Piezoresistance/piezoelectric composite material, manufacturing method of material, sensor utilizing material and manufacturing method of sensor

A piezoelectric composite material and sensor technology, which is applied in the direction of using electric/magnetic devices to transmit sensing components, can solve the problems of dynamic vibration signal sensitivity, static signal insensitivity, and low sensing accuracy, and achieve good synchronous monitoring capabilities, The effect of high durability and high frequency response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

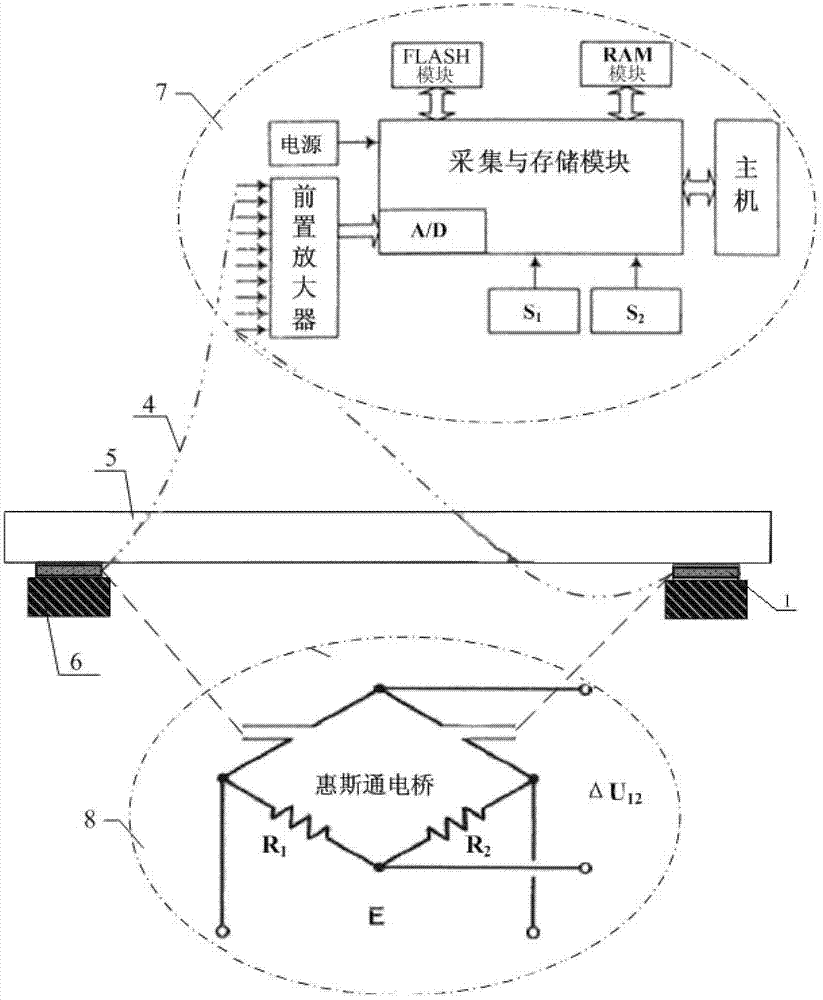

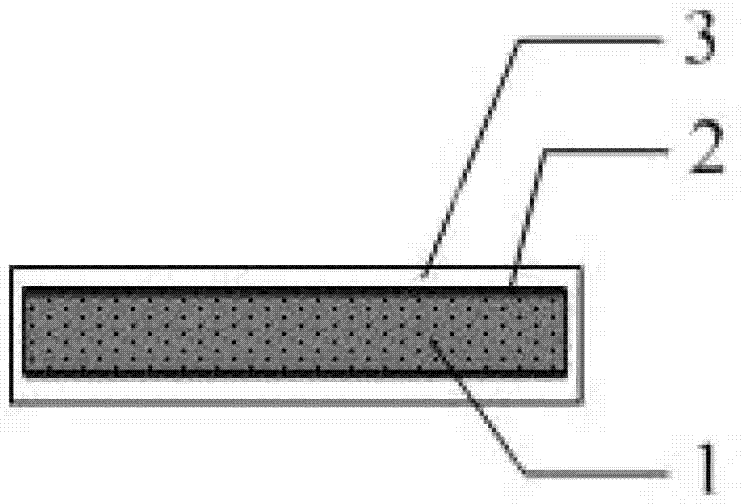

[0034] Such as figure 1 , figure 2As shown, the self-powered piezoresistive / piezoelectric composite sensor system between the bridge deck units 5 supported by the support 6 of the present invention includes an inductive element, a packaging shell, and a dynamic signal acquisition system 7, (quasi) static signal acquisition System 8. The inductive element includes a piezoresistive / piezoelectric composite material layer 1 and a pair of electrodes 2 located on the upper and lower surfaces of the piezoresistive / piezoelectric composite material. A pair of electrodes are connected through the electromagnetic shielding wire 4 that runs through the package shell. The electromagnetic shielding wire 4 is connected to the sensing signal acquisition and processing system through the shielding joint.

