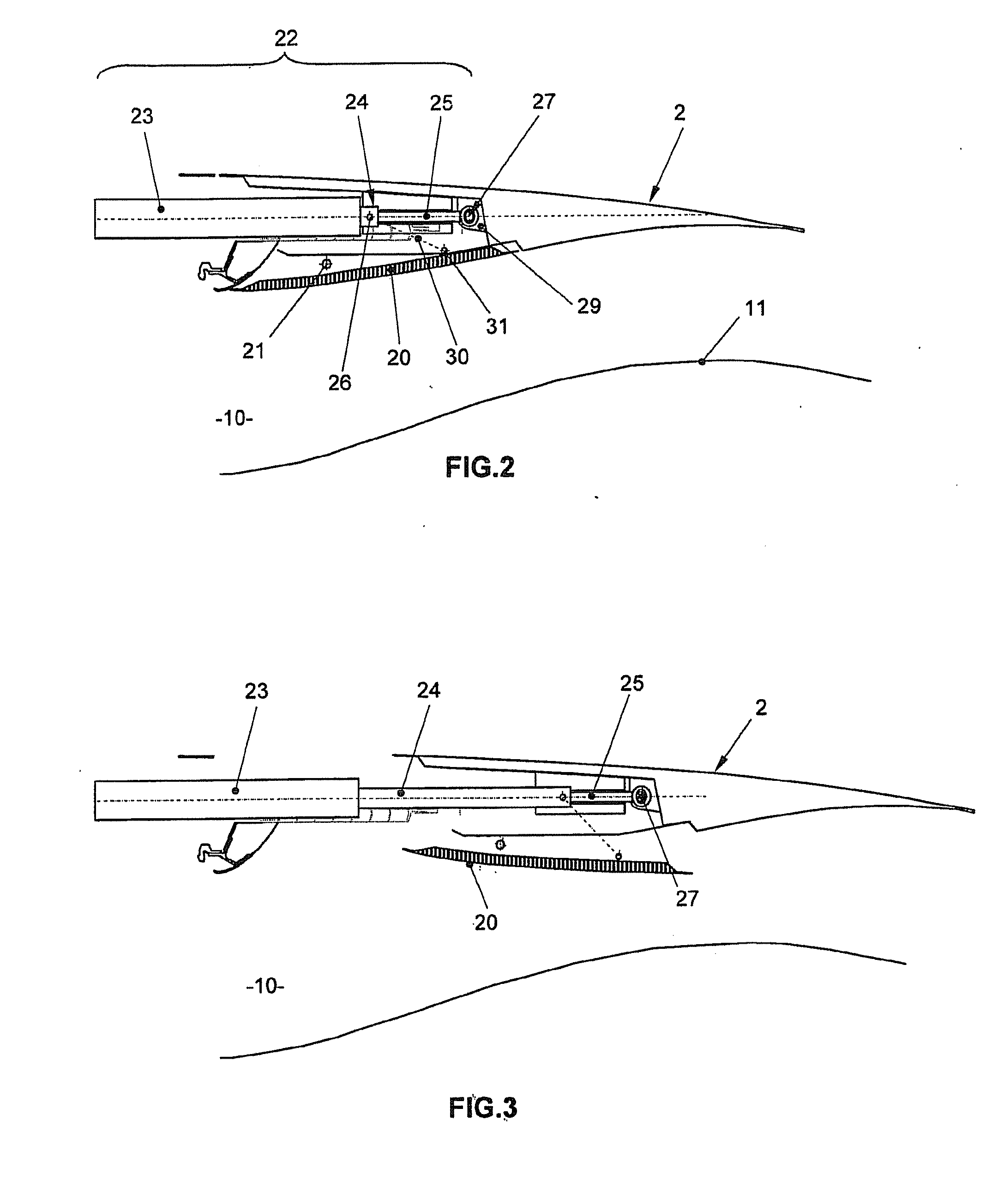

Thrust reverser with grids for jet engine

InactiveUS20100139242A1Simplicity lightnessEasy maintenanceEngine fuctionsGearingJet engineEngineering

The invention relates to a thrust reverser (1) comprising an opening with fixed grids (4) that is closed by a sliding lid (2) in case of direct thrust, and opened by the downstream longitudinal translation displacement of the lid (2) in case of thrust reversal. A flap (20) is pivotally mounted at one upstream end on the lid (2) and can move between a retracted position and an expanded position in which, in case of thrust reversal, it blocks an annular channel (10) in order to redirect a gas flow towards the grid opening (4). A slider (24) for driving the flap (20) is mounted so as to be capable of displacement in at least one translation guiding rail (33) provided in the structure of the lid (2), and is connected to a downstream end of the flap (20) through a driving connecting rod (30) so that a translation movement of the slider (24) in the guiding rail (33) results in a pivoting of the connecting rod (30) and of the flap (20). Actuation means (22) are provided for driving the slider (24) in a translation movement in the guiding rail (33) when the lid (2) is in a downstream translation phase.

