Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2916 results about "Ultrasonic assisted" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultrasonic assisted deposition of anti-stick films on metal oxides

InactiveUS20020130441A1Inhibit entry and adhesionLiquid surface applicatorsOptical articlesUltrasonic assistedCasting mold

A method and apparatus for ultrasonic assisted deposition of a release agent onto a workpiece is disclosed. The release agent can be any fluorinated or non-fluorinated phosphorous-containing organic acid. The workpiece can be any workpiece desired to be coated with the release agent, such as a surface needing an anti-stick coating required in a plastic casting or injection mold. Metal oxide workpiece surfaces strongly bond to fluorinated phosphorus-containing organic acids. In particular, the present invention can deposit anti-stick coatings onto smooth or porous surfaces, such as anodized aluminum and its alloys, using ultrasonic assisted deposition

Owner:KORRY ELECTRONICS

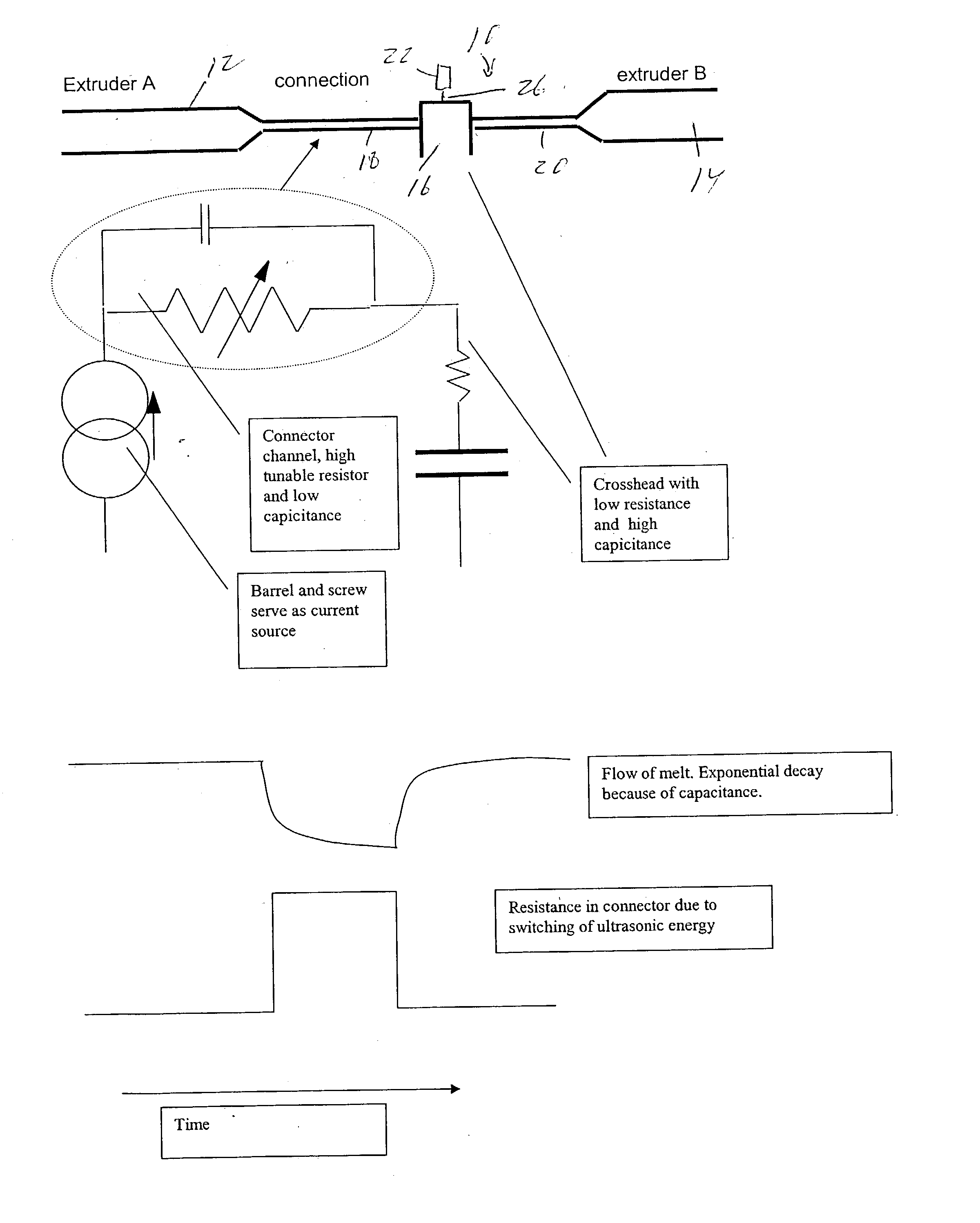

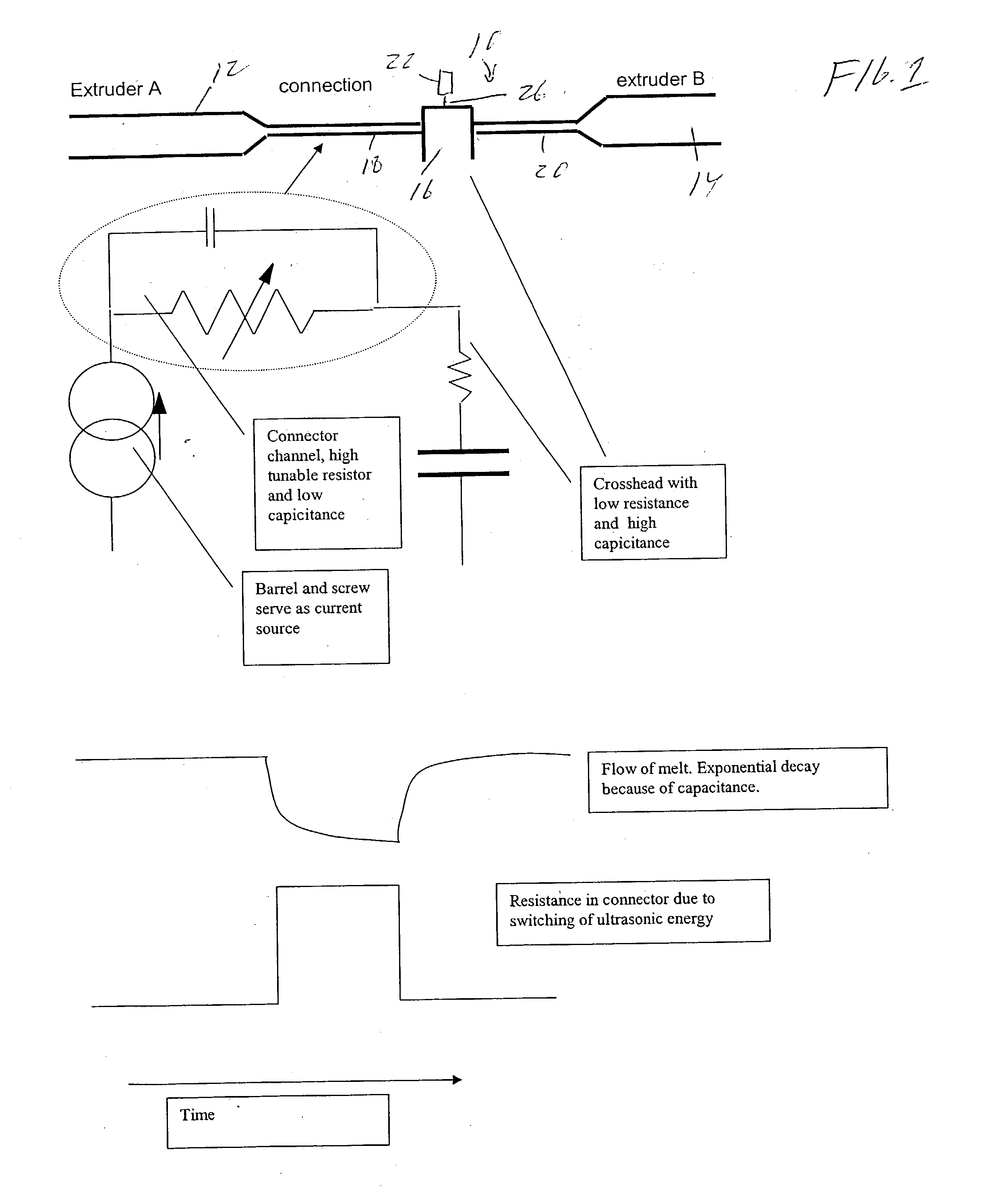

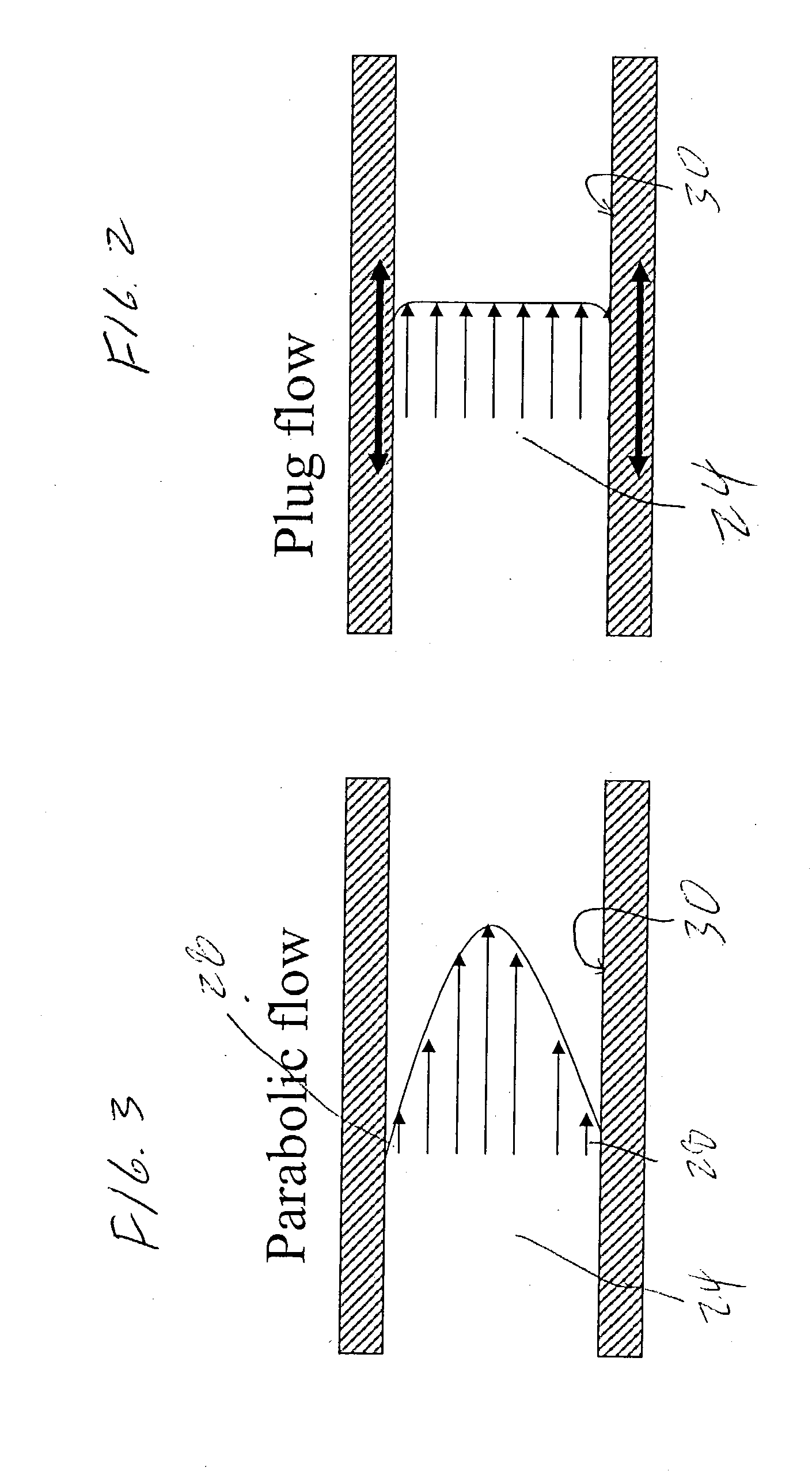

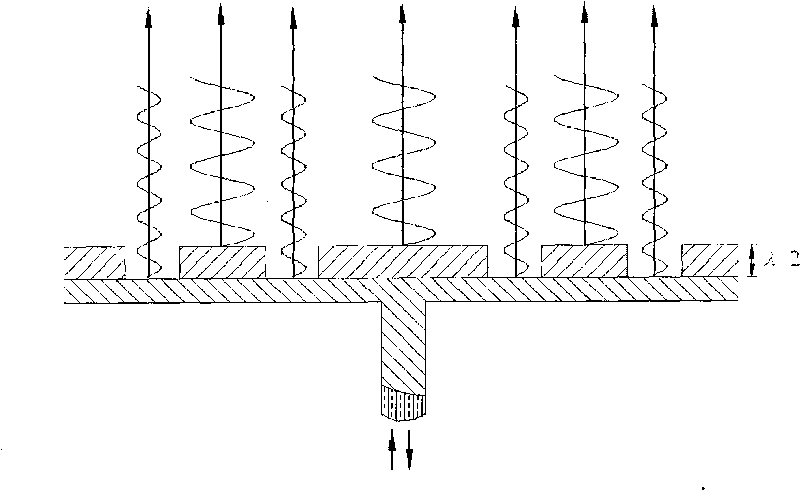

Ultrasonic assisted processes

InactiveUS20030201581A1Shorten deflation timeReduce inflationStentsConfectioneryUltrasonic assistedEngineering

Method and apparatus for applying ultrasonic energy to a variety of manufacturing processes, particularly for producing an extrudate product from an extruder wherein one or more ultrasonic transducers are utilized to uniformly ultrasonically vibrate at least a portion of an extruder assembly.

Owner:BOSTON SCI SCIMED INC

Method of effectively extracting ganoderma triterpenoids and ganoderan from mythic fungus germ entity

ActiveCN101530436AIncrease profitPrevent volatilizationAntipyreticAnalgesicsSolventUltrasound assisted

The invention provides a method of effectively extracting ganoderma triterpenoids and ganoderan from mythic fungus germ entity by ultrasonic-alcohol extracting, complex enzyme-water extracting integration technology. The method is characterized by comprising the steps of: crashing the mythic fungus germ entity, using the ultrasound assisted alcohol extract (ultrasonic-alcohol extracting) to extract the ganoderma triterpenoids, then using complex enzyme assisted water extracting (complex enzyme-water extracting) to prepare ganoderan, then sponging drying to obtain ganoderma triterpenoids and ganoderan extractive. The solvents used by the method used in the invention is safe, innoxious and avoids the pollution to the environment by using chloroform, methanol and other organic solvents in the traditional method. And the invention has the features of low extraction temperature, simple device, convenient operation, low cost, fast speed, high effects and so on. Using the process to comprehensively extract triterpenoids and ganoderan active substances in glossy ganoderma can significantly increase the total active substance yield than the single extracting method.

Owner:ZHEJIANG ESSENCE FUNGI DEV

Method for producing instant straw mushroom chips by adopting vacuum low-temperature dehydration technology

ActiveCN102406161AEfficient crushingIncrease penetration rateFood preparationUltrasonic assistedSulfur

The invention discloses a method for producing instant straw mushroom chips by adopting a vacuum low-temperature dehydration technology, and belongs to the technical field of deep processing of agricultural products. The method for producing the instant straw mushroom chips comprises the following main processes of: performing pretreatments such as conventional picking, cleaning, segmenting, blanching, non-sulfur color protecting, ultrasonic aid impregnating, sodium alginate film coating and the like on fresh straw mushrooms, and then, performing hot air and vacuum frying combined dehydrating, centrifugal oil removing, seasoning and packing. By adopting the new processes of non-sulfur color protecting, ultrasonic aid impregnating, sodium alginate film coating and hot air and vacuum fryingcombined dehydrating, the oil content of the product is remarkably reduced while the sensory quality of the product is improved and the impregnating efficiency is increased. In the method, necessary freezing treatment in the conventional fruit and vegetable chip frying process is not needed, so that the processing time is greatly reduced, and the production period of the product is effectively shortened. The product obtained by using the method has the characteristics of high puffing rate, low oil content, good sensory quality and the like; and a feasible new path is provided for deep processing utilization of the straw mushrooms.

Owner:NANJING UNIV OF FINANCE & ECONOMICS +1

Method for producing instant pleurotus eryngii chips

The invention relates to a method for producing instant pleurotus eryngii chips, and belongs to the technical field of the deep processing of agricultural products. The main pleurotus eryngii chip production process comprises: performing pretreatment such as conventional selection, washing, precise segmenting, blanching, enzyme killing, cooling and the like on pleurotus eryngii, and performing ultrasonic auxiliary dipping, hot-air drying, vacuum frying and dewatering, centrifugal deoiling, seasoning and packaging. In the method, due to the adoption of a new process of combining the ultrasonic auxiliary dipping, the hot-air drying, the vacuum frying and dewatering, the dipping efficiency is improved, the moisture content of pleurotus eryngii pieces is reduced due to hot-air predrying, and the vacuum frying time is shortened greatly; and products of the pleurotus eryngii chips have the characteristics of high puffing rate, low oil content, excellent sensory quality and the like. In the method, the pleurotus eryngii is not processed by conventional freezing, so the production period of the finished products is shortened greatly, the production cost is saved, and a feasible new path is provided for the deep processing of the pleurotus eryngii.

