Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1434results about "Conjugated diene hydrocarbon coatings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

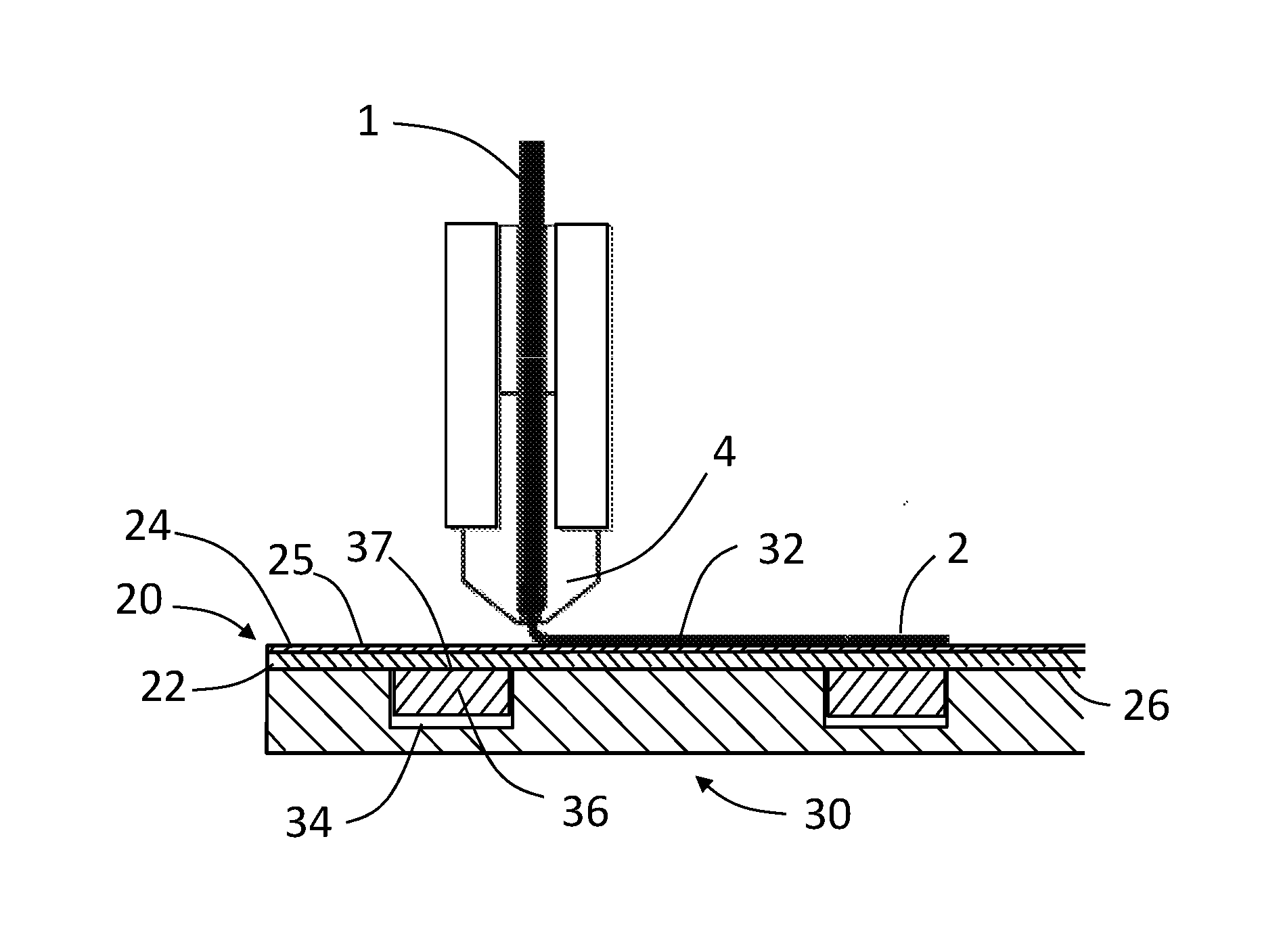

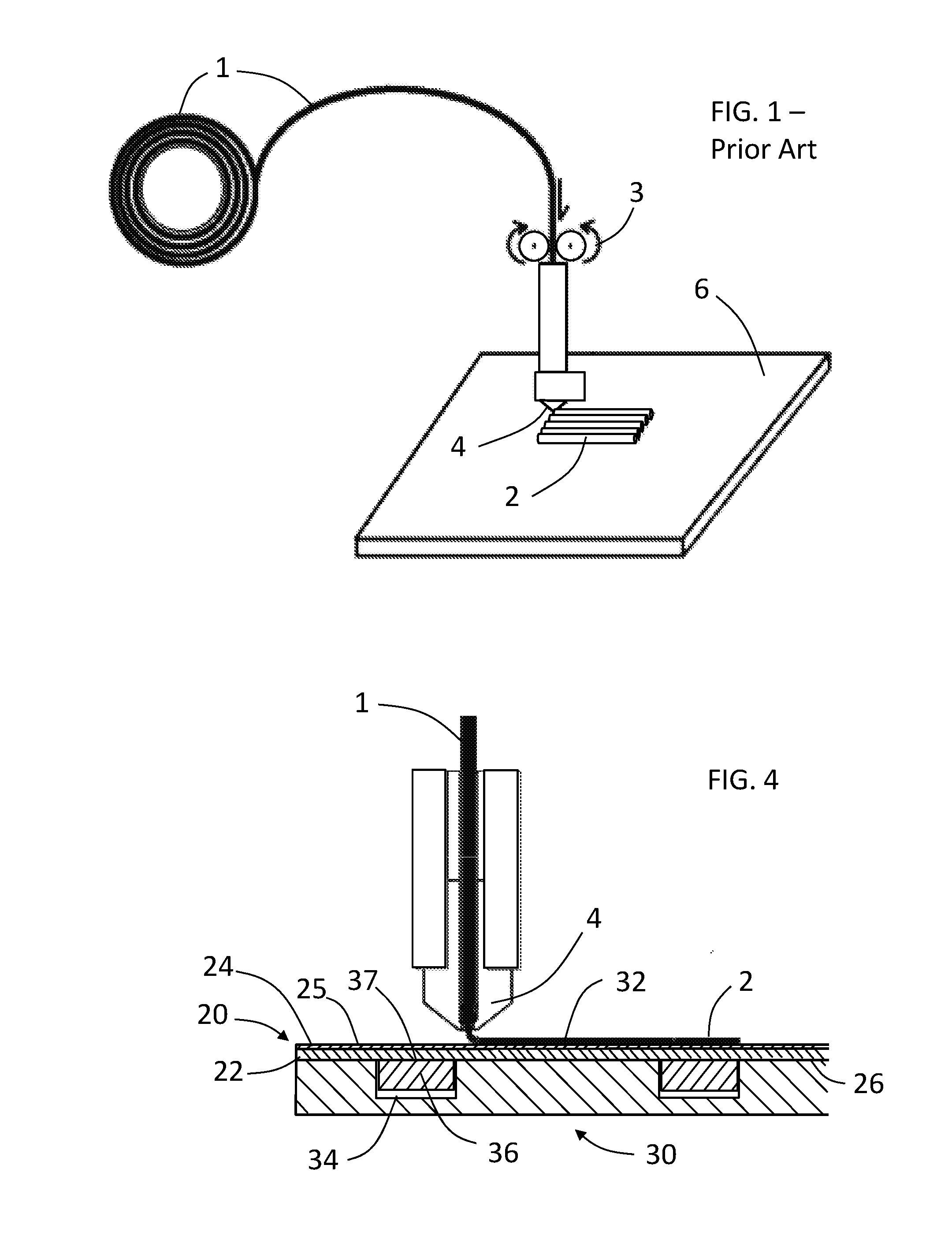

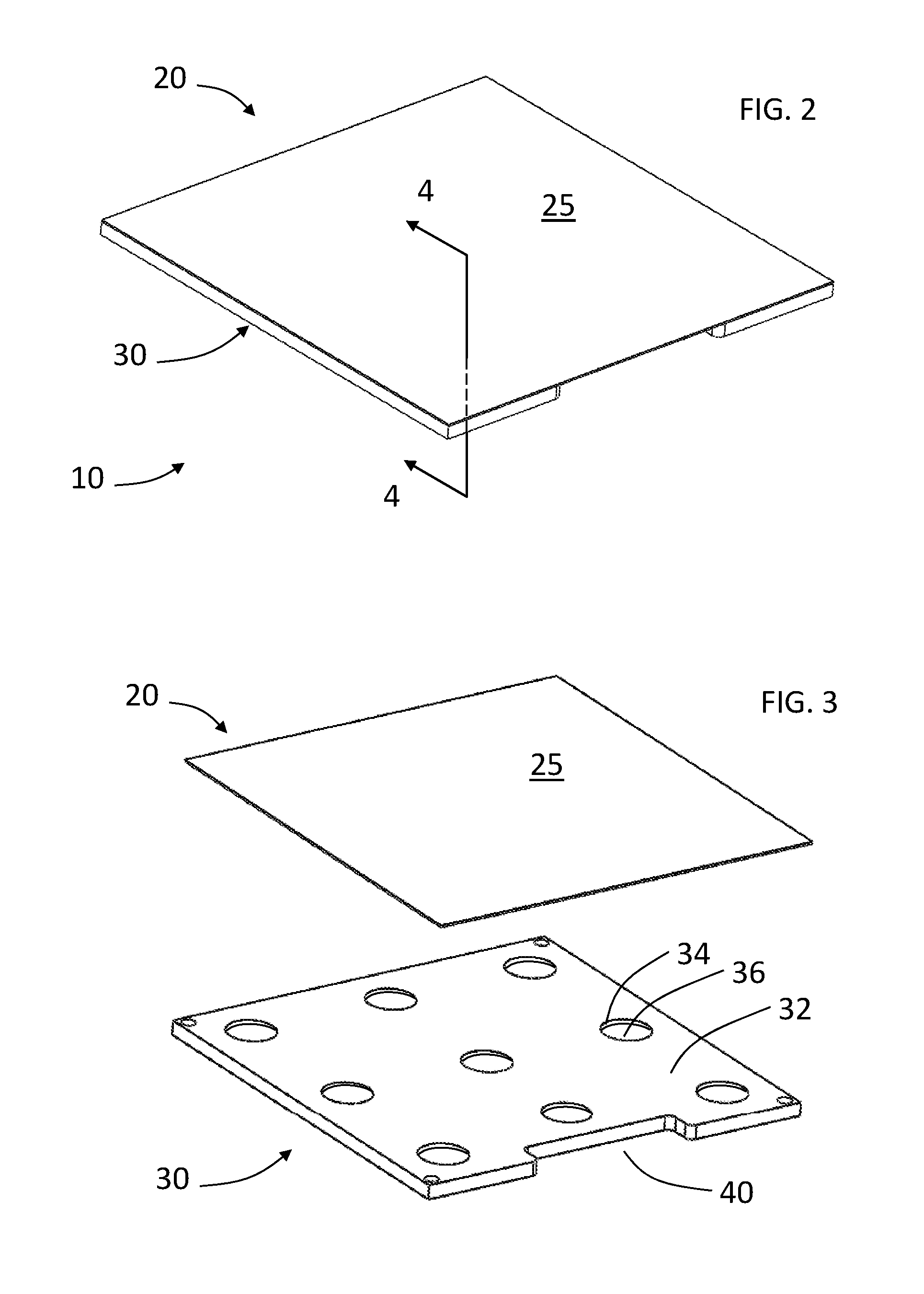

3D Print Bed Having Permanent Coating

PendingUS20170036403A1Improve adhesionSufficient level of adhesionManufacturing platforms/substratesPretreated surfacesEpoxyWater based

A coated print bed for a 3D printer having a permanent print-surface coating permanently secured to a print bed substrate plate, having a smooth, planar surface that provides an adhesive interface layer between a first layer of an applied plastic print material and the coated print bed. The coating contains a matrix-forming compound, such as a solvent- or water-based epoxy resin, an adhesive material, and optionally a filler. The user can print a series of print object directly onto the permanent print surface coating of the coated print bed, without having to refresh or refurbish the print surface, such as by applying to the print bed surface a temporary coating such as painter's tape, or a liquid adhesive.

