Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

172results about How to "High monomer conversion rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High activity olefin polymerization catalyst and process

ActiveUS6953764B2High catalytic efficiencyHigh monomer conversionGroup 4/14 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsOlefin polymerizationPolymerization catalysts

Group 4 metal complexes useful as addition polymerization catalysts of the formula: whereinG1 is a group containing from 1 to 40 atoms not counting hydrogen;T is a divalent bridging group of from 10 to 30 atoms not counting hydrogen, selected from mono- or di-aryl-substituted methylene or silylene groups or mono- or di-heteroaryl-substituted methylene or silylene groups, wherein at least one such aryl- or heteroaryl-substituent is substituted in one or both ortho-positions with a secondary or tertiary alkyl-group, a secondary or tertiary heteroalkyl group, a cycloalkyl group, or a heterocycloalkyl group,G2 is a C6-20 heteroaryl group containing Lewis base functionality,M is the Group 4 metal,X″″ is an anionic, neutral or dianionic ligand group,x″″ is a number from 0 to 5, andbonds, optional bonds and electron donative interactions are represented by lines, dotted lines and arrows respectively.

Owner:DOW GLOBAL TECH LLC

Temperature and salt resistant grafted polyacrylamide and preparation method thereof

ActiveCN102050913AHigh monomer conversion rateGood temperature resistanceDrilling compositionMethacrylamideWater soluble polymers

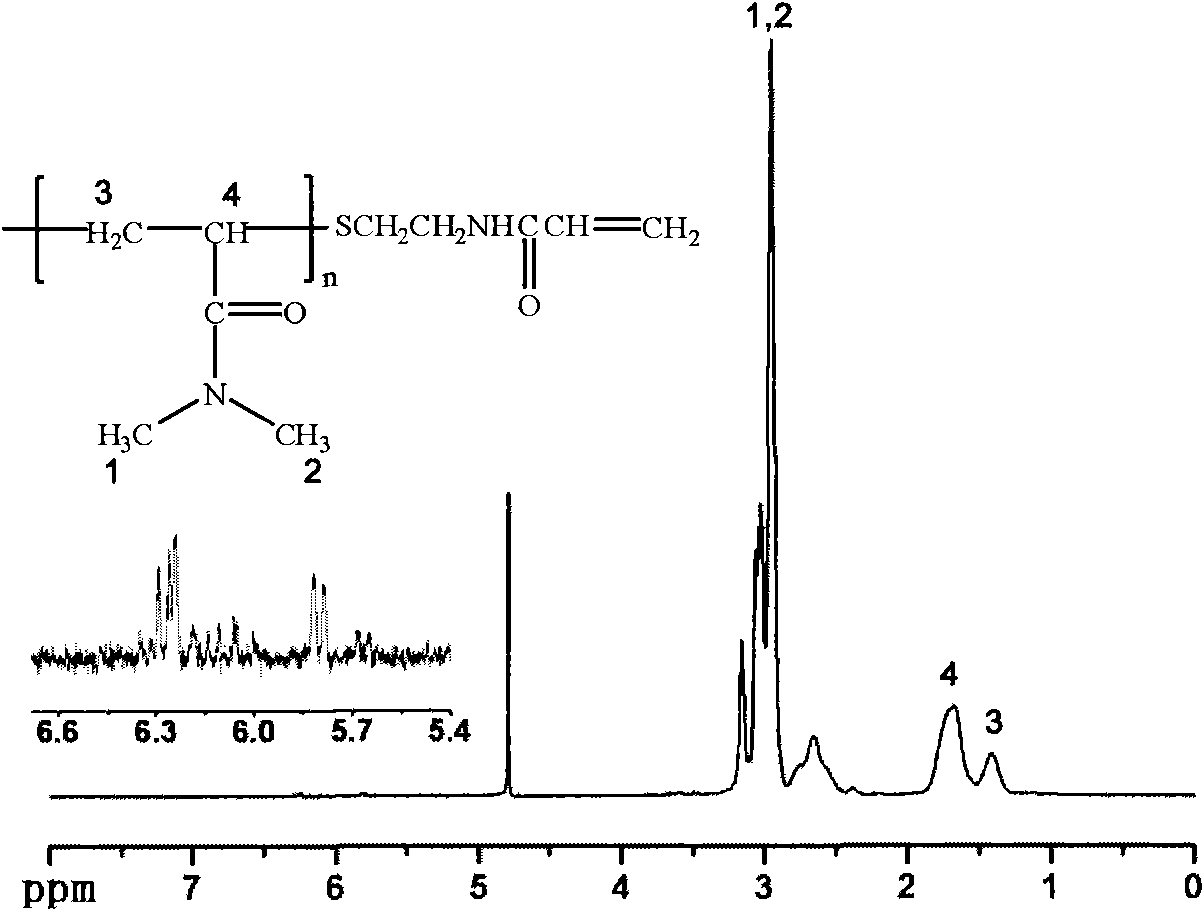

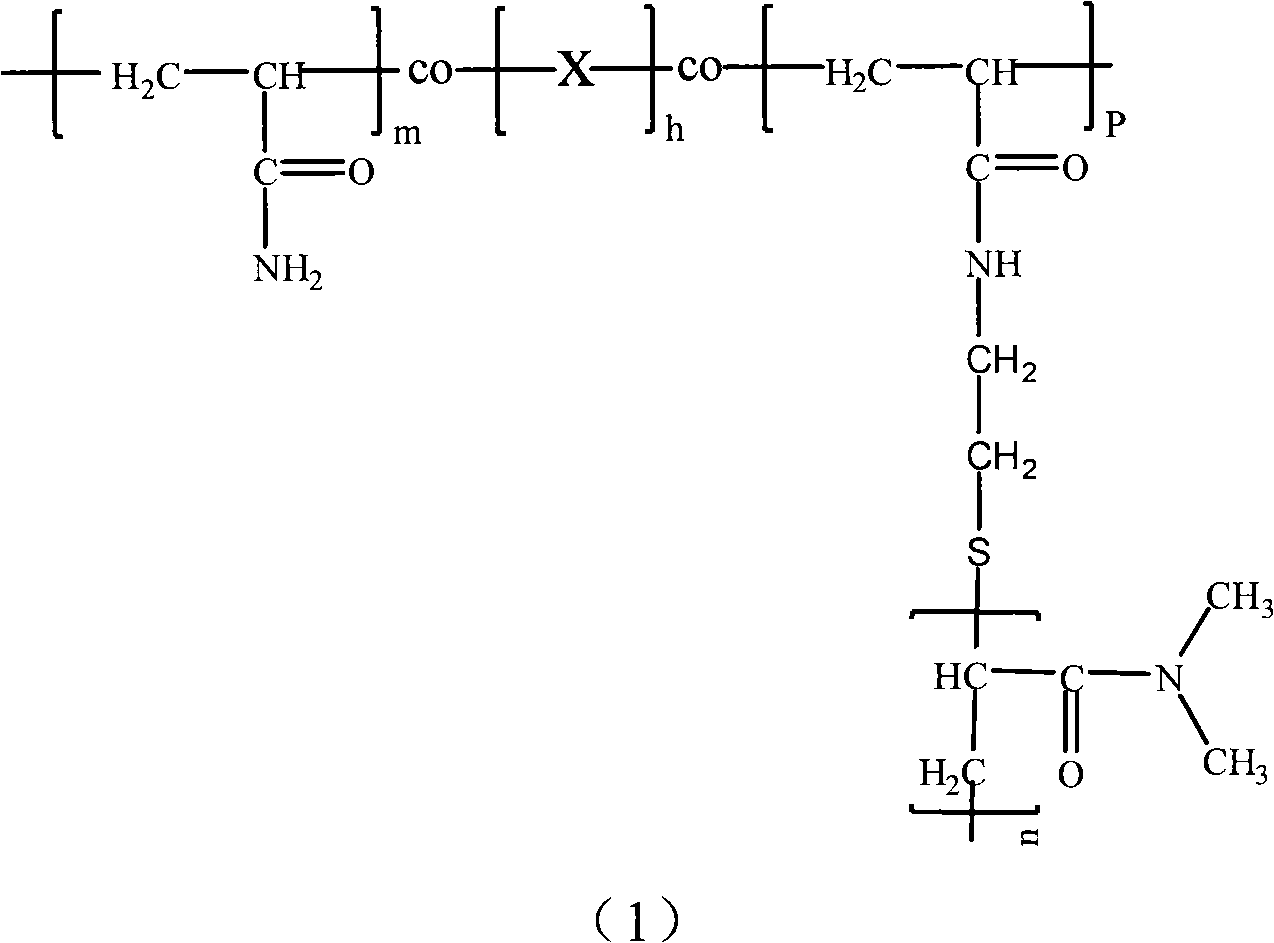

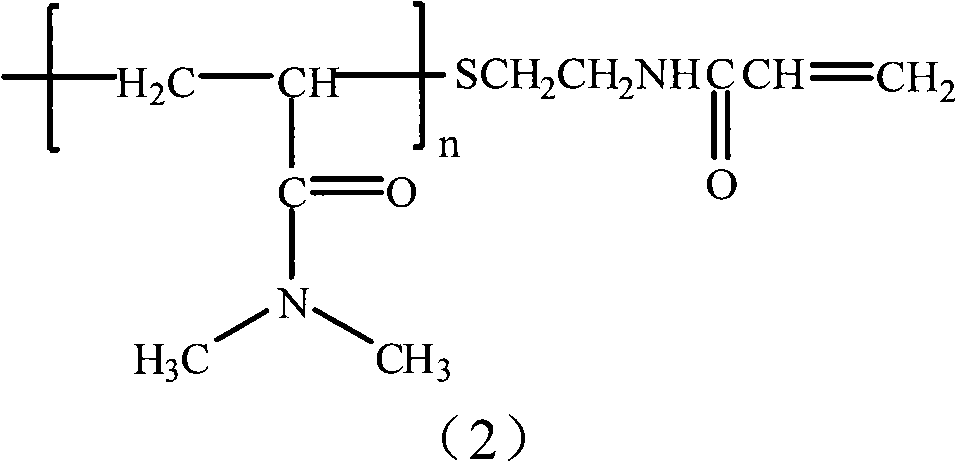

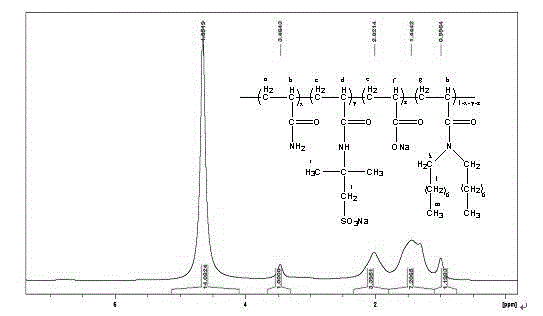

The invention relates to a temperature and salt resistant grafted polyacrylamide synthesized by a macromonomer route, belonging to the research field of water-soluble polymer used for displacement of reservoir oil. A method of chain transfer free radical polymerization and terminal group replacement is adopted to obtain a polyacrylamide (N,N-dimethylacrylamide) type macromonomer. Under an oxidation-reduction complex initiation system, temperature and salt resistant monomers, such as the macromonomer, acrylamide, N-polyvinyl pyrrolidone, N,N-dimethylacrylamide, 2-Acryloylamino-2-methyl propanesulfonic acid and the like, are copolymerized to obtain a target product. From molecular design, a functional long-grafted side chain can increase the viscoelasticity of the polymer molecule and lower solution surface tension. The product provided by the invention can be used for three-class oil deposit and provides a possible solution for improving the recovery ratio for chemical displacement of reservoir oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing monodisperse polymer microspheres

InactiveCN102731698AStrong microscopic mixing propertiesStrong microscopic mixing properties effectively increase the frequency of molecular collisionsPolymer scienceUltracentrifuge

The invention relates to a method for preparing monodisperse polymer microspheres. The method comprises the following process steps: adding a dispersion medium with a stabilizing agent dissolved inside to an impinging stream reactor, heating the dispersion medium, adding a monomer with an initiating agent dissolved inside in one step, carrying out constant-temperature polymerization reaction, obtaining polymer microsphere emulsion after stopping cooling, then using an ultracentrifuge to carry out centrifugal sedimentation, adding absolute ethyl alcohol after removing supernatant, carrying out ultrasonic washing multiple times and drying the washed microspheres to constant weight, thus obtaining the monodisperse polymer microspheres. Compared with the prior art, the method has the following advantages: the prepared polymer microspheres have good apparent morphology, good smoothness and monodispersity and uniform grain sizes; the process is simple to operate; the grain sizes of the microspheres can be well controlled according to the formula; and the grain size range applicability is better.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

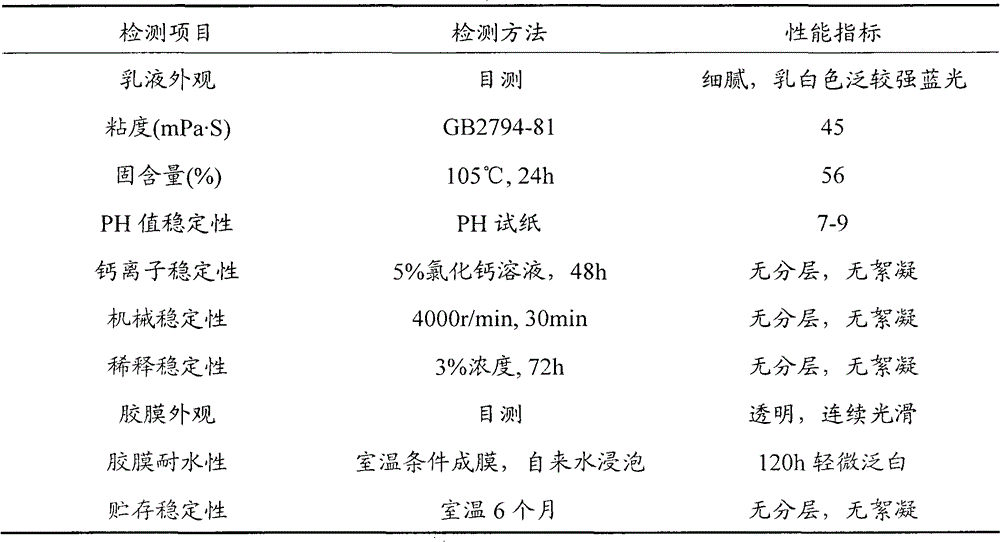

Automobile industry filter paper impregnation emulsion and method for modifying the same by using polymerizable emulsifier

ActiveCN101230553AImprove film formation and water resistanceImprove water resistanceSurfactants additionNon-macromolecular organic additionFunctional monomerEmulsion

The invention disclose a filter paper impregnating emulsion in the automotive industry and a method for modifying the filter paper impregnating emulsion by using a polymeric emulsifier, and relates to a filter paper water-soluble impregnated resin in the automotive industry and the method for modifying the filter paper impregnating emulsion in the automotive industry by using the polymeric emulsifier. The emulsion of the invention comprises the polymeric emulsifier of 0.5 percent to 4 percent, a general emulsifier of 0 to 3 percent, hard-monomer styrene of 40 percent to 55 percent, soft-monomer acrylic ester of 40 percent to 55 percent, crosslinking monomer of 2 percent to 5 percent, and functional monomer of 2 percent to 10 percent according to the mixture ratio of the mass percent. The invention has the modification method that: the hard-monomer, the soft-monomer, the crosslinking monomer and the functional monomer are used as a copolymer, and the automobile air filter paper water-soluble impregnated resin is synthetized through a semicontinuous pre-emulsification emulsion polymerization method. The invention greatly enhances the hydrolytic resistance, solvent resistance and strength character of the filter paper after the impregnating in the water-soluble resin, lowers the emulsion manufacturing cost, and reduces the environment pollution caused by dissociative emulsifier after the general emulsion is applied. The invention has the advantages of high monomer percent conversion, stable emulsion, etc.

Owner:MUDANJIANG HENGFENG PAPER CO LTD

Use of 2-methyl-1, 3-propanediol and polycarboxylate builders in laundry detergents

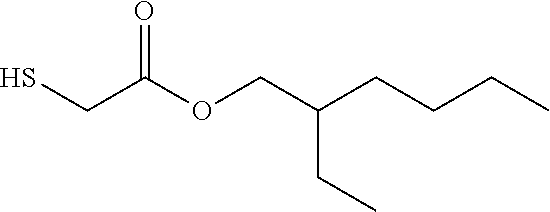

InactiveUS6511952B1High monomer conversion rateImprove processing efficiencyOrganic detergent compounding agentsNon-surface-active detergent compositionsCarboxylic acid1,3-Propanediol

A liquid laundry detergent formulation is described including a surfactant, a polycarboxylate builder and a 2-methyl-1,3-propanediol carrier solvent. A particularly preferred builder comprises a non-hydrophobically modified, acrylic / polyether comb-branched copolymer, wherein the polyether portion comprises moieties derived from at least two constituents selected from the group consisting of ethylene oxide, propylene oxide, and butylene oxide. Preferably, the comb-branched copolymer is made according to a process selected from the group consisting of: (i) copolymerizing an unsaturated macromonomer with at least one ethylenically unsaturated comonomer selected from the group consisting of carboxylic acids, carboxylic acid salts, hydroxyalkyl esters of carboxylic acids, and carboxylic acid anhydrides, and (ii) reacting a carboxylic acid polymer and a polyether prepared by polymerizing a C2-C4 epoxide, wherein the carboxylic acid polymer and the polyether are reacted under conditions effective to achieve partial cleavage of the polyether and esterification of the polyether and cleavage products thereof by the carboxylic acid polymer.

