Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5543results about "Refining to eliminate hetero atoms" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for the manufacture of diesel range hydrocarbons

ActiveUS20070010682A1Fatty oils/acids recovery from wasteHydrocarbon by isomerisationIsomerizationReaction temperature

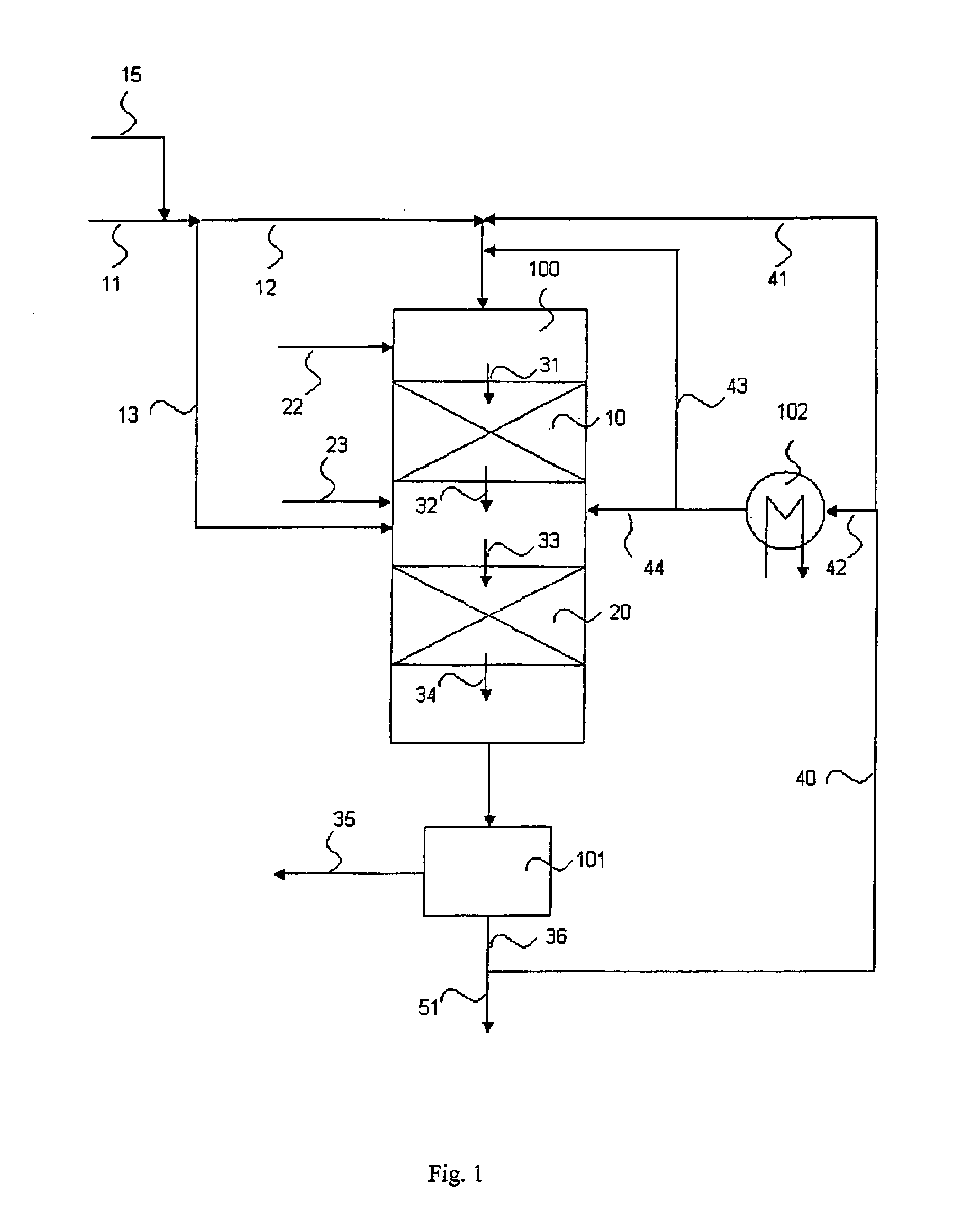

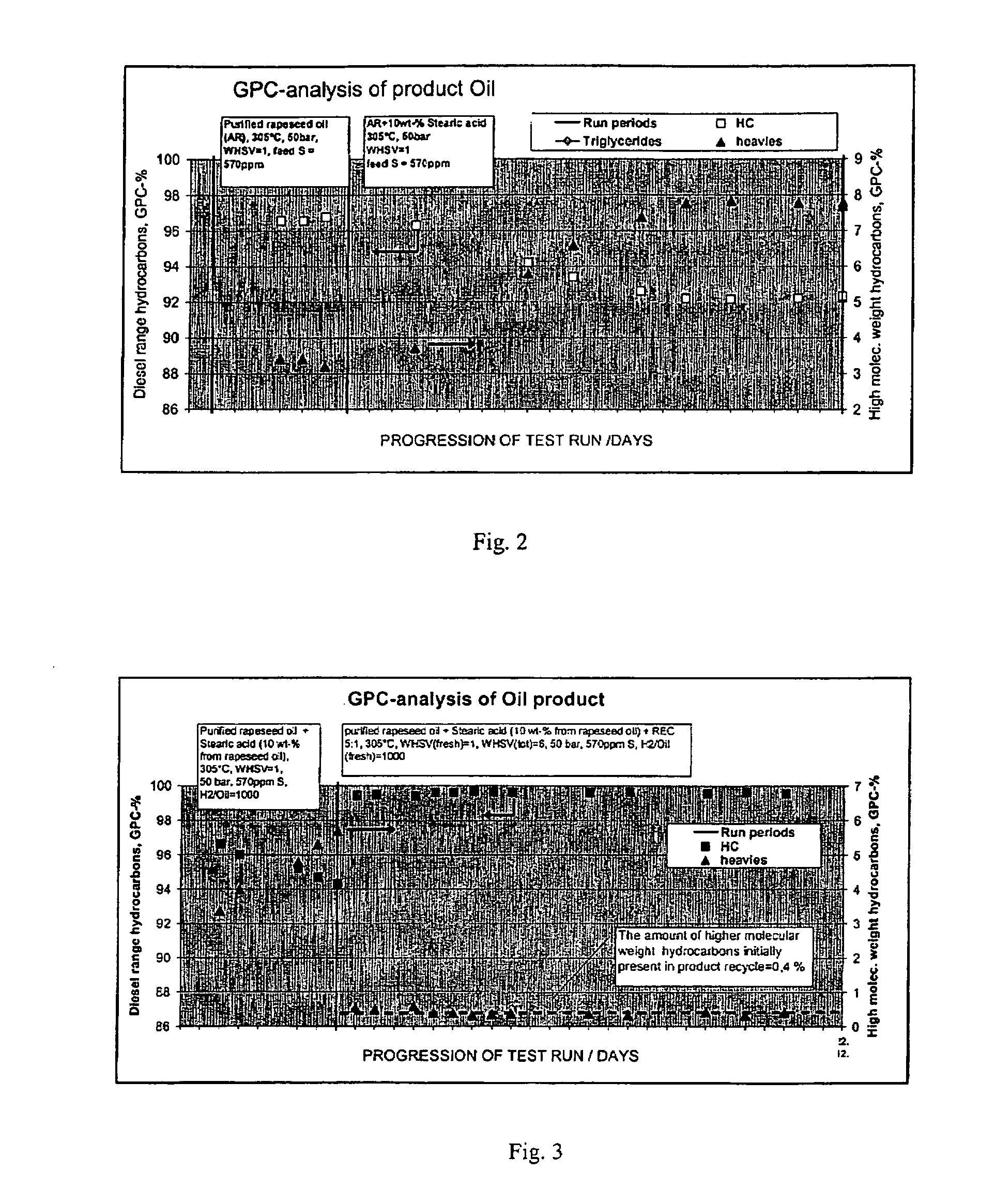

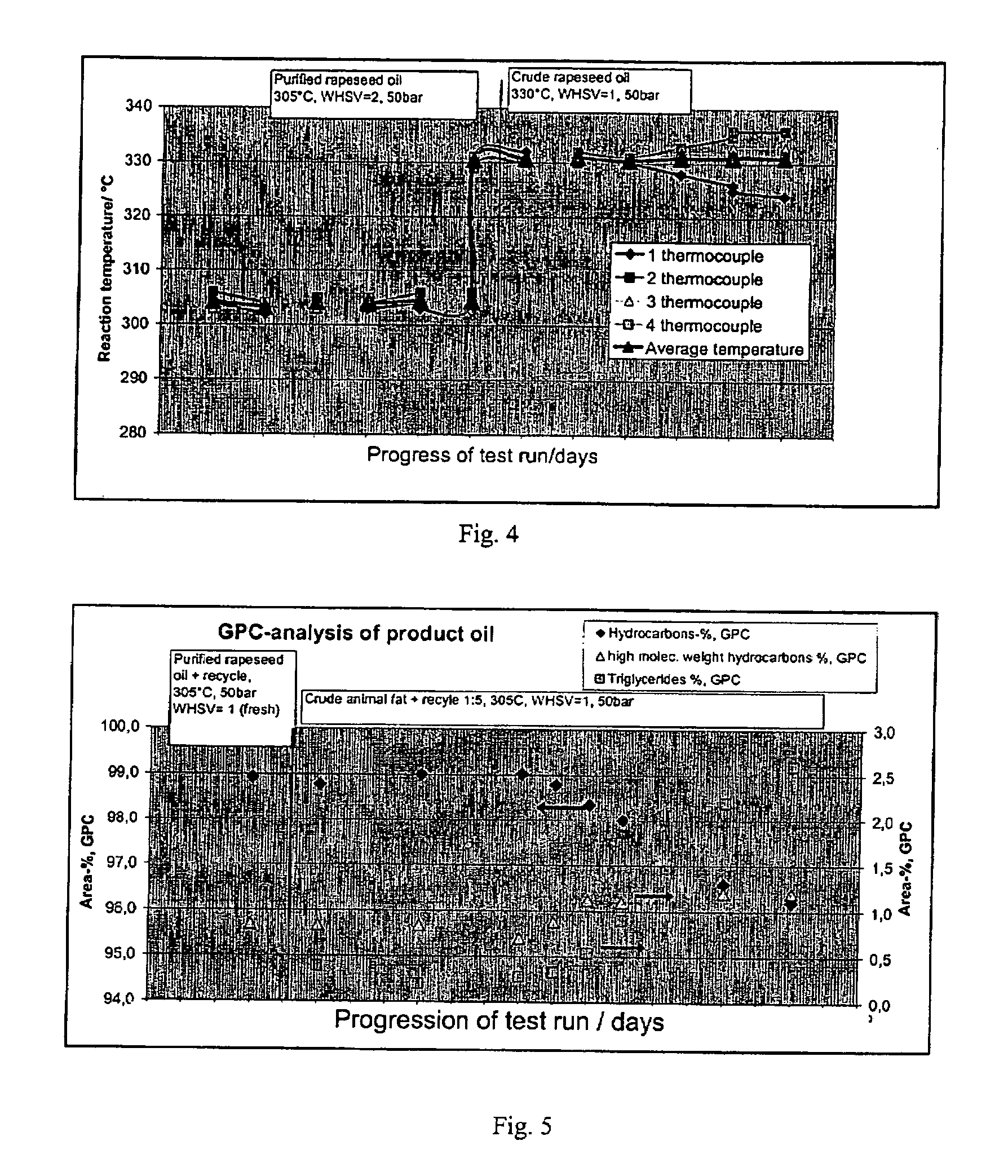

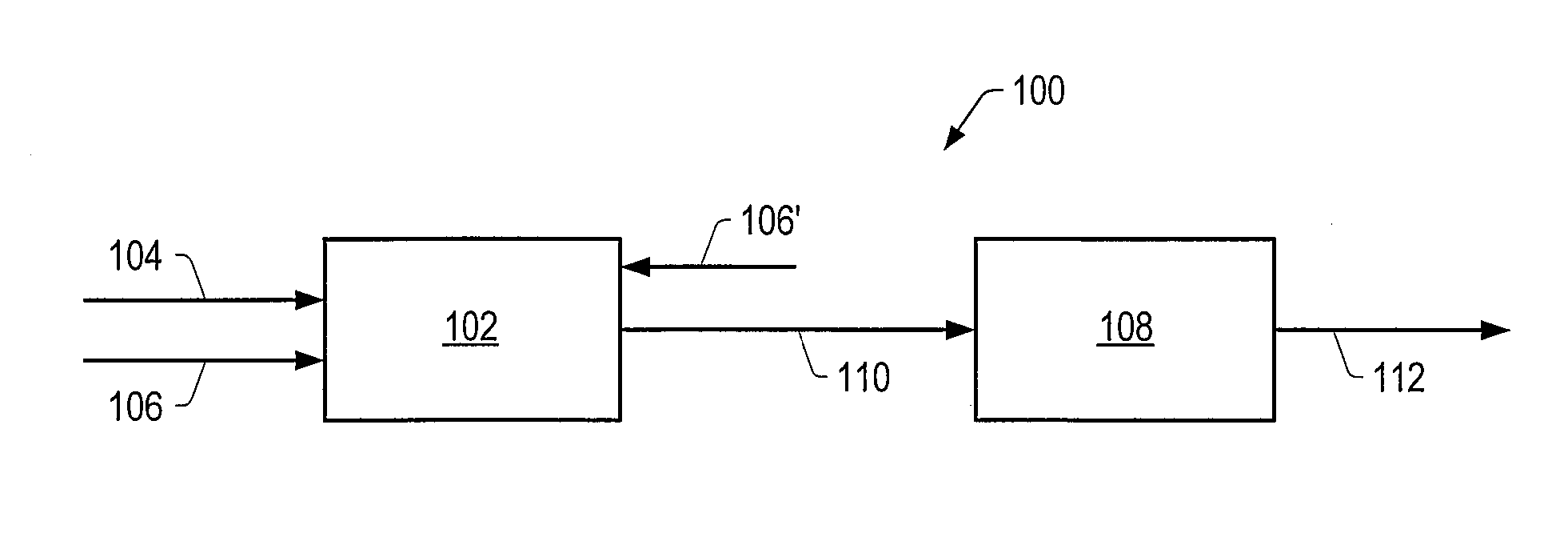

The invention relates to a process for the manufacture of diesel range hydrocarbons wherein a feed is hydrotreated in a hydrotreating step and isomerised in an isomerisation step, and a feed comprising fresh feed containing more than 5 wt % of free fatty acids and at least one diluting agent is hydrotreated at a reaction temperature of 200-400° C., in a hydrotreating reactor in the presence of catalyst, and the ratio of the diluting agent / fresh feed is 5-30:1.

Owner:NESTE OIL OY

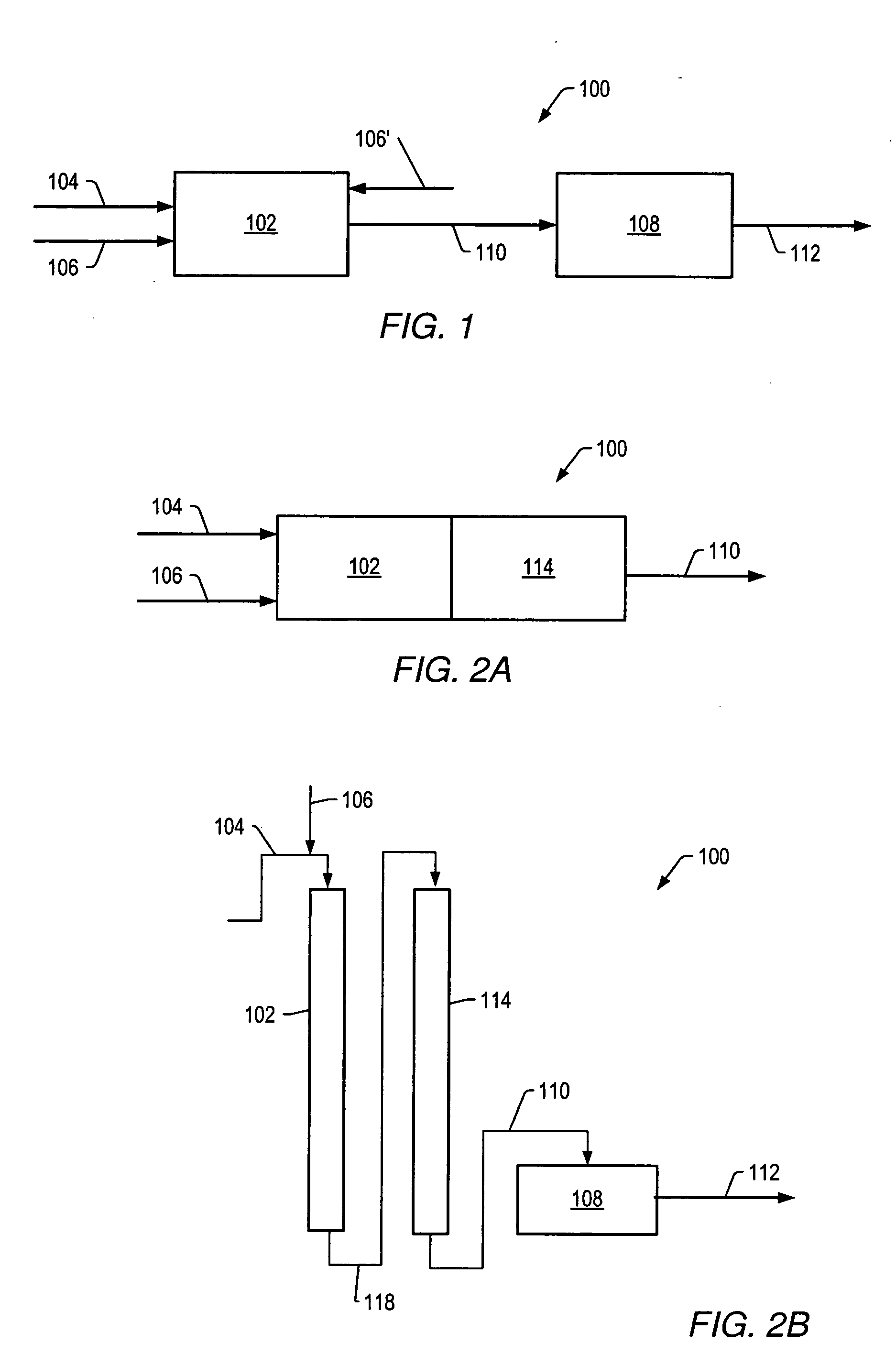

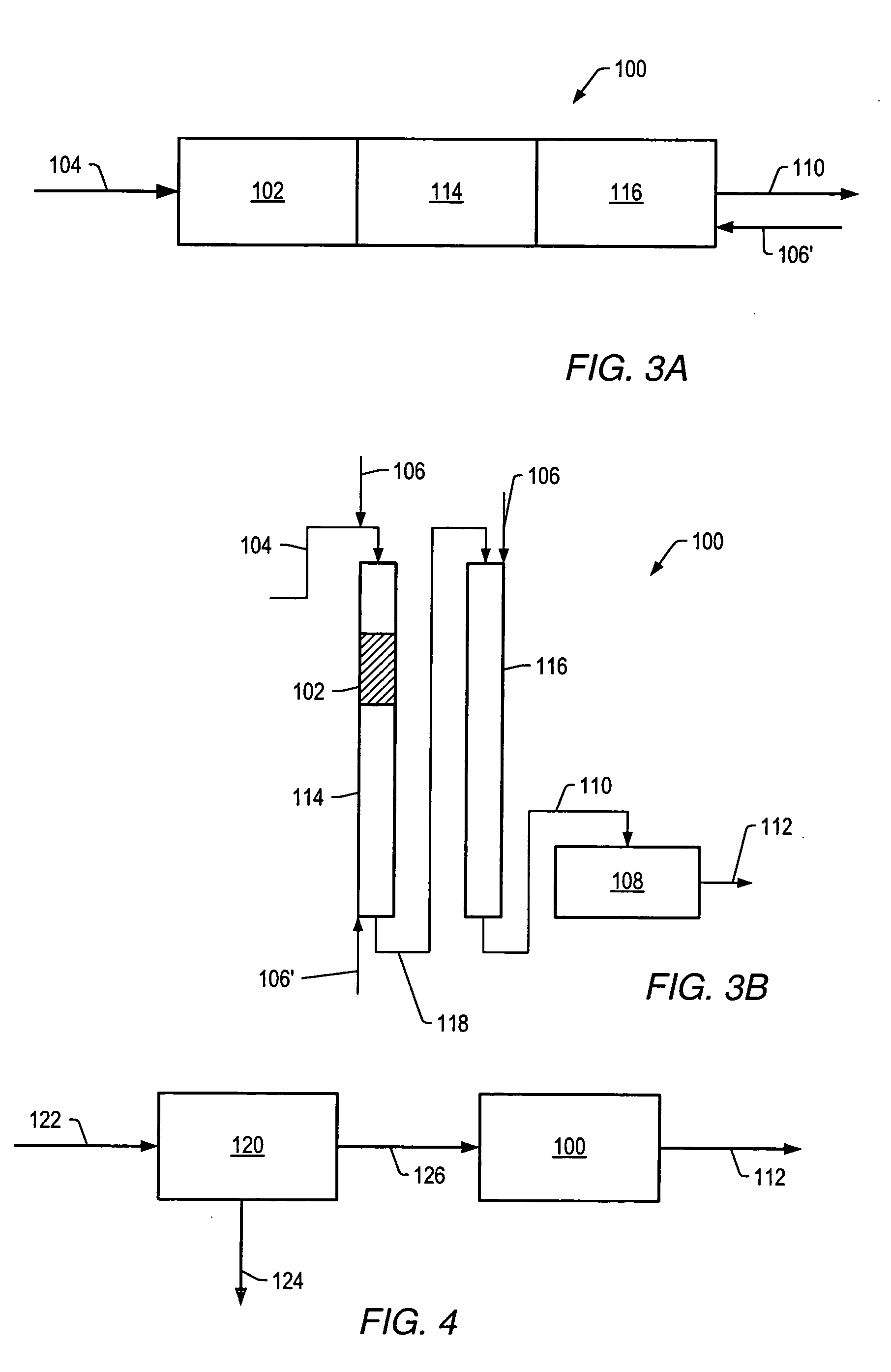

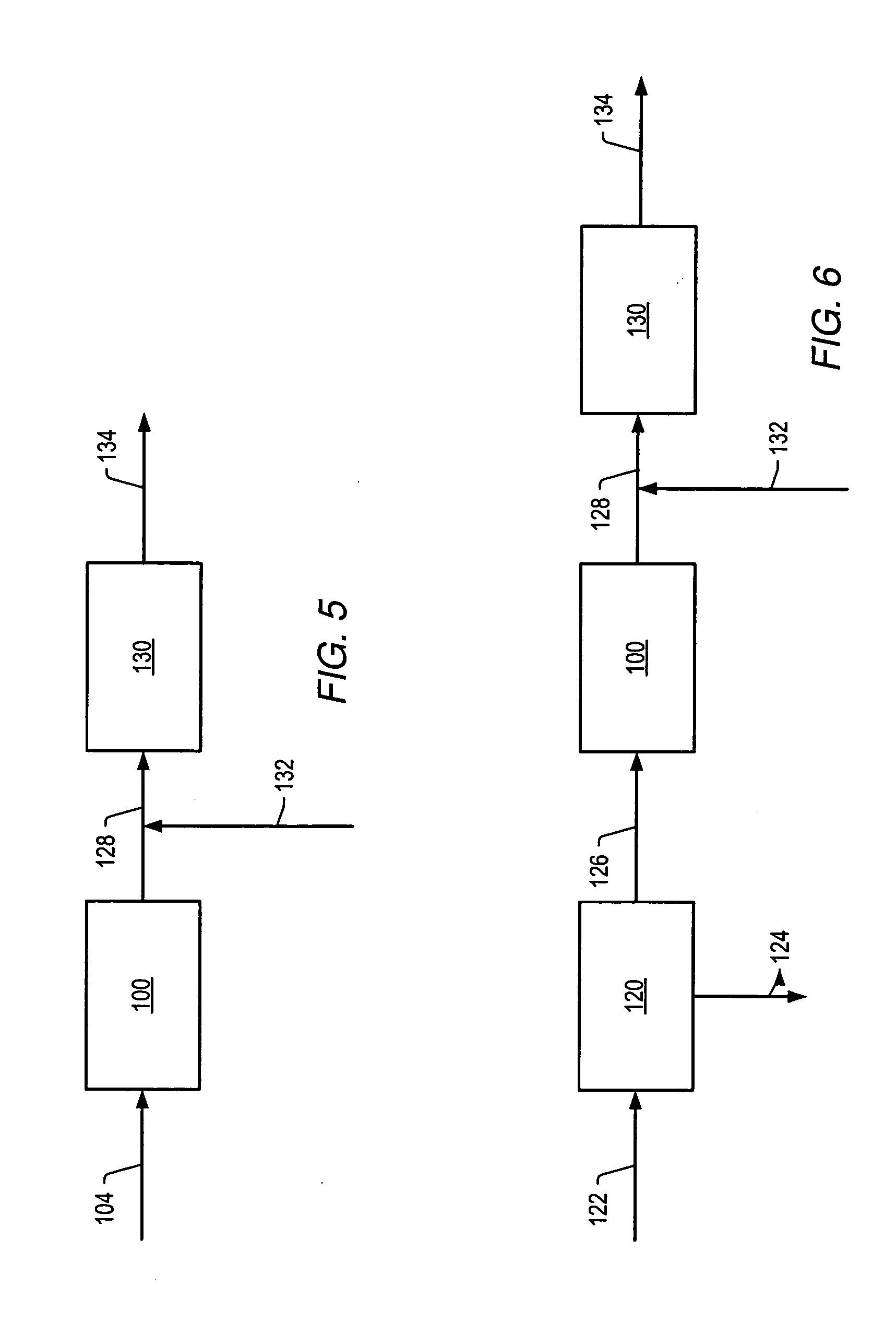

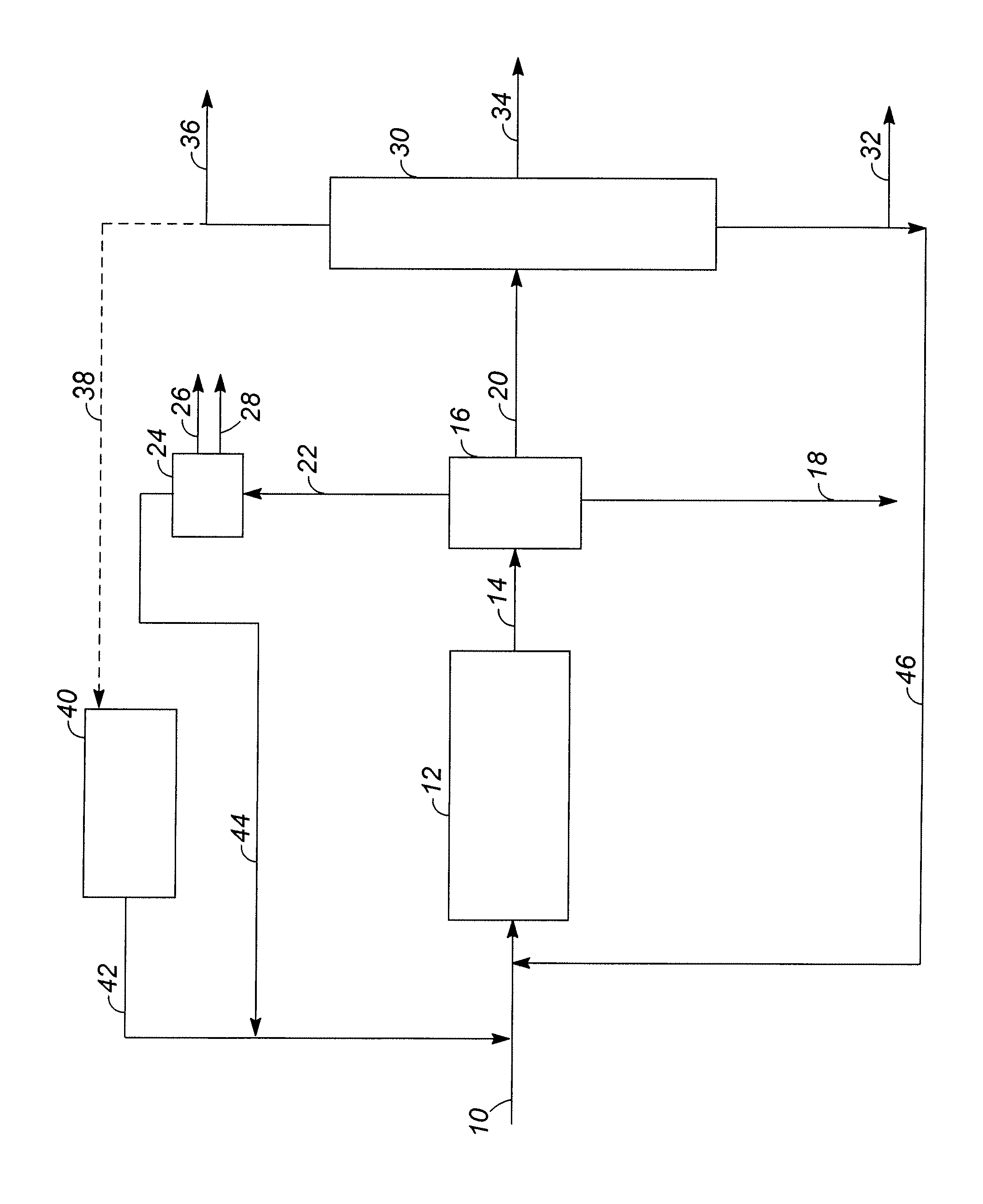

Method for producing a crude product with reduced tan

InactiveUS20070000810A1Catalytic crackingRefining with metal saltsOrganic chemistryContact condition