Owner:EZ PRINT

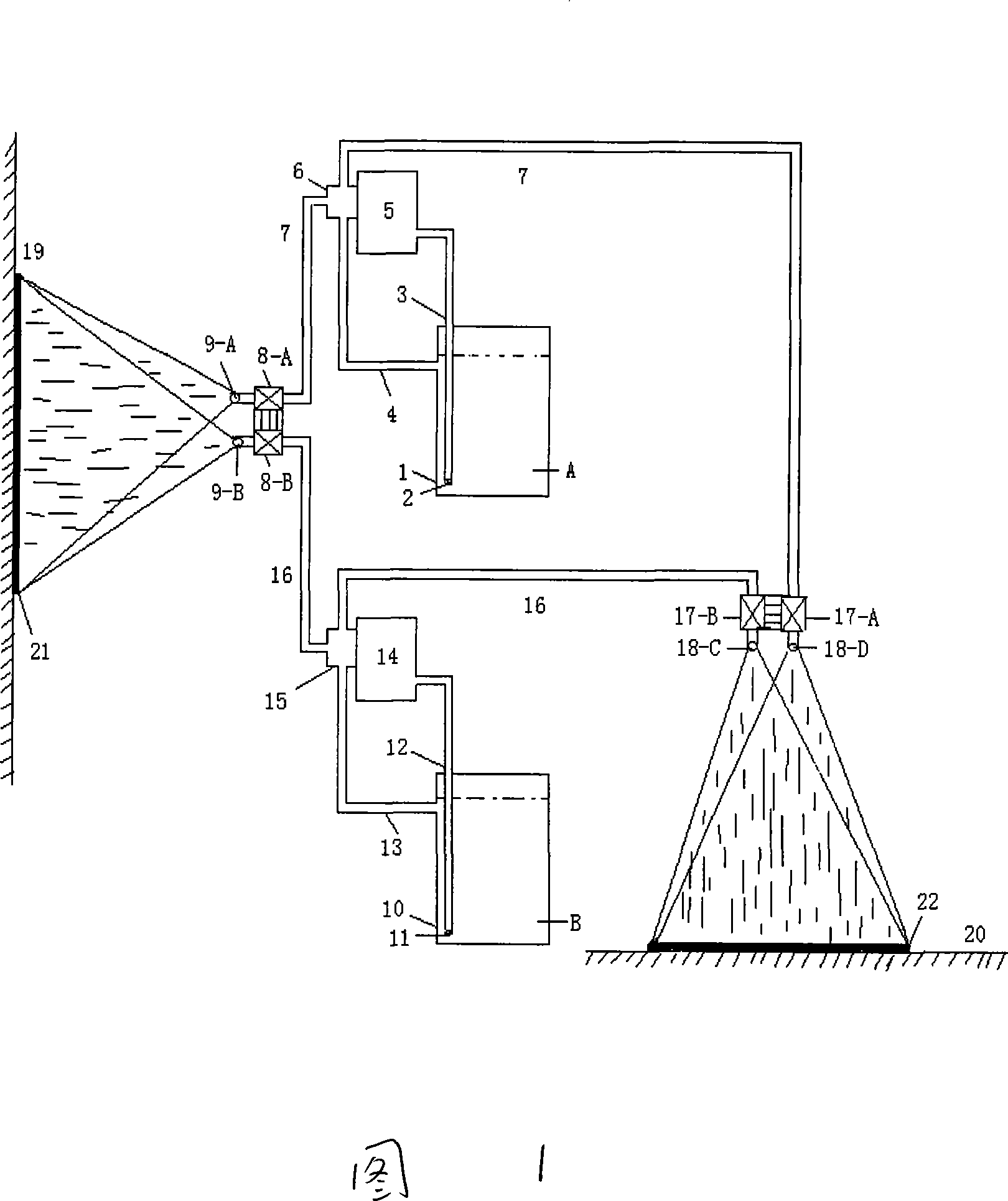

Multifunctional liquid rubber spray-coating material, preparation method, using method and special-purpose device

InactiveCN101235252AGood extensibilityImprove performanceSpraying apparatusConjugated diene hydrocarbon coatingsPolymer scienceSpray coating

Multifunctional liquid rubber spray coating comprises components of A, B, wherein A component comprises liquid rubber asphalt emulsion whose solid content is 50-75%, wherein 2-65% rubber elusion content, 30-97% asphalt elusion content, 0.0-5.0% carbon black, 0.0-6.0% ultra-fine powder, 0.025-2.50% anion dispersing agent and 0.025-3.00% anion surface activator, which is waterborne spray coating, and B component is water solution which comprises 3.0-18.0% concentration calcii chloridum (89.0-99.2%), sodium chloride (0.50-4.0%) and composite aluminum iron polymer (0.3-7.0%). The two components are sprayed on the same basal plane through adopting a double-component airless spraying device to form a gelatin film with 0.5-4mm after 3-5 seconds solidification, which has the characteristics of strong bonding, temperature resistance, weather resistance, and excellent chemical stability, heat insulation and puncture resistance. The A component can be individually sprayed, or can be combined with the double components.

Owner:大连美宸特环保节能产品有限公司

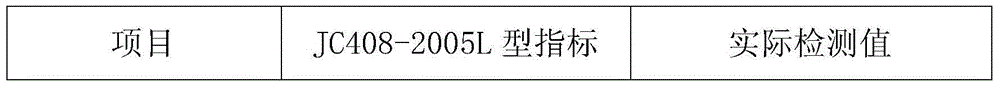

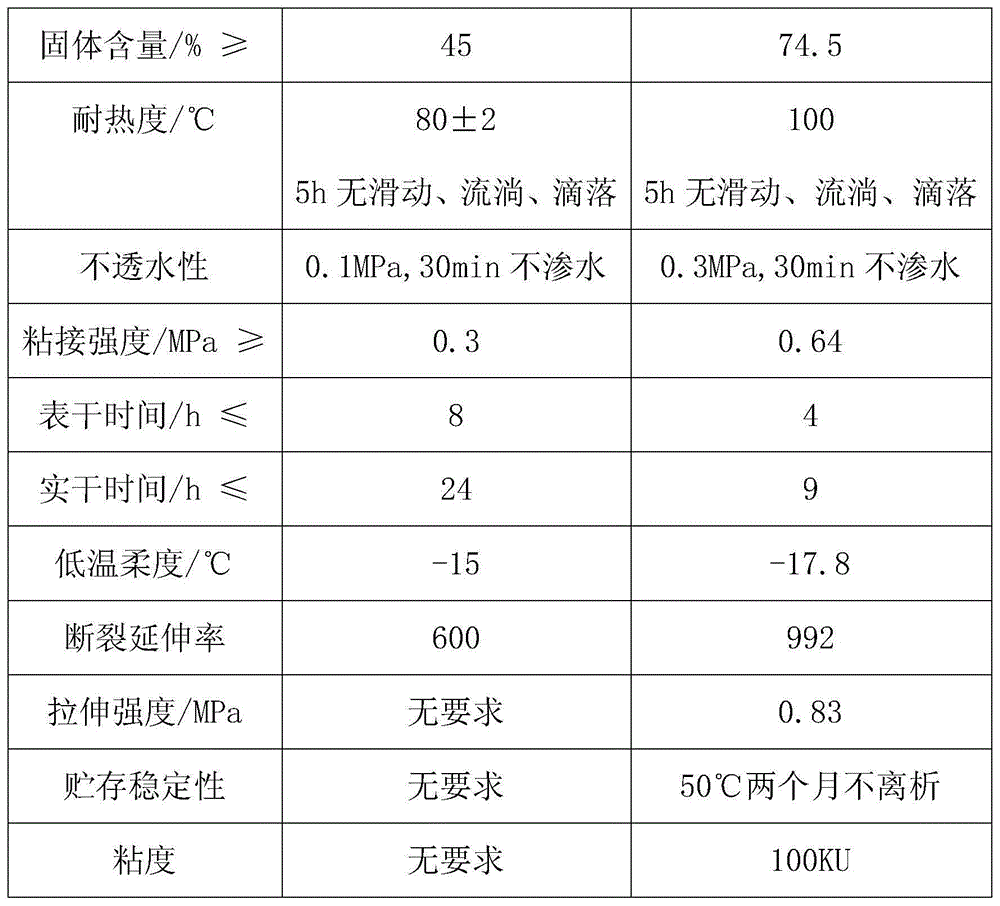

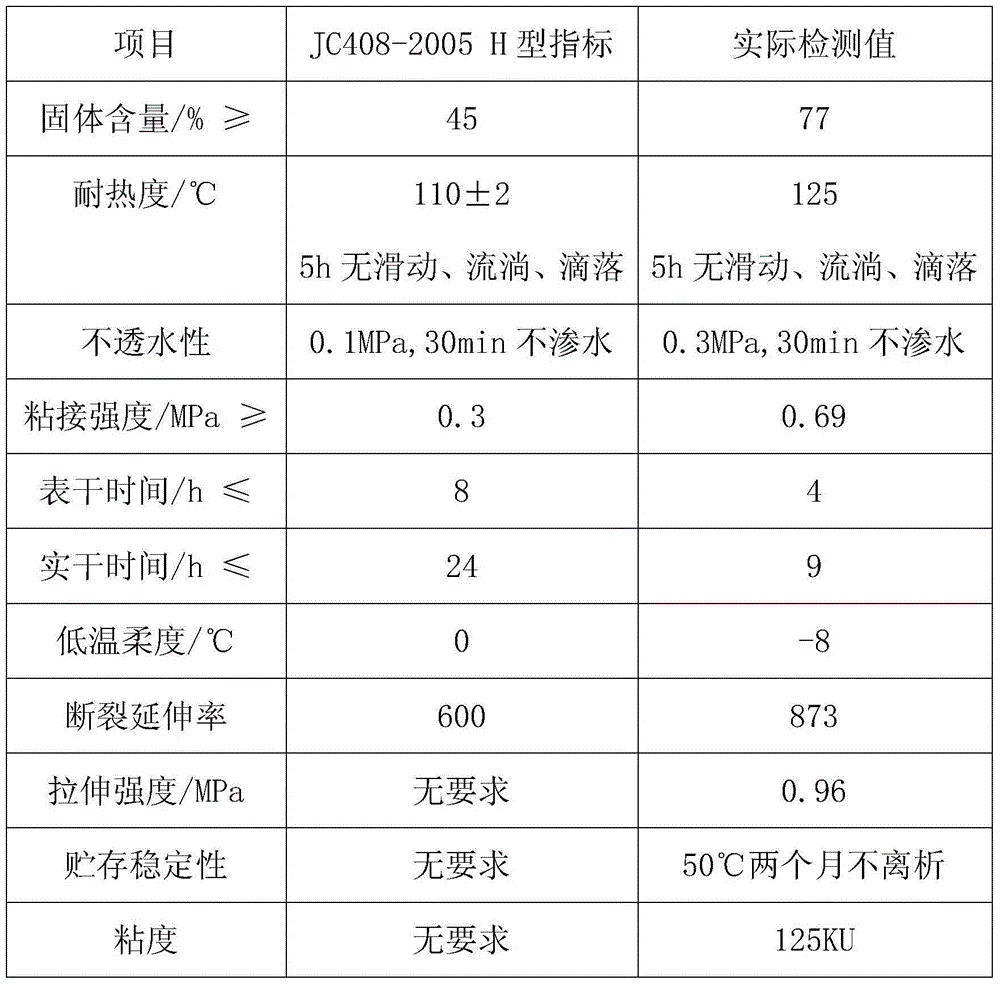

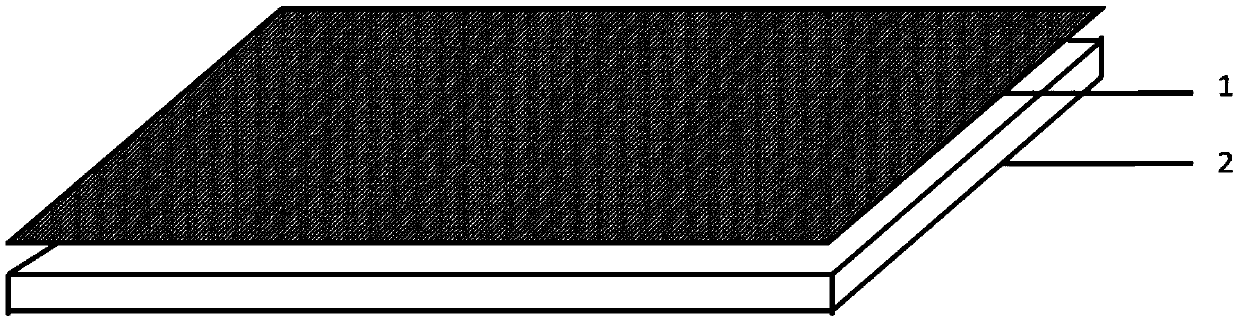

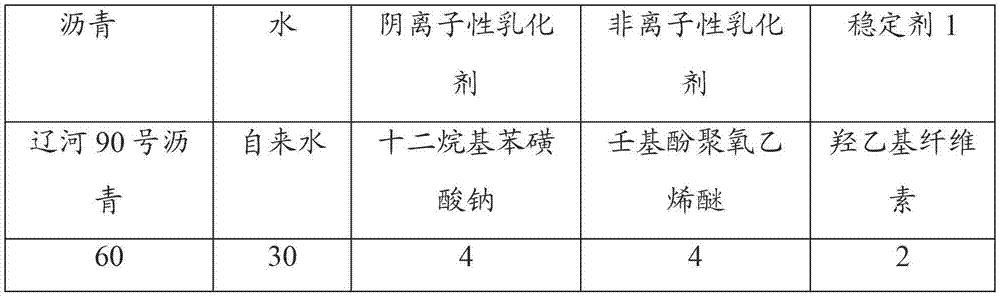

Composite emulsified asphalt waterproof coating and preparation method thereof

InactiveCN104449381AGood dispersionHigh viscosityConjugated diene hydrocarbon coatingsNatural rubber coatingsBituminous waterproofingEmulsion

