Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2483results about How to "Improve low temperature performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

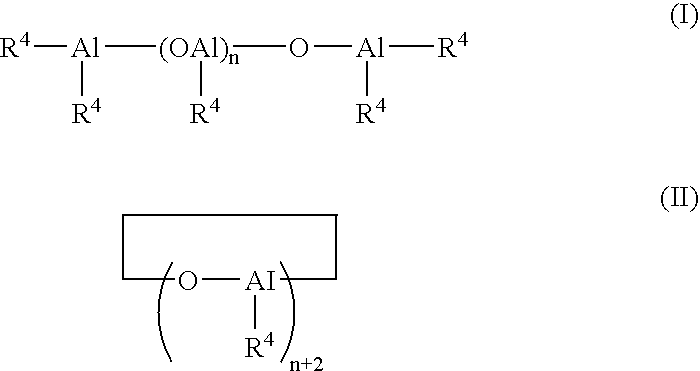

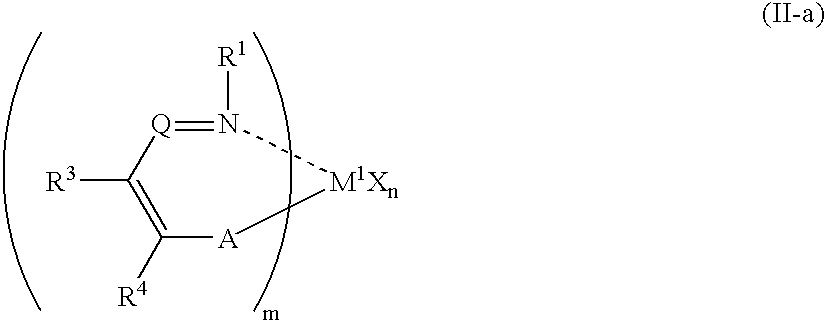

Functionalized high cis-1,4-polybutadiene prepared using novel functionalizing agents

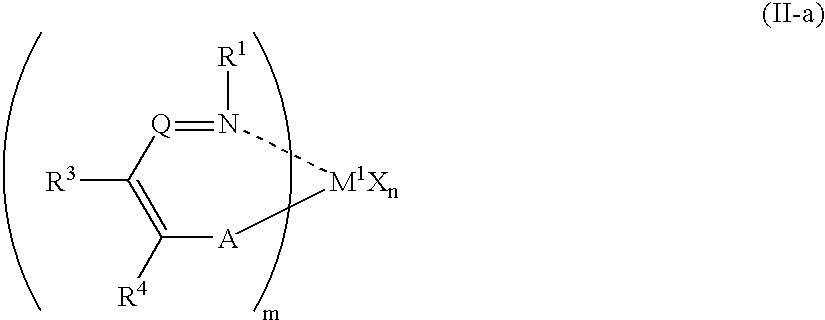

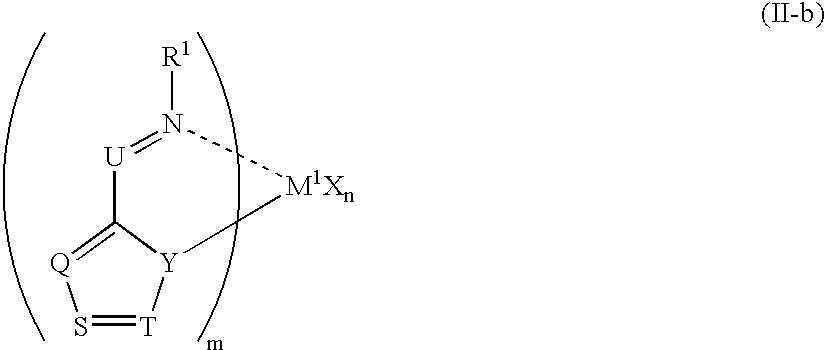

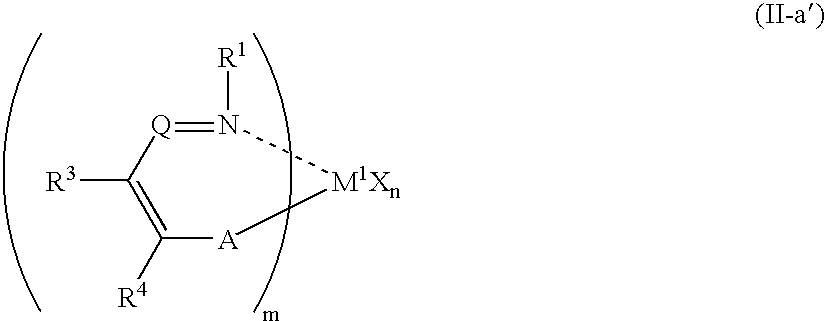

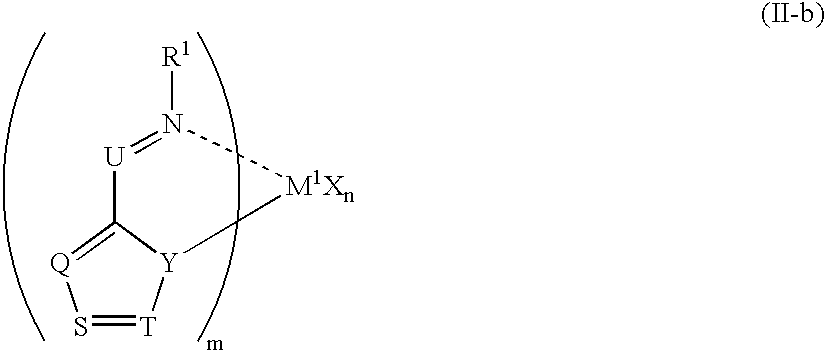

InactiveUS20060004131A1High ci microstructureLower glass transition temperatureInksActive polymerPolymer science

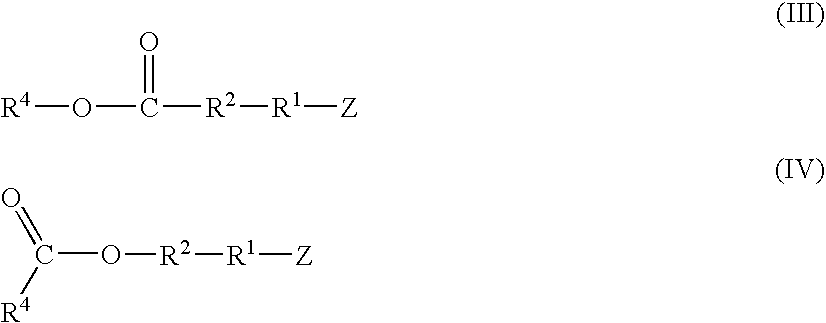

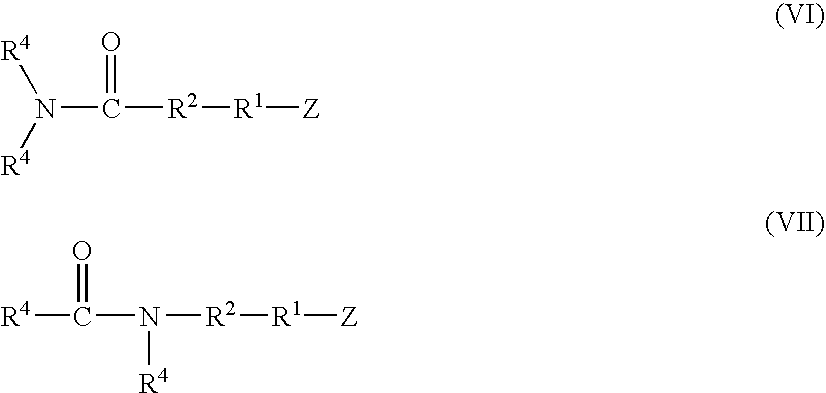

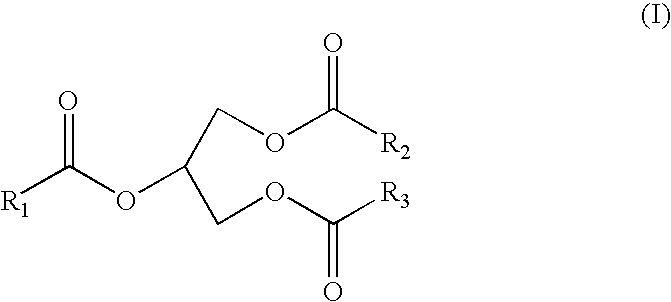

A functionalized polymer prepared by a process comprising the steps of preparing a pseudo-living polymer by polymerizing conjugated monomer with a lanthanide-based catalyst, and reacting the pseudo-living polymer with a functionalizing agent defined by the formula (I) A-R1-Z (I) where R1 is a divalent bond or divalent organic group comprising from 0 to about 20 carbon atoms, A is a substituent that will undergo an addition reaction with a pseudo-living polymer, and Z is a substituent that will react or interact with silica or carbon black reinforcing fillers, with the proviso that A, R1, and Z are substituents that will not protonate a pseudo-living polymer.

Owner:BRIDGESTONE CORP

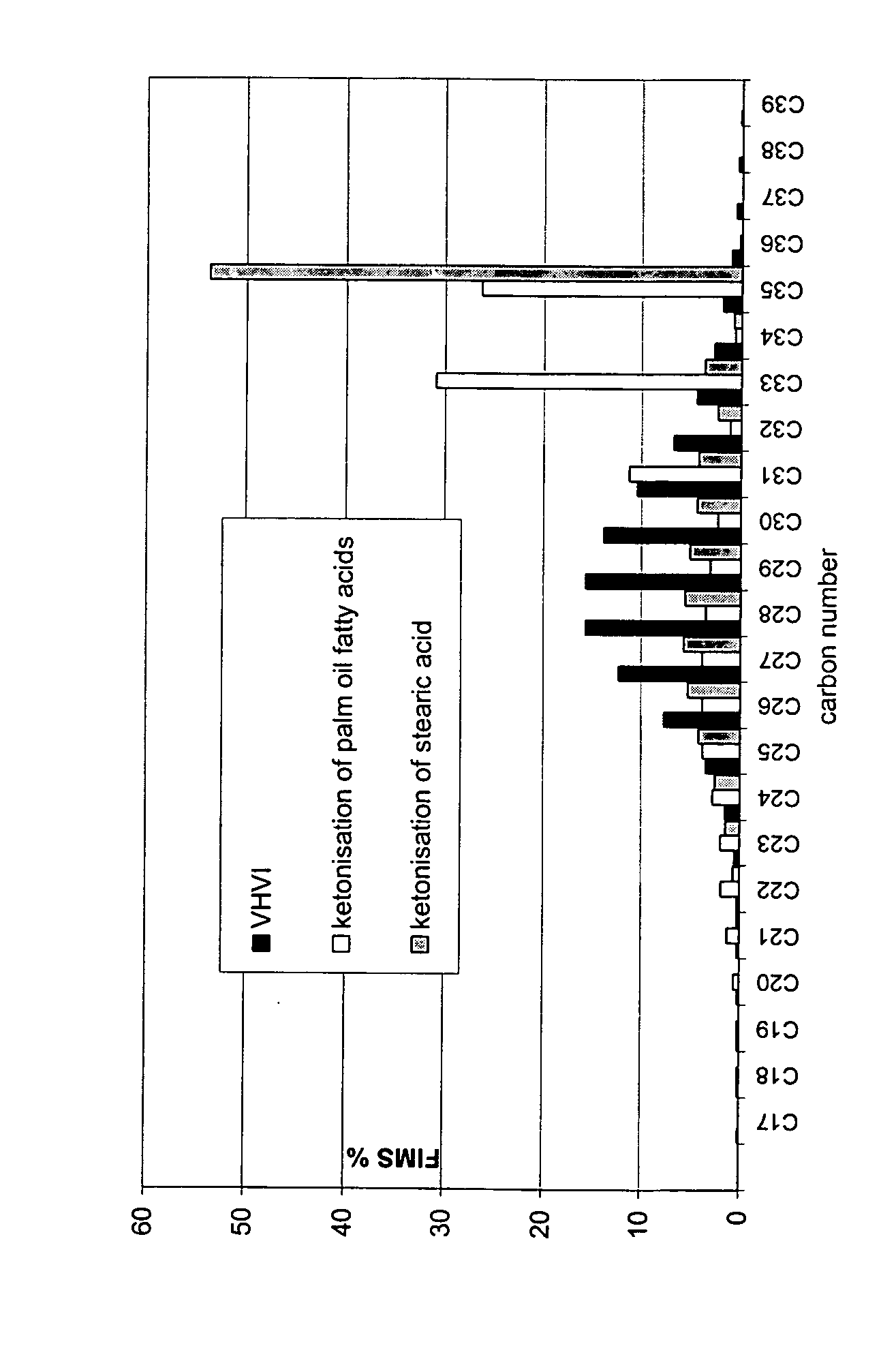

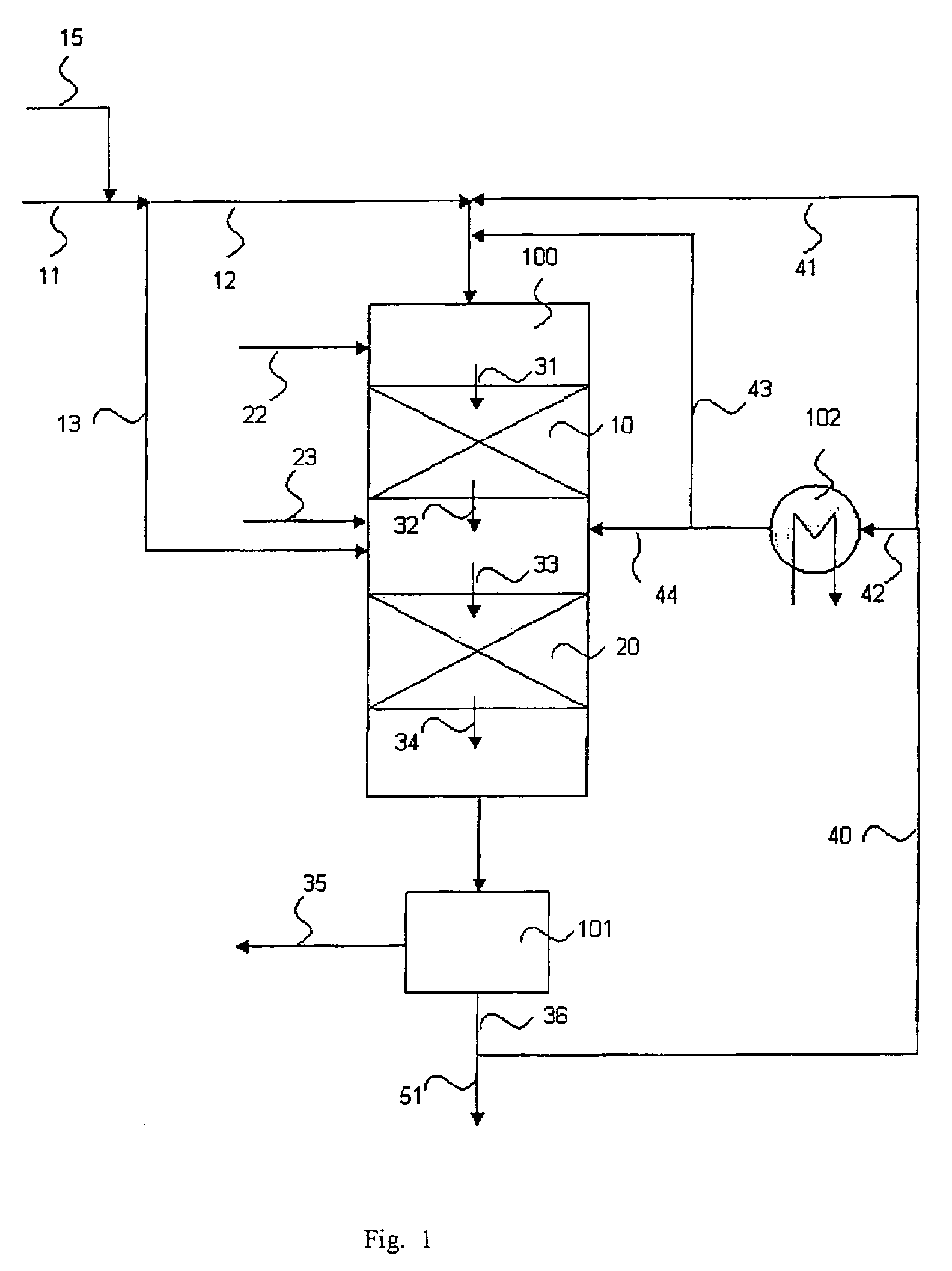

Process for producing a hydrocarbon component

ActiveUS20070161832A1Reduce carbon dioxide emissionsImprove low temperature performanceFatty oils/acids recovery from wasteFatty acid hydrogenationIsomerizationHydrodeoxygenation

The invention relates to a process for producing a new type of high-quality hydrocarbon base oil of biological origin. The process of the invention comprises ketonisation, hydrodeoxygenation, and isomerization steps. Fatty acids and / or fatty acid esters based on a biological raw material are preferably used as the feedstock.

Owner:NESTE OIL OY

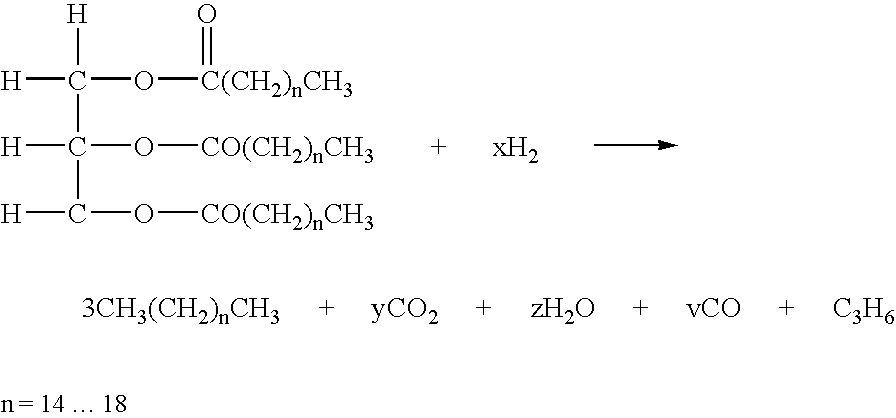

Process for the manufacture of diesel range hydro-carbons

ActiveUS20070006523A1Improve low temperature performanceBig ratioBiofuelsLiquid carbonaceous fuelsChemical industryAlkane

The invention relates to chemical industry and is directed to the production of middle distillate from vegetable oils. In the first step of the production method, the fatty acids or triglycerides of said vegetable oils are hydrogenated to give n-paraffins, and in the second step, the n-paraffins are catalytically converted to paraffins with branched chains. Using this process having two steps, a high-quality middle distillate useful as a component of diesel fuels without any particular specifications may be produced.

Owner:NESTE OIL OY

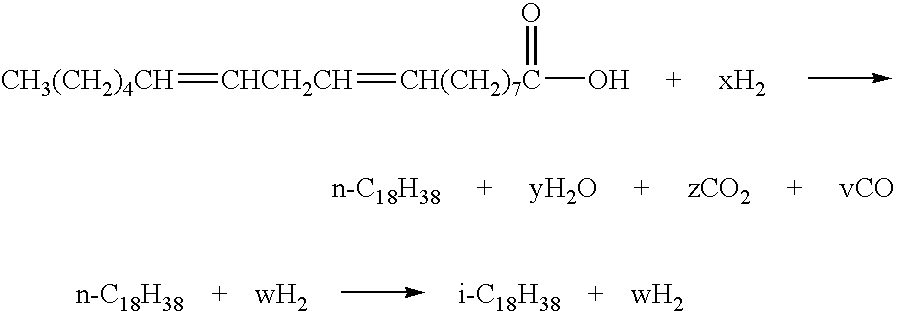

Process for the manufacture of hydrocarbons

ActiveUS20070135669A1Quality improvementImprove low temperature performanceFatty acid chemical modificationBiofuelsDeoxygenationDistillation

A feedstock originating from renewable sources is converted to branched and saturated hydrocarbons without heteroatoms in the diesel fuel distillation range by skeletal isomerisation and deoxygenation carried out by hydrodeoxygenation or alternatively by combined decarboxylation and decarbonylation reactions, whereby the consumption of hydrogen is decreased.

Owner:NESTE OIL OY

Fuel composition for a diesel engine

InactiveUS20040055209A1Meet quality requirementsImprove low temperature performanceSolid fuelsLiquid carbonaceous fuelsProcess engineeringDiesel engine

The invention is directed to a fuel composition for diesel engines. The fuel composition comprises 0.1-99% by weight of a component or a mixture of components produced from biological raw material originating from plants and / or animals and / or fish. The fuel composition comprises 0-20% of components containing oxygen. Both components are mixed with diesel components based on crude oil and / or fractions from Fischer-Tropsch process.