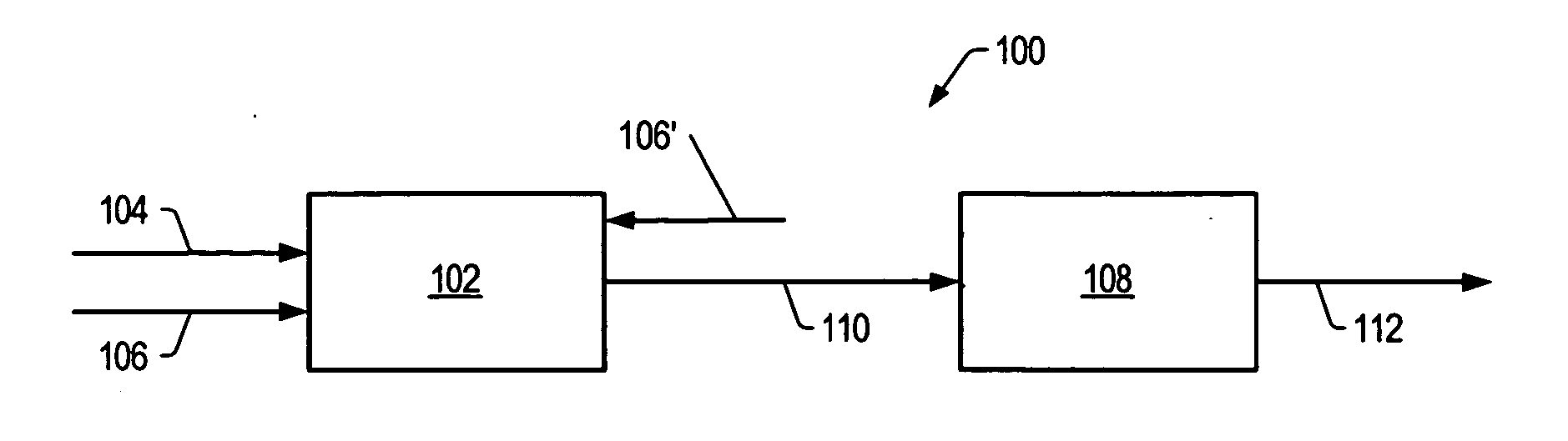

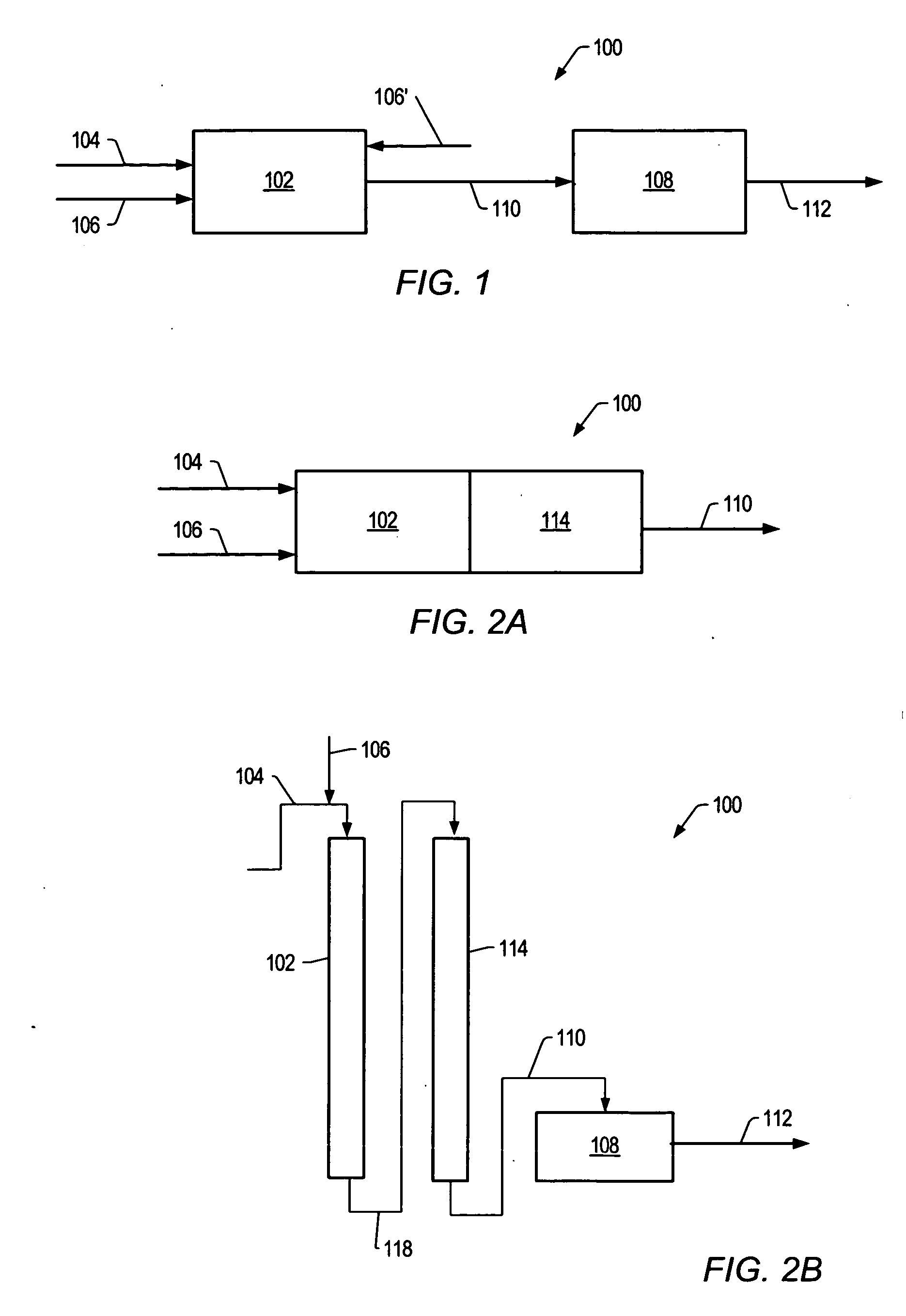

Contacting a crude feed with one or more catalysts to produce a total product that includes the crude product is described. The crude feed has a TAN of at least 1. At least one of the catalysts includes one or more metals from Columns 6-10 of the Periodic Table and / or one or more compounds of one or more metals from Columns 6-10 of the Periodic Table. Contacting conditions are controlled contacting such that the crude product has a TAN from about 0.001 to about 0.5.

Owner:SHELL OIL CO

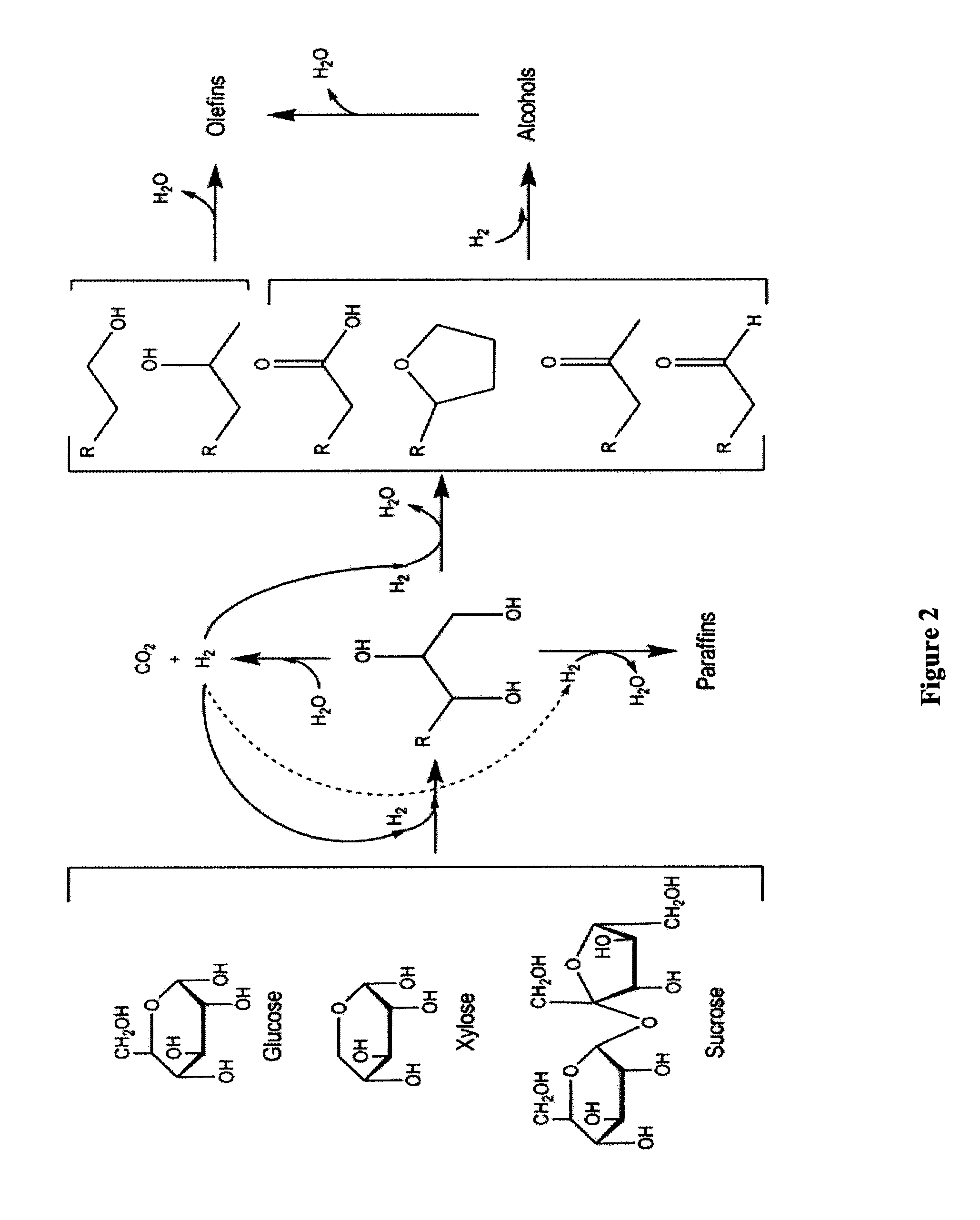

Synthesis of liquid fuels from biomass

ActiveUS20100076233A1Hydrocarbon by metathesis reactionLiquid hydrocarbon mixture productionFuranAlkane

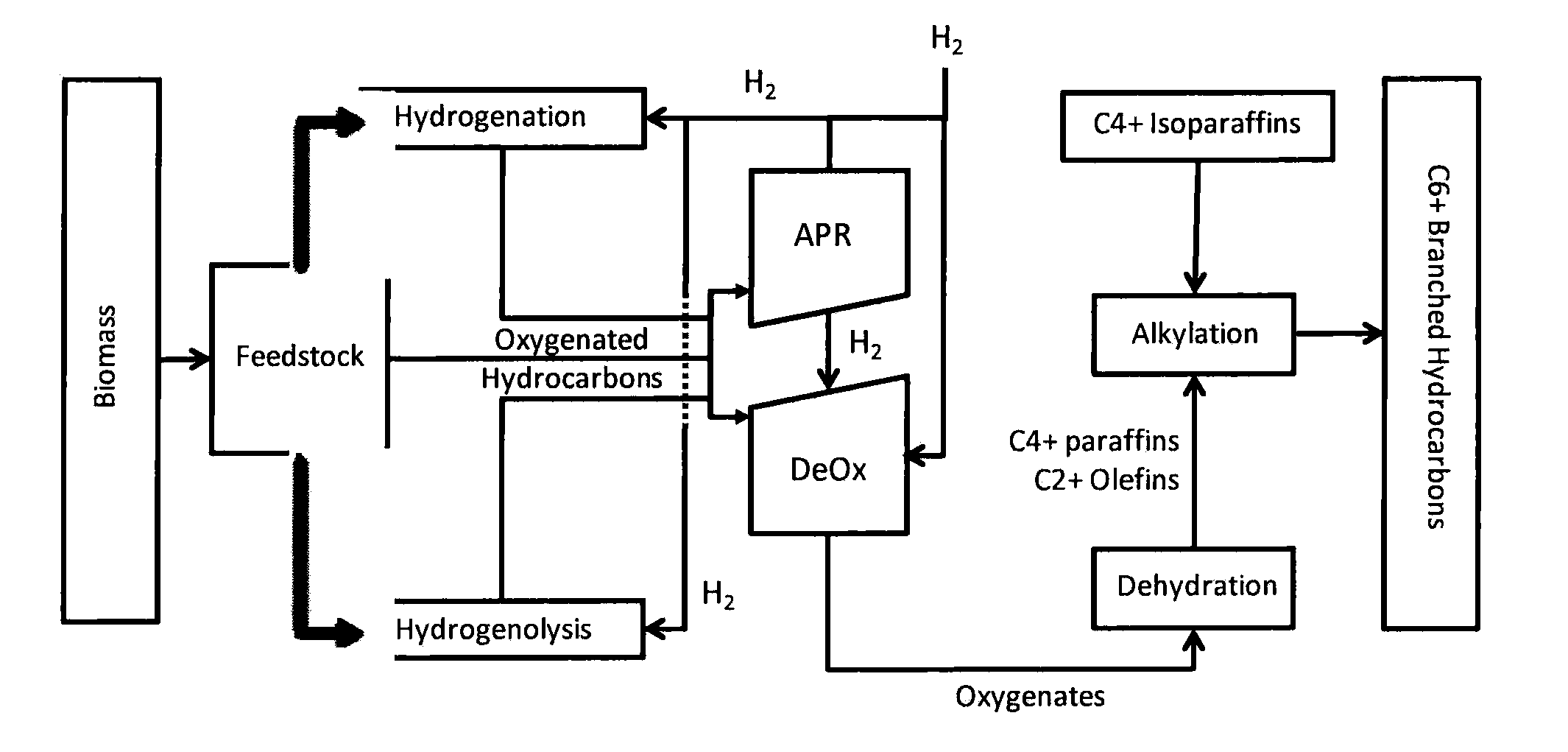

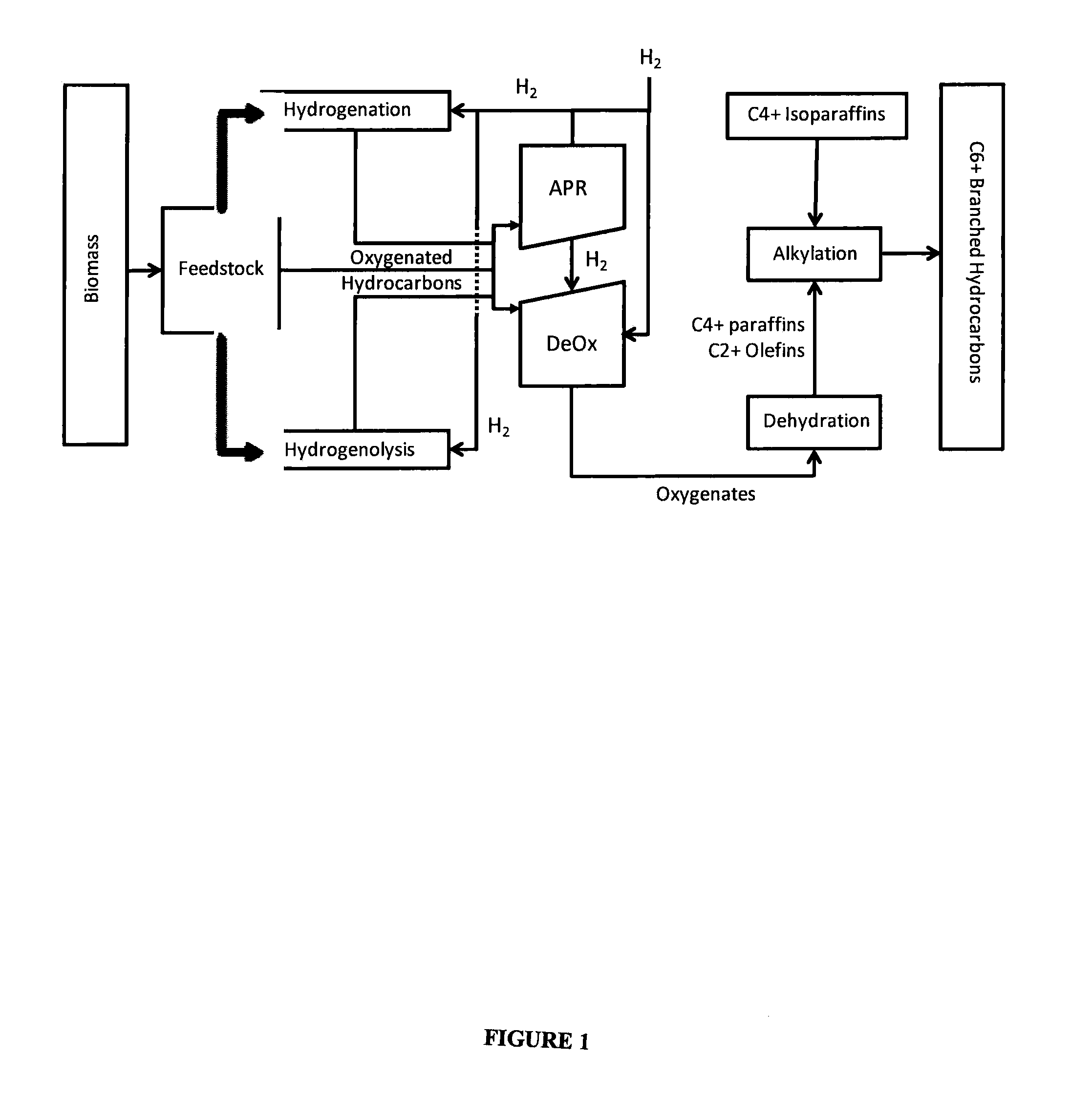

Processes and reactor systems are provided for the conversion of oxygenated hydrocarbons to paraffins useful as liquid fuels. The process involves the conversion of water soluble oxygenated hydrocarbons to oxygenates, such as alcohols, furans, ketones, aldehydes, carboxylic acids, diols, triols, and / or other polyols, followed by the subsequent conversion of the oxygenates to paraffins by dehydration and alkylation. The oxygenated hydrocarbons may originate from any source, but are preferably derived from biomass.

Owner:VIRENT

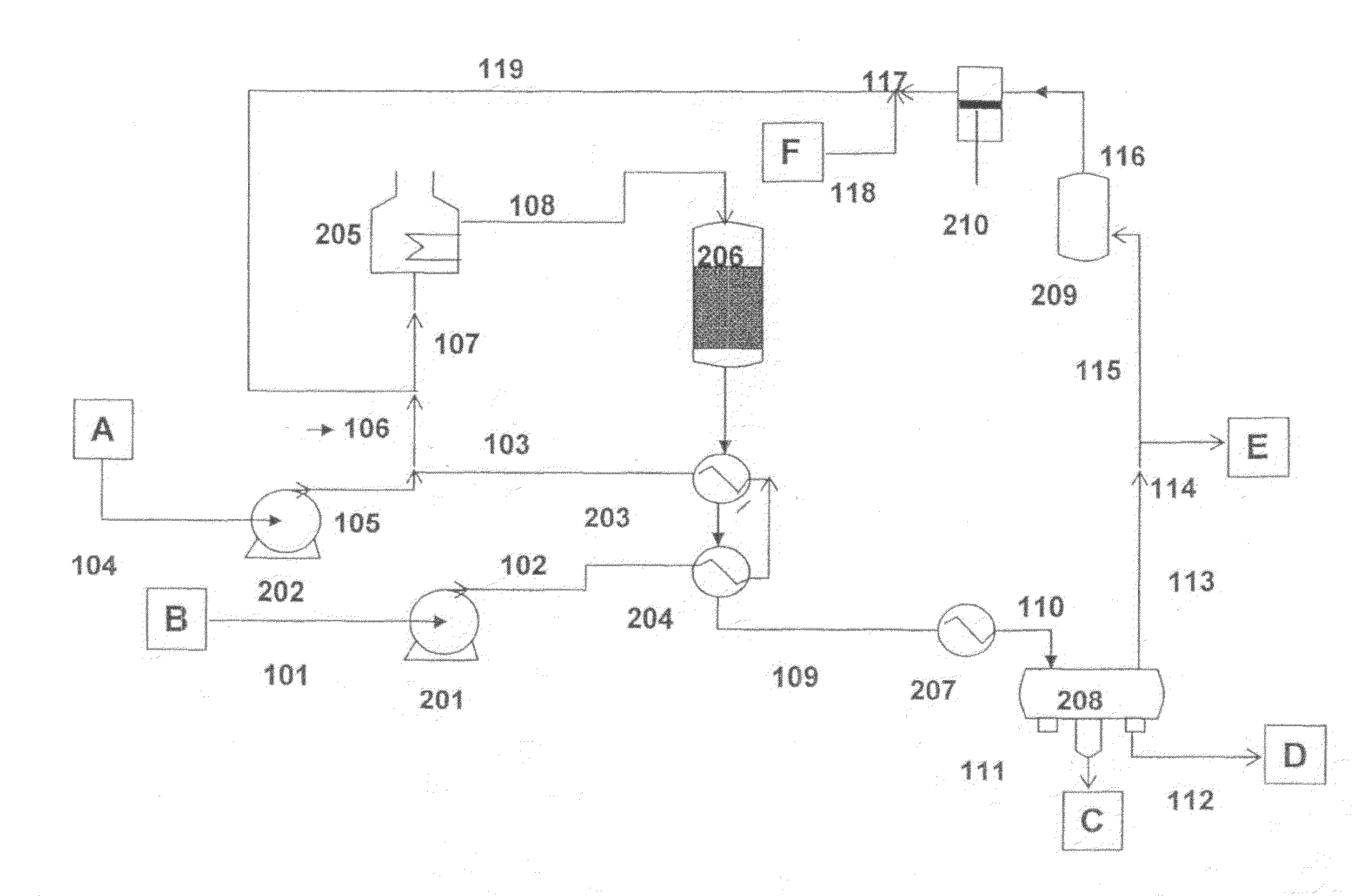

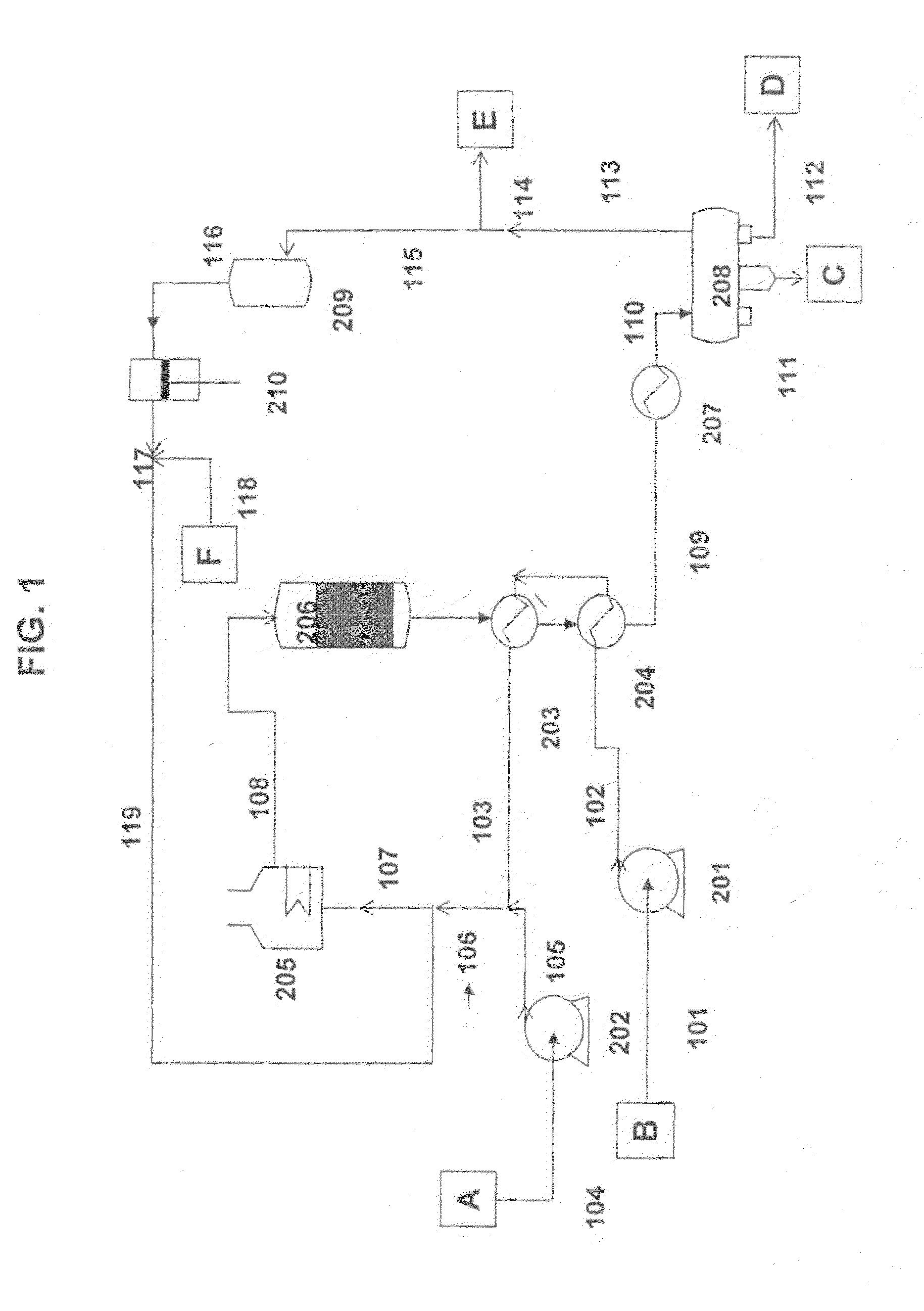

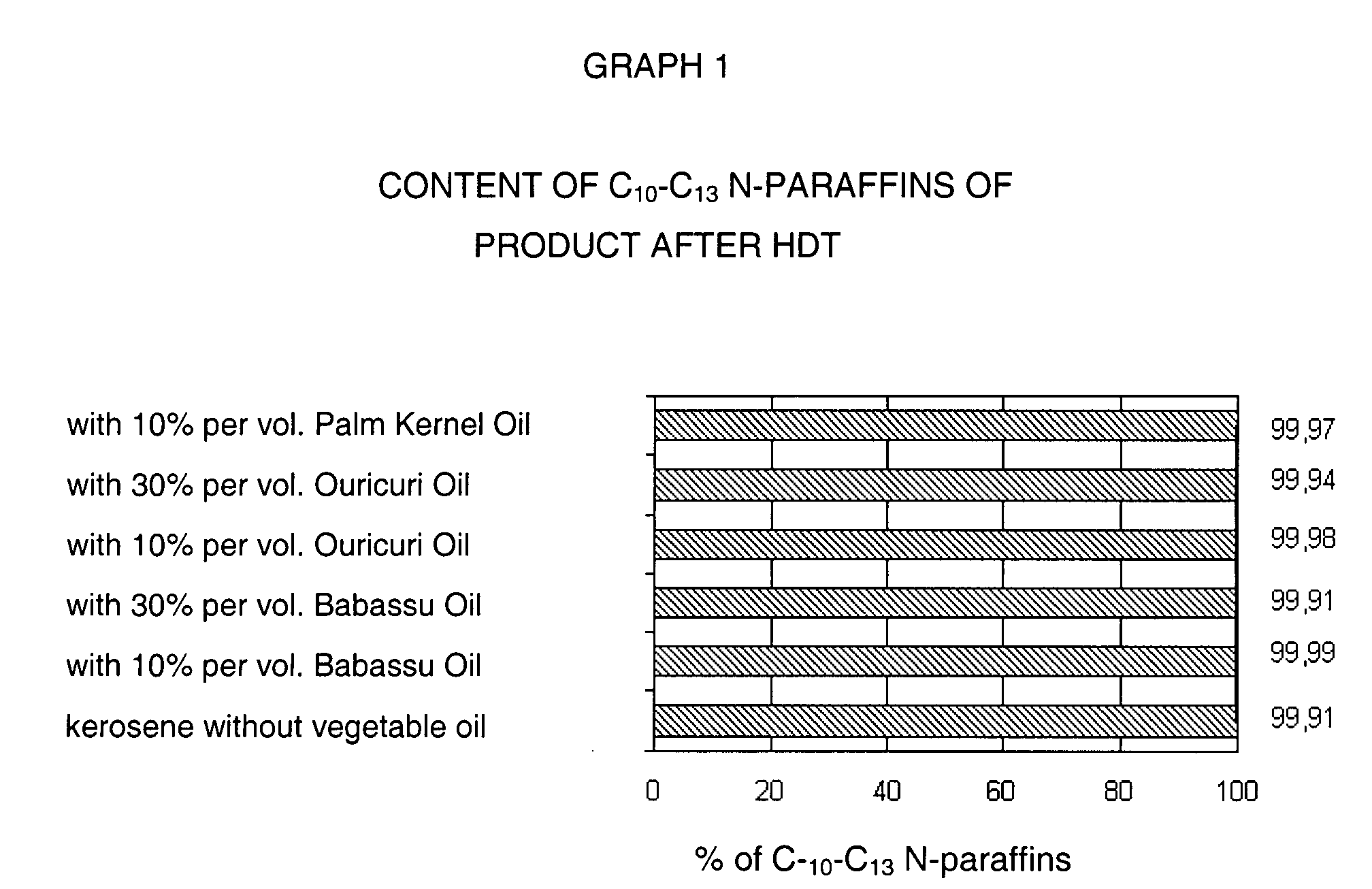

Process to obtain N-paraffins from vegetable oil

The process described by this invention involves the hydroconversion of vegetable oils appropriately selected for the production of N-paraffins, through hydrotreatment of a stream of vegetable hydrocarbon oils in and / or natural fats that may be used in a pure state or in a mixture with mineral hydrocarbon oil. This mixture flow is submitted to the process of hydrotreatment, obtaining as a result, a product flow with an elevated content of N-paraffins in the range of C10-C-13. This process provides an alternative to the usual process that uses a mineral hydrocarbon oil load (petroleum kerosene of paraffin base) to produce C10-C13 N-paraffins that are raw materials for the production of detergents (LAB), being, therefore, especially advantageous for use in situations where kerosene is a limiting factor for producing N-paraffins, resulting in a product of good quality with a reasonable gain in the production of N-paraffins.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

