Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3967 results about "Superplasticizer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Superplasticizers (SP's), also known as high range water reducers, are additives used in making high strength concrete. Plasticers are chemical compounds that enable the production of concrete with ca. 15% less water content. Superplasticers allow reduction in water content by 30% or more. These additives are employed at the level of a few weight percent. Plasticizers and superplasticizers retard the curing of concrete.

Thermally conductive cementitious grout for geothermal heat pump systems

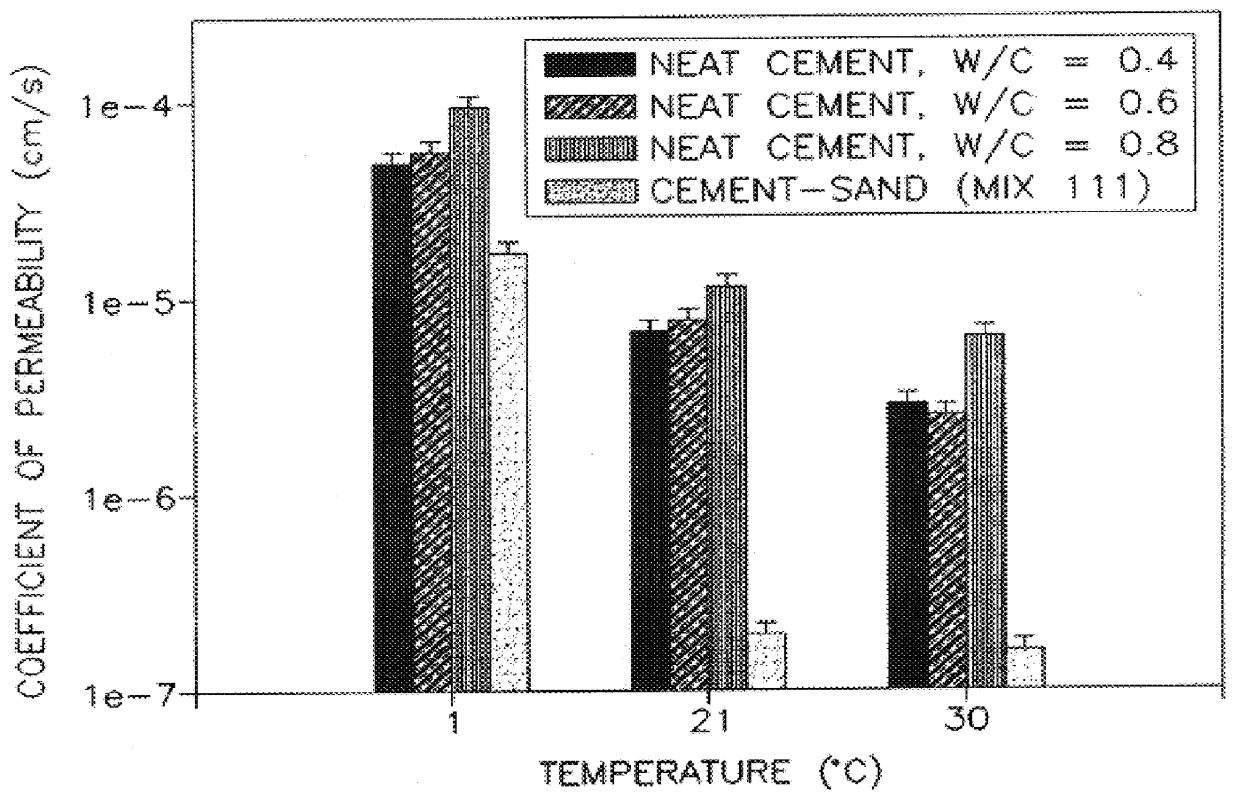

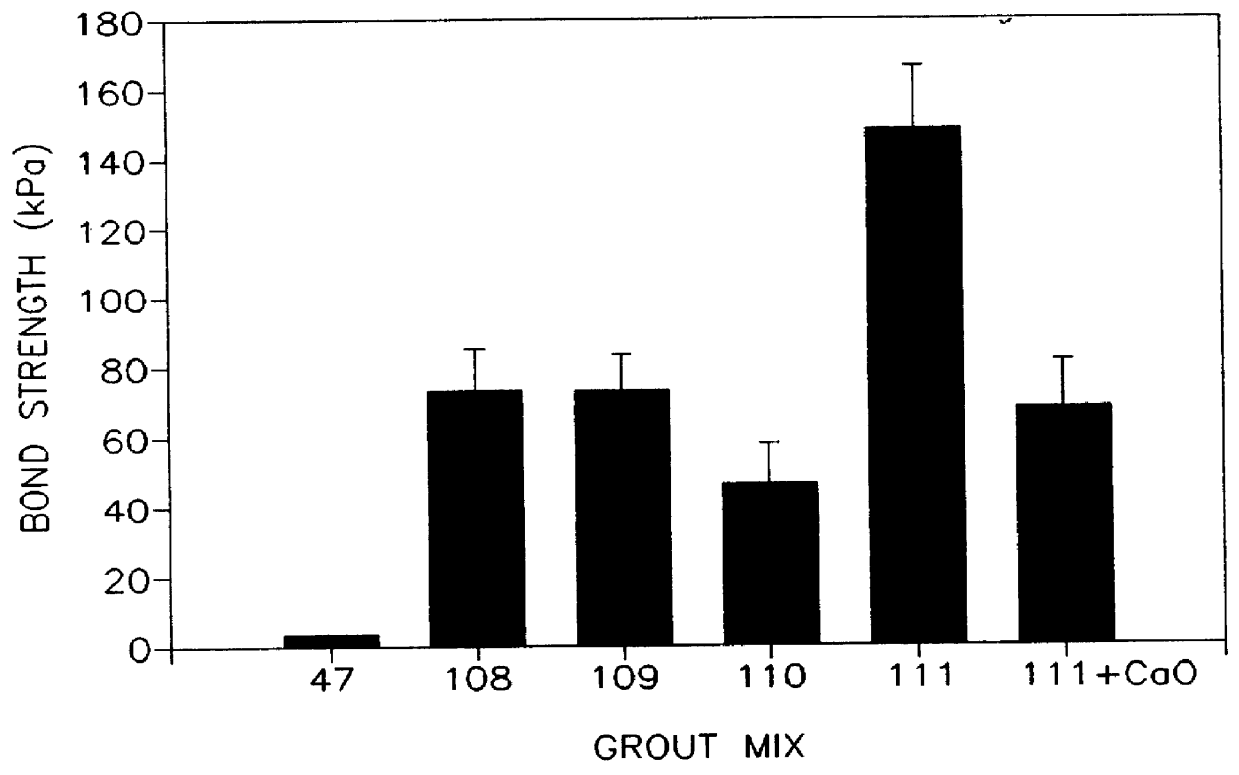

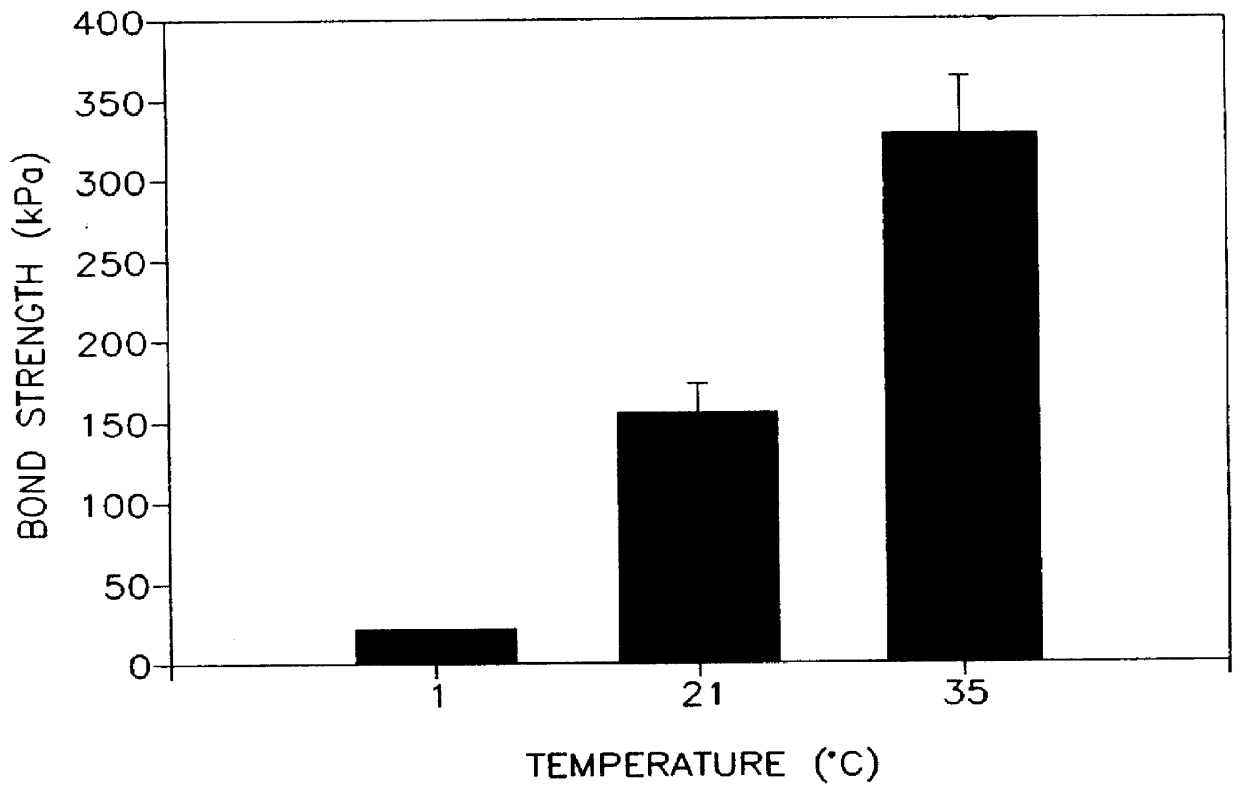

A thermally conductive cement-sand grout for use with a geothermal heat pump system. The cement sand grout contains cement, silica sand, a superplasticizer, water and optionally bentonite. The present invention also includes a method of filling boreholes used for geothermal heat pump systems with the thermally conductive cement-sand grout. The cement-sand grout has improved thermal conductivity over neat cement and bentonite grouts, which allows shallower bore holes to be used to provide an equivalent heat transfer capacity. In addition, the cement-sand grouts of the present invention also provide improved bond strengths and decreased permeabilities. The cement-sand grouts can also contain blast furnace slag, fly ash, a thermoplastic air entraining agent, latex, a shrinkage reducing admixture, calcium oxide and combinations thereof.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

