Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4475 results about "Resin matrix" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

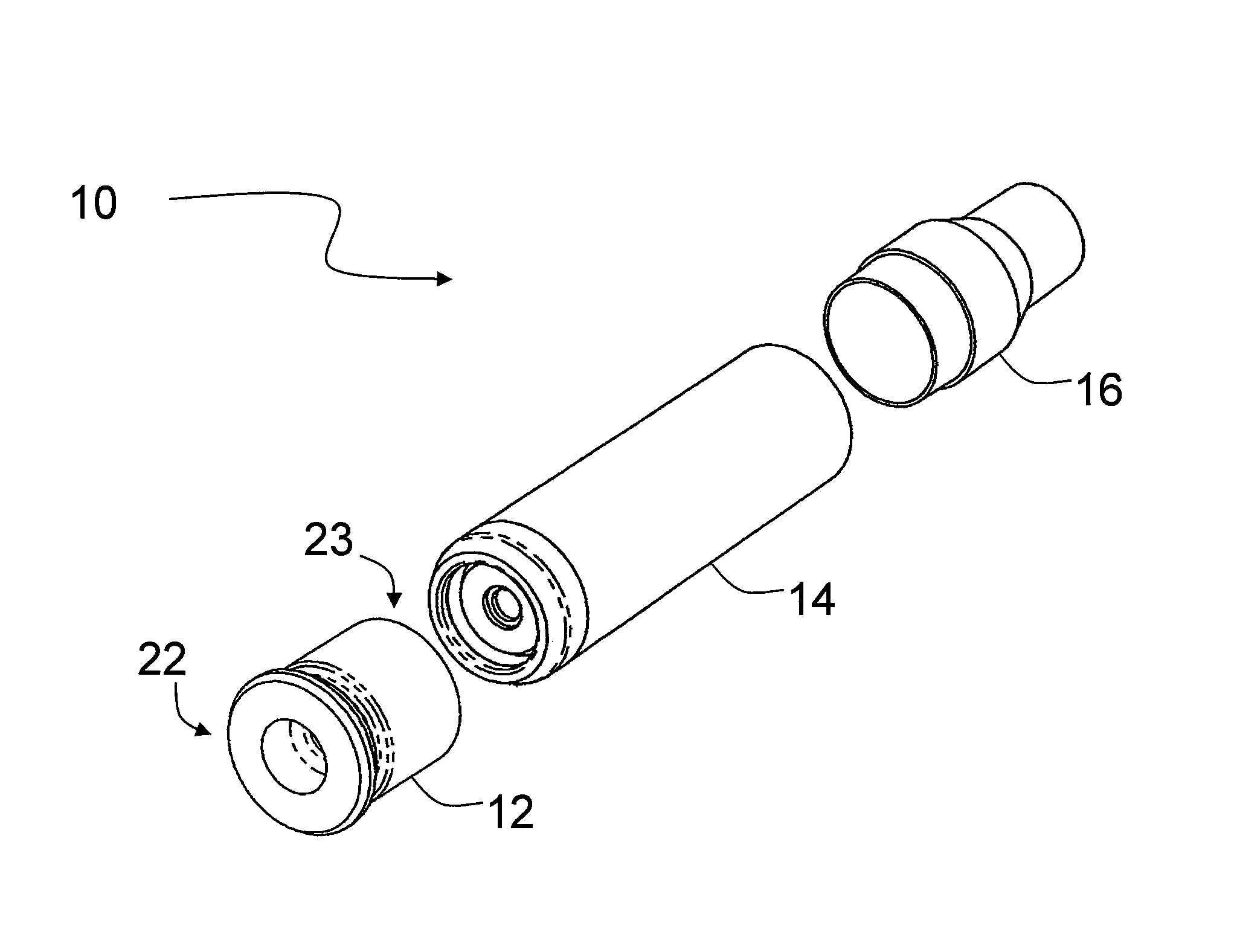

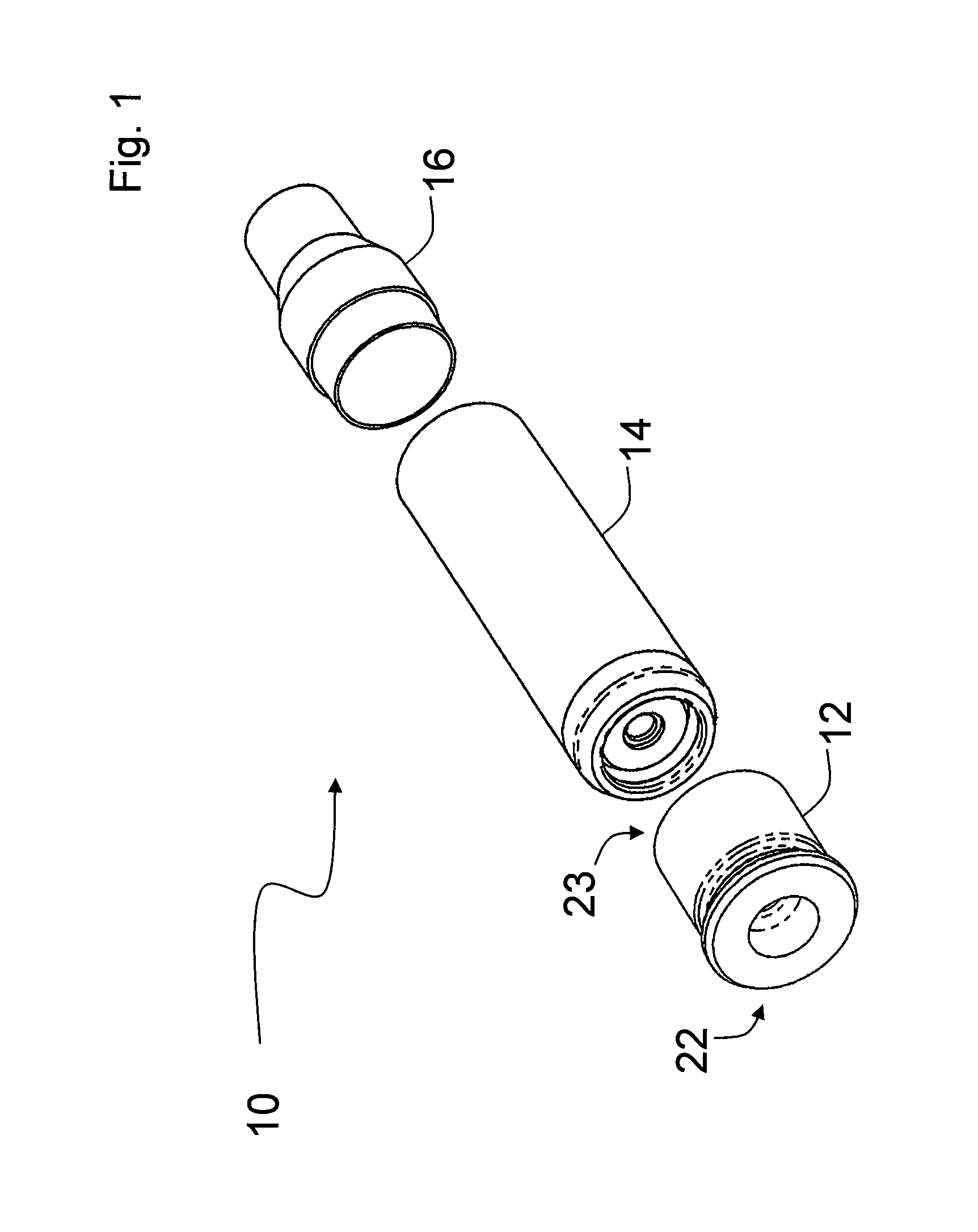

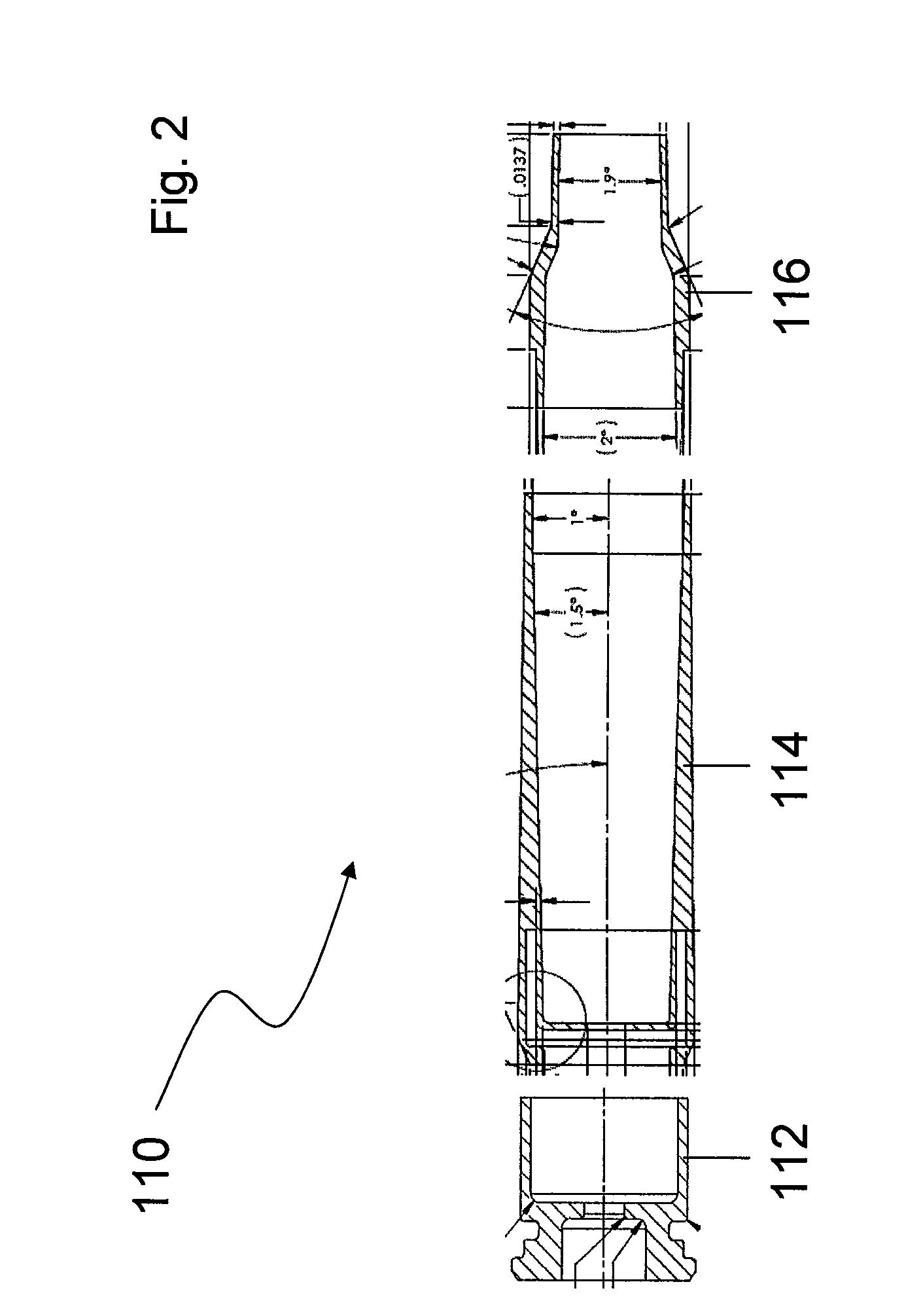

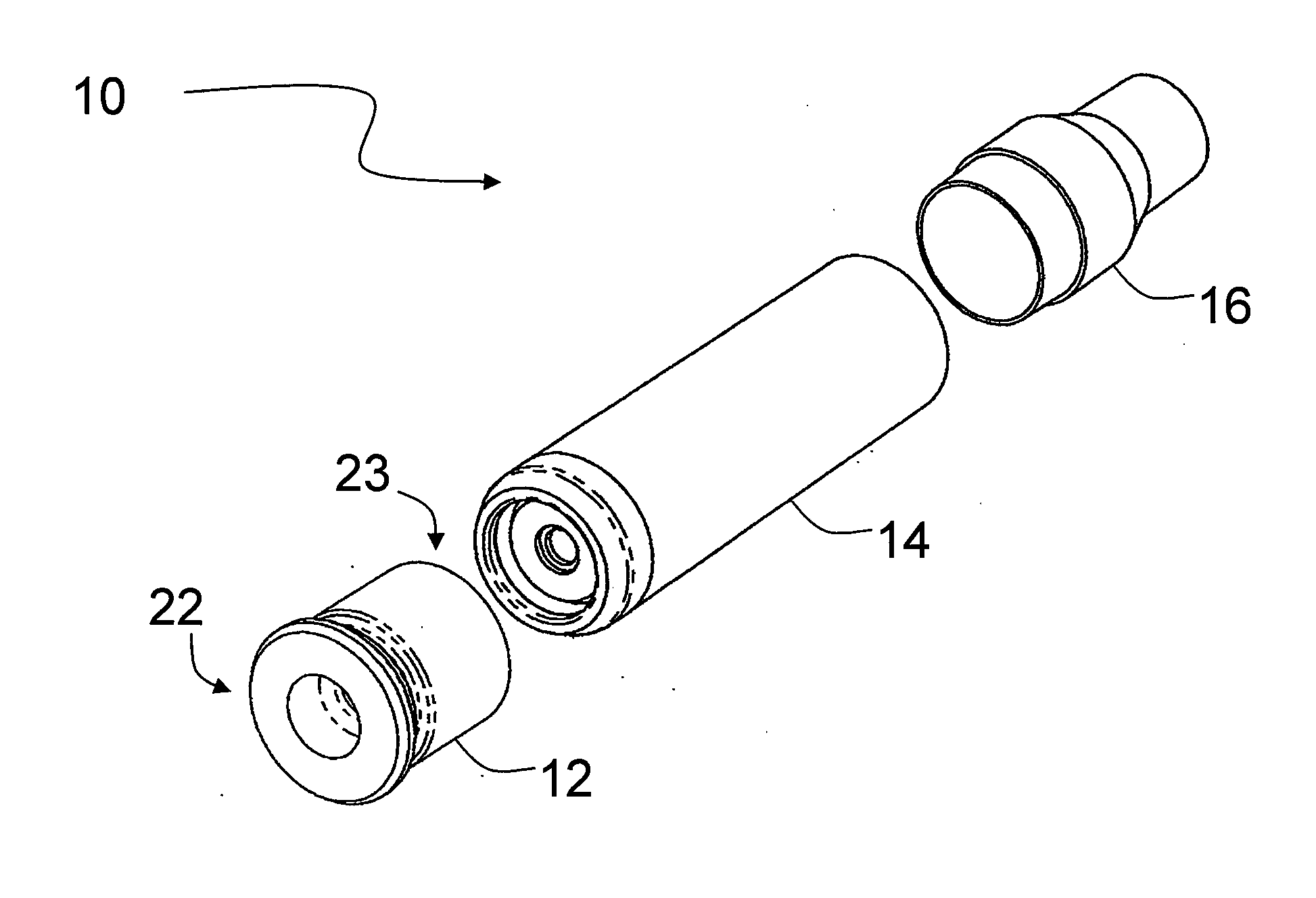

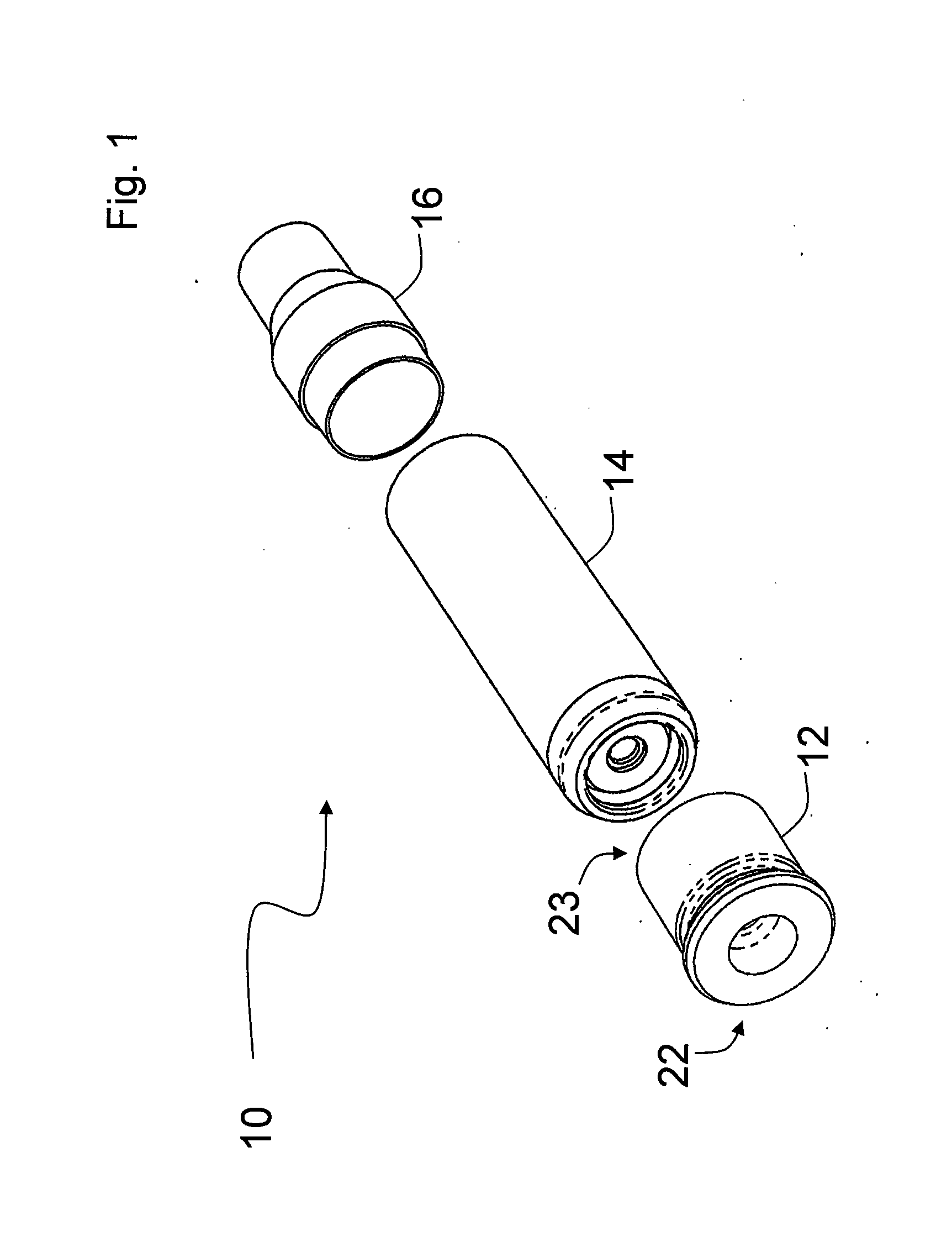

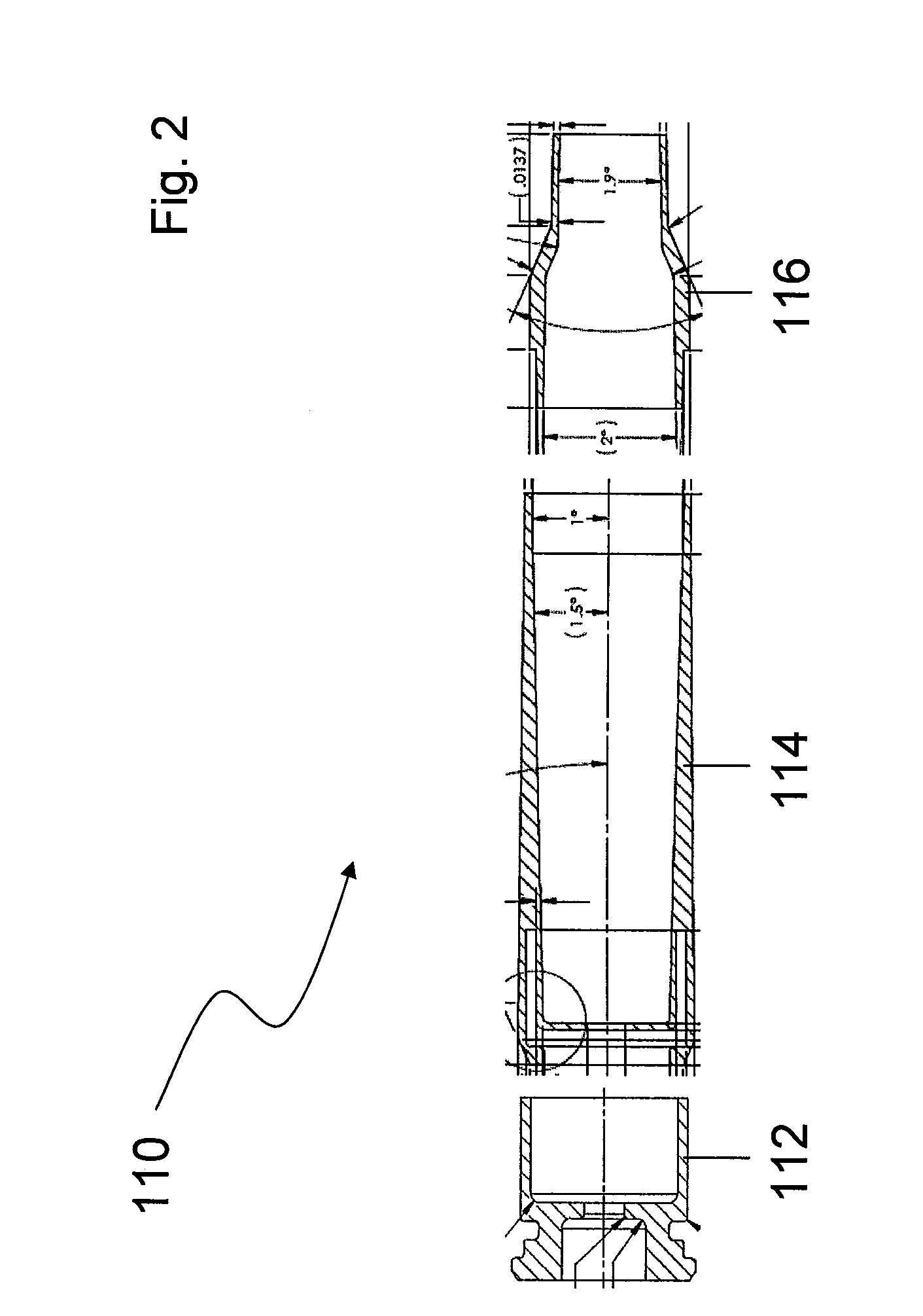

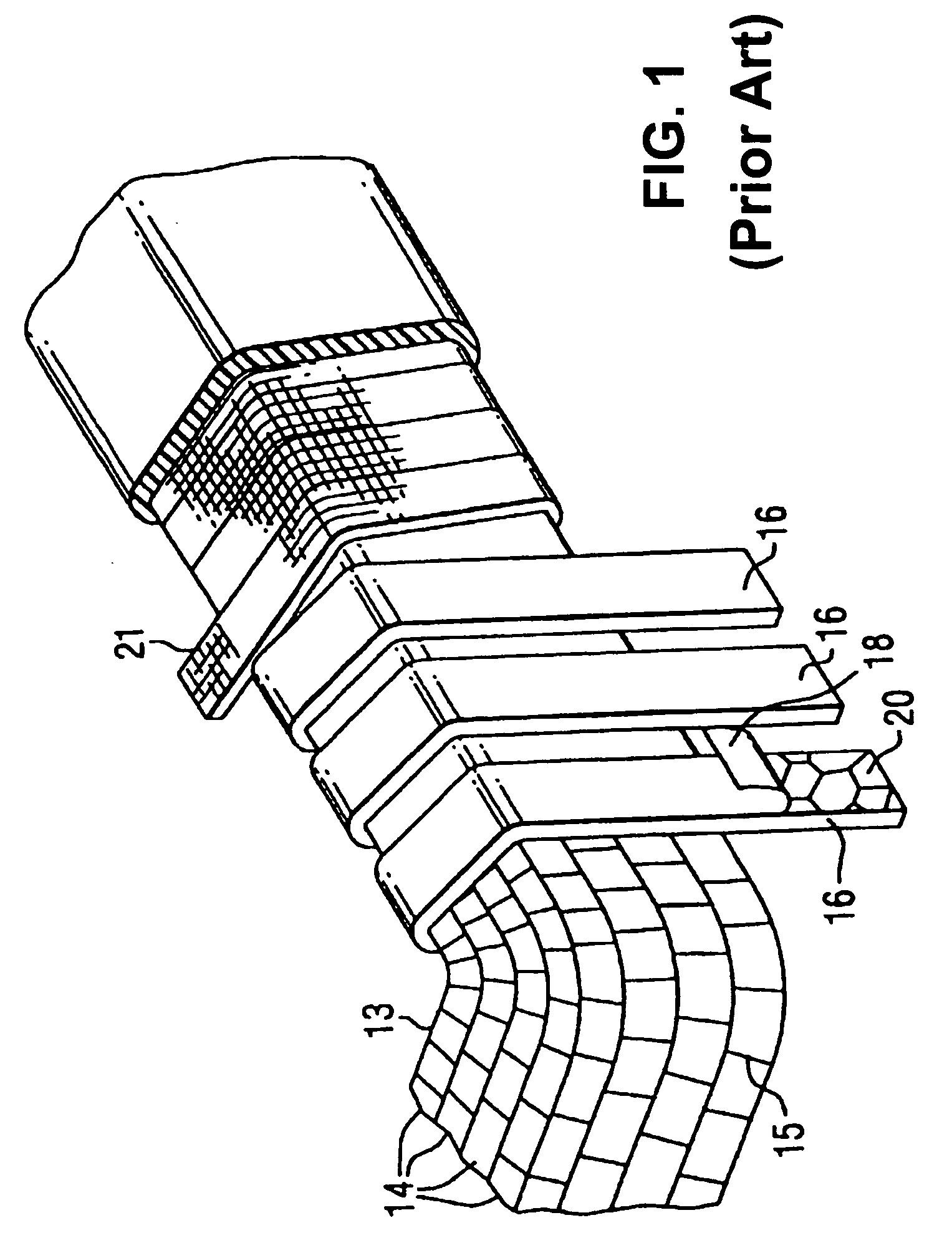

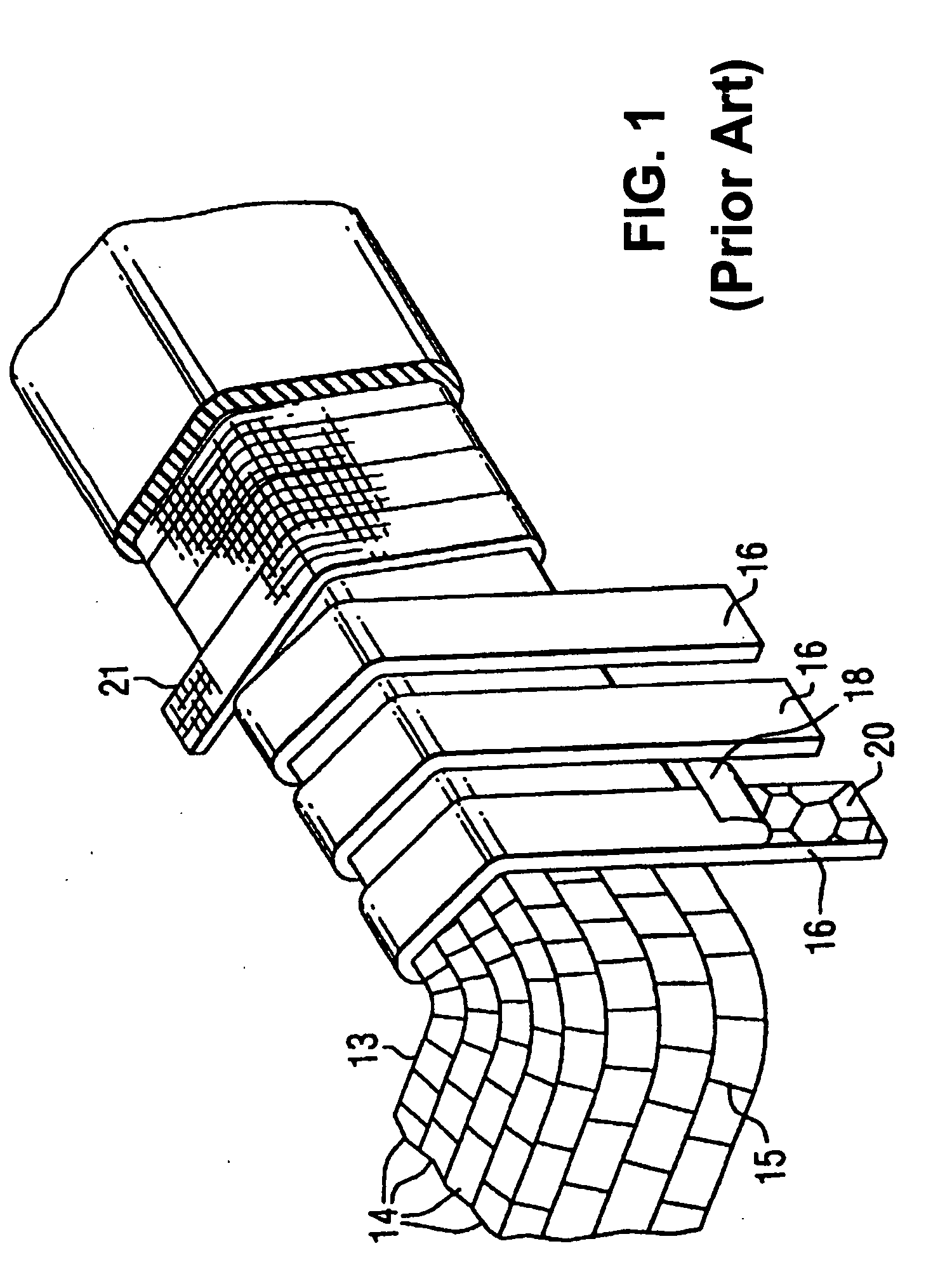

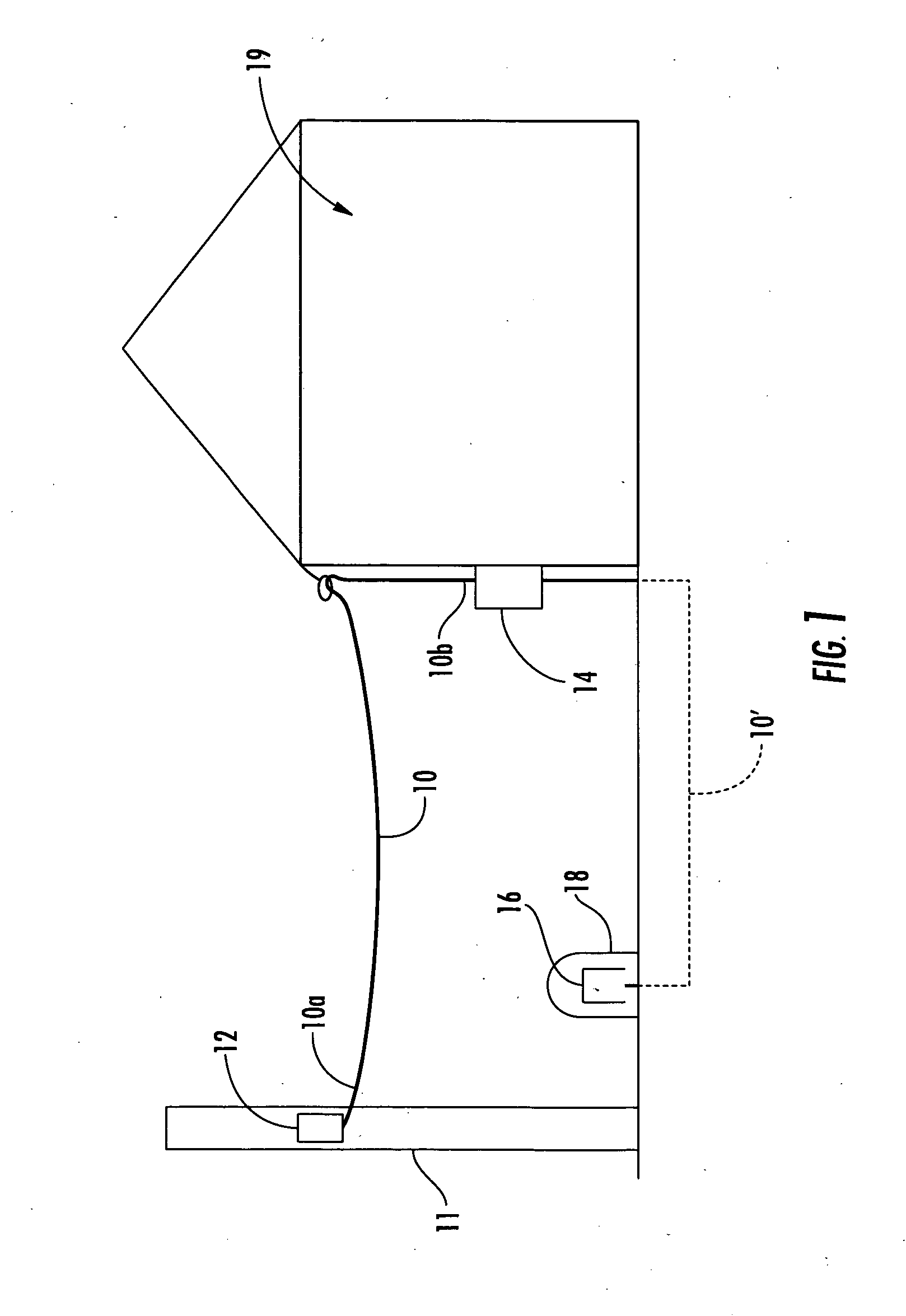

Ammunition cartridge case bodies made with polymeric nanocomposite material

The present invention is directed to a three-part ammunition cartridge casing body comprising a head or base portion, a case portion and a cap portion. The cartridge casing body further comprises: the base portion, made of metal or polymeric resin, having a closed end and an open end; a substantially cylindrical case portion, open on both ends, joined to the open end of the base portion and comprising a nanocomposite material of a nanoclay dispersed in a polyamide resin matrix; and a cap portion, made of a nanocomposite material of a nanoclay dispersed in a polyamide resin matrix and further comprising glass fibers, joined to the other end of the case portion, wherein the case portion is more ductile than the cap portion.