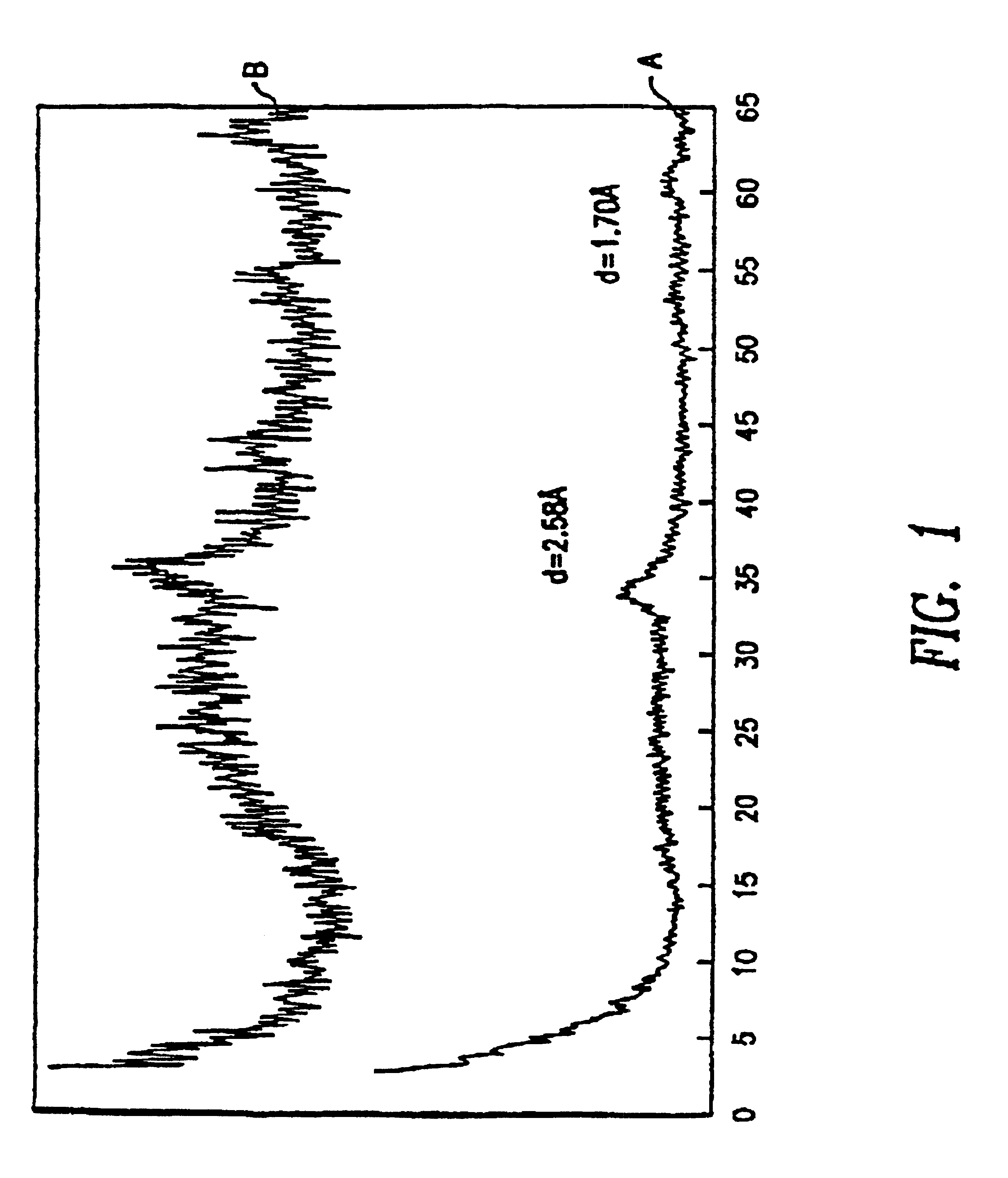

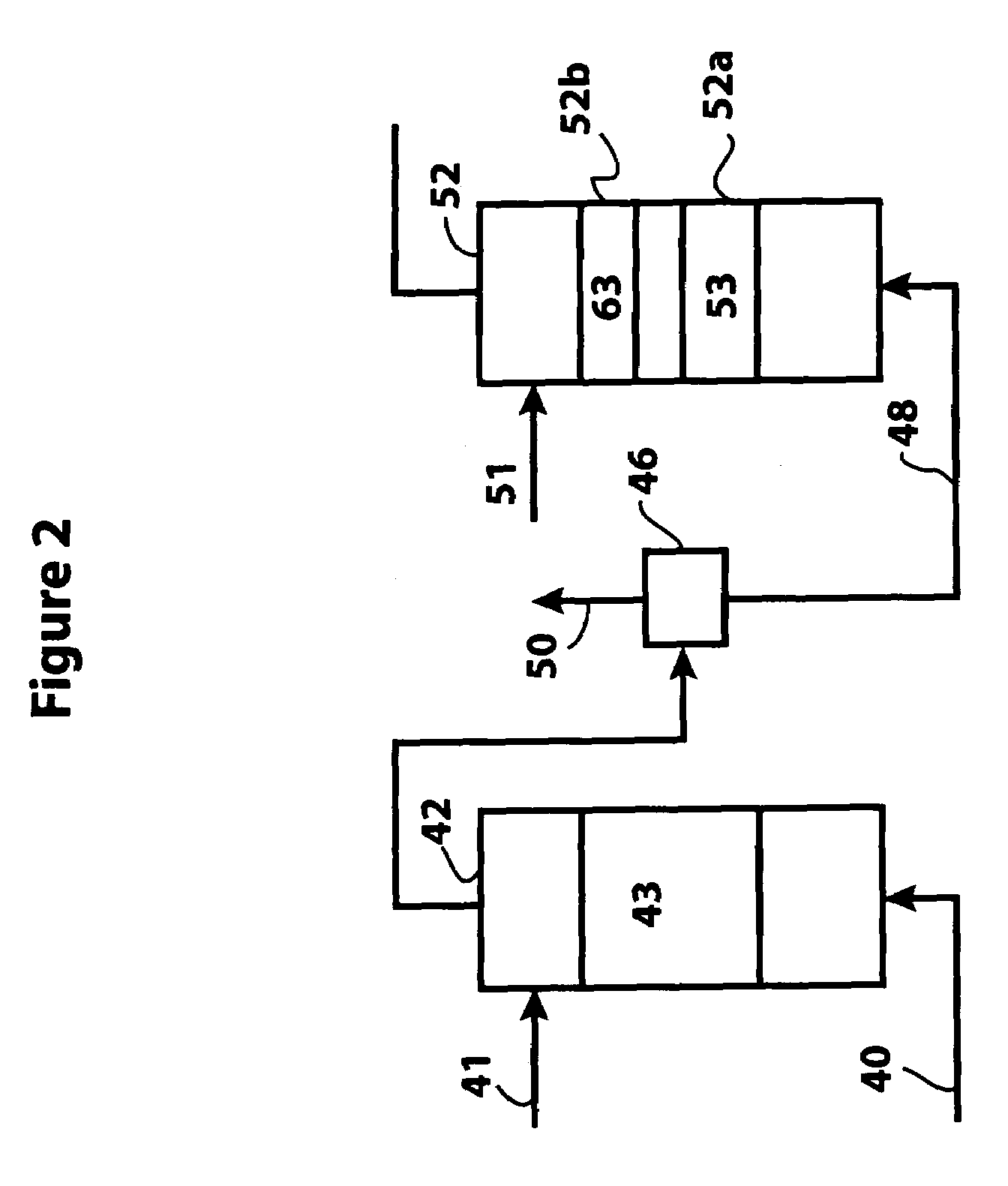

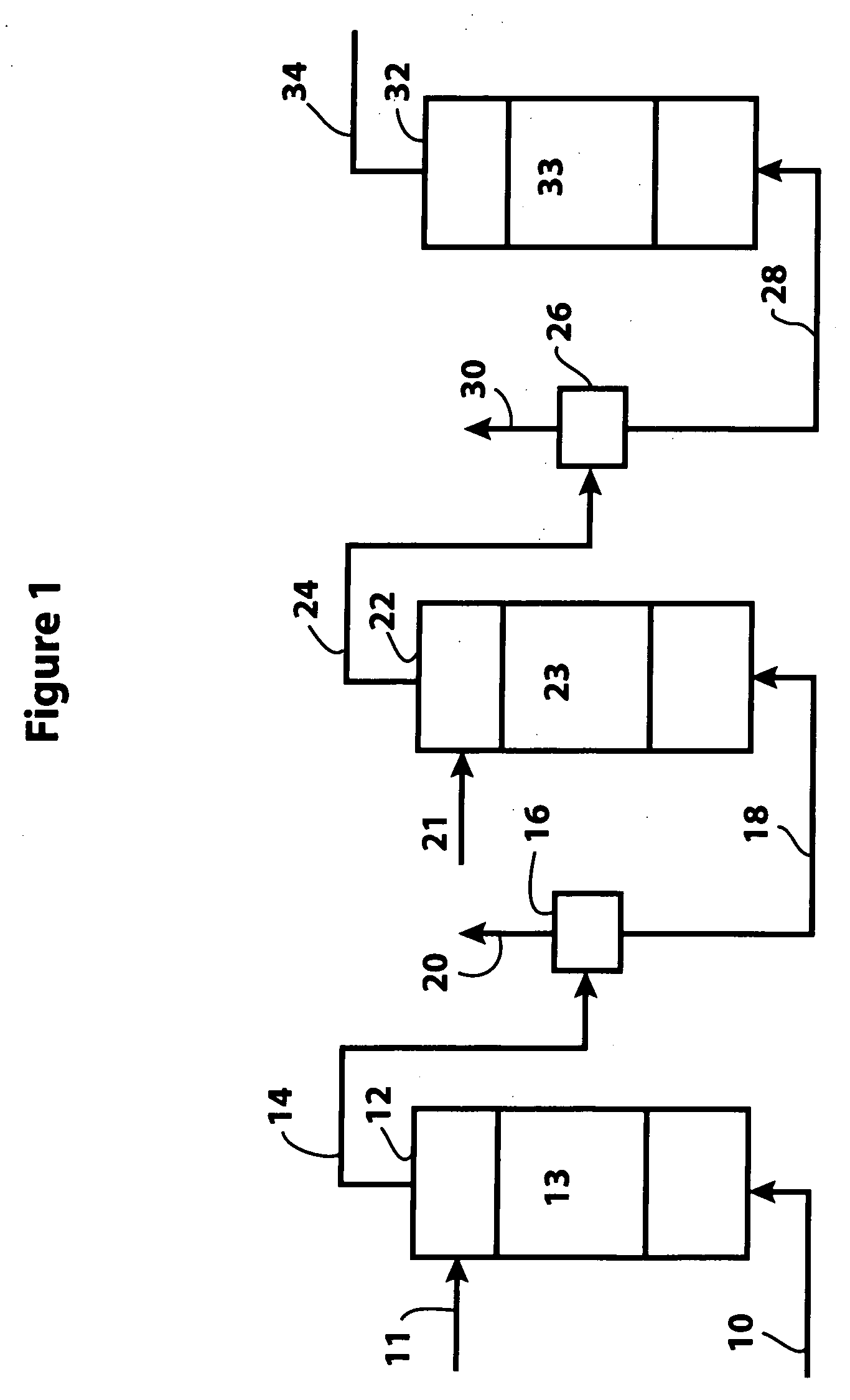

Two stage process for hydrodesulfurizing distillates using bulk multimetallic catalyst

InactiveUS6929738B1Preparation by oxo-reaction and reductionOrganic compound preparationLiquid productHydrogen

A two stage hydrodesulfurizing process for producing low sulfur distillates. A distillate boiling range feedstock containing in excess of about 3,000 wppm sulfur is hydrodesulfurized in a first hydrodesulfurizing stage containing one or more reaction zones in the presence of hydrogen and a hydrodesulfurizing catalyst. The liquid product stream thereof is passed to a first separation stage wherein a vapor phase product stream and a liquid product stream are produced. The liquid product stream, which has a substantially lower sulfur and nitrogen content then the original feedstream is passed to a second hydrodesulfurizing stage also containing one or more reaction zones where it is reacted in the presence of hydrogen and a second hydrodesulfurizing catalyst at hydrodesulfurizing conditions. The catalyst in any one or more reaction zones is a bulk multimetallic catalyst comprised of at least one Group VIII non-noble metal and at least two Group VIB metals.

Owner:EXXON RES & ENG CO

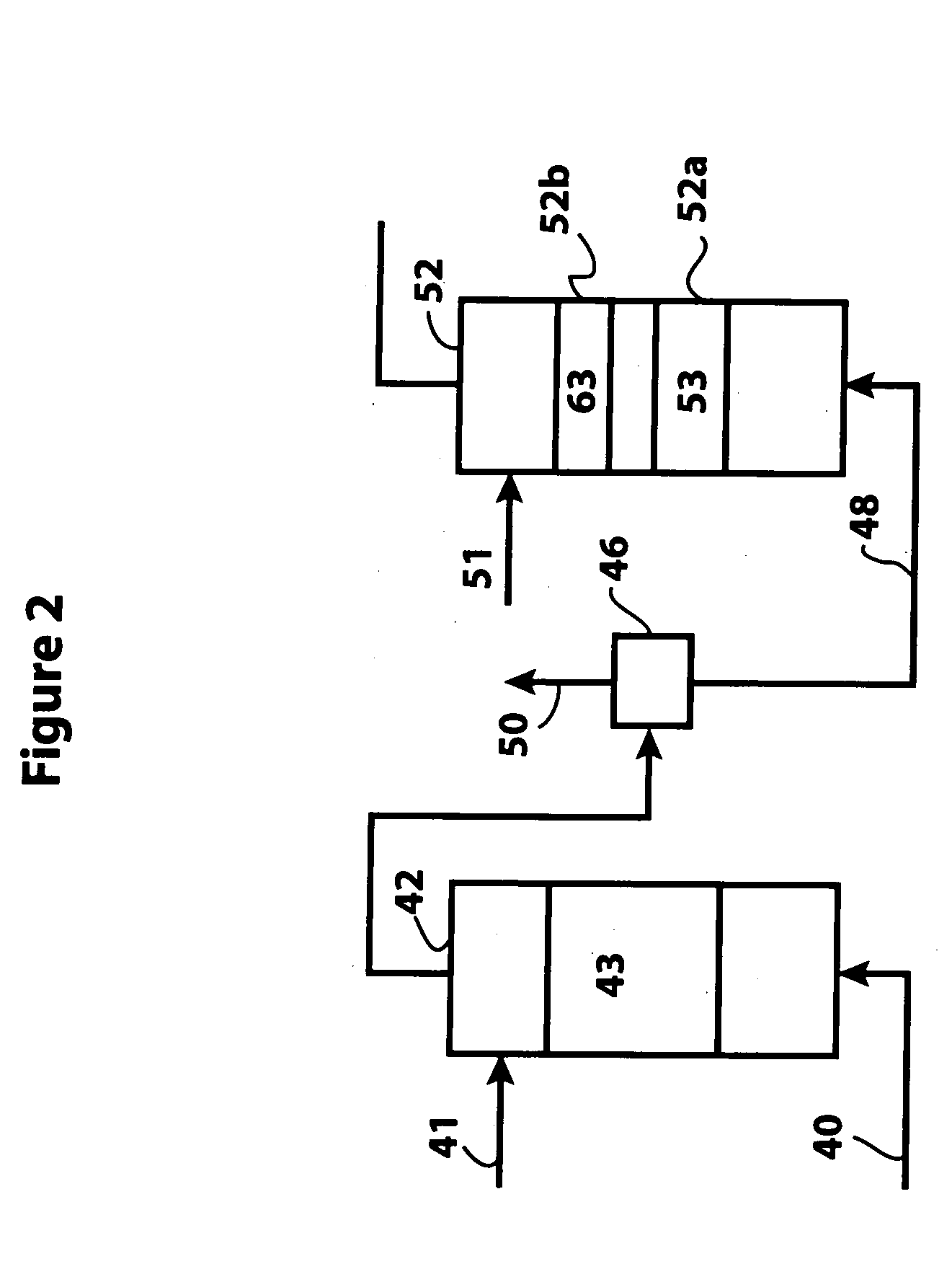

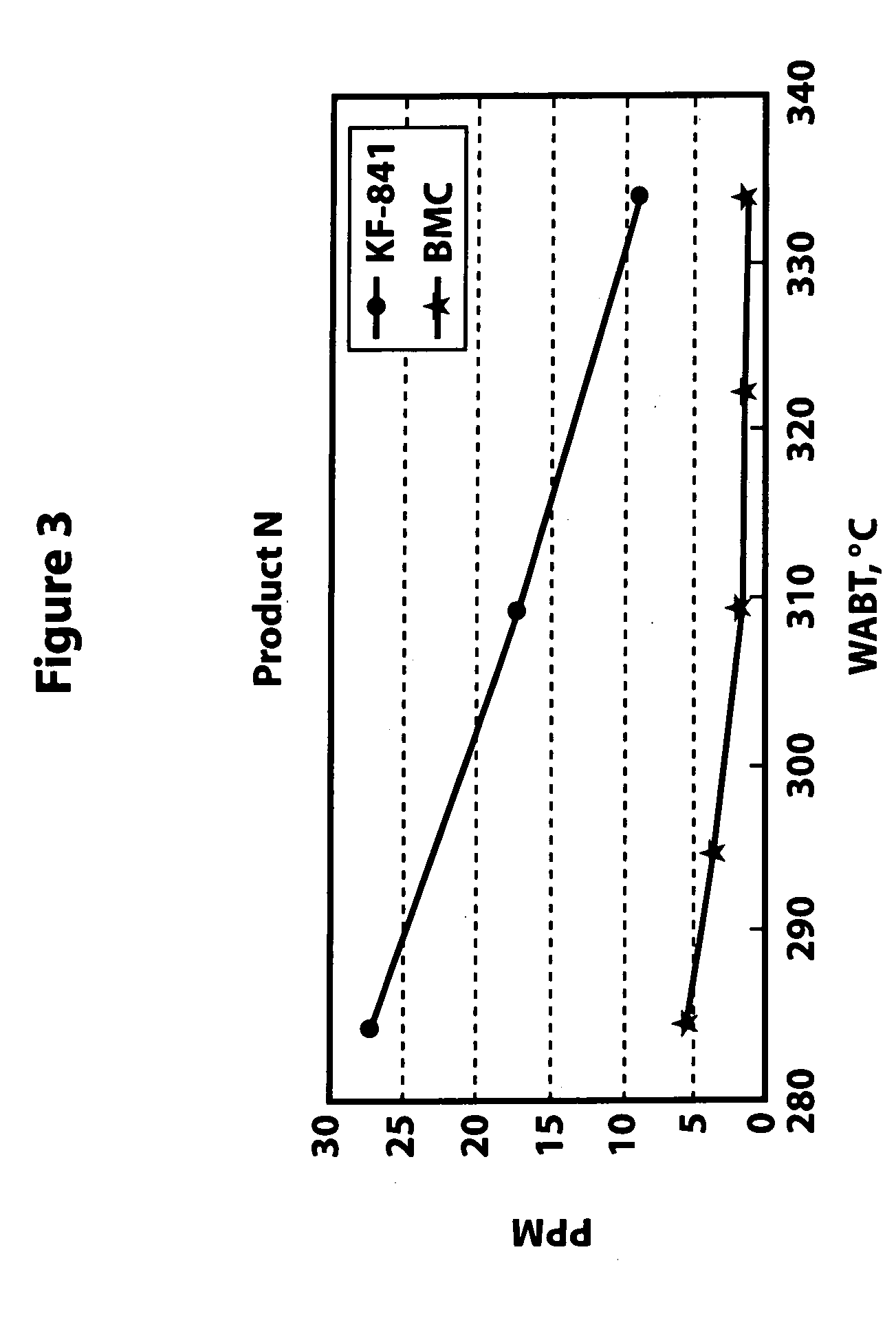

Process for upgrading naphtha

A method for upgrading a naphtha feed to a naphtha product containing less than about 10 wppm of nitrogen and less than about 15 wppm sulfur, the method comprising contacting said naphtha feed with hydrogen in the presence of a bulk multimetallic catalyst under effective reactor conditions to hydrodesulfurize and hydrodenitrogenize said naphtha feed to produce said naphtha product, wherein said bulk multimetallic catalyst comprises at least one Group VIII non-noble metal and at least two Group VIB metals.

