Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2539 results about "Pour point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The pour point of a liquid is the temperature below which the liquid loses its flow characteristics. In crude oil a high pour point is generally associated with a high paraffin content, typically found in crude deriving from a larger proportion of plant material. That type of crude oil is mainly derived from a kerogen Type III.

Premium synthetic lubricant base stock having at least 95% non-cyclic isoparaffins

InactiveUS6080301ARefining to change hydrocarbon structural skeletonHydrocarbon purification/separationParaffin waxAlkane

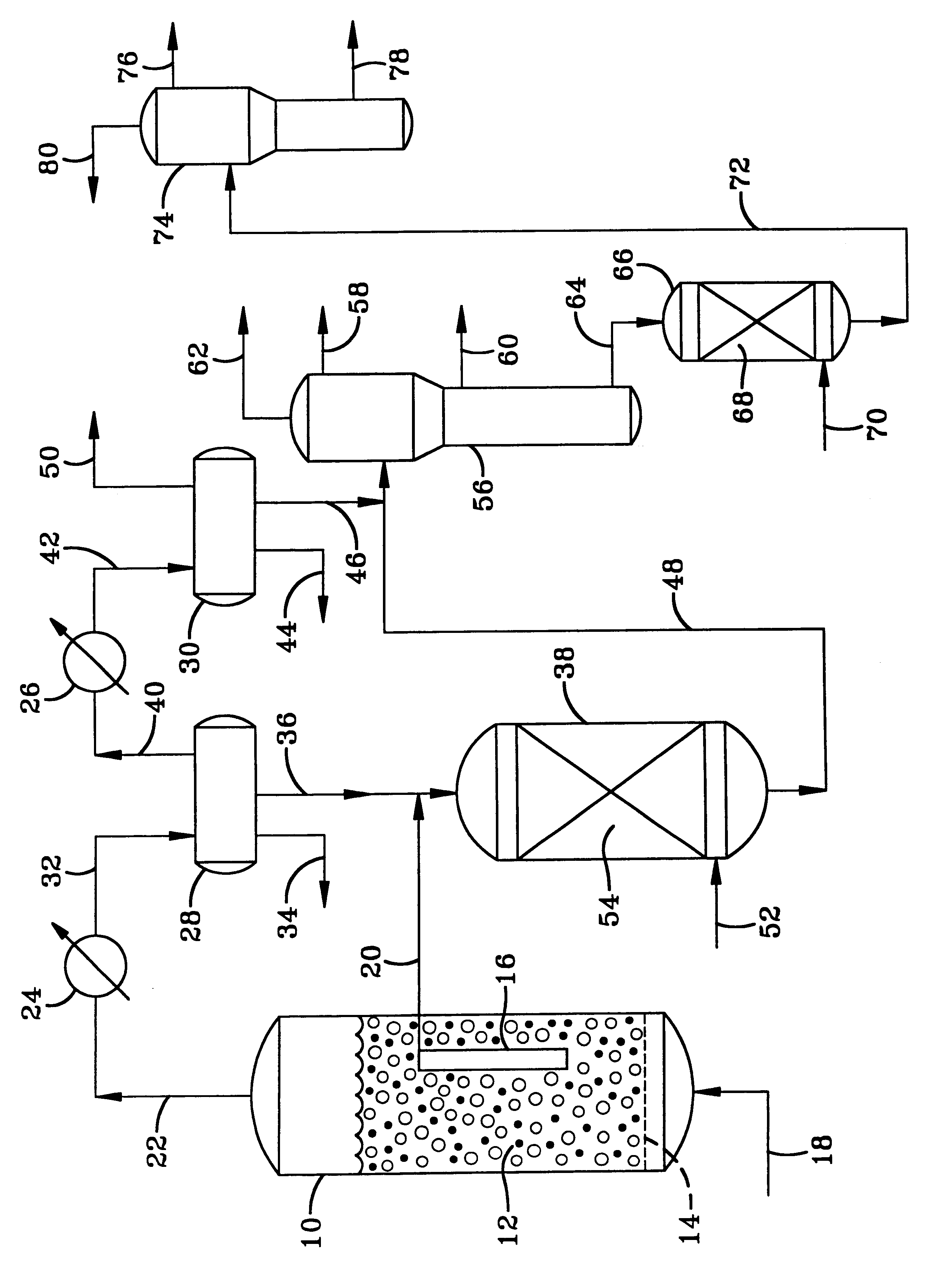

A premium synthetic lubricating oil base stock having a high VI and low pour point is made by hydroisomerizing a Fischer-Tropsch synthesized waxy, paraffinic feed wax and then dewaxing the hydroisomerate to form a 650-750 DEG F.+ dewaxate. The waxy feed has an initial boiling point in the range of about 650-750 DEG F., from which it continuously boils up to at least 1050 DEG F. and has a T90-T10 temperature difference of at least 350 DEG F. The feed is preferably hydroisomerized without any pretreatment, other than optional fractionation. The 650-750 DEG F.+ dewaxate is fractionated into two or more base stocks of different viscosity.

Owner:EXXON RES & ENG CO

Catalytic dewaxing with trivalent rare earth metal ion exchanged ferrierite

InactiveUS6013171AMolecular sieve catalystsRefining to change hydrocarbon structural skeletonCation-exchange capacityIon exchange

A process for dewaxing waxy hydrocarbonaceous materials, such as hydrocarbon fuel and lubricating oil fractions to reduce their cloud and pour points comprises reacting the material with hydrogen in the presence of a dewaxing catalyst comprising at least one metal catalytic component and ferrierite in which at least a portion of its cation exchange positions are occupied by one or more trivalent rare earth metal cations. The rare earth ion exchanged ferrierite catalyst has good selectivity for lubricating oil production, particularly when dewaxing a Fischer-Tropsch wax hydroisomerate. Preferably at least 10% and more preferably at least 15% of the ferreirite cation exchange capacity is occupied by one or more trivalent rare earth metal cations.

Owner:EXXON RES & ENG CO

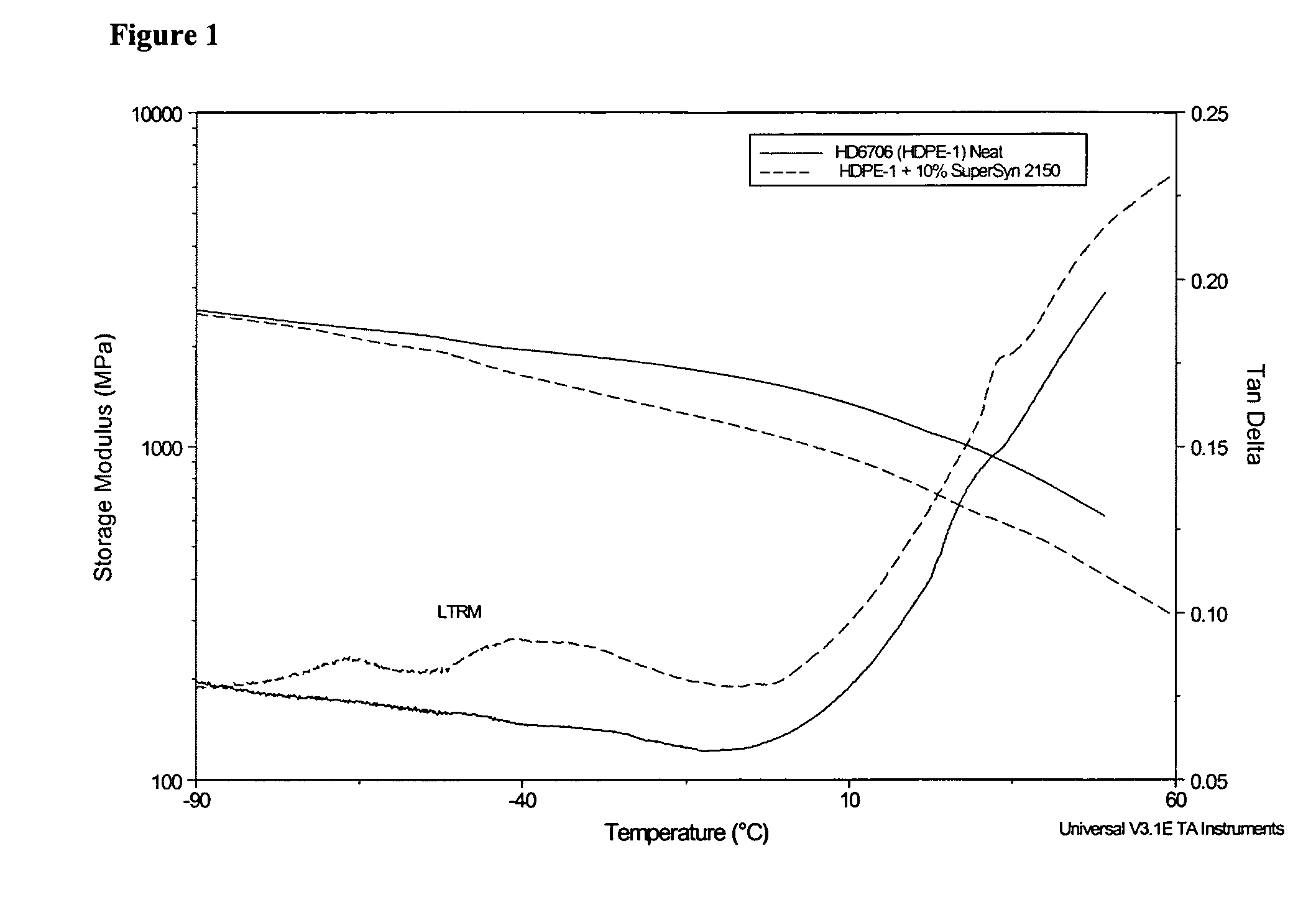

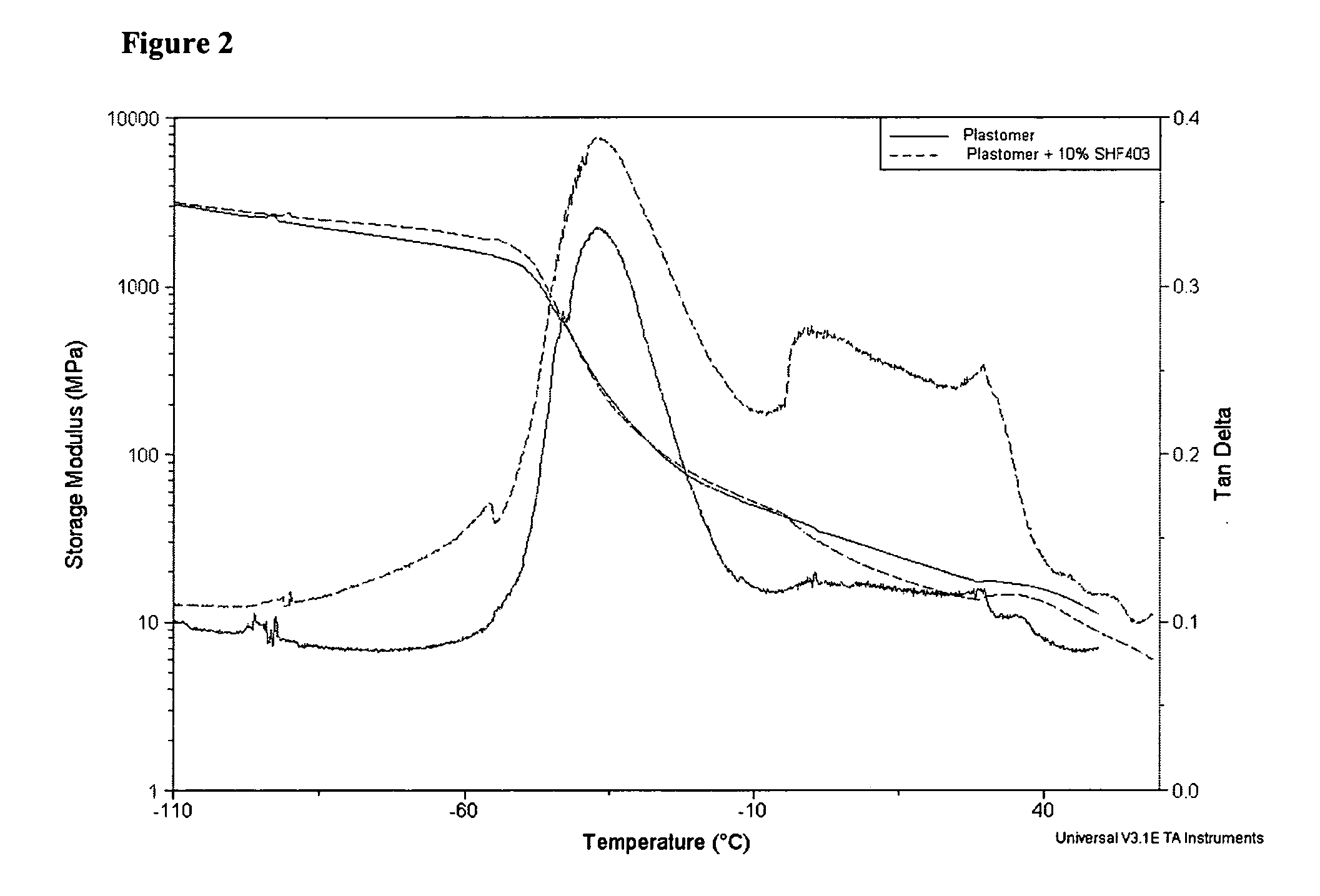

Modified polyethylene compositions

The present invention relates to a composition comprising more than 25 weight % (based on the weight of the composition) of one or more ethylene polymers having an Mw of 20,000 g / mole or more and at least 0.1 weight % of a liquid hydrocarbon modifier where the modifier has: 1) a viscosity index of 120 or more, and 2) an kinematic viscosity of 3 to 3000 cSt at 100° C., and 3) a pour point of −10° C. or less, and 4) a flash point of 200° C. or more; and wherein the modifier contains less than 5 weight % of functional groups selected from hydroxide, aryls, substituted aryls, halogens, alkoxys, carboxylates, esters, acrylates, oxygen, nitrogen, and carboxyl, based upon the weight of the modifier.