Owner:NESTE OIL OY

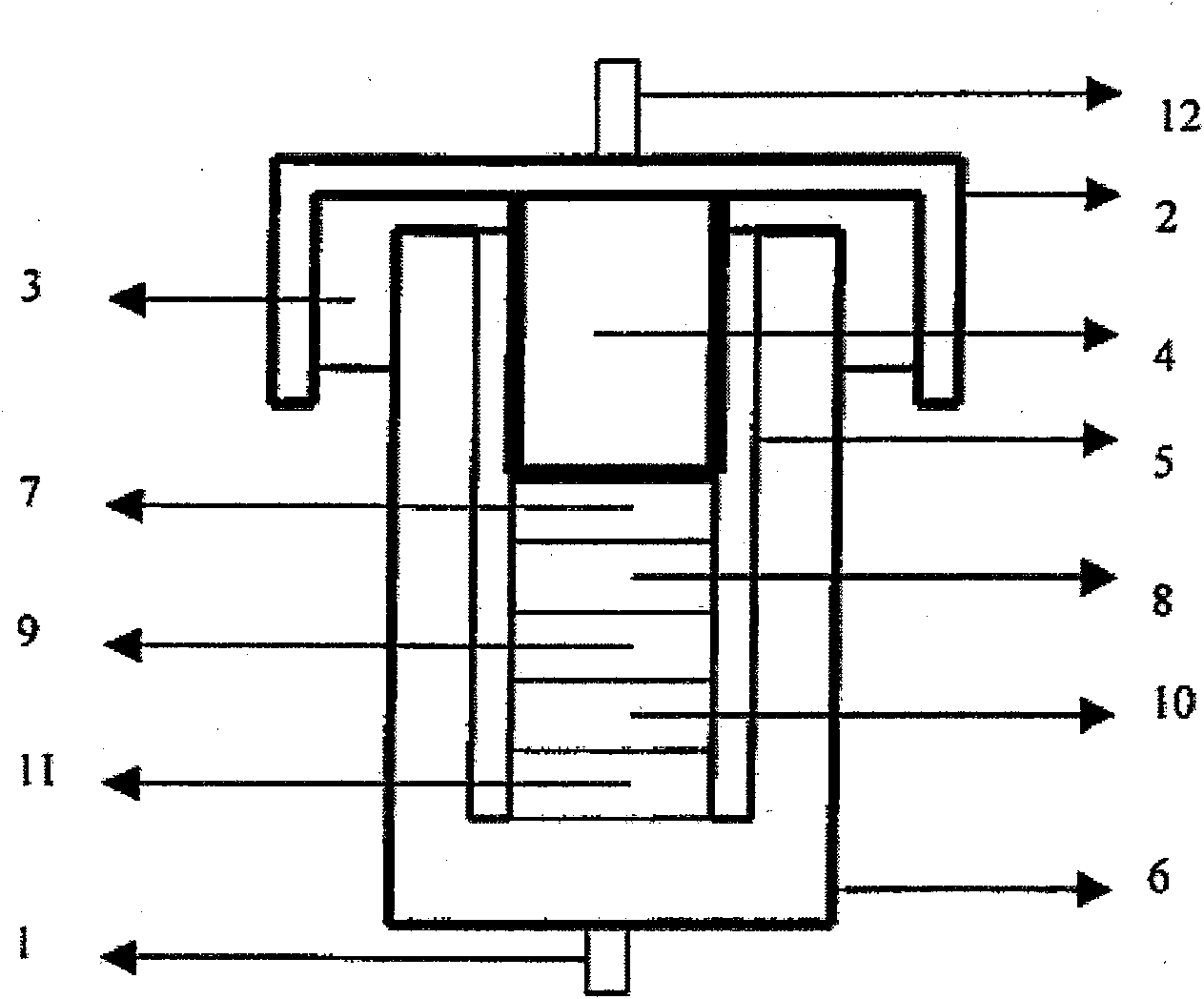

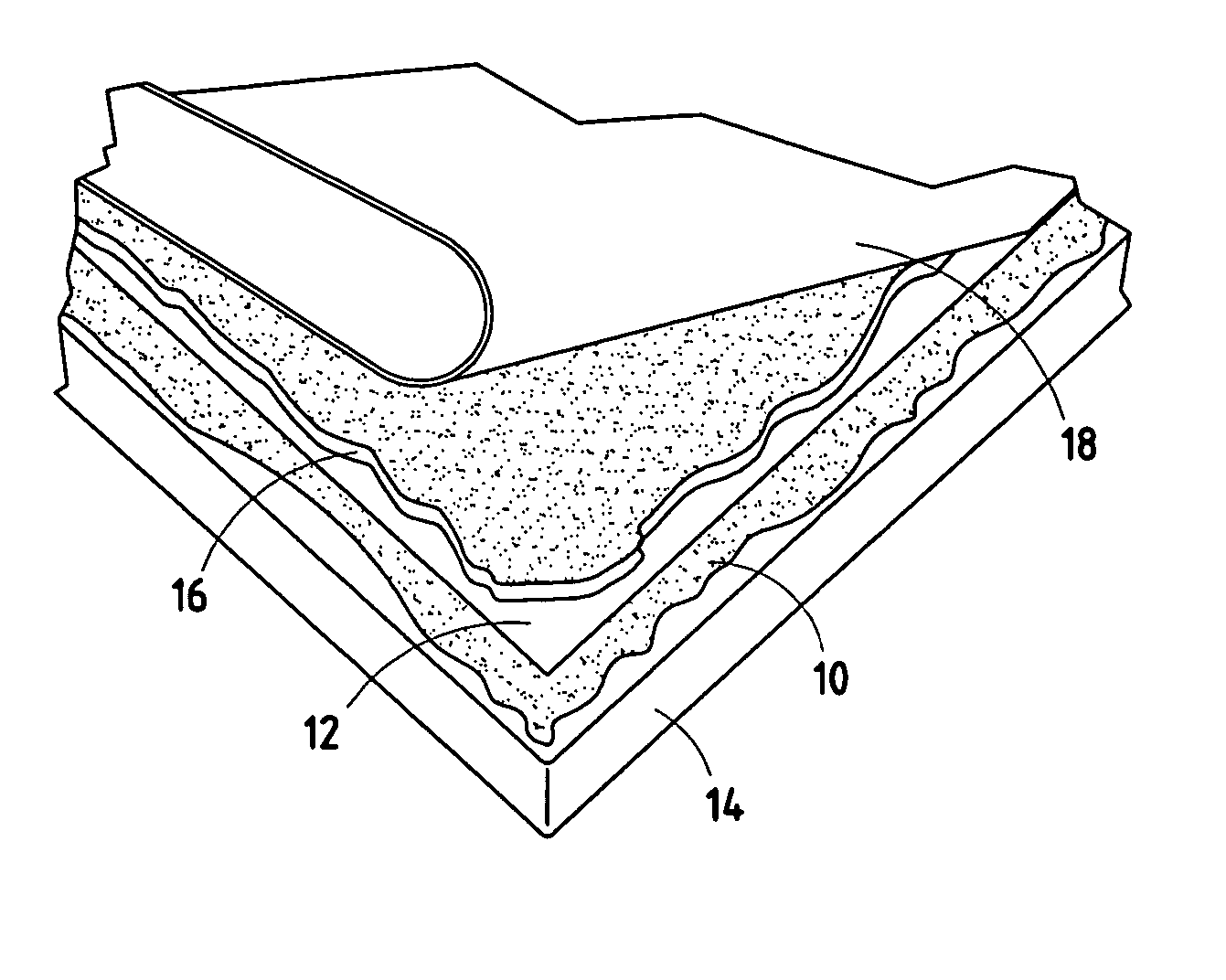

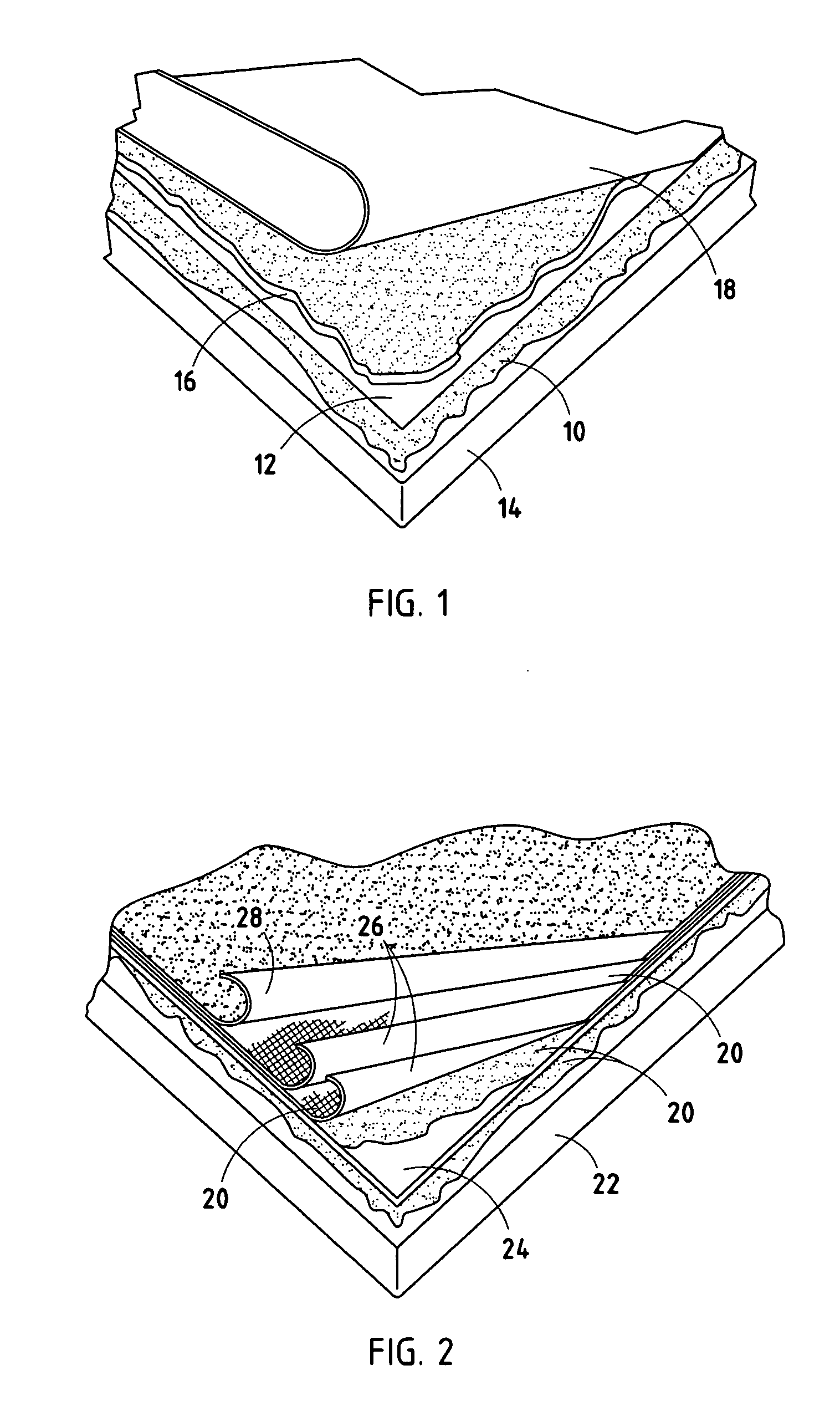

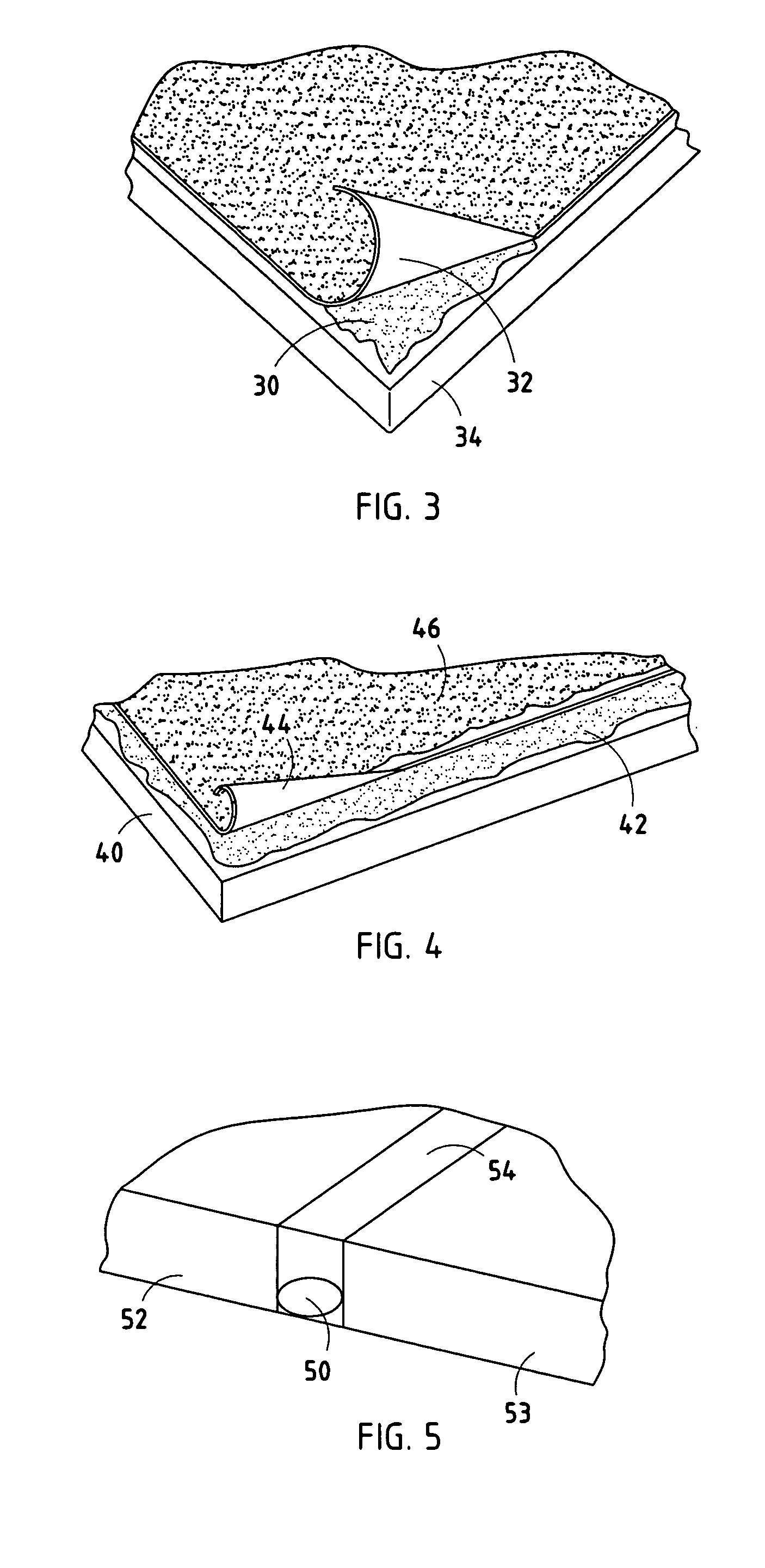

Compliant seal structures for protected active metal anodes

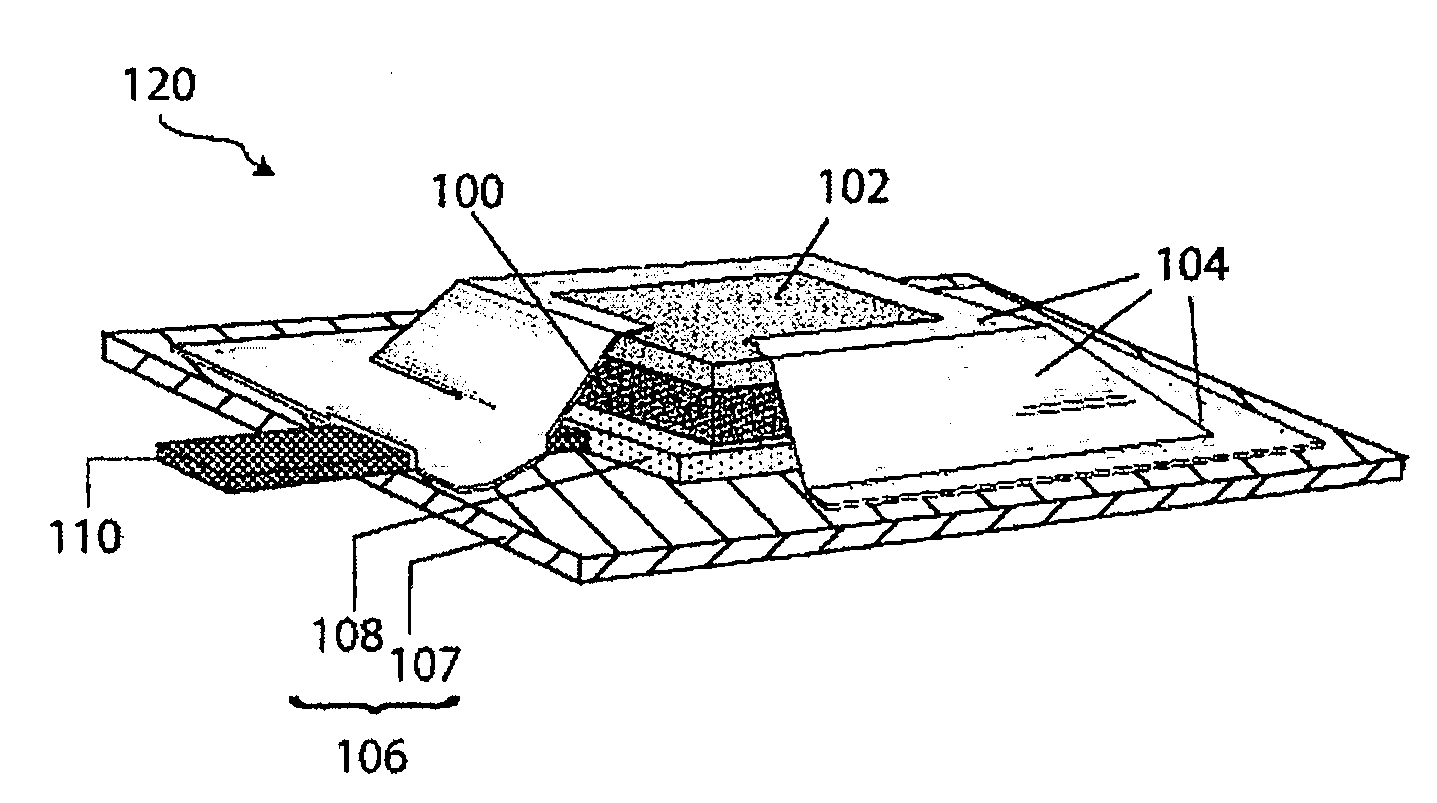

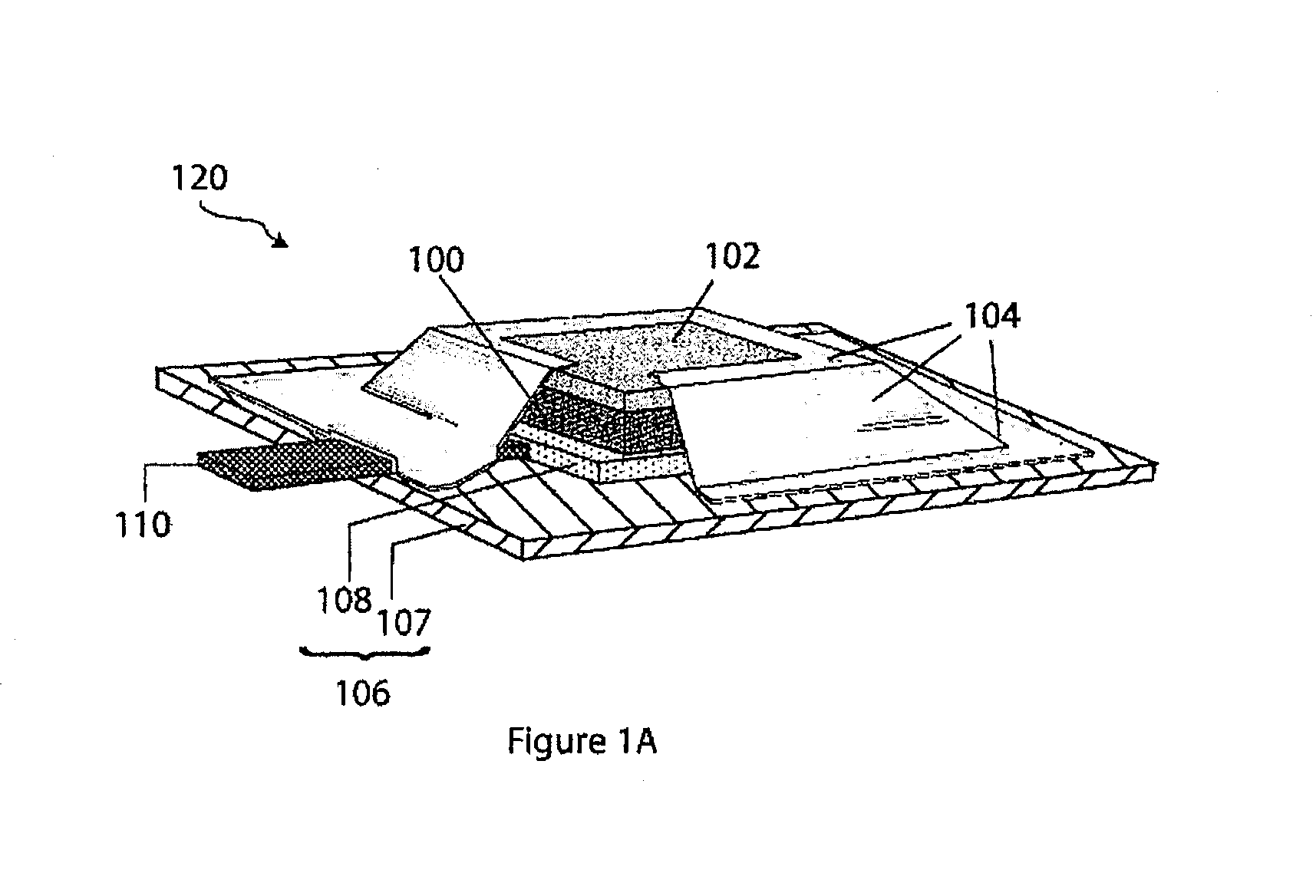

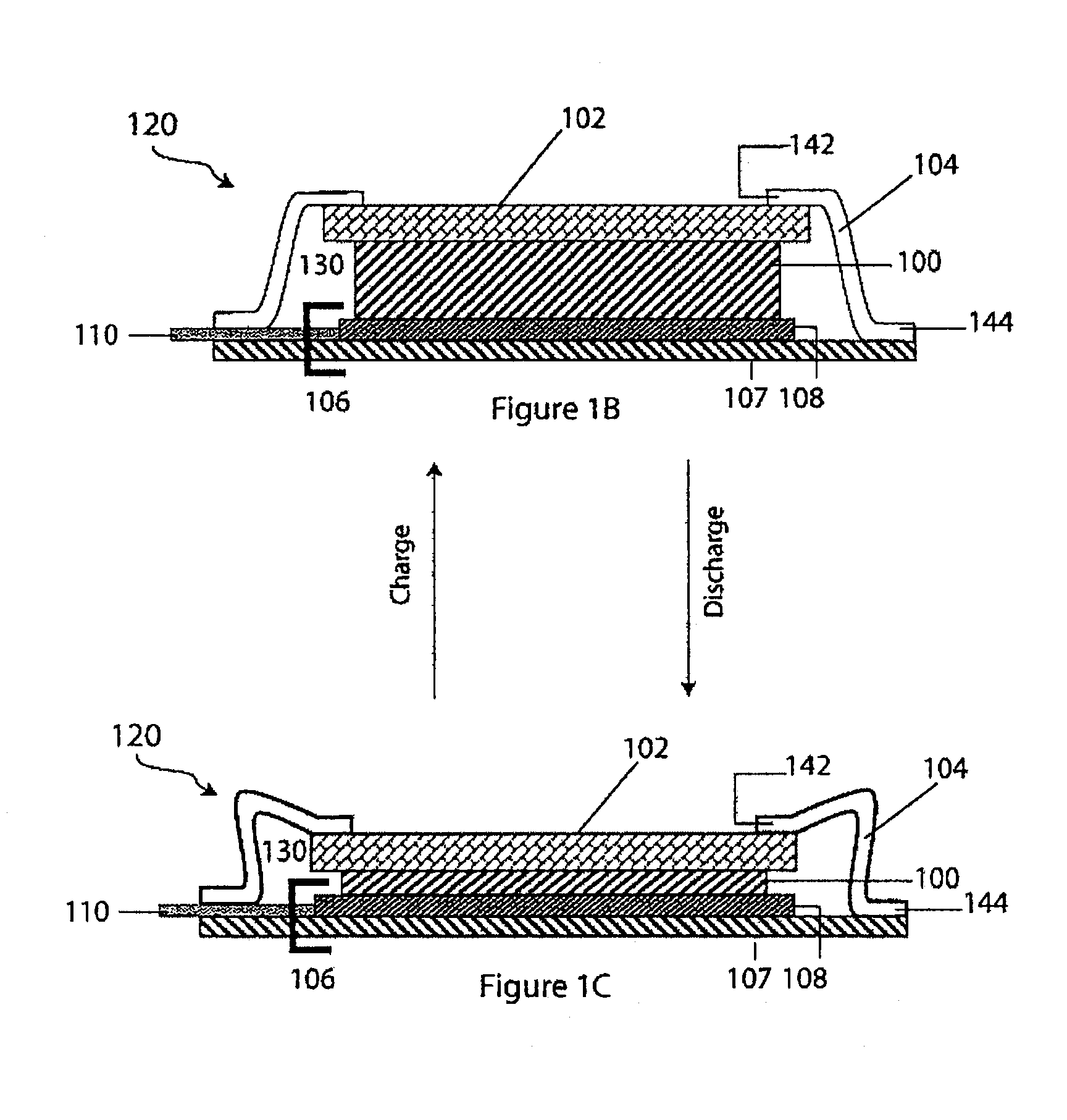

ActiveUS20100112454A1Avoid lostReduced ionic contact areaPrimary cell to battery groupingFuel and primary cellsOptoelectronicsAnodic protection

