Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4098 results about "Aluminum silicate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminium silicate (or aluminum silicate) is a name commonly applied to chemical compounds which are derived from aluminium oxide, Al 2 O 3 and silicon dioxide, SiO 2 which may be anhydrous or hydrated, naturally occurring as minerals or synthetic. Their chemical formulae are often expressed as xAl 2 O 3.ySiO 2.zH 2 O. It is known as E number E559

Attapulgite argil powder with air purifying function

ActiveCN102173743BImprove adhesionImprove plasticityDispersed particle separationDeodrantsFiberHazardous substance

The invention discloses an attapulgite argil powder with an air purifying function. The technical scheme is as follows: the attapulgite argil powder with an air purifying function is prepared from high-viscosity attapulgite clay, an attapulgite constant-humidity conditioner, a natural mineral adsorbing / filtering agent, Cacumen Biotae, aluminum silicate fiber and polyacrylamide. The attapulgite argil powder is prepared by the following steps: pulverizing the materials, soaking and aging to obtain a wet mixture, extruding the wet mixture into a strip, airing the strip, pulverizing to obtain powder, and packaging to obtain the finished product. The attapulgite argil powder has favorable cohesive property, plasticity, thixotropy, fire resistance and thermal stability; the pottery prepared from the attapulgite argil powder with an air purifying function contains a great deal of micropores and activated carbon, thus, has the characteristics of low shrinkage, no cracking or deformation and favorable adsorbability, and can effectively adsorb formaldehyde, ammonia, benzene and other harmful substances in the air, thereby protecting the environment and improving good health of people. The invention is suitable for producing pottery artware with an air purifying function.

Owner:江苏世澳非金属应用科技有限公司

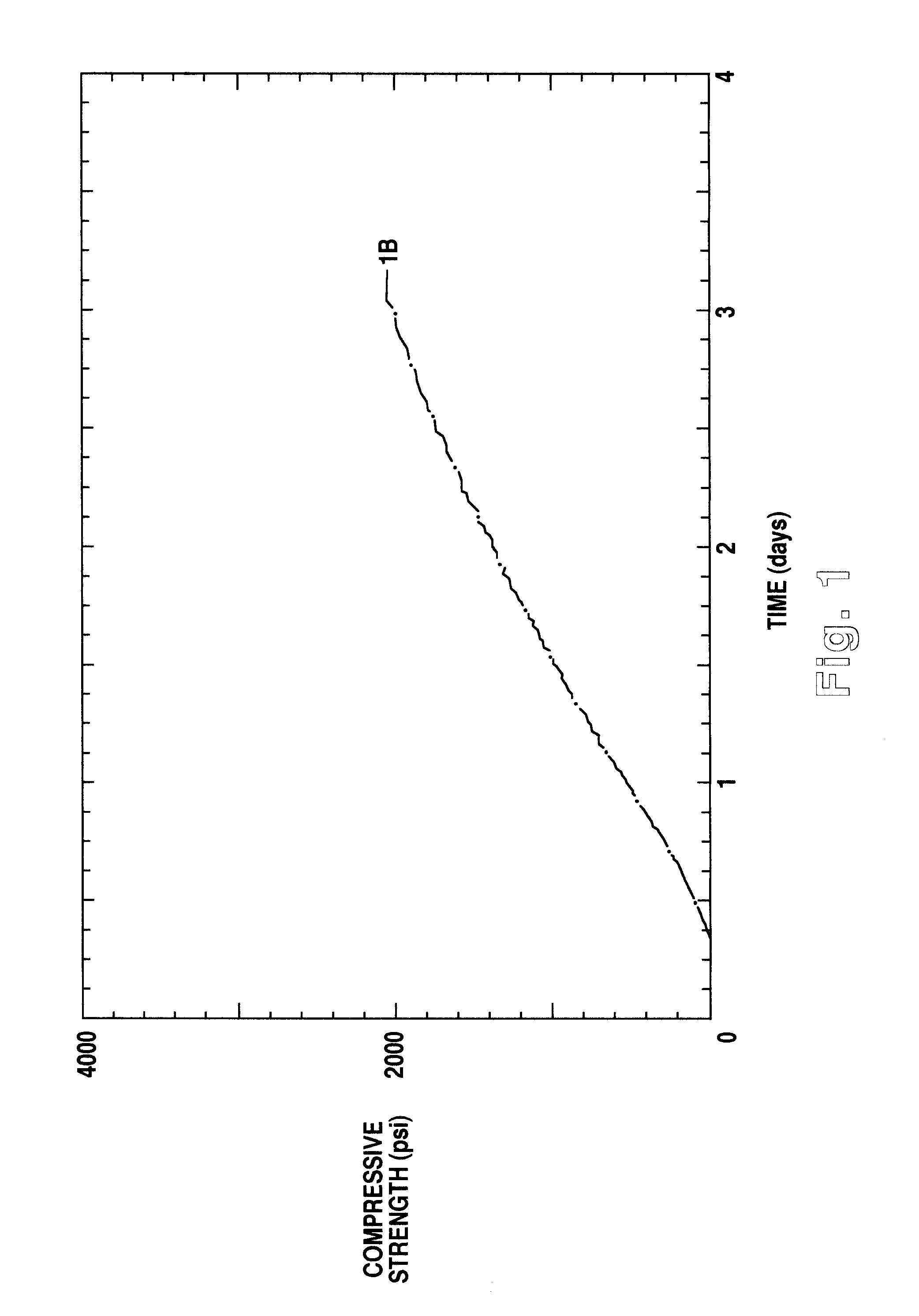

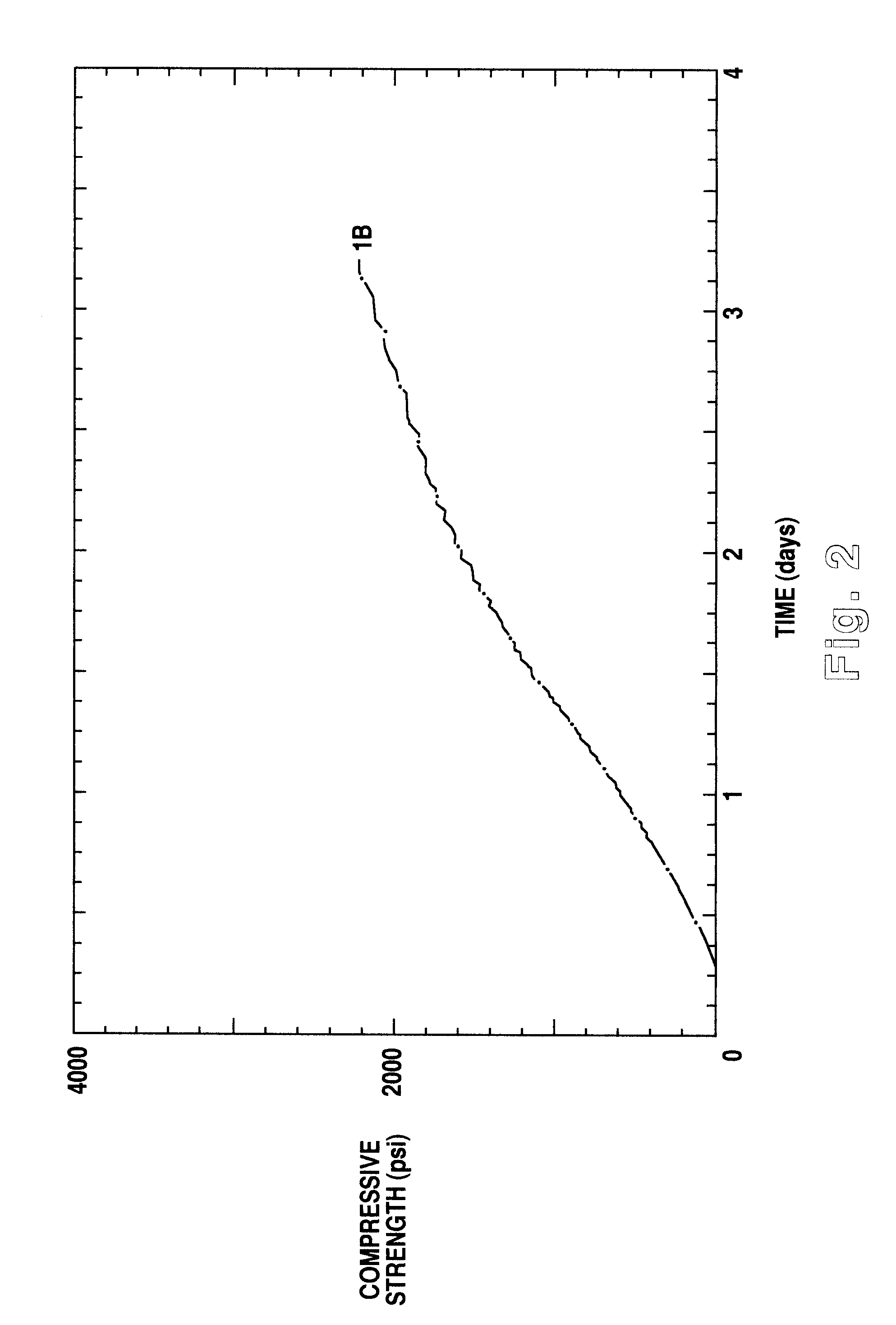

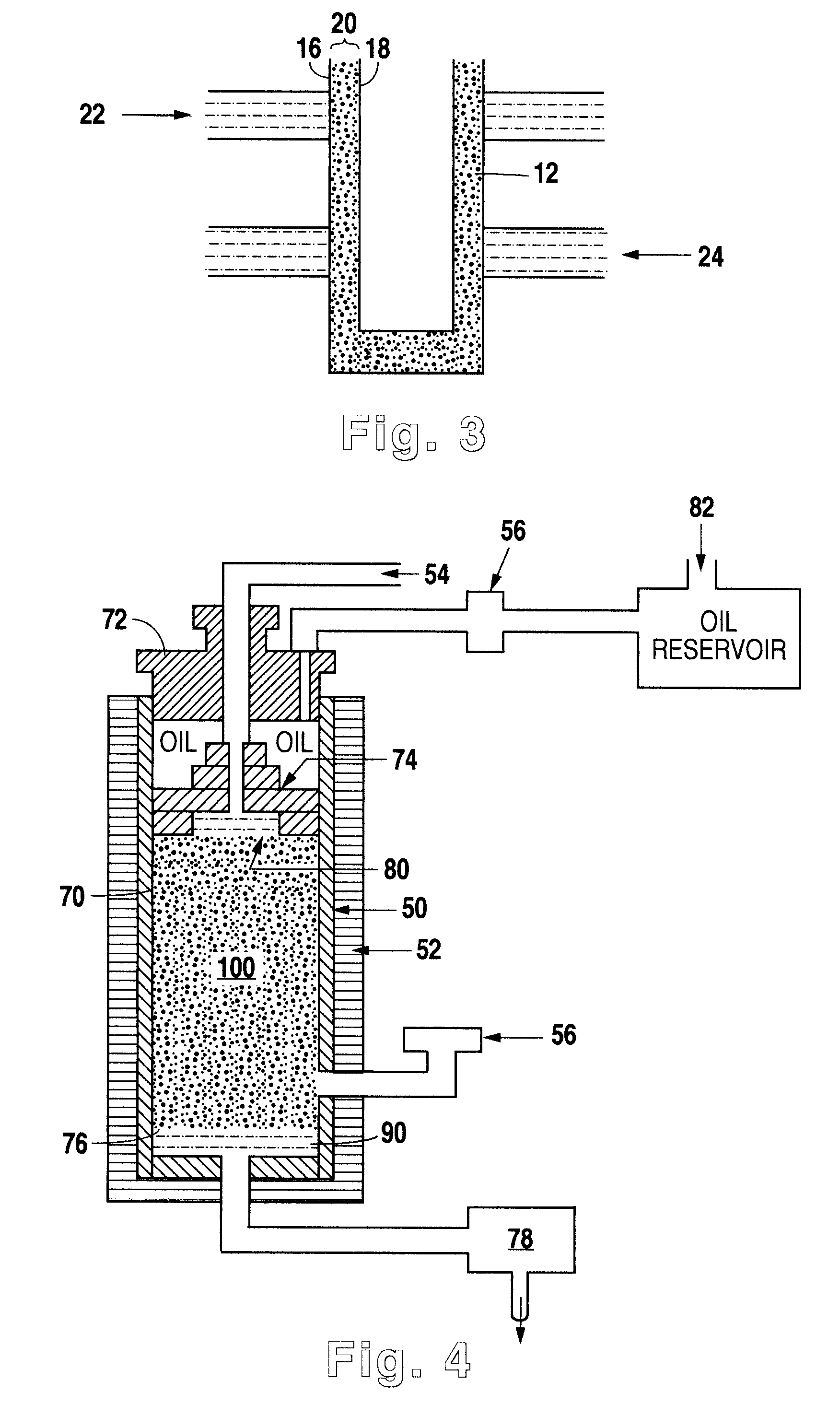

Methods and compositions for use in cementing in cold environments

Cement compositions for cementing wellbores in cold environments. The cement compositions may include a mixture of a reactive aluminum silicate, aluminum sulfate and hydraulic cement, and may include one or more other additives. The cement compositions may be formulated to have reduced heat of hydration as compared to conventional cements, making them suited for cementing in permafrost environments. The cement slurries may optionally be foamed using a foaming agent and energizing phase.

Owner:AMERICAN CEMENTING LLC

Attapulgite argil powder with air purifying function

The invention discloses an attapulgite argil powder with an air purifying function. The technical scheme is as follows: the attapulgite argil powder with an air purifying function is prepared from high-viscosity attapulgite clay, an attapulgite constant-humidity conditioner, a natural mineral adsorbing / filtering agent, Cacumen Biotae, aluminum silicate fiber and polyacrylamide. The attapulgite argil powder is prepared by the following steps: pulverizing the materials, soaking and aging to obtain a wet mixture, extruding the wet mixture into a strip, airing the strip, pulverizing to obtain powder, and packaging to obtain the finished product. The attapulgite argil powder has favorable cohesive property, plasticity, thixotropy, fire resistance and thermal stability; the pottery prepared from the attapulgite argil powder with an air purifying function contains a great deal of micropores and activated carbon, thus, has the characteristics of low shrinkage, no cracking or deformation and favorable adsorbability, and can effectively adsorb formaldehyde, ammonia, benzene and other harmful substances in the air, thereby protecting the environment and improving good health of people. The invention is suitable for producing pottery artware with an air purifying function.

