Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6058results about How to "Shorten drying time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

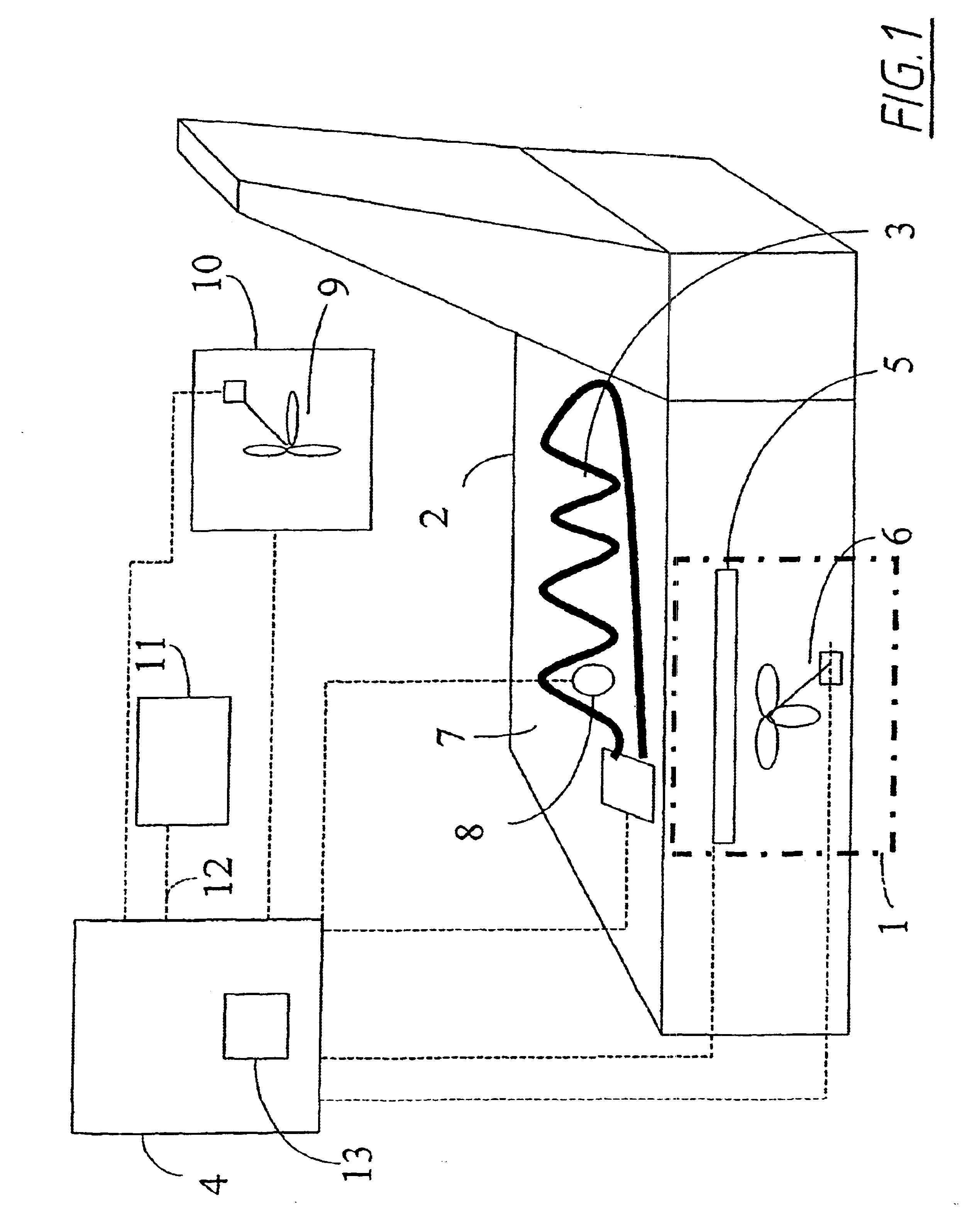

Seat with temperature control and ventilation and safety system for a vehicle

InactiveUS6892807B2Shorten drying timeReduce the negative local chillingDomestic cooling apparatusPower to electric heating circuitsTemperature controlEngineering

Methods and apparatus for controlling the temperature of a seat such as a vehicle seat are disclosed. The apparatus includes an electrical heater disposed in the seat, a cooling unit such as a cooling element and a fan, a detector for detecting the temperature associated with the electrical heater, and a controller for controlling the electrical heater and the cooler based upon the detected temperature and upon the humidity algorithm comprising a predetermined set of calculations of the humidity of air at different temperatures.

Owner:LEAR CORP

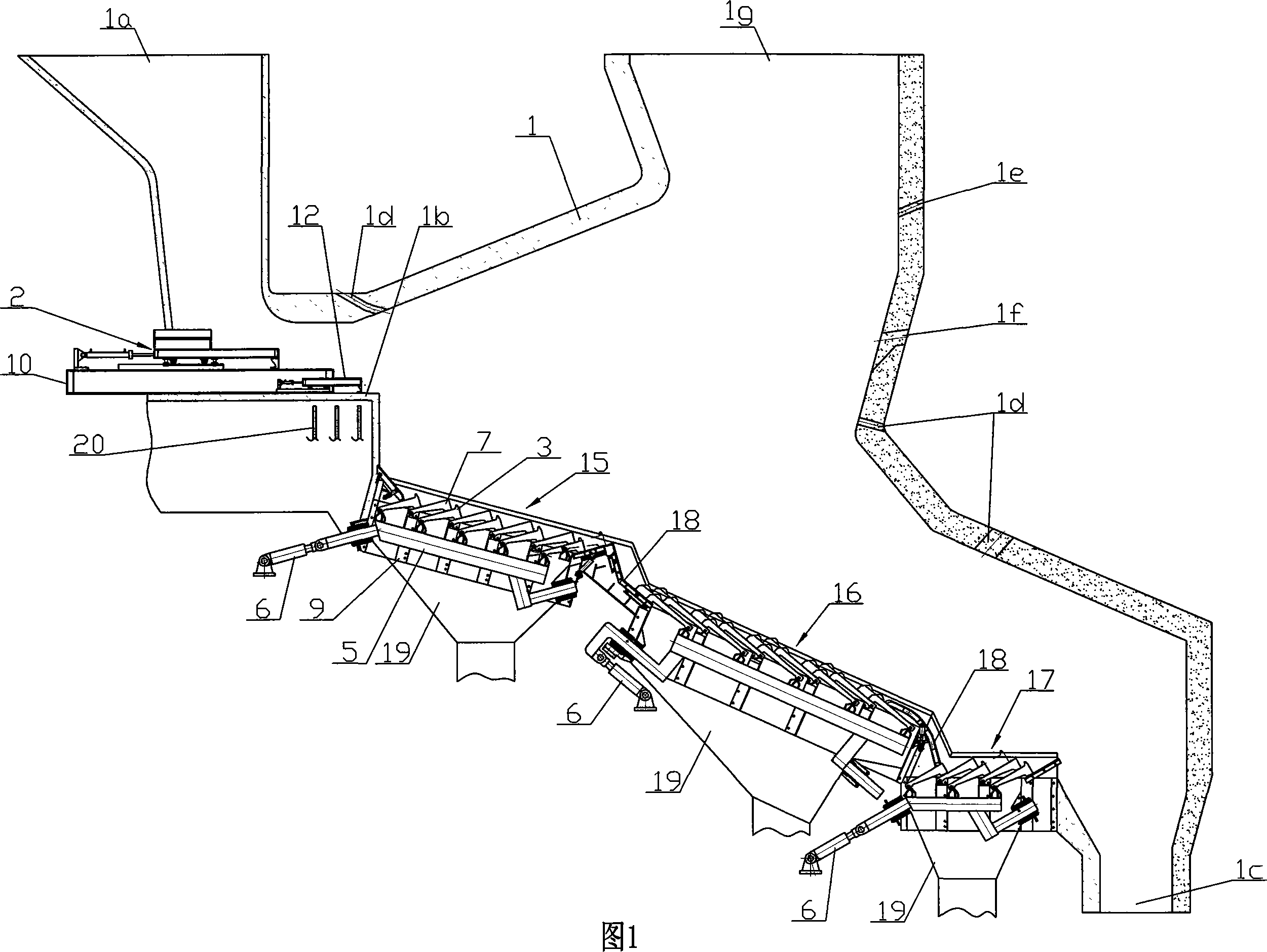

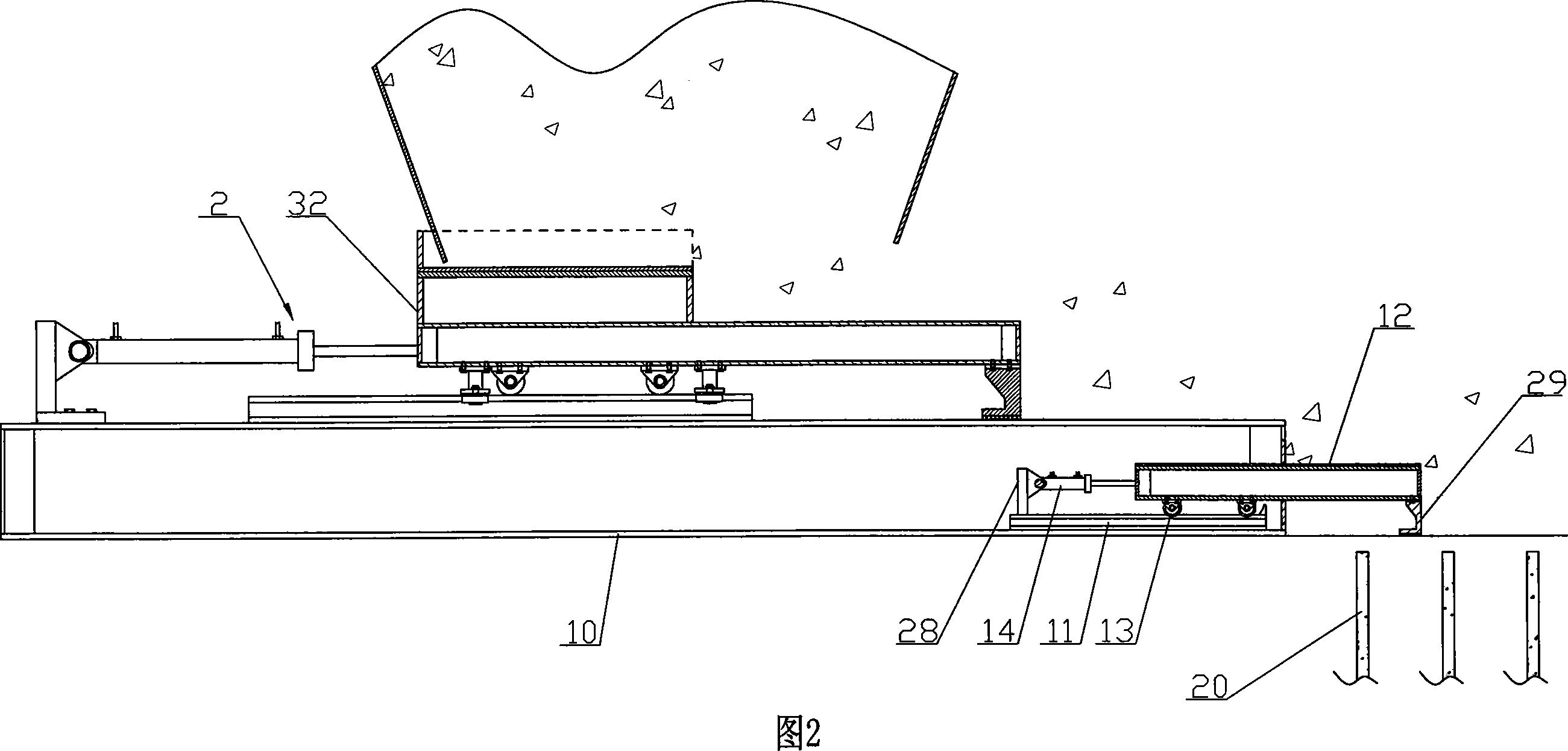

Multiple row sectional drive combined type domestic garbage incinerator

The invention relates to multi-column sectional drive combined type domestic incinerator. It is set three fire-grates that drying section, burning section, and firing section. The middle fire grate is connected between them. There is altitude fall between them that the drying section is the highest point; the firing one is the lowest point. The primary air chamber is respectively set under them. The incinerator fire grate system of the invention has independent drive mechanism, air supply system, and air chamber for each section which is convenient for controlling technical parameter that traveling speed, air quantity, air temperature, air pressure etc to realize full drying and burning for whole garbage layer.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP

Catalyst and process for the selective hydrogenation of unsaturated compounds in hydrocarbon streams

InactiveUS6350717B1Maintain good propertiesHigh selectivityOrganic chemistry methodsHydrocarbon by hydrogenationHydrocarbonChemistry

A catalyst comprising at least one metal of the 10th group of the Periodic Table of the Elements and at least one metal of the 11th group of the Periodic Table of the Elements on an aluminum oxide support, wherein the metal or metals of the 10th group is or are essentially concentrated in an outer layer close to the surface of the catalyst particle, the metal or metals of the 11th group is or are distributed essentially uniformly over the volume of the catalyst particle and the weight ratio of the metal or metals of the 11th group to the metal or metals of the 10th group is not more than 1.95.

Owner:BASF AG

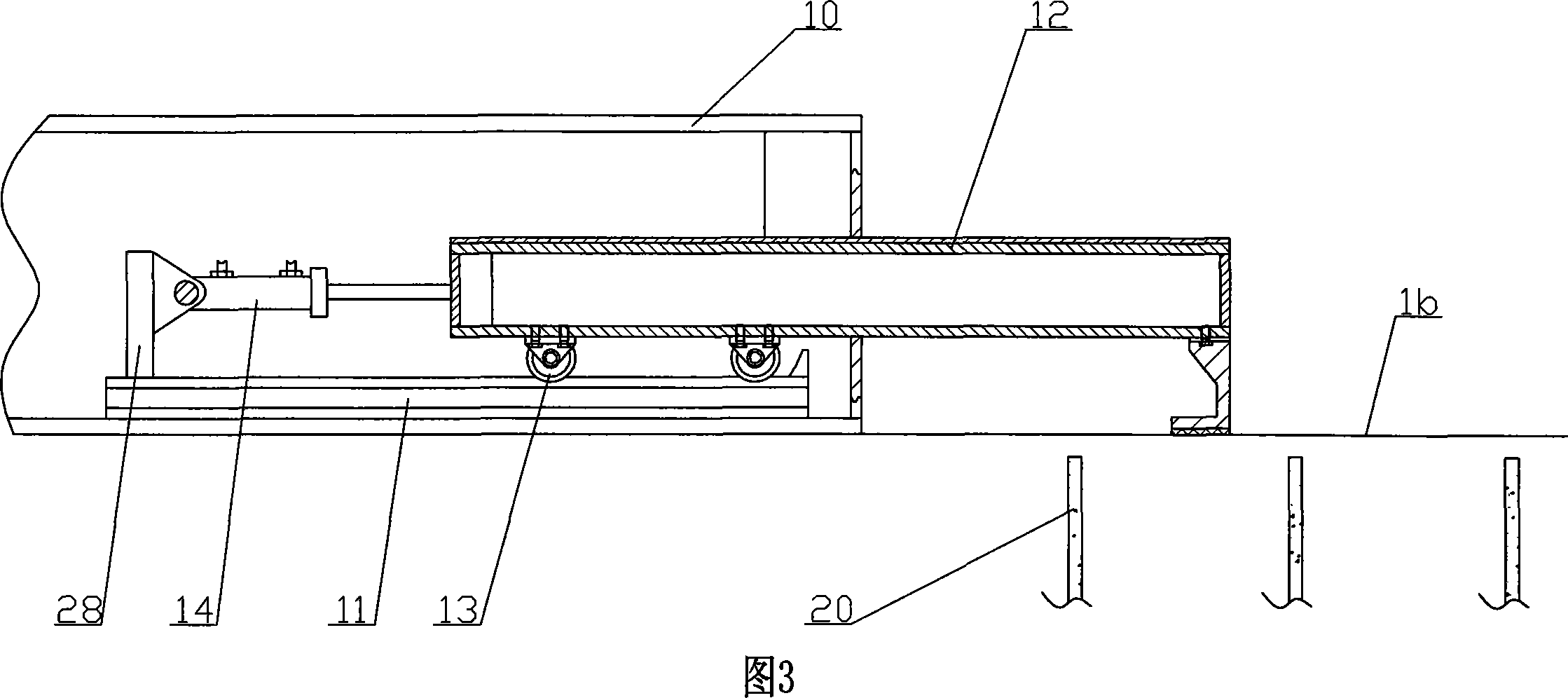

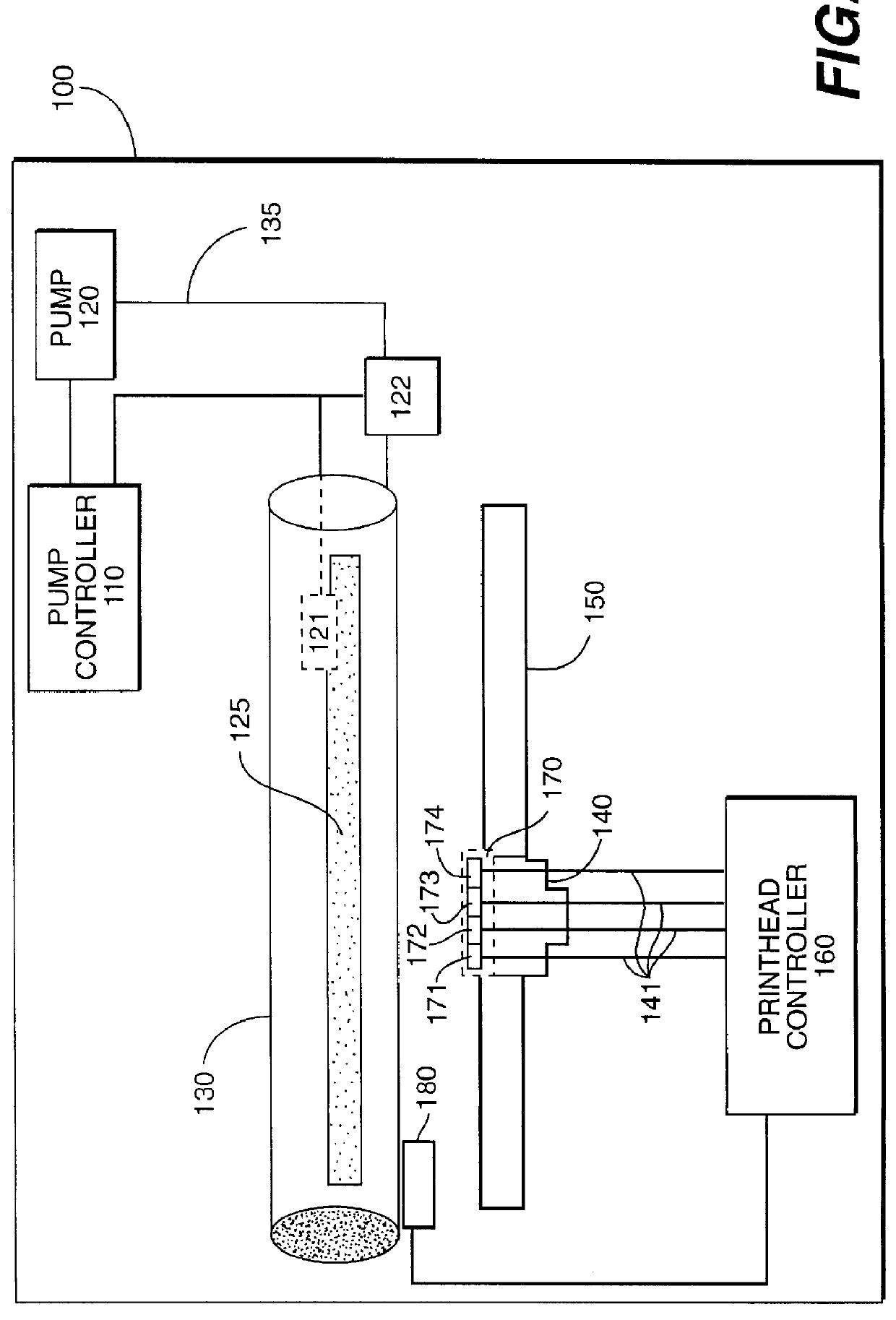

Method and apparatus for reducing intercolor bleeding in ink jet printing

In an ink jet printing process, a desired vacuum is applied to the back side of a print substrate with proper feedback and control. The optimum vacuum exerts a suction force on ink dispersed on the front side of the print substrate to accelerate penetration of the ink into the print substrate and to reduce smear and intercolor bleeding. In addition, the vacuum may be applied in the ink jet printing process in combination with various other techniques including heating of the print substrate at any stage of printing process including before, during, after, and combinations thereof and delaying the time between ink dispersing of two different inks as in the checkerboard printing method. The employment of proper vacuum, inks, and printheads including partial-width or full-width array printheads allows a fast speed multi-color ink jet printing process to be carried out on a print substrate to give high resolution (e.g., 600 spi) multi-color images with good print quality.

Owner:XEROX CORP

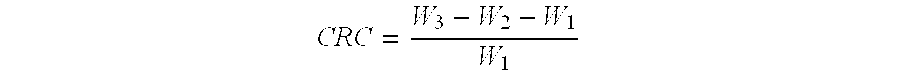

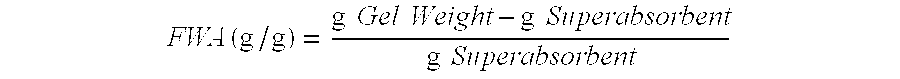

Superabsorbent polymers having delayed water absorption characteristics

InactiveUS6514615B1Shorten drying timeReduce removalNon-fibrous pulp additionPaper/cardboardMicrometerSuperabsorbent polymer

A superabsorbent polymer comprising a delayed absorption superabsorbent polymer having a free water absorbency property of absorbing less than about 3 grams of aqueous saline per gram of superabsorbent polymer in about 6 seconds, for a full particle size distribution of superabsorbent polymer ranging from about 40 micrometers to about 890 micrometers.

