Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4384results about How to "Low shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Attapulgite argil powder with air purifying function

ActiveCN102173743BImprove adhesionImprove plasticityDispersed particle separationDeodrantsFiberHazardous substance

The invention discloses an attapulgite argil powder with an air purifying function. The technical scheme is as follows: the attapulgite argil powder with an air purifying function is prepared from high-viscosity attapulgite clay, an attapulgite constant-humidity conditioner, a natural mineral adsorbing / filtering agent, Cacumen Biotae, aluminum silicate fiber and polyacrylamide. The attapulgite argil powder is prepared by the following steps: pulverizing the materials, soaking and aging to obtain a wet mixture, extruding the wet mixture into a strip, airing the strip, pulverizing to obtain powder, and packaging to obtain the finished product. The attapulgite argil powder has favorable cohesive property, plasticity, thixotropy, fire resistance and thermal stability; the pottery prepared from the attapulgite argil powder with an air purifying function contains a great deal of micropores and activated carbon, thus, has the characteristics of low shrinkage, no cracking or deformation and favorable adsorbability, and can effectively adsorb formaldehyde, ammonia, benzene and other harmful substances in the air, thereby protecting the environment and improving good health of people. The invention is suitable for producing pottery artware with an air purifying function.

Owner:江苏世澳非金属应用科技有限公司

Optical articles comprising isosorbide polyesters and method for making same

InactiveUS6126992AHigh light transmittanceEasy to copySynthetic resin layered productsPretreated surfacesPolyesterPolymer science

An optical article made of a transparent polymer which includes terephthaloyl moieties, optionally, other aromatic diacid moieties; ethylene glycol moieties; isosorbide moieties; and, optionally, one or more other diol moieties, wherein the polymer has an inherent viscosity of at least about 0.35 dL / g as measured on a 1% solution (weight / volume) in o-chlorophenol at 25 DEG C.

Owner:EI DU PONT DE NEMOURS & CO

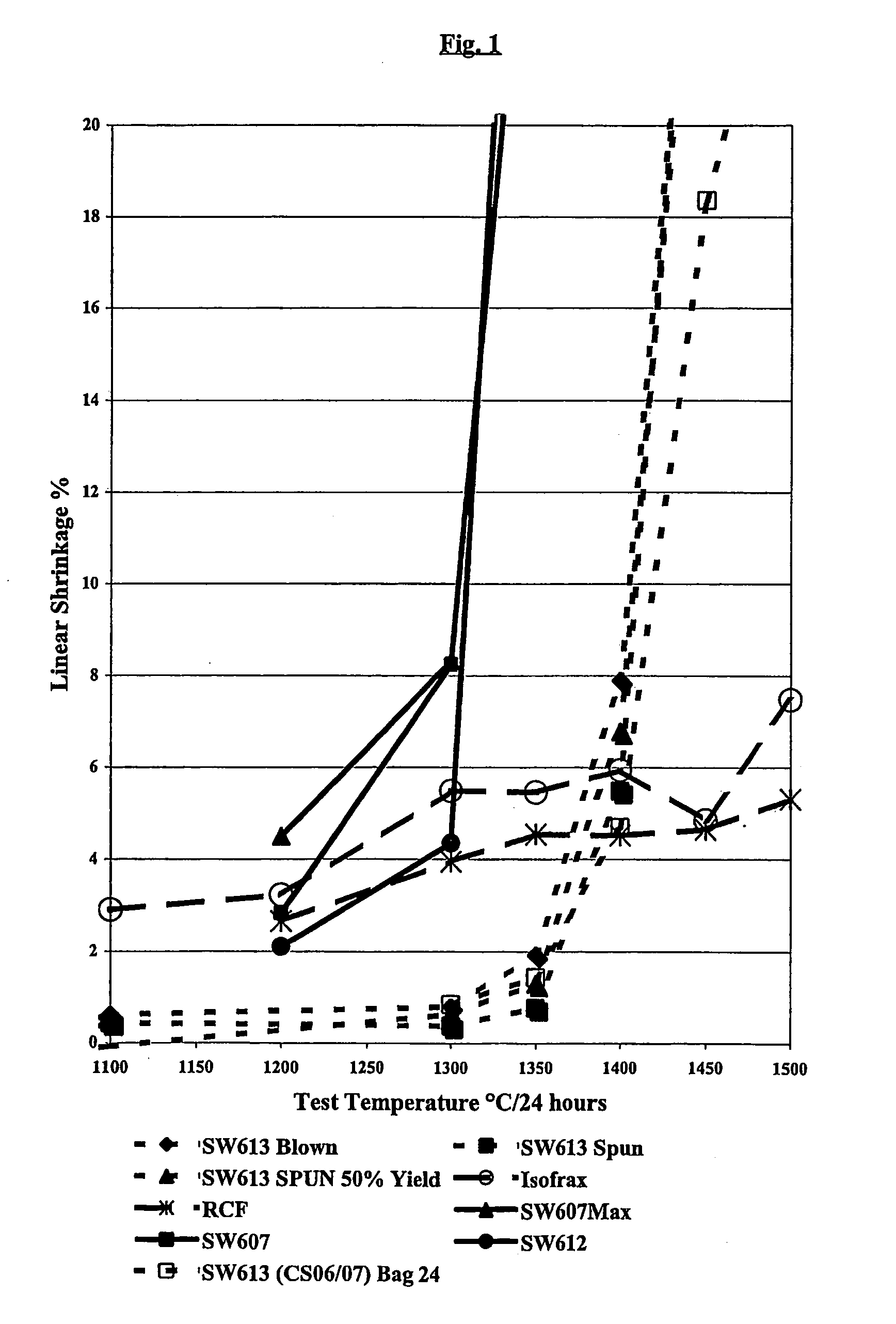

High temperature a resistant vitreous inorganic fiber

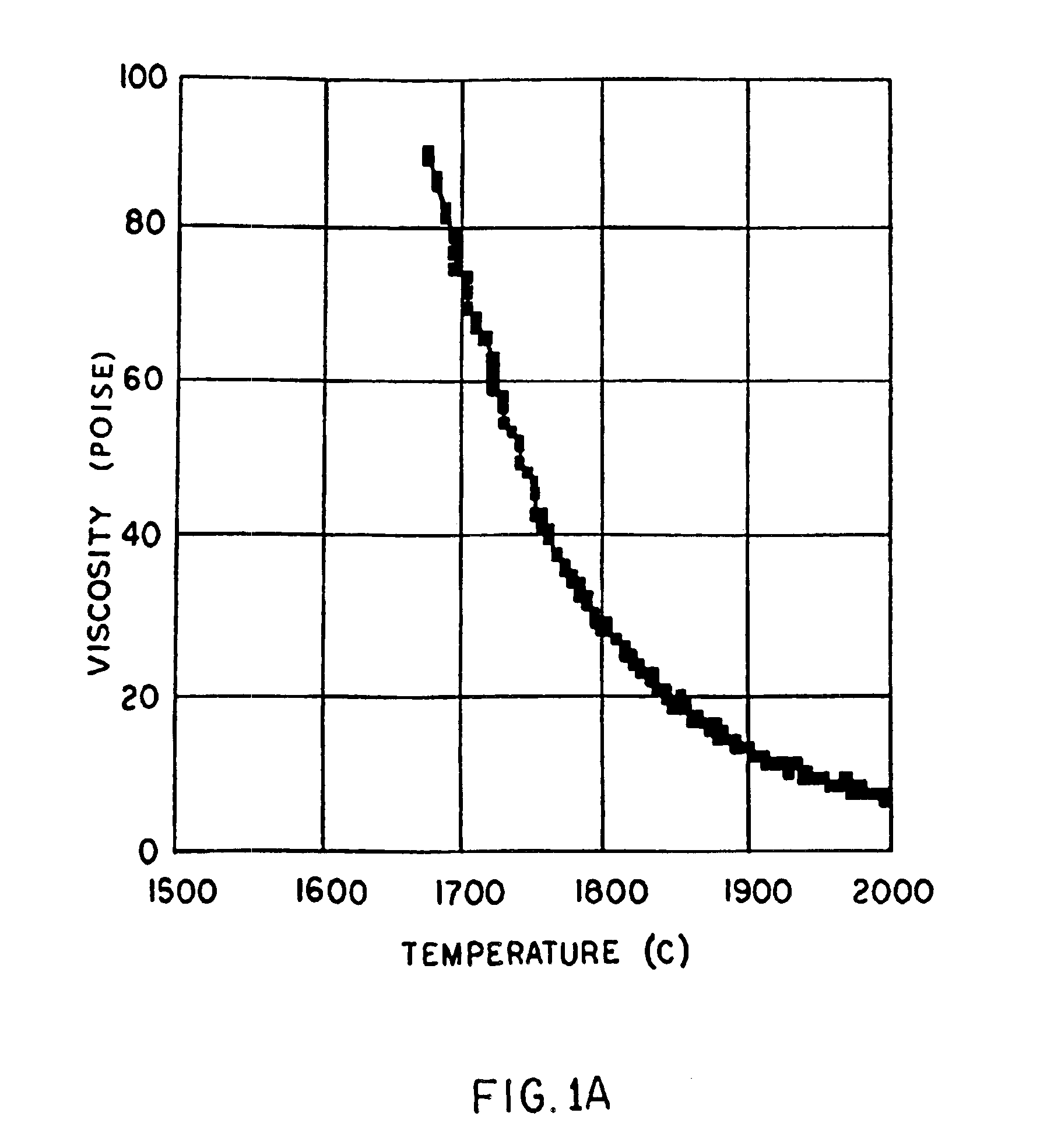

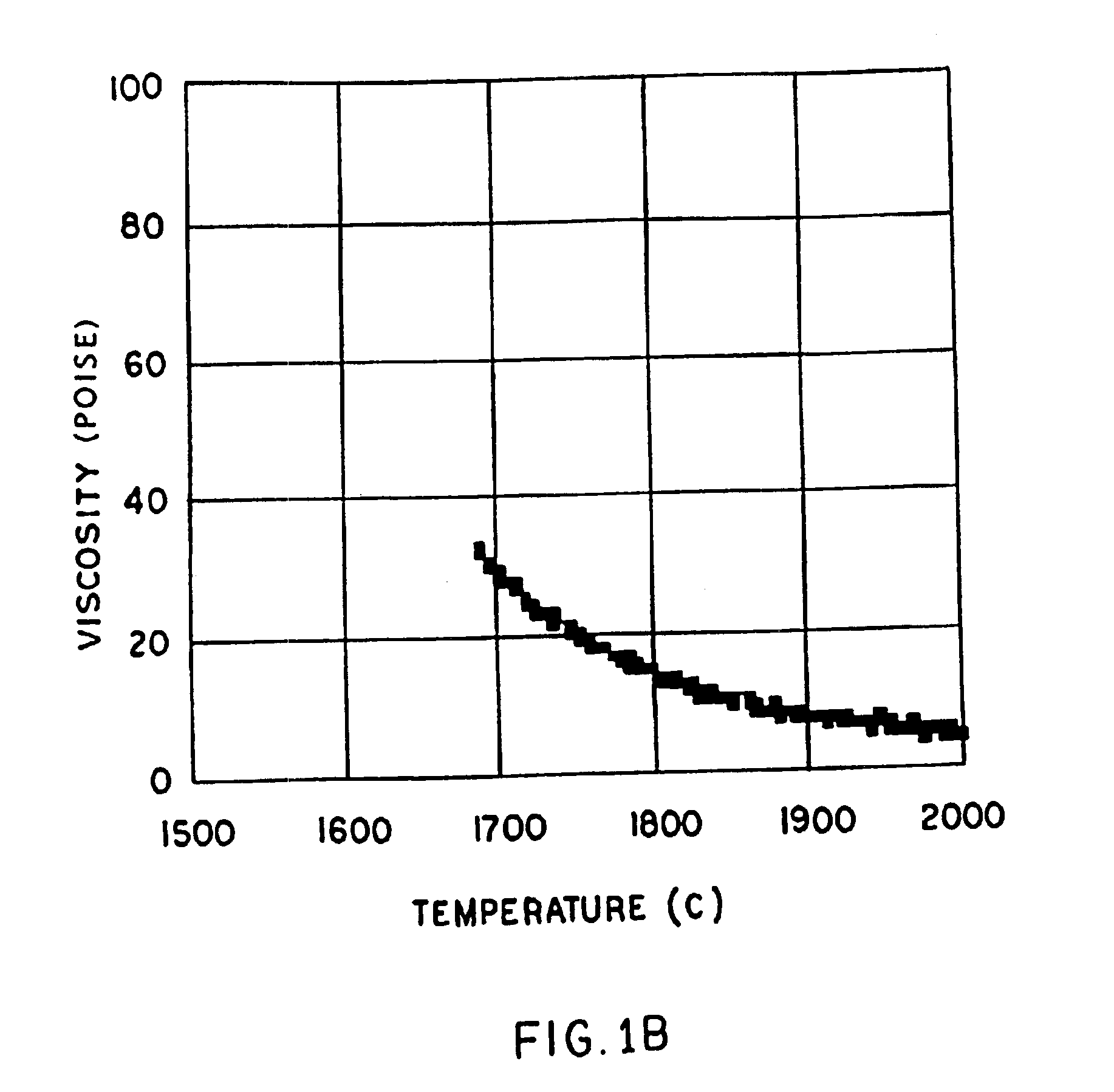

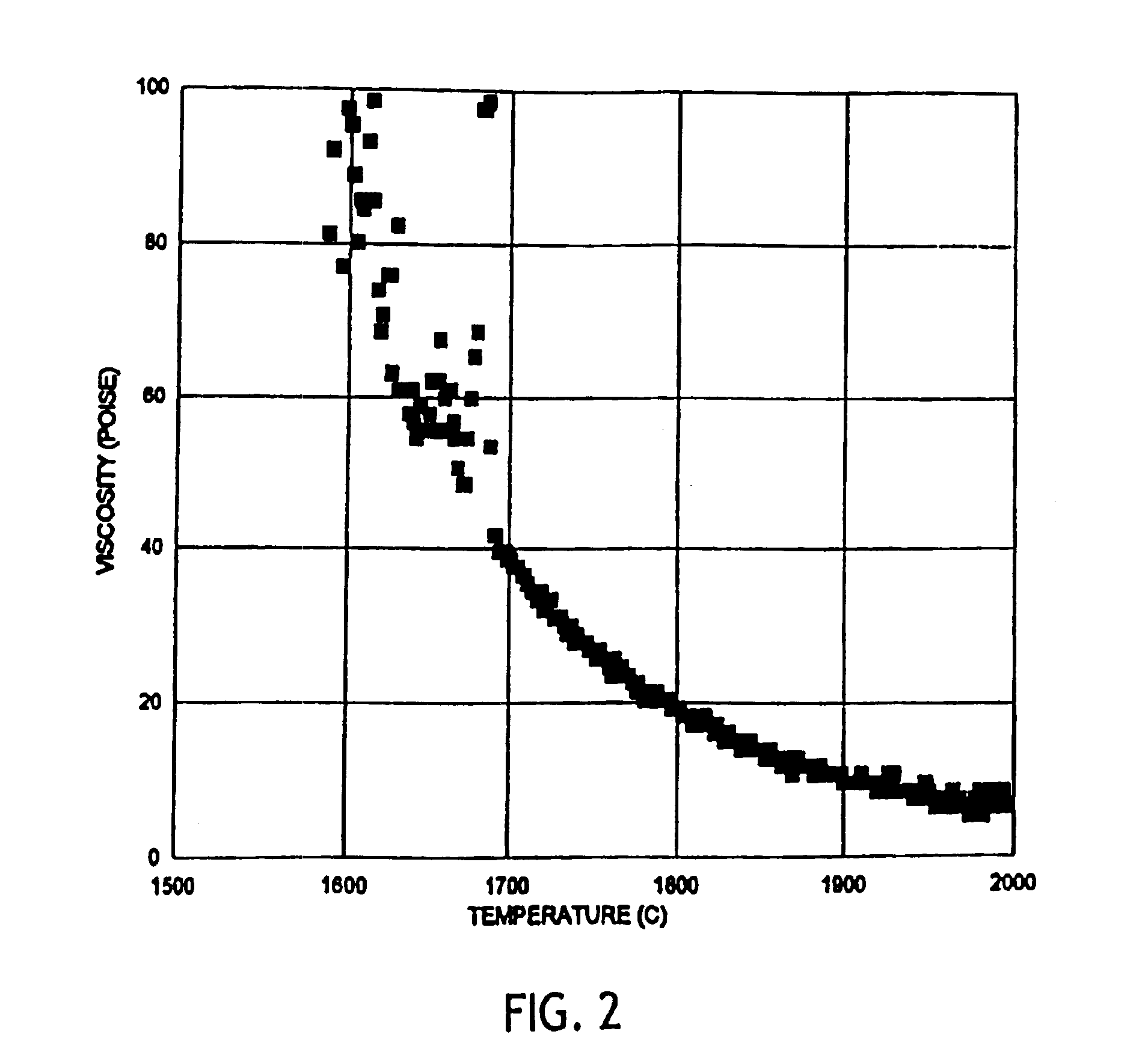

InactiveUS6953757B2Easy to manufactureLow shrinkageInorganic fibres/flakesInorganic material artificial filamentsFiberPhysiological fluid

A low shrinkage, high temperature resistant vitreous inorganic fiber having a use temperature up to at least 1330° C., which maintains mechanical integrity after exposure to the use temperature and which is non-durable in physiological fluids, is prepared by the method of forming a melt with ingredients including greater than 71.25 weight percent silica, 0 to about 20 weight percent magnesia, and about 5 to about 28.55 weight percent of calcia, 0 to about 5 weight percent zirconia, and optionally a viscosity modifier in an amount effective to render the product fiberizable; and producing fibers from the melt.