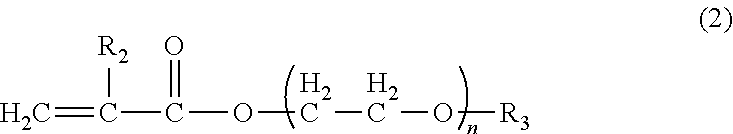

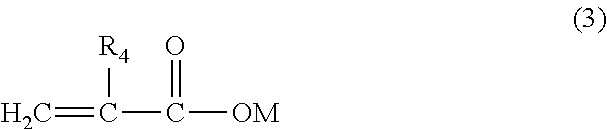

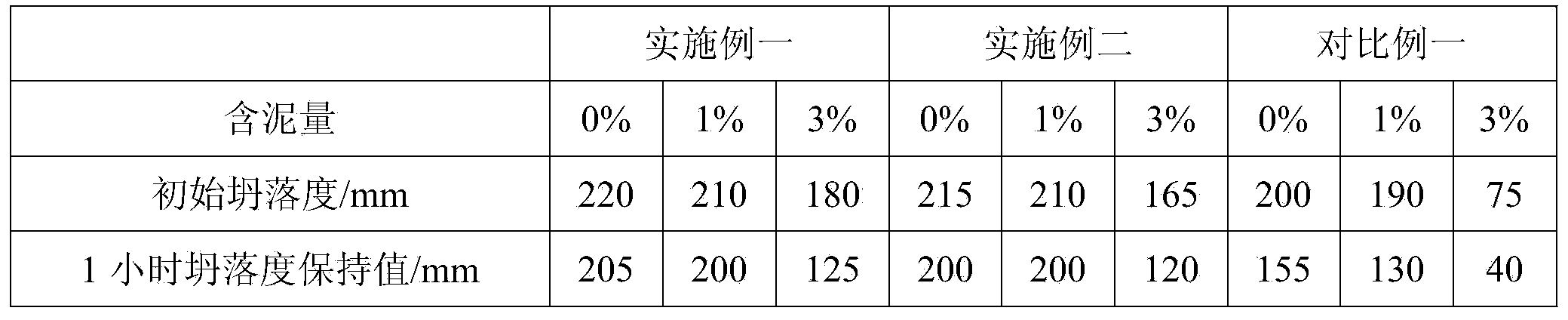

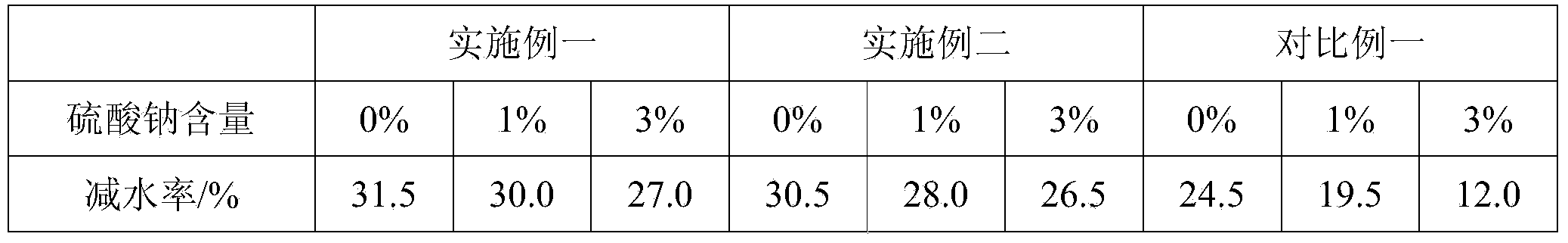

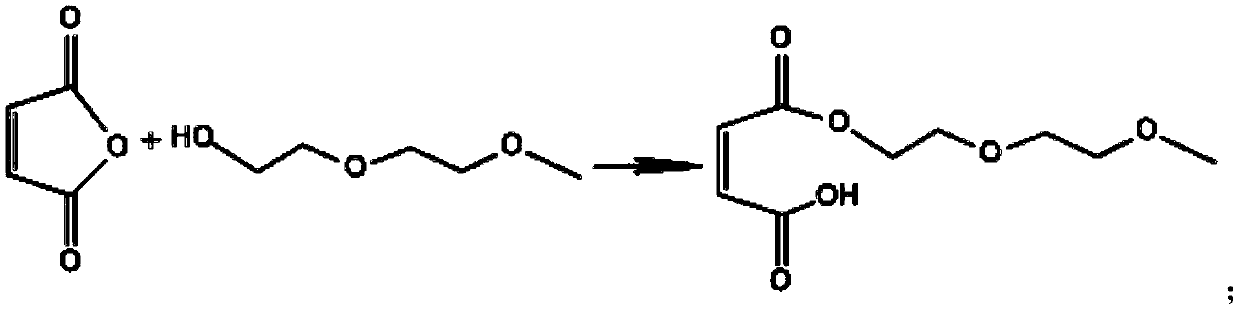

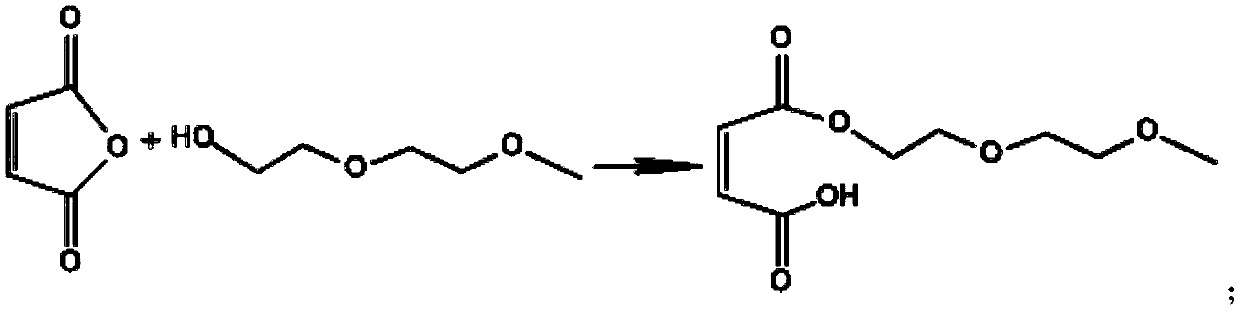

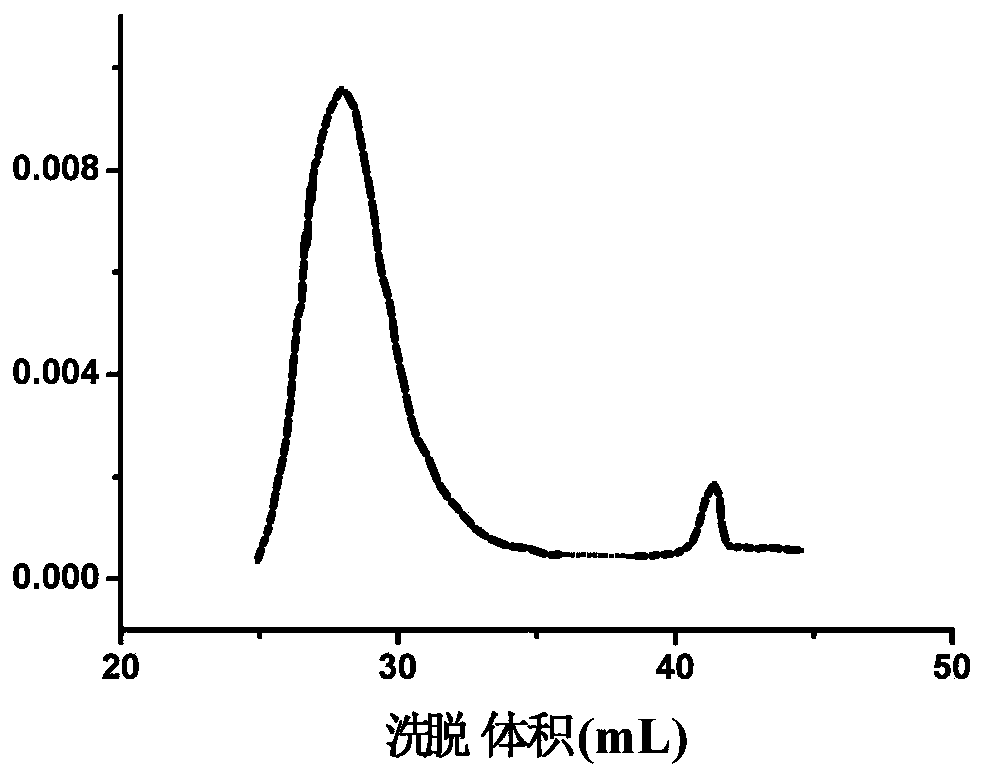

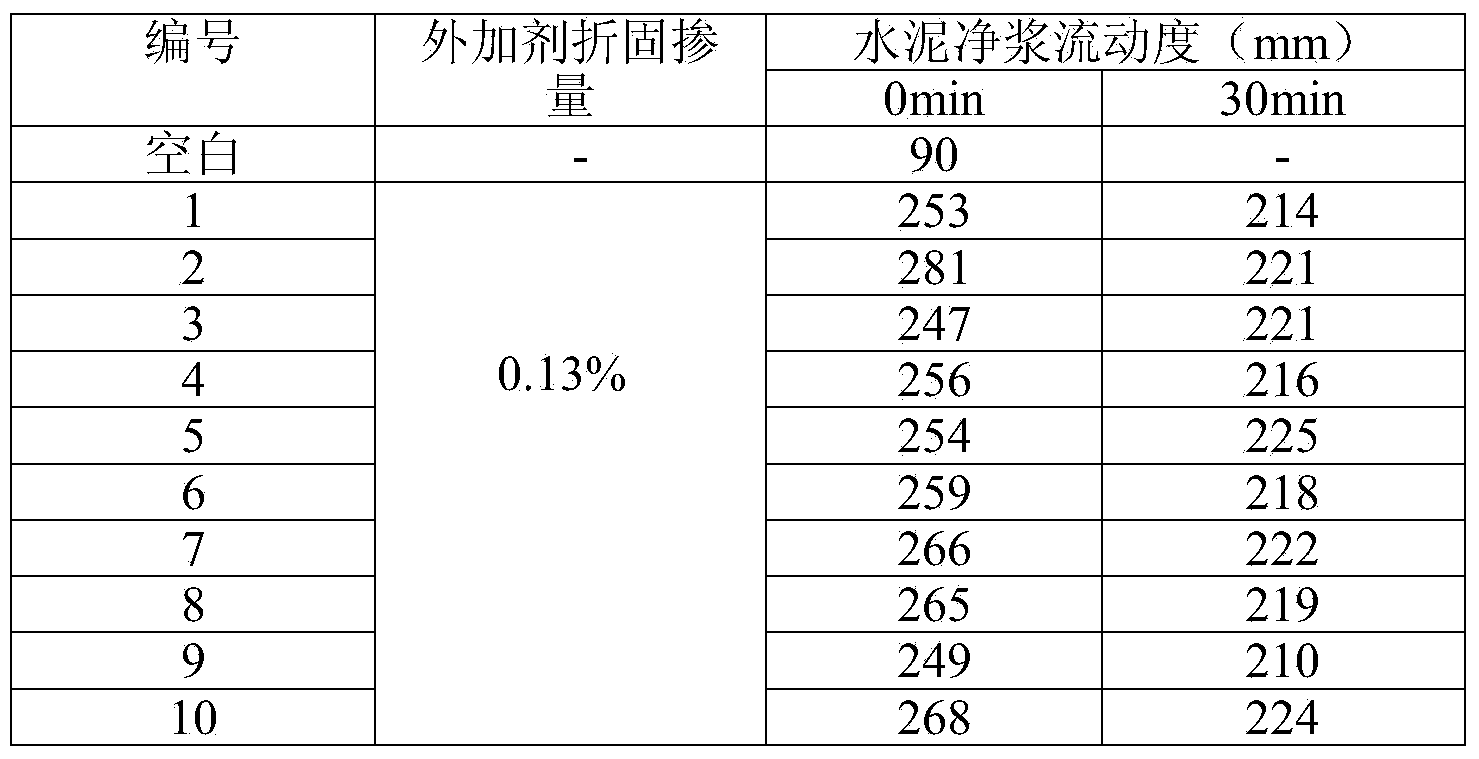

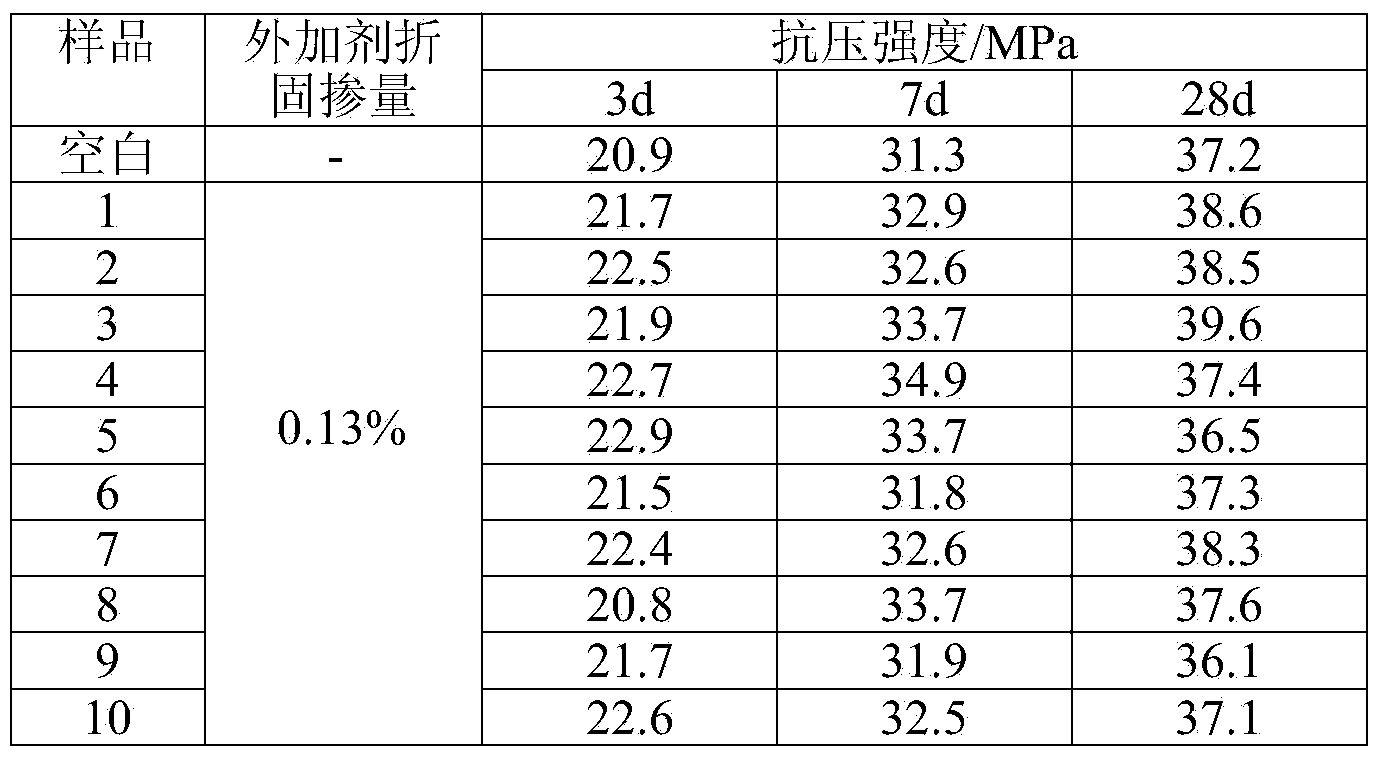

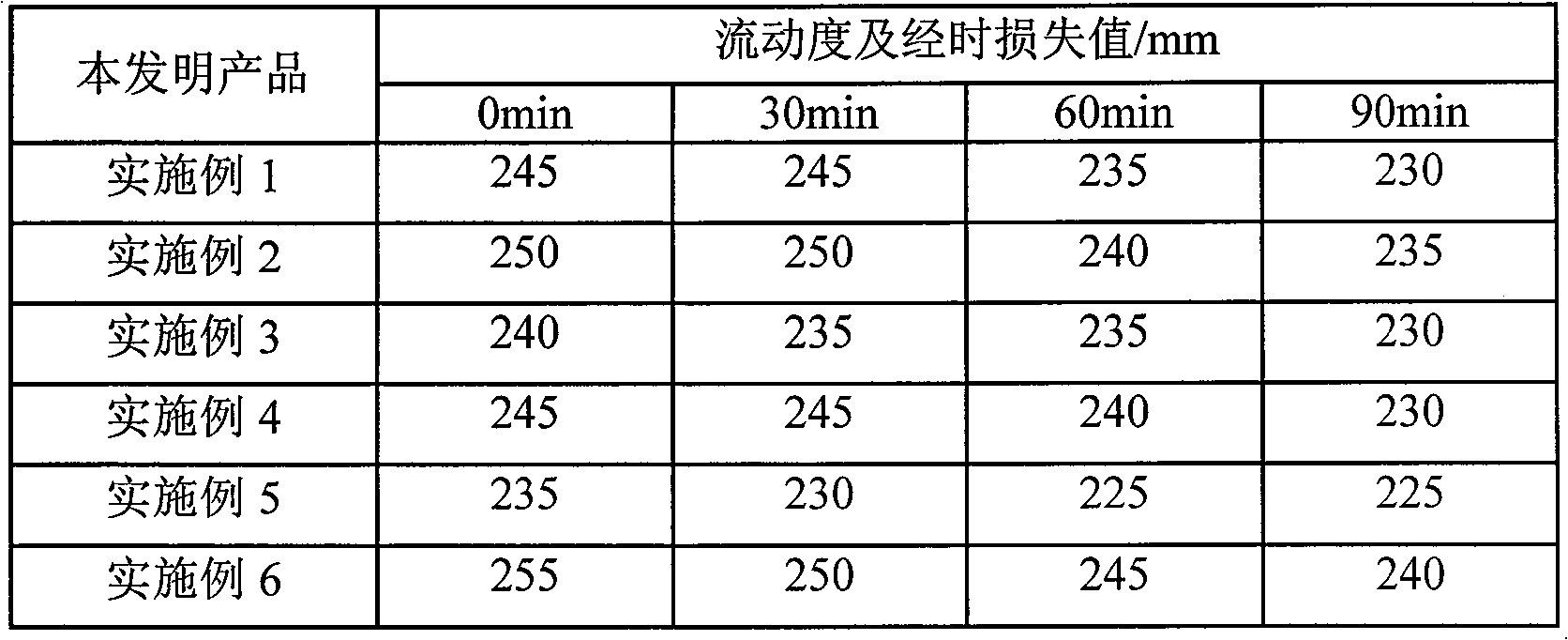

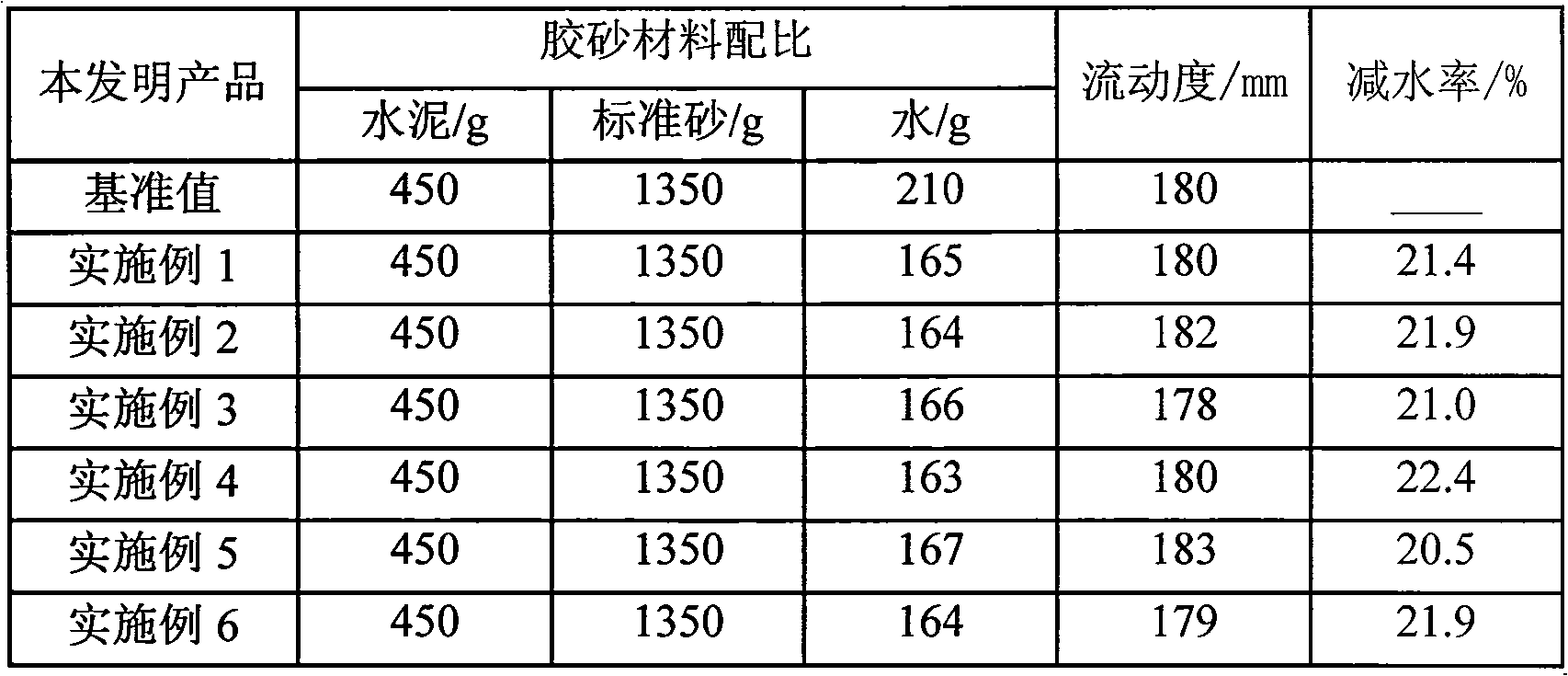

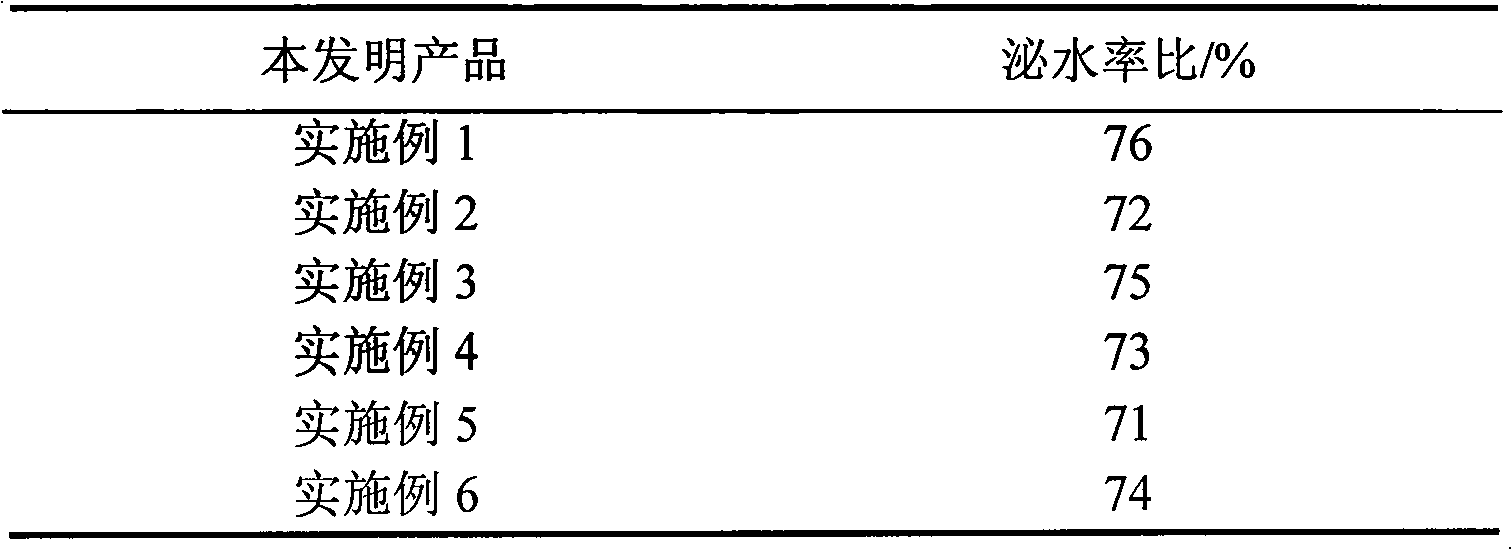

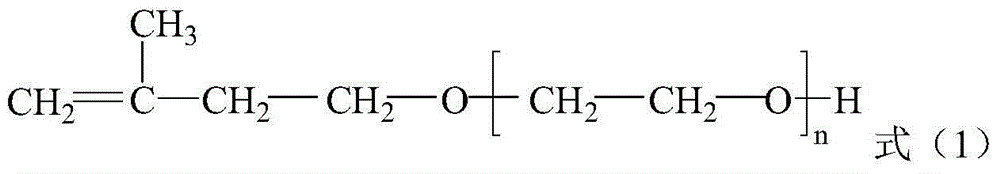

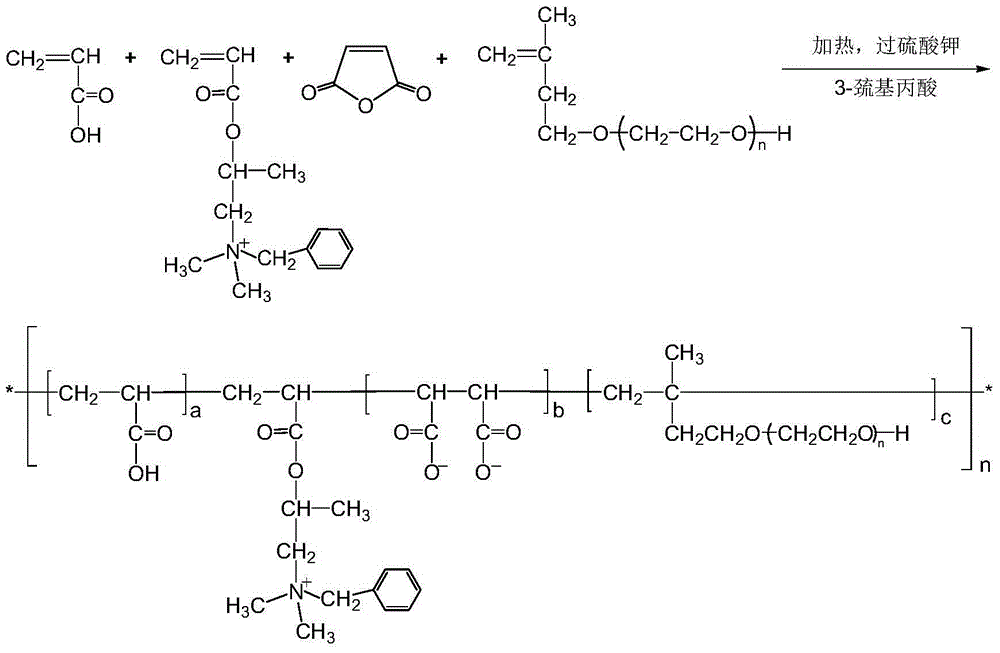

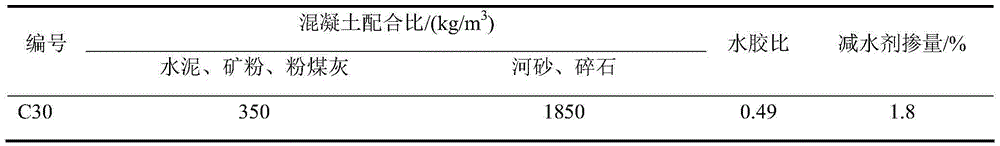

Slump retaining polycarboxylic acid superplasticizer

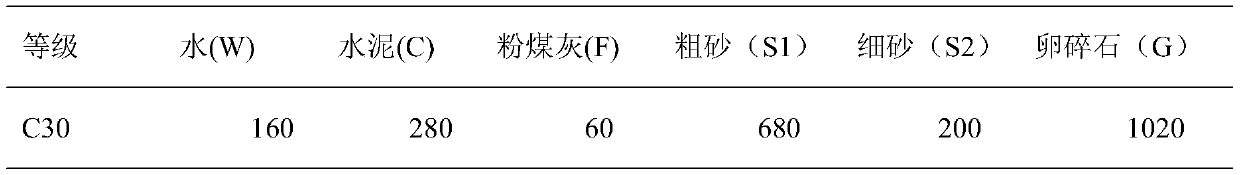

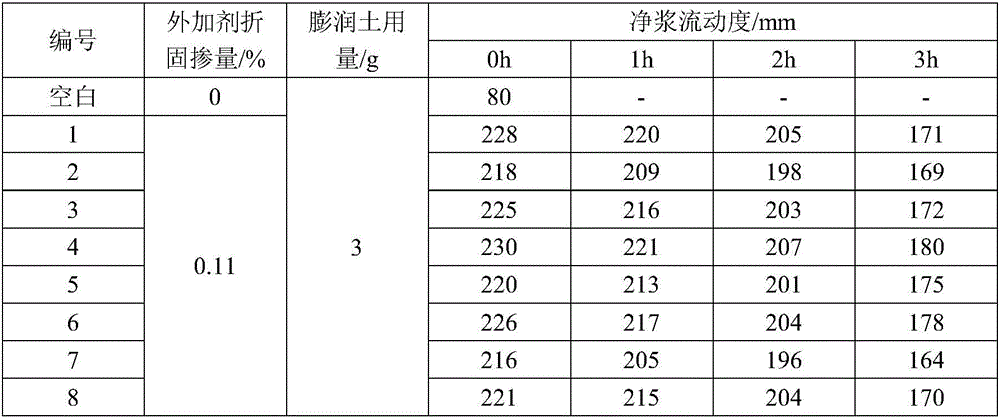

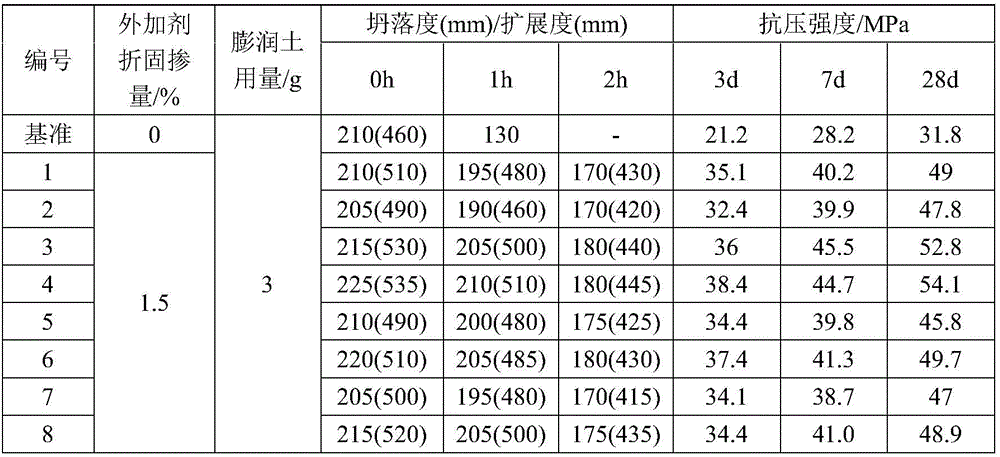

A slump retaining polycarboxylic acid superplasticizer. A weight average molecular weight of the superplasticizer is 20,000-80,000. The slump retaining polycarboxylic acid superplasticizer is prepared by performing polymerization reaction on a monomer A, a monomer B, a monomer C and a monomer D in an aqueous solution in the presence of a redox initiator, wherein a molar ratio of (the monomer A+the monomer B):the monomer C:the monomer D is 1:(3-8):(4-12), and a molar ratio of the monomer A to the monomer B is 1:(1-4).

Owner:JIANGSU SOBUTE NEW MATERIALS +1

Preformed material for post-tensioned prestressing pipeline vacuum grouting or mudjacking and preparation method thereof

ActiveCN101602589AWide variety of sourcesSimple preparation processSolid waste managementMixing operation control apparatusNeutral phPre stress

The invention discloses a preformed material for post-tensioned prestressing pipeline vacuum grouting or mudjacking and a preparation method thereof. The preformed material includes the following components by weight percent: 65 to 95 percent of silicate cement, 0.01 to 3 percent of high-range water-reducing agent, 0 to 1 percent of stabilizing agent, 0.05 to 5 percent of retarding agent, 1 to 20 percent of expanding agent, 0.2 to 2 percent of corrosion inhibitor, 0.01 to 1 percent of air entraining agent and 0 to 30 percent of mineral materials, wherein by uniformly and proportionally mixing the silicate cement, the high-range water-reducing agent, the stabilizing agent, the retarding agent, the expanding agent, the corrosion inhibitor, the air entraining agent and the mineral materials, the post-tensioned prestressing pipeline vacuum grouting or mudjacking preformed material can be obtained. After being uniformly mixed and stirred with water with neutral pH value according to the water cement ratio ranging from 0.24 to 0.32, the preformed material can be used, the obtained grouting material has the advantages of low water cement ratio, favorable flowability, no water bleeding and delamination, and favorable pumpability; meanwhile, the preparation method of the preformed material is simple and the raw material sources of the preformed material are wide.

Owner:HUBEI CHIDGE TECH

Concrete super instant coagulant

The invention discloses a concrete early-strength agent, which is characterized in comprising the following components according to weight percentage: inorganic salt early-strength component 35-55 percent, organic early-strength component 5-10 percent, water reducing component 15-25 percent, wherein the inorganic salt early-strength component is prepared by at least two among sulfate, carbonate, nitrate, and nitrite; the organic early-strength component selects any one among calcium formate, sodium acetate, calcium oxalate, triethanolamine, tri-iso-propanolamine and carbamide; the water reducing component selects one among naphthalenesulfuric acid type, melamine type and polycarboxylate type. The invention makes the concrete be coagulated and hardened rapidly under the condition of low temperature, so that the early strength of the concrete is greatly improved as well as later strength is ensured.