Owner:EXXONMOBIL CHEM PAT INC

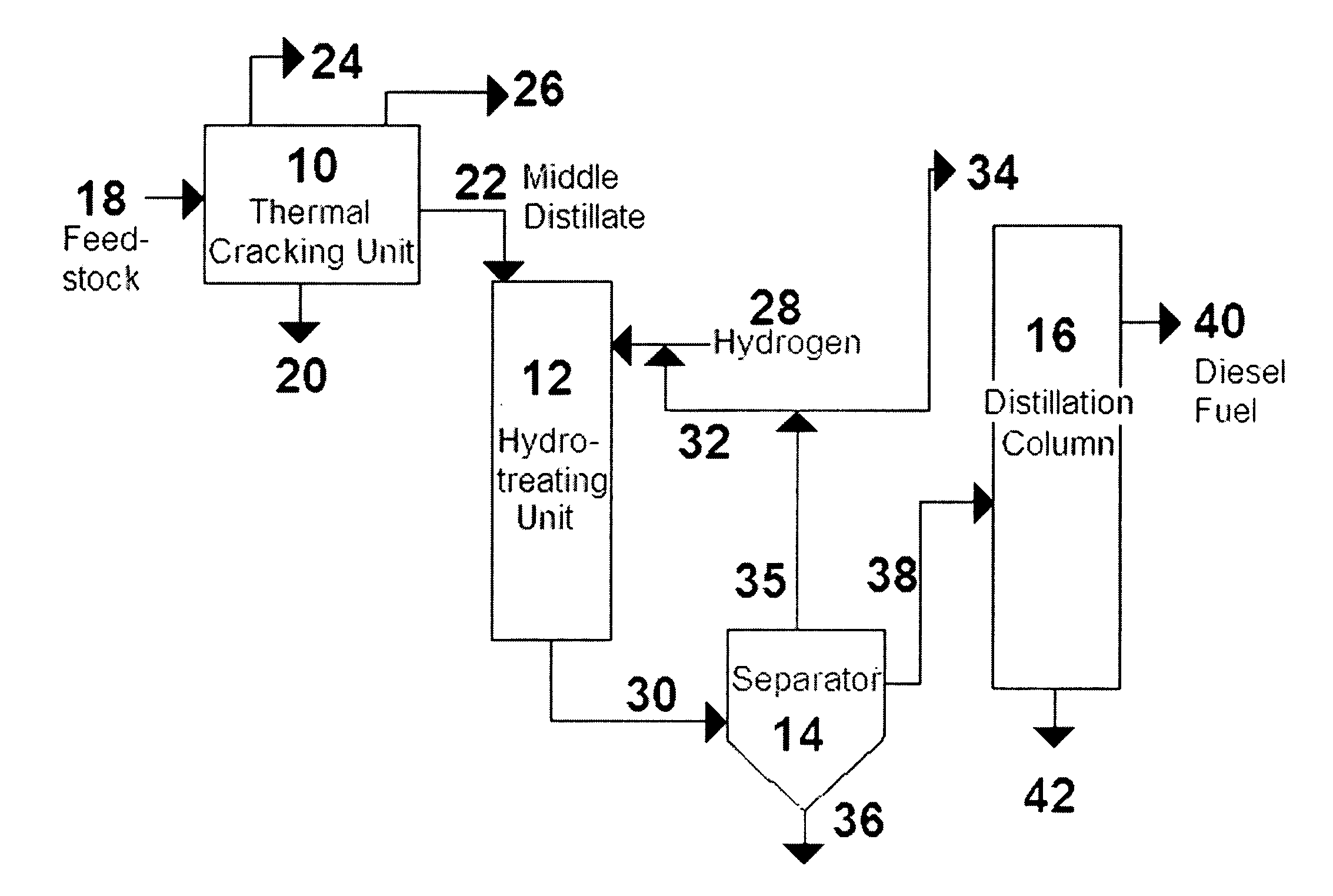

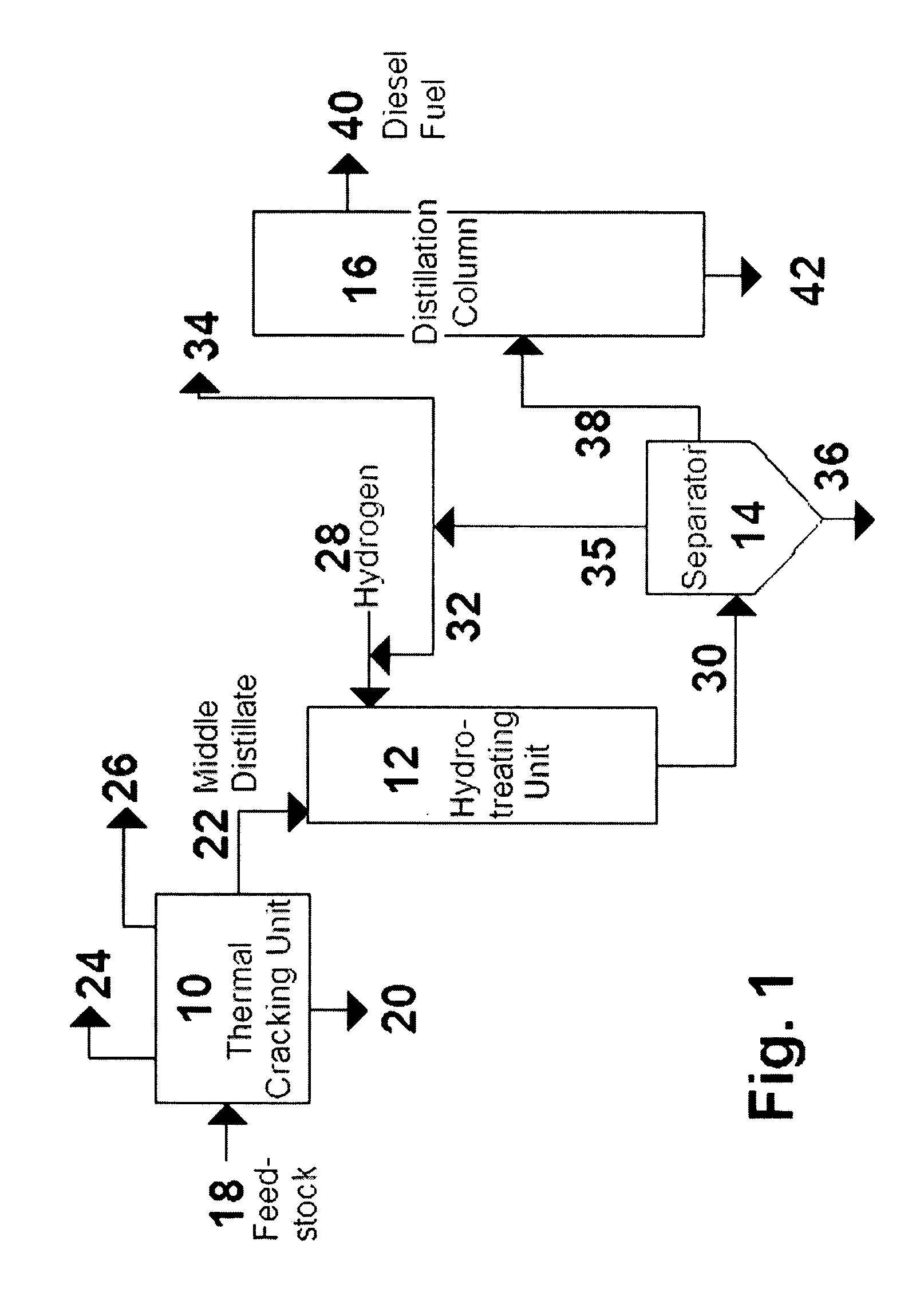

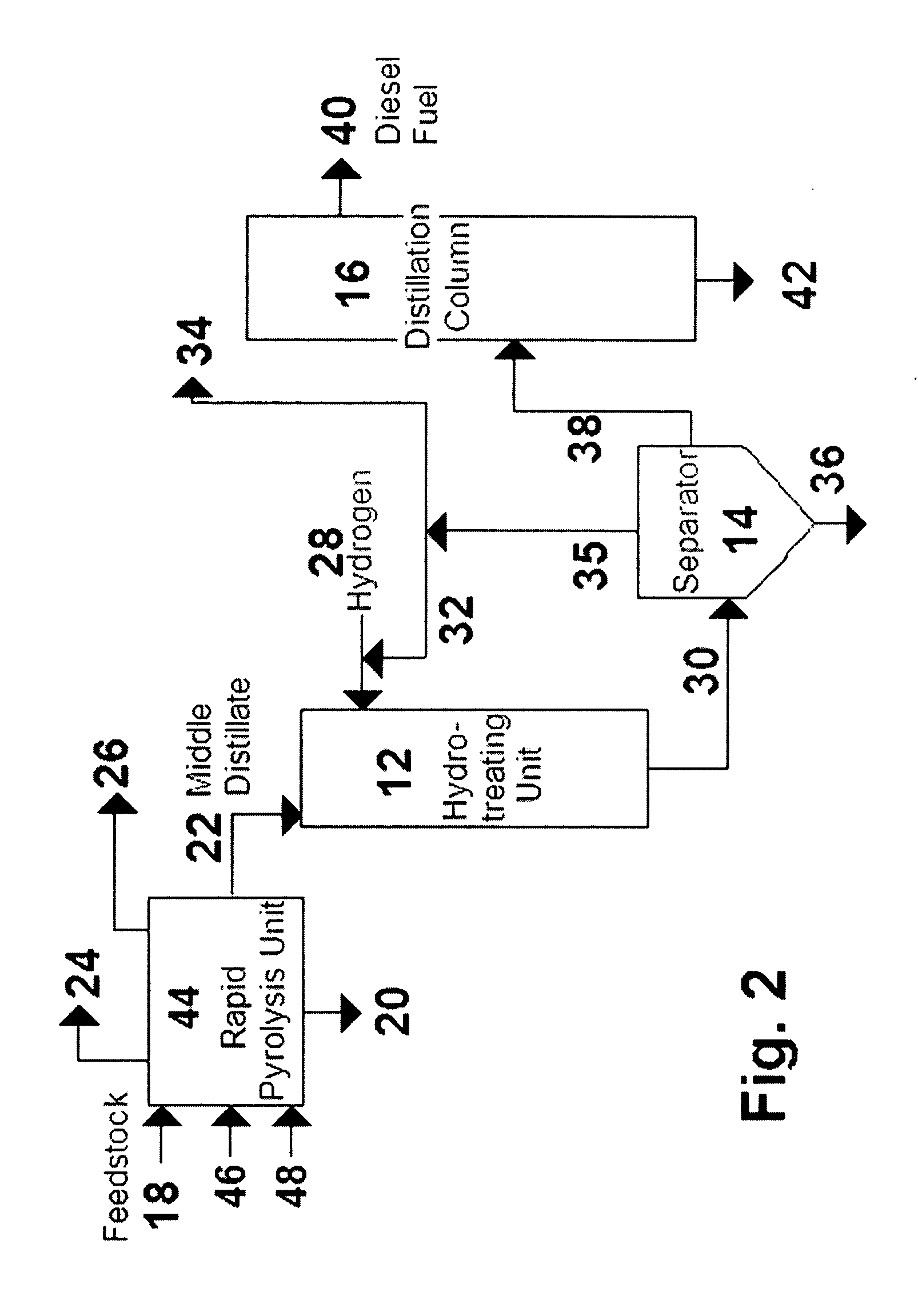

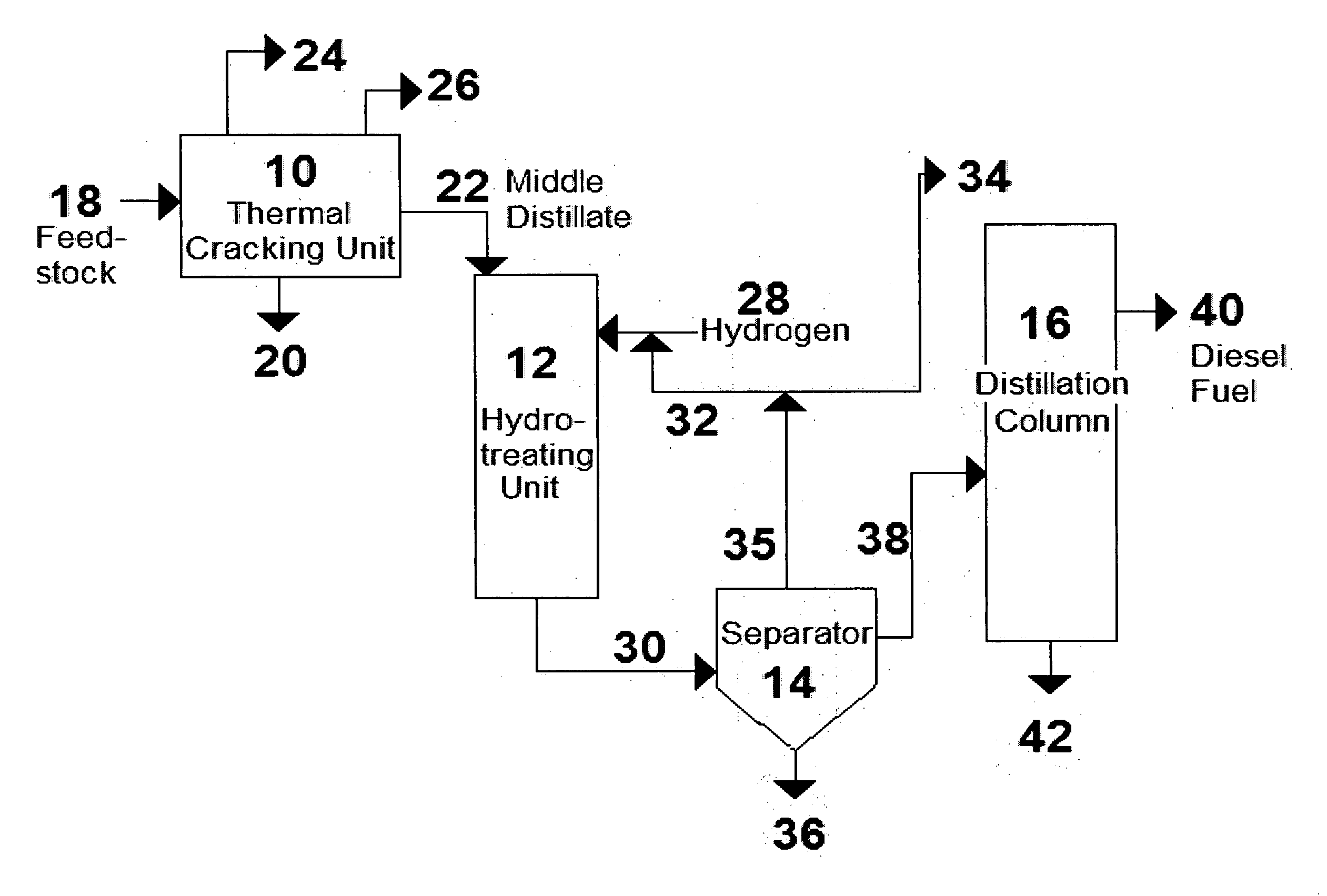

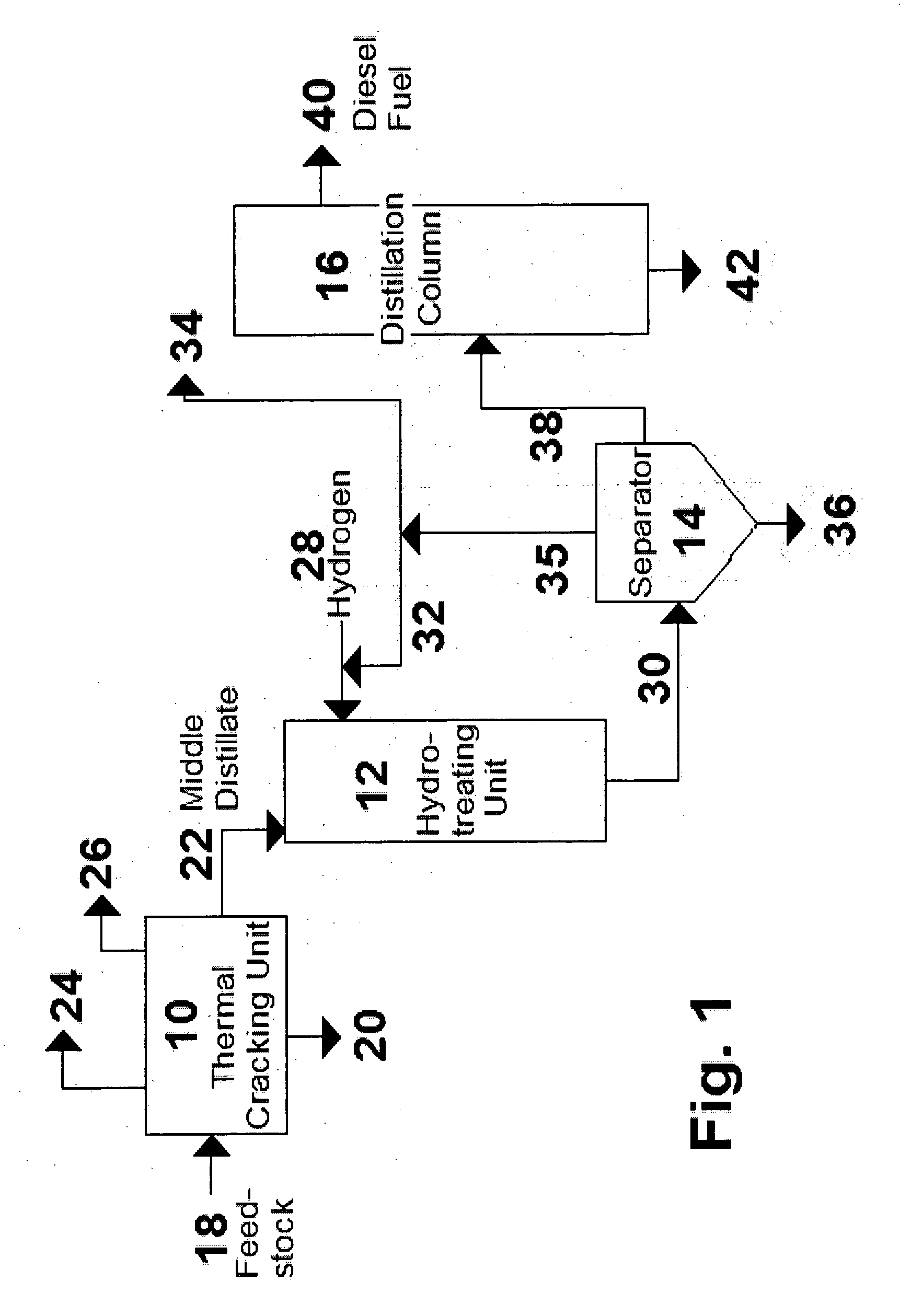

Production of high-cetane diesel fuel from low-quality biomass-derived feedstocks

A method is taught for producing diesel fuels of high cetane value from a triglyceride feedstock, comprising pretreating the triglyceride feedstock by thermal cracking or rapid pyrolysis to partially convert the triglycerides and produce a middle distillates stream, and catalytically hydrotreating the middle distillate fraction to produce high cetane value diesel fuels. A biomass-derived diesel fuel is also taught having sulphur content below 10 ppm, a cetane-value of at least 70, a cloud point below 0° C. and a pour point of less than −4° C. A blended diesel fuel is also taught comprising 5 to 20 vol. % of the biomass-derived diesel fuel of the present invention and 80 to 95 vol. % of a petroleum diesel, based on total volume of the blended diesel fuel.

