Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

549results about How to "Good water dispersibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Latex polymer blends for improving the permanence of ink-jet inks

InactiveUS6057384AImprove adhesionPromotes increased adhesionDuplicating/marking methodsInksGlass transitionPolymer chemistry

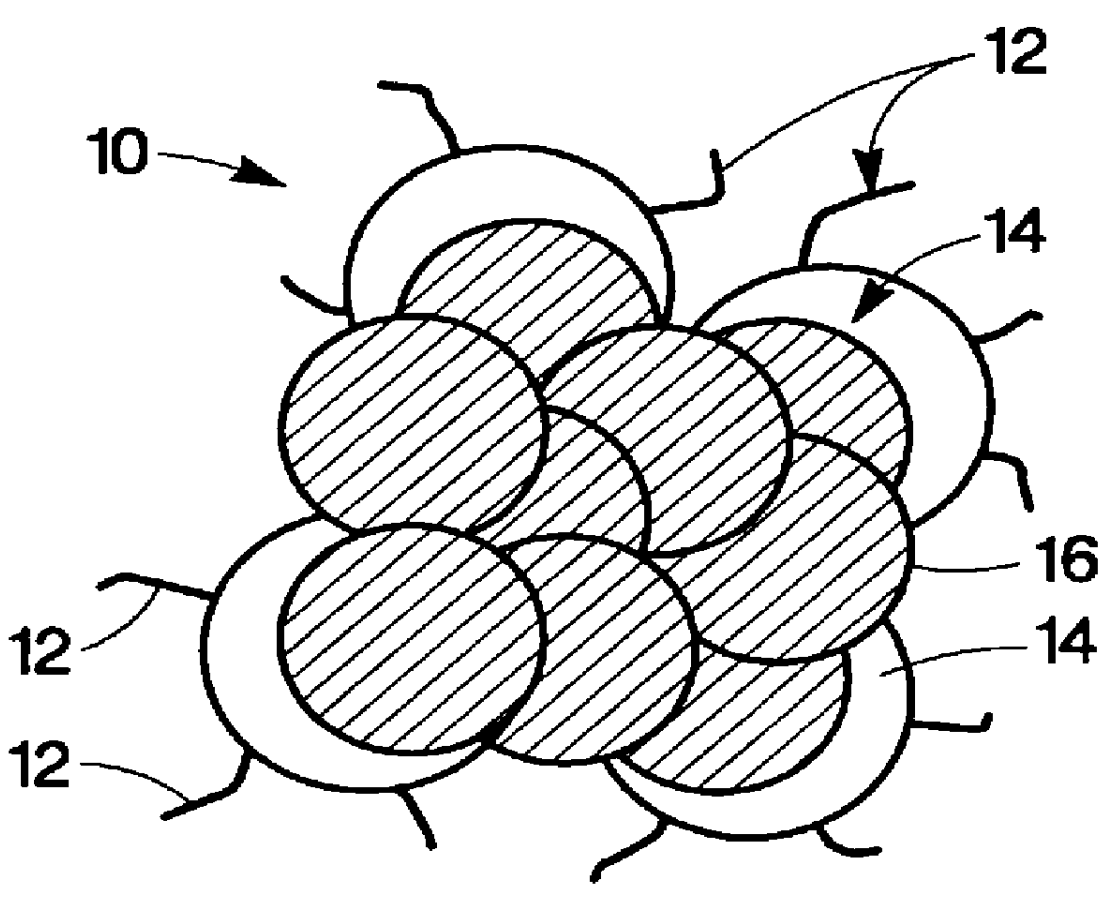

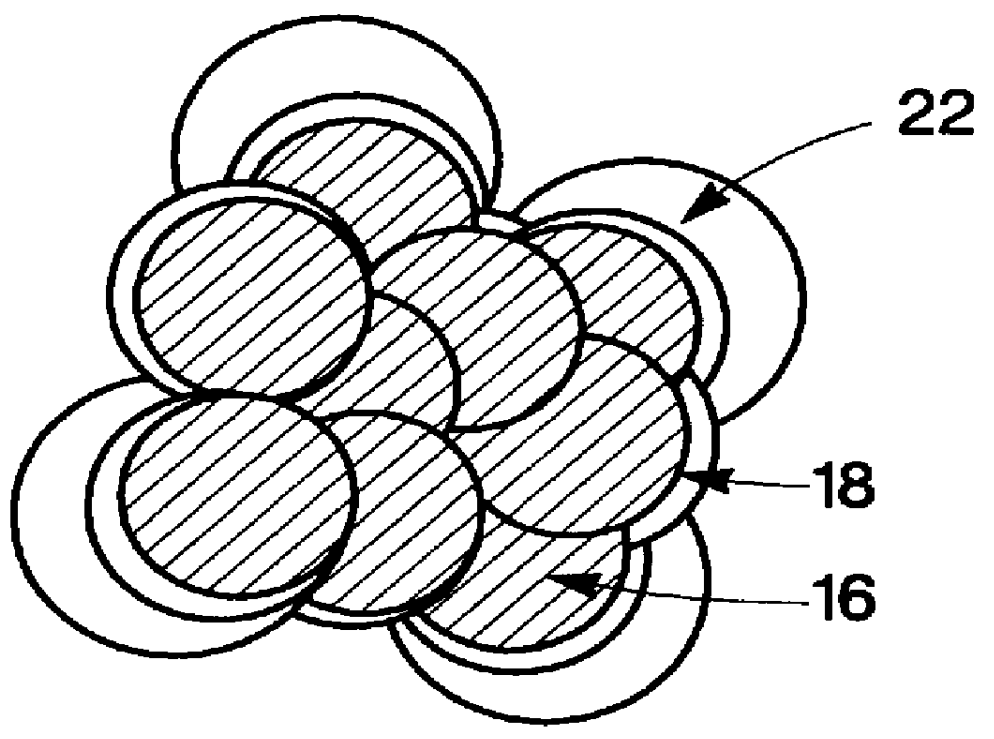

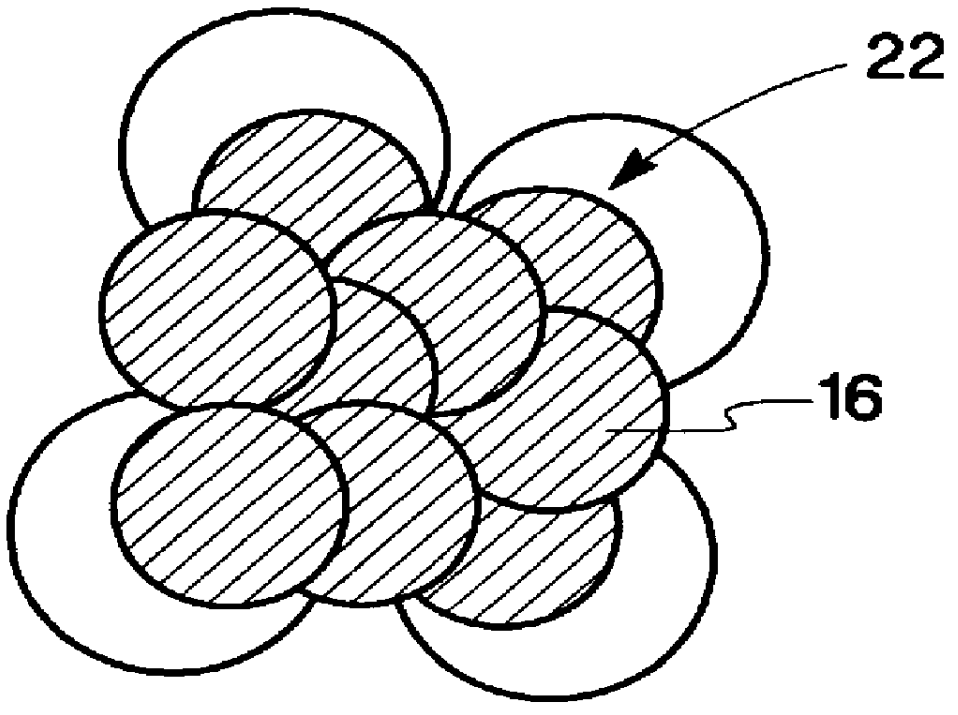

Ink-jet inks for ink-jet printing are provided which include a vehicle and a colorant, the colorant associated with a primer core / shell polymer to form a primer / colorant combination, and the primer / colorant combination, upon printing on a print medium, encapsulated by a durable core / shell polymer. The primer core / shell polymer serves to promote adhesion of the durable core / shell polymer to the colorant and to disperse the colorant in the ink and the durable core / shell polymer serves to provide a smear-fast film upon drying of the ink on a print medium. The primer core / shell polymer comprises a hydrophobic core and a hydrophilic shell comprising a polar component, while the durable core / shell polymer comprises a hydrophobic core comprising a first Tg component, which, when homopolymerized, has a glass trnnsition temperature, Tg, between -150 DEG C. to +25 DEG C. and a second Tg component, which, when homopolymerized, has a glass transition temperature above +25 DEG C. and a hydrophilic shell selected from the group consisting of neutral shells, cationic shells, and anionic shells.

Owner:HEWLETT PACKARD DEV CO LP

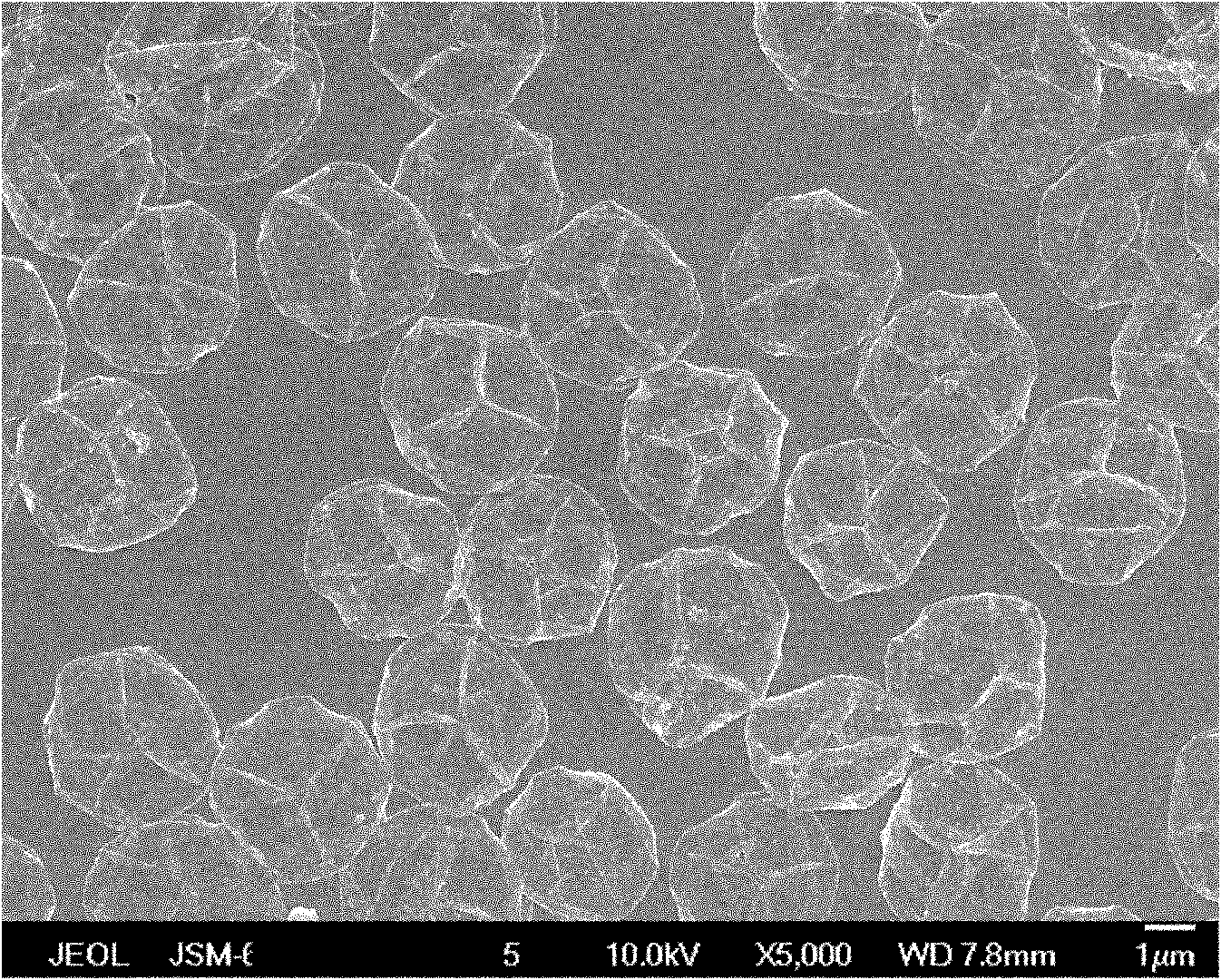

Cast form water borne coating and technique for preparing the same

InactiveCN101497105AGood water dispersibilityGood suspensionFoundry mouldsFoundry coresDefoaming AgentsCorrosion

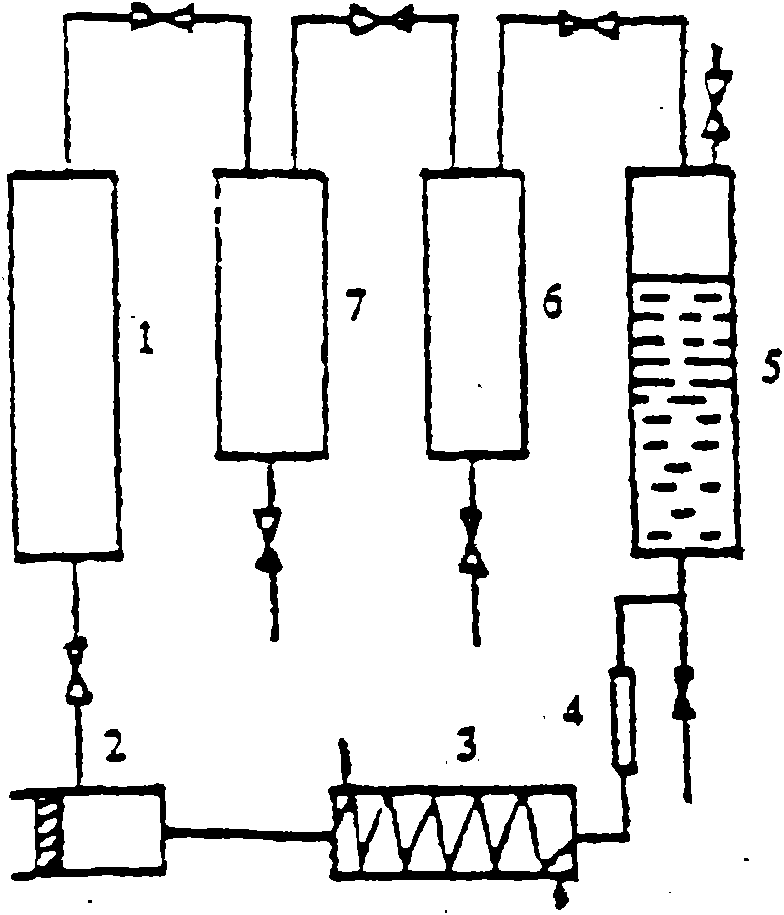

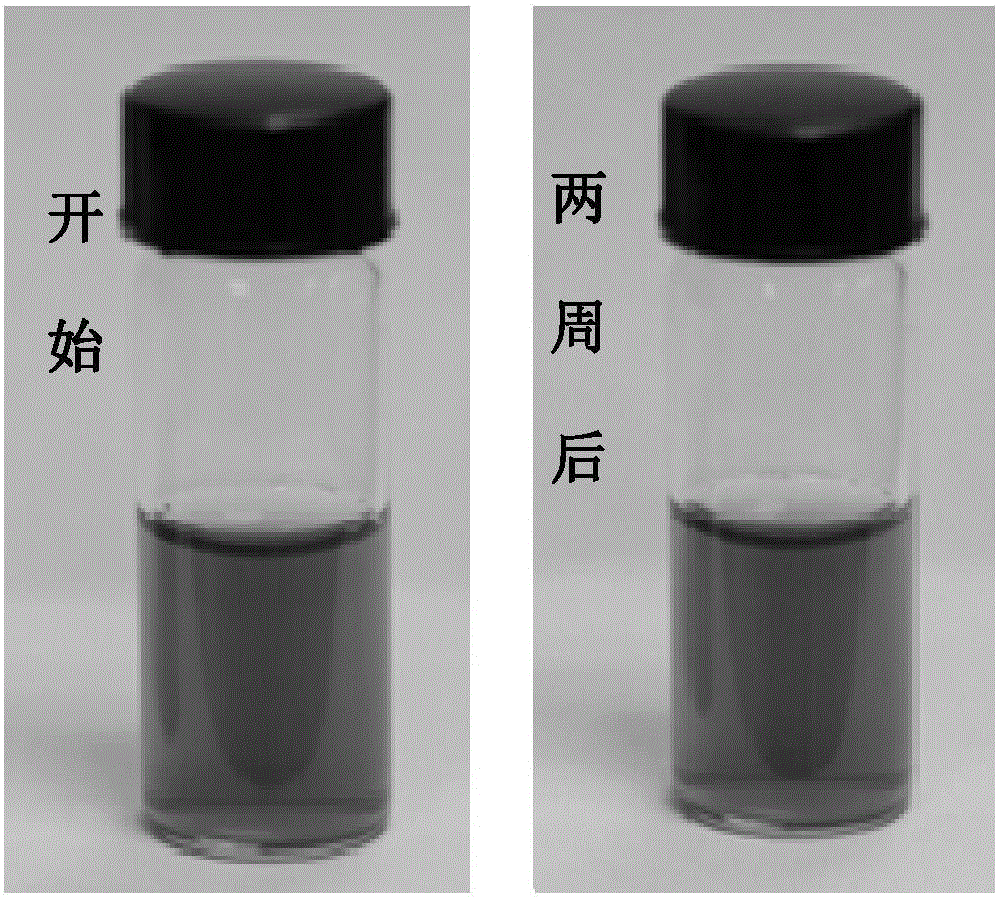

The invention relates to an auxiliary material for casting a mould, in particular to a casting mould water-based coating formulation for a sand mould or an expendable pattern casting (EPC), and a process for preparing the same. The casting mould water-based coating formulation consists of refractory powder, a suspending agent, a bonding agent, a surfactant, a defoaming agent, a corrosion remover and water. The process comprises the following steps: adding the suspending agent to the water directly, and mixing and dispersing the mixture in a high speed dispersion machine; adding auxiliary agents including the defoaming agent, the surfactant, the corrosion remover, and the like to the water, and mixing the auxiliary agents; adding the refractory powder to the mixture to be mixed; and adding the bonding agent to the mixture to be mixed, and then adding water to adjust the coating until the coating has the thickness in a using state to obtain the finished product. The coating prepared by the process has the effects that the coating ensures that a high-density low-viscosity coating has excellent suspension property and storage stability, a coating layer is not easy to crack after drying, the coating is advantageous to improve the capacity of the coating to resist high temperature metal corrosion, and the like.