Owner:EXXON RES & ENG CO

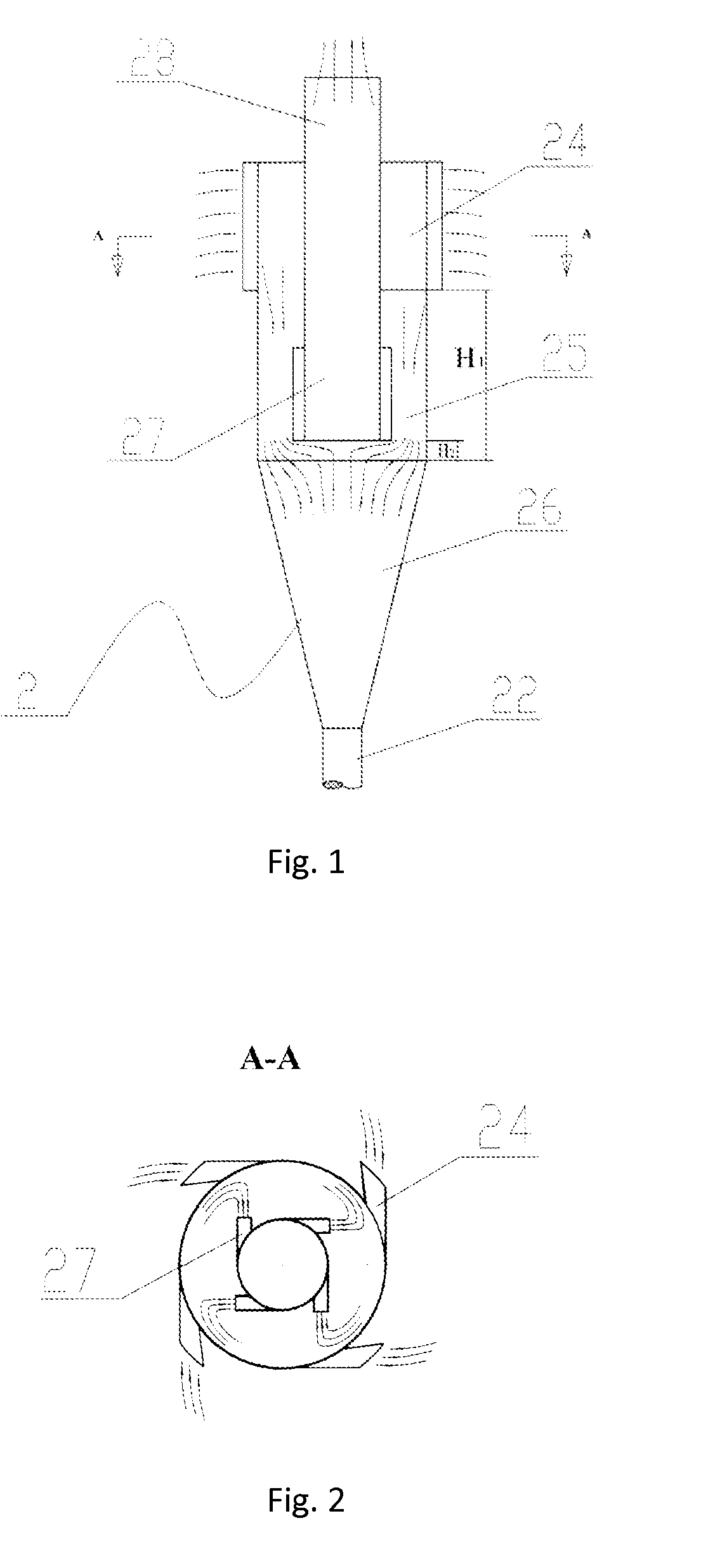

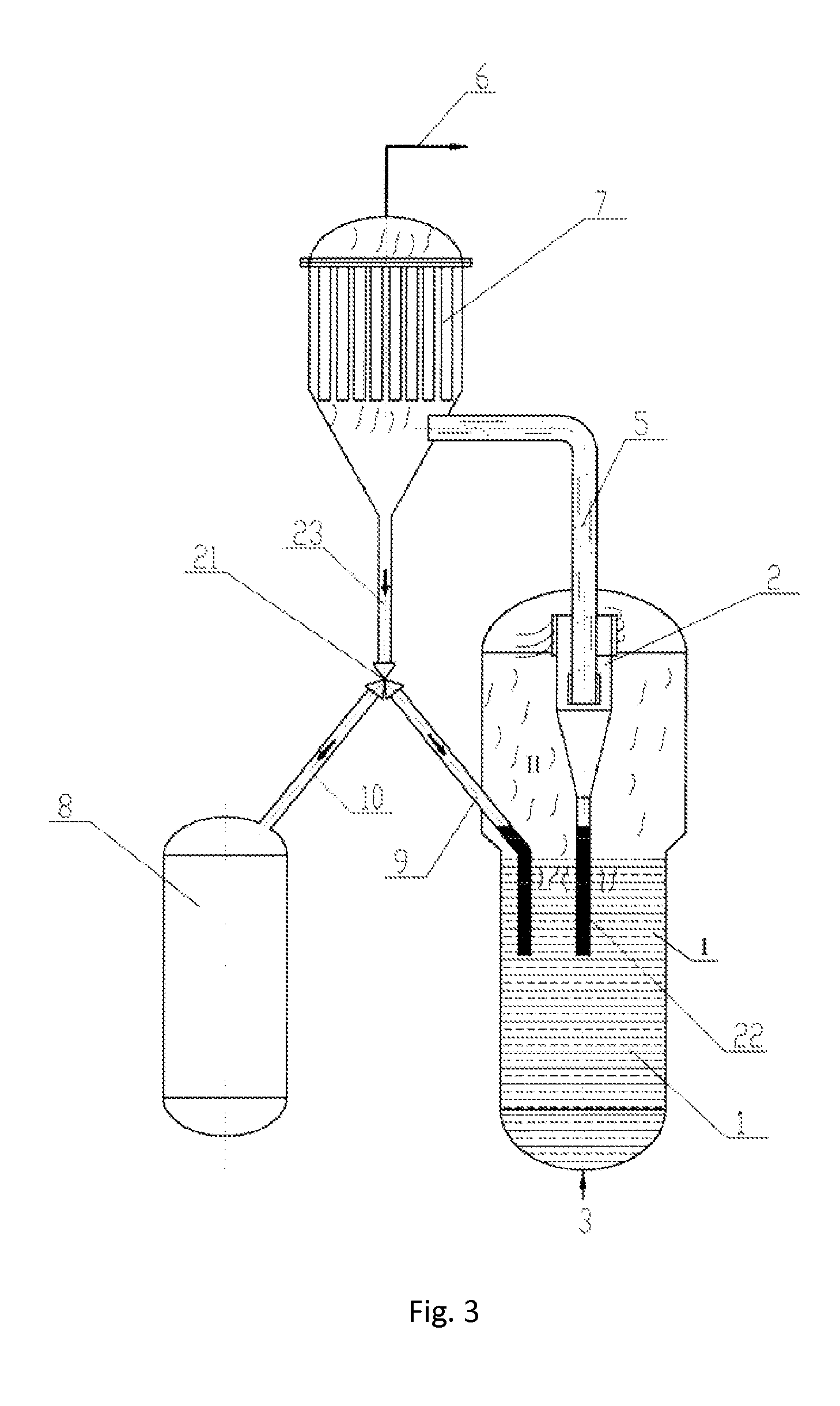

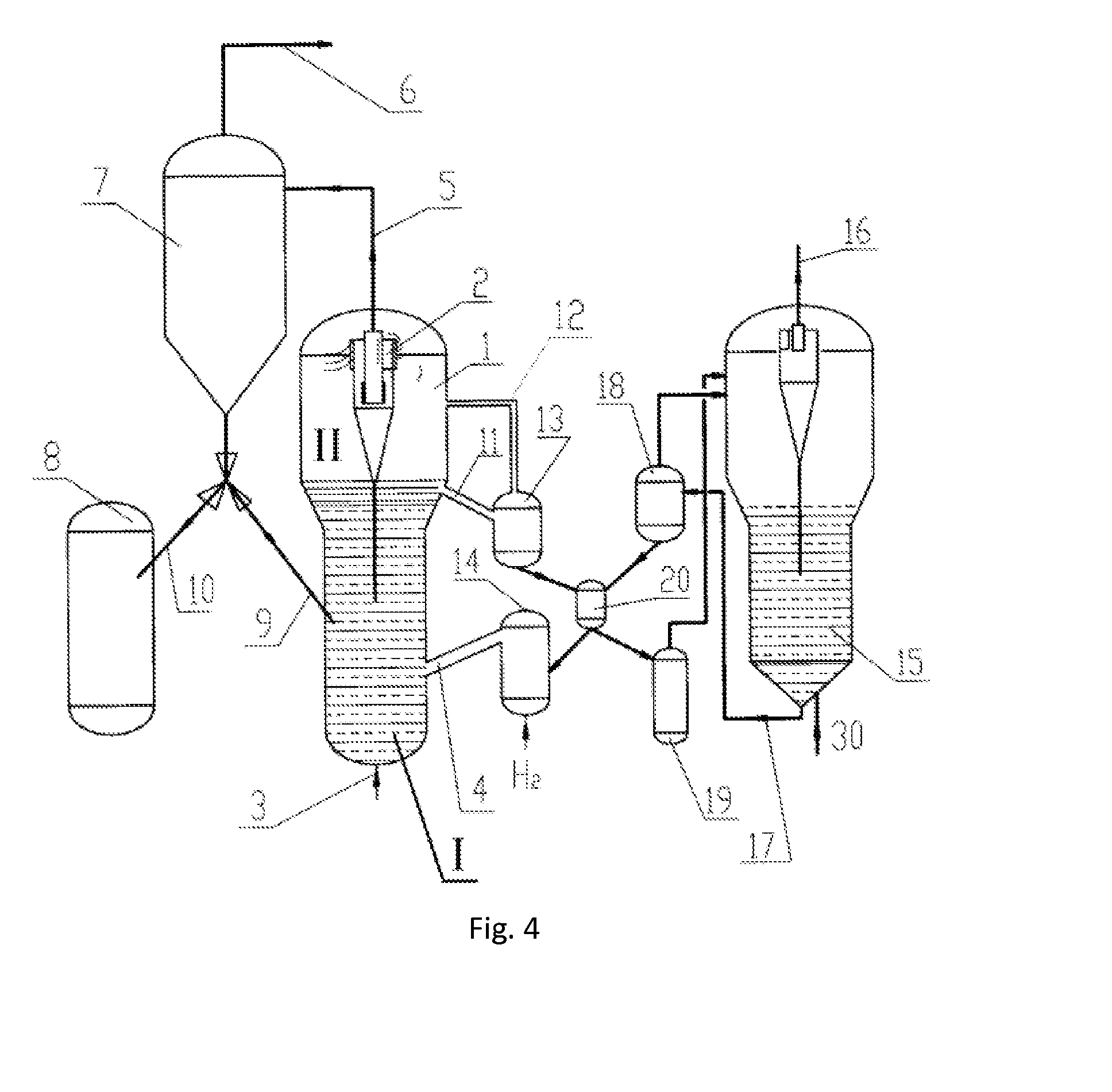

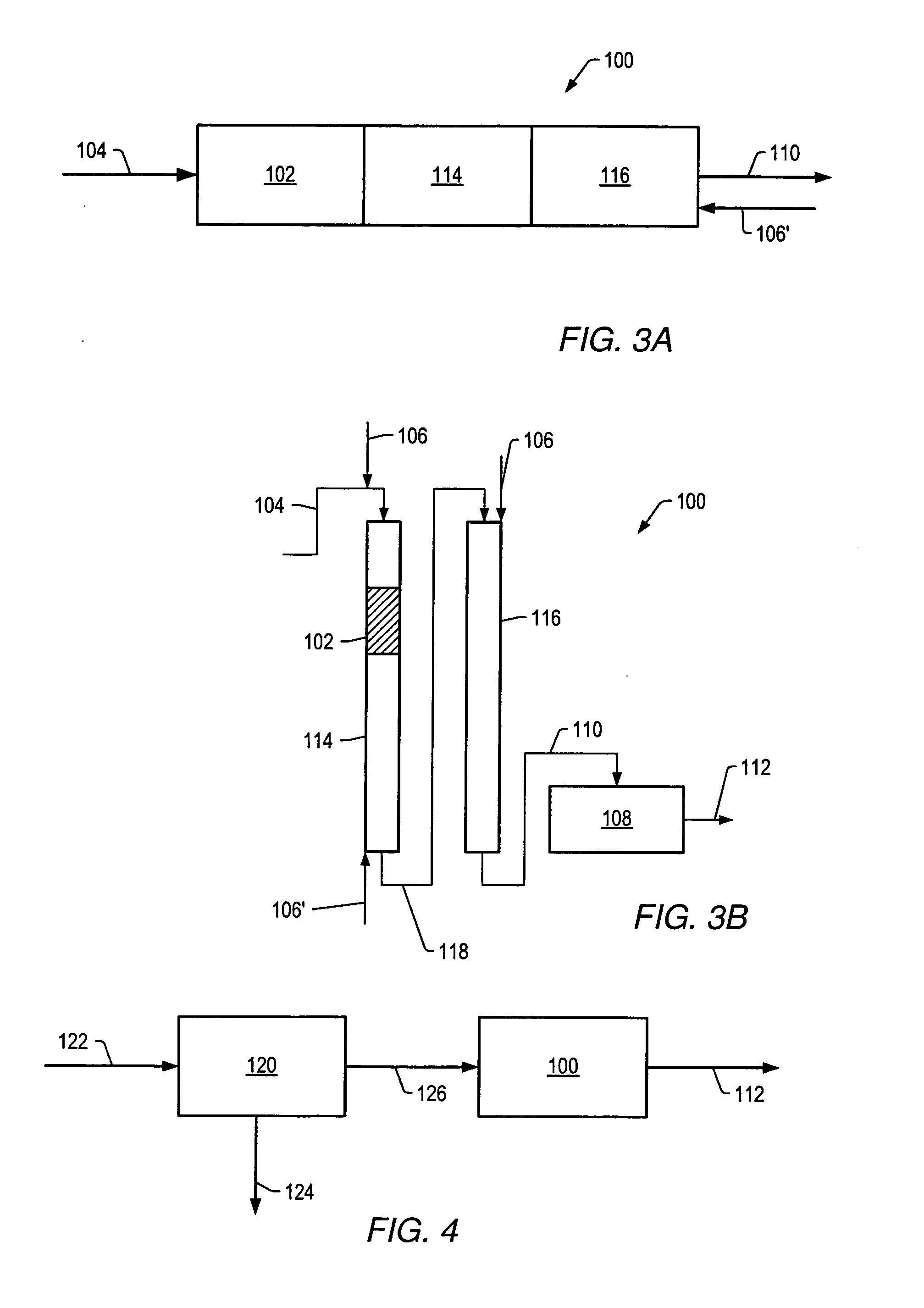

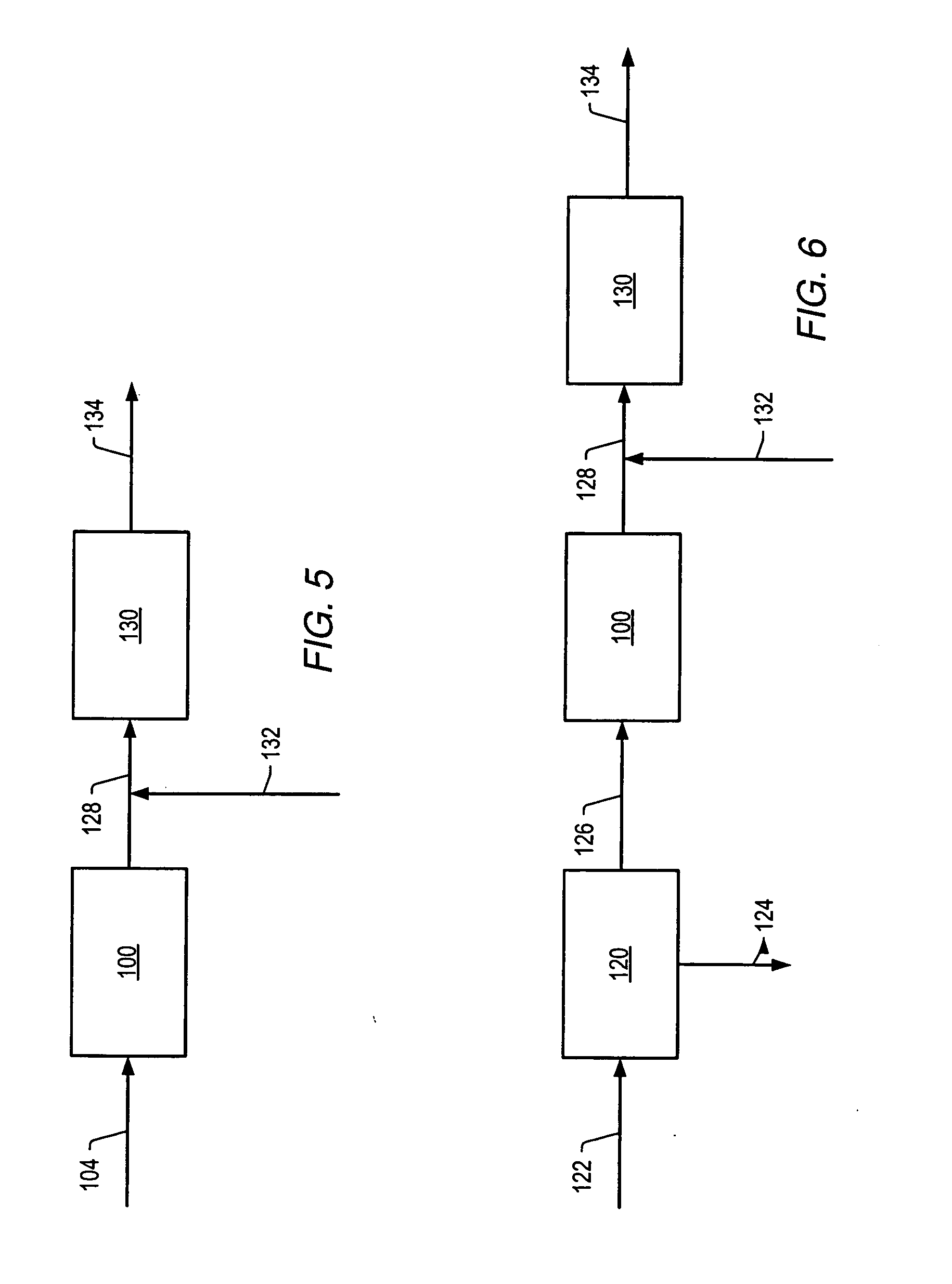

Adsorption Desulfurization Process for Hydrocarbons and a Reaction Apparatus Therefor

ActiveUS20140121438A1Efficient removalReduce flow rateReversed direction vortexHydrocarbonsFluidized bedStraight tube

The present invention relates to an airflow particle sorter, comprising: a top-sealed sorter main body, a discharge port, an outtake tube and at least one directing-intake port; the inner space of the sorter main body, from the above to the bottom, includes, a straight tube zone and a cone zone, the conical bottom of the cone zone is connected to the straight tube zone; the discharge port is located at the bottom of the cone zone; the directing-intake port is installed in the upper part of the straight tube zone in a tangential direction of the straight tube zone, and is communicated with the inner space of the sorter main body; the outtake tube is hermetically inserted into the top of the sorter main body, and extends downwardly to the lower part of the straight tube zone, and the outtake tube has a sealed bottom end; the lower part of the outtake tube is installed with at least one directing-outtake port, which communicates the outtake tube with the inner space of the sorter main body, the directing-outtake port is installed in a tangential direction of the outtake tube. The present invention further relates to a fluidized bed reactor and an adsorption desulfurization reaction apparatus as well as an adsorption desulfurization process.

Owner:CHINA PETROCHEMICAL CORP +1

Slag oil hydro-demetallization catalyst and its preparing method

ActiveCN1782031AImprove performanceEasy to operateRefining to eliminate hetero atomsAluminum CarbonateAlumina hydrate

The slag oil hydrodemetallizing catalyst contains a kind of double-peak hole alumina carrier and supported Mo and / or W and Ni and / or Co metal components. The double-peak hole alumina carrier has pore volume of 0.8-1.6 ml / g, specific surface area 150-350 sq m / g, pore volume fraction of 10-30 nm size holes in 40-90 % and pore volume fraction of 100-2000 nm size holes in 10-60 %, and is prepared through mixing alumina hydrate and ammonium aluminum carbonate, forming and roasting. The slag oil hydrodemetallizing catalyst has simple preparation process and high hydrodemetallizing performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Systems, methods, and catalysts for producing a crude product

InactiveUS20060231465A1Reduce contentRefining with metalsOrganic-compounds/hydrides/coordination-complexes catalystsChemistryCrude oil

Owner:SHELL OIL CO

Method for preparing alumina supporter

InactiveCN1488441ANo pollution in the processNo special pollutionCatalyst carriersRefining to eliminate hetero atomsContaminationMetal

The invention discloses a manufacturing method for aluminium dioxide, blends two kinds of different thin water aluminium wafer powder evenly, and then carries on dissolving and forming, drying, baking and gets the aluminum oxide. The first kind of thin water aluminum mine has a hole capacity of 0.50ml / g~0.80ml / g, the proportion accounts for 5w%~50w% of Al2O3 . the hole capacity of the second aluminum mine is about 0.85ml / g ~1.50ml / g. There has no contamination by using the method; the diameter of the carrier is in the range of 6nm~35nm and 100nm~2000nm; the carrier can be used as carrier of protection agent in heavy oil producing, metal eliminating catalyst and so on.

Owner:CHINA PETROLEUM & CHEM CORP +1

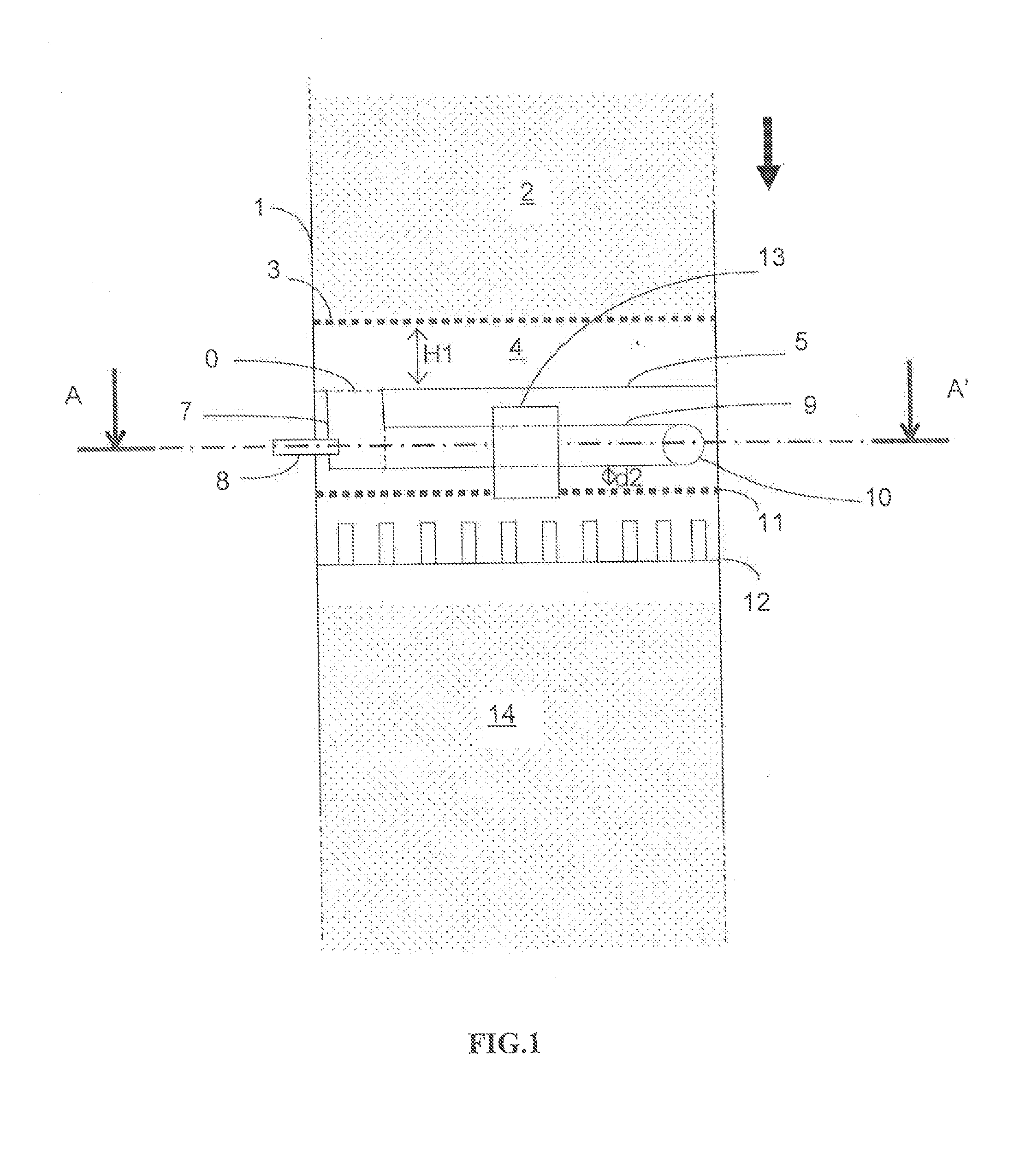

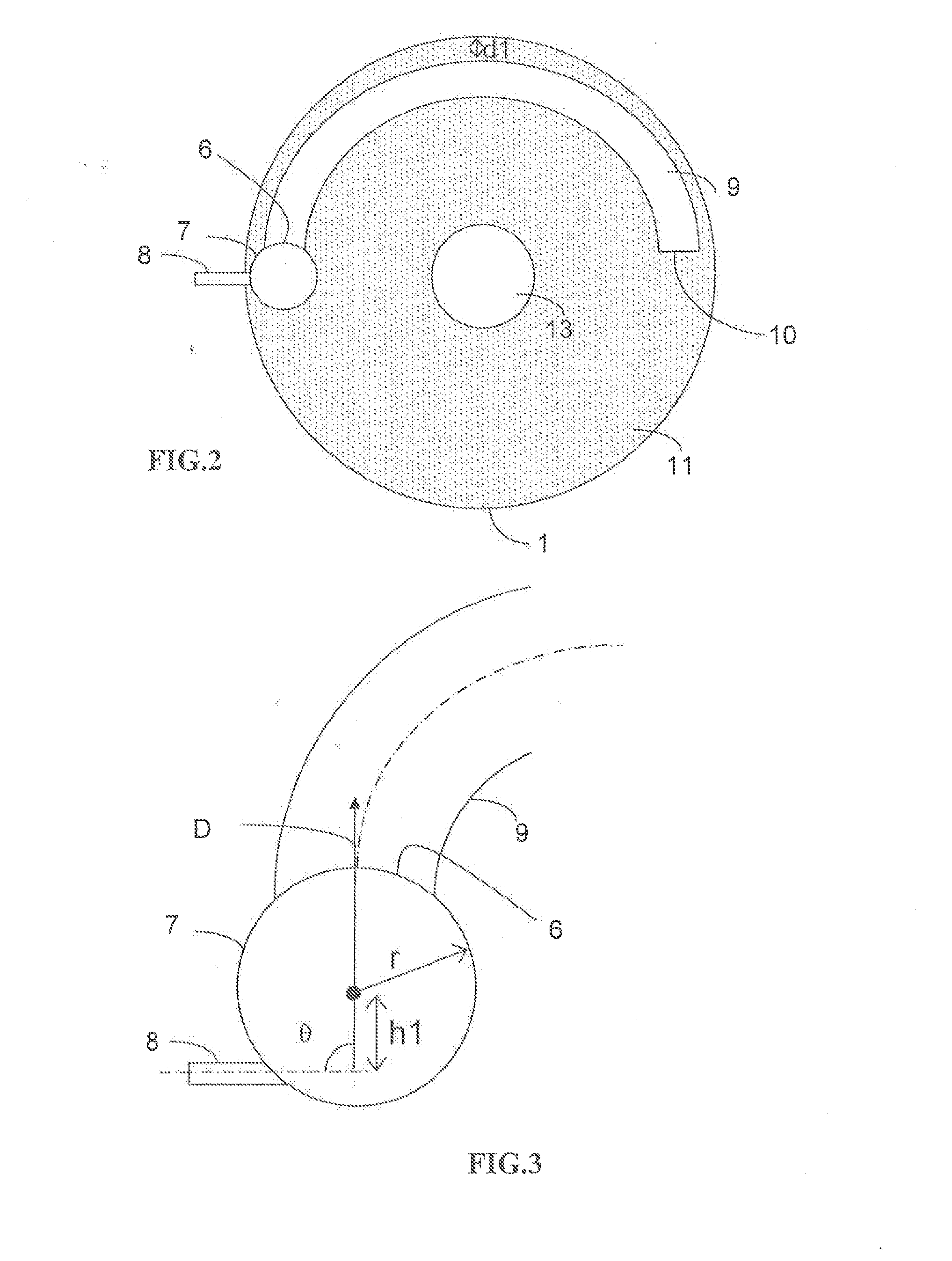

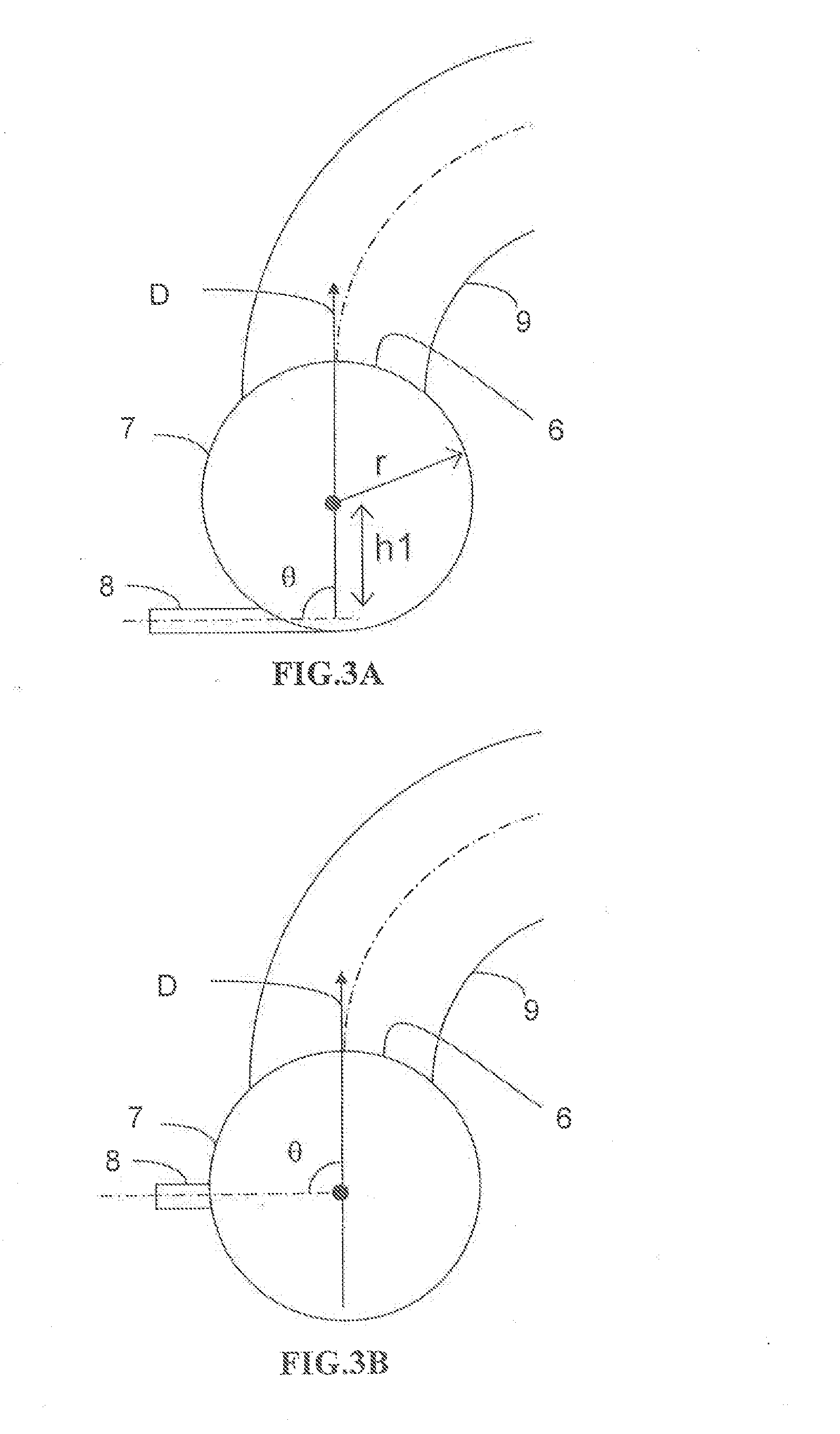

Device for injecting and mixing fluids in a downward-flow reactor

The catalytic reactor with downward flow comprises a chamber (1) containing at least two solid catalyst beds (2; 11) separated by an intermediate zone comprising an essentially horizontal collecting plate (5) communicating with a vertical collecting pipe (7) for receiving fluids collected by the collecting plate, with a means for injecting a quenching fluid (8) emptying into the collecting pipe. An annular mixing chamber (9) is located below the collecting plate (5). A predistribution plate (11) is arranged below the chamber (9).The injection means (8) comprises a tubular portion that empties into the collecting pipe (7) in such a way as to inject quenching fluid in a direction forming an angle θ between 45° and 135° with the direction D from the axis of the mixing chamber measured at its input end.

Owner:INST FR DU PETROLE

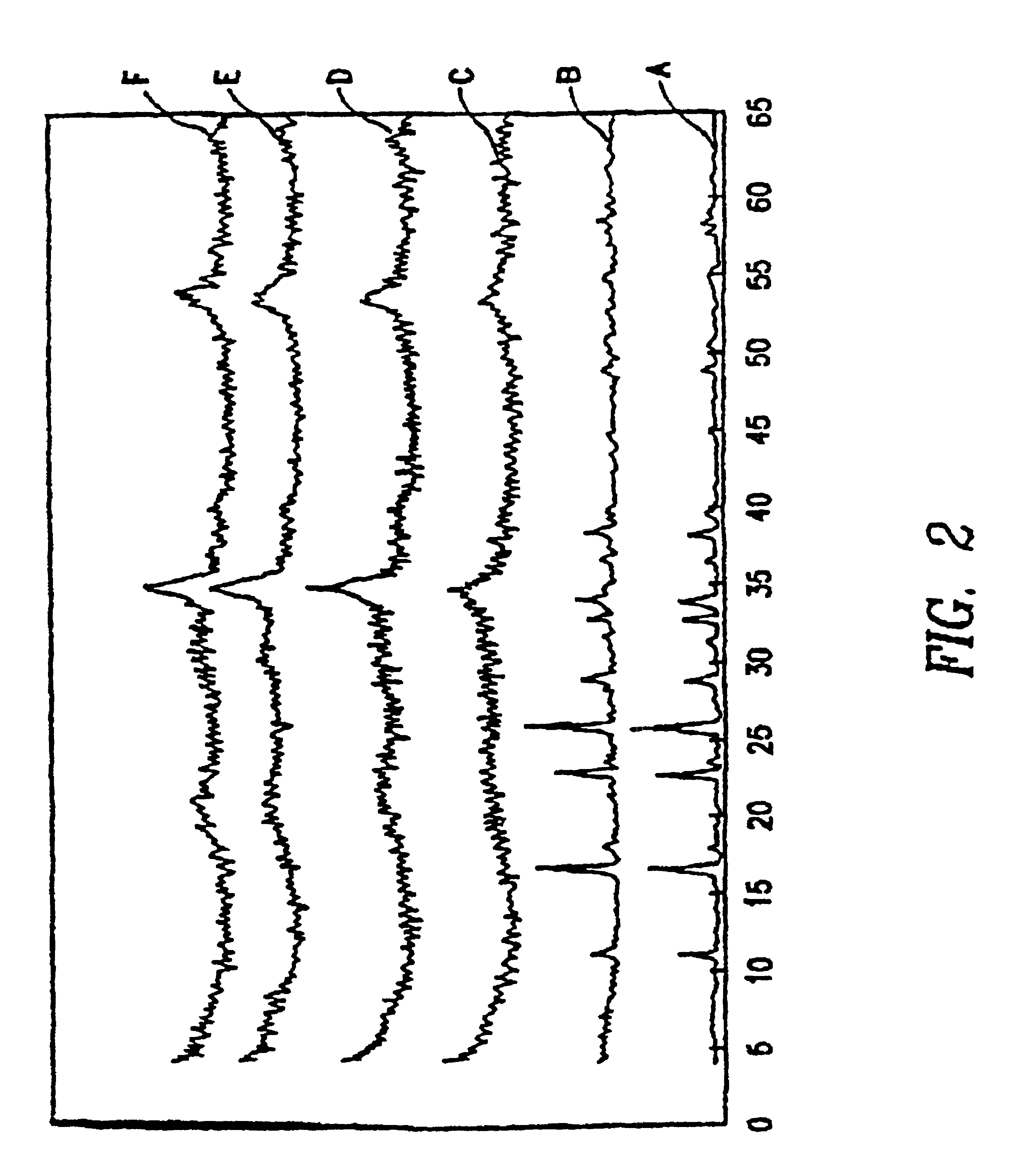

Bulk bimetallic catalysts, method of making bulk bimetallic catalysts and hydroprocessing using bulk bimetallic catalysts

ActiveUS20070084754A1Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationSulfurNitrogen

The invention relates to a process for upgrading hydrocarbonaceous feedstreams by hydroprocessing using bulk bimetallic catalysts. More particularly, the invention relates to a catalytic hydrotreating process for the removal of sulfur and nitrogen from a hydrocarbon feed such as a fuel or a lubricating oil feed. The catalyst is a bulk catalyst comprising a Group VIII metal and a Group VIB metal.

