Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

88539 results about "Corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Corrosion is a natural process that converts a refined metal into a more chemically-stable form such as oxide, hydroxide, or sulfide. It is the gradual destruction of materials (usually metals) by chemical and/or electrochemical reaction with their environment. Corrosion engineering is the field dedicated to controlling and stopping corrosion.

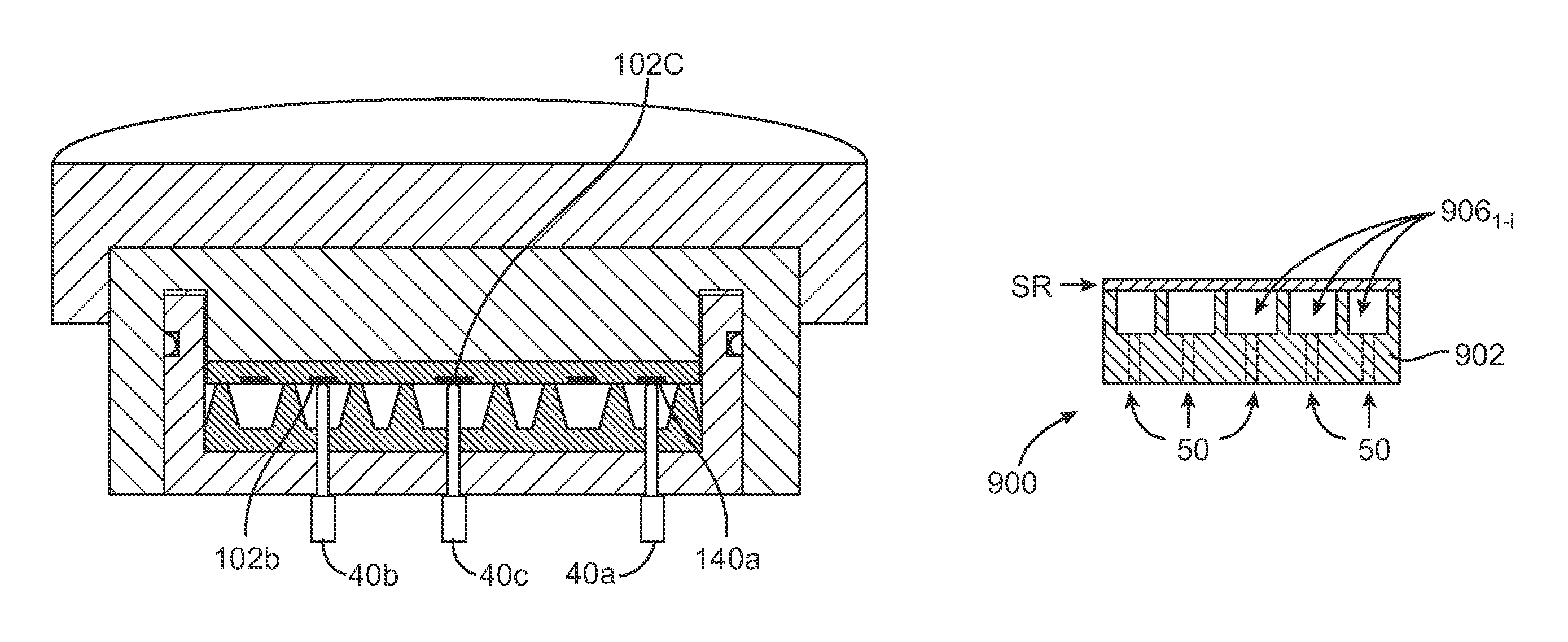

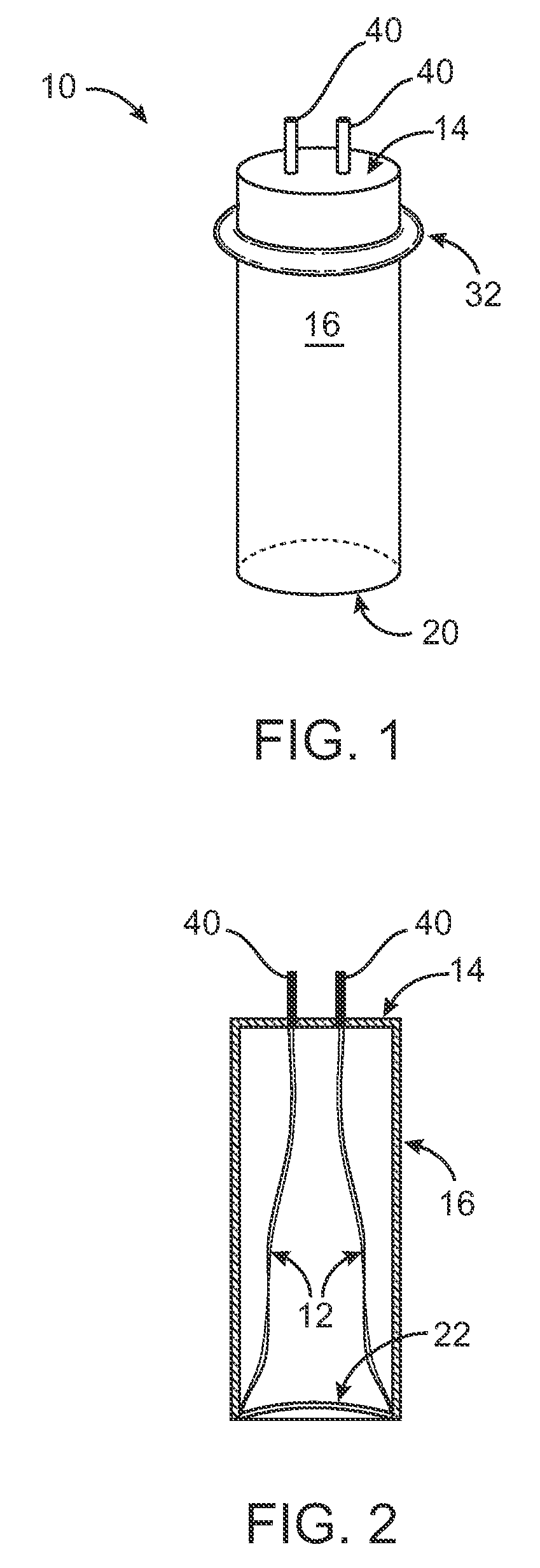

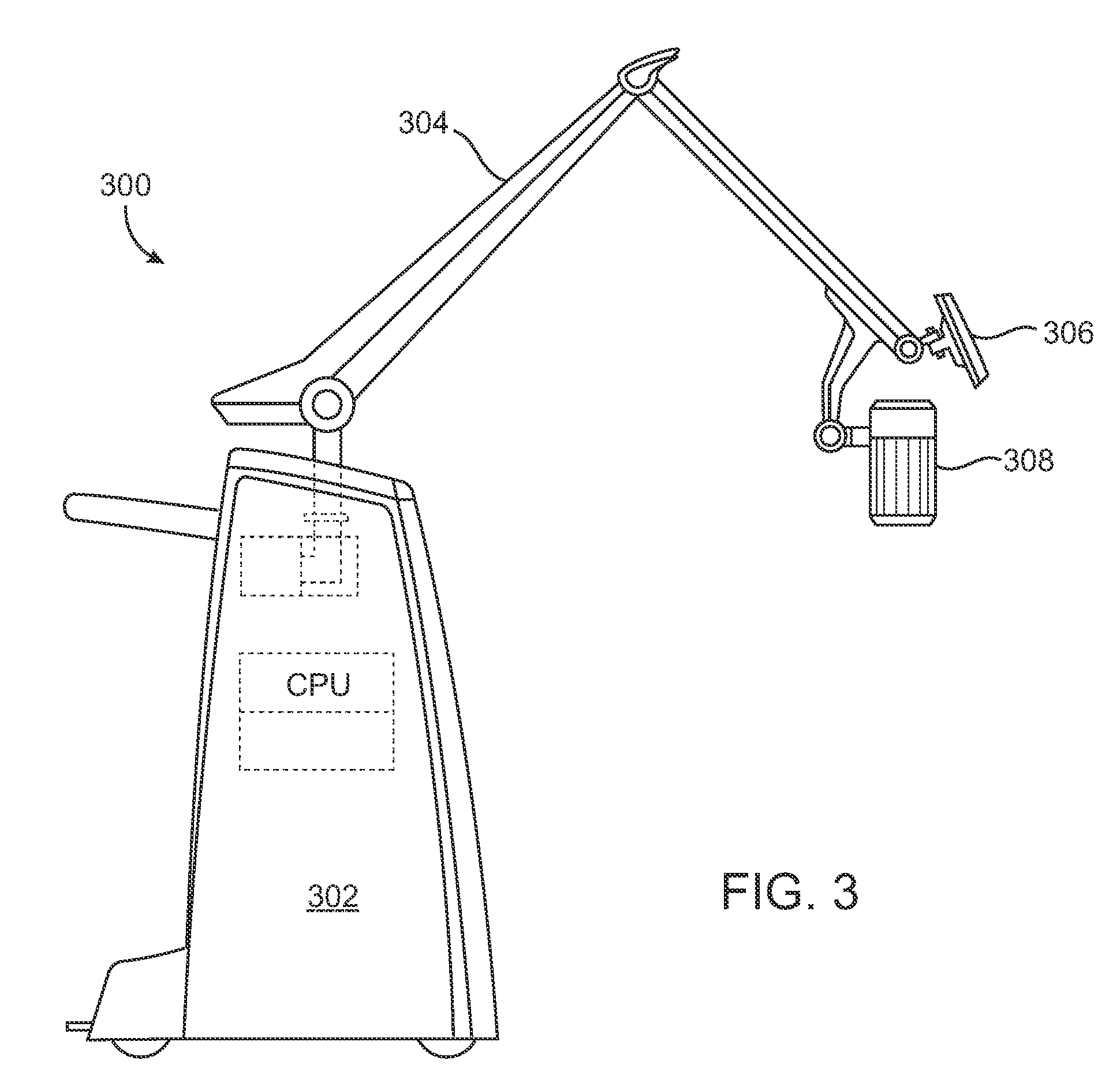

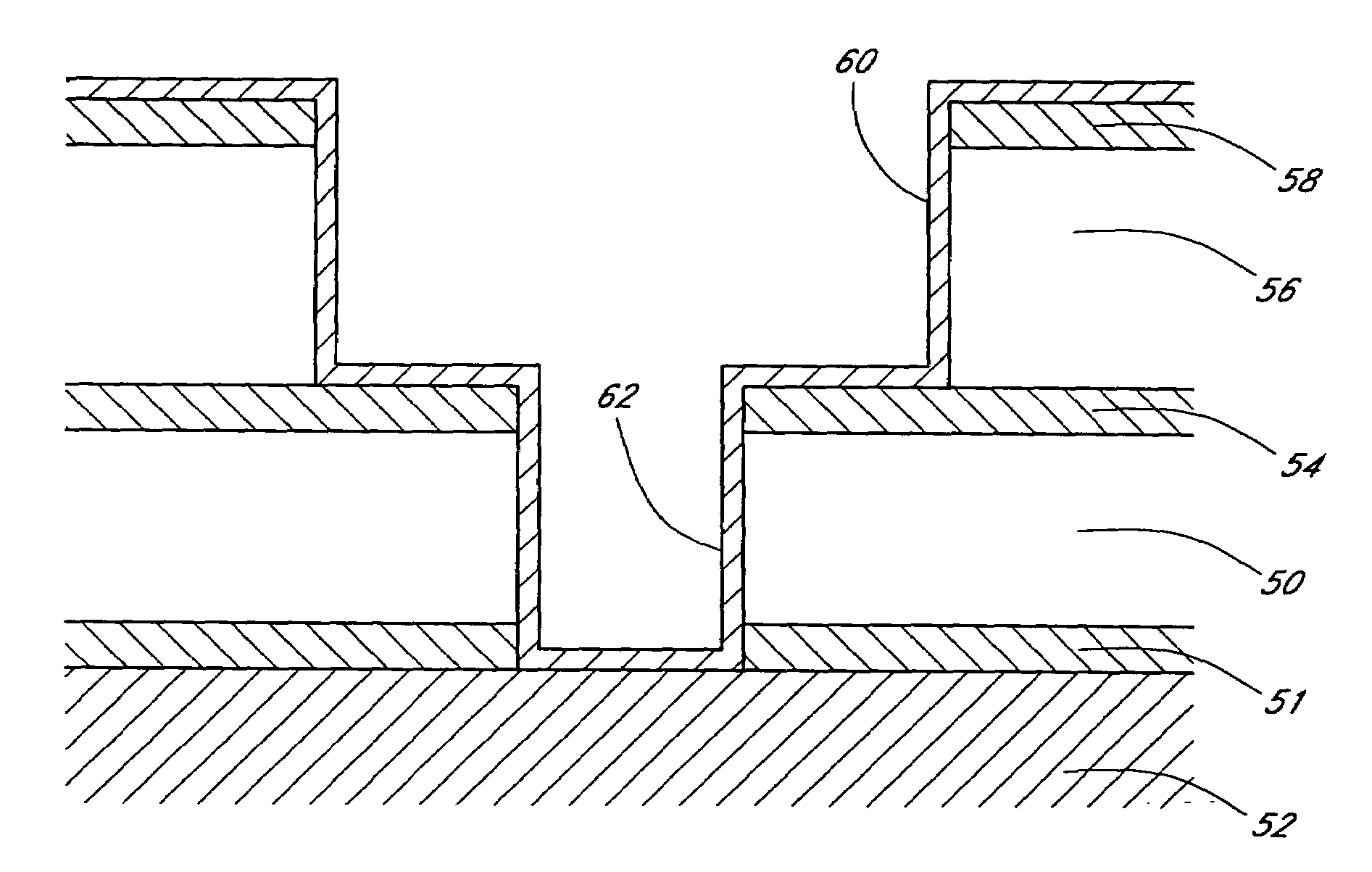

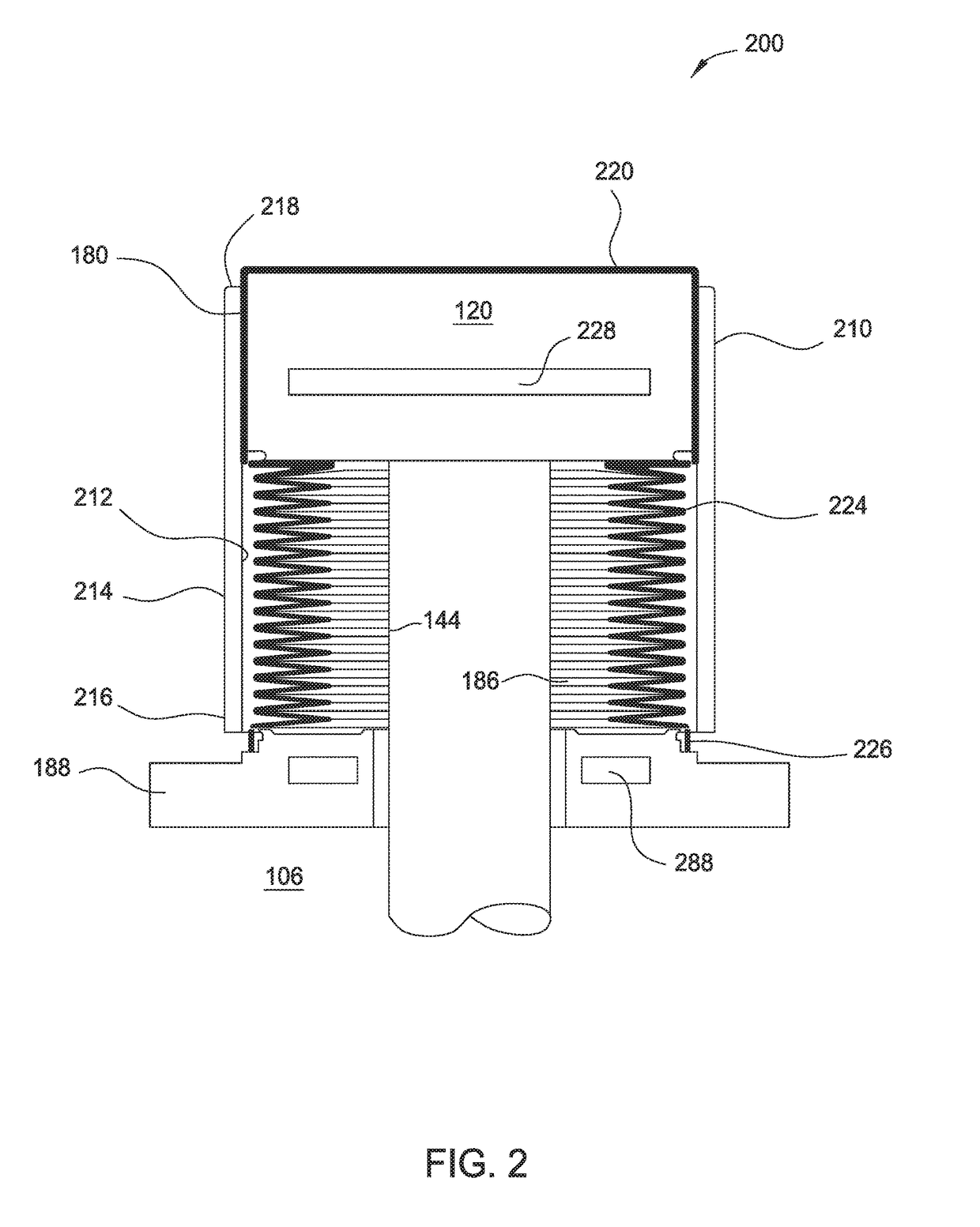

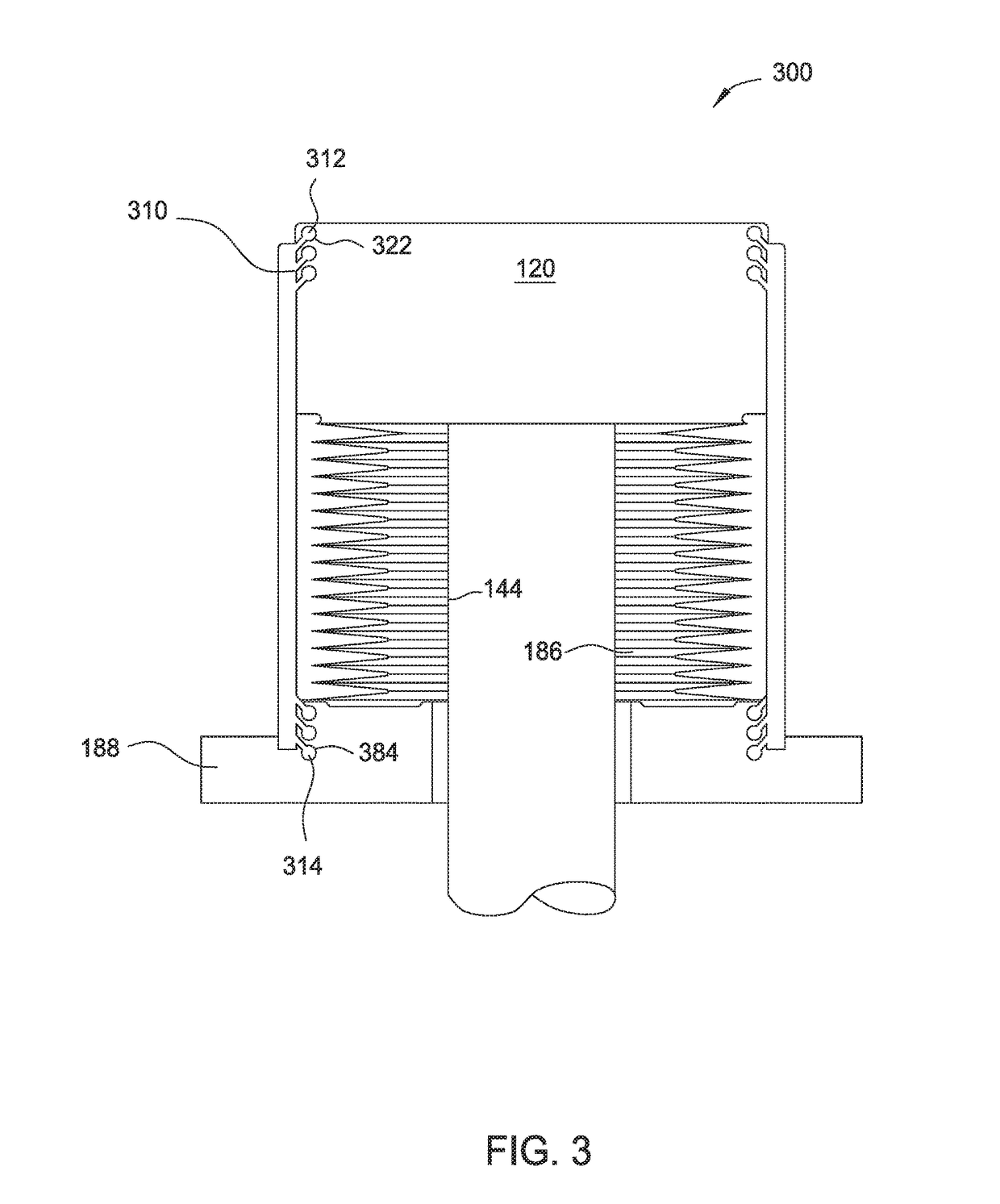

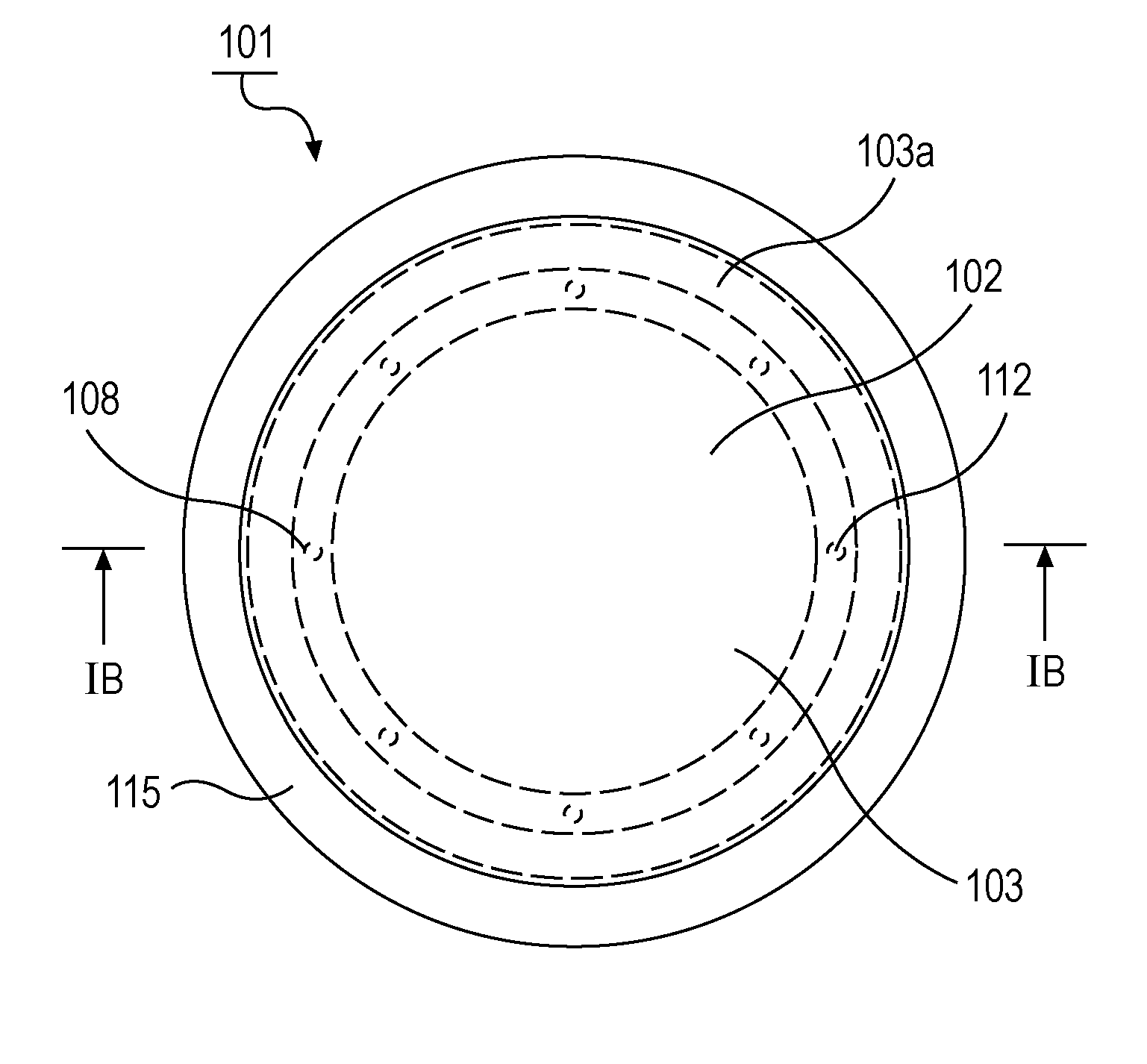

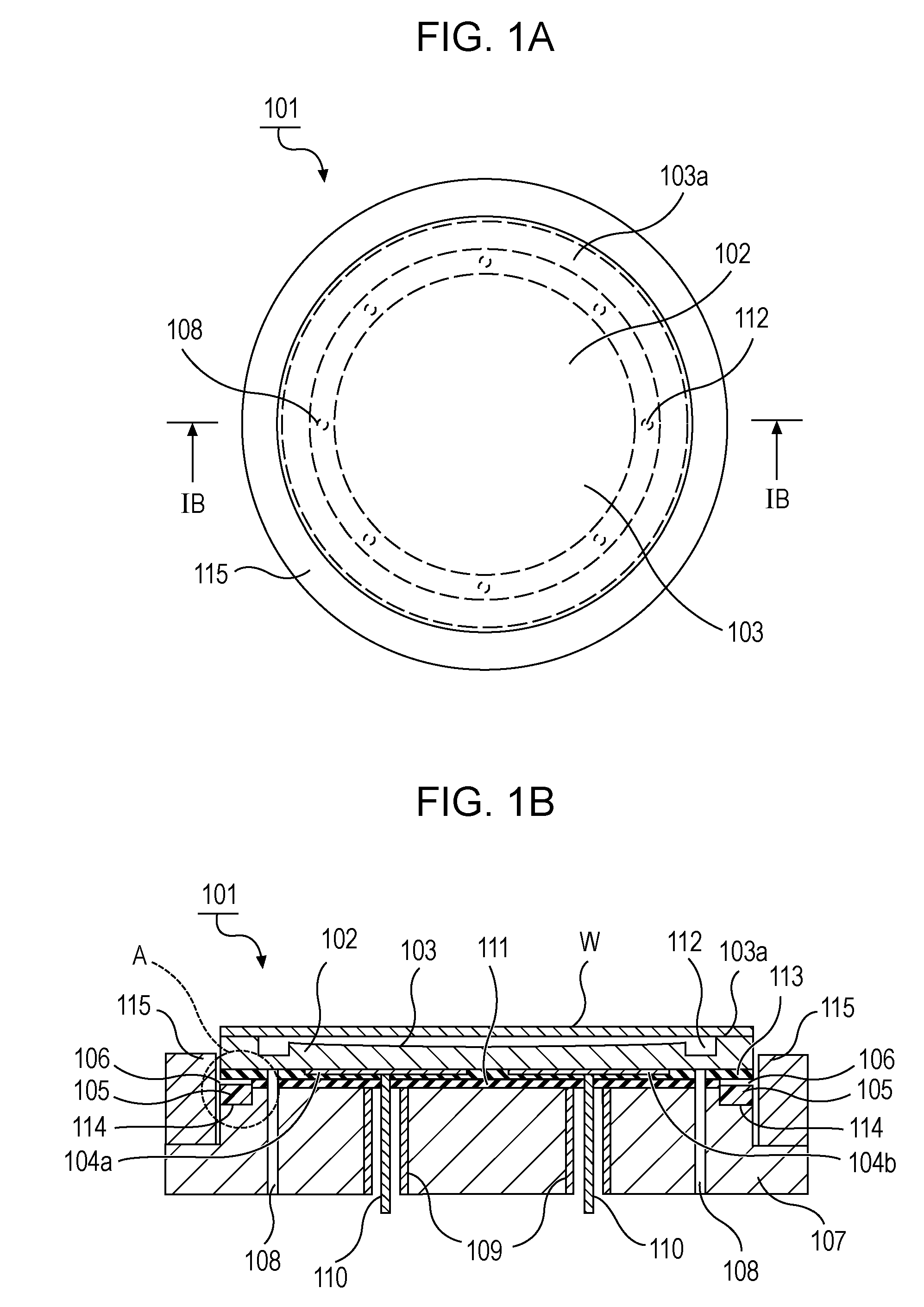

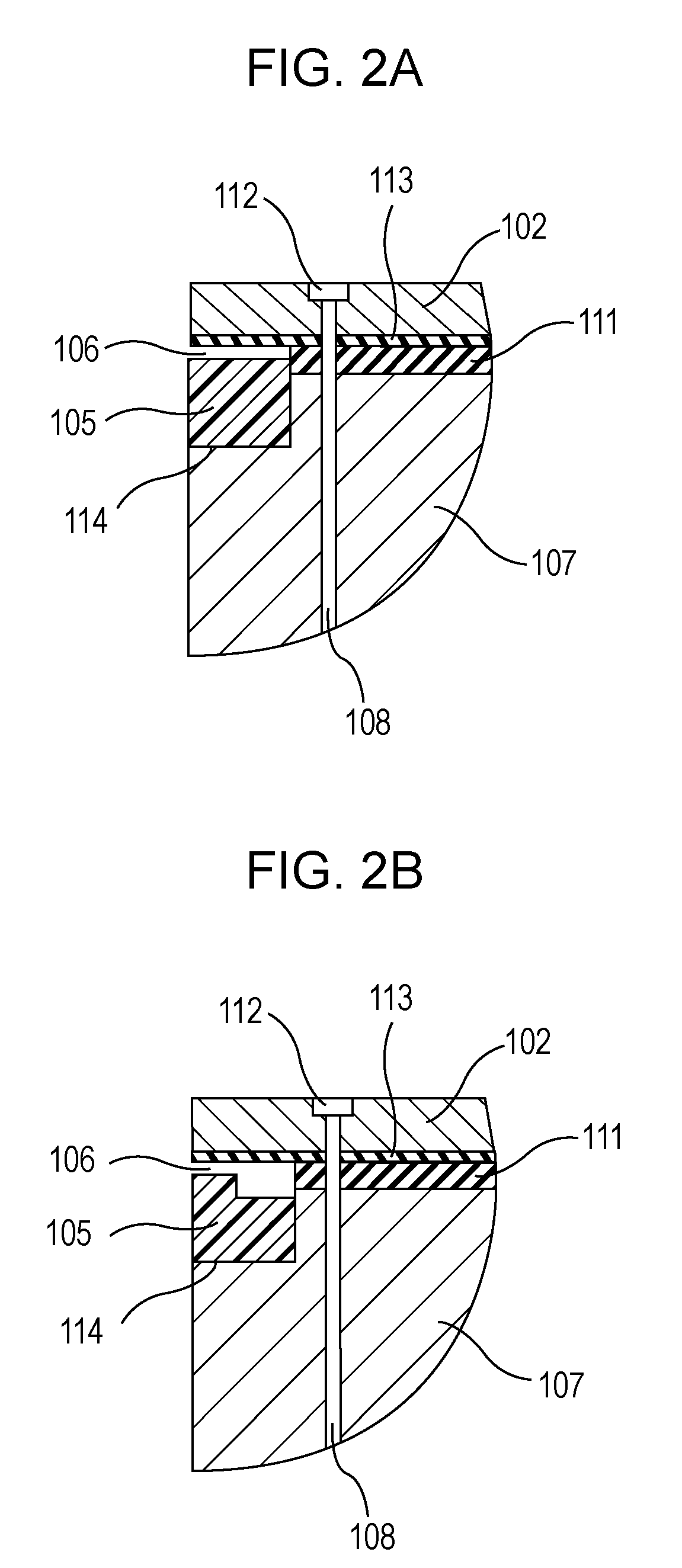

Slip ring spacer and method for its use

ActiveUS8142200B2Easy extractionEasy to insertUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyUltrasonic sensorTransducer

