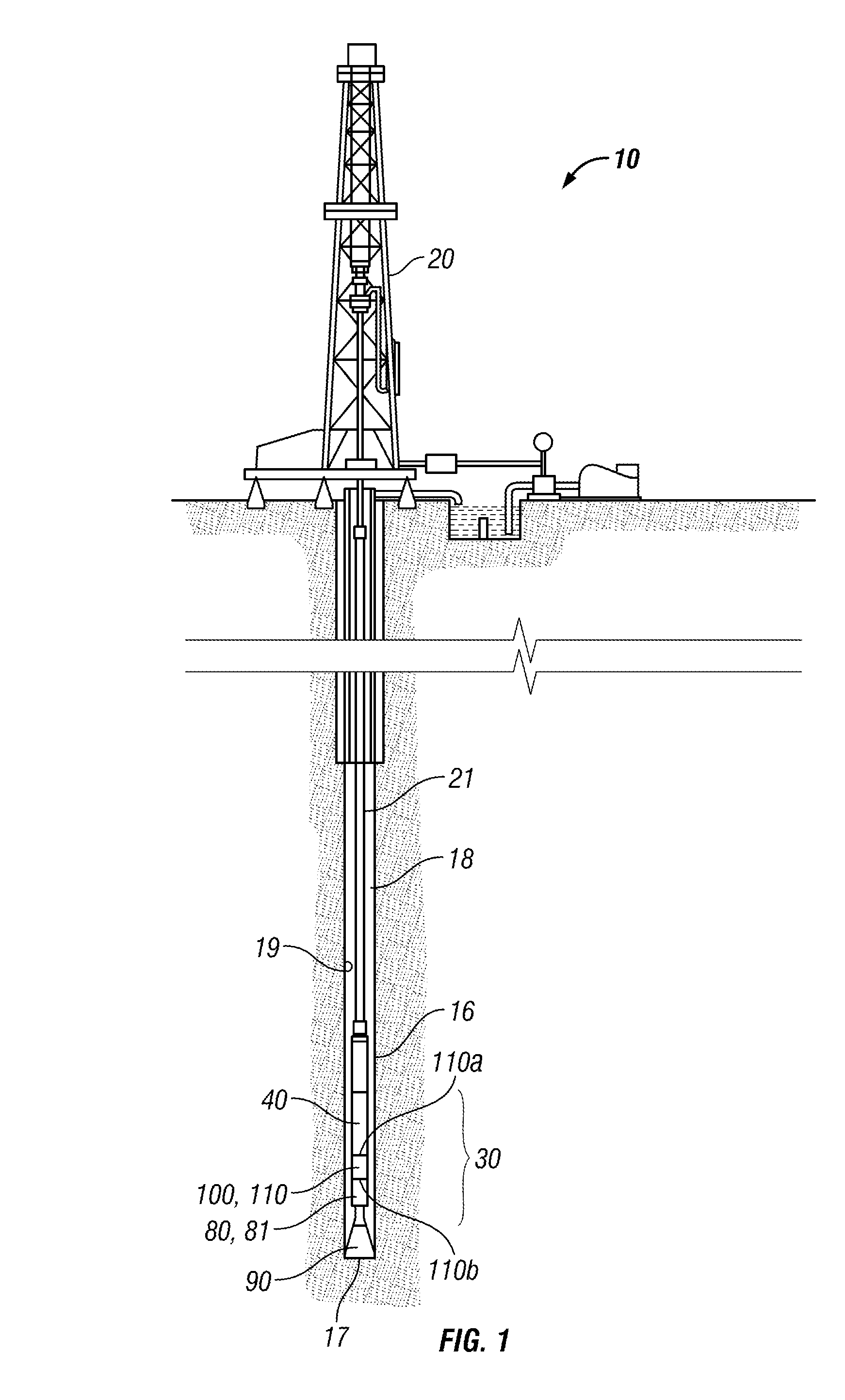

Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1420 results about "Counterbore" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A counterbore (symbol: ⌴) is a cylindrical flat-bottomed hole that enlarges another coaxial hole, or the tool used to create that feature. A counterbore hole is typically used when a fastener, such as a socket head cap screw, is required to sit flush with or below the level of a workpiece's surface.