Owner:LYONDELL CHEM TECH LP

Low migration free radical radiation curable inkjet inks

ActiveUS9701856B2High monomer conversion rateHigh viscosityInksThin material handlingVinyl etherVitrification

Owner:AGFA NV

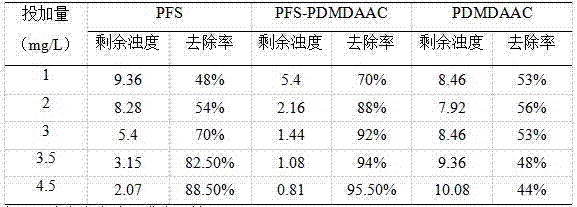

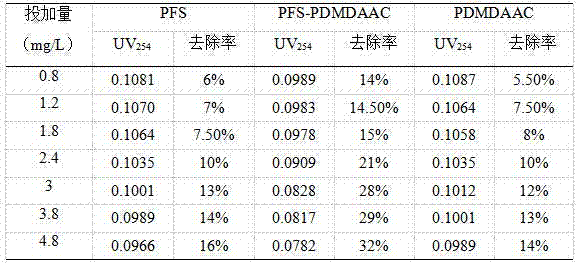

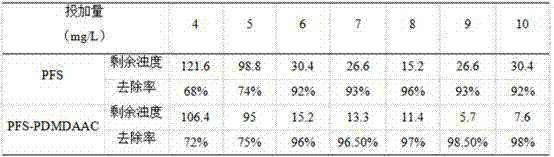

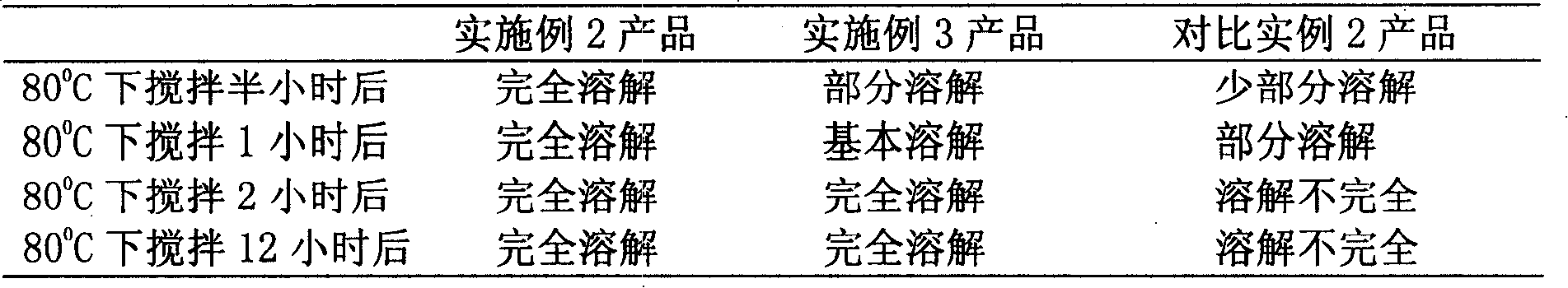

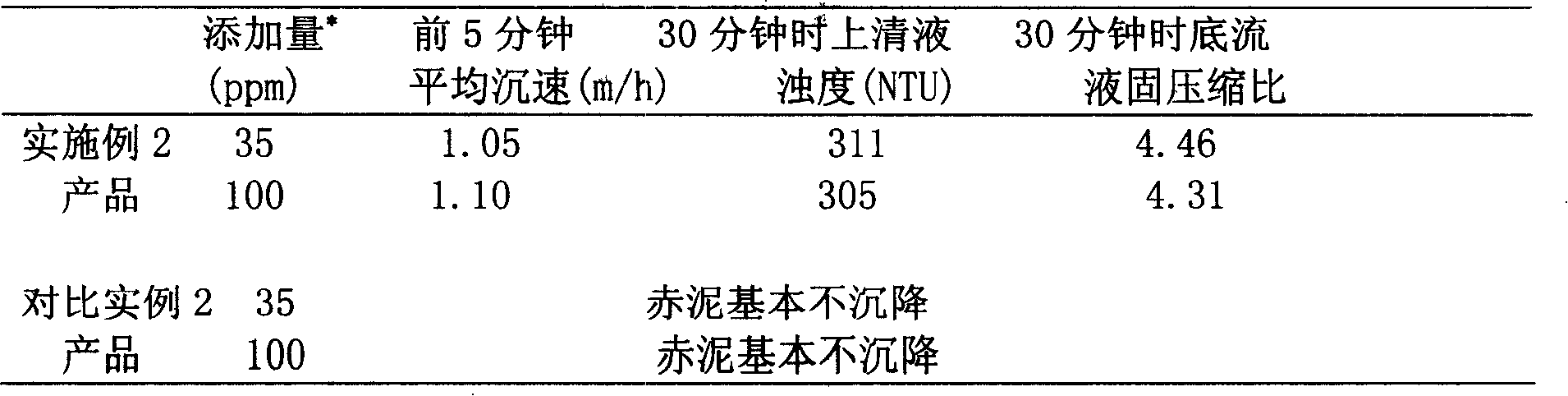

Preparation method of organic high-polymer flocculant, and preparation method and application of inorganic-organic high-polymer composite coagulant

InactiveCN104761038AGood effectSimple processWater/sewage treatment by flocculation/precipitationEngineeringPolymer composites

The invention discloses a preparation method of an organic high-polymer flocculant, and a preparation method and application of an inorganic-organic high-polymer composite coagulant. The preparation method of the organic high-polymer flocculant comprises the following step: in the presence of an initiator and a chelator, carrying out solution polymerization on dimethyl diallyl ammonium chloride monomer to obtain a polydimethyl diallyl ammonium chloride colloidal solution which is the organic high-polymer flocculant. The preparation method of the composite coagulant comprises the following steps: 1) heating and mixing a polyferric sulfate solution with the colloidal solution to obtain a colloid mixed solution; and 2) keeping the temperature, and dispersing until the mixed solution forms a homogeneous system. The invention also discloses application of at least one of the prepared flocculant and inorganic-organic high-polymer composite coagulant in coagulative purification or sludge dewatering treatment of polluted water bodies. The technique is simple, and the prepared composite flocculant has favorable effect. The flocculant and coagulant can be used for micropolluted water source-water coagulative purification, special wastewater treatment, sludge dewatering and the like, and are simple and quick to operate.

Owner:DONGGUAN UNIV OF TECH +1

Technique for preparing high solid-content low oil-water ratio water-soluble polymer reversed phase emulsion

The invention relates to a water soluble polymer reverse micro emulsion with high solid content and low oil-water ratio, which comprises (1) preparing water-soluble vinyl monomer into 40-70% vinyl monomer water solution, (2) feeding high-purity nitrogen into the mixture of oil phase, emulsifier and stabilizer, mixing completely, increasing temperature to 30-50DEG C, adding vinyl monomer water solution, mixing, synchronously adding inducer and polymerization speed control agent, feeding high-purity nitrogen, reacting for 3-5h to obtain reverse micro emulsion. The prepared reverse micro emulsion has 35-42% solid content and 99.5-100% monomer conversion rate, while the stable storage period is longer than half yield, the product is easily dissolved in water and the application effect is better than the water soluble polymer reverse micro emulsion which oil-water ratio is higher than 1:1.

Owner:CENT SOUTH UNIV

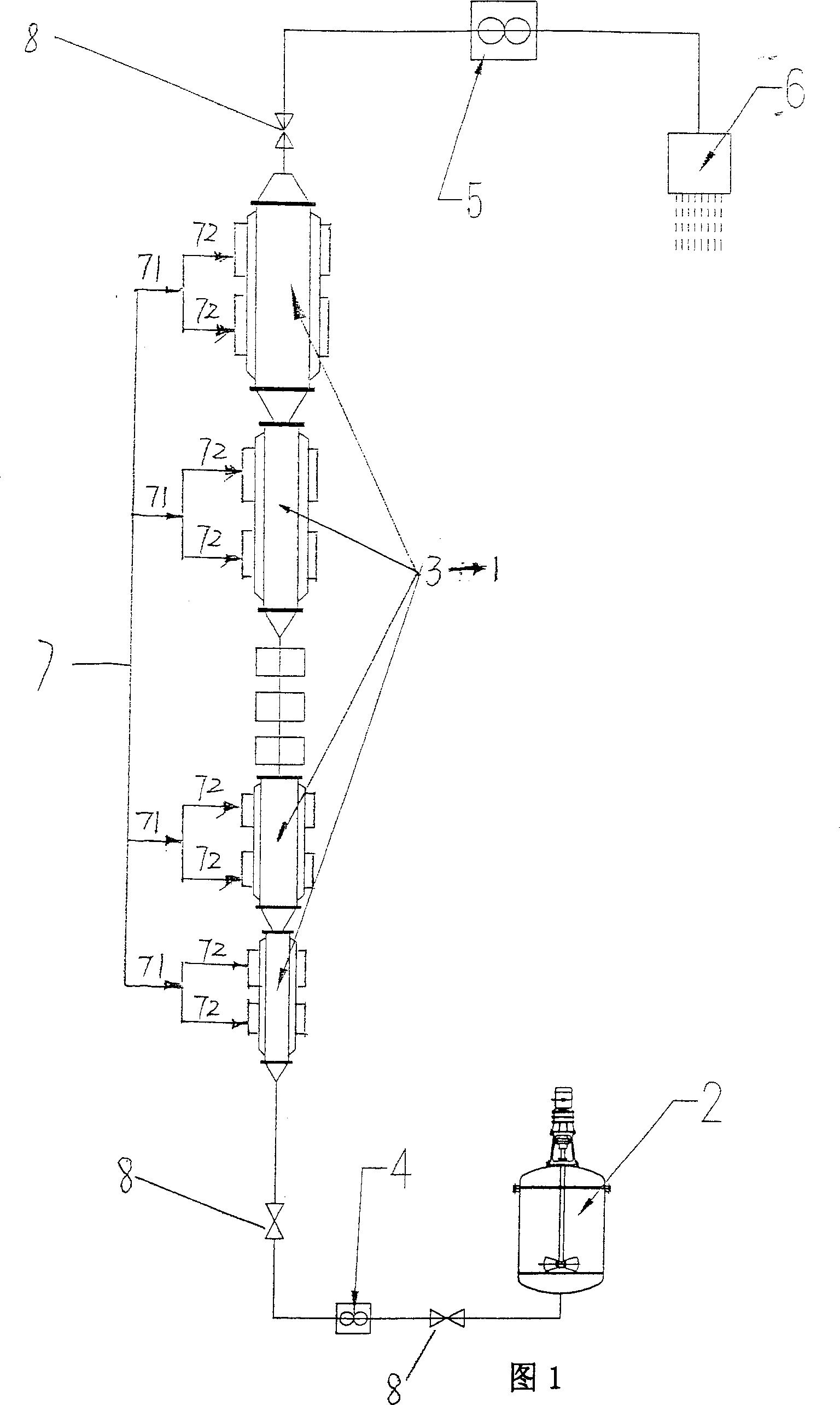

Lactide analog monomer continuous polymerization device and process

ActiveCN1879958AHigh monomer conversion rateGood controllabilityChemical/physical/physico-chemical stationary reactorsPolymerization reactorEngineering

The invention relates to a device for continuously polymerizing lactide monomer, wherein said device comprises a tubular polymer reactor, a meter pump and a fuser, which are serially connected; the tubular polymer reactor is formed by several serially connected tubular stable mixers whose diameters are increased stepped; the meter and the fuser are serially connected to the small end of reactor. The invention also provides a relative method, which comprises: adding material into the fuser, to be fused and mixed; using meter pump to feed the mixture into the small end of reactor, to pass all stable mixers; the polymer will be extruded from the large end. The invention has high transform rate, high yield and high quality.

Owner:CHINESE TEXTILE ACAD

Method for preparing silicone acrylic emulsion with high solid content and high silicon content

The invention relates to a method for preparing a silicone acrylic emulsion with high solid content (of over 50 percent), high organic silicon content (of over 15 percent) and low emulsifier consumption (of less than 2.5 percent), in particular a silicone acrylic emulsion for preparing high-grade exterior wall coating materials. The method comprises steps of preparing a vinyl polysiloxane emulsion by using octamethylcyclotetrasiloxane, tetravinyl tetramethylcyelo tetrasiloxane, dodecylbenzene sulfonic acid, sodium dodecyl benzene sulfonate, a non-ionic emulsifier NP-40 and deionized water through acid catalyzed ring opening, and performing silicone acrylic emulsion copolymerization of the vinyl polysiloxane emulsion and acrylic monomers in the presence of a thermal initiator to prepare the stable silicone acrylic emulsion with high solid content, high organic silicon content and low emulsifier consumption. By the method, problems that the silicon content cannot be improved substantially, the solid content is low and the emulsifier consumption is high in the preparation of the silicone acrylic emulsion are effectively solved. The silicone acrylic emulsion has excellent weather resistance, stain resistance, water resistance and the like, and has high cost performance; and the application range of the silicone acrylic emulsion is greatly widened.

Owner:武汉强力荷新材料有限公司

Method of preparing UV-curable Inkjet Pigment Ink for Textile Printing

ActiveUS20150111981A1High monomer conversion rateImprove fluencyConjugated diene hydrocarbon coatingsInksEmulsionWater soluble

The present invention provides a method of preparing UV-curable inkjet pigment ink for textile printing, in which mini-emulsion techniques are used to encapsulate monomer, photo initiator, thermal initiator and pigment in mini-emulsion particles to make a UV-curable pigment paste, and the UV-curable pigment paste is mixed with water-soluble co-solvent, surfactant and water to make a UV-curable pigment ink. The preparation process is simple and easy. The UV-curable inkjet pigment ink of the invention exhibits good fluency during printing, bright color and strong color fastness in printed products.

Owner:JIANGNAN UNIV

Semi-continuous process for preapring organofluorine polymer grafted polyether polyol

A process for semi-continuously preparing organofluorine polymer grafted polyether polyol includes such steps as adding mixed solvent, xylene and methylisobutyl methanone to reactor, adding the monomer mixture liquid including vinyl or acryl ester, unsaturated polyether polyol, AIBN, etc and the organofluorine monomer liquid to reactor, and copolymerizing reaction. The product can be used to prepare F-C paint which features high weatherability and resistance to acid, alkali, chemical corrosion and ultraviolet ray, and high adhesion.

Owner:QINGDAO CHEM COLLEGE

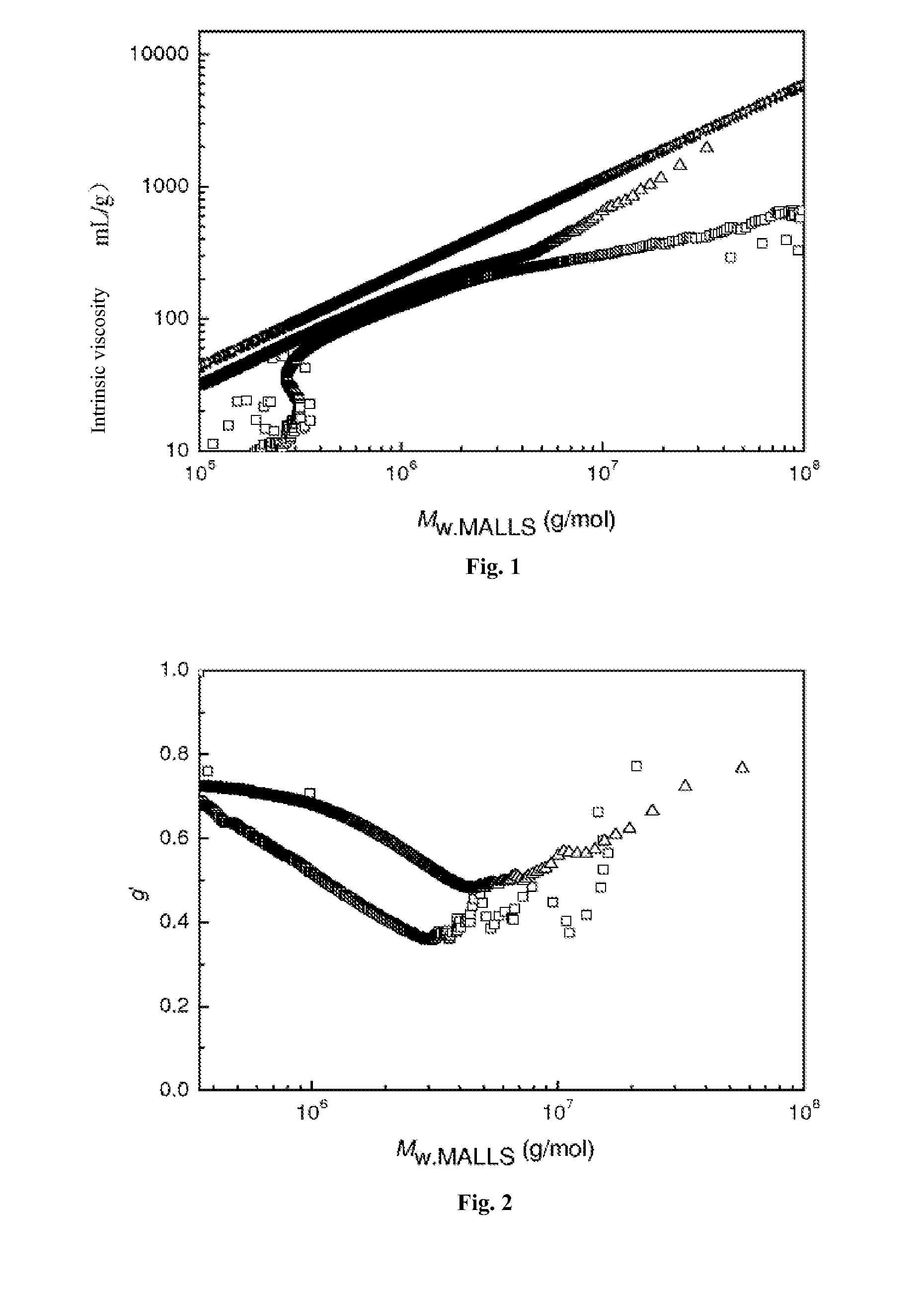

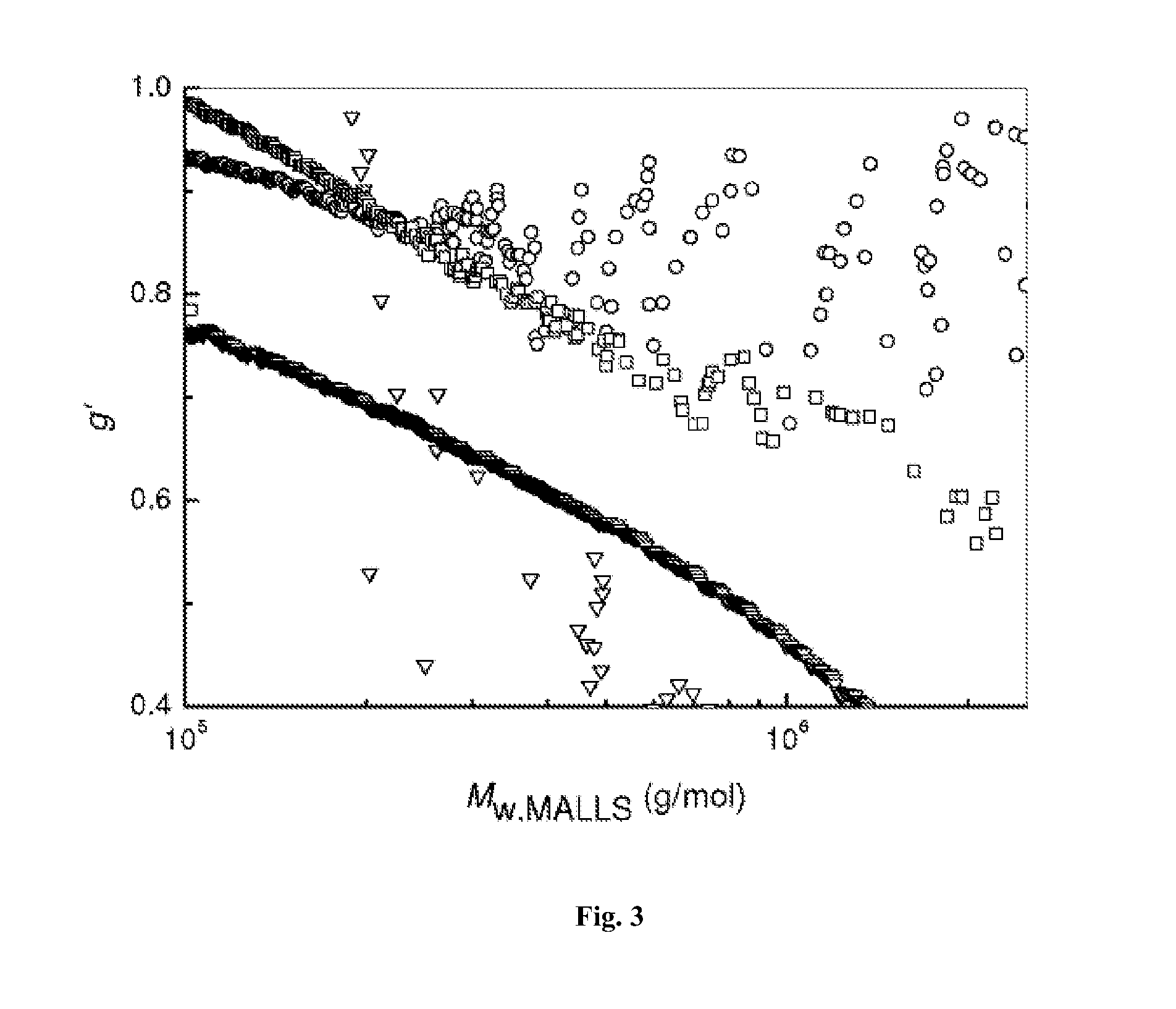

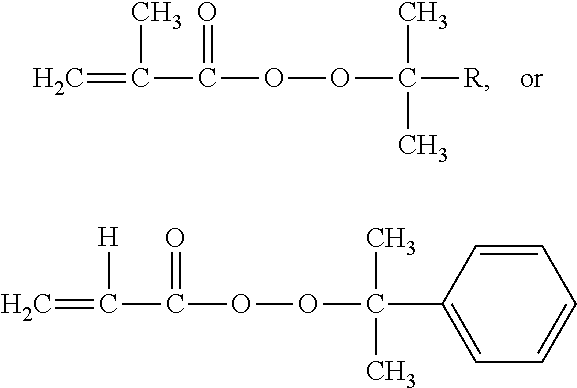

Process for preparing branched polymer

A process for preparing a branched polymer, belonging to the fields of polymer synthesis and preparation of functional polymers. A vinyl monomer, such as styrene, toluene (benzene, xylene) as a solvent, is subjected to a self-initiated free radical polymerization at 60˜100° C. with a new type of compound (methyl (meth)acrylate peroxide) as the initiator and the branched monomer containing both polymerisable double bond and peroxide bond, which can be used to synthesize the branched polymers. The degree of branching of the polymer can be adjusted by adjusting the molar ratio of the new type of compound to polymerisable monomer. The process for preparing a branched polymer is carried out under the conditions of conventional free radical polymerization without the addition of the branched monomer and other assist initiators. The polymerization is simple and feasible, has a high monomer conversion, a controllable degree of branching for the polymer, and is highly suitable for synthesizing branched polymers from various monomers. Another advantage of this process is its low production cost.