Owner:深圳市景鼎现代科技有限公司

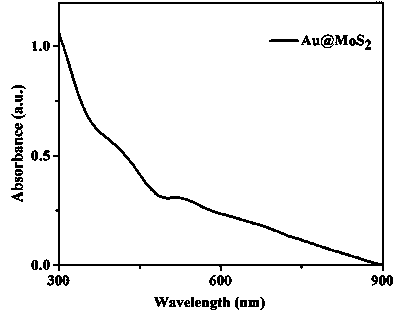

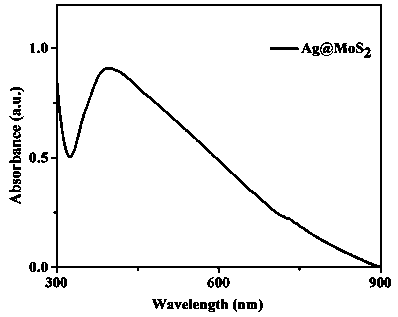

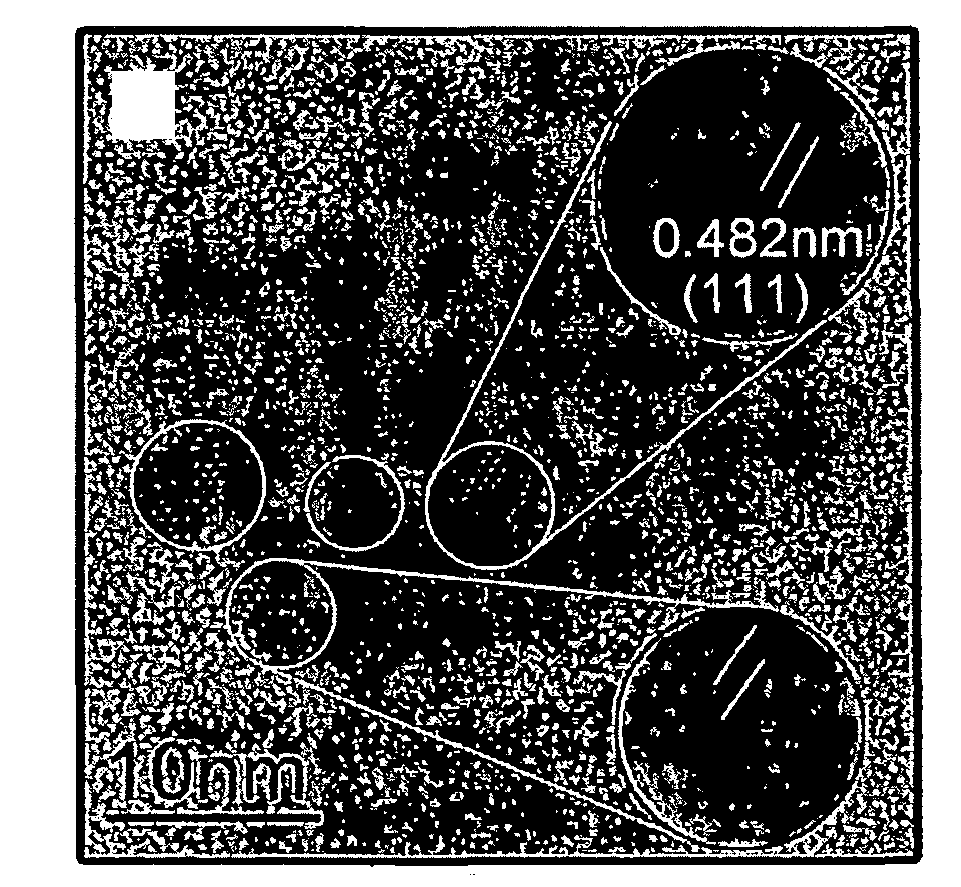

Method for preparing nanocomposite by using two-dimensional transition metal chalcogenide nanosheets and metal

InactiveCN103480856AOvercome limitationsEasy to operateMaterial nanotechnologySulfide/polysulfide preparationNanocompositeReducing agent

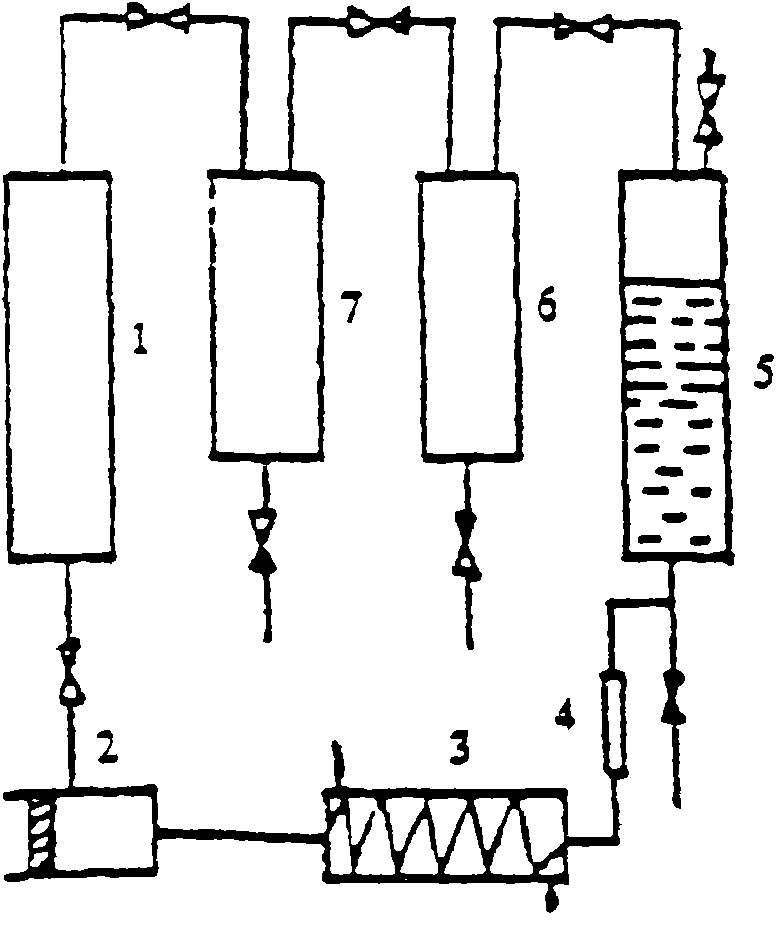

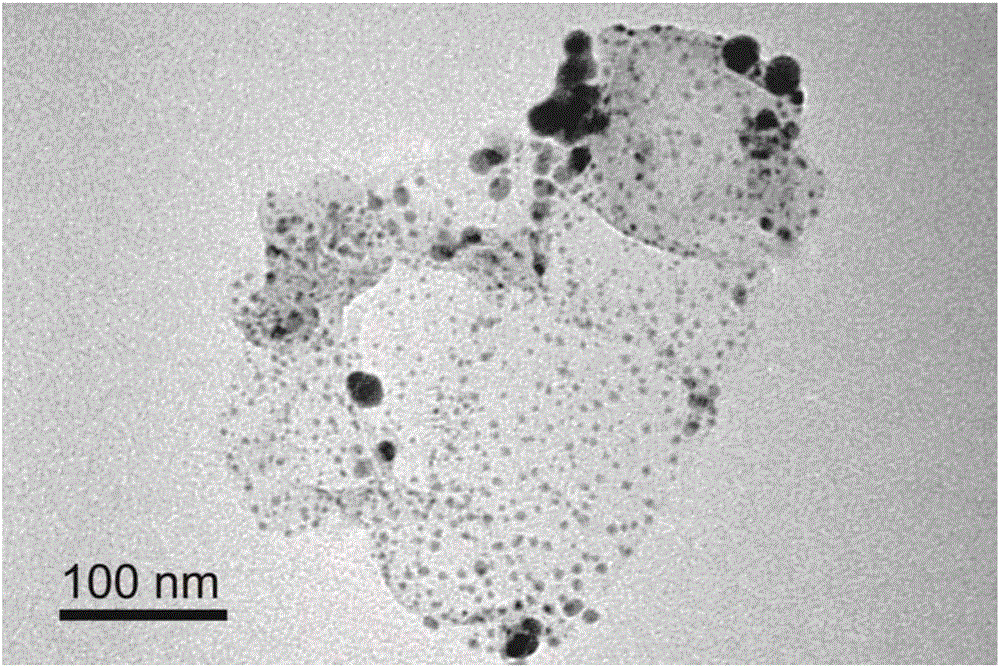

The invention relates to a method for preparing a nanocomposite by using two-dimensional transition metal chalcogenide nanosheets and metal, and belongs to the field of nanomaterial synthesis. The method mainly includes adding a reducing agent and a stabilizing agent into monolayer or multi-layer two-dimensional transition metal chalcogenide nanosheet aqueous dispersion obtained after chemical intercalation, then injecting a certain amount of metal salt solution, and preparing the metal nanocomposite based on monolayer or few-layer two-dimensional transition metal chalcogenide nanosheets on the conditions of ice bath, hydrothermal method, microwaves, ultrasound and the like. In the composite, metal nanoparticles can be evenly distributed on the surfaces of the nanosheets, and the obtained composite can be evenly dispersed in water, and can be used in the solution phase and further processed. Through compositing of the metal nanoparticles, photoelectric property of two-dimensional transition metal chalcogenide can be improved, and the nanocomposite has good application prospects in the fields of supercapacitors, fuel cells and biosensors based on surface enhanced Raman detection, and the like.