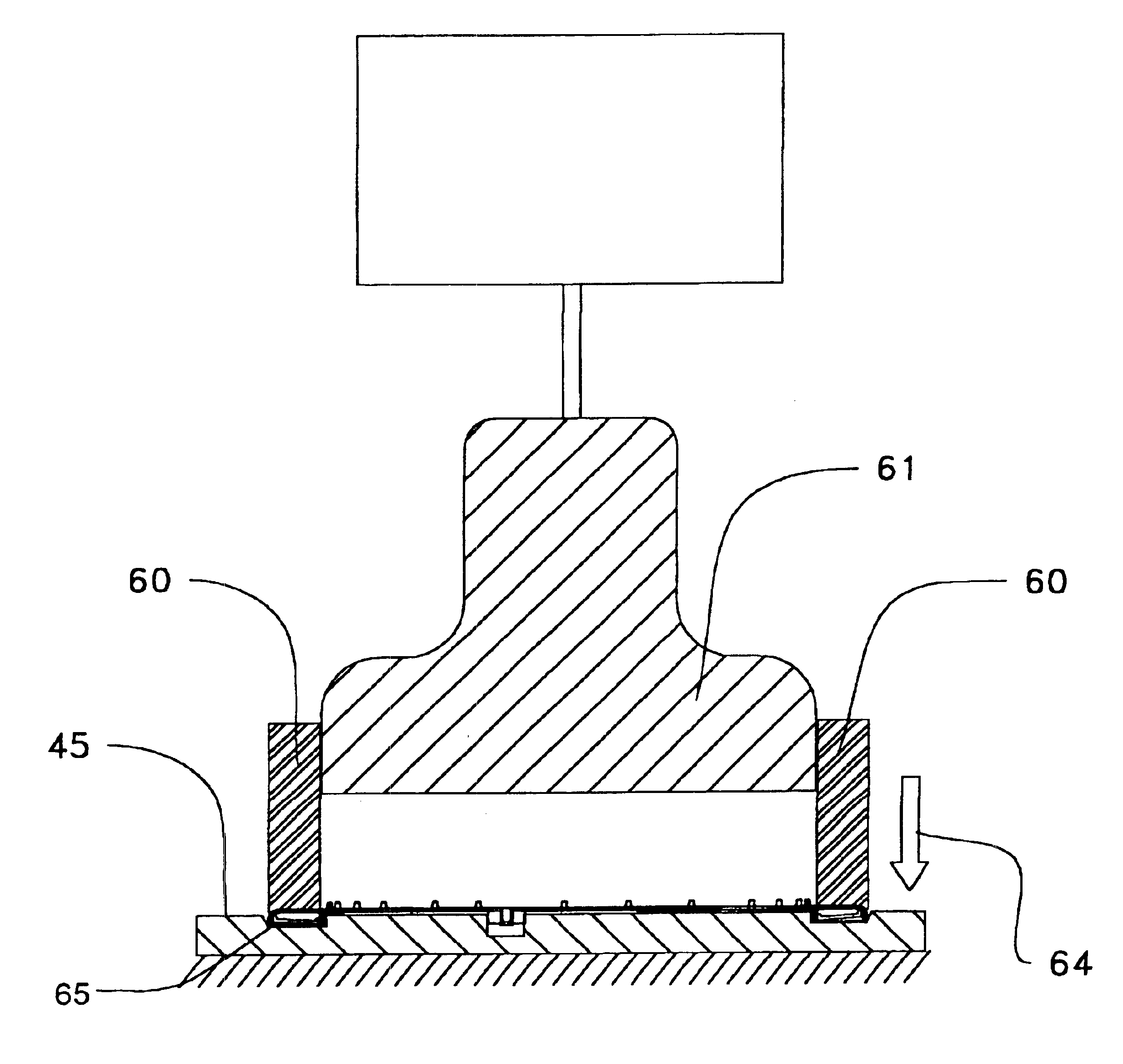

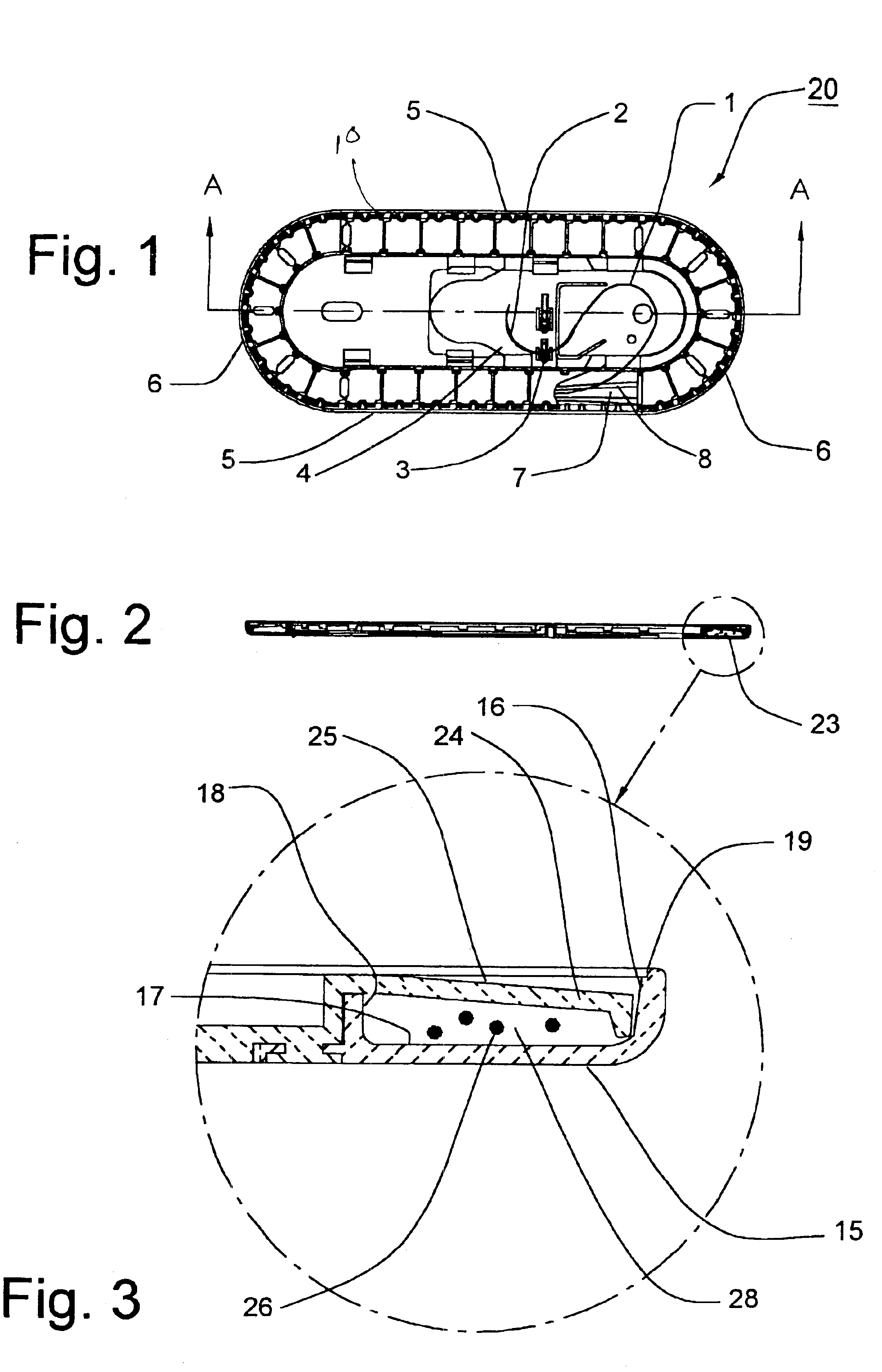

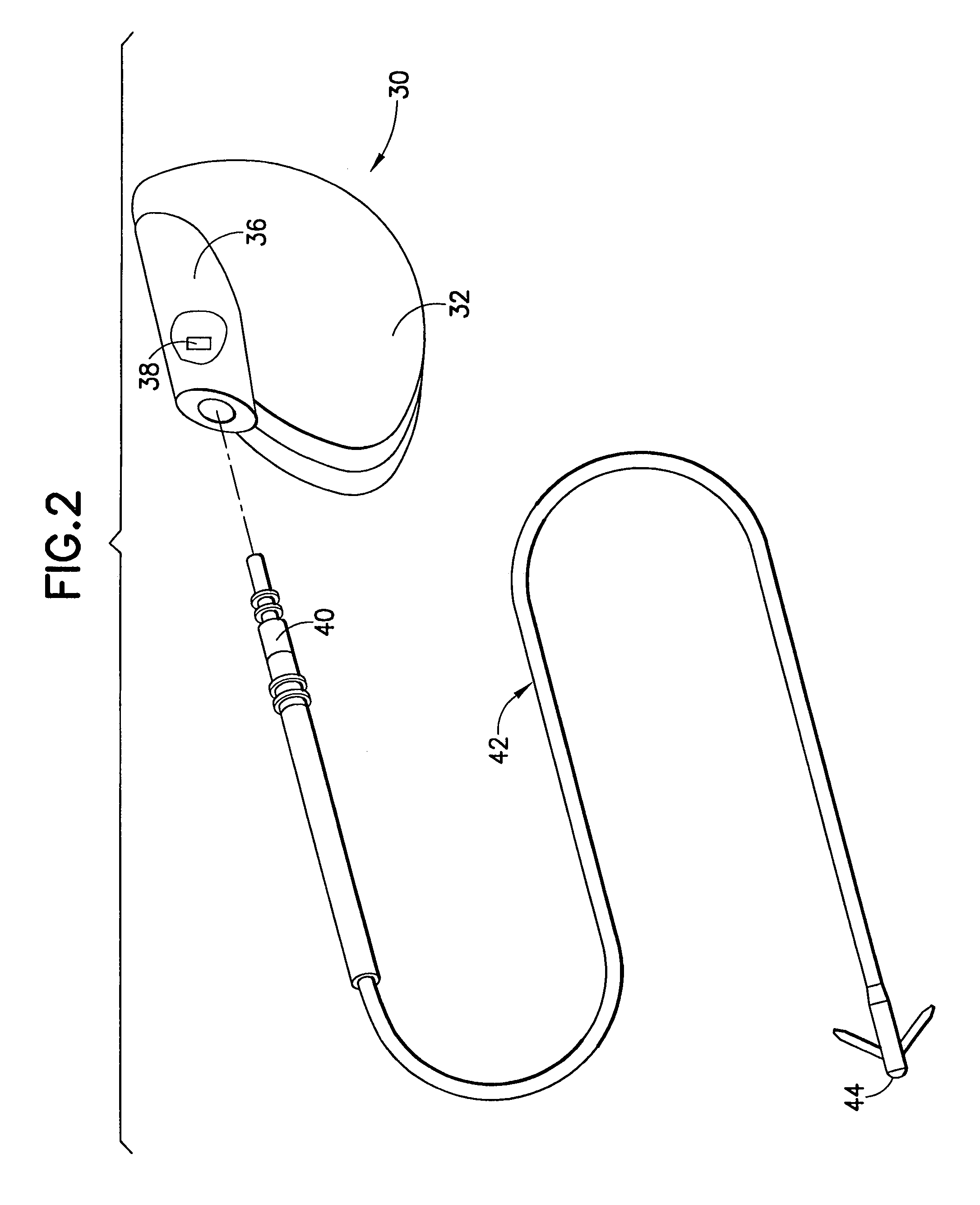

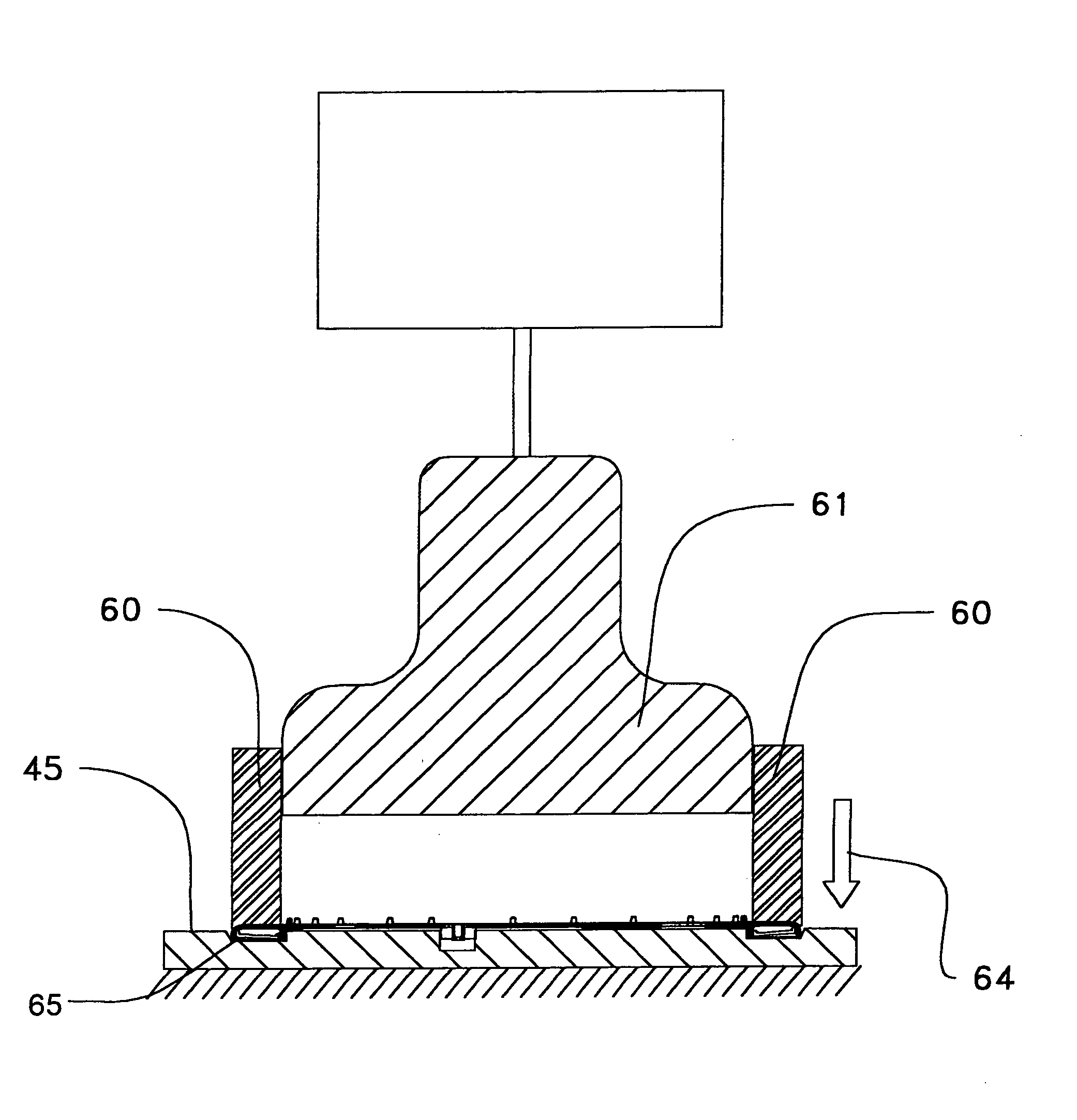

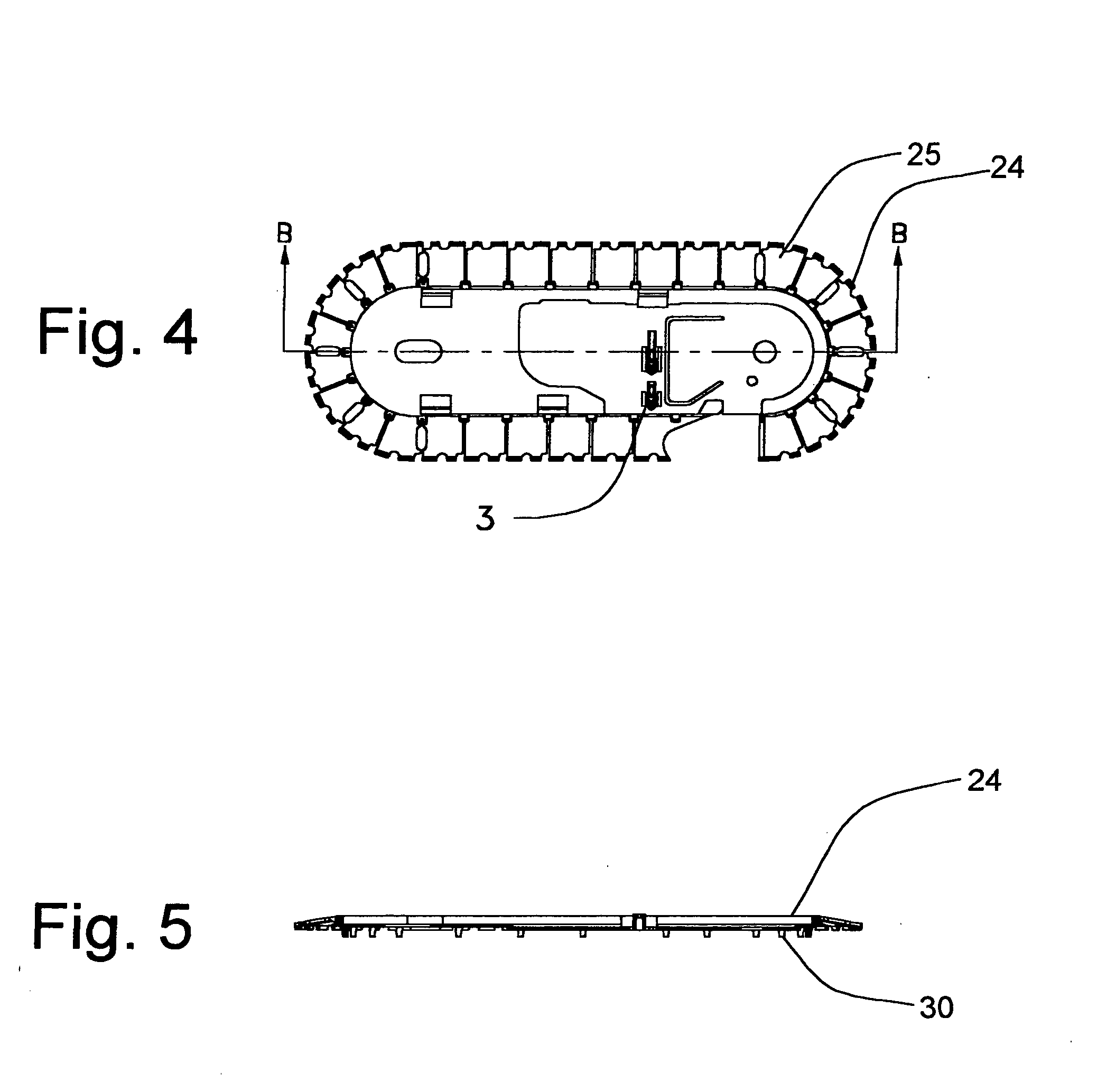

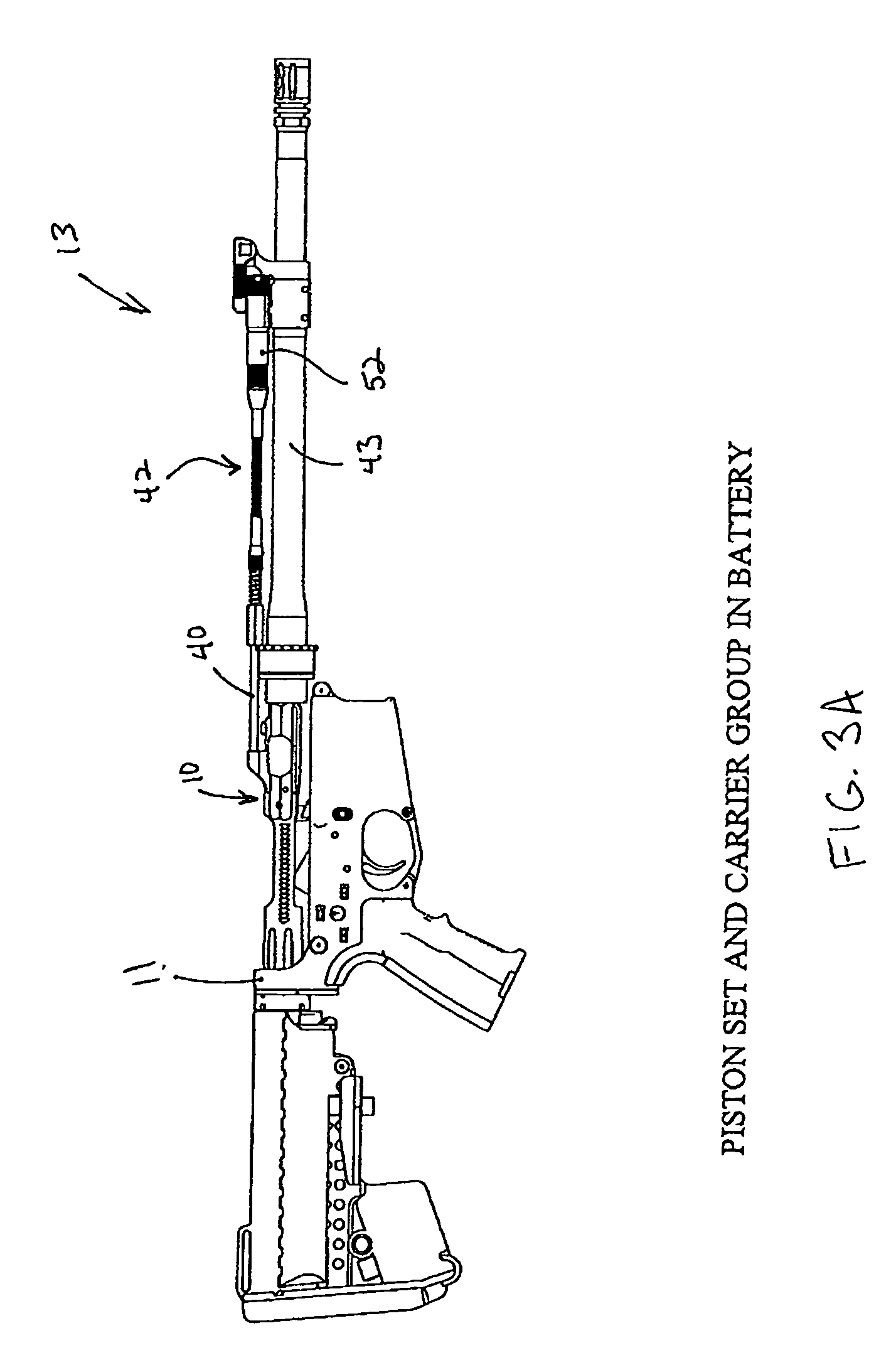

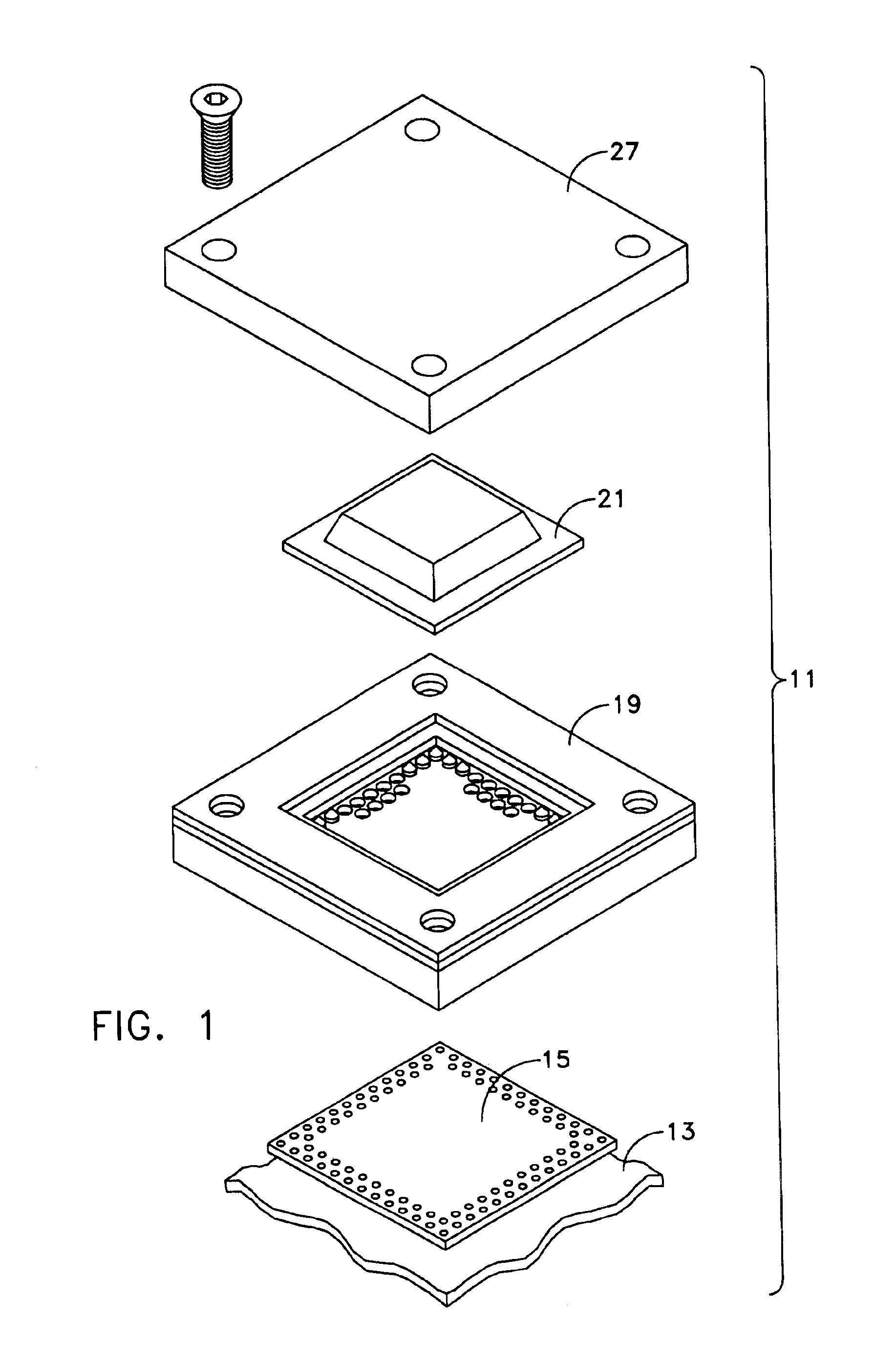

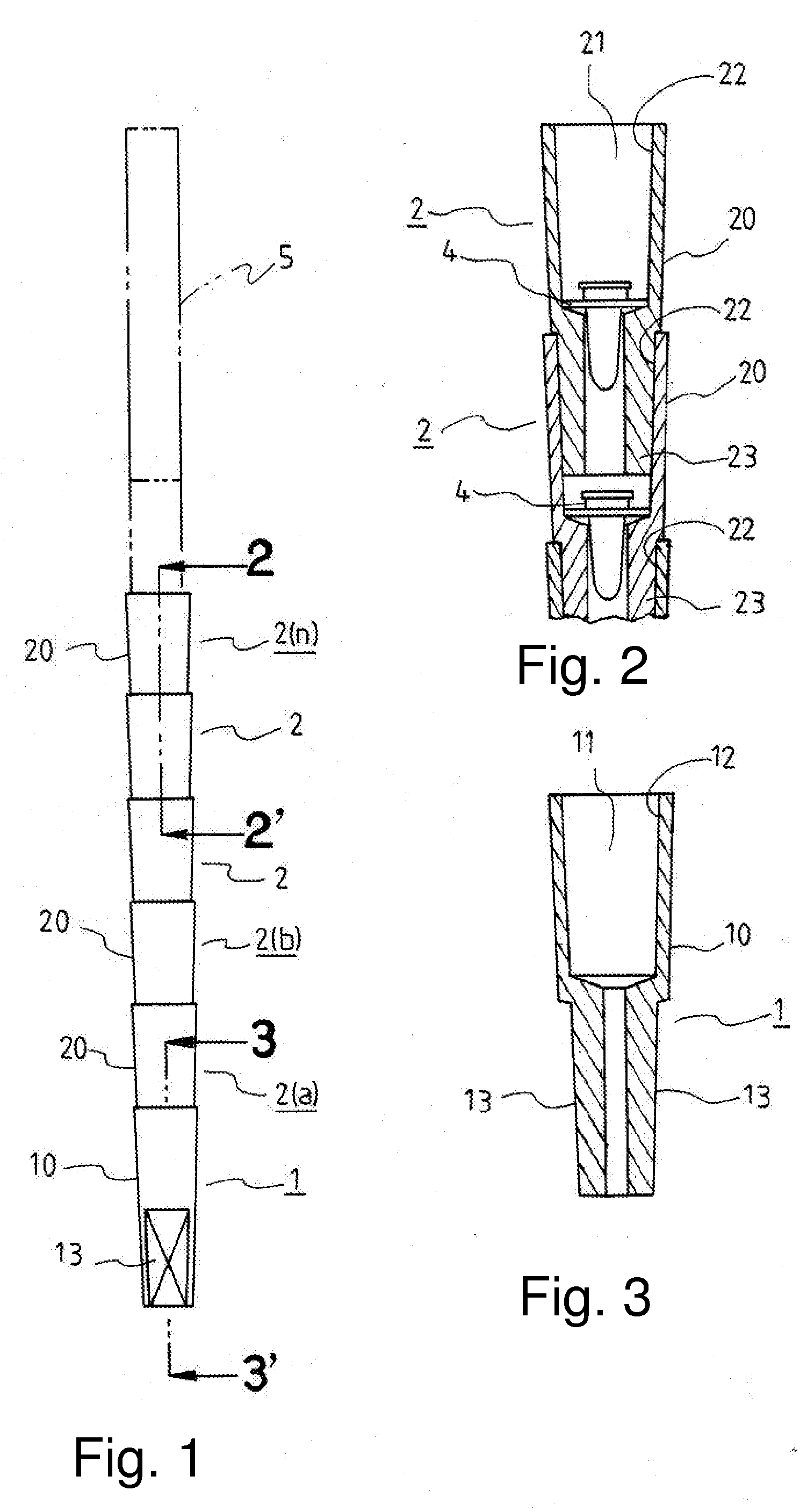

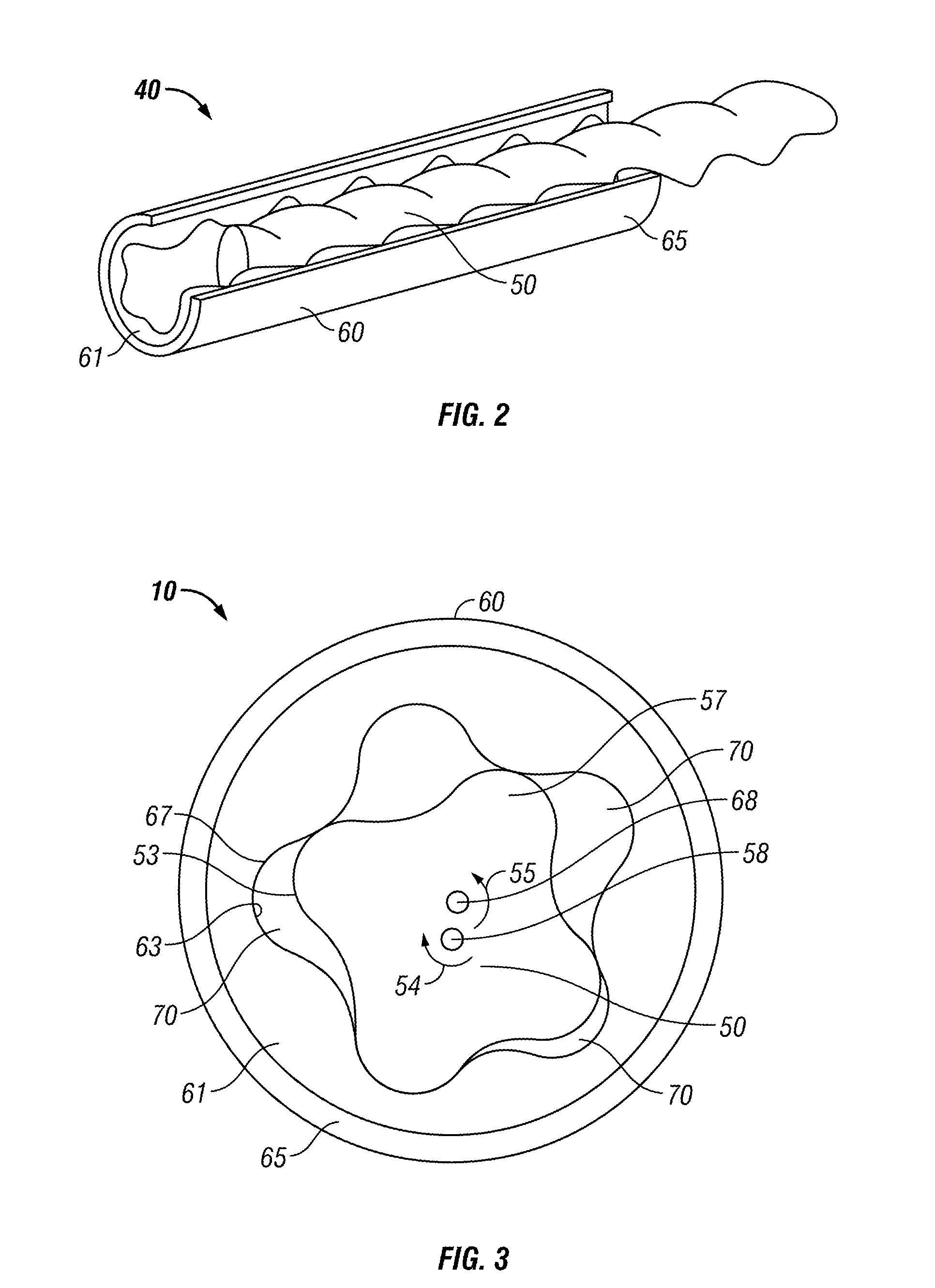

Method for assembling a package for sutures

InactiveUS6915623B2Not slowing downReduce manufacturing costSuture equipmentsSurgical needlesCounterboreUltrasonic generator

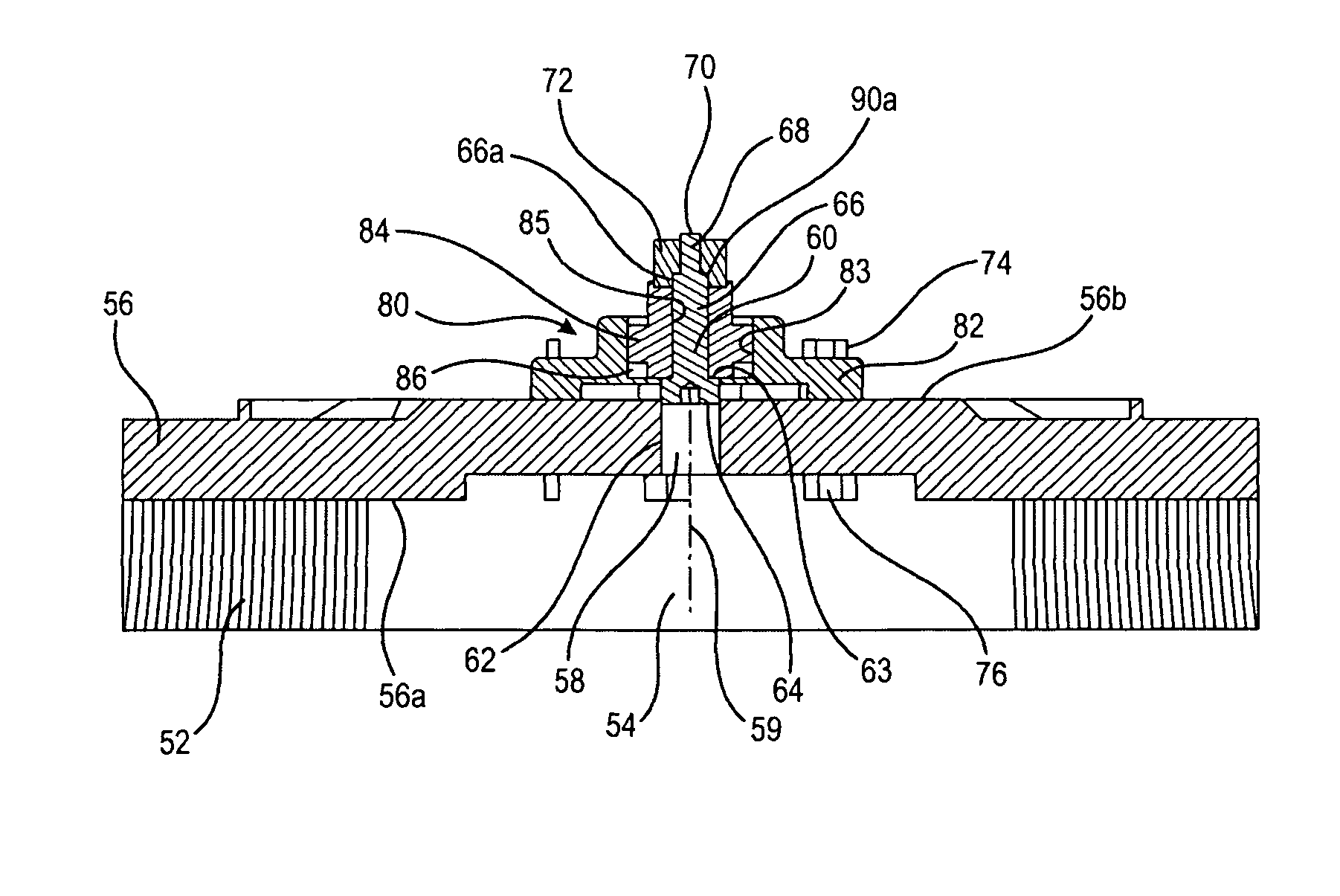

A novel method and apparatus for riveting a two-piece suture tray package. A two-piece suture tray assembly is provided having a top member and a bottom member. The top member has a top and a bottom, and plurality of rivet members extending down from the bottom of the top member. The rivet members have free ends. The bottom member has a top and a flat bottom surface, and a plurality of rivet receiving openings extending therethrough. A counterbore surrounds each rivet receiving opening in the flat bottom surface. An ultrasonic riveting apparatus is provided having a clamp member with a cavity, and an ultrasonic horn member having a flat bottom moveably mounted in the cavity. The assembly is mounted in the riveting apparatus and engaged by the clamp member. The flat bottom of the horn member engages the free ends of the rivet members, and when energized by an ultrasonic generator, causes the free ends of the rivet members to deform into the counterbores, such that the free ends are flat and in alignment with the bottom surface of the bottom member.