Owner:CHANGZHOU UNIV

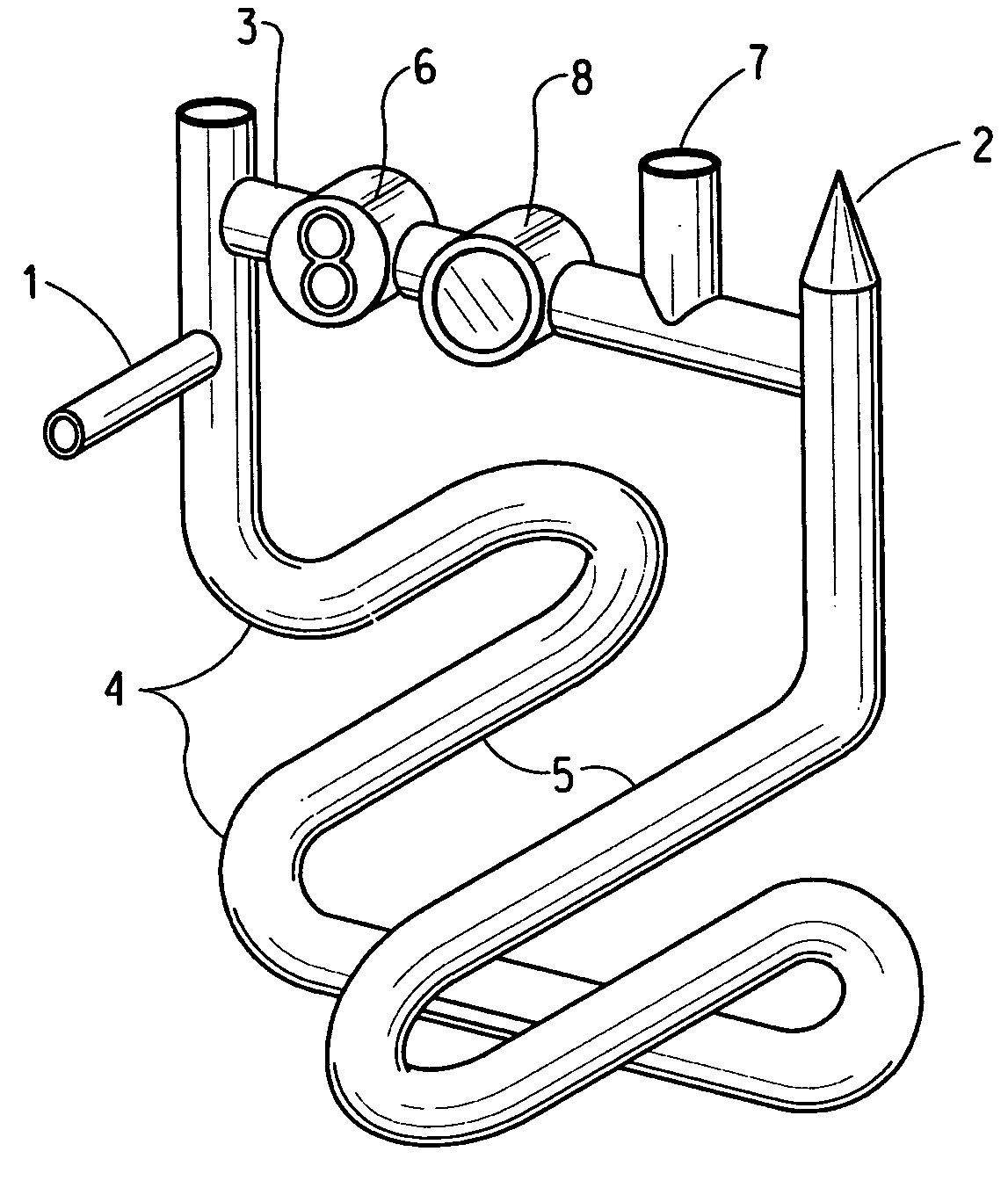

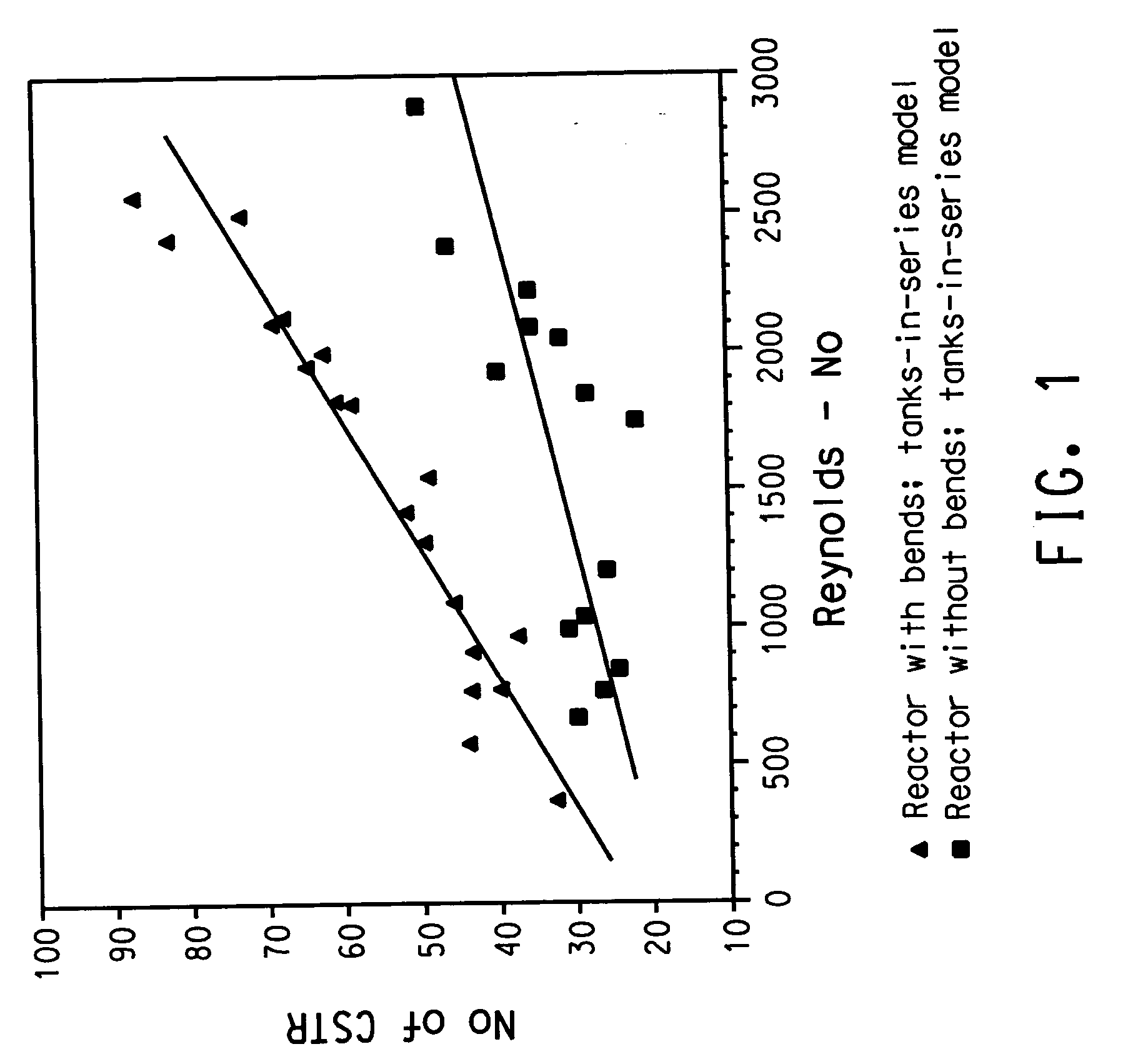

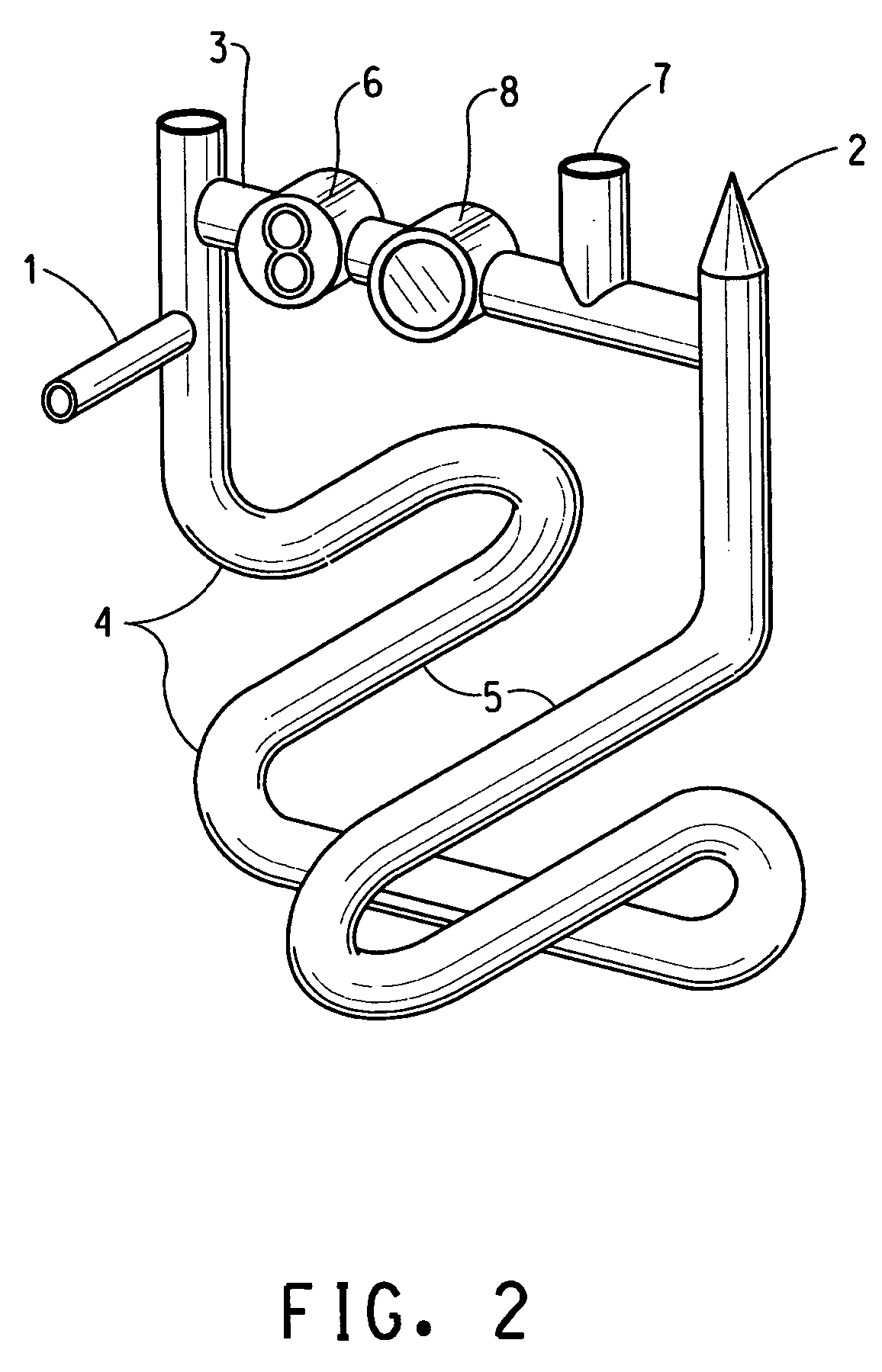

Device and method of producing low molecular polymers

InactiveUS20060036047A1High monomer conversion rateImprove cooling effectChemical/physical/physico-chemical stationary reactorsEngineeringTube bending

The invention relates to a loop reactor for carrying out continuous polymerization reactions for the production of polymers with adjustable polymer properties comprising a three-dimensional tubular loop comprising at least two tube bends with interposed tube segments, the tube bends having a curving angle of greater than 30°, and the distance between two tube bends being at least three times the tube diameter, the tube bends and the tube segments being arranged in a direction reversed to the curving direction of the tube bends arranging in succession.

Owner:EI DU PONT DE NEMOURS & CO

Manufacturing method of (METH) acrylic polymer

ActiveUS20130197175A1Narrow molecular weight distributionHigh conversion rateWeight distributionAcrylic polymer

In a method for polymerizing a (meth)acrylic monomer by living radical polymerization in the presence of a transition metal complex catalyst, the combined use of a multidentate amine (A), a base (B) and a reducing agent (C) makes it possible to achieve a rapid polymerization reaction and high monomer conversion rate and obtain a polymer having a narrow molecular weight distribution when 5-30 ppm by weight of copper atoms and a mole amount of 7 mmol % or less of multidentate amine (A) are used, each based on the total amount of (meth)acrylic monomer introduced.