Protected anode architectures have ionically conductive protective membrane architectures that, in conjunction with compliant seal structures and anode backplanes, effectively enclose an active metal anode inside the interior of an anode compartment. This enclosure prevents the active metal from deleterious reaction with the environment external to the anode compartment, which may include aqueous, ambient moisture, and / or other materials corrosive to the active metal. The compliant seal structures are substantially impervious to anolytes, catholyes, dissolved species in electrolytes, and moisture and compliant to changes in anode volume such that physical continuity between the anode protective architecture and backplane are maintained. The protected anode architectures can be used in arrays of protected anode architectures and battery cells of various configurations incorporating the protected anode architectures or arrays.

Owner:POLYPLUS BATTERY CO INC

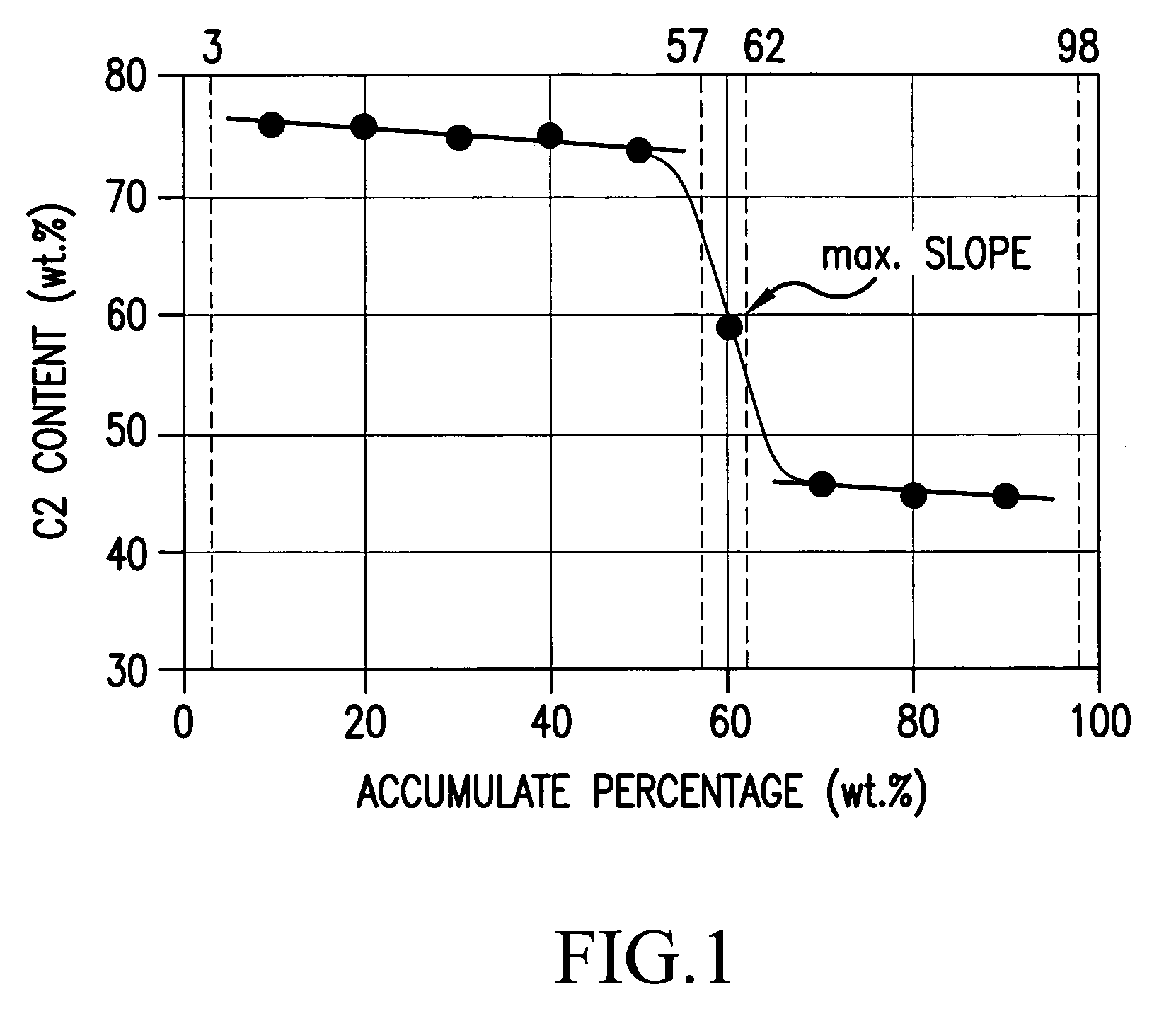

Olefin block copolymer, viscosity index improver for lubricating oils and lubricating oil composition

InactiveUS20040121922A1Good low temperature propertyGood balanceLiquid carbonaceous fuelsAdditivesChemical compositionViscosity index

The present invention provides an olefin block copolymer for a viscosity index improver capable of preparing a lubricating oil composition having excellent low temperature properties and excellent balance between viscosity and shear stability, a viscosity index improver and a lubricating oil composition comprising the viscosity index improver. The olefin block copolymer has a Mw / Mn of not more than 1.5, and comprises: (i) a polymer block comprising ethylene and an alpha-olefin of 3 to 20 carbon atoms, having a molar ratio (ethylene / alpha-olefin) of ethylene units to alpha-olefin units of from 20 / 80 to 65 / 35, a Mw of 50,000 to 2,000,000, and having a slope of an intramolecular composition distribution of absolute value of 0.1 to 0, and (ii) a polymer block comprising ethylene and an alpha-olefin of 3 to 20 carbon atoms, having a molar ratio (ethylene / alpha-olefin) of ethylene units to alpha-olefin units of from 70 / 30 to 85 / 15, a Mw of 10,000 to 400,000, and having a slope of an intramolecular composition distribution of absolute value of 0.1 to 0.

Owner:MITSUI CHEM INC

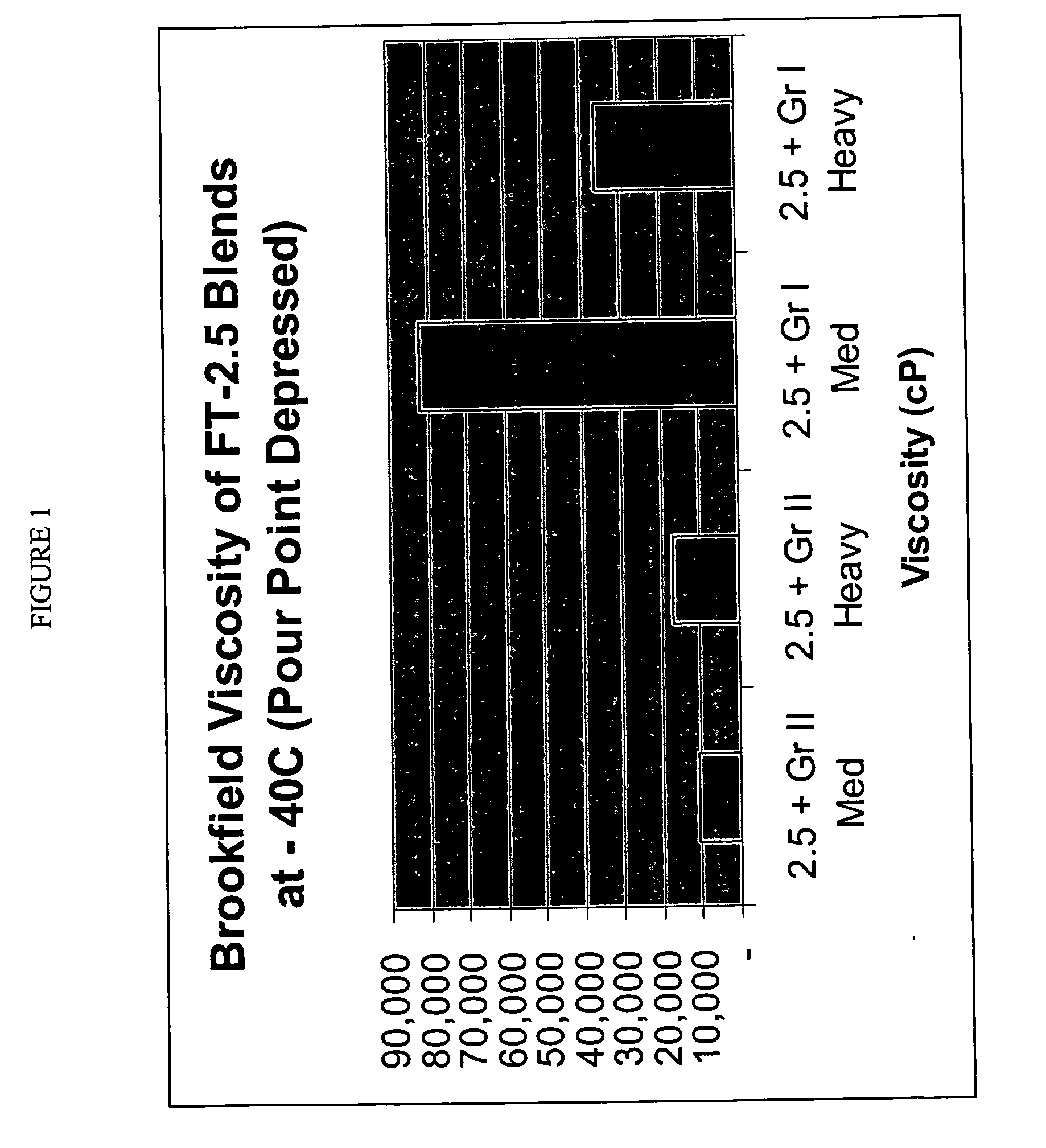

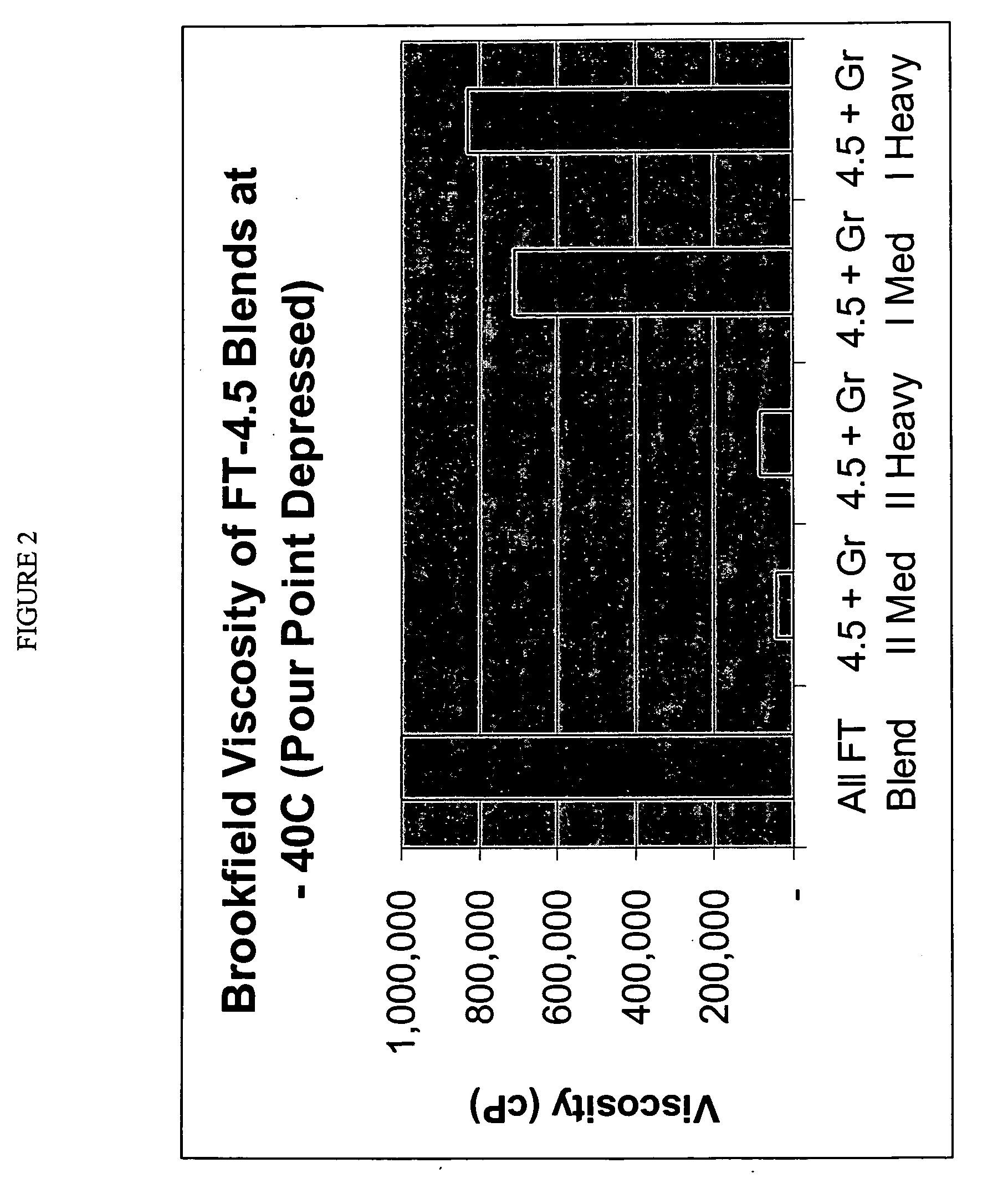

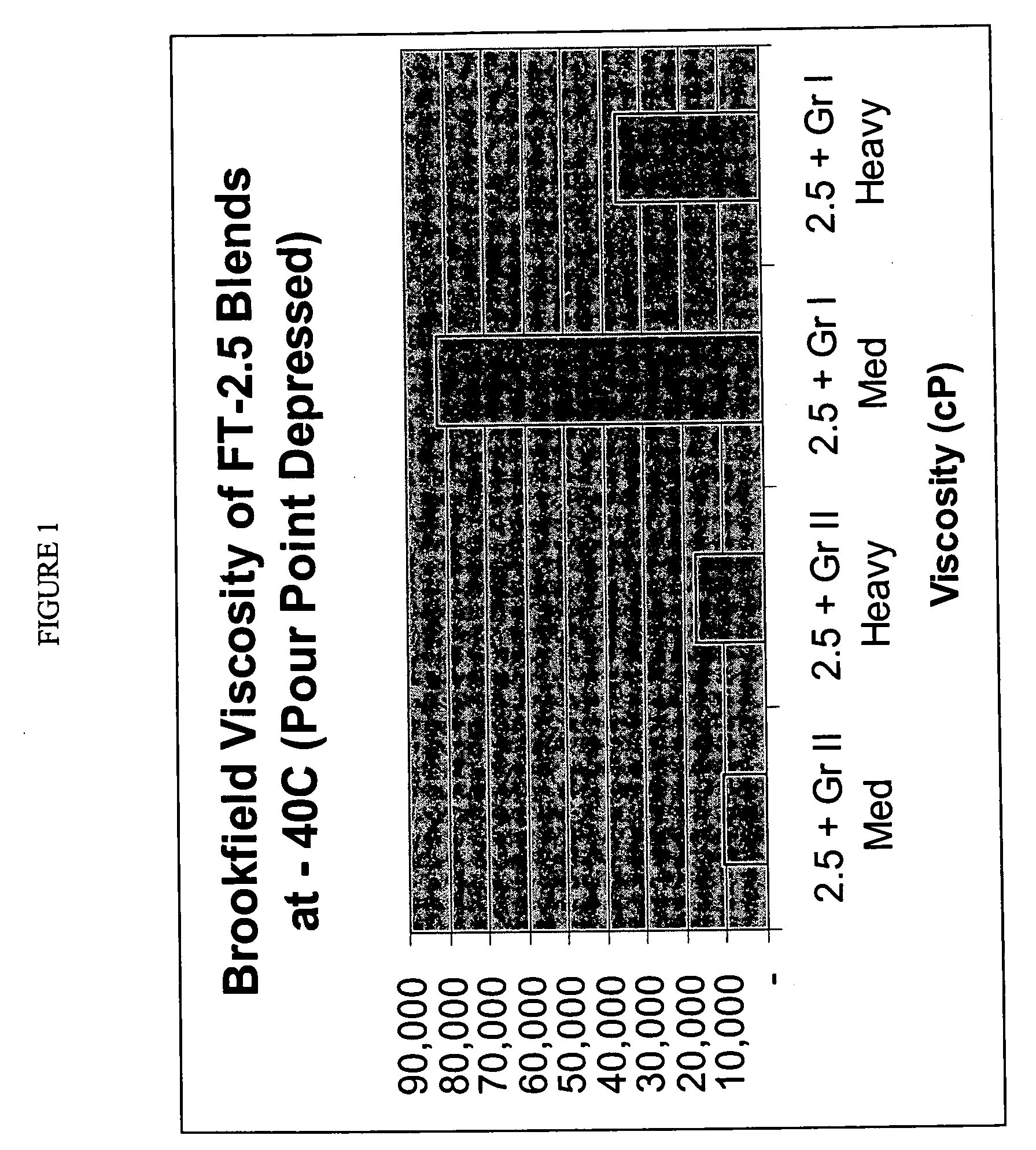

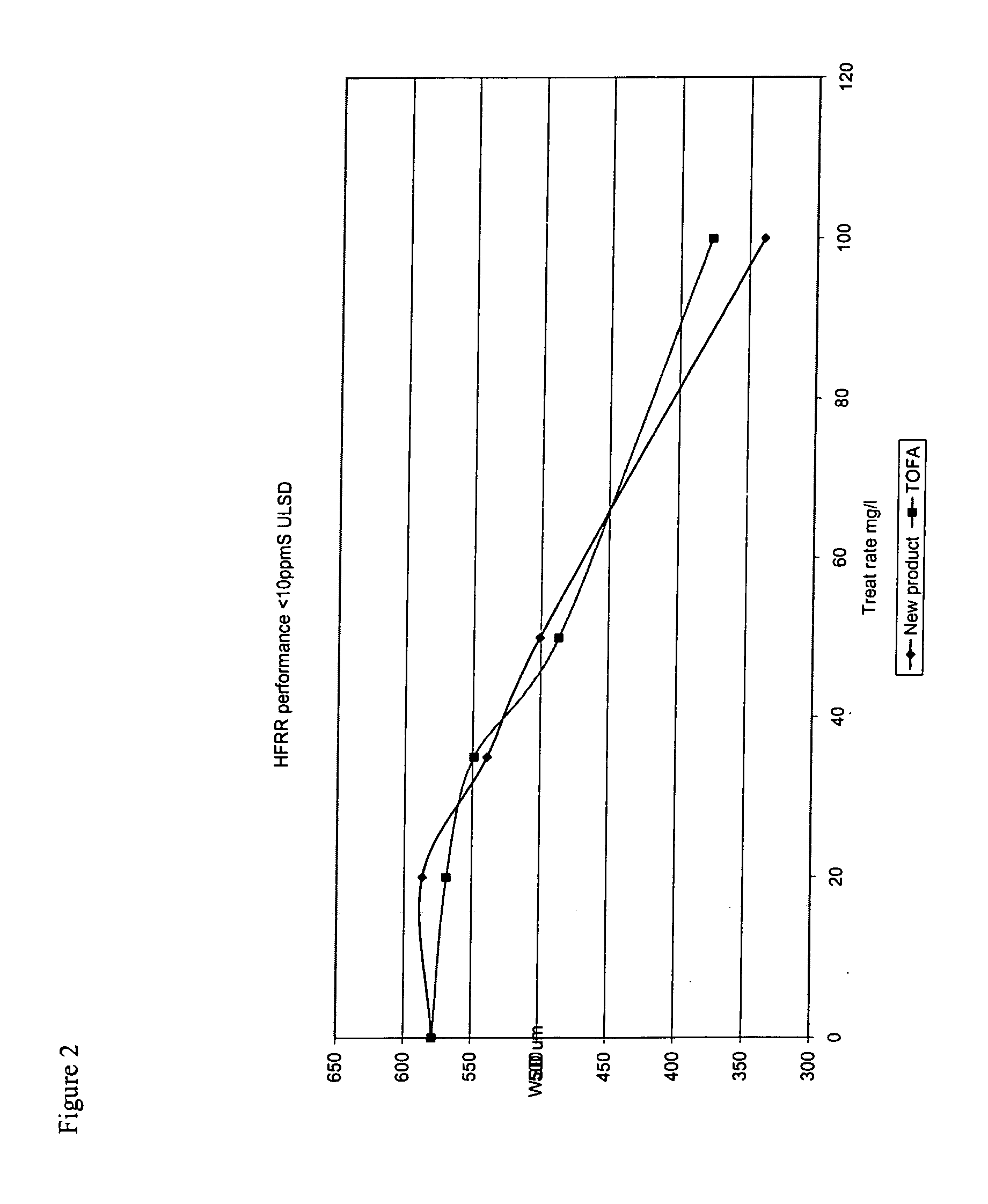

Lubricant blends with low brookfield viscosities

ActiveUS20050261145A1Improve low temperature performanceLow viscosityOrganic compound preparationOxygen compounds preparation by reductionSulfurBase oil

Lubricant blends and finished gear oils comprising a Fischer-Tropsch derived lubricant base oil fraction, a petroleum derived base oil, and a pour point depressant are provided. The Fischer-Tropsch derived lubricant base oil fraction comprises less than 0.30 weight percent aromatics, greater than 5 weight percent molecules with cycloparaffinic functionality, and a ratio of weight percent of molecules with monocycloparaffinic functionality to weight percent of molecules with multicycloparaffnic functionality greater than 15. The petroleum derived base oils comprises greater than 90 weight percent saturates and less than 300 ppm sulfur and is preferably selected from the group consisting of a Group II base oil, a Group III base oil, and mixtures thereof. These lubricant blends have surprising low Brookfield viscosities at −40° C.