Owner:NANJING UNIV OF POSTS & TELECOMM

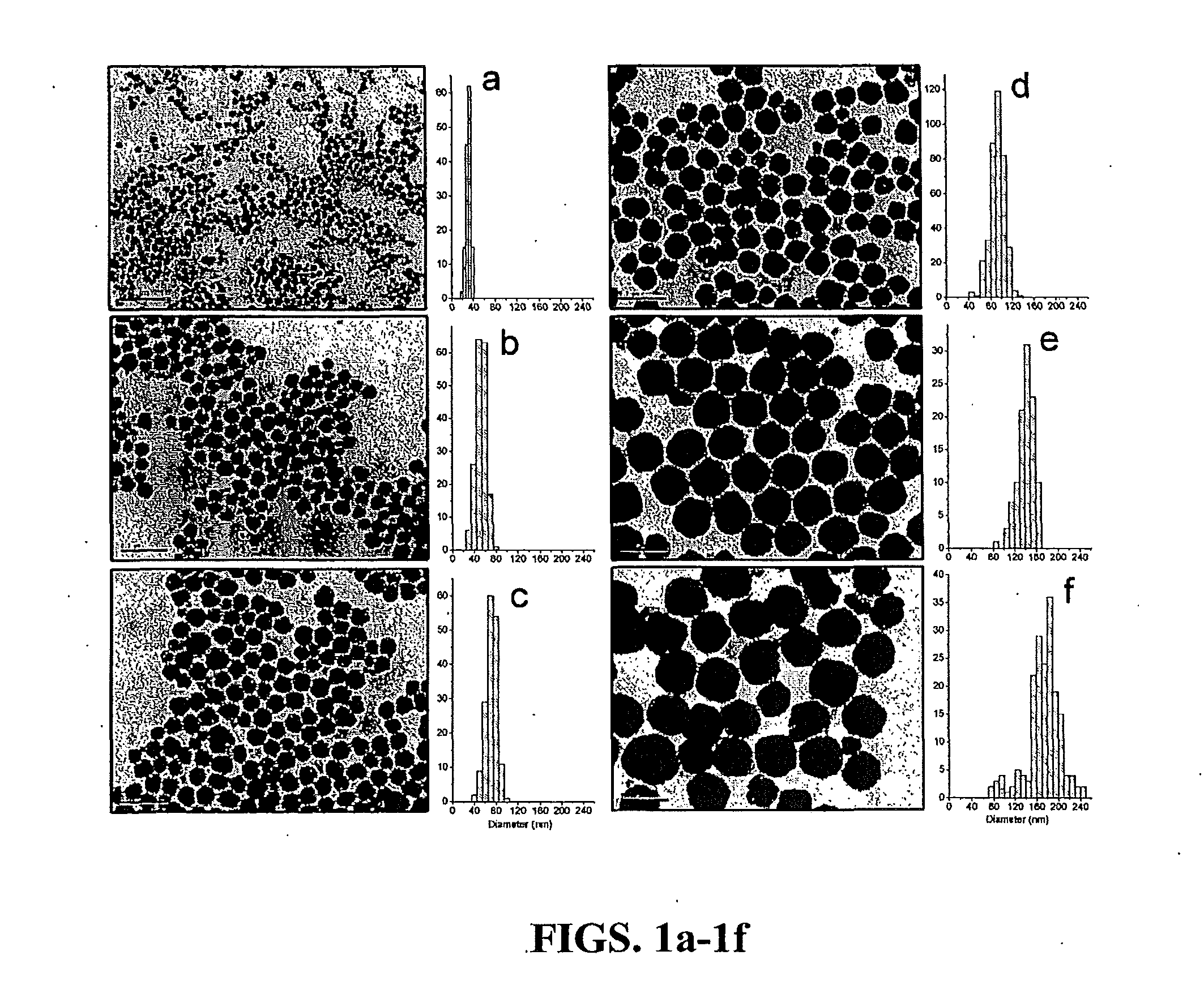

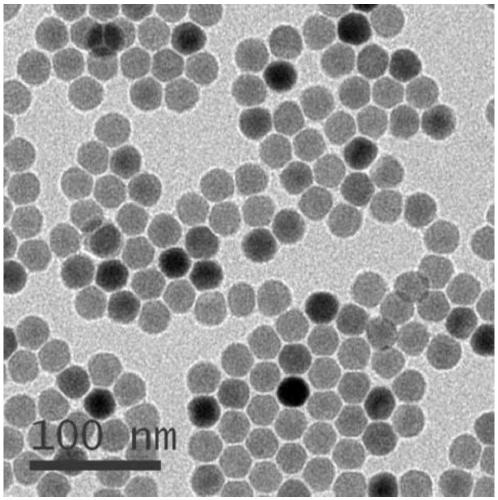

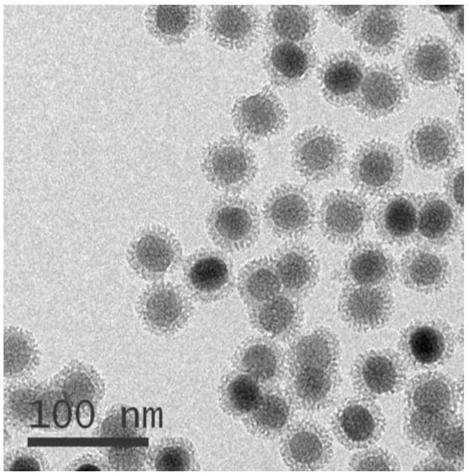

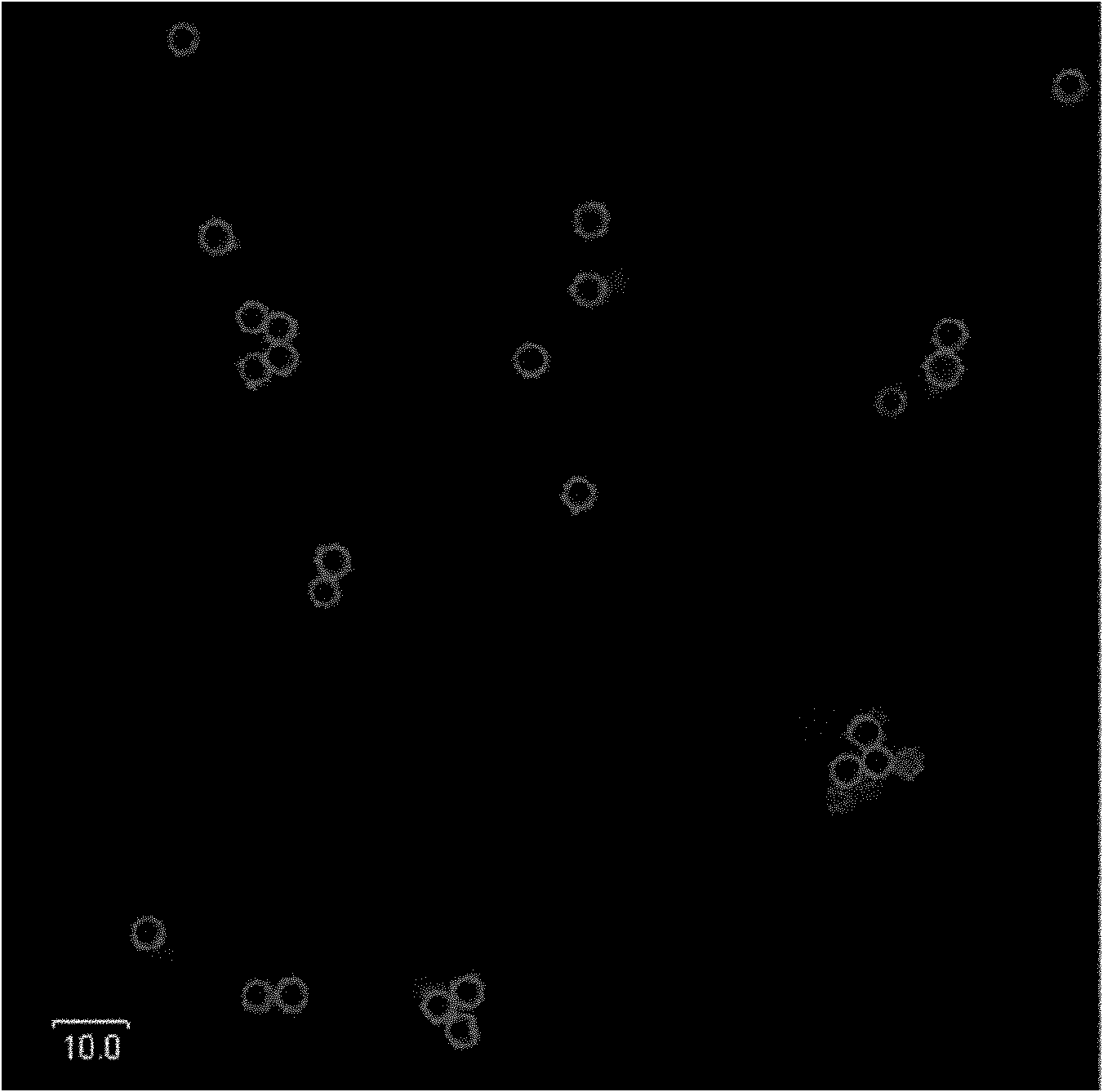

Superparamagnetic colloidal nanocrystal structures

ActiveUS20100224823A1High magnetizationGood water dispersibilityMaterial nanotechnologyPigmenting treatmentMagnetitePhotonics

Monodisperse colloidal nanocrystal clusters of magnetite (Fe3O4) with tunable sizes from about thirty to about three hundred nanometers have been synthesized using a high-temperature hydrolysis process. The colloidal nanocrystal clusters are capped with polyelectrolytes, and highly water soluble. Each cluster is composed of many single magnetite crystallites, thus retaining the superparamagnetic behavior at room temperature. The combination of superparamagnetic property, high magnetization, and high water dispersibility makes the colloidal nanocrystal clusters ideal candidates for various important biomedical applications such as drug delivery and bioseparation. The present invention is further directed to methods for forming colloidal photonic crystals from both aqueous and nonaqueous solutions of the superparamagnetic colloidal nanocrystal clusters with an external magnetic field applied thereto. The diffraction of the photonic crystals can be tuned from near infrared to visible and further ultraviolet spectral region by varying the external magnetic field.

Owner:RGT UNIV OF CALIFORNIA

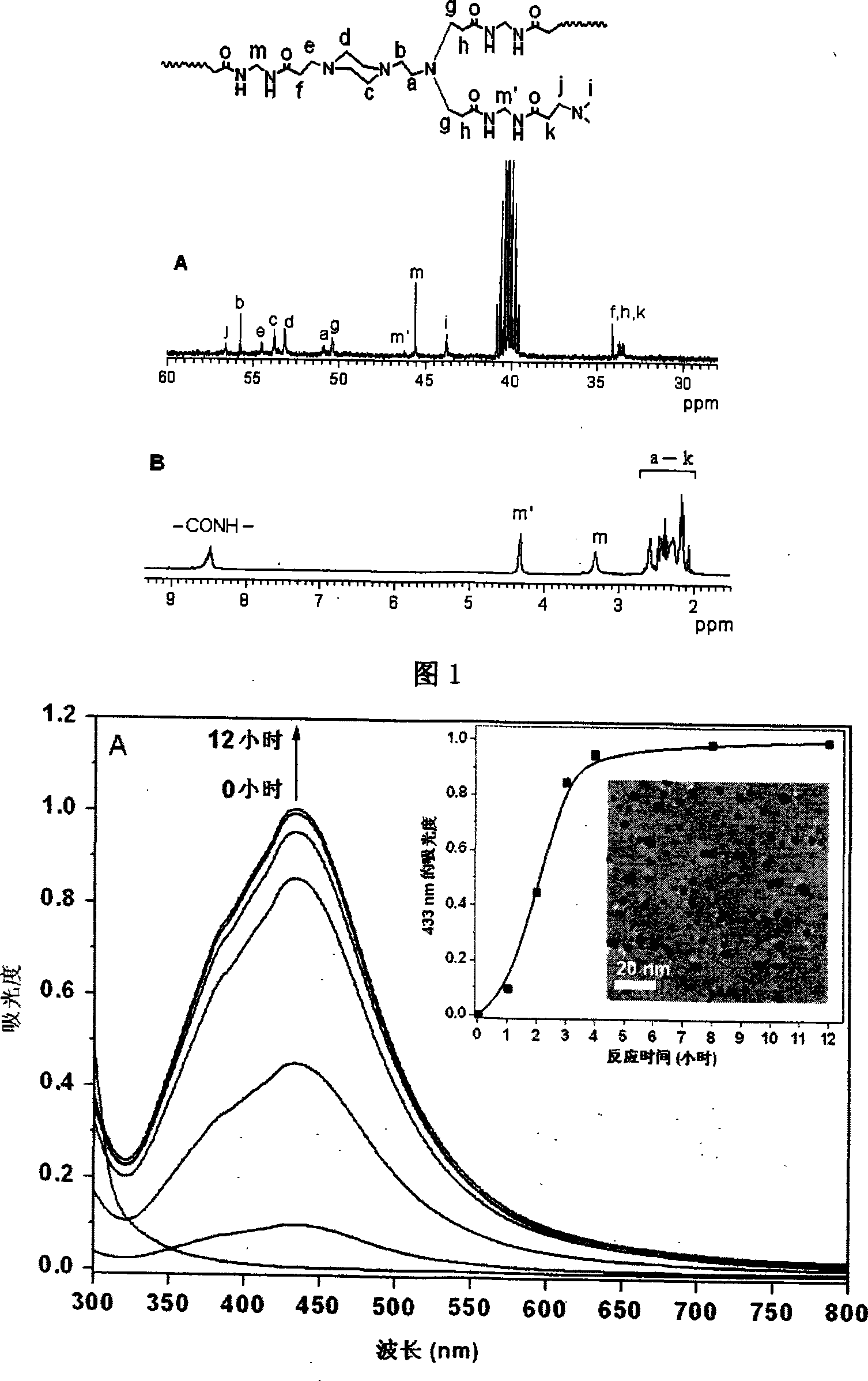

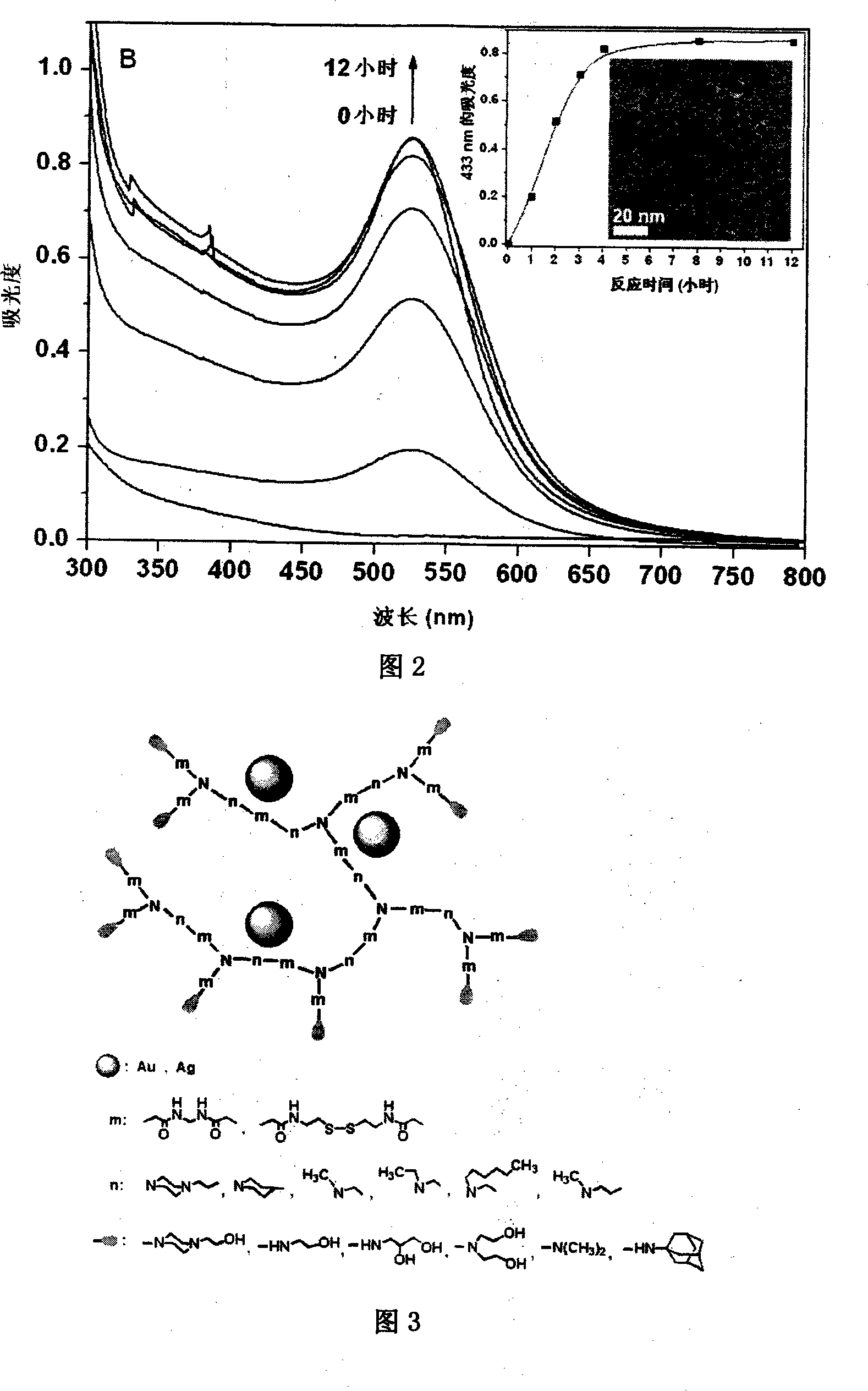

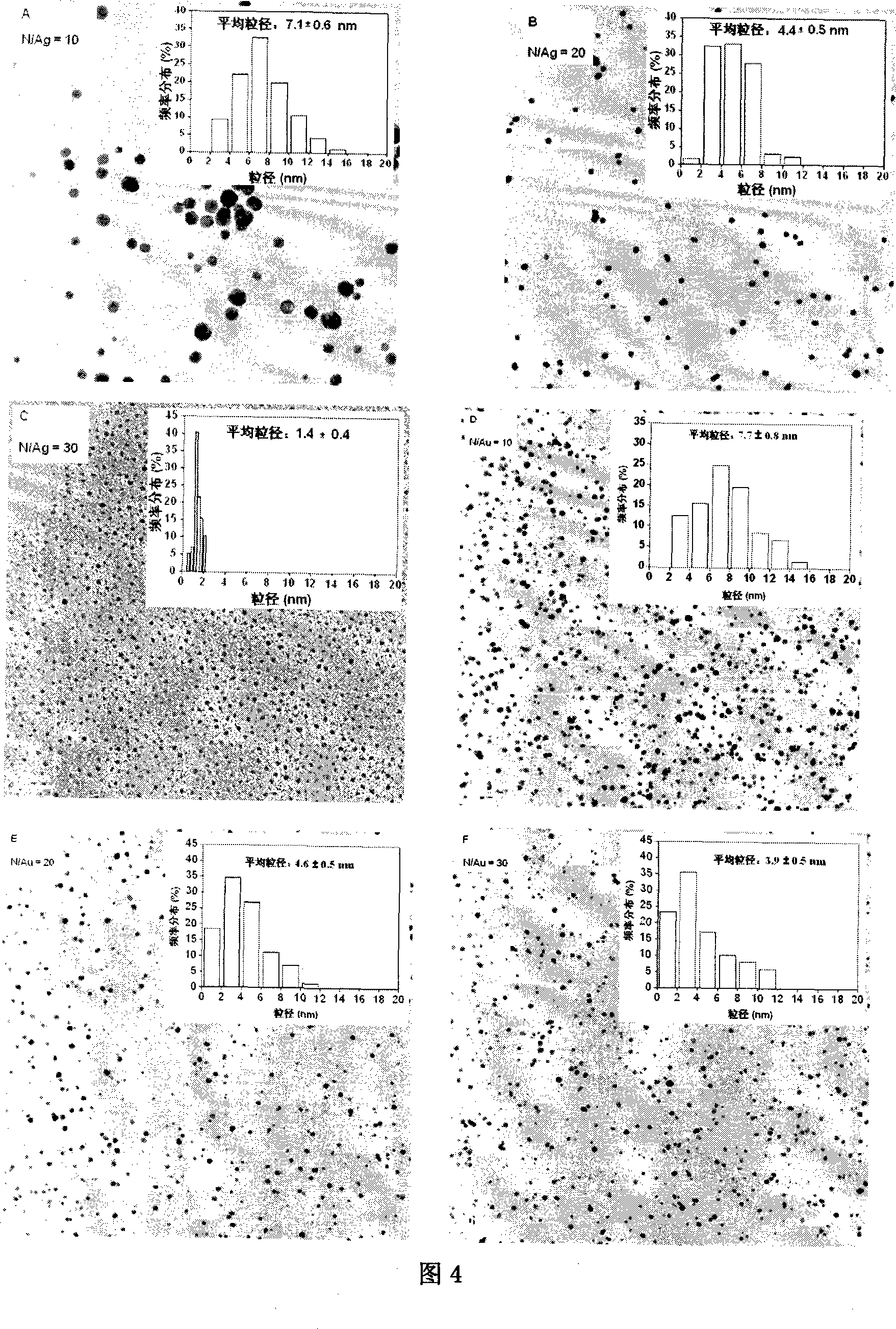

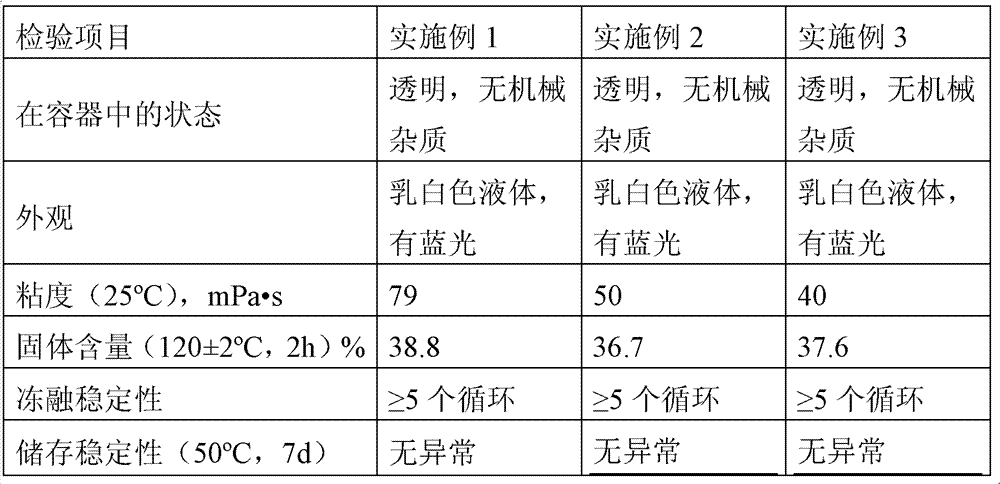

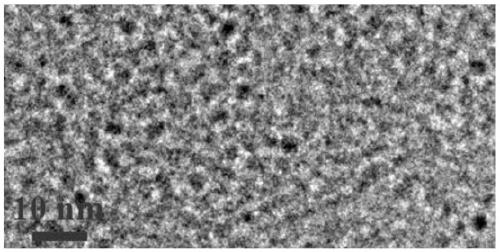

Over-branched polyamidoamine and metal nano compound as well as preparation method and uses thereof

InactiveCN101225227AGood water dispersibilityGood antibacterial effectBiocideAnimal repellantsMethod testWater dispersible

The invention relates to a hyper branched polyamide amine and metal nanometer compound and the preparation method and the application, belonging to the technical field of nanotechnology which is characterized in that: the compound comprises a polymer and metal nanometer particles, the polymer is the hyper branched polyamide amine made of blocking modification the hyper branched polyamide amine of the vinyl-terminated through different small organic molecules with amine, the content of the polymer is 89wt percent to 98wt percent; the metal nanometer particles are golden or silver nanometer particles, the content of the metal nanometer particles is 2wt percent to 11wt percent. During the preparation course, no reducing agent or ultraviolet irradiation is required, the precursor metal compounds are directly added into the hyper branched polyamide amine solution, and the metal nanometer particles with perfect water dispersion is generated only through one-step reaction under ambient temperature, the average particle size of which is one to eight nm, and the size is controllable. The inhibition zone method and the optical density method tested show that: the hyper branched polyamide amine and the metal nanometer particle compound have perfect antibacterial effects to a plurality of bacteria and fungus.