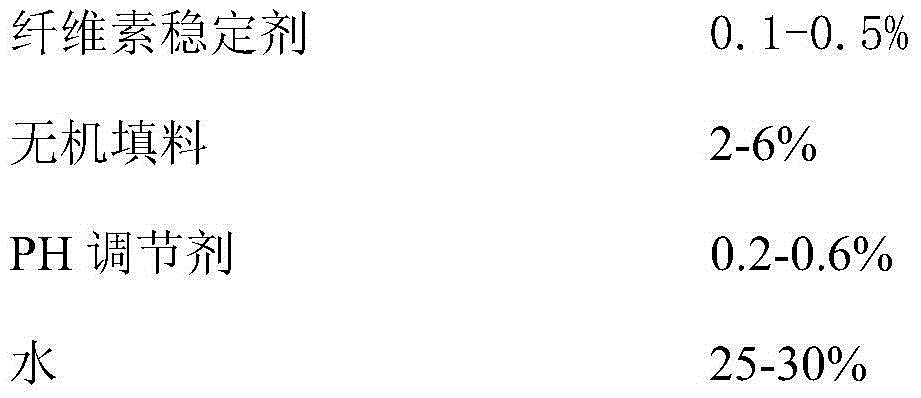

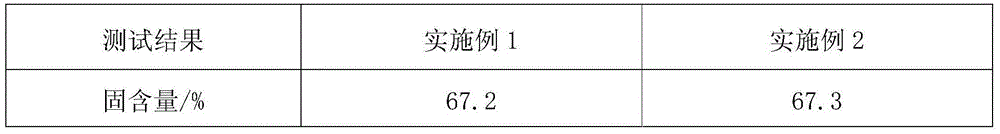

The invention relates to a composite emulsified asphalt waterproof coating and a preparation method thereof. The composite emulsified asphalt waterproof coating is prepared from the following raw materials in parts by weight: 150-220 parts of emulsified asphalt, 50-105 parts of a polymeric emulsion, 70-130 parts of inorganic powder, 0.5-2 parts of a stabilizer, 6-10 parts of a dispersant, 2-5 parts of a wetting agent, 1-3 parts of a thickener I, 1-3 parts of a thickener II, 2-7 parts of a defoaming agent and 15-40 parts of water. The invention further relates to a preparation method of the composite emulsified asphalt waterproof coating. The viscosity, strength, application property, solid content and storage stability of the emulsified asphalt waterproof coating are remarkably improved, and the cost is lowered to a great extent.

Owner:JINZHOU DONGFANG YUHONG BUILDING MATERIALS

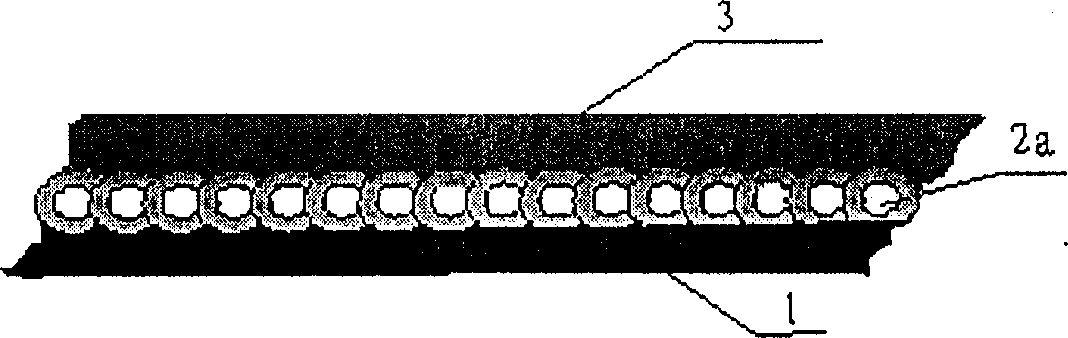

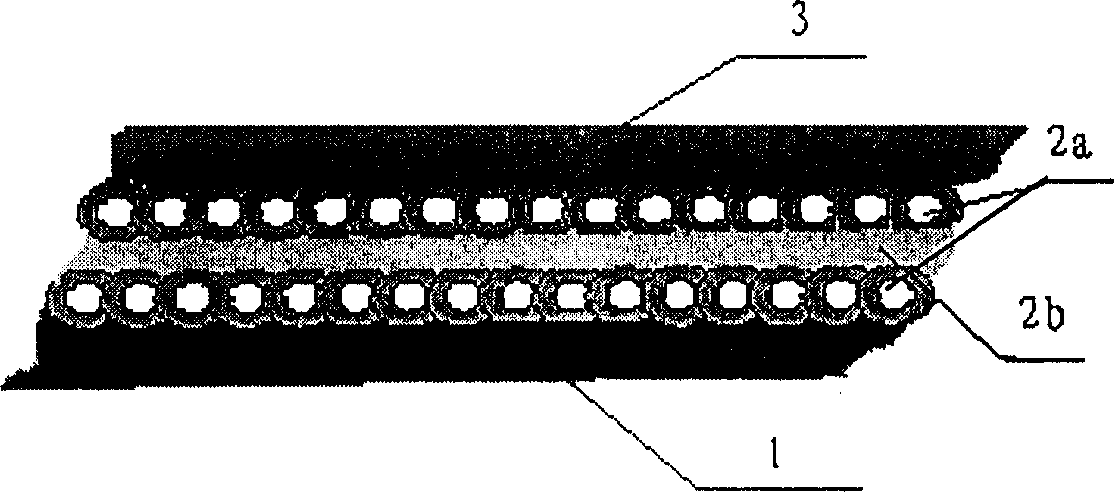

Composite graphene infrared radiation and heat conduction film and manufacturing method thereof

ActiveCN105514066AImprove infrared radiation performanceFast heat conductionSemiconductor/solid-state device detailsConjugated diene hydrocarbon coatingsOptoelectronicsHeat sink

The invention discloses a composite graphene infrared radiation and heat conduction film and a manufacturing method of the composite graphene infrared radiation and heat conduction film, and is characterized in that a substrate is provided with a composite graphene infrared radiation coating layer. According to the manufacturing method of the composite graphene infrared radiation and heat conduction film disclosed by the invention, a thin film manufactured by utilizing good infrared radiation capacity and good heat conduction capacity of a composite graphene infrared radiation material has the good heat conduction capacity in both directions which are parallel to and vertical to the substrate, so that heat can be rapidly transferred from a heating part to a heat sink device or an environment, the heat conduction efficiency is increased, local hot points in a device are removed, and temperature gradient in a heat conduction path is reduced; the composite graphene infrared radiation and heat conduction film disclosed by the invention has the advantages that the manufacturing is simple and convenient, and a powerful support is provided for high integration of electronic devices and rapid heat conduction of heating devices.

Owner:宿州晶禾科技有限公司

Polymer/graphene anti-static coating, preparation method and application thereof

InactiveCN104449010AEasy reunionSolving Dispersion ProblemsConjugated diene hydrocarbon coatingsPolyurea/polyurethane coatingsStatic performanceCompound system

The invention discloses a polymer / graphene anti-static coating, a preparation method and application thereof. The coating comprises the following constituents by weight percent: 0.01 portions to 0.5 portions of graphene; 0 portion to 10 portions of conductive additive; 90 portions to 100 portions of polymer; and solvent; the preparation method thereof comprises the following steps: completely and uniformly mixing graphene and conductive additive in advance by various manners; preparing a graphene-conductive additive compound system; using the compound system as a base, adding in conductive additive and polymer along with the solvent, completely and uniformly mixing to obtain the coating. Additionally, an anti-static film can be prepared by using different film forming technologies. The polymer / graphene anti-static coating, the preparation method and application thereof effectively solve the problems that graphene in polymer is easy to agglomerate and difficult to be uniformly dispersed in the preparation process of anti-static coating and film; the anti-static performance and mechanical performance of the coating and the film are greatly increased; meanwhile, the preparation technology is easy to be operated; the production is continuous, and the coating and film are suitable for industrial production.

Owner:苏州格瑞丰纳米科技有限公司

Composite epoxy anticorrosive paint and preparation method thereof

ActiveCN104231857AHigh glass transition temperatureGood flexibilityConjugated diene hydrocarbon coatingsAnti-corrosive paintsEpoxyPolymer science

The invention discloses composite epoxy anticorrosive paint and a preparation method thereof. The composite epoxy anticorrosive paint is composited by a component A and a component B at a ratio of 2:1, wherein the component A comprises constituents as follows: organosilicon modified epoxy resin, a pigment, filler, a plasticizer, a dispersant, a coalescing agent and a antifoaming agent; the component B comprises constituents as follows: polyphenyl ether resin powder, styrene-butadiene rubber, toluene, a plasticizer, a coupling agent, auxiliary materials and a flame retardant; and the components A and B are mixed respectively for preparation, and B is sprayed on A to form the composite epoxy anticorrosive paint. The composite epoxy anticorrosive paint is prepared by two components, has superior high-temperature resistance and abrasion resistance as well as good adhesion and low shrinkage simultaneously, has good corrosion resistance and penetration resistance to water, medium acid, alkali and other solvents and further has superior flexibility and paint application simultaneously; and the preparation method of the composite epoxy anticorrosive paint is simple and low in cost.