Owner:CHEVROU USA INC

Solid golf ball

InactiveUS20080312008A1Improve spin performanceIncrease distanceGolf ballsSolid ballsOrganosulphur compoundPolymer science

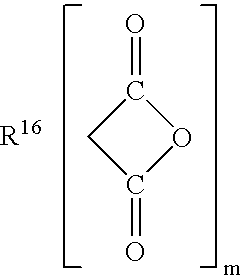

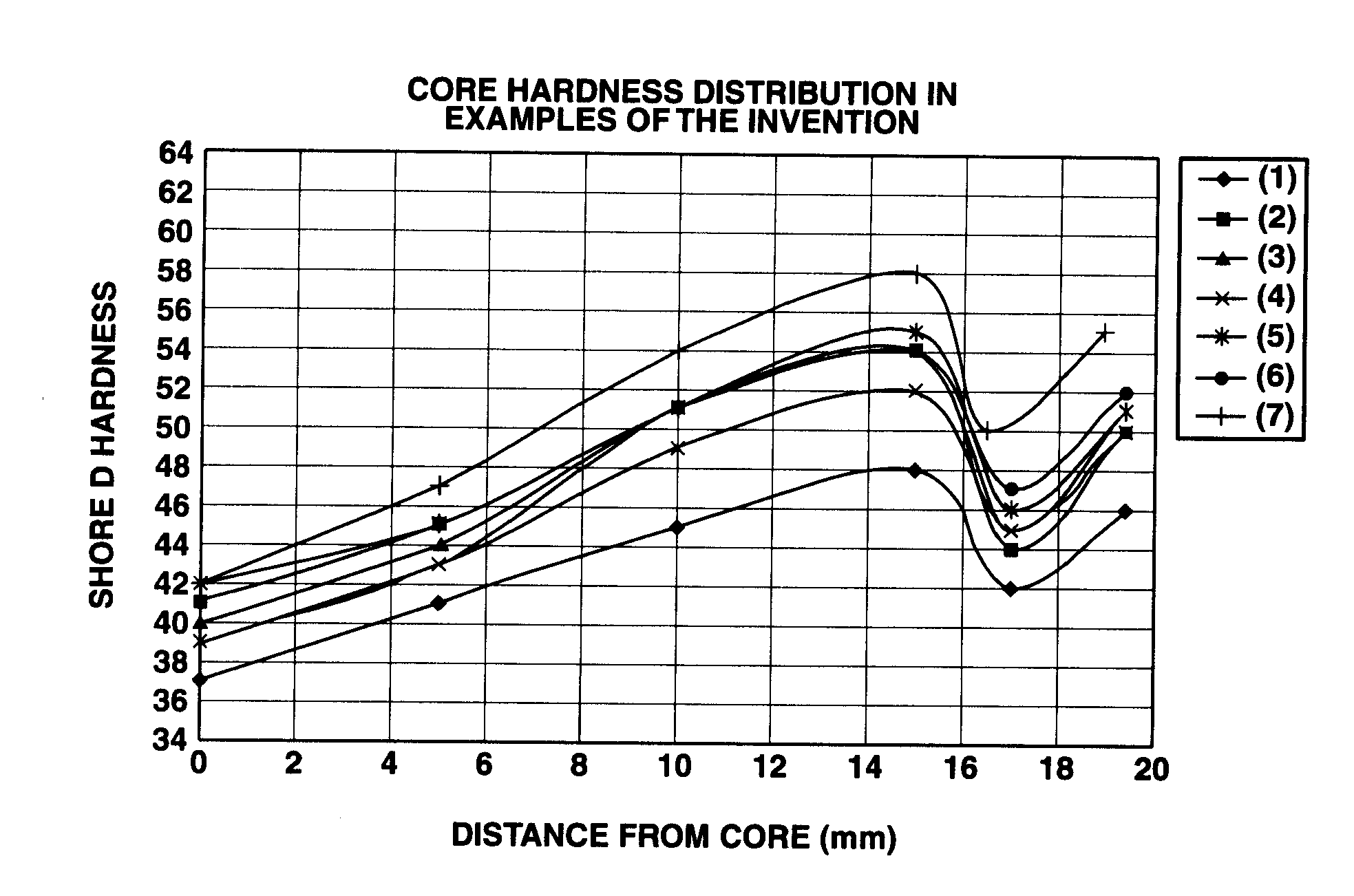

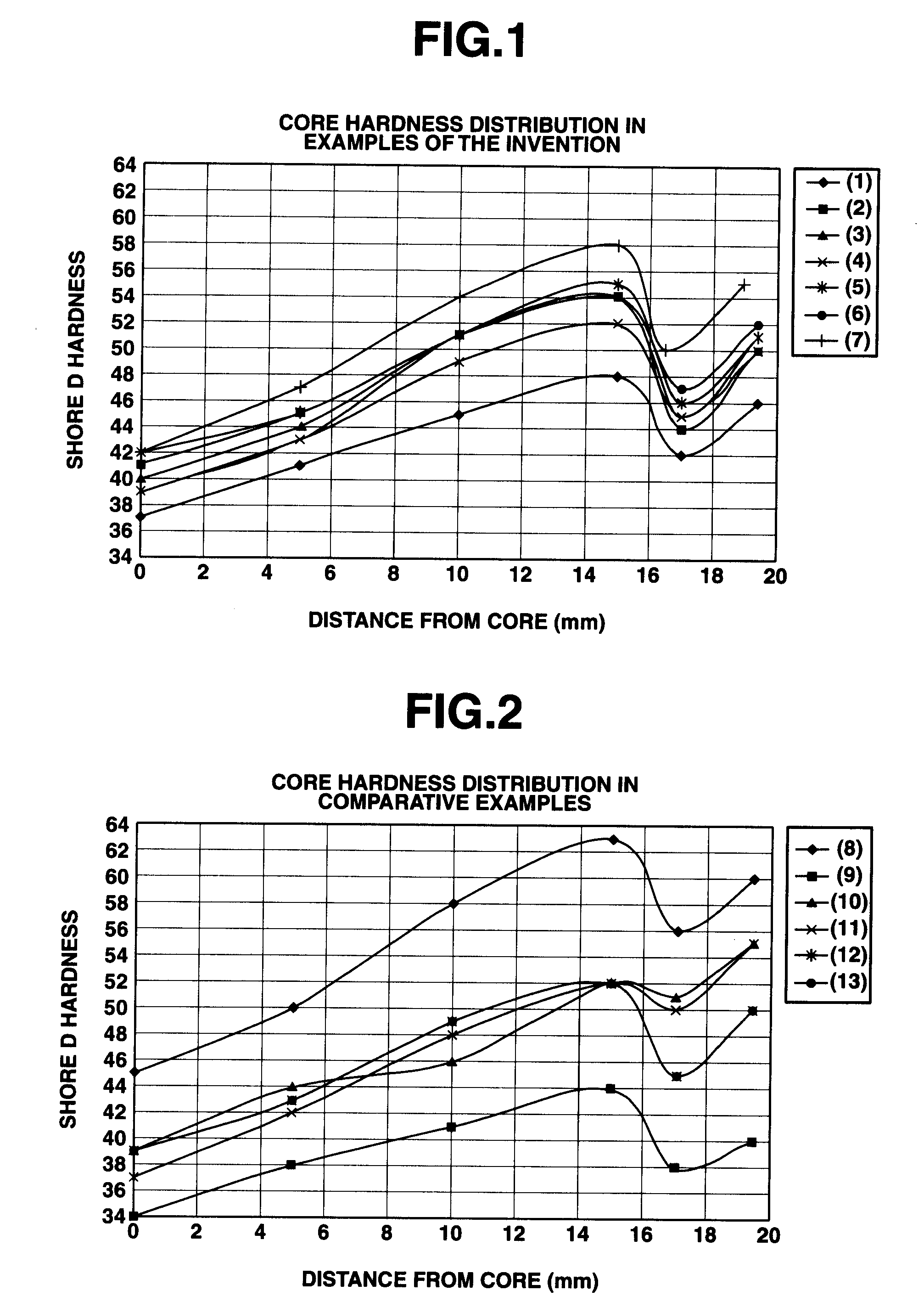

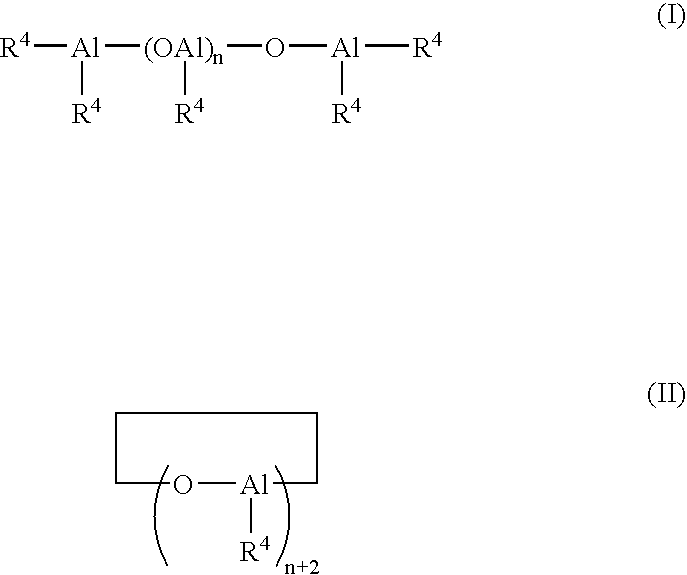

The invention provides a solid golf ball having a solid core and a cover layer that encases the core and has an outermost layer on an outside surface of which are formed a plurality of dimples. The solid core is formed of a rubber composition composed of 100 parts by weight of a base rubber that includes 60 to 100 parts by weight of a polybutadiene rubber having a cis-1,4 bond content of at least 60% and synthesized using a rare-earth catalyst, 0.1 to 5 parts by weight of an organosulfur compound, an unsaturated carboxylic acid or a metal salt thereof, and an inorganic filler. The solid core has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of 2.0 to 4.0 mm, and has a specific hardness distribution. The cover layer is formed by injection molding a single resin blend composed primarily of (A) a thermoplastic polyurethane and (B) a polyisocyanate compound, which resin blend contains a polyisocyanate compound in at least some portion of which all the isocyanate groups on the molecule remain in an unreacted state, and has a thickness of 0.5 to 2.5 mm, a Shore D hardness at the surface of 50 to 70. The golf ball has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of 2.0 to 3.8 mm. The solid golf ball is advantageous overall in competitive use.

Owner:BRIDGESTONE SPORTS

Process for producing a branched hydrocarbon component

InactiveUS20070135316A1Reduce carbon dioxide emissionsImprove stabilityOrganic compound preparationCatalytic naphtha reformingIsomerizationHydrodeoxygenation

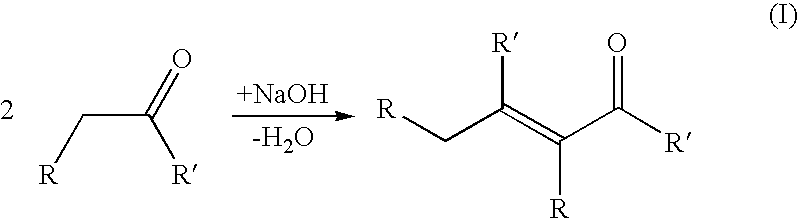

The invention relates to a process for producing high-quality hydrocarbon base oil particularly of biological origin. The process of the invention comprises aldol condensation, hydrodeoxygenation, and isomerization steps. Aldehydes and / or ketones, preferably of biological origin are used as the feedstock.

Owner:NESTE OIL OY

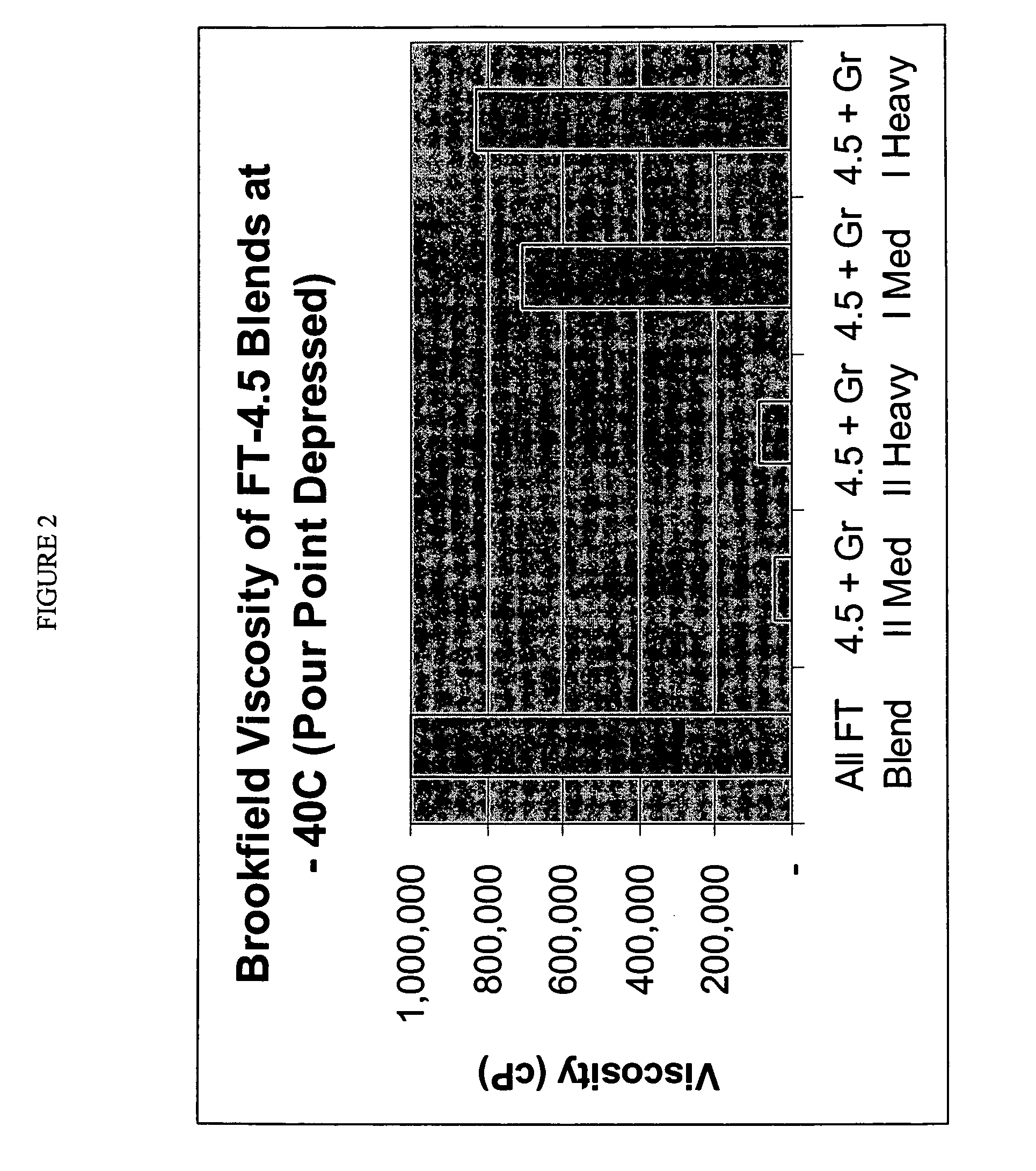

Processes for making lubricant blends with low brookfield viscosities

InactiveUS20050261146A1Improve low temperature performanceLow viscosityRefining to change hydrocarbon structural skeletonHydrocarbon purification/separationParaffin waxSulfur

Lubricant blends and finished gear oils comprising a lubricant base oil fraction derived from highly paraffinic wax, a petroleum derived base oil, and a pour point depressant are provided. The lubricant base oil fraction derived from highly paraffinic wax comprises less than 0.30 weight percent aromatics, greater than 5 weight percent molecules with cycloparaffinic functionality, and a ratio of weight percent of molecules with monocycloparaffinic functionality to weight percent of molecules with multicycloparaffinic functionality greater than 15. The petroleum derived base oils comprises greater than 90 weight percent saturates and less than 300 ppm sulfur and is preferably selected from the group consisting of a Group II base oil, a Group III base oil, and mixtures thereof. These lubricant blends have surprising low Brookfield viscosities at −40° C.