Owner:ZHONGYIFENG CONSTR GRP +1

Permeable recycled aggregate and ceramsite concrete doped with industrial and agricultural solid waste and preparation

The invention discloses permeable recycled aggregate and ceramsite concrete doped with industrial and agricultural solid waste and preparation. The permeable recycled aggregate and ceramsite concrete doped with industrial and agricultural solid waste is characterized in that recycled coarse aggregates and ceramsites are taken as coarse aggregates of concrete, an appropriate amount of pretreated industrial and agricultural solid waste such as industrial waste, agricultural waste, household garbage and the like is taken as an admixture, a cementing agent is prepared from cement, water, a superplasticizer and a reinforcement material, and the materials are mixed with a preset stirring process and preparation method, so that ecological concrete with good mechanical property, permeable property and durability is produced. According to the concrete, the waste utilization rate is up to about 80%, the concrete is environment-friendly, locally available materials can be used, the economic benefit is remarkable, ceramist pore is smaller, and sewage can be continuously and stably treated, so that the concrete is commonly used in water environment comprehensive improvement engineering; and besides, the concrete has light weight, high strength and good water permeability and can be also used in permeable pavement engineering such as a sidewalk, a parking lot and the like as well as plant engineering such as ecological riverway slope protection, roof landscape planting and the like.

Owner:YANGZHOU UNIV

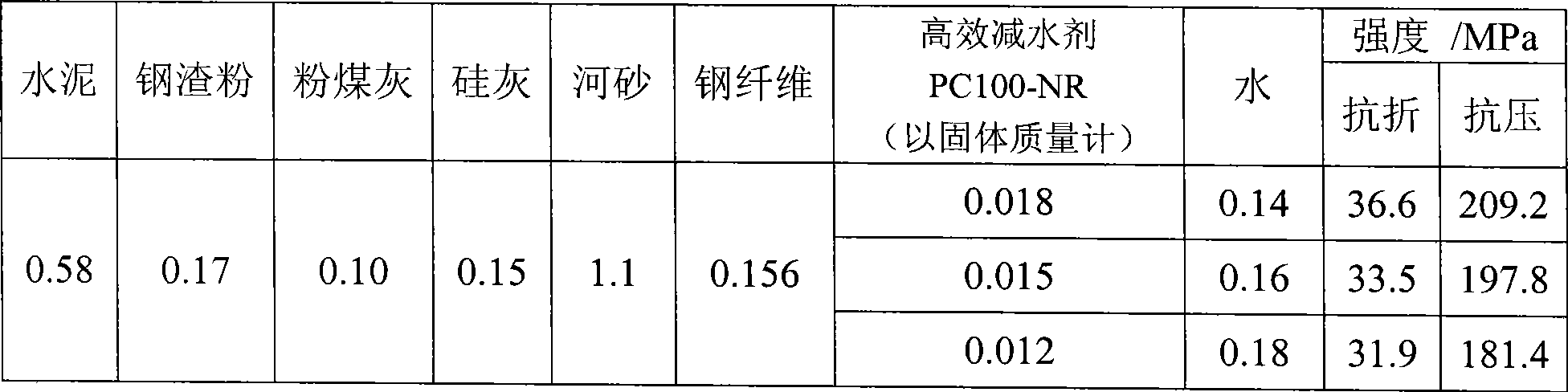

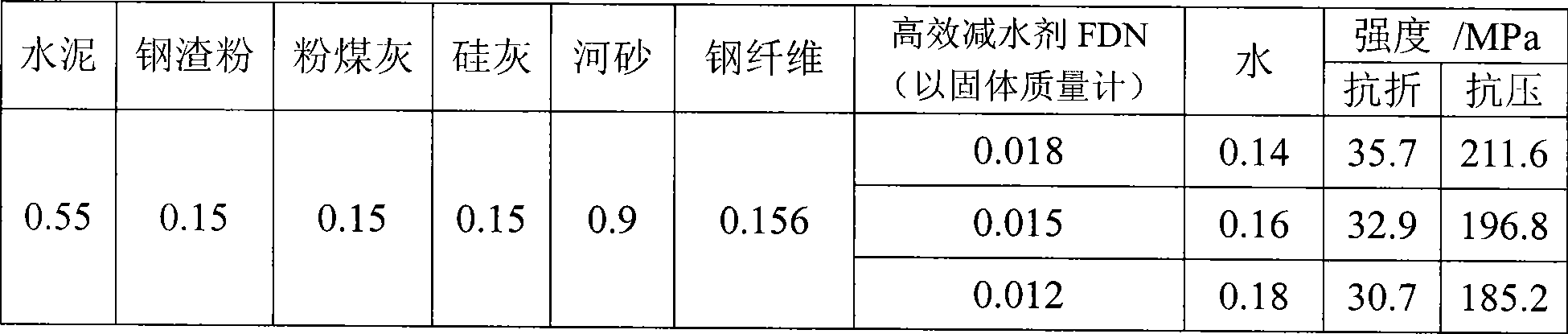

Low cost active powder concrete and preparation thereof

InactiveCN101486554ALow raw material costReduce maintenance costsSolid waste managementMixing operation control apparatusFiberSlag

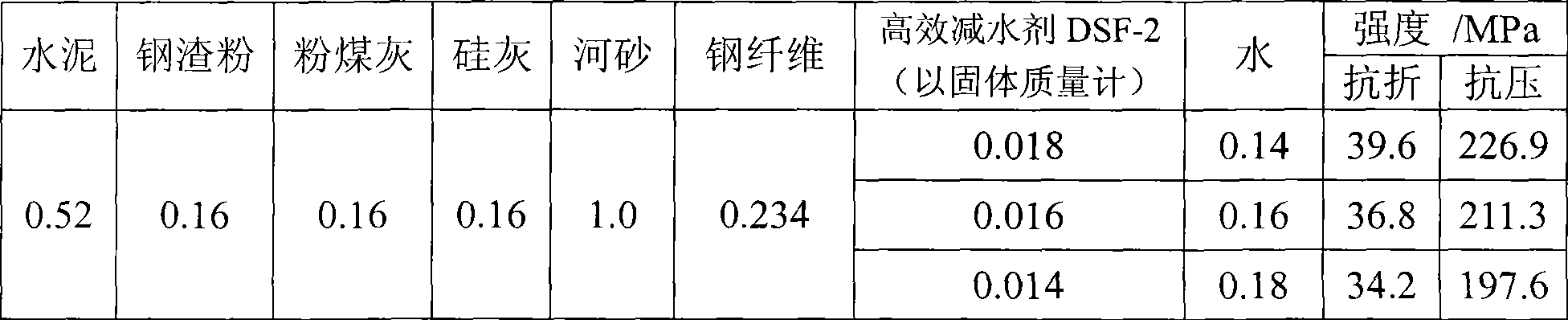

The invention discloses active powder concrete which is prepared by Portland cement, steel slag powder, fly ash, silicon ash, effective water reducing agent, river sand, mixing water and steel fiber with the mass ratios of 0.52 to 0.58 : 0.16 to 0.18 : 0.10 to 0.16 : 0.13 to 0.16 : 0.012 to 0.018 : 0.9 to 1.1 : 0.14 to 0.18 : 0.156 to 0.234. The preparation method thereof is as follows: each component is sequentially added into a stirring machine for being uniformly stirred and shaped; then after the components are maintained, the temperature is raised to 80 to 90 DEG C at the temperature rising speed of 15 to 20 DEG C / h and then constant temperature maintaining is carried out for 72 to 96h; then, the components are cooled to room temperature at the cooling speed of not more than 20 DEG C / h to obtain the active powder concrete product. The invention employs the industrial wastes like steel slag powder and fly ash to replace quartz powder, partial cement and silicon ash, and employs thin river sand to replace quartz sand to prepare the active powder concrete of 200 grade under the maintaining conditions of normal pressure below 100 DEG C, thus not only being capable of remarkably reducing the material cost and the shaping maintaining cost, but also playing important roles on saving resources and energies, protecting the environment and promoting sustainable development as a large amount of industrial waste slag is used.