Owner:UNIFRAX I LLC

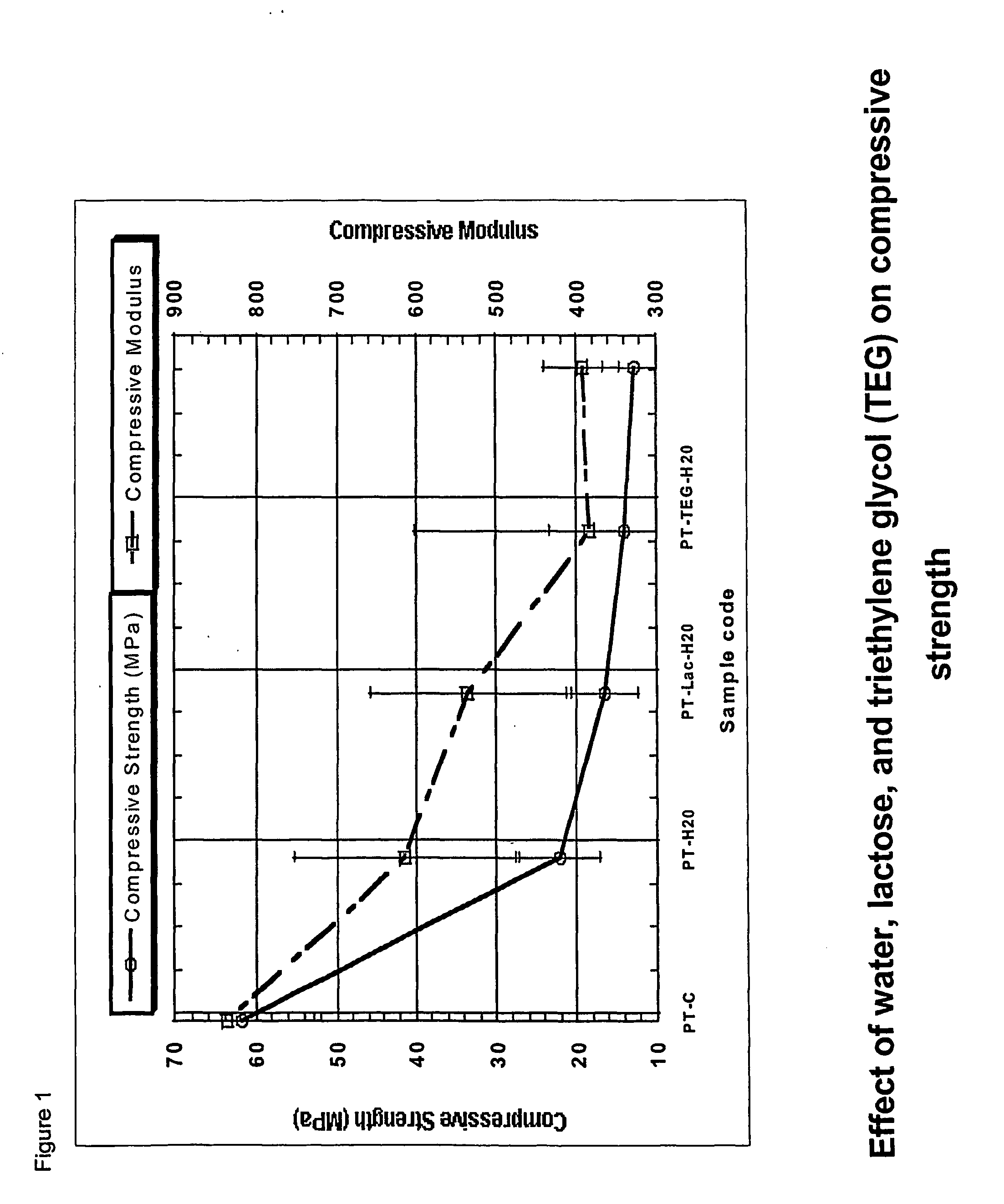

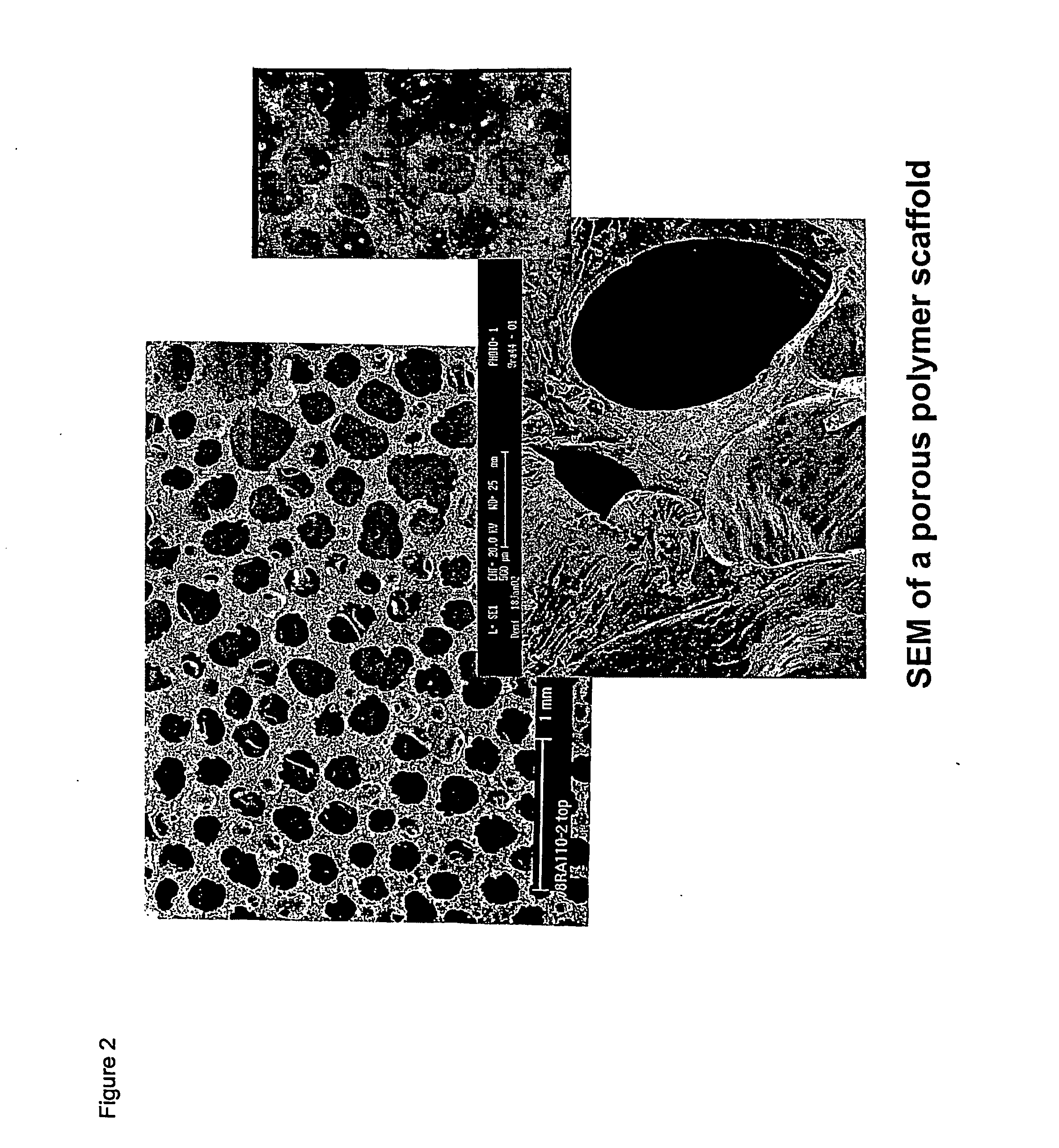

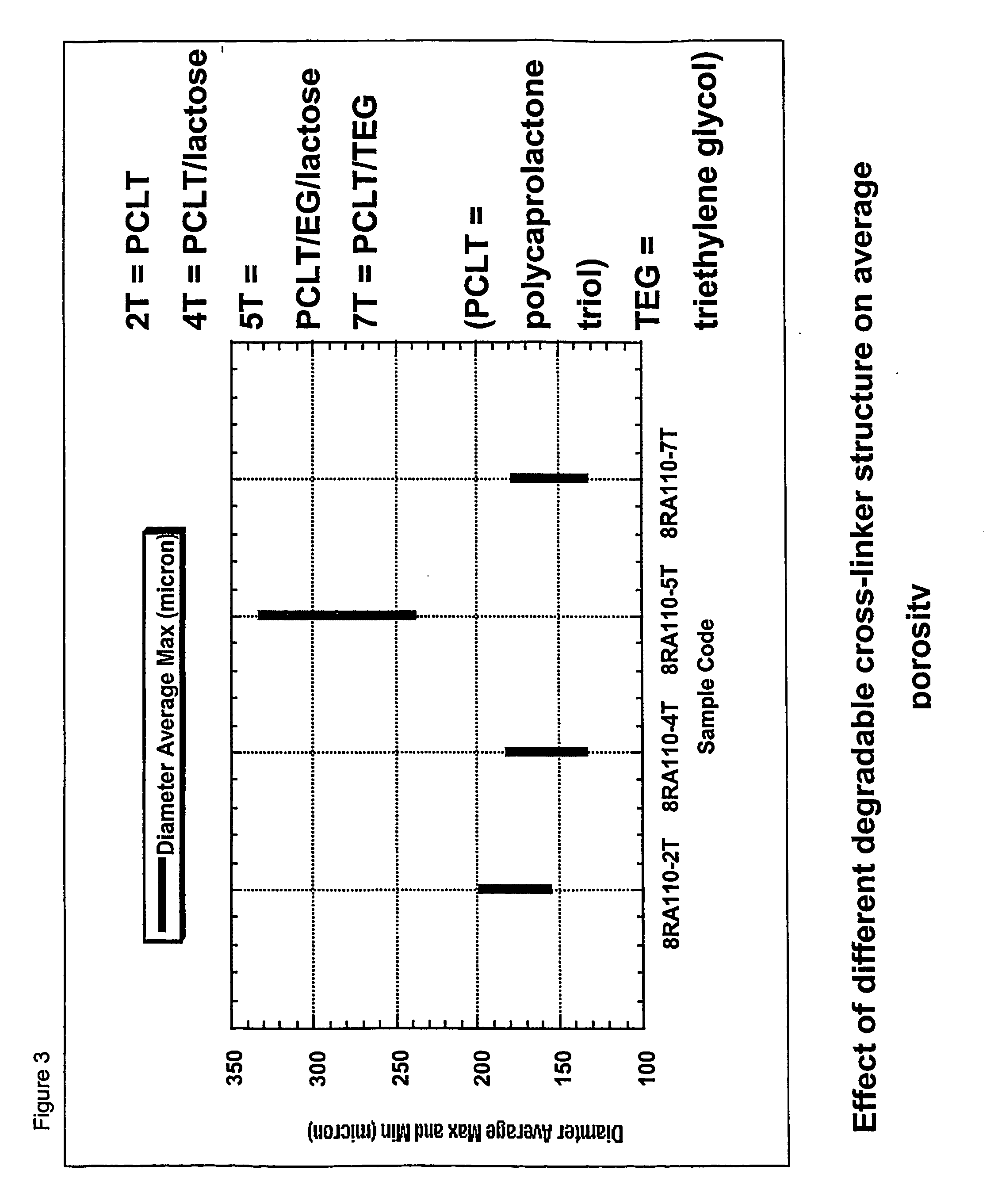

Biodegradable polyurethane/urea compositions

The present invention relates to biocompatible, biodegradable polyurethane / urea polymeric compositions that are capable of in-vivo curing with low heat generation to form materials suitable for use in scaffolds in tissue engineering applications such as bone and cartilage repair. The polymers are desirably flowable and injectable and can support living biological components to aid in the healing process. They may be cured ex-vivo for invasive surgical repair methods, or alternatively utilized for relatively non-invasive surgical repair methods such as by arthroscope. The invention also relates to prepolymers useful in the preparation of the polymeric compositions, and to methods of treatment of damaged tissue using the polymers of the invention.

Owner:POLYNOVO BIOMATERIALS PTY LTD

Saline soluble inorganic fibres

InactiveUS7153796B2Improve fiber qualityMinimise reduction is solubilityInorganic material artificial filamentsHeat proofingFiberThermal insulation

Thermal insulation is provided for use in applications requiring continuous resistance to temperatures of 1260° C. without reaction with alumino-silicate firebricks, the insulation comprises fibers having a composition in wt %65%<SiO2<86%MgO<10%14%<CaO<28%Al2O3<2%ZrO2<3%B2O3<5%P2O5<5%72%<SiO2+ZrO2+B2O3+5*P2O5 95%<SiO2+CaO+MgO+Al2O3+ZrO2+B2O3+P2O5 Addition of elements selected from the group Sc, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, Y or mixtures thereof improves fiber quality and the strength of blankets made from the fibers.

Owner:THE MORGAN CRUCIBLE CO PLC

Coated powder particles for producing three-dimensional bodies by means of a layer constituting method

InactiveUS20060251535A1Good storage stabilityHigh distinctnessAdditive manufacturing apparatusTransportation and packagingOrganic solventLaser light

The invention relates a powder material consisting of coated particles for a powder-based rapid generative prototyping methods, in particular by compressing a 3D binder. Said powder material consists of individual plastic, metal and / or ceramic particles and / or granules. A coating essentially consists of an adhesive agent which can be activated by a liquid binder, light or laser light, and of sinterable or glass-forming fine-grained material. Said invention also relates to a method for compressing 3D binder with the aid of an organic solvent having a water content less than 45% and to sintered bodies, in particular for moulding or precision mechanical engineering, which are fixed to each other by sintering or glass formation from a fine grained material.

Owner:PFEIFER ROLF +2

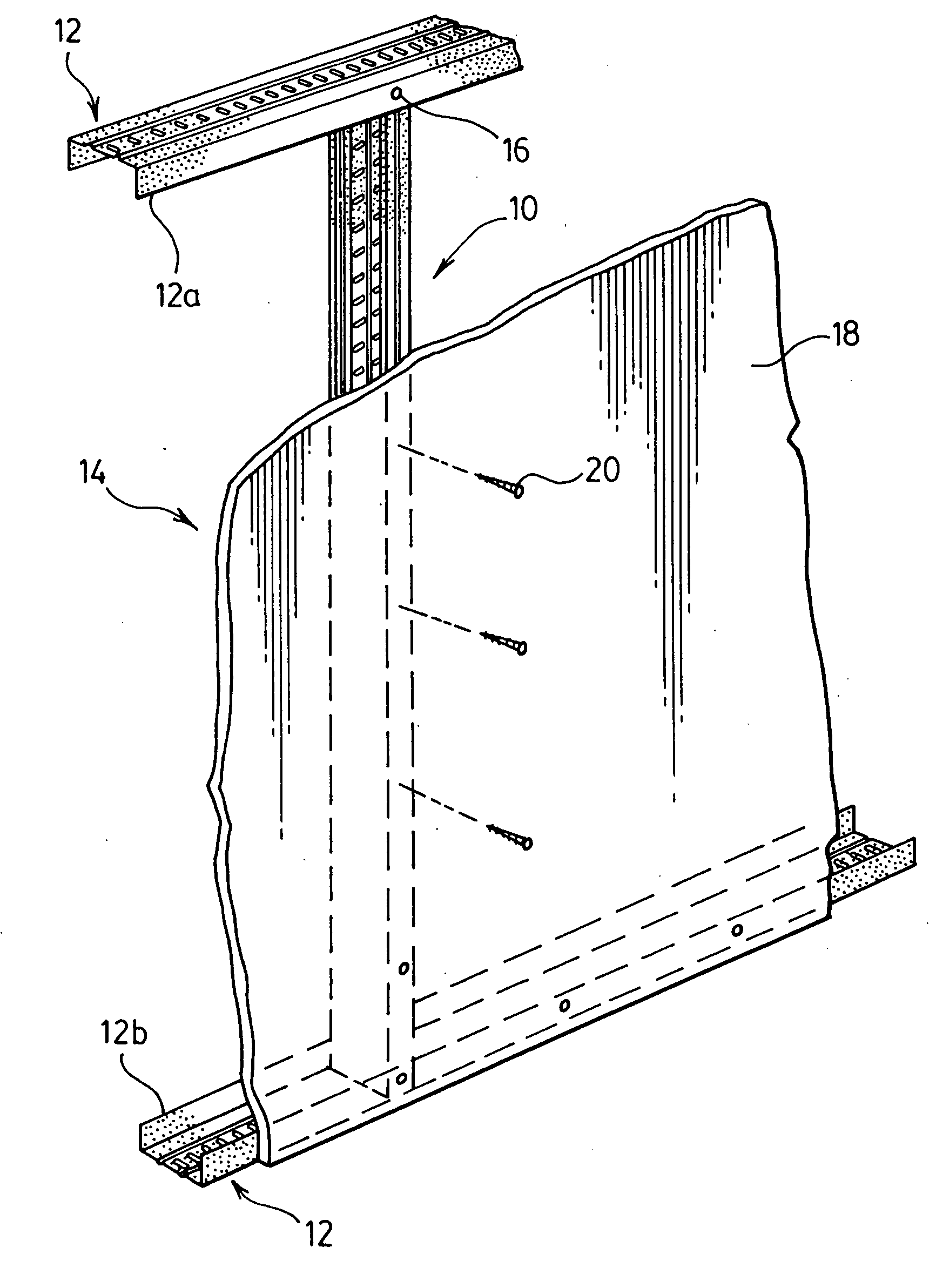

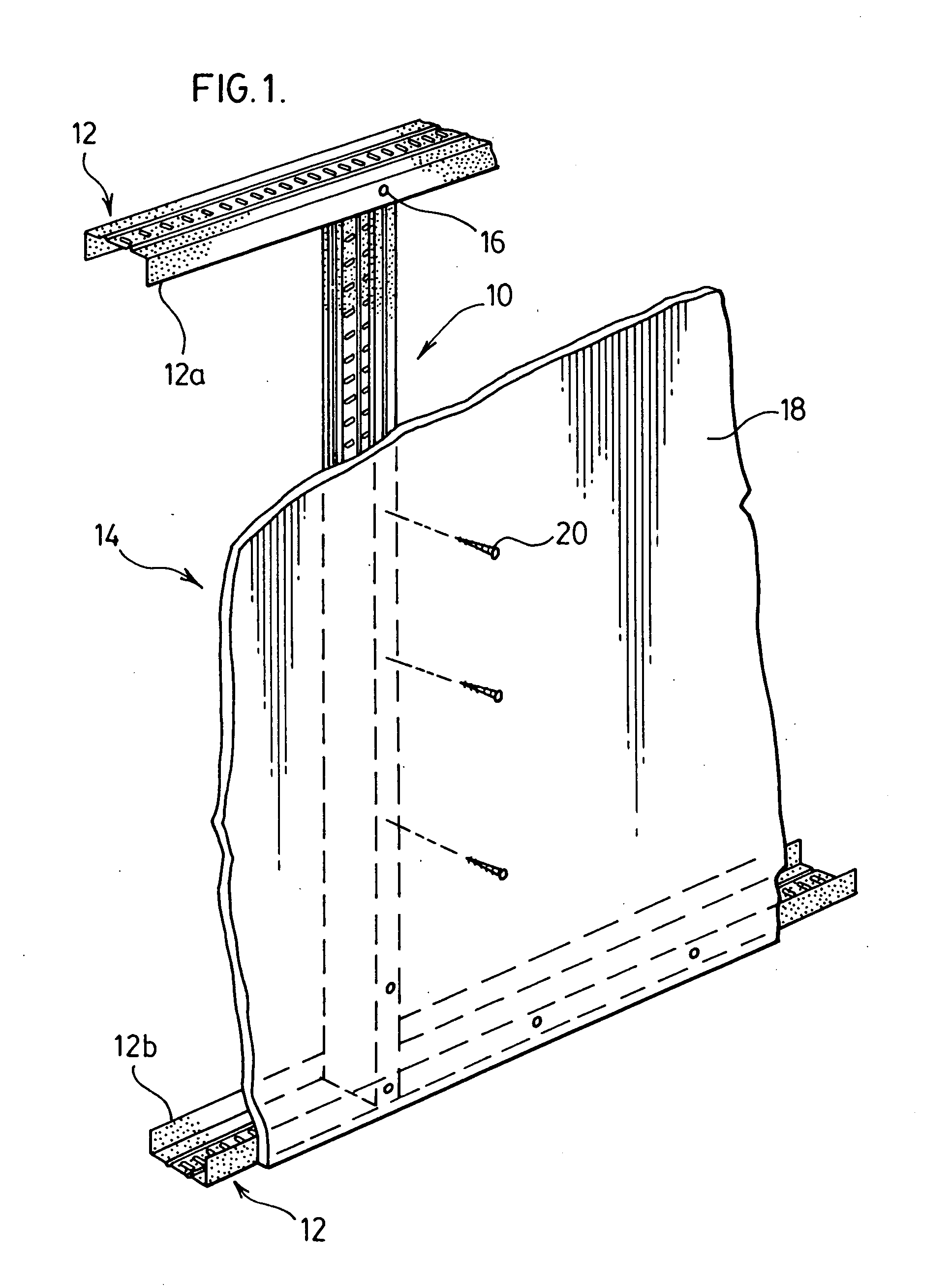

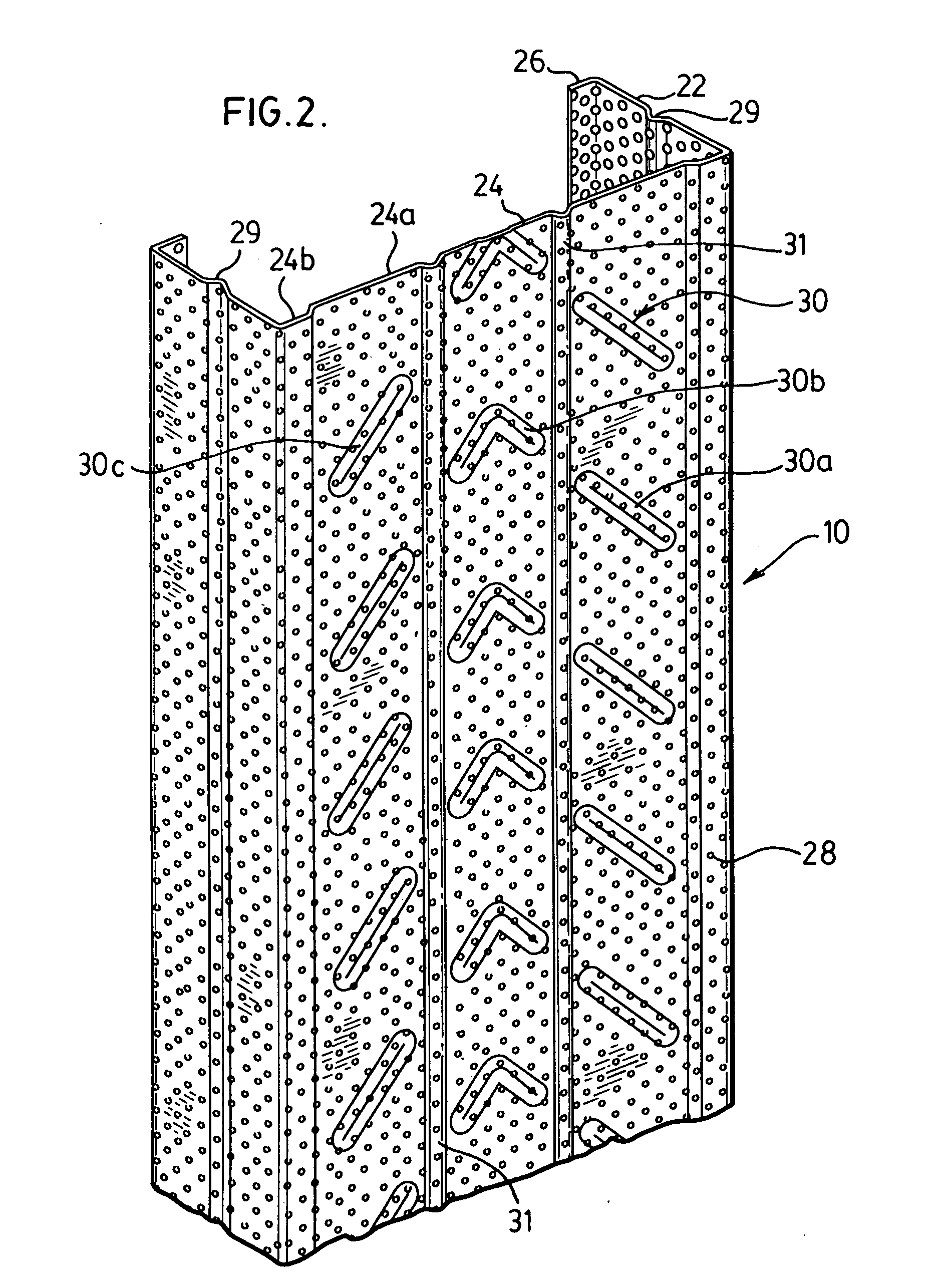

Light weight metal framing member

InactiveUS20080250738A1Low shrinkageReduce twistWallsPublic buildingsEngineeringMechanical engineering

The present invention provides for a lightweight metal framing member having a central web and two parallel spaced apart side walls extending upwardly from the sides of the web. The framing member has at least one longitudinally oriented rib extending the length of the web of the framing member to aid in reducing shrinkage and twisting of the framing member when non-symmetrical reinforcing structures are found in the framing member.