Owner:江苏世澳非金属应用科技有限公司

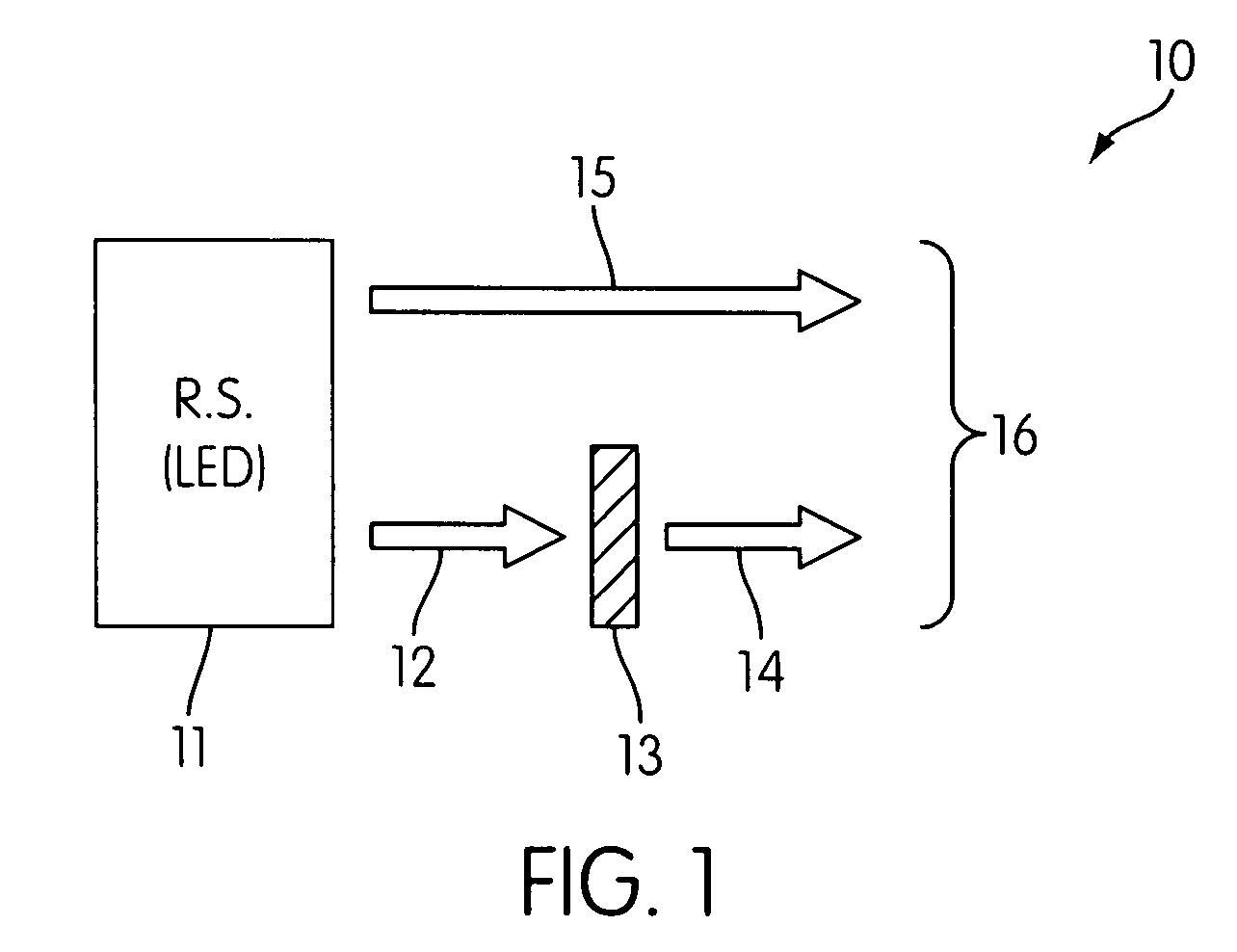

Aluminum-silicate based orange-red phosphors with mixed divalent and trivalent cations

InactiveUS20080111472A1Discharge tube luminescnet screensElectroluminescent light sourcesPhosphorAluminum silicate

Novel aluminum-silicate based orange-red phosphors, with mixed di- and trivalent cations are disclosed. The phosphors have the formula (Sr1−x−yMxTy)3−mEum(Si1−zAlz)O5, where M is at least one of Ba, Mg, Ca, and Zn in an amount ranging from 0≦x≦0.4. T is a trivalent metal in an amount ranging from 0≦y≦0. This phosphor is configured to emit visible light having a peak emission wavelength greater than about 580 nm. The phosphors may contain a halogen anion such as F, Cl, and Br, at least some of which is substitutionally positioned on oxygen lattice sites. The present aluminum-silicate phosphors have applications in white and orange-red illumination systems, as well as plasma display panels.

Owner:INTEMATIX

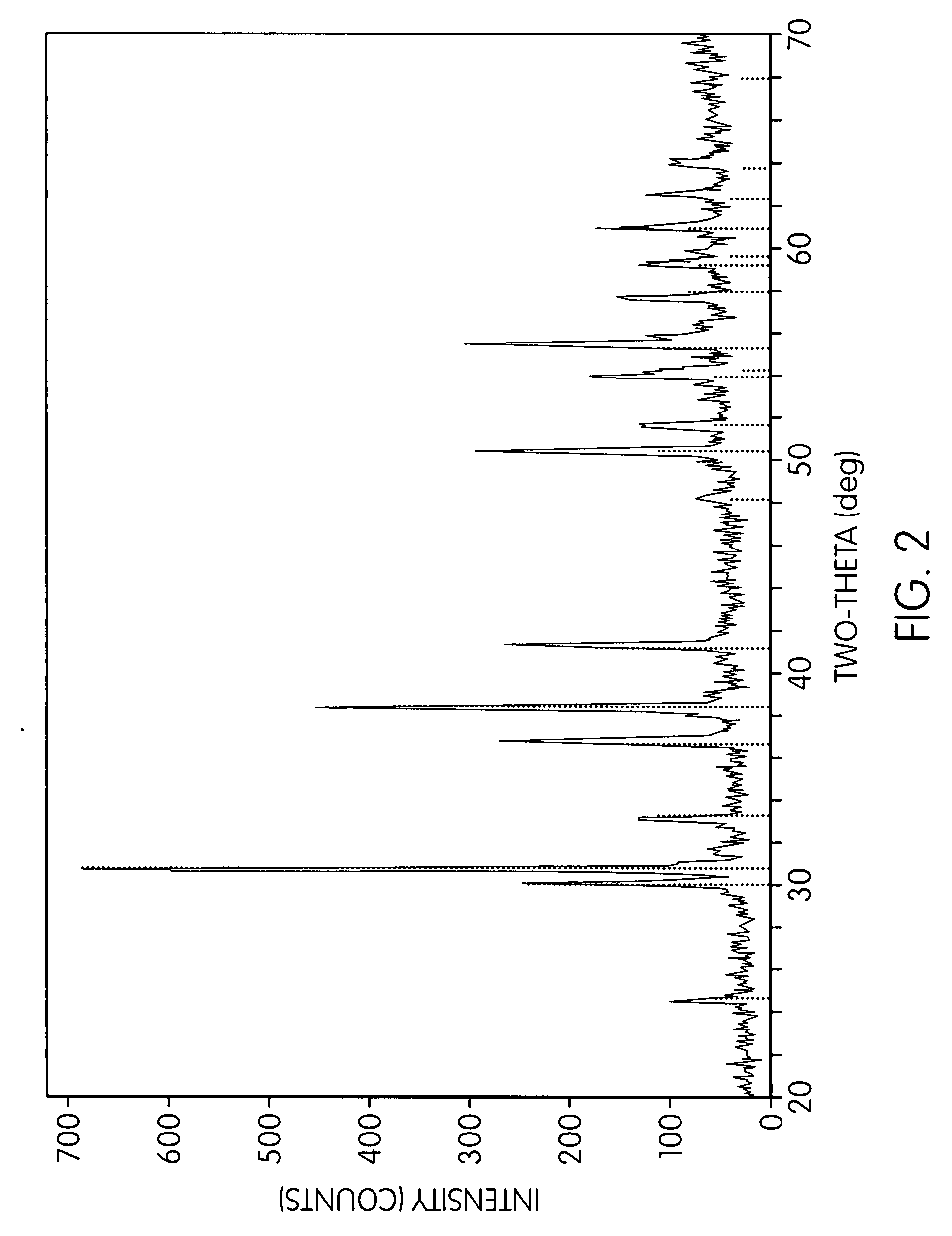

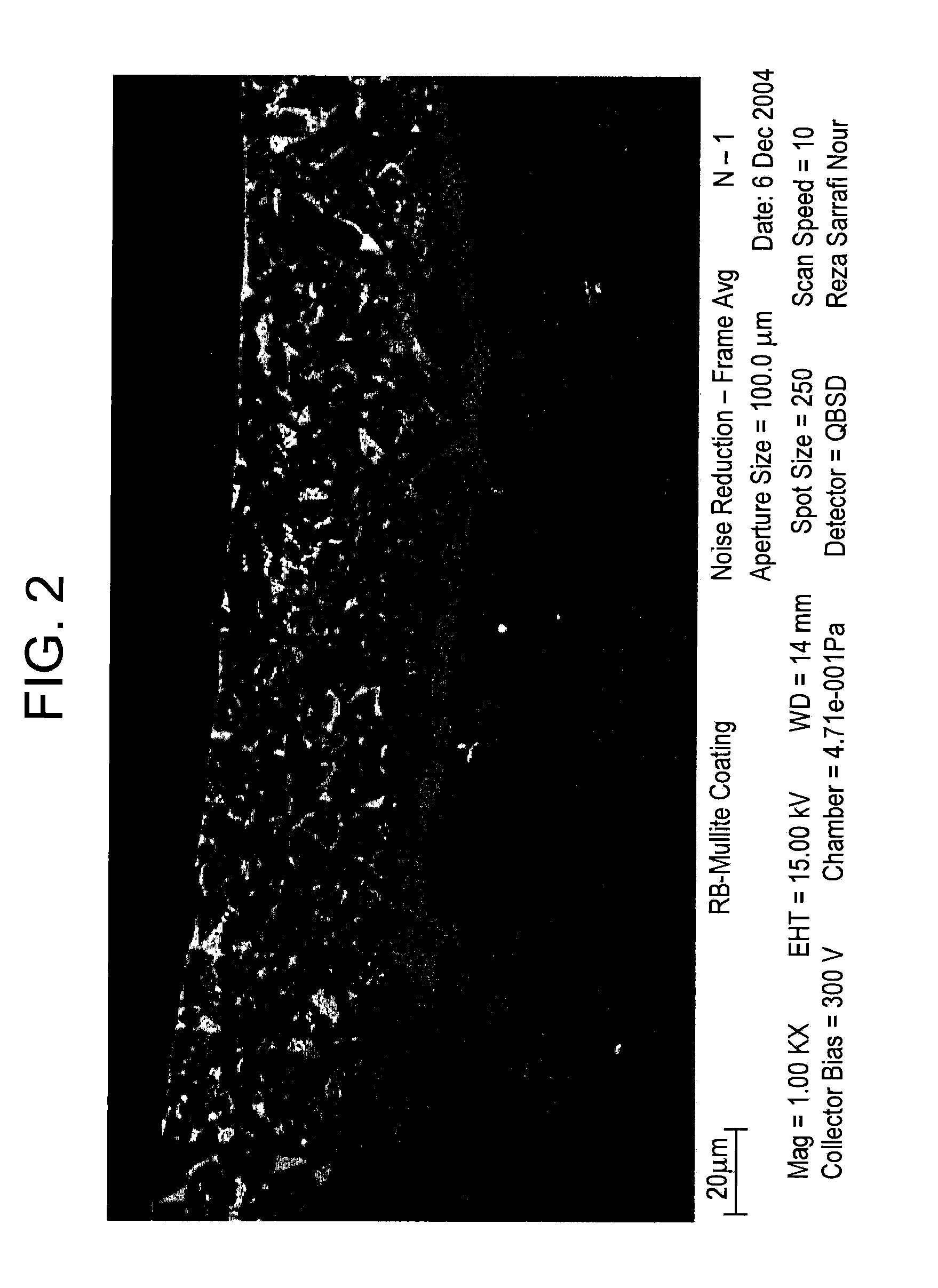

Methods of fabricating environmental barrier coatings for silicon based substrates

A method of protecting an article from a high temperature environment, the method includes providing a substrate comprising silicon, forming a slurry coating composition, wherein the composition comprises a metallic silicon powder, a rare-earth oxide, an alkaline earth metal oxide, an aluminum oxide, or a combination comprising at least one of the foregoing, and a binder effective to chemically stabilize the slurry coating, applying a layer of the slurry coating over the substrate, and heat-treating the slurry coating under conditions sufficient to oxidize the metallic silicon powder and form an alkaline earth metal aluminosilicate, a rare-earth silicate, an aluminum silicate, or a combination comprising at least one of the foregoing bonded to the substrate.