Owner:HER MAJESTY THE QUEEN & RIGHT OF CANADA REPRESENTED BY THE MIN OF NATURAL RESOURCES

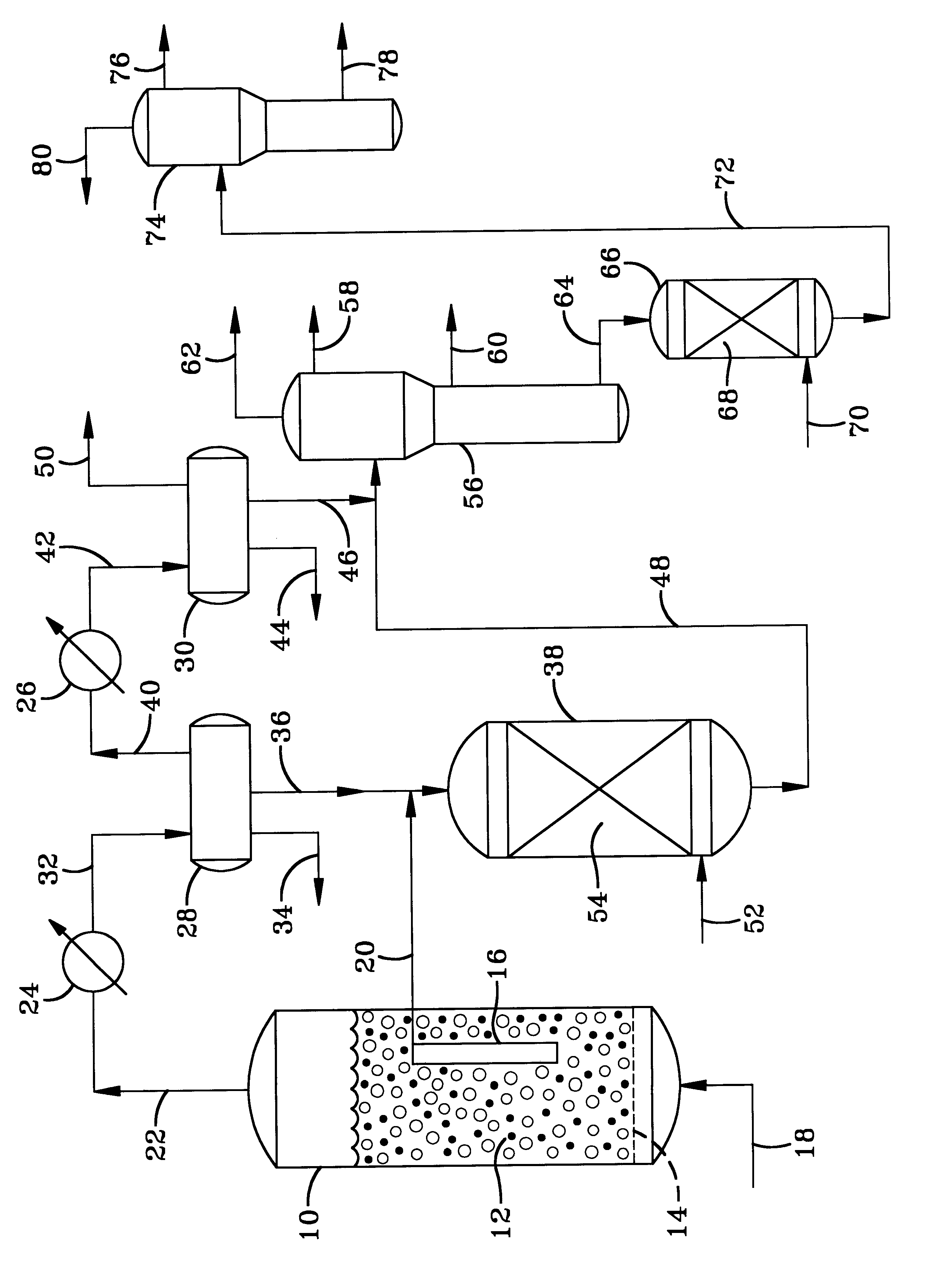

Isoparaffinic base stocks by dewaxing fischer-tropsch wax hydroisomerate over Pt/H-mordenite

A high VI and low pour point lubricant base stock is made by hydroisomerizing a high purity, waxy, paraffinic Fischer-Tropsch synthesized hydrocarbon fraction having an initial boiling point in the range of 650-750° F., followed by catalytically dewaxing the hydroisomerate using a dewaxing catalyst comprising a catalytic platinum component and an H-mordenite component. The hydrocarbon fraction is preferably synthesized by a slurry Fischer-Tropsch using a catalyst containing a catalytic cobalt component. This combination of the process, high purity, waxy paraffinic feed and the Pt / H-mordenite dewaxing catalyst, produce a relatively high yield of premium lubricant base stock.

Owner:EXXON RES & ENG CO

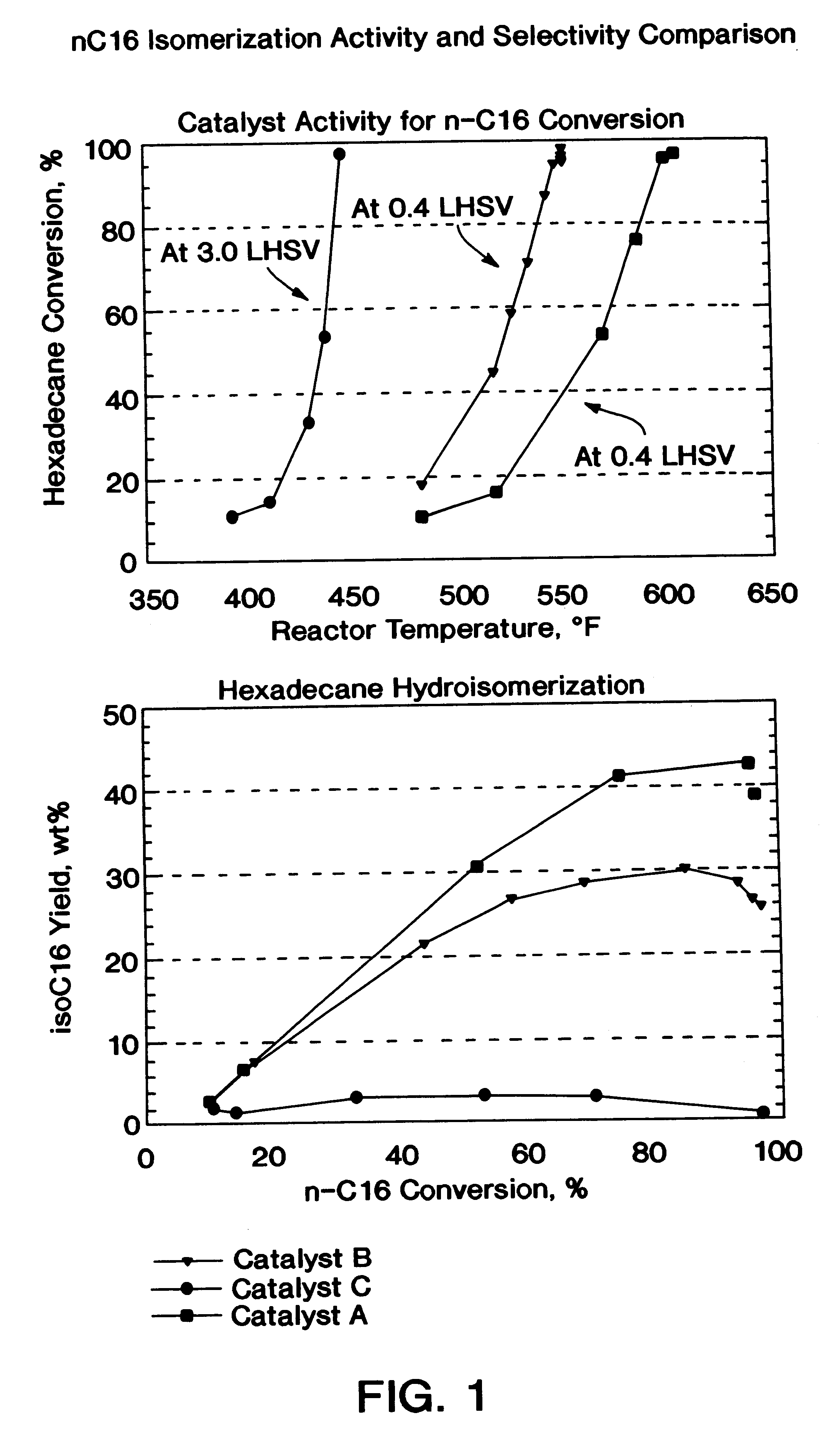

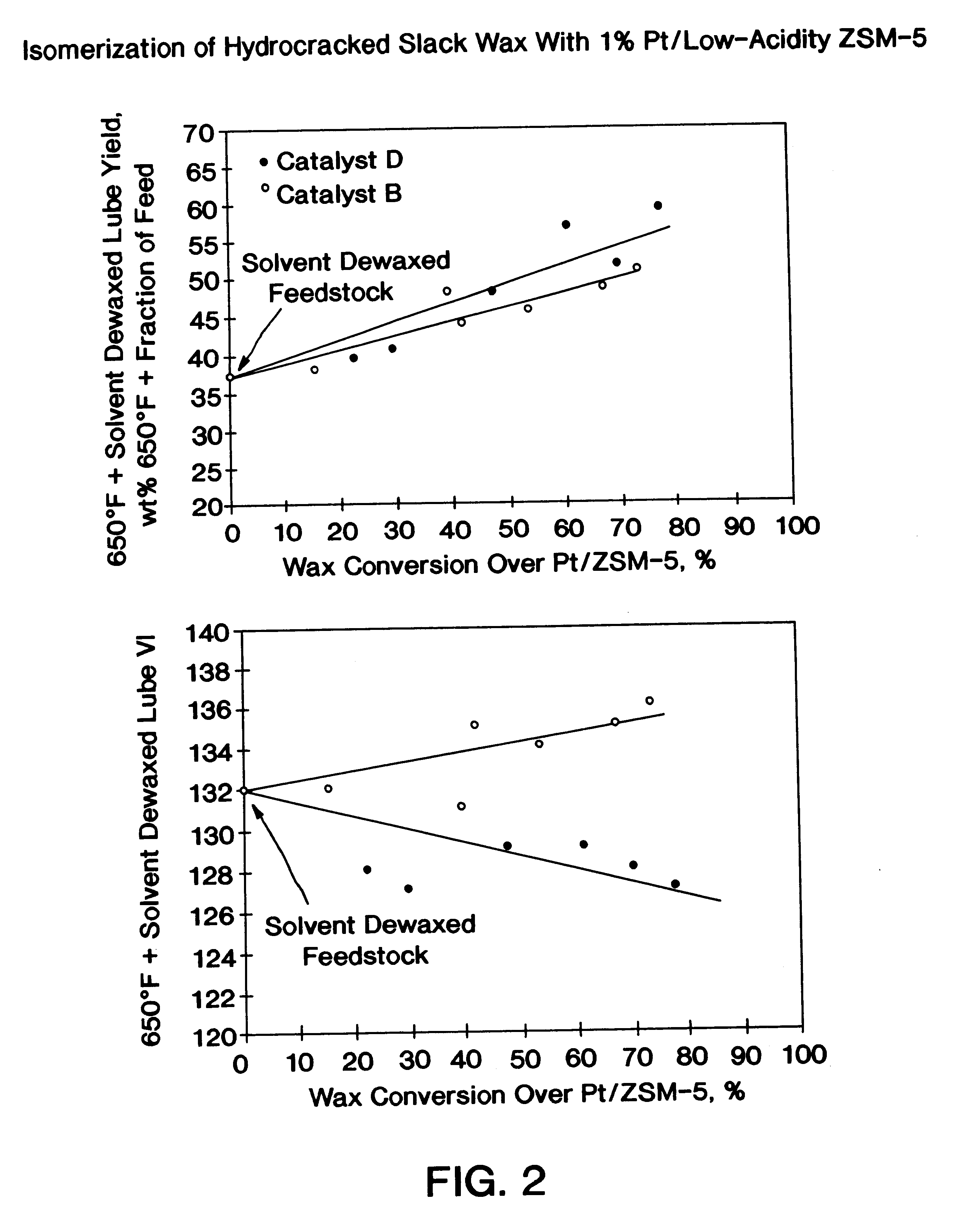

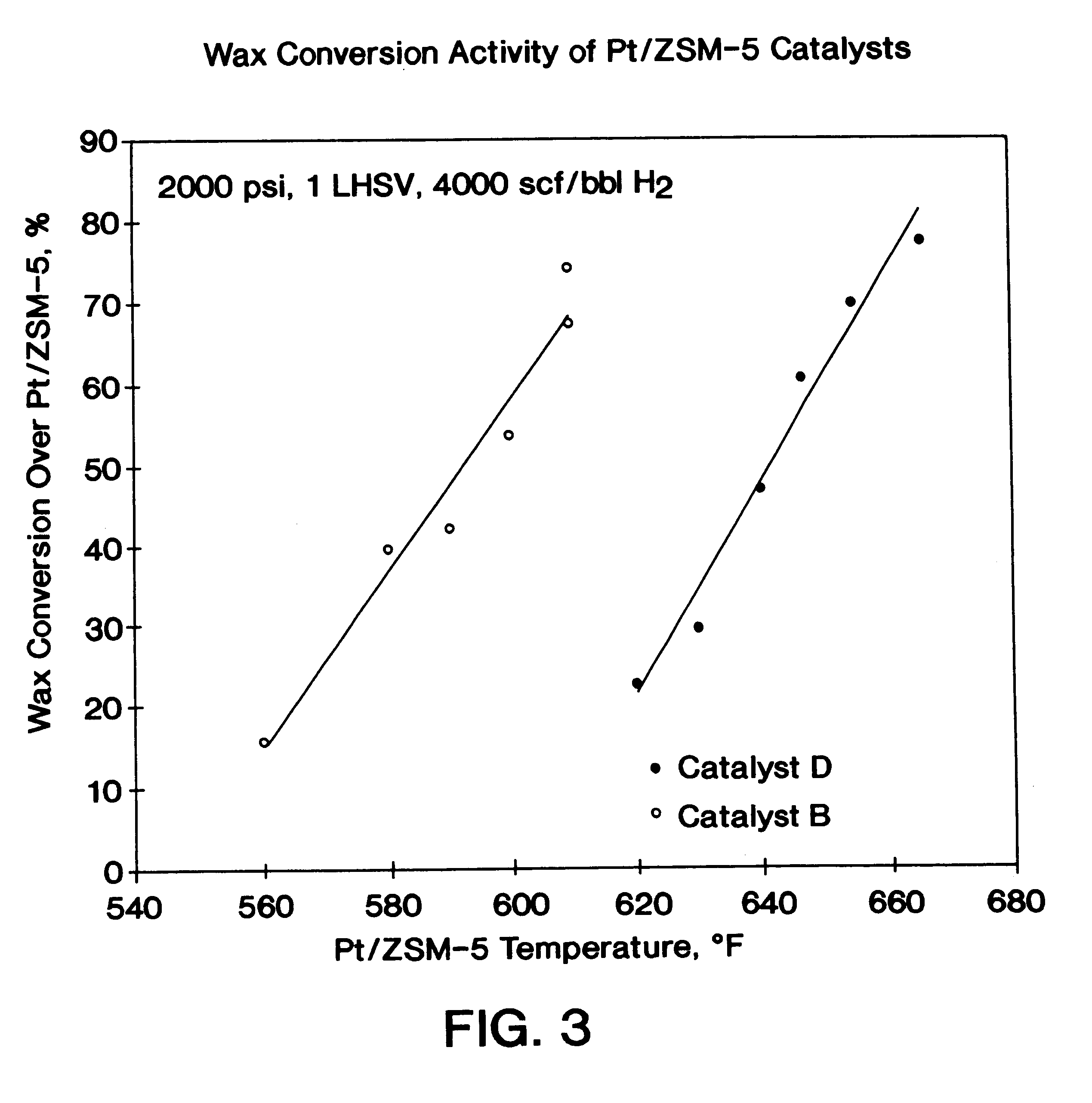

Production of high viscosity lubricating oil stock with improved ZSM-5 catalyst

InactiveUS6294077B1Low pour pointHigh viscosity indexMolecular sieve catalystsRefining to change hydrocarbon structural skeletonHydrogenParaffin oils

The present invention is a process for producing a high viscosity index and low pour point lubricating oil base stock which comprises catalytically converting a hydrotreated hydrocarbon lube oil feedstock containing waxy paraffins in the presence of hydrogen and in the presence of a low acidity ZSM-5 catalyst having a highly dispersed noble metal component. The ZSM-5 catalyst is subjected to controlled acidity reduction to an alpha value below 15 prior to incorporation of the noble metal component.