Owner:BAILEY METAL PROD

Hot melt adhesive composition based on a random copolymer of isotactic polypropylene and a secondary polymer

InactiveUS7262251B2Broad processibilityImprove thermal stabilityOther chemical processesFilm/foil adhesivesWaxPlasticizer

Owner:ATO FINDLEY

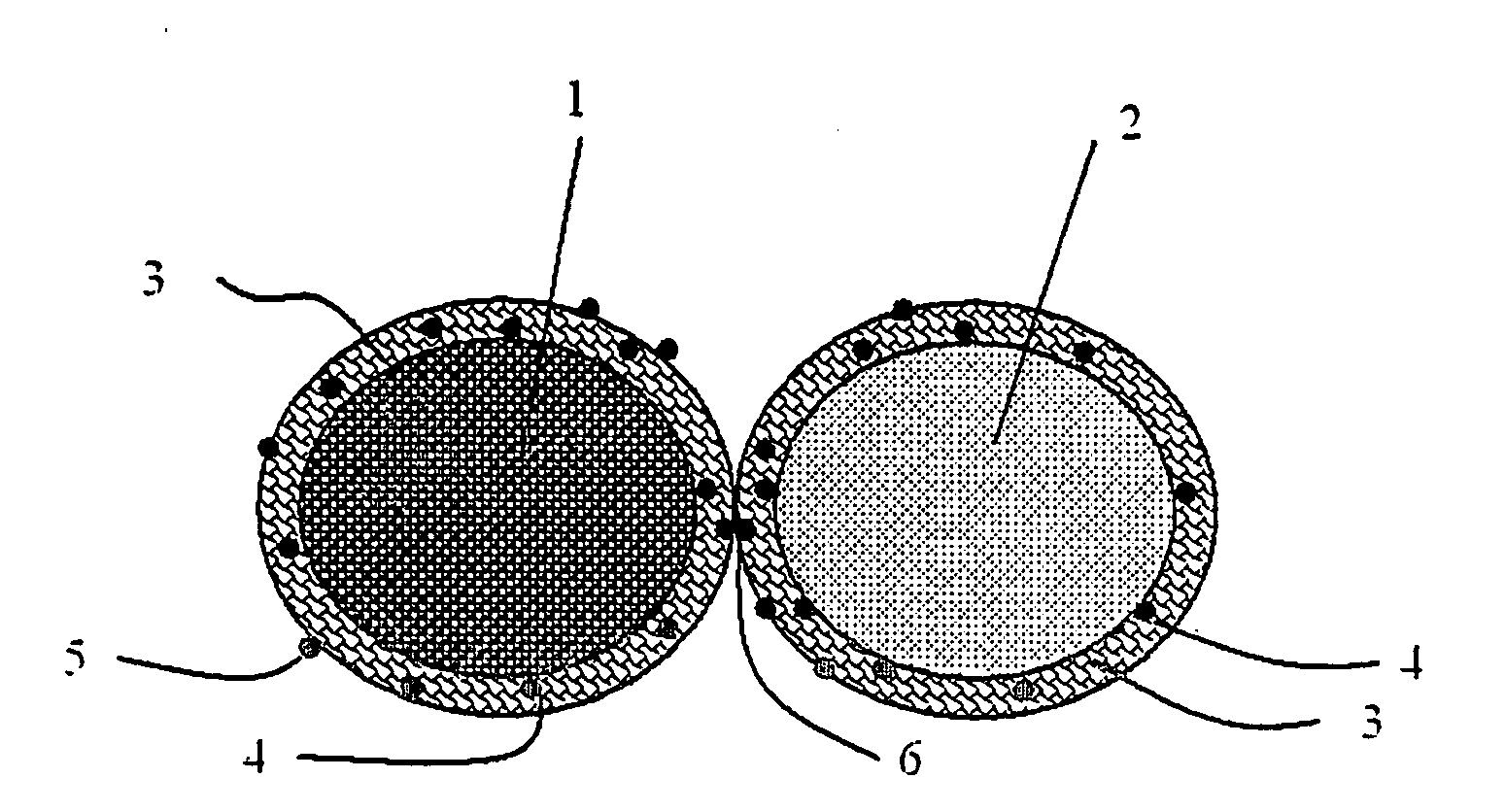

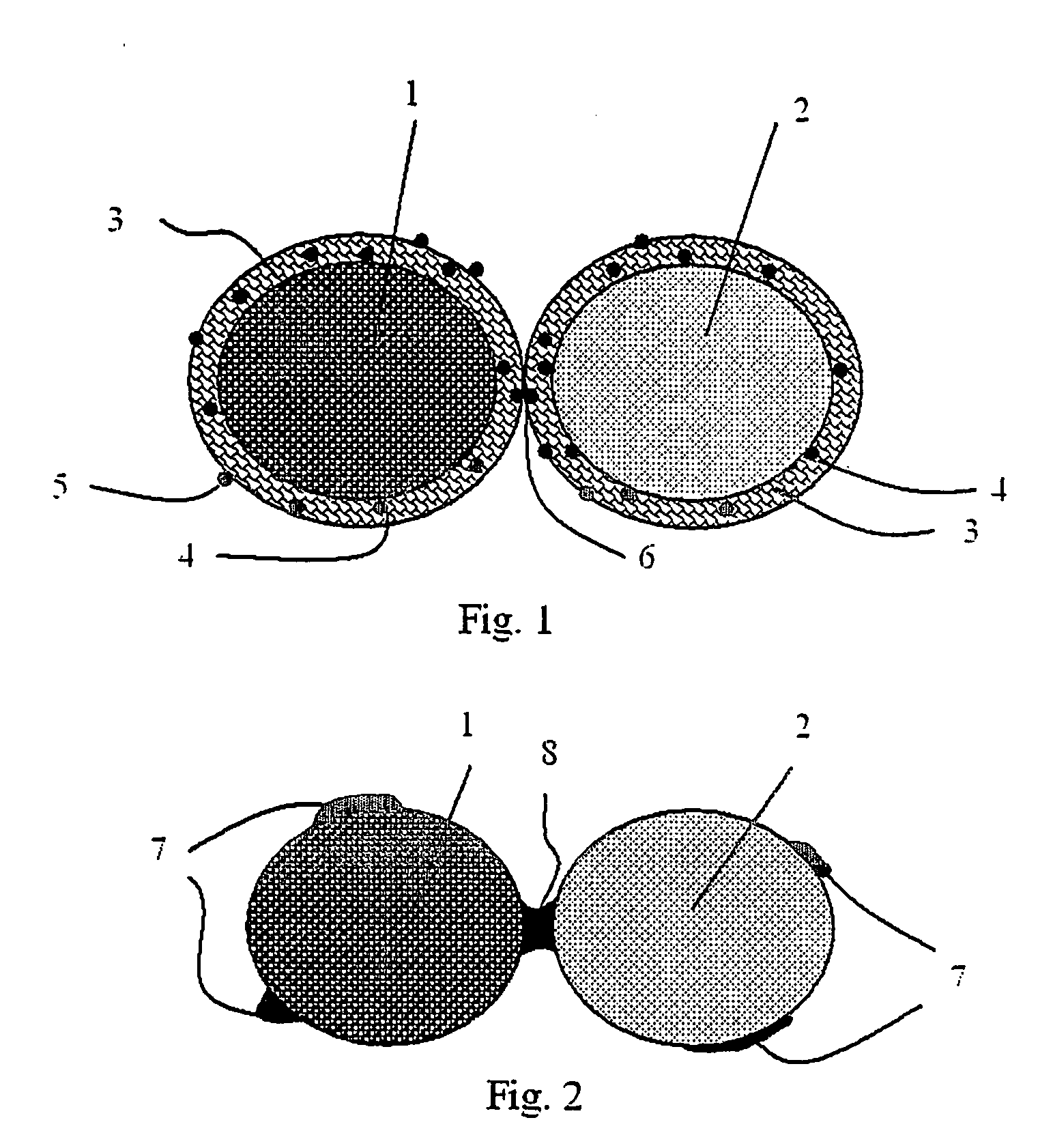

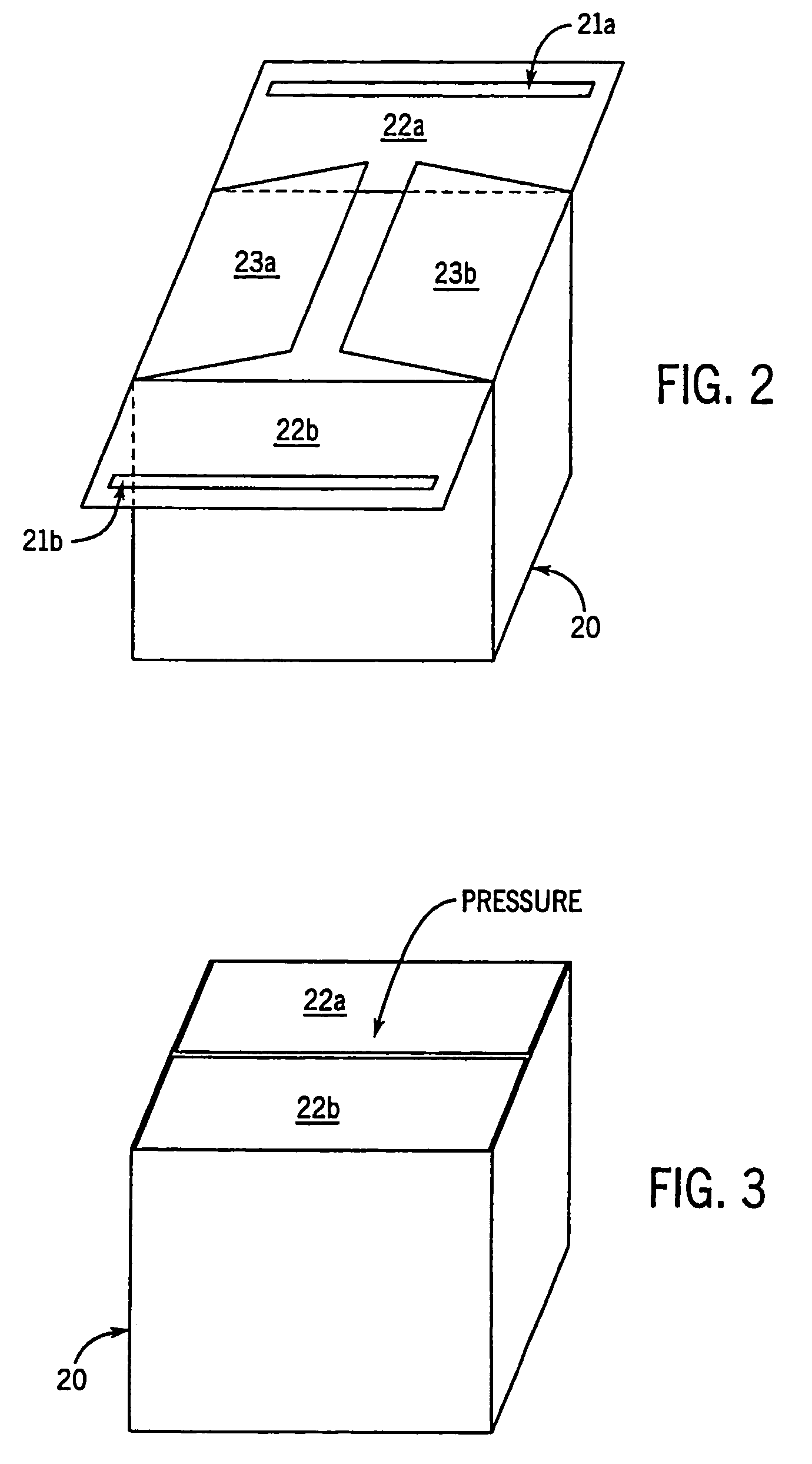

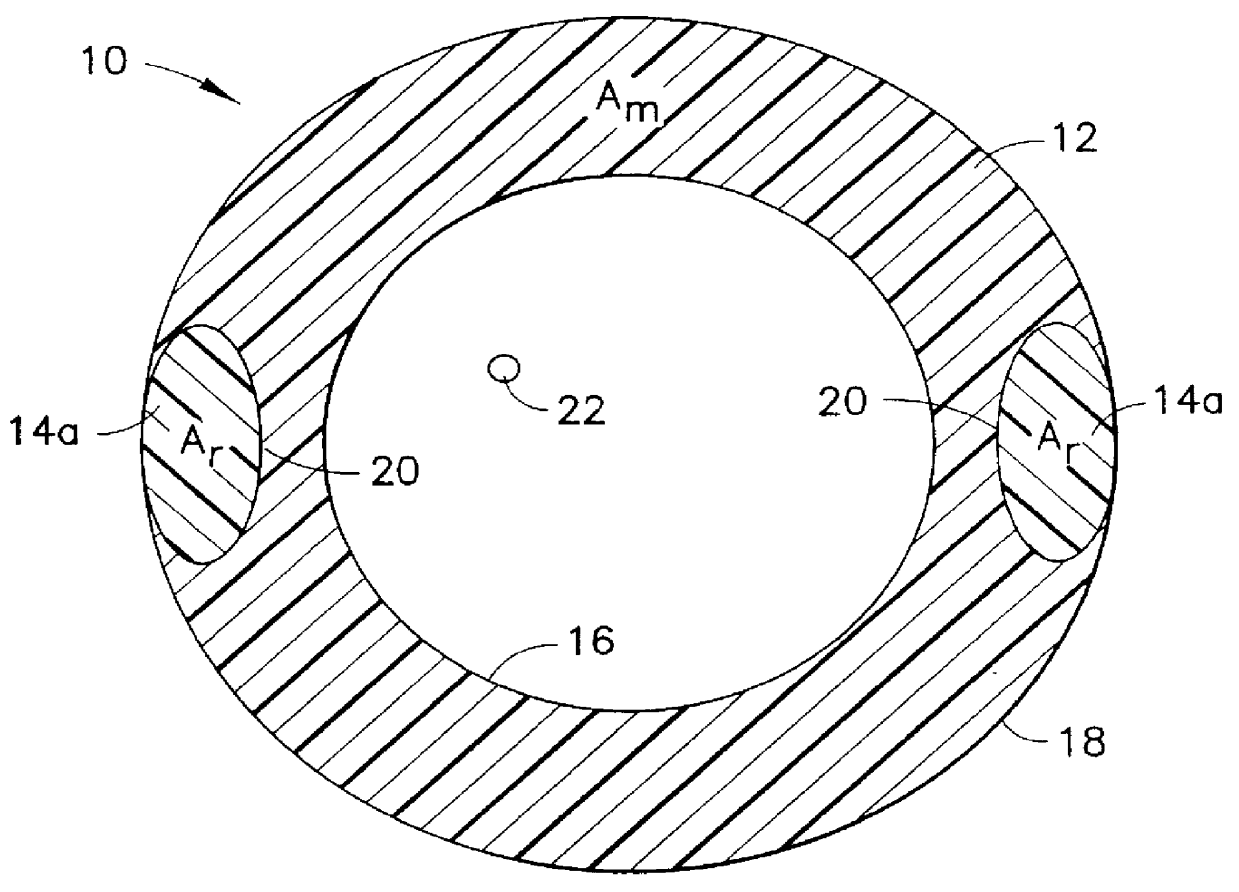

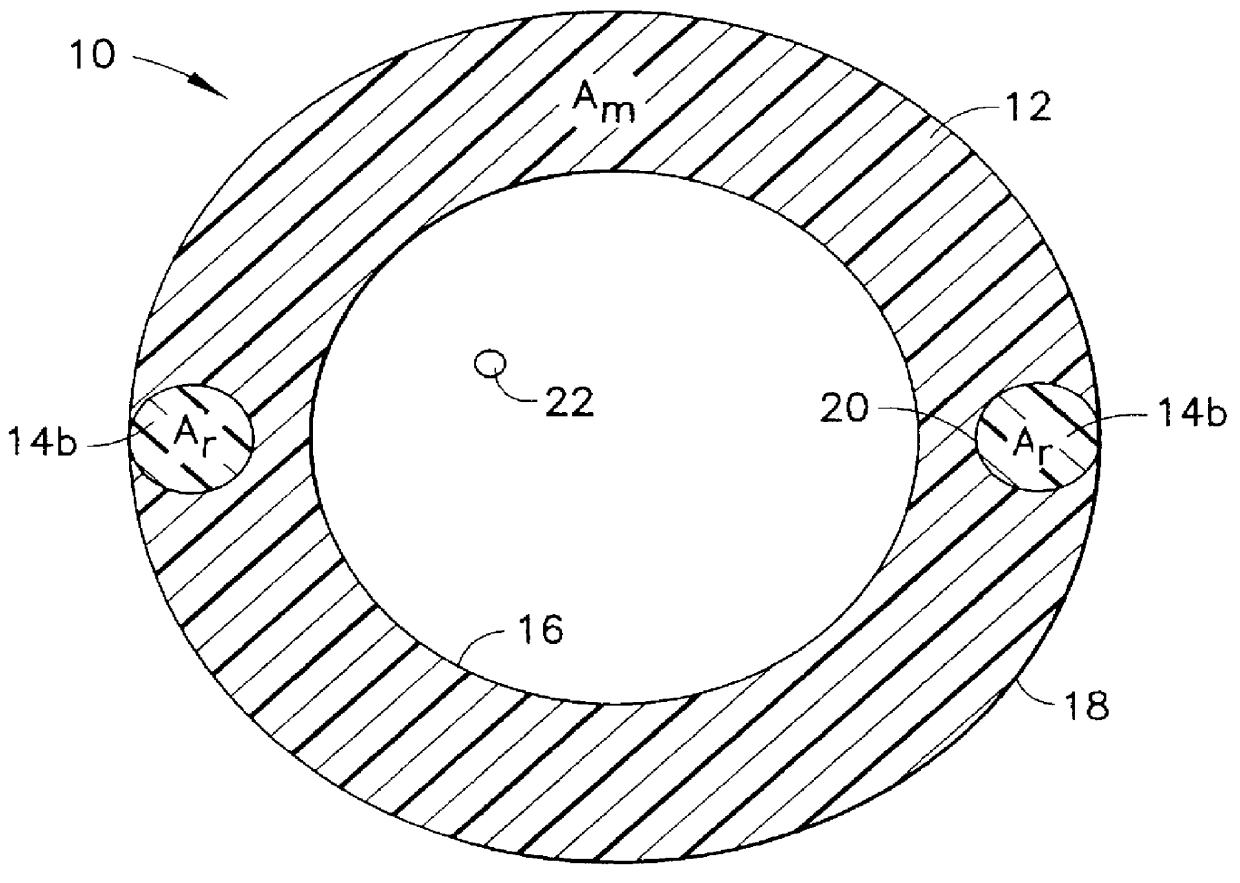

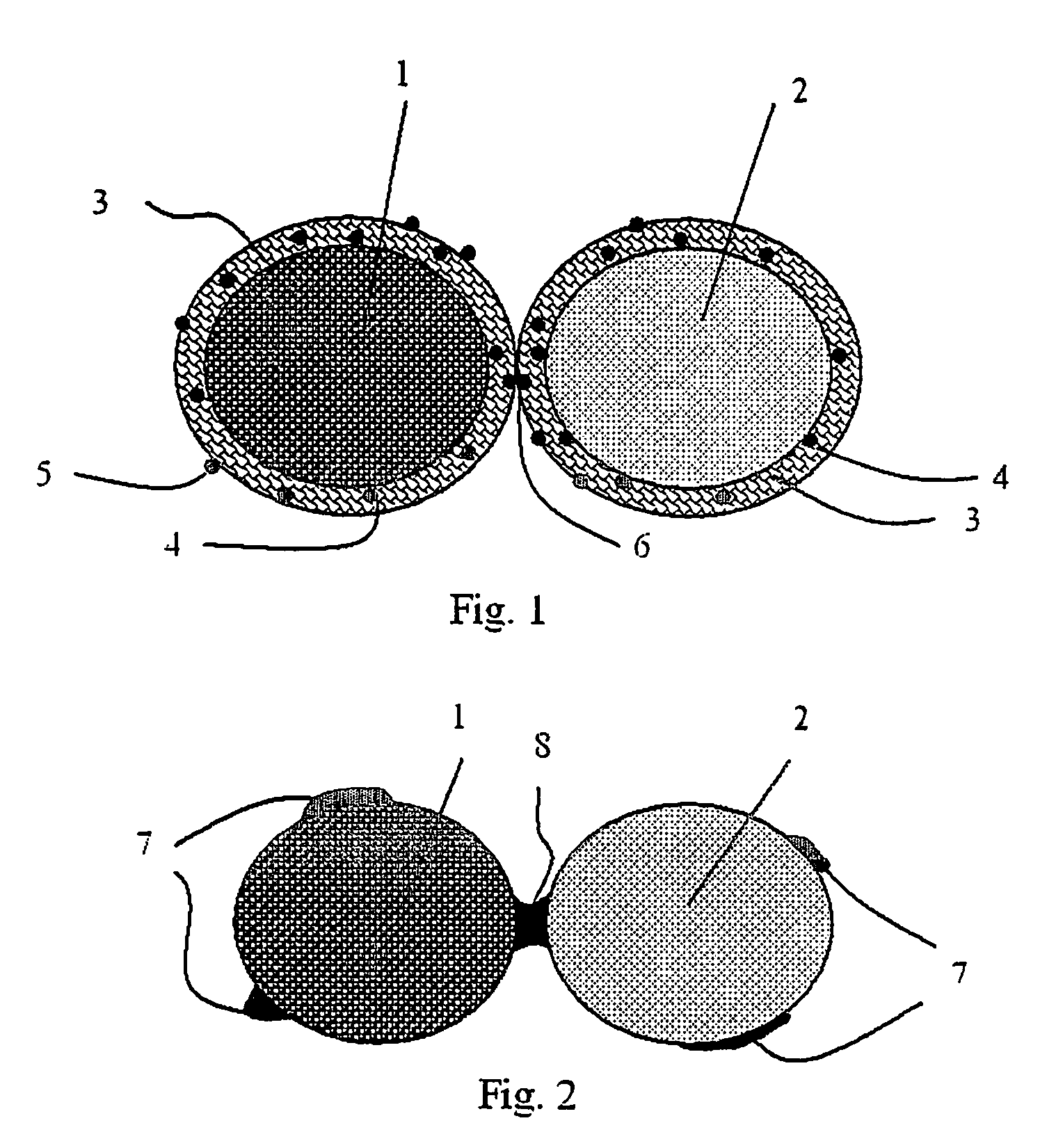

Polymerization process and materials for biomedical applications

InactiveUS20050090612A1Avoid problemsPromote sportsOptical articlesOptical partsPolymer scienceAqueous solubility

A molded component or article for biomedical use is prepared from a crosslinkable non-water-soluble polymer which when crosslinked and saturated with water forms a hydrogel. The polymer is formulated as a composition containing a non-aqueous diluent in addition to the polymer, the diluent being present in a volumetric proportion that is substantially equal to the volumetric proportion of water in the hydrogel that would be formed when the polymer is crosslinked and saturated with water. The composition is cast in a mold where the composition is exposed to conditions that cause crosslinking to occur by a reaction to which the non-aqueous diluent is inert. The crosslinking reaction produces a molded non-aqueous gel which is then converted to a hydrogel by substituting an aqueous liquid such as water or physiological saline for the non-aqueous diluent. The use of a molding composition whose curing consists essentially entirely of crosslinking results in a molding process that entails little or no shrinkage, and dimensional integrity is maintained up through the formation of the hydrogel by using the non-aqueous diluent in essentially the same volumetric proportion as water in the hydrogel.