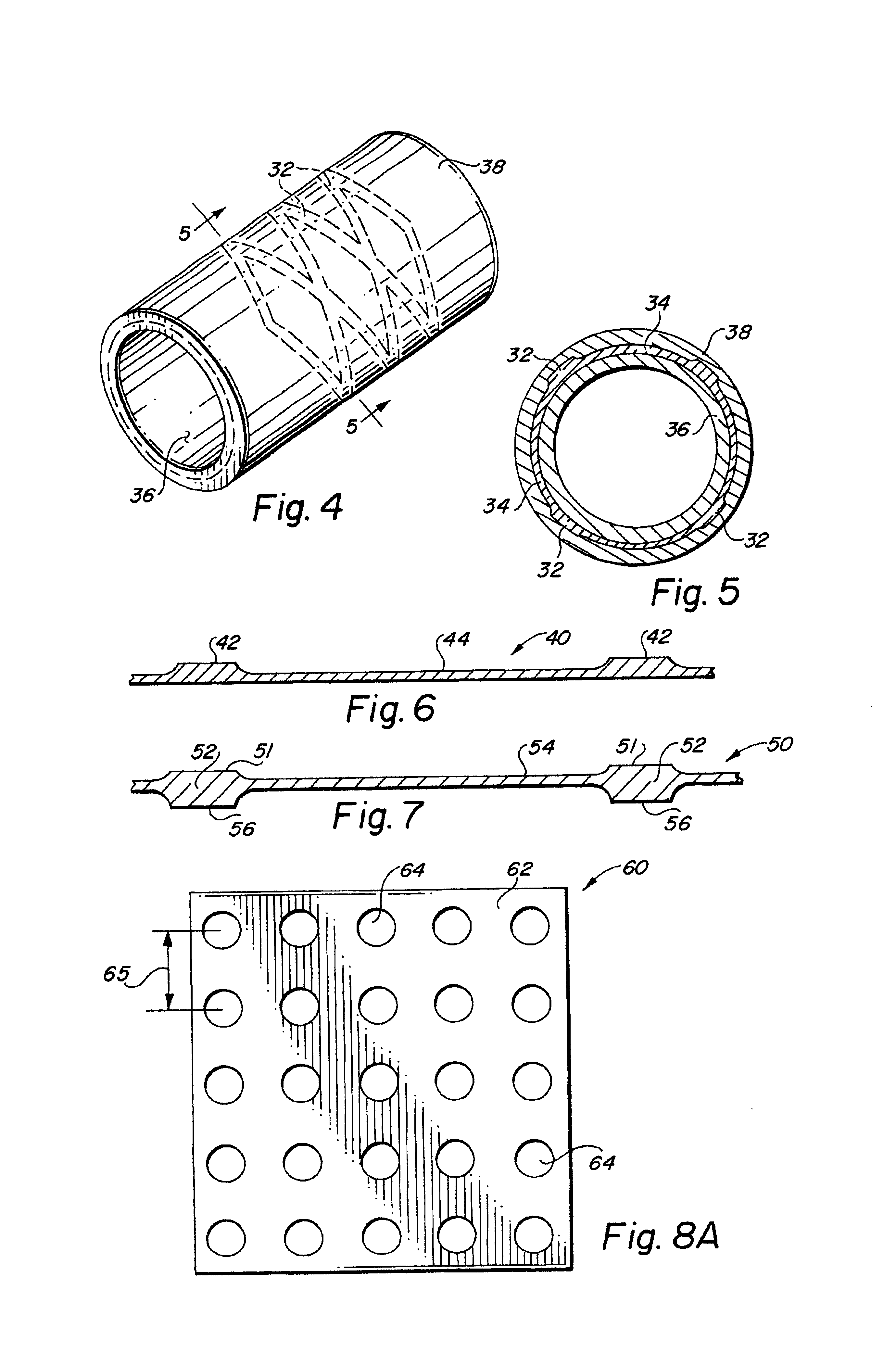

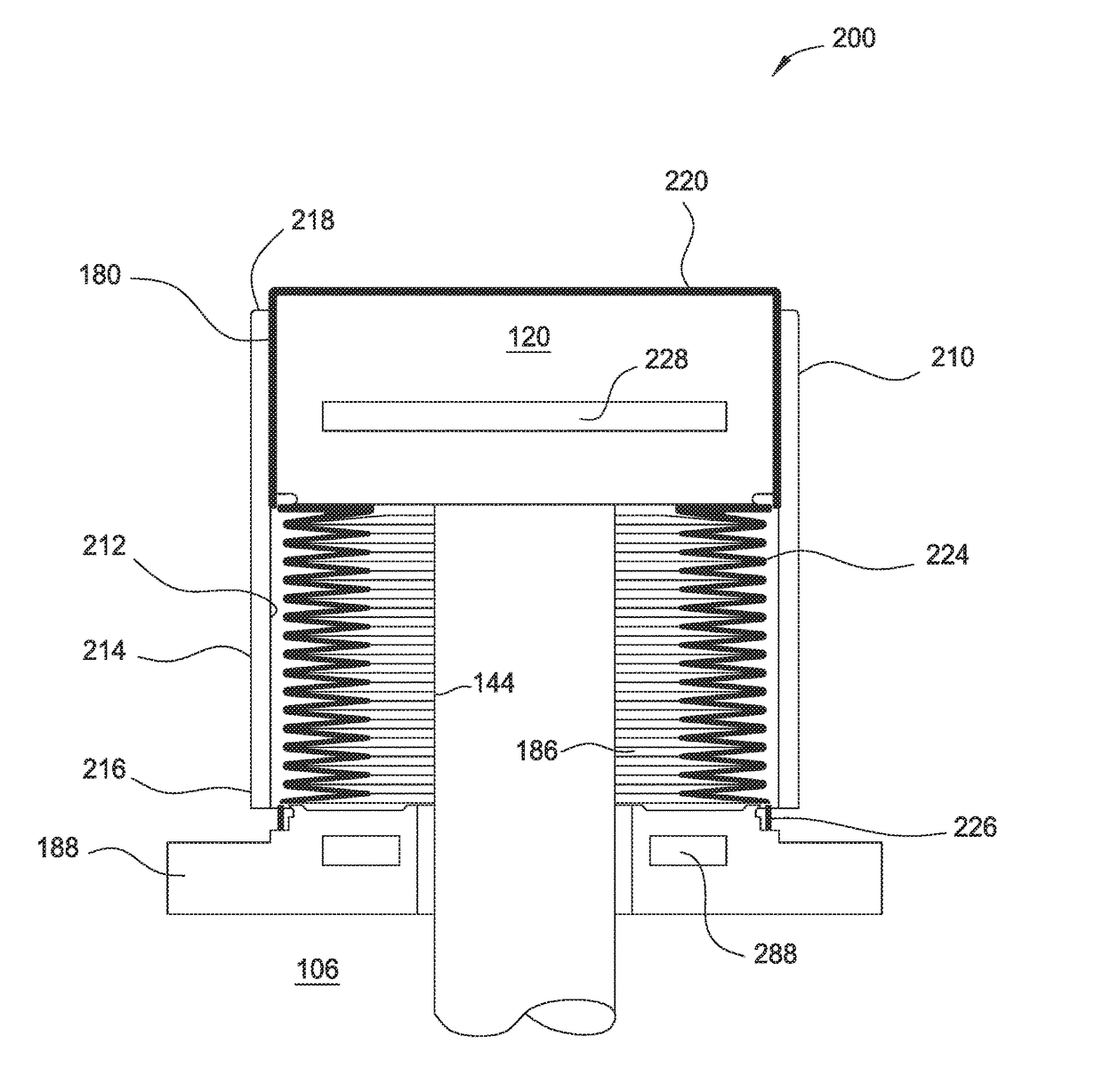

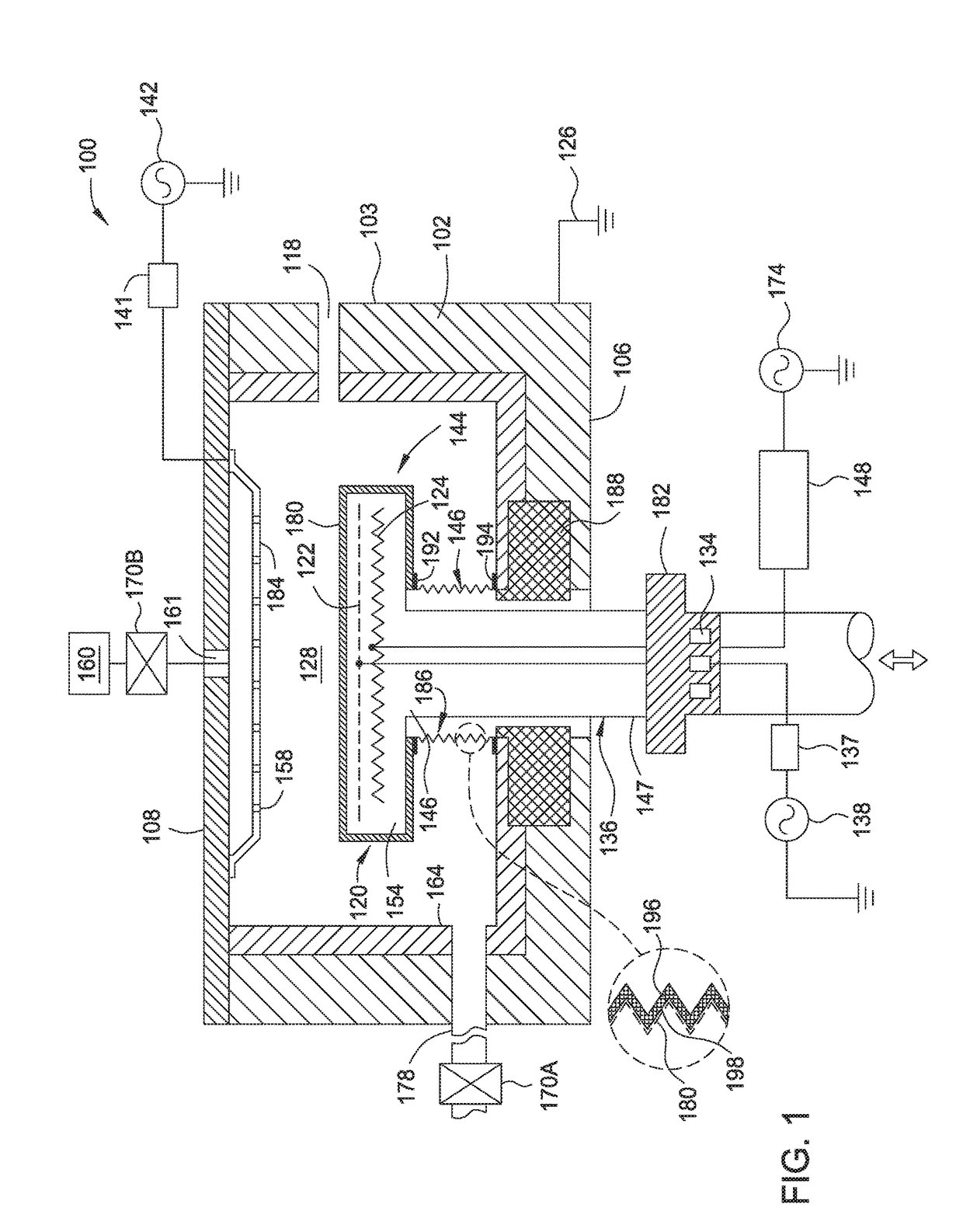

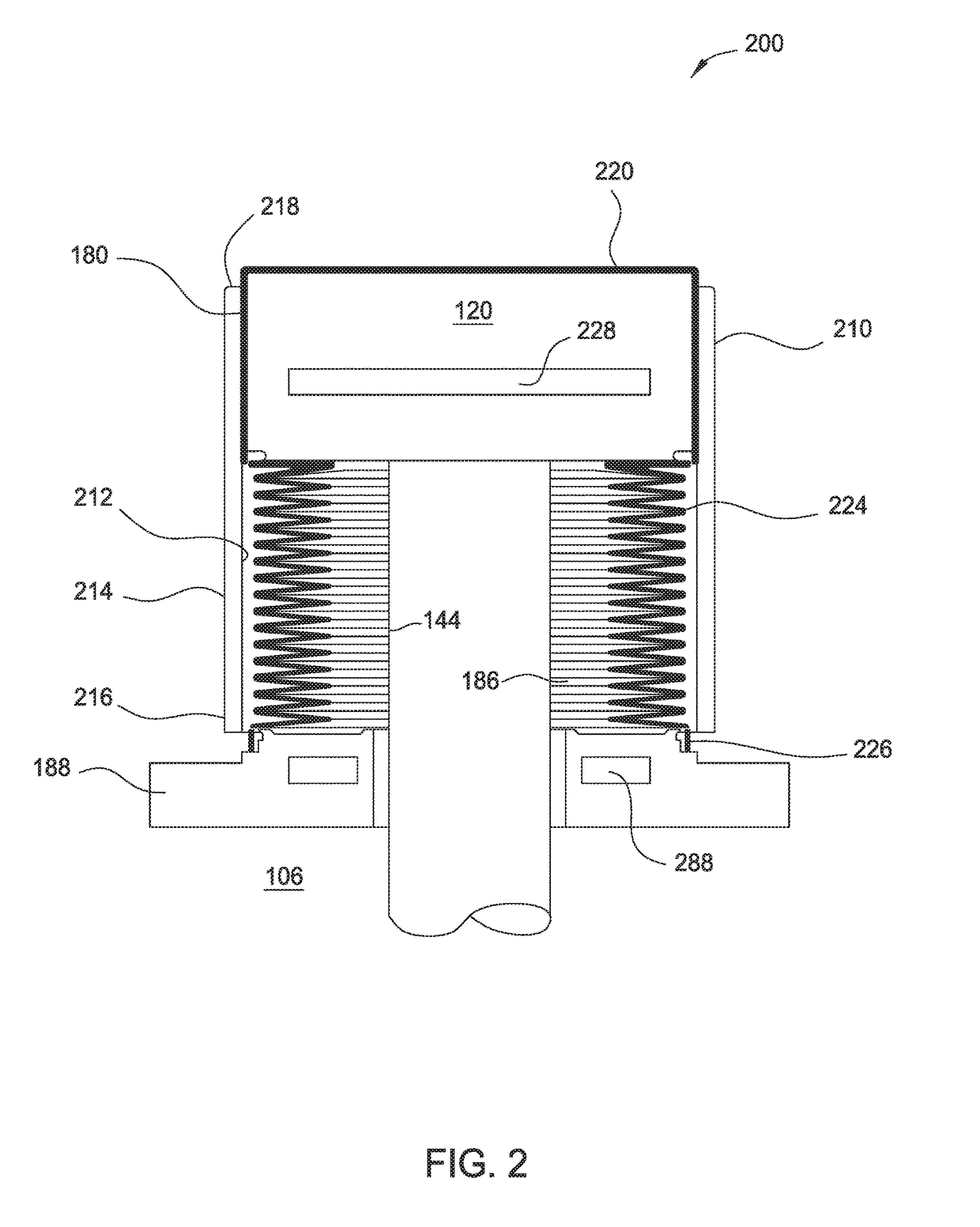

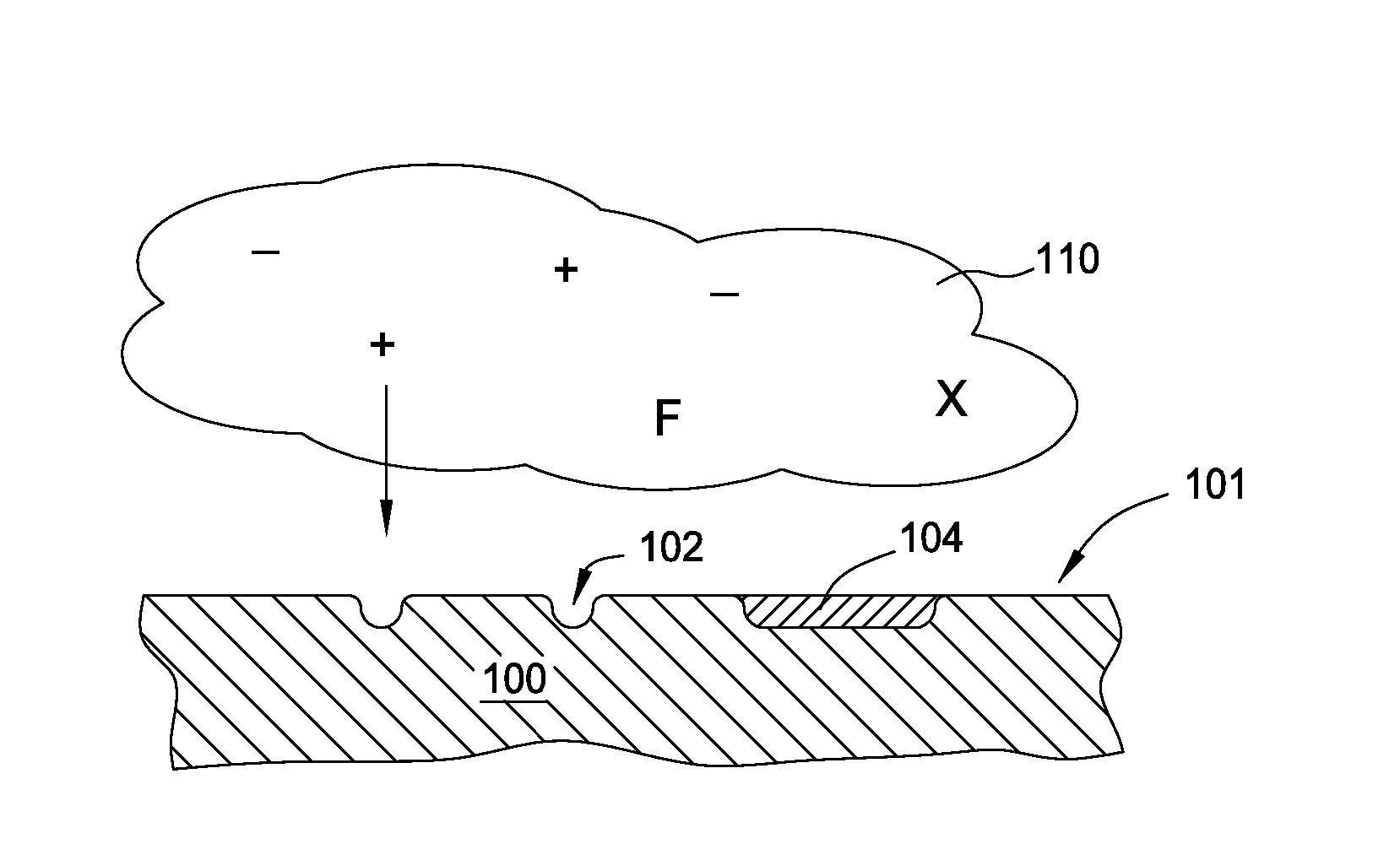

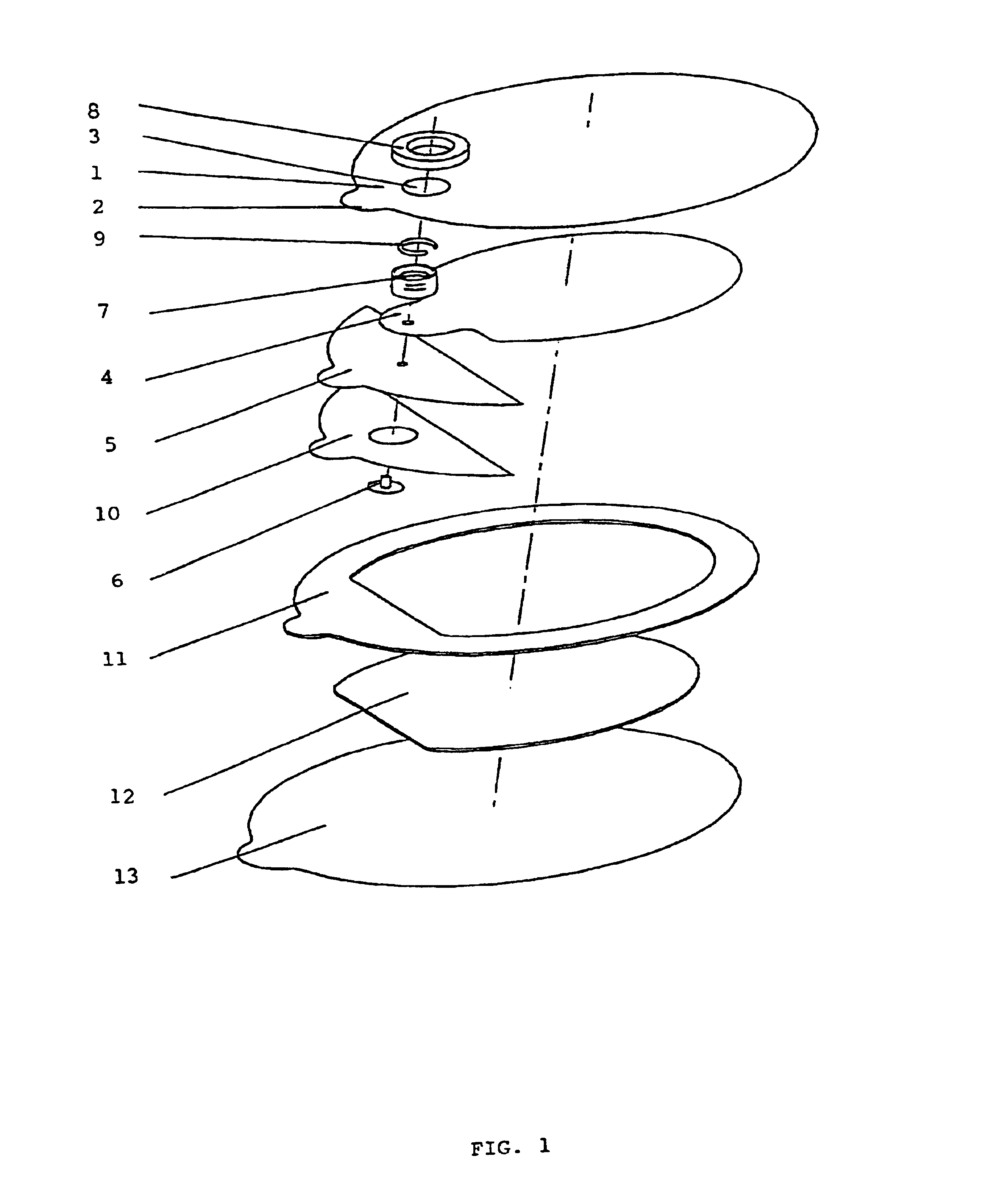

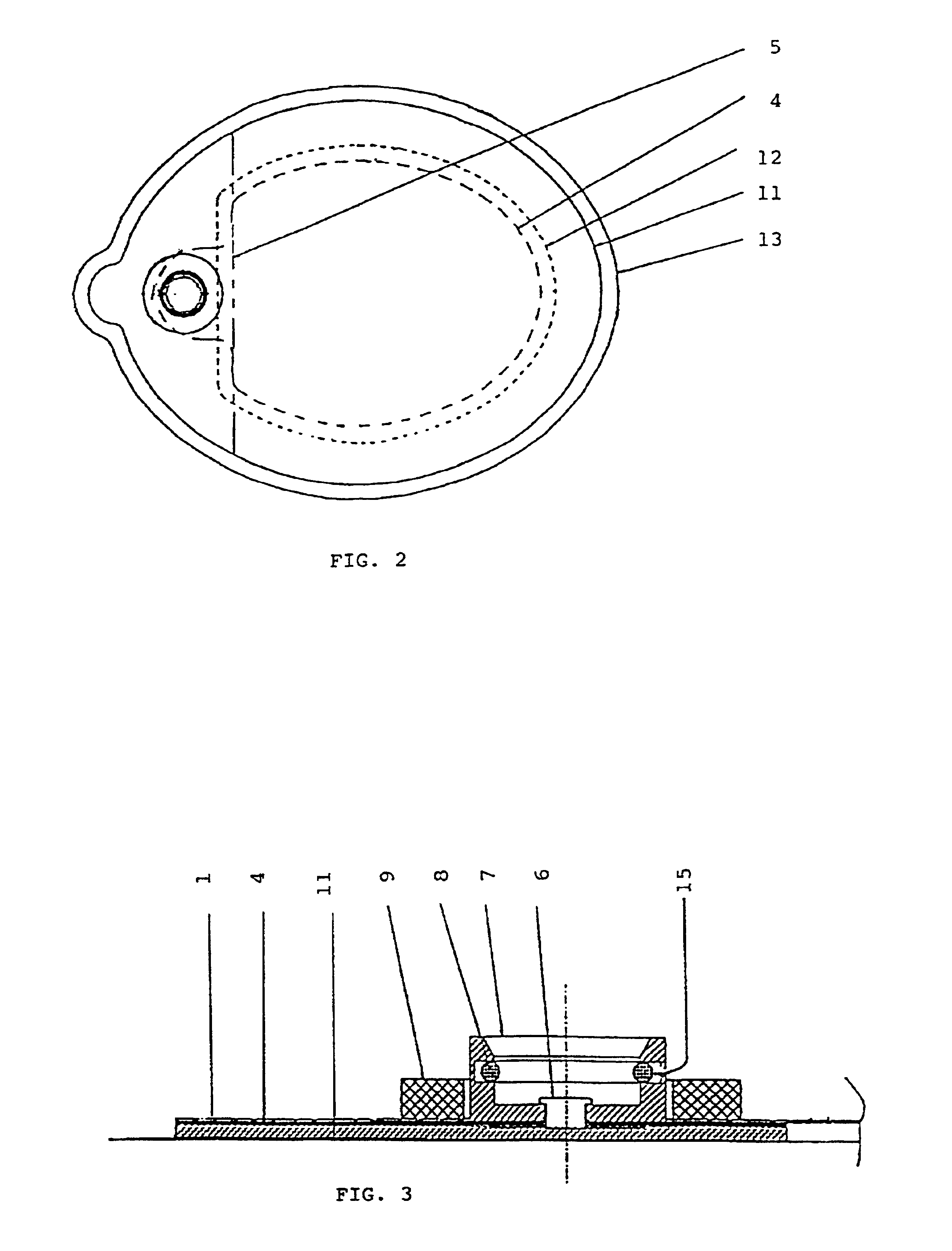

An interchangeable transducer for use with an ultrasound medical system having a keyless adaptor and capable of operating in a wet environment. The interchangeable transducer has an adaptor for engaging a medical system, an ultrasound transducer and additional electronics to provide a self-contained insert for easy replacement and usage in a variety of medical applications. A slip ring spacer is also disclosed, the slip ring spacer for use with a pancake slip ring having a base and flange configuration to form one or more channels around each contact ring of the pancake slip ring. The channels provide fluid isolation around each connector to help reduce electronic cross talk and contact corrosion between the connector pads of the slip ring while the slip ring is immersed in a wet environment.

Owner:SOLTA MEDICAL

Metal nitride carbide deposition by ALD

InactiveUS7410666B2Material nanotechnologySemiconductor/solid-state device detailsHydrogen halideCorrosive chemical

Owner:ASM INTERNATIONAL

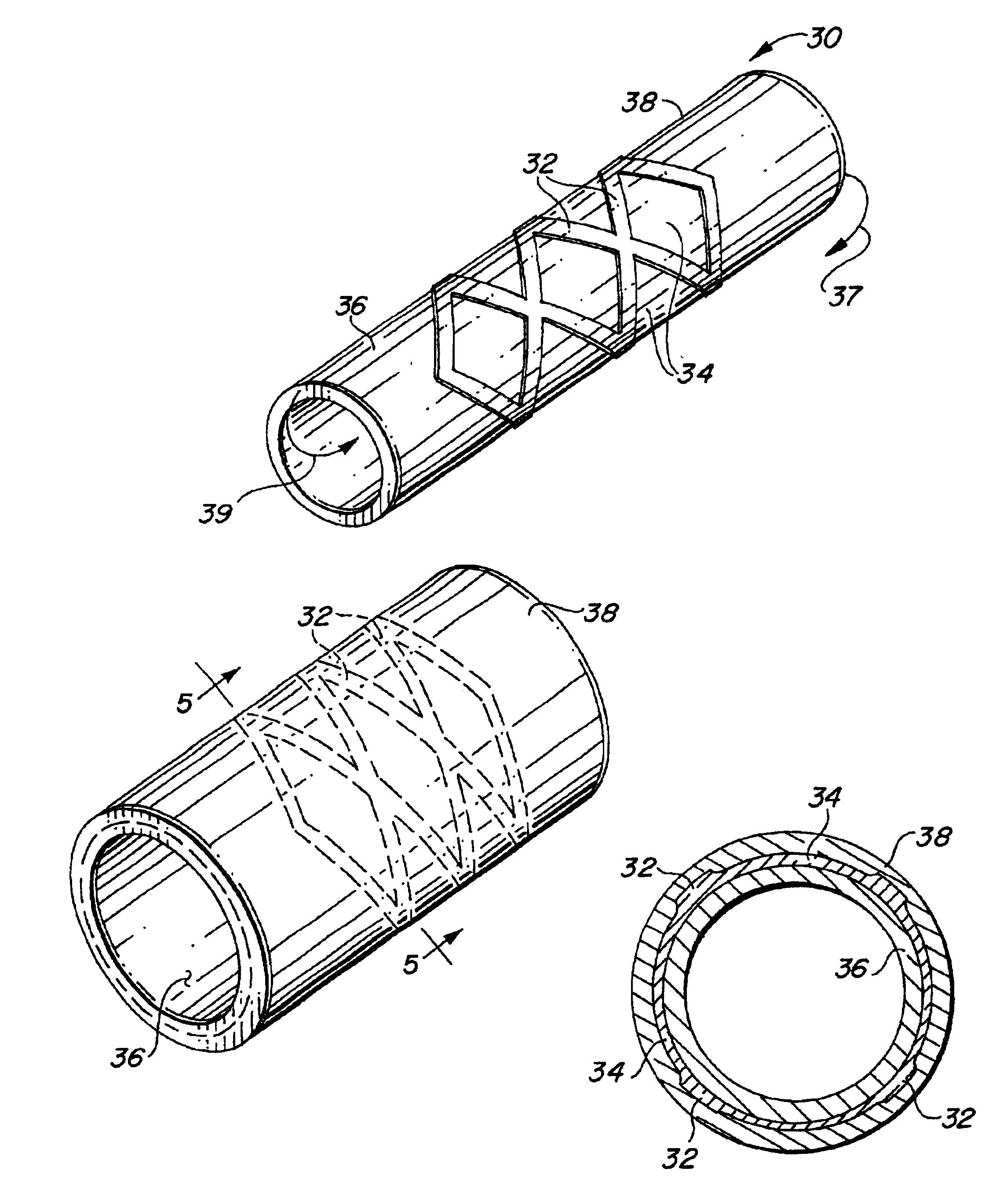

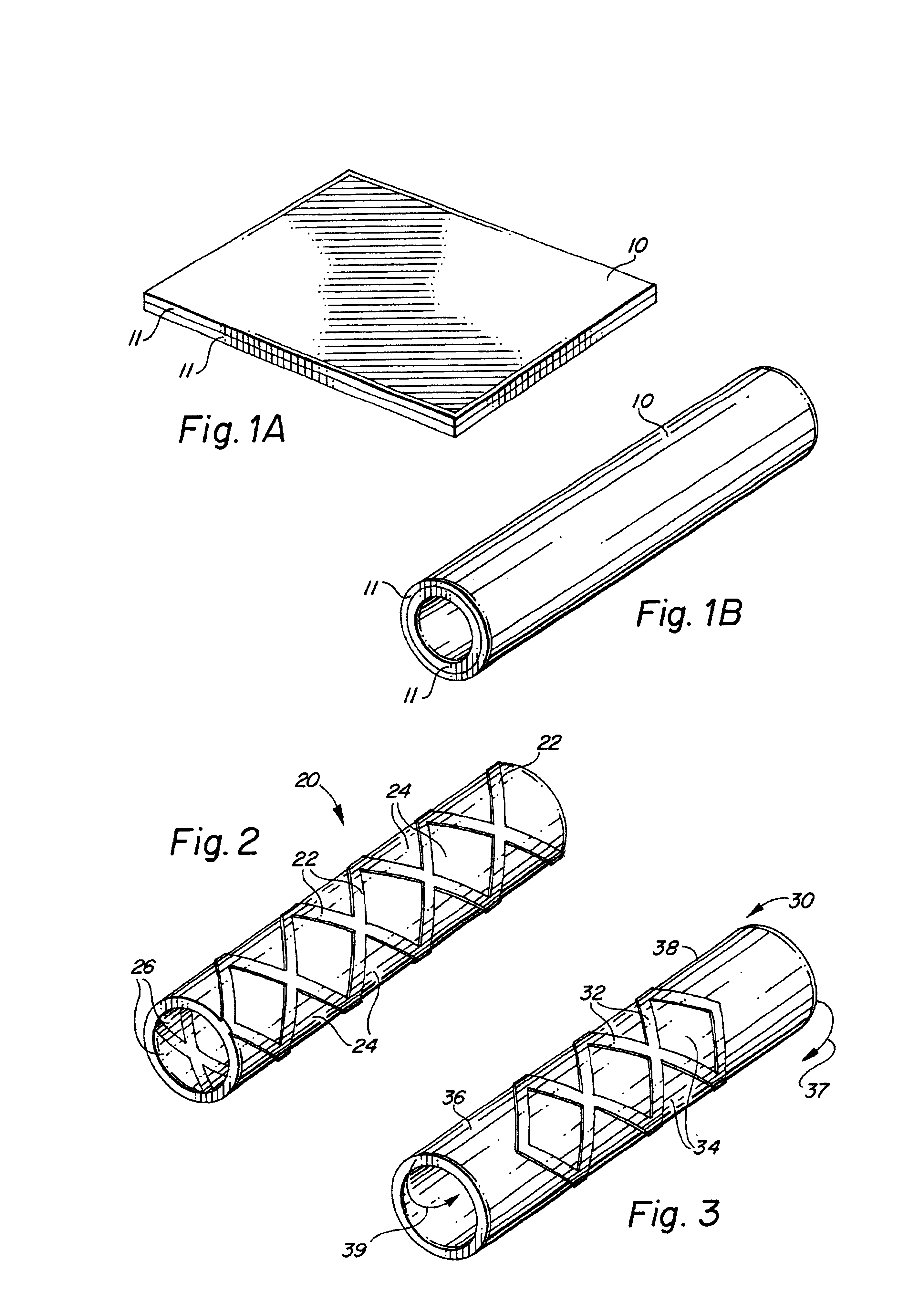

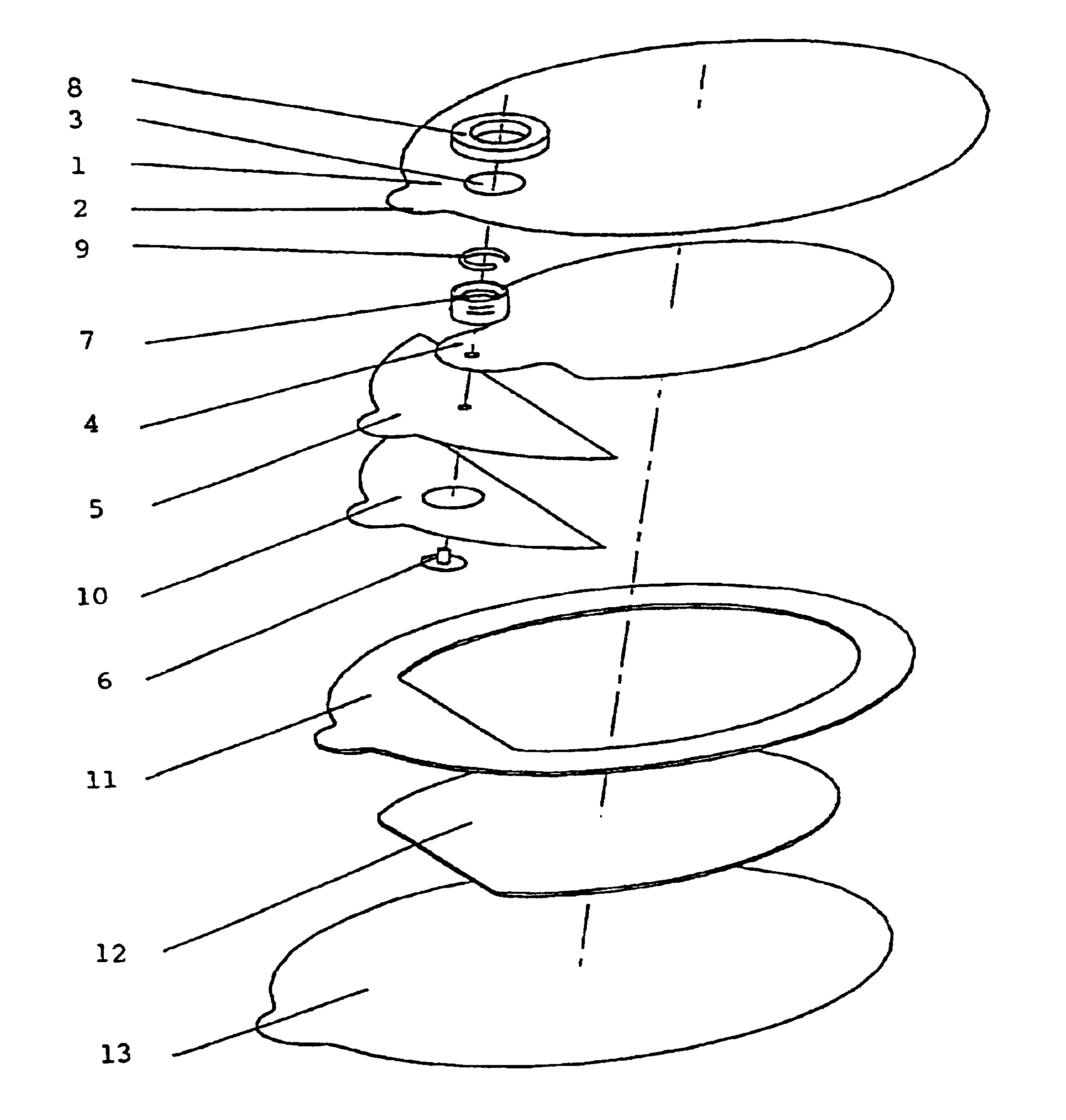

Self-supporting laminated films, structural materials and medical devices manufactured therefrom and methods of making same