Owner:MOBIL OIL CORP

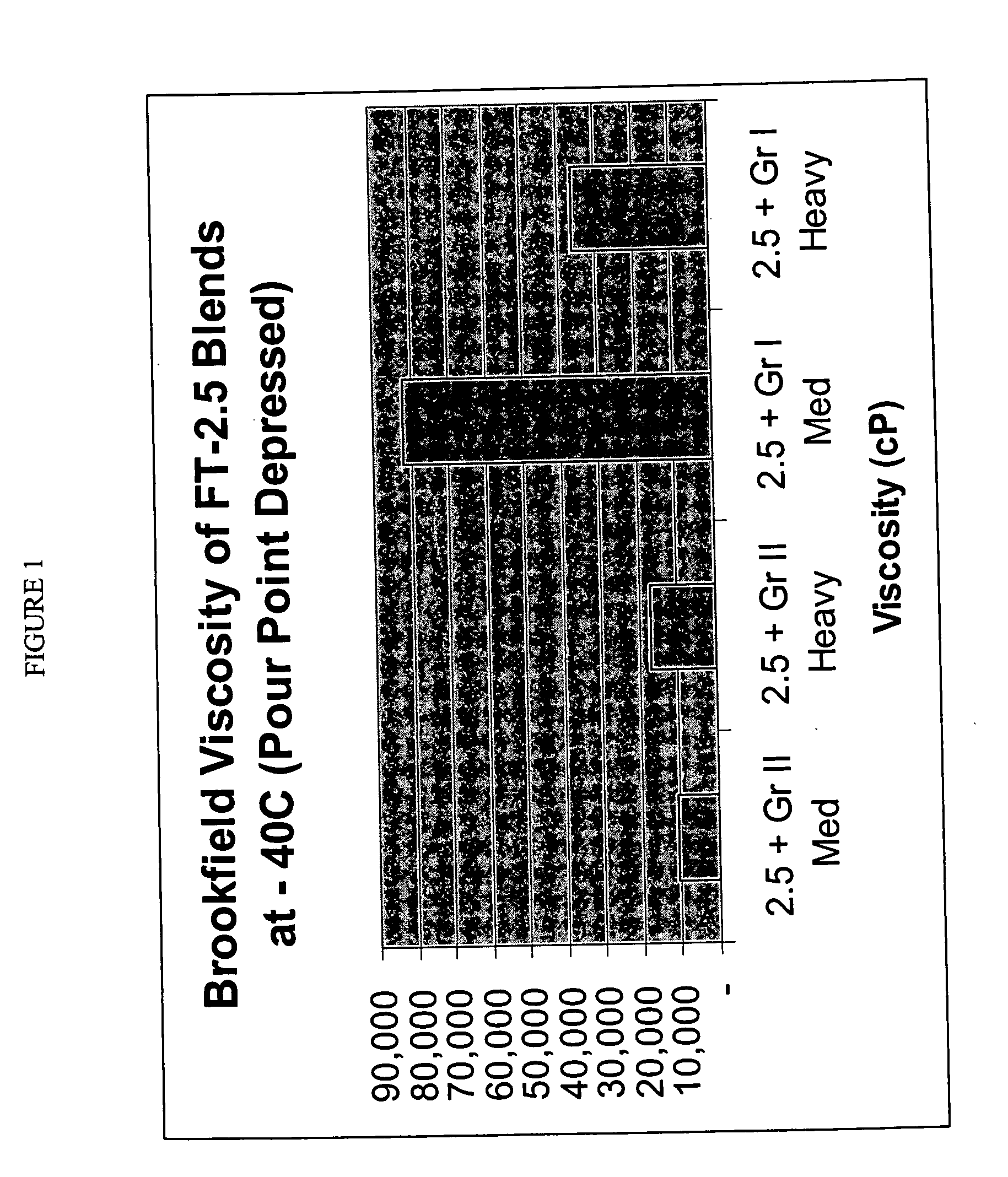

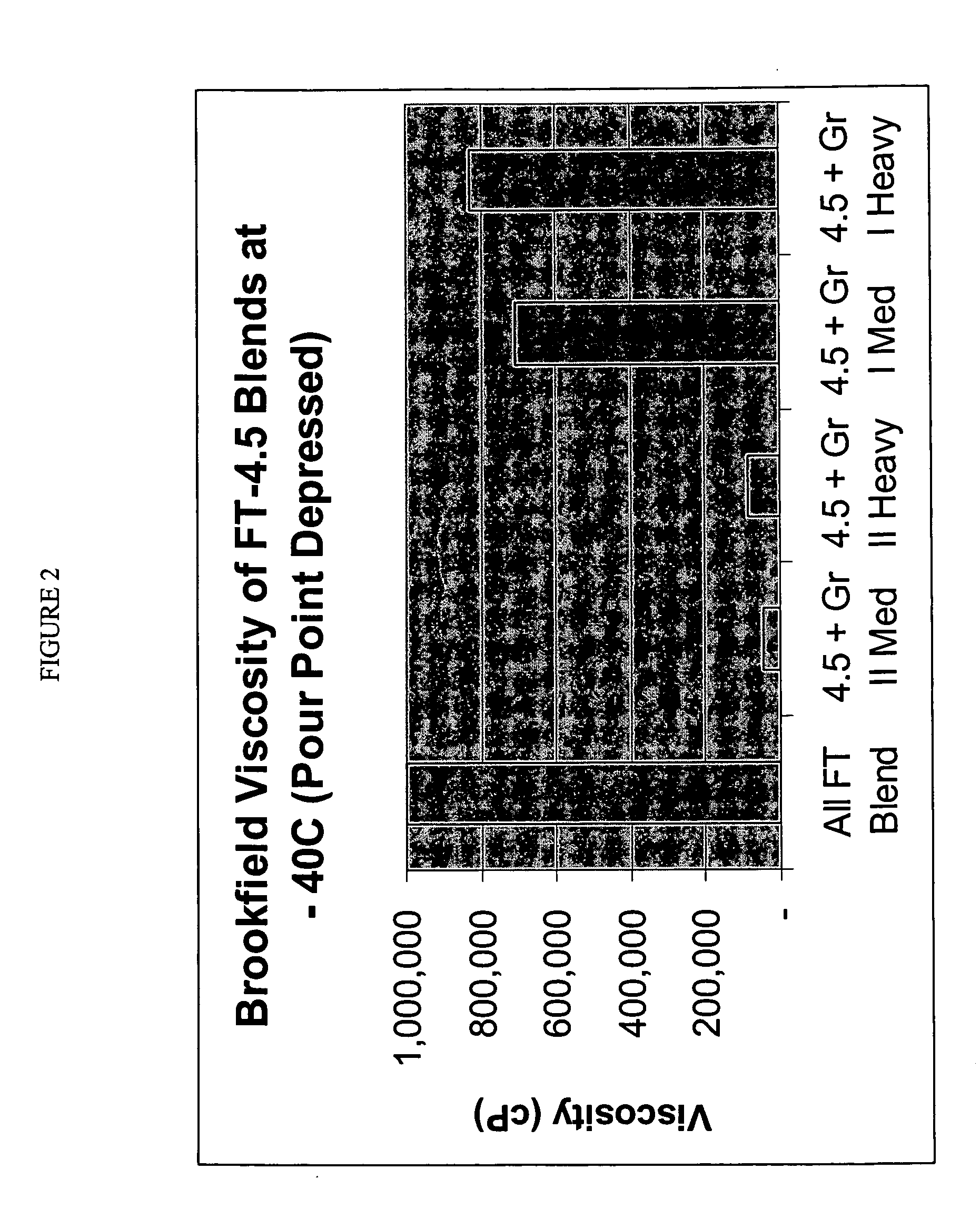

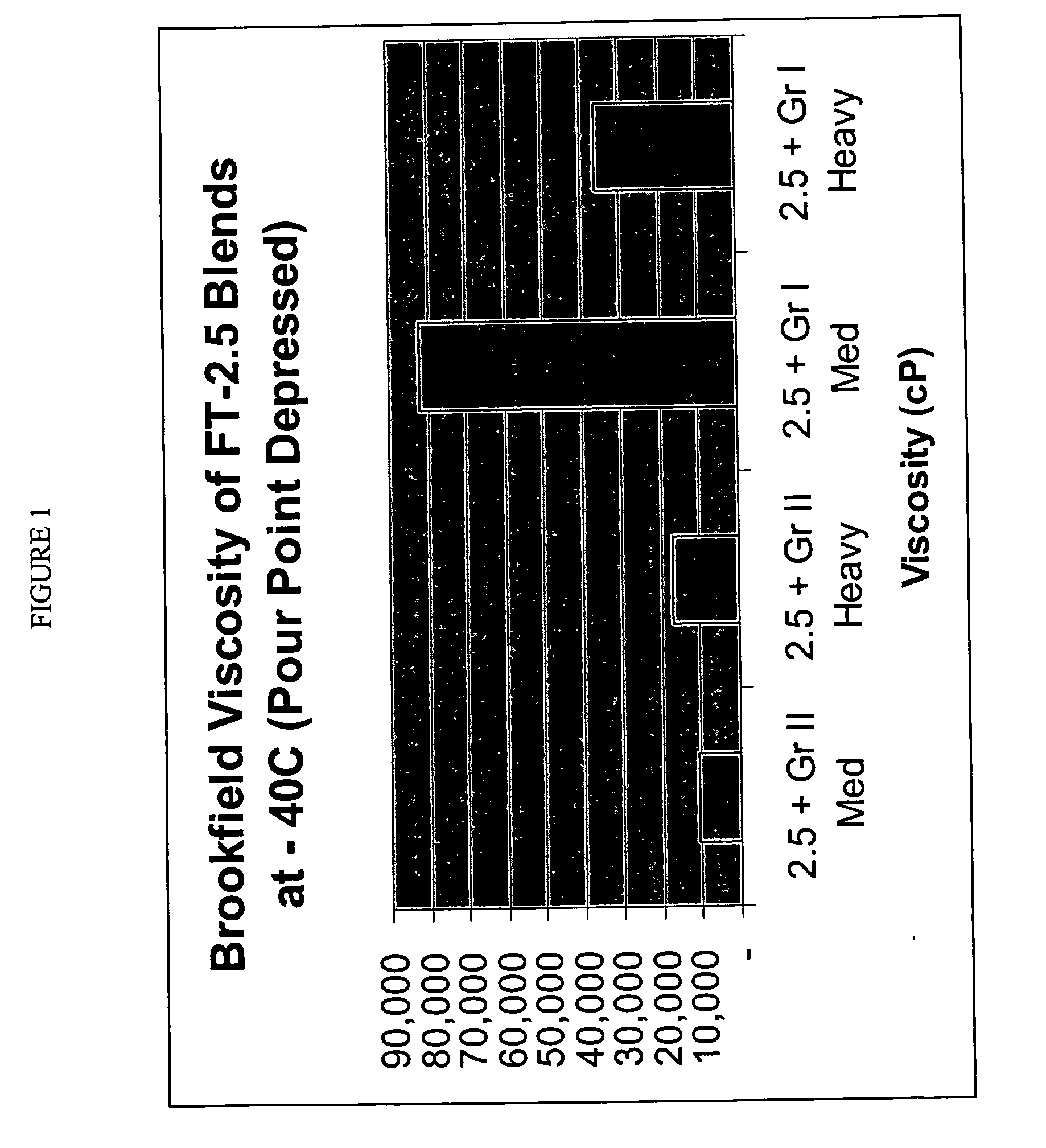

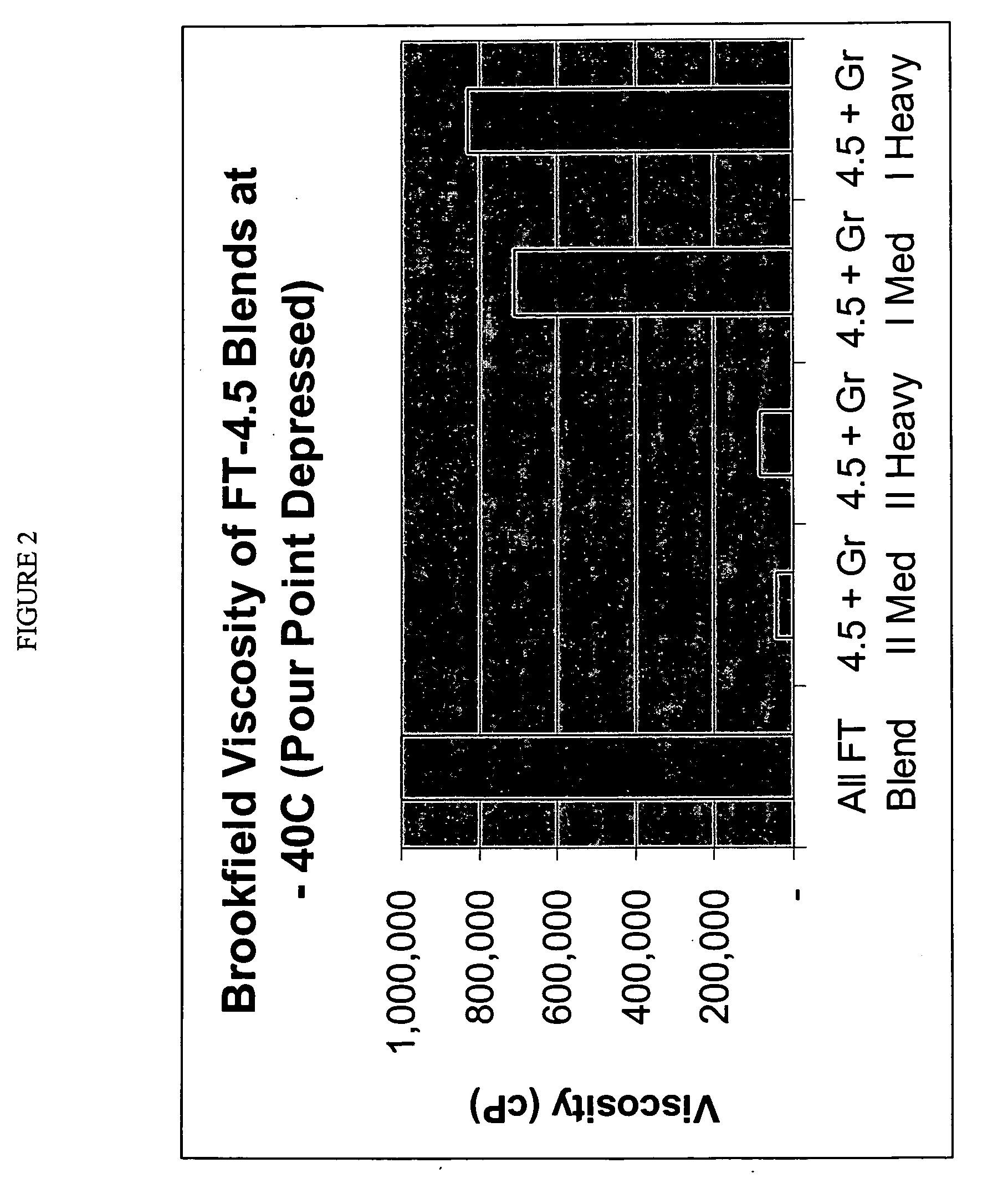

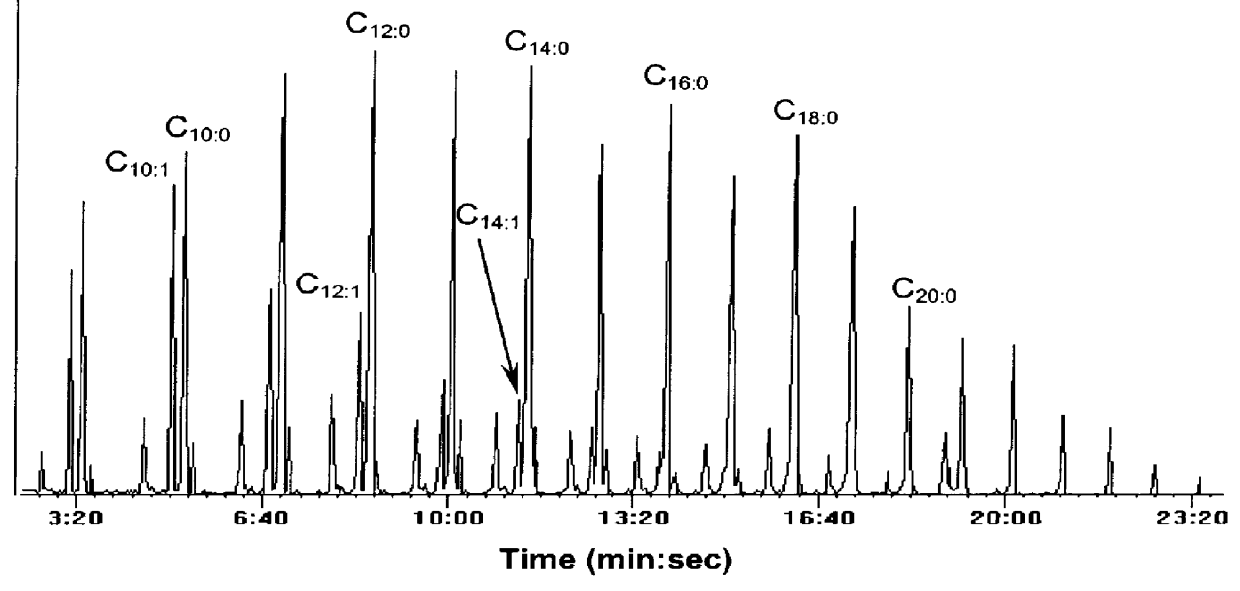

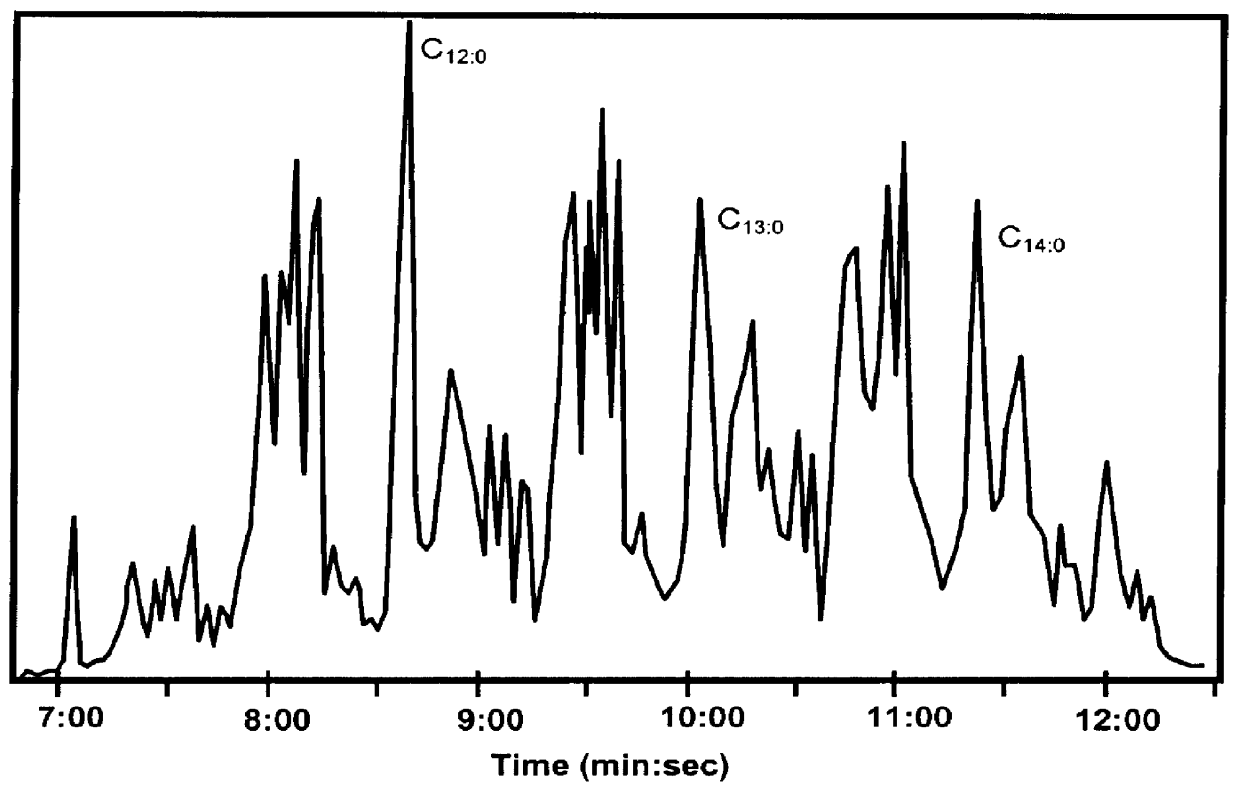

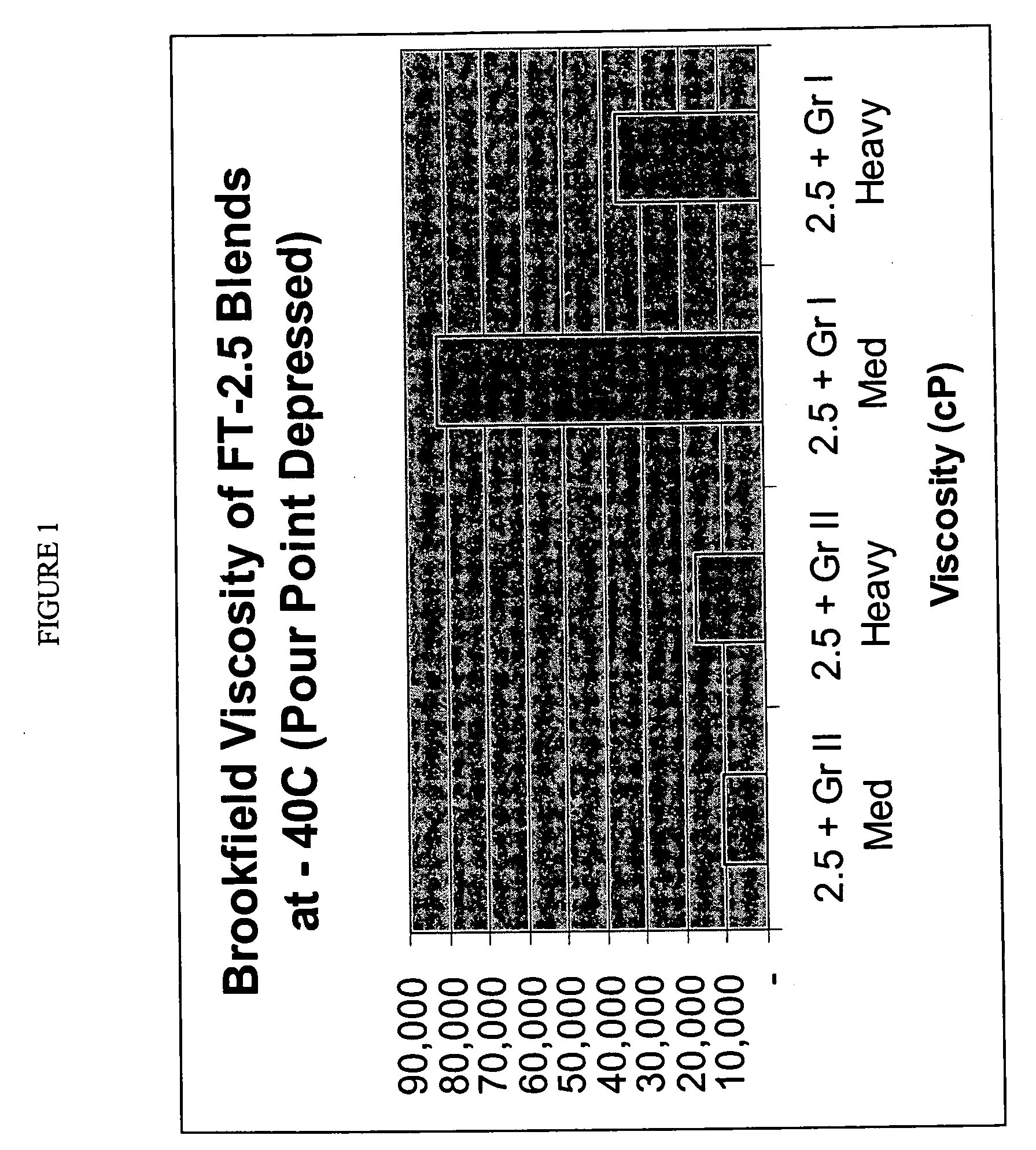

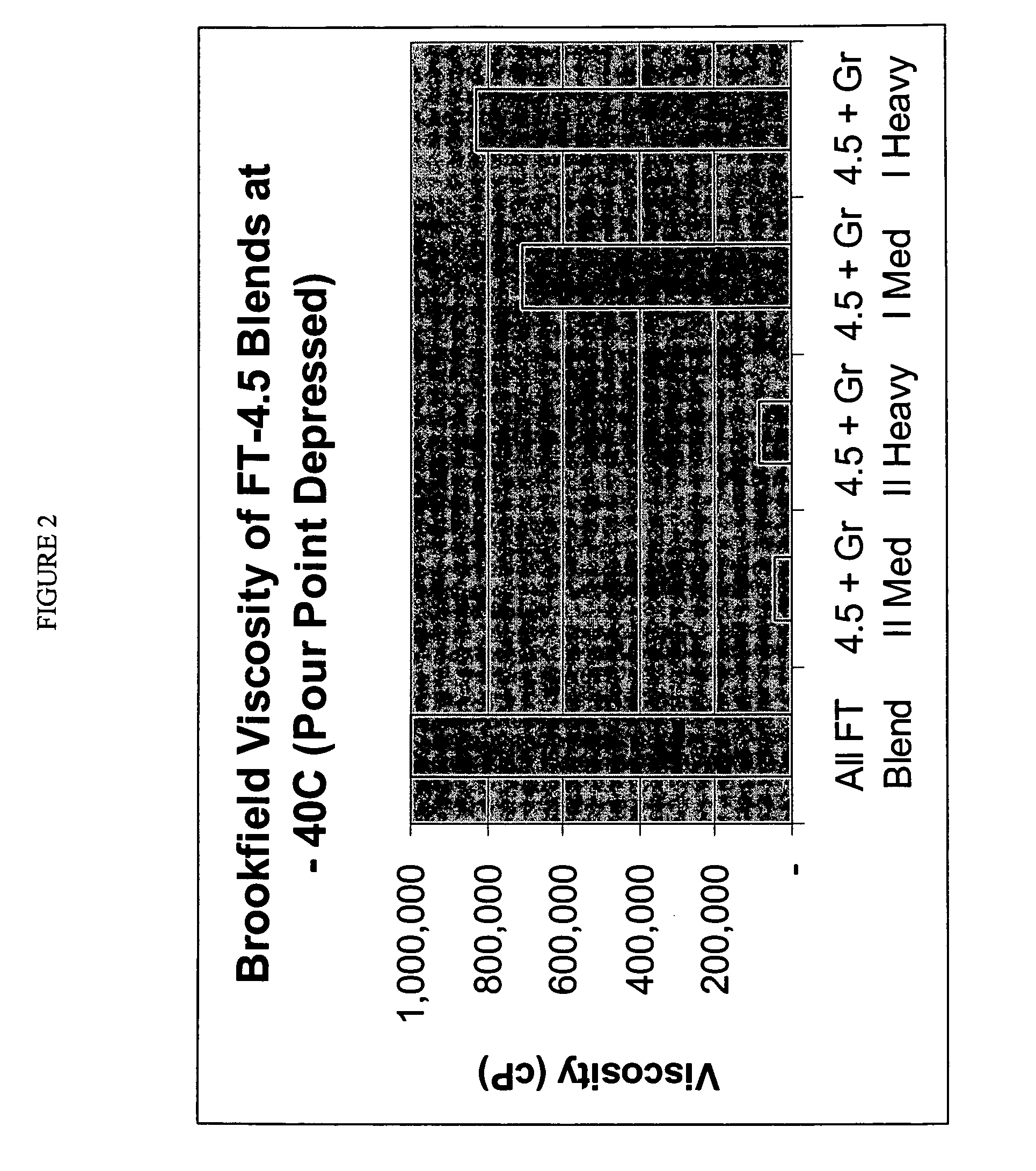

Lubricant blends with low brookfield viscosities

InactiveUS20050261147A1Improve low temperature performanceExcellent low Brookfield viscosityOrganic chemistryLiquid carbonaceous fuelsWaxSulfur

Lubricant blends and finished gear oils comprising a lubricant base oil fraction derived from highly paraffinic wax, a petroleum derived base oil, and a pour point depressant are provided. The lubricant base oil fraction derived from highly paraffinic wax comprises less than 0.30 weight percent aromatics, greater than 5 weight percent molecules with cycloparaffinic functionality, and a ratio of weight percent of molecules with monocycloparaffinic functionality to weight percent of molecules with multicycloparaffinic functionality greater than 15. The petroleum derived base oils comprises greater than 90 weight percent saturates and less than 300 ppm sulfur and is preferably selected from the group consisting of a Group II base oil, a Group III base oil, and mixtures thereof. These lubricant blends have surprising low Brookfield viscosities at −40° C.

Owner:CHEVROU USA INC

Lubricant blends with low brookfield viscosities

ActiveUS20050261145A1Improve low temperature performanceLow viscosityOrganic compound preparationOxygen compounds preparation by reductionSulfurBase oil

Lubricant blends and finished gear oils comprising a Fischer-Tropsch derived lubricant base oil fraction, a petroleum derived base oil, and a pour point depressant are provided. The Fischer-Tropsch derived lubricant base oil fraction comprises less than 0.30 weight percent aromatics, greater than 5 weight percent molecules with cycloparaffinic functionality, and a ratio of weight percent of molecules with monocycloparaffinic functionality to weight percent