Owner:GENERAL ELECTRIC CO

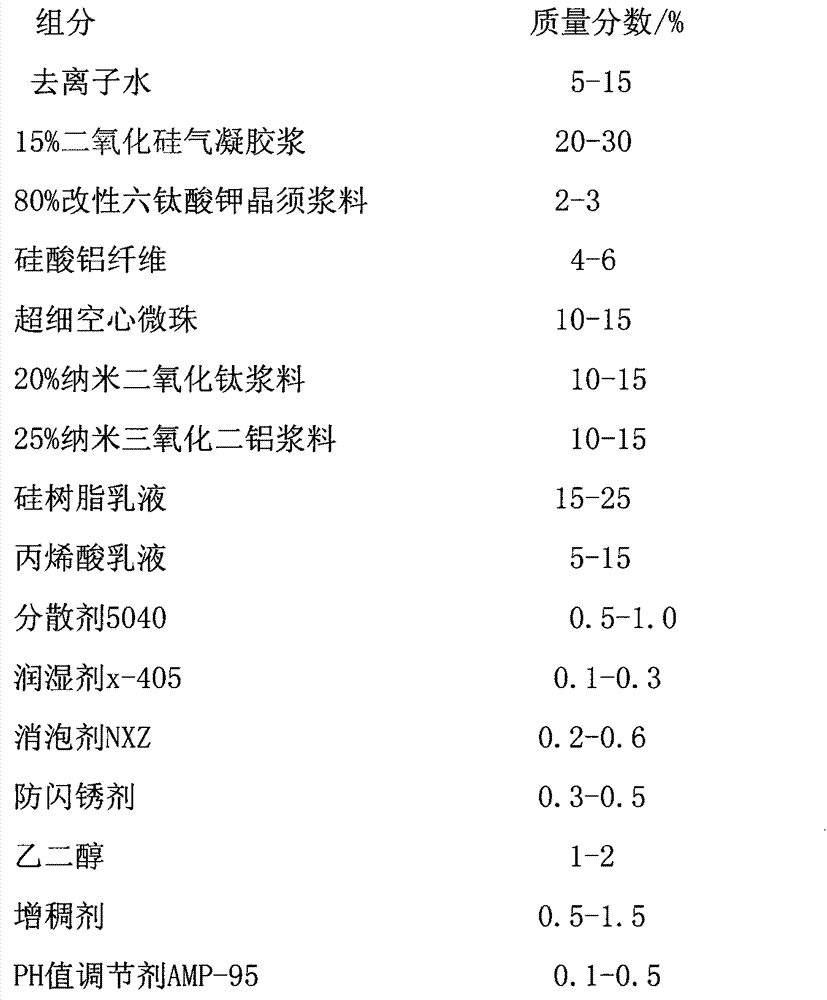

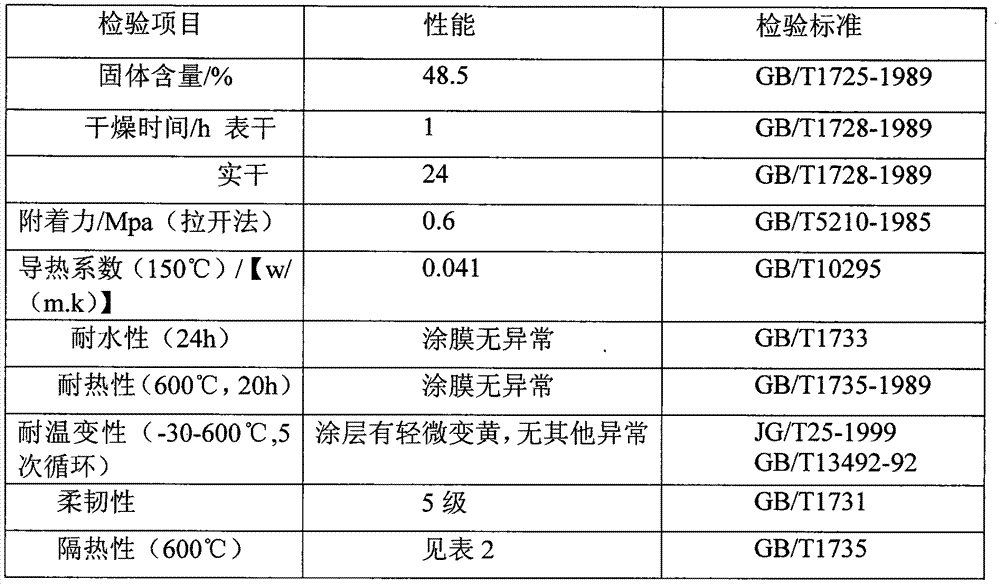

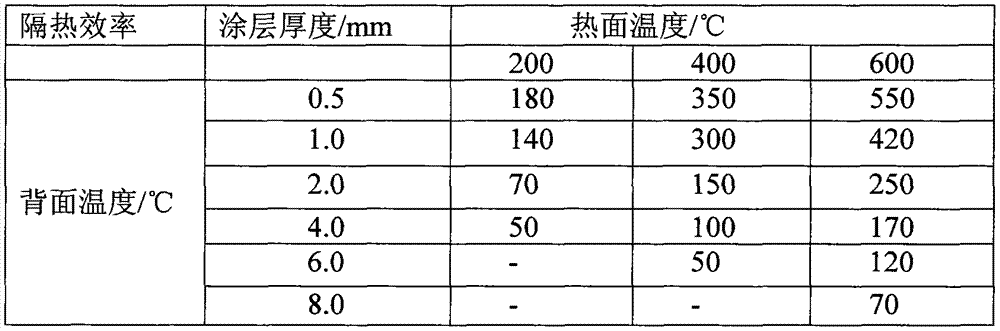

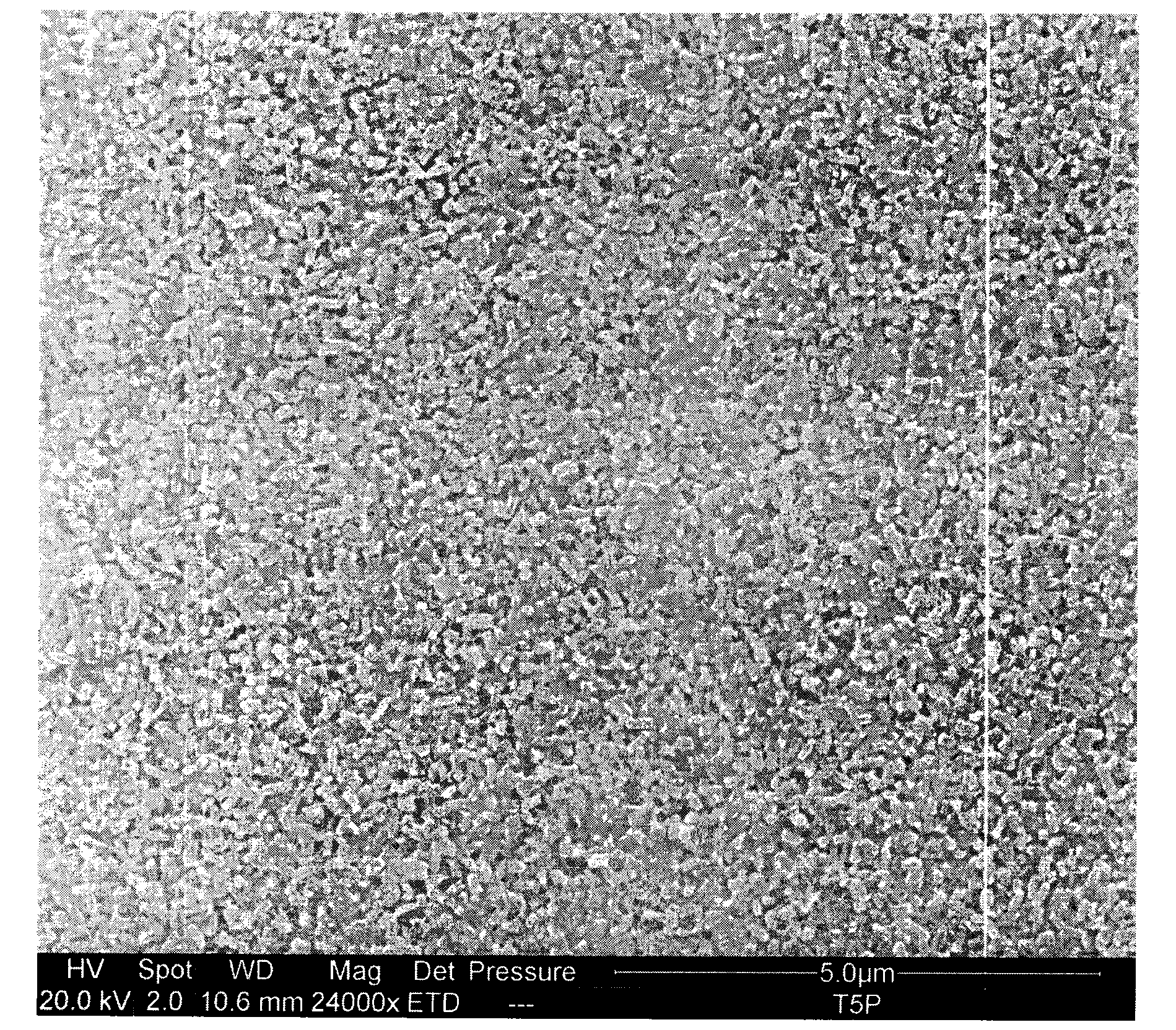

Nanometer high temperature resistant thermal insulation and prevention coating

The invention discloses a nanometer high temperature resistant thermal insulation and prevention coating. SiO2 aerogel, modified potassium hexatitanate whisker, aluminum silicate fiber, ultra-fine cenosphere, nanometer TiO2 and nanometer Al2O3 are used as a thermal insulation filler. A vacuum thermal insulation layer is formed by nano porous structures of SiO2 aerogel and cenosphere. The aluminum silicate fiber is used as a reinforcing and toughening material. The infrared shading performance of potassium hexatitanate whisker, nanometer TiO2 and nanometer Al2O3 are used as a thermal radiation shielding layer. A silicon resin emulsion and an acrylic emulsion are compounded to be an adhesive. Therefore, the nanometer 600 DEG C temperature resistant thermal insulation and prevention coating is prepared with matching of a variety of functional additives. The nanometer high temperature resistant thermal insulation and prevention coating has the characteristics of scumbling, thermal insulation, waterproofing, anti-crack, anti-corrosion, high temperature resistance, weather-proofing, durability and the like and is applicable to the field of industrial high temperature resistant thermal insulation energy conservation.

Owner:株洲中铁中南制造有限公司

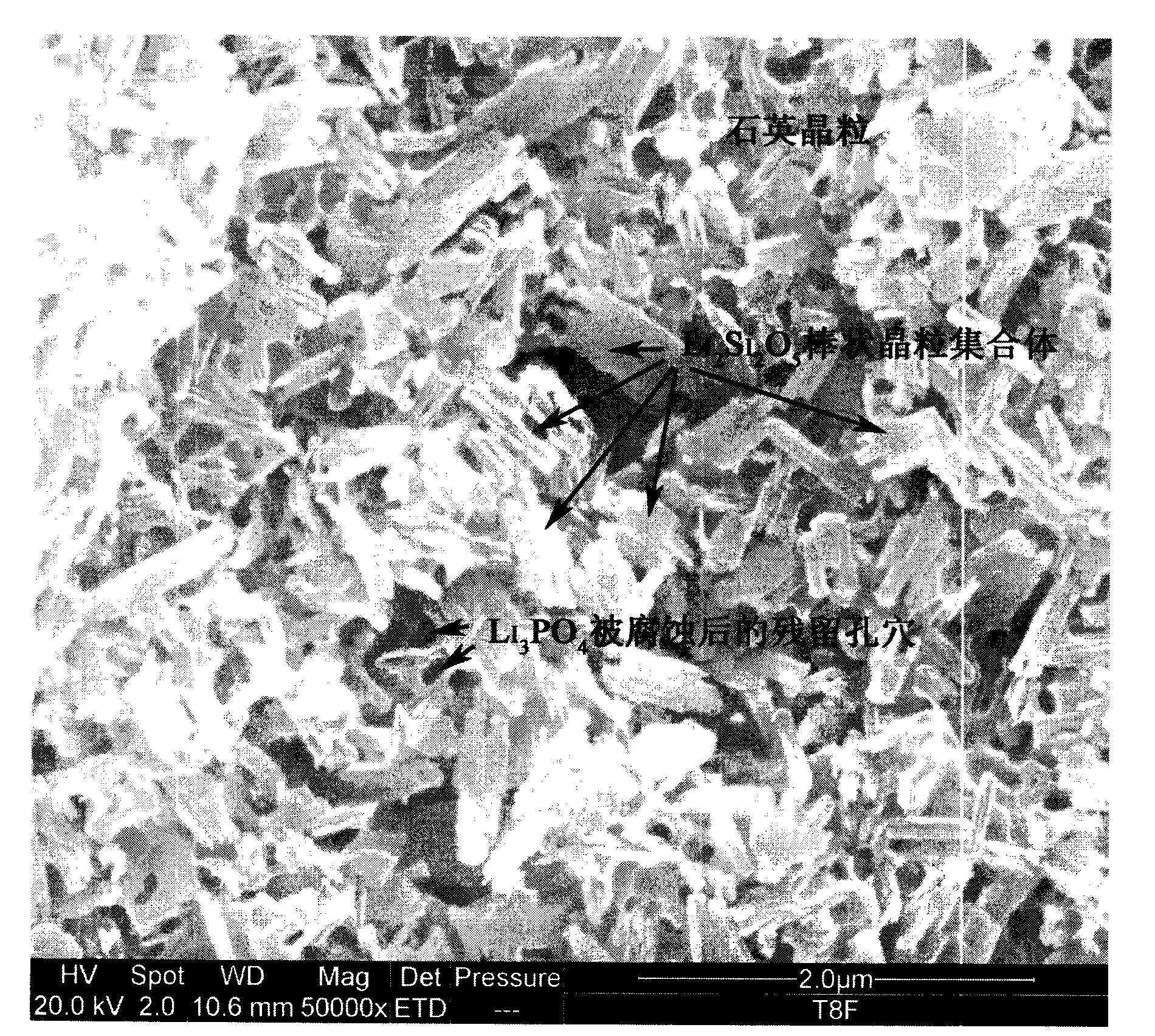

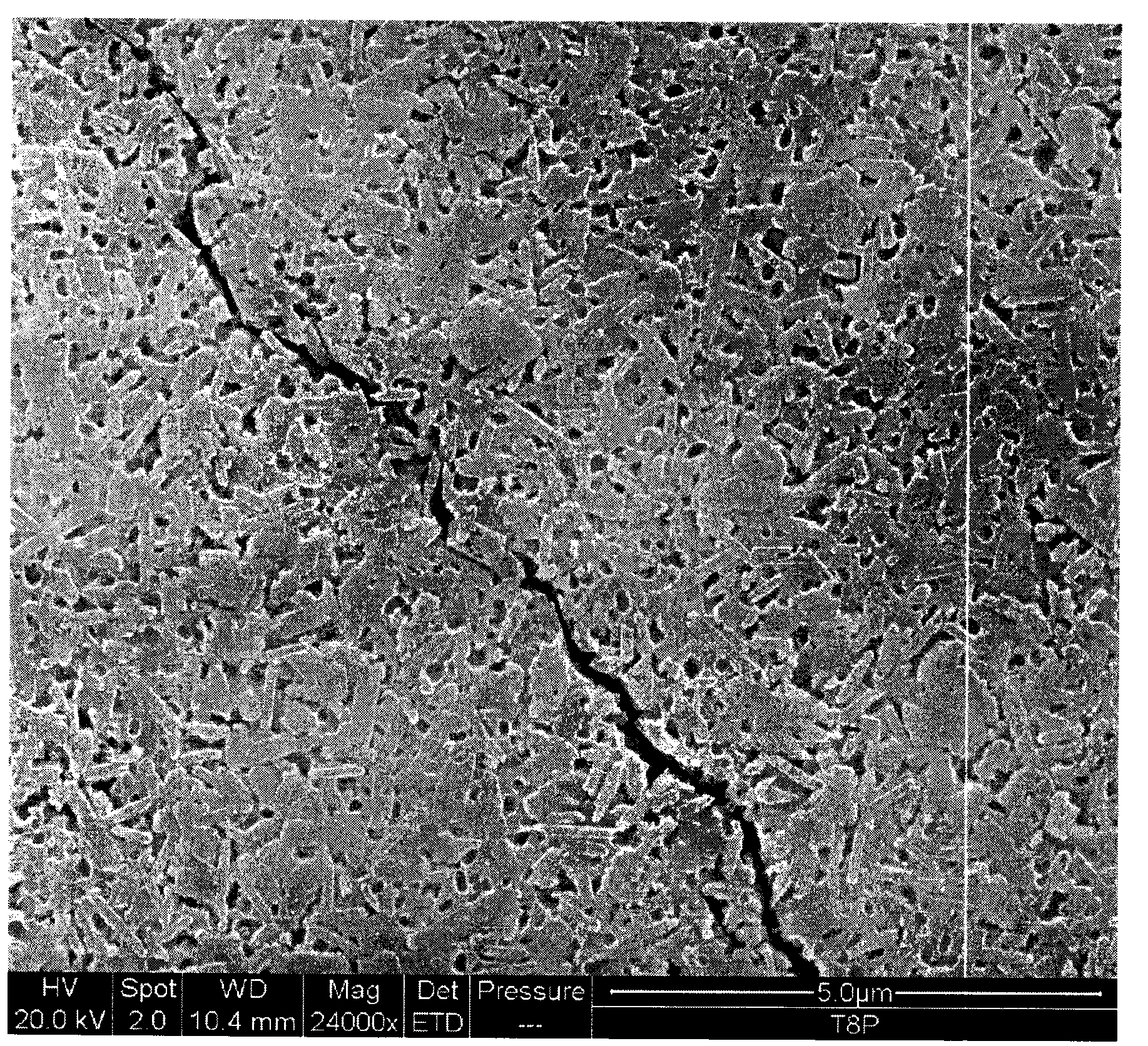

High-strength lithium disilicate glass ceramic and preparation method thereof

The invention discloses high-strength lithium disilicate glass ceramic and a preparation method thereof. The glass ceramic comprises the following chemical components in percentage by weight: 59-80% of SiO2, 10-18% of Li2O, 0.1-14% of MgO, 0-15% of Al2O3, 1-8% of P2O5, 0-5% of Na2O, 0-7% of CaO, 0-9% of K2O, 0.5-8% of stabilizer and 0-10% of colorant, wherein the stabilizer is selected from one or more of ZrO2, SrO, BaO and Y2O3, and the colorant is selected from one or more of Eu2O3, CeO<+>, Tb4O7, La2O3, Ta2O5, MnO2 and Fe2O3. The lithium disilicate glass ceramic is a material which contains a residual glass phase, a Li2Si2O5 principal crystalline phase and a small quantity of Li3PO1, quartz, cristobalite, zirconium oxide or magnesium-aluminum silicate phase and is prepared by controlling nucleation and crystallization processes after carrying out heat treatment on lithium disilicate matrix glass. The lithium disilicate glass ceramic is very high in bending strength and fracture toughness and favorable in translucence and chemical stability and can serve as a full-ceramic dental material applied to the field of dental restoration.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Process for removal of catalyst residues from poly-alpha-olefins

ActiveUS20050101761A1Reduce raw material usageOperation efficiency can be improvedHydrocarbonsAdsorption purification/separationCalcium silicateHalogen

A method is disclosed for reducing levels of residual halogen and Group IIIb metals in a crude poly(α-olefin) polymerized in the presence of a catalyst comprising the halogen and Group IIIb metals, wherein the method comprises: A) washing the crude poly(α-olefin) with water; B) separating the aqueous and organic phases; C) then adding an adsorbent selected from the group consisting of magnesium silicates, calcium silicates, aluminum silicates, aluminum oxides, and clays to the organic phase to form a slurry; D) heating the slurry under reduced pressure at a temperature of at least about 180° C. for at least about thirty minutes; and then E) separating the adsorbent from the slurry.