Owner:NANJING AGRICULTURAL UNIVERSITY +1

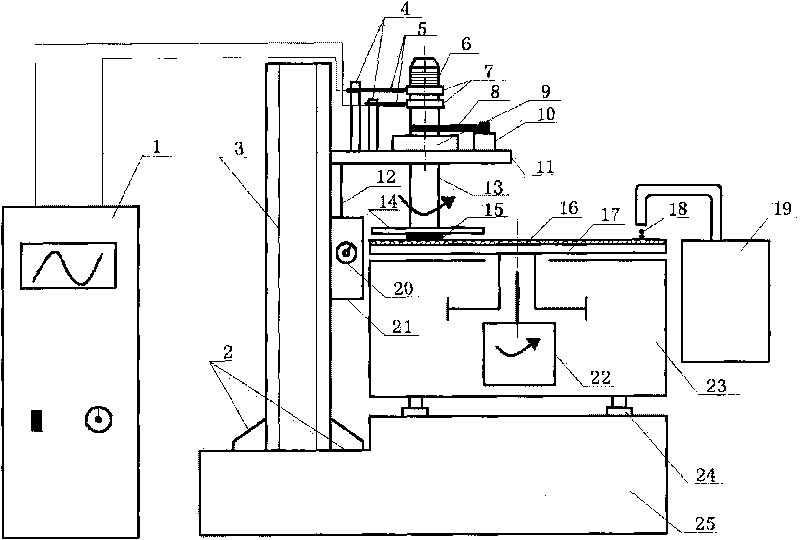

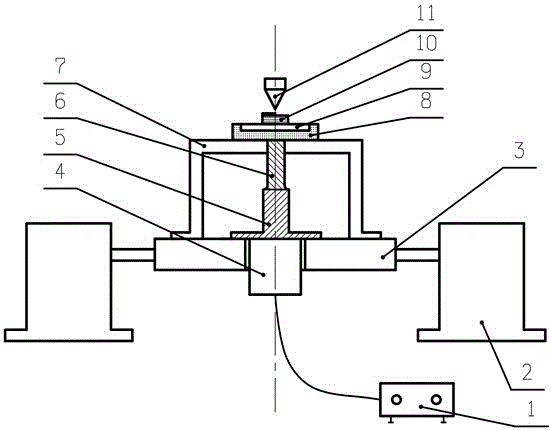

Device and method for polishing sapphire substrate material by ultrasound assisted chemical machinery

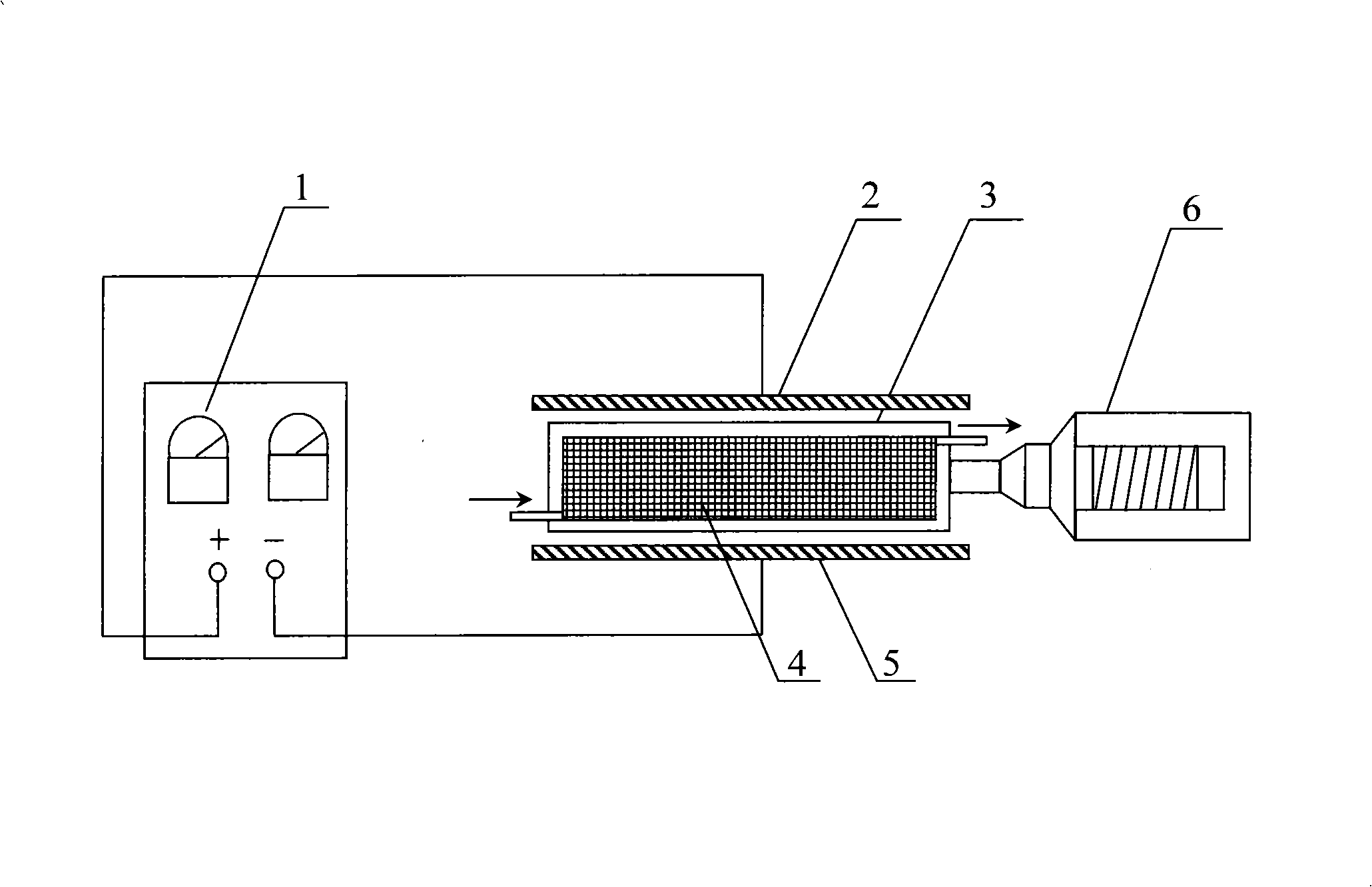

InactiveCN101716745AReduce polishing costsShorten polishing timeLapping machinesFine working devicesUltrasonic assistedTransformer

The invention discloses a device and a method for polishing a sapphire substrate material by ultrasound assisted chemical machinery, which belong to the technical field of polishing of sapphire substrate materials. An ultrasound power supply is connected to a positive terminal and a negative terminal of an ultrasonic transducer through a conducting wire, a carbon brush and a copper slip ring; the ultrasonic transducer converts an electrical signal into a mechanical vibration signal; and ultrasonic vibration is transmitted to a polishing head and a sapphire substrate arranged on the polishing head through an amplitude transformer. Compared with the traditional chemical mechanical polishing process, the method has the advantages that: due to the adoption of a composite action structure of ultrasonic vibration and chemical machinery, the method reduces the polishing cost and the polishing time of the sapphire substrate, improves surface topography precision of the sapphire substrate, meets the performance requirement of serving as the substrate material, and improves the polishing efficiency and the polishing quality; the polishing efficiency is improved by over one time; and the surface roughness of the polished sapphire is less than angstrom level. The ultrasonic assisted chemical mechanical polishing process is characterized by simple operation, convenience and practicability.

Owner:TSINGHUA UNIV

Method for extracting refined cordycepin and cordycepin polysaccharide from cordyceps mititaris

ActiveCN101124988ALow costReduce pollutionSugar derivativesSugar derivatives preparationAmylaseAdditive ingredient

The present invention relates to a method for extracting the purificatory cordycepin and the cordyceps amylase from the cordyceps militaris, belonging to the fields of medicines and health protection and chemical engineering. The cordyceps militaris powder is extracted and filtrated by a cooling seep method, the filter residue is mixed with ethanol, the supersonic wave assists to extract and offcenter, the supernatant has the processes of concentration and alcohol-precipitating, then the alcohol-precipitated supernatant has the processes of decompression, concentration and elution, the eluted liquid has the processes of concentration and crystallization and recrystallization using the n-butyl alcohol, at last the purificatory amylase is obtained after freezing and drying. The preparation progress of the present invention only uses water and ethanol as the solvent, thus reducing the pollution, the resin is capable of being reused a plurality of times with low cost. The present invention fully exploits the biological activity ingredients of the cordyceps militaris, realizes the coextraction of the cordycepin and the cordyceps amylase, guarantees the biological activities of the cordycepin and the cordyceps amylase, farthest increases the utilization rate of the raw material to the largest extent, reduces the manufacturing cost. The present invention is suitable for the large-scale industrialized manufacture.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

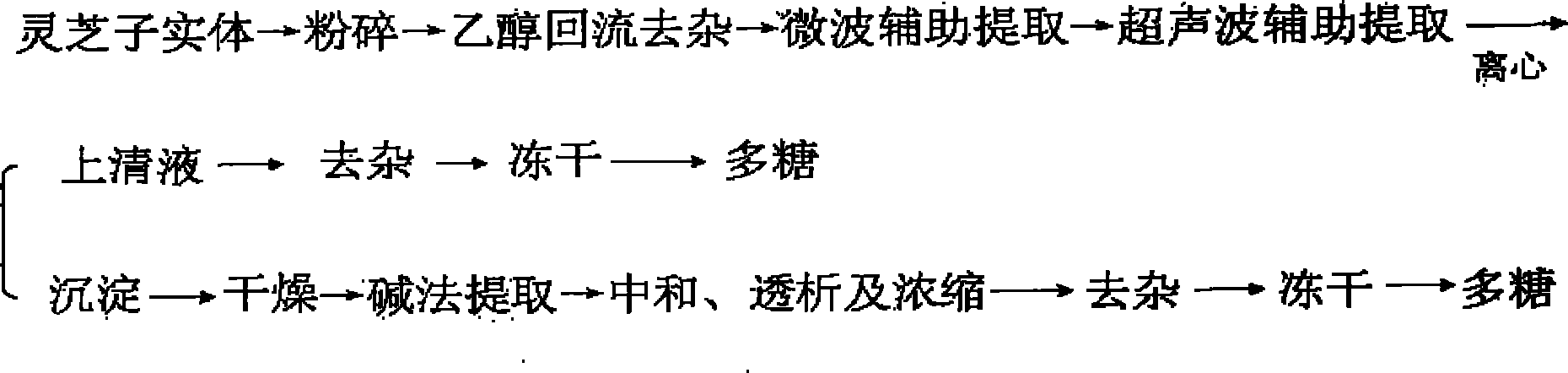

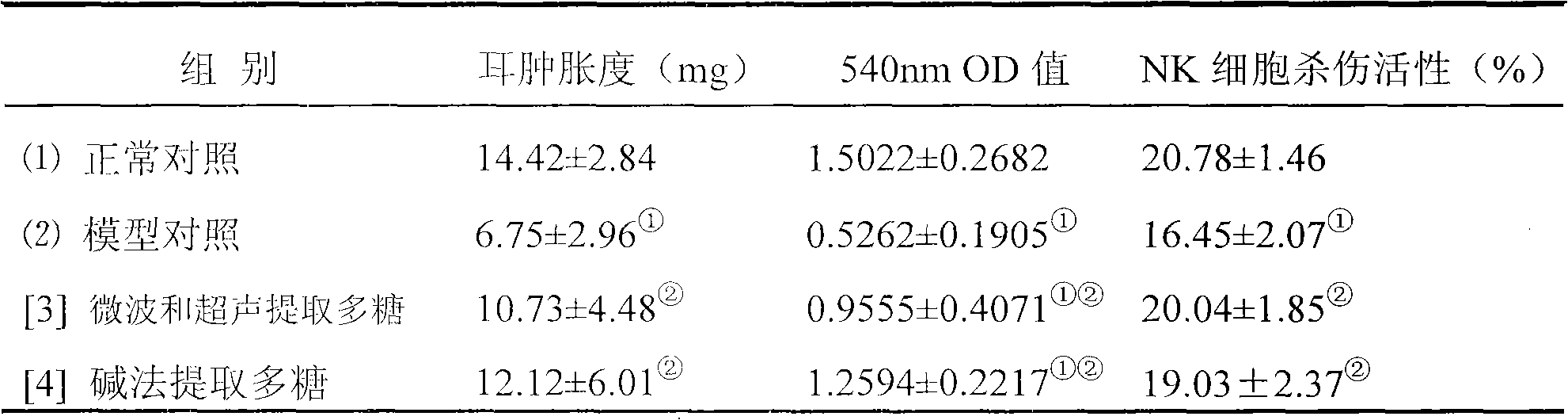

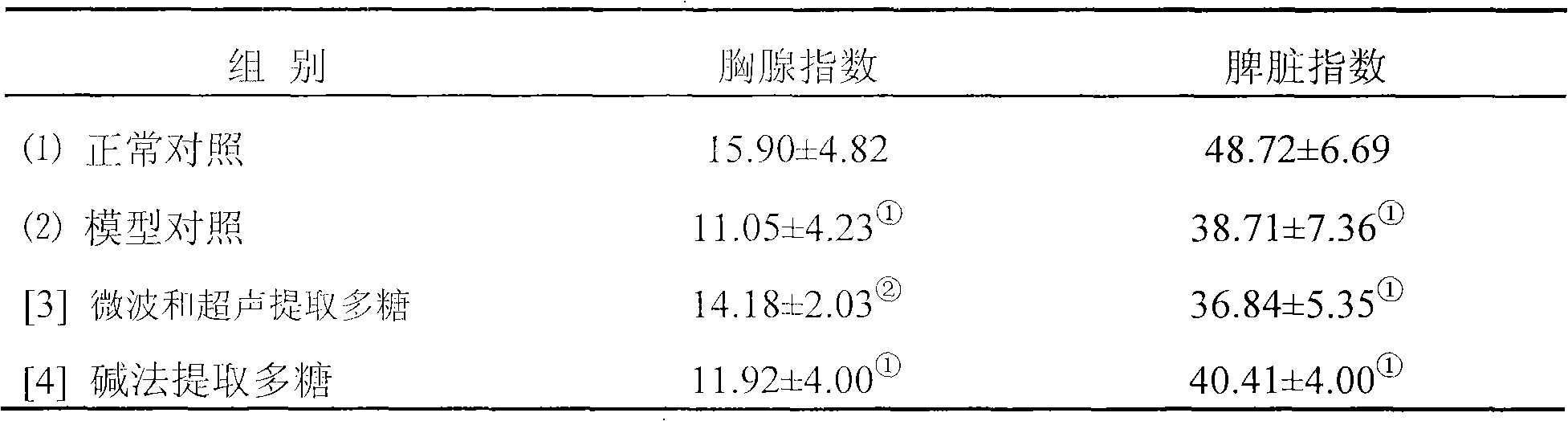

Preparation method of ganoderma lucidum polysaccharide with high yield

The invention discloses a preparation method of ganoderma lucidum polysaccharide with high yield, which comprises the following steps: firstly, crushing ganoderma lucidum fruiting bodies into ganoderma lucidum powder, then sequentially extracting the ganoderma lucidum powder by adopting a microwave-assisted hot water extraction method and an ultrasonic-assisted hot water extraction method, and carrying out concentration, impurity removal, concentration, alcohol precipitation and drying on the obtained extracting solution to obtain water-soluble ganoderma lucidum polysaccharide; and extracting the ganoderma lucidum residues by adopting an alkali extraction method, and carrying out neutralization, dialysis, concentration, impurity removal, alcohol precipitation and drying on the obtained extracting solution to obtain alkali-soluble ganoderma lucidum polysaccharide. The method is used for extracting the ganoderma lucidum polysaccharide by combining microwave heating action and ultrasonic cavitation and extracting the alkali-soluble polysaccharide in the ganoderma lucidum by utilizing the alkali extraction method, thereby reducing the loss of the ganoderma lucidum polysaccharide; and the prepared ganoderma lucidum polysaccharide has the characteristics of high production yield, strong immunological activity and the like.

