Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

476results about How to "Reduce inflow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

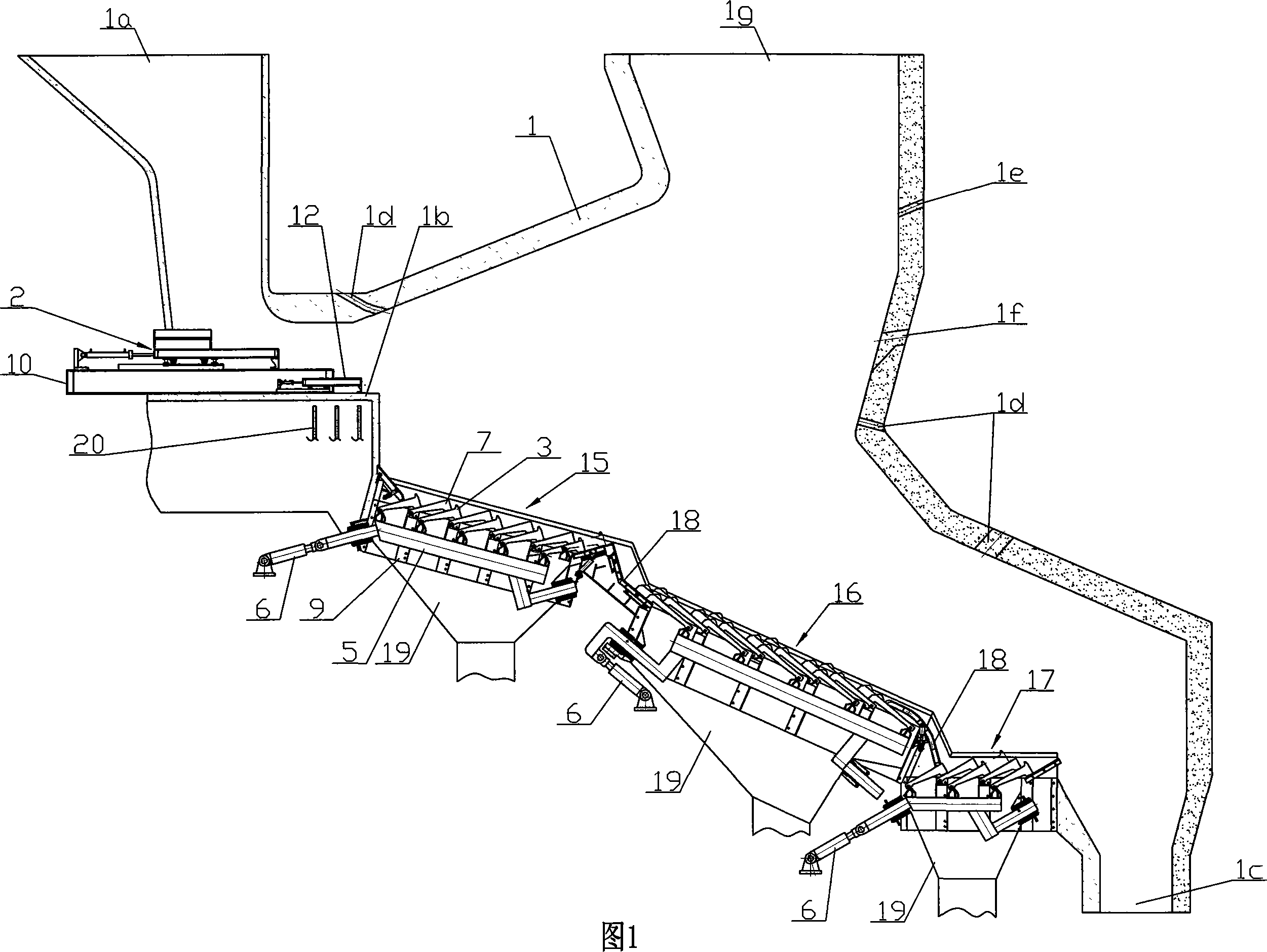

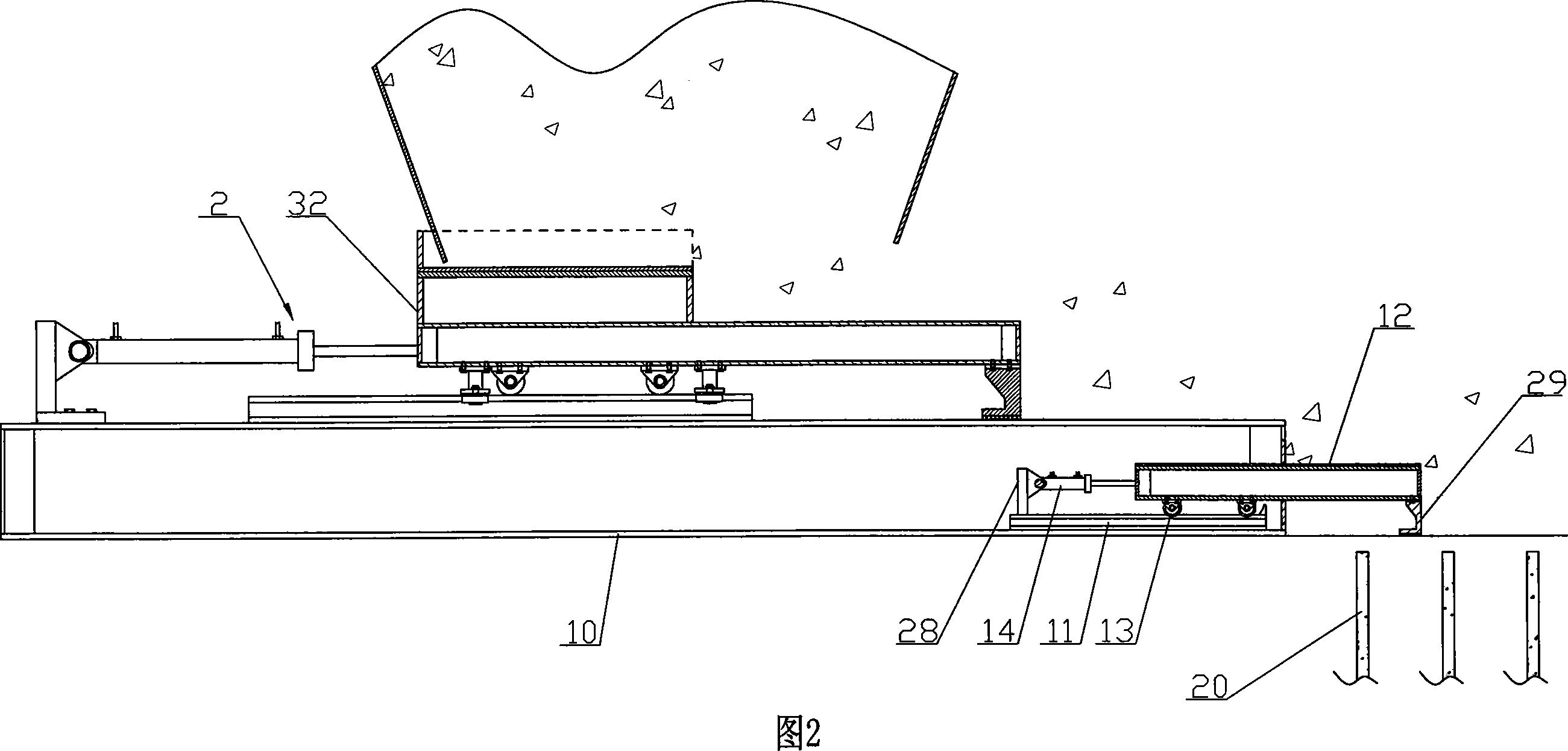

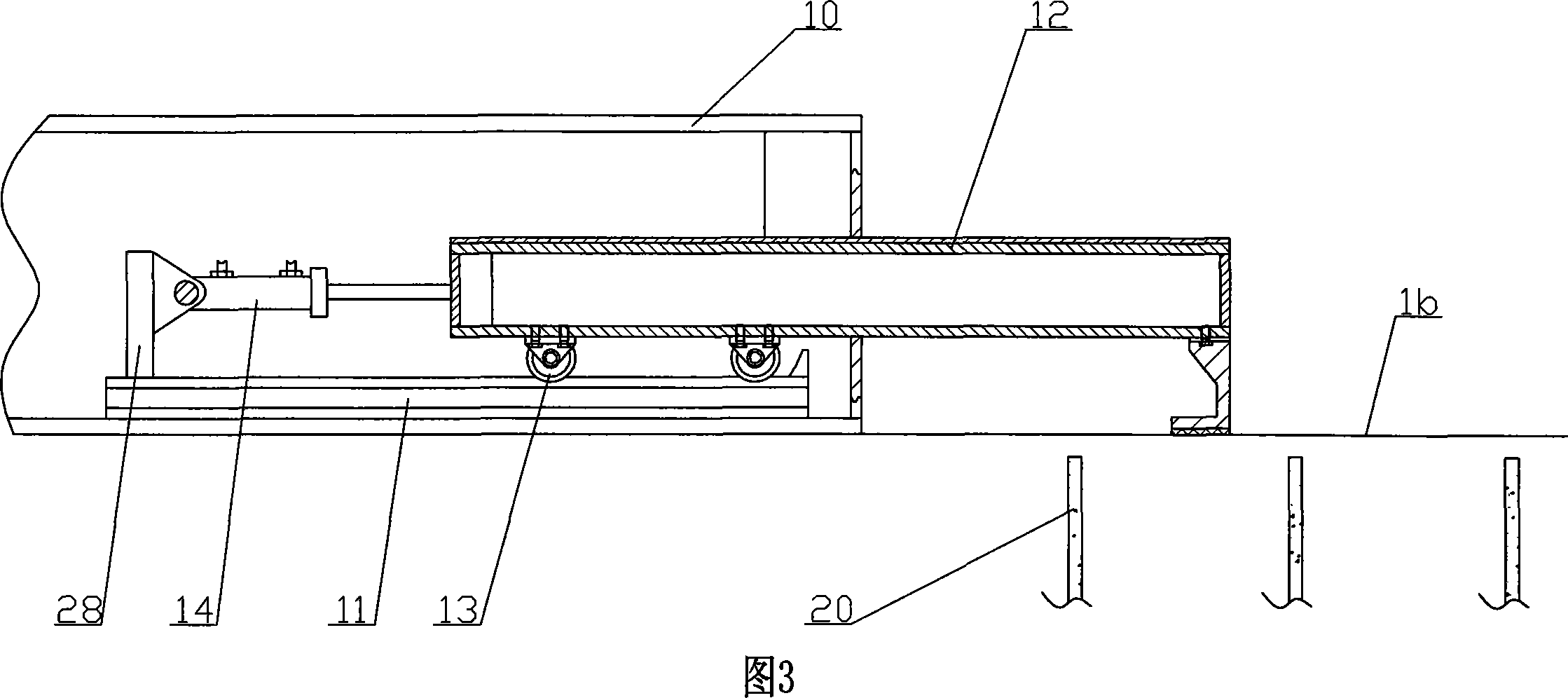

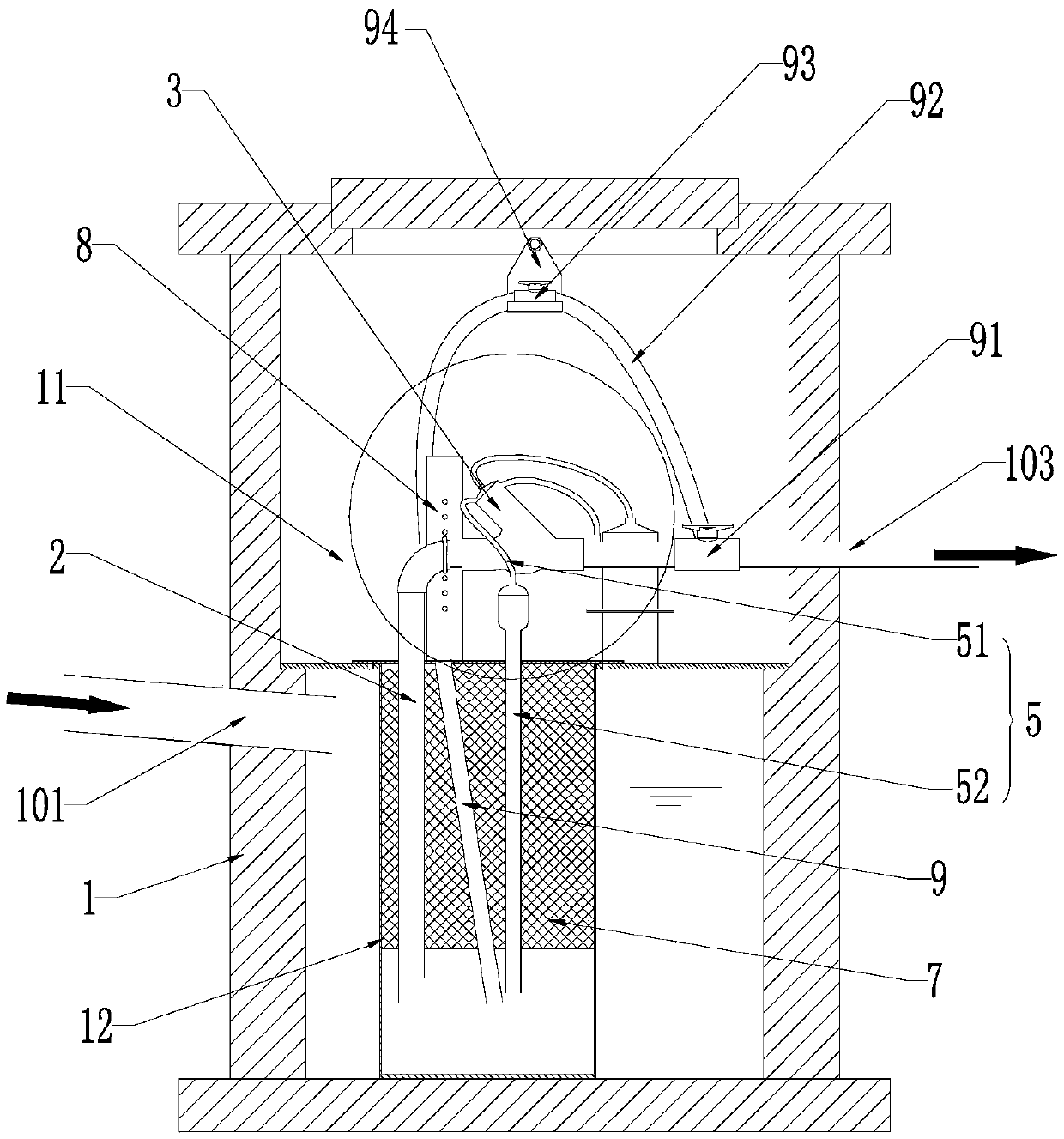

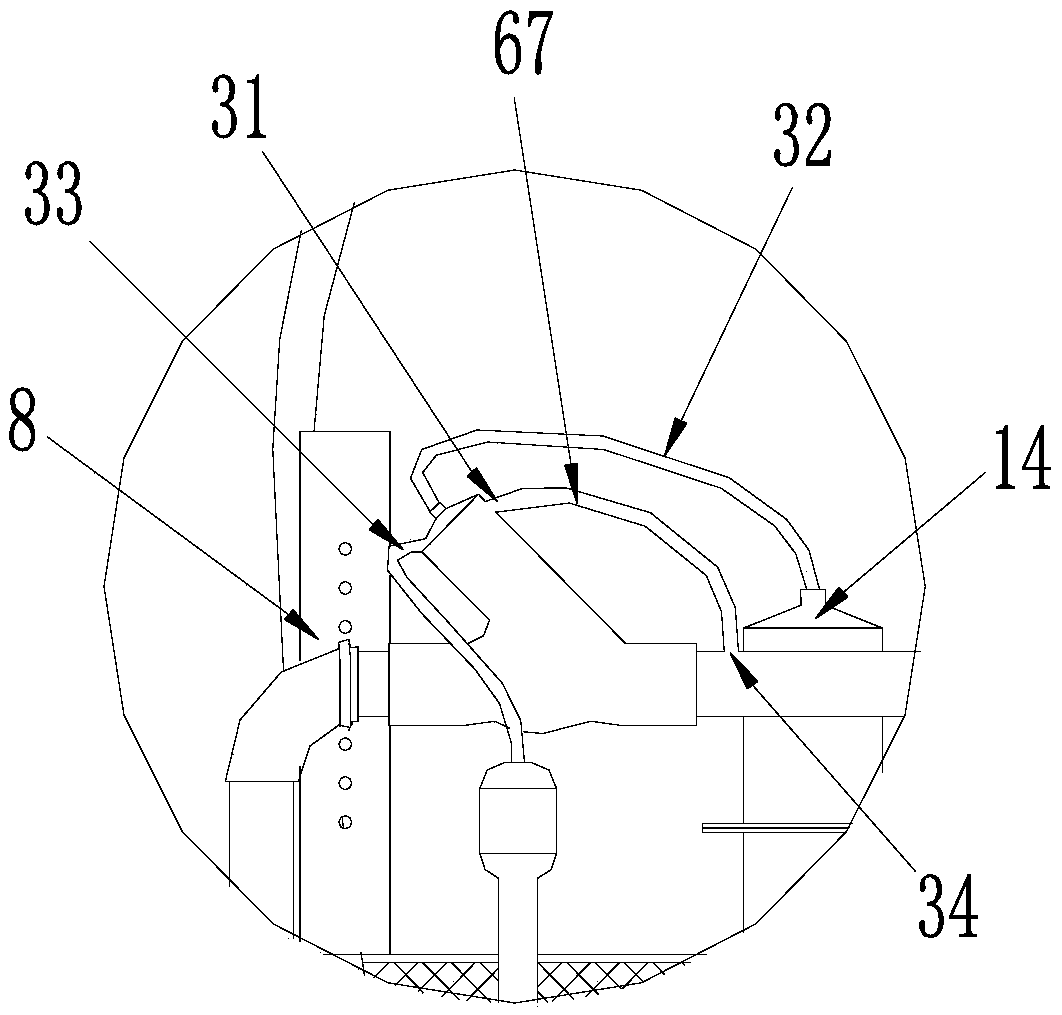

Multiple row sectional drive combined type domestic garbage incinerator

The invention relates to multi-column sectional drive combined type domestic incinerator. It is set three fire-grates that drying section, burning section, and firing section. The middle fire grate is connected between them. There is altitude fall between them that the drying section is the highest point; the firing one is the lowest point. The primary air chamber is respectively set under them. The incinerator fire grate system of the invention has independent drive mechanism, air supply system, and air chamber for each section which is convenient for controlling technical parameter that traveling speed, air quantity, air temperature, air pressure etc to realize full drying and burning for whole garbage layer.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP

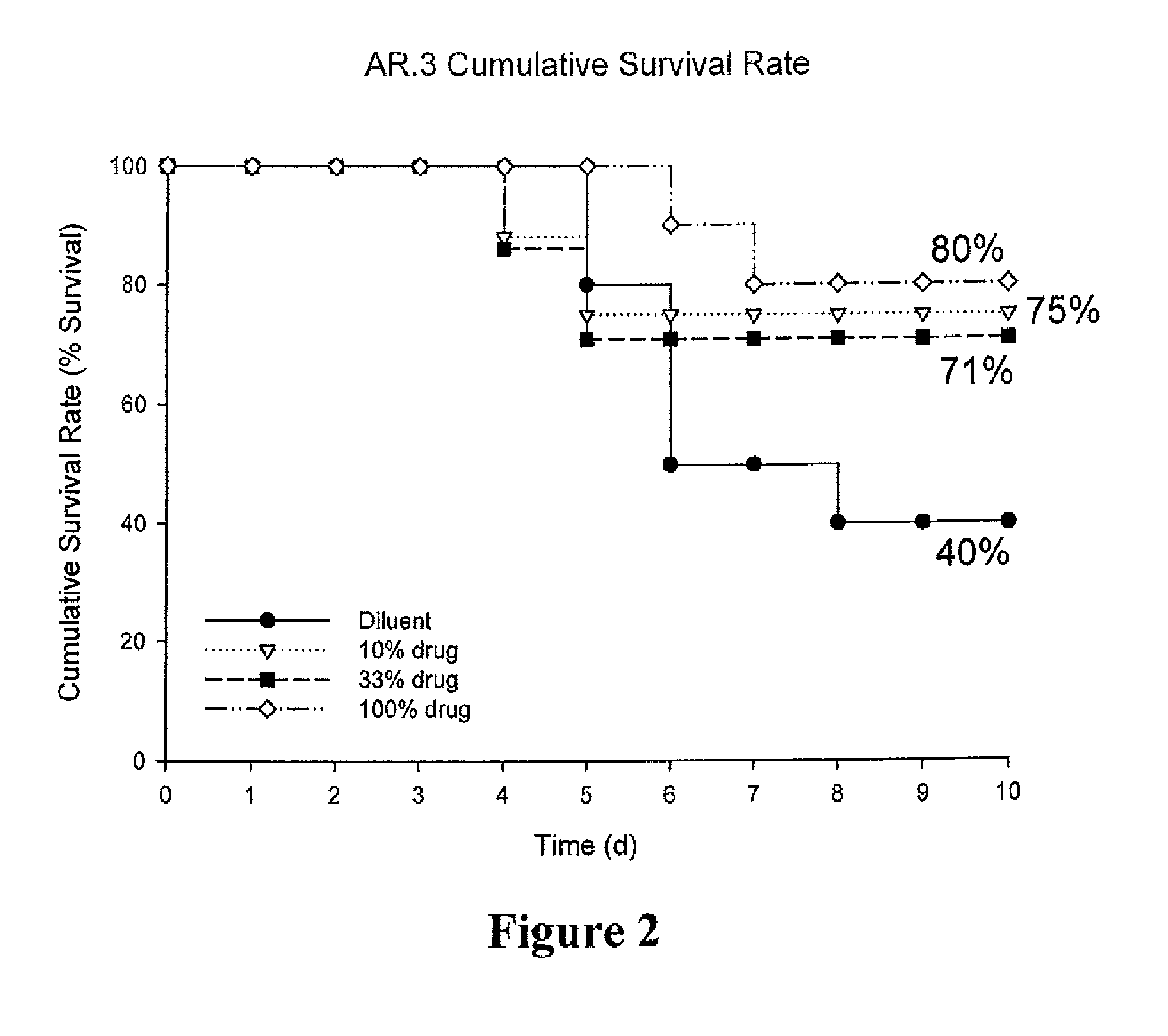

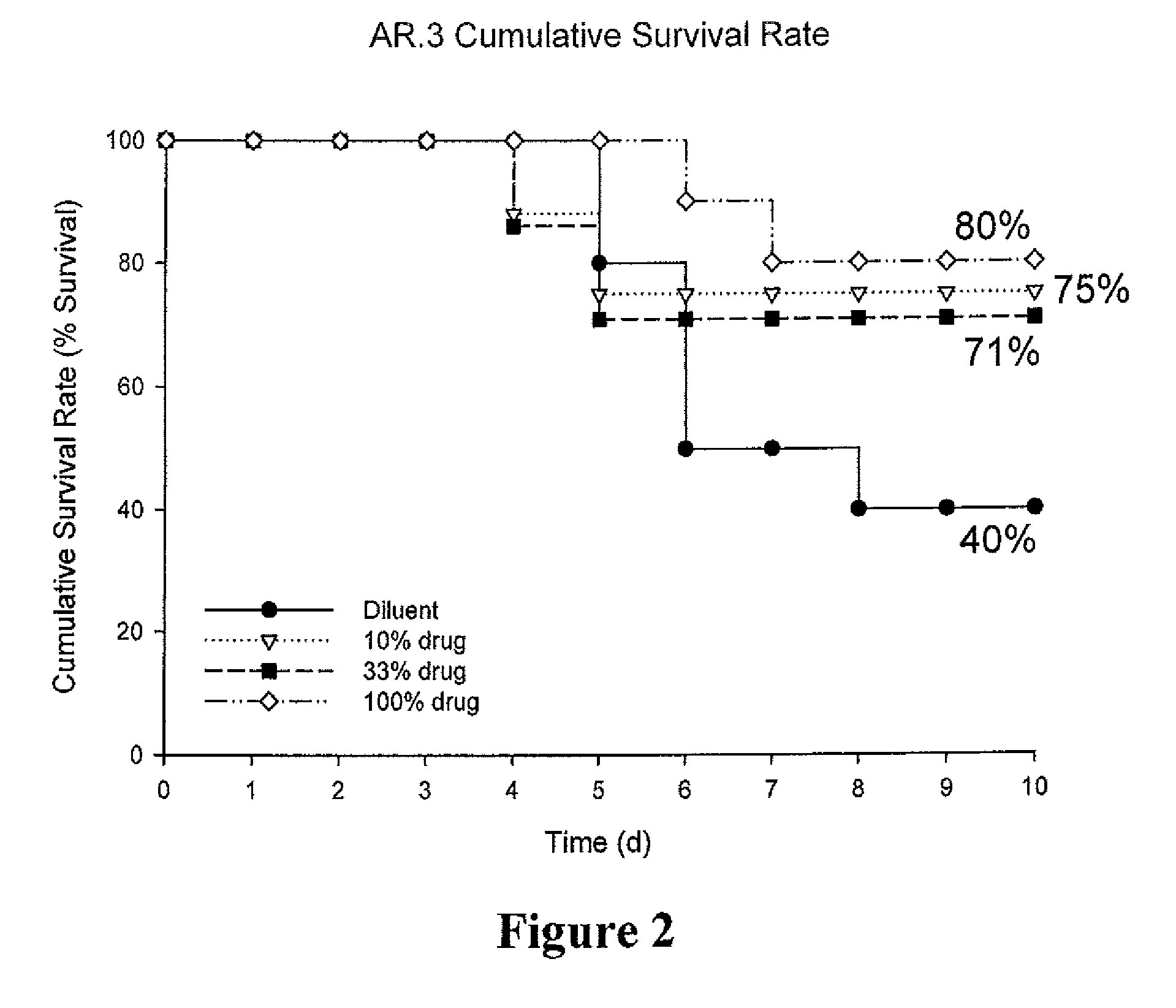

Dual action, inhaled formulations providing both an immediate and sustained release profile

ActiveUS20090269396A1Improve treatmentSustained release of anti-infective over timePowder deliveryBiocideDual actionAnesthesia

Methods for formulating immediate and sustained release anti-infectives and delivery of such for treatment of respiratory tract infections and other medical conditions, and devices and formulations used in connection with such are described.

Owner:GRIFOLS

Method and means for traffic route control

InactiveUS6427114B1Outflow from the link will increaseReduce inflowAnalogue computers for vehiclesInstruments for road network navigationTraffic capacityRoad networks

The invention concerns a method and means for control of traffic on a network by route control. The method and the means are based on functions in a traffic management system. The invention includes control of traffic from a first route, which passes a bottleneck, which can be a part of the network, e g a node or a link, with low capacity relative to the demand of traffic through the node or the link,-to at least another alternative route. That alternative route is separated from the first route at a node upstream of the bottleneck and is routing at least parts of the traffic another road passing the bottleneck of the first route. The method is built on several cooperating method steps and route control can be applied on several different hierarchic levels in the network, locally and more comprehensive. Essential method steps are estimating and controlling traffic margins on selected links and nodes in the network and utilizing those margins at the route control. The invention concerns traffic control of vehicles on a road network as a first hand application. But the method can also be used for other applications, as traffic control of data packets on a communication network.