Owner:SHANGHAI JIAO TONG UNIV

Multiple crosslinking ultraviolet light solidifying water polyurethane dispersoid and its preparation method and application

The invention discloses a multiple crosslink ultraviolet solidification aqueous polyurethane disperser, a relative preparation method and an application. The preparation method comprises synthesizing polyurethane initial polymerized compound I, synthesizing polyurethane prepolymer II, synthesizing polyurethane prepolymer III, synthesizing polyurethane acrylate oligomer and synthesizing ultraviolet solidification aqueous polyurethane disperser. The invention mainly utilizes aromatic diisocyanate, diatomic alcohol prepolymer, polyhydroxy carboxylic acid, epoxy resin and hydroxyl acrylate as raw materials, with better water dispersity and storage stability, which leads in light inducer, levelling agent, defoaming agent and thickener to prepare ultraviolet solidification aqueous wood paint better than solvent ultraviolet solidification photosensitive resin, with stable storage, low fineness, high rigidity, high brightness, better flow leveling property, better water resistance, better solvent resistance, excellent abrasion resistance, environment protection, easy process and fire hazard resistance.

Owner:SOUTH CHINA UNIV OF TECH

Composite modified aqueous polyurethane resin and its preparation method

A composite modified aqueous polyurethane resin comprises 6-19wt% of diisocyanate, 6-15wt% of a macro-molecular polyol, 2-15wt% of castor oil, 1-5wt% of a micro-molecular chain extender, 1-8wt% of an epoxy resin, 2-10wt% of a hydrophilic chain extender, 1-4wt% of a neutralizer, 0.01-0.1wt% of a catalyst, 5-15wt% of a vinyl monomer, 2-15wt% of a solvent, 0.5-2wt% of a post chain extender, 0.01-0.5wt% of an initiator and 50-60wt% of deionized water. A preparation method of the composite modified aqueous polyurethane resin comprises the following steps: 1, adding the macro-molecular polyol, the castor oil and the diisocyanate to a reaction vessel, stirring, heating to 80-90DEG C, and maintaining the temperature for 2h; 2, adding the micro-molecular chain extender, the epoxy resin, the catalyst, the hydrophilic chain extender and the solvent, and maintaining the temperature at 80-84DEG C for 30min; 3, detecting NCO, cooling to below 40DEG C, and adding the vinyl monomer; 4, adding the neutralizer, stirring at a high speed for 30ming, adding the deionized water and the post chain extender, stirring at a middle speed for 10min, and heating to 80DEG C; and 5, adding the initiator, maintaining the temperature for 2h, cooling to 30DEG C, and filtering to obtain the composite modified aqueous polyurethane. The composite modified aqueous polyurethane resin synthesized in the invention has the advantages of very good water dispersity and very good storage stability.

Owner:上海展辰涂料有限公司 +2

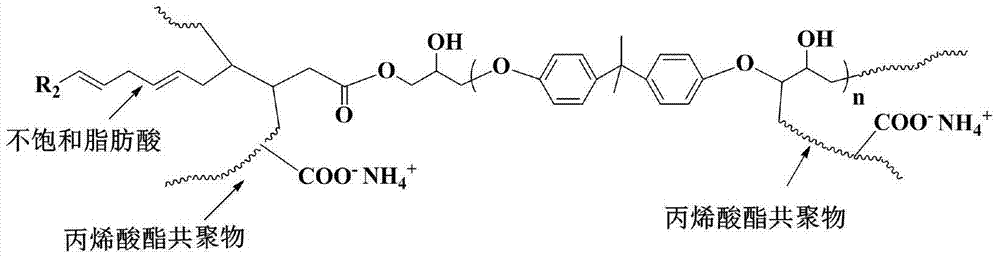

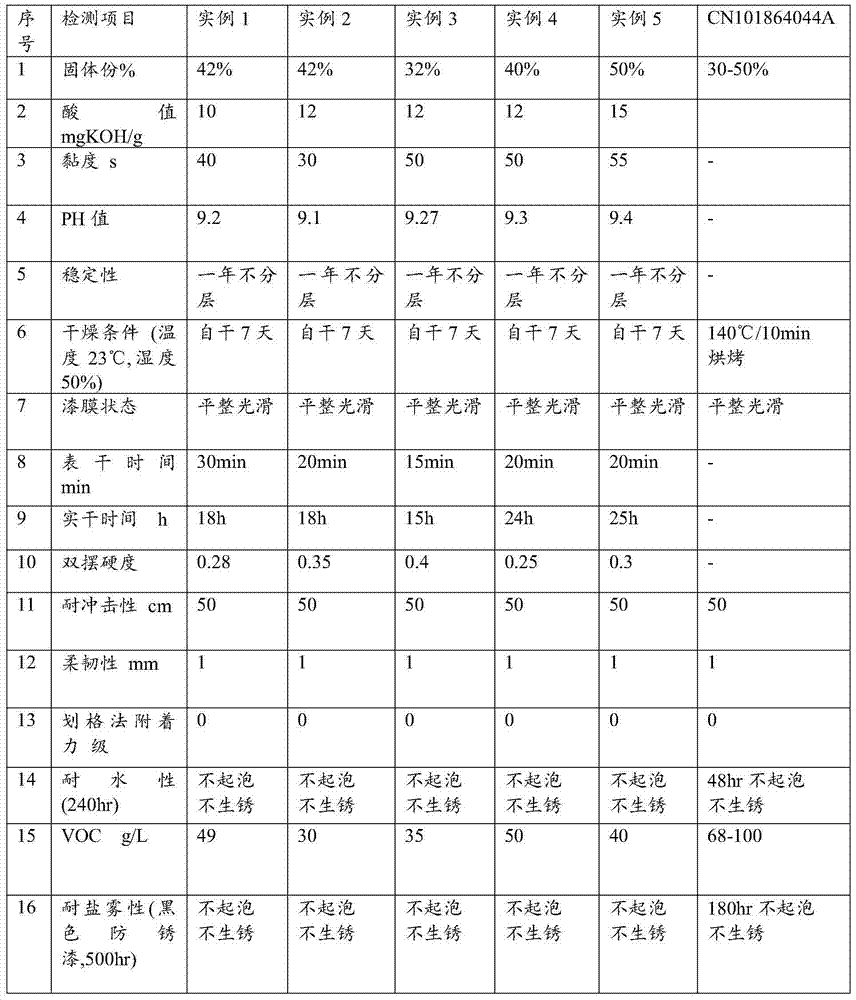

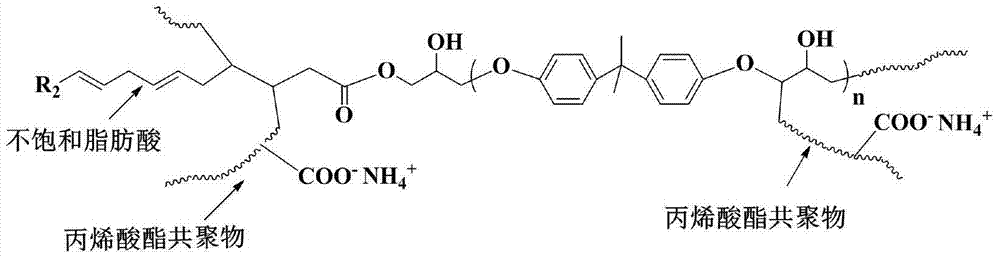

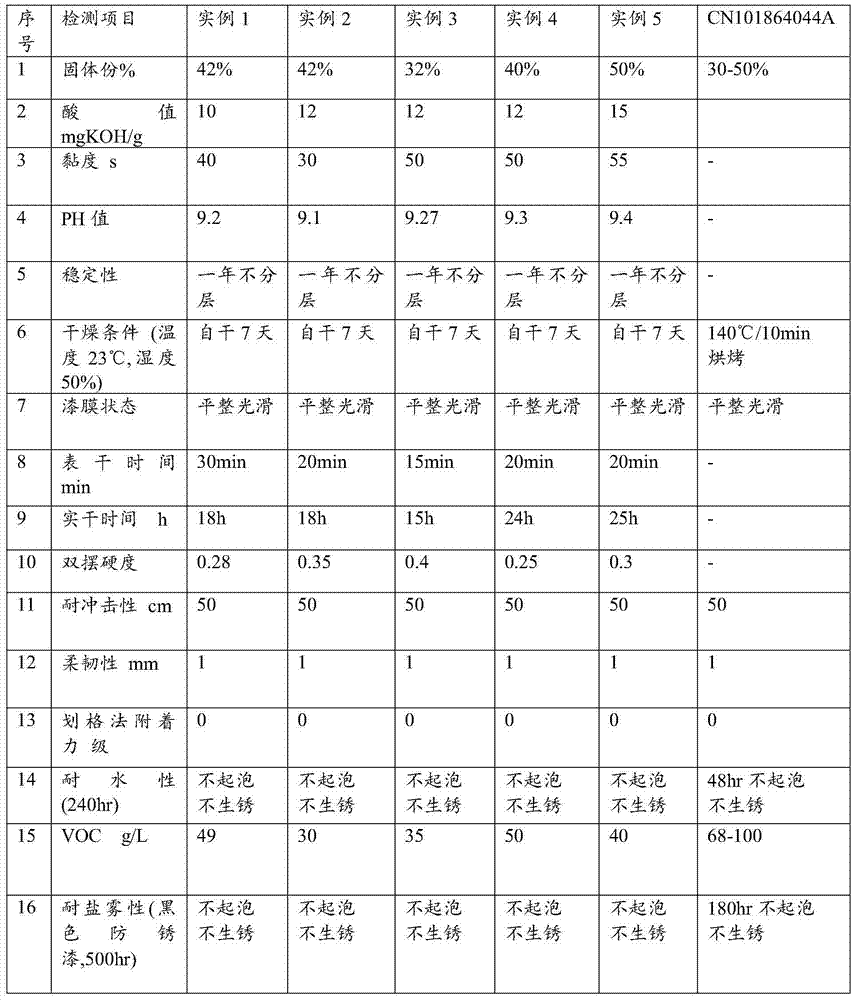

Preparation method for low acid value and low VOC waterborne acrylic acid and fatty acid modified epoxy resin

Belonging to the paint field, the invention relates to a preparation method for a low acid value and low VOC waterborne acrylic acid and fatty acid modified epoxy resin. The method includes: firstly modifying epoxy resin with fatty acid, then conducting modification with acrylic acid and acrylate monomer under the action of an initiator, then adding a neutralizer and a drier, adding water to perform emulsification, and reducing pressure to remove the solvent, thus obtaining a low acid value and low VOC waterborne acrylic acid and fatty acid modified epoxy resin emulsion, which has an acid value of 10-15mgKOH / g, a solid content of 30-50%, and a VOC content of less than 7%. Due to a low acid value, the obtained resin has excellent water resistance, and because of the extremely low VOC content, the emission of pollutants is greatly reduced, and the harm to the human is lowered. In addition, due to high unsaturated fatty acid content and epoxy resin content and adding of the drier, the resin itself can have the characteristics of natural drying at room temperature, excellent anti-rust performance and the like.

Owner:BEIJING JINHWEILI APPLIED CHEM PROD

Polyester aqueous dispersion and method for preparation thereof

A polyester aqueous dispersion having excellent properties in waterproof, weatherproof, processibility and adhesion, which provides a large allowance for controlling liquid physical properties by post treatment and is advantageous in making dry powders from the dispersion, and an efficient method for preparing the aqueous dispersion at low costs in a simple manner. The polyester aqueous dispersion comprising (i) a water-insoluble polyester and (ii) a polyester containing a sulfonate group bound to a polymer in a concentration of 0.1 to 1.5 mmol equivalents when calculated as -SO3- group per gram of the polymer, and method for preparing a polyester aqueous dispersion comprises a step of melt-kneading a resin composition comprising the water-insoluble polyester (i) and polyester (ii) and a step of phase inversion of adding water or a basic aqueous solution to the molten kneaded mixture thereby to shift the resin composition into the aqueous dispersion.

Owner:MITSUI CHEM INC

Attapulgite washable inner wall paint

InactiveCN101531494AGood water dispersibilityExcellent optical performanceCoatingsSodium silicateTitanium

The invention discloses attapulgite washable inner wall paint. The technical proposal comprises the following key points that: the attapulgite washable inner wall paint consists of creamy attapulgite clay, nano-alumina, polyvinyl alcohol superfine powder, instant sodium silicate, anatase type titanium pigments, tributyl phosphate, optical bleaching agent VBL and deionized water. A production method of the attapulgite washable inner wall paint comprises: compounding, crushing, stirring, dispersing, dissolving, homogenizing, emulsifying, defoaming, grinding, and canning into the finished product of the attapulgite washable inner wall paint. The attapulgite washable inner wall paint has the characteristics of no toxicity, odorlessness, hard paint film, fine and soft hand feel, water resistance, alkali resistance and good adhesion. The washable time can be more than 1,000 times, and stains cannot be left after washing for many times. The attapulgite washable inner wall paint is applicable to decorating inner walls of various civil and public buildings and the like.

Owner:LIWANG CHEM NANTONG

High strength chitosan complex fiber and preparing method thereof

InactiveCN106435830AImprove performanceHigh dry breaking strengthWet spinning methodsConjugated synthetic polymer artificial filamentsFiberDosage adjustment

The invention relates to a high strength chitosan complex fiber which has a mold resistance and is applicable to medical treatment and clothing textile fabric, and a preparing method thereof. The chitosan complex fiber obtained according to the technical scheme has a much higher overall performance than the products obtained through the prior art, has a good spinning property and good stitchability, and can be further prepared into fabrics through a knitting machine or a weaving machine as well as non-woven fabrics through a nonwoven equipment. The adopted oxidized graphene in itself has a good antibiosis effect, and compared with a graphene material, the oxidized graphene has the advantages of being easy to prepare, high in performance, low in cost, good in water dispersibility, good in adsorptive property, capable of easily conducting various kinds of functional modification and the like. Dosage adjustment and chemical modification can maintain superiority of the graphene and at the same time prevent the graphene from inducing biotoxicity so that the research and application of the graphene in the field of biomedical engineering can be broadened. The preparing method of the high strength chitosan complex fiber has the advantages of being simple in producing technology, low in preparing cost; meanwhile, the obtained high strength chitosan complex fiber has a stable performance. Therefore, the preparing method is very suitable for popularization and market expanding of the chitosan fiber and graphene industries.