Owner:CHEVROU USA INC

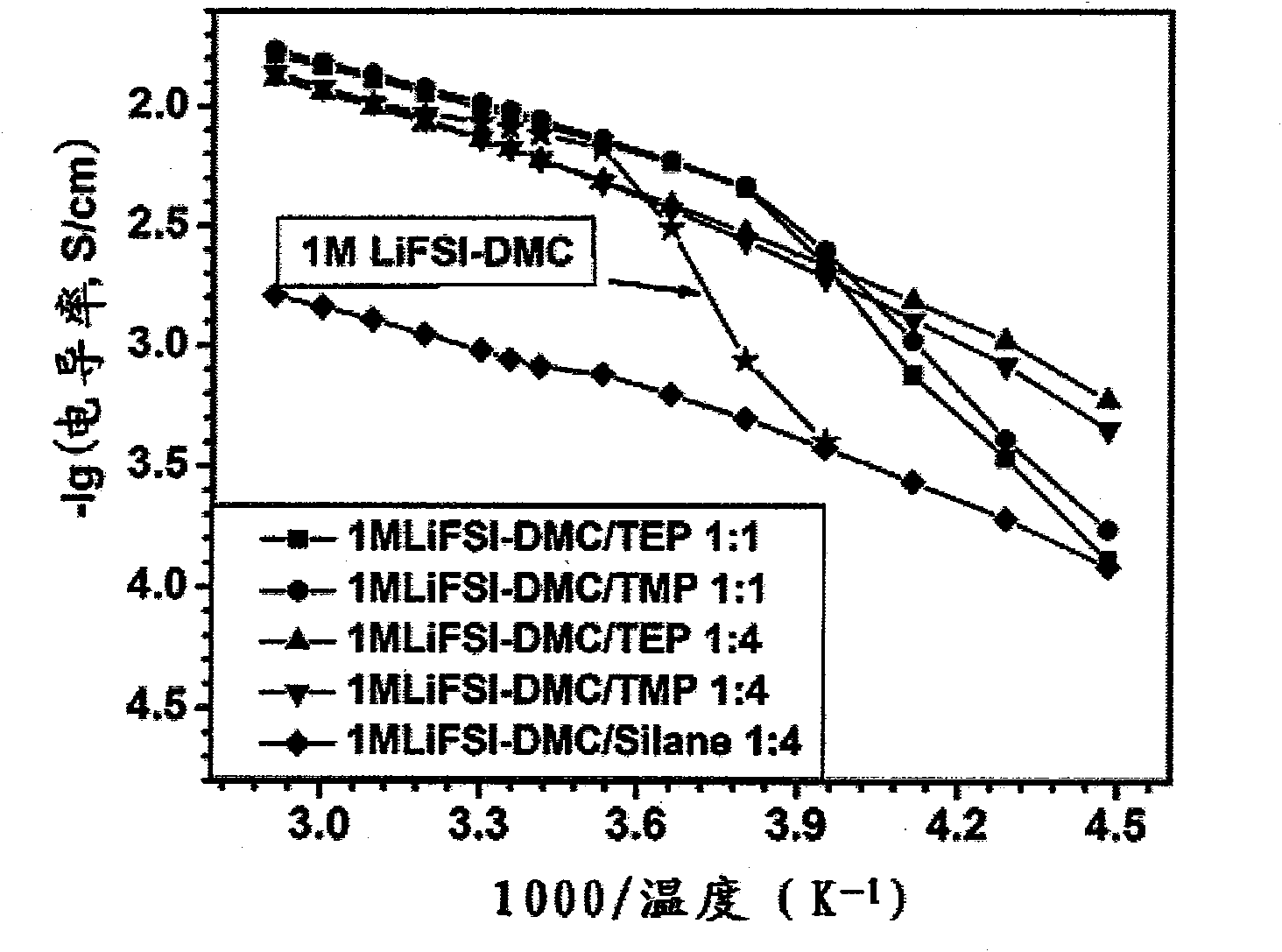

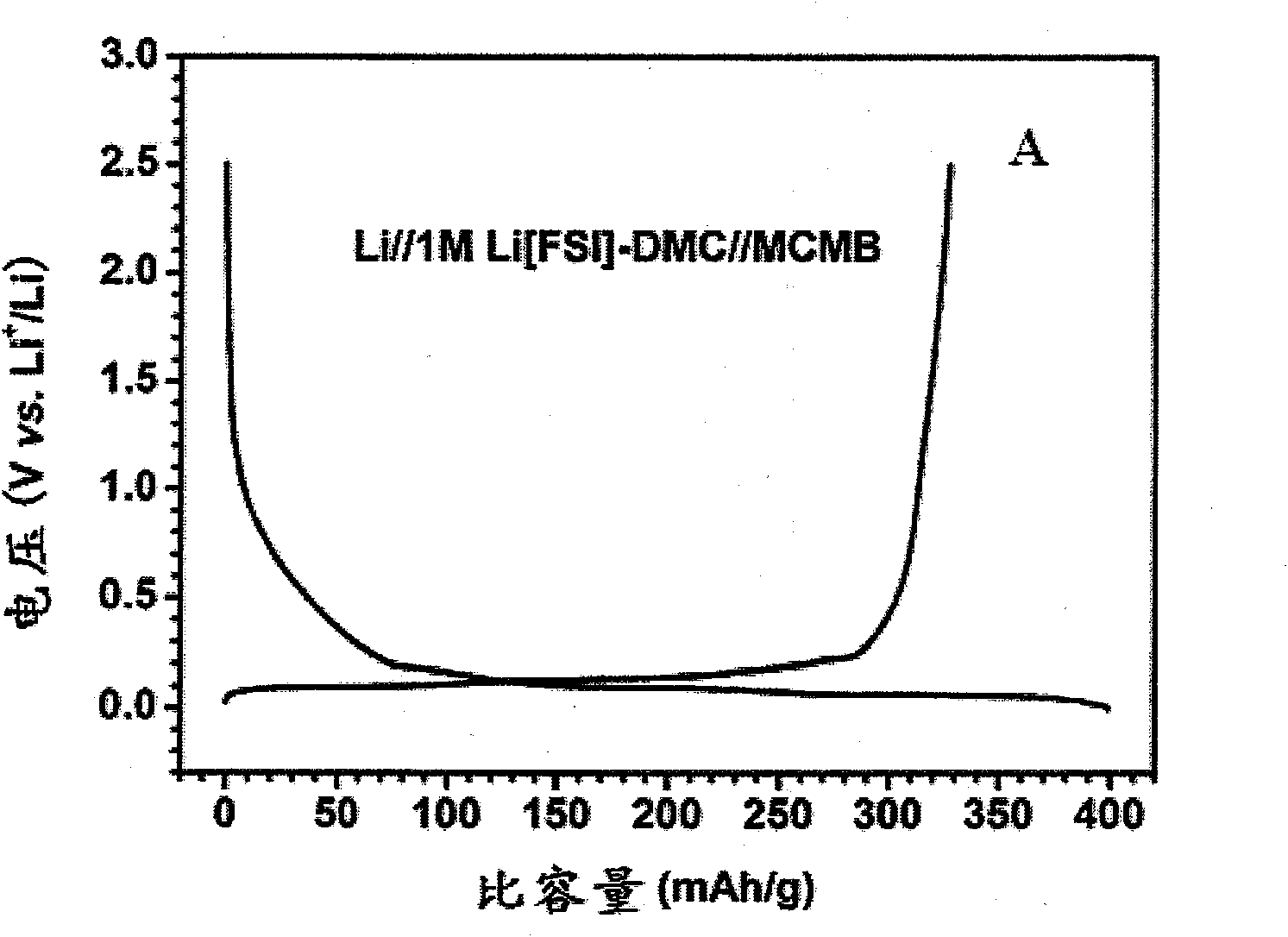

Nonaqueous electrolyte material of fluorosulfonylimide lithium and application thereof

ActiveCN101882696AImprove solubilityNot easy to crystallizeOrganic chemistryCapacitor electrolytes/absorbentsDielectricPhosphate

The invention provides a nonaqueous electrolyte material, which consists of fluorosulfonylimide lithium and organic solvent with dielectric constant less than 30, and the organic solvent is selected from one or more of chain-like carbonate solvent, phosphate solvent, siloxane solvent, boroxane solvent, acetate solvent, propionate solvent, butyrate solvent, CF3OCH2CH2OCF3 solvent, C2H5OCH2CH2OCH3 solvent, C2F5OCH2CH2OCF3 solvent, 1,3-dioxolane solvent and aliphatic nitrile solvent with more than two carbon atoms. The ionic conductivity of the nonaqueous electrolyte material is 0.01mS / cm to 18mS / cm, the lithium ion transference number is tLi plus equal to 0.2 to 0.8, and the applicable temperature range is 80DEG C below zero to 60DEG C below zero. The invention also provides an application of the nonaqueous electrolyte material in the preparation of lithium batteries and super capacitors. Furthermore, the invention provides a lithium battery and a super capacitor which contain the nonaqueous electrolyte material of fluorosulfonylimide lithium.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Solid golf ball

InactiveUS20080194359A1Large deformationIncreased durabilityGolf ballsSolid ballsAntioxidantRare earth

The invention provides a solid golf ball having a solid core and a cover layer that encases the core and has an outermost layer on an outside surface of which are formed a plurality of dimples. The solid core is formed of a rubber composition composed of 100 parts by weight of a base rubber that includes from 60 to 100 parts by weight of a polybutadiene rubber having a cis-1,4 bond content of at least 60% and synthesized using a rare-earth catalyst, from 0.1 to 5 parts by weight of an organosulfur compound, an unsaturated carboxylic acid or a metal salt thereof, an inorganic filler, and an antioxidant. The solid core has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of from 2.0 to 4.0 mm, and has a specific hardness distribution. The cover layer has a thickness of from 0.5 to 1.9 mm, and a Shore D hardness at the surface of from 50 to 70. The ball has at least one intermediate layer between the core and the cover, any one of which intermediate layer or layers has a surface hardness in Shore D units of from 40 to 60, the intermediate layer or layers having a total thickness of from 0.9 to 7.0 mm. The golf ball has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of from 2.0 to 3.8 mm. The solid golf ball is advantageous overall in competitive use.

Owner:BRIDGESTONE SPORTS

Solid golf ball

InactiveUS20080214325A1Increase elasticityImprove low temperature performanceGolf ballsSolid ballsAntioxidantRare earth

The invention provides a solid golf ball having a solid core and a cover layer that encases the core and has an outermost layer on an outside surface of which are formed a plurality of dimples. The solid core is formed of a rubber composition composed of 100 parts by weight of a base rubber that includes from 60 to 100 parts by weight of a polybutadiene rubber having a cis-1,4 bond content of at least 60% and synthesized using a rare-earth catalyst, from 0.1 to 5 parts by weight of an organosulfur compound, an unsaturated carboxylic acid or a metal salt thereof, an inorganic filler, and an antioxidant. The solid core has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of from 2.0 to 4.0 mm, and has a specific hardness distribution. The cover layer is formed by injection molding a single resin blend composed primarily of (A) a polyurethane material and (B) a polyisocyanate compound, which resin blend includes a polyisocyanate compound in at least some portion of which all the isocyanate groups on a molecule remain in an unreacted state. The cover layer has a thickness of from 0.5 to 2.5 mm and a Shore D hardness at the surface of from 50 to 70. The golf ball has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of from 2.0 to 3.8 mm. The solid golf ball is advantageous overall in competitive use.

Owner:BRIDGESTONE SPORTS

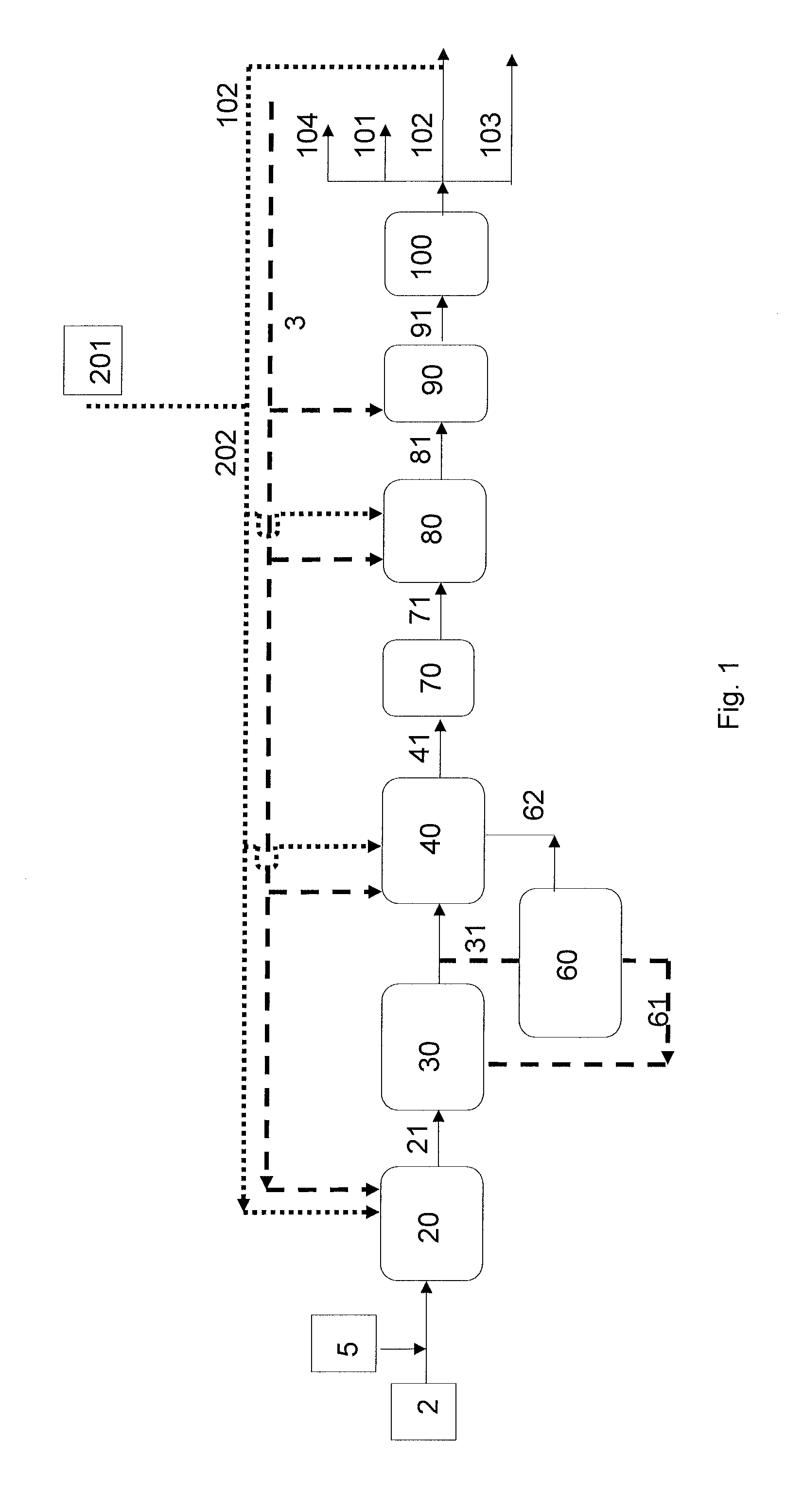

Process and System for producing synthetic liquid hydrocarbon fuels

ActiveUS7420004B2High volumetric and gravimetric energy densityExcellent resistance to thermal oxidation processLiquid hydrocarbon mixture productionOxygen compounds purification/separationOcean thermal energy conversionElectric power

A process for producing synthetic hydrocarbons that reacts carbon dioxide, obtained from seawater of air, and hydrogen obtained from water, with a catalyst in a chemical process such as reverse water gas shift combined with Fischer Tropsch synthesis. The hydrogen is produced by nuclear reactor electricity, nuclear waste heat conversion, ocean thermal energy conversion, or any other source that is fossil fuel-free, such as wind or wave energy. The process can be either land based or sea based.

Owner:NAVY U S A AS REPRESENTED BY THE SEC OF THE THE

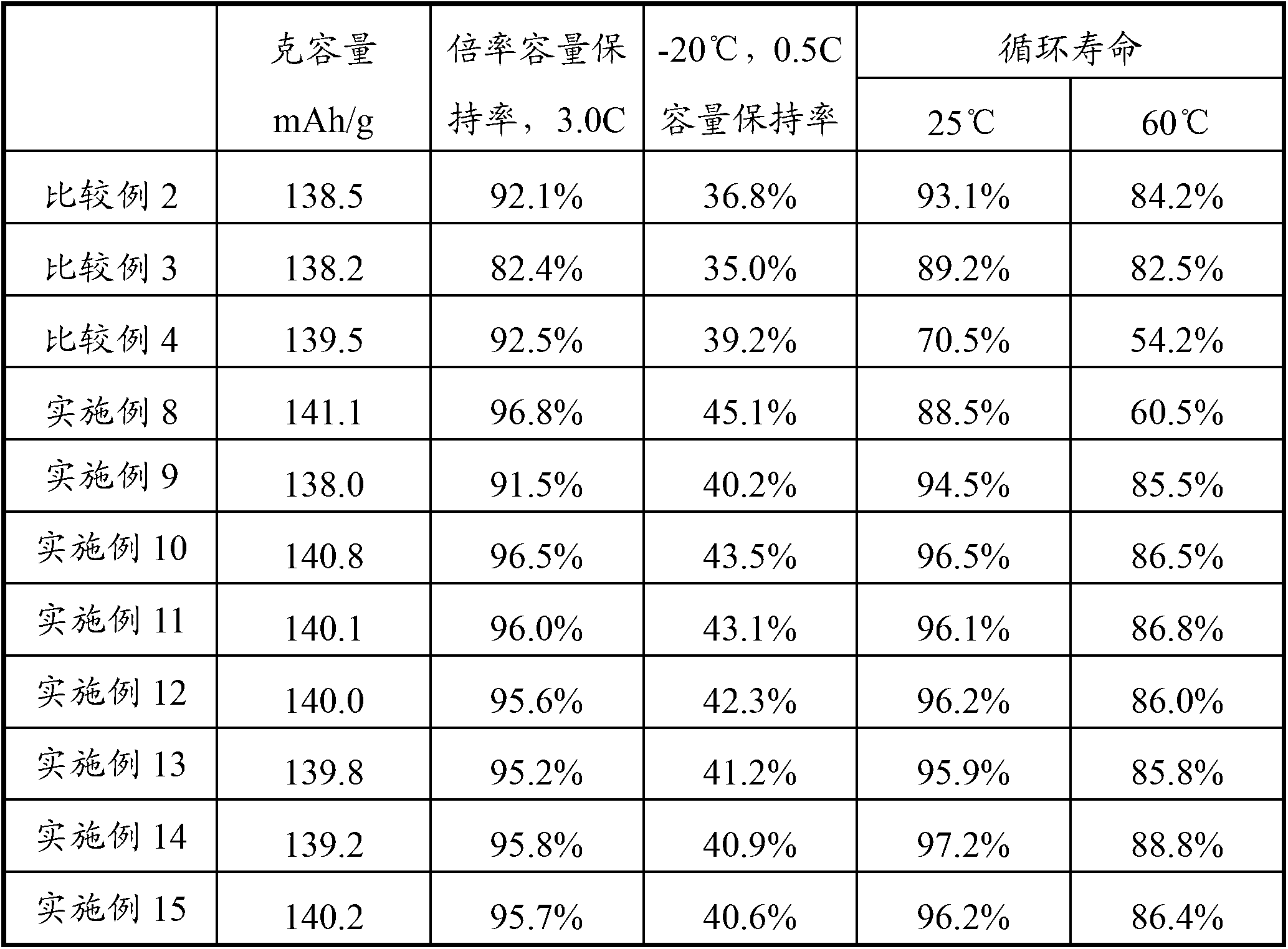

Lithium-ion secondary battery and electrolyte thereof

InactiveCN103078141AFacilitated DiffusionImproved magnification performanceSecondary cellsNon-aqueous electrolyte accumulator electrodesMethyl carbonateCarbonate

The invention discloses a lithium-ion secondary battery and an electrolyte thereof. The electrolyte comprises a solvent, lithium salt and a film forming additive, wherein the solvent comprises a first solvent and a second solvent; the first solvent comprises linear carboxylic ester and ethylene carbonate; the second solvent is one or more of ethyl methyl carbonate, diethyl carbonate, dimethyl carbonate and propylene carbonate; and the film forming additive is one or more of fluoroethylene carbonate, vinylene carbonate, 1,3-propane suhone, succinonitrile, adiponitrile, lithium bis(oxalato)borate, and lithium oxalyldifluoroborate. Due to the collocation of linear carboxylic ester and ethylene carbonate, a solvent system with a higher dielectric constant and low viscosity is obtained; the film forming additive improves poor compatibility between linear carboxylic ester and graphite; and finally the lithium-ion secondary battery adopting the electrolyte presents high-power discharge capacity, excellent high-temperature cycling stability and low-temperature charge and discharge properties.

Owner:NINGDE AMPEREX TECH

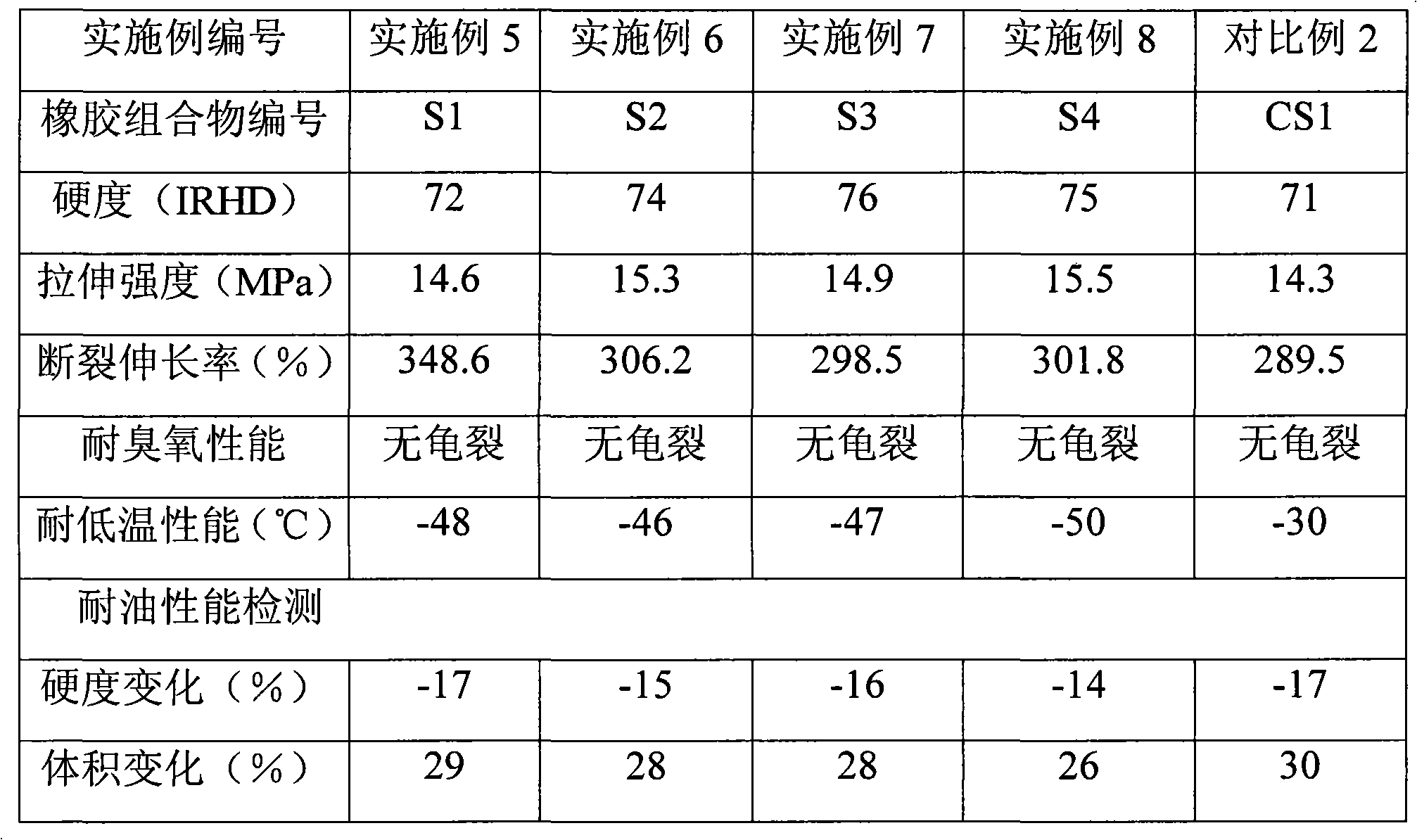

Oil resistant low temperature resistant rubber composition

InactiveCN101353451AGuaranteed oil resistanceGuaranteed ozone resistancePolymer scienceNitrile rubber

The invention relates to a rubber composite, comprising nitrile rubber, polyvinyl chloride, carbon soot, activator, vulcanizator, age inhibitor, antiscorcher, accelerant and plasticizer, wherein, the plasticizer is ethylhexyl sebacate and adipate. The rubber composite of the invention obviously improves the anti-low temperature performance of the rubber composite while ensuring the anti-oil performance, anti-ozone performance, tensile strength and elongation at break.

