Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

14032 results about "Propene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Propene, also known as propylene or methyl ethylene, is an unsaturated organic compound having the chemical formula C₃H₆. It has one double bond, and is the second simplest member of the alkene class of hydrocarbons. It is a colorless gas with a faint petroleum-like odor

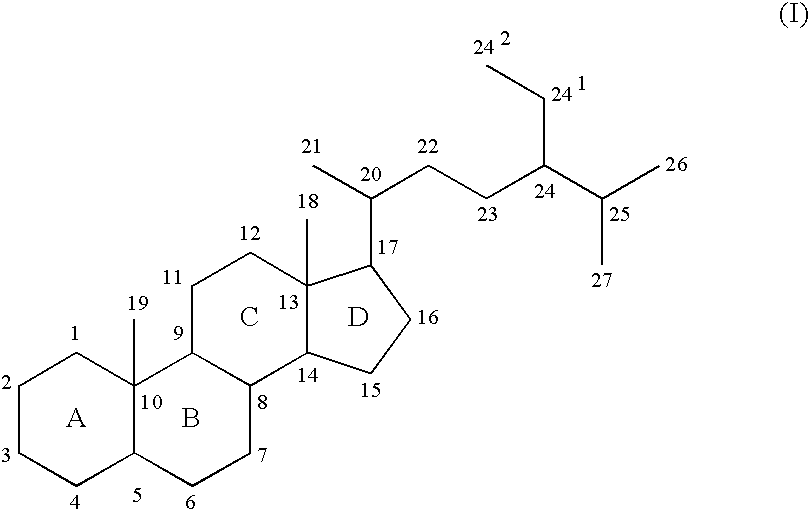

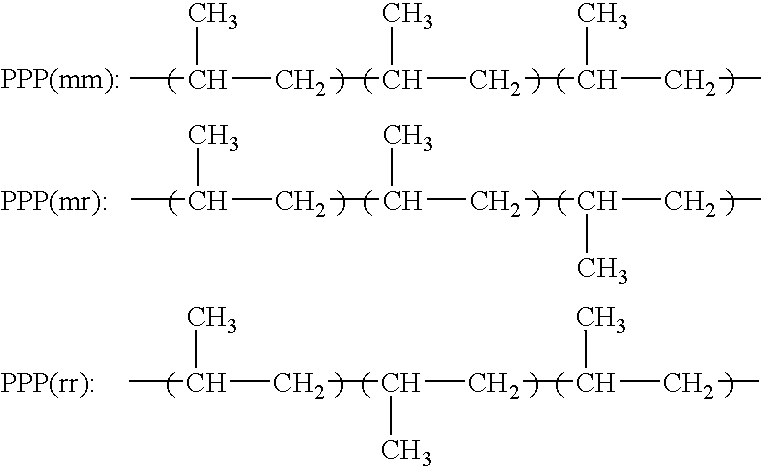

Isotactic propylene copolymers, their preparation and use

InactiveUS6960635B2Group 4/14 element organic compoundsOther chemical processesFiberZiegler–Natta catalyst