Owner:ETHICON INC

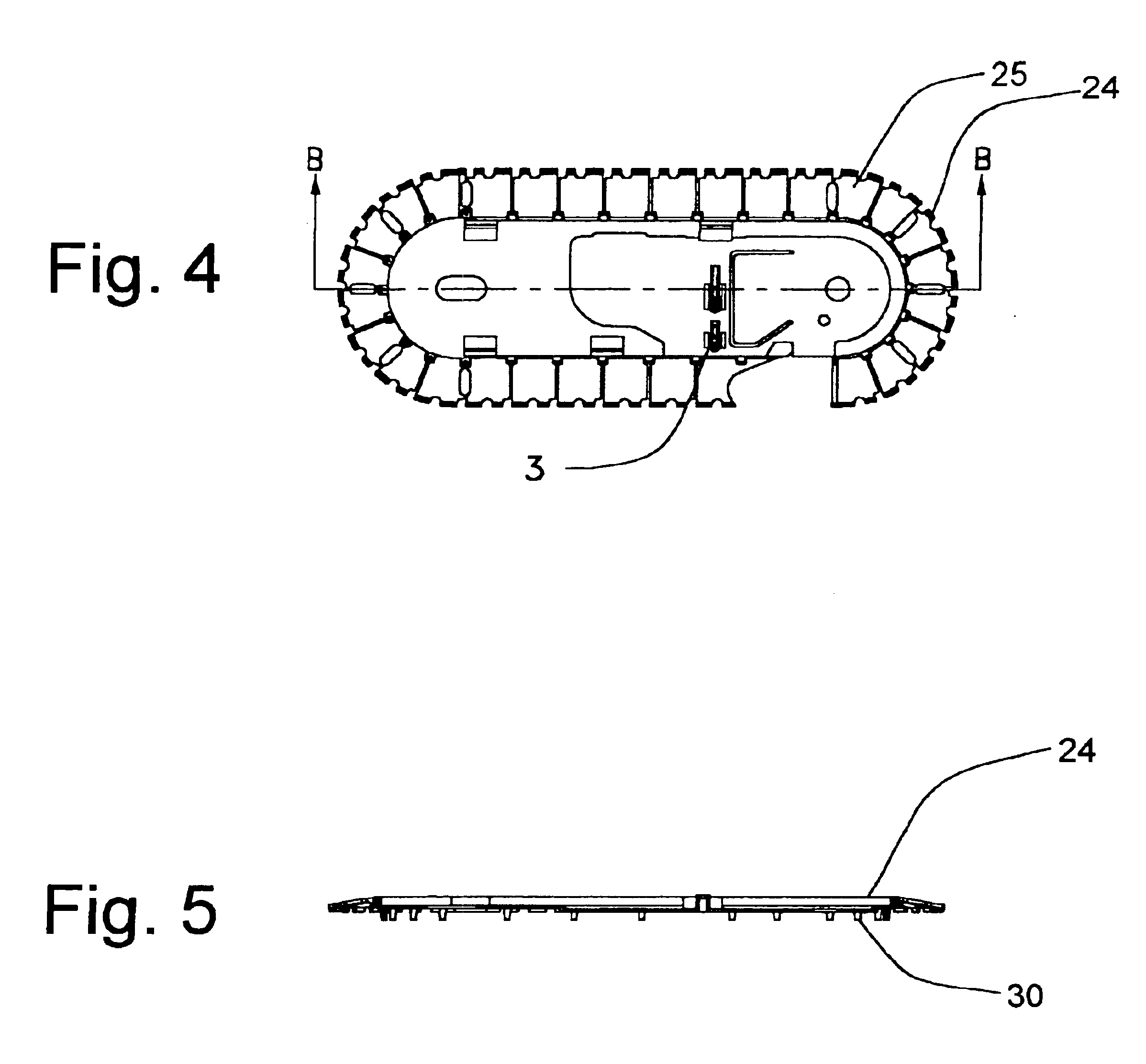

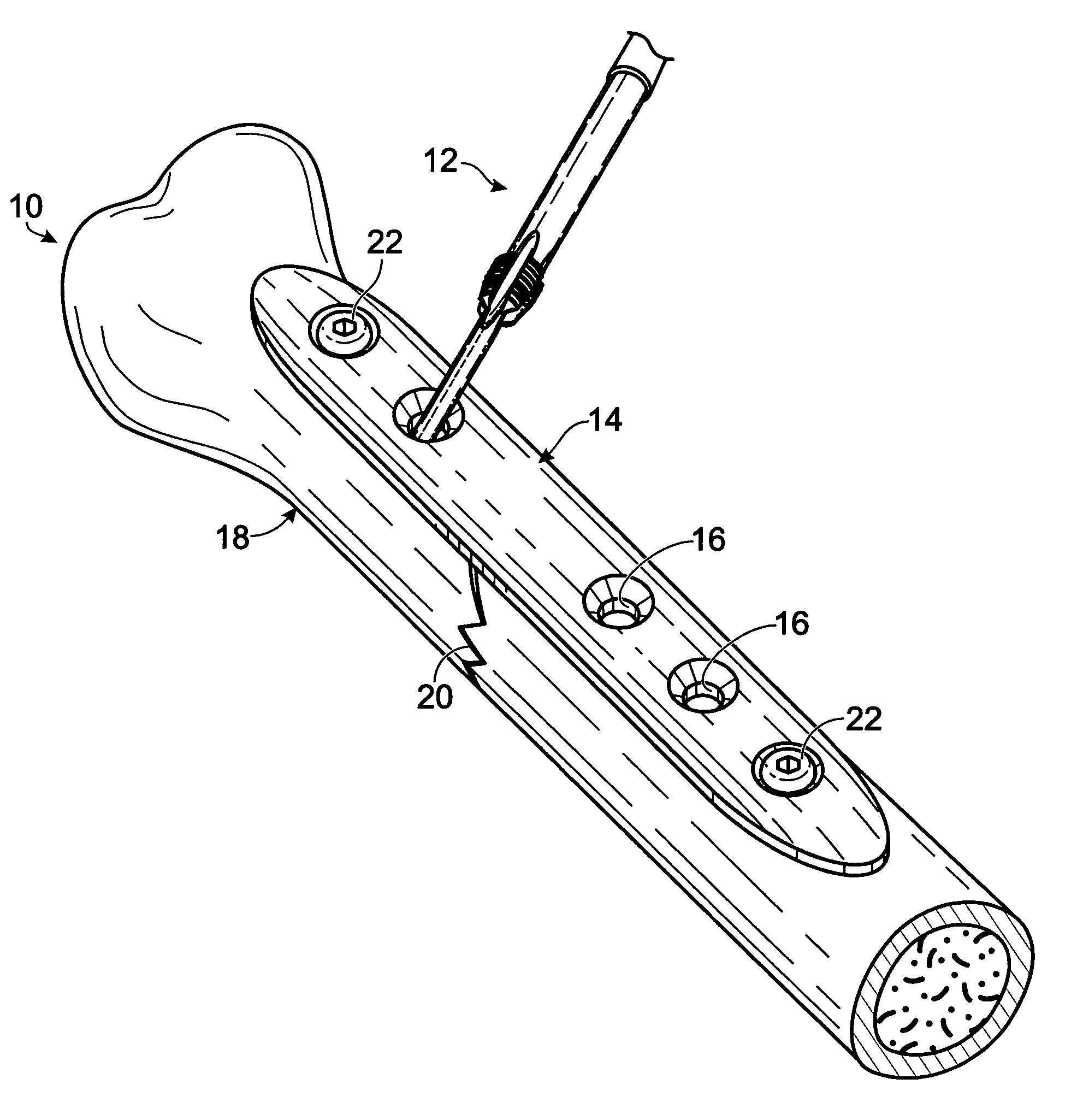

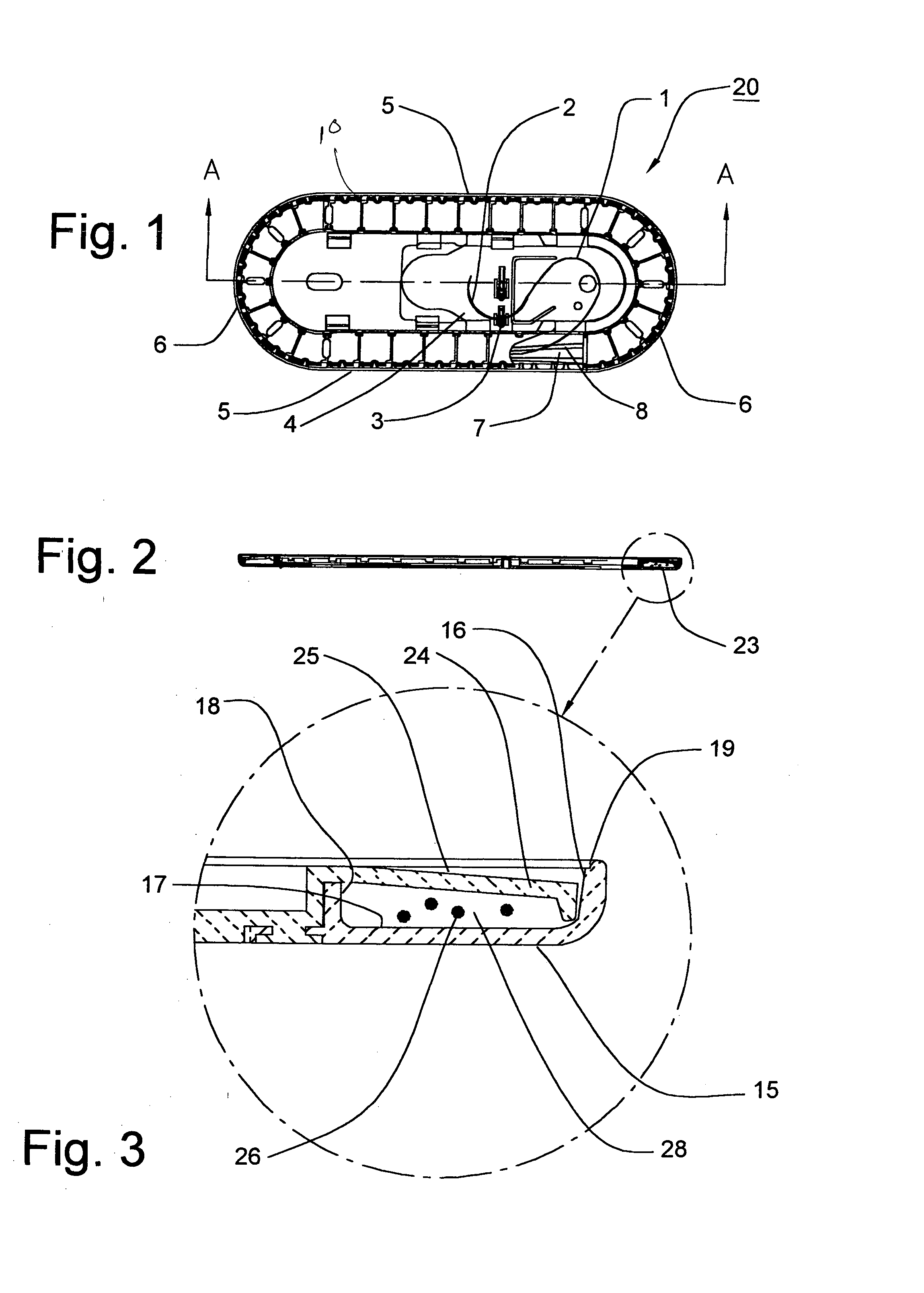

Bone plates with intraoperatively tapped apertures

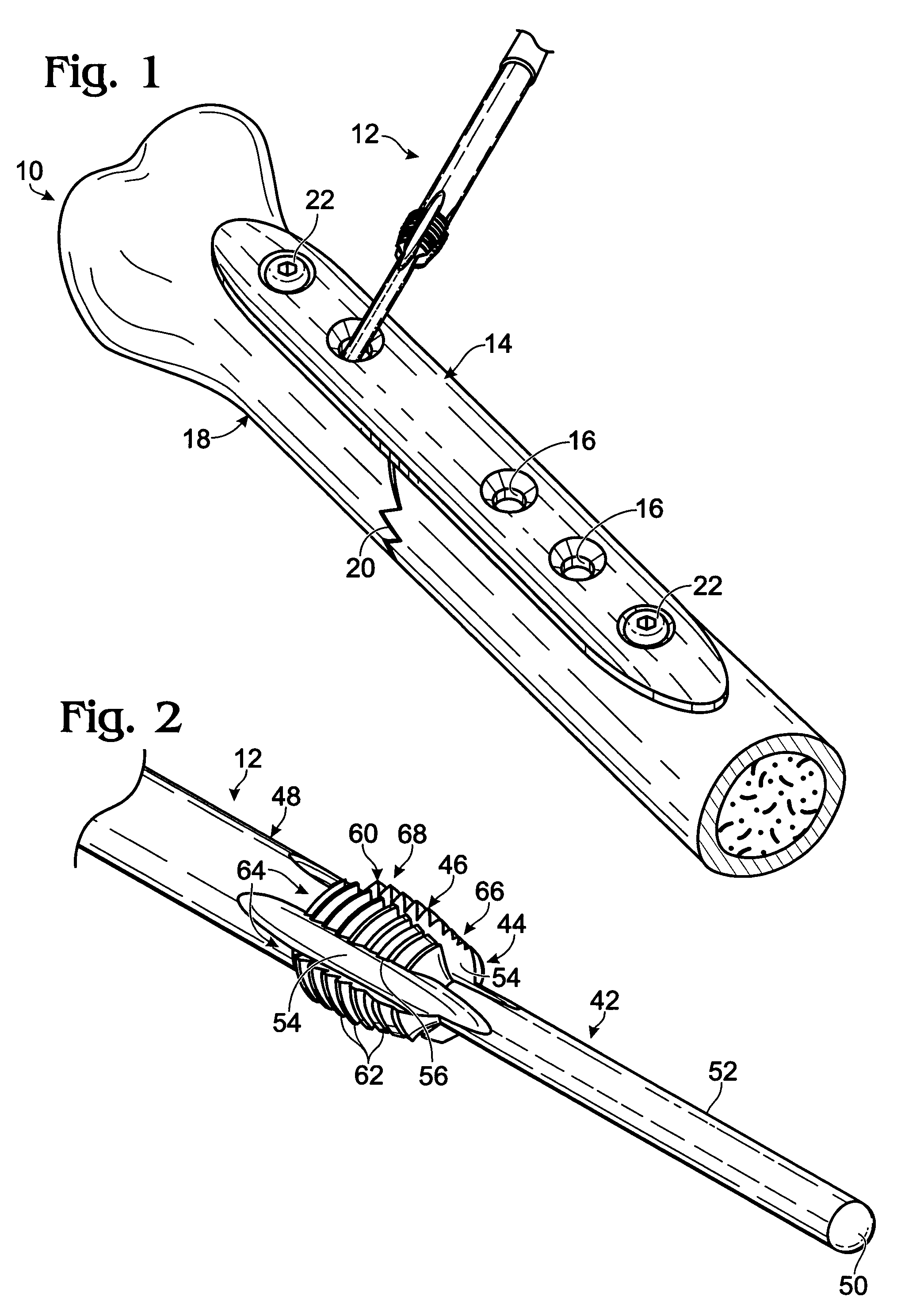

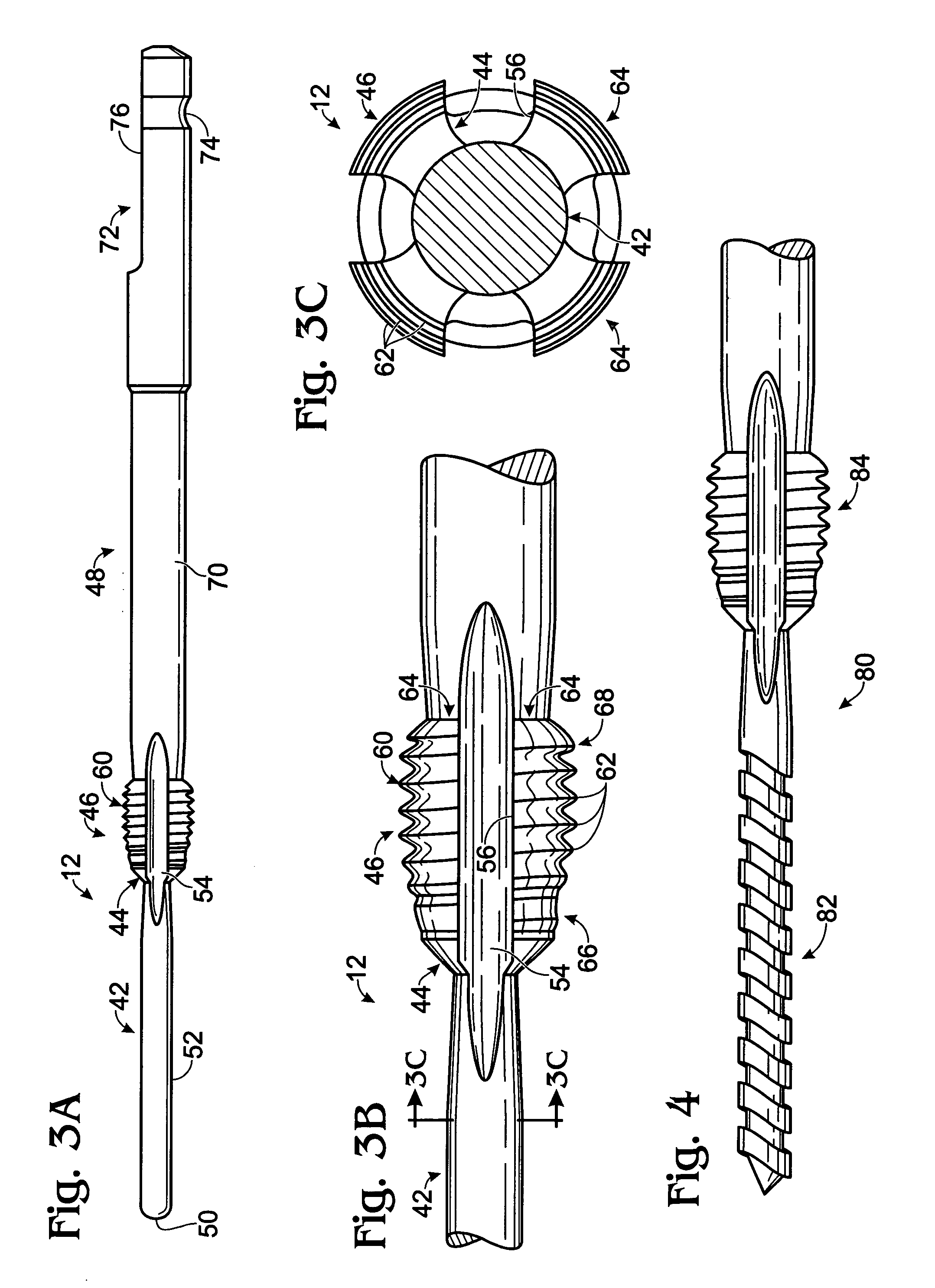

InactiveUS7537596B2Relieve painMinimally invasiveSuture equipmentsInternal osteosythesisCounterboreBiomedical engineering

Method of tapping a bone plate intraoperatively. A bone plate having an aperture may be selected, and the bone plate may be placed on a bone. A thread may be formed in the aperture using a tap device with the bone plate disposed on the bone. A hole may be formed in the bone, with the hole in alignment with the aperture. The hole may be widened adjacent the aperture to create a counterbore in the bone. A fastener may be advanced into threaded engagement with the thread after removal of the tap device from the aperture.