Owner:DINBIS

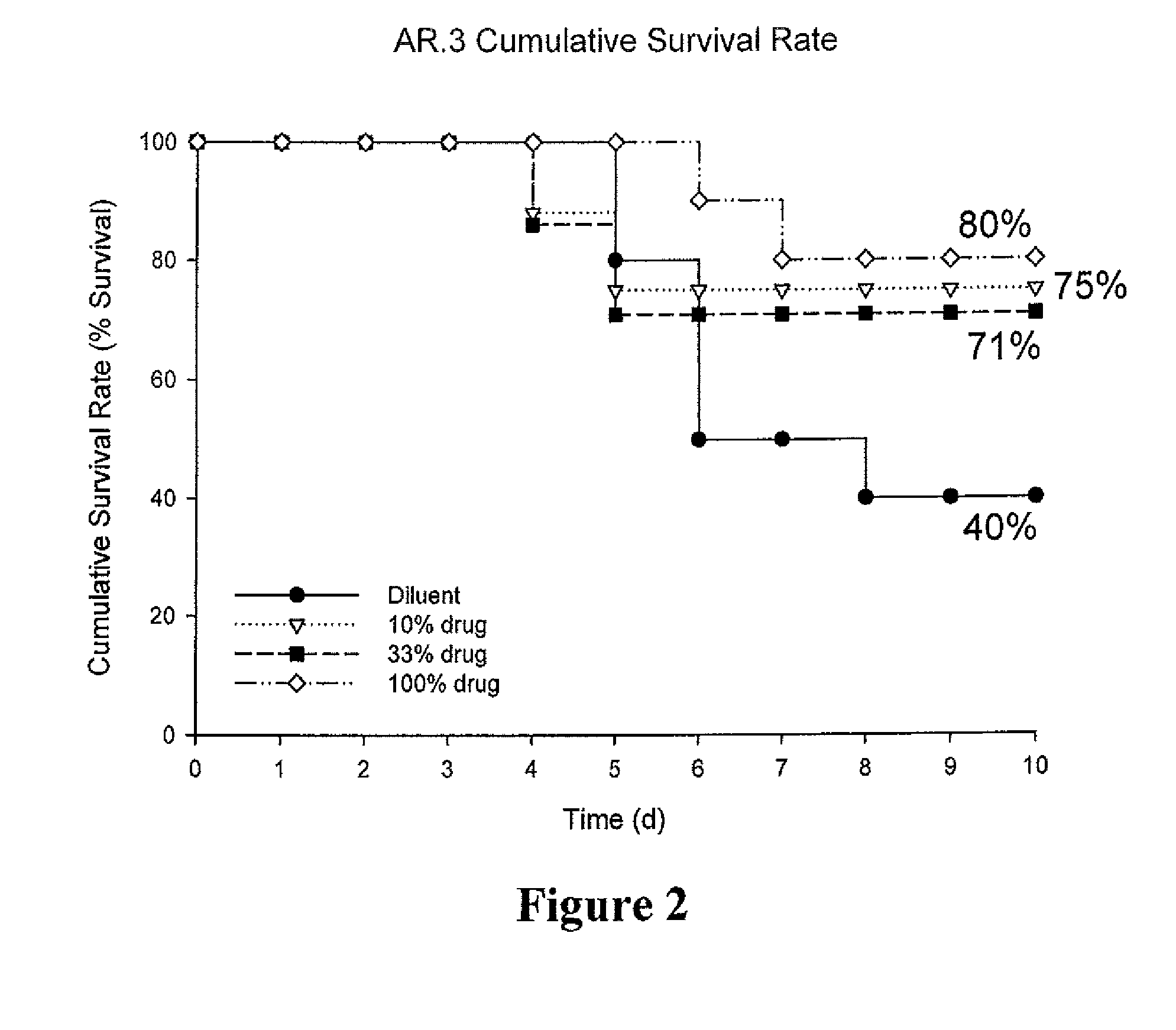

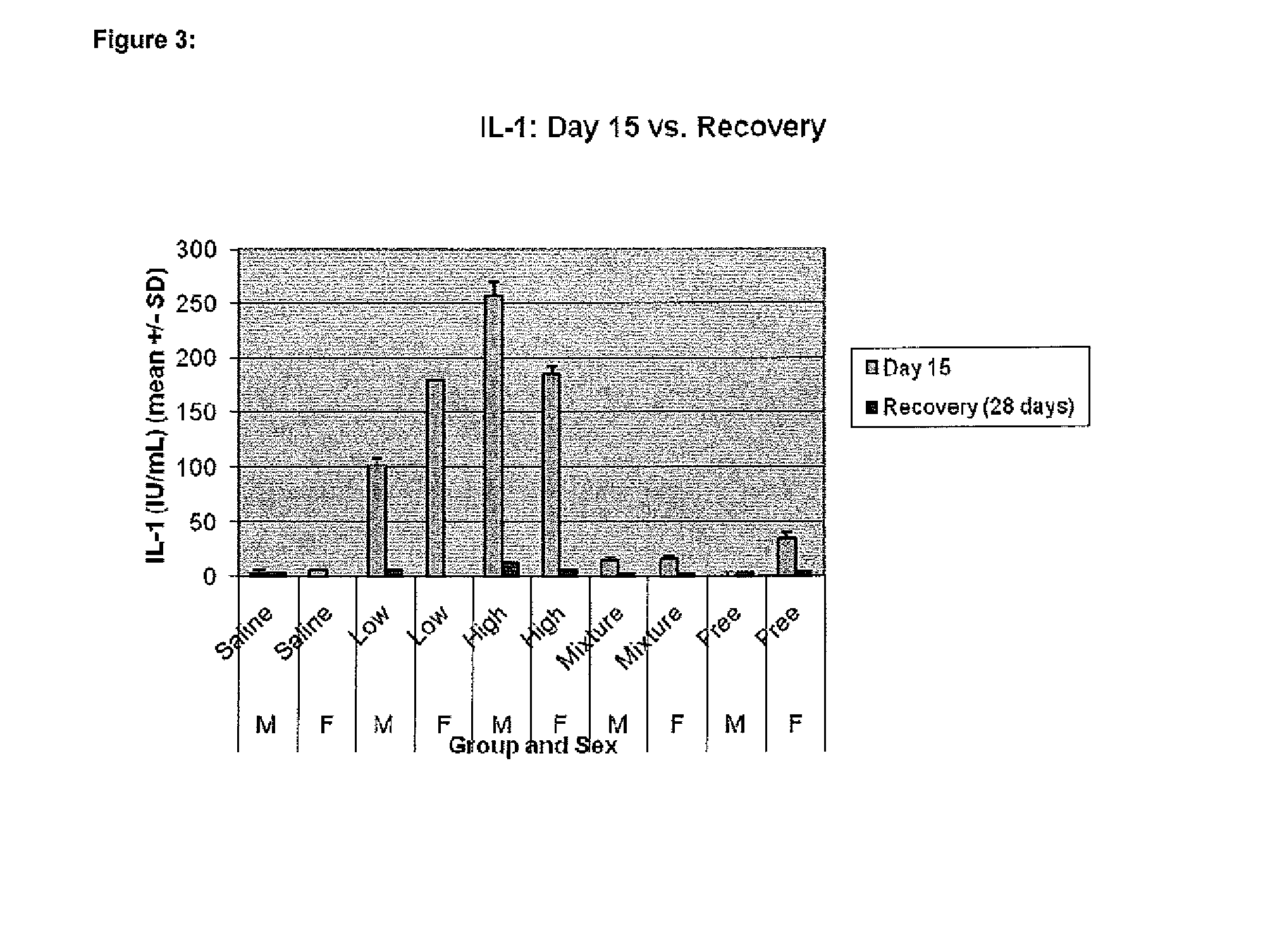

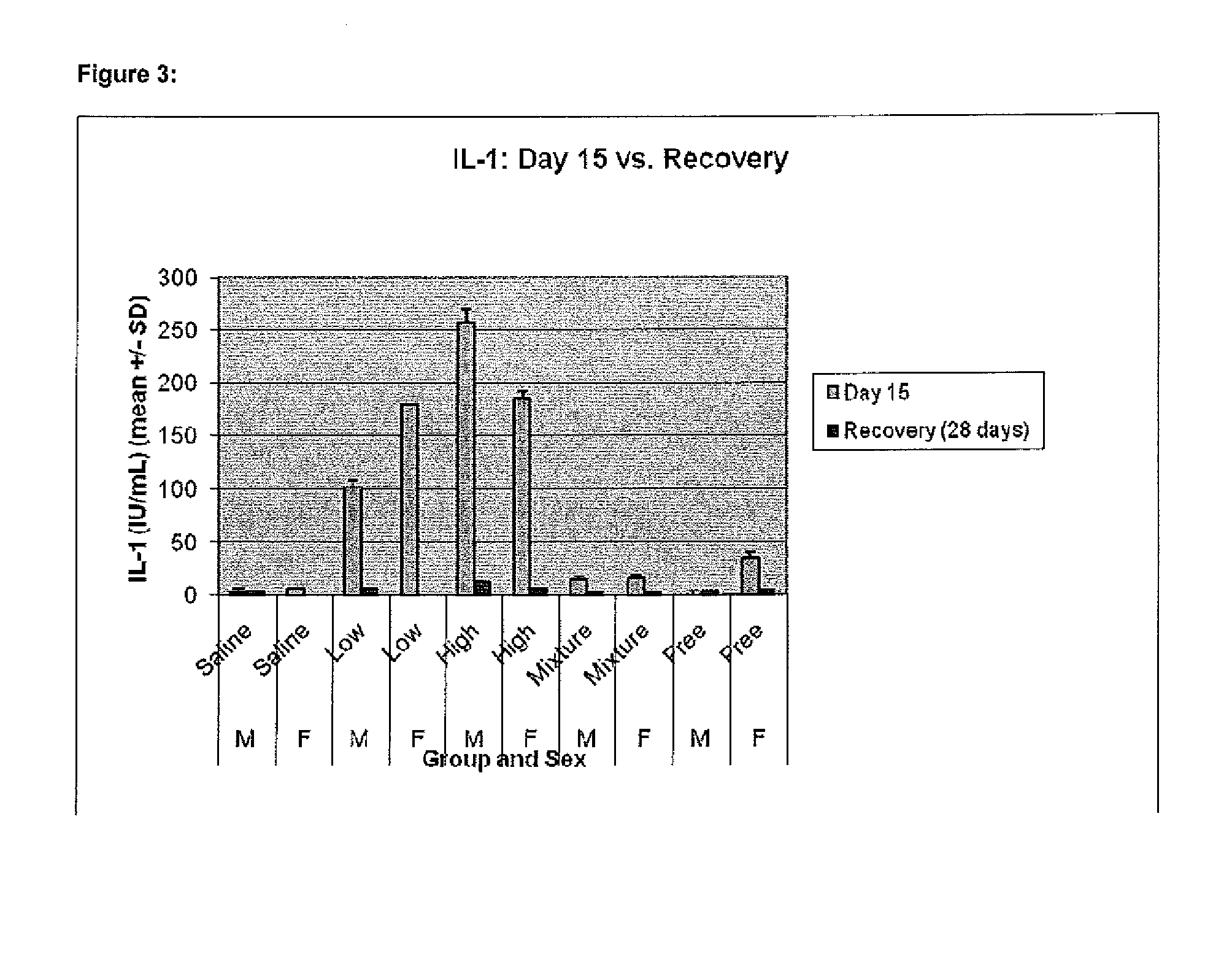

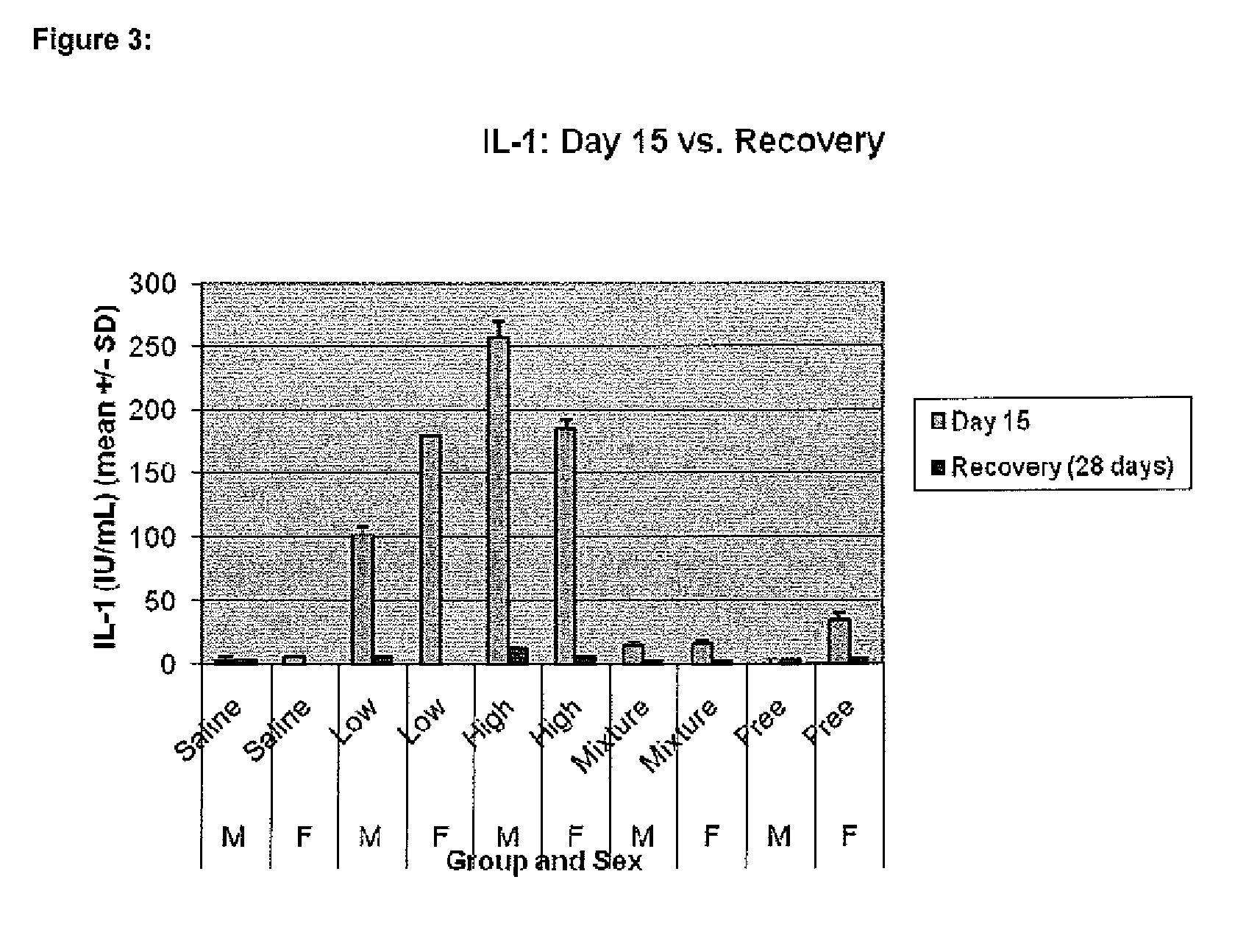

Reduction of adverse inflammation

InactiveUS20050025804A1Reduce the possibilityReduction of the flux of nutrientsBiocideNervous disorderPeroxynitriteIsomerization

Reduction of the likelihood of adverse inflammatory reaction to an implant or a transplant is achieved through several mechanisms including the catalysis of isomerization of peroxynitrite by a hydrogel-bound peroxynitrite isomerization catalysts. A second mechanism controls acceptable and unacceptable dimensions of surface features of implants, such as vascular stents. A third mechanism fabricates implants from materials which are substantially free from alloys transition metals which produce ions of which catalyze cell killing radical formation.

Owner:HELLER ADAM

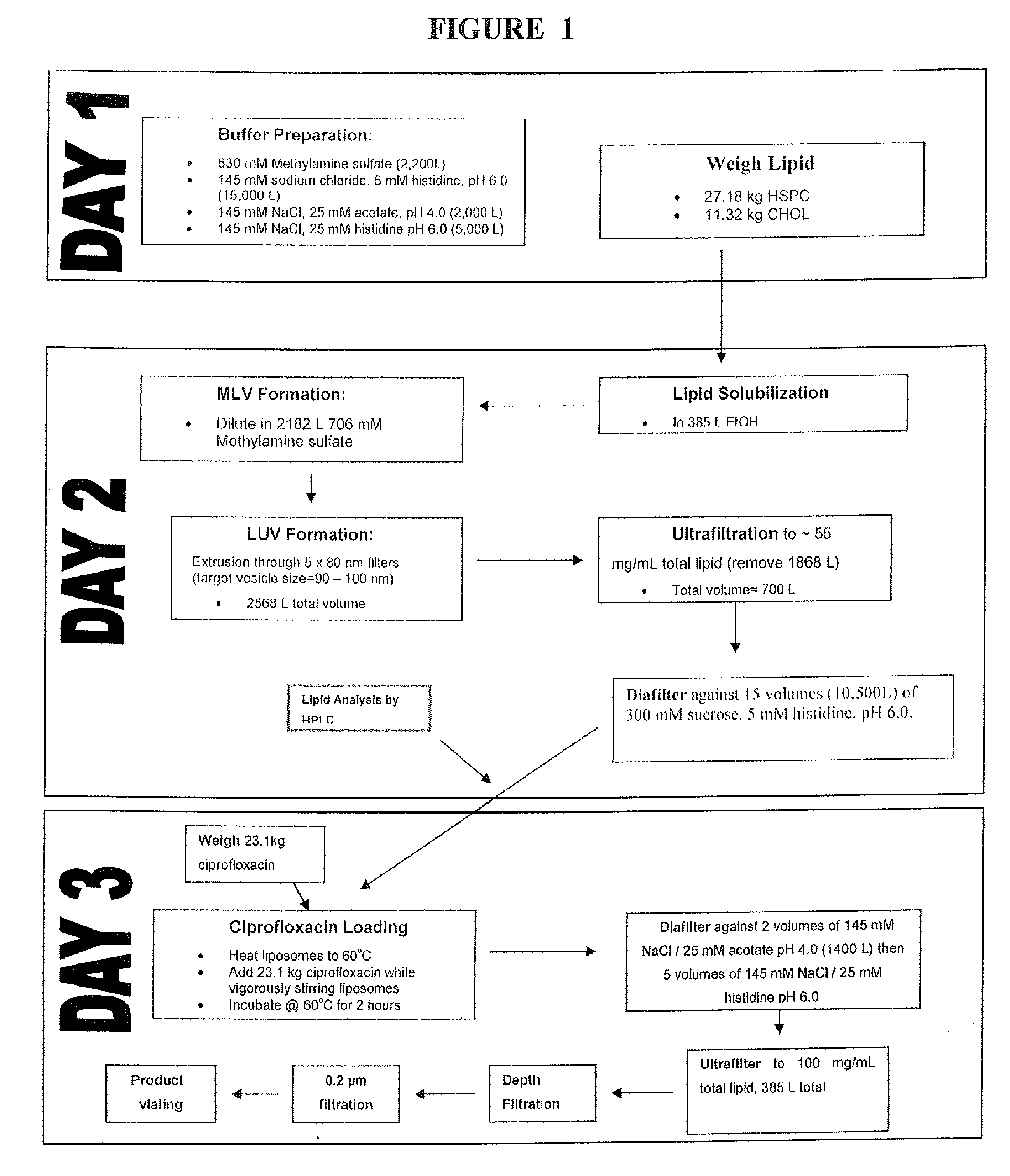

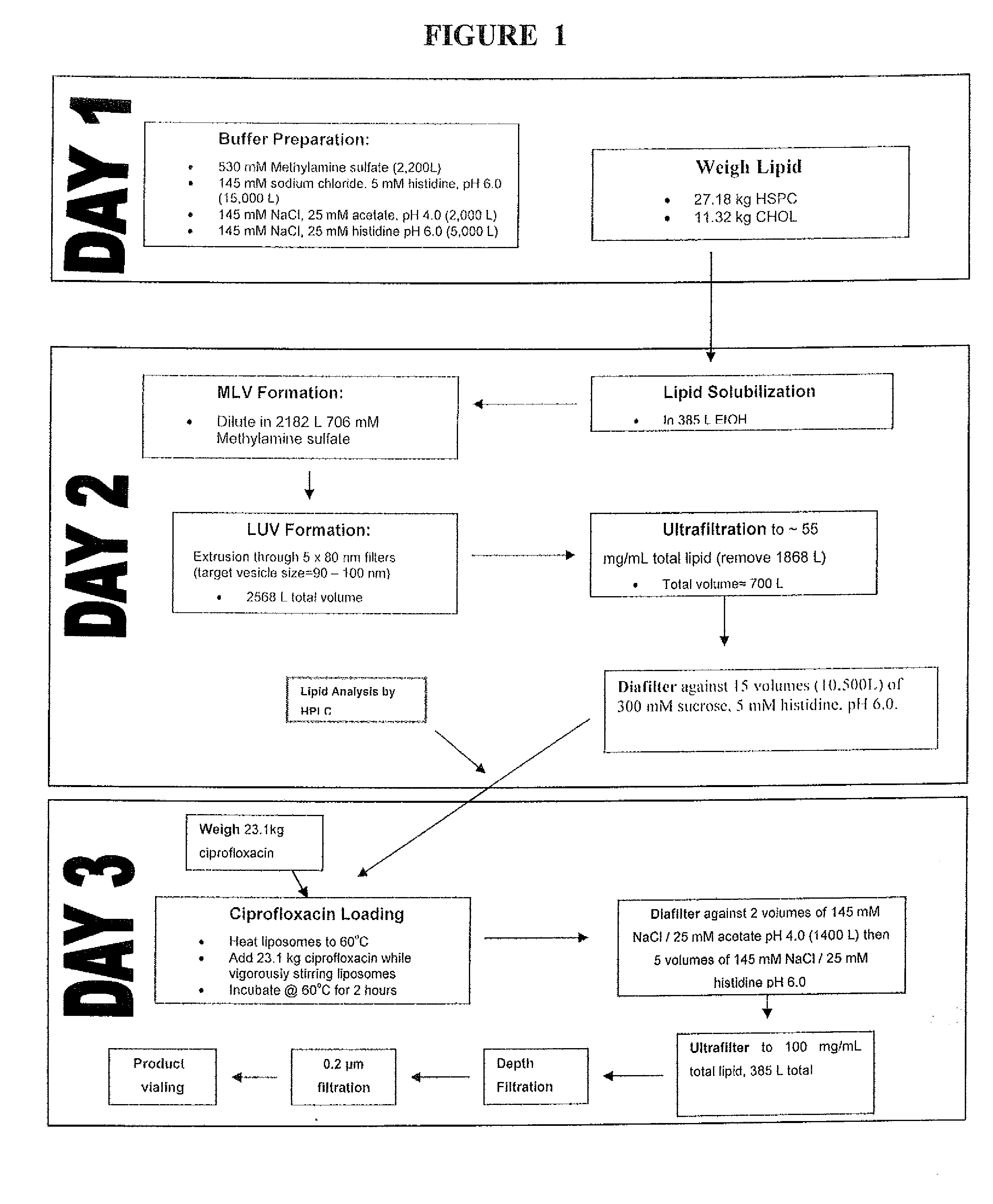

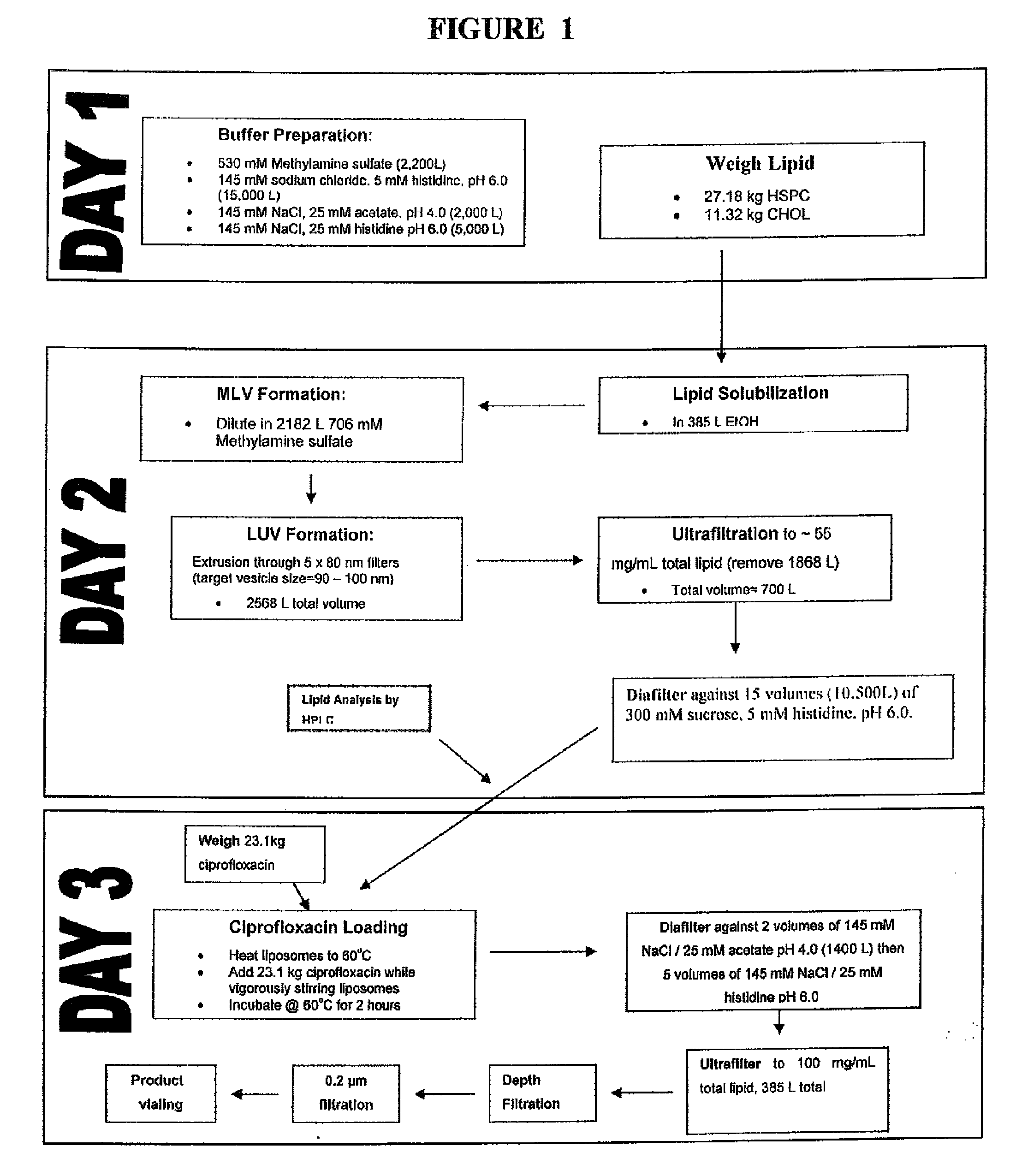

Concentrated, inhalable antibiotic formulation

InactiveUS20110064796A1Improve treatmentSustained release of anti-infective over timePowder deliveryOrganic active ingredientsSodium acetateLiposome

A concentrated inhalable formulation of an antibiotic drug such as ciprofloxacin is disclosed. The antibiotic is formulated with sodium acetate and liposome which incorporate antibiotic. The formulation is aerosolized and inhaled for treatment of respiratory tract infections and other medical conditions.

Owner:GRIFOLS

Dual action, inhaled formulations providing both an immediate and sustained release profile

ActiveUS8071127B2Improve treatmentSustained release of anti-infective over timePowder deliveryBiocideDual actionAnesthesia

Methods for formulating immediate and sustained release anti-infectives and delivery of such for treatment of respiratory tract infections and other medical conditions, and devices and formulations used in connection with such are described.

Owner:GRIFOLS

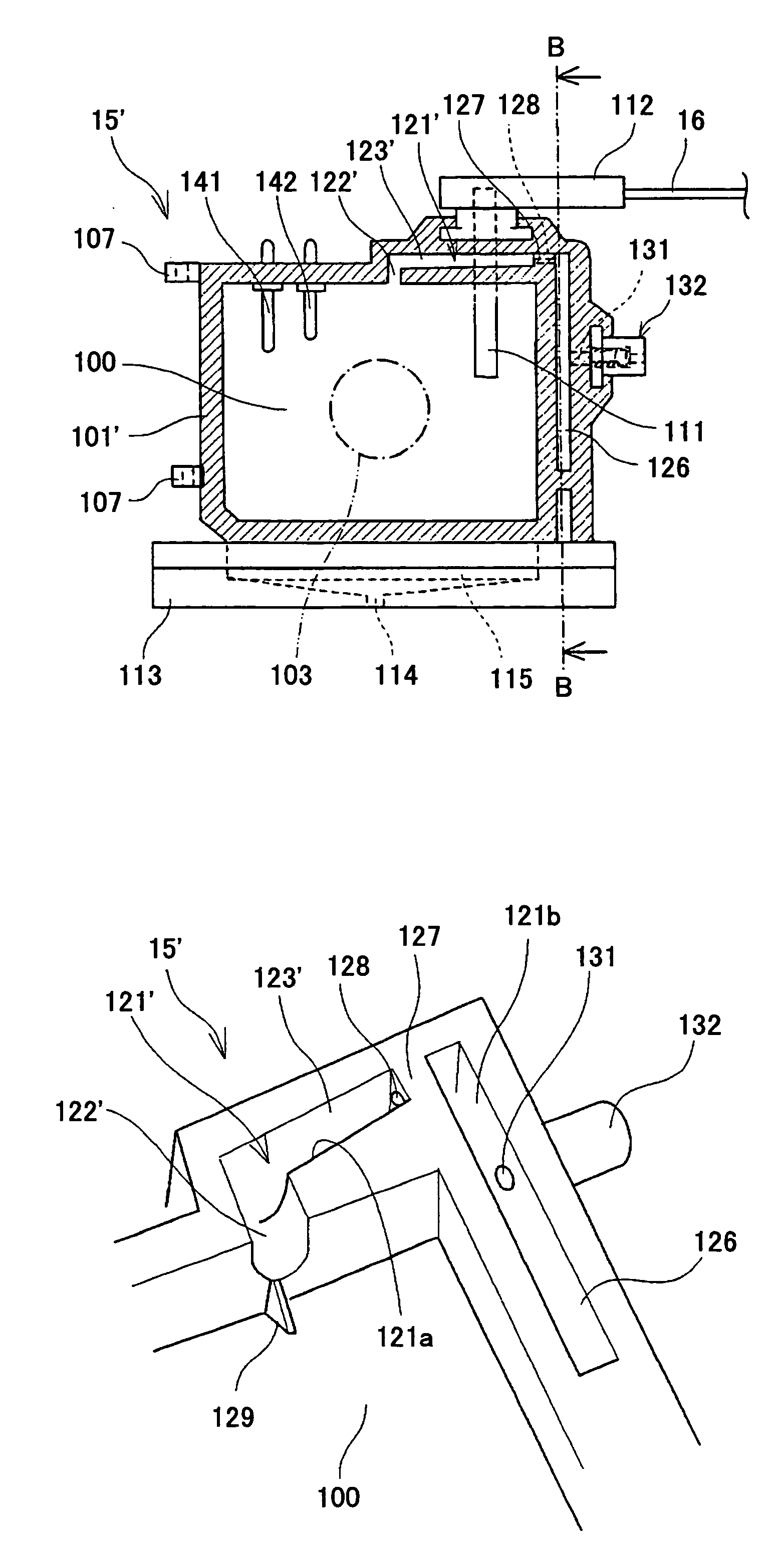

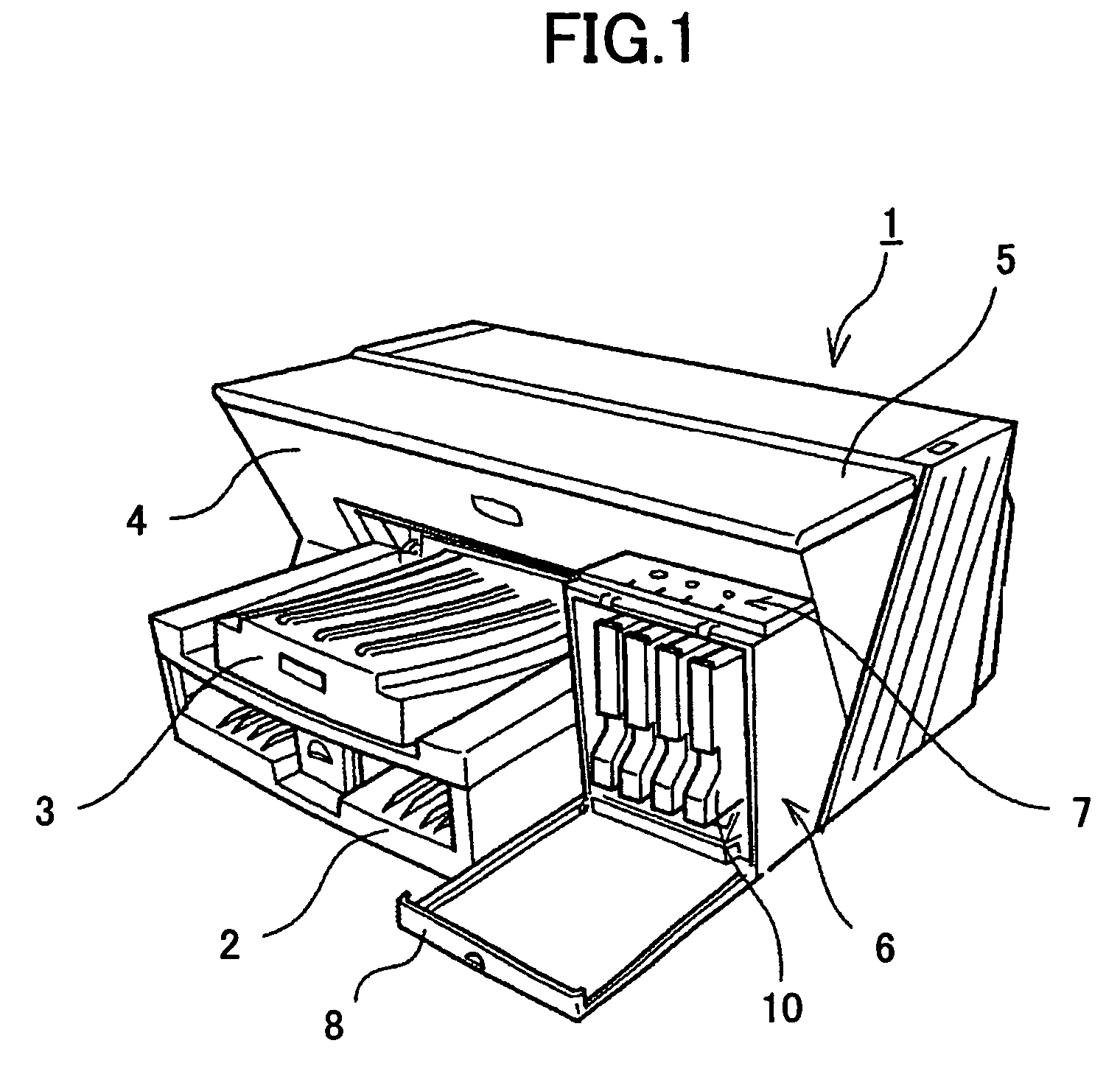

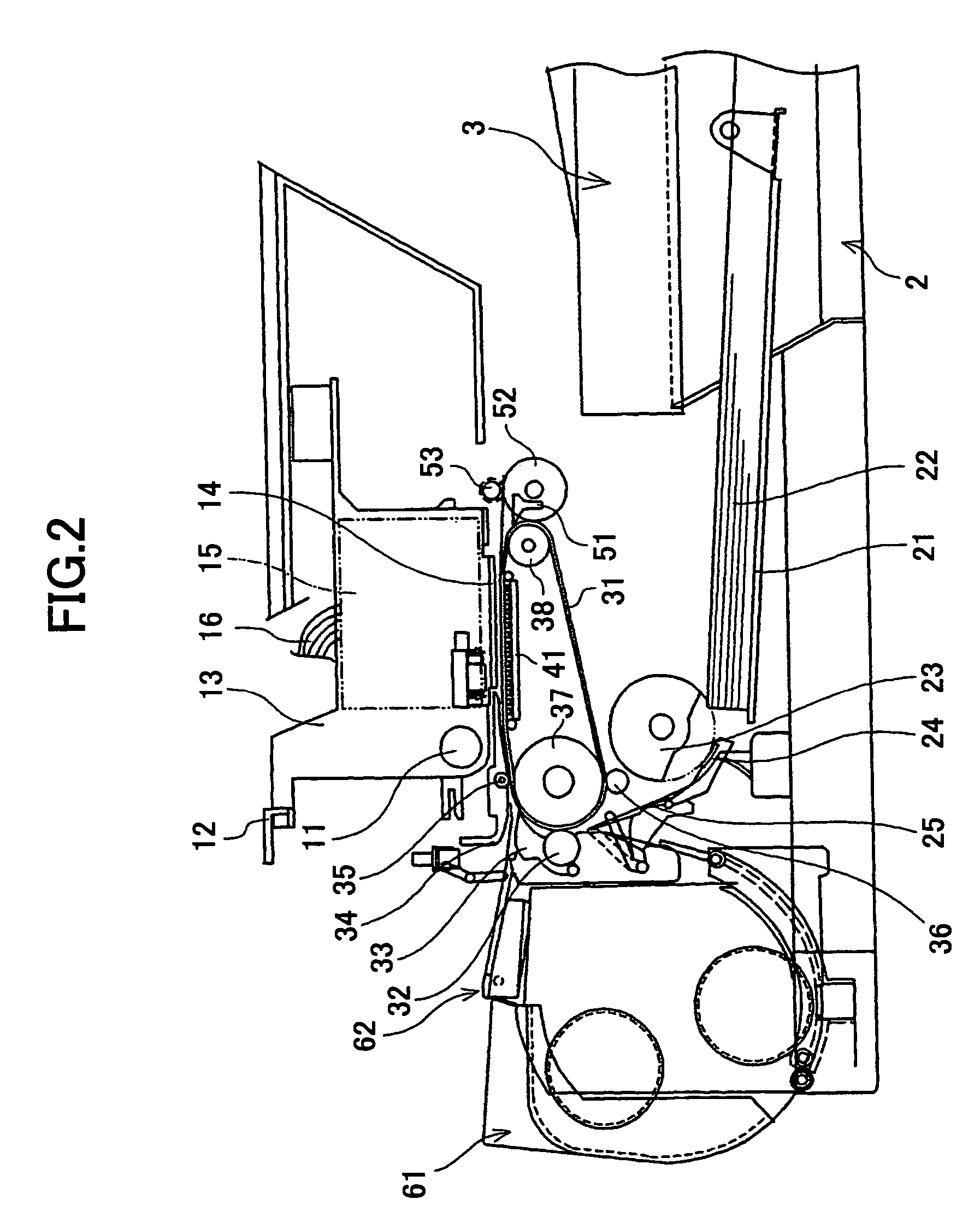

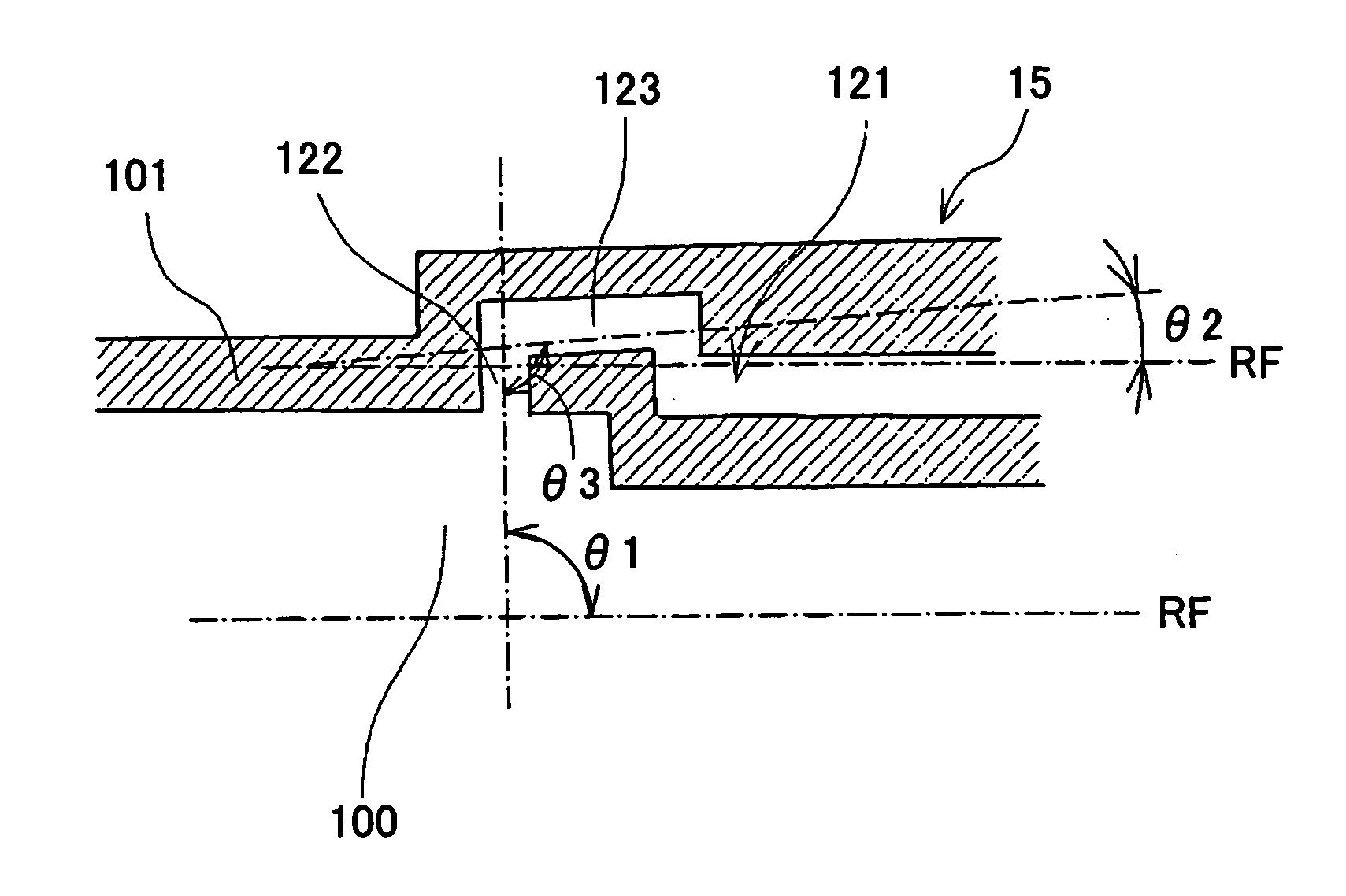

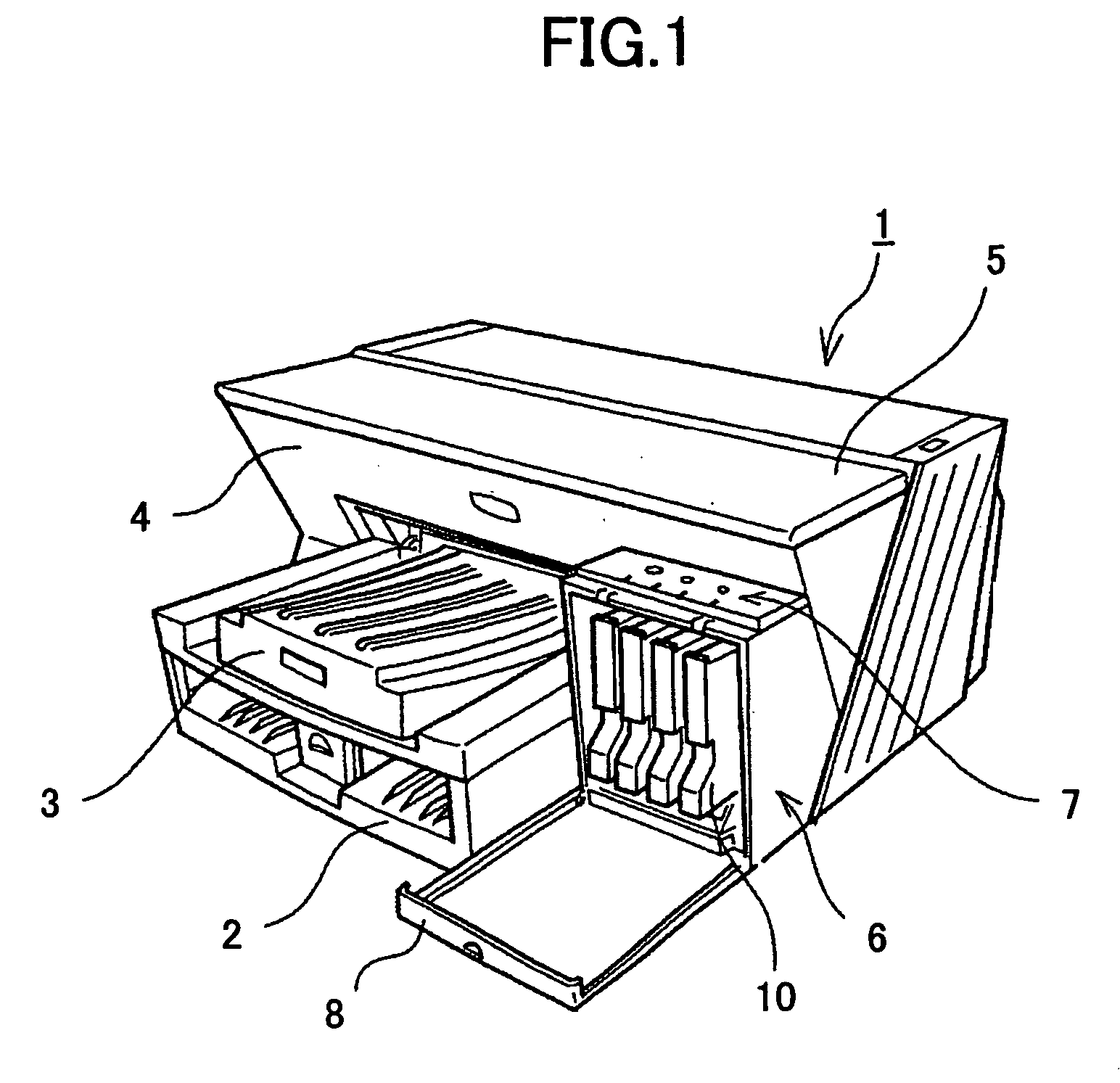

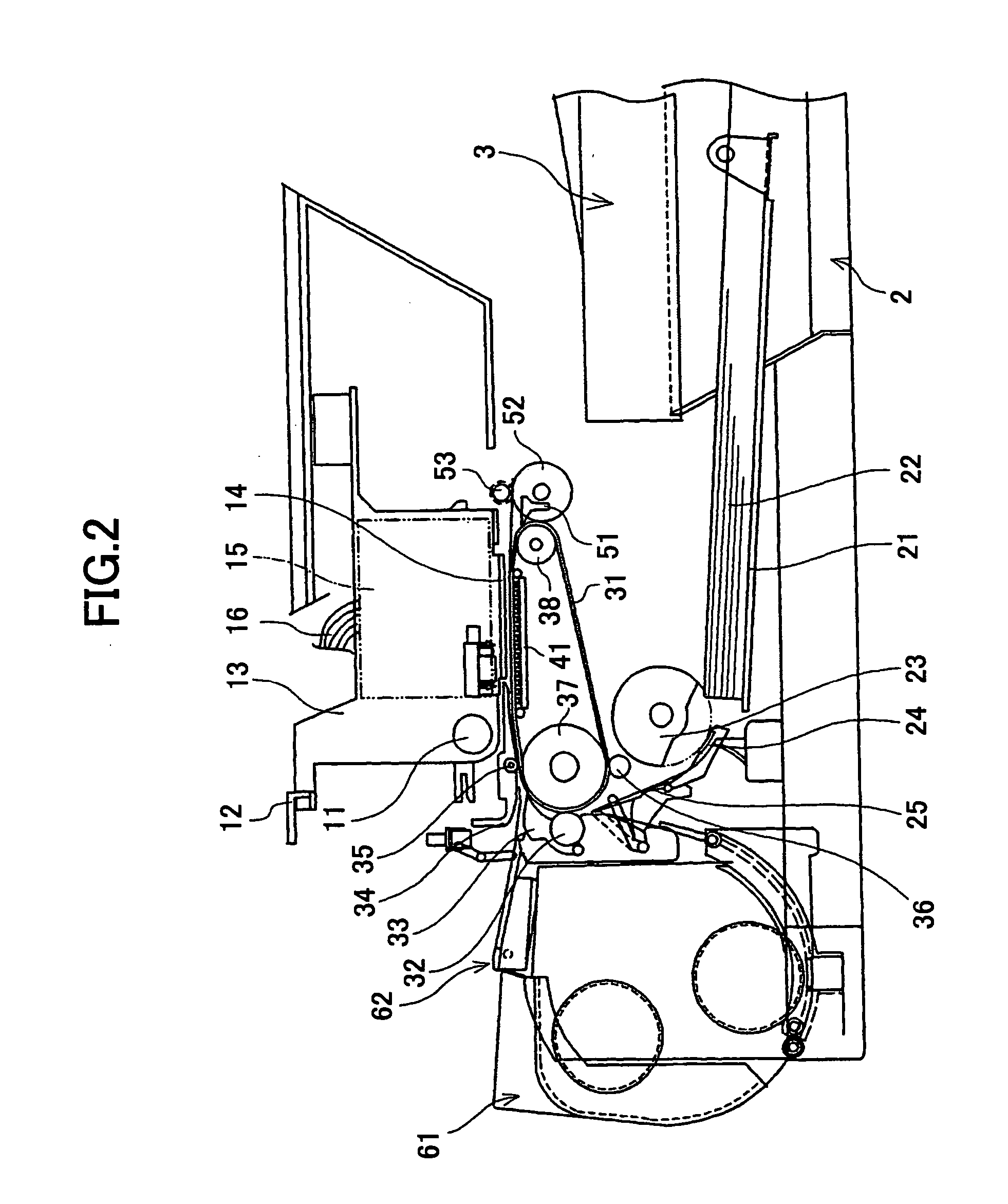

Liquid container, sub tank, liquid discharge apparatus, liquid supply apparatus, and imaging apparatus

A sub tank is provided that includes a case at which an air flow path is formed, the air flow path including an entrance flow path portion that is connected to an ink accommodating portion of the case, and a cross flow path portion that continues from the entrance flow path portion. The cross flow path portion extends in an upper diagonal direction with respect to a reference plane corresponding to the ink liquid level at a standstill state. Another sub tank is provided that includes a case forming an ink accommodating portion, on which case a flexible film member is attached through bonding or welding to seal an opening of the ink accommodating portion and to form one side of the sub tank. A spring is disposed within the ink accommodating portion between the case and the flexible film member, the spring forcing the flexible film member outward.