Owner:KANEKA CORP

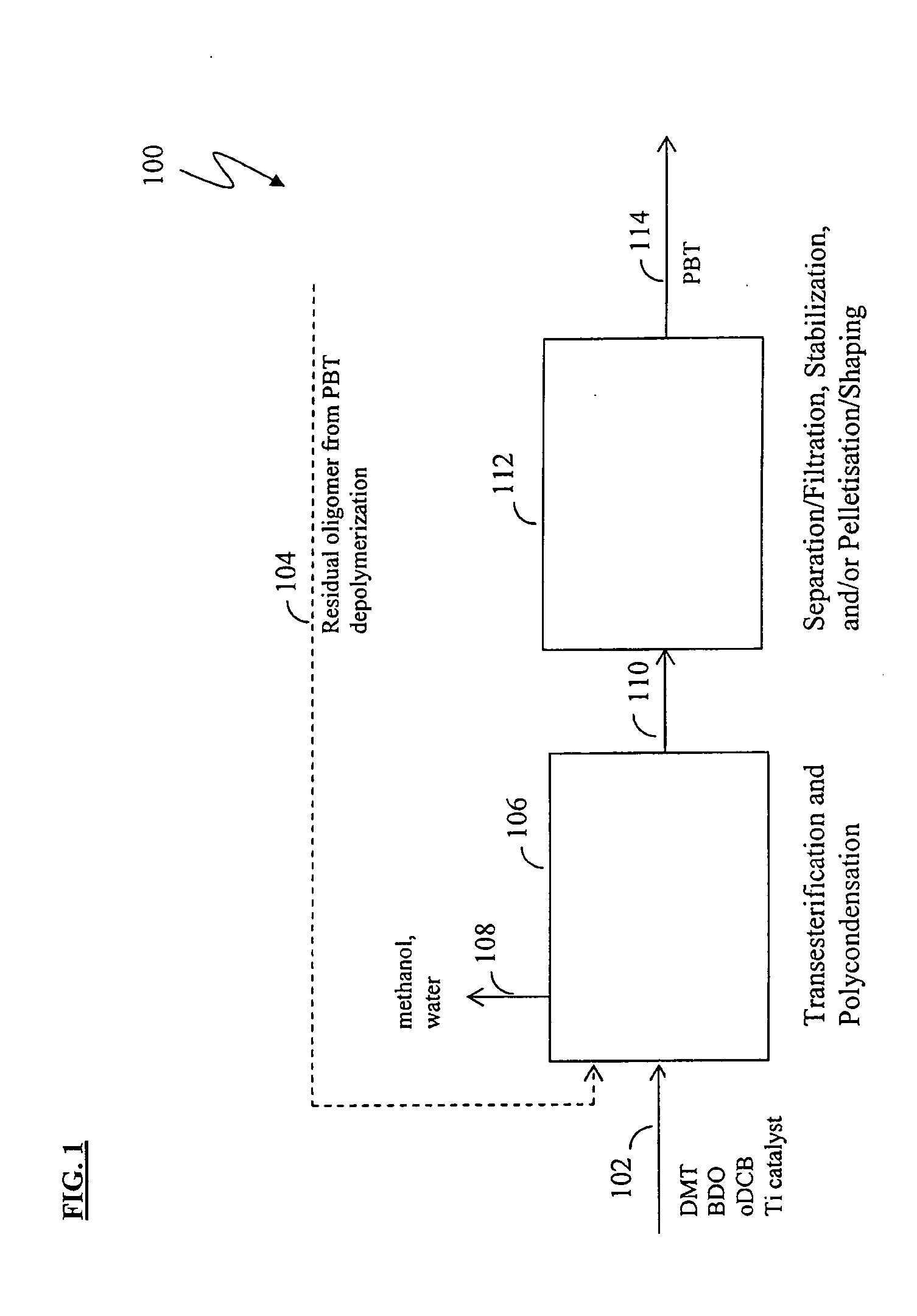

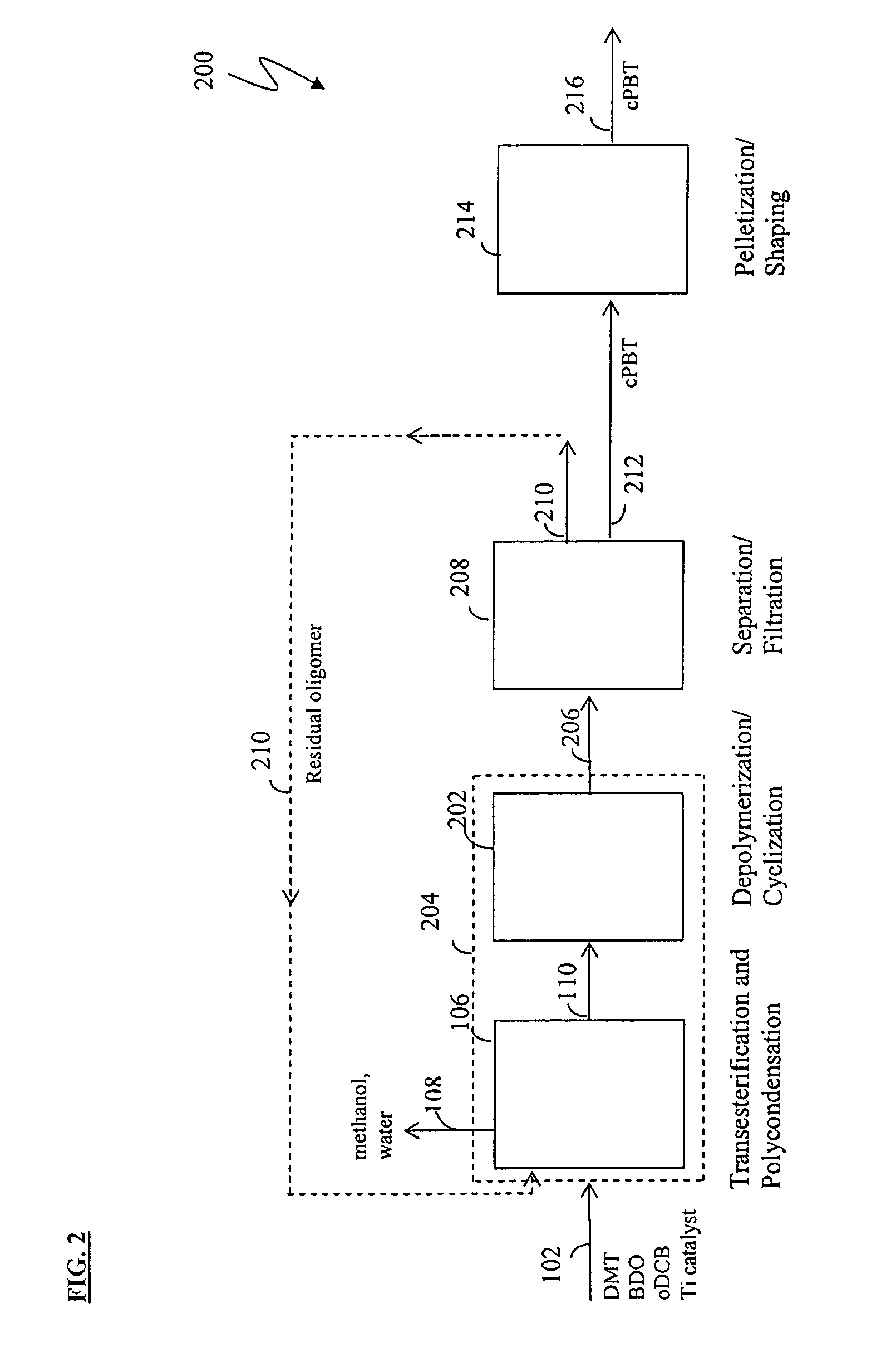

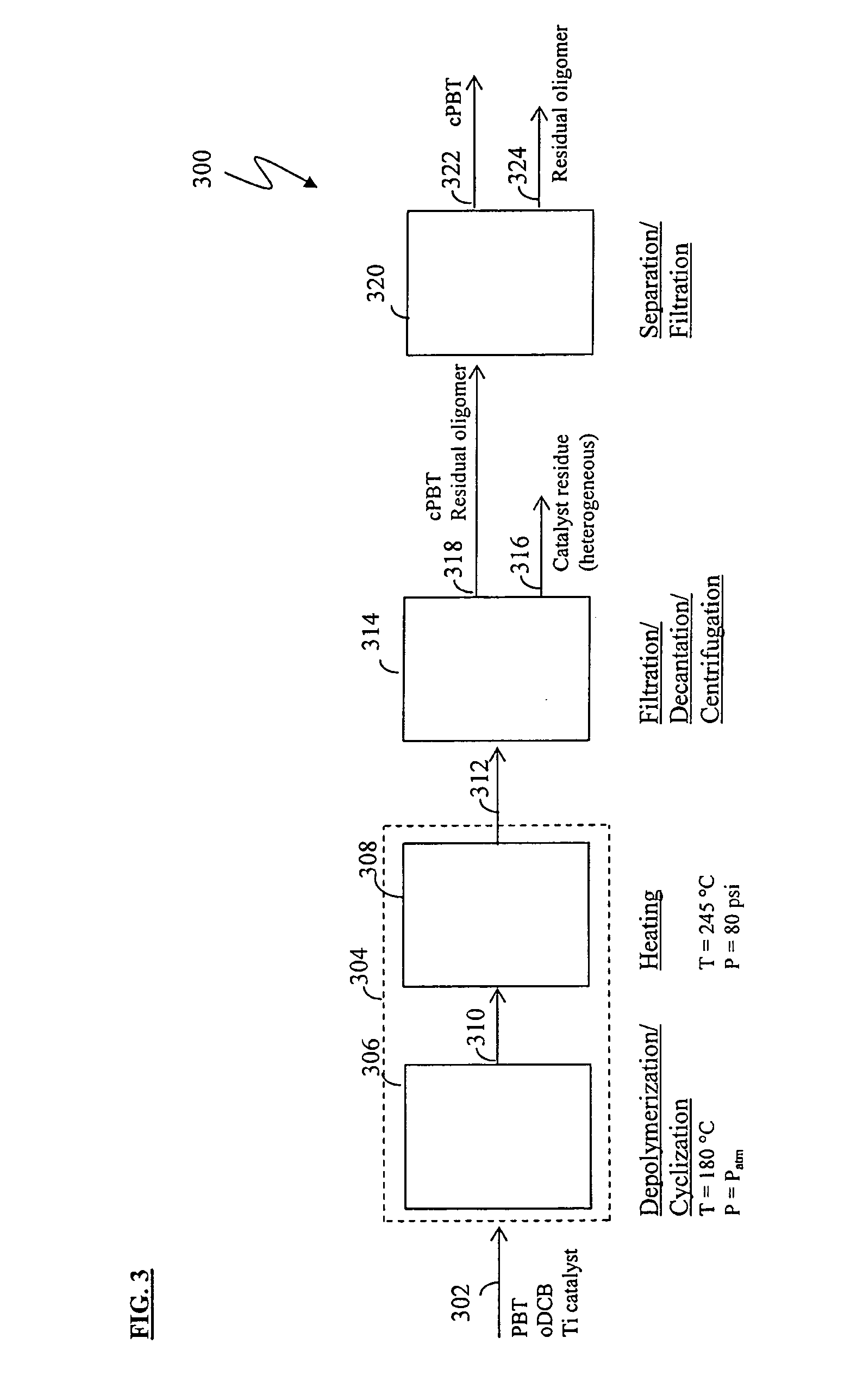

Use of a residual oligomer recyclate in the production of macrocyclic polyester oligomer

InactiveUS20060235186A1Solve low usageHigh monomer conversion rateOrganic chemistryChemical recyclingPolyesterDepolymerization

The invention relates to methods and systems for the use of an oligomer recyclate from a depolymerization product stream. The oligomer byproduct of a polyester depolymerization reaction can be used as a reactant in the formation of a polyester. For example, linear oligomer byproduct can be used as a reactant in a solution polymerization to form a low-acid polyalkylene terephthalate.

Owner:LIQUID THERMO PLASTICS

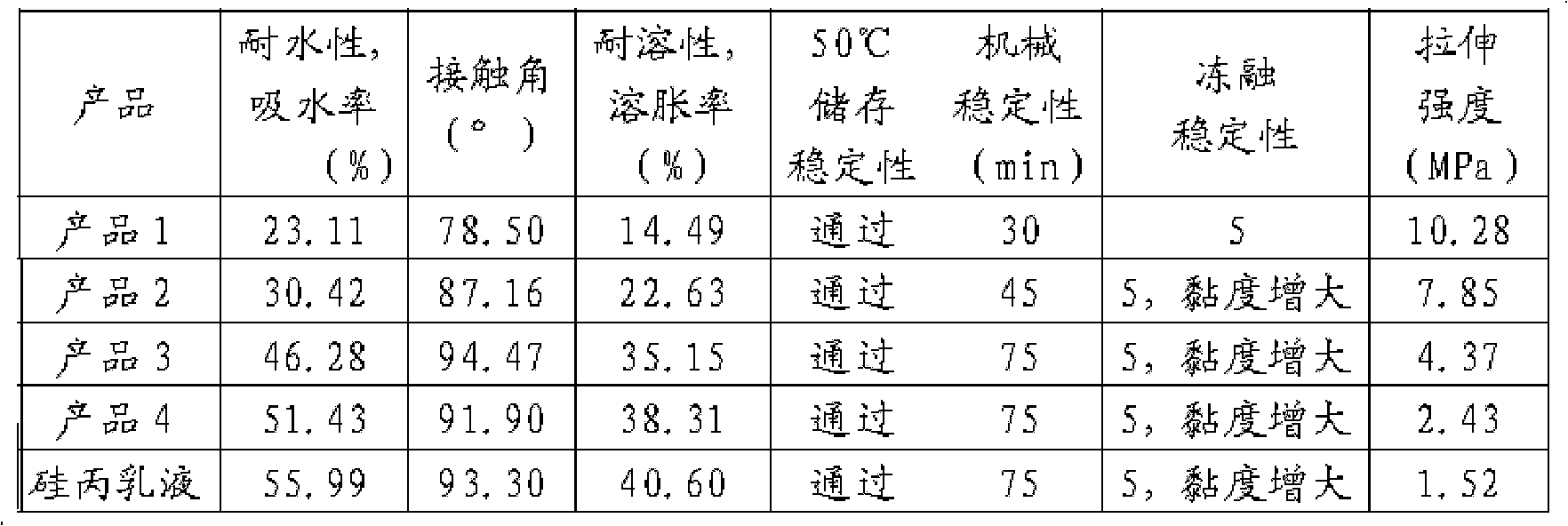

Acrylate/silicone-acrylate compound emulsion and method for preparing same

ActiveCN102020818AGood compatibilityGood hydrophobicityEmulsion paintsFunctional monomerAmmonium sulfate

The invention discloses an acrylate / silicone-acrylate compound emulsion and a method for preparing the same. Acrylate emulsions are prepared from acrylate as a main monomer, polyoxyethylene alkyl ether ammonium sulfate as emulsifier and various functional monomers containing carboxyl and are compounded with an silicone-acrylate emulsion to prepare the novel compound emulsion. The process for preparing the compound emulsion is simple, and the compound emulsion not only has the good hydrophobicity, stain resistance, washability and recoatability of the silicone-acrylate emulsion, but also has the good film forming performance, glossiness and solvent resistance of the acrylate emulsion. The compound emulsion film has higher mechanical strength and stronger adhesive force, the problems that the silicone-acrylate emulsion film has lower strength, poor adhesion and the like are solved, and the application range of the silicone-acrylate emulsion film is enlarged. The acrylate / silicone-acrylate compound emulsion can be applied to the field of emulsion coatings for coating roofs, internal walls, external walls, kitchens and the like and also can be applied to the water-proof stain-resistance occasions. The acrylate / silicone-acrylate compound emulsion can improve the grade of the emulsion coating.

Owner:HUBEI JIAJI SYNTHESIS MATERIALS CO LTD

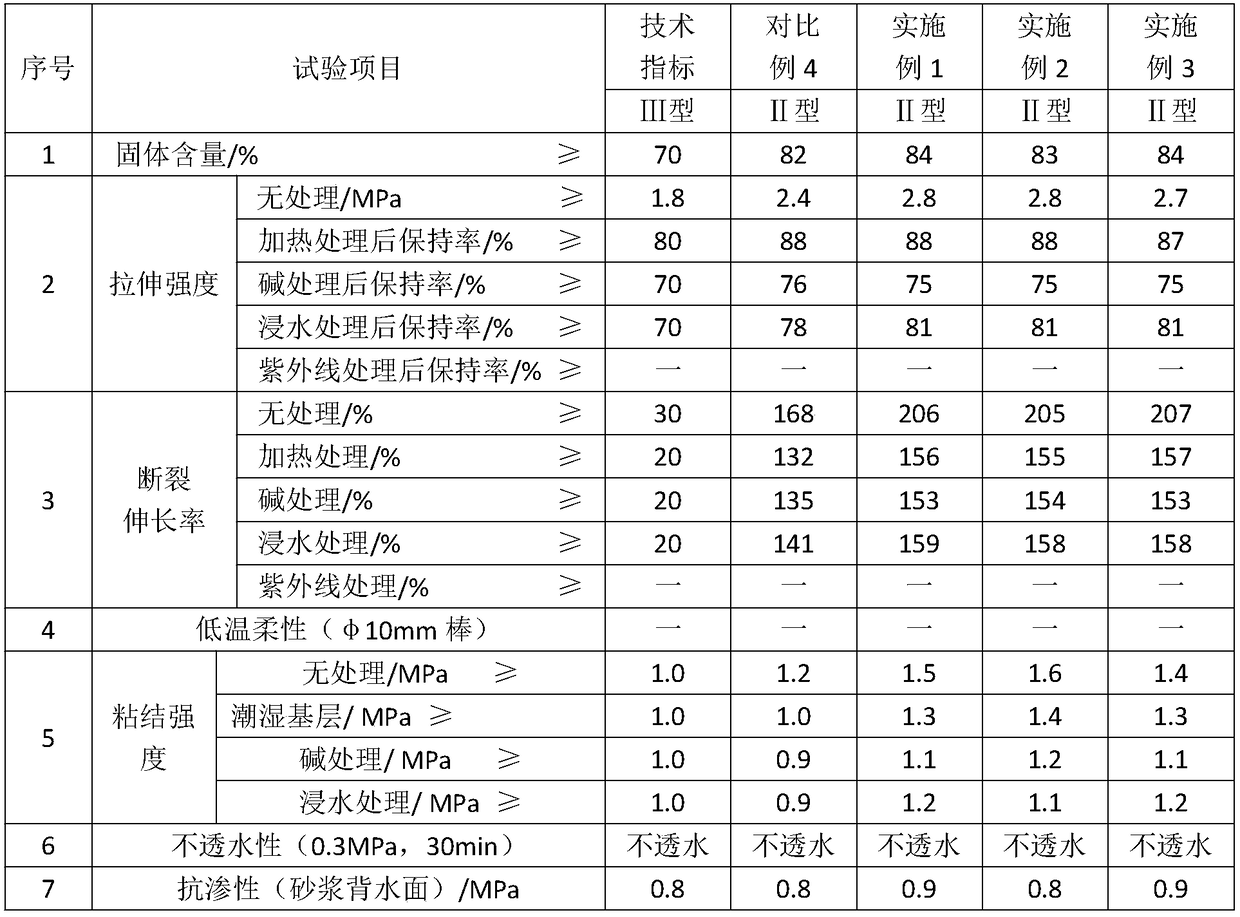

Styrene-acrylic waterproof latex and preparation method thereof

The invention discloses a styrene-acrylic waterproof latex and a preparation method thereof. The latex comprises the following raw materials in parts by weight: 20-30 parts of styrene, 10-18 parts ofmethyl methacrylate, 12-20 parts of methyl acrylate, 40-50 parts of butyl acrylate, 0.2-0.8 parts of acrylic acid, 1.0-2.0 parts of acrylamide, 1-3 parts of an emulsifier, 0.5-1.5 parts of an evocating agent and 0.2-0.8 parts of a buffering agent. The waterproof latex provided by the invention has low coagulating rate and moderate viscosity, thereby effectively solving the compatibility problem between the styrene-acrylic waterproof latex and powder materials such as cement, and also solving the difficult problem of poor compatibility between a macromolecule polymer and the cement with a filmformed on the surface. The latex has super flexibility, the tensile strength and the elongation at break are much higher than the requirements in the national standard and better than the waterproof latex sold with good performance on the market, and the product quality is stable, so that the bond strength between the film and the base is ensured to be high and the performances in water resistance, alkali resistance and weather resistance are high in practical application.

Owner:北京宝辰联合科技股份有限公司

Preparation method of small particle sized polybutadiene latex used for the production of ABS

A preparation method of small particle-sized polybutadiene latex used for the production of ABS is disclosed, which includes putting components comprising 34.00-45.00% by weight of the butadiene, 0-6.0% by weight of the second monomer, 52.11-63.13% by weight of the desalinized water, 0.12-0.22% by weight of the mercaptan(TDM), 0.80-2.60% by weight of the emulsifiers composed of potassium abietate and potassium oleate, into the same polymerization reactor, then heating the mixture of the components and stirring the same at a temperature range of 60-75° C. The reaction lasts for 9-12 hours and the conversion is higher than 97%. The method has the advantages such as higher conversion, shorter reaction period and lower latex viscosity. During the first stage of the reaction, more heat is released by increasing the reaction rate. When the conversion reaches 40-80%, the heat release rate of intermediate stage is depressed by decreasing the reaction temperature. When the conversion is higher than 80%, the reaction temperature reaches the highest. Thus, severe heat release is avoided. Moreover, the butadiene polymerization can be controlled steadily and the reaction period is shortened.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