Owner:WUHAN UNIV OF TECH

Ultrahigh-strength active powder concrete and preparation method thereof

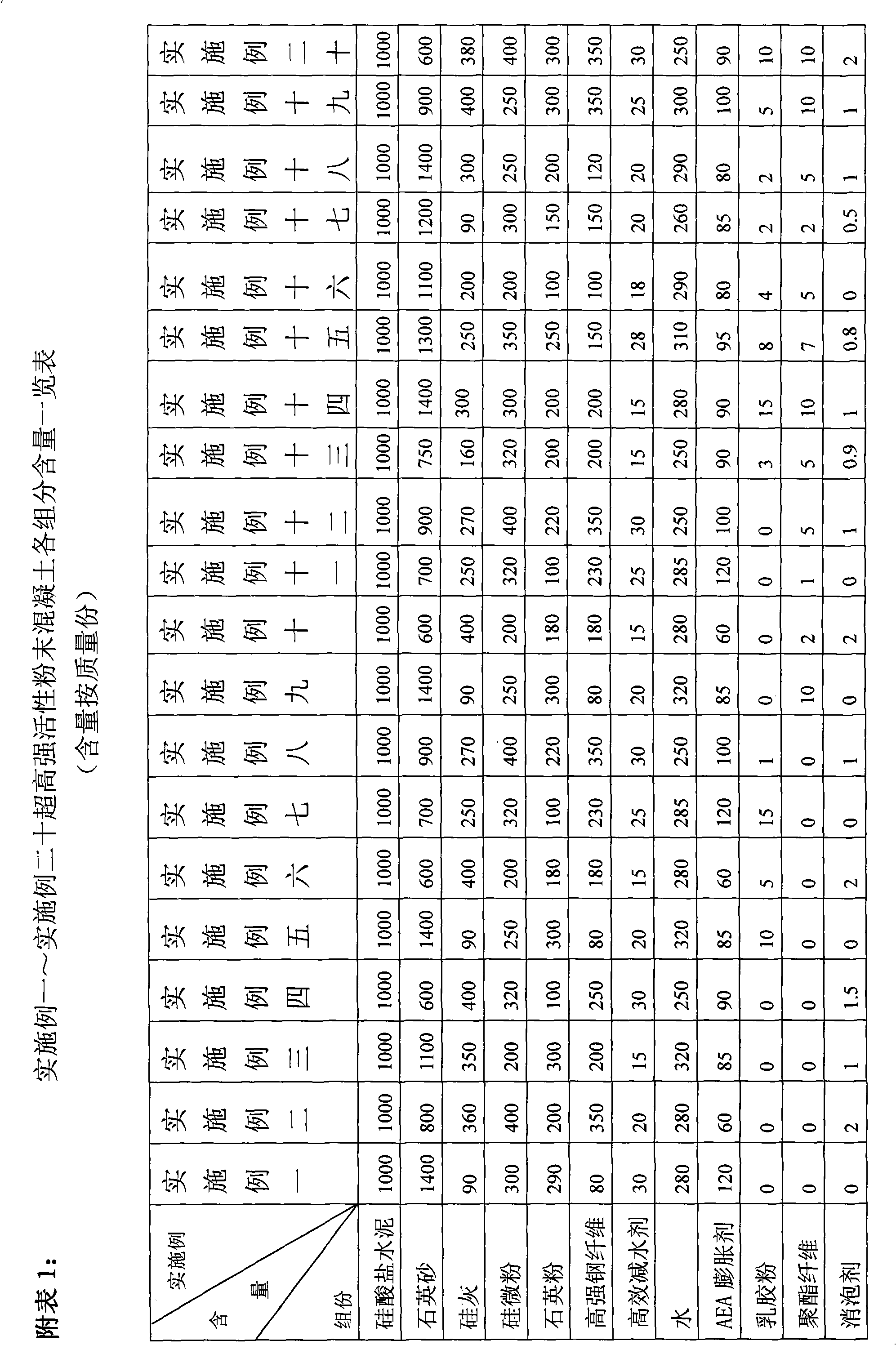

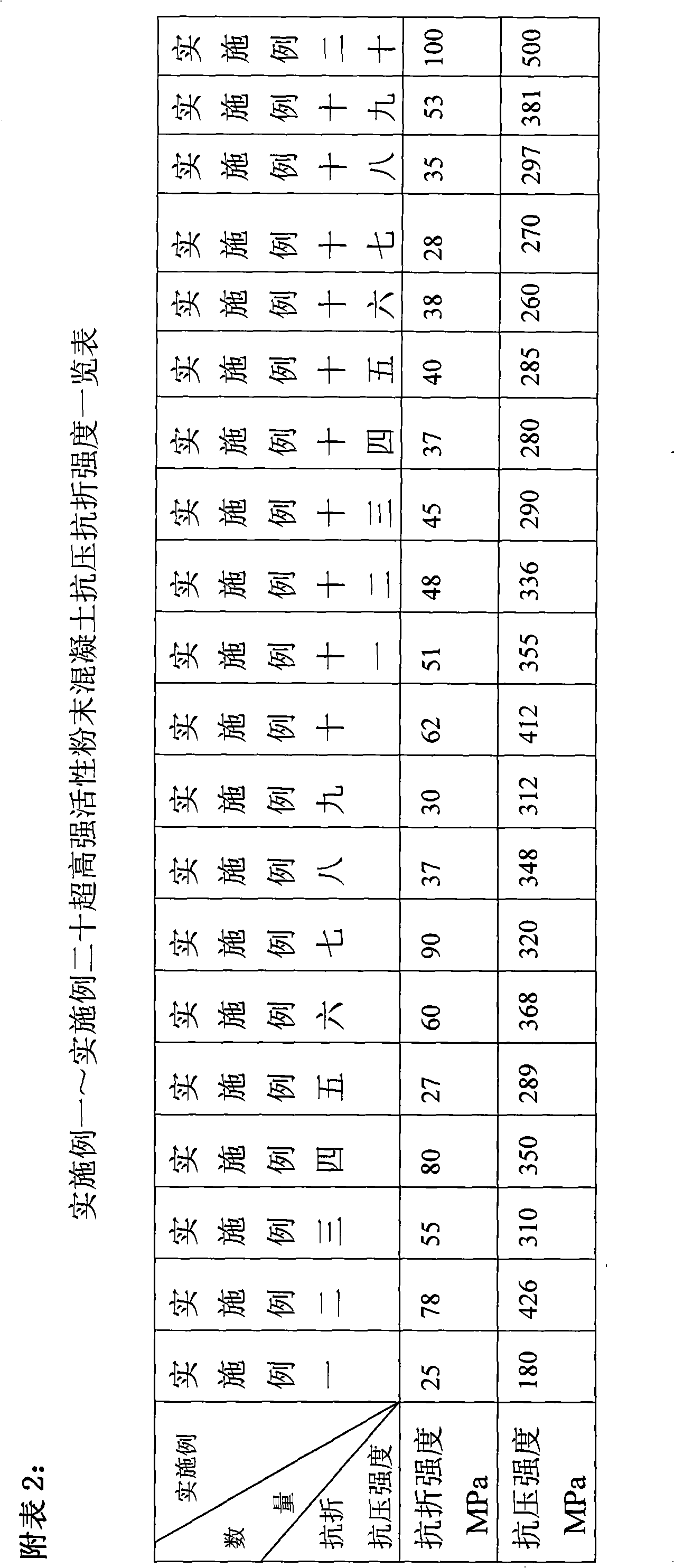

An ultrahigh-strength active powder concrete is a mixture prepared by mixing the following materials according to weight portion: 1000 portions of Portland cement, 600-1400 portions of quartz sand, 90-400 portions of siliceous dust, 200-400 portions of silicon powder, 100-300 portions of quartz powder, 80-350 portions of high-strength steel fiber, 15-30 portions of high-efficiency water reducing agent, 250-320 portions of water, 60-120 portions of AEA expanding agents, 0-15 portions of latex powder, 0-10 portions of polyester fiber and 0-2 portions of antifoam agents. The preparation method comprises the following steps: preparing the materials according to the weight proportion, firstly mixing water, cement, quartz sand, siliceous dust, silicon powder, quartz powder, AEA expanding agents, high-efficiency water reducing agent, latex powder, polyester fiber, and antifoam agents into pasty state; then adding high-strength steel fiber, and mixing for 4-6 minutes. The prepared active powder concrete has super-high compressive and bending strengths, high mechanical property and high durability.

Owner:LIUZHOU OVM MASCH CO LTD

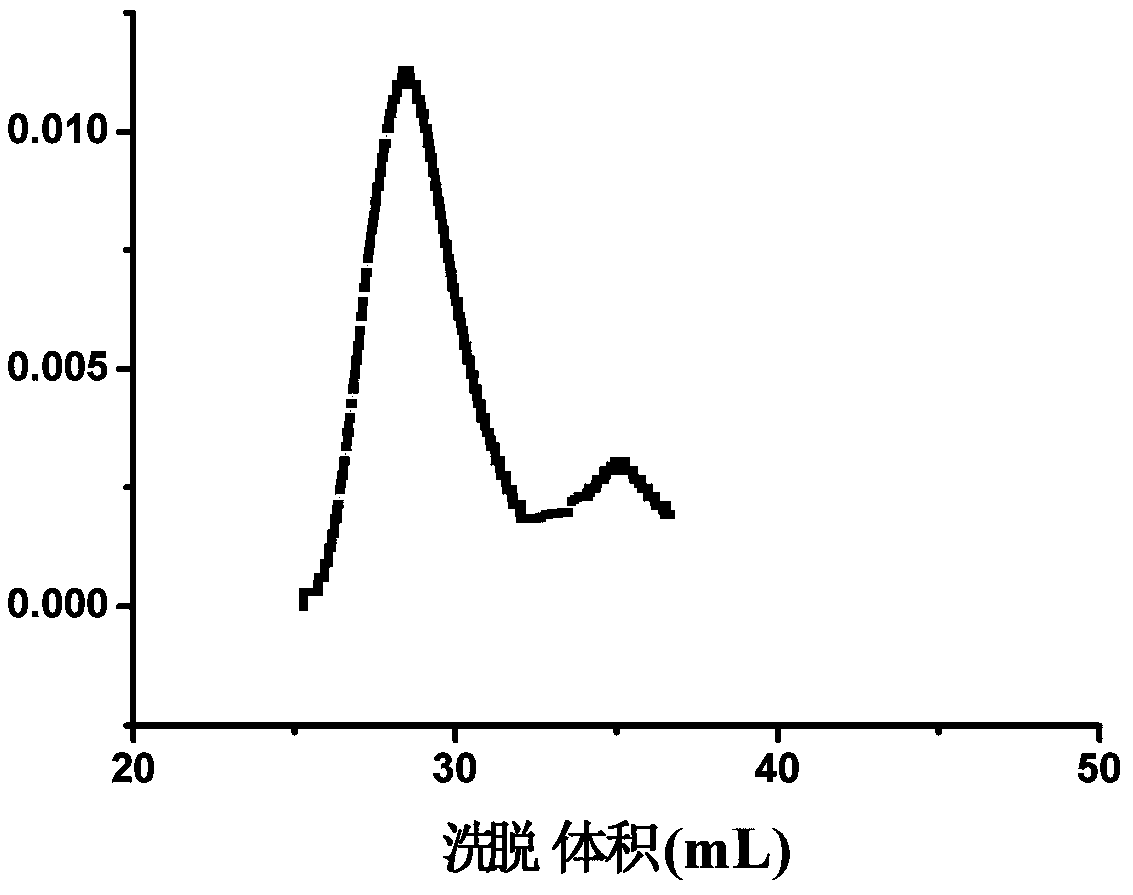

Silane coupling agent modified polycarboxylate superplasticizer and preparation method thereof

The invention discloses a silane coupling agent modified polycarboxylate superplasticizer and a preparation method thereof, belonging to the field of cement additives. The preparation method comprises the following steps: adding a certain amount of acrylic acid into a polyether macromonomer solution, and stirring uniformly; adding a double bond-containing silane coupling agent; stirring the solution to a clear state and continuously stirring; adding an oxidizing agent, an initiator solution and a small monomer solution while keeping the stirring state; after the stirring, curing for 1-2h; adding liquid caustic soda for neutralization and stabilizing the pH value at 6; and adding a silane coupling agent without double bond to obtain a finished product of silane coupling agent modified polycarboxylate superplasticizer. In the invention, a functional group with a siloxane structure is introduced into the main chain of polycarboxylate molecule, and an anchoring ability in chemical bonding strong interaction with cementing material particles is provided for the branch chain of the comb-shaped polycarboxylate superplasticizer; and with the increase of the anchoring ability, the adaptability and slump loss resistance of the superplasticizer can be remarkably enhanced, and the application of the superplasticizer in the field of mineral micropowder dispersion is expanded to a certain degree.

Owner:HAINAN TAIHOO TECH CO LTD

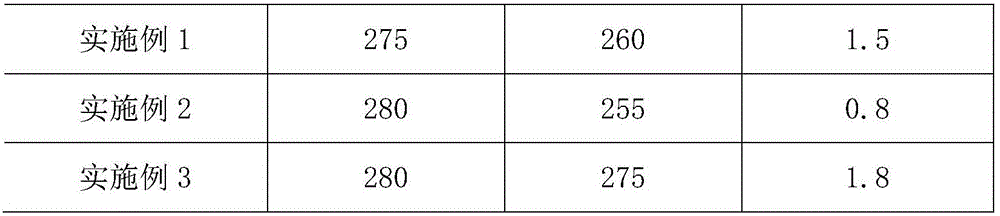

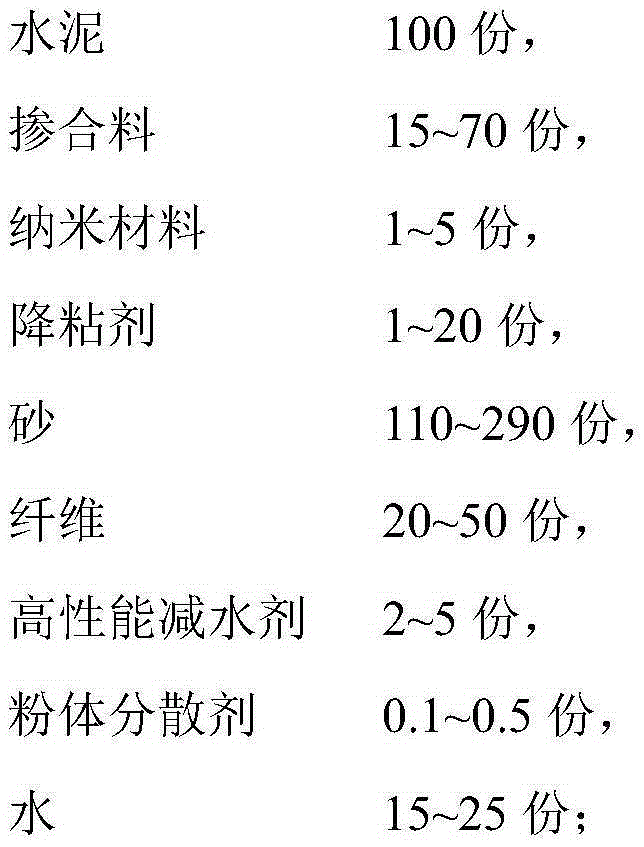

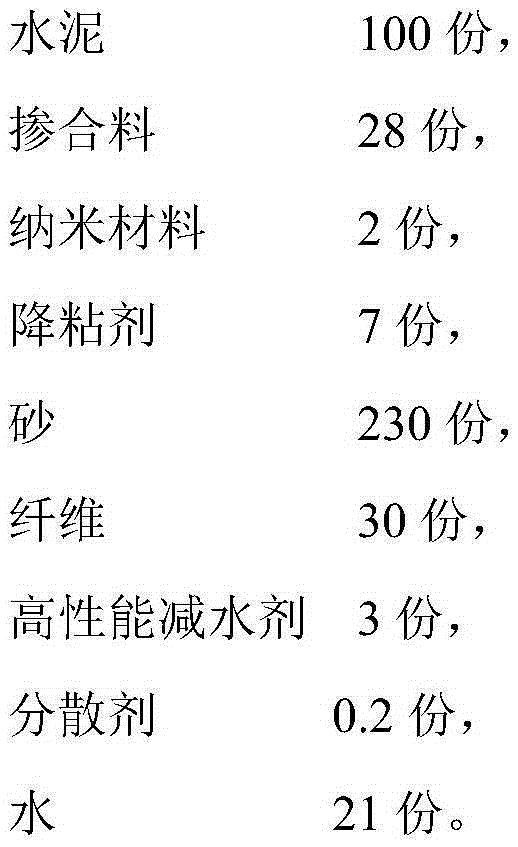

Ultra-high performance concrete with compressive strength of 300MPa or more and preparation method

The present invention discloses an ultra-high performance concrete with compressive strength of 300MPa or more and a preparation method, and the ultra-high performance concrete comprises the following components in parts by mass: 100 parts of cement, 15 to 70 parts of an admixture, 1 to 5 parts of a nanomaterial, 1 to 20 parts of a viscosity reducer, 110 to 290 parts of sand, 20-50 parts of fibers, 2 to 5 parts of a superplasticizer, 0.1 to 0.5 part of a powder dispersing agent and 15 to 25 parts of water. The ultra-high performance concrete has ultrahigh mechanical properties, the compressive strength after heat curing at 85 DEG C-90 DEG C in standard atmospheric pressure environment can be 300MPa or more, the flexural strength is greater than 55MPa, and the ultra-high performance concrete has excellent working performance and ultrahigh durability.

Owner:JIANGSU SOBUTE NEW MATERIALS

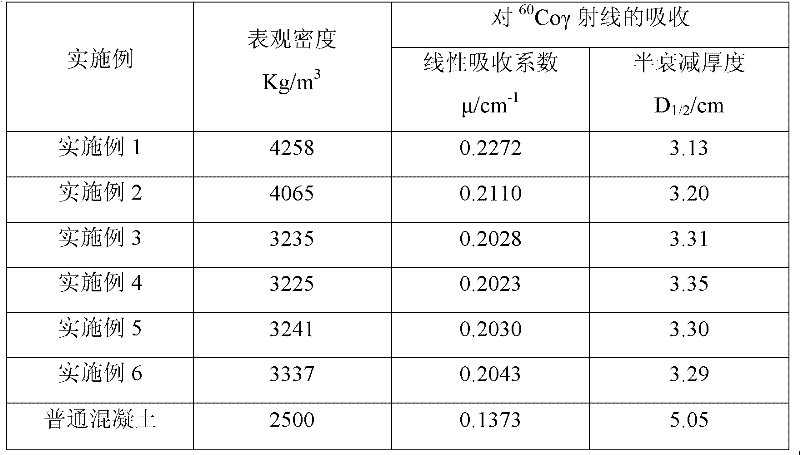

Radiation shield concrete and preparation method thereof

InactiveCN102219459AReduce water-cement ratioLow shrinkageSolid waste managementShieldingSlagSuperplasticizer

The invention relates to radiation shield concrete and a preparation method thereof. The radiation shield concrete is characterized by comprising a cementing material, coarse aggregates, fine aggregates, steel fibre, a high-efficiency slushing agent and water; the cementing material is composed of ordinary portland cement and inorganic mineral admixtures; the inorganic mineral admixtures are siliceous dust and coal ash; the fine aggregates are natural sand, boron glass powder and steel slag powder; the coarse aggregates are steel sections or a mixture of the steel sections and steel slag; the proportions of various types of components are as follows: 500 kg / m<3> of cementing material, 1400-2215 kg / m<3> of coarse aggregates, 750-950 kg / m<3> of fine aggregates, and 155-200 kg / m<3> of water; the high-efficiency slushing agent is 0.5-1.0% of the total weight of the cementing material by weight; and the steel fibre is 1.0-1.5% of the total volume of the concrete by volume. The radiation shield concrete has good mechanical property and lasting quality, good shielding effect on gamma rays, good effect on shielding neutron rays, can be used or comprehensively recycling wastes and has low cost.

Owner:WUHAN UNIV OF TECH

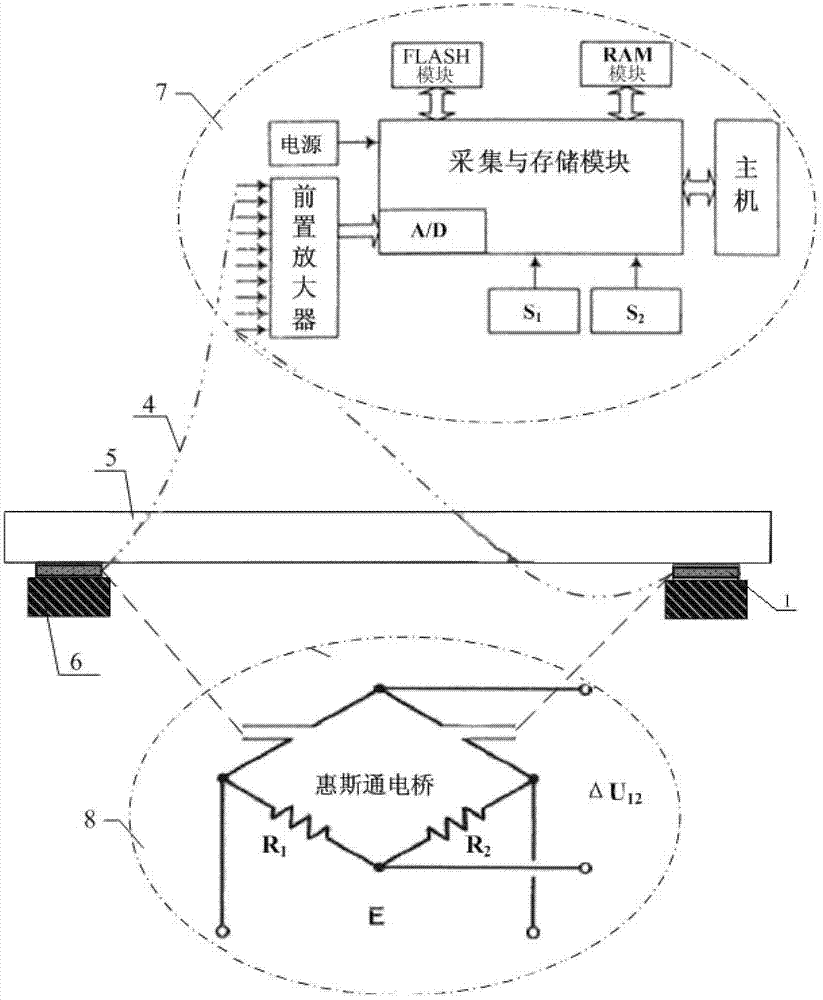

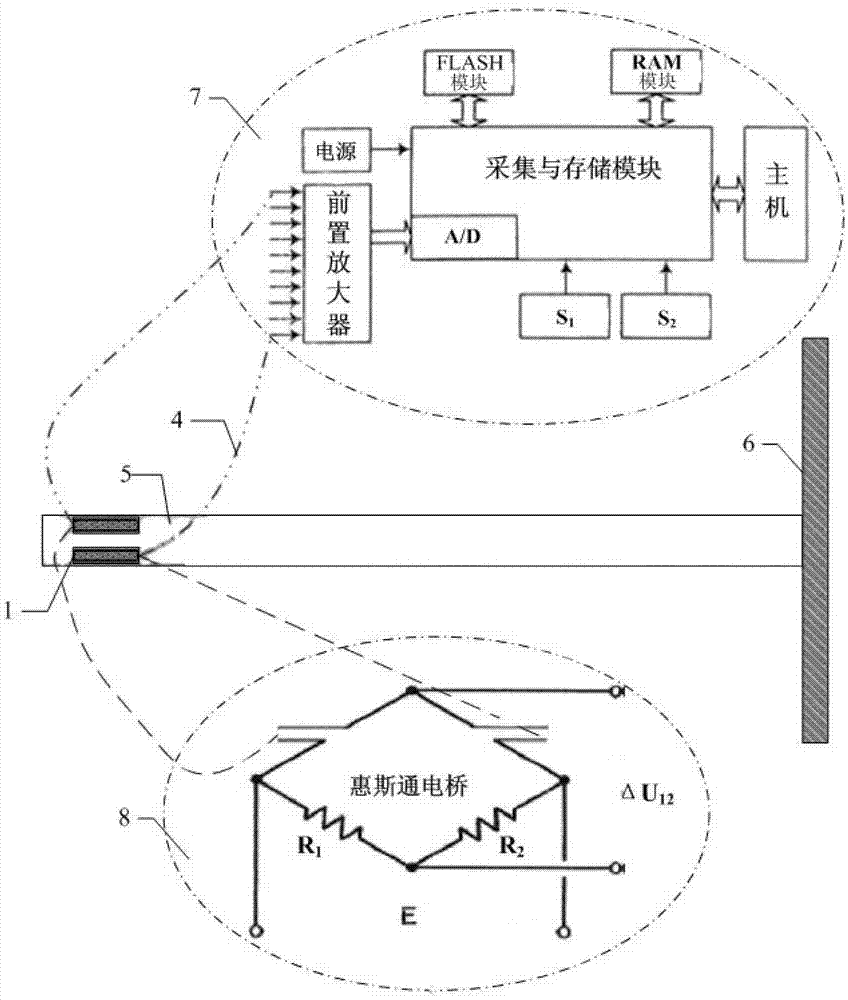

Piezoresistance/piezoelectric composite material, manufacturing method of material, sensor utilizing material and manufacturing method of sensor