Owner:ZMS LLC

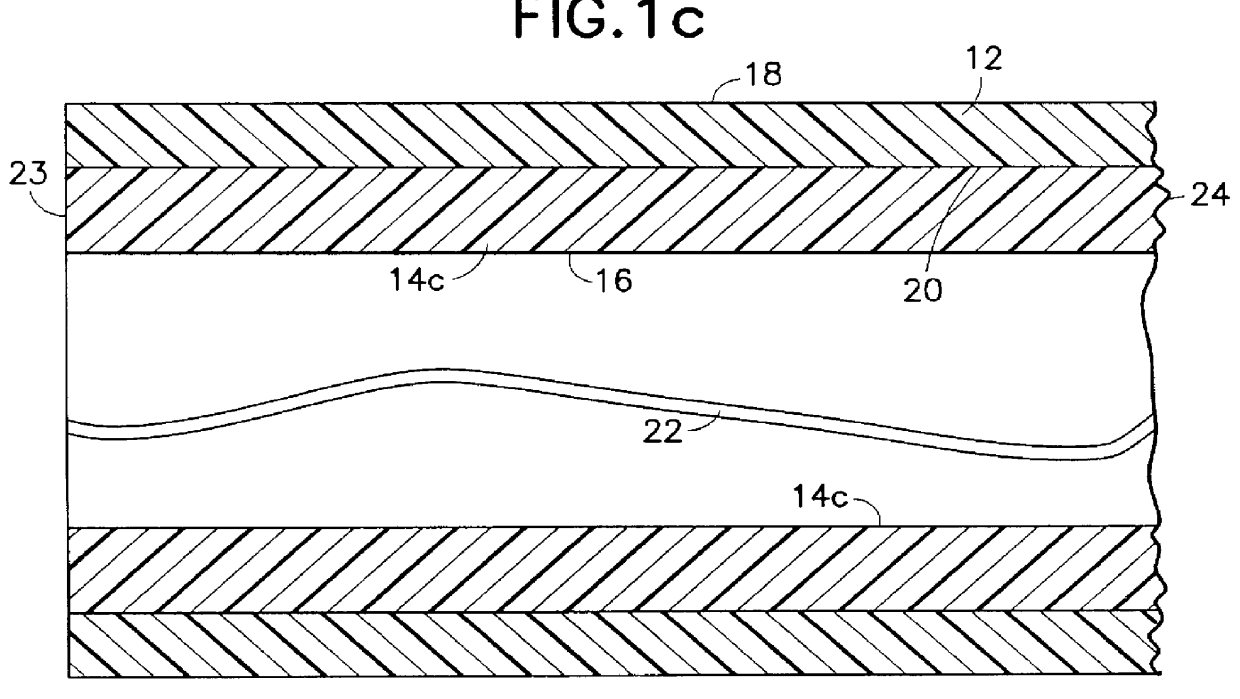

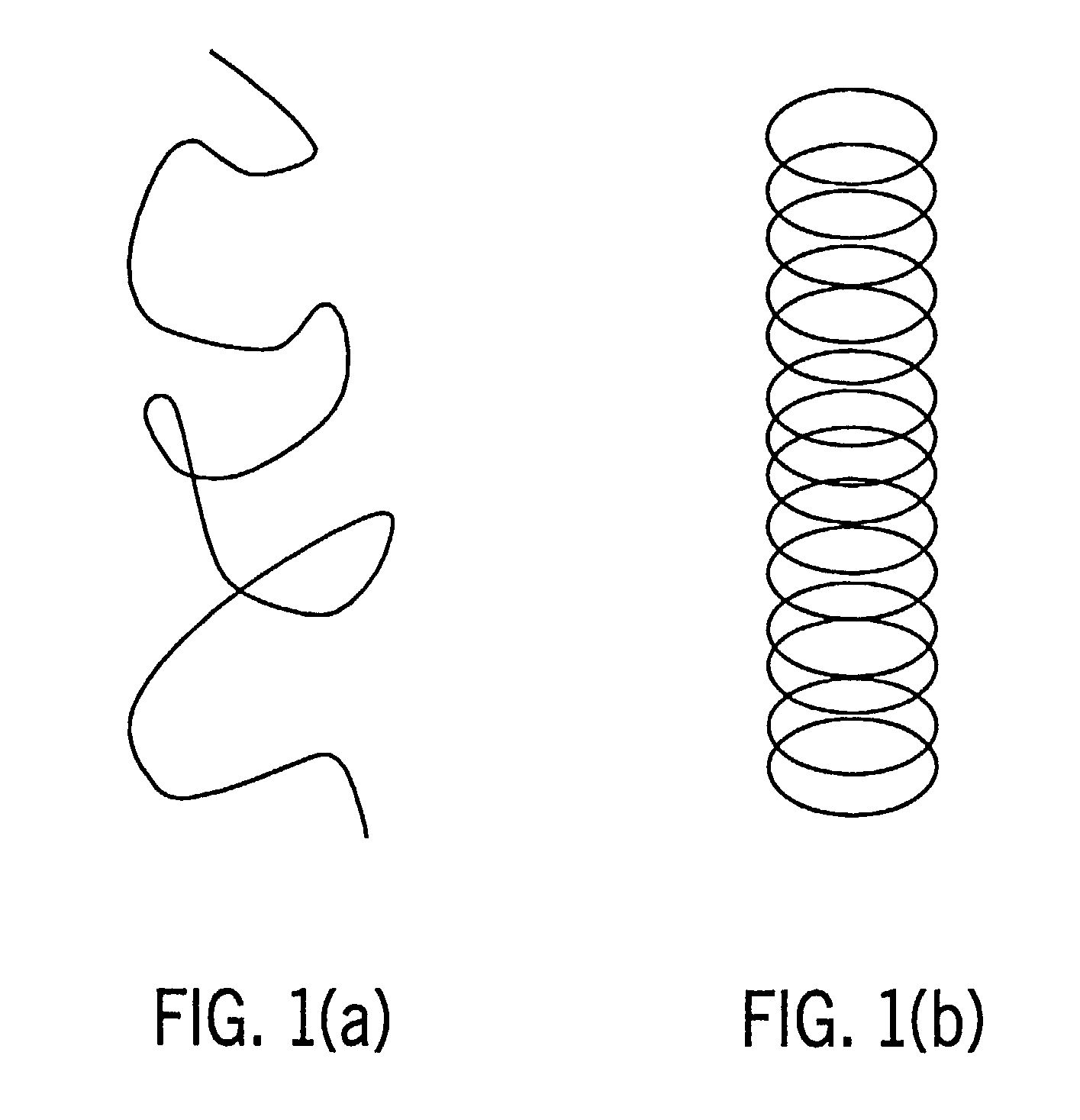

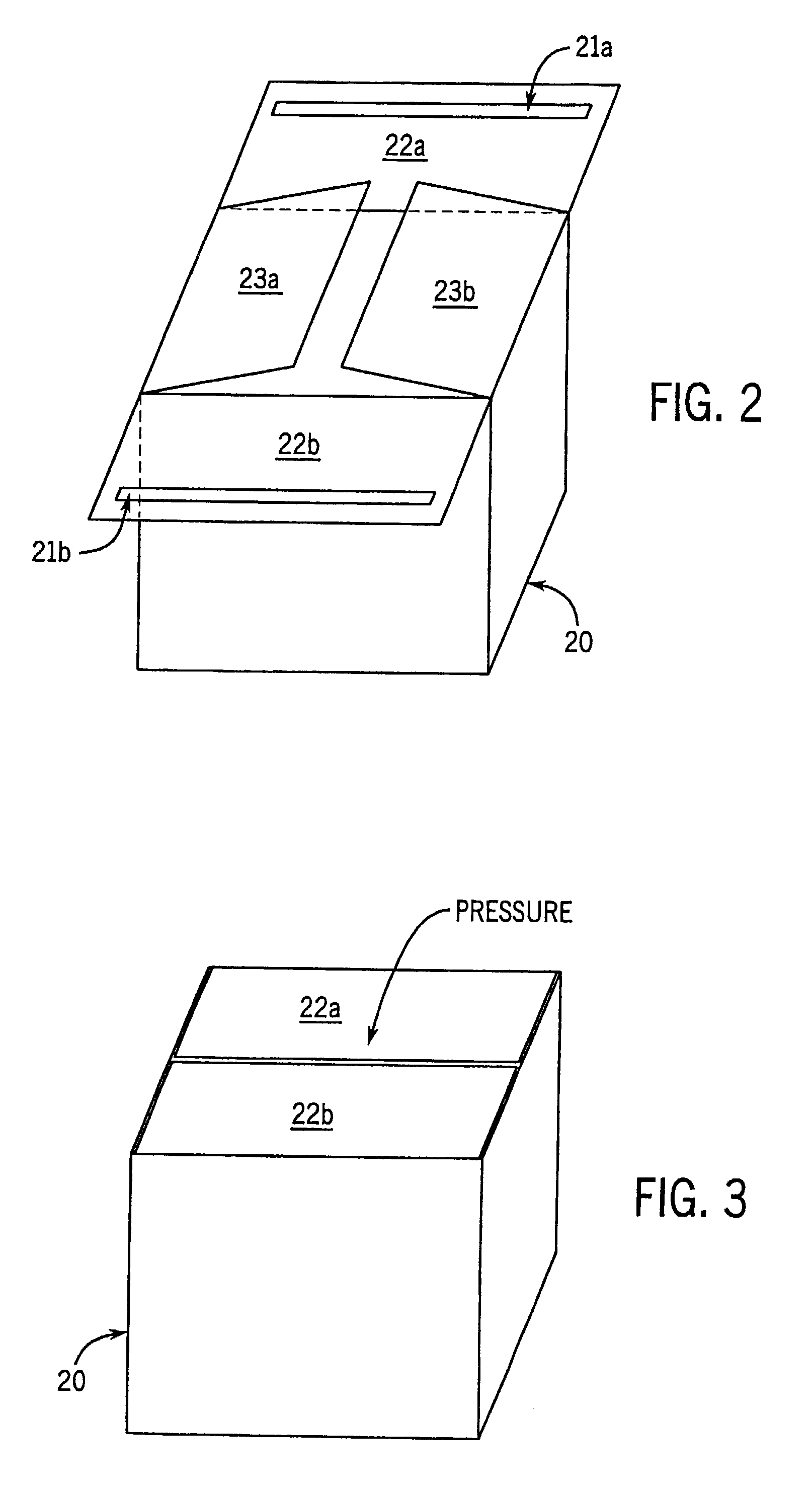

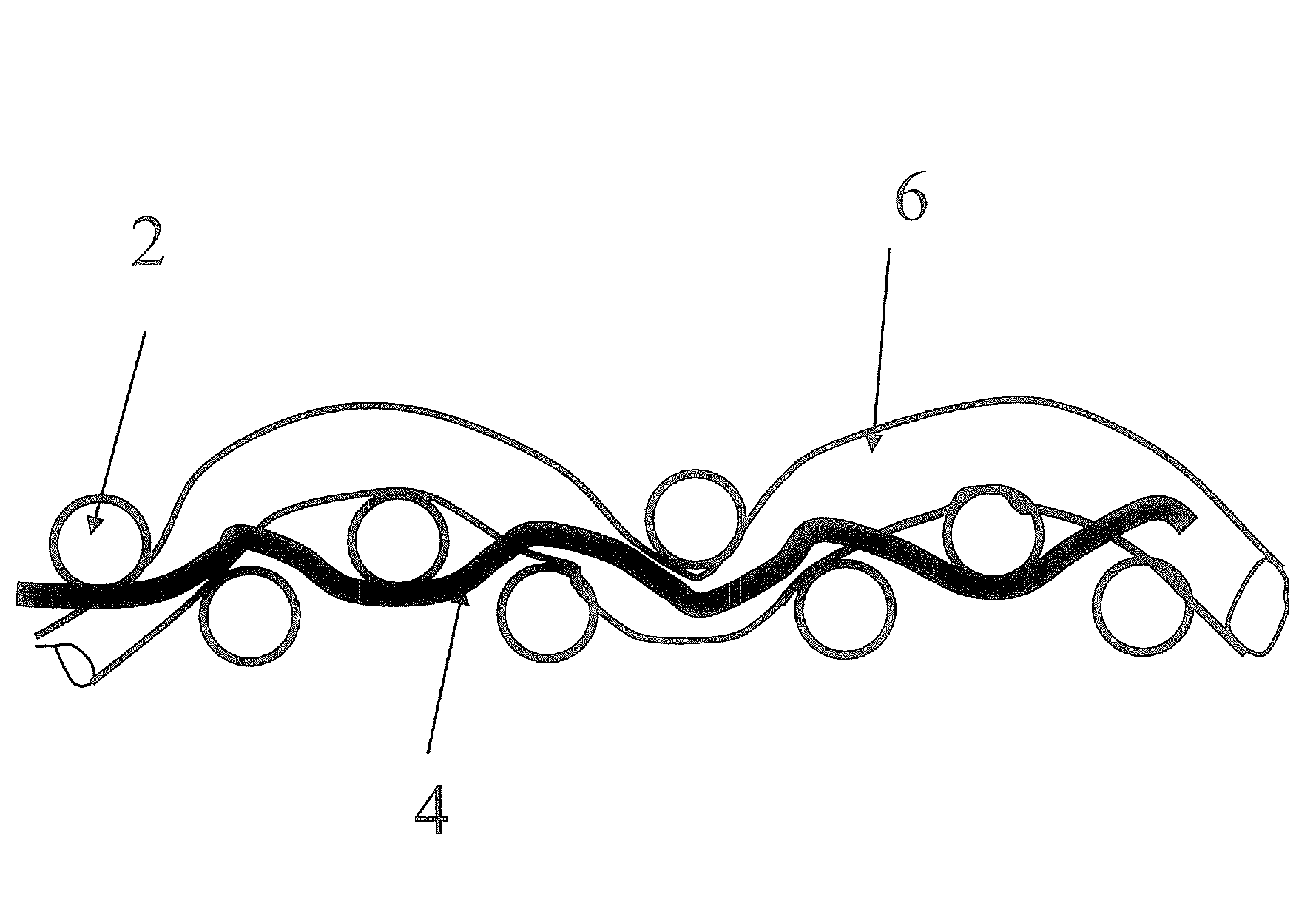

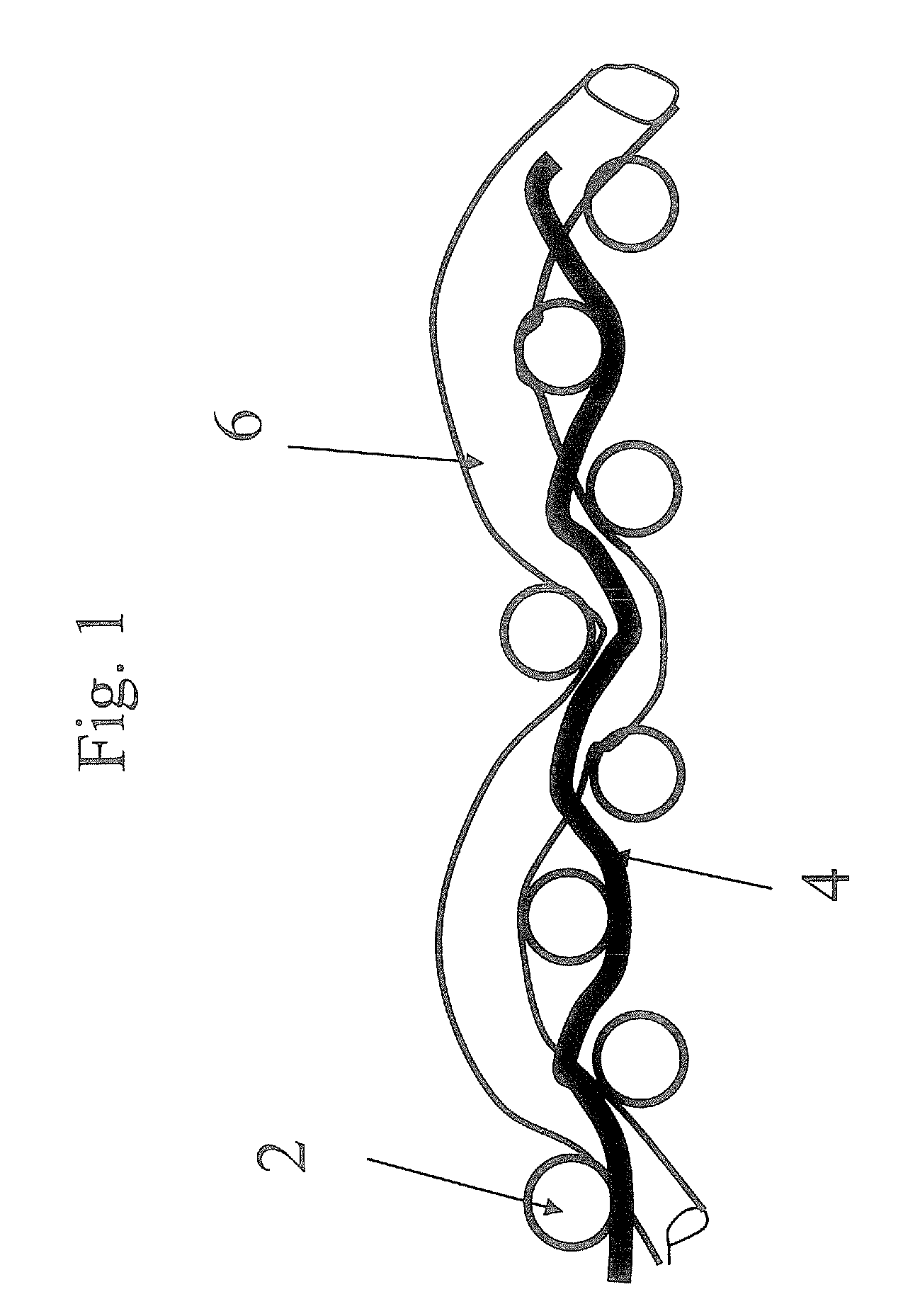

Continuous composite reinforced buffer tubes for optical fiber cables

InactiveUS6041153AHigh strengthLow shrinkageOptical articlesFibre mechanical structuresEngineeringThermal expansion

A composite reinforced buffer tube for an optical fiber cable is disclosed. The composite reinforced buffer tube comprises an extruded elongated thermoplastic matrix having an elongated, substantially continuous, reinforcement incorporated therein along its length between its inside and outside walls. The substantially continuous reinforcing is co-extruded with the elongated thermoplastic matrix and bonded to the matrix at interface regions therebetween. The material forming the reinforcement has a higher modulus of elasticity than the material forming the thermoplastic matrix, and the reinforcement material has a coefficient of thermal expansion that is less than the thermoplastic matrix material. The strength properties of the buffer tube can be finely tailored by the size, shape and positioning of the co-extruded reinforcement as well as the number of reinforcements.