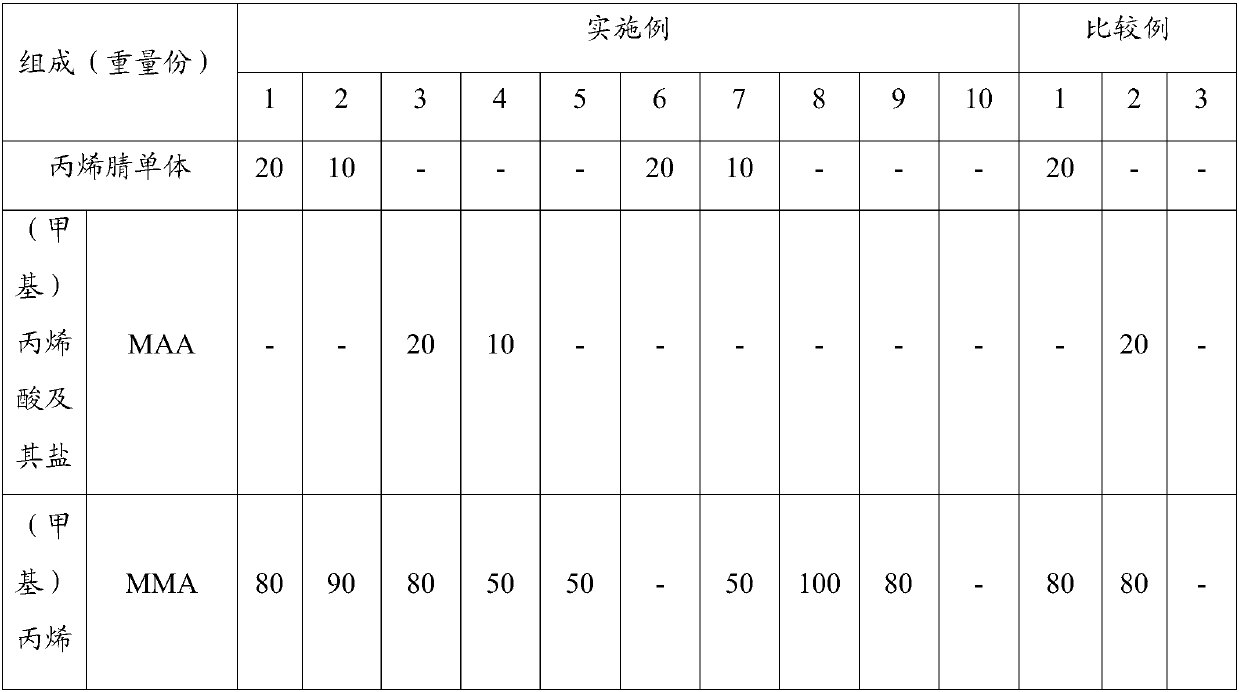

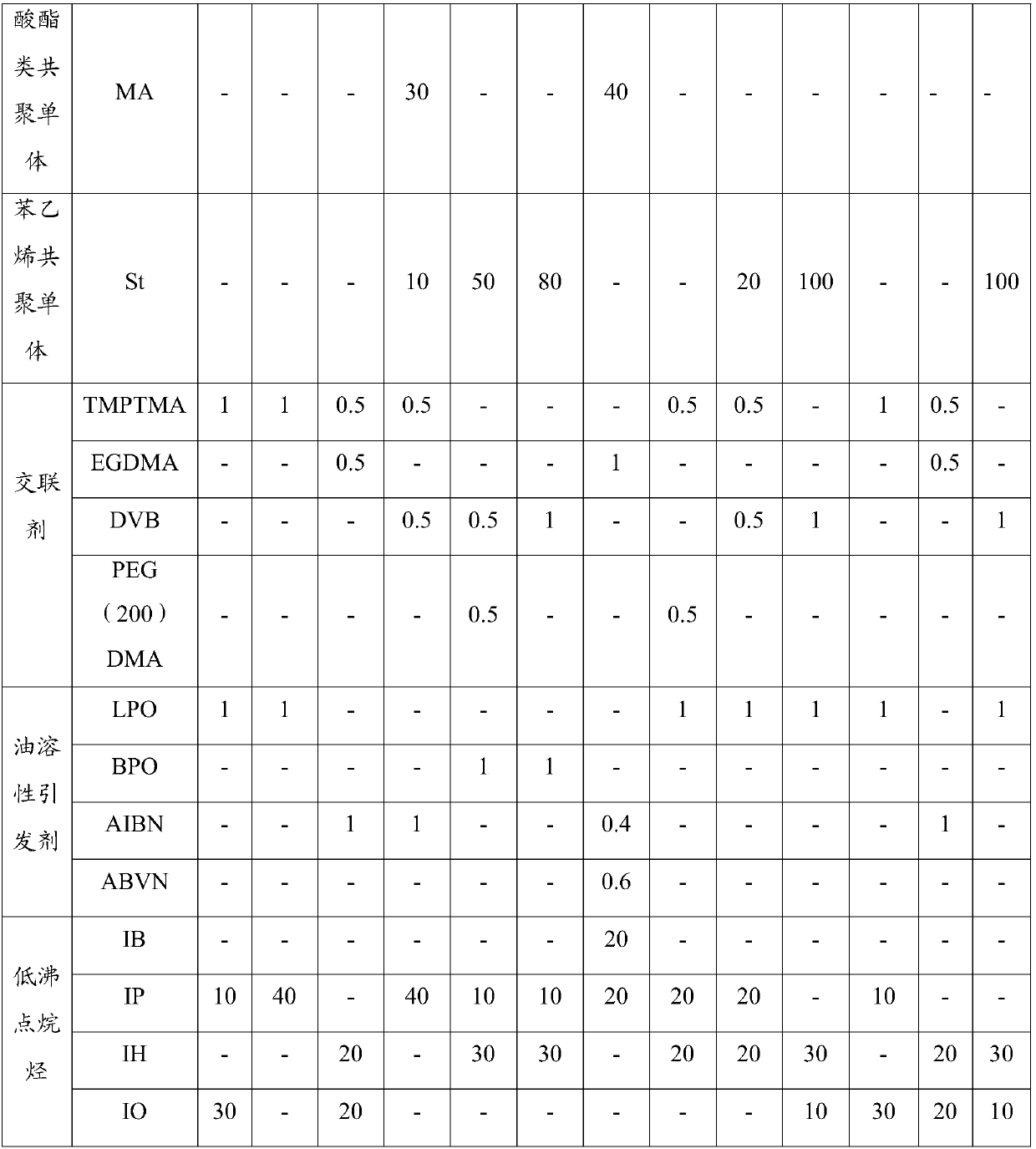

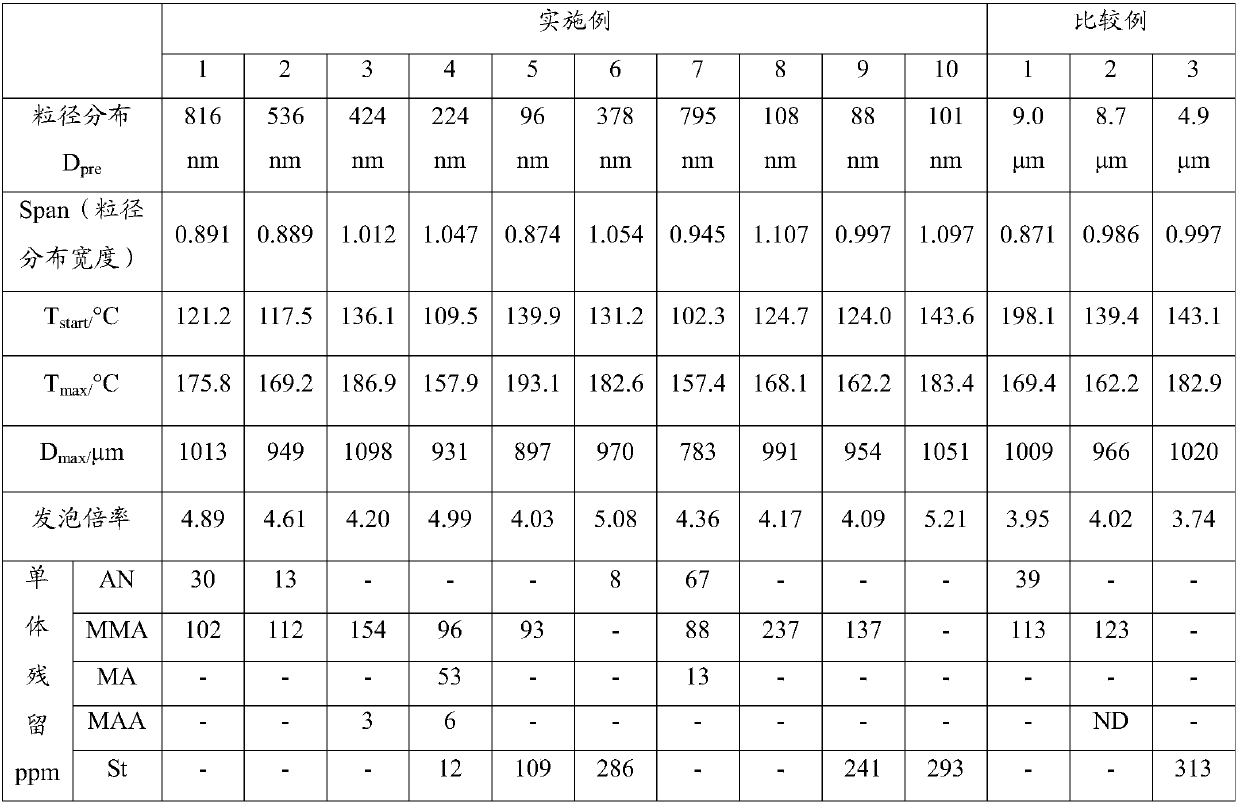

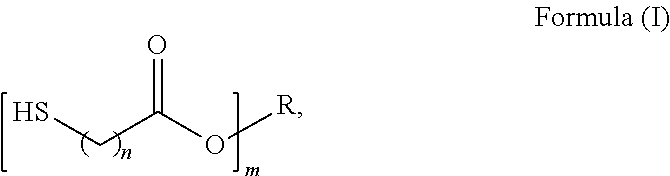

Superfine environment-friendly thermal expansion microcapsule and preparation method thereof

ActiveCN108097182ASimple and fast operationSimple preparation processMicroballoon preparationMicrocapsule preparationPolymer scienceEmulsion polymerization

The invention discloses a superfine environment-friendly thermal expansion microcapsule which is prepared from a suspension dispersing liquid of an oil phase composition and a water phase compositionby a microwave radiation emulsion polymerization method. A particle size of the superfine environment-friendly thermal expansion microcapsule is of a submicron level; and the microcapsule is high in foaming ratio, environment-friendly, nontoxic and applicable to the fields of textile, papermaking, printing ink, engineering plastics and the like. The invention further discloses a preparation methodof the superfine environment-friendly thermal expansion microcapsule. The thermal expansion microcapsule is prepared on a basis of a microwave radiation radical emulsion polymerization technology; and the preparation method is easy and simple to operate, simple in preparation technology and high in production efficiency.

Owner:三明市锦浪新材料科技有限公司

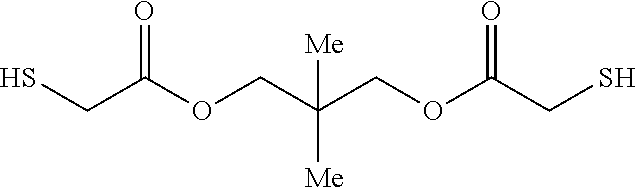

Low migration free radical radiation curable inkjet inks

ActiveUS20150203696A1High monomer conversion rateHigh viscosityDecorative surface effectsDuplicating/marking methodsMethacrylateVinyl ether

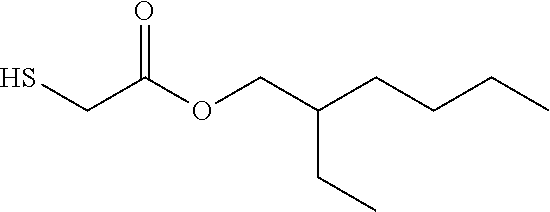

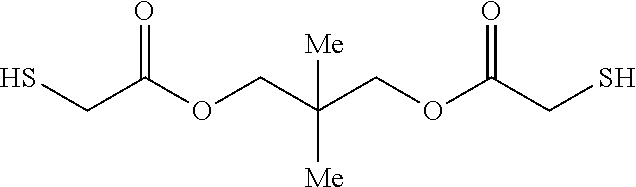

A free radical radiation curable inkjet ink having a viscosity smaller than 30 mPa·s at 40° C. and at a shear rate of 1,000 s−1 includes a polymeric or polymerizable photoinitiator; a thiol compound; and a vitrification control monomer. The vitrification control monomer includes a (meth)acrylate group and an ethylenically unsaturated functional group selected from the group consisting of a vinyl ether group, an allyl ether group, and an allyl ester group, and the thiol compound includes no more than six thiol groups.

Owner:AGFA NV

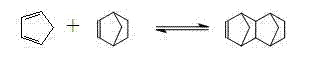

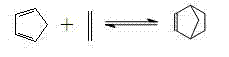

Method for preparing norbornene in loop reactor

InactiveCN102249839AHigh selectivityHigh monomer conversion rateHydrocarbons from unsaturated hydrocarbon additionNorborneneEthylene

The invention discloses a method for preparing norbornene in a loop reactor. The method disclosed by the invention comprises the following steps of: (1) heating and pre-decomposing dicyclopentadiene in a heat exchanger to partially or wholly decompose the dicyclopentadiene into cyclopentadiene, wherein the temperature for heating and pre-decomposing is in a range of 120-240 DEG C and the absolute pressure is in a range of 5-30 MPa; (2) transporting the heated and pre-decomposed product of the step (1) into the loop reactor through the heat exchanger, adding ethylene into the loop reactor at the same time and reacting to obtain the norbornene, wherein the reaction conditions are as follows: the temperature is in a range of 180-300 DEG C, the absolute pressure of an outlet of the loop reactor is in a range of 5-30 MPa, the mol ratio of the ethylene to the dicyclopentadiene which is not heated and pre-decomposed is 1-20 to 1, the recycle ratio is 100-300 to 1, and the temperature and the pressure of the ethylene in the process of adding the ethylene into the loop reactor are the same as those in the reaction conditions. According to the method provided by the invention, the safety of the preparation process can be remarkably improved and higher selectivity and conversion rate of the cyclopentadiene can be realized.

Owner:ZHEJIANG UNIV

Polycarboxylic acid water reducing agent with narrow molecular weight distribution and preparation method thereof

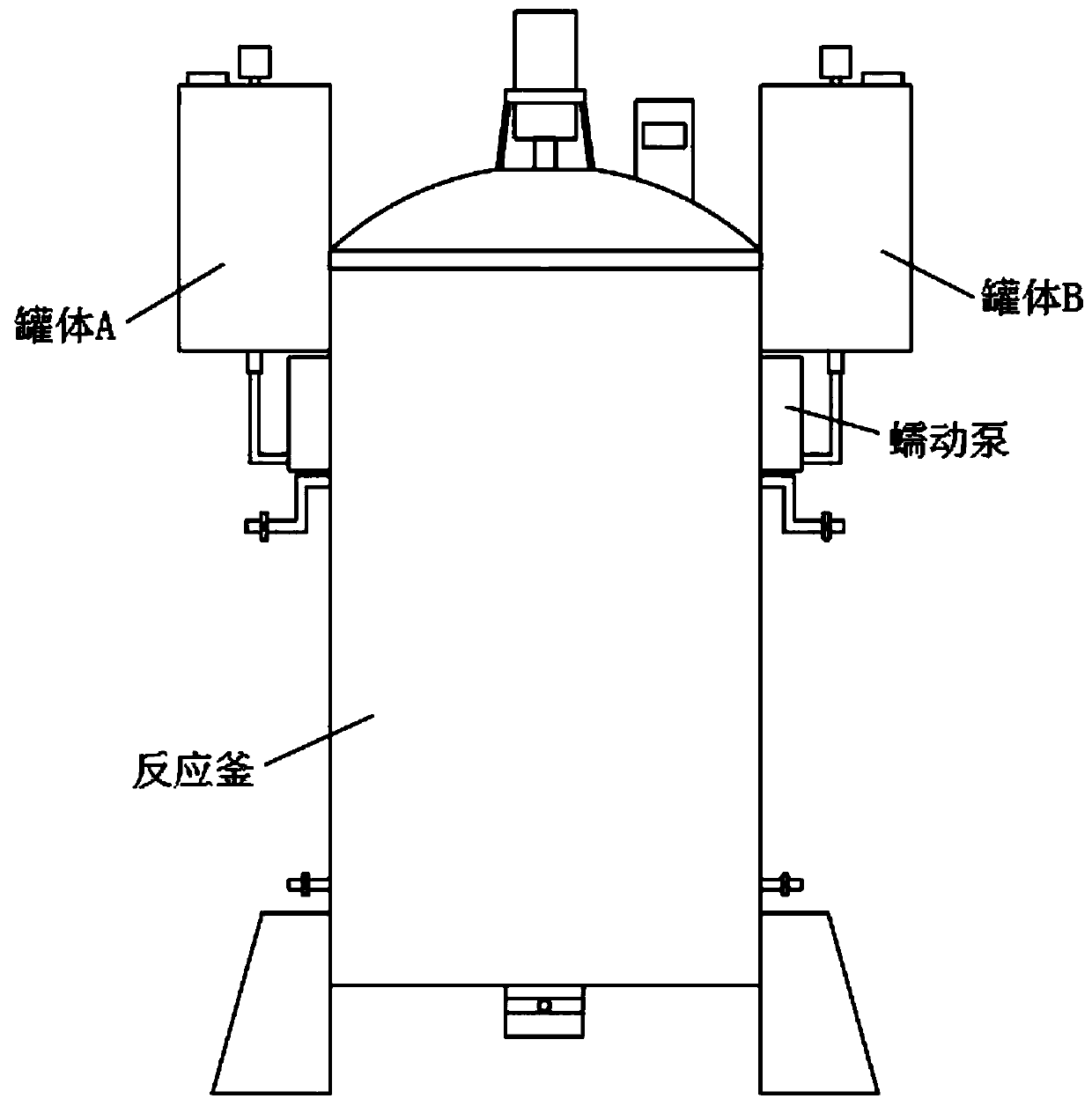

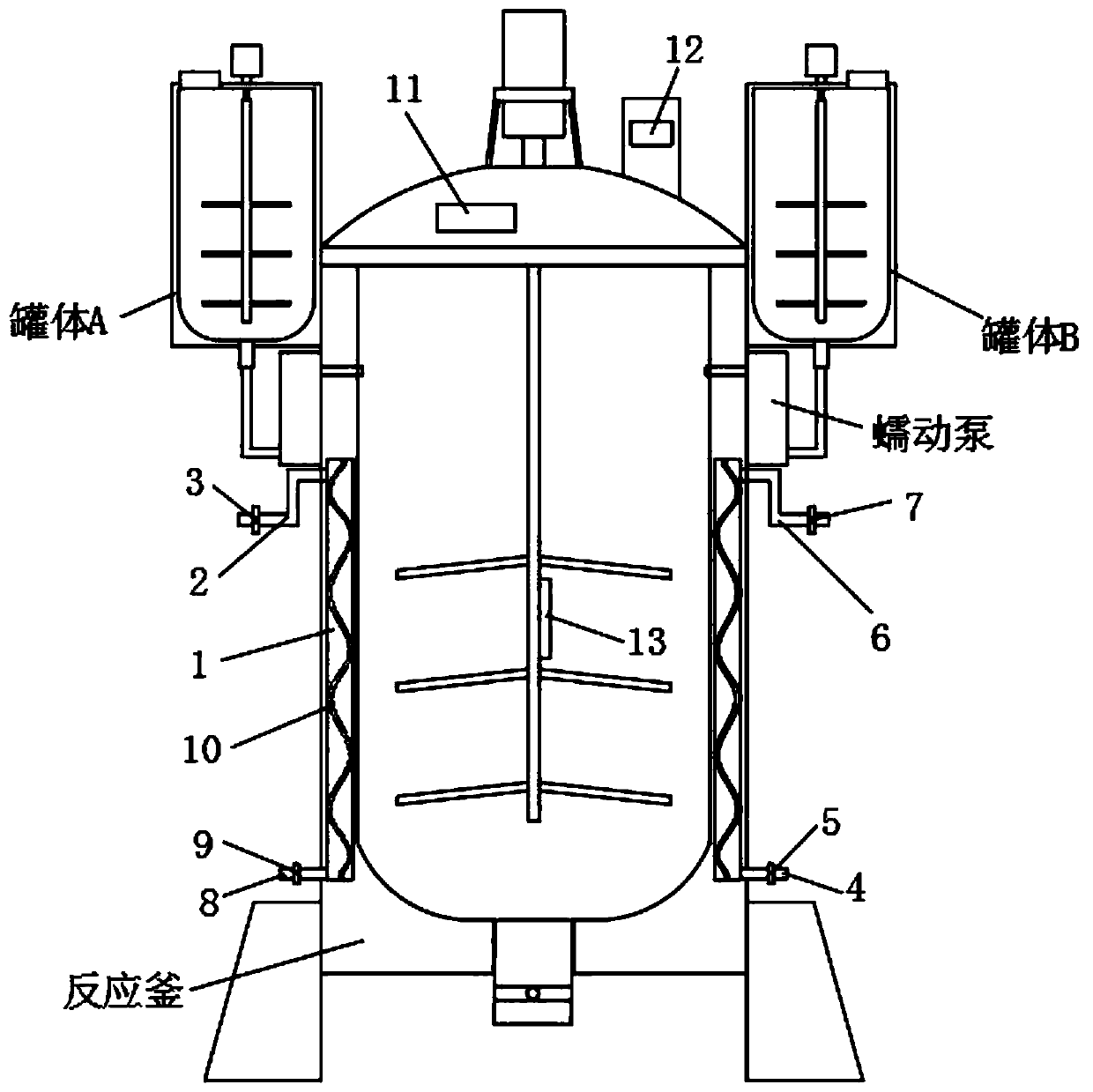

PendingCN110407985APromote circulationSpeed up heat transferChemical/physical/physico-chemical stationary reactorsPolymer scienceControllability

The invention discloses a polycarboxylic acid water reducing agent with narrow molecular weight distribution and a preparation method thereof, belonging to the technical field of slump retaining agentpreparation. The polycarboxylic acid water reducing agent with narrow molecular weight distribution and the preparation method thereof realize that the molecular weight distribution and controllability of the obtained polycarboxylic acid high-efficiency water reducing agent are greatly improved. After propyl polyoxyethylene ether is mixed with a water-soluble initiator and a water-soluble activechain transfer agent, the obtained molecular weight distribution is narrower, and the dispersibility of the product is better. At the same time, sodium methacrylate sulfonate and modified acrylate compounds are added to facilitate improving of the early strength, slump retention, reinforcement and other properties of the prepared polycarboxylic acid water reducing agent; moreover, a heat preservation interlayer with an automatic regulation function is arranged in a reaction kettle, is beneficial to realizing the conversion of heat transfer and cold transfer in the heat preservation interlayer,improving the lifting sensitivity of the temperature in the reaction kettle, eliminating the need for manual temperature regulation, and effectively avoiding the influence on the preparation of the polycarboxylic acid water reducing agent caused by large temperature control difficulty.