Owner:吴玉松

Water-dispersible HDI-TDI mixed tripolymer curing agent and preparation method thereof

InactiveCN105949436ANo reduction in functionalityLow costPolyurea/polyurethane coatingsPolymer sciencePtru catalyst

The invention discloses a water-dispersible HDI-TDI mixed tripolymer curing agent and a preparation method thereof. The method comprises steps as follows: (1) diisocyanate monomers and a nonionic hydrophilic modifying agent are put into a round-bottom flask under the protection of nitrogen and heated to reach 50-70 DEG C for a thermal reaction; (2) after the mixture reacts for 2-4 h, a trimerization catalyst is added, the mixture is subjected to a thermal reaction continuously, a polymerization inhibitor is added after the percentage composition of -NCO of the system reaches the target, and the mixture is subjected to the thermal reaction for 0.5-1.5 h; (3) an anion hydrophilic modifying agent is added to a tripolymer obtained in the step (2), the mixture is continuously stirred and subjected to the thermal reaction at the temperature of 60-80 DEG C, a neutralizing agent is added after the mixture reacts for 5-7 h, and the mixture is stirred uniformly, subjected to the thermal reaction for 0.5-1.5 h and discharged after being cooled. The preparation method is simple, and the prepared curing agent has the advantages of good water dispersibility, good storage stability and good film water resistance and can be applied to a water-based bi-component polyurethane coating well.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method and application of rare earth doped NaYF4/carbon quantum dot dual-mode fluorescent nanocomposite

InactiveCN109181687AImprove hydrophilicityEasy to waterMaterial nanotechnologyInksSilicic acidActive agent

The invention relates to a preparation method and application of a rare earth doped NaYF4 / carbon quantum dot dual-mode fluorescent nanocomposite in the technical field of nanocomposites. The preparation method comprises the steps of mixing an aqueous dispersion solution of a rare earth doped NaYF4 up-conversion nanoparticle modified by a cationic surfactant with a carbon quantum dot solution; then, adding an alkaline solution, ethyl acetate and ethyl orthosilicate into the mixed solution; coating the surface of the rare earth doped NaYF4 particle with a silicon dioxide shell by utilizing a sol-gel chemical principle; and meanwhile, packaging the carbon quantum dot into the shell to prepare the core-shell nanocomposite. By using the preparation method, the aggregation quenching of the carbon quantum dot is effectively avoided, and the optical and chemical stability of the prepared composite is good. The obtained composite is prepared into ink, the prepared composite is applied to the anti-fake field by ink jet printing, and the composite has the characteristics of high concealing property and copying difficulty caused by dual-mode detection and is better in anti-fake effect.

Owner:HUNAN UNIV OF TECH

Low-acid-value and low-VOC aqueous acrylic acid and fatty acid modified epoxy resin

The invention belongs to the field of paints, and relates to a low-acid-value and low-VOC aqueous acrylic acid and fatty acid modified epoxy resin, which comprises the following synthetic raw materials: 15-40 parts of epoxy resin, 11-40 parts of unsaturated fatty acid, 2-8 parts of an acrylic monomer, 5.5-35 parts of an acrylate monomer (containing styrene), 0-0.1 part of a catalyst, 0.6-2 parts of an initiator, 20-40 parts of a solvent, 5-15 parts of a neutralizer, 1-5 parts of a drier, and 100-200 parts of water. The synthetic raw materials are synthesized according to a process to obtain the low-acid-value and low-VOC aqueous acrylic acid and fatty acid modified epoxy resin emulsion, wherein the emulsion has an acid value of 10-15mgKOH / g, a solid content of 30-50%, and a VOC content of less than 7%. The resulting resin has excellent water resistance because of the low acid value, and the emission of pollutants is greatly reduced, and the harm to people is reduced because of the very low VOC content. In addition, the contents of unsaturated fatty acids and epoxy resin are high, and the drier is added, so that the resin has the characteristics of room-temperature air drying, excellent anti-corrosion performance and the like.

Owner:BEIJING JINHWEILI APPLIED CHEM PROD

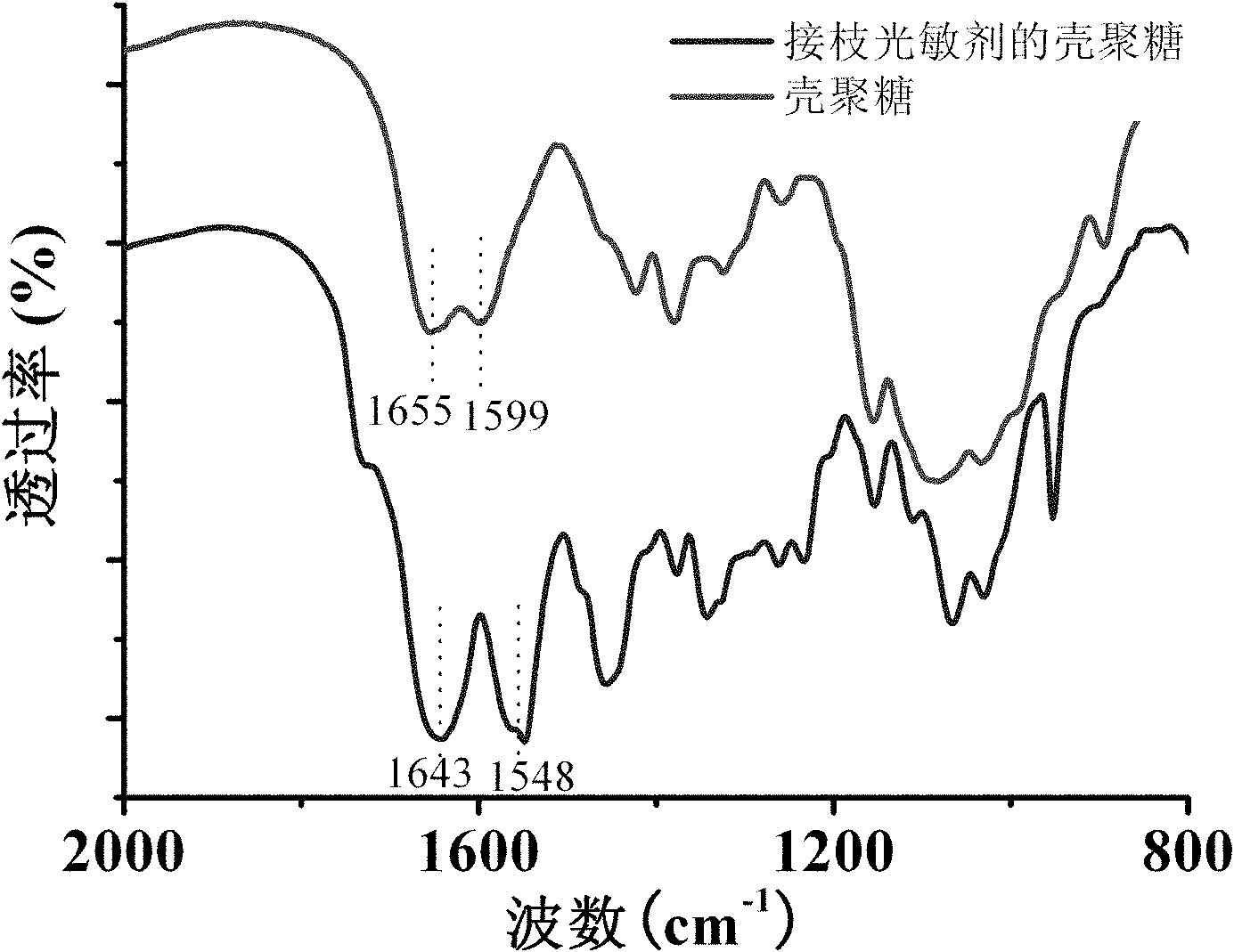

Photosensitive microcapsule used for photodynamic therapy and preparation method thereof

InactiveCN102133208AIncrease surface chargeEasy to assembleEnergy modified materialsPharmaceutical non-active ingredientsCancer cellMicrosphere

The invention discloses a photosensitive microcapsule used for photodynamic therapy and a preparation method thereof, belonging to the technical field of photosensitive polymer thin film materials. The photosensitive microcapsule is prepared by the following steps: firstly, preparing photosensitive polymer materials of photosensitizer molecule graft polymer, and then adopting the layer self assembly technology, assembling polyelectrolyte materials with opposite charges on a microballoon template, and preparing a hollow capsule assembled by a plurality of capsule walls, wherein materials of the capsule walls include natural polymer glycan (CHI) or glucan directly grafted with photosensitizer by chemical bonds. The photosensitive microcapsule has good biocompatibility, fixes photosensitive molecules, can kill cancer cells effectively, can be applied to (Photodynamic Therapy) PDT, and is good in water dispersion and uniform in particle size, high in single-state oxygen content yield under the illumination of beams with specific wavelength, simple in process and easy in operation.

Owner:BEIJING UNIV OF CHEM TECH

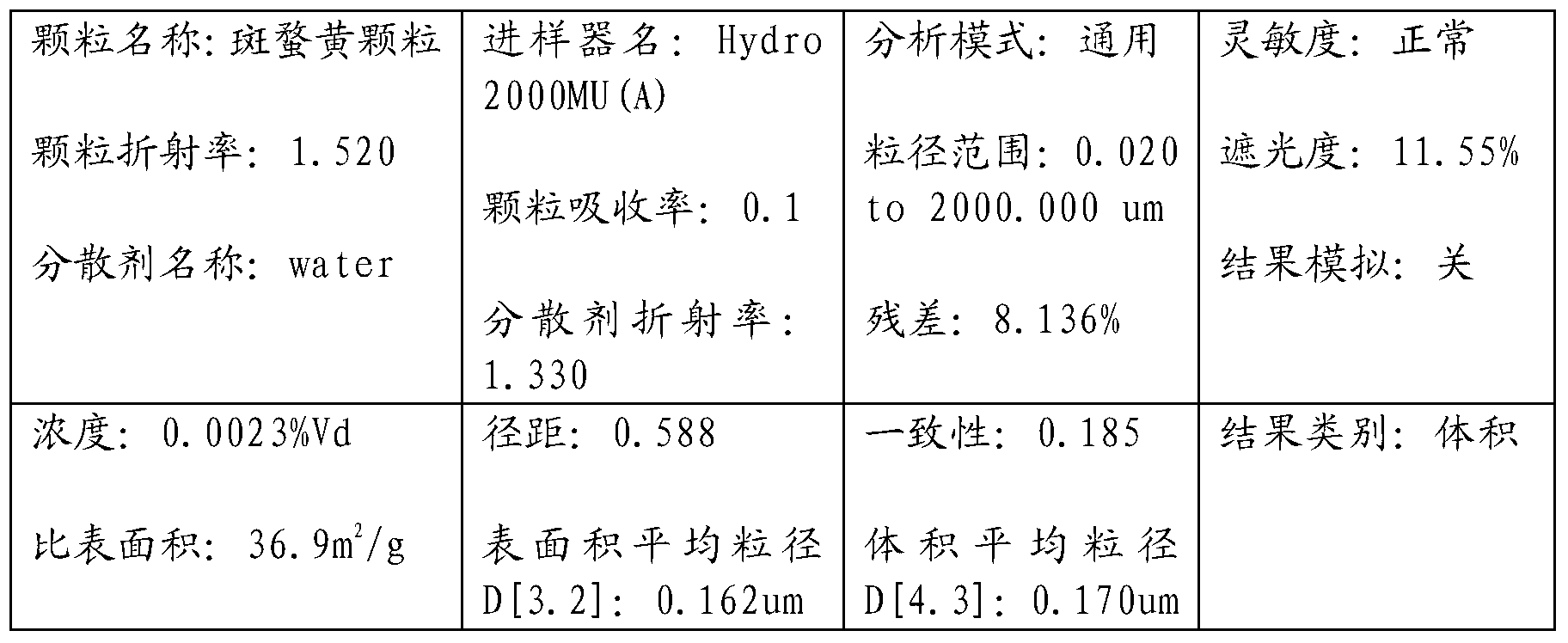

A stable method for microencapsulating carotenoid

ActiveCN103315370AImprove stabilityGood light transmissionFood shapingFood preparationSucroseOil phase

The invention discloses a stable method for microencapsulating carotenoid. The method comprises 1) a step of completely dissolving a protecting colloid, sucrose or glucose, ascorbyl palmitate and EDTA into water, and adjusting pH to 10-11 to obtain a water phase A; 2) a step of completely dissolving carotenoid and an antioxidant into a solvent to obtain an oil phase B; 3) a step of adding the oil phase B into the water phase A under a condition of high-speed shearing and high-speed stirring; emulsifying the mixture to form an initial emulsion by stirring at a high speed; and heating and removing the solvent to obtain a microemulsion; and 4) a step of adding the obtained microemulsion into a spray drying system; and obtaining carotenoid particles or powder after spray drying. The carotenoid particles or powder prepared by the method have advantages of good dispersibility, high stability, good light permeability and small particle sizes.

Owner:肇庆巨元生化有限公司

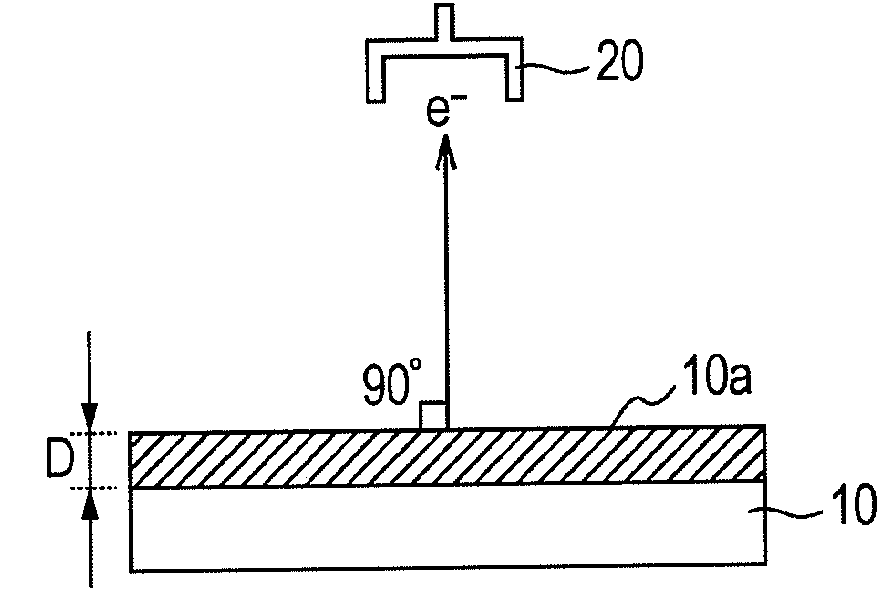

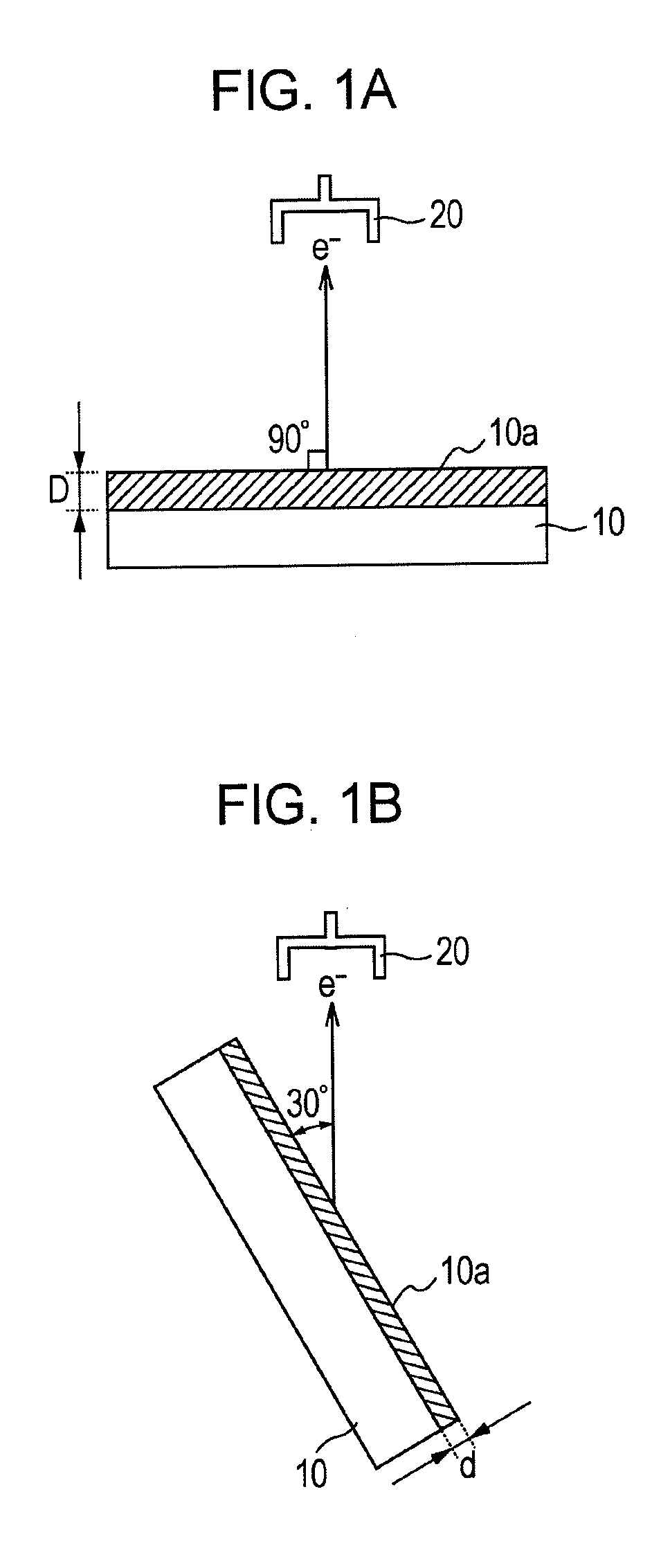

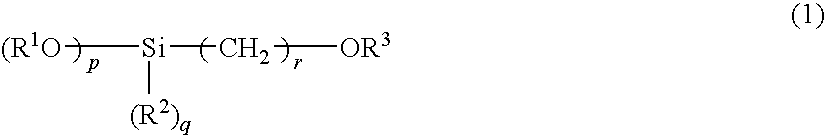

Water-resistant aluminum pigment, water-resistant aluminum pigment dispersion, aqueous ink composition containing the aforementioned, and method for producing water-resistant aluminum pigment dispersion

InactiveUS20100251929A1Good water dispersibilityAvoid whiteningMaterial nanotechnologyDuplicating/marking methodsOrganic solventPhosphate

A method for producing a water-resistant aluminum pigment dispersion includes (a) adding a treatment agent containing a compound of general formula (1) described below to an aluminum pigment dispersion containing aluminum pigment particles dispersed in an organic solvent and reacting a hydroxy group present on a surface of each of the aluminum pigment particles with the compound of general formula (1) described below to form a film on the surface of each aluminum pigment particle, (b) removing at least a portion of the organic solvent, and (c) adding an aqueous solution containing at least one selected from polyoxyethylene alkyl ether phosphate and salts thereof,(wherein p represents an integer of 1 to 3, q represents an integer that satisfies the equation p+q=3, r represents an integer of 2 to 10, R1 and R2 each independently represent an alkyl group having 1 to 4 carbon atoms, and R3 represents an acrylic group, an acryloyl group, or a methacryloyl group).