Metal foils, wires, and seamless tubes with increased mechanical strength are provided. As opposed to wrought materials that are made of a single metal or alloy, these materials are made of two or more layers forming a laminate structure. Laminate structures are known to increase mechanical strength of sheet materials such as wood and paper products and are used in the area of thin films to increase film hardness, as well as toughness. Laminate metal foils have not been used or developed because the standard metal forming technologies, such as rolling and extrusion, for example, do not lend themselves to the production of laminate structures. Vacuum deposition technologies can be developed to yield laminate metal structures with improved mechanical properties. In addition, laminate structures can be designed to provide special qualities by including layers that have special properties such as superelasticity, shape memory, radio-opacity, corrosion resistance etc. Examples of articles which may be made by the inventive laminate structures include implantable medical devices that are fabricated from the laminated deposited films and which present a blood or body fluid and tissue contact surface that has controlled heterogeneities in material constitution. An endoluminal stent-graft and web-stent that is made of a laminated film material deposited and etched into regions of structural members and web regions subtending interstitial regions between the structural members. An endoluminal graft is also provided which is made of a biocompatible metal or metal-like material. The endoluminal stent-graft is characterized by having controlled heterogeneities in the stent material along the blood flow surface of the stent and the method of fabricating the stent using vacuum deposition methods.

Owner:VACTRONIX SCI LLC

Conveyor system

InactiveUS6450757B1Increase resistanceAccurately and surely carrying a workpieceProgramme-controlled manipulatorMechanical apparatusMostly TrueHeat resistance

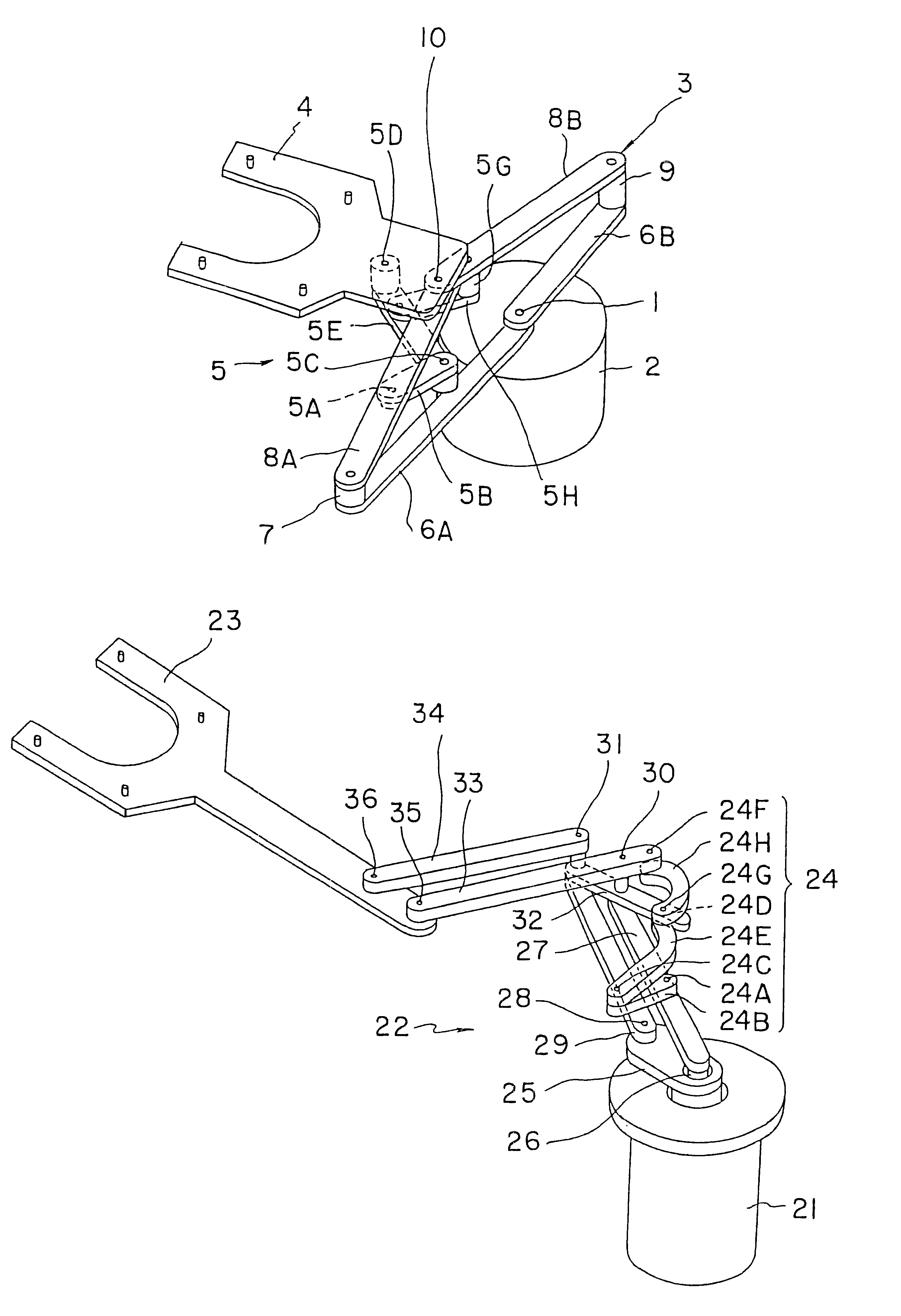

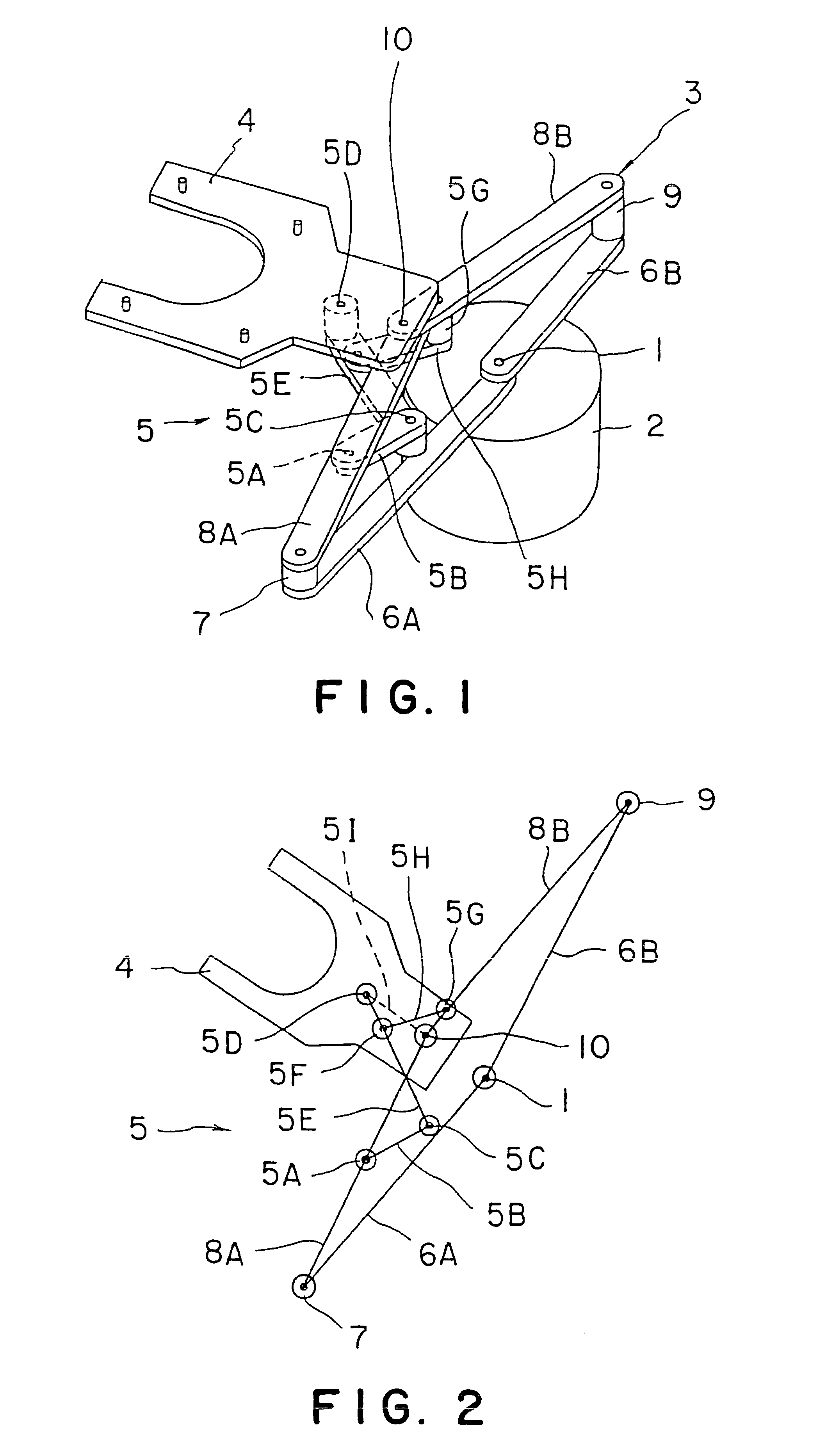

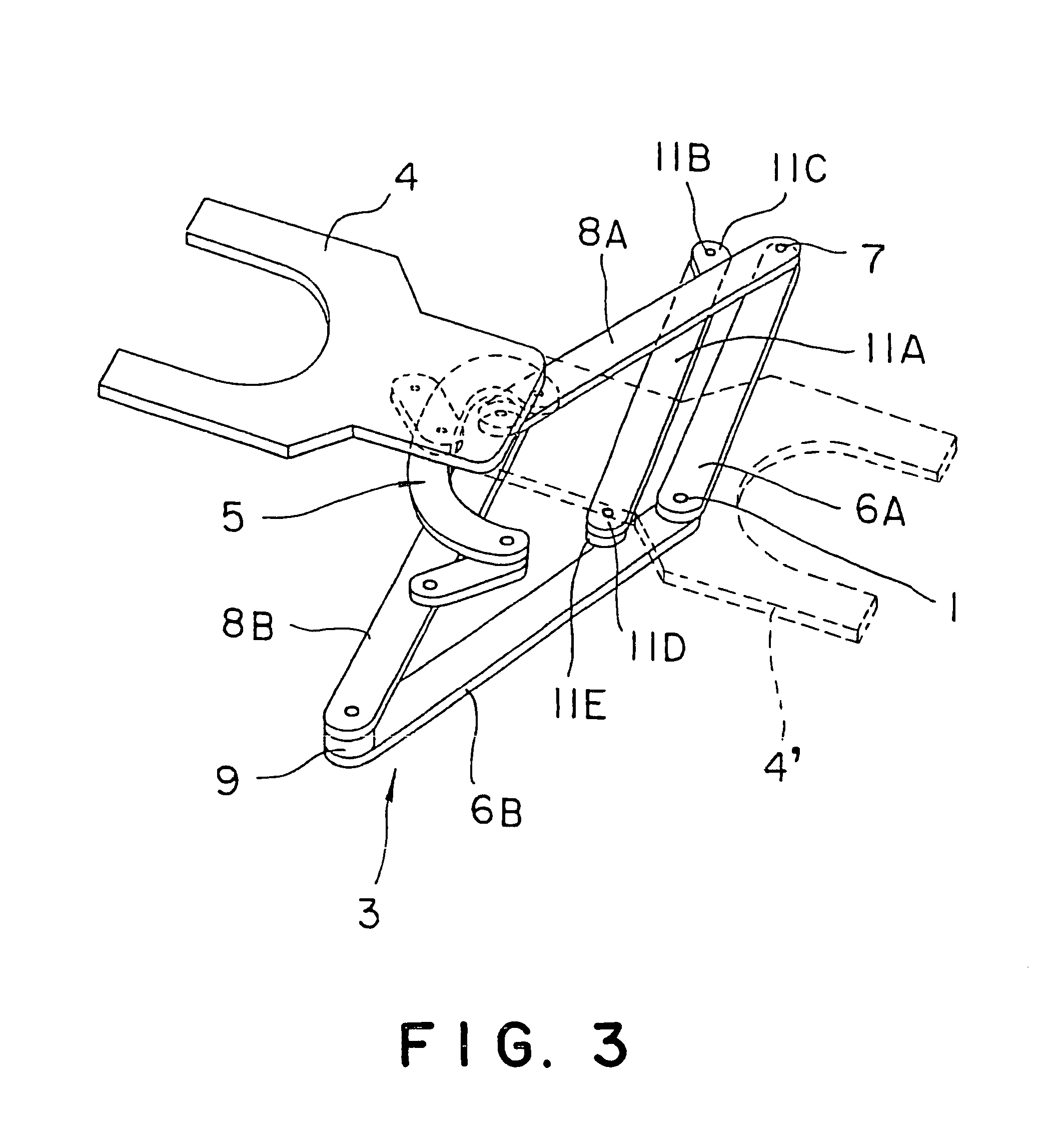

In most cases, a hot, corrosive atmosphere is created in, for example, a semiconductor wafer processing chamber. When an arm including belts, such as steel belts, is moved into such a semiconductor wafer processing chamber, the belts are exposed to the hot, corrosive atmosphere. Belts, such as steel belts, have limited heat resistance and corrosion resistance and the hot, corrosive atmosphere in the processing chamber shortens the life of the belts. A carrying device of the present invention has a frog leg type arm (3) and a wafer holder (4) connected to the frog leg type arm (3). The wafer holder (4) is pivotally connected to front end parts of a first front arm (8A) and a second front arm (8B) by coaxial joints (10). The wafer holder (4) is linked to the first front arm (8A) and the second front arm (8B) by a posture maintaining linkage (5) including two antiparallel linkages capable of controlling the turning of the wafer holder (4) relative to the first and the second front arms (8A, 8B).

Owner:TOKYO ELECTRON LTD

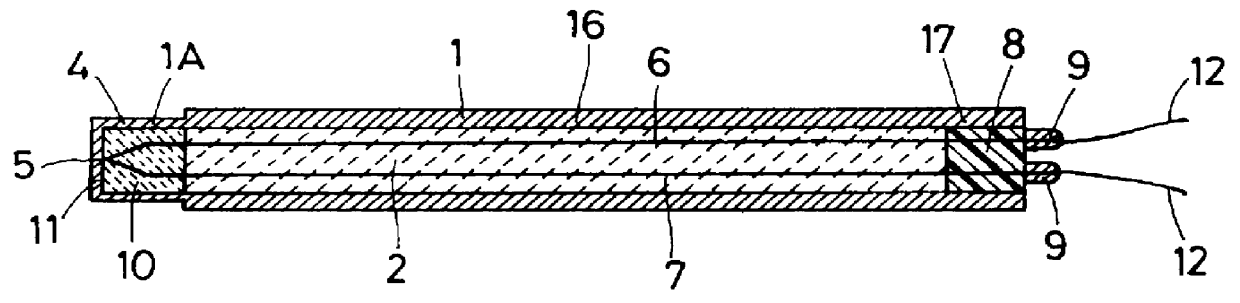

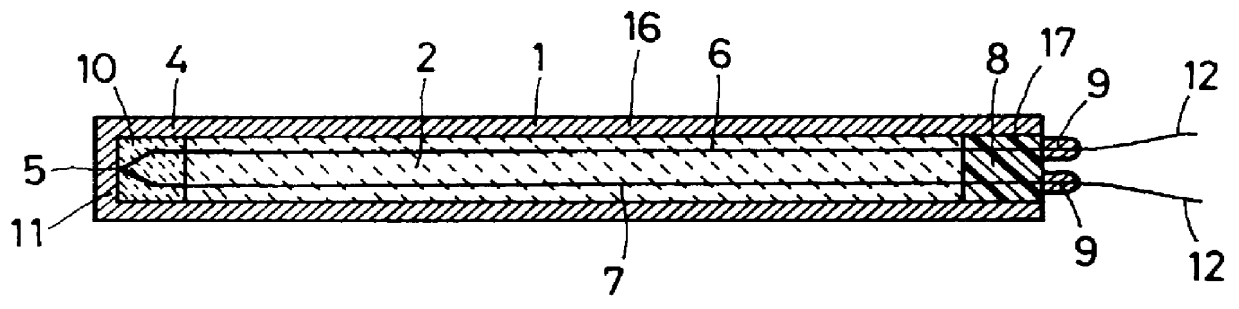

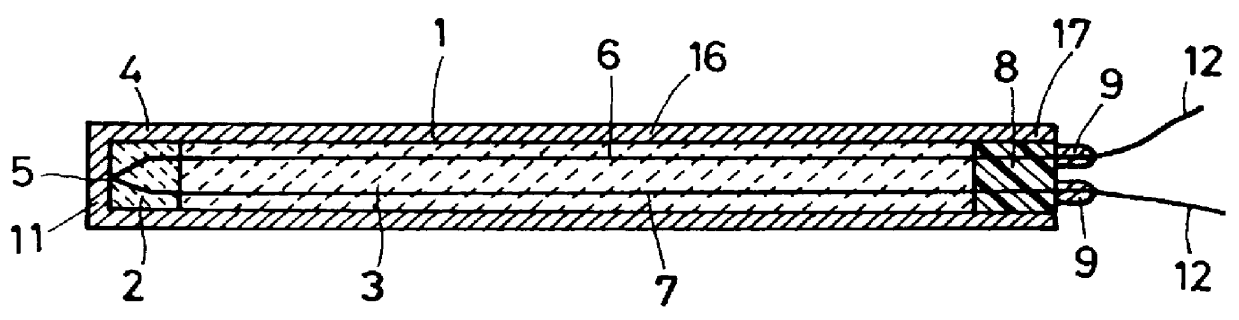

Ceramic sheath type thermocouple

InactiveUS6102565AThermometer detailsThermometers using electric/magnetic elementsHeat resistanceWhiskers

This ceramic sheath type thermocouple has a long service life, an improved temperature measuring responsibility and an improved temperature measuring precision, and enables repetitive use. The ceramic sheath type thermocouple has its protective tube 1 formed of a heat resisting ceramics selected from silicon nitride, sialon and silicon carbide. In the protective tube 1 are installed a pair of W-Re wires that are connected to form a joint portion constituting a temperature measuring point 5. A filler made of Si3N4 reaction-sintered ceramics is loaded into the front end portion of the protective tube to enclose the W-Re wires. Another filler made of SiC whisker with a heat conductivity smaller than that of the filler of the front end portion is loaded into the rear portion of the protective tube. An inert gas is sealed in the protective tube. Alternatively, the temperature measuring portion may be formed by exposing from the front end portion of the protective tube the joint portion where the ends of the W-Re wires are connected. The temperature measuring portion is coated with a cover film that is made of silicon carbide, silicon nitride or a composite of these, all having excellent heat resisting and corrosion resisting properties.

Owner:ISUZU MOTORS LTD

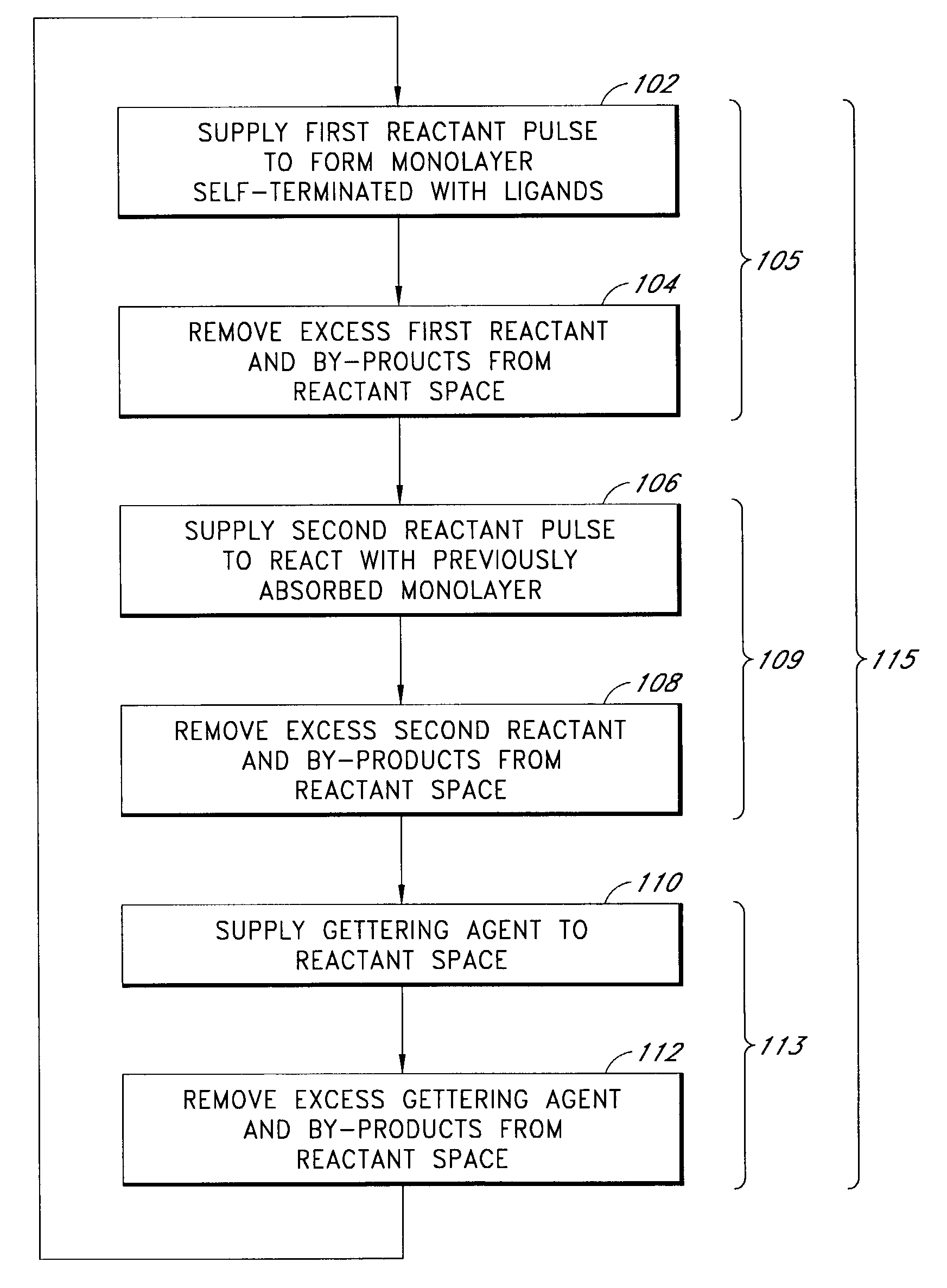

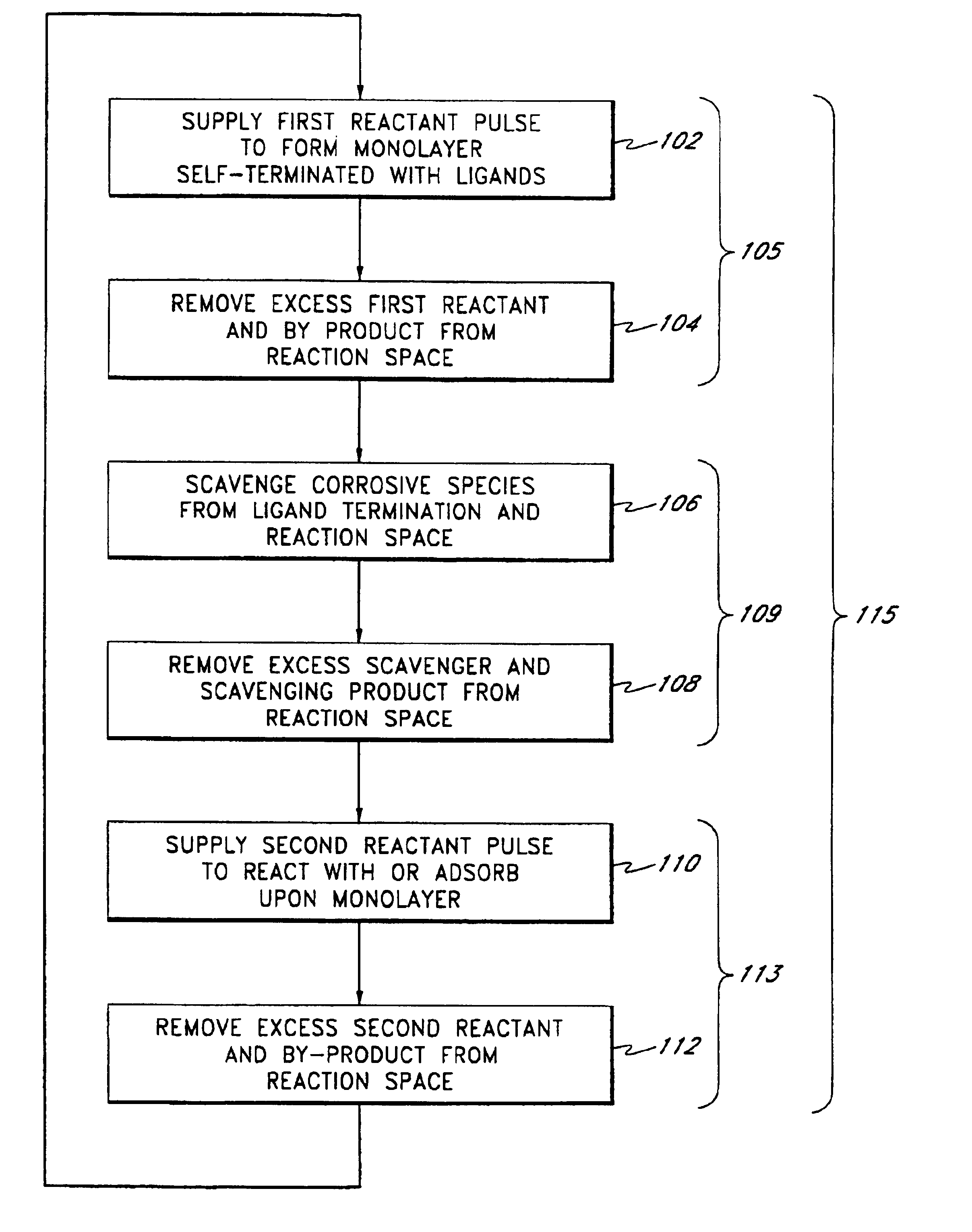

Metal nitride deposition by ALD with reduction pulse

The present methods provide tools for growing conformal metal thin films, including metal nitride, metal carbide and metal nitride carbide thin films. In particular, methods are provided for growing such films from aggressive chemicals. The amount of corrosive chemical compounds, such as hydrogen halides, is reduced during the deposition of transition metal, transition metal carbide, transition metal nitride and transition metal nitride carbide thin films on various surfaces, such as metals and oxides. Getter compounds protect surfaces sensitive to hydrogen halides and ammonium halides, such as aluminum, copper, silicon oxide and the layers being deposited, against corrosion. Nanolaminate structures incorporating metallic thin films, and methods for forming the same, are also disclosed.