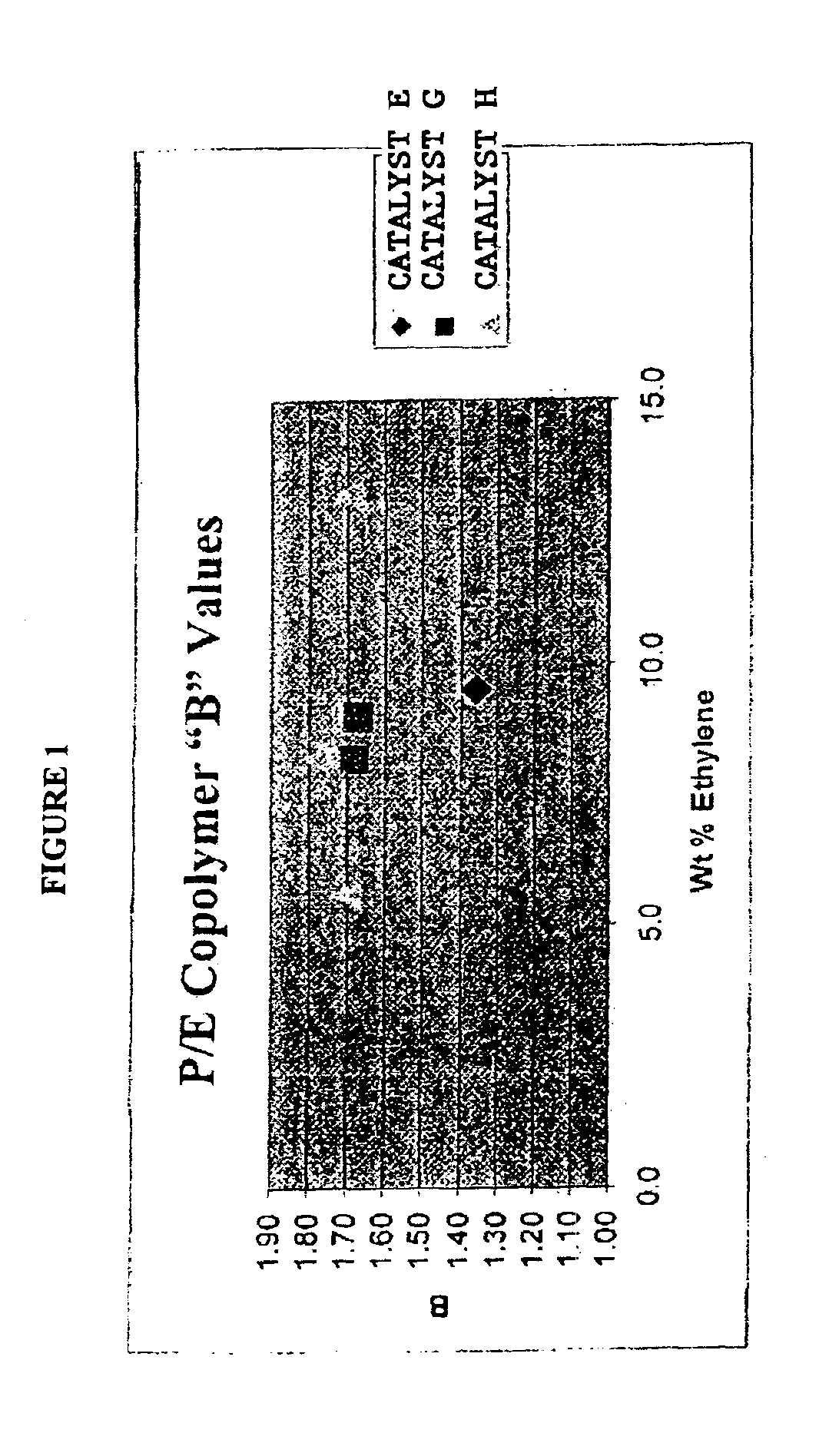

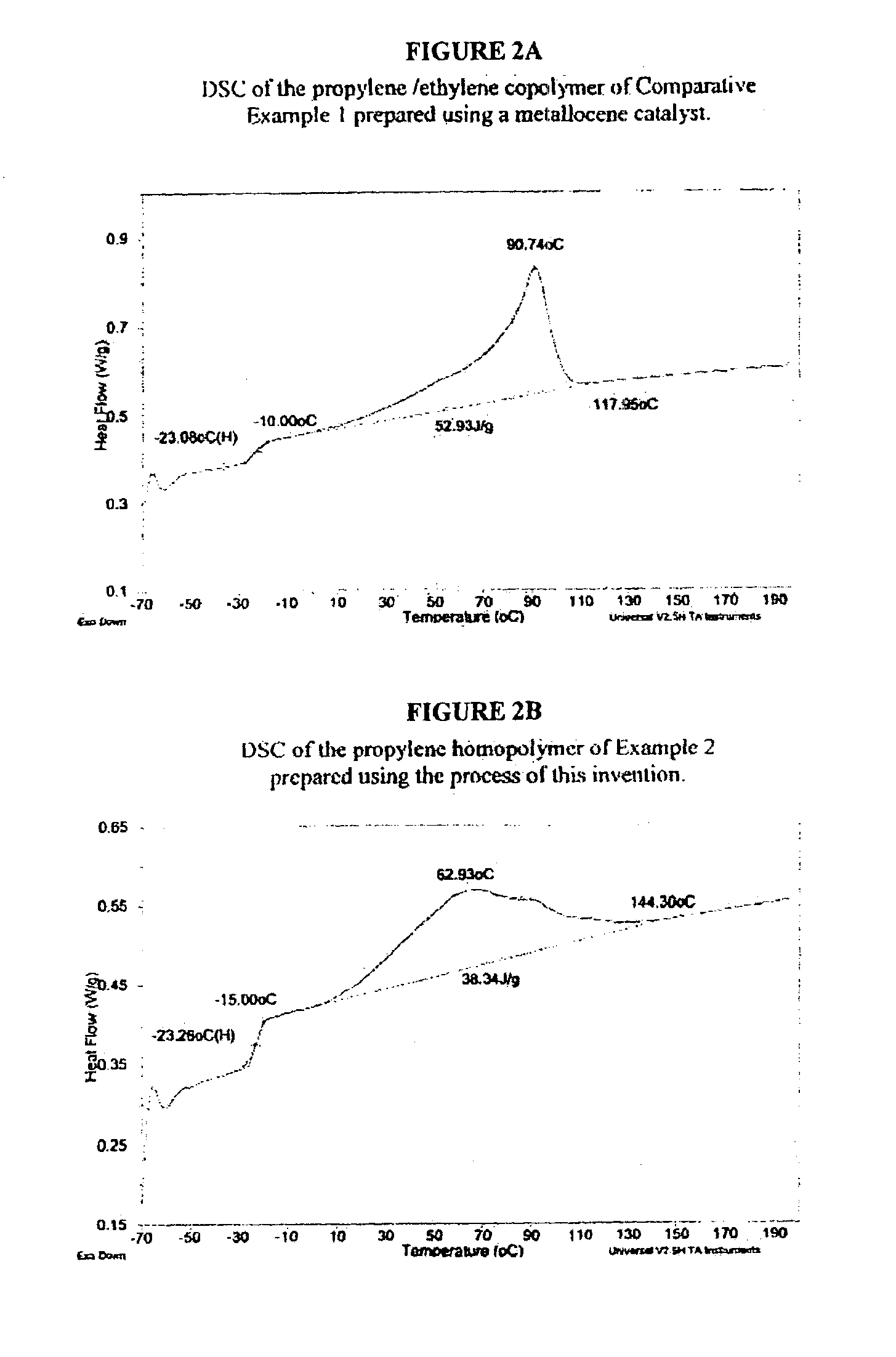

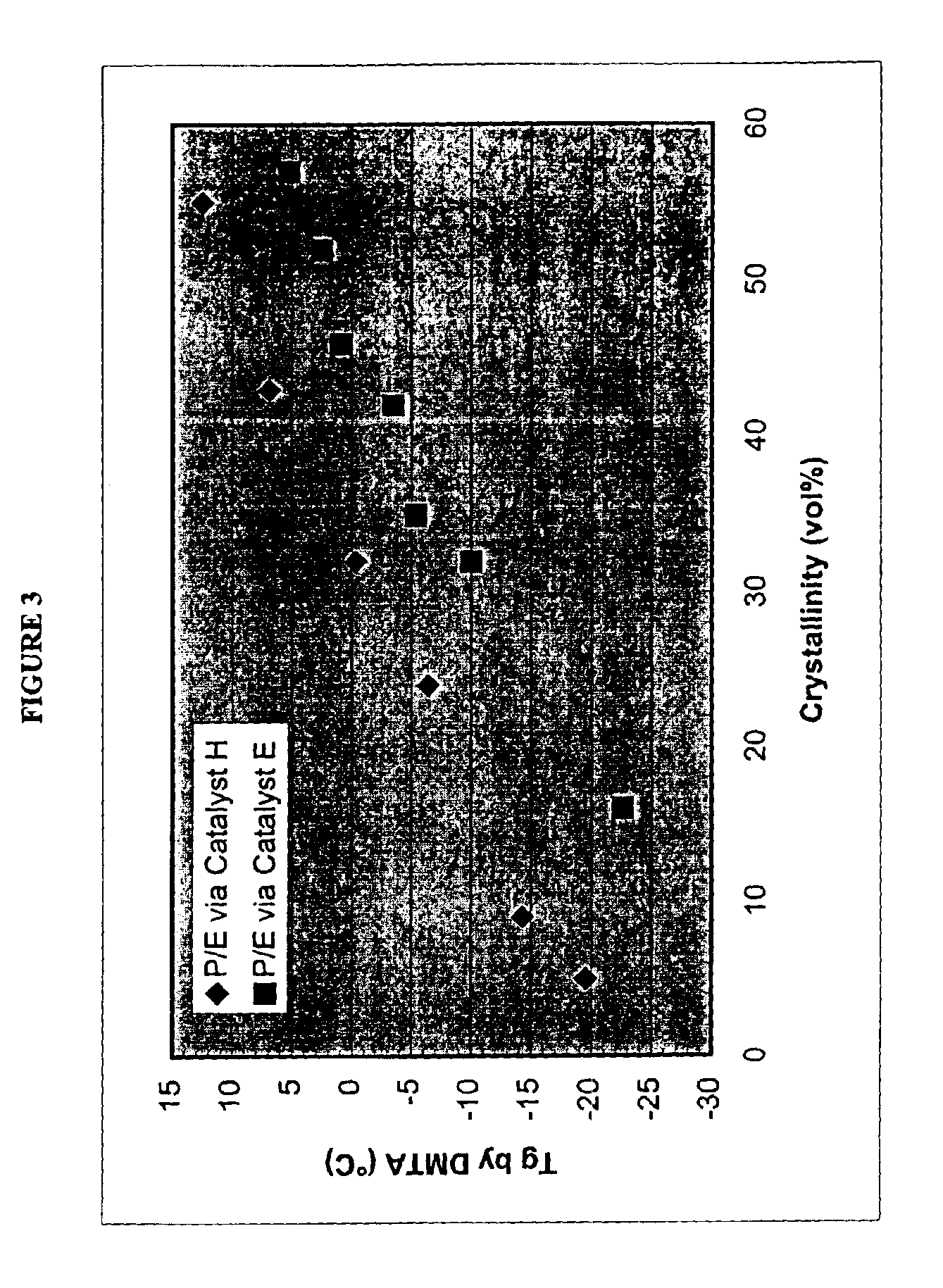

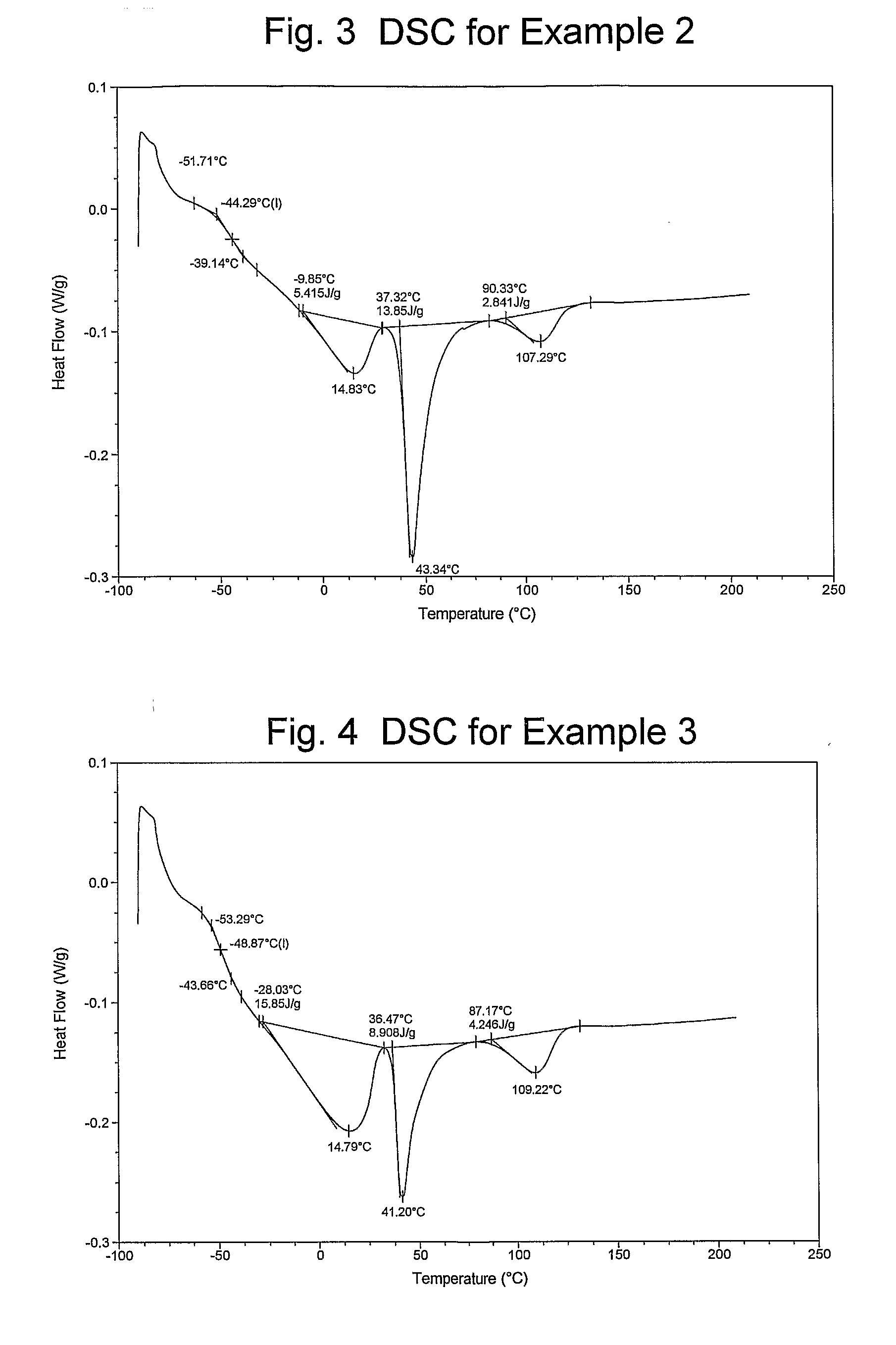

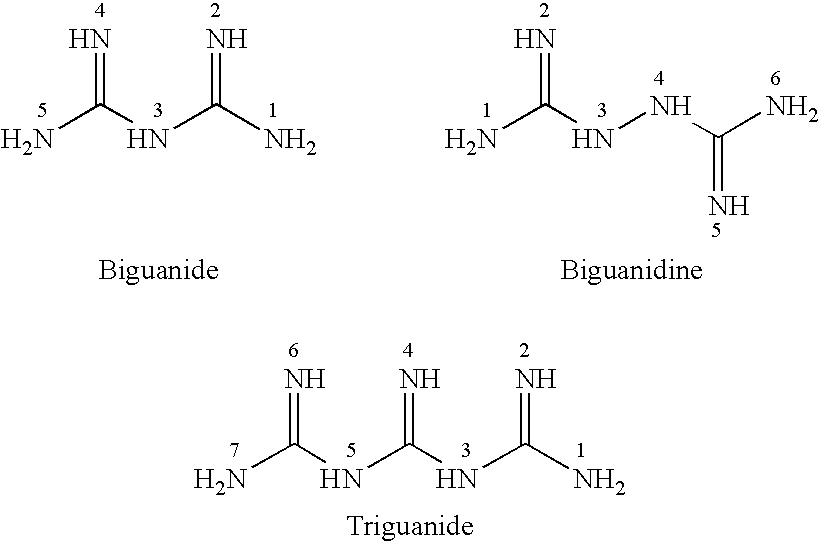

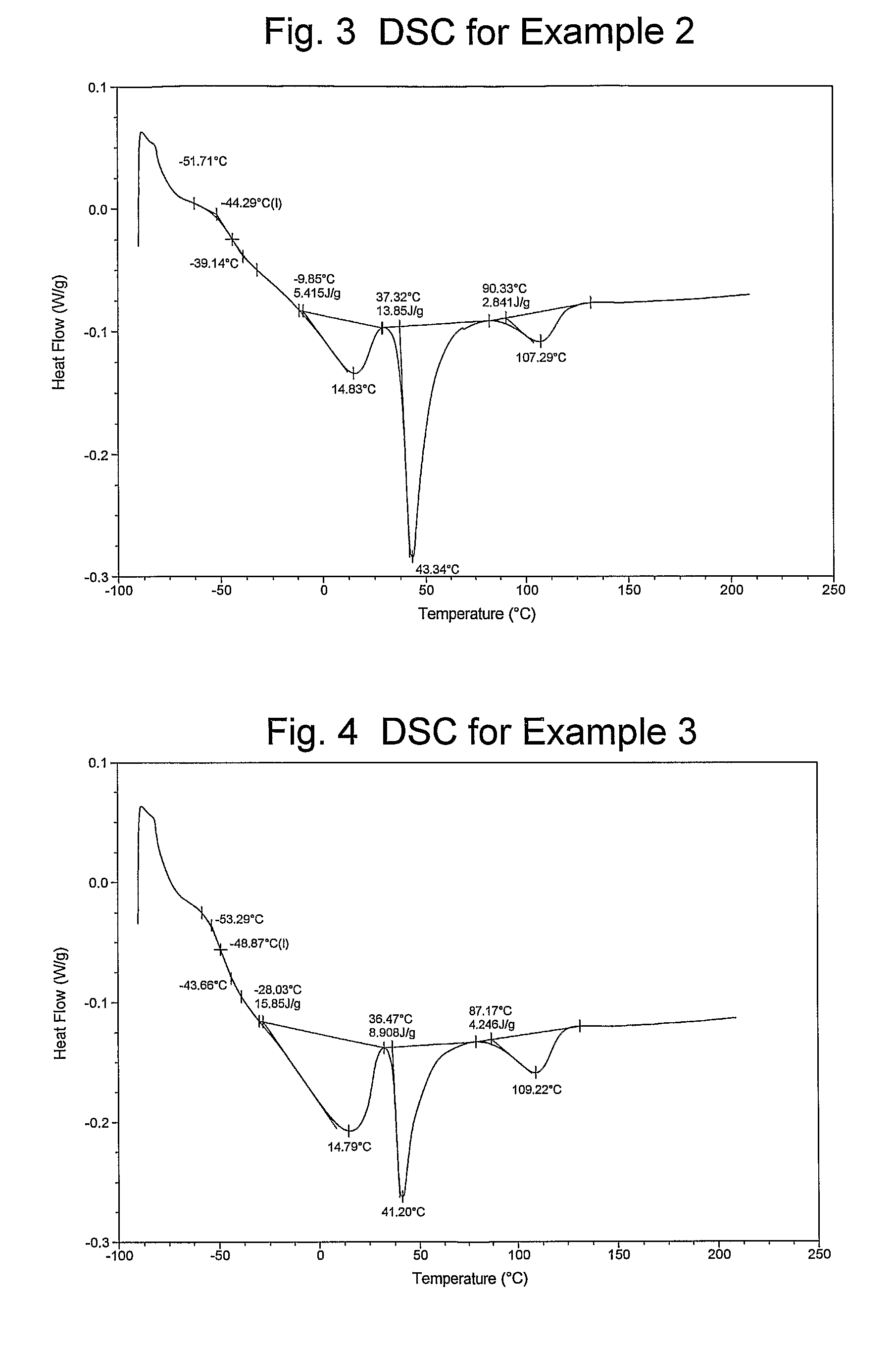

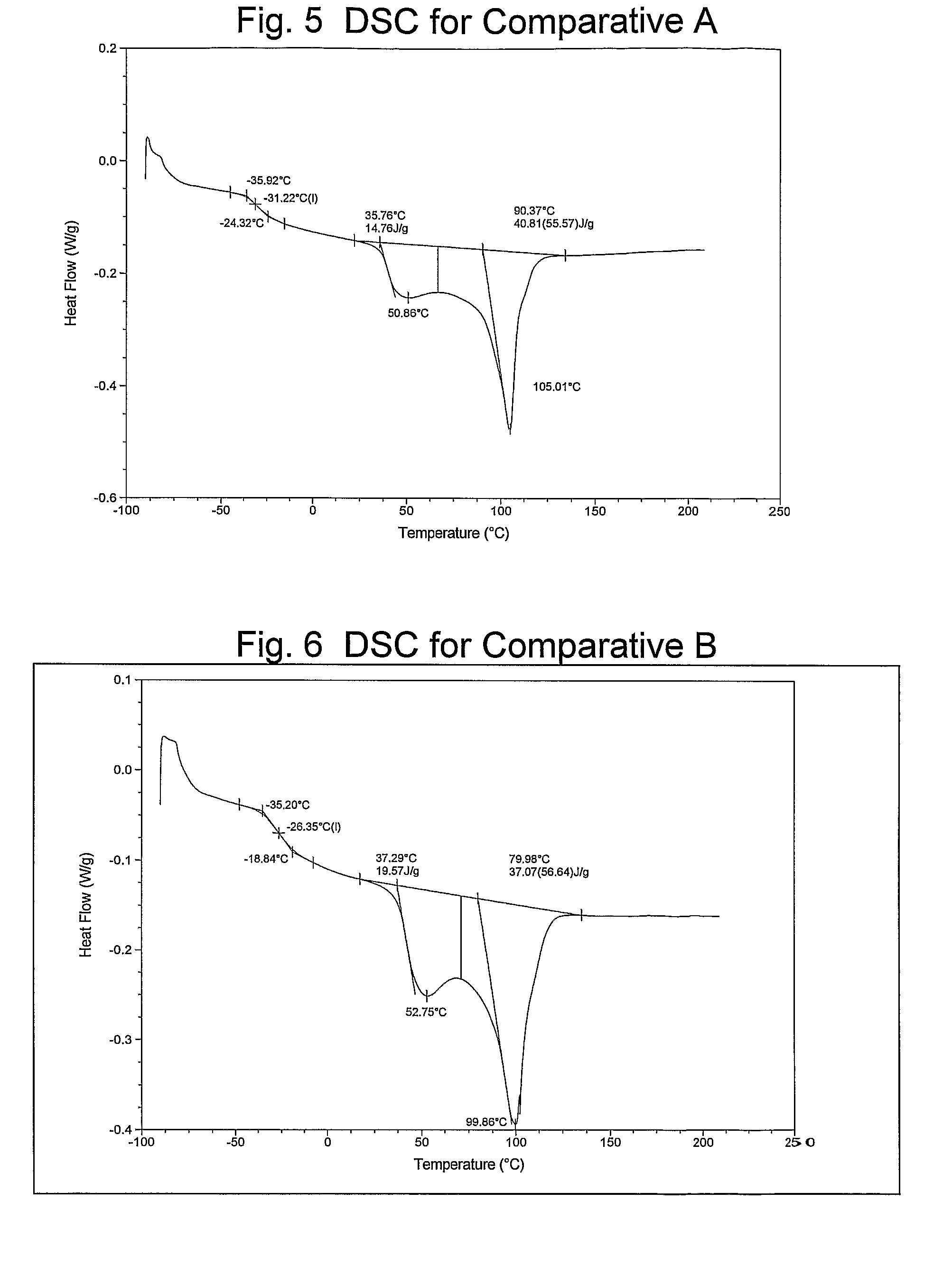

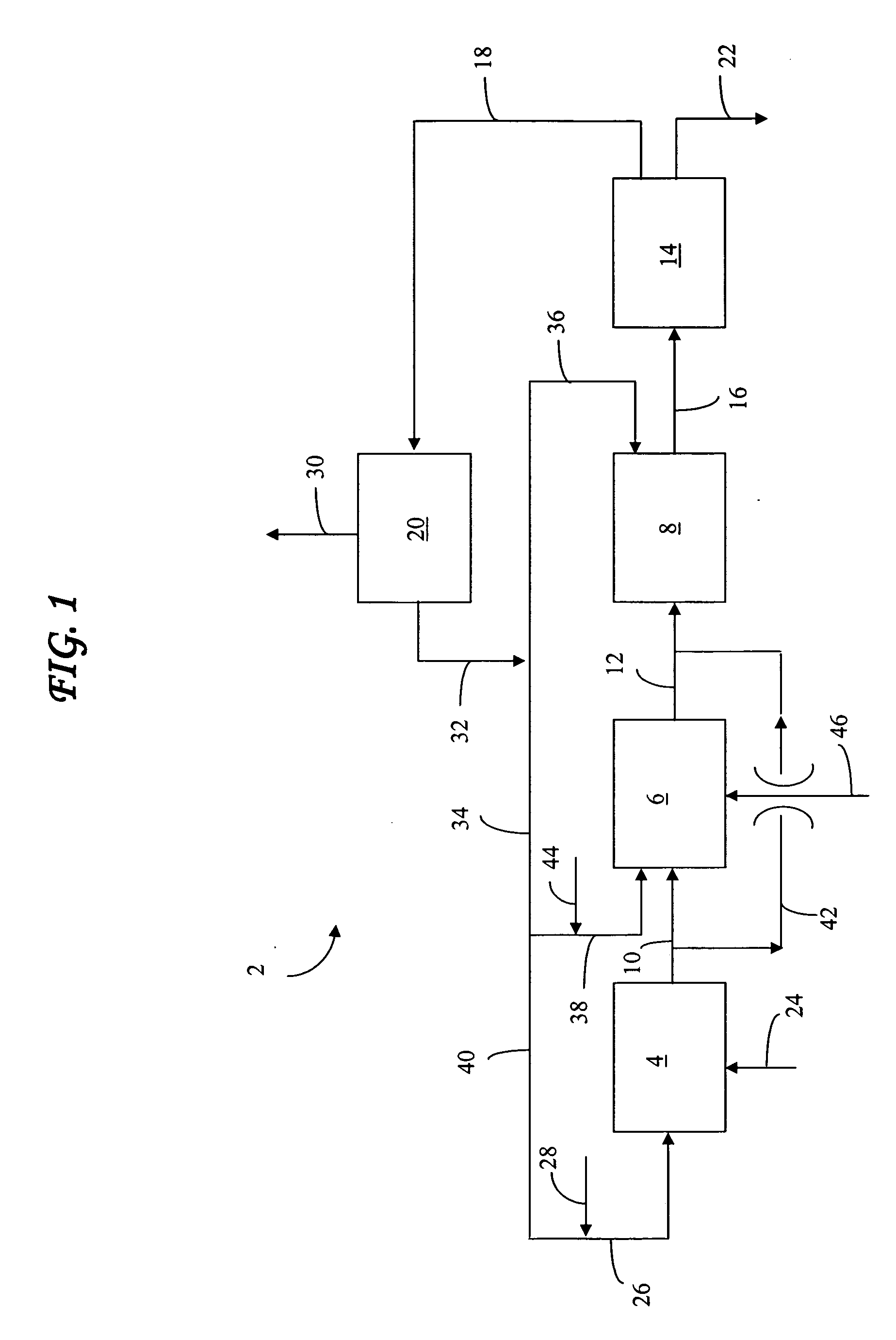

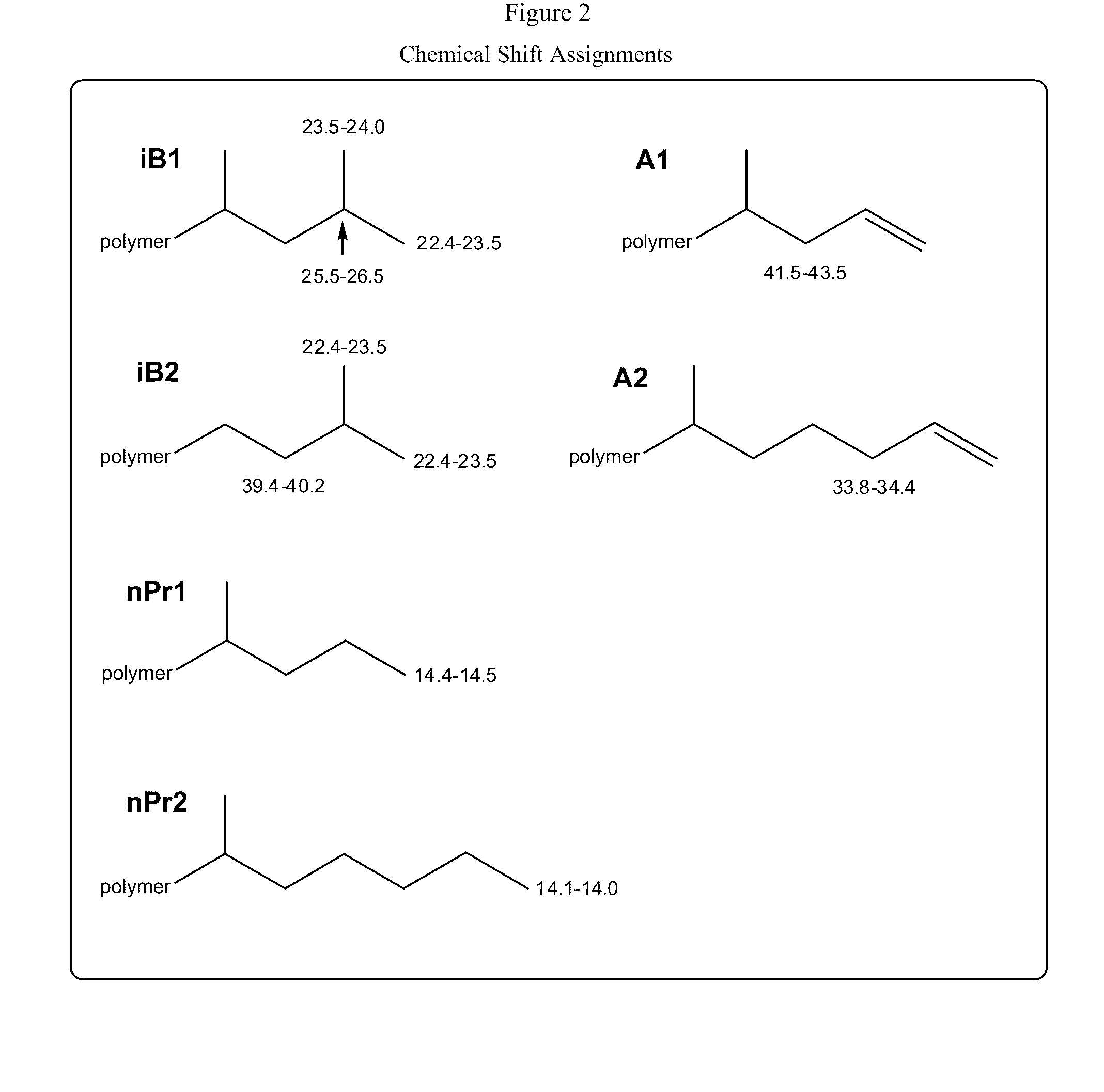

Unique copolymers comprising propylene, ethylene and / or one or more unsaturated comonomers are characterized as having: at least one, preferably more than one, of the following properties: (i) 13C NMR peaks corresponding to a regio-error at about 14.6 and about 15.7 ppm, the peaks of about equal intensity, (ii) a B-value greater than about 1.4 when the comonomer content of the copolymer is at least about 3 wt %, (iii) a skewness index, Six, greater than about −1.20, (iv) a DSC curve with a Tme that remains essentially the same and a Tmax that decreases as the amount of comonomer in the copolymer is increased, and (v) an X-ray diffraction pattern that reports more gamma-form crystals than a comparable copolymer prepared with a Ziegler-Natta catalyst. These polypropylene polymers are made using a nonmetallocene, metal-centered, heteroaryl ligand catalyst. These polymers can be blended with other polymers, and are useful in the manufacture of films, sheets, foams, fibers and molded articles.

Owner:DOW GLOBAL TECH LLC

Catalyst Composition Comprising Shuttling Agent for Higher Olefin Multi-Block Copolymer Formation

ActiveUS20080311812A1Improve efficiencyHigh monomer conversion rateWoven fabricsNon-woven fabrics4-Methyl-1-penteneOlefin polymerization