InactiveCN102924020AImprove structural toughnessGood compatibilityConverting sensor output electrically/magneticallyFiberBridge deck

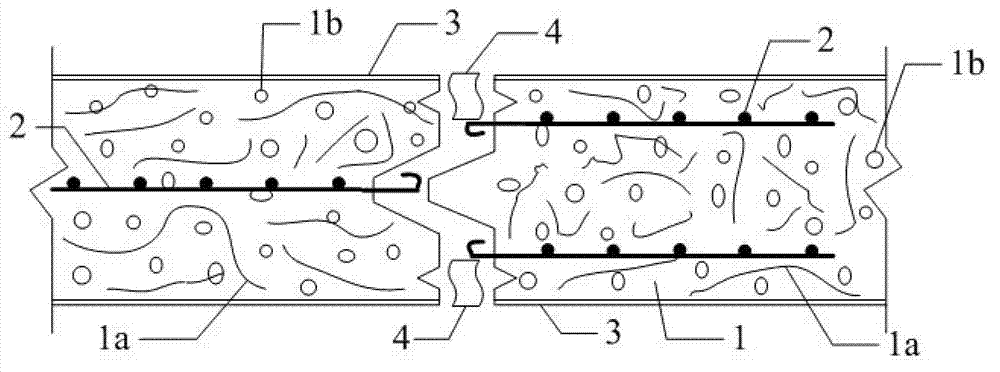

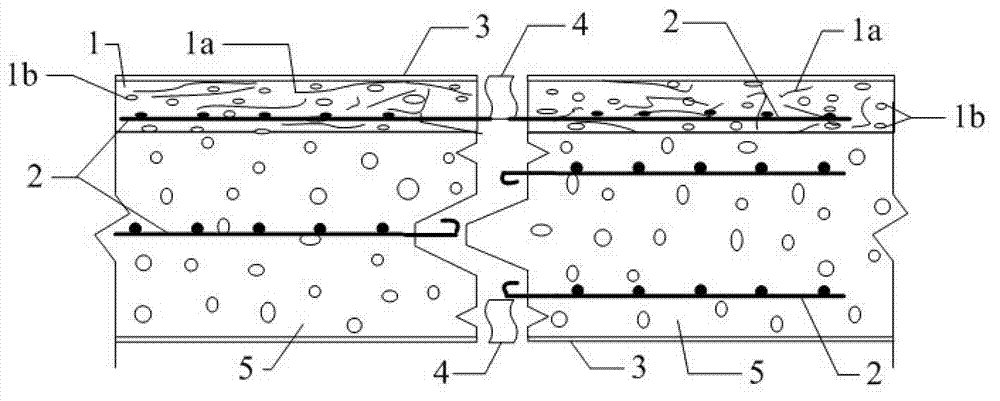

The invention relates to a piezoresistance / piezoelectric material system and production and application methods of the piezoresistance / piezoelectric material system. The piezoresistance / piezoelectric composite material comprises the following components in parts by weight: 100 parts of cement, 105-500 parts of micro / nano grade piezoelectric ceramic powder body, 10-30 parts of fly ash, 15-50 parts of water, 0.01-2 parts of super plasticizer, 0.1-10 parts of toughness fiber and 0.01-15 parts of conductive fillers. A sensor utilizing the piezoresistance / piezoelectric composite material comprises a piezoresistance / piezoelectric composite material layer, wherein the upper surface and the lower surface of the piezoresistance / piezoelectric composite material layer are respectively provided with one electrode, the piezoresistance / piezoelectric composite material layer and the electrodes are coated in a package shell, the upper electrode and the lower electrode are connected by an electromagnetic shielding wire passing through the package shell, and the sensor is arranged between a bracket and a support bridge deck unit or is embedded in the support bridge deck unit. The sensor utilizing the material, disclosed by the invention, has intrinsic structure toughness and synchronous monitoring capability of covering a whole-frequency-domain static / dynamic traffic and structure parameters.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

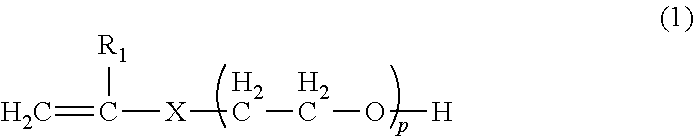

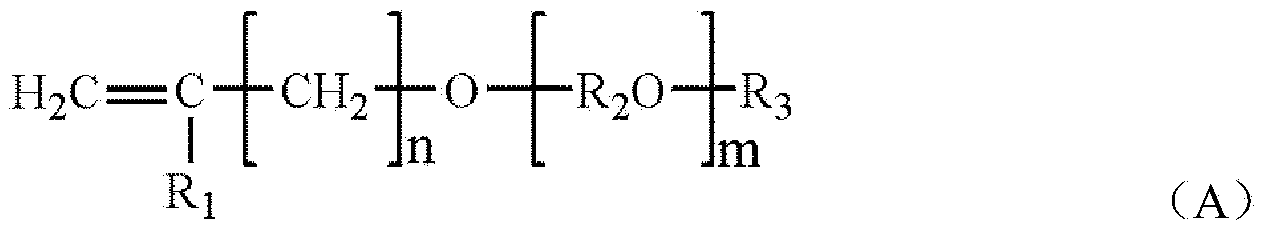

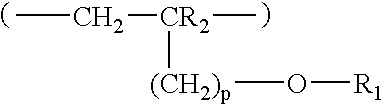

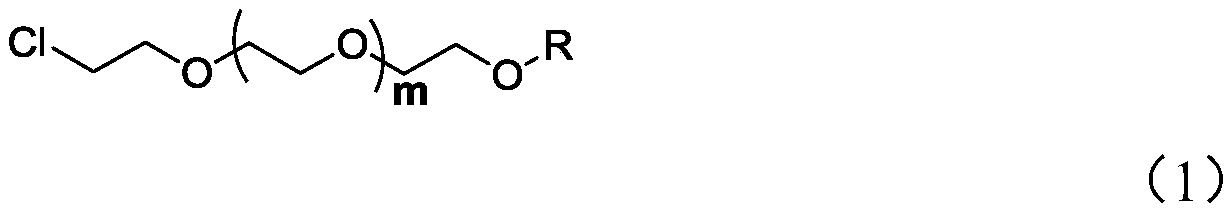

Mud-resistant and salt-resistant polycarboxylate superplasticizer and preparation method thereof

The invention provides a mud-resistant and salt-resistant polycarboxylate superplasticizer, which is prepared from a monomer mixture comprising a monomer a, a monomer b and a monomer c in a copolymerization manner, wherein the monomer a is one or a mixture of more than two of unsaturated polyethers according with a general formula (A) as shown in the specification; n is an integer of 0-3; m is an integer of 10-90; R1 represents hydrogen or methyl; R2O represents ethyoxyl or propoxy or a mixture thereof; R3 represents hydrogen or methyl or ethyl; the monomer b is an unsaturated acid, an unsaturated anhydride or a mixture thereof; the monomer c is represented by a general formula (B); Y is vinyl, methyl vinyl, acrylyl oxygroup, or methylacryloyl oxygroup; X is chlorine group, methoxyl, ethyoxyl, methoxyethoxy or acetoxyl; k is an integer of 0-3. By adopting the mud-resistant and salt-resistant polycarboxylate superplasticizer provided by the invention, the adaptability of the cement in concrete can be greatly improved, the mud-resistant and salt-resistant effects are improved, and meanwhile, the mud-resistant and salt-resistant polycarboxylate superplasticizer has the advantages of low mixing amount, high water-reducing rate, low slump loss and the like.

Owner:北京联绿技术集团有限公司

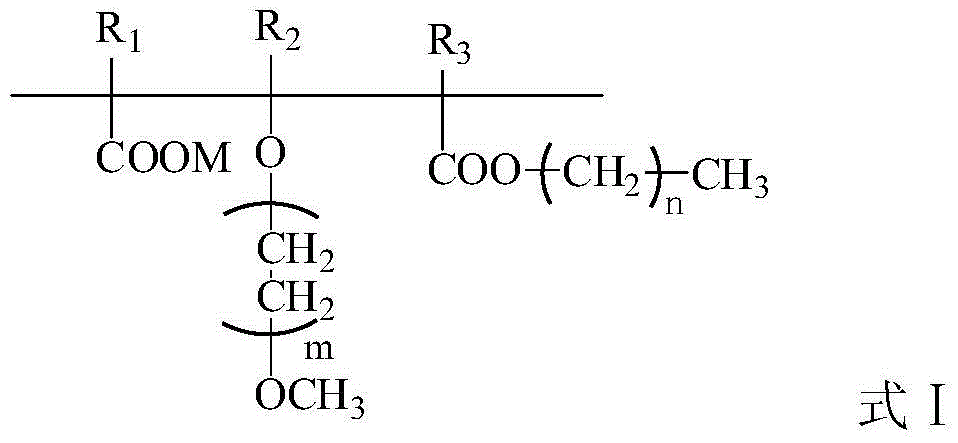

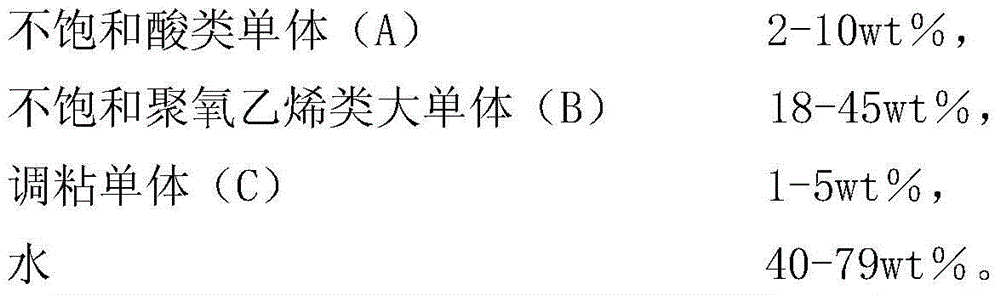

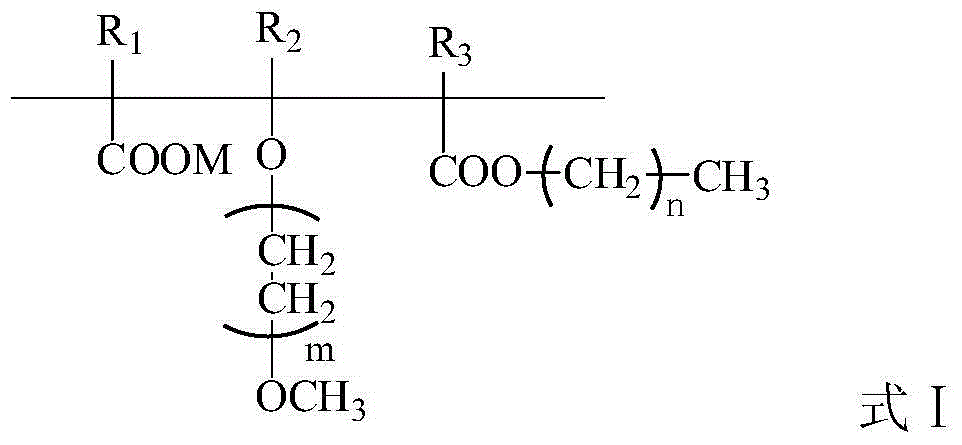

Viscosity-control type polycarboxylate superplasticizer and preparation method thereof

The invention discloses a viscosity-control type polycarboxylate superplasticizer and a preparation method thereof. The method includes: mixing 2-10wt% of an unsaturated acid monomer (A), 18-45wt% of an unsaturated polyoxyethylene macromonomer (B), 1-5wt% of a viscosity-control monomer (C) and the balance water (a total weight of 100%), then adding the mixture into a reaction kettle, adding an initiator solution dropwisely for 2-4h under 70-90DEG C to trigger polymerization, further performing heat preservation reaction for 1-3h under 70-90DEG C, then carrying out natural cooling to 45DEG C, and adjusting the pH value to 6.0-8.0, thus obtaining the viscosity-control type polycarboxylate superplasticizer. The viscosity-control type polycarboxylate superplasticizer has stable performance, and the dosage of each raw material component can be adjusted according to needs, so that the flowability and viscosity requirements of construction concrete can be satisfied, and the bleeding and segregation problems of fresh concrete are solved. The viscosity-control type polycarboxylate superplasticizer provided by the invention has the advantages of easily available raw materials, simple preparation process, cleanliness and safety, easy industrial production and the like, and has broad industrial application prospects.

Owner:CHINA BUILDING MATERIALS ACAD

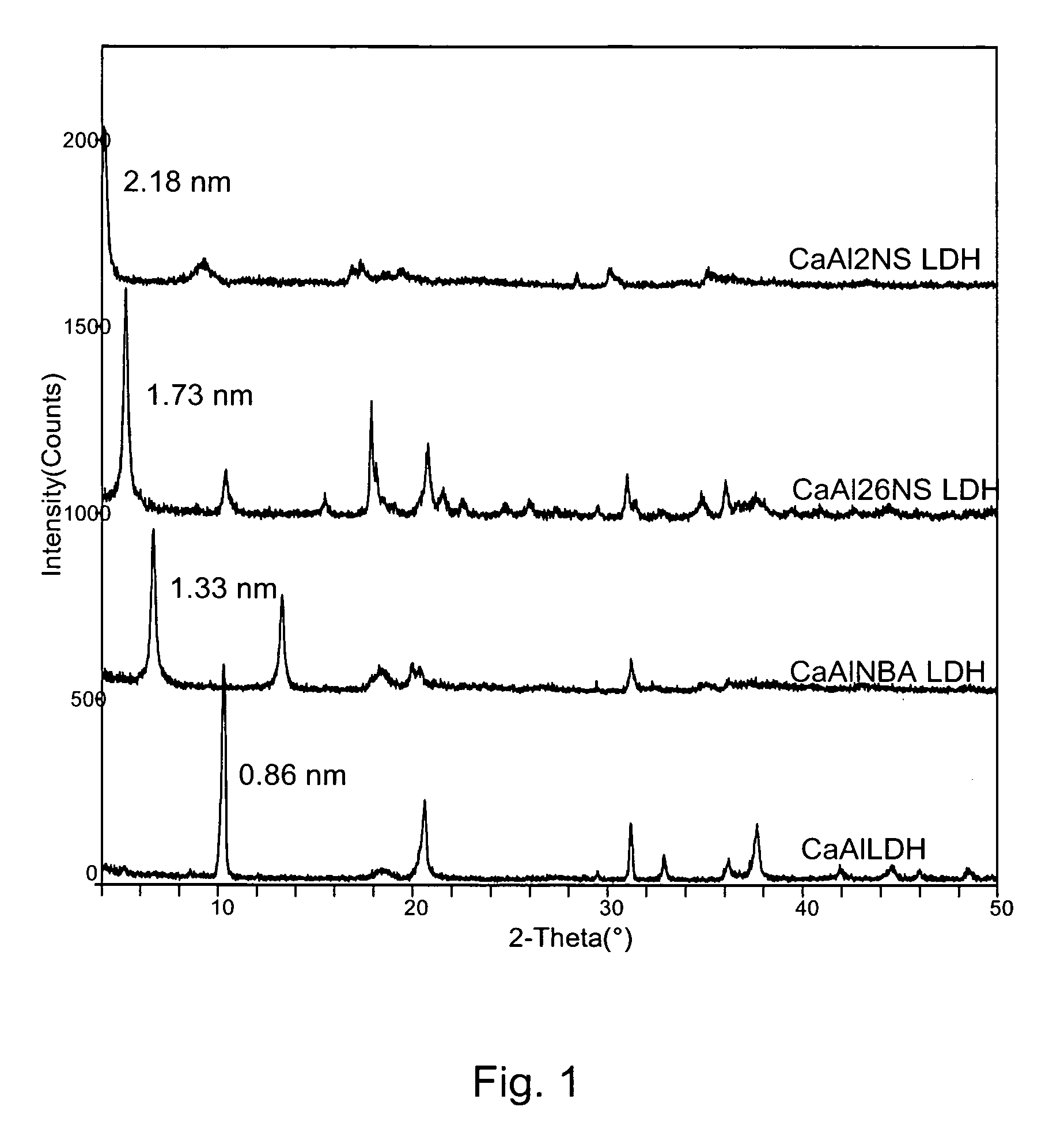

Controlled release of chemical admixtures

InactiveUS7879146B2Improved modulation of slump lossImprove performanceSolid waste managementChemical admixtureSuperplasticizer

