Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5097results about "Joists" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

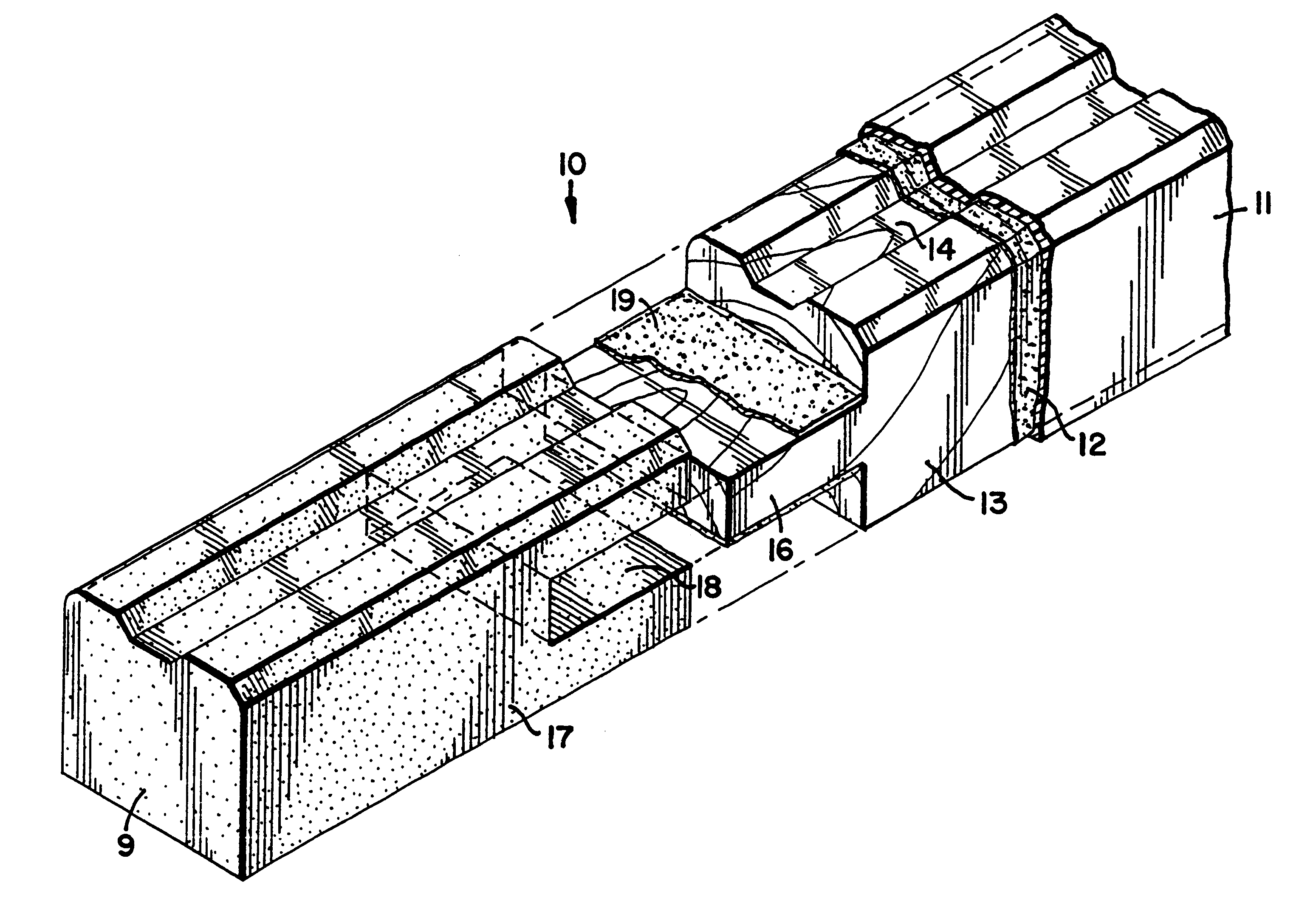

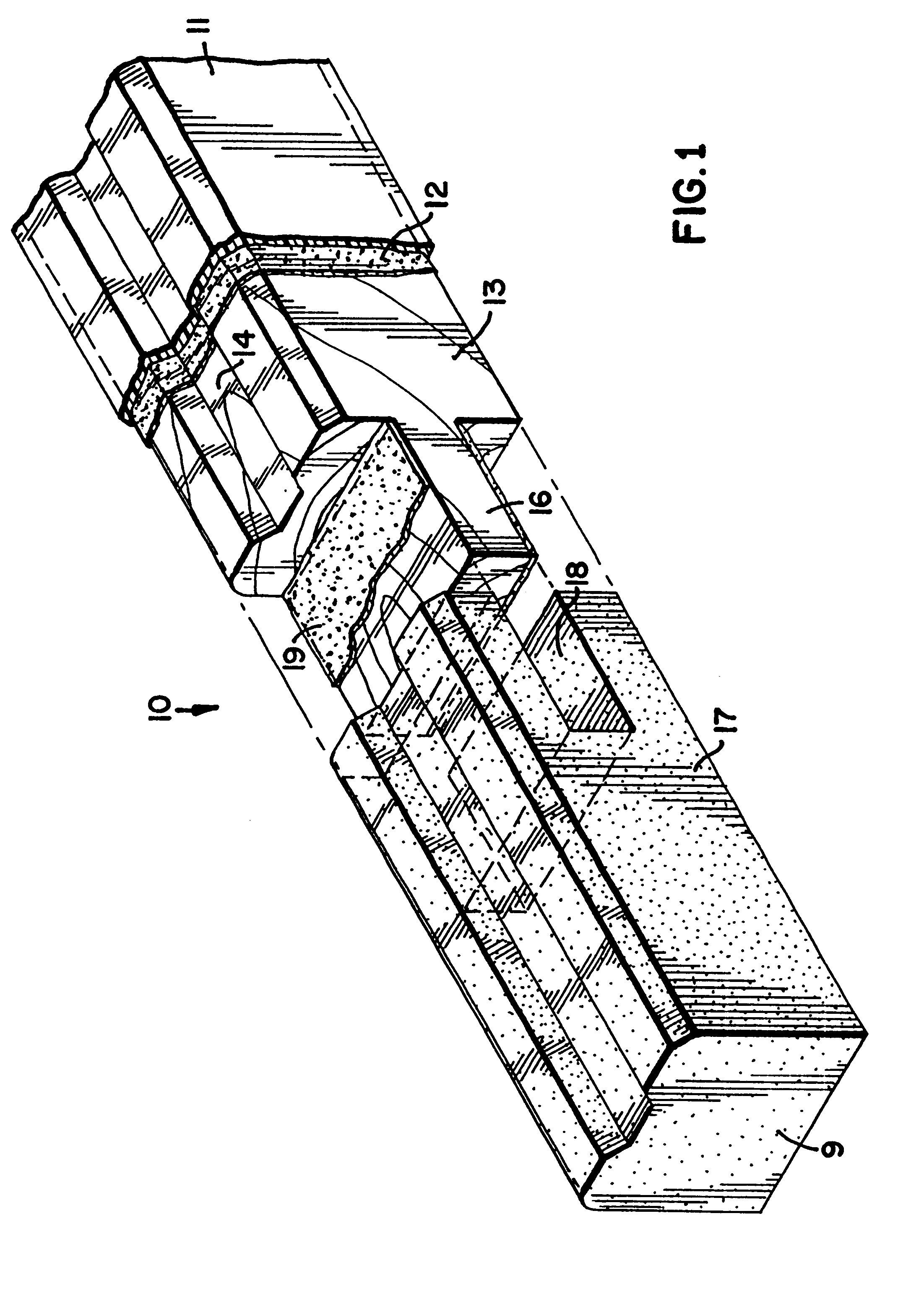

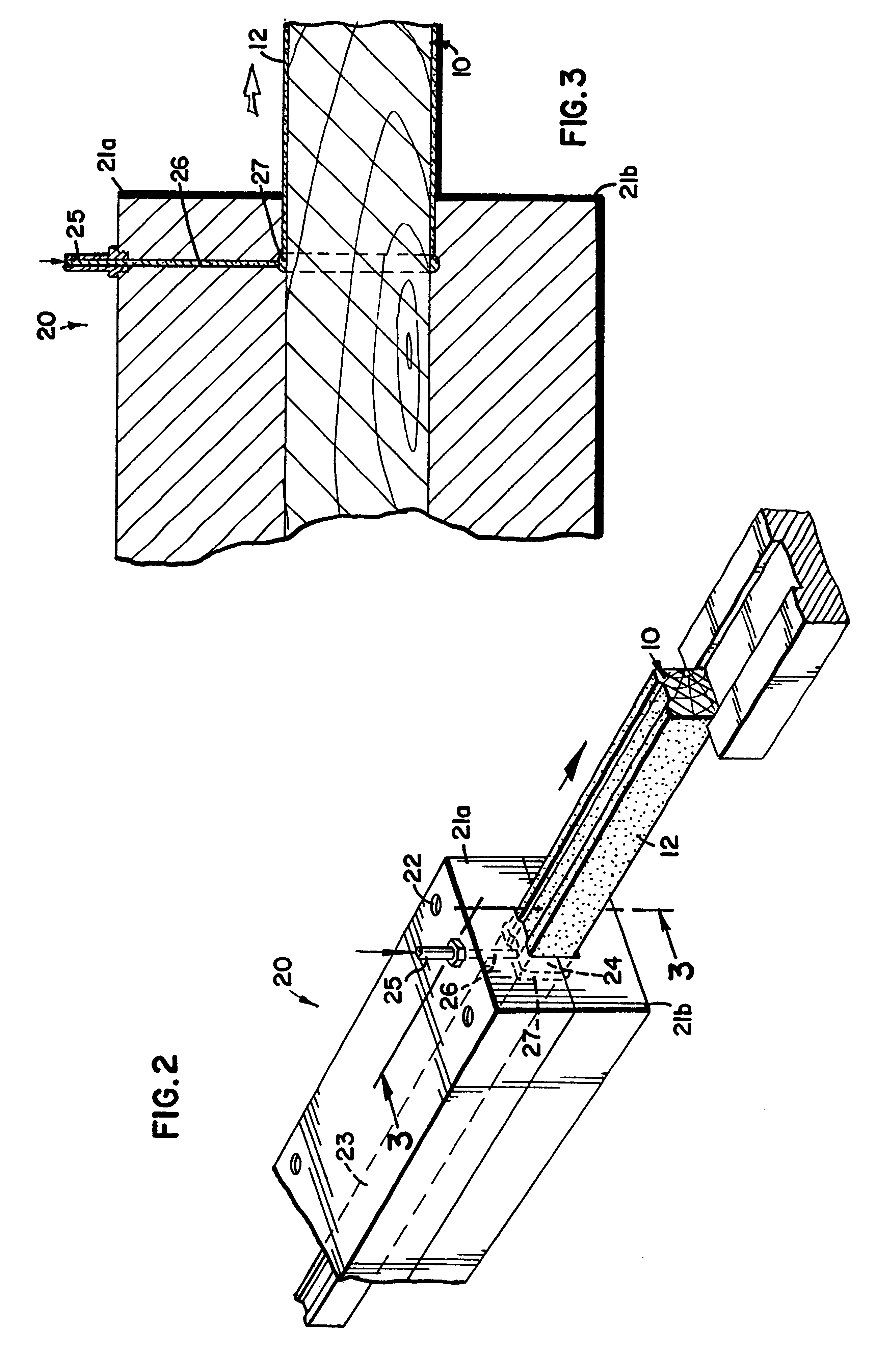

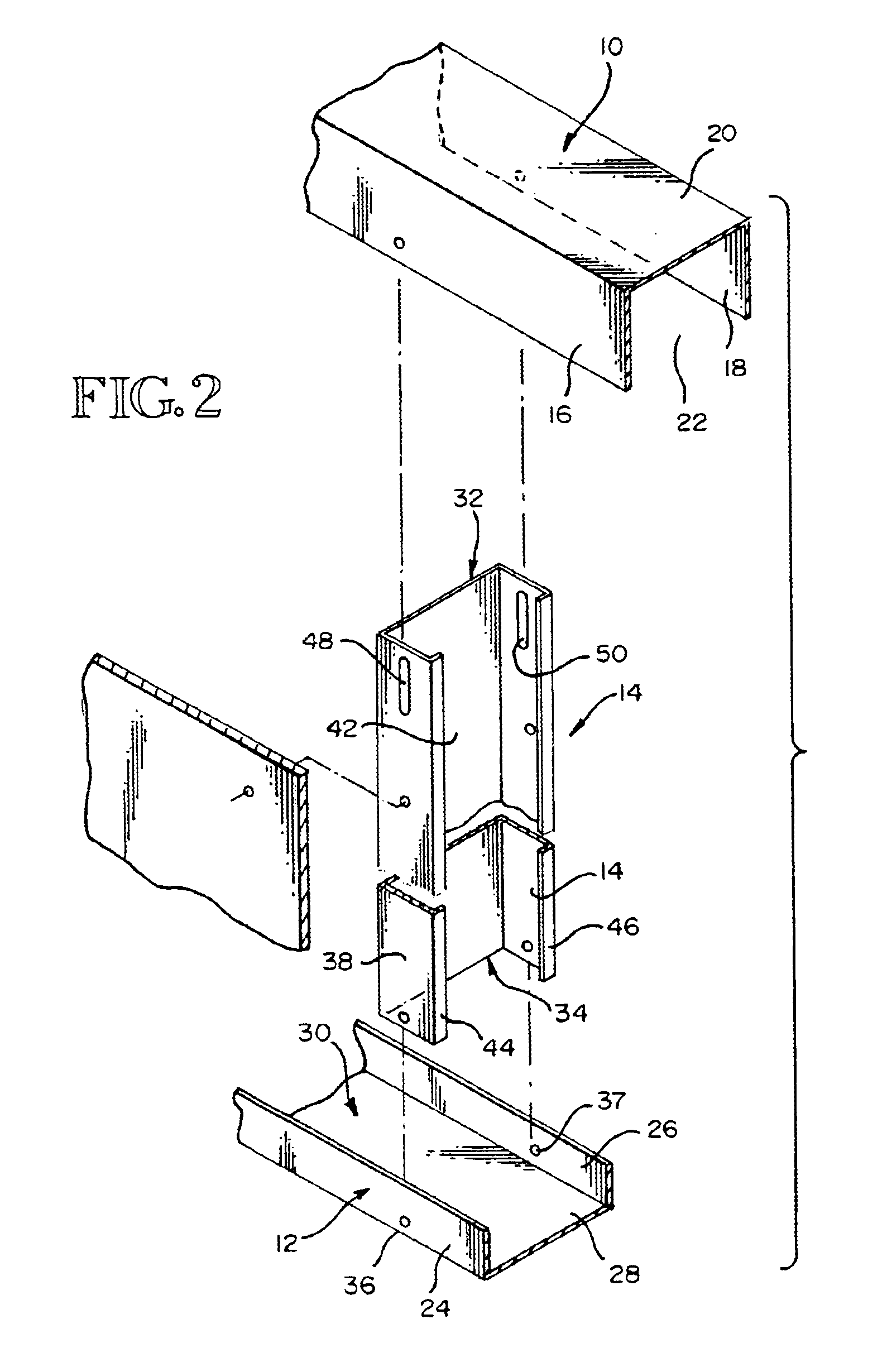

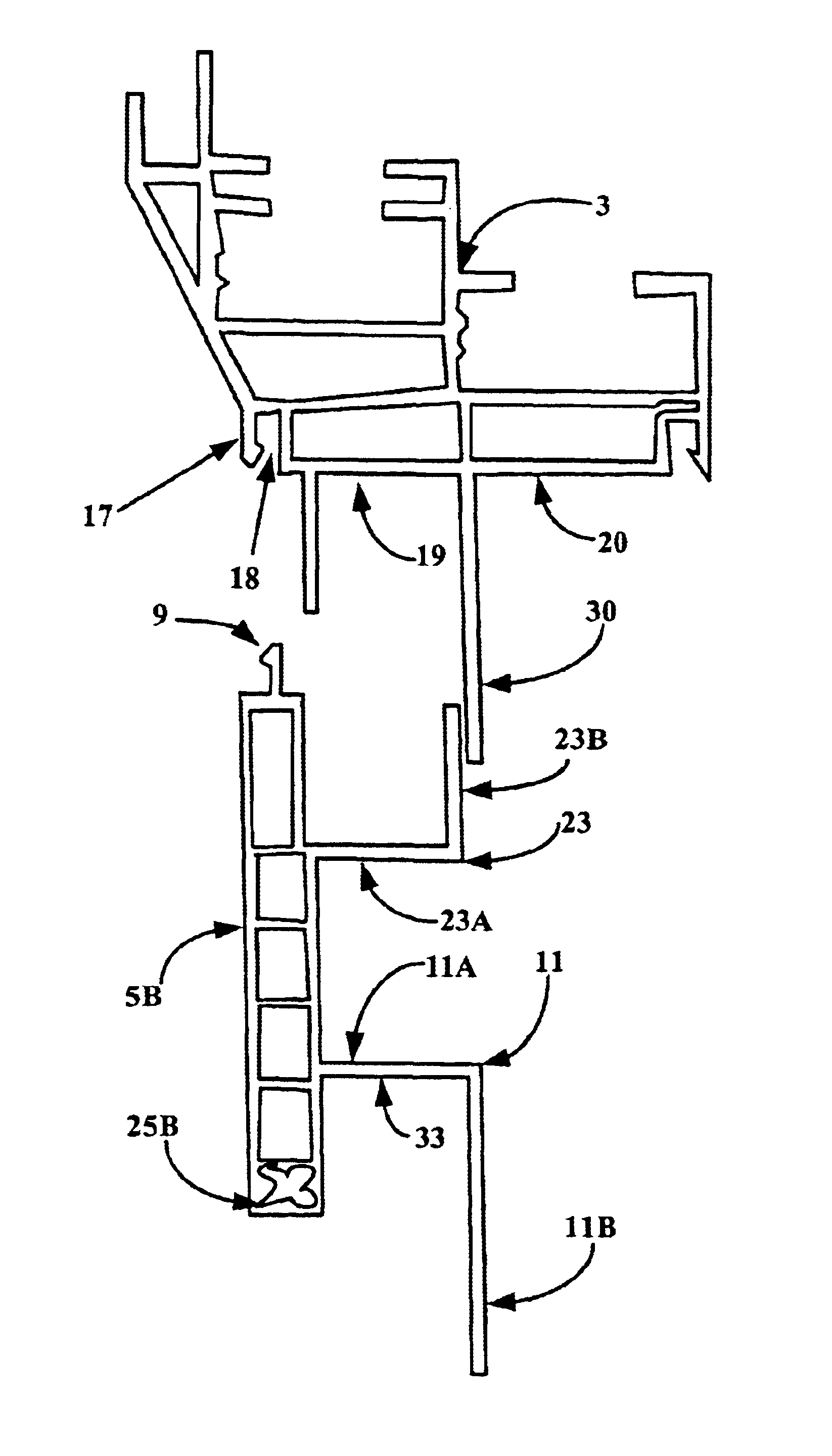

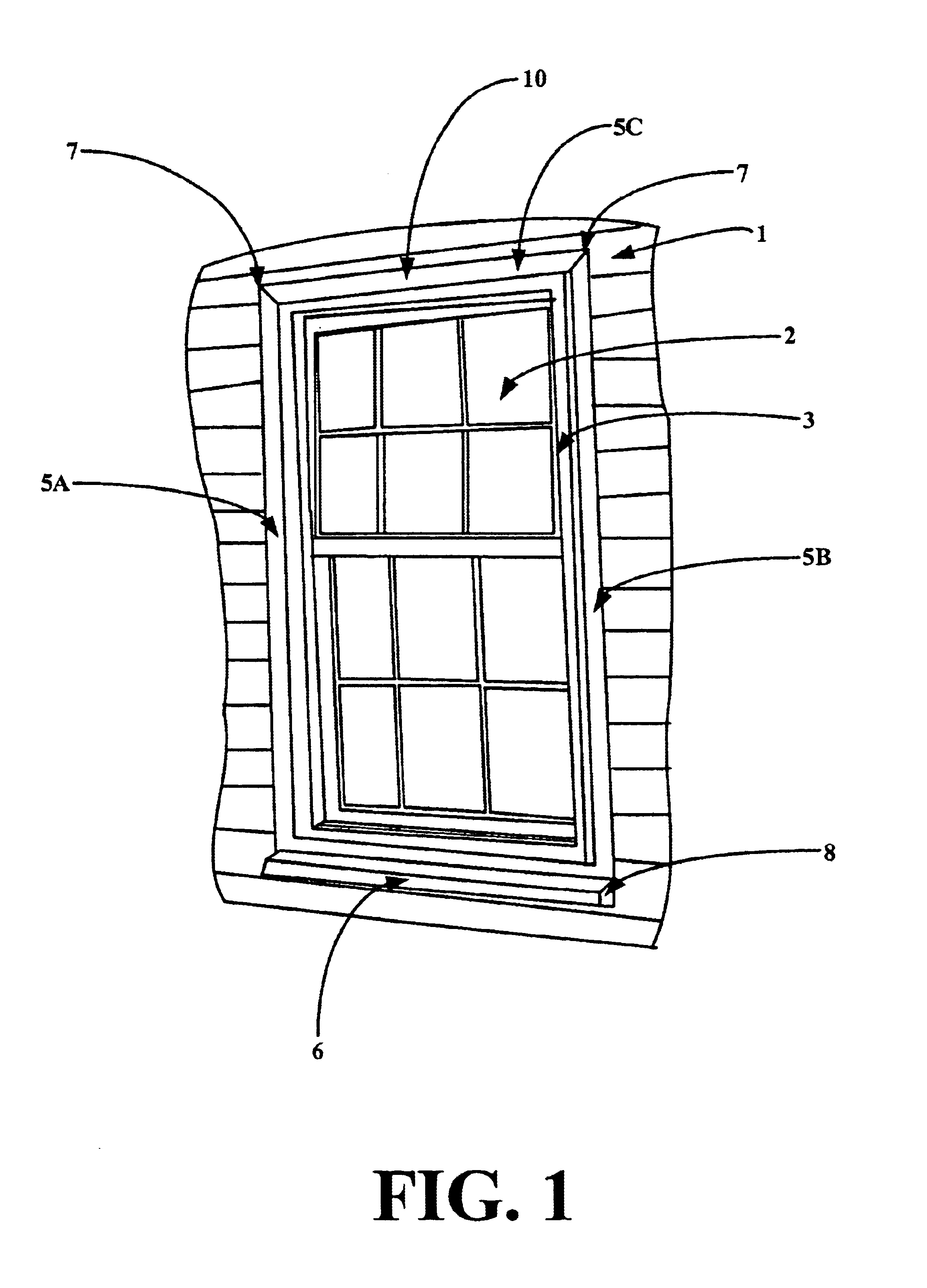

Polymer covered advanced polymer/wood composite structural member

InactiveUS6357197B1Corner/edge jointsMetal rolling stand detailsComposite constructionMoisture absorption

A composite structural member of the invention comprises a linear member having a first end and a second end attached to each end of the linear member as an end piece or end cap structure. Covering the composite member is a thermoplastic envelope preferably adherently bonded to the composite member. The end caps or end pieces are preferably thermoplastic materials typically thermoplastic composites comprising a thermoplastic resin and a fiber. Such a member is environmentally stable, resists moisture absorption, forms strong mitered joints and can be used in the assembly of fenestration products for commercial and residential real estate.

Owner:ANDERSEN CORPORATION

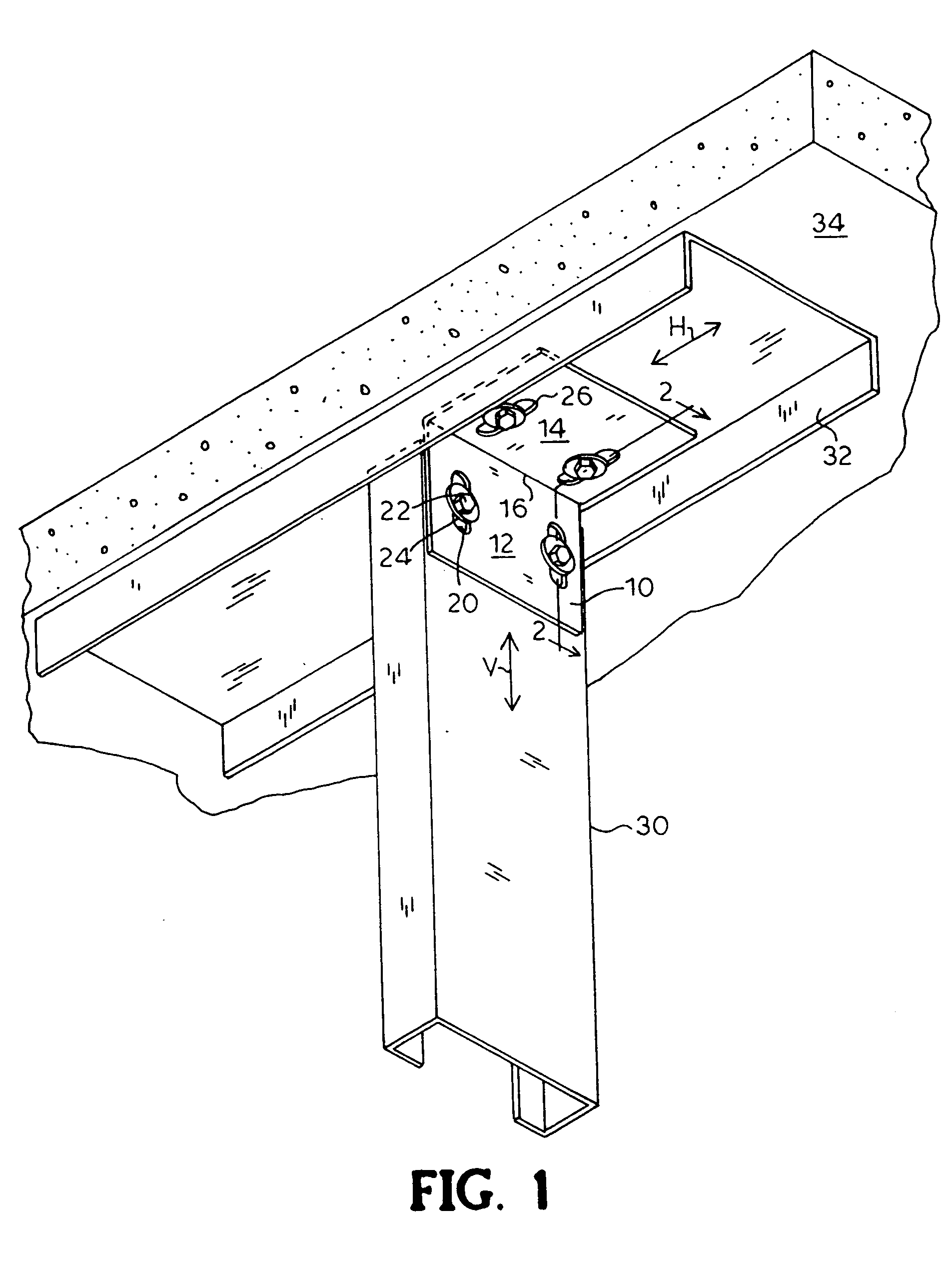

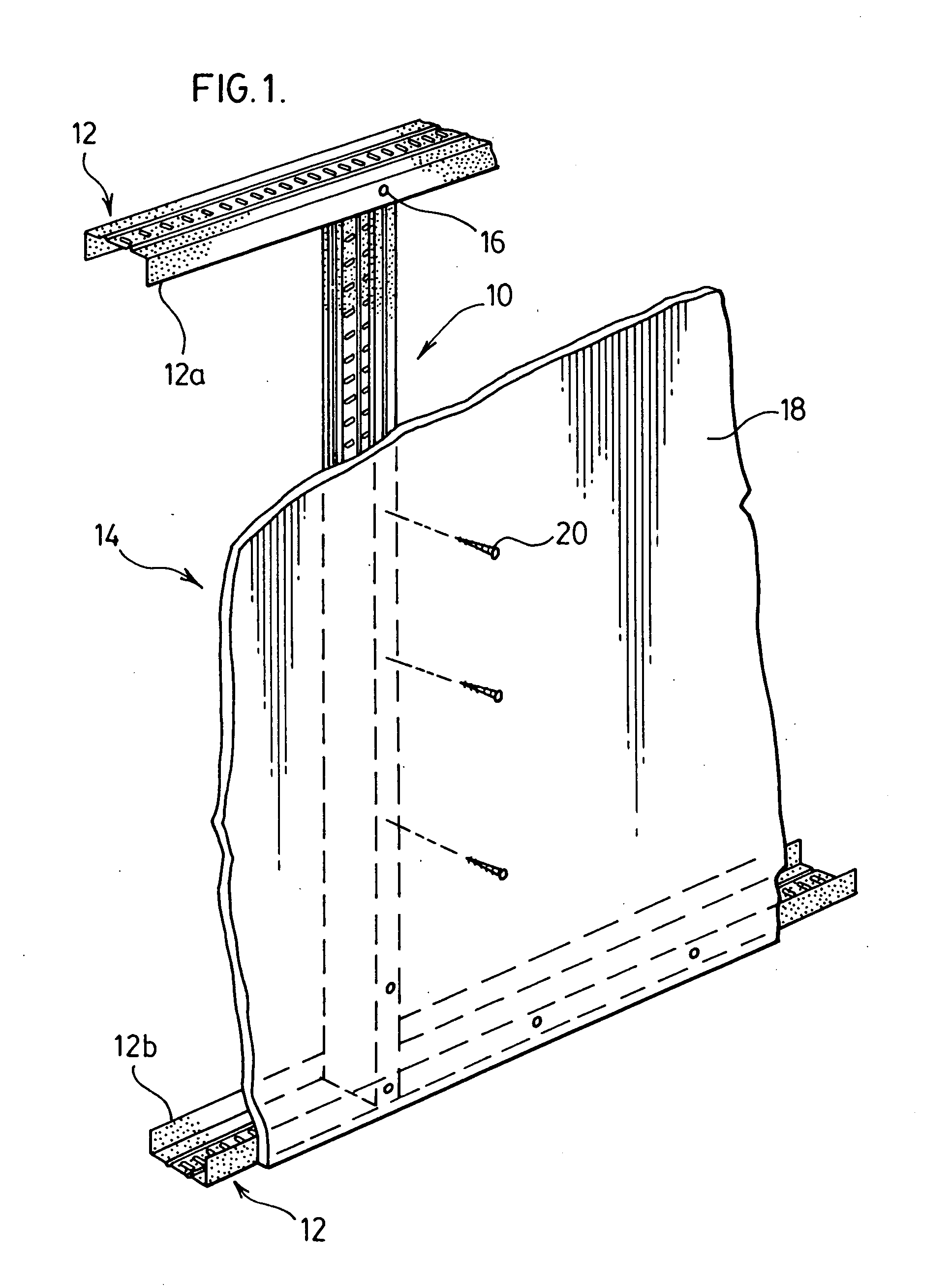

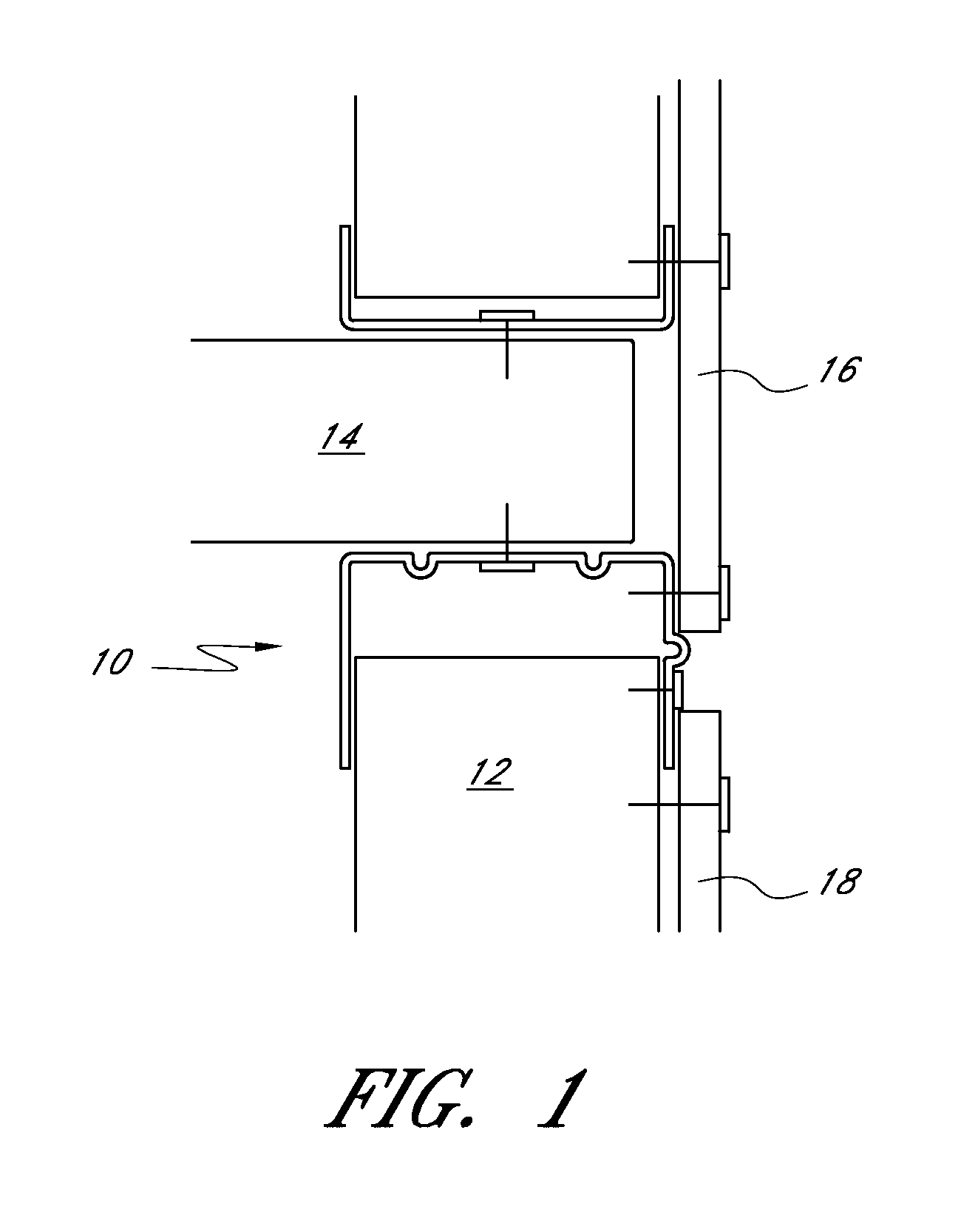

Connector for connecting two building members together that permits relative movement between the building members

ActiveUS7104024B1Permit some movementScaffold connectionsWallsArchitectural engineeringRelative motion

Owner:THE STEEL NETWORK

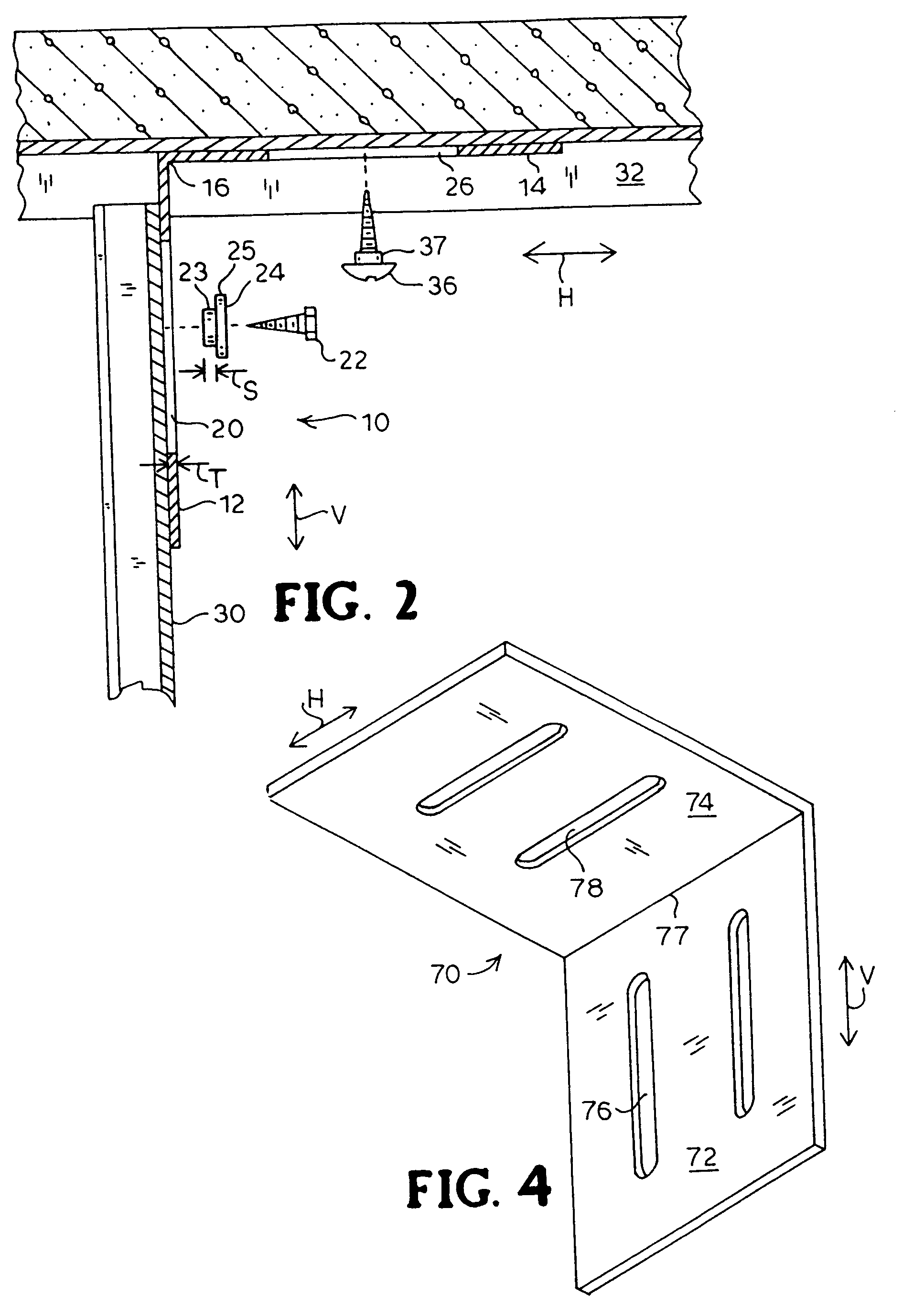

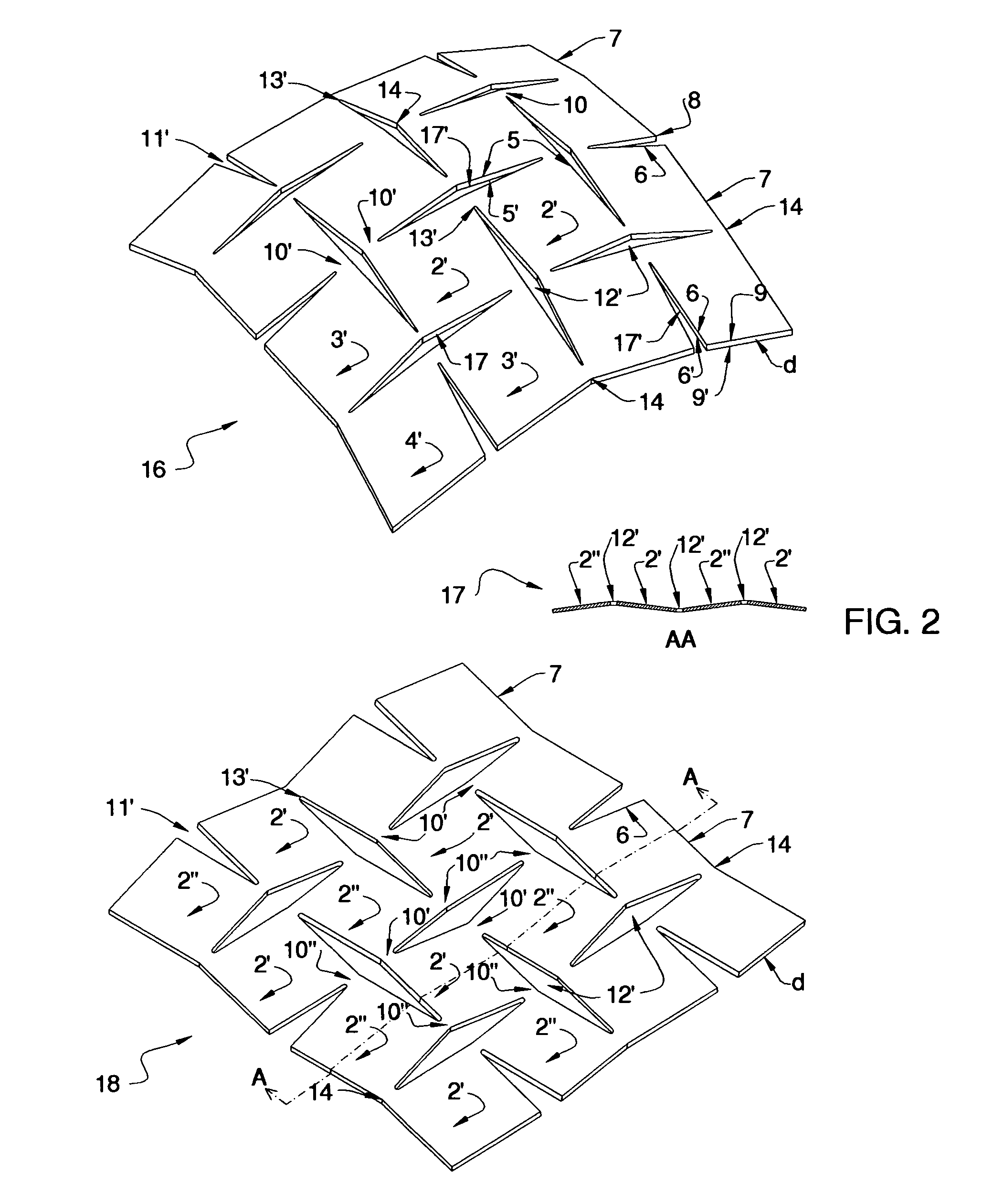

Multi-directional and variably expanded sheet material surfaces

ActiveUS8084117B2Efficient use ofIncrease surface areaPaper/cardboard articlesFloorsLaser cuttingMulti directional