Owner:NYLON CORP OF AMERICA

Ammunition cartridge case bodies made with polymeric nanocomposite material

The present invention is directed to a three-part ammunition cartridge casing body comprising a head or base portion, a case portion and a cap portion. The cartridge casing body further comprises: the base portion, made of metal or polymeric resin, having a closed end and an open end; a substantially cylindrical case portion, open on both ends, joined to the open end of the base portion and comprising a nanocomposite material of a nanoclay dispersed in a polyamide resin matrix; and a cap portion, made of a nanocomposite material of a nanoclay dispersed in a polyamide resin matrix and further comprising glass fibers, joined to the other end of the case portion, wherein the case portion is more ductile than the cap portion.

Owner:NYLON CORP OF AMERICA

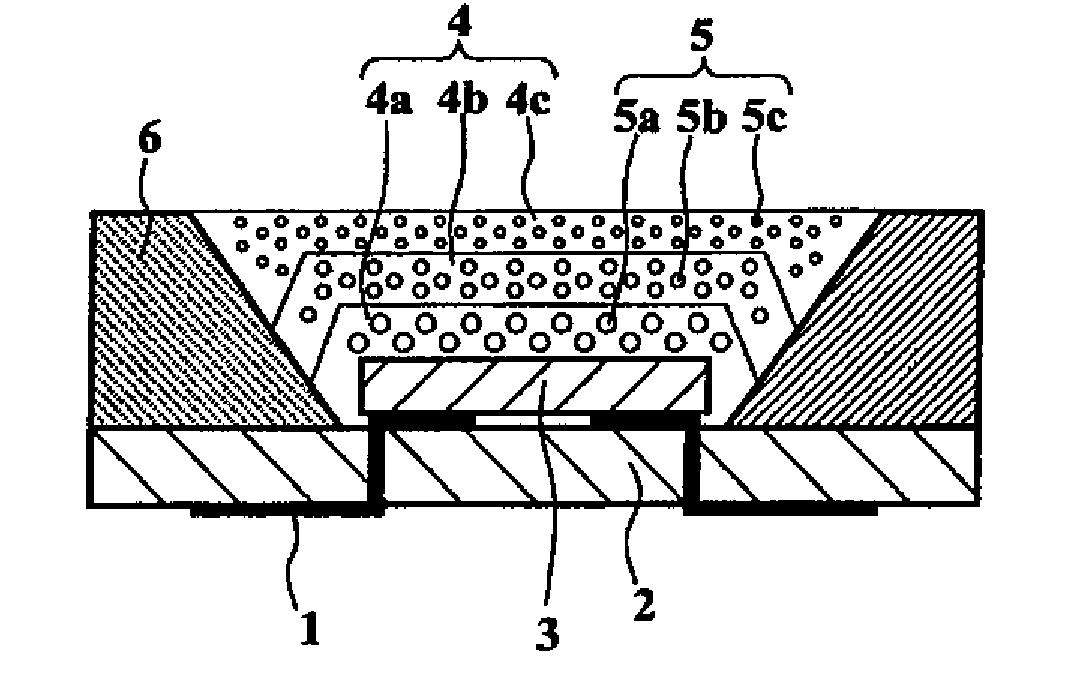

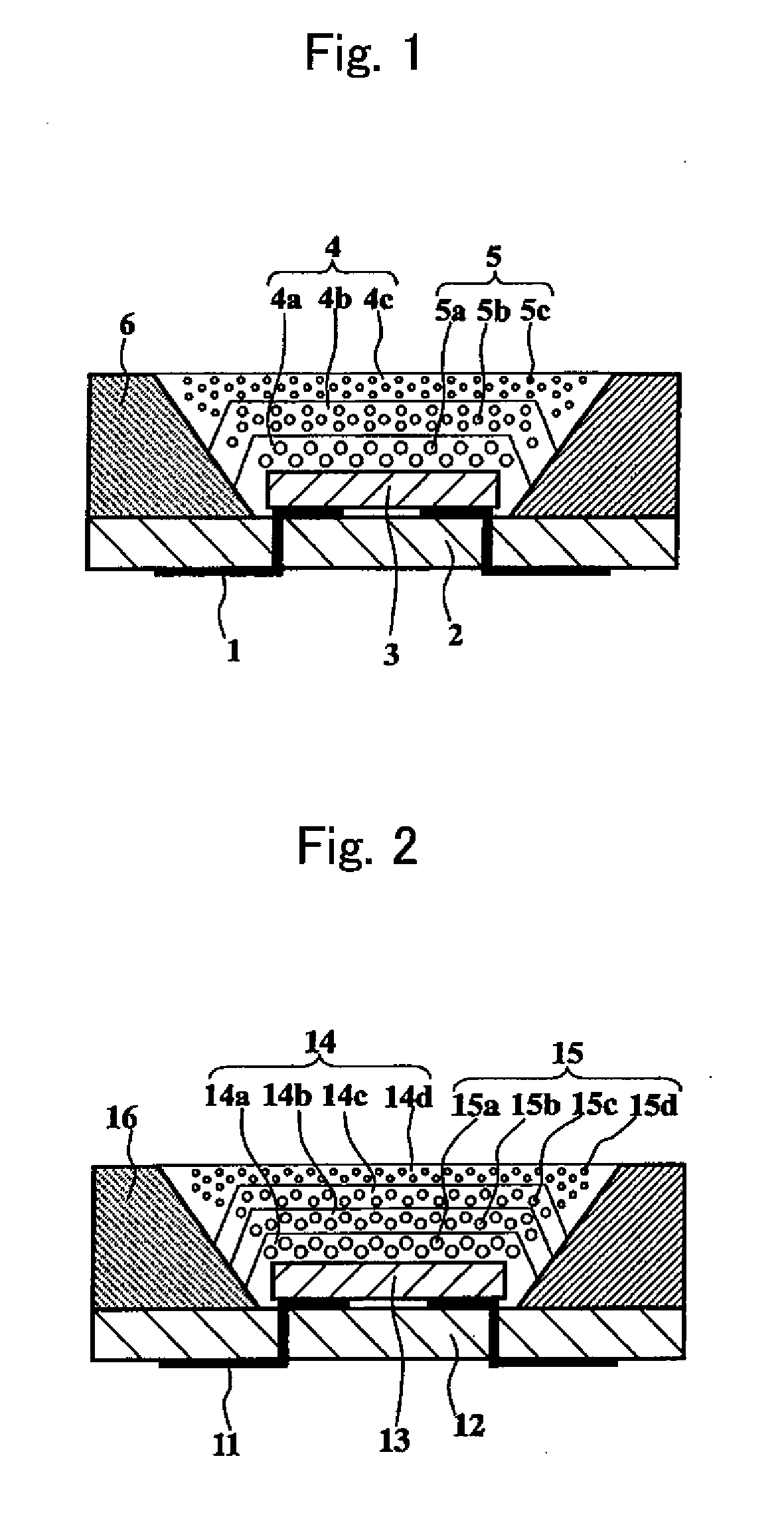

Wavelength Converter, Light-Emitting Device, Method of Producing Wavelength Converter and Method of Producing Light-Emitting Device

InactiveUS20080231170A1Reduce self-quenchingSolve low luminous efficiencyDischarge tube luminescnet screensLamp detailsPhosphorFluorescence

A light-emitting device comprises a light-emitting element 3 that is provided on a substrate 2 and emits excitation light, and a wavelength converter 4 that converts the excitation light into visible light. The visible light is output light. The wavelength converter 4 comprises a plurality of wavelength conversion layers 4a, 4b and 4c which respectively contain, as phosphors, at least one type of semiconductor ultrafine particles having a mean particle size of not more than 20 nm and at least one type of fluorescent substance having a mean particle size of not less than 0.1 μm in a resin matrix. Thereby, self-quenching of phosphors is reduced and high luminous efficiency is attained.

Owner:KYOCERA CORP

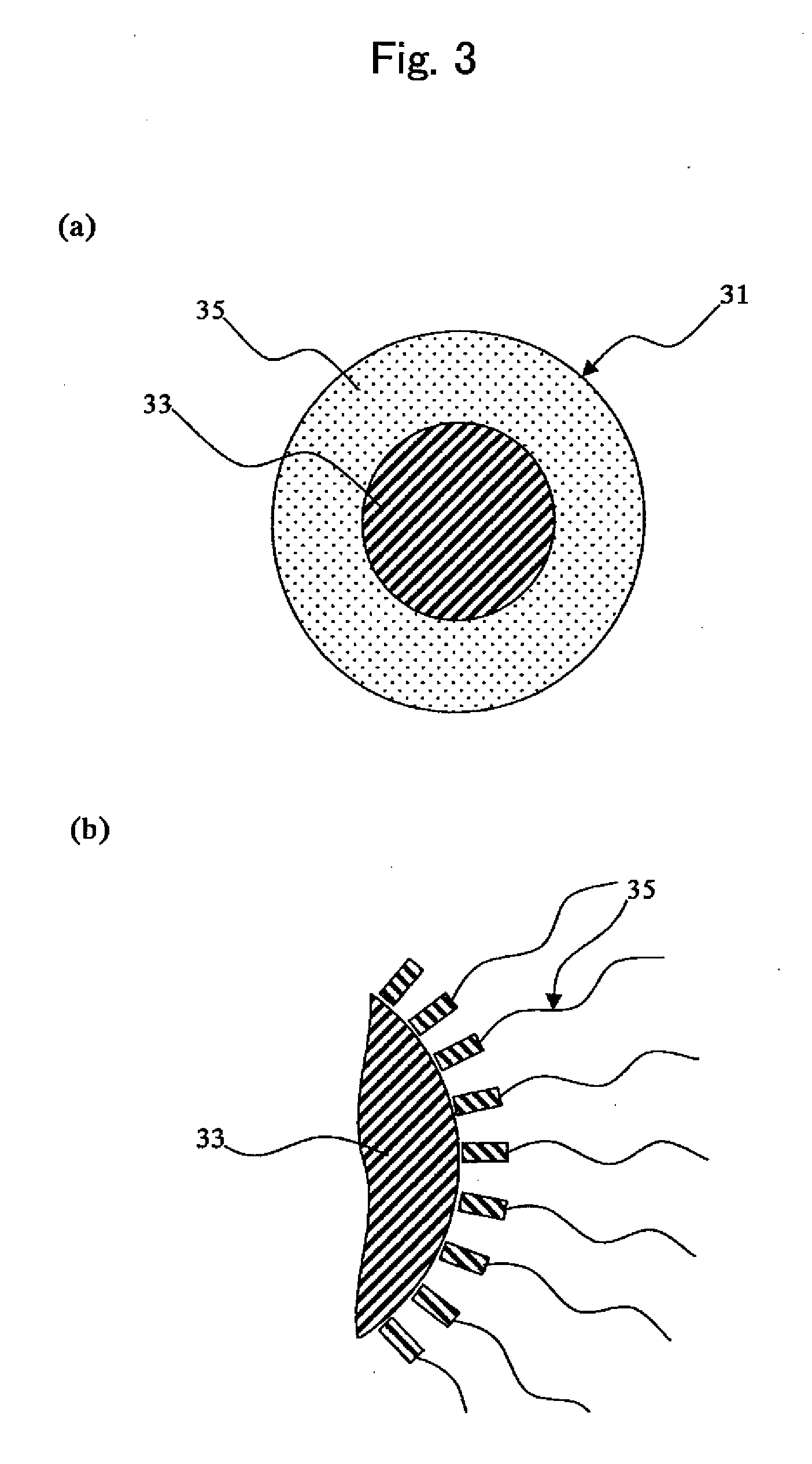

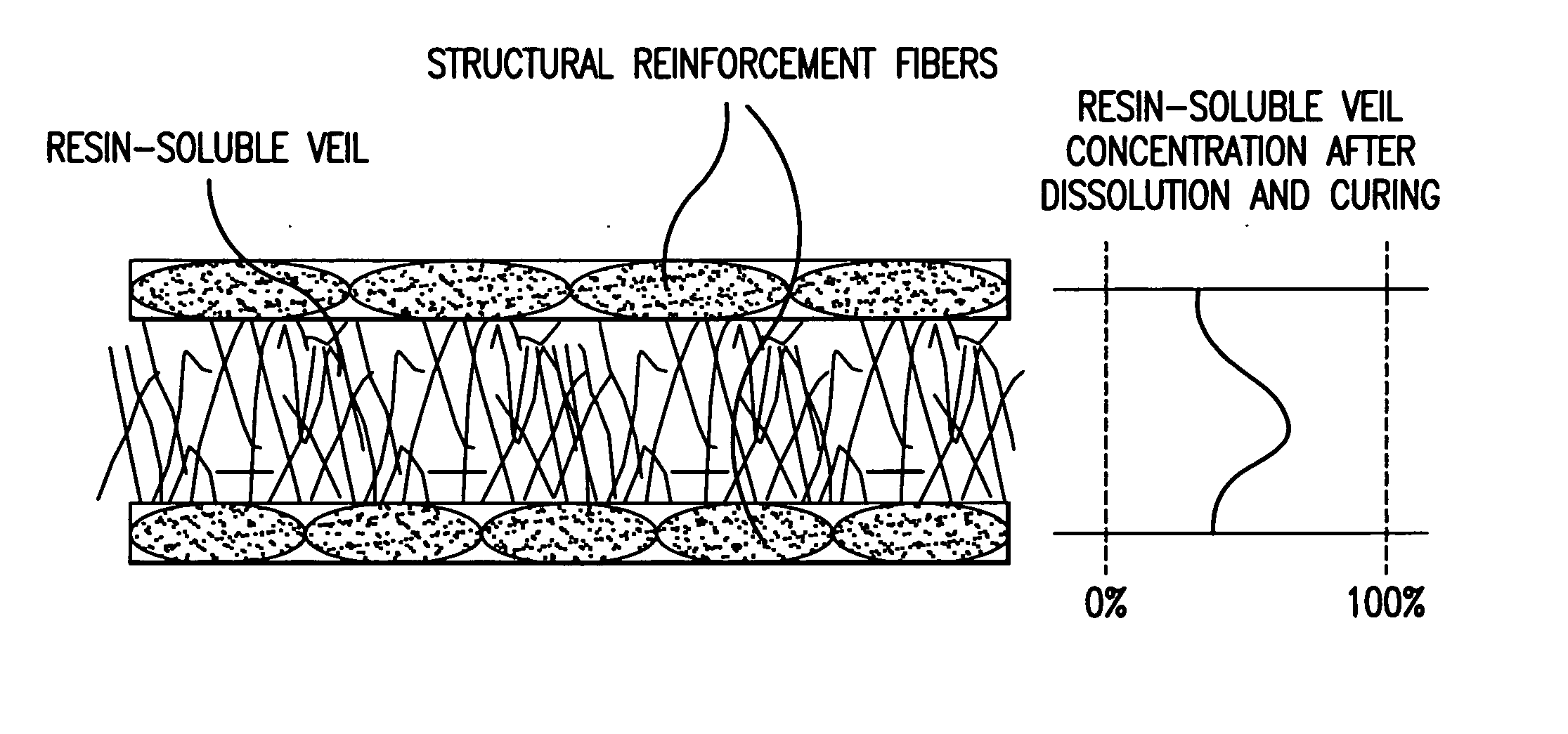

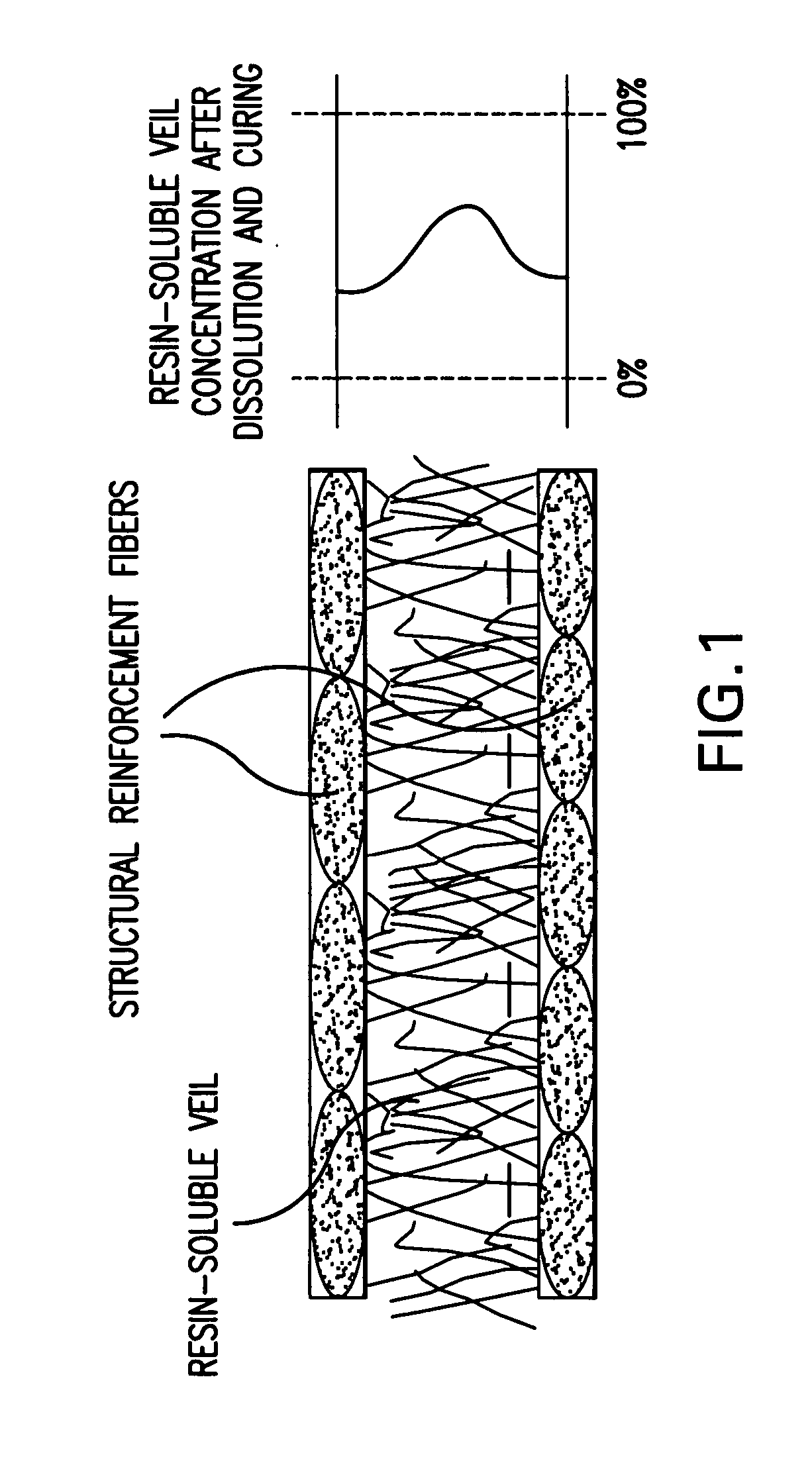

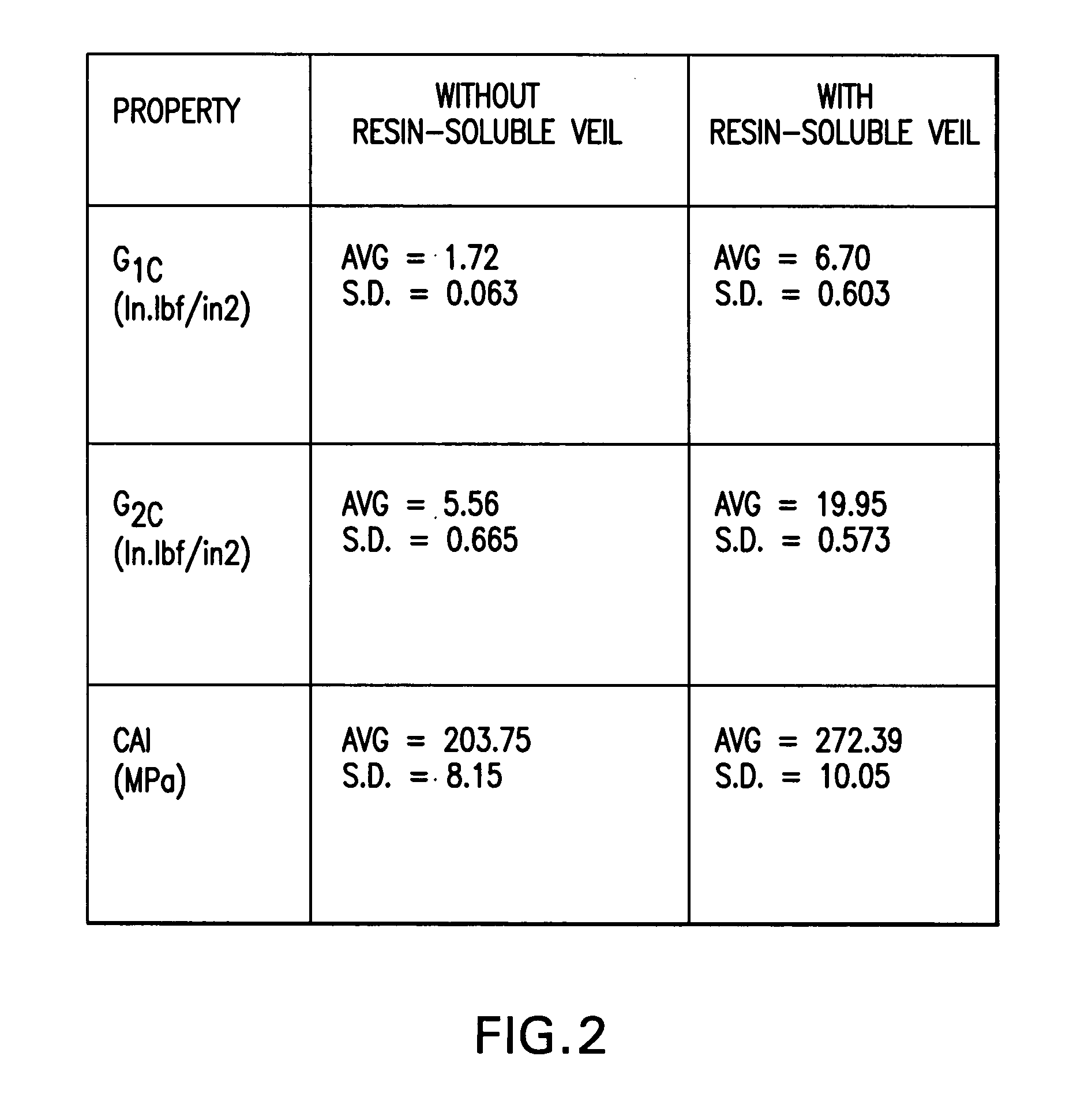

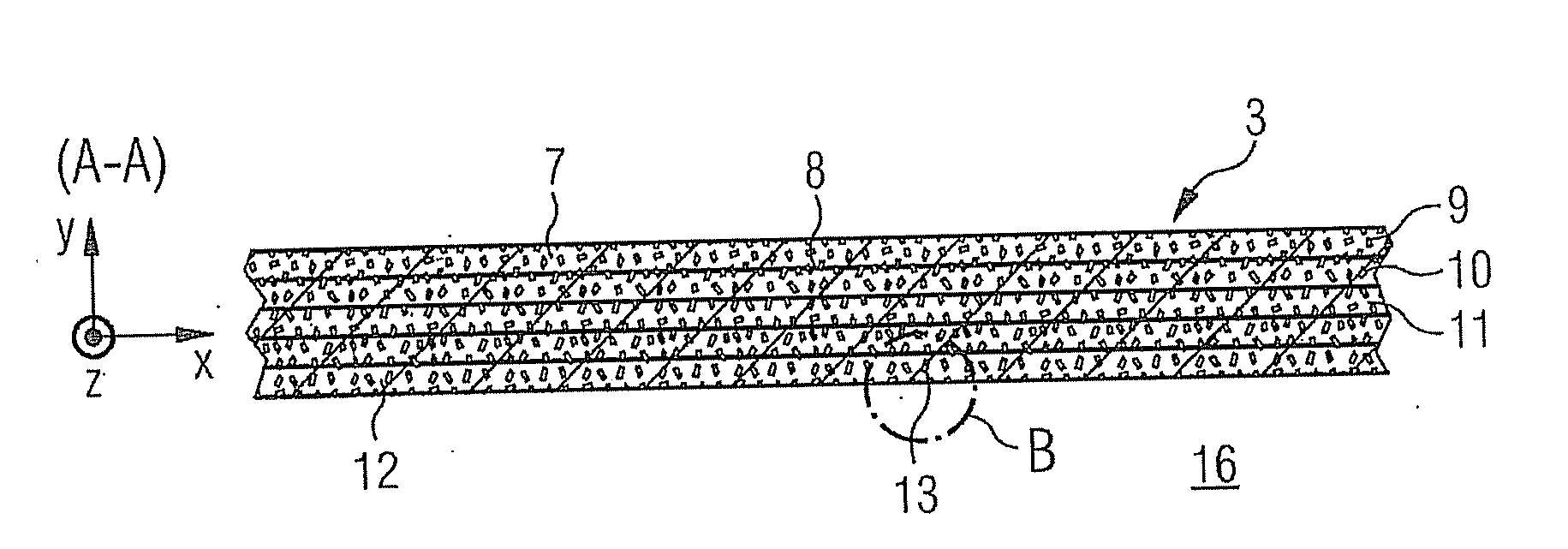

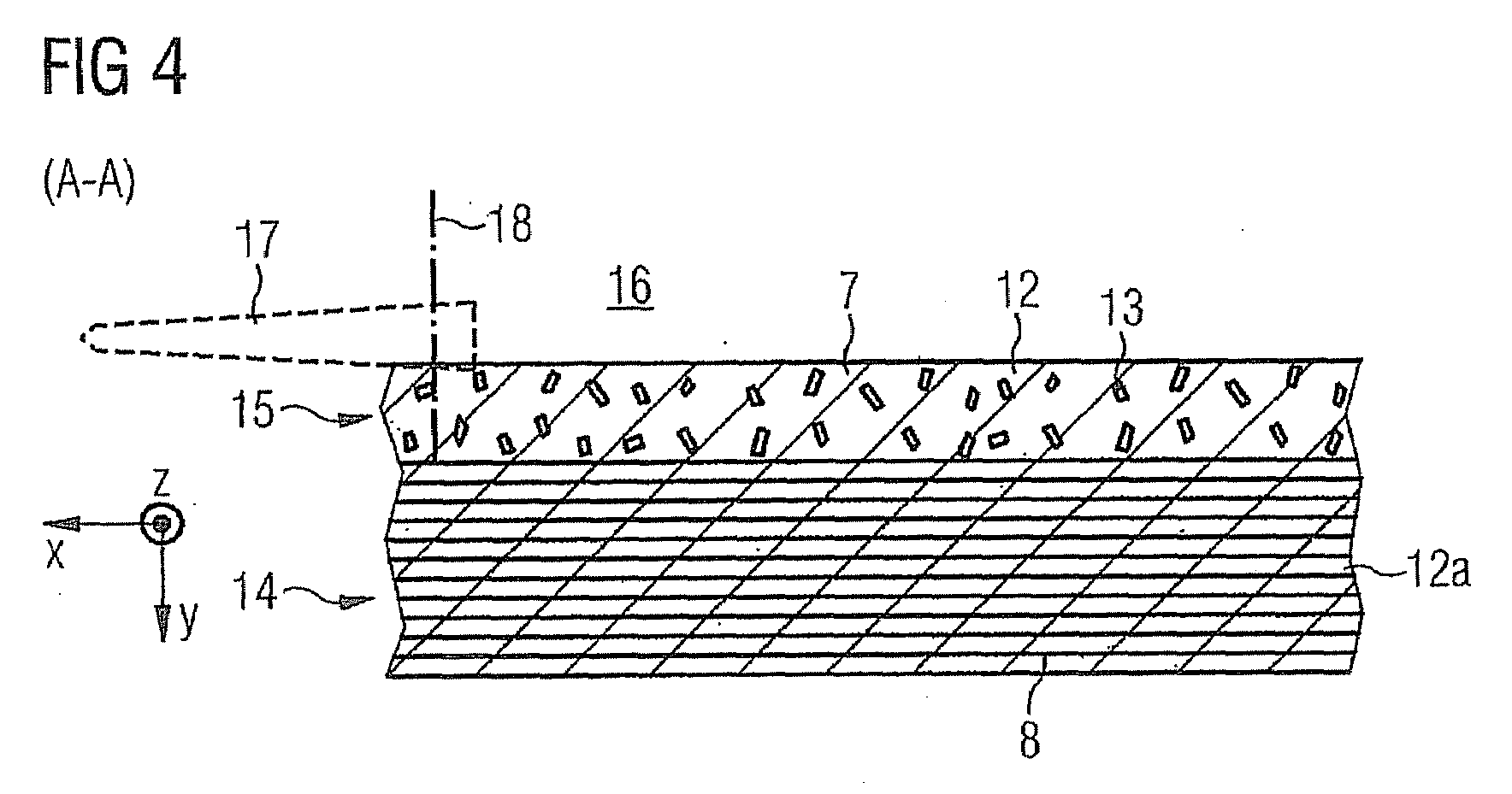

Resin-soluble thermoplastic veil for composite materials

ActiveUS20060252334A1Improve the level ofImprove toughnessWood working apparatusVehicle componentsFiberResin matrix

A resin-soluble thermoplastic polymer veil toughening element for a curable composition wherein the polymer element is a non-woven veil in solid phase adapted to undergo at least partial phase transition to fluid phase on contact with a component of the curable resin matrix composition in which it is soluble at a temperature which is less than the temperature for substantial onset of gelling and / or curing of the curable composition and which temperature is less than the polymer elements melt temperature; a method for the preparation thereof, a preform support structure for a curable composition comprising the at least one thermoplastic veil element together with structural reinforcement fibers, methods for preparation thereof, a curable composition comprising the at least one thermoplastic veil element or the support structure and a curable resin matrix composition, a method for preparation and curing thereof, and a cured composite or resin body obtained thereby, and known and novel uses thereof.