Owner:EXXON RES & ENG CO

Systems, methods, and catalysts for producing a crude product

InactiveUS20050133414A1Reduce contentCatalytic crackingRefining with metal saltsOxygen contentChemistry

Contact of a crude feed with one or more catalysts produces a total product that includes a crude product. The crude feed may include Micro-Carbon Residue (MCR), oxygen, sulfur, or mixtures thereof. The crude product is a liquid mixture at 25° C. and 0.101 MPa. The crude product may have a MCR residue and / or oxygen content of at most 90% of the MCR residue content and / or oxygen content of the crude feed. In some instances, the crude product may have a sulfur content of about 30% to about 70% of the sulfur content of the crude feed. One or more other properties of the crude product may be changed by at least 10% relative to the respective properties of the crude feed.

Owner:SHELL OIL CO

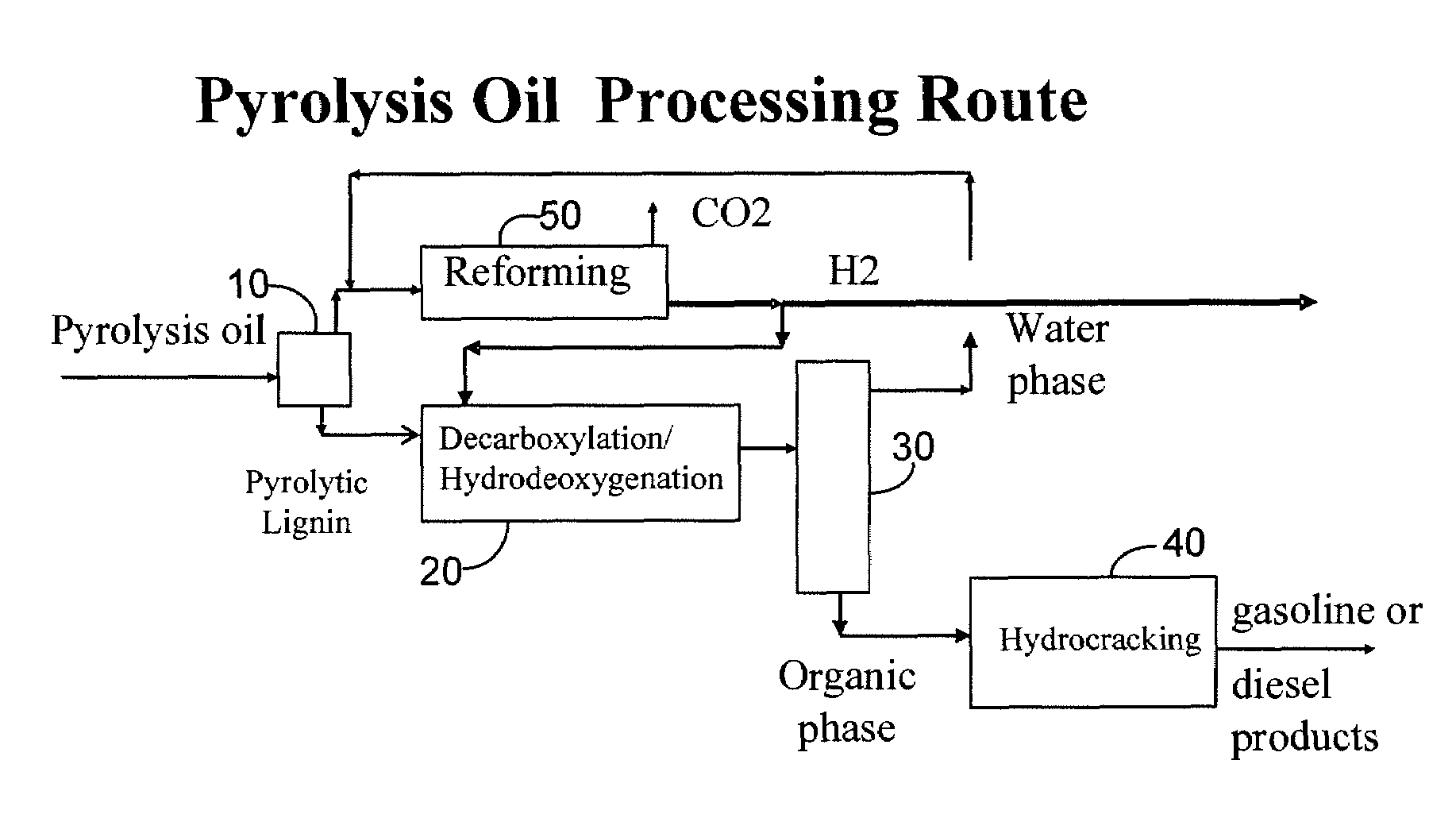

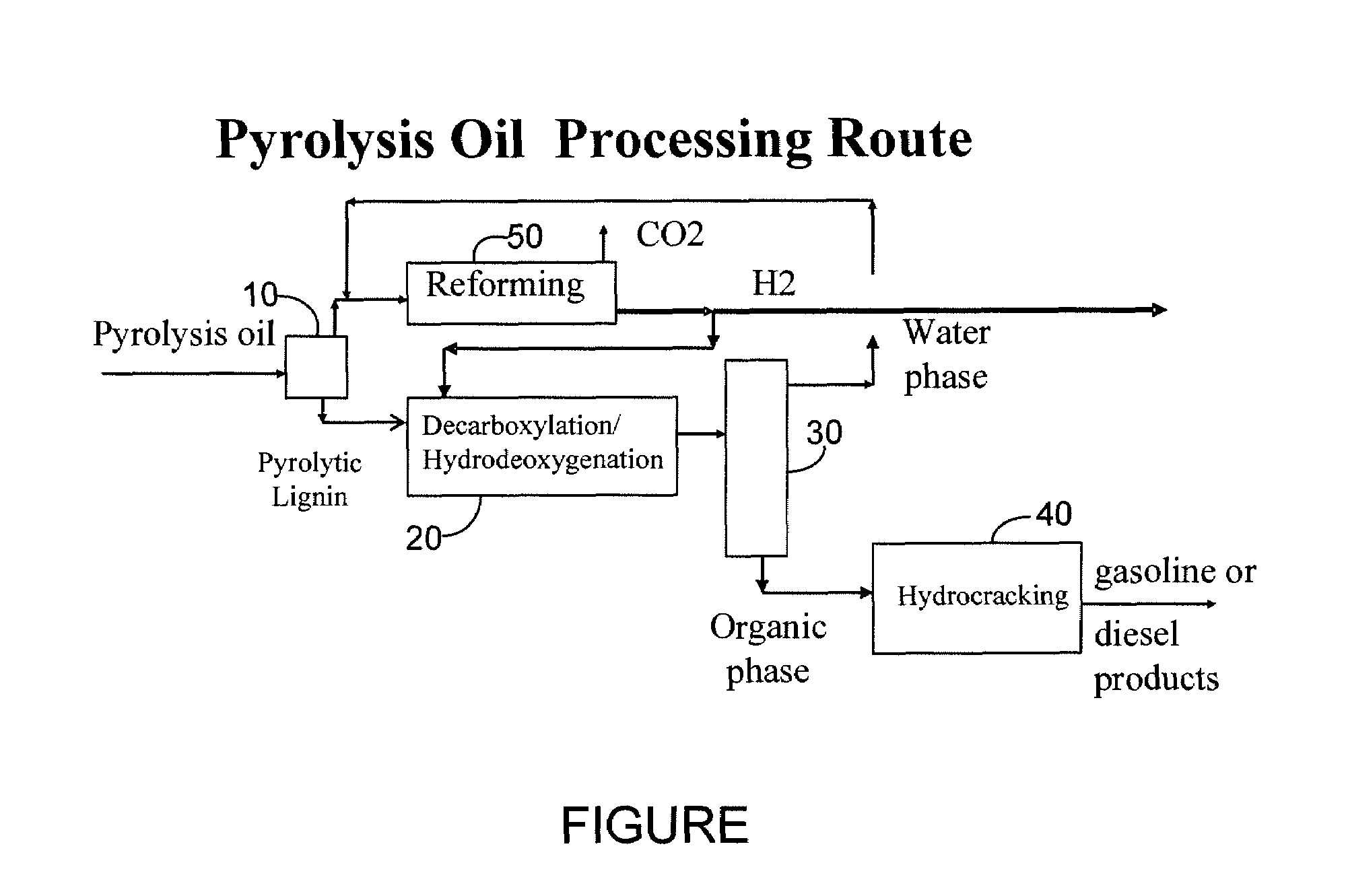

Gasoline and diesel production from pyrolytic lignin produced from pyrolysis of cellulosic waste

InactiveUS7578927B2Treatment with plural serial cracking stages onlyTreatment with plural serial stages onlyCelluloseNaphtha

A process for the conversion of biomass to a liquid fuel is presented. The process includes the production of diesel and naphtha boiling point range fuels by hydrocracking of pyrolysis lignin extracted from biomass.

Owner:UOP LLC

Systems, methods, and catalysts for producing a crude product

InactiveUS20050133417A1Reduce contentCatalytic crackingRefining with metal saltsAcid valueTotal acid

Contact of a crude feed with one or more catalysts produces a total product that include a crude product. The crude feed may a total acid number of at least 0.3. The crude product is a liquid mixture at 25° C. and 0.101 MPa. The crude product may have a total acid number of at most 90% of the total acid number of the crude feed. At least one of the catalysts may include one or more Column 6 metals of the Periodic Table and one or more Column 10 metals of the Periodic Table. One or more other properties of the crude product may be changed by at least 10% relative to the respective properties of the crude feed.

Owner:SHELL OIL CO

Production of Aviation Fuel from Biorenewable Feedstocks

ActiveUS20090158637A1Refining to change hydrocarbon structural skeletonHydrocarbon purification/separationAlkaneVegetable oil

A process has been developed for producing aviation fuel from renewable feedstocks such as plant oils and animal fats and oils. The process involves treating a renewable feedstock by hydrogenating and deoxygenating to provide n-paraffins having from about 8 to about 24 carbon atoms. At least some of the n-paraffins are isomerized to improve cold flow properties. At least a portion of the paraffins are selectively cracked to provide paraffins meeting specifications for different aviation fuels such as JP-8.

Owner:UOP LLC

Method for preparing high-quality ethylene raw material with petroleum naphtha hydrogenation

ActiveCN101343557AImprove qualityIncrease productionOrganic chemistryBulk chemical productionVegetable oilPetroleum naphtha

The invention relates to a method for generating the high quality ethylene raw material through naphtha hydrogenation. The method takes naphtha fraction and animal and vegetable oil as the raw material oil, under the condition of hydrofining, the raw material oil and hydrogen are mixed and passed through a hydrofining reaction area, the hydrogen-rich gas recycling utilization can be acquired through separating the hydrofining generated oil, and low Sulfur, low hydrogen and low aromatic naphtha can be acquired through removing hydrogen sulfide of the separated liquid with an air stripping tower. Compared with the prior art, the method has the advantages that the oil is mixed in the naphtha hydrogenation raw material, the quality of the product as the ethylene cracking raw material, in particular to aromatic long chain hydrocarbon nC16 to 18 and propane acquired through the animal and vegetable oil hydrogenation, can be remarkably improved, the cracking furnace ethylene output can be increased and the cracking furnace life can be prolonged through adding the aromatic long chain hydrocarbon nC16 to 18 and propane in the ethylene cracking raw material.

Owner:CHINA PETROLEUM & CHEM CORP +1

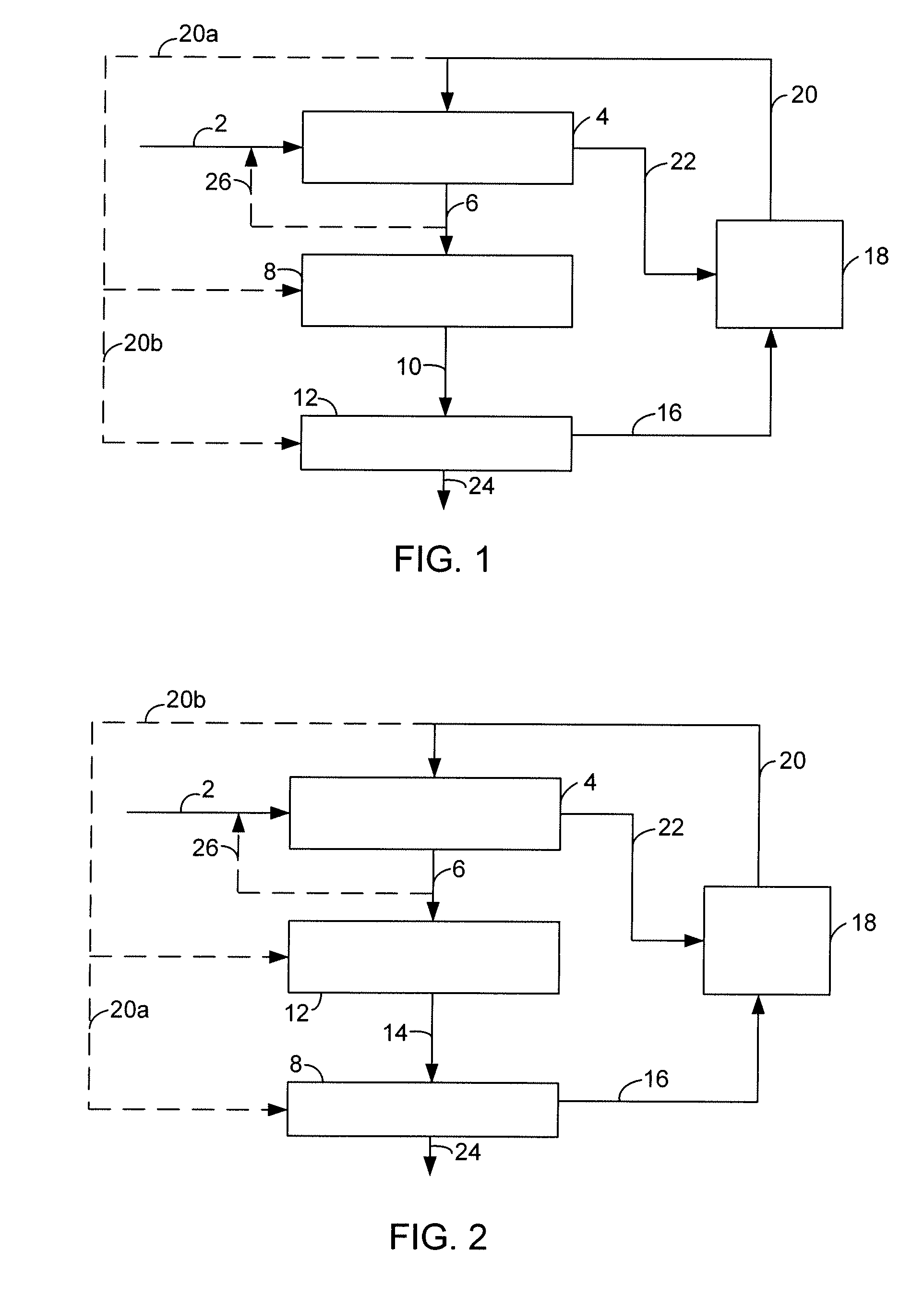

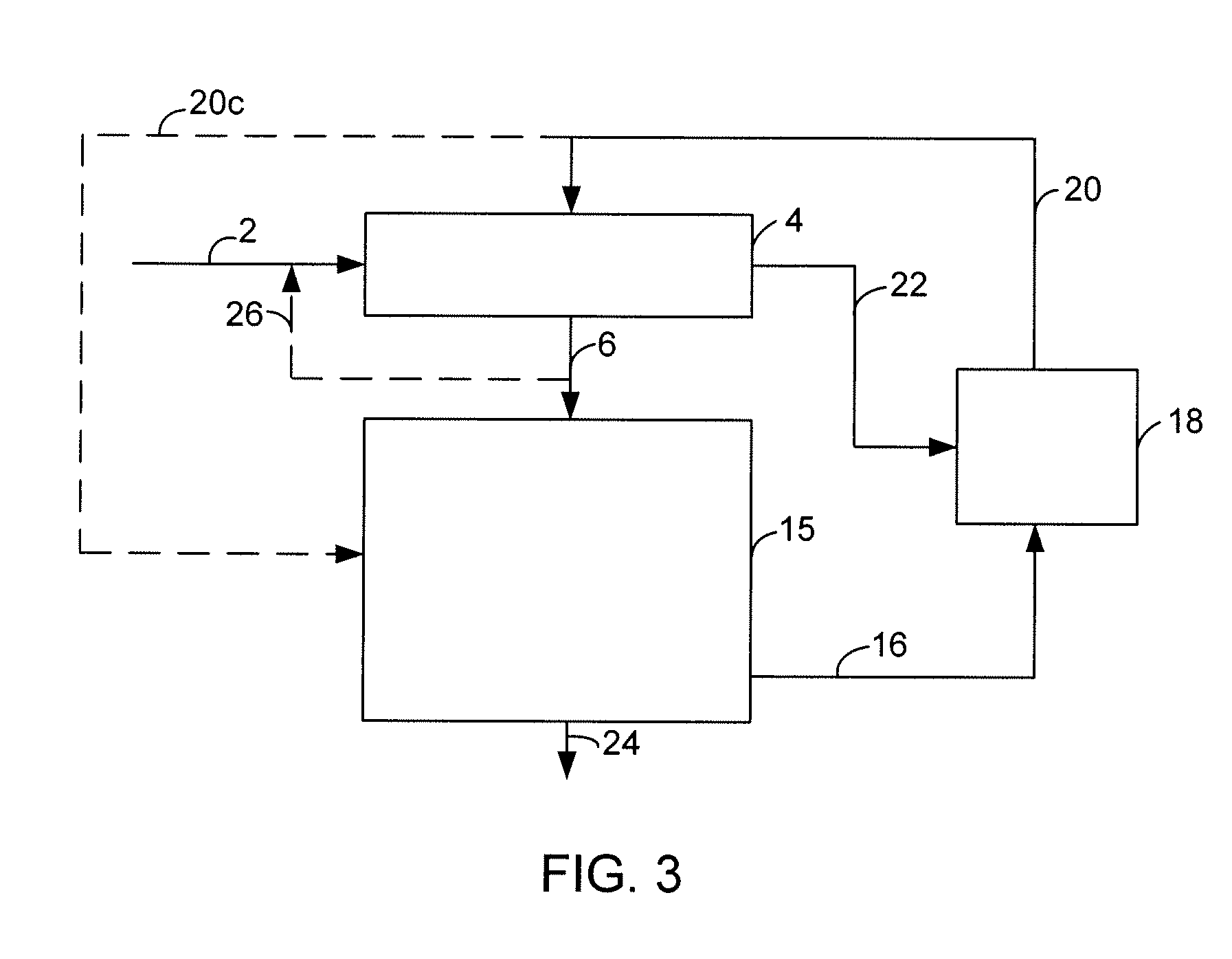

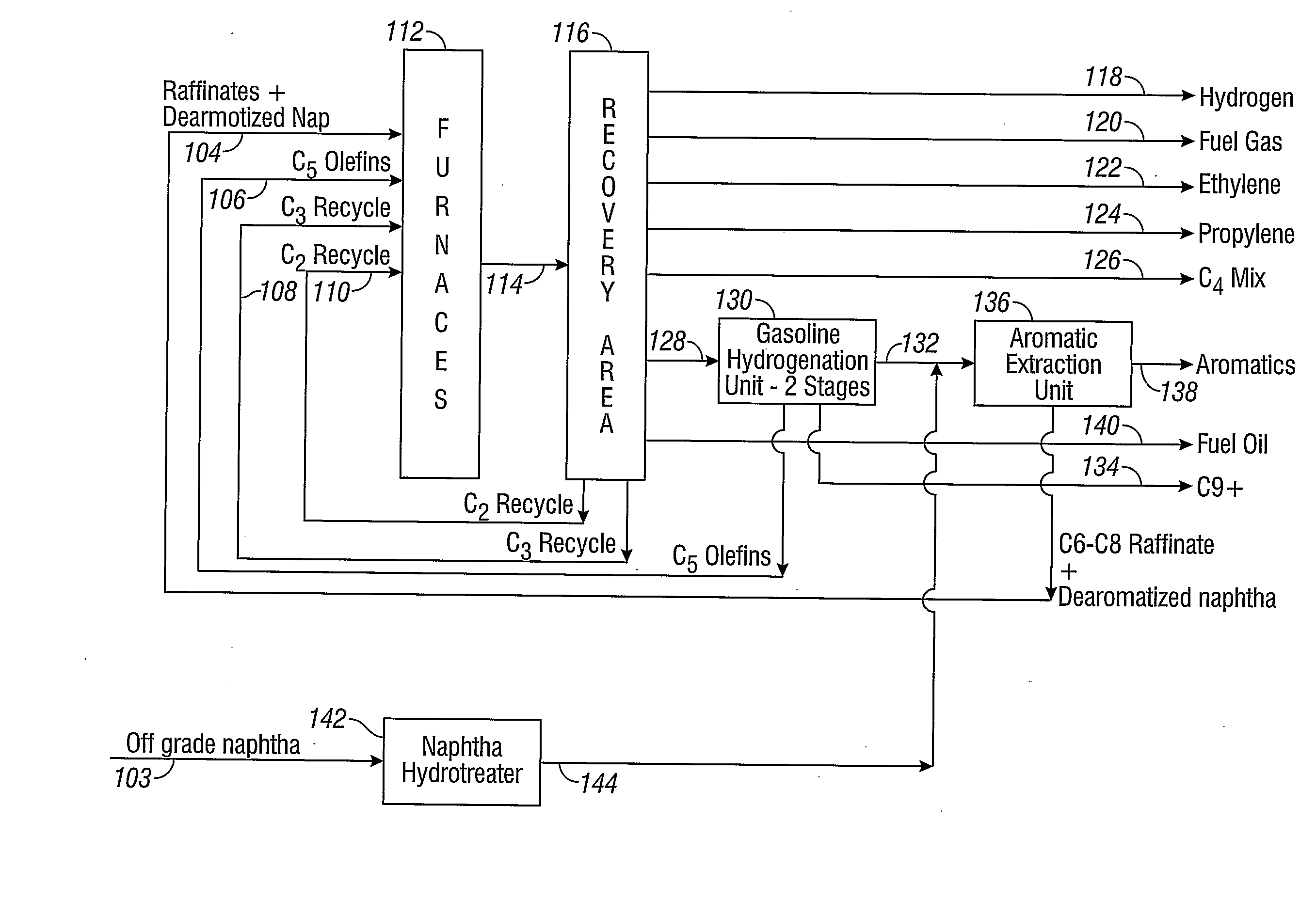

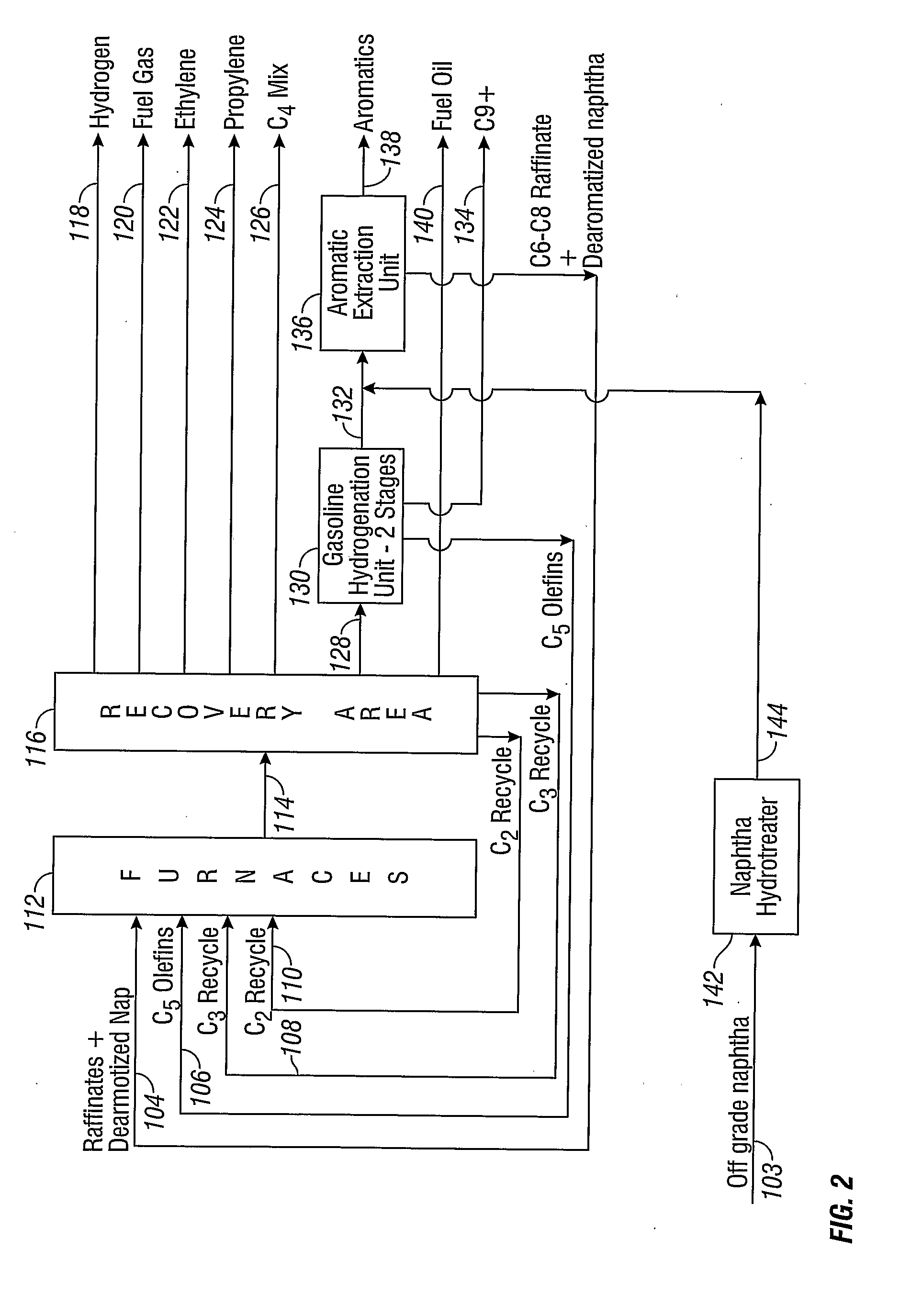

Steam Cracking with Naphtha Dearomatization

Disclosed is a process for upgrading a naphtha feed stream comprising light naphtha, heavy naphtha, or a combination thereof, for supplying to a cracking process. A naphtha feed stream can be supplied to a hydrotreater 142 to remove impurities, followed by dearomatization in an aromatics extraction unit 136. A dearomatized naphtha stream 104 can be supplied to a cracking process 112 and a recovery process 116 to produce various streams including ethylene 122 and propylene 124 for collection, ethane 110 and propane 108 for recycle to the cracking process 112, and a pyrolysis gas stream 128 which can be further treated to produce a C5 olefins stream 106, a C6-C8 stream 104, a C9+ stream 134, and a fuel oil stream 140.