Owner:ASM INTERNATIONAL

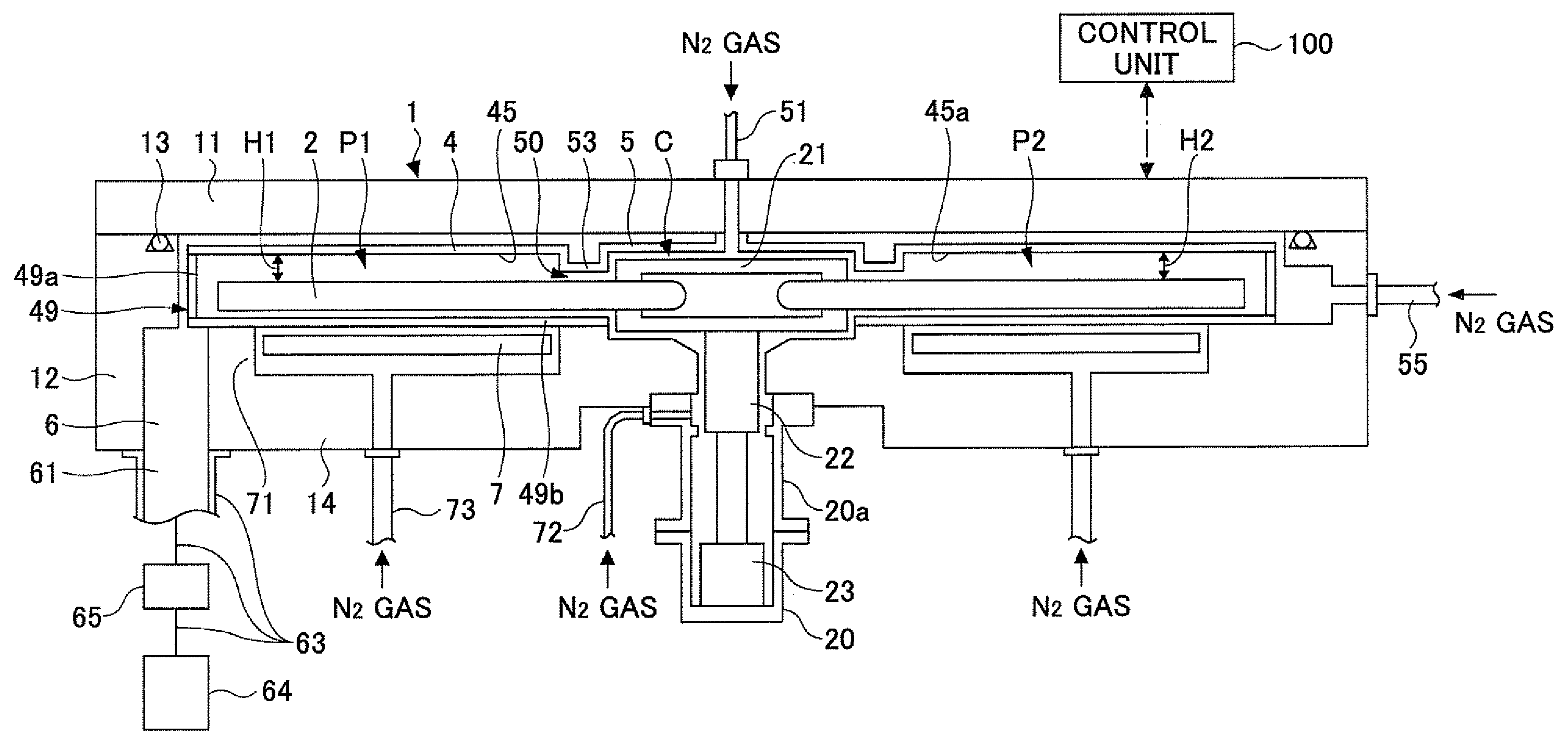

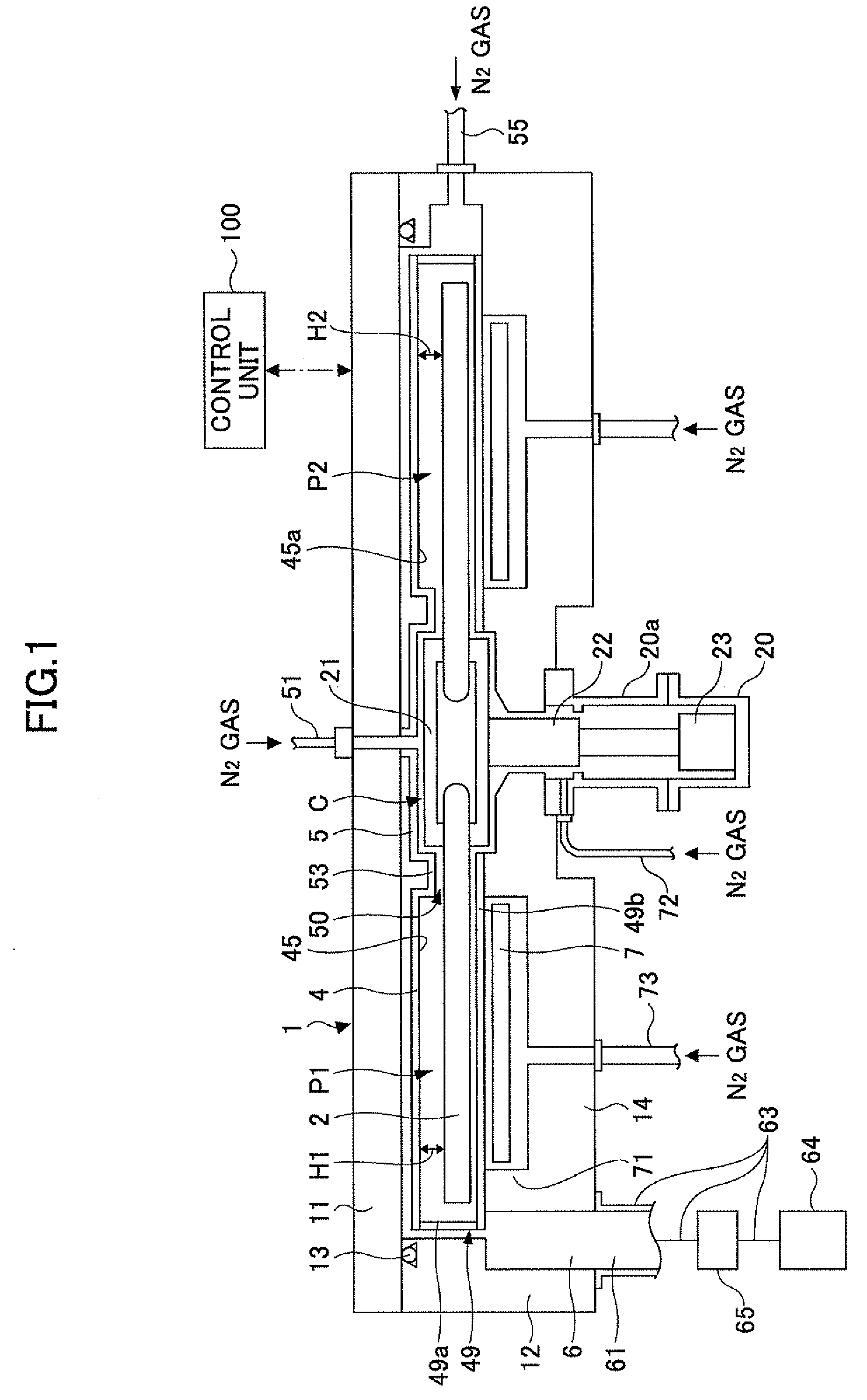

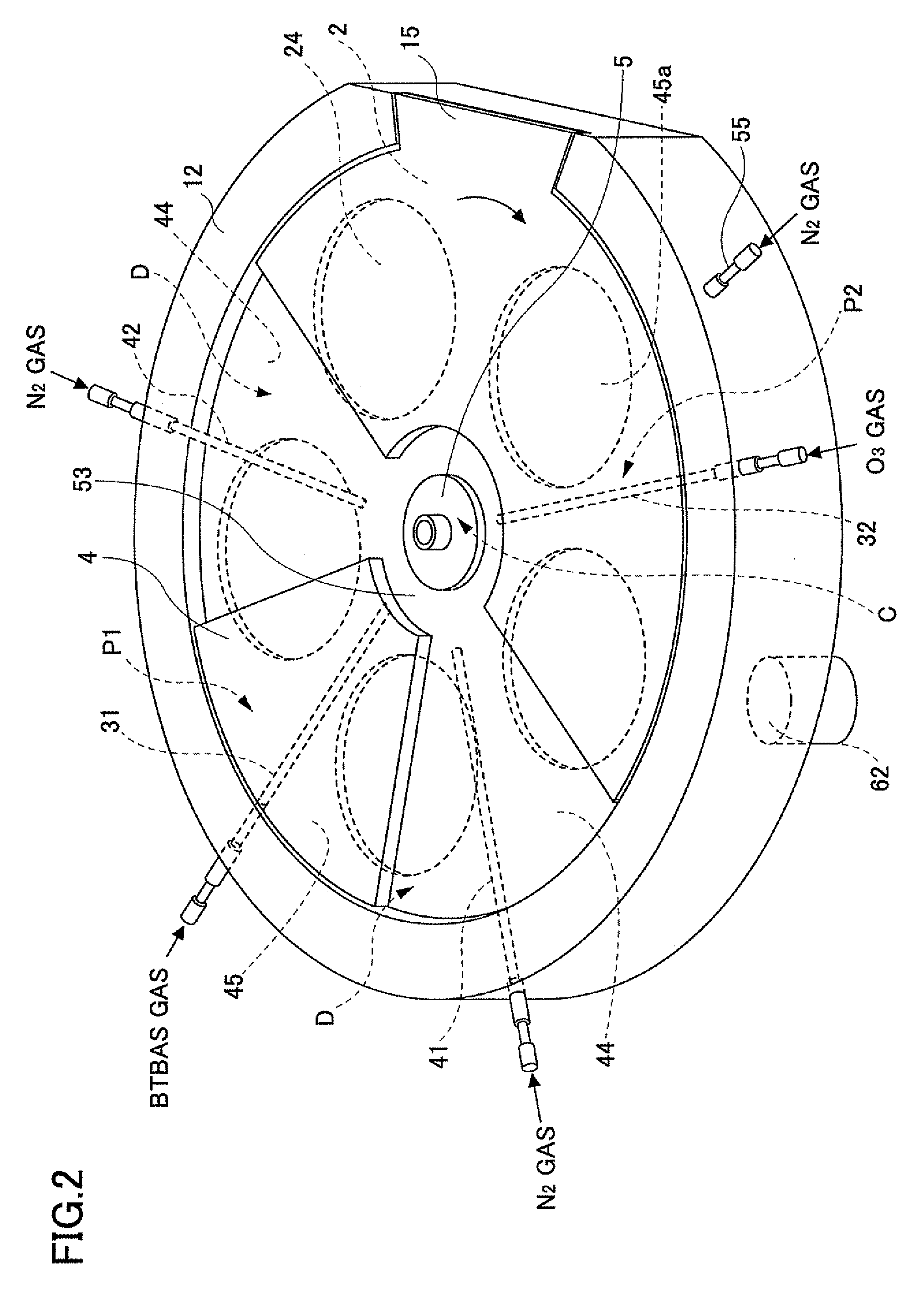

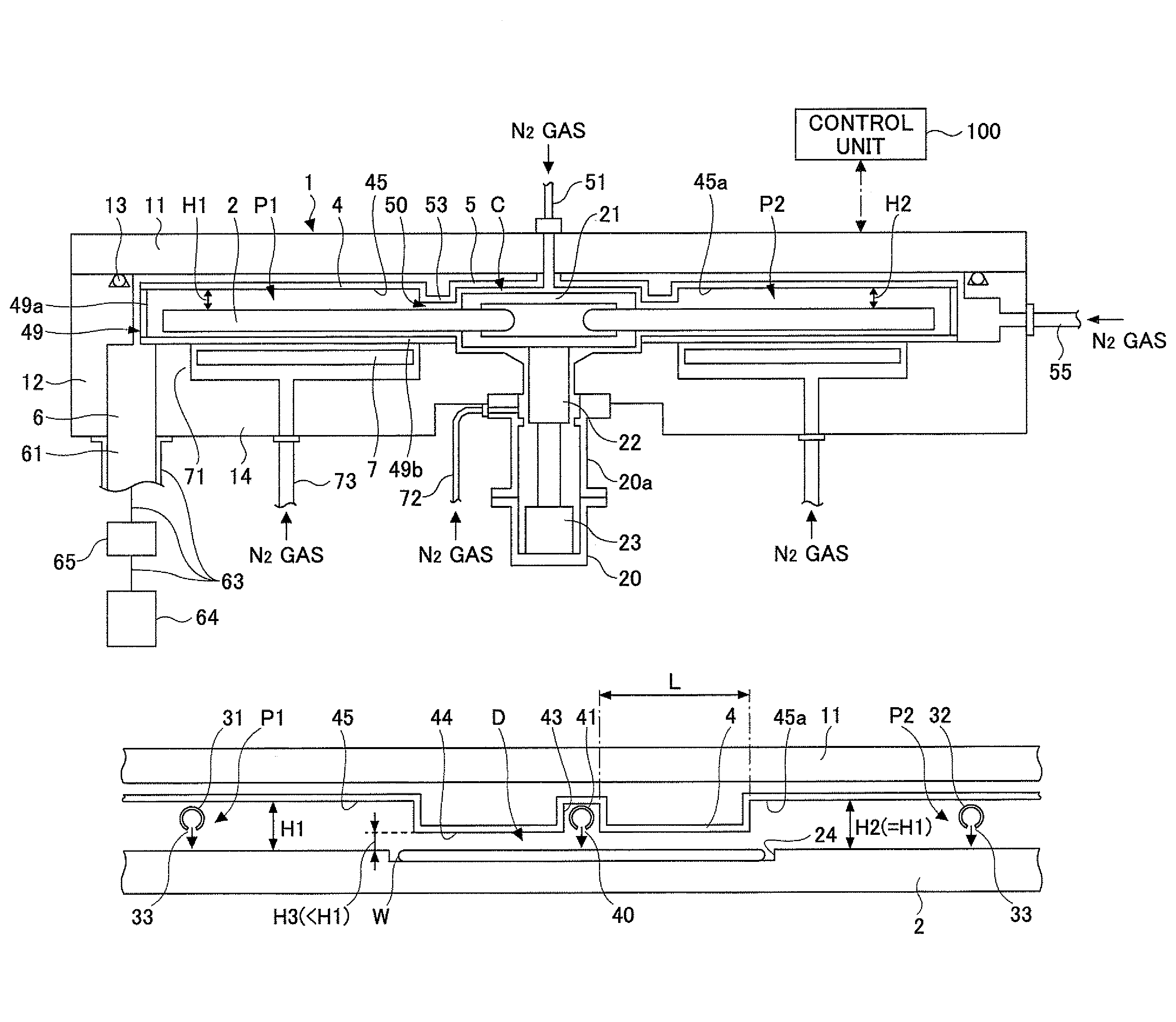

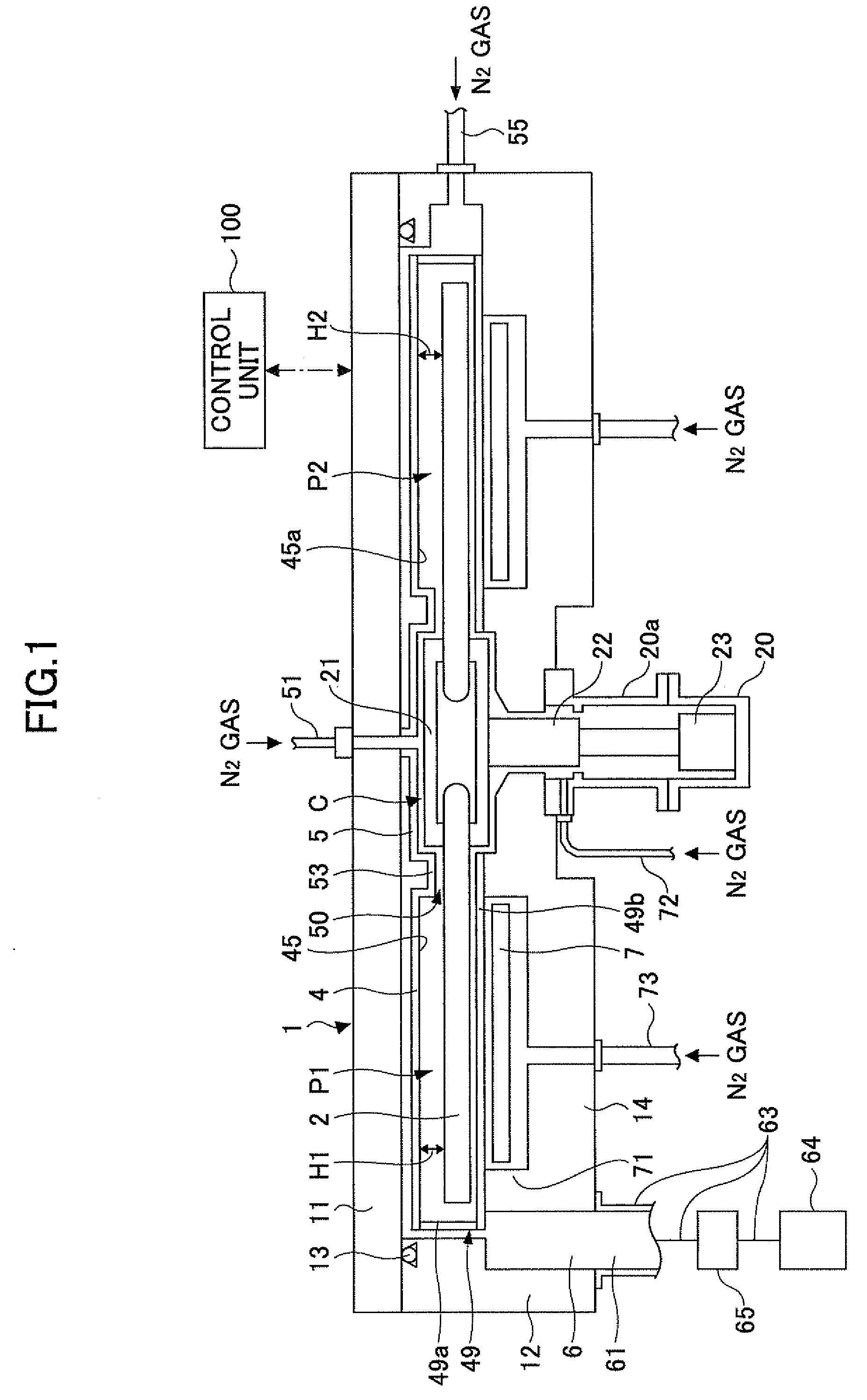

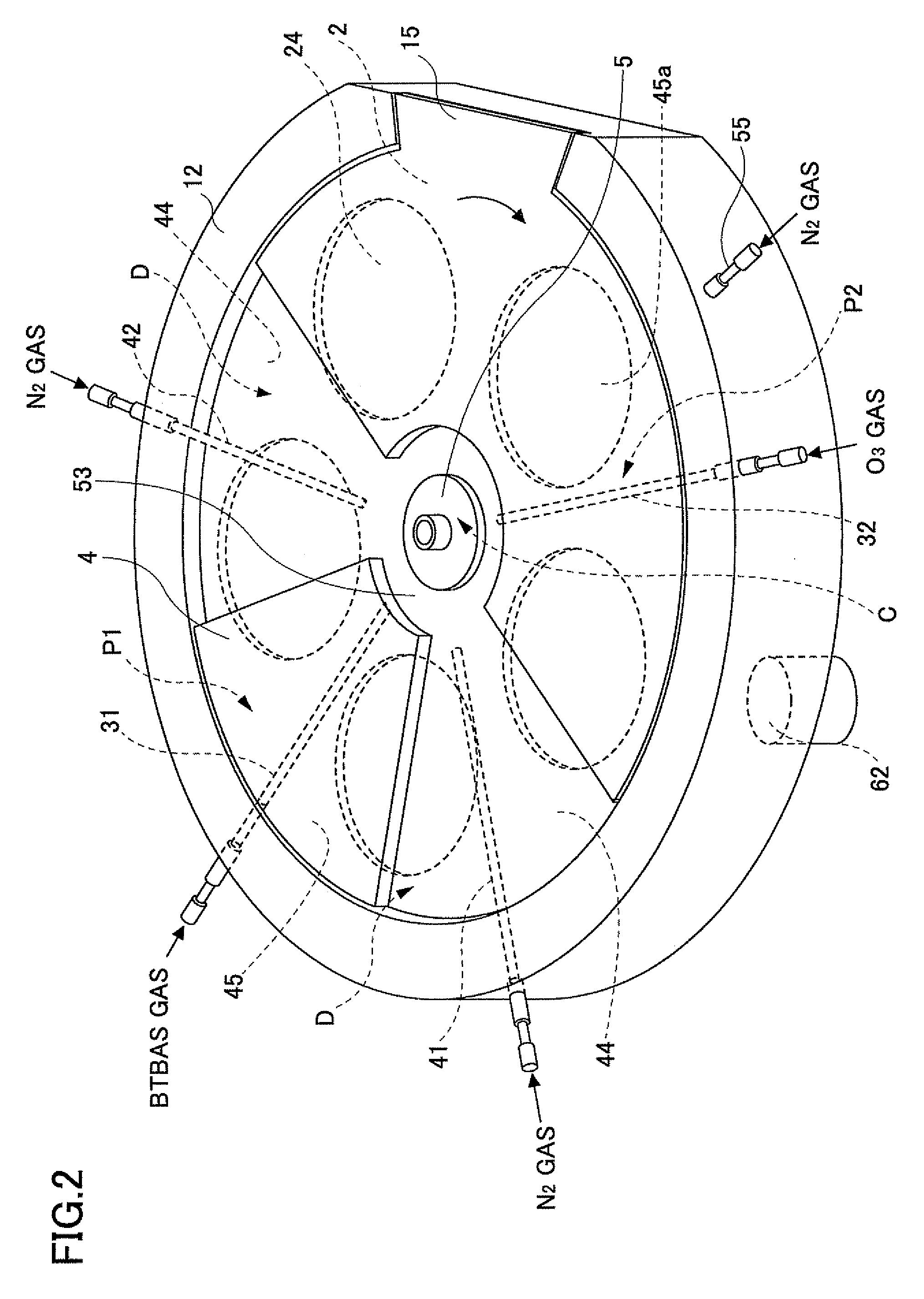

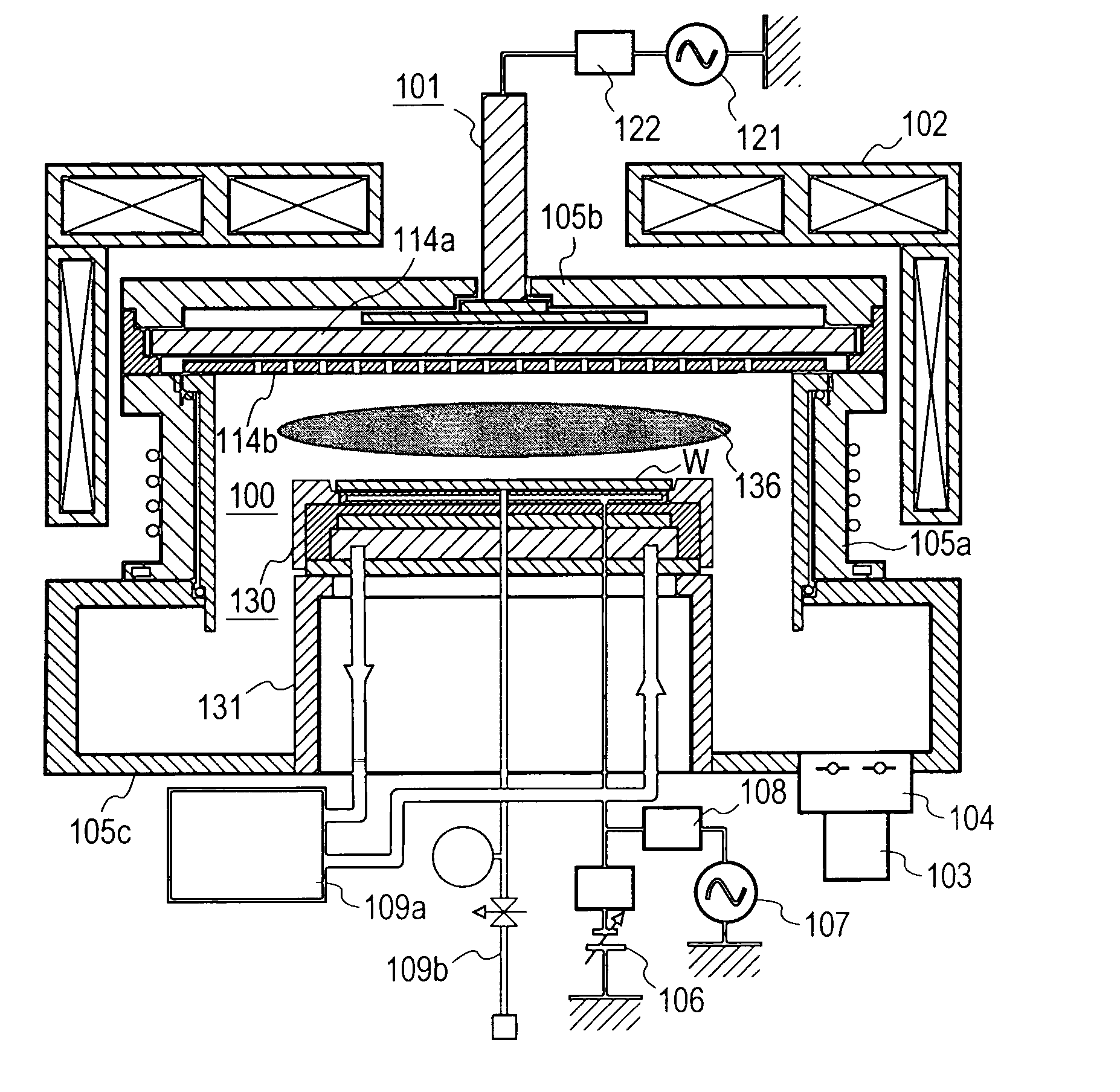

Film deposition apparatus, substrate processing apparatus, film deposition method, and storage medium

ActiveUS20100055316A1Improve throughputSatisfy processingSemiconductor/solid-state device manufacturingChemical vapor deposition coatingGas supplyVacuum chamber

A film deposition apparatus to form a thin film by supplying first and second reaction gases within a vacuum chamber includes a turntable, a protection top plate, first and second reaction gas supply parts extending from a circumferential edge towards a rotation center of the turntable, and a separation gas supply part provided therebetween. First and second spaces respectively include the first and second reaction gas supply parts and have heights H1 and H2. A third space includes the separation gas supply part and has a height H3 lower than H1 and H2. The film deposition apparatus further includes a vacuum chamber protection part which surrounds the turntable and the first, second and third spaces together with the protection top plate to protect the vacuum chamber from corrosion.

Owner:TOKYO ELECTRON LTD

Film deposition apparatus, substrate processing apparatus, film deposition method, and storage medium

ActiveUS9267204B2Improve throughputAvoid mixingSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringVacuum chamber

A film deposition apparatus to form a thin film by supplying first and second reaction gases within a vacuum chamber includes a turntable, a protection top plate, first and second reaction gas supply parts extending from a circumferential edge towards a rotation center of the turntable, and a separation gas supply part provided therebetween. First and second spaces respectively include the first and second reaction gas supply parts and have heights H1 and H2. A third space includes the separation gas supply part and has a height H3 lower than H1 and H2. The film deposition apparatus further includes a vacuum chamber protection part which surrounds the turntable and the first, second and third spaces together with the protection top plate to protect the vacuum chamber from corrosion.