Owner:CYTEC TECH CORP

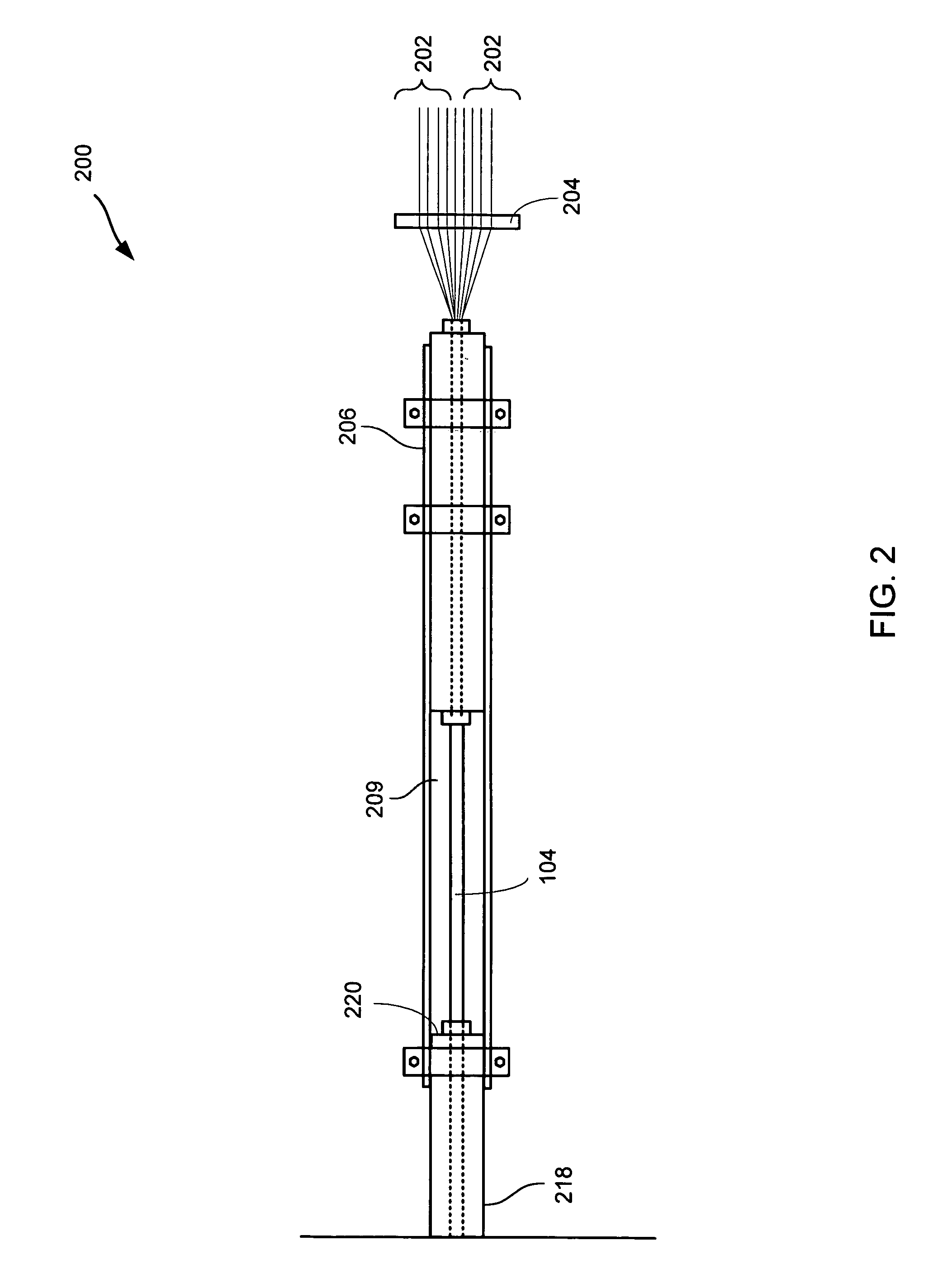

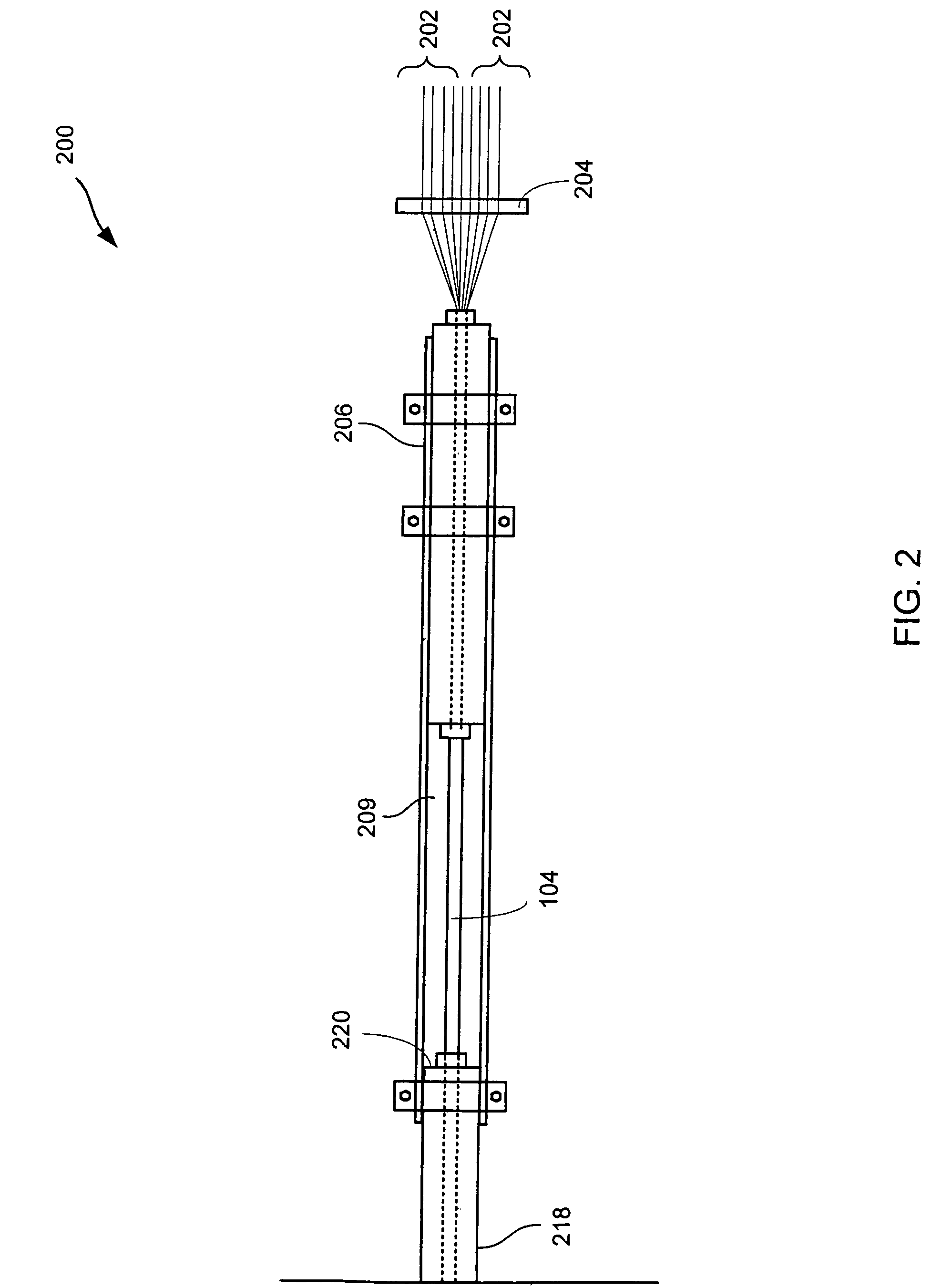

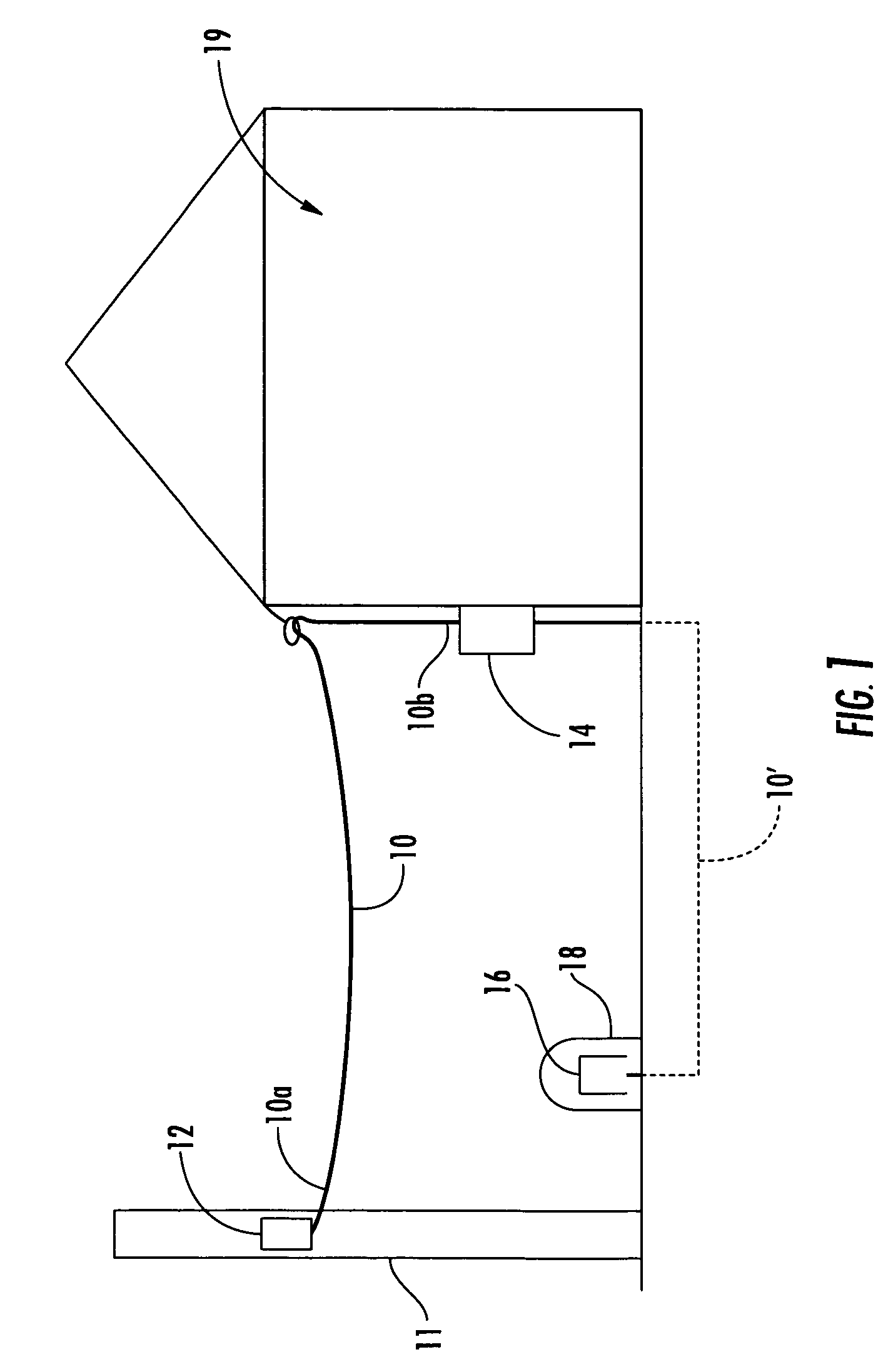

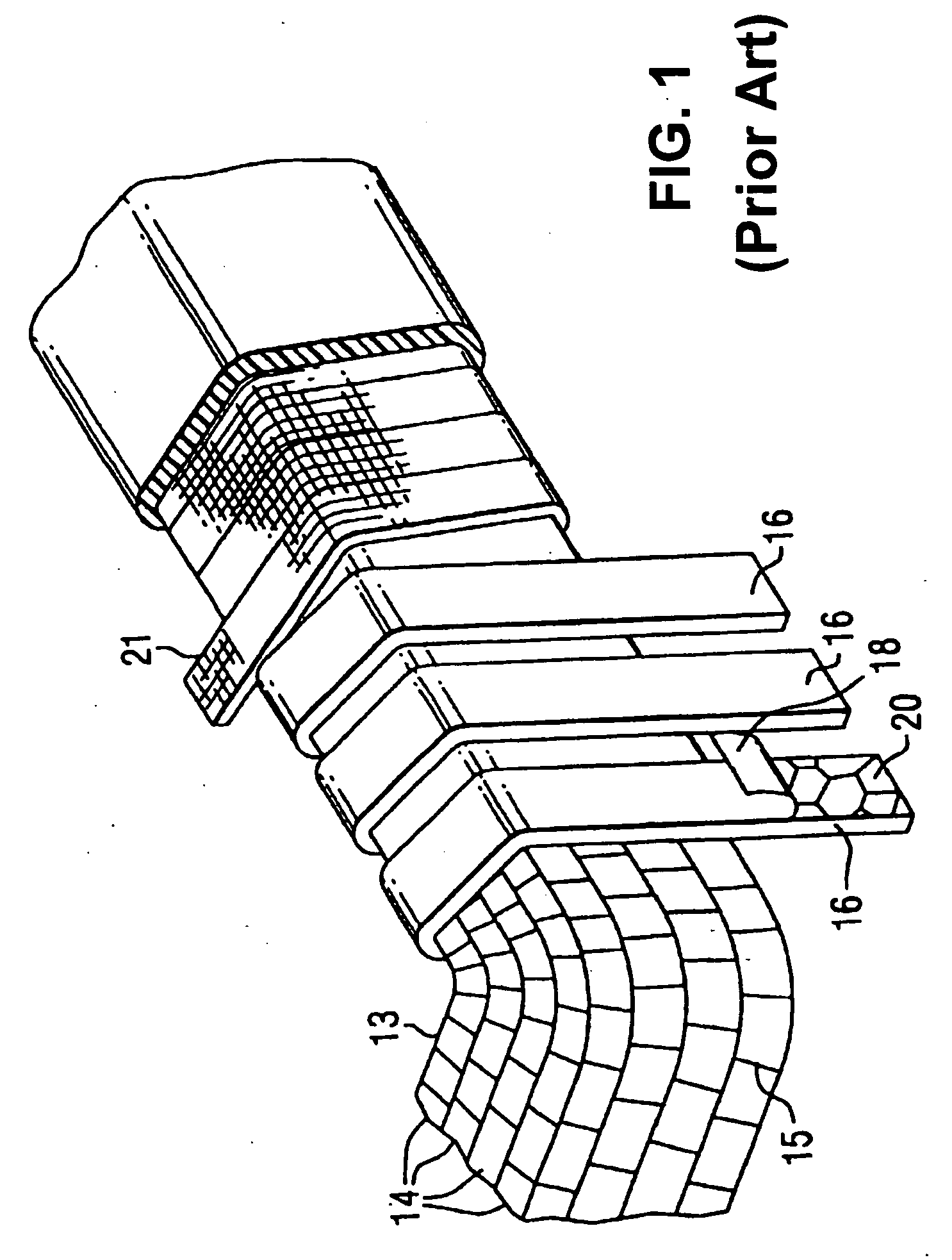

Aluminum conductor composite core reinforced cable and method of manufacture

This invention relates to an aluminum conductor composite core reinforced cable and method of manufacture. The composite core comprises a plurality of longitudinally extending fibers embedded in a resin matrix. The composite core comprises the following characteristics: tensile strength ranging from about 250 to about 350 Ksi; a tensile modulus of elasticity ranging from about 12 to about 16 Msi; and a coefficient of thermal expansion less than or equal to about 6×10−6 cm / cm·° C. The composite core is further manufactured according to a two die pultrusion system, the system comprising tooling designed in accordance with the processing speed, selection of composite core fibers and resin and desired physical characteristics of the end composite core.

Owner:CTC GLOBAL CORP

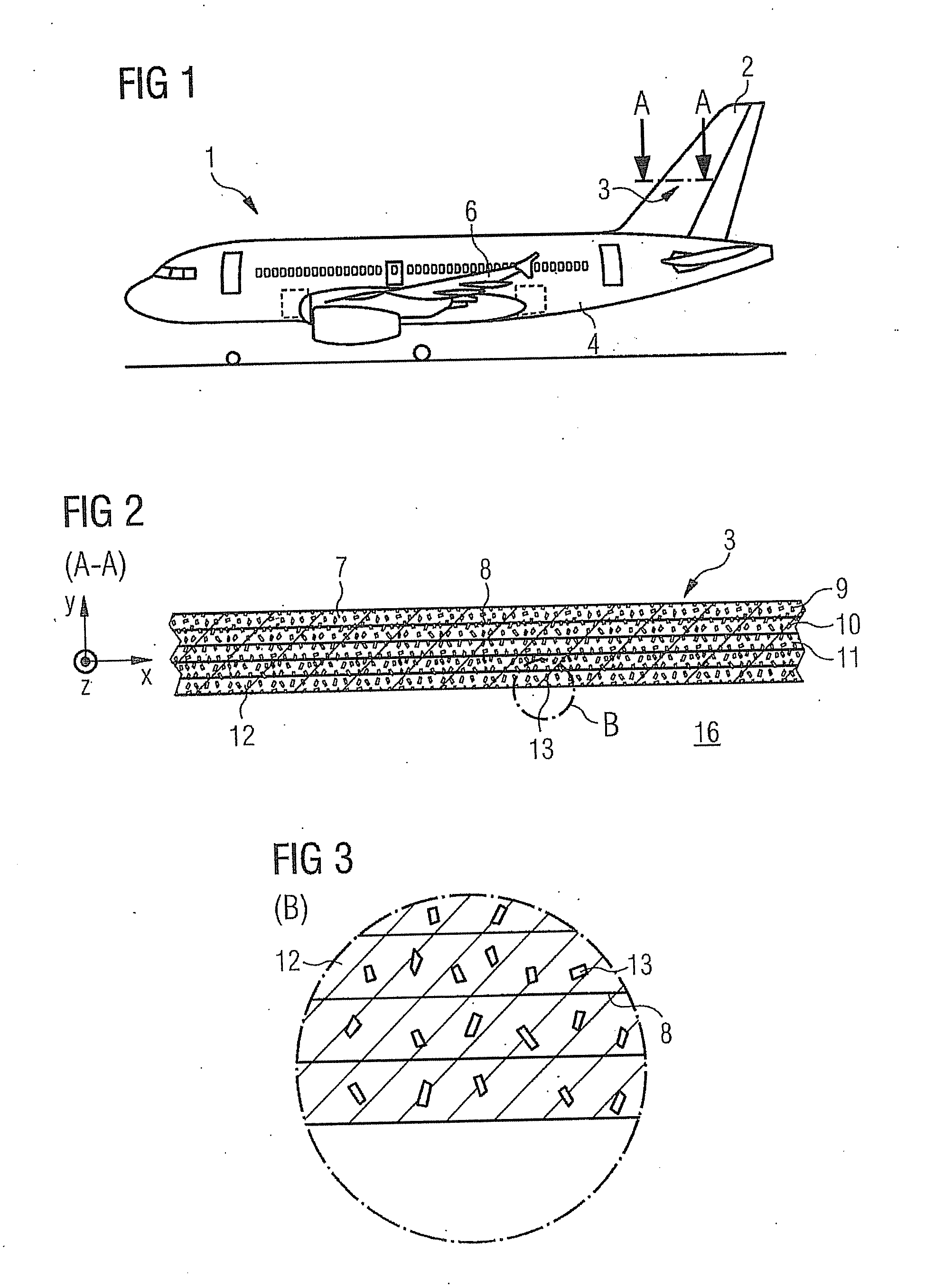

Component with carbon nanotubes

InactiveUS20090140098A1Lightning protection is goodAircraft lighting protectorsMilitary adjustmentAviationCarbon nanotube

The present invention relates to a component, in particular in the field of aviation and spaceflight, having a resin matrix in which carbon nanotubes are embedded for high conductivity of the component.

Owner:AIRBUS OPERATIONS GMBH

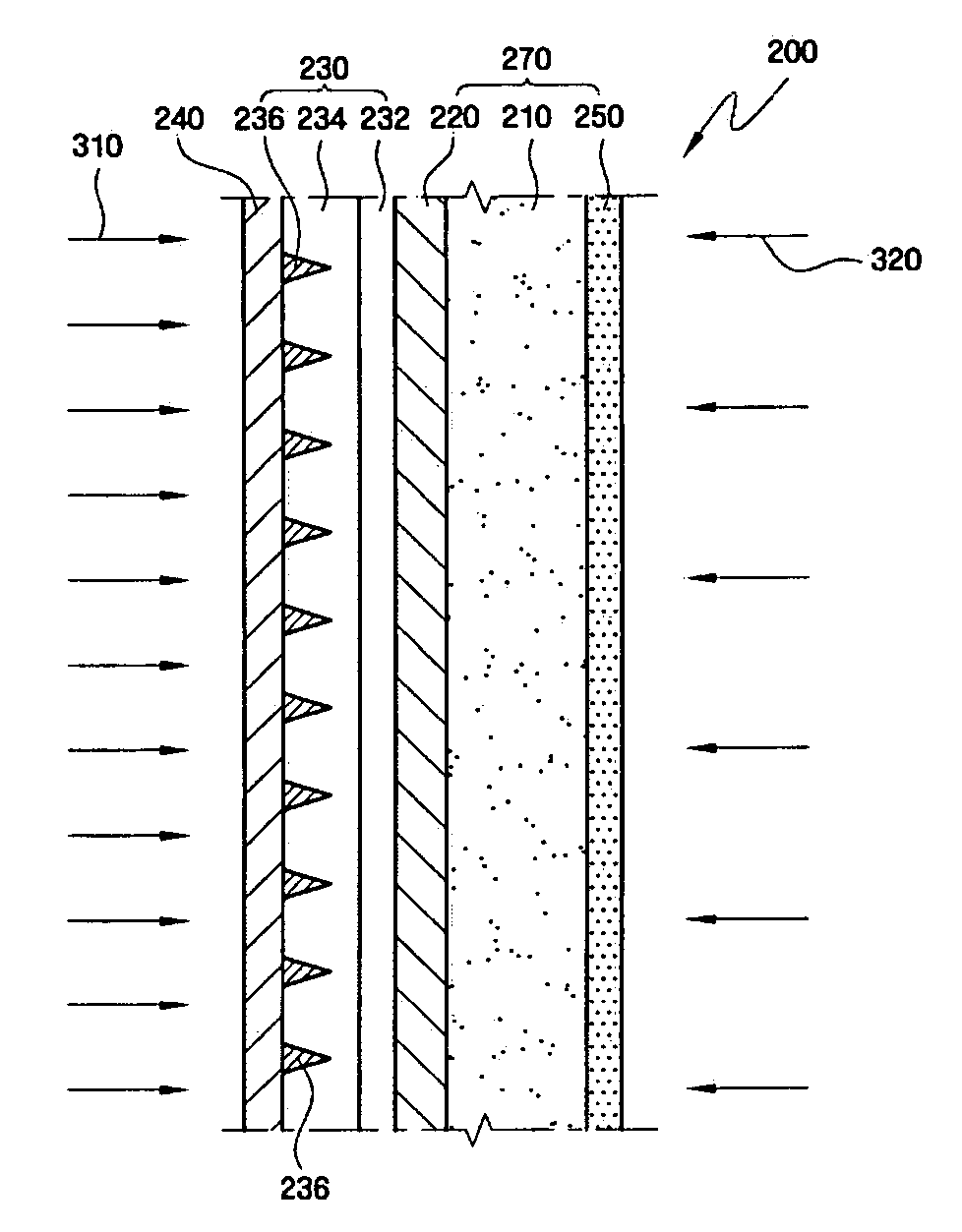

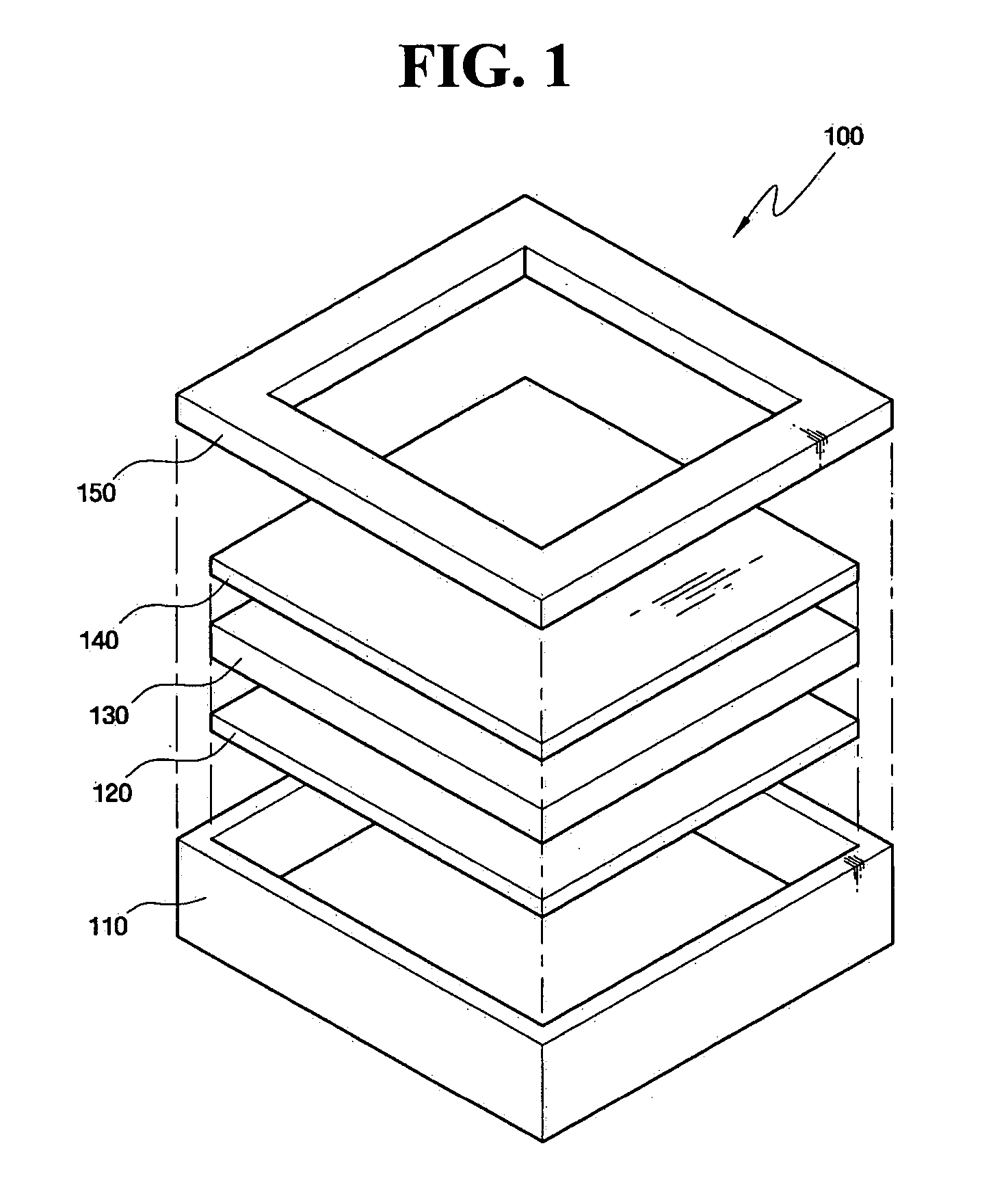

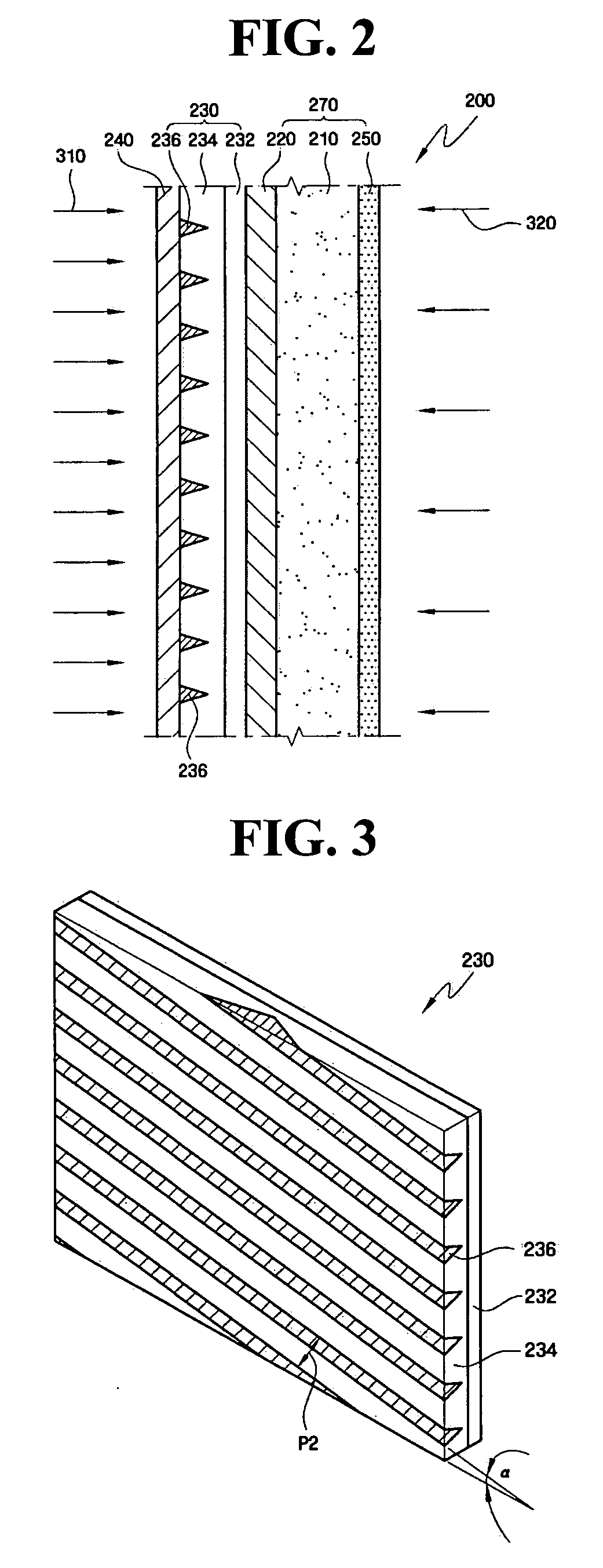

External light-shielding layer, filter for display device including the external light-shielding layer and display device including the filter

InactiveUS20060250064A1Increase contrastPrevent a Moire phenomenonIncadescent screens/filtersDischarge tube luminescnet screensTransmittanceDisplay device

An external light-shielding layer capable of enhancing a visible light transmittance and a contrast ratio and preventing Moire fringe and Newton ring phenomena, a display filter including the external light-shielding layer, and a display device including the display filter. The external light-shielding layer includes a transparent resin matrix, and a plurality of light-shielding patterns formed on the transparent resin matrix and spaced apart from each other in a predetermined interval, wherein a bias angle (α) formed between a traveling direction of the light-shielding patterns and the longer side of the matrix is in a range of about 5 to 80 degrees.