Owner:CHEMTURA CORP

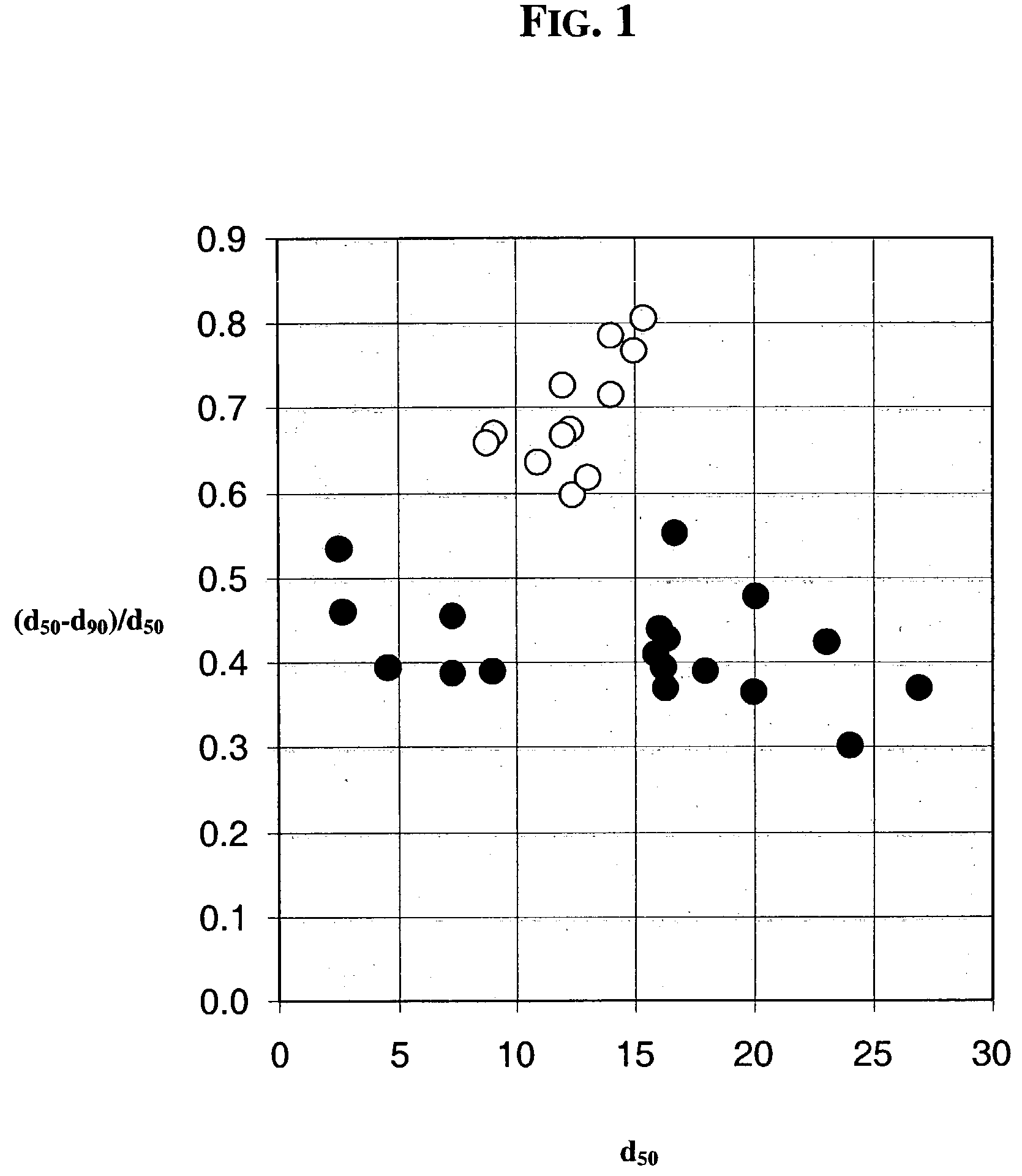

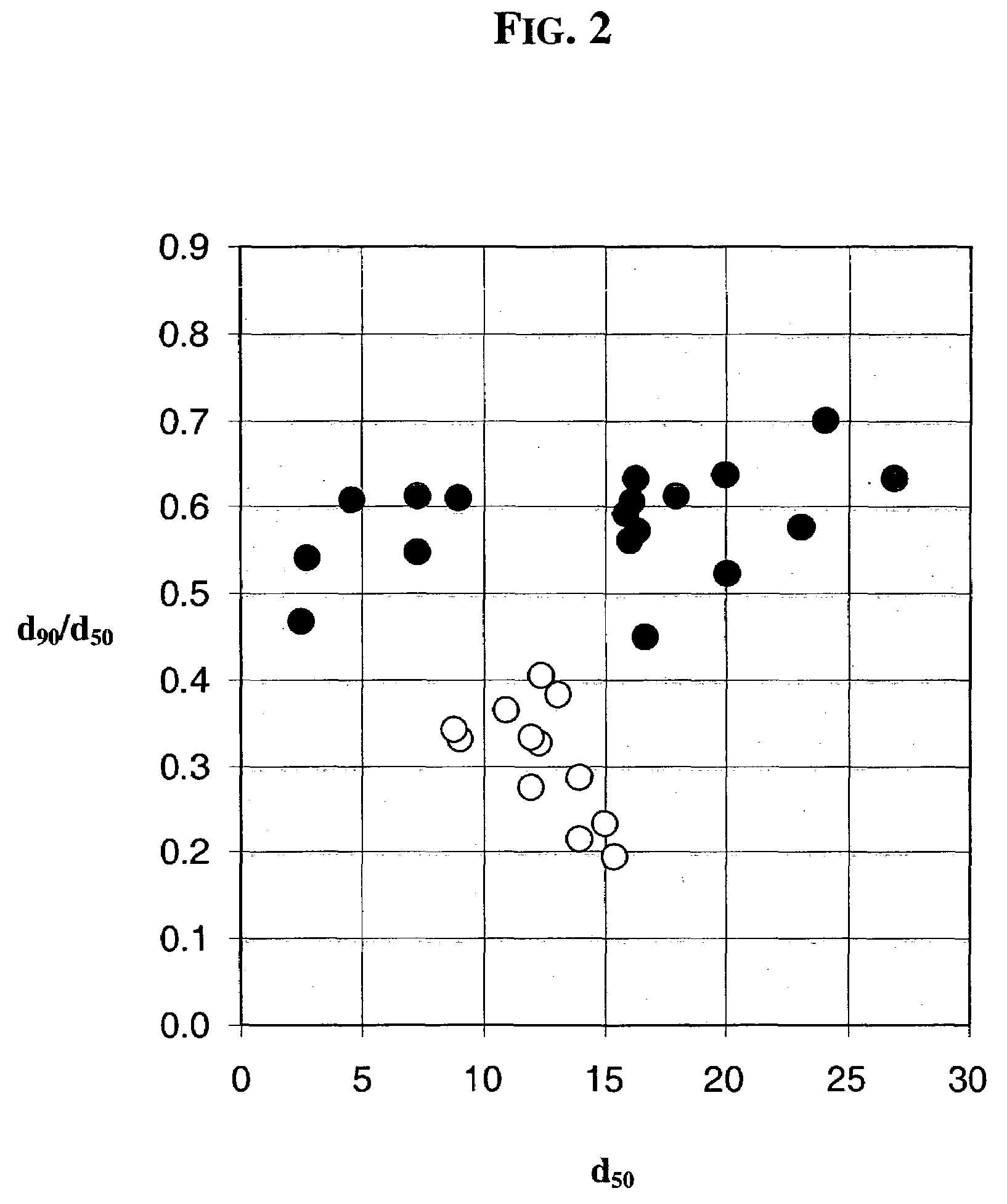

Magnesium aluminum silicate structures for DPF applications

ActiveUS7141089B2Reduce anisotropyGood pore connectivityCombination devicesAuxillary pretreatmentParticulatesAluminum silicate

A ceramic filter for trapping and combusting diesel exhaust particulates composed of an end-plugged cordierite honeycomb structure exhibiting a pore size distribution as determined by mercury porosimetry in which the quantity d50 / (d50+d90) as related to pore size distribution is less than 0.70, a soot loaded permeability factor Sf, as defined by the equation [d50 / (d50+d90)] / [% porosity / 100], of less than 1.55, and, a coefficient of thermal expansion (25–800° C.) of no greater than 17×10−7 / ° C. The ceramic filter further exhibits a median pore diameter, d50, of at least 4 micrometers and up to 40 micrometers. A method of making the filter is provided.

Owner:CORNING INC

Composition and method for oxidizing mercury in combustion processes

InactiveUS7413719B2Emission reductionExcessive emissionUsing liquid separation agentEmission preventionCombustion chamberCombustor

The invention can be summarized as follows. There is provided a method for oxidizing elemental mercury in a combustion process comprising, adding a composition comprising an aluminum silicate to a combustion chamber, boiler or kiln downstream from the burner region combustion zone. There is further provided a method for reducing the emission of one or more heavy metals in a combustion process by adding a composition comprising an aluminum silicate to a combustion chamber downstream from the burner region combustion zone. There is also provided a composition comprising an aluminum silicate that may be employed to oxidize elemental mercury generated in a combustion process. The composition also may be employed to reduce the emission of one or more heavy metals generated in a combustion process.

Owner:DIGDON WILLIAM TROY

Catalyst for purifying the exhaust gases of diesel engines, and process for the preparation thereof

InactiveUS20010043896A1Increase lytic activityLow ignition temperatureNitrogen compoundsInternal combustion piston enginesIridiumAluminum silicate

A catalyst for purifying the exhaust gases of diesel engines, which catalyst contains at least one zeolite and, additionally, at least one of the support oxides aluminum oxide, silicon dioxide, titanium dioxide and aluminum silicate and at least one of the noble metals platinum, palladium, rhodium and iridium. In this catalyst the atoms of the noble metals have a mean oxidation number of less than +2.5, on average more than 3 metal ligands and less than 3 oxygen ligands and are present on the zeolites and support oxides in the form of crystallites having a mean particle size of from 1 to 6 nm.