Owner:ACUMED

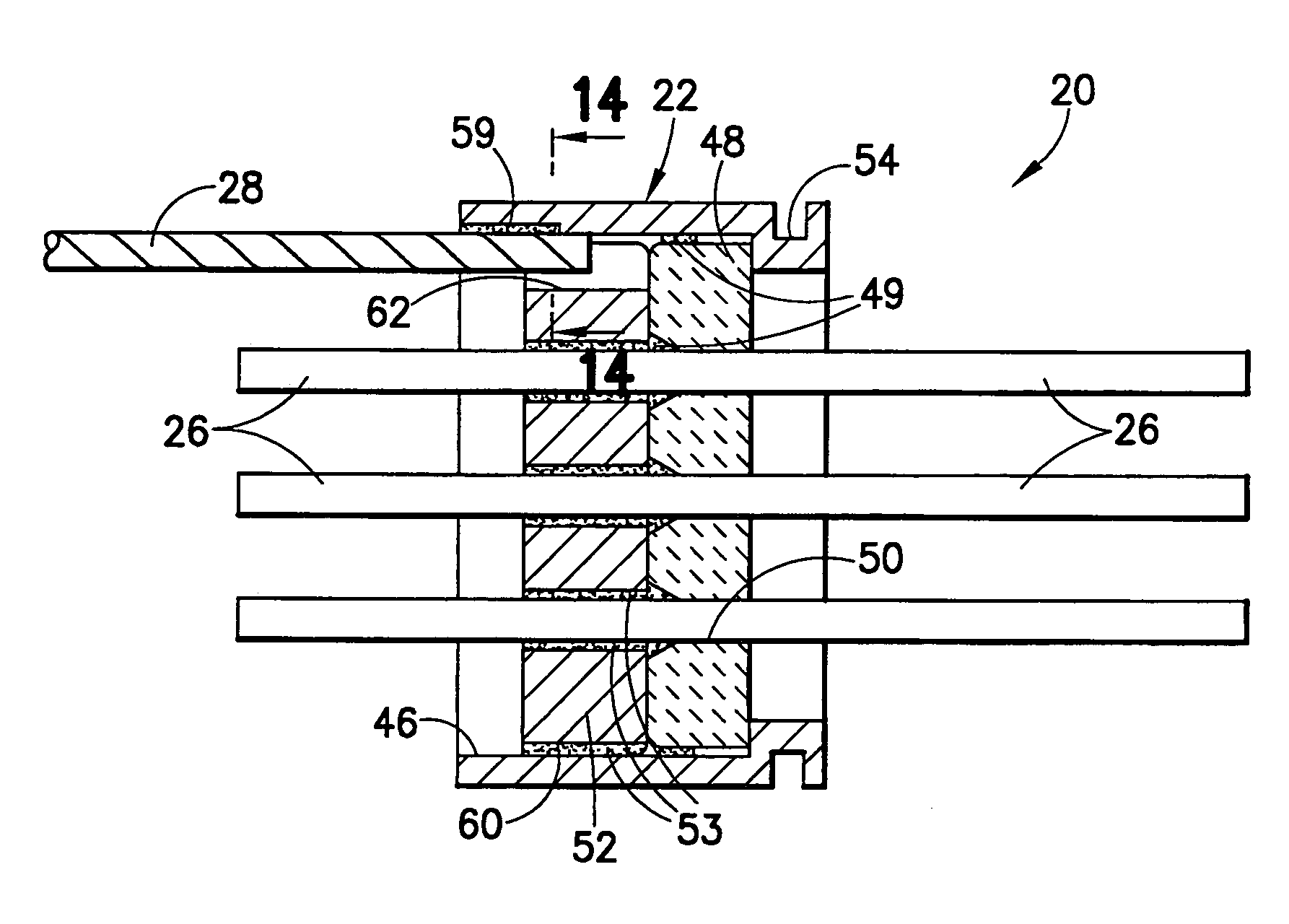

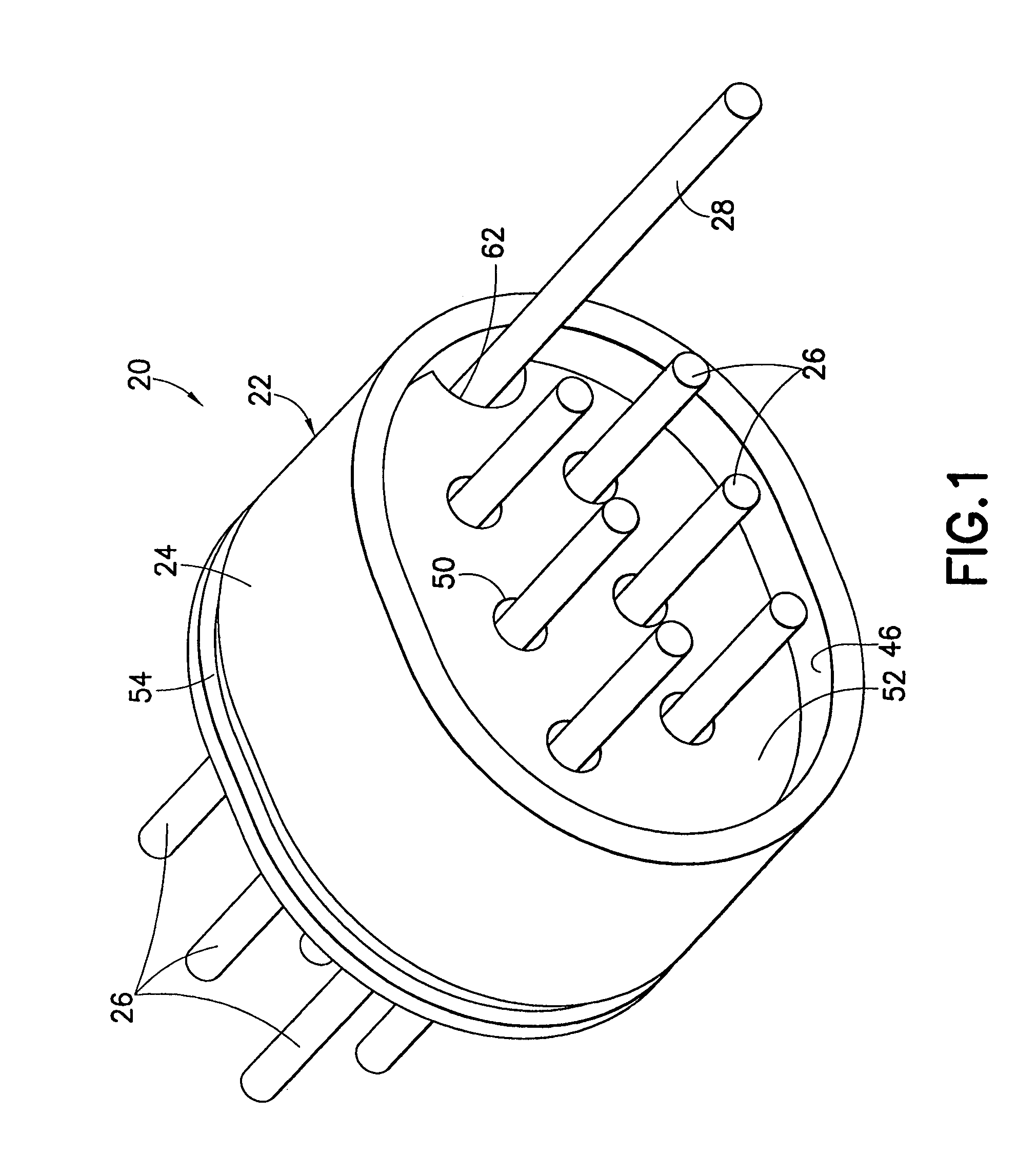

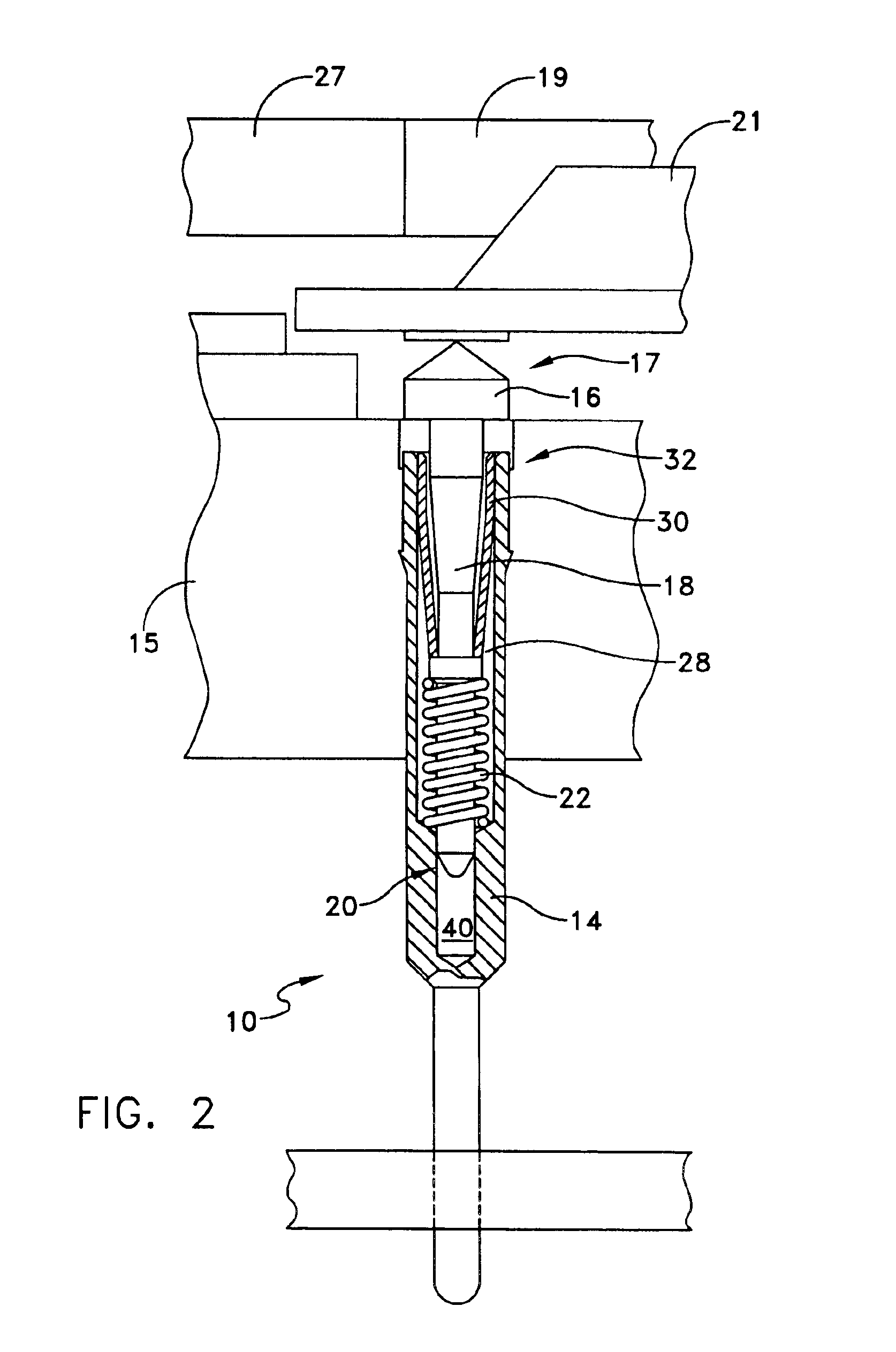

Internally grounded filtering feedthrough

ActiveUS7046499B1Save additional assembly stepMinimize functional impactAnti-noise capacitorsElectrotherapyCounterboreFilter capacitor

A feedthrough device includes a conductive ferrule having an outer peripheral surface defining the outermost boundary of the feedthrough device, an insulator, a lead wire electrically isolated from the ferrule extending through the insulator, a filter capacitor adjacent the insulator through which the lead wire extends in conductive relation therewith, and a ground wire coupled to the ferrule and to the insulator within the outermost boundary of the feedthrough device. The ferrule has an inner peripheral surface defining an opening therethrough and each of the insulator and the filter capacitor has an outer peripheral surface proximate the inner peripheral surface, a counterbore in the outer peripheral surface of each of the insulator and filter capacitor, an end of the ground wire being received in the counterbore and brazed to the ferrule and insulator. Alternatively, an end of the ground wire is welded to the inner peripheral surface of the ferrule.