Owner:JIANGSU MARINE VICTORY COATING

Reaction bonding modified emulsified asphalt waterproof paint and preparation method thereof

ActiveCN102898947AImprove stabilityImprove bindingConjugated diene hydrocarbon coatingsChloropene polymer coatingsCross-linkBituminous waterproofing

The invention aims to provide a reaction bonding modified emulsified asphalt waterproof paint and a preparation method thereof. The reaction bonding modified emulsified asphalt waterproof paint comprises asphalt, a modifying agent, an emulsifying agent, a cross-linking agent and water. In the formula system of the reaction bonding modified emulsified asphalt waterproof paint, more modifying agents in an appropriate amount are adopted compared with the prior art, so that a rubber-asphalt mixture can achieve a good emulsifying effect, the elasticity and strength of a dried sealing layer are greatly improved, and the sealing effect can be better and lasting; and by using the cross-linking agent, a chemical coupling effect is achieved between the paint and concrete, so that the cohesive force of the concrete is promoted. The reaction bonding modified emulsified asphalt waterproof paint can be applied to waterproof construction of wall surfaces, roofs, roads, bridges and the like, and has a very high practical value.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

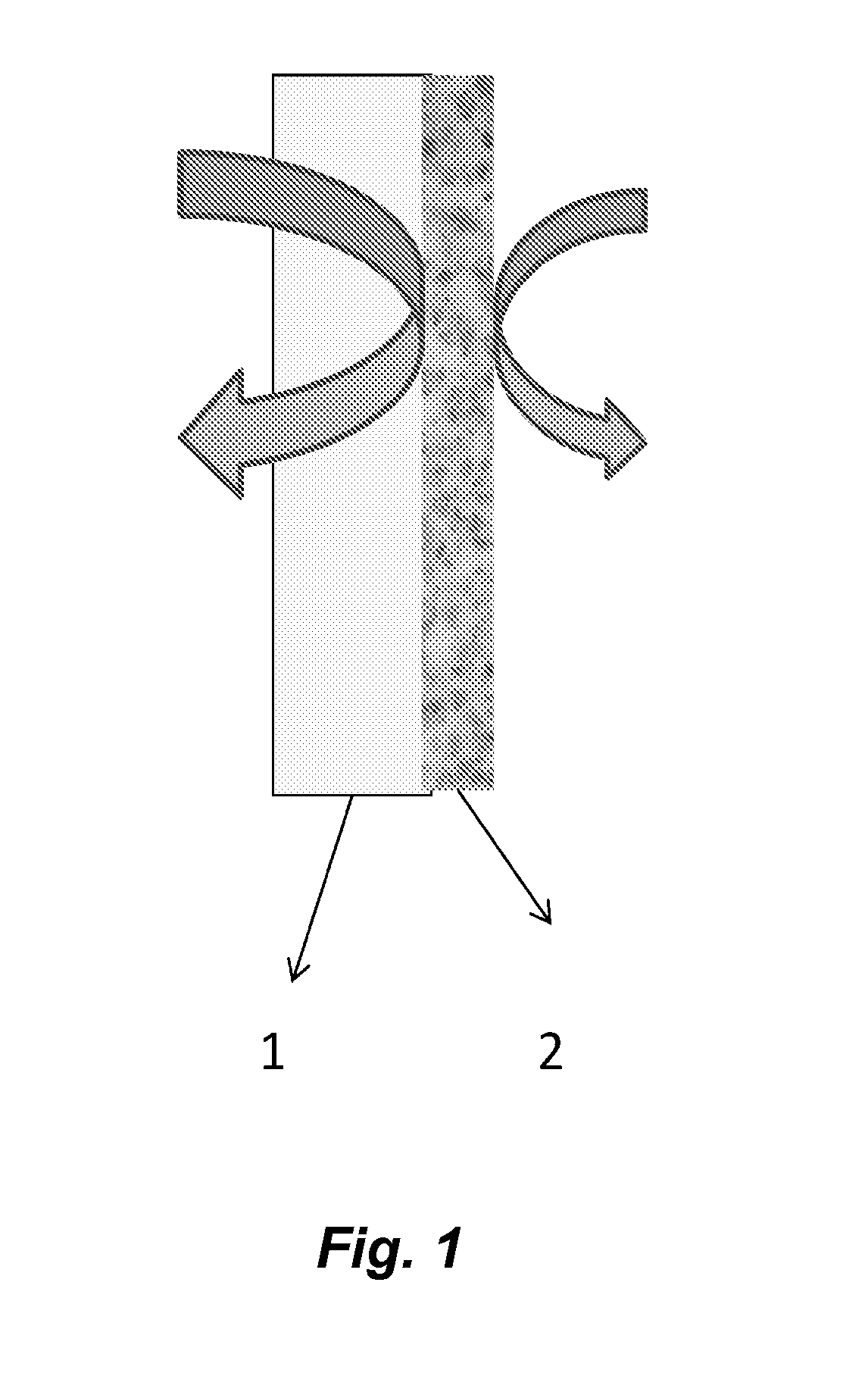

Coated substrate, a process for production of a coated substrate, a package and a dispersion coating

InactiveUS20130017349A1High strengthEasy to recycleMaterial nanotechnologyStarch dervative coatingsFiberCellulose

The present invention relates to a coated fiber based substrate comprising a dispersion coating wherein said dispersion coating comprises microfibrillated cellulose and colloidal particles of a polymer. The invention further relates to a package formed from said substrate, a dispersion coating and process for the production of mentioned substrate.

Owner:STORA ENSO OYJ

Waterproof coating capable of chemical crosslinking and physical mortise and tenon with cement

ActiveCN103333555AImprove adhesionGood extensibilityRosin coatingsConjugated diene hydrocarbon coatingsMortise and tenonSynthetic rubber

The invention provides a waterproof coating capable of chemical crosslinking and physical mortise and tenon with cement. The waterproof coating is characterized by comprising the following raw materials by weight: 20-50 parts of a synthetic rubber latex, 20-50 parts of emulsified asphalt, 0.5-2 parts of a functional additive and 0.5-2 parts of a dispersant, 20-40 parts of a filler and 10-25 parts of water. The principle is that through coupling effect of the functional additive, part of the molecules in the synthetic rubber and most molecules in the asphalt couple into large molecules with reaction activity; when the large molecules contact with a base plane, the non-reactive molecule segments of the rubber and asphalt and the base plane form physical adsorption, and the molecular segments with reaction activity conduct react with the base plane to form chemical bond effect, so as to generate strong adhesive force; and after bonding, the coating is hardly influenced by environmental factors. Therefore, the waterproof coating provided by the invention has excellent waterproof performance.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

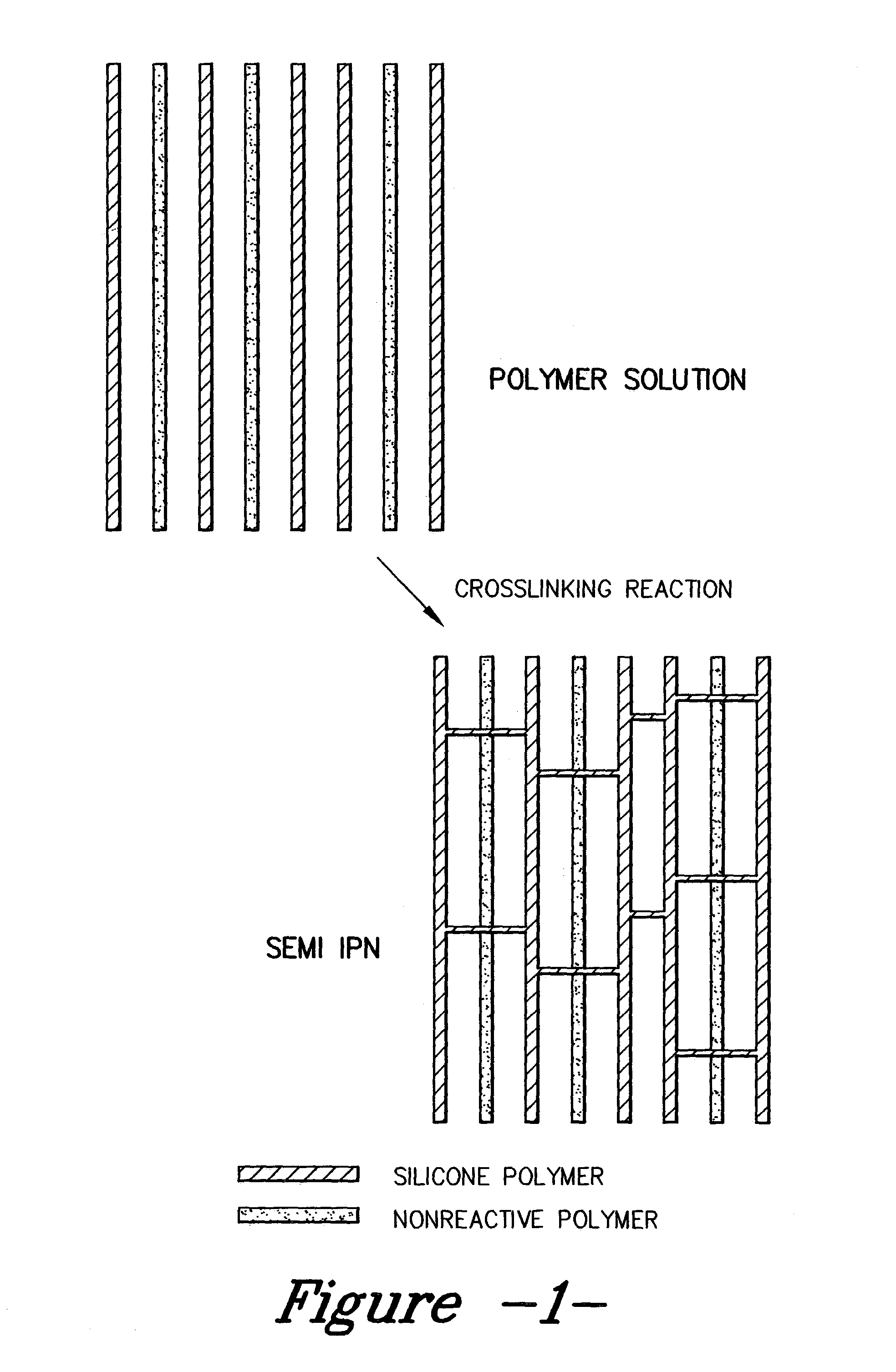

Polymer coating blends

InactiveUS7132170B2Improve adhesionAbility to efficientlyPedestrian/occupant safety arrangementFibre typesPolymer sciencePolymer coatings

An adhesive coating composition for fabric substrates, such as automotive airbags. The coating is formed from a blend including a silicone polymer and a second polymer which is thermodynamically compatible with silicone. In particular, the second polymer has a cohesion parameter (δ / MPa1 / 2) that is similar to that of silicone so that any thermodynamic barrier to the second polymer dissolving in silicone is removed.

Owner:MILLIKEN & CO

Asphalt rubber waterproof coating material

ActiveCN102936460AUniform procedure is goodNot easy to embrittleConjugated diene hydrocarbon coatingsNatural rubber coatingsAcrylic resinStearic acid

The present invention provides a rubber asphalt waterproof coating material, and belongs to the technical field of coating materials. The coating material is prepared from the following raw materials, by weight, 20-35 parts of a natural rubber, 10-15 parts of a thermoplastic styrene-butadiene rubber, 5-10 parts of acrylic resin, 3-5 parts of ethylene glycol ethyl ether, 20-30 parts of asphalt, 5-10 parts of chlorinated polyethylene, 1-2 parts of silicon carbide crystal whiskers, 3-6 parts of talc powder, 2-4 parts of diatomite , 2-4 parts of stearic acid, 3-8 parts of polyacrylamide, 6-9 parts of an ethylene-vinyl acetate copolymer, 3-5 parts of a plasticizer, 1-2 parts of a defoaming agent, 8-15 parts of a pigment, 2-3 parts of a surfactant, and 40-50 parts of water. The waterproof coating material provided by the embodiments still has good watertightness and good mechanical property after high temperature and high humidity destruction.

Owner:武汉飞盛建设工程有限公司

High-strength rubber asphalt waterproof paint and preparation method thereof

ActiveCN103205204AHigh strengthIncrease elasticityConjugated diene hydrocarbon coatingsChloropene polymer coatingsEmulsionPolymer science

The invention discloses a high-strength rubber asphalt waterproof paint. The high-strength rubber asphalt waterproof paint is prepared from 55-65wt% of emulsified asphalt, 25-35wt% of modified latex, 5-10wt% filler and the like. The high-strength rubber asphalt waterproof paint is prepared from the following steps of adding the emulsified asphalt, the modified latex and the filler into a stirring cylinder, stirring for 20min at a high speed, standing for 1 hour and then filtering to obtain the rubber asphalt waterproof paint. According to the high-strength rubber asphalt waterproof paint disclosed by the invention, high-strength composite modified emulsion is used for modification. The high-strength rubber asphalt waterproof paint has the remarkable characteristics of high strength, perfect fit, high elasticity, seamlessness and the like and can be manually scrapped and coated; therefore, the defect that the strength of the traditional asphalt coating is insufficient is solved.

Owner:KUNMING FENGXING WATERPROOF MATERIAL +3

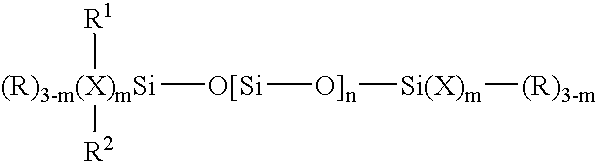

Polymer compositions and adhesives, coatings, and sealants made therefrom

ActiveUS20060270770A1Improve performanceImprove stabilityOther chemical processesPolyureas/polyurethane adhesivesPolymer scienceSilanes

Polymer compositions for preparing sealants, adhesives and coatings are provided. The polymer compositions comprise from 1 to 99% by weight of an organic polymer comprising functional silane groups, from 1 to 45% by weight (based on total polymer) of at least one reactive or non-reactive organopolysiloxane polymer; from 0 to 98% by weight (based on total polymer) of an organic polymer that lacks functional silane groups.