Owner:SAFRAN NACELLES

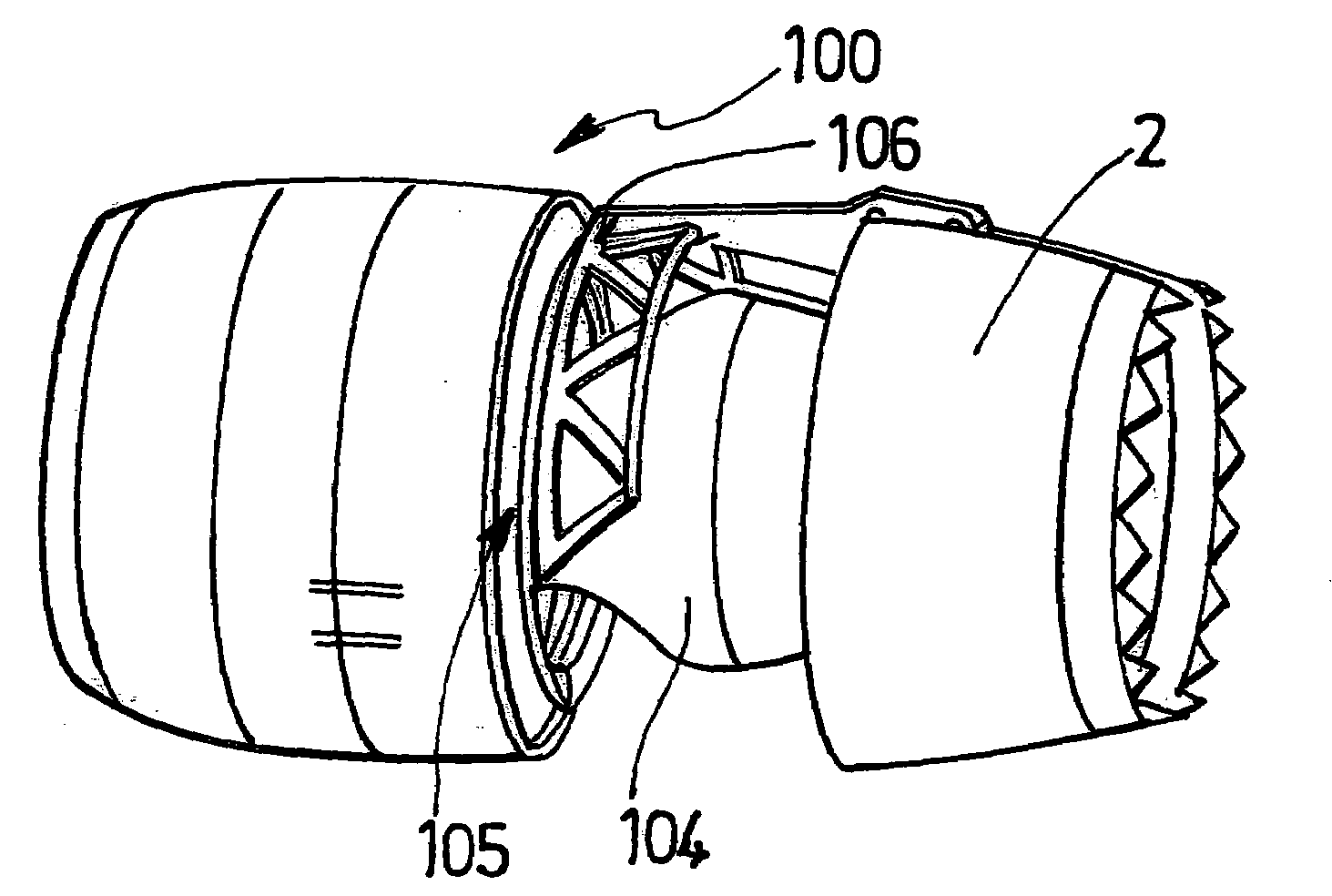

Translatable thrust inverter for jet engine

InactiveUS20100001123A1Simply openedPower plant arrangements/mountingAircraft power plant componentsNacelleJet engine

Owner:SAFRAN NACELLES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com