Owner:ASAHI GLASS CO LTD

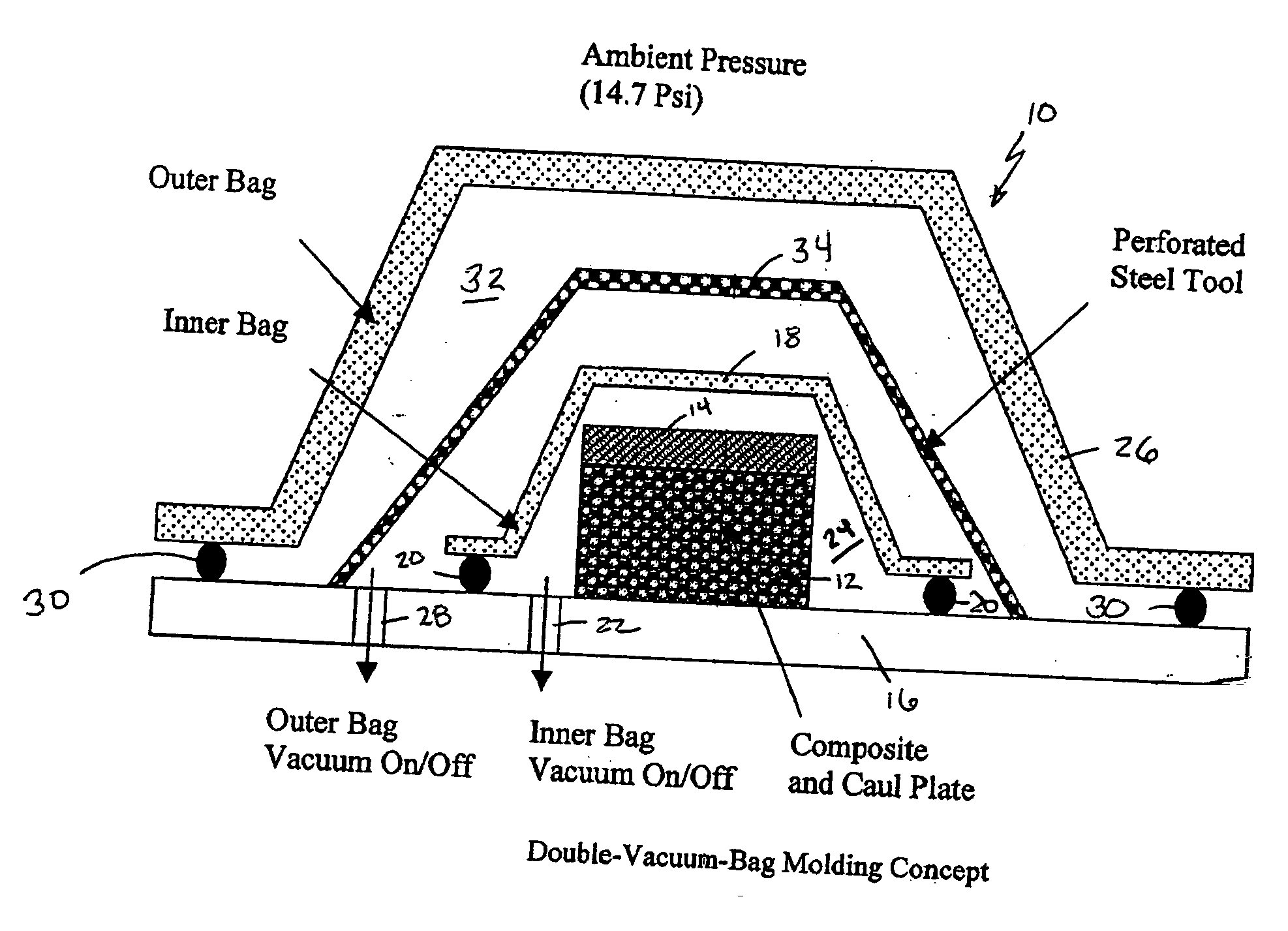

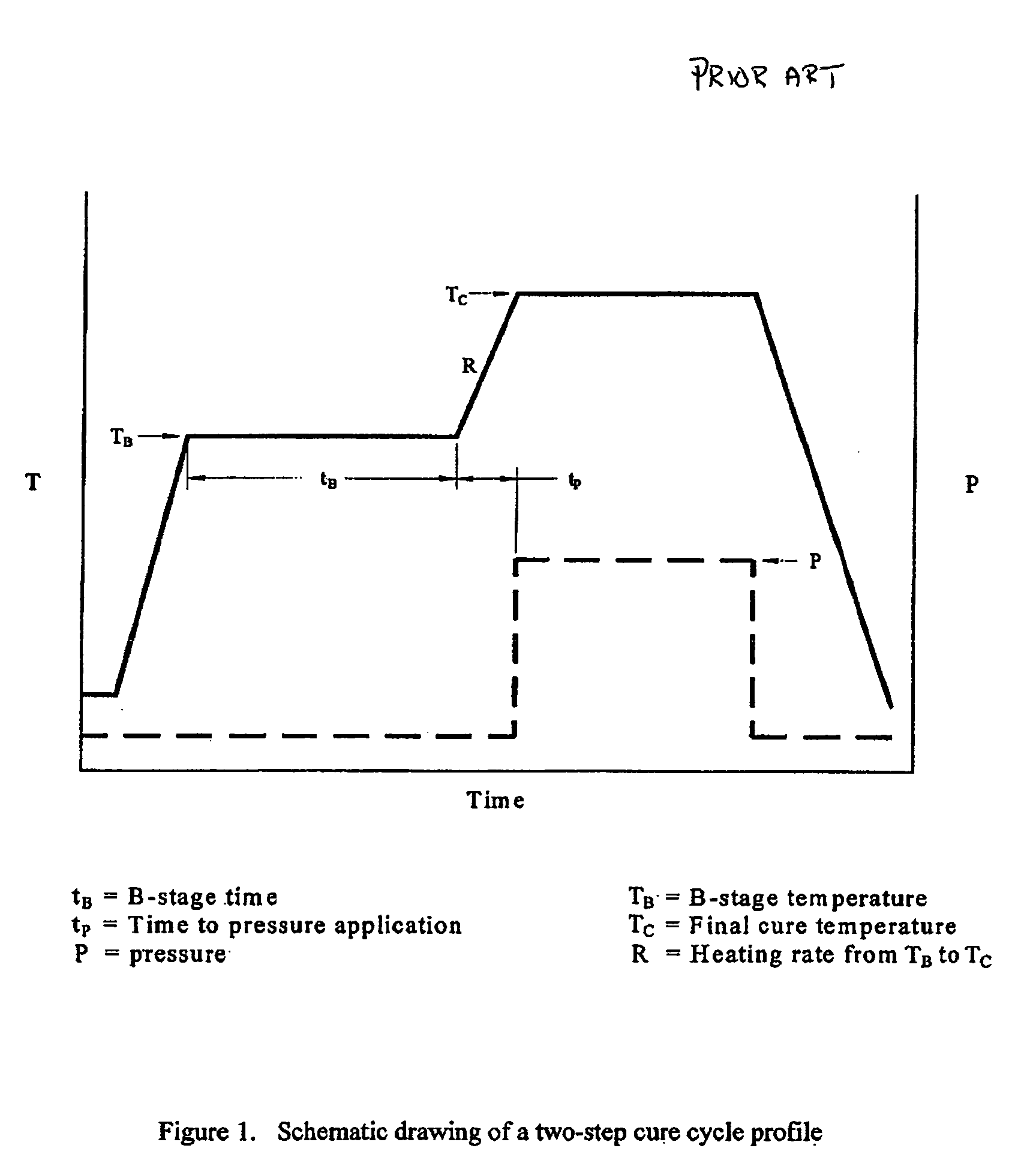

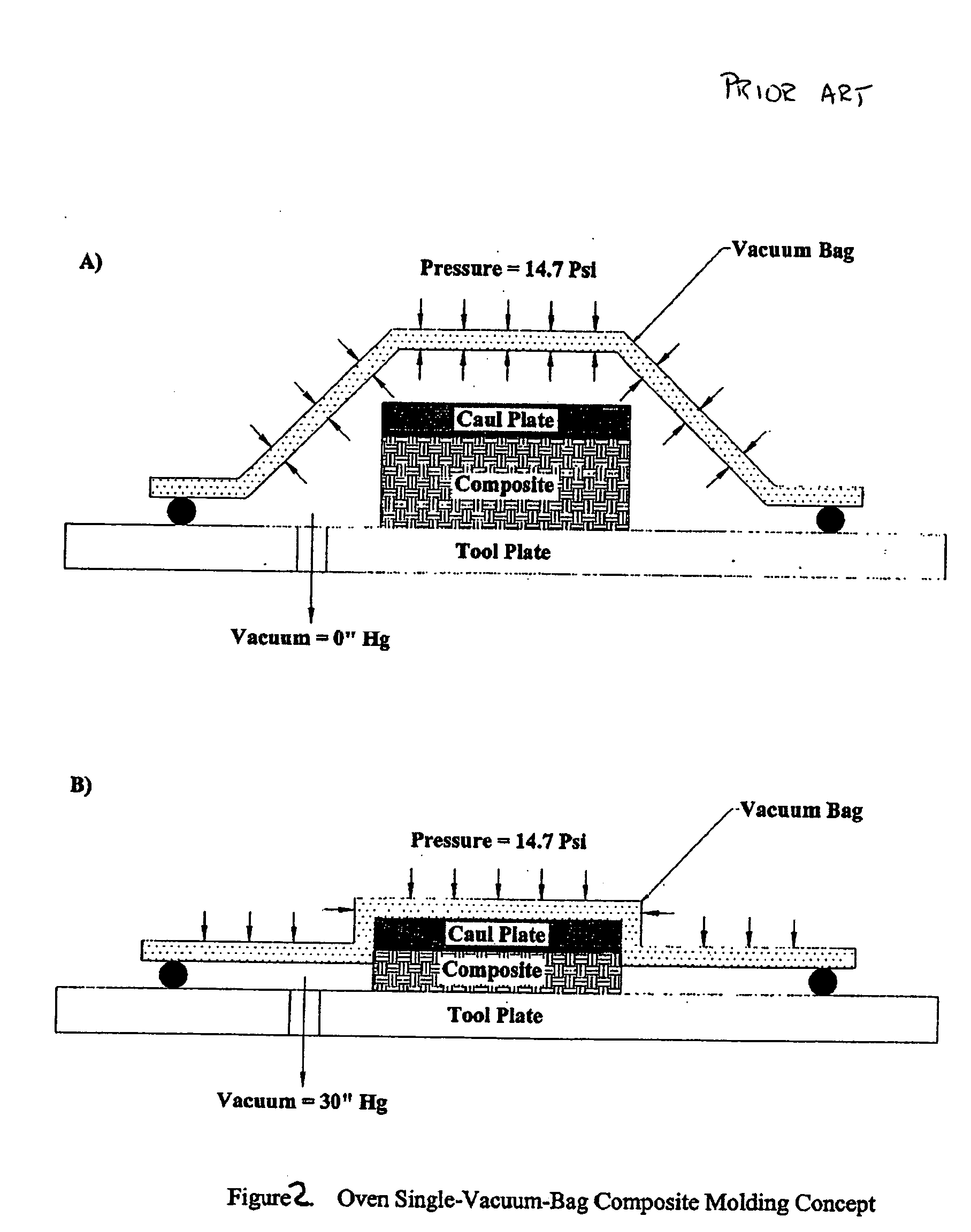

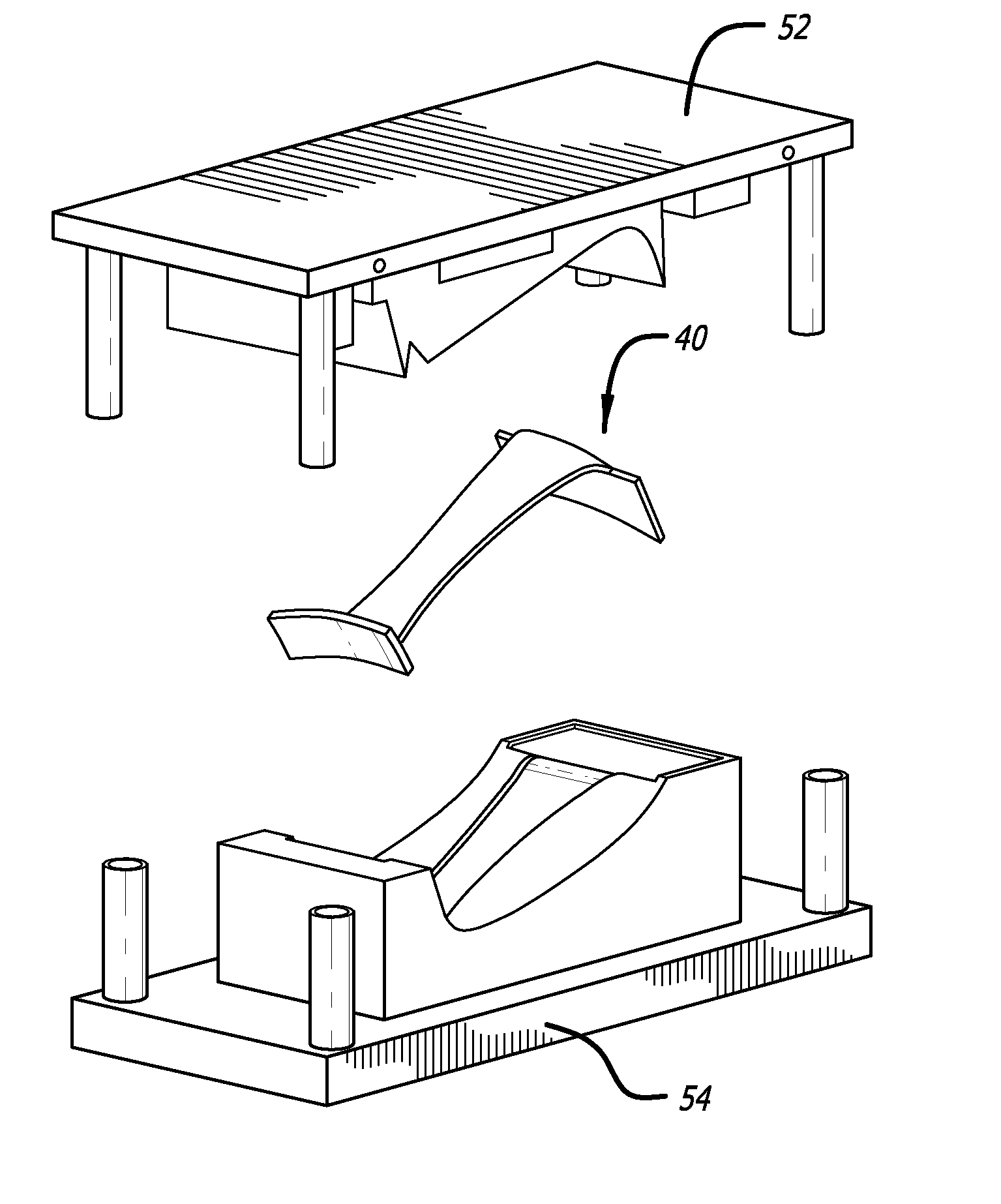

Double vacuum bag process for resin matrix composite manufacturing

InactiveUS20050253309A1Improve performanceImprove propertiesLaminationLamination apparatusRelative pressureResin matrix

A double vacuum bag molding assembly with improved void management and laminate net shape control which provides a double vacuum environment for use in fabricating composites from prepregs containing air and / or volatiles such as reactive resin matrix composites or composites from solvent containing prepregs with non-reactive resins matrices. By using two vacuum environments during the curing process, a vacuum can be drawn during a B-stage of a two-step cycle without placing the composite under significant relative pressure. During the final cure stage, a significant pressure can be applied by releasing the vacuum in one of the two environments. Inner and outer bags are useful for creating the two vacuum environments with a perforated tool intermediate the two. The composite is placed intermediate a tool plate and a caul plate in the first environment with the inner bag and tool plate defining the first environment. The second environment is characterized by the outer bag which is placed over the inner bag and the tool plate.

Owner:NASA

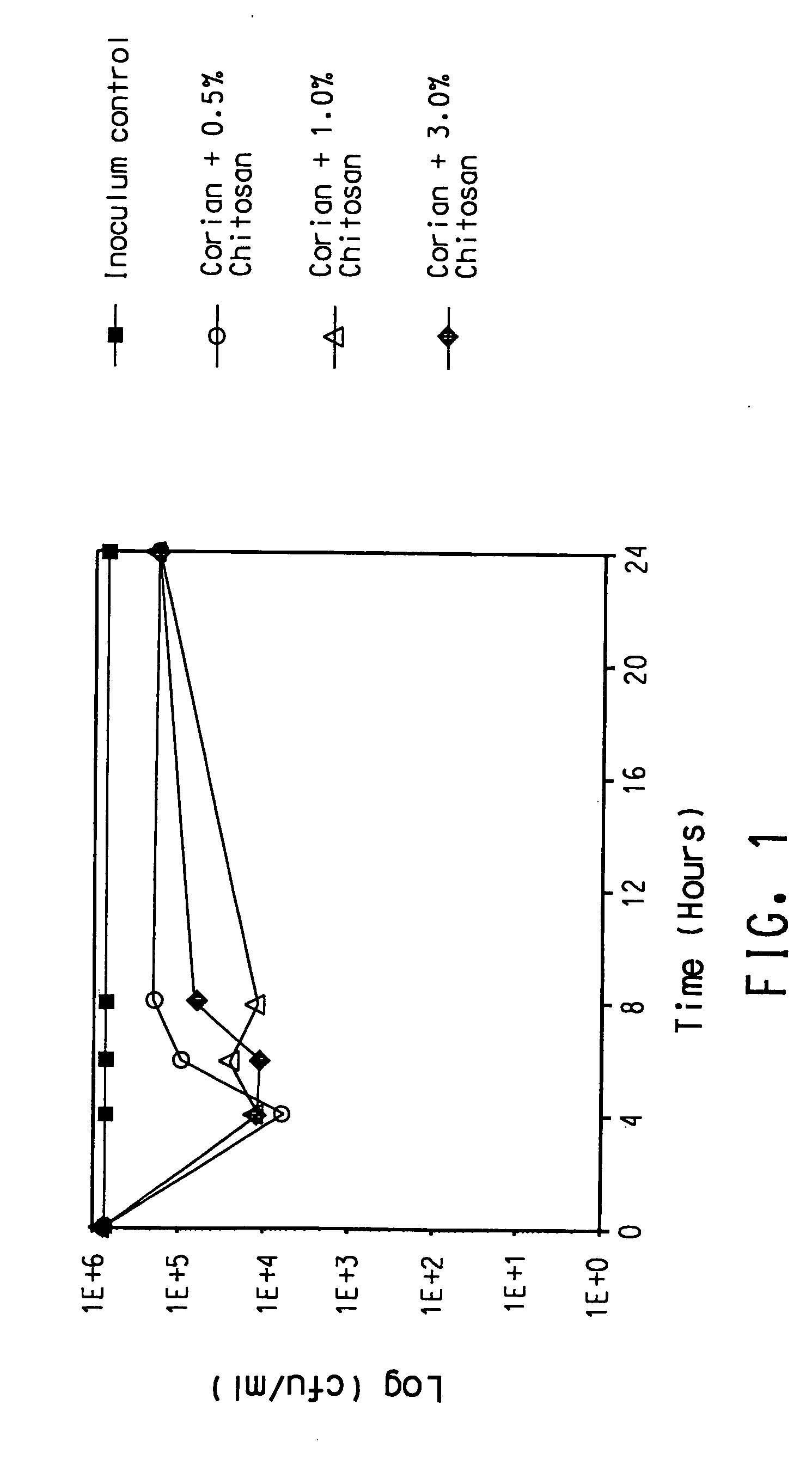

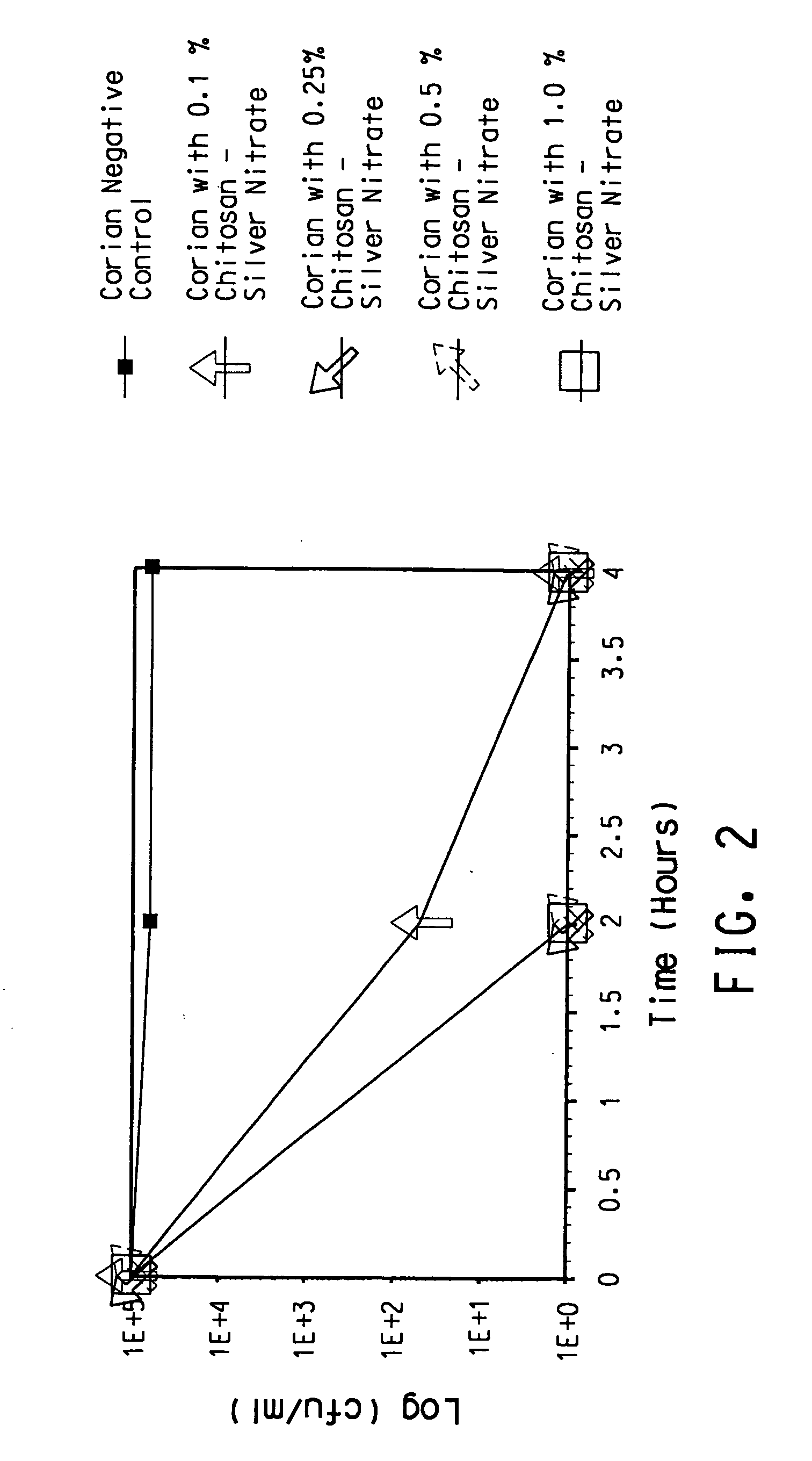

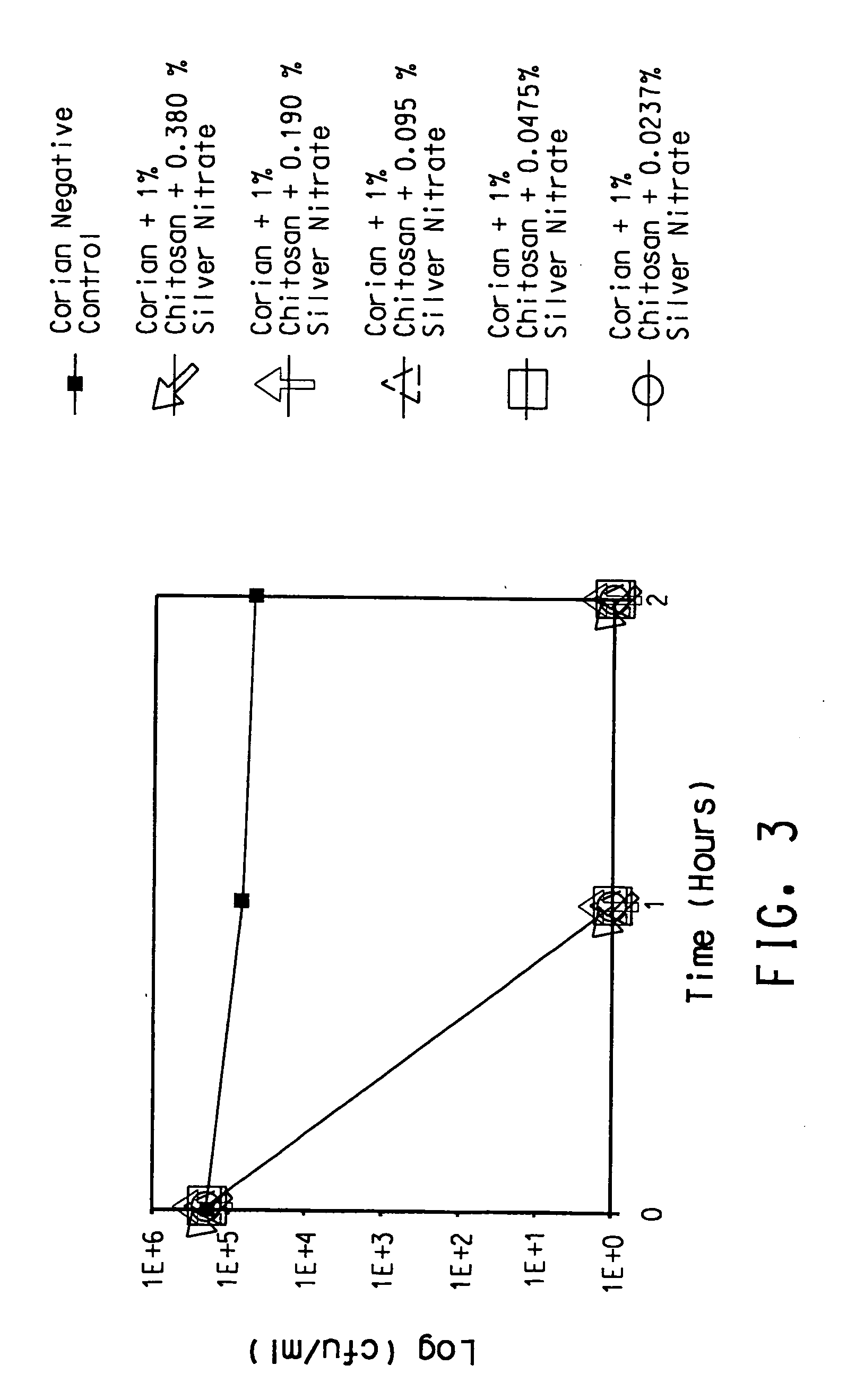

Antimicrobial solid surface materials containing chitosan-metal complexes

A solid surface material with an antimicrobial agent in a thermoset and / or thermoplastic resin matrix where the antimicrobial agent comprises a chitosan-metal complex.

Owner:EI DU PONT DE NEMOURS & CO

Aluminum conductor composite core reinforced cable and method of manufacture

InactiveUS7438971B2Non-insulated conductorsSynthetic resin layered productsElectrical conductorResin matrix

This invention relates to an aluminum conductor composite core reinforced cable and method of manufacture. The composite core comprises a plurality of longitudinally extending fibers embedded in a resin matrix. The composite core comprises the following characteristics: tensile strength ranging from about 250 to about 350 Ksi; a tensile modulus of elasticity ranging from about 12 to about 16 Msi; and a coefficient of thermal expansion less than or equal to about 6×10−6 cm / cm·° C. The composite core is further manufactured according to a one or more die pultrusion system, the system comprising tooling designed in accordance with the processing speed, selection of composite core fibers and resin and desired physical characteristics of the end composite core.

Owner:CTC GLOBAL CORP

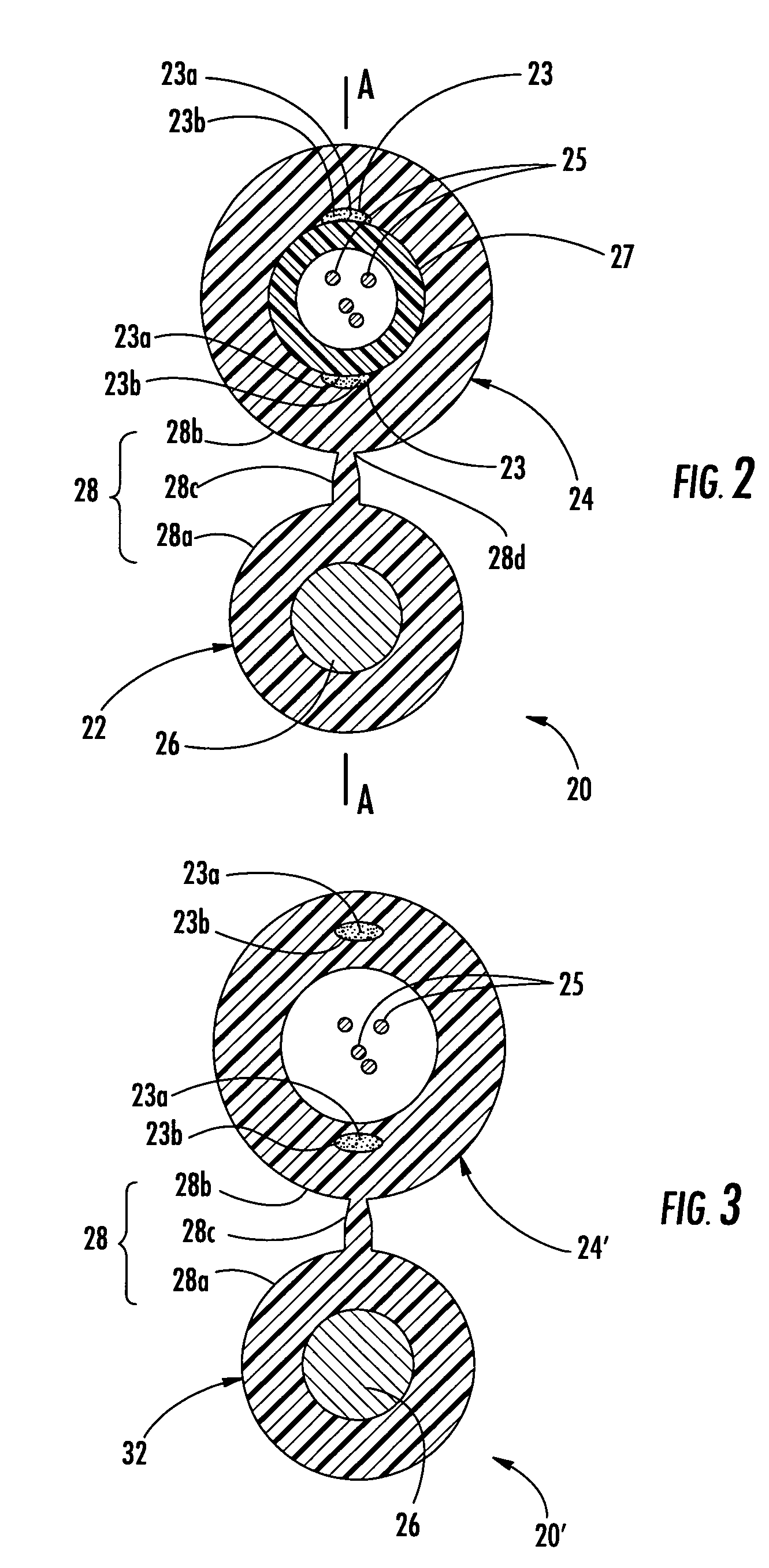

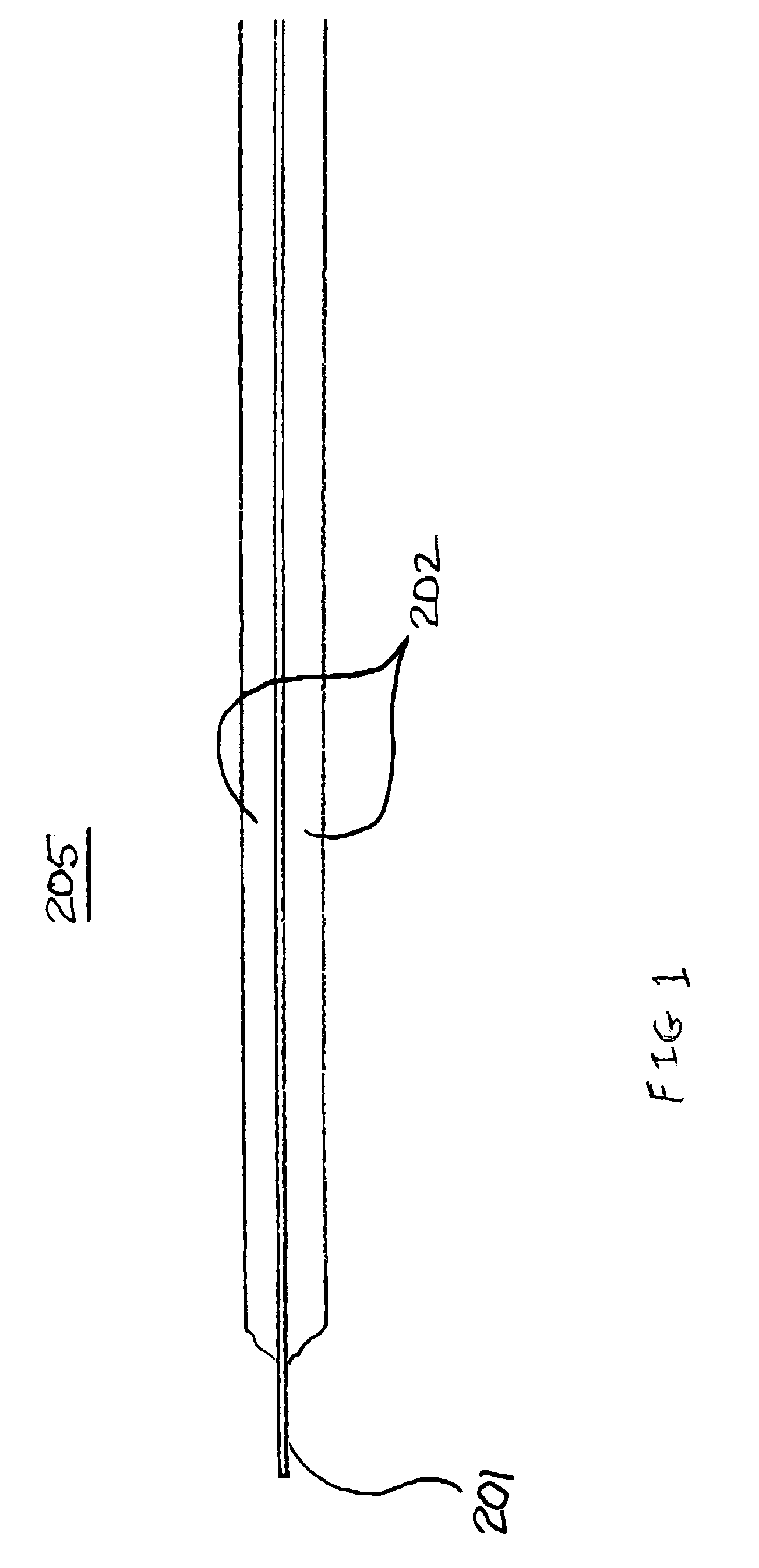

Fiber optic drop cables suitable for outdoor fiber to the subscriber applications

A fiber optic drop cable including at least one optical waveguide, at least one roving, and a cable jacket. In one embodiment, the at least one roving includes a resin matrix having a water-based acrylic composition that includes an ethylene-acrylic acid and a water-swellable component. The resin matrix has a percent by weight of about 10 percent or less of the flexible roving so that the at least of one roving is at least partially bonded with the cable jacket, thereby inhibiting buckling of the cable jacket. In another embodiment, a plurality of rovings are arranged in clusters in the cable for influencing the bonding between the rovings and cable jacket. Also, disclosed is a protective casing for protecting and routing optical fibers along with preconnectorized cable assemblies.

