Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

774 results about "Catalytic pyrolysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalytic pyrolysis of solid biomass and related biofuels, aromatic, and olefin compounds

ActiveUS20090227823A1Minimize coke productionLiquid hydrocarbon mixture productionHydrocarbonsHigh rateCatalytic pyrolysis

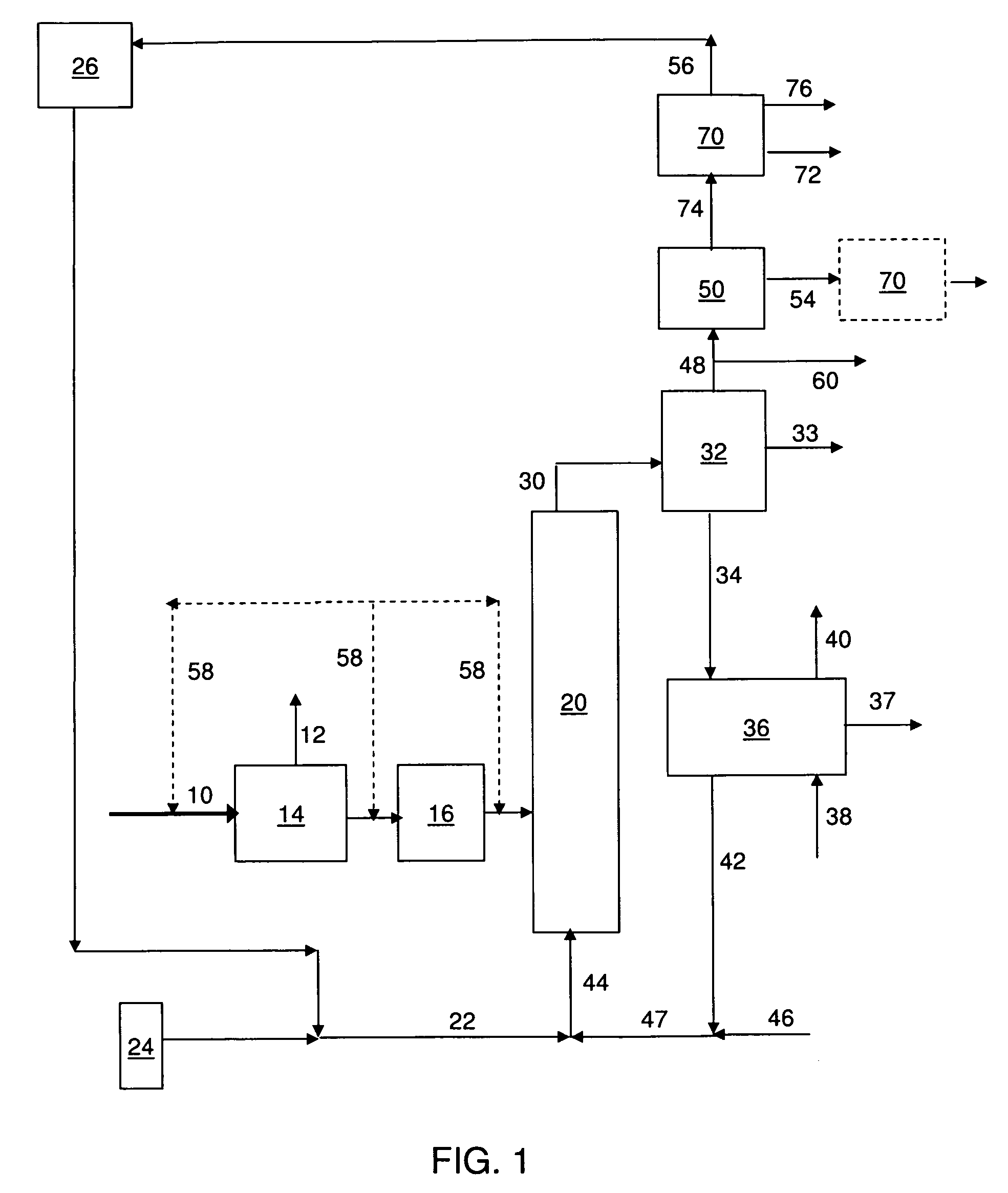

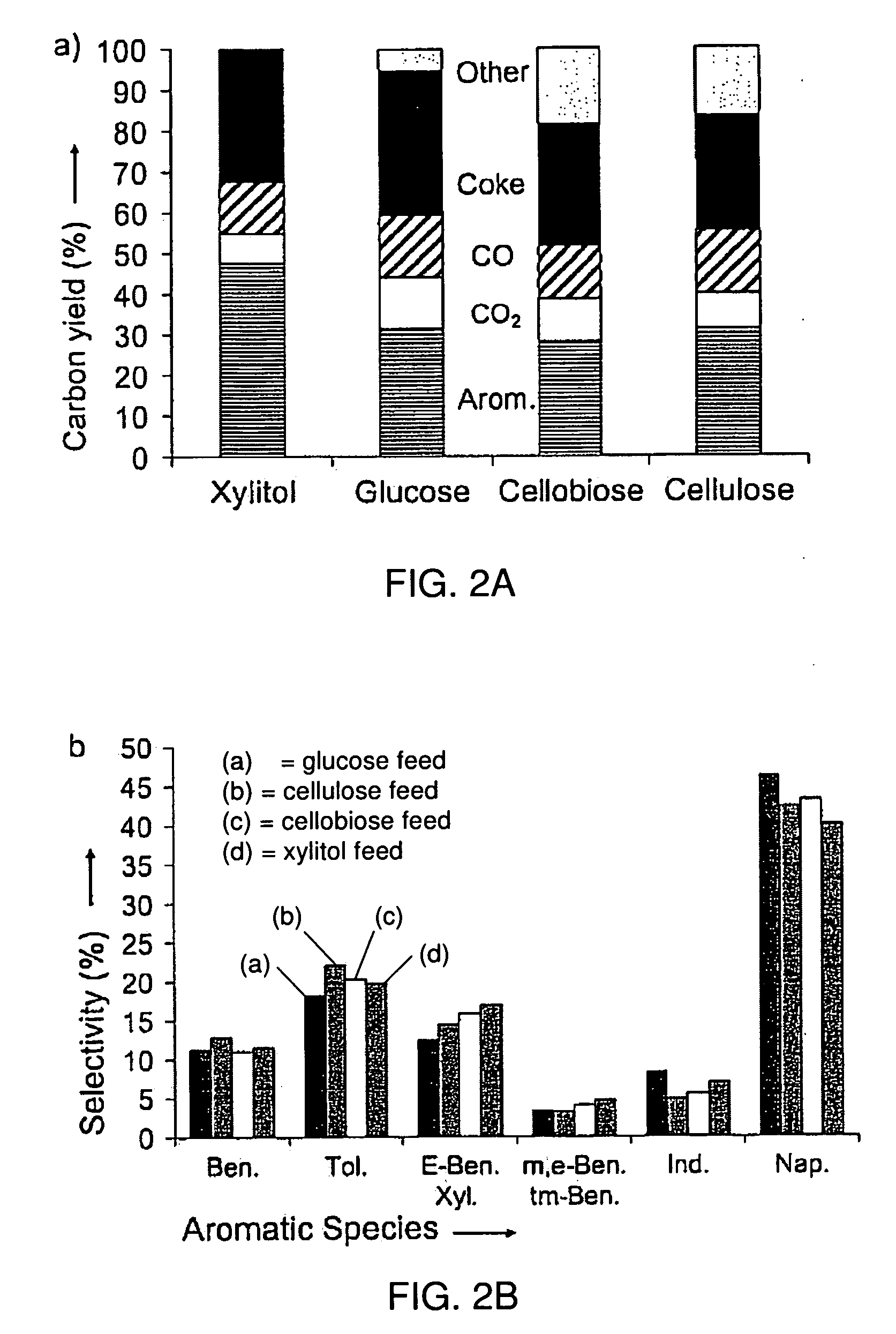

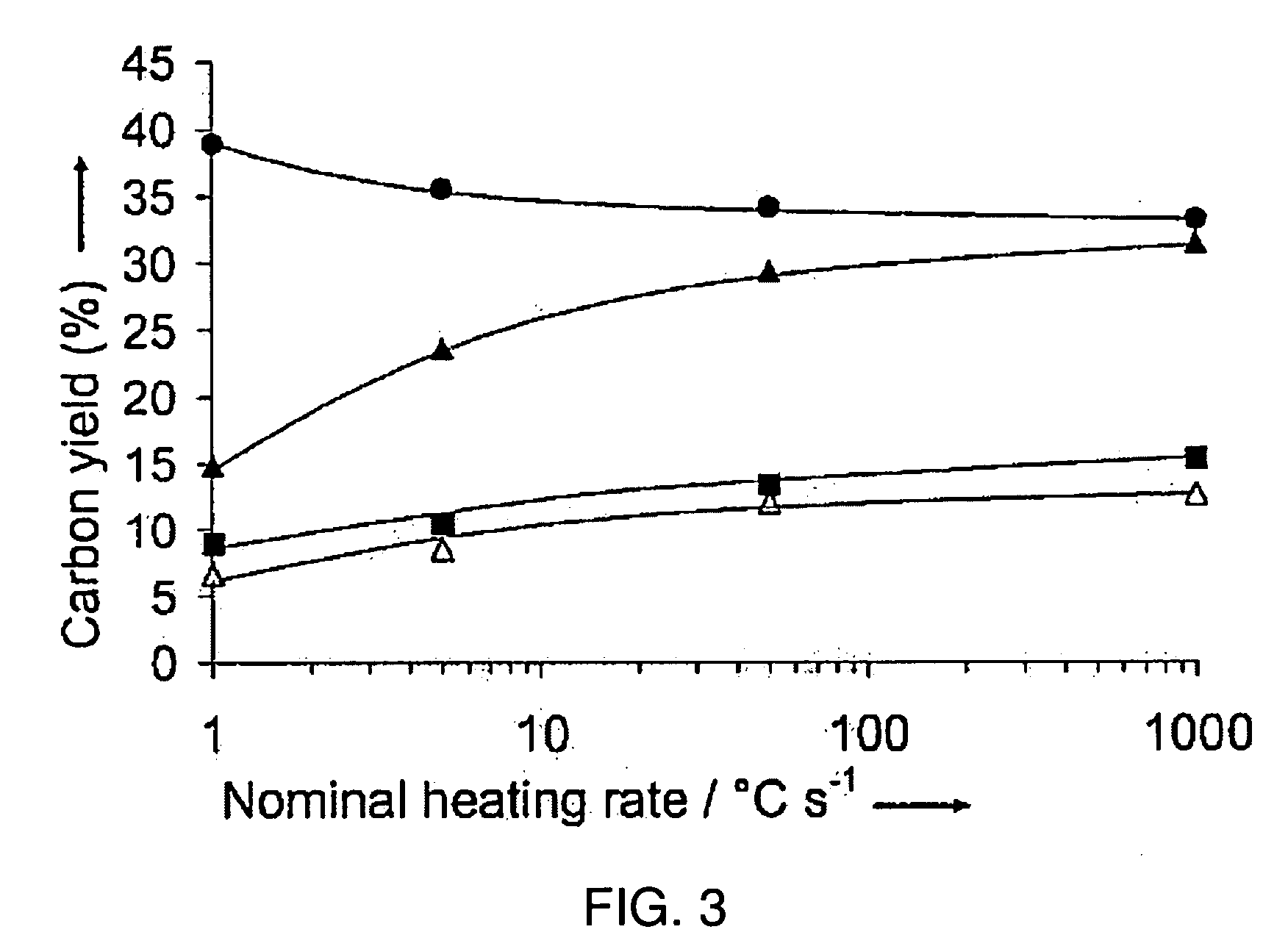

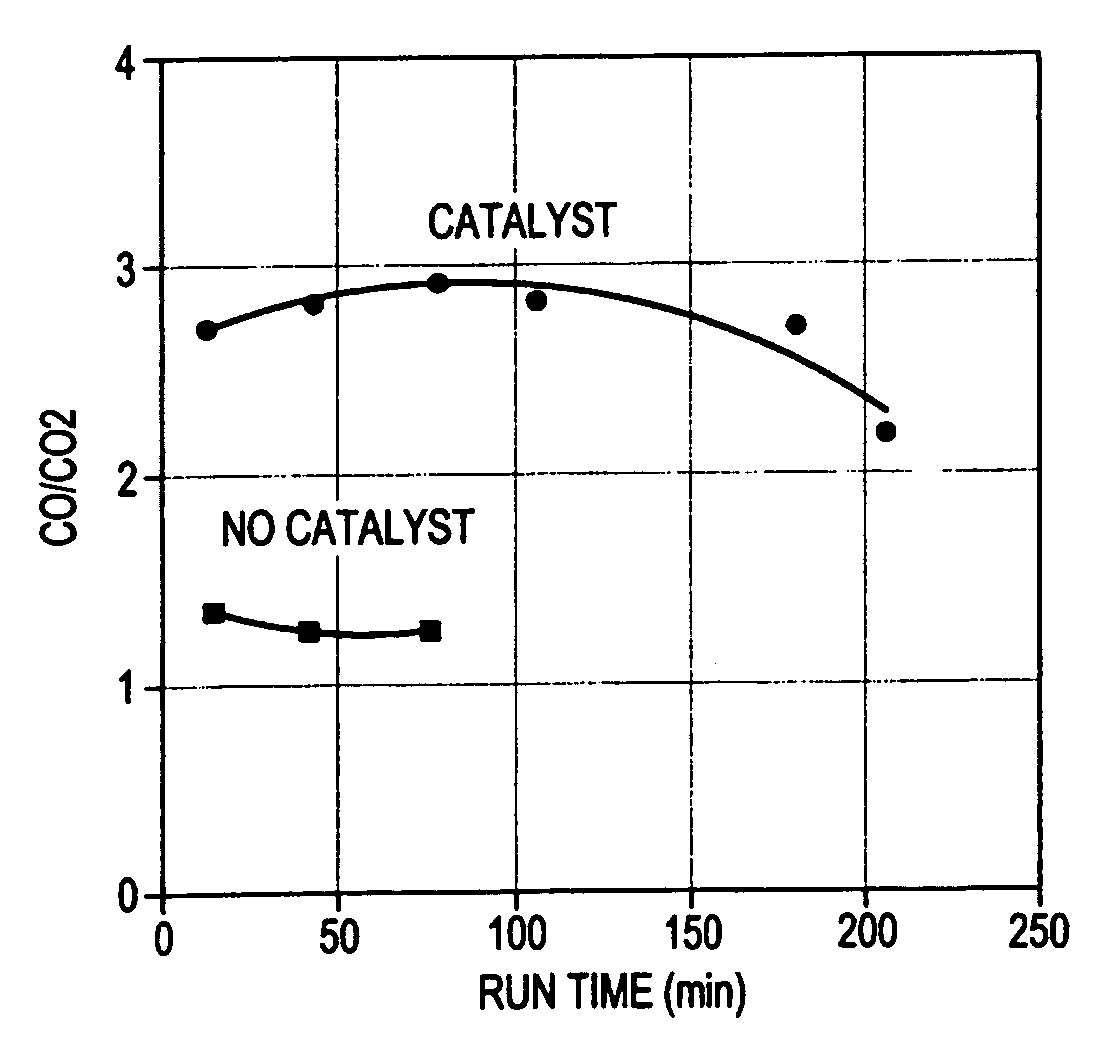

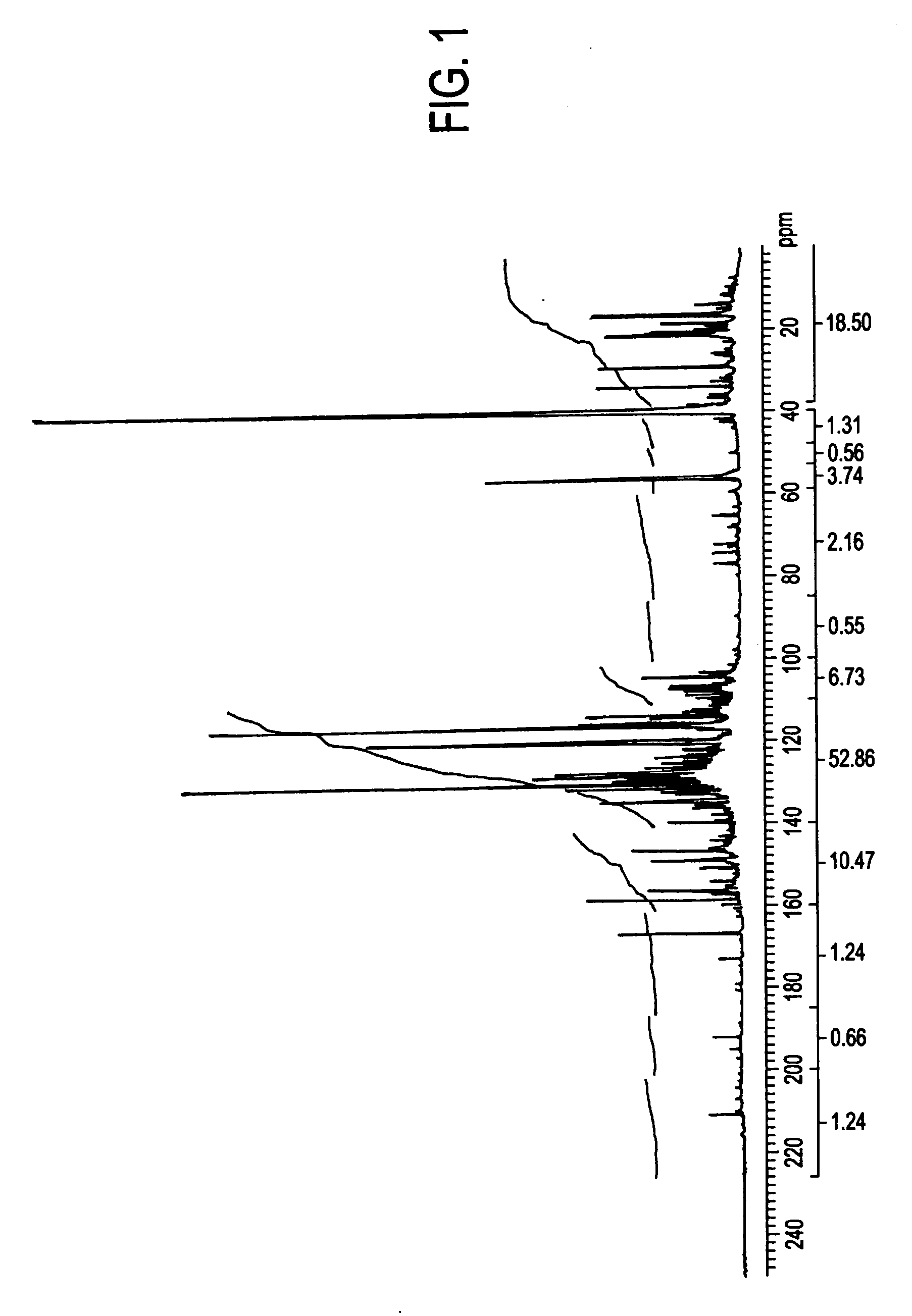

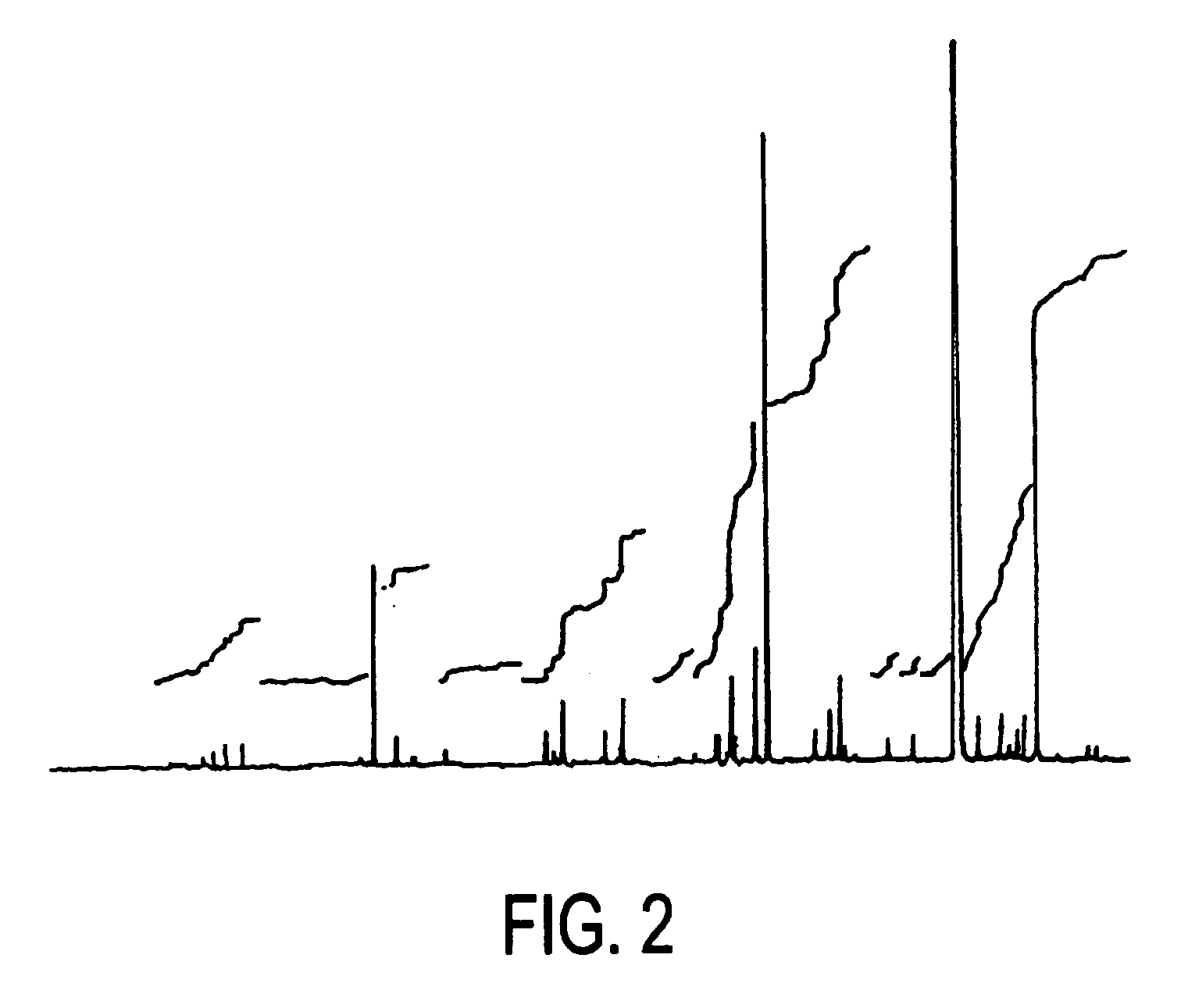

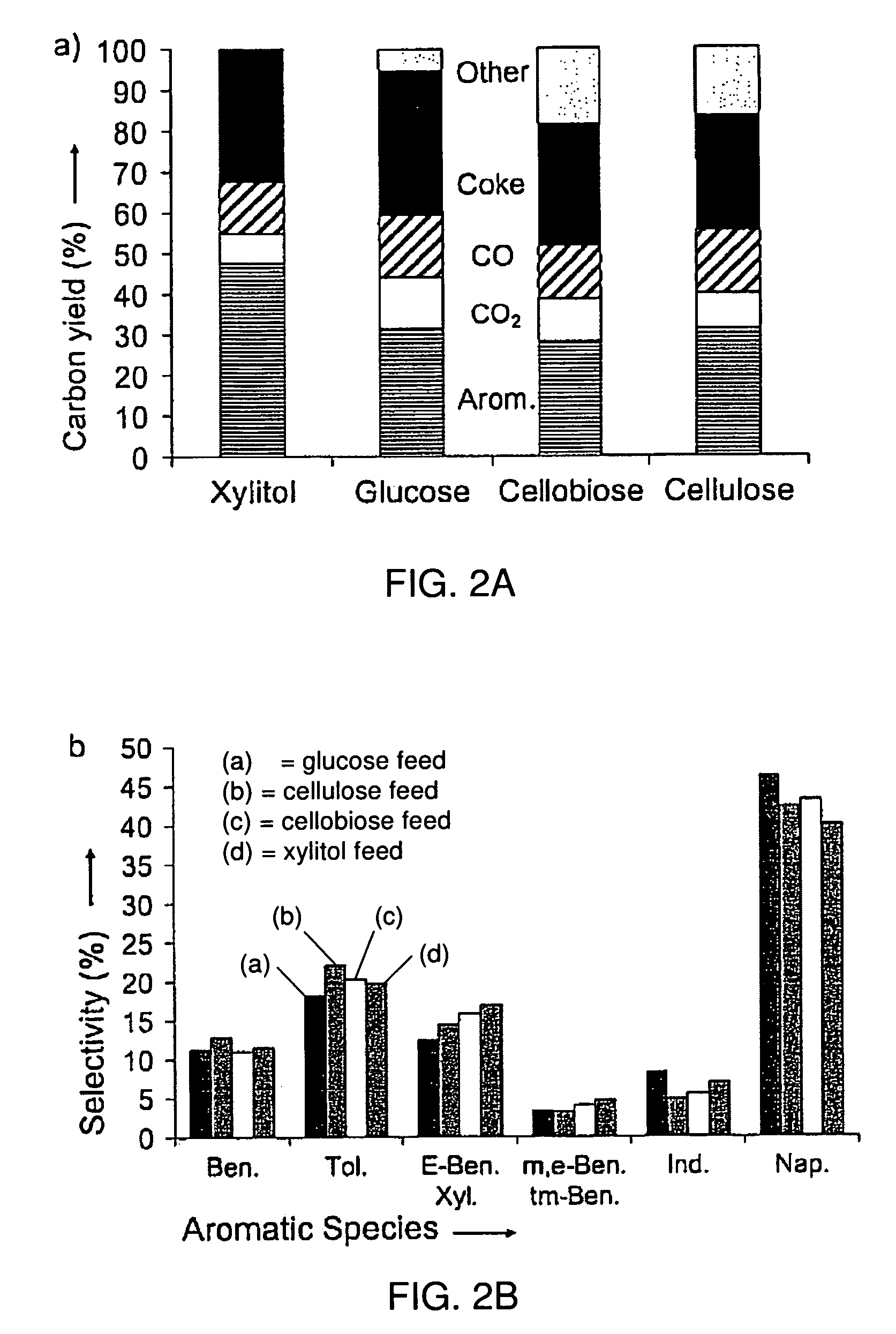

This invention relates to compositions and methods for fluid hydrocarbon product, and more specifically, to compositions and methods for fluid hydrocarbon product via catalytic pyrolysis. Some embodiments relate to methods for the production of specific aromatic products (e.g., benzene, toluene, naphthalene, xylene, etc.) via catalytic pyrolysis. Some such methods may involve the use of a composition comprising a mixture of a solid hydrocarbonaceous material and a heterogeneous pyrolytic catalyst component. In some embodiments, the mixture may be pyrolyzed at high temperatures (e.g., between 500° C. and 1000° C.). The pyrolysis may be conducted for an amount of time at least partially sufficient for production of discrete, identifiable biofuel compounds. Some embodiments involve heating the mixture of catalyst and hydrocarbonaceous material at high rates (e.g., from about 50° C. per second to about 1000° C. per second). The methods described herein may also involve the use of specialized catalysts. For example, in some cases, zeolite catalysts may be used; optionally, the catalysts used herein may have high silica to alumina molar ratios. In some instances, the composition fed to the pyrolysis reactor may have a relatively high catalyst to hydrocarbonaceous material mass ratio (e.g., from about 5:1 to about 20:1).

Owner:UNIV OF MASSACHUSETTS

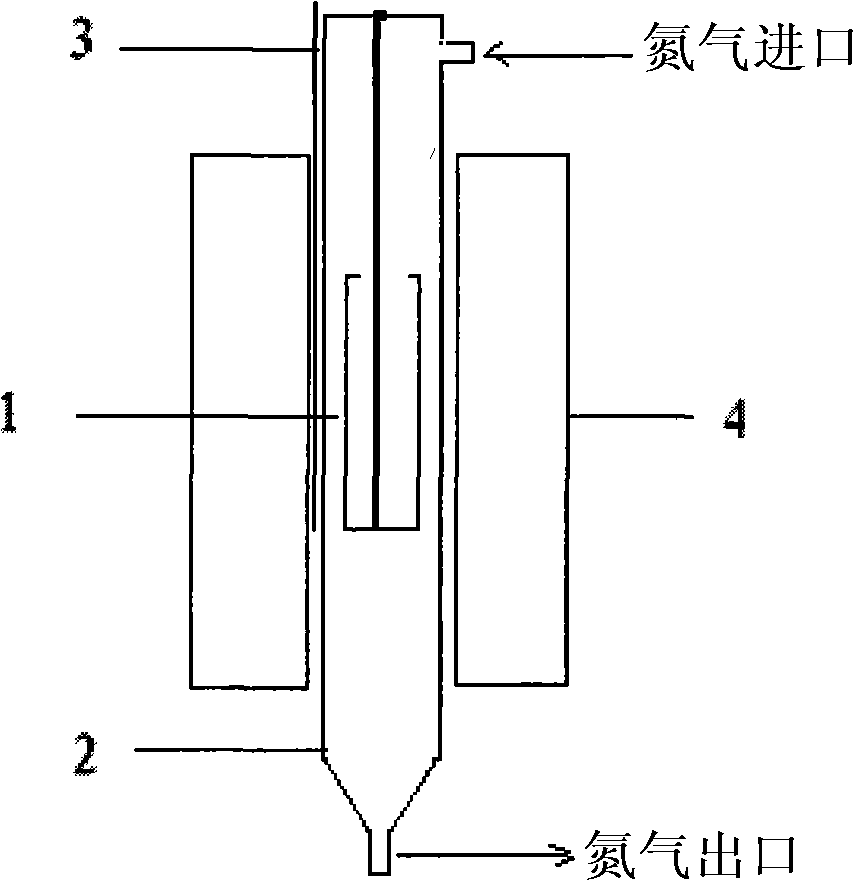

Fractional catalytic pyrolysis of biomass

ActiveUS20090165378A1Eliminate needBiofuelsIndirect heating destructive distillationCatalytic pyrolysisReactive gas

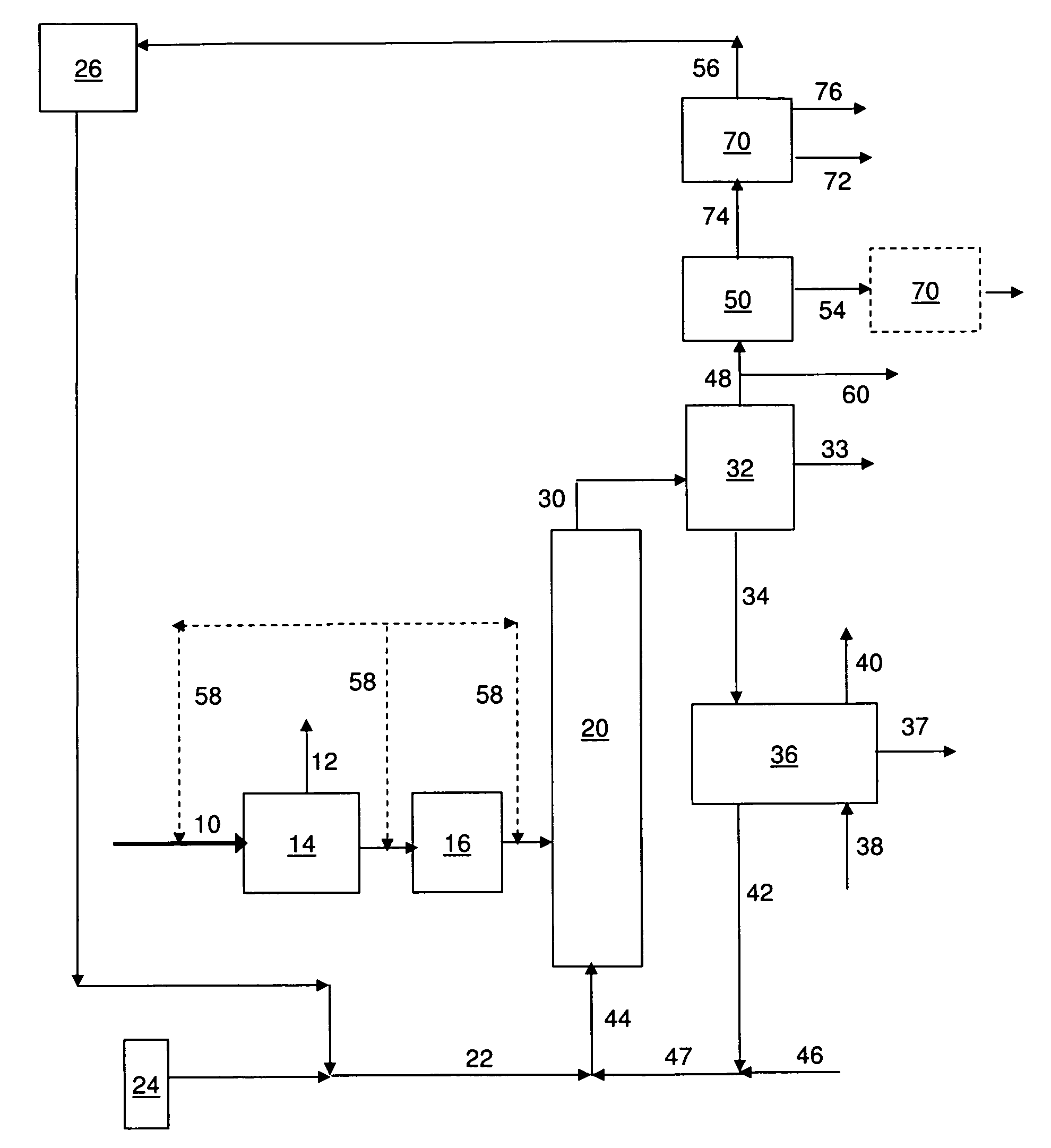

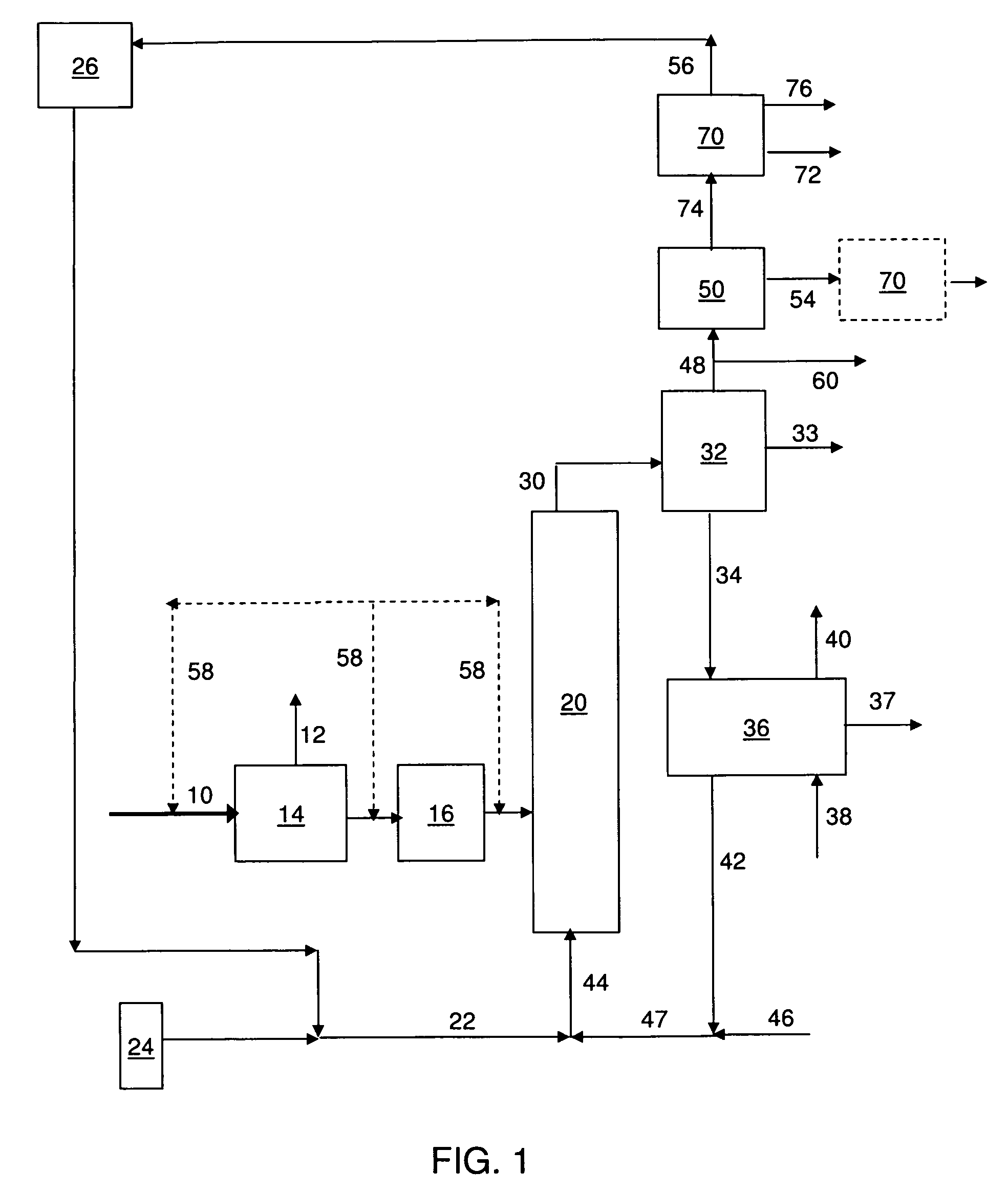

Methods for fractional catalytic pyrolysis which allow for conversion of biomass into a slate of desired products without the need for post-pyrolysis separation are described. The methods involve use of a fluid catalytic bed which is maintained at a suitable pyrolysis temperature. Biomass is added to the catalytic bed, preferably while entrained in a non-reactive gas such as nitrogen, causing the biomass to become pyrolyzed and forming the desired products in vapor and gas forms, allowing the desired products to be easily separated.

Owner:VIRGINIA TECH INTPROP INC

Catalytic pyrolysis of solid biomass and related biofuels, aromatic, and olefin compounds

ActiveUS8277643B2Minimize coke productionSolid fuelsHydrocarbon from oxygen organic compoundsCatalytic pyrolysisHigh rate

