Biologic organic fertilizer and preparation method thereof

A bio-organic fertilizer and raw material technology is applied in the preparation of organic fertilizers, organic fertilizers, and the treatment of bio-organic parts. It can solve the problems of organic fertilizers with few functions, single raw materials, and complex sludge structures, and achieve sustainable development. Apply a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

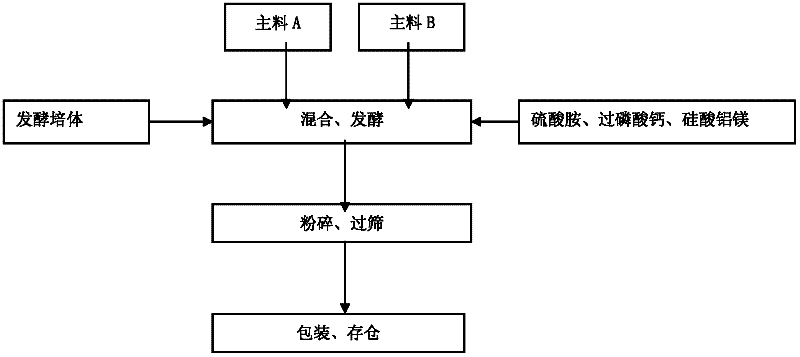

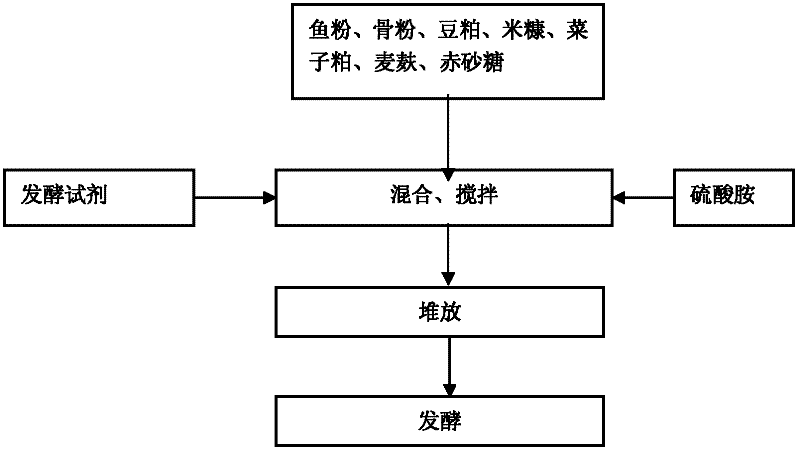

Method used

Image

Examples

Embodiment 1

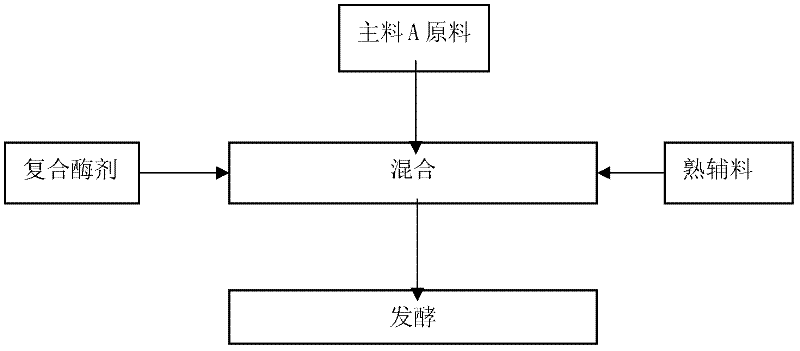

[0086] Production of powdered bio-organic fertilizers. The raw material of main ingredient A is wet chicken manure, the raw material of main ingredient B is sewage sludge, and the raw material of cooked auxiliary material is traditional Chinese medicine residue.

[0087] The preparation method is as follows:

[0088] 1. Add 0.1 kg of compound enzyme to 1,000 kg of traditional Chinese medicine residue, spread evenly, mix evenly with a forklift, pile up to a height of 1-2 meters, turn the pile twice during the decomposing period, stack and decompose for 30 days, and crush to 3-2 meters 5mm after the mature accessories.

[0089] 2. Add 300 kg of cooked auxiliary materials and 0.1 kg of compound enzyme to 700 kg of wet chicken manure, spread and mix evenly, pile up between 1-2 meters high, turn the pile once after 15 days, pile and rot for 30 days, and make the main ingredient a.

[0090] 3. Add 300 kg of cooked auxiliary materials and 0.2 kg of compound enzyme to 700 kg of sew...

Embodiment 2

[0096] Production of powdered bio-organic fertilizers. The raw material of main ingredient A is wet chicken manure and wet pig manure, and the raw material of cooked auxiliary material is mushroom dregs.

[0097] The preparation method is as follows:

[0098] 1. First crush the mushroom dregs, add 0.2 kg of compound enzyme to 1000 kg of mushroom dregs, spread and mix evenly, add an appropriate amount of water until the water content is about 50-70%, and pile up to 1-2 meters high. During this period, turn the pile twice, pile it up for 40 days, and make mature auxiliary materials after crushing to 3-5mm.

[0099] 2. Add 300 kg of cooked auxiliary materials and 0.1 kg of compound enzyme to 700 kg of wet chicken manure, spread and mix evenly, pile up between 1-2 meters high, turn the pile once after 15 days, and pile up for 30 days to mature.

[0100] 3. Add 300 kg of cooked auxiliary materials and 0.1 kg of compound enzyme to 700 kg of wet pig manure, spread and mix evenly, p...

Embodiment 3

[0107] Production of powdered bio-organic fertilizers. The raw material of main ingredient A is wet chicken manure and wet pig manure, the raw material of main ingredient B is sugar factory filter mud, and the raw material of cooked auxiliary material is bagasse.

[0108] The preparation method is as follows:

[0109] 1. Add 0.3 kg of compound enzyme to 1000 kg of bagasse, spread evenly, pile up between 1-2 meters high, turn the pile twice during the stacking and decomposing period, stack and decompose for 40 days, and make mature auxiliary materials after crushing to 3-5 mm.

[0110] 2. Add 300 kg of cooked auxiliary materials and 0.1 kg of compound enzyme to 700 kg of wet chicken manure, spread and mix evenly, pile up between 1-2 meters high, turn the pile once after 15 days, and pile up for 30 days to mature.

[0111] 3. Add 300 kg of cooked auxiliary materials and 0.1 kg of compound enzyme to 700 kg of wet pig manure, spread and mix evenly, pile up between 1-2 meters high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com