Owner:PACESETTER INC

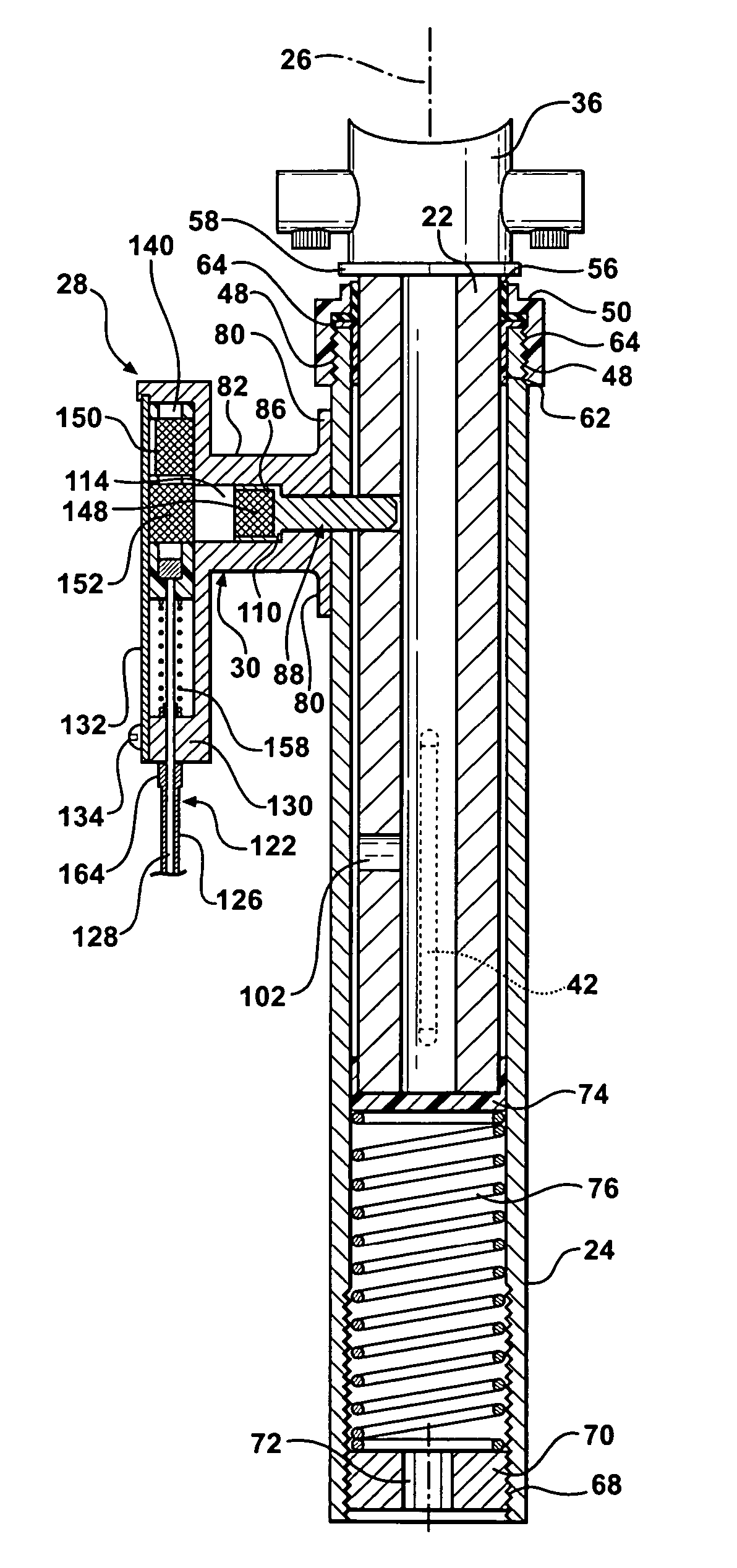

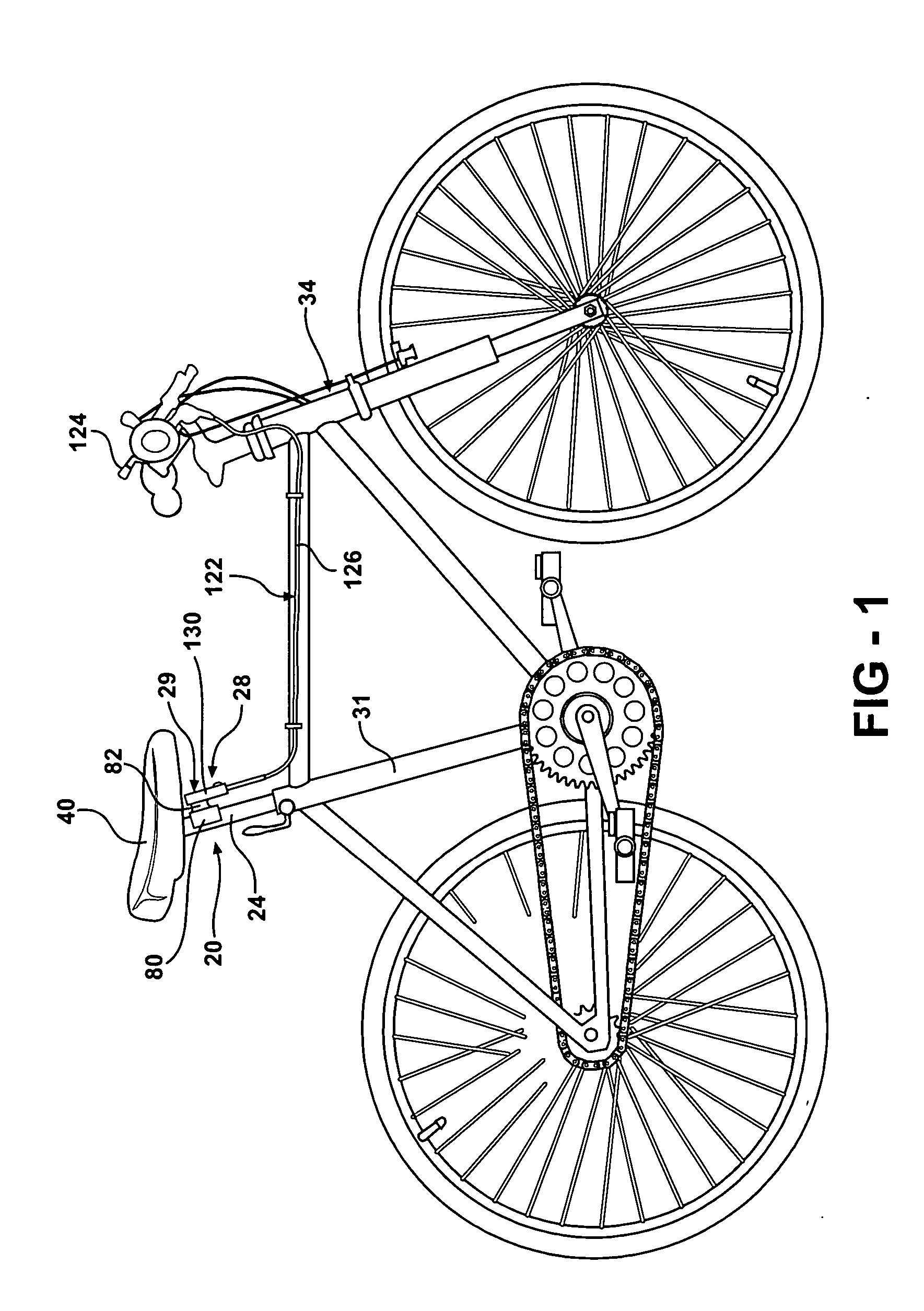

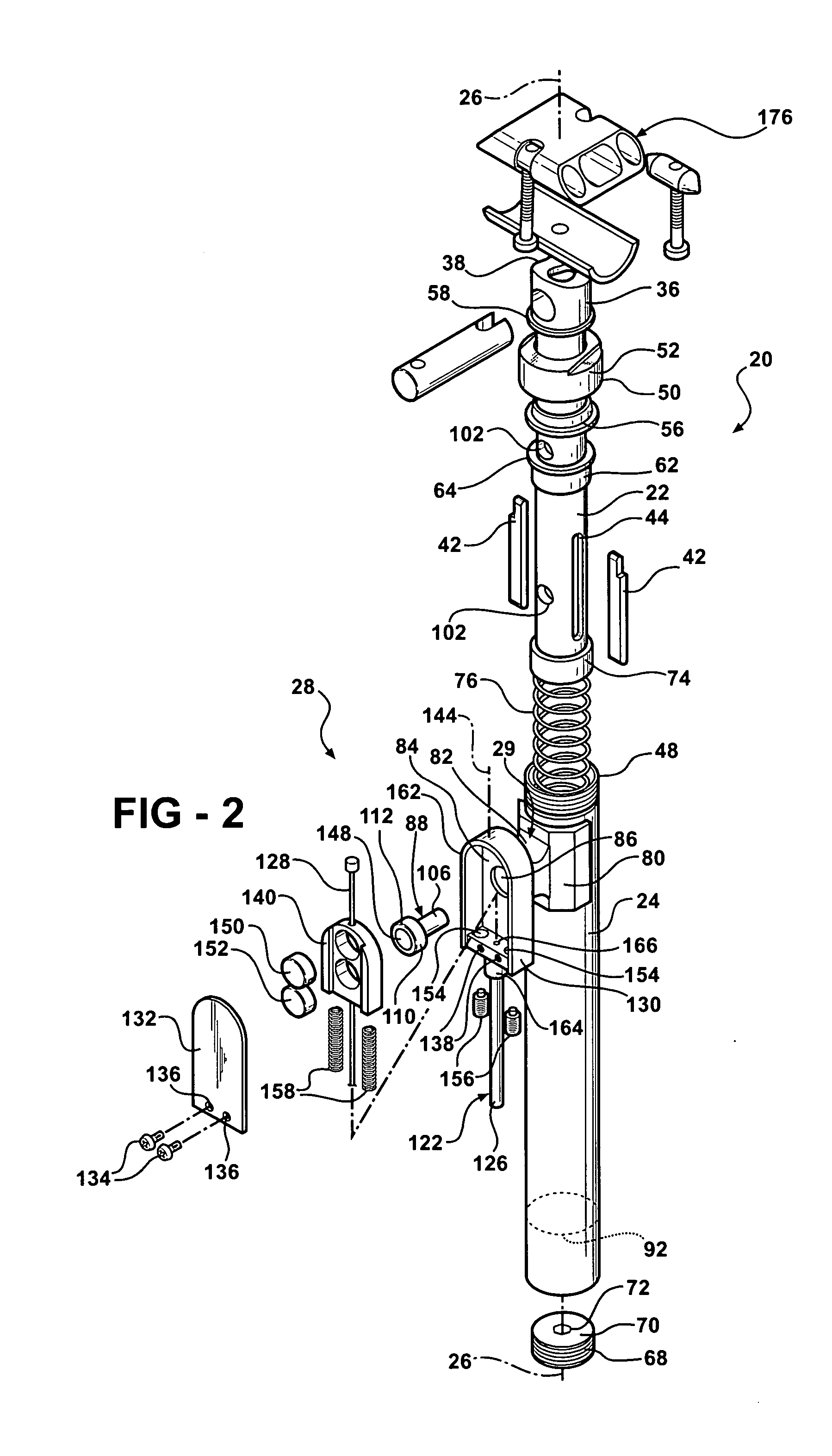

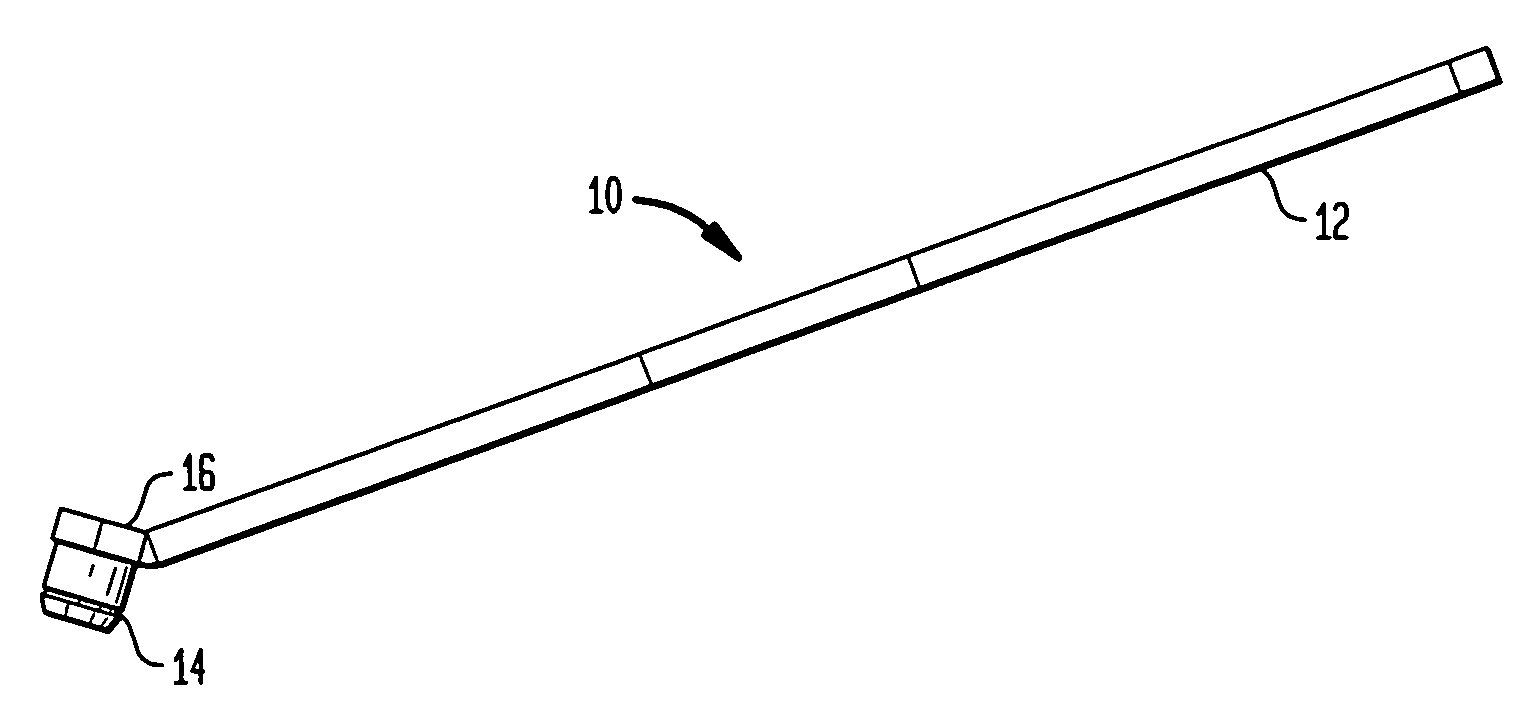

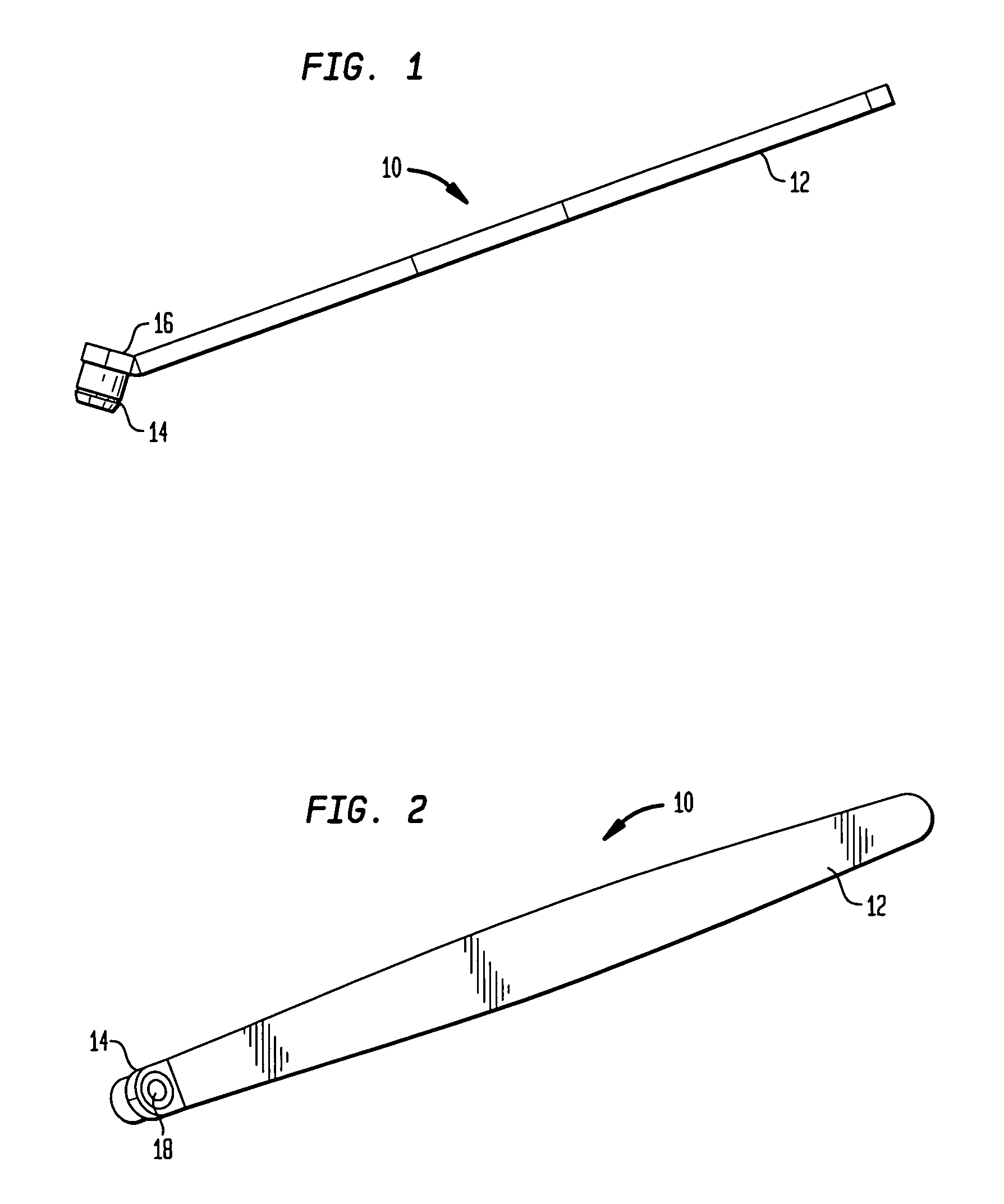

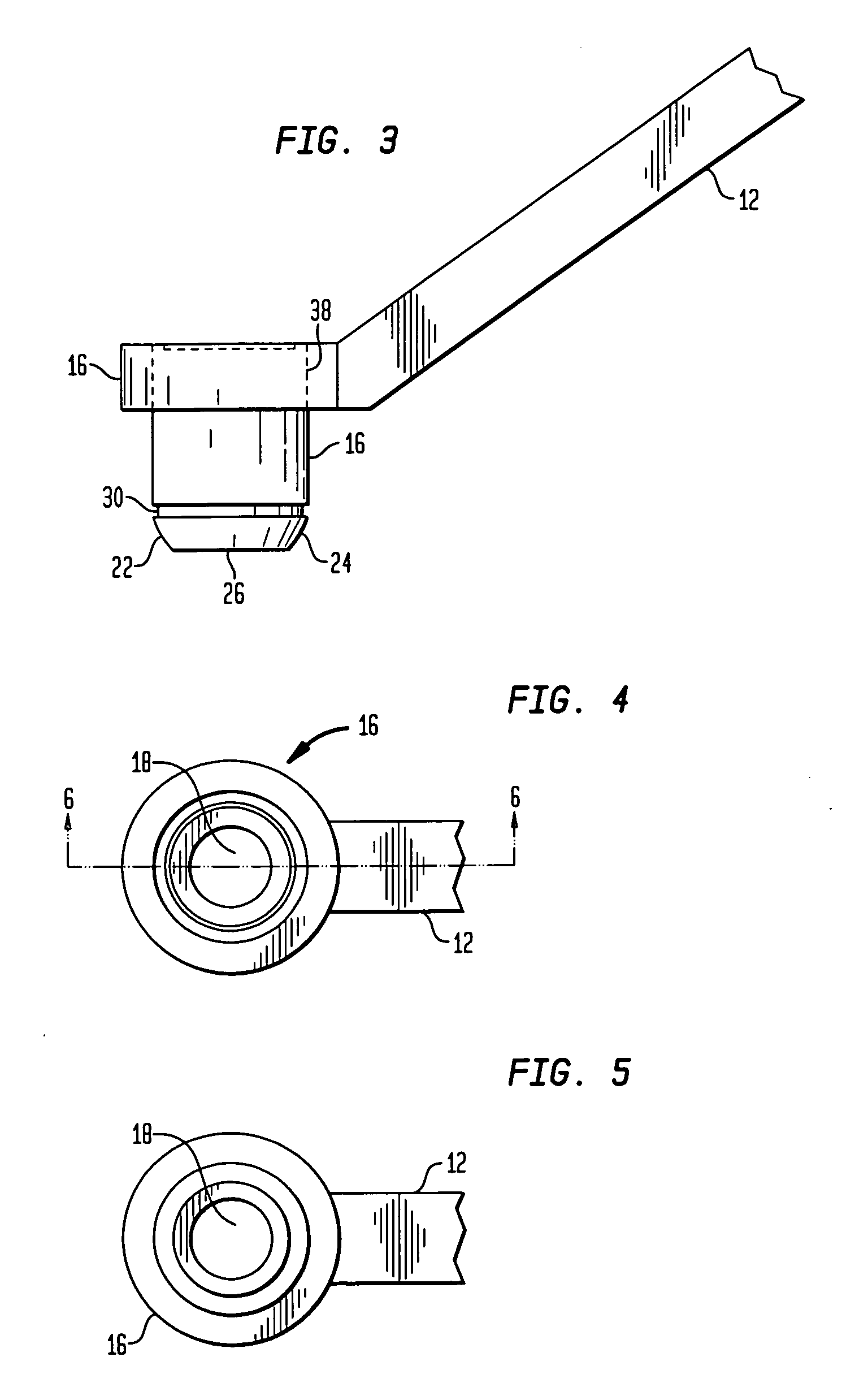

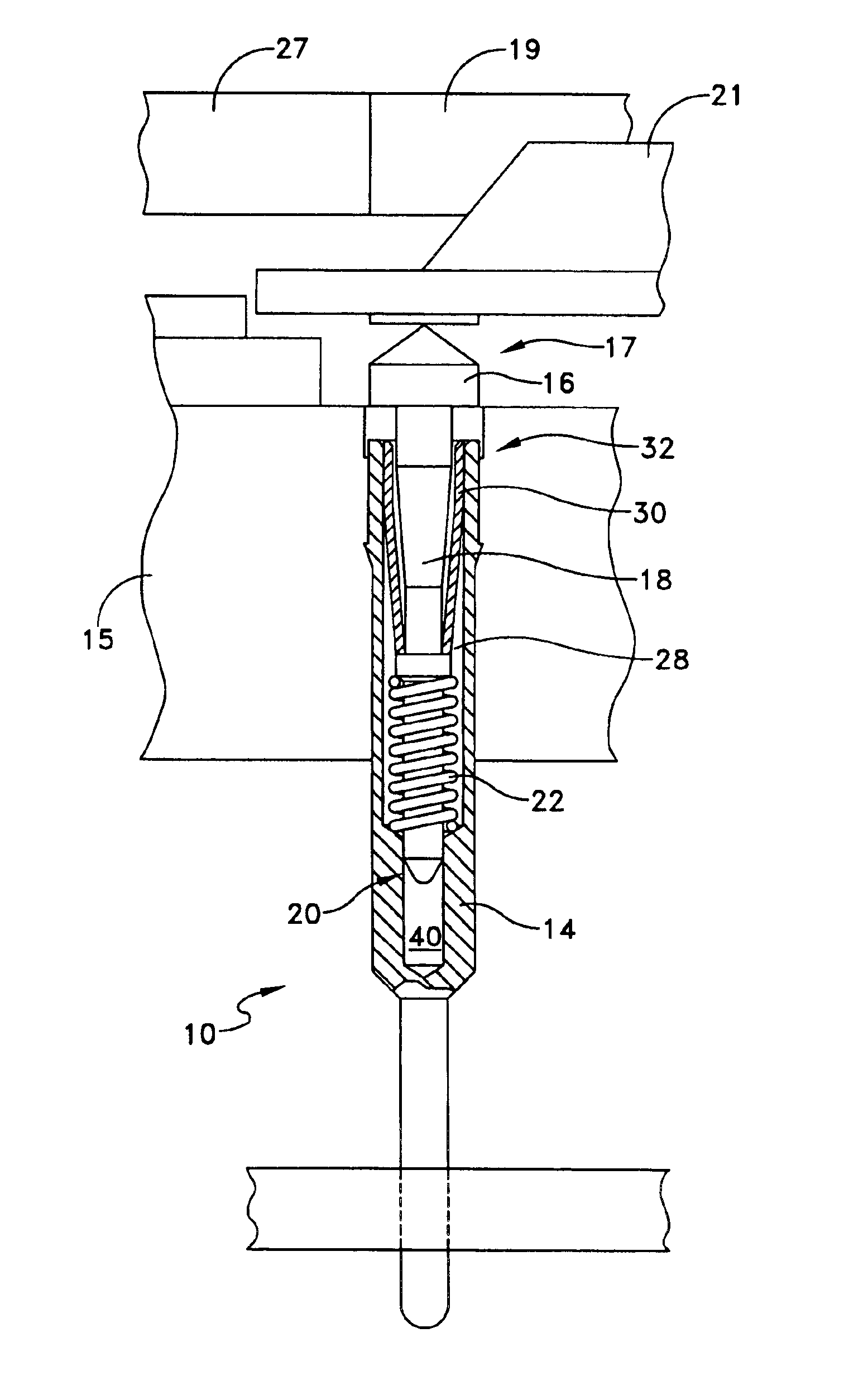

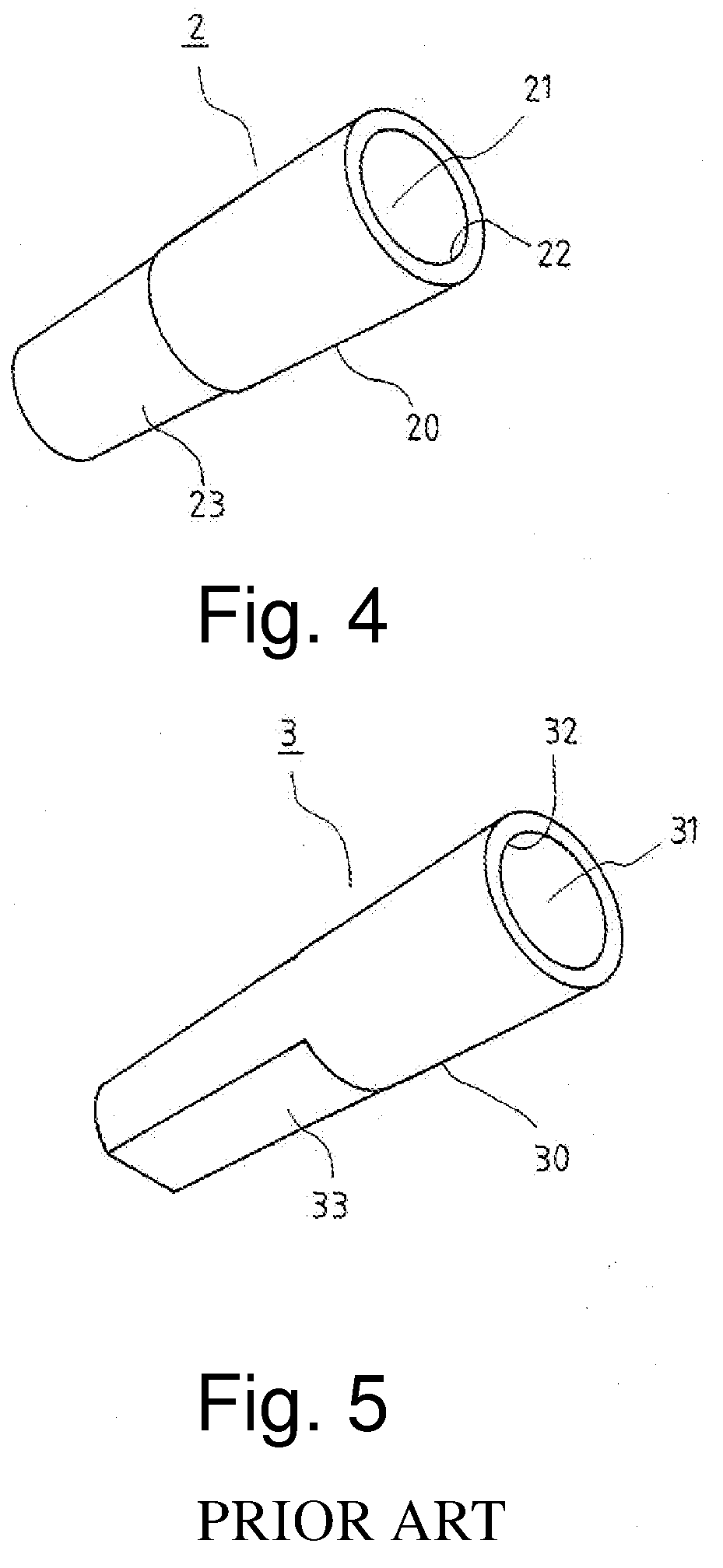

Adjustable bicycle seat post assembly

InactiveUS20040208687A1Reduce structural weightEasy to disassembleFoot-driven leversFurniture joining partsLocking mechanismSpring force

An adjustable height bicycle seat post assembly comprises a hollow seat post for supporting a bicycle seat slidably supported on plastic shims inside a hollow tube. The hollow tube clamps into the frame of a bicycle. A main spring forces the post upward, but a locking mechanism interconnects the post with the tube in various fixed positions relative to the tube. The locking mechanism includes a foundation and a projection extending from the foundation having a counterbore for guiding a plunger into holes on the post. The locking mechanism adheres to the outside of the tube to bear shearing forces on the plunger. An endcap on the locking mechanism and a top cap on the tube protect the assembly from foreign debris. The locking mechanism may be manipulated remotely using a magnetic switch assembly or manually using a manual assembly.