Owner:BYD CO LTD

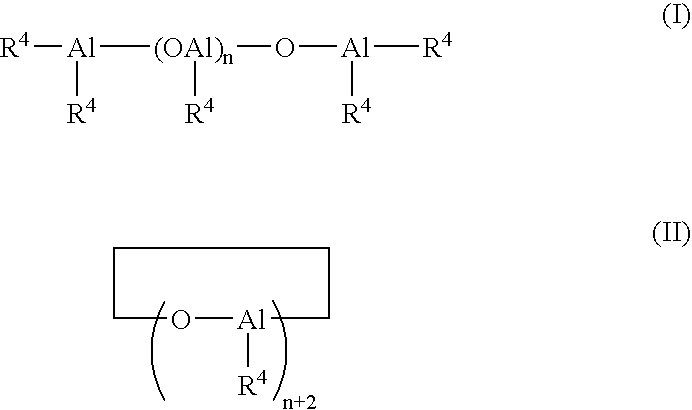

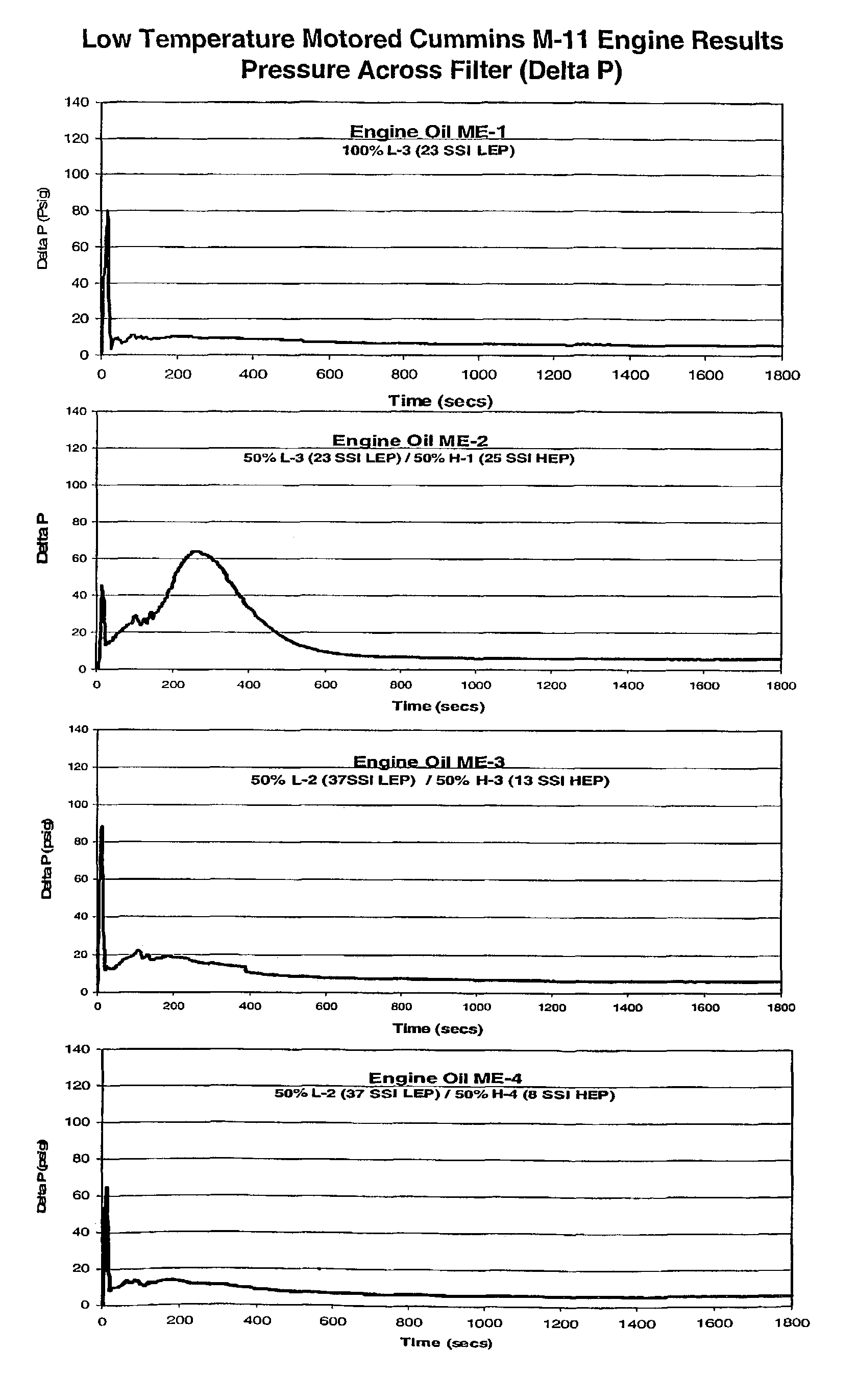

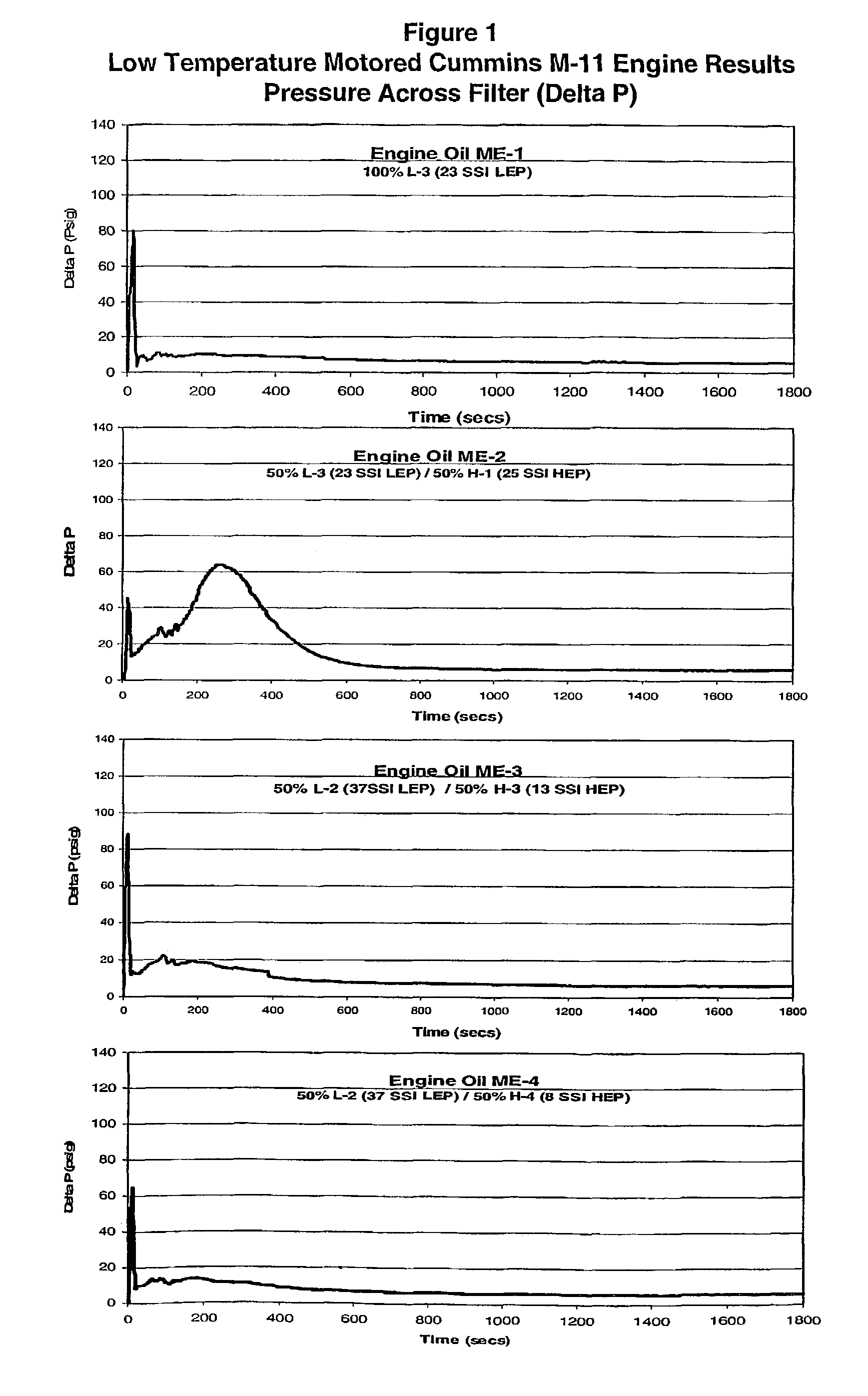

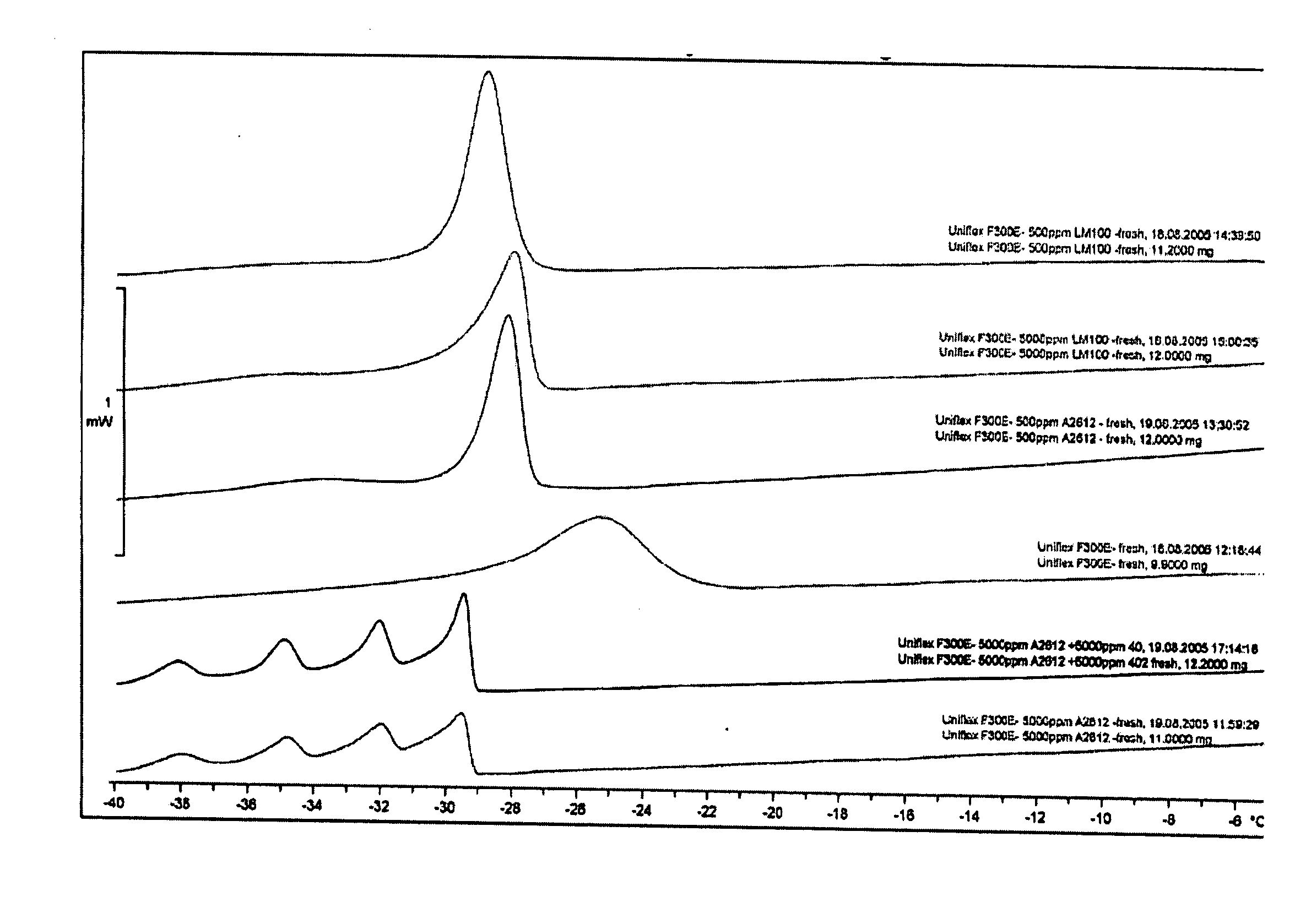

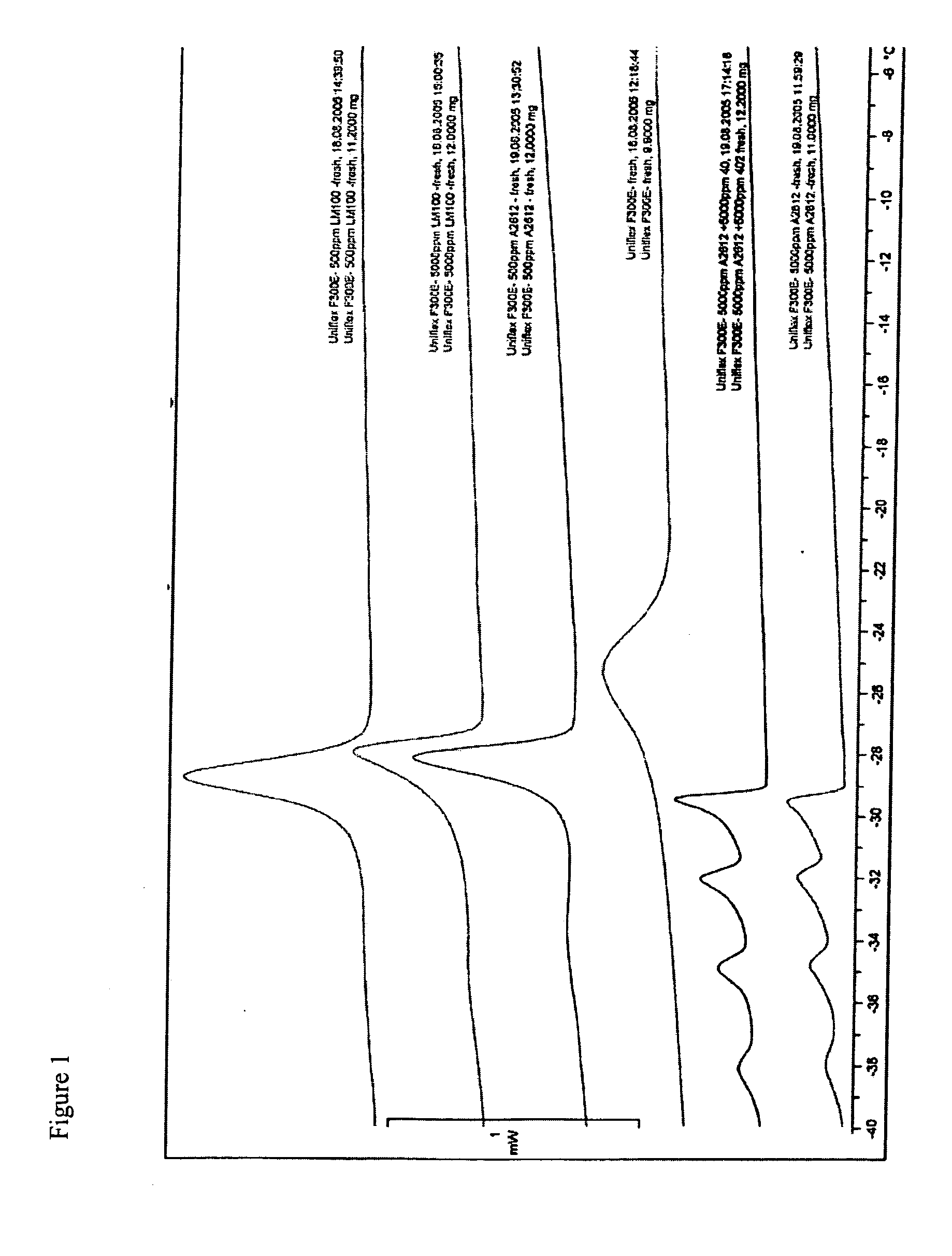

Viscosity improver compositions providing improved low temperature characteristics to lubricating oils

InactiveUS7402235B2Improved viscosity propertiesPolymeric viscosity improver compositionOrganic detergent compounding agentsOrganic chemistryPolymer sciencePolystyrene

A mixture comprising A) a copolymer comprising from about 70 to about 79% by weight of units derived from ethylene, and having (a) Mw measured by gel permeation chromatography employing polystyrene standard ranging from about 50,000 up to less than 130,000 and / or (f) SSI≦18; (b) density (D) ranging from about 845 to about 895 kg / m3; (c) Mw / Mn less than 3; (d) melting point (Tm) measured by differential scanning calorimeter ranging from about 15° C. to about 60° C.; and (e) degree of crystallinity≧15%, and B) an amorphous polymer having Mw ranging from about 130,000 to about 1,000,000 having degree of crystallinity≦5%. In one embodiment the density and the melting point of the copolymer A) fulfill the expression Tm≦1.247 D−1037. In another embodiment, the percentage content (E: % by weight) of repeating units derived from ethylene and melting point (Tm: ° C.) of the copolymer A) fulfill the expression 3.44E−206≧Tm. Also, additive concentrates and lubricating compositions comprising the components making up the mixture.