Owner:DMC2 DEGUSSA METALS CATALYSTS CERDEC +1

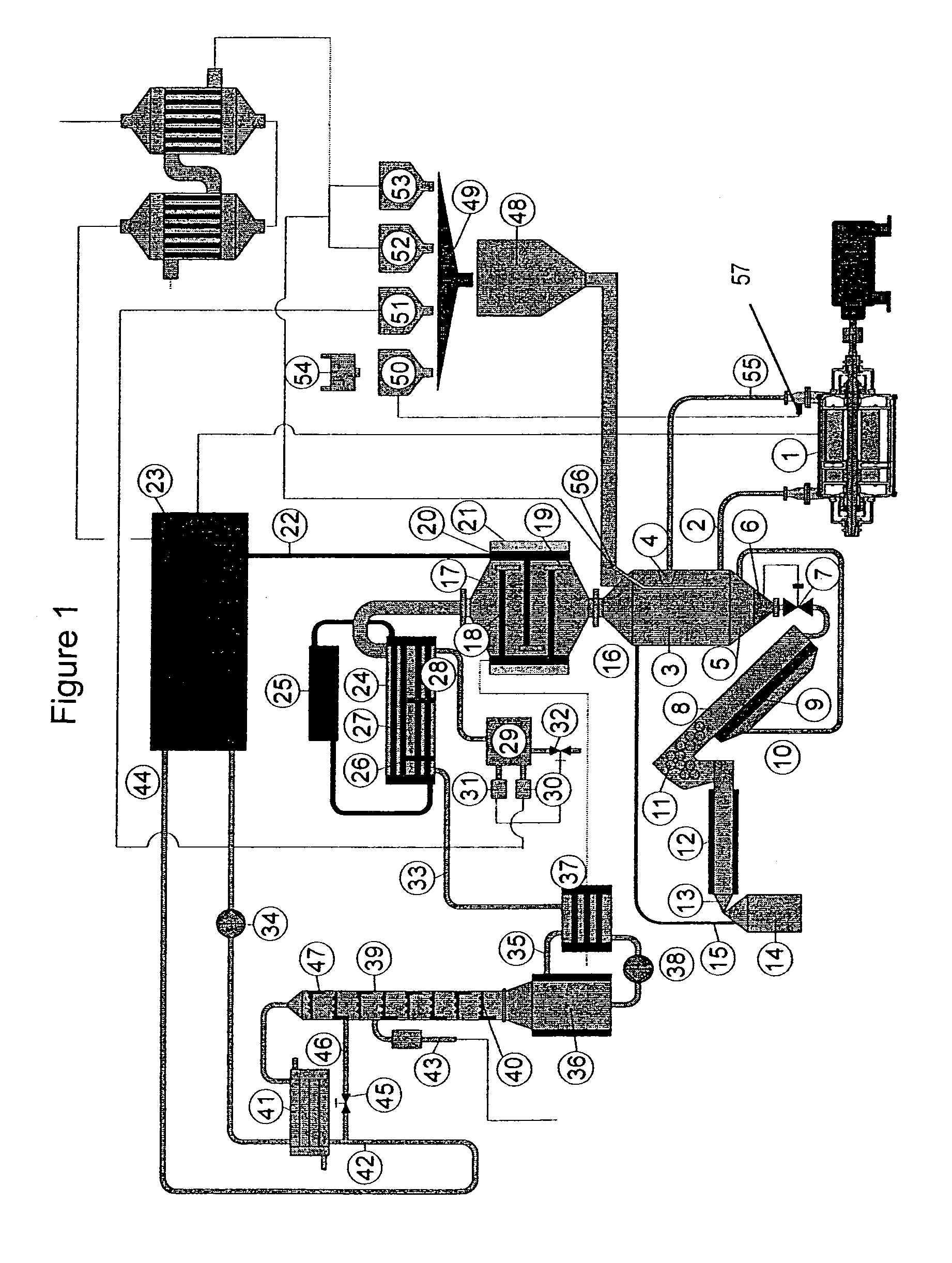

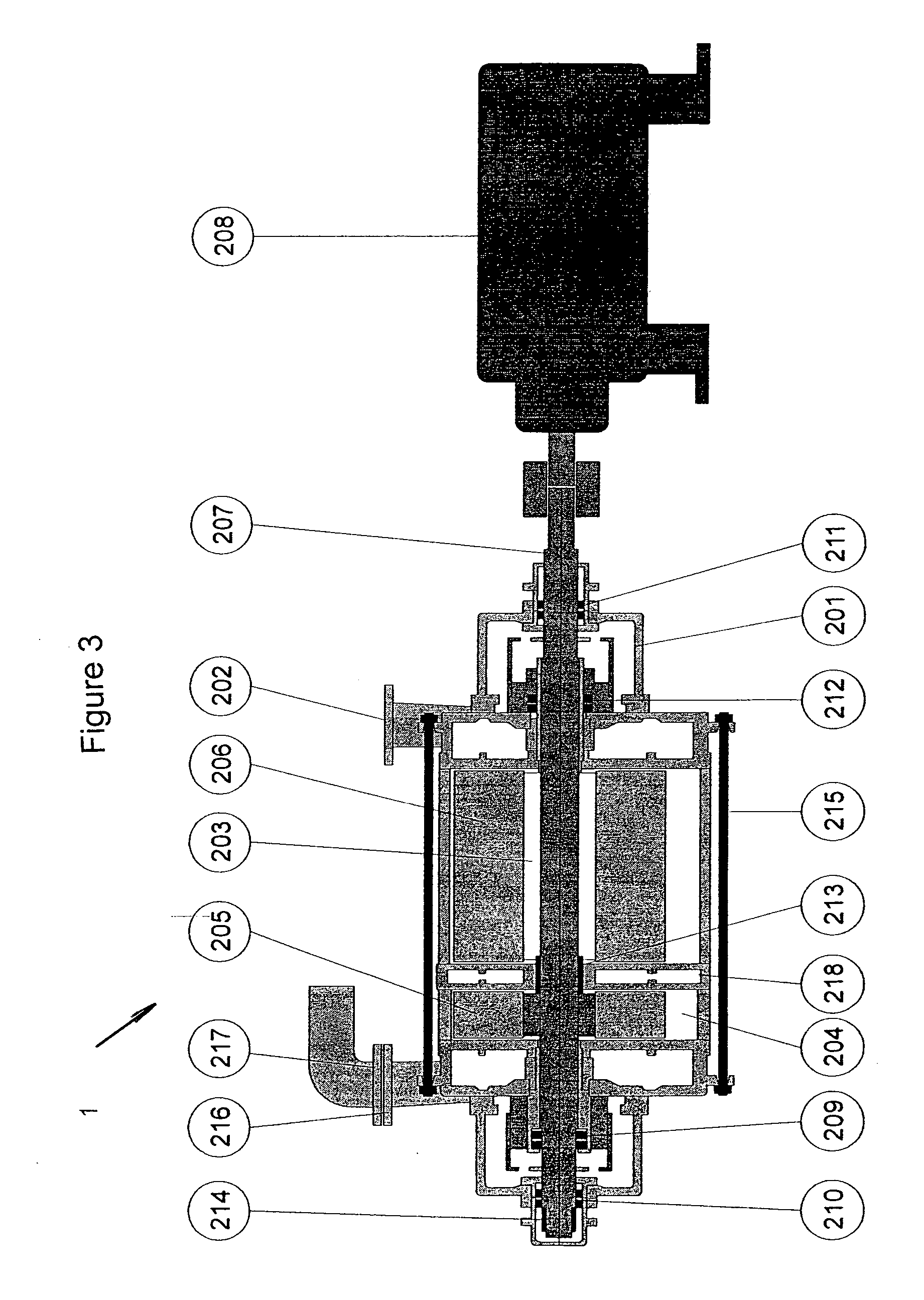

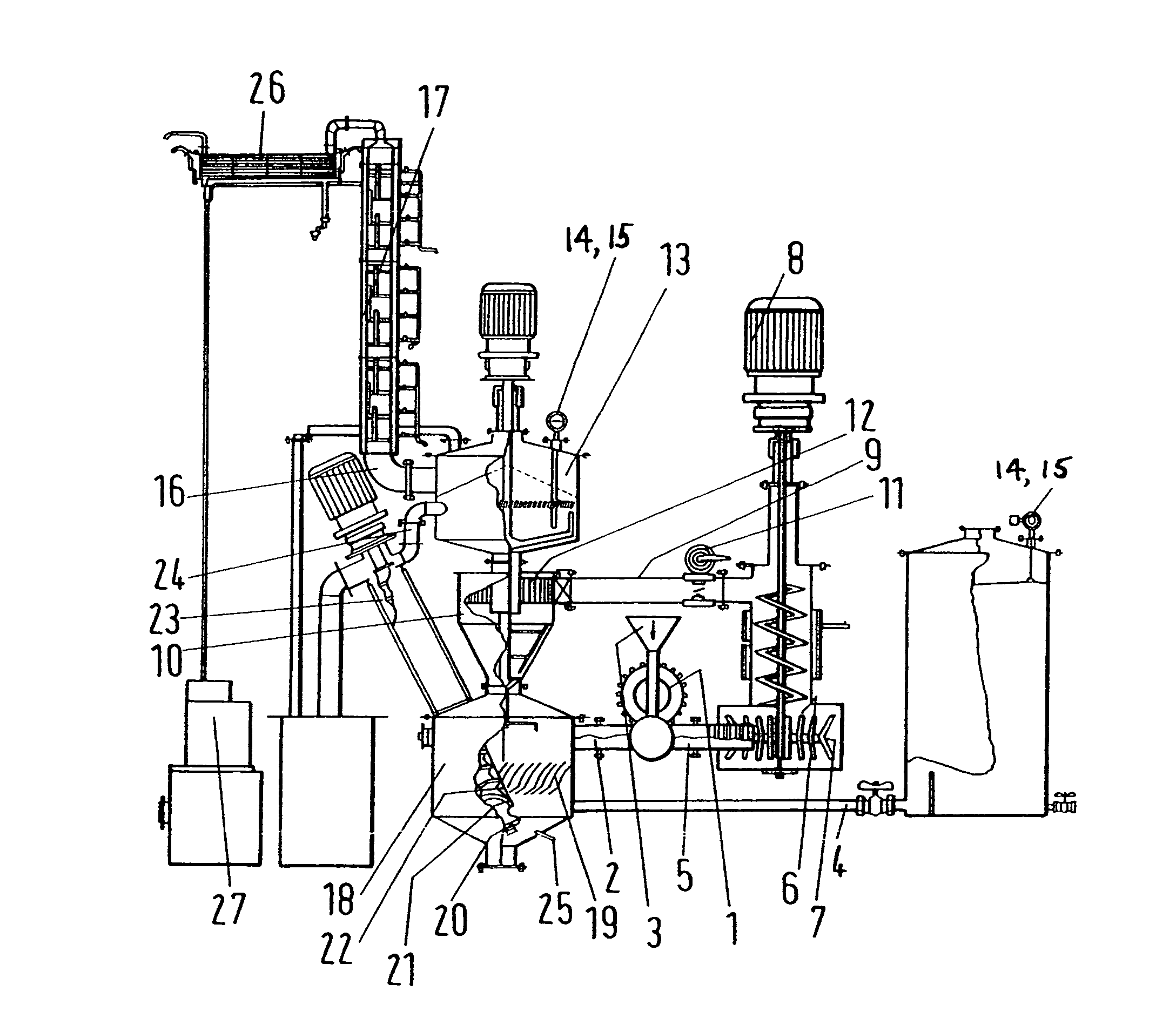

High-speed chamber mixer for catalytic oil suspensions as a reactor for the depolymerization and polymerization of hydrocarbon-containing residues in the oil circulation to obtain middle distillate

InactiveUS20070131585A1Eliminate disadvantagesQuality improvementThermal non-catalytic crackingCatalytic crackingDepolymerizationDistillation

Production of diesel oil from hydrocarbon-containing residues in an oil circulation with separation of solids and product distillation for the diesel oil product by energy input with a high-speed chamber mixer and the use of fully crystallized catalysts that consist of potassium-, sodium-, calcium-, and magnesium-aluminum silicates, wherein the energy input and conversion occur primarily in the high-speed chamber mixer.

Owner:KOCH CHRISTIAN

Catalyst for purifying the exhaust gases of diesel engines, and process for the preparation thereof

InactiveUS6685900B2Increase lytic activityLow ignition temperatureNitrogen compoundsInternal combustion piston enginesIridiumAluminum silicate

A catalyst for purifying the exhaust gases of diesel engines, which catalyst contains at least one zeolite and, additionally, at least one of the support oxides aluminum oxide, silicon dioxide, titanium dioxide and aluminum silicate and at least one of the noble metals platinum, palladium, rhodium and iridium. In this catalyst the atoms of the noble metals have a mean oxidation number of less than +2.5, on average more than 3 metal ligands and less than 3 oxygen ligands and are present on the zeolites and support oxides in the form of crystallites having a mean particle size of from 1 to 6 nm.

Owner:DMC2 DEGUSSA METALS CATALYSTS CERDEC +1

Ceramic fiber building fireproof plate

The present invention is fireproof building board of ceramic fiber, and belongs to the field of ceramic fiber material technology. The fireproof building board of ceramic fiber is produced with aluminum silicate fiber or light refractory stuffing as base material, and through adding one or several kinds of enhancing fiber; adding proper amount of organic binding agent or inorganic binding agent, stuffing and additive; pulping; forming; drying and other steps. The fireproof building board of ceramic fiber is used as the heat insulating board in building, and has high fire rating, high fire resistance, high heat isolating performance, high strength, low density and low cost.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

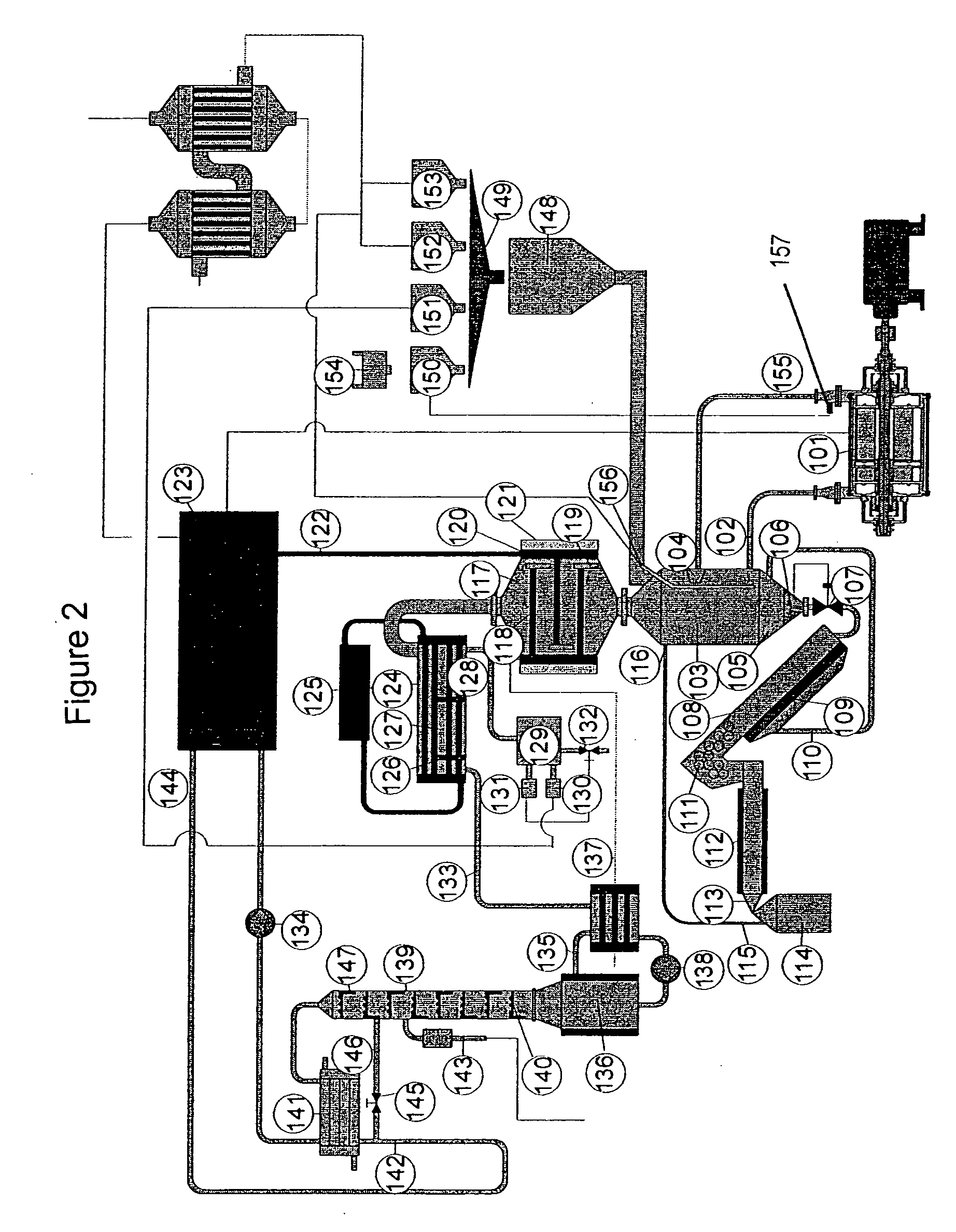

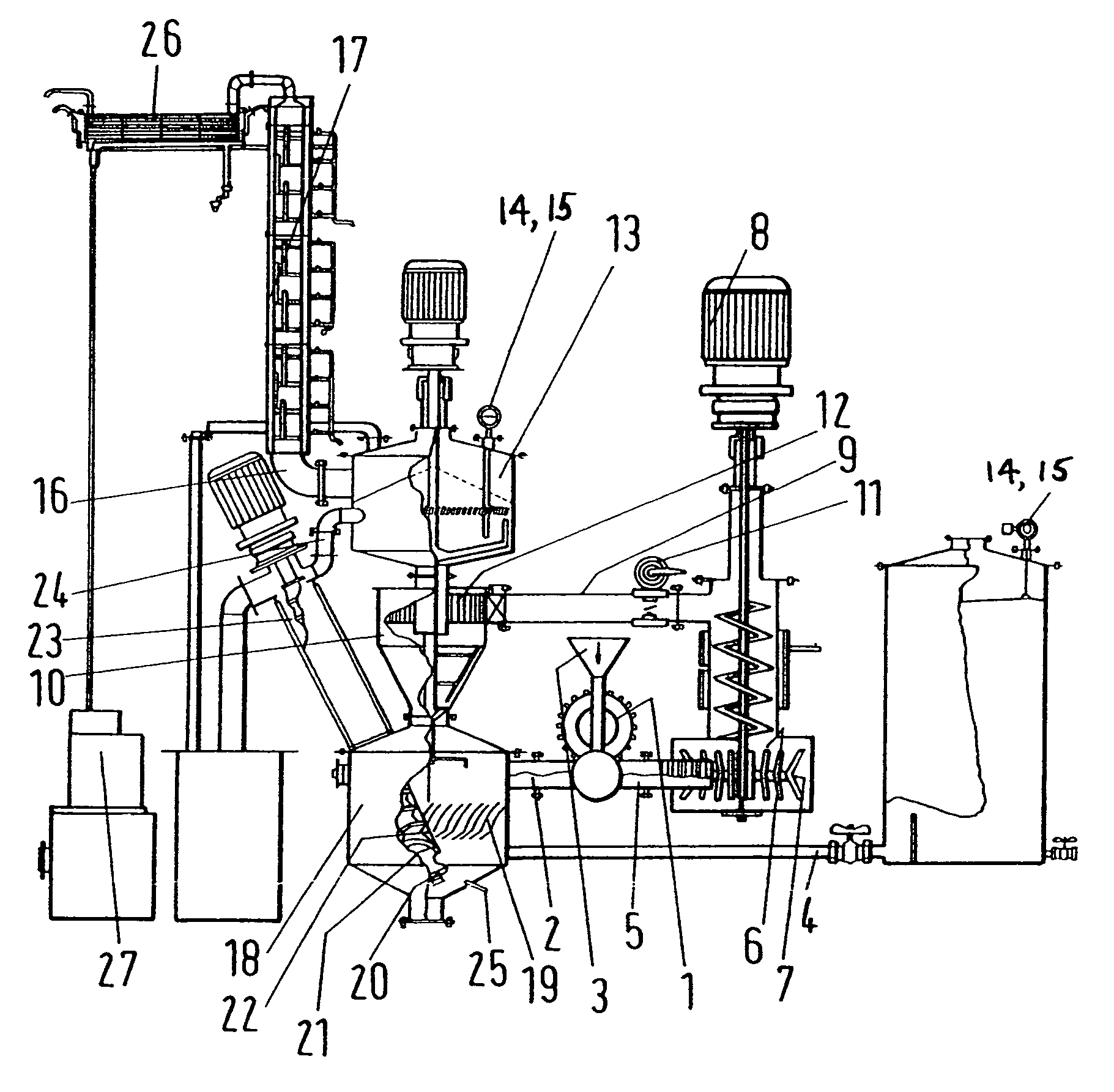

Diesel oil from residues by catalytic depolymerization with energy input from a pump-agitator system

Production of diesel oil from hydrocarbon-containing residues in an oil circuit with solids separation and product distillation for the diesel product with energy input by means of pumps and counterrotating agitators and by the use of fully crystallized catalysts of potassium, sodium, calcium, and magnesium-aluminum silicates, where all surfaces are cleaned continuously by the agitator mechanisms.