Owner:SEIKO EPSON CORP

Polyether amine modified waterborne epoxy floor hardener and preparation method thereof

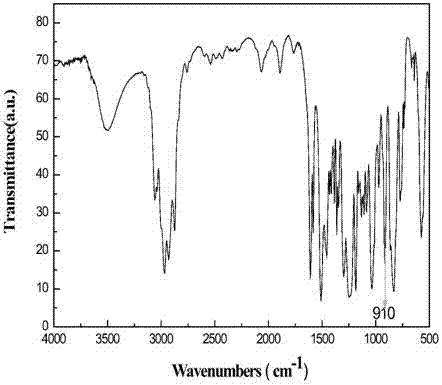

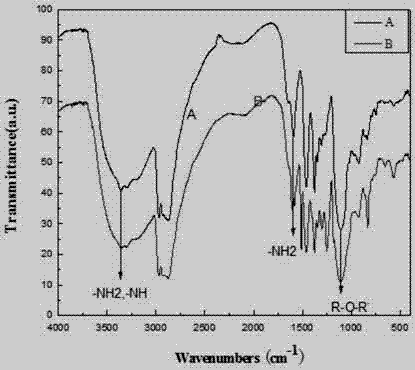

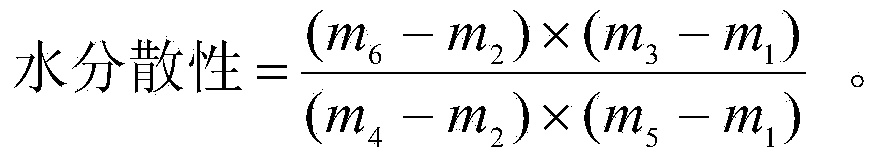

InactiveCN104231232AGood water dispersibilitySimple processEpoxy resin coatingsReaction temperatureEpoxy amine

The invention relates to a polyether amine modified waterborne epoxy floor hardener and a preparation method thereof. The polyether amine modified waterborne epoxy floor hardener is prepared through modification of polyether amine, synthesis of epoxy-amine and dispersion of deionized water; the molar ration of the polyether amine, epoxy-terminated glycidyl ether and epoxy resin is 2-6:0.5-4.5:0.5-4.5; during reaction, the polyether amine is firstly added into a reactor, then the epoxy-terminated glycidyl ether is added, the epoxy resin is added in drops, and lastly, the reactants are dispersed through the deionized water to obtain the polyether amine modified waterborne epoxy floor hardener. The preparation method of the polyether amine modified waterborne epoxy floor hardener is simple in process; the reaction temperature is easy to control; waterborne epoxy floor paints produced with the polyether amine modified waterborne epoxy floor hardener are high in hardness and glossiness, reach level-1 impact resistance and obtain high acid and alkali resistance.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Method for preparing high water dispersibility titanium dioxide

ActiveCN103965659AAdjust pHGood dispersionInorganic pigment treatmentWater dispersibleHydrated alumina

The invention discloses a method for preparing a high water dispersibility titanium dioxide. The method comprises the following steps sequentially: a, adding a dispersing agent into a titanium dioxide slurry, and stirring uniformly; b, adding a phosphorus-containing solution, and curing; c, adding an aluminum sulfate solution to control the pH value of the titanium dioxide slurry to be 1.5 to 4.5, and curing; d, adding a sodium metaaluminate solution to control the pH value of the titanium dioxide slurry to be 8.5 to 10.5, and curing; e, adjusting the pH value of the titanium dioxide slurry to be 7.0 to 7.8, and curing; f, filtering, washing, drying, and pulverizing to obtain the high water dispersibility titanium dioxide. According to the method, before coating, the dispersing agent is added to improve a dispersing condition of the titanium dioxide slurry, then the phosphorus-containing solution and the aluminum-containing solution are used as a coating agent, and then the coating agent is deposited on the surface of titanium dioxide in forms of aluminum phosphate and hydrated alumina, so that the water dispersibility of a product is effectively improved, and the titanium dioxide product with the high water dispersibility is obtained.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

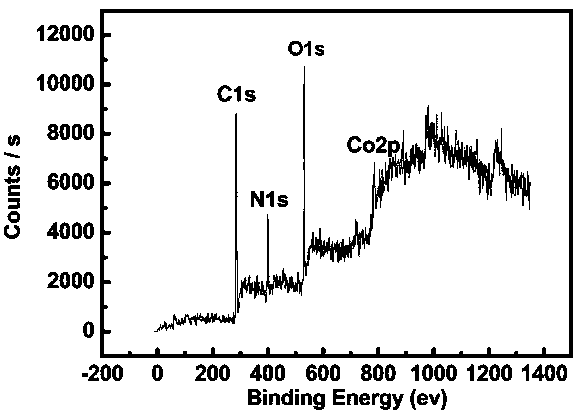

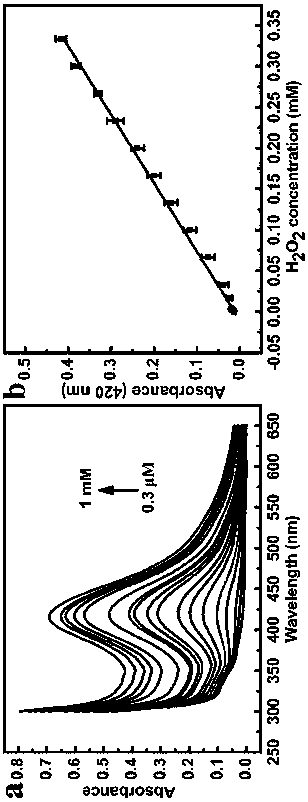

Preparation method of carbon nano-enzyme co-doped with active metal and nitrogen element and application thereof as nano biological probe for detecting hydrogen peroxide

PendingCN109107596AEasy to prepareRaw materials are cheap and easy to getMaterial analysis by observing effect on chemical indicatorCatalyst activation/preparationFluoProbesPhotochemistry

The invention discloses a preparation method of a carbon nano-enzyme co-doped with active metal and nitrogen element and application thereof as a nano biological probe for detecting hydrogen peroxide.The method comprises the steps that: EDTA disodium and active metal are used as precursors, and are chelated to obtain an intermediate, the intermediate is subjected wot thermal polymerization underan inert atmosphere, and the reactant is ground, dispersed in water, ultrasonicated, filtered, dried to finally obtain the carbon nano-enzyme co-doped with the active metal and the nitrogen element. The method is simple and convenient to operate, and the large-scale preparation of carbon fluorescent quantum dots can be co-doped with the active metal and the nitrogen element without harsh reactionconditions, obtained carbon dots have good dispersibility and wider fluorescence emission range in aqueous solution. The nano-enzyme can be applied to the detection of hydrogen peroxide as a fluorescent probe, and has potential application value in the fields of medical imaging and detection of other biomolecules.

Owner:HENAN NORMAL UNIV

Self-emulsifying waterborne polyurethane curing agent and preparation method thereof

ActiveCN107082860AGood water dispersibilityStable storagePolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsWater dispersibleAdhesive

The invention discloses a self-emulsifying waterborne polyurethane curing agent and a preparation method thereof. The self-emulsifying waterborne polyurethane curing agent takes micromolecule dihydric alcohol containing a sulfonic acid group with a molecular weight of 350 to 1,000 and diisocyanates as raw materials to prepare the sulfonic acid group modifying self-emulsifying waterborne polyurethane curing agent with a multifunctional NCO group on a terminal. The invention also discloses a preparation method of the self-emulsifying waterborne polyurethane curing agent. The self-emulsifying waterborne polyurethane curing agent has the advantages of good water dispersibility, good storage stability, good water resistance of coating film, high strength property and the like, and is suitable for mating with waterborne polyurethane dispersion, waterborne acrylic emulsion and waterborne alkyd resin and the like, prepared two-component polyurethane coatings and adhesives by the self-emulsifying waterborne polyurethane curing agent are especially suitable for some special performance requirements of waterborne products. The self-emulsifying waterborne polyurethane curing agent disclosed by the invention can also be used for mating with hydroxyl components of the solvent-type two-component coatings and the adhesives to produce a two-component solvent type and has a wide range of application.

Owner:FOSHAN JINGXIN HUIMING TECH CO LTD

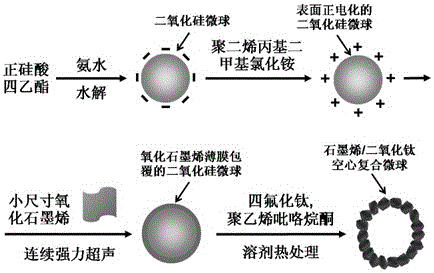

Graphene/titanium dioxide composite adopting hollow microspherical structure and preparation method of composite

ActiveCN105056929AUnique hollow microsphere structureLarge specific surface areaPhysical/chemical process catalystsWater/sewage treatment by irradiationTitanium tetrafluorideMicro nano

The invention relates to graphene / titanium dioxide composite adopting a unique hollow microspherical structure and a simple preparation method convenient to implement and belongs to the technical field of synthesis and preparation of graphene-based micro-nano composite. Firstly, an improved Stober method is adopted for preparing silicon dioxide microspheres, then each silicon dioxide microsphere is coated with an oxidized graphene layer with an ultrasonic assisted self-assembly method, titanium tetrafluoride is taken as a precursor, titanium dioxide is precipitated and crystallized on surfaces of silicon dioxide / oxidized graphene composite microspheres with a solvothermal method, silicon dioxide inner cores are dissolved and removed, the oxidized graphene component coating the spheres is further reduced, and accordingly, the graphene / titanium dioxide composite hollow microspheres are prepared. The composite hollow microspheres show good water dispersibility, has efficient catalytic activity for light degradation of organic dye and have wide application prospects.

Owner:哈尔滨悟山青环保科技有限公司

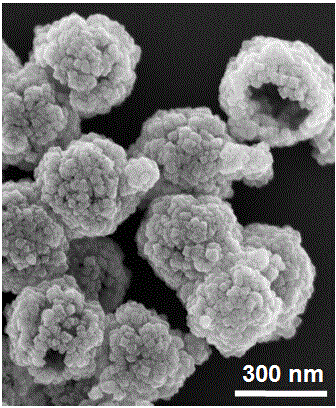

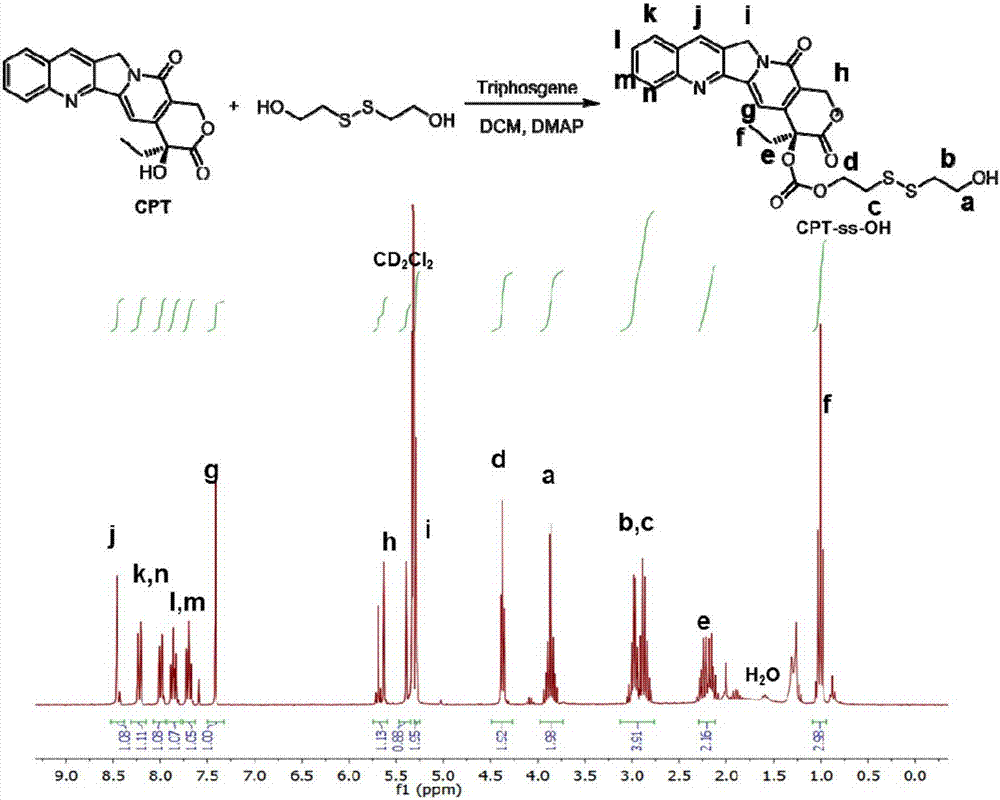

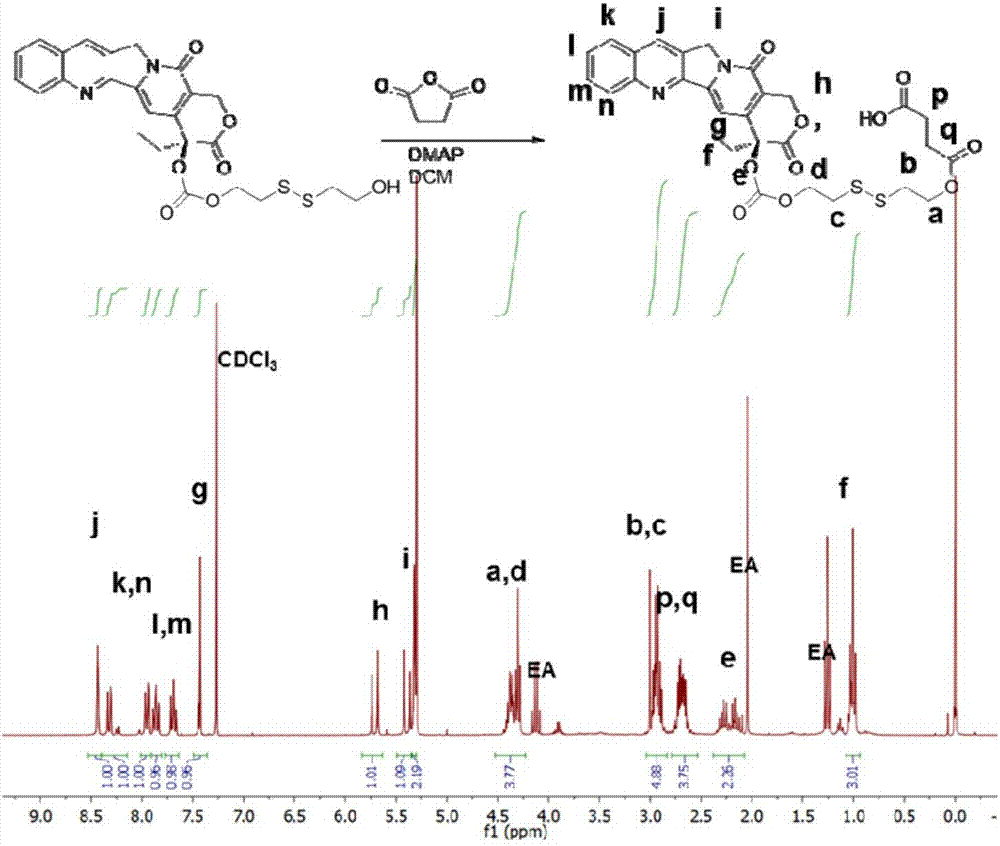

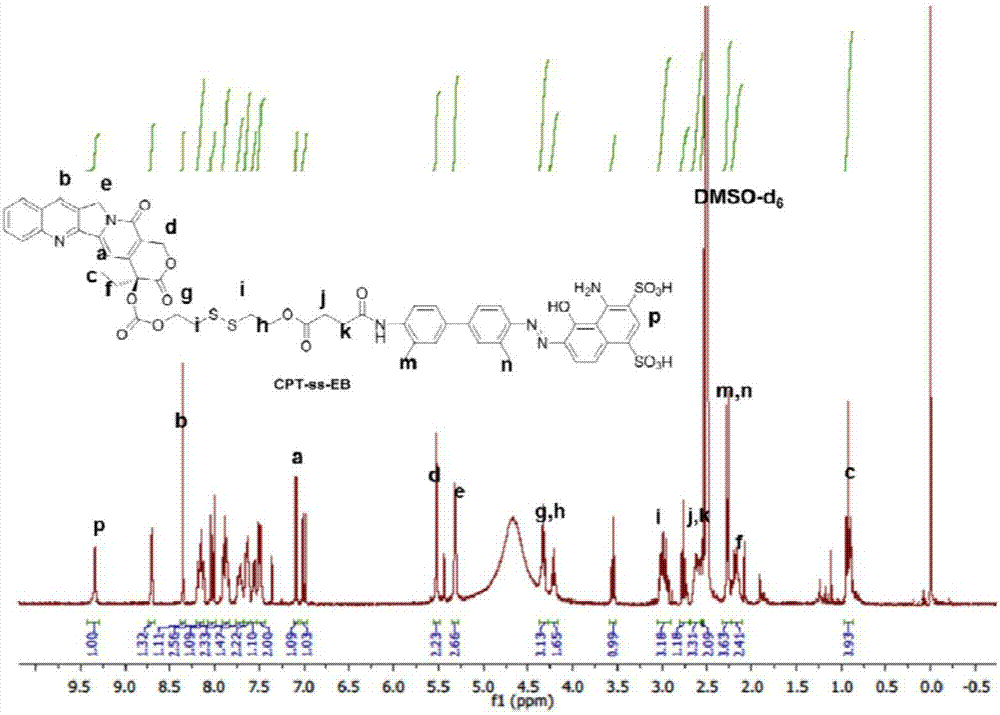

Camptothecin prodrug, and preparation method and application thereof

ActiveCN106946899AEasy to makeGood water dispersibilityMaterial nanotechnologyOrganic chemistryCancer cellStructural formula