Owner:BHIRUD VASANT L

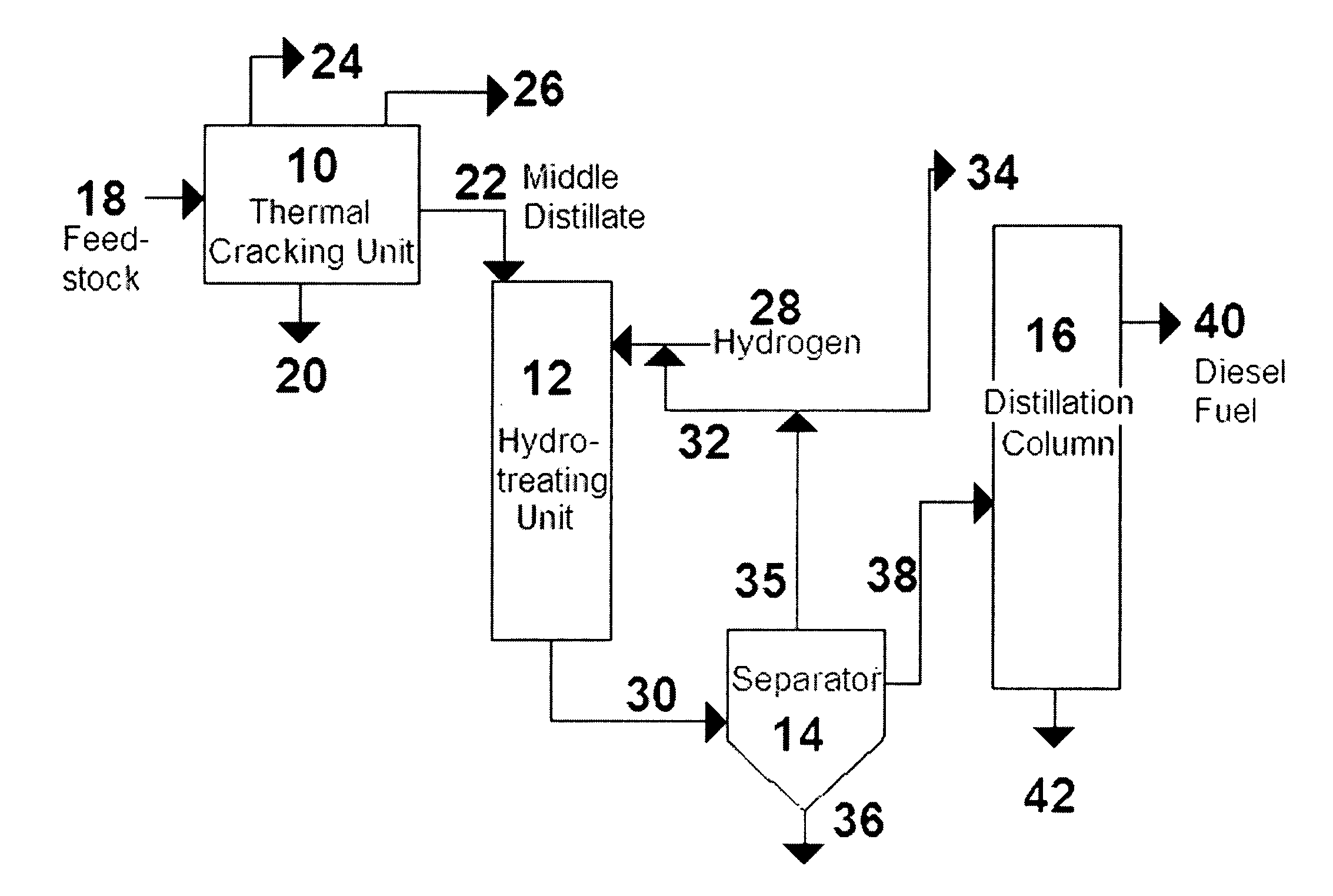

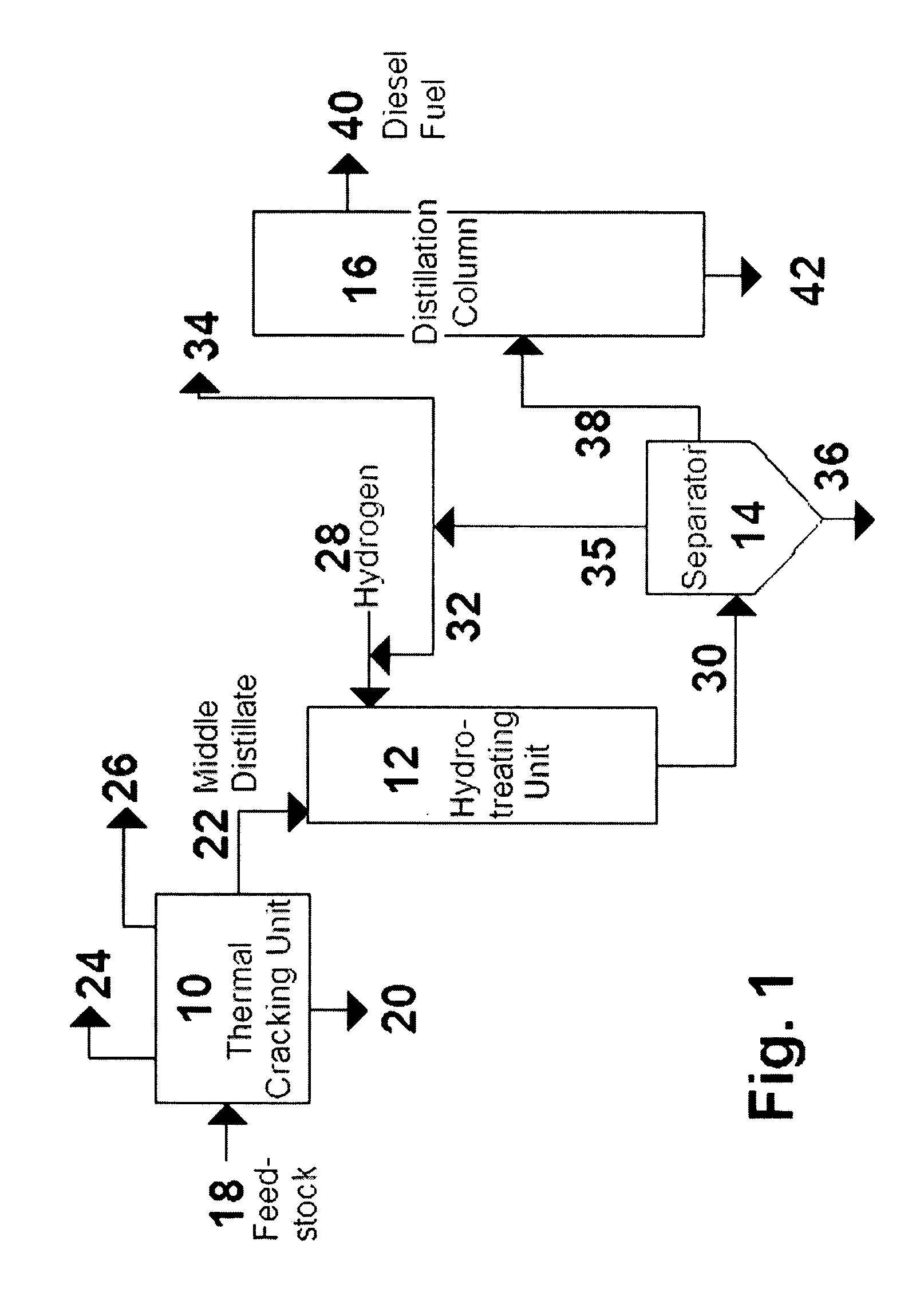

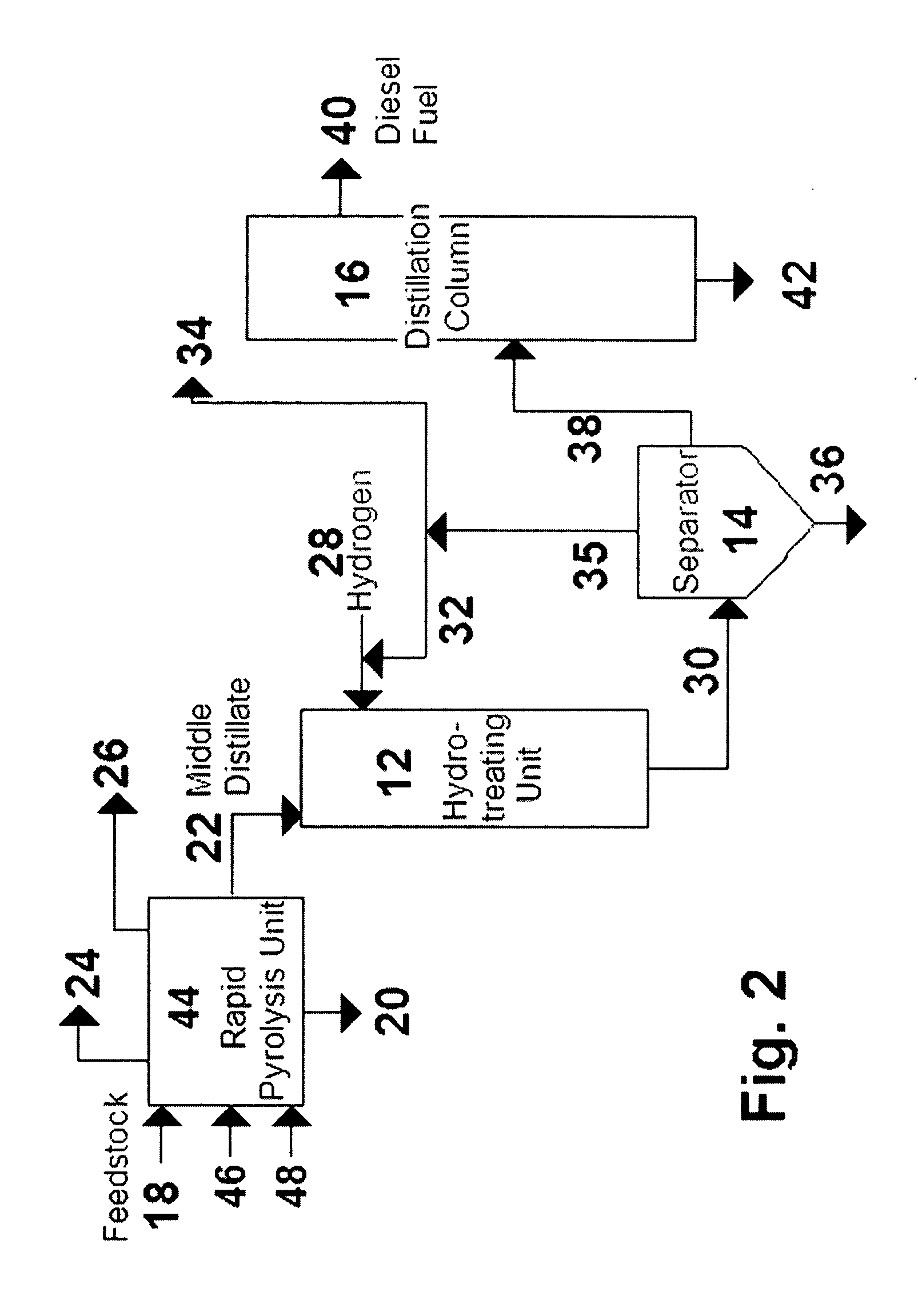

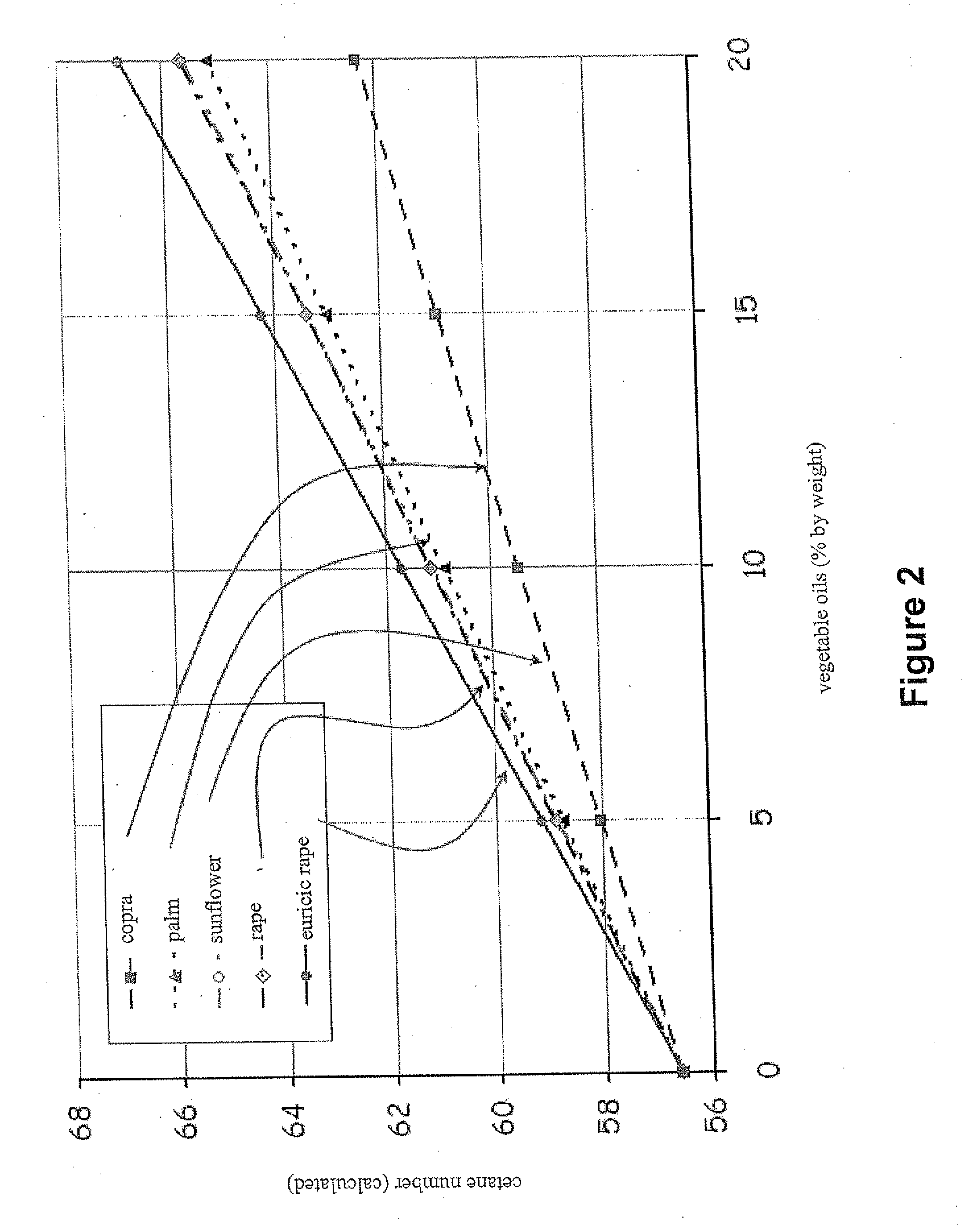

Production of high-cetane diesel fuel from low-quality biomass-derived feedstocks

A method is taught for producing diesel fuels of high cetane value from a triglyceride feedstock, comprising pretreating the triglyceride feedstock by thermal cracking or rapid pyrolysis to partially convert the triglycerides and produce a middle distillates stream, and catalytically hydrotreating the middle distillate fraction to produce high cetane value diesel fuels. A biomass-derived diesel fuel is also taught having sulphur content below 10 ppm, a cetane-value of at least 70, a cloud point below 0° C. and a pour point of less than −4° C. A blended diesel fuel is also taught comprising 5 to 20 vol. % of the biomass-derived diesel fuel of the present invention and 80 to 95 vol. % of a petroleum diesel, based on total volume of the blended diesel fuel.

Owner:HER MAJESTY THE QUEEN & RIGHT OF CANADA REPRESENTED BY THE MIN OF NATURAL RESOURCES

Method for manufacturing cleaner fuels

InactiveUS6248230B1Long catalyst lifeReduce hydrogen consumptionLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesBoiling pointGasoline

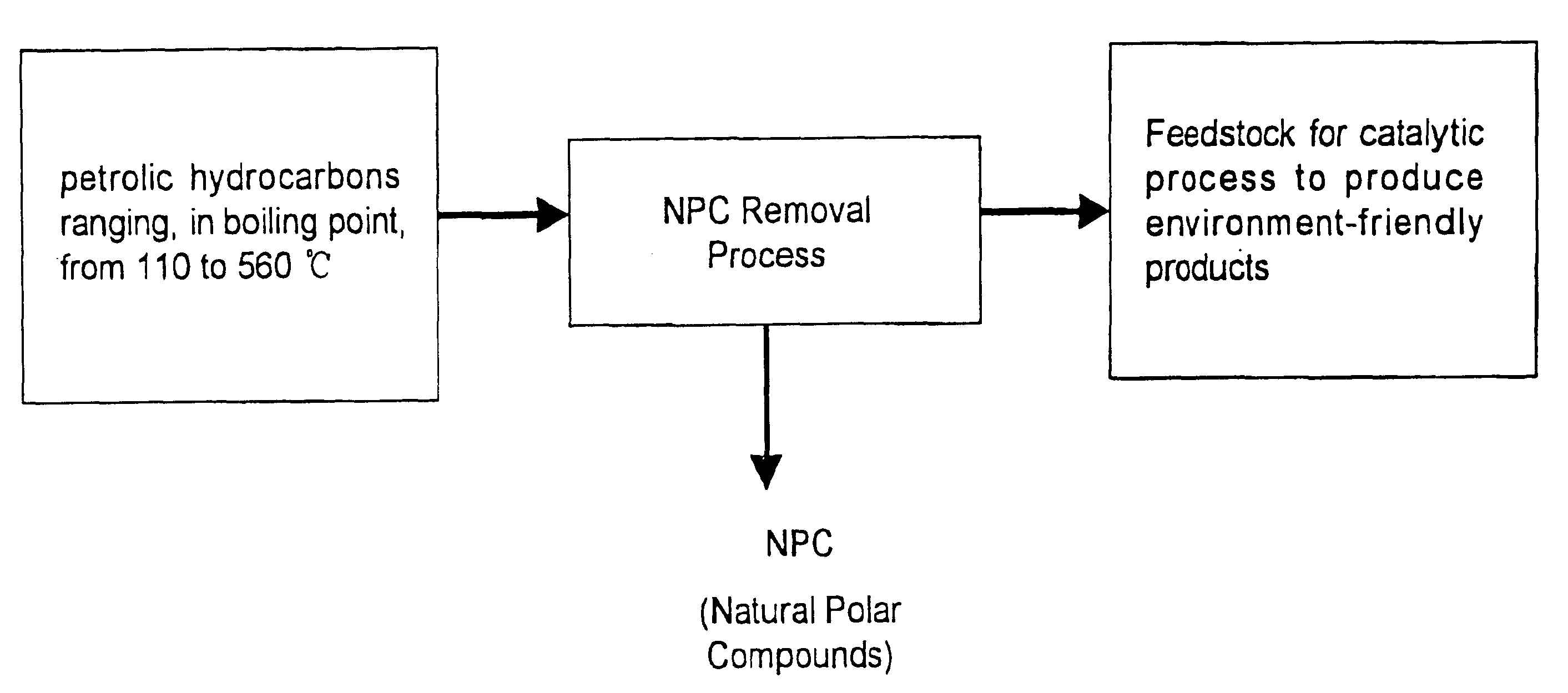

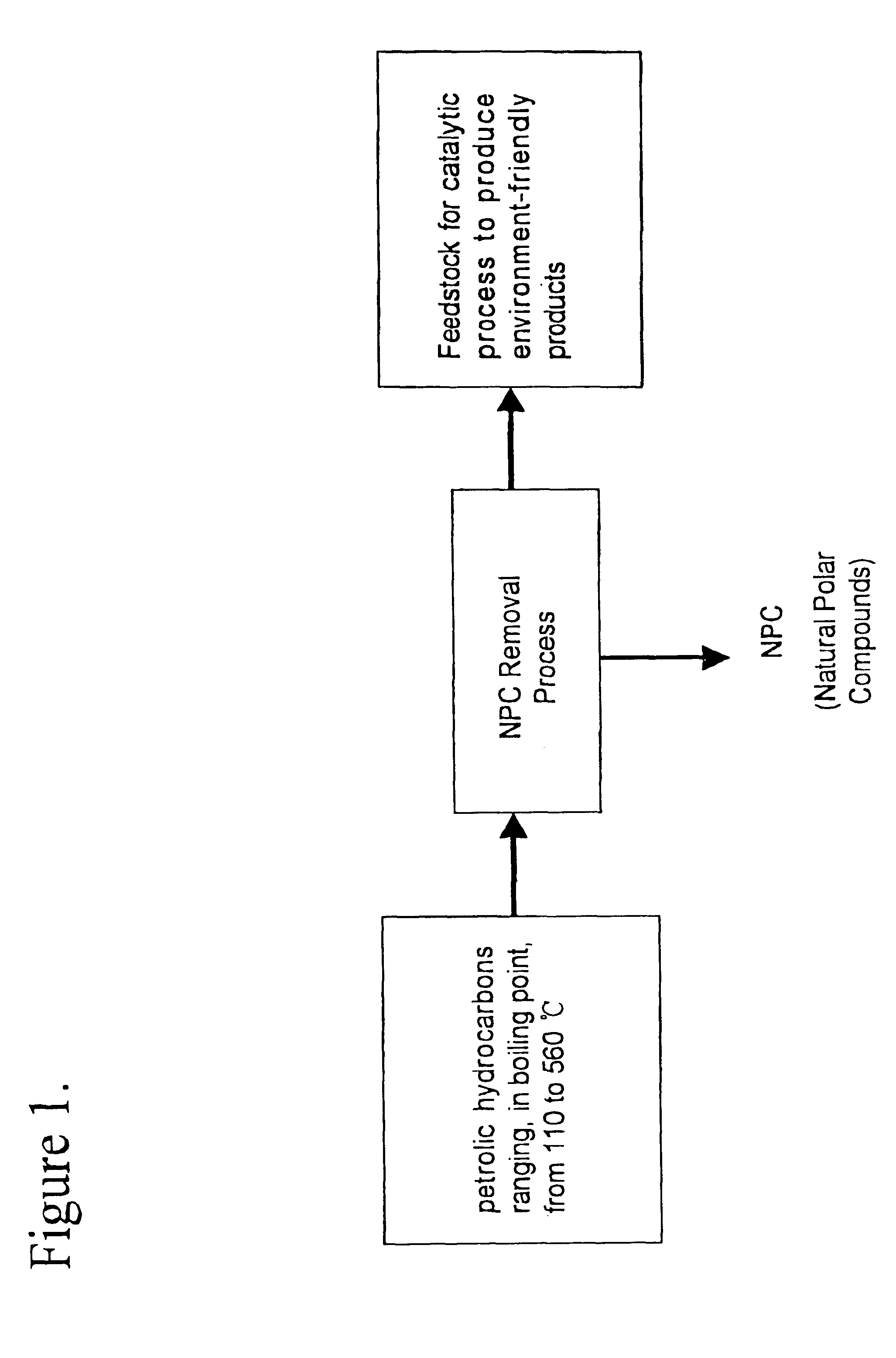

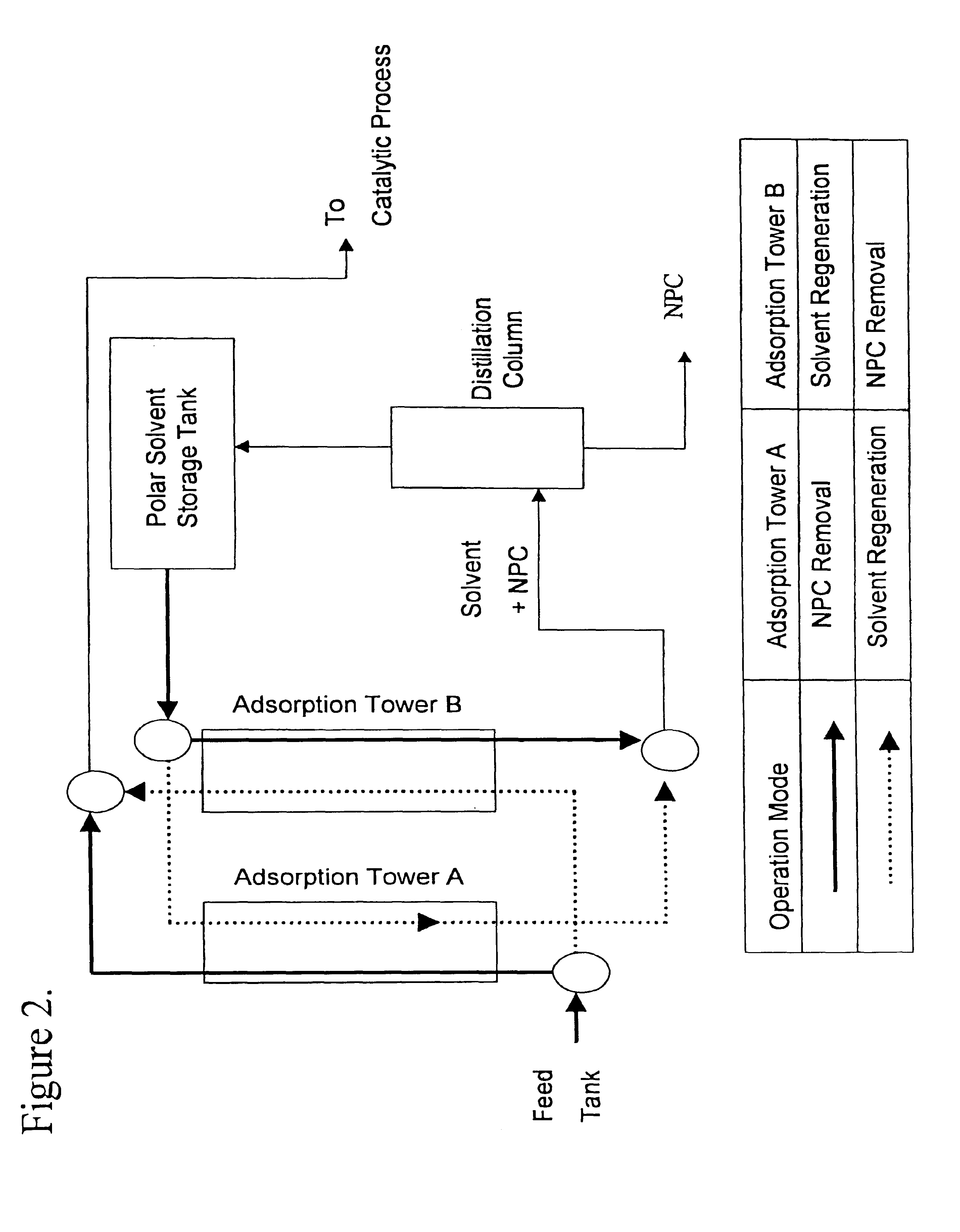

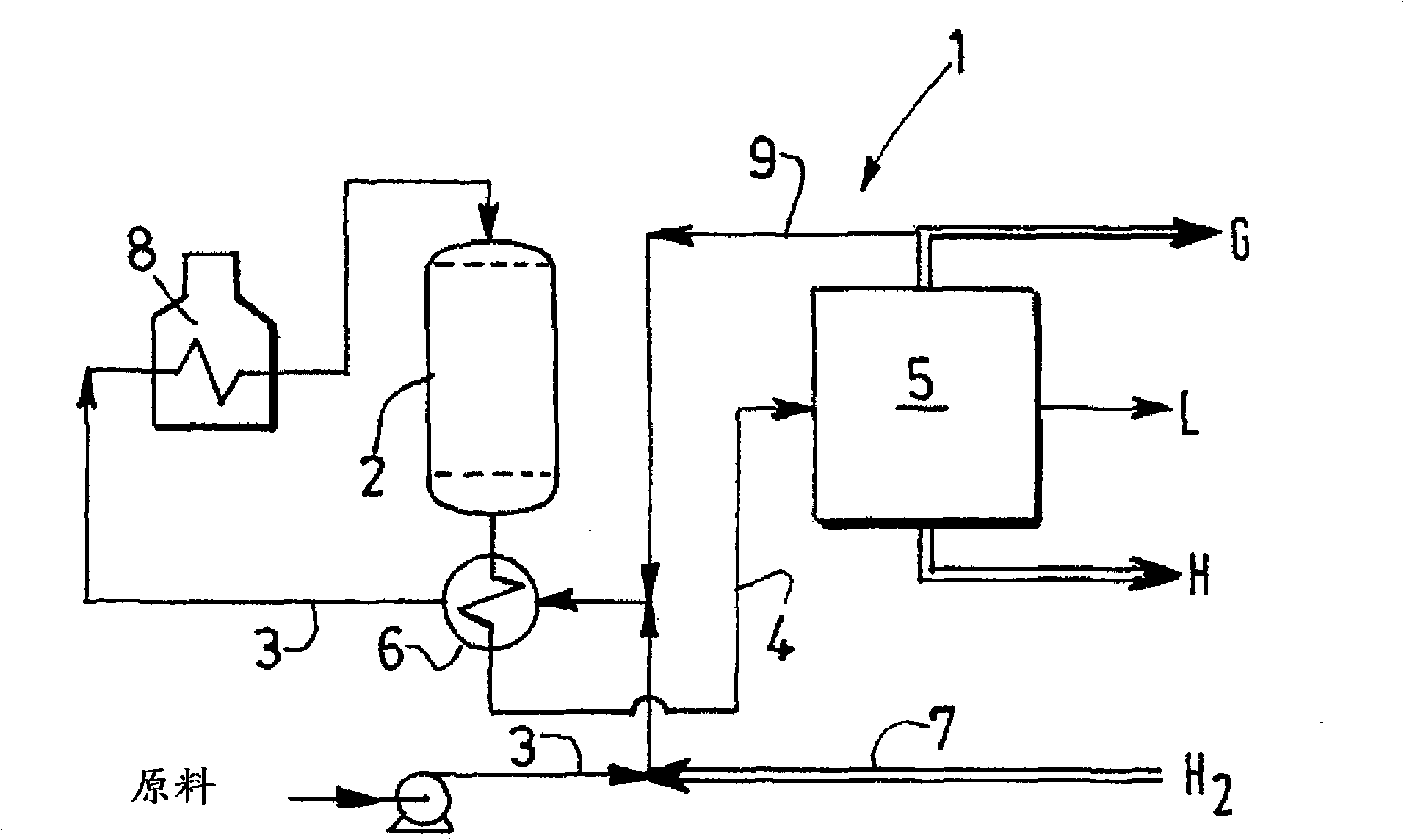

A method is provided for manufacturing cleaner fuels, in which NPC (Natural Polar Compounds), naturally existing in small quantities within various petrolic hydrocarbon fractions, are removed from the petrolic hydrocarbon fractions ranging, in boiling point, from 110 to 560° C. and preferably from 200 to 400° C., in advance of catalytic hydroprocessing. The removal of NPC improves the efficiency of the catalytic process and produces environment-friendly products, such as diesel fuel with a sulfur content of 50 ppm (wt) or lower. Also, the NPC can be used to improve fuel lubricity.