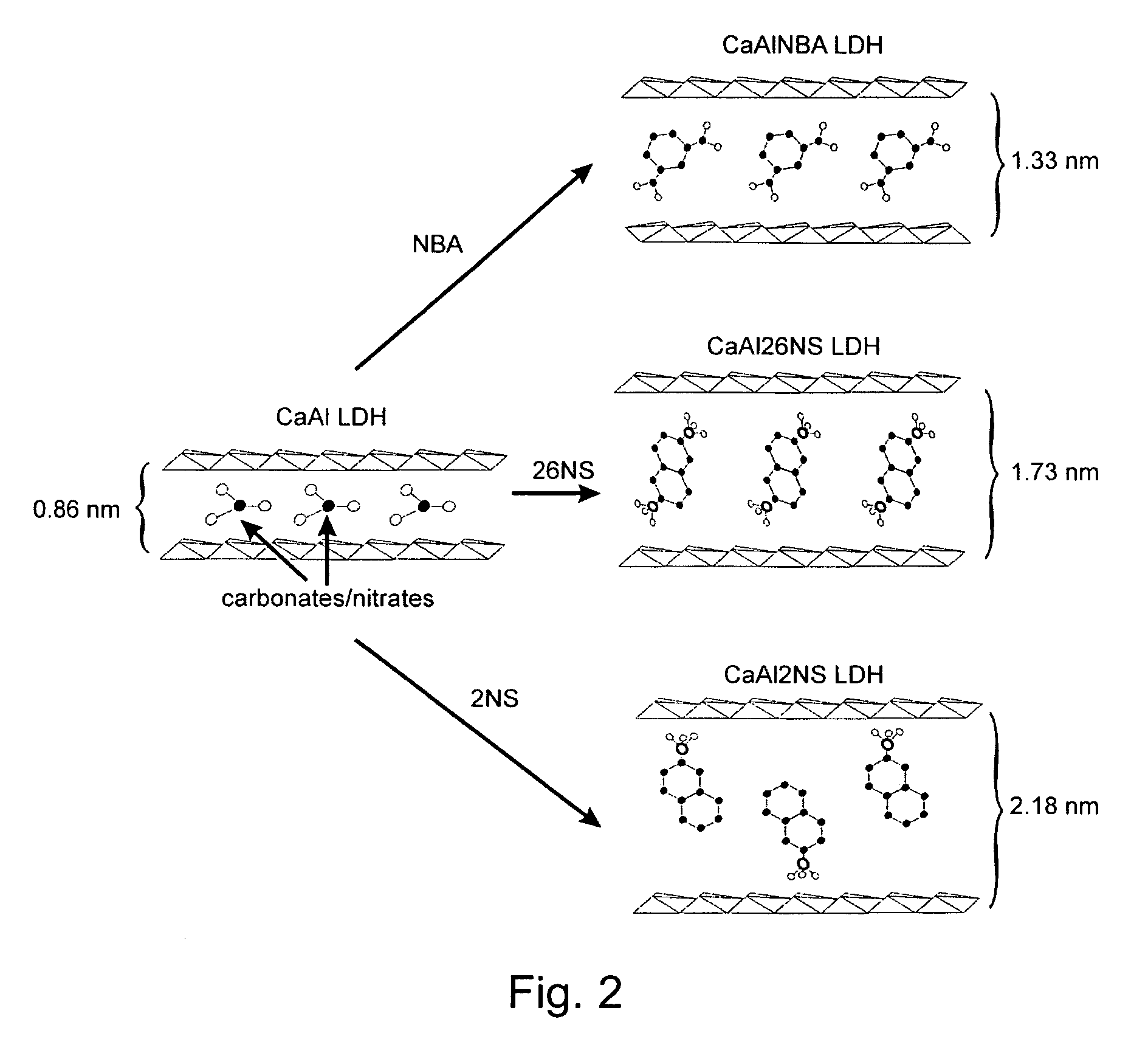

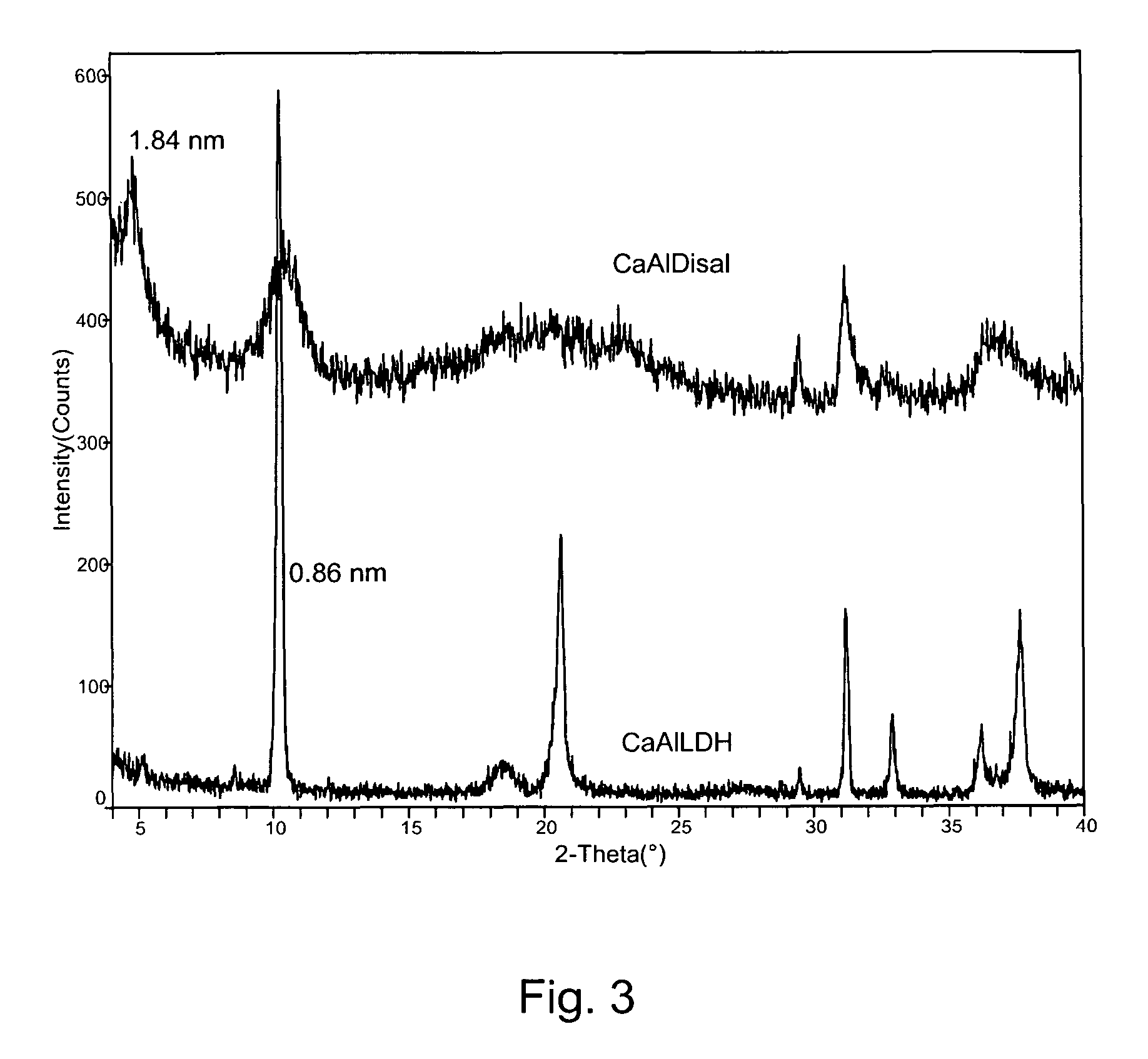

A controlled release formulation for a cement-based composition can be produced by intercalating an admixture (e.g. an accelerator, a set retarder, a superplasticizer) for the cement-based composition into a layered inorganic material (e.g. a layered double hydroxide (LDH)). A cement-based composition containing a cement-based material (e.g. cement, mortar or concrete) and such a controlled release formulation has better workability, especially in respect of slump-loss characteristics. With such a formulation release of an admixture in a cement-based composition may be controlled.

Owner:NAT RES COUNCIL OF CANADA

Nano foamed concrete, reinforced insulation wallboard and preparation method of reinforced insulation wallboard

ActiveCN103359997AAvoid interferenceAvoid pollutionBuilding componentsFoam concreteAdditive ingredient

The invention belongs to the field of building materials and construction technologies and relates to nano foamed concrete, a reinforced insulation wallboard and a preparation method of the reinforced insulation wallboard. The nano foamed concrete disclosed by the invention is prepared from the following ingredients in parts by weight: 100 parts of cement, 0.1-5 parts of desulfurized oil coke ash residue, 0.012 part of waterproofing agent, 10-30 parts of fly ash, 0.1-6 parts of superplasticizer, 50-200 parts of water, 1-20 parts of foamer and 0.01-5 parts of nano wave absorbing agent. Thus, when a wallboard product, prepared by embedding steel wire meshes in the nano foamed concrete disclosed by the invention, is applied nearby airports, docks, navigation marks, television stations and receiving stations or applied to concrete-based retaining walls of electromagnetic wave interference preventing scientific research departments, precise instrument plants and information leakage prevention high-grade buildings of national confidential units and the like, the most basic physical, mechanical, heat preservation and heat insulation properties are guaranteed on one hand, and the wallboard product has the capabilities of lowering noise and insulating sound on the other hand.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Abrasion resistant ceramic coating

The invention discloses a brushing-proof abrasion-proof and erosion-proof ceramic paint, which is characterized by the following: selecting at least one of electric-melting brown corundum, electric-melting subwhite corundum, electric-melting white corundum, carborundum and electric melting mullite with different grain sizes as main material and at least one of compact corundum, electric-melting subwhite corundum, electric-melting white corundum, carborundum, silicon nitride and boron nitride as auxiliary material; using CA50 calcium aluminate cement or pure calcium aluminate cement as binder and nanometer micro-silica powder and active alpha-Al2O3 micropowder as reinforcer; making hyperdrying active high-effective dehydragent, sodium citrate and sodium hexametaphosphate as composite additive; loading in the strength stirrer to stir 12-17min; blending evenly; packing.

Owner:CHONGQING LUOMAN NEW MATERIAL TECH CO LTD

Light cast-in-situs concrete wallboard

InactiveCN1530501AStrong and durable connectionImprove the seismic performance of structuresSolid waste managementWallsFiberglass meshGlass fiber

A light concrete wall slab cast in-situ is composed of main body and welded reinforcing steel bar net in said main body. Said main body is made up of water, cement, powdered coal ash, slag powder, silicon powder, efficient composite water-reducing agent, polypropylene fibres, glass fibre fabric or alkali-resistant plastic-coated glass staple, modified cement polymer emulsion (or powder), haydite, and sand. Its advantages are light weight, high strength, low shrinkage, not deforming and cracking, and low cost.

Owner:张英保

Mud-proof slump-retaining type polycarboxylate superplasticizer with low shrinkage and high adaptability and low-temperature preparation method thereof

InactiveCN110003402AImprove adaptabilityImprove mud slump performanceSuperplasticizerCarboxylic acid

The invention discloses a mud-proof slump-retaining type polycarboxylate superplasticizer with low shrinkage and high adaptability and a low-temperature preparation method thereof. The polycarboxylatesuperplasticizer is mainly prepared by the following steps: carrying out free radical polymerization on 4-hydroxybutylvinyl polyoxyethylene ether, unsaturated carboxylic acid, an unsaturated amide-type monomer, dipolyethylene glycol maleate, an unsaturated quaternary ammonium cationic monomer, an oxidizing agent, a catalyst, a reducing agent, a chain transfer agent and deionized water at 5-15 DEGC through an aqueous solution, regulating pH value by adding a sodium hydroxide solution, and supplementing water. The preparation method of the invention has advantages of low-temperature production, no heat source, simple equipment, no pollution, short reaction time and high production efficiency. The prepared mud-proof slump-retaining type polycarboxylate superplasticizer endows concrete withgood workability, good adaptability, low shrinkage and high strength, has excellent mud-proof slump-retaining property, and greatly reduces construction difficulty.

Owner:SICHUAN TONGZHOU CHEM TECH

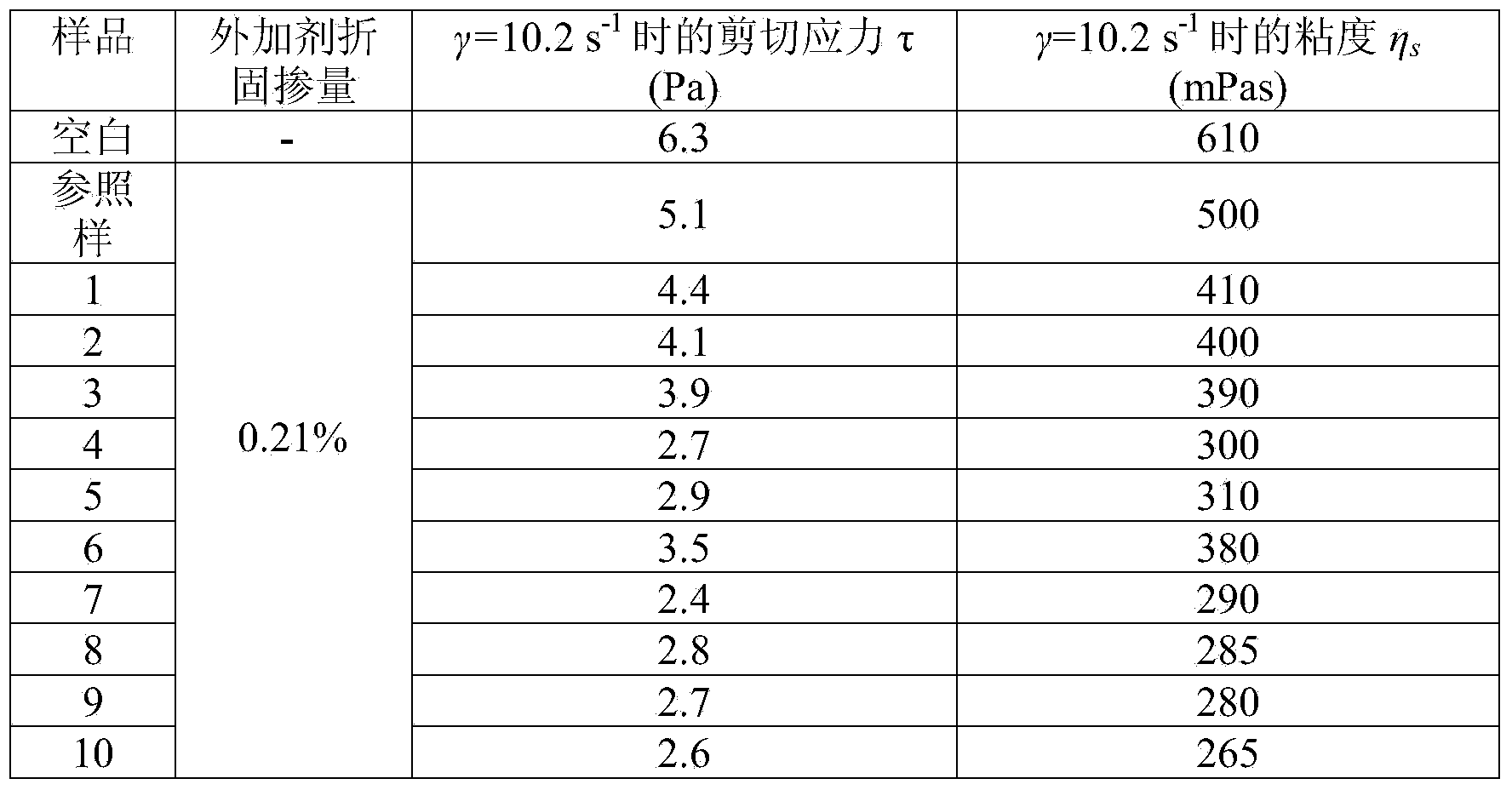

Method for preparing viscosity-reduction-type polycarboxylic acid superplasticizer and application of viscosity-reduction-type polycarboxylic acid superplasticizer

The invention provides a method for preparing a viscosity-reduction-type polycarboxylic acid superplasticizer and application of the viscosity-reduction-type polycarboxylic acid superplasticizer. The method is simple in operating process, and the prepared polycarboxylic acid superplasticizer is applied to high- and ultrahigh-strength concrete, can be used for effectively lowering the viscosity of concrete and improving the placeability and flow velocity of the concrete and is beneficial to pumping construction. According to the method, the viscosity-reduction-type polycarboxylic acid superplasticizer is prepared through carrying out free-radical copolymerization on a carboxylic monomer a, a branched side chain containing monomer b and a rigid cyclic group containing monomer c which are in the mole ratio of (4-15): 1: (0.5-2). The polycarboxylic acid superplasticizer prepared by the method provided by the invention can serve as a cement dispersant so as to greatly lower the water-cement ratio of concrete; and the polycarboxylic acid superplasticizer can be used for effectively lowering the viscosity of the high- and ultrahigh-strength concrete and improving the placeability and flow velocity of the concrete, so that the pumpability is excellent.

Owner:JIANGSU SOBUTE NEW MATERIALS +2

Preparation method of mud resisting and slump retaining type phosphate group containing polycarboxylate superplasticizer

The invention discloses a preparation method of a mud resisting and slump retaining type phosphate group containing polycarboxylate superplasticizer. The preparation method comprises the following specific steps that 1, a halogen containing polycarboxylate superplasticizer prepolymer is prepared, wherein halogen containing unsaturated monomers, halogen containing unsaturated acid small monomers and halogen containing unsaturated polyether macromonomers or unsaturated ester macromonomers are subjected to an oxidation-reduction radical polymerization reaction to obtain the halogen containing polycarboxylate superplasticizer prepolymer; 2, the halogen containing polycarboxylate superplasticizer prepolymer and alkyl phosphate are subjected to an Arbuzov reaction to obtain a phosphate group containing copolymerization product, the pH value is adjusted after reacting is completed, water is added, and then the polycarboxylate superplasticizer is obtained. The mud resisting and slump retaining type phosphate group containing polycarboxylate superplasticizer prepared through the method has the advantages of being low in mixing amount, high in water reducing ratio, long in slump retaining time and high in mud resisting property, can avoid the adverse effect brought by mud containing aggregate in concrete and is simple in synthesis process, easy to control and low in production cost.