This invention relates to compositions and methods for fluid hydrocarbon product, and more specifically, to compositions and methods for fluid hydrocarbon product via catalytic pyrolysis. Some embodiments relate to methods for the production of specific aromatic products (e.g., benzene, toluene, naphthalene, xylene, etc.) via catalytic pyrolysis. Some such methods may involve the use of a composition comprising a mixture of a solid hydrocarbonaceous material and a heterogeneous pyrolytic catalyst component. In some embodiments, the mixture may be pyrolyzed at high temperatures (e.g., between 500° C. and 1000° C.). The pyrolysis may be conducted for an amount of time at least partially sufficient for production of discrete, identifiable biofuel compounds. Some embodiments involve heating the mixture of catalyst and hydrocarbonaceous material at high rates (e.g., from about 50° C. per second to about 1000° C. per second). The methods described herein may also involve the use of specialized catalysts. For example, in some cases, zeolite catalysts may be used; optionally, the catalysts used herein may have high silica to alumina molar ratios. In some instances, the composition fed to the pyrolysis reactor may have a relatively high catalyst to hydrocarbonaceous material mass ratio (e.g., from about 5:1 to about 20:1).

Owner:UNIV OF MASSACHUSETTS

Fractional catalytic pyrolysis of biomass

ActiveUS8202332B2Eliminate needBiofuelsLiquid hydrocarbon mixture productionCatalytic pyrolysisReactive gas

Methods for fractional catalytic pyrolysis which allow for conversion of biomass into a slate of desired products without the need for post-pyrolysis separation are described. The methods involve use of a fluid catalytic bed which is maintained at a suitable pyrolysis temperature. Biomass is added to the catalytic bed, preferably while entrained in a non-reactive gas such as nitrogen, causing the biomass to become pyrolyzed and forming the desired products in vapor and gas forms, allowing the desired products to be easily separated.

Owner:VIRGINIA TECH INTPROP INC

Method for deep desulfurization olefin hydrocarbon reduction of inferior gasoline

ActiveCN101492608AStructuring reaction does not affectReduce olefin contentRefining to eliminate hetero atomsCatalytic pyrolysisHydrogen

The invention discloses a gasoline deep desulphurization and olefin reduction method, comprising that the gasoline raw material and hydrogen are contacted with hydrogenation absorption desulphurization and olefin aromatization difunctional catalyst to remove sulfur in the gasoline and reduce the olefin content in the gasoline product. The method of the invention can produce gasoline product with the sulfur content lower than 50 micrograms per gram, and can further produce gasoline product with the sulfur content lower than 10 micrograms per gram while the olefin content is lower than 20v%, and meanwhile the antiknock quality index loss is low. The method of the invention can be applied to deep desulphurization and olefin reduction process of FCC gasoline, catalytic pyrolysis gasoline, coker gasoline, pyrolysis gasoline and pressure gasoline or the mixed gasoline raw material thereof.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production of stable biomass pyrolysis oils using fractional catalytic pyrolysis

ActiveUS20100212215A1Eliminate needImprove stabilityMolecular sieve catalystsMultiple metal hydridesCatalytic pyrolysisReactive gas

Methods for fractional catalytic pyrolysis which allow for conversion of biomass into a slate of desired products without the need for post-pyrolysis separation are described. The methods involve use of a fluid catalytic bed which is maintained at a suitable pyrolysis temperature. Biomass is added to the catalytic bed, preferably while entrained in a non-reactive gas such as nitrogen, causing the biomass to become pyrolyzed and forming the desired products in vapor and gas forms, allowing the desired products to be easily separated.