Owner:LALVANI HARESH

Light steel structural members

Owner:PARADIGM FOCUS PROD DEV

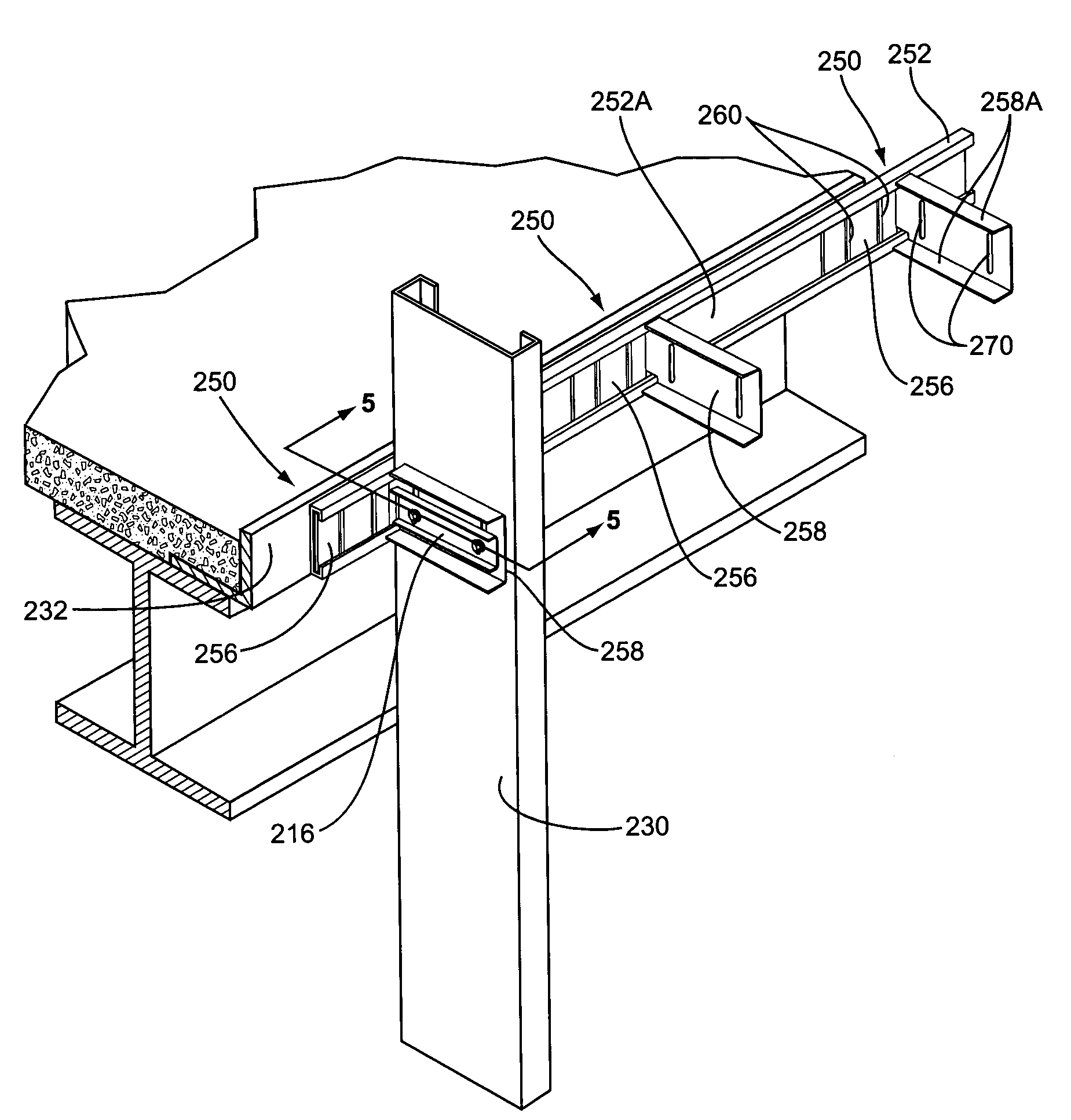

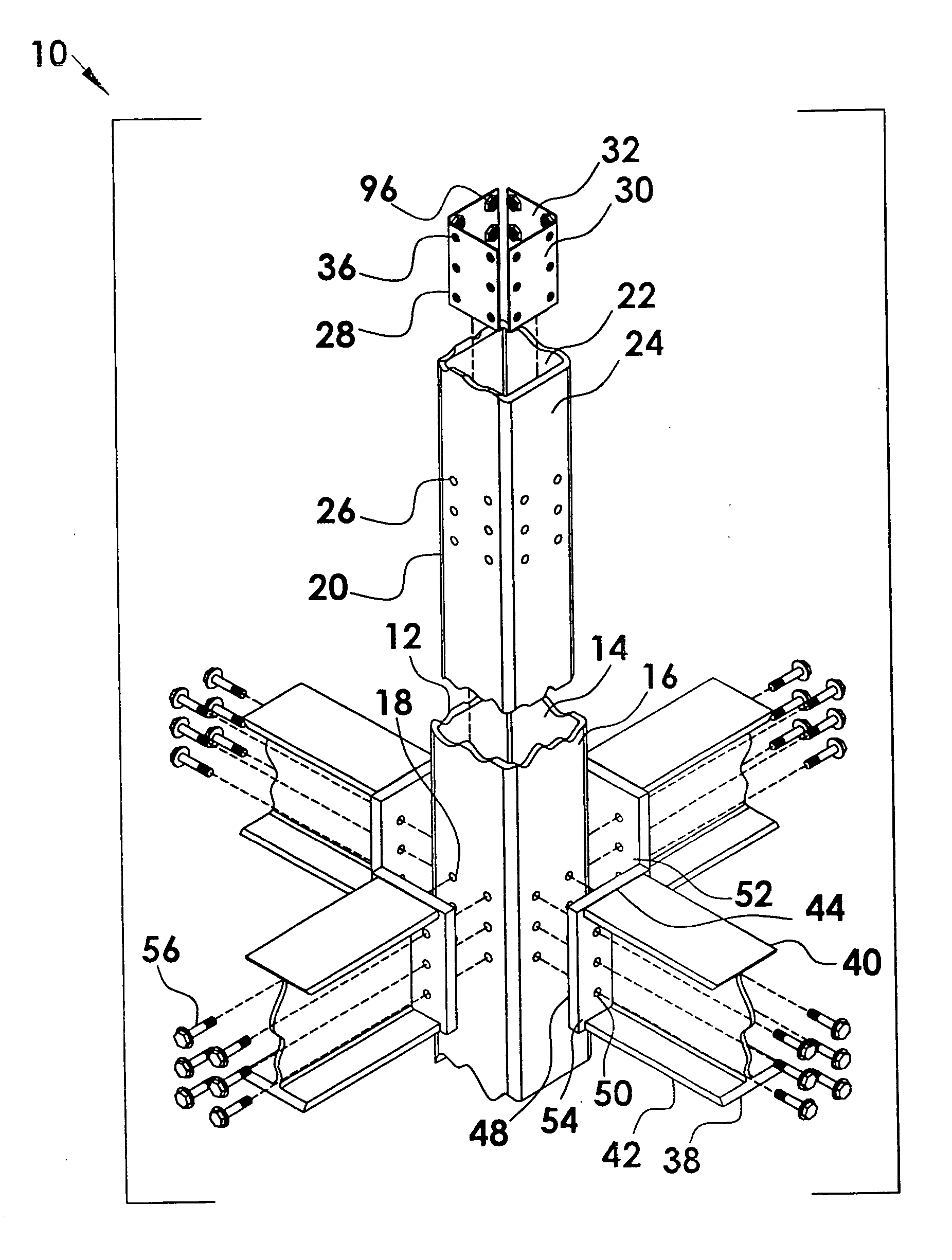

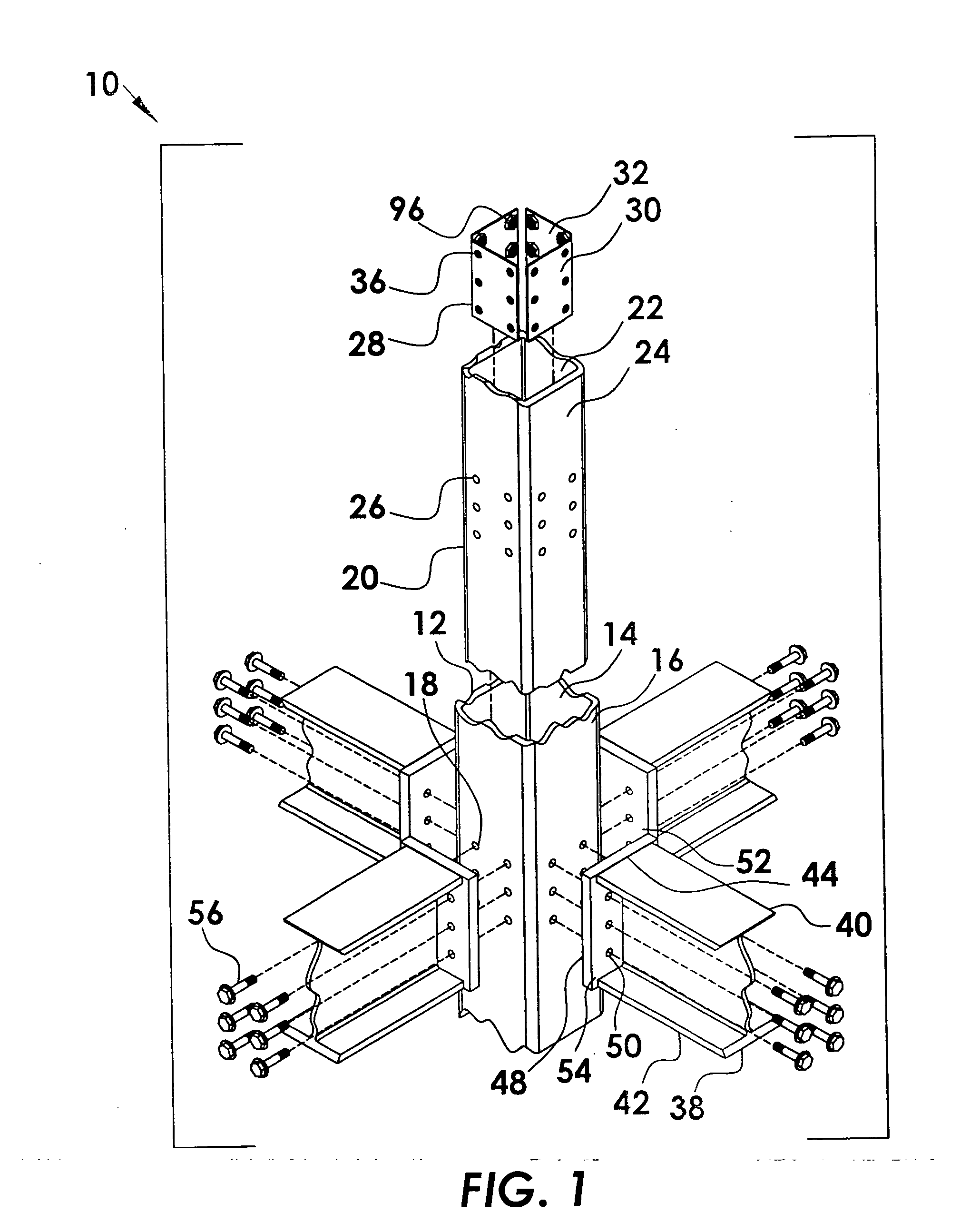

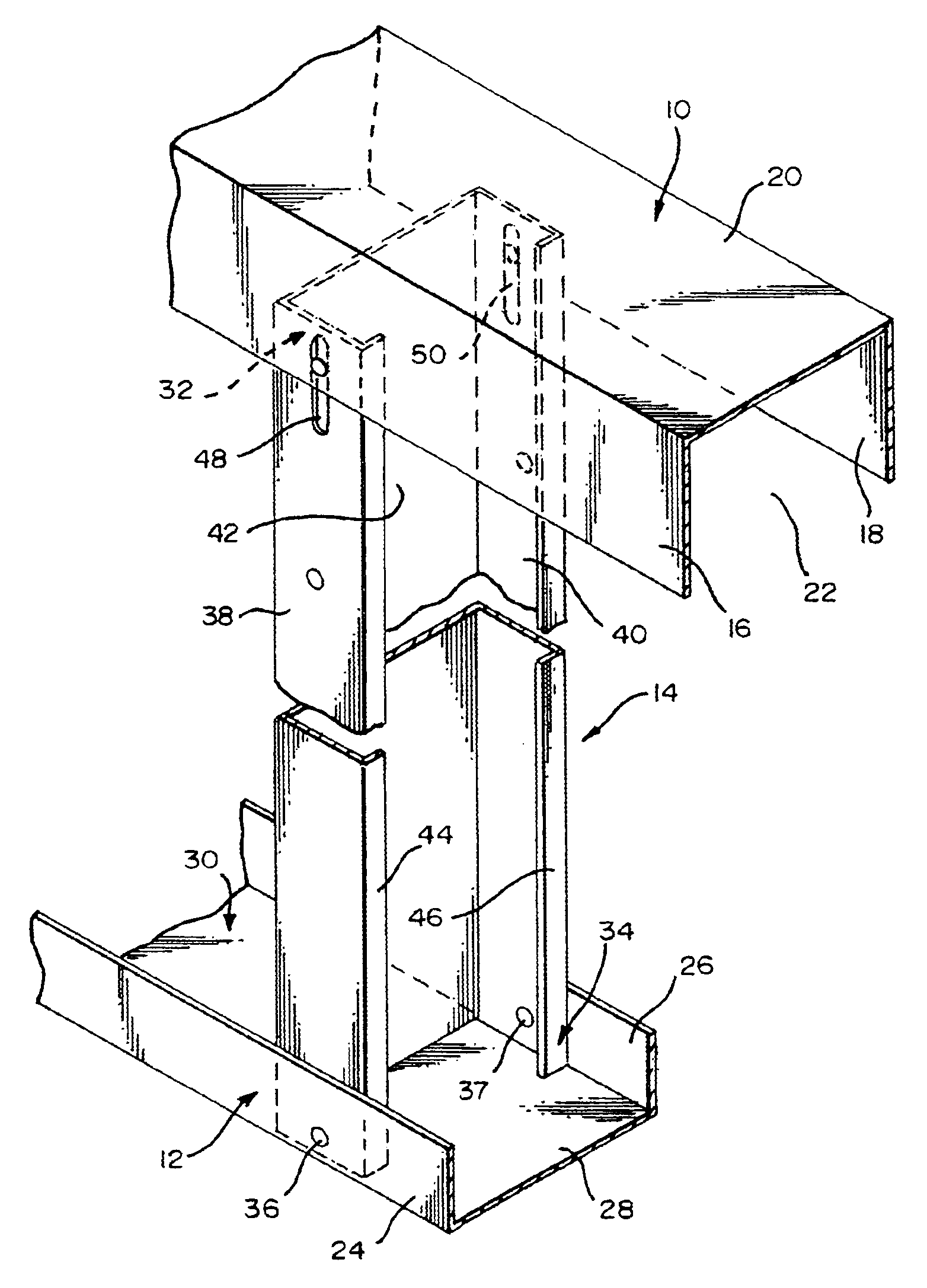

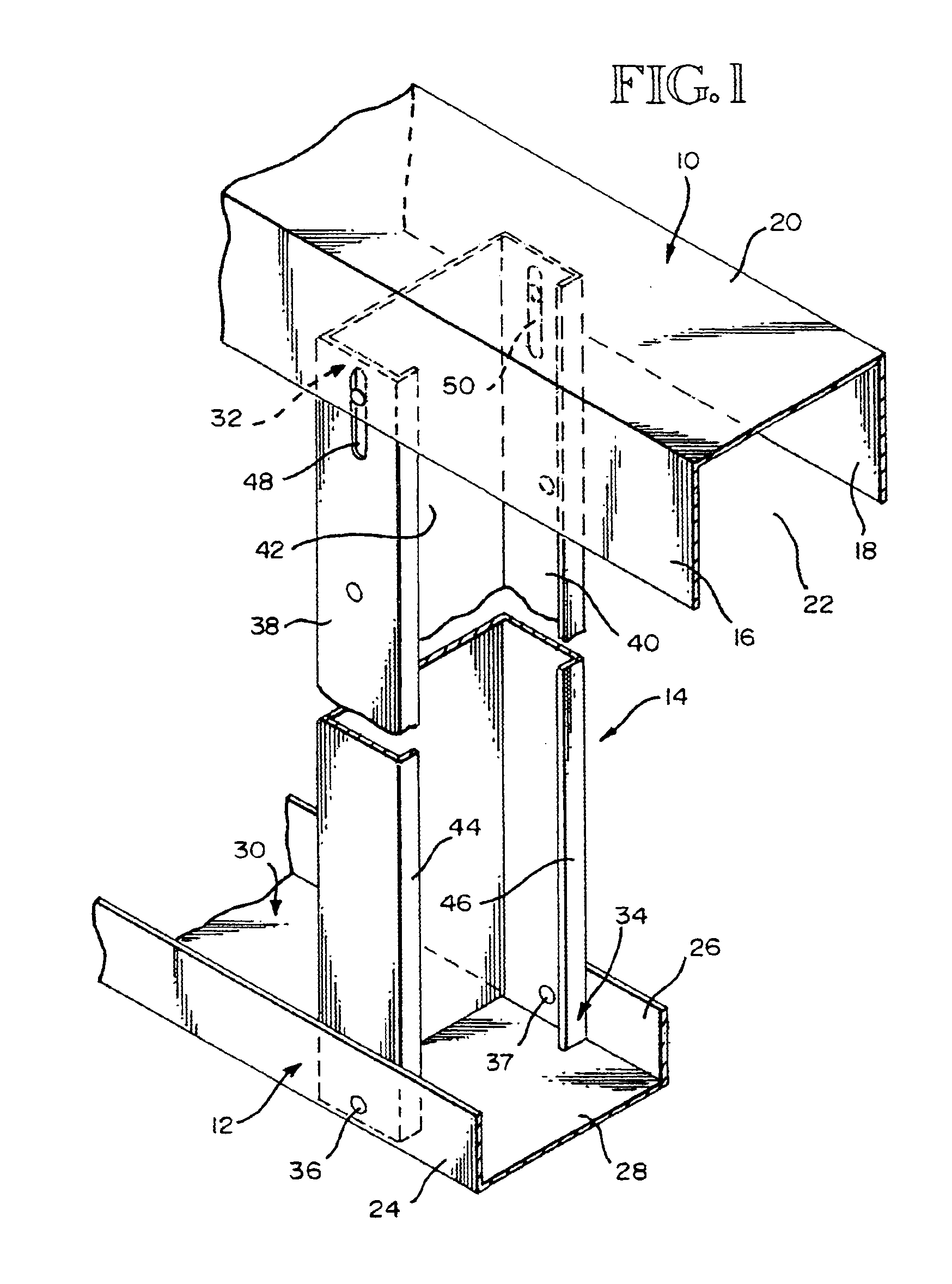

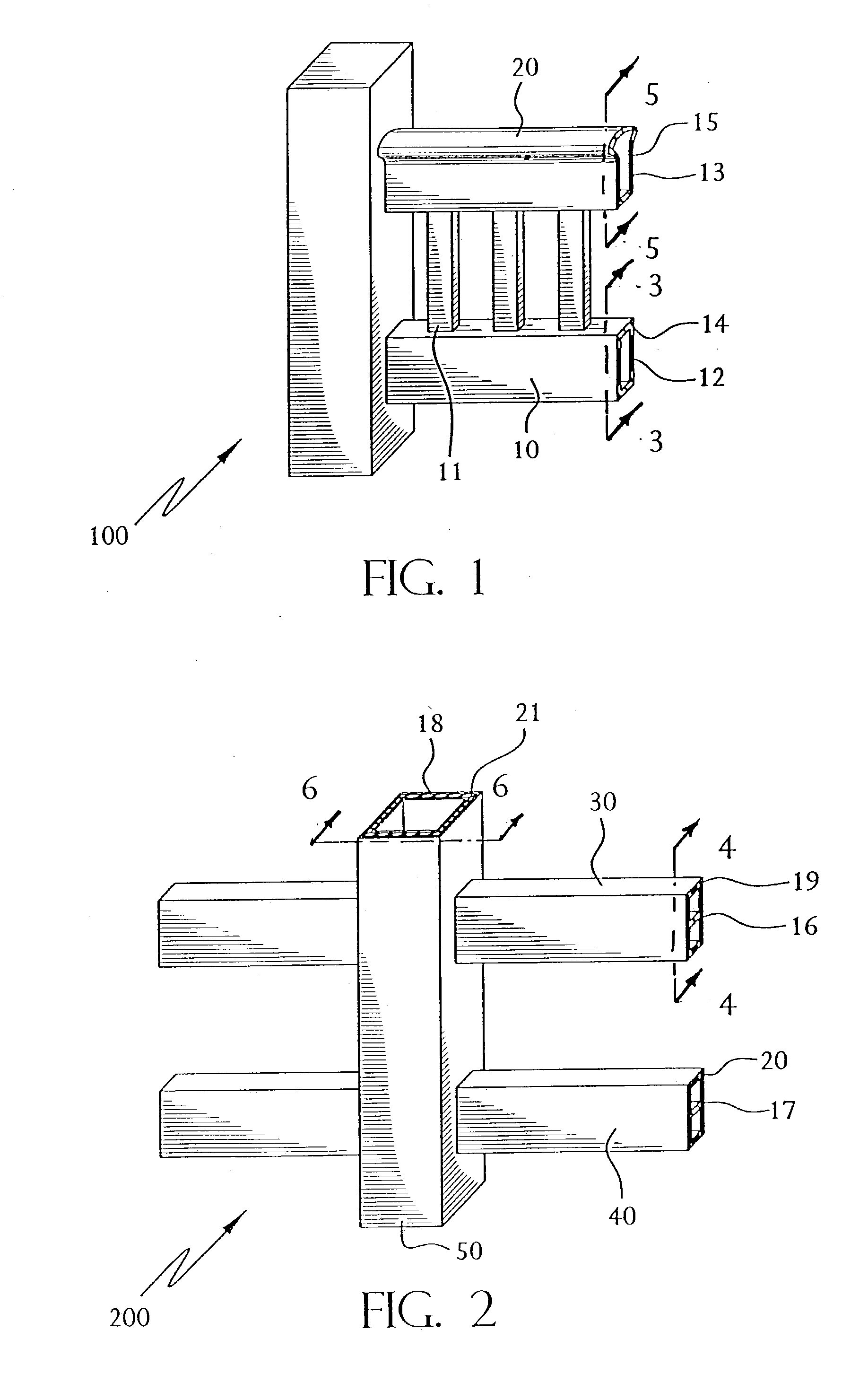

Moment-resistant building column insert system and method

InactiveUS20070209314A1Improves building column strength strengthImprove connection strengthBuilding roofsFloorsArchitectural engineeringVertical load

The invention is a novel moment-resistant building column insert system for distributing lateral and vertical loads between the column-beam and column-foundation connections. Loads are distributed between the column and beam using a column insert, nut plates and beam end plates incorporated to beam-ends. The column insert is hollow and similar cross-section shape to the building column for inserting there to. The column, column insert, nut plates and endplates have patterns of mounting holes for receiving mounting bolts tightened to nuts held by nut plates. Loads are distributed between the column and foundation using a base plate, column insert, and insert plates integrated with anchor bolts, nuts and washers in a concrete foundation. The base plate having mounting holes is incorporated to the building column bottom end to receive the plurality of anchor bolts there through for fixedly tightening as an exposed end of the column insert fits in the column.

Owner:VAUGHN WILLAIM B

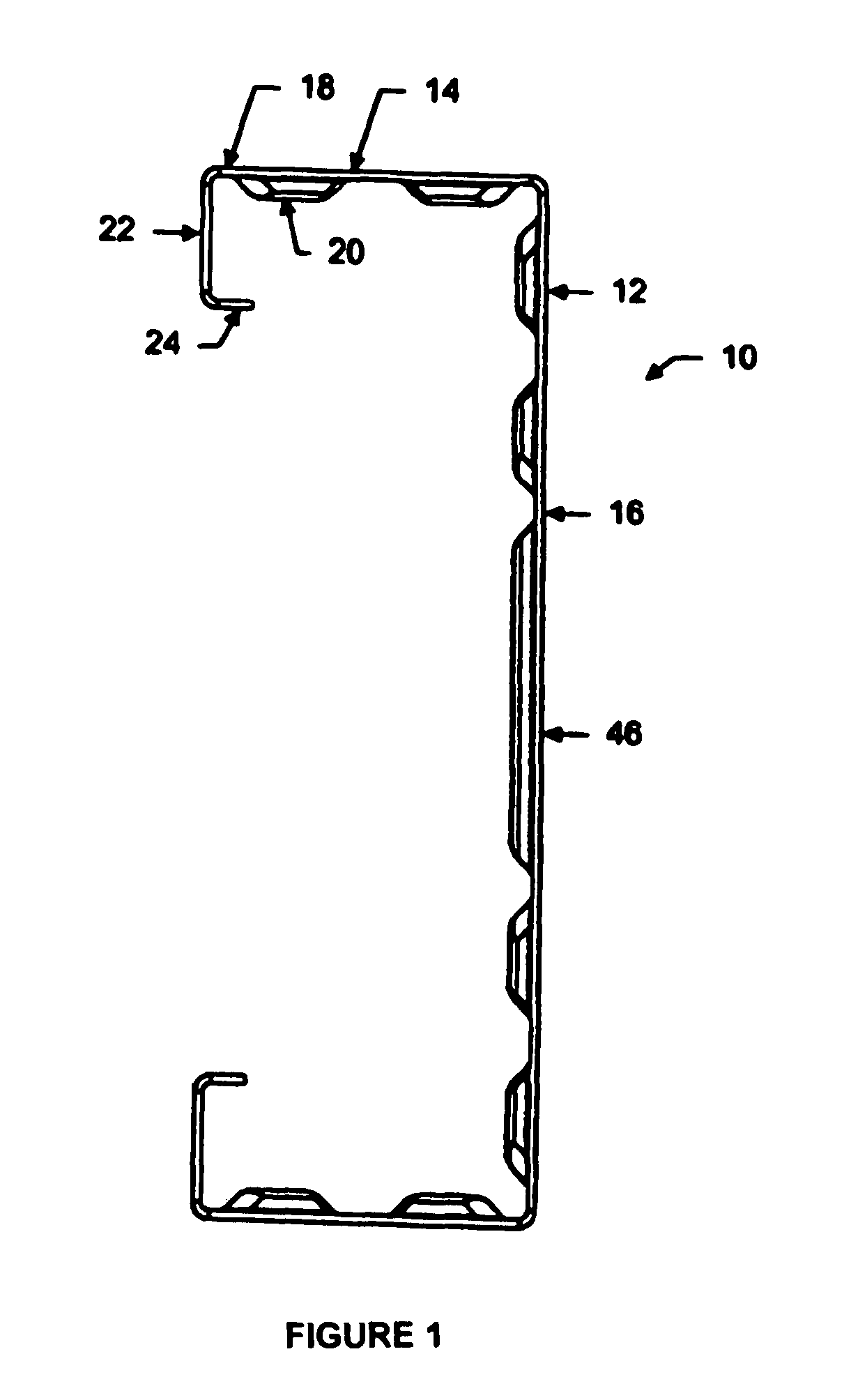

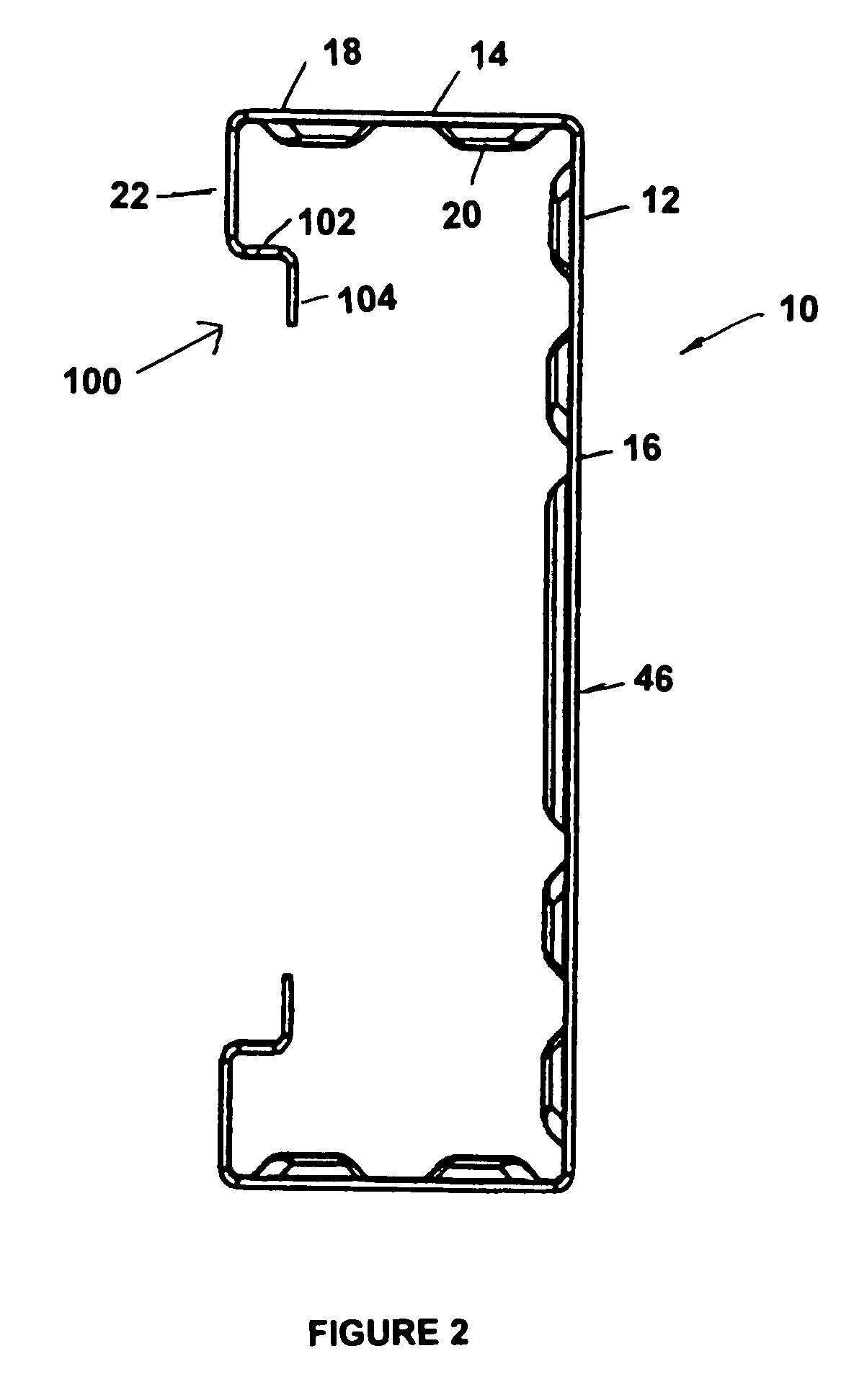

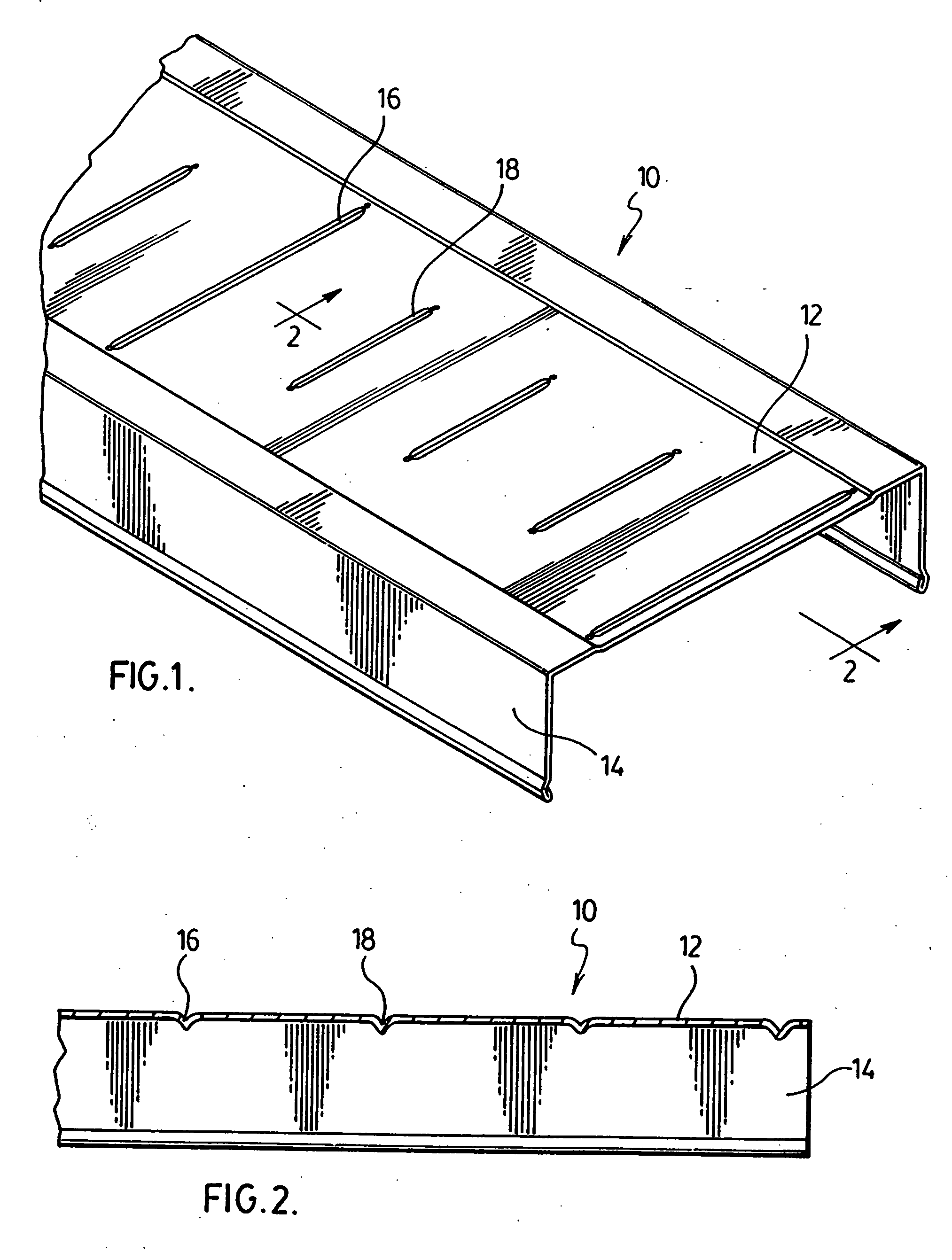

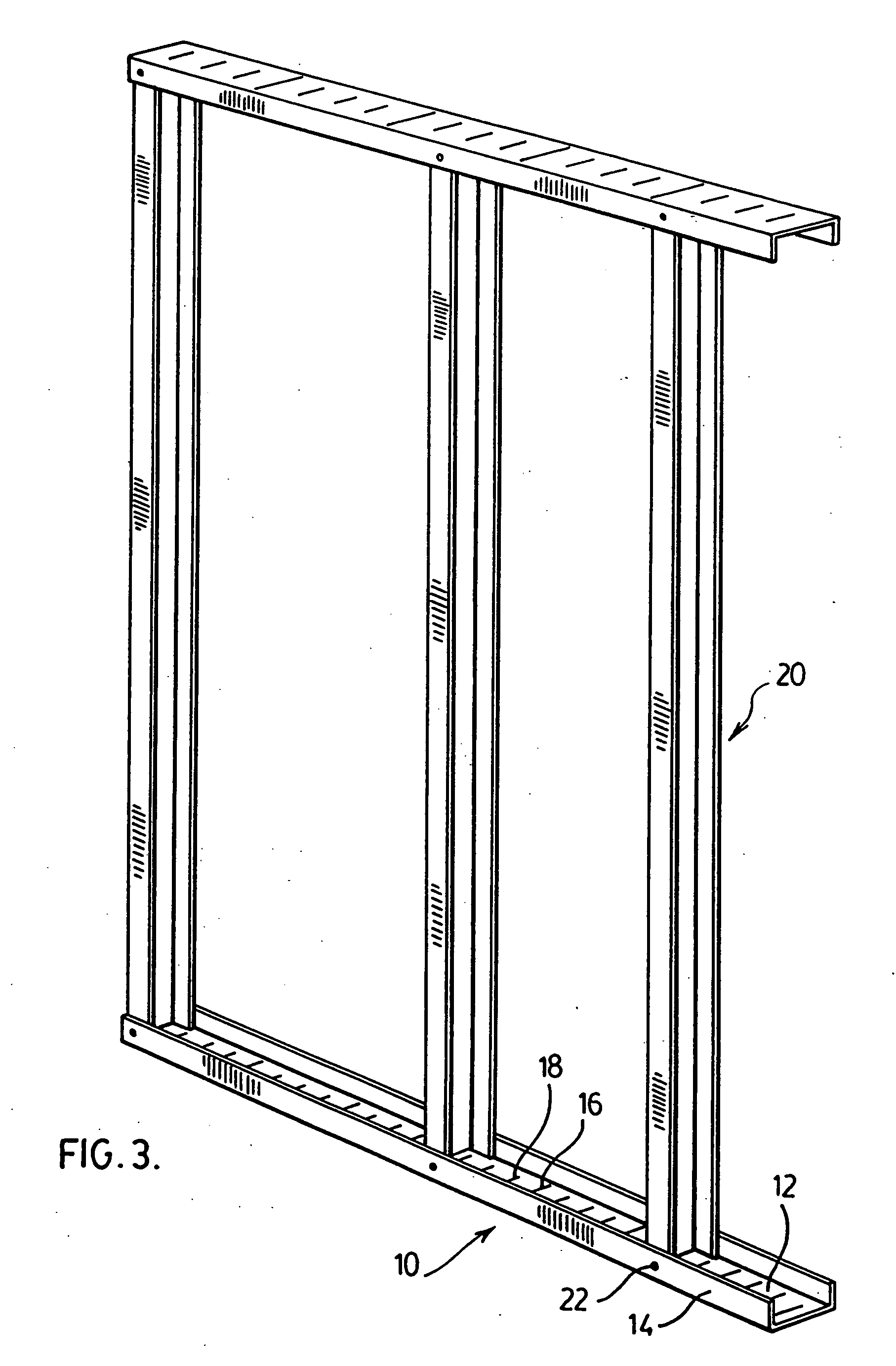

Light weight metal framing member

InactiveUS20080250738A1Low shrinkageReduce twistWallsPublic buildingsEngineeringMechanical engineering

The present invention provides for a lightweight metal framing member having a central web and two parallel spaced apart side walls extending upwardly from the sides of the web. The framing member has at least one longitudinally oriented rib extending the length of the web of the framing member to aid in reducing shrinkage and twisting of the framing member when non-symmetrical reinforcing structures are found in the framing member.