Owner:RICOH KK

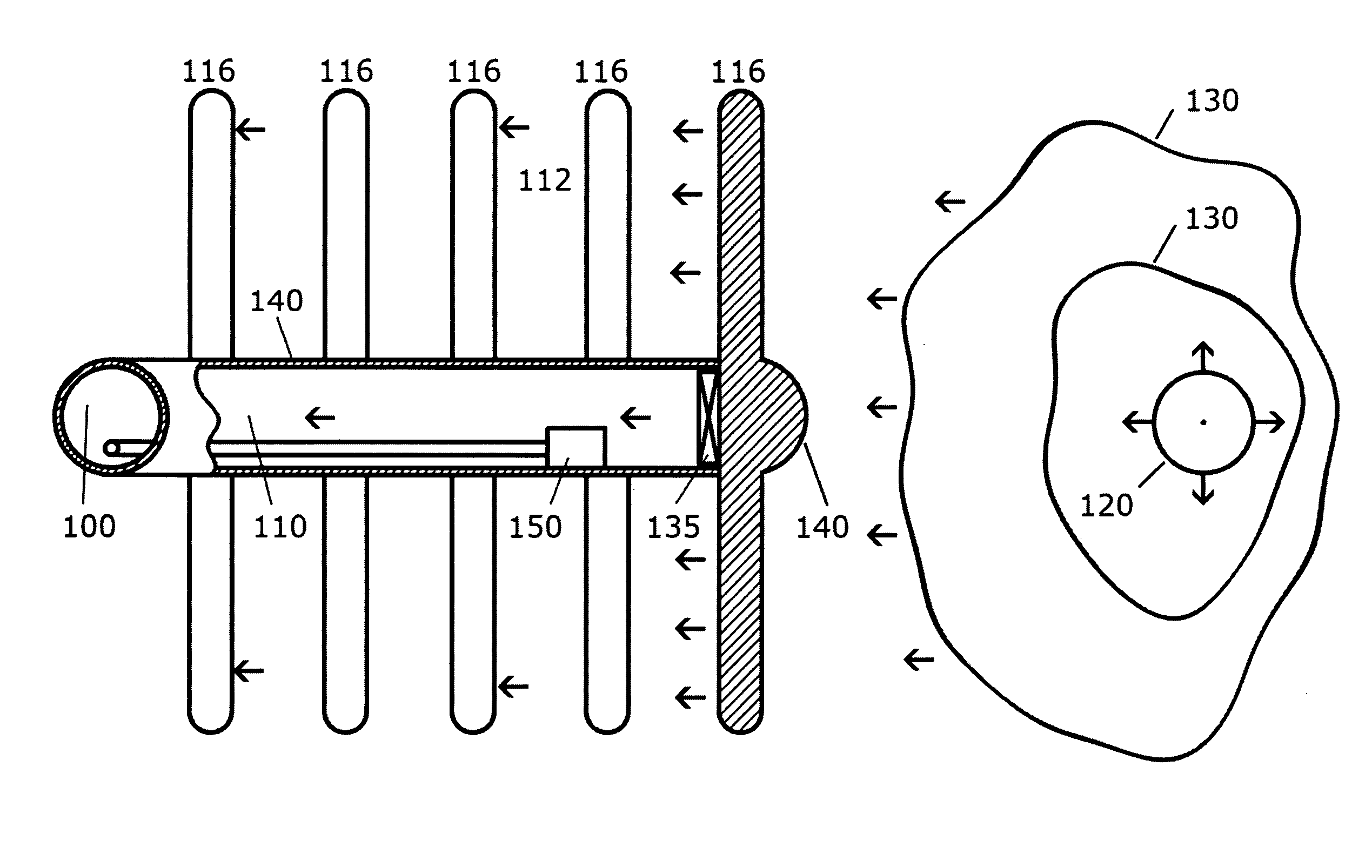

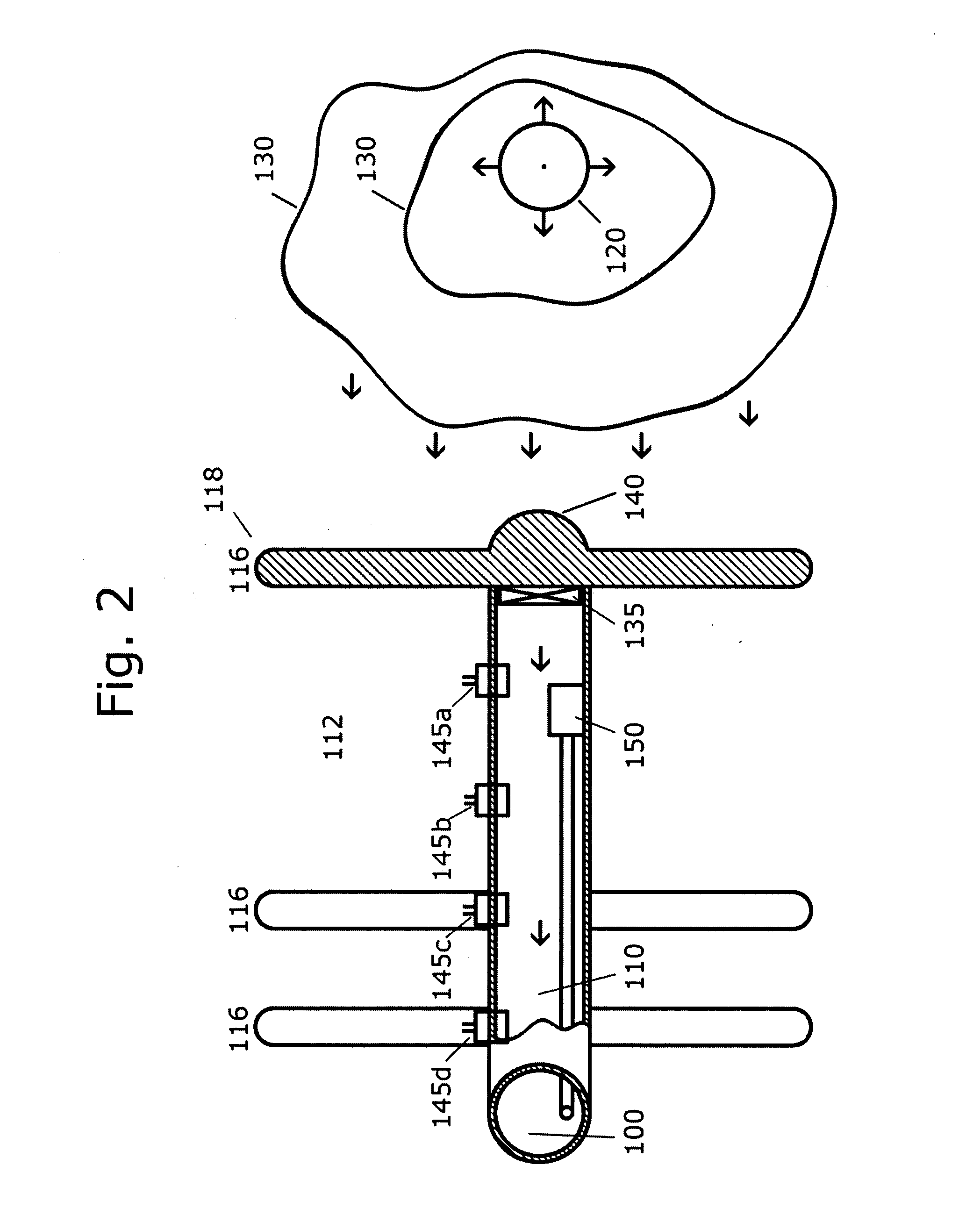

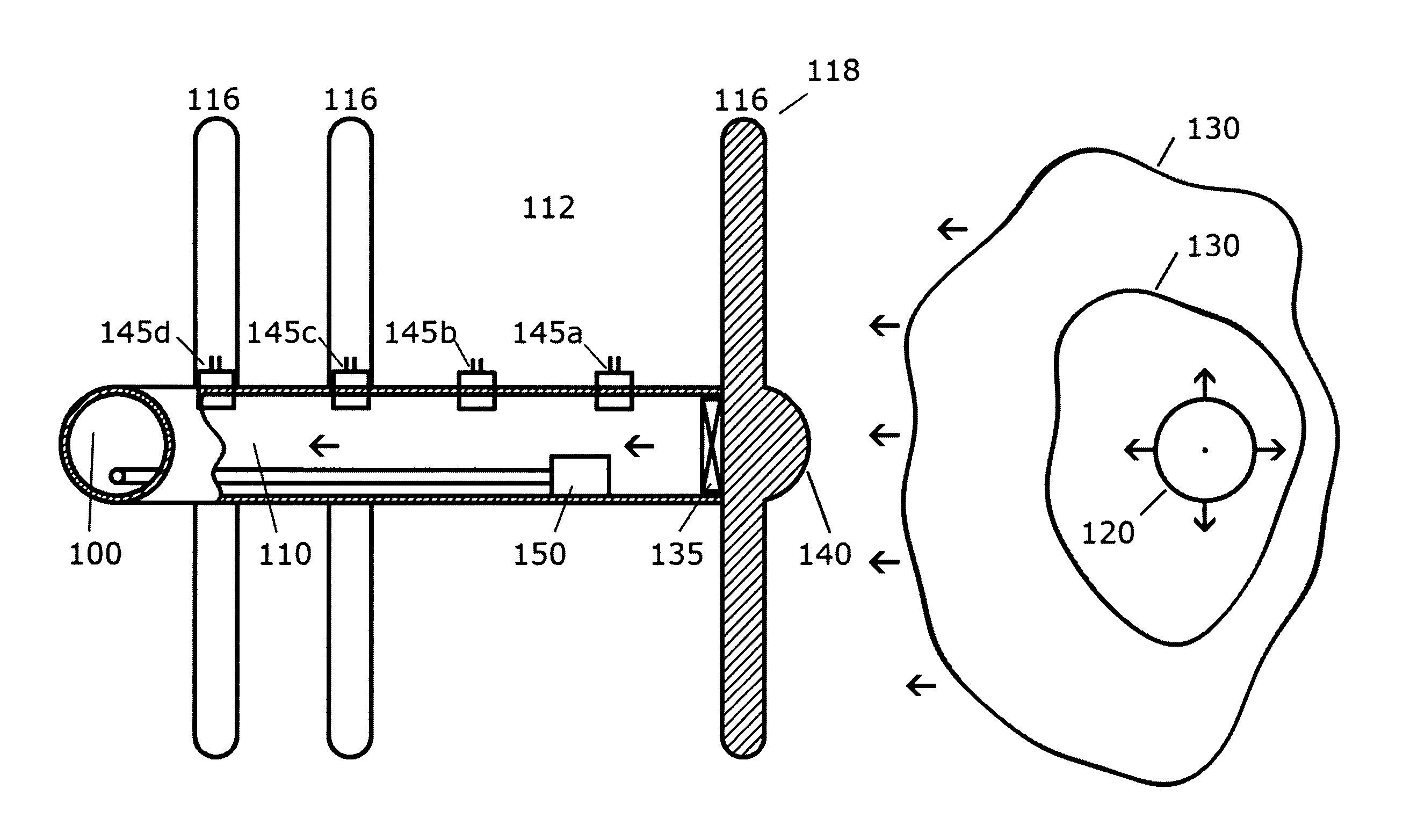

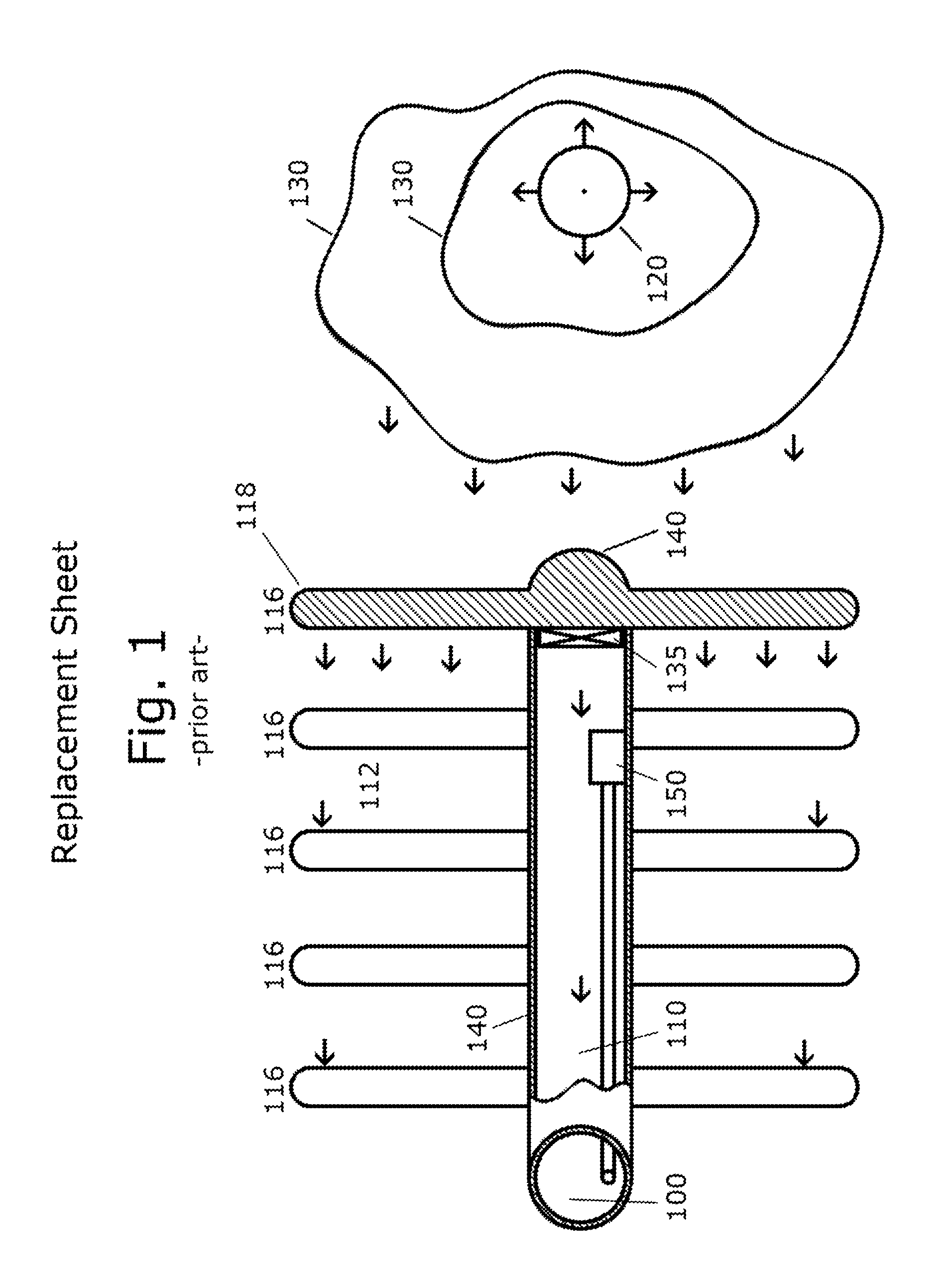

Method of improving waterflood performance using barrier fractures and inflow control devices

ActiveUS20110042083A1Reduce inflowImprove scanning efficiencySurveyFluid removalSweep efficiencyTransverse fracture

The present invention is directed to a method of hydrocarbon production from a hydrocarbon reservoir. The method includes providing a substantially horizontal wellbore having at least one productive interval within a hydrocarbon reservoir and forming at least one non-conductive transverse fracture in the reservoir along the substantially horizontal wellbore. An injection well is also provided. A fluid is injected into the reservoir through the injection well to displace hydrocarbons within the reservoir toward a production portion of the substantially horizontal wellbore. Hydrocarbons are drained from the reservoir into at least one production interval of the substantially horizontal wellbore. Fluid production from the at least one production interval into the substantially horizontal wellbore flows through an inflow control device that can restrict the fluid flow. A non-conductive transverse fracture can form a barrier within the reservoir to divert injected fluids to increase sweep efficiency and reduce the influx of injected fluids into the production interval.