Owner:VIRGINIA TECH INTPROP INC

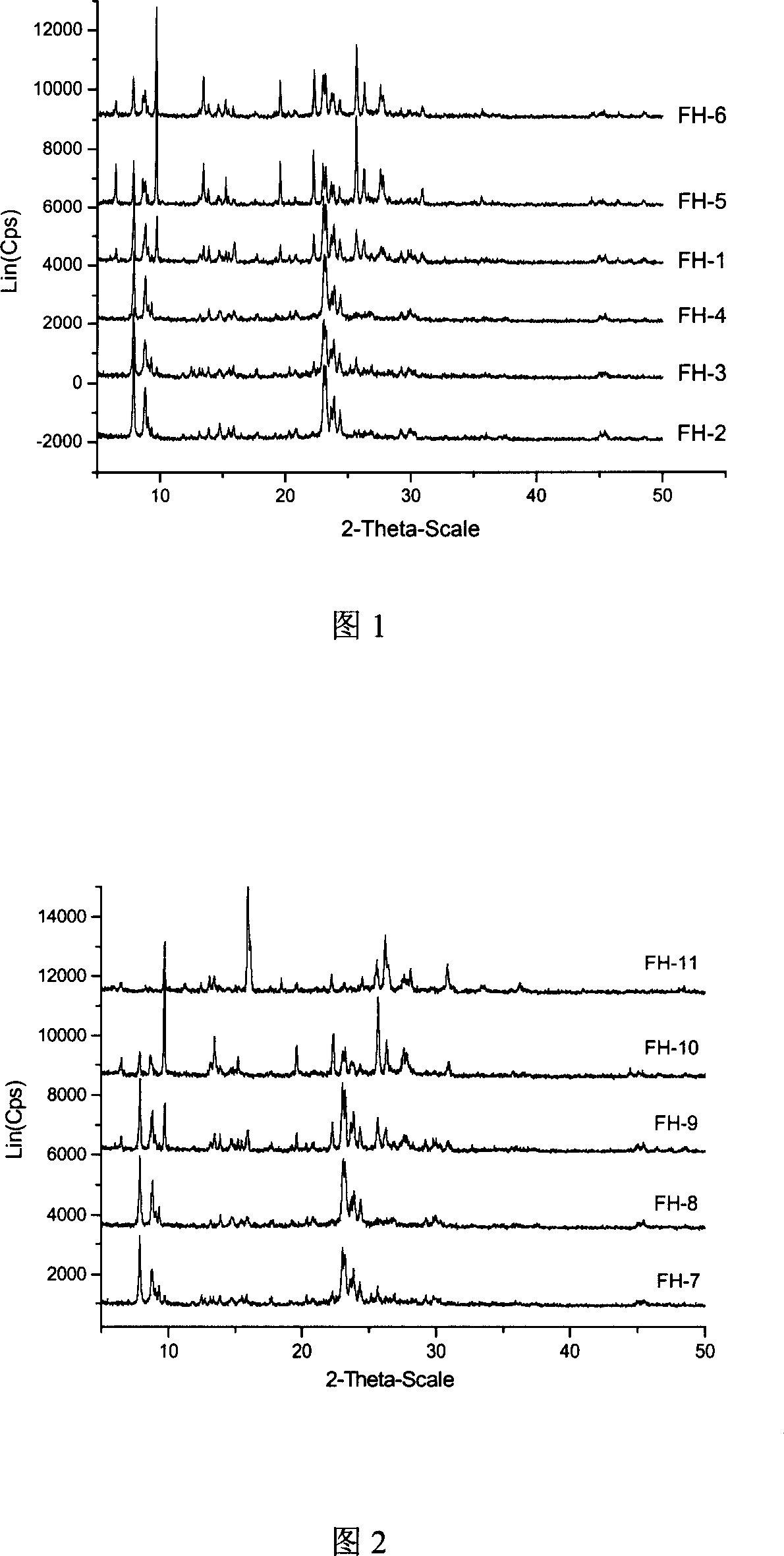

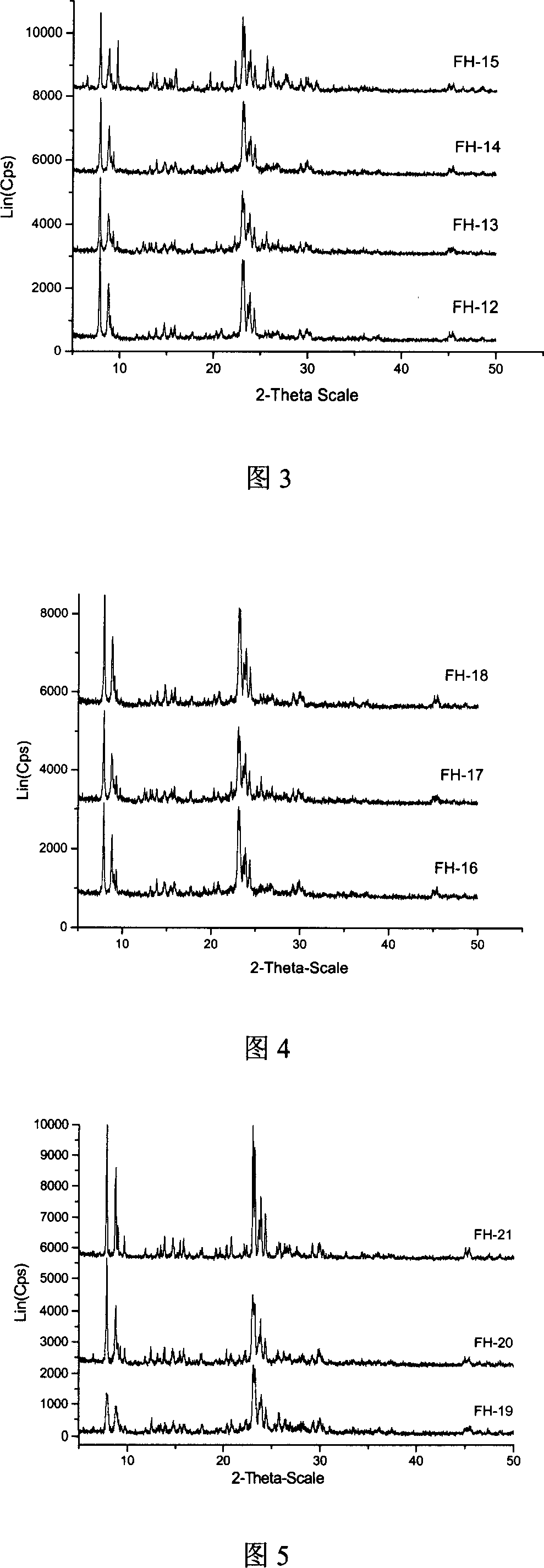

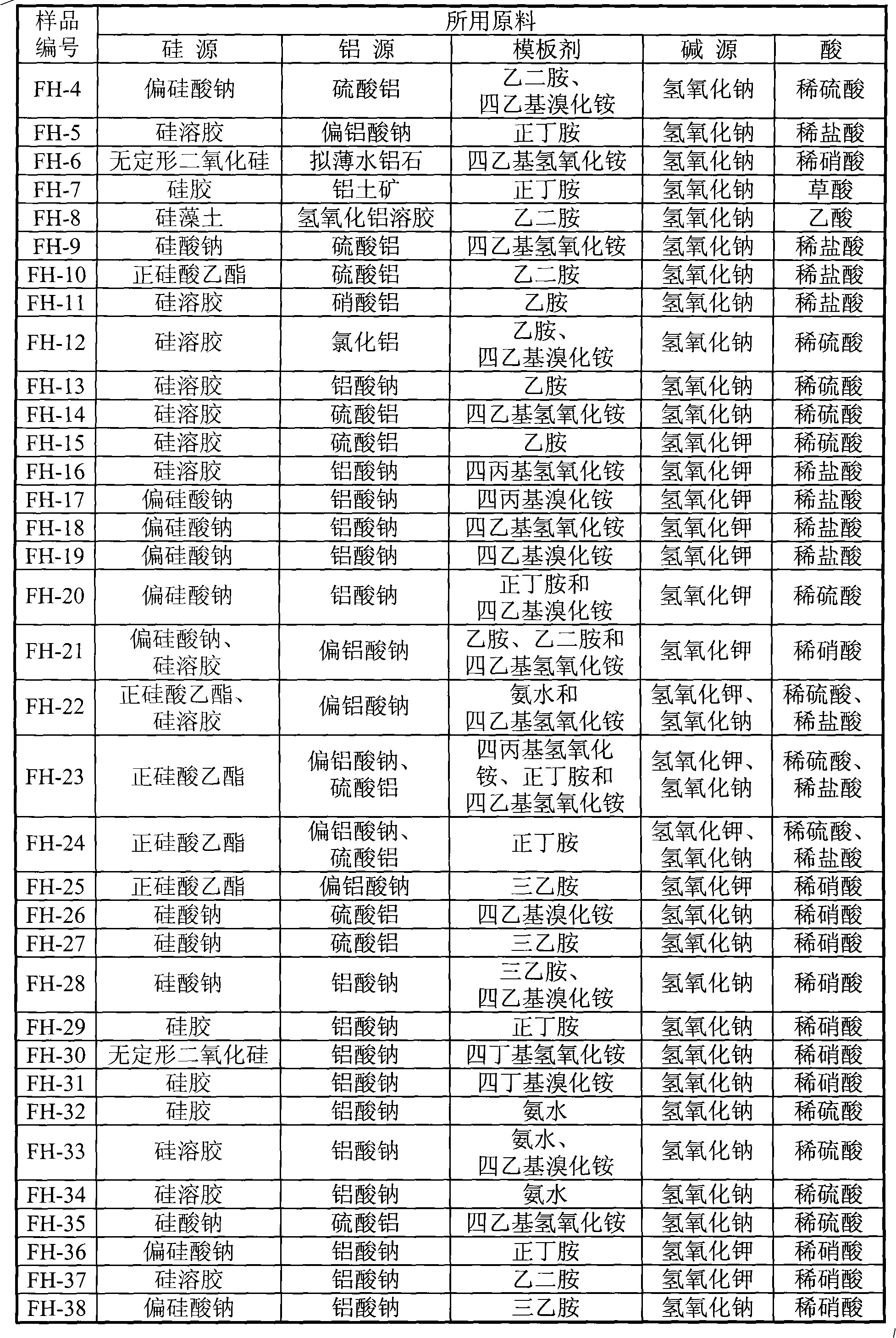

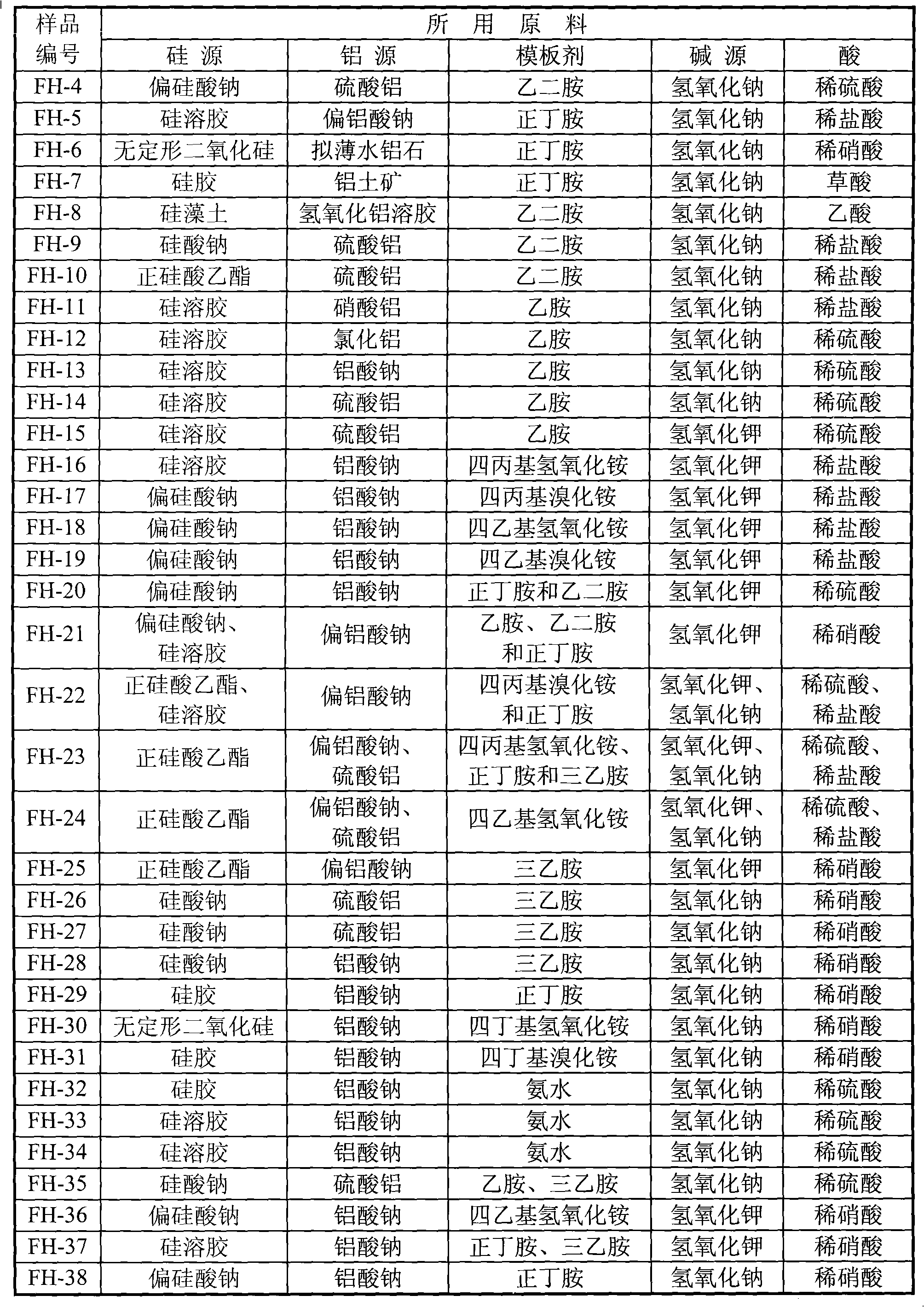

Method for preparing composite molecular sieve of ZSM 5/ mordenite

ActiveCN101091920AImprove catalytic performanceImprove technical effectMolecular sieve catalystsCatalytic pyrolysisNaphtha

The invention relates to a preparation method of the ZSM-5 / mordenite compound molecular sieve, mainly solves the complex question which needs to add the seed crystal or subsect the crystallization in the existing compound molecular sieve synthesize process. Through controls the certain silicon aluminum ratio and the pH value in the molecular sieve synthesize process, the invention prepares the compound molecular sieve with the adjustable ZSM-5 and the mordenite proportion, the technical program solves the problem preferably. The molecular sieve which is prepared by the invention can be used in the industrial production of the naphtha catalytic pyrolysis system ethylene propylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