Owner:BAILEY METAL PROD

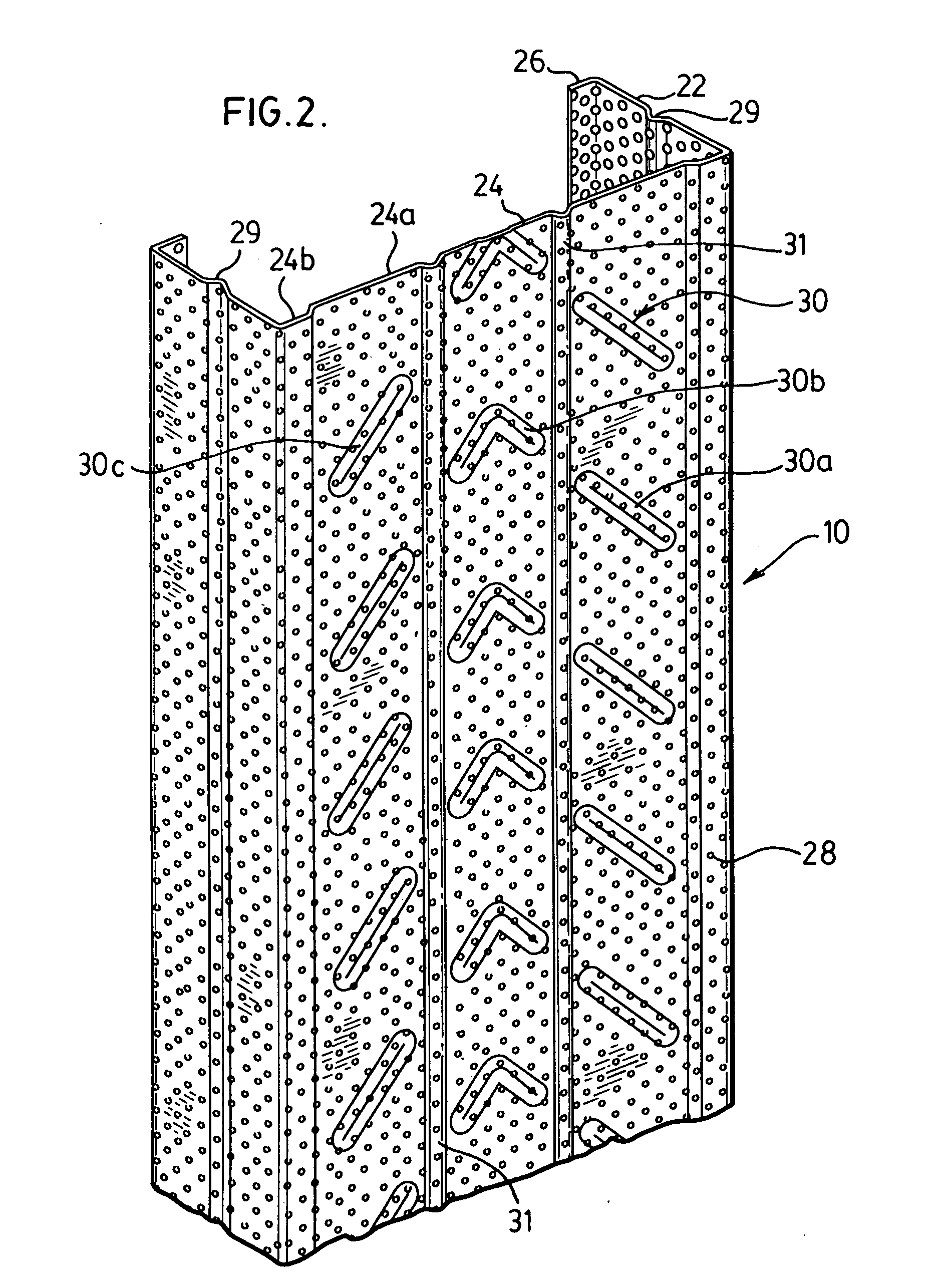

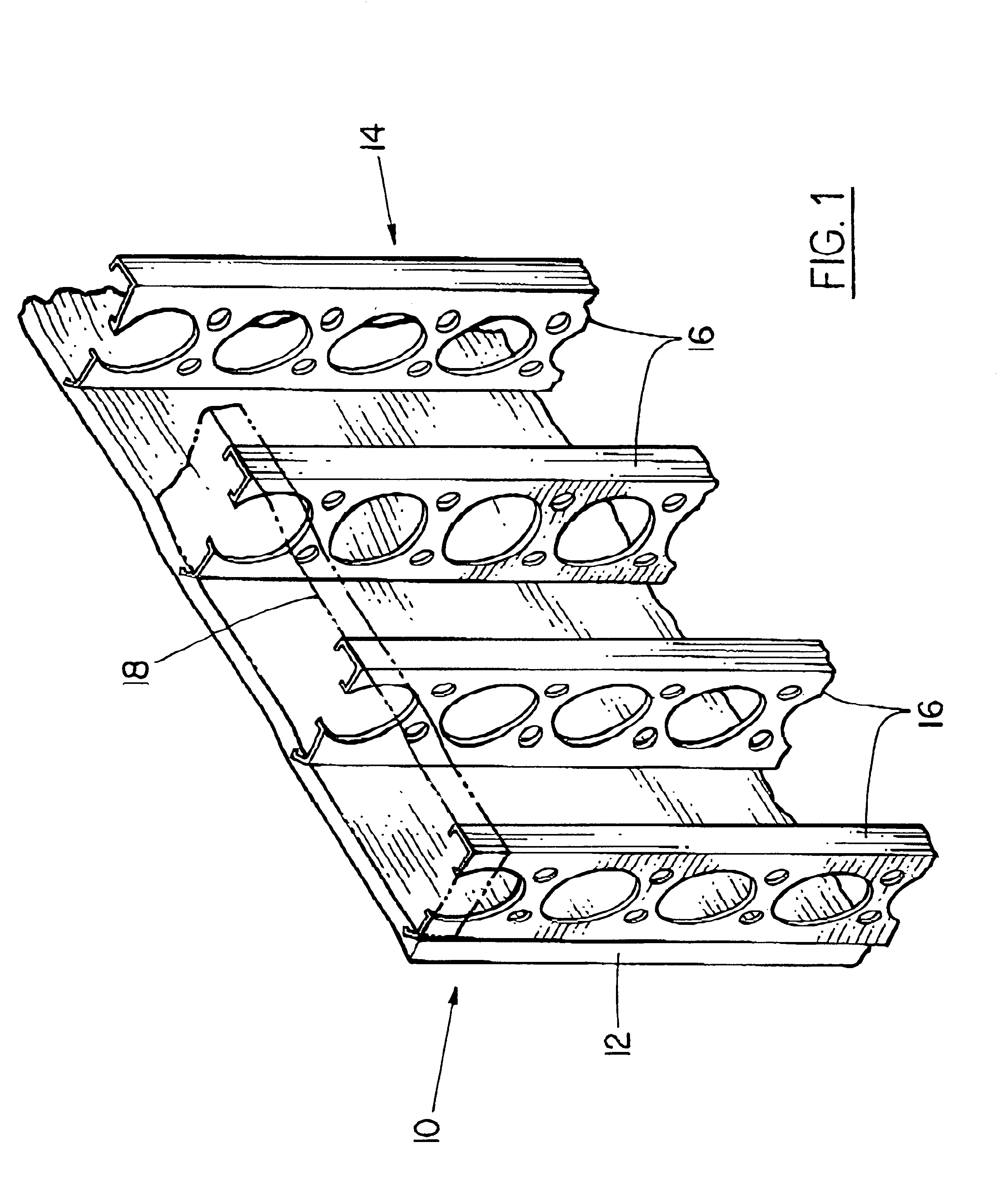

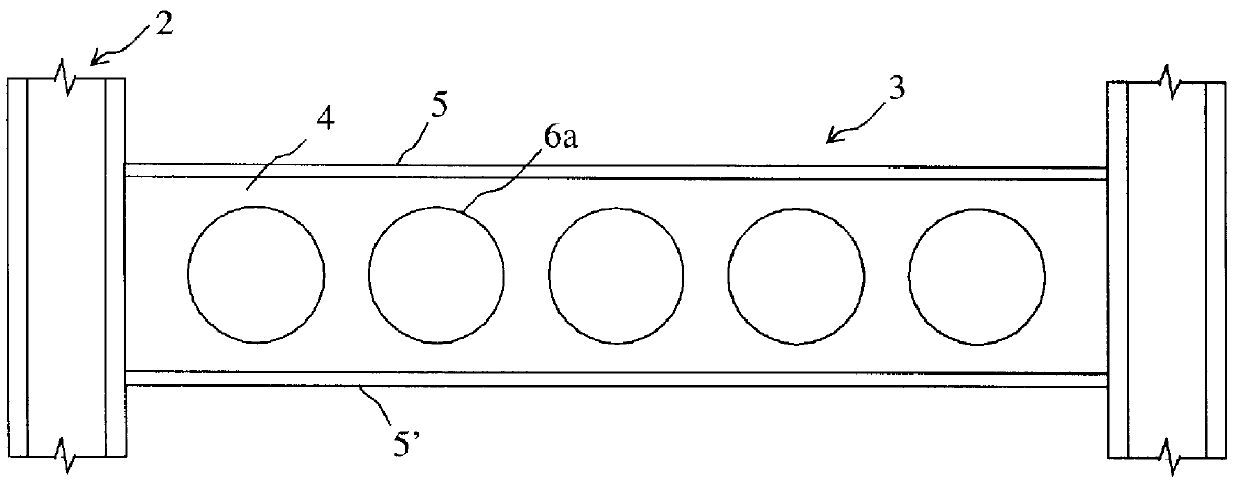

Laminated composite building component

InactiveUS6205728B1Maximized encapsulationHigh strengthBuilding roofsConstruction materialAdhesiveEngineering

A laminated composite building component, capable of sustained axial stress as a primary support structure and enclosure of a building structure, comprising a lamination of rigid and resilient material, said rigid material formed of sheets with continuous corrugations parallel to the supporting axis and which have opposite faces being bonded to and encapsulated by said resilient material, said resilient material being a cellular foam matrix, an adhesive or fusion that bonds the rigid and resilient material together in either a static or continuous laminating process, said resilient material forming two outer surfaces spaced from the rigid material, said rigid material having opposite lateral edges being exposed from said resilient material, said lateral edges of the rigid material having return flanges for interlocking said laminated composite building component with adjacent building component, and said building components capable of being supplied and distributed in generic lengths and custom field-cut like lumber.

Owner:RYN SUTELAN

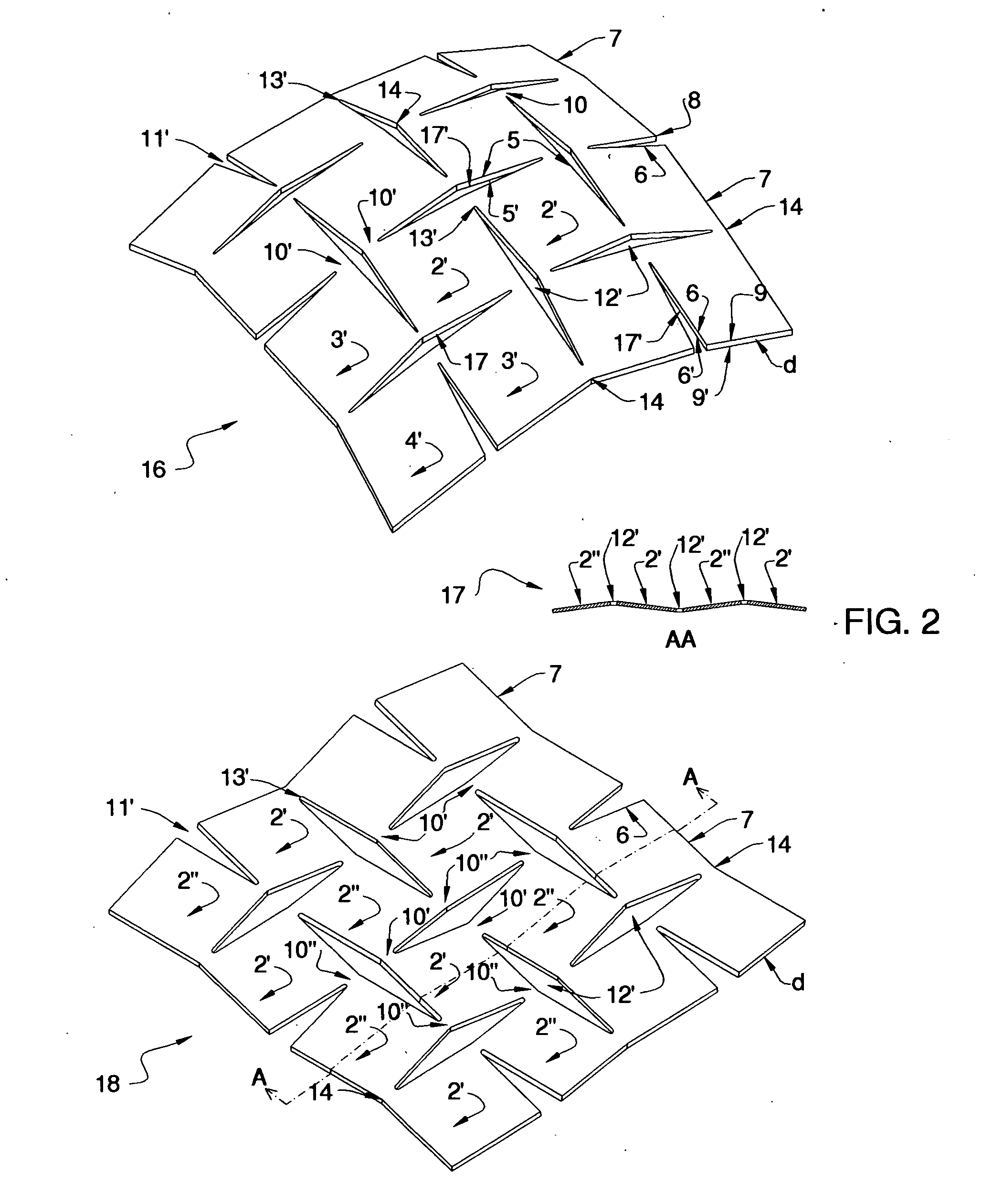

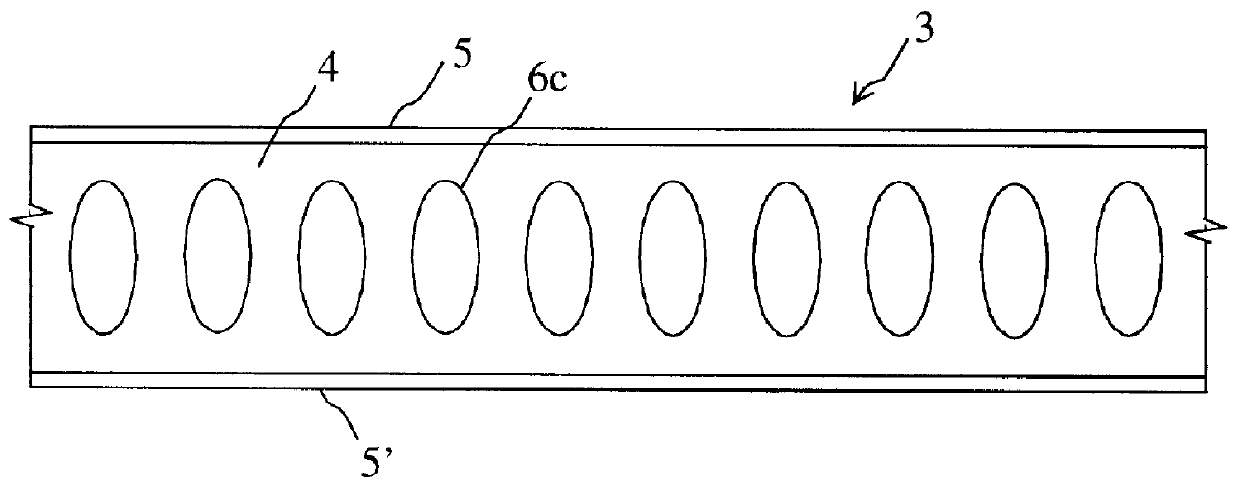

Multi-directional and variably expanded sheet material surfaces

ActiveUS20070122590A1Efficient use ofIncrease surface areaPaper/cardboard articlesFloorsLaser cuttingNanoscopic scale

Expandable surfaces made from sheet materials with slits distributed on the surface of sheet material where the surfaces expand by application of force along or / and across the surface of sheet material. The unexpanded surfaces are flat sheets, or closed surfaces like cylinders, spheres, tubes, or custom-designed organic shapes marked with pre-formed or post-formed slit designs. The expanded surfaces can be single units or modules which can be attached to one another through various means. The sheet materials range from hard surfaces like metals, to softer materials like papers and plastics, or pliable materials like fabrics, rubbers, synthetic surfaces or bio-surfaces. The slits are arranged in patterns ranging from periodic, non-periodic to irregular designs. The slits can be straight, bent, curved or irregularly shaped with even or uneven spacing. Slitting can be achieved by digital cutting or punching devices like laser-cutting, water-jet cutting, digital punching, automated dies, etc. or pre-formed when casting the sheet material. Force can be applied manually with tools or through the use of machines and special set-ups. Applications range from architectural surfaces, walls, ceilings, panel systems, structures and sculpture. On a smaller scale, applications include containers, packaging material, fabrics and human wear. On micro- to nano-scale, applications range from expandable surfaces for gauzes, band-aids, stent designs, skin grafts, semi-permeable membranes and micro-filters for various industries including purification of fluids and chemical substances.

Owner:LALVANI HARESH

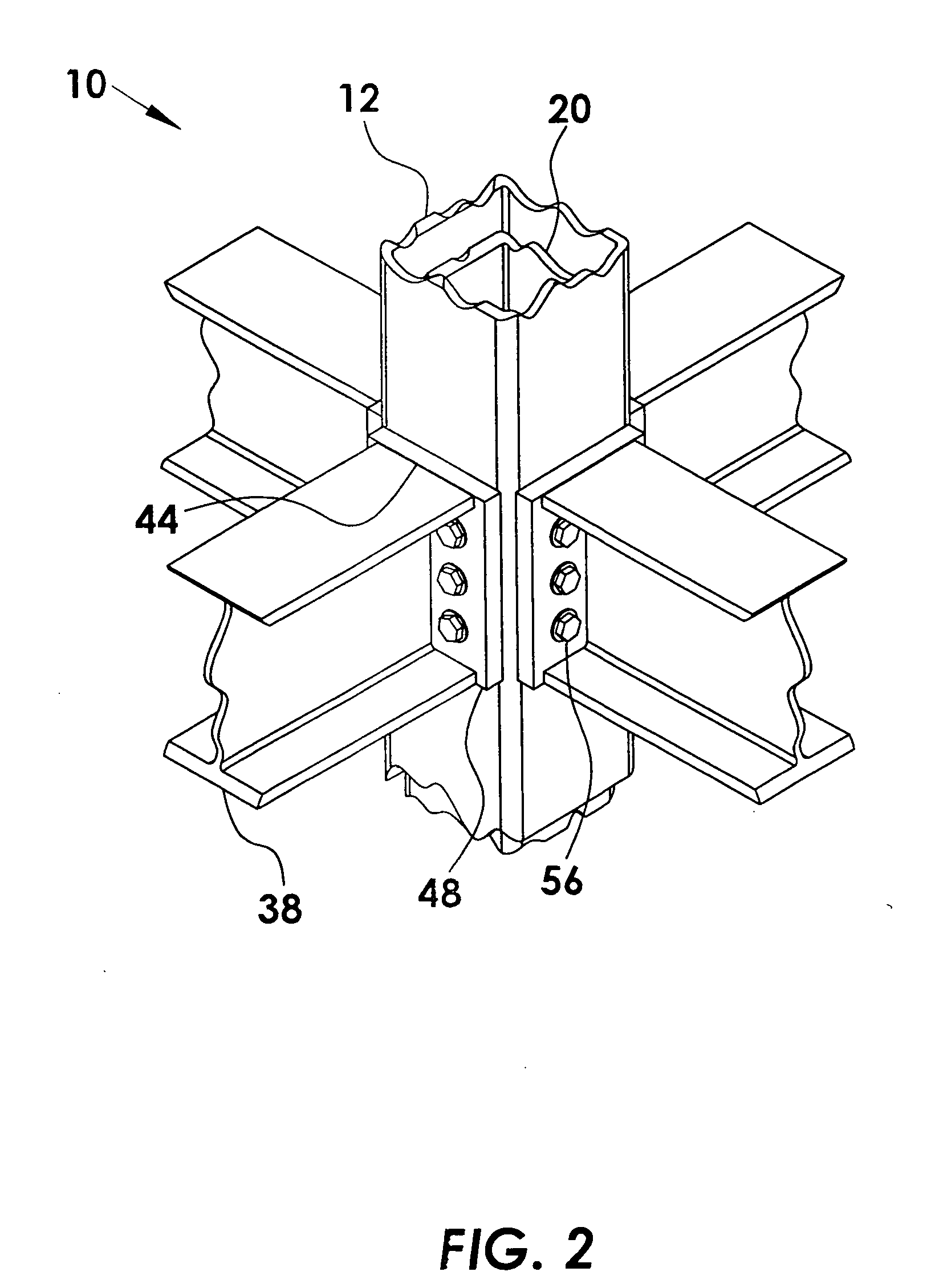

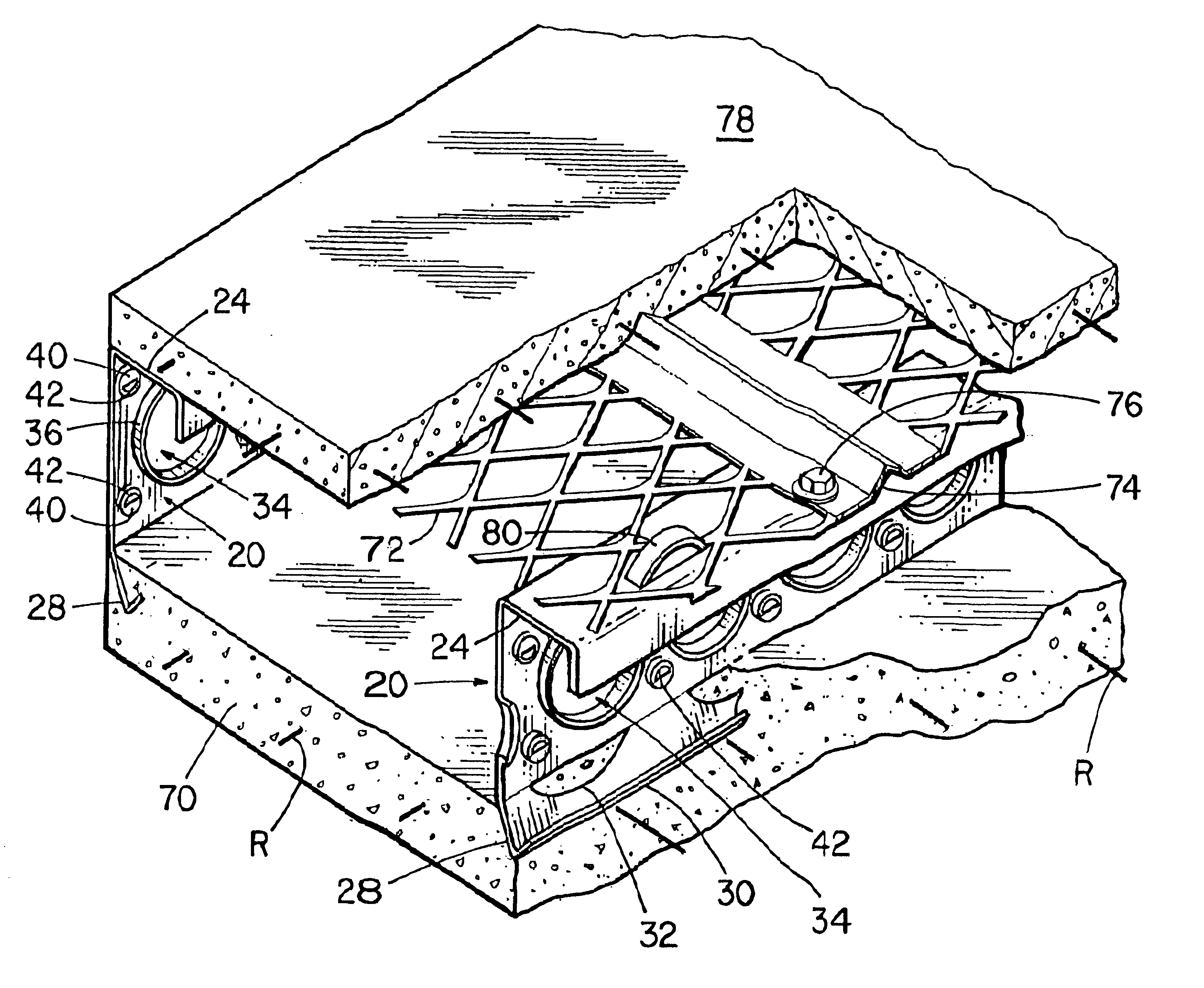

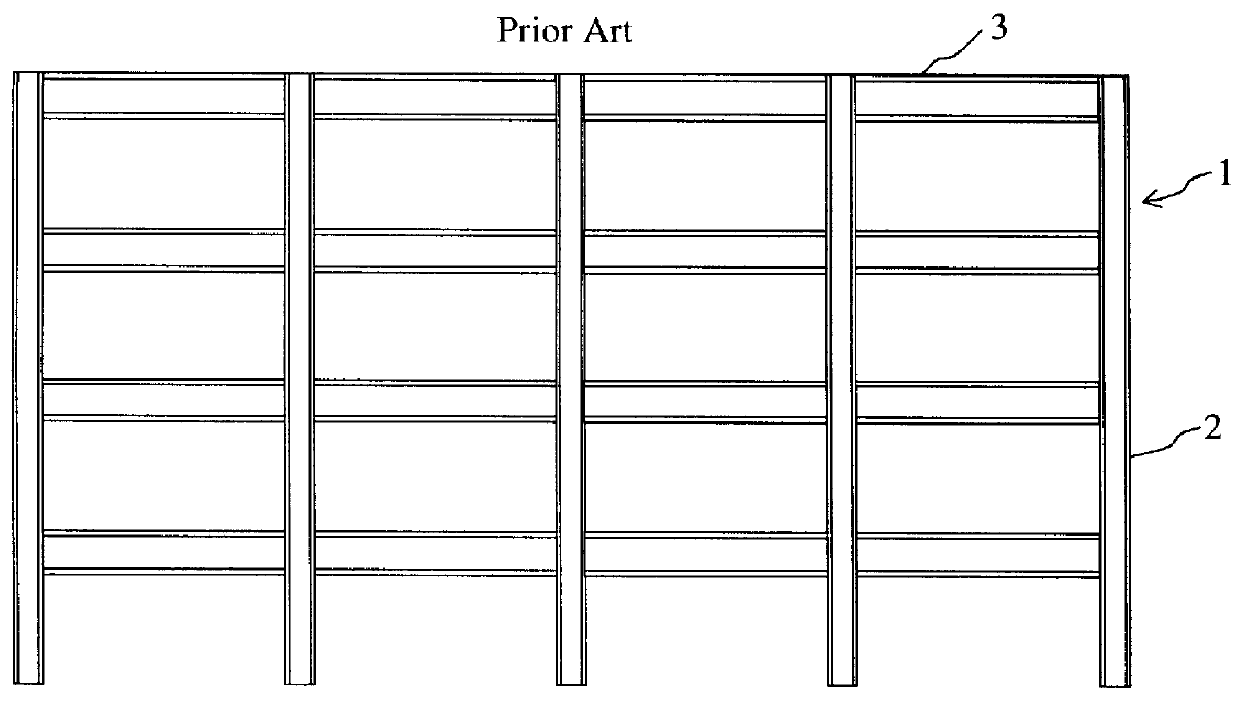

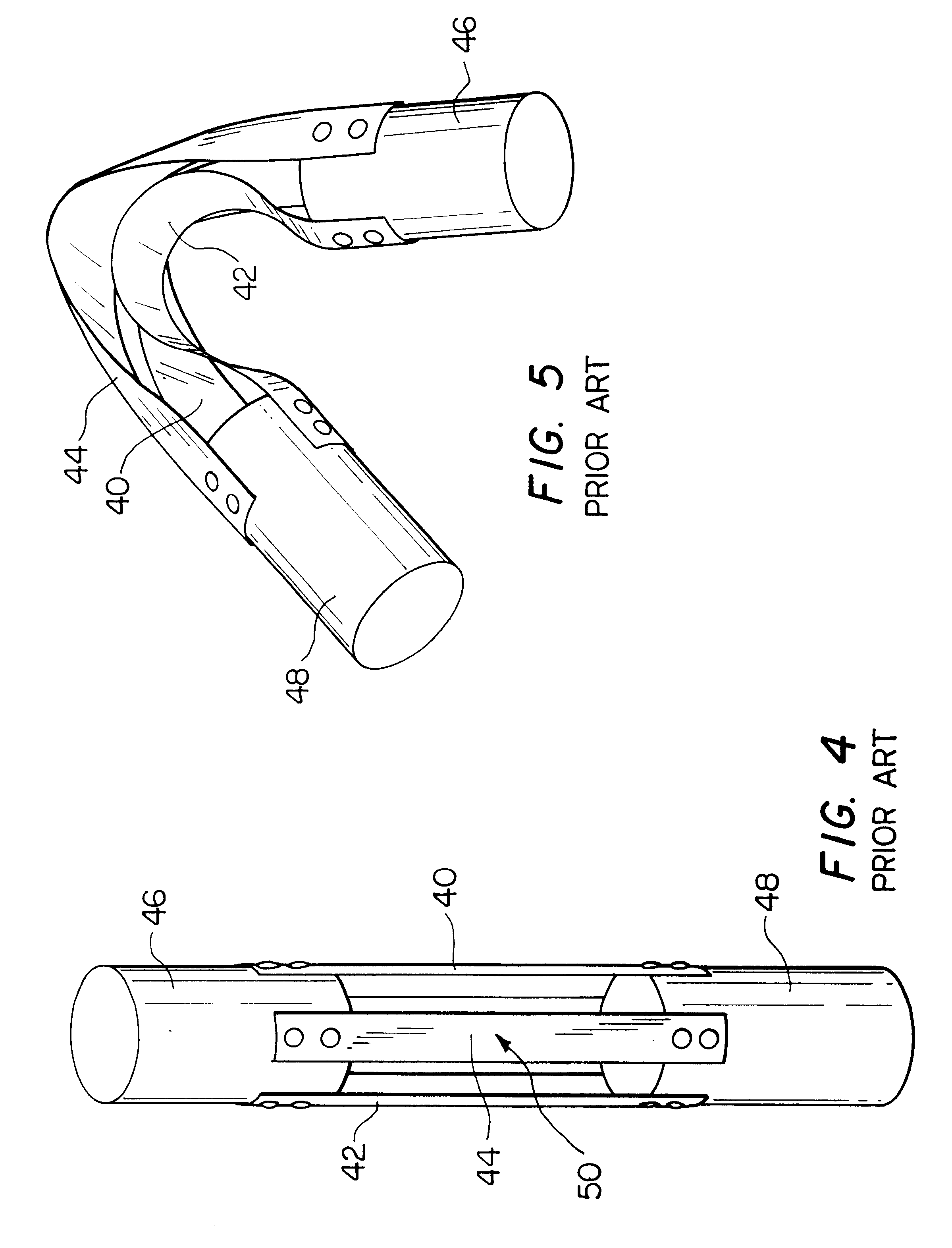

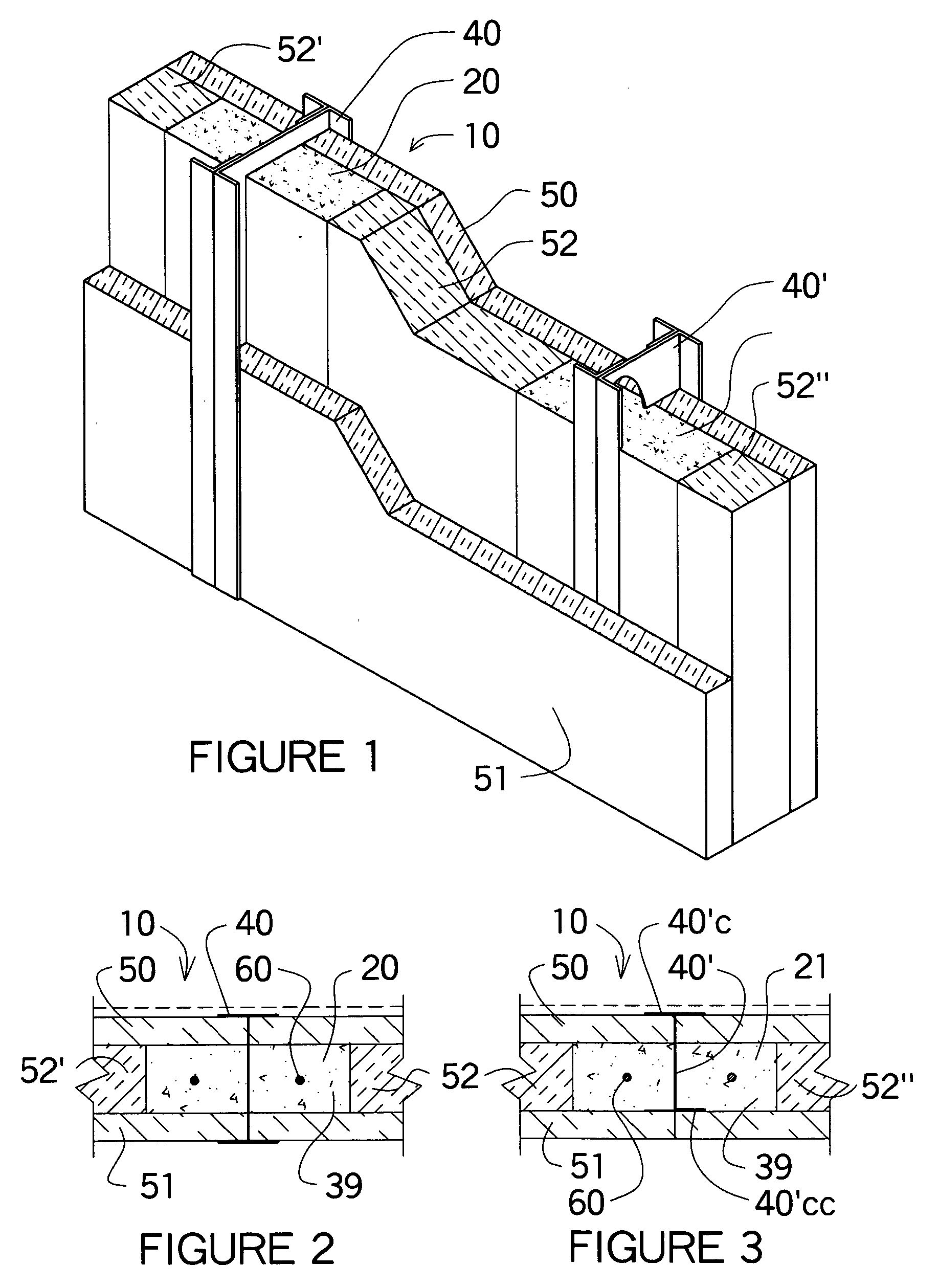

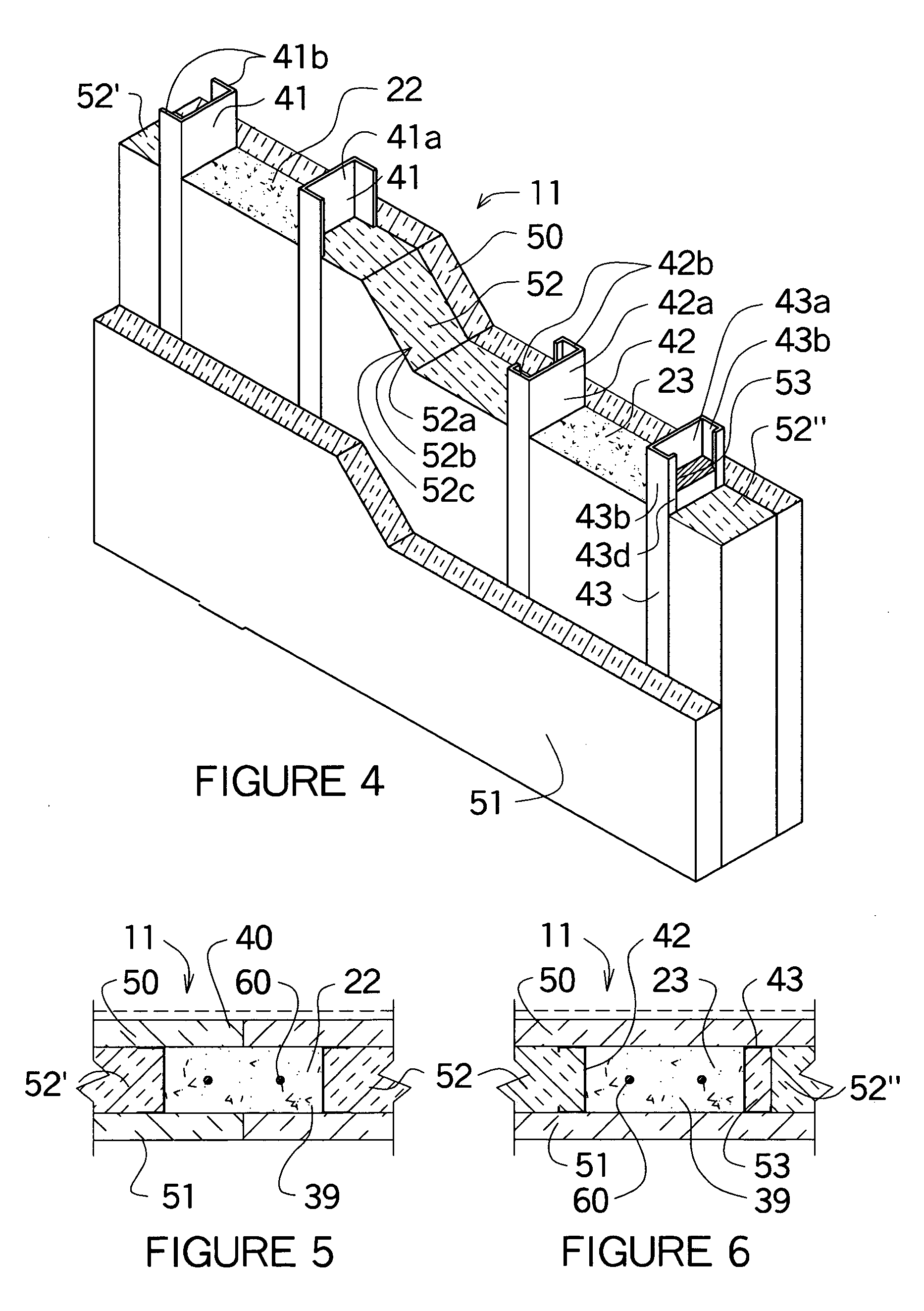

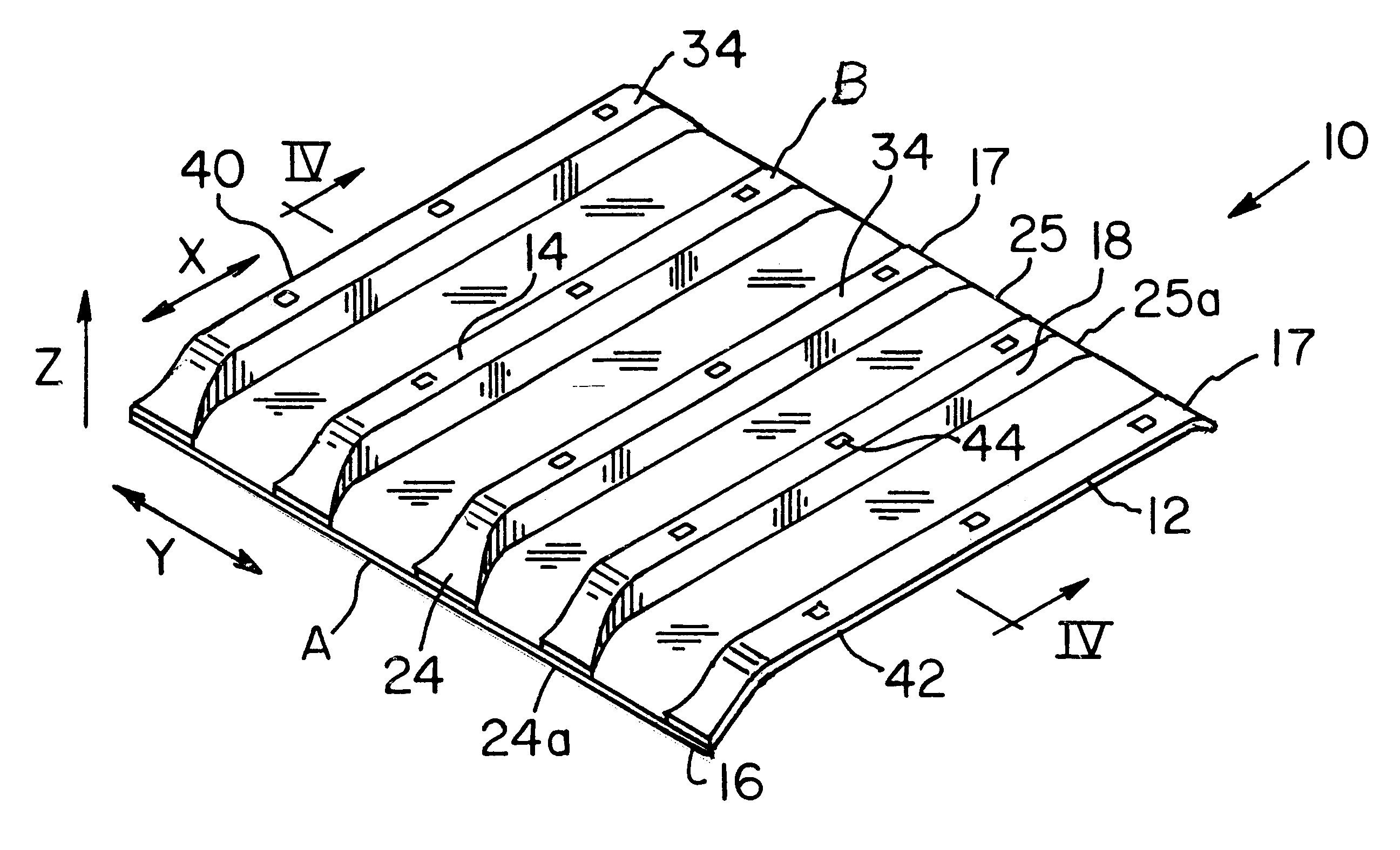

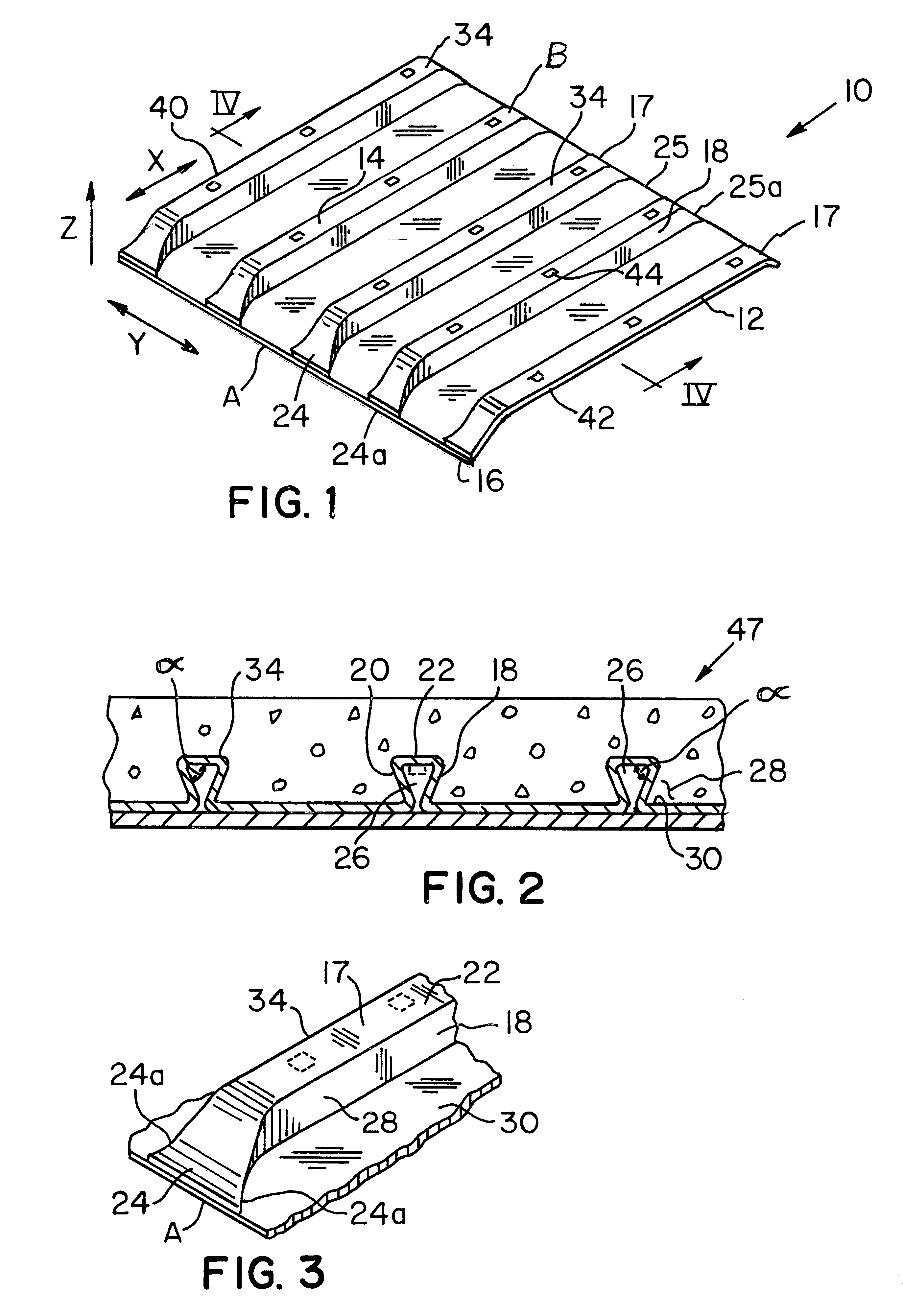

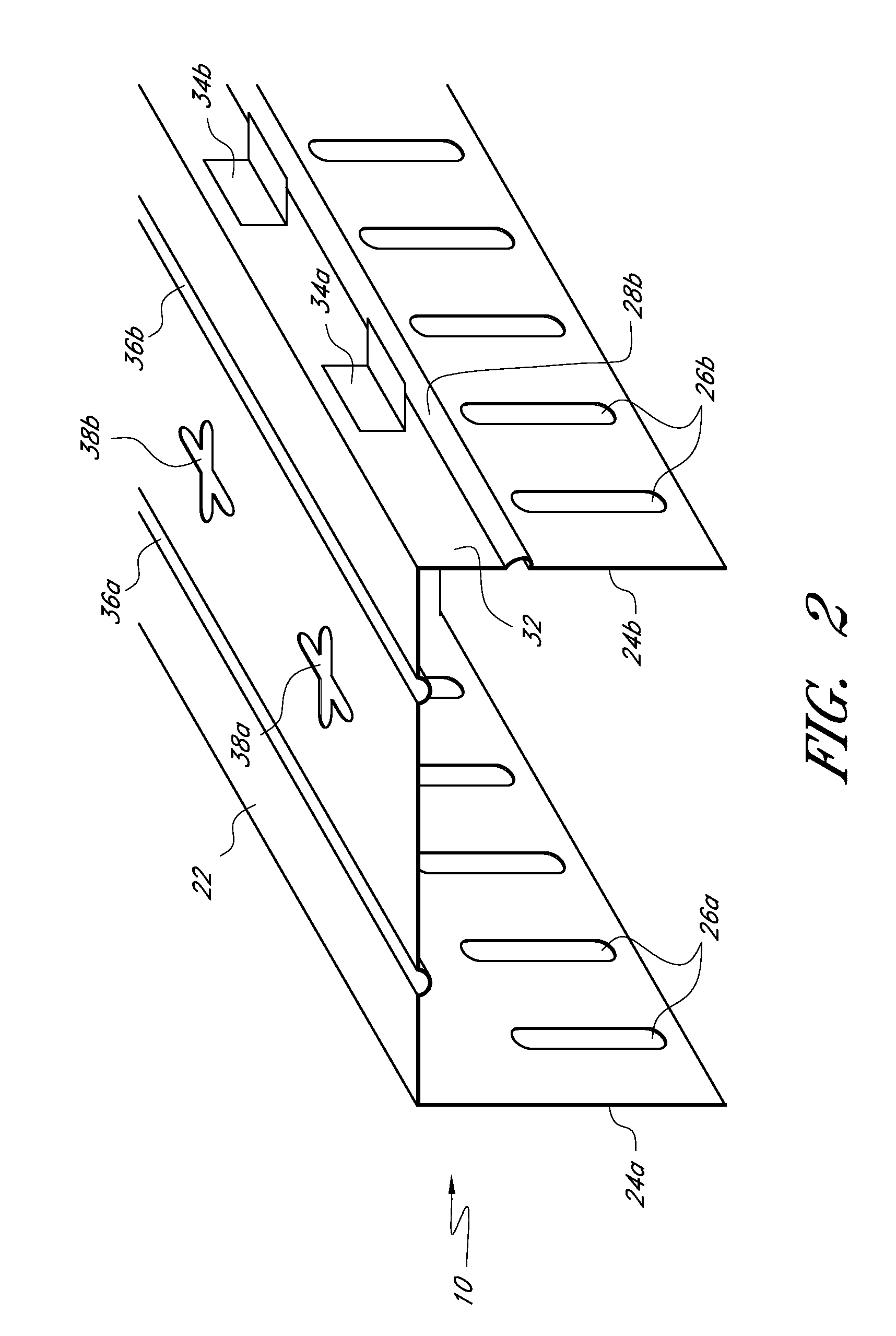

Sheet metal stud and composite construction panel and method

A composite construction panel having a thin panel of concrete material and a reinforcing grid of sheet metal studs with embedment portions which are actually embedded into the concrete panel, each of the studs having a web, main web openings through the web, a right angular flange formed on a free edge of the web, an embedment angled flange portion formed along the opposite edge of the web, an edge strip formed on the angled flange at an angle thereto; and, spaced apart angled flange openings formed in the angled flange for flow of concrete therethrough. An alternate form of stud has a triangular tube structure along one edge of the web. Another form of stud has a discontinuous webs defining spaces between them. In one embodiment two concrete panels may be secured to the studs in spaced relation to create a hollow structure.