The invention provides a camptothecin prodrug. The camptothecin prodrug is a prodrug formed bycamptothecin or a derivative thereof and Evans blue, the structural formula of the prodrug is represented by formula (I); and in the formula, R<1> is camptothecin or a derivative group thereof, R<2> is one of -CH2- and -O-, R<3> is one of -CH2-, -O-CO- and -O-CO-NH-, X is one of S and -CH2-, and n1 and n2 are the repeating unit number, and are integers in a range of 0-10. The camptothecin prodrug has an excellent tumor cell uptake effect in vivo and in vitro, and a part of the prodrug has a substantial cancer cell inhibition effect. The invention also provides a preparation method of the camptothecin prodrug and an application of the camptothecin prodrug in the preparation of cancer treatment drugs.

Owner:YANTAI LANNACHENG BIOTECHNOLOGY CO LTD

Method for extracting chilli oil resin from chilli

InactiveCN102061130AHigh extraction rateImprove performanceNatural resin processBulk chemical productionSolubilityWater dispersible

The invention relates to a method for extracting chilli oil resin from chilli. The method comprises the following steps: 1, extracting and separating the chilli oil resin by utilizing supercritical CO2; 2, purifying the extracted chilli oil resin by means of short-path molecular distillation; and 3, increasing the water solubility of the purified chilli oil resin by utilizing an emulsification solubilizing technology, and finally wrapping the chilli oil resin by utilizing a microcapsule technology to obtain an antiseptic seasoning. The method provided by the invention has the advantages that 1, the extraction efficiency of the chilli oil resin is improved by adopting the CO2 supercritical extraction technology; 2, the purity of the chilli oil resin reaches over 95% by using the short-path molecular distillation technology; 3, the water dispersion of the chilli oil resin is improved by adopting the emulsification solubilizing technology; 4, the chilli oil resin is powdered by utilizing the microcapsule technology, so that the product performance is more stable; and 5, the extracted chilli oil resin does not contain organic solvent and heavy metal residue.

Owner:TIANJIN FOOD RES INST

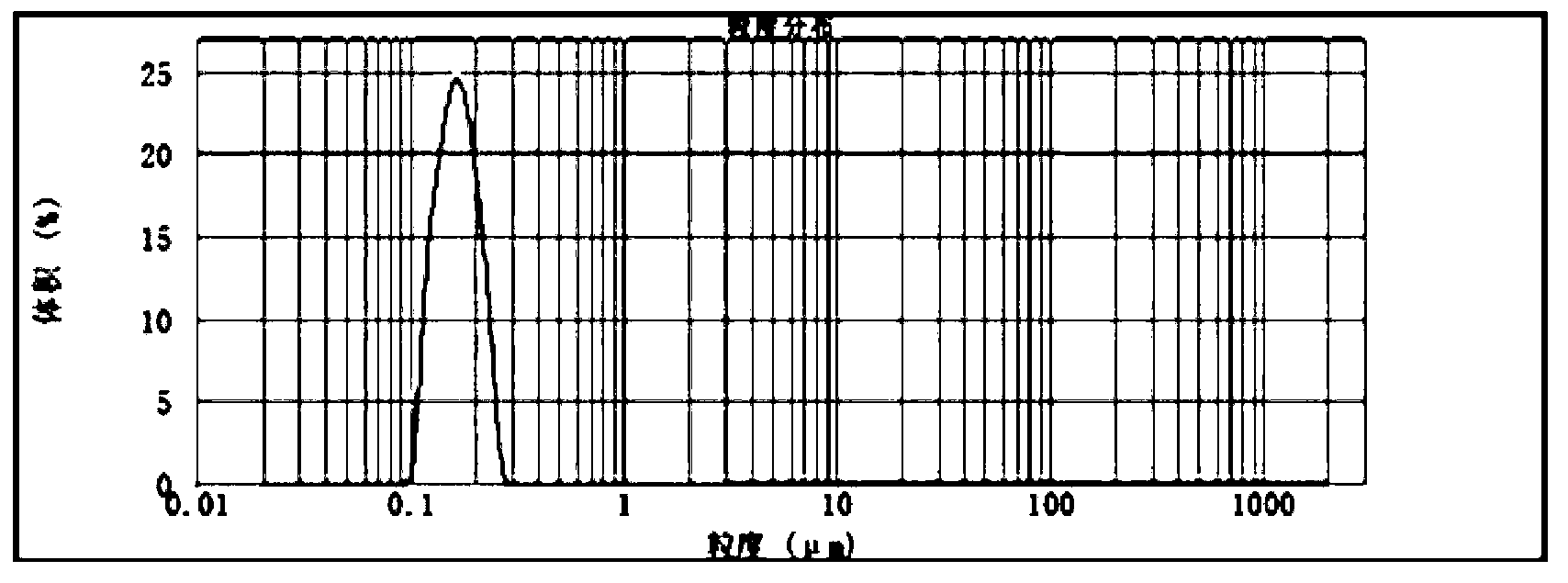

Highly Water Dispersible Powder and Production Method Thereof

InactiveUS20100034956A1Good water dispersibilityPowder deliveryHydroxy compound active ingredientsWater dispersibleEmulsion

Provided is a highly water dispersible powder which exhibits a high water dispersibility in spite of the inclusion of a poorly water soluble component, and maintains the high water dispersibility stably over time.The highly water dispersible powder includes a poorly water soluble component, a water soluble polymer having a protective colloid effect, and a saponin. The highly water dispersible powder can be produced by a method including: emulsifying a poorly water soluble component in an aqueous solvent under the presence of a water soluble polymer having a protective colloid effect and a saponin, thereby preparing an emulsion; and drying the obtained emulsion.

Owner:FREUNT IND

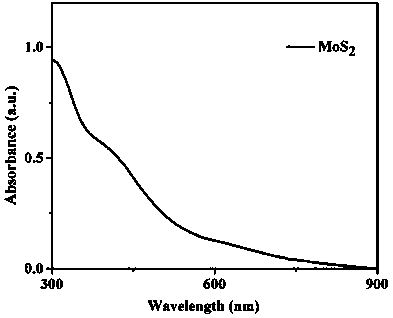

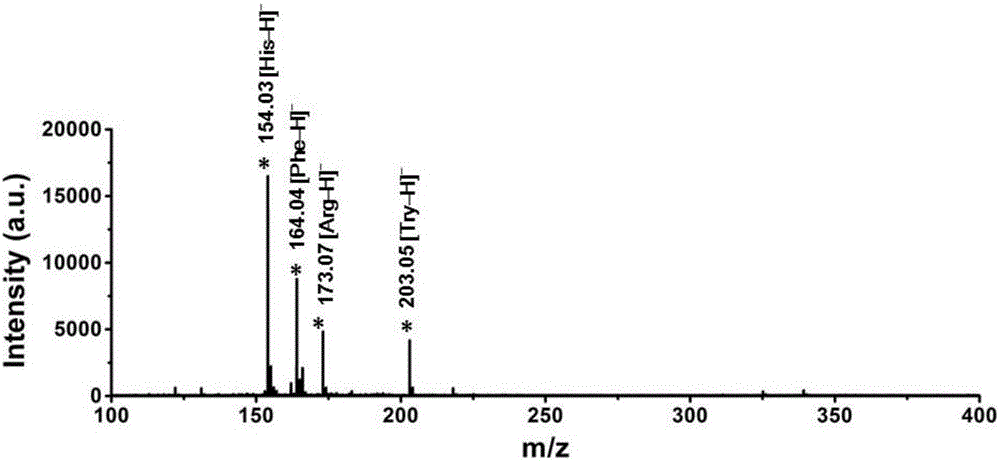

Application of molybdenum disulfide/nanosilver composite serving as matrix to matrix-assisted laser desorption/ionization time of flight mass spectrometry

ActiveCN105929017AThe synthesis method is simpleOvercoming Matrix Background Interference ProblemsPreparing sample for investigationMaterial analysis by electric/magnetic meansBiomarker discoveryMass spectrometry imaging

The invention discloses application of a molybdenum disulfide / nanosilver composite serving as a matrix to MALDI (matrix-assisted laser desorption / ionization) time of flight mass spectrometry. Few-layer molybdenum disulfide is prepared according to an improved chemical lithium ion intercalation and exfoliation method, on the basis of which the molybdenum disulfide / nanosilver composite is prepared through in-situ reduction of silver nitrate. An analysis method taking molybdenum disulfide / nanosilver composite as an MALDI matrix is applicable to mass spectrometry of micromolecules with molecular weight smaller than 1000 and suitable for molecules of amino acids, oligopeptides, fatty acids, alkaloids, hormones, antibiotics, antibacterial drugs, anticancer drugs and the like. Matrix background interference is avoided when the method is adopted for detection of molecules with a mass-to-charge ratio (m / z) smaller than 1000. The method can be effectively applied to fields of organic and biomass spectrometry, imaging mass spectrometry, protein mass spectrometry, metabonomics, biomarker discovery, environmental analysis and the like.