Owner:EVONIK OPERATIONS GMBH

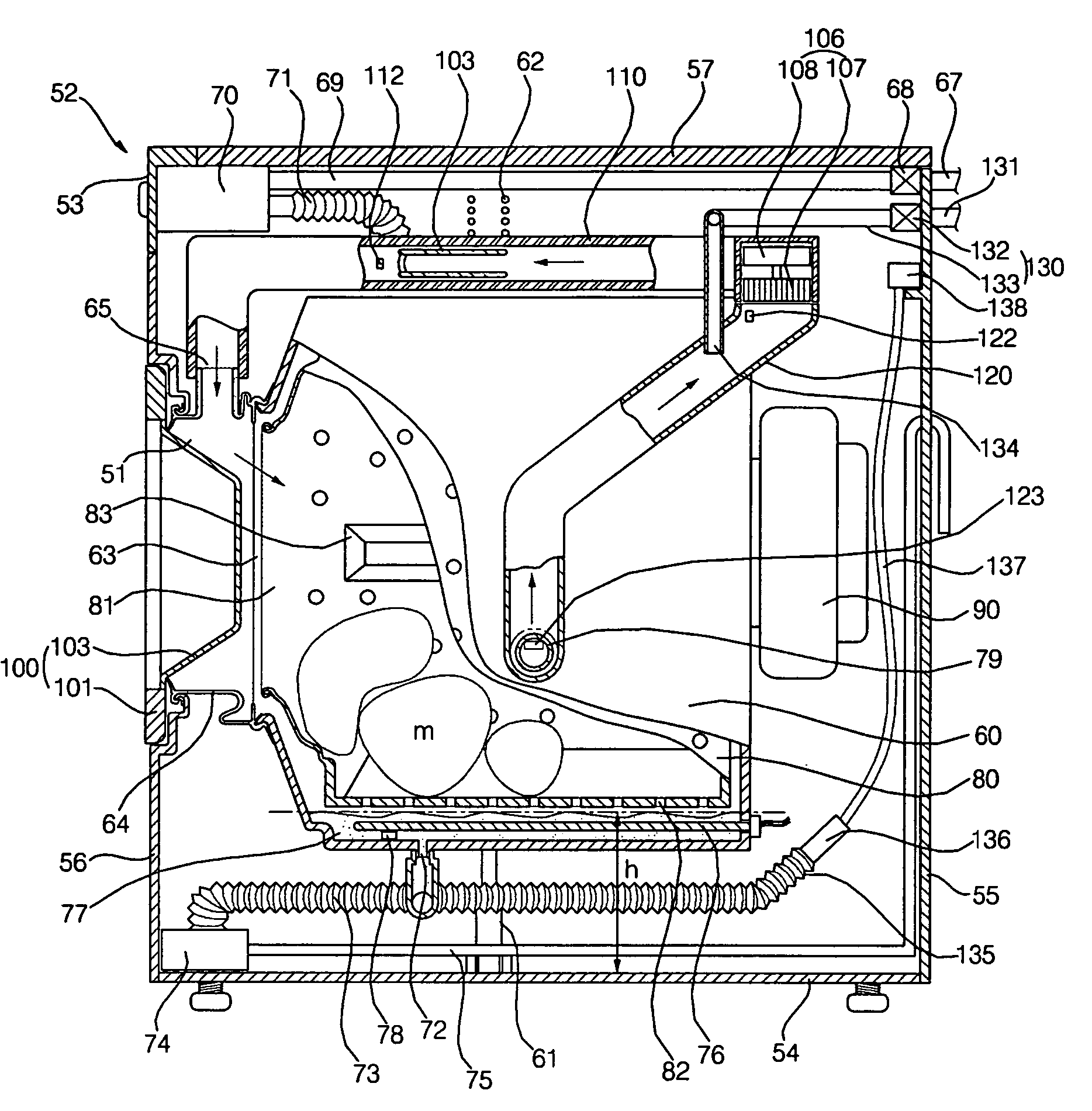

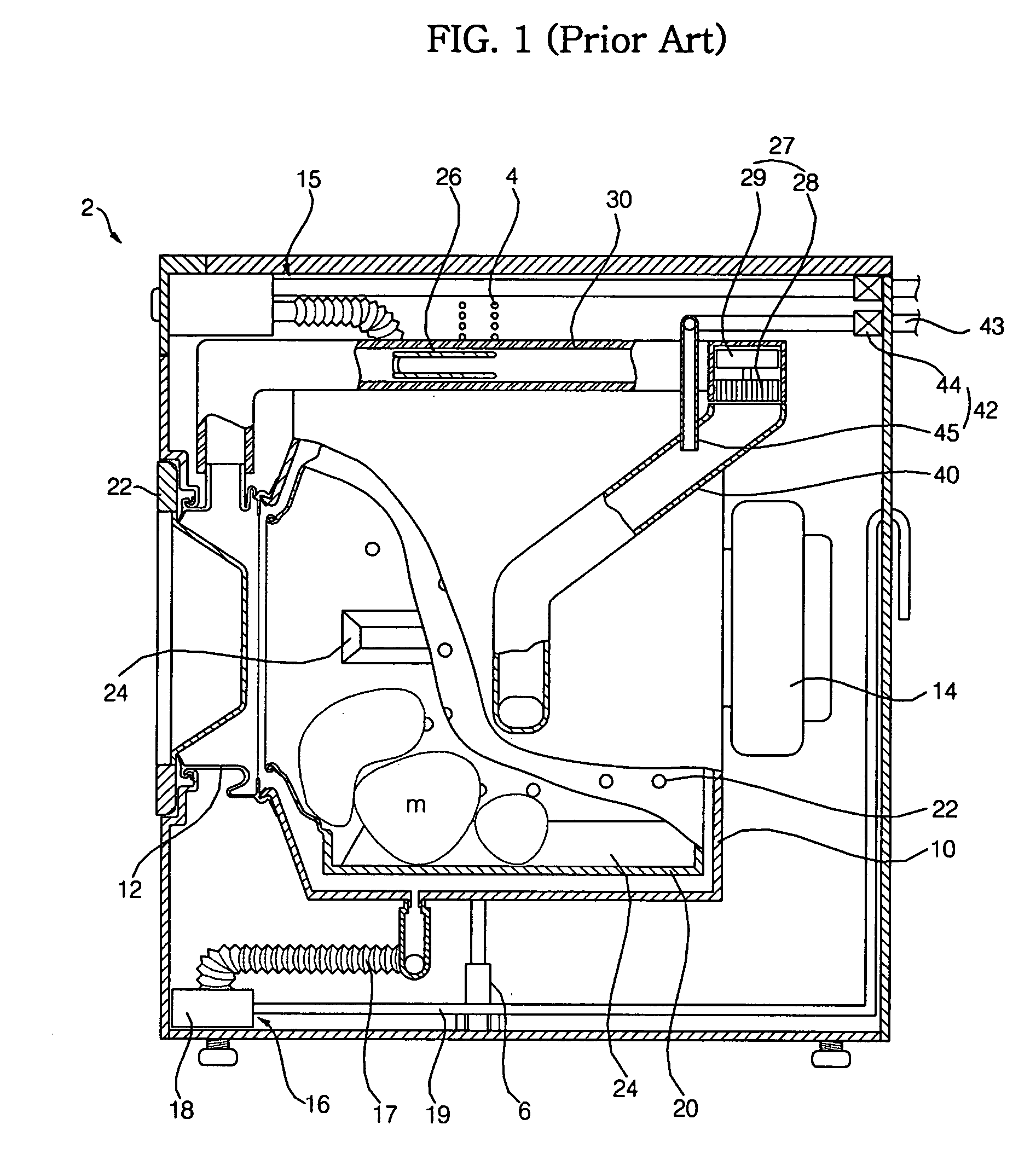

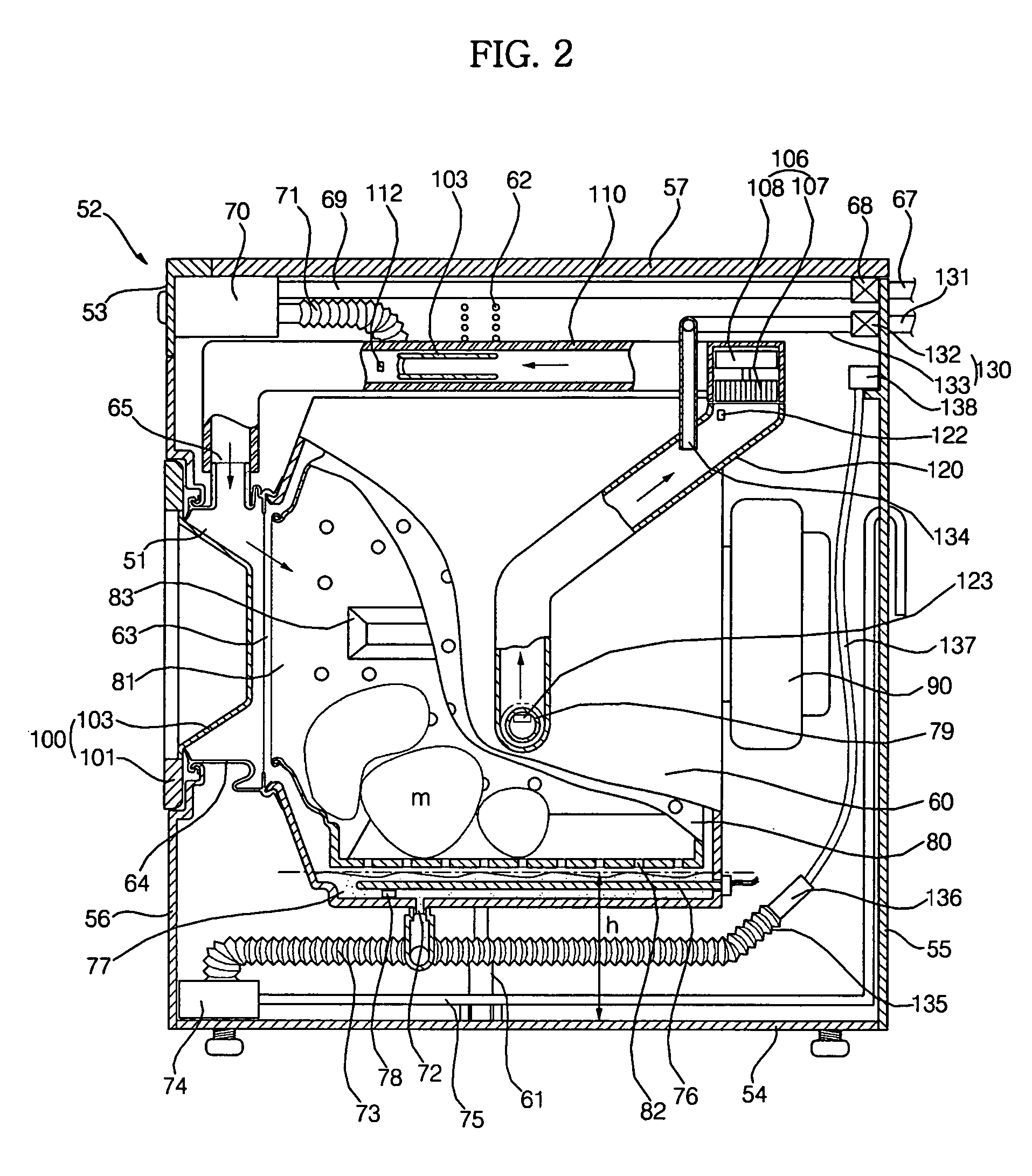

Drying control apparatus and method of washing and drying machine

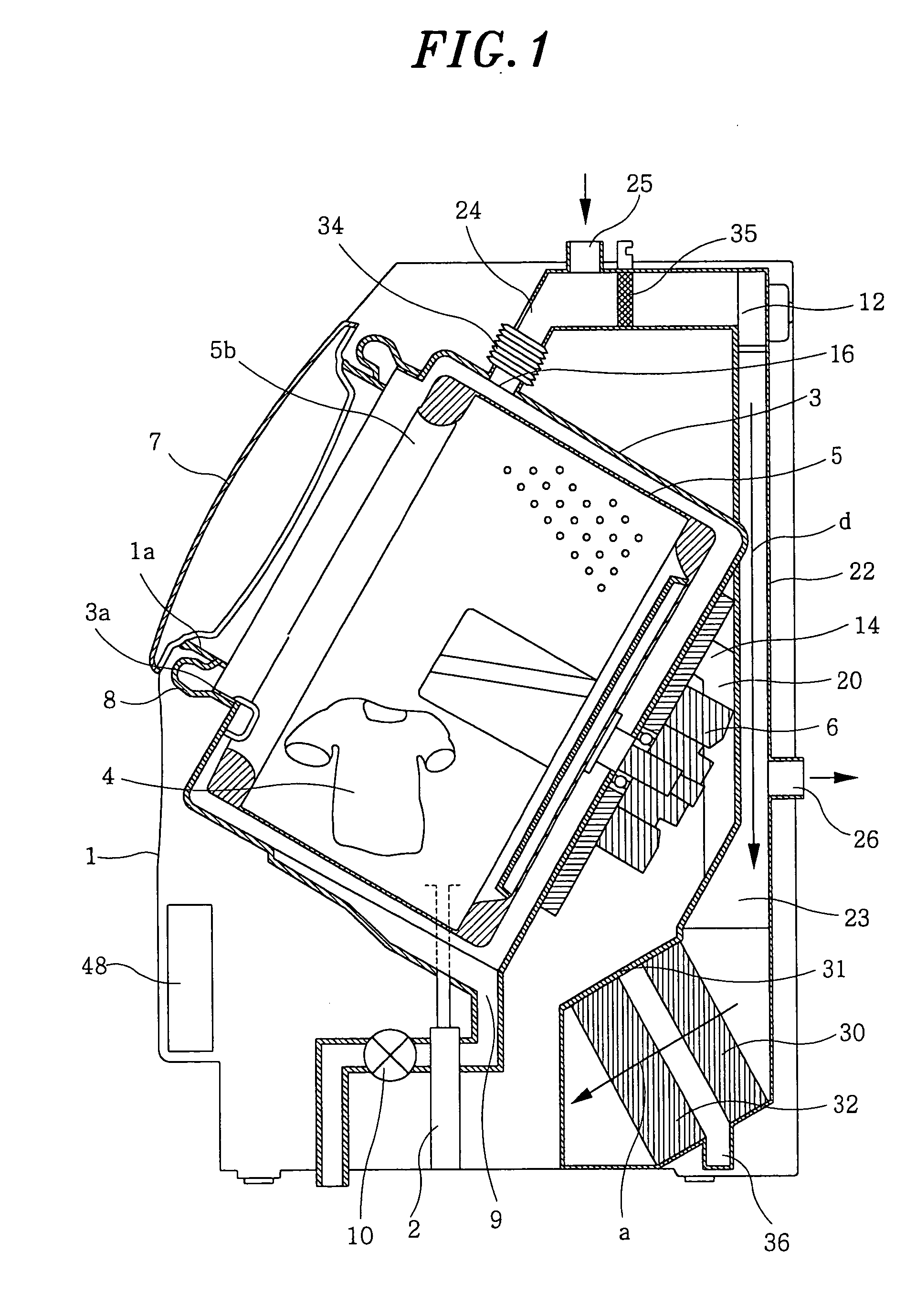

InactiveUS20060137105A1Improve condensation effectMinimizing rateOther washing machinesWashing machine with receptaclesCold airProcess engineering

A drying control method and apparatus of a washing and drying machine, in which cooling water dropped from a condensation duct to a tub accelerates the condensation of moisture contained in circulated air so as to improve condensing capability, a cold air drying time is differently set according to load so that when the load is small, a drying time is shortened, and the drying of laundry is rapidly performed, a power consumption rate is minimized, or a cooling water consumption rate is minimized according to user's desire, and a drying operation is controlled using a difference between a temperature of air and a temperature of cooling water so that the drying operation is efficiently performed according to load conditions so as to improve the drying capability.

Owner:LG ELECTRONICS INC

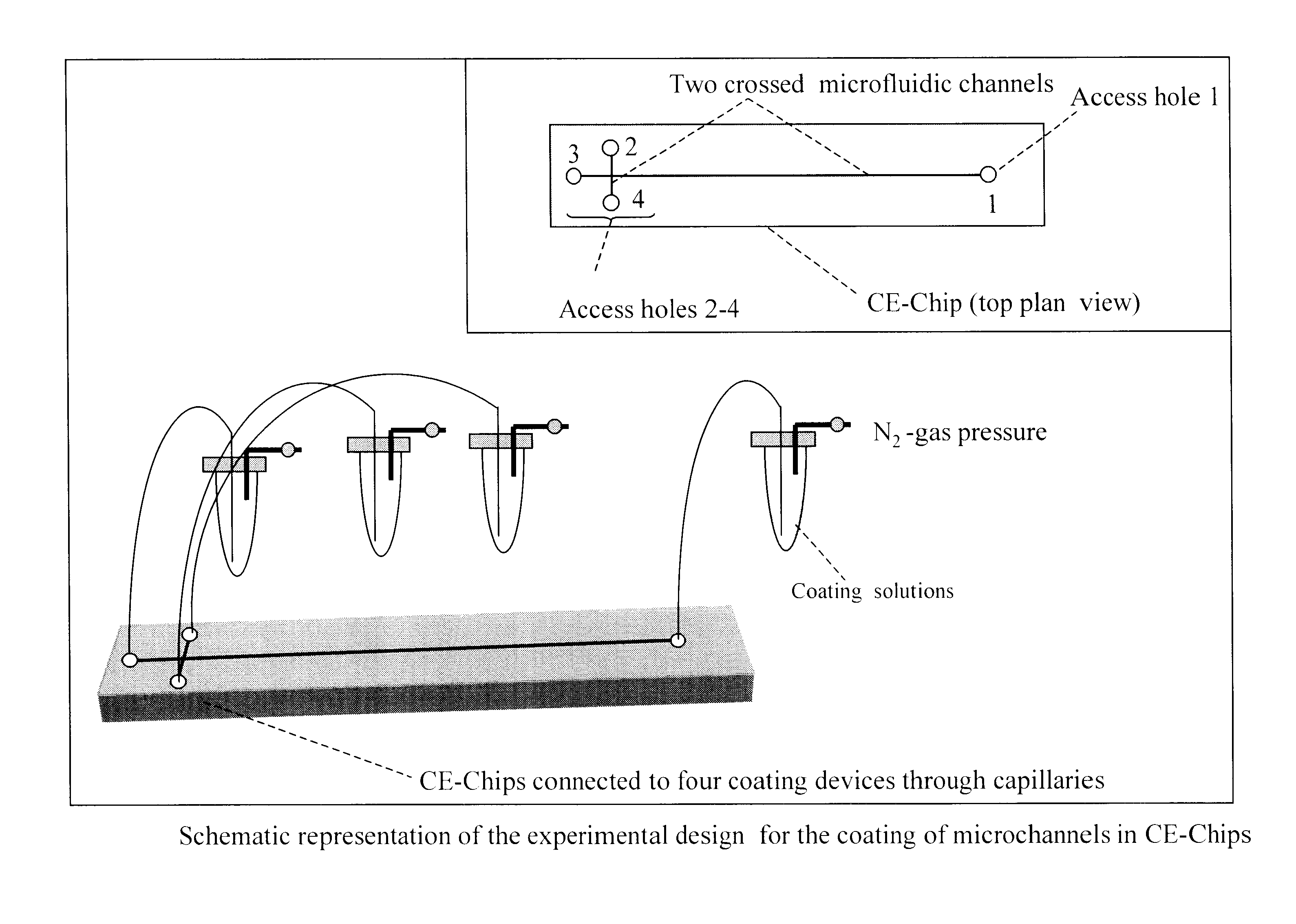

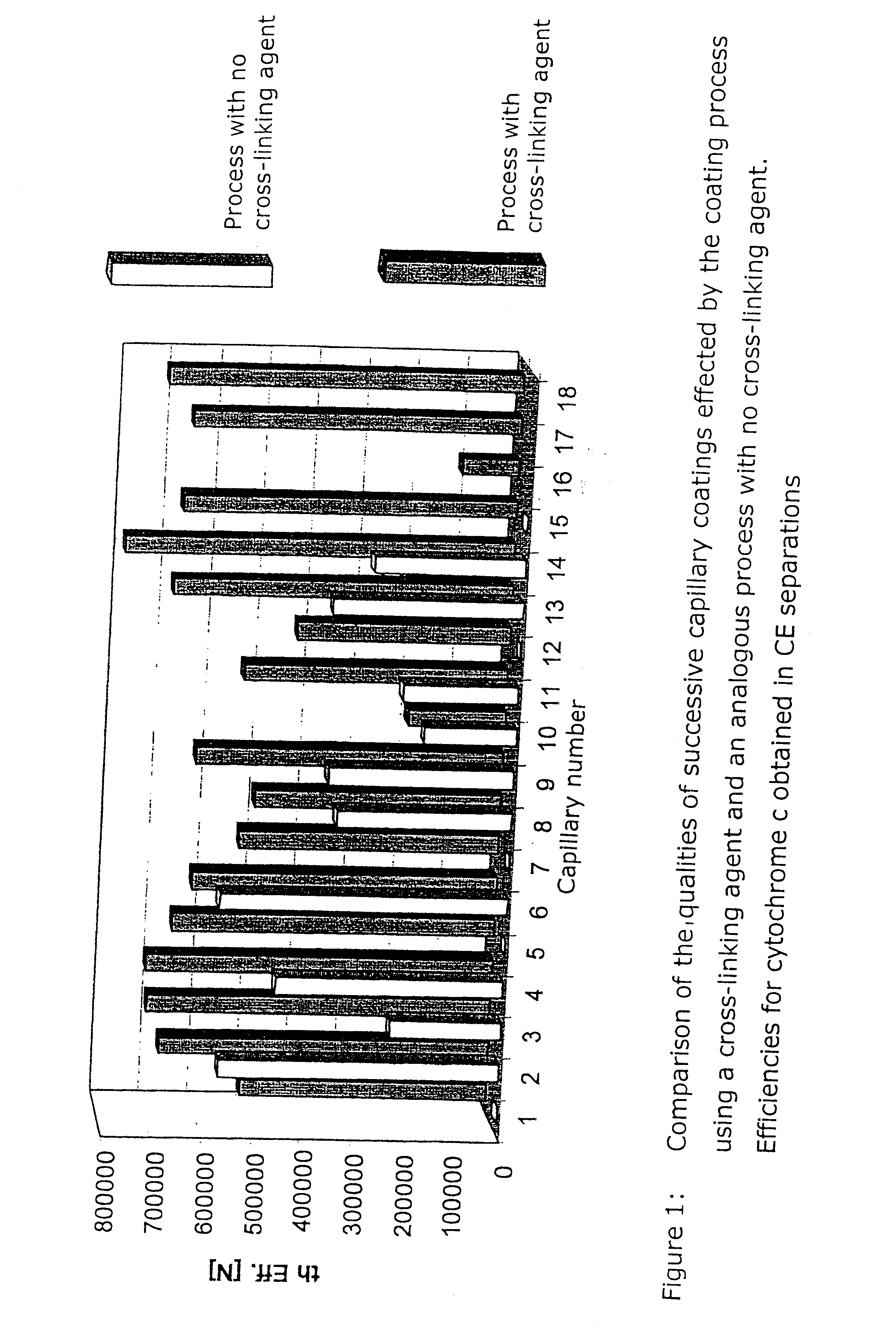

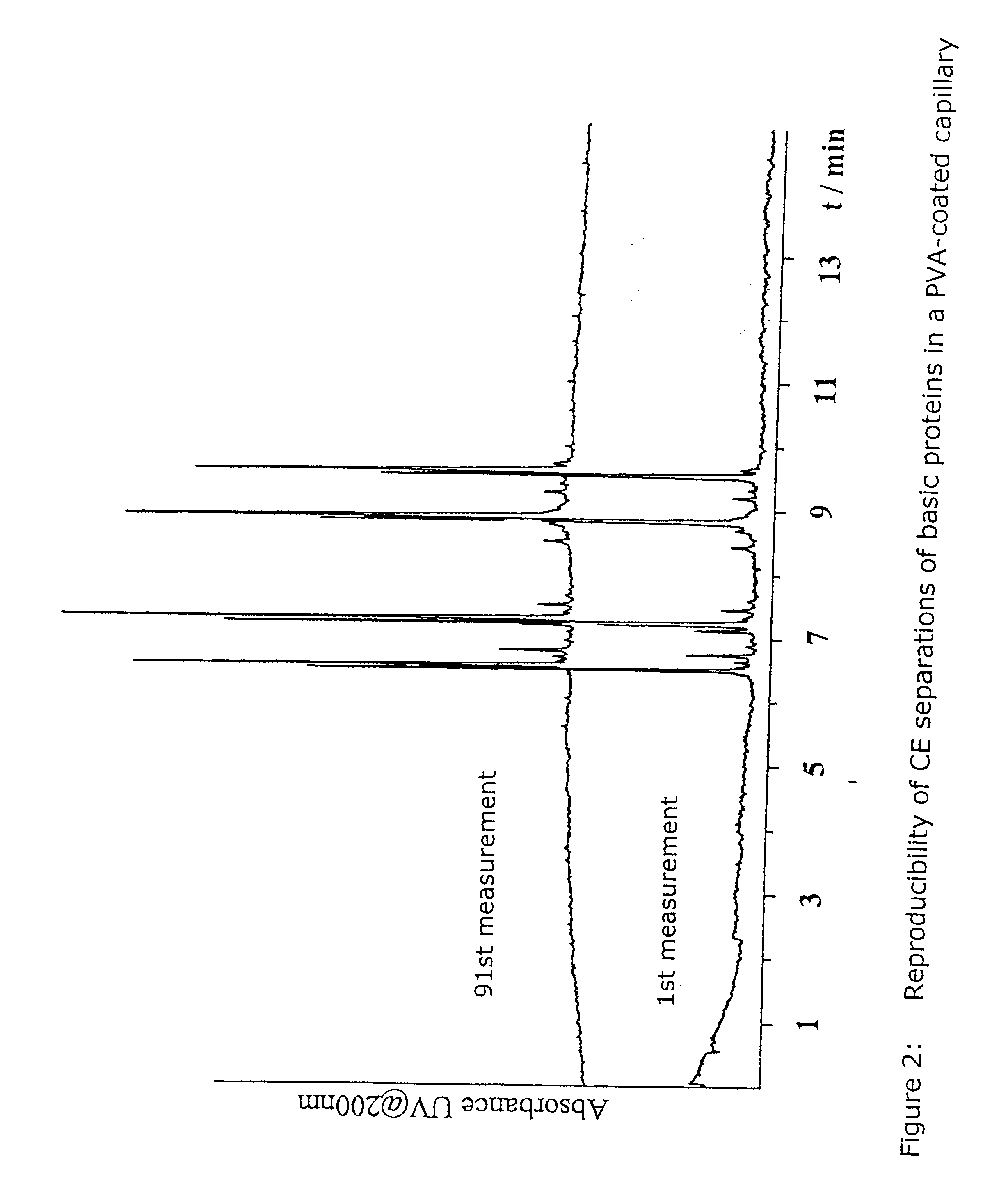

Coatings with cross-linked hydrophilic polymers

InactiveUS6596238B1Improve wettabilityEasy to separateSludge treatmentVolume/mass flow measurementCross-linkHydrophilic polymers

The present invention relates to a process for permanently coating the inner surface of columns, capillaries and microchannel systems with hydroxylic polymers, such as polyvinyl alcohol, and to the thus prepared columns, capillaries and microchannel systems and their use.