Owner:SK ENERGY CO LTD (KR)

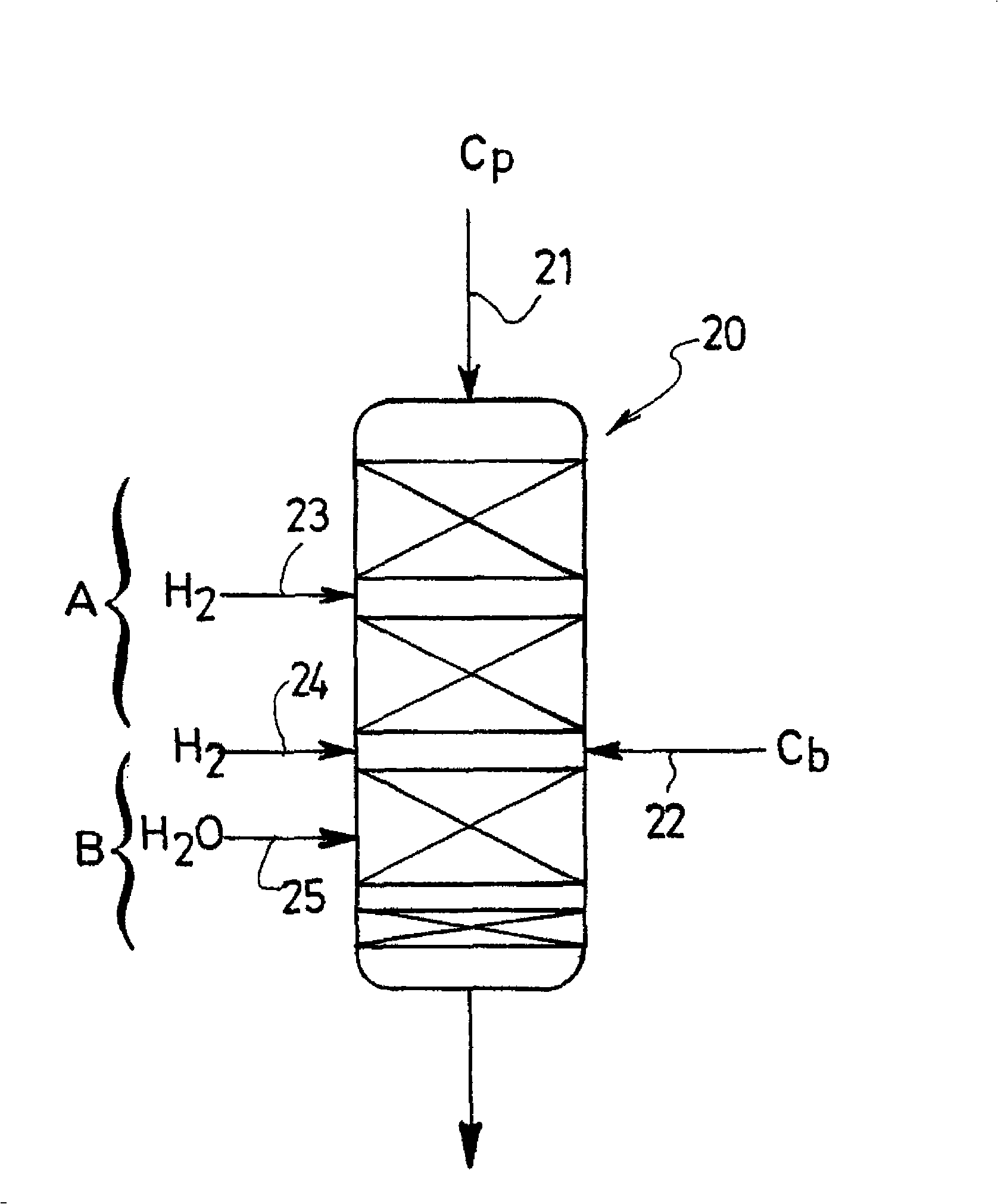

Method for the hydro-processing of a gas oil feedstock, and corresponding hydro-refining unit

InactiveCN101517038AShort stayReduce volumeLiquid hydrocarbon mixture productionEthylene productionFixed bedPetroleum

The invention relates to a method for the catalytic hydro-processing of a petroleum feedstock of the gas oil type and of a biological feedstock containing vegetal oils and / or animal fats, in a catalytic fixed-bed hydro-processing unit, said method being characterised in that the petroleum feedstock is introduced into the reactor upstream from the biological feedstock. The invention also relates to a catalytic hydro-processing unit for implementing said method, and to a corresponding hydro-refining unit.

Owner:TOTAL RAFFINAGE MARKETING

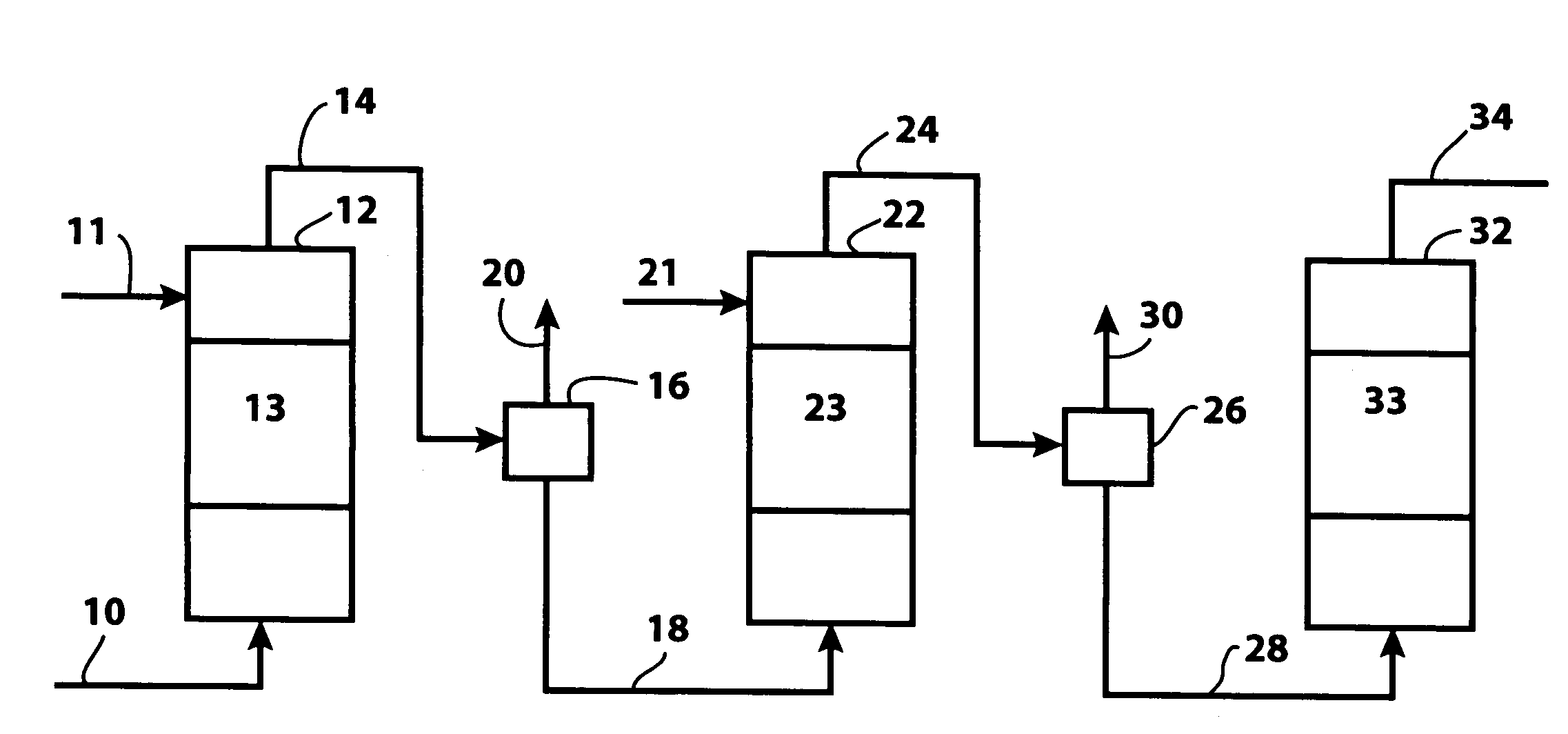

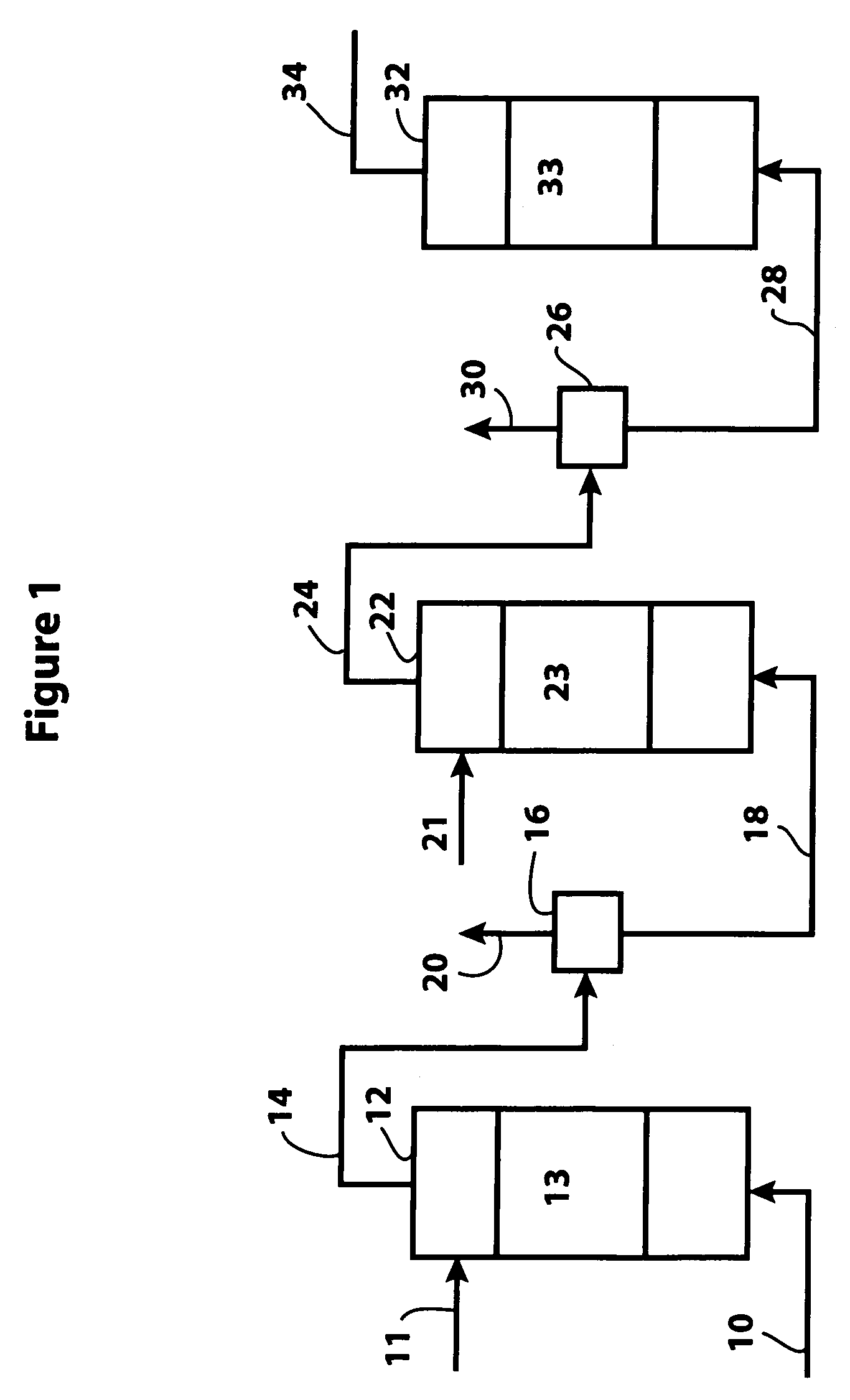

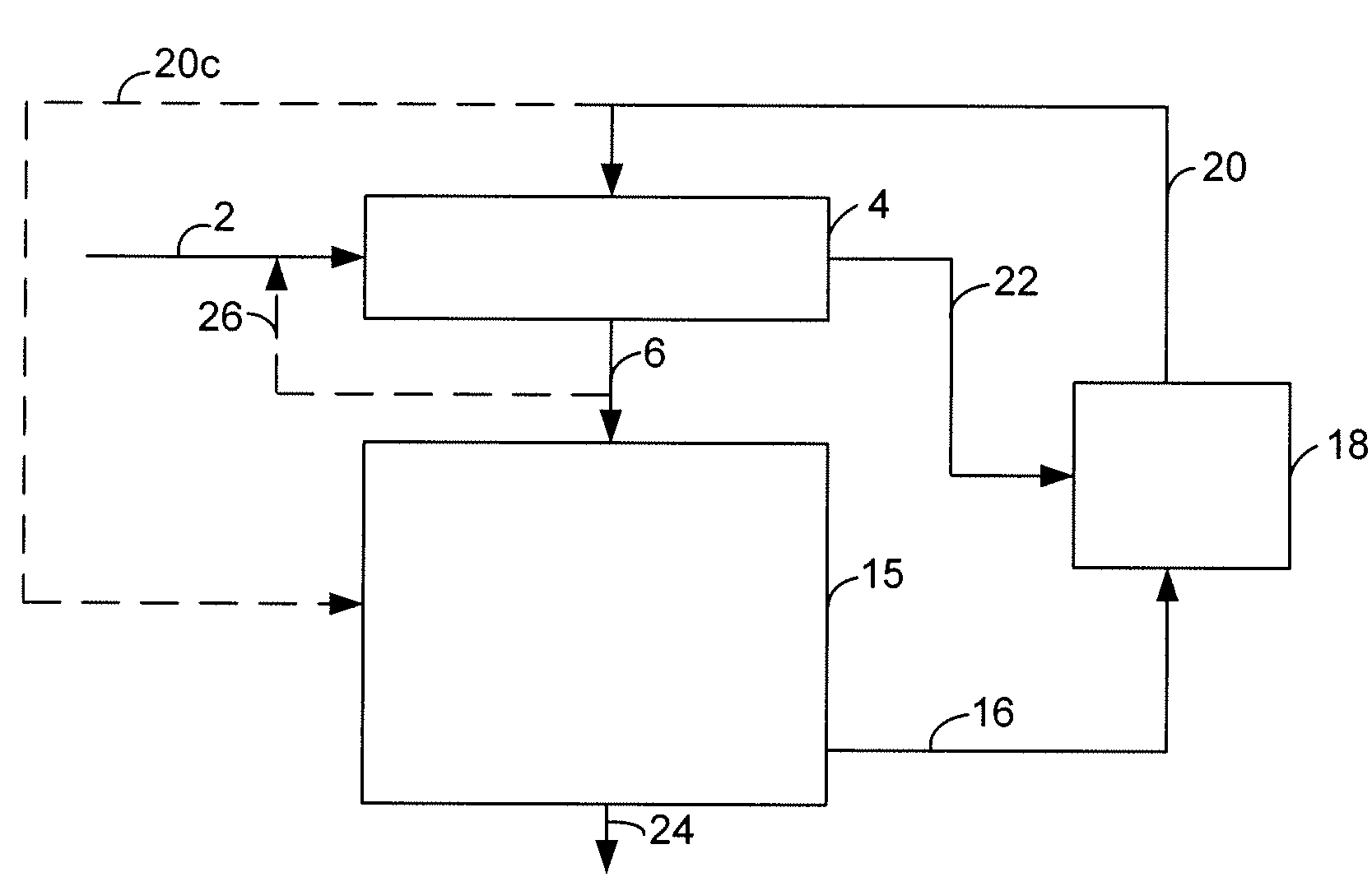

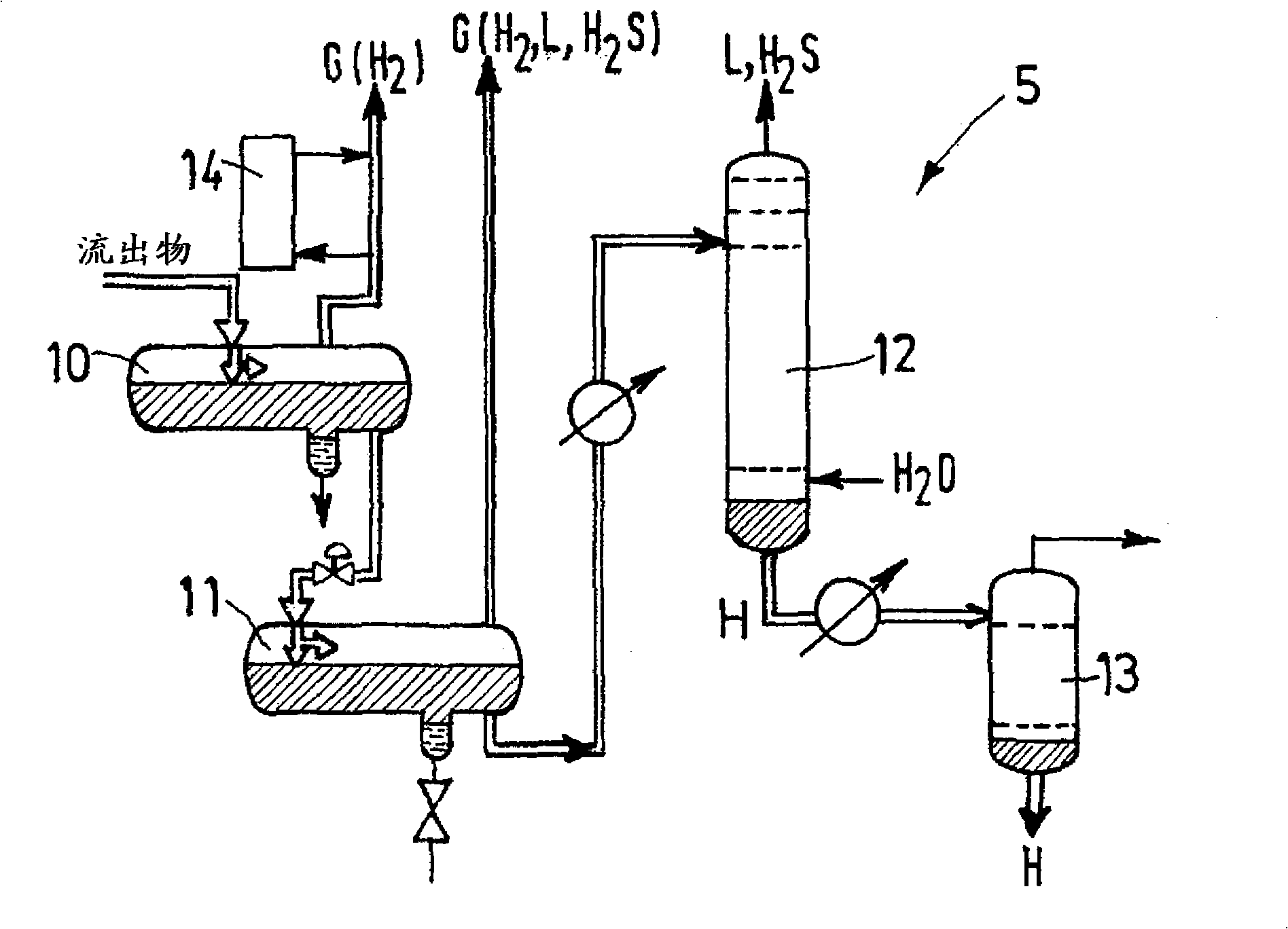

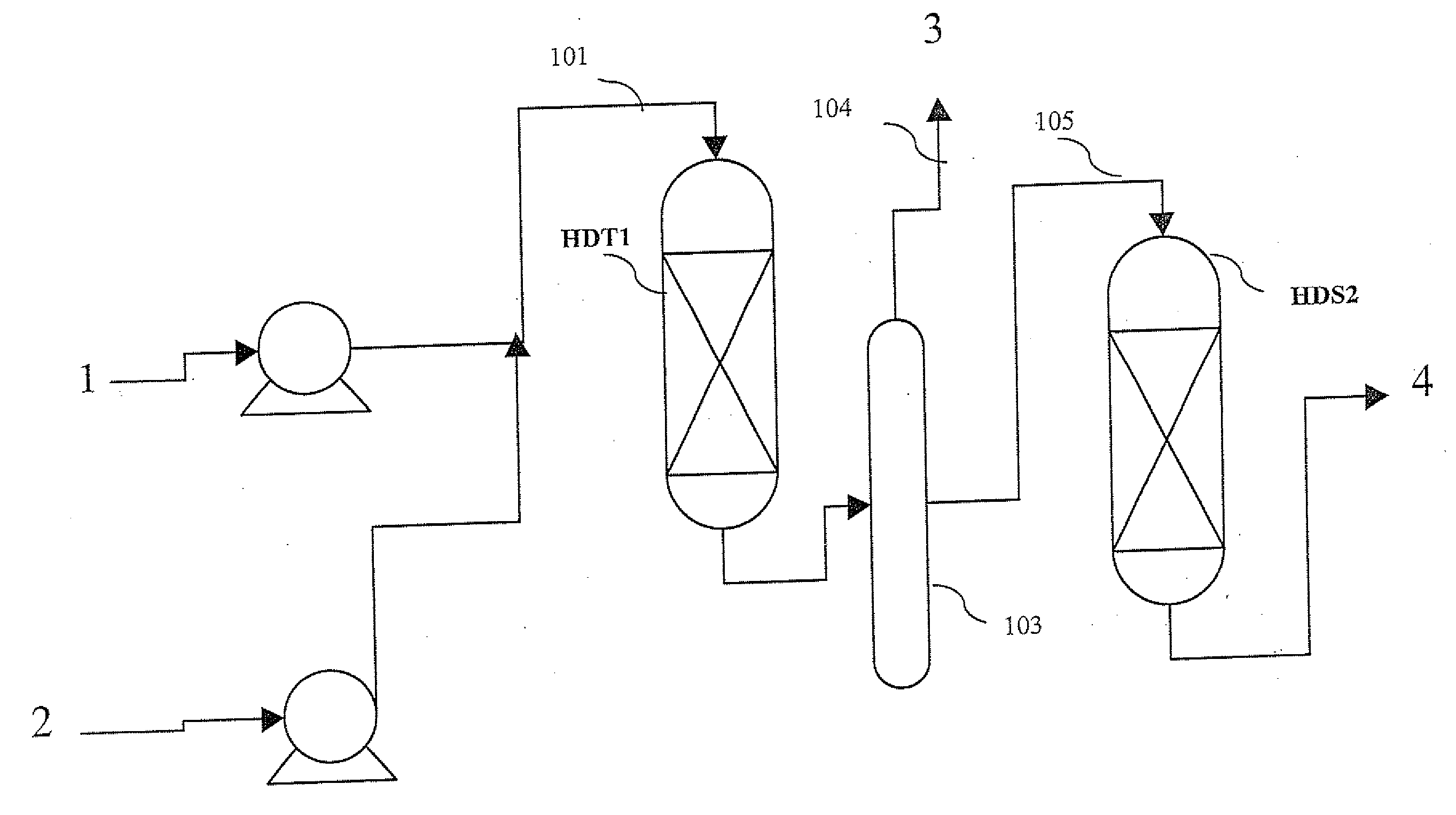

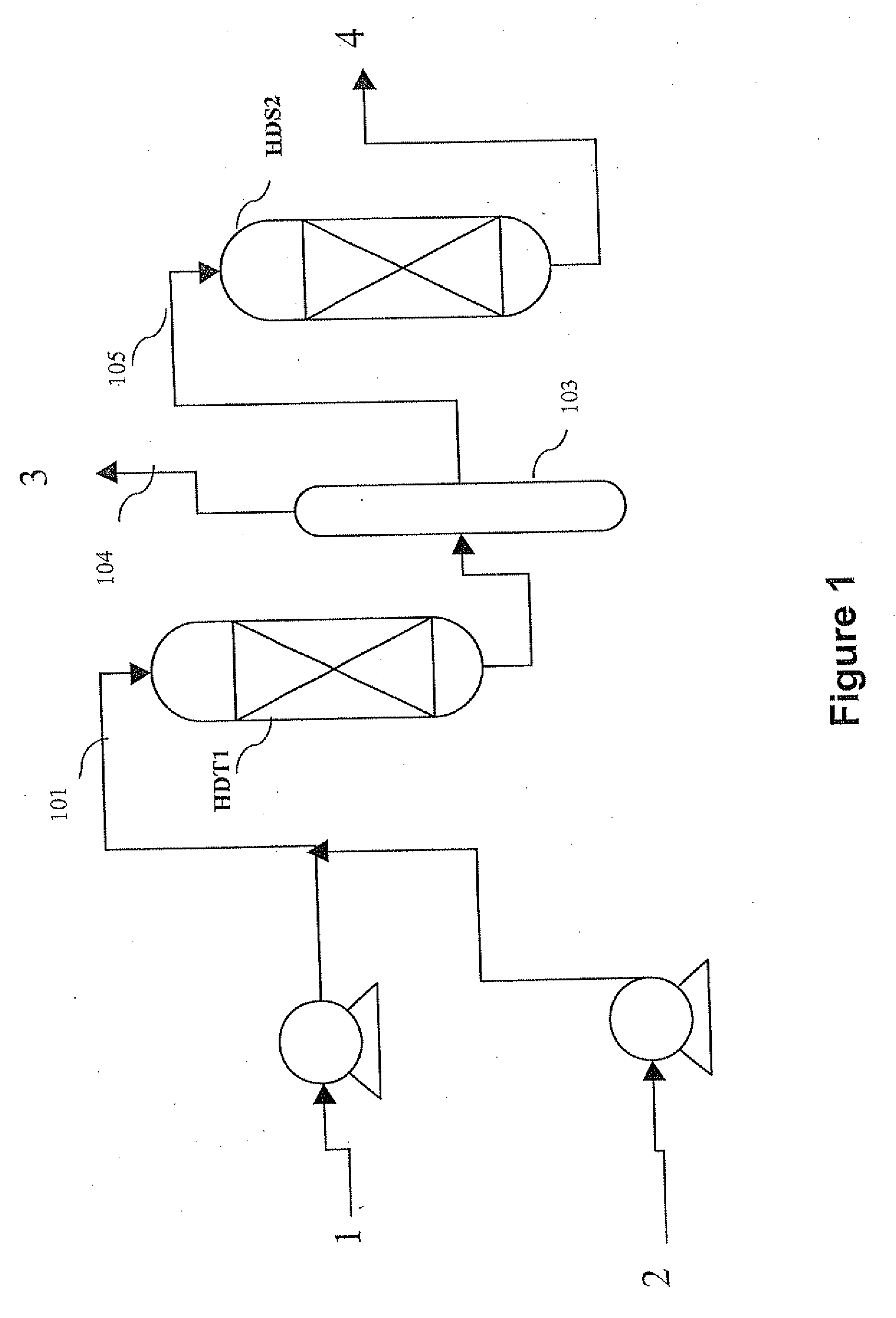

Methods of hydrotreating a mixture made up of oils of animal or vegetable origin and of petroleum cuts with intermediate stripping

ActiveUS20080161614A1Low costLimit consumption of hydrogenThermal non-catalytic crackingCatalytic crackingVegetable oilVolumetric Mass Density

The invention relates to a hydrotreating method (HDT) using two plants working under different operating conditions with an intermediate stripping for co-treating a mixture made up of oils of vegetable or animal origin and petroleum cuts (gas oil cuts (GO) and middle distillates) in order to produce gas oil fuel bases meeting specifications. The first plant (HDT1) is more particularly dedicated to the reactions concerning oils of vegetable or animal origin in comixture while pretreating the hydrocarbon feed, whereas the second plant (HDS2) works under more severe conditions to obtain diesel fuel according to standards, in particular in terms of effluent sulfur content, density and cold properties. The process economy, the activity and the stability of the catalyst of the second plant are greatly improved by the intermediate stripping.