Owner:JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

Method for producing high-strength high damping concrete

InactiveCN101172820AHigh strengthImprove damping performanceSolid waste managementReduction treatmentSuperplasticizer

The invention relates to a preparation method of concrete with high strength and high damp. The invention is characterized in that the preparation method includes the following steps: firstly, the pretreatment of the light aggregate: (1) the feeding and vibration reduction treatment of the light aggregate: the light aggregate adsorbs the polymer to obtain feeding and vibration reduction treatment light aggregate; (2) sealing and reinforcing treatment on the surface of the feeding and vibration reduction treatment light aggregate: the feeding and vibration reduction treatment light aggregate obtained at the first step is put into sealing and reinforcing treatment slurry to mix for 1 to 3 minutes, then being fished out, and then conserved for 3 days in the condition of 85 percent to 95 percent of relative humidity and the temperature of 23 DEG C to 27 DEG C, wherein, pretreatment light aggregate is obtained; secondly, preparation for the concrete with high strength and high toughness: the concrete with high strength and high toughness is formed by evenly mixing water, common coarse aggregate, the pretreatment light aggregate, cement, fine aggregate, mineral addition, fibre, emulsified polymer and high efficiency water reducing agent. The invention can effectively increase the strength and the damp performance of the concrete.

Owner:WUHAN UNIV OF TECH

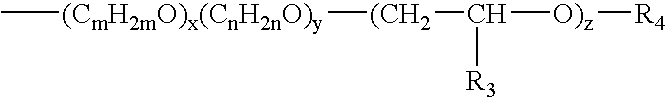

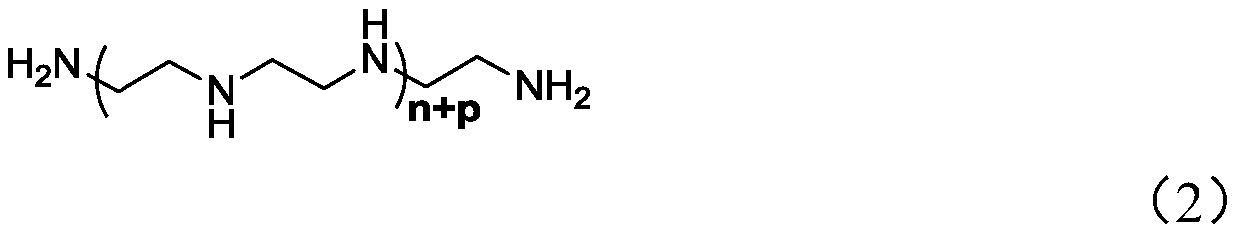

Slump Retaining and Dispersing Agent for Hydraulic Compositions

InactiveUS20130231415A1Avoid settingLow and no air entraining effectDrilling compositionLignosulfonatesSuperplasticizer

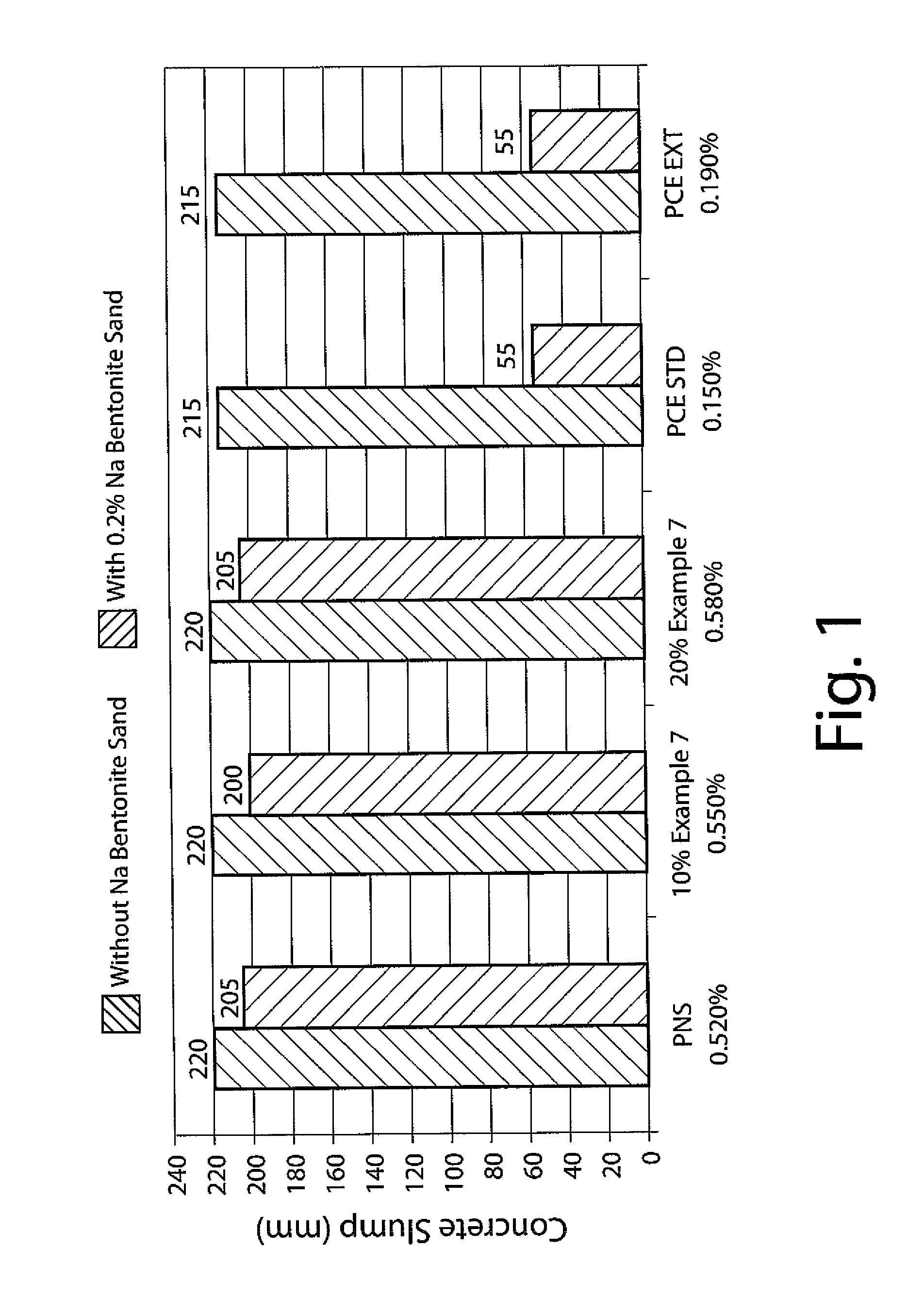

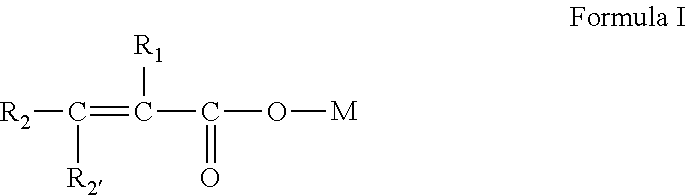

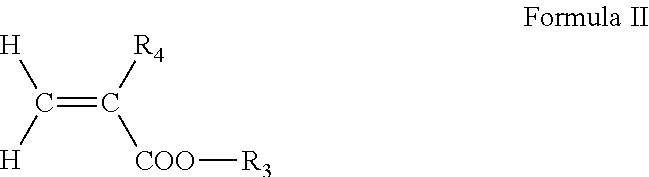

The invention relates to copolymers effective as slump retention agents for hydraulic compositions such as cement, mortar and concrete. The copolymers are formed by reacting monomers A, B and C, wherein monomer A is a compound of formula I, monomer B is a compound of formula II, and monomer C is a compound of formula III or IV as shown herein. The copolymers may be used alone or in combination with a water reducing agent or slump retaining agent, e.g. a superplasticizer such as PNS or PMS or a low range water reducer such as lignosulfonate. The copolymer includes a group that is hydrolyzable at elevated pH (e.g. around pH 12) typically present in hydraulic compositions, so that the group hydrolyzes when present in such compositions and forms a charged group that provides extended slump retention properties without introducing undesirable air-entraining characteristics.

Owner:RUETGERS POLYMERS LTD

Block poly-carboxylic acid concrete high-efficiency water reducing agent and preparation method thereof

ActiveCN103482897AControl structureControl its molecular weight distributionStructural regularityPolymer science

The invention provides a block poly-carboxylic acid concrete high-efficiency water reducing agent with an ordered structure and a preparation method thereof. The block poly-carboxylic acid is prepared by using atom transfer radical polymerization, the structural regularity and the molecular weight distribution of the poly-carboxylic acid are controlled effectively, and the water reducing agent is used in a cement dispersing process. By adoption of the block poly-carboxylic acid concrete high-efficiency water reducing agent and the preparation method thereof, the problems of uncontrollable molecular weight of the poly-carboxylic acid, wider molecular weight distribution, un-designable molecular structure and the like are solved.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