Owner:THE LUBRIZOL CORP

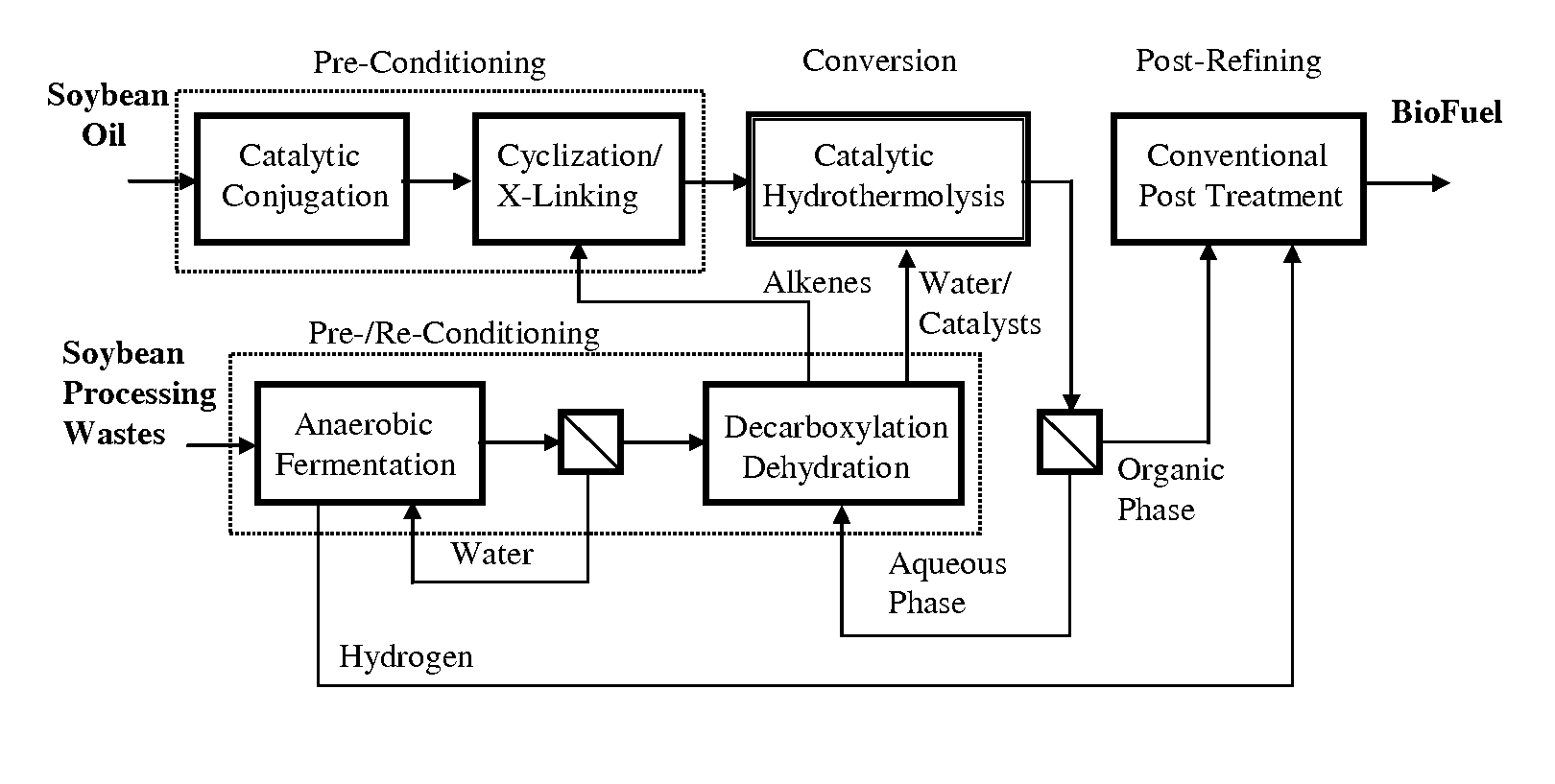

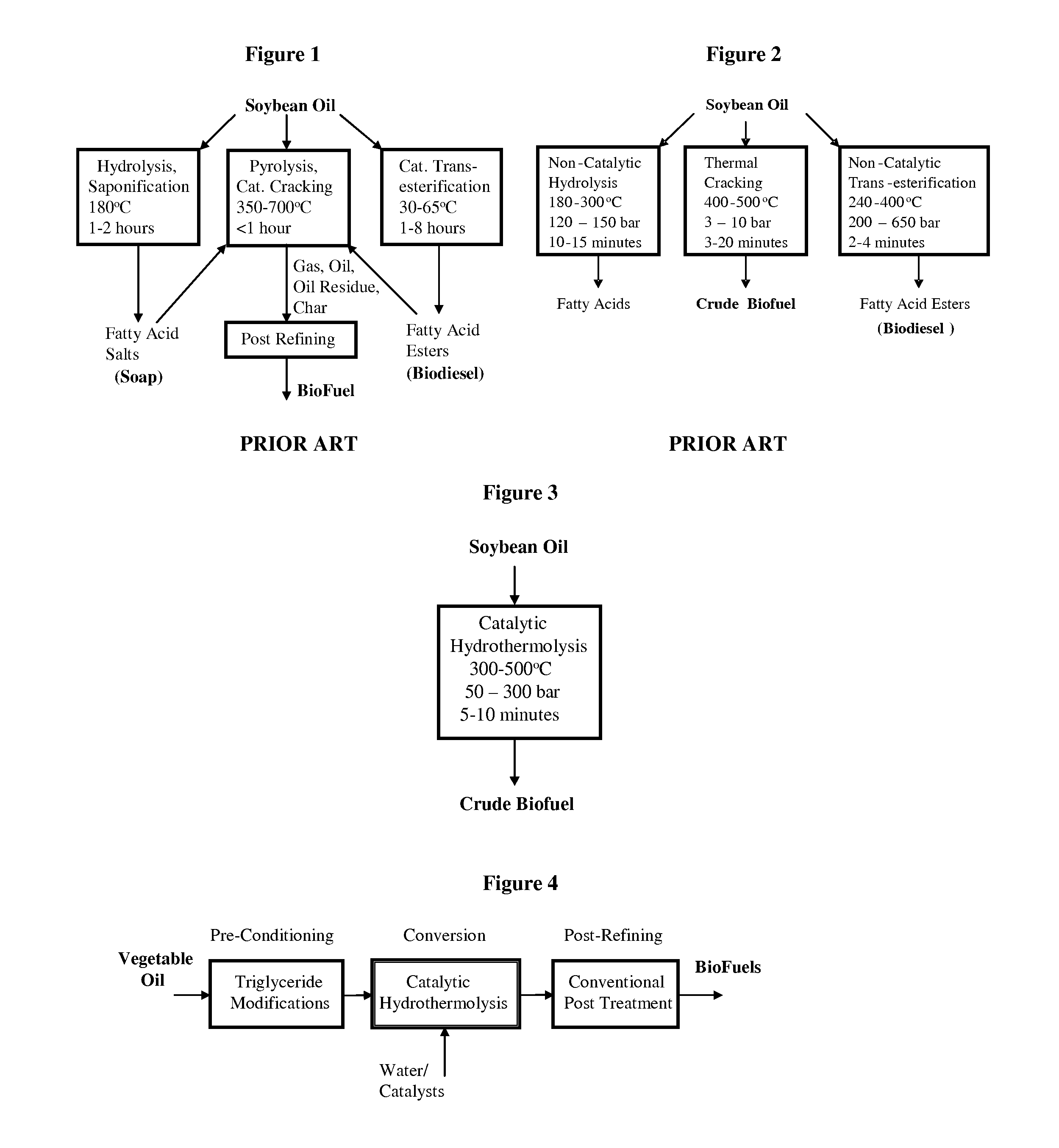

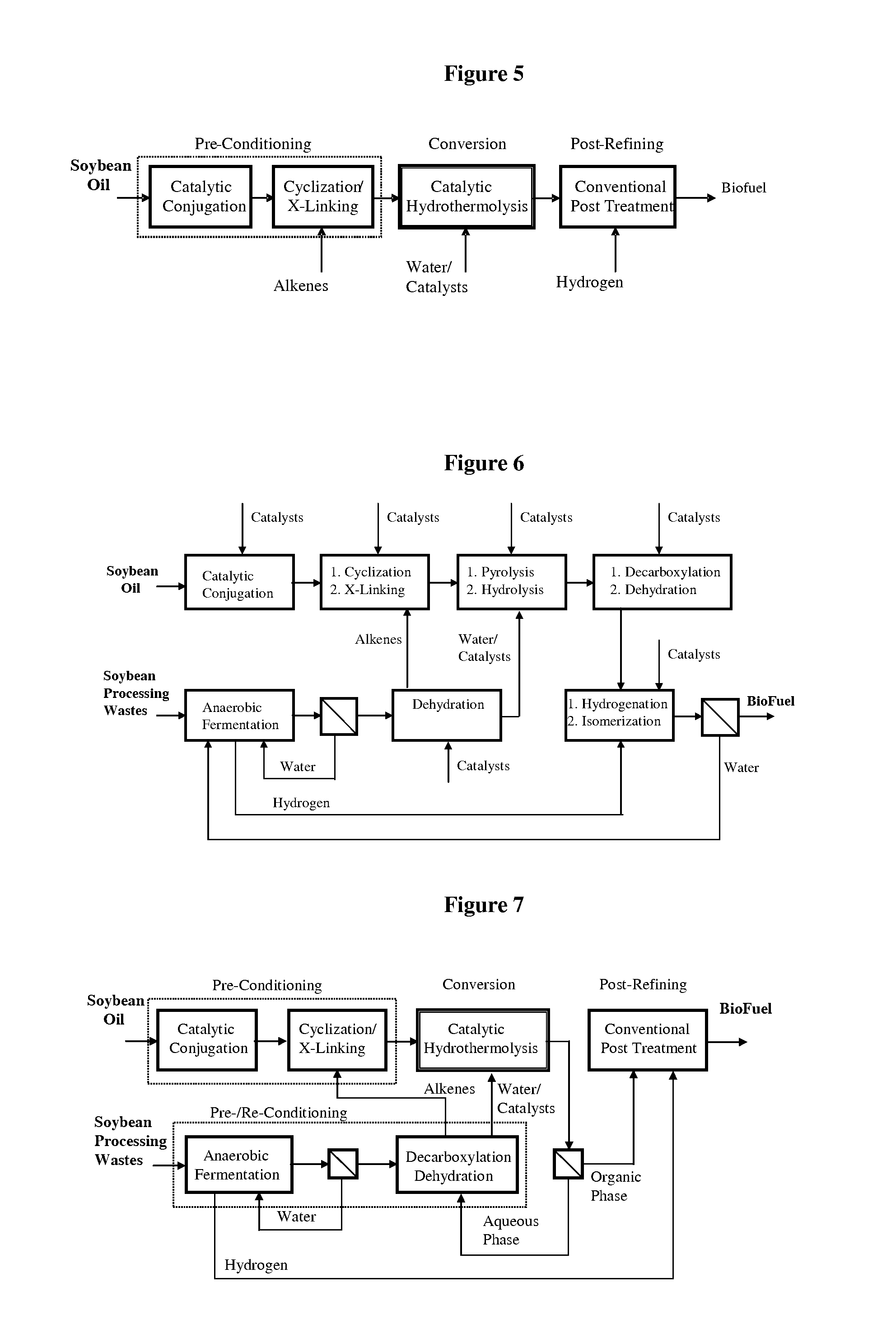

Method of Converting Triglycerides to Biofuels

ActiveUS20080071125A1Improve chemical and physical and combustion qualityImprove thermal stabilityFatty acid chemical modificationBiofuelsIsomerizationPtru catalyst

A triglyceride-to-fuel conversion process including the steps of (a) preconditioning unsaturated triglycerides by catalytic conjugation, cyclization, and cross-link steps; (b) contacting the modified triglycerides with hot-compressed water containing a catalyst, wherein cracking, hydrolysis, decarboxylation, dehydration, aromatization, or isomerization, or any combination thereof, of the modified triglycerides produce a crude hydrocarbon oil and an aqueous phase containing glycerol and lower molecular weight molecules, and (c) refining the crude hydrocarbon oil to produce various grades of biofuels. A triglyceride-to-fuel conversion process further including the steps of (a) carrying out anaerobic fermentation and decarboxylation / dehydration, wherein the anaerobic fermentation produces hydrogen, volatile acids, and alcohols from fermentable feedstocks, and the decarboxylation / dehydration produces alkenes from the volatile acids and alcohols, respectively; (b) feeding the alkenes to the cyclization process; (c) feeding the hydrogen to the post refining process; and (d) recycling the aqueous phase containing glycerol to the decarboxylation / dehydration process. A biofuel composition including straight-chain, branched and cyclo paraffins, and aromatics. The paraffins are derived from conversion of triglycerides. The aromatics are derived from conversion of either triglycerides, petroleum, or coal.

Owner:APPLIED RES ASSOCS INC

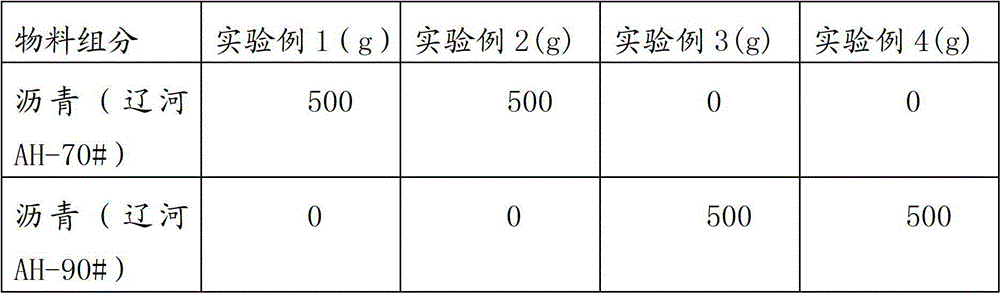

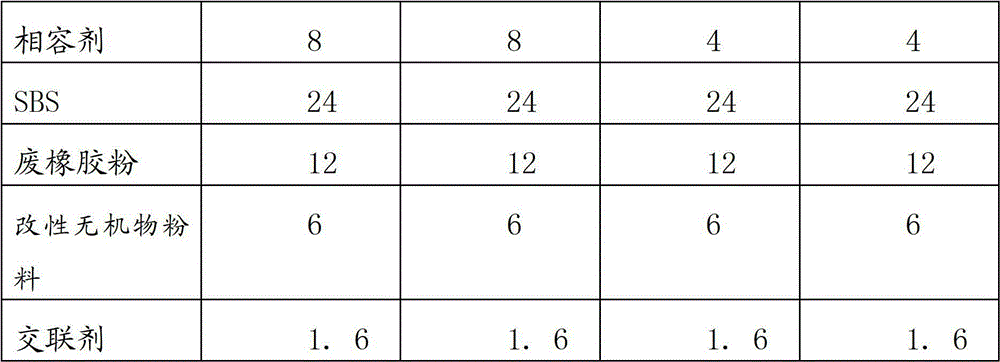

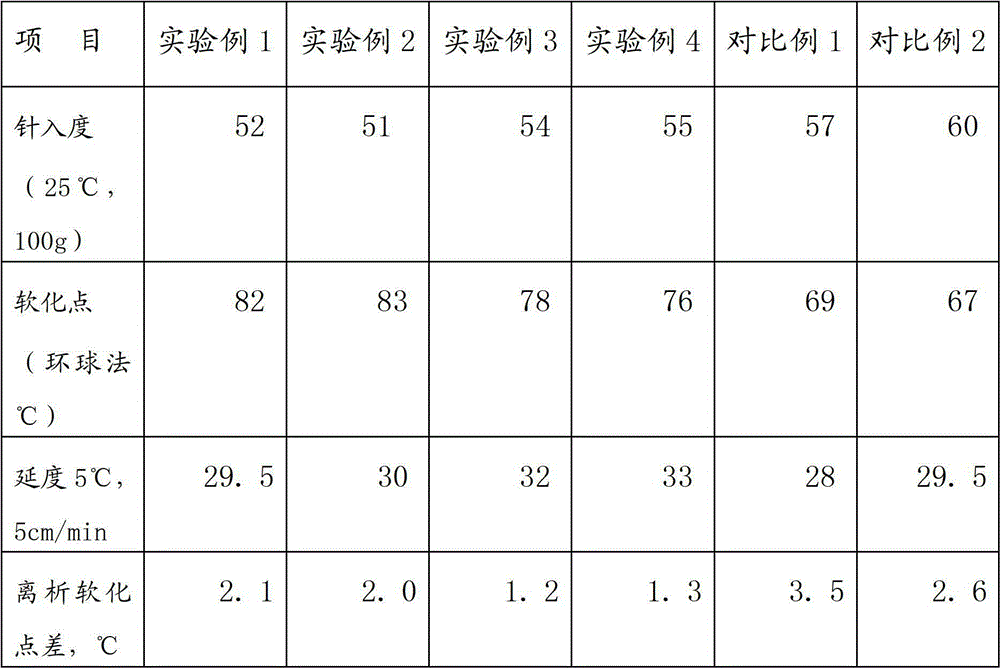

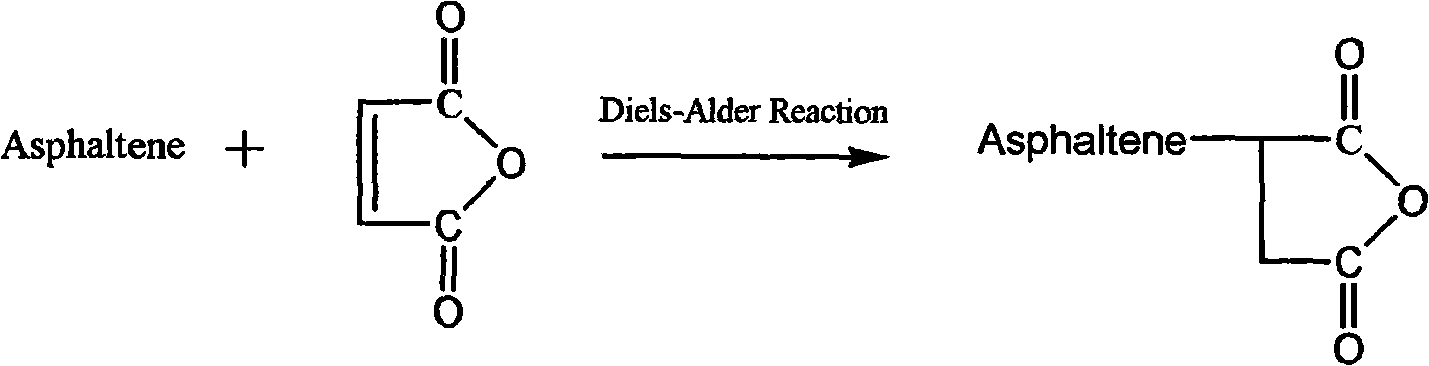

SBS (styrene-butadiene-styrene)/scrap rubber powder composite modified asphalt and preparation method thereof

InactiveCN102977621AImprove anti-aging propertiesReduce material costsBuilding insulationsHigh temperature storagePolymer science

The invention relates to an SBS (styrene-butadiene-styrene) / scrap rubber powder composite modified asphalt which comprises the following components in parts by weight: 75-96 parts of matrix asphalt, 0.5-12 parts of scrap rubber powder, 0.5-6 parts of SBS, 0.2-8 parts of modified inorganic substance powder, 0.1-8 parts of compatilizer and 0.1-3 parts of crosslinking agent. The preparation method comprises the following steps: preparing the scrap rubber powder; heating the matrix asphalt to 160-180 DEG C, adding the compatilizer while stirring, and evenly mixing; adding the SBS scrap rubber powder and modified inorganic substance powder, stirring at the speed of 1000-5000 rpm for 5-125 minutes while keeping the temperature, and adding the crosslinking agent; and quickly stirring for 20-300 minutes while keeping the temperature. The key technical indexes of the product are higher than those of the SBS modified asphalt; and the invention enhances the high / low-temperature properties and aging resistance, prolongs the high-temperature storage stabilization period, and completely satisfies the property requirements for national high-grade roads.

Owner:TIANJIN HI TECH ENVIRONMENT DEV CO LTD

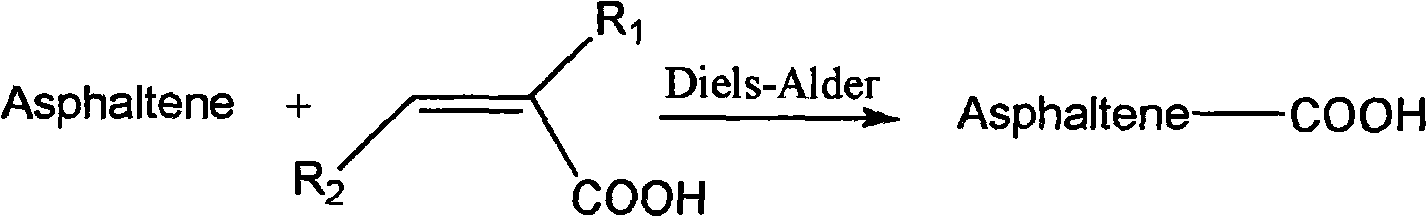

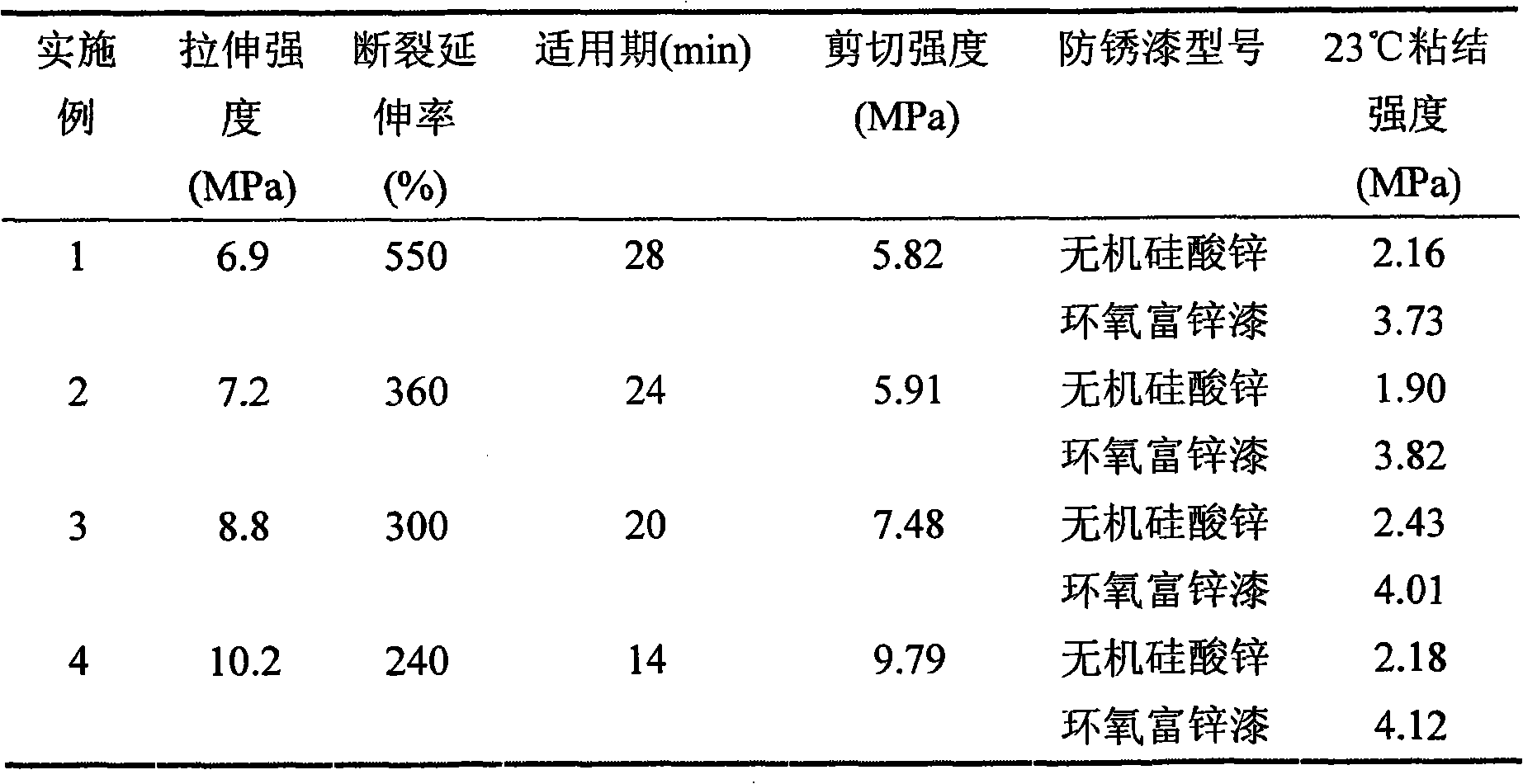

Epoxy asphalt material for road-bridge and environment-friendly preparation method thereof

The invention provides an epoxy asphalt material for bridge and green preparation method, comprising A part and B part, wherein the weight constitute of the A part is: modified asphaltum with carboxyl or anhydride group 60-76 parts, monohydric alcohol or polyhydric alcohol 2-20 parts, aliphatic diprotic acid, dimer acid or alkyd resin 11-25 parts, fatty acid anhydride 10-25 parts, solidified promoter 0.05-0.65 parts; and the constitute of the B part is epoxy resin. The mass ratio of A and B part is 2.2:1-10:1. The epoxy resin modified asphalt material has excellent property with high intensity and good flexibility; provides corresponding operation time according to different requirement and adjust the operation time to satisfy the different performance requirement at will with good storage stability. The corresponding epoxy asphalt concrete has excellent high, low temperature performance and fatigue endurance, and the environment is friendly, suitable for occasion with higher requirement such as autoroute and bridge, and arterial street, bus stop and airfield path. The invention also provides a preparation method thereof.