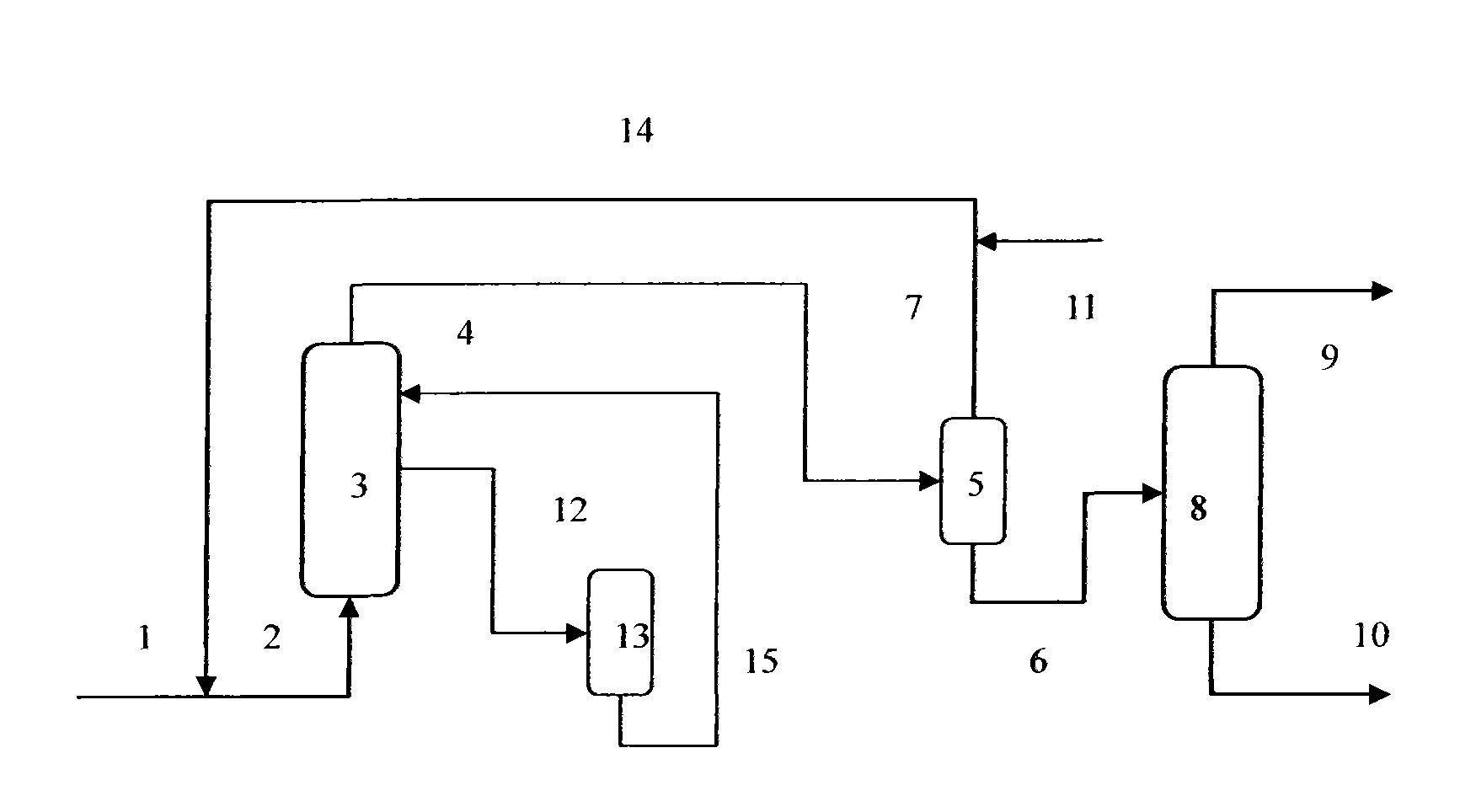

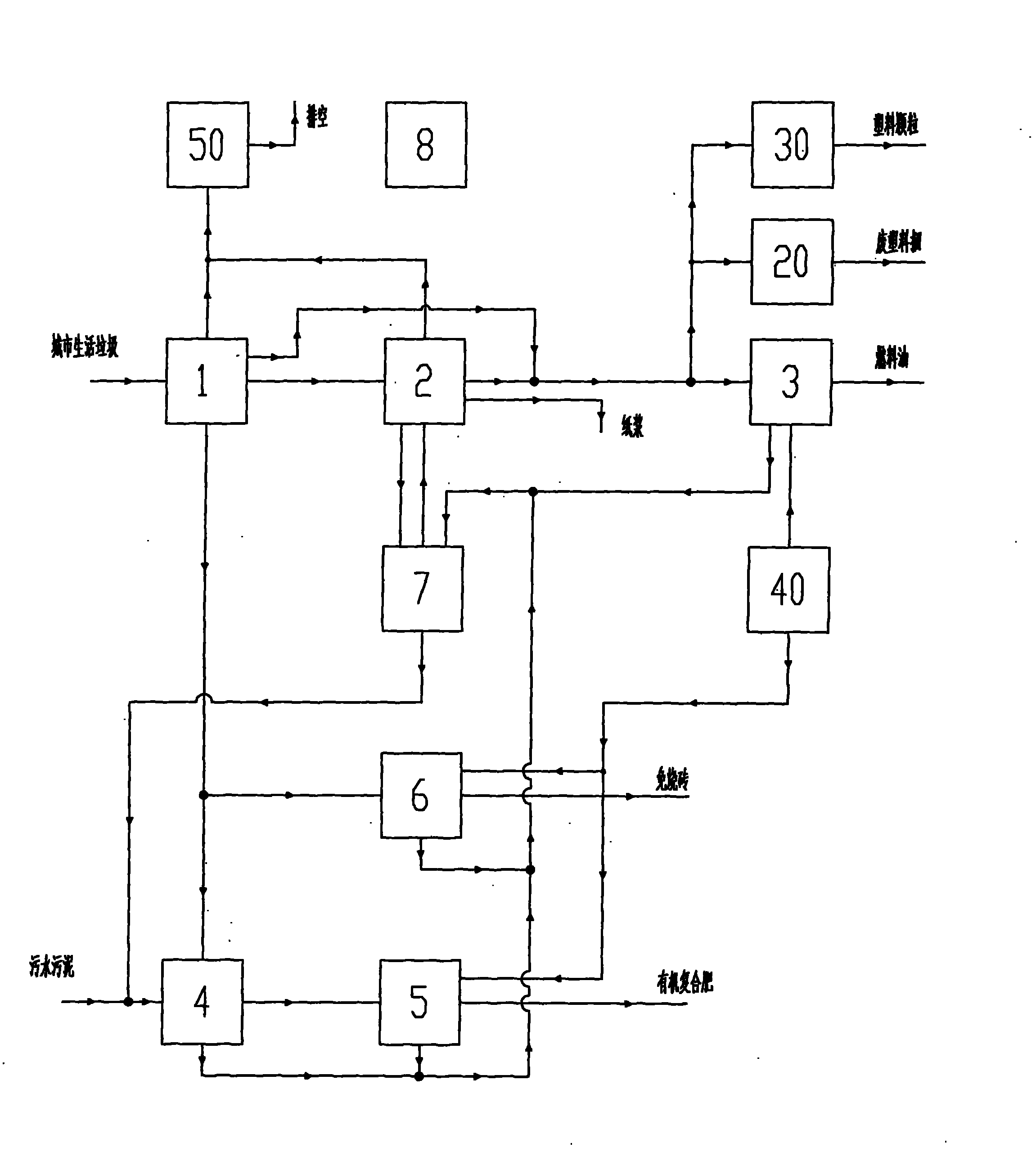

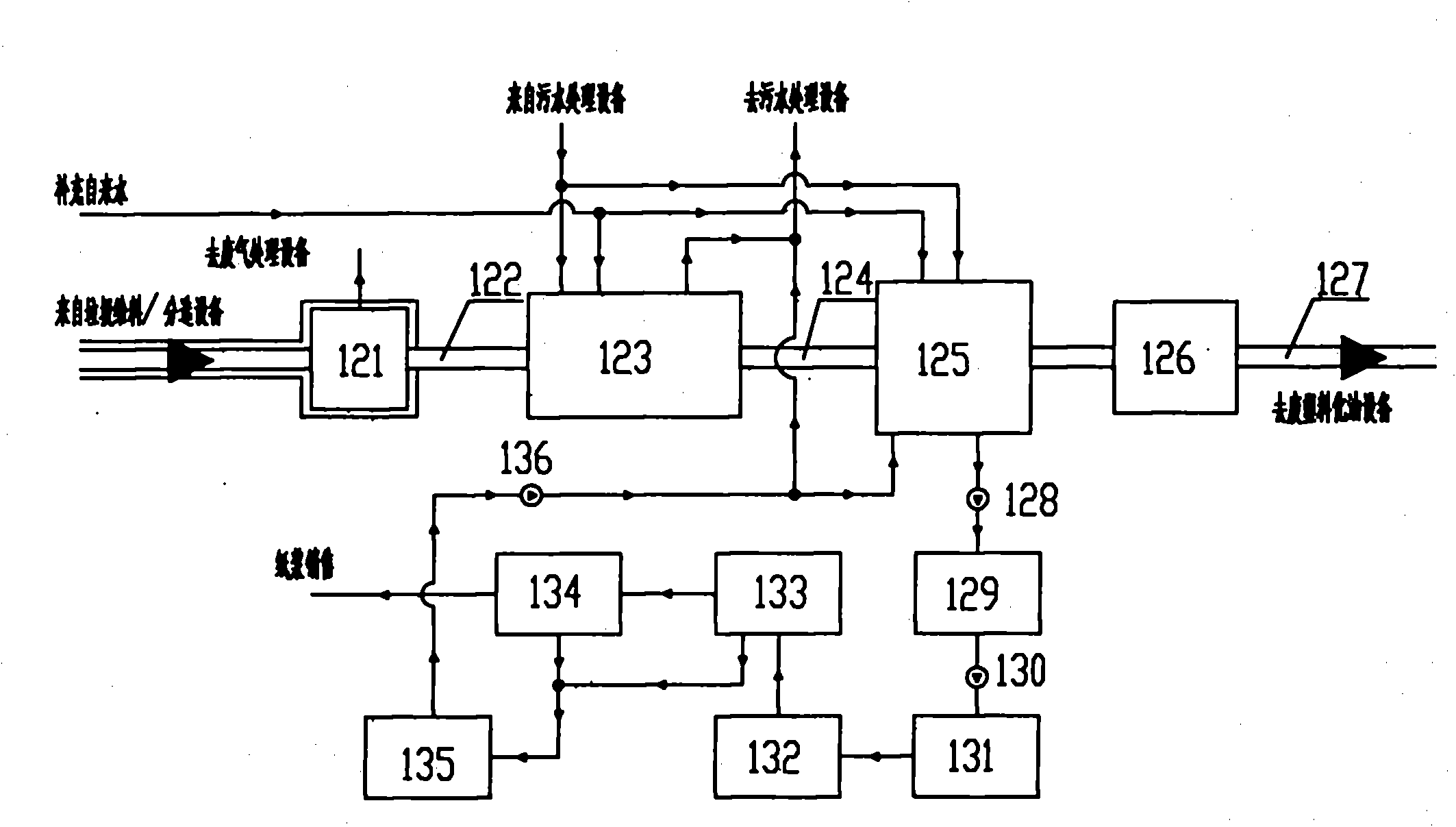

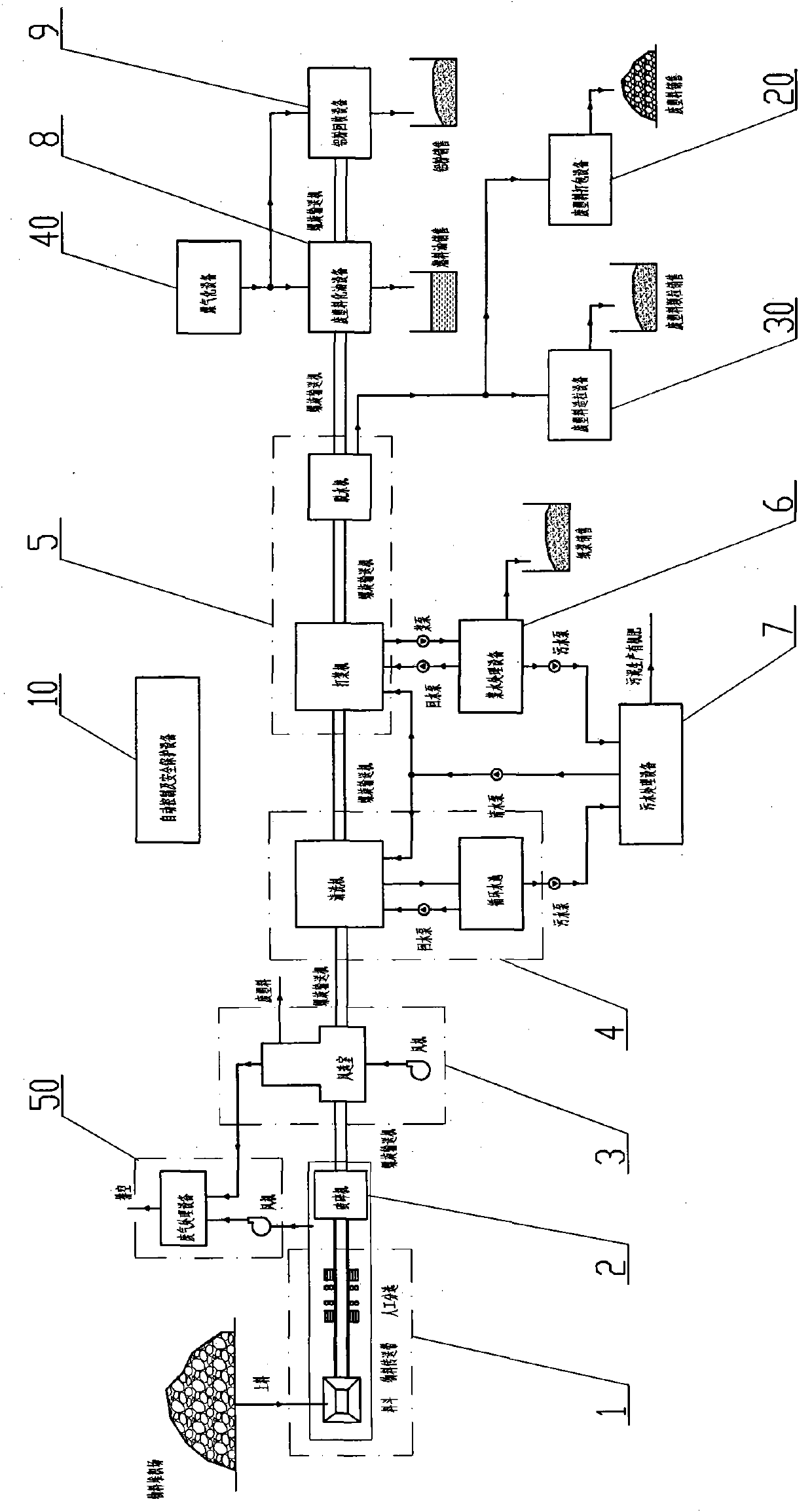

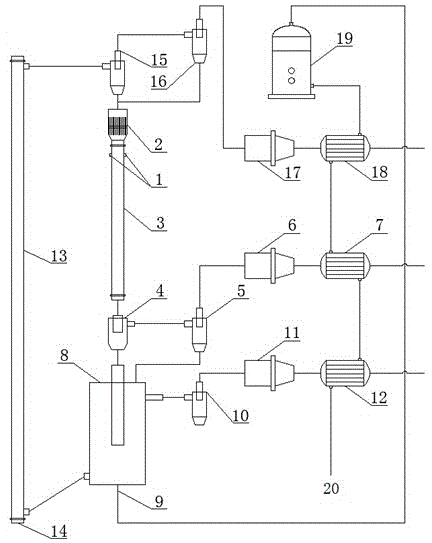

Urban garbage and sludge resource comprehensive utilization system

InactiveCN101955388AGuaranteed uptimeReduce processing timeSolid waste managementSolid waste disposalCatalytic pyrolysisBrick

The invention discloses an urban garbage and sludge resource comprehensive utilization system. Urban garbage is fed into garbage feeding / sorting equipment (1) and, after primary sorting, primary rough crushing and primary screening, is divided into two parts: oversize materials and undersize materials. The oversize materials include paper and paper plastic composite materials left after air separation and secondary sorting and plastic, wherein the paper and paper plastic composite materials are fed into paper pump recovery equipment (2) to recover high-quality paper pulp; the waste plastic is fed into waste plastic oil producing equipment (3) for recovering fuel oil by low-temperature catalytic pyrolysis, and the slag (active carbon powder) is used in waste gas purification equipment (50) directly. The undersize materials include inorganic materials and organic materials, which are separated by secondary screening by a vibrating screen, wherein the inorganic materials are fed into a baking-free brick production equipment (6), dried, crushed and added with ingredients such as coagulator to produce baking-free bricks; and the organic materials are mixed with sludge from sludge feeding equipment (4) in a ratio and then fed into organic fertilizer production equipment (5) for producing organic fertilizers by special processes such as high-temperature high-pressure degradation and microbial fermentation.

Owner:朱海生 +1

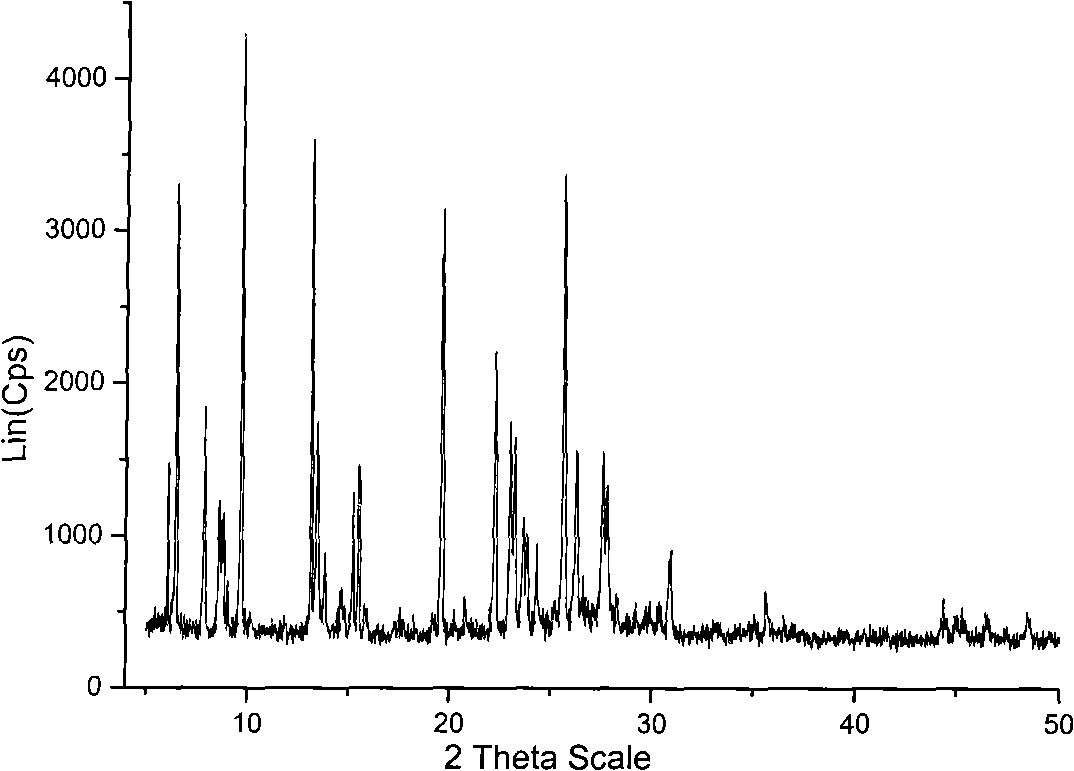

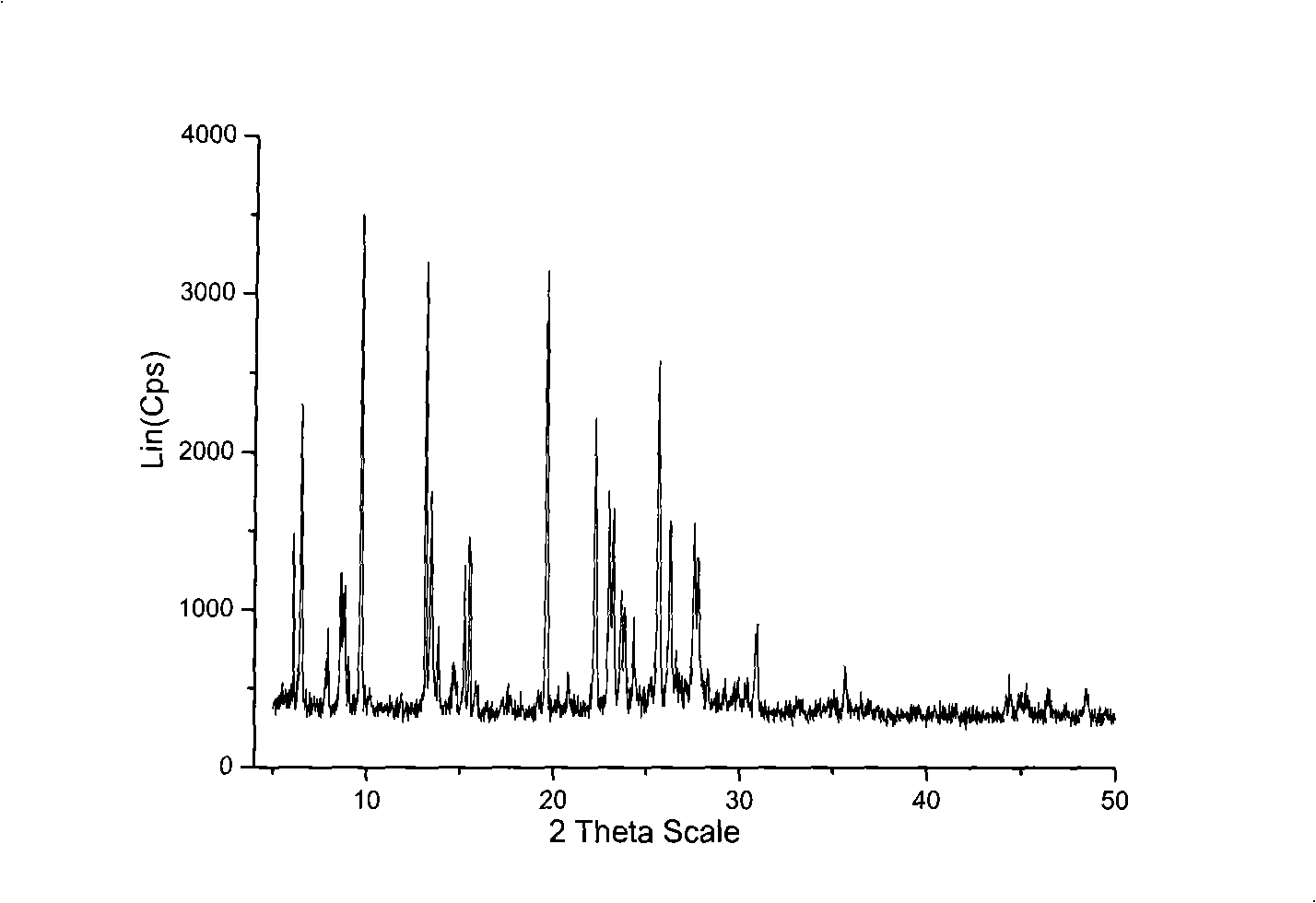

Mordenite/beta zeolite/Y zeolite coexisting material and method for synthesizing same

ActiveCN101514009AStrong acidImprove catalytic performanceFaujasite aluminosilicate zeoliteMordenite aluminosilicate zeoliteCatalytic pyrolysisNaphtha

The invention relates to a mordenite / beta zeolite / Y zeolite coexisting material and a method for synthesizing the same, and mainly solves the problems that a porous material synthesized by the prior art is single in pore-size, weak in acid and low in activity. The method prepares the mordenite / beta zeolite / Y zeolite coexisting material by adding a seed crystal containing a Y zeolite precursor during a synthesis process of mordenite / beta zeolite / Y zeolite coexisting material. A mole relation of the components of the synthesized mordenite / beta zeolite / Y zeolite coexisting material is nSiO2 :Al2O3, wherein n is between 4 and 400; the XRD diffraction pattern of the mordenite / beta zeolite / Y zeolite coexisting material comprises a technical proposal that a maximum value of a distance d is at positions between 14.52-0.1 and 14.52+0.1 A, 13.52-0.1 and 13.52+0.1 A,11.32-0.1 and 11.32+0.1 A, 8.96-0.1 and 8.96+0.1 A, 6.71-0.1 and 6.71+0.1 A, 5.71-0.1 and 5.71+0.1 A, 4.51-0.05 and 4.51+0.05 A, 4.15-0.05 and 4.15+0.05 A, 3.97-0.05 and 3.97+0.05 A, 3.78-0.05 and 3.78 +0.05 A, 3.51-0.05 and 3.51+0.05 A, 3.02-0.05 and 3.02+0.05 A, and 2.86-0.1 and 2.86+0.1 A; therefore, the problems are solved well. The mordenite / beta zeolite / Y zeolite coexisting material can be used in the industrial production of ethylene and propylene through the catalytic pyrolysis of naphtha.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for catalytic pyrolysis

ActiveCN101428233AHigh hydrothermal stabilityIncrease acidityMolecular sieve catalystsBulk chemical productionCatalytic pyrolysisPetroleum naphtha

The invention relates to a catalyst for catalytic cracking and mainly solves the problems of high service temperature and low yield of ethylene-propylene copolymer in the prior catalyst for catalytic cracking in ethylene-propylene copolymer synthesis. In order to solve the problems, the technical scheme is as follows: the catalyst is obtained by loading at least one element of the group IB or the group IIB in the periodic table of elements on a ZSM-5 / mordenite molecular sieve, ZSM-5 / beta-zeolite molecular sieve or ZSM-5 / Y-zeolite molecular sieve. The catalyst is applied to the industrial production of ethylene-propylene copolymer via catalytic cracking of petroleum naphtha.

Owner:CHINA PETROLEUM & CHEM CORP +1

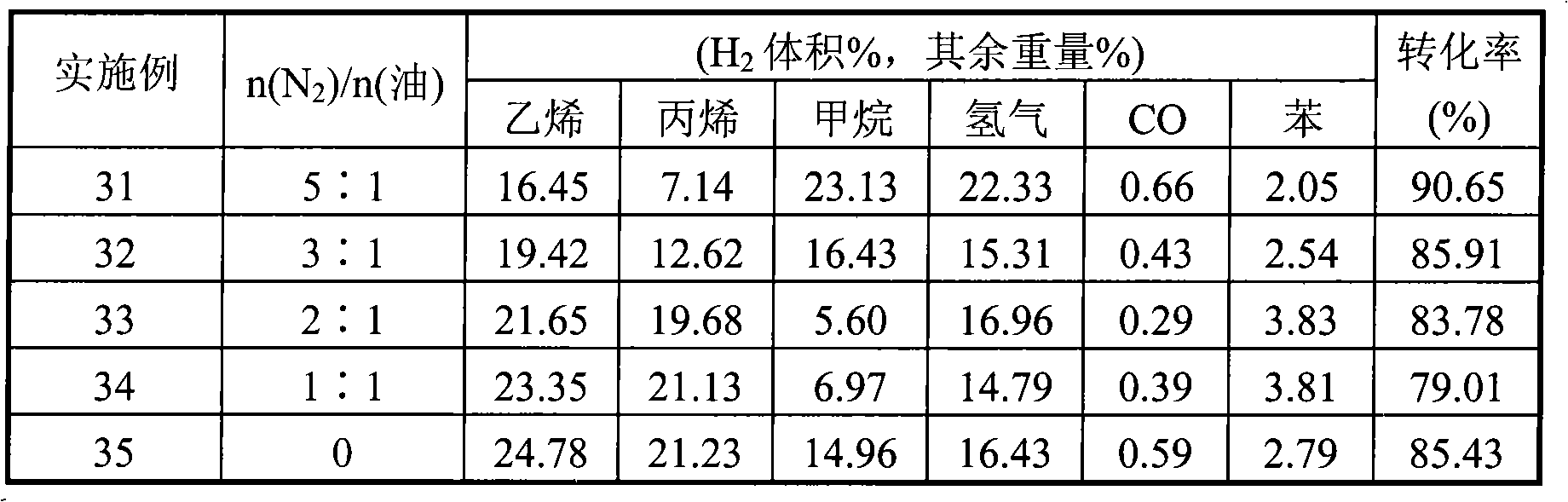

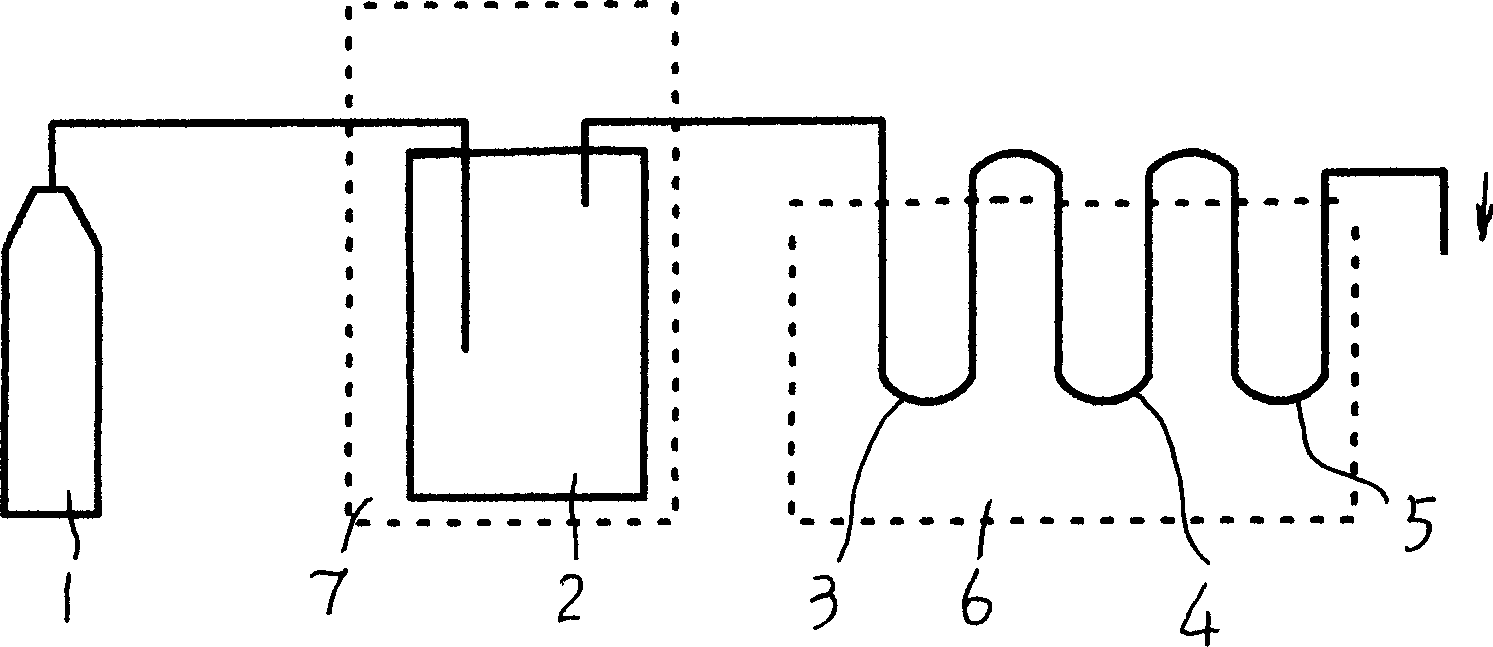

Method for preparing ethylene and propylene by benzin naphtha catalytic pyrolysis

ActiveCN101279881AHigh yieldMolecular sieve catalystsBulk chemical productionCatalytic pyrolysisWater vapor

The invention relates to a method for producing ethylene propylene by catalytic cracking naphtha, which mainly solves the problems of short service life caused by coking of the catalyst and high consumption of vapor in the reaction of ethylene propylene preparation by catalytic cracking the naphtha. The invention properly solves the problems by adopting the technical proposals that: a naphtha of C4 to C10 hydrocarbon is taken as a raw material, the material hydrocarbon is firstly mixed with a gas inert to reaction after the vaporization, wherein the inert gas and the naphtha are present in a mole ratio of more than 0-5.0: 1, the material mixed gas contacts with a catalyst to generate an ethylene propylene under the conditions of a reaction temperature of between 580 and 750 DEG C, a pressure gauge reaction pressure of more than 0 to 0.5MPa, a weight space velocity of between 0.5 and 3 / h, and water / naphtha being present in a weight ratio of 0-5: 1, wherein the adopted catalyst is selected from at least one of ZSM-5 / mordenite intergrown molecular sieve, ZSM-5 / zeolite beta intergrown molecular sieve or ZSM-5 / zeolite Y intergrown molecular sieve, and the method of preparation can be used for the industrial production of preparing the ethylene propylene by catalytic cracking the naphtha.