Owner:HALLIBURTON ENERGY SERVICES INC

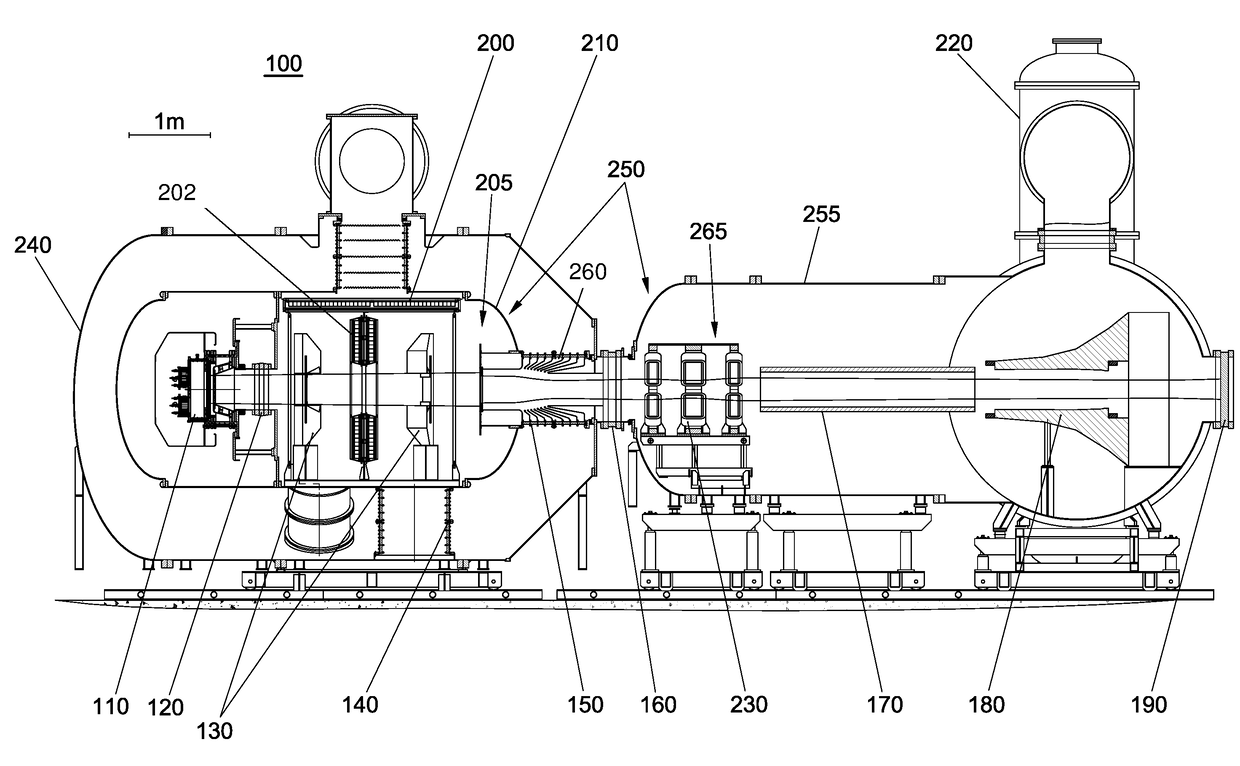

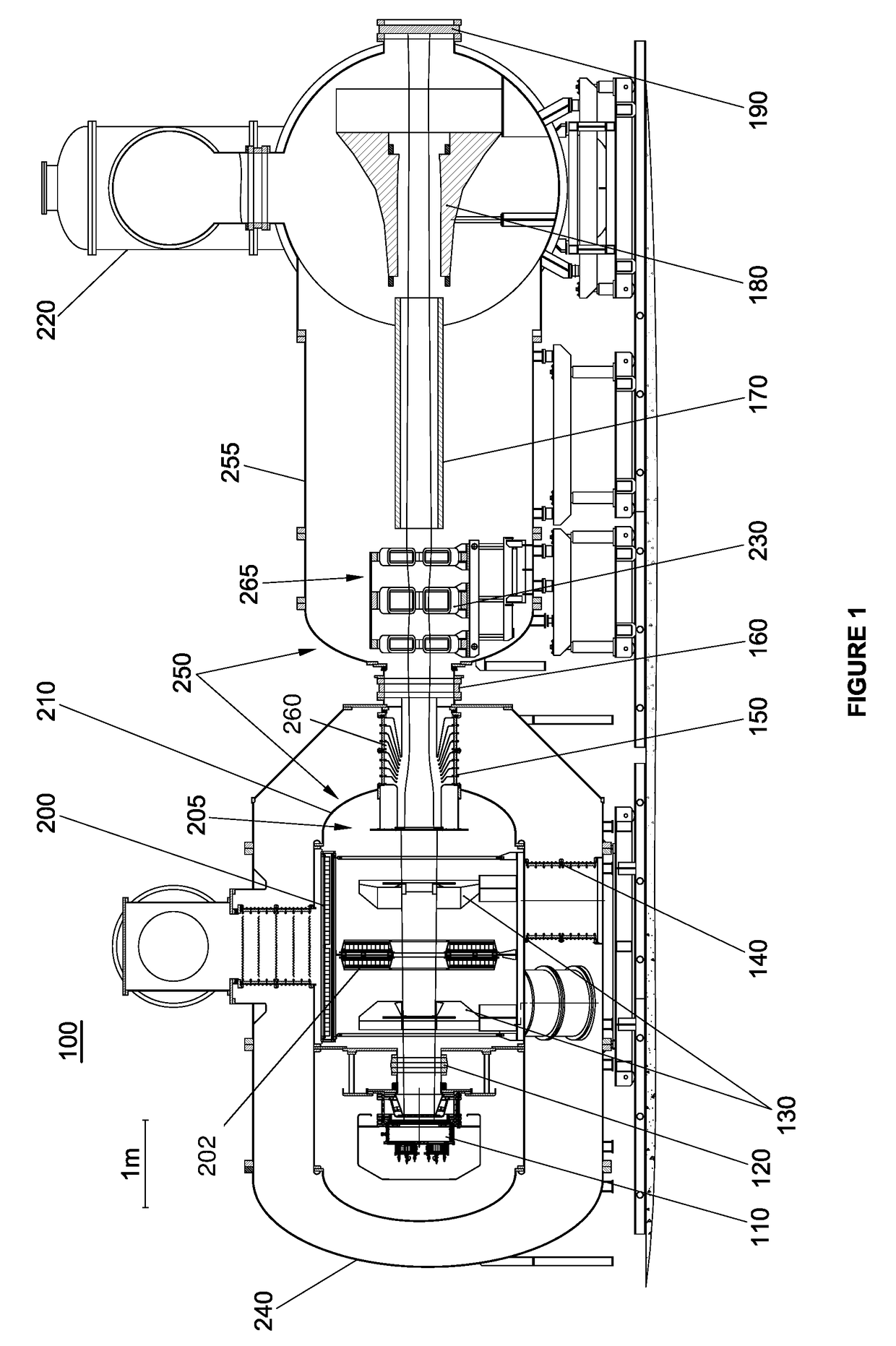

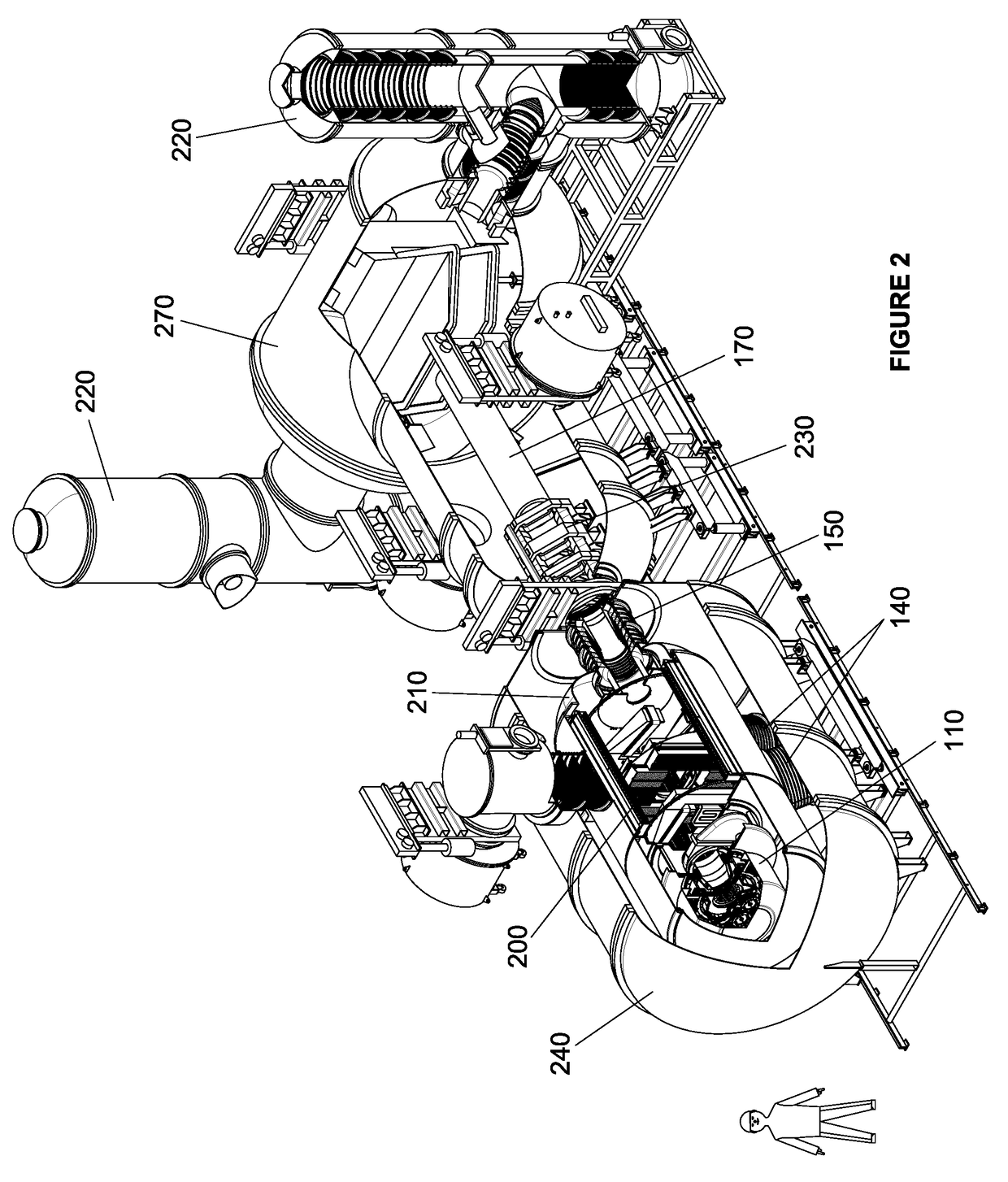

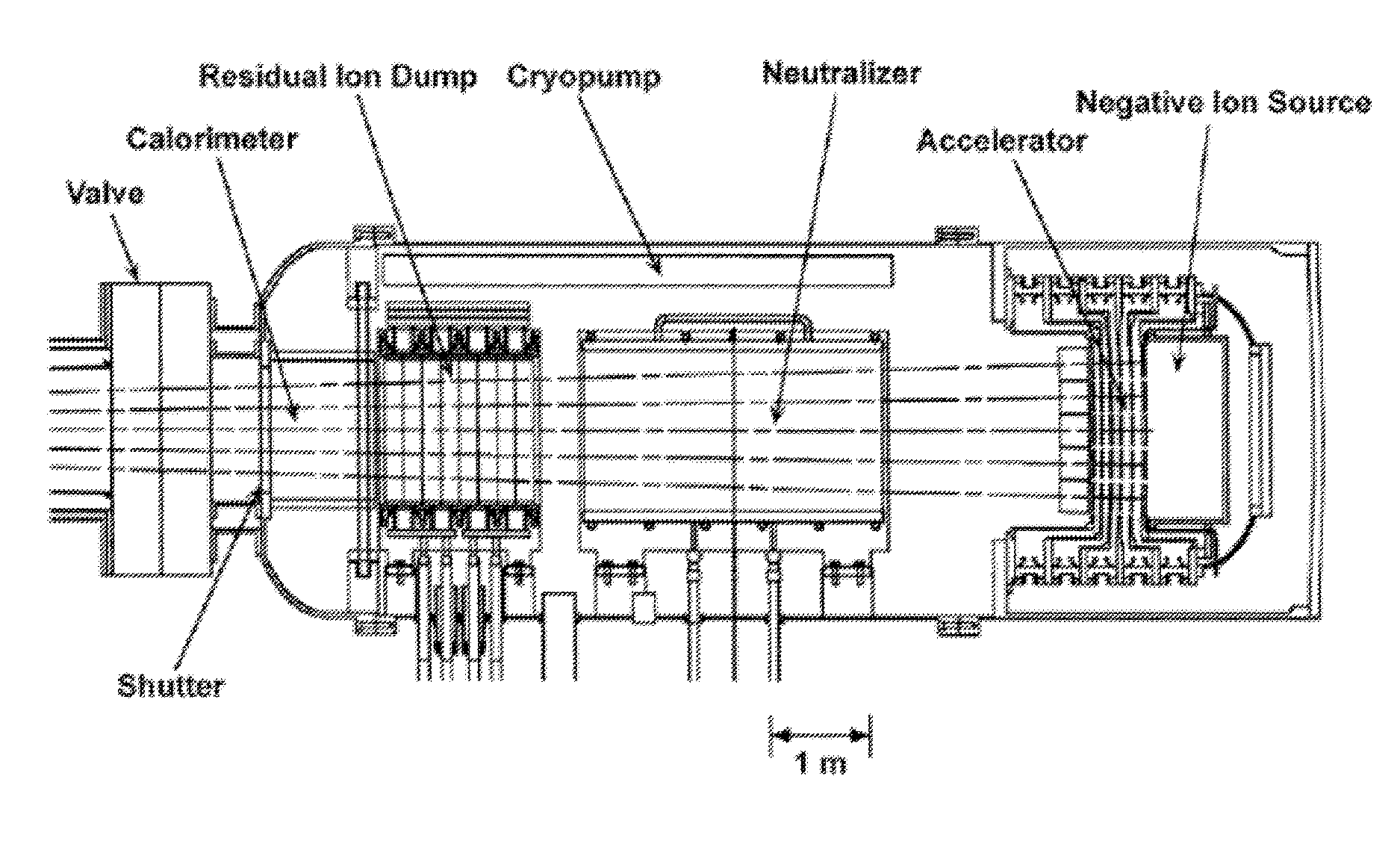

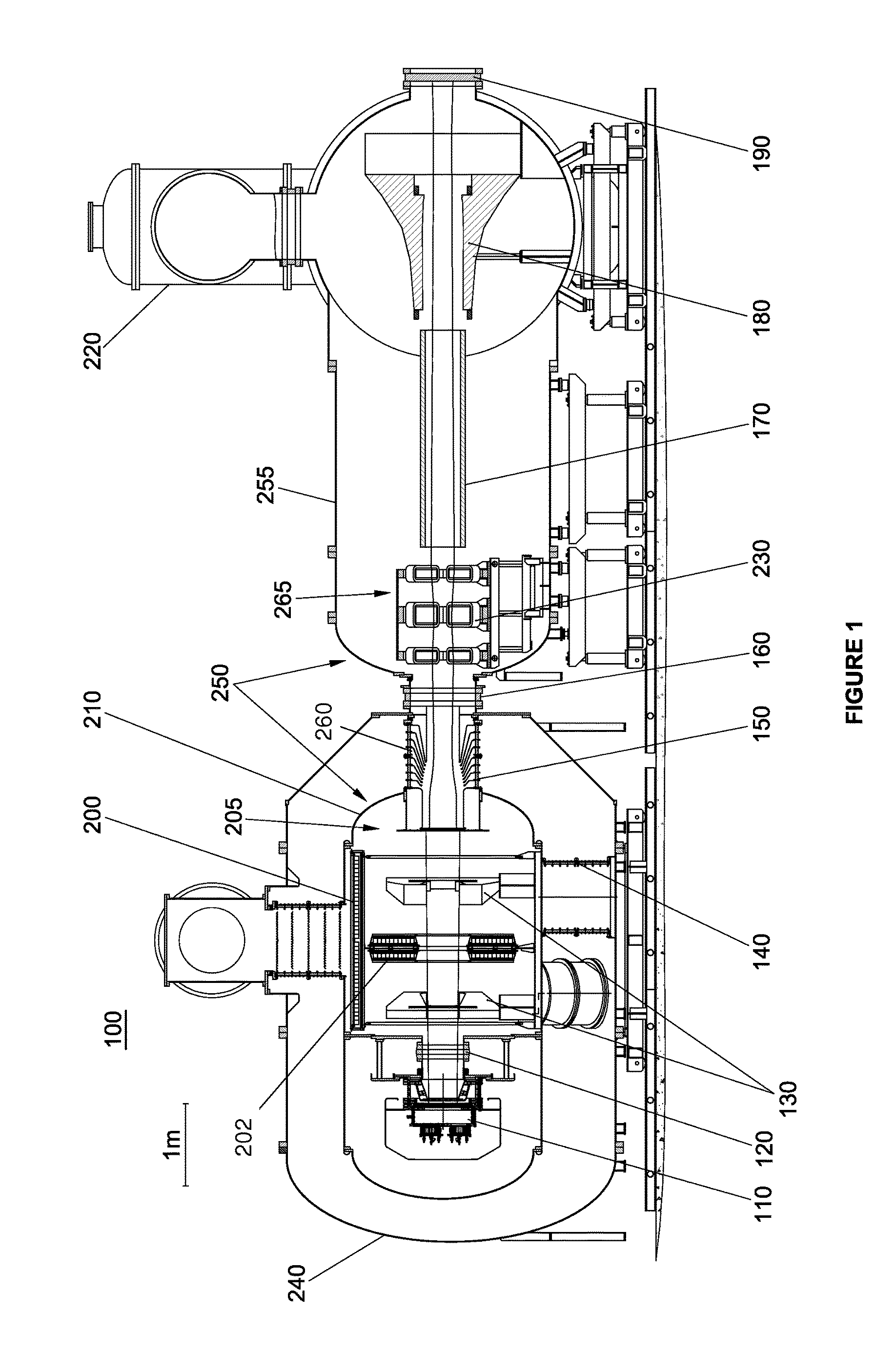

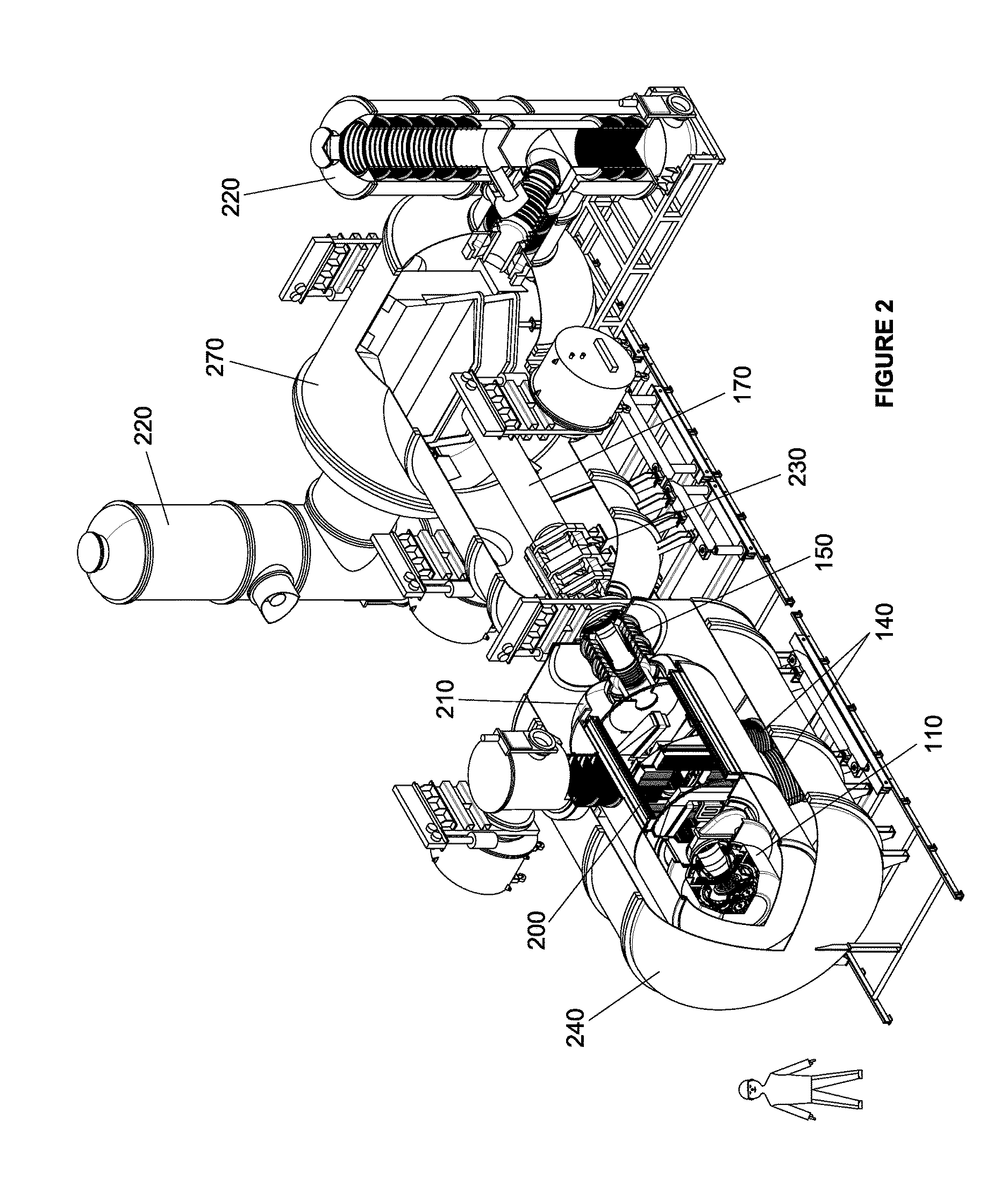

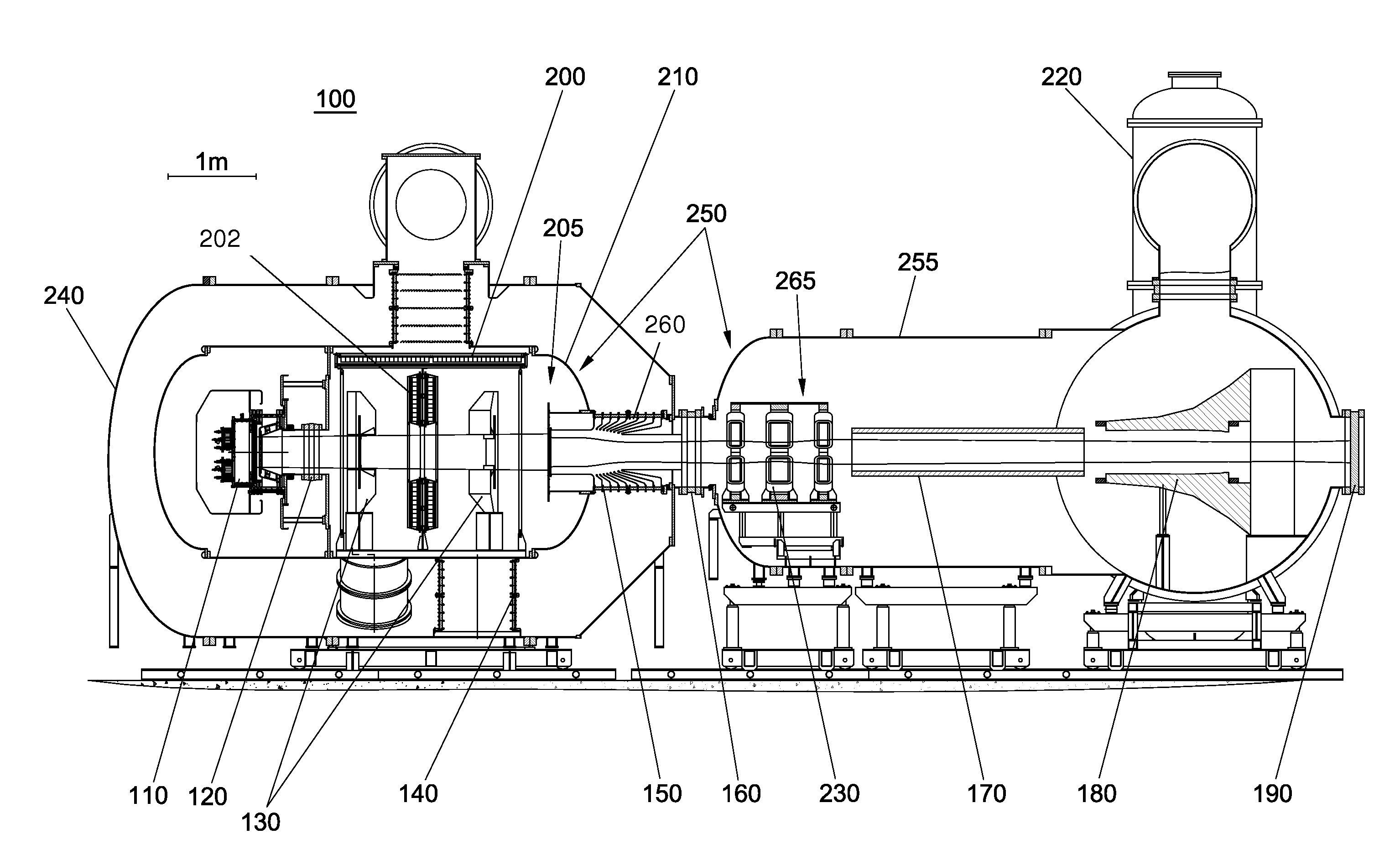

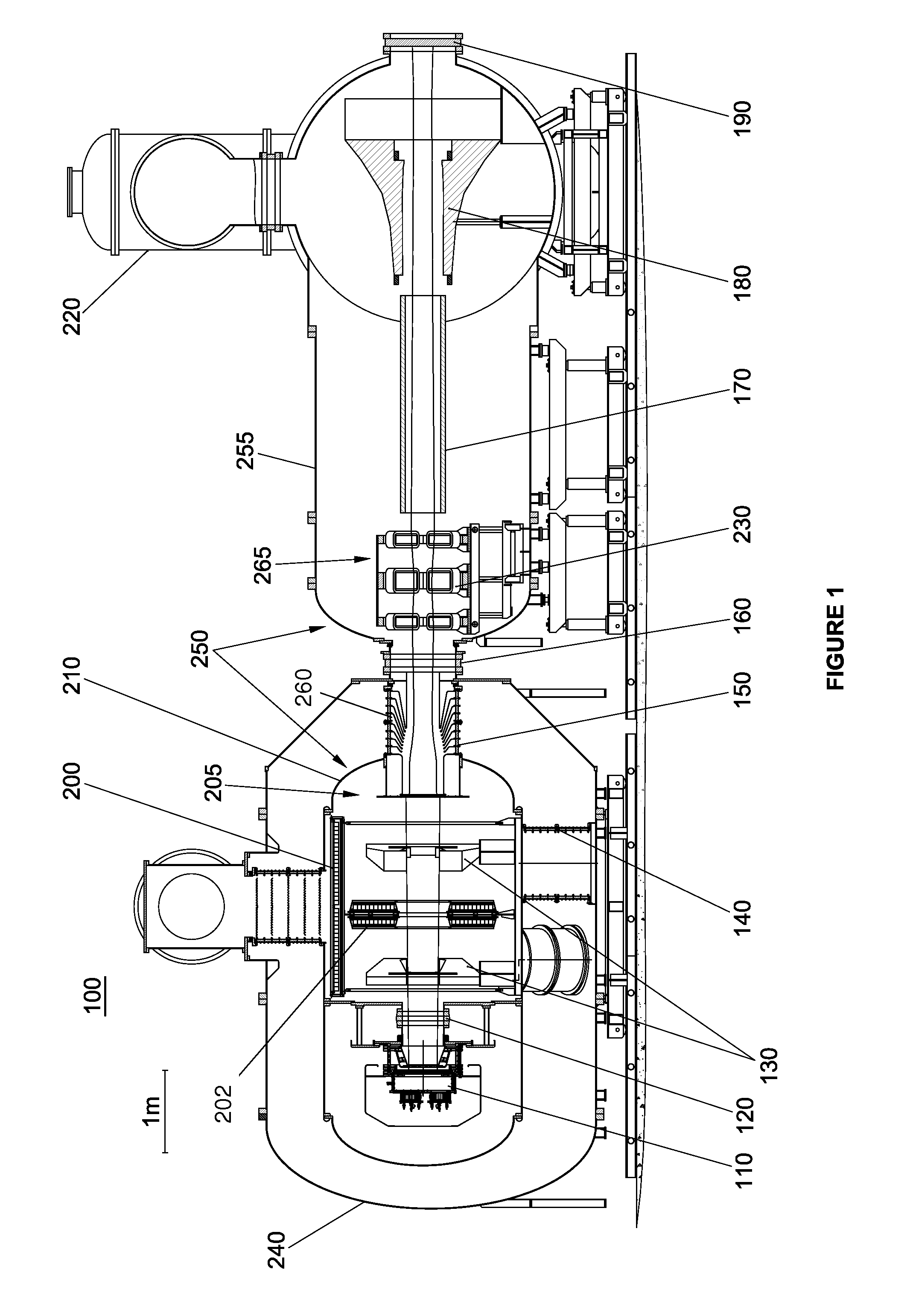

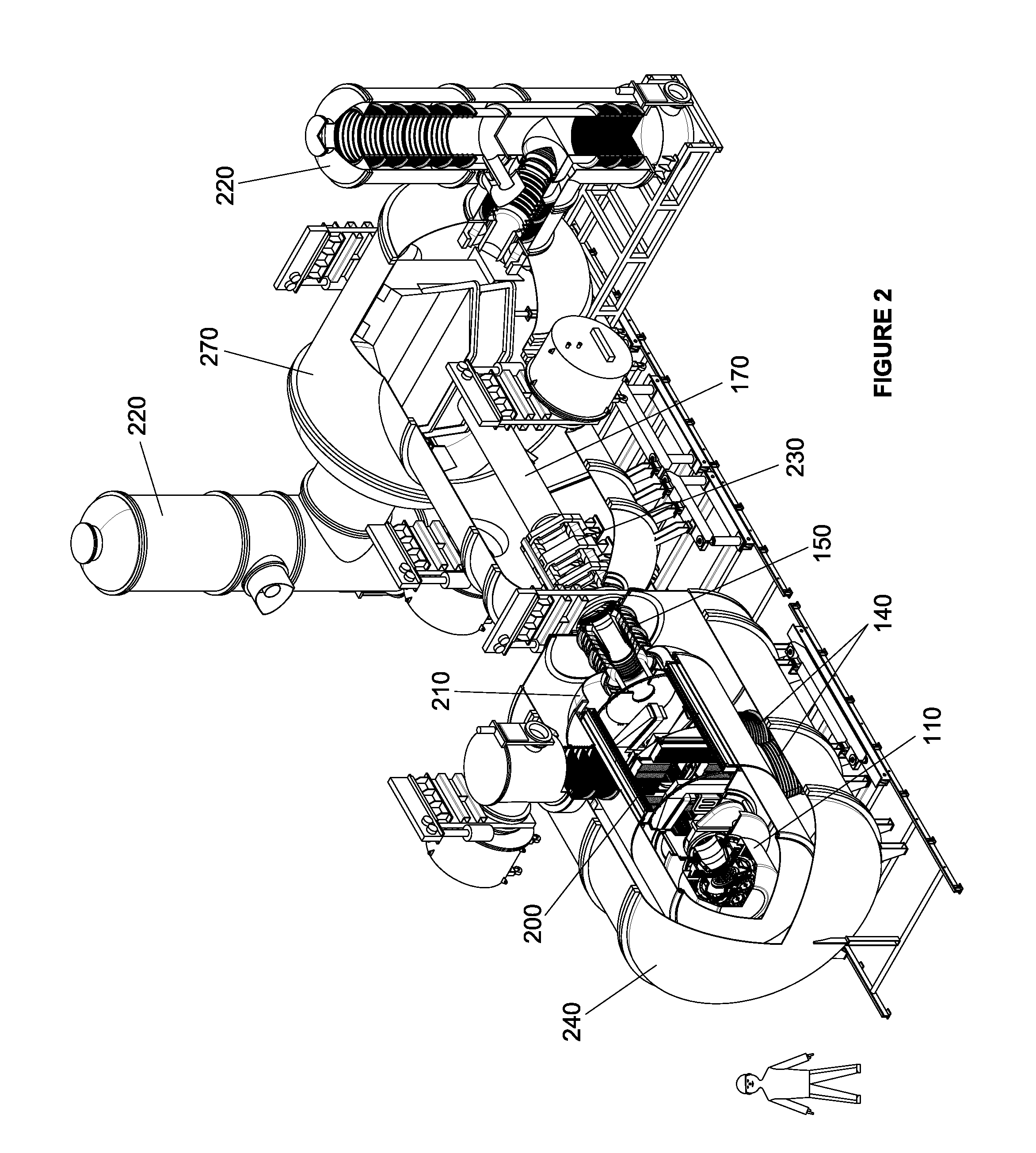

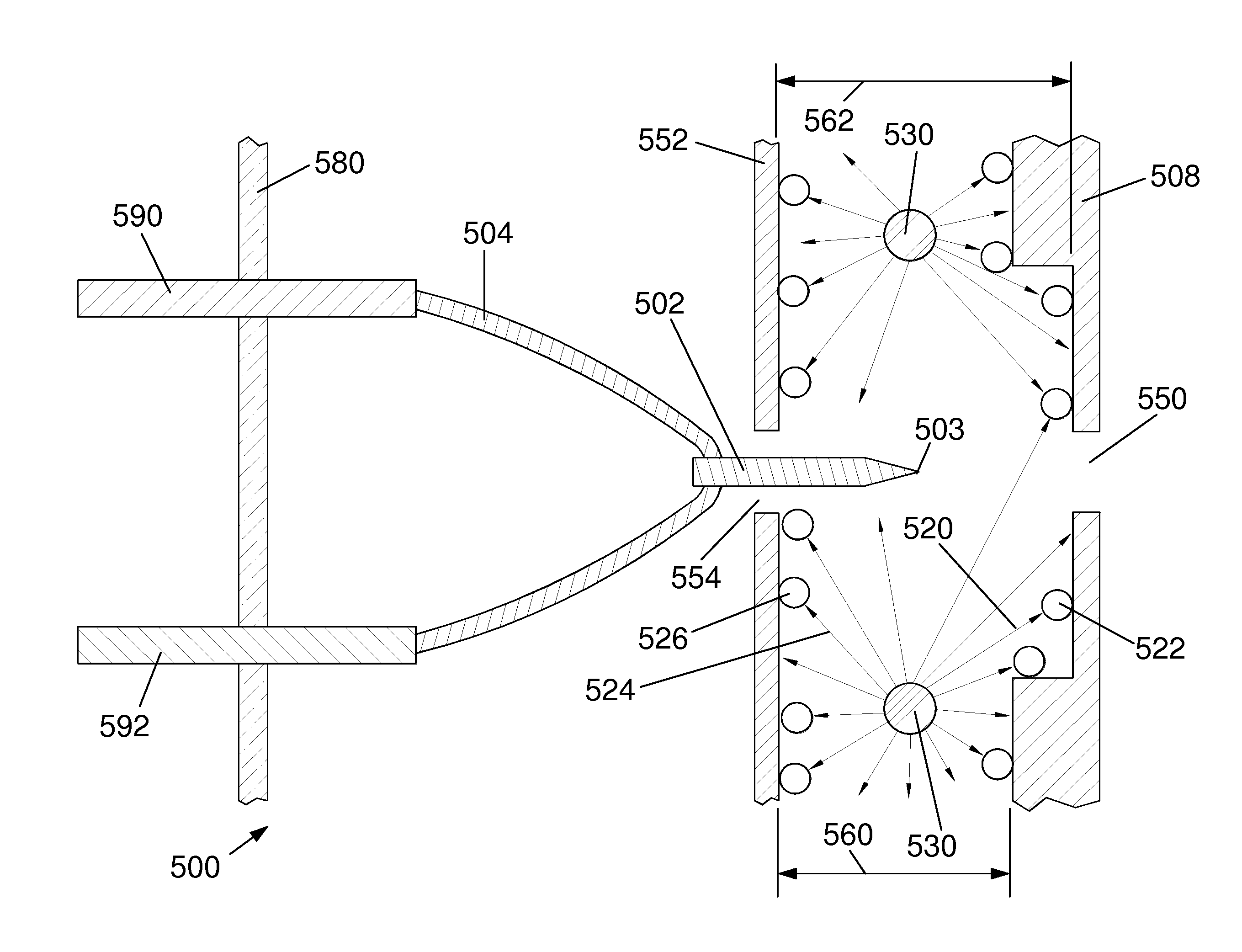

Negative ion-based neutral beam injector

ActiveUS20170135194A1Improve homogeneityReduce inflowRadiation/particle handlingMasersBeam energyPlasma chamber

A negative ion-based neutral beam injector comprising a negative ion source, accelerator and neutralizer to produce about a 5 MW neutral beam with energy of about 0.50 to 1.0 MeV. The ions produced by the ion source are pre-accelerated before injection into a high energy accelerator by an electrostatic multi-aperture grid pre-accelerator, which is used to extract ion beams from the plasma and accelerate to some fraction of the required beam energy. The beam from the ion source passes through a pair of deflecting magnets, which enable the beam to shift off axis before entering the high energy accelerator. After acceleration to full energy, the beam enters the neutralizer where it is partially converted into a neutral beam. The remaining ion species are separated by a magnet and directed into electrostatic energy converters. The neutral beam passes through a gate valve and enters a plasma chamber.

Owner:TAE TECH INC

Negative ion-based neutral beam injector

ActiveUS9591740B2Improve homogeneityReduce inflowRadiation/particle handlingMasersBeam energyHigh energy accelerator

A negative ion-based neutral beam injector comprising a negative ion source, accelerator and neutralizer to produce about a 5 MW neutral beam with energy of about 0.50 to 1.0 MeV. The ions produced by the ion source are pre-accelerated before injection into a high energy accelerator by an electrostatic multi-aperture grid pre-accelerator, which is used to extract ion beams from the plasma and accelerate to some fraction of the required beam energy. The beam from the ion source passes through a pair of deflecting magnets, which enable the beam to shift off axis before entering the high energy accelerator. After acceleration to full energy, the beam enters the neutralizer where it is partially converted into a neutral beam. The remaining ion species are separated by a magnet and directed into electrostatic energy converters. The neutral beam passes through a gate valve and enters a plasma chamber.

Owner:TAE TECH INC

Liquid container, sub tank, liquid discharge apparatus, liquid supply apparatus, and imaging apparatus

A sub tank is provided that includes a case at which an air flow path is formed, the air flow path including an entrance flow path portion that is connected to an ink accommodating portion of the case, and a cross flow path portion that continues from the entrance flow path portion. The cross flow path portion extends in an upper diagonal direction with respect to a reference plane corresponding to the ink liquid level at a standstill state. Another sub tank is provided that includes a case forming an ink accommodating portion, on which case a flexible film member is attached through bonding or welding to seal an opening of the ink accommodating portion and to form one side of the sub tank. A spring is disposed within the ink accommodating portion between the case and the flexible film member, the spring forcing the flexible film member outward.

Owner:RICOH KK

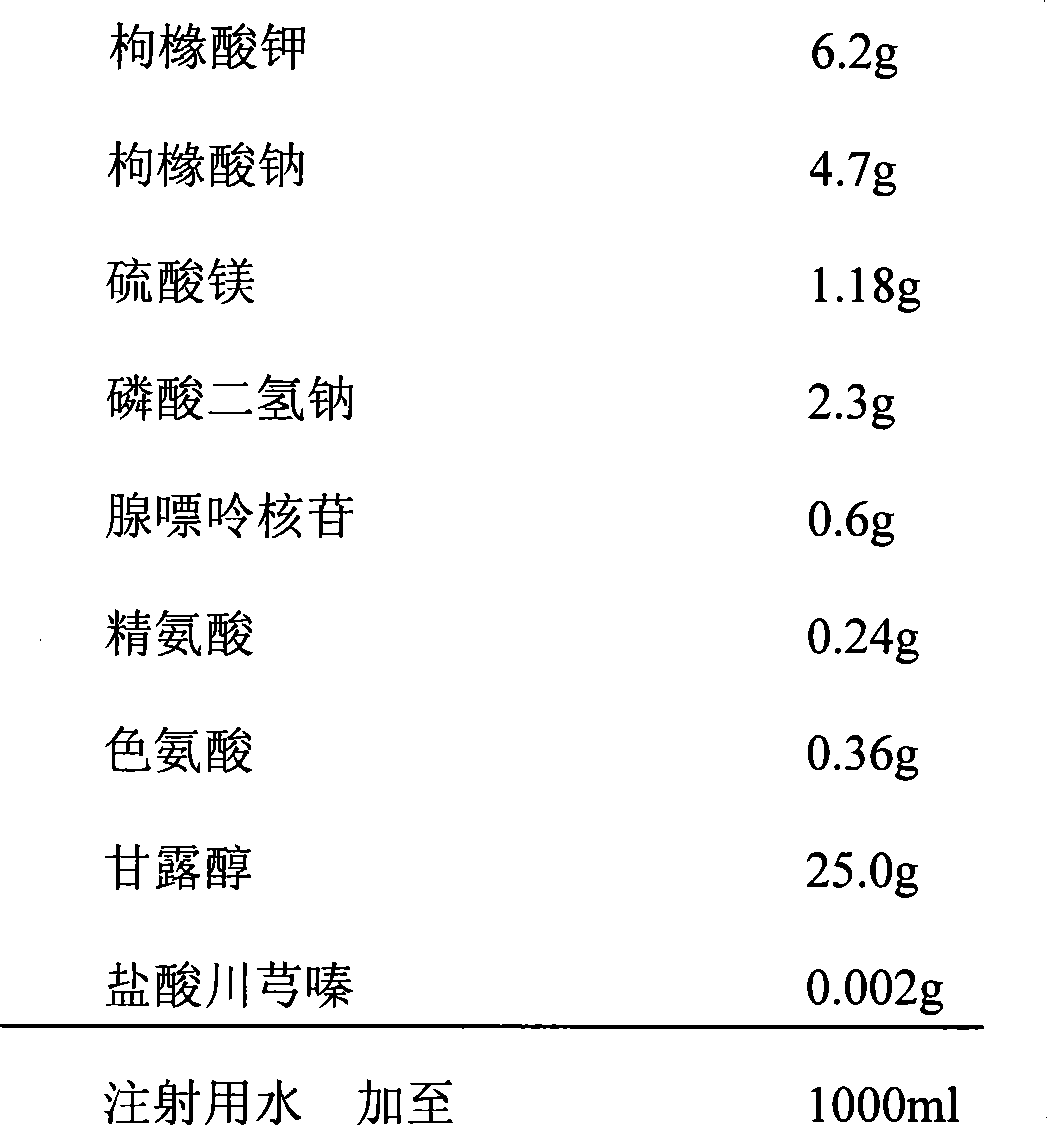

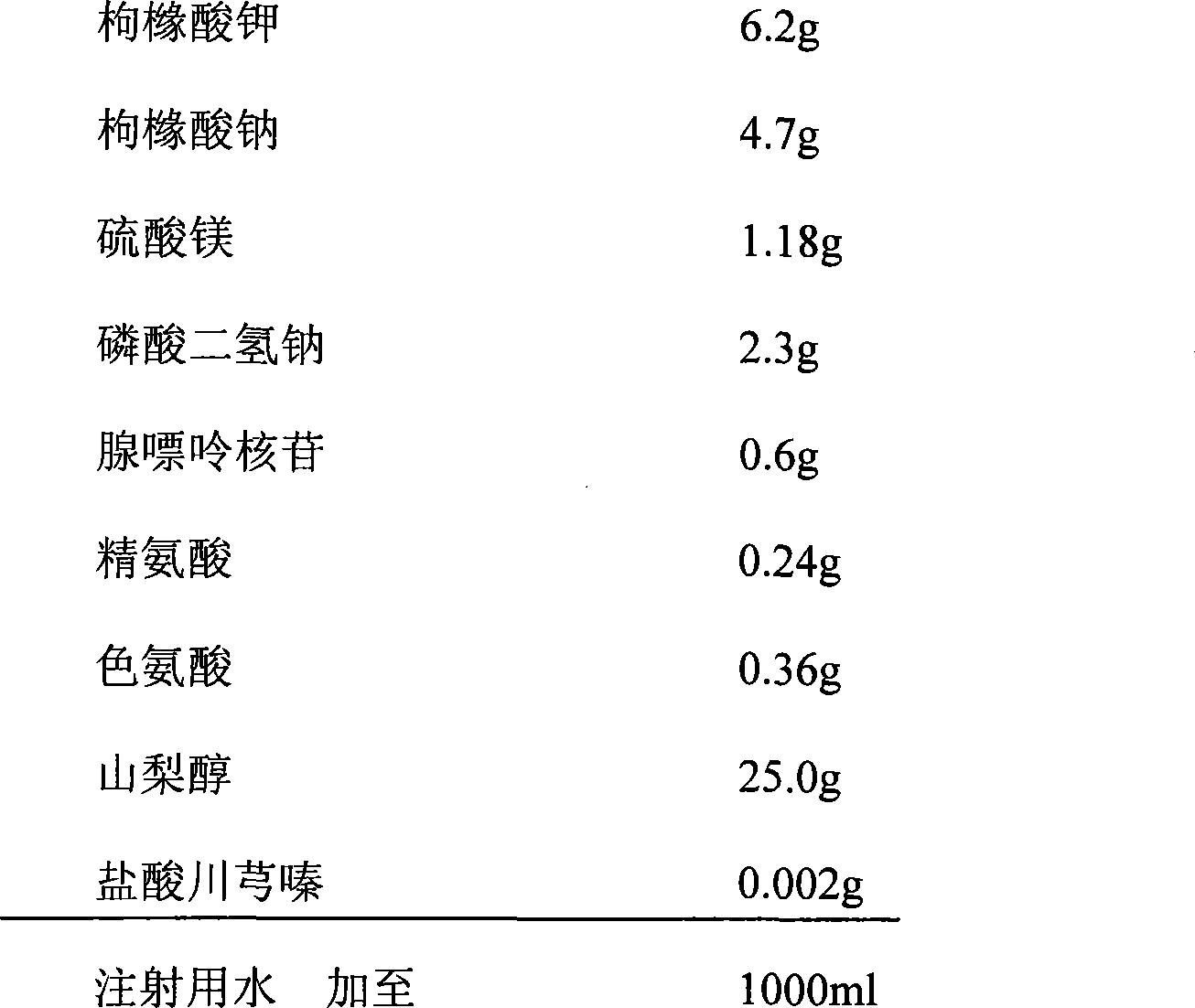

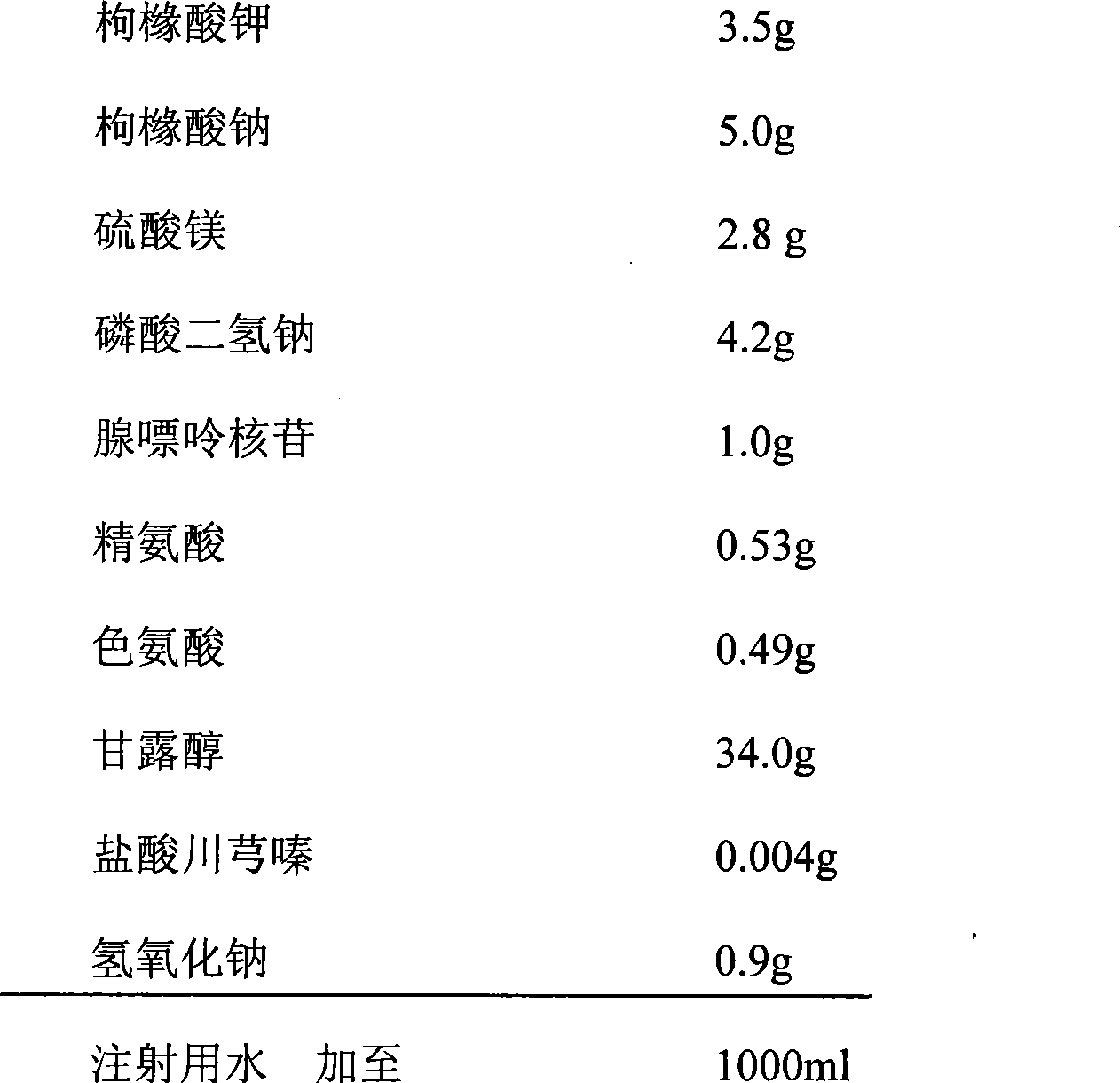

Organ preservative fluid and preparation method thereof

InactiveCN101496512AEffective preservationPrevent ischemia-reperfusion injuryDead animal preservationReperfusion injuryTetramethylpyrazine hydrochloride

The invention relates to a preservation solution for organs, tissues or cells of human bodies or animals. The organ preservation solution comprises sodium citrate, potassium citrate, magnesium sulfate, sodium dihydrogen phosphate, sodium hydroxide, adenosine, arginine, tryptophan, mannitol, tetramethylpyrazine hydrochloride and other components. The organ preservation solution can be used for cooling, lavaging and preserving the organs of the human bodies or the animals, can effectively preserve human in vitro kidneys for 48 hours and animal in vitro kidneys for 72 hours, can prevent ischemia-reperfusion injury, and has great value for clinical application.