of molecules with multicycloparaffnic functionality greater than 15. The petroleum derived base oils comprises greater than 90 weight percent saturates and less than 300 ppm sulfur and is preferably selected from the group consisting of a Group II base oil, a Group III base oil, and mixtures thereof. These lubricant blends have surprising low Brookfield viscosities at −40° C.

Owner:CHEVROU USA INC

Premium synthetic lubricant base stock (Law734) having at least 95% noncyclic isoparaffins

A premium synthetic lubricating oil base stock having a high VI and low pour point is made by hydroisomerizing a Fischer-Tropsch synthesized waxy, paraffinic feed wax and then dewaxing the hydroisomerate to form a 650-750° F.+ dewaxate. The waxy feed has an initial boiling point in the range of about 650-750° F., from which it continuously boils up to at least 1050° F. and has a T90-T10 temperature difference of at least 350° F. The feed is preferably hydroisomerized without any pretreatment, other than optional fractionation. The 650-750° F.+ dewaxate is fractionated into two or more base stocks of different viscosity.

Owner:EXXON RES & ENG CO

Production of high-cetane diesel fuel from low-quality biomass-derived feedstocks

ActiveUS20070068848A1Increase cetane numberBiofuelsLiquid hydrocarbon mixture productionTG - TriglyceridePre treatment

A method is taught for producing diesel fuels of high cetane value from a triglyceride feedstock, comprising pretreating the triglyceride feedstock by thermal cracking to partially convert the triglycerides and produce a middle distillates stream, and catalytically hydrotreating the middle distillate fraction to produce high cetane value diesel fuels. A biomass-derived diesel fuel is also taught having sulphur content below 10 ppm, a cetane-value of at least 70, a cloud point below 0° C. and a pour point of less than −4° C. A blended diesel fuel is also taught comprising 5 to 20 vol. % of the biomass-derived diesel fuel of the present invention and 80 to 95 vol. % of a petroleum diesel, based on total volume of the blended diesel fuel.