Owner:GCG HLDG

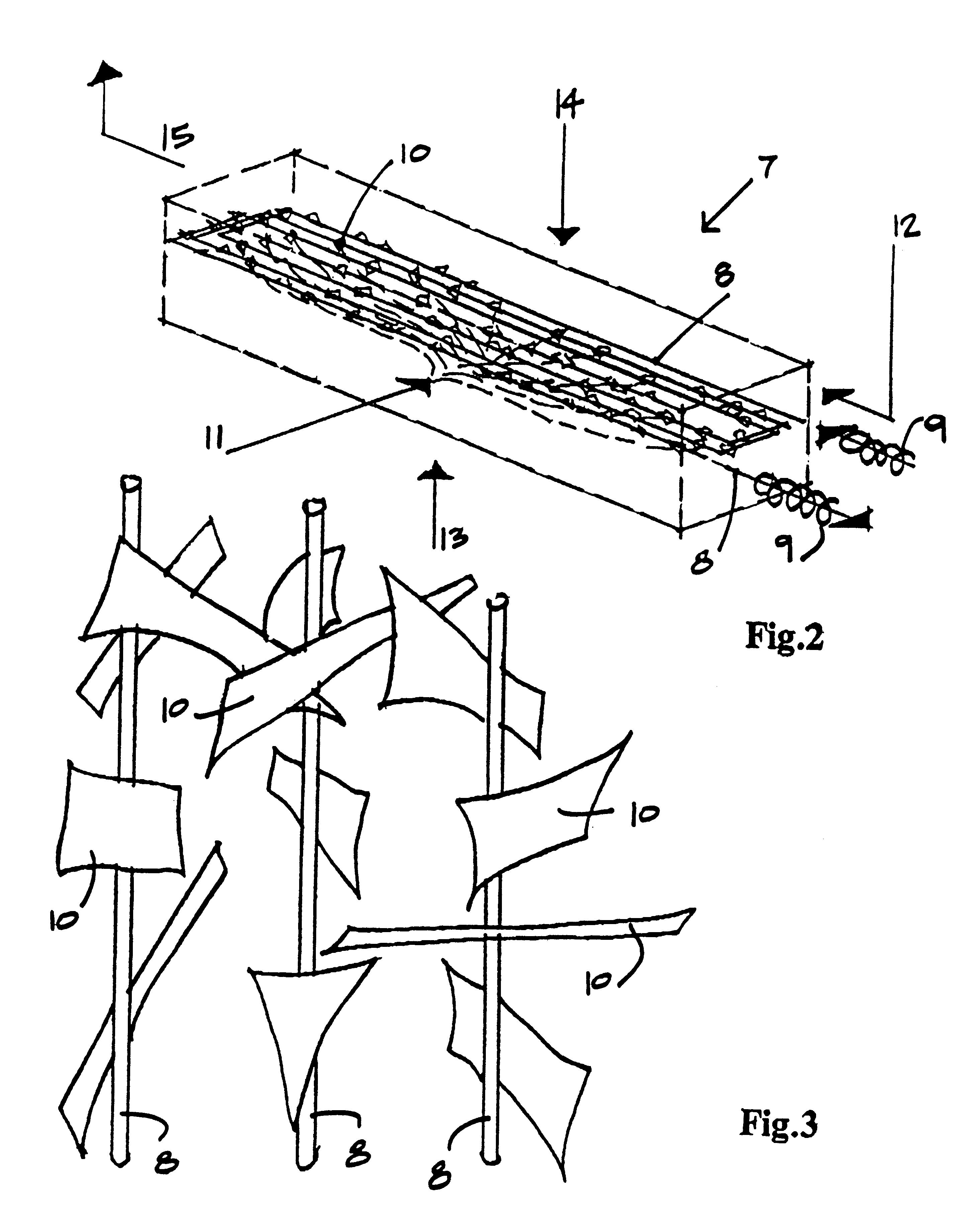

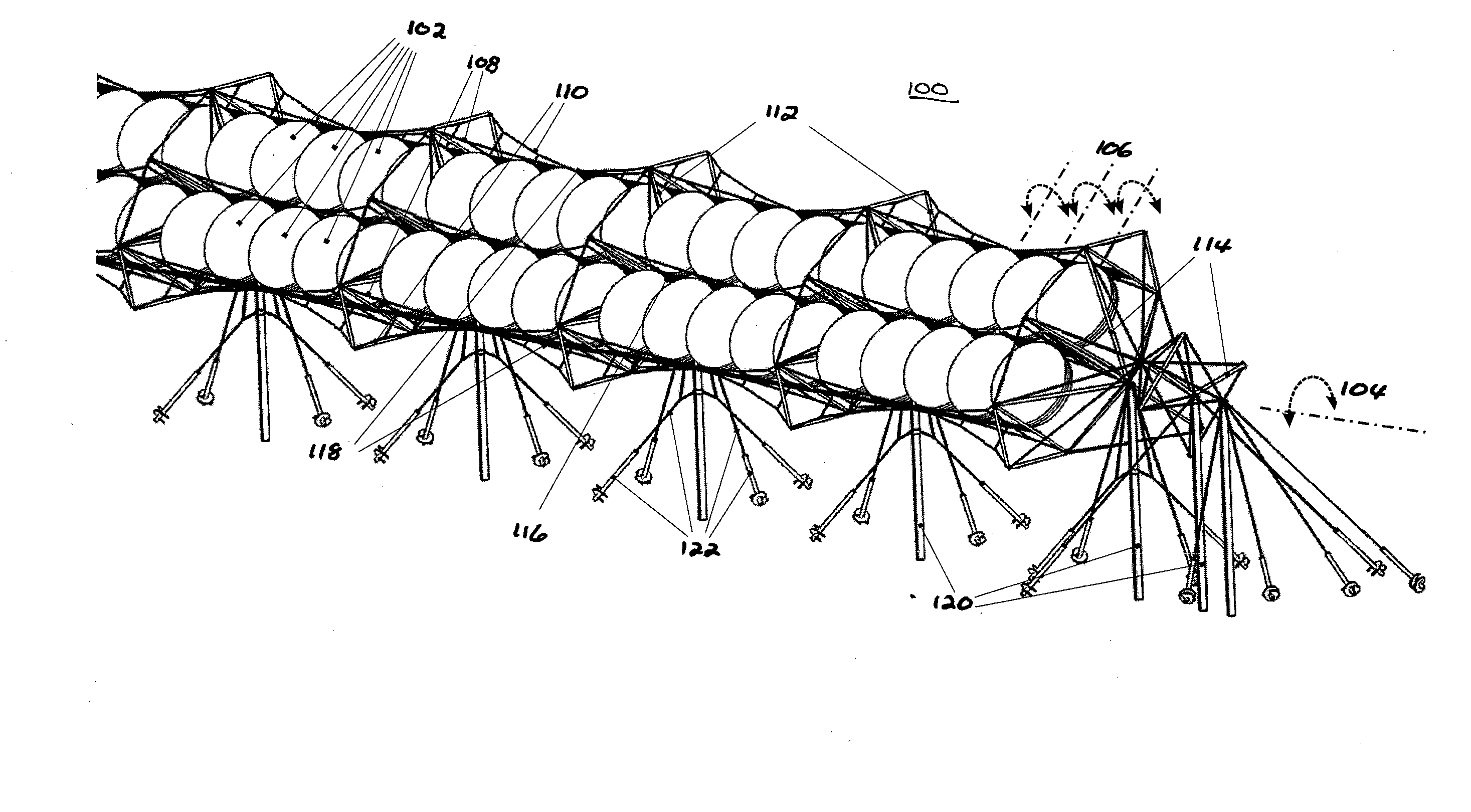

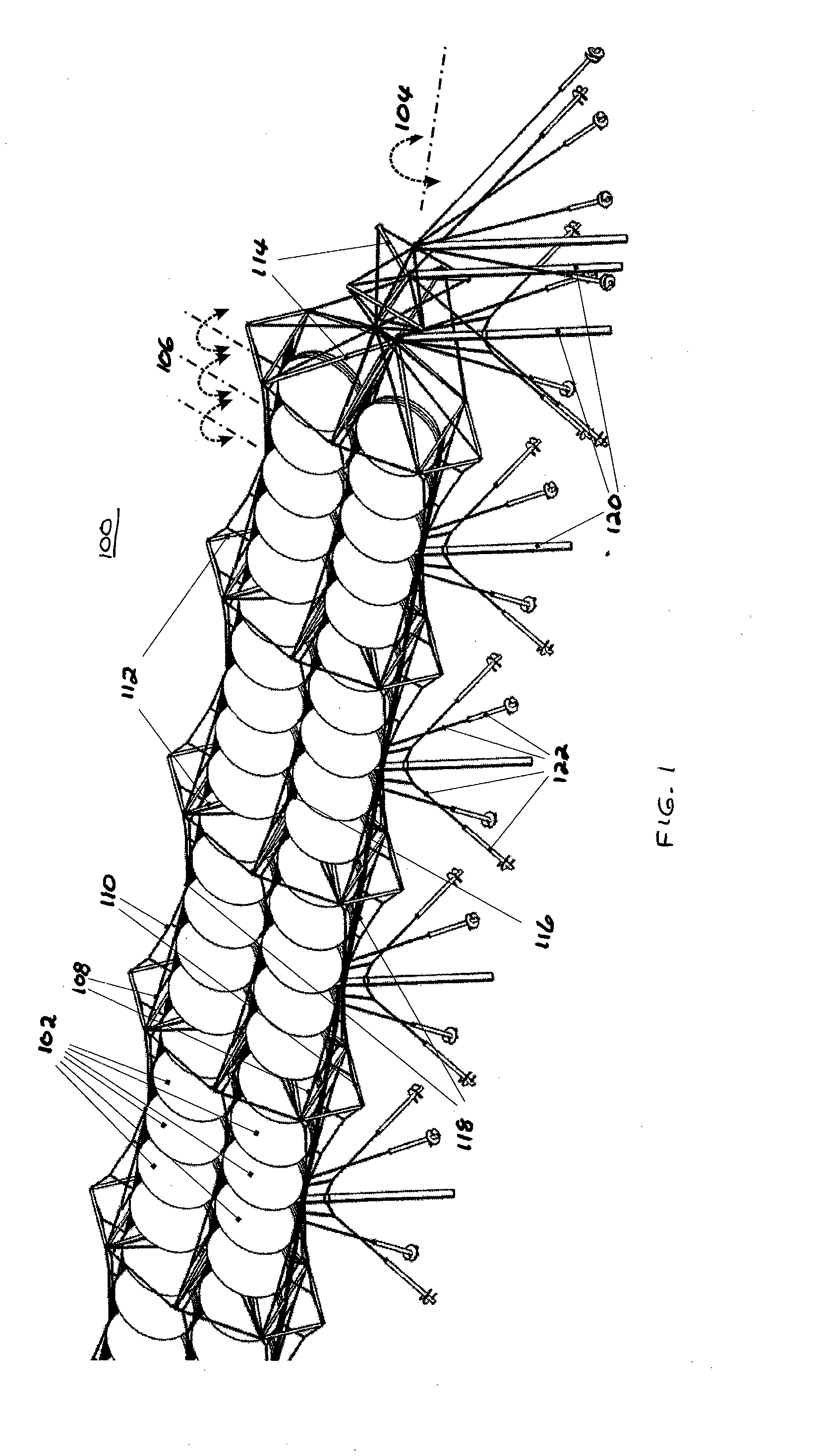

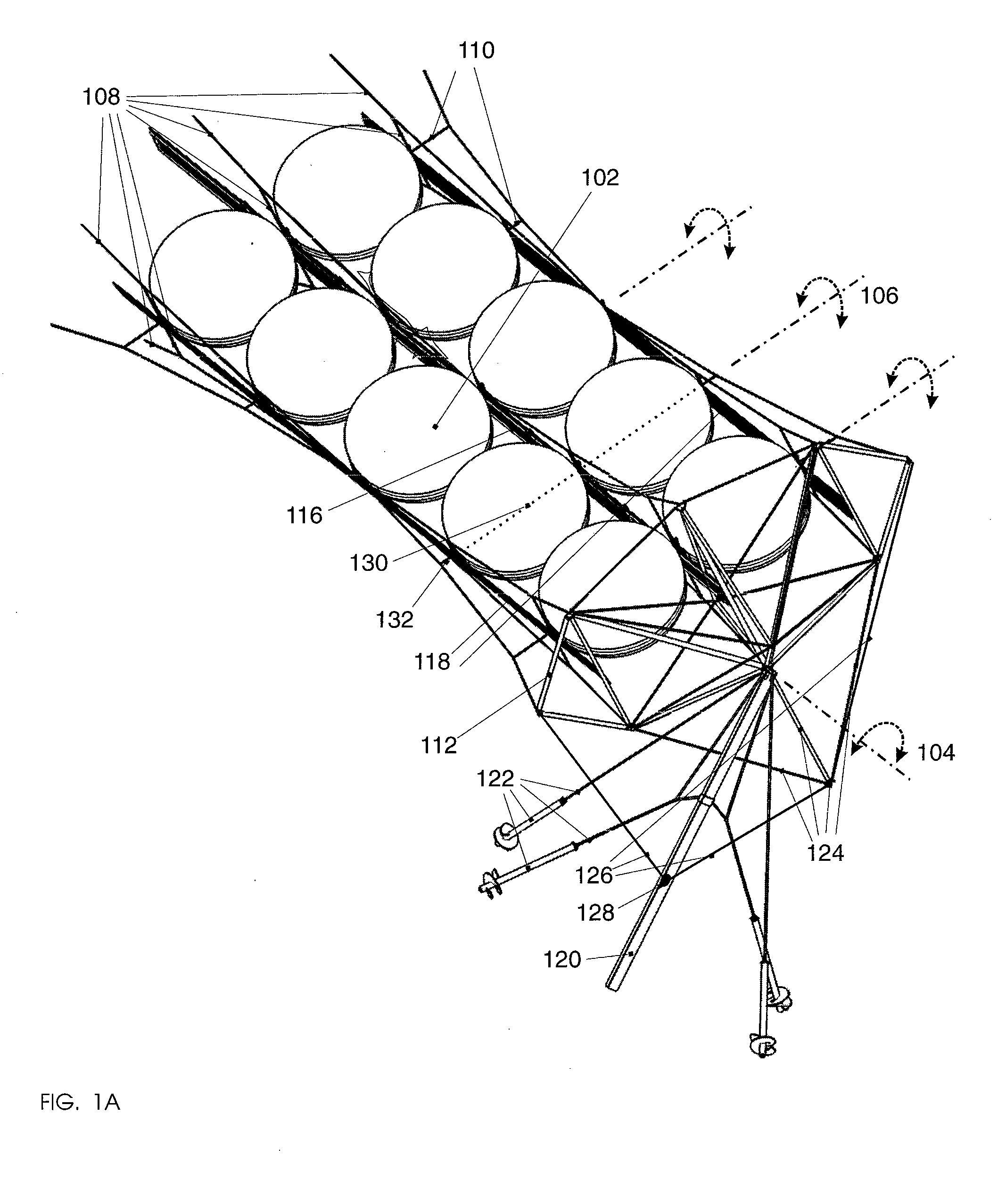

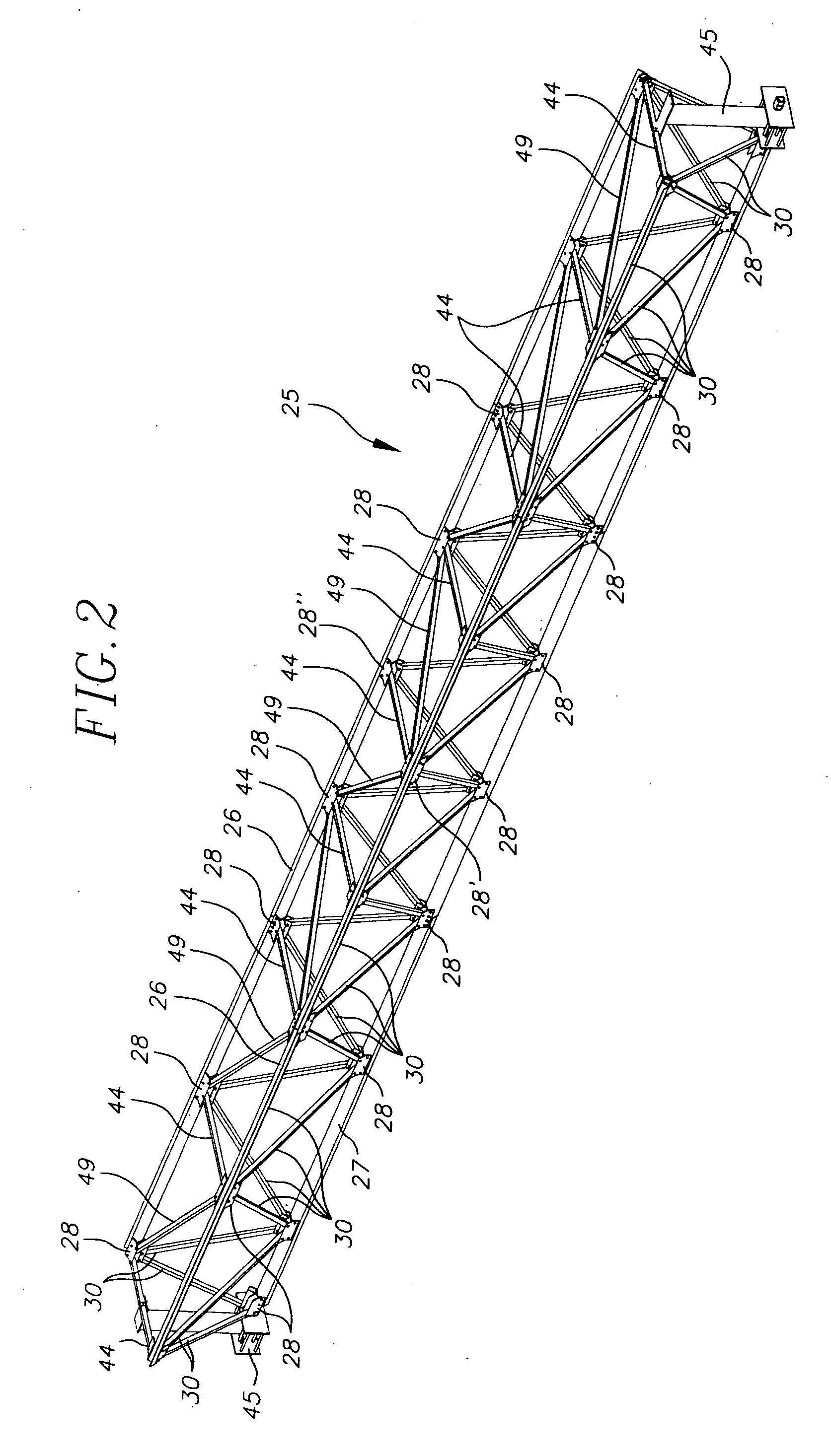

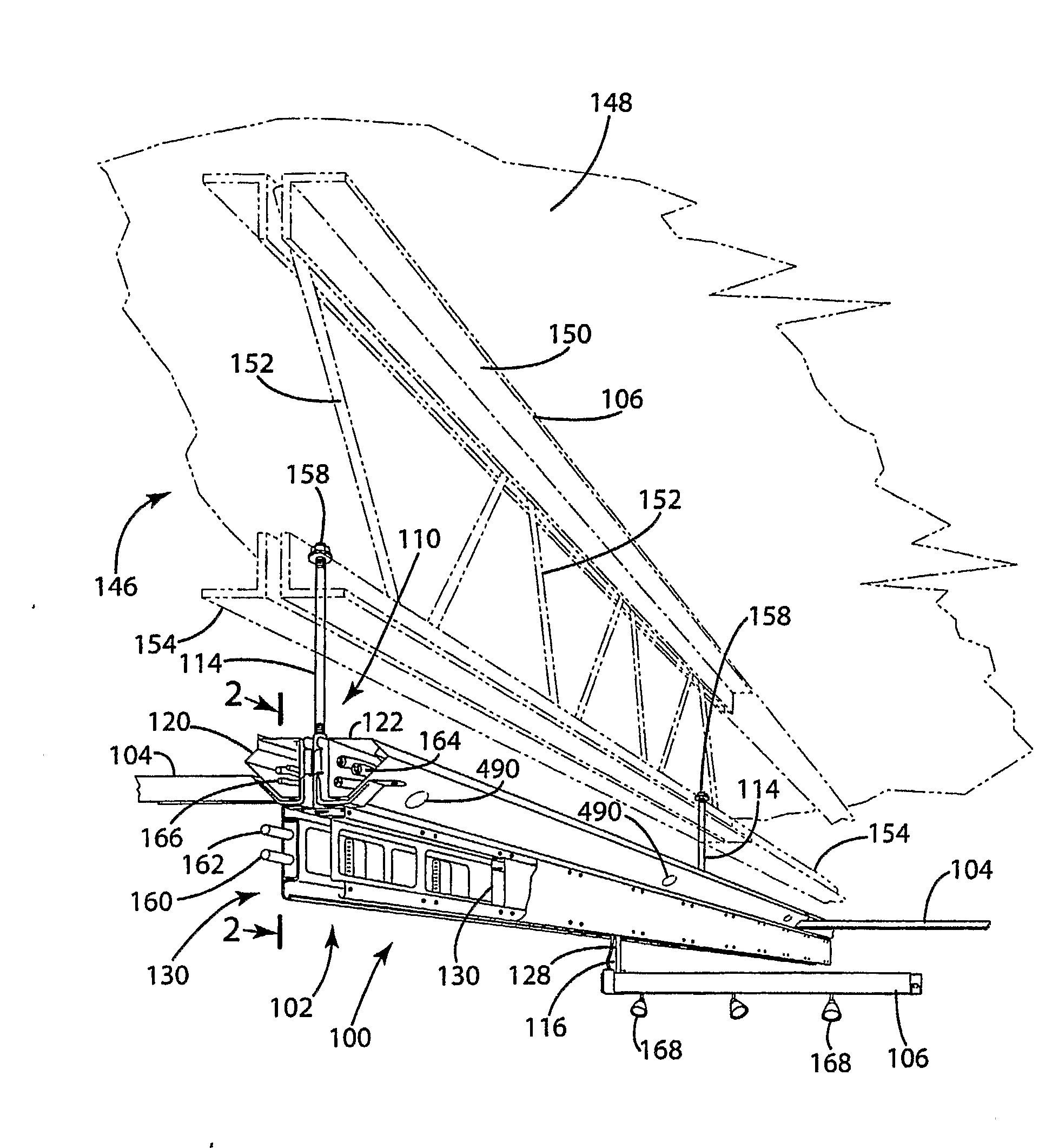

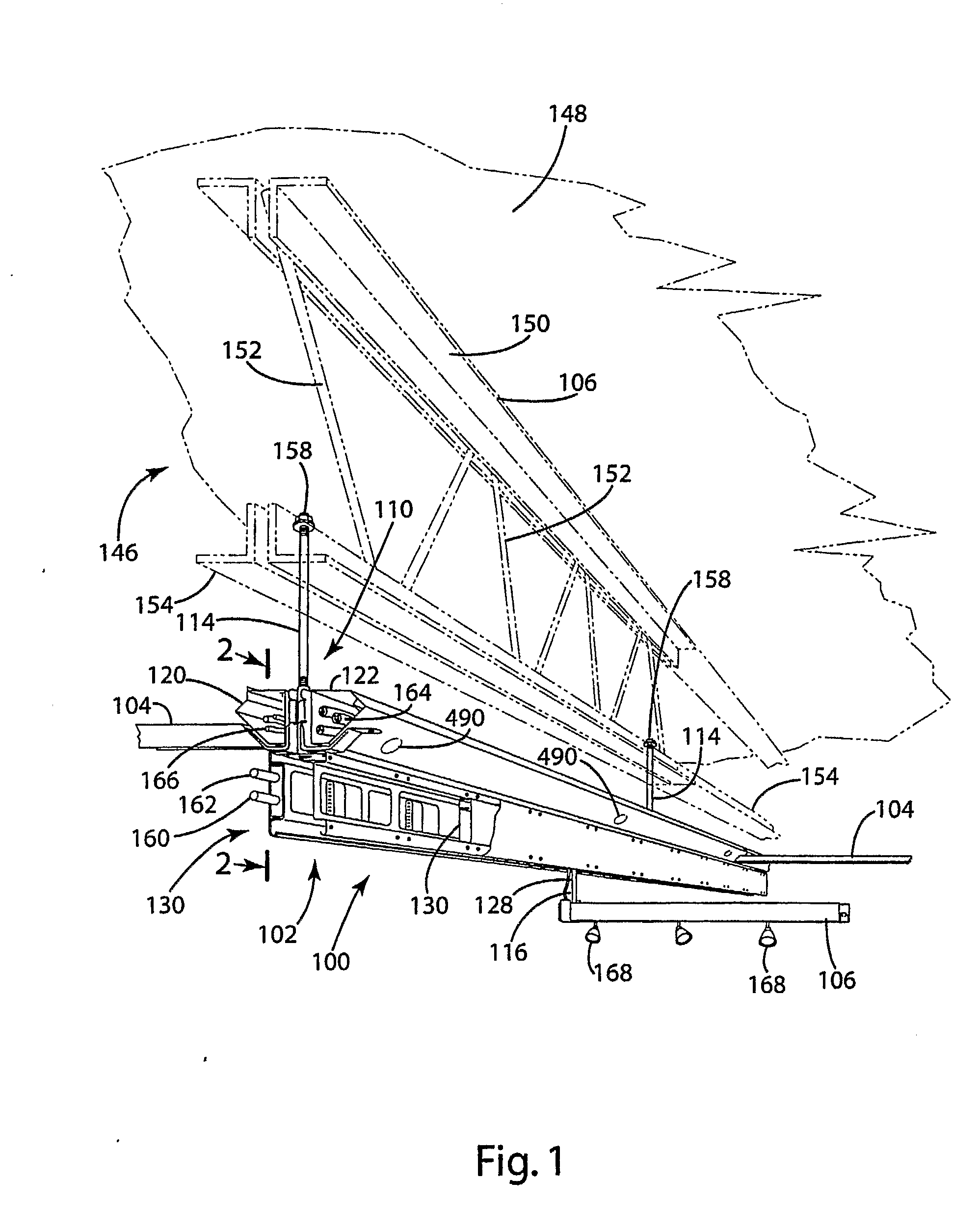

Rigging system for supporting and pointing solar concentrator arrays

InactiveUS20080168981A1Reduce bending forceConvenient and reliable cable-tension adjustmentPhotovoltaic supportsSolar heating energyTerrainRotational axis

Embodiments in accordance with the present invention relate to the design of inexpensive mounting and pointing apparatuses for linear arrays of solar energy collectors and converters. Particular embodiments in accordance with the present invention disclose a rigging system comprising at least one, and preferably a plurality of, tensile cables onto which a plurality of solar modules are fastened. Such an arrangement provides a way of suspending solar modules over land, vegetation, bodies of water, and other geographic features without substantial perturbation of the underlying terrain. Certain embodiments comprise additional tensile cables fastened to the solar modules, such that differential axial motion of the cables produces a rotational motion component of the individual solar modules of the array. This rotational motion component effects an orientation control along one rotational axis.

Owner:COOLEARTH SOLAR

Structural walls

Owner:STEELER

Top plate

InactiveUS6430881B1Easy to manufactureEasy to installBuilding roofsStrutsMechanical engineeringEngineering