Owner:AGILENT TECH INC

Intelligent hot-air drying control device

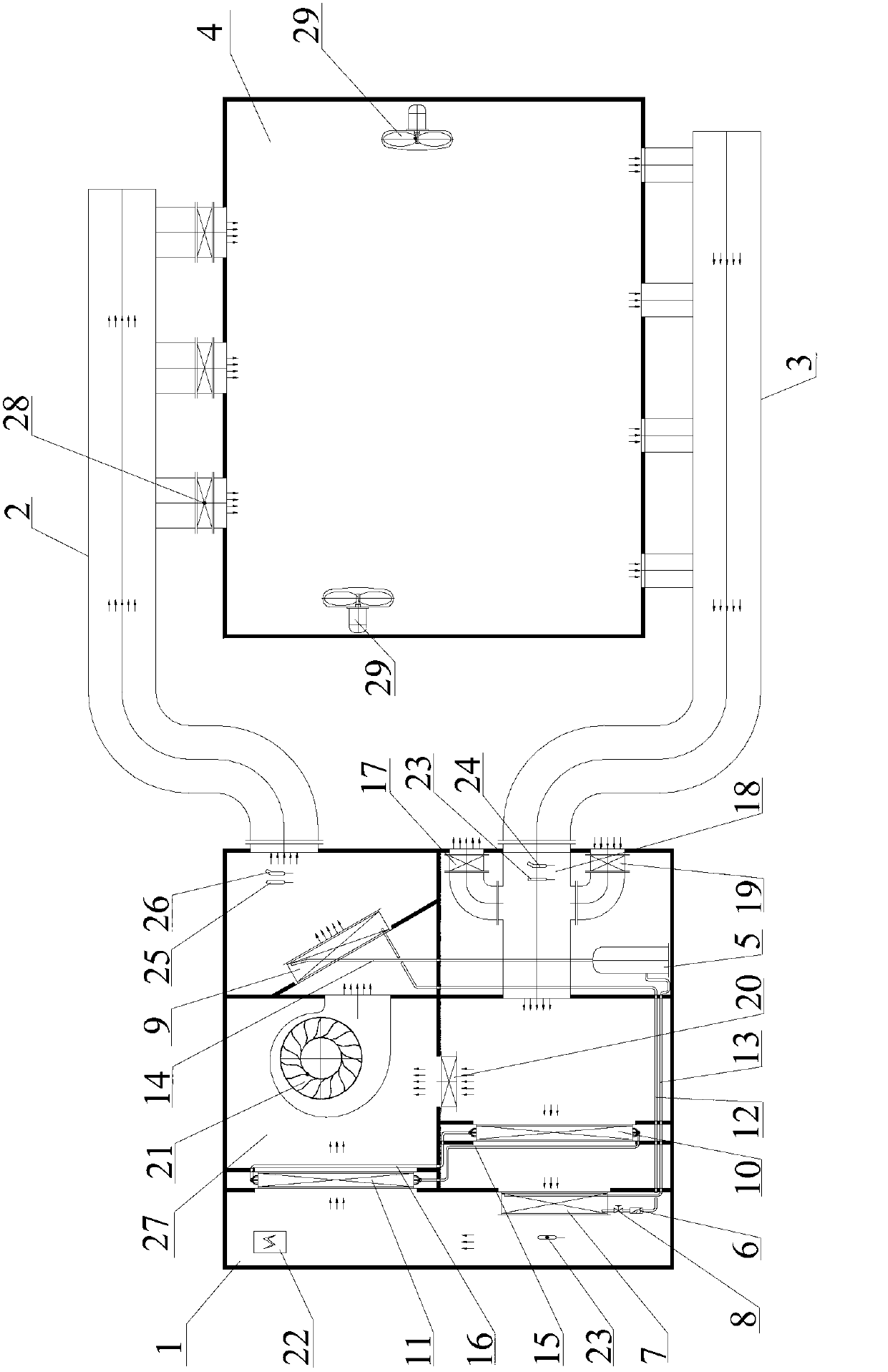

InactiveCN103123215AReduce energy consumptionReduced dehumidification loadDrying gas arrangementsEngineeringAir blower

The invention discloses an intelligent hot-air drying control device which comprises a heat exchange box and a drying chamber, wherein he heat exchange box is separated into multiple spaces, and the drying chamber is connected with the heat exchange box through an air supplying main pipe and a general air return pipe. A heat pump dehumidifying and heating system, a heat pipe return heat exchange system, a hot air circulating system and an intelligent control system are arranged in the heat exchange box. The heat pump dehumidifying and heating system which is composed of a compressor, a drying filter, a dehumidifying evaporator, a throttle valve and a heating condenser. The heat pipe return heat exchange system is composed of a heat pipe evaporator and a heat pipe condenser. The hot air circulating system is composed of a high-pressure refrigerant liquid connecting pipe, a low-pressure refrigerant return gas connecting pipe, a high-pressure refrigerant gas connecting pipe, a liquid refrigerant connecting pipe, a gas refrigerant connecting pipe, an air exhaust regulating valve, a mixed air box, a fresh air regulating valve, a secondary air flow regulating valve and an air blower assembly. The intelligent control system is composed of the a temperature sensor, a humidity sensor, a hot air temperature sensor and a hot air humidity sensor, wherein the temperature sensor, the humidity sensor, the hot air temperature sensor and the hot air humidity sensor are connected in the various systems. The intelligent hot-air drying control device can regulate the temperature and the humidity of drying air automatically and improve the material drying efficiency.

Owner:孙应真

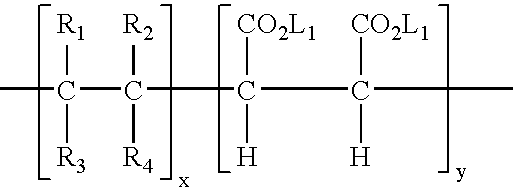

Clothes dryer

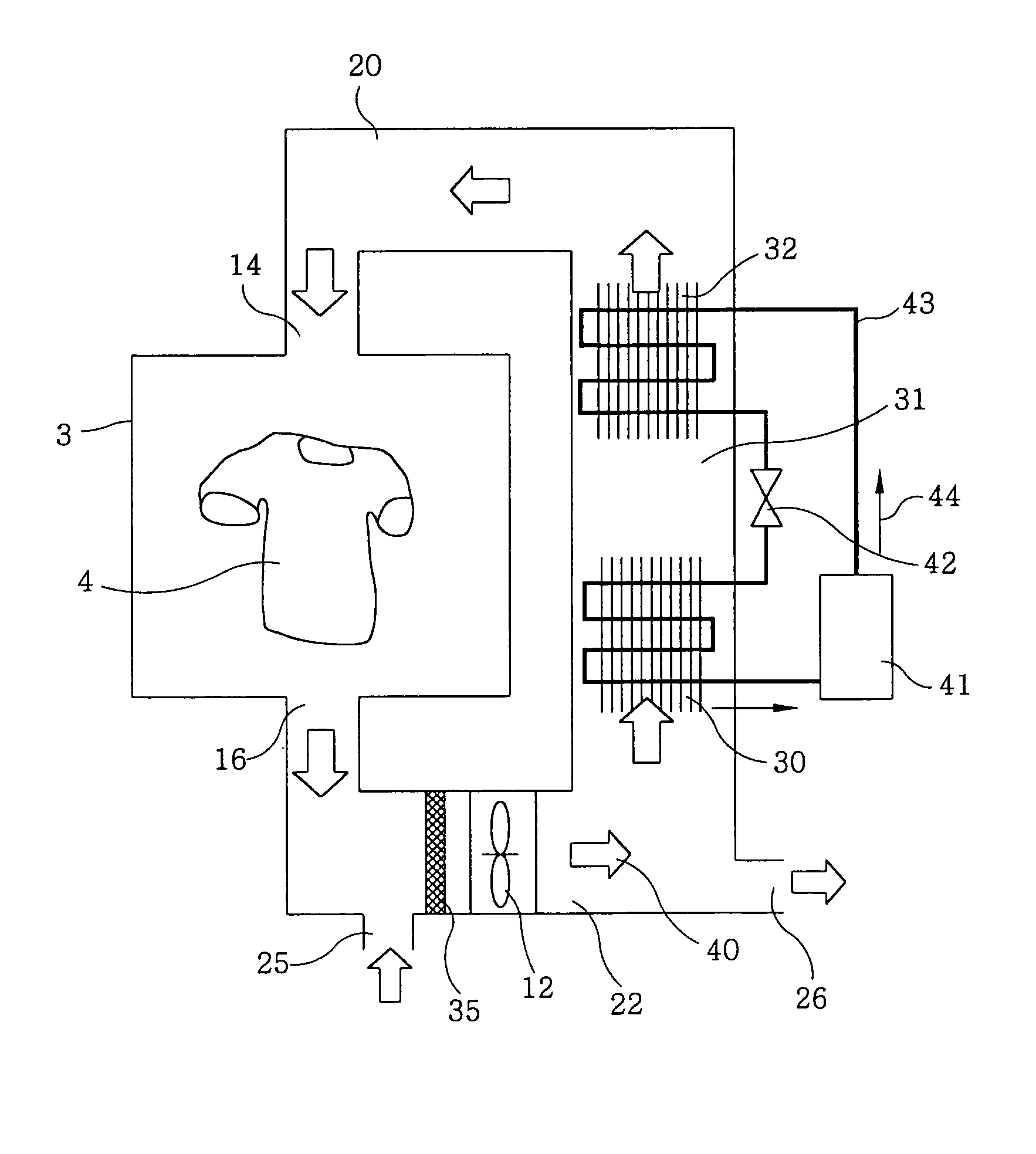

InactiveUS20050246920A1Shorten drying timeSave energyDrying solid materials with heatDomestic cooling apparatusEngineeringHigh pressure

A clothes dryer includes a drying chamber, a heat pump mechanism, and an air circulation path. The heat pump mechanism includes a compressor, a heat radiator for radiating the heat of compressed coolant, a throttle unit for reducing the pressure of the high-pressure coolant, and a heat absorber for absorbing heat using the low-pressure coolant. An air circulation path circulates drying air from the drying chamber through the heat absorber and the heat radiator back to the drying chamber. The air circulation path is provided with an air discharge port at a position between the drying chamber and the heat absorber so that a part of the drying air flowing through the air circulation path from the drying chamber to the heat absorber is discharged through the air discharge port to outside of the air circulation path.