Owner:CORNING OPTICAL COMM LLC

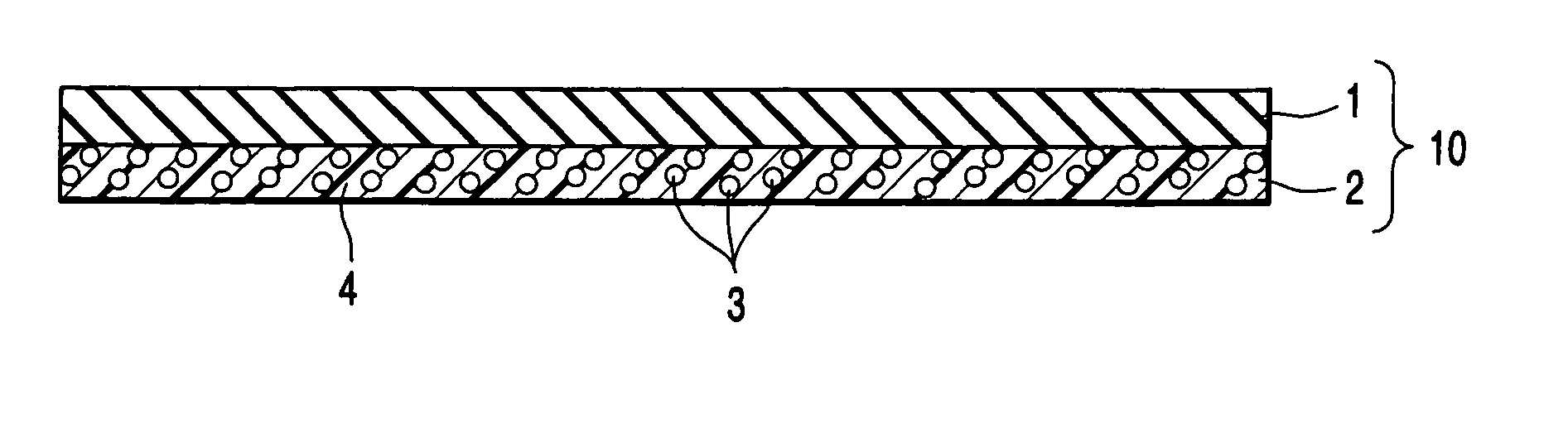

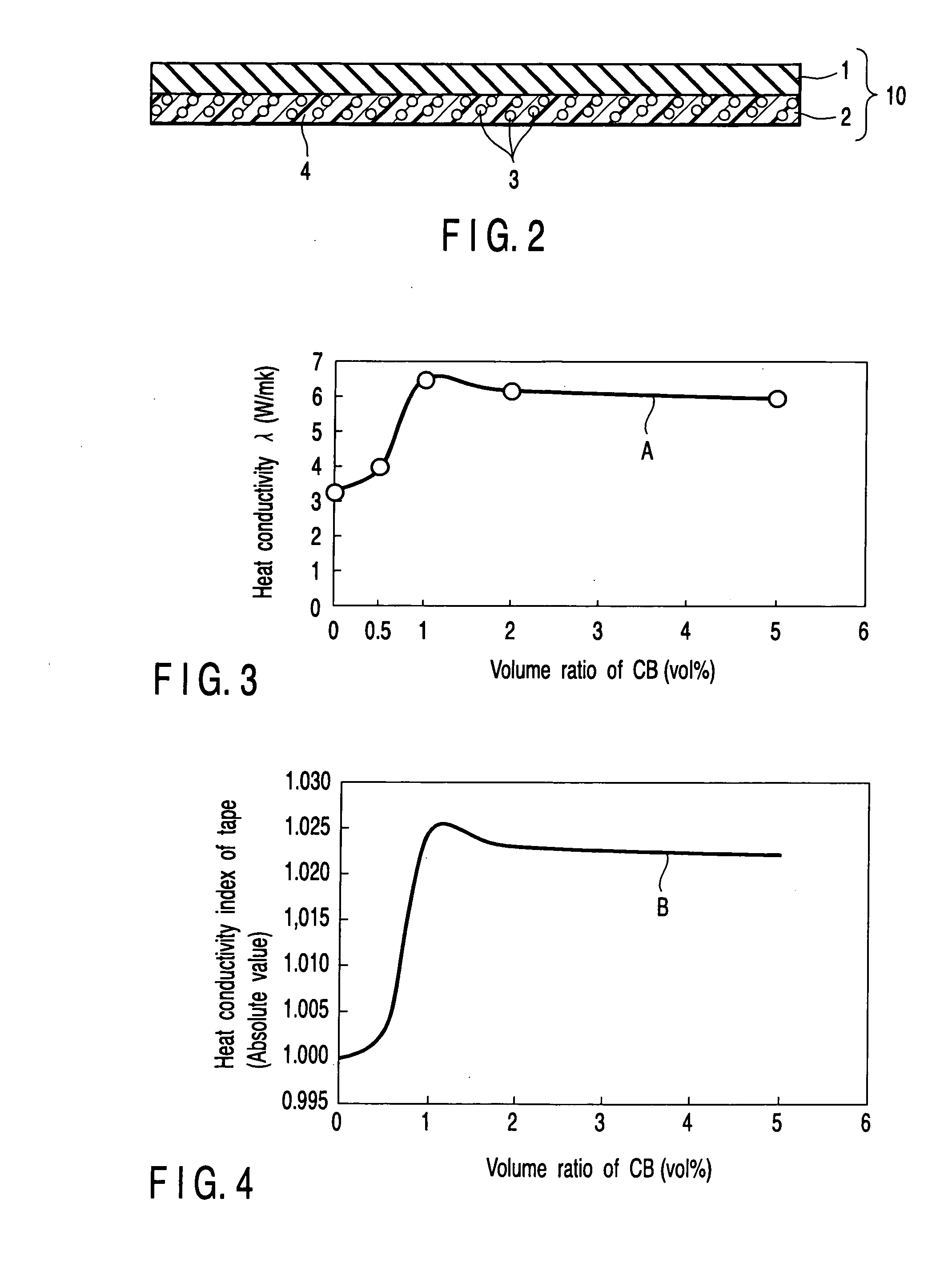

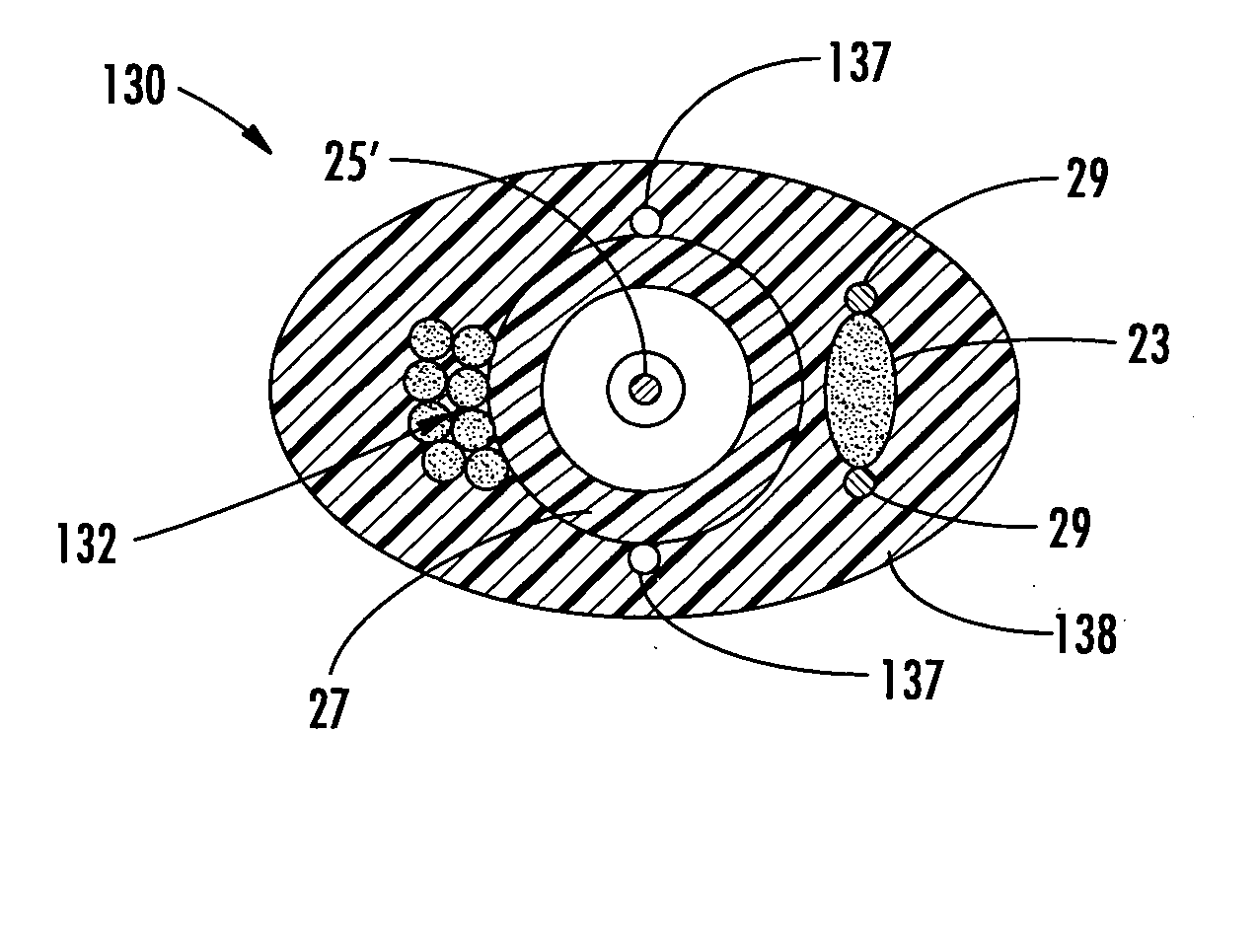

Highly heat conductive insulating member, method of manufacturing the same and electromagnetic device

ActiveUS20050208301A1Easy to manufactureImprove thermal conductivityPlastic/resin/waxes insulatorsSynthetic resin layered productsResin matrixMaterials science

The present invention provides a solution to the above-described drawbacks, and more specifically, as the tape-like or sheet-like insulation member, the resin matrix in which the first particles having a heat conductivity of 1 W / mK or higher and 300 W / mK or lower, that are diffused in the resin matrix, and the second particles having a heat conductivity of 0.5 W / mK or higher and 300 W / mK or lower, are diffused, is employed.

Owner:KK TOSHIBA

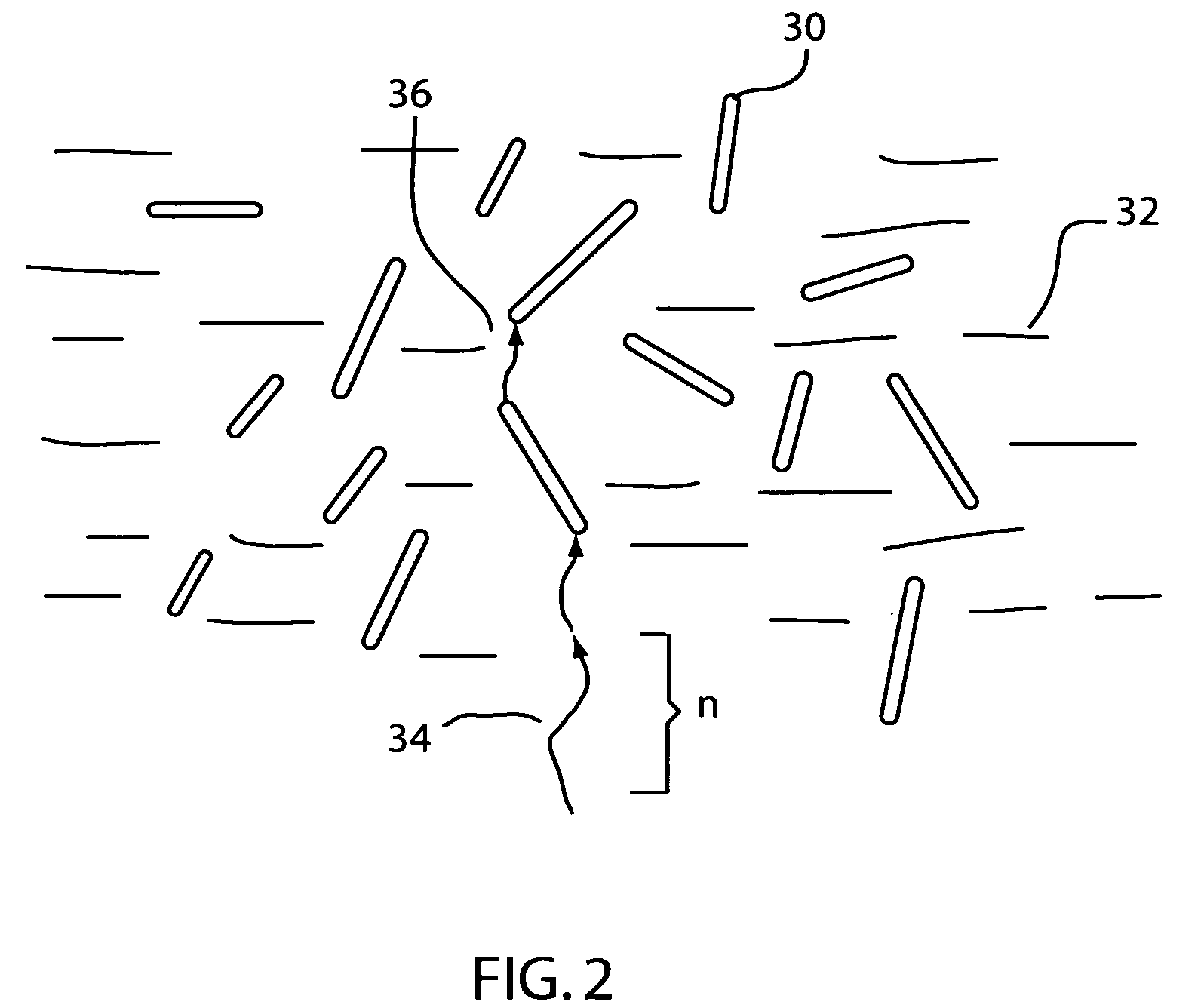

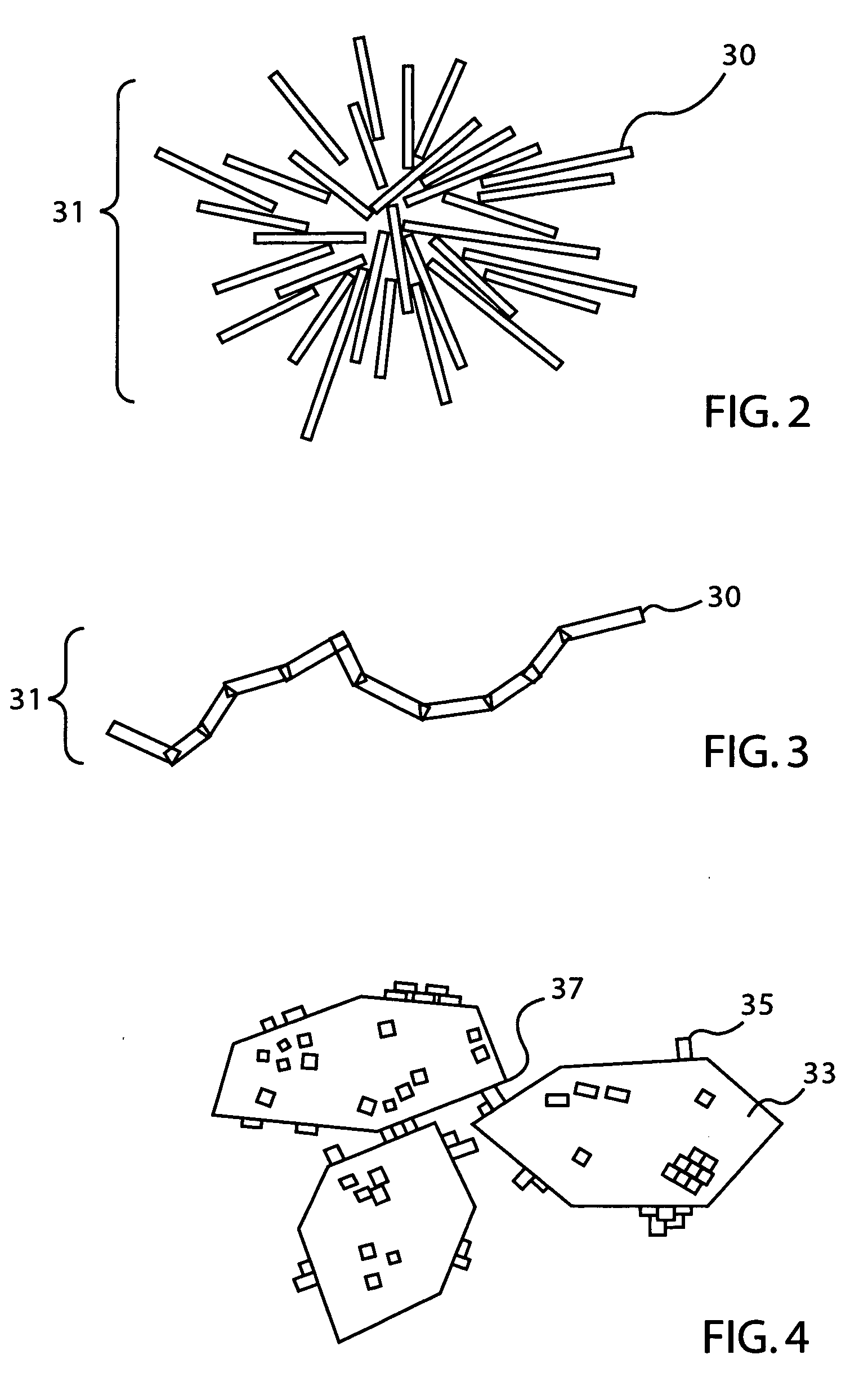

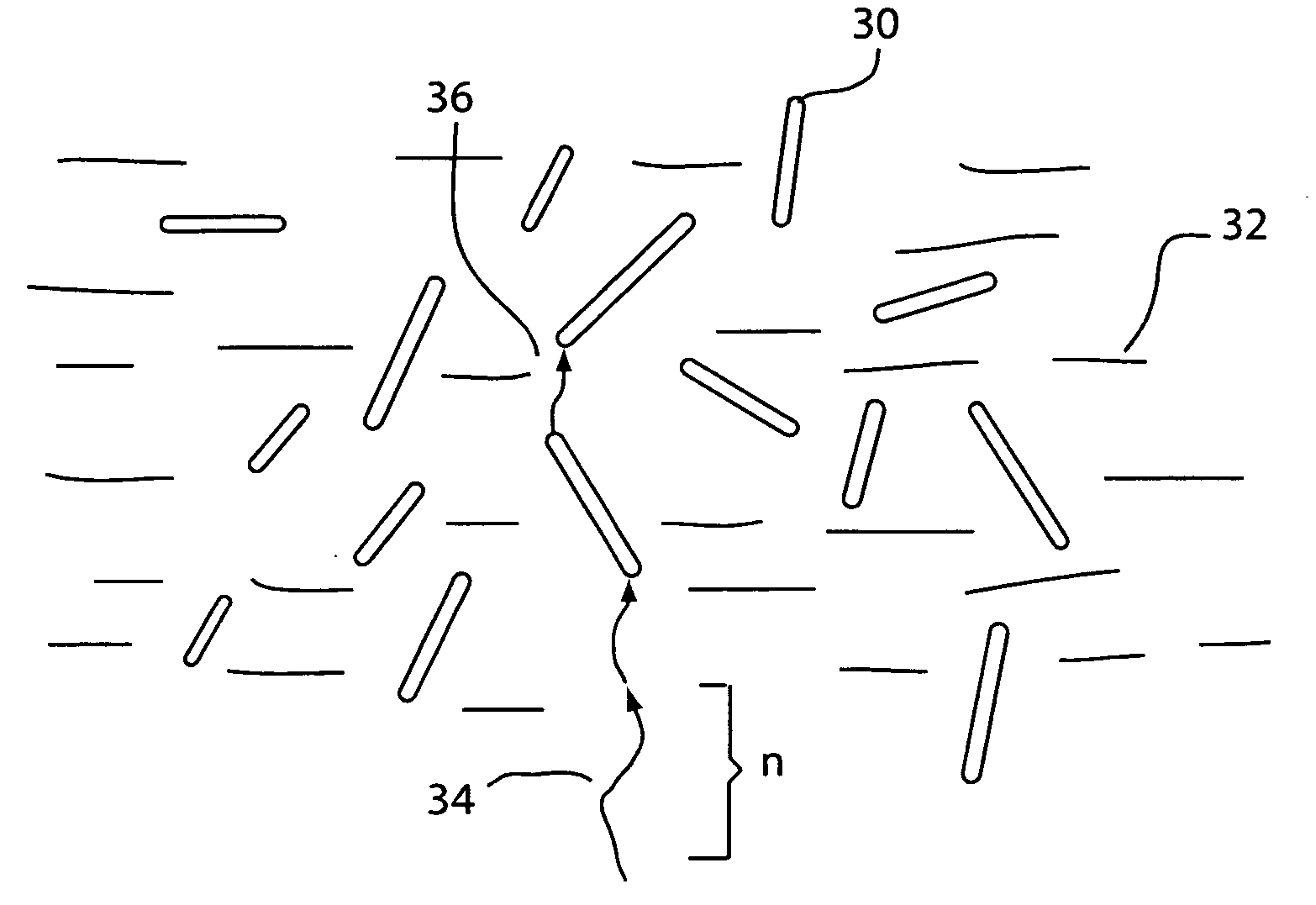

High thermal conductivity materials incorporated into resins

InactiveUS20050277349A1Easy to transportReduce distanceSpecial paperSynthetic resin layered productsResin matrixElectrical resistivity and conductivity

In one embodiment the present invention provides for a high thermal conductivity resin that comprises a host resin matrix 32 and a high thermal conductivity filler 30. The high thermal conductivity filler forms a continuous organic-inorganic composite with the host resin matrix, and the high thermal conductivity fillers are from 1-1000 nm in length and have an aspect ratio of between 3-100.

Owner:SIEMENS ENERGY INC

Carbon fiber reinforced composite and preparation thereof

The invention discloses carbon fiber reinforced thermoplastic resin composite material which is composed of the components according to the percentage by weight: carbon fibers with the surface modified accounting for 5 percent to 50 percent, thermoplastic resin accounting for 44 percent to 75 percent, polytetrafluoroethylene accounting for 5 percent to 15 percent and processing auxiliary agent accounting for 1 percent to 5 percent; the carbon fibers with the surface modified is manufactured by processing the carbon fibers in specially mixed acidic solution under the temperature of 40 DEG C to 80 DEG C for 30 minutes to 120 minutes and dried at the temperature of 80 DEG C to 150 DEG C. The invention also discloses the preparation method of the carbon fiber reinforced thermoplastic resin composite material. The carbon fibers of the carbon fiber reinforced thermoplastic resin composite material provided by the invention are dispersed in a state of 3 mm to 5 mm in a resin matrix, the original high intensity of the carbon fibers is maintained to the maximum, so as to ensure the prepared composite material to have high intensity, high modulus, high heat resistant and high wear resistant performances.

Owner:宁波益德新材料有限公司

Morphological forms of fillers for electrical insulation

InactiveUS20070026221A1Easy to transportReduce distanceWindings insulation shape/form/constructionPrinted circuit aspectsElectricityResin matrix

A high thermal conductivity resin that has a host resin matrix, and a high thermal conductivity filler. The high thermal conductivity filler (30) forms a continuous organic-inorganic composite with the host resin matrix. The fillers are from 1-1000 nm in length, and have average aspect ratios of between 3-100. At least a portion of the high thermal conductivity fillers comprise morphologies (31) chosen from one or more of hexagonal, cubic, orthorhombic, rhombohedral, tetragonal, whiskers and tubes. In particular, some of the fillers will aggregate into secondary structures.

Owner:SIEMENS ENERGY INC

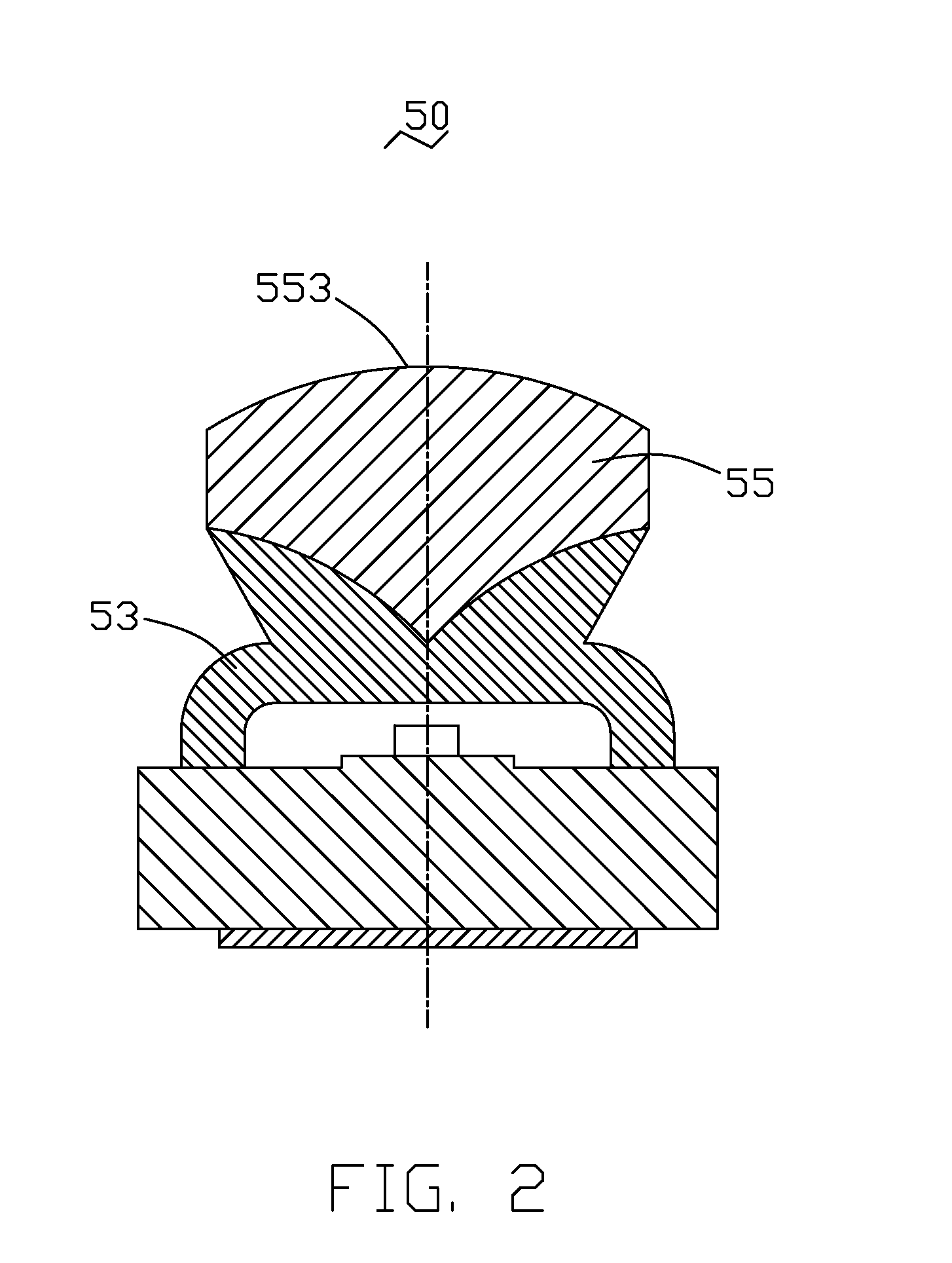

Method for making light emitting diode

InactiveUS7572654B2Semiconductor/solid-state device manufacturingDisplay meansResin matrixLight-emitting diode

An exemplary light emitting diode (30) includes a light output unit (31), an optical lens (33) and a reflective film (35). The optical lens includes a light input surface (331) facing the light output unit, a top interface (333) opposite to the light input surface, and a light output surface (335) between the light input surface and the top interface. The reflective film is integrally formed on and in immediate contact with the top interface of the optical lens. The reflective film is made of a transparent resin matrix material dispersed with a plurality of reflective particles. A method for making the light emitting diode is also provided.