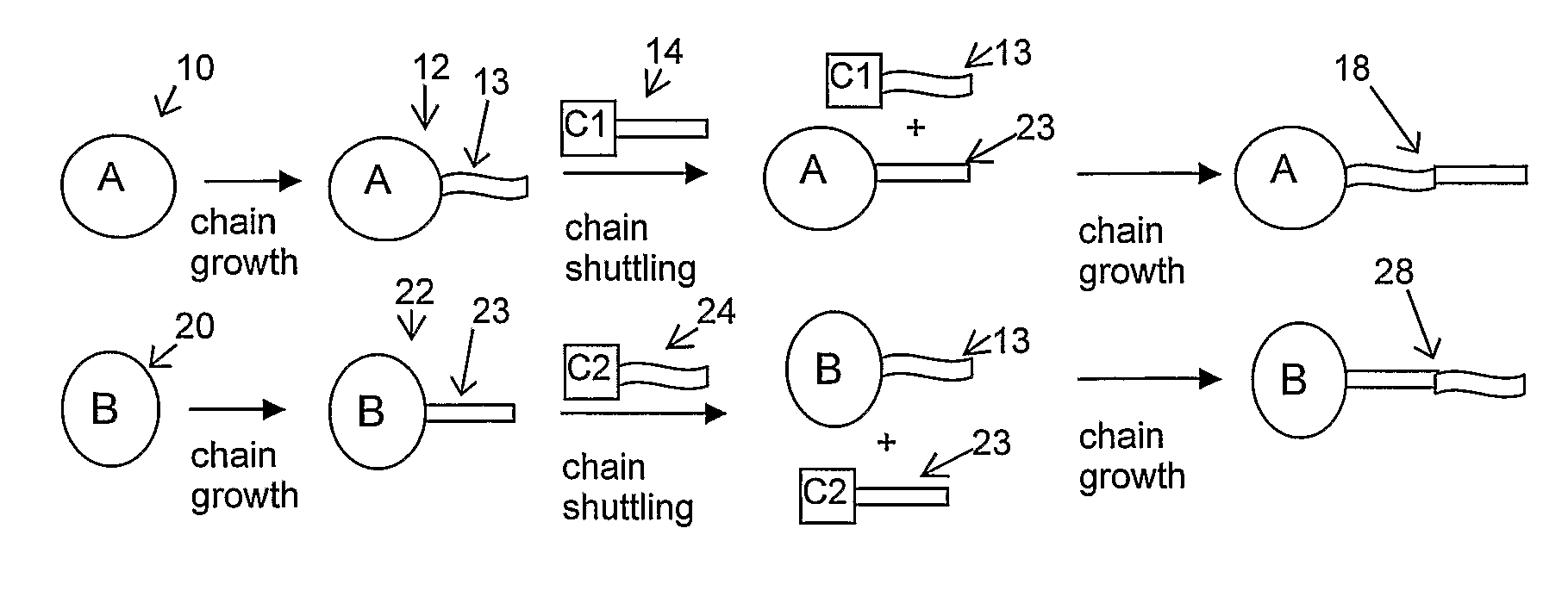

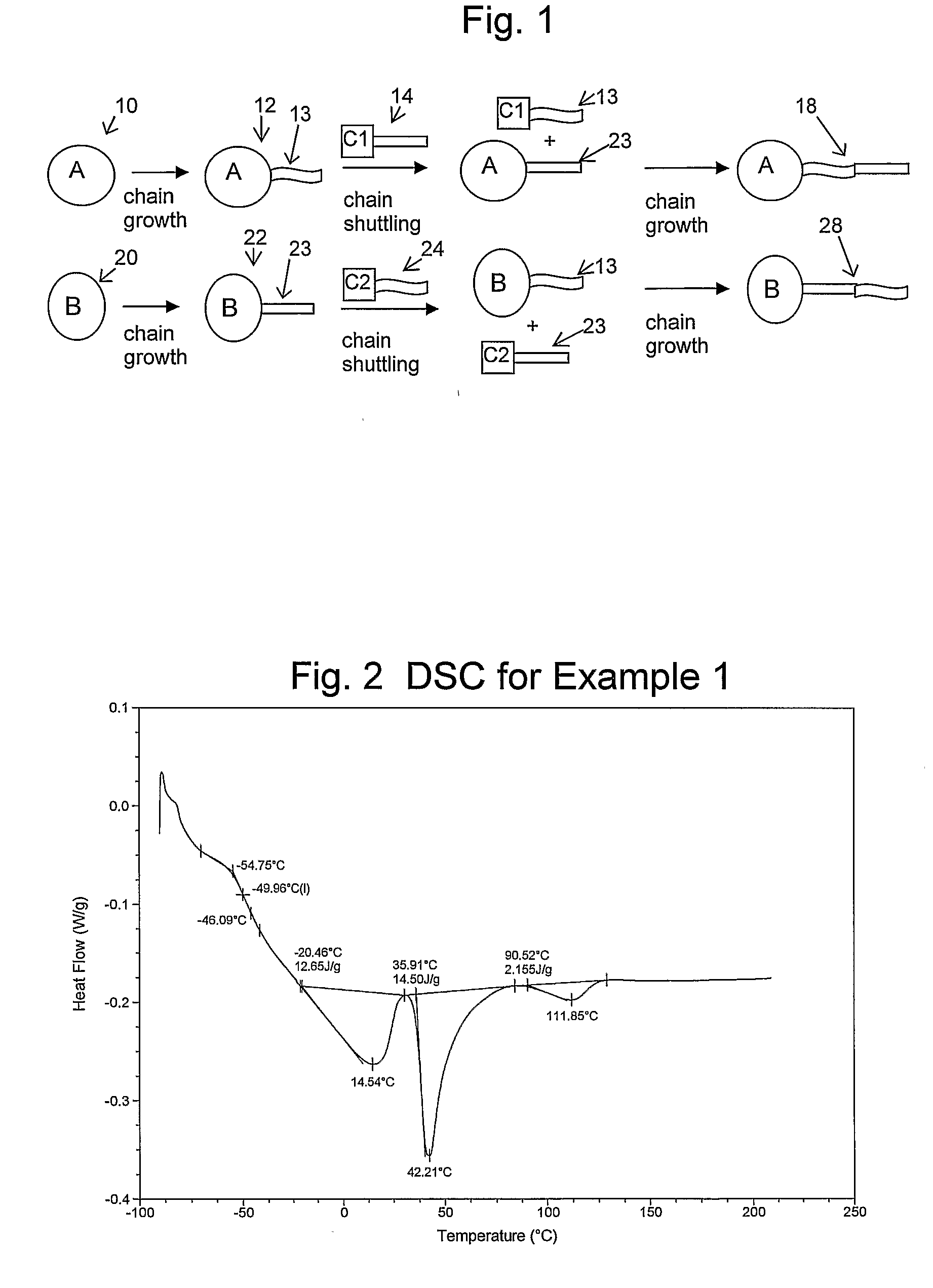

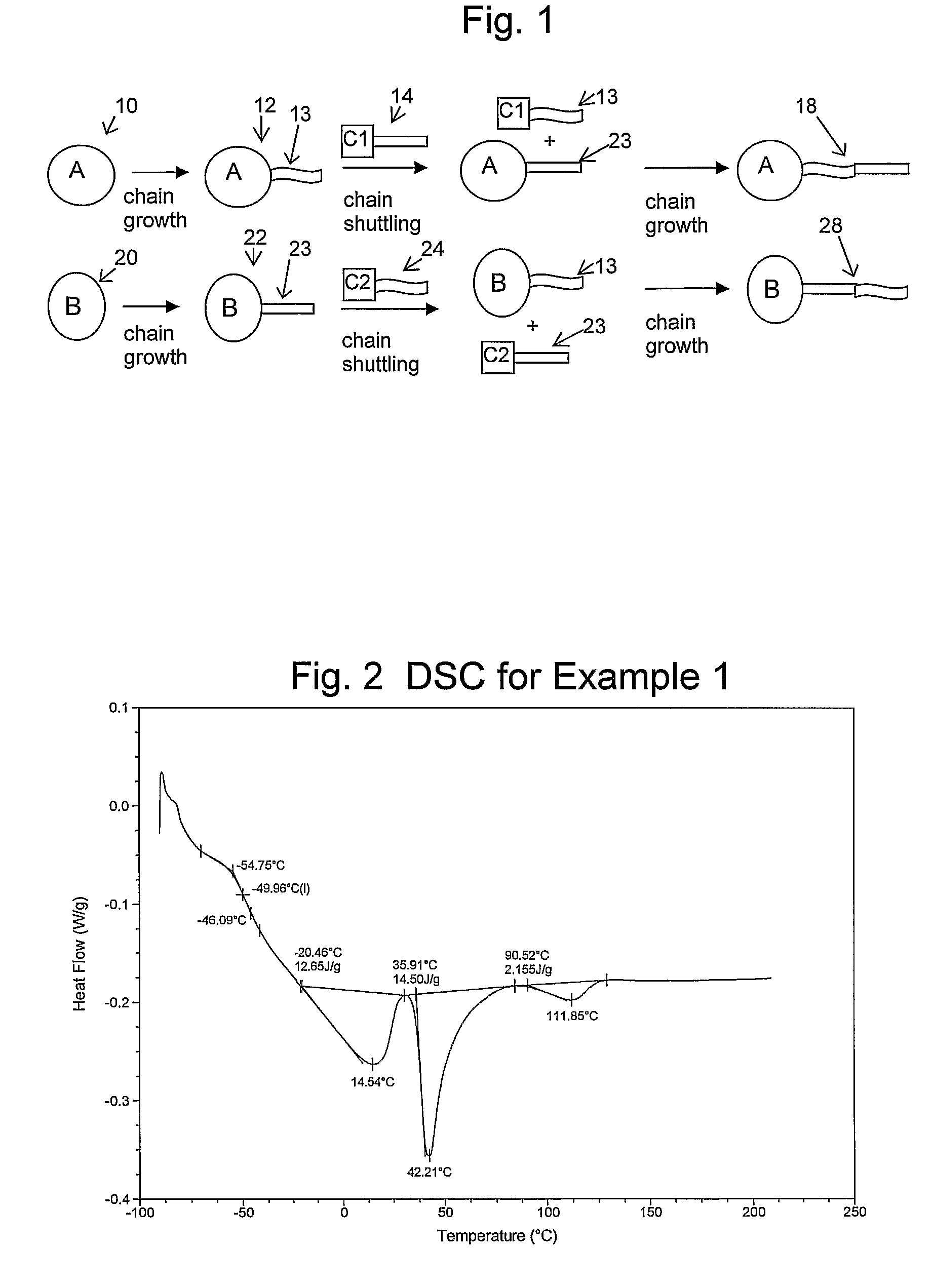

Copolymers, especially multi-block copolymer containing therein two or more segments or blocks differing in chemical or physical properties, are prepared by polymerizing propylene, 4-methyl-1-pentene, or other C4-8α-olefin and one or more copolymerizable comonomers, especially ethylene in the presence of a composition comprising the admixture or reaction product resulting from combining: (A) a first metal complex olefin polymerization catalyst, (B) a second metal complex olefin polymerization catalyst capable of preparing polymers differing in chemical or physical properties from the polymer prepared by catalyst (A) under equivalent polymerization conditions, and (C) a chain shuttling agent.

Owner:DOW GLOBAL TECH LLC

Oleaginous pharmaceutical and cosmetic foam

InactiveUS20070292461A1Pleasant and easy to spreadPatient compliance is goodCosmetic preparationsMetabolism disorderActive agentPolyethylene glycol

The invention relates to stable pharmaceutical or cosmetic foam compositions containing certain active agents, having unique therapeutic properties and methods of treatment using such compositions. The foamable composition includes at least one solvent comprising polyethylene glycol (PEG) or PEG derivative and mixtures thereof, or comprising propylene glycol, wherein the solvent is present at a concentration of about 70% to about 96.5% by weight of the total composition, at least a non-ionic surface-active agent at a concentration of about 0.1% to less than about 10% by weight of the total composition.

Owner:FOAMIX PHARMACEUTICALS LIMITED

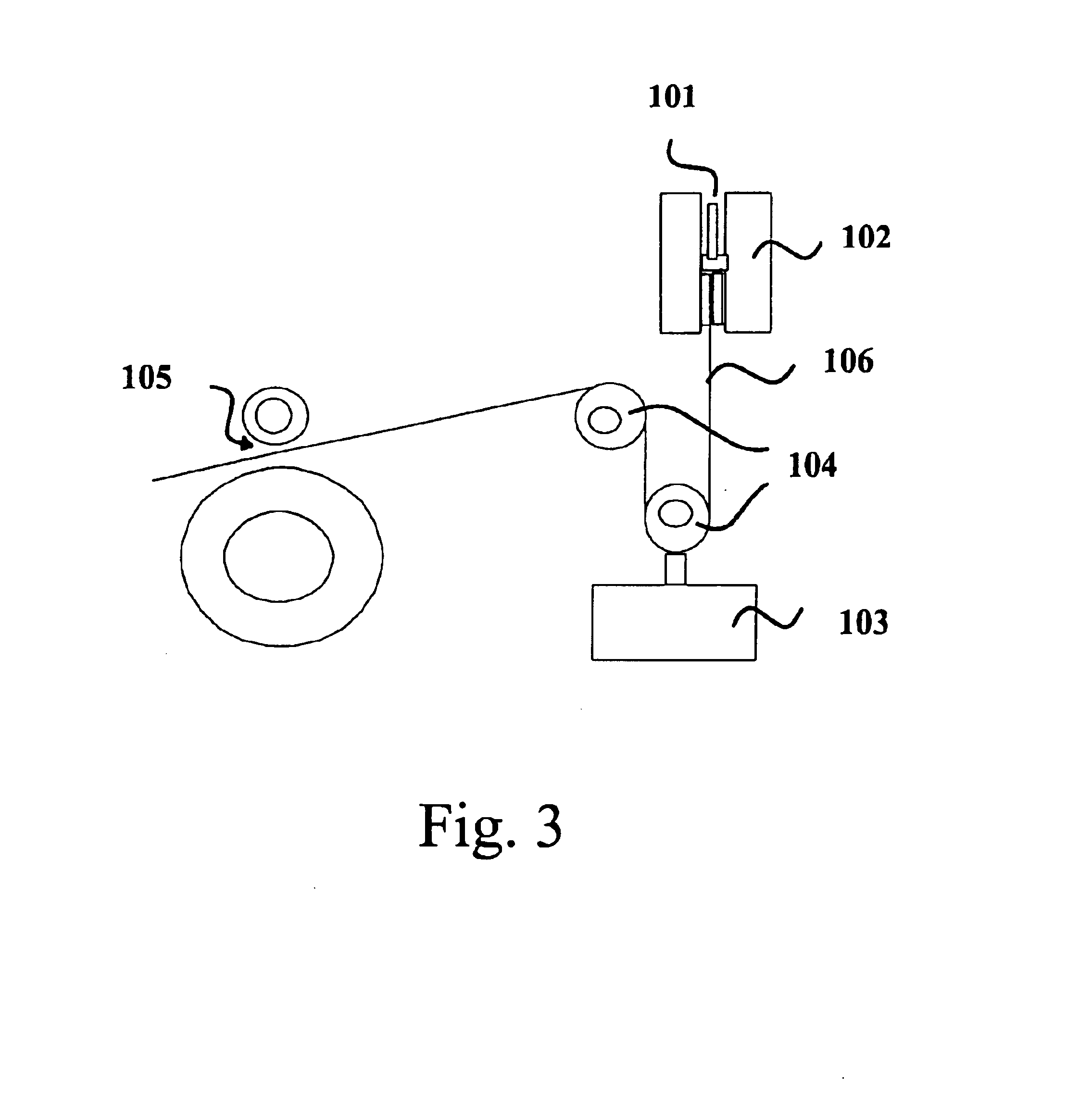

Fibers made from copolymers of propylene/alpha-olefins

ActiveUS7504347B2Monocomponent synthetic polymer artificial filamentWoven fabricsFiberVolumetric Mass Density

A fiber is obtainable from or comprises a propylene / α-olefin interpolymer characterized by an elastic recovery, Re, in percent at 300 percent strain and 1 cycle and a density, d, in grams / cubic centimeter, wherein the elastic recovery and the density satisfy the following relationship: Re>1481-1629 (d). Such interpolymer can also be characterized by other properties. The fibers made therefrom have a relatively high elastic recovery and a relatively low coefficient of friction. The fibers can be cross-linked, if desired. Woven or non-woven fabrics can be made from such fibers.

Owner:DOW GLOBAL TECH LLC

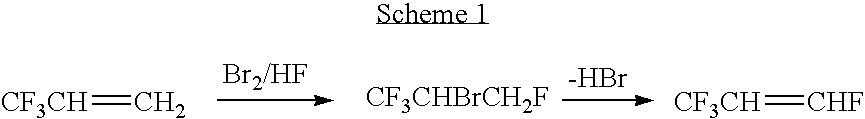

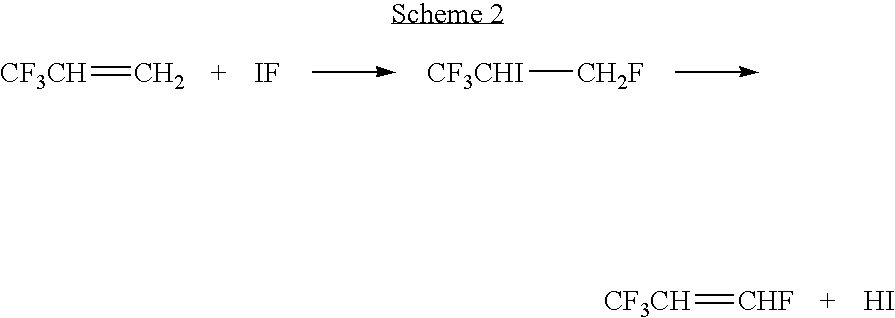

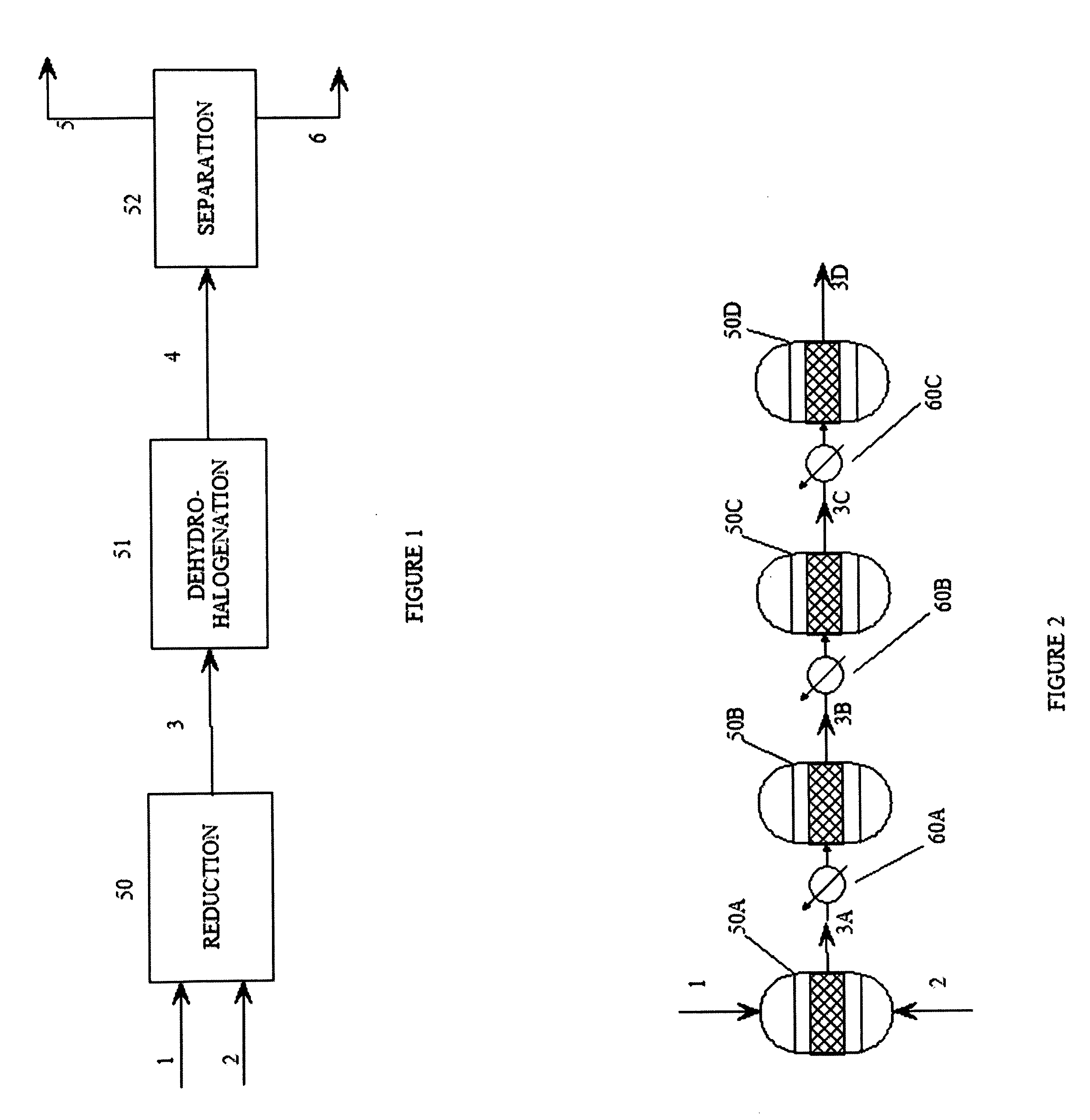

Processes for synthesis of tetrafluoropropene

ActiveUS7189884B2Preparation by hydrogen halide split-offPreparation by halogen halide additionBromineCombinatorial chemistry

Disclosed in one embodiment is a process for the synthesis of 1,3,3,3-tetrafluoropropene that comprises (a) reacting a compound of formula (I) X1X2 with a compound of formula (II) CF3CH═CH2 to produce a reaction product comprising a compound of formula (III) CF3CHX1CH2X2, wherein X1 and X2 are each independently selected from the group consisting of hydrogen, chlorine, bromine and iodine, provided that X1 and X2 are not both hydrogen; (b) when X2 in formula (III) is not fluorine, fluorinating the compound of formula (III) to produce a reaction product comprising a compound of formula (III) wherein X1 is as described above and X2 is fluorine; and (c) exposing said compound of formula (III) to reaction conditions effective to convert said compound to 1,3,3,3-tetrafluoropropene.

Owner:HONEYWELL INT INC

Plasticized hetero-phase polyolefin blends

InactiveUS20080045638A1Increase stiffnessImprove impact toughnessPigment pastesPolyolefinHigh stiffness

This invention relates to hetero-phase polyolefin compositions comprising: a) 30 to 99.7 wt % of a polypropylene-based TPO comprising at least 50 wt % propylene and at least 10 wt % ethylene, and b) 0.1 to 20 wt % of one or more non-functionalized plasticizer, and c) 0.2 to 50 wt % of one or more filler; based upon the weight of the composition, and having: i) an MFR of 5 dg / min or more, and ii) a flexural modulus of 500 MPa or more, and iii) a notched Charpy impact strength at −30° C. of 1 kJ / m2 or more or a notched Izod impact strength at −18° C. of 50 J / m or more.These compositions are especially useful in applications such as automotive parts that demand both high stiffness and high impact toughness, as well as good processibility during fabrication.

Owner:EXXONMOBIL CHEM PAT INC

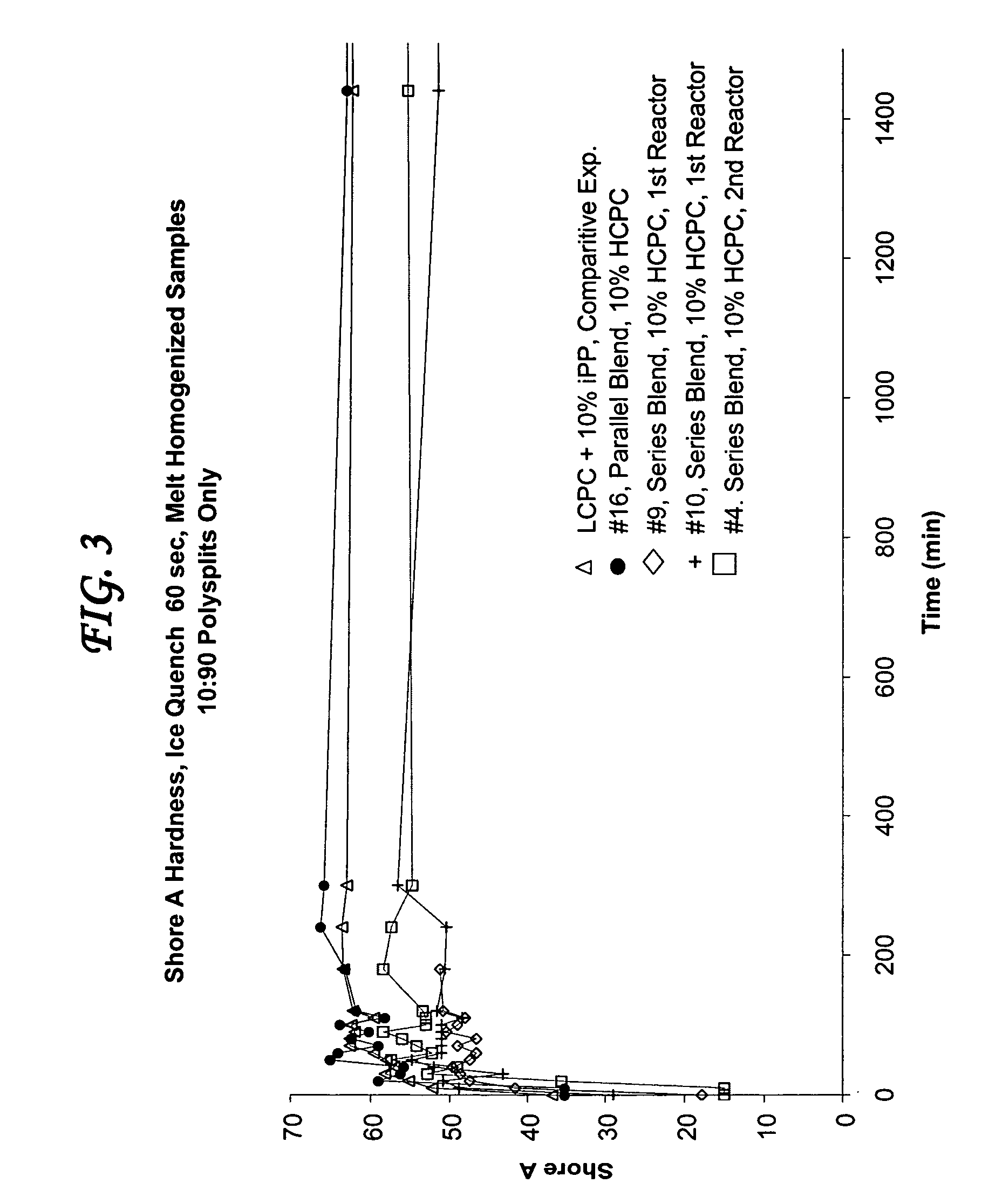

Elastic blends comprising crystalline polymer and crystallizable polymers of propylene

Improved thermoplastic polymer blend compositions comprising an isotactic polypropylene component and an alpha-olefin and propylene copolymer component, said copolymer comprising crystallizable alpha-olefin sequences. In a preferred embodiment, improved thermoplastic polymer blends are provided comprising from about 35% to about 85% isotactic polypropylene and from about 30% to about 70% of an ethylene and propylene copolymer, wherein said copolymer comprises isotactically crystallizable propylene sequences and is predominately propylene. The resultant blends manifest unexpected compatibility characteristics, increased tensile strength, and improved process characteristics, e.g., a single melting point.

Owner:EXXONMOBIL CHEM PAT INC

Process for manufacture of fluorinated olefins

A process for the production of fluorinated olefins, preferably fluorinated propenes, by contacting a feed stream containing a fluorinated olefin and hydrogen with a first amount of catalyst to produce the hydrofluorocarbon, wherein a first exit stream contains unreacted fluorinated olefin and hydrogen; contacting the first exit stream with a second amount of catalyst to produce a hydrofluorocarbon, wherein the second amount of catalyst is preferably greater than the first amount of catalyst; and contacting the hydrofluorocarbon with a catalyst for dehydrohalogenation to produce a product stream of fluorinated olefin.

