Zinc-aluminum alloy coated steel wire for high-strength-and-ductility durable bridge cables

A zinc-aluminum alloy and bridge cable technology, which is applied in the field of bridge cables, can solve the problems of insufficient anti-corrosion performance and inconvenient installation of steel wire cables, etc., and achieve the effects of prolonging the performance and service life, good tightness, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

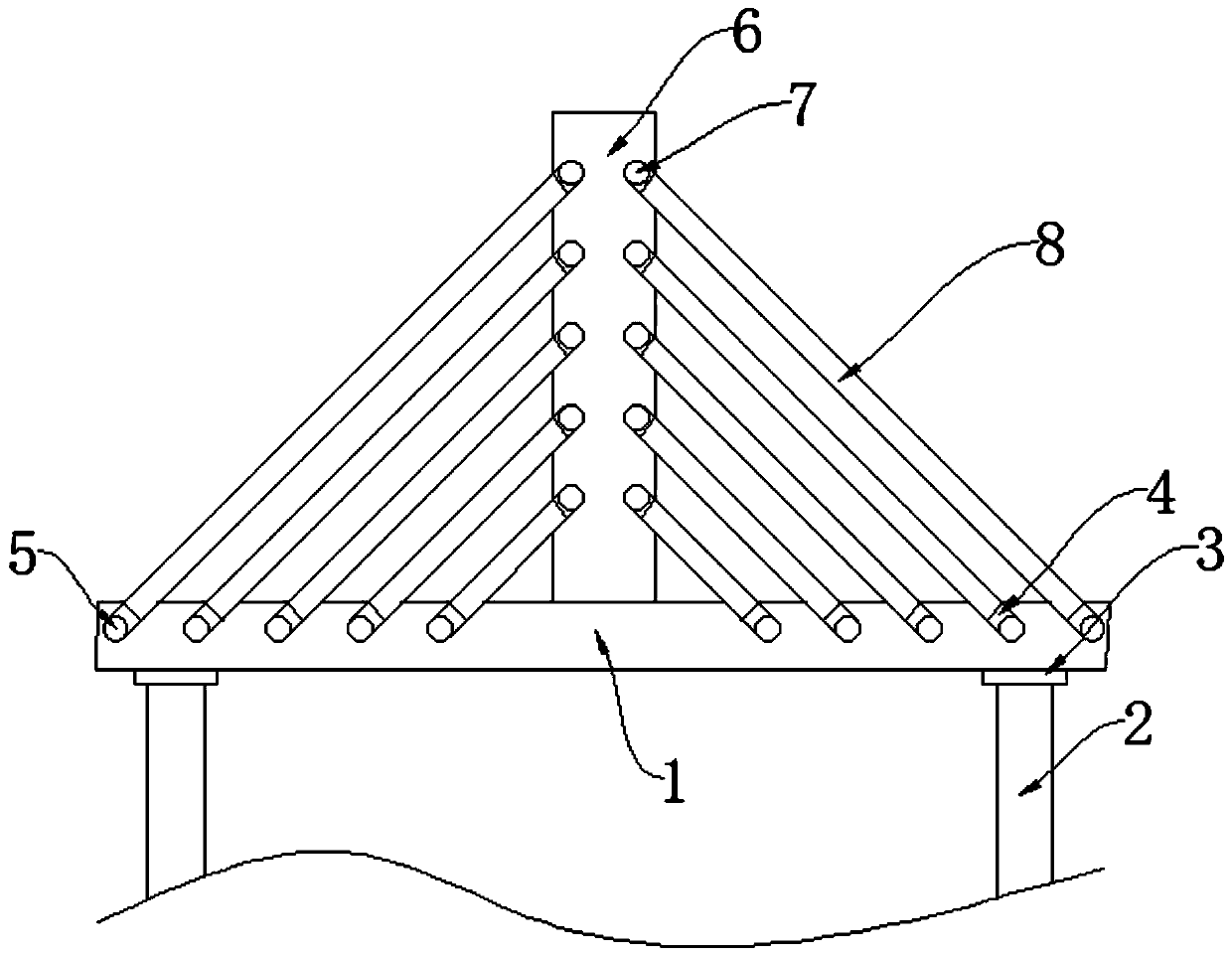

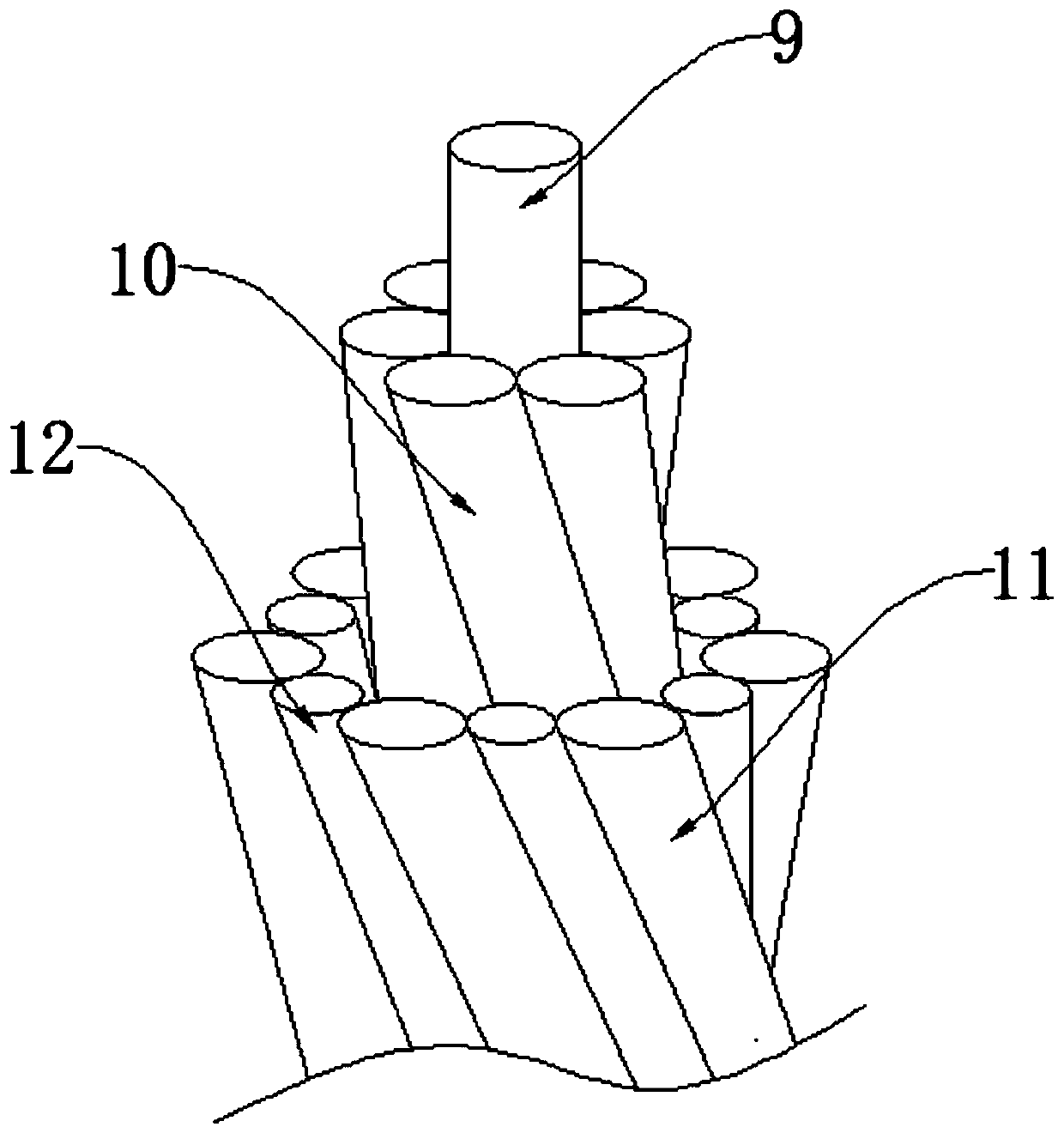

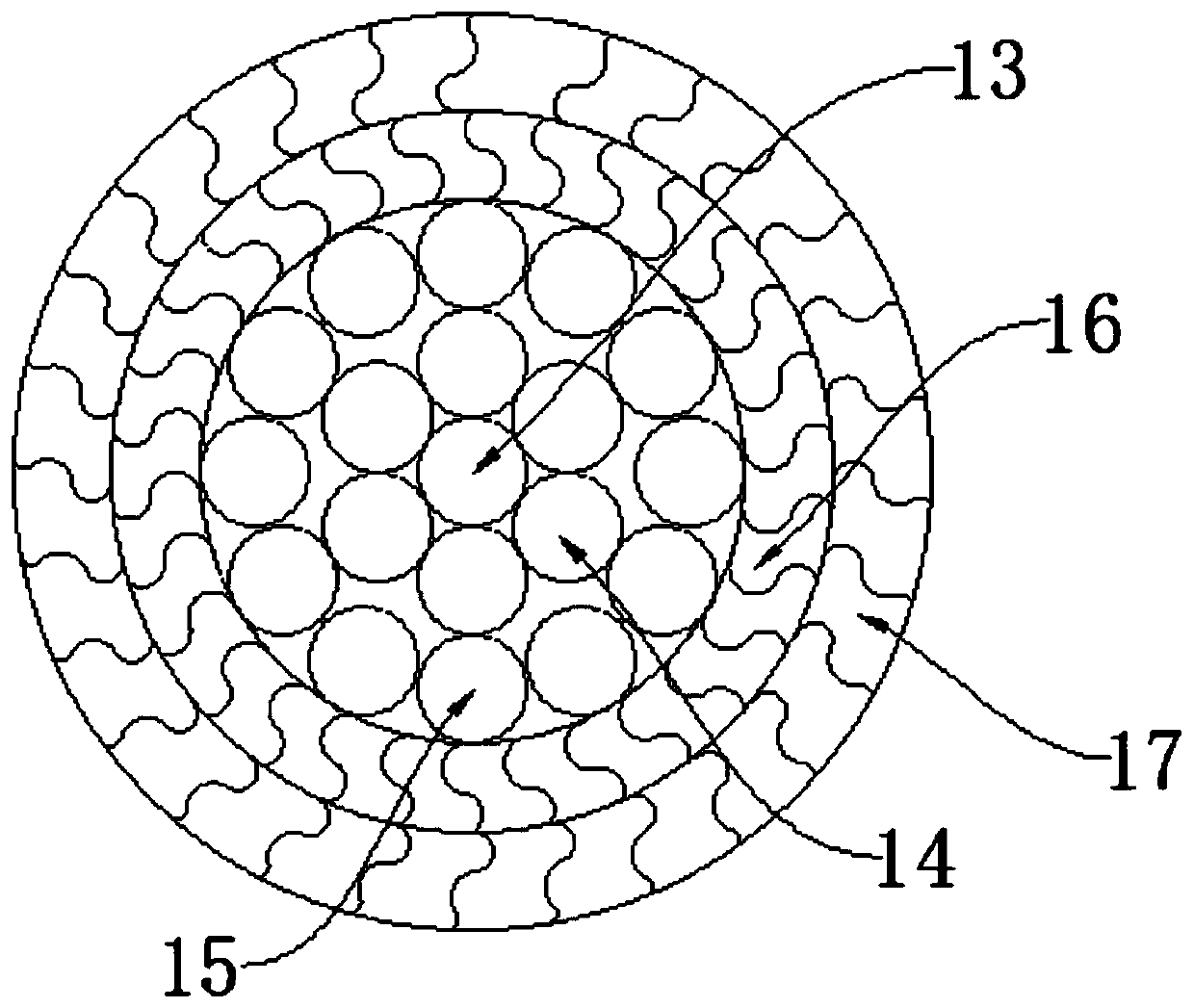

[0028] see Figure 1-7 , an embodiment provided by the present invention: high-strength, tough, durable zinc-aluminum alloy plated steel wire for bridge cables, including a bridge support main board 1, the lower end of the bridge support main board 1 is provided with a connecting and stabilizing block 3, and the connecting and stabilizing block 3 is provided with two one, and two connecting and stabilizing blocks 3 are respectively positioned at both sides of the lower end of the bridge supporting main board 1, and the overall supporting performance has been guaranteed to a certain degree, and supporting and fixing blocks 2 are installed under the connecting and stabi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com