Owner:NANJING UNIV

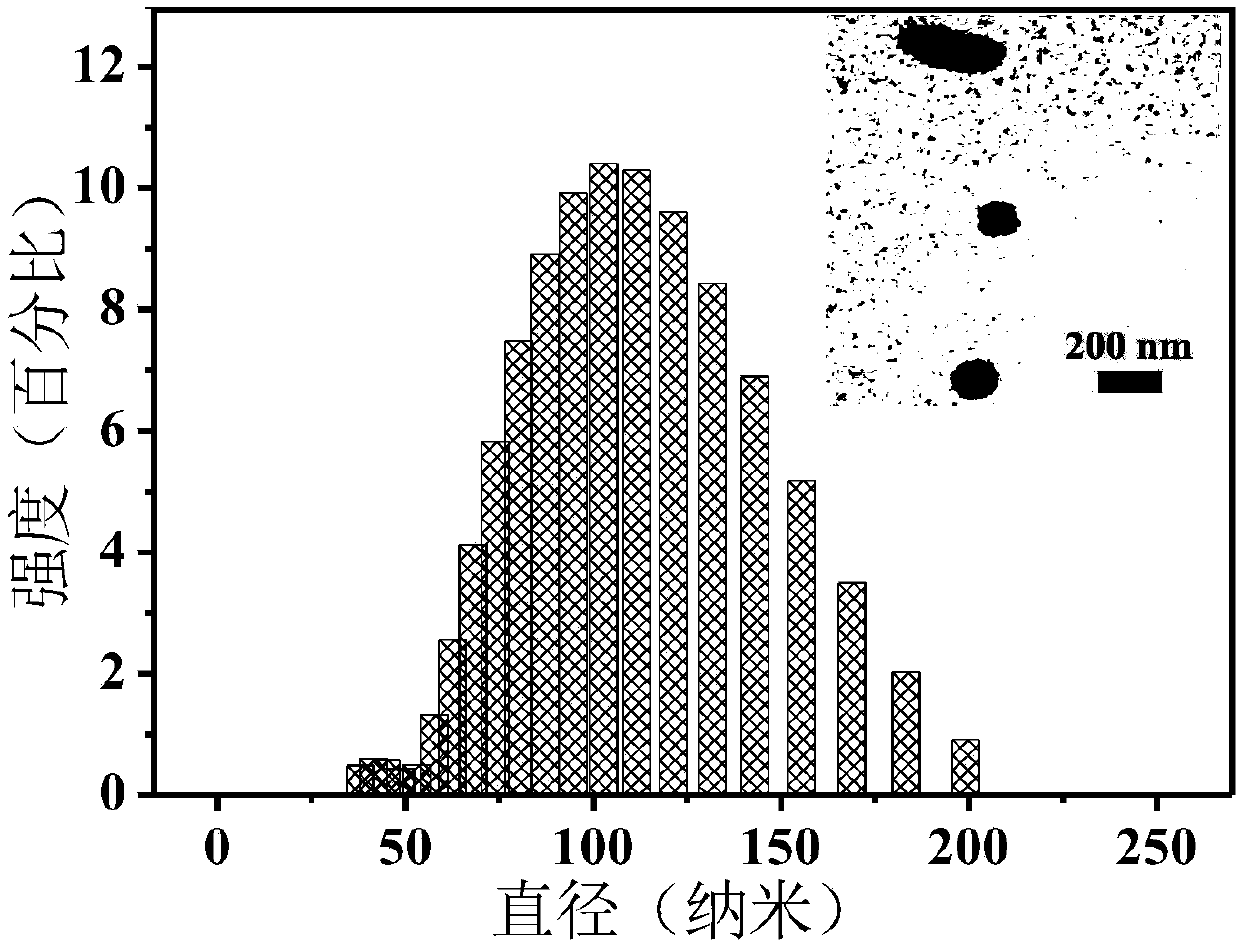

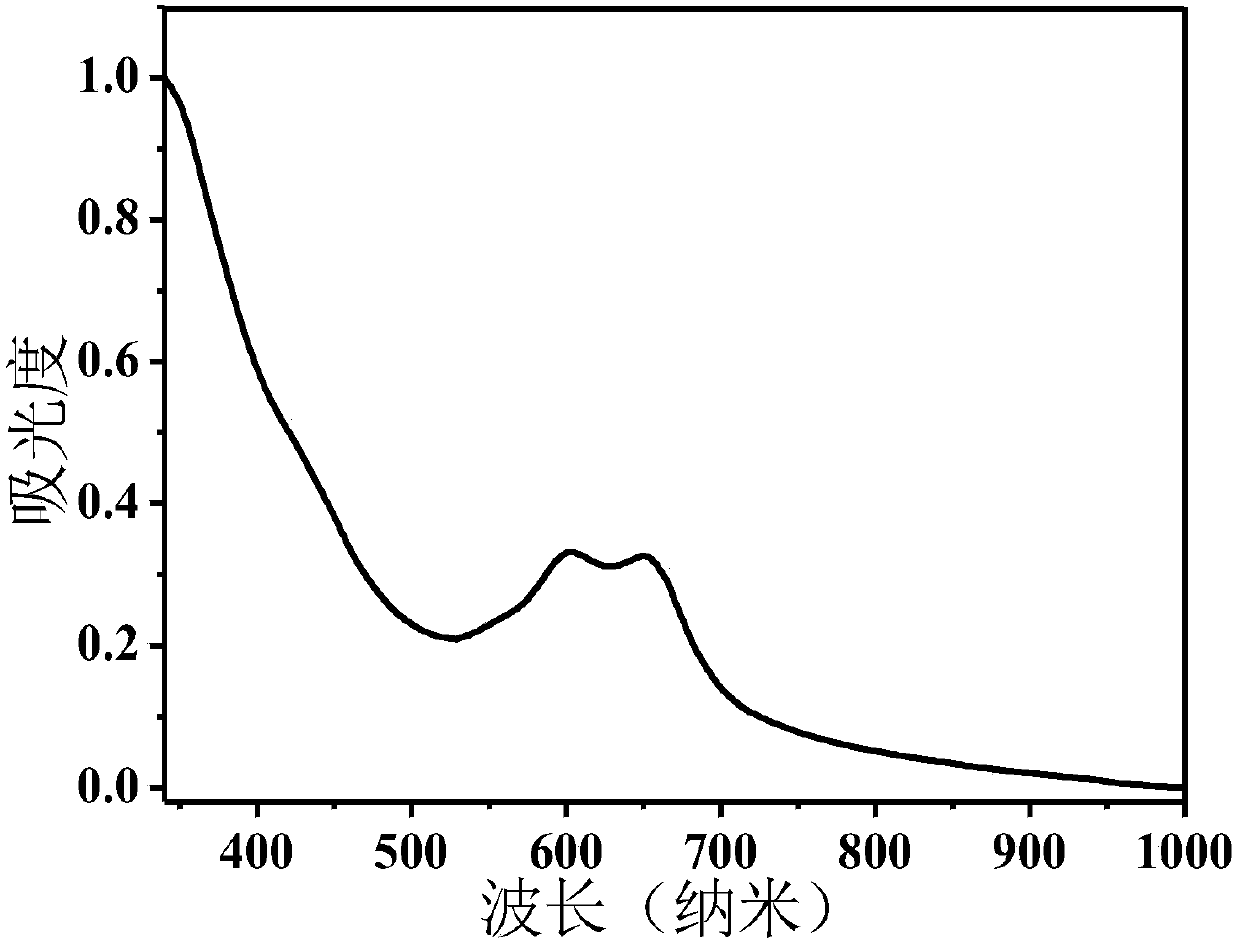

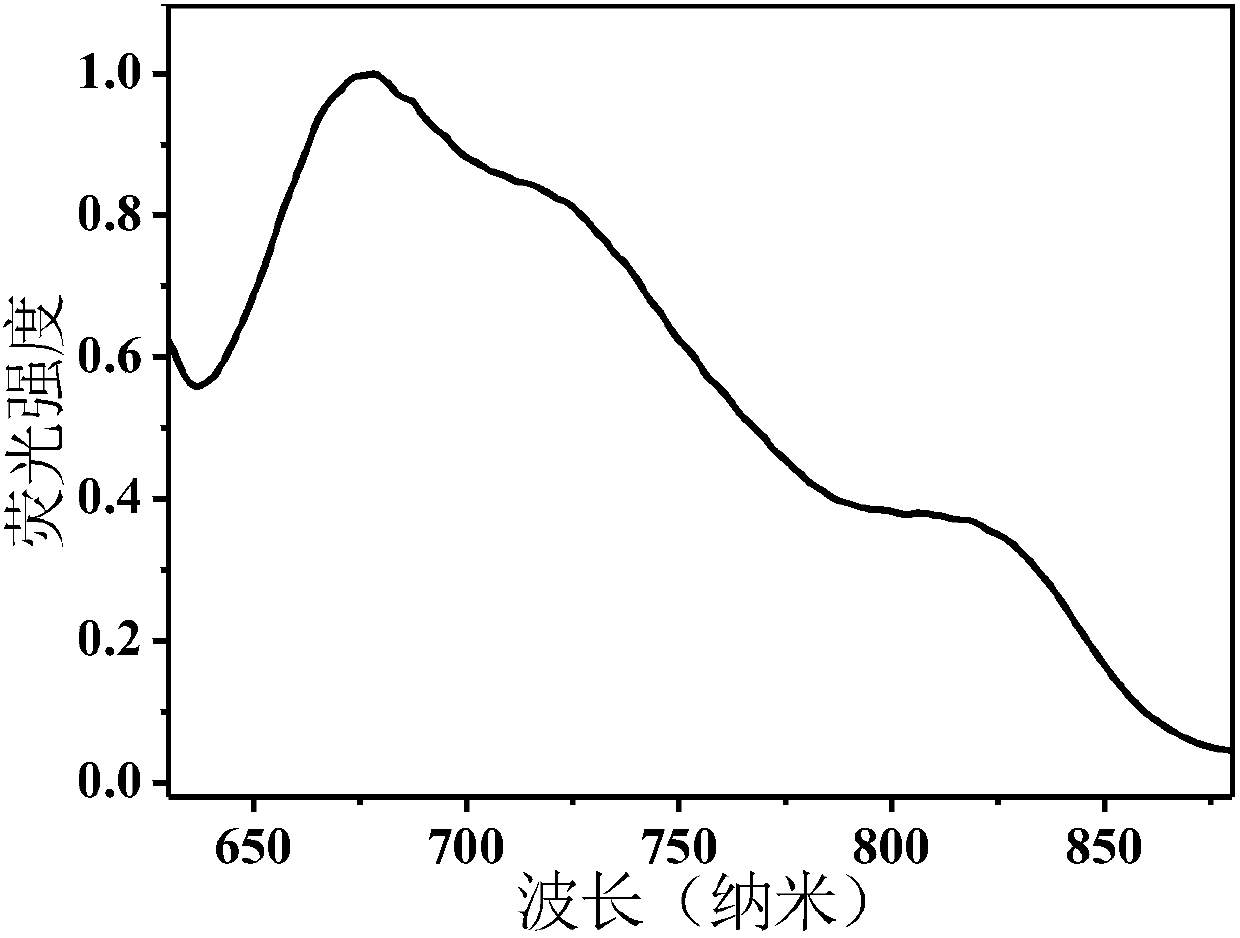

Novel D-A-D organic near-infrared tumor therapy reagent based on diketopyrrolopyrrole and preparation method thereof

InactiveCN107698608AClear structureTumor-specific targetingOrganic chemistryPhotodynamic therapyWater dispersibleTumor targeting

The invention discloses design synthesis and application performance of a novel D-A-D organic near-infrared tumor therapy reagent based on diketopyrrolopyrrole. The reagent provided by the invention is mainly obtained by Suzuki coupling reaction of 3, 6-bis(thieno[3, 2-c]thiophene)-2, 5-dihydropyrrolo[3, 4-c]pyrrole-1, 4-dione derivative and phenothiazine borate. By means of a reprecipitation method, the reagent can acquire a nano material with absorption wavelength in a near-infrared area, the nano material has high singlet oxygen yield, good photothermal conversion efficiency, excellent water dispersibility and tumor tissue targeting properties, can be applied to tumor cell and living body treatment, can effectively inhibit tumor cell migration while effectively killing tumor cells, thereby achieving the photothermal and photodynamic synergistic treatment effect. Therefore, the reagent can have enormous application prospects in tumor therapy.

Owner:NANJING UNIV OF TECH

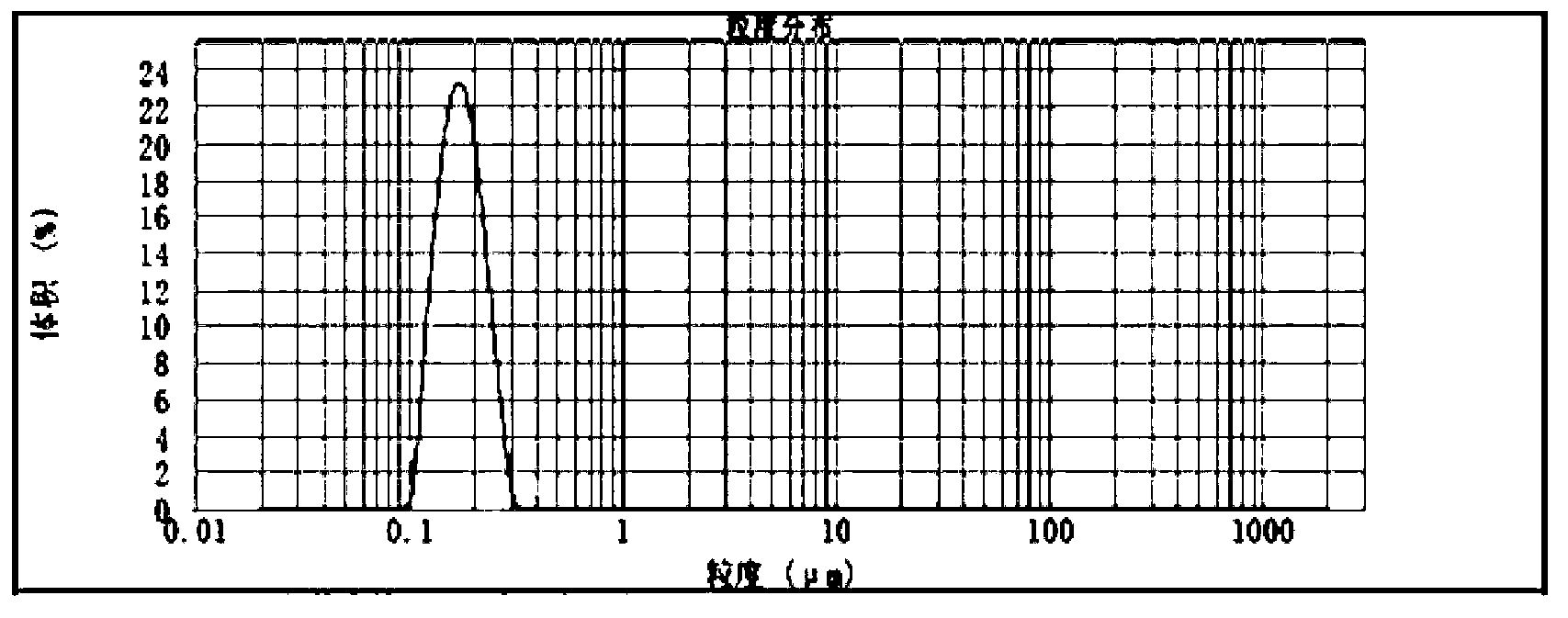

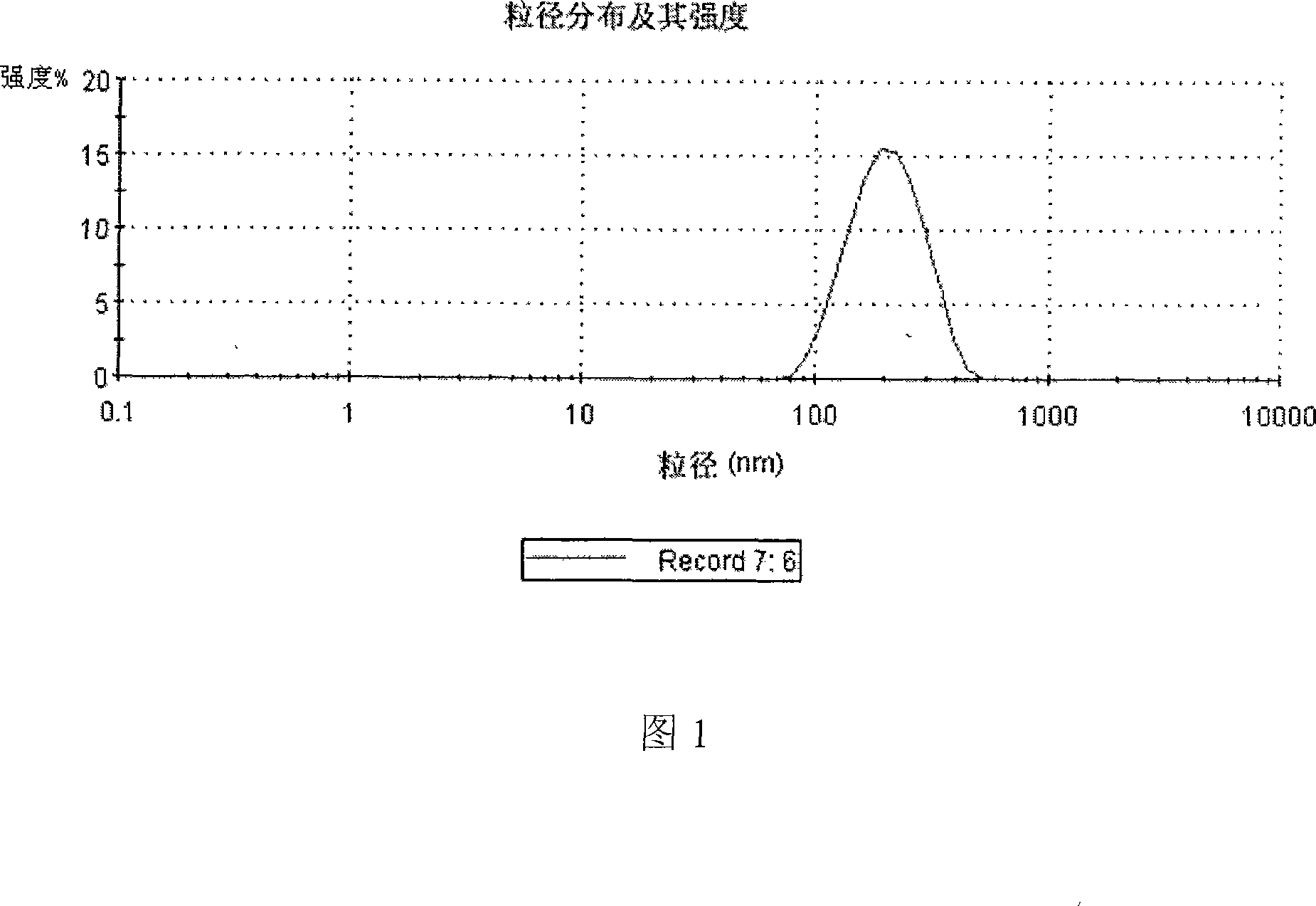

Product of Nano disperseion of water-soluble lycopene

InactiveCN101092521AGood water dispersibilitySolve the dissolution problemNatural dyesWater dispersibleWater soluble

This invention discloses a method for preparing water-soluble lycopene nanoscale dispersion product. The method comprises: dissolving lycopene or its oleoresin in an organic solvent, mixing the organic phase with an aqueous phase dissolved with an appropriate emusilfier, breaking lycopene into nanoscale by ultrahigh pressure homogenization or ultrasonic breakage, and vacuum-distilling the organic solvent to obtain uniform and stable water-soluble lycopene nanoscale dispersion (50-500 nm). The water-soluble lycopene nanoscale dispersion product can be added into water-based foods at any ratio, which solves the problem of lycopene dissolution in water-based foods. Besides, the nanoscale lycopene particles can easily infiltrate into human cells, which can increase the biological value of lycopene.

Owner:JIANGNAN UNIV

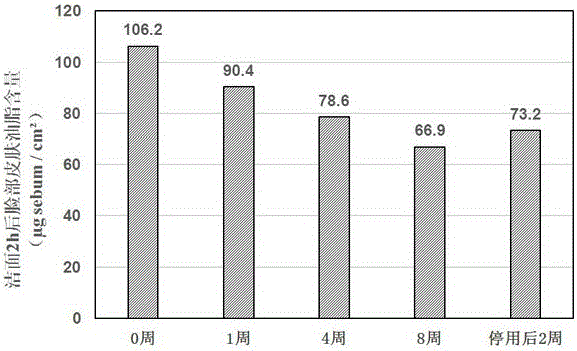

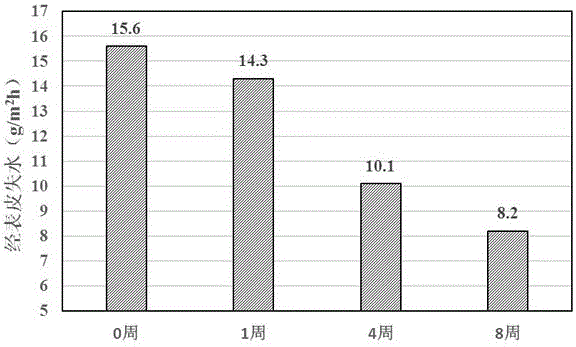

Acne-removing composition and preparation method thereof

ActiveCN106265264AImprove stabilityStrong proteolytic abilityCosmetic preparationsToilet preparationsConeflower extractActive matter

The invention relates to an acne-removing composition and a preparation method thereof. The acne-removing composition is characterized by comprising 1%-20% by mass of acne-removing active matter; the acne-removing active matter is composed of 10-15 parts of zinc pyrrolidone carboxylic acid, 4-6 parts of sophorolipid, 5-8 parts of bromelain, 8-12 parts of amur cork tree bark extract, 8-16 parts of purple coneflower extract, 12-18 parts of lithospermum extract, 3-8 parts of humic acid and 40-50 parts of isomalt. The acne-removing composition has the advantages of being excellent in acne-removing effect, safe, stable and convenient to prepare.

Owner:PROYA COSMETICS

Preparation method of organic fluorine modified hyperbranched water-based polyurethane

The invention provides a preparation method of organic fluorine modified hyperbranched water-based polyurethane. The method comprises the following steps: (1), synthesizing water-based terminal hydroxyl hyperbranched polyurethane core; (2), synthesizing a double bond end capped linear polyurethane prepolymer through diisocyanate, low polymer divalent alcohol, a chain extendor, an end-capping reagent and the like; (3), grafting linear polyurethane onto terminal hydroxyl hyperbranched polyurethane; (4), leading a fluorine element onto a polymer through an emulsion method, so as to obtain the organic fluorine modified hyperbranched water-based polyurethane. According to the organic fluorine modified hyperbranched water-based polyurethane provided by the invention, raw materials are cheap and readily available, and are wide in sources, the synthesis process is simple, and industrialized production is facilitated. The organic fluorine modified hyperbranched water-based polyurethane is appropriate to be used independently, can be matched with other water-based resins, can be applied to the fields of water-resistant paints, environment-friendly water-based adhesives, water-based paints and the like, and has a broad application prospect.

Owner:ANHUI UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com