Owner:TREMCO CPG INC

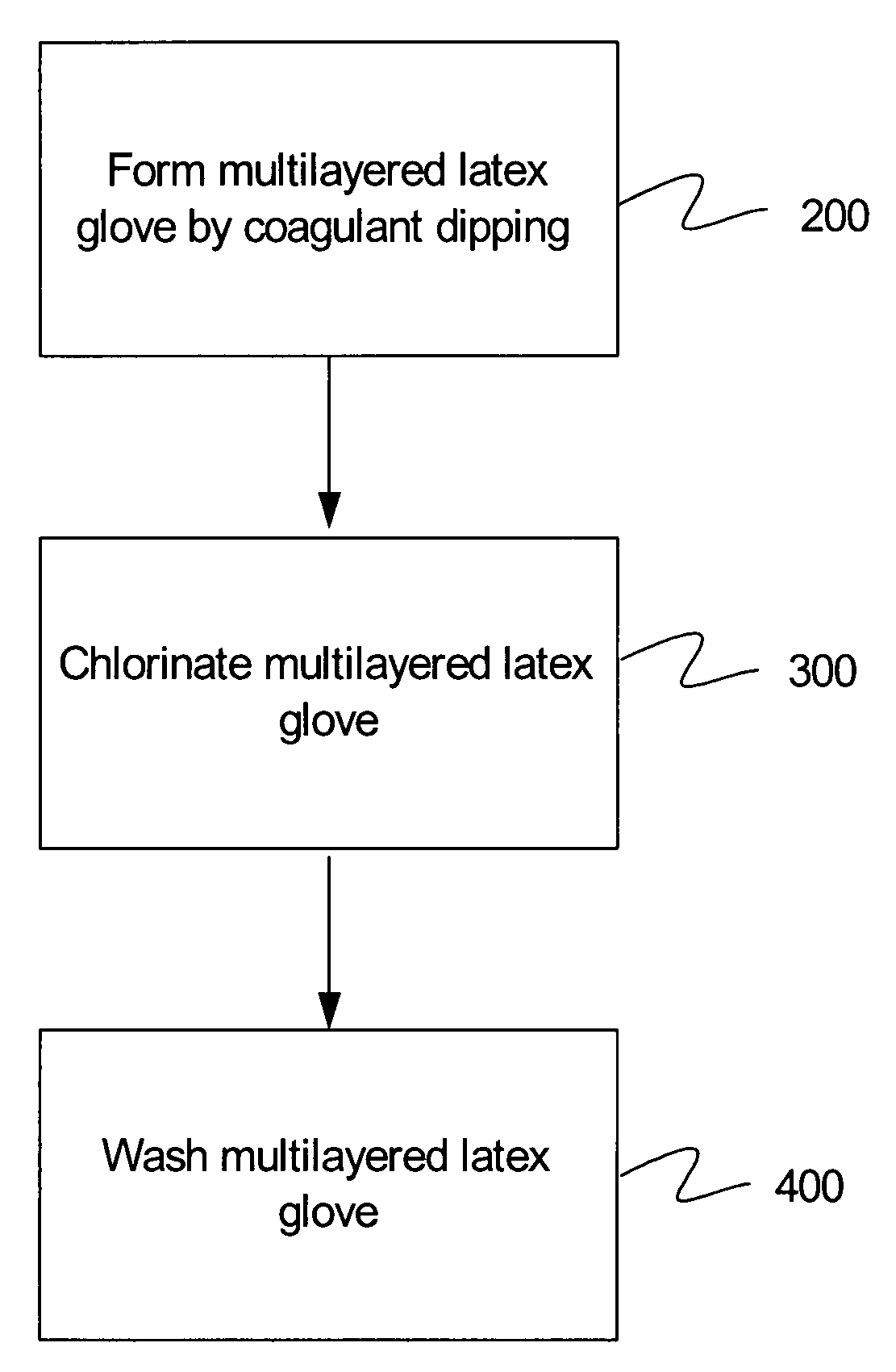

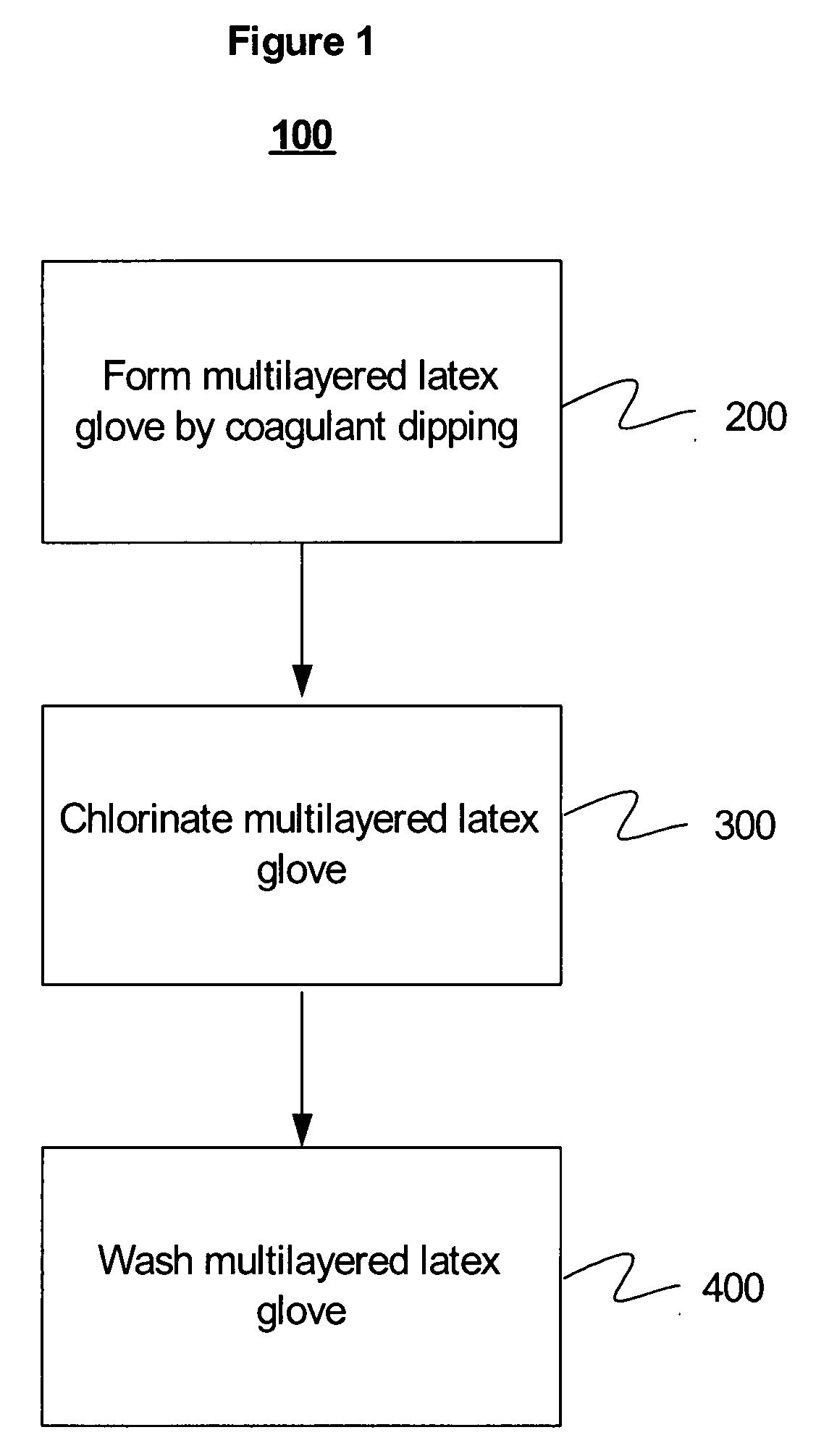

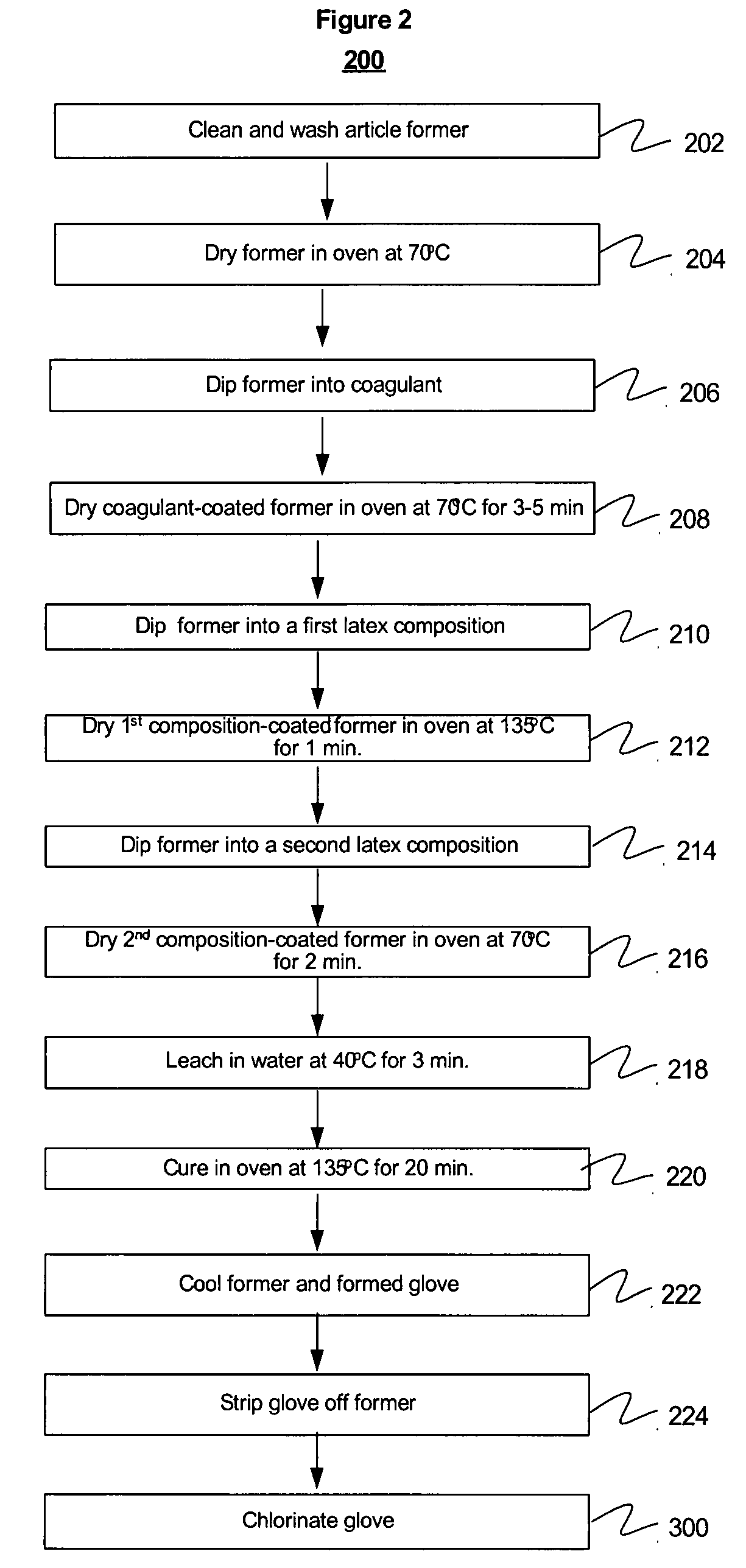

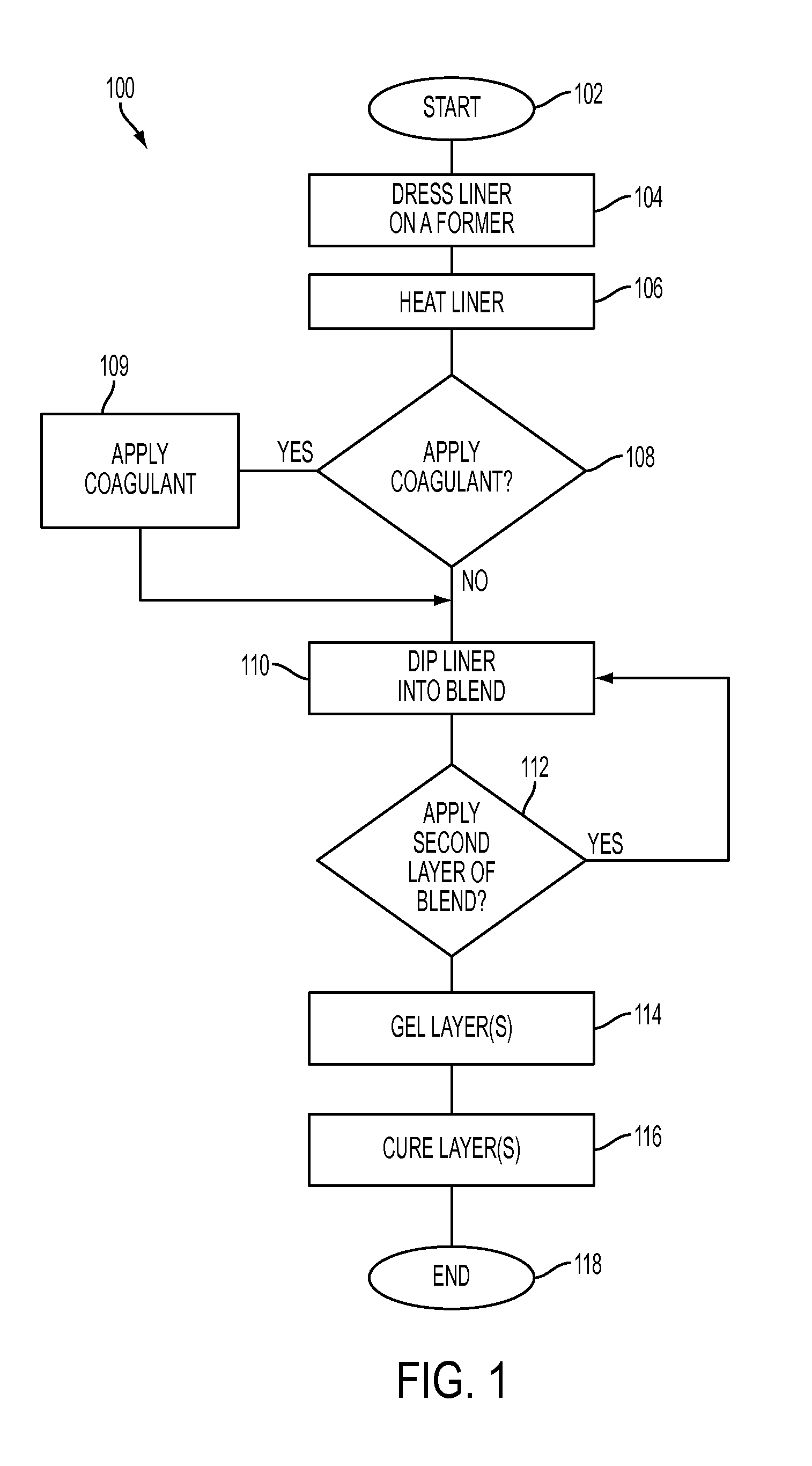

Antistatic gloves and process for making same

InactiveUS20080306200A1Desirable antistatic propertyDesirable propertyGlovesConjugated diene hydrocarbon coatingsPolymer scienceAntistatic agent

The present invention is directed to antistatic elastomeric articles and methods of making the same. The articles can be single layered or multilayered. The single layered articles possess desirable antistatic properties and desirable properties of comfort and feel. The multilayered articles have an outermost layer / surface that possesses desirable antistatic properties and an innermost layer / surface that exhibits desirable properties of comfort and feel. In preferred embodiments, the elastomeric articles are made form a nitrile / natural rubber blend. Articles of the present invention have antistatic properties measured as having a surface resistivity below about 1014 Ω / sq and a static decay time of less than about 60 seconds.

Owner:ALLEGIANCE CORP

High-permeability liquid rubber spray coating

InactiveCN102329566AHigh bonding strengthImprove waterproof and anti-seepage performanceUnspecified rubber coatingsConjugated diene hydrocarbon coatingsPolymer scienceSpray coating

The invention discloses a high-permeability liquid rubber spray coating, and relates to the technical field of spray coatings. The high-permeability liquid rubber spray coating comprises a component A and a component B, wherein the component A is anionic liquid rubber asphalt emulsion; the component B is a coagulant solution; the component A has the solid content of liquid rubber asphalt emulsion of 50-75 weight percent, and comprises the following components in percentage by mass: 1 to 35 percent of rubber emulsion, 10 to 50 percent of asphalt emulsion, 0.01 to 2 percent of anionic dispersing agent, 0.01 to 2 percent of anionic surfactant, 0.1 to 10 percent of fatty alcohol-polyoxyethylene ether, 0.1 to 10 percent of alkali resistant wetting agent OEP-70 and 0.1 to 10 percent of alkali resistant wetting agent AEP; and the component B is an aqueous solution at the concentration of 3-18 percent, which is prepared by mixing calcium chloride and composite aluminum-iron polymer in percentage by mass. The wetting agents are added into the spray coating, and the coating has high permeability and wider application range.

Owner:DALIAN MEICHENTE TECH

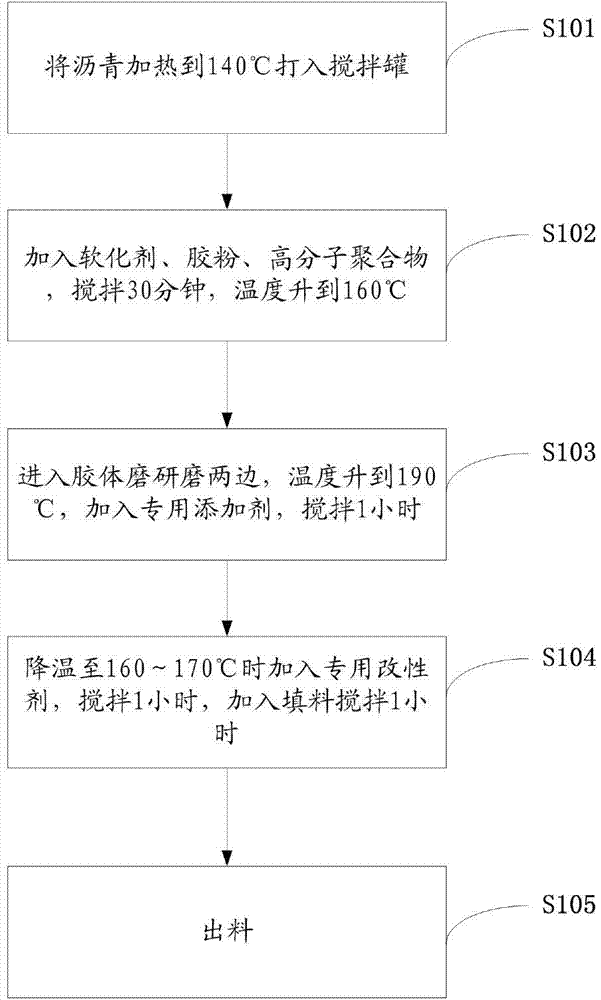

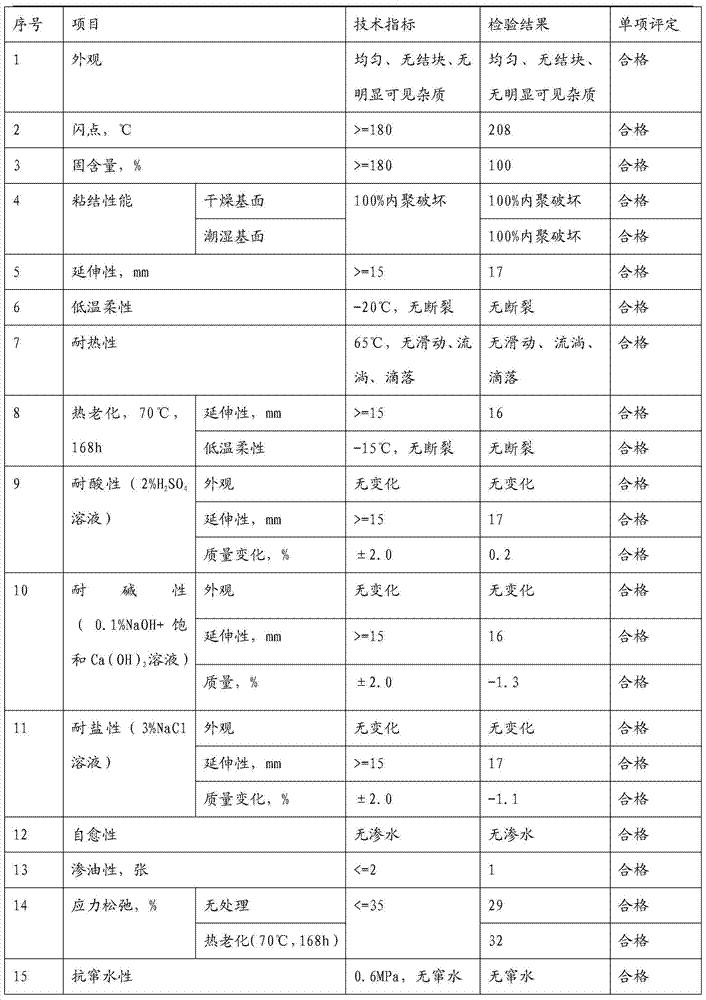

Non-cured rubber asphalt waterproof paint

InactiveCN104119799AWill not harmCompletely sealed and waterproofUnspecified rubber coatingsConjugated diene hydrocarbon coatingsBituminous waterproofingPolymer science