Owner:HONEYWELL INT INC

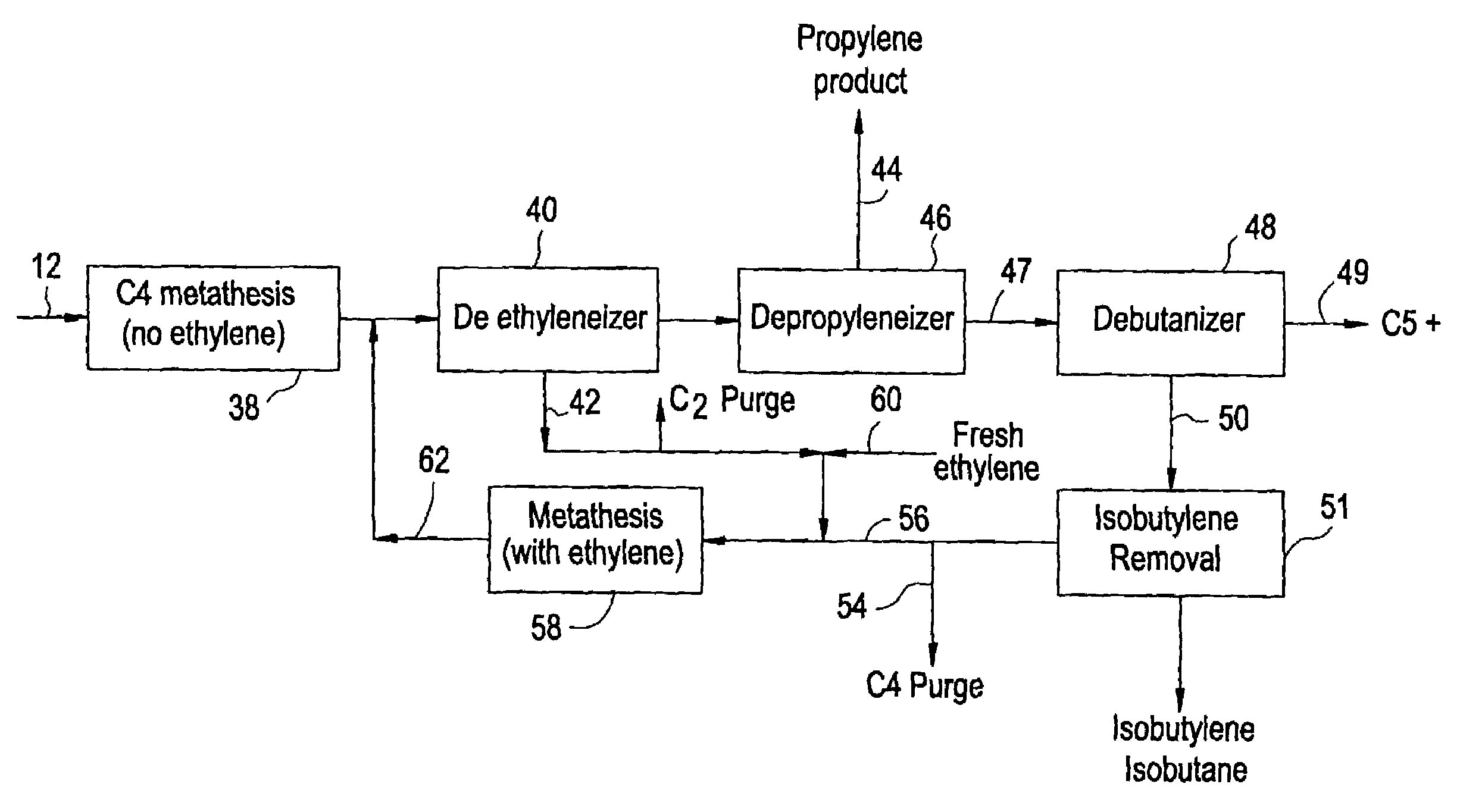

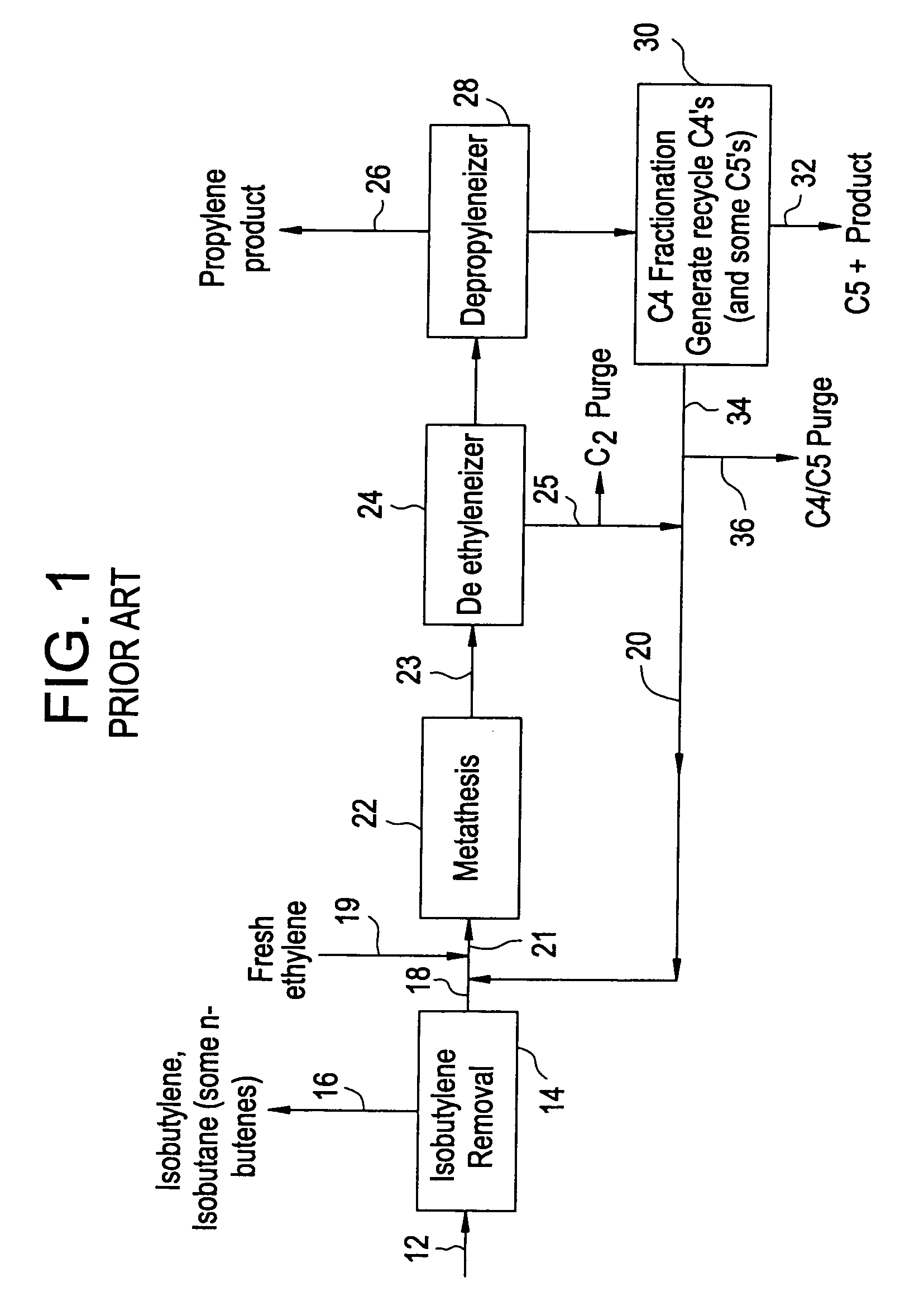

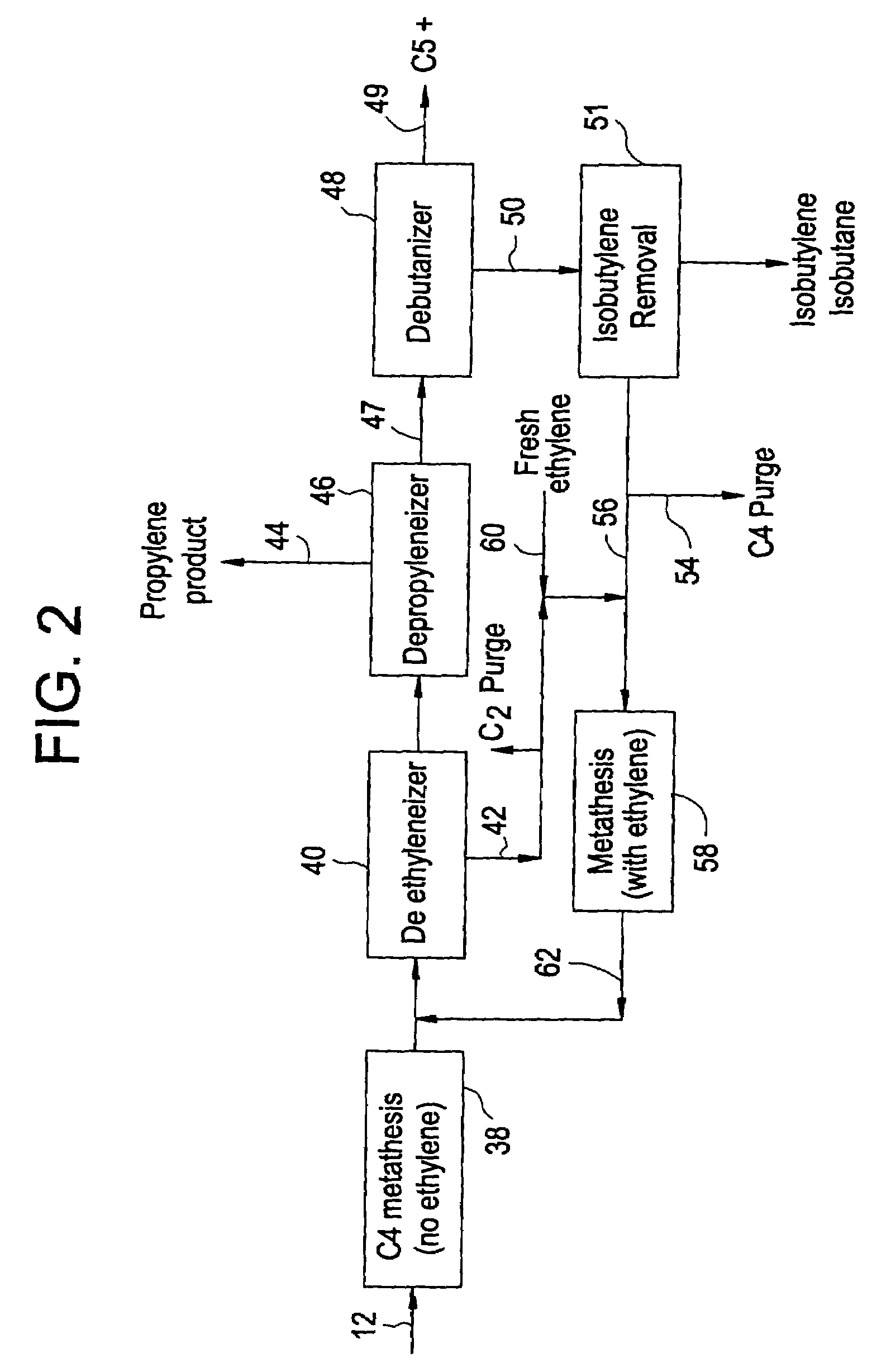

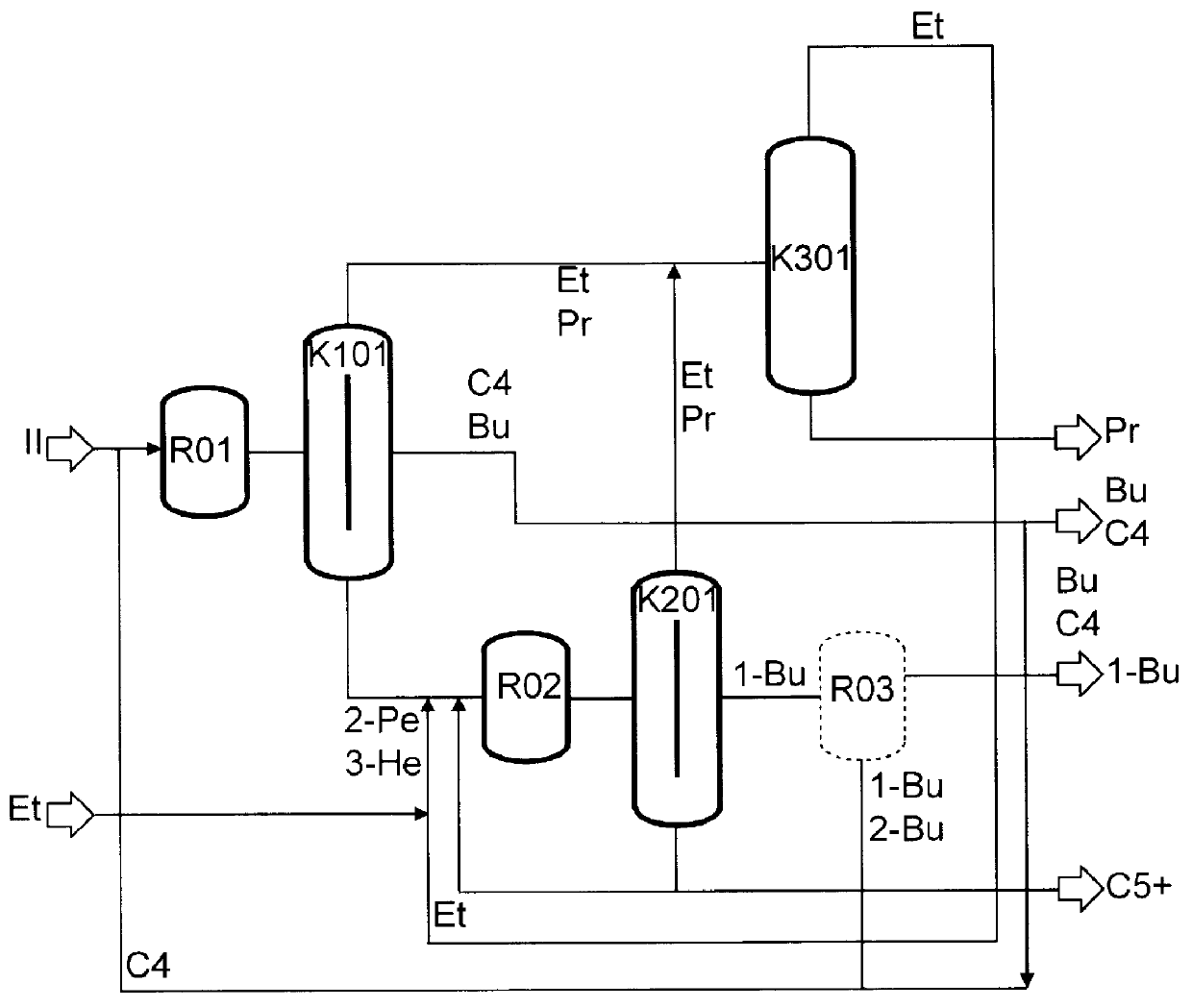

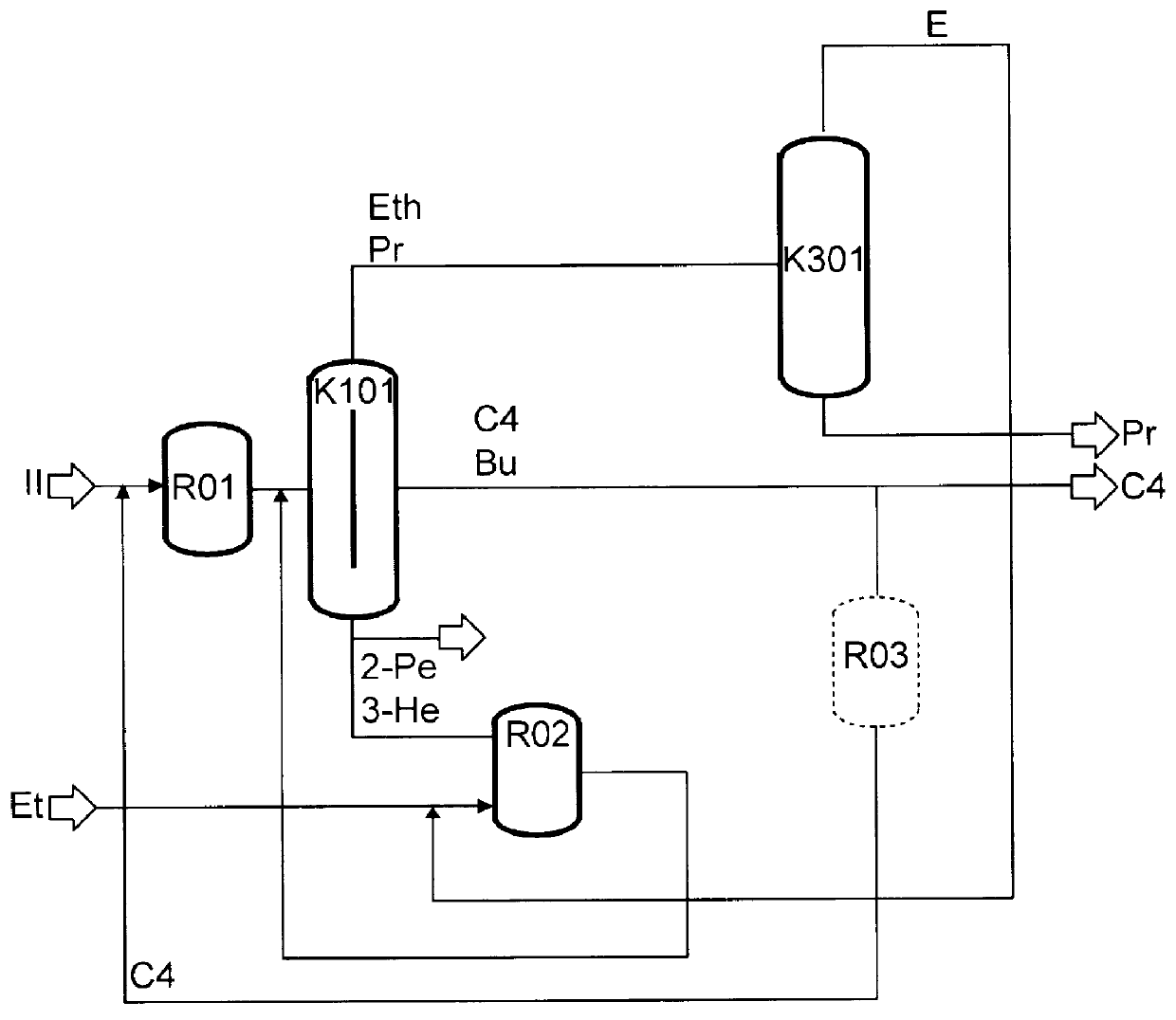

Processing C4 olefin streams for the maximum production of propylene

ActiveUS7214841B2Maximize productionImprove the level ofChemical industryCatalystsCatalytic distillation2-Butene

In order to maximize the production of propylene when the external supply of ethylene is limited, the C4 cut from a hydrocarbon cracking process is first subjected to autometathesis prior to any isobutylene removal and without any ethylene addition. This favors the reactions which produce propylene and pentenes. The ethylene and propylene produced are then removed leaving a stream of the C4's and heavier components. The C5 and heavier components are then removed leaving a mixture of 1-butene, 2-butene, isobutylene, and iso- and normal butanes. The isobutylene is next removed preferably by a catalytic distillation hydroisomerization de-isobutyleneizer. The isobutylene-free C4 stream is then mixed with the product ethylene removed from the autometathesis product together with any fresh external ethylene needed and subjected to conventional metathesis producing additional propylene.

Owner:ABB LUMMUS GLOBAL INC

High melt strength polypropylene

InactiveUS7365136B2Improve melt strengthHigh viscosityChemical/physical/physico-chemical stationary reactorsPolymer sciencePtru catalyst

The present invention concerns a high melt strength propylene polymer or copolymer suitable for manufacturing foams and thermoformed product exhibiting a melt strength of at least 3 g and comprising a high molar mass portion and a low or medium molar mass portion. The polymers are produced by subjecting propylene and optionally other olefins to polymerization in a plurality of polymerization reactors connected in series, employing different amounts of hydrogen as a molar mass modifier in at least two of the reactors, and carrying out the polymerization reaction in the presence of a catalyst system capable of catalyzing the formation of a high molar mass polymerization product having a MFR2 of less than 0.1 g / 10 min and a low or medium molar mass polymerization product having a MFR2 of more than 0.5 g / 10 min.

Owner:BOREALIS TECH OY

Preparation of olefins

The preparation of olefins from steam cracker or refinery C4 streams is carried out by selective hydrogenation of butadienes and acetylenic impurities in the steam cracker or refinery C4 stream, with simultaneous or subsequent, at least partial isomerization of 1-butene to 2-butene, followed by removal of i-butene from the C4 stream by reaction with an alcohol to form an ether, followed by removal of oxygen-containing impurities from the C4 stream using adsorber materials, followed by two-stage metathesis of the butenes in the C4 stream by conversion of 1-butene and 2-butene present in the C4 stream into propene and 2-pentene and subsequent reaction of the 2-pentene with ethene in the presence of a metathesis catalyst to form propene and 1-butene. Optionally, butadiene may be removed from the C4 stream by extractive distillation in a preliminary step.