Owner:TOKYO ELECTRON LTD

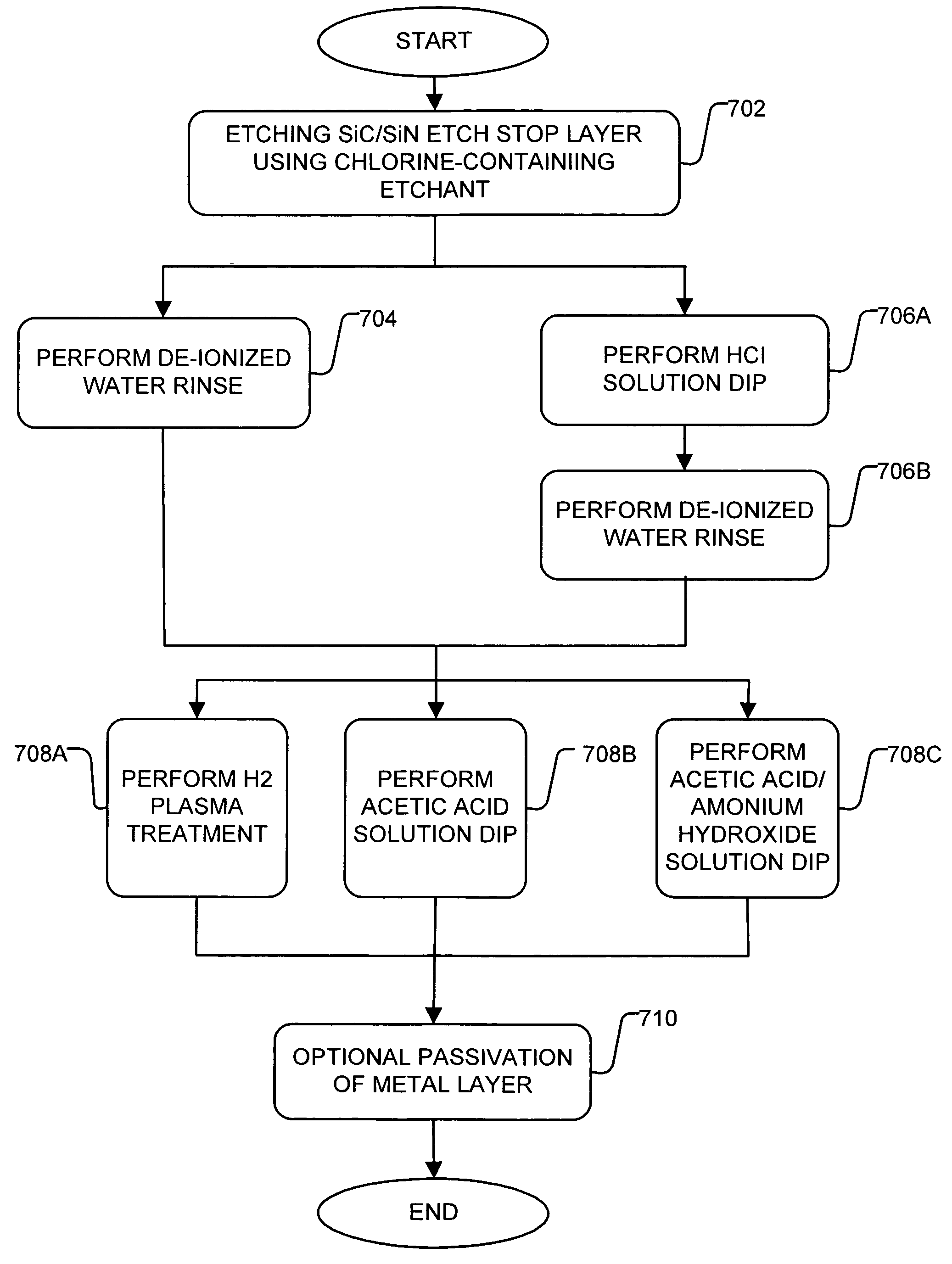

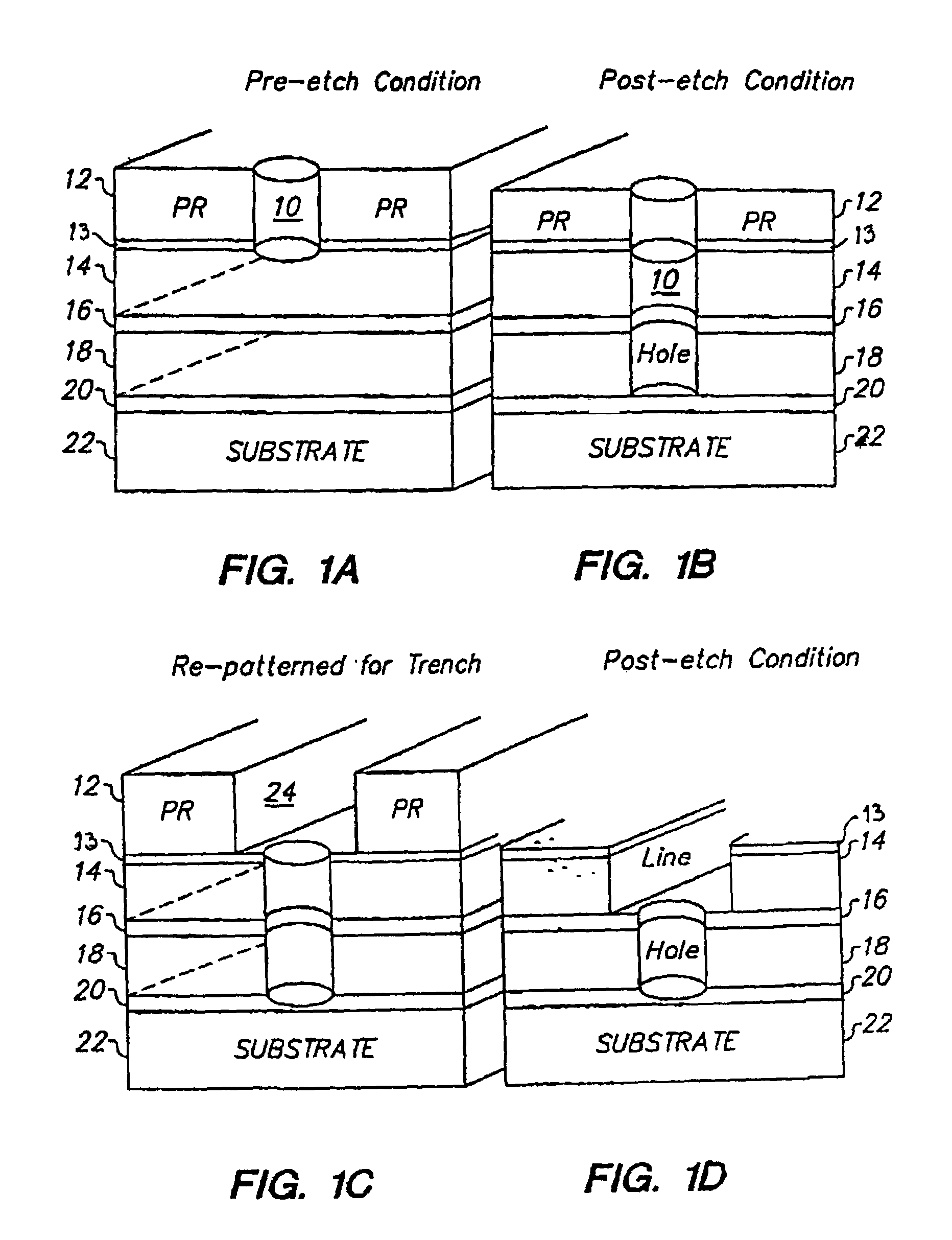

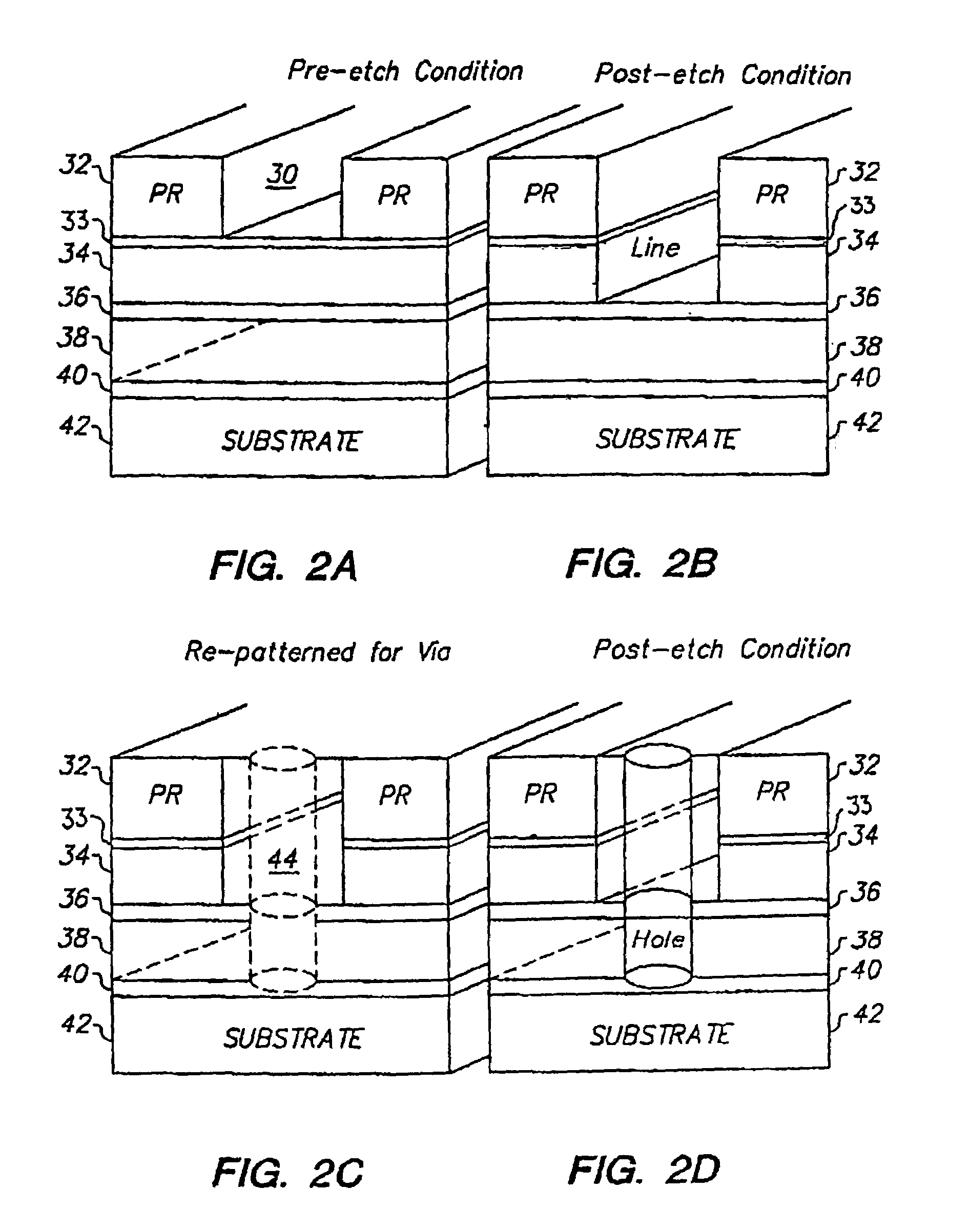

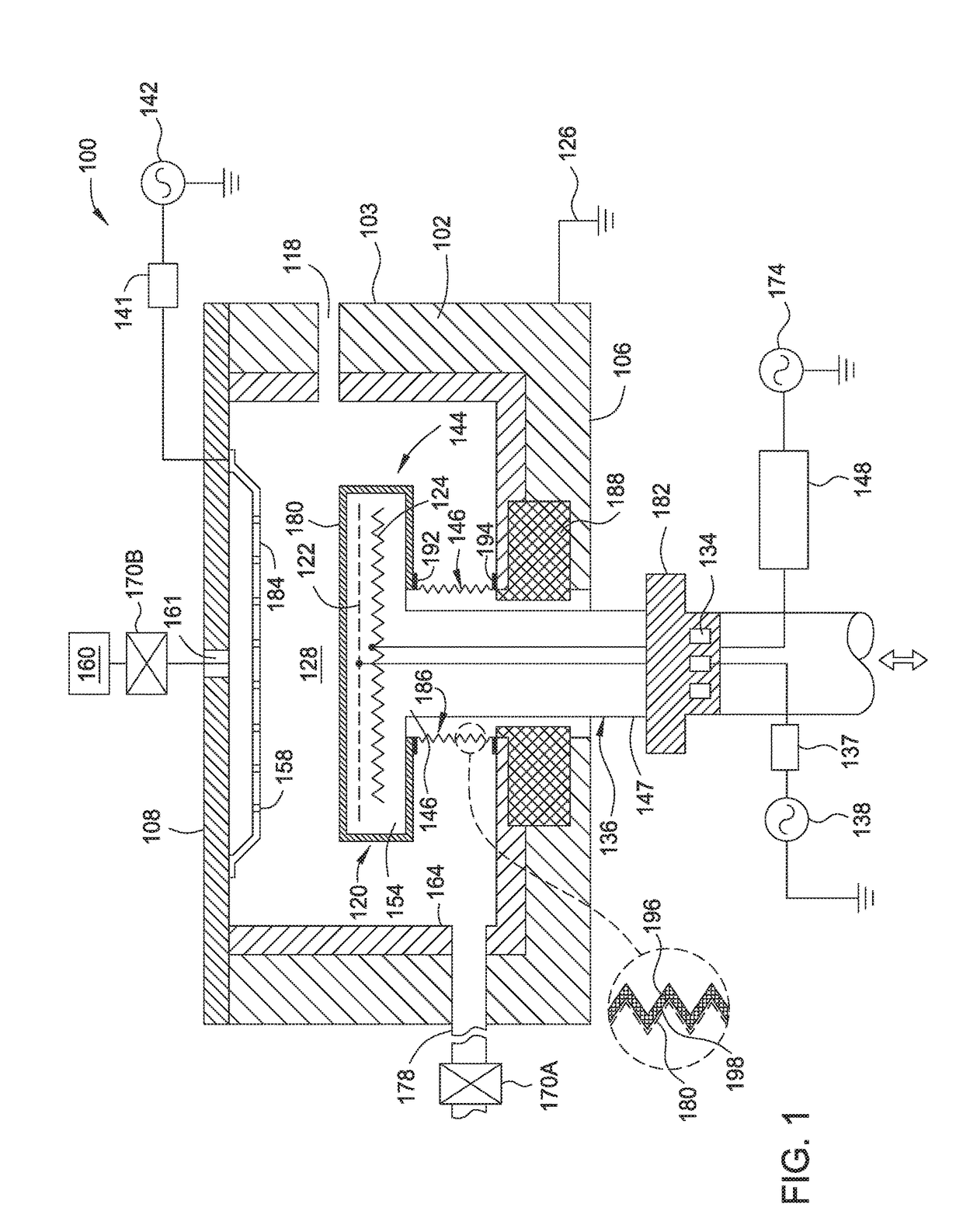

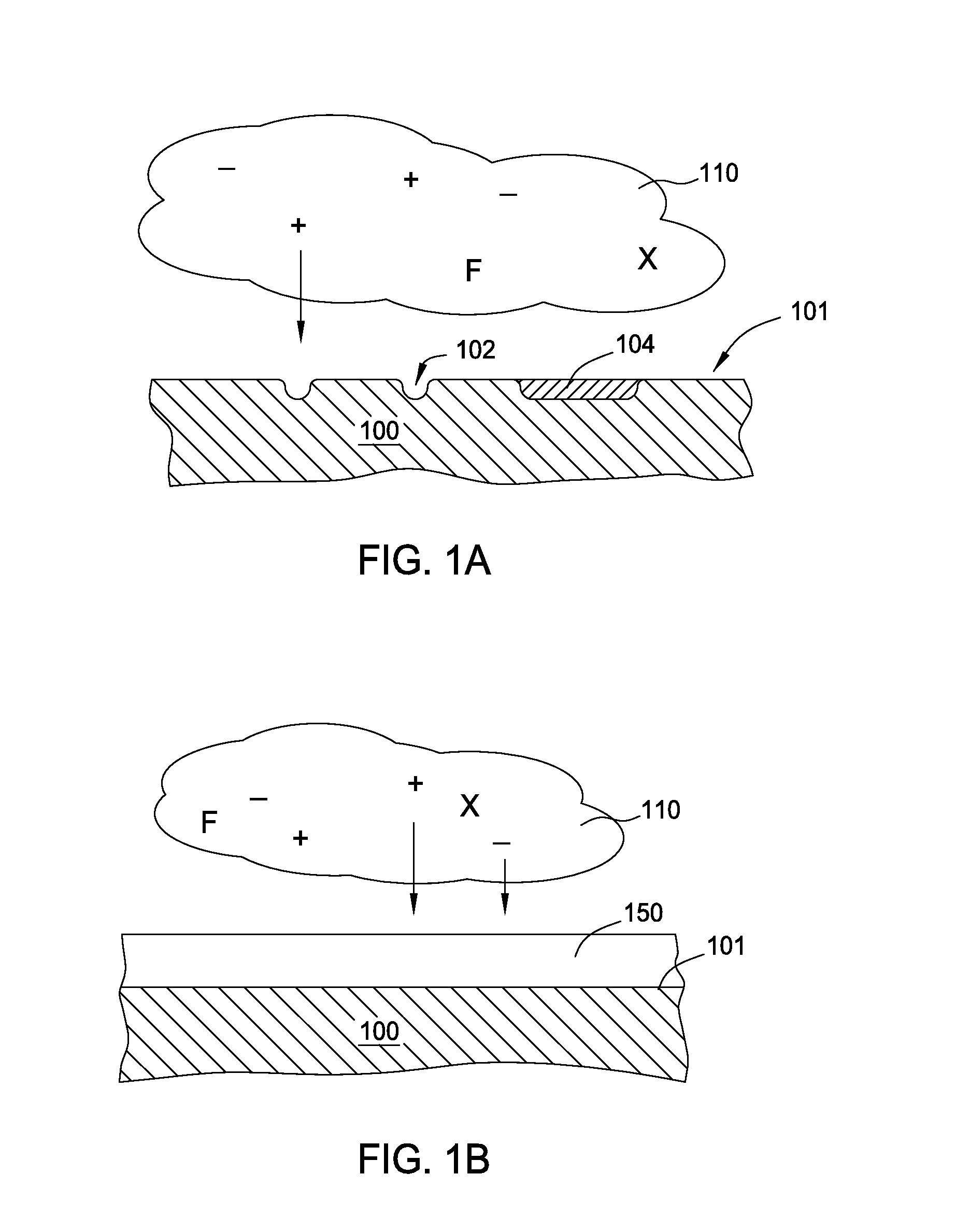

Treatment for corrosion in substrate processing

InactiveUS7084070B1Semiconductor/solid-state device manufacturingElectrostatic cleaningAcetic acidAmmonium hydroxide

A method for processing substrate to form a semiconductor device is disclosed. The substrate includes an etch stop layer disposed above a metal layer. The method includes etching through the etch stop layer down to the copper metal layer, using a plasma etch process that utilizes a chlorine-containing etchant source gas, thereby forming etch stop layer openings in the etch stop layer. The etch stop layer includes at least one of a SiN and SiC material. Thereafter, the method includes performing a wet treatment on the substrate using a solution that contains acetic acid (CH3COOH) or acetic acid / ammonium hydroxide (NH4OH) to remove at least some of the copper oxides. Alternatively, the copper oxides may be removed using a H2 plasma. BTA passivation may be optionally performed on the substrate.

Owner:LAM RES CORP

Corrosion control for chamber components

Owner:APPLIED MATERIALS INC

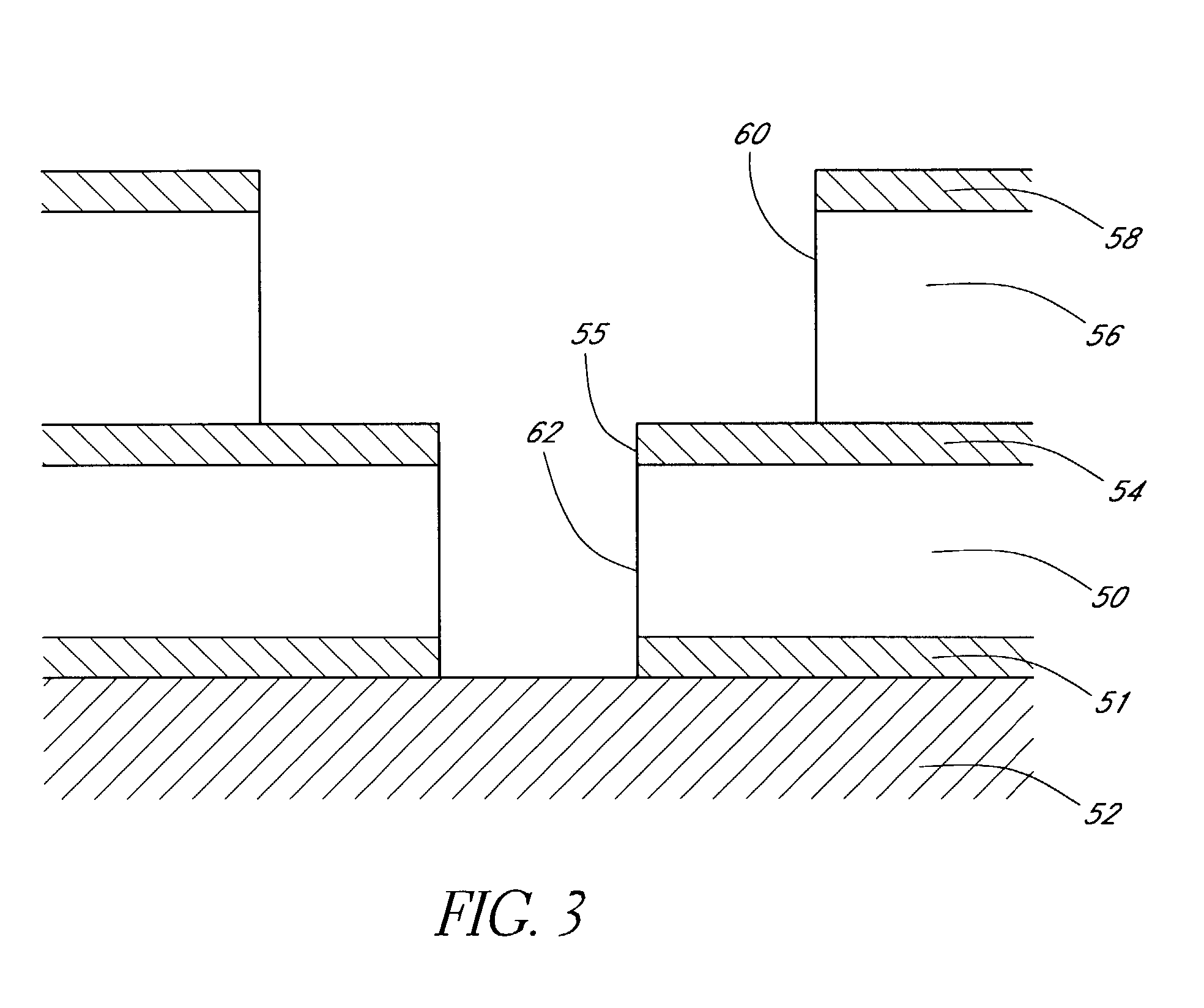

Sub-quarter-micron copper interconnections with improved electromigration resistance and reduced defect sensitivity

InactiveUS6069068ASemiconductor/solid-state device detailsVacuum evaporation coatingGas phaseInterconnection

A method of providing sub-half-micron copper interconnections with improved electromigration and corrosion resistance. The method includes double damascene using electroplated copper, where the seed layer is deposited by chemical vapor deposition, or by physical vapor deposition in a layer less than about 800 angstroms.

Owner:GLOBALFOUNDRIES INC

Chamber component with protective coating suitable for protection against fluorine plasma

Owner:APPLIED MATERIALS INC

Corrosion control for chamber components

ActiveUS20170152968A1Protection cleanSpindle sealingsElectric discharge tubesParyleneDiamond-like carbon

Implementations described herein protect a chamber components from corrosive cleaning gases used at high temperatures. In one embodiment, a chamber component includes at least a bellows that includes a top mounting flange coupled to a bottom mounting flange by a tubular accordion structure. A coating is disposed on an exterior surface of at least the tubular accordion structure. The coating includes of at least one of polytetrafluoroethylene, parylene C, parylene D, diamond-like carbon (DLC), yttria stabilized zirconia, nickel, alumina, or aluminum silicon magnesium yttrium oxygen compound. In one embodiment, the chamber component is a valve having an internal bellows.

Owner:APPLIED MATERIALS INC

Chamber component with protective coating suitable for protection against flourine plasma

InactiveUS20150218700A1Increased resistance againstChemical vapor deposition coatingCorrosionCoating

Owner:APPLIED MATERIALS INC

Stable solid block metal protecting warewashing detergent composition

InactiveUS6156715AFit tightlyEasy to cleanInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsAlkalinityIndustrial setting

The dimensionally stable alkaline solid block warewashing detergent uses an E-form binder forming a solid comprising a sodium carbonate source of alkalinity, a metal corrosion protecting alkali metal silicate composition, a sequestrant, a surfactant package and other optional material. The solid block is dimensionally stable and highly effective in removing soil from the surfaces of dishware in the institutional and industrial environment. The E-form hydrate comprises an organic phosphonate and a hydrated carbonate.