Owner:INFINITUS (CHINA) CO LTD

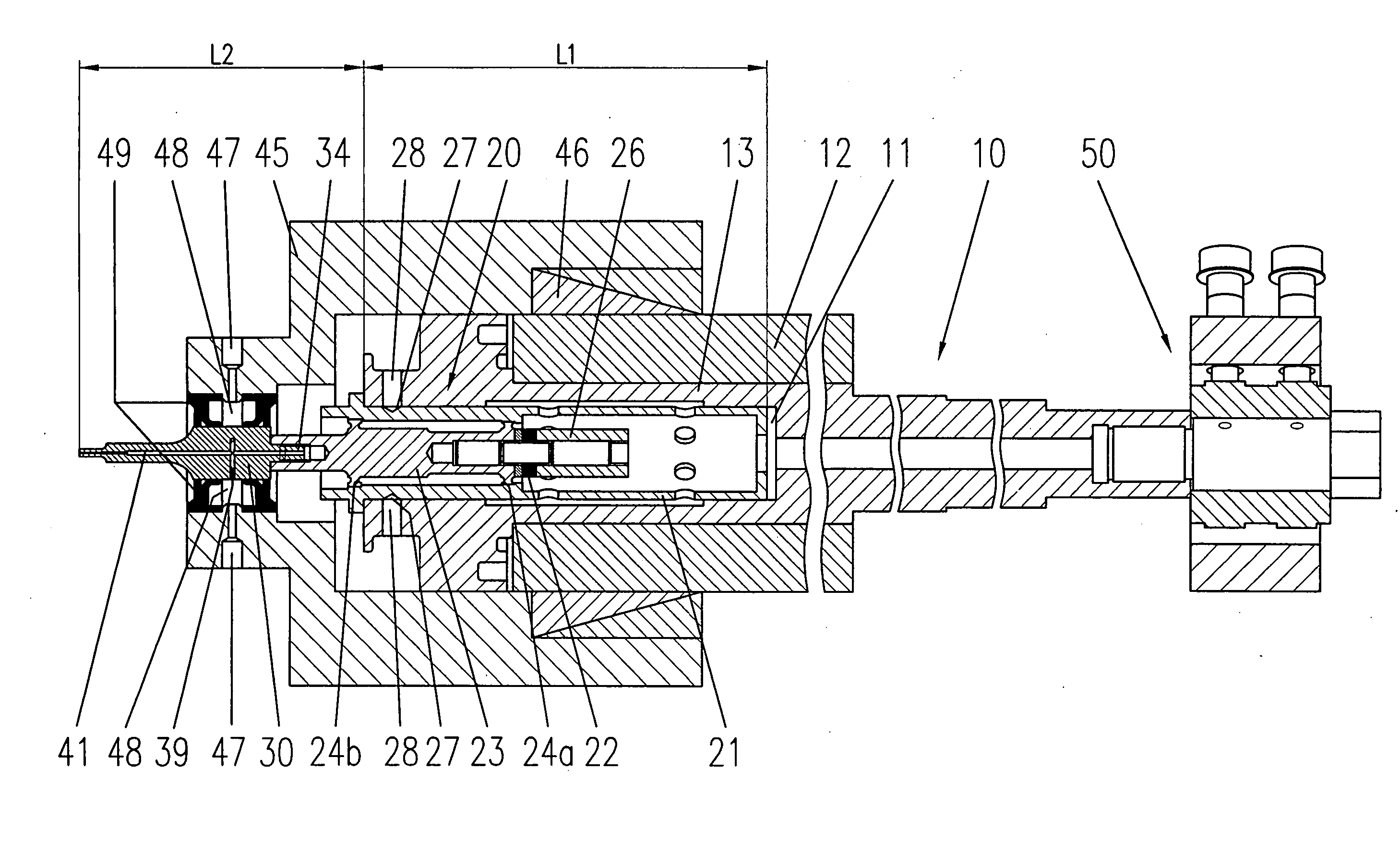

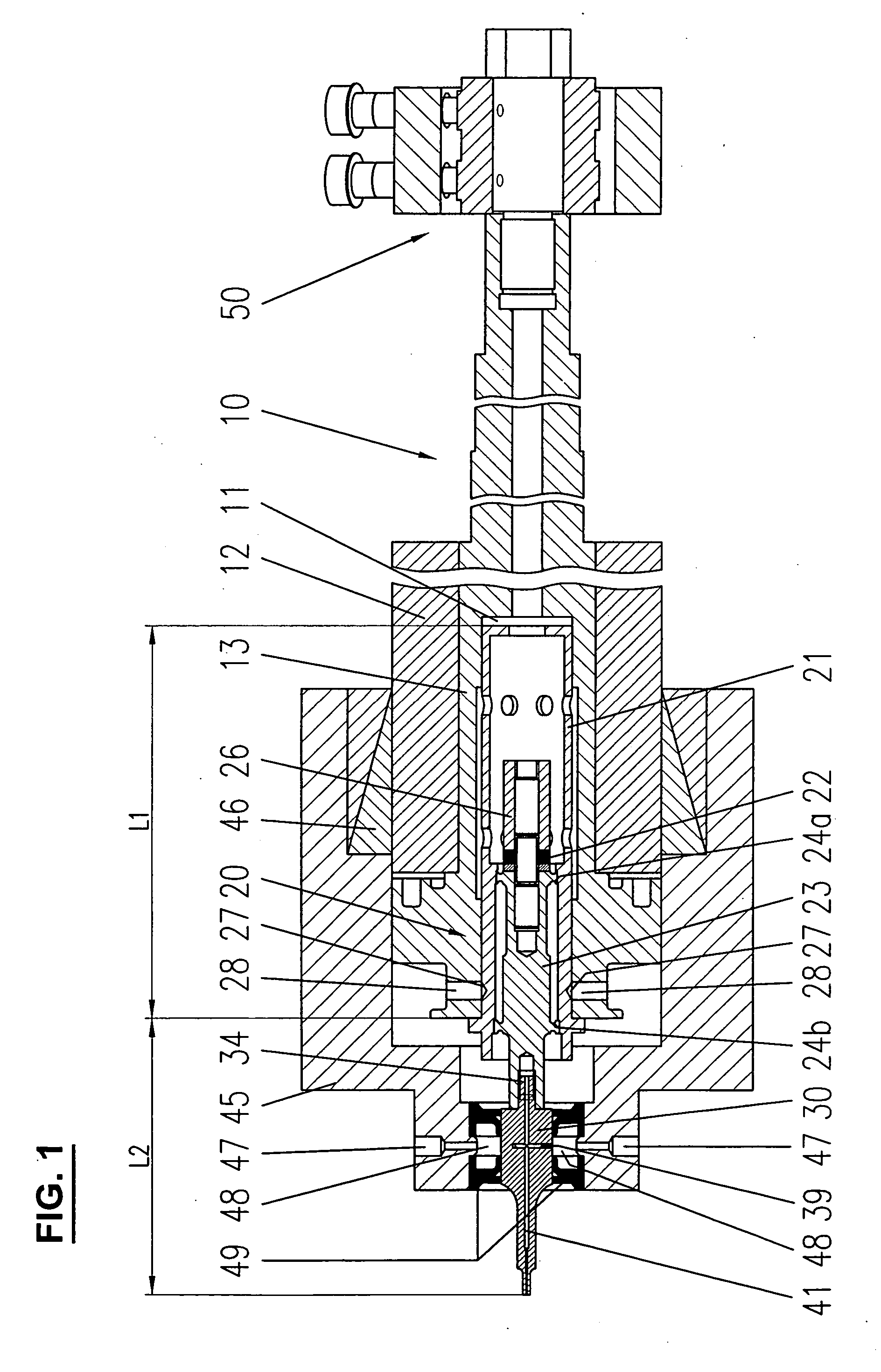

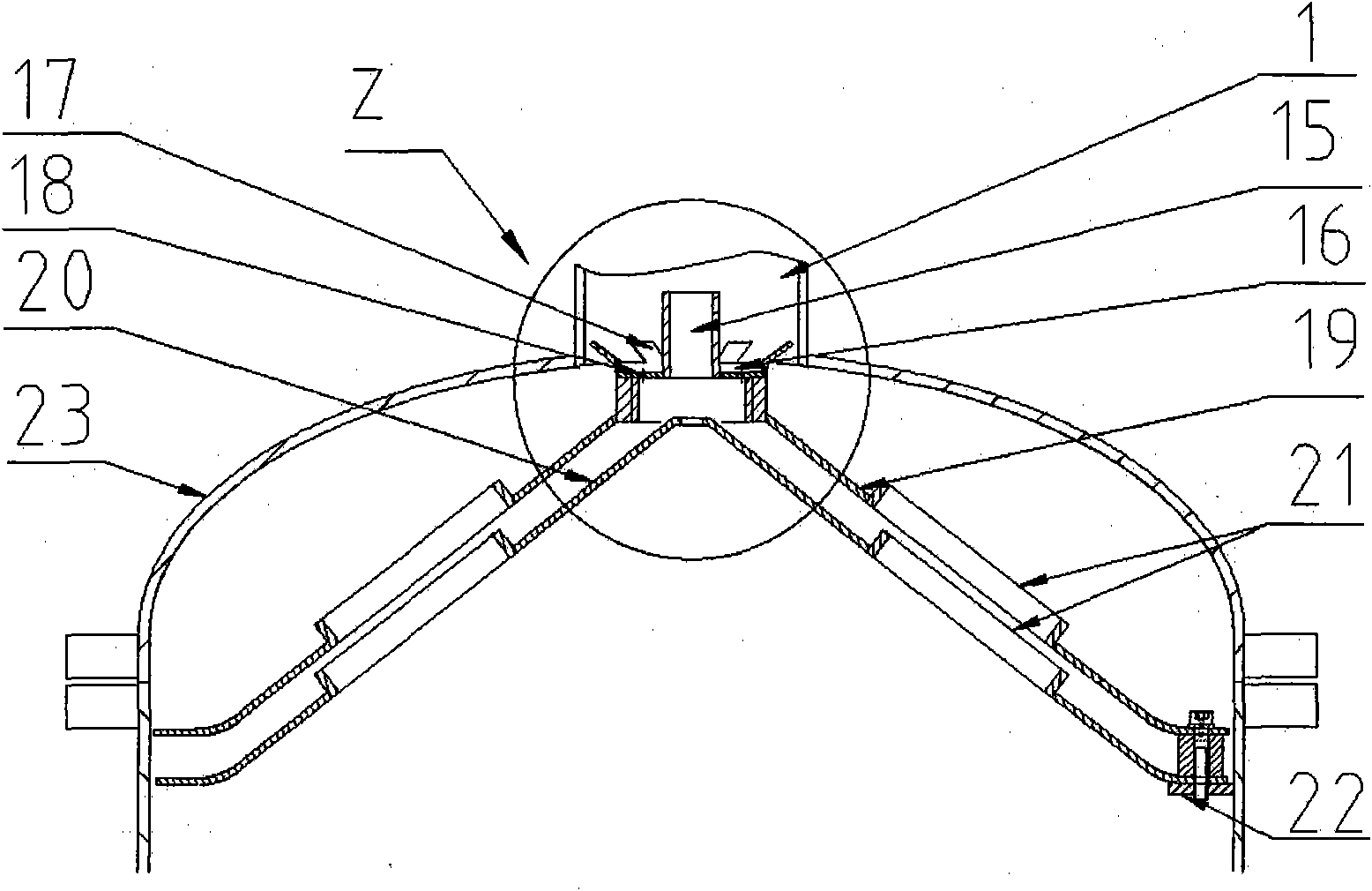

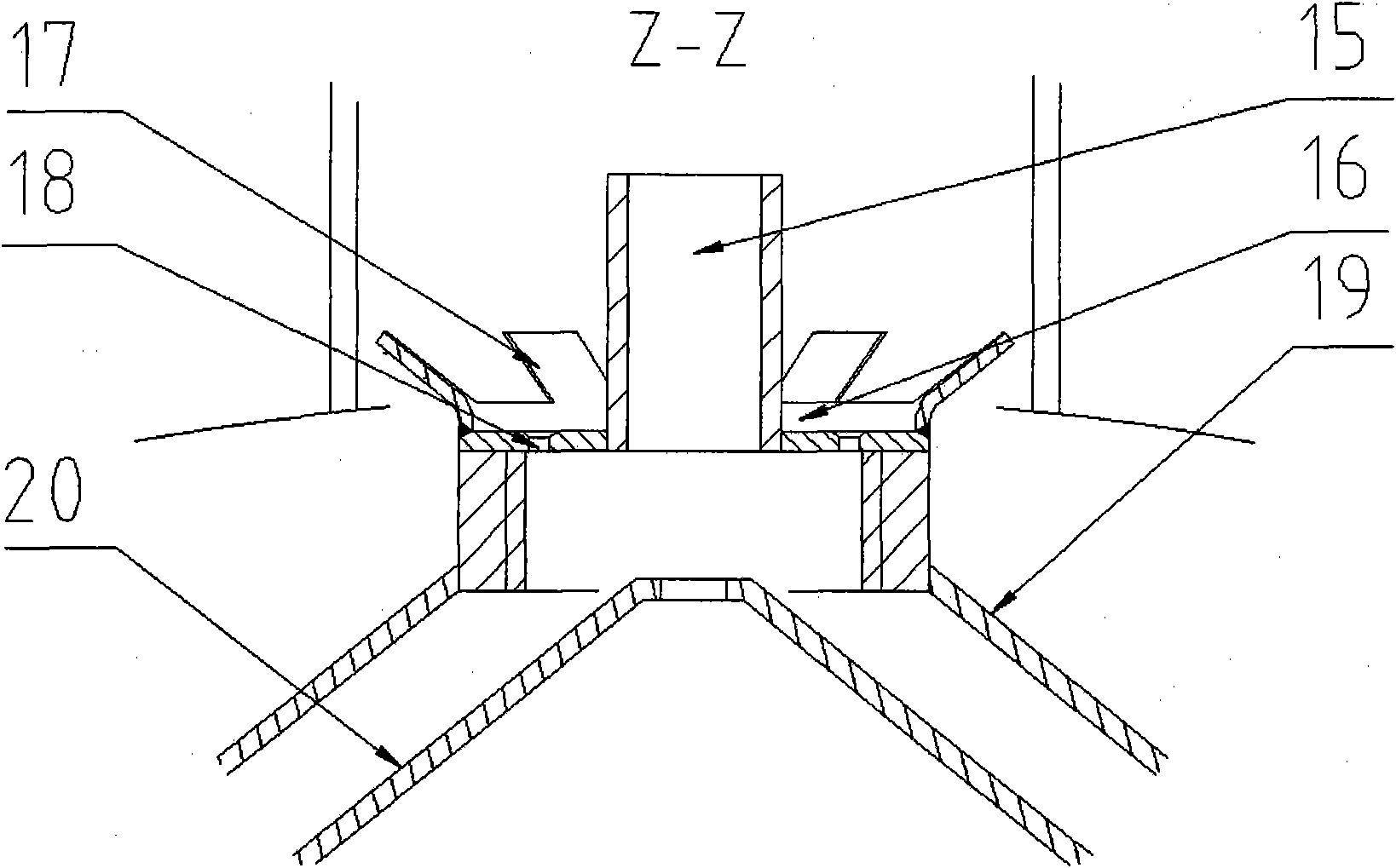

Tool unit for ultrasonically assisted rotary machining

ActiveUS20060128283A1Easy to replaceCompact designEdge grinding machinesTurning machine accessoriesUltrasonic assistedTransducer

The tool unit for the ultrasonically assisted rotary machining of a workpiece comprises a converter (23) including at least one electroacoustic transducer (22) for generating and transmitting ultrasonic oscillations, a tool (30) that is coupled to the converter, and a holder (21) in which the converter including the transducer is arranged and which is insertable at least partially in the retainer (11) of a tool spindle (10) and connectable thereto by means of a detachable connection (27).

Owner:FRITZ STUDER AG

Ultrasonic-assisted tea oil extraction method using subcritical CO2

ActiveCN102041164AHigh nutritional valueImprove qualityFatty-oils/fats productionUltrasonic assistedWorking pressure

The invention discloses an ultrasonic-assisted tea oil extraction method using subcritical CO2, comprising the steps as follows: (1) taking dry tea seed, hulling, crushing, and placing in an extraction kettle; (2) injecting the subcritical CO2 into the extraction kettle to mix with the tea seed; (3) extracting the raw material for 0.5-5 hours; (4) decompressing and evaporating so as to completelygasify the subcritical CO2 liquid, wherein the temperature in evaporation process is controlled at 30-70 DEG C, and finally discharging the extracted tea oil from the bottom of a separation kettle. The method has the advantages that (1), the advantages of the subcritical CO2 extraction technology and the ultrasonic extraction technology are sufficiently utilized to shorten the extraction time andimprove the extraction yield; (2), the work pressure is low, and the natural activity of heat-sensitive material cannot be influenced since the extraction temperature is less than 30 DEG C, and the nutritional value and quality of the tea oil are improved; (3), the device cost is low, the refining process is less, the tea oil loss is less and the product oil yield is high; (4) a natural green food is obtained since the CO2 solve is residue-free.