Owner:GUANGZHOU JIANSHENG BUILDING MATERIALS CO LTD

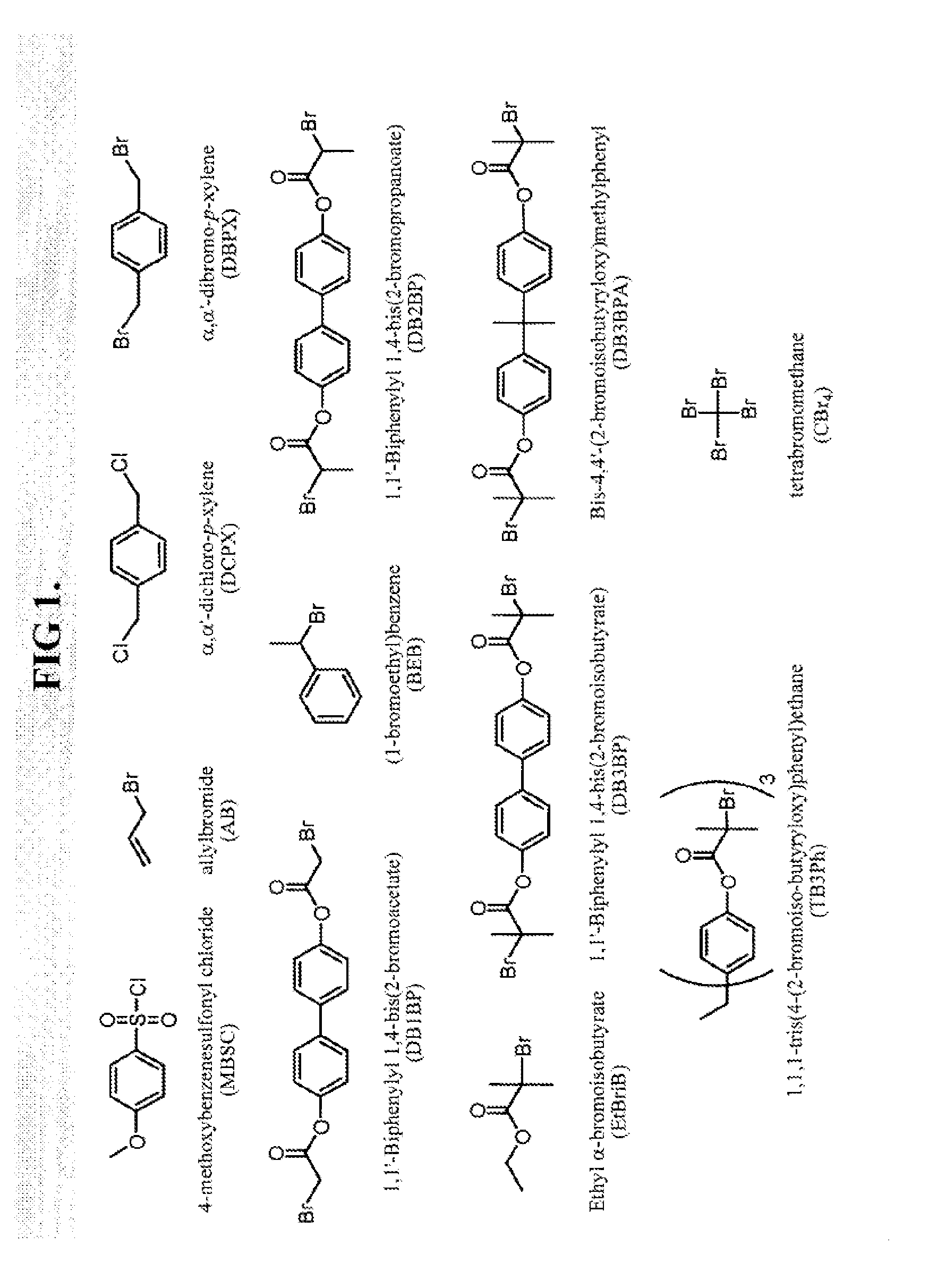

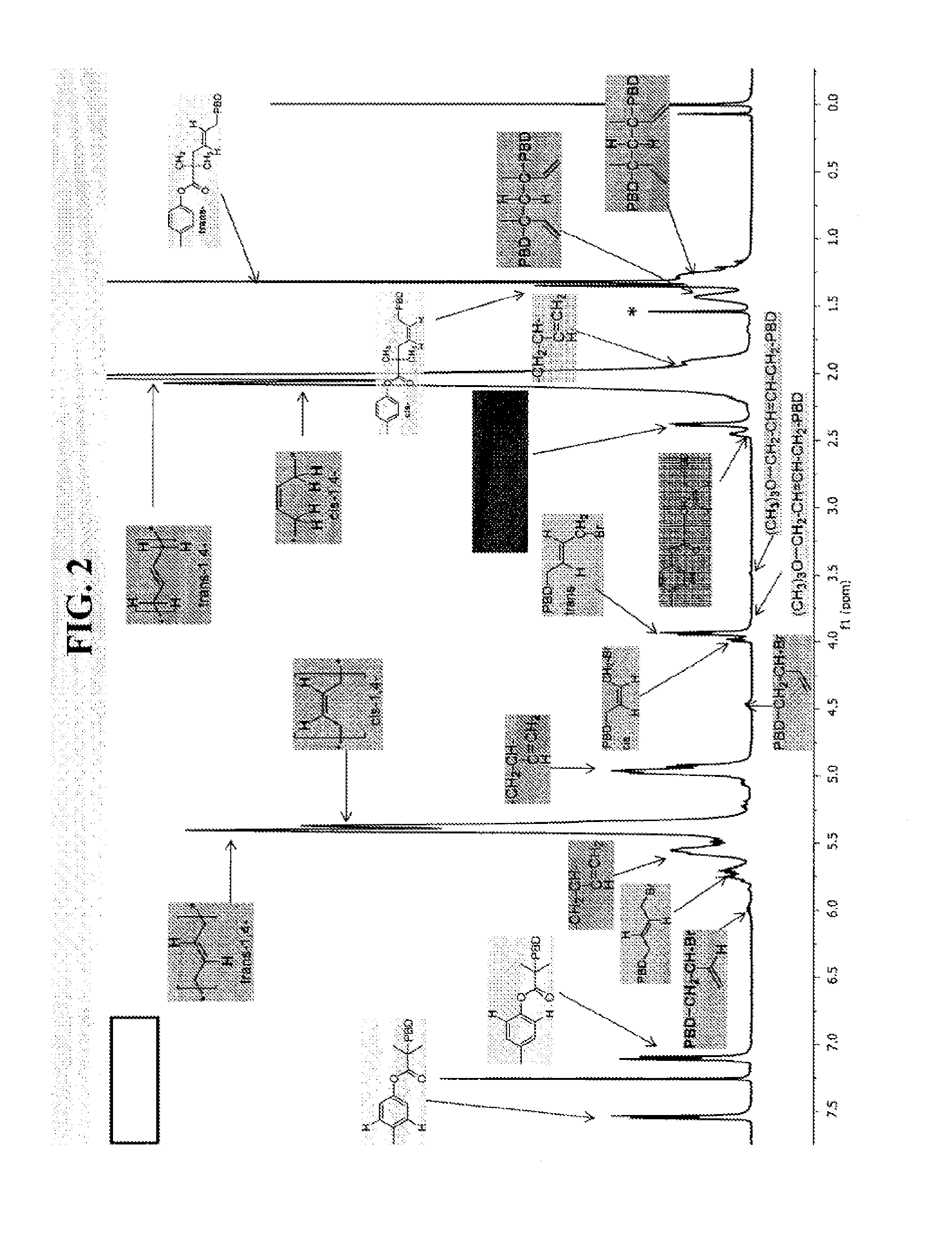

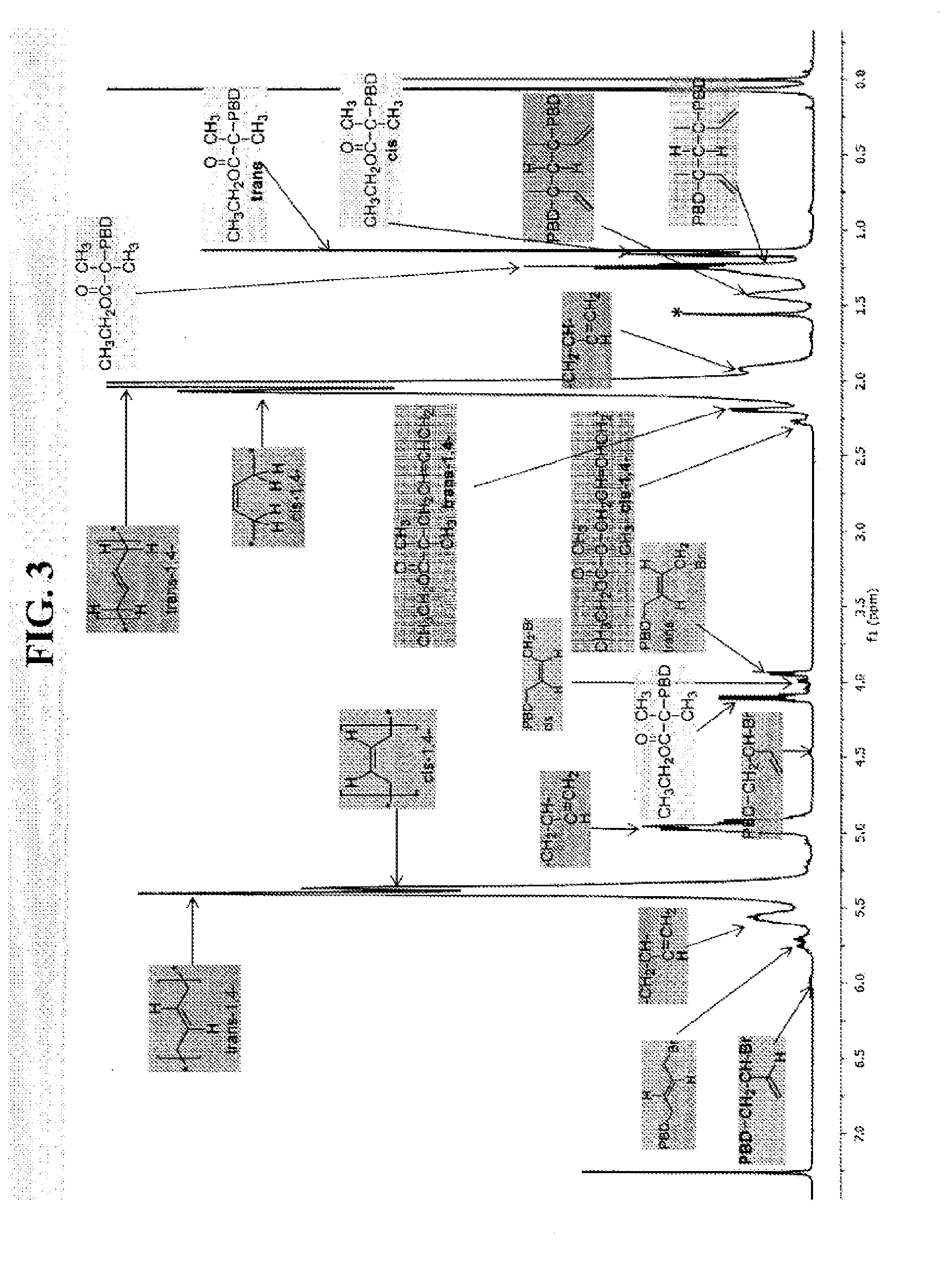

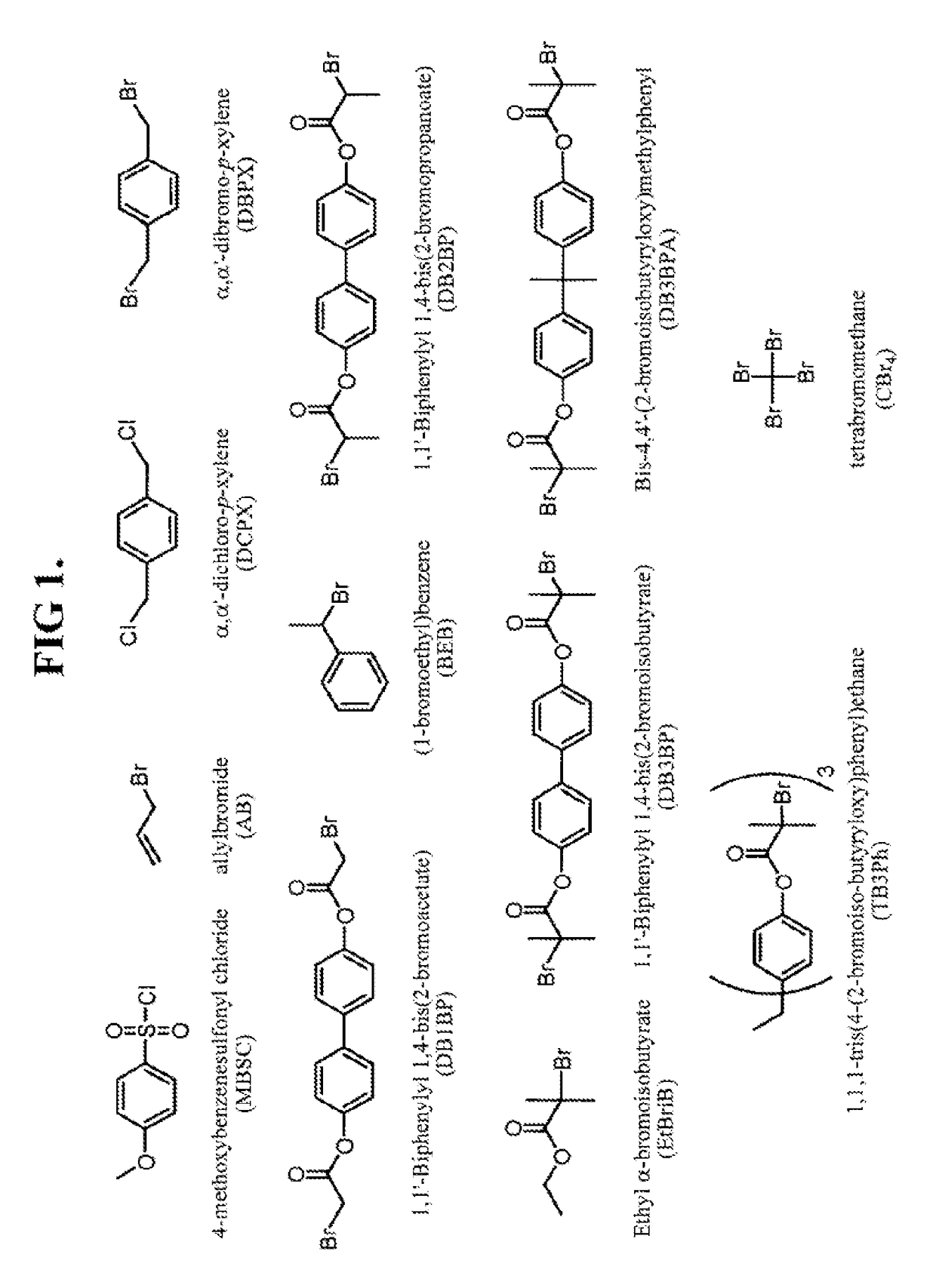

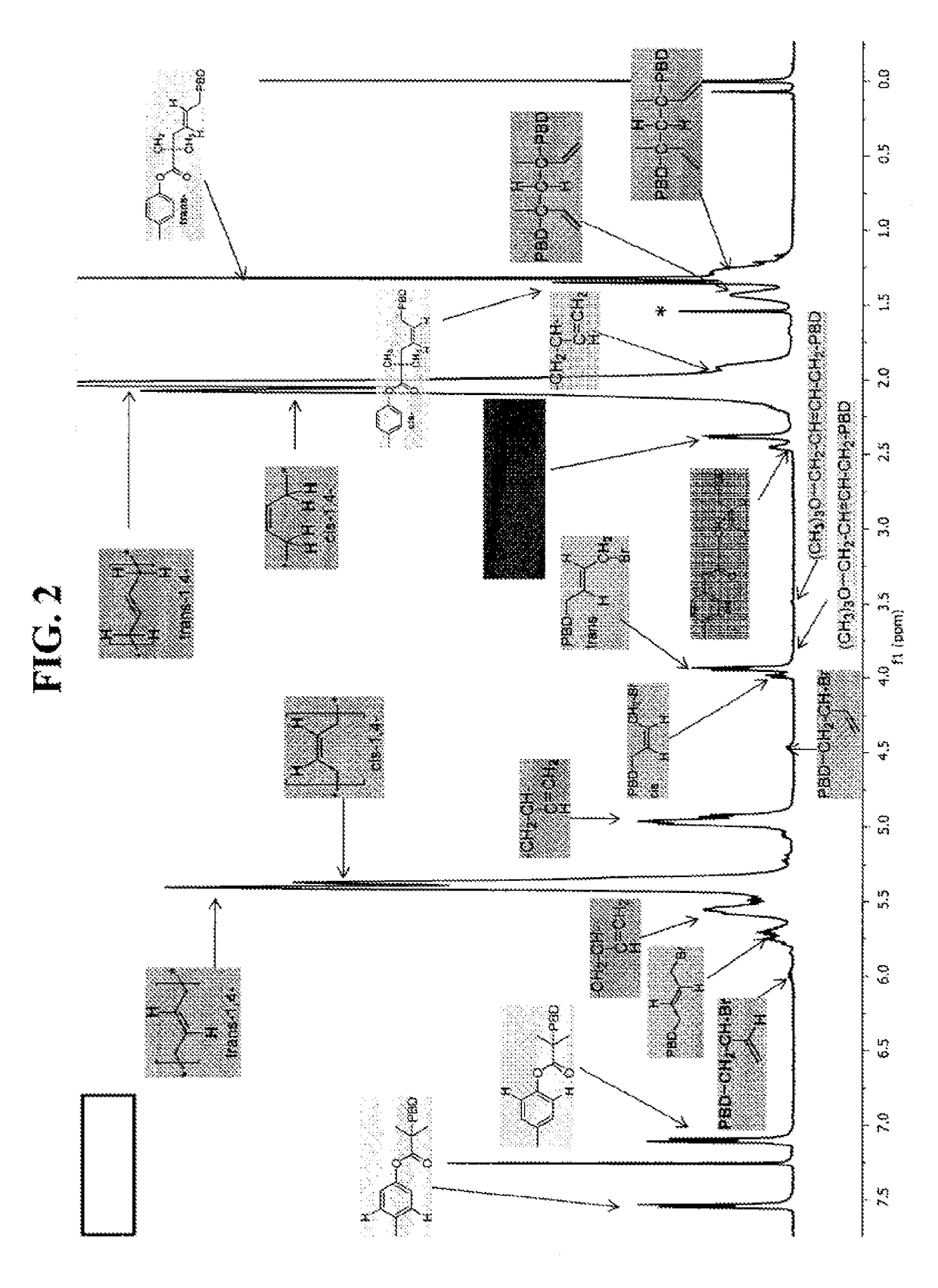

Polymerization of diene monomers

A free radical or controlled radical polymerization process of atom or group transfer radical polymerization. The process comprises radically polymerizing one or more radically (co)polmerizable monomers in the presence of a polymerization system. The one or more radically (co)polymerizable monomers comprise at least one or more radically (co)polymerizable diene monomers. The polymerization system comprises: an initiator having one or more radically transferable atoms or groups; a transition metal-ligand complex catalyst, wherein the ligand comprises any C-, N-, O-, P- or S-containing ligand which coordinates with the transition metal; an optional reducing agent capable of regenerating the lower oxidation state of the transition metal catalyst; and an optional organic solvent or water capable of solubilizing the transition metal-ligand complex catalyst. (Co)polymers produced by the free radical or controlled radical polymerization process of atom or group transfer radical polymerization.