Owner:BASF AG

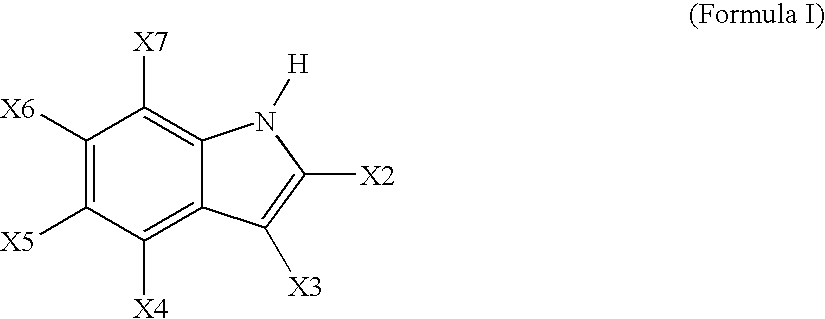

Preparation of polymerization catalyst activators utilizing indole-modified silica supports

InactiveUS20070055028A1High catalytic yieldLow catalyst loadingOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationHydrogenSlurry

A process for polymerizing propylene is provided. The process comprises contacting propylene and optionally one or more monomers with a catalyst system comprising a bis-indenyl Group 4 metallocene compound supported on silica, the silica treated with one or more organoaluminum compounds and one or more heterocyclic compounds, under slurry conditions in the presence of hydrogen at a temperature of about 50° C. to about 160° C. and a pressure of from about 3 MPa to about 5 MPa to provide a catalyst activity of greater than 30,000 pounds of product per pound of catalyst; and then recovering isotactic polypropylene having a melt flow rate of 20 dg / min or less as measured according to ASTM D-1238 at 230° C. and 2.16 kg.

Owner:EXXONMOBIL CHEM PAT INC

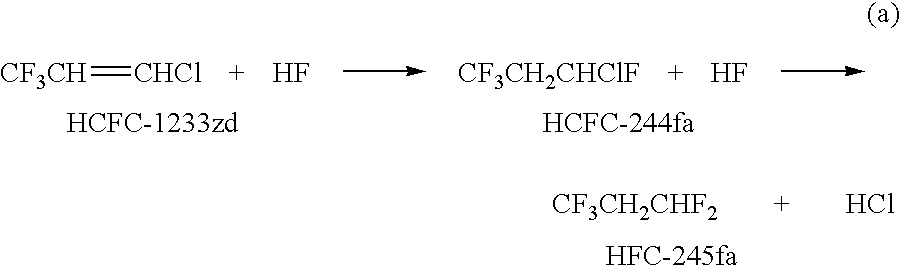

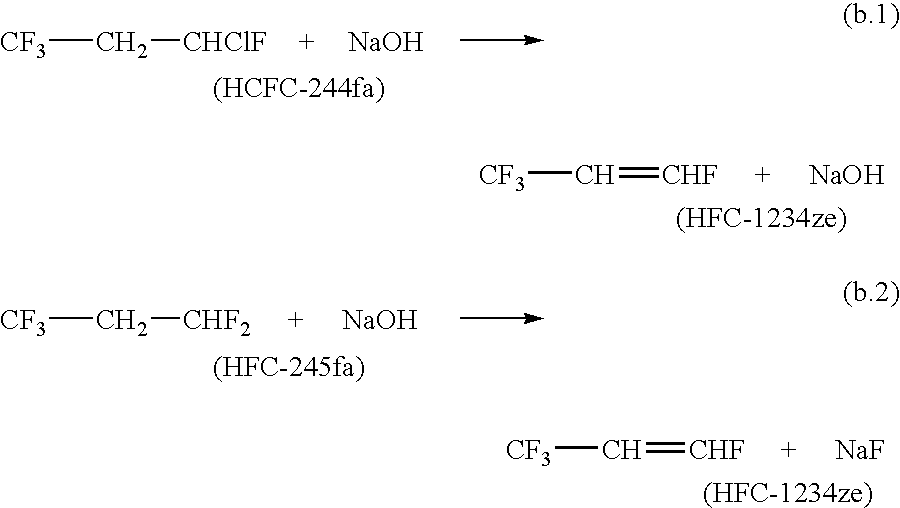

Process for the manufacture of 1,3,3,3-tetrafluoropropene

ActiveUS20050020862A1Physical/chemical process catalystsPreparation by hydrogen halide split-offPentafluoropropaneChemistry

The invention provides an economic process for the manufacture of 1,3,3,3-tetrafluoropropene (HFC-1234ze) by a two stage process. A hydrofluorination of 1-chloro-3,3,3-trifluoropropene (HCFC-1233zd) into 1-chloro-1,3,3,3-tetrafluoropropane (HCFC-244fa) and 1,1,1,3,3-pentafluoropropane (HFC-245fa) is conducted, followed by the dehydrochlorination of HCFC-244fa and dehydrofluorination of HFC-245fa into HFC-1234ze.

Owner:HONEYWELL INT INC

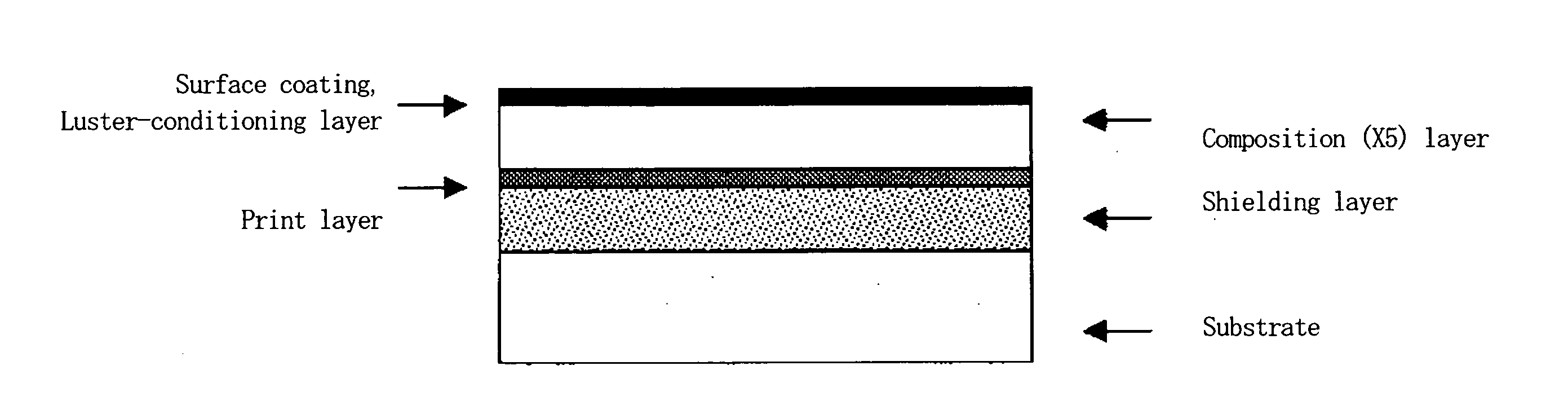

Propylene resin composition and use thereof

ActiveUS20070251572A1Improve mechanical propertiesGood rubber elasticitySolesPlastic/resin/waxes insulatorsElastomerAlpha-olefin

The thermoplastic resin composition (Xi) of the present invention comprises (A1), (B1), (C1), and optionally (D1) below: 1 to 90 wt % of an isotactic polypropylene (A1); 9 to 98 wt % of a propylene / ethylene / α-olefin copolymer (B1) containing 45 to 89 mol% of propylene-derived structural units, 10 to 25 molt of ethylene-derived structural units, and optionally, 0 to 30 mol% of C4-C20 α-olefin-derived structural units (a1); 1 to 80 wt % of a styrene-based elastomer (C1); and 0 to 70 wt % of an ethylene / α-olefin copolymer (D1) whose density is in the range of 0.850 to 0.910 g / cm3, wherein (A1)+(B1)+(C1)+(D1)=100 wt %.

Owner:MITSUI CHEM INC

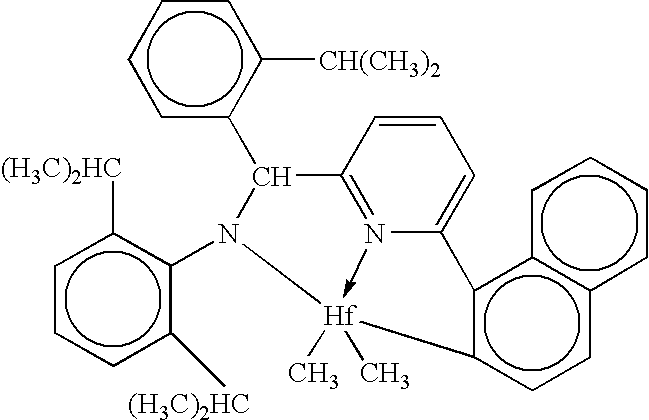

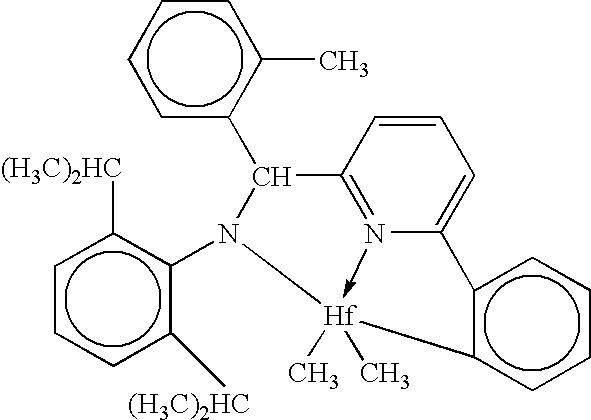

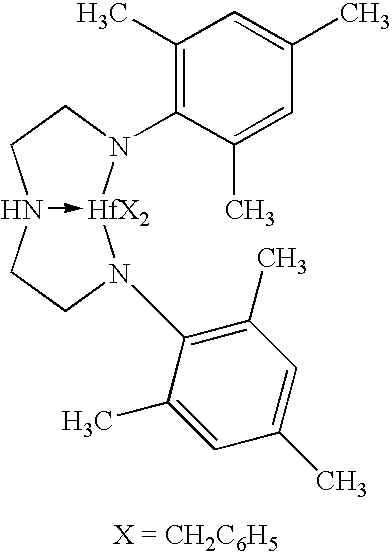

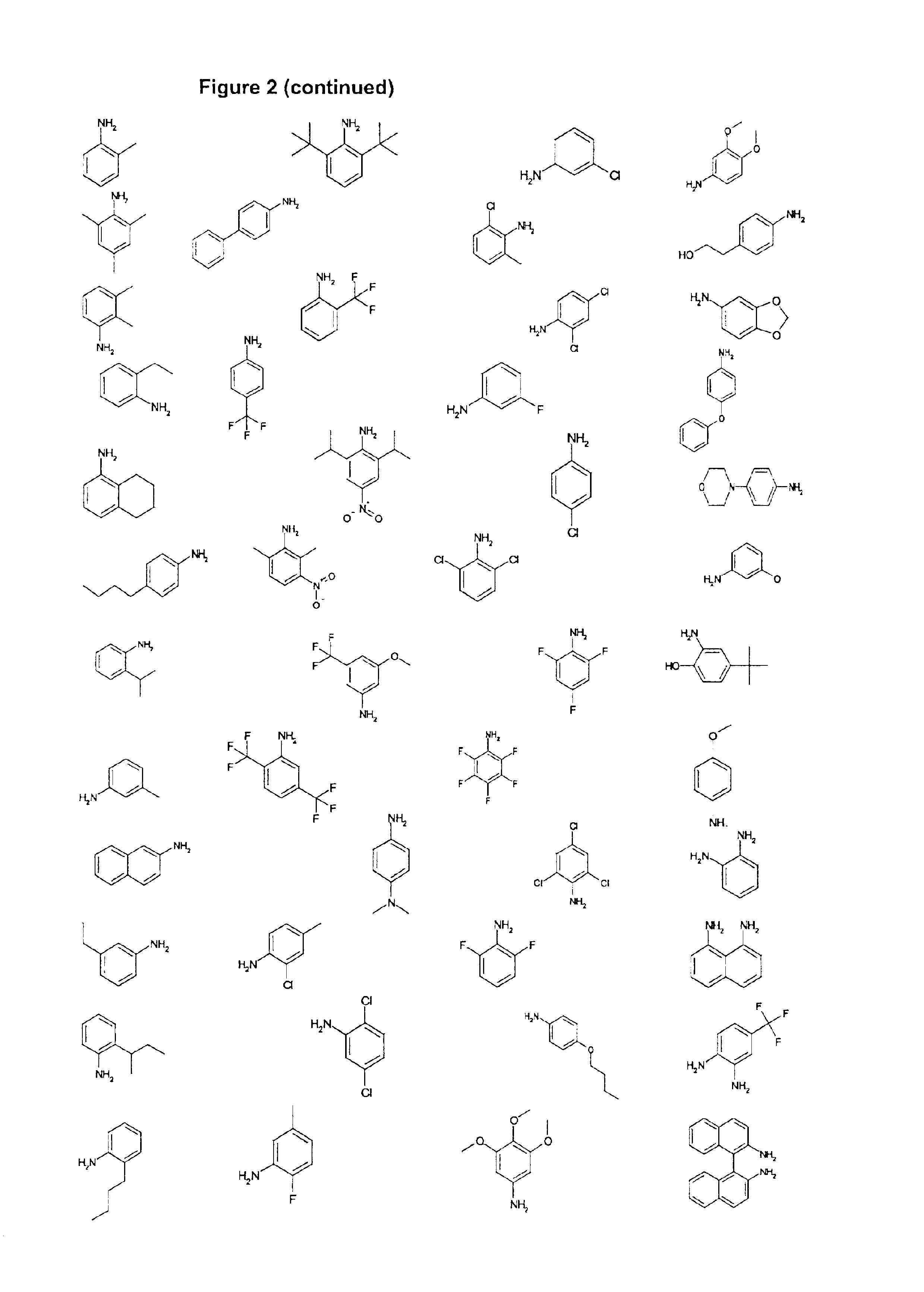

Substituted pyridyl amine complexes, and catalysts

InactiveUS6900321B2Improve catalytic performanceIncrease temperatureSilicon organic compoundsMacromolecular libraries1-OcteneHafnium

New ligands, compositions, metal-ligand complexes and arrays with pyridylamine ligands are disclosed that catalyze the polymerization of monomers into polymers. Certain of these catalysts with hafnium metal centers have high performance characteristics, including higher comonomer incorporation into ethylene / olefin copolymers, where such olefins are for example, 1-octene, isobutylene or styrene. Certain of the catalysts are particularly effective at polymerizing propylene to high molecular weight isotactic polypropylene in a solution process at a variety of polymerization conditions.

Owner:FREESLATE

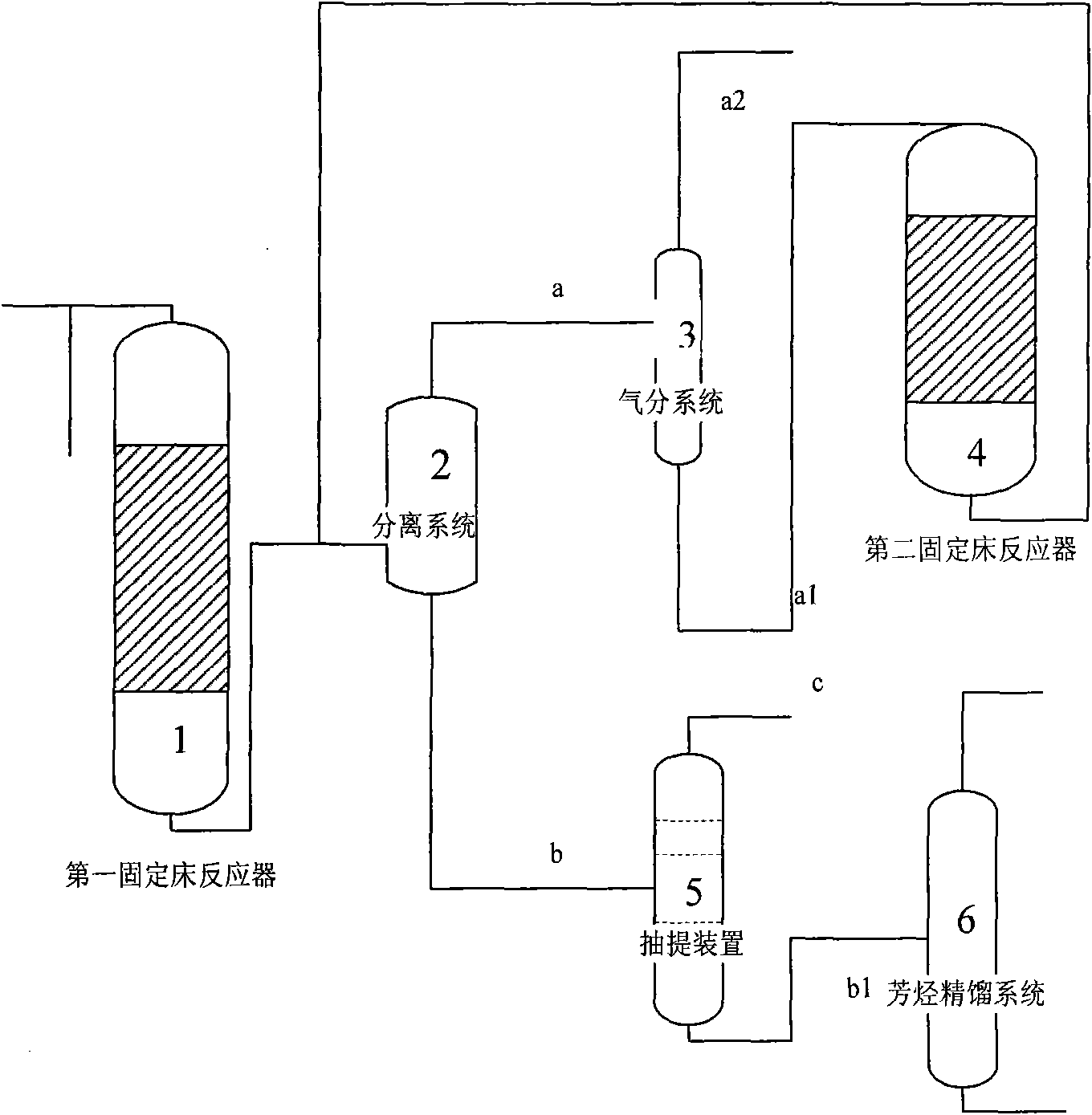

Method for preparing aromatic hydrocarbons and propylene simultaneously employing methanol/dimethyl ether

InactiveCN101607858AHigh selectivityIncrease added valueMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsMolecular sieveFixed bed

The invention discloses a method for preparing aromatic hydrocarbons and propylene simultaneously employing methanol / dimethyl ether, comprising the following steps: 1) placing raw materials containing methanol or / and dimethyl ether, metals and molecular sieve based catalyst which is modified through silanizing in a first fixed bed reactor to perform catalytic reaction; 2) separating the products obtained in step 1) to obtain propylene, then placing propylene in a second fixed bed reactor with molecular sieve based catalyst which is modified by using metals to react, then performing aromatization on the obtained product in step 1) and obtaining aromatic hydrocarbons; then separating to obtain toluene and sending toluene back to the outlet of the first fixed bed reactor as a raw material. In the method, methanol is converted and prepared to aromatic hydrocarbons while propylene is produced at the same time and the content of paraxylene in aromatic hydrocarbons is high. In the products prepared by the method, the content of propylene can reach above 20%, the content of aromatic hydrocarbons can reach above 58wt% and the content of paraxylene in aromatic hydrocarbons is more than 35wt%.

Owner:CHINA NAT OFFSHORE OIL CORP +2

High melt strength polypropylene

The present invention concerns a high melt strength propylene polymer or copolymer suitable for manufacturing foams and thermoformed product exhibiting a melt strength of at least 3 g and comprising a high molar mass portion and a low or medium molar mass portion. The polymers are produced by subjecting propylene and optionally other olefins to polymerization in a plurality of polymerization reactors connected in series, employing different amounts of hydrogen as a molar mass modifier in at least two of the reactors, and carrying out the polymerization reaction in the presence of a catalyst system capable of catalyzing the formation of a high molar mass polymerization product having a MFR2 of less than 0.1 g / l0 min and a low or medium molar mass polymerization product having a MFR2 of more than 0.5 g / 10 min.

Owner:BOREALIS TECH OY

METHOD FOR PRODUCING 2-CHLORO-3,3,3-TRIFLUOROPROPENE (HCFC-1233xf)

ActiveUS20090030244A1Speed up the conversion processLess resource-intensivePreparation by hydrogen halide split-offPreparation by halogen replacementHydrogen fluorideGas phase

The present invention relates to an improved method for manufacturing 2-chloro-3,3,3,-trifluoropropene (HCFC-1233xf) by reacting 1,1,2,3-tetrachloropropene, 1,1,1,2,3-pentachloropropane, and / or 2,3,3,3-tetrachloropropene with hydrogen fluoride, in a vapor phase reaction vessel in the presence of a vapor phase fluorination catalyst and stabilizer. HCFC-1233xf is an intermediate in the production of 2,3,3,3-tetrafluoropropene (HFO-1234yf) which is a refrigerant with low global warming potential.