Owner:NANCHANG TONGXIN ZICHAO BIOENG +1

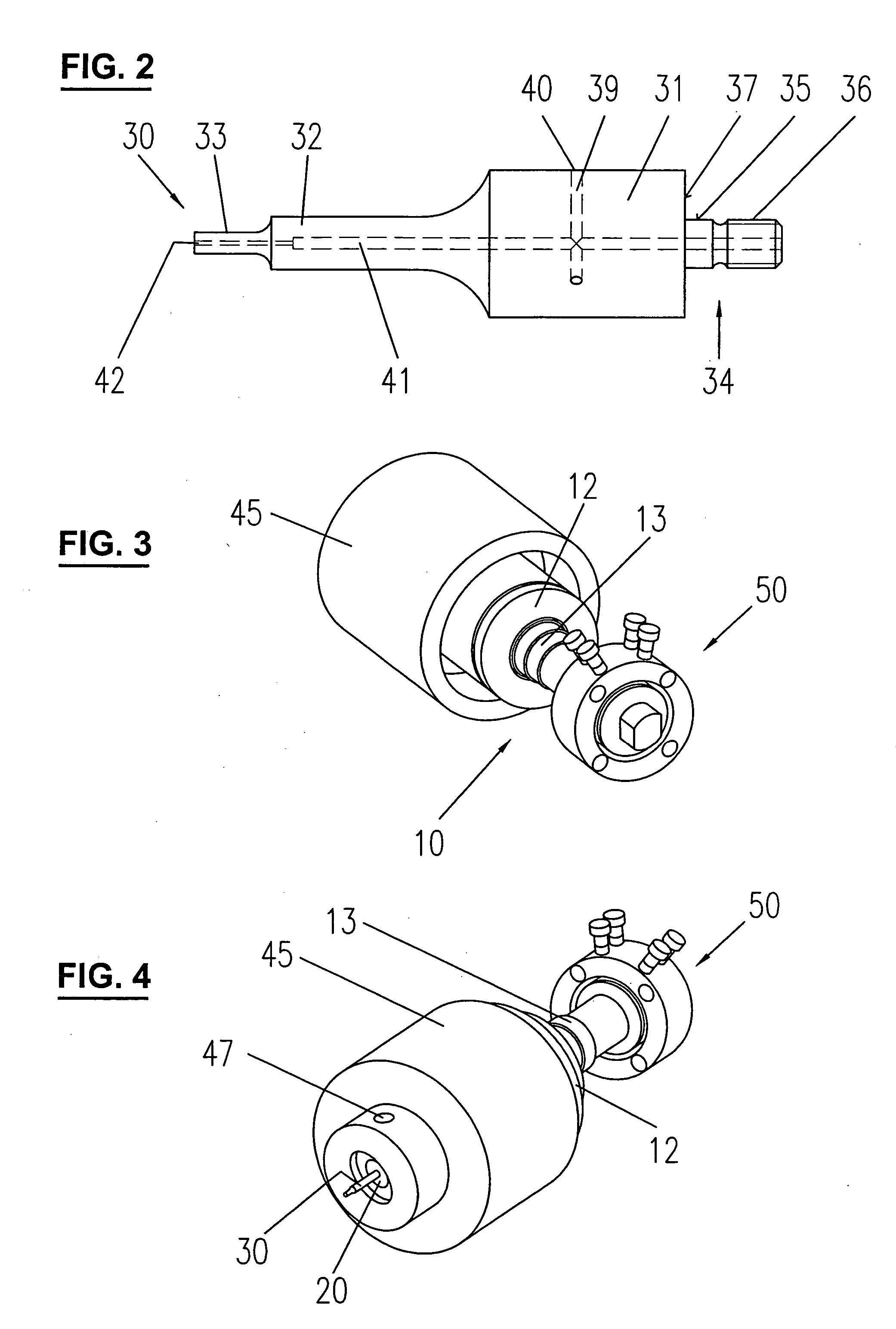

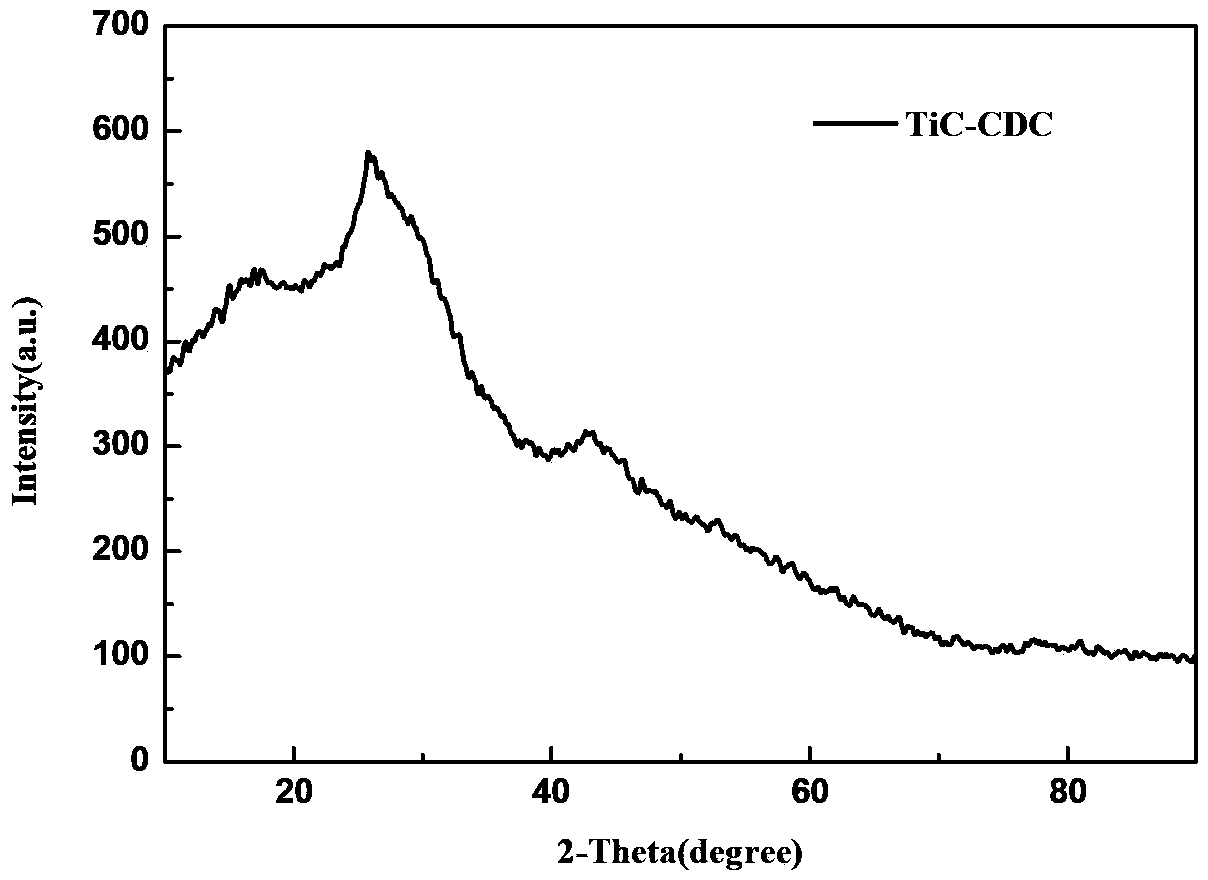

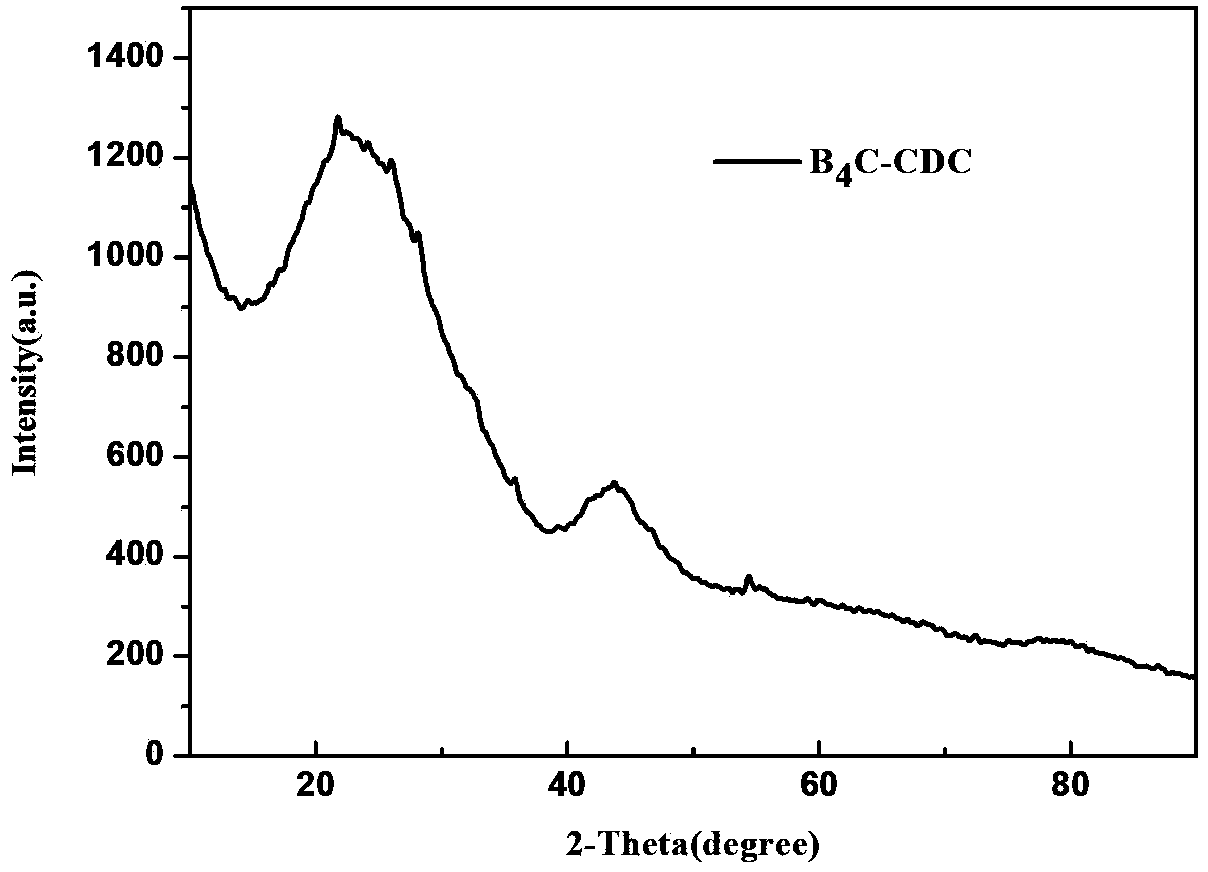

Method for preparing carbide derived carbon by fused salt electrolysis method

InactiveCN103436904AHigh purityUniform pore size distributionElectrolysis componentsCarbon preparation/purificationElectrolysisArgon atmosphere

The invention discloses a method for preparing carbide derived carbon by a fused salt electrolysis method. The method mainly comprises the steps that metal carbide serves as a raw material, and is subjected to die pressing sintering to form a metal carbide sheet to serve as an anode; by taking fused salt as an electrolyte, and a high-purity and high-density graphite rod as a cathode, fused salt electrolysis is performed in an electrolysis furnace in an argon atmosphere with the electrolysis temperature of 400-1300 DEG C, the electrolysis voltage of 1.8-3.2V, and the electrolysis time of 2-60h; after the electrolysis, an anode product is taken out, and subjected to water washing, ultrasonic-assisted pickling, water washing and drying treatment; and the carbide derived carbon is prepared. According to the method, the low-cost metal carbide can serve as the raw material for preparing the carbide derived carbon by the fused salt electrolysis method, so that a preparation technology is simplified; the cost is lowered; and the prepared carbide derived carbon serves as an electrode material of a supercapacitor, and has high specific capacity and good cycling stability.

Owner:YANSHAN UNIV

Conditioning and making method and high-efficiency even drying method for small trash fish marine product

The invention provides a conditioning and making method and a high-efficiency even drying method for a small trash fish marine product, belonging to the technical fields of food conditioning and aquatic product processing. The main process of the invention comprises the following steps of: removing three parts (fish scale, fish head and viscera) of a fresh or iced and fresh small trash fish marine product, washing the small trash fish marine product with clear water, slicing the small trash fish marine product into fish chips with the length of 6-10cm, deodorizing preprocessed fish meat for 4hours with compound rinsing fluid, then carrying out ultrasonic assisted vacuum impregnation conditioning (pickling and seasoning), secondary rinsing, draining, medium-short wave infrared drying pre-dehydrating, pulse spraying negative pressure microwave drying, packaging and sterilizing, thus the small trash fish dried fish prepared food product is obtained. The small trash fish marine product disclosed by the invention has good colour, fragrance and taste, beautiful appearance, low moisture content and complete nutrition, is a high-protein and low-fat food, is beneficial to reducing cholesterol and preventing cardiovascular and cerebrovascular diseases after being eaten for a long time, can be used for adjuvant therapy on leukaemia, stomach cancer and the like and is a high-quality leisure food for both the old and the young.

Owner:JIANGNAN UNIV +1

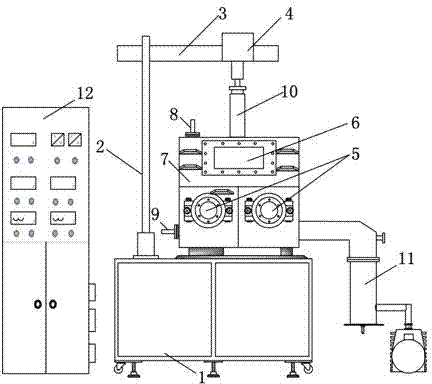

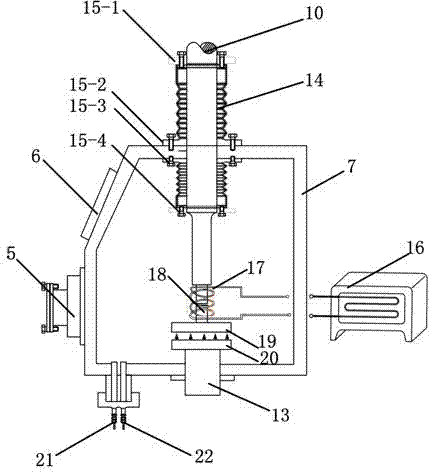

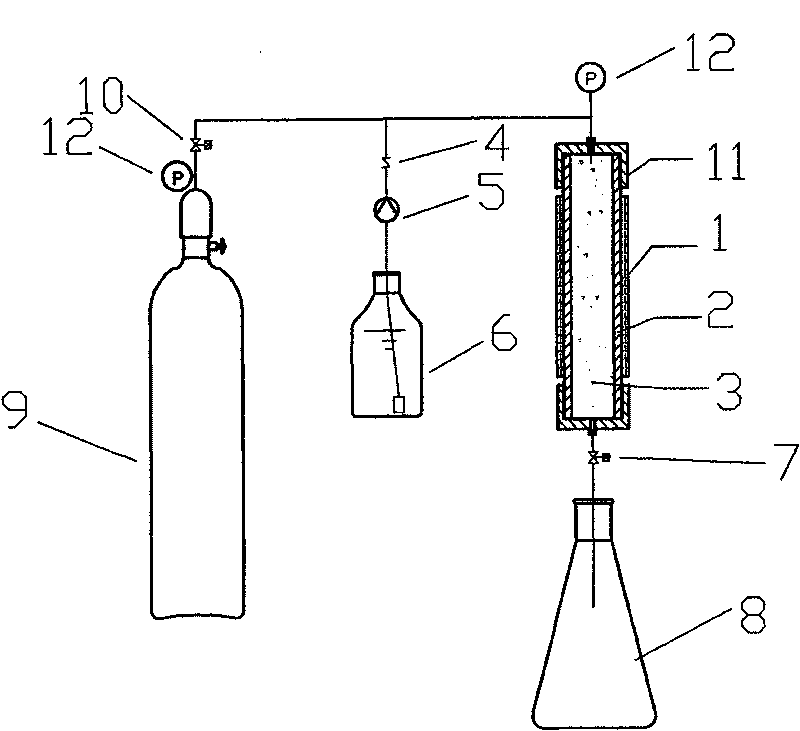

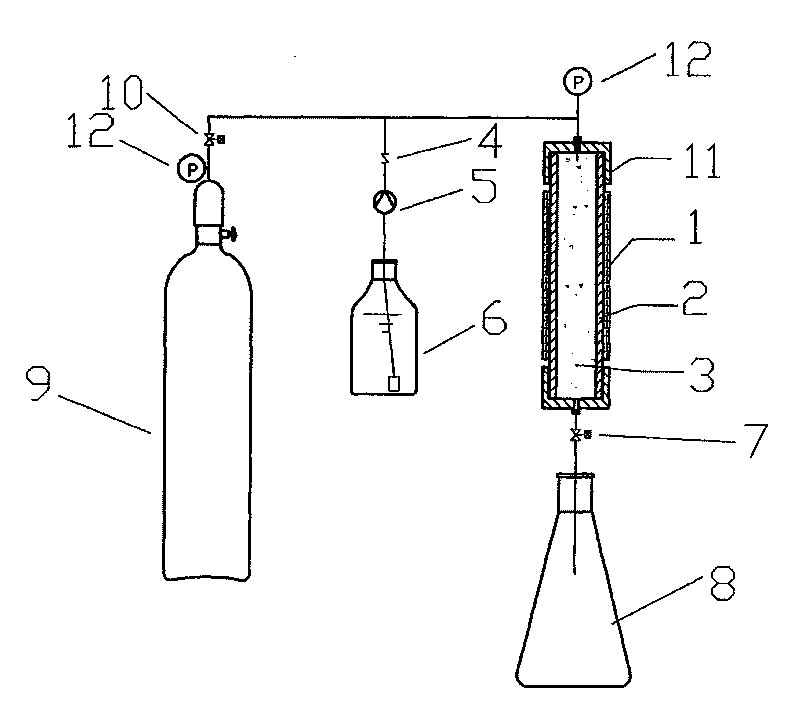

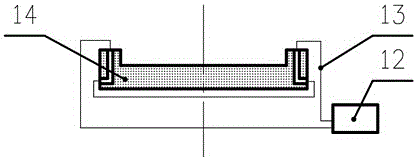

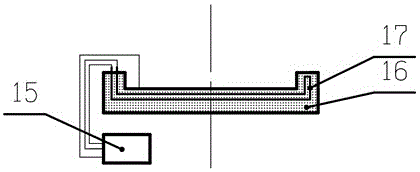

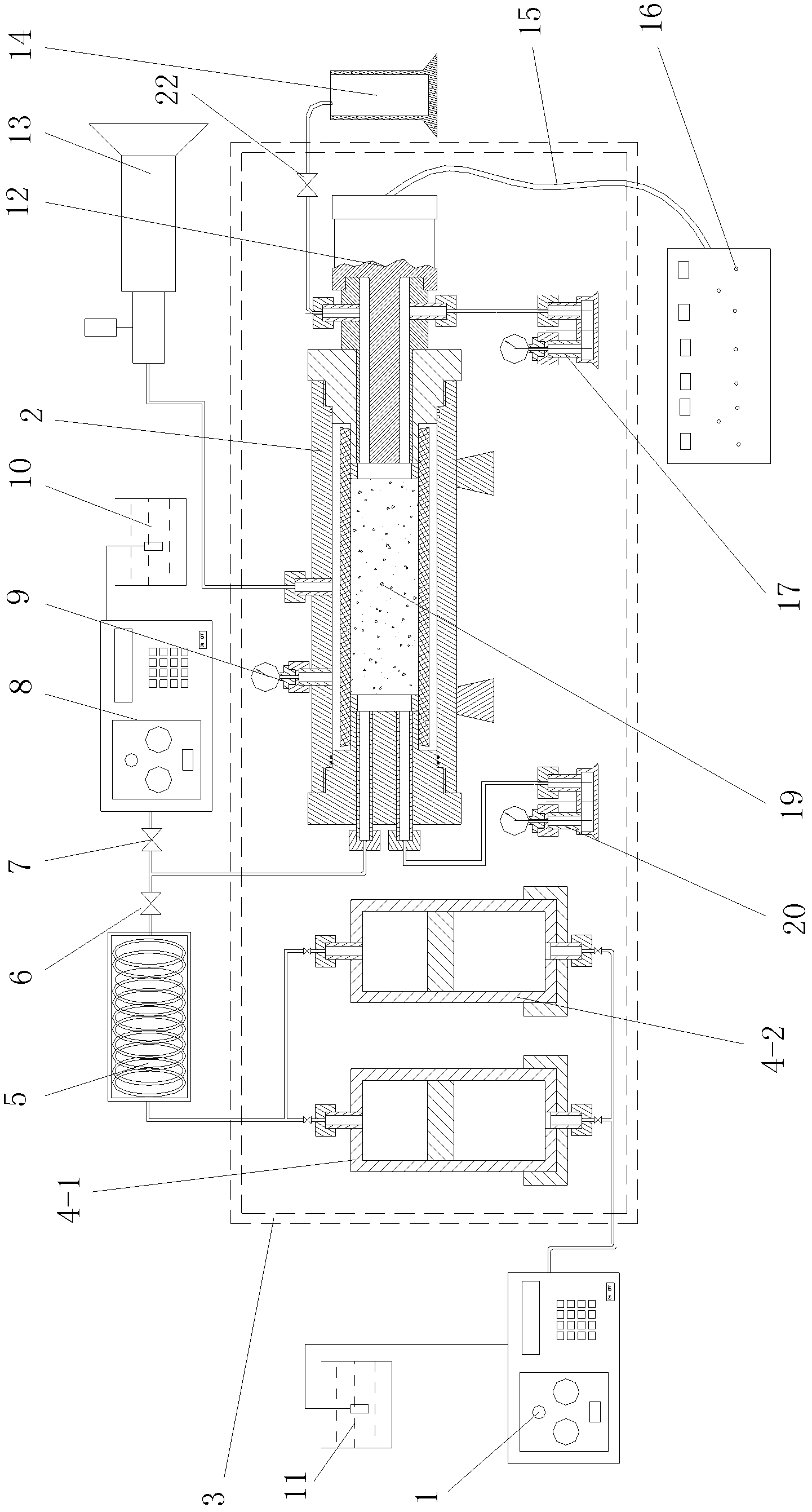

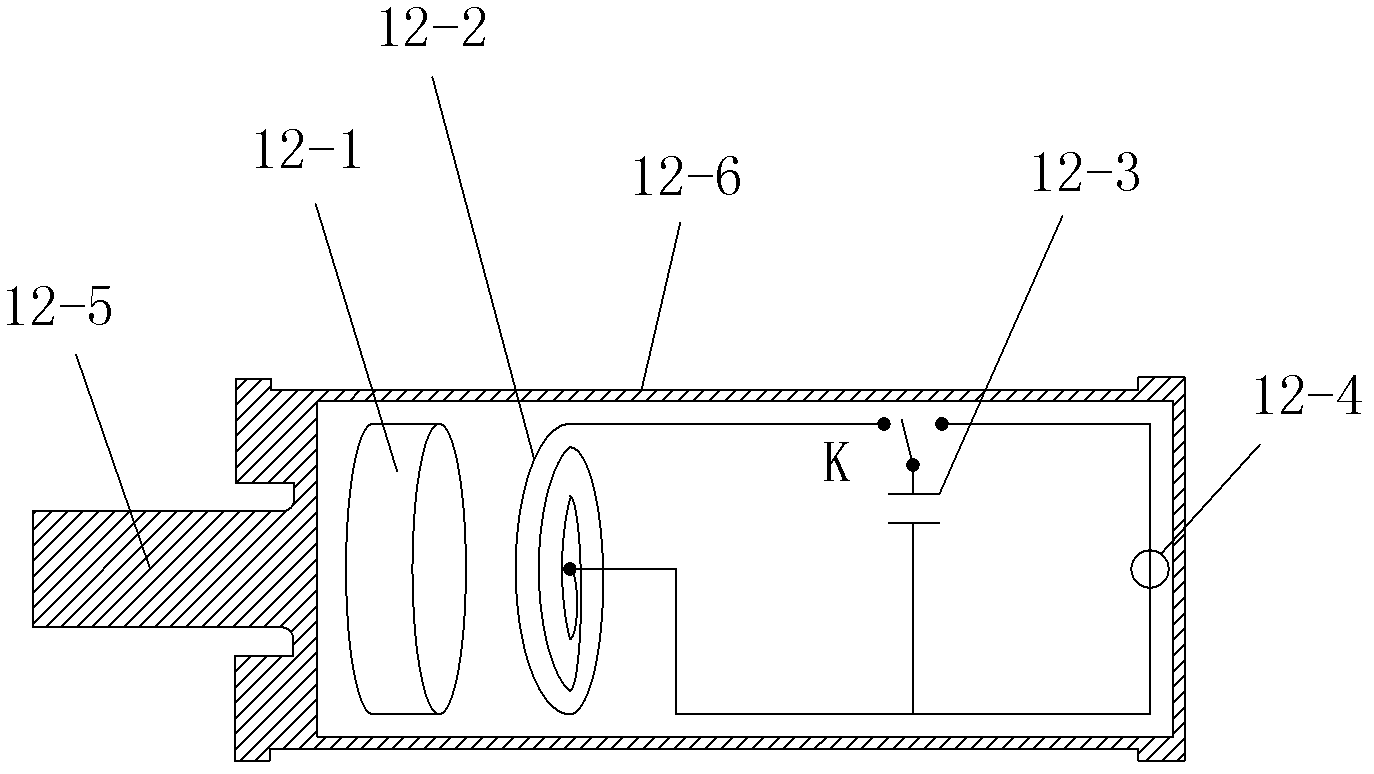

Ultrasonic-assisted vacuum brazing equipment

ActiveCN103394783AImprove connection strengthAssembly real-time monitoringSoldering apparatusMetal working apparatusUltrasonic assistedThermocouple

Owner:HARBIN INST OF TECH AT WEIHAI

Method for preparing naringin or hesperidin

InactiveCN101704867AAdvancedQuick extractionSugar derivativesSugar derivatives preparationNaringinUltrasonic assisted

The invention relates to a method for preparing naringin or hesperidin, which comprises the following operating steps of: 1) drying and crushing fruits, fruit peels and fruit residues containing the naringin or the hesperidin, and respectively filling the crushed materials into an extraction kettle of a pressure solvent extraction device; 2) selecting an extraction solvent, setting an extraction pressure, an extraction temperature, an extraction static time and an extraction frequency, extracting with the pressure solvent extraction device, and collecting the extract liquor; and 3) concentrating the extract liquor in vacuum, centrifugating the extract liquor or filtering the extract liquor to remove insoluble substances, adjusting pH of the clear liquid, cooling the clear liquid to crystallize or precipitate, recrystallizing the coarse crystals, drying the coarse crystals, or re-dissolving the precipitate for re-precipitation, and obtaining a pure product of the naringin or the hesperidin. Compared with the conventional solvent extraction method, ultrasonic-assisted extraction method and microwave-assisted extraction method, the preparation method has the advantages of high speed, capability of repeatedly extracting, safety, high efficiency, and simple post treatment such as concentration and purification.