Owner:MITEK HLDG INC

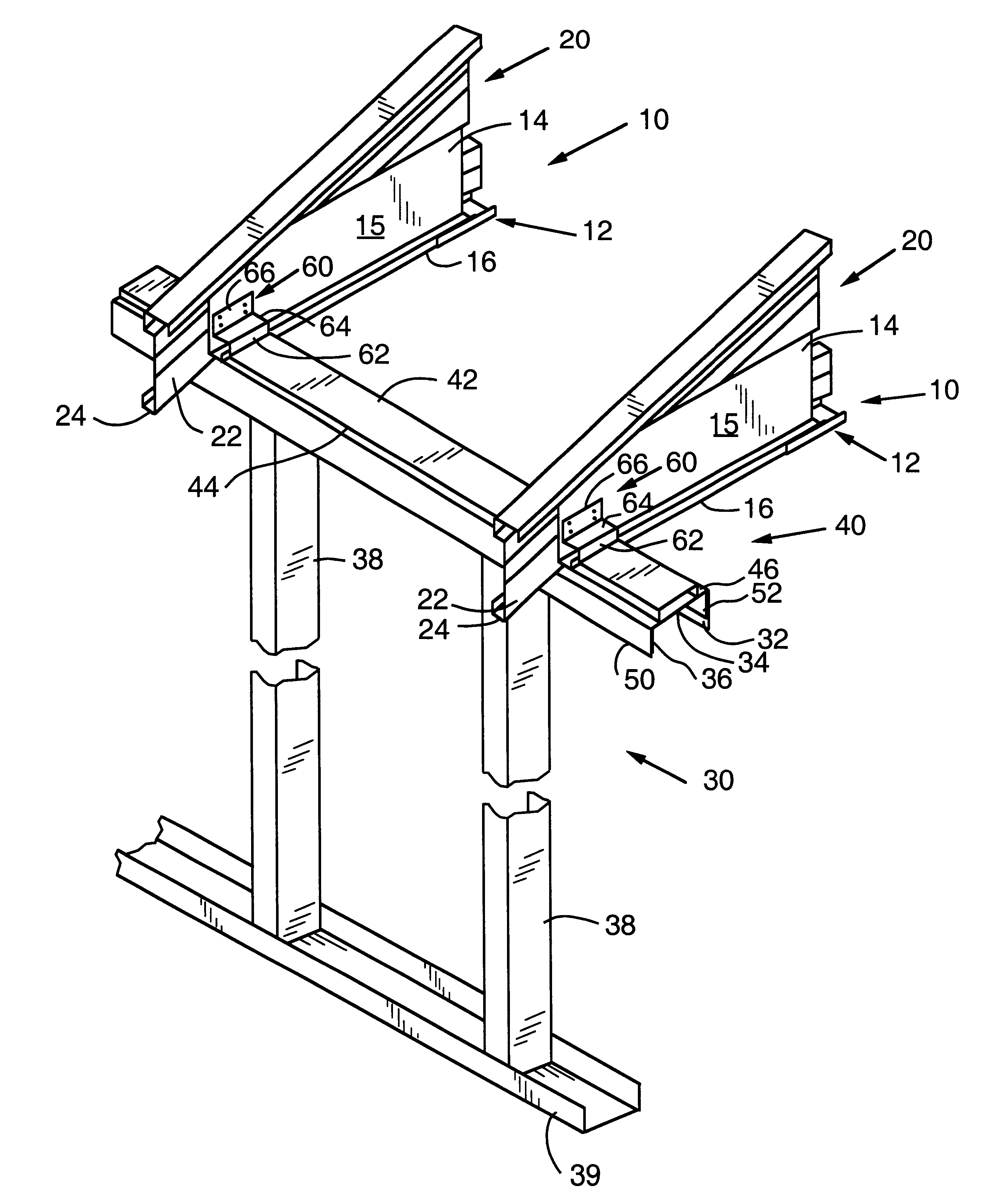

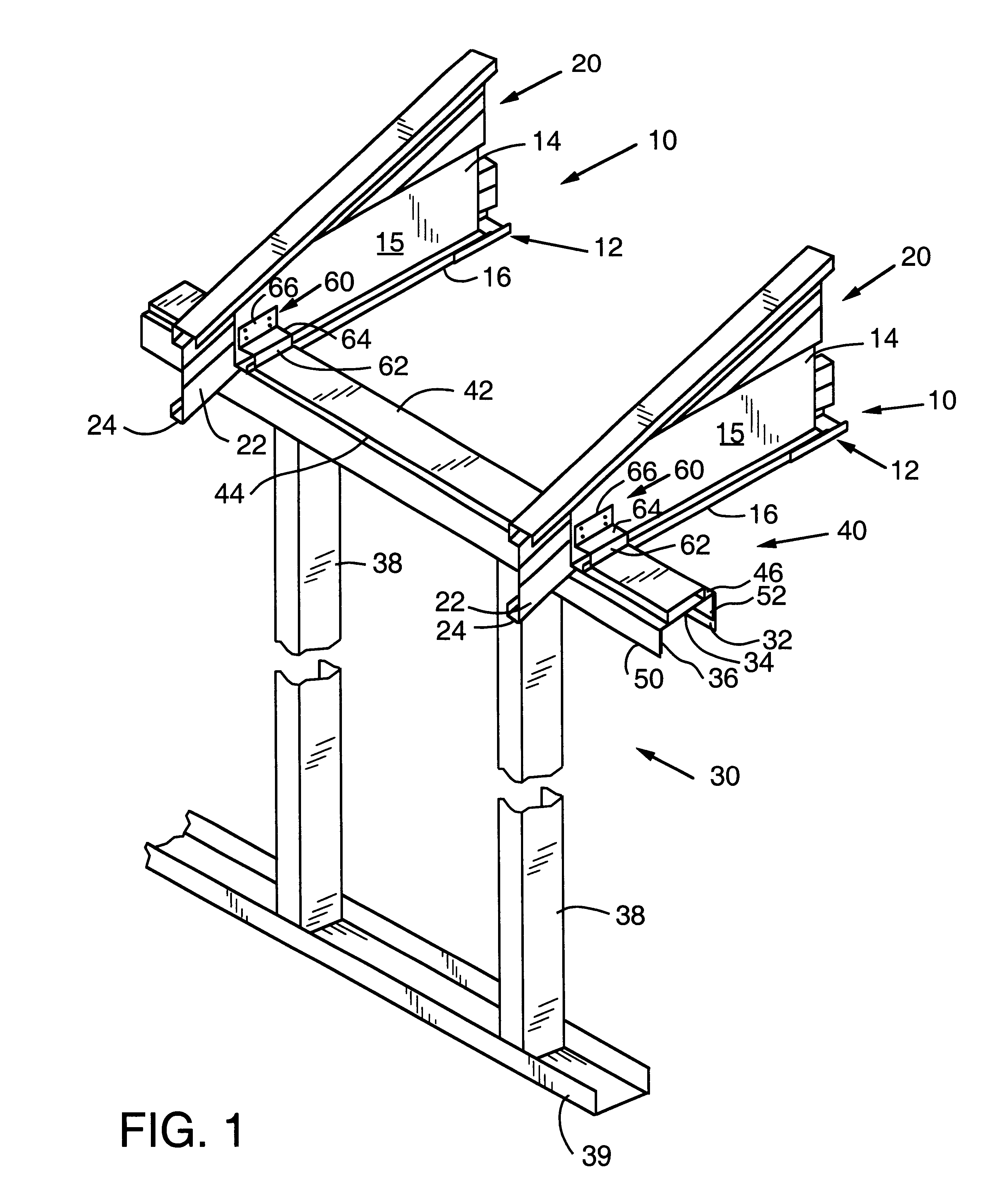

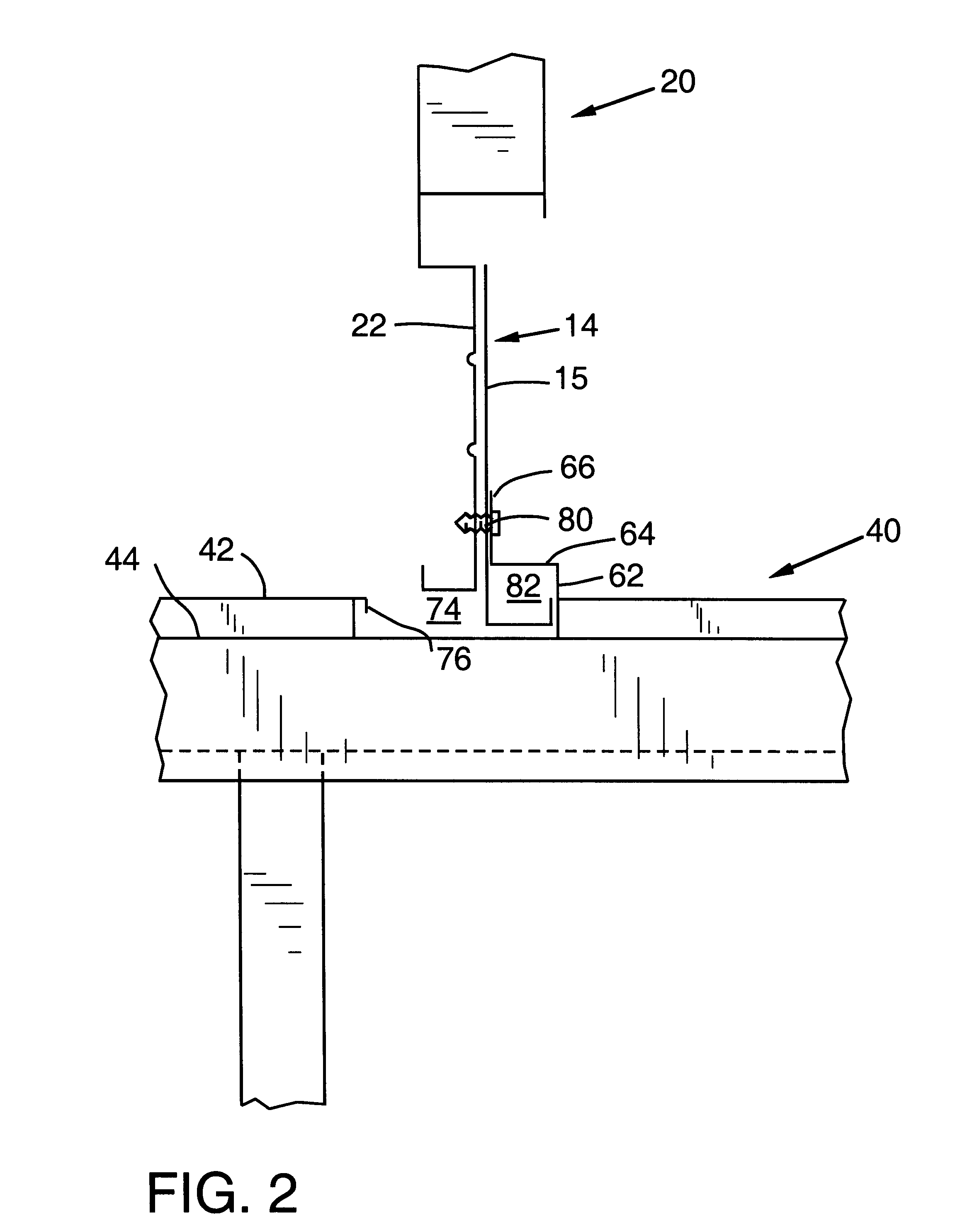

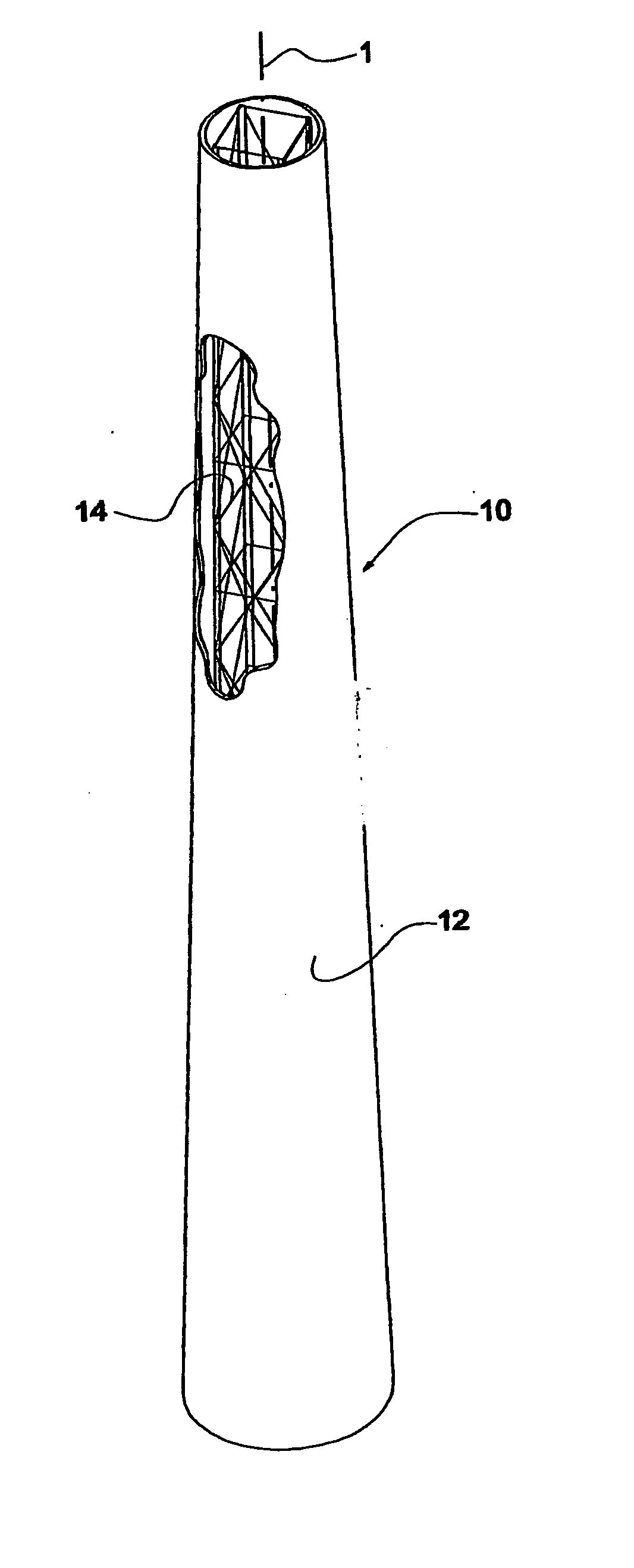

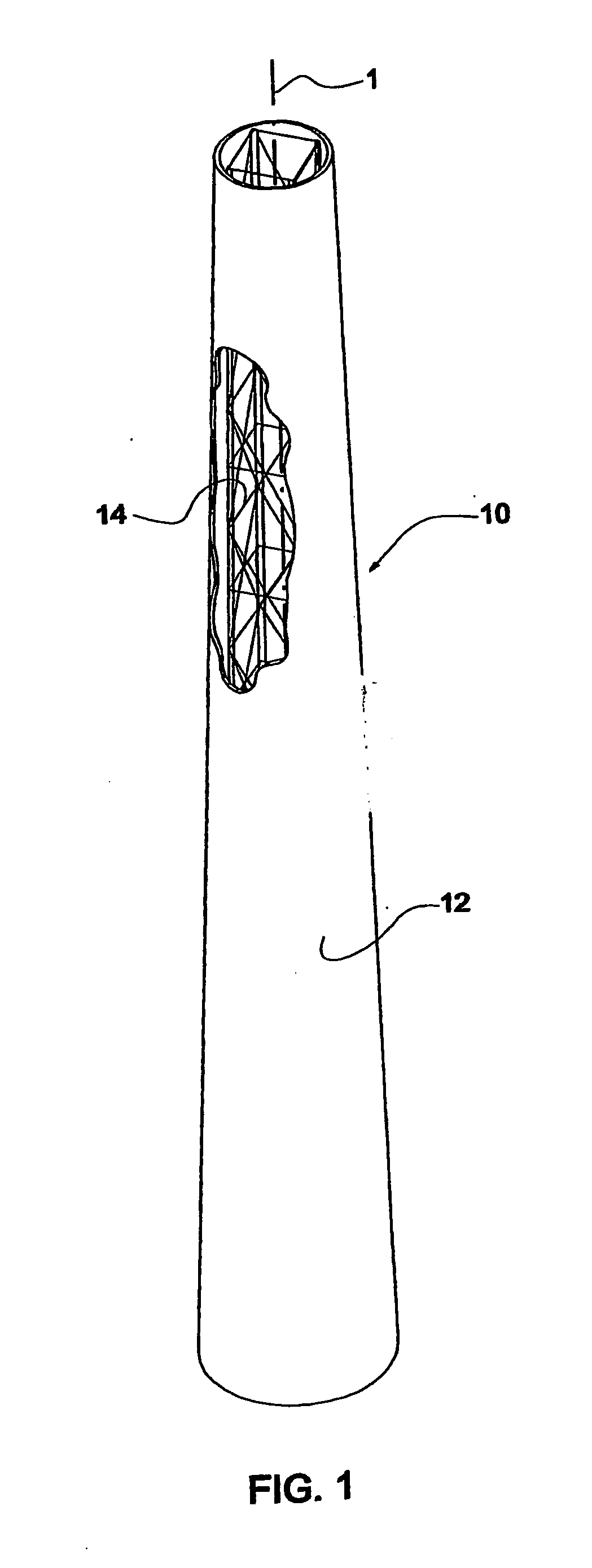

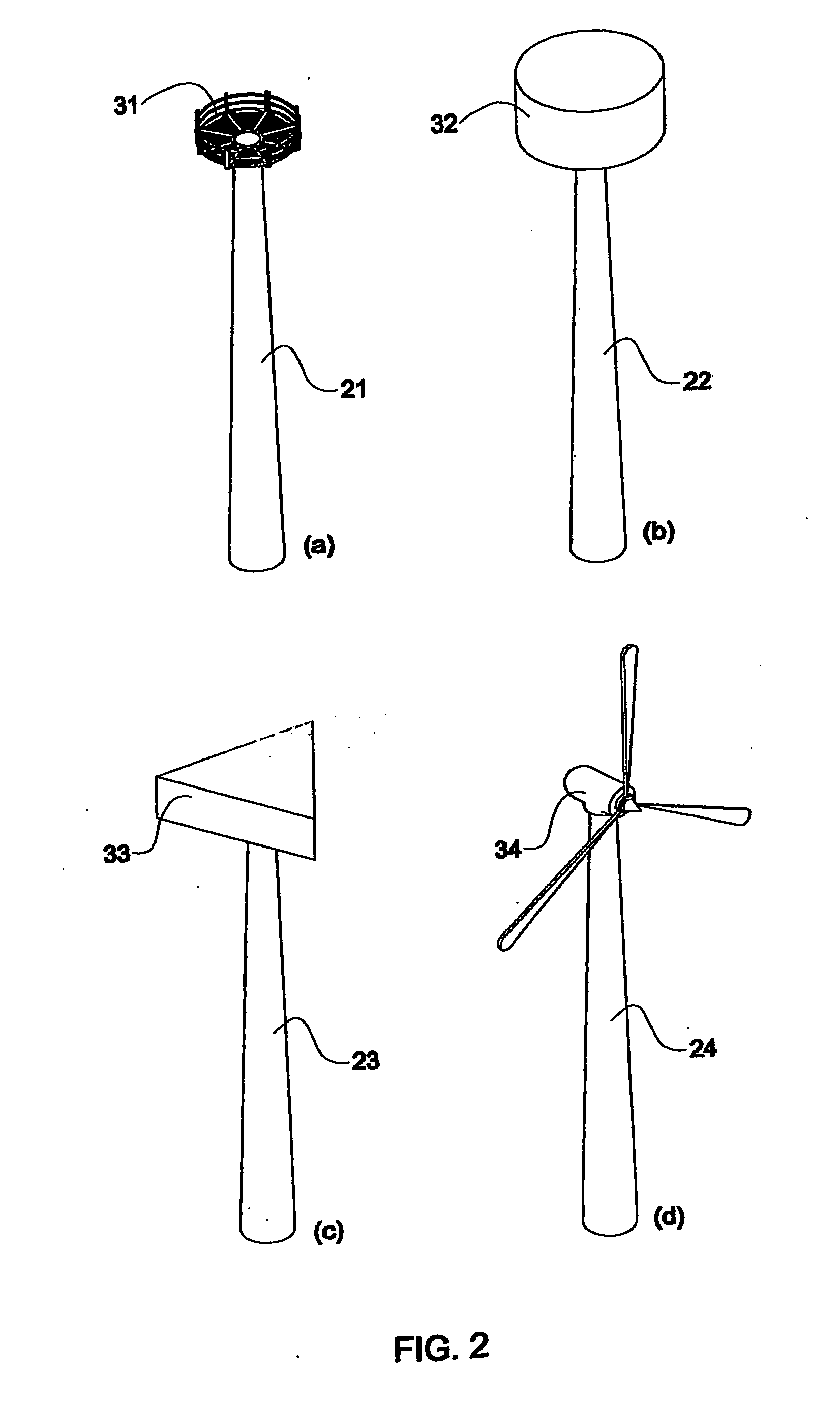

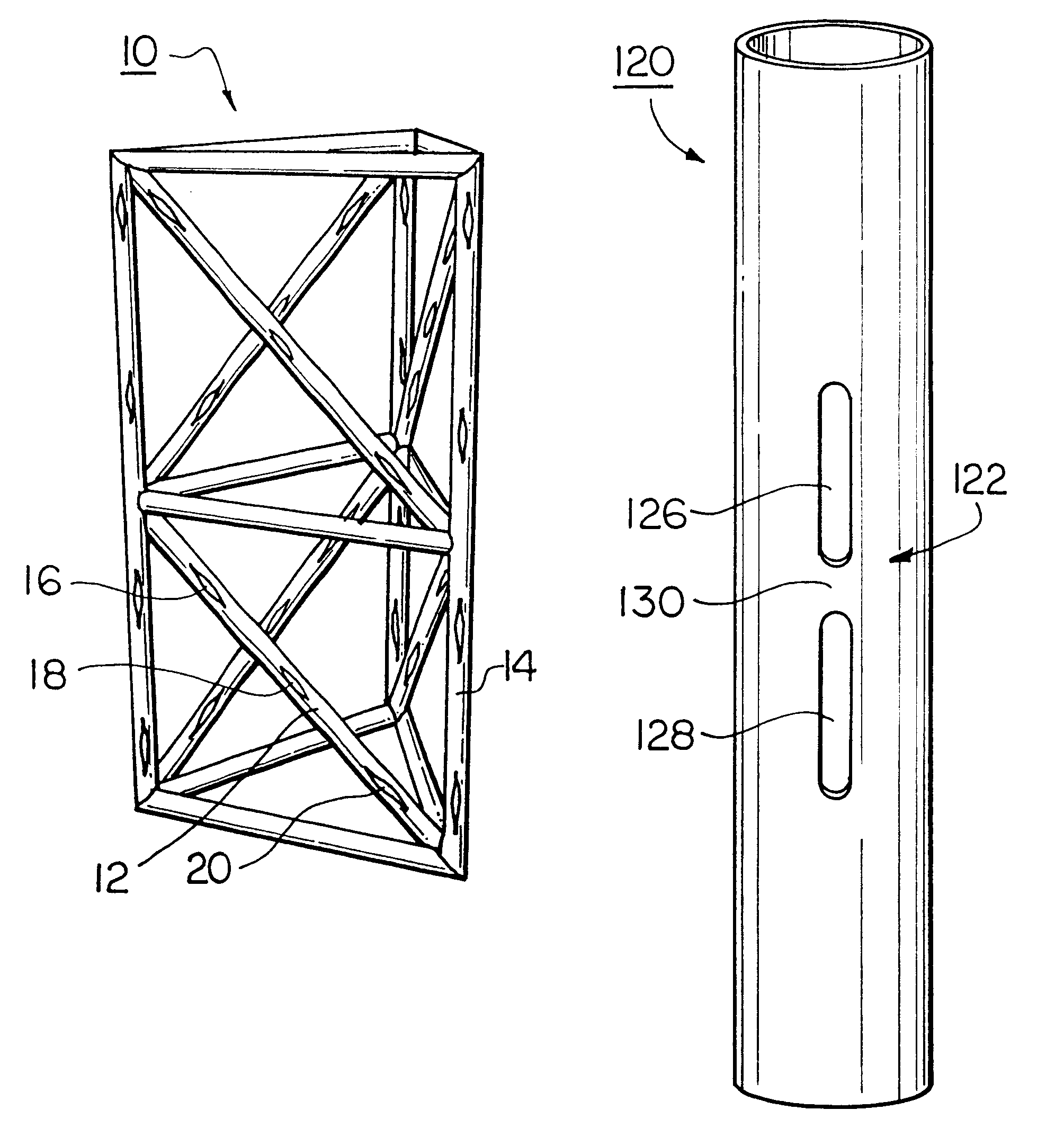

Lattice tower disguised as a monopole

InactiveUS20050166521A1Efficient solutionTransmission of vertical forceFloorsGirdersEngineeringMetal lattice

A solution for a tower (10) that may be substantially tall, characterized by the appearance of a monopole, the capacity to support large objects and consequently sustain great lateral loads generated by wind or earthquake, the facility to conceal vertical access ladder and all other installations, such as antenna feeder cables, and the availability at an acceptable cost level. The heart of the invention is the basic concept of separation between the structurally functioning elements, which are kept concealed, and a non-structural shell (12) which provides the tower (10) the shape of a monopole. The tower (10) comprises, therefore, a tall metal lattice structure (14) having a central vertical axis (1) and certain apparatus for its anchoring to a foundation, concealed within a shell (12) concentric with said central vertical axis (1) and further characterized, at any given level, by a closed cross-section which is either circular or equi-sided polygonal, said shell (12) being internally secured to and supported by said lattice metal structure (14) in an appropriate density throughout its area, so as to maintain its shape when subjected to wind loads or any other likely loads.

Owner:SILBER MEIR

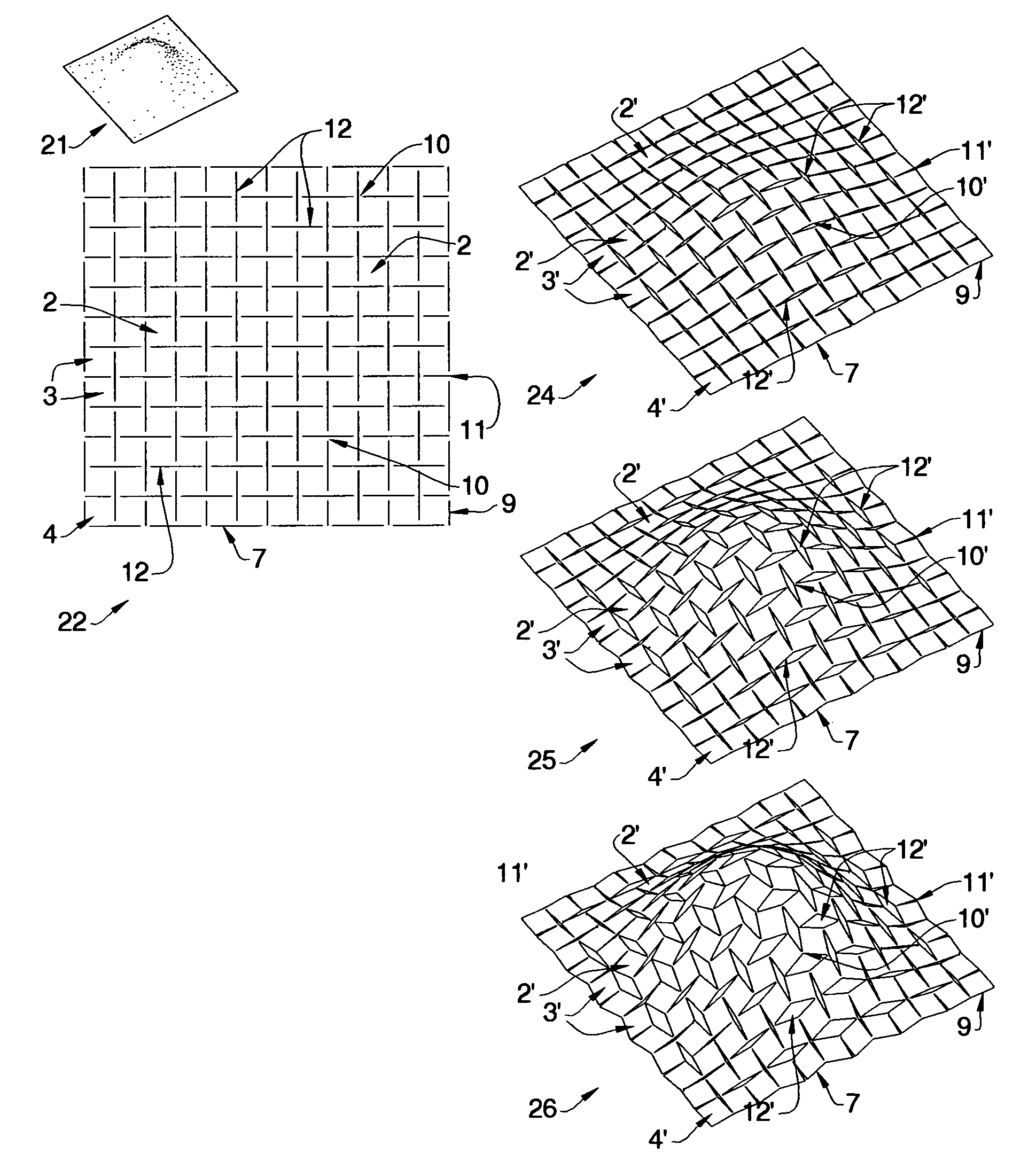

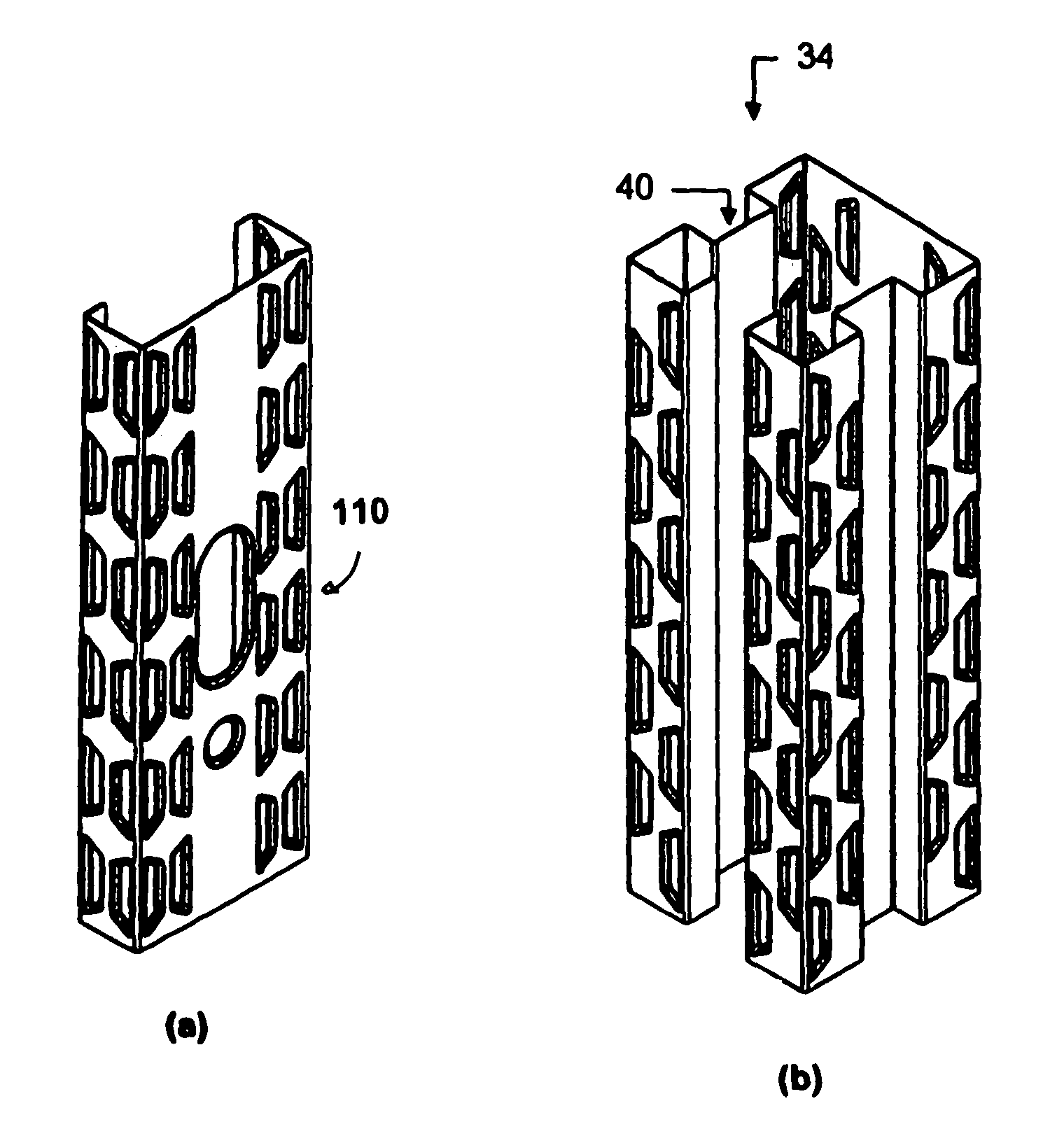

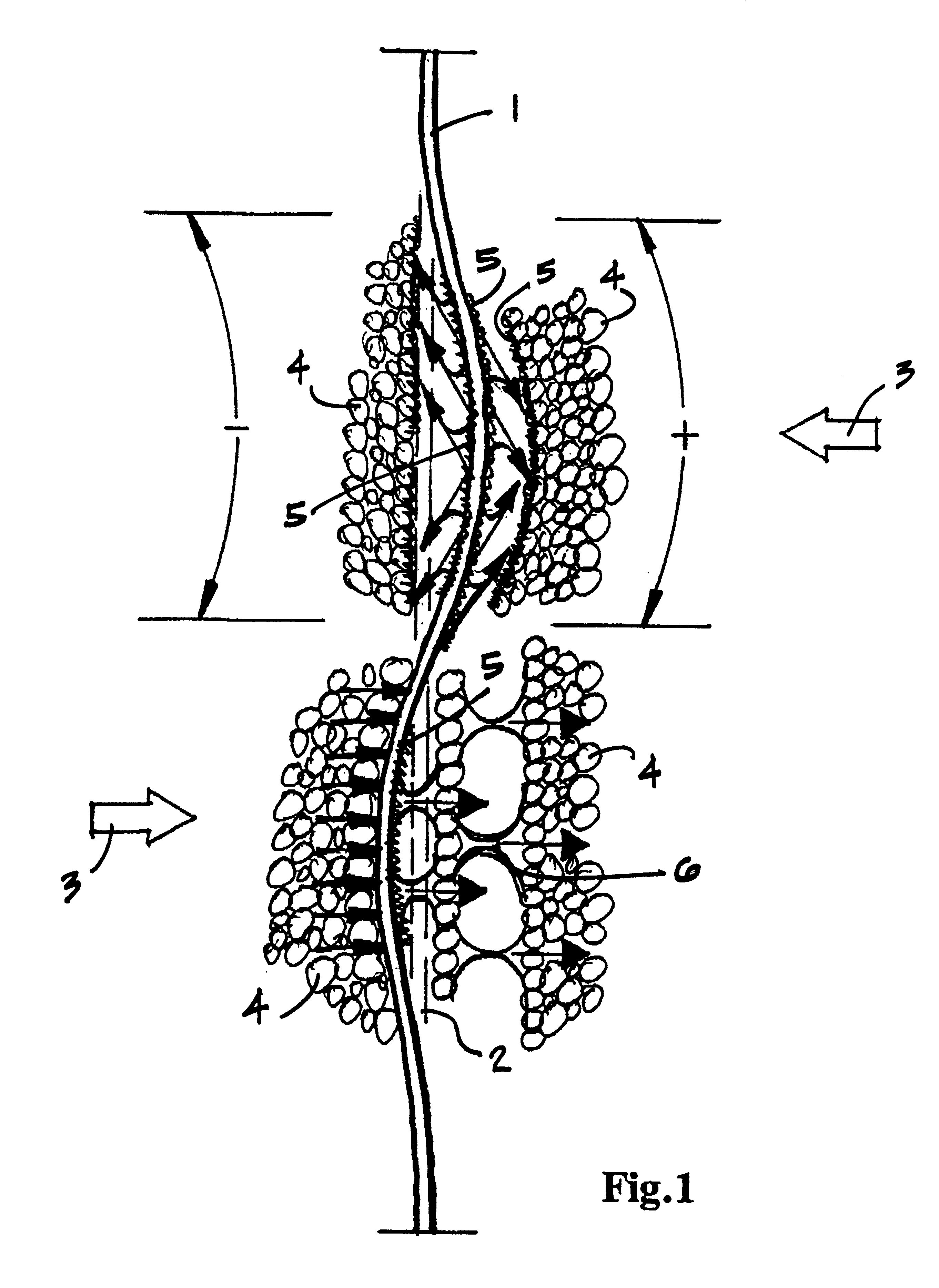

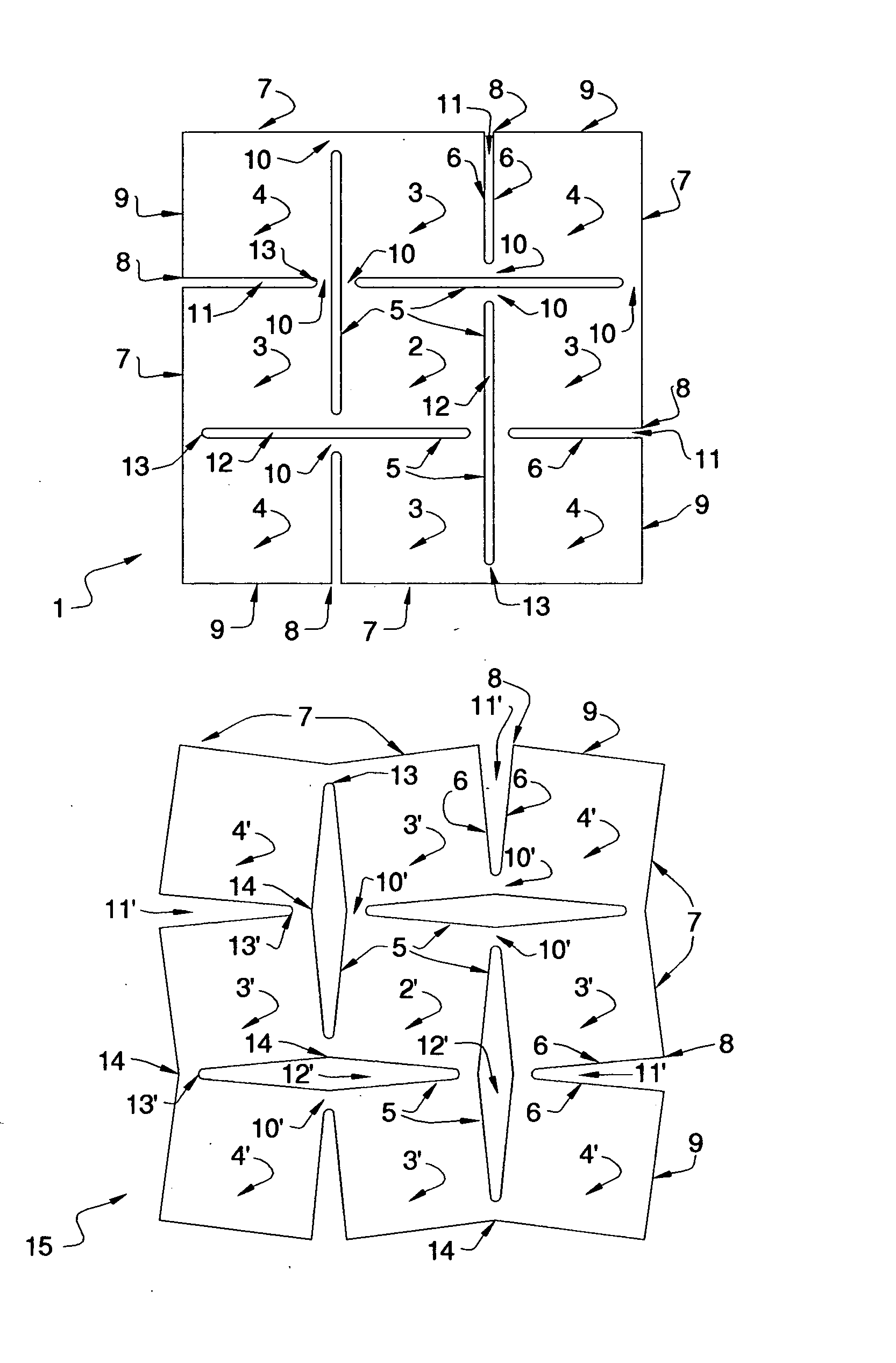

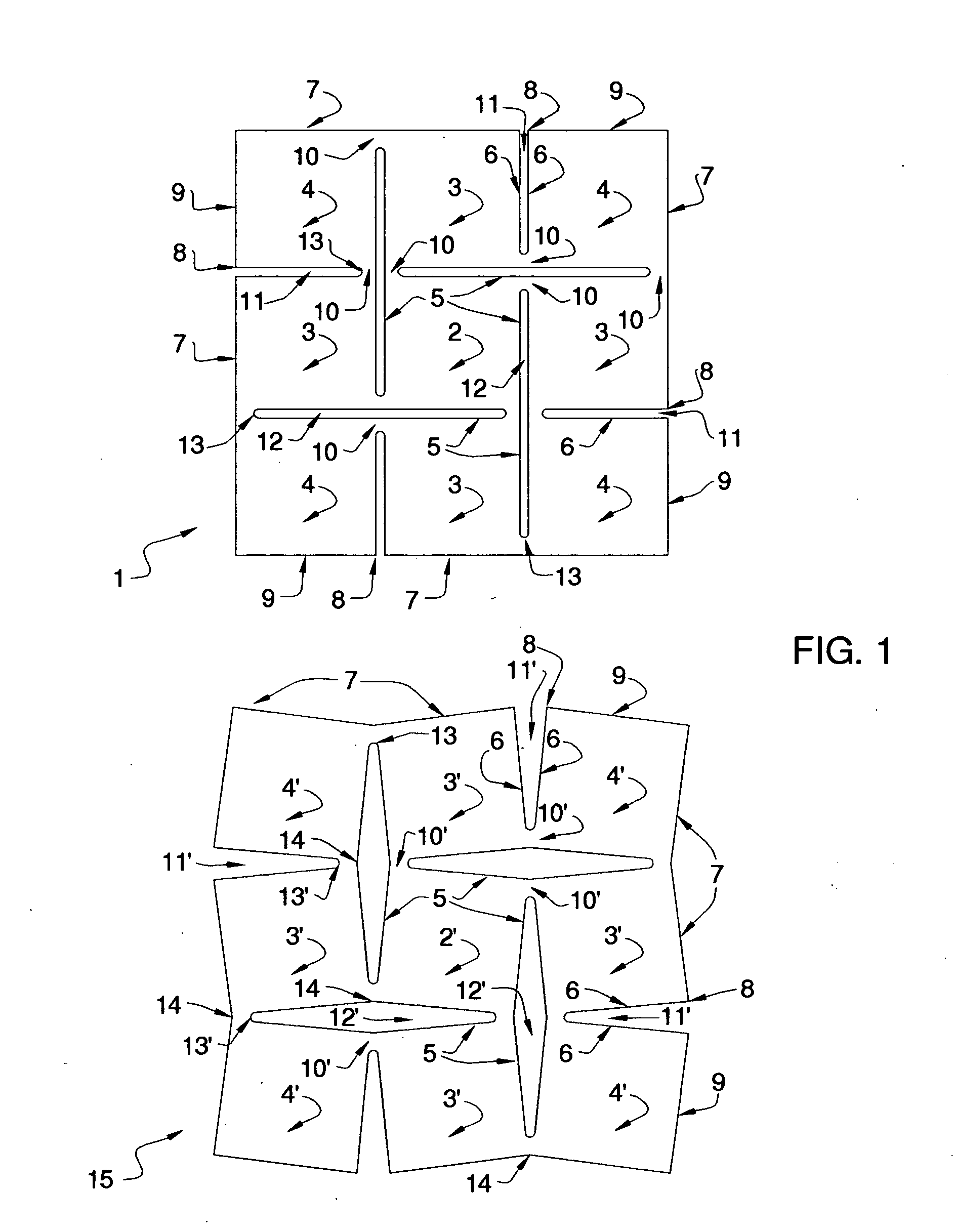

Moment-resistant structure, sustainer and method of resisting episodic loads

The present invention relates to a moment-resistant structure, sustainer, and method of construction for deformably resisting episodic loads, particularly those of high intensity. The episodic loads may be due to earthquake, impact, or other intense episodic sources. The structure and sustainer may be in buildings, bridges, or other civil works, land vehicles, watercraft, aircraft, spacecraft, machinery, or other structural systems or apparati. Deformation capacity is enhanced by the use of multiple dissipative zones. Dissipative zones that function in a manner similar to plastic hinges are determined by one or more voids that are located in the web of a sustainer. The one or more voids are of a size, shape, and configuration to assure that the dissipative zones deform inelastically when a critical stress, i.e., a maximum allowable demand, is reached, thereby developing the action of a structural fuse, preventing the occurrence of stress and strain demands sufficient to cause fracture of the connection welds or adjacent heat-affected zones, i.e., preventing the stress and strain demands from exceeding the strength capacity of the connection welds or adjacent heat-affected zones. The sustainers may be removably connected to the remainder of the structure, facilitating their replacement after inelastic deformation. The structure, sustainer, and method of construction may be utilized in new construction and in the rehabilitation of existing construction. Mechanical equipment and utilities may pass through the voids.

Owner:ASCHHEIM MARK AMOS

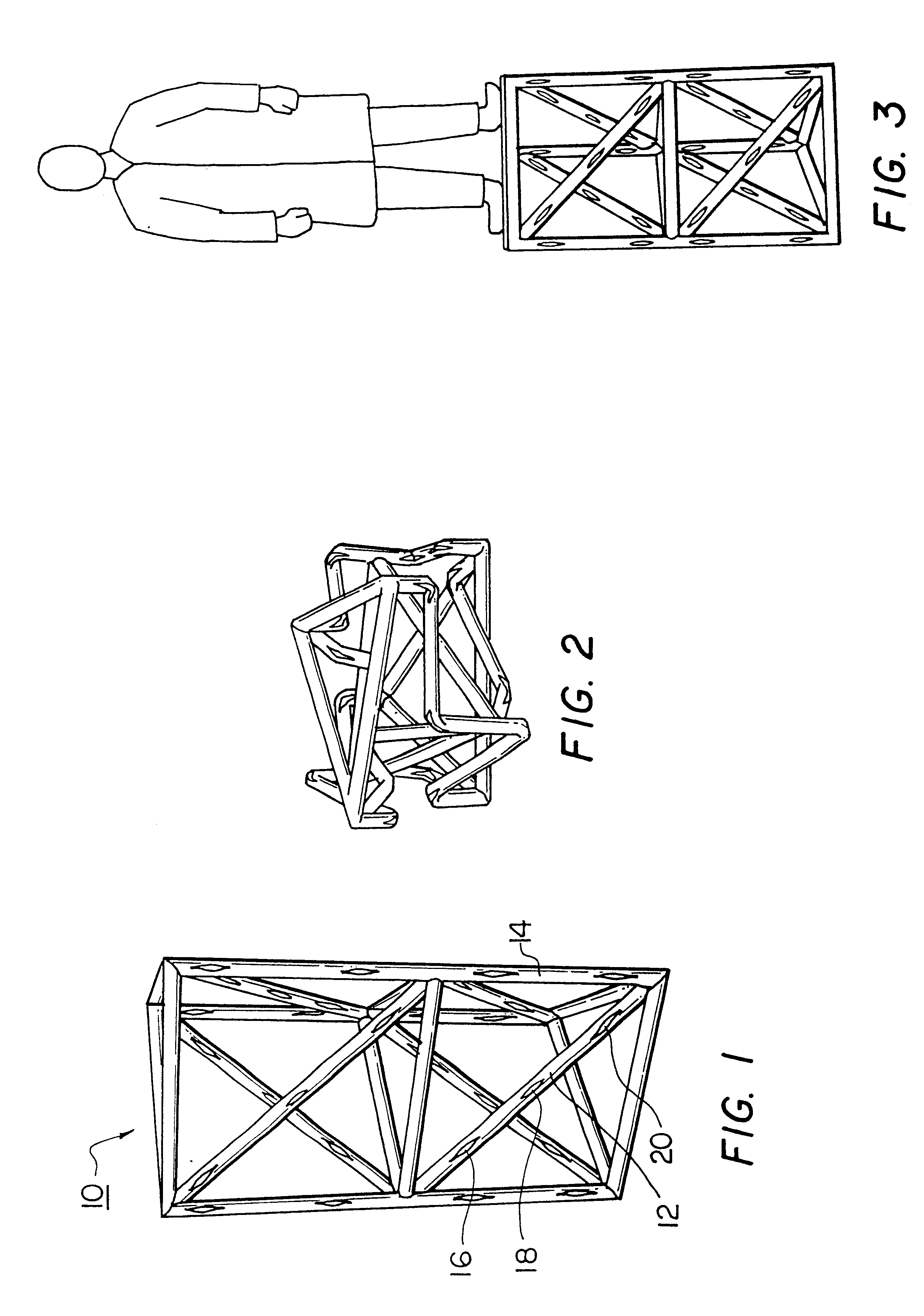

Foldable member

InactiveUS6374565B1Weight increaseDimensional instabilityBuilding roofsCosmonautic vehiclesMechanical engineeringEngineering

Owner:FOSTER-MILLER

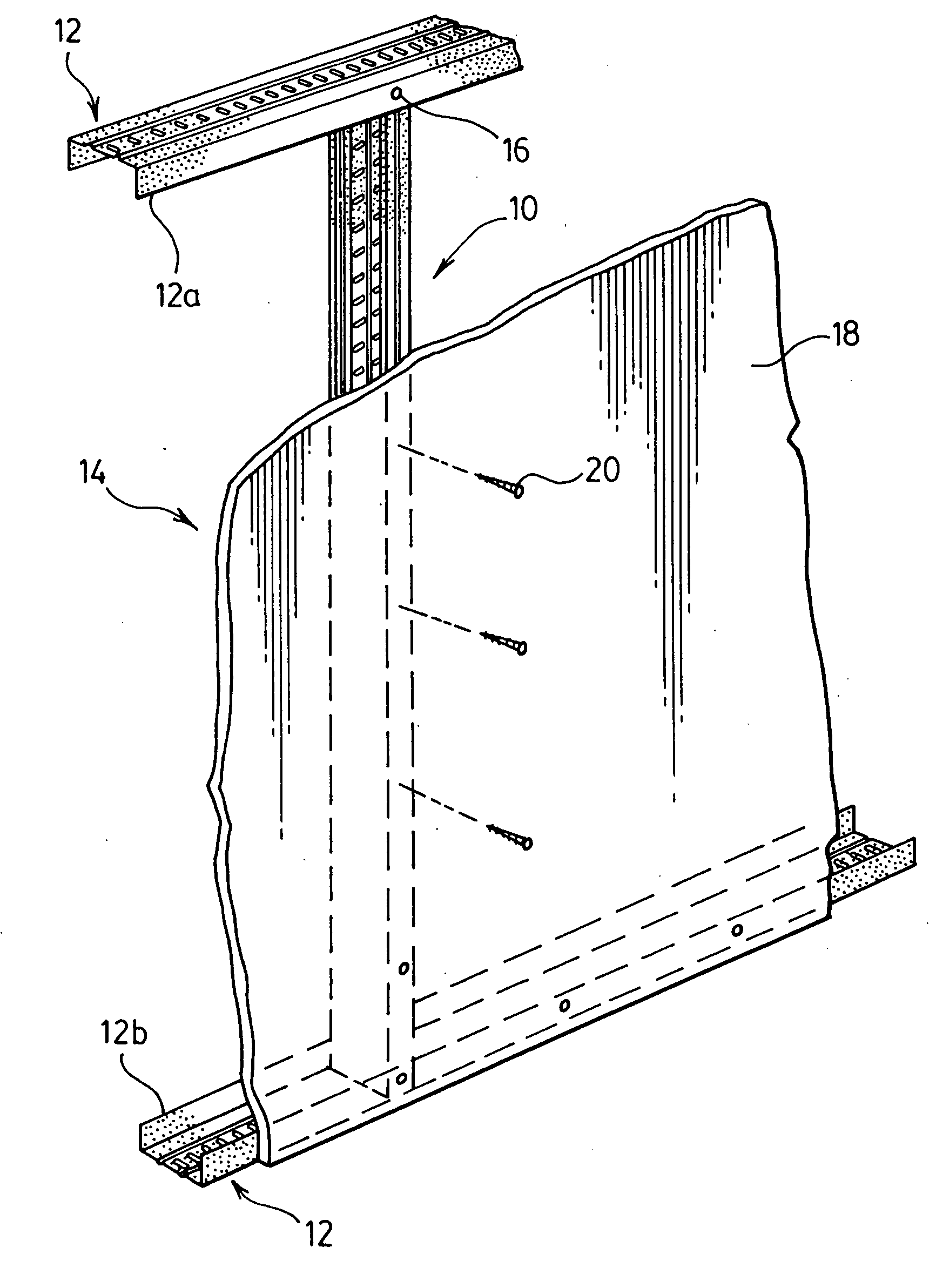

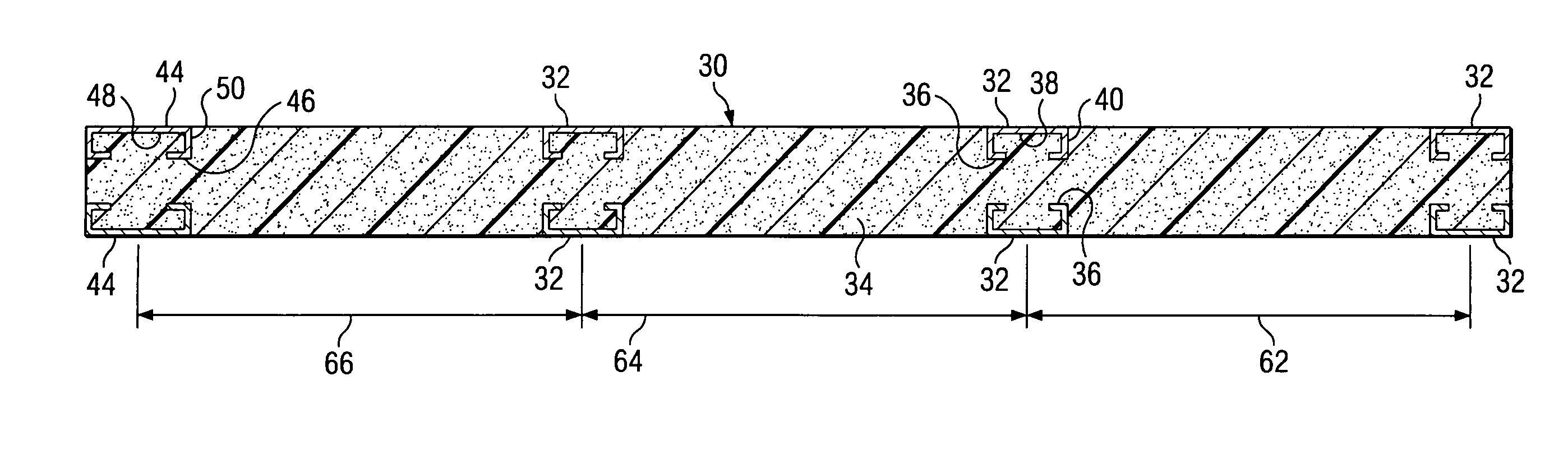

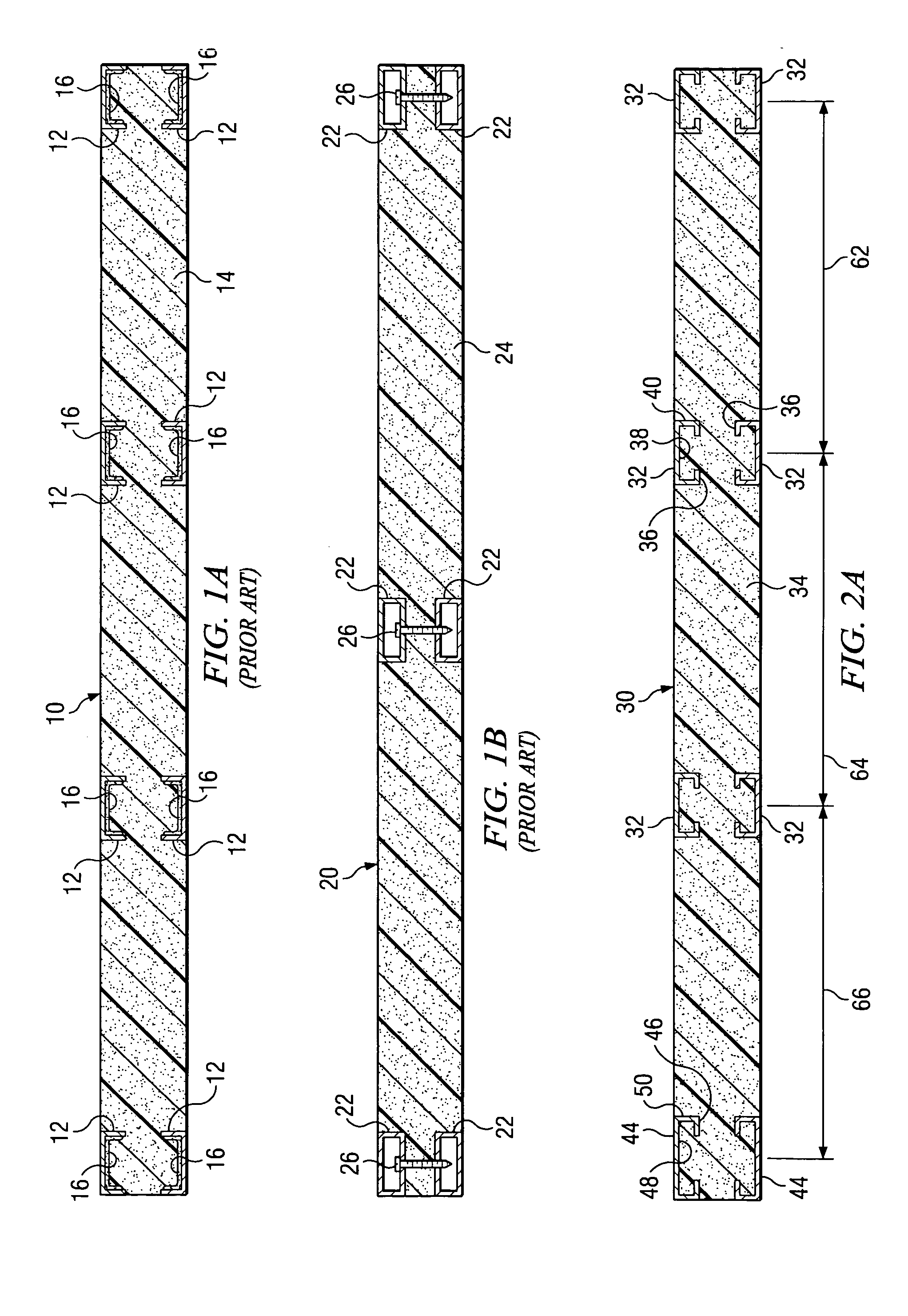

Insulated structural building panel and assembly system

An insulated structural building panel and header system, comprising a rectangular panel body molded of a rigid foam material and a plurality of elongated, channel-shaped framing members oriented parallel to each other and embedded during molding in each first and second face of the panel body. Each framing member is retained in place in the panel body by return lips formed into first and second edges of an open side of the framing members without the use of adhesive or mechanical fasteners. The panels may include utility recesses formed in one face of the panel and mortised edges for keying the panels securely together. The panels may be formed with alternate framing member spacings. Auxiliary framing members are disclosed having T and L shaped cross sections for joining panels together or reinforcing the panels to support greater loads.