Owner:UNIV OF CONNECTICUT

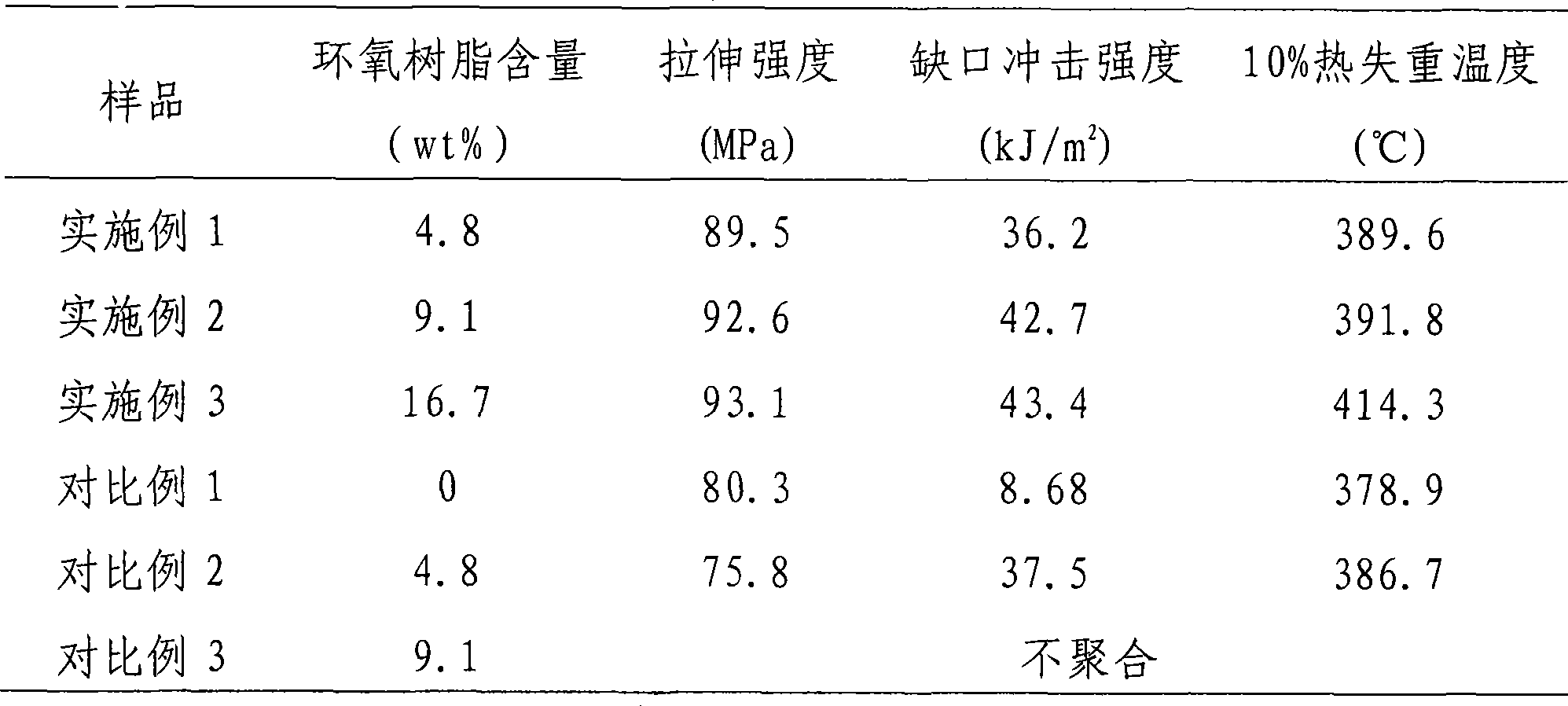

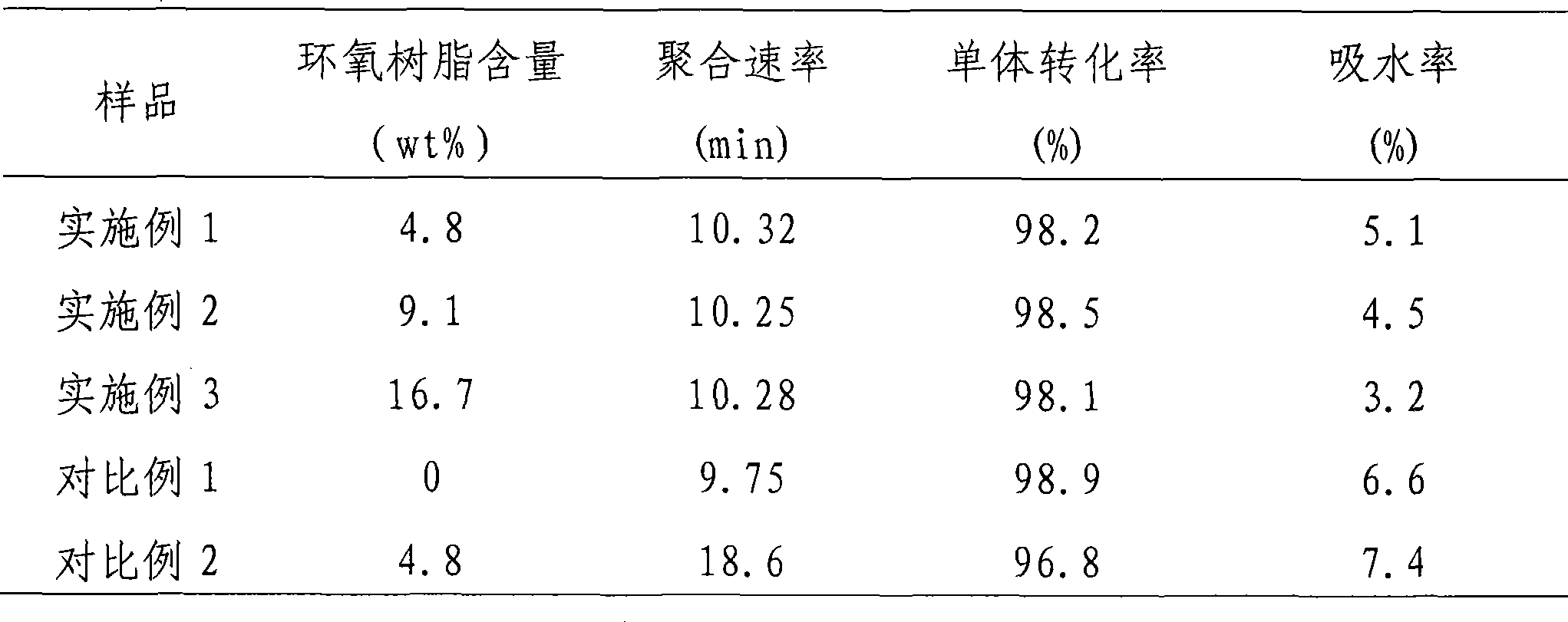

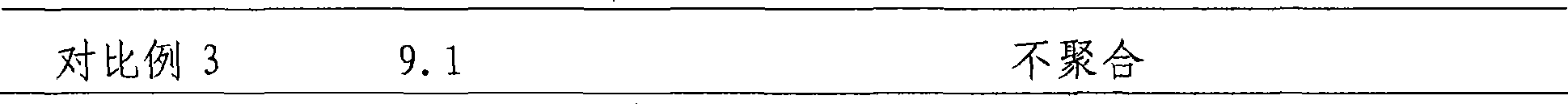

Process for producing epoxy resin//MC nylon composite material

The invention discloses a preparation method of an epoxy resin / MC nylon composite material; 100 weight portions of caprolactam is taken as the reference, and the weight portions of other components are as follows: 1 portion to 50 portions of epoxy resin, 0.005 portion to 20 portions of curing agent, 0.01 portion to 5 portions of catalyst and 0.01 portion to 5 portions of activating agent; (a) under the protection of nitrogen, the epoxy resin is added into caprolactam melt to be evenly stirred; (b) the curing agent is added to pre-cure the epoxy resin under 80 DEG C to 150 DEG C; (c) the catalyst and the activating agent are added in to initiate ring opening polymerization of caprolactam anion, to obtain the epoxy resin / MC nylon composite material. The preparation method has the advantages that: 1. the method has short gelation time, high polymerization speed, high monomer conversion rate, low water absorption and the like; 2. the method improves the deformation resistance of the MC nylon substrate, so that the tensile and impact strength of the composite material are greatly improved; 3. the heat resistant performance is greatly improved; 4. the method has low production cost and simple and convenient process, and is application to industrialized production.

Owner:XIANGTAN UNIV

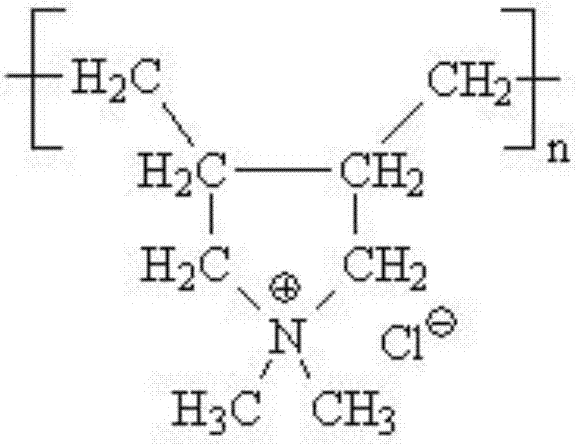

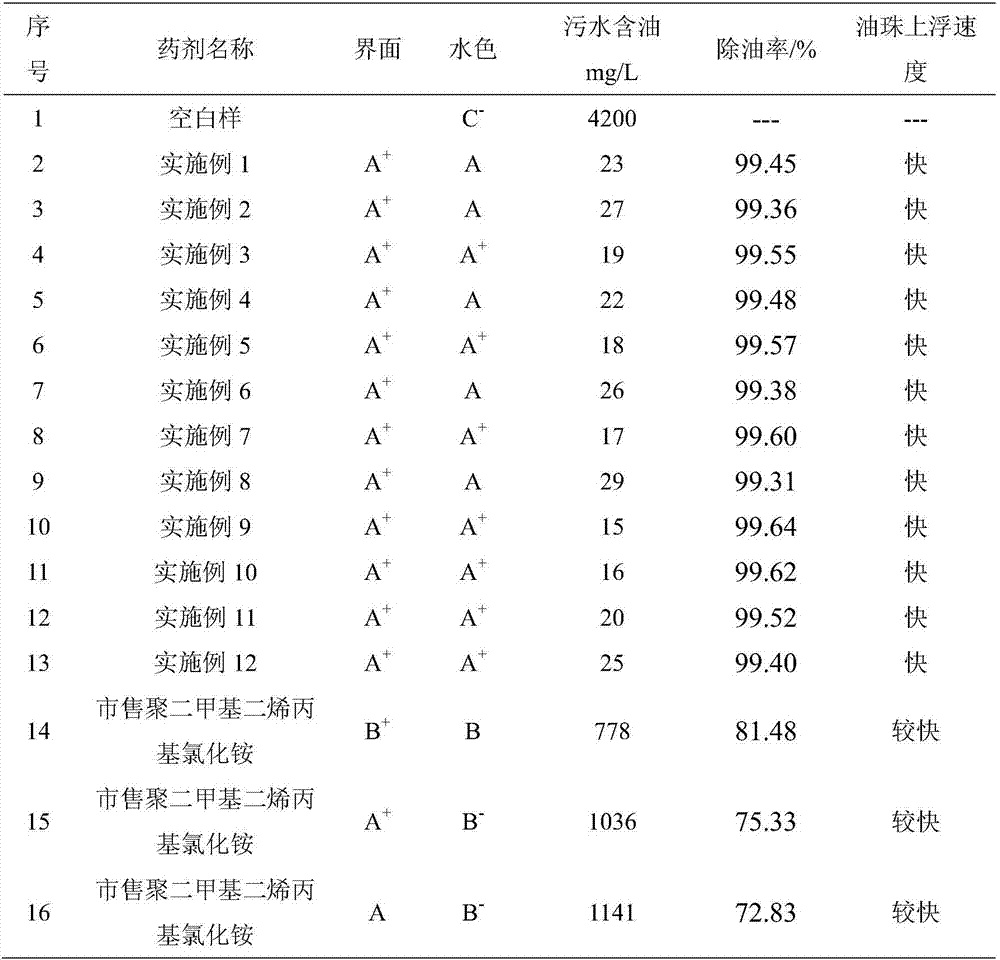

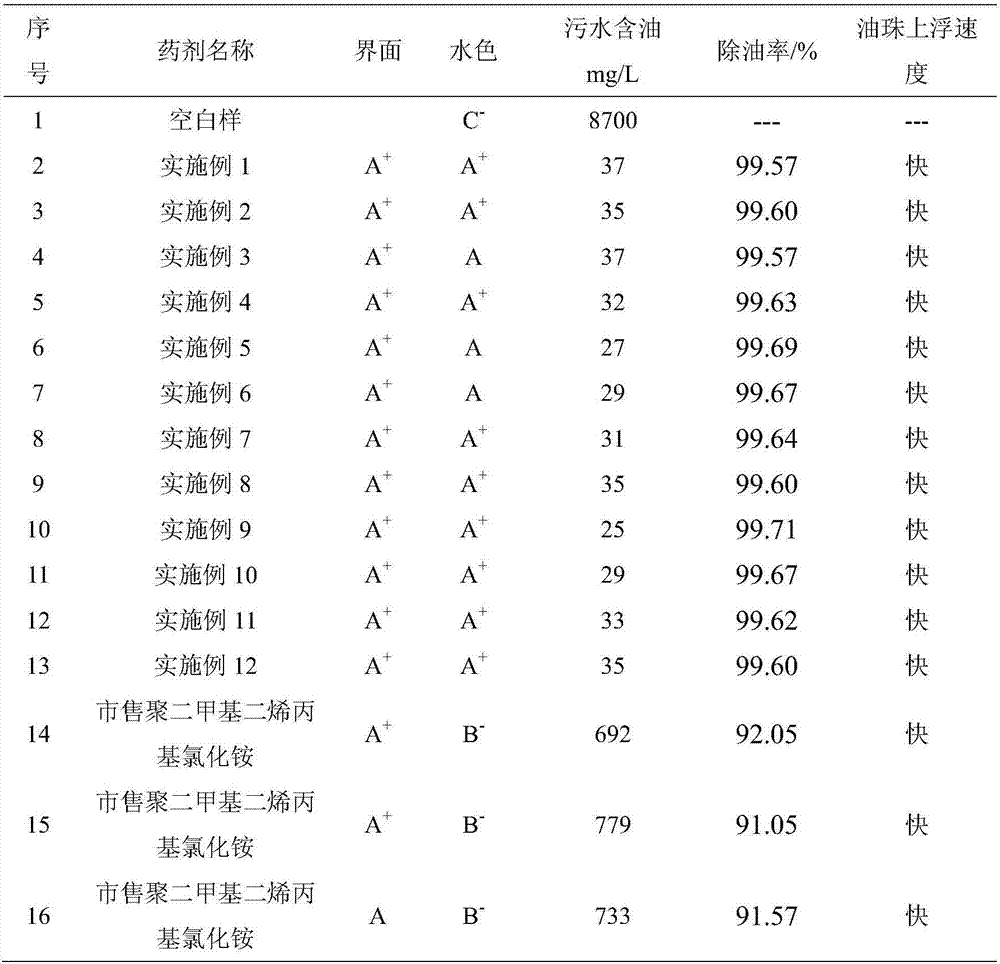

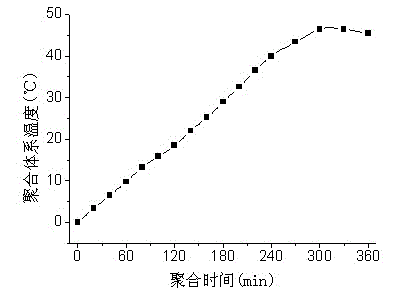

Preparation method of poly (diallyldimethylammonium chloride) as flocculating agent for treating sewage

ActiveCN106986959ALow oil removal rateLow monomer conversionWaste water treatment from quariesWater/sewage treatment by flocculation/precipitationLow speedReaction temperature

The invention discloses a preparation method of poly (diallyldimethylammonium chloride) as flocculating agent for treating sewage. The preparation method comprises the following steps: (1) adding an initiator, a complexing agent and ethylene glycol as a chain transfer agent in an aqueous solution of diallyldimethylammonium chloride, stirring uniformly, and feeding nitrogen to remove air in a reaction container; (2) heating reaction liquid obtained from the step (1) while stirring, and carrying out polymerization reaction; (3) heating to the temperature of 65-85 DEG C, adding the initiator in the reaction liquid again, and adding water in the reaction liquid for reaction; and (4) under protection of the nitrogen, carrying out insulation and curing to obtain the poly (diallyldimethylammonium chloride). The method is simple in process and easy to operate, the reaction temperature is convenient to control, polymerization reaction is stably carried out at low speed, products with medium and low relative molecular mass are easily obtained, and the preparation method is suitable for treatment of oilfield chemical flooding output liquid. The prepared flocculating agent for treating the sewage is high in oil removal rate, high in monomer conversion rate, good in water purification effect, low in viscosity of products and convenient to inject, and has universal applicability.