Owner:SICZ WAYNE +1

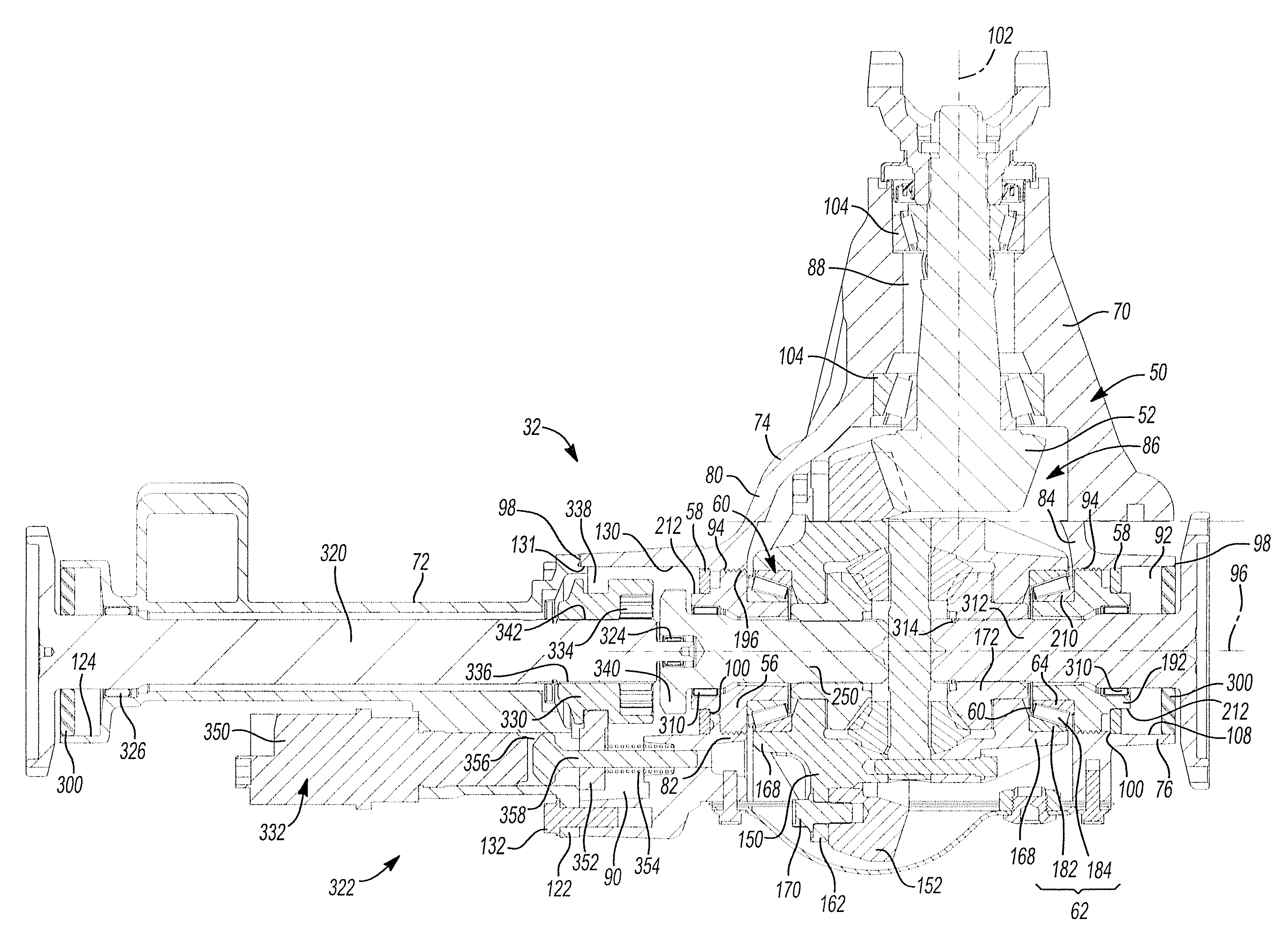

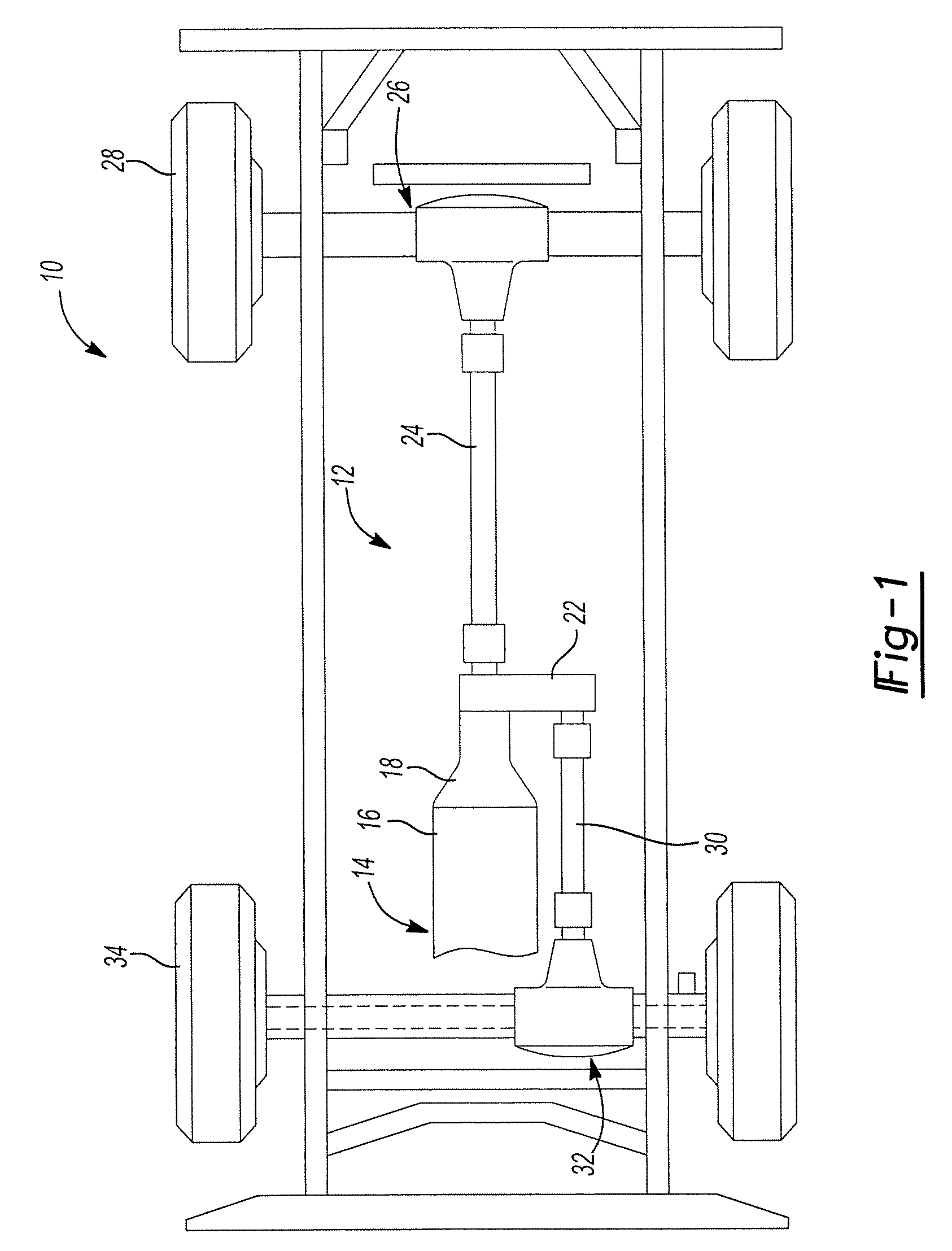

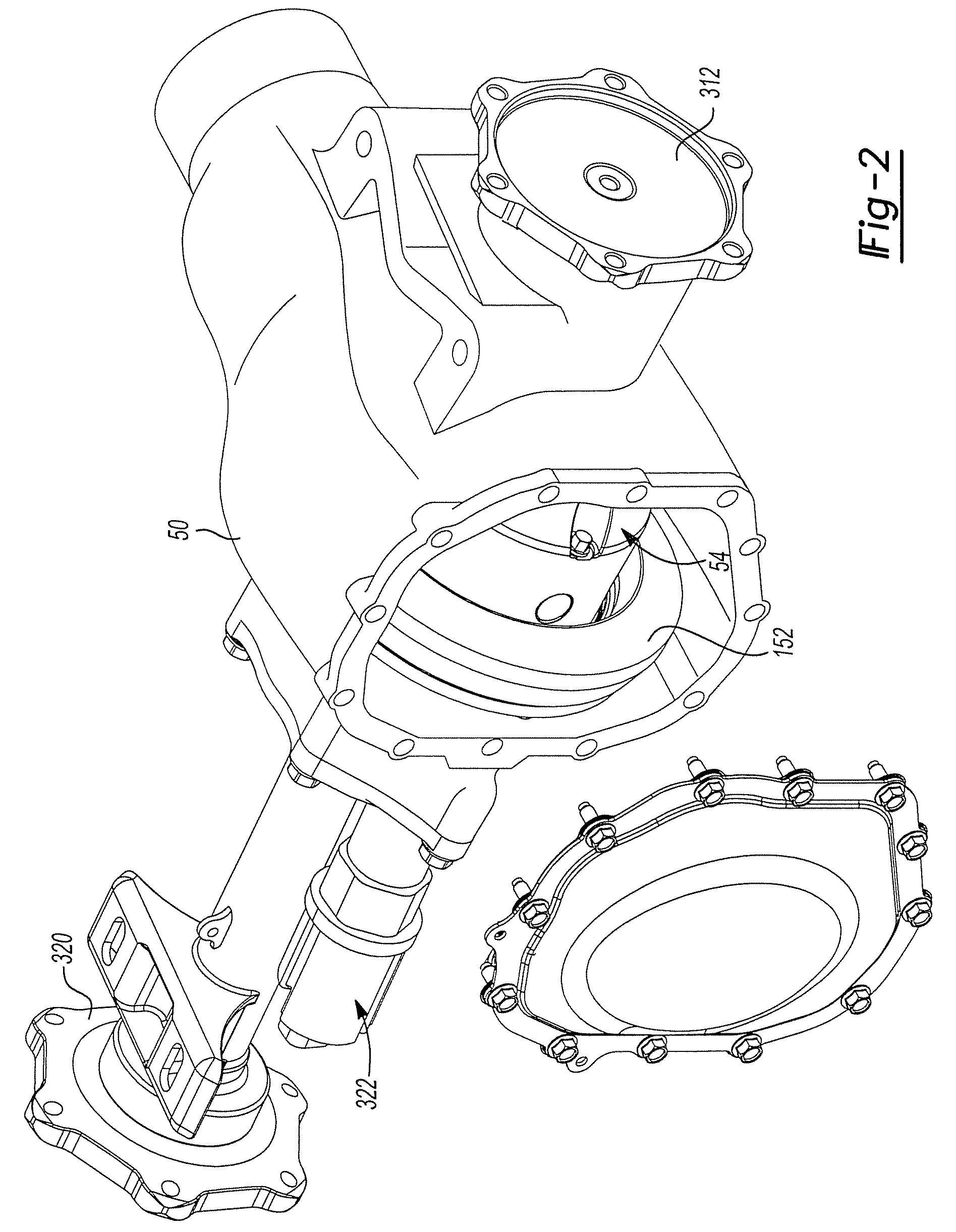

Differential and bearing arrangement

Owner:AMERICAN AXLE & MFG

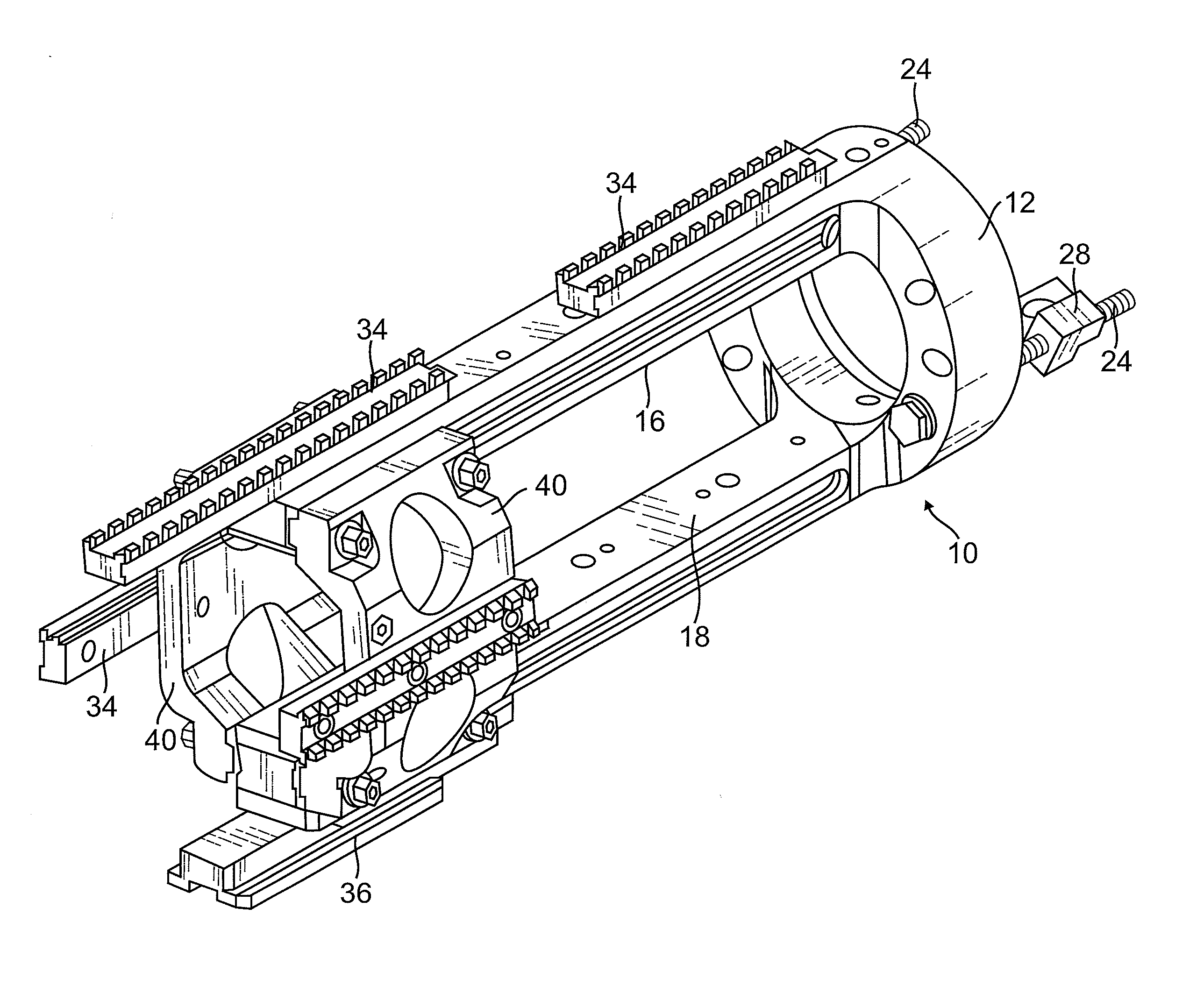

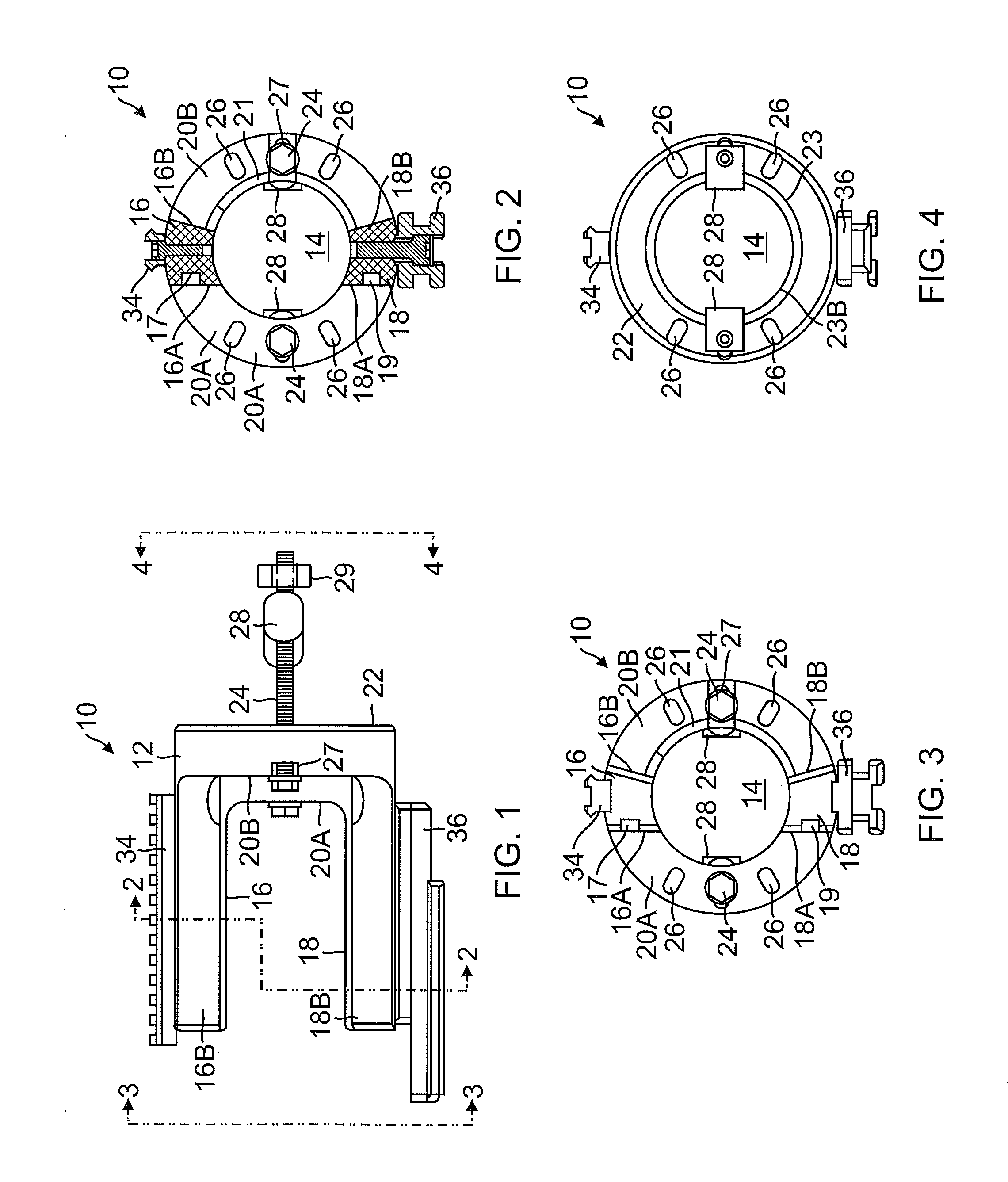

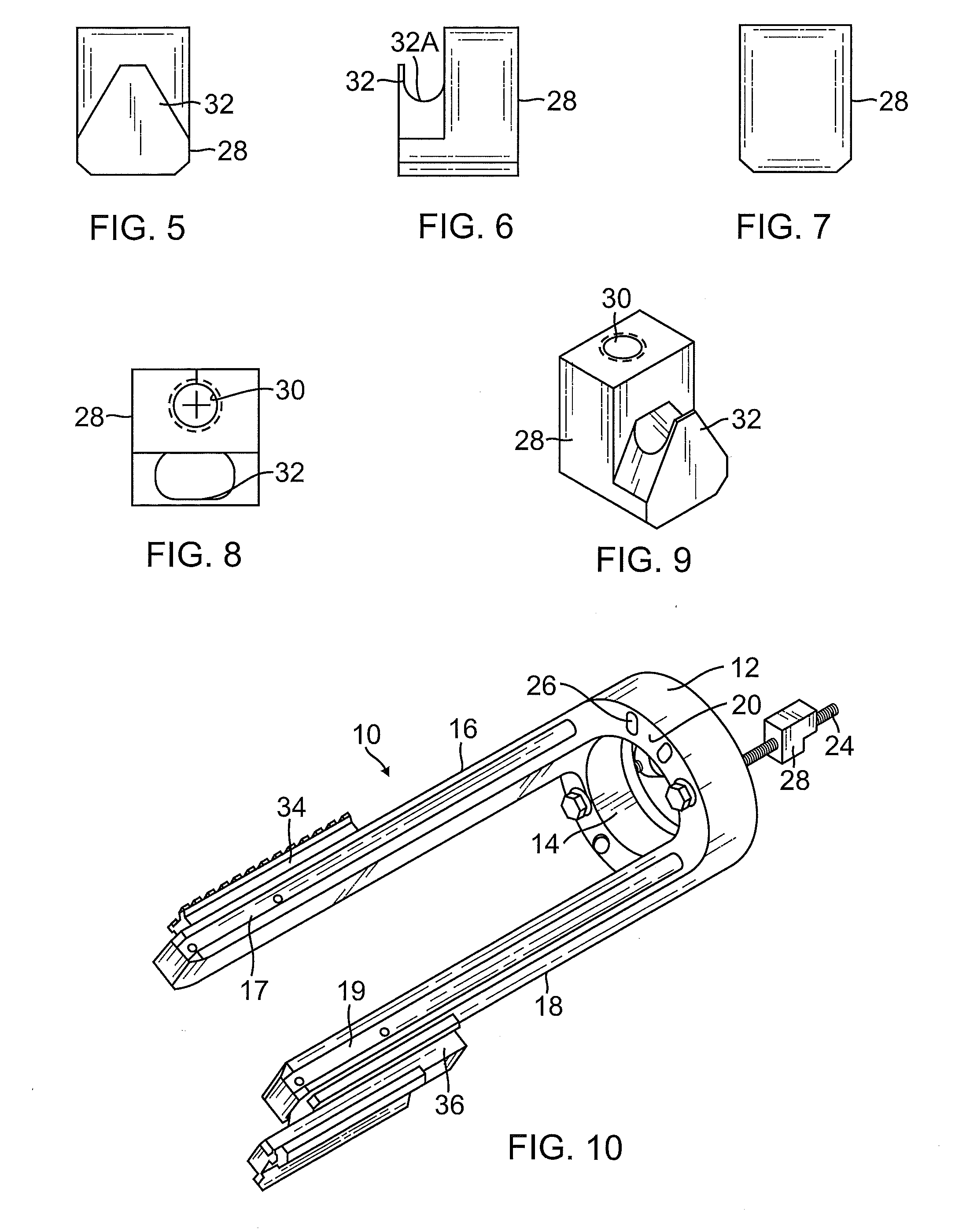

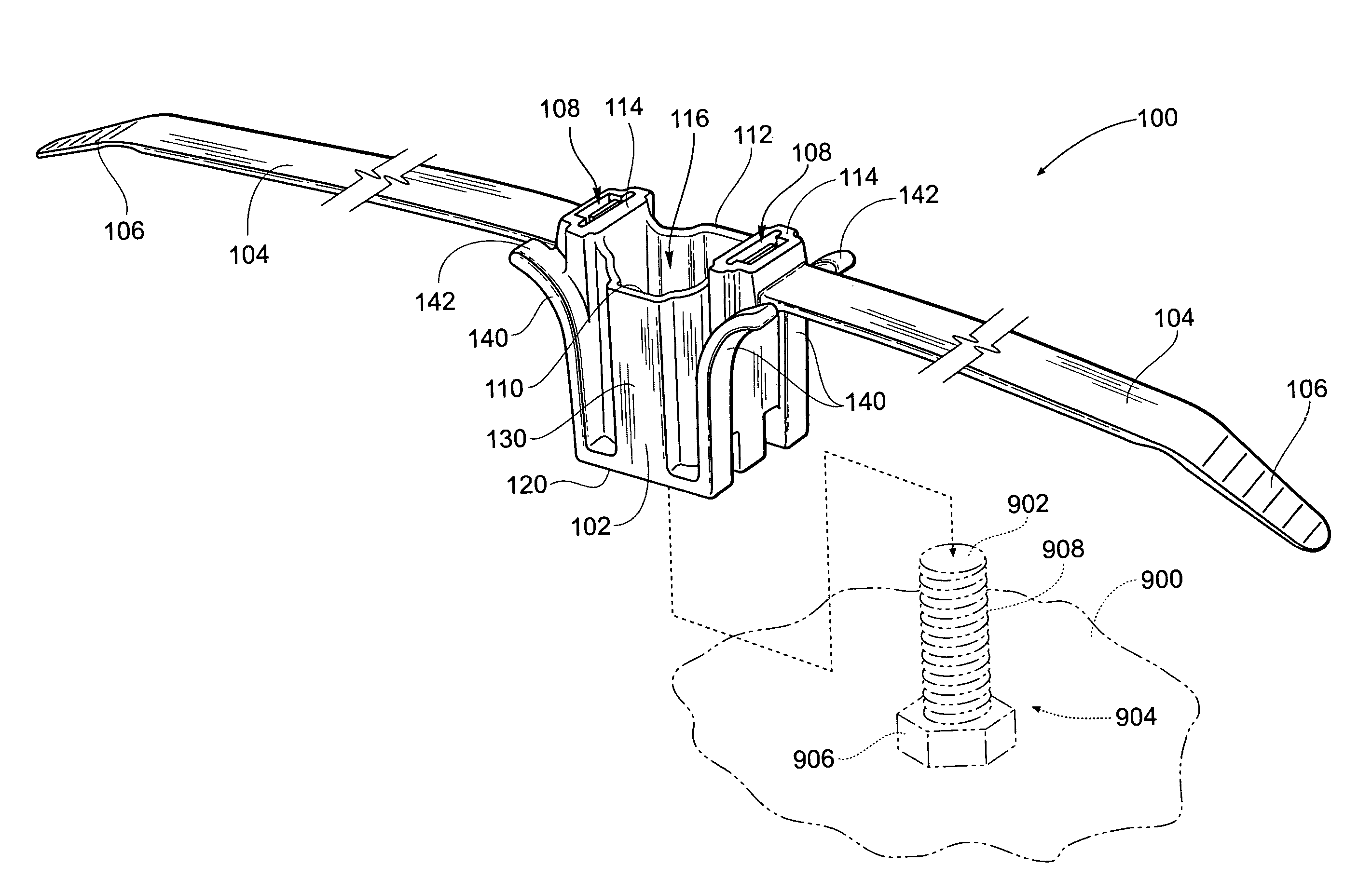

Machine gun accessory mount

A universal accessory mount for a heavy machine gun includes an annular base adapted to be disposed concentrically over a front end of a shroud of the gun and having diametrically opposing upper and lower accessory mounting tines extending forwardly therefrom. A holding mechanism pulls a planar floor of a counterbore in the rear of the base into contact with a planar front surface of the shroud of the gun. The holding mechanism includes a pair of threaded bolts extending rearwardly from the base through respective ones of a pair of diametrically opposing bolt apertures contained in the base, and a pair of cleats, each having an opening into which a rear end portion of a respective one of the bolts is received and a respective hook adapted to grip the shroud of the gun through a respective hole in the shroud.