Owner:TGE IP LLC

Oxygen-containing coal bed gas deoxidation catalyst and preparation thereof as well as applications

InactiveCN101322942ALow priceSulfur resistanceMolecular sieve catalystsGaseous fuelsMordeniteAluminum silicate

The invention discloses a deoxidizing catalyst for a coal-seam gas containing oxygen and a preparation method as well as an application thereof. The deoxidizing catalyst of the invention consists of an active component, an active auxiliary and a porous carrier. The active component is the compound of Co; the active auxiliary is one or more compounds of Mn, Fe, Zn and Cu; the porous carrier is one or more of aluminum oxide, titanium oxide, zirconium oxide, magnesium oxide, calcium oxide, silicon oxide, a phosphor-aluminium molecular sieve, an A-typed molecular sieve, an X-typed molecular sieve, a Y-typed molecular sieve, a mordenite, a ZSM-5 zeolite, diatomaceous earth, kaolinite, natural clay, aluminum silicate and magnesium silicate; calculated by oxide, the weight percentage of the active component is 1 to 60 percent; the weight percentage of the active auxiliary is 1 to 50 percent; the rest is the carrier. The catalyst of the invention has certain sulfur-resistance performance, is applicable to the deoxidization treatment of coal-seam gas with an oxygen content of 3 to 6 percent (V / V) and is capable of causing the oxygen content in the coal-seam gas to be lower than 0.5 percent by deoxidization.

Owner:HAO HUA CHENGDU TECH

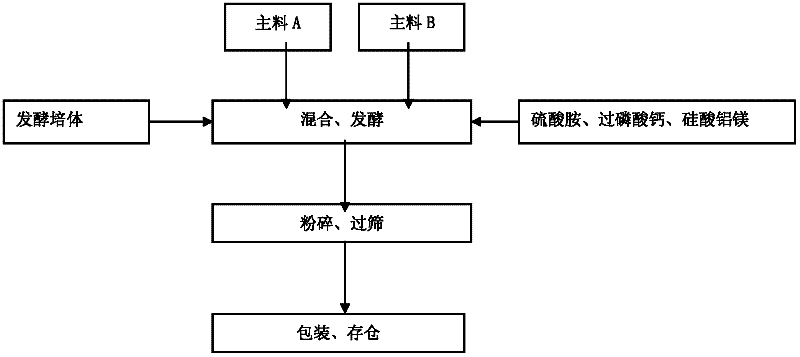

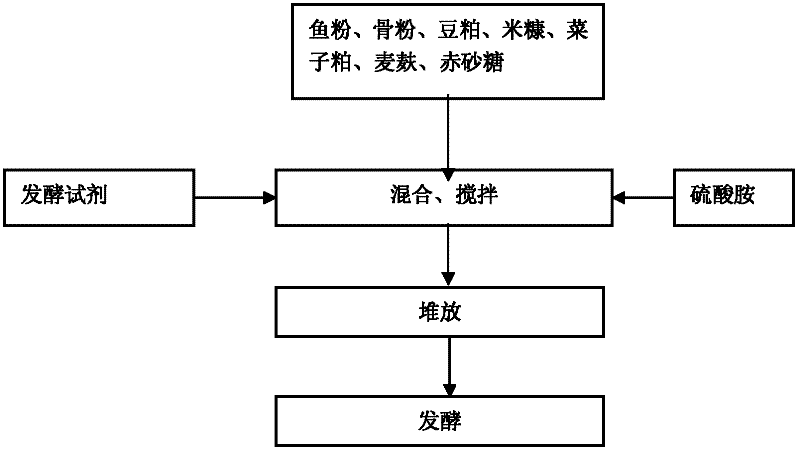

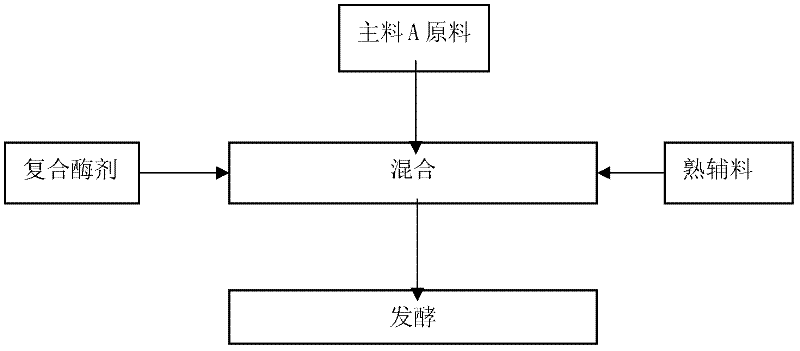

Biologic organic fertilizer and preparation method thereof

ActiveCN102584364APromote sustainable developmentBio-organic fraction processingOrganic fertiliser preparationEcological environmentAdditive ingredient

The invention discloses a biologic organic fertilizer and a preparation method thereof. The technical problem is solved, so that the prepared biologic organic fertilizer has multiple functions and high efficiency. The biologic organic fertilizer comprises the following raw materials in part by mass: 600 to 1,000 parts of major ingredient A, 30 parts of fermentation culture body, 50 parts of ammonium sulfate, 50 parts of calcium superphosphate and 50 parts of magnesium aluminum silicate powder, wherein the major ingredient A is livestock excrement and / or urban living garbage. The preparation method comprises the following steps of: uniformly mixing 600 to 1,000 parts of major ingredient A, 30 parts of fermentation culture body, 50 parts of ammonium sulfate, 50 parts of calcium superphosphate and 50 parts of magnesium aluminum silicate powder, stacking, fermenting and rotting for 20 to 25 days. Compared with the prior art, the invention has the advantages that: a large quantity of regenerative organic waste resources are used; the waste is turned into wealth; and the biologic organic fertilizer prepared by a pollution-free treatment method of a comprehensive biologic technology is applied widely, so that the sustainable development of agricultural and ecological environments is promoted.

Owner:陆少英

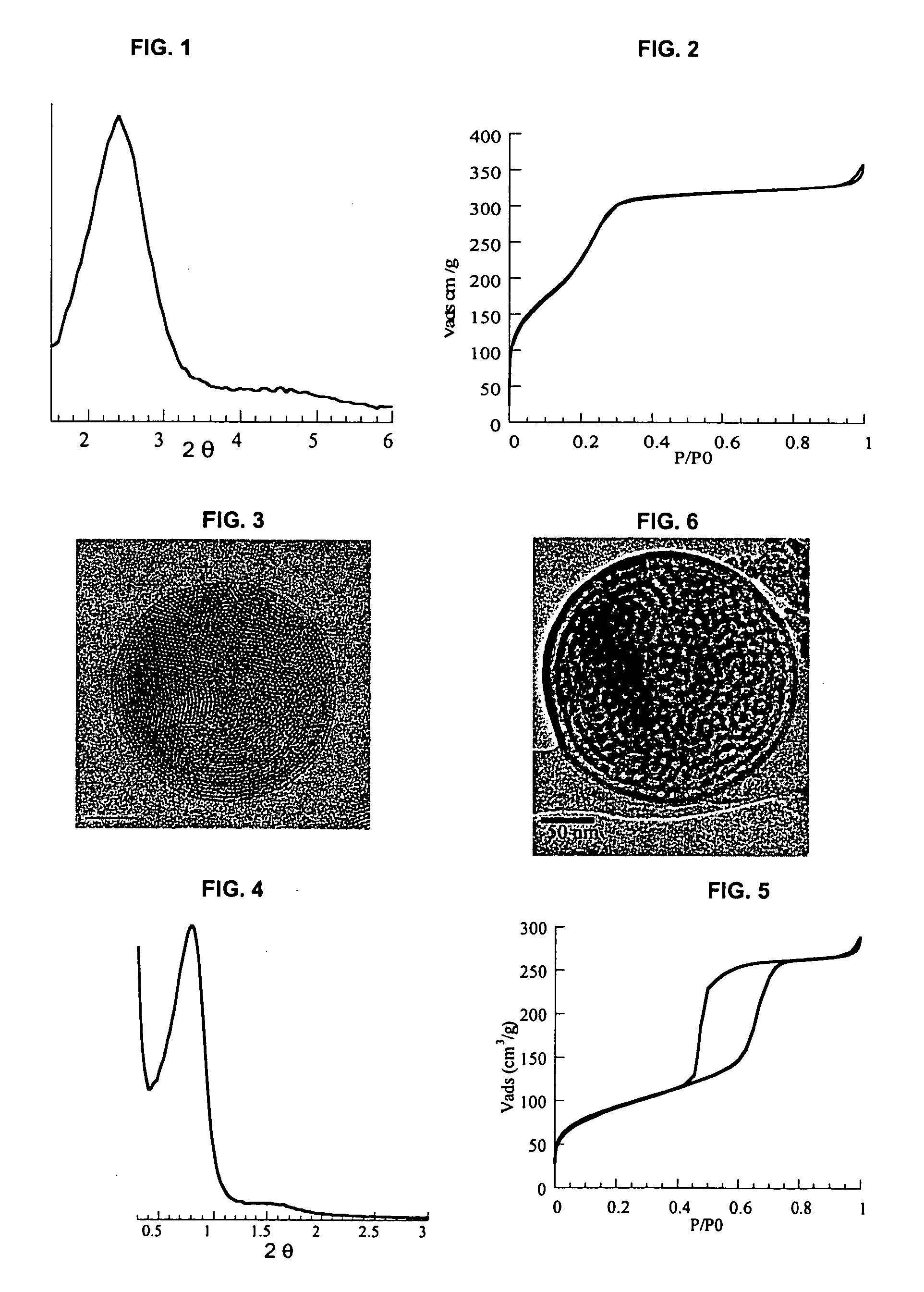

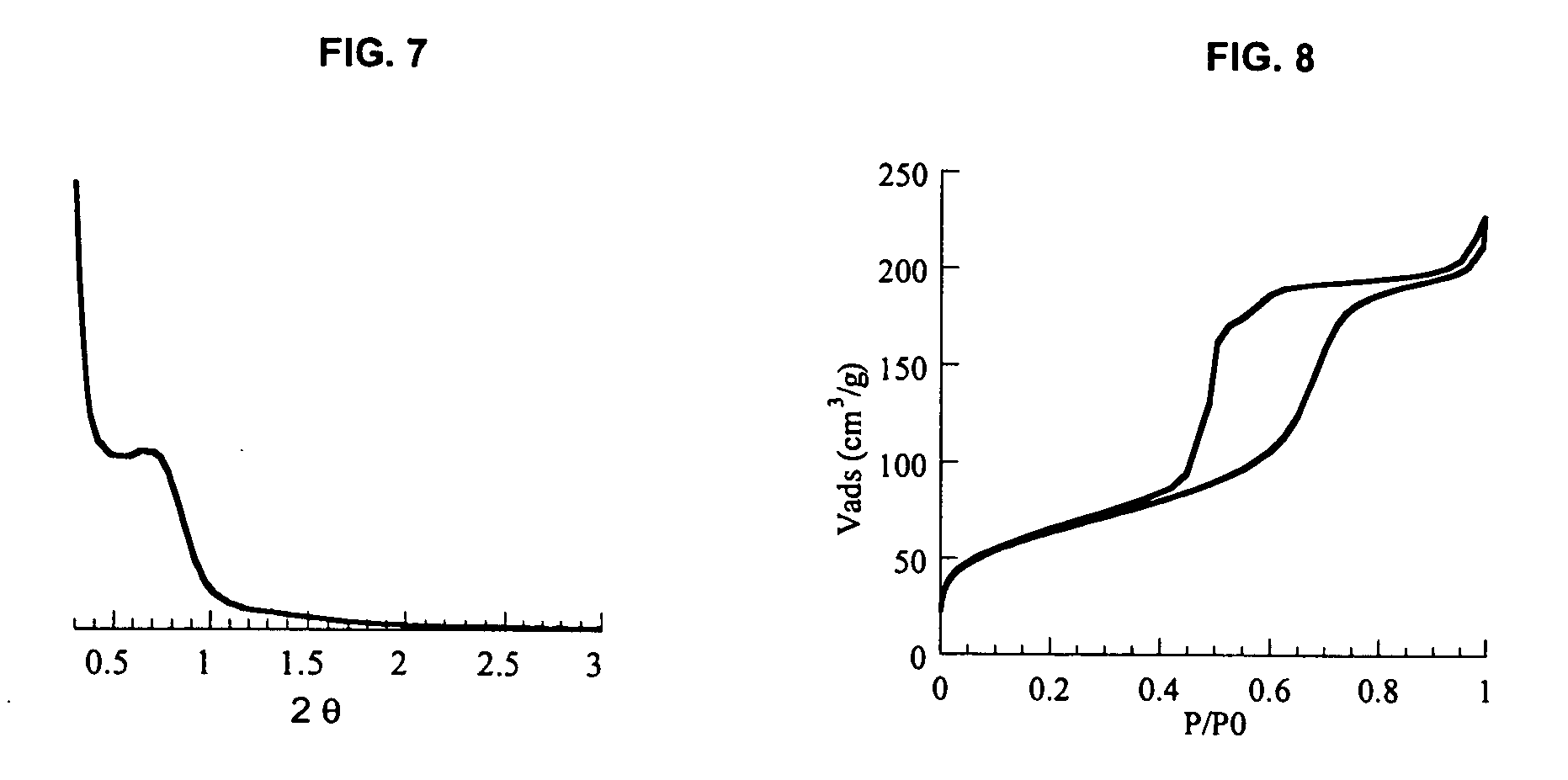

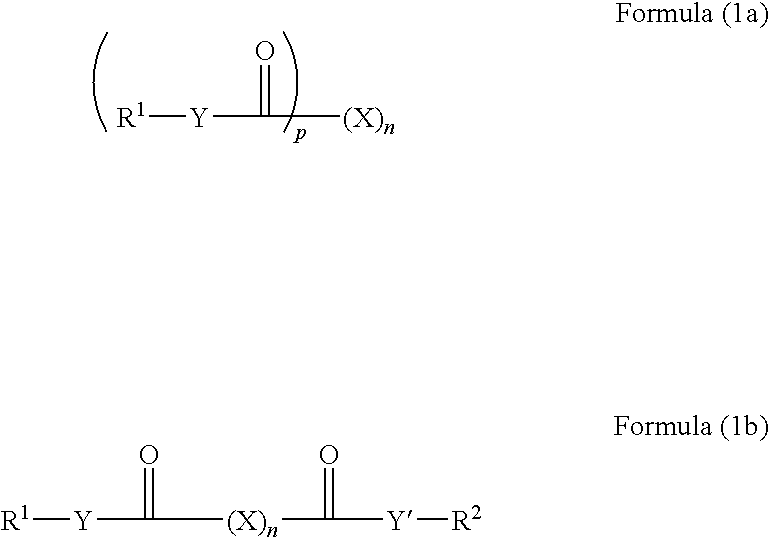

Mesostructured aluminosilicate material

A mesostructured aluminosilicate material is described, constituted by at least two spherical elementary particles, each of said spherical particles being constituted by a matrix based on silicon oxide and aluminium oxide, having a pore size in the range 1.5 to 30 nm, a Si / Al molar ratio of at least 1, having amorphous walls with a thickness in the range 1 to 20 nm, said spherical elementary particles having a maximum diameter of 10 μm. A process for preparing said material and its application in the fields of refining and petrochemistry are also described.