The invention discloses a non-cured rubber asphalt waterproof paint. The preparation technology of the paint comprises the following steps: heating the asphalt to 140 DEG C, loading the heated asphalt into a stirring tank, adding a softening agent, rubber powder, and polymer, stirring for 30 minutes, heating to 160 DEG C, delivering the mixture to a colloid mill to grind the two edges, heating to 190 DEG C, adding a special additive, stirring for one hour, cooling to 160 to 170 DEG C, adding an auxiliary agent, stirring for one hour, adding a filling material, stirring for one hour, and finally discharging. The paint solves the problems of waterproof layer fracture due to the cracking stress, which is transferred from the basic layer to the waterproof layer, and the accelerated aging due to the flexural fatigue and high stress state of the waterproof layer. Moreover, because of the cohesiveness of the paint, the capillary pores and cracks in the basic layer can be perfectly sealed by the paint, thus the problem of water leaking in the waterproof layer is solved, and the waterproof reliability is greatly improved.

Owner:徐立

Spraying quick-setting rubber asphalt waterproof coating material

ActiveCN103627258AWith anti-adhesive effectImprove adhesionConjugated diene hydrocarbon coatingsNatural rubber coatingsComposite constructionWater based

The invention relates to a spraying quick-setting rubber asphalt waterproof coating material. A special technology is adopted for preparation of the spraying quick-setting rubber asphalt waterproof coating material. The spraying quick-setting rubber asphalt waterproof coating material is a water-based spraying paint prepared according to a ratio, and a preparation method of the spraying quick-setting rubber asphalt waterproof coating material comprises following steps: a liquid rubber asphalt latex emulsion is prepared by mixing superfine, suspended and micro-emulsion modified emulsified asphalt with high-molecular polymer rubber latex; and the liquid rubber asphalt latex emulsion is mixed with a coagulant. Cold spraying construction is adopted for preparation of the spraying quick-setting rubber asphalt waterproof coating material; elastic coating film elongation is more than 1000%; restoration ratio is more than 95%. The spraying quick-setting rubber asphalt waterproof coating material possesses ultraviolet resistance, high construction efficiency, high bonding strength, excellent high-temperature resistance, excellent low temperature flexibility, and better quick setting effect; and is capable of forming films in 3 seconds. The spraying quick-setting rubber asphalt waterproof coating material is water based; is friendly to the environment; possesses no toxicity, and excellent endurance; is quick and convenient for construction; and is a novel environmental friendly waterproof paint with a wide application range. The spraying quick-setting rubber asphalt waterproof coating material is mainly used for various waterproof and anticorrosion projects. The spraying quick-setting rubber asphalt waterproof coating material is used for individual construction of waterproof projects, for composite construction of waterproof projects together with waterproof roll, and for individual construction of anticorrosion projects.