Owner:HONEYWELL INT INC

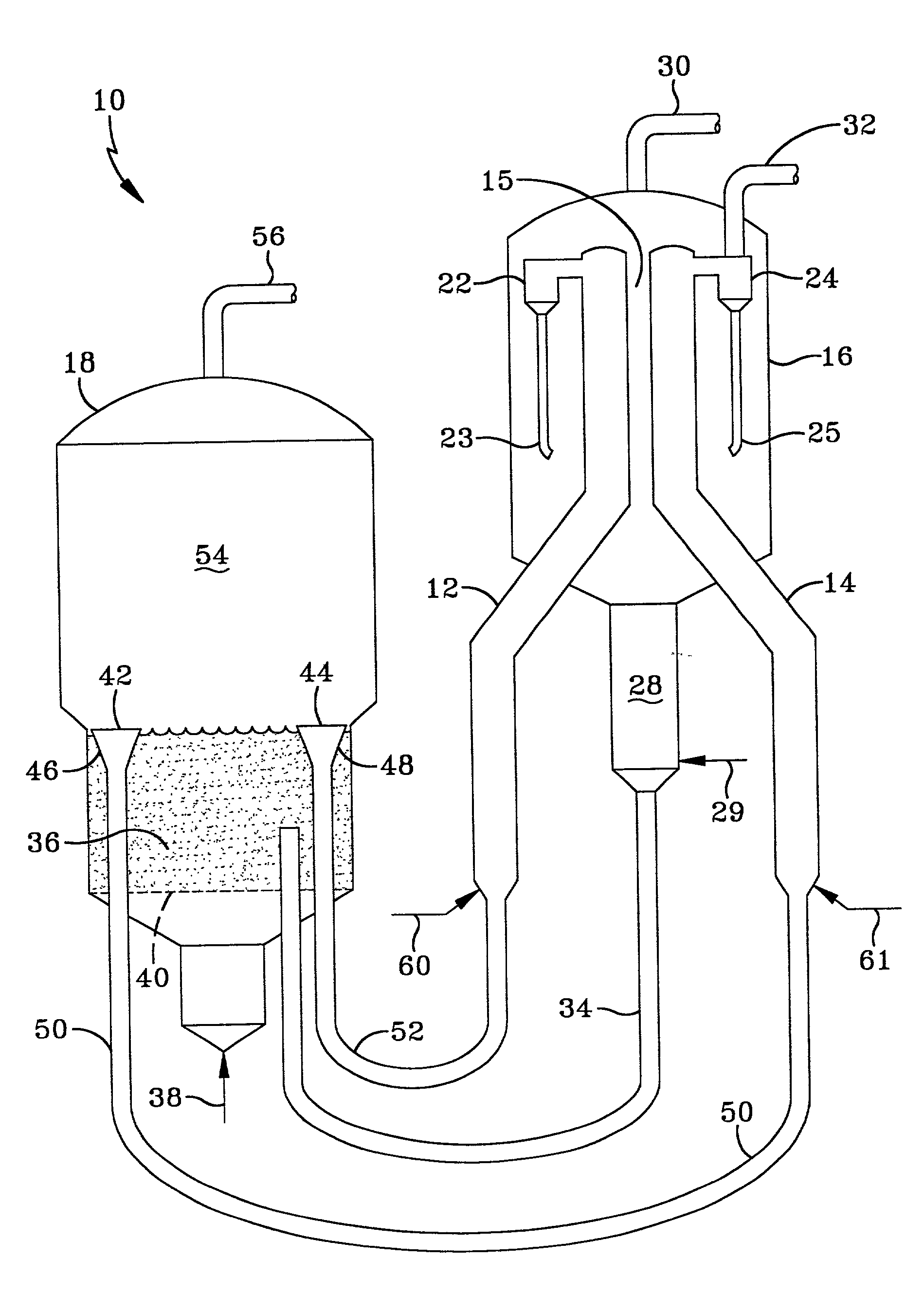

Fluid cat cracking with high olefins prouduction

InactiveUS20020003103A1Increase productionMaximize lightThermal non-catalytic crackingTreatment with plural serial cracking stages onlyNaphthaOrganic chemistry

The propylene production of a fluid catalytic cracking unit employing a large pore zeolite cracking catalyst, produces more propylene by adding a naphtha cracking riser and a medium pore zeolite catalytic component to the unit, and recycling at least a portion of the naphtha crackate to the naphtha riser. The large pore size zeolite preferably comprises a USY zeolite and the medium pore size is preferably ZSM-5. Propylene production per unit of naphtha feed to the naphtha riser is maximized, by using the 60-300.degree. F. naphtha crackate as the feed.

Owner:EXXON RES & ENG CO

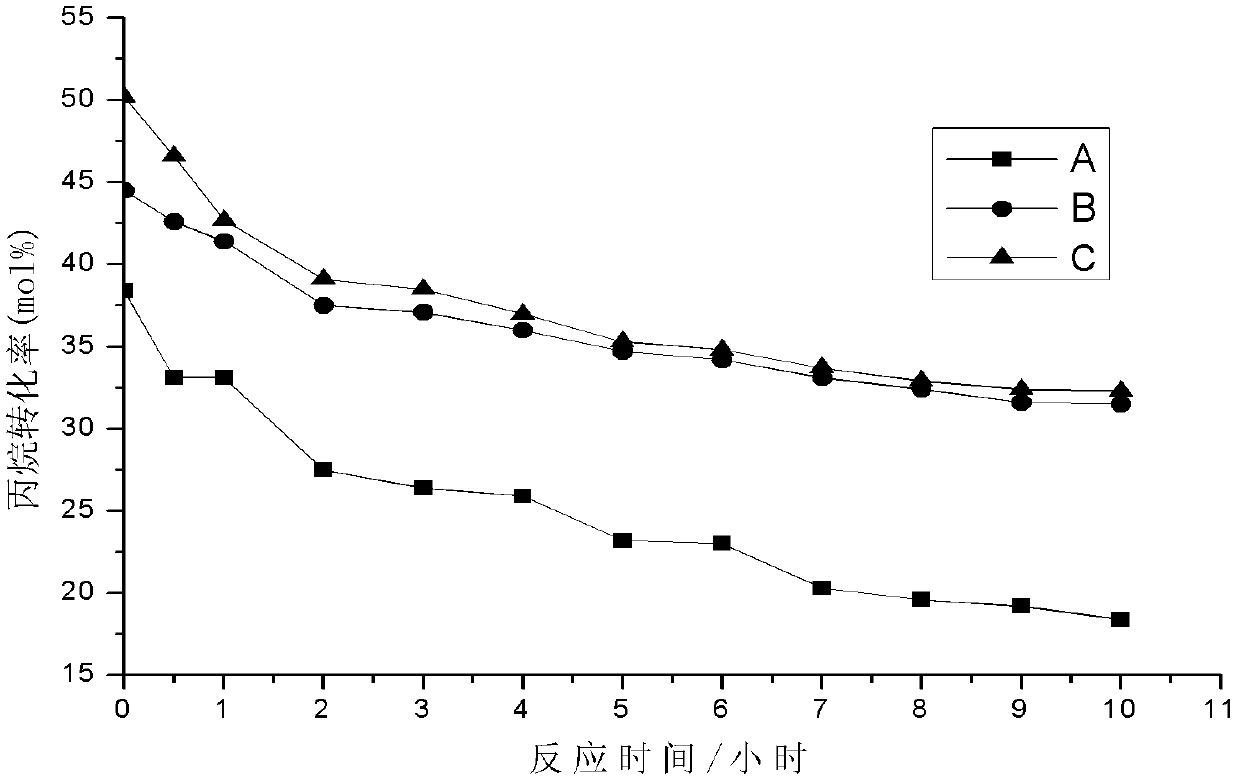

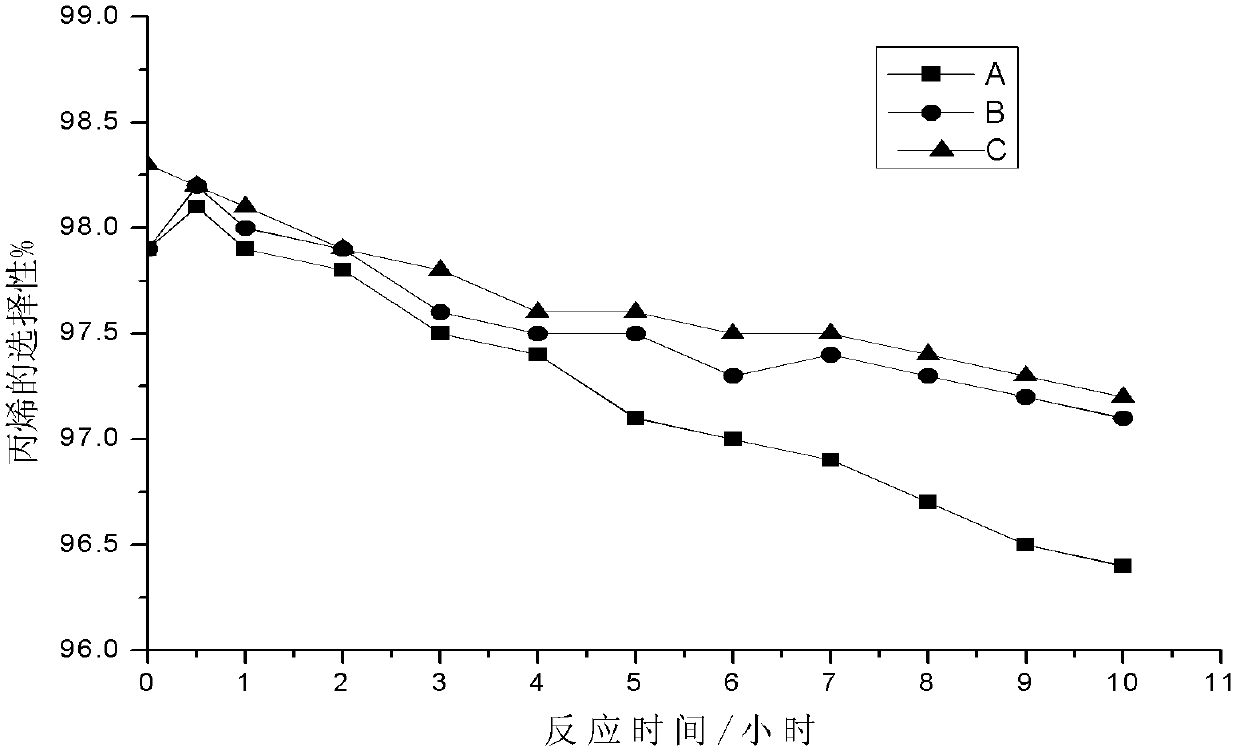

Catalyst propane using aluminium oxide modified mesonore molecular sieve as carrier for dehydrogenation producing propylene

InactiveCN101125298AHigh propane conversionGood dehydrogenation stabilityMolecular sieve catalystsHydrocarbonsMolecular sievePlatinum

The invention relates to a catalyst to make the propene by dehydrogenation propane which takes the modifying alumina medium molecular sieve as the carrier. The catalyst takes the modifying medium molecular sieve by the Al2O3 as the carrier; the platinum and tin double metal catalyst has an alumina weight proportion of 5.0 to 30.0 percent. The active component of the catalyst is the platinum; the weight proportion of the platinum is 0.4 percent; and the weight proportion of the accessory ingredient Sn is 0.1 to 2.0 percent.

Owner:NANJING UNIV

PROCESS TO MANUFACTURE 2-CHLORO-1,1,1,2-TETRAFLUOROPROPANE (HCFC-244bb)

InactiveUS20100036179A1Preparation by dehalogenationPreparation by hydrogen halide split-offHydrogen fluorideHydrogen chloride

The invention provides an improved process to manufacture 2-chloro-1,1,1,2-tetrafluoropropane (HCFC-244bb) by reacting 2-chloro-3,3,3,-trifluoropropene (HCFO-1233xf) with hydrogen fluoride, in a liquid phase reaction in the presence of hydrogen chloride and a liquid phase fluorination catalyst. The hydrogen chloride is added into the reaction from an external source at a pressure of about 100 psig or more. The HCFC-244bb is an intermediate in the production of 2,3,3,3-tetrafluoropropene-1 (HFO-1234yf).

Owner:HONEYWELL INT INC

Catalyst for preparing propylene through propane catalytic dehydrogenation and preparation method thereof

InactiveCN102389831ALarge specific surface areaHigh catalytic activityMolecular sieve catalystsHydrocarbonsDehydrogenationEconomic benefits

The invention relates to a catalyst for preparing propylene through propane catalytic dehydrogenation, which is a load type platinum-based catalyst and is characterized in that home-made mesoporous molecular sieves MCM-41 are used as carriers, metal Pt is used as an active ingredient, and metals Sn, Sn-Ce or Sn-Ce-Ca are used as auxiliary agents. In a preparation method, an isovolumetric continuous immersion method is adopted for preparation. The catalyst and the preparation method have the advantages that the isovolumetric continuous immersion method is adopted for preparing multi-component catalysts, wherein the content of any one component is easy to control, the prepared catalyst has higher specific surface area (700 to 900m<2> / g) and has high catalytic activity, the propane conversion rate is high, the propylene selectivity is good, the one-path stability is good, in addition, the service life is longer, the preparation method of the catalyst carriers is simple and feasible, the economic benefit is obvious, and good industrial development and application prospects are realized.

Owner:NANKAI UNIV

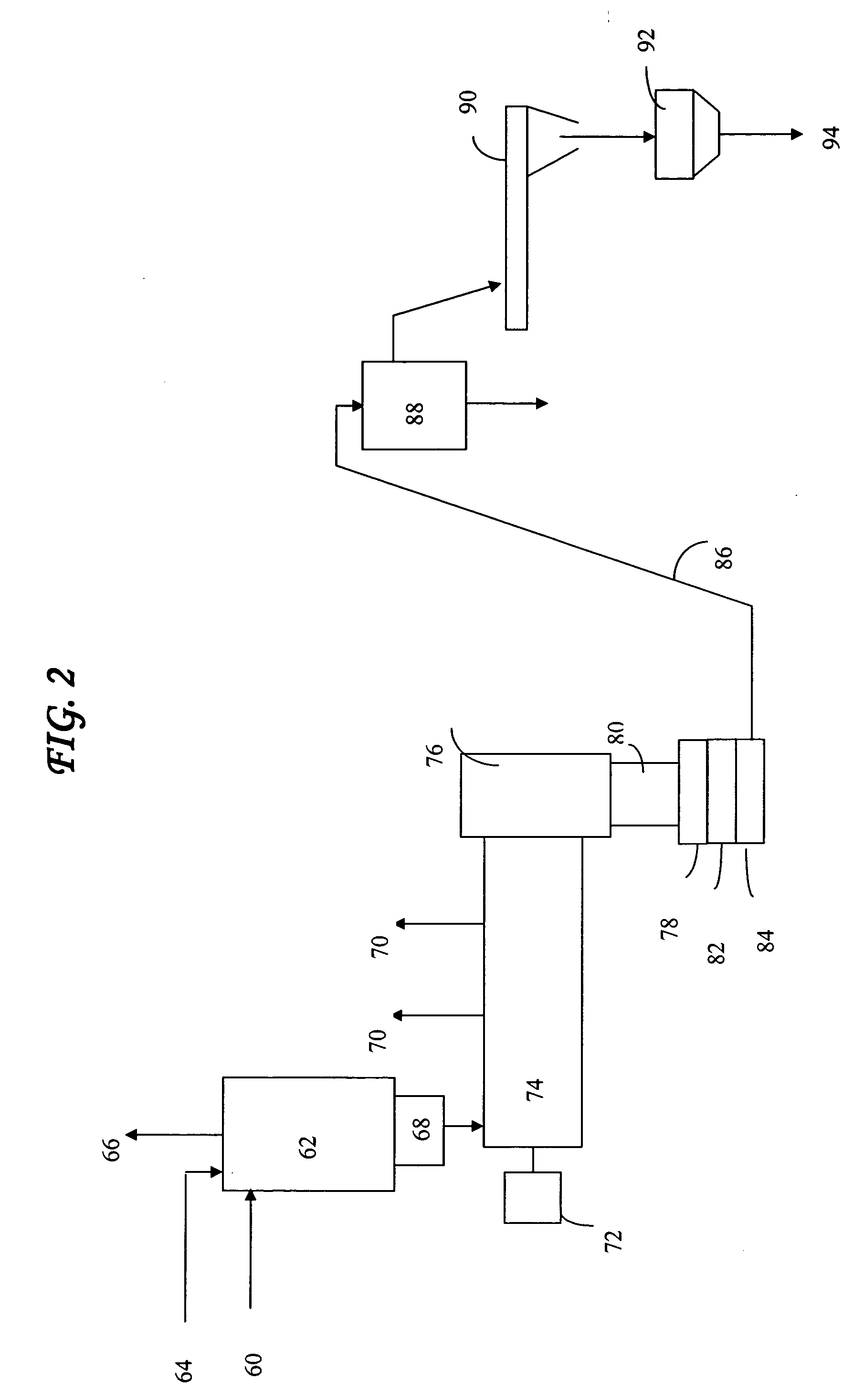

Process for producing propylene based polymer compositions

A process for the production of a propylene based polymer, the process comprising the following steps: (a) a first polymerization stage comprising homopolymerizing propylene or copolymerizing propylene and at least one alpha-olefin in the presence of an alpha-olefin polymerization catalyst whereby to produce a polypropylene component; (b) a second polymerization stage comprising copolymerizing ethylene and at least one alpha-olefin in the presence of an alpha-olefin polymerization catalyst whereby to produce an ethylene / alpha-olefin copolymer component; and (c) blending the polymer components produced in steps (a) and (b) whereby to produce a polymer blend, wherein the first and second polymerization stages are effected in separate polymerization reactors connected in parallel. Also provided are polymer compositions comprising: (i) 30 to 97% by weight, based on the total weight of the polymer composition, of a propylene based polymer; and (ii) 3 to 70% by weight, preferably 5 to 20% by weight, based on the total weight of the polymer composition, of an ethylene copolymer plastomer (e.g., an ethylene-propylene plastomer) containing at least 60% by weight ethylene.