Owner:THIRD INST OF OCEANOGRAPHY STATE OCEANIC ADMINISTATION

Method for extracting mulberry cyanidin

ActiveCN102212053AHigh puritySimple processOrganic chemistryNatural dyesUltrafiltrationMacroporous resin

The invention relates to a method for extracting cyaniding and belongs to the technical field of extracting natural medicaments. The method adopts the process of ultrasonic-assisted enzyme method extraction, flocculation, ultrafiltration, macroporous resin adsorption, nanofiltration condensation, spray drying and high-purity cyaniding. Compared with the traditional processes, the method has the advantages of overcoming the defects in the traditional processes, effectively improving the yield and the quality of the product, greatly lowering the consumption and the loss of the organic solvents,reducing energy consumption, lowering production cost, having practicability and progress and reaching the domestic leading level.

Owner:湖州柳荫生物科技有限公司

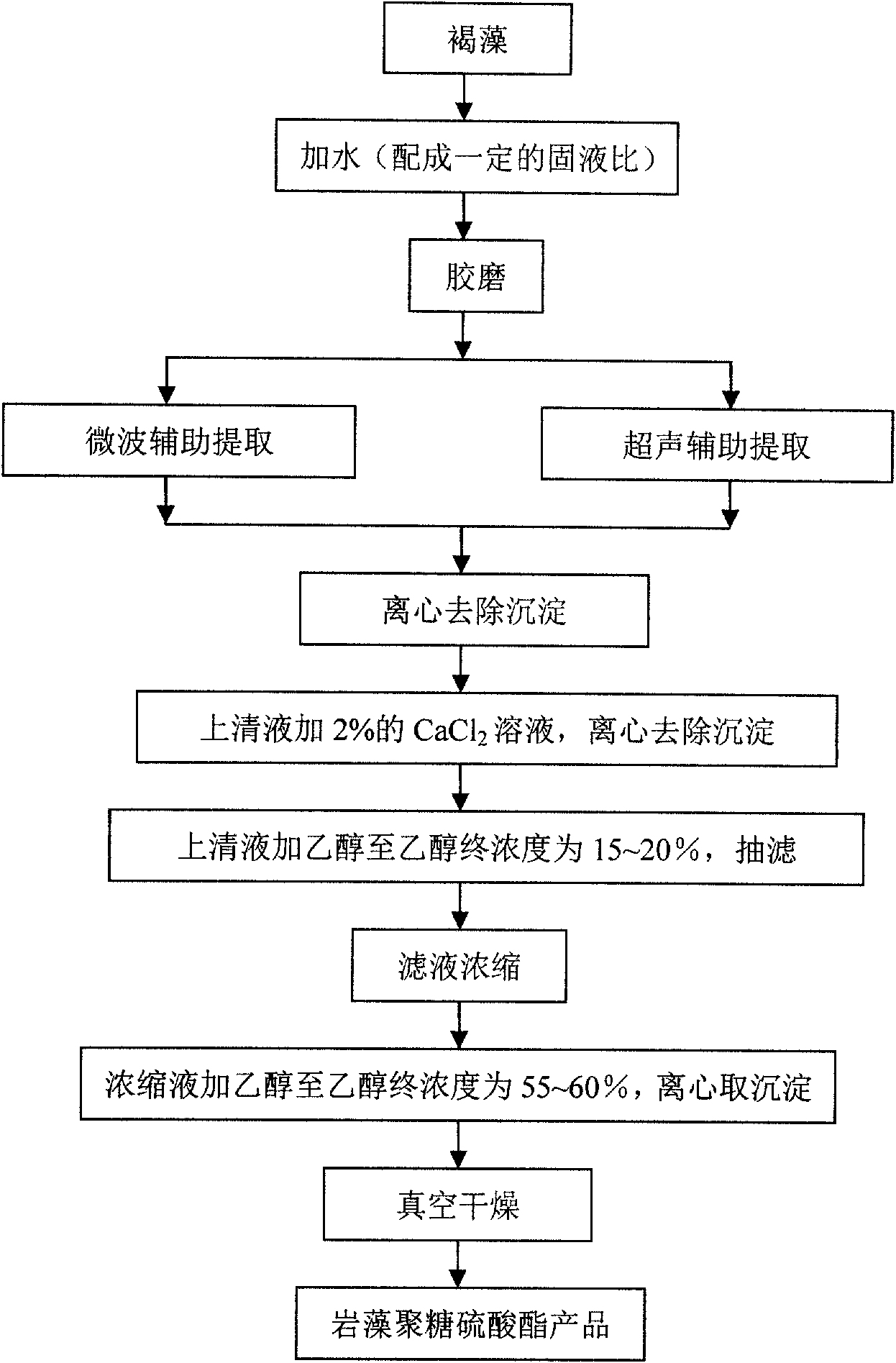

Method for preparing fucoidan

InactiveCN101993501AComprehensive utilization value has no impactComprehensive utilization value impactFood additiveLiquid ratio

The invention provides a method for preparing fucoidan, relating to the field of production and application of food additives. The method comprises the following steps of: adding distilled water according to a material to liquid ratio of 1:40-4:80 g / mL with brown algae, such as kelps, undaria pinnatifida, and the like as raw materials; treating by a colloid mill and then carrying out microwave-assisted extraction or ultrasonic wave-assisted extraction, wherein, in the microwave-assisted extraction process, the microwave time lasts 20-40min, the microwave extraction temperature is 60-80 DEG C, and the microwave power is 400-500W; and in the ultrasonic wave-assisted extraction process, the ultrasonic power is 800-100W, the microwave time lasts 20-40min, and the extraction temperature is 60-90 DEG C; and centrifuging an extracting solution, adding a proper amount of 2% CaCl2 solution into a supernatant, stirring, keeping constant temperature for 20-30h at 35-40 DEG C, centrifuging, adding 50-100% ethanol into the supernatant until the ethanol concentration of the solution is 15-20%, stirring, filtering, concentrating, adding 90-100% ethanol into a concentrated solution until the ethanol concentration of the solution is 55-60%, centrifuging again and drying a precipitate in vacuum to obtain white or yellow-white fucoidan powder.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

A method for preparing wheat bran food fibre using ultrasound wave assistance enzymolysis

InactiveCN101156684AEffective value-addedEfficient use ofFood preparationPeripheral nerveUltrasound assisted

The invention relates to a method for preparing wheat bran dietary fiber by utilizing ultrasound-assisted enzymatic hydrolysis, and in particularly belongs to the technical field of the agricultural and sideline product development, the functional food additive and the nutritional heath caring. The invention is characterized in that the invention adopts wheat bran as the raw material, and the wheat bran dietary fiber preparation is realized through utilizing the ultrasound treatment, and removing starch and protein by enzymatic method, and then the preparation of fine dietary fiber with different grain size is realized by crumbling with a grinder. The invention realizes the effective value increment and the utilization of the wheat bran, the prepared functional dietary fiber has important physiological function, and thereby can realize the functions of preventing constipation, colon cancer, intestina diverticulum, hemorrhoid and varicose veins of the lower extremities; the serum cholesterol is lowered, and the heart disease caused by coronary sclerosis can be prevented; the sensitivity of the peripheral nerve tissue to the insulin is improved, and the blood sugar level of the diabetes patient can be regulated, the invention is very useful for human health, and the economic benefit as well as the social benefit are greatly increased.

Owner:JIANGNAN UNIV

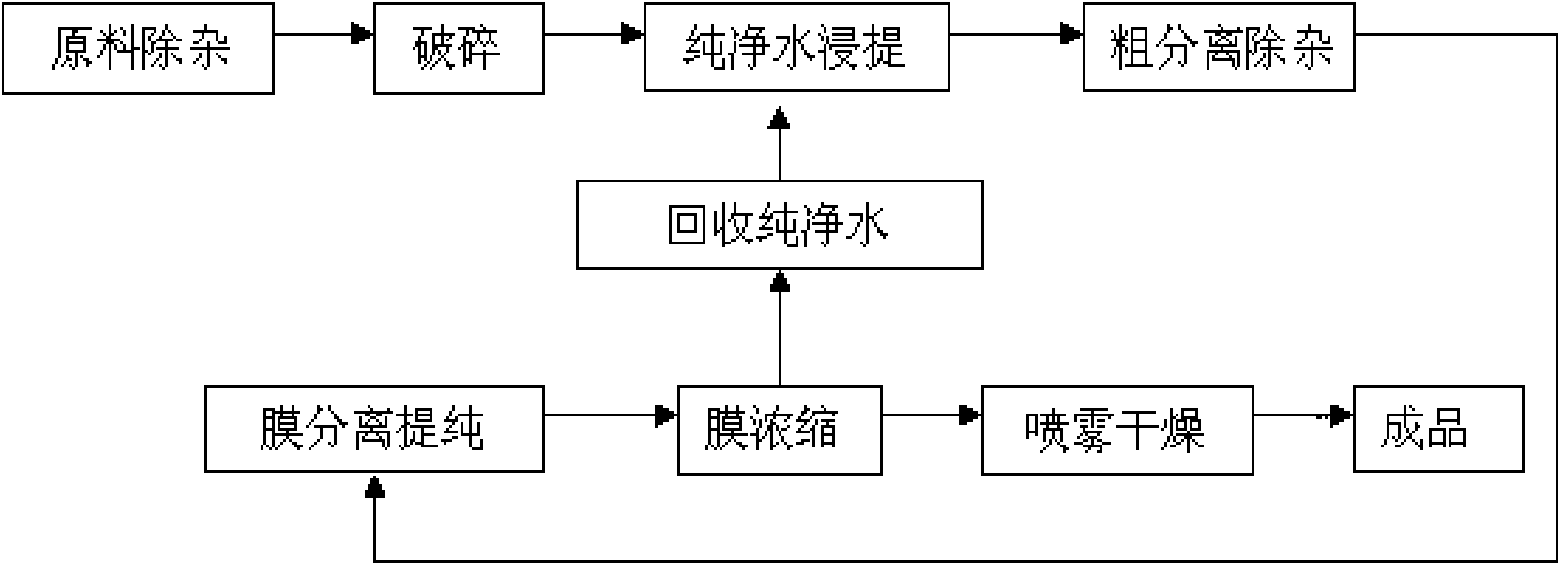

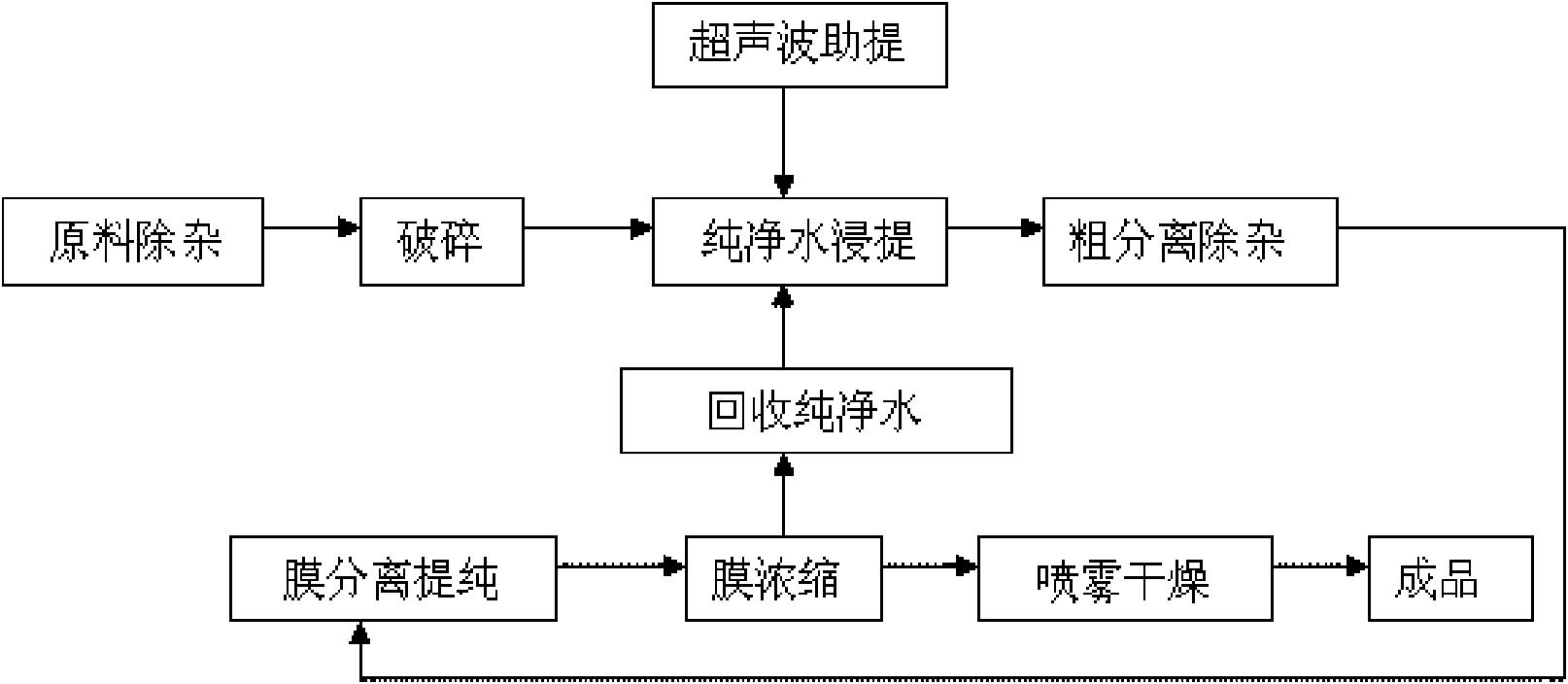

New process for extracting high-purity gardenia yellow pigment by membrane separation and purification technology

InactiveCN101659794AImprove environmental performanceImprove extraction efficiencySemi-permeable membranesNatural dyesFiltration membraneUltrafiltration

The invention relates to a new process for extracting high-purity gardenia yellow pigment by a membrane separation and purification technology. The new process comprises processes of purified water leaching, crude separation and impurity removal, membrane separation and purification, and membrane concentration. After purified water extraction and ultrasonic assisted extraction, raw gardenia is separated by three centrifuges with different specifications and then obtained leaching liquor enters a membrane separation, purification and concentration system which consists of a microfiltration membrane (MF), an ultrafiltration membrane (UF), a nano-filtration membrane (NF) and a reverse osmosis membrane (RO), thus an OD value of the obtained gardenia yellow pigment can be controlled below 0.4 and color number can be increased to be more than 400. The finished product obtained by the process has no residual organic solvent and completely meets technical requirements for exporting to developed countries, including Europe and America, etc. as well as developed areas. The process is safe and clean in the whole production process, capable of realizing zero pollution and zero emission, has high environmental protection performance, and has advantages of greatly reducing energy consumption and lowering production cost due to the membrane concentration technology. The process further has advantages of simple process, stable product quality, high purity, etc.