Owner:ECOLAB USA INC

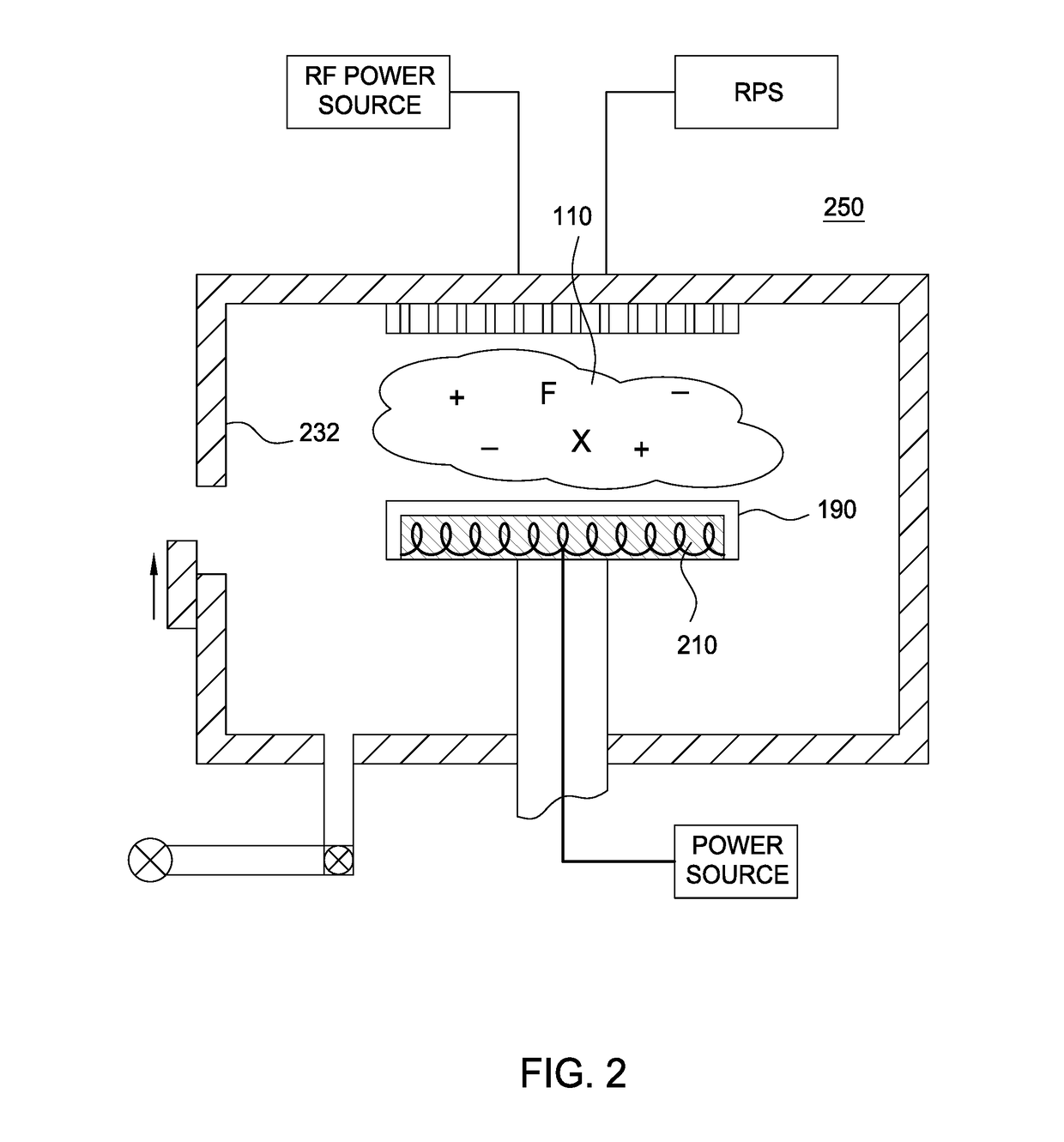

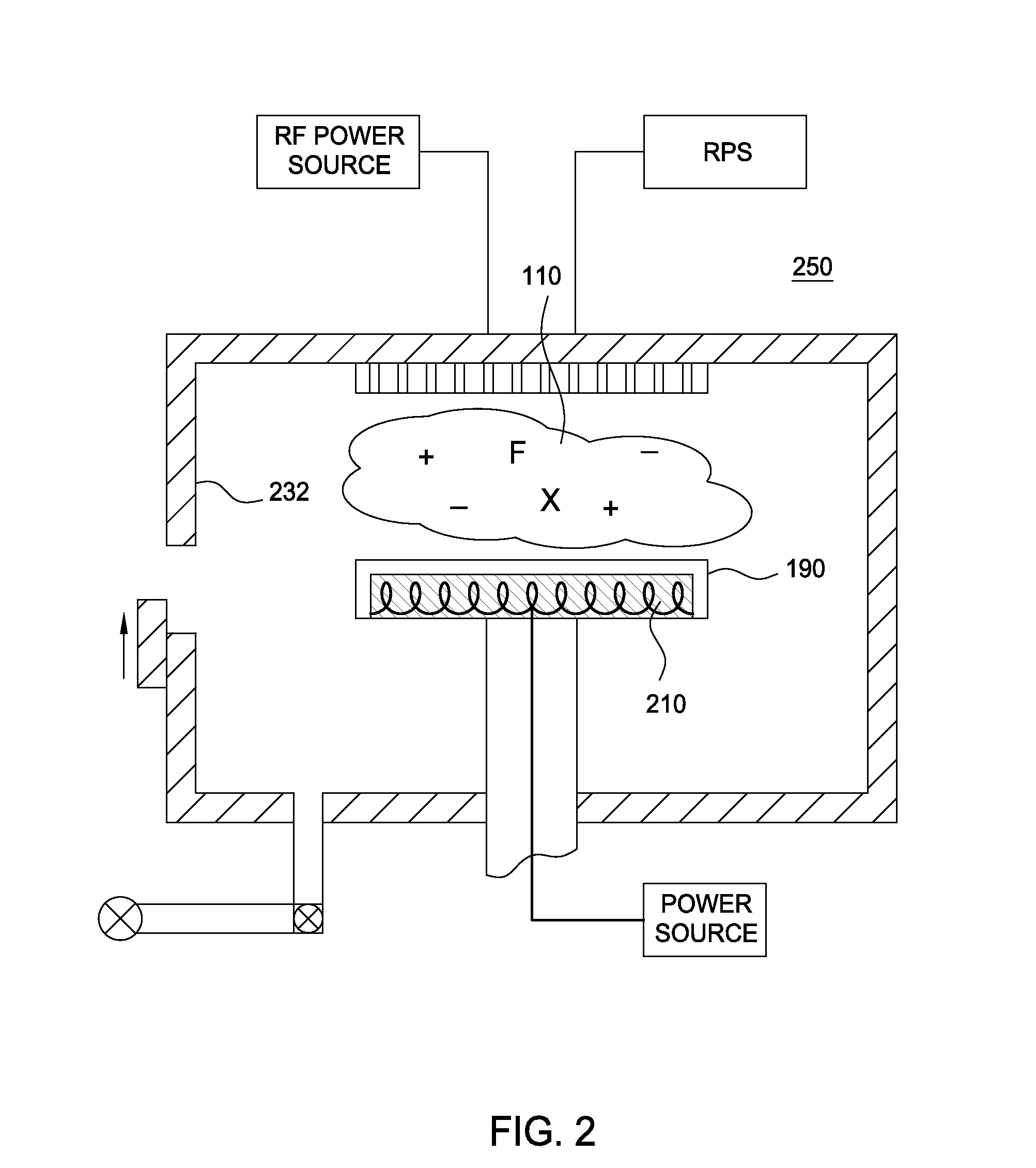

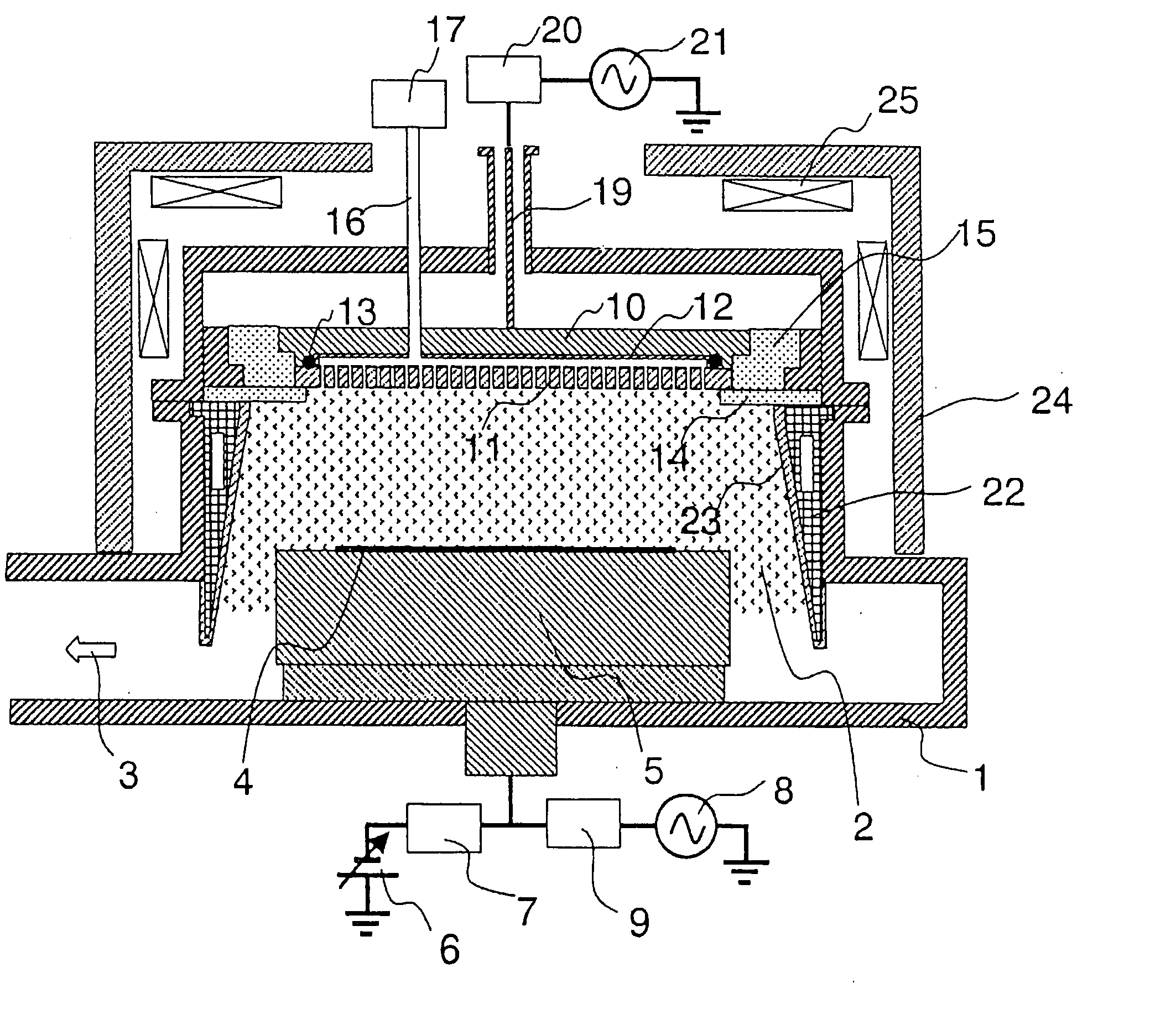

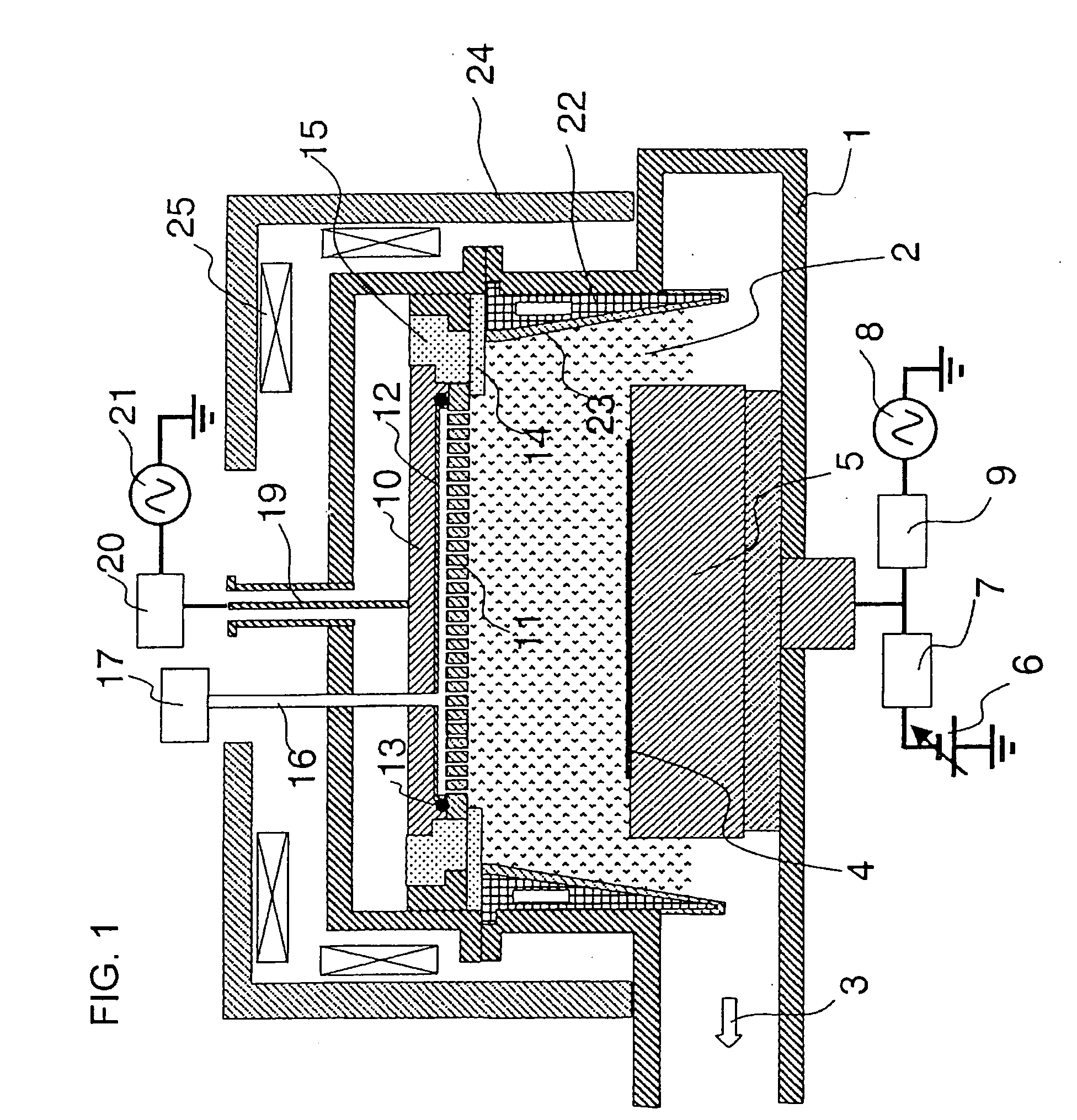

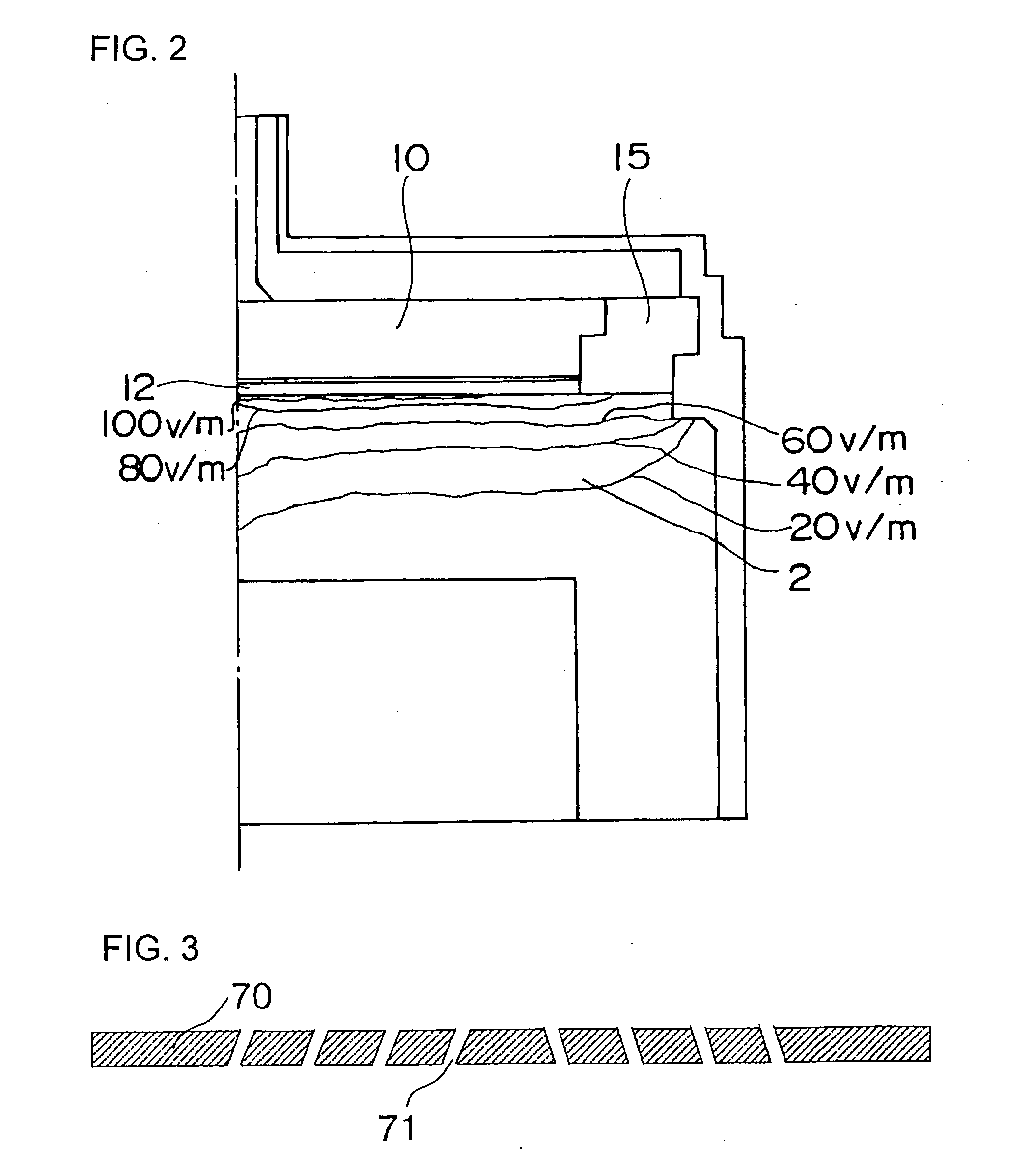

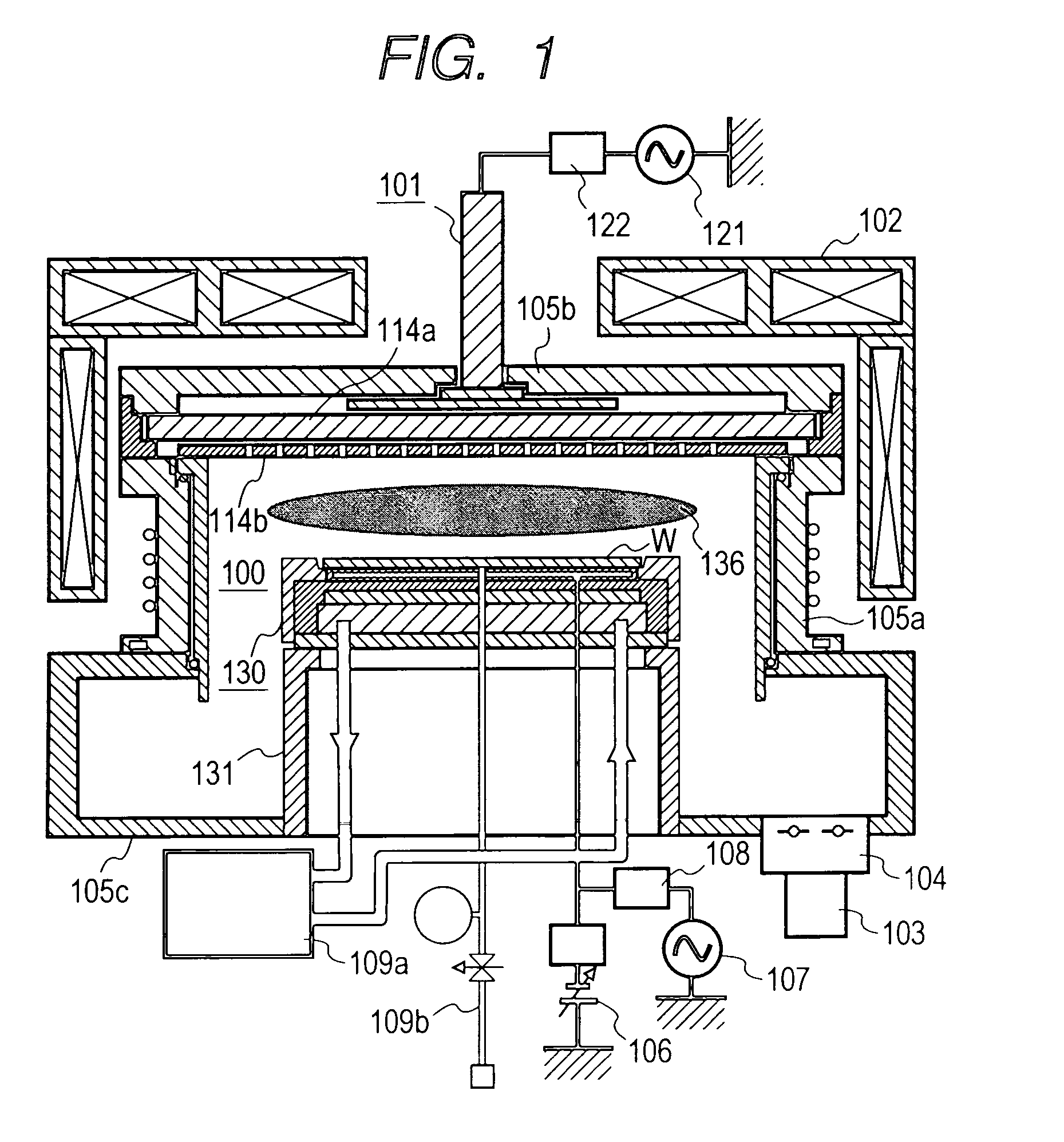

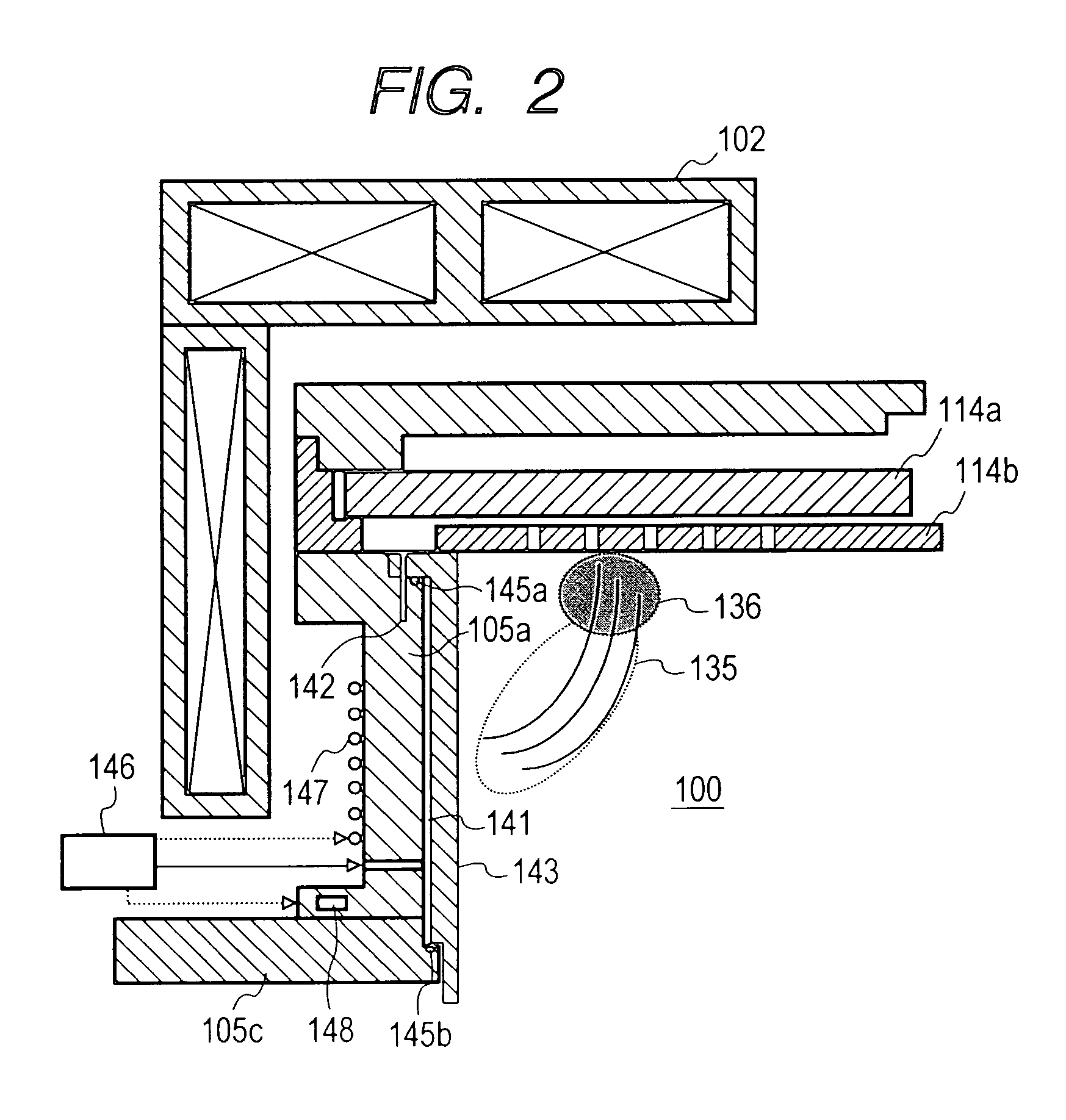

Plasma processing apparatus

ActiveUS20070044716A1Free from pollutionAvoid damageElectric discharge tubesChemical vapor deposition coatingTectorial membraneElectrical conductor

The invention provides a plasma processing apparatus aimed at suppressing the corrosion caused by reactive gas and heavy-metal contamination caused by plasma damage of components constituting the high-frequency electrode and gas supply unit. The plasma processing apparatus comprises a processing chamber 1 for subjecting a processing substrate 4 to plasma processing, gas supply means 17, 16 and 11 for feeding gas to the processing chamber 1, and an antenna electrode 10 for supplying high-frequency radiation for discharging the gas to generate plasma, wherein the gas supply means includes a gas shower plate 11 having gas discharge holes on the surface exposed to plasma, and a portion of or a whole surface of the conductor 10 exposed to gas constituting the antenna-electrode side of the gas supply means is subjected to ceramic spraying containing no heavy metal to form a protecting film 12.

Owner:HITACHI HIGH-TECH CORP

Nontoxic antifouling paint for oceanographic ship and facilities and method for preparing paint

ActiveCN101967316AInhibit Adhesive CorrosionTo achieve non-toxicRubber derivative coatingsAntifouling/underwater paintsNon toxicityBiofouling

The invention discloses a nontoxic antifouling paint for an oceanographic ship and facilities and a method for preparing the paint. The paint consists of the following components in percentage by weight: 15 to 55 percent of base material, 0.01 to 10 percent of antifouling agent, 10 to 30 percent of filler, 0.3 to 25 percent of pigment, 2 to 8 percent of auxiliary agent and 3 to 55 percent of solvent, wherein the antifouling agent is silver grains with average grain diameter of between 1 and 200nm. The paint does not contain toxic agents, such as dichloro-diphenyl-trichloroethane, organic tin,cuprous oxide and the like, at all while effectively suppressing corrosion of marine biological attachments, meets the related regulations of international maritime organization and future development trend of the antifouling paint, realizes non-toxicity and environmental friendliness of the marine antifouling technology, and can be widely applied to the facilities and the fields, such as ships, floating piers, marine oil platforms, submarine cables, cooling pipes of power plant near the sea, sea water culture net cage and the like.

Owner:CHINA LUCKY FILM CORP +1

Cast form water borne coating and technique for preparing the same

InactiveCN101497105AGood water dispersibilityGood suspensionFoundry mouldsFoundry coresDefoaming AgentsCorrosion

The invention relates to an auxiliary material for casting a mould, in particular to a casting mould water-based coating formulation for a sand mould or an expendable pattern casting (EPC), and a process for preparing the same. The casting mould water-based coating formulation consists of refractory powder, a suspending agent, a bonding agent, a surfactant, a defoaming agent, a corrosion remover and water. The process comprises the following steps: adding the suspending agent to the water directly, and mixing and dispersing the mixture in a high speed dispersion machine; adding auxiliary agents including the defoaming agent, the surfactant, the corrosion remover, and the like to the water, and mixing the auxiliary agents; adding the refractory powder to the mixture to be mixed; and adding the bonding agent to the mixture to be mixed, and then adding water to adjust the coating until the coating has the thickness in a using state to obtain the finished product. The coating prepared by the process has the effects that the coating ensures that a high-density low-viscosity coating has excellent suspension property and storage stability, a coating layer is not easy to crack after drying, the coating is advantageous to improve the capacity of the coating to resist high temperature metal corrosion, and the like.

Owner:深圳市景鼎现代科技有限公司

Method for preventing a metal corrosion in a semiconductor device

InactiveUS7468319B2Improved profileImprove reliabilitySemiconductor/solid-state device manufacturingPresent methodPhotoresist

Owner:DONGBU ELECTRONICS CO LTD

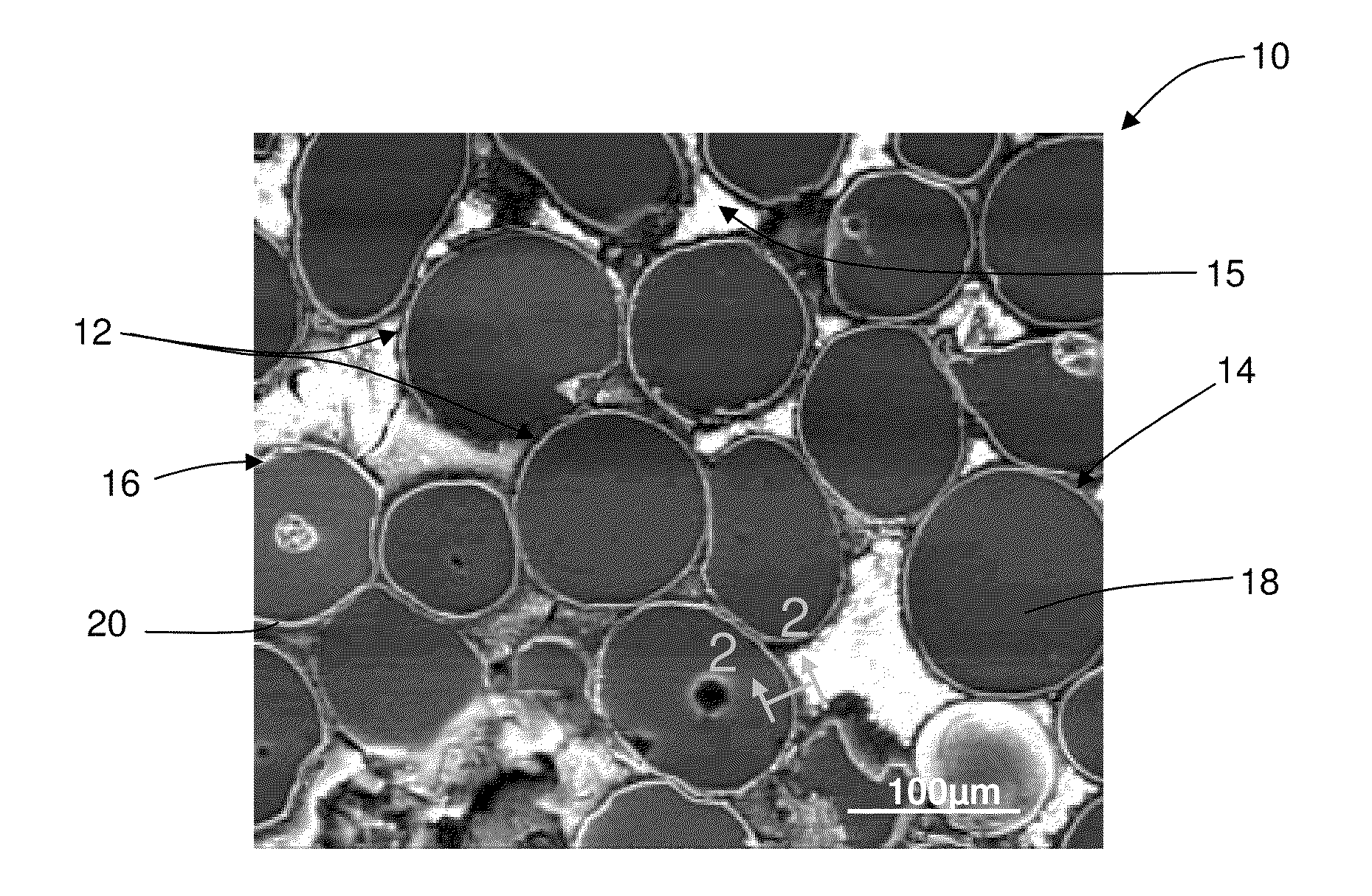

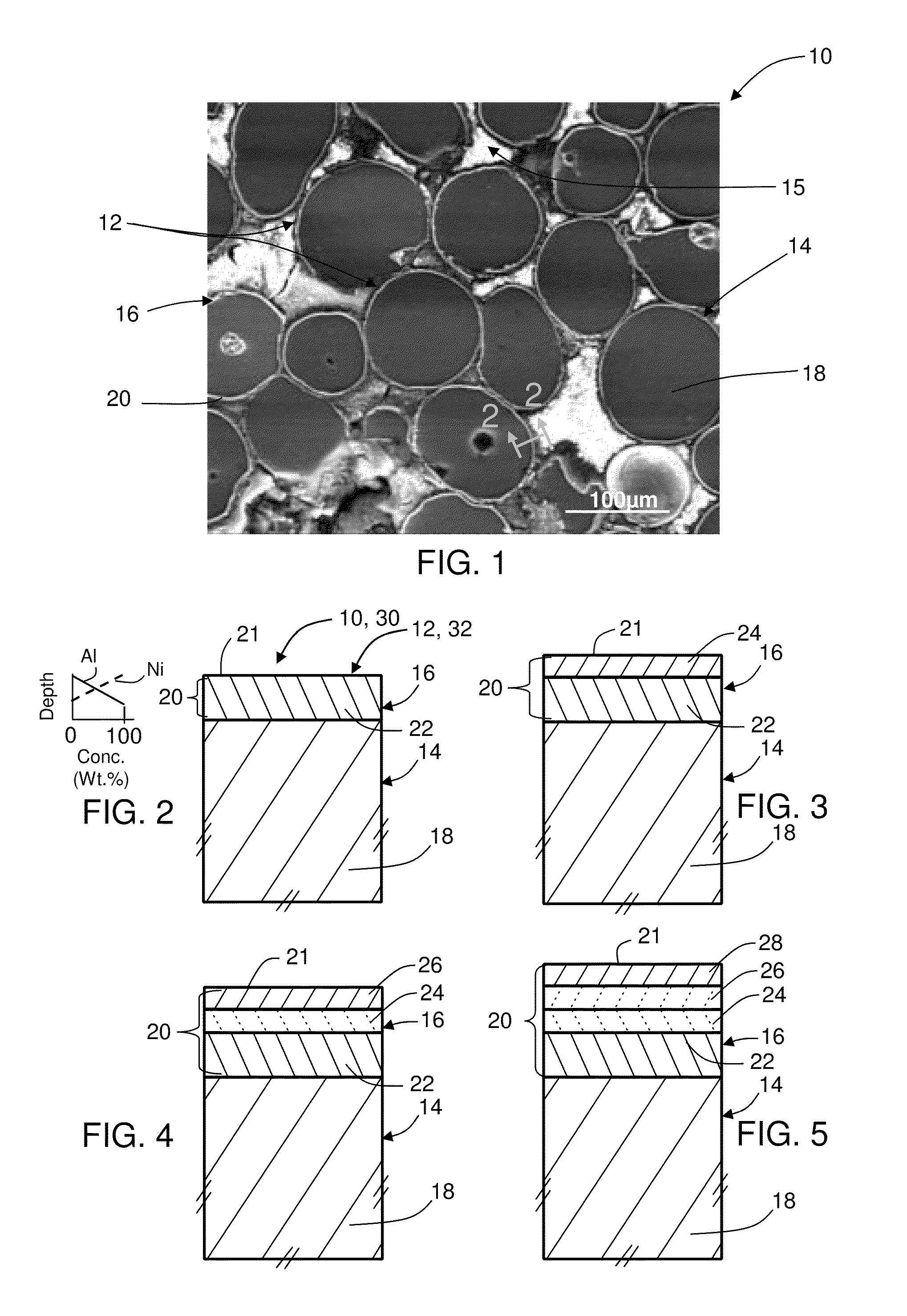

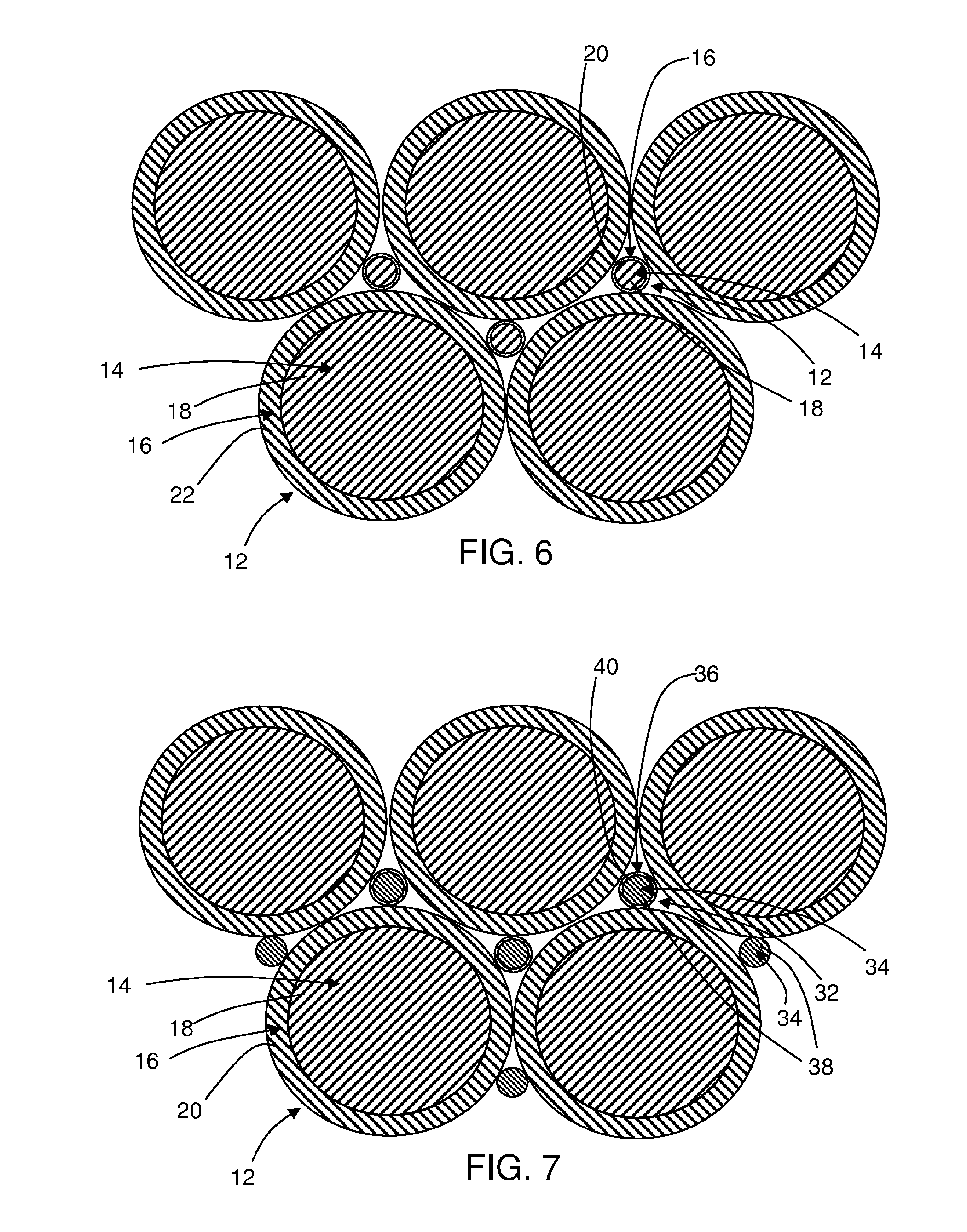

Nanomatrix powder metal compact

ActiveUS20110132143A1Transportation and packagingMetal-working apparatusUltimate tensile strengthNanometre

A powder metal compact is disclosed. The powder metal compact includes a substantially-continuous, cellular nanomatrix comprising a nanomatrix material. The compact also includes a plurality of dispersed particles comprising a particle core material that comprises Mg, Al, Zn or Mn, or a combination thereof, dispersed in the nanomatrix and a solid-state bond layer extending throughout the nanomatrix between the dispersed particles. The nanomatrix powder metal compacts are uniquely lightweight, high-strength materials that also provide uniquely selectable and controllable corrosion properties, including very rapid corrosion rates, useful for making a wide variety of degradable or disposable articles, including various downhole tools and components.