Owner:ALCATEL LUCENT SAS

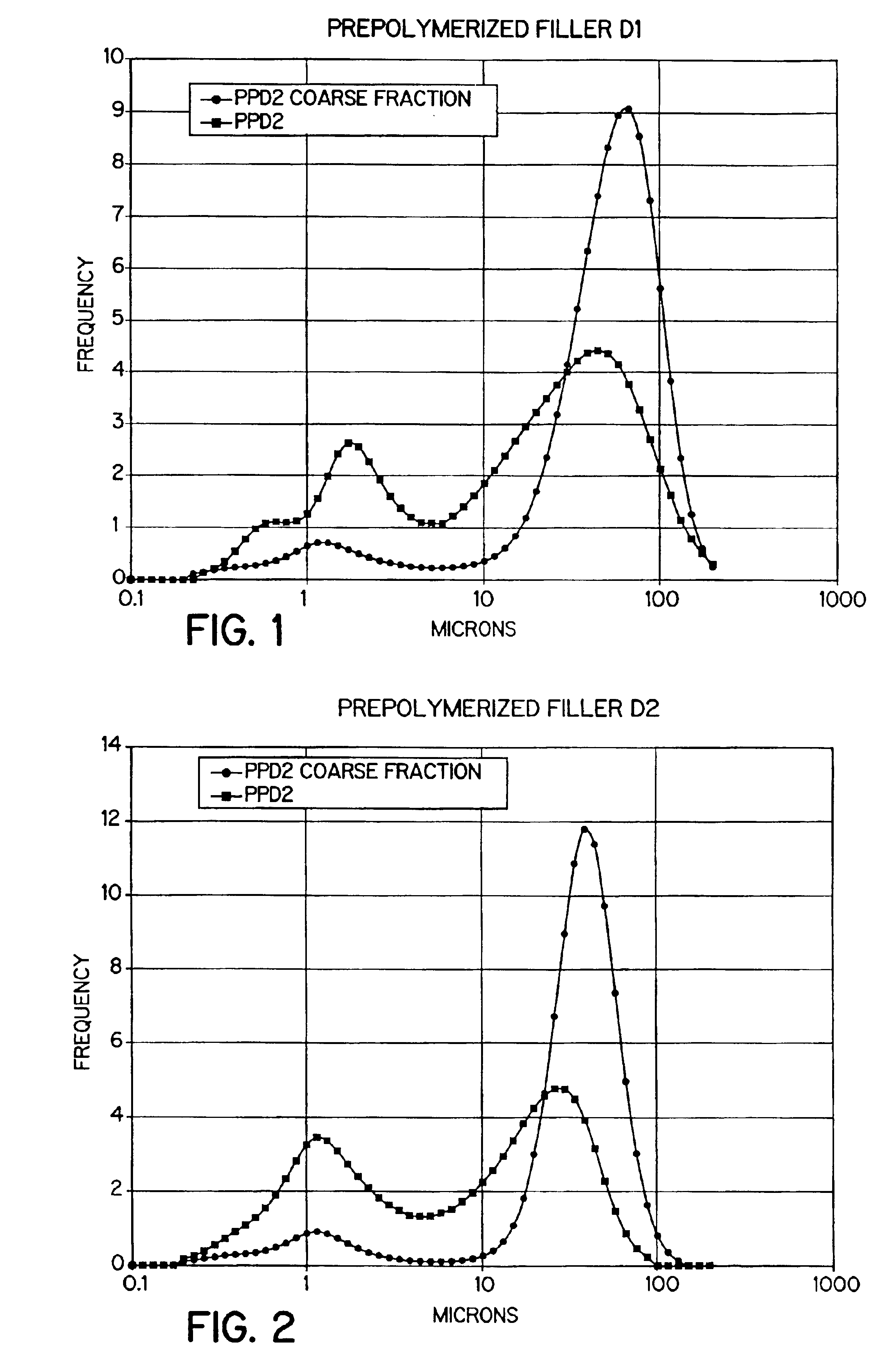

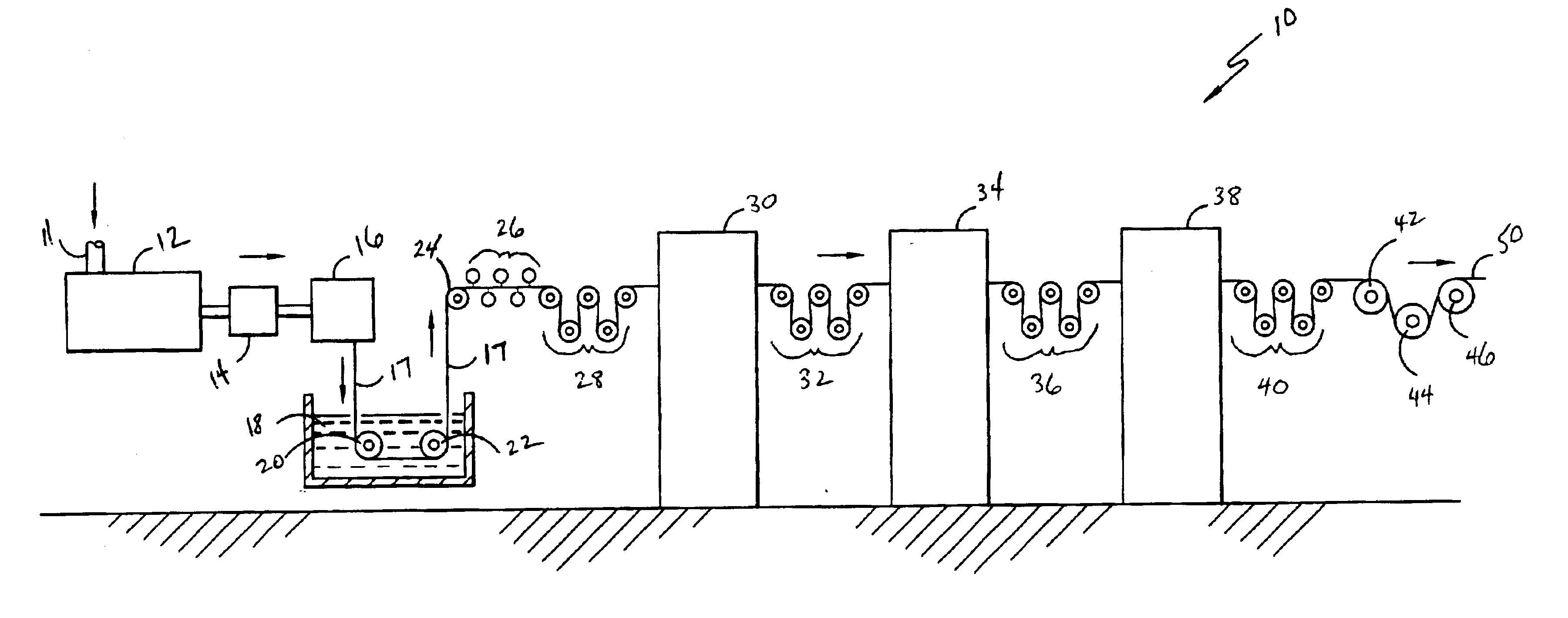

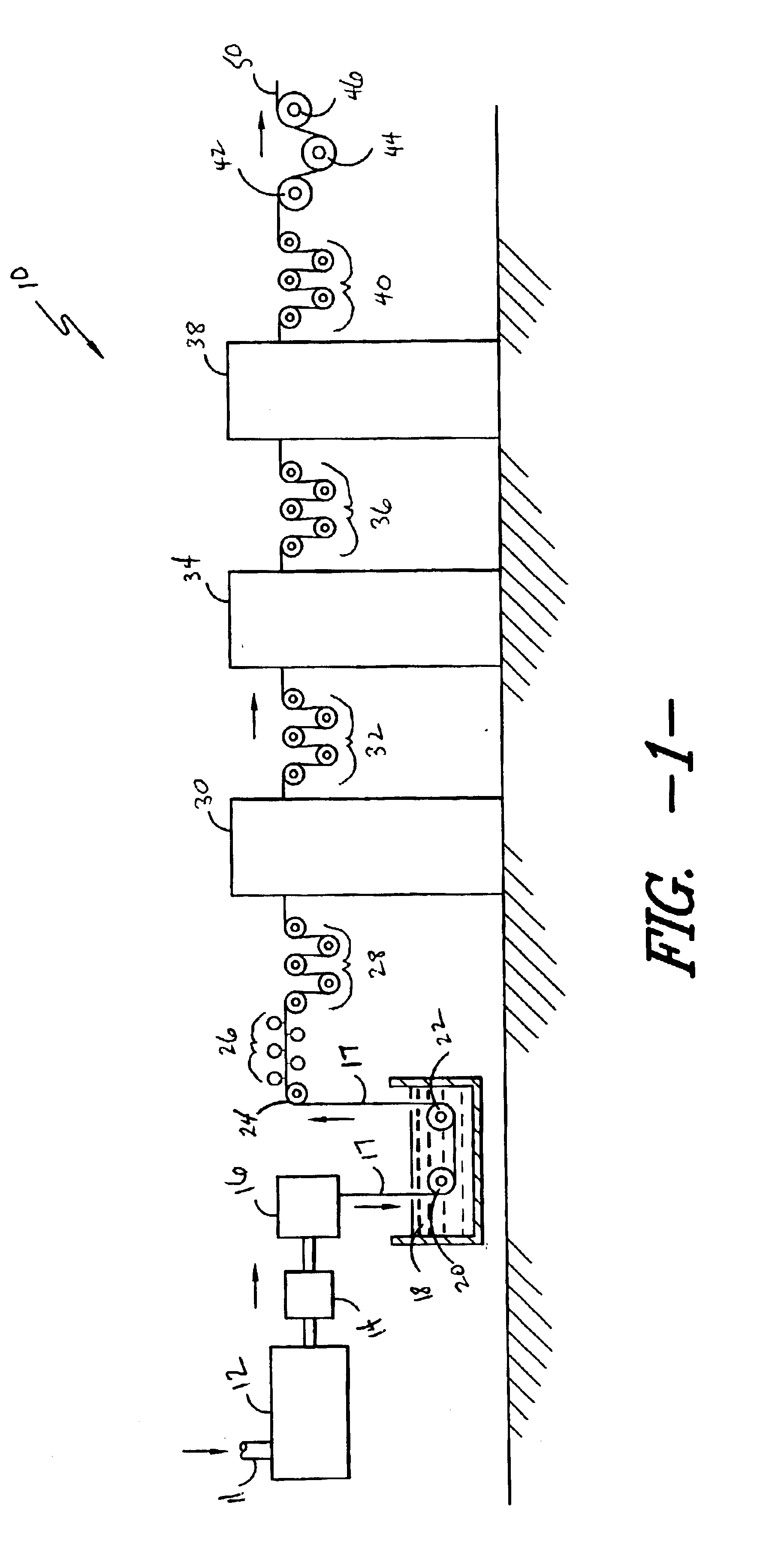

Prepolymerized filler in dental restorative composite

InactiveUS6890968B2High filler loadingReduce Shrinkage ProblemsImpression capsSurgical adhesivesDental compositeUltimate tensile strength

A dental composite having high filler loading and low shrinkage thereby providing good strength and marginal integrity. Through the use of prepolymerized filler particles in combination with a structural filler and a nanofiller, the composite exhibits very low shrinkage and is useful in stress bearing restorations and in cosmetic restorations. The structural filler used is ground to a mean particle size of less than 0.5 μm and the nanofiller has discrete particles of a mean particle size less than 100 nm to improve handling and mechanical characteristics. The prepolymerized filler particles also allow for less viscosity and better handling characteristics of the composite.

Owner:THE KERR

Micron nano material composite modified water-based adhesive

InactiveCN101210157ALow shrinkageImprove performanceMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesMicro nanoExtensibility

The invention relates to an aqueous binder which is compounded and modified by micro nano material. The modified aqueous binder of the invention adopts emulsion adhesive as matrix and micro-size and nano-size inorganic powder as modifier to prepare the compound and modified aqueous binder. The method of the invention can not only enhance the interface binding force of the aqueous binder, but also greatly improve the properties of water resistance, toughness and extensibility, leading comprehensive performance of the aqueous binder to be improved.

Owner:郑旷宇

Flame-resistant fiber blend, yarn, and fabric, and method for making same

InactiveUS20060292953A1Improve flame retardant performanceReduce weightWarp knittingWoven fabricsYarnAramid

A fiber blend, a yarn spun from the fiber blend, and a fabric made from the yarn, wherein the fiber blend comprises: (a) about 40 wt.% to about 65 wt.% modacrylic fibers containing antimony, or FR acrylic fibers; (b) about 10 wt.% to about 50 wt.% cotton fibers or FR cotton fibers; (c) up to about 25 wt.% nylon fibers; and (d) greater than about 3 wt.% and less than 10 wt.% para-aramid fibers. The fabric is over 90 percent dyeable and is capable of achieving ASTM F1506 certification with an Arc Thermal Performance Value greater than 8.0 cal / cm2. The fabric is woven or knitted, and has a weight of about 4.0 oz. / yd.2 to about 10.5 oz. / yd.2. The fabric is suitable for garments worn during activities in which there is potential for exposure to flame and / or electrical arc.

Owner:SPRINGFIELD

Thermoplastic monofilament fibers exhibiting low-shrink, high tenacity, and extremely high modulus levels

InactiveUS6759124B2High tensile strengthLow shrinkageSynthetic resin layered productsFilament/thread formingThermoplasticYarn

Unique thermoplastic monofilament fibers and yarns that exhibit heretofore unattained physical properties are provided. Such fibers are basically manufactured through the extrusion of thermoplastic resins that include a certain class of nucleating agent therein, and are able to be drawn at high ratios with such nucleating agents present that the tenacity and modulus strength are much higher than any other previously produced thermoplastic fibers, particularly those that also simultaneously exhibit extremely low shrinkage rates. Thus, such fibers require the presence of certain compounds that quickly and effectively provide rigidity to the target thermoplastic (for example, polypropylene), particularly after heat-setting. Generally, these compounds include any structure that nucleates polymer crystals within the target thermoplastic after exposure to sufficient heat to melt the initial pelletized polymer and allowing such an oriented polymer to cool. The compounds must nucleate polymer crystals at a higher temperature than the target thermoplastic without the nucleating agent during cooling. In such a manner, the "rigidifying" nucleator compounds provide nucleation sites for thermoplastic crystal growth. The preferred "rigidifying" compounds include dibenzylidene sorbitol based compounds, as well as less preferred compounds, such as [2.2.1]heptane-bicyclodicarboxylic acid, otherwise known as HPN-68, sodium benzoate, certain sodium and lithium phosphate salts [such as sodium 2,2'-methylene-bis-(4,6-di-tert-butylphenyl)phosphate, otherwise known as NA-11]. Specific methods of manufacture of such inventive thermoplastic fibers, as well as fabric articles made therefrom, are also encompassed within this invention.

Owner:MILLIKEN & CO

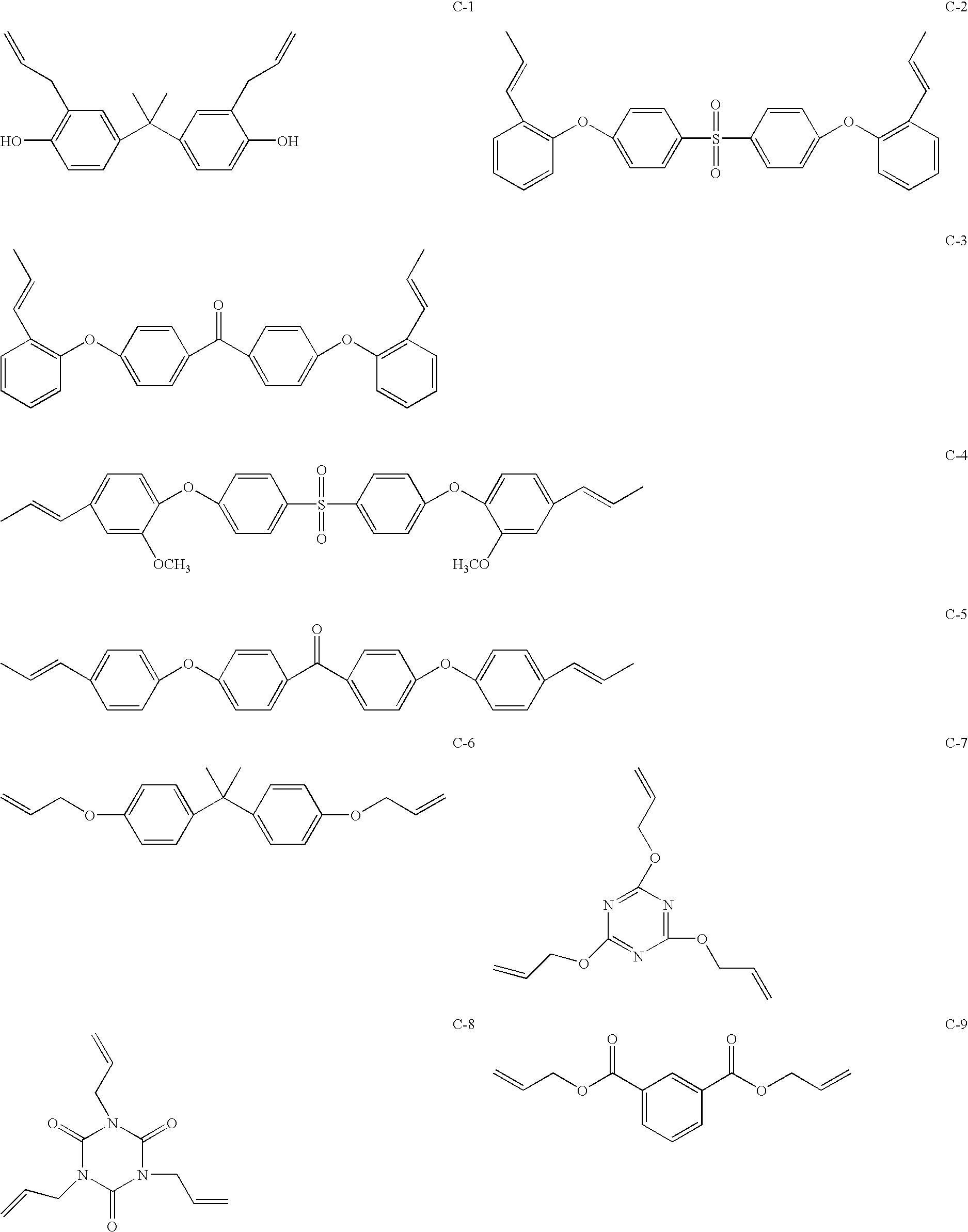

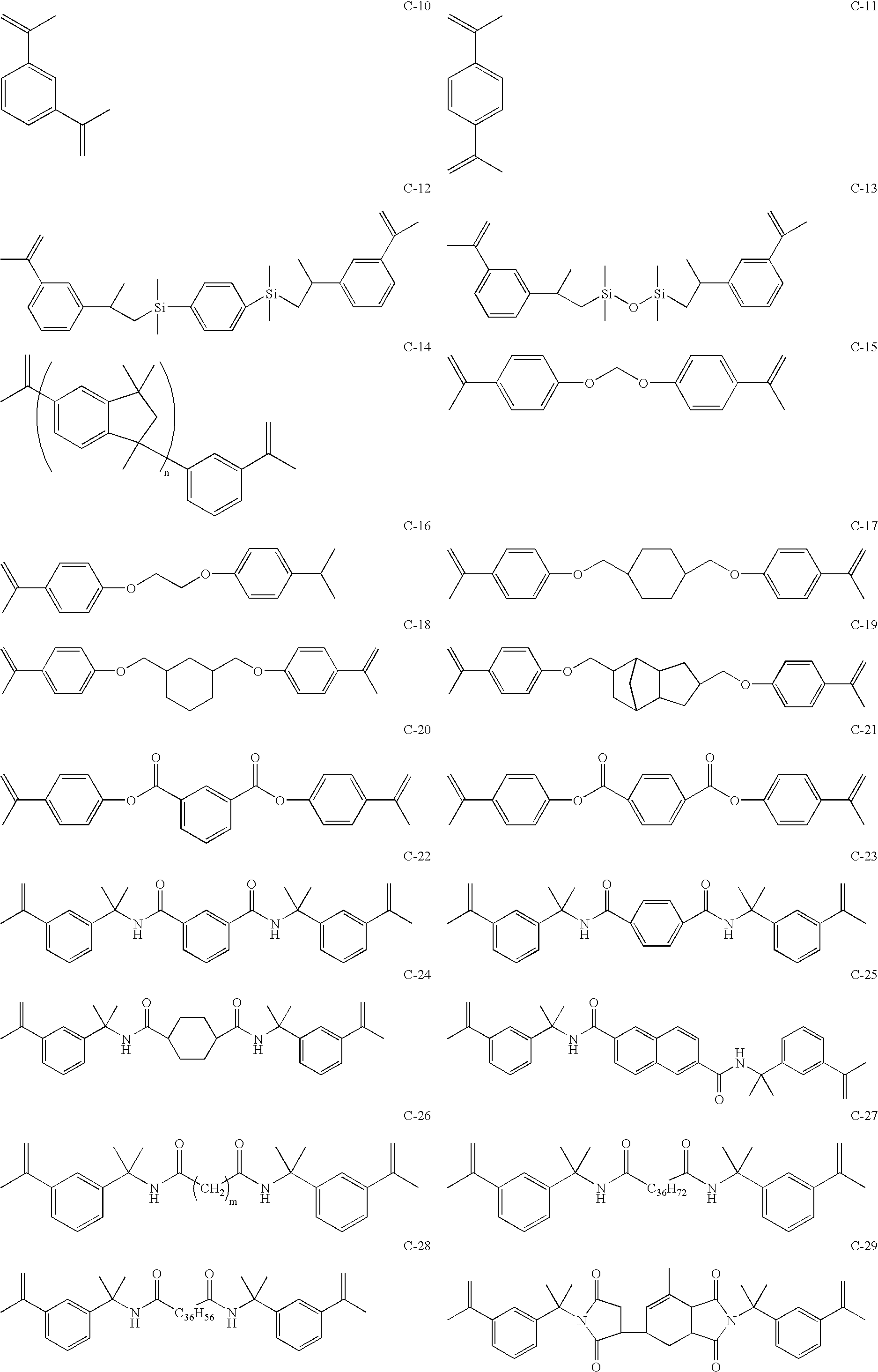

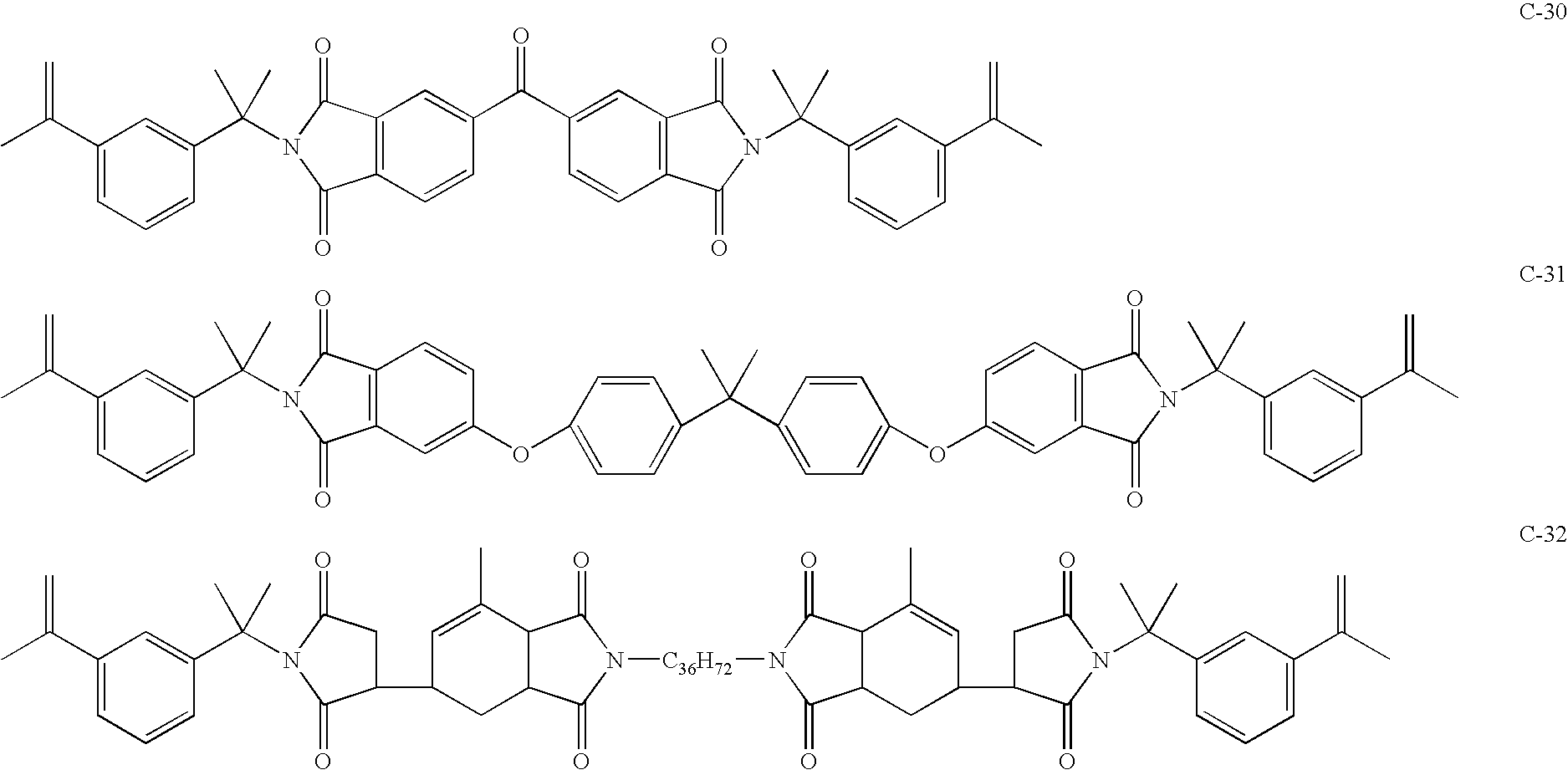

Maleimide compositions and methods for use thereof

ActiveUS20080075965A1Efficient curingIncrease application of useMixing methodsConductive materialElectronic packagingMaleimide

The invention is based on the discovery that compositions containing certain maleimide compounds and aromatic diene compounds are useful as thermosetting resins for the electronic packaging industry. The invention compositions described herein can be cured in a variety of ways, with or without a catalyst. In some embodiments, the well-known “ene” reaction can be used to cure the compositions described herein, and therefore no catalyst is required.