Owner:HER MAJESTY THE QUEEN & RIGHT OF CANADA REPRESENTED BY THE MIN OF NATURAL RESOURCES

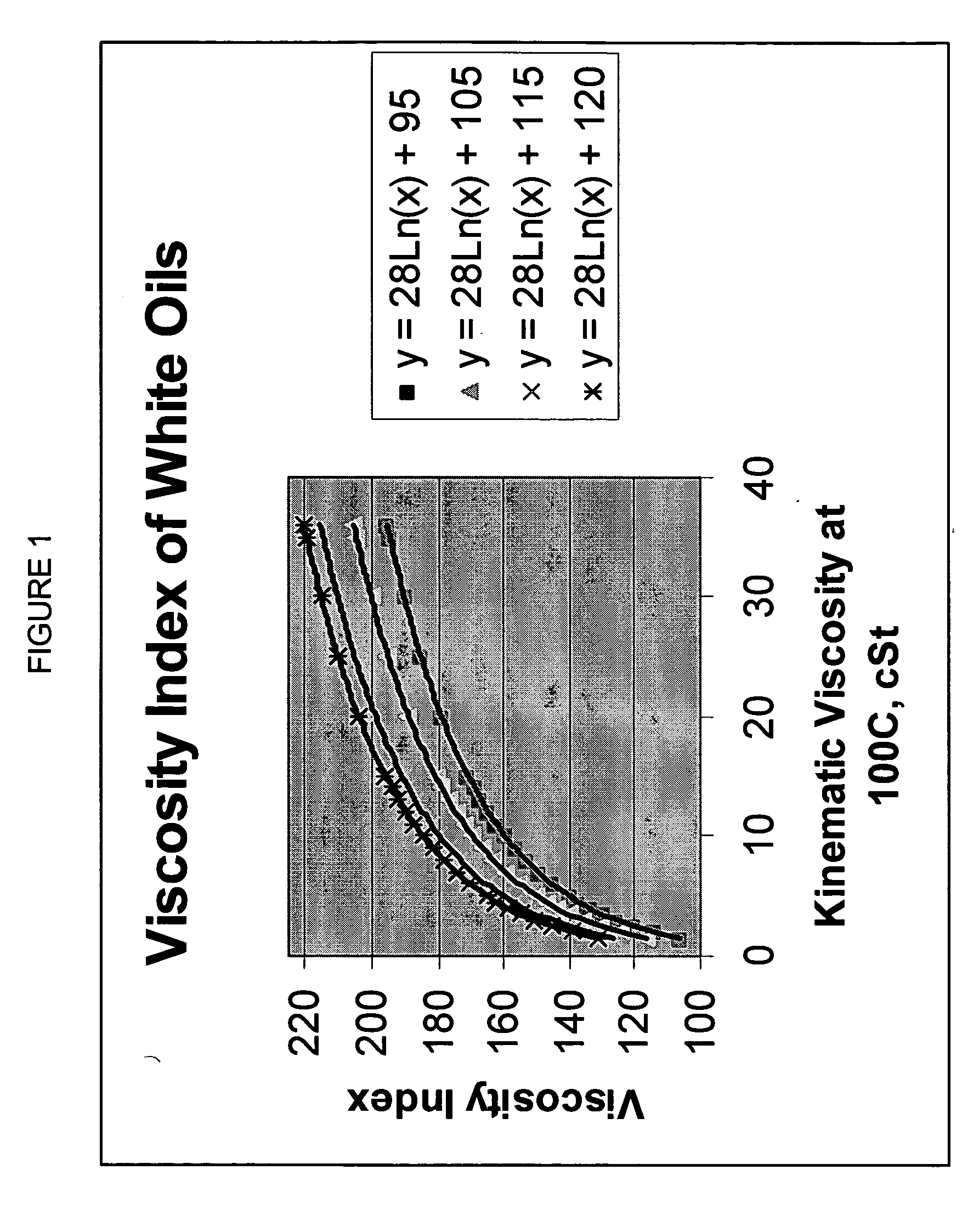

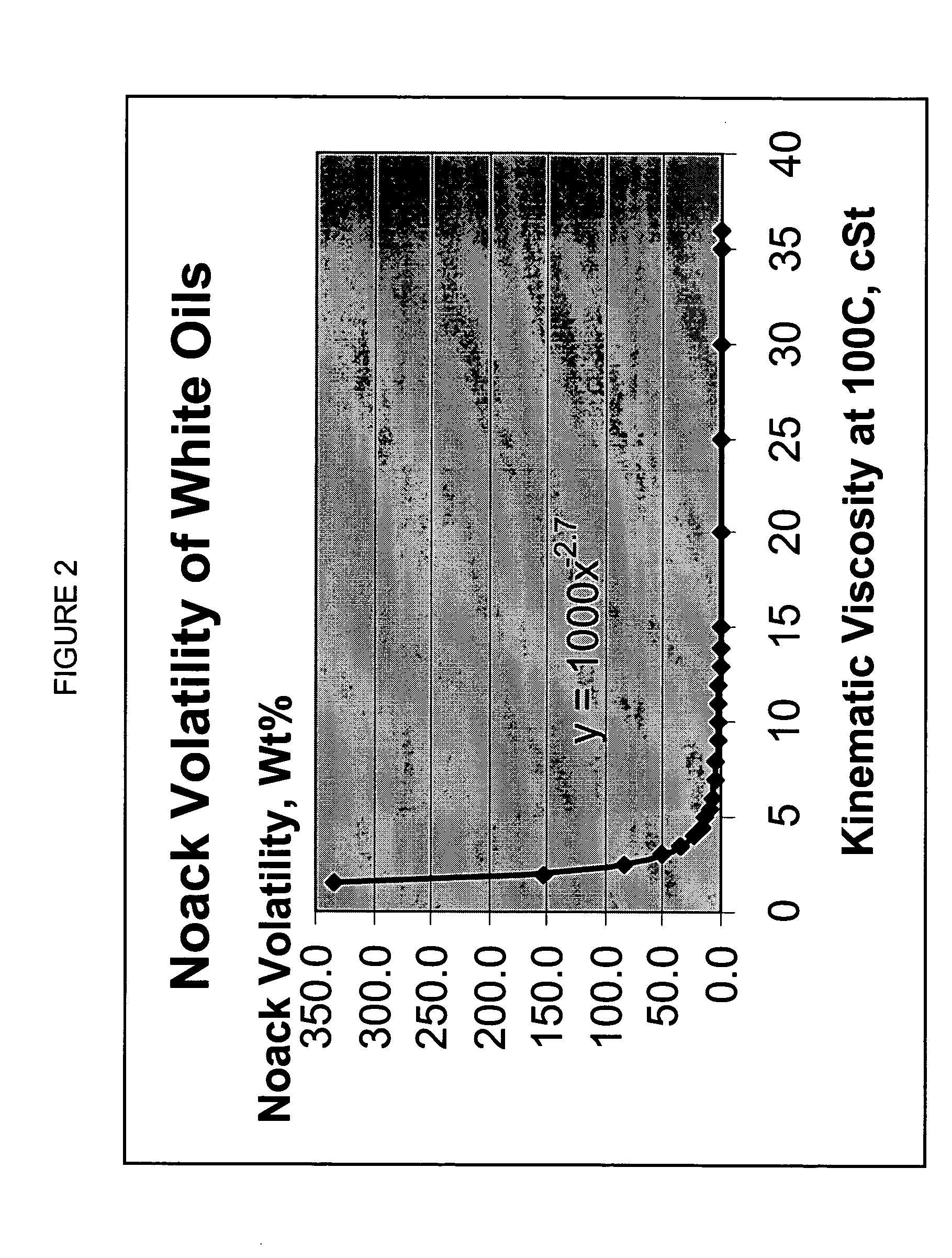

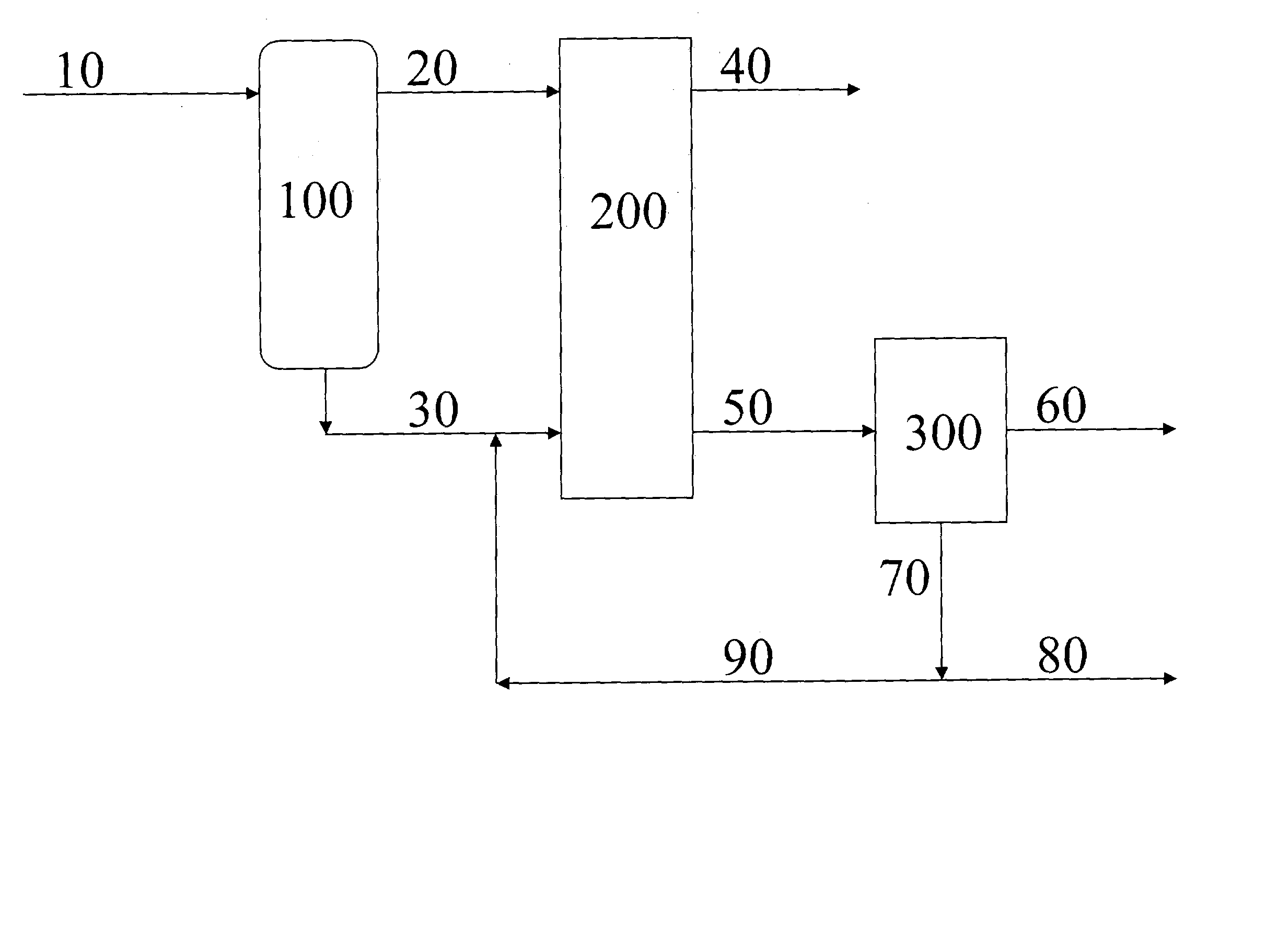

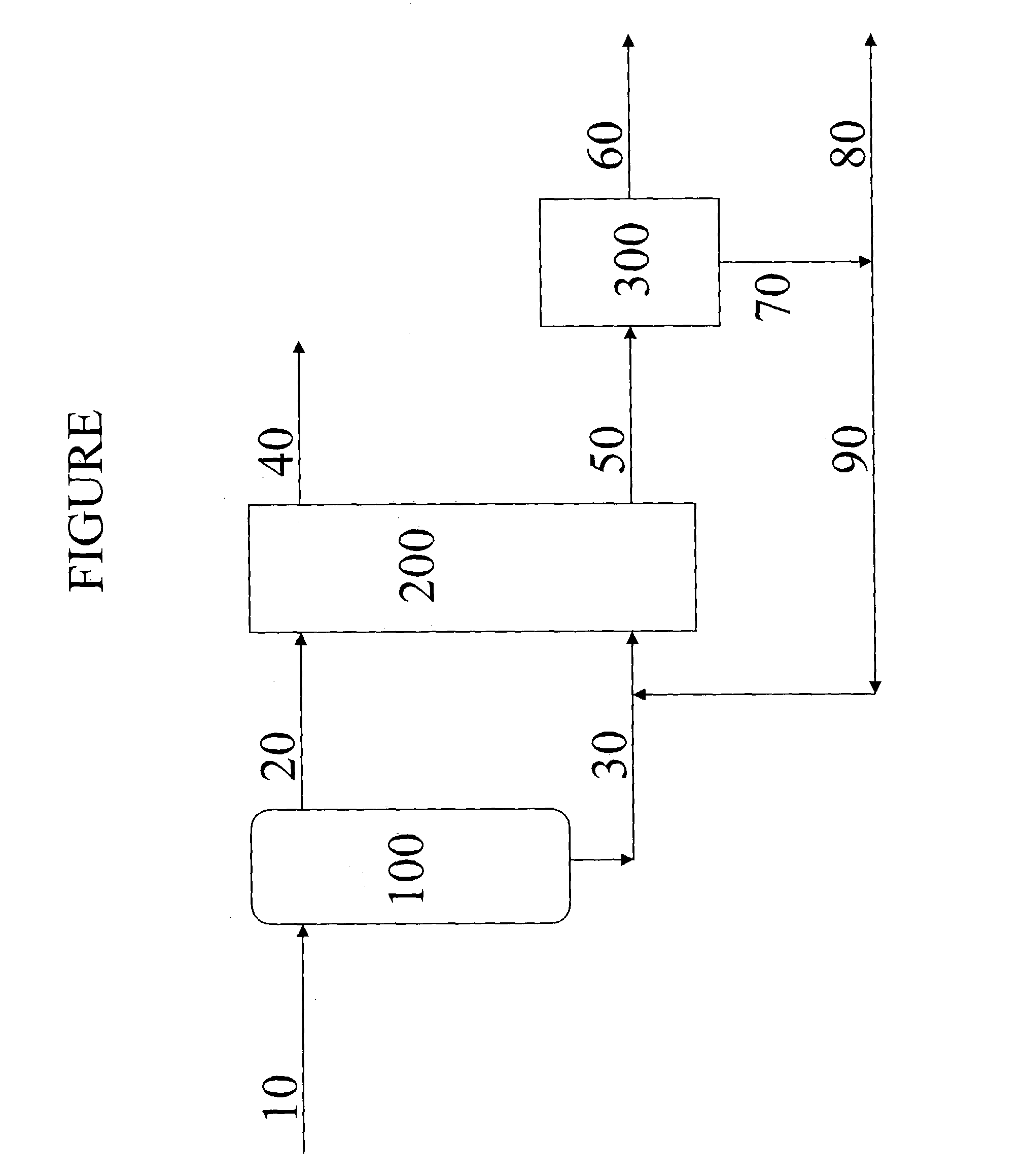

Process to make white oil from waxy feed using highly selective and active wax hydroisomerization catalyst

A process for producing one or more white oils, by: a) hydroisomerization dewaxing a waxy feed with a defined composition over a highly selective and active wax hydroisomerization catalyst with a defined composition under conditions sufficient to produce a white oil; and b) collecting one or more white oils, wherein the yield of white oils is high, and they have a low pour point and a good Saybolt color. Also, a process for producing medicinal grade white oils, by a)hydroisomerization dewaxing a waxy feed with a defined composition over a highly selective and active wax hydroisomerization catalyst with a defined composition under conditions sufficient to produce a white oil, b) collecting technical grade white oils having a low pour point and good Saybolt color in high yield, and c) hydrofinishing the technical grade white oils at conditions sufficient to produce medicinal grade white oils that pass the RCS test.

Owner:CHEVROU USA INC

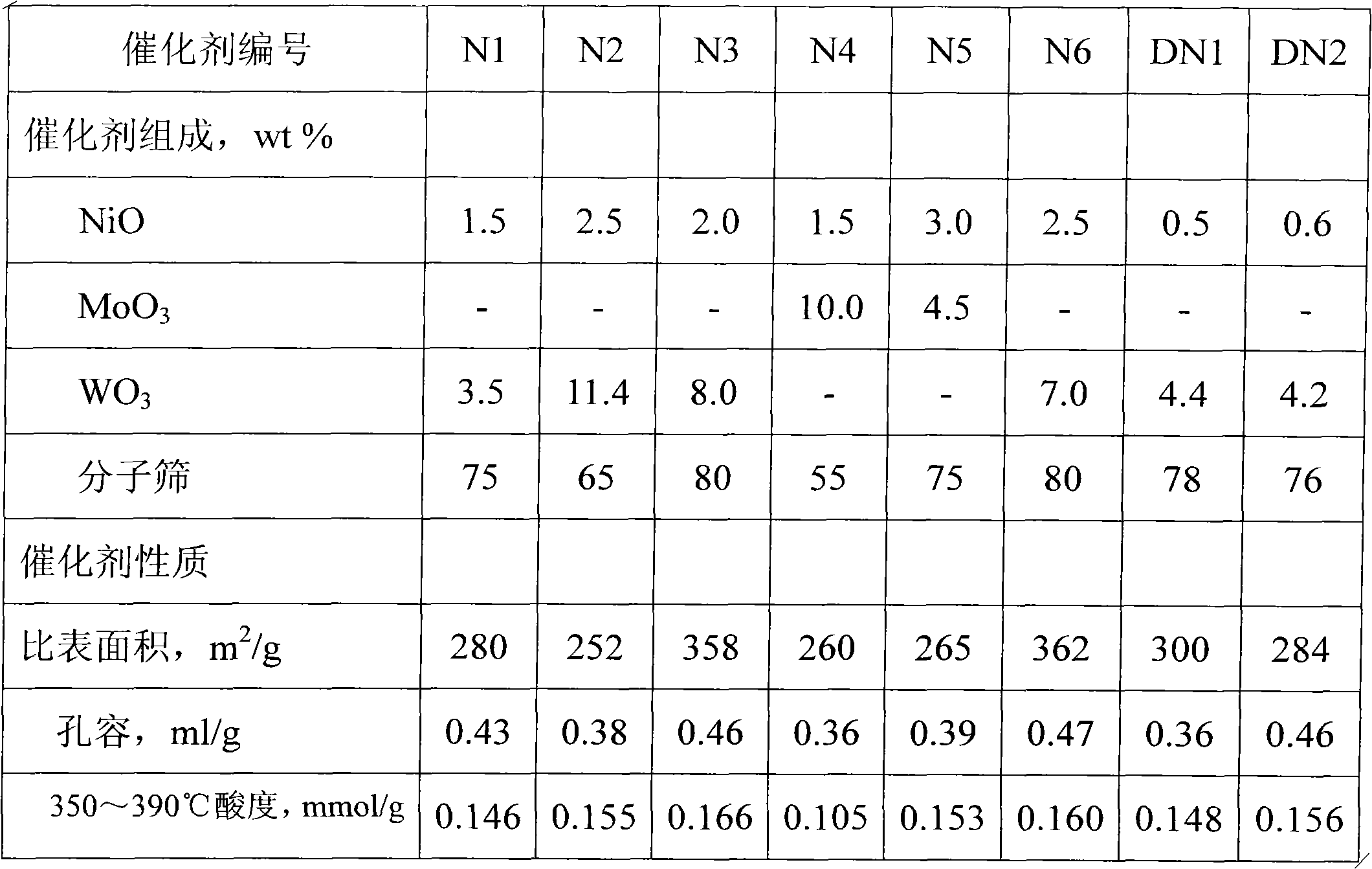

Hydrogenating and pour point depressing catalyst and its preparing method

ActiveCN101143333AControl contentUnobstructed channelMolecular sieve catalystsRefining to eliminate hetero atomsPartial oxidationAdhesive

Owner:CHINA PETROLEUM & CHEM CORP +1

Isomerization/dehazing process for base oils from Fischer-Tropsch wax

InactiveUS7198710B2Hydrocarbon by hydrogenationTreatment with hydrotreatment processesWaxMolecular sieve

A method for producing lubricant base oils is provided comprising the steps of: (a) separating a feedstock into a light lubricant base oil fraction and a heavy fraction; (b) hydroisomerizing the fractions over a medium pore size molecular sieve catalyst under hydroisomerization conditions to produce an isomerized light lubricant base oil fraction having a pour point less than or equal to a target pour point of the lubricant base oils and an isomerized heavy fraction having a pour point of equal to or greater than the target pour point of the lubricant base oils and a cloud point greater than the target cloud point of the lubricant base oils; and (c) dehazing the isomerized heavy fraction to provide a heavy lubricant base oil having a pour point less than or equal to the target pour point of the lubricant base oils and a cloud point less than or equal to the target cloud point of the lubricant base oils.