Owner:INST FR DU PETROLE

Method of Lubricating an Aluminum Silicate Composite Surface with a Lubricant Comprising Ashless, Sulphur, Phosphorous Free Antiwear Agent

The present invention relates to a method of lubricating an aluminium-composite surface by supplying to the aluminium composite surface (typically an internal combustion engine aluminium surface) a lubricating composition comprising an oil of lubricating viscosity and an ashless antiwear agent.

Owner:THE LUBRIZOL CORP

Dry thermal interface material

InactiveUS6900163B2Efficient use ofImprove actionSemiconductor/solid-state device detailsSolid-state devicesAntioxidantPolystyrene

A thermal interface material including a compound which has high thermal conductivity, is dry-to-the-touch, but naturally tacky, and may be formed into various shapes, such as sheets and blocks, to serve as a heat transfer material for electronic components. The compound includes a pre-blend of a polyol ester and an antioxidant, a boron nitride filler, a high viscosity oil, and either a solvent, a surfactant, and a polystyrene-based polymer, or aluminum silicate. A method for using the compound includes the steps of providing a heat generating electronic component with a first surface; providing a heat dissipating component with a second surface with which the first surface is to interface; and disposing the compound between the respective surfaces to effectuate efficient heat transfer therebetween. Further, a removable liner can be applied to an exposed surface of the compound.

Owner:AOS THERMAL COMPOUNDS

Method for preparing flame-retardant low-smoke halogen-free hot-vulcanized silicone rubber compounds for metro vehicles

The invention relates to a method for preparing flame-retardant low-smoke halogen-free hot-vulcanized silicone rubber compounds for metro vehicles, which is characterized in that the method comprises the following technological process: adding methyl vinyl silicone rubber to a kneading machine; adding white carbon black and hydroxyl silicone oil; mixing the materials for 1+ / -0.1 hour at a nitrogen-supplying speed of 5+ / -0.1 cubic meter / hour at a temperature between 170 and 190 DEG C; cooling to 60+ / -5 DEG C; adding porcelainizing powder, aluminum silicate, chloroplatinic acid, zinc stannate and aluminum hydroxide; continuing to mix for 0.5+ / -0.05 hour; discharging the materials; filtering rubber in a rubber filter; cooling the obtained product to room temperature; adding 2,5-dimethyl-2,5-bis(tert-butylperoxy) hexane or peroxide bis(2,4-dichloro-benzoyl) serving as a curing agent to an open mill; mixing well; and obtaining the flame-retardant low-smoke halogen-free hot-vulcanized silicone rubber compounds for metro vehicles. As the method adopts halogen-free flame retardant and particularly adopts a porcelainizing smoke-cutting technique, smoke almost completely disappears after the product produced by the method burns for a plurality of minutes, and the inside of the product can be kept in good condition.

Owner:JIANGYIN HAIDA RUBBER & PLASTIC GROUP

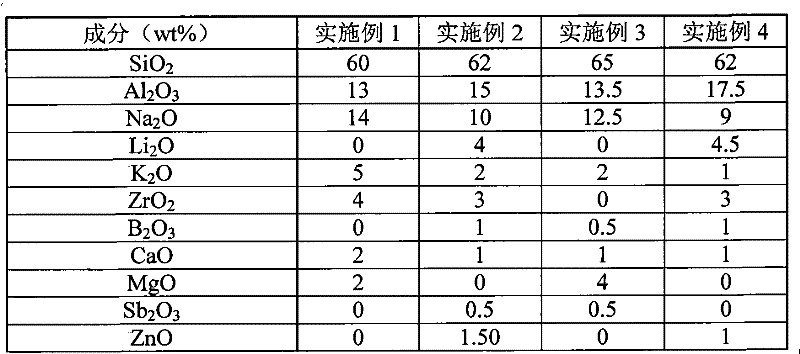

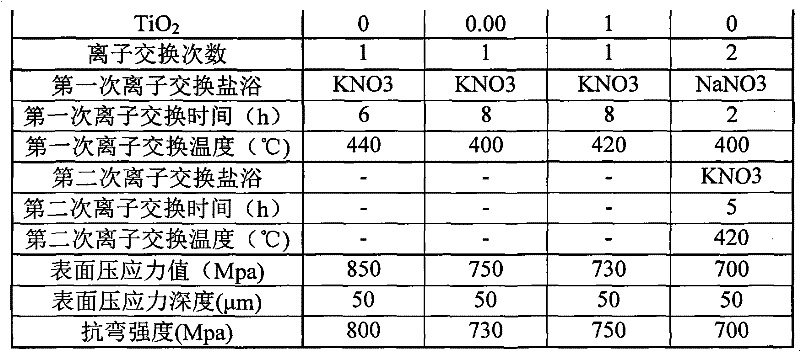

Aluminum silicate glass and preparation method thereof

InactiveCN102336521AImprove impact resistanceImprove flexural strengthAlkali metal oxideAluminum silicate

The invention relates to aluminum silicate glass. The toughness of the ultrathin glass is increased by adopting an ion exchange chemical reinforcing method in a subsequent process. The aluminum silicate glass comprises the following components in percentage by weight: 55 to 70 percent of SiO2, 10 to 20 percent of Al2O3, 8 to 25 percent of at least one alkali metal oxide and the balance of additive, wherein ions of chemical reinforcing ion exchange are from alkali metal ions in the alkali metal oxide. After ion exchange chemical reinforcing, the surface pressure value of the aluminum silicate glass can reach over 700MPa, and the depth of the pressure stress layer can reach over 50 microns, so cracks on the surface of the glass can be totally covered, and the safety of the glass in application is greatly promoted. The invention also relates to a method for preparing the aluminum silicate glass.

Owner:吴艺菲

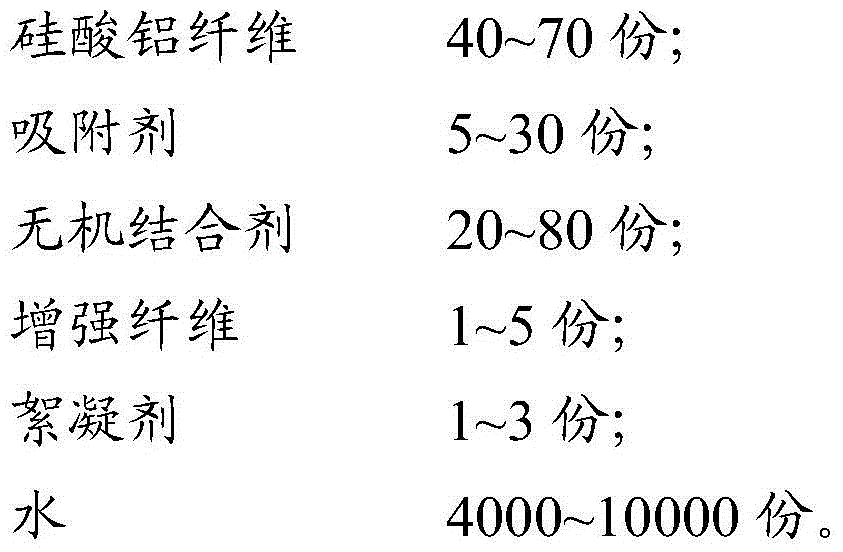

Ceramic fiber plate and preparation method thereof

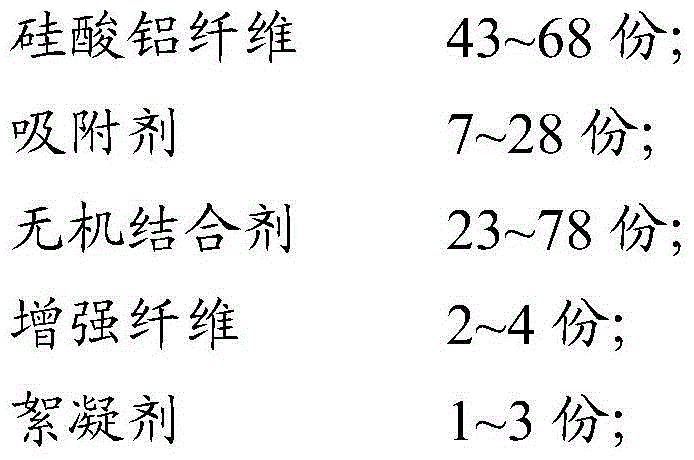

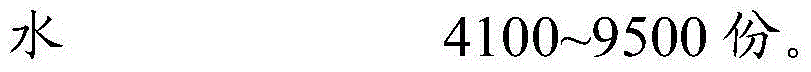

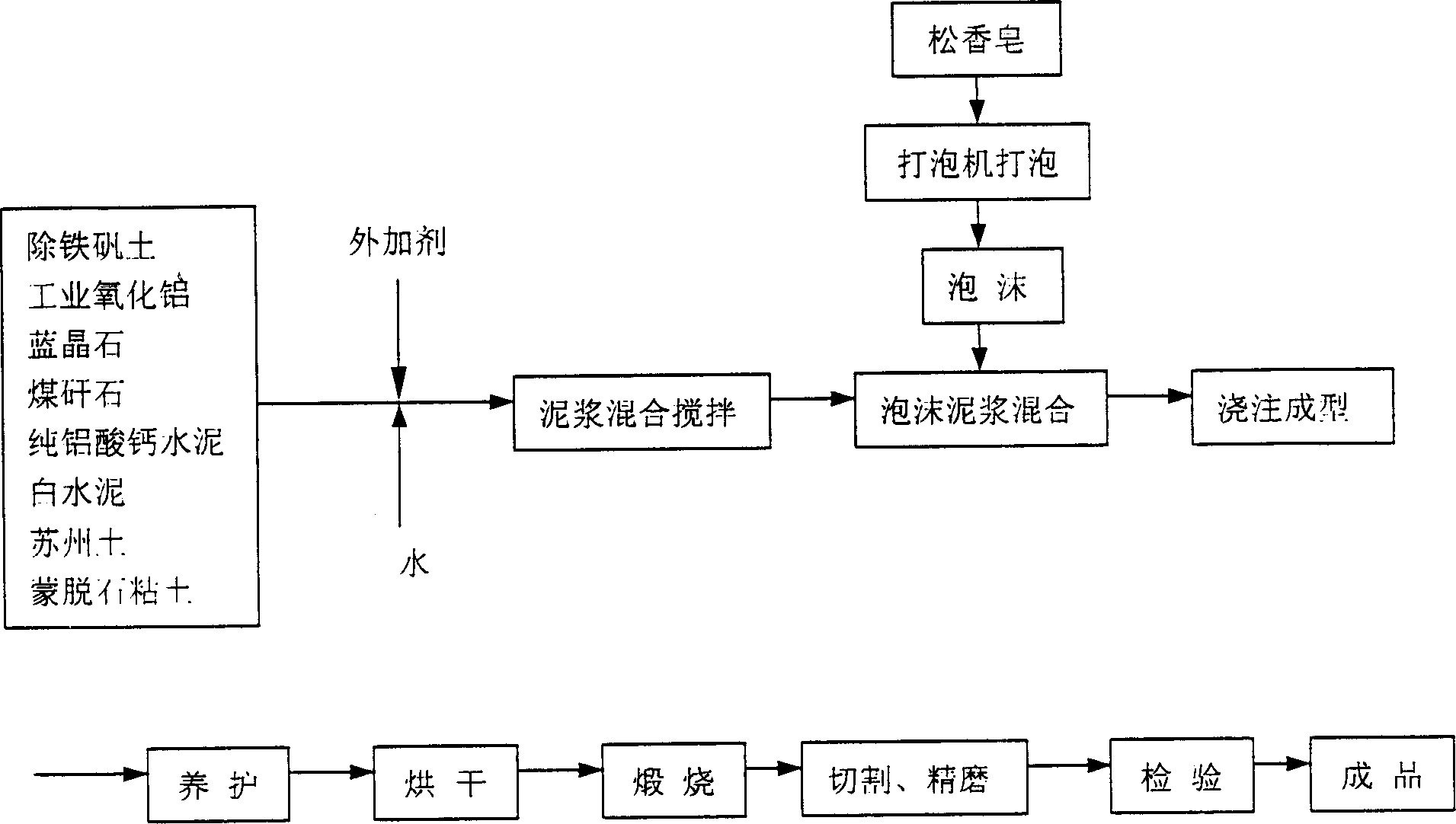

The invention provides a ceramic fiber plate which is prepared from the following raw materials in parts by weight: 40-70 parts of aluminum silicate fibers, 5-30 parts of adsorbents, 20-80 parts of inorganic binding agents, 1-5 parts of reinforcing fibers, 1-3 parts of flocculants and 4000-10000 parts of water. The ceramic fiber plate contains no organic binding agent and can not generate the environmental protection problems of blackening, smoking, pungent smell and the like. The ceramic fiber plate provided by the invention can be obtained with no need of calcination through the matching use of the inorganic binding agents and the adsorbents, has the advantages of no embrittlement and good toughness, is high in compression strength through the matching use of the aluminum silicate fibers, the reinforcing fibers and the flocculants and is reduced in cost through no need of the calcination. An experimental result indicates that the ceramic fiber plate provided by the invention achieves the compression strength more than 0.25 MPa.

Owner:新疆鲁阳陶瓷纤维有限公司

Light refractory bricks

InactiveCN1424280AIncrease optionalityReduce manufacturing costFurnace componentsCeramicwareMulliteAluminum silicate

A light-weight refractory brick used for liner of high-temp furnace is prepared from mullite as primary crystal phase, huronite as binding phase, disthene and coal gangue. Its main chemical components are Al2O3 (54-57 wt.%), SiO2 (40-43), CaO (1-2), Fe2O3 (0.1-1) and impurities (0.1-0.7). Its advantages are light weight, low heat conductivity and volume density, and high strength.