Owner:DESIGNER MOLECULES

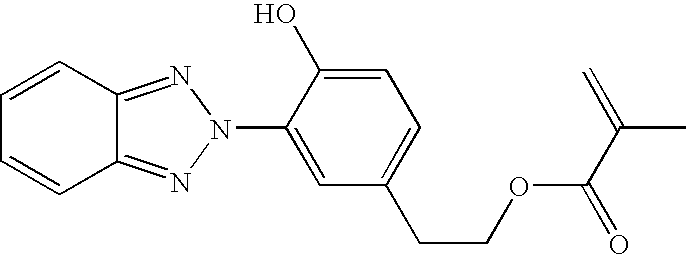

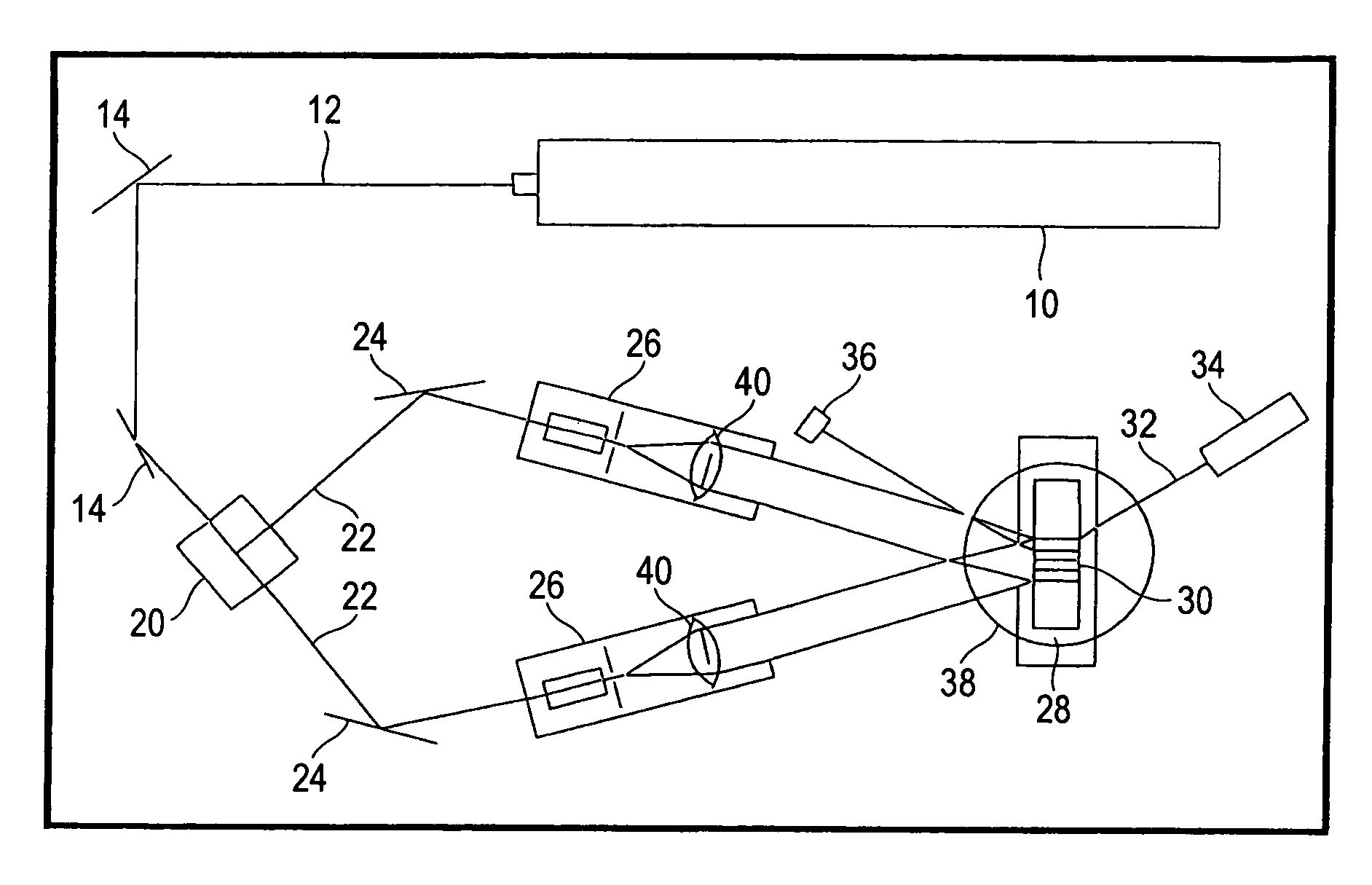

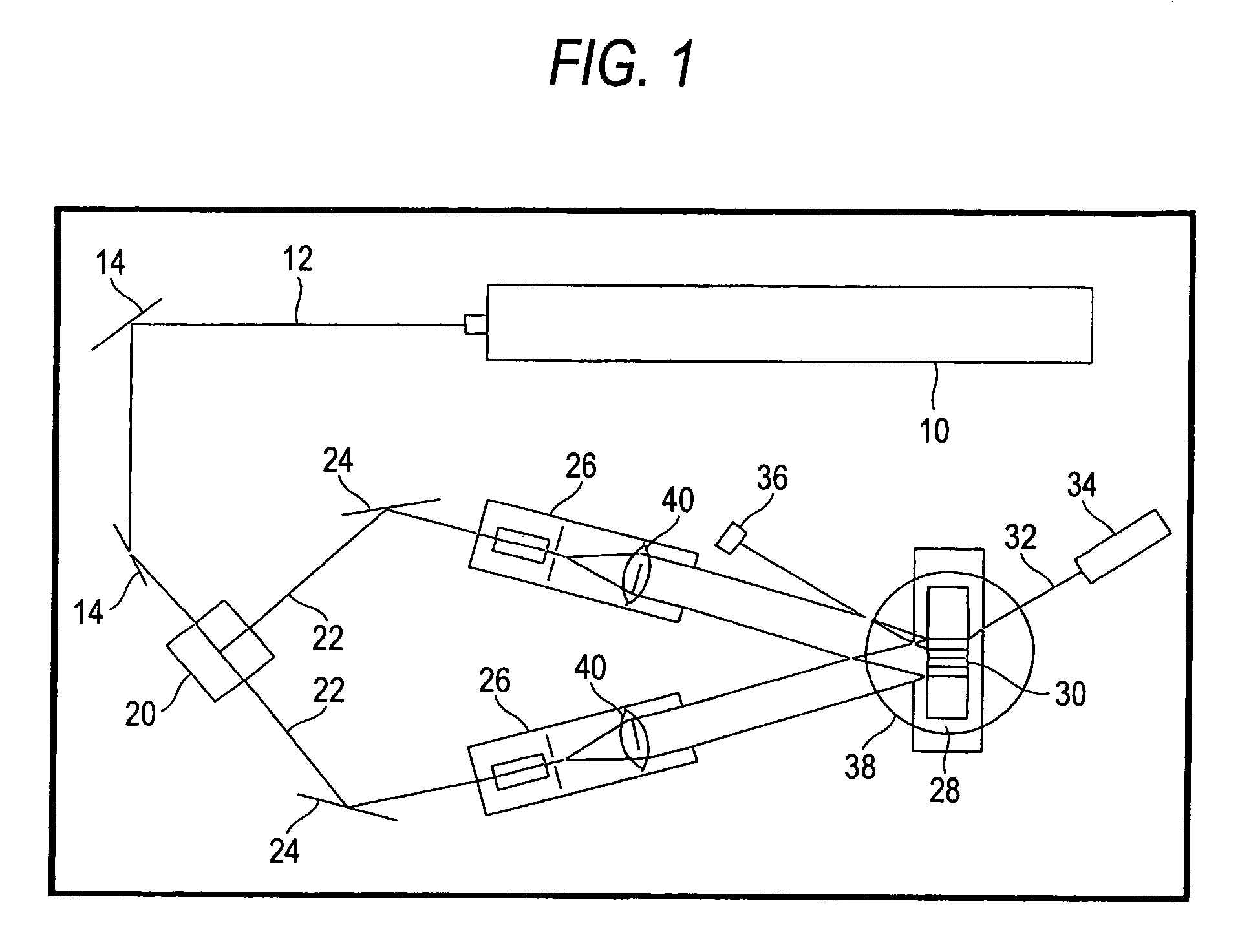

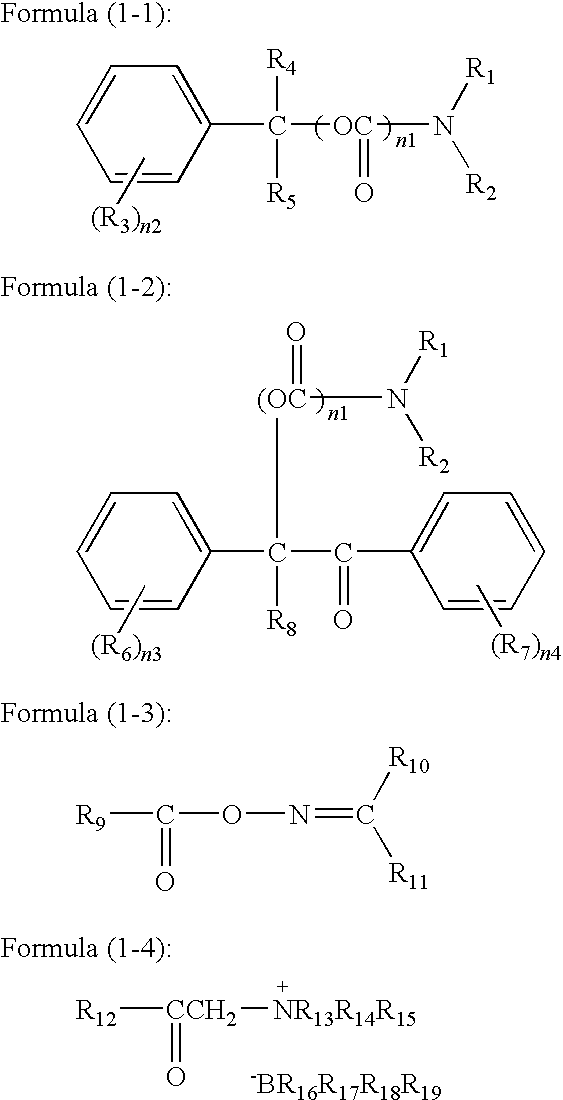

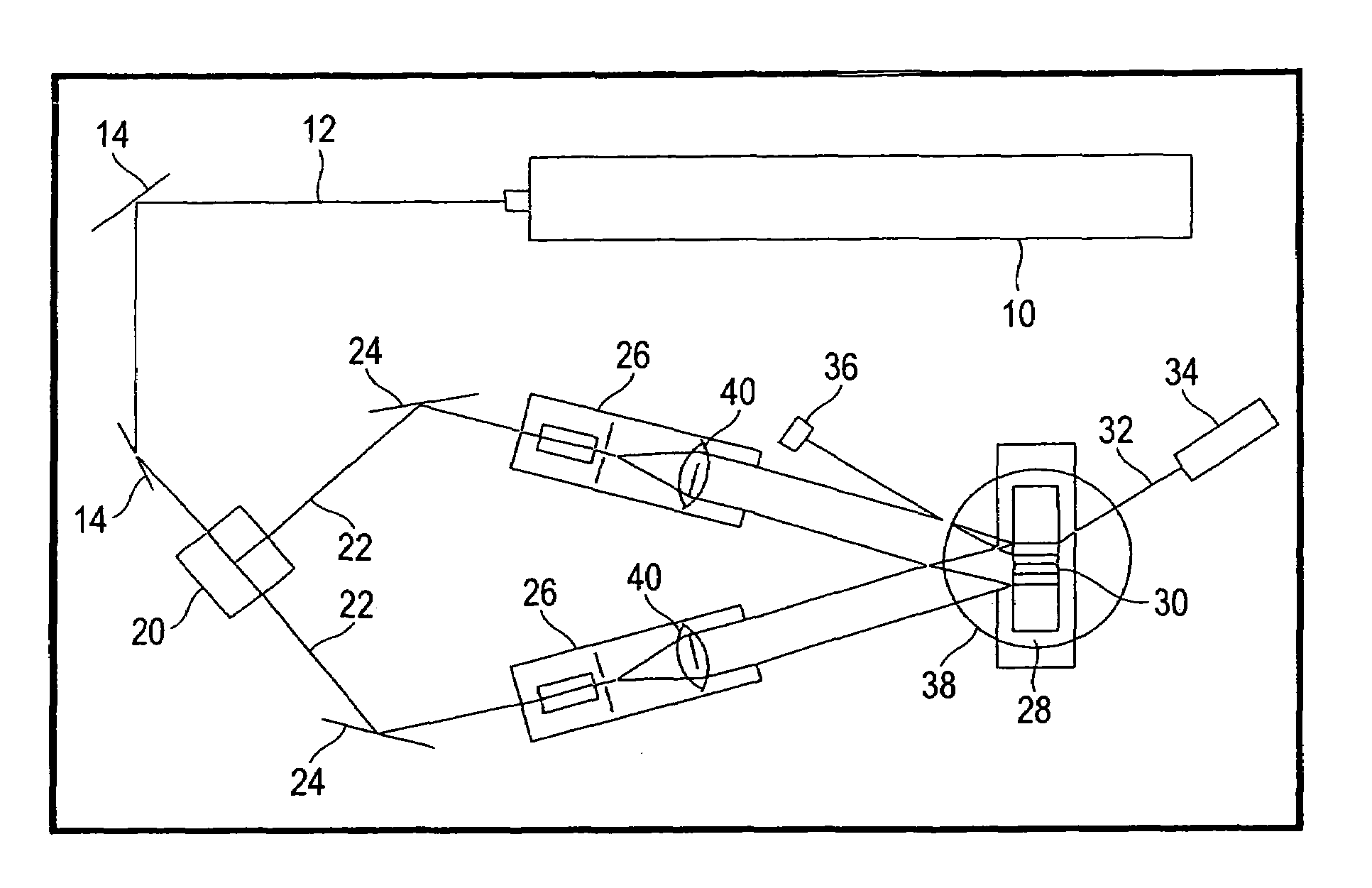

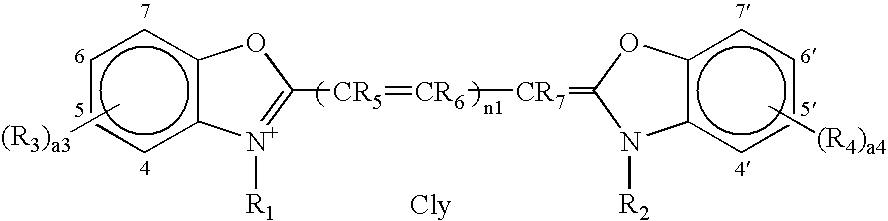

Hologram recording method and hologram recording material

InactiveUS7588863B2High sensitivityHigh diffraction efficiencyPolyhalogenated compound compositionsPhotomechanical apparatusLatent imageCOLORED MATERIAL

Owner:FUJIFILM CORP +1

Hologram recording material, hologram recording method and optical recording medium

InactiveUS7572555B2Low shrinkageImprove recording densityPhotomechanical apparatusPhotosensitive material auxillary/base layersEnergy transferExcited state

Owner:FUJIFILM CORP +1

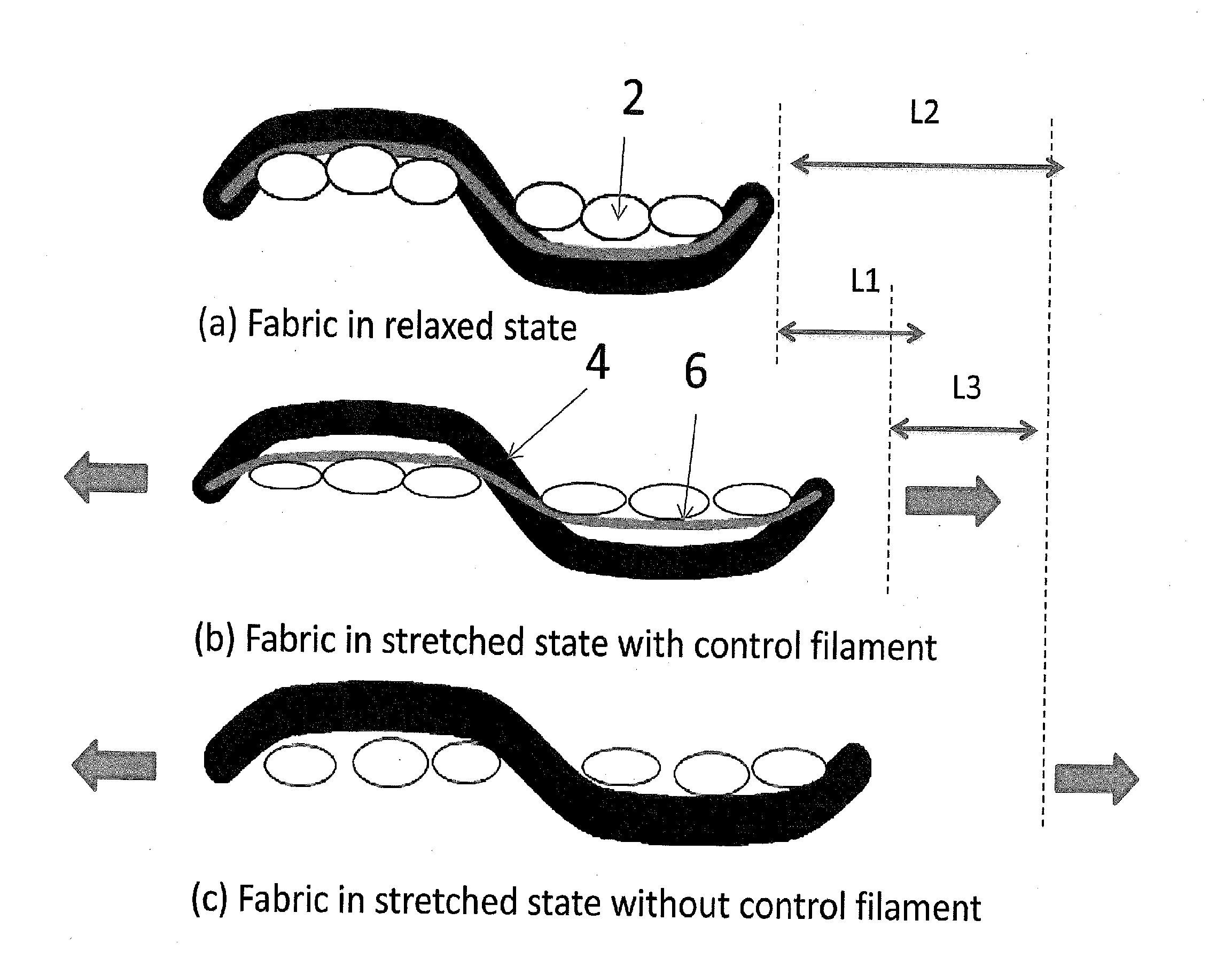

Stretch wovens with a control yarn system

ActiveUS20150133017A1Better recovery powerImprove the level ofShrinkingPattern makingEngineeringElastic fiber

An article including a woven fabric comprising warp yarns and weft yarns, wherein at least one of either the warp yarns or the weft yarns includes: (a) a corespun elastic base yarn having a denier and including staple fiber and an elastic fiber core; and (b) a separate control yarn selected from the group consisting of a single filament yarn, a multiple filament yarn, a composite yarn, and combinations thereof; having a denier greater than zero to about 0.8 times the denier of the corespun elastic base yarn; wherein the woven fabric includes (1) a ratio of corespun base yarn ends to control yarn ends of up to about 6:1; or (2) a ratio of corespun base yarn picks to control yarn picks of up to about 6:1; or (3) both a ratio of corespun base yarn ends to control yarn ends of up to about 6:1; and a ratio of corespun base yarn picks to control yarn picks of up to about 6:1.