Owner:CHEVROU USA INC

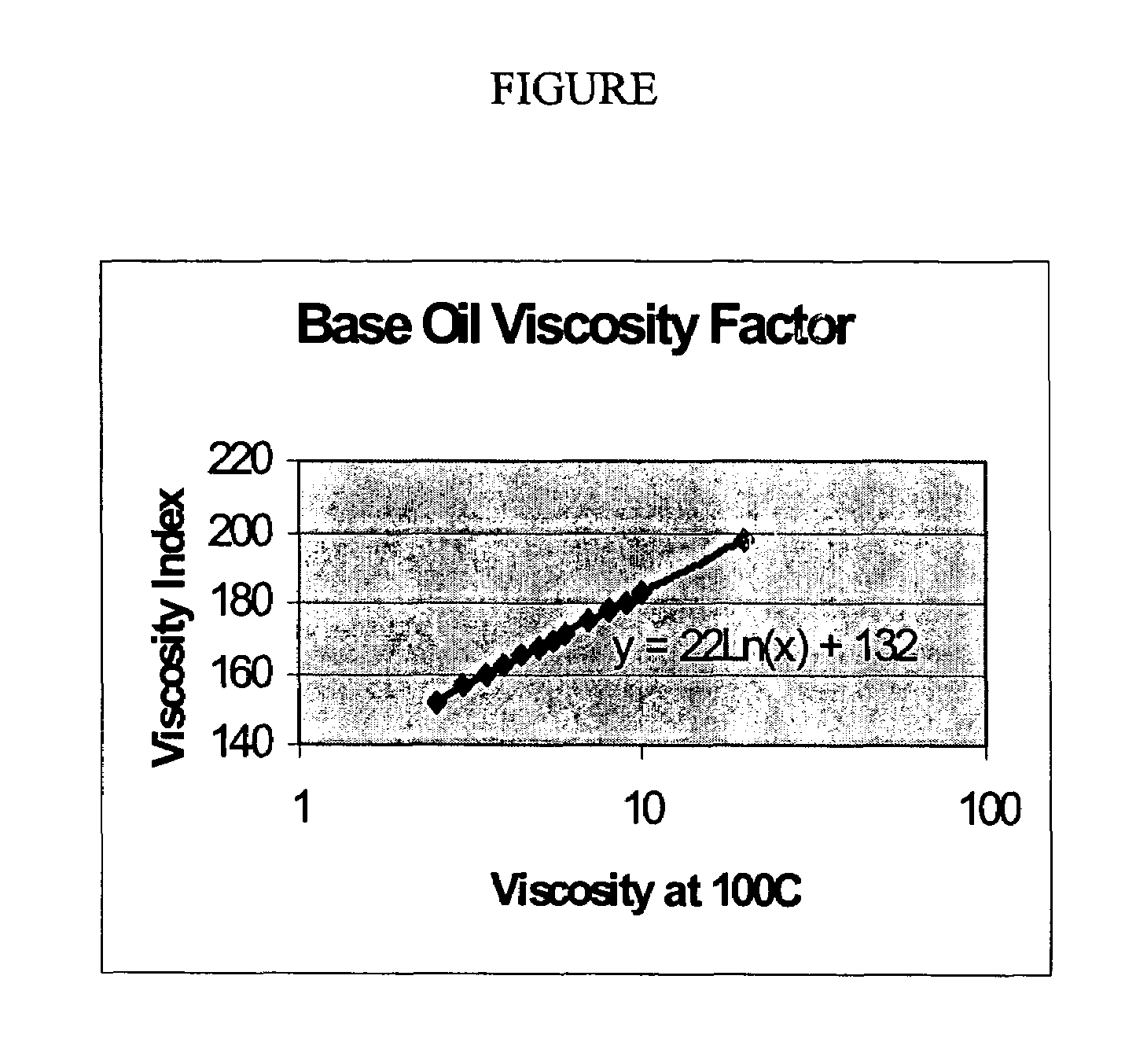

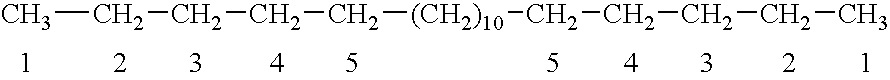

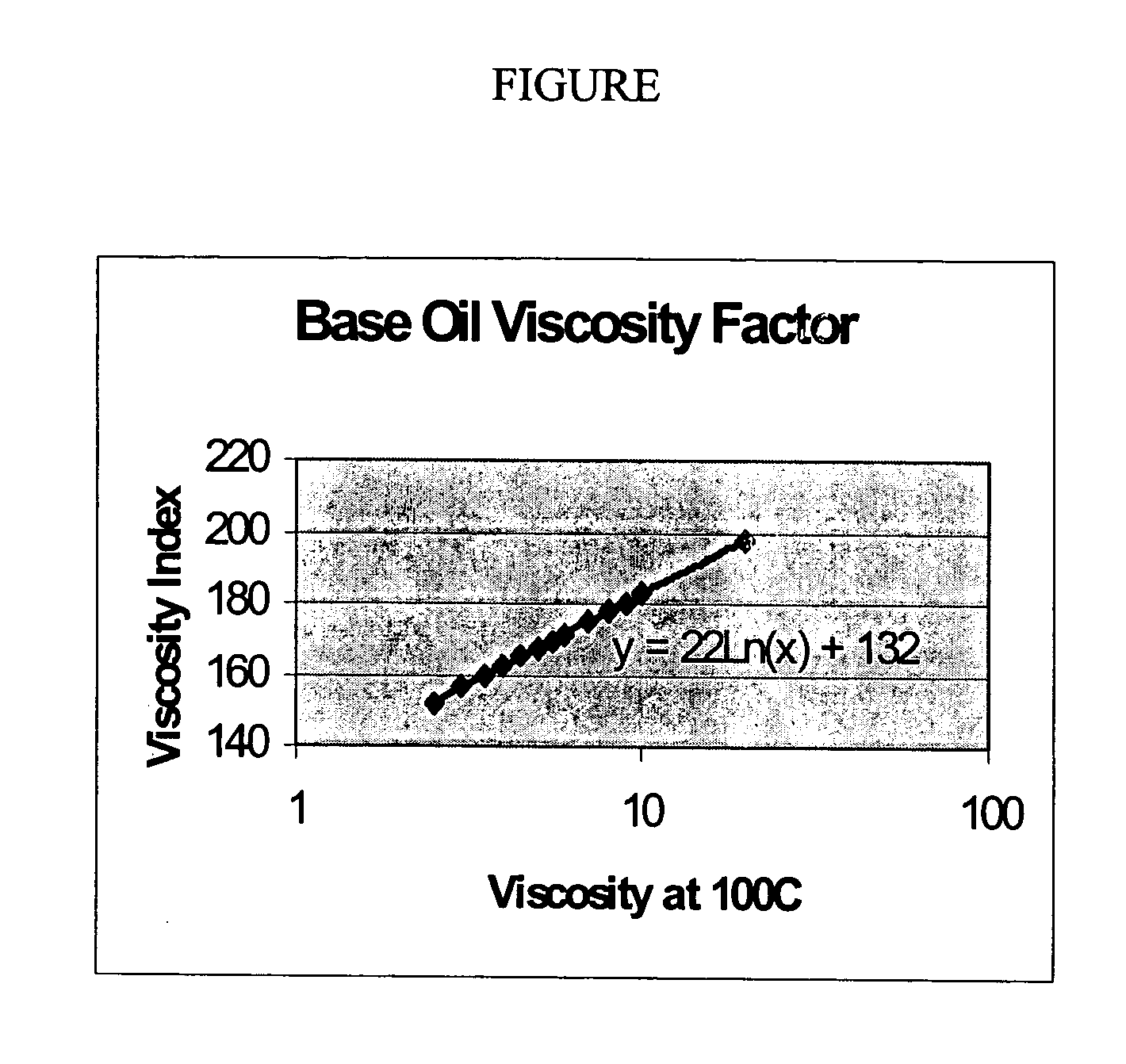

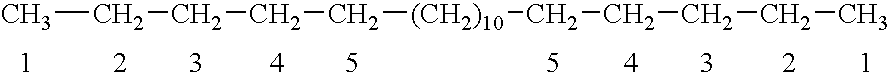

Processes for producing lubricant base oils with optimized branching

InactiveUS7018525B2Treatment with hydrotreatment processesHydrocarbon oils refiningViscosity indexBase oil

This invention relates to processes of producing lubricant base oils comprising paraffinic hydrocarbon components that have optimized branching. The lubricant base oils comprising paraffinic hydrocarbon components with optimized branching have low amounts of branching with the branching concentrated toward the center of the lubricant base oil molecules. The lubricant base oils comprising paraffinic hydrocarbon components with optimized branching have low pour points and extremely high viscosity indexes. The invention further relates to processes of producing commercial lubricants comprising the lubricant base oils comprising paraffinic hydrocarbon components with optimized branching from waxy feeds.

Owner:CHEVROU USA INC

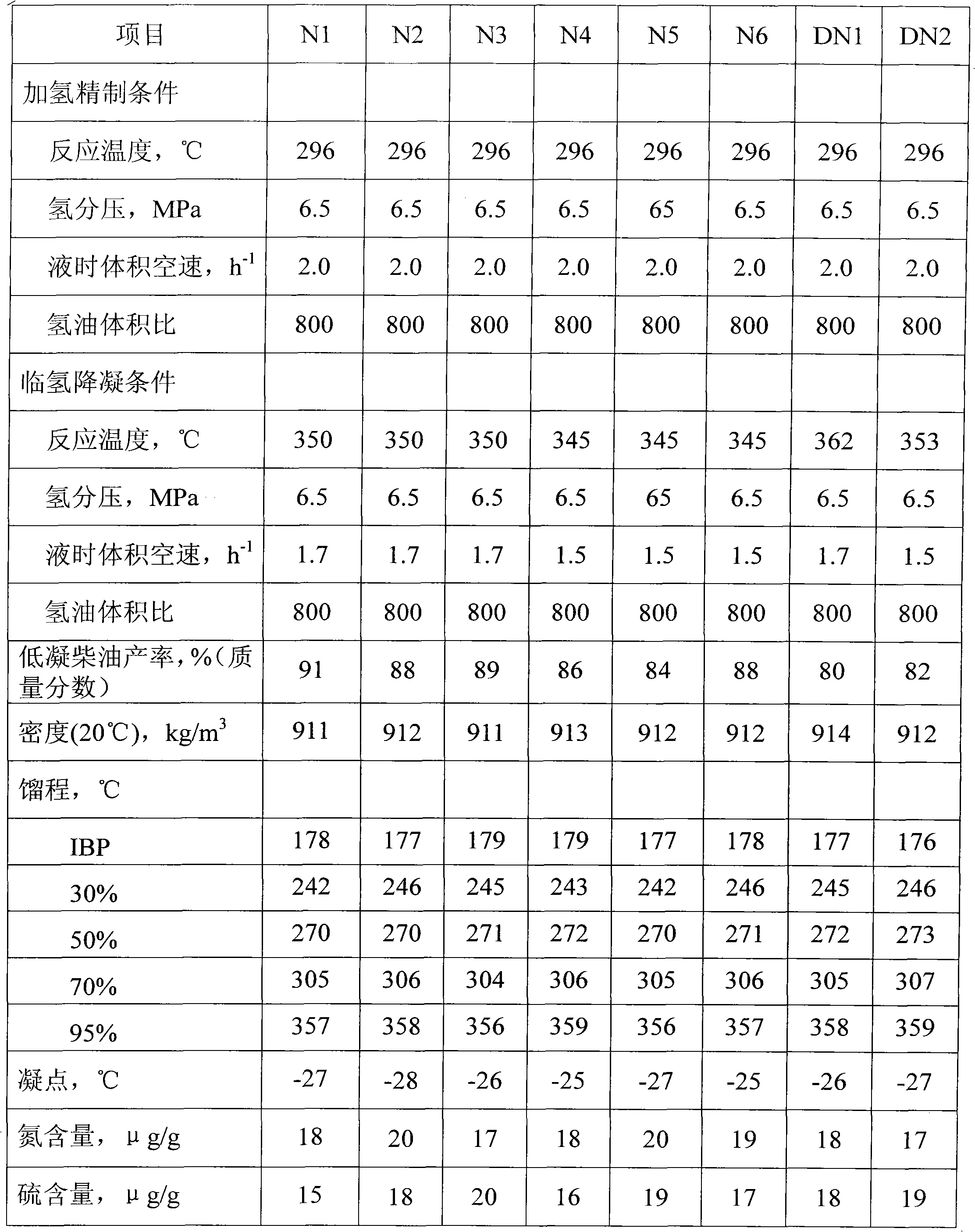

Diesel oil hydrogenation pour point depressing method

ActiveCN102051232ASuitable pore structureAppropriate pore inner surface propertiesCatalyst carriersMolecular sieve catalystsMolecular sieveWax

The invention discloses a diesel oil hydrogenation pour point depressing method. A series flow of hydrofining and hydrogenation pour point depressing is adopted in the method, wherein a hydrogenation pour point depressing catalyst is modified by metal auxiliary agent and silicon, effectively regulates the acidity and orifice shape of the inner surface and the outer surface of a shape-selective cracking molecular sieve, is favorable for dispersing wax molecules in a diesel oil raw material into pore canals of the molecular sieve to perform shape-selective cracking reaction, and has high catalytic activity and selectivity of a target product; and because the acidity of the outer surface of the molecular sieve is weak, side reactions such as secondary cracking and the like are reduced, the pour point depressing effect of the diesel oil is good, and the fraction yield of the diesel oil is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

Processes for producing lubricant base oils with optimized branching

InactiveUS20050077209A1Treatment with hydrotreatment processesHydrocarbon oils refiningViscosity indexBase oil

This invention relates to processes of producing lubricant base oils comprising paraffinic hydrocarbon components that have optimized branching. The lubricant base oils comprising paraffinic hydrocarbon components with optimized branching have low amounts of branching with the branching concentrated toward the center of the lubricant base oil molecules. The lubricant base oils comprising paraffinic hydrocarbon components with optimized branching have low pour points and extremely high viscosity indexes. The invention further relates to processes of producing commercial lubricants comprising the lubricant base oils comprising paraffinic hydrocarbon components with optimized branching from waxy feeds.

Owner:CHEVROU USA INC

Blended compression-ignition fuel containing light synthetic crude and blending stock

InactiveUS6056793AImprove performanceEmission reductionLiquid carbonaceous fuelsFuel additivesAlcoholIgnition delay

This invention is a composition of matter useful as a compression-ignition fuel. The composition has from about 30 to about 95 mass % of a light synthetic crude or syncrude, preferably from Fischer-Tropsch synthesis or related processes, and from about 5 to about 70 mass % of a blending stock that improves one or more desirable fuel property(s) including but not limited to pour point temperature, viscosity and emissions generated during combustion in a diesel engine. The blend stock preferably has an average molecular weight less than the average molecular weight of the light syncrude. Preferred blending stocks include hydrocarbons and oxygenates, such as alcohols, and ethers, having average molecular weights less than 200, preferably less than 160. The composition may optionally also contain pour point depressants, cetane improvers, carbon-containing compounds which react with water, and / or emulsifiers.

Owner:REG SYNTHETIC FUELS LLC +1

Processes for making lubricant blends with low brookfield viscosities

InactiveUS20050261146A1Improve low temperature performanceLow viscosityRefining to change hydrocarbon structural skeletonHydrocarbon purification/separationParaffin waxSulfur

Lubricant blends and finished gear oils comprising a lubricant base oil fraction derived from highly paraffinic wax, a petroleum derived base oil, and a pour point depressant are provided. The lubricant base oil fraction derived from highly paraffinic wax comprises less than 0.30 weight percent aromatics, greater than 5 weight percent molecules with cycloparaffinic functionality, and a ratio of weight percent of molecules with monocycloparaffinic functionality to weight percent of molecules with multicycloparaffinic functionality greater than 15. The petroleum derived base oils comprises greater than 90 weight percent saturates and less than 300 ppm sulfur and is preferably selected from the group consisting of a Group II base oil, a Group III base oil, and mixtures thereof. These lubricant blends have surprising low Brookfield viscosities at −40° C.

Owner:CHEVROU USA INC

Hydrodewaxing catalyst and its preparation method

ActiveCN102451748AImprove the effect of impurity removalInhibit carbon depositionMolecular sieve catalystsRefining to eliminate hetero atomsImpurityChemistry

The invention discloses a hydrodewaxing catalyst and its preparation method. With the weight of the catalyst as the reference, the catalyst contains the following components of: by weight, 5-10% of tungsten oxide, 1-5% of nickel oxide, 40-50% of nanometer ZSM-5 molecular sieve, 10-40% of macroporous alumina and the balance being a binder. The catalyst is prepared by the following steps of: firstly kneading the nanometer ZSM-5 molecular sieve, macroporous alumina and the binder to prepare a carrier, dipping loaded active metal, and finally carrying out hydrothermal treatment. The hydrodewaxing catalyst provided by the invention has a good shape-selective catalysis function and simultaneously has a good hydrofinishing function, and is especially suitable for the hydrofinishing and pour point reduction processes of a waxy hydrocarbon oil material containing high content of impurities such as sulfur, nitrogen and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Isoparaffinic base stocks by dewaxing fischer-tropsch wax hydroisomerate over Pt/H-mordenite

A high VI and low pour point lubricant base stock is made by hydroisomerizing a high purity, waxy, paraffinic Fischer-Tropsch synthesized hydrocarbon fraction having an initial boiling point in the range of 650-750° F., followed by catalytically dewaxing the hydroisomerate using a dewaxing catalyst comprising a catalytic platinum component and an H-mordenite component. The hydrocarbon fraction is preferably synthesized by a slurry Fischer-Tropsch using a catalyst containing a catalytic cobalt component. This combination of the process, high purity, waxy paraffinic feed and the Pt / H-mordenite dewaxing catalyst, produce a relatively high yield of premium lubricant base stock.

Owner:EXXON RES & ENG CO

Process for isomerization dewaxing of hydrocarbon streams

InactiveUS20030168379A1Yield maximizationReduce pointsMolecular sieve catalystsHydrocarbon by hydrogenationMolecular sieveIsomerization

A process for isomerization dewaxing of a hydrocarbon feed which includes contacting the hydrocarbon feed with a large pore size, small crystal size, crystalline molecular sieve and an intermediate pore size, small crystal size, crystalline molecular sieve to produce a dewaxed product with a reduced pour point and a reduced cloud point. In a preferred embodiment, the feed is contacted with the molecular sieves sequentially, first with the large pore sieve followed by the intermediate pore sieve.

Owner:EXXON RES & ENG CO

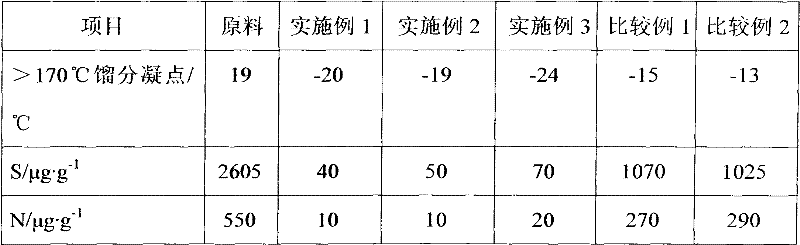

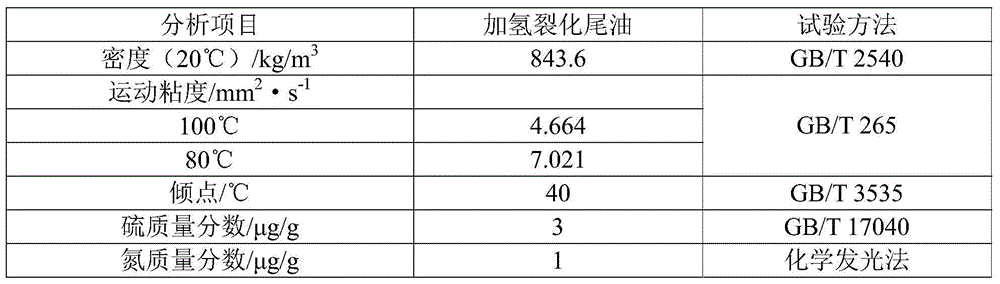

Hydroisomerization catalyst, preparation method and application thereof, and hydroisomerization method for hydrocracked tail oil

ActiveCN105582992AHigh catalytic activityHigh isomerization reaction selectivityMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveHalogen

The invention discloses a hydroisomerization catalyst, a preparation method and an application thereof. The preparation method comprises the following steps: a) providing a catalyst precursor containing a carrier, and a compound containing noble metals in the VIII group and a compound containing a second metal which are both supported on the carrier, wherein the two compounds hereinabove are both non-oxides, the second metal is one or more than two selected from the metal in the VB group, the metal in the VIB group, non-noble metal in the VIII group and lanthanum-series metals, the carrier containing mesoporous molecular sieve; and b) roasting the catalyst precursor in an atmosphere formed by a gas containing an oxidizing gas and a halogen-containing compound. The invention also discloses a hydroisomerization method for hydrocracked tail oil with the hydroisomerization catalyst. The hydroisomerization catalyst, when being used in the hydroisomerization for the hydrocracked tail oil, can be used for producing an isomerized product having high viscosity index and low pour point, which is suitable for being used as lubricant basic oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for improving the lubricating properties of base oils using a Fischer-Tropsch derived bottoms

InactiveUS20050098476A1High viscosityReduce pointsRefining to change hydrocarbon structural skeletonHydrocarbon purification/separationProcess engineeringBase oil

A method for improving the lubricating properties of a distillate base oil characterized by a pour point of 0 degrees C. or less and a boiling range having the 10 percent point falling between about 625 degrees F. and about 790 degrees F. and the 90 percent point falling between about 725 degrees F. and about 950 degrees F., the method comprises blending with said distillate base oil a sufficient amount of a pour point depressing base oil blending component to reduce the pour point of the resulting base oil blend at least 3 degrees C. below the pour point of the distillate base oil, wherein the pour point depressing base oil blending component is an isomerized Fischer-Tropsch derived bottoms product having a pour point that is at least 3 degrees C. higher than the pour point of the distillate base oil.