Owner:RUE JERRY RANDALL

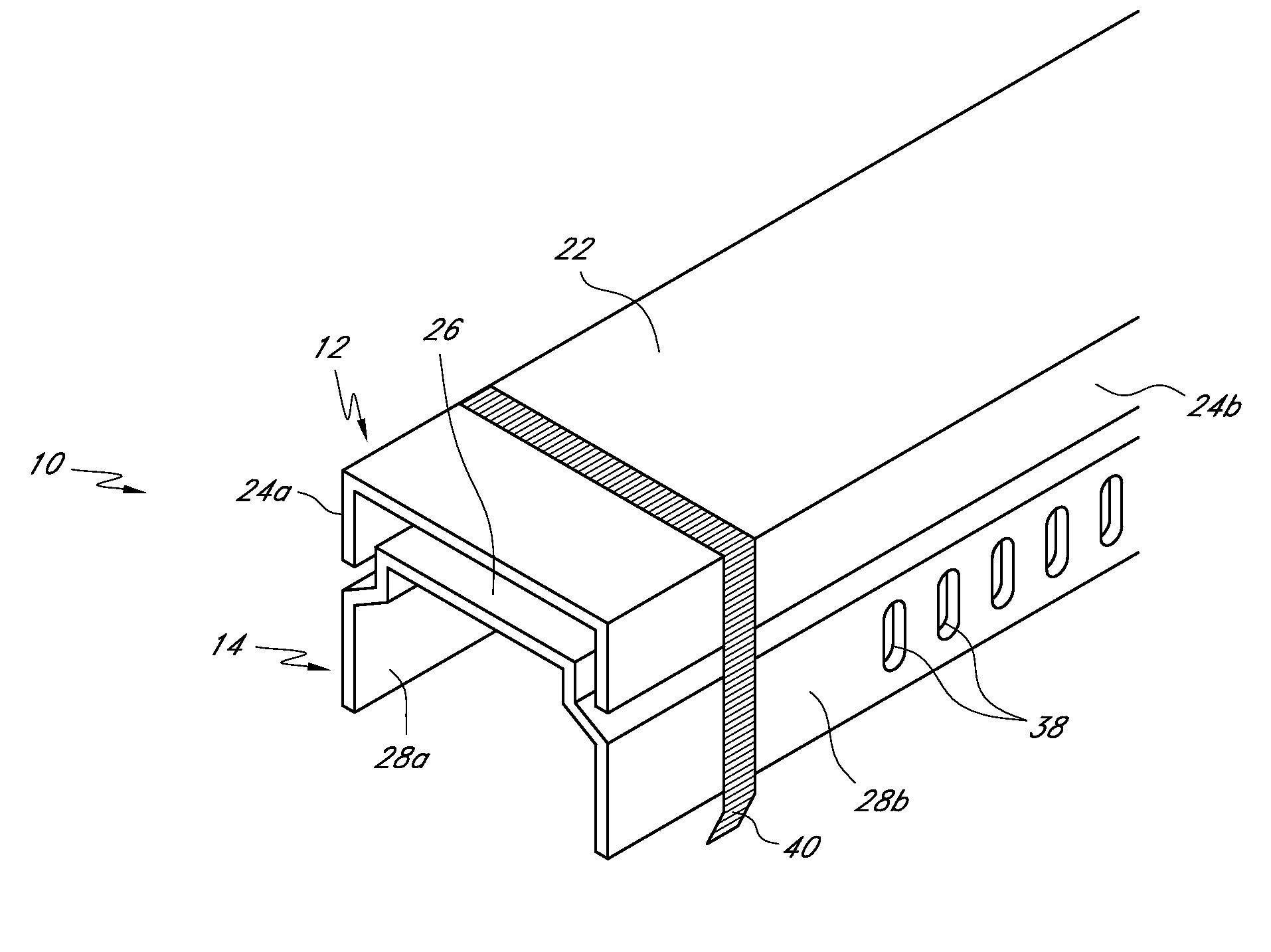

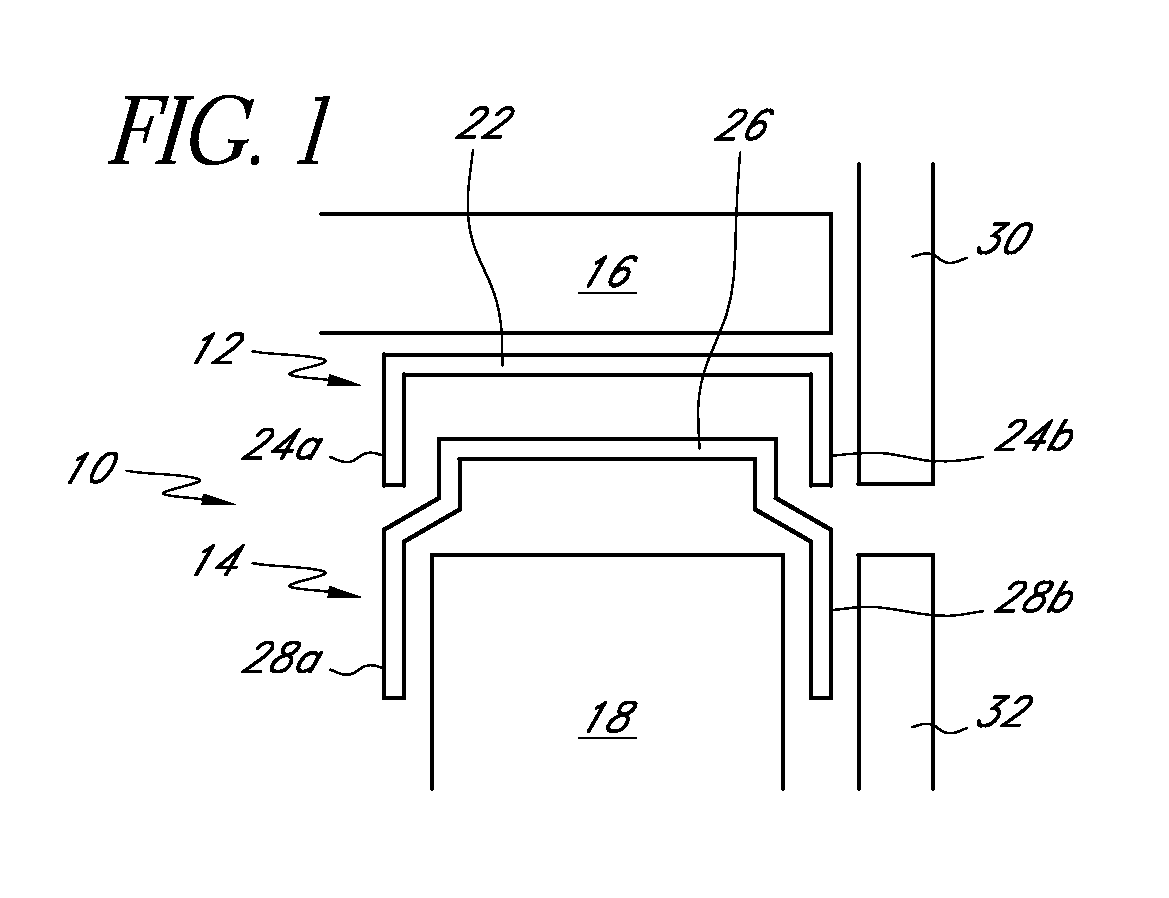

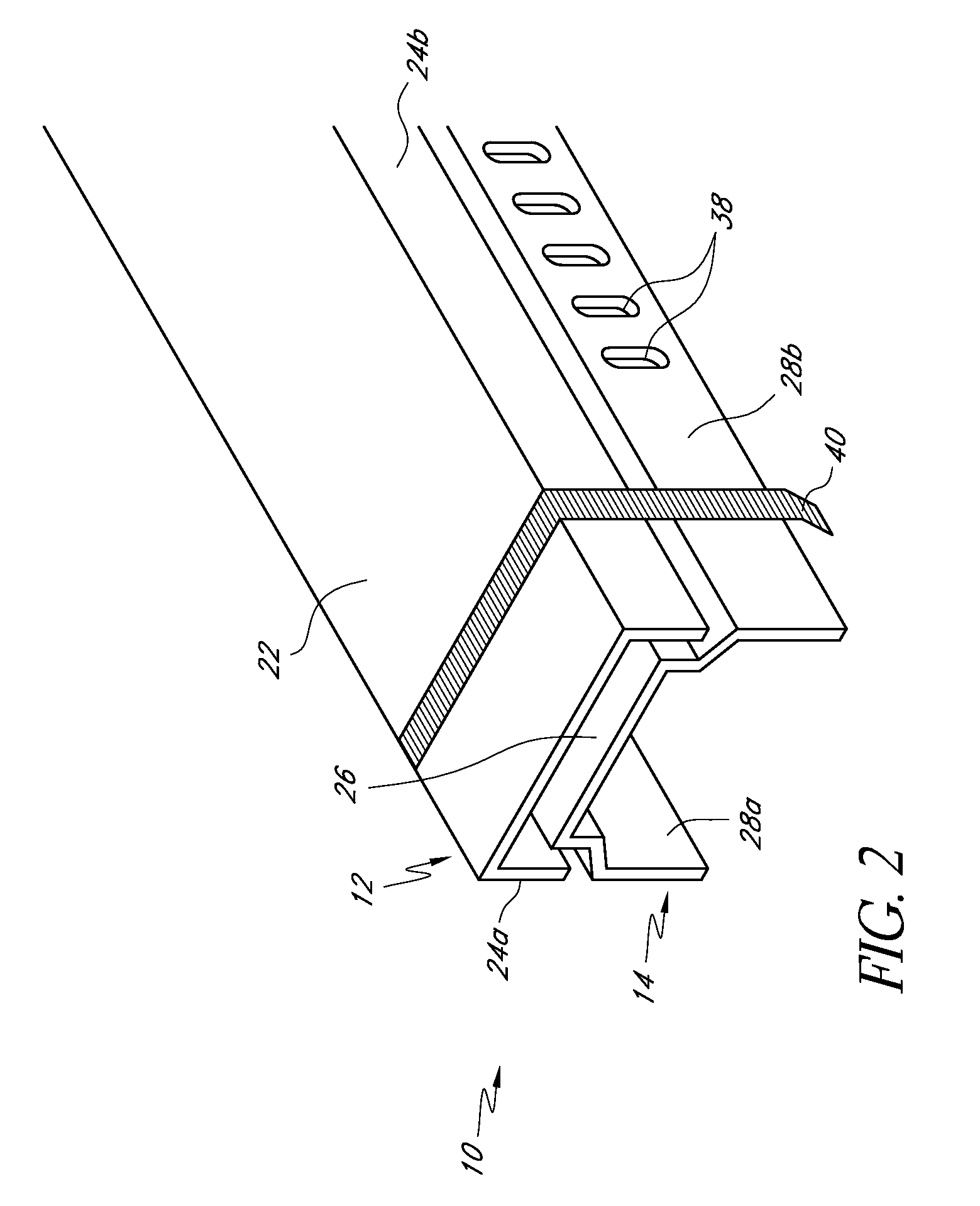

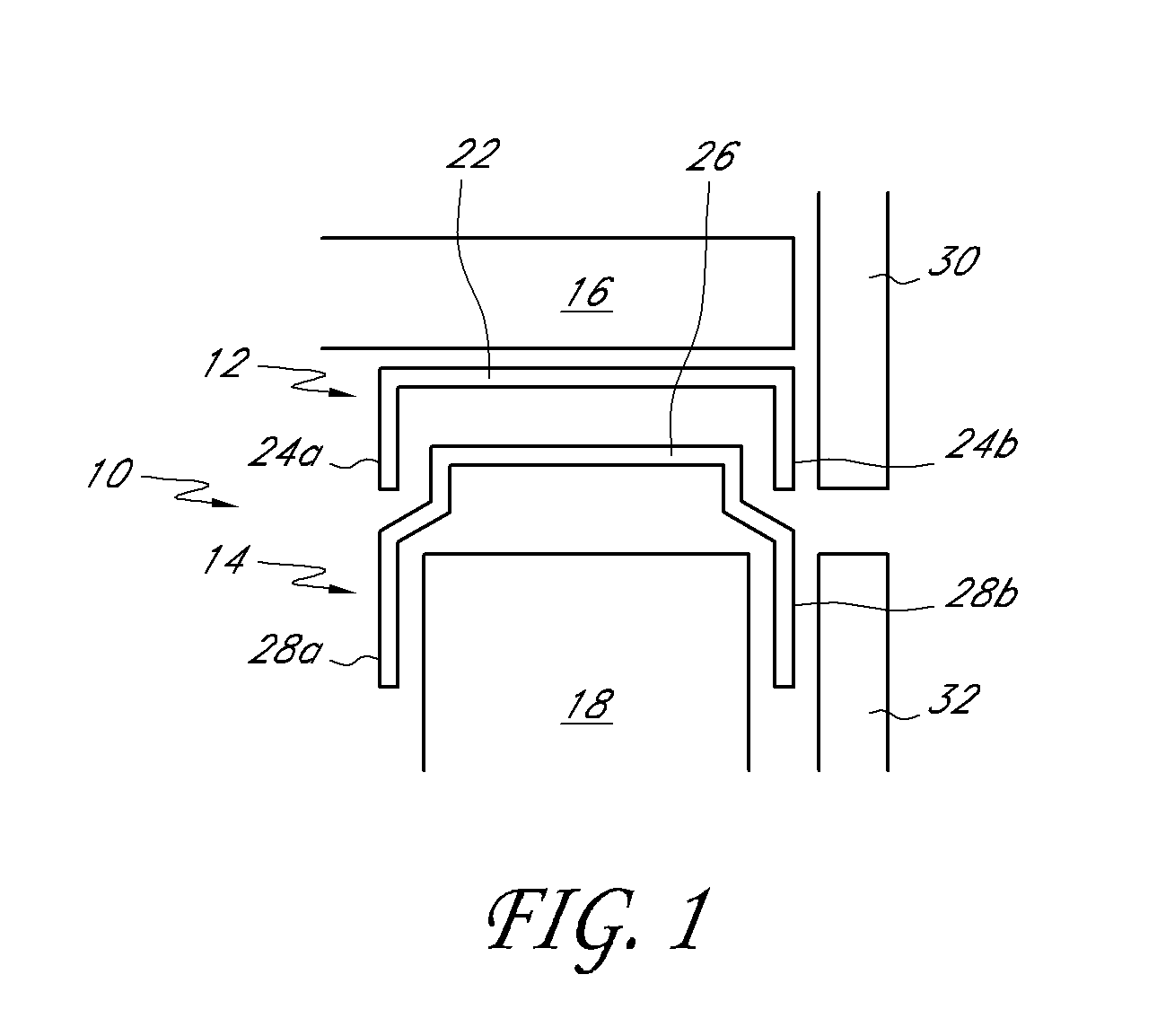

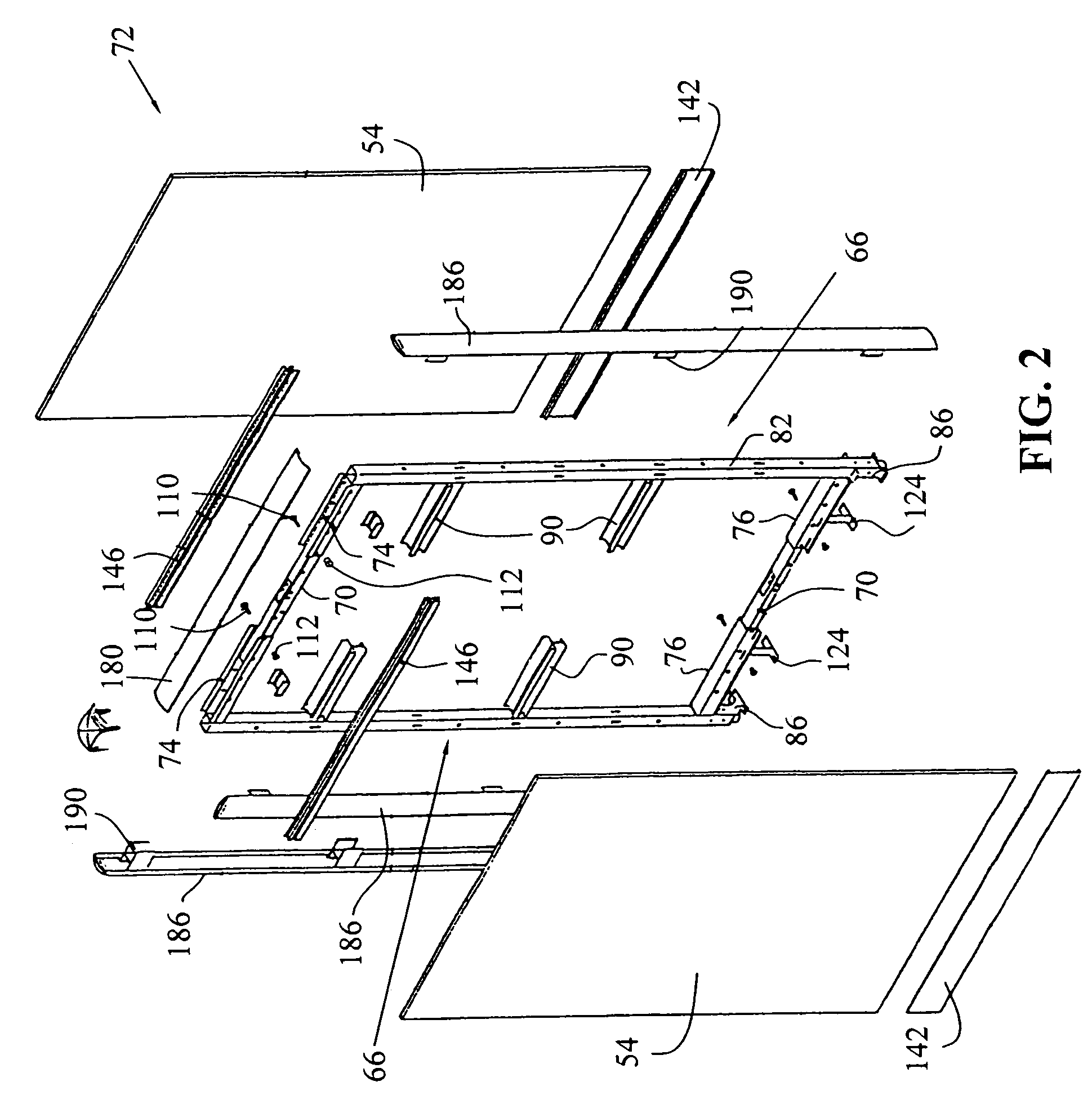

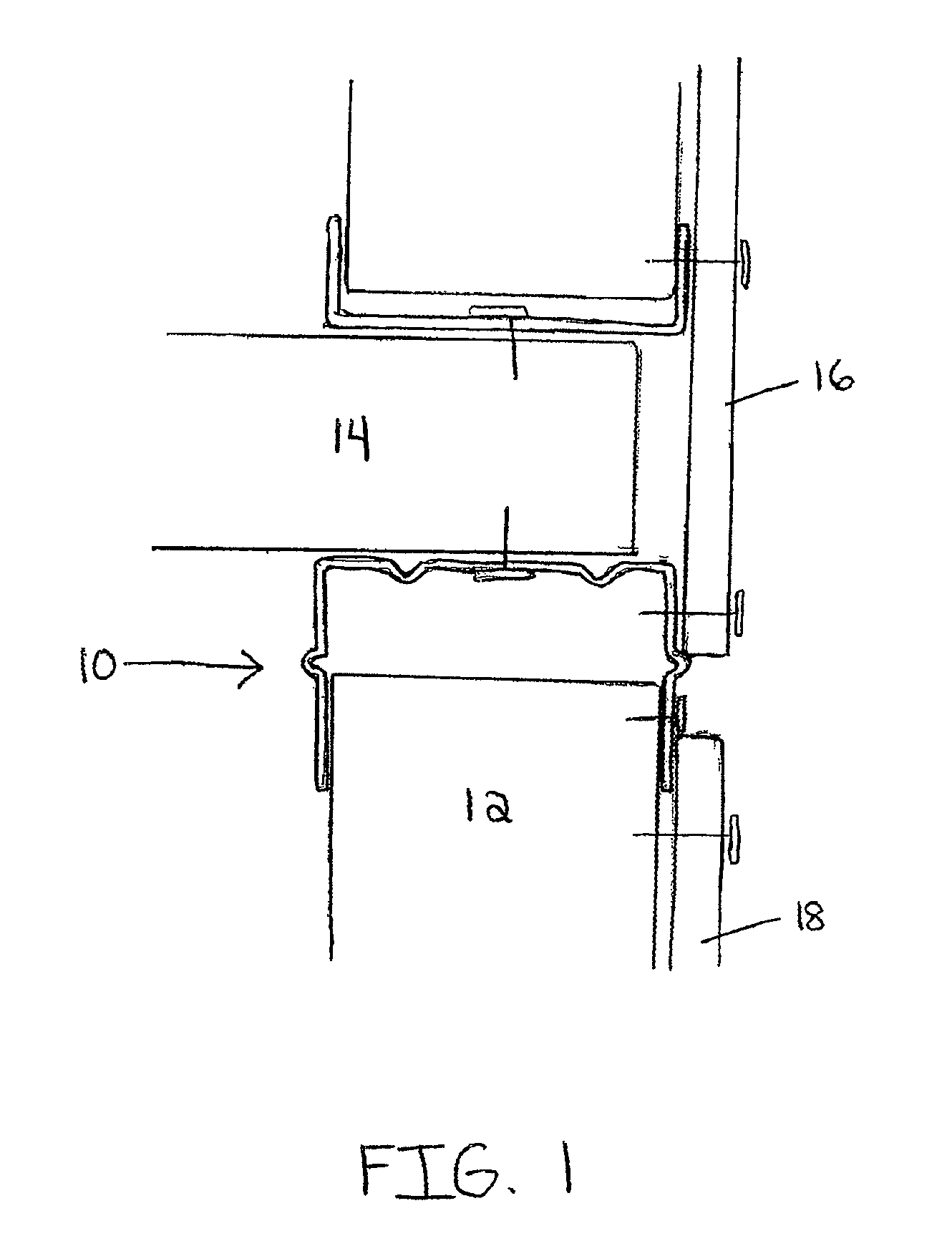

Two-piece track system

The present invention is directed toward a track assembly comprising two nested tracks, an inner track and outer track. The assembly is designed so that the outside width of the outer track is equal to or less than the outside width of the inner track to present a substantially flush external surface for attachment of exterior sheathing elements when the assembly is used in an external wall. The system may further comprise a strap or series of engaging surfaces on the inner and outer tracks that generally restrain the inner track relative to the outer track.

Owner:CALIFORNIA EXPANDED METAL PRODS

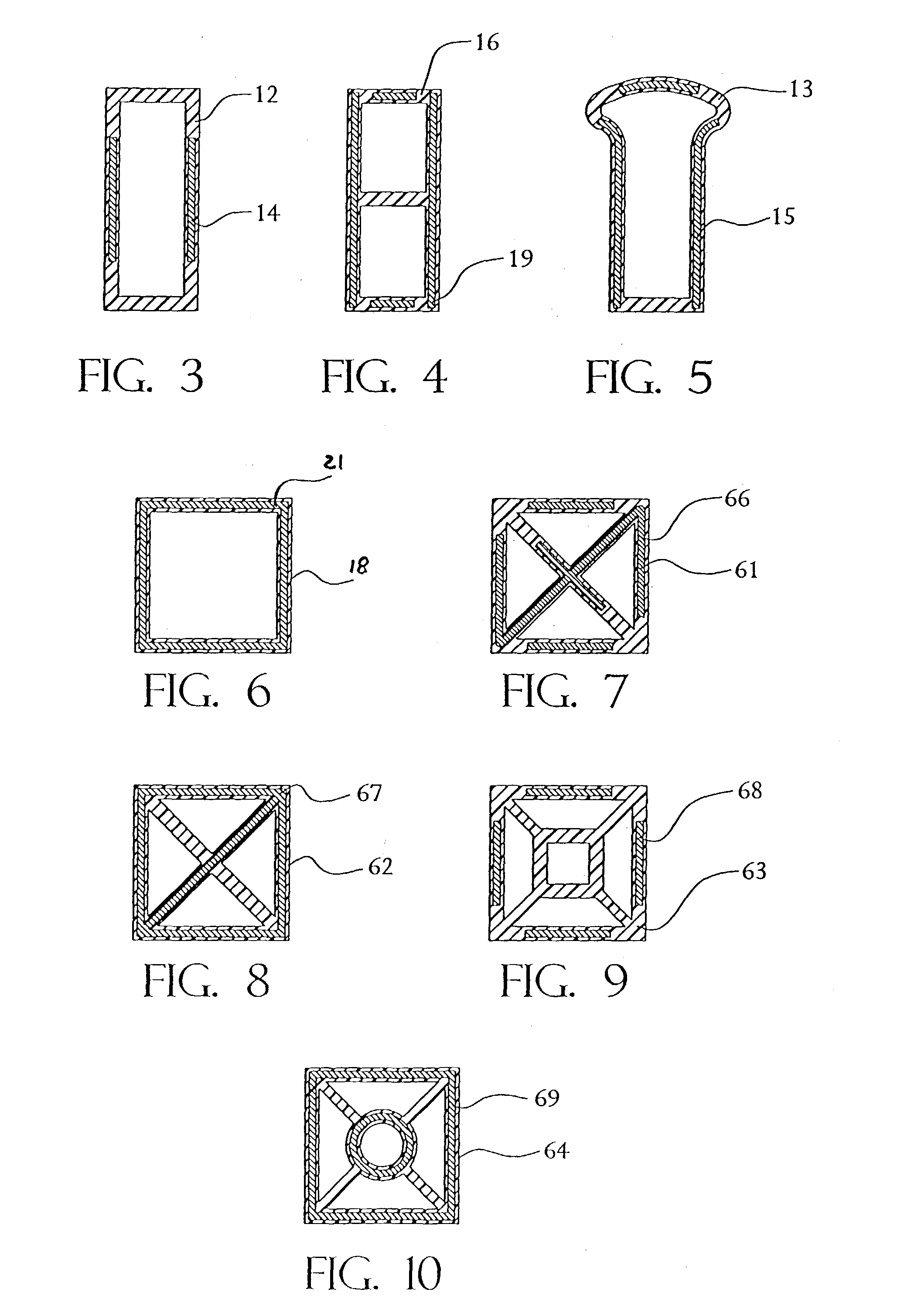

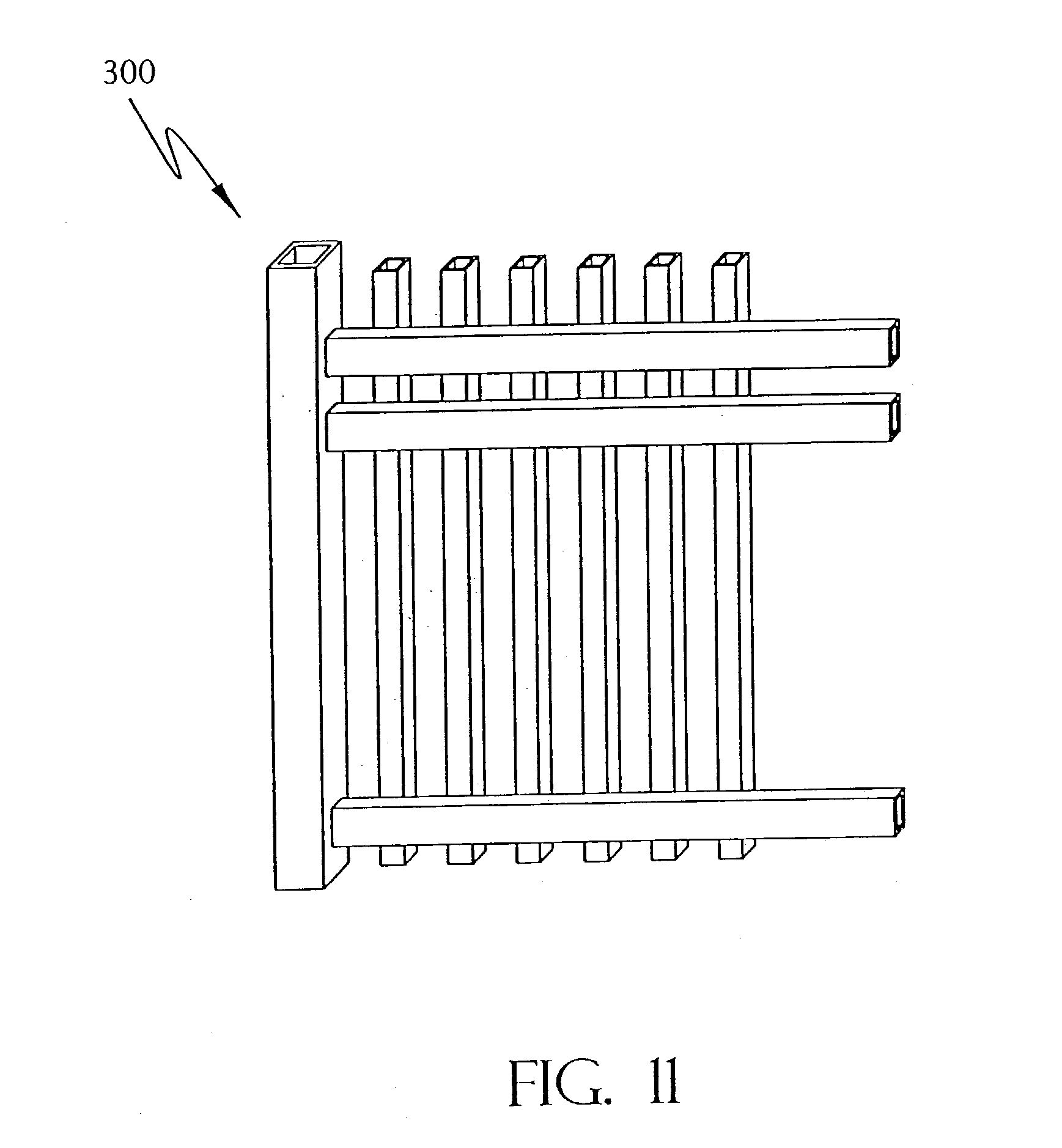

Plastic rail system and other building products reinforced with polymer matrix composites

InactiveUS20040009338A1Reduce air pressureBalustersSynthetic resin layered productsBuilding productUltimate tensile strength

Polymeric building materials are provided which include a composite reinforcement comprising continuous filaments of fibers substantially oriented in at least a first direction within a polymeric matrix. The composite reinforcement includes a higher tensile strength and a lower rigidity than aluminum. The building material further includes a capstock polymeric material disposed substantially over the composite reinforcement. The building material is resistant to heat deformation and corrosion. This invention also includes methods for constructing such polymeric composite building materials, including in the preferred embodiments, pultrusion and extrusion steps.

Owner:CERTAINTEED CORP

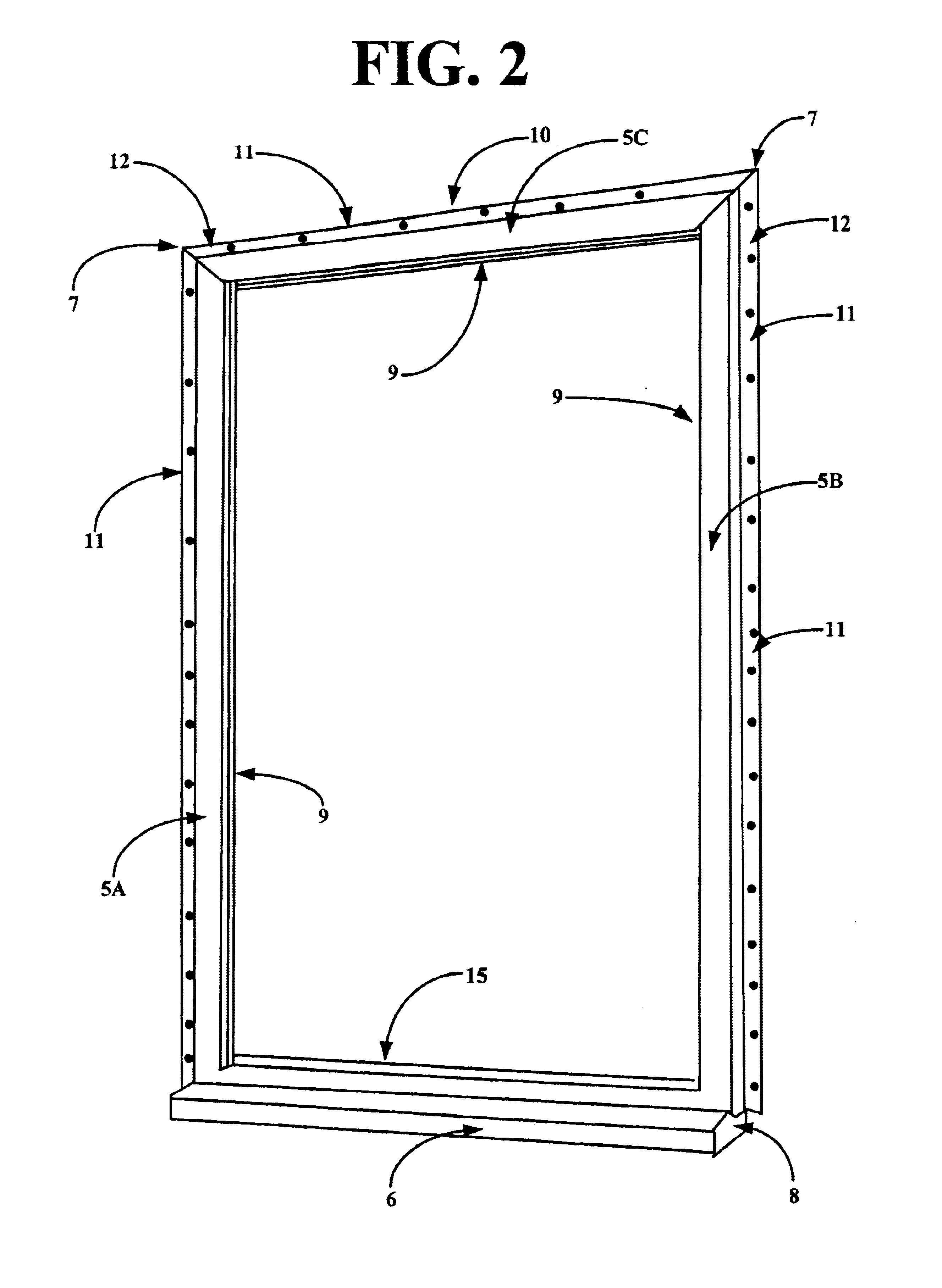

Window and door casing

InactiveUS6857232B2Simple to fitEasy to installWindow/door framesSills/thresholdMechanical engineeringEngineering

Owner:RIVERSIDE MILLWORK

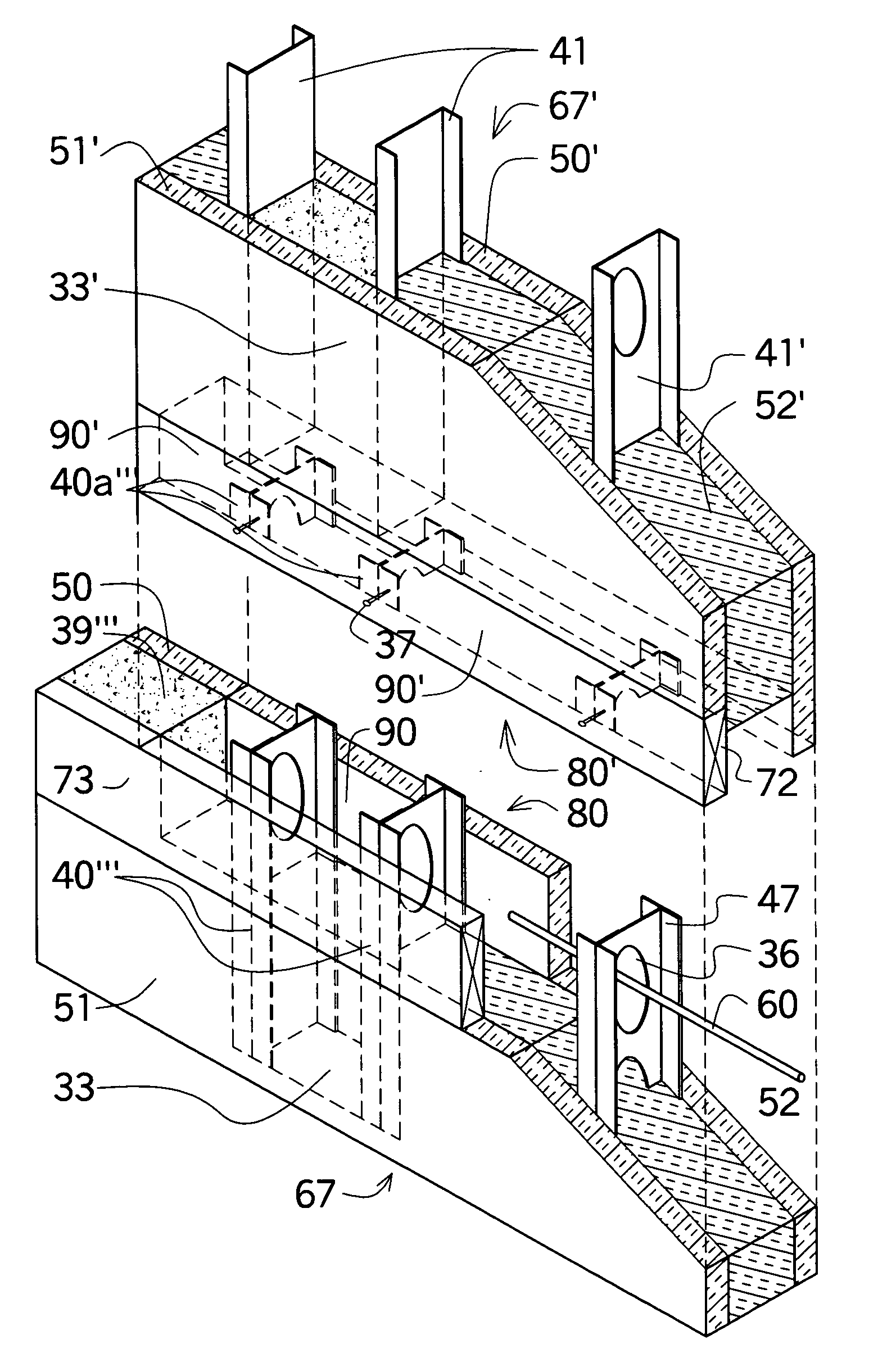

Building construction for forming columns and beams within a wall mold

InactiveUS20090107065A1Simple structureGood adhesionWallsHeat proofingConcrete beamsStructural insulated panel

The present invention relates to an improved wall system where a wall form mold has a structural insulated core assembled to form a structural insulated panel (SIP) to form a concrete beam and concrete column to be poured anywhere within the wall as well as between building modules when placed together and erected vertically. The interlocking wall molds interlock within the wall as well as between panels and modules. The wall panels allow concrete columns and beams to be formed in any size and shape. The structural insulated core consists of interlocking foam spacers and support channels which can be glued or screwed together to form an independent wall or as part of a precast wall with columns and beams integrated within the wall panels. Insulated flanges within the wall forming mold separates the wall forming structure from the wall surfaces.