Owner:PANASONIC CORP

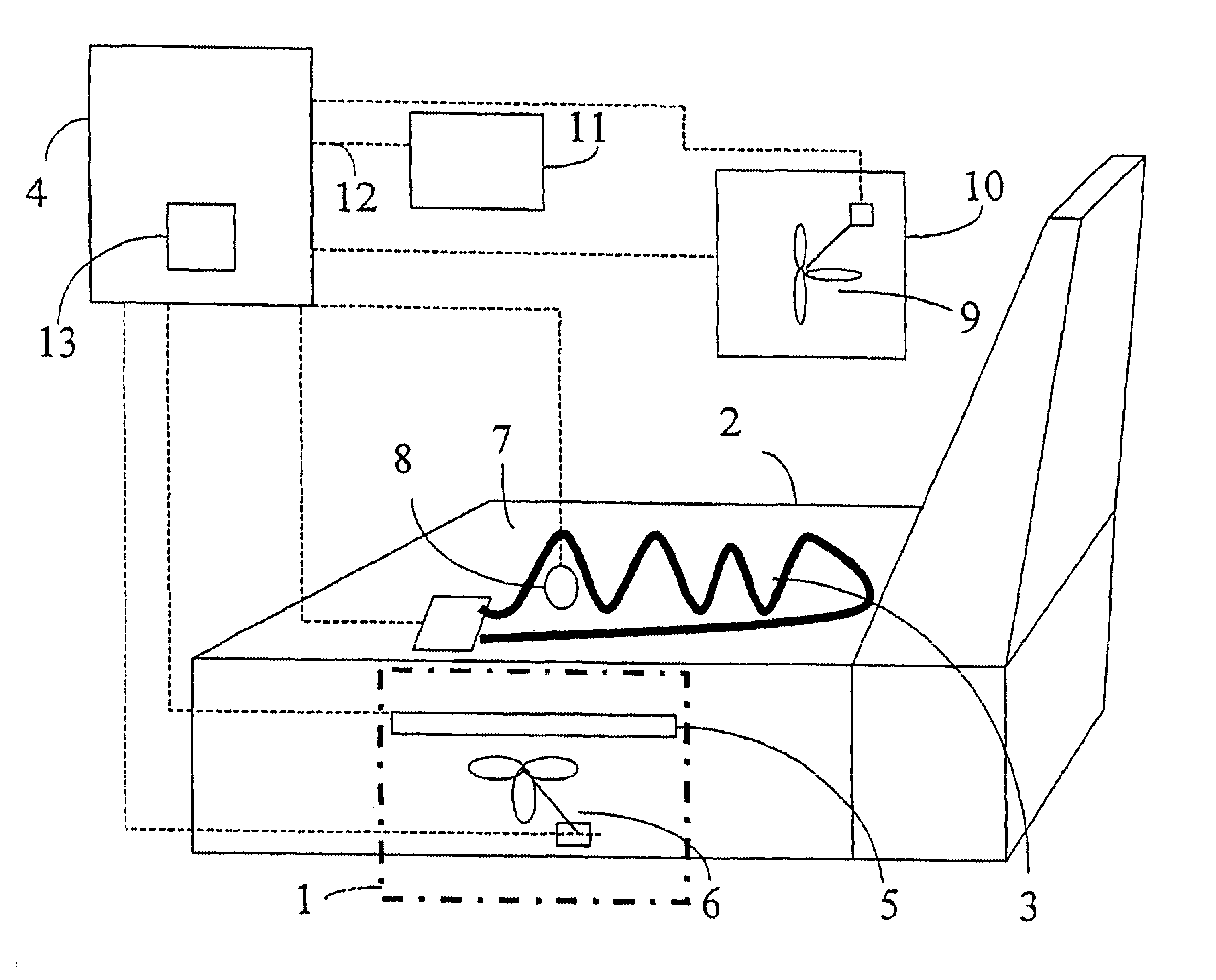

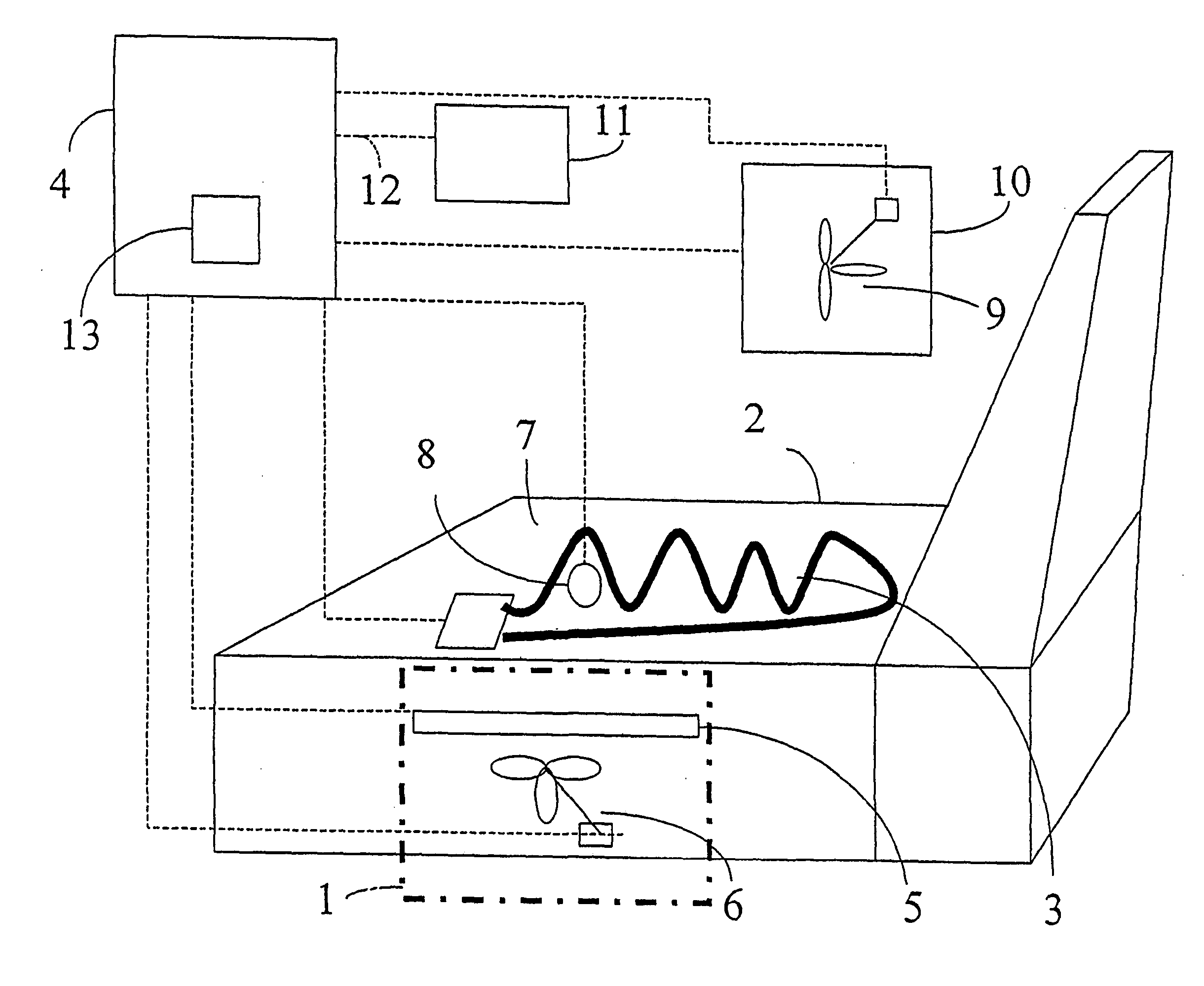

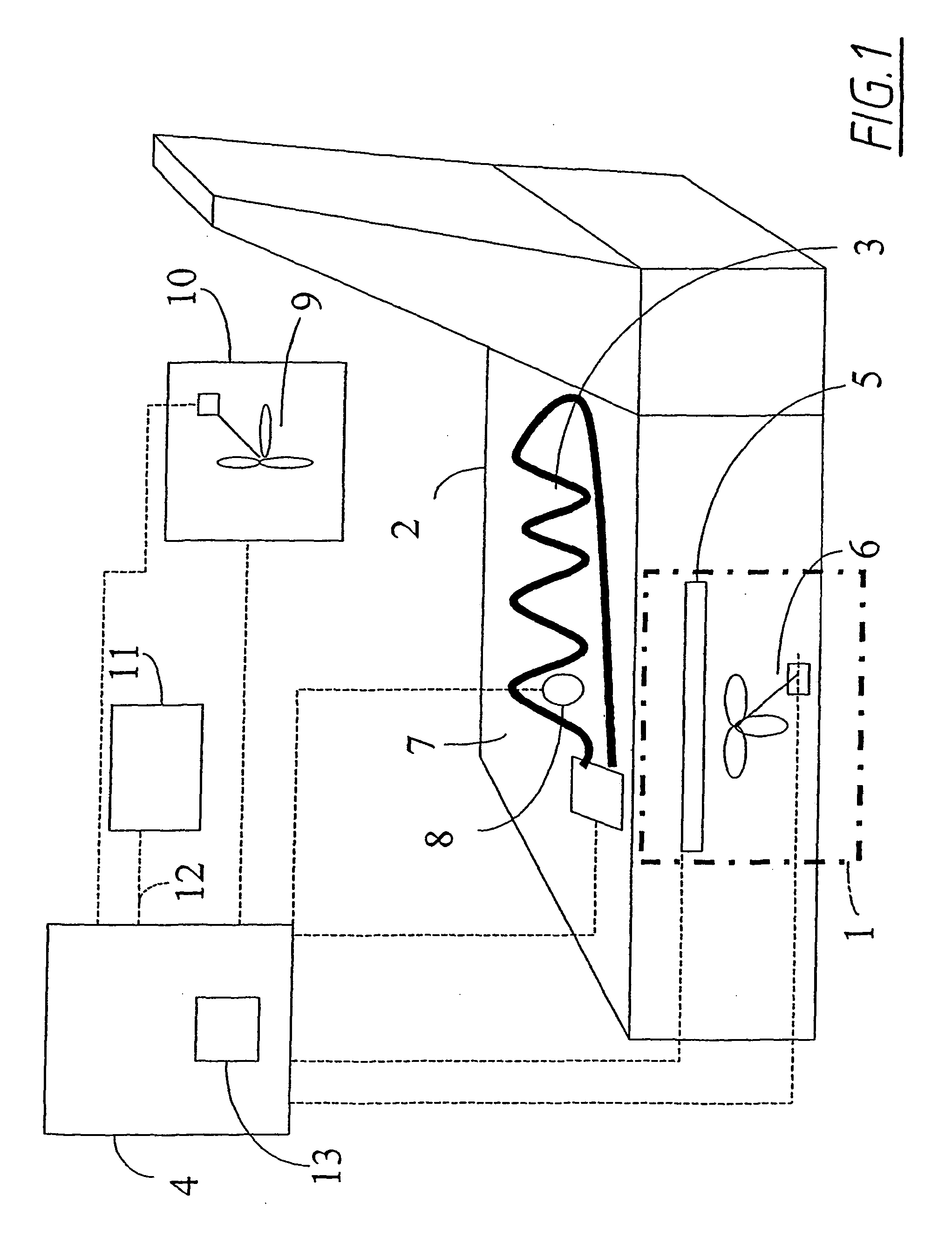

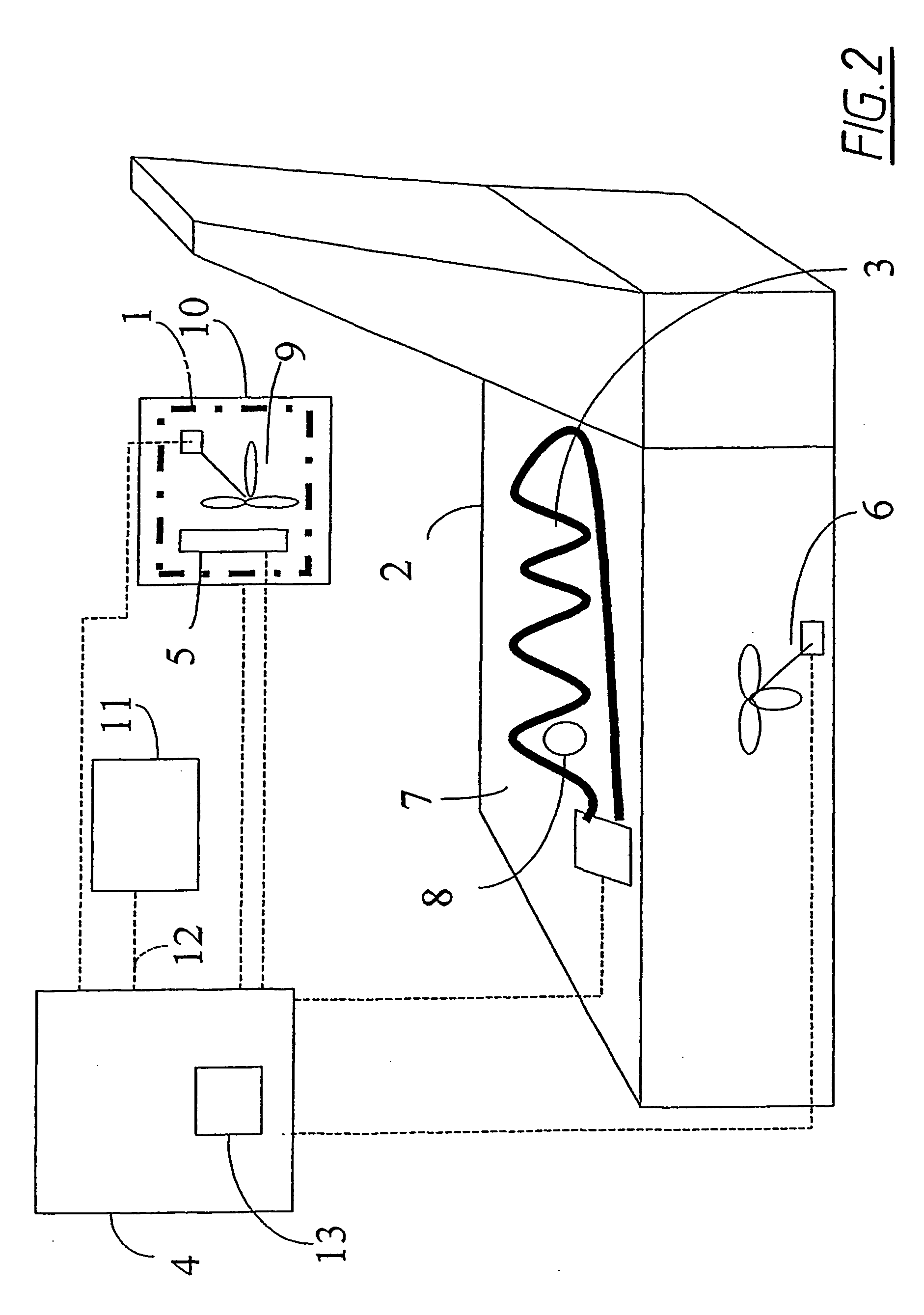

Seat with temparature control and ventilation and safety system for a vehicle

InactiveUS20040118555A1Improve cooling effectAccelerated dryingDomestic cooling apparatusPower to electric heating circuitsTemperature controlEngineering

Methods and apparatus for controlling the temperature of a seat such as a vehicle seat are disclosed. The apparatus includes an electrical heater disposed in the seat, a cooling unit such as a cooling element and a fan, a detector for detecting the temperature associated with the electrical heater, and a controller for controlling the electrical heater and the cooler based upon the detected temperature and upon the humidity algorithm comprising a predetermined set of calculations of the humidity of air at different temperatures.

Owner:LEAR CORP

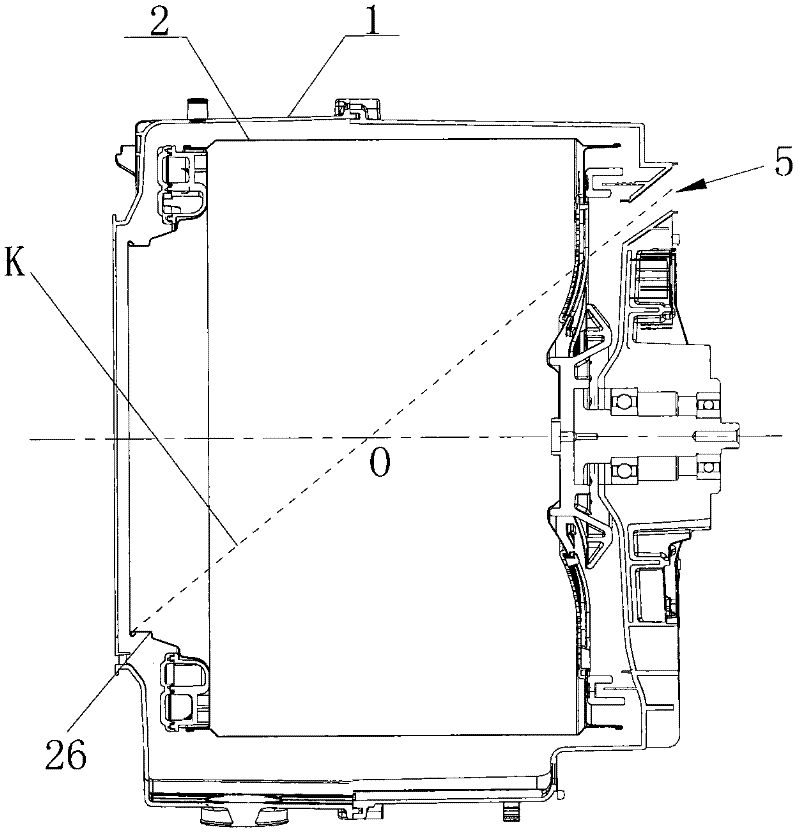

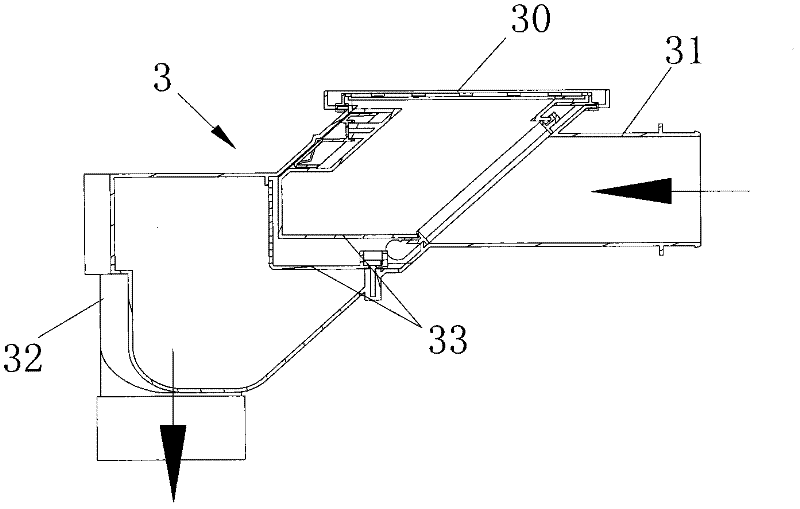

A washer-dryer with heat pump drying and dehumidification functions

The invention discloses a washing and drying machine with heat pump drying and dehumidification functions, which comprises an outer cylinder, an inner cylinder coaxially arranged inside the outer cylinder, a heat pump system, and a drying circulation air path between the outer cylinder and the heat pump system. The drying circulation air path successively passes through the heat pump air outlet, the outer cylinder air inlet, the inside of the outer cylinder, the outer cylinder air outlet, the heat pump air inlet, the heat pump system and then to the heat pump air outlet. The humid air inlet and dry air outlet of the humid air flow from the outside to the outside through the humid air inlet, heat pump inlet, heat pump system, heat pump outlet, dry air outlet and then to the outside to form a dehumidification circulation air path. There is a switching mechanism between the drying and dehumidification circulation air passage to realize the switching between clothes drying and dehumidification functions. The drying circulation air passage and the dehumidification circulation air passage are equipped with the same double-layer lint filter. The washing and drying machine of the invention has multiple functions, and can not only dry clothes, but also dehumidify and dry rooms.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