Owner:YANGZIJIANG PHARMA GROUP SHANGHAI HAINI PHARMA

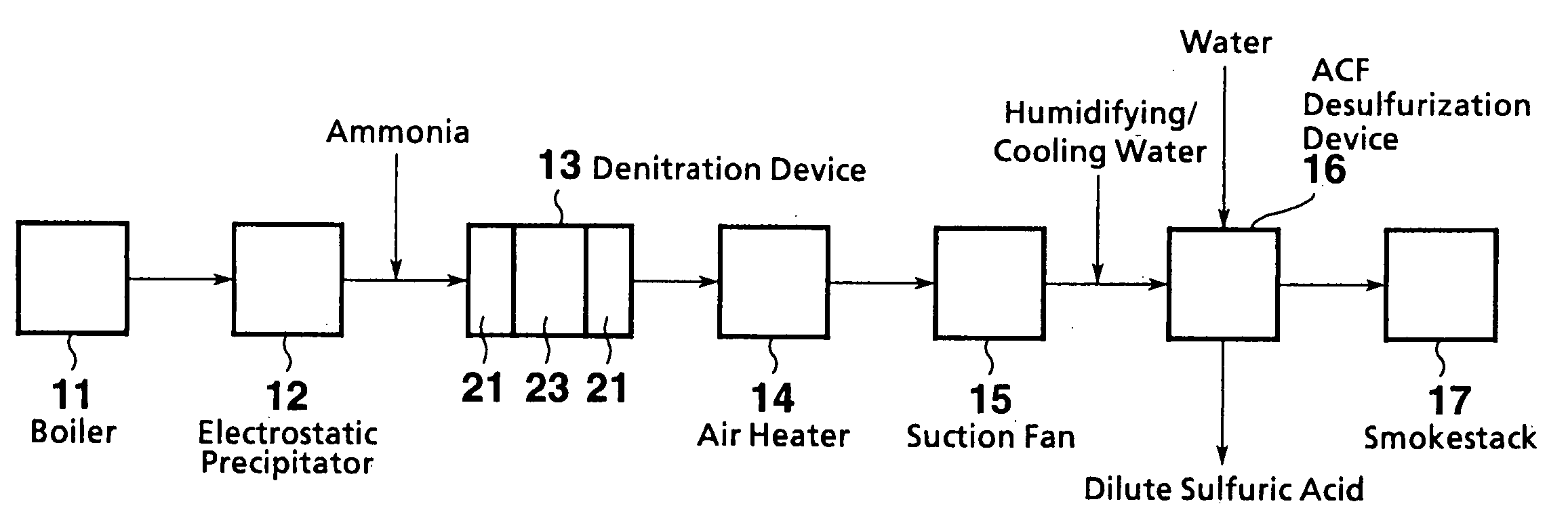

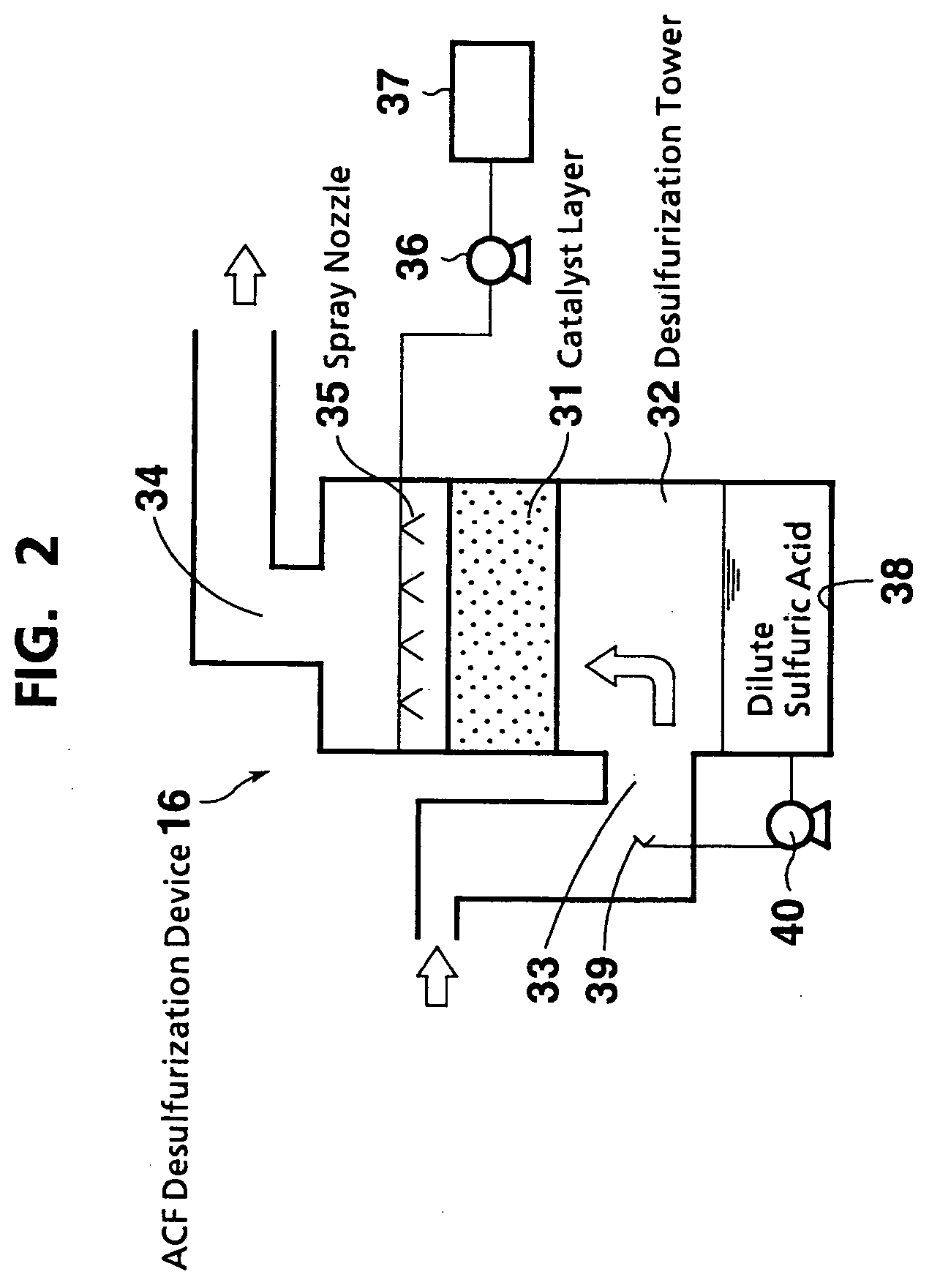

Exhaust gas treatment system

InactiveUS20050008546A1Low costSystem degradationCombination devicesExhaust apparatusEngineeringCost of treatment

In an exhaust gas treatment system, dust in a high temperature exhaust gas is caught by a high temperature dry electrostatic precipitator, a nitrogen oxide NO2 in the exhaust gas is removed by denitration means, then the exhaust gas is cooled by an air heater, and the exhaust gas is passed through an activated carbon fiber layer of activated carbon treatment means to remove sulfur oxides SO2 and SO3 contained in the exhaust gas. The exhaust gas treatment system reduces the costs of treatment and equipment, and downsizes the system.

Owner:MITSUBISHI HEAVY IND LTD

Negative ion-based neutral beam injector

ActiveUS20150245461A1Improve homogeneityReduce inflowLaser detailsRadiation/particle handlingBeam energyHigh energy accelerator

A negative ion-based neutral beam injector comprising a negative ion source, accelerator and neutralizer to produce about a 5 MW neutral beam with energy of about 0.50 to 1.0 MeV. The ions produced by the ion source are pre-accelerated before injection into a high energy accelerator by an electrostatic multi-aperture grid pre-accelerator, which is used to extract ion beams from the plasma and accelerate to some fraction of the required beam energy. The beam from the ion source passes through a pair of deflecting magnets, which enable the beam to shift off axis before entering the high energy accelerator. After acceleration to full energy, the beam enters the neutralizer where it is partially converted into a neutral beam. The remaining ion species are separated by a magnet and directed into electrostatic energy converters. The neutral beam passes through a gate valve and enters a plasma chamber.

Owner:TAE TECH INC

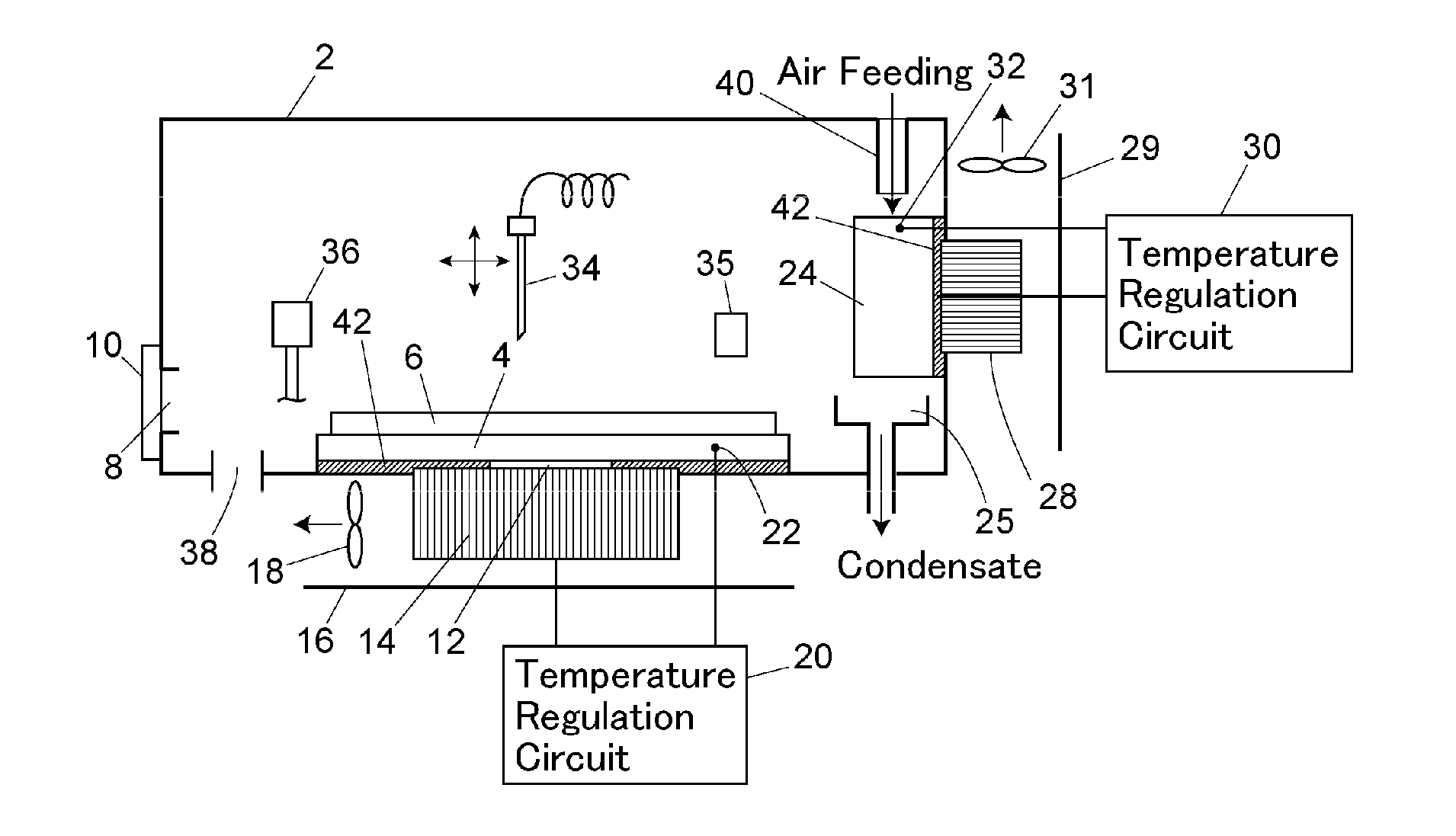

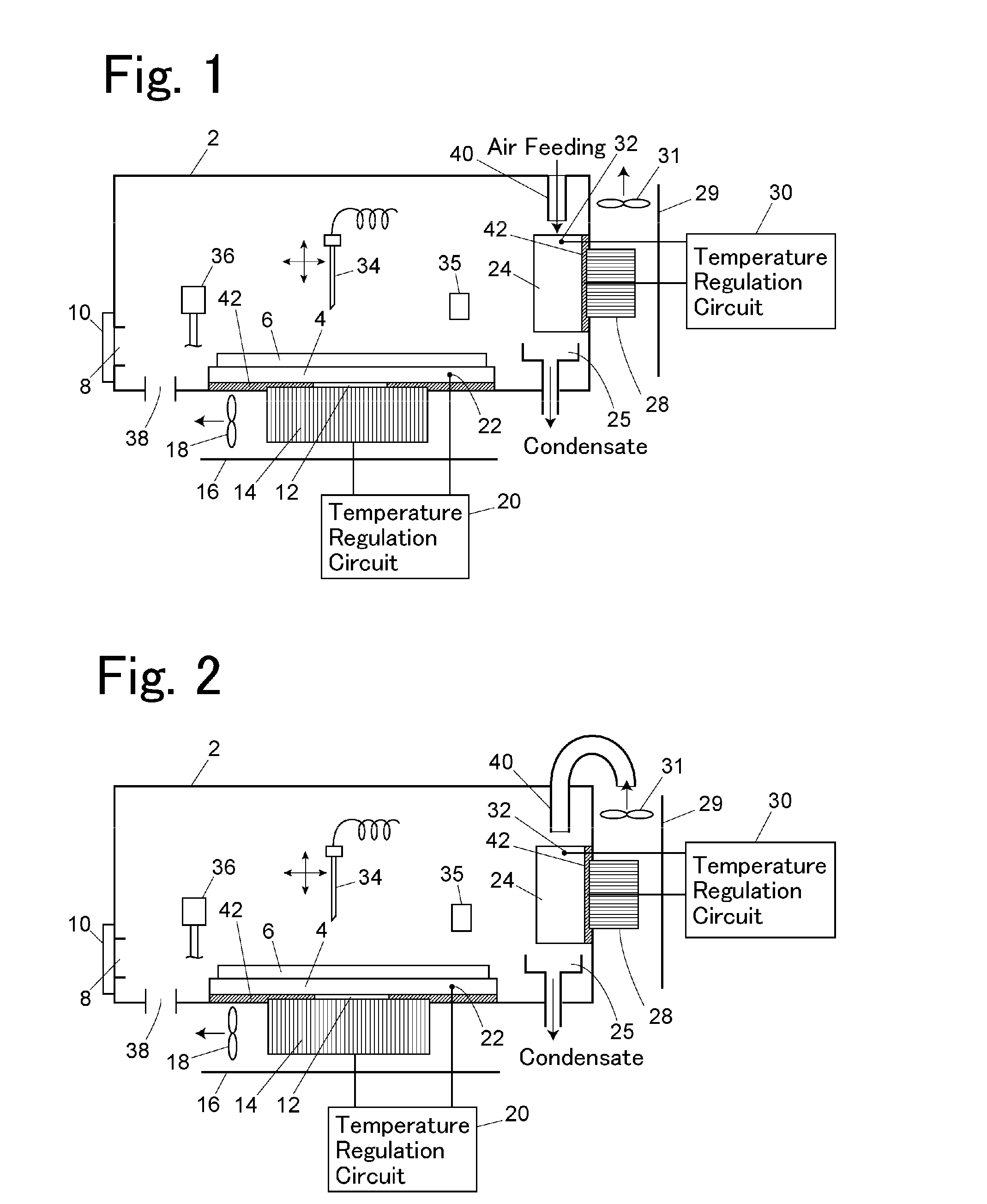

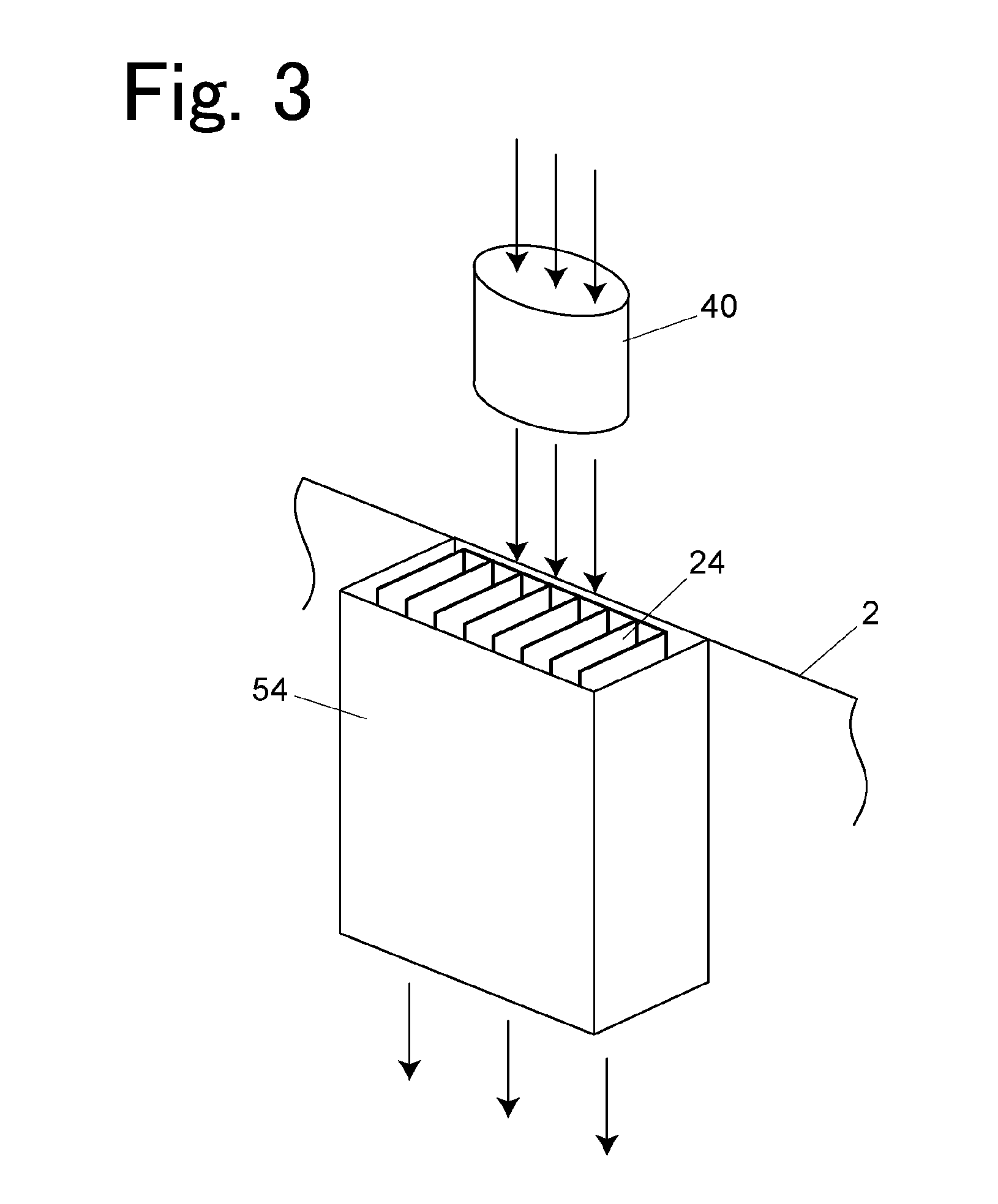

Sample cooling device

ActiveUS20140250938A1Avoid it happening againAvoid flowDomestic refrigeratorsFood preservationEngineeringExternal pressure

A sample cooling device is provided with, inside a sample storage which stores therein a sample rack, a first heat transfer member arranged at a position in contact with the sample rack, a second heat transfer member which cools the inside of the sample storage, and a condensate discharge mechanism which discharges condensate condensing on the second heat transfer member to the outside of the sample storage. An internal space of the sample storage is not sealed due to the existence of a leak path for air formed between the inside and the outside of the sample storage, the leak path including at least the channel. The sample storage includes an outside air introduction unit which forcibly blows the outside air into the internal space so that the pressure inside the sample storage becomes higher than the outside pressure thereof. The position and the direction of an outside air outlet of the outside air introduction unit inside the sample storage are set so that the outside air blown into the sample storage directly heads for the second heat transfer member.

Owner:SHIMADZU CORP

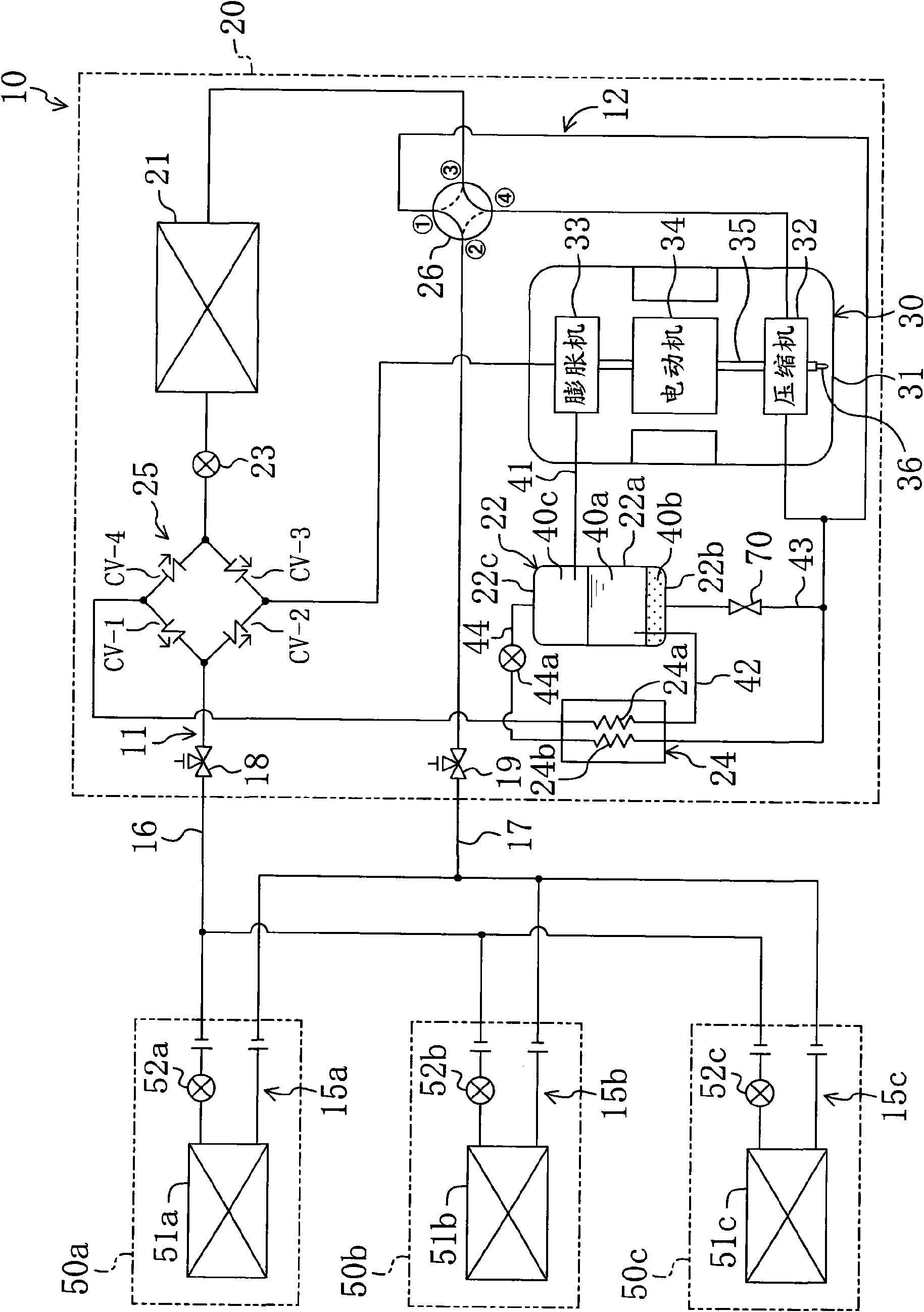

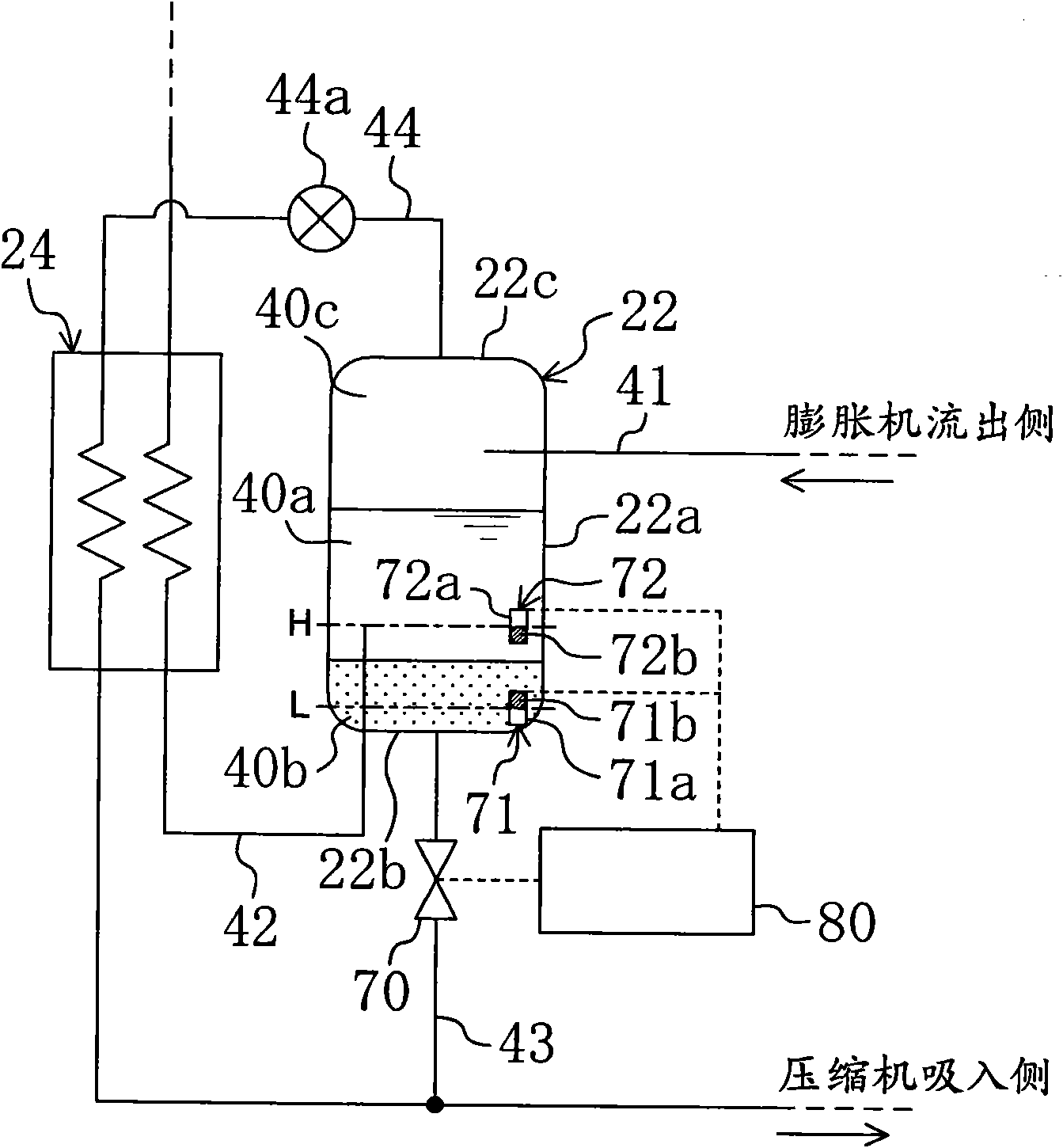

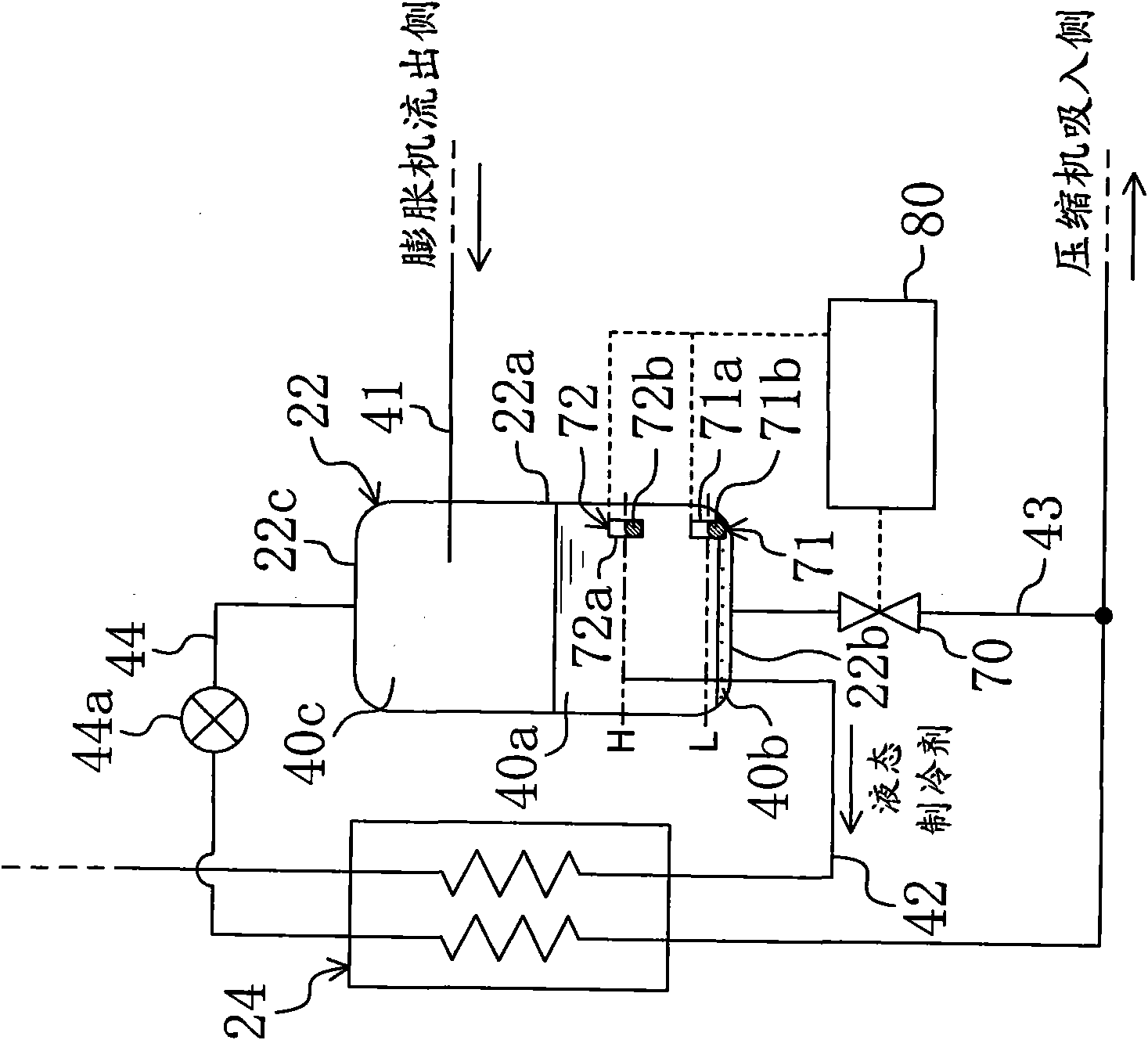

Refrigerating device

ActiveCN101646908AAvoid inhalationPrevent suction sideCompressorCompression machines with non-reversible cycleRefrigerantMechanical engineering

An opening / closing valve (70) is provided in an oil feed pipe (43). When a liquid refrigerant enters from an oil separator (22) into the oil feed pipe (43), the temperature of the liquid refrigerant depressurized by the opening / closing valve (70) is suddenly lowered. When the lowering amount of the temperature detected by a temperature sensor (73) exceeds a prescribed value, it is judged that theliquid refrigerant enters into the oil feed pipe (43), and the valve (70) is closed.

Owner:DAIKIN IND LTD

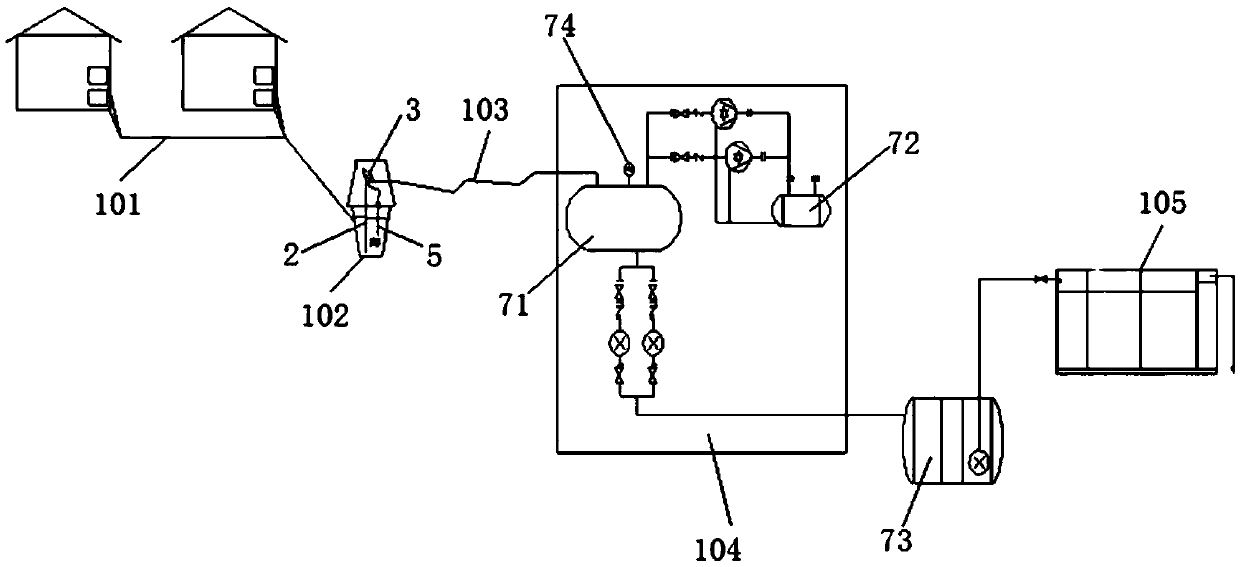

Vacuum sewage collecting and treating system

ActiveCN105507410AChange the singularityImprove securityCesspoolsFatty/oily/floating substances removal devicesSites treatmentSewage

The invention discloses a vacuum sewage collecting and treating system. The vacuum sewage collecting and treating system comprises a sewage gathering pipeline, a vacuum collection well, a vacuum conveying pipeline, a vacuum pump station and a sewage treating device, wherein the sewage enters the vacuum collection well through the sewage gathering pipeline; when the sewage collected in the well reaches a certain amount, the sewage enters the vacuum pump station along the vacuum conveying pipeline; when the liquid level of the sewage in a vacuum sewage storage tank reaches a predetermined liquid level, the sewage conveying pump is started and is used for conveying the sewage to the sewage treating device to purify the sewage. Through the vacuum sewage collecting and treating system, the domestic sewage collection method is changed from the conventional gravity collection into vacuum collection; the sewage treatment is charged from a manner of discharging the sewage into a sewage pipe net and carrying out centralized treatment on the sewage to a process of carrying out on-site treatment by using a small integrated membrane treatment device; collection and treatment are integrated to a complete set of system; the system is not limited by basic supporting facilities and is not required to relay on urban drainage facilities; the system is integrated with the ecological environmental protection technology with efficient collection and efficient treatment functions and is especially suitable for regions such as small towns and countries and the like in which sewage treatment plants are unsuitably built.

Owner:清环拓达(苏州)环境科技有限公司

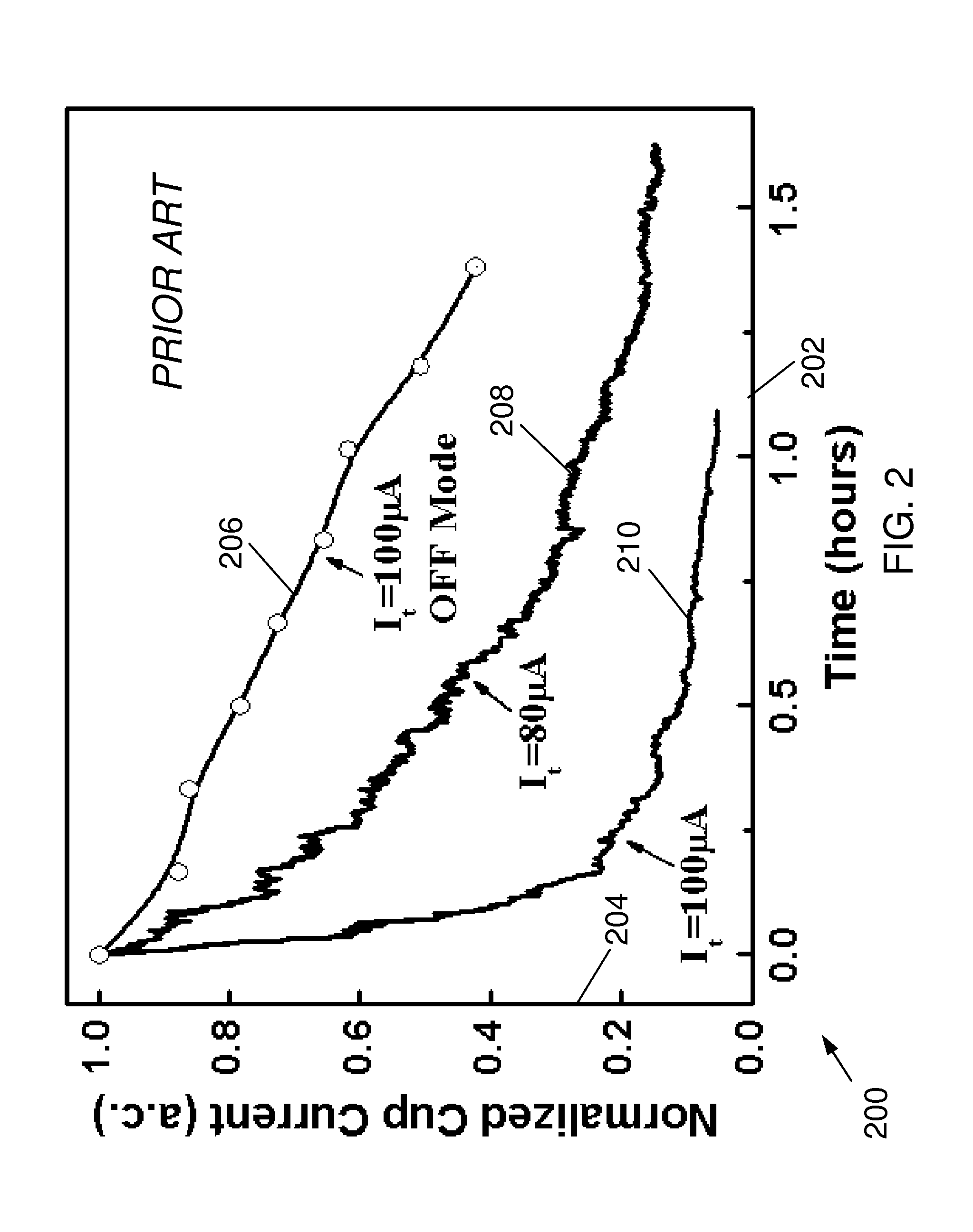

Stable cold field emission electron source

ActiveUS8736170B1Improved emission stabilityReduce noiseMagnetronsTransit-tube electron/ion gunsConventional transmission electron microscopeDesorption

A cold field emission (CFE) electron source for a focused electron beam system such as a transmission electron microscope (TEM), scanning transmission electron microscope (STEM), or scanning electron microscope (SEM) is disclosed. The source employs an emitter enclosure electrode behind the CFE tip which, in conjunction with the extractor electrode, defines a closed volume that can be thoroughly cleaned by electron impact desorption (EID) and radiative heating from a heated filament located between the emitter enclosure electrode and extractor electrode. The extractor electrode may have a counterbore which restricts backscattered electrons generated at the extractor from reaching portions of the source and gun which have not been cleaned by EID. Pre-cleaning of the emitter enclosure electrode and extractor electrode prior to cold field emission substantially improves both source emission stability and frequency noise characteristics, enabling source operation over time intervals adequate for application to TEMs, STEMs, and SEMs.