Owner:LEBLANG DENNIS WILLIAM

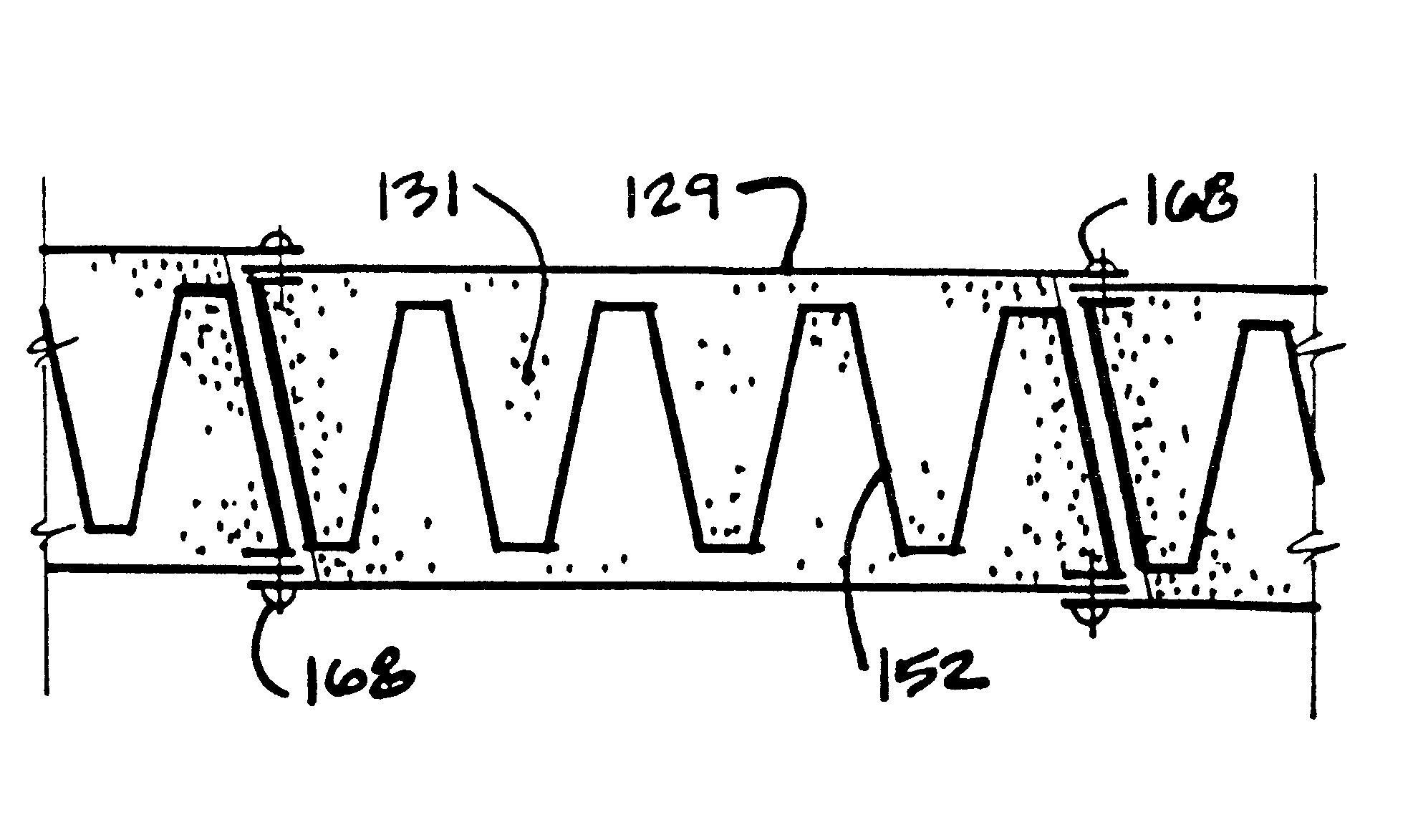

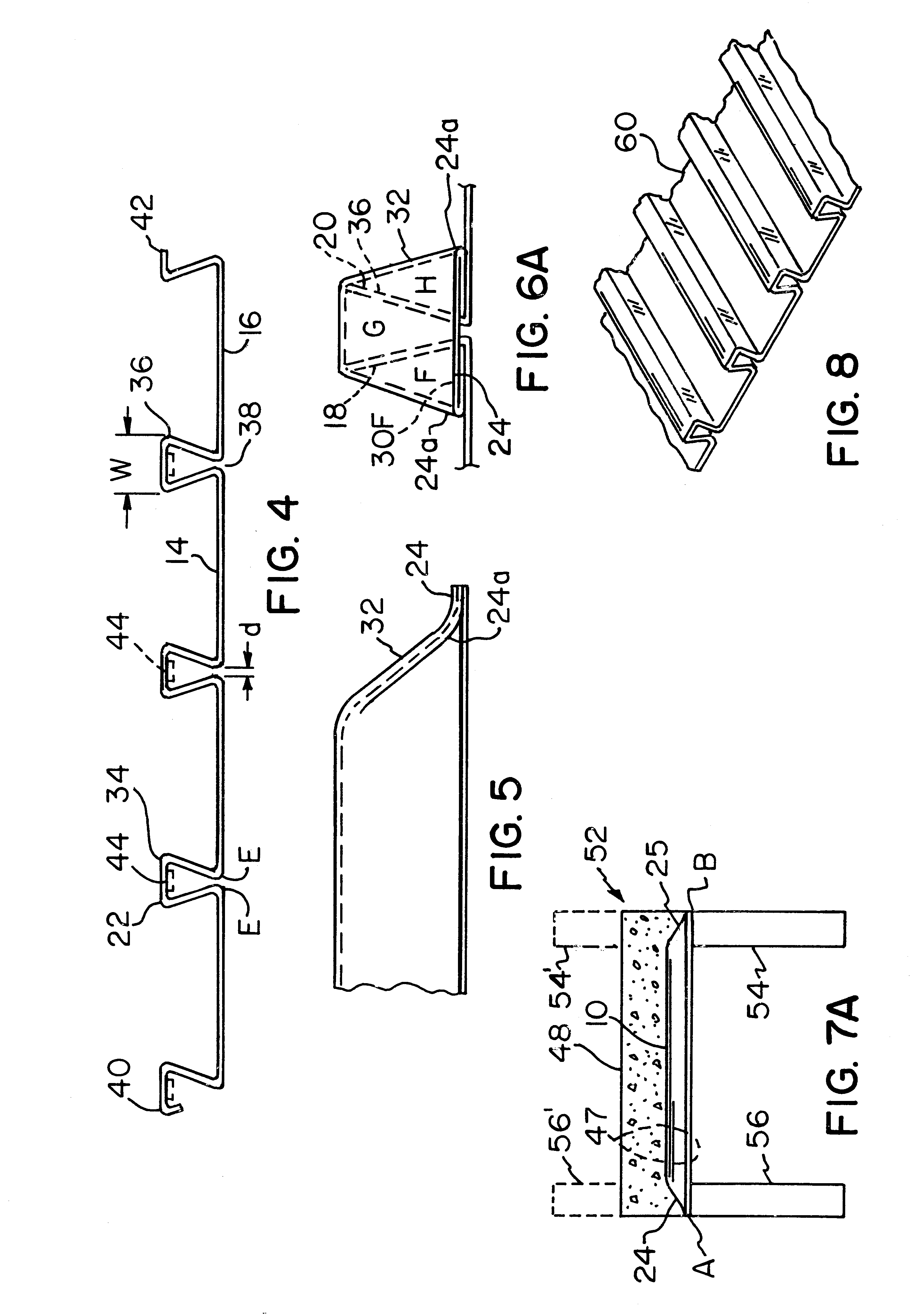

Composite deck

InactiveUS6357191B1Improve the quality of sound insulationImproved rodent and insect controlBuilding roofsCeilingsComposite slabMechanical engineering

A ribbed metal plate for a composite slab that includes a substantially planar plate having an upper surface and a lower surface and a plurality of laterally-spaced, longitudinally-extending ribs that have a keystone profile and wherein the sidewalls are angled toward each other. Ends of the ribs are integrally formed. The rib plate is secured to bearing walls in a structure and concrete is poured on the ribs to form a composite deck. The ends of the ribs extend in the lateral direction to form a composite structure retarding movement of cured concrete in a longitudinal direction. The ribbed plate can also be used in composite beams.

Owner:EPIC METALS

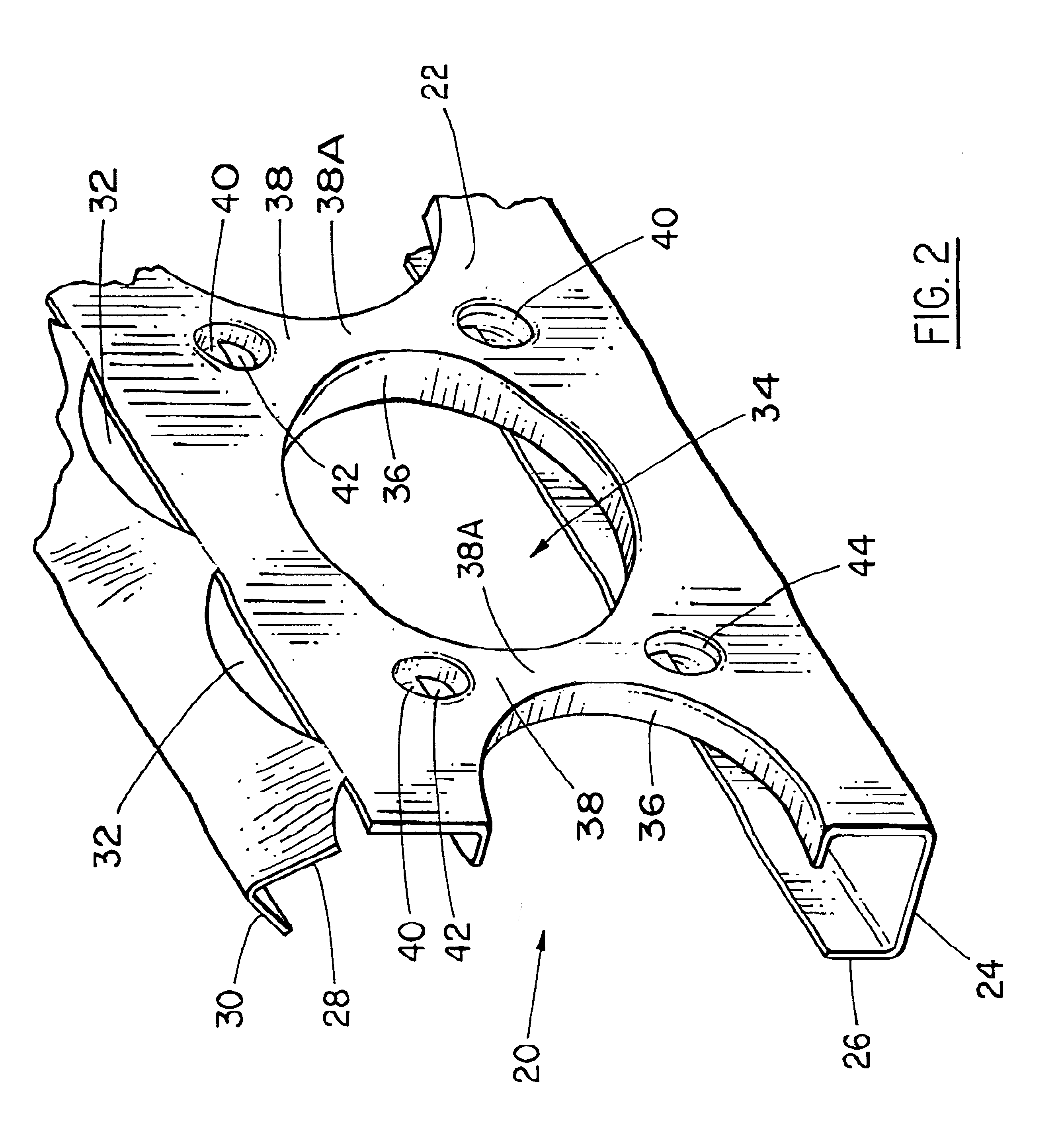

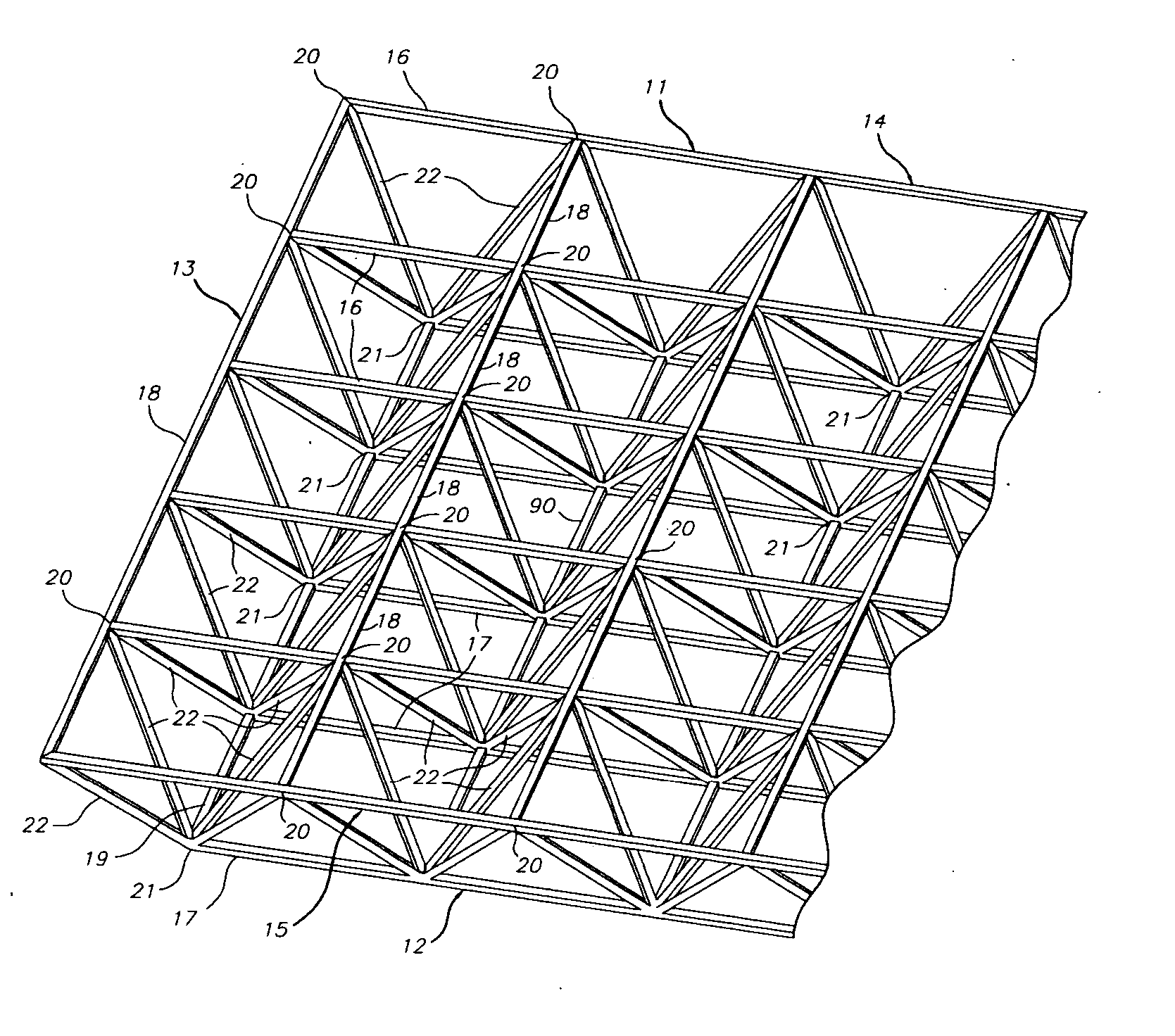

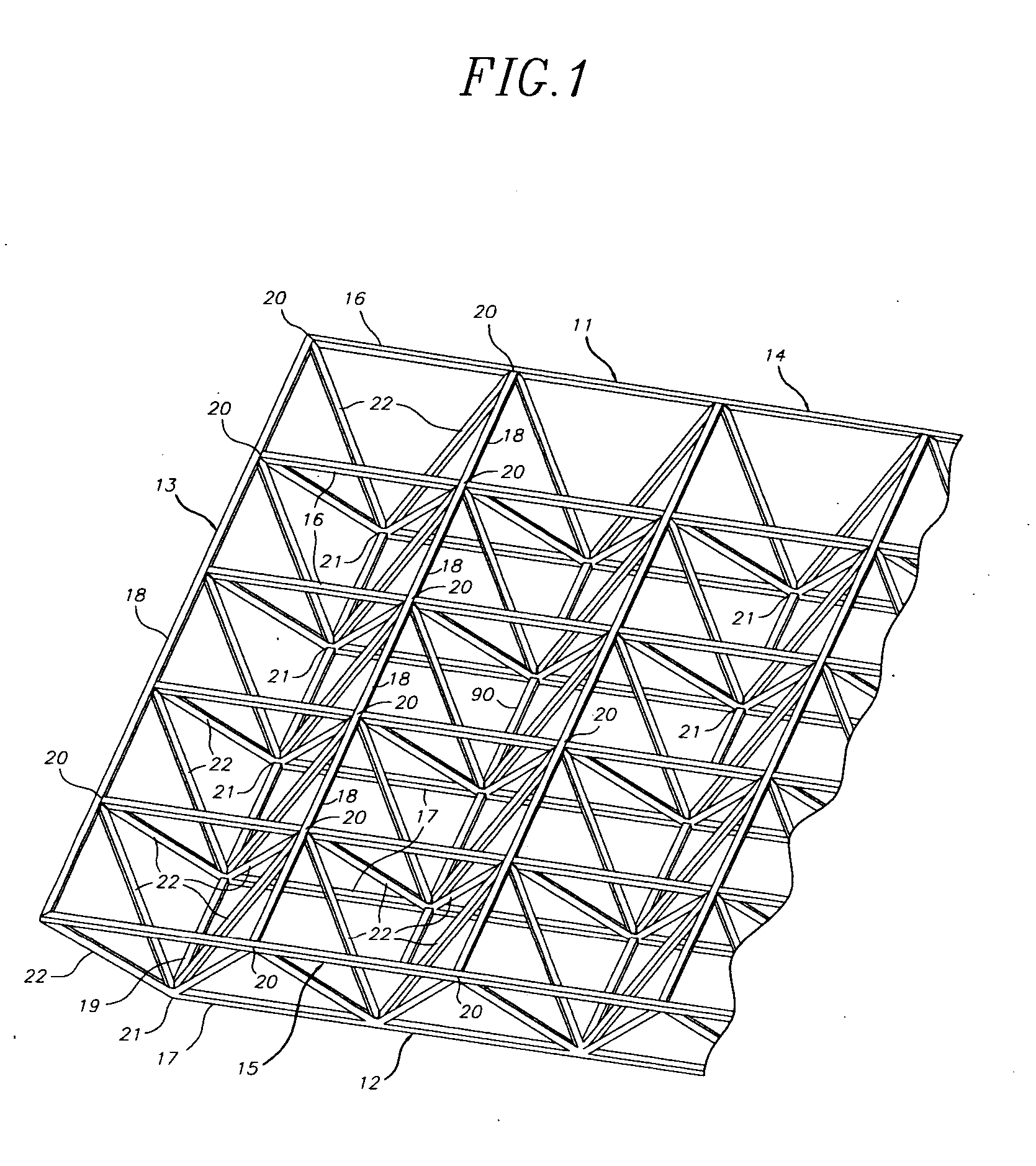

Space frames and connection node arrangement for them

ActiveUS20070011983A1Easy to useEfficiently carry design loadSolar heating energySolar heat devicesEngineeringSpace frame

A node connector in a double layer grid-type of space frame preferably is an extrusion which includes an open-ended tubular portion for snugly at least substantially encircling a frame chord member of desired cross-sectional configuration which is disposable in the passage. The node connector has fixed external elements which extend along the connector parallel to the passage. Those elements define facing parallel flat surfaces arranged in at least two pairs of such surfaces. The surfaces of each pair lie equidistantly from a center plane between them. Each center plane is parallel to the passage axis and preferably includes the passage axis. Each pair of facing flat surfaces of the node connector can cooperate closely with opposite flat surfaces at the end of each of other frames framing member placed between the facing surfaces. The node connector can be secured to a chord member in its passage and to ends of other framing members by shear pins which have zero clearances in node connector holes and in holes or passages through the respective framing members. The space frame can be a movable armature for a curved solar reflector, the space frame having a V-shaped major surface. At least some of the framing members can be thin wall tubes modified to have opposing, flat-exterior wall zones along the length of each tube and in which the wall thickness is locally increased and through which shear pin holes are defined.

Owner:GOSSAMER SPACE FRAMES

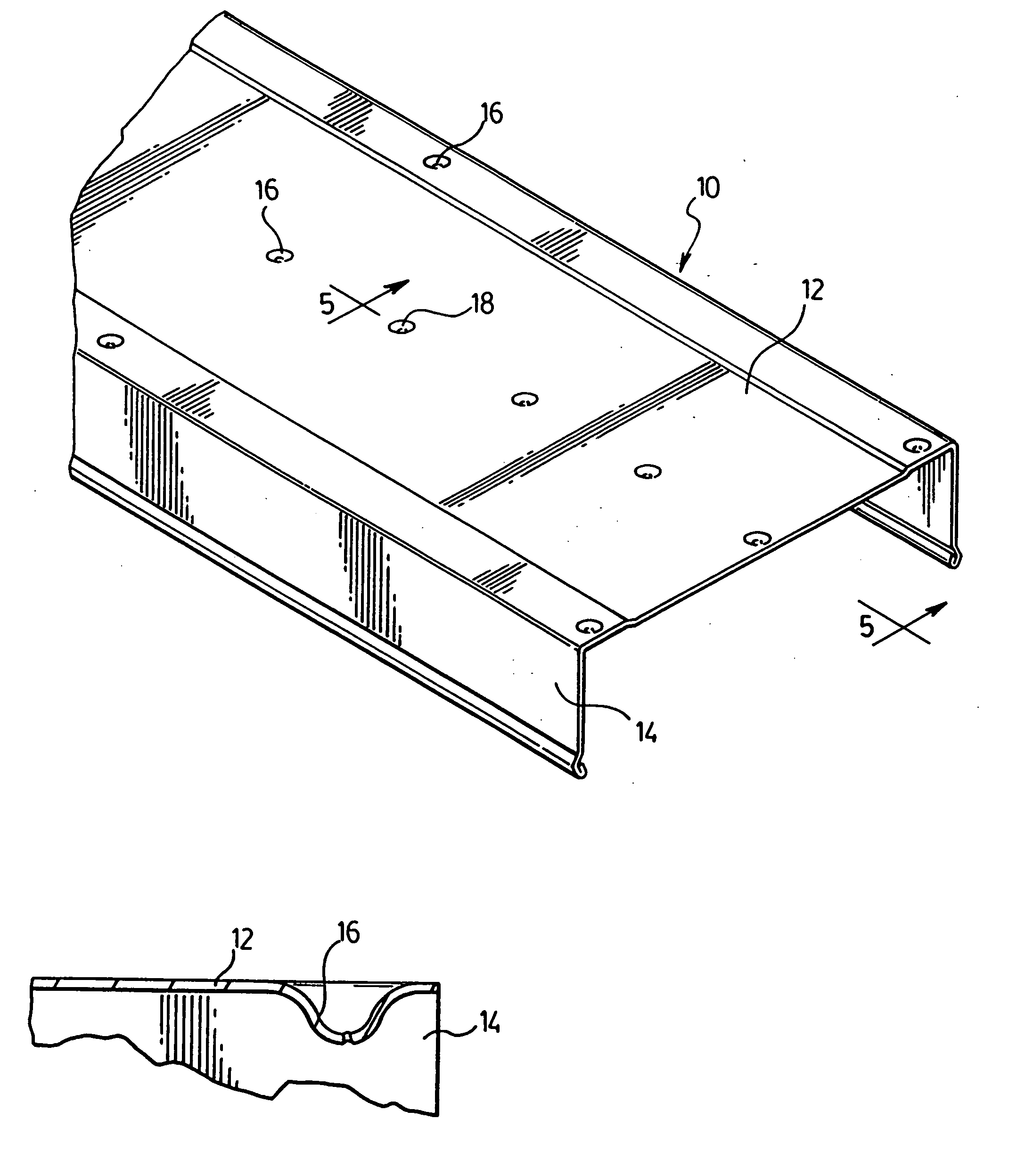

Track for metal stud walls

The present invention provides for track for use in constructing metal stud walls. The track is a generally U-shaped channel having a base and upstanding side walls extending along either side of the base. The base is provided with a plurality of embossed indicator means evenly spaced along the length of the base. The spacing of the embossed indicator means provides a guide for the proper spacing of the studs placed in the base.

Owner:BAILEY METAL PROD

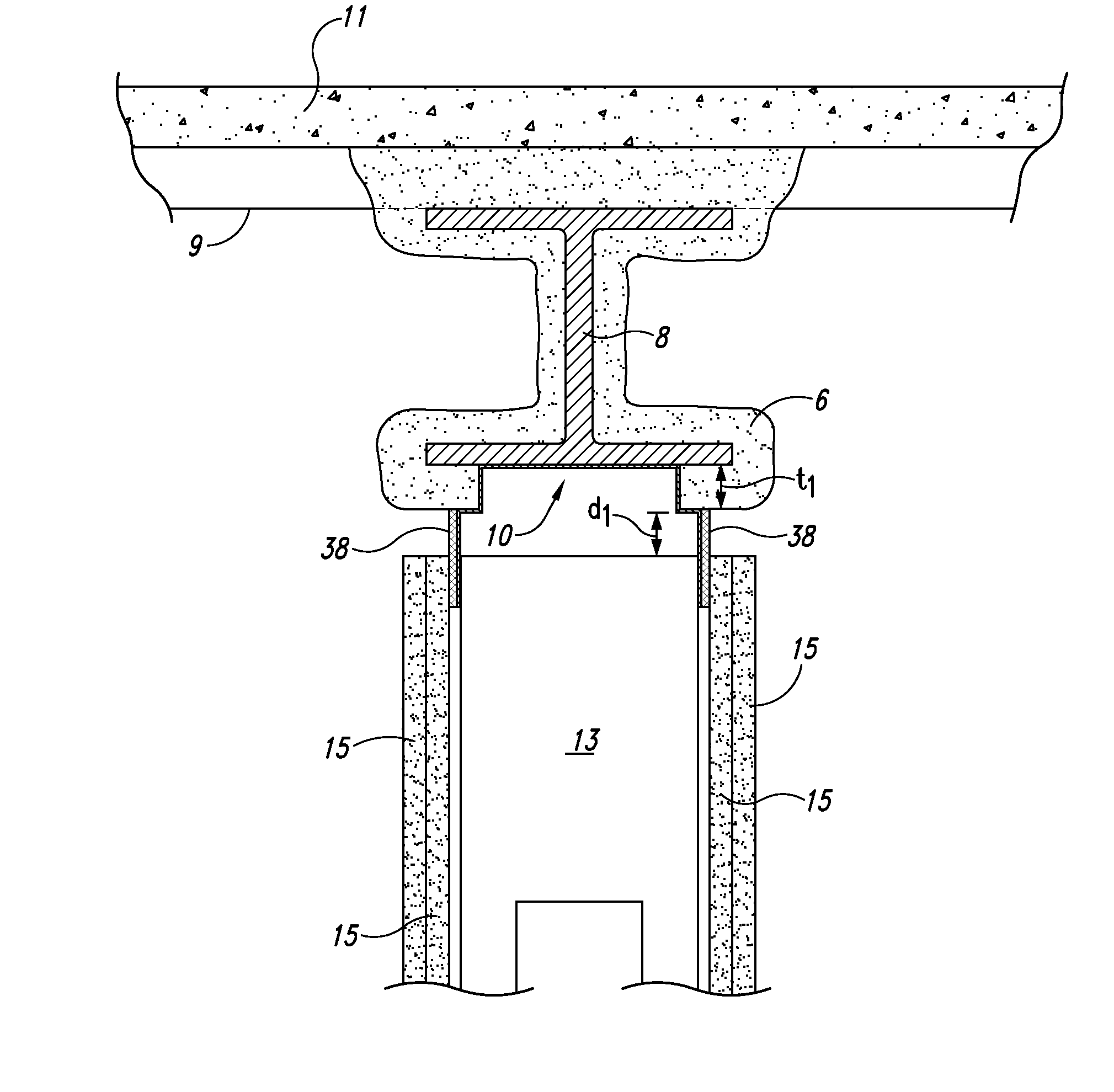

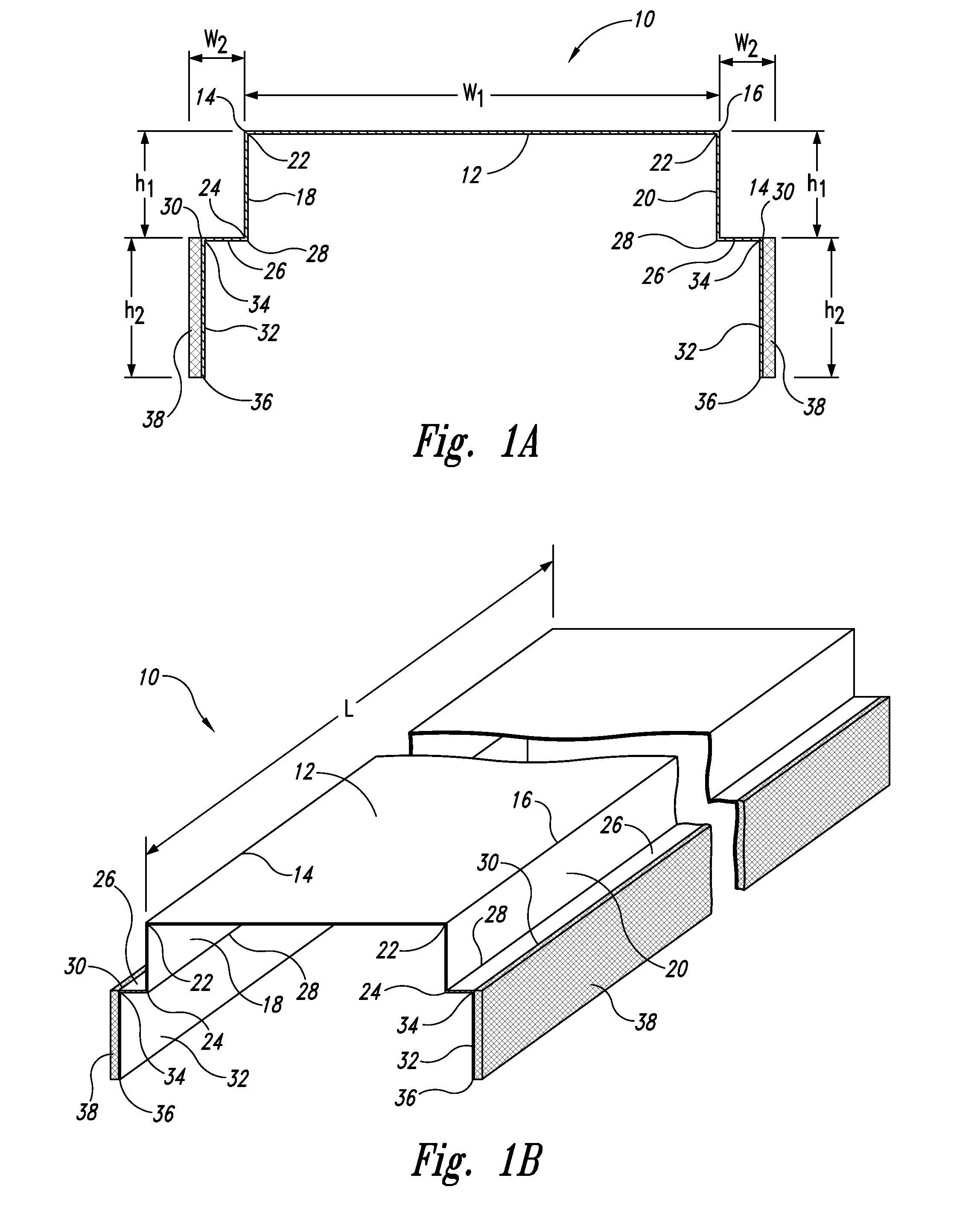

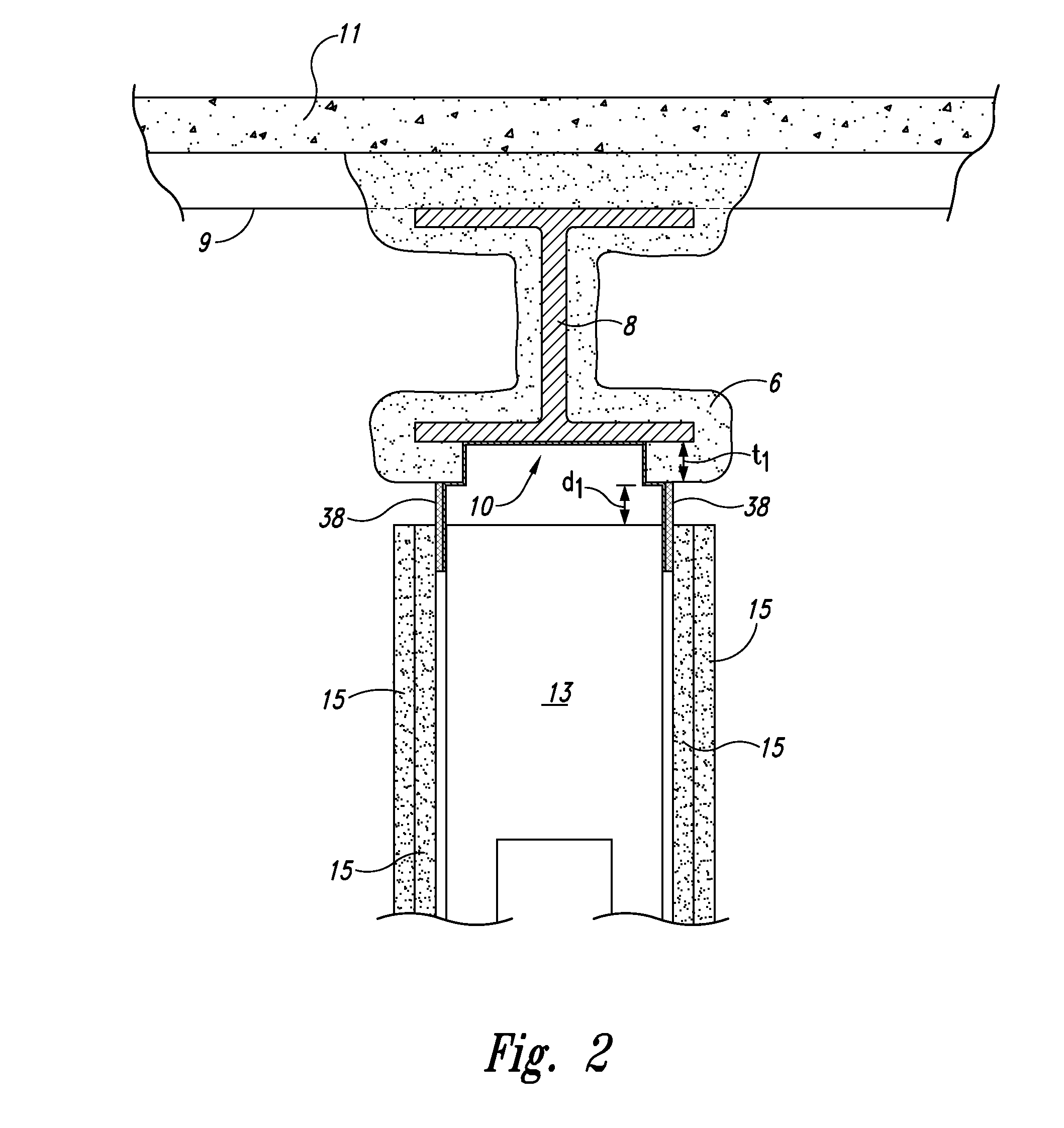

Offset leg framing element for fire stop applications

The invention disclosed herein is directed to an offset leg framing element for use in a fire rated assembly and comprises: a web section having opposing edges; a pair of outwardly extending sidewalls integrally connected to the web, wherein the sidewalls are substantially parallel and confront each other. In addition, at least one laterally extending ledge section is integrally connected to one of the pair of outwardly extending sidewalls; and at least one downwardly extending leg is integrally connected to the at least one ledge section. The offset leg framing element may be characterized in that the ratio the sidewall height (h1) over the ledge section width (w2) is greater than or equal to one (h1 / w2≧1), and wherein the ratio the sidewall height (h1) over the web section width (w1) is greater than or equal to one sixth (h1 / w1≧0.1667).