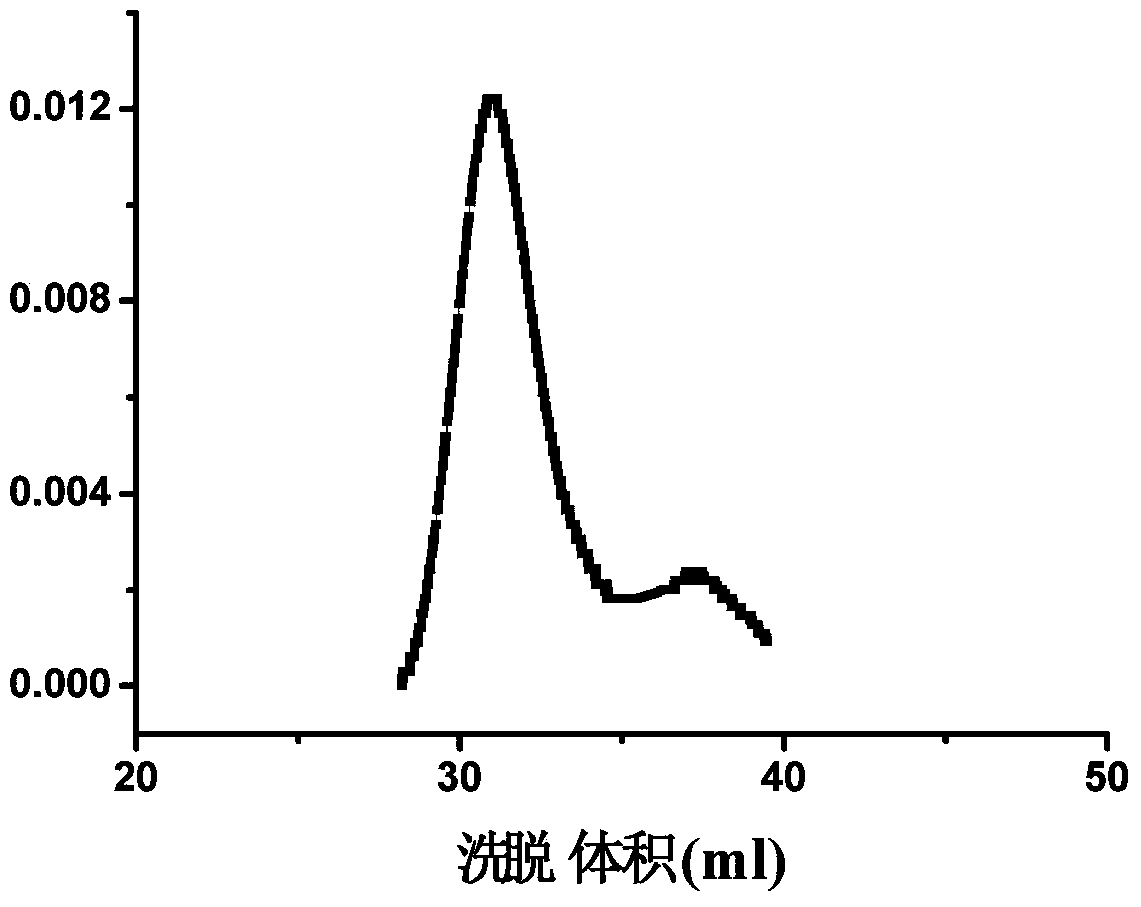

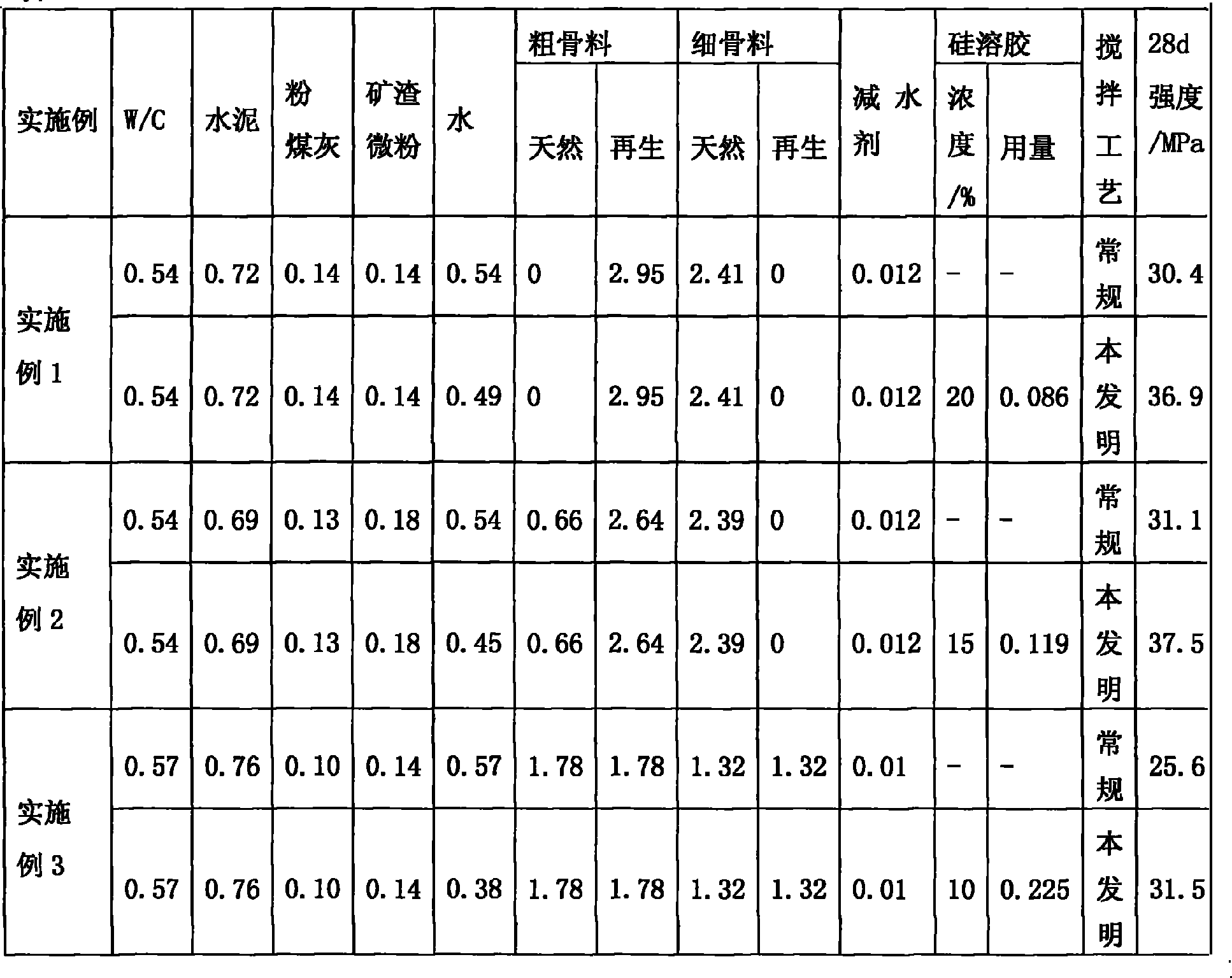

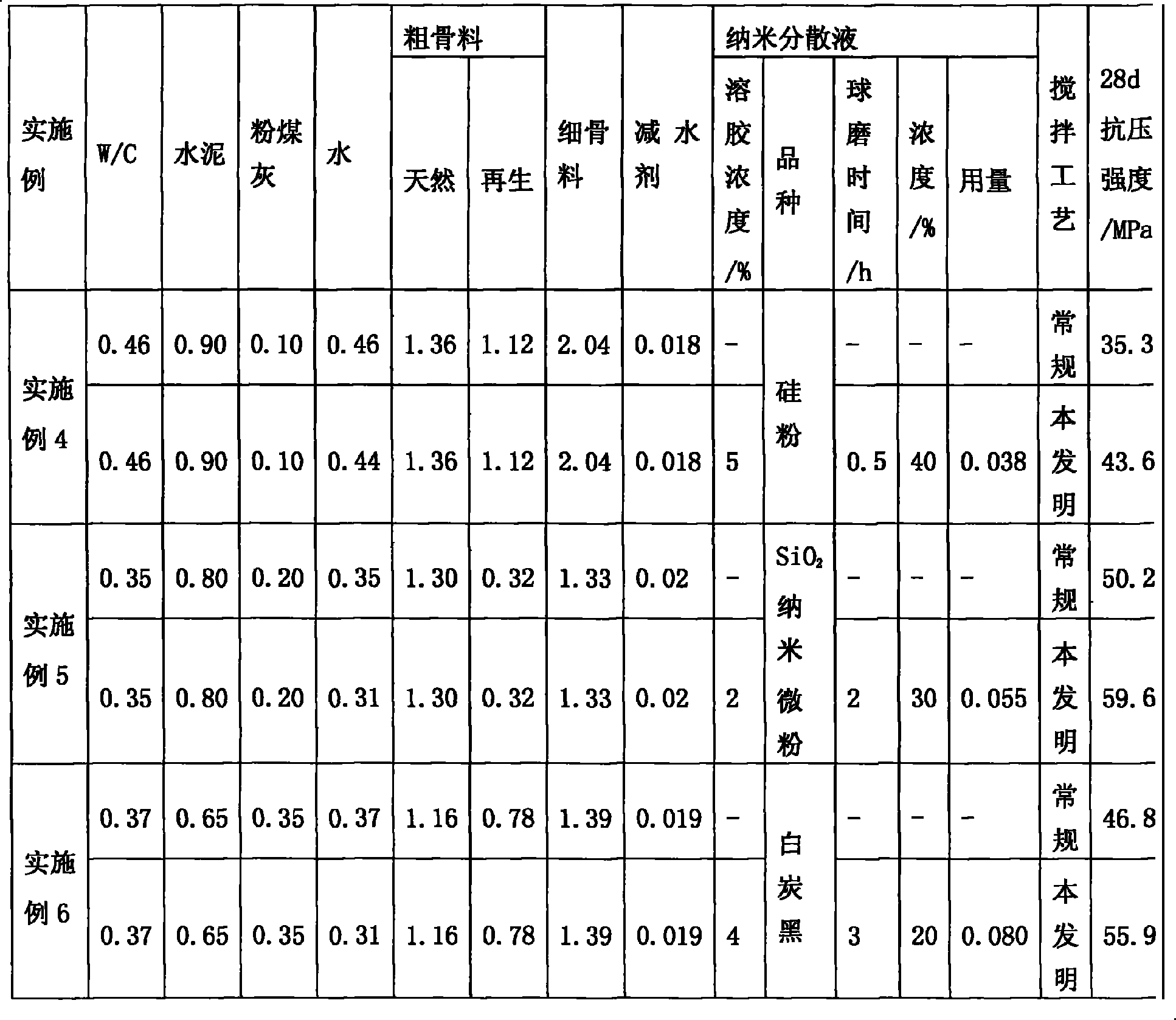

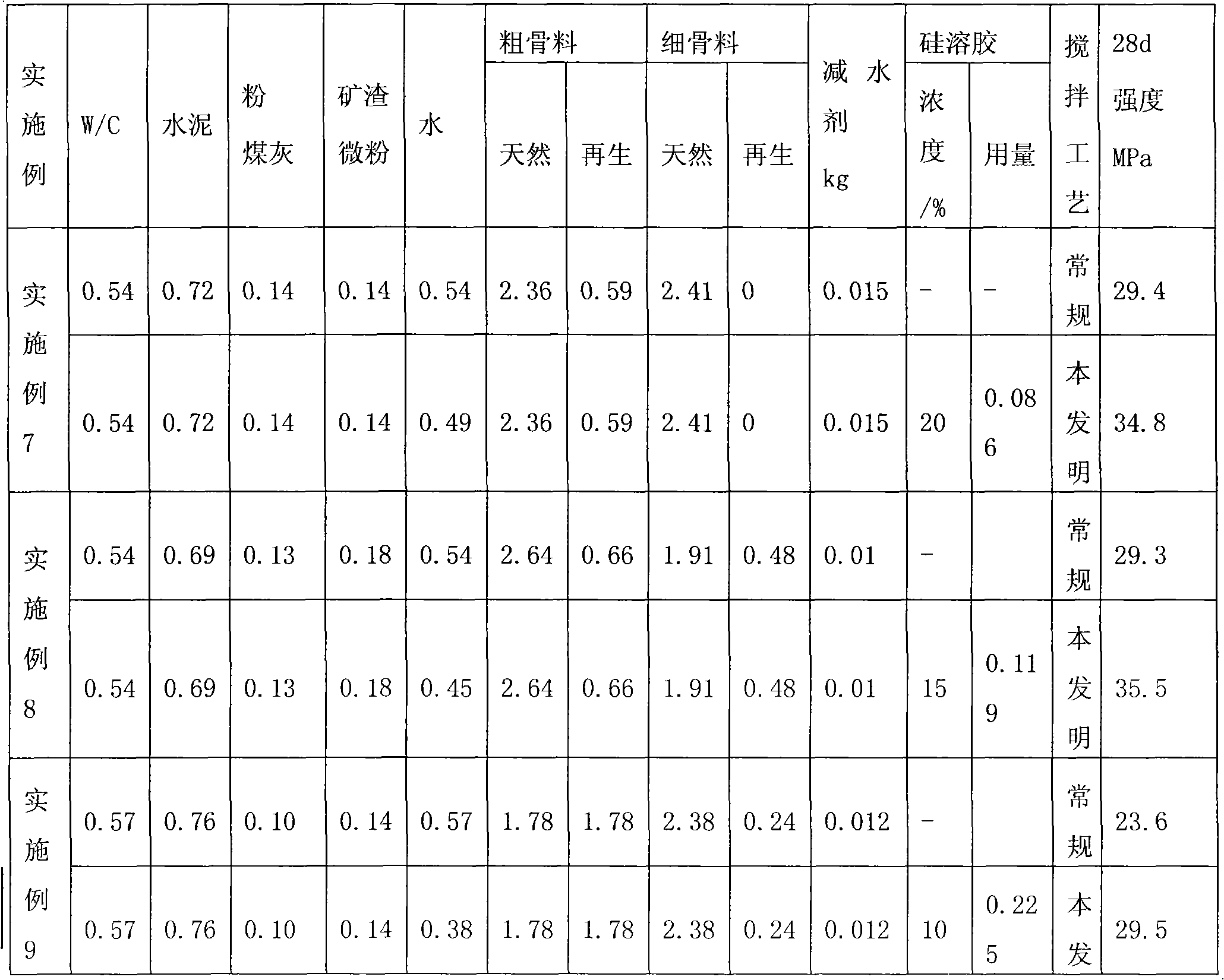

Nano reinforcing method for recycled aggregate concrete

InactiveCN102092993AHigh strengthImprove interfacial bond strengthSolid waste managementSuperplasticizerWater reducer

The invention discloses a nano reinforcing method for recycled aggregate concrete, which belongs to the technical fields of recycling comprehensive utilization of waste and production of building materials, and is mainly characterized by comprising the steps of: mixing and stirring a recycled aggregate and a nano particle dispersion for 5-10s; after the surface of the recycled aggregate is in a moist state, further mixing the recycled aggregate with all admixtures for 5-10s; and mixing and stirring with cement, water and a high-efficiency water reducing agent for 20-45s to obtain a nano-reinforced recycled aggregate concrete mixture. The nano reinforcing method has a principle that by changing a stirring process and introducing the nano dispersion, nano particles can be adsorbed into the opening pores and microcracks of the recycled aggregate, an admixture enriched layer is further formed on the surface of the recycled aggregate, the nano particles permeating into the interiors of the opening pores of the recycled aggregate and the admixture enriched layer formed on the surface of the recycled aggregate are used for jointly absorbing calcium hydroxide enriched on the surface and the pores of the recycled aggregate in the strength development process of the recycled aggregate concrete, a gelling material with higher strength is generated through hydration, liquid-phase or solid-phase reactions so as to reinforce the recycled aggregate per se and an interface between the recycled aggregate and set cement, and thus, the strength of the recycled aggregate concrete is enhanced. After the nano reinforcement, the recycled aggregate concrete has the 28-day compression strength improved by around 15-20%.

Owner:ZHEJIANG UNIV +1

Polyether-containing copolymer

Owner:BASF CONSTR SOLUTIONS

Preparation method of viscosity-reducing type polycarboxylate superplasticizer

The invention relates to a preparation method of a viscosity-reducing type polycarboxylate superplasticizer. The preparation method comprises the following specific steps: firstly stirring acid anhydride small monomers containing unsaturated double bonds and binary primary amine type organic small molecules at a certain temperature to generate unsaturated primary amine type small monomers; then adding organic small molecules containing epoxy groups and the organic small molecules containing halogen groups into a generated reaction system of the unsaturated primary amine type small monomers and continuously stirring for 5-72h to obtain products, namely quaternary ammonium salt type unsaturated small monomers; and further performing water-phase free radical polymerization reaction on the quaternary ammonium salt type unsaturated small monomers, unsaturated ester type small monomers, unsaturated acid type small monomers and unsaturated polyester large monomers under the action of an initiator and a chain transfer agent, adjusting the pH value after the reaction and adding water to obtain the viscosity-reducing type polycarboxylate superplasticizer. The viscosity-reducing type polycarboxylate superplasticizer prepared by the method provided by the invention has the advantages of simple reaction, easiness in control, low cost and the like. Furthermore, the viscosity of concrete can be reduced, the slump retention can be improved.

Owner:JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

Modified aliphatic high-efficiency water-reducing agent by utilizing lignosulfonate and preparation method thereof

The invention relates to a method for preparing a modified aliphatic high-efficiency water-reducing agent by utilizing lignosulfonate, belonging to the field of concrete water-reducing agents. The invention adopts acetone and formaldehyde as condensation monomers and lignosulfonate as a modifying agent and carries out sulfonating and condensation reactions under an alkaline condition to produce anovel high-efficiency concrete water-reducing agent. The preparation method of the novel high-efficiency concrete water-reducing agent comprises the following steps: (1) adding a sulfonating agent, acetone and water to a reactor, increasing the temperature to 25-65 DEG C and reacting for 0.1-1.5 hours; (2) dipping part of formaldehyde solution for 0.25-2.5 hours, increasing the temperature to 70-95 DEG C and reacting for 1-6 hours; and (3) decreasing the temperature to below 60 DEG C, adding the lignosulfonate and the rest of the formaldehyde solution to the reactor, using an alkaline regulator to regulate a pH value of the system to be 8.0-14.0, increasing the temperature to 70-98 DEG C, reacting for 1-5 hours and decreasing the temperature before discharging. The modified aliphatic high-efficiency water-reducing agent is suitable for producing commercial concrete which has similar color as normal concrete and has smaller collapsed slump loss. By adjusting the process, such as proportioning raw materials, and the like and effectively utilizing the lignosulfonate, the invention not only decreases the product cost, but also lessens environmental pollutants and has favorable industrialized prospects.

Owner:NANJING FORESTRY UNIV

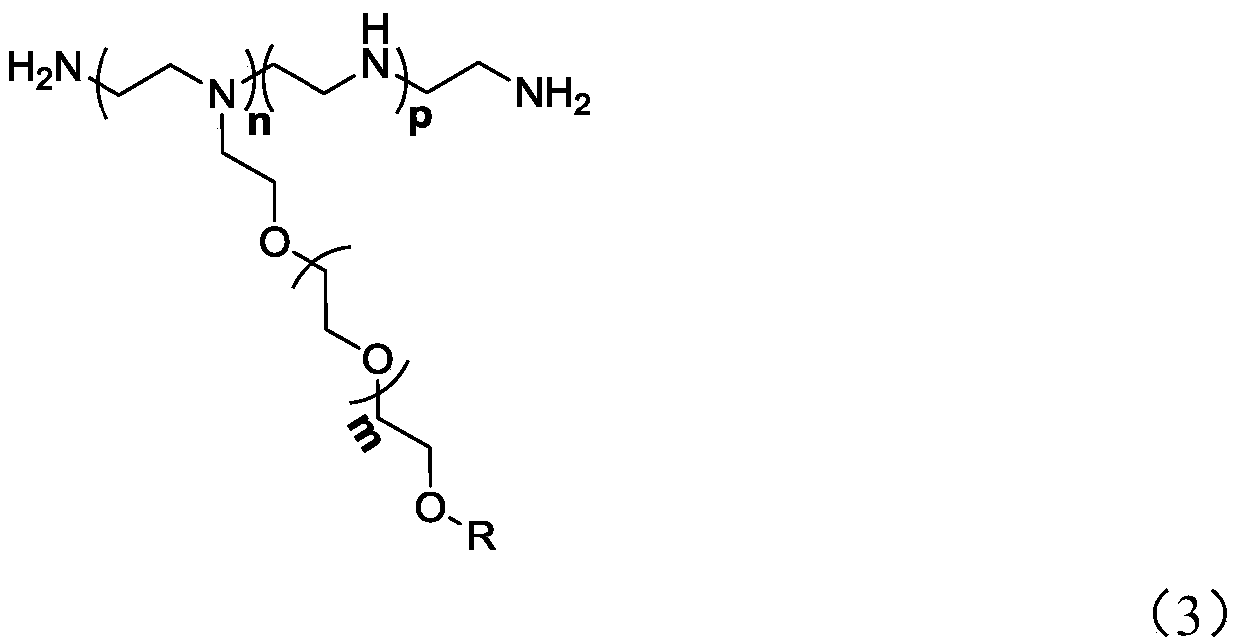

Phosphorous acid concrete super plasticizer with polyethyleneimine structure as well as preparation method and application thereof

The invention provides a new phosphorous acid concrete super plasticizer with a polyethyleneimine structure as well as a preparation method and an application thereof. The phosphorous acid concrete super plasticizer with a polyethyleneimine structure can effectively improve the concrete fluidity, and the preparation method is simple and effective. The preparation method comprises the following steps: a) making chloro-substituted polyether react with polyethyleneimine so that a part of amino groups H of the polyethyleneimine are substituted to obtain polyethyleneimine with a polyoxyethylene ether branch structure, wherein the molar ratio of the chloro-substituted polyether to the imino groups contained in the polyethyleneimine is 1:(3-8); and b) performing phosphorylation of the remaining amino groups H of the polyethyleneimine with a polyoxyethylene ether branch structure to obtain the phosphorous acid concrete super plasticizer with a polyethyleneimine structure.

Owner:JIANGSU SOBUTE NEW MATERIALS

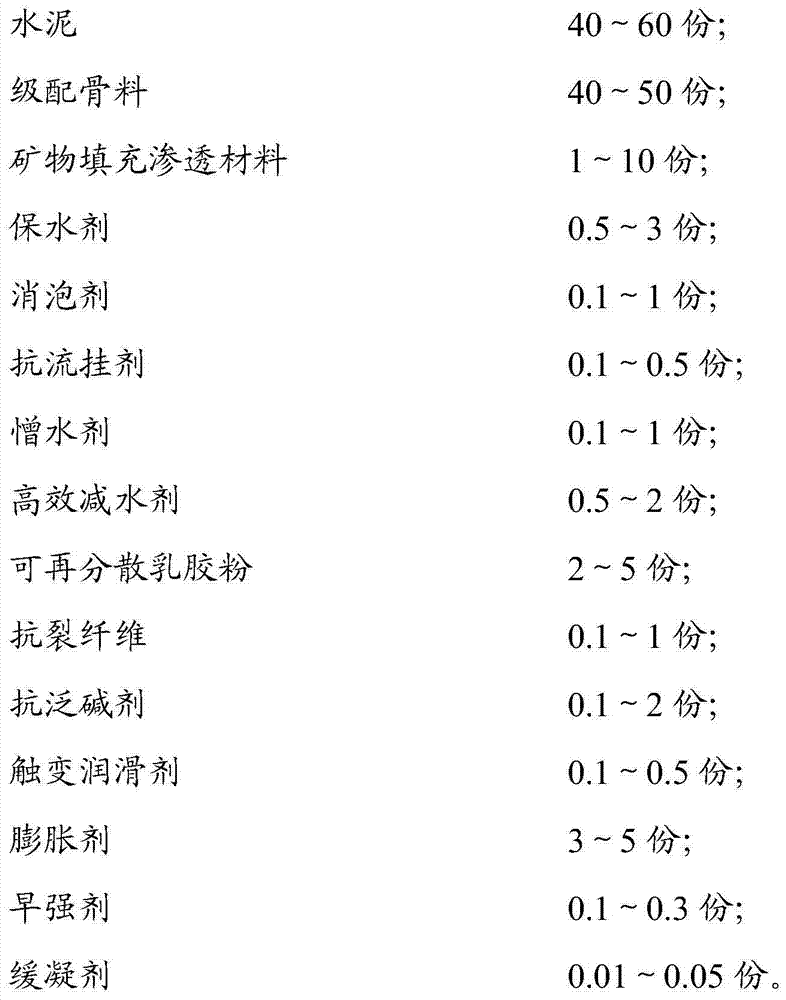

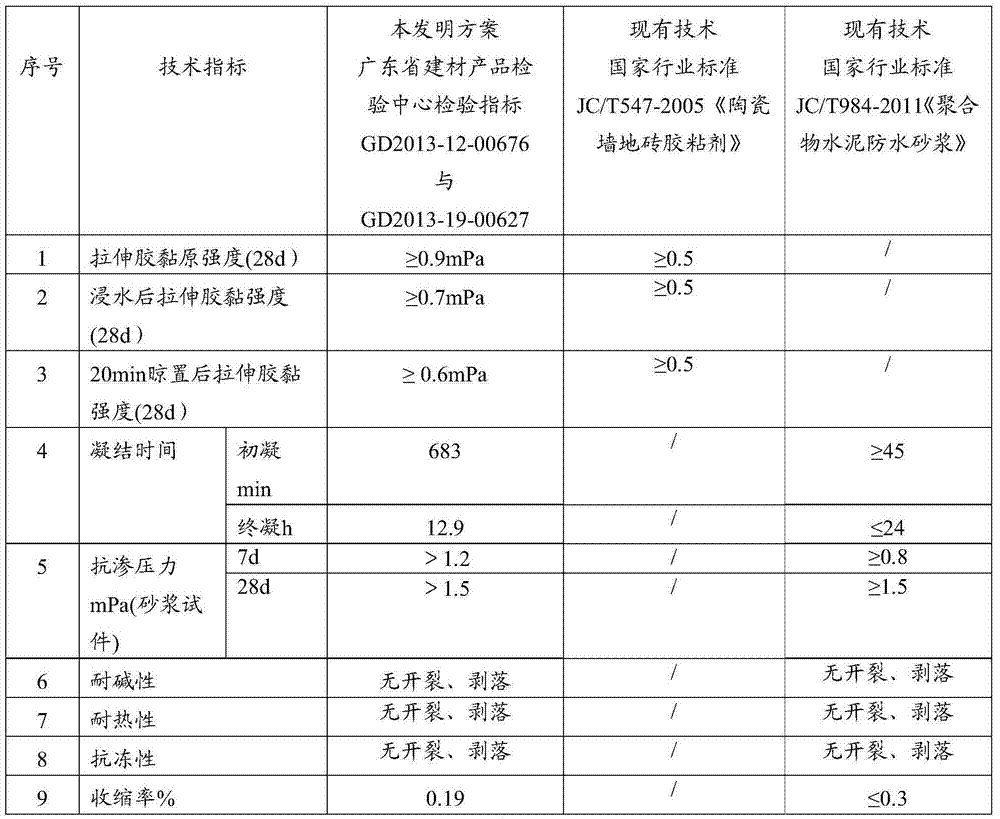

Waterproof ceramic tile adhesive material

The invention discloses a waterproof ceramic tile adhesive material which is prepared from the following components in parts by weight: 40-60 parts of cement, 40-50 parts of grading aggregate, 1-10 parts of mineral filling permeable material, 0.5-3 parts of water retaining agent, 0.1-1 part of antifoaming agent, 0.1-0.5 part of anti-sagging agent, 0.1-1 part of water repellent, 0.5-2 parts of superplasticizer, 2-5 parts of re-dispersible latex powder, 0.1-1 part of anti-cracking fiber, 0.1-2 parts of anti-saltpetering agent, 0.1-0.5 part of thixotropic lubricant, 3-5 parts of expanding agent, 0.1-0.3 part of early strength agent and 0.01-0.05 part of retarder. The waterproof ceramic tile adhesive material disclosed by the invention can be used for pasting ceramic tiles, realizes a waterproof anti-permeation function with low shrinkage and high compaction, has the characteristics of high bonding strength and strong environmental adaptability, and provides a guarantee to the building and personal safety.

Owner:广东龙马新材料科技有限公司

Cation modified polycarboxylate superplasticizer and preparation method thereof

The invention discloses a cation modified polycarboxylate superplasticizer which is characterized by being prepared from isoamyl alcohol polyoxyethylene ether monomer a, unitary unsaturated carboxylic acid and a derivative monomer b thereof, cationic monomer c as well as binary unsaturated carboxylic acid and a derivative monomer d thereof through copolymerization in a 7-70 DEG C water solution for 3-8h under the action of an initiator e and a chain transfer agent f and addition of alkali to realize neutralization until the pH is 5-8. Compared with the traditional anionic polycarboxylate superplasticizers, the cation modified polycarboxylate superplasticizer can be adsorbed on the surfaces of cement minerals with positive charge and negative charge when being added into concrete as a cation group is introduced into the molecular structure, and undergoing molecular chain extension in cement paste alkaline environment due to the existence of antipolyelectrolyte effect to make the adsorption form more stretch, so that the water reducing rate of the superplasticizer is higher and the cement particles can be dispersed more sufficiently.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com