Owner:THE LYCRA CO LLC

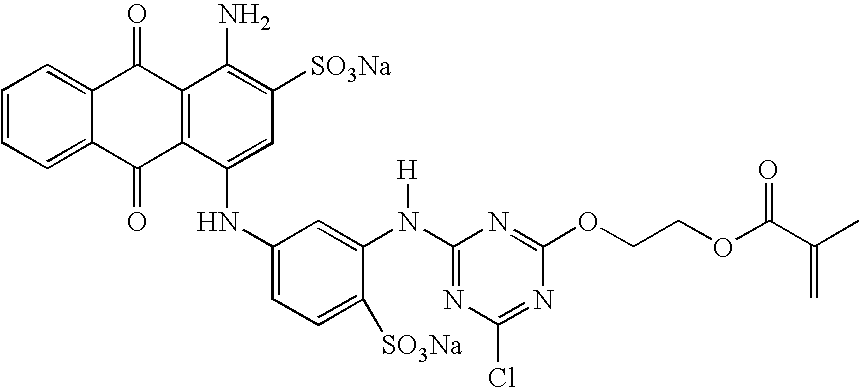

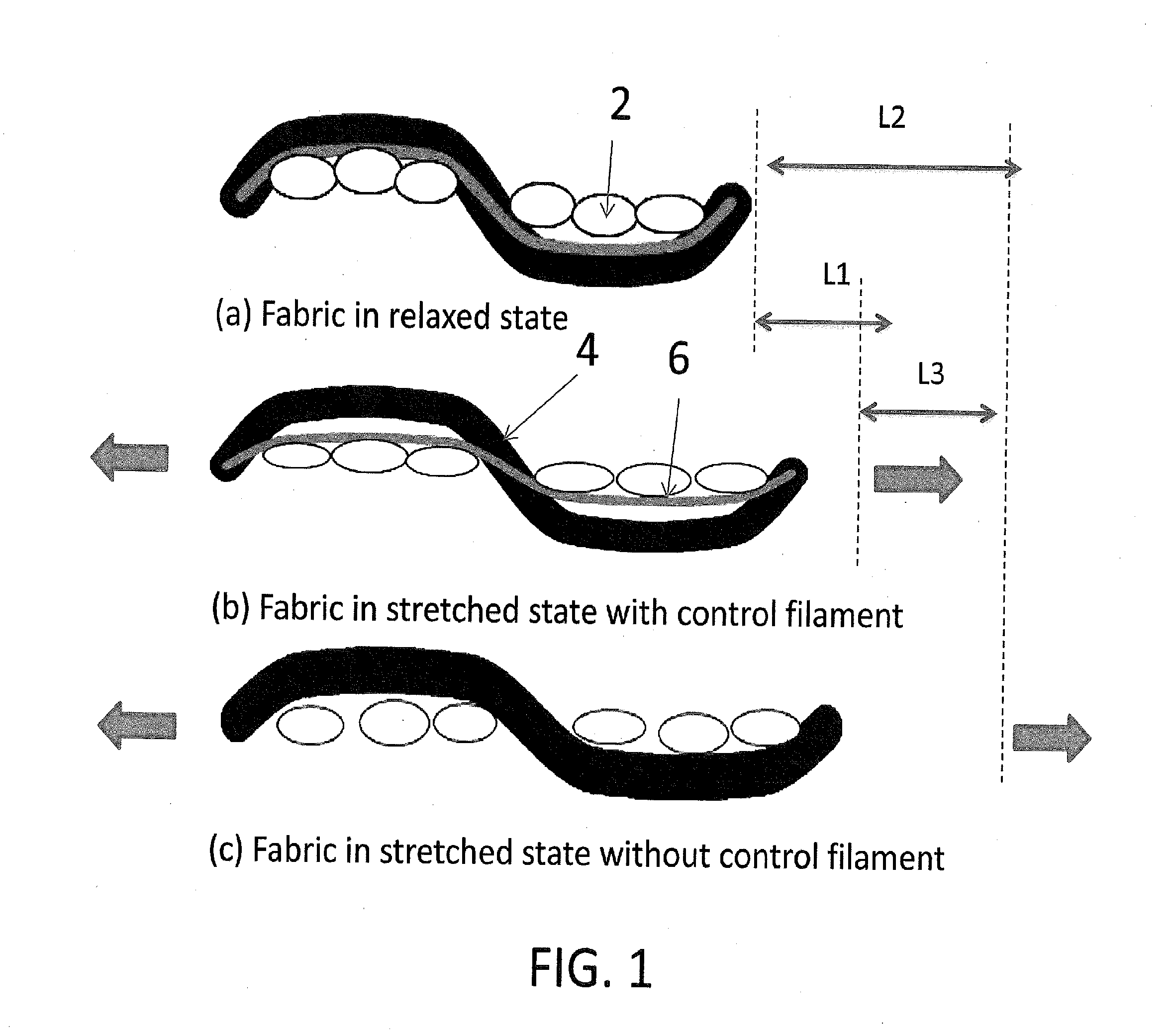

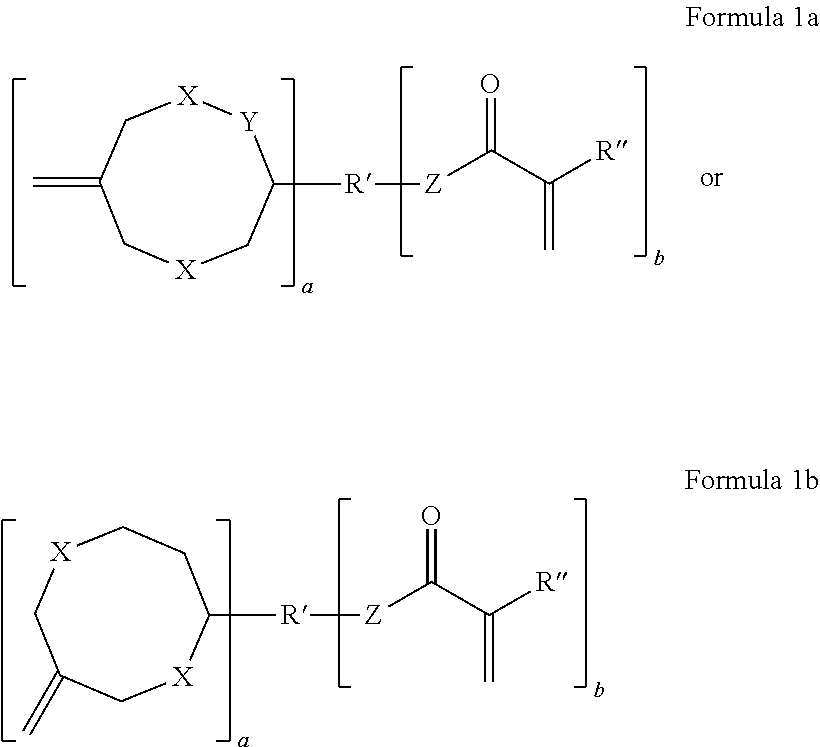

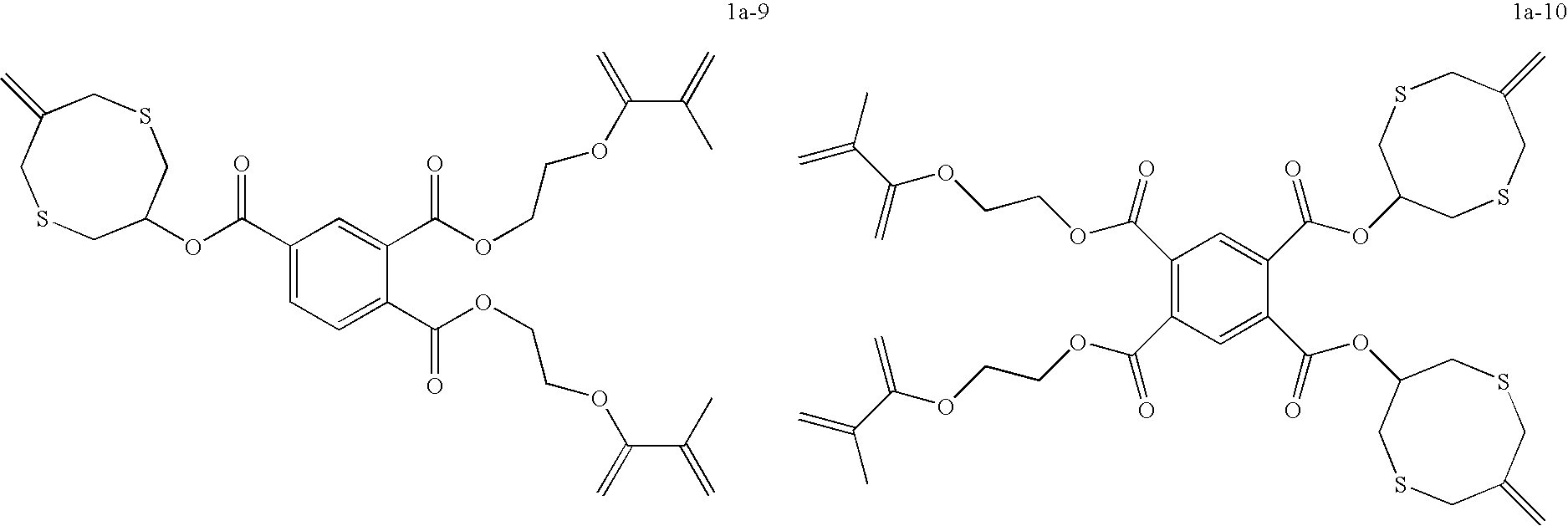

Dental compositions containing hybrid monomers

InactiveUS7888400B2Low shrinkageImprove mechanical propertiesCosmetic preparationsImpression capsChemical structureMonomer

The invention features dental compositions comprising at least one hybrid monomer that comprises a cyclic allylic sulfide moiety attached to a (meth)acryloyl moiety. These two functional moieties are typically joined either directly to each via a chemical bond or through some chemical structure or spacer molecule. The composition may optionally contain additional polymerizable compounds, such as ethylenically unsaturated compounds, that are typically used in dental compositions.

Owner:3M INNOVATIVE PROPERTIES CO

Non-halogen flame-retardant polypropylene composite material and preparation thereof

InactiveCN101412830AImprove flame retardant performanceImprove mechanical propertiesFlexural modulusAcrylonitrile

The invention provides a halogen-free flame-retardant polypropylene composite material, which is characterized by consisting of the following raw materials in weight portion: 82.5 to 12 portions of polypropylene, 0.3 to 2 portions of heat stabilizer, 0.2 to 1 portion of processing aid, 1 to 10 portions of toughening agent, 10 to 40 portions of flame retardant, 1 to 5 portions of glass fiber compatibilizer and 5 to 30 portions of glass fiber. The invention also provides a method for preparing the material. The material has the flame retardancy up to 1.6mm V0, the tensile strength higher than or equal to 50 MPa, the flexural modulus higher than or equal to 3,000 MPa, the notched impact strength more than or equal to 8KJ / m<2>, the shrinkage between 4 and 6 per thousand, the heat distortion temperature higher than or equal to 140 DEG C, as well as the other technical indexes up to or exceeding the standard of flame-retardant acrylonitrile-butadiene-styrene copolymer materials. As the material uses the phosphorus-nitrogen flame retardant containing no halogen, the flame-retardant effect of the material completely reaches UL94-V0 grade.

Owner:SHANGHAI KINGFA SCI & TECH +1

Natural fiber reinforcement halogen-free flame retardant polypropylene composite material and preparation method thereof

InactiveCN101418099AImprove flame retardant performanceImprove mechanical propertiesGlass fiberHeat deflection temperature

The invention provides a natural fiber reinforced halogen-free flame-retardant polypropylene composite material, which is characterized by consisting of the following raw materials in weight portion: 82.5 to 12 portions of polypropylene, 0.3 to 2 portions of heat stabilizer, 0.2 to 1 portion of processing assistant, 1 to 10 portions of toughening agent, 10 to 40 portions of flame retardant, 1 to 5 portions of compatilizer, and 5 to 30 portions of natural fiber. The invention also provides a method for preparing the material. The composite material has the advantages that the composite material has excellent flame-retardant effect and excellent comprehensive mechanical property; the flame-retardant property of the composite material can reach 1.6mm V0; the tensile strength is more than or equal to 60MPa; the bending modulus is more than or equal to 4,000MPa; the gap impact strength is more than or equal to 10KJ / m<2>; the shrinkage ratio is between 4 and 6 per thousand; the heat distortion temperature is more than or equal to 140 DEG C; and the composite material is a novel environment-friendly material, and has no safety and health problems of glass fibers.

Owner:SHANGHAI KINGFA SCI & TECH +1

Hot melt adhesive composition based on a random copolymer of isotactic polypropylene

InactiveUS7067585B2High bond strength retentionGood adhesionOther chemical processesFilm/foil adhesivesWaxPlasticizer

A hot melt adhesive composition is based on an isotactic polypropylene random copolymer (RCP). The composition contains about 4%–50% by weight of the RCP copolymer, about 20%–65% by weight of a compatible tackifier, about 0%–40% by weight of a plasticizer, about 0%–3% by weight of a stabilizer, about 0%–40% by weight of a wax, and optionally about 0%–60% by weight of an atactic poly-α-olefin (APAO). The adhesive composition may be used in a number of applications such as, for example, in disposable nonwoven hygienic articles, paper converting, flexible packaging, wood working, carton and case sealing, labeling and other assembly applications.

Owner:BOSTIK INC

Stretch wovens with separated elastic yarn system

In some embodiments are an article including a woven fabric having warp yarns and weft yarns. Either warp yarn or weft yarn or both warp and weft yarns have two separate systems of yarns. The systems of yarns include a hard yarn forming the main body of fabric and a composite covered elastic yarn with an elastic fiber core; wherein the fabric has an outer face side, a back side, and the fabric includes at least one of: (a) a weaving pattern where the composite yarn and at least one adjacent hard yarn pass over the same pick when the composite yarn is on the outer surface; (b) the ratio of hard yarn denier to composite yarn denier is at least 1:1; and (c) the composite yarn floats over no more than 5 picks on the outer face side.

Owner:THE LYCRA CO LLC

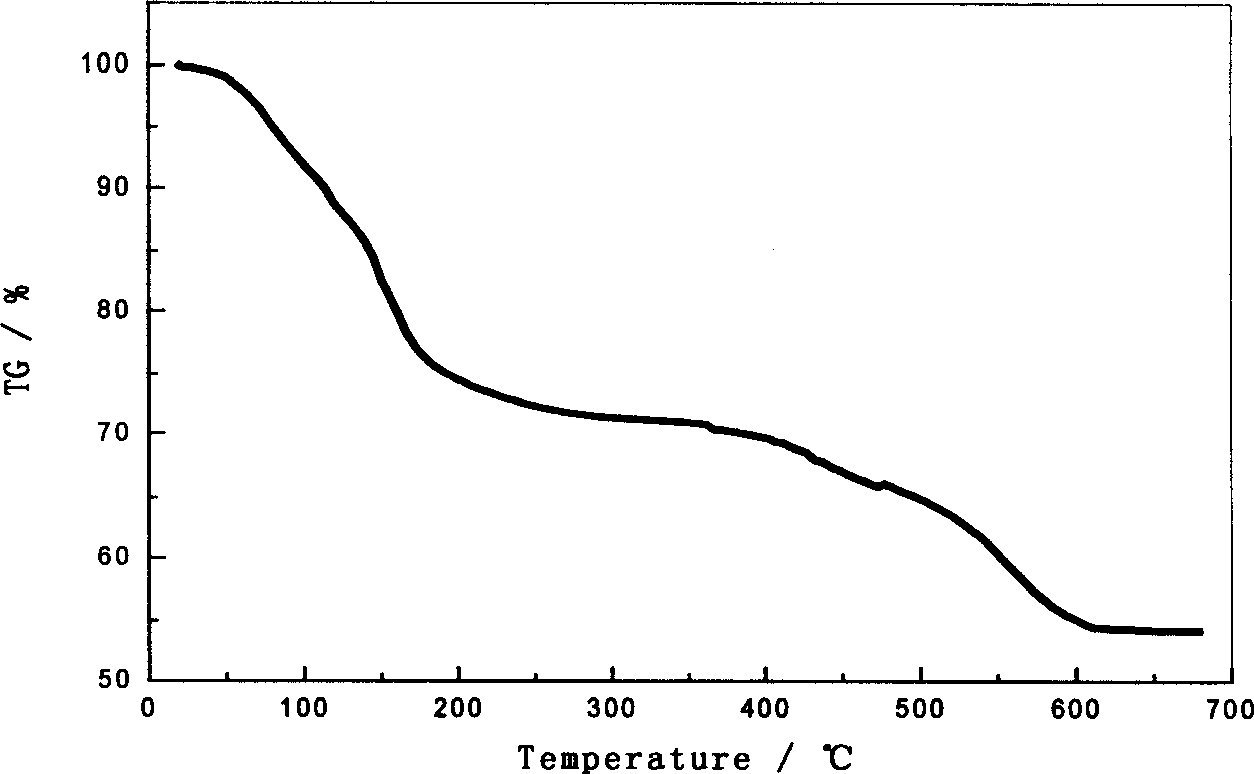

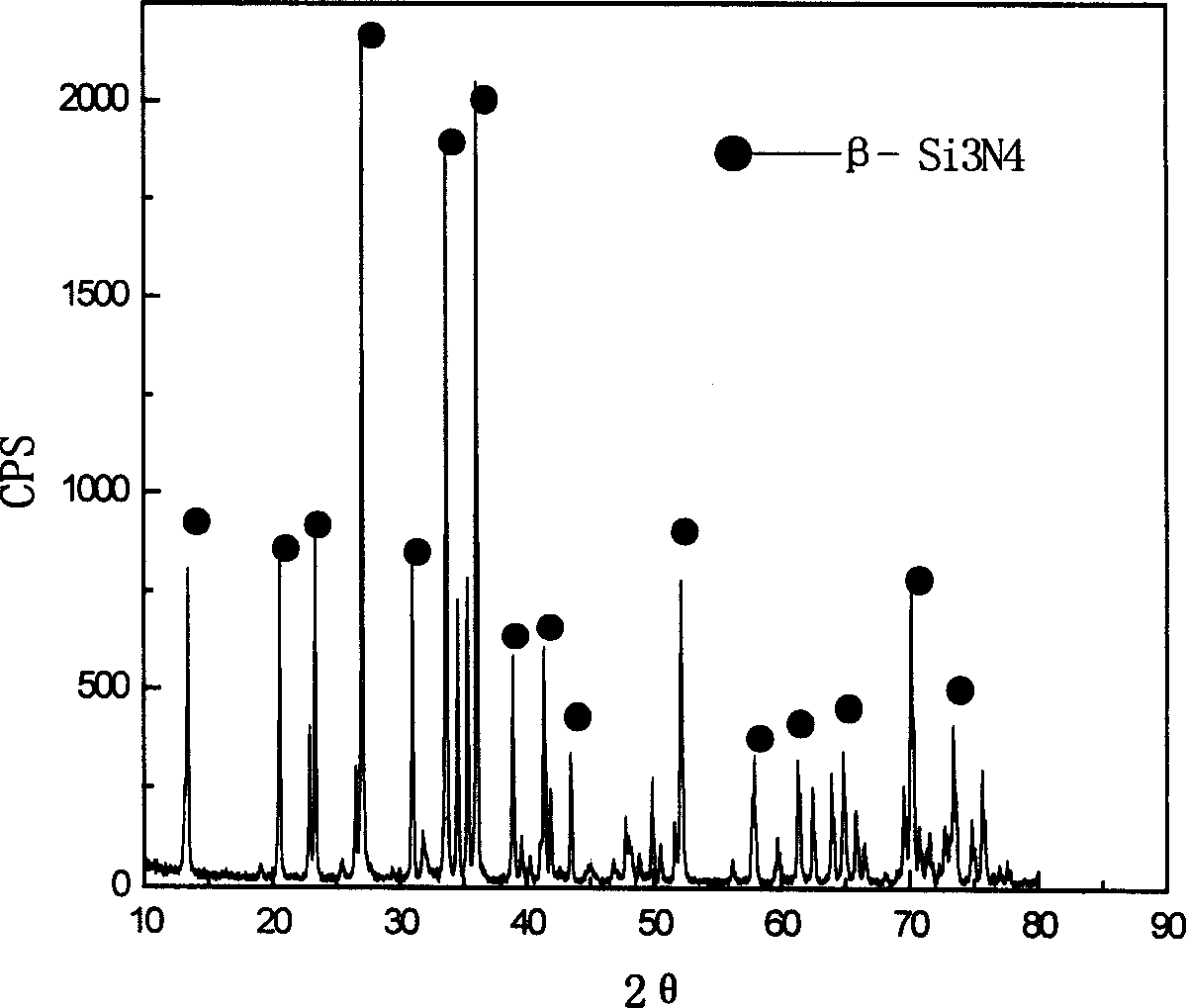

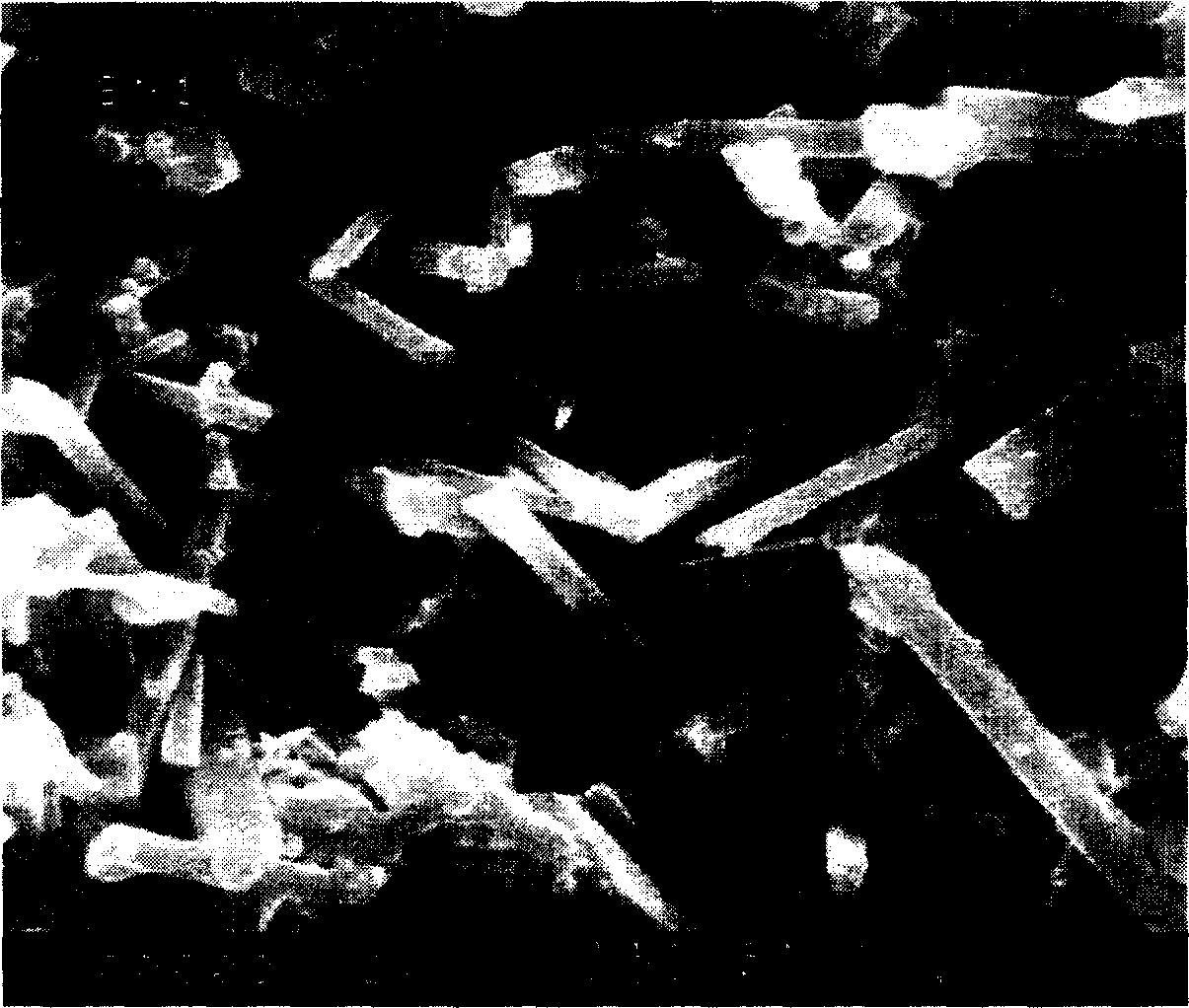

Method for preparing silicon nitride/silicon carbide porous ceramic

The present invention belongs to the field of porous ceramic material technology, and is the preparation process of one low cost and high performance porous silicon nitride / silicon carbide ceramic. The preparation process includes compounding material, forming and sintering as the conventional ceramic material preparing steps. It features that phenolic resin used as pore creating agent and carbon source is in-situ produced into SiC phase through the carbon hot reduction during sintering; and that Si3N4, Al2O3, Y2O3 and phenolic resin in certain proportion are produced into slurry through adding anhydrous alcohol and mixing for 12-24 hr and stoved into powder; and that the ceramic powder is processed through formation, cracking to eliminate glue, carbon hot reduction and sintering to produce the porous ceramic material with porosity of 40-70 %, strength of 70-160 MPa and low cost.