Owner:广西山云生化科技股份有限公司

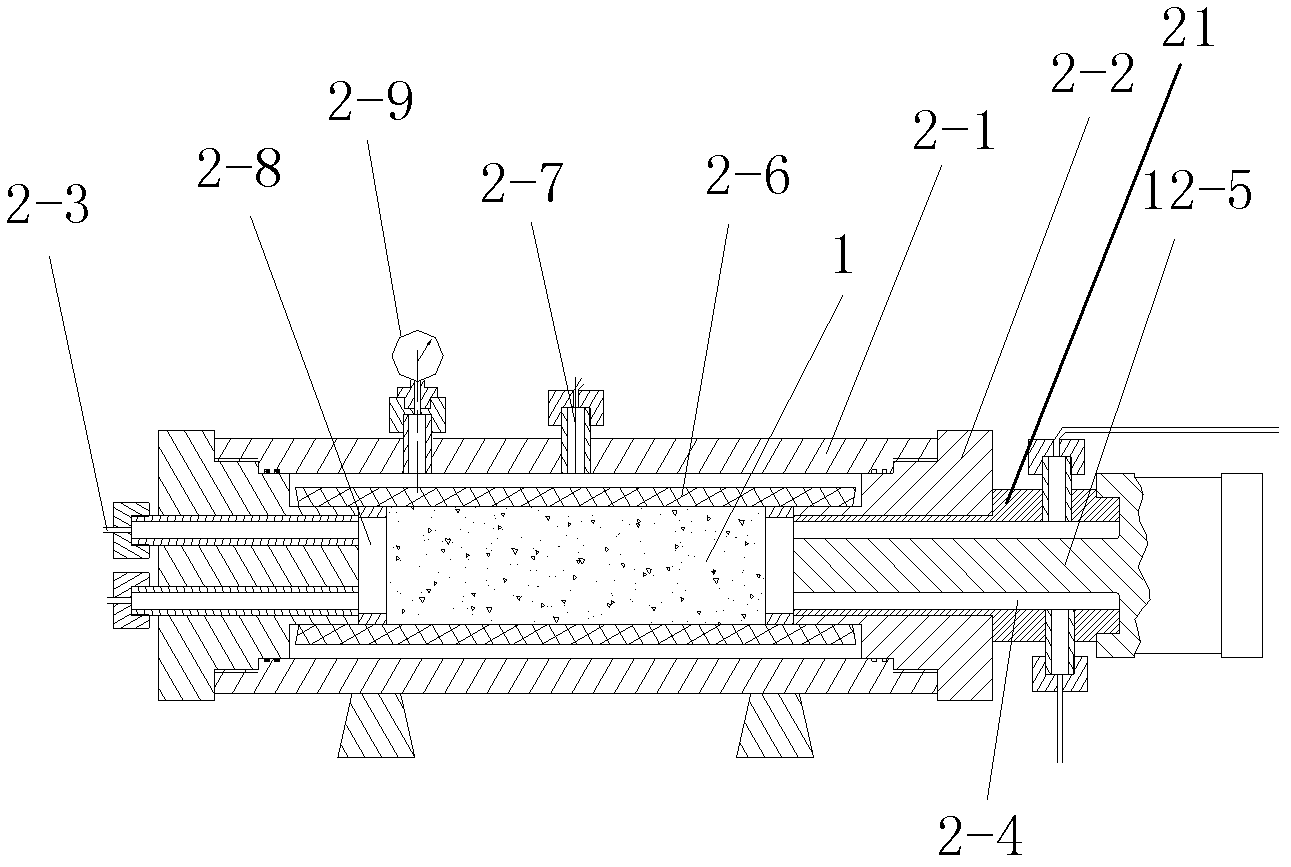

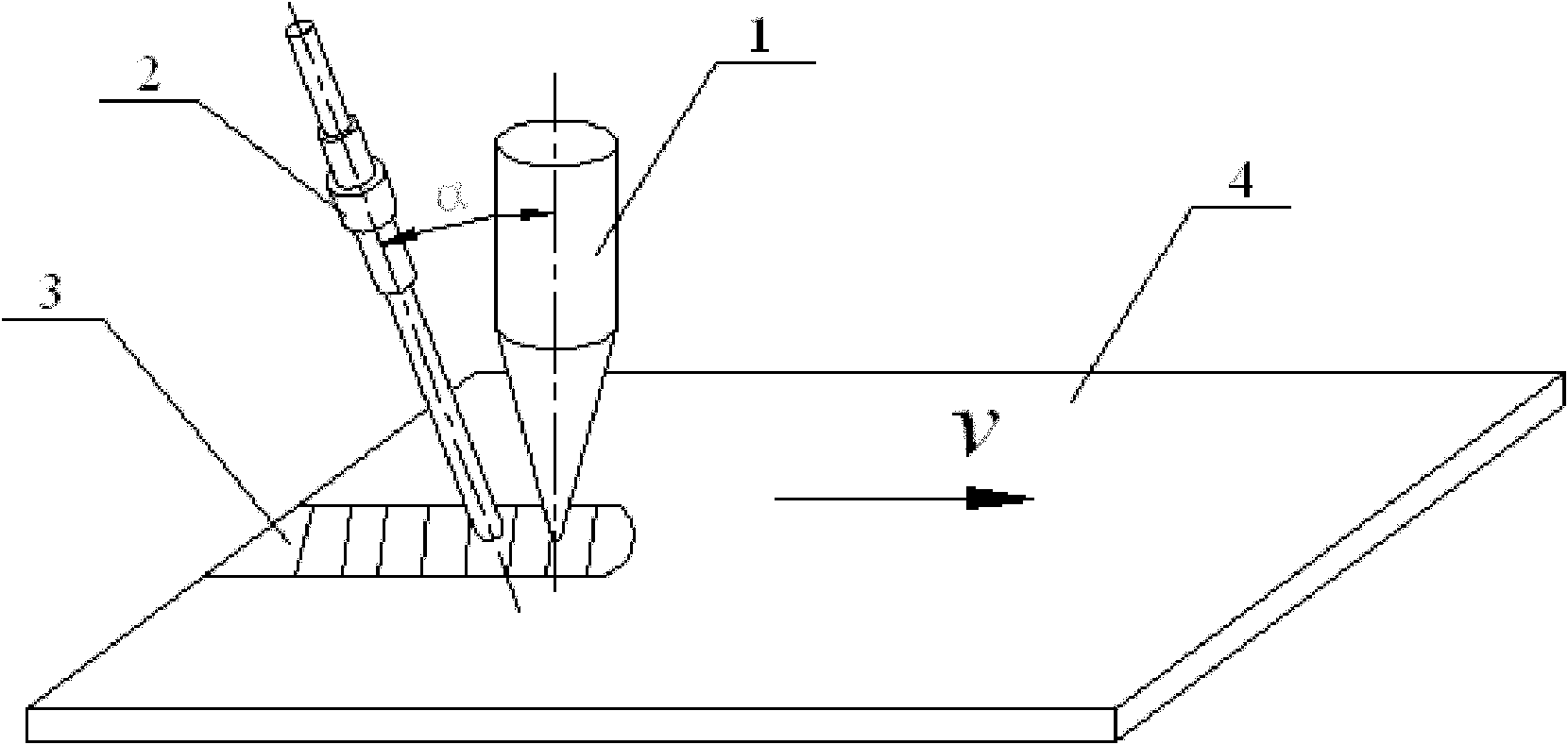

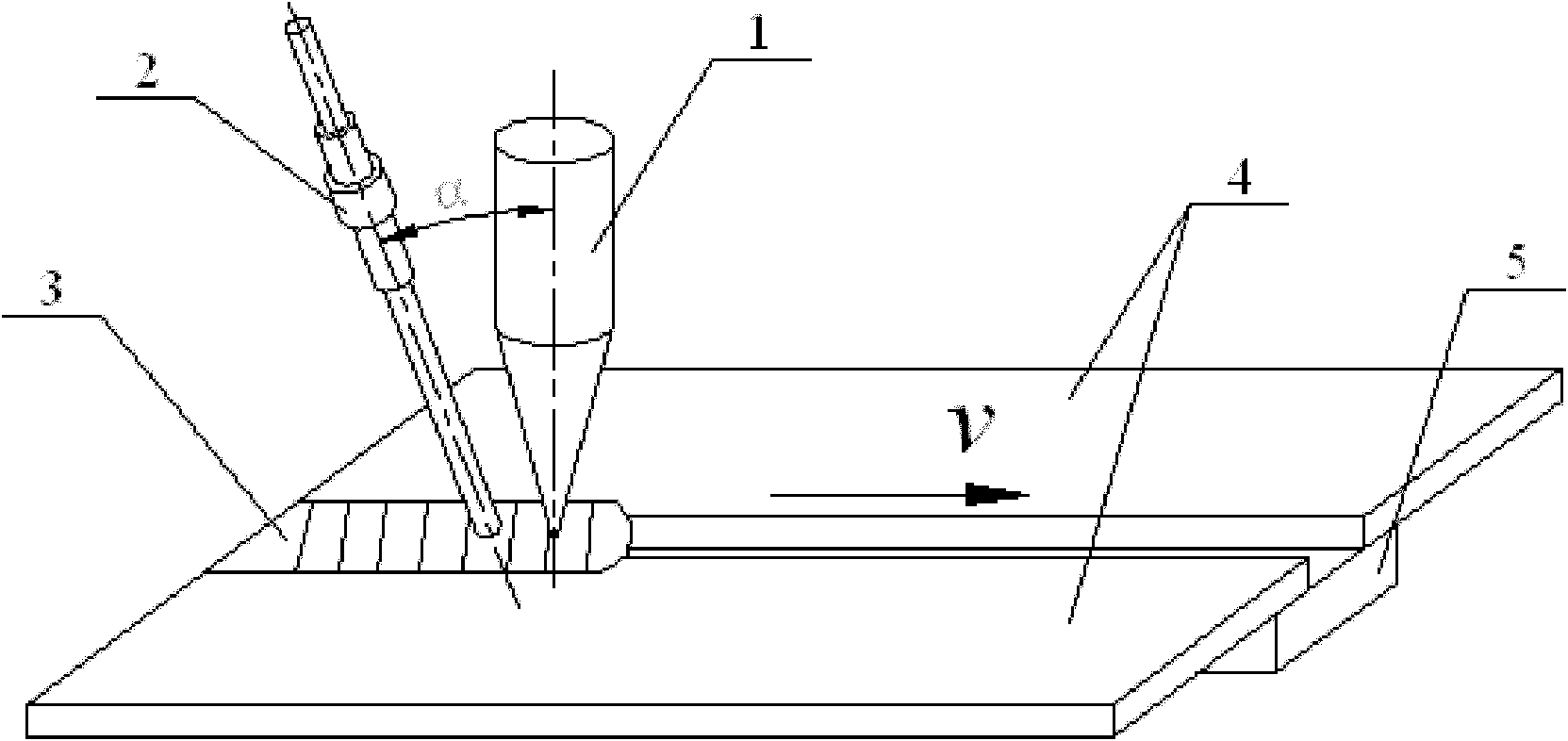

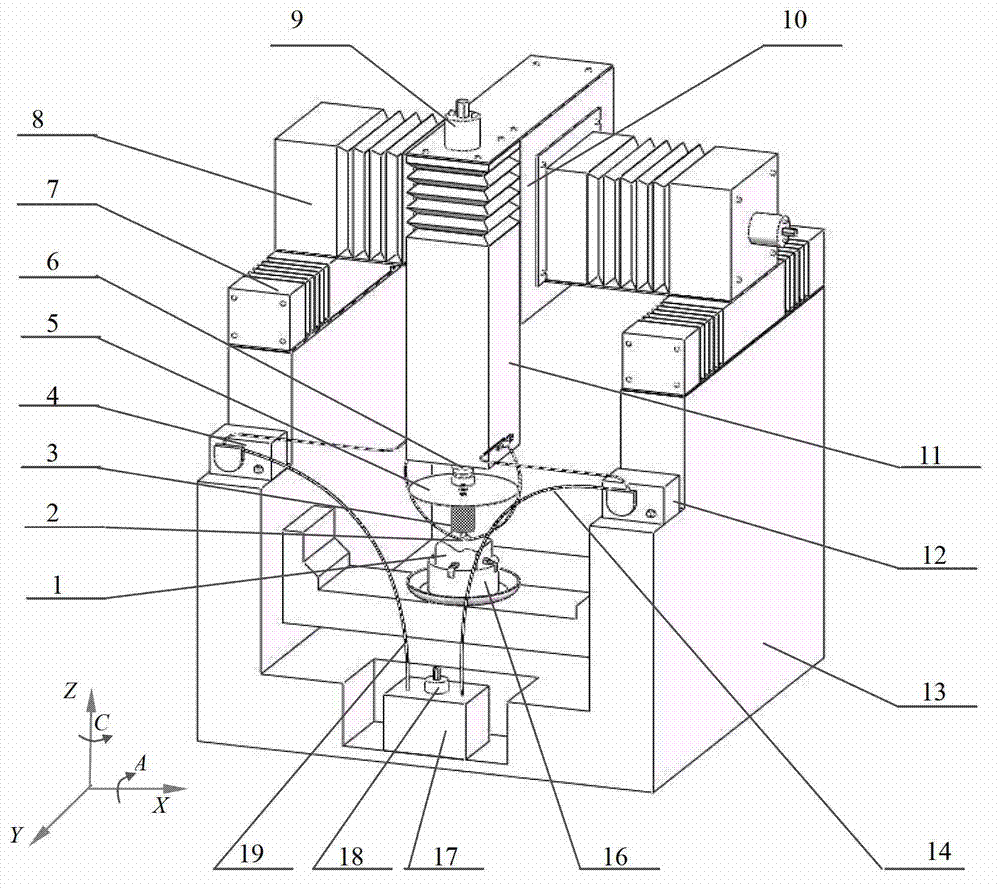

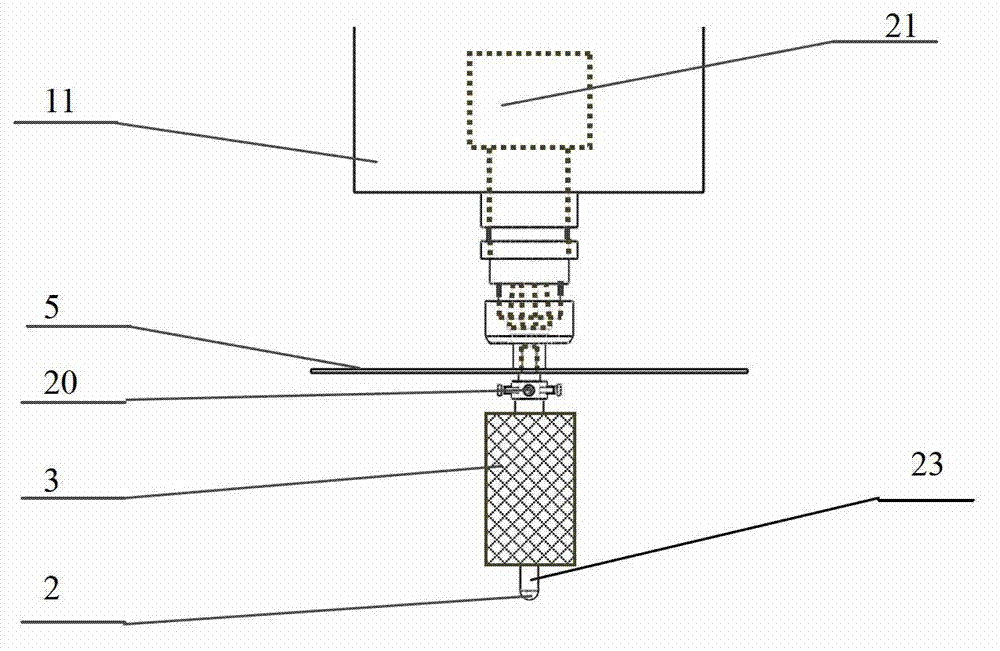

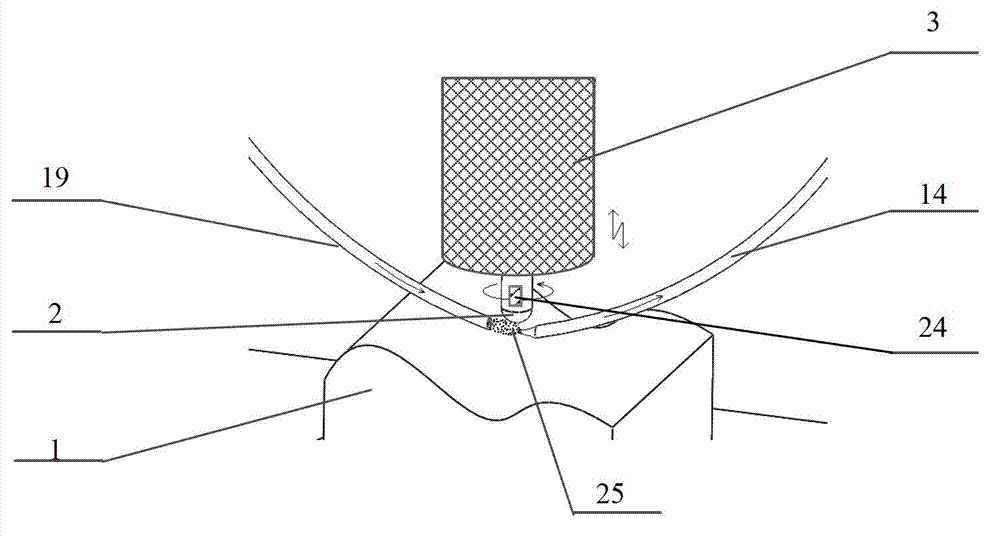

Ultrasonic-assisted laser material additive manufacturing device and realization method thereof

ActiveCN106363173AImprove bonded stateGood mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencyNumerical controlCavitation

The invention discloses an ultrasonic-assisted laser material additive manufacturing device, which comprises a precise double-shaft numerical control rotating table, a support fastening base, a mold, an ultrasonic device, a base plate and a powder supply spray nozzle, wherein the precise double-shaft numerical control rotating table mainly consists of a double-support rotating table and a processing table; the support fastening base is arranged on the processing table; the mold is arranged on the support fastening base and is provided with a groove; the ultrasonic device is arranged in a way of passing through the processing table and the support fastening base and is connected with the bottom of the mold; the base plate is arranged in the groove formed in the mold; the powder supply spray nozzle is positioned above the base plate. The invention also provides a realization method of the ultrasonic-assisted laser material additive manufacturing device. The ultrasonic vibration is transmitted to the base plate, so that the base plate generates resonance; ultrasonic vibration stirring is performed in a molten pool formed under the laser effect in the laser material additive manufacturing process; a cavitation effect and a mechanical effect are generated; the combination state between layers can be improved; the formation probability of microsegregation and air holes inside forming elements can be reduced; meanwhile, crystal grains are refined; the residue stress is reduced; the forming elements with the good mechanical property are obtained.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

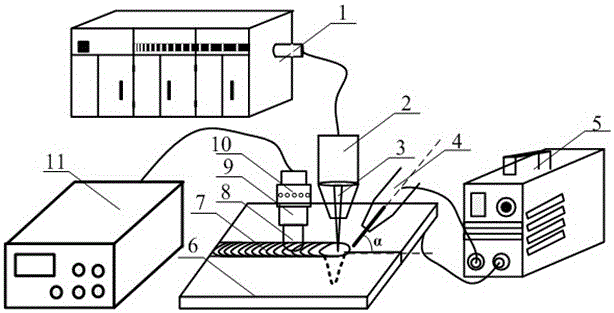

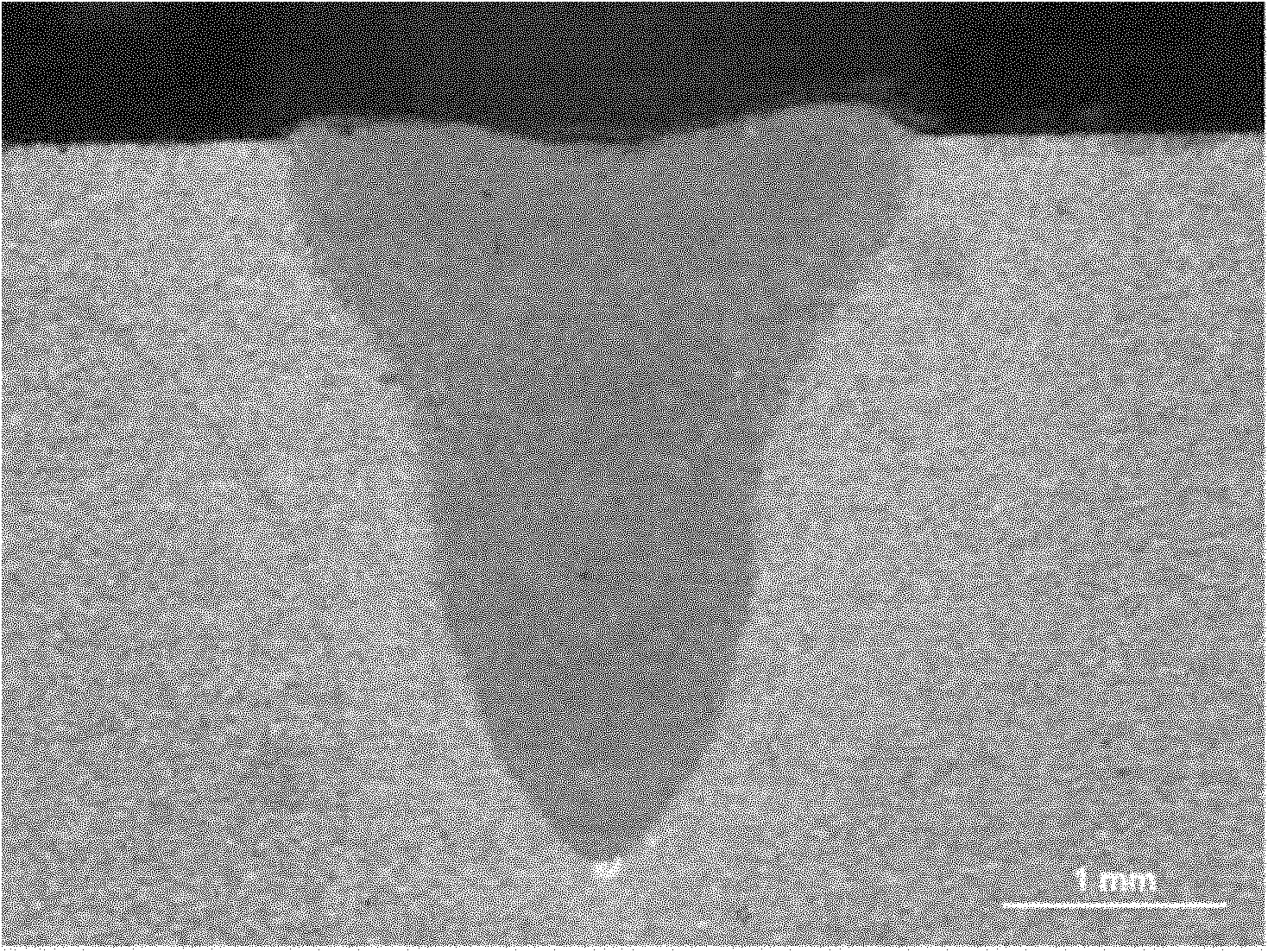

Ultrasonic assistec laser electric arc composite welding method of aluminum alloy

InactiveCN105710537AEfficient weldingPromote escapeWelding/soldering/cutting articlesLaser beam welding apparatusCavitationWelding residual stress

The invention relates to an ultrasonic assisted laser electric arc composite welding method of an aluminum alloy. On the basis of carrying out a welding scheme by combining TIG electric arc welding and laser welding, ultrasonic vibration pressure is introduced into a welding seam, wherein a designed vibration head is in direct contact with the welding seam, so that ultrasonic resources can be more sufficiently utilized, and gas in the welding seam can be rapidly escaped; most of gas in the welding seam is removed so that welding seam gas pore defects are reduced or avoided; tissue crystal grains of the welding seam are remarkably refined by utilizing cavitation effect and acoustic streaming effect caused by the fact that ultrasonic waves are transmitted in liquid, and furthermore, tissue alloy elements of the welding seam are more uniform, segregation is reduced, the strength and corrosion resistance performance of the welding seam are improved, and the performance of a welding connector is improved; and welding residual stress is effectively eliminated or reduced and the strength and corrosion resistance performance of the connector are enhanced, so that the efficient welding of the aluminum alloy is realized.