Owner:CHINA PETROLEUM & CHEM CORP +1

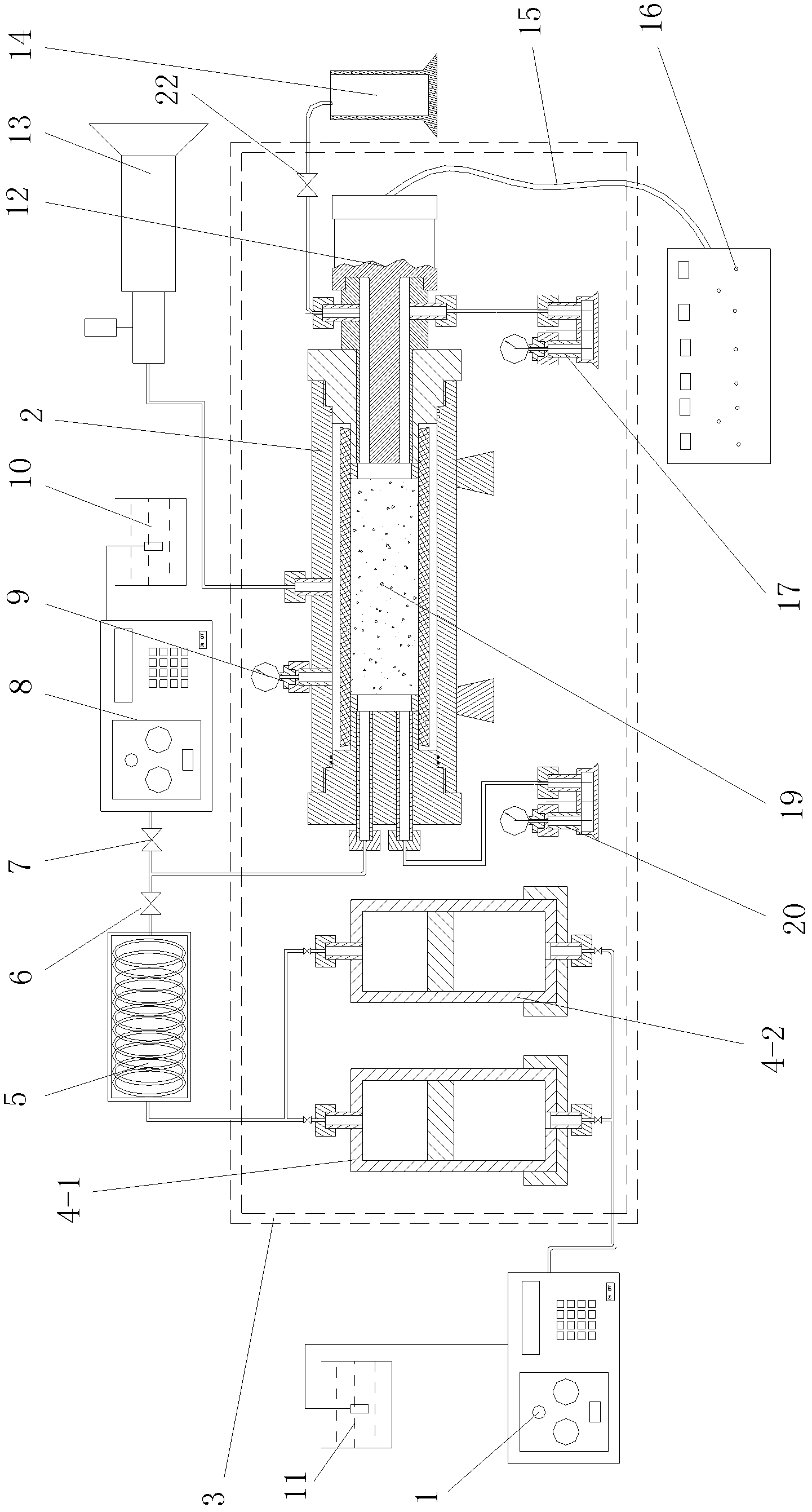

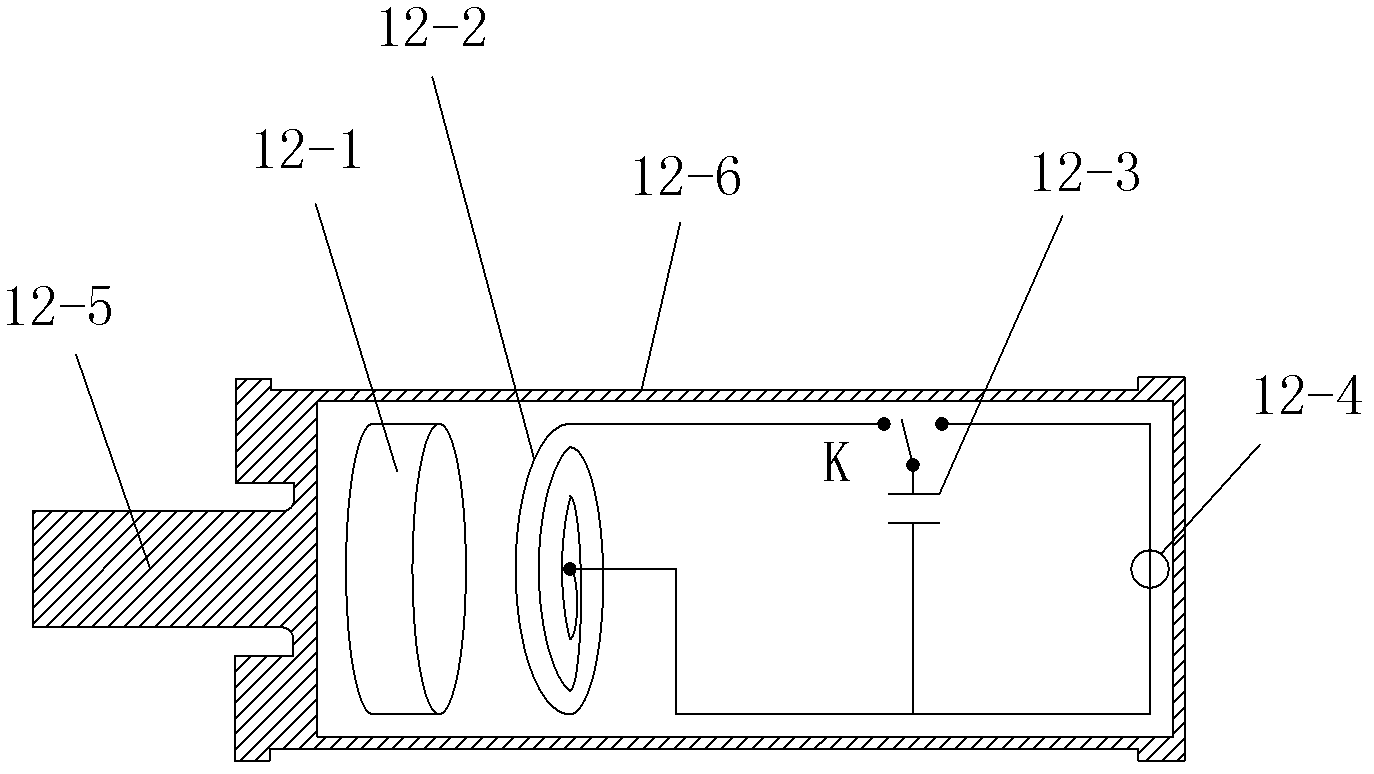

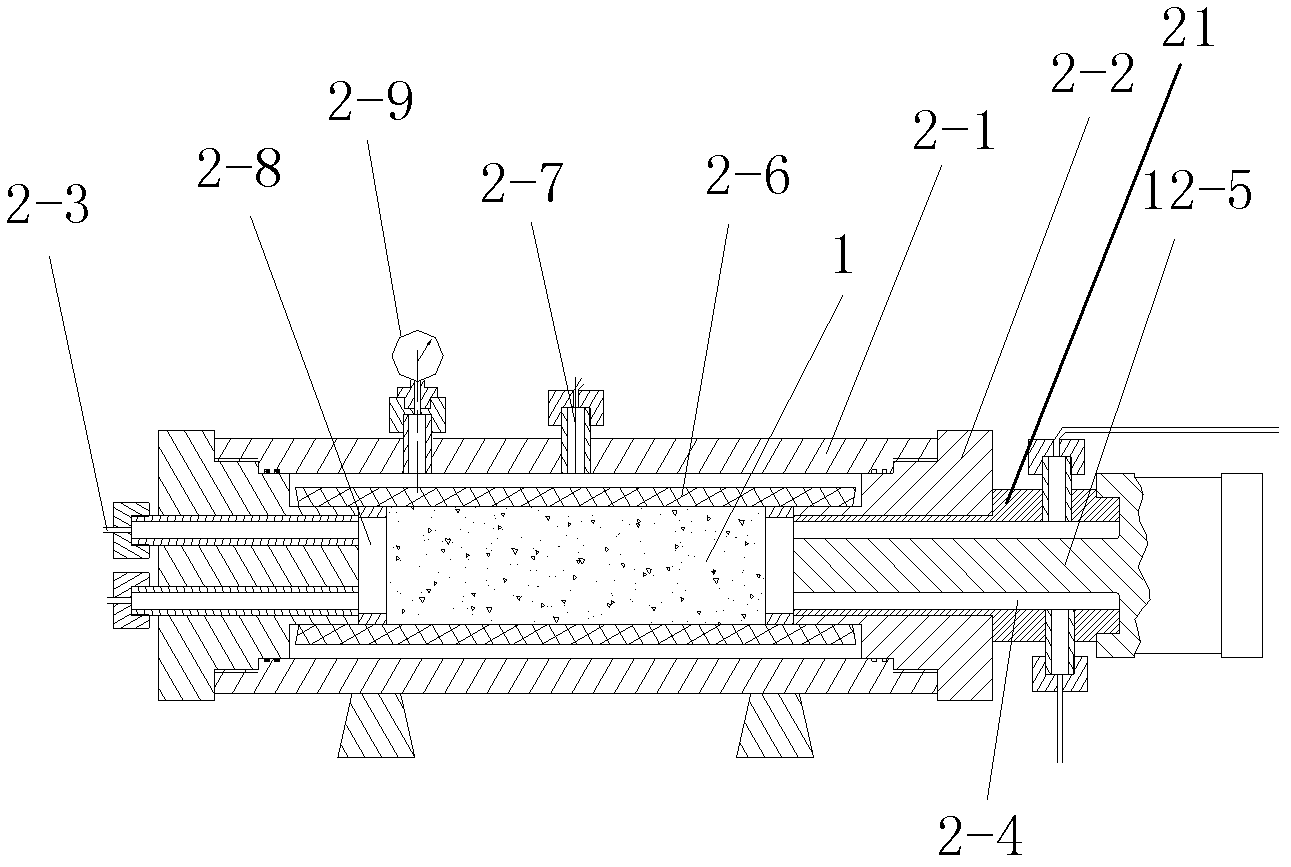

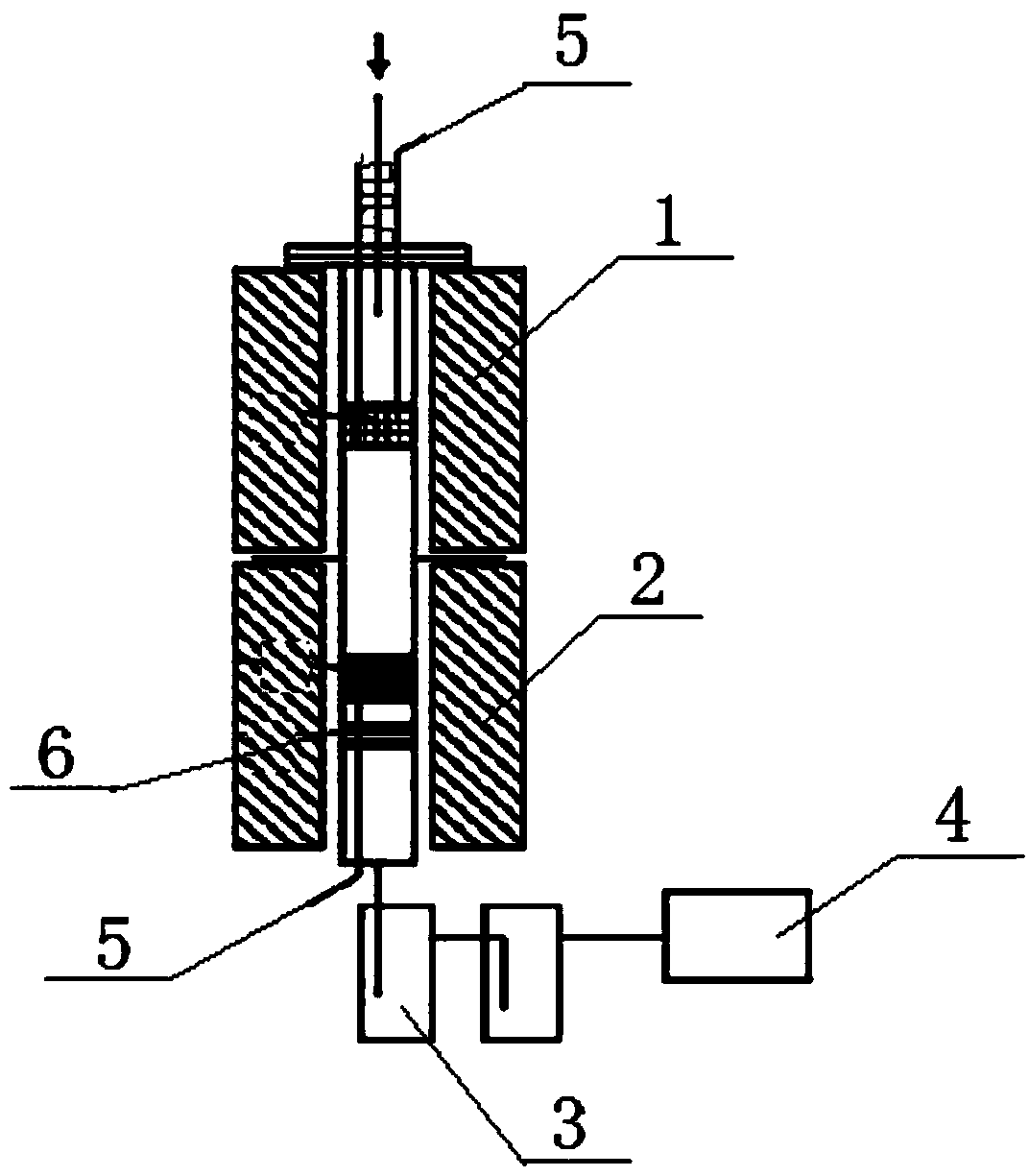

Experimental device and experimental method for hydrothermal catalytic pyrolysis in heavy oil layer by means of ultrasonic wave

ActiveCN102587874AComplete efficientlyFinish quicklySurveyFluid removalCatalytic pyrolysisExperimental methods

The invention discloses an experimental device and an experimental method for hydrothermal catalytic pyrolysis in a heavy oil layer by means of ultrasonic wave, wherein the experimental device comprises a core holder, a ring pressure supply device, a water storage tank, an oil storage tank, an ultrasonic transducer, an ultrasonic generator, a liquid container, a catalyst, a reaction assistant storage device and a constant temperature box; a steam generator is arranged on a water pipe between the water storage tank and the core holder; the experimental method comprises the following steps: 1, pre-treating tested core; 2, performing water-flooding experiment and measuring original water-flooding permeability of the tested core; 3, performing oil-flooding experiment and measuring original oil saturation degree of the tested core; 4, performing hydrothermal pyrolysis simulation experiment; and 5, preparing data. The experimental device and the experimental method have rational design. The device is convenient to install and distribute, has complete function, is convenient to use and operate and has good usage effect. The problems that the prior normal steam thermal driving heavy oil has easily-rebounding viscosity and short measure validity period, and the normal hydrothermal catalytic pyrolysis technology has limited effect during the heavy oil recovery process can be solved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