Owner:UNIV OF SCI & TECH BEIJING

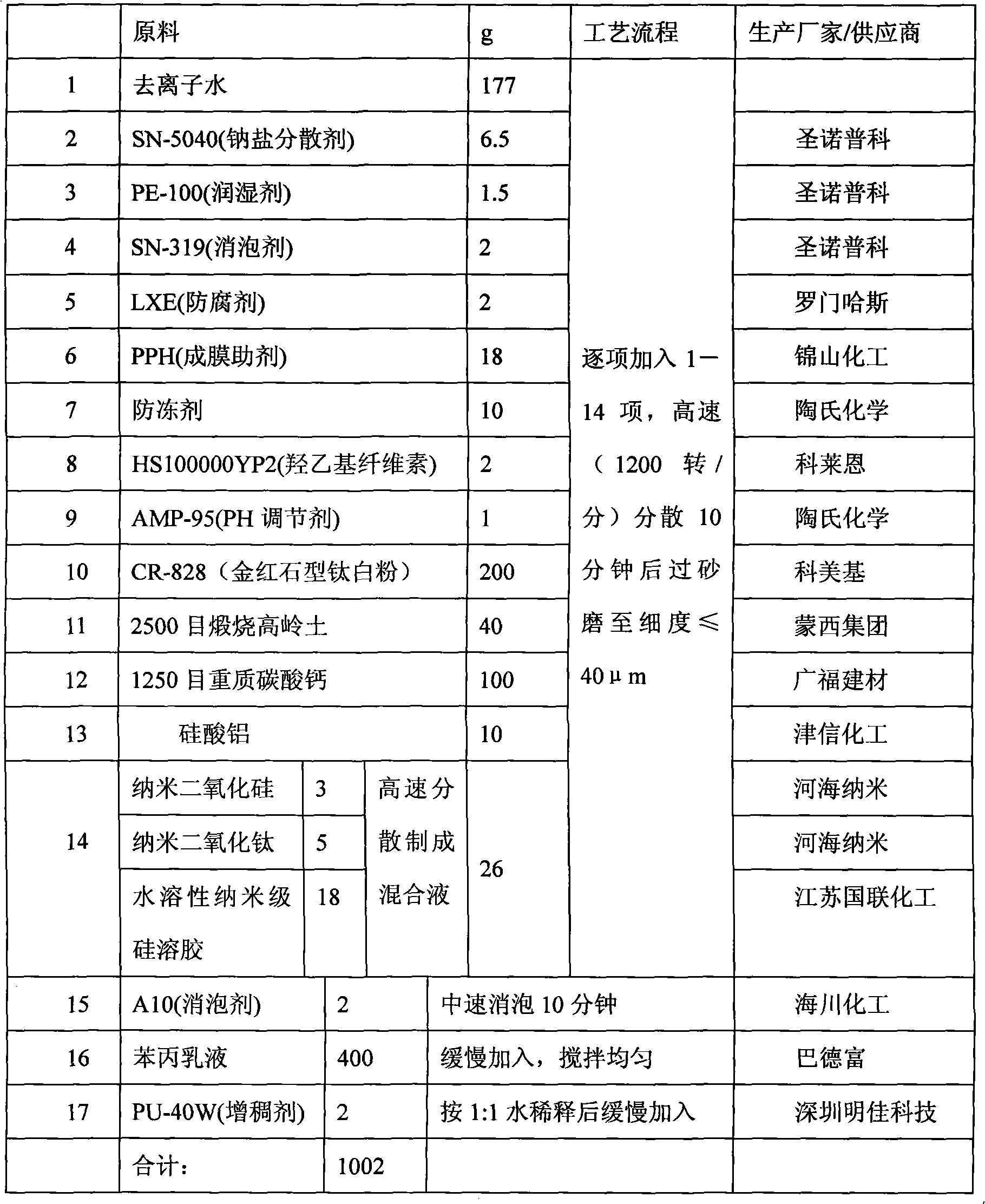

Nanometer interior wall coating g

InactiveCN101338101AImprove performanceImprove pollution resistanceEmulsion paintsMetallurgyAluminum silicate

The invention relates to a nano interior wall coating; the composition by the weight percent is as follows: 35 percent to 45 percent of film-forming material, 28 percent to 42 percent of pigment and filler, 4 percent to 7 percent of assistant, 0.6 percent to 1.2 percent of nano powdery material, 1.0 percent to 2.0 percent of water-soluble nano silica sol, and 10 percent to 30 percent of deionized water. The film-forming material can be styrene-acrylic latex or acrylic latex; the pigment and filler is one or more than one type among rutile titanium dioxide powder, calcined kaolin, heavy calcium carbonate and super-fine aluminum silicate; the assistant comprises one or more than one type among dispersant, wetting agent, foam killer, preservative, thickener, anti-freezing agent, ph regulator and film-forming assistant. The coating of the invention can continuously release negative ions under the radiation of a fluorescent lamp, and can effectively degrade the dissociative TVOC and formaldehyde content in the air; the washing resistant times reaches 20000 to 50000 times, and the manual aging resistance reaches more than 1000 hours. In addition, the coating saves the consumption of nano powdery material and reduces the production cost.

Owner:广州市星冠化工涂料有限公司

High-temperature-resisting easy collapse molding sand and preparation method thereof

InactiveCN103495693AImprove breathabilityImprove liquidityFoundry mouldsFoundry coresWet bondingSodium metasilicate

High-temperature-resisting easy collapse molding sand is made from, by weight, 240-280 parts of quartz sand, 50-55 parts of lightweight calcium carbonate powder, 20-30 parts of hollow ceramic microspheres, 10-15 parts of hollow glass microspheres, 40-55 parts of aluminum silicate powder, 25-30 parts of titanium dioxide, 35-40 parts of fluorite nano-powder, 30-40 parts of gypsum whisker, 60-70 parts of expanded perlite, 10-15 parts of talcum powder, 2-4 parts of sodium metasilicate, 1-2 parts of glucose powder, 1-2 parts of urea, 1-2 parts of chlorinated paraffin, and a proper amount of water. The materials such as the hollow ceramic microspheres and the hollow glass microspheres are used, so that the molding sand is fine in breathability and fluidity; meanwhile, the lightweight calcium carbonate, the glucose, the urea and the like are used, so that the molding sand is fine in high temperature collapsibility, high dry strength of sand molds, high in wet bonding power, excellent in sticking resistance and applicable to various hardening manners; drying time after CO2 hardening is shortened, and reuse rate of used sand can be increased significantly.

Owner:HEFEI CITY TENVER PRECISION CASTING

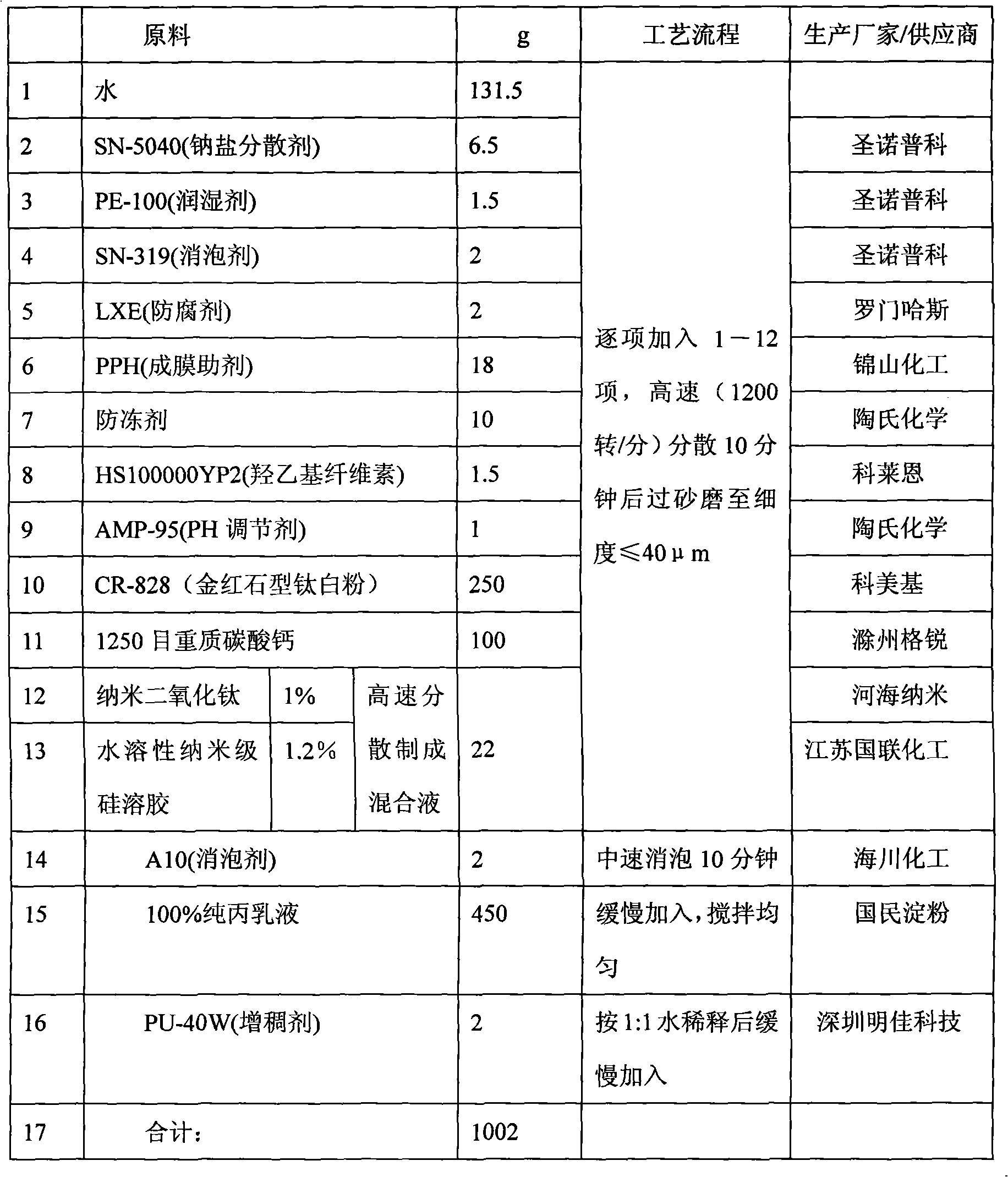

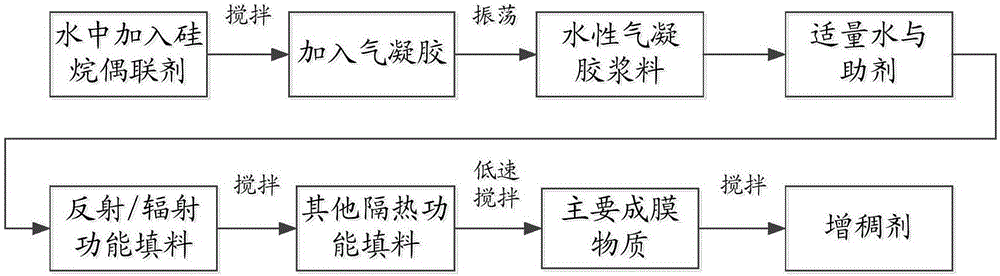

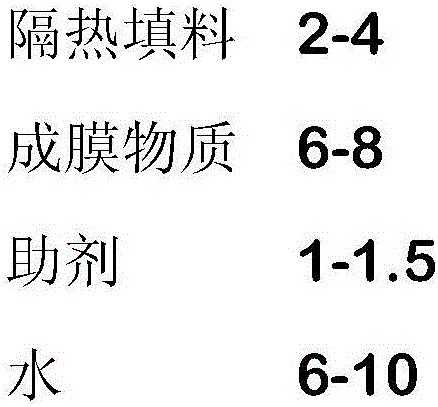

Composite aerogel thermal insulation coating and preparation method thereof

InactiveCN106752561AStable storageNo delaminationFireproof paintsAlkali metal silicate coatingsWater basedThermal insulation

The invention relates to composite aerogel thermal insulation coating and a preparation method thereof. The coating has good heat insulation performance, high reflection performance and high radiation performance, contains aerogel, and belongs to the technical field of heat insulation of building materials. The preparation method mainly comprises the steps of preparing water-based aerogel slurry, selecting filler with a high reflection / high radiation function, and selecting other filler with an auxiliary heat insulation function. The filler with the high reflection / high radiation function comprises one or more of high white aluminum silicate, titanium dioxide and zinc oxide; the filler with the auxiliary heat insulation function comprises one or more of glass microbeads, ceramic microbeads, expanded perlite and expanded vermiculite. Water glass and silicone acrylic emulsion (or pure acrylic emulsion) are used as film forming matters at the same time. In the step of preparing the water-based aerogel slurry, a silane coupling agent is taken as a dispersing agent.

Owner:BEIJING SATELLITE MFG FACTORY

Low density cements for use in cementing operations

A cement mix suitable for blocking or plugging an abandoned pipeline or back filling a mine shaft, tunnel or excavations contains (i) Portland cement or a mixture of at least two components selected from Portland cement, fly ash, slag, silica fume, gypsum, bentonite and limestone; (ii) diatomaceous earth; (iii) zeolite, (iv) an aluminum silicate and (v) an inorganic salt accelerator. The cement mix may further contain an alkali metasilicate and / or alkali silicate. A cementitious slurry, formulated from the cement mix, may have a density less than or equal to 1500 kg / m3, and exhibits good compressive strength.

Owner:BAKER HUGHES INC

Sulfur-tolerance deoxidation catalyst and preparation and use thereof

InactiveCN101301611ALow priceSulfur resistanceMolecular sieve catalystsGaseous fuelsAluminum silicateMordenite

The invention discloses a sulfur-tolerant deoxidizing catalyst, preparation method and application thereof. The catalyst of the invention is composed of active components and porous carriers, the active components are one or more of compound of iron and / or copper, the porous carriers are selected from one or more of aluminium oxide, titanium oxide, zirconium oxide, zinc oxide, magnesium oxide, calcium oxide, silicon dioxide, aluminophosphate molecular sieves, A type molecular sieves, X type molecular sieves, Y type molecular sieves, mordenite, ZSM-5 zeolite, kieselguhr, kaoline, natural clay, aluminum silicate and magnesium silicate. Based on the oxide content, the active components loading amount is 1-95% by weight, the rest are porous carriers. The catalyst of the invention has definite sulfur-tolerant performance, is suitable for deoxidation treatment of coal seam gas with oxygen content of 3-6% (V / V), and can deoxidize the coal seam gas to make the oxygen content less than 0.5%.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Nanometer heat-insulating outer wall coating and preparation method thereof

InactiveCN103788798AGood safety and fire performanceEnvironmental protection and energy savingCoatingsWater basedFiber

The invention provides a nanometer heat-insulating outer wall coating and a preparation method thereof. The nanometer heat-insulating outer wall coating comprises the following components in parts by weight: 5-10 parts of deionized water, 1-2 parts of ethylene glycol, 3-5 parts of fibers, 3-5 parts of diatomite, 30-40 parts of acrylic emulsions, 15-25 parts of glass microballoons, 20-40 parts of 20% silicon dioxide aerogel water-based slurry and 1.4-2.9 parts of auxiliary agents. The nanometer heat-insulating outer wall coating provided by the invention is prepared by matching multiple auxiliary agents by taking the self-crosslinking acrylic emulsions as film-forming materials and SiO2 aerogels, hollow glass microspheres and aluminum silicate chopped fibers as fillers. The coating achieves the heat insulation by adopting nanopores, and has the advantages of thin construction layer, good safety property and fire resistance, environmental friendliness, energy conservation, high performance-price ratio and the like.

Owner:BEIJING XINYUAN YONGLI INTEGRATION HOUSE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com