Owner:FEI CO

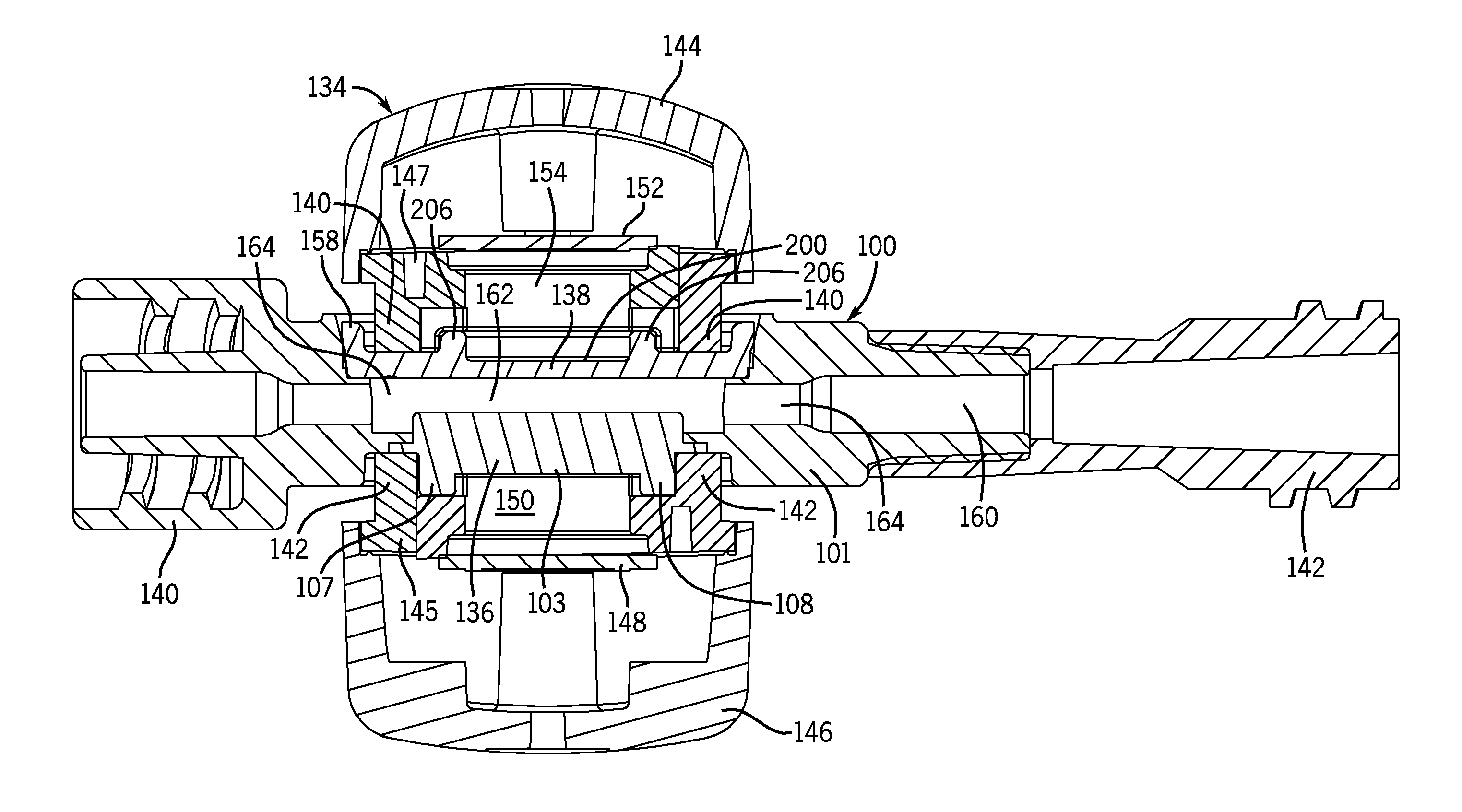

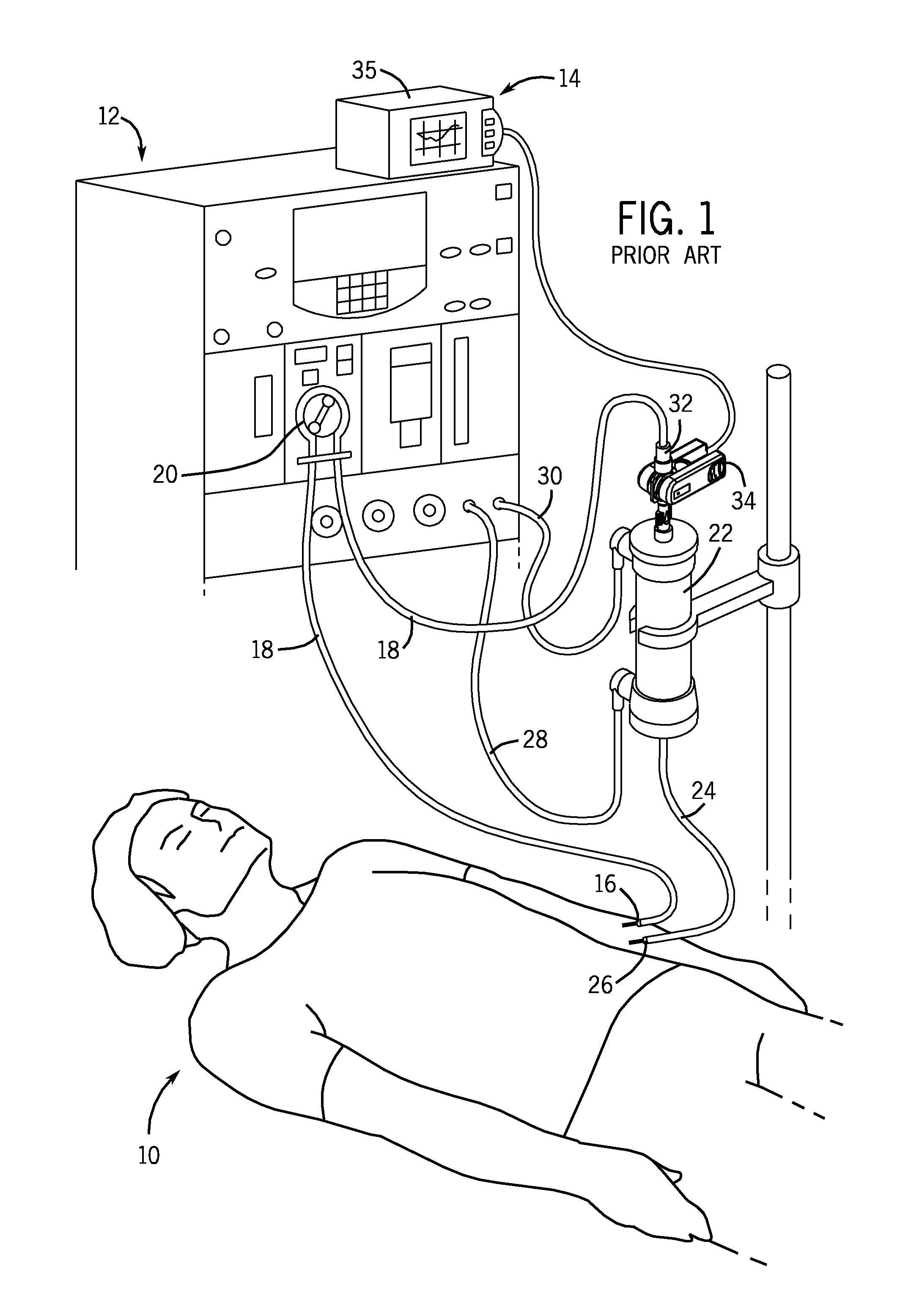

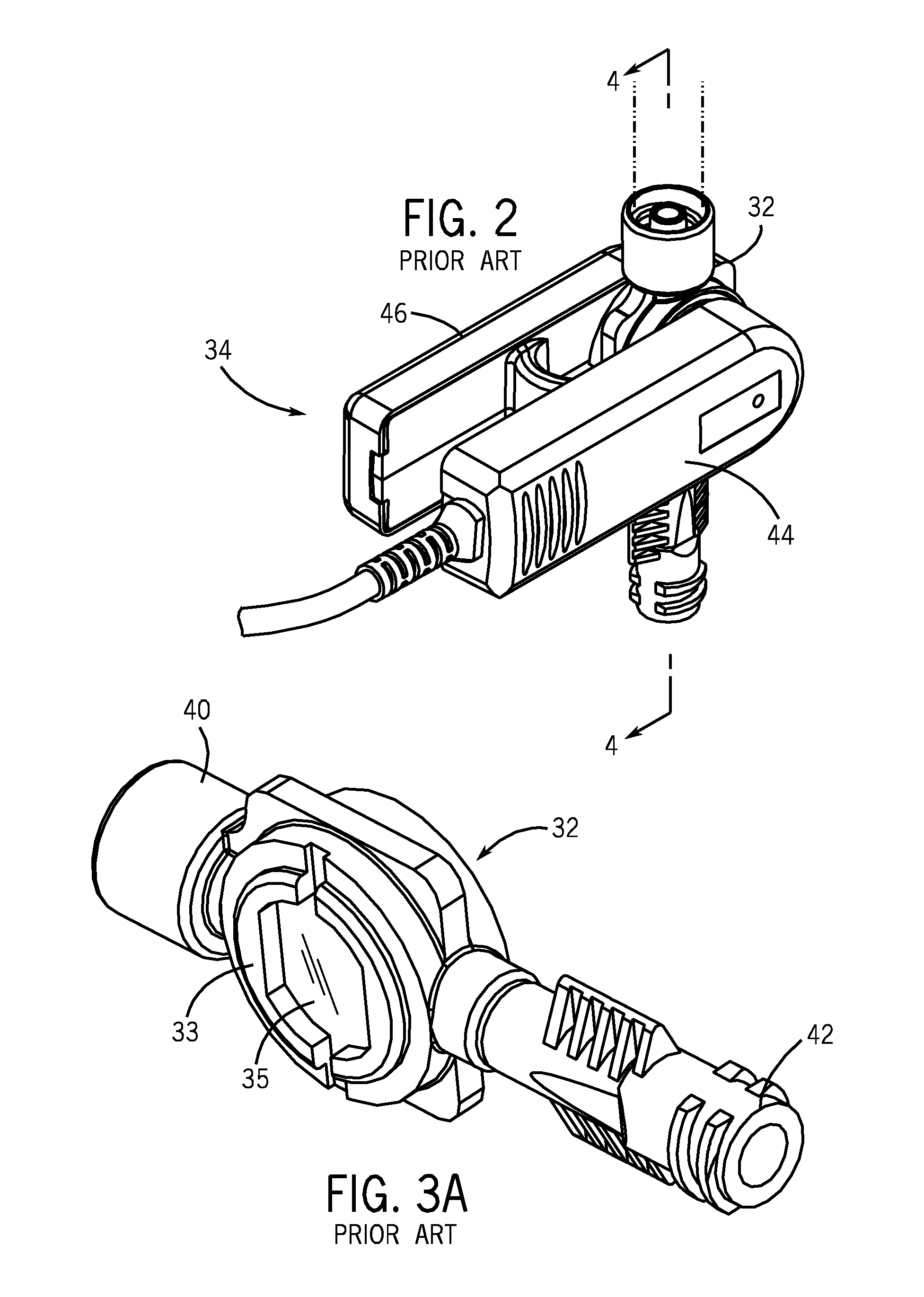

Shrouded sensor clip assembly and blood chamber for an optical blood monitoring system

ActiveUS8517968B2Minimizing possible light pipingReduce the amount requiredMedical devicesDiagnostic recording/measuringPhotodetectorBlood flow

An optical blood monitoring system includes a sensor clip assembly and a blood chamber. The blood chamber has an internal flow cavity for extracorporeal blood flow and viewing lenses to enable the sensor clip assembly to monitor the blood when it is mounted on the blood chamber. The sensor clip assembly includes an annular shroud surrounding the LED emitters and another annular shroud surrounding the photodetectors, both for the purpose of blocking ambient light and limiting light piping. The blood chamber includes separate, distinct shroud mating surfaces to engage the shrouds on the sensor clip assembly.

Owner:FRESENIUS MEDICAL CARE HLDG INC

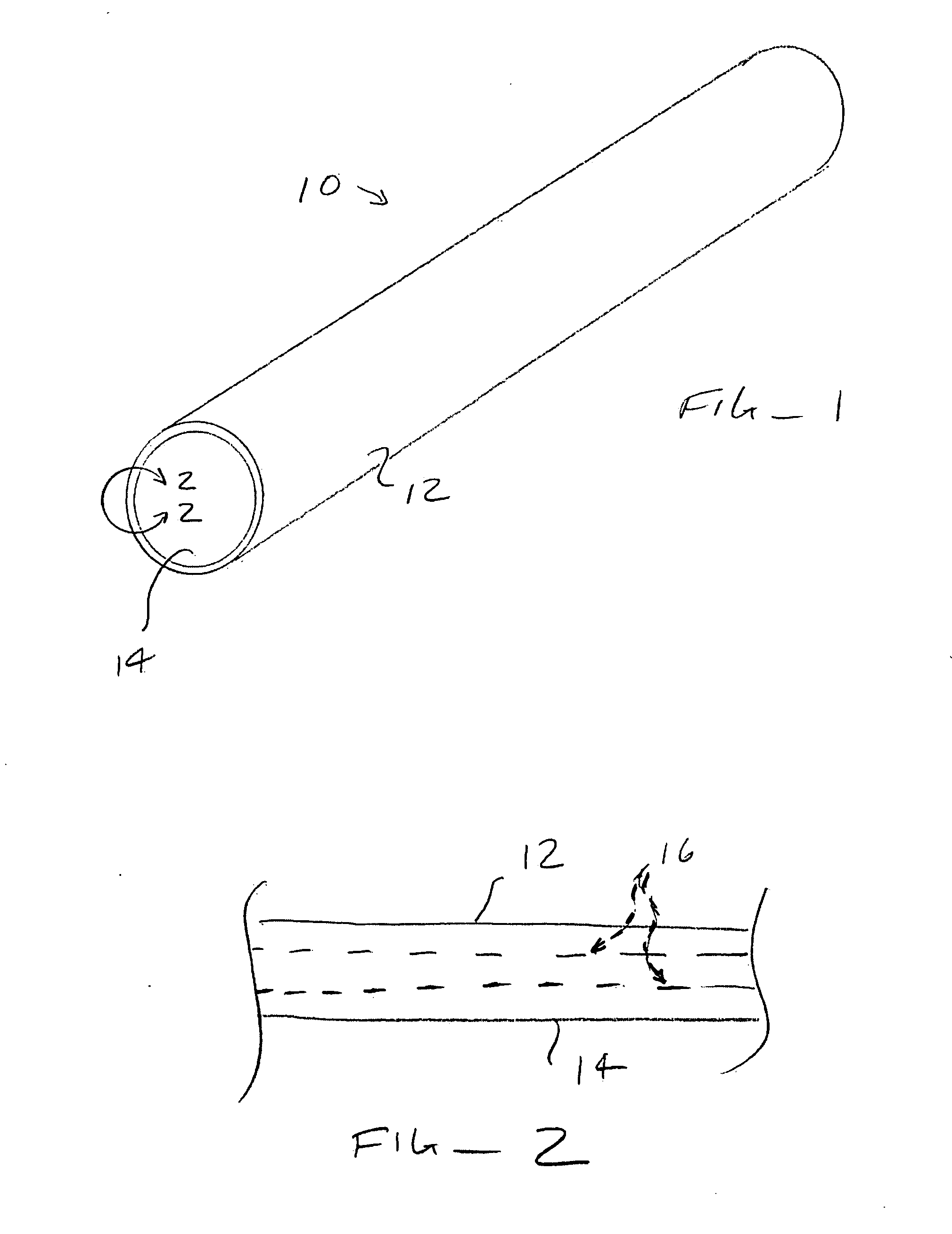

Method of improving waterflood performance using barrier fractures and inflow control devices

ActiveUS8104535B2Reduce inflowImprove scanning efficiencySurveyFluid removalSweep efficiencyTransverse fracture

The present invention is directed to a method of hydrocarbon production from a hydrocarbon reservoir. The method includes providing a substantially horizontal wellbore having at least one productive interval within a hydrocarbon reservoir and forming at least one non-conductive transverse fracture in the reservoir along the substantially horizontal wellbore. An injection well is also provided. A fluid is injected into the reservoir through the injection well to displace hydrocarbons within the reservoir toward a production portion of the substantially horizontal wellbore. Hydrocarbons are drained from the reservoir into at least one production interval of the substantially horizontal wellbore. Fluid production from the at least one production interval into the substantially horizontal wellbore flows through an inflow control device that can restrict the fluid flow. A non-conductive transverse fracture can form a barrier within the reservoir to divert injected fluids to increase sweep efficiency and reduce the influx of injected fluids into the production interval.

Owner:HALLIBURTON ENERGY SERVICES INC

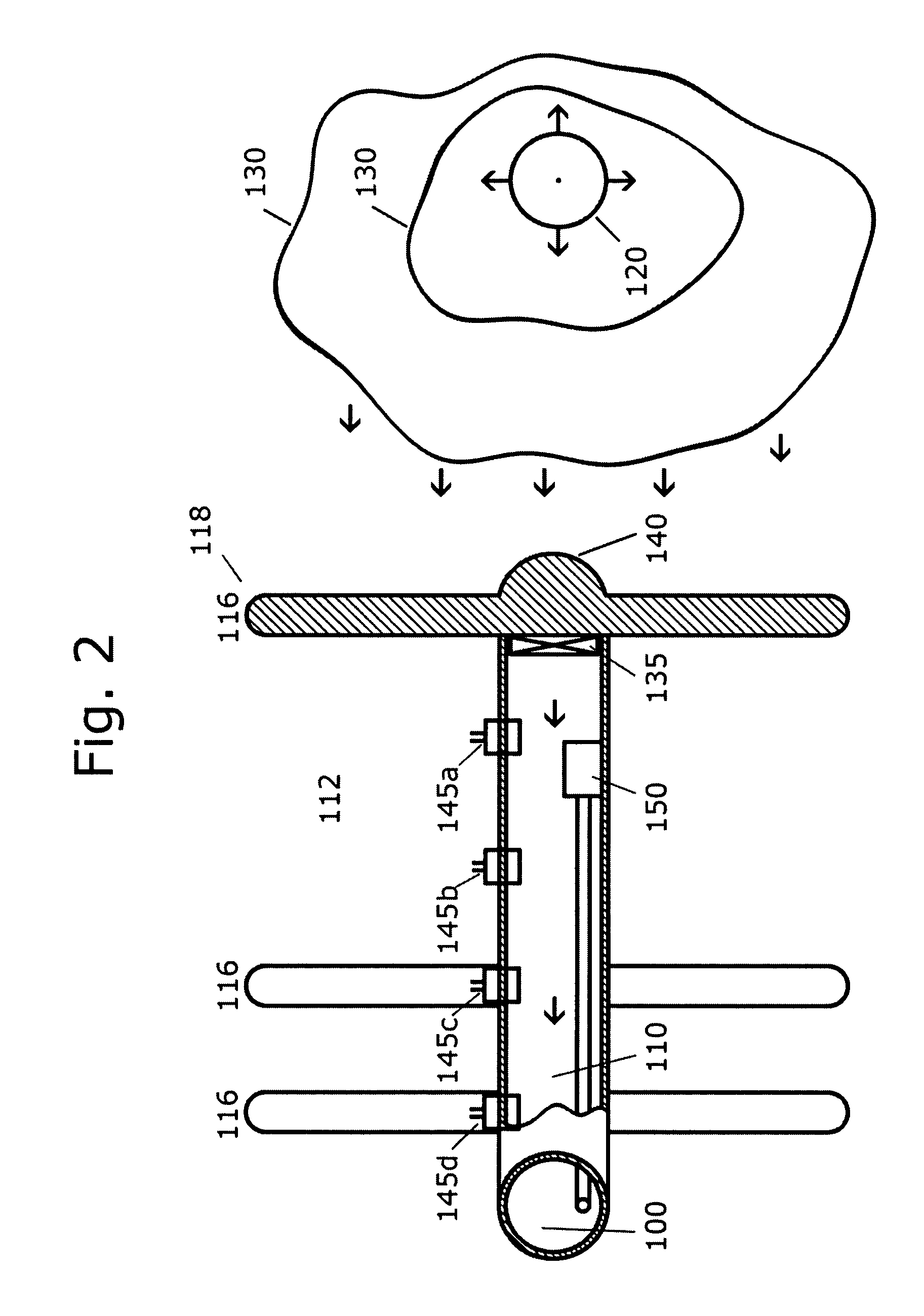

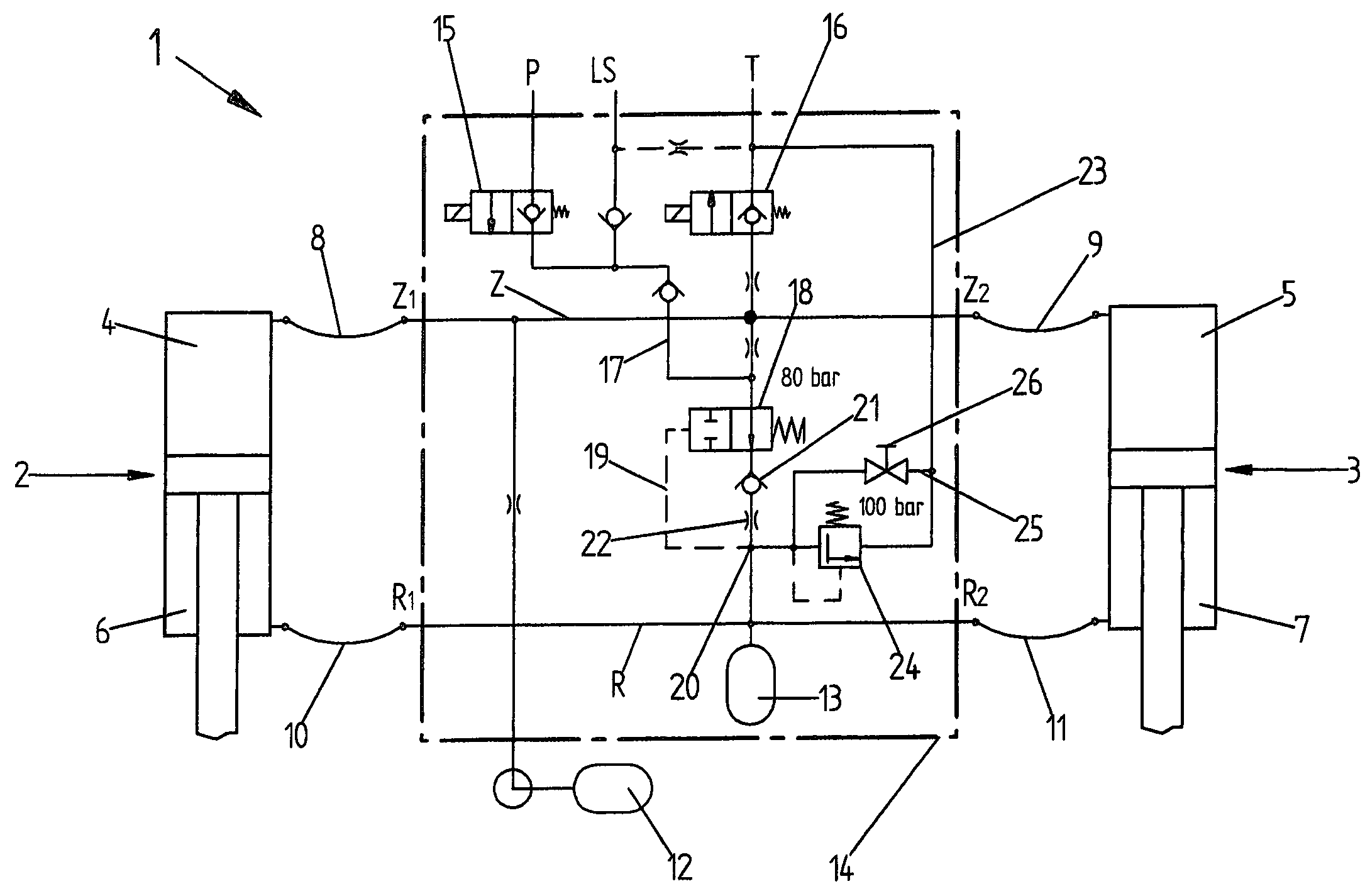

Hydropneumatic suspension system for vehicles

ActiveUS7163208B2Promote resultsFlow outVehicle cleaning apparatusLoading/unloading vehicle arrangmentHydropneumatic suspensionEngineering

A hydropneumatic suspension system for a vehicle with a level control, in particular for the front axle of a tractor, includes a first 2 / 2 directional control valve having a regulating-up function communicating with the pressurized oil pump and a second 2 / 2 directional control valve having a regulating-down function communicating with a reservoir.

Owner:CARL FREUDENBERG KG

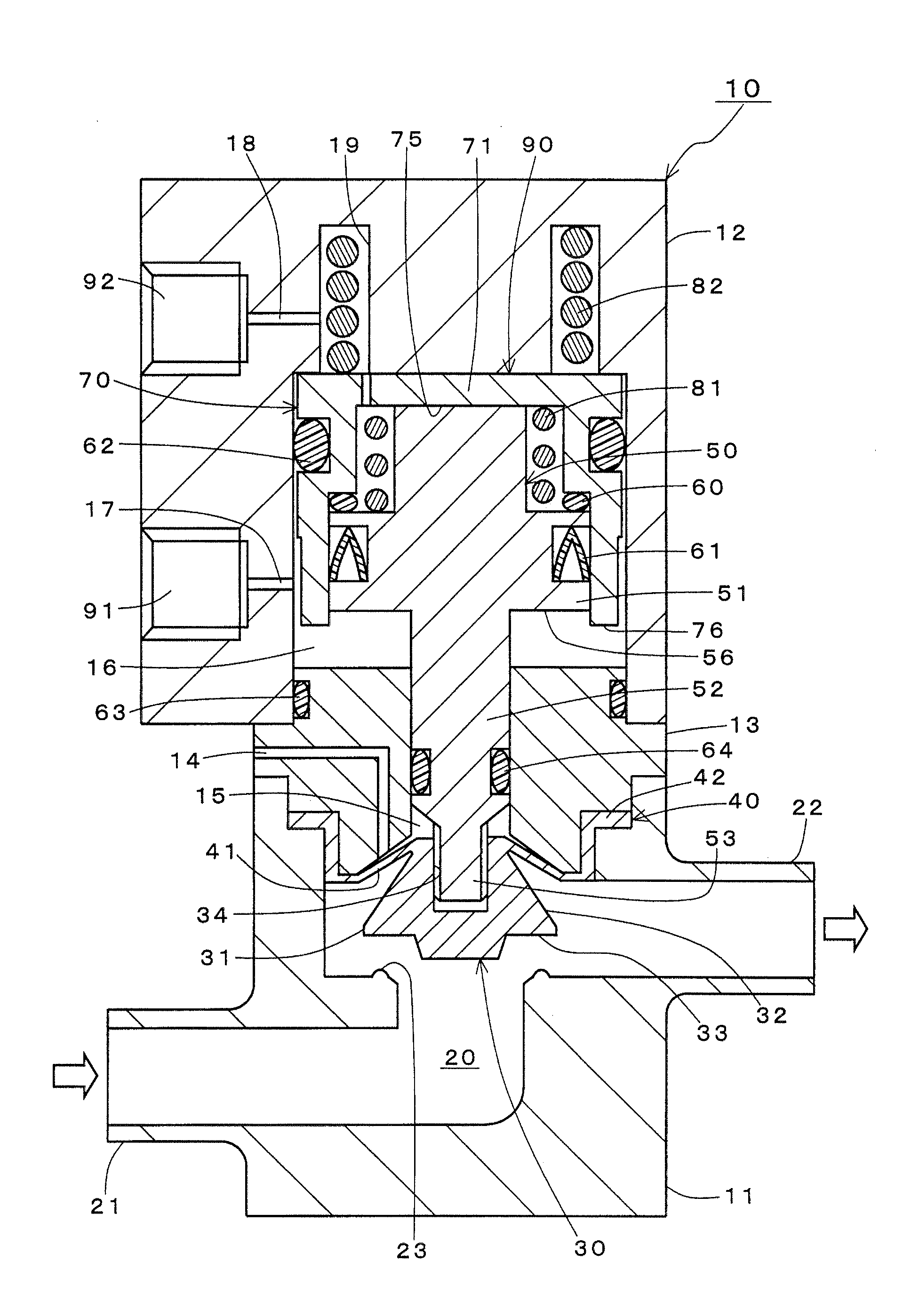

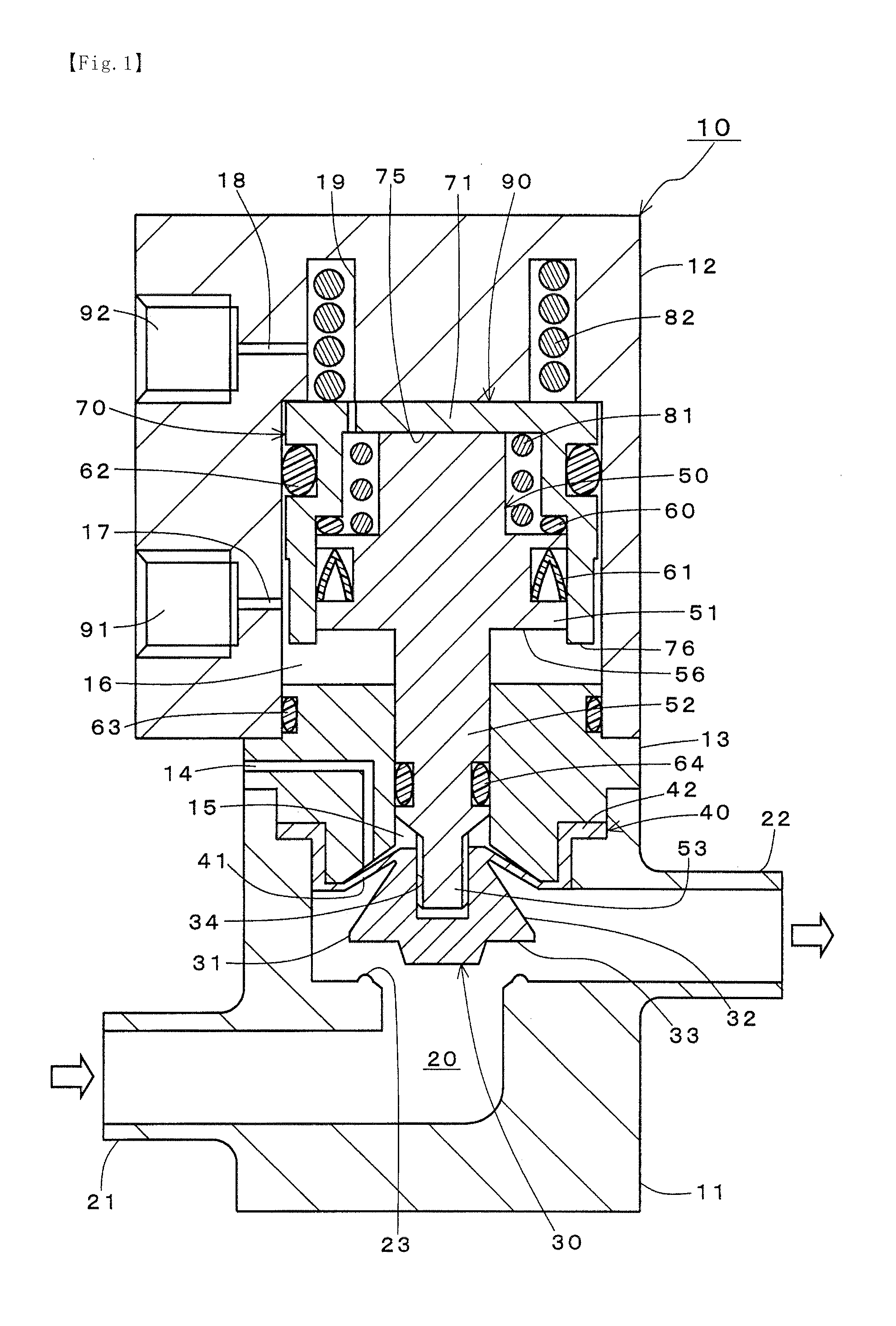

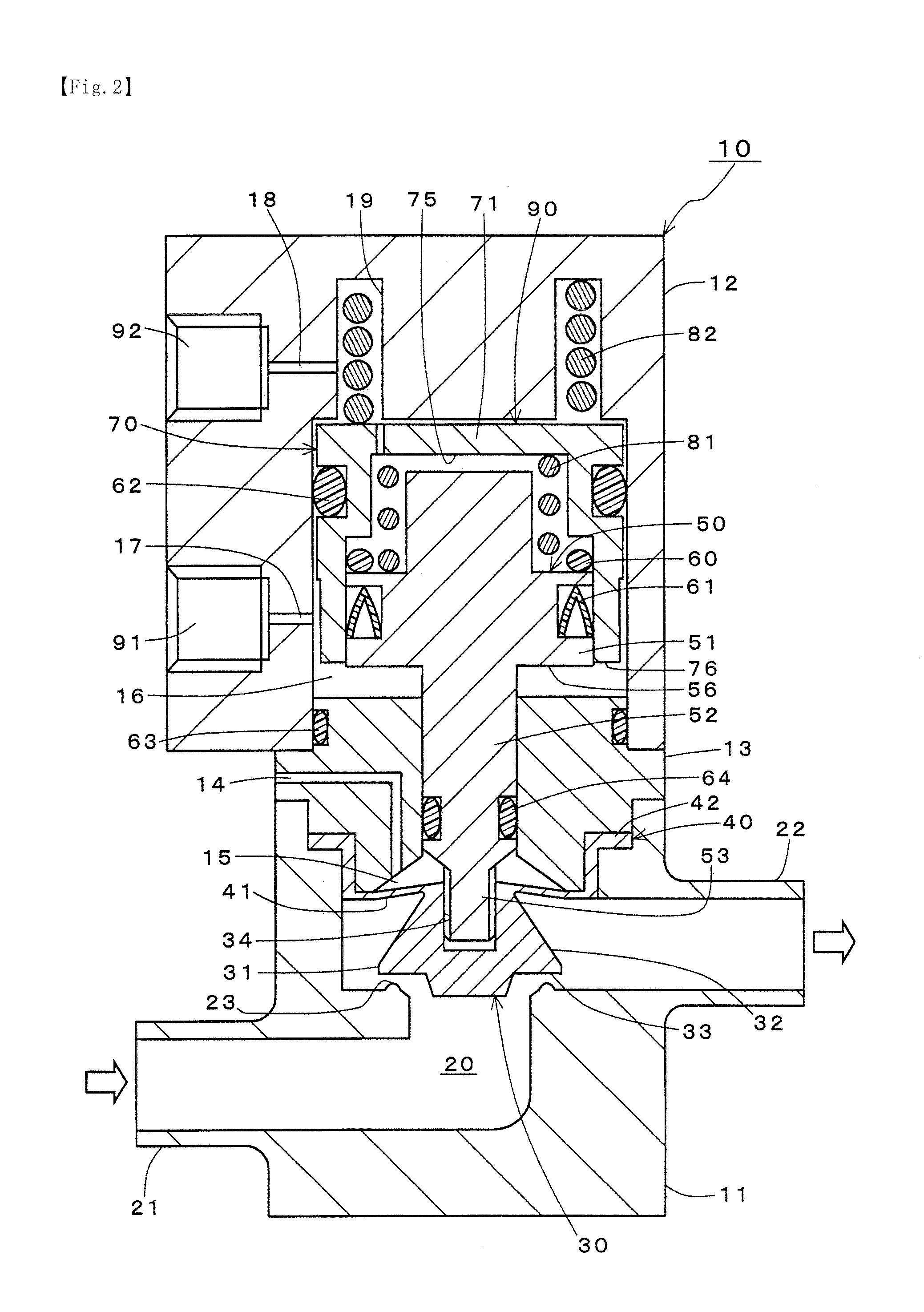

Air-operated valve

ActiveUS20120119129A1Reduce inflowImprove cleanlinessDiaphragm valvesOperating means/releasing devices for valvesSpring forceEngineering

An air-operated valve which can keep the impact at the time a valve part sits on a seat from causing material from shedding and thereby generating particles which contaminate a controlled fluid and thereby can maintain a high cleanliness of the controlled fluid, that is, an air-operated valve which is provided with a valve chamber body which has a valve chamber which forms a seat, a valve mechanism which is provided with a valve part which seals the seat and with a diaphragm in the valve chamber, and a housing body which houses a drive mechanism which uses working air to make the valve mechanism advance and retract to drive and control it to open and close the seat, the drive mechanism provided with a first piston, a first spring which biases the first piston, a second piston which is slidably housed in the housing body and slidably houses the first piston inside it and which pushes the first piston, and a second spring which biases the second piston, the spring force of the second spring being made larger than the spring force of the first spring.