Owner:XI AN JIAOTONG UNIV

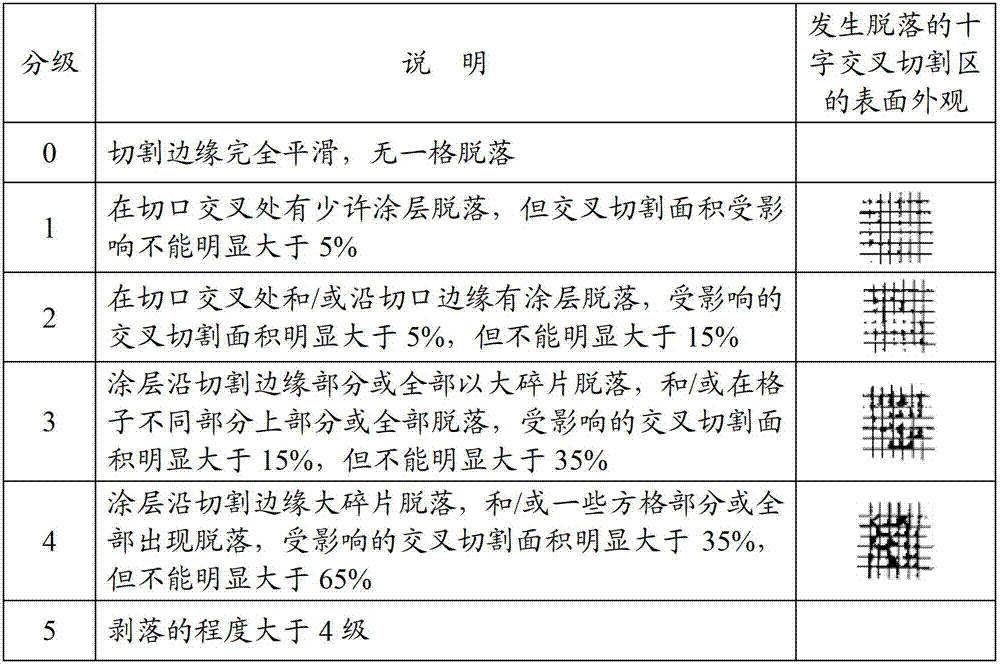

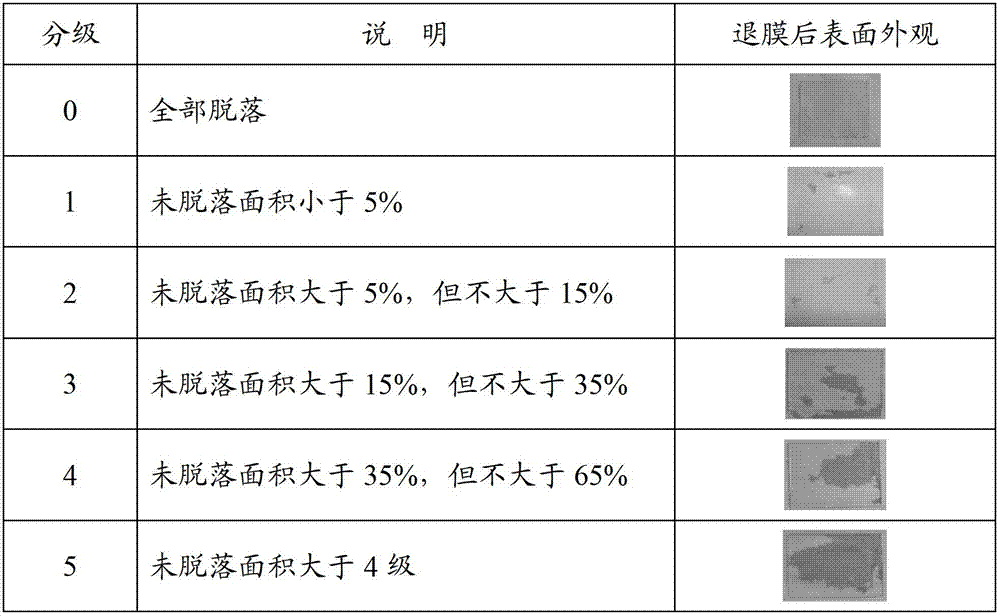

Glass protecting ink and preparation method thereof

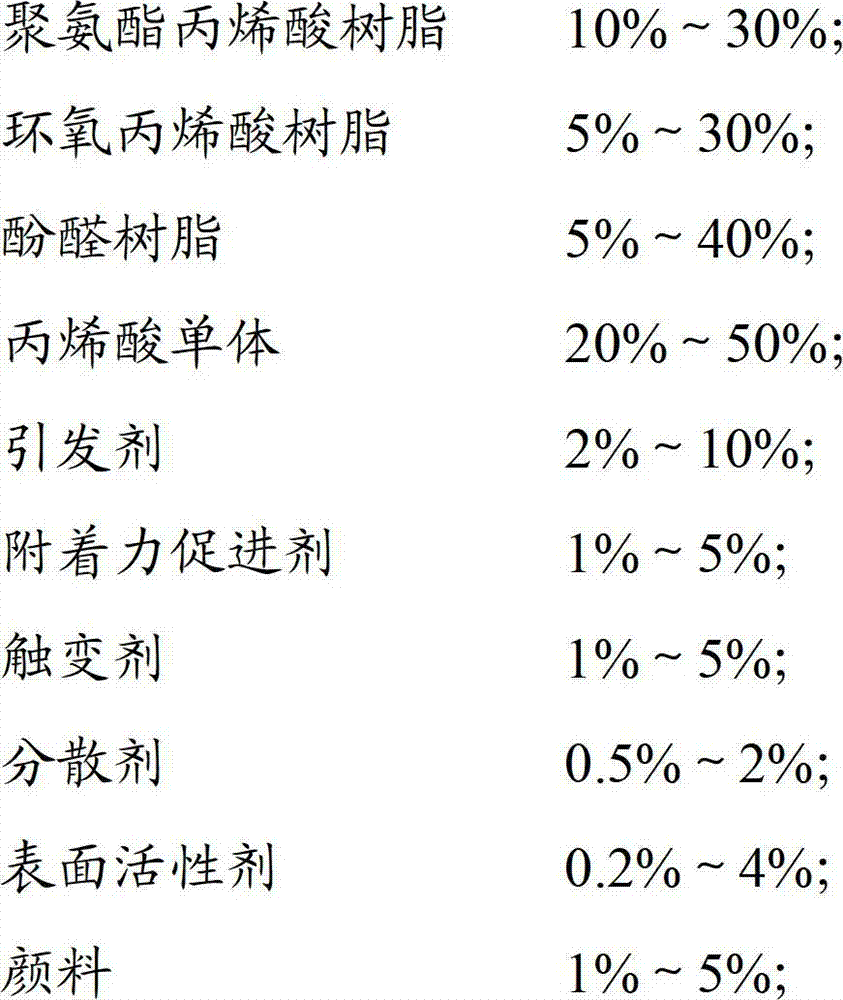

The invention discloses a glass protecting ink and a preparation method thereof. The glass protecting ink comprises the following components in percentage by weight: 10%-30% of polyurethane acrylate, 5%-30% of epoxy acrylic resin, 5%-40% of phenolic resin, 20%-50% of acrylic monomer, 2%-10% of initiator, 1%-5% of adhesion promoter, 1%-5% of thixotropic agent, 0.5%-2% of dispersing agent, 0.2%-4% of surface active agent, 1%-5% of pigment and 10%-30% of filler. The glass protecting ink disclosed by the invention has a good glass protecting performance, is easy to strip, and is convenient to operate.

Owner:FOSHAN 3Q ELECTRONICS MATERIALS

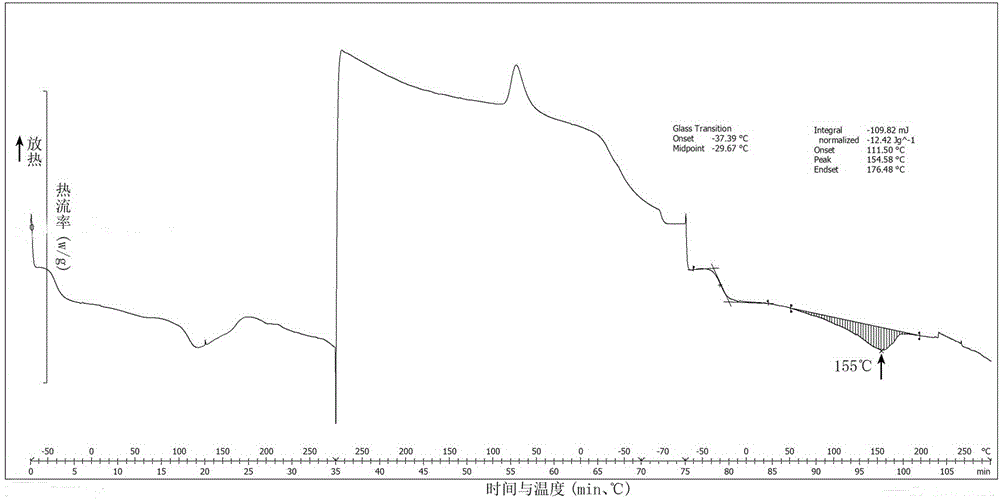

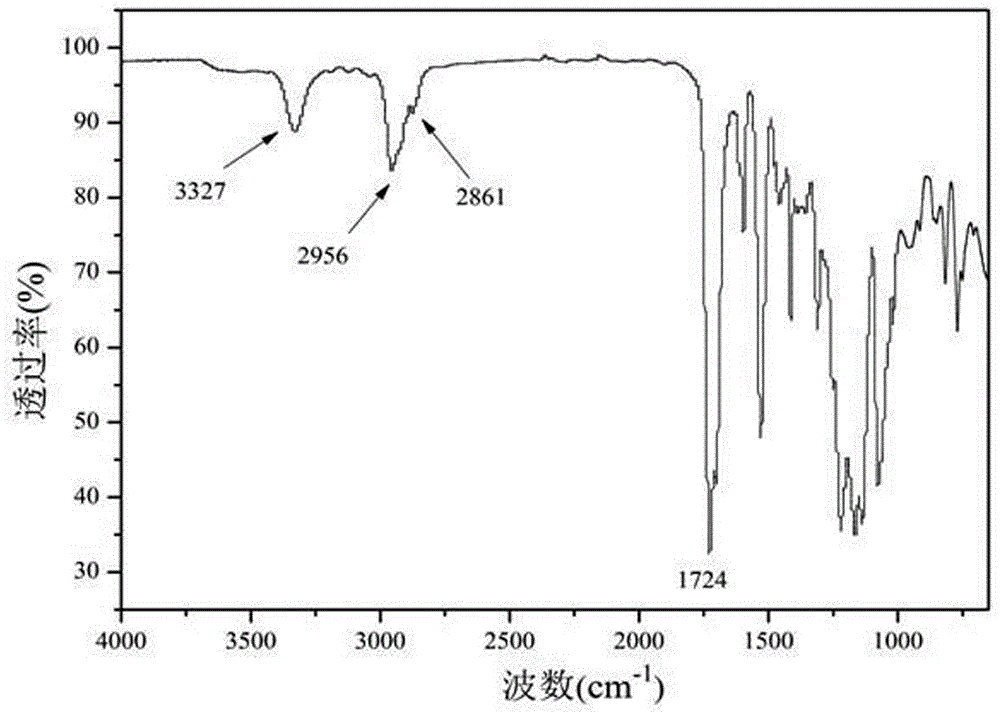

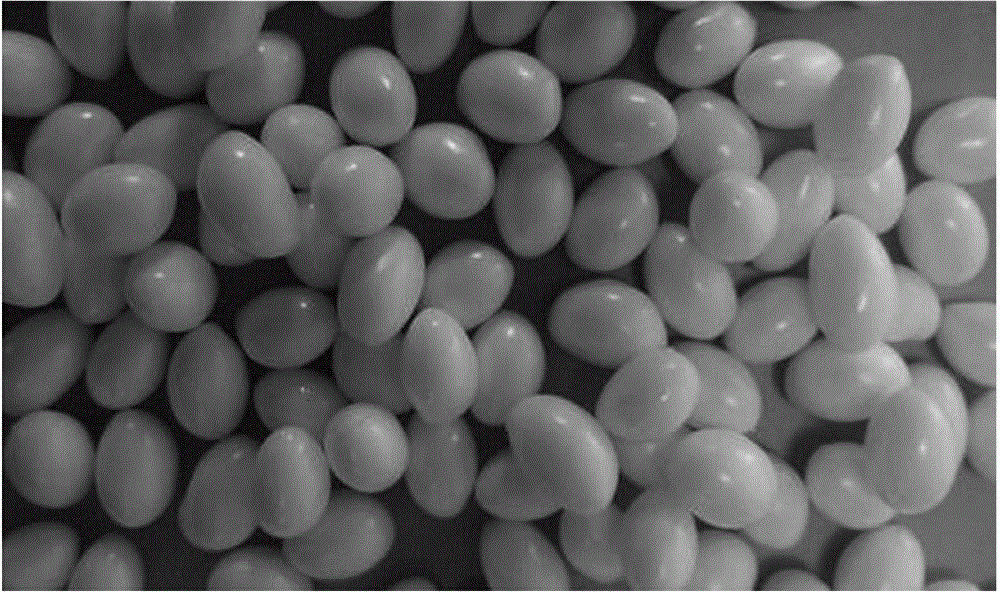

Preparation method of thermoplastic polyurethane beads and bead molding technology

The present invention discloses a preparation method of thermoplastic polyurethane beads and a bead molding technology. High foaming thermoplastic polyurethanes (TPU) beads are obtained through: melting and granulating TPU, melt viscosity modifiers, fillers and age resisters to prepare TPU co-blending granules; using clean, cheap, environmentally-friendly CO2 and / or N2 as foaming agents; and performing medium-temperature and high-pressure soakage, dissolution equilibrium, pressure relief and pre-foaming, saturated steam secondary foaming and other techniques. The obtained high foaming TPU beads are small in shrinkage ratio and smooth in surface. The invention further discloses the bead molding technology which uses a water vapor assisted mould pressing technology to prepare molded bodies of the TPU foaming beads, the prepared molded bodies of the TPU foaming beads are low in density, small in shrinkage ratio and uniform in surface texture, and also have an unique property of TPU resin. The TPU beads can be widely applied in the fields of vibration-absorptive materials, packaging materials, toys for children, sporting goods, aviation models, heat insulating materials, automotive interior materials, etc.

Owner:CHANGZHOU SHUNXIANG NEW MATERIAL TECH CO LTD

Light energy conservation insulating concrete

The invention relates to a lightweight energy-saving insulating concrete, belonging to building materials. The invention comprises the master batches and accessories in accordance with the following parts by weight: master batches: 30-70 parts of cementing materials, 25-60 parts of fillers, 5-10 parts of strength activators, and accessories: 1-3 parts of waterproof agents, 2.0-3.0 parts of bleeding agents, 2.0-5.0 parts of suspending agents, 0.1-0.5 part of foam stabilizer, 38-60 parts of honeycomb agents, 0.5-1.5 parts of rusty retardant agents, 0.02-10 parts of reinforcing agents, 1.2-4.2 parts of early strength agents and expanding agents and 0.6-1.4 parts of acid and alkali resistant fibers. The concrete has the advantages of high early tensile and compressive strength, no decrease and crack of later strength and simple manufacturing process. According to the requirement of the building structure, the technical target of the concrete can be realized by regulating the mixing proportion. The concrete can be used for manufacturing various products at normal temperature and is widely applied to insulating and self-waterproof building engineering.

Owner:徐东亮 +4

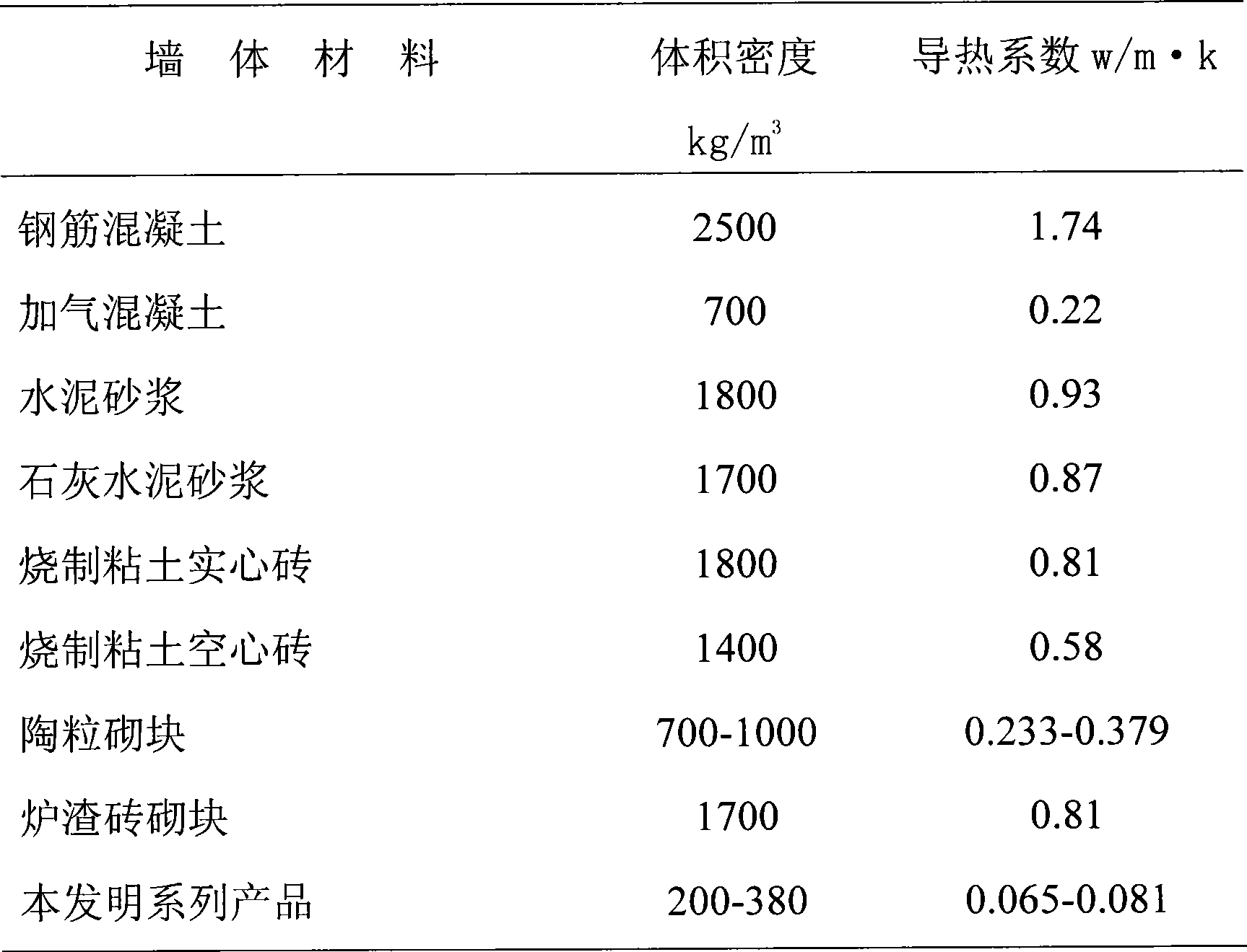

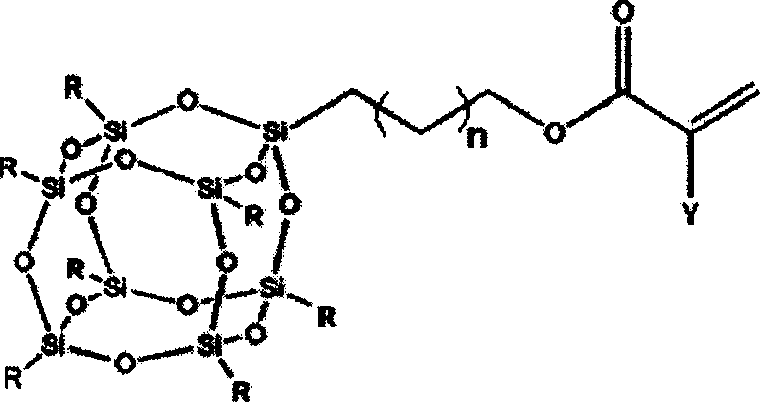

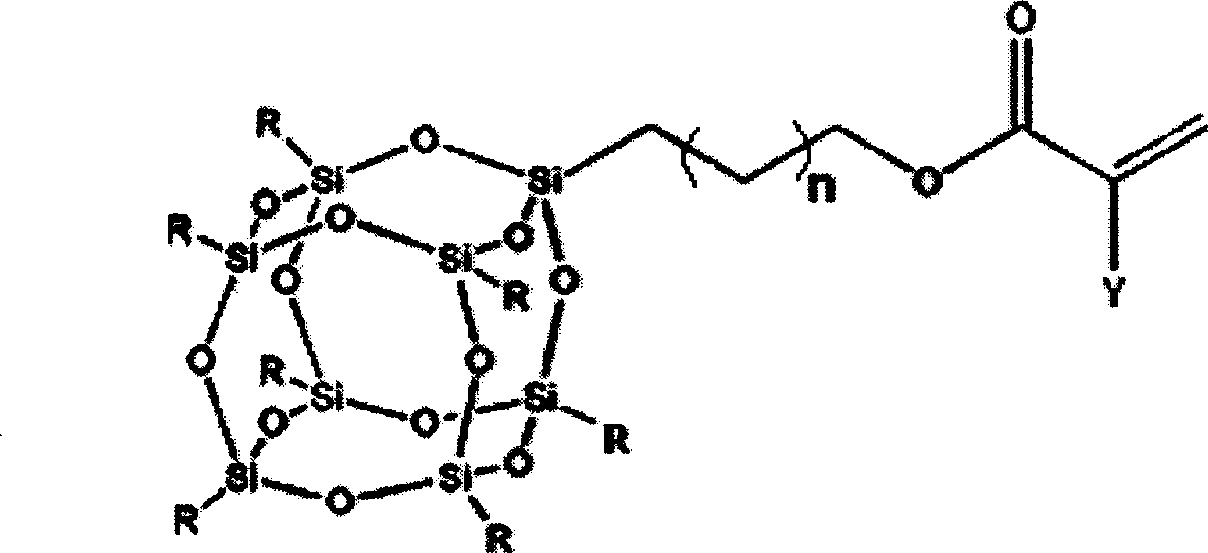

Coating material containing POSS acrylate copolymer and preparing method

The invention relates to a manufacturing method for coat material containing POSS acrylate copolymer. It takes free radical copolymerized to acr monomer and other acr monomer, and uses as modifier adding into the base compounding of UV coat, after taking UV solidification the coat material of high rigidity would be gained. The constituent includes 40-55% light-cured resin, 5-20% active modifier, 20-45% spike, 1-10% photoinitiator, 2-10% anti-foam additive. The rigidity of coat could reach to 6H, and the shrinkage ratio could reach 2%.

Owner:XIAMEN UNIV

Exterior wall composite insulation heat-proof plastering material

InactiveCN101229970ARealize resource utilizationImprove protectionSolid waste managementFiberResource utilization

The invention relates to compound thermal insulation plastering material for external wall, which consists of a compound cementing material and a lightweight aggregate. The compound cementing material consists of cement, active admixture, lime powder, promoter, surfactant, anti-crack and waterproof agent, water retaining agent, flame retardant, re-dispersible emulsion powder, alkali-resistance fiber and coal flying ash cenosphere; the lightweight aggregate consists of EPS grain and expanded perlite. The invention has the advantages of low density, thermal performance, high strength, good impact resistance, bond strength and low shrinkage. The compound cementing material adopts a plurality of polymeric cementing materials, allows the insulation material to have good bond performance and simultaneously ensures falling and slipping resistance performance. The invention has good water resistance and high softening coefficient. By using cement-based cementing material as main material and organic reinforced material and waterproof component as auxiliary materials, the invention has a hydrophobic rate more than 98 percent and a softening coefficient more than 0.7. The invention can save energy and protect environment. A great deal of industrial waste residue is used in the materials, which can save a great number of energy, realize resource utilization of the waste residue and is in favor of environmental protection.

Owner:SHANGHAI TONGBIAO INSULATION TECH

Coated powder particles for producing three-dimensional bodies by means of a layer constituting method

InactiveUS7722802B2High distinctnessGood storage stabilityAdditive manufacturing apparatusTransportation and packagingOrganic solventShell molding

The invention relates a powder material consisting of coated particles for a powder-based rapid generative prototyping methods, in particular by compressing a 3D binder. Said powder material consists of individual plastic, metal and / or ceramic particles and / or granules. A coating essentially consists of an adhesive agent which can be activated by a liquid binder, light or laser light, and of sinterable or glass-forming fine-grained material. Said invention also relates to a method for compressing 3D binder with the aid of an organic solvent having a water content less than 45% and to sintered bodies, in particular for moulding or precision mechanical engineering, which are fixed to each other by sintering or glass formation from a fine grained material.

Owner:PFEIFER ROLF +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com