Owner:SHANDONG NORTH CHUANGXIN WATERPROOF SCI & TECH GRP CO LTD

Non-curable rubber asphalt waterproof coating and preparation method and composite waterproof roll material thereof

ActiveCN105885693AImprove heat resistanceLow viscosityFireproof paintsConjugated diene hydrocarbon coatingsBituminous waterproofingElastic plastic

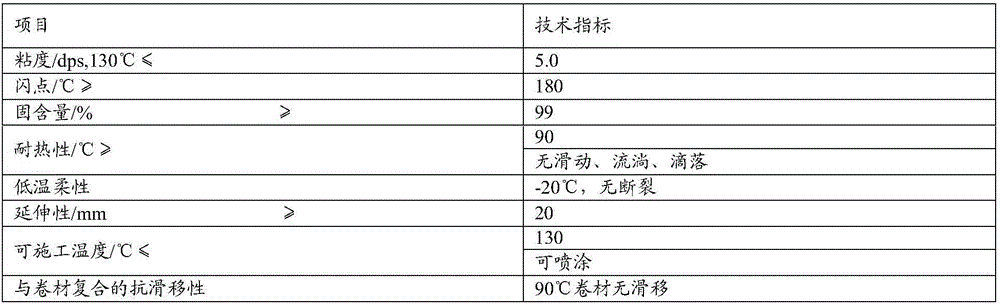

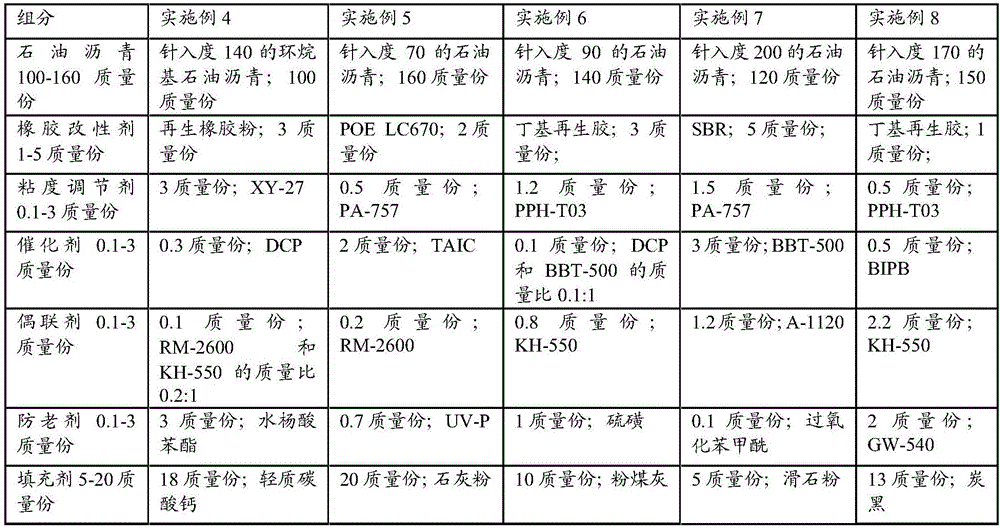

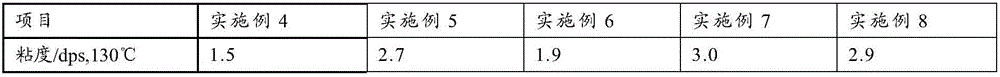

The invention provides a non-curable rubber asphalt waterproof coating and a preparation method and a composite waterproof roll material thereof. The non-curable rubber asphalt waterproof coating is prepared from, by mass, 100-160 parts of petroleum asphalt, 1-5 parts of rubber modifier, 0.1-3 parts of viscosity regulator and 0.1-3 parts of a catalyst. The chemical crosslinking reaction of the petroleum asphalt and the rubber modifier is achieved by adding the viscosity regulator and the catalyst in the petroleum asphalt and the rubber modifier of the non-curable rubber asphalt waterproof coating, so that the non-curable rubber asphalt waterproof coating has high heat resistance (greater than or equal to 90 DEG C) and low viscosity (smaller than or equal to 5.0 dps), can be sprayed or scraped at the low temperature (sprayable at the temperature of 130 DEG C) and also has energy saving and consumption reducing properties and other special properties on the basis that the common properties of an elastic-plastic paste body are kept within the service life, the comprehensive performance of the non-curable rubber asphalt waterproof coating is improved, and the service life of the non-curable rubber asphalt waterproof coating is prolonged.

Owner:TANGSHAN DONGFANG YUHONG WATERPROOF TECH CO LTD +1

High-polymer modified water-emulsion asphalt-based thick waterproof paint and preparation method thereof

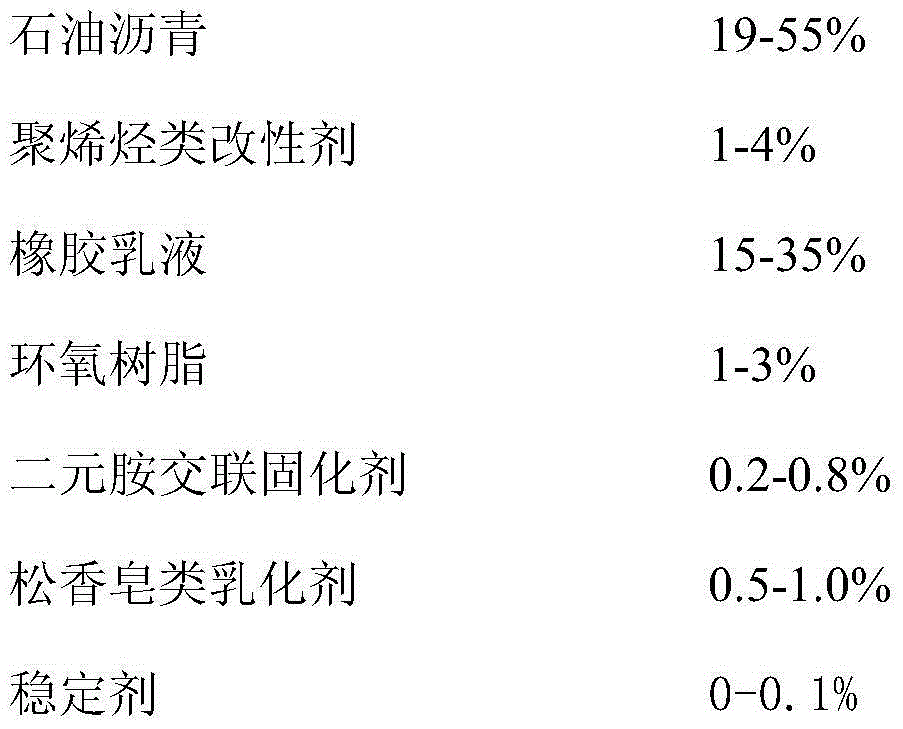

ActiveCN103555204AImprove low temperature performanceIncrease elasticityCellulose coatingsConjugated diene hydrocarbon coatingsHigh concentrationEpoxy

The invention discloses a high-polymer modified water-emulsion asphalt-based thick waterproof paint and a preparation method thereof. The paint is prepared by taking high-concentration ultrafine suspension microemulsion anion modified emulsified asphalt, a polyolefins modifier, rubber emulsions such as chloroprene rubber or butadiene styrene rubber or the like, multiple synthetic high-molecular polymers such as epoxy resin and the like, inorganic powders such as SiO2 and bentonite and the like as raw materials and mixing by employing a special production technology. Tests show that after a film is formed from the paint, no embrittlement happens at a low temperature of -20 DEG C, no flow happens at a high temperature of 120 DEG C, the elasticity recovery rate reaches up to 90%, and the paint can be stored stably for one year or more.

Owner:ZHEJIANG YUXI CORROSION CONTROL CORP

Fire Retardant Coating Composition

ActiveUS20170029632A1Minimizing fire spreadFireproof paintsConjugated diene hydrocarbon coatingsPolystyreneGraphite

A fire retardant, vapor impermeable coating composition is disclosed which is useful for protecting gypsum, wood, polyurethane, polystyrene, and other construction materials and surfaces, such as components for buildings. The composition does not require halogenated compounds and is considered environmentally friendly. The composition is provided in the form of a liquid-applicable aqueous latex comprising at least one latex polymer and an expandable graphite, optionally a hydrophobic thickener, and optionally other fire retardants such as metal hydroxides, wherein the polymer is selected such that the composition, when coated onto a substrate and allowed to dry, has a vapor permeability not exceeding one perm (5.70×10−8 g / Pa.s.m2 when tested according to ASTM E96B-10 at an average dry film thickness of 40 mils). The invention provides fire retardant air barrier layers for construction materials, such as polyurethane or polystyrene insulation beads or panels, as well as vapor impermeable laminates for construction applications.

Owner:GCP APPL TECH INC

Themally insulating and reducing composite paint and its preparing process and application

InactiveCN1396219AGood heat insulation and heat reduction effectConjugated diene hydrocarbon coatingsSpecial surfacesAntistatic agentThermal radiation

A composite coated layer for thermal insulating and heat reflecting is composed of a thermal insualting layer on the surface of a substrate and a heat reflecting layer on the said thermal insulating laye. The thermal insulating layer contains filming agent, hollow microbeads arranged by one or more layers, thermal insulating filler and / or stress reducing material. The reflecting layer contains filming agent, antiageing agent, antistatic agent and reflecting pigment.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

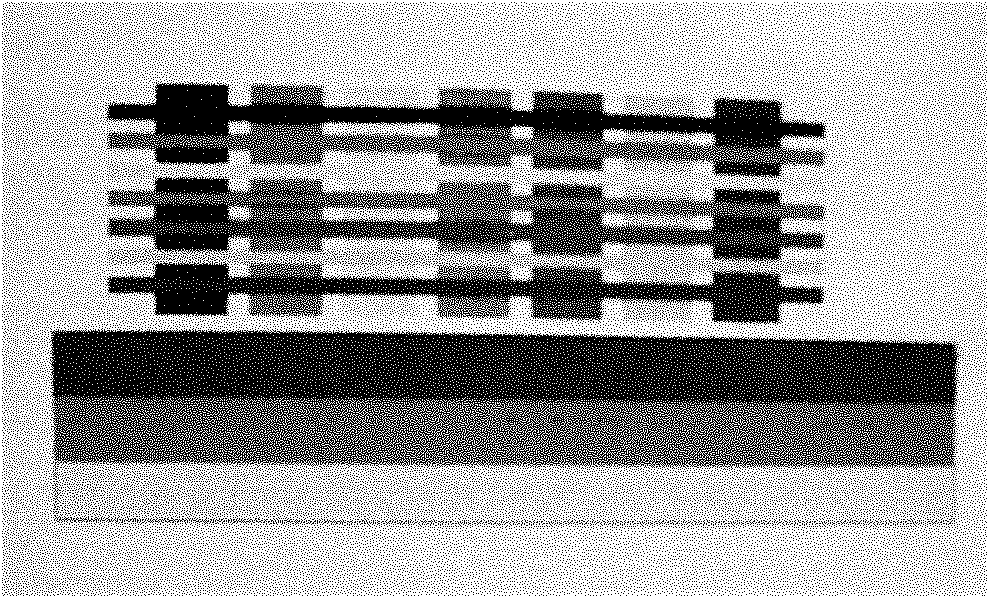

Polymer blends of nitrile rubber and polychloroprene

Polymer compositions including blends of approximately 90 to approximately 60 percent by weight acrylonitrile butadiene copolymer and approximately 10 to approximately 40 percent by weight polychloroprene copolymer are disclosed. Methods for manufacturing unsupported gloves and for supported gloves including a knitted liner with the polymer compositions, producing gloves having an ANSI abrasion resistance level 4, are also disclosed.