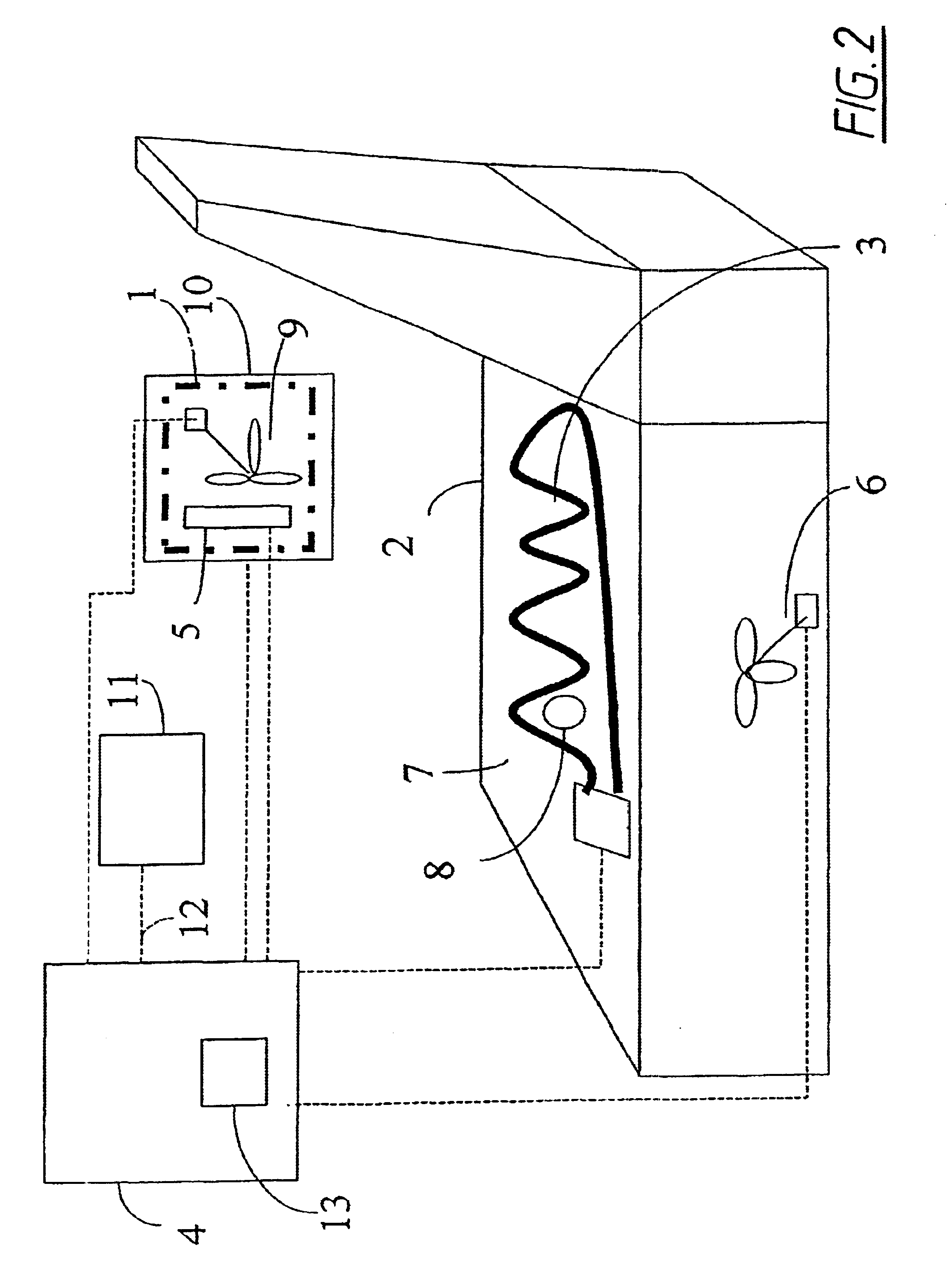

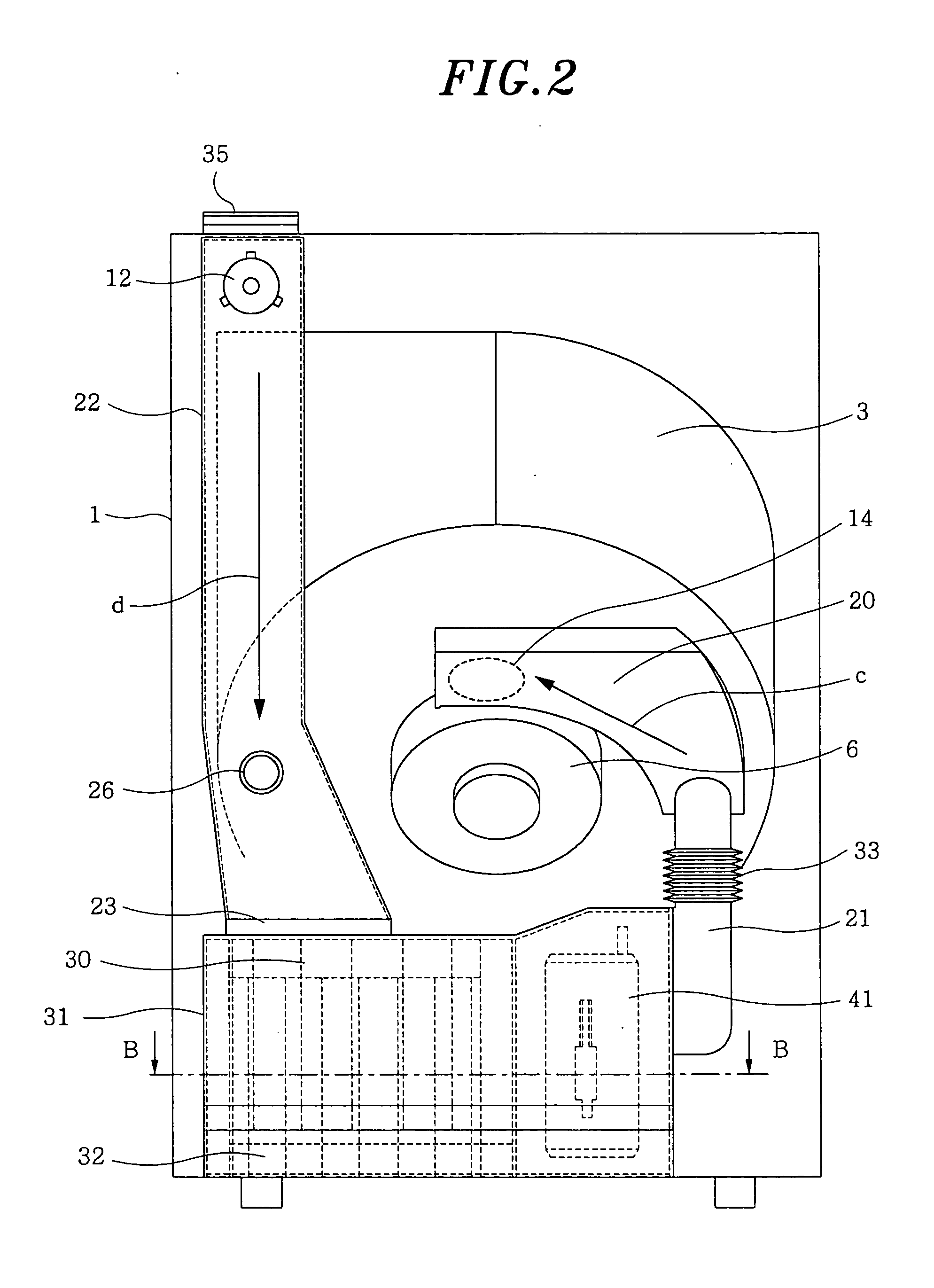

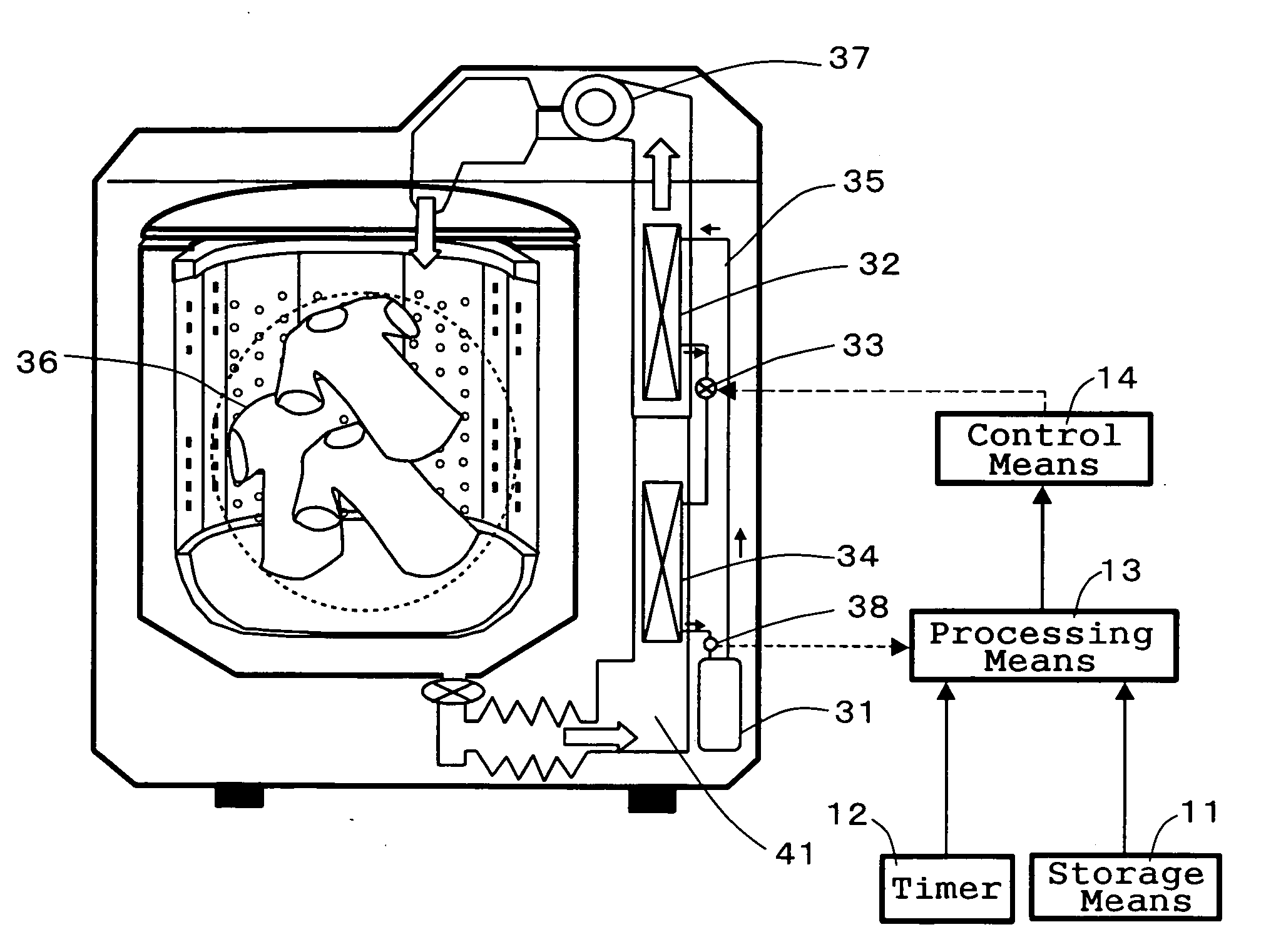

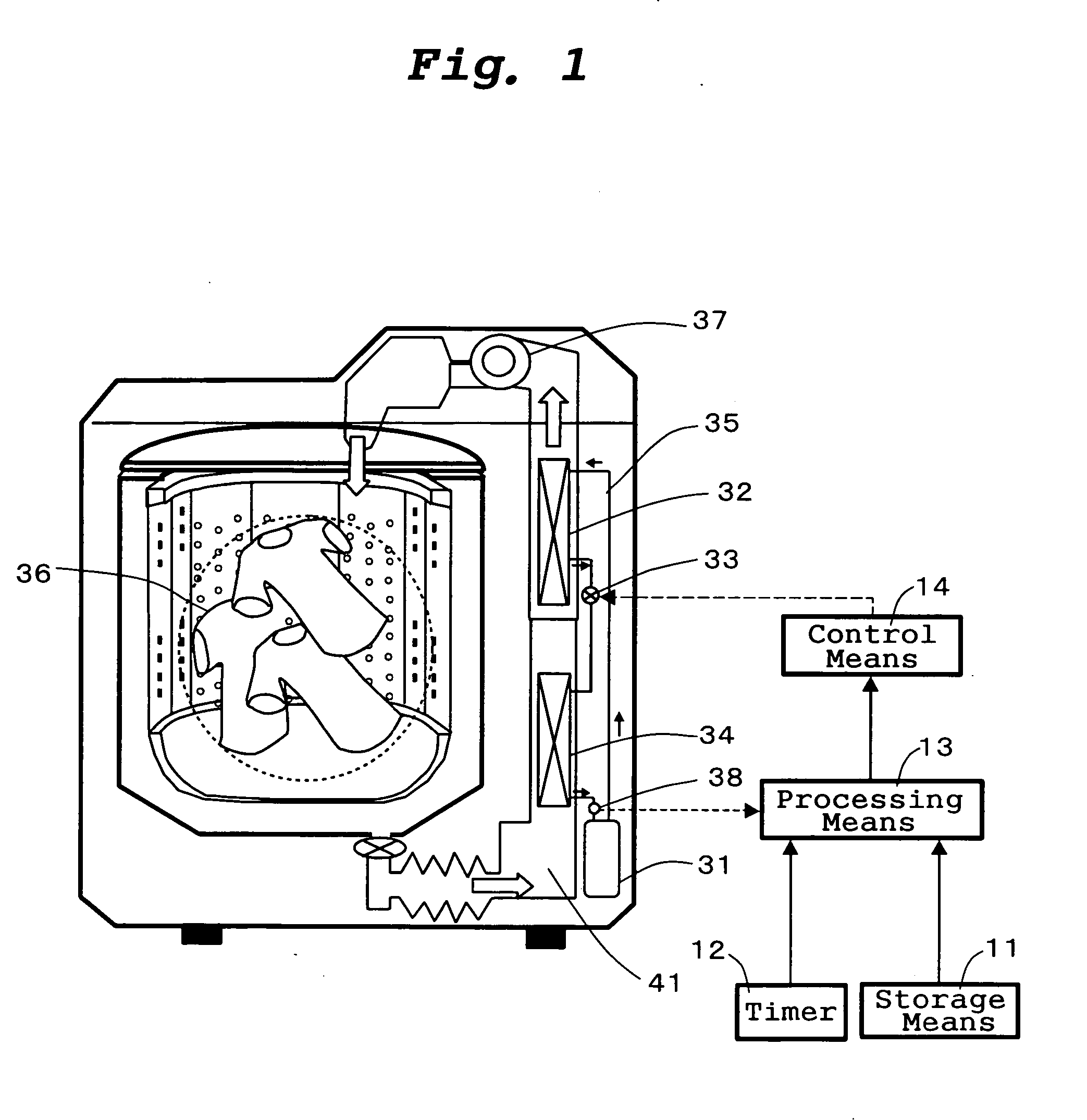

Drying apparatus

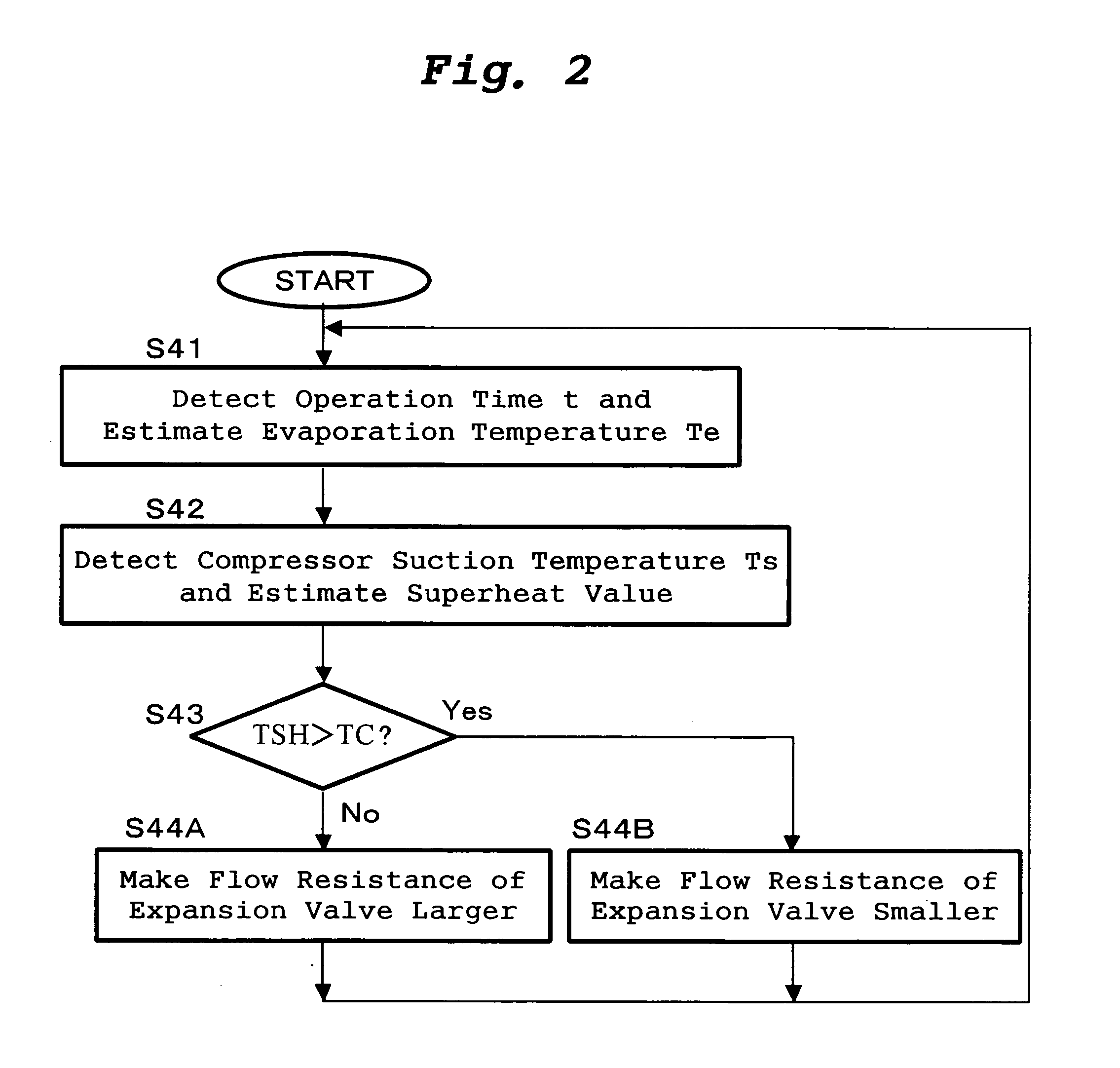

InactiveUS20070107255A1Shorten drying timeDrying solid materials with heatCompression machines with non-reversible cycleProcess engineeringRefrigerant

It has been difficult to operate a drying apparatus in a stable and high-efficiency state where a superheat value is changed in a drying process. A drying apparatus includes: a first temperature sensor 38 which detects the temperature of a refrigerant between the outlet of an evaporator 34 and the inlet of a compressor 31; and control means 14 for controlling a superheat value by changing flow resistance of an expansion valve 33 based on a detected value of the first temperature sensor 38. The control means 14 controls the superheat value in the drying process to become a target value.

Owner:PANASONIC CORP

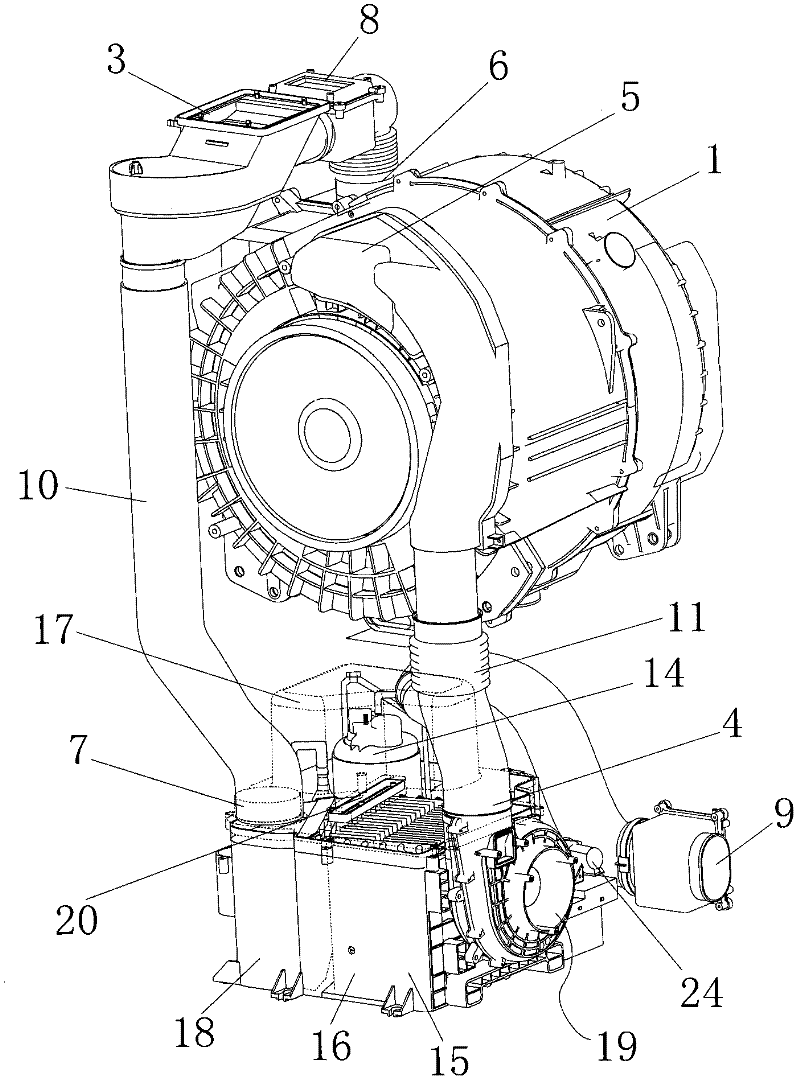

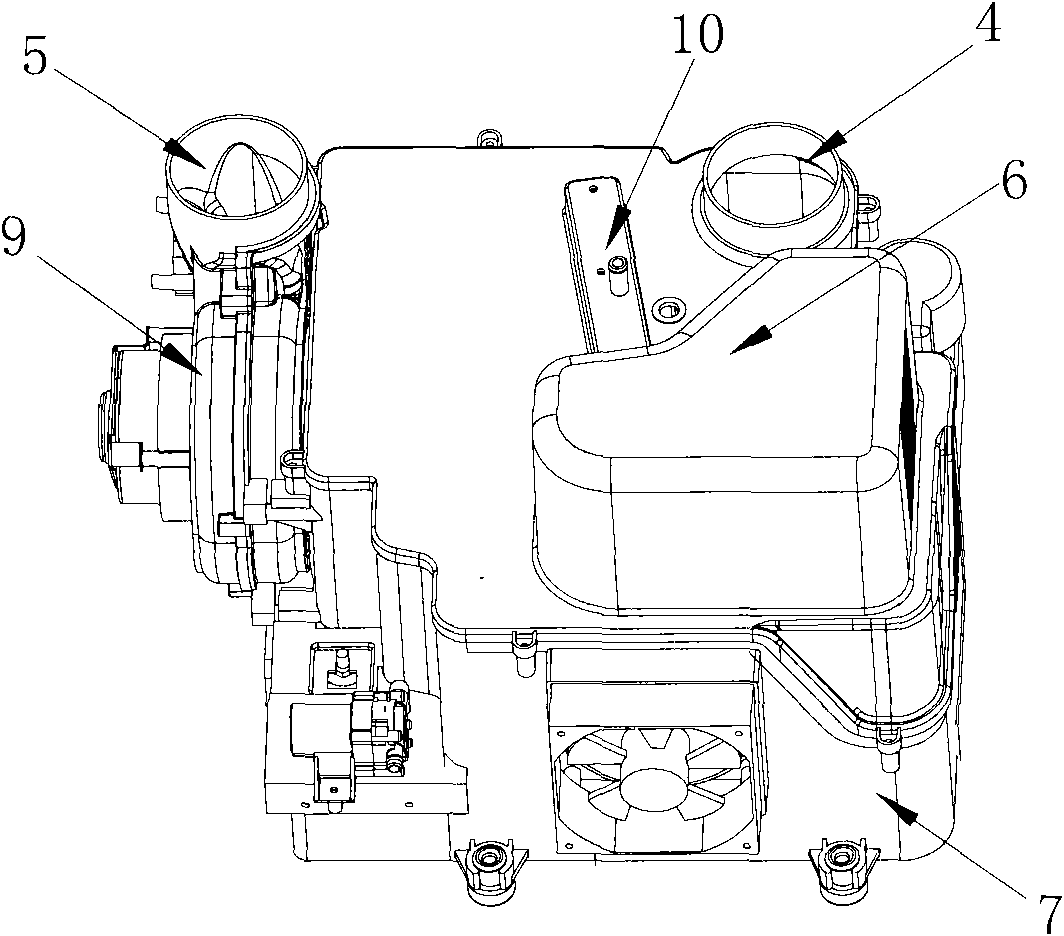

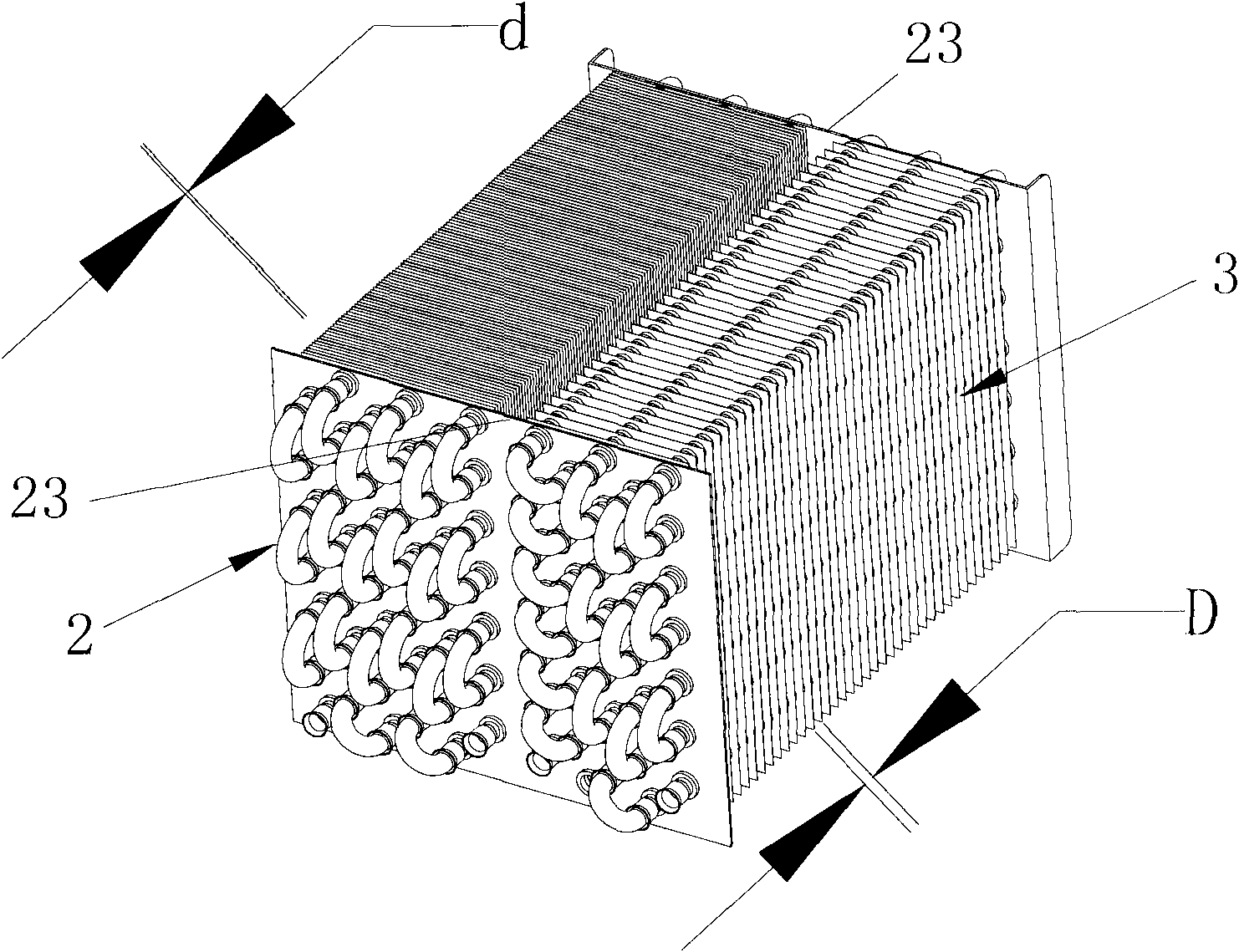

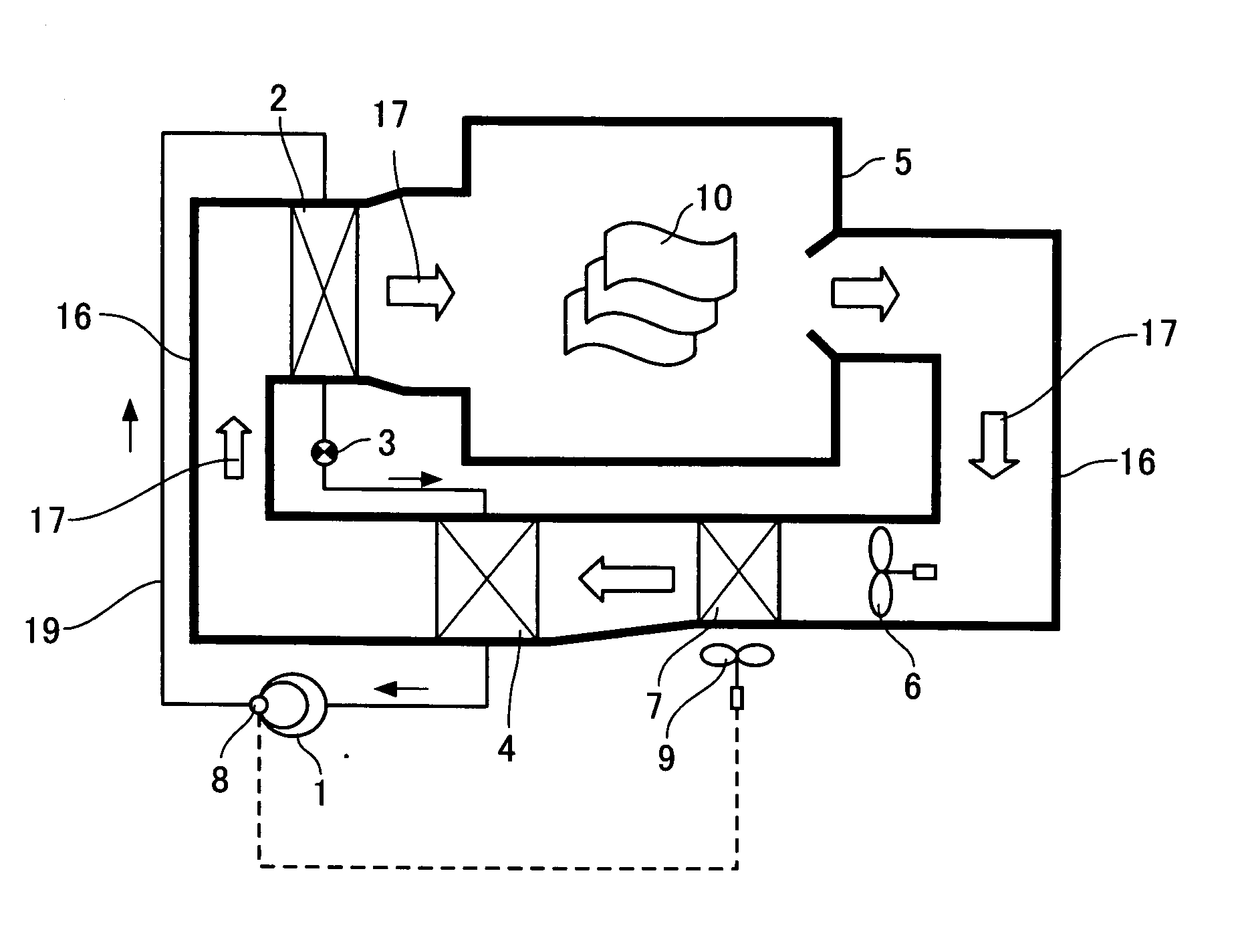

Heat pump drying system for drying clothes by using roller and control method of heat pump drying system

ActiveCN102206916AExtend your lifeImprove condensation effectLaundry dryer apparatusTextiles and paperProcess engineeringDrying time

The invention discloses a heat pump drying system for drying clothes by using a roller and a control method of the heat pump drying system. The system comprises a heat pump system for drying the clothes, and an air inlet and an air outlet which are communicated with the roller for accommodating the clothes respectively, wherein the heat pump system comprises a compressor, a condenser, a throttling device and an evaporator which are connected with one another in turn through a refrigerant circulating pipeline to form a circulating system; the heat pump system, the air inlet and the air outlet are integrated through an upper cover plate and a lower cover plate; an air deflector, the evaporator, the condenser and an air supply fan are arranged between the air inlet and the air outlet in turn to form an air circuit; the compressor is sealed in closed space by the upper cover plate and the lower cover plate; and the air supply fan is a direct-current fan with a controllable rotating speed, and the rotating speeds at different drying stages are correspondingly controlled to reduce the load of the compressor. The heat pump drying system has the characteristics of saving energy and shortening drying time.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