Owner:BAKER HUGHES OILFIELD OPERATIONS LLC

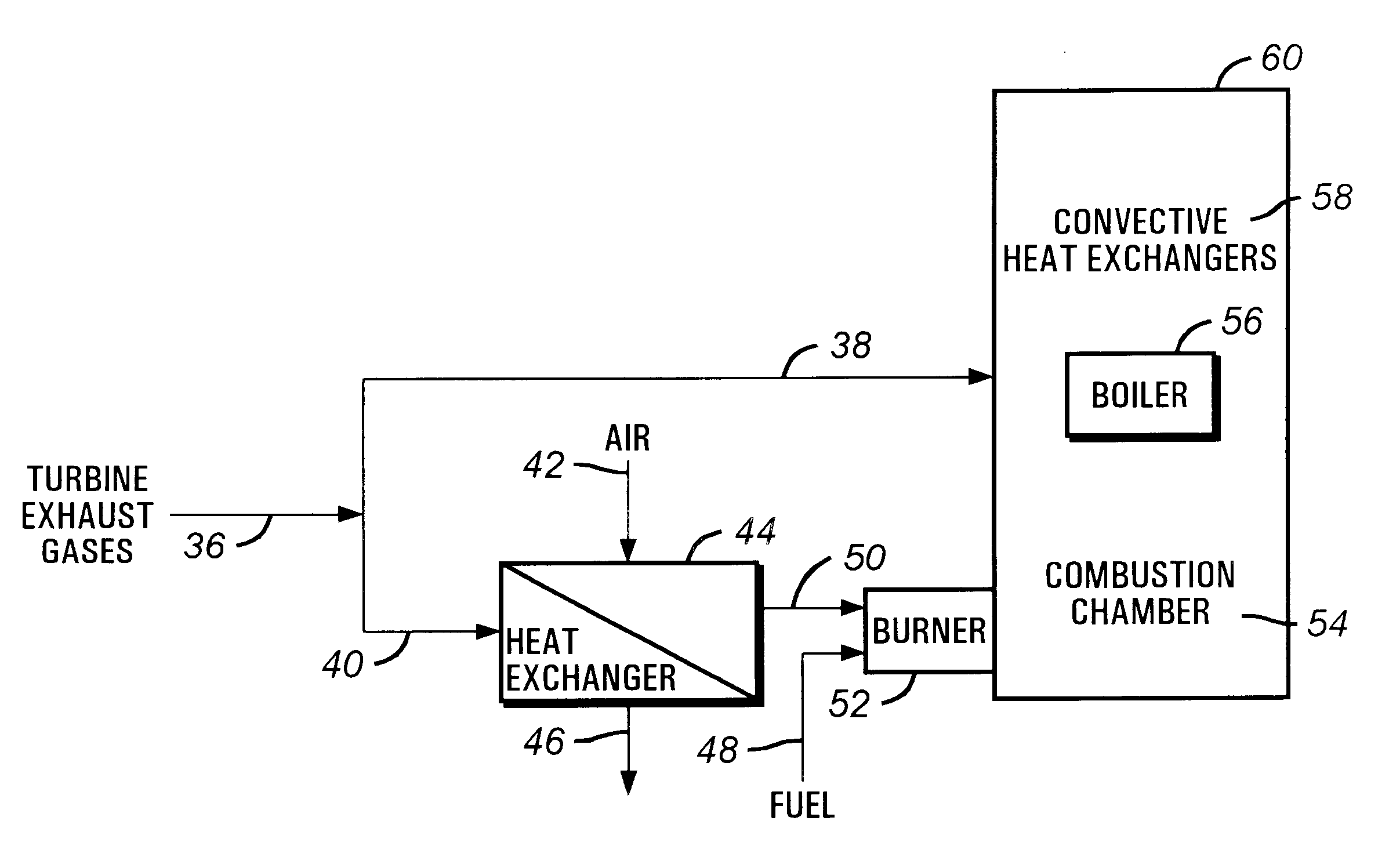

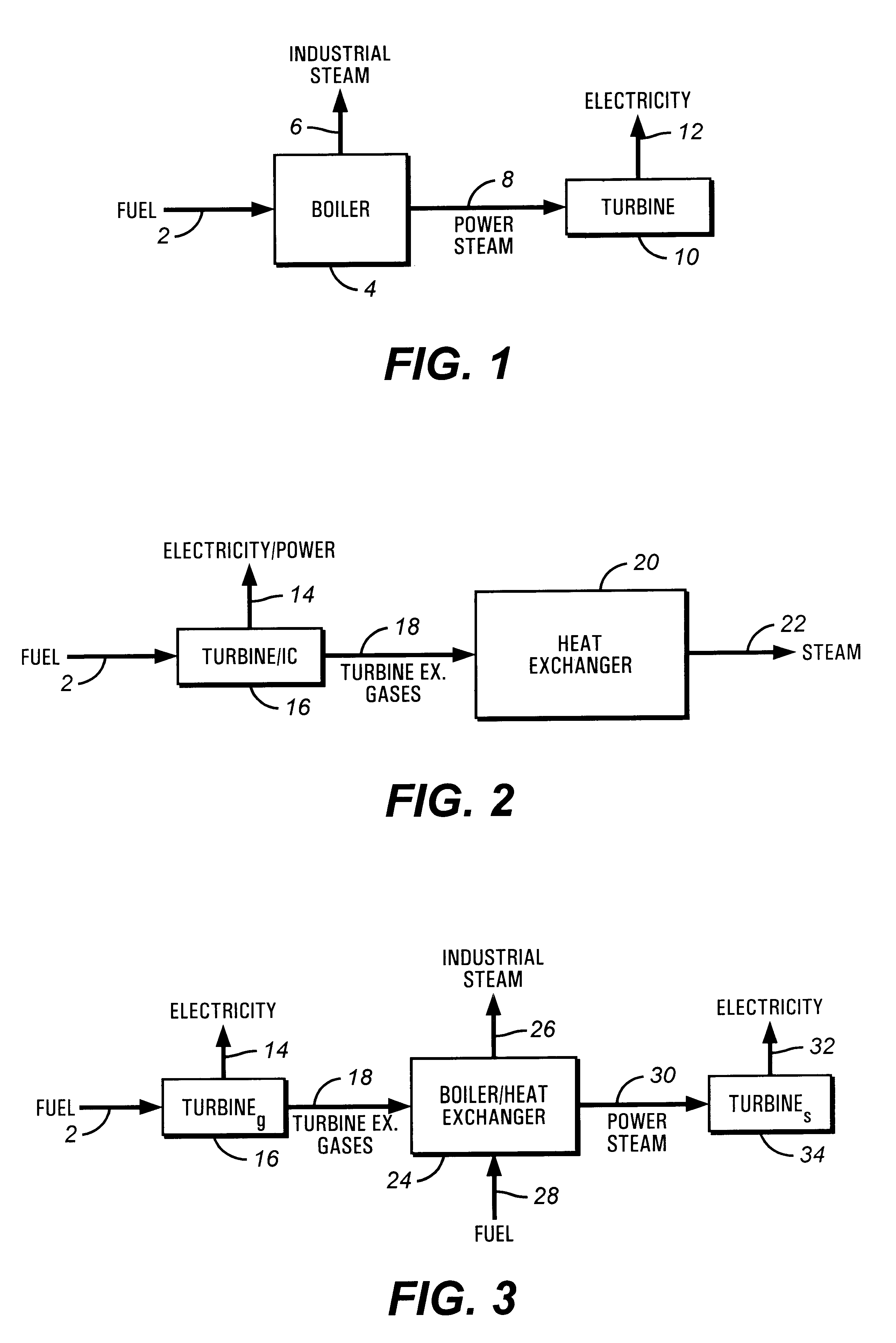

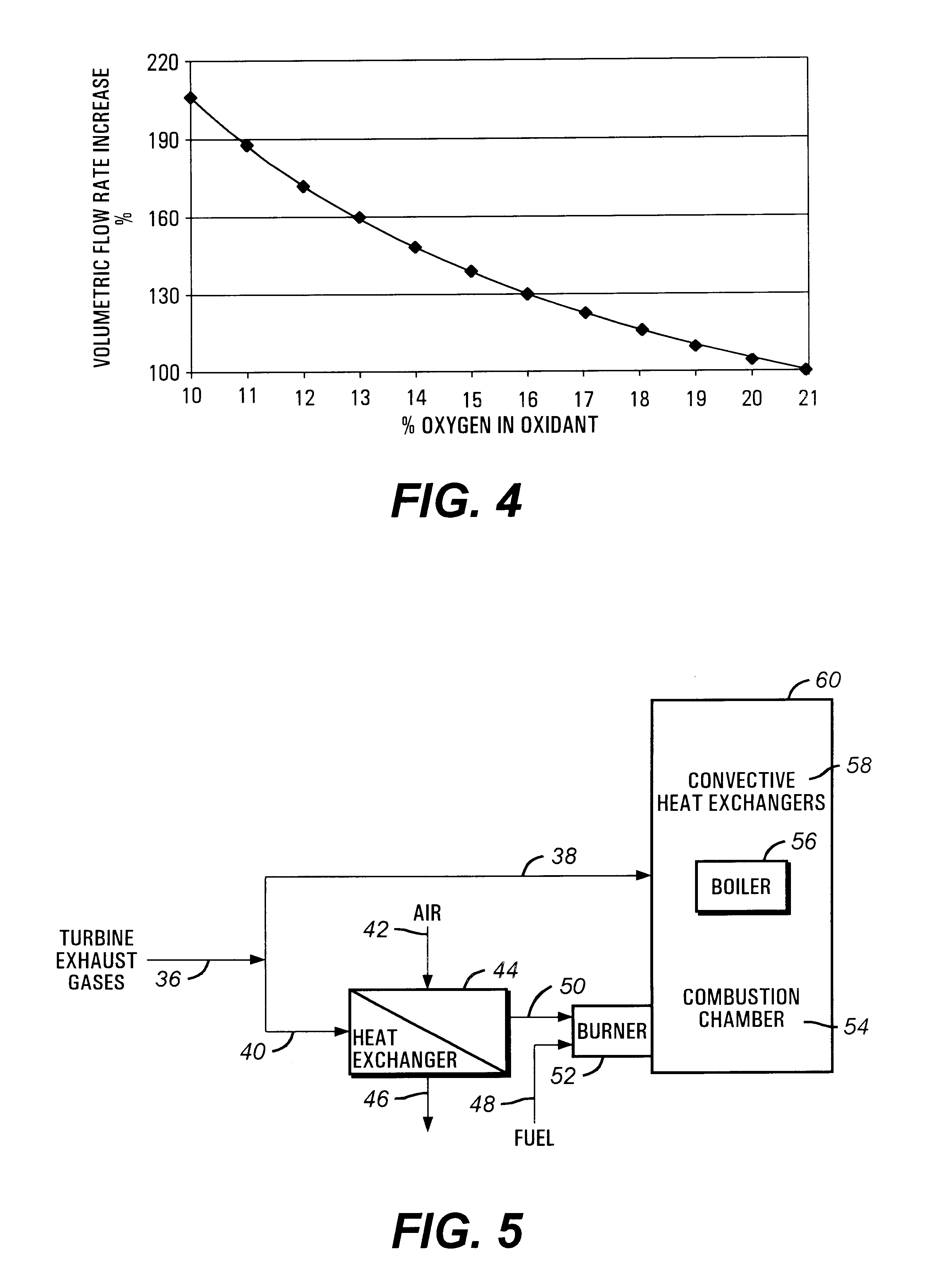

Oxidant control in co-generation installations

InactiveUS6247315B1Steam regenerationIndirect carbon-dioxide mitigationControl system designCogeneration

This invention is related to so-called combined cycle co-generation installations, and it addresses present concerns of the industry. Among these, combustion stability, corrosion (due to large water content in the flue gases), large heat transfer areas, and the like. In some embodiments, an additional heat exchanger is added to heat combustion air with a portion of the exhaust gases resulting from an engine, preferably a gas turbine. As a result, the efficiency of the cycle will improve, the oxidant will be enriched by above 50% oxygen, the combustion process will be enhanced, and the dimensions of the boiler may be reduced. It is considered that the combustion air will require between 10% and 80% of the total flue gas volume, more preferably between 20% and 40%. This is the portion of the flue gases sent through the heat exchanger. A control system designed to optimize the flow of the different streams is also presented. Other inventive embodiments forego heat exchanges in lieu of precise control of two flows of exhaust gas, with preferred addition of additional oxidant to the boiler bumers.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE +1

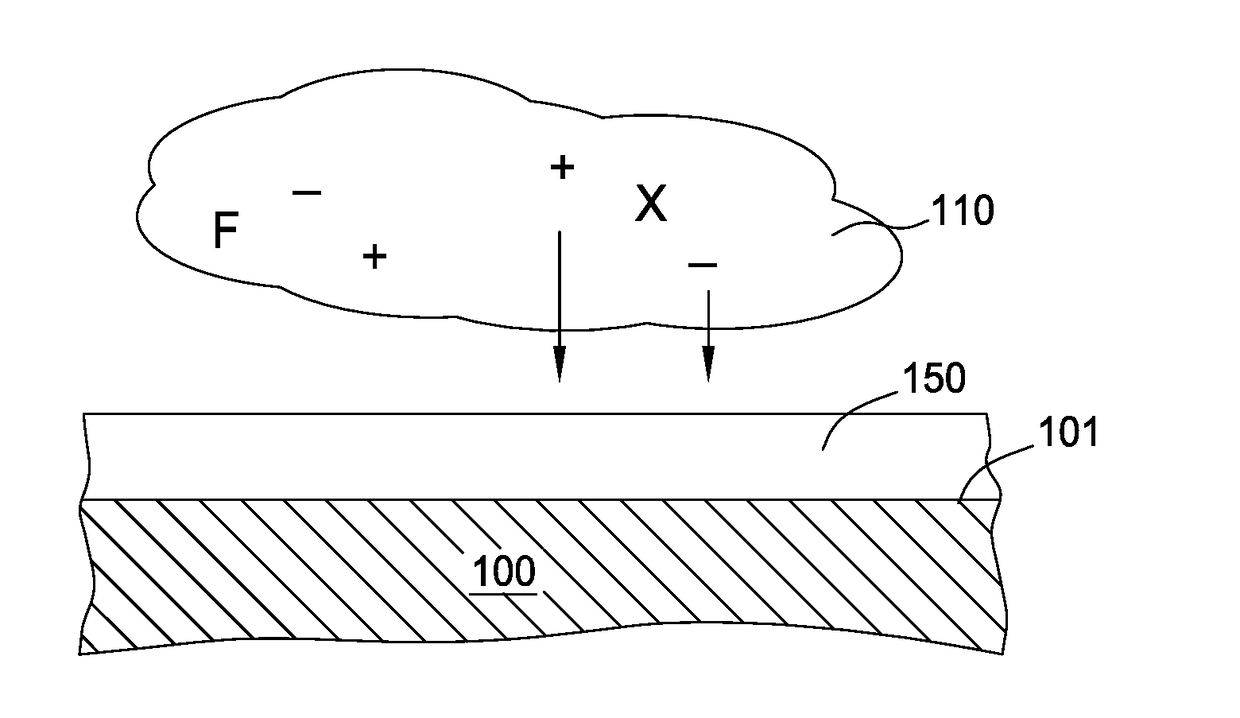

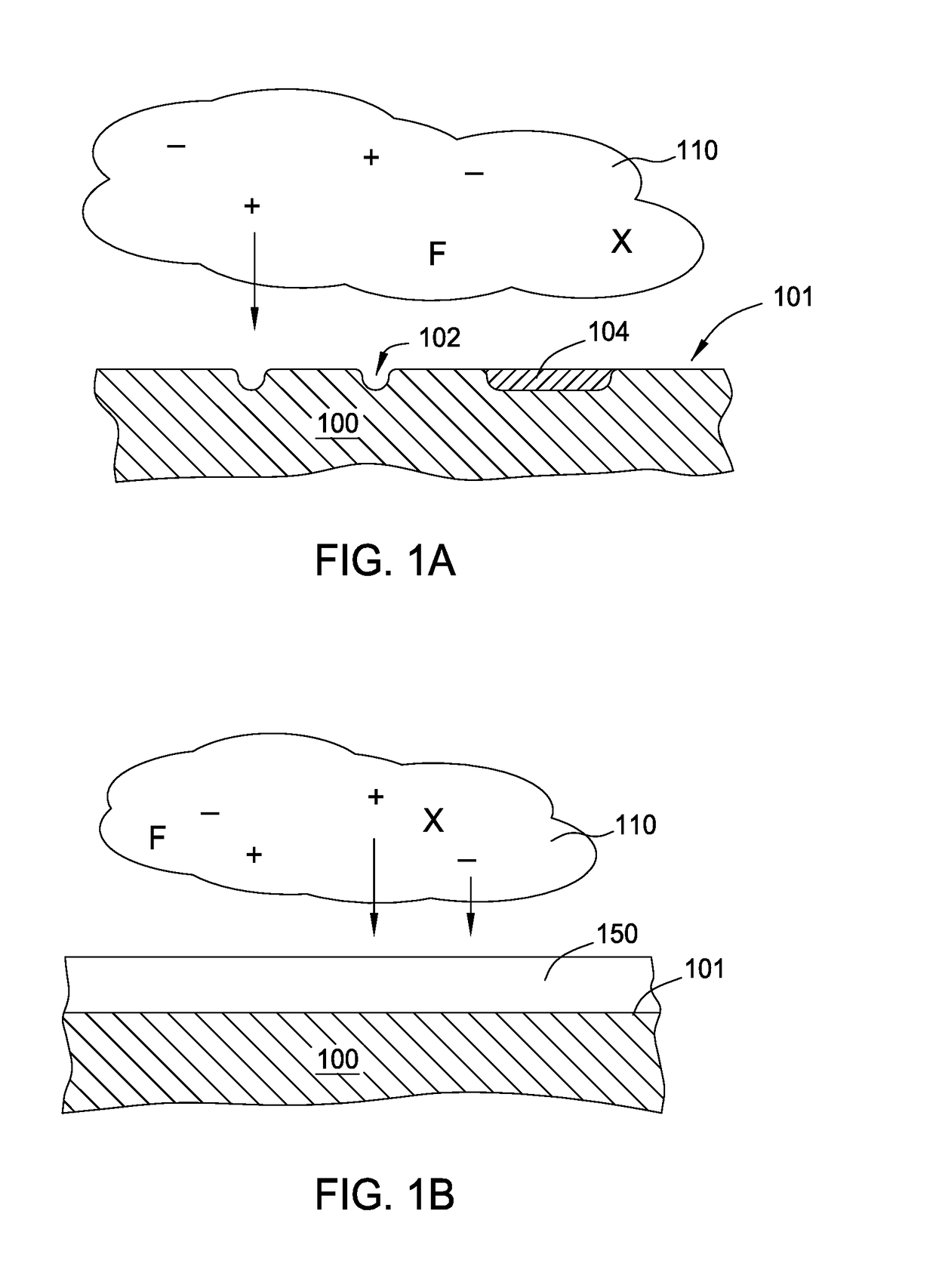

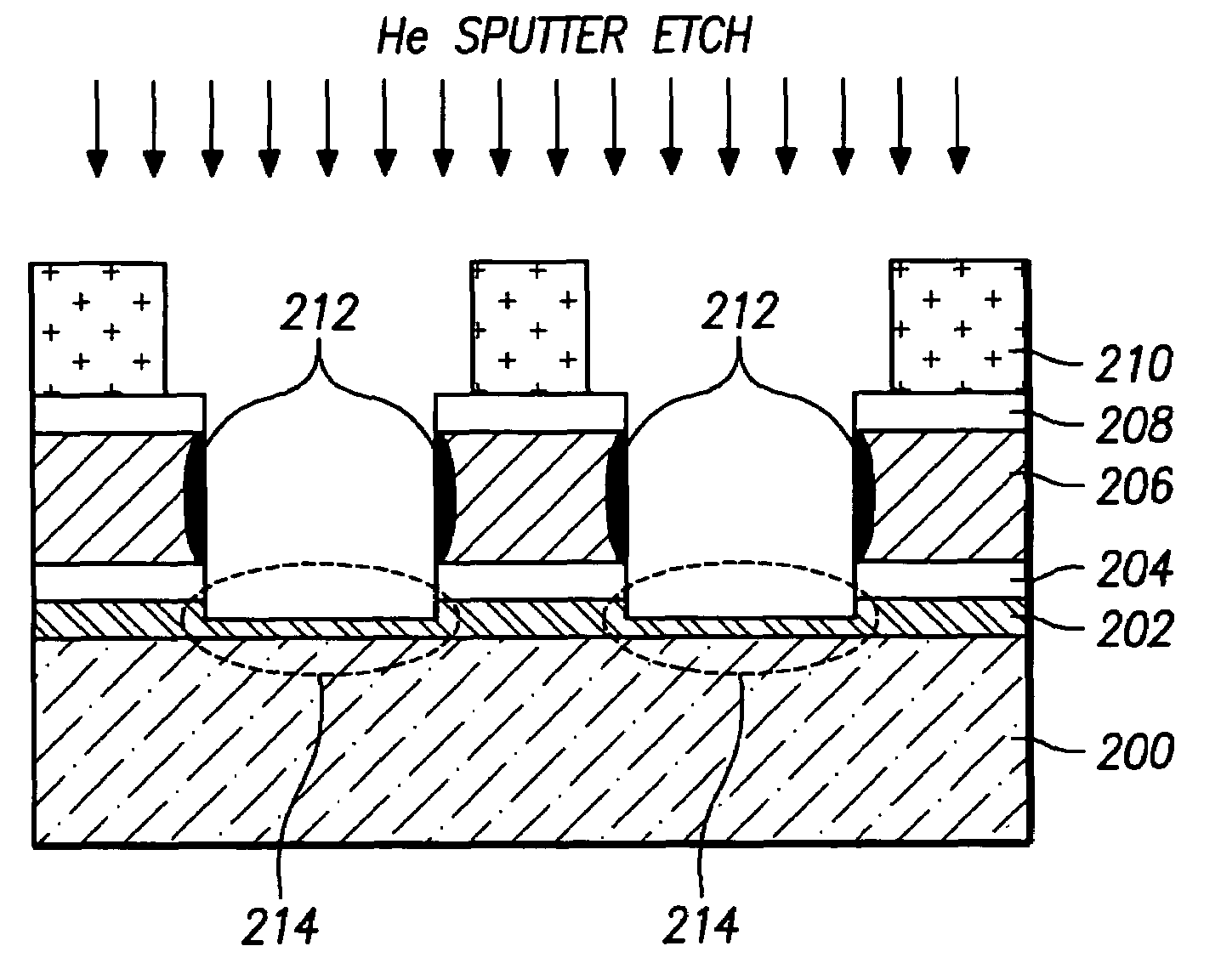

Method for depositing nanolaminate thin films on sensitive surfaces

The present method provides tools for growing conformal metal nitride, metal carbide and metal thin films, and nanolaminate structures incorporating these films, from aggressive chemicals. The amount of corrosive chemical compounds, such as hydrogen halides, is reduced during the deposition of transition metal, transition metal carbide and transition metal nitride thin films on various surfaces, such as metals and oxides. Getter compounds protect surface sensitive to hydrogen halides and ammonium halides, such as aluminum, copper, silicon oxide and the layers being deposited, against corrosion. Nanolaminate structures (20) incorporating metal nitrides, such as titanium nitride (30) and tungsten nitride (40), and metal carbides, and methods for forming the same, are also disclosed.

Owner:ASM INTERNATIONAL

Susceptor

ActiveUS20070144442A1Suppress leakage of gasAvoid it happening againElectric discharge tubesSemiconductor/solid-state device manufacturingSusceptorMechanical engineering

The present invention provides a susceptor including a plate member having an upper surface on which a substrate is placed and a lower surface, a base member bonded to the lower surface of the plate member with a bonding layer, and an annular protective member disposed in an annular recess formed along a rim of a bonding portion of the plate member and the base member, in which a space is formed between the lower surface of the plate member and an upper surface of the protective member and / or between an upper surface of the base member and a lower surface of the protective member. The susceptor can inhibit generation of particles resulting from plasma corrosion, and can suppress extensive leakage of gas from a space or a gap between the plate member and a substrate.

Owner:KYOCERA CORP

Lubricating oil formulations

Lubricating oil compositions having excellent thermal and oxidative stability, wear control, copper corrosion control and compatibility with seal materials comprising a mineral oil having a) a Viscosity Index of greater than 110 and an aniline point of greater than 110 DEG C. and / or b) a linear+single ring paraffin content of greater than 68 wt %, and at least one polymer selected from olefin (co) polymer(s), polyalkyl (meth) acrylate(s) and mixtures thereof. The lubricating oil compositions are particularly useful as manual transmission and axle lubricants.

Owner:AFTON CHEM INTANGIBLES

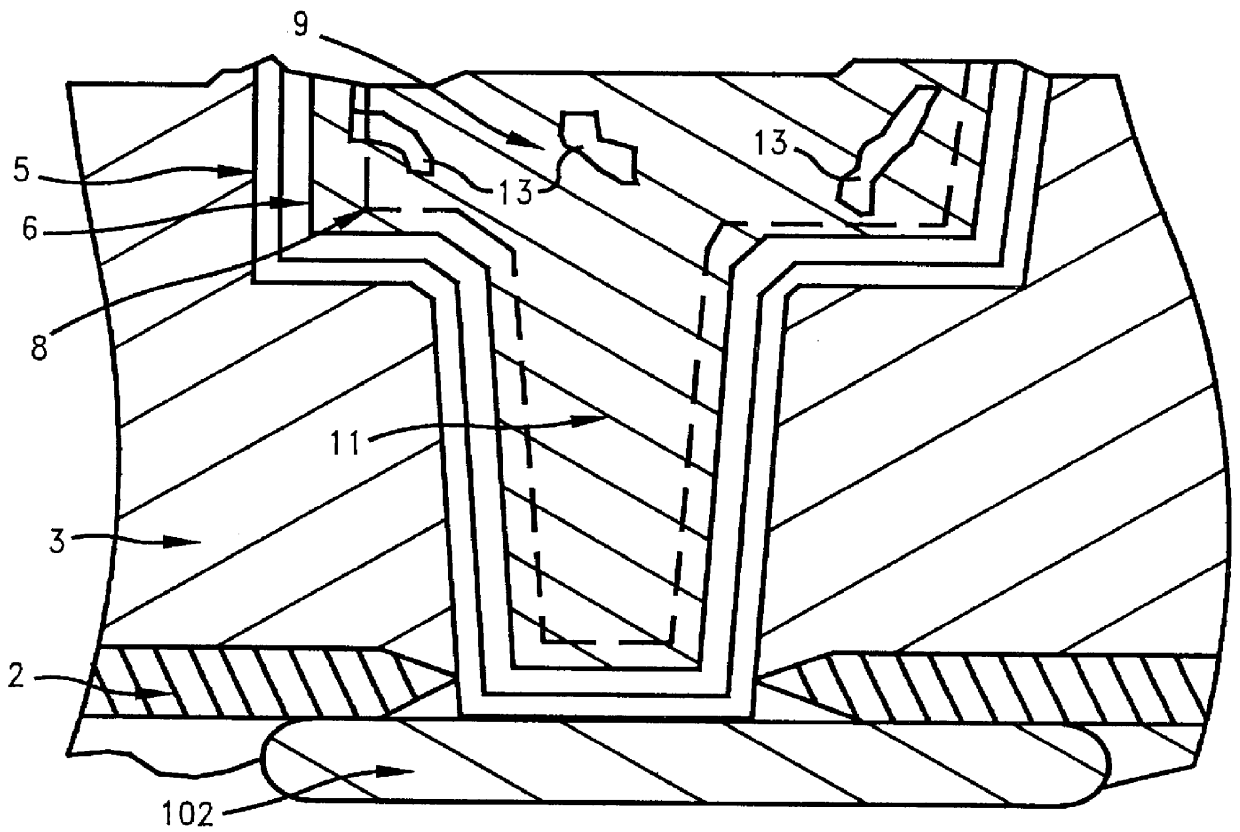

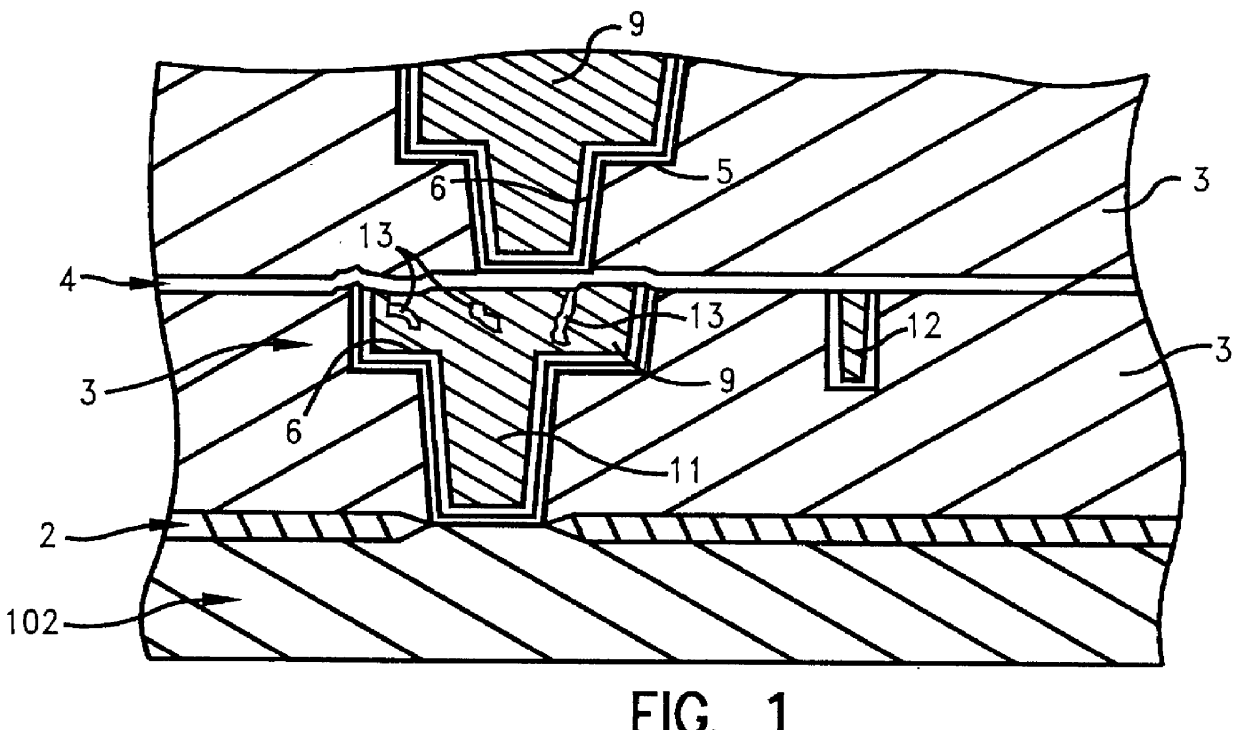

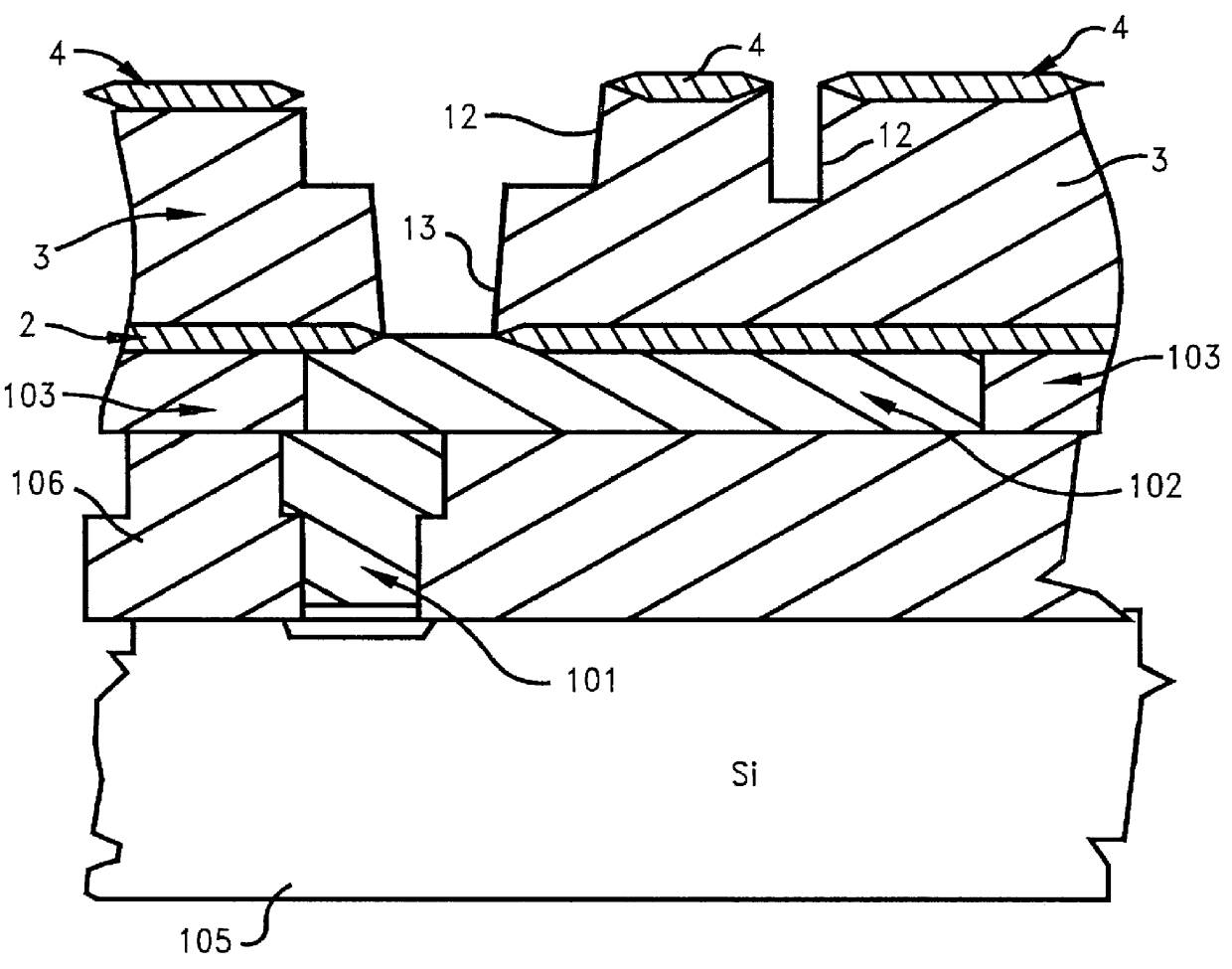

Skin electrode

InactiveUS6845272B1Reduced shelf lifeExtended shelf lifeElectrocardiographySensorsMaterials scienceMetal

An electrode for establishing electrical contact with the skin is disclosed, said electrode having a low impedance and comprising an electrically conductive metallic layer (4) and an electrically conductive gel (12) attached to said metallic layer, wherein the pH of the electrically conductive gel (12) is chosen so as to provide a corrosion of the metallic layer (4).