Owner:BLAZEFRAME IND

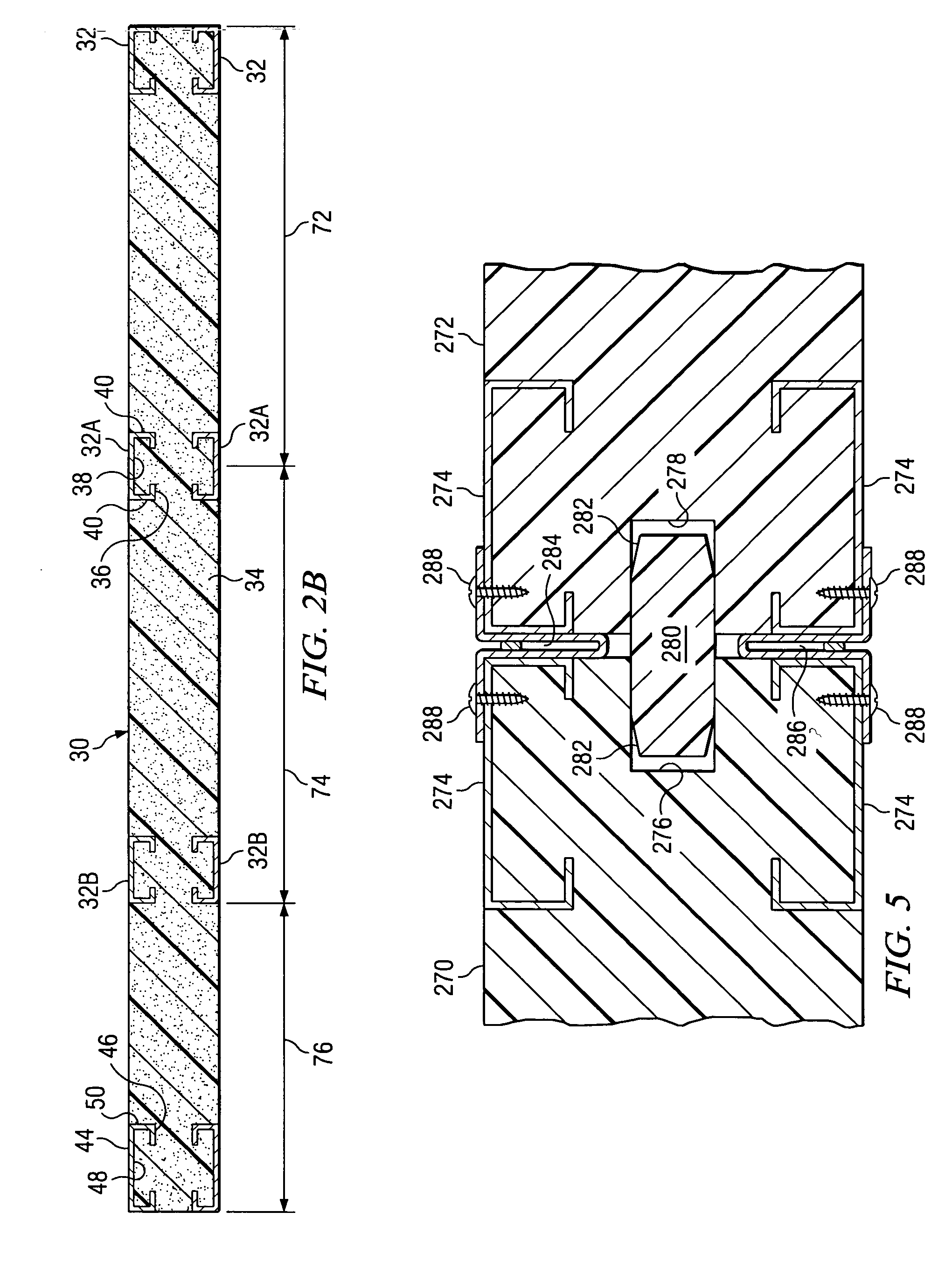

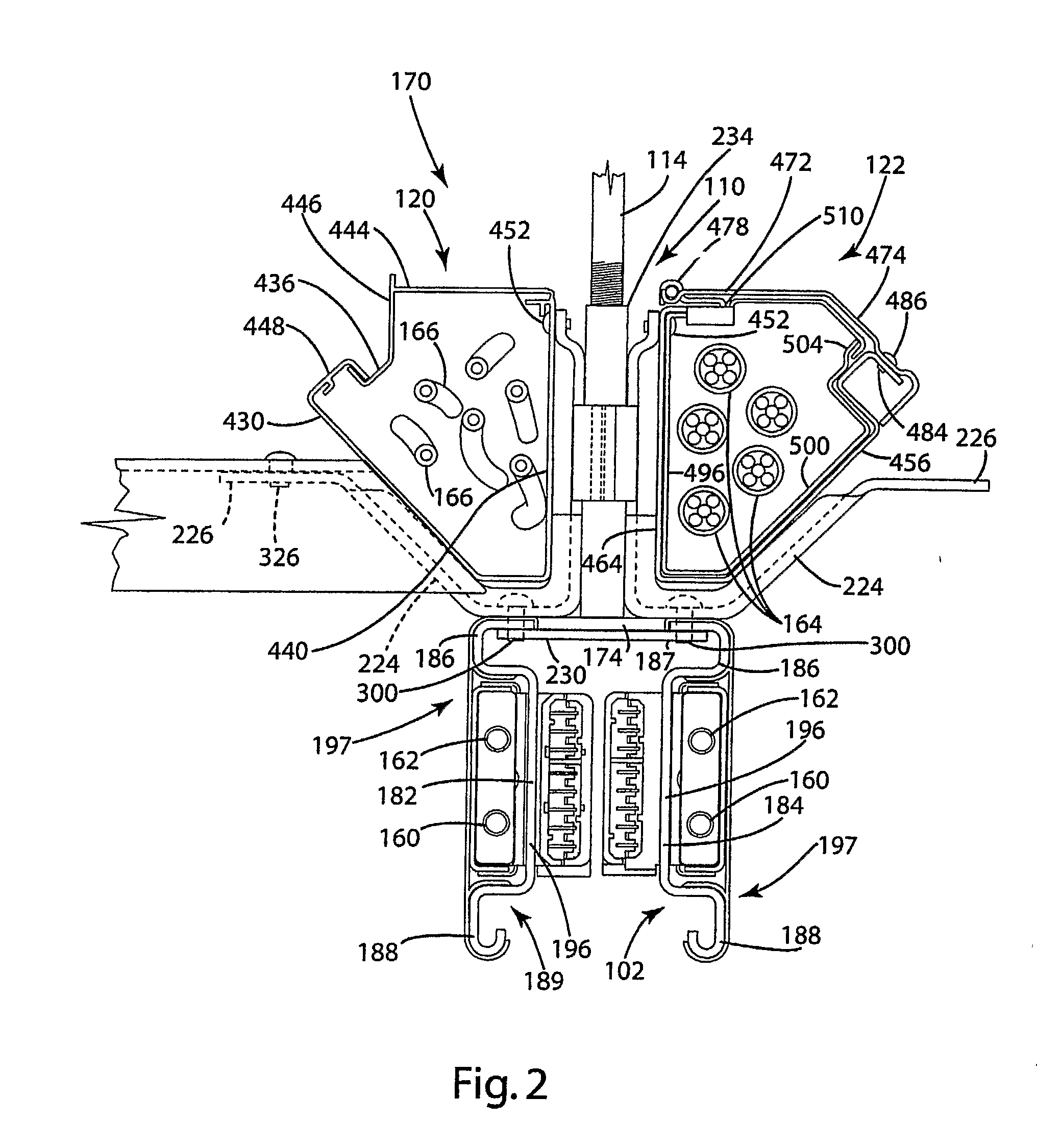

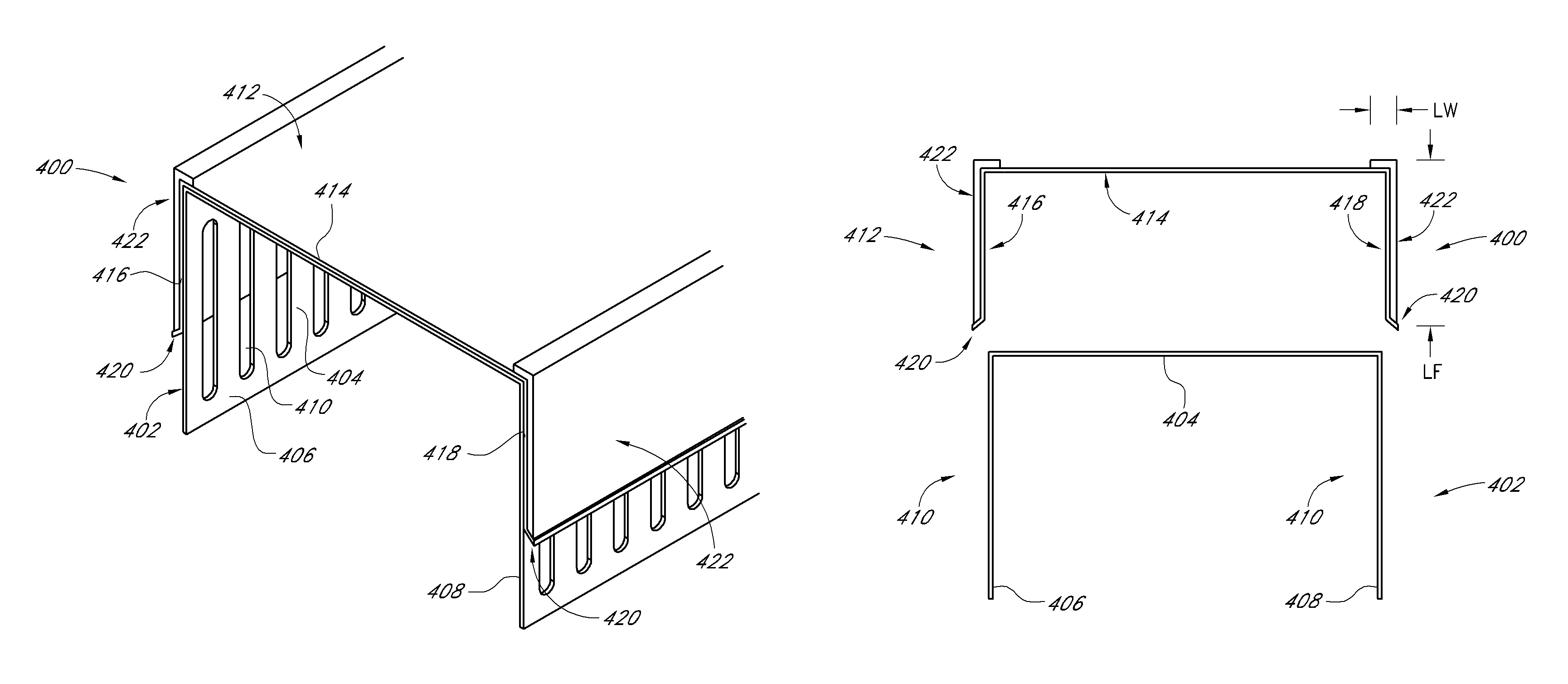

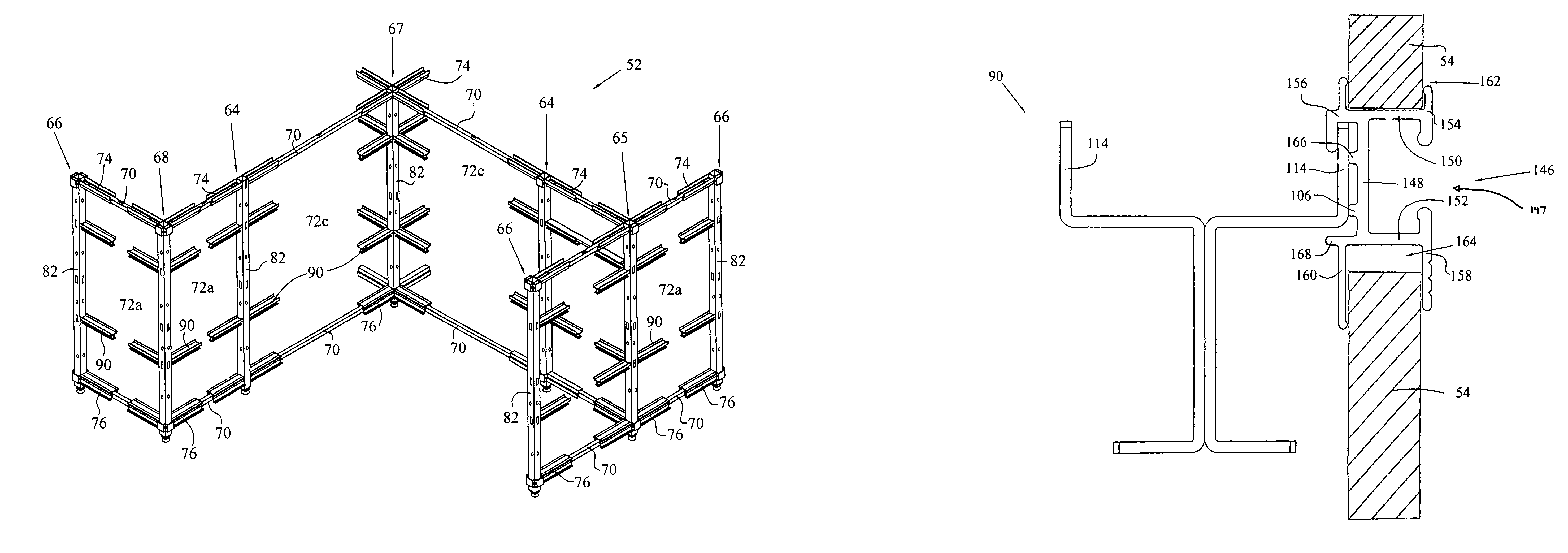

Power and Communication Distribution Using a Structural Channel Stystem

A structural channel system (100) includes a main structural channel rail (102), cross-channels (104) and cross-rails (106). A modular plug assembly (130) couples electrical power and communication signals to connector modules (132, 140, 144) which, in turn, control application of power to application devices (939, 969) based on the communication signals.

Owner:HOWE RUSSEL +3

Two-piece track system

ActiveUS8555566B2Enhances and maximizes deflection lengthEasy to createWallsPublic buildingsSill plateMechanical engineering

A fire-rated receiver channel includes at least one intumescent or other fire-resistant material strip. The receiver channel can nest with a framing member, such as metal tracks, headers, header tracks, sill plates, bottom tracks, metal studs, wood studs or wall partitions, and placed at a perimeter of a wall assembly to create a fire block arrangement. In other arrangements, a track assembly includes two nested tracks, an inner track and outer track. The assembly is designed so that the outside width of the outer track is equal to or less than the outside width of the inner track to present a substantially flush external surface for attachment of exterior sheathing elements when the assembly is used in an external wall.

Owner:CEMCO LLC

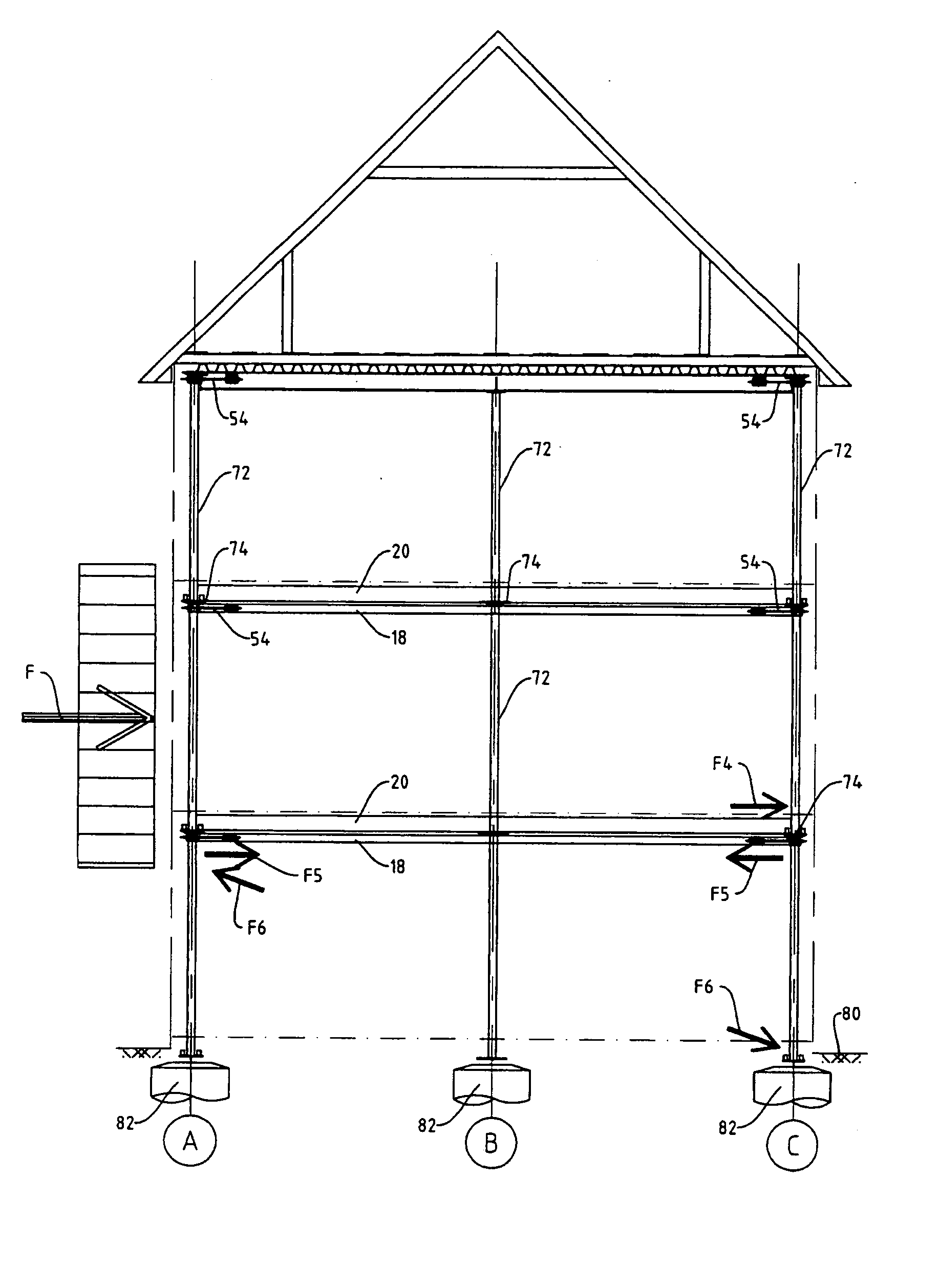

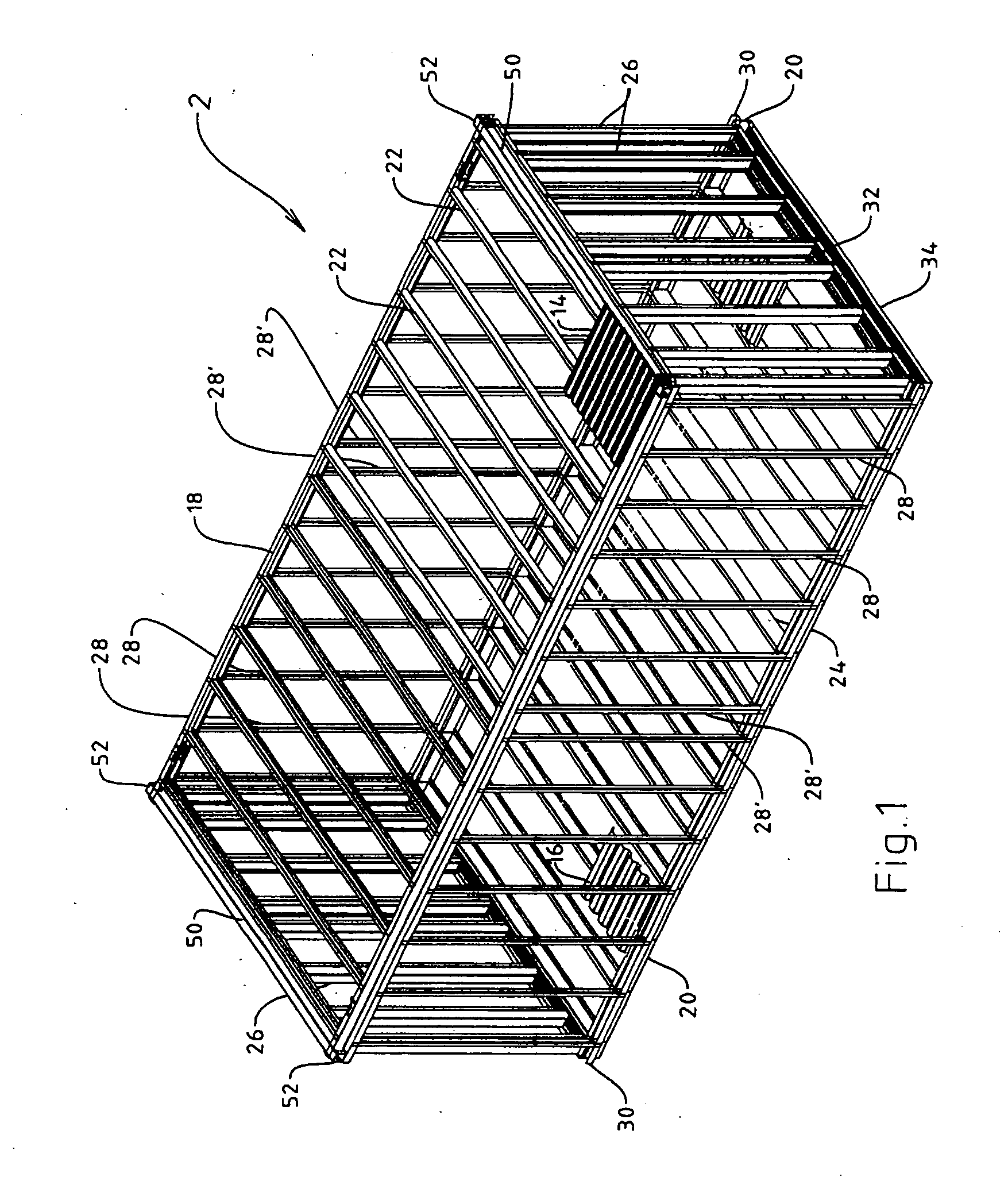

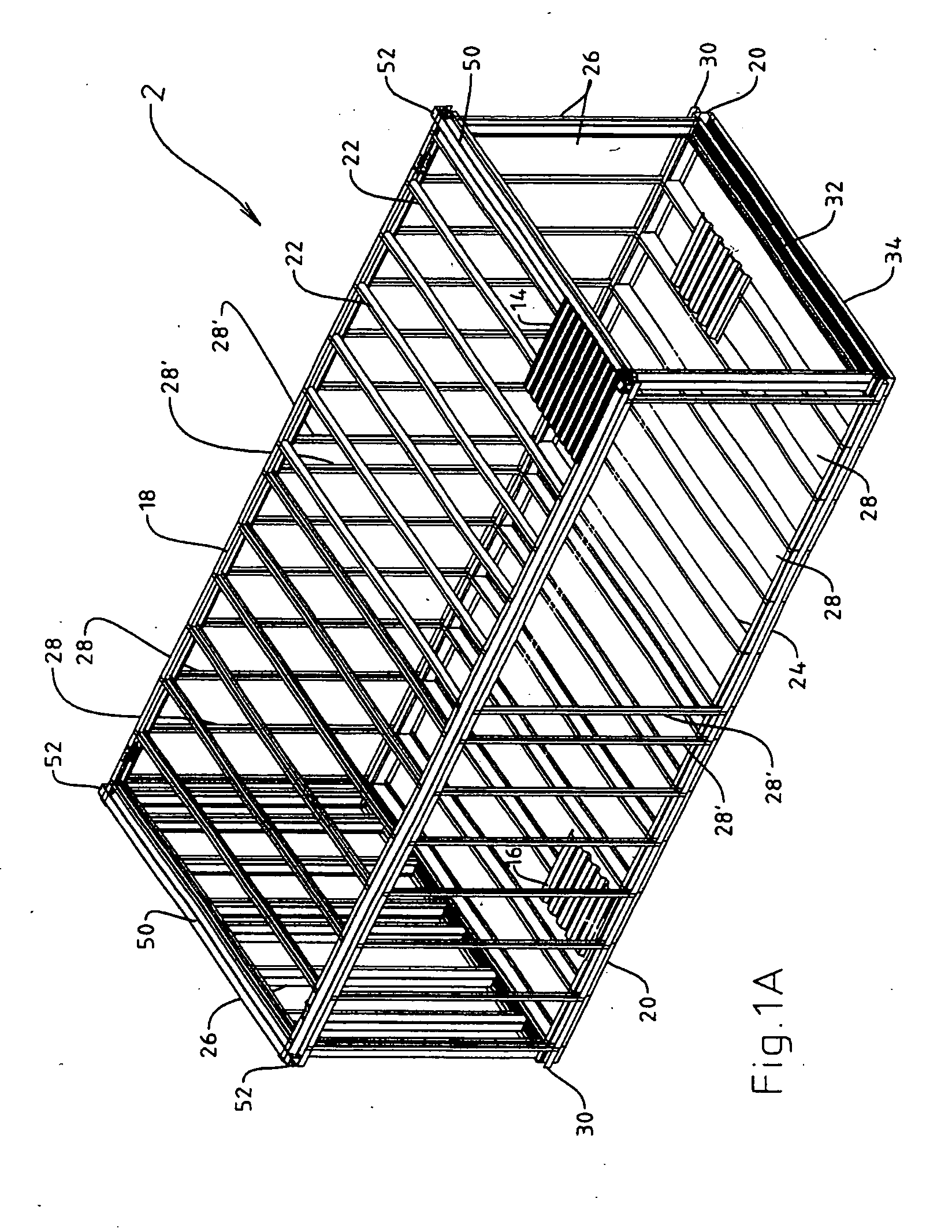

Modular building, prefabricated volume-module and method for production of a modular building

The invention relates to a modular building of the type that comprises vertical frame columns (70) and a plurality of volume modules (2) prefabricated of sheet metal profiles (18-32) and being of rectangular horizontal section, which are supported by the columns (70) on two or more floor levels. The volume modules (2) are prefabricated with two frame edge beams (50) which are stronger than said sheet metal profiles (18-32) and which are horizontally extended along a respective upper end wall edge of the volume module (2) and which are on the one hand linearly connected with frame edge beams (50) of adjoining modules (2) on the same floor level and, on the other hand, connected to the columns (70) in such a manner that the horizontal position of the frame edge beams (50) relative to the columns (70) is fixed. The invention also relates to such a module and a method for manufacturing such a building.

Owner:OPEN HOUSE SYST

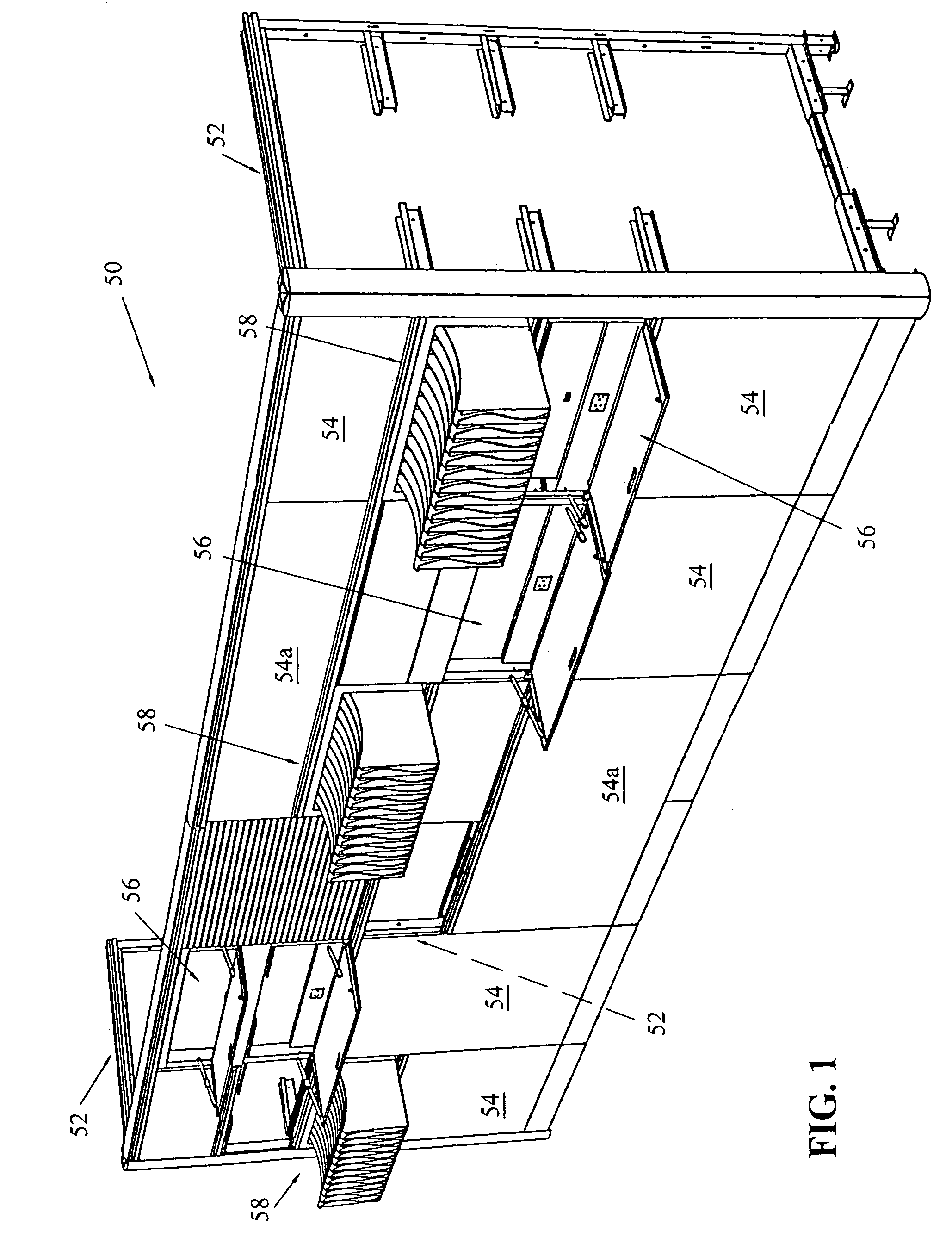

Partition system

InactiveUS7150127B2Easily attachable to the frameworkEasy to changeCorner/edge jointsLight protection screensBrickEngineering

Owner:KIMBALL INTERNATIONAL

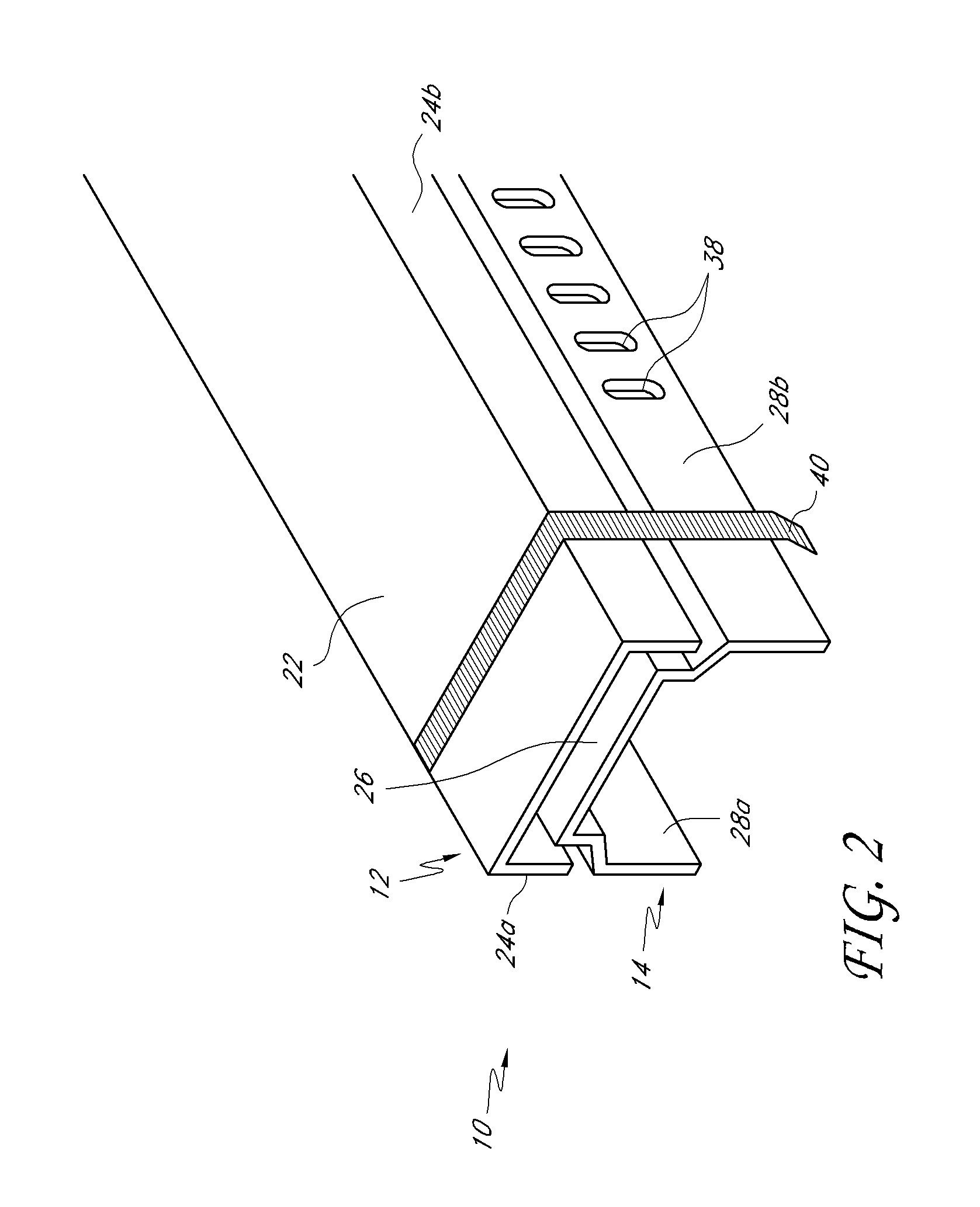

Exterior wall construction product

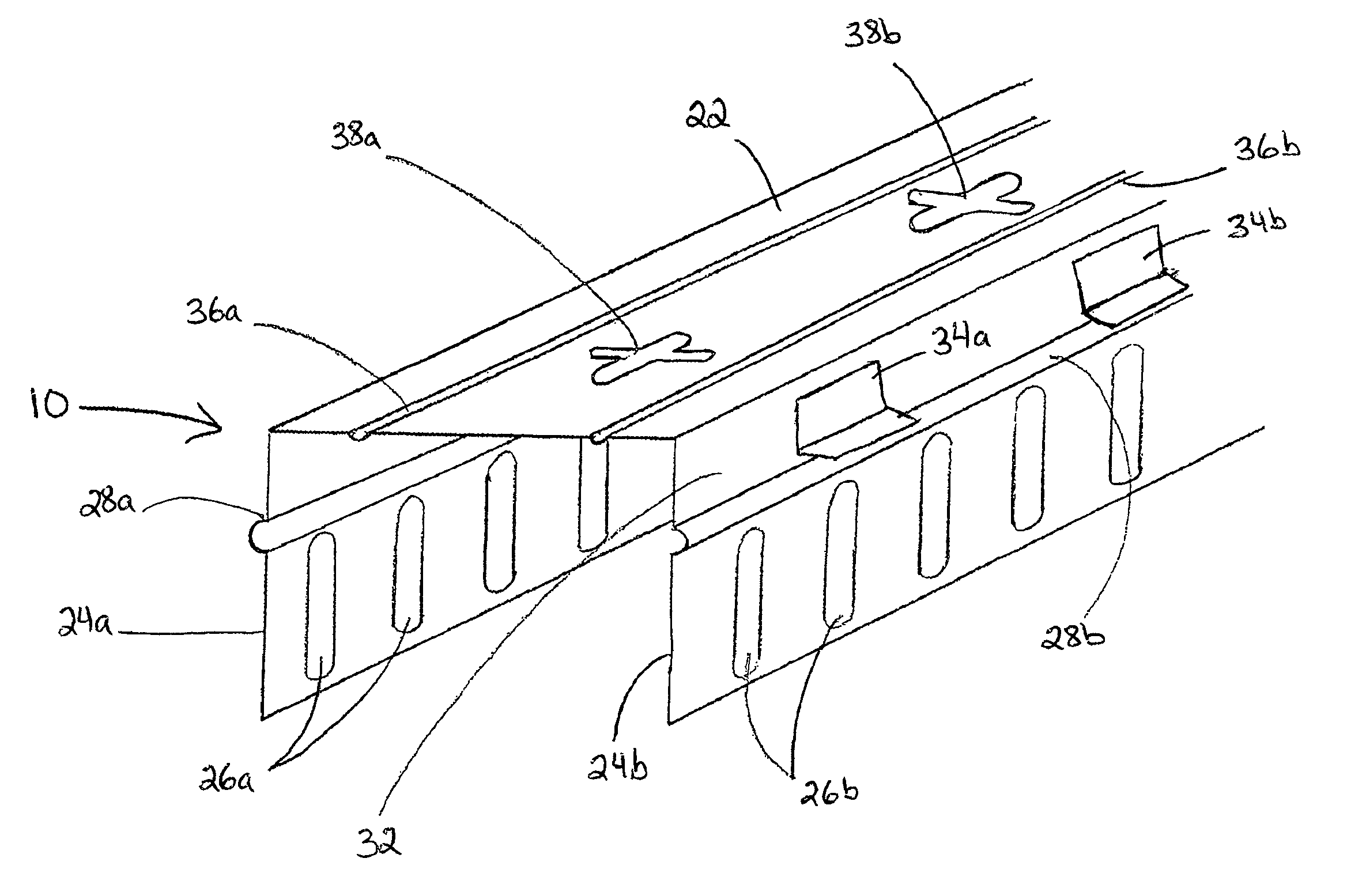

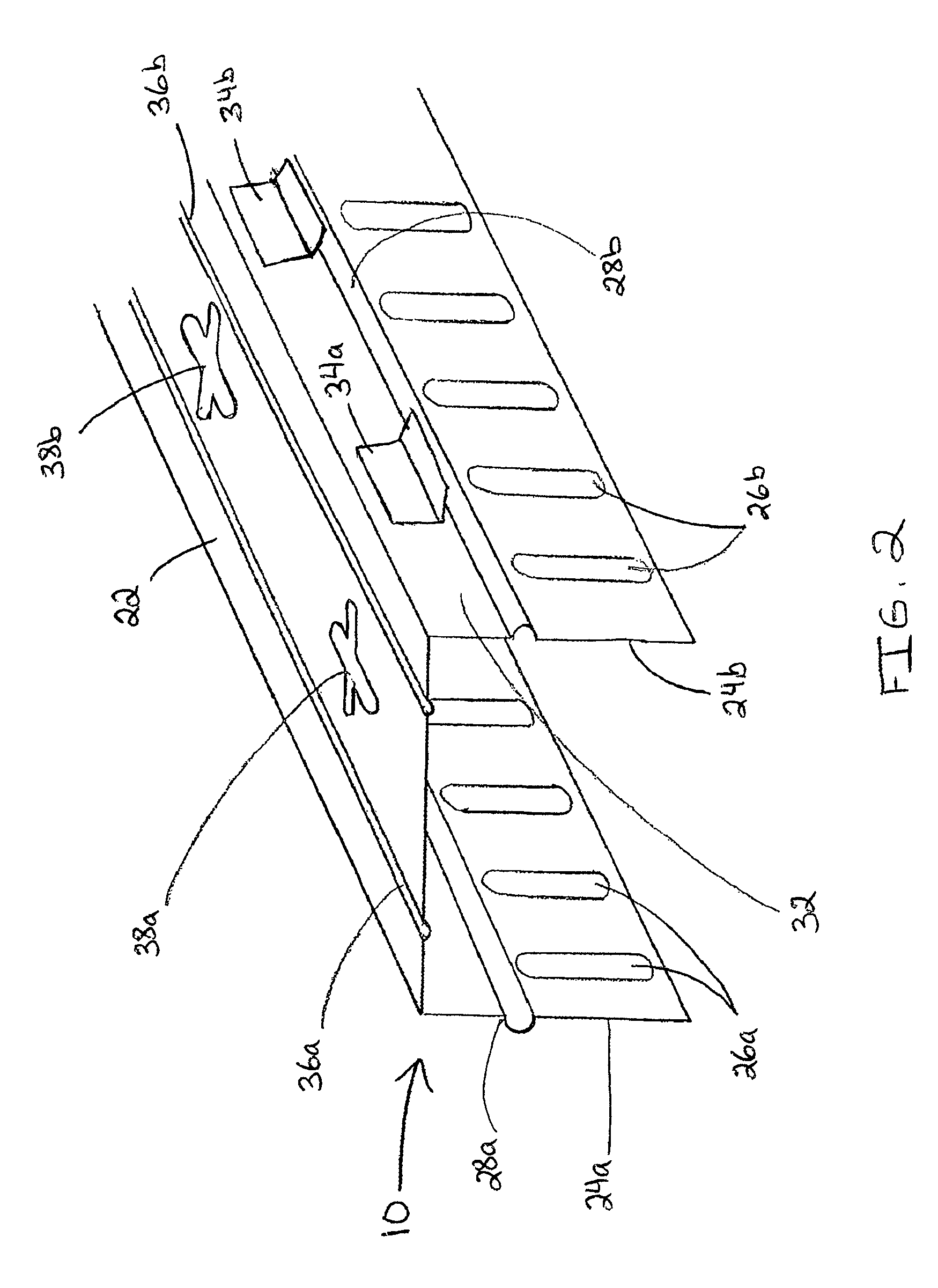

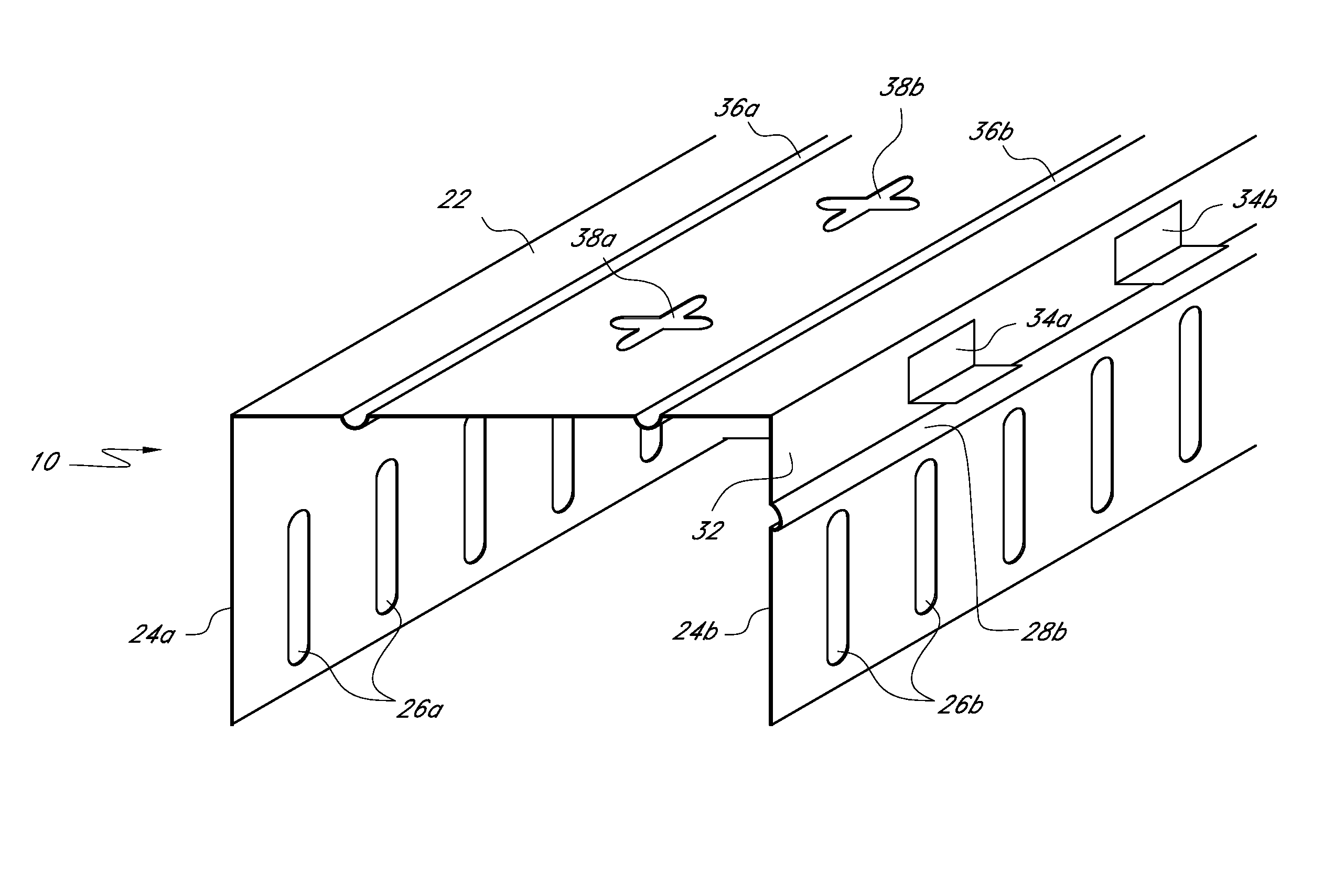

Slotted header tracks for exterior wall applications. In exterior wall framing, the exterior wall sheathing is required to have a horizontal gap at or near the floor line for anticipated vertical movement between the floors. To accommodate orthogonal movement of the studs relative to the track, a plurality of slots are located along the flanges of the header track. An area for exterior sheathing attachment is created by leaving the upper portion of the flange solid for sheathing attachment and providing slots on the lower portion of the flange. Embodiments may include elongate reinforcing grooves on the slotted track's flanges and / or web, tabs for supporting and positioning exterior sheathing elements, connector elements for connecting the track to another surface, and second slots along the length of the web of the track to allow for limited drift movement of the track.

Owner:CEMCO LLC +1

Exterior wall construction product

Owner:CEMCO LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com