Owner:中海油(天津)油田化工有限公司 +2

Composite initiator of hydrophobic associated polymer and preparation method of hydrophobic associated polymer

ActiveCN104672355ALow residual acrylamide contentUniform polymerizationPotassium persulfatePolymer science

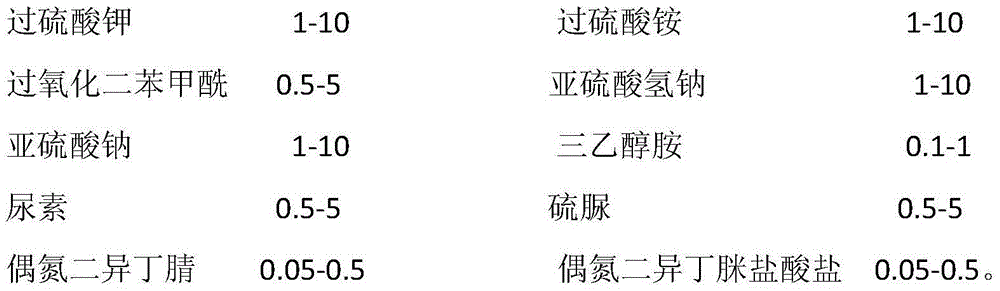

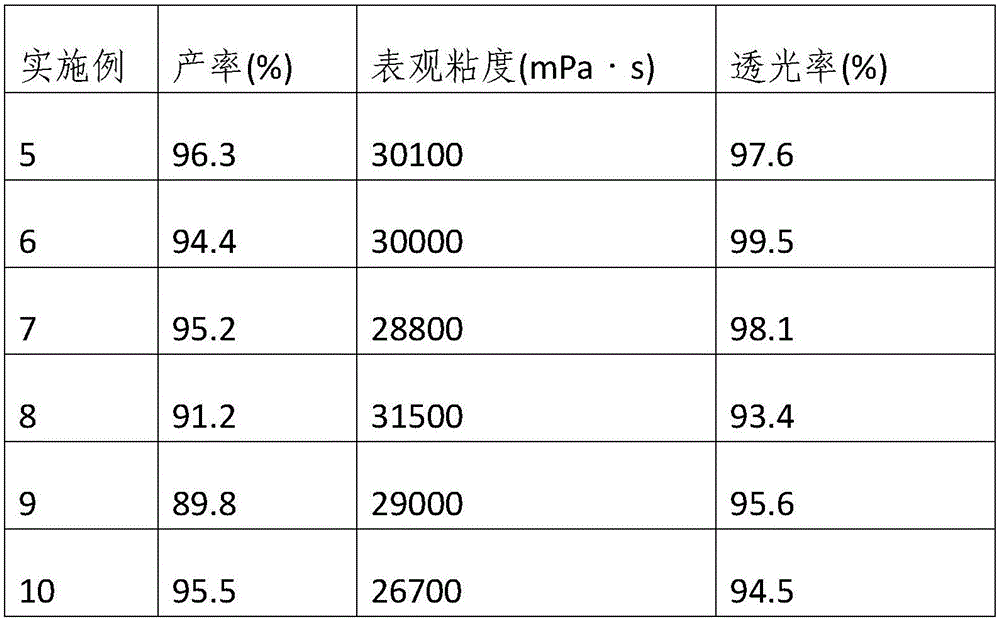

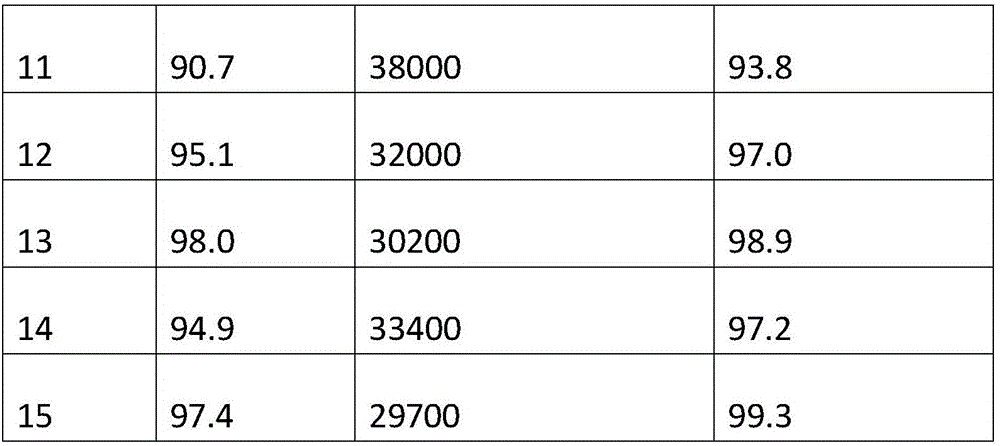

The invention provides a composite initiator of a hydrophobic associated polymer and a preparation method of the hydrophobic associated polymer. The composite initiator is prepared from the following raw materials in parts by weight: 1-10 parts of potassium persulfate, 1-10 parts of ammonium persulfate, 0.5-5 parts of dibenzoyl peroxide, 1-10 parts of sodium hydrogen sulfite, 1-10 parts of sodium sulfite, 0.1-1 part of triethanolamine, 0.5-5 parts of urea, 0.5-5 parts of thiourea, 0.05-0.5 part of azodiisobutyronitrile and 0.05-0.5 part of azobis(isobutylamidine hydrochloride). The method comprises the following steps: a sequentially adding disodium ethylenediamine tetraacetate, sodium formate, lauryl sodium sulfate, acrylamide, AMPS-Na and DiC8AM to deionized water under a magnetic stirring condition, and fully stirring evenly; b introducing high-purity nitrogen into a mixed solution obtained from the step a, adding the composite initiator, and polymerizing to obtain hydrophobic associated polymer gel; and c coarsely crushing the hydrophobic associated polymer gel obtained from the step b, adding sodium hydroxide, hydrolyzing, drying in a blast drying oven, drying and crushing to obtain the product.

Owner:CHINA PETROLEUM & CHEM CORP +1

Carbopol and preparation method thereof

InactiveCN106632803AIncrease activation energyPrevent reversible reactionsNon-macromolecular adhesive additivesAcid polymer adhesivesActivated carbonAntioxidant

The invention relates to the technical field of resin materials, in particular to carbopol and a preparation method thereof. The carbopol is prepared by taking acrylic acid as a monomer and matching with an initiating agent, a corss-linking agent, an assistant, purified water, a solvent and activated carbon, wherein the solvent is prepared from tertiary butanol and sorbitol; the assistant is prepared from an antioxidant and a chain modifier. According to the preparation method disclosed by the invention, abnormal phenomena of wall sticking and instable acid values are effectively prevented; by utilizing the preparation method disclosed by the invention, the yield and the light transmittance of a product are better, the thickening effect is good, the odor is low, and the product also has good mechanical performance.

Owner:贵州省欣紫鸿药用辅料有限公司

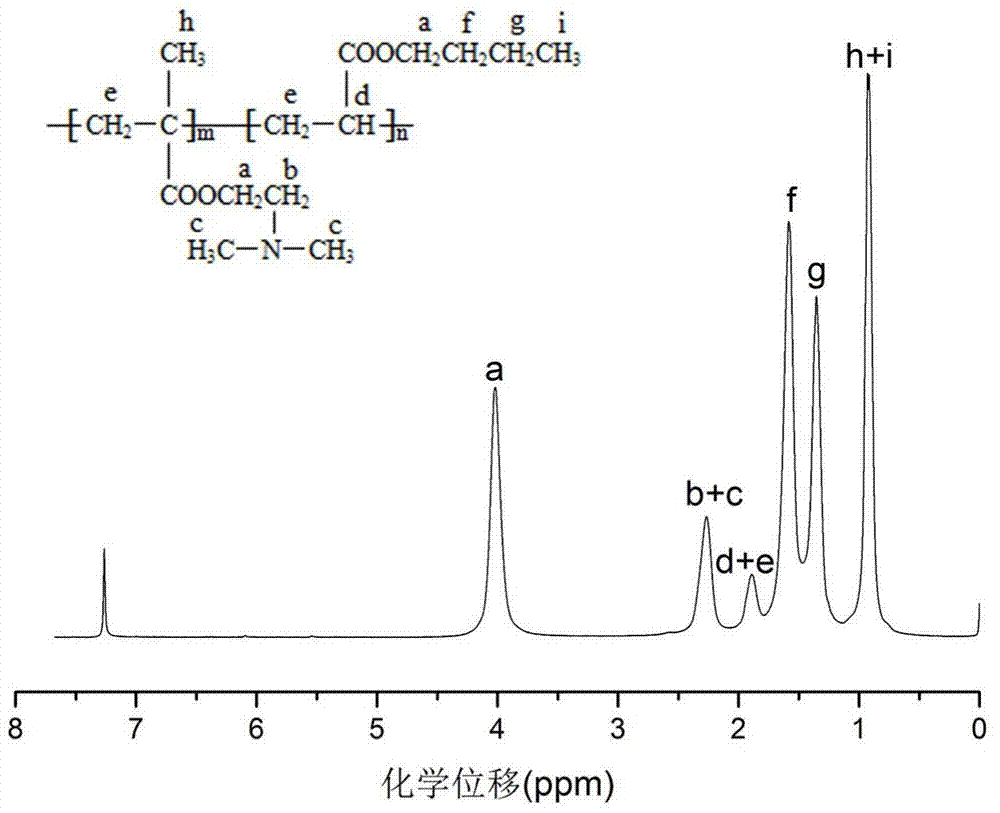

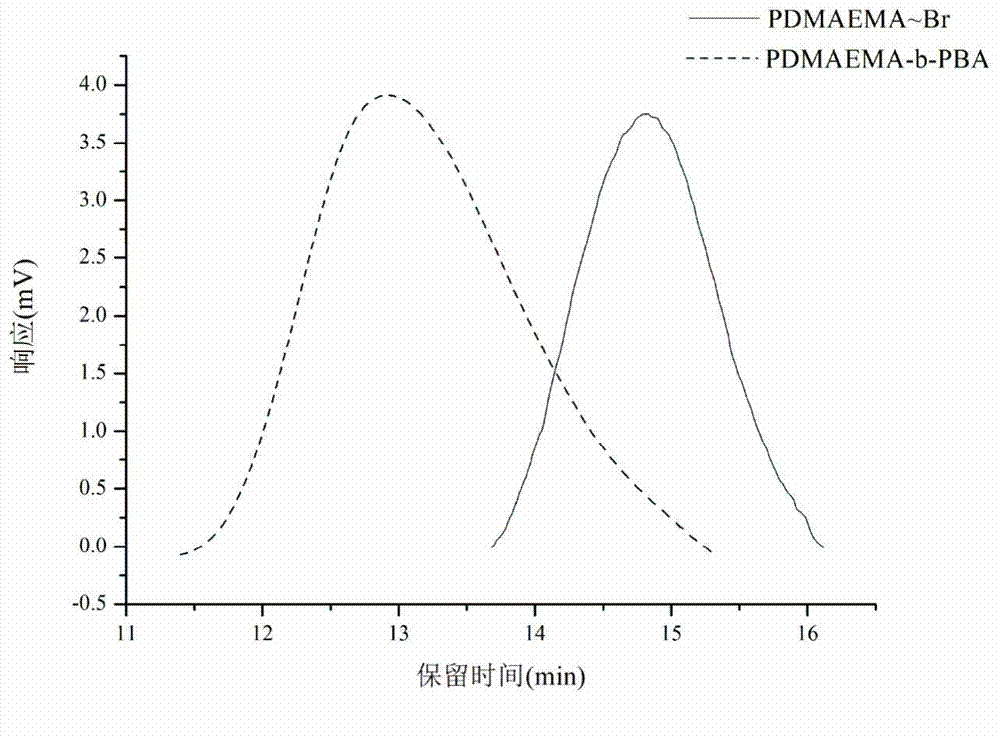

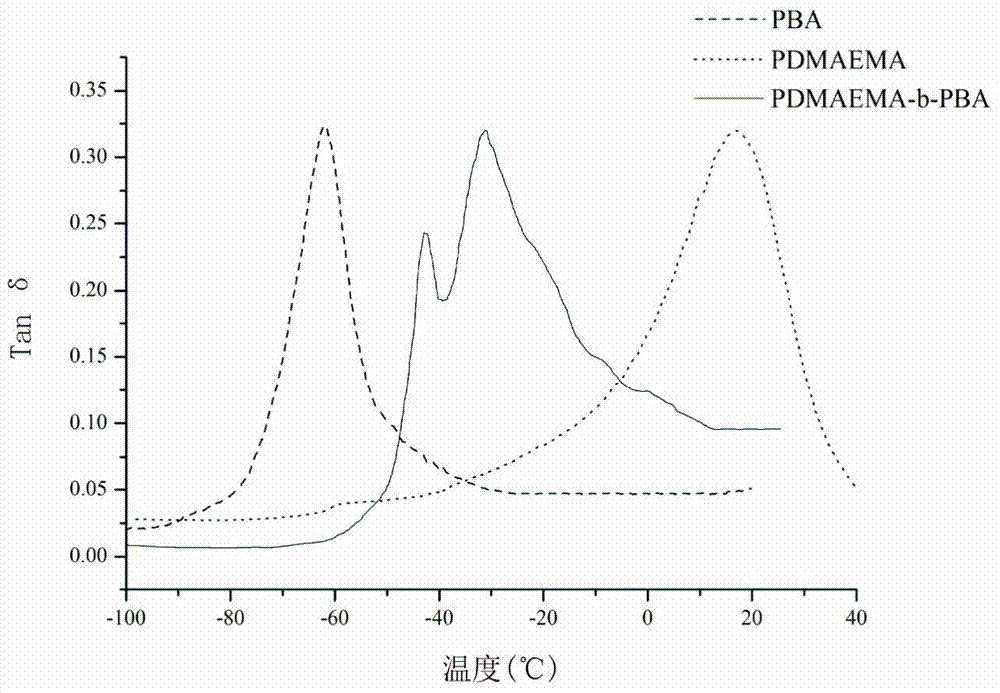

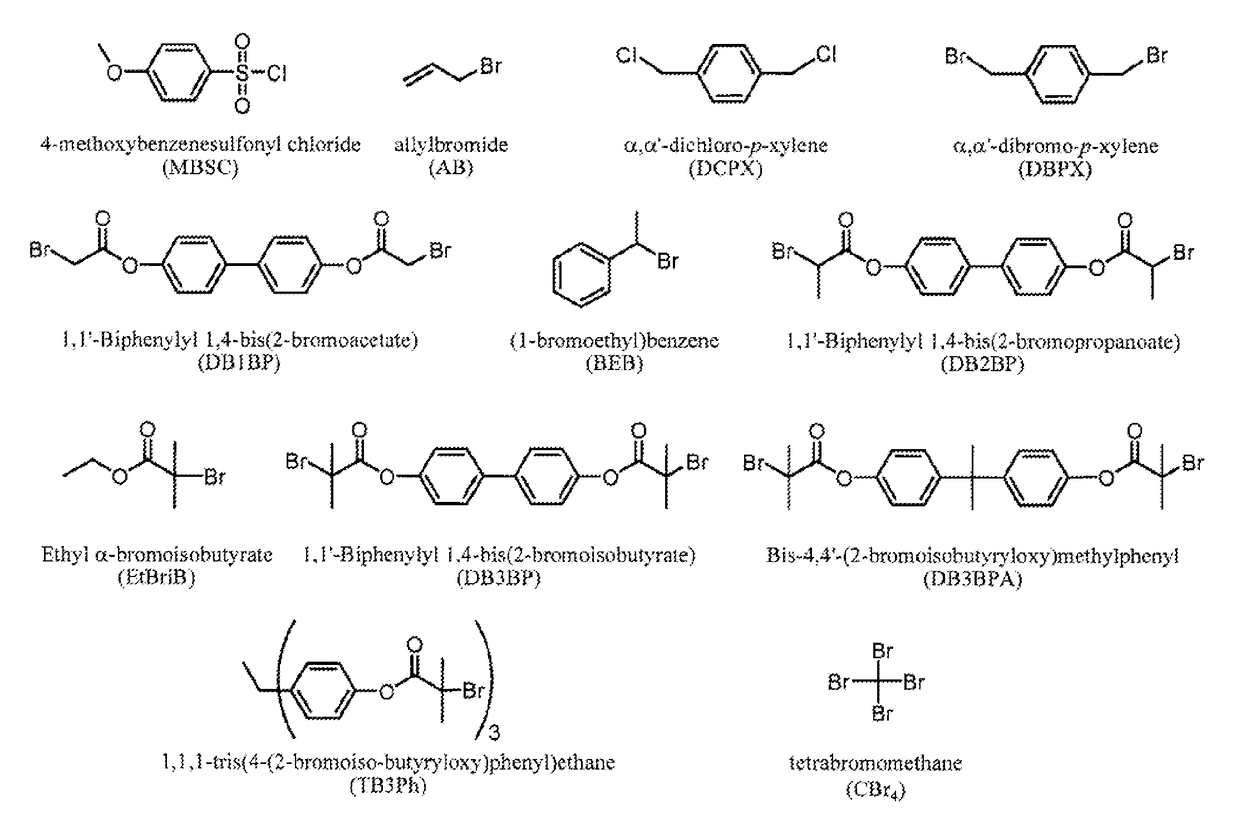

Method for preparing DMAEMA based amphiphilic block copolymer through single electron transfer living free radical polymerization

ActiveCN103497293AMolecular weight controllableNarrow molecular weight distributionCopper wireNitrogen gas

The invention relates to a method for preparing a DMAEMA based amphiphilic block copolymer through single electron transfer living free radical polymerization. The method comprises the following steps: adding an initiator, a monomer, deionized water and a catalyst into a reactor, filling nitrogen, stirring for 20 min, adding a ligand under the protection of nitrogen, maintaining the nitrogen atmosphere, reacting at 0-90 DEG C for 10-150 min, taking out the catalyst, dewatering and vacuum drying to obtain a target product. The catalyst is a copper wire, and the initiator is active polymethylacrylic acid dimethyl amino ethyl ester; and the monomer is oil soluble acrylate. The preparation method provided by the invention is high in polymerization speed, high in monomer conversion rate (67% can be achieved within 60 min) and narrow in molecular weight distribution (the minimum can be 1.40), and the molecular weight of each segment of the block copolymer is controllable. The preparation method is simple, convenient and easy to realize and is clean and environment-friendly, thereby providing convenience for industrial production.

Owner:HEBEI UNIV OF TECH

Polymerization of diene monomers

A free radical or controlled radical polymerization process of atom or group transfer radical polymerization. The process comprises radically polymerizing one or more radically (co)polymerizable monomers in the presence of a polymerization system. The one or more radically (co)polymerizable monomers comprise at least one or more radically (co)polymerizable diene monomers. The polymerization system comprises: an initiator having one or more radically transferable atoms or groups; a transition metal-ligand complex catalyst, wherein the ligand comprises any C-, N-, O-, P- or S-containing ligand which coordinates with the transition metal; an optional reducing agent capable of regenerating the lower oxidation state of the transition metal catalyst; and an optional organic solvent or water capable of solubilizing the transition metal-ligand complex catalyst. (Co)polymers produced by the free radical or controlled radical polymerization process of atom or group transfer radical polymerization.

Owner:UNIV OF CONNECTICUT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com