Owner:SUREFIRE LLC

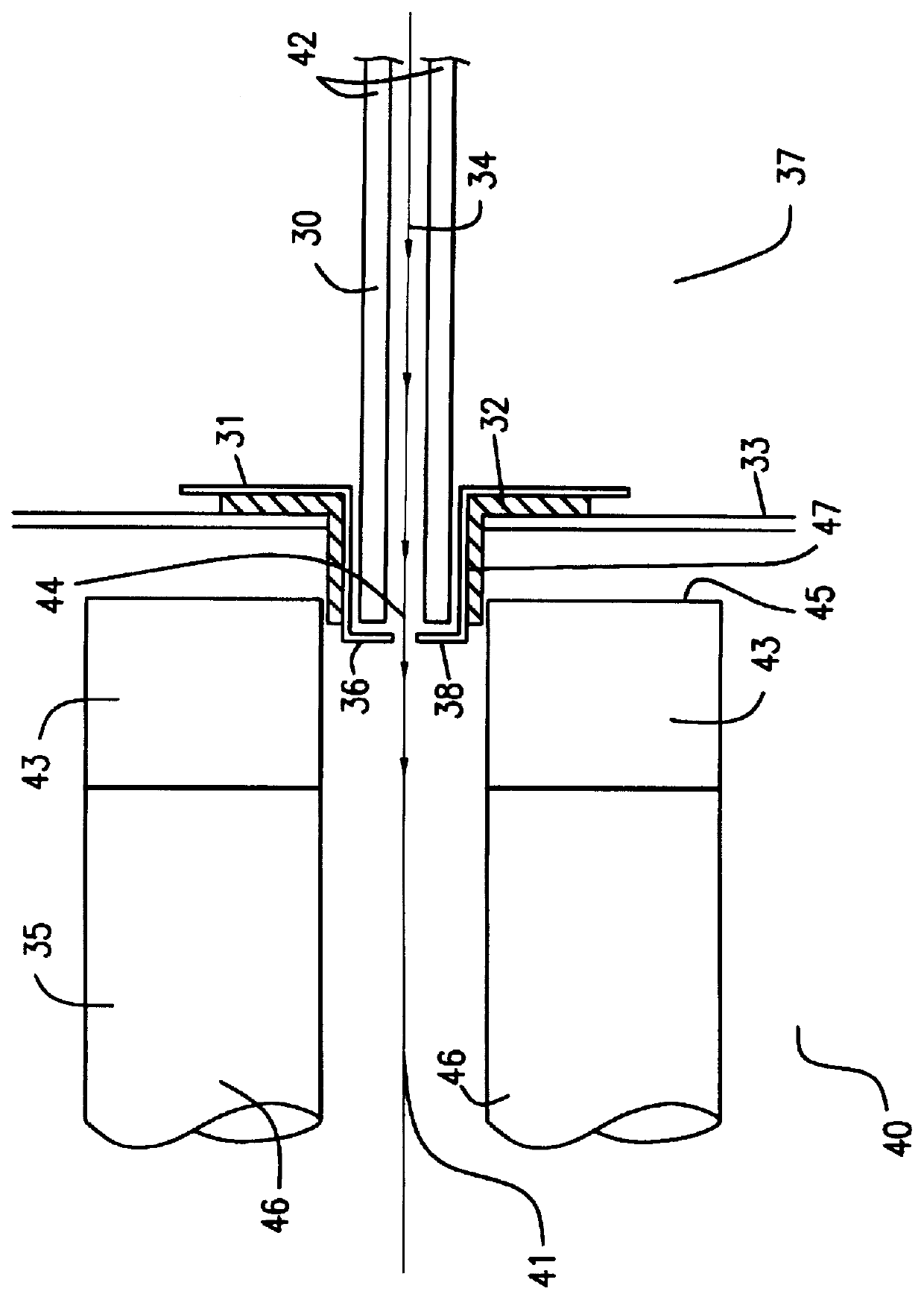

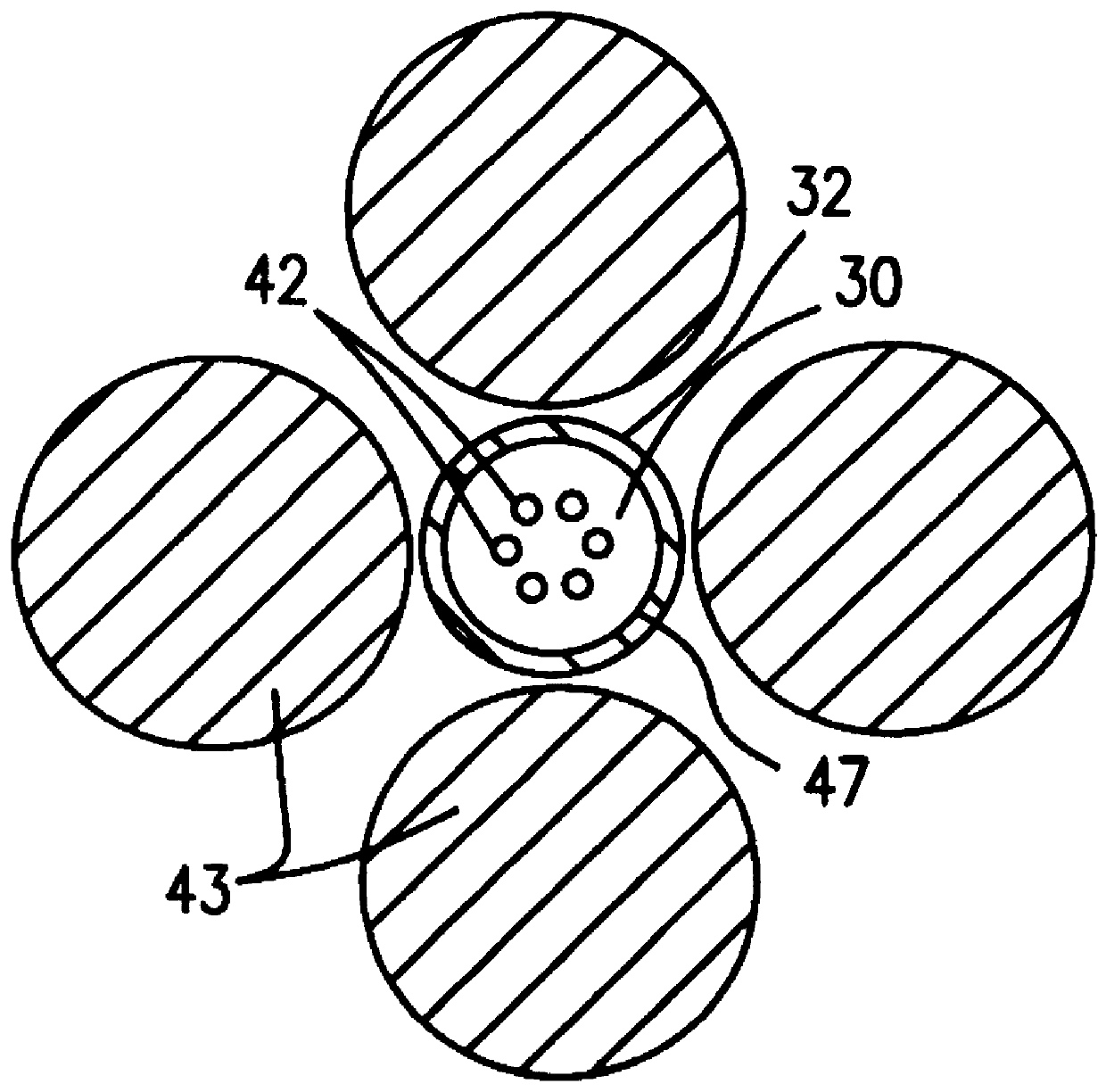

Ion transfer from multipole ion guides into multipole ion guides and ion traps

InactiveUS6121607AReduce the overall diameterImprove ion transfer efficiencyStability-of-path spectrometersSamples introduction/extractionIon trap mass spectrometryReduced size

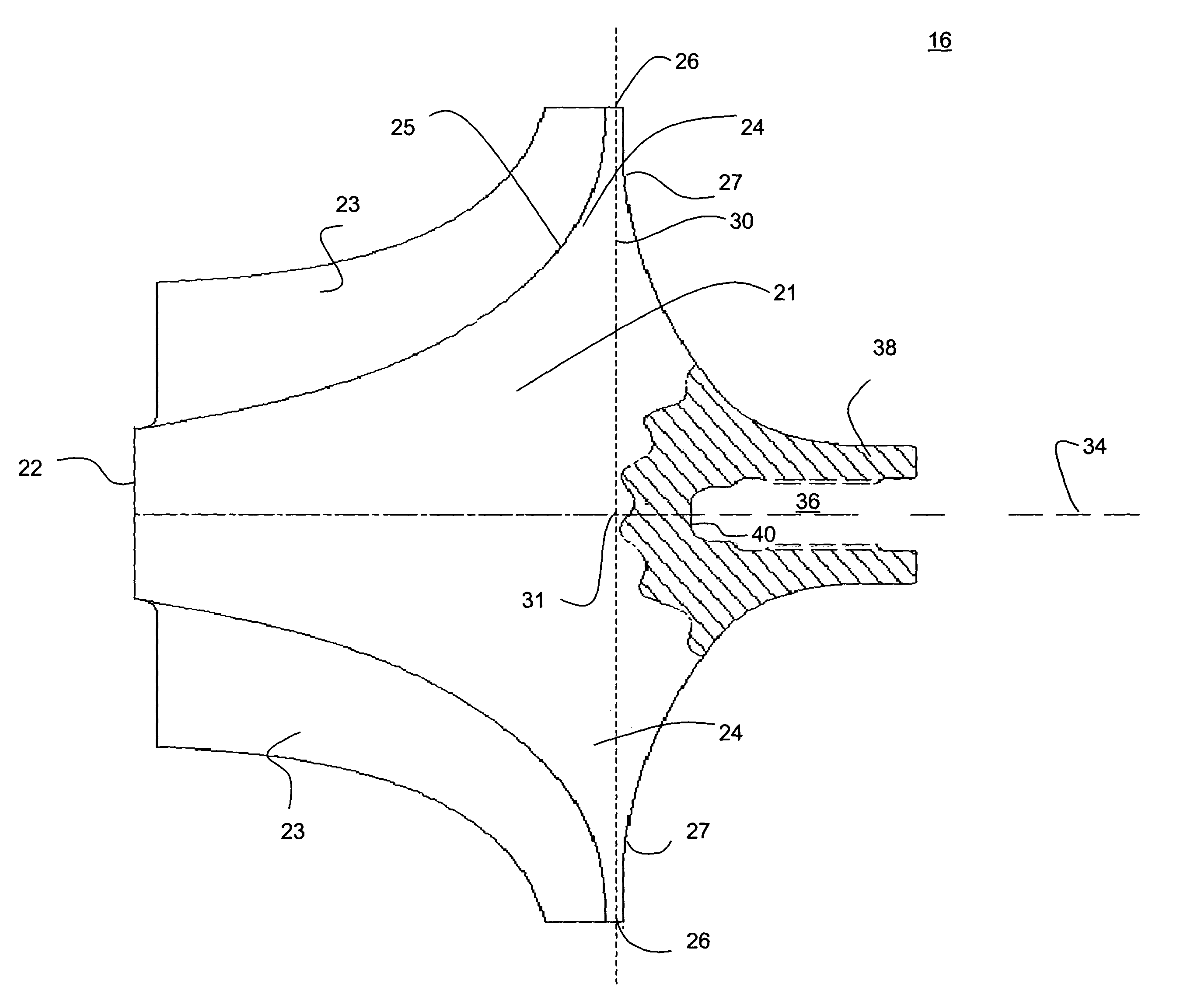

A multipole ion guide is configured to improve the transmission efficiency of ions which traverse the length of one ion guide and enter either another multipole ion guide such as a quadrupole mass analyzer or a three dimensional ion trap. The ion transfer multipole ion guide radial dimensions are reduced such that the pole assembly and an appropriately shaped exit lens can be positioned within a portion of the internal space defined by the larger radius second multipole ion guide poles. Ions exiting the first ion guide of reduced size find themselves inside the second ion guide close to the centerline. In this manner ions can be efficiently transferred from one ion guide to another, even for those ions with low kinetic energies. In a second embodiment of the invention, the exit region of a multipole ion guide is configured such that the multipole ion guide poles can be extended into a counterbore of a three dimensional ion trap end cap electrode. With this configuration, ions (including those with low kinetic energies) can be transferred into a three dimensional ion trap with increased trapping efficiency.

Owner:PERKINELMER HEALTH SCIENCES INC

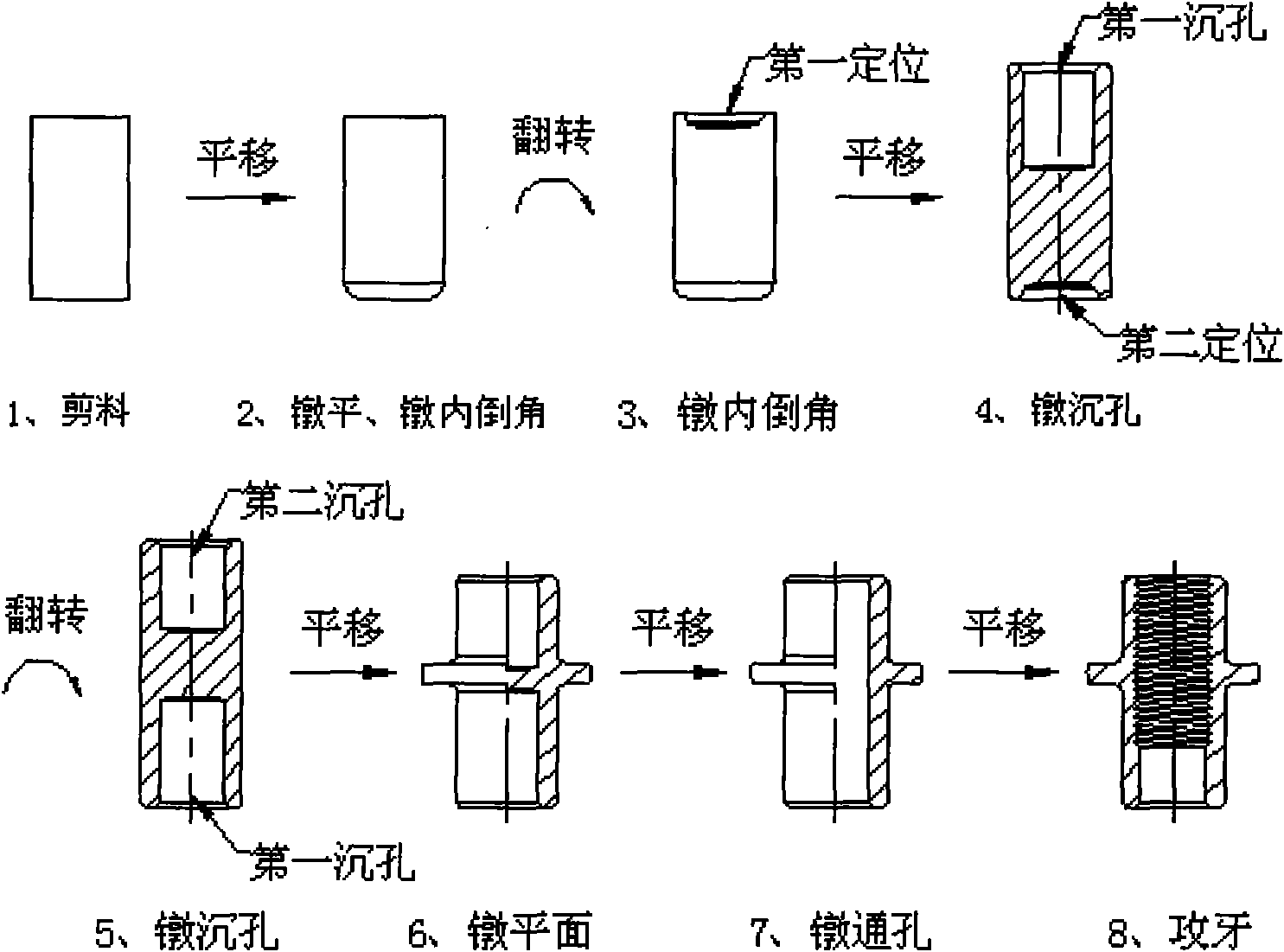

Manufacturing process of adjusting nut

InactiveCN101618498ALess consumablesCompact structureNutsMetal-working apparatusWire rodMolding machine

The invention discloses a manufacturing process of an adjusting nut. The steel billet raw materials are manufactured into wire rod materials, surface treatment is performed on the wire rod materials by using phosphate, spheroidizing annealing, phosphating and fine-drawing and sizing treatment are respectively performed on the wire rod materials after roughing, and finally, the molding working procedure of the adjusting nut is carried out in a cold-heading molding machine; the molding working procedure of the adjusting nut comprises the following steps: material fracturing; material shaping and upsetting, upsetting an inner chamfer at the upper end; material turning, shaping and upsetting a positioning hole at the upper end and an inner chamfer at the lower end; material translating, upsetting a counterbore at the front end and a positioning hole at the rear end; material turning, upsetting a counterbore at the other end; material translating, upsetting a plane in the middle by using the PKO male die technology; discharging the residual scrap iron at a middle hole out and manufacturing a through hole product; and performing tapping to an inner hole of a blank of the adjusting nut. The invention is molded at one time by adopting a cold heading machine, thereby improving the production efficiency and the product quality of the adjusting nut, saving the raw material and reducing the manufacturing cost.

Owner:NINGBO ANCHOR FASTENERS INDAL

Method for assembling a package for sutures

InactiveUS20050034431A1Quick applicationReduce manufacturing costSuture equipmentsSurgical needlesEngineeringCounterbore

A novel method and apparatus for riveting a two-piece suture tray package. A two-piece suture tray assembly is provided having a top member and a bottom member. The top member has a top and a bottom, and plurality of rivet members extending down from the bottom of the top member. The rivet members have free ends. The bottom member has a top and a flat bottom surface, and a plurality of rivet receiving openings extending therethrough. A counterbore surrounds each rivet receiving opening in the flat bottom surface. An ultrasonic riveting apparatus is provided having a clamp member with a cavity, and an ultrasonic horn member having a flat bottom moveably mounted in the cavity The assembly is mounted in the riveting apparatus and engaged by the clamp member. The flat bottom of the horn member engages the free ends of the rivet members, and when energized by an ultrasonic generator, causes the free ends of the rivet members to deform into the counterbores, such that the free ends are flat and in alignment with the bottom surface of the bottom member.