Owner:BOREALIS TECH OY

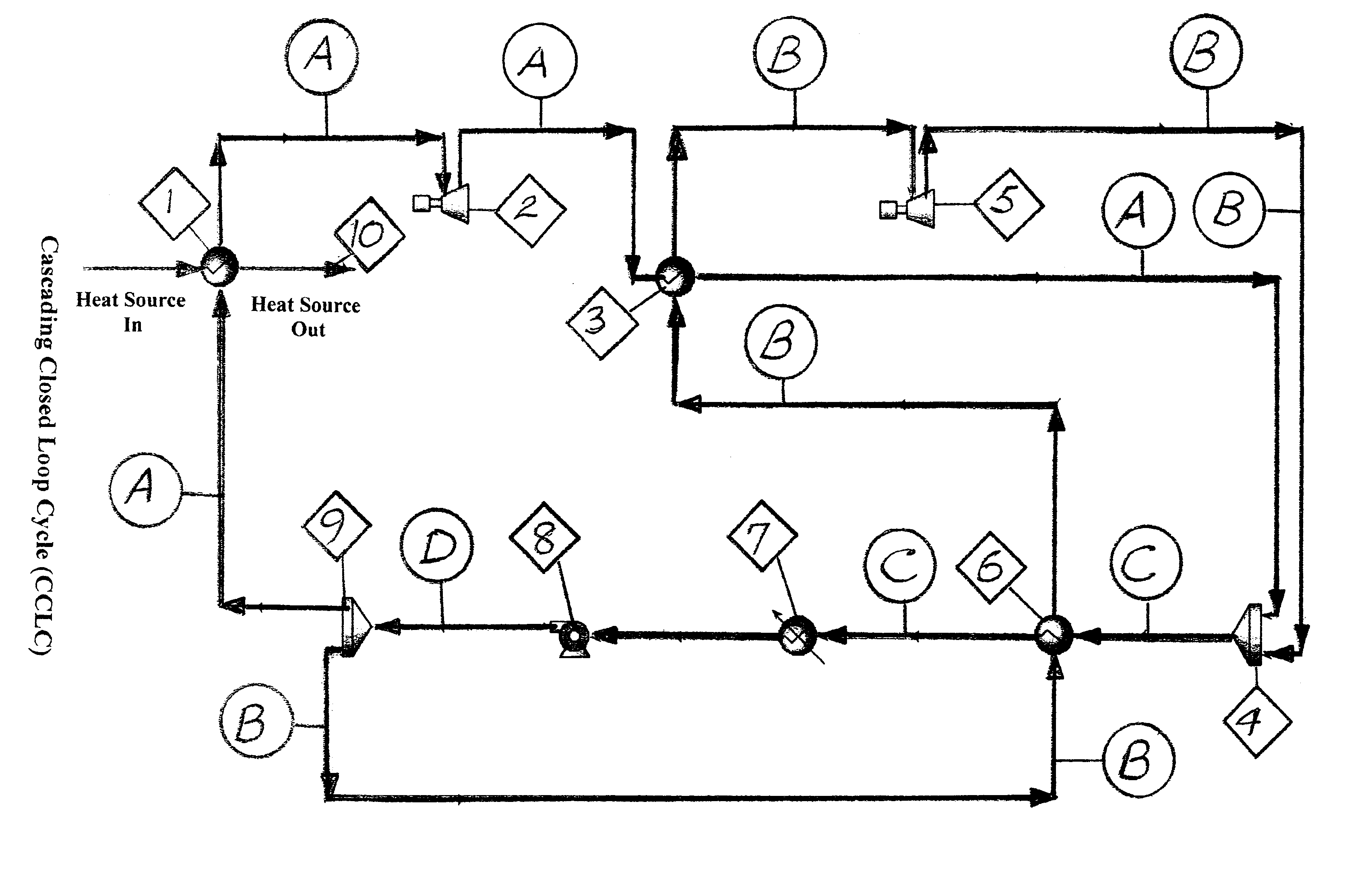

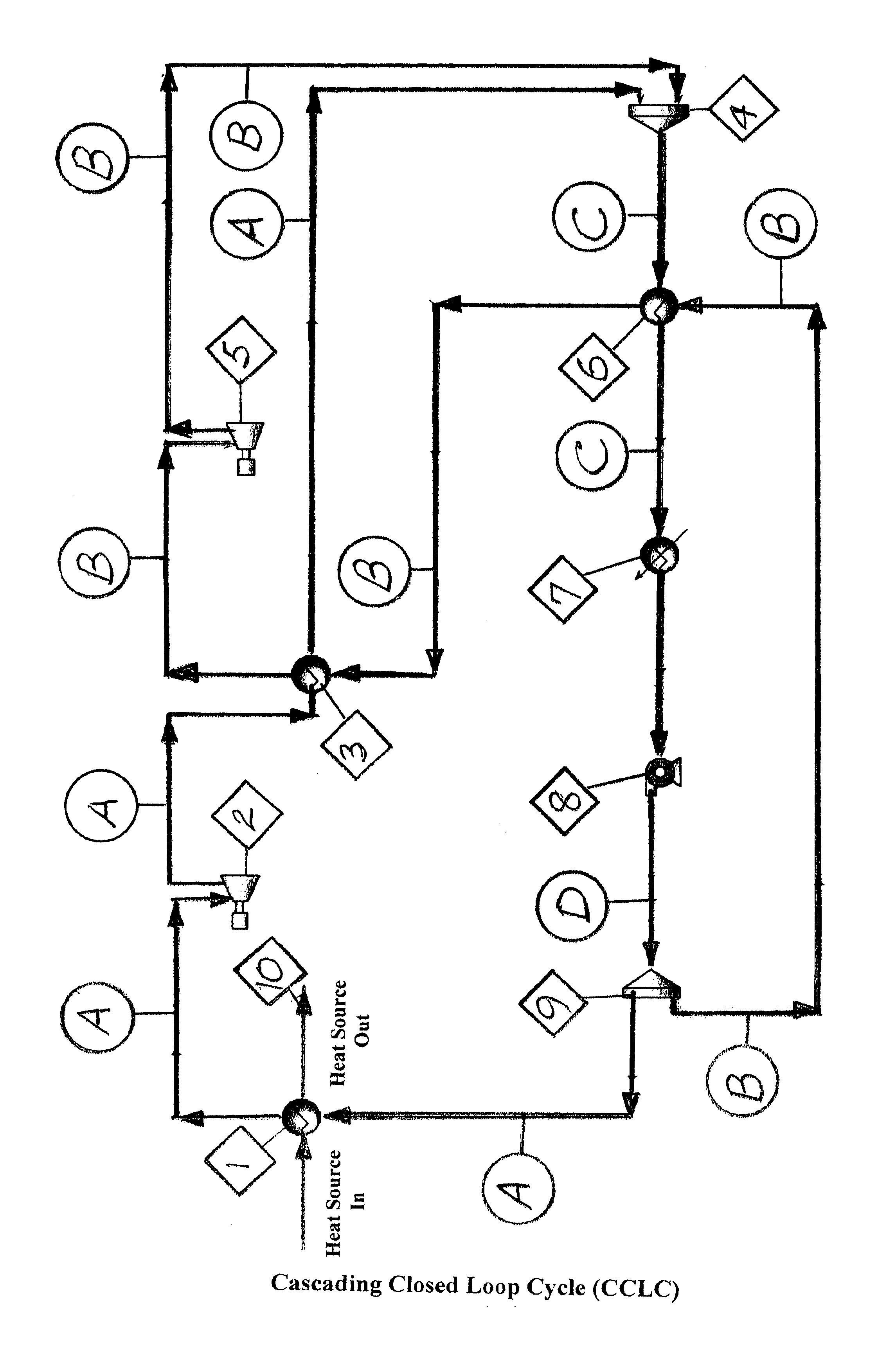

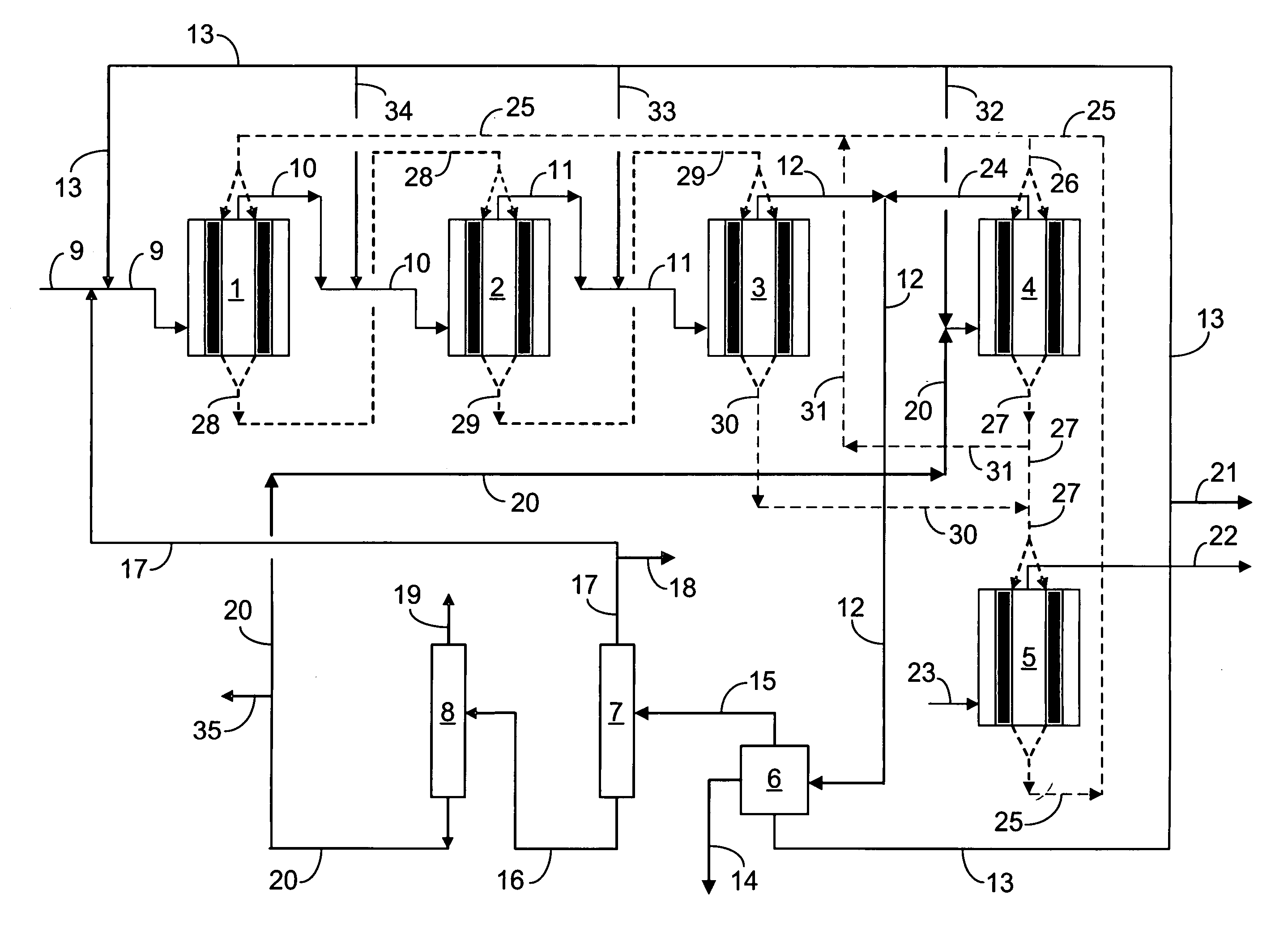

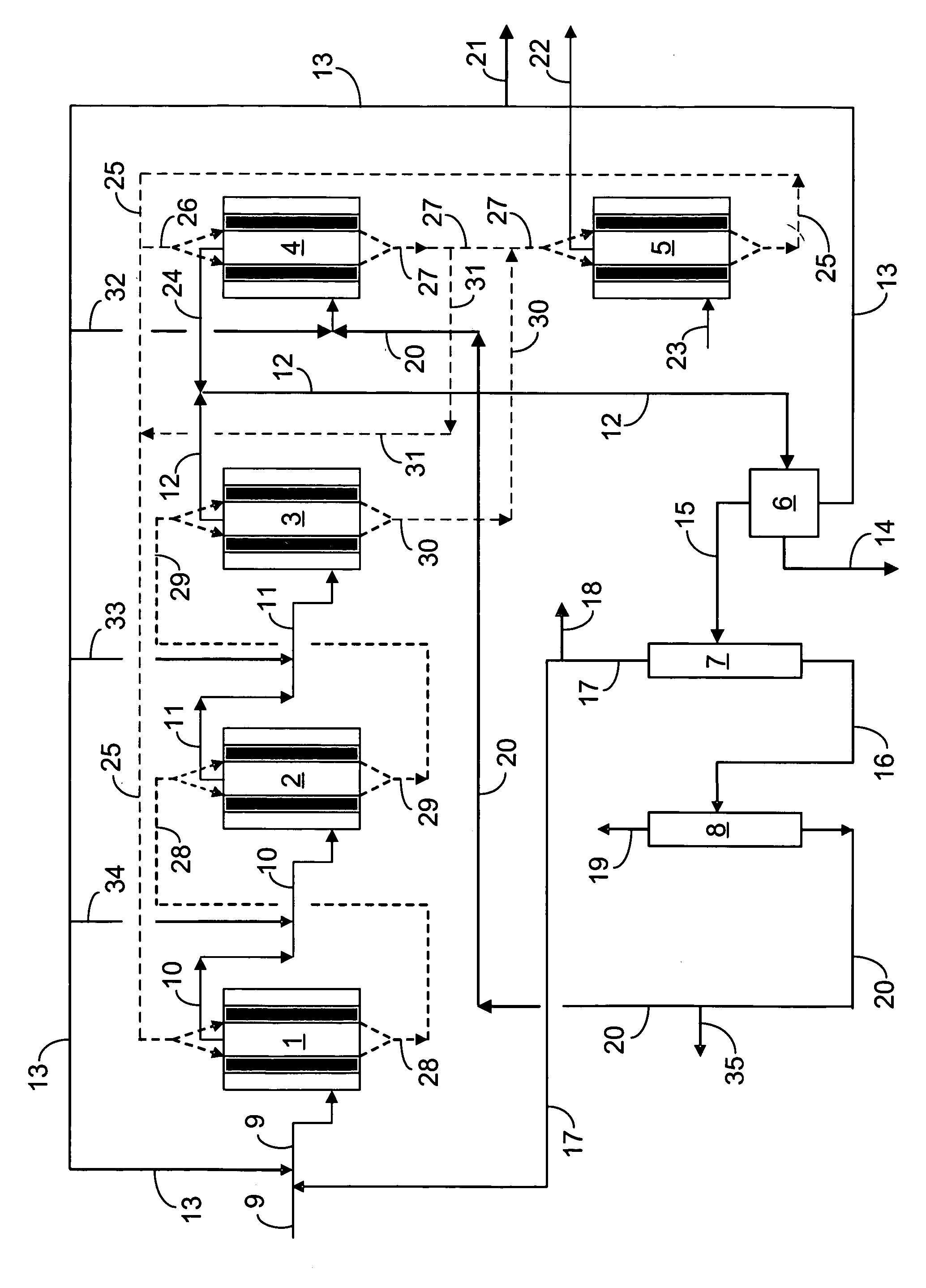

Cascading closed loop cycle (CCLC)

InactiveUS6857268B2Reduce pressureEnergy industrySteam engine plantsProcess engineeringElectric energy

A Cascading Closed Loop Cycle (CCLC) system is described for recovering power in the form of mechanical or electrical energy from any thermal energy source whose temperature is sufficiently high to vaporize a pressurized light hydrocarbon medium such as propane or propylene. A light hydrocarbon medium is vaporized in multiple indirect heat exchangers; expanded in multiple cascading expansion turbines to generate useful power; and condensed to a liquid using a cooling system. The light hydrocarbon liquid medium is then pressurized with a pump and returned to the indirect heat exchangers to repeat the vaporization, expansion, liquefaction and pressurization cycle in a closed, hermetic process.

Owner:WOW ENERGY

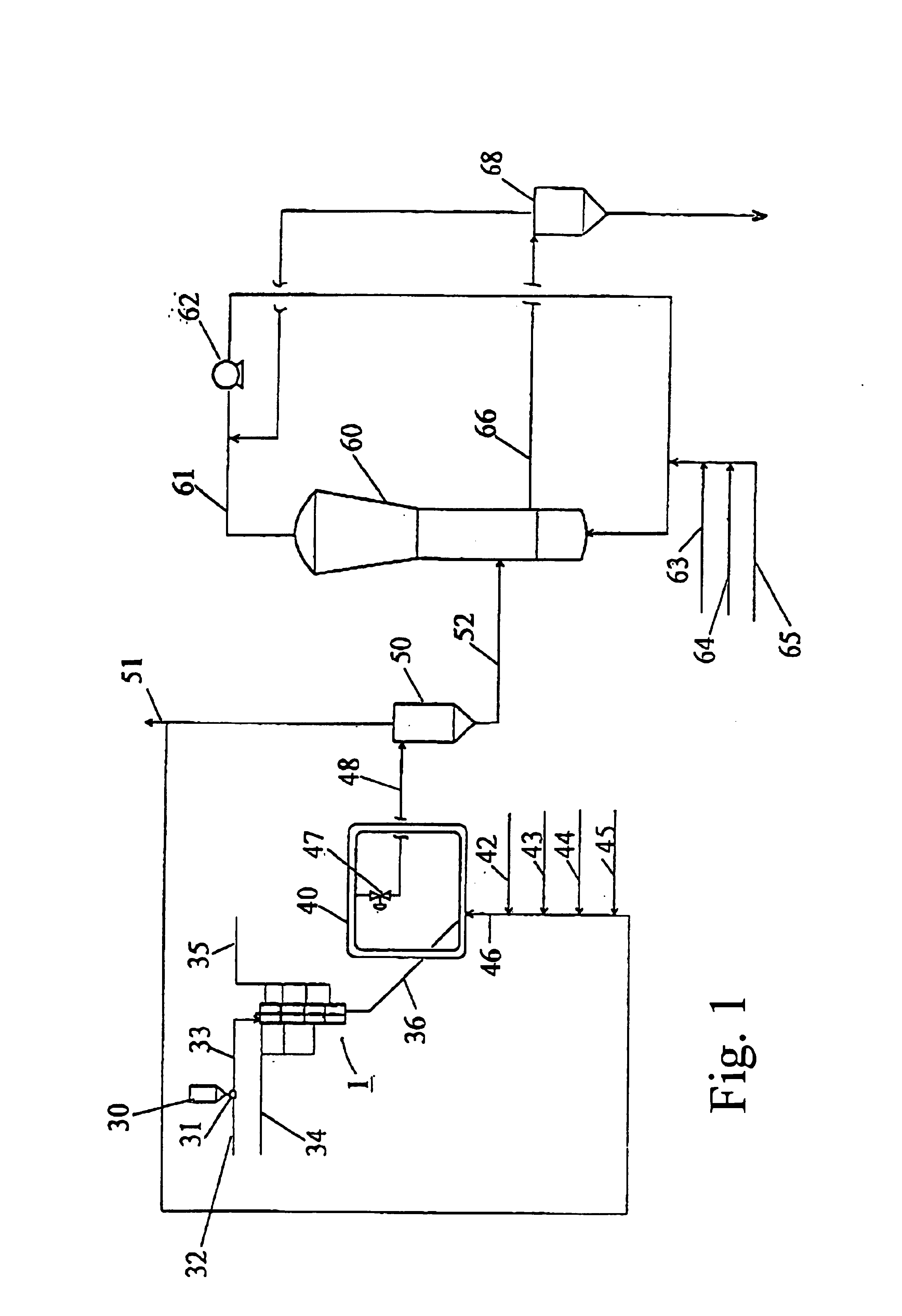

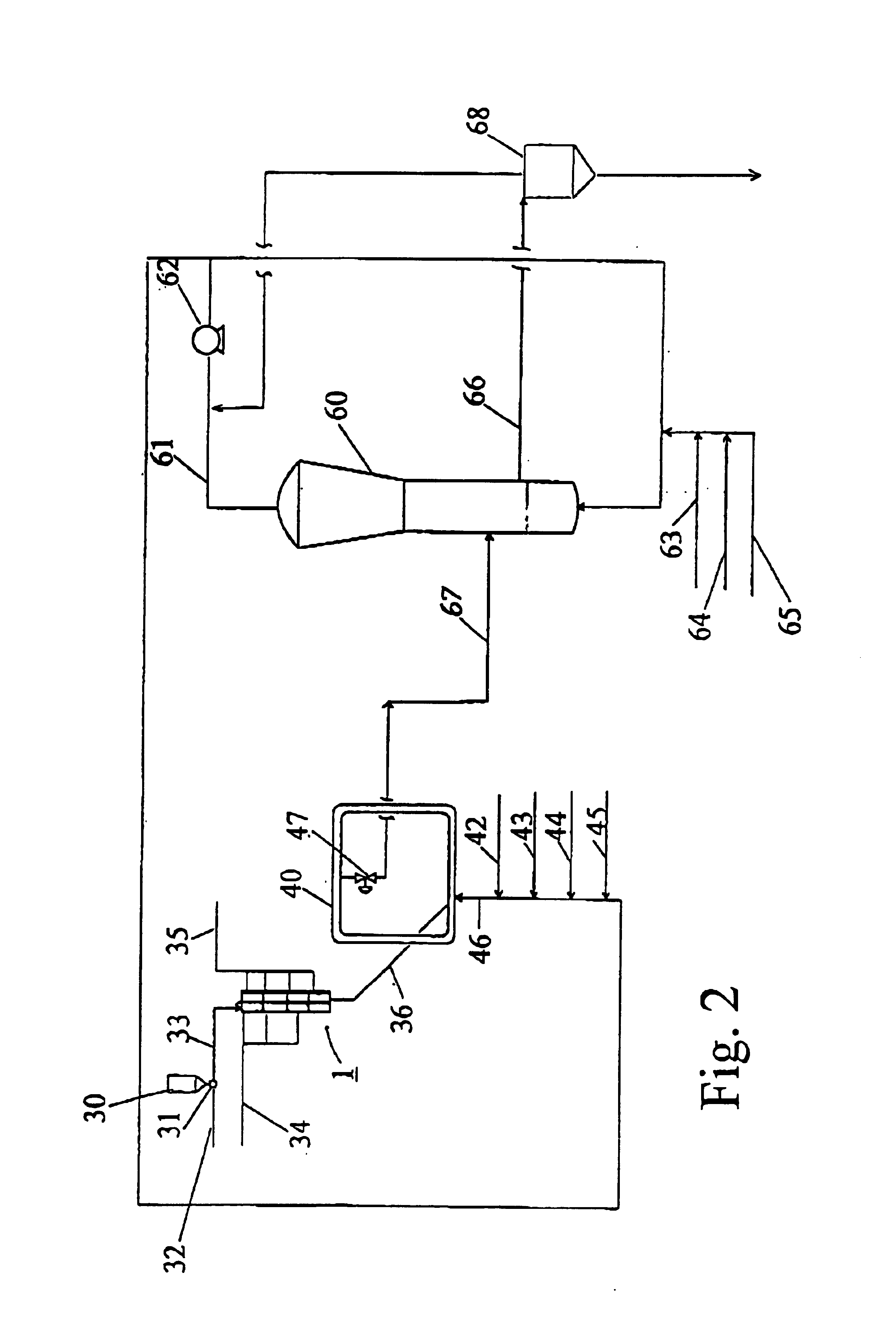

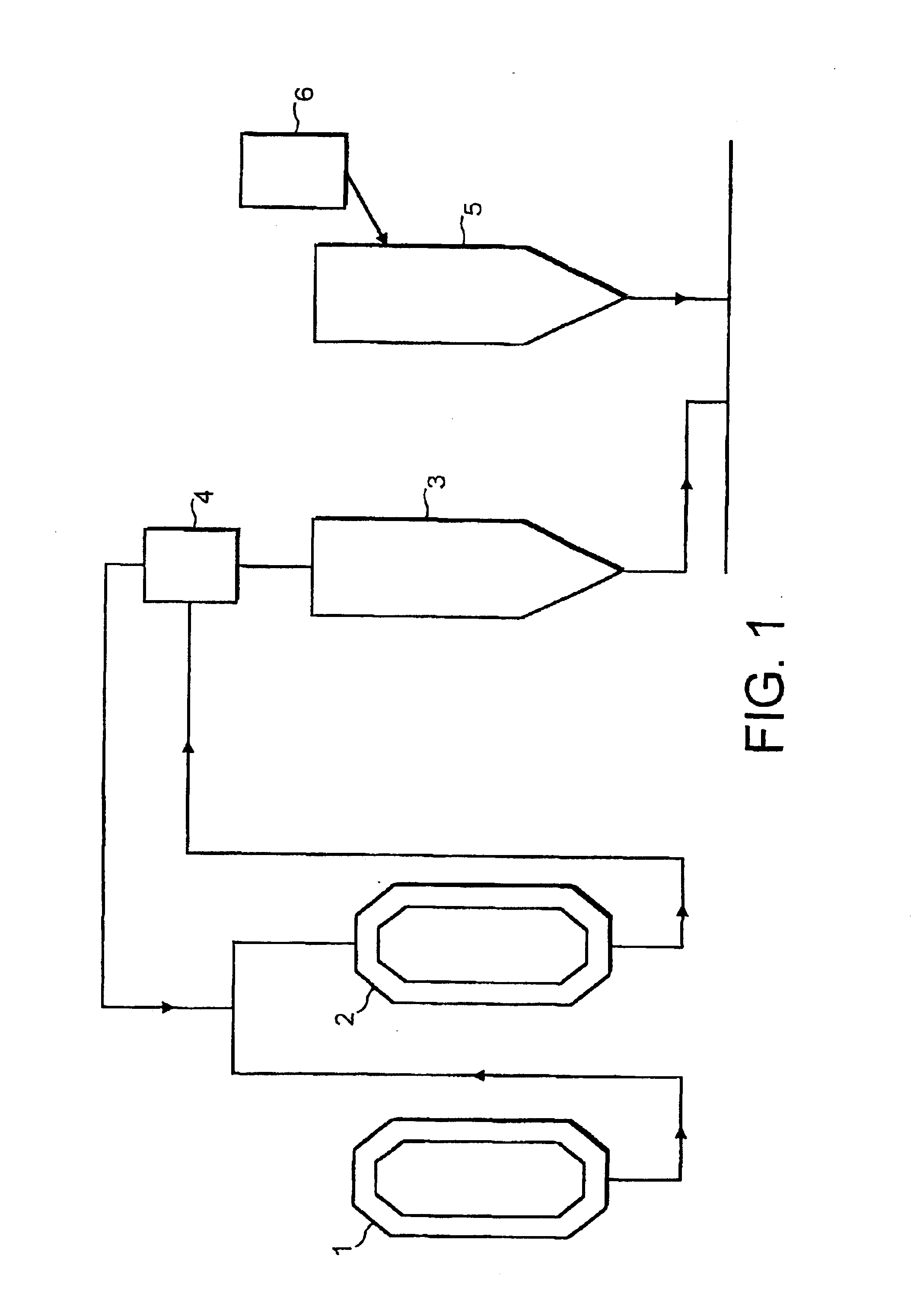

Conversion of oxygenate to propylene using moving bed technology and a separate heavy olefin interconversion step

ActiveUS20060161035A1Improve economyEfficient OTP processMolecular sieve catalystCatalystsFixed bedOxygenate

The average propylene cycle yield of an oxygenate to propylene (OTP) process using a dual-function oxygenate conversion catalyst is substantially enhanced by the use of a combination of: 1) moving bed reactor technology in the catalytic OTP reaction step in lieu of the fixed bed technology of the prior art; 2) a separate heavy olefin interconversion step using moving bed technology and operating at an inlet temperature at least 15° C. higher than the maximum temperature utilized in the OTP reaction step; 3) C2 olefin recycle to the OTP reaction step; and 4) a catalyst on-stream cycle time of 700 hours or less. These provisions hold the build-up of coke deposits on the catalyst to a level which does not substantially degrade dual-function catalyst activity, oxygenate conversion and propylene selectivity, thereby enabling maintenance of average propylene cycle yield for each cycle near or at essentially start-of-cycle levels.