Owner:SOUTHEAST UNIV

Production method of biodiesel oil using high acid ralue animal and vegetable grease

InactiveCN1556174AAchieve cycleAchieve recyclingBiofuelsLiquid hydrocarbon mixture productionOil and greaseAlcohol

A process for preparing the biological diesel oil from the animal fat or vegetative oil with high acid number includes esterifying by glycerine under existance of strong acid catalyst, distilling in azeotropic solvent for removing water, mixing with methanol, transesterifying reacting to remove glycerine, water washing, and low-temp treating for removing high-smelting-point substances to obtain methyl ester of fatty acid, which is just the biological diesel oil.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

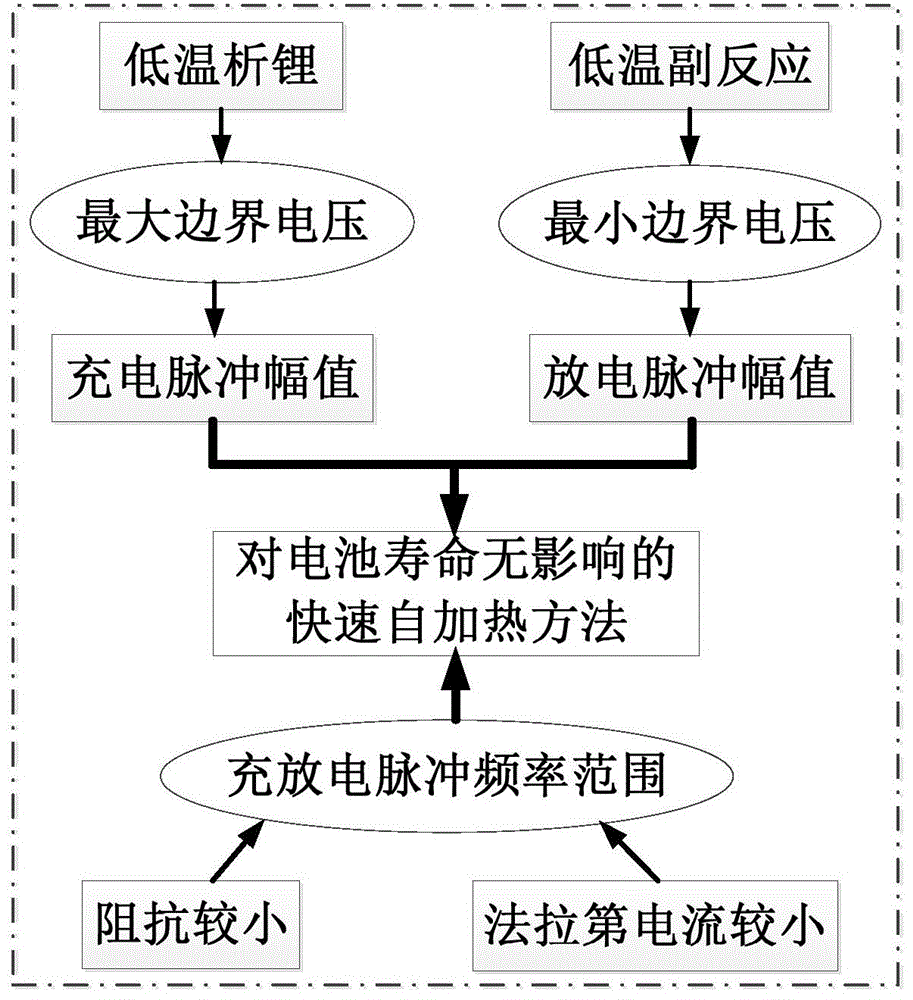

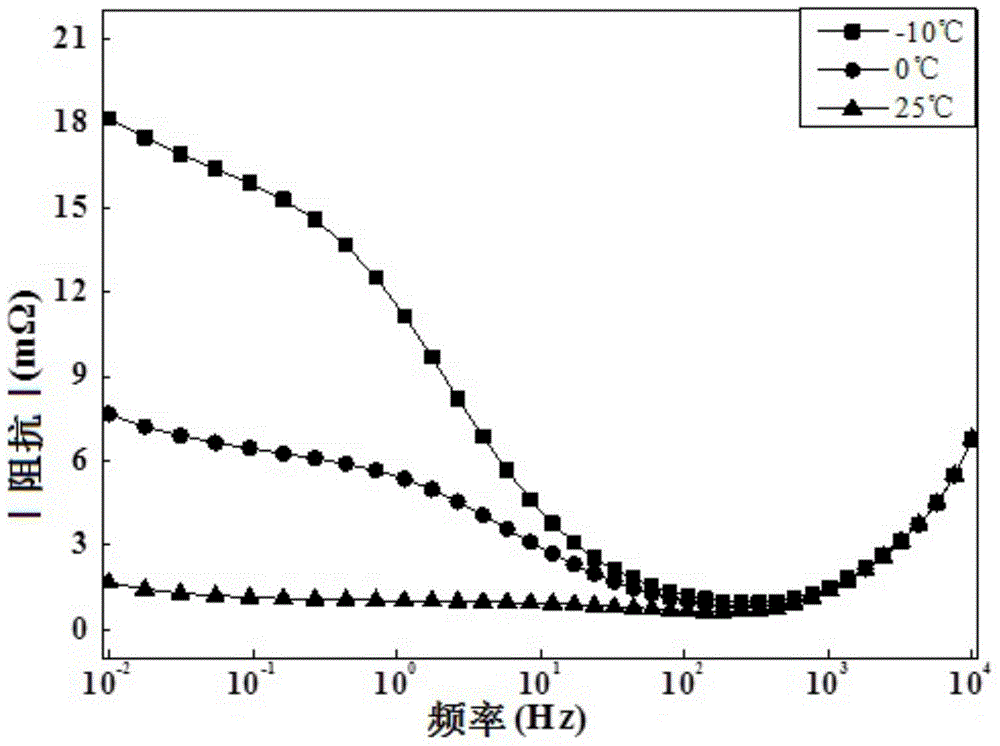

Low-temperature self-heating method for lithium ion battery

ActiveCN104064836ANo effect on service lifeReduced service lifeCell temperature controlInternal resistanceEngineering

The invention discloses a low-temperature self-heating method for a lithium ion battery. The method comprises the steps of determining a frequency range in which the service life of the lithium ion battery cannot be affected, and selecting frequencies of charging and discharging pulses according to the range; setting a pulse current amplitude value selection basis under a selected charging and discharging mode, and calculating a charging current amplitude value Ic and a discharging current amplitude value Id; performing no-life-loss heating on the battery to be heated according to charging and discharging pulse signals of the determined frequencies and the amplitude values, wherein the inner resistance of the self-heated battery is greatly reduced, and the charging performance is greatly improved. According to the technical scheme, the low-temperature self-heating method has the effects of high self-heating speed, obvious low-temperature performance improvement and no influence on the service life of the battery.

Owner:BEIJING BEIJIAO NEW ENERGY TECH CO LTD

Moisture curable sealer and adhesive composition

ActiveUS20050107499A1Low costExcellent propertyRoof covering using flexible materialsBituminous material adhesivesIsocyanatePliability

A low cost moisture curable sealer and adhesive composition containing a polymer having reactive silyl groups and a bituminous material and having many advantages over conventional moisture cure sealer compositions, including greater elastomeric properties, improved flexibility and pliability, lower durometer, faster and deeper cure, low temperature cure. The composition is also free of carcinogens such as coal tar, toxic isocyanates, and volatile solvents.

Owner:CHEMLINK

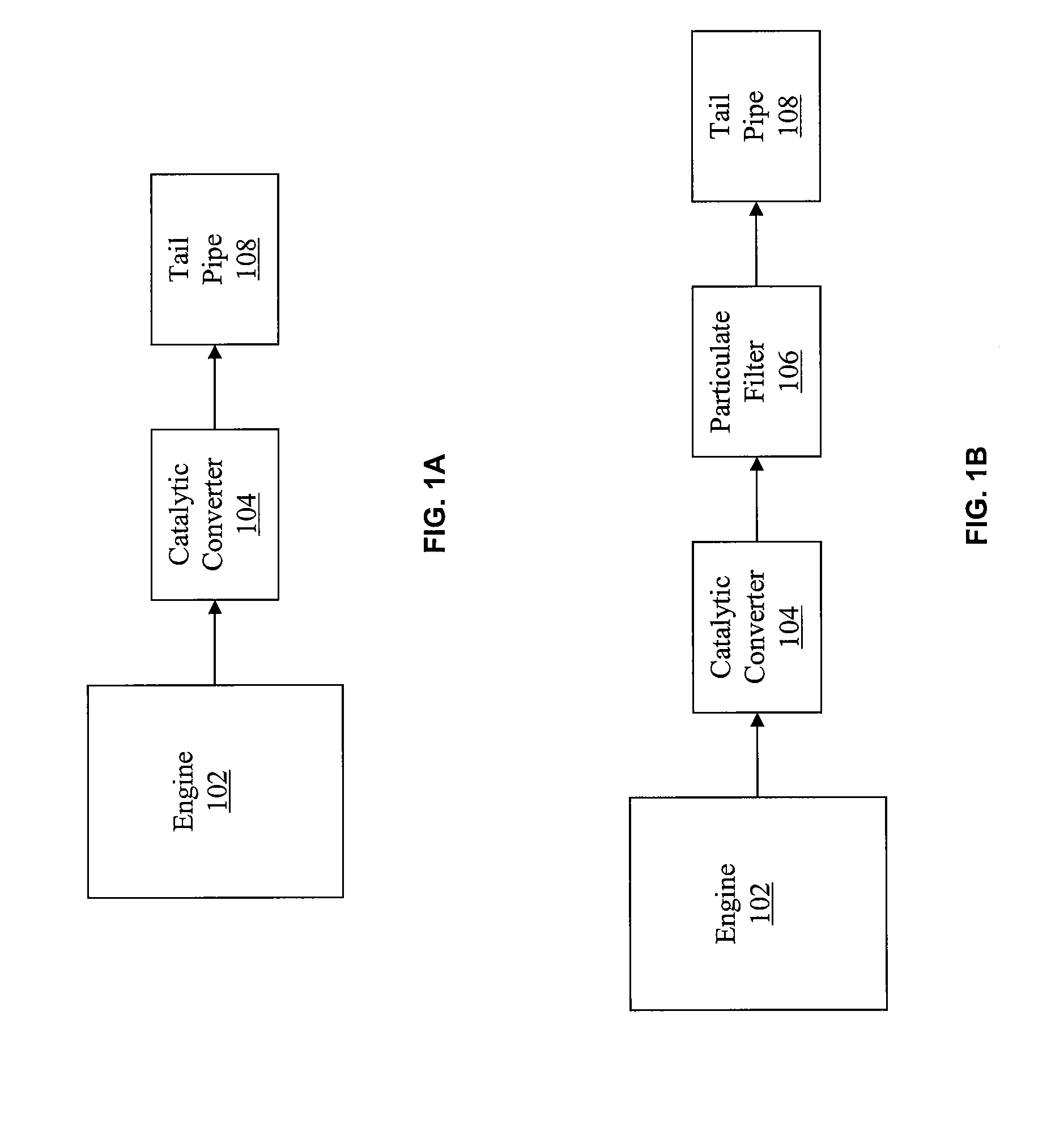

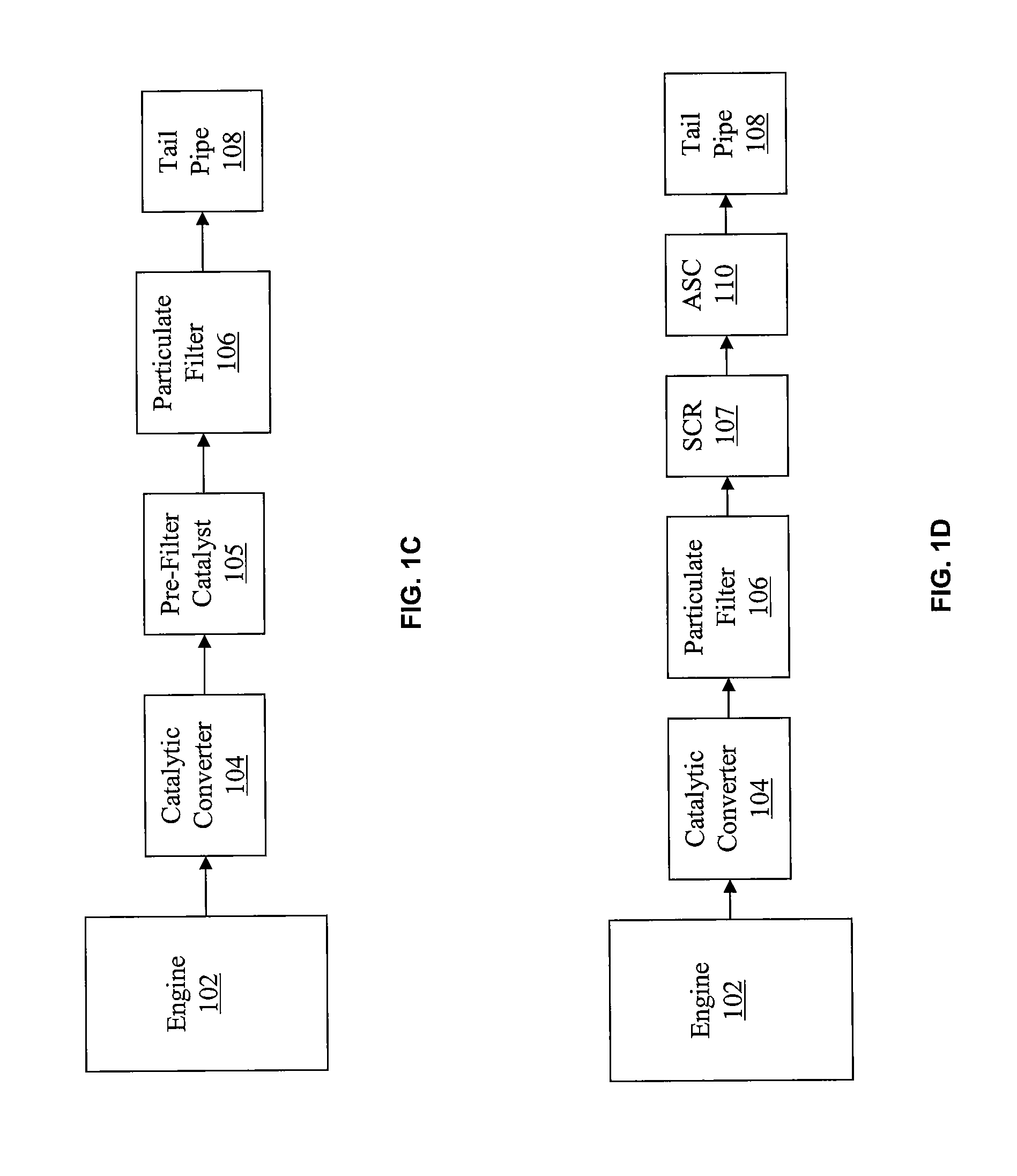

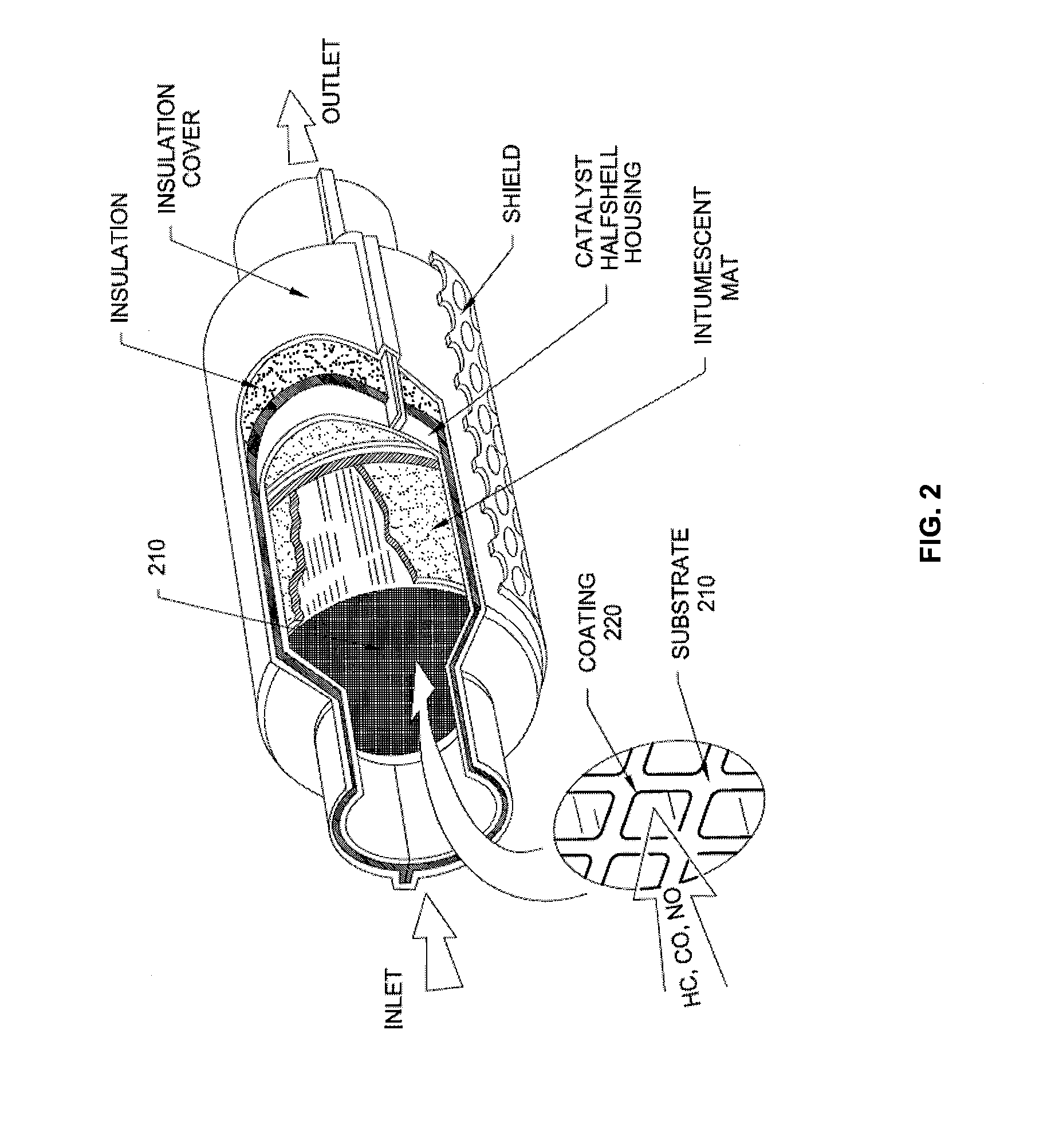

Engine exhaust catalysts containing palladium-gold

InactiveUS8258070B2Improved CO and HC reduction performanceImprove low temperature performanceMolecular sieve catalystsInternal combustion piston enginesMetal catalystPalladium

An emission control catalyst that exhibits improved CO and HC reduction performance includes supported precious group metal catalysts that are coated onto different layers of the substrate for the emission control catalyst. Zeolites of one or more types are added to the emission control catalyst as a hydrocarbon absorbing component to boost the low temperature performance of the emission control catalyst. Y zeolite is used by itself or mixed with other zeolites to enhance hydrocarbon storage at low temperatures.

Owner:WGCH TECH LIMITED WORLD GOLD COUNCIL

Positive lead plaster for lead-acid storage battery and preparation method of positive lead plaster

ActiveCN103762358APromote formationReduce the difficulty of formationCell electrodesPolyesterSulfuric acid

The invention discloses positive lead plaster for a lead-acid storage battery and a preparation method of the positive lead plaster. The positive lead plaster is characterized by consisting of the following raw materials by weight percent: 7 to 10 percent of 1.4g / ml dilute sulfuric acid, 8 to 12 percent of deionized water, 5 to 20 percent of red lead, 0.1 to 0.4 percent of colloid graphite, 0.1 to 0.3 percent of stannous sulfate, 0.1 to 0.3 percent of anhydrous sodium sulfate, 0.2 to 0.5 percent of 4BS, 0.1 to 0.3 percent of diantimony trioxide, 0.05 to 0.2 percent of polyester short fibers, and the balance being lead powder. After the lead plaster which is prepared by utilizing the formula and the preparation method is prepared into the storage battery, the storage battery has the characteristics of high primary capacity, long service life, good low-temperature performance and good charging capacity.

Owner:江苏海宝电池科技有限公司

Non-aqueous electrolytic solution

ActiveUS7255965B2Improve battery performanceGood SEIOrganic electrolyte cellsSecondary cellsHigh temperature storageLithium

The use of lithium bis(oxalate)borate (LiBOB) as an additive in a lithium secondary battery provides improved battery performance such as long life and high capacity retention after high temperature storage.

Owner:SHENZHEN CAPCHEM TECH CO LTD

Olefin block copolymer, viscosity index improver for lubricating oils and lubricating oil composition

InactiveUS7022766B2Improve low temperature performanceImprove balanceLiquid carbonaceous fuelsAdditivesPolymer scienceChemical composition

The present invention provides an olefin block copolymer for a viscosity index improver capable of preparing a lubricating oil composition having excellent low temperature properties and excellent balance between viscosity and shear stability, a viscosity index improver and a lubricating oil composition comprising the viscosity index improver.The olefin block copolymer has a Mw / Mn of not more than 1.5, and comprises:(i) a polymer block comprising ethylene and an α-olefin of 3 to 20 carbon atoms, having a molar ratio (ethylene / α-olefin) of ethylene units to α-olefin units of from 20 / 80 to 65 / 35, a Mw of 50,000 to 2,000,000, and having a slope of an intramolecular composition distribution of absolute value of 0.1 to 0, and(ii) a polymer block comprising ethylene and an α-olefin of 3 to 20 carbon atoms, having a molar ratio (ethylene / α-olefin) of ethylene units to α-olefin units of from 70 / 30 to 85 / 15, a Mw of 10,000 to 400,000, and having a slope of an intramolecular composition distribution of absolute value of 0.1 to 0.

Owner:MITSUI CHEM INC

Steel rope grease with high dropping point and preparation method of steel rope grease

InactiveCN102618371AAlleviate lubrication and corrosion problemsExtended service lifeLubricant compositionAntioxidantBase oil

The invention relates to steel rope grease with high dropping point and a preparation method of the steel rope grease. The steel rope grease with high dropping point comprises the following compositions in percentage by weight: 65%-85% of base oil, 5%-20% of thickening agent, 2%-15% of adhesion agent, 1%-6% of rust inhibitor, 0-5% of antioxidant, 0-5% of polar additive and 0.5%-6% of solid lubricant. According to the steel rope grease, the dropping point of the steel rope grease is high (no less than 100 DEG C), the adhesion property is good (a slump test is qualified), the low temperature performance is good, superior adhesion property and oil film forming capacity are realized, and comprehensive performances such as waterproofing, corrosion resistance, oxidation resistance and wear resistance are also realized; and high-quality steel rope grease products required by the imported steel rope products can be partially replaced by the steel rope grease, so that the production cost is reduced for enterprises, the lubrication and corrosion resistant problems of the steel rope can be relieved, and the service life of the steel rope can be greatly prolonged.

Owner:HENAN COAL SCI RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com