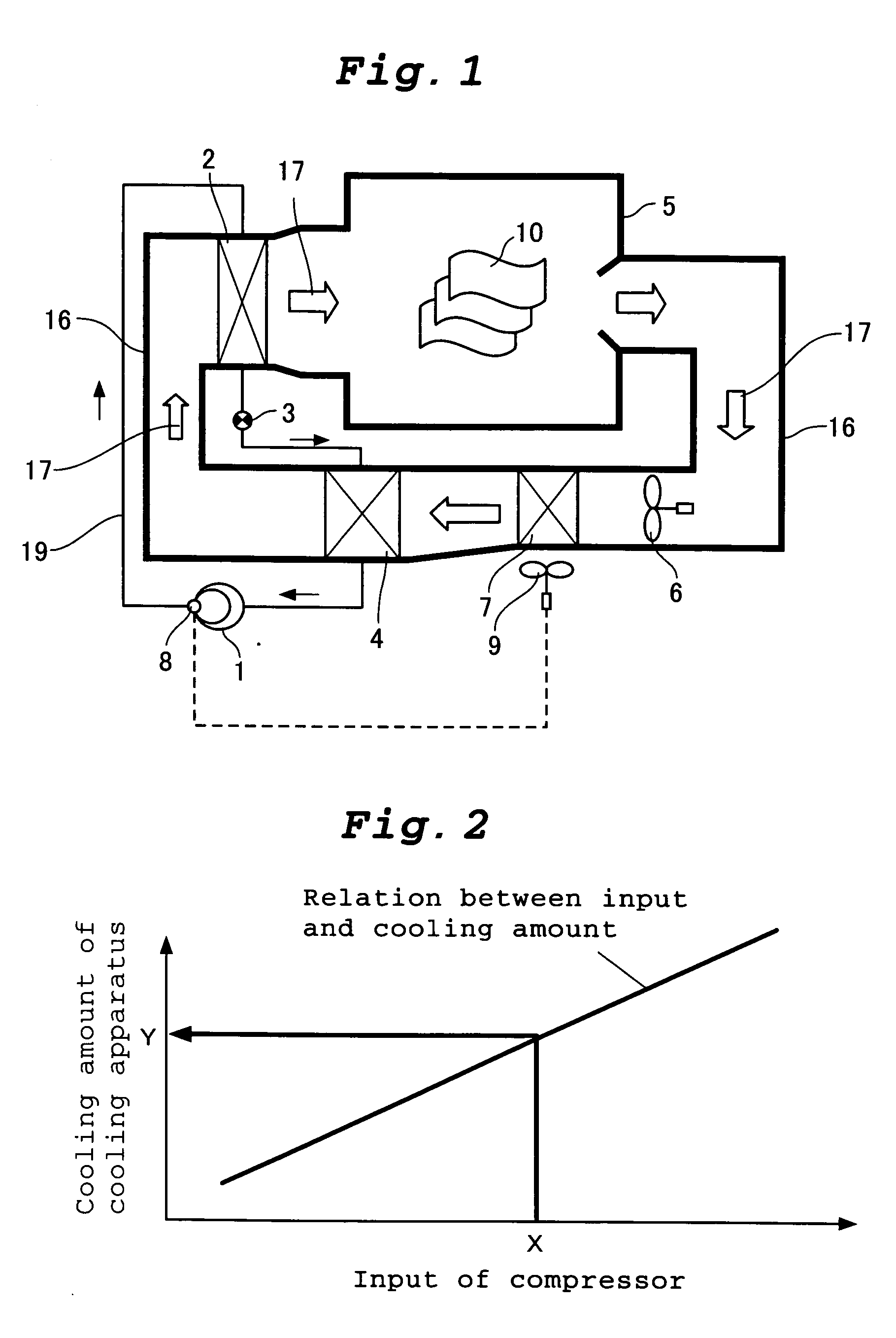

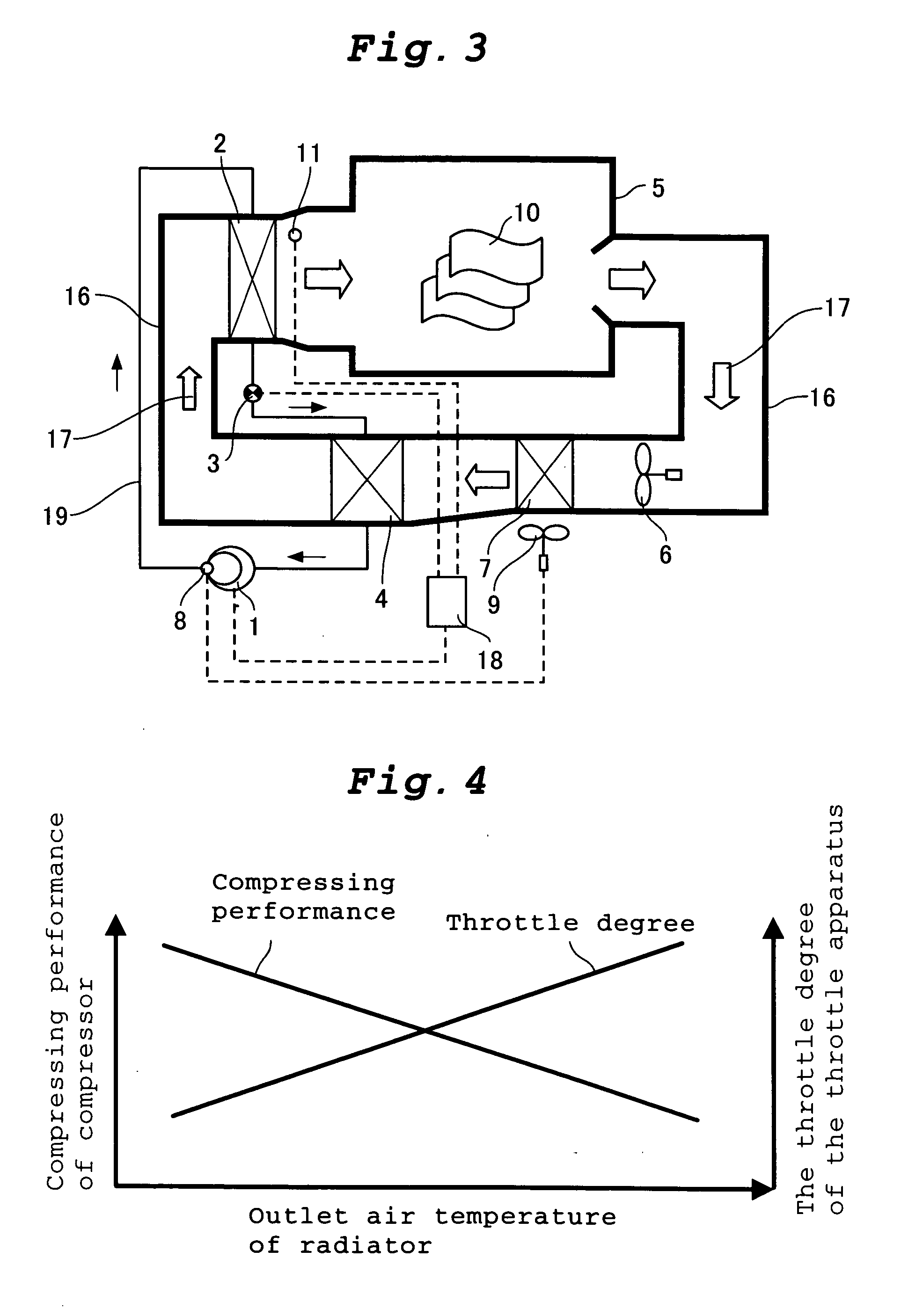

Drying device and method of operation therefor

InactiveUS20050217133A1High reliabilityIncrease drying speedDrying solid materials with heatCompression machinesRefrigerantEvaporator

A drying apparatus comprising a heat pump apparatus in which a refrigerant circulates through a compressor, a radiator, a throttle apparatus and an evaporator in this order, in which air heated by the radiator is introduced into a dry chamber, the air coming out from the dry chamber is cooled by a cooling apparatus, the air cooled by the cooling apparatus is dehumidified by the evaporator, and the air dehumidified by the evaporator is again heated by the radiator, wherein the drying apparatus further comprises compressor input detecting means for detecting input of the compressor, and cooling quantity control means for controlling a cooling quantity of the cooling apparatus using a value detected by the compressor input detecting means.

Owner:PANASONIC CORP

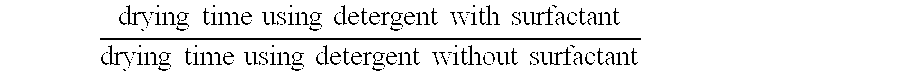

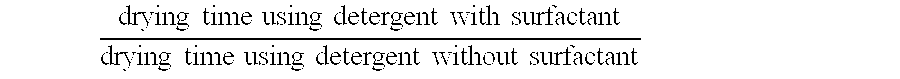

Warewashing system containing low levels of surfactant

ActiveUS20070017553A1Reduce thicknessFast dryingTableware washing/rinsing machine detailsSurface-active detergent compositionsOrganic chemistrySURFACTANT BLEND

A method of washing ware in an automatic institutional warewashing machine, using a cleaning composition containing a surfactant which eliminates the need for a surfactant in the rinse step. A surfactant is employed in the wash step in an amount not to exceed 15 wt % based on weight of the detergent. The amount of surfactant is sufficient to provide a layer of surfactant on the ware so as to afford a sheeting action in an aqueous rinse step without any added rinse agent.

Owner:JOHNSONDIVERSEY INC

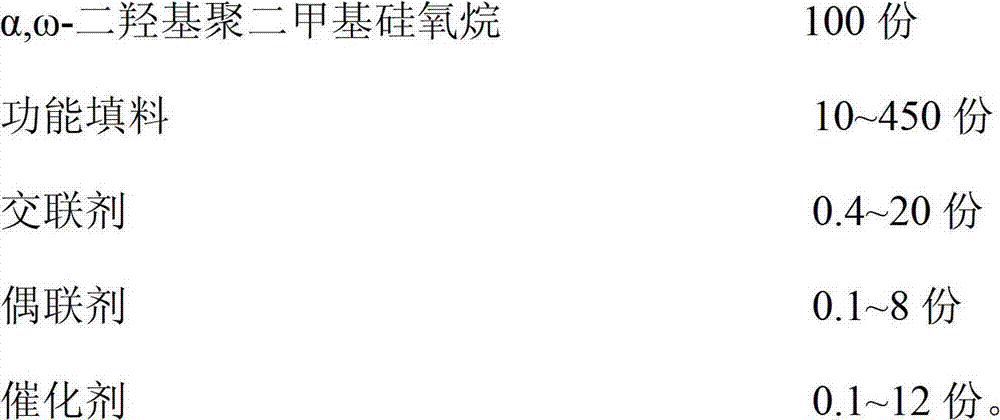

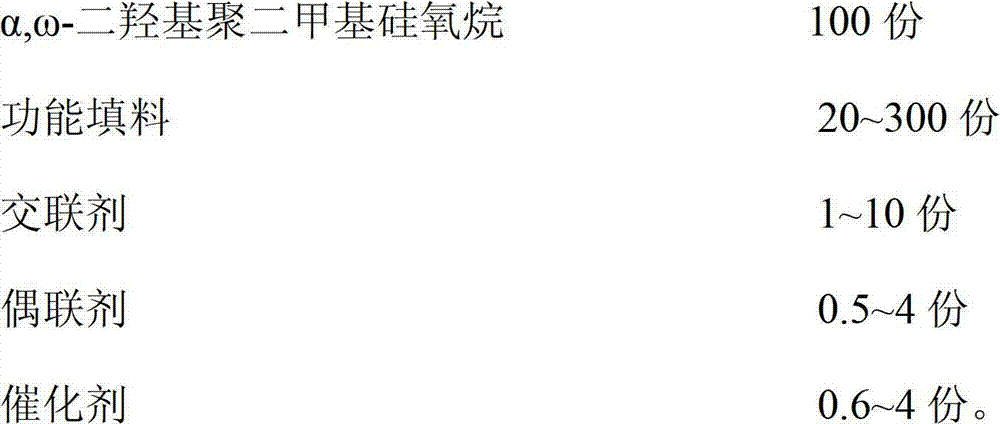

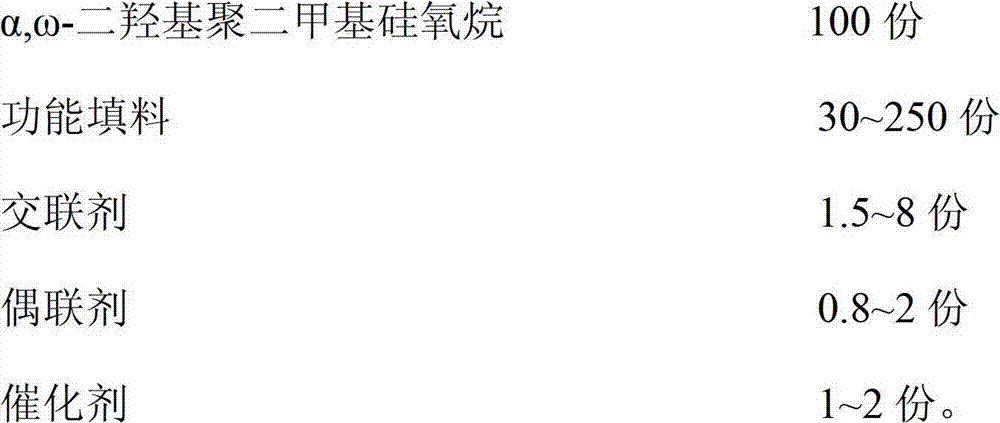

Single-component catalytic dealcoholized room temperature vulcanized (RTV) silicone rubber and preparation method thereof

InactiveCN102757647ANo viscosity peaksSimple processNon-macromolecular adhesive additivesOther chemical processesPolymer scienceRoom temperature

The invention relates to a single-component catalytic dealcoholized room temperature vulcanized (RTV) silicone rubber which comprises the following components in parts by weight: 100 parts of alpha, omega-dihydroxyl polydimethylsiloxane, 10-450 parts of function filler, 0.4-20 parts of crosslinking agent, 0.1-8 parts of coupling agent and 0.1-12 parts of catalyst. The invention also relates to a preparation method of the single-component catalytic dealcoholized RTV silicone rubber, and the method comprises the following steps of: preparing a ground mass, namely dewatering and blending the alpha, omega-dihydroxyl polydimethylsiloxane and the function filler to obtain the ground mass; stirring the taken ground mass in a vacuum state, adding the crosslinking agent, and stirring the materials in a vacuum state; adding the coupling agent, and stirring the materials; and adding the catalyst, vacuumizing, introducing inert gas, stirring, vacuumizing, and stirring to obtain the single-component catalytic dealcoholized RTV silicone rubber. The method provided by the invention has the advantages of no generation of viscosity peak, simple process and cost saving; and the single-component catalytic dealcoholized RTV silicone rubber has excellent comprehensive properties.

Owner:兆舜科技(广东)有限公司

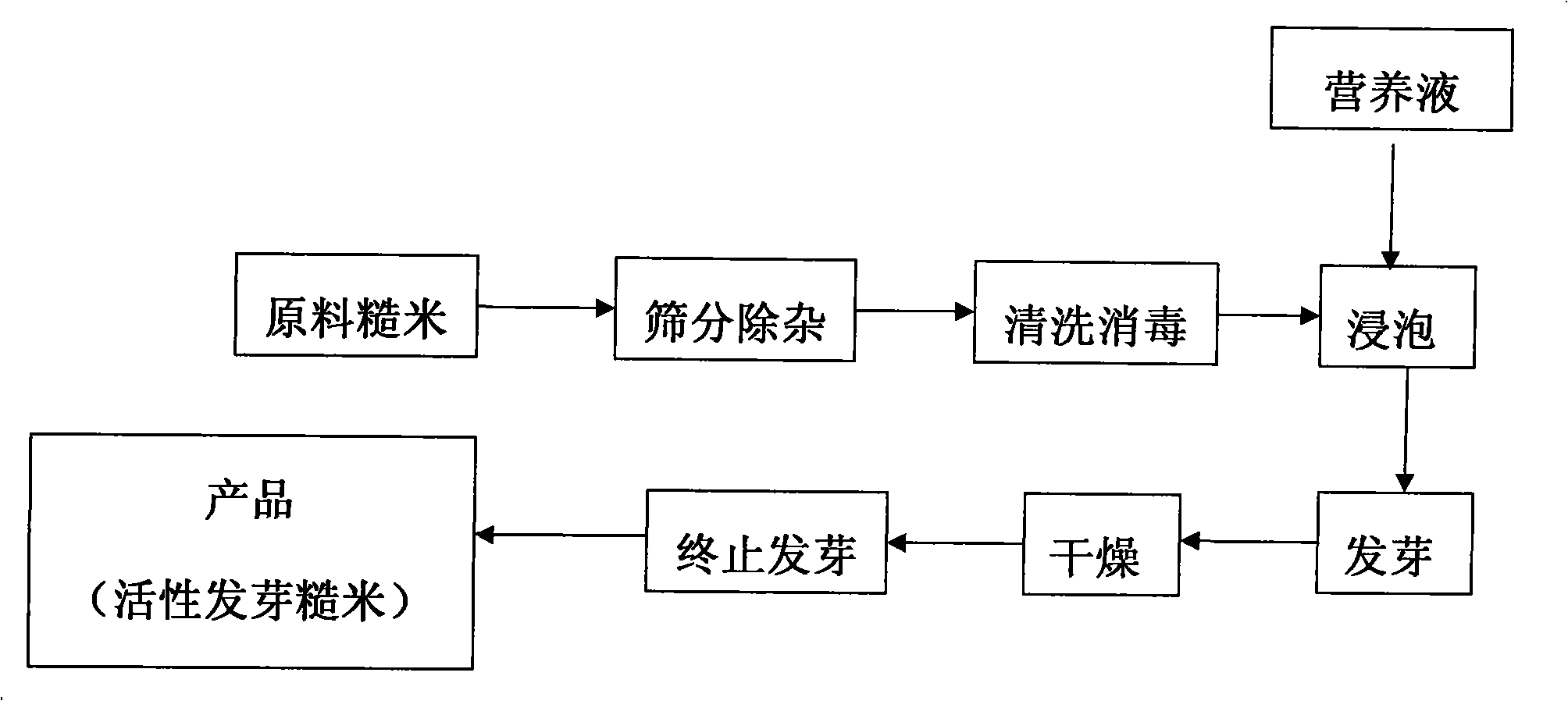

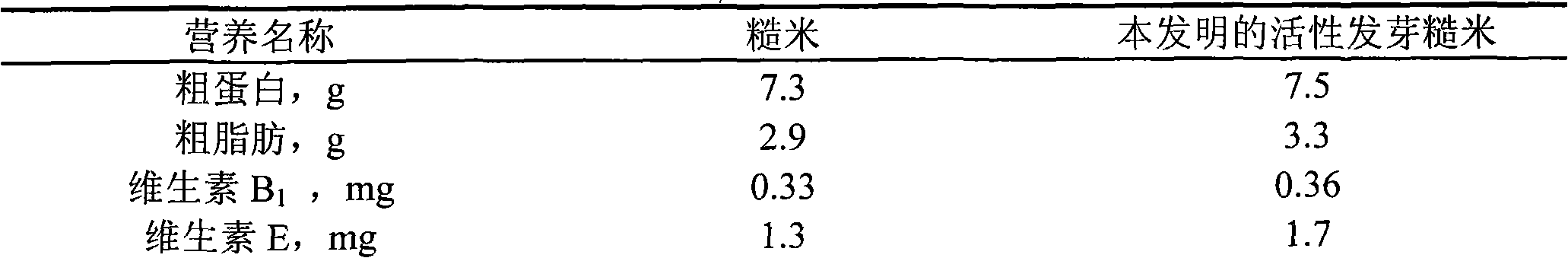

Production method of active germinated unpolished rice and its products

InactiveCN101283754APromote digestion and absorptionRich varietyFood preparationFertilizer mixturesNutritive valuesVitamin C

The invention belongs to the technology field of grain processing, specifically a method for producing active germinated brown rice and products thereof. The method comprises the following steps: screening brown rice raw material to remove impurity, washing, sterilizing, soaking in a nutrient fluid supplemented with calcium lactate, gibberellin, phytase, cellulase and vitamin C for 10-36 hours at 10-40 DEG C, draining, incubating for 10-36 hours at 10-40 DEG C under relative humidity of 50-90% to allow germination, drying with hot air of 40-55 DEG C for 0.5-3 hours until the sprout grows about 0.5-1.2 mm in height, drying with 2-10 w / g microwave for 2-10 minutes until the water content of germinated brown rice is below 15%. Compared with the prior art, the germinated brown rice is nutritious, retains almost all nutrients of brown rice and has high nutritional value.