Owner:MEDICOTEST SYSTR

Cement compositions with improved corrosion resistance and methods of cementing in subterranean formations

InactiveUS6904971B2Improve corrosion resistanceSolid waste managementDrilling compositionPhosphateSlurry

Owner:HALLIBURTON ENERGY SERVICES INC

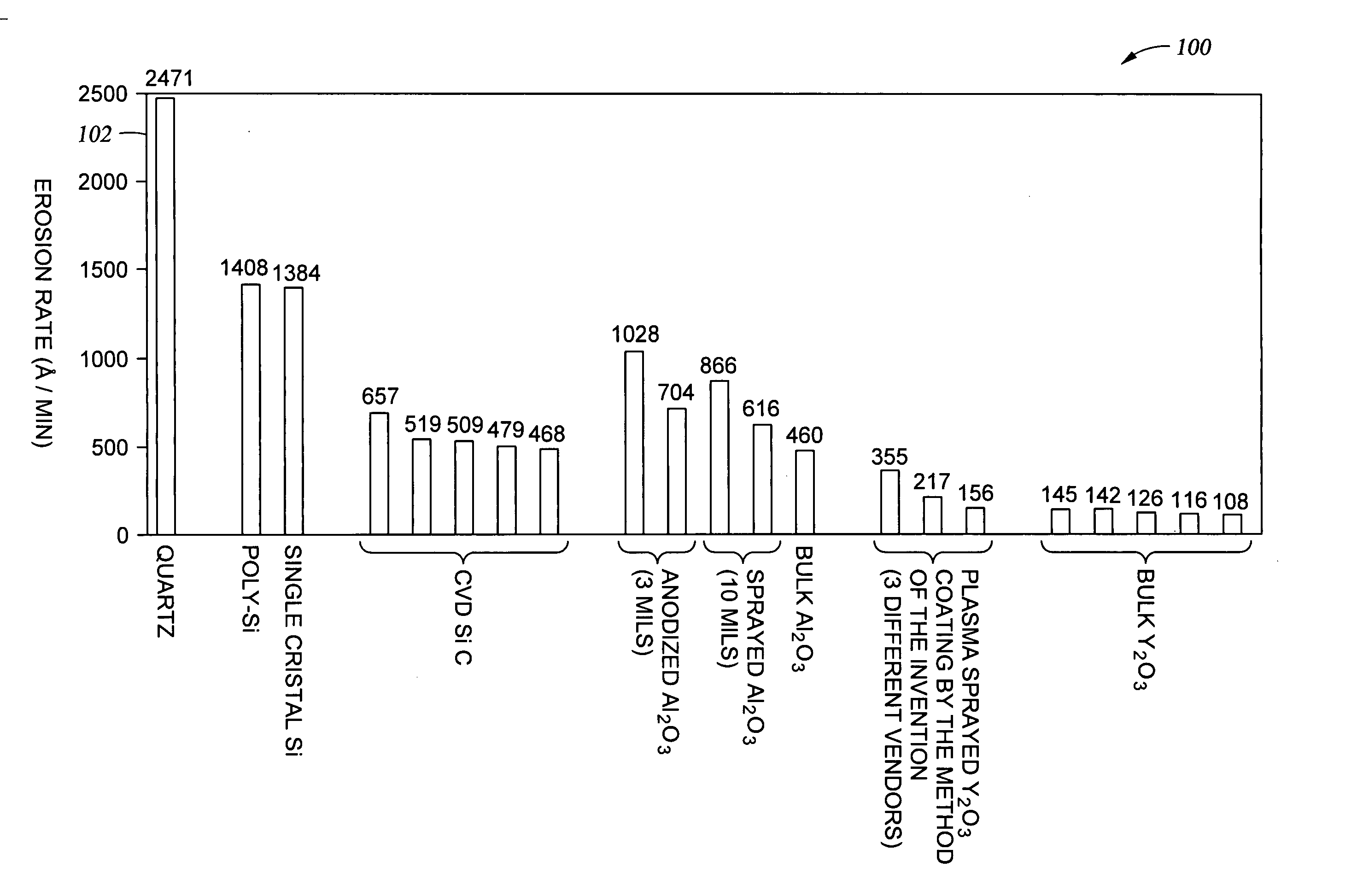

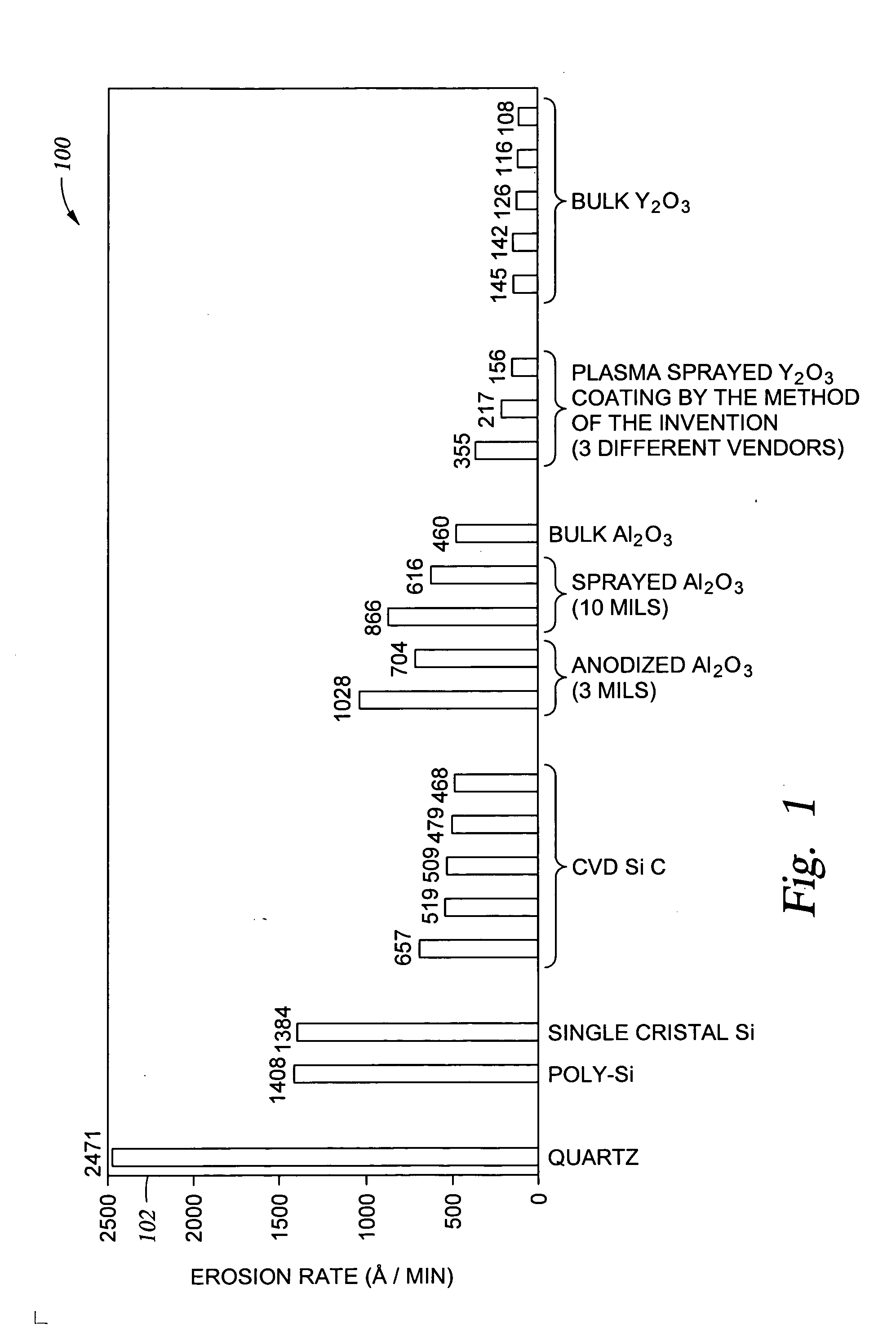

Clean, dense yttrium oxide coating protecting semiconductor processing apparatus

ActiveUS20050037193A1Extended service lifeExcellent plasma corrosion-resistanceLiquid surface applicatorsMolten spray coatingPlasma coatingChemical vapor deposition

Disclosed herein is a method for applying plasma-resistant coatings for use in semiconductor processing apparatus. The coatings are applied over a substrate which typically comprises an aluminum alloy of the 2000 series or the 5000 through 7000 series. The coating typically comprises an oxide or a fluoride of Y, Sc, La, Ce, Eu, Dy, or the like, or yttrium-aluminum-garnet (YAG). The coating may further comprise about 20 volume % or less of Al2O3. The coatings are typically applied to a surface of an aluminum alloy substrate or an anodized aluminum alloy substrate using a technique selected from the group consisting of thermal / flame spraying, plasma spraying, sputtering, and chemical vapor deposition (CVD). To provide the desired corrosion resistance, it is necessary to place the coating in compression. This is accomplished by controlling deposition conditions during application of the coating.

Owner:APPLIED MATERIALS INC

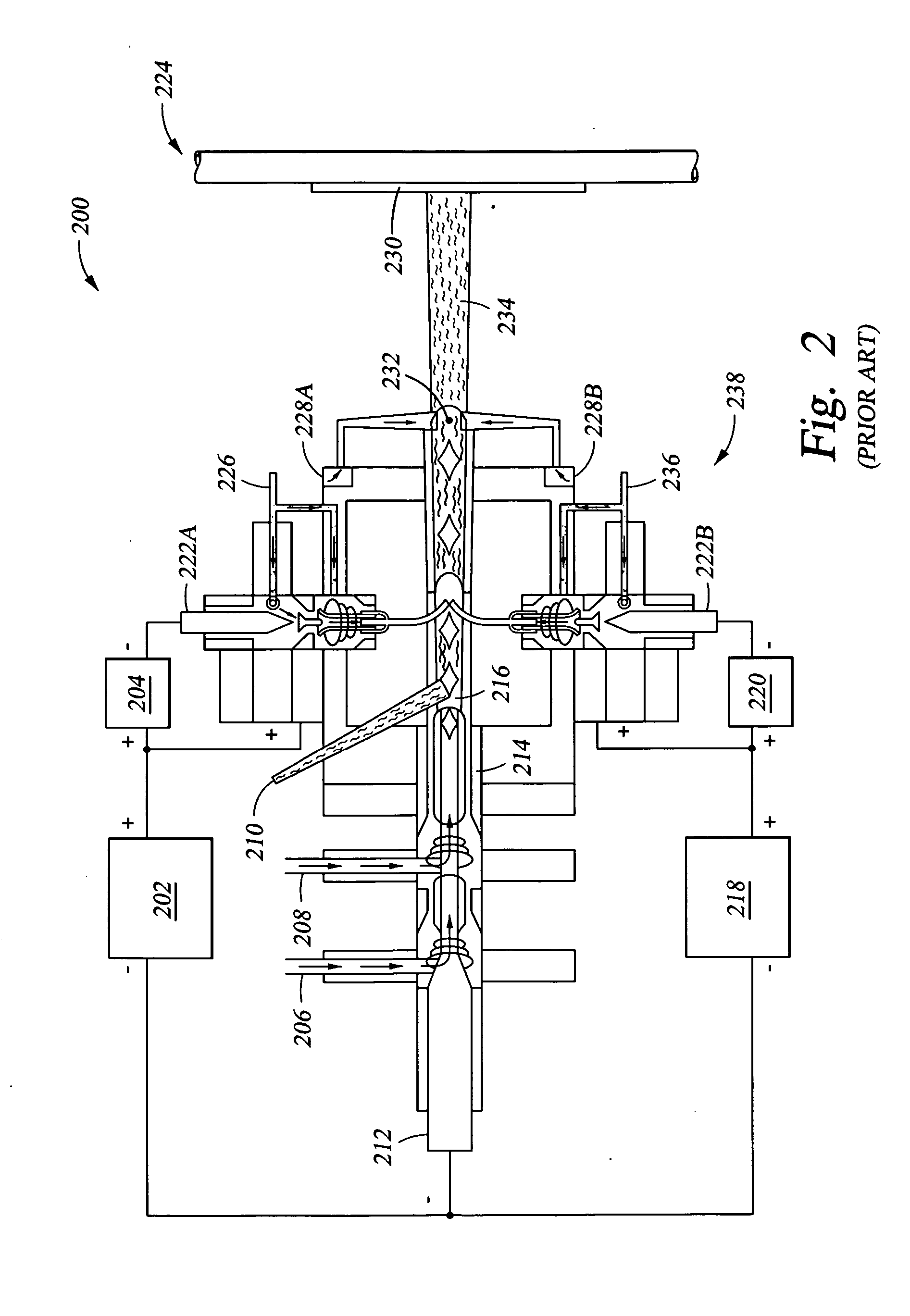

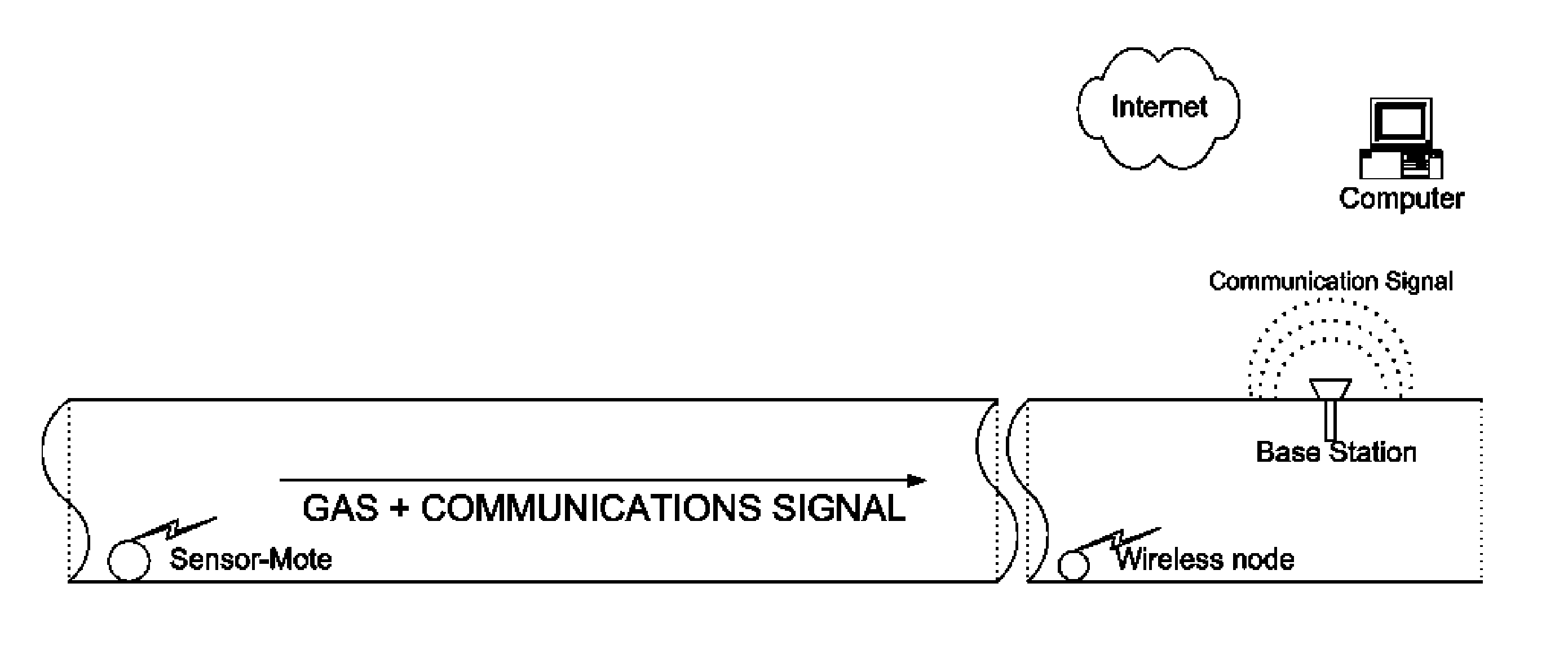

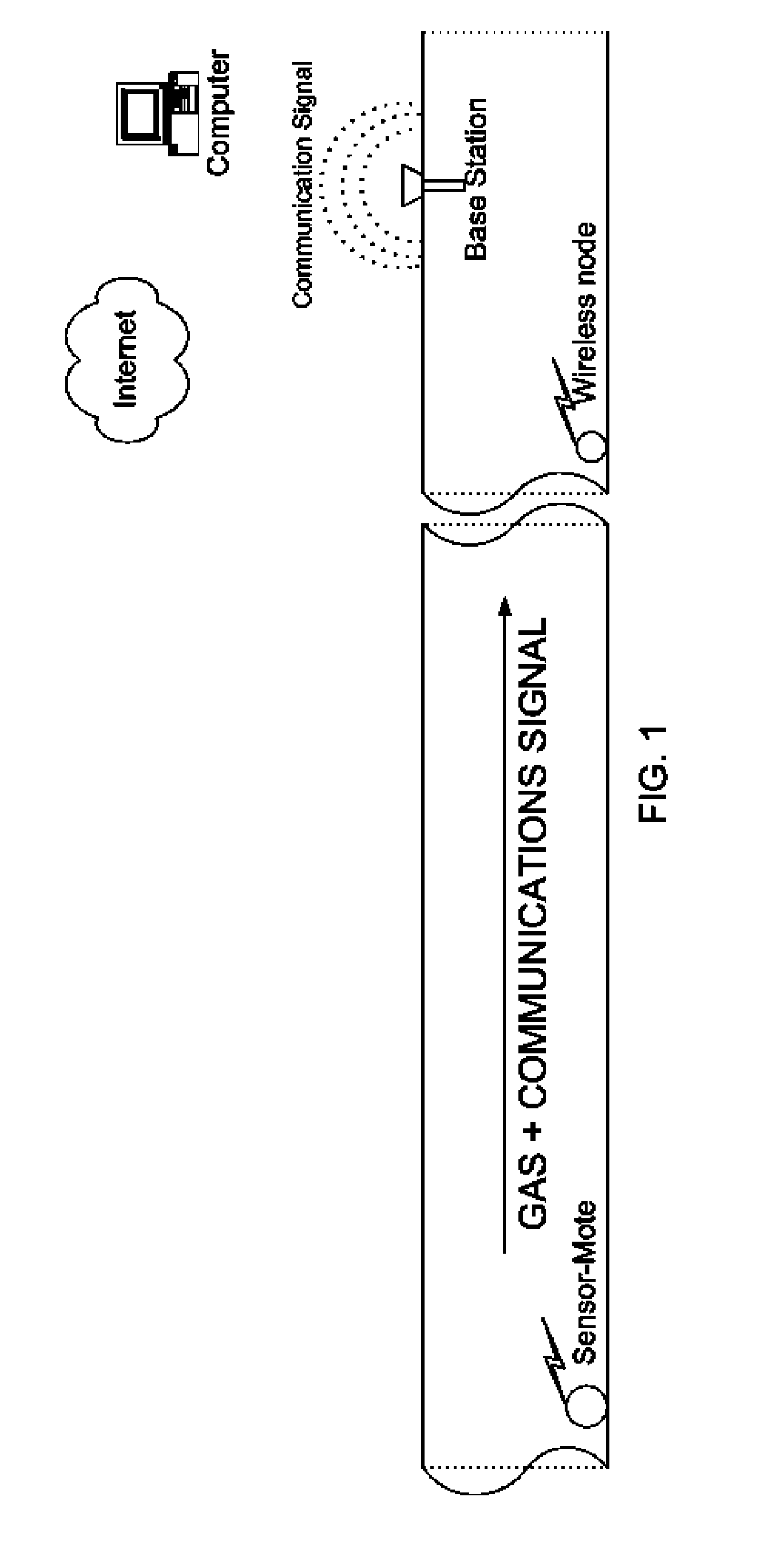

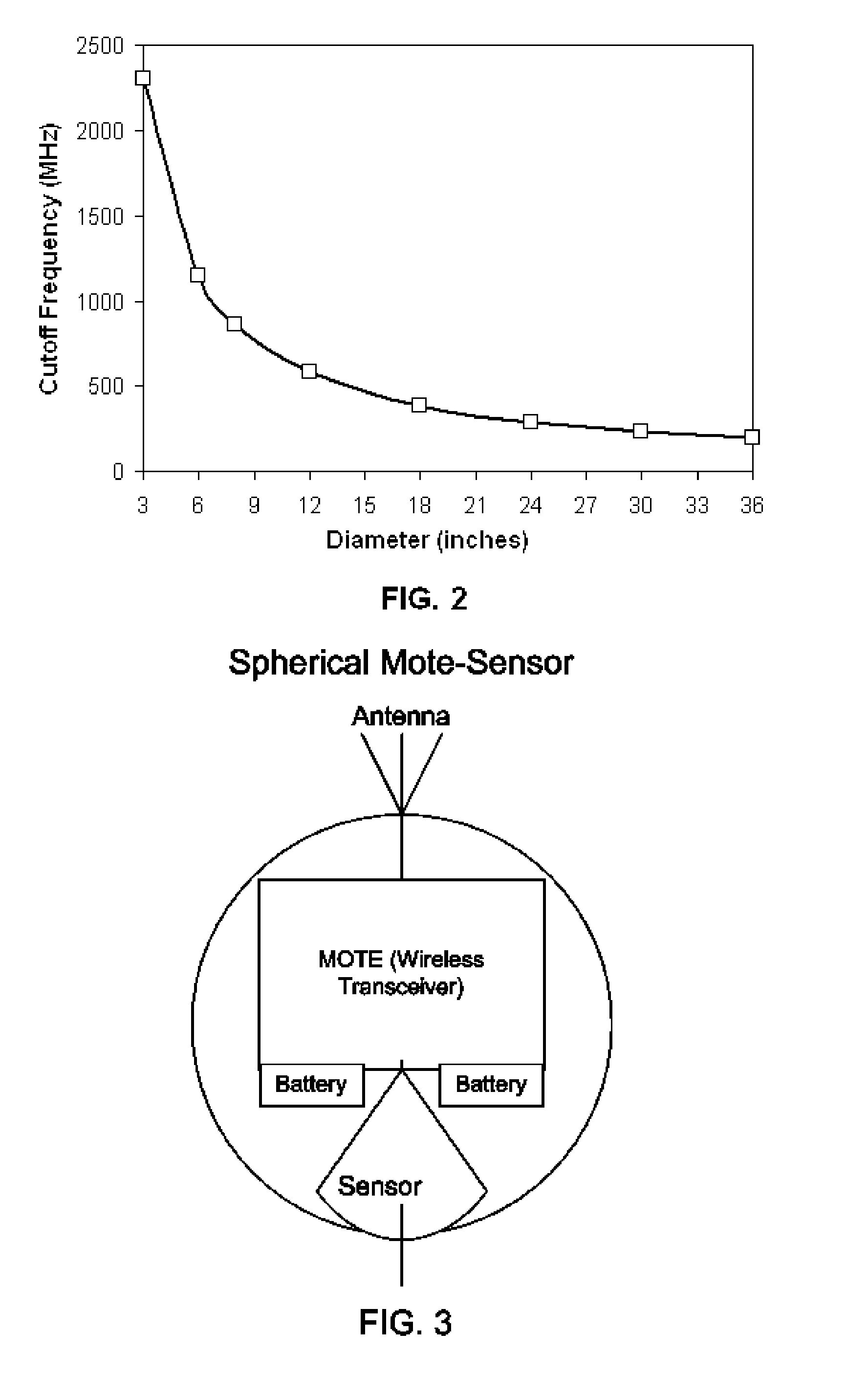

Remote Monitoring of Pipelines using Wireless Sensor Network

InactiveUS20050145018A1Low costLittle powerVehicle testingDetection of fluid at leakage pointLine sensorWireless transceiver

A wireless sensor system is installed inside pipelines using sensors and wireless transceivers that are small, low-cost, and rugged. The objective is monitoring the pipeline and recommending maintenance and repair at specific locations in the pipeline. Maintenance includes detection of leaks and prevention of catastrophic failures as a result of internal corrosion or other damage, such as third party mechanical damage, using multitude of sensors. After establishing the wireless sensor network the network is activated so the sensor can make measurements periodically or continuously using instructions transmitted via the base station. The sensor data from the various sensors are transmitted inside the pipe and extracted to access points in the pipeline to a remote computer that stores the data within the computer memory. The sensed information can be used for monitoring as well as analysis using a recommendation engine to provide maintenance and repair alerts.

Owner:SOUTHWEST RES INST

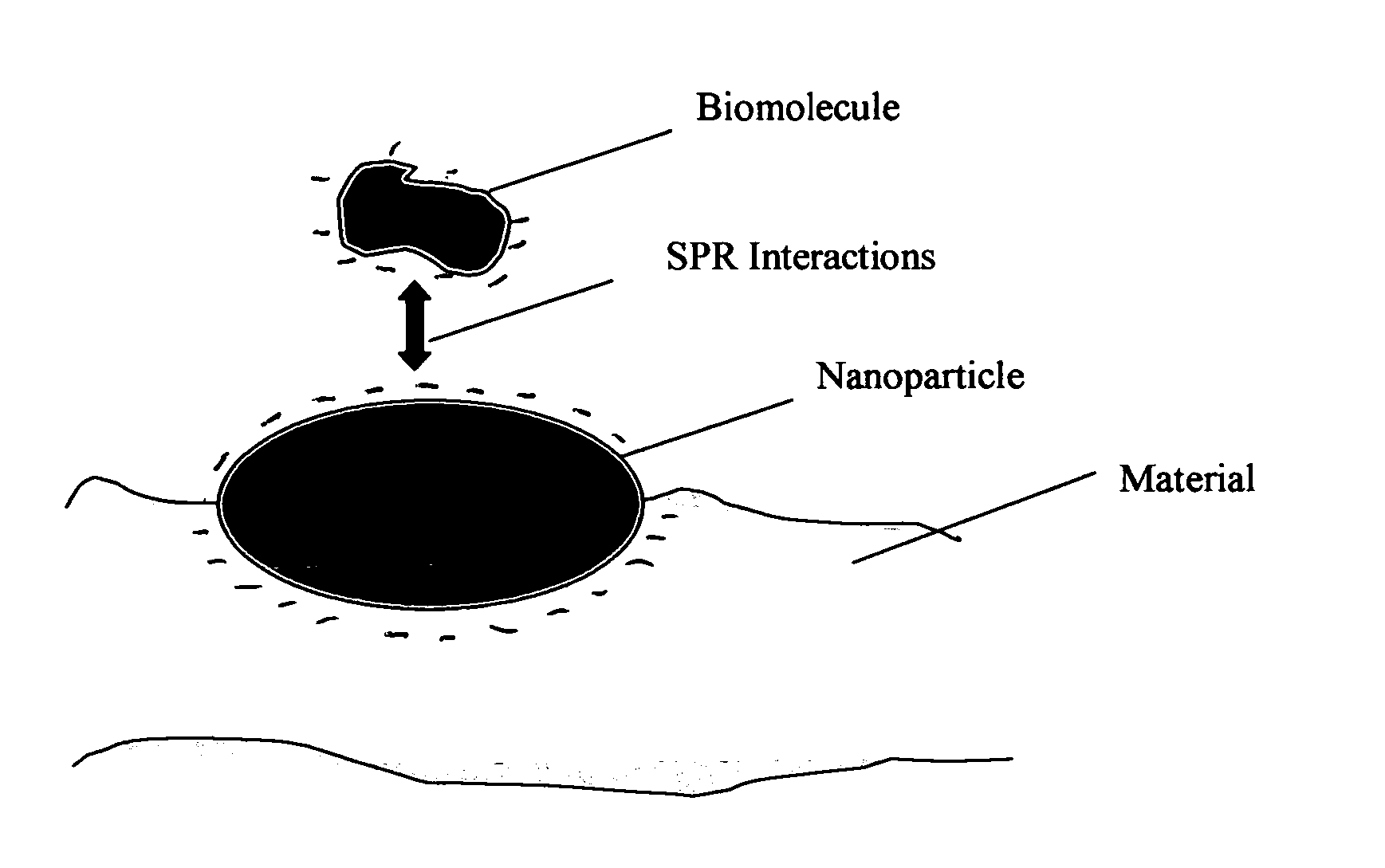

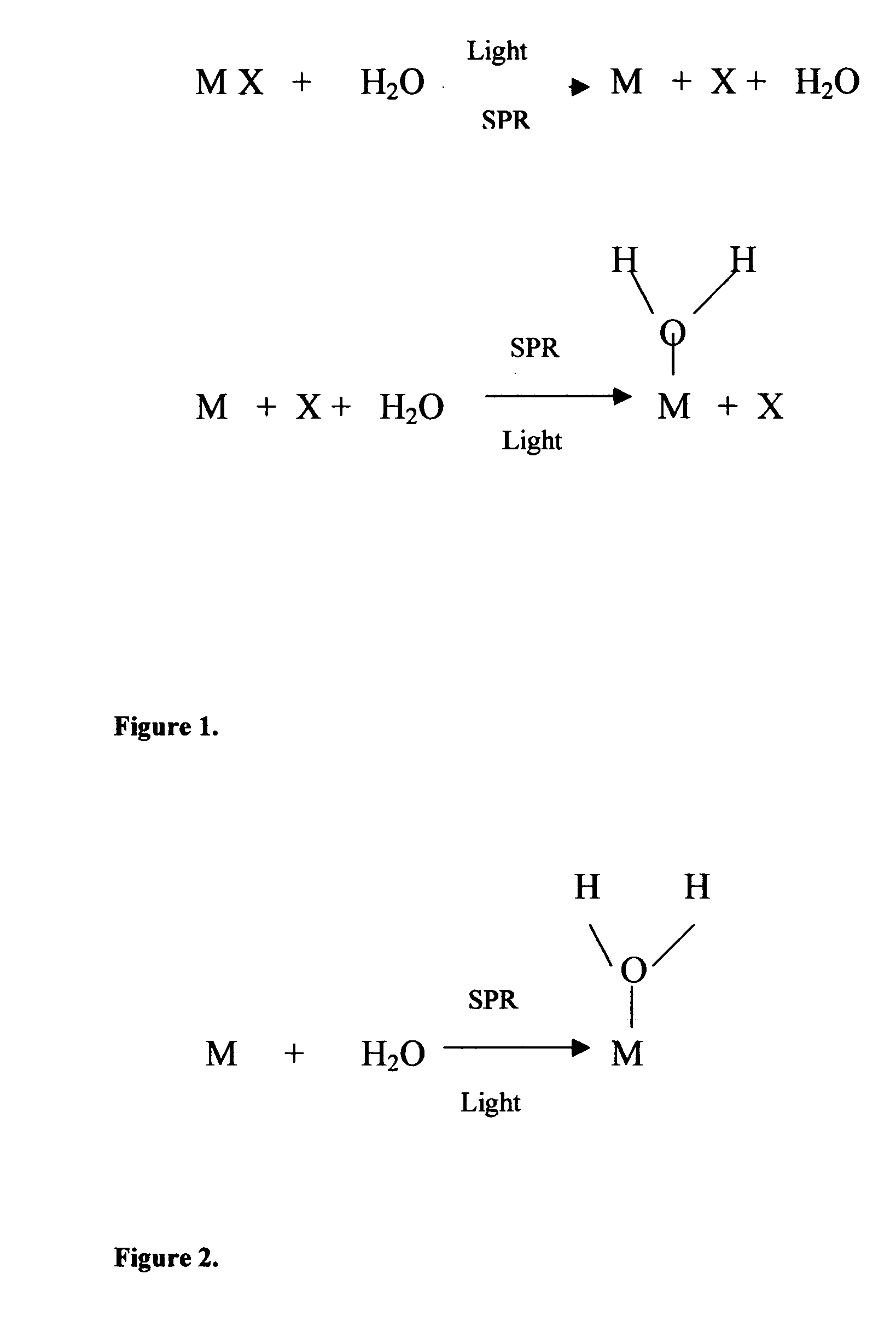

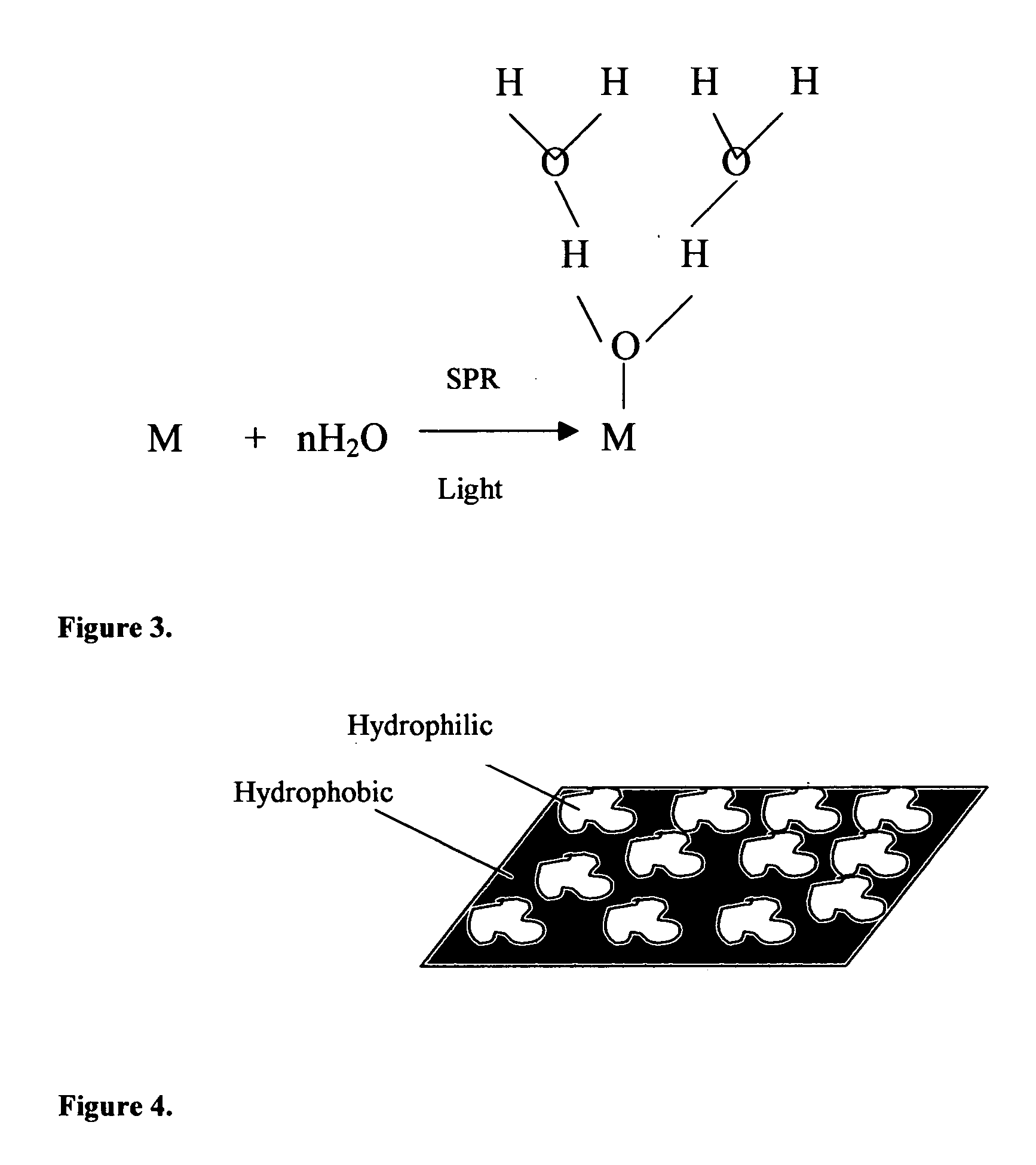

Method of plasmon-enhanced properties of materials and applications thereof

InactiveUS20050164169A1Bioreactor/fermenter combinationsMaterial nanotechnologyInfraredThermochromism

Methods and applications of surface plasmon resonance-enhanced antibacterial, anti-adhere, adhere, catalytic, hydrophilic, hydrophobic, spectral change, biological and chemical decomposition properties of materials with embedded nanoparticles are disclosed. A method of the nonlinear generation of surface plasmon resonance enables the use of light with wavelengths from X-Ray to IR to enhance properties of materials by several orders of magnitude. The nanoparticle size is crucial for the enhancement and their size is considered to be in the proposed methods and applications within a range of 0.1 nm to 200,000 nm. The nanoparticles preferably are made of noble metals and / or semiconductor oxides. The invention describes a very broad spectrum of applications of surface plasmon resonance-enhanced properties of materials with embedded nanoparticles, from environmental cleanup by road pavement and construction materials, self-cleaning processes of surface materials, thermochromic effects on heat blocking materials, corrosion preventing paint, to sanitization by antibacterial textile fabrics, filters, personal clothing, contact lenses and medical devices.

Owner:SPR ADVANCED TECH INC

Plasma etching apparatus and method for forming inner wall of plasma processing chamber

InactiveUS20070215278A1Reduce corrosionDecreasing amountElectric discharge tubesSemiconductor/solid-state device manufacturingProduction rateHeat resistance

A plasma etching apparatus is provided which can prevent corrosion of an aluminum substrate constituting an etching processing chamber or an inside component thereof, thereby avoiding a reduction in productivity due to scattering of a sprayed coating. In the plasma etching apparatus, an anodic oxide film is disposed between a ceramic sprayed coating with excellent resistance to plasma, and the etching processing chamber and the inside component thereof made of aluminum alloy. The anodic oxide film has a thickness of 5 μm or less to have heat resistance.

Owner:HITACHI HIGH-TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com