Owner:HON HAI PRECISION IND CO LTD

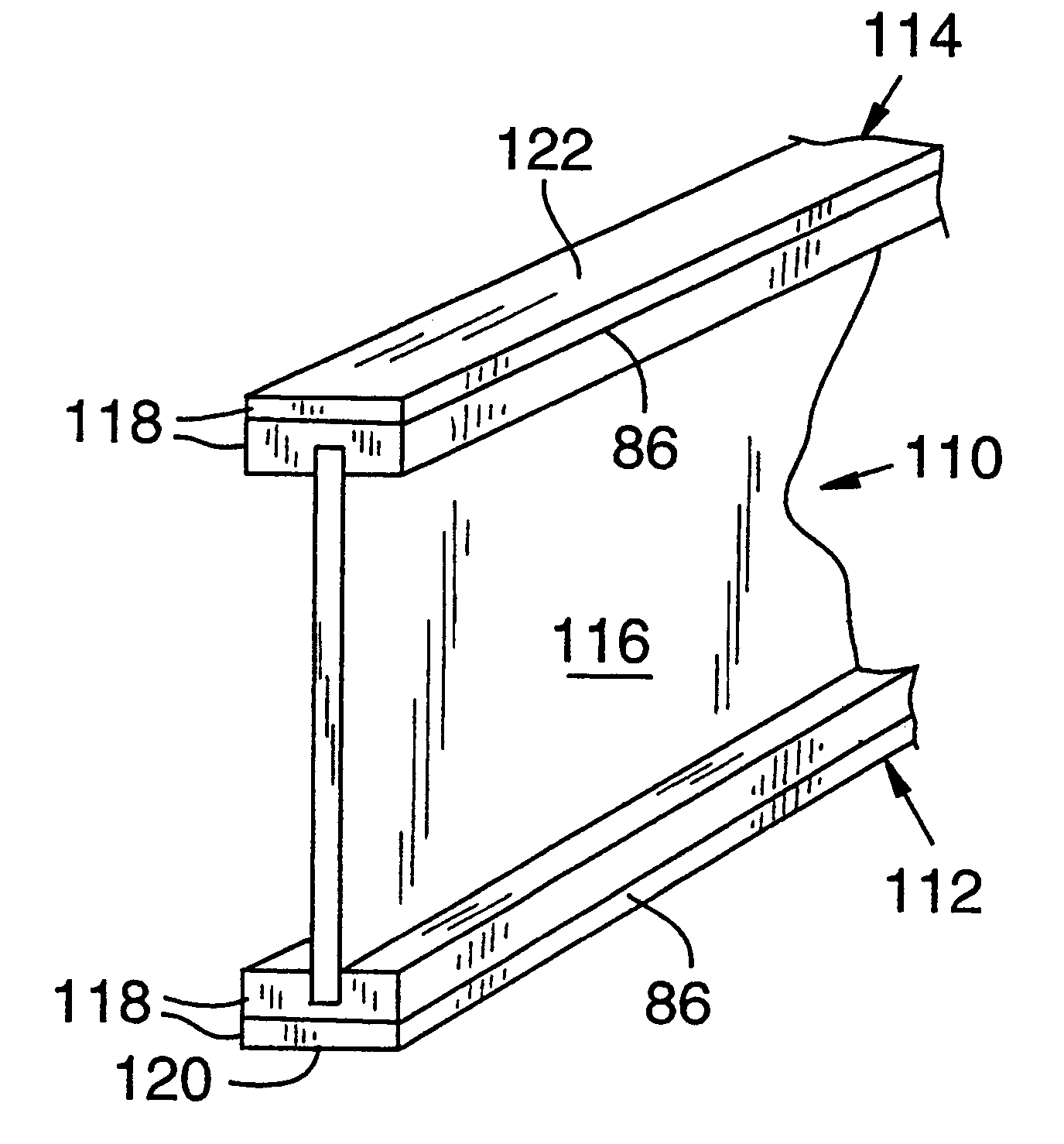

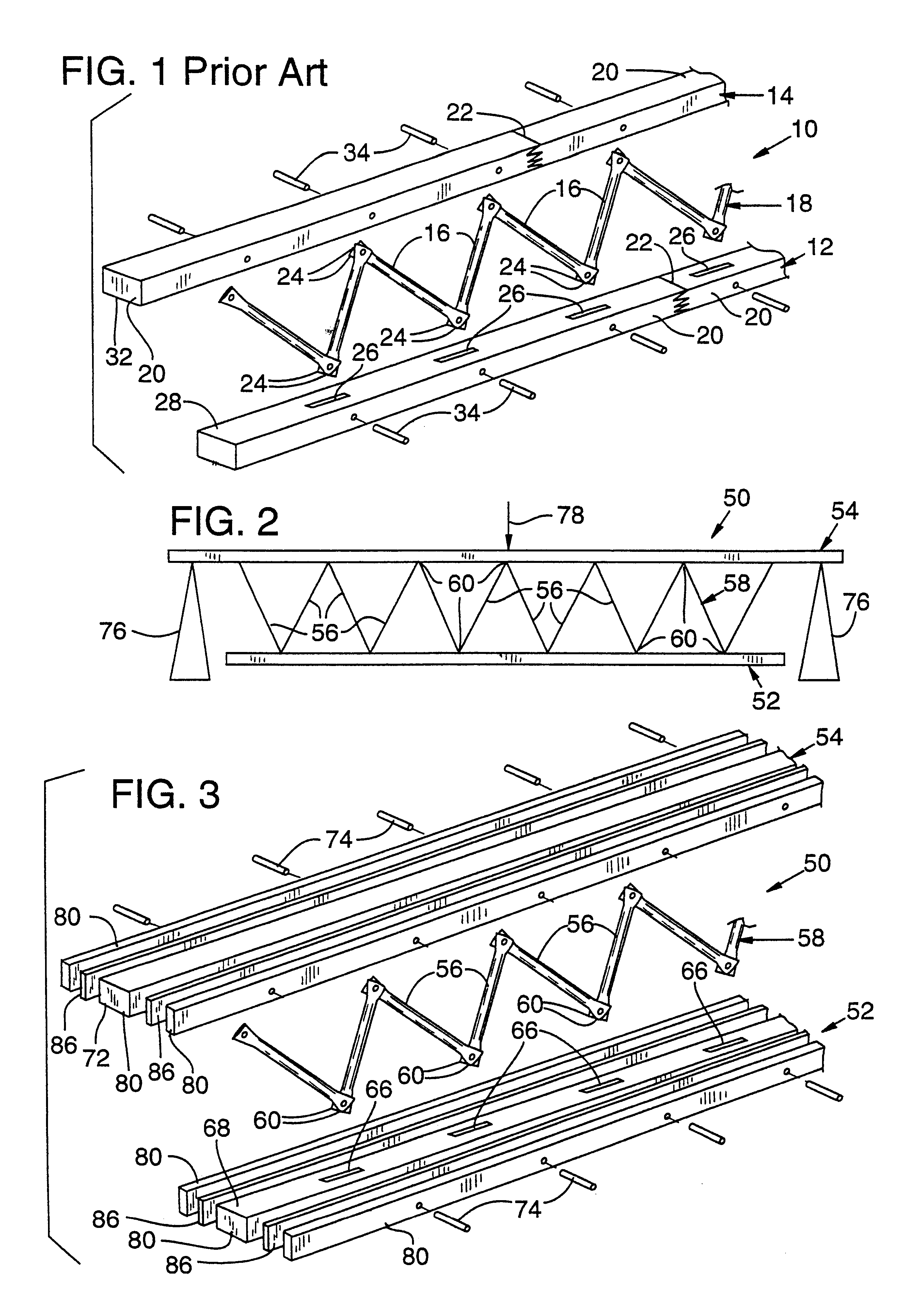

Wood I-beam conditioned reinforcement panel

InactiveUS6173550B1Improve the immunityComparable and great strengthGirdersJoistsResin matrixEngineering

The present invention includes wood I-beams with fiber reinforcement. In a preferred embodiment, a wood I-beam includes an opposed pair of elongated wood flanges and a substantially continuous web positioned between them. In one embodiment, the web includes multiple metal tubes that extend between the wood flanges and form a zig zag pattern. The ends of the metal tubes are flattened parallel to the plane of the metal web so the ends can fit within either slots in the top surface of the bottom wood flange or slots in the bottom surface of the top wood flange. Metal pins pass through the sides of the wood flanges and the flattened ends of the metal tubes to secure the tubular metal web to the flanges. In other embodiments the web includes oriented strand board (OSB) or plywood. Reinforcements are adhered to the wood flanges so that the metal pins also pass through the reinforcements. The reinforcements preferably include multiple fiber strands held within a resin matrix.

Owner:OREGON CASCADES WEST COUNCIL OF GOVERNMENTS

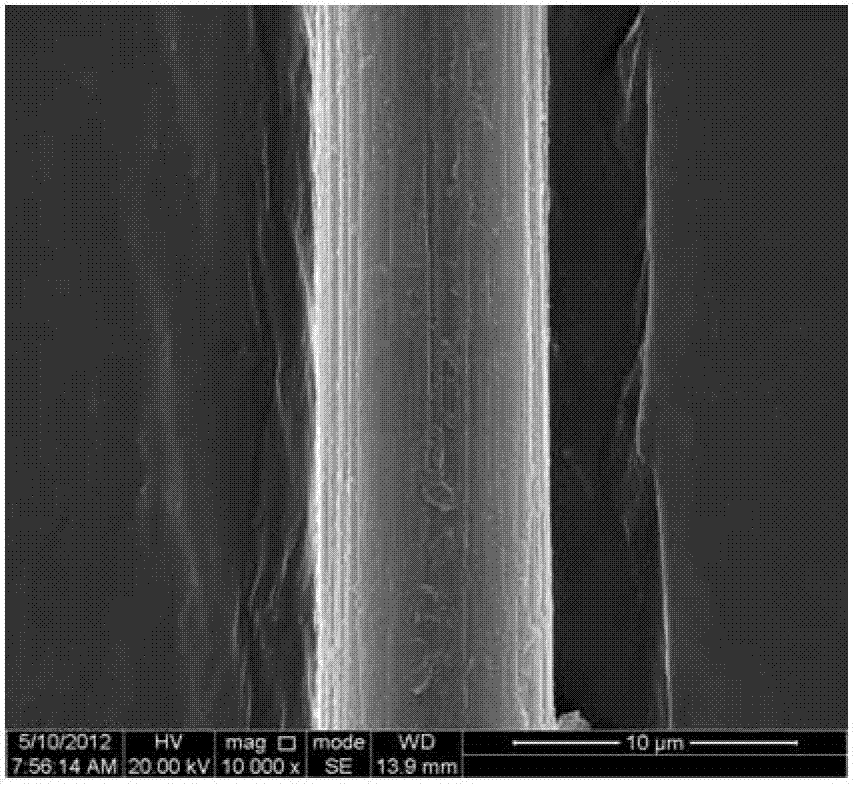

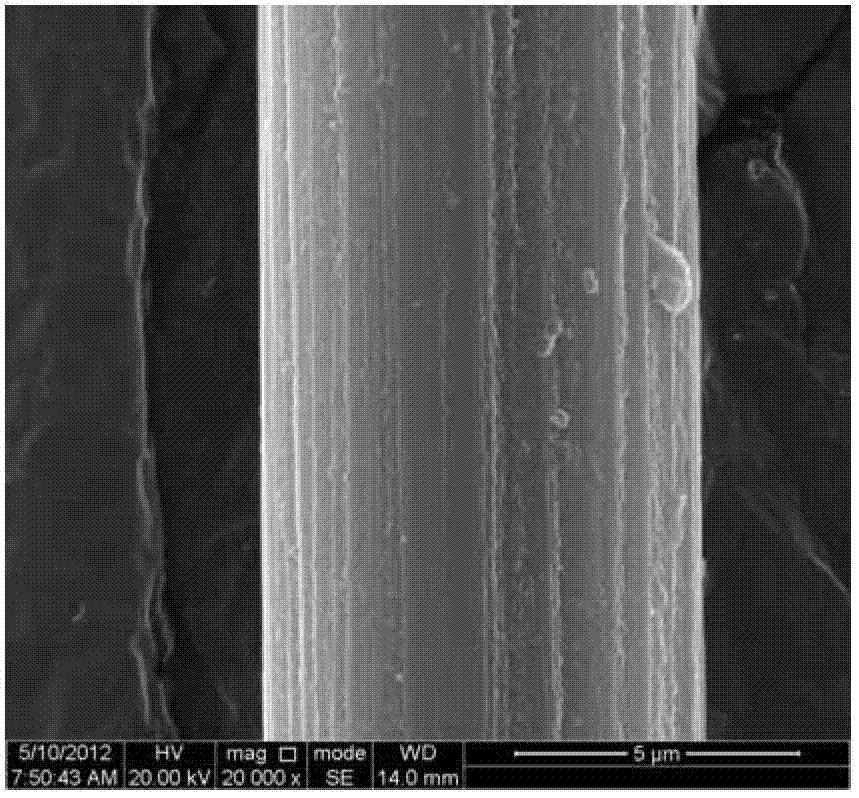

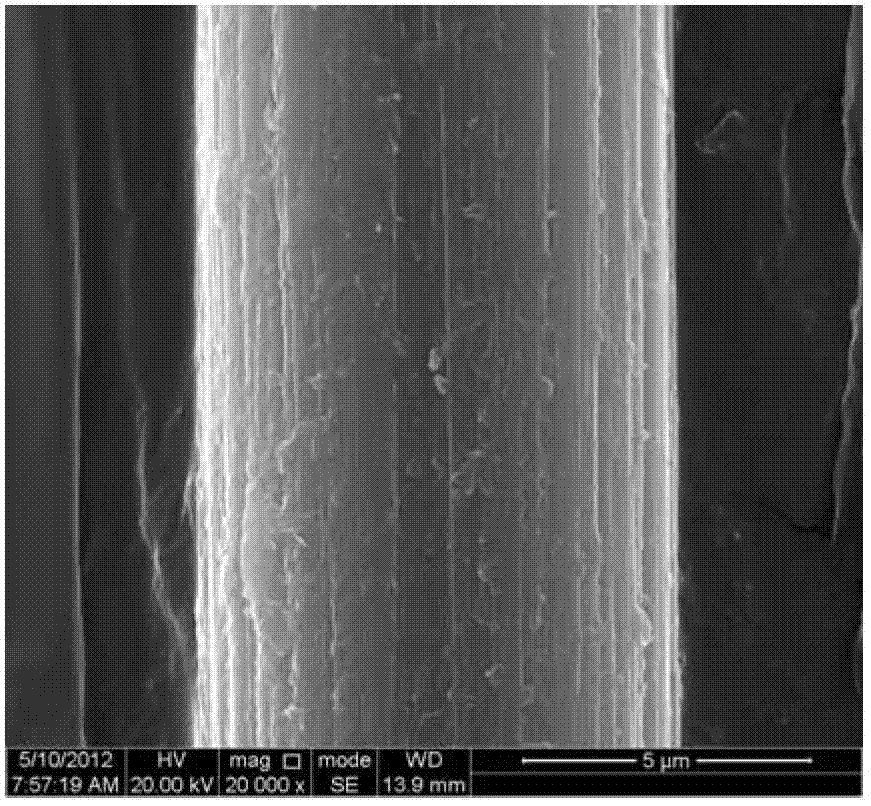

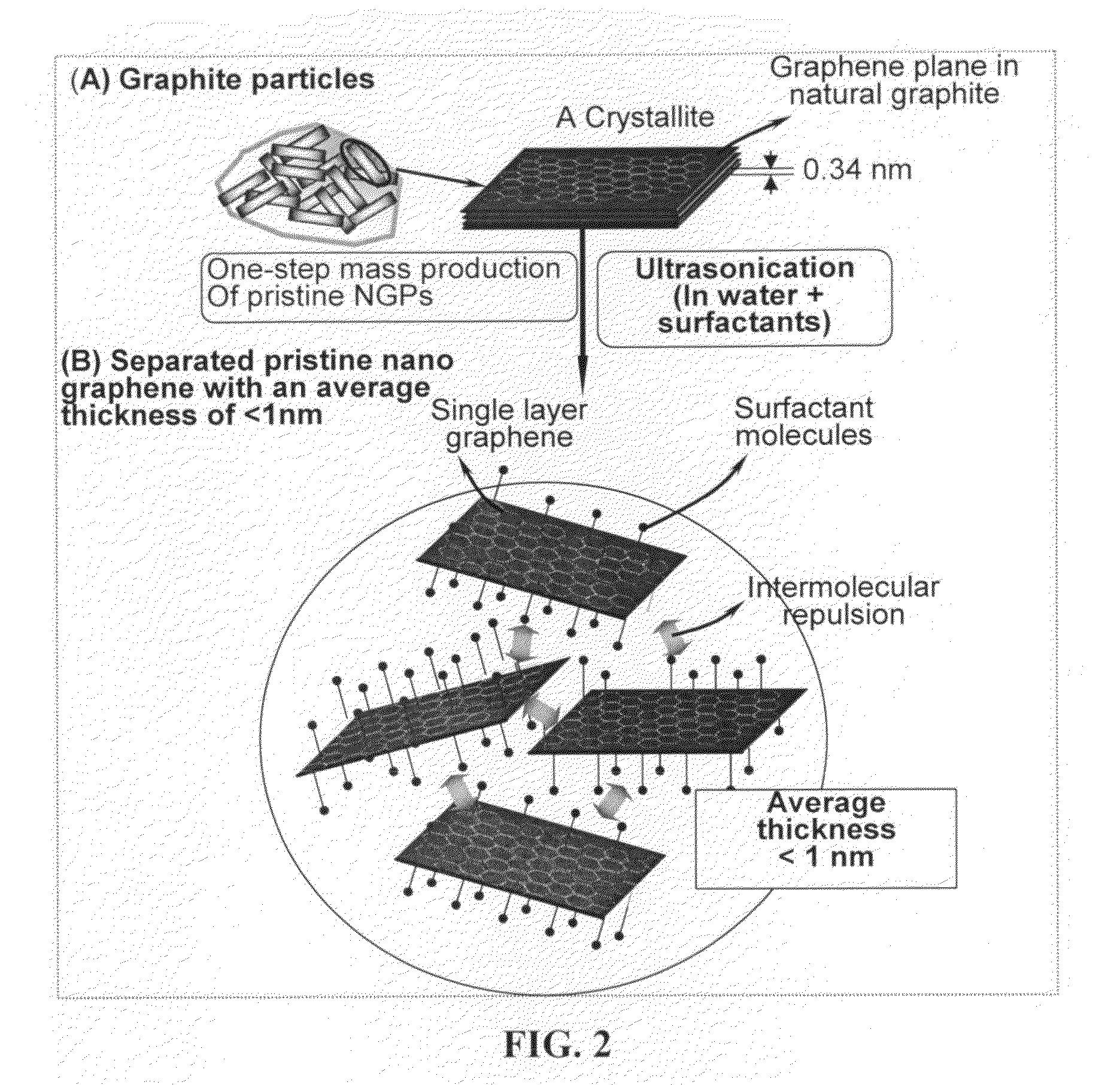

Method for preparing graphene oxide grafting surface modification carbon fiber

ActiveCN102787488AIncrease roughnessImprove interface performanceCarbon compoundsCarbon fibresCarbon compositesResin matrix

A method for preparing a graphene oxide grafting surface modification carbon fiber relates to a carbon fiber modification method, and is used for solving the technical problems that the existing carbon fiber has low surface activity, reduced surface tension and poor wettability with a resin matrix, and the interlaminar shear strength of a composite material is caused to reduce. The method comprises the steps as follows: 1, graphite oxidization; 2, separation of graphite oxide mother liquor; 3, functionalization of graphite oxide; 4, carbon fiber surface functionalization; and 5, carbon fiber surface graphite oxide treatment. The graphite oxide uniformly covers the carbon fiber surface, the roughness of the carbon fiber surface can be greatly improved, and accordingly, the interfacial properties of a carbon fiber reinforced composite material can be improved by an anchoring action. The interfacial shear strength of the surface grafting graphene oxide carbon fiber / carbon composite material which is prepared through graphene oxide grafting modification can be improved by 25% in comparison with that of the untreated surface grafting graphene oxide carbon fiber / carbon composite material.

Owner:HARBIN INST OF TECH

Dendritic polyester macromolecule in thermosetting resin matrix

A partially or fully cured thermosetting product which includes a cured and molded product of a thermosetting composition. The composition includes 70% to 99% by weight of at least one thermosetting resin or compound and 1% to 30% by weight of at least one toughening agent. The toughening agent is at least one hyperbranched dendritic macromolecule formed of ester units, optionally in combination with ether units.

Owner:PERSTORP AB

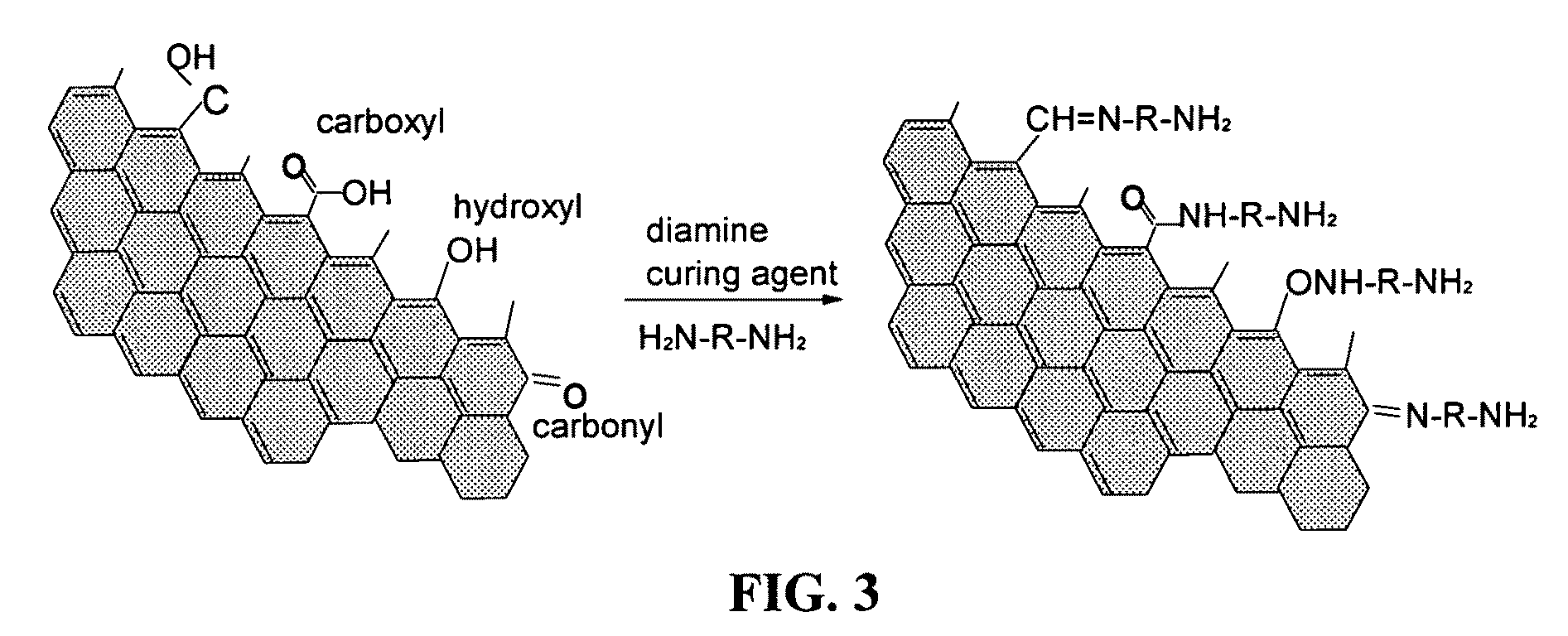

Nano graphene-modified curing agents for thermoset resins

ActiveUS20110017955A1Good dispersionGood physical propertiesOther chemical processesConductive materialEpoxyCross-link

The present invention provides a modified curing agent for a thermosetting resin, such as epoxy resin. As one example, the epoxy curing agent comprises: (a) multiple nano graphene platelets; (b) a chemical functional group having multiple ends with a first end being bonded to a nano graphene platelet and at least a second end reactive with the epoxy resin; and (c) reactive molecules acting as a primary cross-linking agent for the epoxy resin; wherein the nano graphene platelet content is no less than 0.01% by weight based on the total weight of the modified curing agent. A modified curing agent containing reactive molecule-functionalized NGPs enable excellent dispersion of NGP in a resin matrix and the resulting nanocomposites exhibit much better properties than those of corresponding nanocomposites prepared by directly mixing dried NGPs with the thermosetting resins.