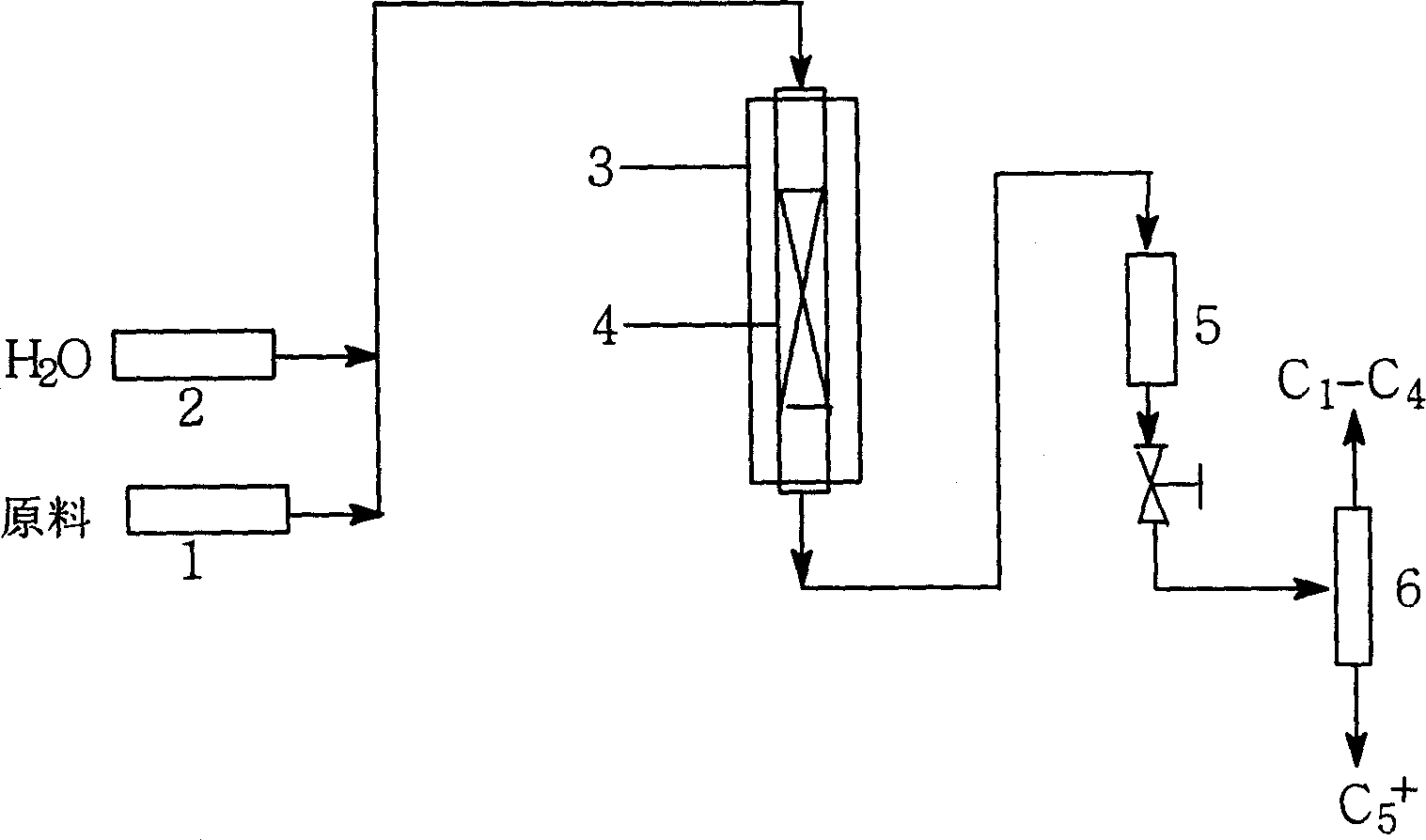

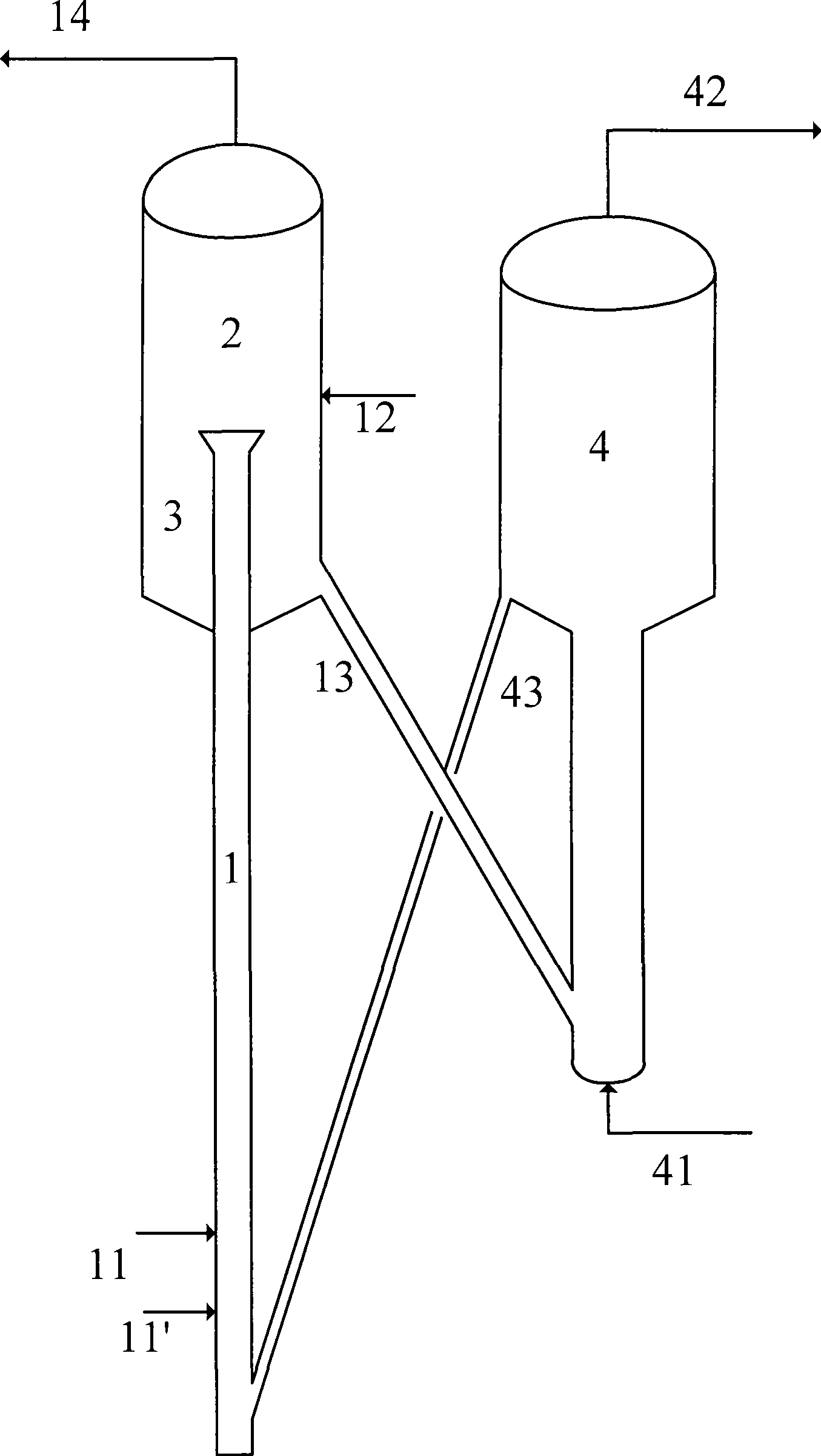

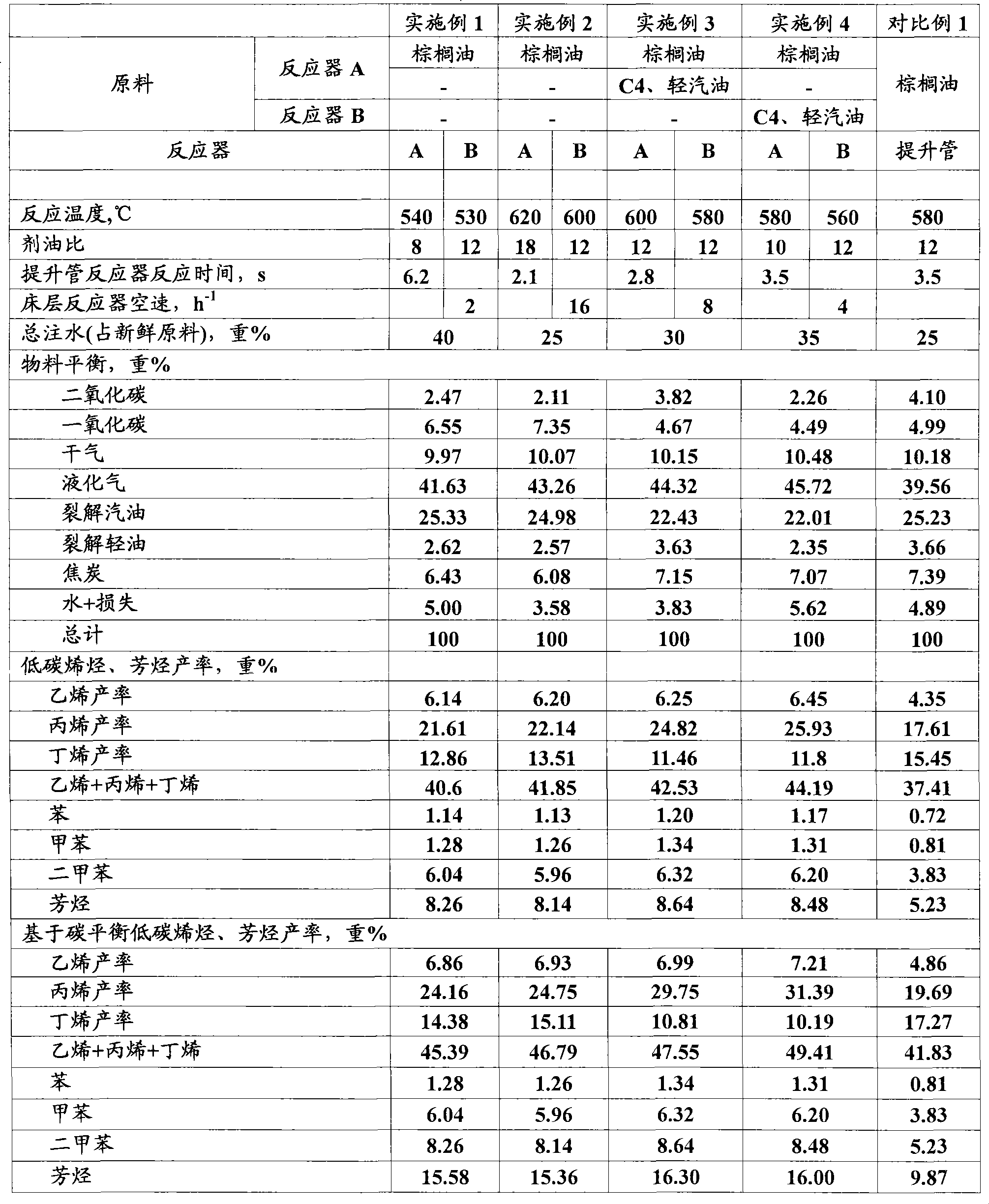

Catalytic pyrolysis process for producing petroleum hydrocarbon of ethylene and propylene

InactiveCN1566267AHigh yieldRaise the reaction temperatureCatalytic crackingCatalytic pyrolysisPetroleum

The invention discloses a catalytic pyrolysis process for producing petroleum hydrocarbon of ethylene and propylene which comprises, feeding preheated petroleum hydrocarbon raw material into lift tubes, contacting phosphor modified five-membered ring high silicon zeolite catalyst for reaction under the condition of catalytic thermal cracking, thus separating the reaction product and catalyst to be produced, then loading the reaction product into subsequent separation system for product separation, stripping and regenerating the catalyst, returning to reactor for circulation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Petroleum hydrocarbon catalytic pyrolysis catalyst and its application

ActiveCN1955255AIncrease throughputHigh airspeedHydrocarbonsNaphtha reformingCatalytic pyrolysisAlkaline earth metal

This invention provides a petroleum hydrocarbon catalytic decomposition accelerant and its application. This accelerant includes following components: (1) lanthanide, its weight amount is 0.1-25%; (2) phosphorus or boron, its weight amount is 0.1-10%; (3) base metal, alkali metal and transition metal, their weight amount is 0.1-15%; (4) The others are ZSM-5,ZRP used as carrier. This accelerant used for production of low carbon alkenes by cracking heavy magnesium alkanes, with space velocity of gas 1-25hr-1, such as naphtha, diesel oil, educed pressure diesel and so on. The yield of ethylene, propylene, butylenes and butadiene will improve by 5%.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for deep desulfurization olefin hydrocarbon reduction of gasoline

ActiveCN101492609AStructuring reaction does not affectReduced responseRefining to eliminate hetero atomsCatalytic pyrolysisHydrogen

The invention discloses a gasoline deep desulphurization and olefin reduction method, comprising that the gasoline raw material and hydrogen are contacted with hydrogenation absorption desulphurization catalyst and olefin aromatization difunctional catalyst to remove sulfur in the gasoline and reduce the olefin content in the product. The method of the invention can produce gasoline product with the sulfur content lower than 50 micrograms per gram, and can further produce gasoline product with the sulfur content lower than 10 micrograms per gram while the olefin content is lower than 20v%, and meanwhile the antiknock quality index loss is low. The method of the invention can be applied to deep desulphurization and olefin reduction process of FCC gasoline, catalytic pyrolysis gasoline, coker gasoline, pyrolysis gasoline and pressure gasoline or the mixed gasoline raw material thereof.

Owner:CHINA PETROLEUM & CHEM CORP +1

Mordenite/Y zeolite coexisting molecular sieve and method for synthesizing same

ActiveCN101514008AIncrease acidityStrong acidFaujasite aluminosilicate zeoliteMordenite aluminosilicate zeoliteMolecular sieveCatalytic pyrolysis

The invention relates to a mordenite / Y zeolite coexisting molecular sieve and a method for synthesizing the same, and mainly solves the problems that a porous material synthesized by the prior art is single in pore-size, weak in acid and low in activity. The method prepares the mordenite / Y zeolite coexisting molecular sieve by adding a seed crystal containing a Y zeolite precursor and well controlling the nucleating and growing process of a molecular sieve during a synthesis process of mordenite. The coexistence phase ratio of the mordenite / Y zeolite coexisting molecular sieve is adjustable, and a mole relation of the components of the synthesized coexisting molecular sieve is nSiO2 :Al2O3, wherein n is between 4 and 400; the coexisting molecular sieve has more than two phases, the XRD diffraction pattern of the coexisting molecular sieve comprises a technical proposal that a maximum value of a distance d is at positions between 14.52-0.05 and 14.52+0.05 A, 13.52-0.05 and 13.52+0.05 A, 8.96-0.05 and 8.96+0.05 A, 8.83-0.05 and 8.83+0.05 A, 6.71-0.1 and 6.71+0.1 A, 5.71-0.1 and 5.71 +0.1 A, 4.51-0.1 and 4.51+0.1 A, 3.98-0.1 and 3.98+0.1 A, 3.78-0.05 and 3.78+0.05 A, 3.47-0.1 and 3.47+0.1 A, and 2.86-0.1 and 2.86+0.1 A; therefore, the problems are solved well. The coexisting molecular sieve can be used in the industrial production of ethylene and propylene through the catalytic pyrolysis of naphtha.

Owner:CHINA PETROLEUM & CHEM CORP +1

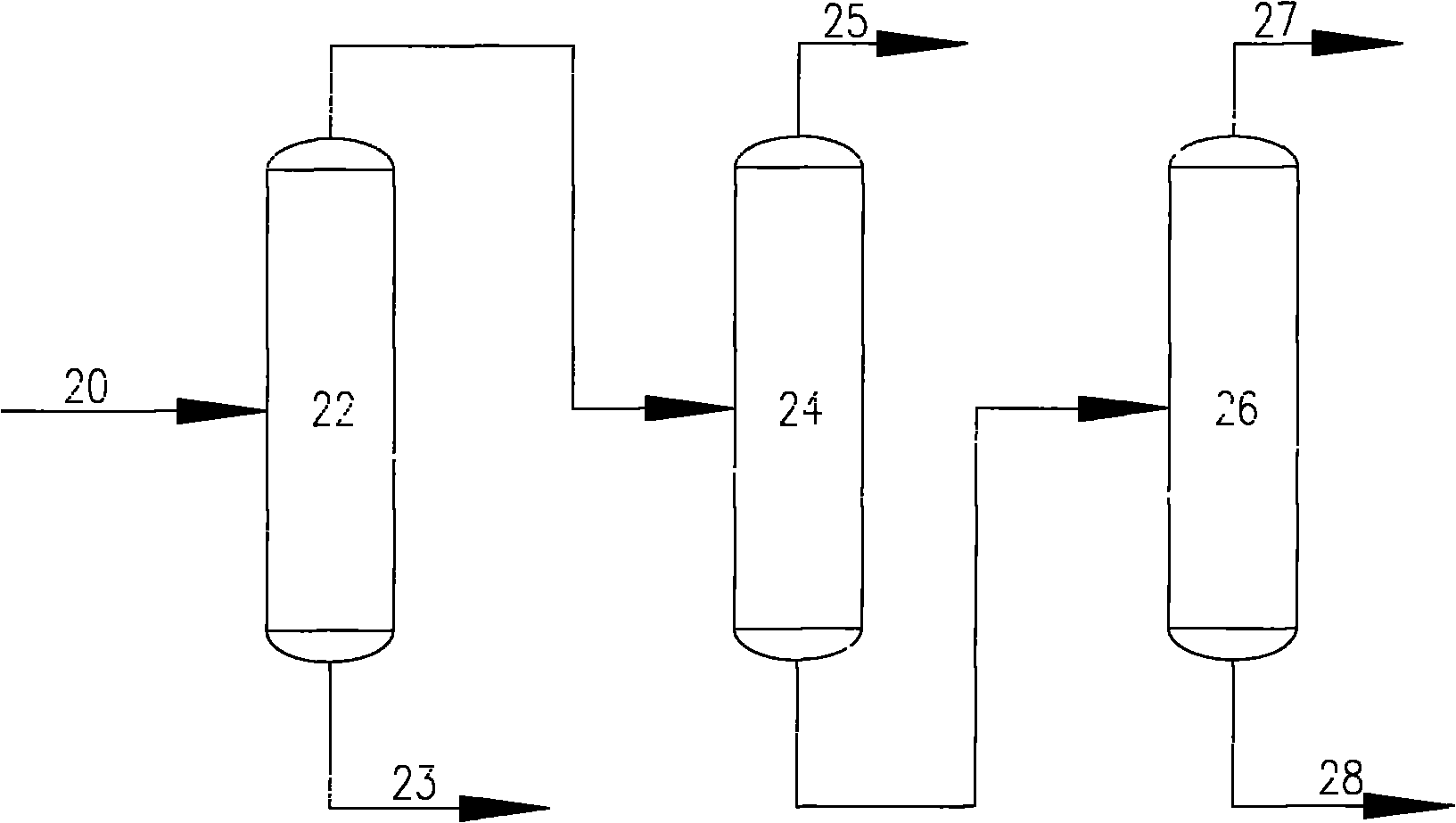

Method for preparing low carbon number olefin by catalytic pyrolysis

ActiveCN1676499AHigh yieldHigh selectivityHydrocarbon by hydrocarbon crackingCarbon numberCatalytic pyrolysis

This invention discloses a method that makes low-carbon olefin hydrocarbon by catalyzing decomposition. This method uses mixture of C4 or C5 without double olefin hydrocarbon as raw materials, mixes the raw materials and water with their volume ratio 0.3-1.5, in the solid bed reactor to react contacting with the zeolite catalyst with high silicon aluminum ratio, and produces the reacting mixture containing propene and ethane. The zeolite catalyst is composed of high silicon zeolite20-65%, the silicon-aluminum ratio 50-300, monox 20-65%, inorganic oxidant 0-20%. This invention can get high yields of ethane and propene, therefore, this invention explores the important way of compound utilization of C4 and C5 cut fractions in the ethane mills and refineries.

Owner:CHINA PETROLEUM & CHEM CORP +1

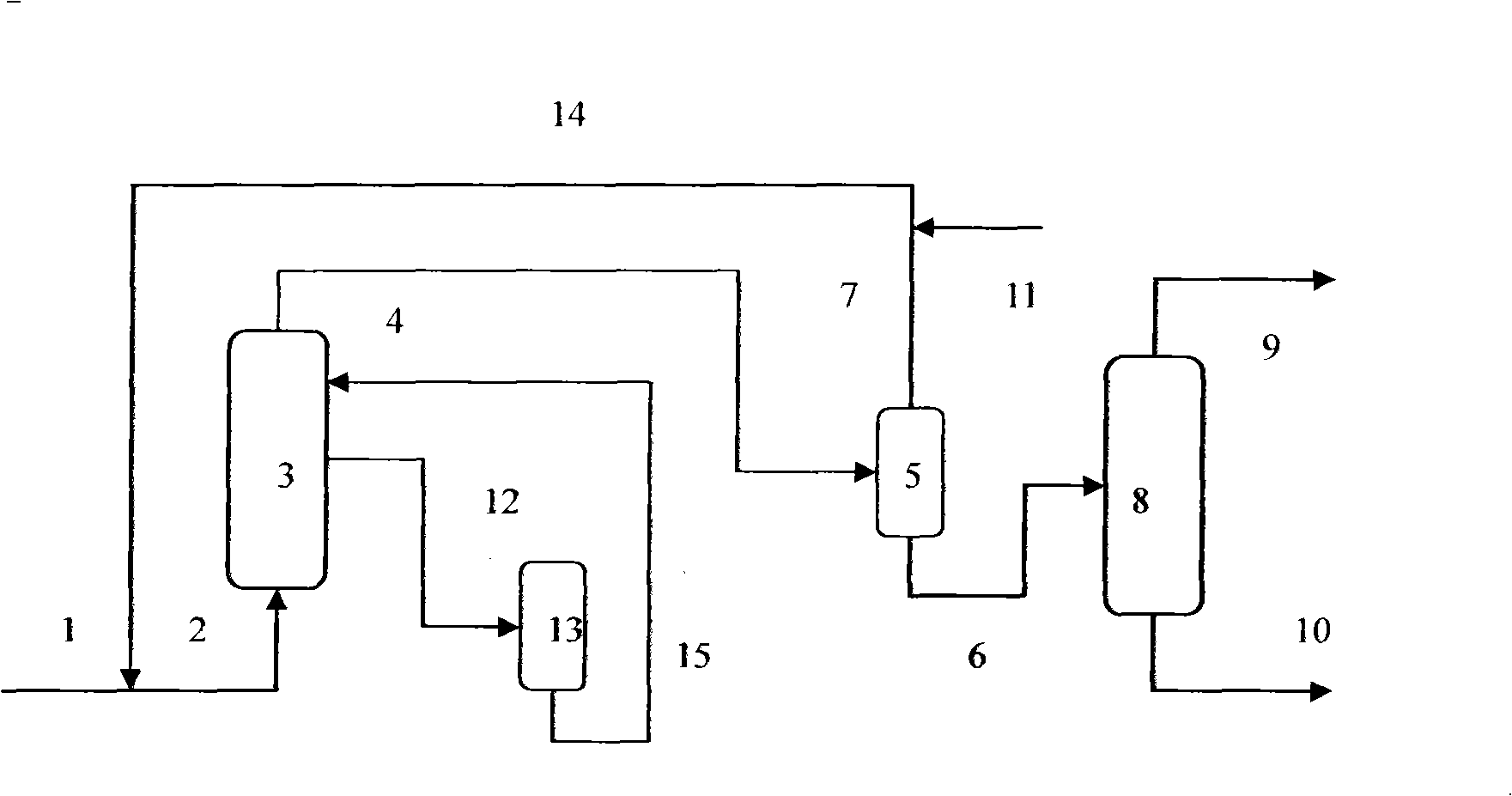

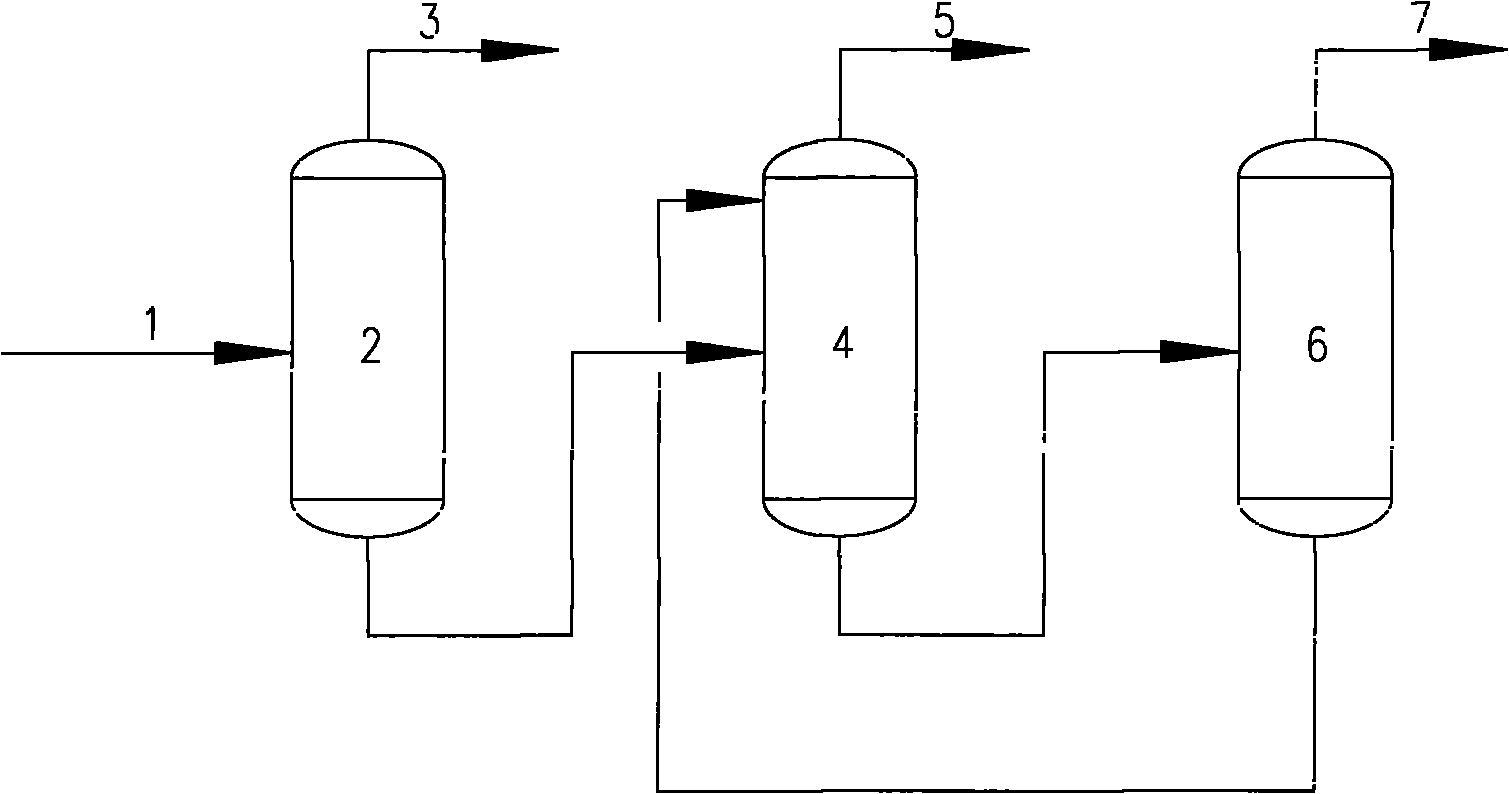

Method for producting propylene by catalytic pyrolysis of liquefied gas

InactiveCN101844960ABulk chemical productionHydrocarbon by hydrocarbon crackingCatalytic pyrolysisExtractive distillation