Owner:北京隆源自动成型系统有限公司

Experimental device and experimental method for hydrothermal catalytic pyrolysis in heavy oil layer by means of ultrasonic wave

ActiveCN102587874AComplete efficientlyFinish quicklySurveyFluid removalCatalytic pyrolysisExperimental methods

The invention discloses an experimental device and an experimental method for hydrothermal catalytic pyrolysis in a heavy oil layer by means of ultrasonic wave, wherein the experimental device comprises a core holder, a ring pressure supply device, a water storage tank, an oil storage tank, an ultrasonic transducer, an ultrasonic generator, a liquid container, a catalyst, a reaction assistant storage device and a constant temperature box; a steam generator is arranged on a water pipe between the water storage tank and the core holder; the experimental method comprises the following steps: 1, pre-treating tested core; 2, performing water-flooding experiment and measuring original water-flooding permeability of the tested core; 3, performing oil-flooding experiment and measuring original oil saturation degree of the tested core; 4, performing hydrothermal pyrolysis simulation experiment; and 5, preparing data. The experimental device and the experimental method have rational design. The device is convenient to install and distribute, has complete function, is convenient to use and operate and has good usage effect. The problems that the prior normal steam thermal driving heavy oil has easily-rebounding viscosity and short measure validity period, and the normal hydrothermal catalytic pyrolysis technology has limited effect during the heavy oil recovery process can be solved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Preparation method of carbon nano tube/carbon fiber multi-dimension mixing composite material

InactiveCN101284423AIncreased interlaminar shear strengthImprove impact resistanceFiberCarbon fibers

The invention relates to a method for preparing a carbon nanometer tube / carbon fiber multi-scale mixed composite material. The invention is technically characterized in that the method adopts the ultrasonic assistant electrochemical deposition manner to prepare a nanometer composite fiber prefabricated part; and then under the double-action of ultrasonic and direct current field, molding is carried out according to the composite material liquid molding process (LCM), such as resin transfer molding (RTM) and resin film infusion (RFI), and the carbon nanometer tubes are dispersed and oriented along the electric field direction, thereby obtaining the multi-scale mixed composite material. The power of the ultrasonic is 100-400W and the frequency is 20-80KHz; the electric field is a direct current field with the voltage of 20-1200V. The method combines the high performance of the carbon nanometer tube with the characteristics of low cost and high performance of the traditional composite material liquid molding process, thereby realizing the complementary and reinforced advantages; the obtained composite material effectively utilizes the characteristics of the carbon nanometer tube, and can be used as the structural and functional material.

Owner:SHENYANG INST OF AERONAUTICAL ENG +1

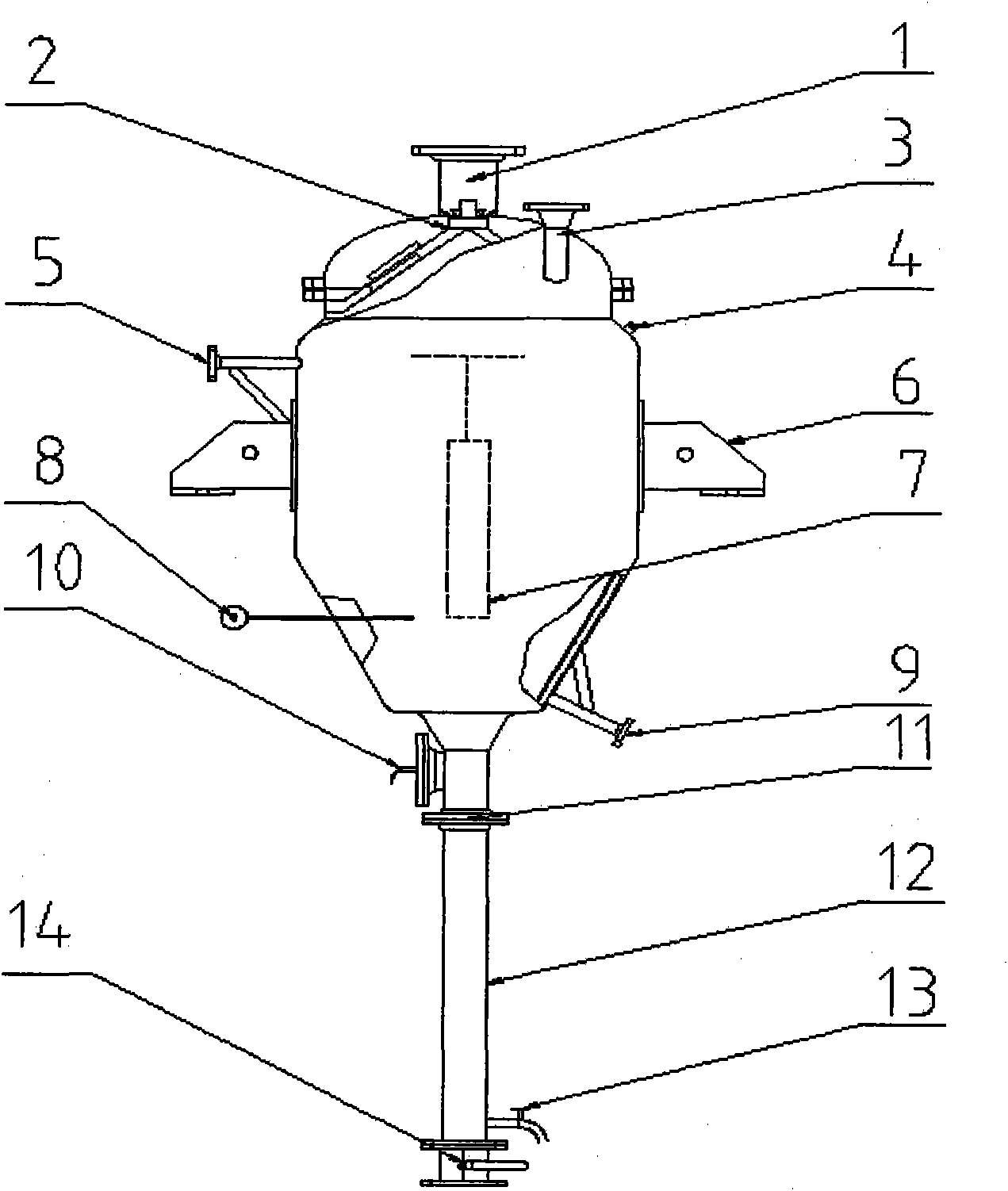

Dynamic demonomerization and defoaming method and device for carbon fiber spinning solution

ActiveCN101856570AContinuous quantitative feedingSingle and degassing continuous dynamicFoam dispersion/preventionCarbon fibersSolvent

The invention discloses a dynamic demonomerization and defoaming method and a dynamic demonomerization and defoaming device for carbon fiber spinning solution. An ultrasonic generator is arranged in the centre of a defoaming kettle; an air guide cylinder and a flow guide disk are arranged on a flow diversion and air guide cover; and the defoaming effect is improved to realize low-temperature high-vacuum demonomerization and defoaming of the spinning solution with different relative molecular masses and different charging rates by the processes of heating a demonomerization and defoaming device, continuous feeding, gravity demonomerization and defoaming, film stretch defoaming and ultrasound-assisted defoaming and controlling the defoaming temperature, the vacuum degree and the rotation speed of a demonomerization tower. The spinning solution obtained by the method has the residual monomer content of less than 0.1 percent, less than 5 small bubbles with diameter of less than 0.03mm and solvent loss of less than 5 percent during the demonomerization and defoaming. The method and the device can realize continuous dynamic demonomerization and defoaming at a low temperature under vacuum condition and has the characteristics of simple and practical process and good defoaming effect.

Owner:XIAN KANGBEN MATERIAL

Non-contact-type ultrasonic-assisted laser welding method

InactiveCN102059453AGrain refinementImprove mechanical propertiesLaser beam welding apparatusCavitationLiquid metal

The invention relates to a non-contact-type ultrasonic-assisted laser welding method belonging to the field of material processing engineering and aiming at solving the technical problems of easy air hole and hot crack generation, joint softening, and the like occurring in the laser welding of metal, such as titanium alloys, aluminum alloys, and the like in the prior art. The invention adopts non-contact-type ultrasonic-assisted laser welding of titanium alloys or aluminum alloys, the generated cavitation action and the breaking theory of ultrasonic waves in a molten pool can be used for thinning grains of a welding line and further improving the mechanical performance of the welding line; the high-frequency vibration of the ultrasonic waves can generate a certain stirring action in the molten pool, and moreover, the ultrasonic waves per se have cavitation action, and thus, the full overflow of gases in the liquid metals and the reduction or avoidance of the generation of air holes are benefited. Compared with contact-type ultrasonic-assisted welding, the method has a wide use range because an ultrasonic tool head is not in contact with a workpiece, is convenient to realize omnidirectional automatic flexible welding and improves the efficiency.

Owner:HARBIN INST OF TECH

Ultrasonic-assisted alkaline pickling treatment method of aluminum electrolysis spent cathode carbon blocks

The invention relates to an ultrasonic-assisted alkaline pickling treatment method of aluminum electrolysis spent cathode carbon blocks. The ultrasonic-assisted alkaline pickling treatment method of the aluminum electrolysis spent cathode carbon blocks belongs to the technical field of aluminum electrolysis solid waste resource recovery, and comprises the following steps of smashing the aluminum electrolysis spent cathode carbon blocks, adding the aluminum electrolysis spent cathode carbon blocks into alkaline liquor for leaching, and filtering to obtain carbon powder and first filter liquor; carrying out alkaline pickling under the ultrasonic environment; leading CO2 into the first filter liquor, crystallizing out, filtering to obtain cryolite, an aluminum hydroxide mixture and second filter liquor, and recycling the second filter liquor. The ultrasonic-assisted alkaline pickling treatment method of the aluminum electrolysis spent cathode carbon blocks is simple in process, and convenient to operate; and through the synergistic effect of ultrasonic wave and alkaline pickling, the reaction rate is accelerated, the purity of the product carbon powder is improved, the maximum purity of the carbon powder is 97.92 percent, and the production cycle is 70min.