Owner:GLOBAL GRAPHENE GRP INC

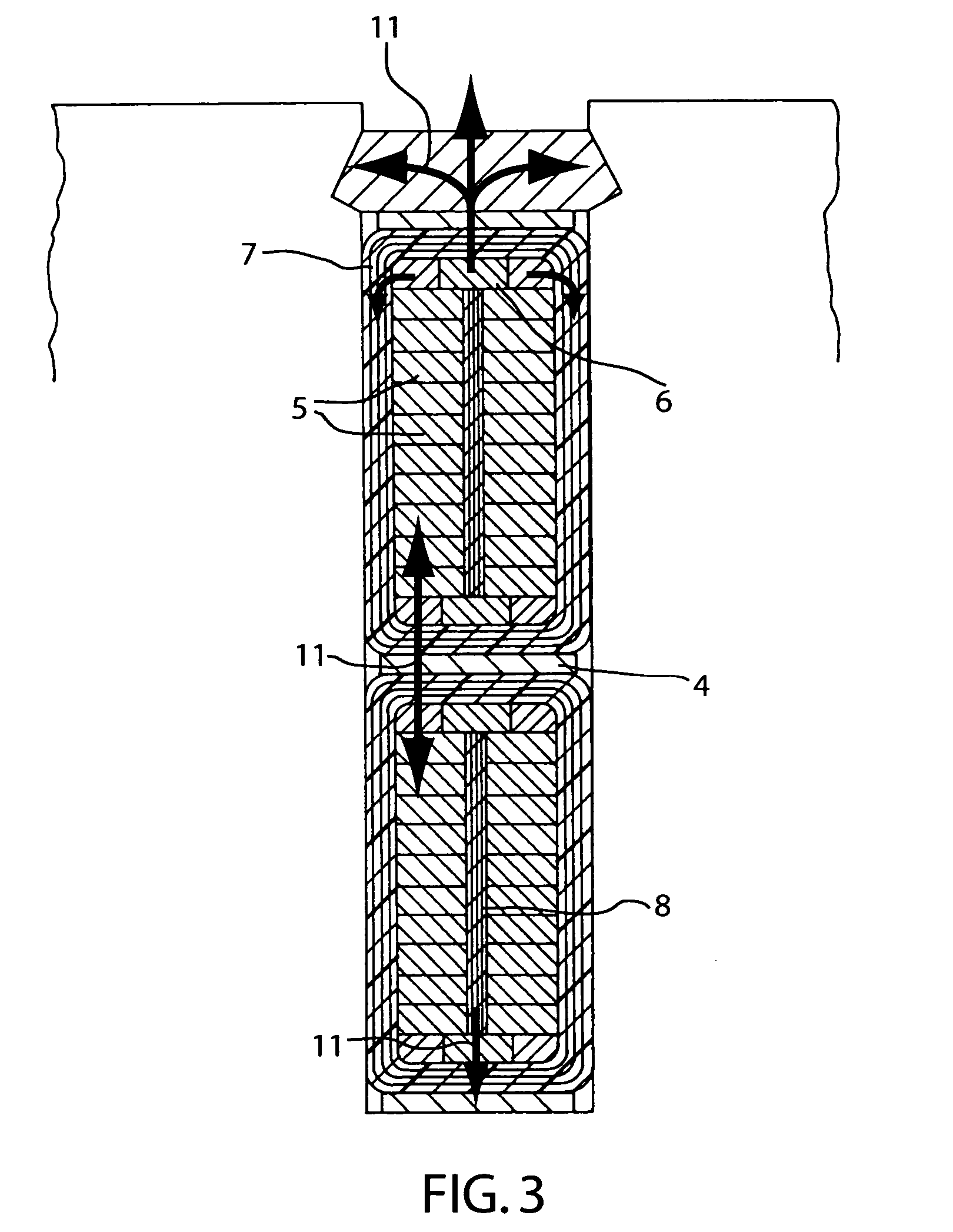

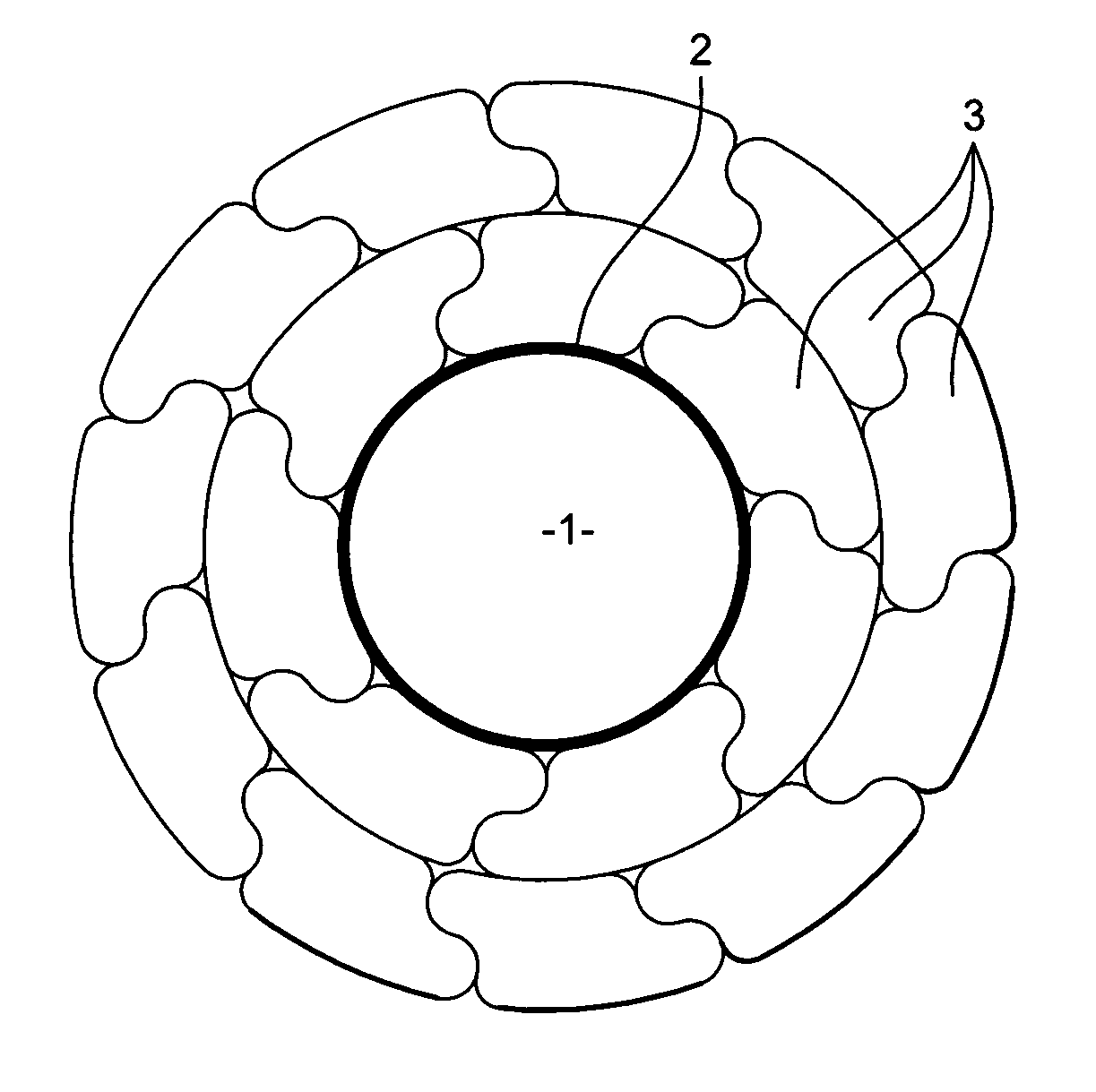

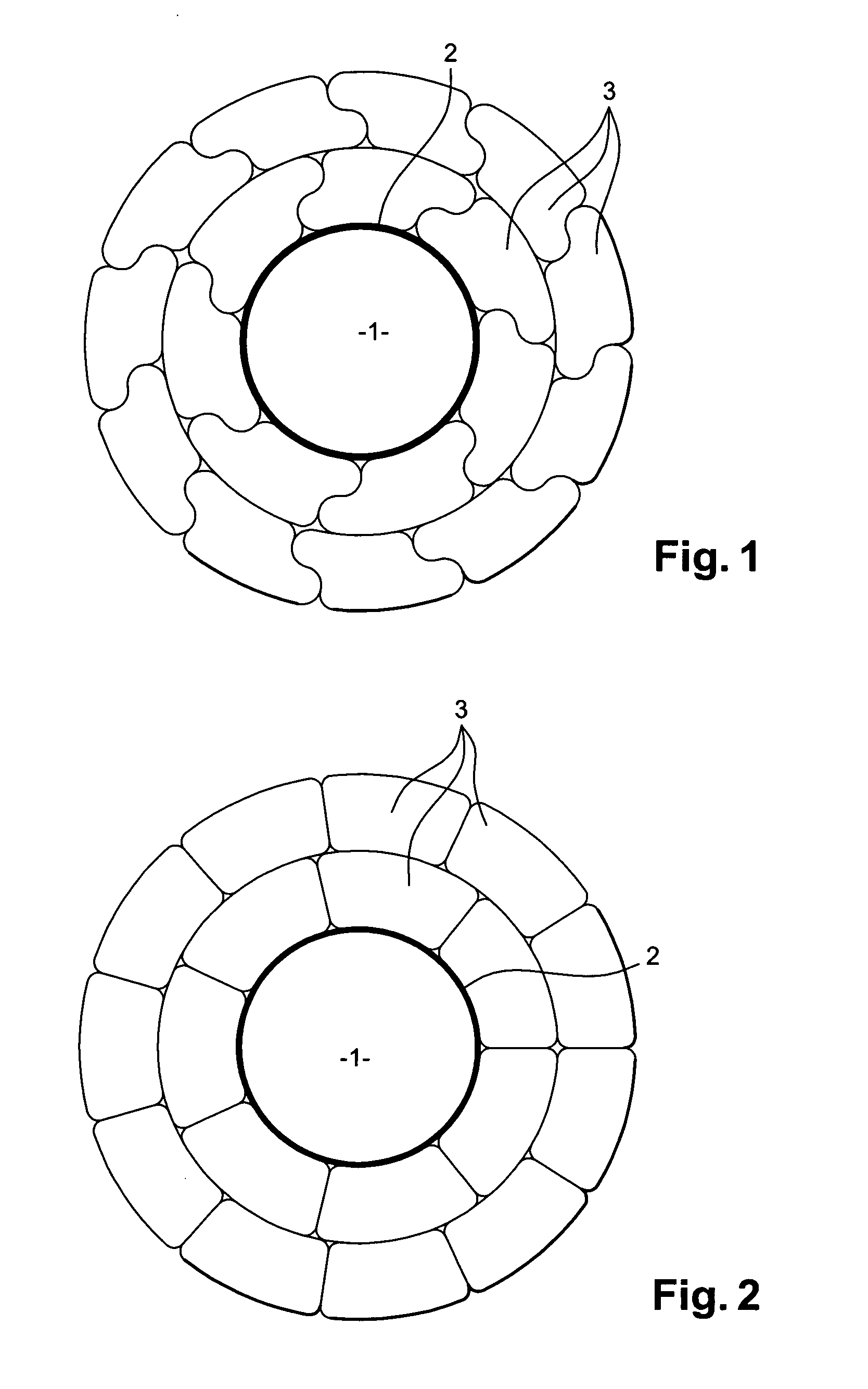

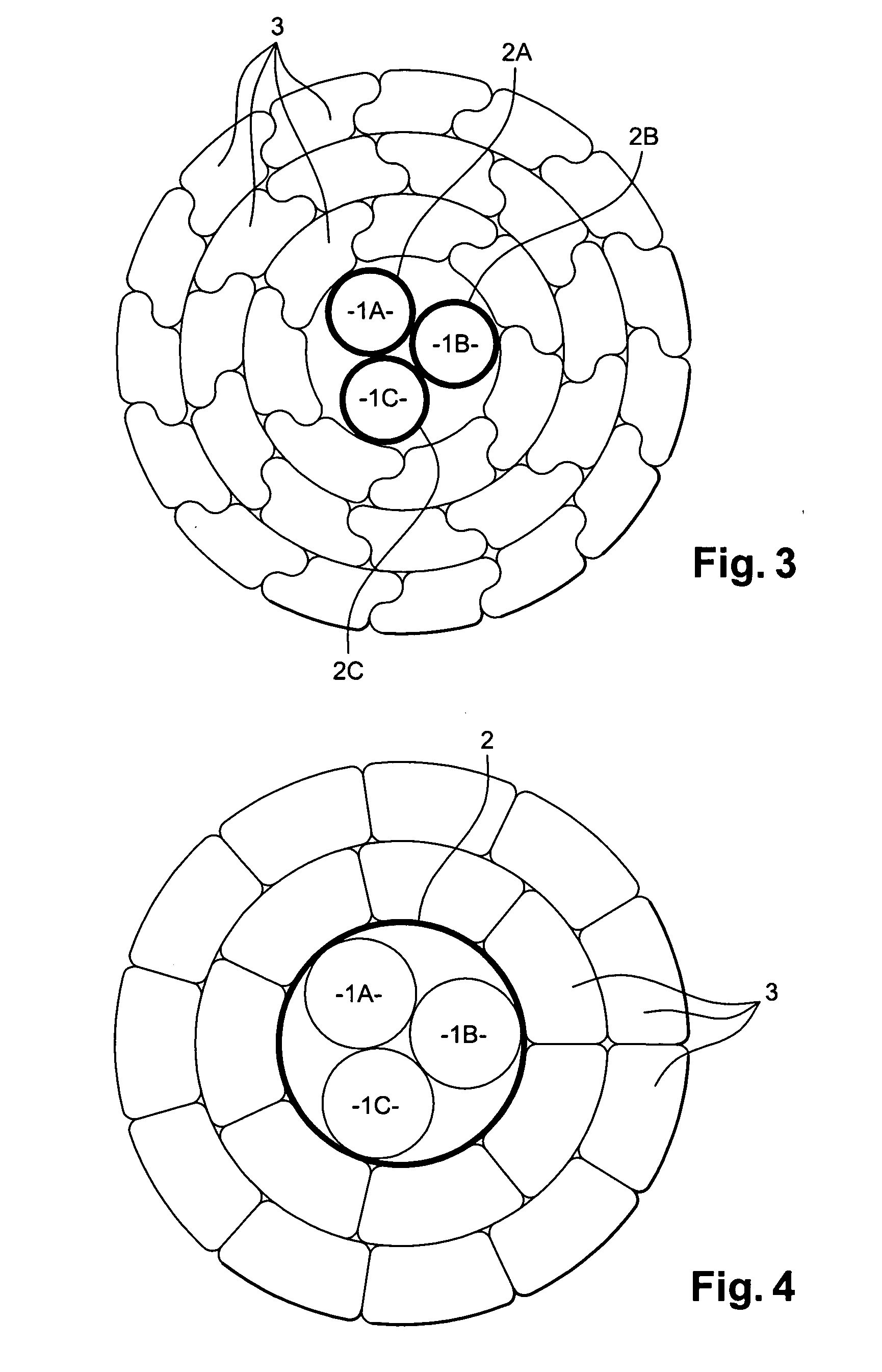

Electricity transport conductor for overhead lines

The invention relates to a method of fabricating an electricity transport conductor, in particular for overhead power lines, that are to operate at an operating temperature greater than or equal to 200° C., and comprising at least one composite central core 1 made of continuous fibers impregnated with an epoxy resin matrix, the core being covered in at least one layer of insulating material 2, and conductor wires 3 of aluminum or aluminum alloy being wound around the core. According to the invention, said insulating material is compatible with said operating temperature and is put into place on said core 1 without subsequent heating.

Owner:NEXANS

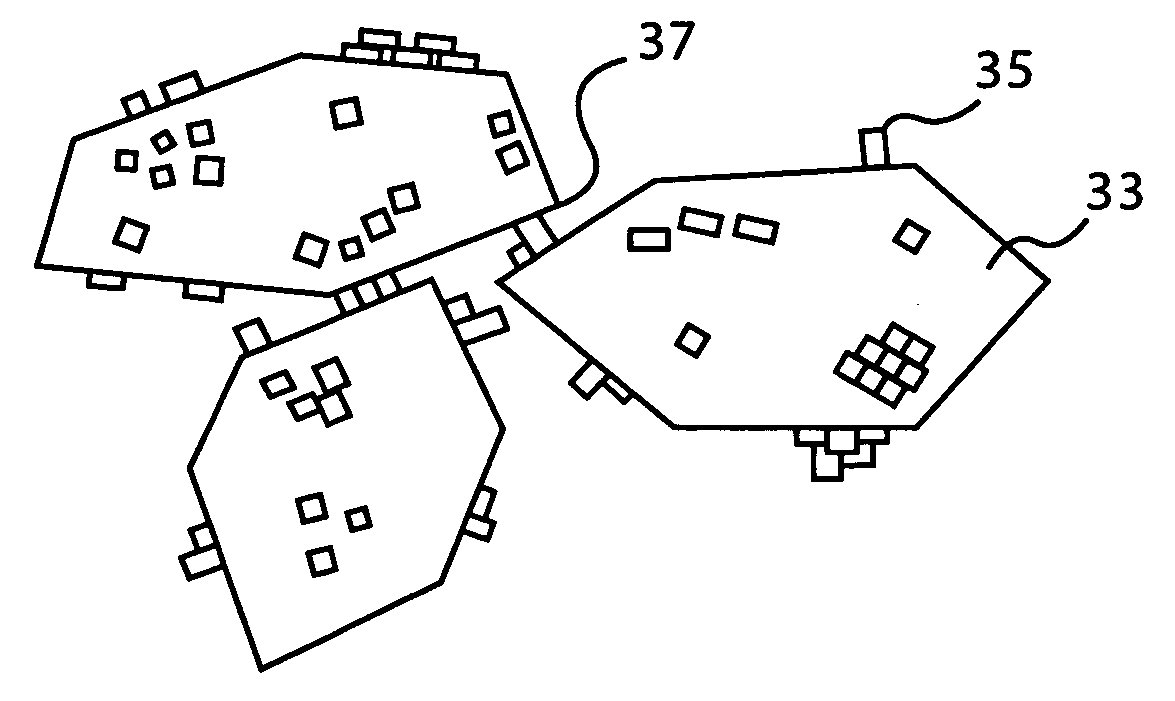

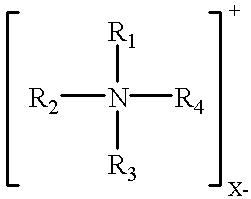

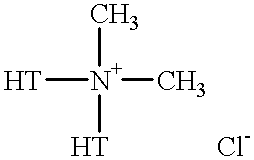

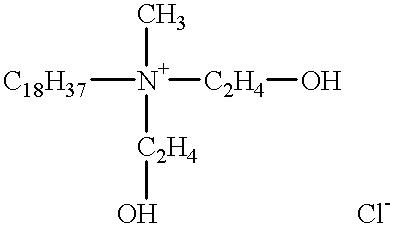

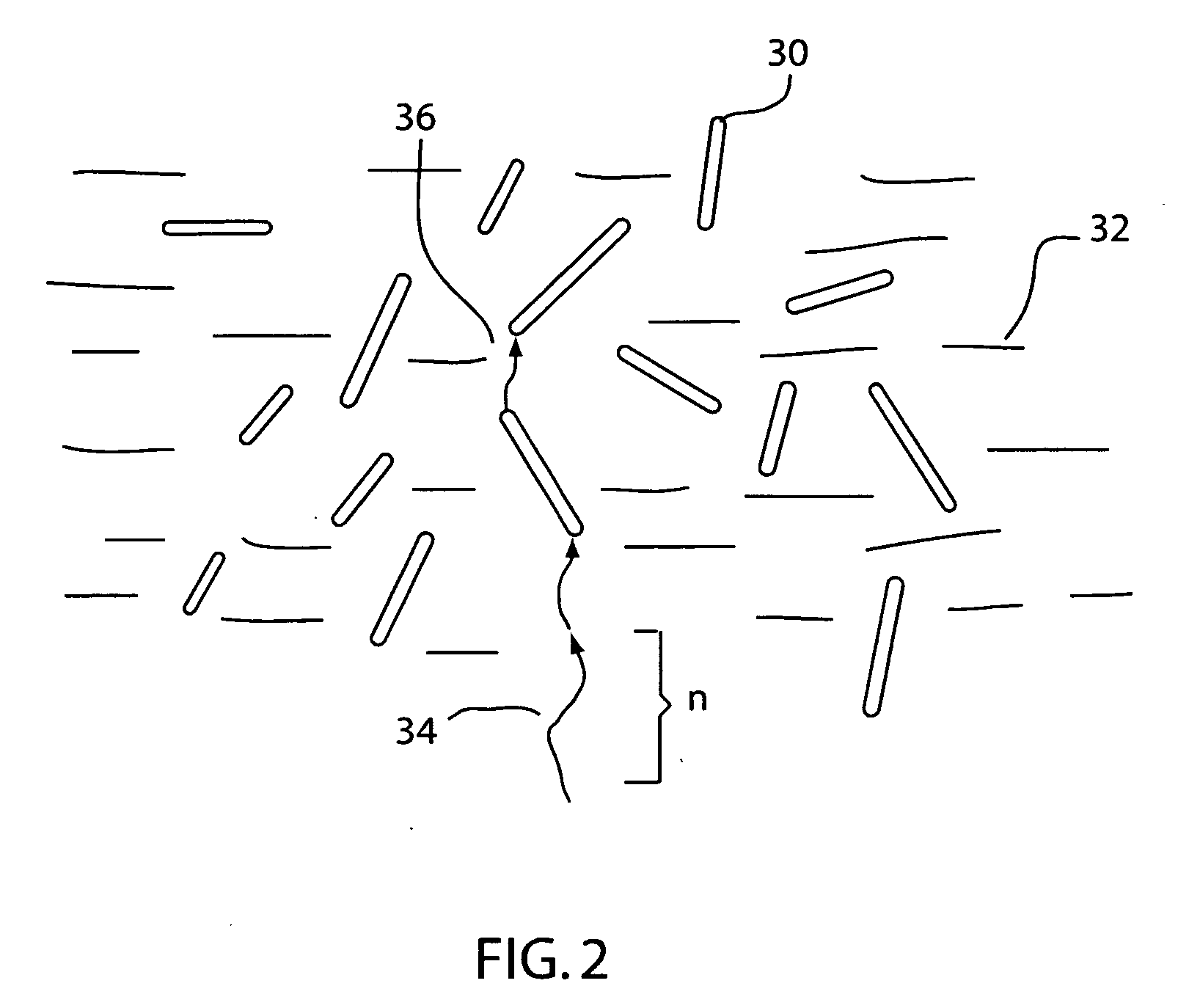

Clay/organic chemical compositions useful as additives to polymer, plastic and resin matrices to produce nanocomposites and nanocomposites containing such compositions

InactiveUS6380295B1Good dispersionImprove structural strengthCoatingsSilicon compoundsAmmonium compoundsWater dispersible

This invention is of a hybrid organoclay that consists of an organic chemical / phyllosilicate clay intercalate that has been ion-exchanged with quaternary ammonium compounds. Since this hybrid organoclay is hydrophobic, it can be washed in water to remove reaction salts and excess water soluble or water dispersible polymers to give a clean product via inexpensive means such as filtration. This allows a better dispersing composition to be prepared without the difficulties of isolation presented by prior art which uses energy intensive means to remove the bulk of the water from the final product and cannot be easily washed. In one aspect, the present invention provides a solid clay / chemical composition that comprises: (a) one or more smectite clays, (b) a quaternary ammonium compound which reacts via an ion exchange mechanism with the smectite clay, and (c) one or more non-anionic organic materials that intercalate with the clay. The invention is useful both as an ingredient to form nanocomposites and as a rheological additive.

Owner:ELEMENTIS SPECIALTIES INC

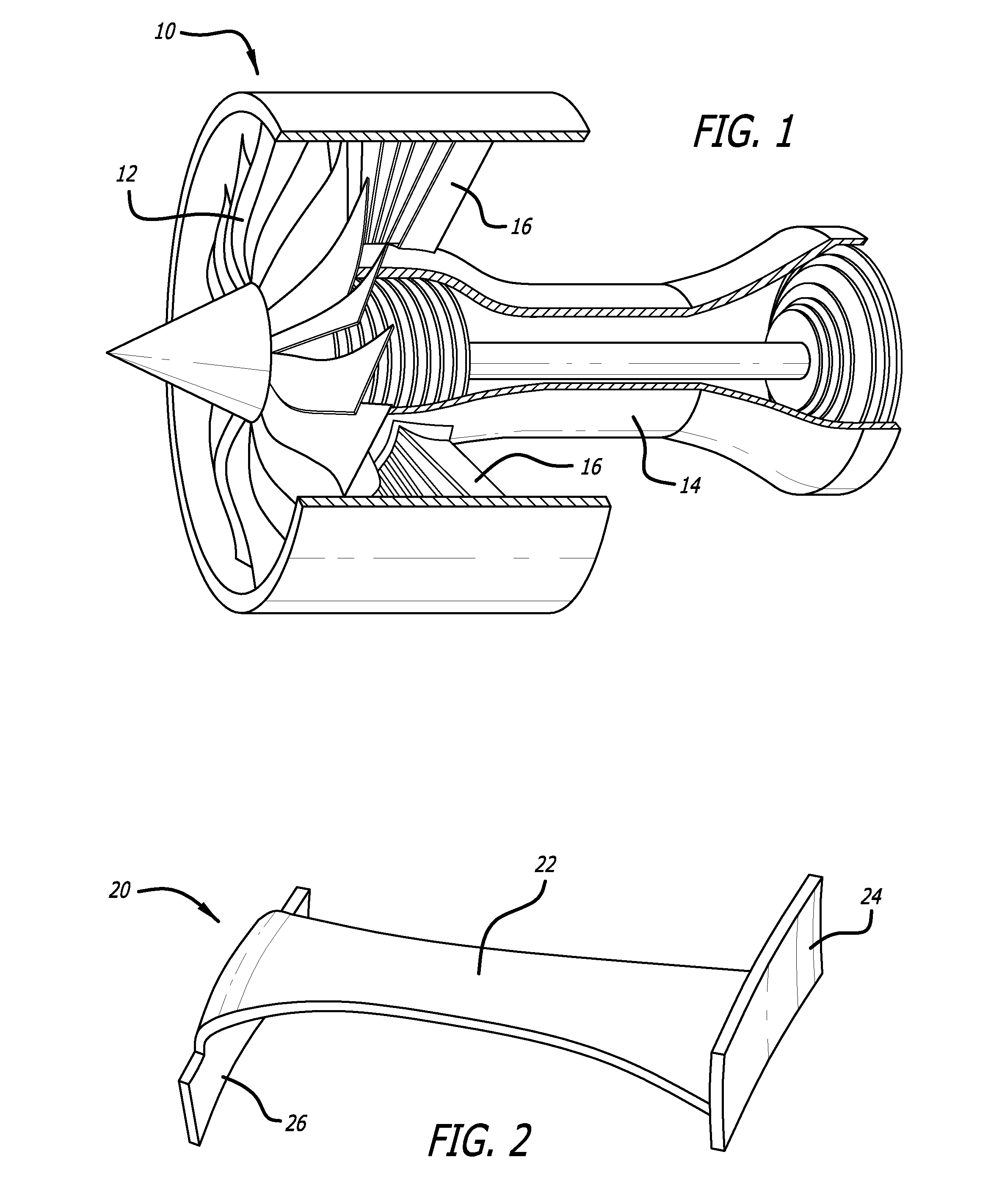

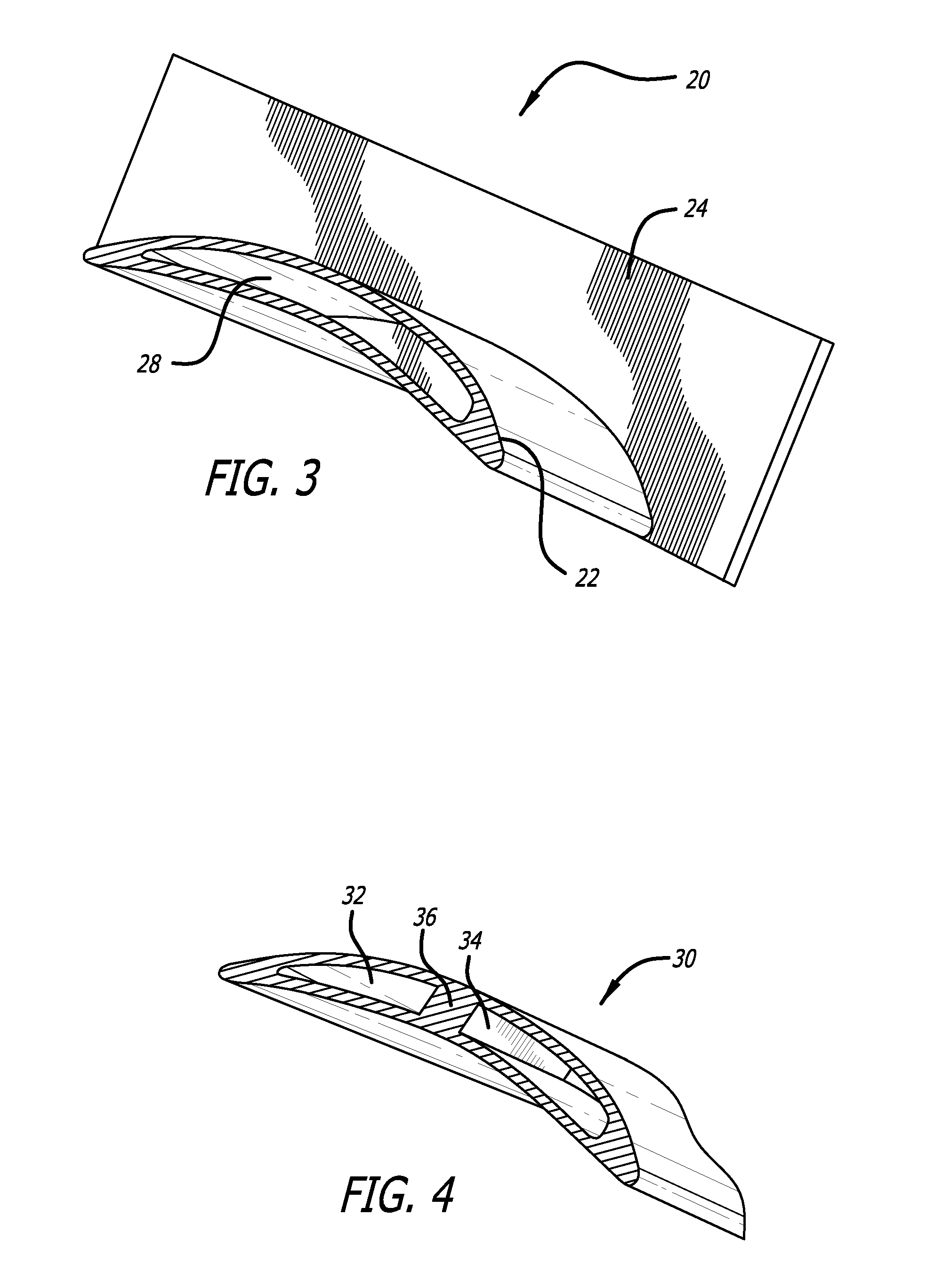

High pressure molding of composite parts

ActiveUS20130101406A1Avoid distortionReduce weightPump componentsReaction enginesJet engineShell molding

Composite pre-forms are molded at high pressure to form composite parts that can be used in place of metal-based high performance parts, such as the outlet guide vanes found in turbofan jet engines. The composite pre-forms include two different fiber orientations that are co-molded in a resin matrix at high pressures to provide composite outlet guide vanes and other high performance parts. Chambers within the composite part are optionally formed during molding of the pre-form at high pressures.

Owner:HEXCEL

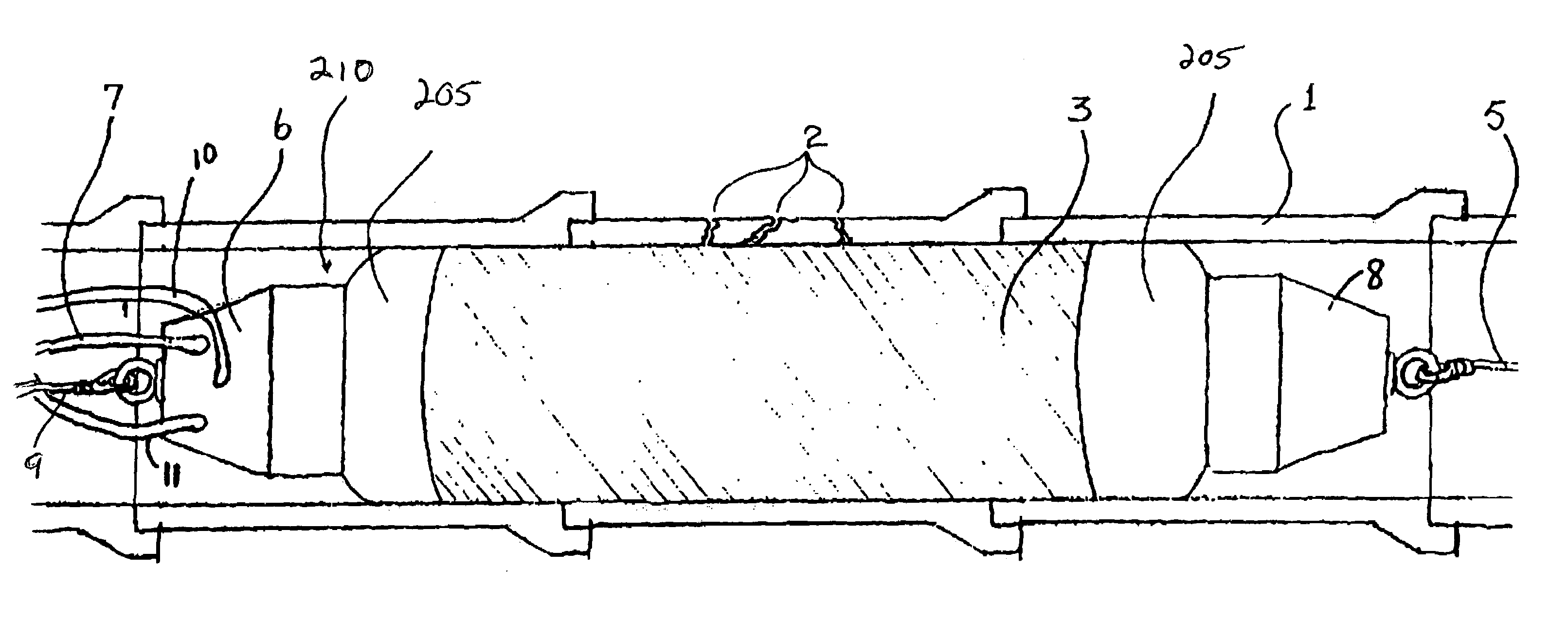

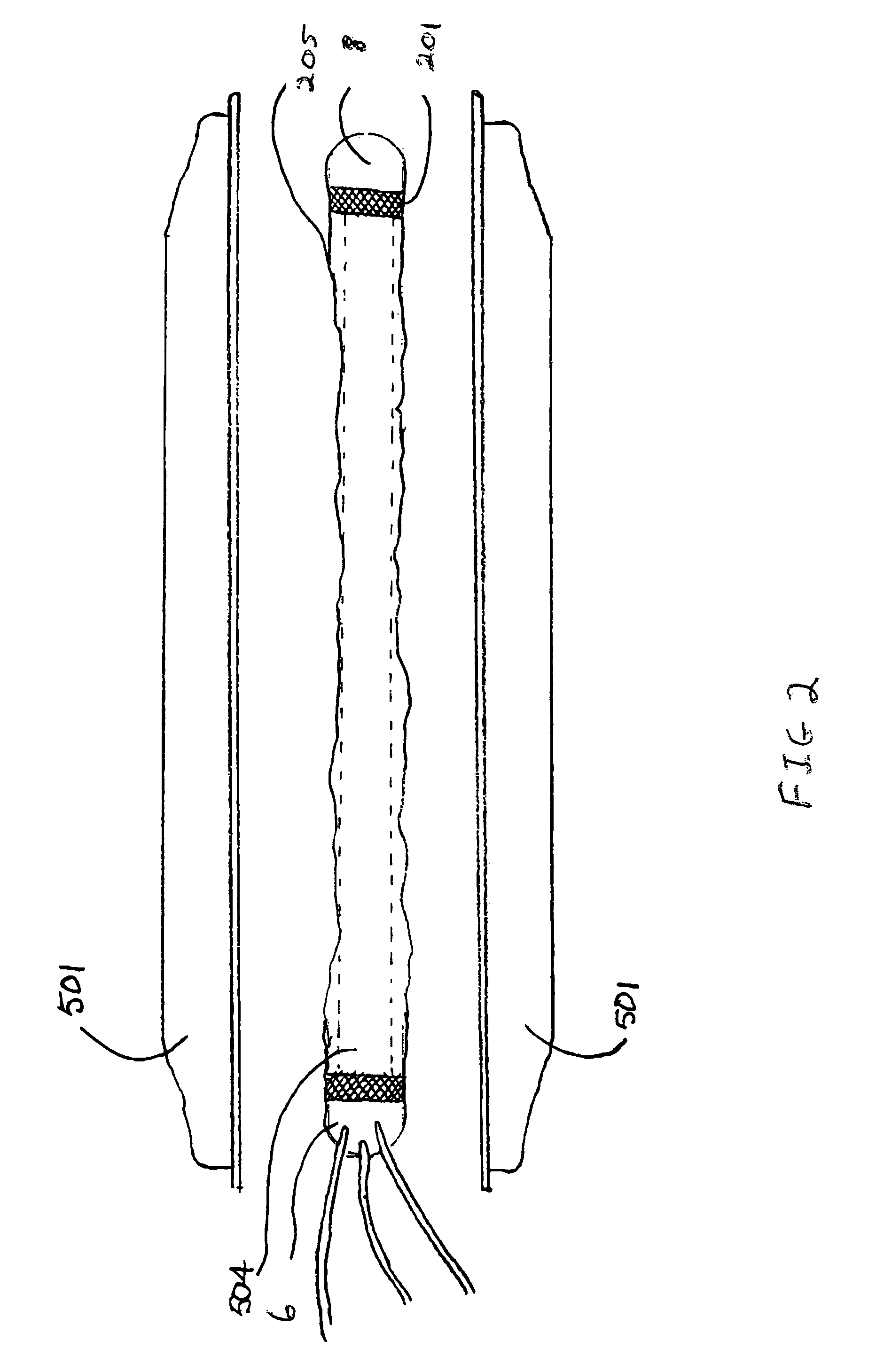

Inflatable heating device for in-situ repair of conduit and method for repairing conduit

InactiveUS7052567B1Extend the life cycleRobust and heatingConfectionerySweetmeatsElastomerResin matrix

The apparatus of the present invention is generally characterized by a heating / inflation module having pressurizable interior and an attached heat curable pre-preg. In particular, an elastomeric, seamless composite is provided that includes a heating element disposed within a thermoset resin matrix. The composite adapted to maintain a consistent temperature profile and an internal air pressure. A first end piece is attached to a first end of the composite and has an air port for communication with a compressed air source, a vacuum port for communication with a vacuum supply source and at least one electrical cable port for communication with a power supply source. A second end piece attached to a second end of the composite. The apparatus further includes a pre-preg removably attached to an outer surface of the composite. The pre-preg includes a structural fiber matrix supporting a heat curable resin. The composite is constructed by applying a liquid silicone matrix to at least one layer of braided or wound and / or tape fibers, wherein a portion of the fibers are electrically conductive. The layer of braided fibers is introduced into a mold, and a removable, expandable inner bladder is then loaded into the mold. The inner bladder is inflated to conform the layer of braided fibers to an interior surface of the mold. An electric current is caused to flow to the conductive fibers to cure the silicone matrix into a stable, elastomeric state. The composite is removed from the mold. A method for repairing a damaged section of a conduit is also disclosed.

Owner:EMS USA HLDG I +1

Structured resin systems with high thermal conductivity fillers

InactiveUS20050277351A1Easy to transportReduce distanceSemiconductor/solid-state device detailsSynthetic resin layered productsDendrimerResin matrix

In one embodiment the present invention provides for a high thermal conductivity highly structured resin that comprises a host highly structured resin matrix, and a high thermal conductivity filler 30. The high thermal conductivity fillers are from 1-1000 nm in length, and high thermal conductivity fillers have an aspect ratio of between 3-100. Particular highly structured highly structured resins include at least one of liquid crystal 40 polymers, interpenetrating networks, dendrimer type matrices, expanding polymers, ladder polymers, star polymers and structured organic-inorganic hybrids 60.