The invention relates to a method for producting propylene by catalytic pyrolysis of liquefied gas, which mainly solves the problems that the existing process limits the source of raw materials and components, the yield of the propylene is low and the one-way service life of the catalyst is short. The common civil-use liquefied gas is preprocessed through depropanization, extractive distillation and the like, then is heated to be 500-600 DEG C after being exchaning heat with a reaction product, and carries out the pyrolysis reaction under the condition with 0.4MPa and mass space velocity of 0.8h-1; after being cooled, the gas-liquid separation is carried out on the reaction product to enter an absorption and stable system to be further separated to obtain the high-octane gasoline component and liquefied petroleum gas containing rich propylene and butylenes; and the liquefied petroleum gas is further separated to obtain fine propylene. The invention makes full use of the common civil-use liquefied gas in markets to product propylene with a high added value, can be used in an industrial unit for producting propylene, can relieve the contradiction between supply and demand of propylene, can improve the economic benefit of petroleum chemical enterprises, better solves the problems of deep processing of liquefied petroleum gas and increasing production of propylene.

Owner:上海傲佳能源科技有限公司

Method for preparing furan chemical by catalytic pyrolysis of biomass

InactiveCN101475544AHigh selectivityHighly selective outputPhysical/chemical process catalystsOrganic chemistryLiquid productFuran

The invention relates to a method for preparing a liquid product rich in furfural and other furan chemicals by biomass. The method comprises the following steps: a catalyst is added into particles of a biomass raw material by a dry method or a wet method; the mixture is dried after the mixture is sufficiently mixed; the mixture is placed in a drying cabinet to remove free moisture for standby; the obtained material is filled into a quartz reactor, the reactor is placed in a microwave purolyzer, and oxygen in the quartz reactor and a condenser pipeline is driven off by inert gas; and microwave is started, power of the microwave is adjusted to pyrolyze the material in the quartz reactor, and the pyrolyzed steam is condensed into a pyrolysis liquid through a two stage water-cooled condenser. The method has the advantages that the yield of the pyrolysis liquid reaches over 50 percent (dry base), the furfural in a liquid product is over 60 percent of the content of organic compositions, which is far higher than the content of quickly pyrolzed furfural by the biomass (below 10 percent), and the time of a pyrolyzing reaction is obviously shortened. The method has the characteristics of simple process, single product, high furfural selectivity, and the like.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

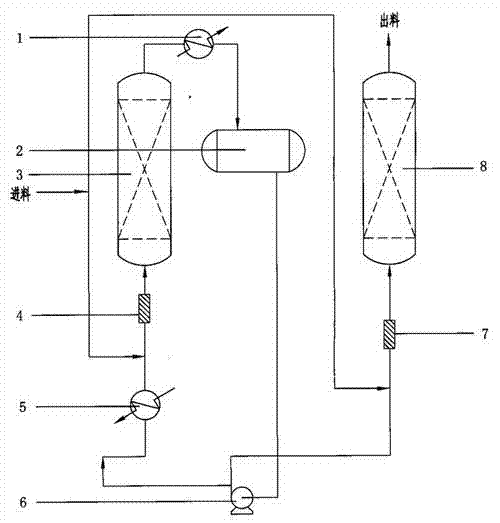

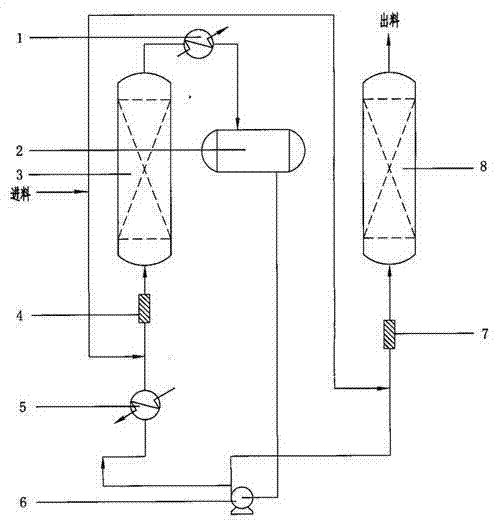

C4 two-stage hydrogenation device and process in catalytic thermal cracking to ethylene

InactiveCN102294203AControl temperature riseControl the content of butadieneChemical/physical processesHydrocarbon by hydrocarbon crackingRefluxCatalytic pyrolysis

A C4 two-stage hydrogenation device in catalytic thermal cracking to ethylene, which includes a hydrogenation reactor, a mixer and a feed heater, and its technical points are: the first-stage hydrogenation reactor and the second-stage hydrogenation reactor The inlet ends are connected to feed mixers, the outlet of the first-stage hydrogenation reactor is connected to the reflux tank through the discharge cooler, the outlet of the reflux tank is connected to the inlet of the reflux pump, and the outlet of the reflux pump is connected to the feed heater and the second-stage feed mixer in parallel. The material heater is connected to the first-stage feed mixer, and the C4 material feed pipe is connected in parallel on the pipeline between the feed heater and the first-stage feed mixer, and on the pipeline between the reflux pump and the second-stage feed mixer. The present invention adopts two-stage selective hydrogenation, which avoids serious coking in the first-stage reactor caused by deep hydrogenation of 1,3-butadiene, and reduces the operation cycle of the device and the service life of the catalyst. In addition, due to the stronger adaptability to raw materials, it is not necessary to separate light and heavy carbon four, and the mixed carbon four can be directly hydrogenated, which improves the utilization rate of raw materials.

Owner:SHENYANG PARAFFIN CHEM

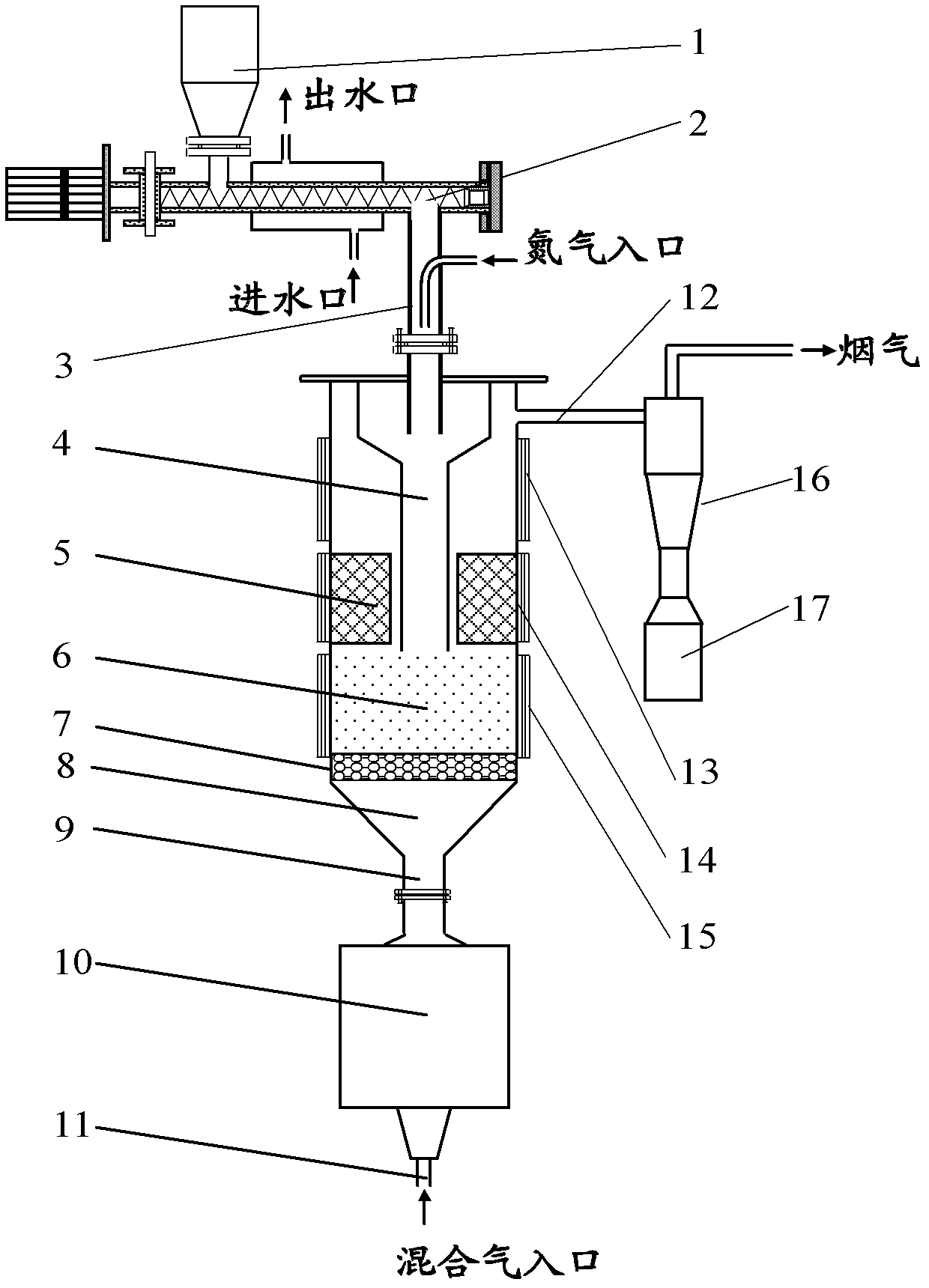

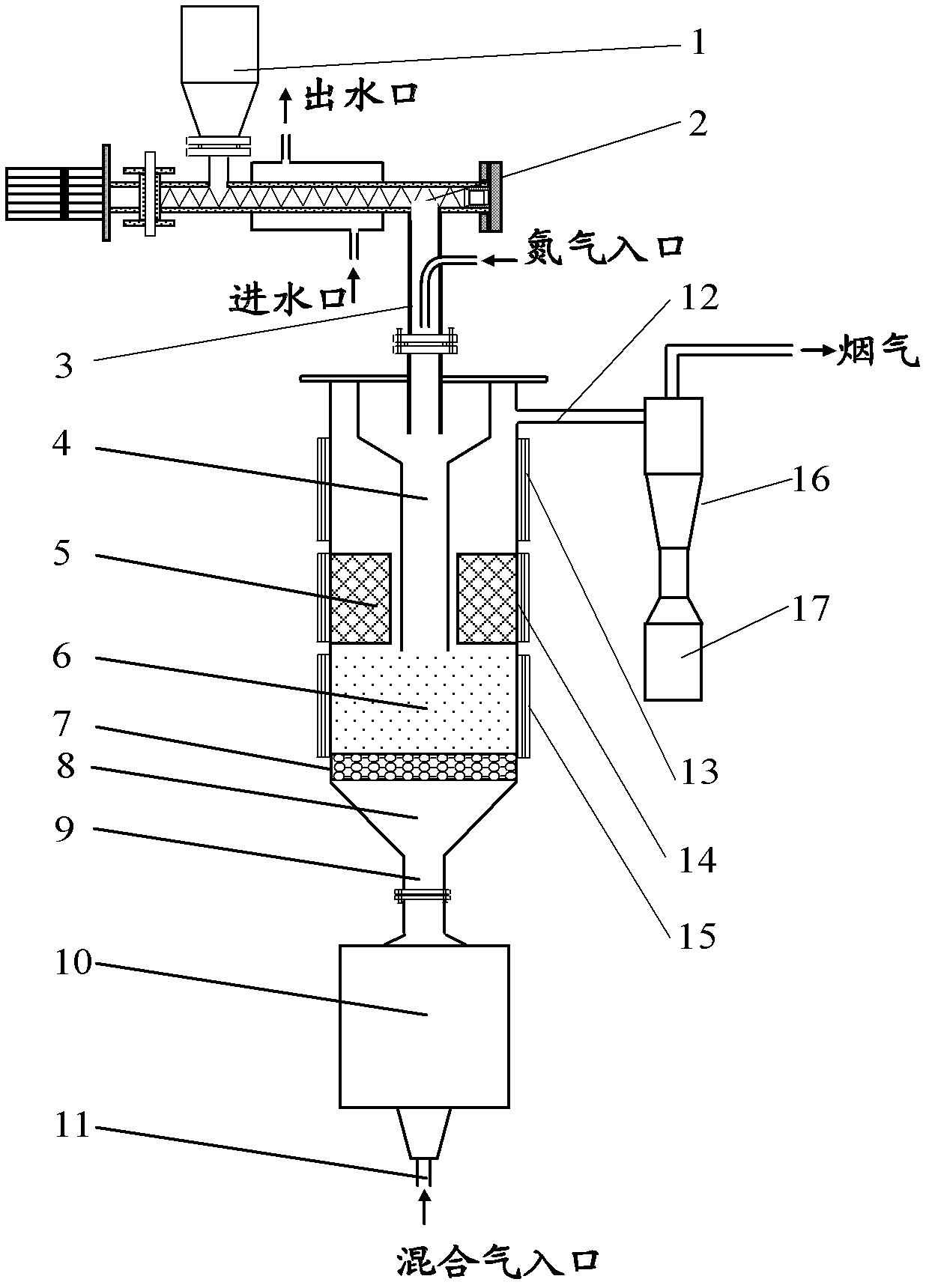

Three-stage gasification device for producing synthesis gas through biomass pyrolysis and gasification

ActiveCN102329651AReduce oxygen consumptionImprove gasification efficiencyChemical industryGranular/pulverulent flues gasificationCatalytic pyrolysisTemperature control

The invention provides a three-stage gasification device for producing synthesis gas through biomass pyrolysis and gasification. The three-stage gasification device is provided with a reacting furnace as a main body, the reacting furnace is in a cylindrical or square structure, an upper pyrolysis hearth inside the reacting furnace is a biomass pyrolysis reaction chamber, a lower gasification hearth is a pyrolysis product steam fluidization and gasification chamber, and a middle hearth of the reacting furnace is provided with an annular catalyst bed layer (a catalytic pyrolysis and gasification chamber). The upper pyrolysis hearth is provided with a feeding device and communicated with the lower gasification hearth. The bottom of the lower gasification hearth is provided with a mixed gas inlet. The upper end of the furnace body of the reaching furnace is provided with a smoke outlet connected with a cyclone separator. A temperature control device is respectively and correspondingly arranged at the outer side of the reacting furnace. An experiment system for the whole production process of synthesis gas is simplified, the gas yield of a gasification furnace is increased, the quality of the synthesis gas is improved, and the tar content in the produced gas is reduced. The device provided by the invention has the advantages of convenience in temperature control, energy saving, environment friendliness, continuation in running, simple structure and the like.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL +1