[0035] The preparation steps of the piezoresistive / piezoelectric composite material used are as follows:

[0036] (1) Preparation of micro / nano piezoelectric ceramic powder

[0037] Me...

Embodiment 2

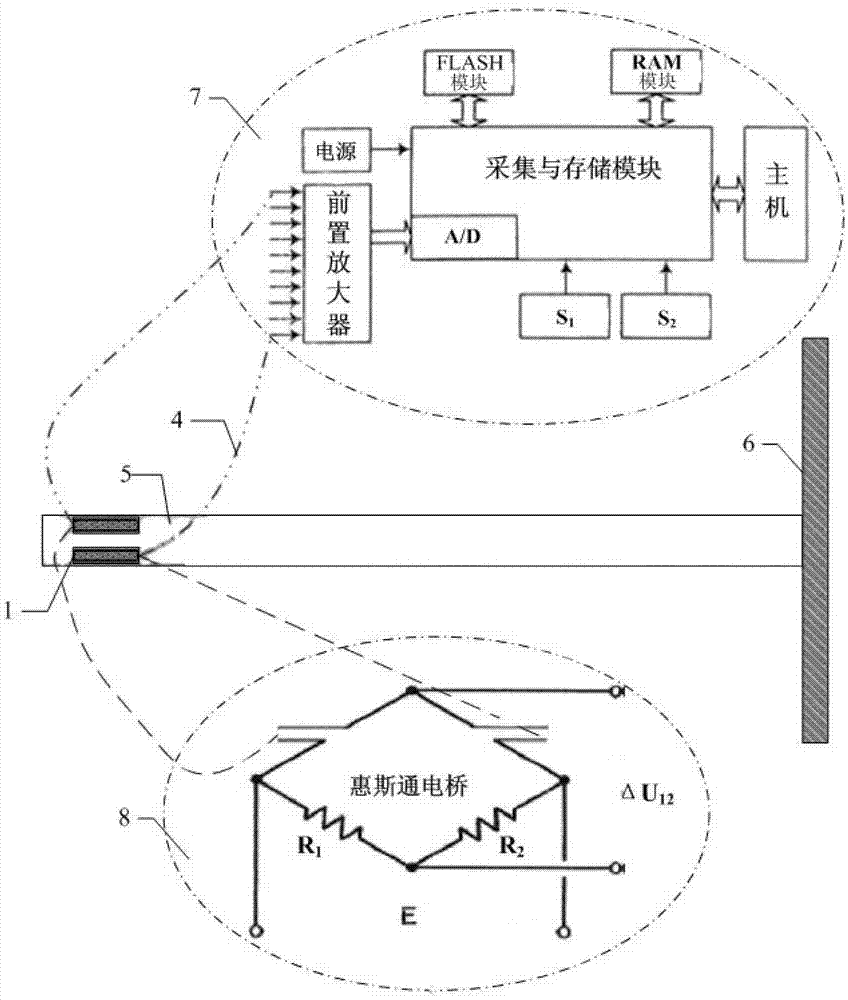

[0050] Such as image 3 As shown, the sensor system is embedded inside the cantilever deck unit 5 .

[0051] Others are with embodiment 1.

Embodiment 3

[0053] The preparation process and structure of the self-powered piezoresistive / piezoelectric composite sensor are the same as in Example 1. The difference is: the cement used is P.O.42.5R ordinary Portland cement, the micro / nano-scale piezoelectric ceramic powder is lead zirconate titanate powder with a particle size of 400-1100nm prepared by hydrothermal method, and the conductive filler is a diameter of 500nm graphene oxide is grafted with carbon nanofibers with a diameter of 60-100nm and a length of 6-30μm. The tough fiber is a polyimide fiber with a diameter of 5-20μm and a length of 8mm. The water-based resin and corresponding curing agent are water-based phenolic resin and supporting water-based Curing agent and superplasticizer are naphthalene sulfonate formaldehyde condensate series FDN, and the electrodes used are grid-type silver electrodes.

[0054] The obtained graphene oxide grafted carbon nanofiber / polyimide fiber / lead zirconate titanate / cement-based piezoresist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Piezoelectric constant | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com