Owner:ANSELL

Ink-jet recording material and preparation method thereof as well as method for preparing ink absorption layer coating liquid

ActiveCN102092209ALow priceIncrease polarityStarch dervative coatingsConjugated diene hydrocarbon coatingsPolymer scienceAdhesive

The invention provides an ink-jet recording material and a preparation method thereof as well as a method for preparing an ink absorption layer coating liquid, and relates to an ink-jet material and a preparation method thereof as well as a method for preparing an ink absorption layer coating liquid, so that the problems of poor ink absorption effect, nonuniform color distribution of printed images, unclear printed images and higher preparation cost of the existing ink-jet recording material can be solved. The ink-jet recording material is prepared from the ink-jet layer coating liquid which is prepared from PVC (polyvinyl chloride) serving as a base material, a 20-30% polyacrylic acid emulsion serving as a primer, an inorganic nano-pigment with the thickness of 10-100nm, a dispersing agent, acetic acid, deionized water and an adhesive aqueous solution. The prepared ink-jet recording material prepared through PVC material corona treatment, PVC substrate glue coating, drying, ink absorption layer coating and drying has the advantages that that the printed image is clear, the ink droplet does not diffuse, and the color is distributed uniformly; and the ink-jet recording material has excellent performances of color definition, color saturation, glossiness and the like. The raw material cost and the manufacture cost are low, so the ink-jet recording material is advantageous to industrial production, popularization and application.

Owner:HARBIN INST OF TECH

Coating for high-temperature-resistant membrane for lithium ion battery and preparation method of high-temperature-resistant membrane

ActiveCN102181204AResistant to reshufflingPuncture resistanceConjugated diene hydrocarbon coatingsCell component detailsCooking & bakingPhysical chemistry

The invention discloses a coating for a high-temperature-resistant membrane for a lithium ion battery. The coating consists of the following raw materials in parts by mass: 2,000-5,000 parts of solvent, 0.5-5 parts of dispersant, 5-50 parts of bonding agent and 5-100 parts of high-temperature-resistant non-conducting powder. A preparation method of the high-temperature-resistant membrane comprises the following steps of: (1) adding the solvent and the dispersant into a dispersion machine for uniform dispersing, adding the bonding agent and the high-temperature-resistant non-conducting powder for uniform dispersing into a sizing agent and filtering the sizing agent; and (2) coating the sizing agent on the original membrane by using a coating machine and drying. The high-temperature-resistant membrane for the lithium ion battery prepared with the method can favorably resist heavy punch, puncture and baking, has good safety, and can be applied to occasions with higher safety requirements on batteries.

Owner:ADVANCED ELECTRONICS ENERGY LIMITED GUANGDONG

High temperature-resistant and wear-resistant heavy-duty anticorrosive paint and preparation method thereof

The invention relates to anticorrosive paint and a preparation method of the paint, in particular to high temperature-resistant and wear-resistant heavy-duty anticorrosive paint and a preparation method of the paint. The high temperature-resistant and wear-resistant heavy-duty anticorrosive paint comprises component A and component B, wherein the component A comprises the raw materials by mass percent: 13-31% of epoxy resin or 14-16% of phenolic epoxy resin, 0-6% of boron-containing phenolic resin, 4-7% of titanium dioxide, 5-8% of barium sulfate, 3-5% of silicon carbide, 5-8% of talcum powder, 0.3-0.5% of white carbon black, 0.9-2% of nano titanium slurry, 6-8% of liquid nitrile butadiene rubber, 0.9-2% of organobentonite, 0.02% of defoaming agent and 30-54% of mixed solvent; and the component B comprises modified amine cured substance or dicyandiamide. The preparation method comprises the steps of: dispersing for 2h by ball milling according to the proportion, and then preparing the component A; and adding the component B into the component A at the room temperature to obtain the high temperature-resistant and wear-resistant heavy-duty anticorrosive paint. The heavy-duty anticorrosive paint is good in high temperature resistance, high in mechanical resistance and ideal in effects of resisting acid, alkali and salt, and can be used for protecting metal material for a long time in the high-temperature environment with acid gas and impurities.

Owner:NANTONG JUNQI MACHINERY

Conductive graphite cream and preparation method thereof

ActiveCN102618107AReduce carbon additionDoes not affect conductivityCellulose coatingsConjugated diene hydrocarbon coatingsConductive polymerGraphite

The invention discloses conductive graphite cream and a preparation method thereof, which solve the technical problem of improving dispersibility of graphite cream. The conductive graphite cream comprises materials including, in weight percent, 10-30% of conductive graphite, 1-30% of matrix resin, 0.1-5% of conductive polymer auxiliaries, 0.1-5% of dispersing auxiliaries and the balance solvents. The preparation method includes the steps: adding the conductive polymer auxiliaries into the solvents to obtain solution 1; adding the matrix resin into the solvents to obtain solution 2; adding the conductive graphite into the solution 2; adding the dispersing auxiliaries into the solution 2 for ball-milling; adding the solution 1 into solution 3; and performing ultrasonic oscillation, high-pressure dispersion and stirring to obtain the conductive graphite cream. Compared with the prior art, the conductive graphite cream and the preparation method have the advantages that nano carbon materials are added, ball-milling, ultrasonic oscillation and high-pressure dispersion are performed for assisting so that the conductive graphite cream is uniformly dispersed, and the preparation method is simple and low-cost.

Owner:BTR NEW MATERIAL GRP CO LTD

Non-curing rubber asphalt waterproof paint

ActiveCN103937407AStir wellHigh solid contentConjugated diene hydrocarbon coatingsNatural rubber coatingsPolymer scienceTackifier

The invention relates to a non-curing rubber asphalt waterproof paint. The technical proposal adopted is that: the non-curing rubber asphalt waterproof paint comprises the following raw materials by weight: 45%-60% of asphalt, 10%-25% of rubber, 5%-15% of a dispersing agent, 5%-10% of a tackifier and 5%-20% of filler. The preparation method is as follows: proportionally taking the raw materials, heating the asphalt to 140-160DEG C; adding the dispersing agent and the tackifier to the asphalt, stirring for about 30 minutes; adding the rubber for mixing; adding the filler, mixing evenly, and discharging. The non-curing rubber asphalt waterproof paint does not cure, and is low temperature resistant, does not flow at high temperature, and good in waterproof performance.

Owner:SHENYANG GUOJIAN XINTEC TECH DEV

Vulcanization composition having reduced allergenic potential, and elastomeric articles formed therewith

ActiveUS20120021155A1Reduced and eliminated allergic potentialAvoid problemsTeeth fillingPretreated surfacesPolymer scienceVulcanization

The present invention generally relates to vulcanization compositions used to vulcanize elastomeric articles, where the vulcanization compositions have reduced allergenic potential as compared to elastomeric articles formed using vulcanization compositions having non-fugitive accelerators. The present invention also relates to elastomeric articles formed using the vulcanization compositions. The invention further relates to methods for making a reduced-allergenicity vulcanization composition, and to methods for using the vulcanization compositions to vulcanize elastomeric articles.

Owner:ALLEGIANCE CORP

Polymer compositions and adhesives, coatings, and sealants made therefrom

ActiveUS7605203B2Improve performanceImprove stabilityOther chemical processesPolyureas/polyurethane adhesivesPolymer scienceSilanes

Polymer compositions for preparing sealants, adhesives and coatings are provided. The polymer compositions comprise from 1 to 99% by weight of an organic polymer comprising functional silane groups, from 1 to 45% by weight (based on total polymer) of at least one reactive or non-reactive organopolysiloxane polymer; from 0 to 98% by weight (based on total polymer) of an organic polymer that lacks functional silane groups.

Owner:TREMCO CPG INC

Room temperature curable functionalized HNBR coating

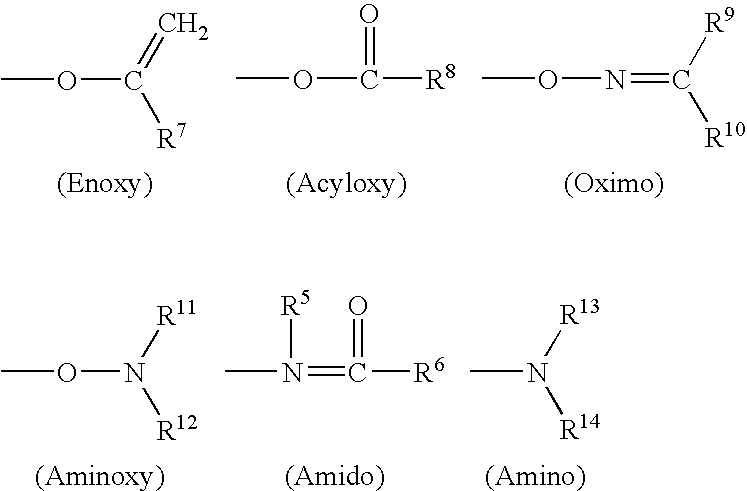

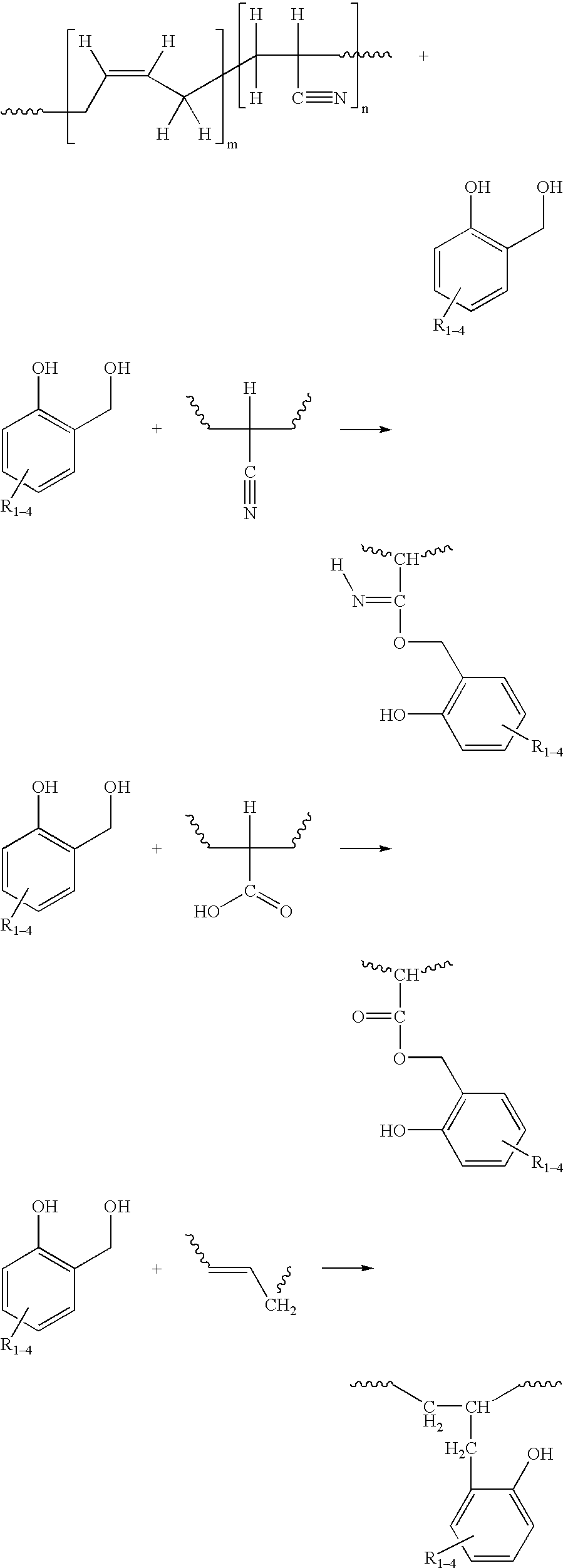

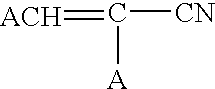

InactiveUS7183354B2Improve adhesionImprove the heating effectRubber derivative coatingsSynthetic resin layered productsElastomerPolymer science

The coating for substrates or materials, preferably elastomers or elastomers bonded to metal. The coating composition comprises (a) a functionalized hydrogenated copolymer comprising at least one repeat unit derived from a conjugated diene monomer; preferably including an unsaturated nitrile monomer; and a functional group containing monomer or graft linked compound or combinations thereof; (b) a curing component comprising at least one isocyanate group, or a carbodiimide compound, or an amino resin, or combinations thereof, and (c) a solvent. The coating compounds can be applied to an substrate either before or after the substrate has been vulcanized. The coatings can be cured at ambient temperatures.

Owner:LORD CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com