Owner:CHEVROU USA INC

Multigrade engine oil prepared from Fischer-Tropsch distillate base oil

InactiveUS20060027486A1Refining to change hydrocarbon structural skeletonLiquid carbonaceous fuelsCycloparaffinsPackage design

A multigrade engine oil meeting the specifications for SAE J300 revised June 2001 requirements and a process for preparing it, said engine oil comprising (a) between about 15 to about 94.5 wt % of a hydroisomerized distillate Fischer-Tropsch base oil characterized by (i) a kinematic viscosity between about 2.5 and about 8 cSt at 100° C., (ii) at least about 3 wt % of the molecules having cycloparaffin functionality, and (iii) a ratio of weight percent molecules with monocycloparaffin functionality to weight percent of molecules with multicycloparaffin functionality greater than about 15; (b) between about 0.5 to about 20 wt % of a pour point depressing base oil blending component prepared from an hydroisomerized bottoms material having an average degree of branching in the molecules between about 5 and 9 alkyl-branches per 100 carbon atoms and wherein not more than 10 wt % boils below about 900° F.; and (c) between about 5 to about 30 wt % of an additive package designed to meet the specifications for ILSAC GF-3.

Owner:CHEVROU USA INC

Method for producing lubricating oil basic oil

ActiveCN101173191AMeet the indicator requirementsLow pour pointTreatment with hydrotreatment processesBase-materialsBase oilPour point

The invention discloses a method for producing lube base oil, which is characterized in that low-pressure hydroisomerization and adsorption treatment are adopted and organically combined, and the lube base oil meeting the standard of HVIW is obtained; the raw material firstly enters a low-pressure hydroisomerizing reactor, and the pour point is lowered; after gas-liquid separation of the heterogeneous product, adsorption treatment is done to the separated lube fraction for color enhancement and stability improvement. The invention has the advantages that adaptability of the raw oil is strong; operating condition is mild; investment and operating cost is low; and the prepared lube base oil meeting the standard of HVIW can be applied to blinding with various brands of high-grade lube.

Owner:CHINA PETROLEUM & CHEM CORP +1

Isomerization dewaxing catalyst and preparing method thereof

InactiveCN1488733AHigh reactivityHigh selectivityMolecular sieve catalystsPetroleum wax recoveryMolecular sieveIsomerization

The present invention discloses an isodewaxing catalyst for producing base oil of lubricating oil and its preparation method. Said catalyst contains a new-type phosphorus silicon aluminium molecular sieve with AEL structure and active metal component, and the surface acidity of said molecular sieve is strong, and its mesopore distribution is more. Said catalyst is used for isodewaxing reaction of lubricating oil fraction, and has the characteristics of low reaction temp. high base oil yield, low product pour point and high viscosity index.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for hydrogenating naphthenic base distillate to produce lubricating oil basic oil

ActiveCN102311785AWeak acidSmall grainTreatment with hydrotreatment processesLubricant compositionHydrogenation processBase oil

The invention relates to a method for hydrogenating naphthenic base distillate to produce lubricating oil basic oil. The naphthenic distillate is used as raw material and a one-stage in series hydrogenation process of hydrotreating-hydrodewaxing-hydrofinishing is adopted to produce the lubricating oil basic oil. Ordinary hydrotreating catalysts are filled in the upper part of a hydrotreating reaction area, and hydrotreating catalysts containing modified zeolites are filled in the lower part of the hydrotreating reaction area. The hydrodewaxing and hydrofinishing reaction areas are the same as those of the prior art, and are filled with hydrodewaxing catalysts and hydrofinishing catalysts. Compared with the prior art, the method disclosed by the invention has the advantages that system energy consumption is reduced, the pour point of a product is properly reduced, and the stability of the product is effectively improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Isomerization dewaxing catalyst and its prepn.

The present invention discloses one kind of isomerizing and dewaxing catalyst for lubricant oil production and its preparation. Specifically, SAPO-11 as acid component and organic matter are used tomodify prepared catalyst carrier and to protect the medium strength acid centers on the carrier, and the dried carrier is loaded with active metal component and high temperature roasted to release its protected acid centers and to produce the catalyst of the present invention. The catalyst is used for the isomerizing and dewaxing reaction of lubricant oil fraction in the presence of hydrogen, and has the advantages of high yield of lubricant oil base oil, low product pour point, high viscosity index and other advantages.

Owner:CHINA PETROLEUM & CHEM CORP +1

Vegetable insulating oil, and preparation method of vegetable insulating oil

InactiveCN102682869AImprove performanceReduce the temperatureLiquid organic insulatorsBase-materialsVegetable oilAnti oxidant

The invention relates to vegetable insulating oil based on vegetable oil, and a preparation method of the vegetable insulating oil. The insulating oil is prepared by the steps of using refined vegetable oil as raw material, carrying out ester exchange reaction on low-molecular alcohol, refining and washing after the reaction, rinsing, distilling under reduced pressure in order to remove water and alcohol, de-coloring, de-acidifying, filtering, de-watering deeply, finally adding antioxidant and pour point depressant. The insulating oil prepared by the method has the characteristics of high flashing point, low viscosity, low pour point, low acidity, low brackish water content, excellent dielectric constant, low dielectric loss and high breakdown voltage and has good physical and chemical performance and electrical performance.

Owner:CHINA ELECTRIC POWER RES INST

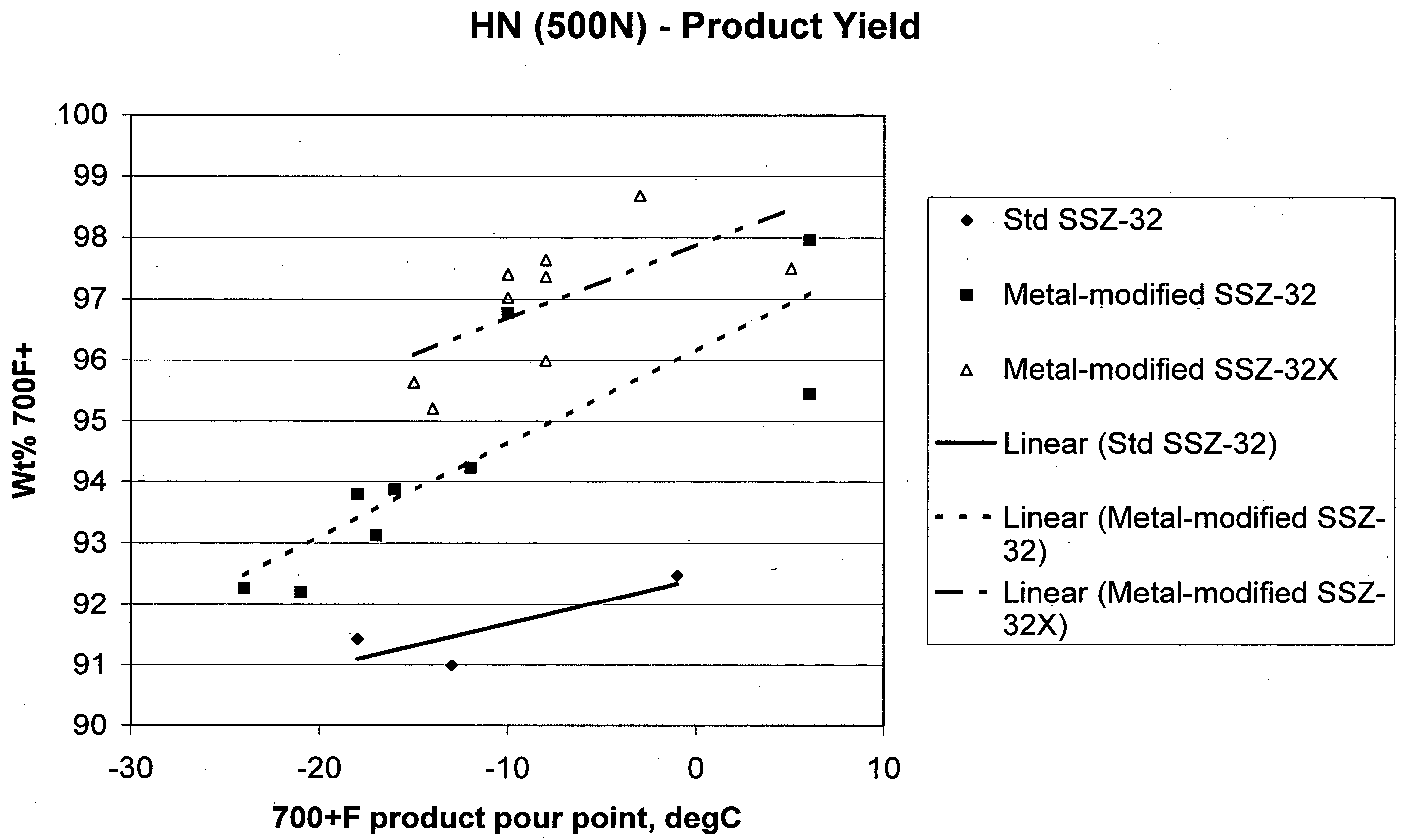

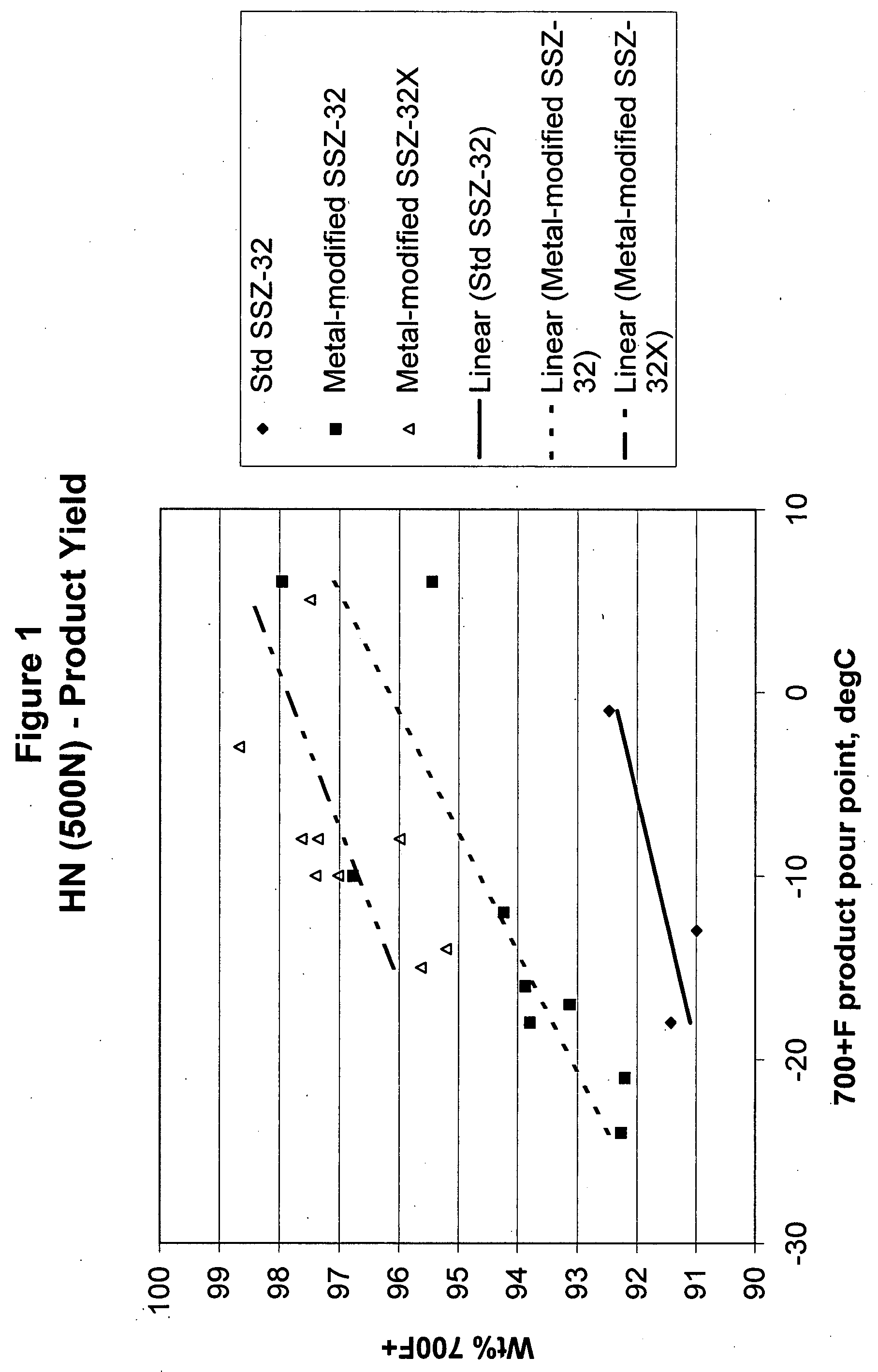

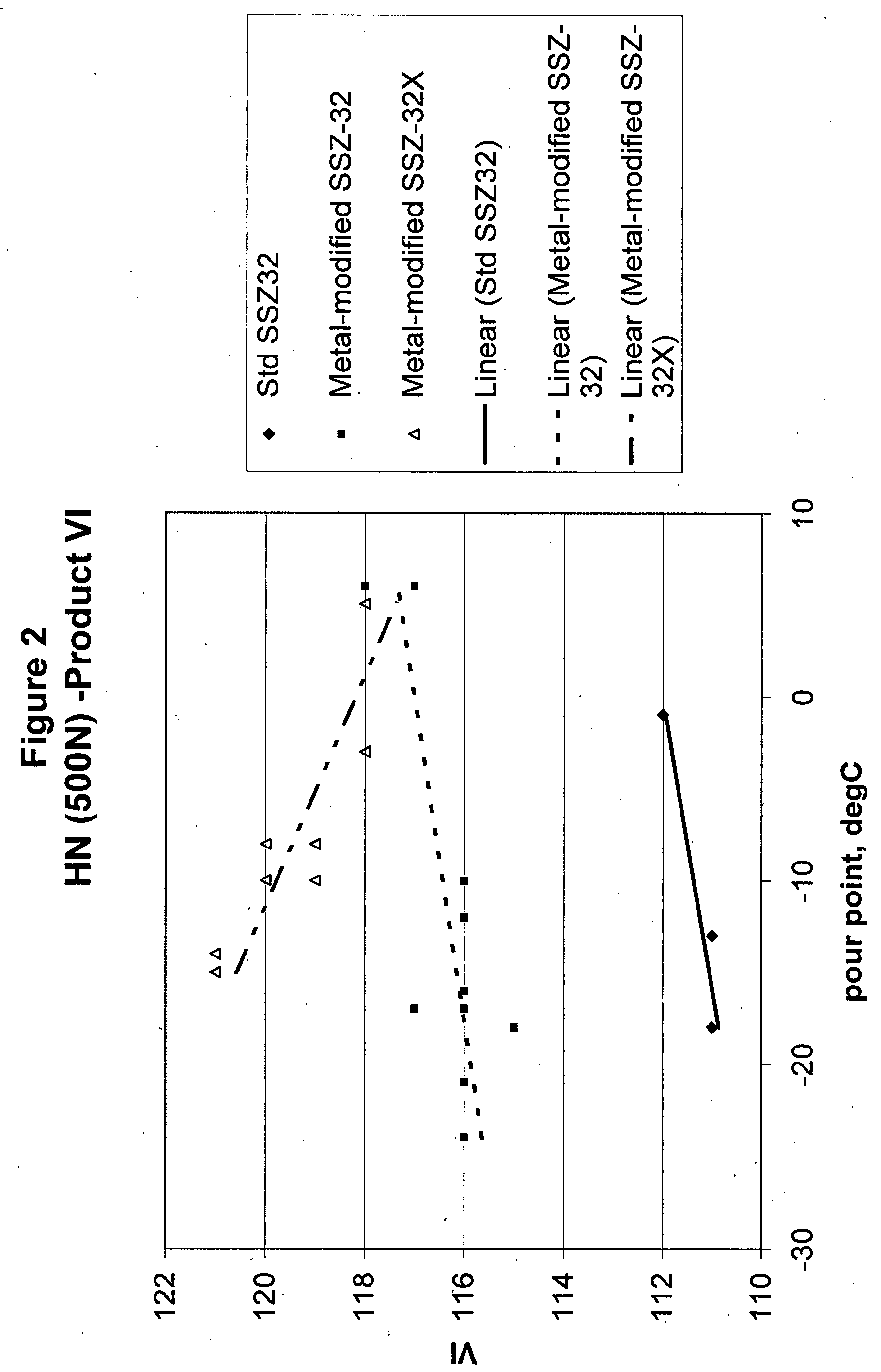

Isomerization process using metal-modified small crystallite mtt molecular sieve

InactiveUS20080083657A1Catalytic naphtha reformingTreatment with hydrotreatment processesMolecular sieveIsomerization

Dewaxing a hydrocarbon feed by isomerizing feed with catalyst comprising small crystallite molecular sieve having MTT framework, the catalyst containing at least one metal selected from the group consisting of Ca, Cr, Mg, La, Na, Pr, Sr, K and Nd, and at least one Group VIII metal. A dewaxing method to produce products boiling at 343° C. (650° F.) or higher with low pour points and high viscosity indexes wherein the line fit to the chart of the pour points and the viscosity indexes has a slope of zero or less. A dewaxing process, comprising isomerization dewaxing feed with a viscosity at 100° C. of 2.5 mm2 / s or greater over a metal-modified molecular sieve to produce products with low pour points and high viscosity indexes; the line fit to the chart of the pour points and the viscosity indexes has a slope of zero or less; and wherein the yield of products is high.

Owner:CHEVROU USA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com