Owner:ADVANCE DENKI KOUGYOU

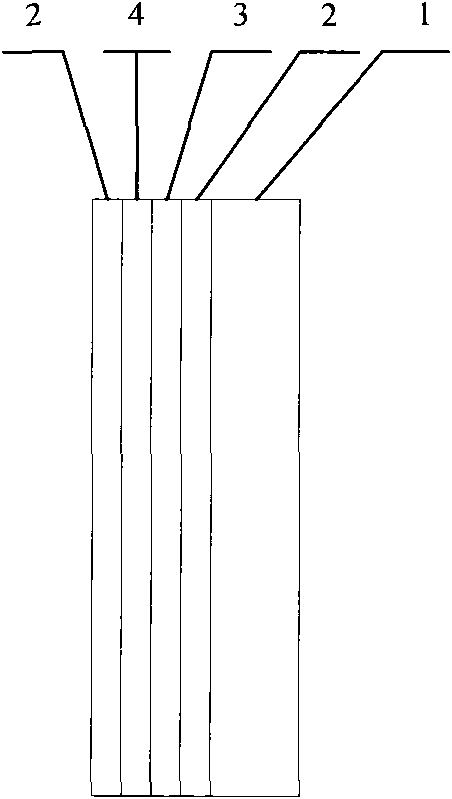

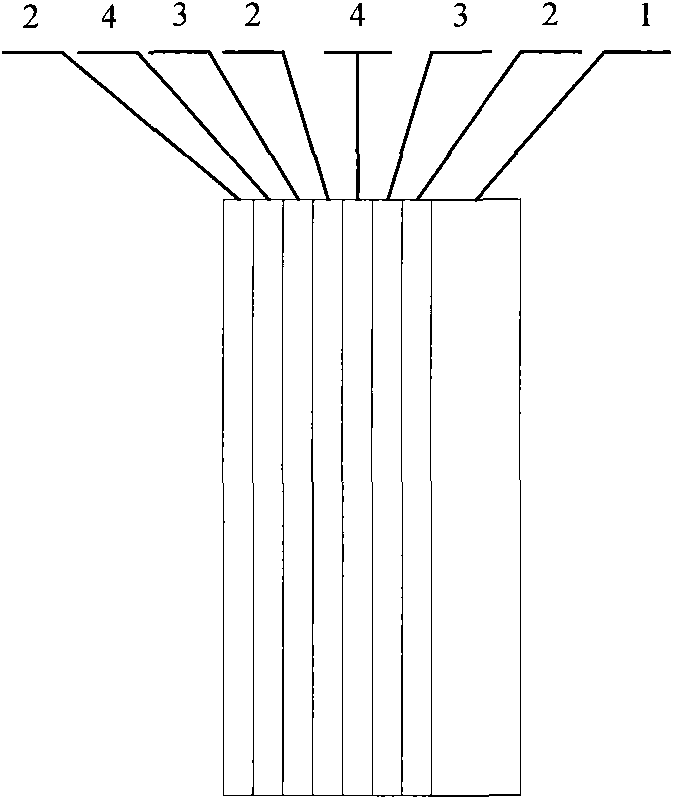

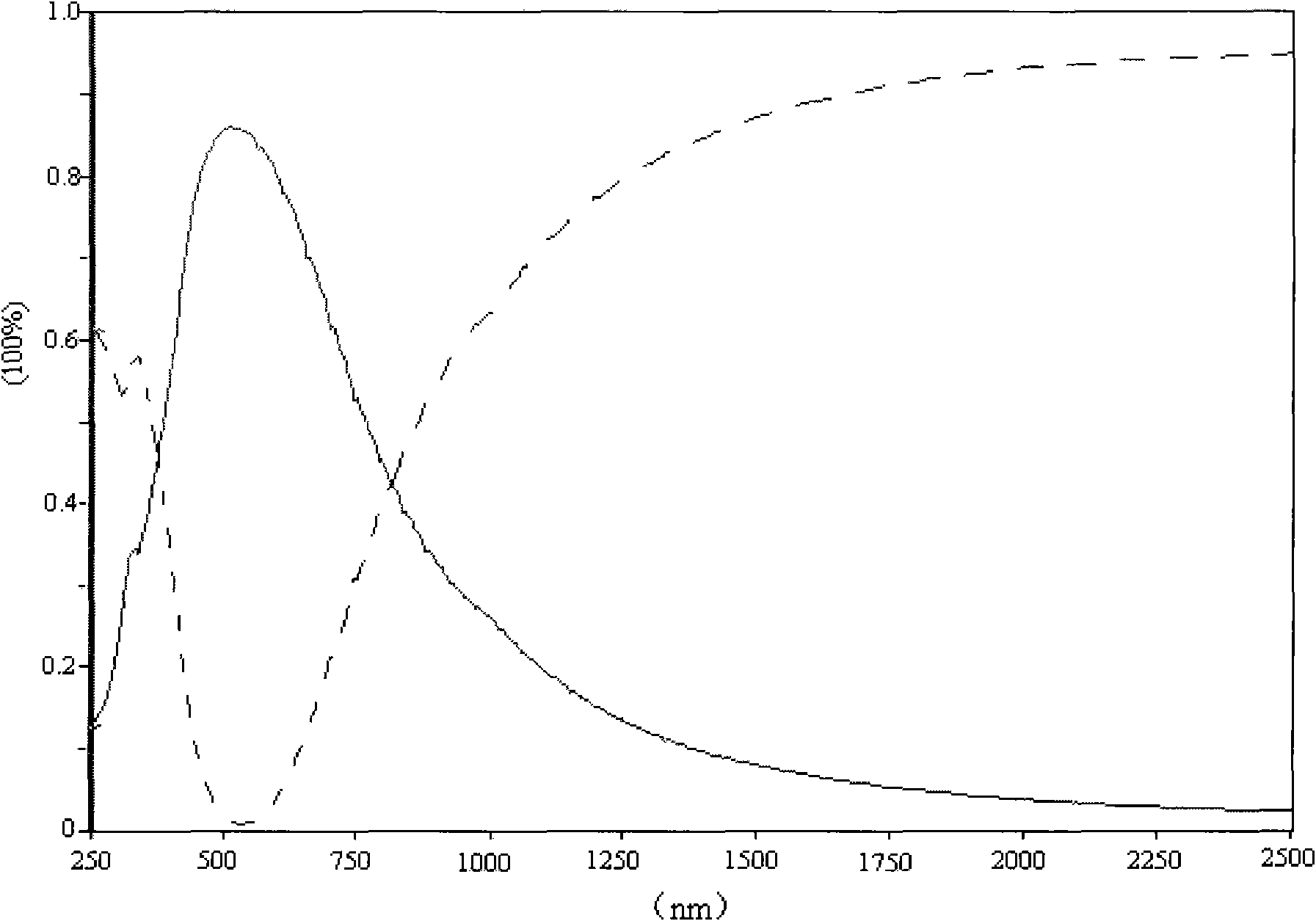

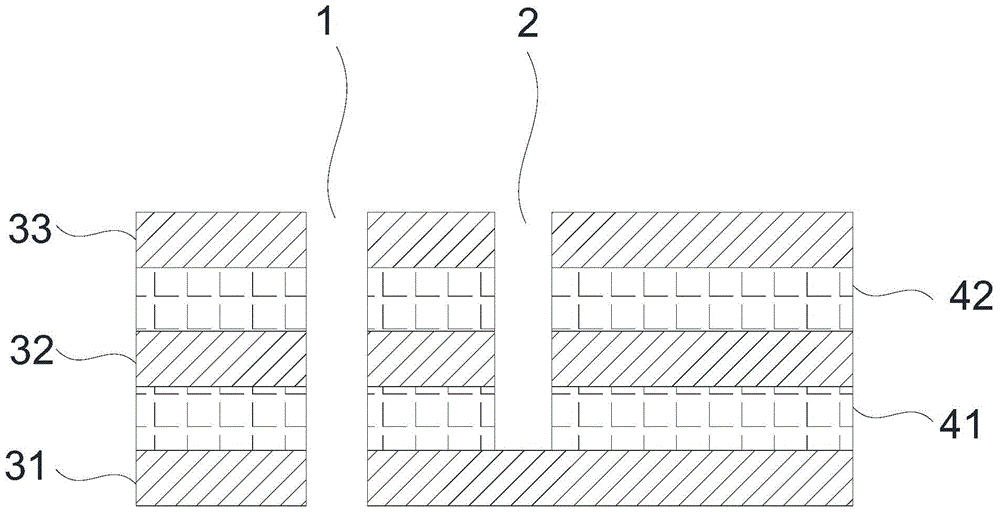

Solar control-low radiation type heat-insulation membrane system

InactiveCN101929590AReduce inflowReduce outflowThermal insulationSynthetic resin layered productsMiddle infraredRadiance

The invention belongs to the technical field of optical coating, and particularly relates to a solar control-low radiation type heat-insulation membrane system, which aims to provide the solar control-low radiation type heat-insulation membrane system capable of functioning in reflecting near infrared rays, middle infrared rays and far infrared rays. The membrane system comprises a PET layer (1), TiO2 layers (2), an Ag layer (3) and a Ti layer (4), wherein the PET layer (1) is a substrate; the first TiO2 layer (2) is covered on the PET layer; the Ag layer (3) is covered on the TiO2 layer (2); the Ti layer (4) is covered on the Ag layer (3); and the second TiO2 layer (2) is covered on the Ti layer (4). The solar control-low radiation type heat-insulation membrane type has low radiance, proper shading coefficient, the functions of sunshade and heat preservation and wide application, can function in reflecting the near, middle and far infrared rays and reduce the inflow and outflow of indoor heat, and is applied in summer, winter and hot and cold regions.

Owner:SOUTHWESTERN INST OF PHYSICS

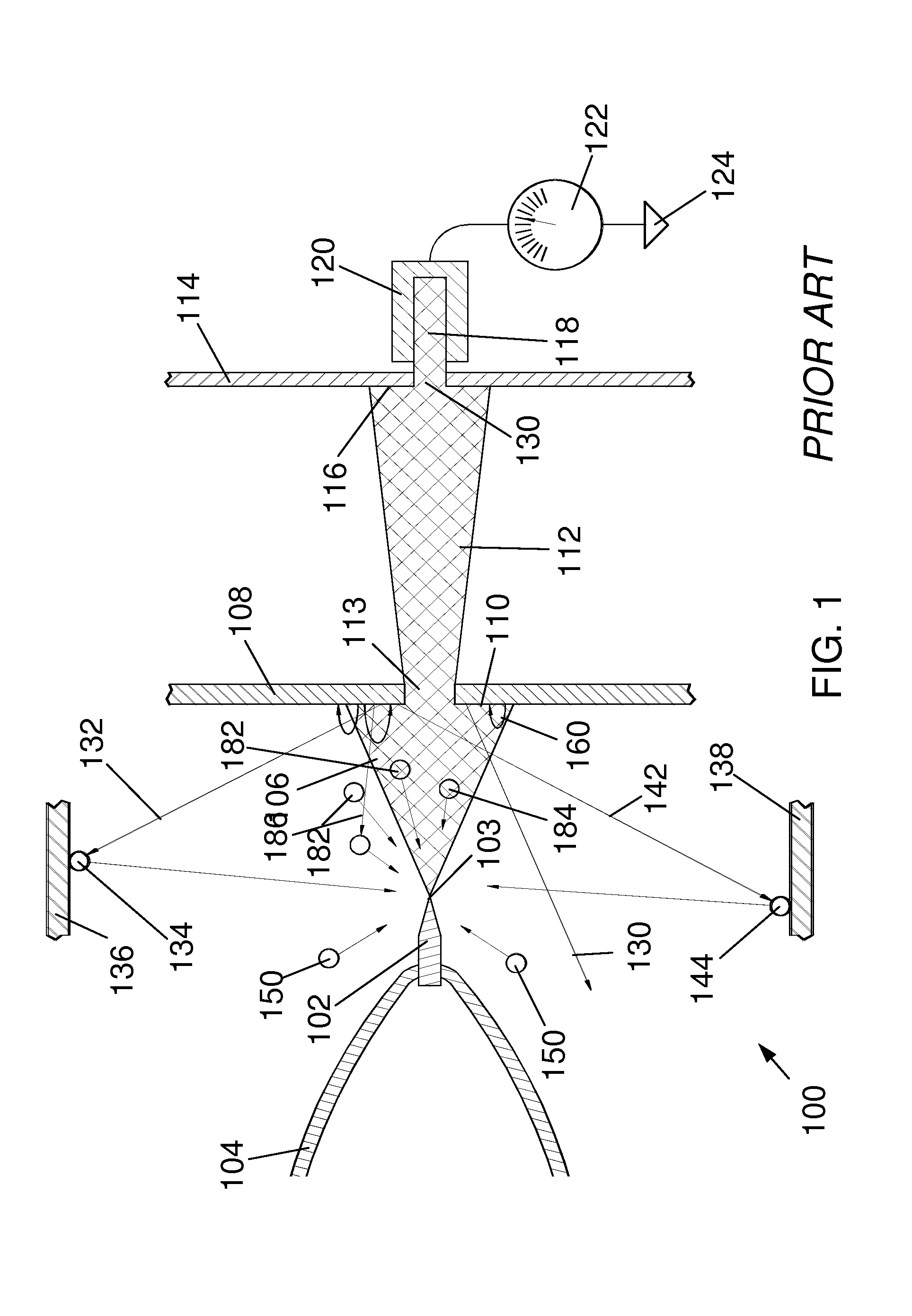

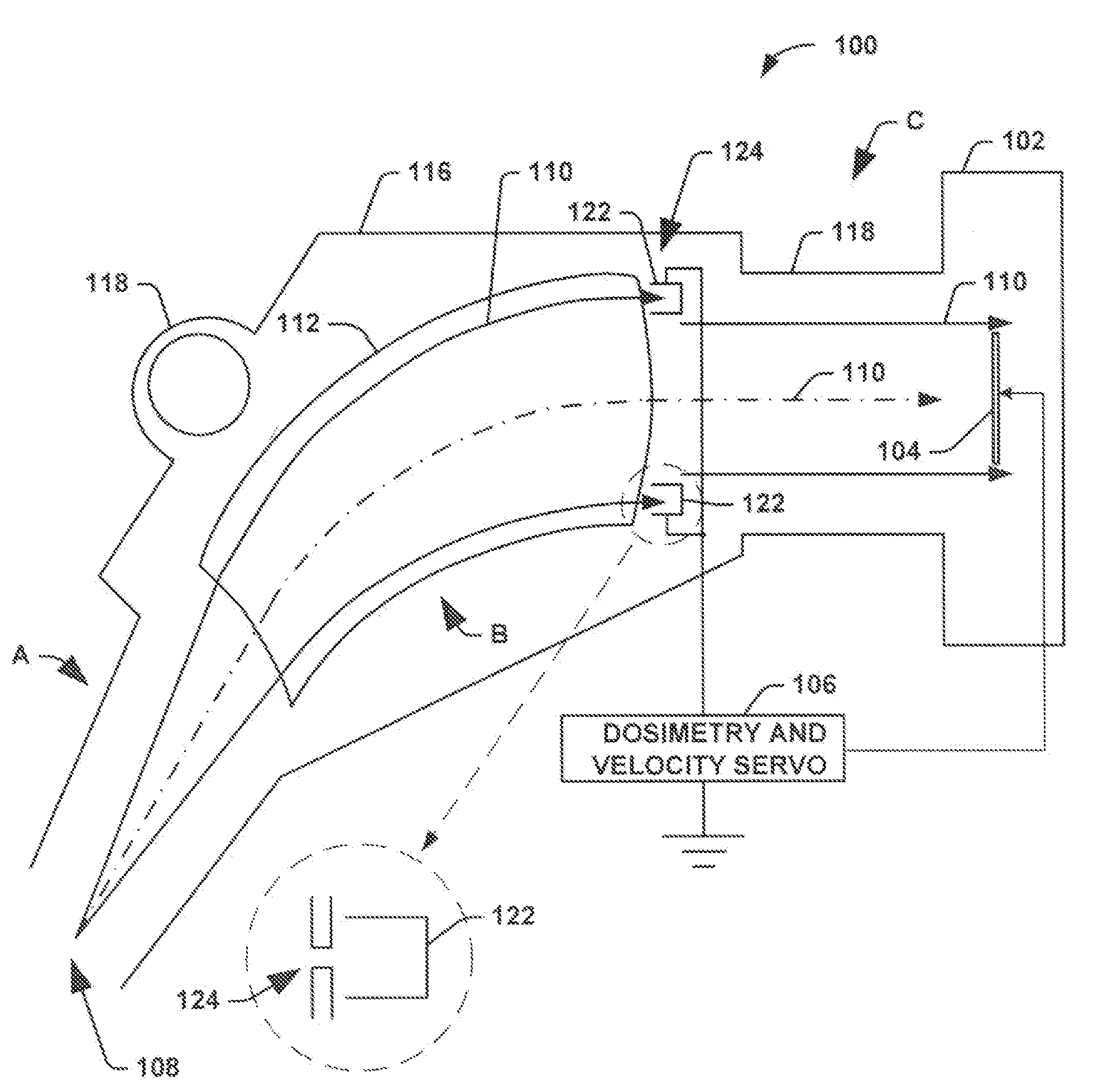

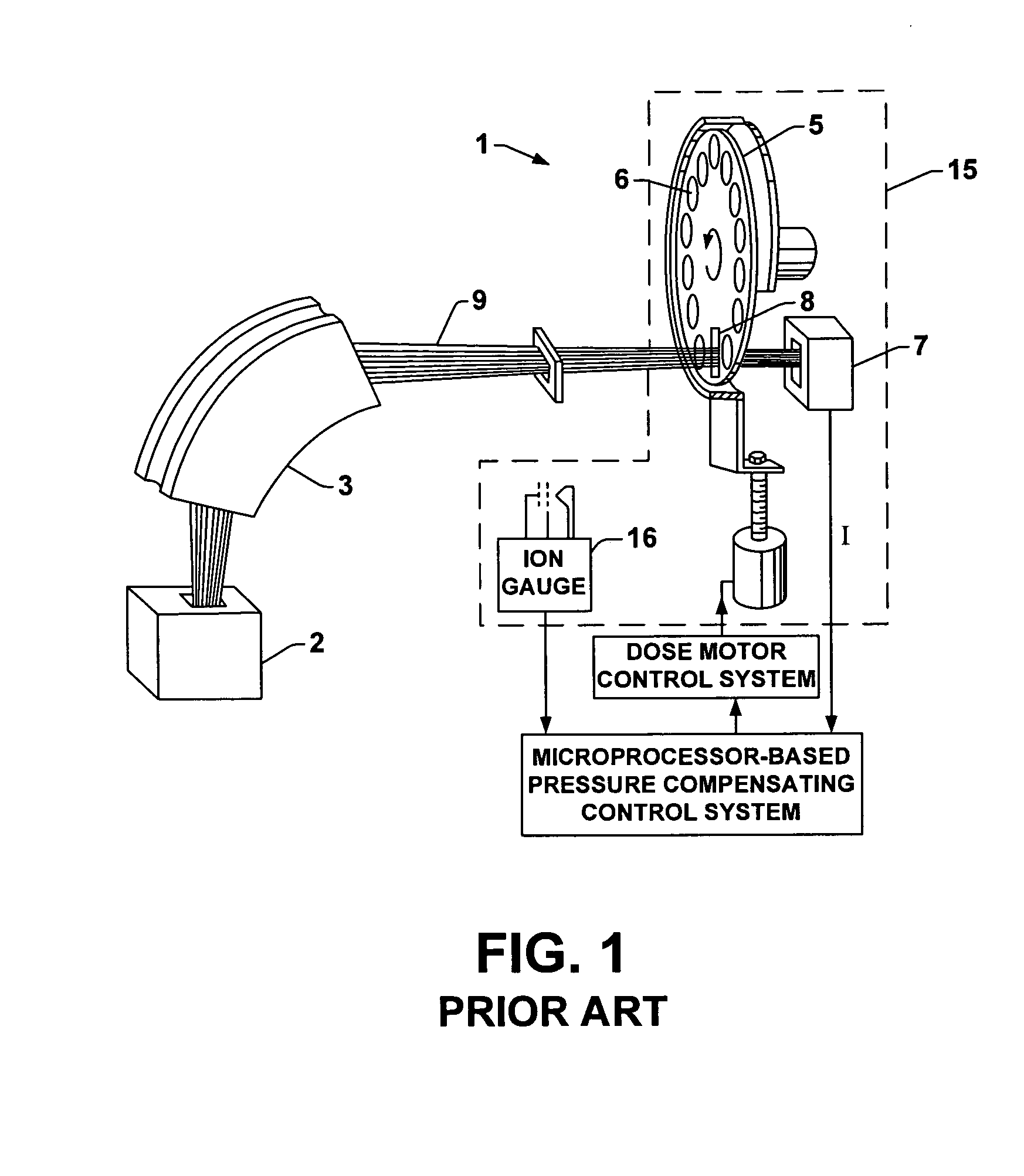

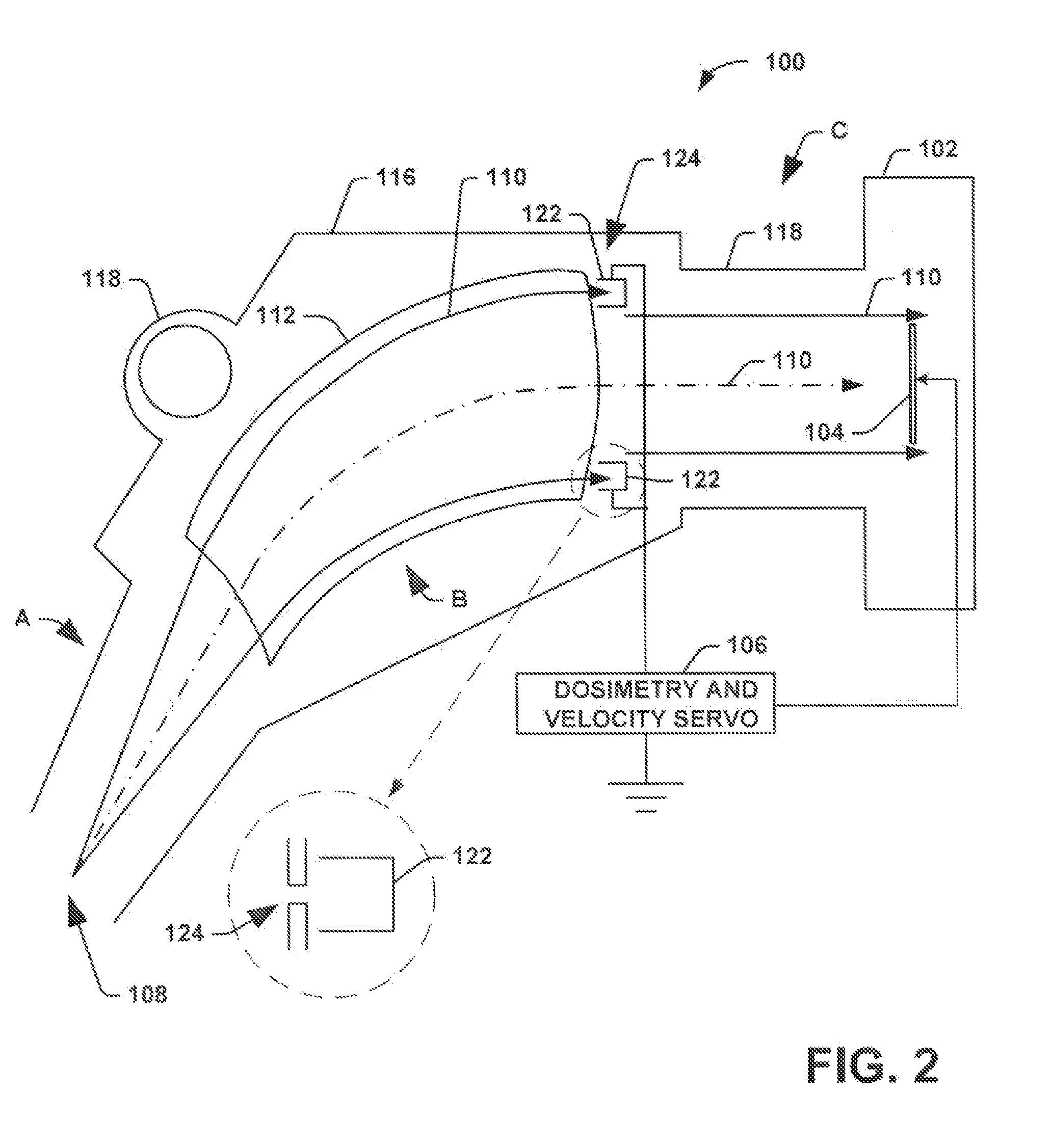

System and method of performing uniform dose implantation under adverse conditions

ActiveUS20090272918A1Reduce outgassingInhibit currentThermometer detailsParticle separator tubesEngineeringLight beam

An ion implantation system and associated method includes a scanner configured to scan a pencil shaped ion beam into a ribbon shaped ion beam, and a beam bending element configured to receive the ribbon shaped ion beam having a first direction, and bend the ribbon shaped ion beam to travel in a second direction. The system further includes an end station positioned downstream of the beam bending element, wherein the end station is configured to receive the ribbon shaped ion beam traveling in the second direction, and secure a workpiece for implantation thereof. In addition, the system includes a beam current measurement system located at an exit opening of the beam bending element that is configured to measure a beam current of the ribbon shaped ion beam at the exit opening of the beam bending element.

Owner:AXCELIS TECHNOLOGIES

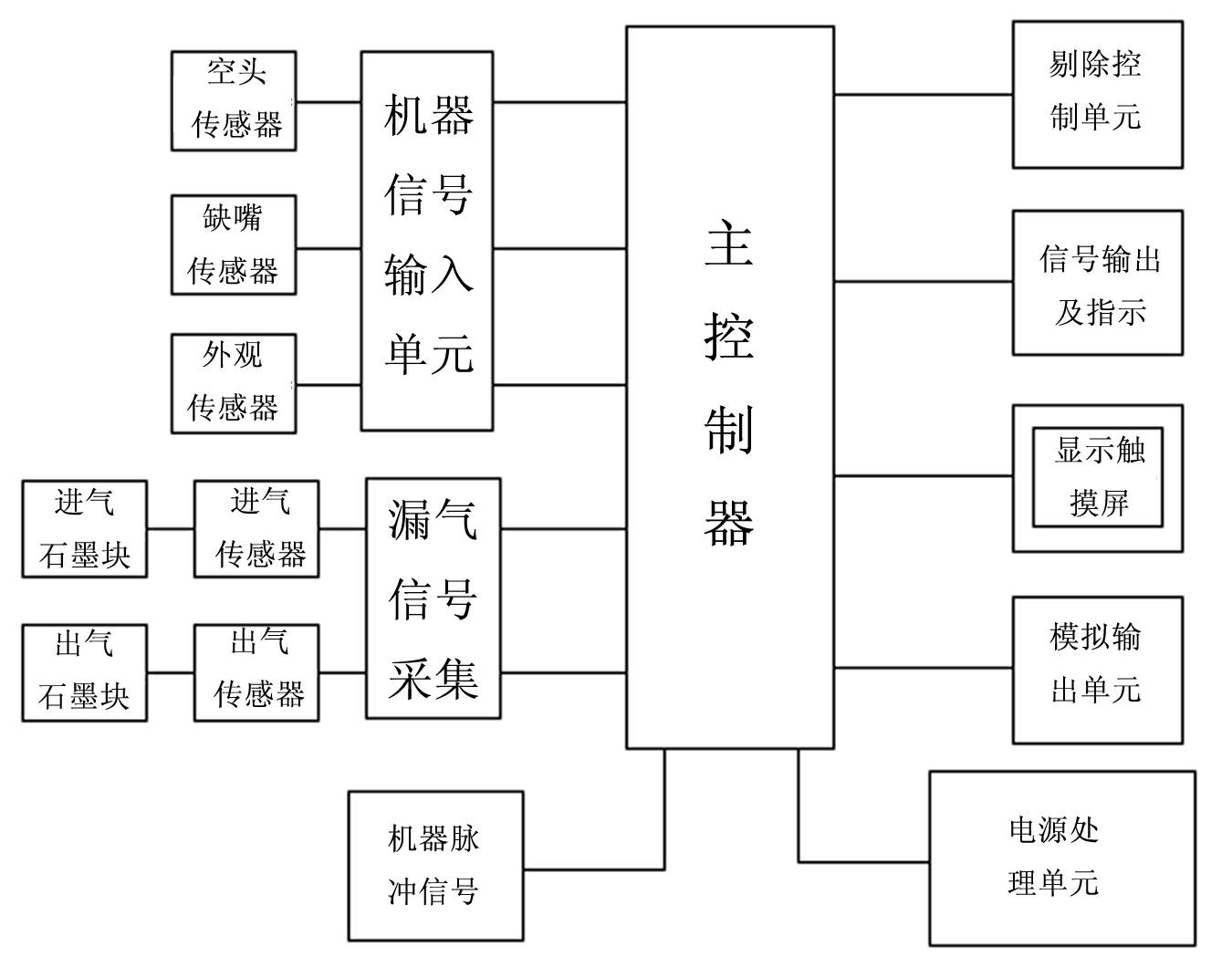

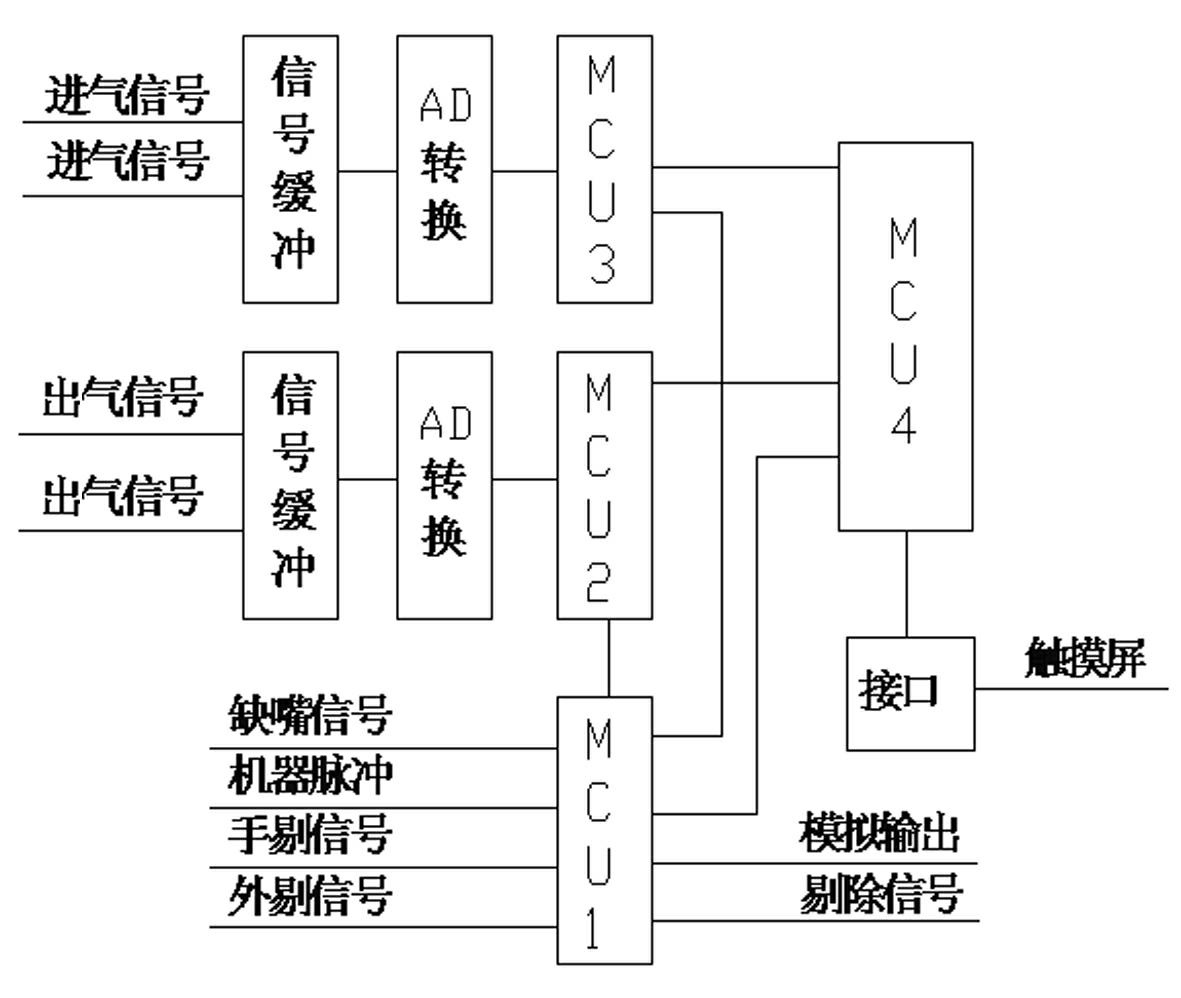

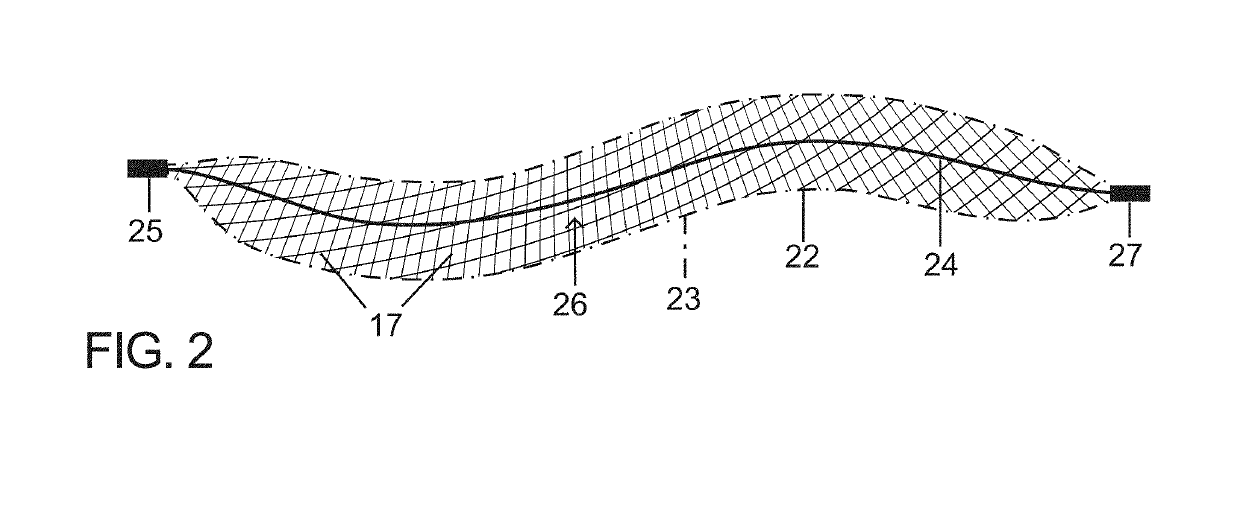

Novel cigarette quality detecting device used for putuo 70/90 cigarette making machine

ActiveCN102160688AImprove accuracyLarge amount of informationCigarette manufactureMicrocontrollerMicrocomputer

The invention relates to tobacco machinery and discloses a novel cigarette quality detecting device used for a putuo 70 / 90 cigarette making machine, which takes a gas leakage signal acquisition and a main controller as a core and also comprises a machine signal input unit, a removing control unit, a power supply processing unit, an analog output unit and a display unit, wherein the main controller receives gas leakage signals, machine sensor signals and touch screen setting signals, carries out computing and processing by a plurality of paths of high-speed analog-to-digital converters and a plurality of single chip microcomputers, controls the rejecting unit to reject cigarettes with quality defects and displays real-time data on a touch screen. In the cigarette quality detecting device, the states of air leakage, end loosing, appearance and no cigarette holders of the cigarettes can be detected in a more comprehensive manner, the cigarettes with quality defects in the production process of cigarettes are correctly rejected, the cigarettes with quality defects flowing into the market are greatly reduced, the product quality is comprehensively improved, simultaneously the working state of the cigarette making machine can be really reflected, and the maintenance working of the cigarette making machine is convenient.