Owner:CENT SOUTH UNIV

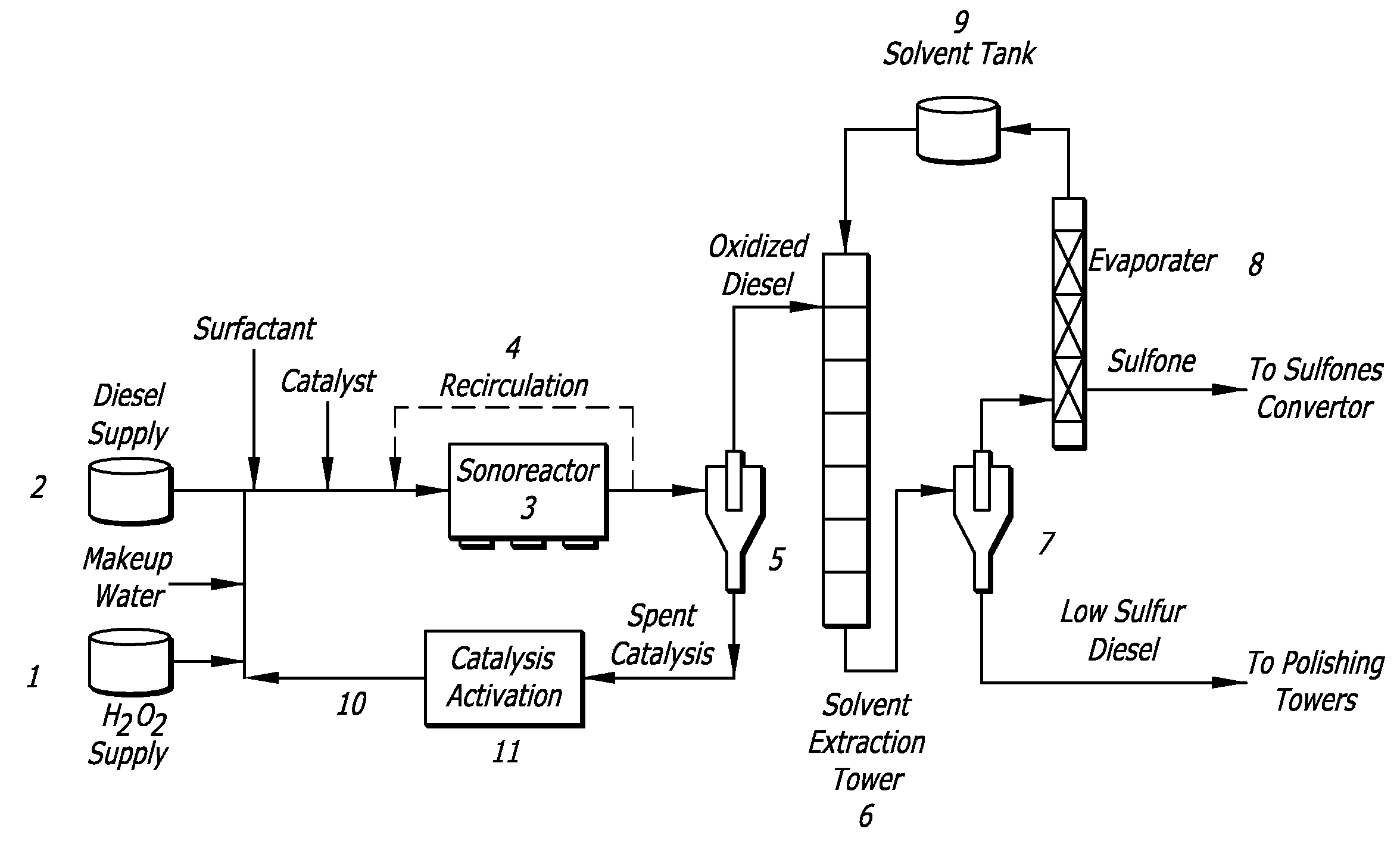

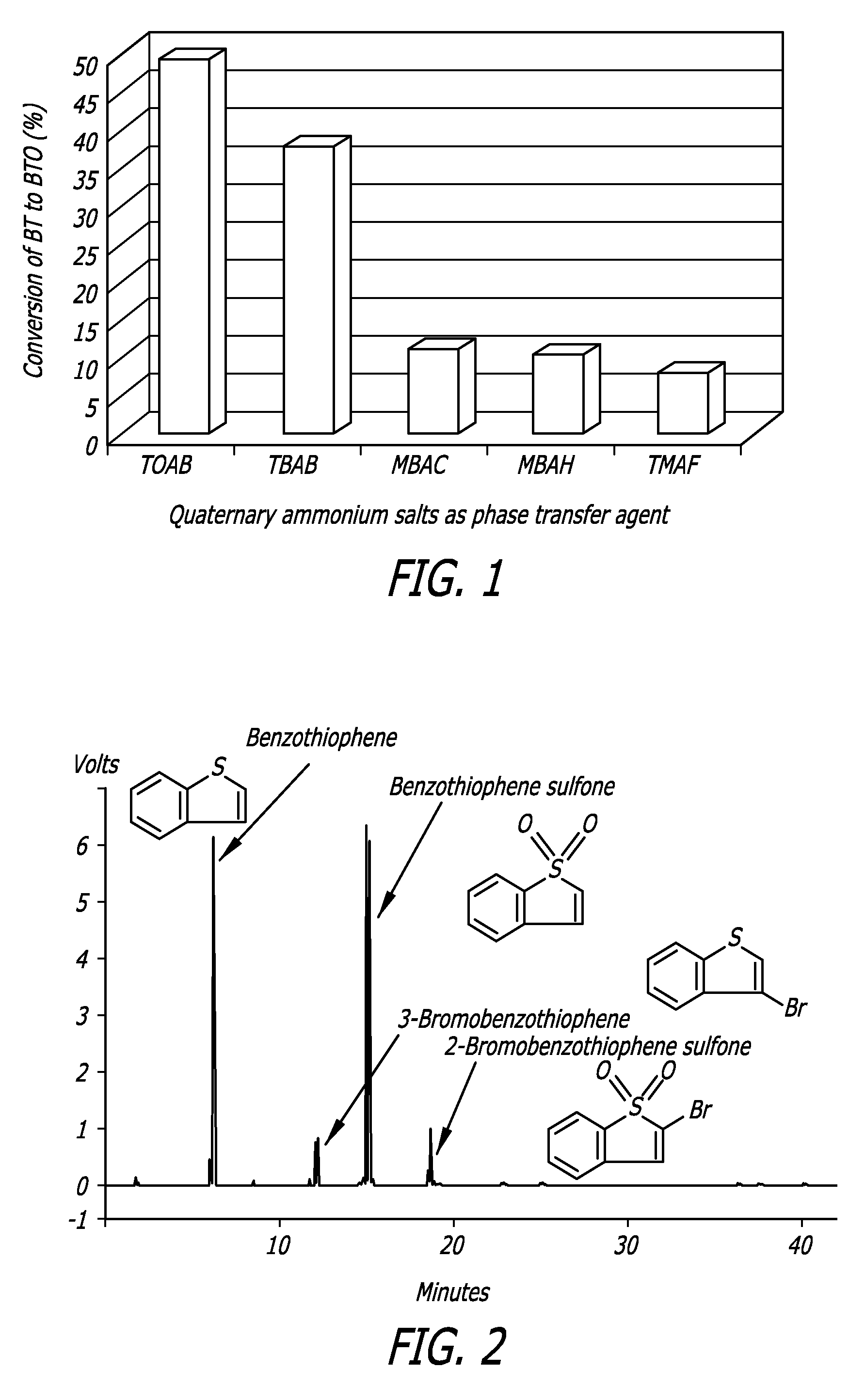

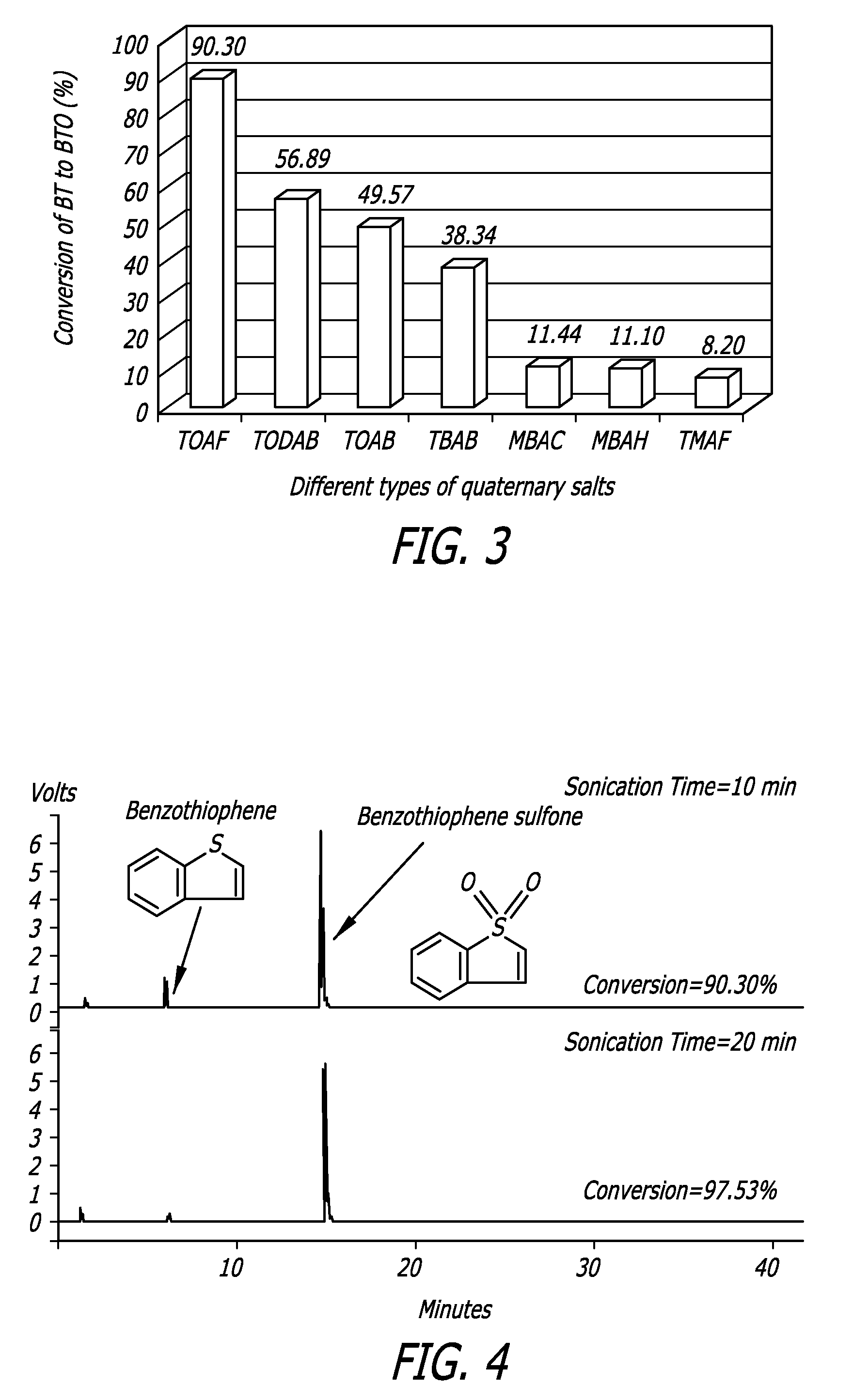

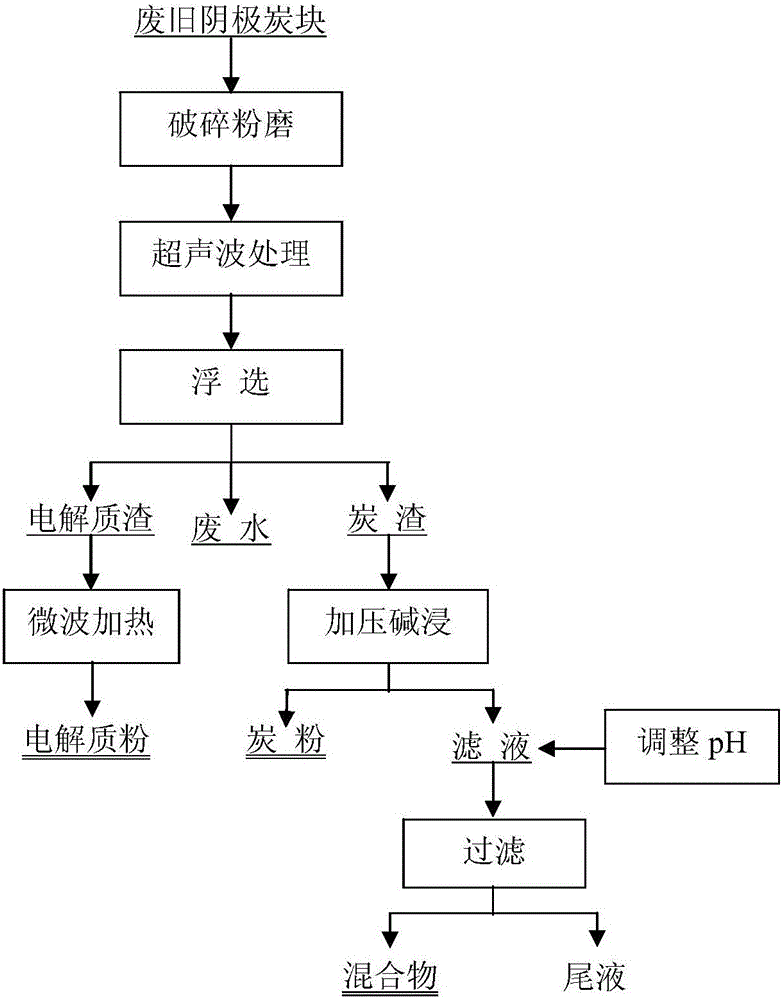

Ultrasound-Assisted Oxidative Desulfurization of Diesel Fuel Using Quaternary Ammonium Fluoride and Portable Unit for Ultrasound-Assisted Oxidative Desulfurization

InactiveUS20080173571A1Intense mixingSpeed upRefining with oxygen compoundsLiquid carbonaceous fuelsUltrasonic assistedUltrasound assisted

The desulfurization of fossil fuels is effected by the combination of fossil fuels with an aqueous mixture of hydroperoxide and quaternary ammonium fluoride phase transfer catalyst, the mixture then subjected to ultrasound to oxidize sulfur compounds present in the fuels. The polar oxidized species are removed via extraction. Another aspect is a portable, continuous ultrasound assisted desulfurization device having a sonoreactor for subjecting mixtures of fossil fuels to sonication to effect removal of sulfur containing compounds.

Owner:UNIV OF SOUTHERN CALIFORNIA

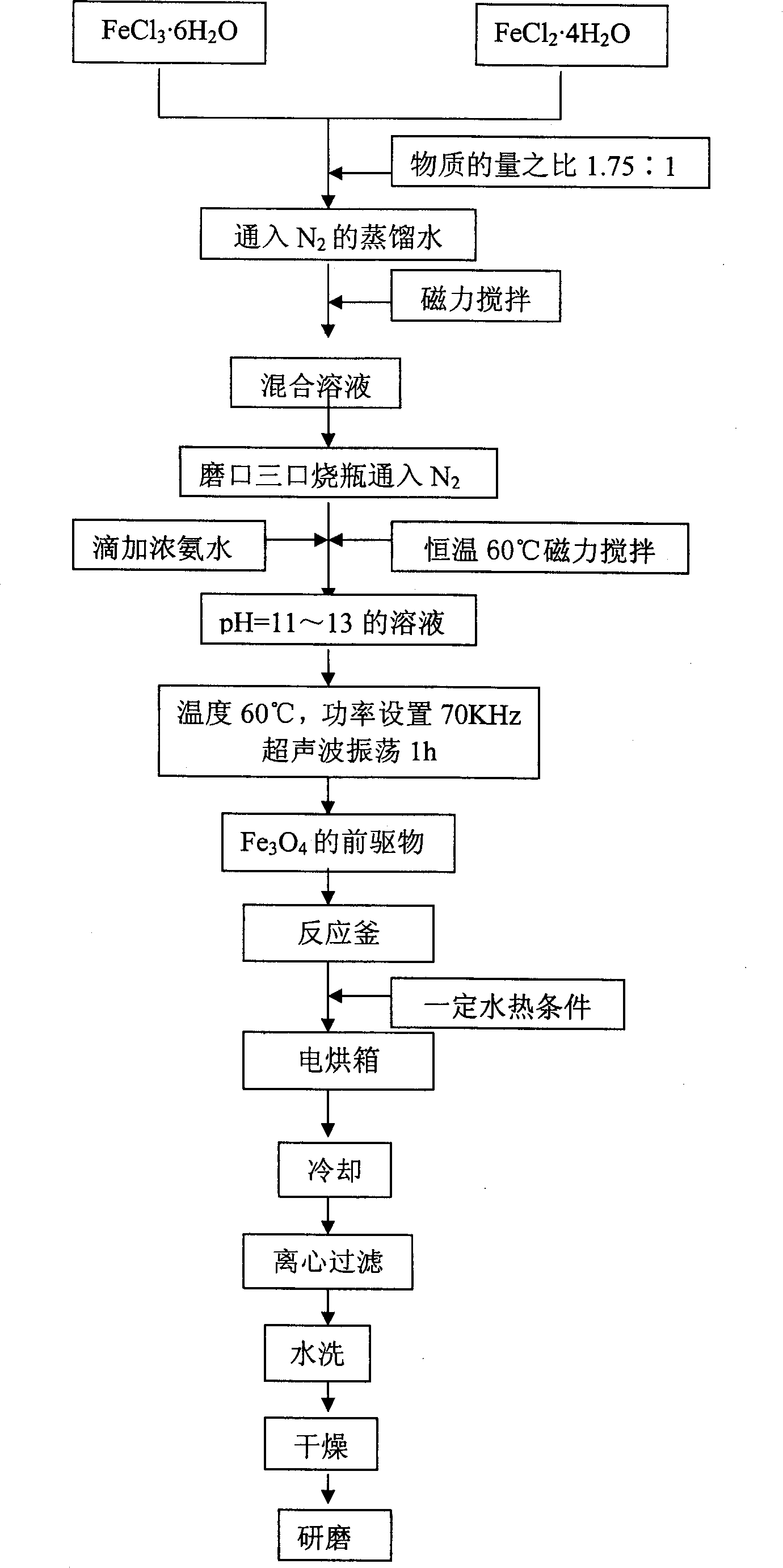

Method for comprehensively recovering aluminum electrolysis waste cathode carbon blocks through ultrasonic-assisted floatation and pressure alkali leaching

ActiveCN106077038AReduce consumptionShorten the alkaline leaching timeSolid waste disposalFiltrationMaterials science

The invention relates to a method for comprehensively recovering aluminum electrolysis waste cathode carbon blocks through ultrasonic-assisted floatation and pressure alkali leaching, and belongs to the technical field of comprehensive utilization of aluminum electrolysis solid waste resources. The method comprises the steps of carrying out ultrasonic pretreatment after crushing and grinding the aluminum electrolysis waste cathode carbon blocks, carrying out floatation on pretreated powder to obtain electrolyte residues and carbon residues, and reusing the wastewater of floatation; removing carbon impurities after the electrolyte residues are subjected to microwave heating to obtain electrolyte powder with high purity, and carrying out pressure alkali leaching on the carbon residues to remove solvend so as to obtain carbon powder with high purity; adjusting the pH of alkali leaching filter liquor to generate sediment, carrying out filtration to obtain electrolyte, and reusing the filter liquor. According to the method, through collaborative assistance action among the ultrasonic pretreatment technology, the microwave heating technology and the pressure alkali leaching technology, the high-efficiency comprehensive recycling of aluminum electrolysis waste cathodes is achieved. The method for comprehensively recovering aluminum electrolysis waste cathode carbon blocks through ultrasonic-assisted floatation and pressure alkali leaching is reasonable in technological design, high in recovery rate of valuable matter, purity of obtained products and processing speed, free of secondary pollutants and applicable to industrial large-scale application.

Owner:CENT SOUTH UNIV

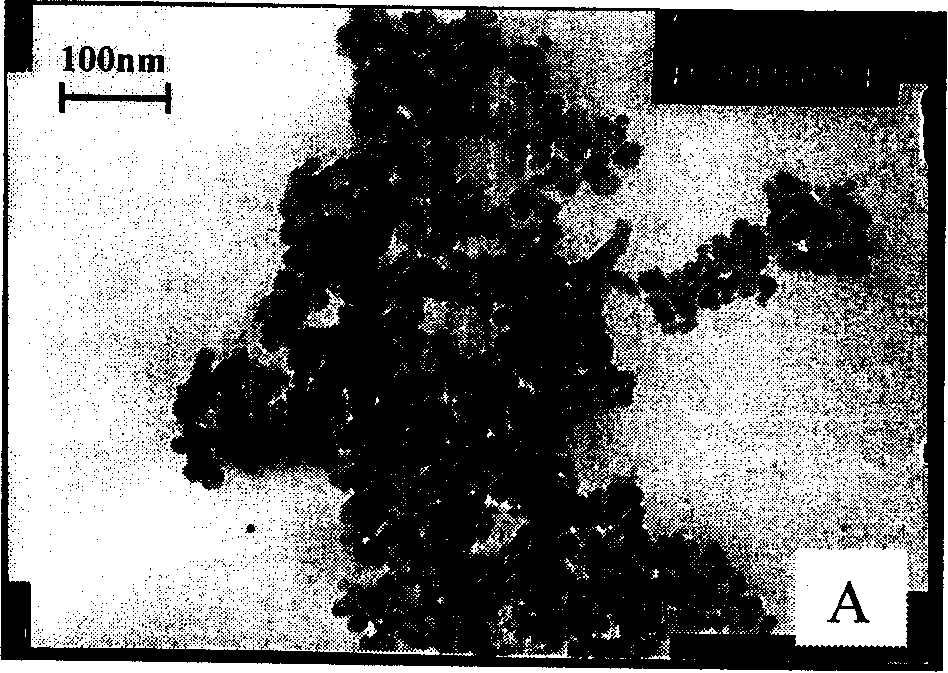

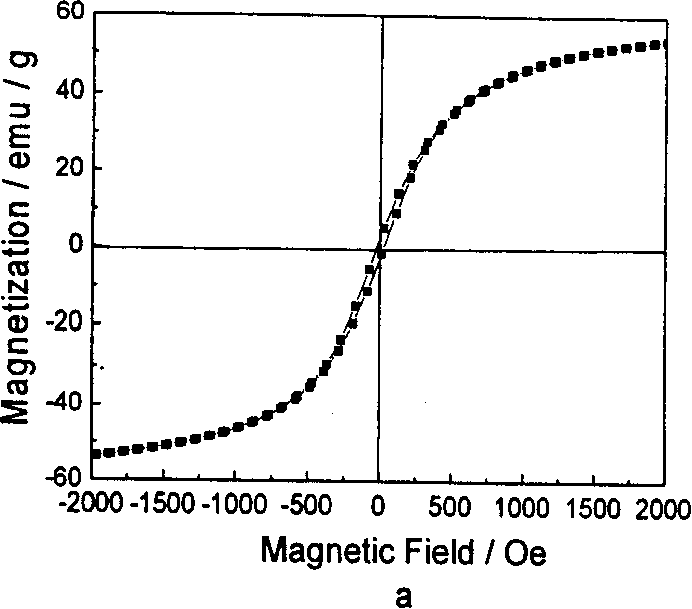

Ultrasound wave auxiliary hydrothermal synthesis technique for magnetic magnetic iron oxide nano ultra-tiny grain

The invention discloses an ultrasonic assistant hydro-thermal synthesis process for magnetic Fe3O4 nanometer super fine grain. The invention solves the problems of impure products and large grain diameter. The invention has the technical proposal that the form of Fe3O4 crystal nucleus is promoted in the cavitation effect of ultrasonic; cavitation gas bubble is produced in mediums; the pH value of strong ammonia is adjusted to 11 to 13; and the nanometer grain diameter size and the magnetic characteristics are controlled by controlling the hydro-thermal synthesis temperature within range from 140 DEG C to 160 DEG C and within time of 3 to 5 hours, and by changing the micro environment of the air bubble chamber, so as to obtain the dry product which is black magnetic Fe3O4 nanometer powder after being milled. The invention comprises no organic solvent, belonging to full green environmental protection which is a break in the field, and the invention is also the first to use the ultrasonic technology for assistant hydro-thermal synthesis. The invention has the advantages of simple technology, low cost, small powder granularity and even grain diameter. The powder not only can be used as duplicate ink powder, but also can be board used in aspects such as medical, biological technology, magnetic immunocyte separation, DNA separation, nucleic acid hybridization, and preparation for magnetic butt directional medicine carrying micron ball.

Owner:CIVIL AVIATION UNIV OF CHINA

Method for recycling carbon from aluminum electrolytic waste cathode through ultrasonic-assisted pressure acid leaching

ActiveCN106180118AEasy to separateConducive to reaction and dissolutionSolid waste disposalMetallurgySodium salt

The invention relates to a method for recycling carbon from an aluminum electrolytic waste cathode through ultrasonic-assisted pressure acid leaching and belongs to the technical field of aluminum electrolytic solid waste recycling. The method comprises the steps that after a carbon block of the aluminum electrolytic waste cathode is crushed, ultrasonic pretreatment is conducted, pretreated powder is added into an acid leaching solution for pressure leaching, carbon and filtrate are obtained through filtering, the filtrate is subjected to evaporative crystallization, and mixed powder of sodium salt and aluminum salt is separated out. According to the method, under the synergistic effect of ultrasonic pretreatment and pressure acid leaching, efficient, clean and high-purity recovery of precious matter in the carbon block of the aluminum electrolytic waste cathode is achieved. The technique is simple, operation is convenient, the reaction speed is high, secondary pollution is not generated, and the method is suitable for large-scale treatment of the carbon blocks of the aluminum electrolytic waste cathodes. The whole carbon recovery technological time is 60 min, the carbon recovery rate is 95.74%, and the purity of carbon powder is 97.42%.

Owner:CENT SOUTH UNIV

Constant pressure ultrasonic wave aiding magnetorheological finishing method and constant pressure ultrasonic wave aiding magnetorheological finishing device

InactiveCN103042438AUniform compositionUniform abrasive distributionUltrasonic assistedControl system

The invention discloses a constant pressure ultrasonic wave aiding magnetorheological finishing method and a constant pressure ultrasonic wave aiding magnetorheological finishing device. The method includes the steps of firstly, mounting a workpiece on a double-rotating workbench; secondly, adjusting distance between a small ball milling head and the workpiece to allow a clearance to be formed between the two, and setting a threshold P1 and a threshold P2 of a force cell at an extending position of an electromagnetic coil iron core mounted above the small ball milling head through a control system; thirdly, starting a spindle to drive the small ball milling head to rotate, simultaneously starting an ultrasonic wave vibrating device to allow ultrasonic vibration of the small ball milling head, and jetting magnetorheological fluid in the clearance formed by the small ball milling head and the workpiece through an output pipeline; and fourthly, repeatedly finishing the workpiece according to the surface shape of the to-be-machined workpiece until the machining of the workpiece is completed. Accurate point removing can be performed on the workpiece surface by the method.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com