Owner:HUAZHONG AGRI UNIV

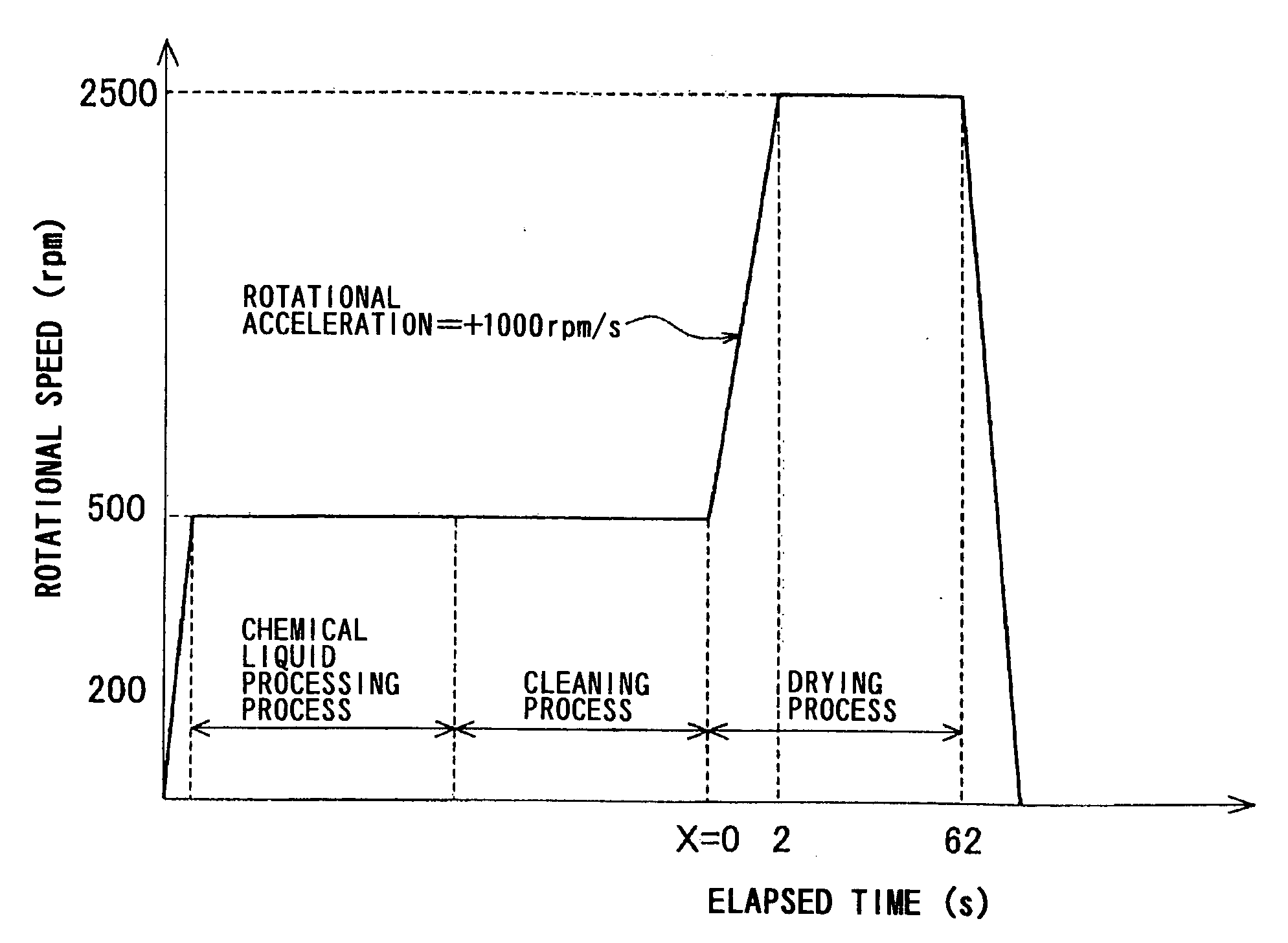

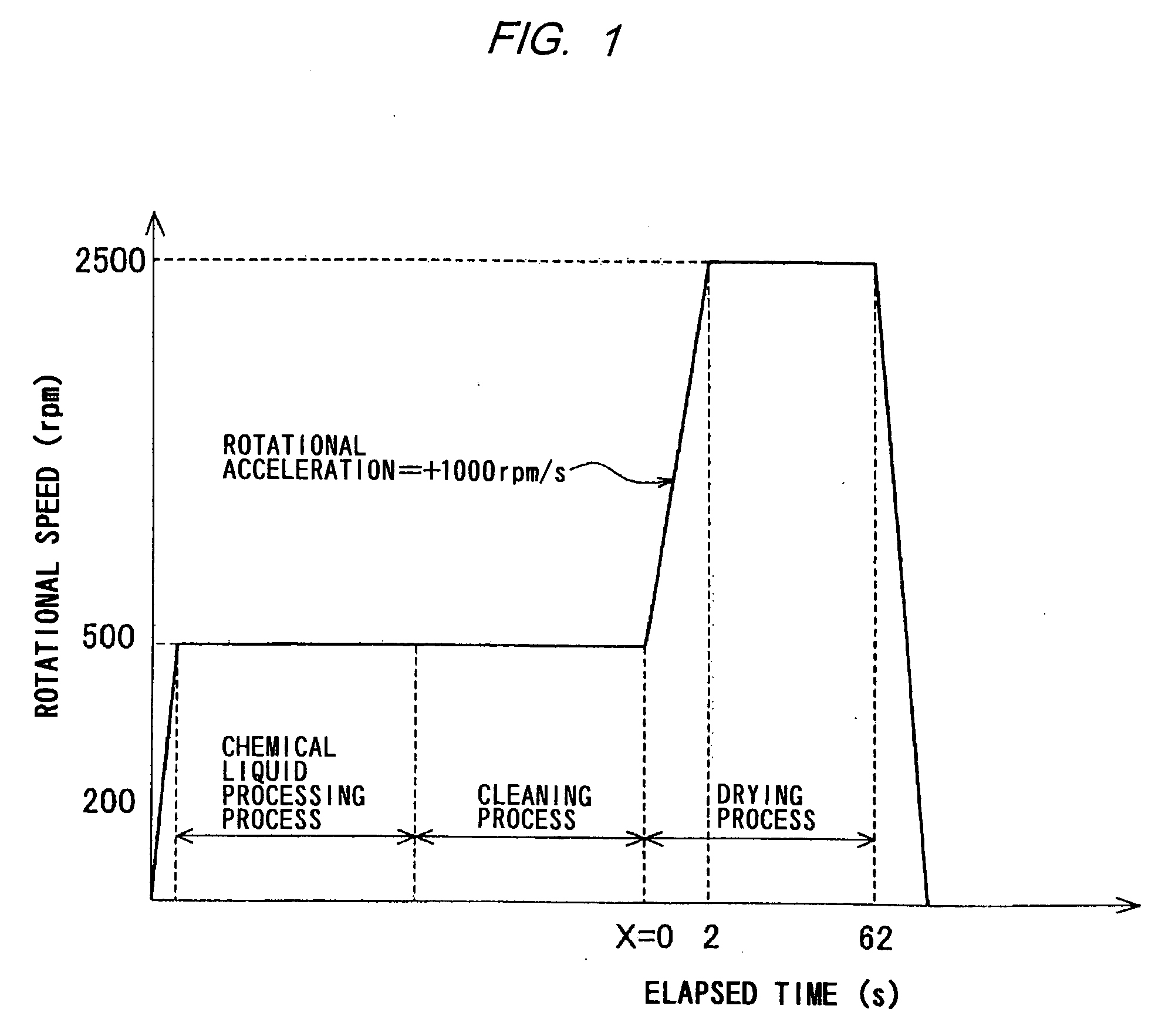

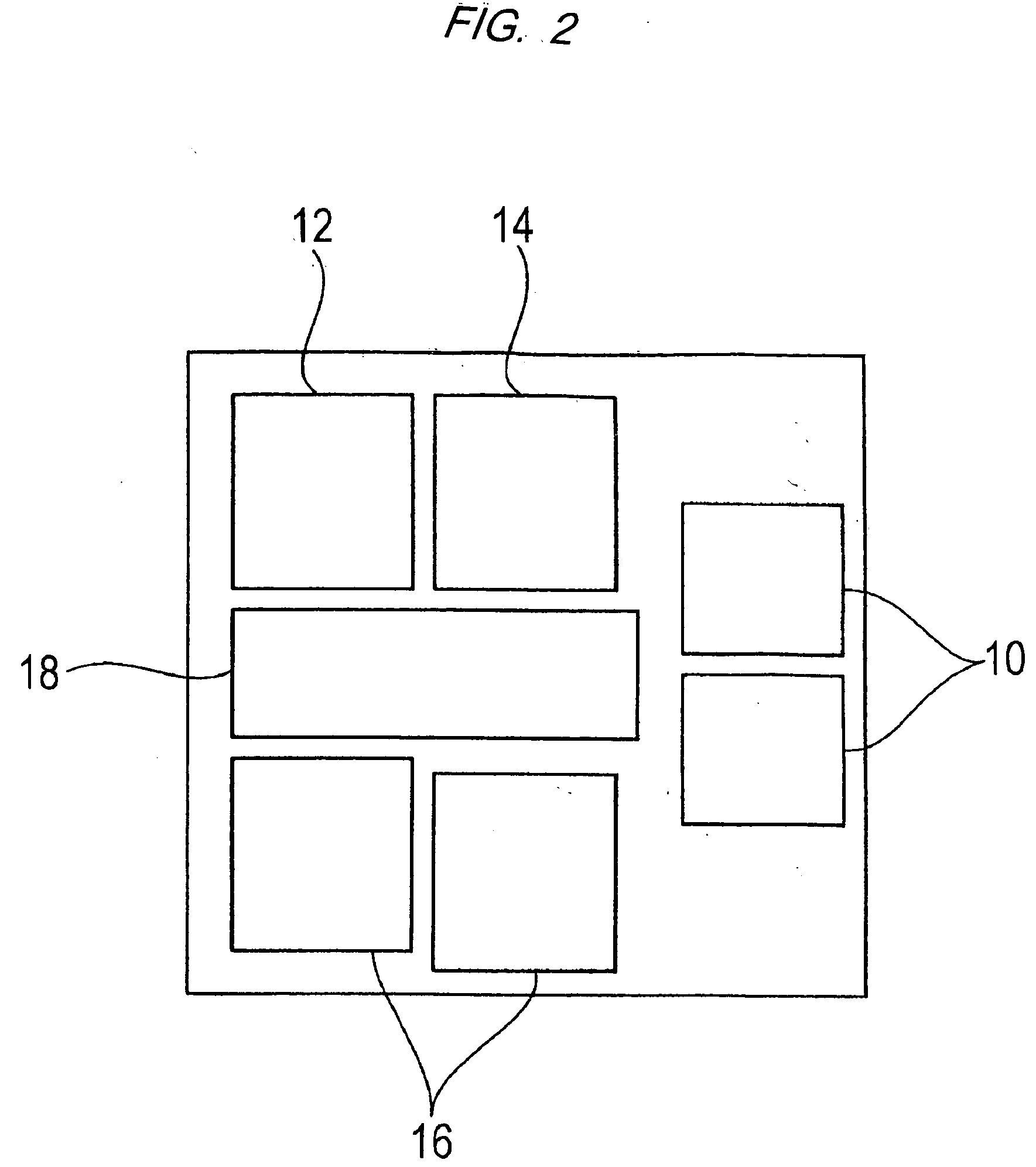

Substrate processing apparatus and substrate processing method

InactiveUS20050026455A1Suppress formationIncreased substrate speedSemiconductor/solid-state device manufacturingEngineeringWet cleaning

The present invention provides a substrate processing apparatus having a drying mechanism for removing water from the surface of a substrate which has been cleaned by a wet cleaning process, and a substrate processing apparatus and a substrate processing method which are capable of efficiently removing an unnecessary thin film deposited on or adhering to a bevel or edge portion of a substrate. The substrate processing apparatus of this invention has a substrate holder for holding a substrate, and a dry gas supply section for turning an atmosphere to which at least a portion of a surface of the substrate held by the substrate holder is exposed into a humidity-controlled dry gas atmosphere.

Owner:EBARA CORP

Conductive polymer solution, antistatic coating material, antistatic hard coat layer, optical filter, conductive coating film, antistatic tacky adhesive, antistatic tacky adhesive layer, protective material, and method for producing the same

ActiveUS20060202171A1Enhance thermostabilityImprove conductivityConductive materialOrganic conductorsConductive coatingPolymer dissolution

The conductive polymer solution of the present invention contains a π-conjugated conductive polymer, a solubilizable polymer, a phase transfer catalyst, and an organic solvent. The method for preparing a conductive polymer solution of the present invention comprises adding a phase transfer catalyst adding an organic solvent to an aqueous polymer solution prepared by dissolving the π-conjugated conductive polymer and a solubilizable polymer in water.

Owner:SHIN-ETSU POLYMER CO LTD

Developer solvent for photopolymer printing plates and method

InactiveUS6248502B1Improved relief depthImproved sidewall structurePhotosensitive material processingOriginals for photomechanical treatmentNon solventOrganic solvent

Flexographic printing plates crosslinkable by photopolymerization are produced by exposing the plates to a light source and washing out (developing) with a solvent the non-crosslinked areas that are masked out during the exposure process. The invention provides terpene ester-based solvents suitable for use in the development of photopolymer printing plates. The solvents, which include terpene esters alone or terpene esters mixed with organic solvents and / or non-solvents, are effective in developing a a large number of different photopolymer printing plates and can produce images superior to those obtained with commercially available solvents currently used in such applications.

Owner:EASTMAN KODAK CO

Water-based coating composition, preparation method thereof and method for taking water-based coating composition as strippable coating protective film

InactiveCN102127345AFast dryingImprove drying speed at room temperatureAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedEmulsion

The present invention relates to a method for forming a strippable coating protective film using a water-based coating composition. The method comprises the following steps: the water-based coating composition is applied to a body surface to form a strippable coating protective film. The water-based coating composition takes synthesized resin emulsion as a substrate and takes water as a dispersion medium. When the water-based coating composition prepared by adopting the method is applied to the surface of an object, the strippable coating protective film can be formed. The formed strippable coating protective film has the advantages of excellent combination property, environmental friendliness, fast drying at normal temperature, wide strippable temperature range and high stripping property.

Owner:WUHAN JIHENG NEW MATERIAL TECH

Water-based ultra-thin fire-retardant coating for steel structures and preparation method of fire-retardant coating

The invention discloses a water-based ultra-thin fire-retardant coating for steel structures. The fire-retardant coating comprises components as follows: a binder emulsion, an intumescent flame retardant system, filler, deionized water and additives, wherein the additives comprise a dispersing agent, an antifoaming agent, a mold inhibitor, an anti-flash-rust agent, a coalescing agent, a leveling agent and a thickener; the intumescent flame retardant system comprises a dehydration catalyst, a carbonizing agent and a foaming agent. The invention further designs a preparation method of the water-based ultra-thin fire-retardant coating for the steel structures. The components are mixed sequentially to be prepared into the water-based ultra-thin fire-retardant coating for the steel structures in a vertical sand mill and a dispersing tank. The prepared coating is large in adhesive force, high in hardness, good in fireproof property, good in anti-scratch performance and excellent in weather resistance and water resistance, the surface layer of the coating is fine and smooth, the decoration performance is improved significantly, and the preparation method is low in energy consumption and has the advantages that the harm to human bodies and the pollution to the environment during preparation are small and the like.

Owner:JIANGSU MARINE VICTORY COATING

Completely fused paper soap and its making process

InactiveCN1357613AImprove solubilityImprove decontamination abilityDetergent materialsPhenolFatty alcohol

The component of the paper soap include carboxymethyl cellulose sodium, fatty alcohol polyioxymethyl ethyleneethere sodium sulfate, sodium dodecyl benzene sulfonate, lauryl sodium sulfate, cocinin diethanolamide, nonly phenol polyoxyethyleneether, glycerine, quaternary ammonium salt and citric acid. Its preparation includes preparing carboxymethyl cellulose sodium mother liquor, adding the mixed solution of other components to prepare solution through stirring, spraying the prepared solution of PVC plate and drying in a sealed room and moisture extract at 35-40 deg.c to form film.

Owner:成都洁利康实业发展有限公司

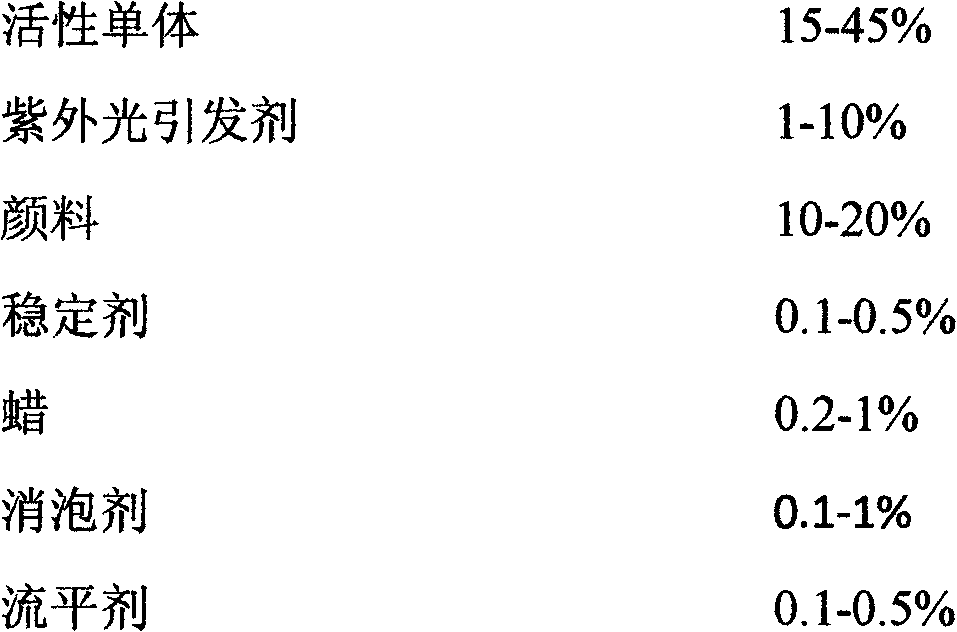

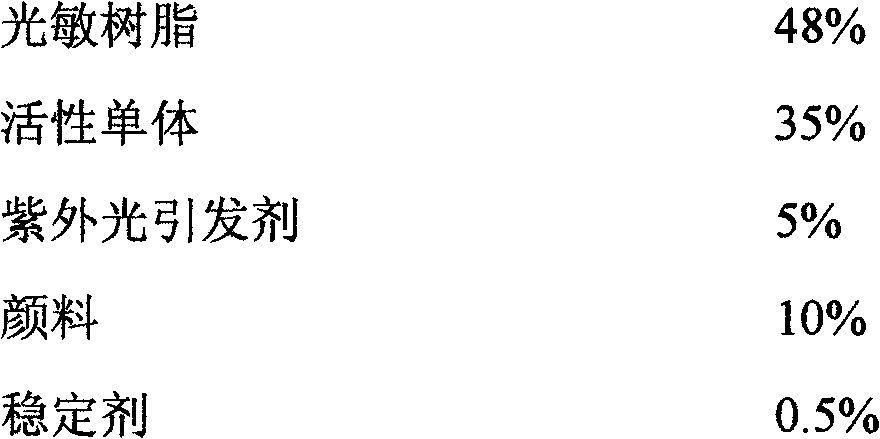

A kind of ultraviolet curing ink and preparation method thereof

The invention relates to an ultraviolet curable ink and a preparation method thereof. The ink comprises 30-60% of light sensitive resins, 15-45% of active monomers, 1-10% of ultraviolet light initiators, 10-20% of pigments and 0.5-2% of auxiliaries by mass and is an ink which is transformed from liquid state to solid state to be cured after binders in the ink are cross-linked under the irradiation of ultraviolet lights with certain wavelengths. The ultraviolet curable ink provided by the invention has the advantages of short light curing time, no need of heating, conservation in energy consumption, no volatile organic solvent VOC (Volatile Organic Compounds) in the ink, no pollution to the atmosphere, smaller effect of temperature variation on system viscosity, high solid content, suitability for multiple production methods and production requirements and excellent comprehensive properties, can be machined and used within a wider temperature range; and very good printing effects of the ultraviolet curable ink on both a hard substrate and a soft substrate can be obtained.

Owner:哈尔滨大东方新材料科技股份有限公司

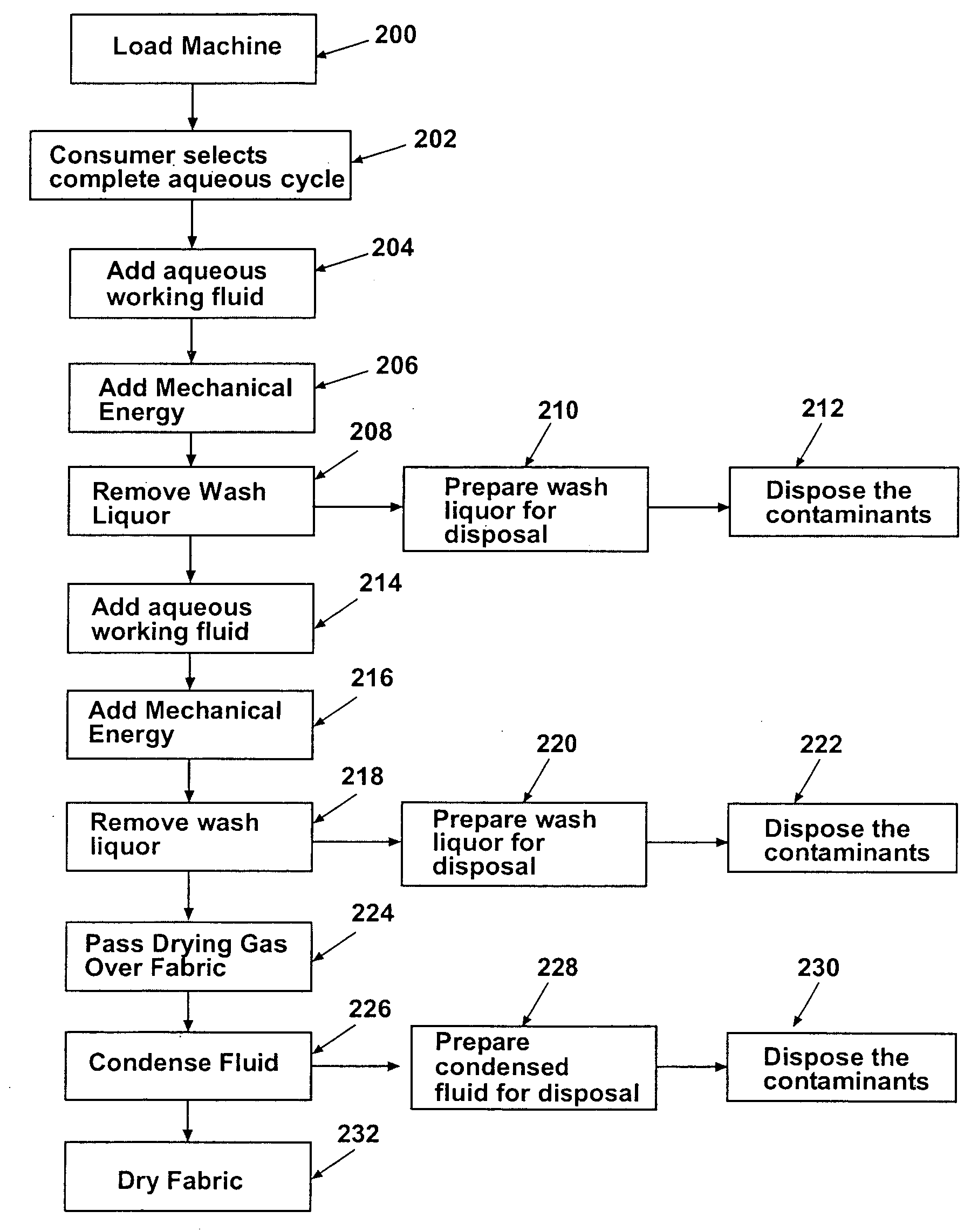

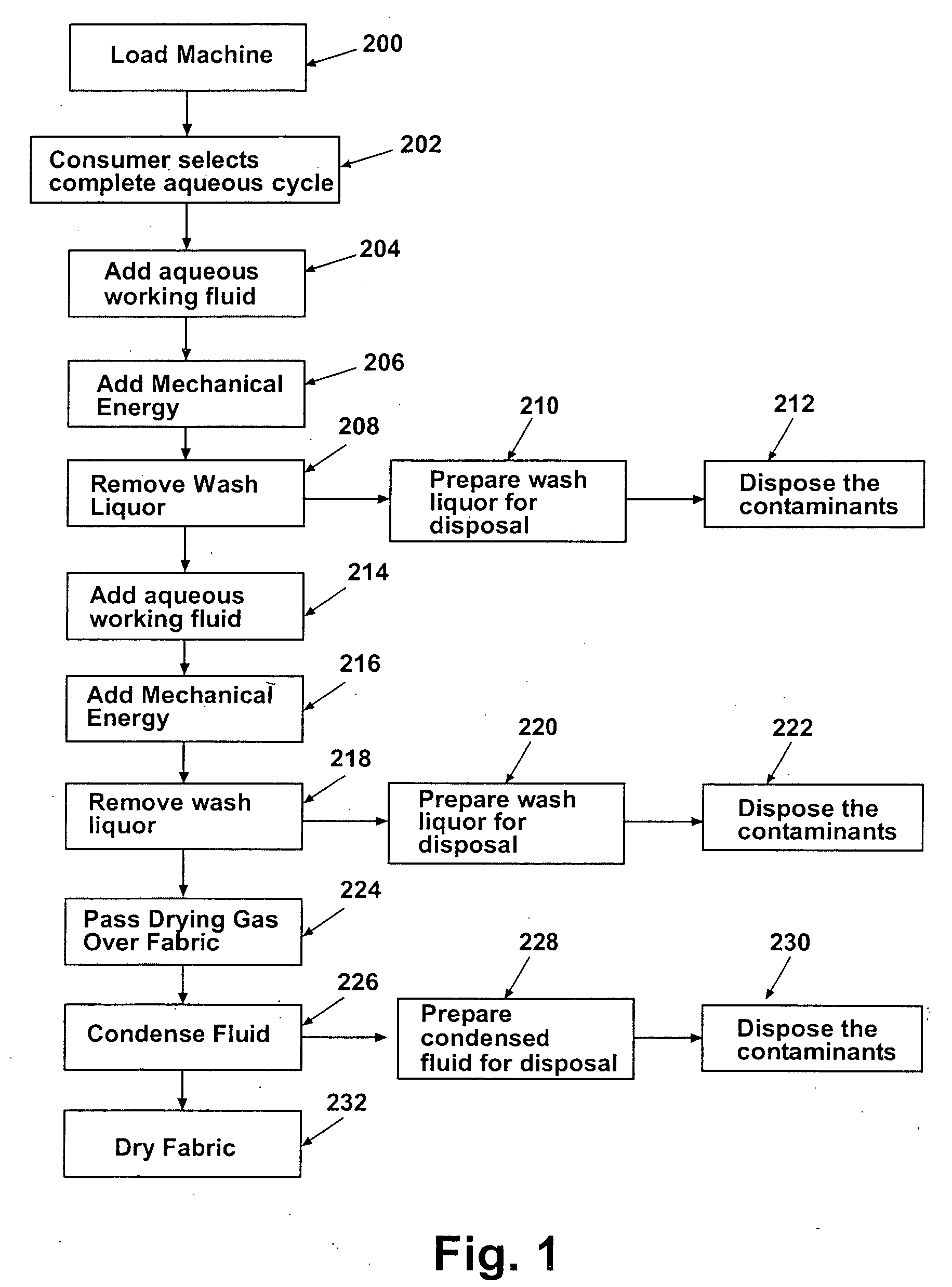

Multifunctioning machine and method utilizing a two phase non-aqueous extraction process

InactiveUS20050257812A1Shorten drying timeFast dryingDry-cleaning apparatusOther washing machinesWorking fluidEngineering

A method and apparatus of laundering a fabric load is disclosed including the steps of processing a fabric load in an aqueous-based working fluid, substantially replacing the aqueous-based working fluid with a non-aqueous working fluid of the type which extracts some of the aqueous-based working fluid from the fabric load.