Owner:UOP LLC

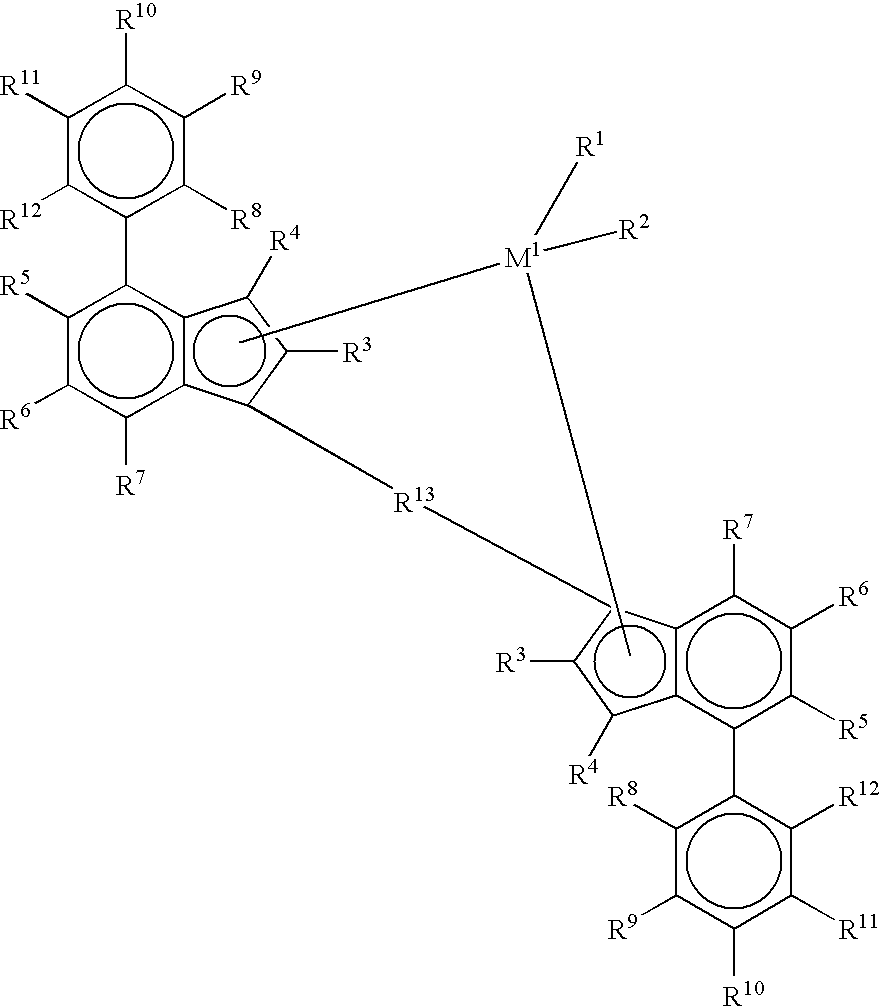

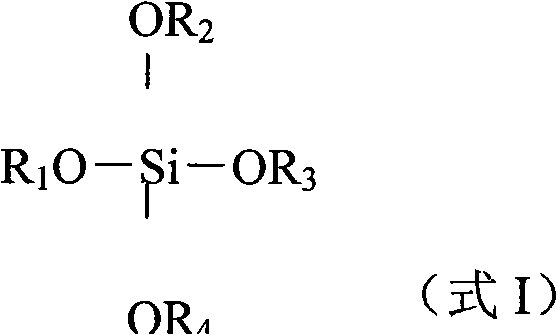

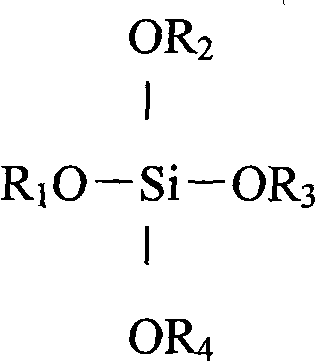

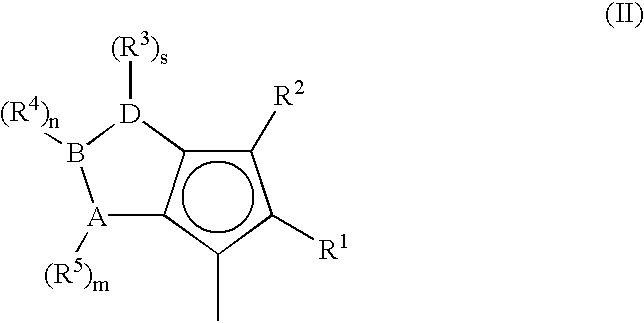

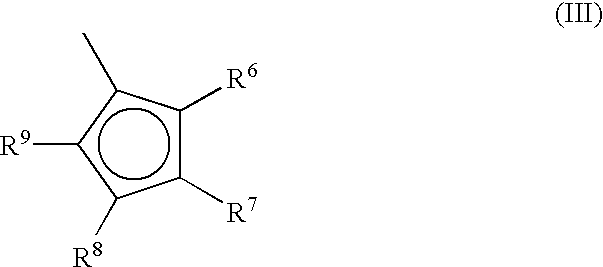

Metallocene compounds, process for their preparation and their use in catalytic systems for the polymerization of olefins

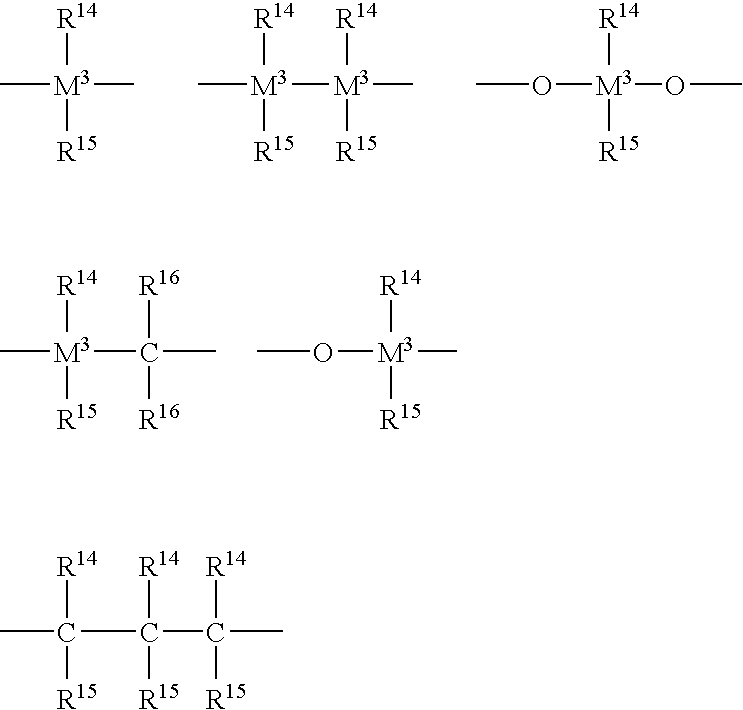

A class of metallocene compounds is disclosed having general formula (I) wherein Y is a moiety of formula (II) wherein A, B, and D, same or different from each other, are selected from an element of the groups 14 to 16 of the Periodic Table of the Elements (new IUPAC version), with the exclusion of nitrogen and oxygen; R<1>, R<2>, R<3>, R<4 >and R<5 >are hydrogen or hydrocarbon groups, Z is selected from a moiety of formula (II) as described above and from a moiety of formula (III) wherein R<6>, R<7>, R<8 >and R<9>, are hydrogen or hydrocarbon groups; L is a divalent bridging group; M is an atom of a transition metal selected from those belonging to group 3, 4, 5, 6 or to the lanthanide or actinide groups in the Periodic Table of the Elements (new IUPAC version), X, same or different, is hydrogen, a halogen, a R<10>, OR<10>, OSO2CF3, OCOR<10>, SR<10>, NR<10>2 or PR<10>2 group, wherein the substituents R<10 >are hydrogen or alkyl groups; p is an integer of from 1 to 3, being equal to the oxidation state of the metal M minus 2. The above metallocenes are particularly useful in the polymerization of propylene.

Owner:BASELL POLYOLEFINE GMBH

Catalyst composition comprising shuttling agent for higher olefin multi-block copolymer formation

ActiveUS7951882B2Improve efficiencyWoven fabricsNon-woven fabricsOlefin polymerization4-Methyl-1-pentene

Copolymers, especially multi-block copolymer containing therein two or more segments or blocks differing in chemical or physical properties, are prepared by polymerizing propylene, 4-methyl-1-pentene, or other C4-8α-olefin and one or more copolymerizable comonomers, especially ethylene in the presence of a composition comprising the admixture or reaction product resulting from combining: (A) a first metal complex olefin polymerization catalyst, (B) a second metal complex olefin polymerization catalyst capable of preparing polymers differing in chemical or physical properties from the polymer prepared by catalyst (A) under equivalent polymerization conditions, and (C) a chain shuttling agent.

Owner:DOW GLOBAL TECH LLC

Polymer having long isotactic sequences and randomly-distributed ethylene content obtained by polymerizing propylene in presence of specific catalysts

InactiveUS6048950AOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationAluminoxanePolymer science

Propylene isoblock polymers with 0.5 to 10 mol %, based on the total polymer, of randomly distributed ethylene content and with a narrow molecular weight distribution and rubber-like properties are obtained when propylene is polymerized using a catalyst comprising an aluminoxane and a chiral metallocene, containing bridges, of formula I: in which M1 is preferably hafnium or zirconium, R1 and R2 are preferably halogen (e.g. C1) atoms, R3 through R6 are hydrogen or C1-C10-alkyl, and pair of adjacent radicals R3, R4, R5, and R6 can form an aromatic ring with the C-atoms to which they are bonded, and R7 is preferably -Si(CH3)2-Si(CH3)2-.

Owner:BASELL POLYOLEFINE GMBH

Polymer blends and pellets and methods of producing same

Blends of at least two polymers incorporating propylene-derived units and processes for producing such blends are provided. The first polymer of the blend is a low crystallinity polymer including propylene-derived units. The second polymer is a high crystallinity polymer including propylene-derived units. The polymer blends exhibit the beneficial performance characteristics of low crystallinity propylene polymers while minimizing certain processing and handling problems associated with low crystallinity propylene polymers. Low crystallinity propylene polymer pellets often exhibit a tendency to agglomerate because of the softness of such particles. Agglomeration of the pellets creates problems in handling and processing the particles. The polymer blends disclosed reduce the tendency of polymer pellets to agglomerate while maintaining the desirable physical properties, such as elastomeric properties, exhibited by low crystallinity propylene polymers. Various processes for producing the polymer blends are also provided.

Owner:EXXONMOBIL CHEM PAT INC

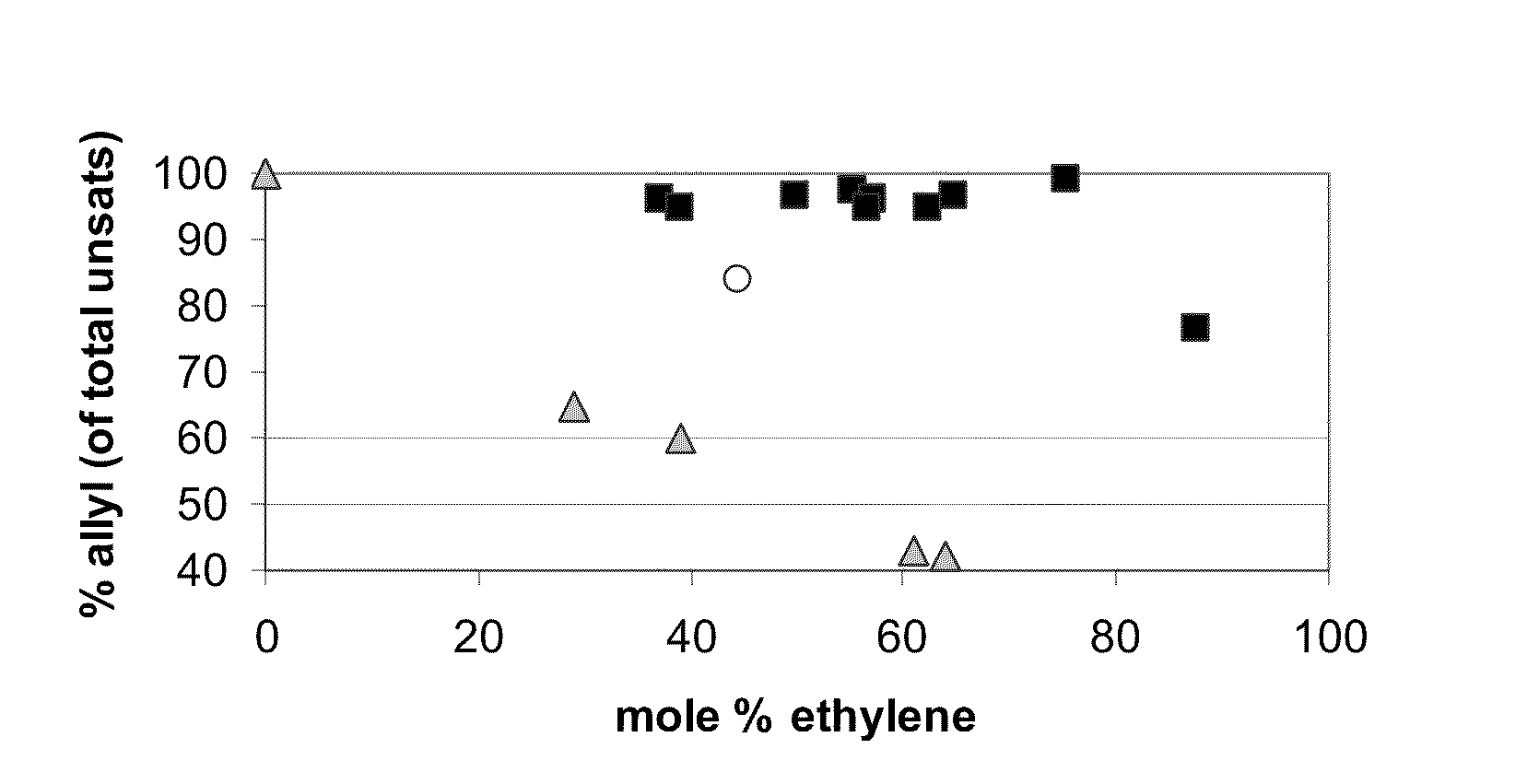

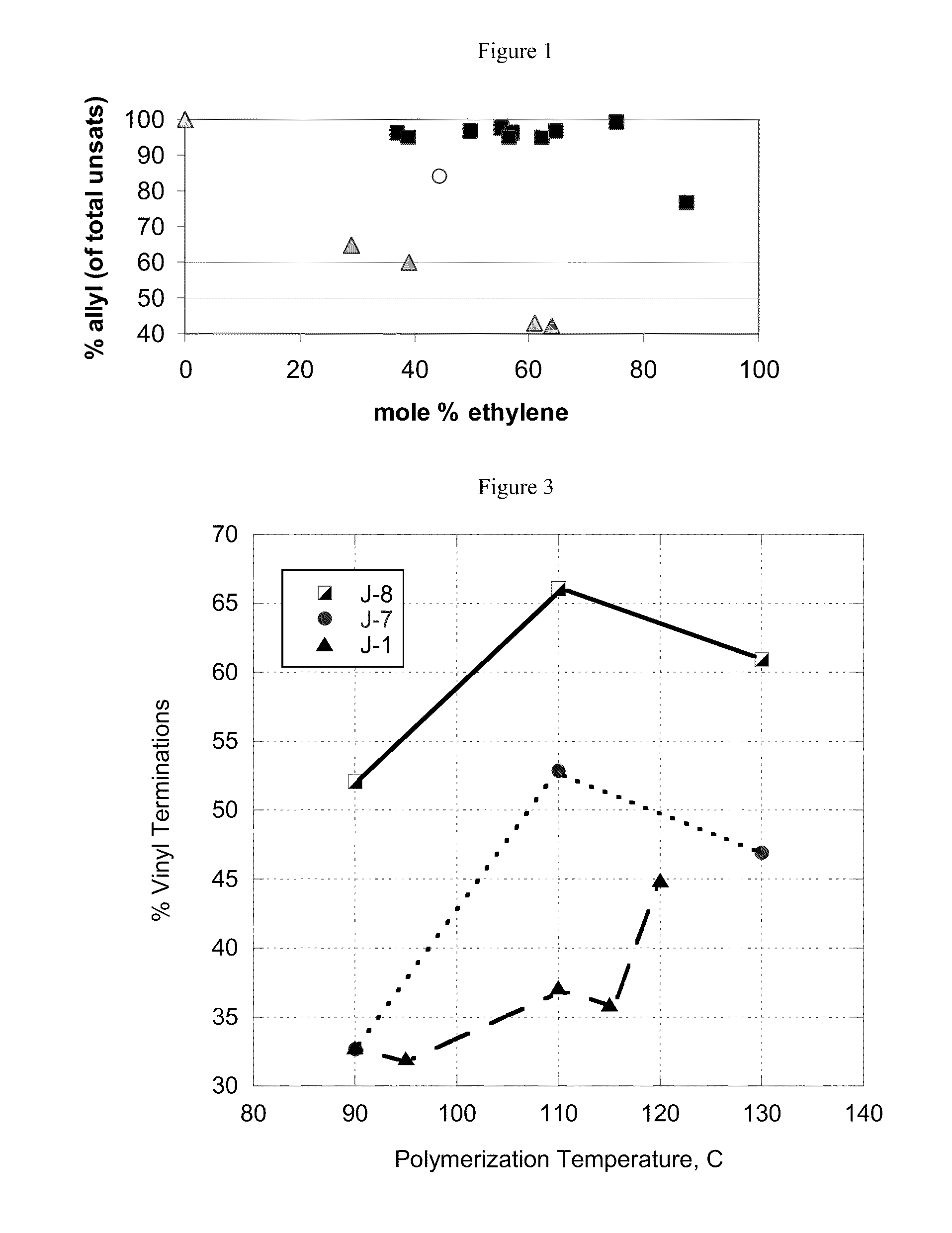

Functionalized High Vinyl Terminated Propylene Based Oligomers

This invention relates to a functionalized co-oligomer having an Mn of 300 to 30,000 g / mol comprising 10 to 90 mol % propylene and 10 to 90 mol % of ethylene, wherein the oligomer has at least X % allyl chain ends, where: 1) X=(−0.94(mole % ethylene incorporated)+100), when 10 to 60 mole % ethylene is present in the co-oligomer, and 2) X=45, when greater than 60 and less than 70 mole % ethylene is present in the co-oligomer, and 3) X=(1.83*(mole % ethylene incorporated)−83), when 70 to 90 mole % ethylene is present in the co-oligomer. This invention also relates to a functionalized homo-oligomer, comprising propylene, wherein the oligomer has: at least 93% allyl chain ends, an Mn of about 500 to about 20,000 g / mol, an isobutyl chain end to allylic vinyl group ratio of 0.8:1 to 1.2:1.0, and less than 100 ppm aluminum. This invention also relates to a process of making functionalized homo-or co-oligomer, comprising propylene, wherein the productivity is greater than 4500 g / mmol Hf (or Zr) / hour.

Owner:EXXONMOBIL CHEM PAT INC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com