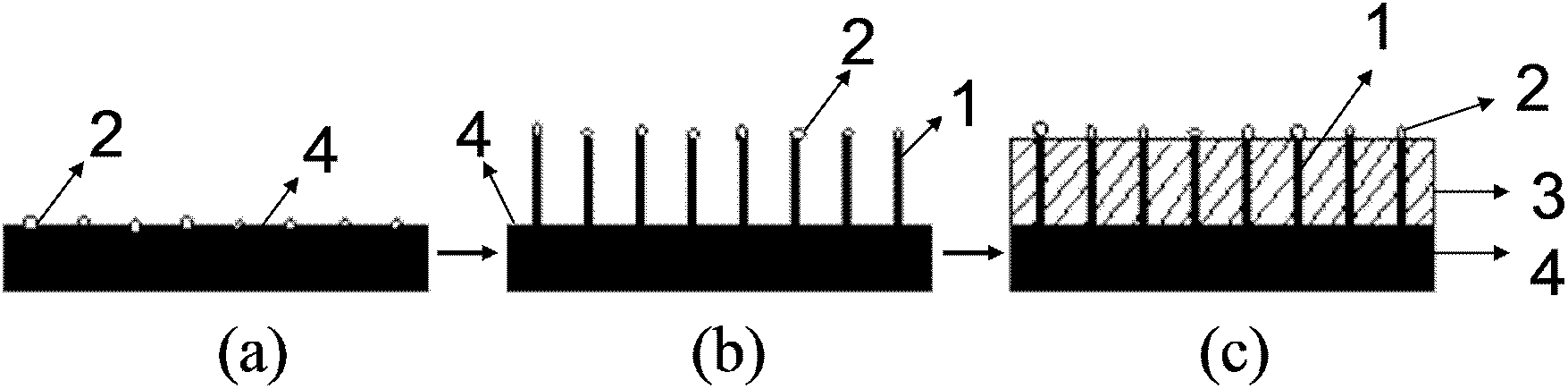

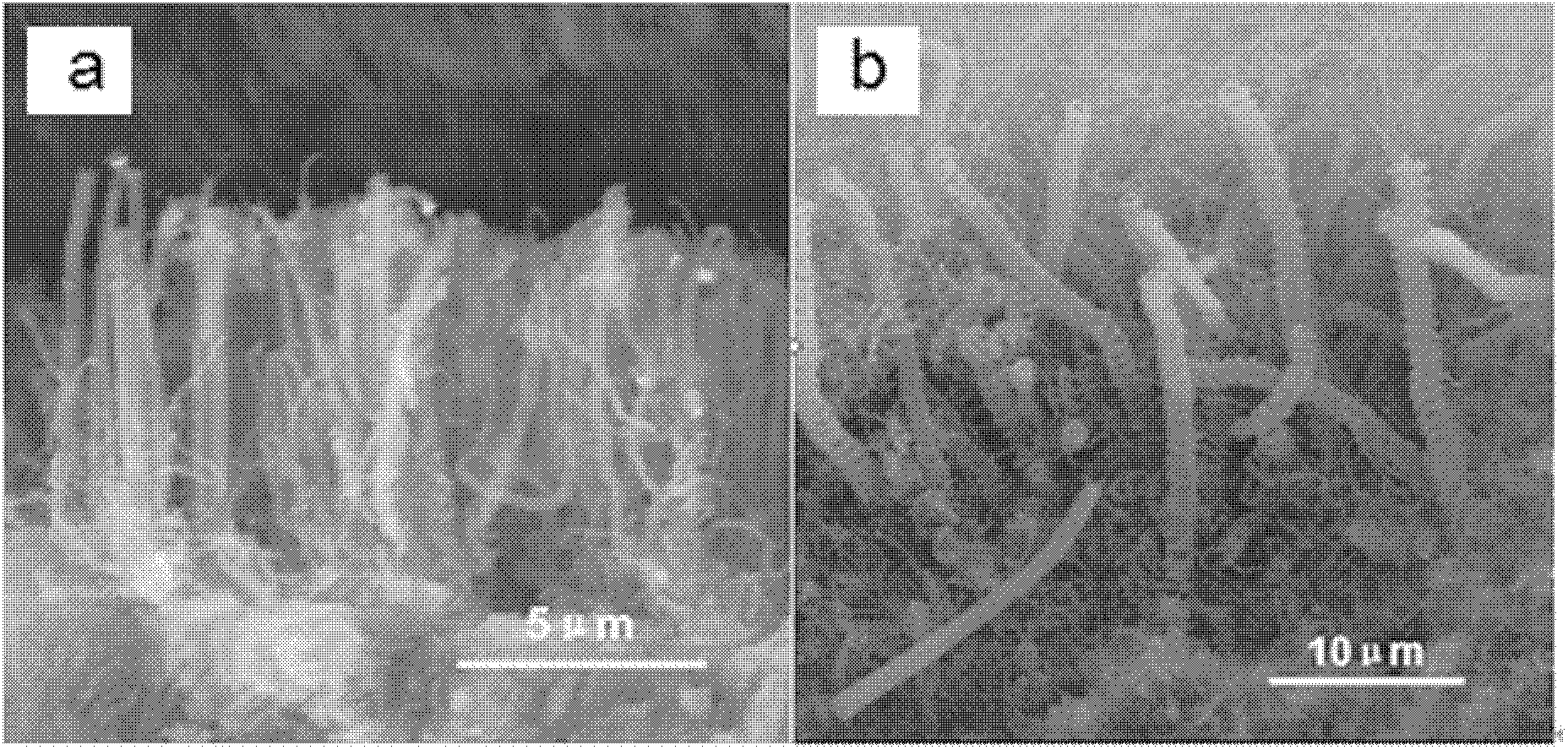

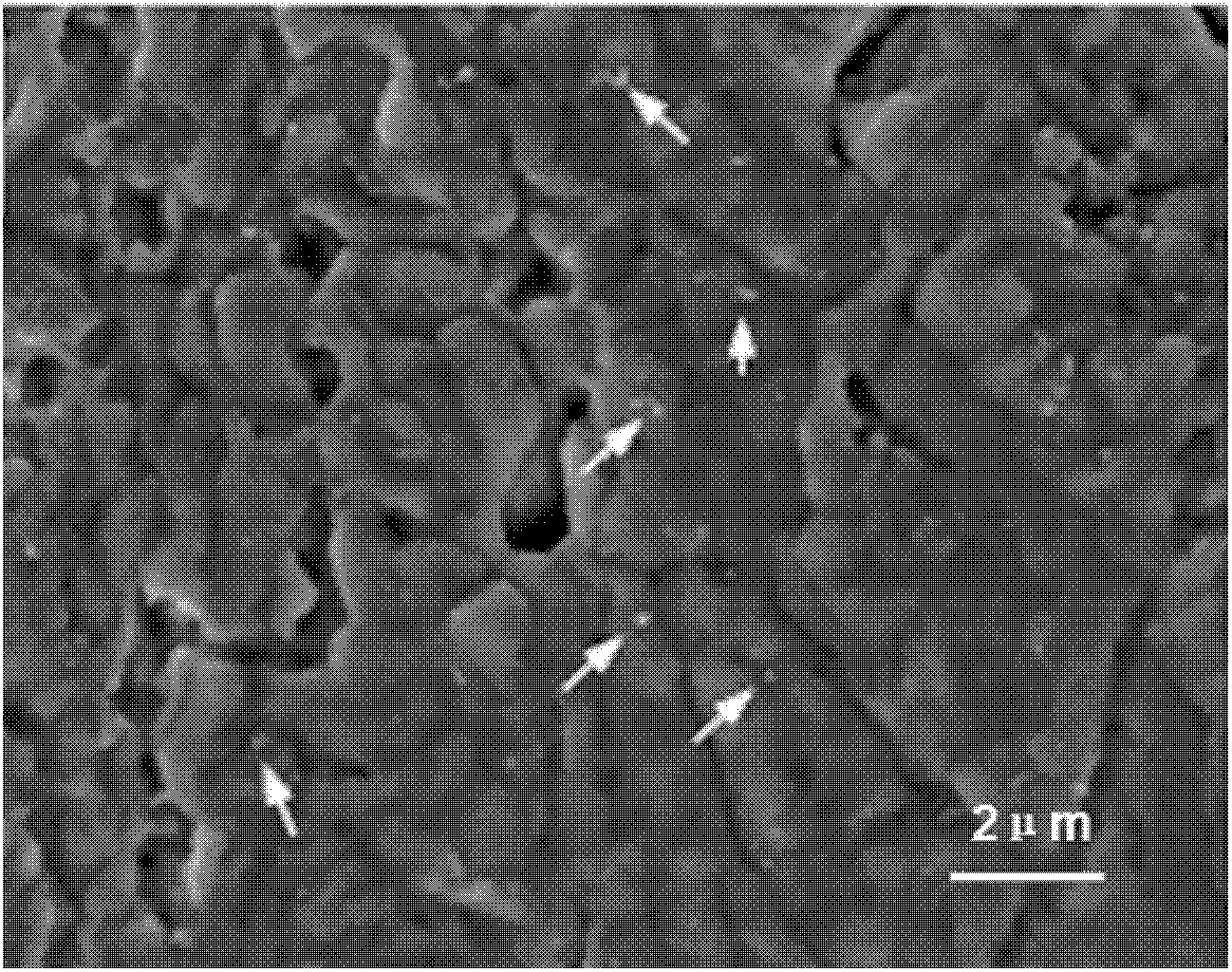

Method for preparing compound electrical contact material

InactiveCN102324335AConducive to play ballistic conduction characteristicsCost-effectiveContact materialsCatalytic pyrolysisCarbon nanotube

The invention discloses a method for preparing a compound electrical contact material. The technical process comprises the following steps of: (1) preparing a catalyst precursor, preparing a Ni-based catalyst from a mixed aqueous solution of hexahydrated nickel nitrate and hexahydrated yttrium nitrate, and depositing on a sample copper sheet which is subjected to plasma treatment and washed to obtain a catalyst precursor, wherein the mass ratio of nickel to yttrium is 1-10; (2) preparing a CNTs (Carbon Nanotube) array, putting the catalyst precursor into a quartz boat, undergoing a decomposition reaction under the protection of argon gas, and undergoing a catalytic pyrolysis reaction to obtain a sample copper sheet on which a CNTs array grows; and (3) preparing a CNTs-Ag-Cu compound electrical contact material, adding a silver nitrate aqueous solution into the sample copper sheet on which the CNTs array grows, soaking the silver nitrate aqueous solution into the CNTs array of the sampler copper sheet under the low ultrasonic action, evaporating and decomposing repeatedly for 3-20 times for 0.2-3 hours every time till the CNTs array is fully filled.

Owner:TIANJIN POLYTECHNIC UNIV

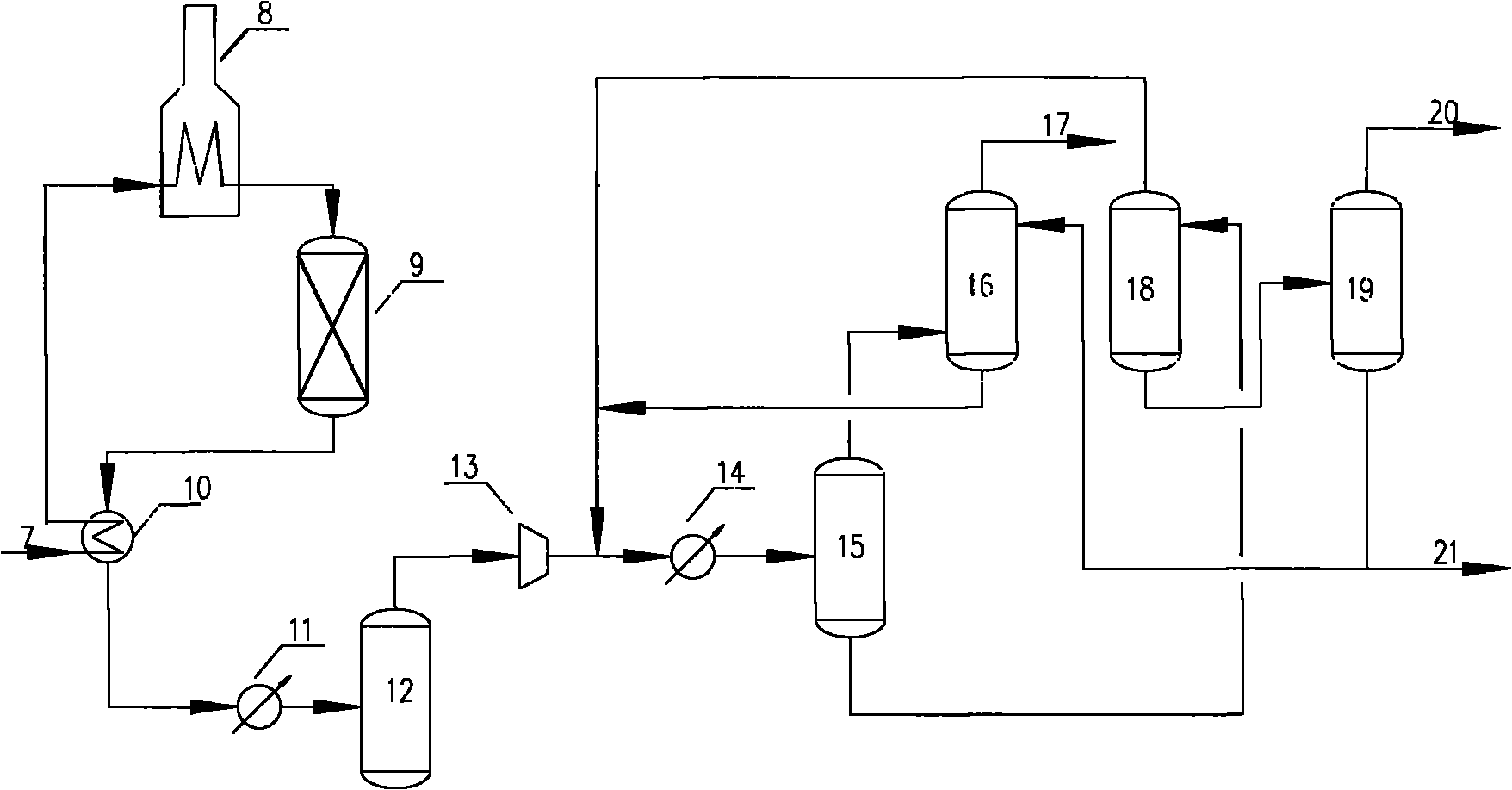

Method for producing light olefin by catalytic pyrolysis of petroleum hydrocarbon

ActiveCN101462916AGood choiceLow reaction temperatureHydrocarbon by hydrocarbon crackingCatalytic pyrolysisNaphtha

The invention relates to a method for producing low-carbon olefin by petroleum hydrocarbon catalytic pyrolysis; the method comprises: catalytic pyrolysis is carried out on the petroleum hydrocarbon; wherein, the method also comprises that the step that catalytic dehydrogenation is carried out on the petroleum hydrocarbon under the catalytic dehydrogenation condition and in the presence of catalytic dehydrogenation catalyst before the catalytic pyrolysis, and then the catalytic pyrolysis is carried out on the catalytic dehydrogenation product under the catalytic pyrolysis condition in the presence of catalytic pyrolysis catalyst. In the method, when the petroleum hydrocarbon is naphtha or light diesel oil, the needed reaction temperature of the conversion rate of the petroleum hydrocarbon and selectivity of the olefin is greatly reduced compared with the existing technique that the light olefin is prepared by the naphtha and light diesel oil through catalytic conversion, and the temperature is reduced to 550-650 DEG C from 750-850 DEG C in the prior art, thus greatly saving energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

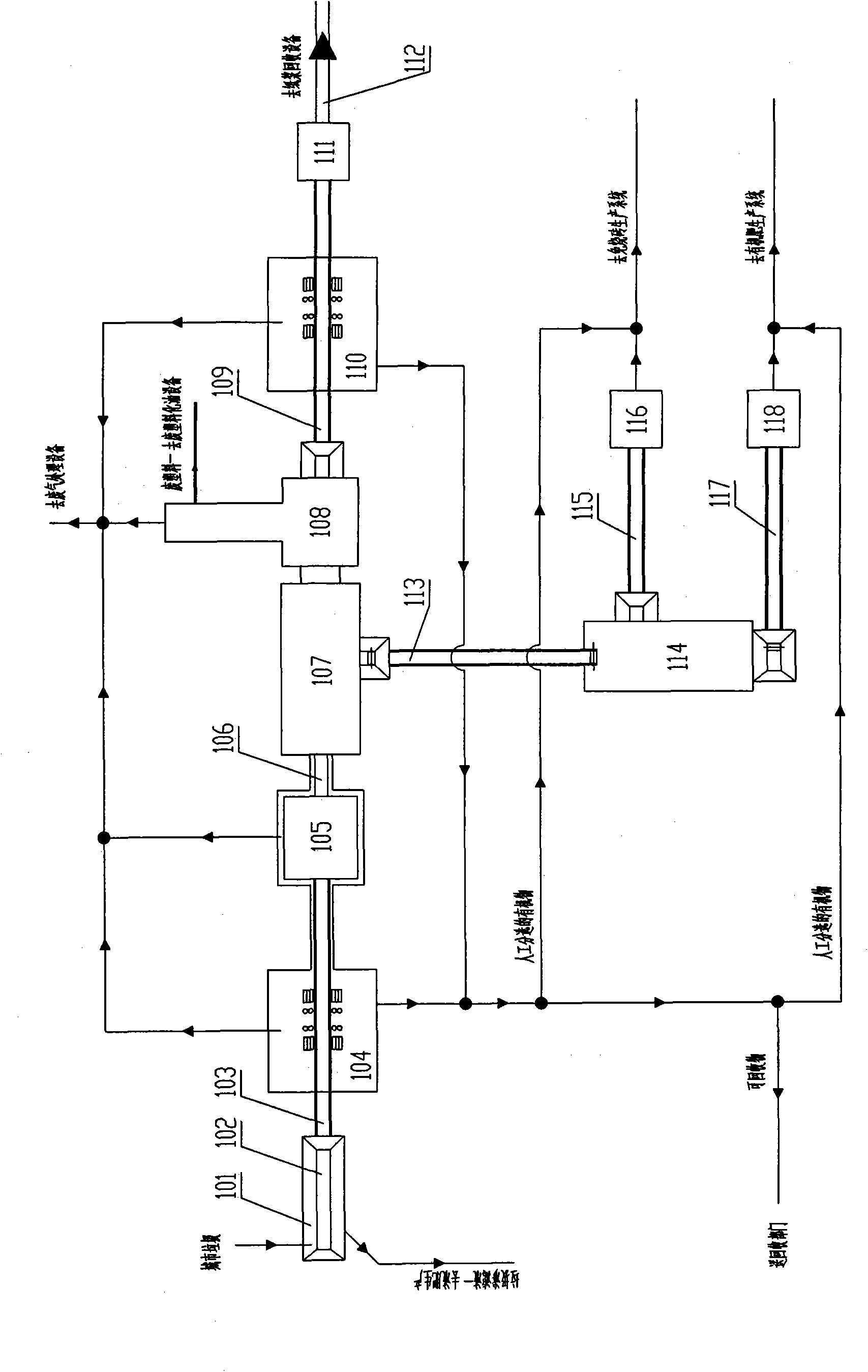

Resource recycling system of discarded papers, plastics or composite materials thereof

InactiveCN101947538AAchieve harmonyAchieve sustainable developmentSolid waste disposalCatalytic pyrolysisSlag

The invention discloses a resource recycling system of discarded papers, plastics or composite materials thereof. The discarded papers, plastics or composite materials thereof are subjected to manual sorting to remove impurities; muddy sand is removed through crushing and cleaning; high-quality paper pulp is recycled by using a powerful water power pulping method; the pulped remained waste plastics are dried and subjected to low-temperature catalytic pyrolysis and cooling to manufacture precious fuel oil; and the cracked residual slag including active carbon powder, aluminum crumbs and the like is subjected to high-temperature baking to recycle nonferrous metal aluminum, so as to realize total resource recycling utilization of the discarded papers, plastics or composite materials thereof. Processes, such as sewage treatment, waste gas treatment and the like in the system, can ensure that harmful pollutants of waste materials are not discharged in the recycling treatment process so as not to bring hazard to the environment. The resource recycling utilization of the discarded papers, plastics or composite materials thereof is beneficial to the realizing of harmonious human and environment and sustainable development of human society.

Owner:朱海生 +1

Pyrolysis and gasification device and technology

ActiveCN104789245AImprove qualityImprove oil yieldDirect heating destructive distillationBiofuelsCatalytic pyrolysisSocial benefits

The invention discloses a pyrolysis and gasification device and technology. The device comprises three main reactors, namely, an uplink bed oxidation combustor, a downlink bed rapid pyrolyzer and a bubbling bed gasifier. Feed coal or a mixture of coal and biomass is added from the upper part of the pyrolyzer, is rapidly heated by high-temperature circulating semicoke from the combustor and has a catalytic pyrolysis reaction, and semicoke, tar and gas are produced; through rapid separation, fresh semicoke produced in the pyrolyzer and the high-temperature circulating semicoke are sent into the gasifier to have a gasification reaction with a gasification agent; the semicoke which is not gasified is continuously sent into the combustor to be partially oxidized and combusted under the action of oxygen, so that a large quantity of high-temperature circulating semicoke is obtained. The device and the technology have the advantages that a combustion-pyrolysis-gasification process in graded utilization of raw materials is coupled, co-production of high-quality tar, gas and synthesis gas is realized by the aid of the catalytic activity and the heat-carrying capability of the semicoke, and the economic benefit and the social benefit are high.

Owner:TAIYUAN UNIV OF TECH

Process of preparing rich furol biological oil by biomass microwave catalytic pyrolysis

InactiveCN100999677AHighly selective generationImprove use valueLiquid hydrocarbon mixture productionLiquid productCatalytic pyrolysis

The microwave catalytic biomass cracking process for preparing biological oil with rich furfural features using ferric sulfate as catalyst, silicon carbide as microwave absorbing medium, microwave source as heat source for cracking biomass, and ice water mixture for cooling volatile component to obtain biological oil with rich furfural. The present invention can obtain liquid product with furfural content of 35-55 % and raise the utilization value of furfural greatly. The present invention uses solid ferric sulfate catalyst and is superior to acid hydrolysis process with corrosion and pollution problems.

Owner:ANHUI UNIV OF SCI & TECH

Method for preparing bio-oil by catalytic pyrolysis of microalgae with high fat content by molecular sieve

InactiveCN101514295AImprove fat contentHigh yieldCatalytic crackingLiquid hydrocarbon mixture productionCatalytic pyrolysisMolecular sieve

In a method for preparing bio-oil by catalytic pyrolysis of microalgae with high fat content by a molecular sieve, HZSM-5, MCM-48 or HY molecular sieve is taken as a catalyst, and the catalytic pyrolysis of the microalgae with high fat content is realized in a down-flow fixed bed reactor. Compared with lignocellulose biomass, the temperature for the catalytic pyrolysis of the microalgae with highfat content is lower, and the yield and the quality of the obtained bio-oil are higher, thereby being very conductive to energy-saving and high efficient production of the bio-oil; furthermore, the composition of the bio-oil can be changed by changing the catalyst, thereby meeting the different market demands and having great market application prospect.

Owner:SICHUAN UNIV

Catalytic conversion method for preparing light olefins and aromatic hydrocarbons from biological oil

ActiveCN101423451AImprove conversion abilityHigh yieldOrganic chemistryLiquid hydrocarbon mixture productionCatalytic pyrolysisAromatic hydrocarbon

The invention discloses a catalytic conversion method for preparing low carbon olefin and aromatic hydrocarbon from biological grease. A biological grease raw material contacts a catalyst containing modified beta zeolite in a composite reactor for a catalytic pyrolysis reaction, then a reaction product is separated from a spent catalyst, the separated spent catalyst is subject to steam stripping and coke-burning regeneration and then returns to the reactor for circulating use, and the separated reaction product is fractionized and separated to obtain target products, namely the low carbon olefin and the aromatic hydrocarbon. The method adopts the modified beta zeolite and zeolite with an MFI structure as the catalyst of necessary active compositions, and converts the biological grease into the low carbon olefin and the aromatic hydrocarbon in the same device in a high selectivity mode.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for catalytic cracking mixed waste plastic and preparation method thereof

InactiveCN101284235AGood technical effectVersatilityMolecular sieve catalystsLiquid hydrocarbon mixture productionCatalytic pyrolysisCatalytic reforming

The invention discloses a catalyst for manufacturing fuel oil through catalytic pyrolysis of mixed-waste plastics, and a preparation method thereof, and relates to catalytic thermal cracking for manufacturing the fuel oil through waste plastic cracking and a second stage catalyst in thermal cracking catalytic reforming. A first stage catalyst comprises a metallic oxide of 2.0wt percent to 30.0wt percent and carclazyte or montmorillonite of 70.0wt percent to 98.0wt percent; the first stage catalyst is innoxious and cheap, increases the reaction velocity of plastic cracking, reduces the temperature in the scission reaction, improves the selectivity of decomposition products, and is dechlorinated and transformed into innocuous substances. The second stage catalyst is composed of ferric oxide, molybdenum oxide, zinc oxide, cerium oxide, lanthana, nickel oxide or copper oxide, and ZSM-5, MCM-22, USY, REY, Beta or MOR molecular sieves; the second stage catalyst performs the second catalytic pyrolysis and isomerization and the aromatization reversion reactions on pyrolysis gas in the first stage, to increase the distillate rate of pyrolysis gasoline and gas oil. The catalyst and the preparation method thereof have good selectivity, and the raw material does not need classification, washing and drying; the operation is flexible, and the running cost is low; the method is particularly applied to the fuel oil manufacture through the cracking of the mixed-waste plastics in the urban and rural domestic refuse, the composition is complicated; the oil yield of the qualified fuel oil can reach up to more than 70 percent calculated on the basis of the waste plastic.

Owner:TONGJI UNIV

Method for preparing carbon nanometer tubes through waste plastic catalytic pyrolysis by two-section process

The invention discloses a method for preparing carbon nanometer tubes through waste plastic catalytic pyrolysis by a two-section process, and belongs to the technical field of carbon nanometer tubes.The method is characterized in that thermolysis gas is generated in an upper layer thermolysis furnace through thermolysis reaction of waste plastics; the thermolysis gas enters a catalytic reaction furnace containing catalysts arranged at the lower layer and is decomposed to form hydrogen gas and the carbon nanometer tubes; the carbon nanometer tubes uniformly grow on the surface of the catalysts; the acting force between the carbon nanometer tubes and the catalysts is weak; the separation is convenient. The preparation method is simple; the obtained carbon nanometer tubes are in hollow fibershapes; the shapes are good.

Owner:武汉光谷环保科技股份有限公司 +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com