Owner:WHIRLPOOL CORP

Assisted rinsing in a single wafer cleaning process

InactiveUS20020062840A1Small thicknessDecreases rinsingElectrostatic cleaningSemiconductor/solid-state device manufacturingRoom temperatureCentrifugal force

The present invention is a method of assisting the rinsing of a wafer in a single wafer cleaning apparatus. According to the present invention, after exposing a wafer to a cleaning and / or etching solution, the cleaning or etching solution is removed from the wafer by spinning the wafer and dispensing or spraying DI water onto the wafer as it is spun. The centrifugal force of the spinning wafer enhances the rinsing of the wafer. In order to enhance the rinsing of the wafer, in an embodiment of the present invention a solution having a lower surface tension than water, such as but not limited to isopropyl alcohol (IPA) is dispensed in liquid or vapor form onto the wafer after the DI water. In a specific embodiment of the present invention, the vapor of a solution with a lower surface tension than DI water, such as IPA vapor, is blown on the wafer in order to break up the DI water bulging up at the center of the spinning wafer. In another embodiment of the present invention, a gas such N2, is blown for a short period of time onto the center of the wafer to break up the DI water bulging up at the center of the spinning wafer. In yet another embodiment of the present invention, acoustic or sonic waves are applied to the wafer as it spins in order to help diffuse the DI water from the wafer. And in still yet another embodiment of the present invention, the DI water which is dispensed onto the spinning wafer is heated to a temperature above room temperature and preferably between 60-70° C. to enhance the diffusion of water from the wafer. The low surface tension liquid, acoustic application, gas blowing, and heated DI water can be used alone or in combination with one another into enhance the rinsing of a wafer and thereby decrease the rinsing time of a single wafer process to less than 20 seconds.

Owner:APPLIED MATERIALS INC

Ink-jet recording material comprising pigment layers

InactiveUS6502935B1Shorten drying timeImprove image qualityDuplicating/marking methodsCoatingsPigmentChemistry

Owner:FELIX SCHOELLER JR FOTO & SPEZIALPAPIERE

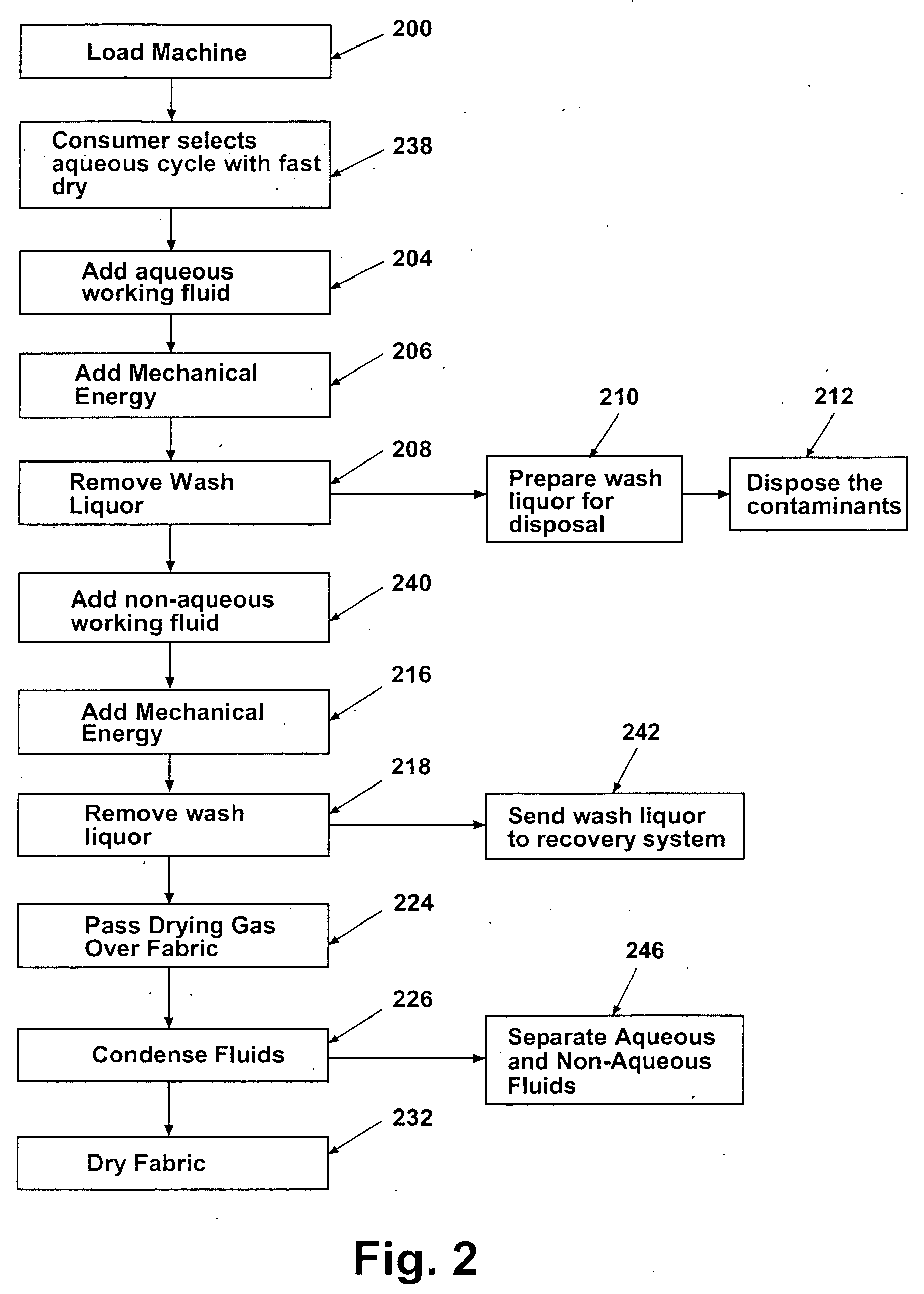

Device and method for supplying radiant energy onto a printing substrate in a planographic printing press

InactiveUS6857368B2Shorten drying timeAssisting or accelerating the drying of printing inkAddressographsPlaten pressesResonancePrinting ink

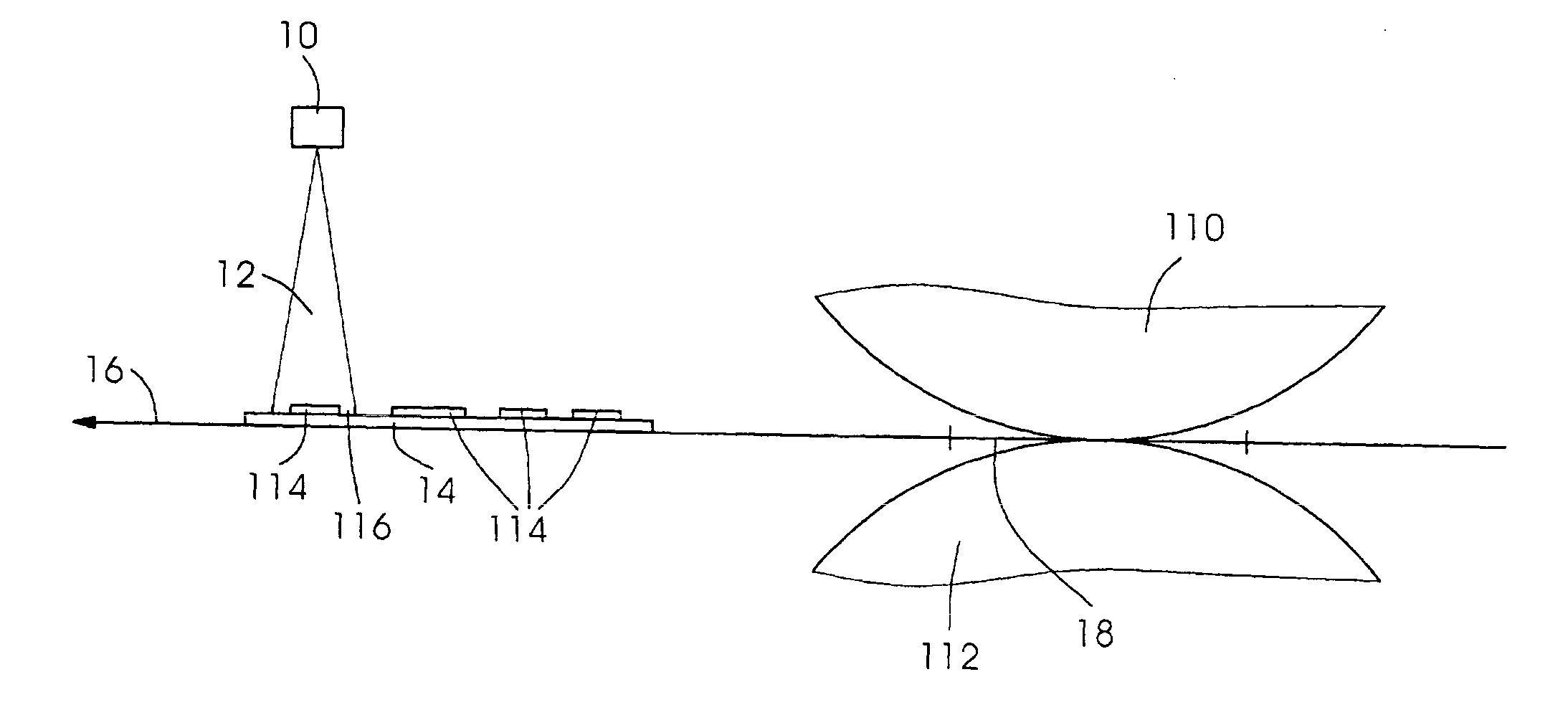

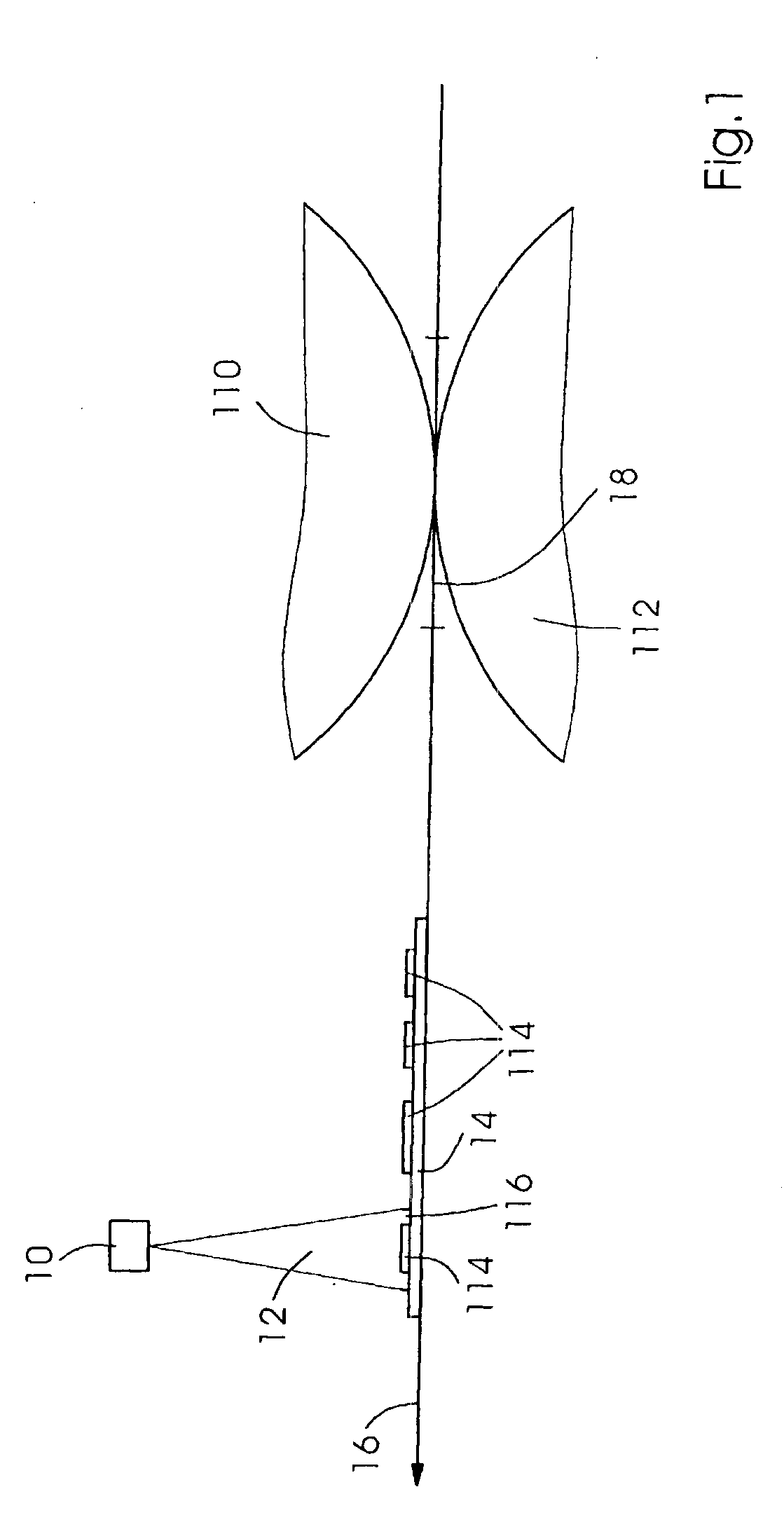

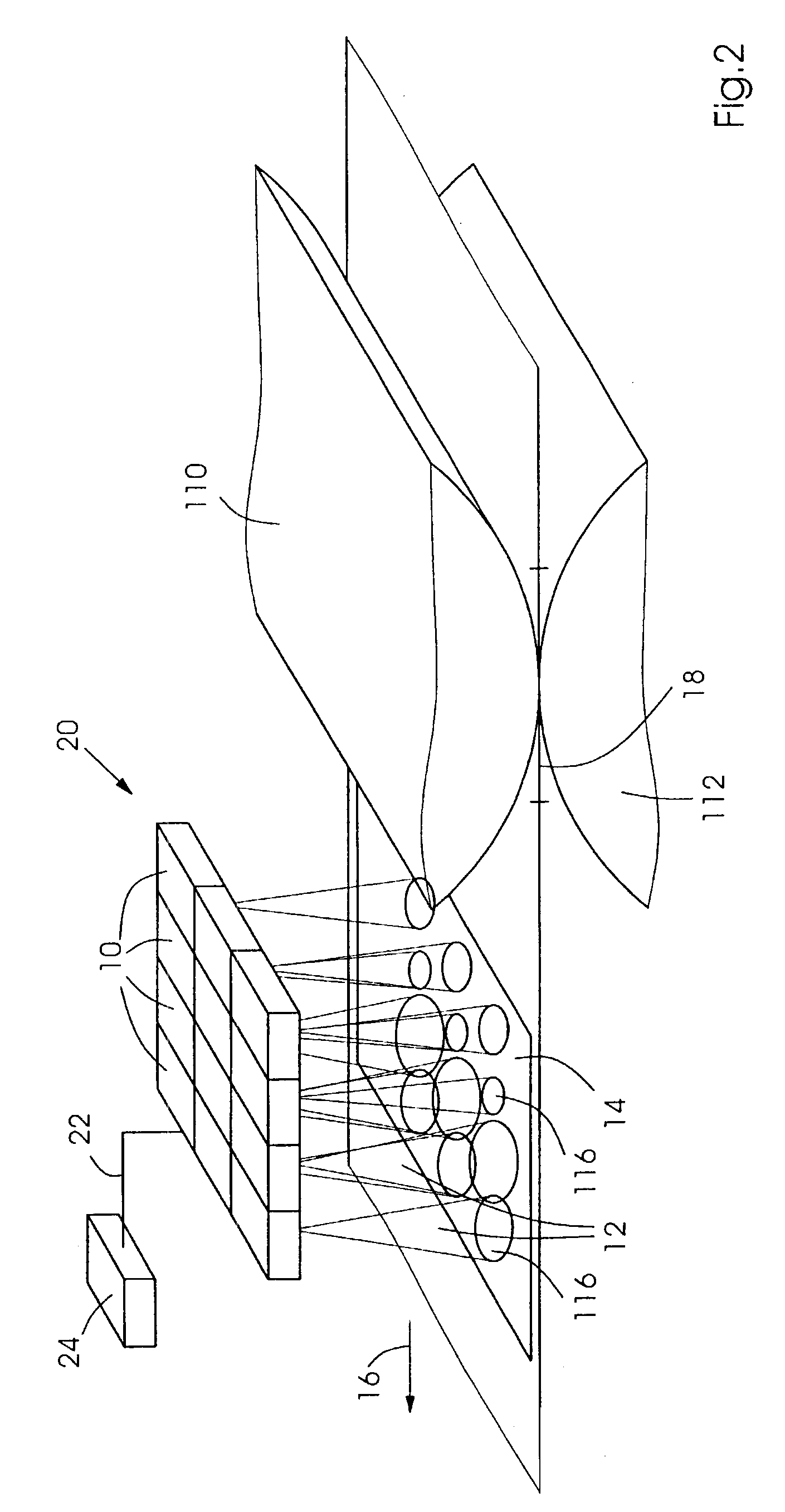

A device for supplying radiant energy of a wavelength in the near infrared onto a printing substrate (14) in a planographic printing press, including at least one radiant energy source (10) whose light (12) impinges on the printing substrate (14) on the path (16) of the printing substrate (14) through the printing press at a position (116) downstream of at least one printing nip (18) in a printing unit is described which has the feature that the radiant energy source (10) emits light (12) only in a narrow band, the wavelength of the light being non-resonant to absorption wavelengths of water and preferably being between 700.00 nm and 2500.00 run. Also disclosed is a method for supplying radiant energy. By supplying energy in this frequency range while avoiding absorption resonances of water, an unwanted drying or unnecessary heating of the printing substrate are advantageously reduced while providing energy to the printing ink for its particular drying process. The input of the radiant energy into the printing ink is assisted by an infrared-absorbing agent which is added to the printing ink.

Owner:HEIDELBERGER DRUCKMASCHINEN AG

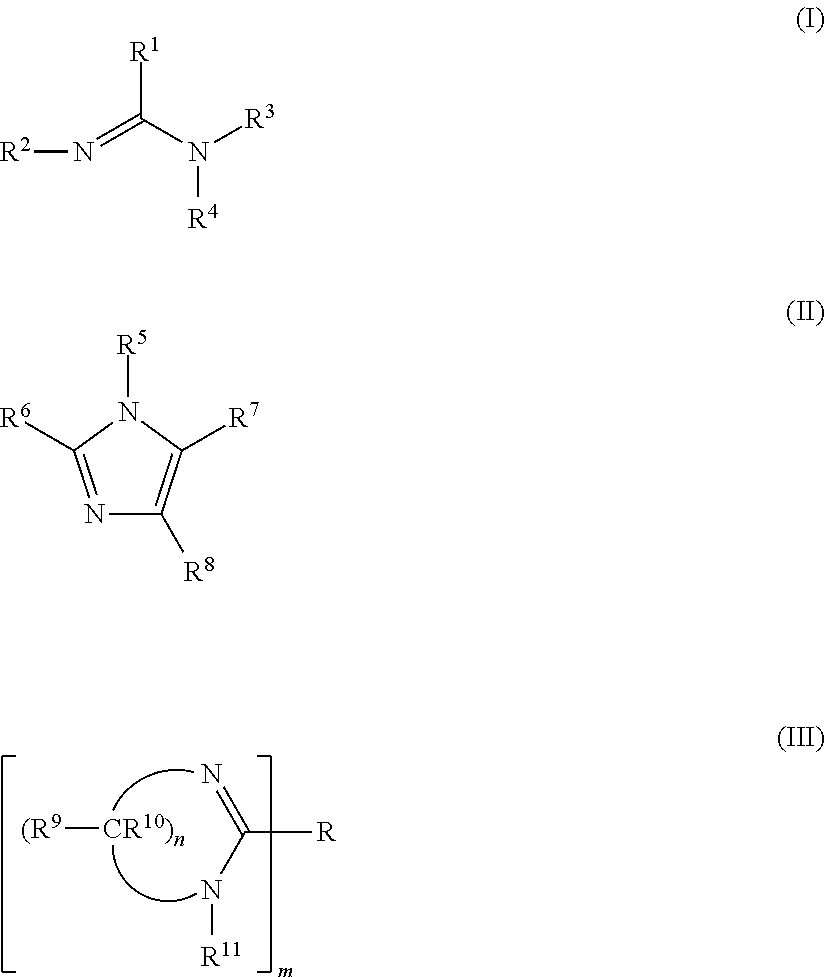

Curable coating compositions of silane functional polymers

There is a tin-free curable composition having (A) one or more organic polymers having a reactive-silicon-containing group, wherein at least one polymer has a main chain skeleton selected from the group consisting of polyoxyalkylene polymers, saturated hydrocarbon polymers, and (meth)acrylic acid ester polymers; (B) from 0.001 to 20 parts by weight for 100 parts by weight of the organic polymer(s) (A) of a silanol condensation catalyst consisting of one or more metal amidine complexes and one or more amine carboxylate salts, (C) a crosslinker or chain extender chosen from an alkoxysilane, an alkoxysiloxane, an oximosilane, an oximosiloxane, an epoxysilane, an epoxysiloxane, an aminosilane, a carboxysilane, a carboxysiloxane, an alkylamidosilane, an alkylamidosiloxane, an arylamidosilane, an arylamidosiloxane, an alkoxyaminosilane, an alkaryaminosiloxane, an alkoxycarbamatosilane, an alkoxycarbamatosiloxane, and combinations of two or more thereof; and (D) at least one adhesion promoter chosen from a silane or siloxane other than the compounds listed under (C). There is also a cured polymer formed from the tin-free curable composition.

Owner:KING INDUSTRIES INC

Preparation method of porous sodium acrylate super absorbent resin

ActiveCN102225981AImprove pass rateRealize continuous productionAbsorbent padsBandagesCross-linkNitrogen gas

The invention relates to a preparation method of a porous sodium acrylate super absorbent resin. The preparation method comprises the following steps: an aqueous solution containing 30 to 45 wt% of acrylic acid monomers with a neutralization rate of 60 to 90 mole%, a cross linking agent, a porogenic agent, and a polymerization initiator are polymerized together under nitrogen protection; and porous particles are prepared through preparing granulums with diameters of 2 to 10 mm from hydrogel prepared through polymerization, and adding the surface cross linking agent and an inorganic filler to carry out surface processing. The preparation method of the invention allows continuous production to be realized, productivity to be improved, manpower to be decreased, a problem of slow imbibition to be solved, drying period to be substantially decreased, product performances to be substantially improved, the qualified rate of products to be high, reaction to be mild, and three wastes to be less.

Owner:浙江卫星新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com