Owner:INST FR DU PETROLE

Hydrogenation process for hydrocarbon resins

InactiveUS20030150778A1Improve productivityIncrease volumePreparation by oxo-reaction and reductionCatalyst activation/preparationProduction rateHalogen

This invention provides a process for hydrotreating hydrocarbon resins, which process comprises contacting a feedstock comprising a hydrocarbon resin or rosin, under suitable hydrotreating conditions, with a bulk multimetallic catalyst comprised of at least one Group VIII non-noble metal and at least two Group VIB metals and wherein the ratio of Group VIB metal to Group VIII non-noble metal is from about 10:1 to about 1:10. The process accord invention can achieve increased hydrocarbon resin productivity through increase in throughput volumes and effective catalyst lifetimes. The process of the invention is desirably practiced with a bulk catalyst consisting of only the combination of the metal species with the active metal components. The absence of carrier substrates largely removes the possibility of halogen accumulation on substrate surfaces that, in turn, can acidify metal catalysts such that additional, progressive cracking of the hydrocarbon resin molecules occurs.

Owner:EXXONMOBIL CHEM PAT INC

Doped spherically-shaped supported catalyst and process for hydrotreating and hydroconverting metal-containing oil fractions

ActiveUS20050211603A1Catalytic crackingCatalyst activation/preparationCatalytic metalSilicon dioxide

The present invention concerns a catalyst for hydrotreating and / or hydroconverting heavy metal-containing hydrocarbon feeds, said catalyst comprising a support in the form of beads based on alumina, at least one catalytic metal or a compound of a catalytic metal from group VIB (column 6 in the new periodic table notation), optionally at least one catalytic metal or compound of a catalytic metal from group VIII (columns 8, 9 and 10 of the new periodic table notation), with a pore structure composed of a plurality of juxtaposed agglomerates, each formed by a plurality of acicular platelets, the platelets of each agglomerate being generally radially orientated with respect to each other and with respect to the center of the agglomerate. The catalyst also comprises at least one doping element selected from the group constituted by phosphorus, boron, silicon (or silica which does not belong to that which could be contained in the selected support) and halogens. The invention also concerns the use of said catalyst in converting metal-containing feeds.

Owner:INST FR DU PETROLE

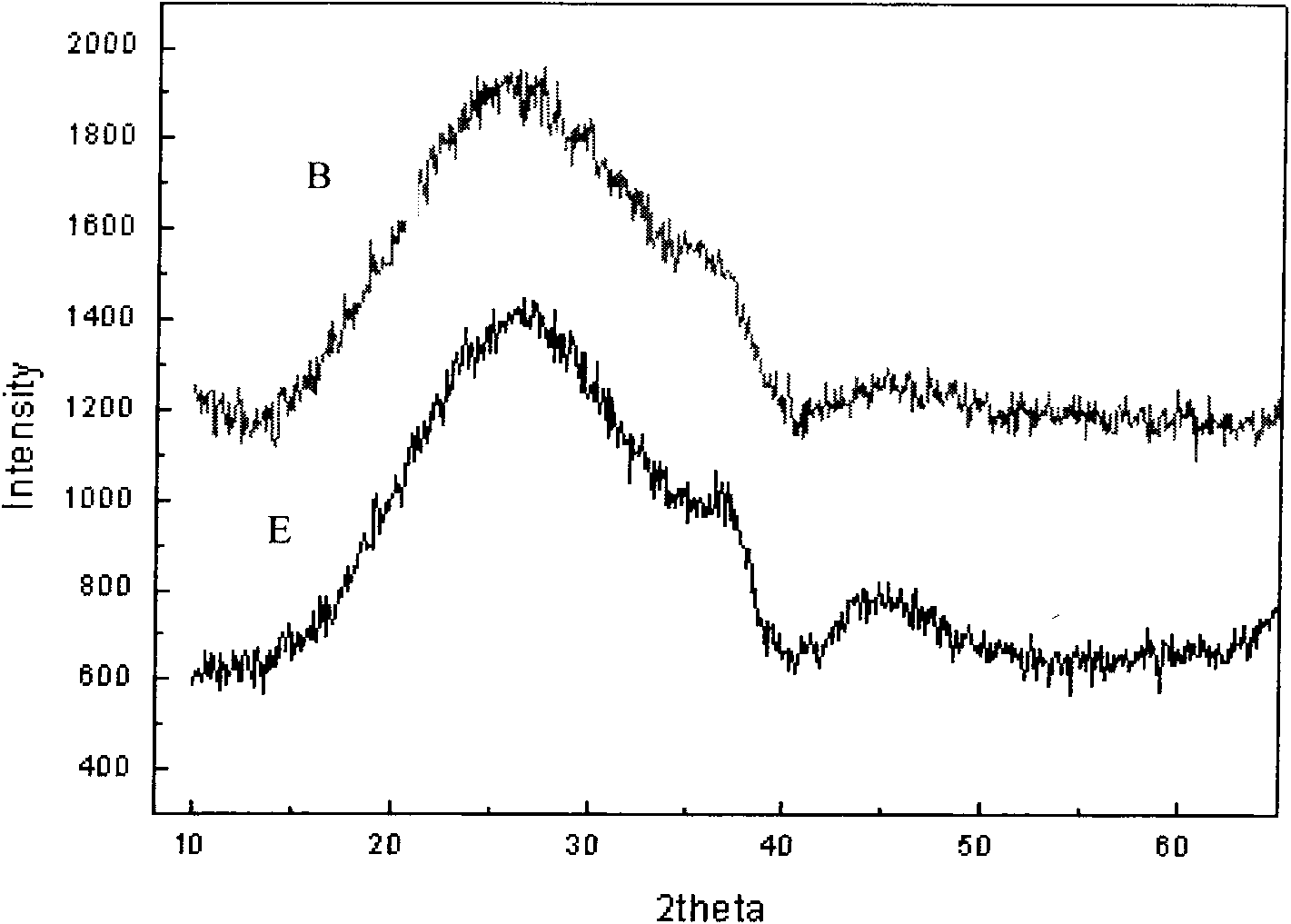

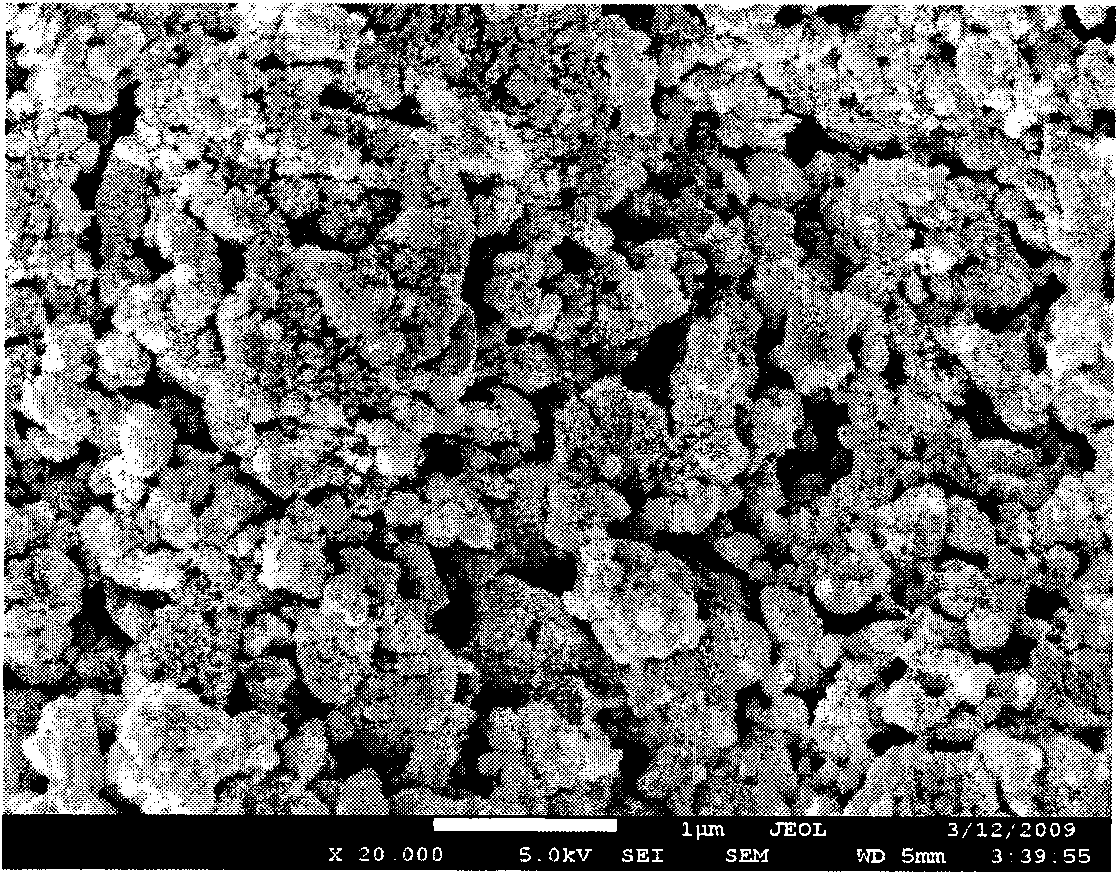

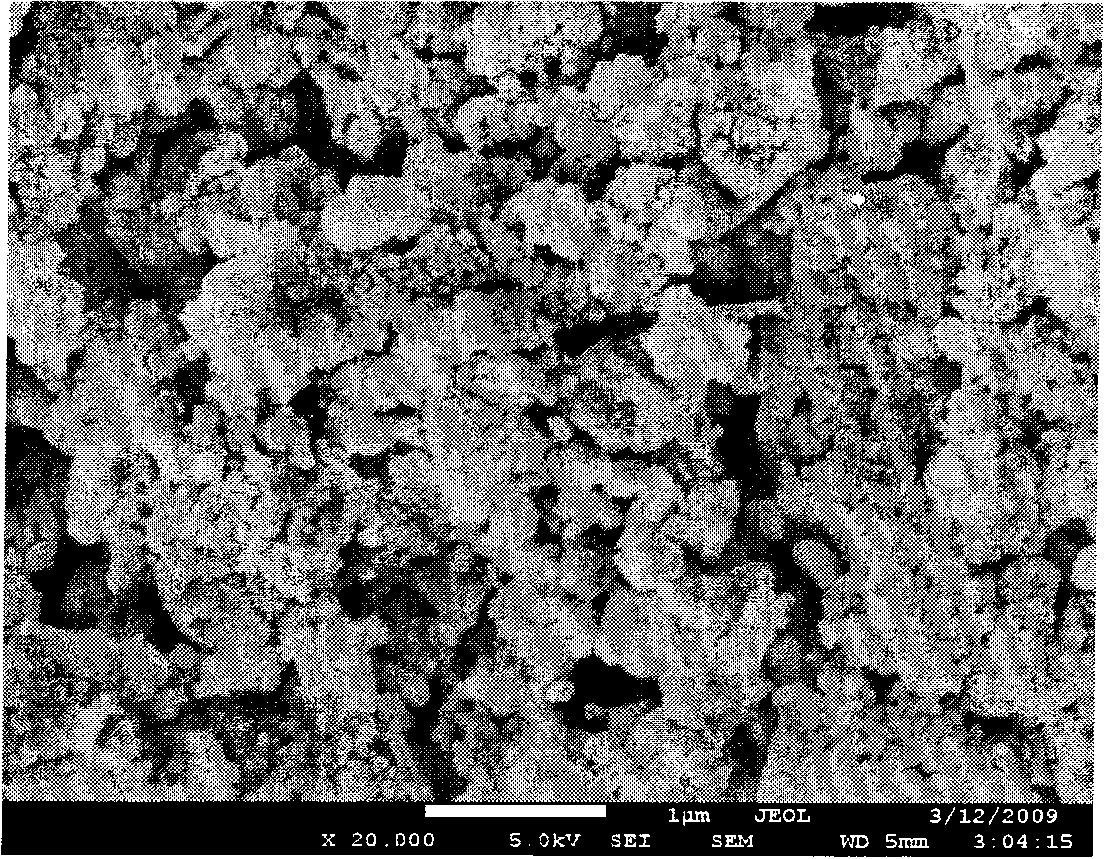

Hydrotreating catalyst and preparation method thereof

ActiveCN102049265AImprove pore structureReduce manufacturing costMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsReactive siteNitrogen

The invention discloses a bulk hydrotreating catalyst and a preparation method thereof. The catalyst comprises three active metal components, namely Mo, W and Ni, and the sum of active metal oxides is 30 to 70 weight percent. In the method, a proper amount of water-soluble nitrogen-containing compound is added in the bulk catalyst gelatinating process, the pore structure of the catalyst is improved, more metal active sites are exposed on the surface of the catalyst, the utilization rate of active metals is improved, the catalyst has obviously high activity compared with the common bulk catalyst under the condition of the same metal content, and the consumption of the active metals for the common bulk catalyst can be reduced and the preparation cost of the catalyst can be reduced under thecondition of the equivalent activity. In addition, the bulk catalyst has increased pore diameter and pore volume, the Ni-W high active center is fully utilized, complicated macromolecules are easier to contact the active center, and the effect is particularly more obvious when the catalyst treats distillates with high macromolecule content.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production of Aviation Fuel from Renewable Feedstocks

ActiveUS20090283442A1Improve solubilityMinimize severityTreatment with plural serial cracking stages onlyRefining to change hydrocarbon structural skeletonIsomerizationBoiling point

A hydrocarbon product stream having hydrocarbons with boiling points in the aviation fuel range is produced from renewable feedstocks such as plant and animal oils. The process involves treating a renewable feedstock by hydrogenating, deoxygenating, isomerization, and selectively hydrocracking the feedstock to produce paraffinic hydrocarbons having from about 9 to about 16 carbon atoms and a high iso / normal ratio in a single reaction zone containing a multifunctional catalyst, or set of catalysts, having hydrogenation, deoxygenation, isomerization and selective hydrocracking functions.

Owner:UOP LLC

Catalyst for hydrorefining and/or hydroconversion and its use in hydrotreatment processes for batches containing hydrocarbons

This invention relates to a catalyst for hydrorefining and / or hydroconversion of hydrocarbon-containing feedstocks that contain compounds whose boiling point is higher than 520° C. and that contain sulfur and possibly metals, as well as its use in hydrorefining and / or hydroconversion processes of heavy feedstocks. A petroleum residue of atmospheric distillation (RA) or of vacuum distillation (RSV) or a deasphalted oil (DAO) are representative feedstocks of the feedstocks treated within the scope of this invention.

Owner:INST FR DU PETROLE

Process for upgrading naphtha

A method for upgrading a naphtha feed to a naphtha product containing less than about 10 wppm of nitrogen and less than about 15 wppm sulfur, the method comprising contacting said naphtha feed with hydrogen in the presence of a bulk multimetallic catalyst under effective reactor conditions to hydrodesulfurize and hydrodenitrogenize said naphtha feed to produce said naphtha product, wherein said bulk multimetallic catalyst comprises at least one Group VIII non-noble metal and at least two Group VIB metals.

Owner:EXXON RES & ENG CO

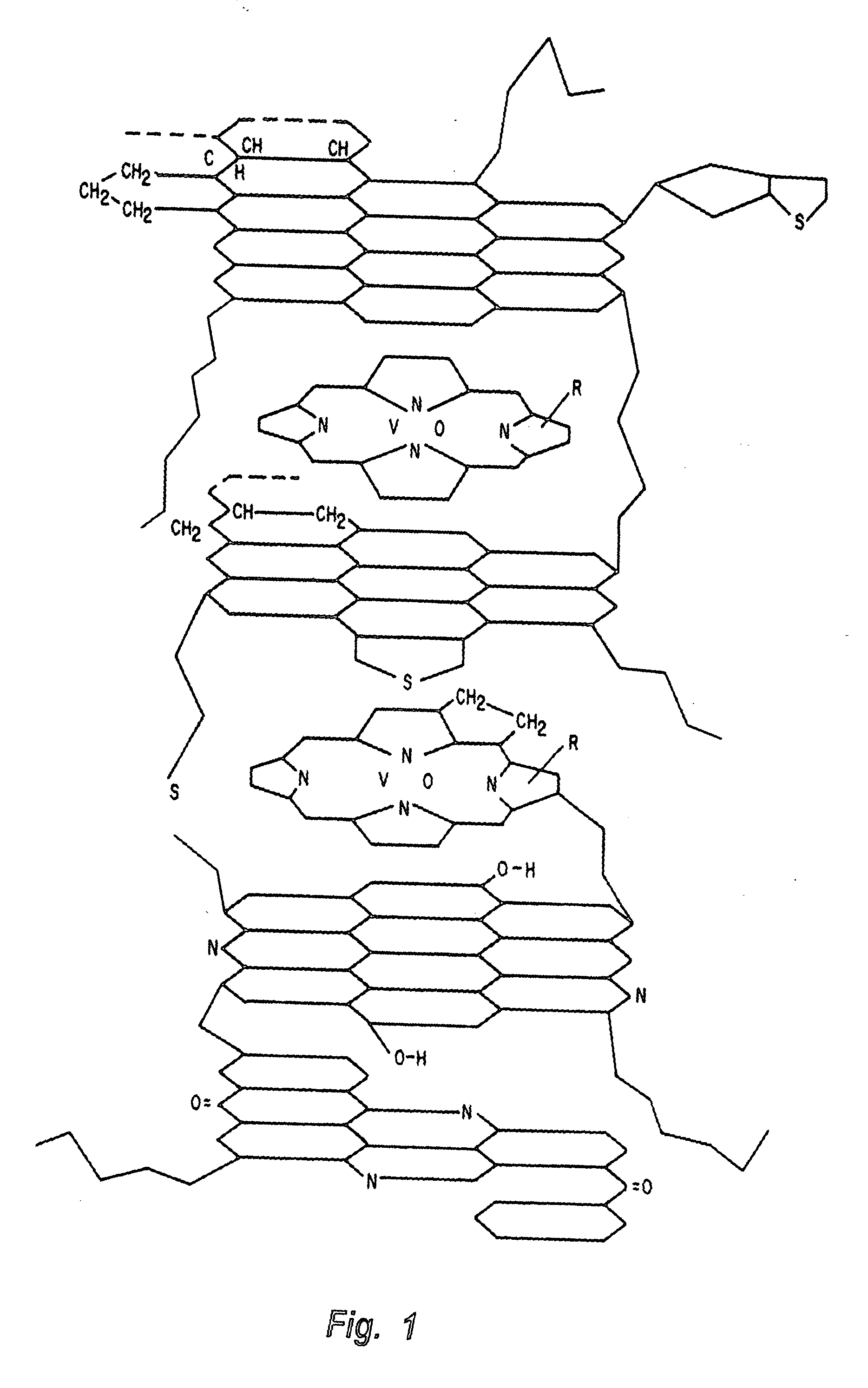

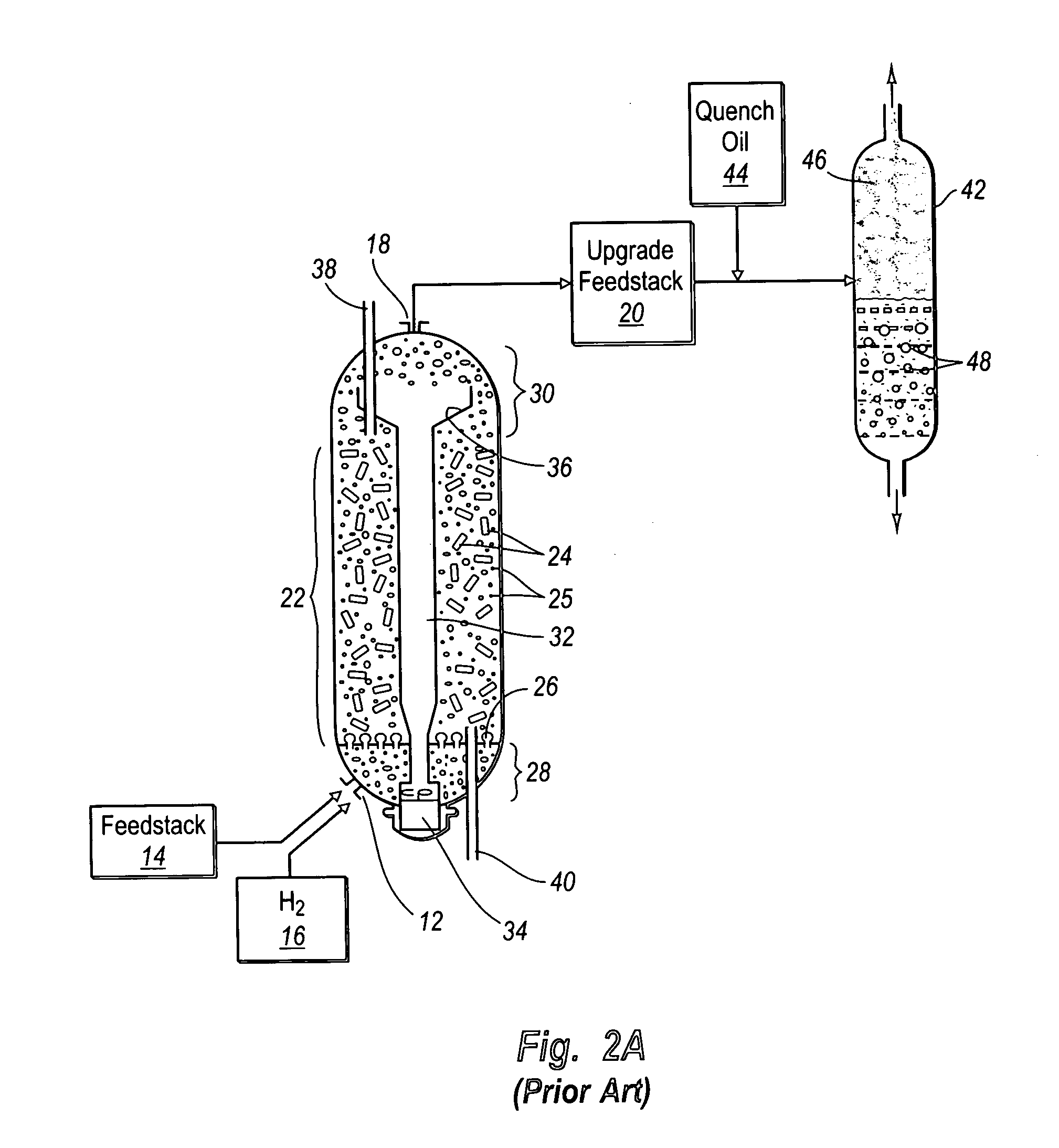

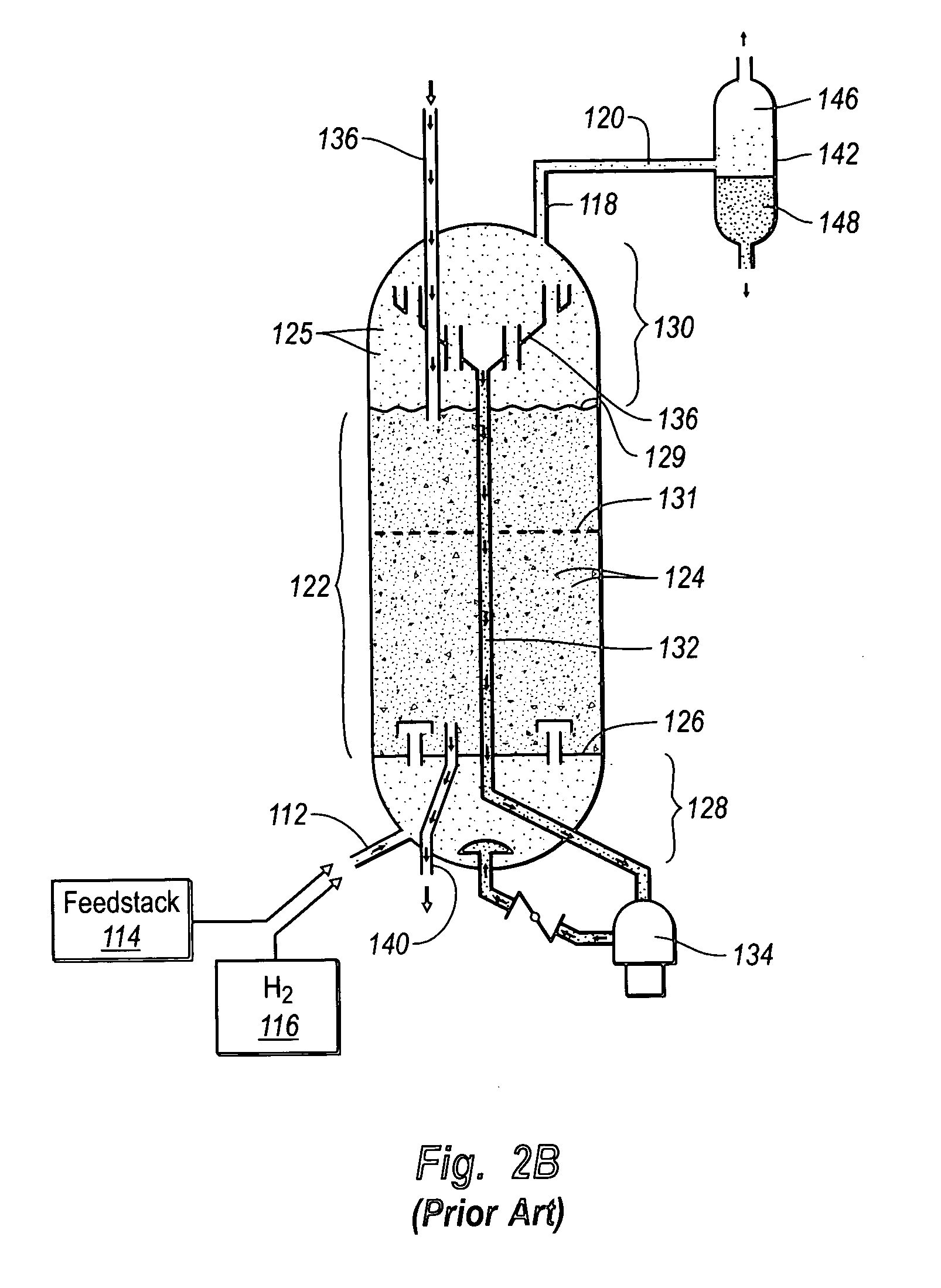

Ebullated bed hydroprocessing methods and systems and methods of upgrading an existing ebullated bed system

ActiveUS20050241991A1Quality improvementReduce formationHydrocarbon oil crackingLiquid hydrocarbon mixture productionHydrogenDecomposition

An ebullated bed hydroprocessing system, and also a method for upgrading a pre-existing ebullated bed hydroprocessing system, involves introducing a colloidal or molecular catalyst, or a precursor composition capable of forming the colloidal or molecular catalyst, into an ebullated bed reactor. The colloidal or molecular catalyst is formed by intimately mixing a catalyst precursor composition into a heavy oil feedstock and raising the temperature of the feedstock to above the decomposition temperature of the precursor composition to form the colloidal or molecular catalyst in situ. The improved ebullated bed hydroprocessing system includes at least one ebullated bed reactor that employs both a porous supported catalyst and the colloidal or molecular catalyst to catalyze hydroprocessing reactions involving the feedstock and hydrogen. The colloidal or molecular catalyst provides catalyst in what would otherwise constitute catalyst free zones within the ebullated bed hydroprocessing system. Asphaltene or other hydrocarbon molecules too large to diffuse into the pores of the supported catalyst can be upgraded by the colloidal or molecular catalyst. A slurry phase reactor may be positioned upstream from one or more ebullated bed reactors or converted from a pre-existing ebullated bed reactor.

Owner:HEADWATERS TECH INNOVATION LLC

Heavy oil hydrogenation catalyst and preparation method thereof

ActiveCN103769118AShorten drying timeAvoid pollutionCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsDry basisBULK ACTIVE INGREDIENT

The invention discloses a heavy oil hydrogenation catalyst and a preparation method thereof. The heavy oil hydrogenation catalyst comprises a carrier and an active ingredient; the carrier is aluminum oxide, and is prepared from pseudo-boehmite with dry basis content below 50% via moulding; the active ingredient are metals selected form family VIII, Co or Ni, and / or family VI B, Mo or W. The preparation method comprises following steps: preparation of pseudo-boehmite, preparation of the carrier, and loading of the active ingredient. The heavy oil hydrogenation catalyst is capable of maintaining high demetalization, desulphurization, and carbon residue removing activities, simplifying drying process of pseudo-boehmite preparation, avoiding dust pollution caused by moulding process, increasing production efficiency, reducing production energy consumption, and reducing catalyst cost further.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com