Owner:云南远足科技有限公司

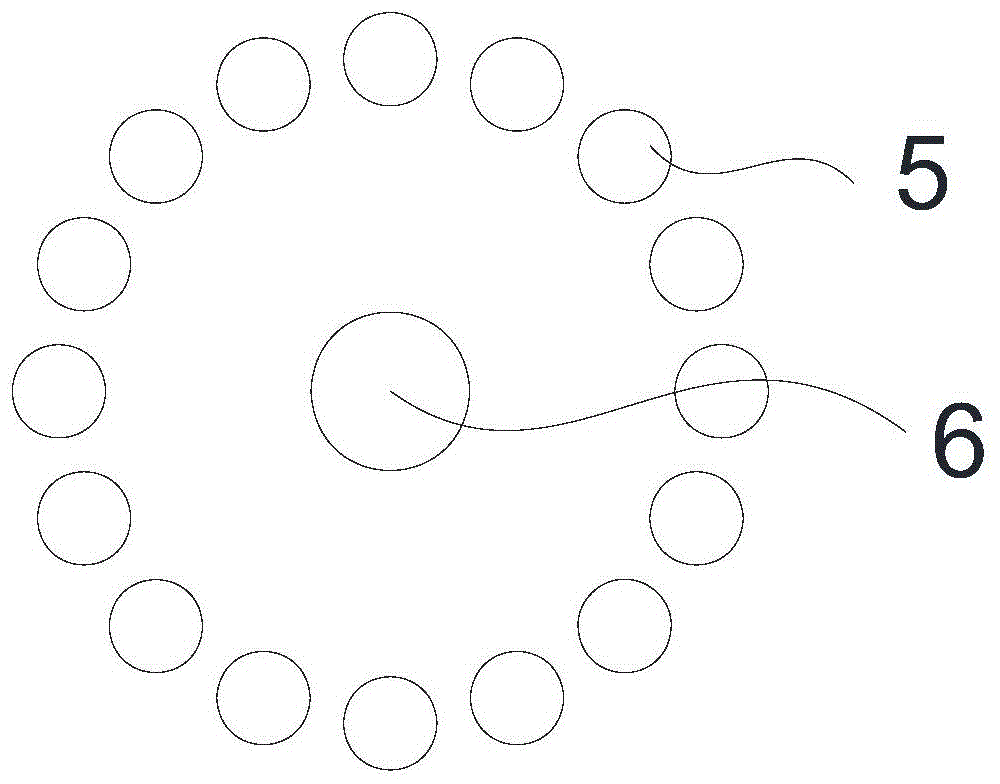

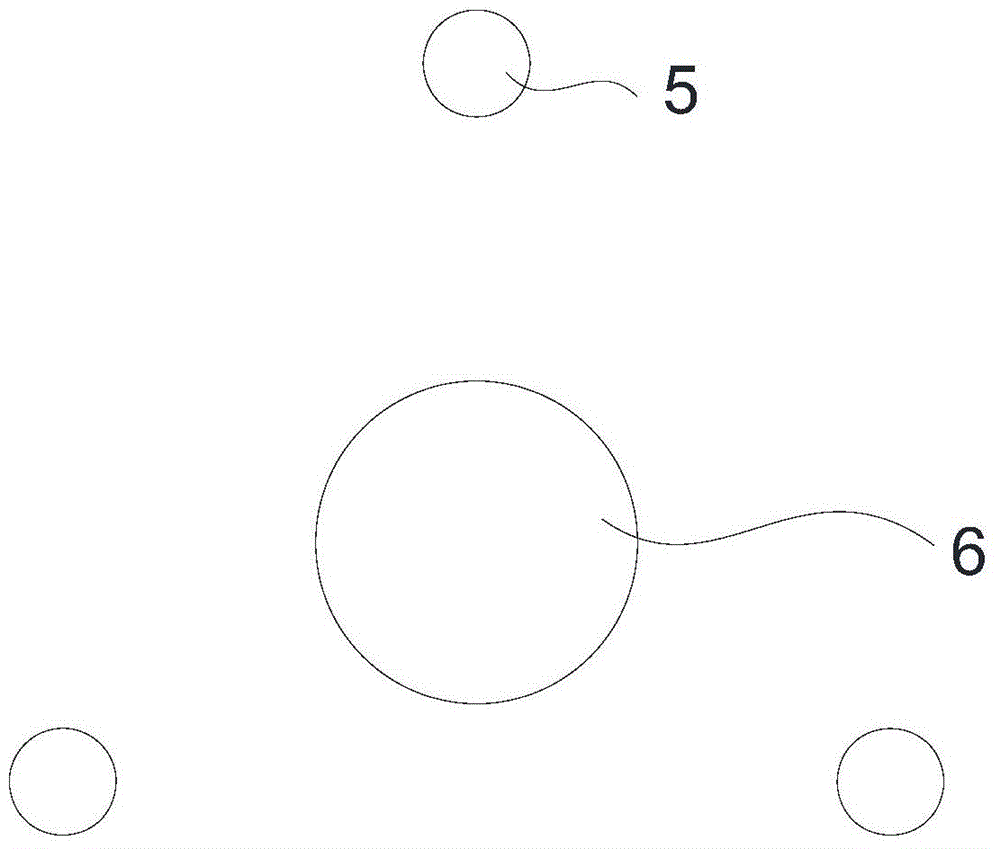

Method for controlling positioning precision of PCB drill holes

The invention discloses a method for controlling positioning precision of PCB drill holes, and belongs to the field of machining of the PCB drill holes. The method for controlling the positioning precision of the PCB drill holes comprises the following steps that a series of marking holes with the same size are drilled in non-wire-arrangement positions on a PCB to form one or more check module patterns; the position of the PCB on a drilling machine is repositioned, and a drill bit is adjusted to the set center positions of the check module patterns for drilling comparison holes; whether the comparison holes are positioned in the center positions of the checking module patterns is detected; the position of the PCB is adjusted or maintained to allow the drilled comparison holes to be positioned in the centers of the check module patterns; and a second drill hole is drilled in the PCB according to the set position coordinates of the second drill hole. The method disclosed in the technical scheme can prevent the hole deflection problem of two or more different positioning drill holes in the PCB due to such factors as expansion and shrinkage, different machining modes or separated production in the manufacturing process, and can reduce the waste of manpower and material costs because plates with deflected holes generated by multiple sets of positioning modes flow to a next process in the prior art.

Owner:大连崇达电子有限公司

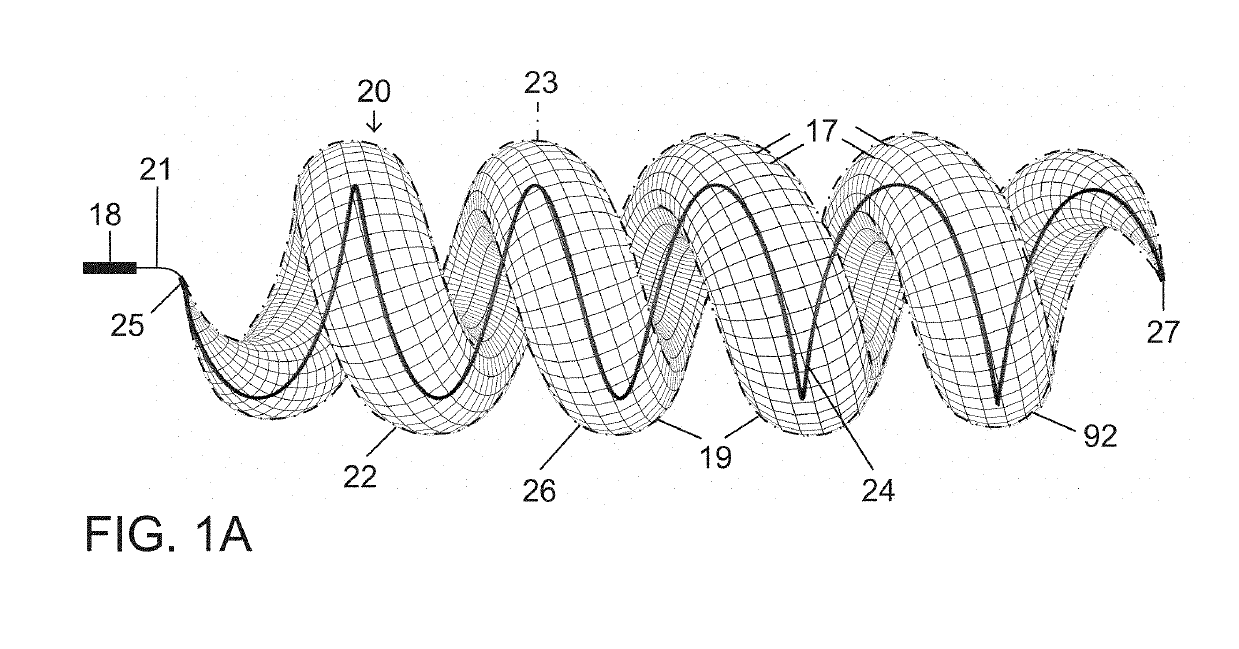

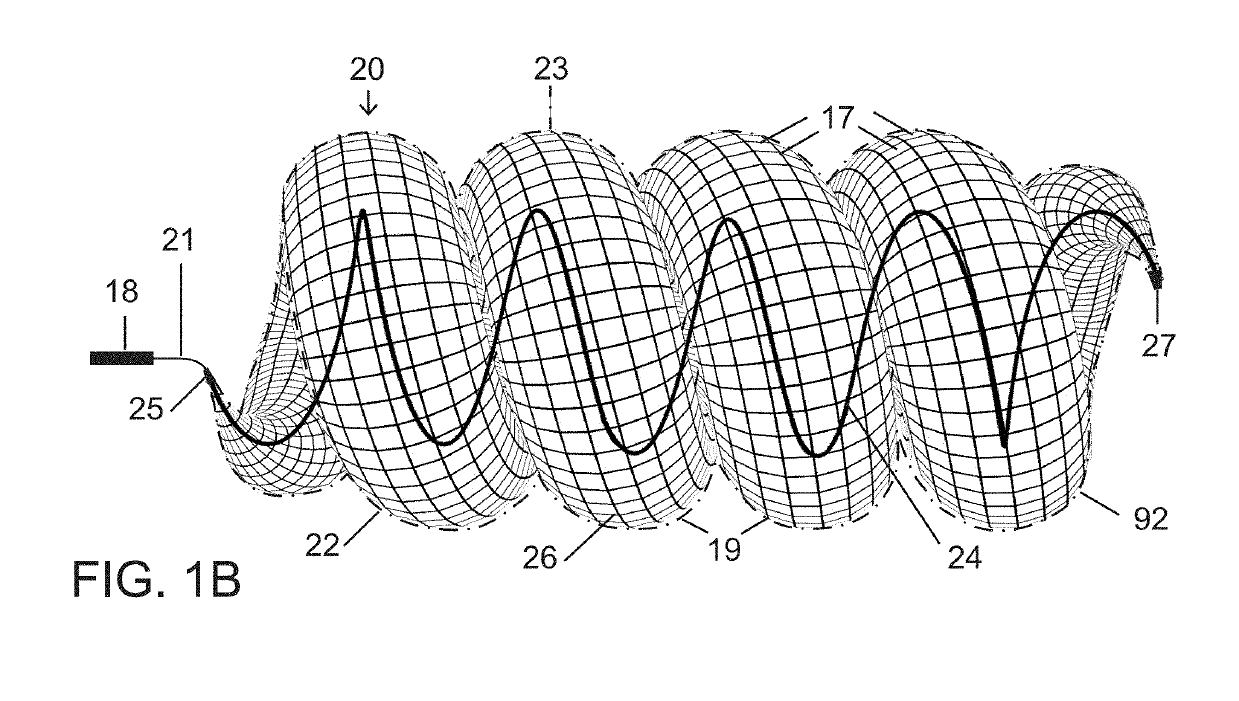

Micro-macro endovascular occlusion device and methodology

ActiveUS10299799B1Large filling capacitySubstantial and total occlusionOcculdersEndovascular occlusionThree dimensional shape

A vascular plug comprises a superstructure expandable from a collapsed percutaneous insertion configuration to an expanded deployment or use configuration. The superstructure is comprised of both primary and secondary three-dimensional shapes allowing for the occlusion of a wide range of vessel sizes from small to large through a disproportionately small delivery catheter. The plug includes a shape memory element for the generation of radial force and the creation of the larger secondary three-dimensional twisting or helical superstructure as is needed for target vessel occlusion.

Owner:DEMERITT JOHN S

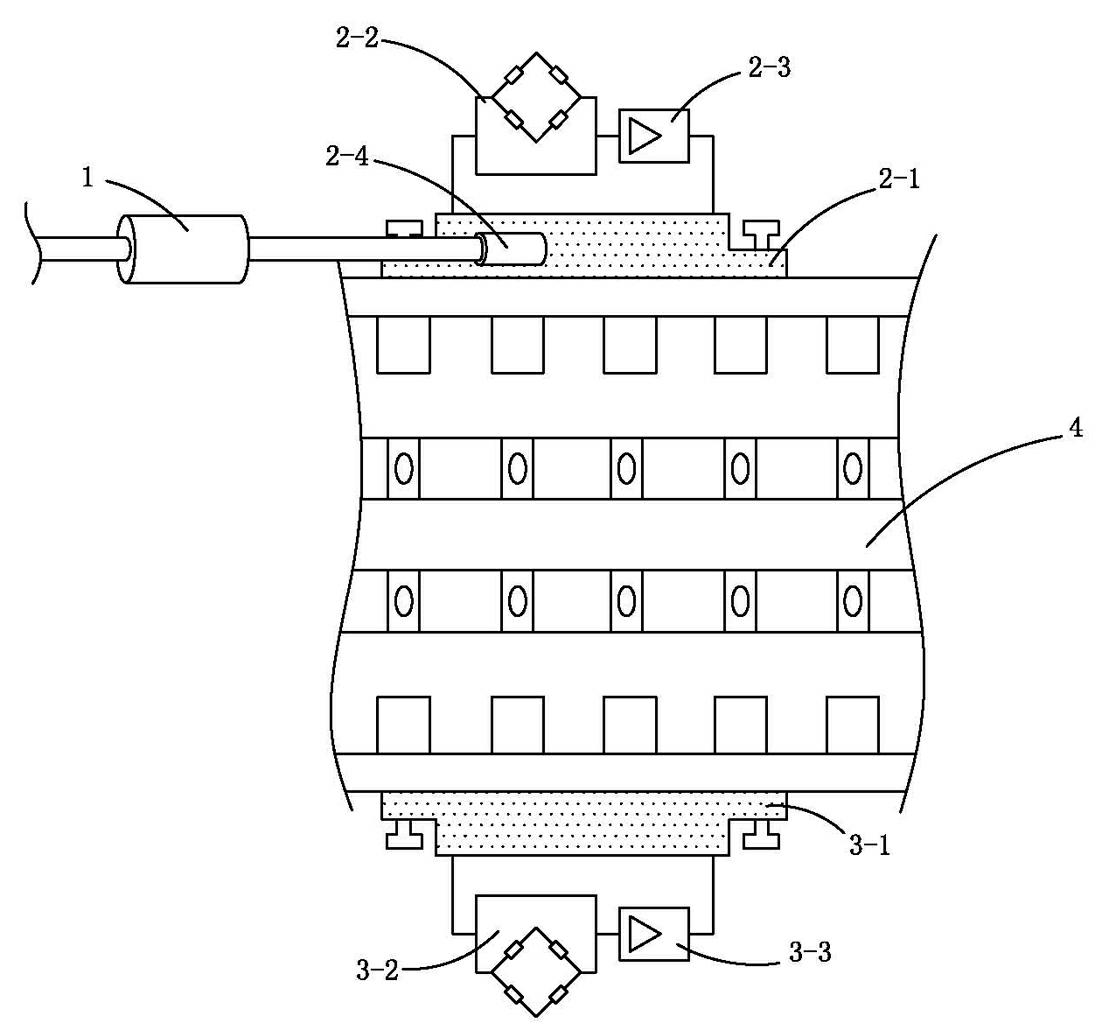

Cigarette permeability detection method

ActiveCN103698096AComplete air leakageImprove precision and accuracyMeasurement of fluid loss/gain ratePneumatic pressureEngineering

The invention discloses a cigarette permeability on-line detection method which is applied to a cigarette making and plug assembling machine set. The method is characterized by comprising the following steps of applying positive-pressure air onto a cigarette ignition end on a detection drum wheel, respectively installing a pressure sensor on two ends of a cigarette to detect the pressure value on the air inlet end and the air outlet end, applying the identical positive-pressure air onto the filter tip end of the cigarette on a next slot, installing a pressure sensor on the cigarette ignition end to detect the pressure value on the air outlet end, transmitting the three pressure values to a controller processing unit to be calculated, judging the cigarette permeability, outputting a removal signal, and removing the cigarette with unqualified permeability on a removal drum wheel. By adopting the method, the influence of the air pressure fluctuation and different brands on the detection of the permeability can be reduced. The online detection precision and accuracy of the cigarette permeability can be improved, the quantity of the cigarettes with unqualified permeability in the market can be reduced, and the cigarette quality can be improved.

Owner:CHENGDU BOFA CONTROL TECH

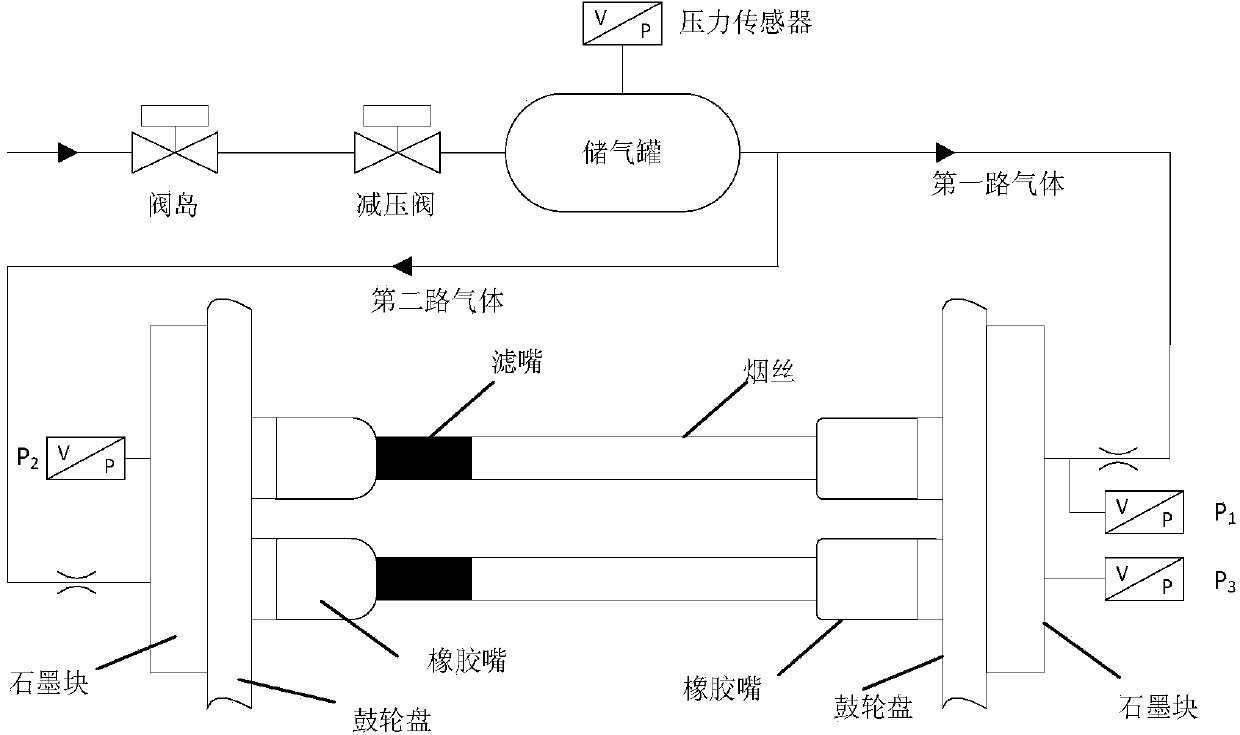

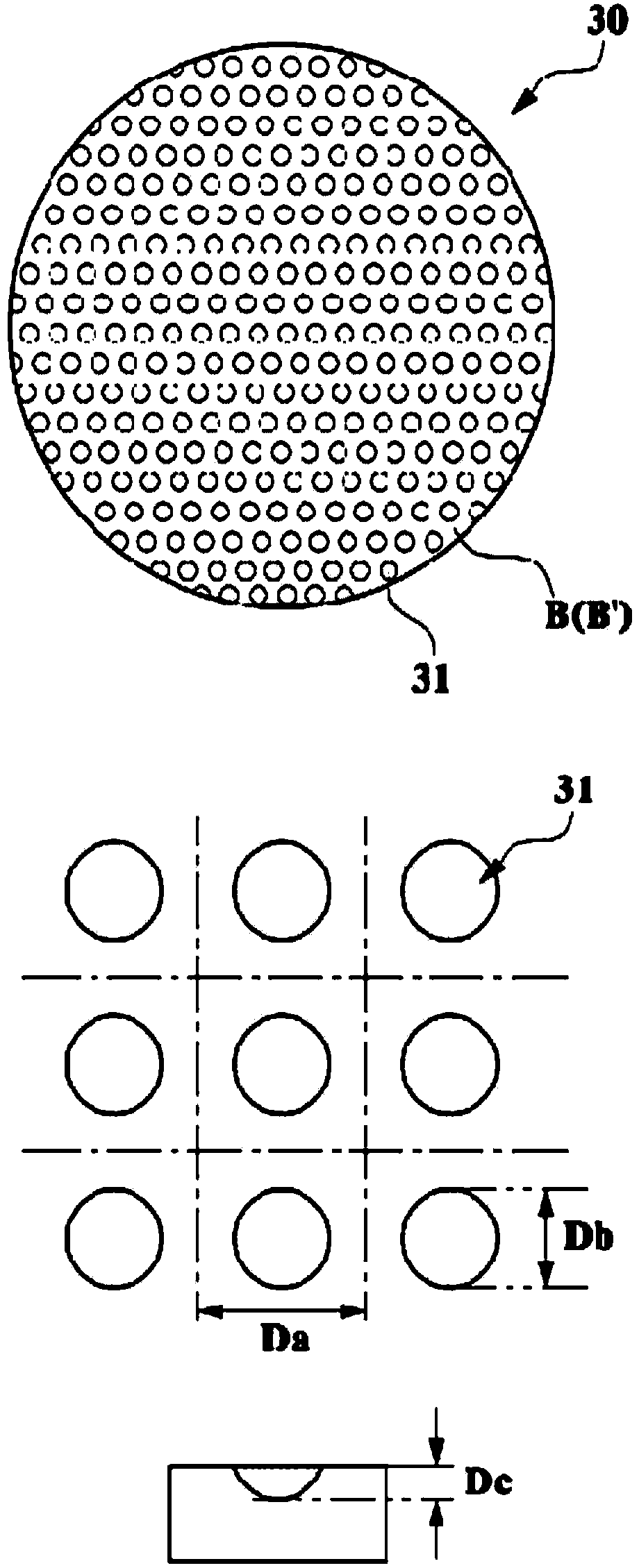

Cylinder device using optimal placement of fine protrusion for improved wear resistance

The present invention relates to a cylinder device which has an optimal placement of a fine protrusion and surface roughness. According to the present invention, the fine protrusion is processed in an optimal selection area on a cylinder bore surface so that lubrication characteristics are improved between a piston ring and the cylinder bore surface and the occurrence of wear on the cylinder bore surface and in the piston ring is reduced. The processing is performed in such a manner that the surface roughness of the cylinder bore surface is in an optimal state, and thereby engine oil consumption can be reduced.

Owner:HYUNDAI DOOSAN INVIGORATE CORP

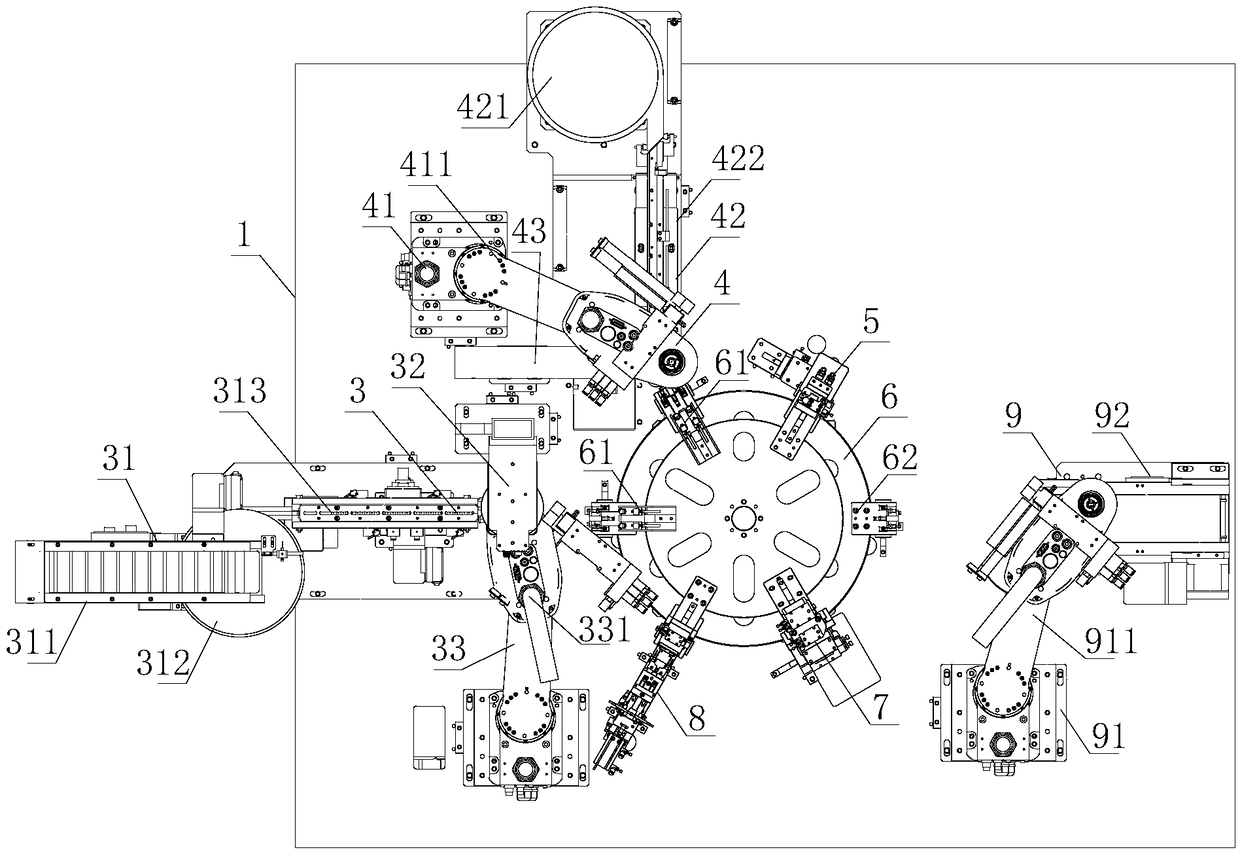

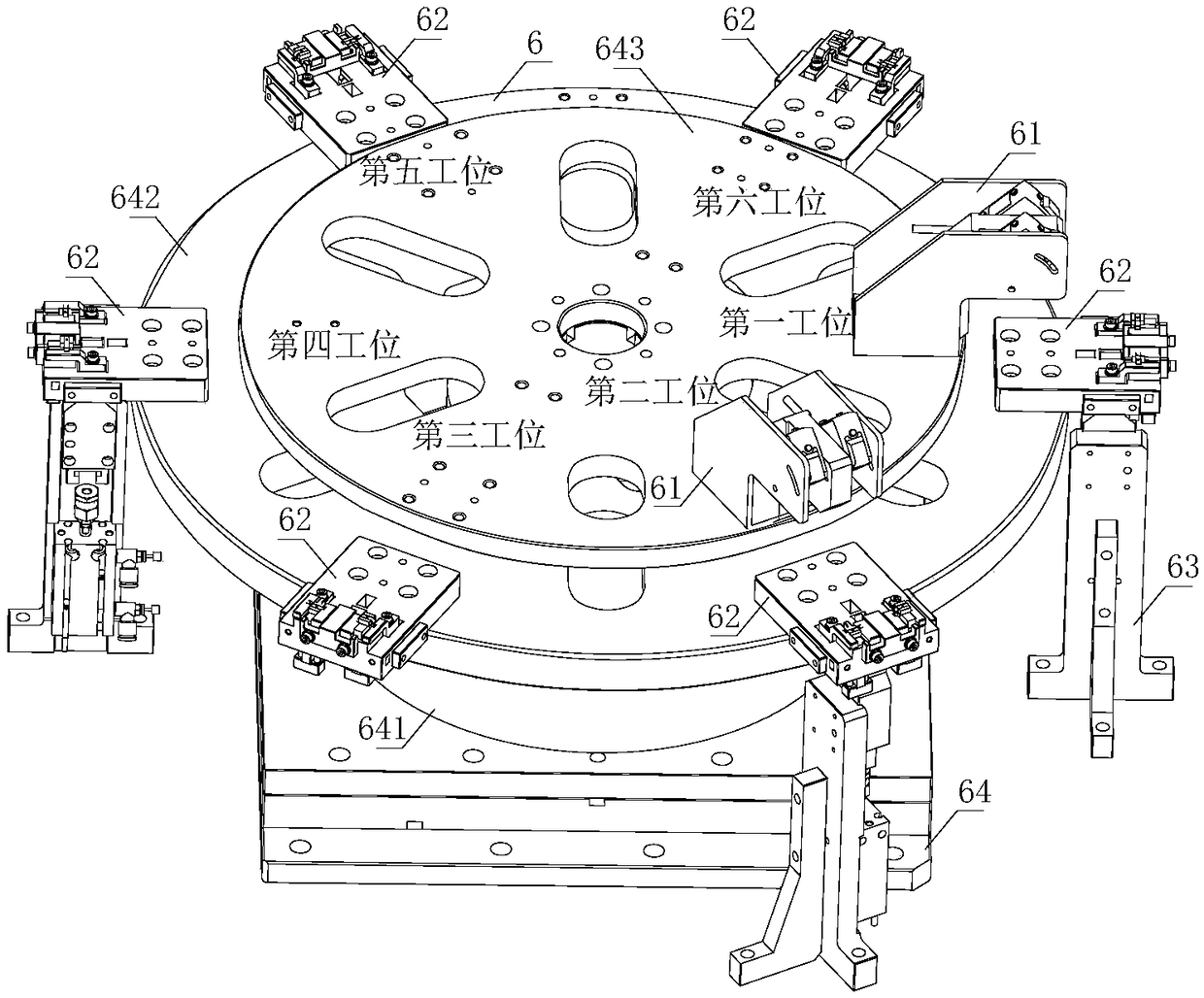

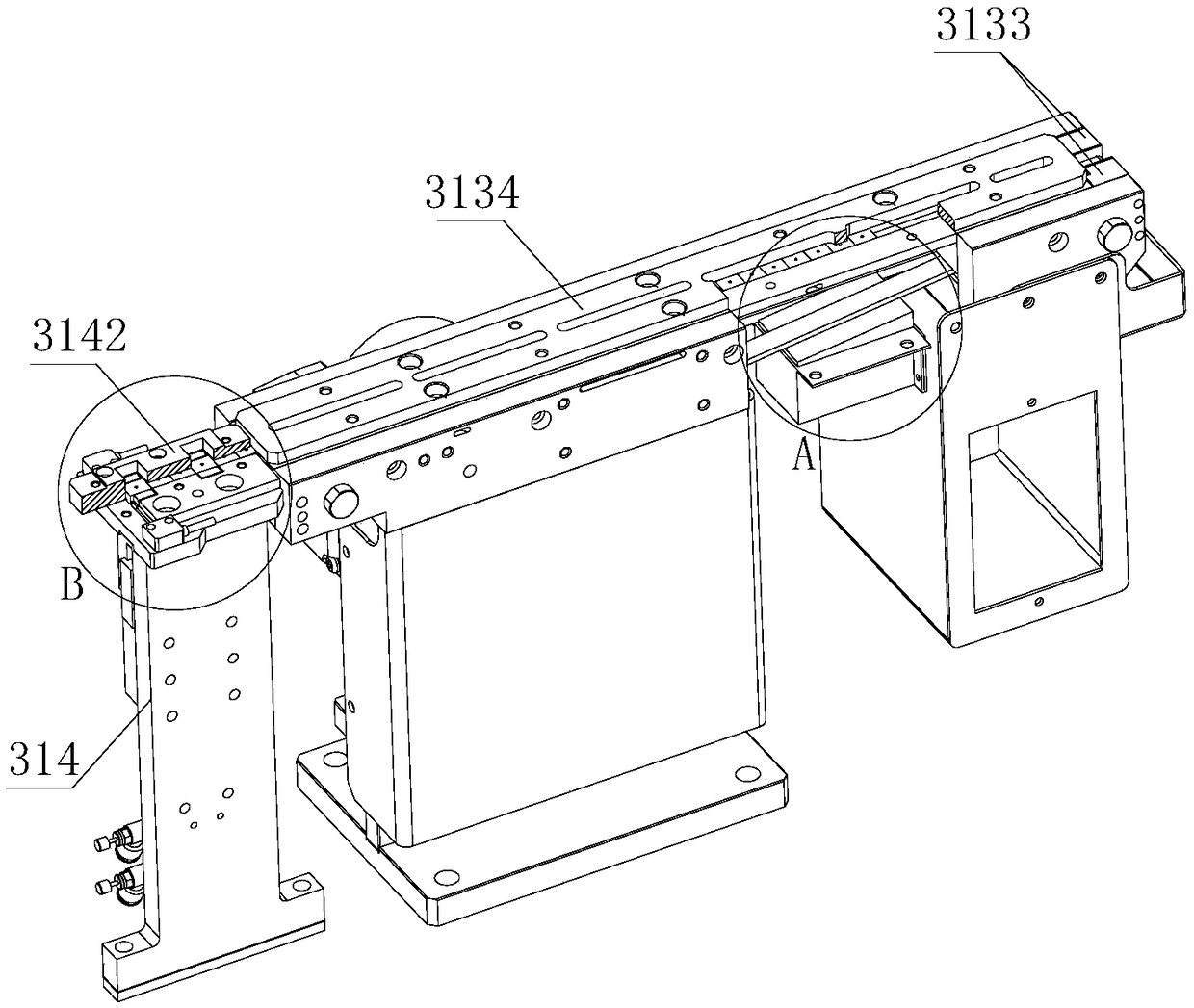

Automatic assembling machine based on mechanical hand and machine vision

ActiveCN108637639AImplement automatic assemblyImprove work efficiencyMetal working apparatusMachine visionEngineering

The invention belongs to the technical field of magnetic core assembling, and discloses an automatic assembling machine based on mechanical hand and machine vision and used for automatically assembling magnetic cores. The automatic assembling machine comprises a rotary disc rotationally arranged along a vertical shaft, the rotary disc is connected with a first driving device driving the rotary disc to rotate, and at least six stations are uniformly distributed in the rotary direction of the rotary disc; each station is provided with a carrying seat, and the carrying seats are fixed to the rotary disc; the first station is provided with a magnetic core body feeding module which is used for placing a magnetic core body into the corresponding carrying seat; the second station is provided witha foot sheet feeding module which is used for placing a foot sheet into the corresponding carrying seat; the third station is provided with a cleaning module which is used for cleaning an assembled magnetic core; the fourth station is provided with a discharging module which is used for transferring the assembled magnetic core to the outside of the automatic assembling machine based on mechanicalhand and machine vision; the fifth station is provided with a riveting module which is used for riveting the foot sheet to the magnetic core body; and the sixth station is provided with a compressingmodule which is used for compressing the foot sheet.

Owner:CHENGDU TIANCHUANG PRECISION MOLD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com