Owner:SIEMENS ENERGY INC

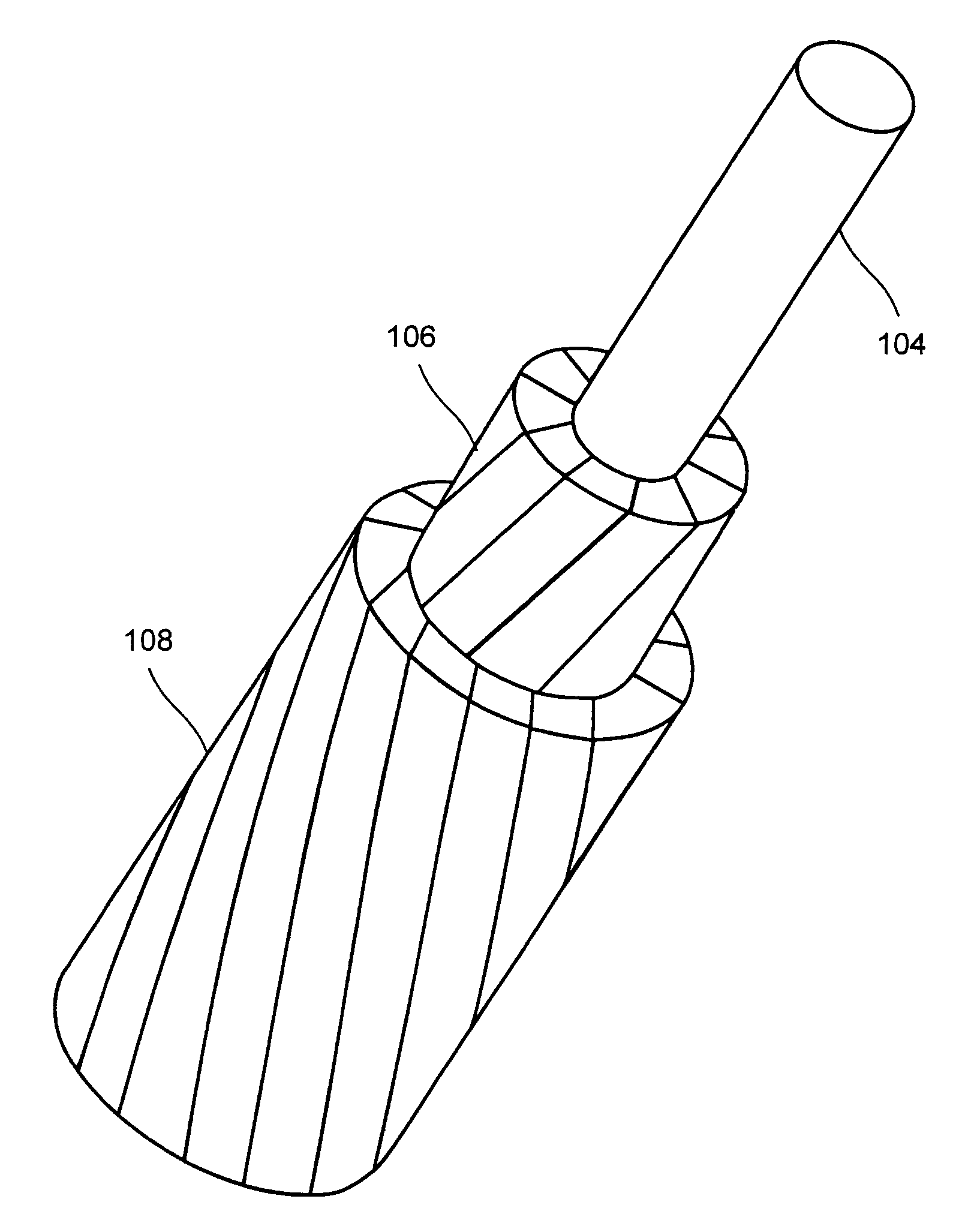

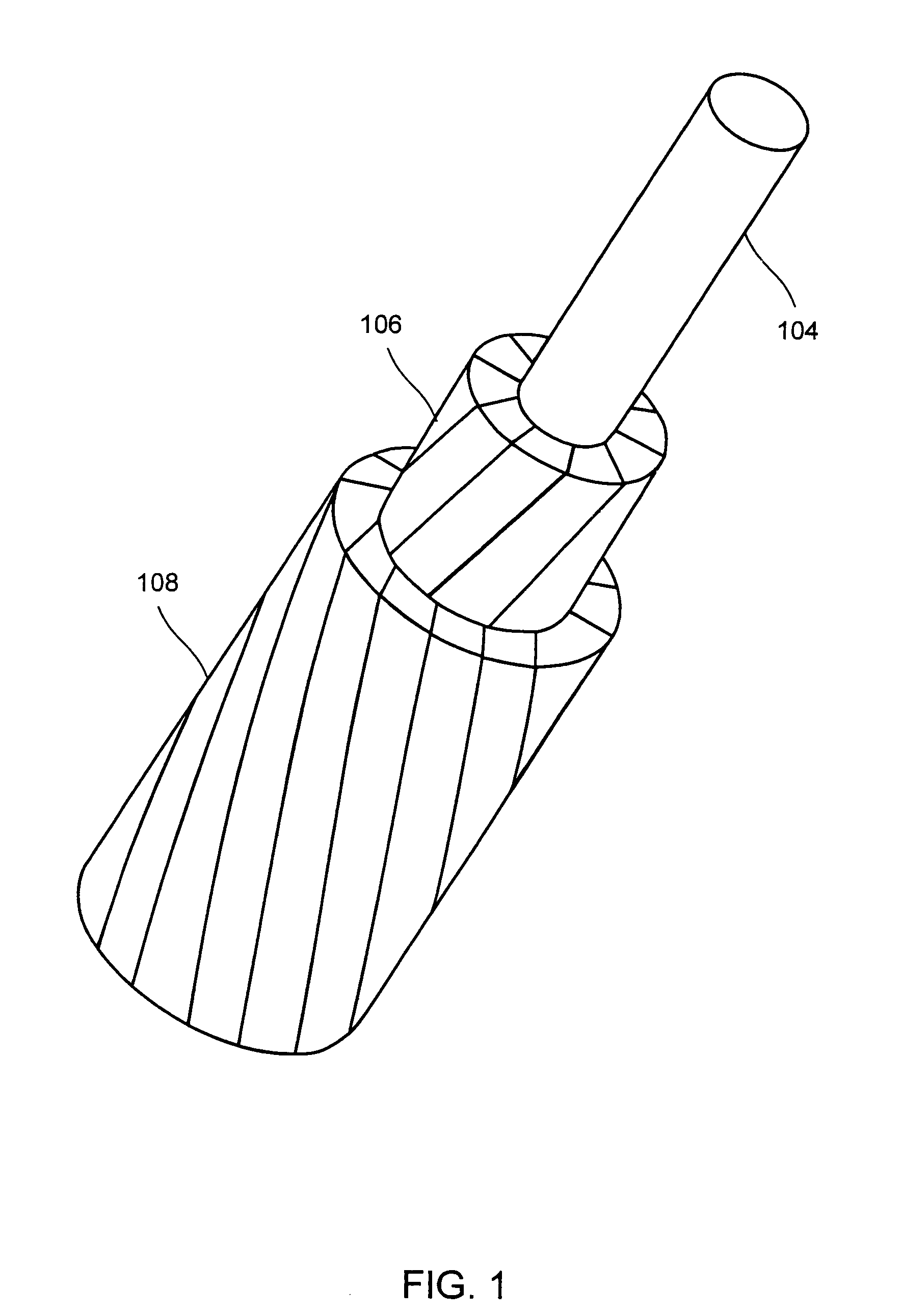

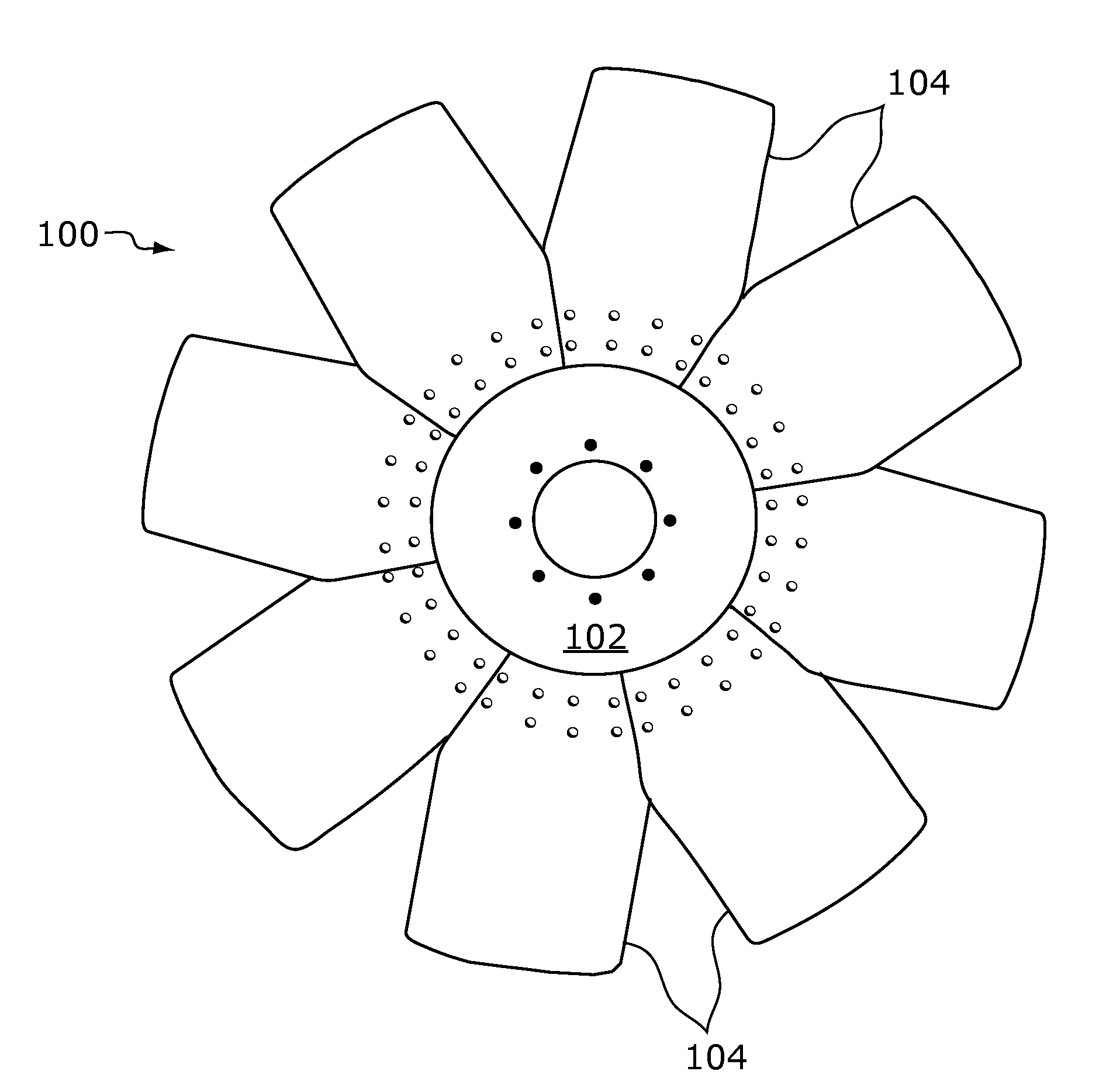

High-strength low-weight fan blade assembly

An engine cooling fan system including a hub disc about which first and / or second pluralities of elongated fan blades characterized by a first and second respective pitch angles may be fastened. Each respective fan blade further comprises a hub-engaging portion, a twisted transition portion and an air-engaging portion. Each fan blade is formed from a composite material having a thermoset resin matrix phase and an evenly dispersed continuous fiber reinforcement phase.

Owner:VEE ENG

Fiber optic drop cables suitable for outdoor fiber to the subscriber applications

A fiber optic drop cable including at least one optical waveguide, at least one roving, and a cable jacket. In one embodiment, the at least one roving includes a resin matrix having a water-based acrylic composition that includes an ethylene-acrylic acid and a water-swellable component. The resin matrix has a percent by weight of about 10 percent or less of the flexible roving so that the at least of one roving is at least partially bonded with the cable jacket, thereby inhibiting buckling of the cable jacket. In another embodiment, a plurality of rovings are arranged in clusters in the cable for influencing the bonding between the rovings and cable jacket. Also, disclosed is a protective casing for protecting and routing optical fibers along with preconnectorized cable assemblies.

Owner:CORNING OPTICAL COMM LLC

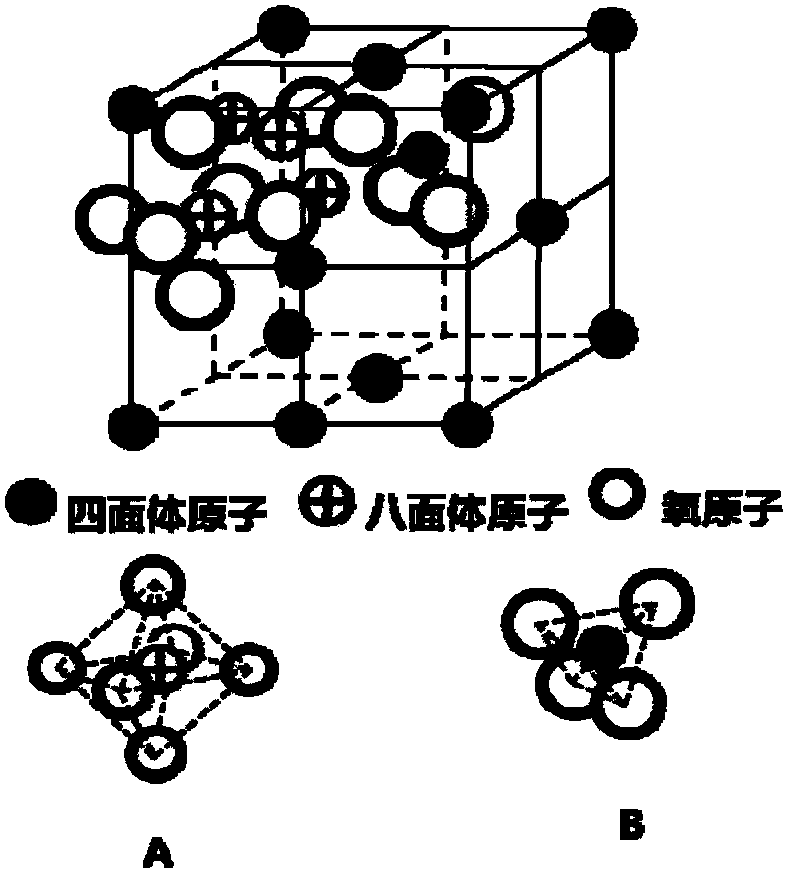

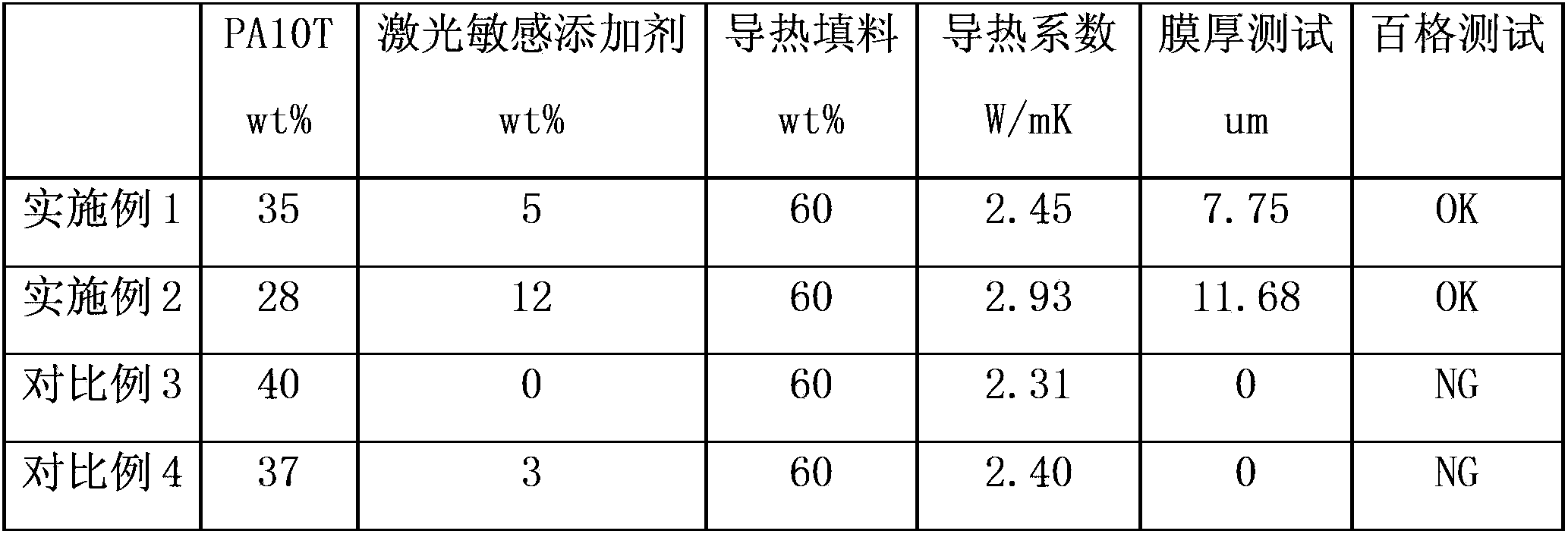

Resin composition having laser direct-structuring function and its preparation method and use

InactiveCN103450675AImprove high temperature resistanceImprove thermal conductivityPoint-like light sourceLighting heating/cooling arrangementsSurface mountingResin matrix

The invention provides a resin composition having a laser direct-structuring function and its preparation method and use. The resin composition comprises 15-60wt% of a resin matrix, 30-70wt% of a heat-conduction filler, 5-12wt% of a laser-sensitive additive and 0-15wt% of other additives. The laser-sensitive additive has a general chemical formula of XY2O4, belongs to an isometric system and has axial length a=b=c and axial angle alpha=beta=gamma=90 degrees, wherein X and Y represent metal elements belonging to an IIIA group, an IB group, an IIB group, a VIB group, a VIIB group and a VIII group of the periodic table of elements. The resin composition has high temperature resistance and good thermal conductivity, realizes optional sedimentation of metals such as Cu, Ni and Au in a laser-scanned area and can be used for surface mounting technology (SMT) products.

Owner:KINGFA SCI & TECH CO LTD +1

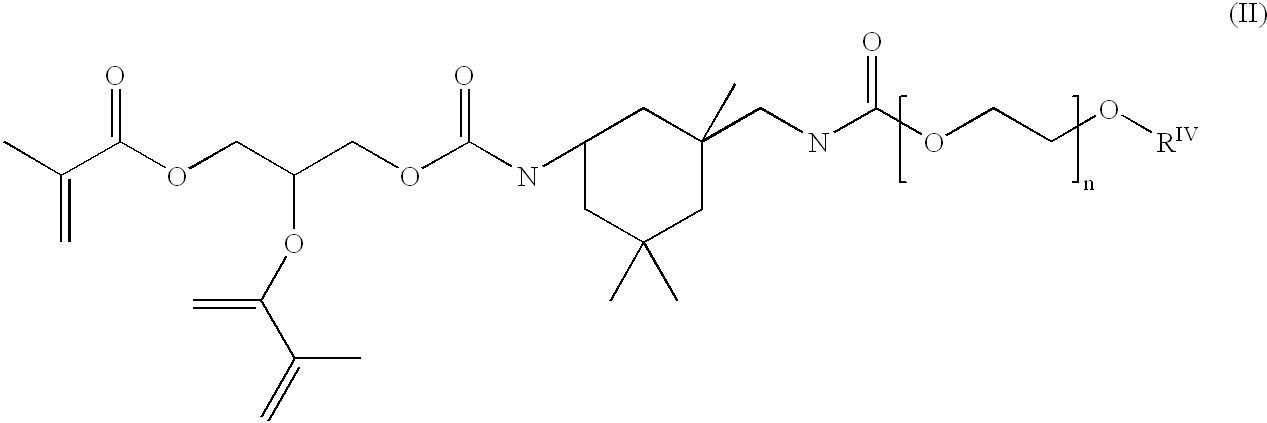

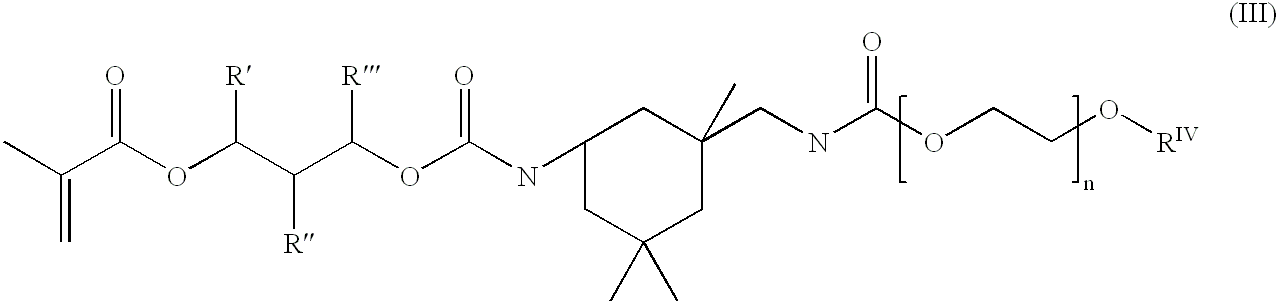

Self etching adhesive primer composition and polymerizable surfactants

The invention provides a self etching adhesive dental primer composition, a method of use of the primer composition and a product formed from the primer. The dental product is formed from the primer composition which includes water, surfactant and polymerizable material in suspension in the water. The polymerizable material includes monomers which are water immiscible. Preferably the monomers have an average molecular weight less than 1000. The primer composition is used by applying the composition to unetched dental tooth enamel and the polymerizable material is polymerized to form a dental product having adhesion to the enamel of more than 13 MPa. Improved surfactants which contain at least one ethenically unsaturated polymerizable group are provided in accordance with the invention. Surfactants of the present invention copolymerize with and become an integral part of any polymerizable resin matrix in which they are incorporated. This prevents migration of the surfactant through the matrix or slow leaching-out through the interfaces, and brings advantages of biocompatibility and stability of the physical properties of the cured matrix. In addition, the surfactant becomes a permanent part of the matrix, and forms part components of the matrix.

Owner:DENTSPLY DETREY GMBH

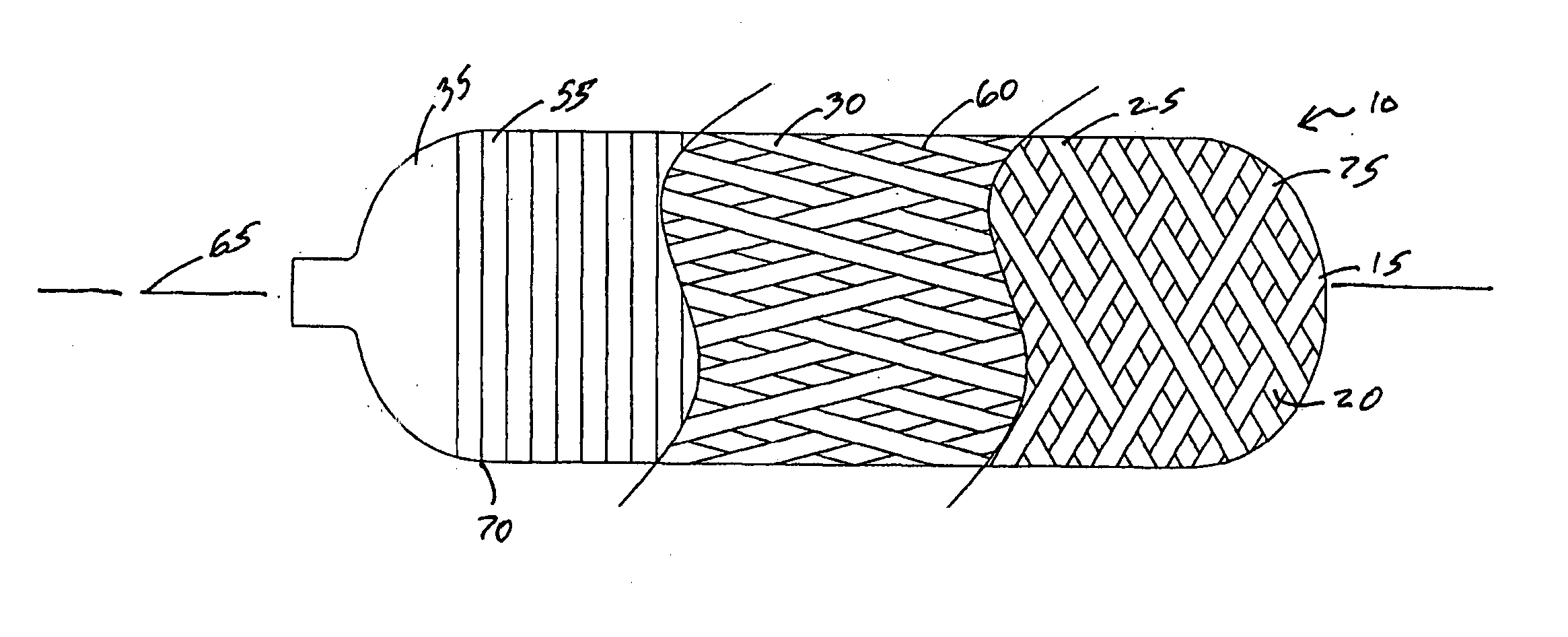

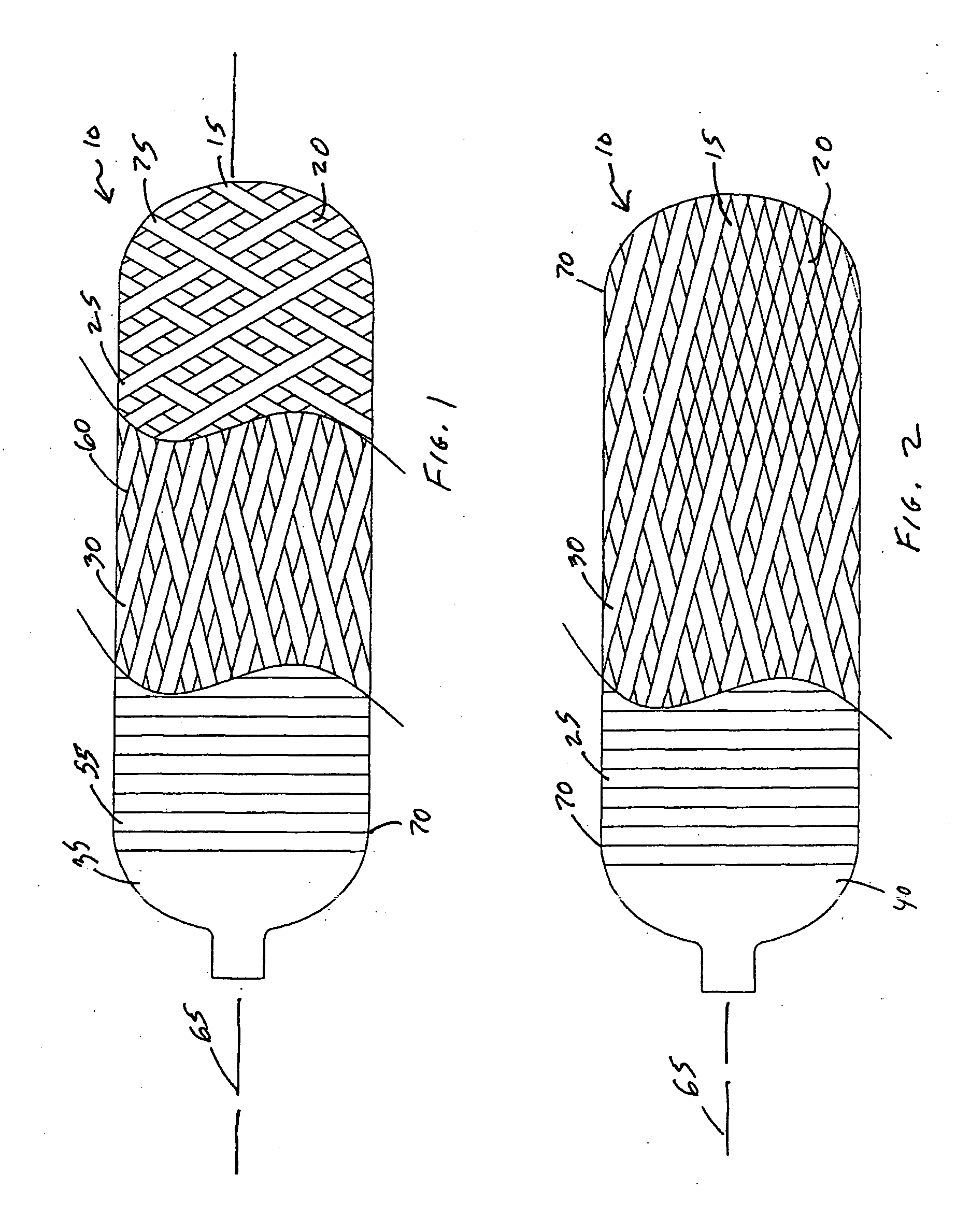

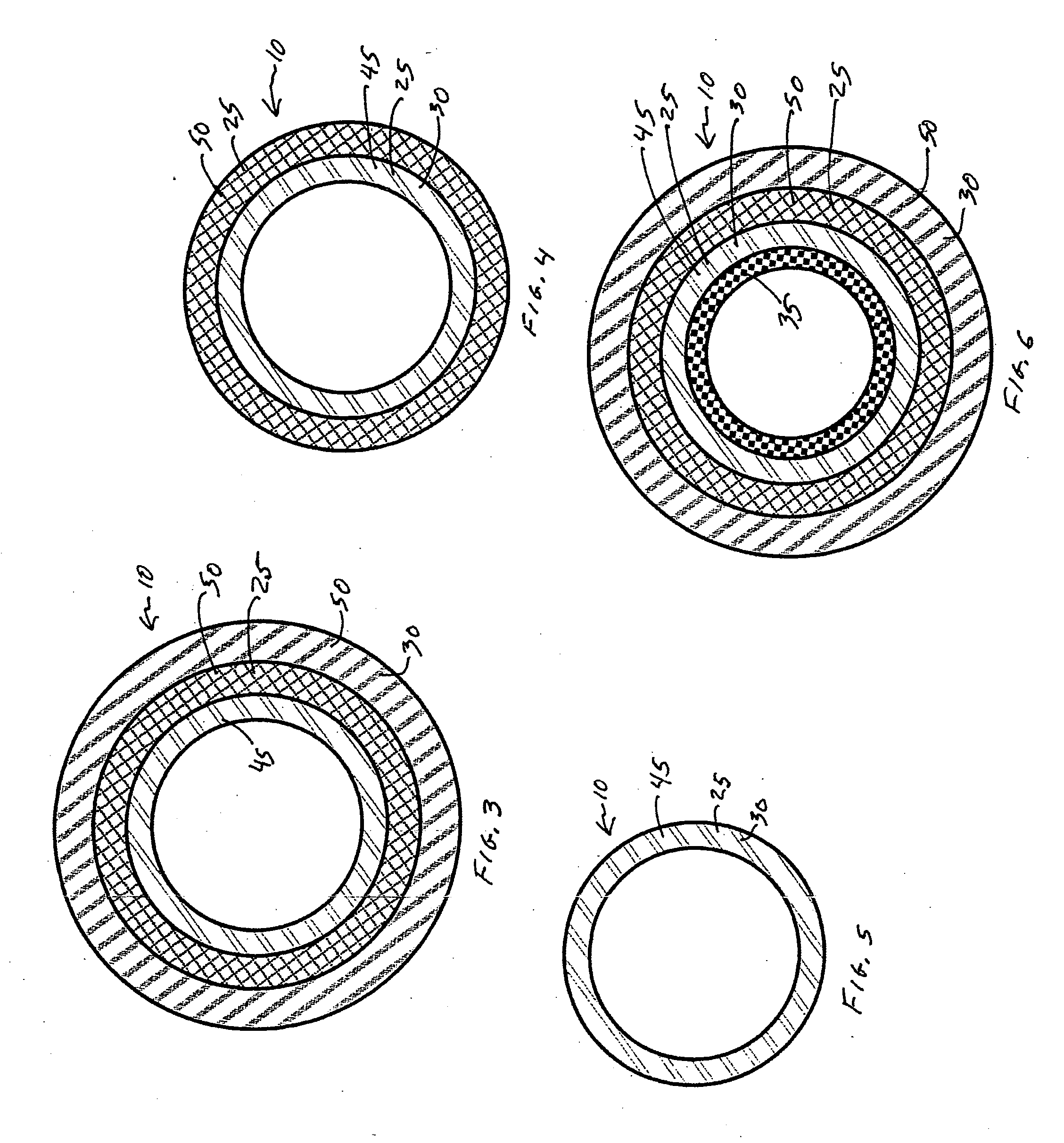

Pressure vessel with improved impact resistance and method of making the same

A composite overwrapped pressure vessel is provided which includes a composite overwrapping material including fibers disposed in a resin matrix. At least first and second kinds of fibers are used. These fibers typically have characteristics of high strength and high toughness to provide impact resistance with increased pressure handling capability and low weight. The fibers are applied to form a pressure vessel using wrapping or winding techniques with winding angles varied for specific performance characteristics. The fibers of different kinds are dispersed in a single layer of winding or wound in distinct separate layers. Layers of fabric comprised of such fibers are interspersed between windings for added strength or impact resistance. The weight percentages of the high toughness and high strength materials are varied to provide specified impact resistance characteristics. The resin matrix is formed with prepregnated fibers or through wet winding. The vessels are formed with or without liners.

Owner:NASA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com