Owner:ETHICON INC

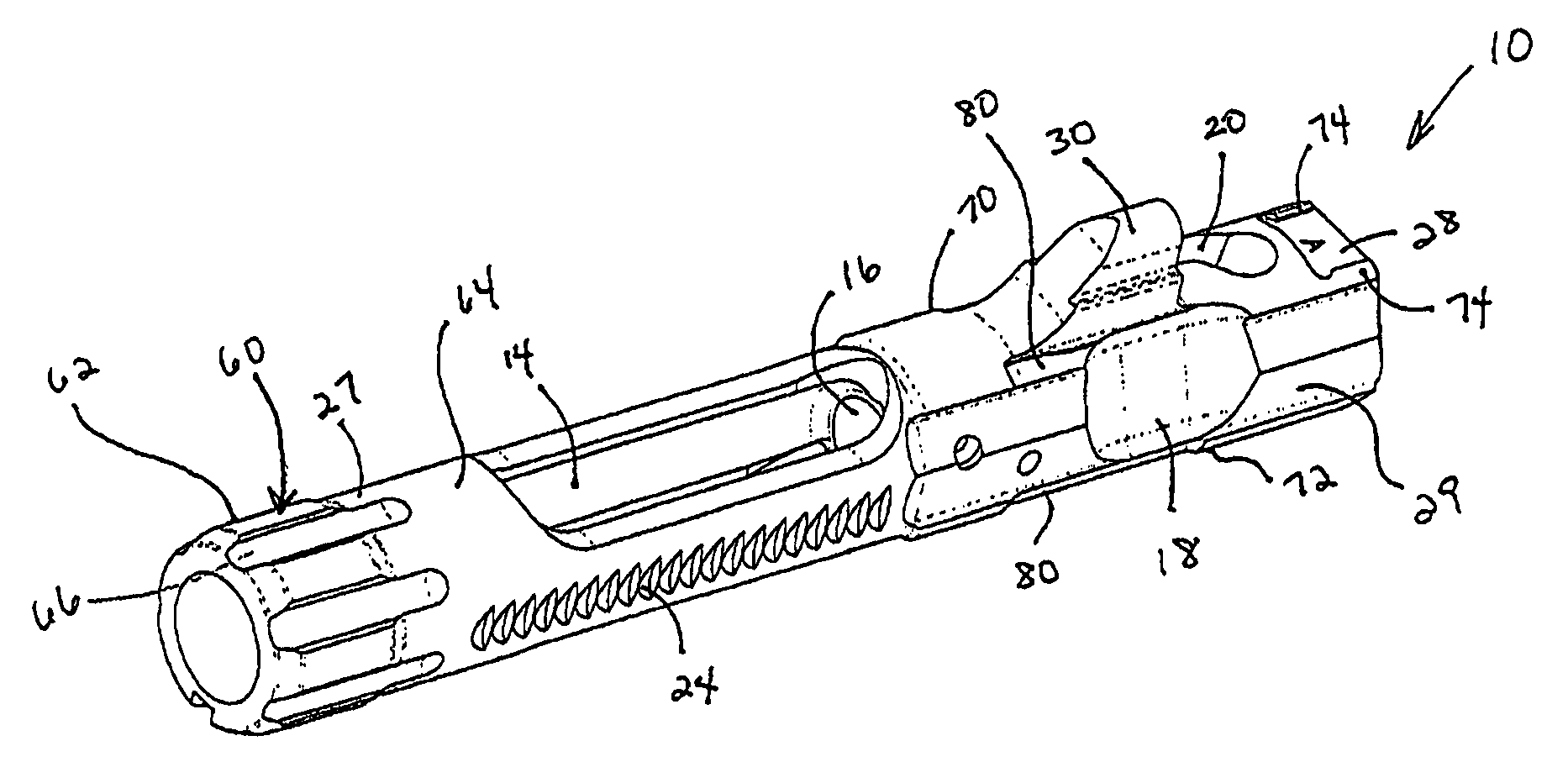

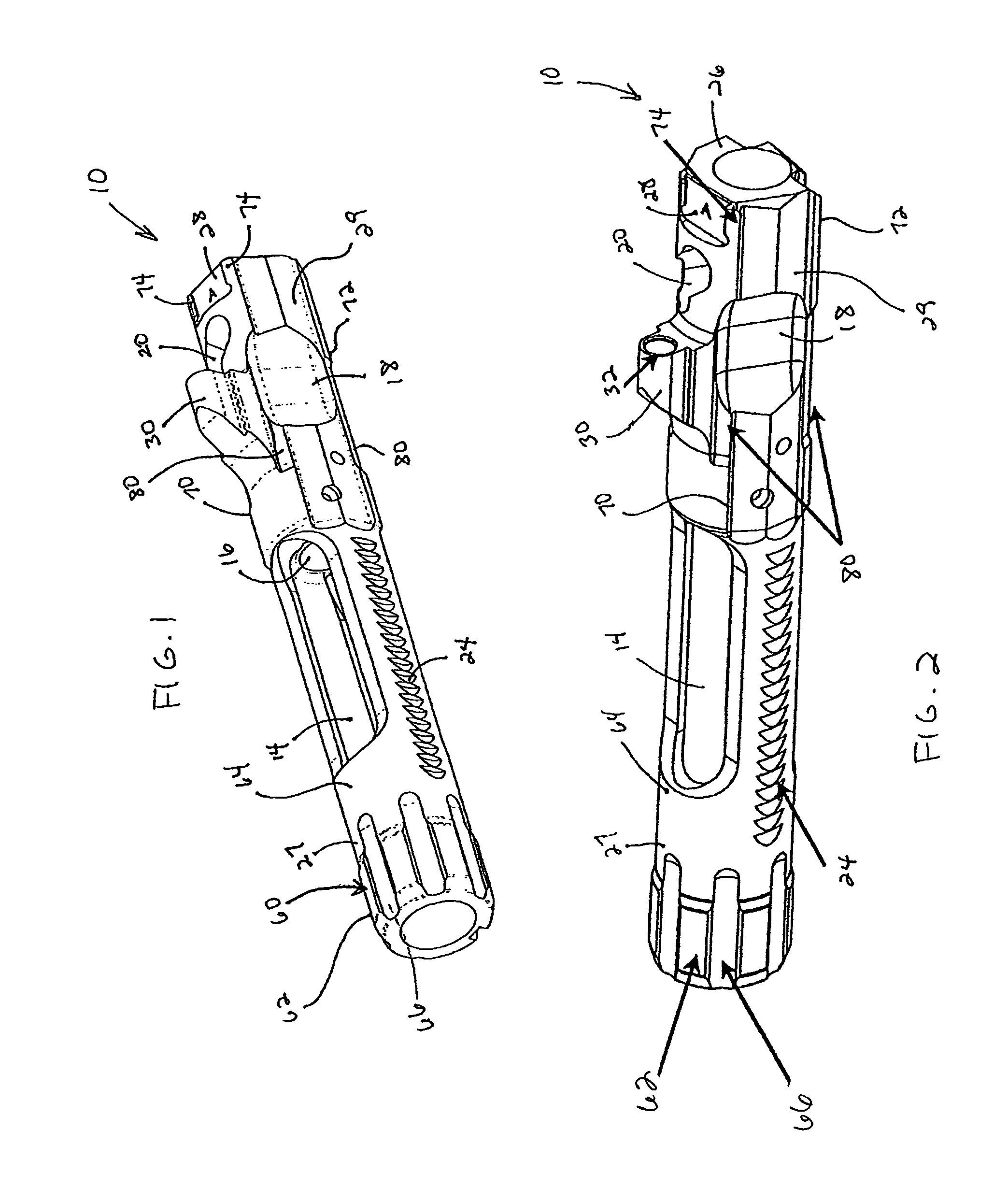

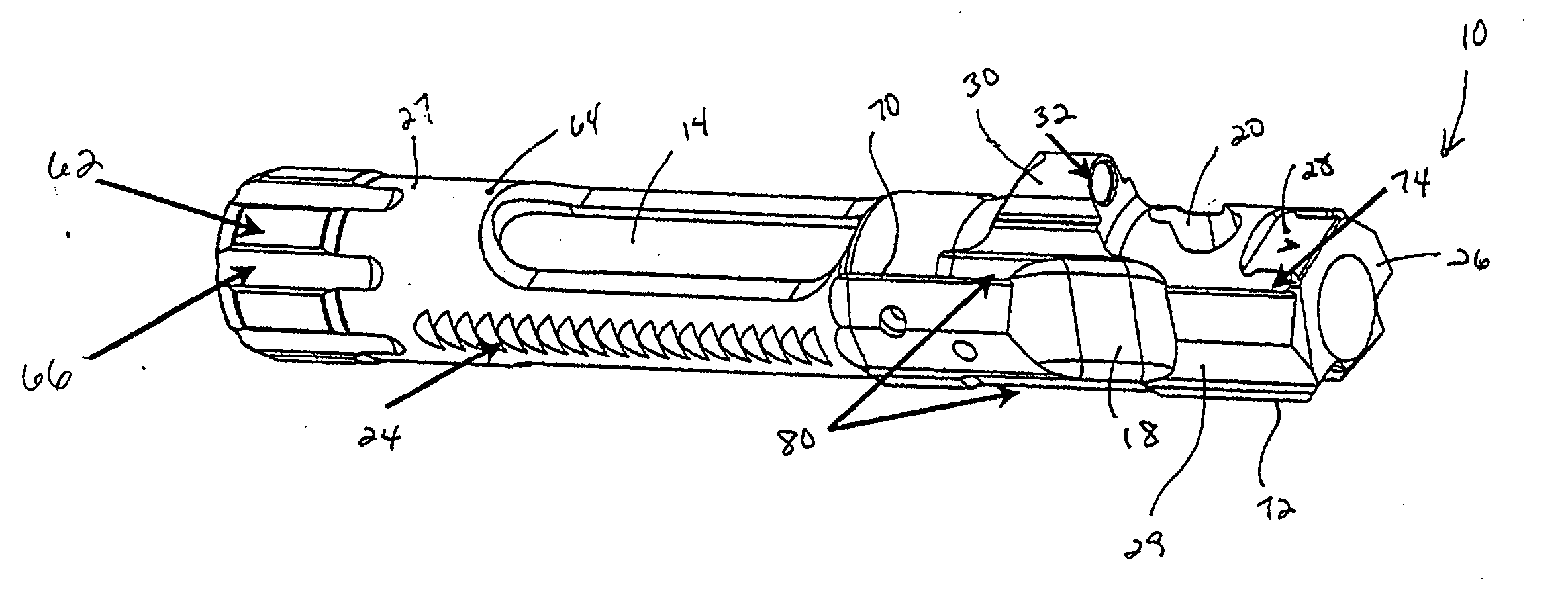

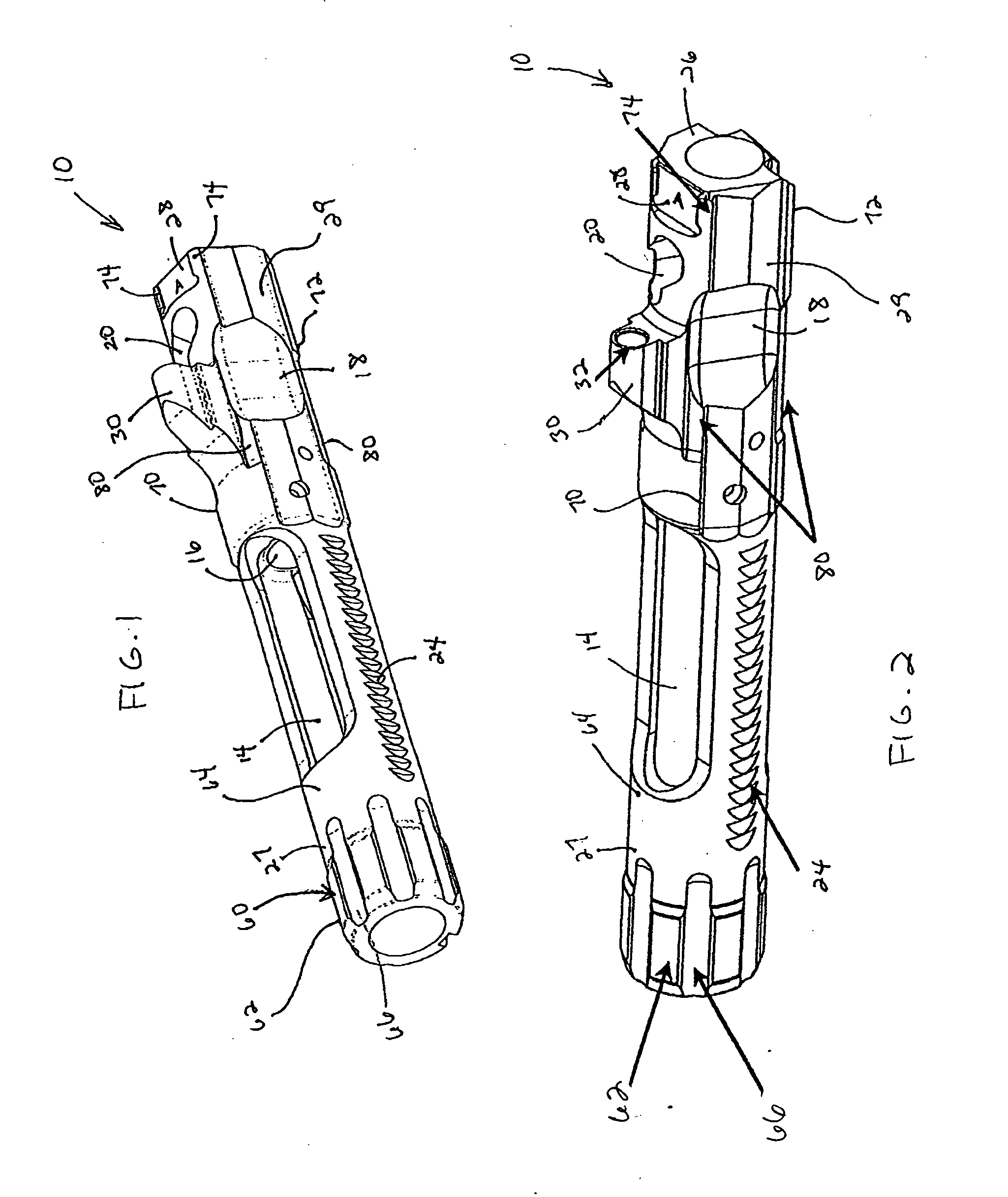

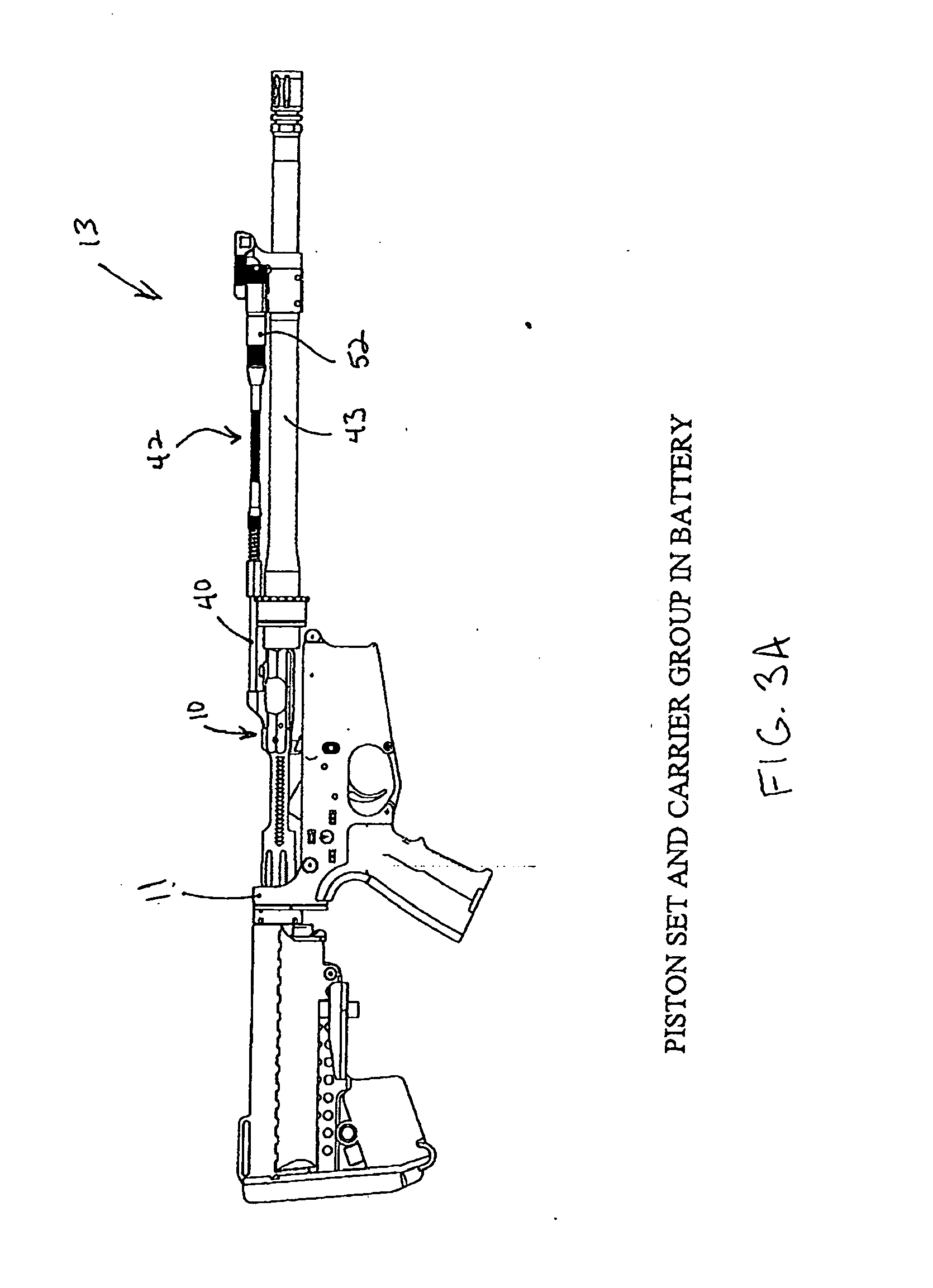

Self loading firearm bolt carrier with integral carrier key and angled strike face

ActiveUS8387513B2Increased durabilityBreech mechanismsShoulder-fired smallarmsCounterboreBearing surface

A bolt carrier for use with the ARI5 / MI6 family of firearms is provided. The bolt carrier includes an integrally formed carrier key and spherical strike face surrounded by a cylindrical counterbore made with a downward angle to act against the tilting force imparted by the operating rod of the firearm's gas operating system. The outer surface of the carrier includes upper and lower running rails that all extend fully to the front face of the carrier to lengthen the carrier's rail support or bearing surfaces against the receiver.

Owner:LWRC INTERNATIONAL

Drill guide with angle verification

A method and instrument is used for inserting a bone screw into a hole in a bone plate and into bone at a maximum angulation of a bone screw central longitudinal axis with respect to a central axis of the hole. The maximum angulation is that which places the head of the bone screw at or below an outwardly facing surface of the bone plate. The instrument has a distal end including a gauge element, spaced proximally from an end surface of the distal end when in contact with a counterbore surrounding the plate hole. The space is less than or equal to a distance from the counterbore surface to the outwardly facing surface of the bone plate. The instrument is tilted with respect to a central axis of the bone plate hole to an angle wherein the gauge element remains at or below the outwardly facing surface of the bone plate adjacent the counterbore. A hole is drilled in the bone through a guide bore in the instrument.

Owner:HOWMEDICA OSTEONICS CORP

Test socket

A test socket including a contactor having a distal end which is received within a tapered retainer for guiding the distal end of the contactor and into a terminal housing having a counterbore such that movement of the distal end of the contactor is restricted by the counterbore of the terminal is disclosed.

Owner:TATE JOHN O

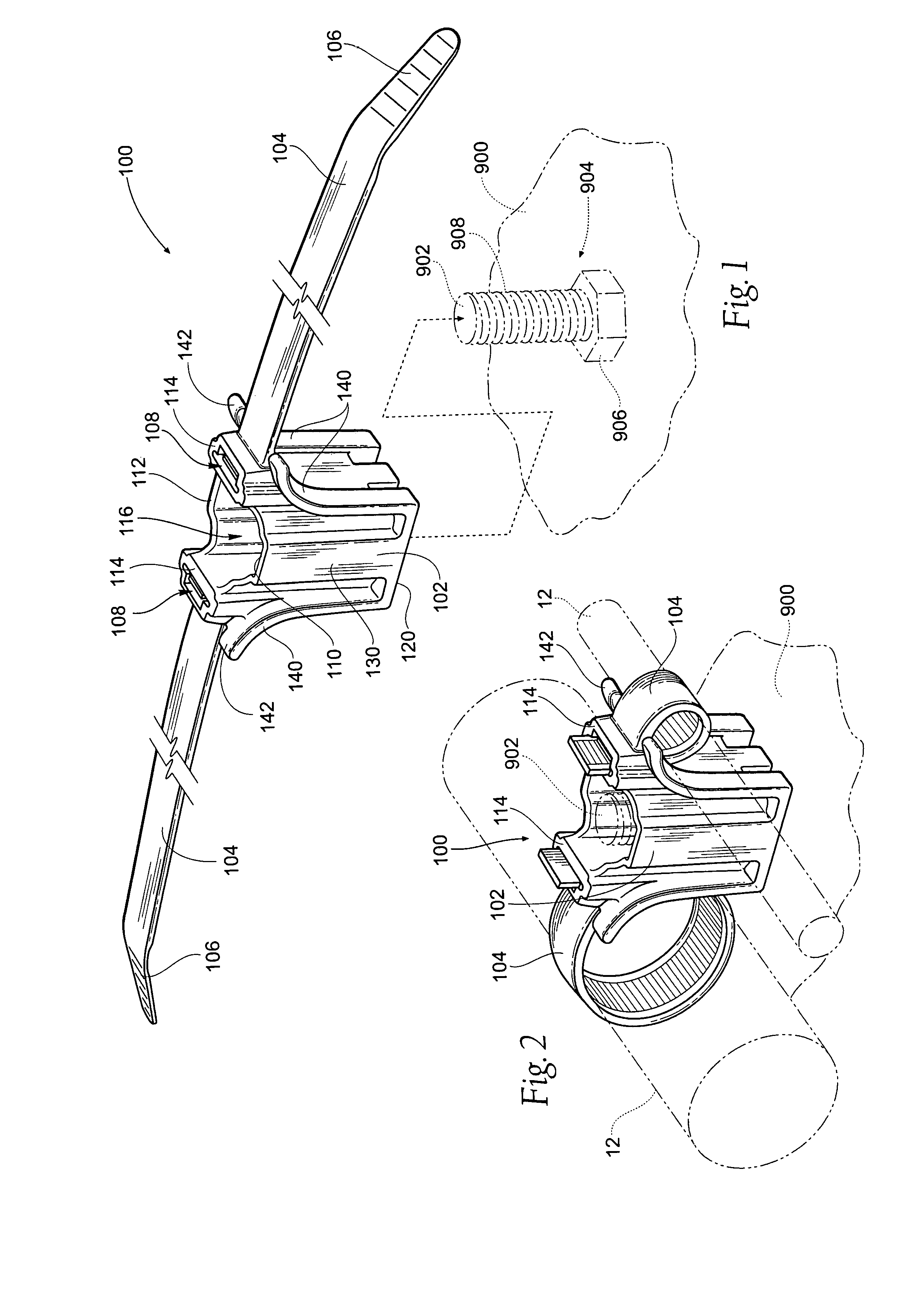

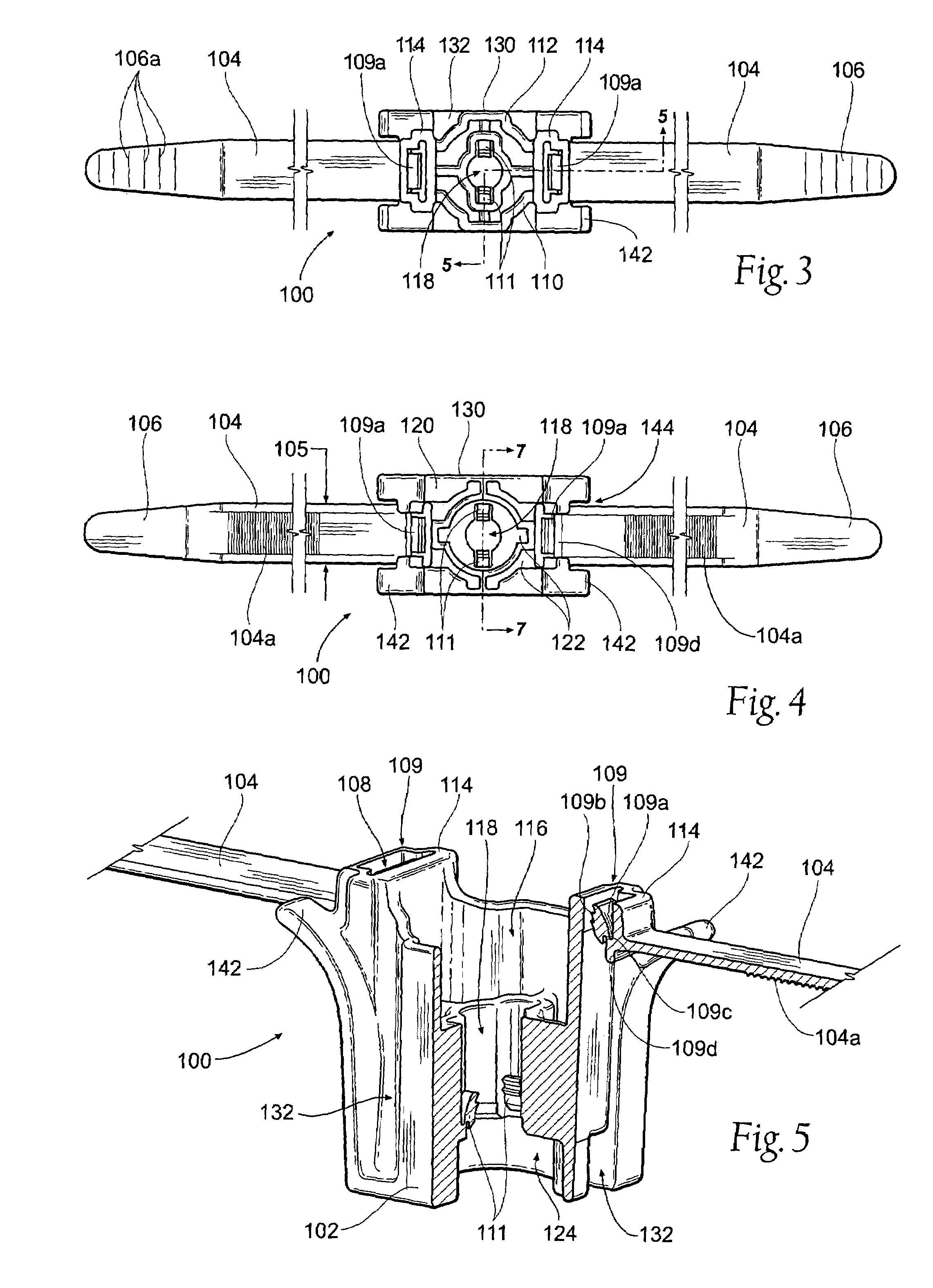

Clamp tie

A clamp tie includes a locking head and flexible straps extending therefrom. The straps are insertable through the locking head to form spaced loops, which may secure items in a spaced relationship. Pawl mechanisms in the locking head secure the straps in looped configuration. An aperture through the locking head is provided for securing the tie to a mounting structure such as a shouldered mounting stud. An additional pawl mechanism may be provided within the aperture to secure the tie to the stud. Arcuate surfaces extend from the locking head, spaced from the straps, to further engage secured items. The upper and lower surfaces of the locking head have counterbores to receive mounting hardware and provide minimal variance of wall thickness throughout the locking head to reduce cure time and materials required for manufacture.

Owner:HELLERMANNTYTON CORP

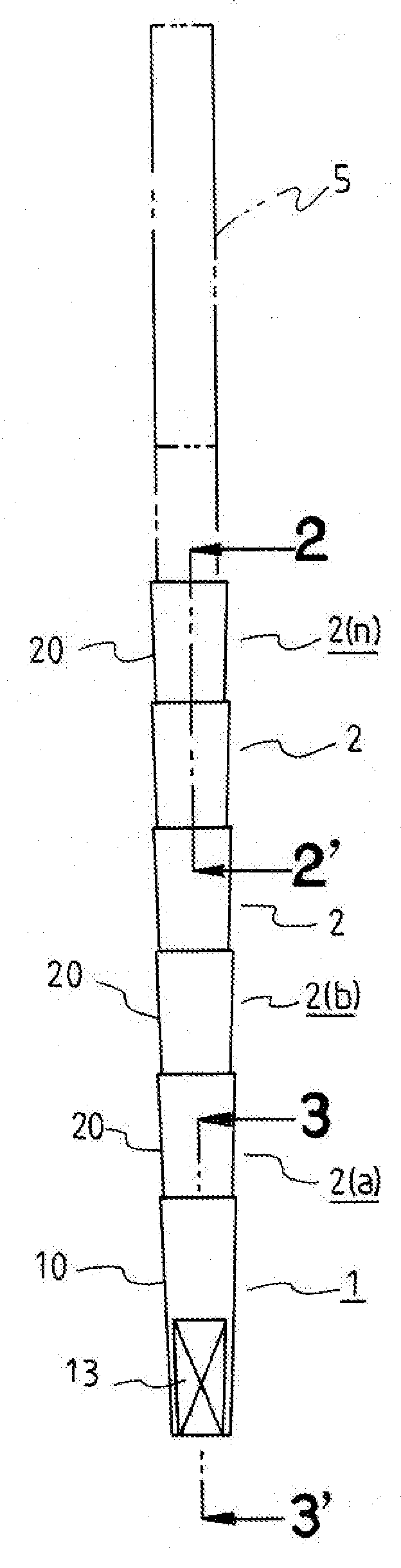

Connectable Cigarette Filter

InactiveUS20100163065A1Reduce filter effectEasily and arbitrarily increaseTobacco smoke filtersTobacco pipesMouth pieceCounterbore

A connectable cigarette filter comprises a mouthpiece and a plurality of, or one to two, or two to three filter units connected with the mouthpiece. The mouthpiece is an inclined cylindrical body centrally provided with a stepped aperture. The stepped aperture has a front section formed as a sloped cavity. The inclined cylindrical body has a rear section whose outer surface is provided with a pair of planes. The filter unit is a stepped cylindrical body with a stepped through-hole comprising a large-diameter through-hole and a small-diameter through-hole. The front section of the stepped through-hole is formed as a sloped counterbore. The stepped cylindrical body has a rear section formed as a small-diameter, sloped cylindrical body which is shaped and sized according to the sloped counterbore, so that the small-diameter, sloped cylindrical body of one filter unit is insertable into the sloped counterbore of another filter unit.

Owner:CHANG PI HSIU

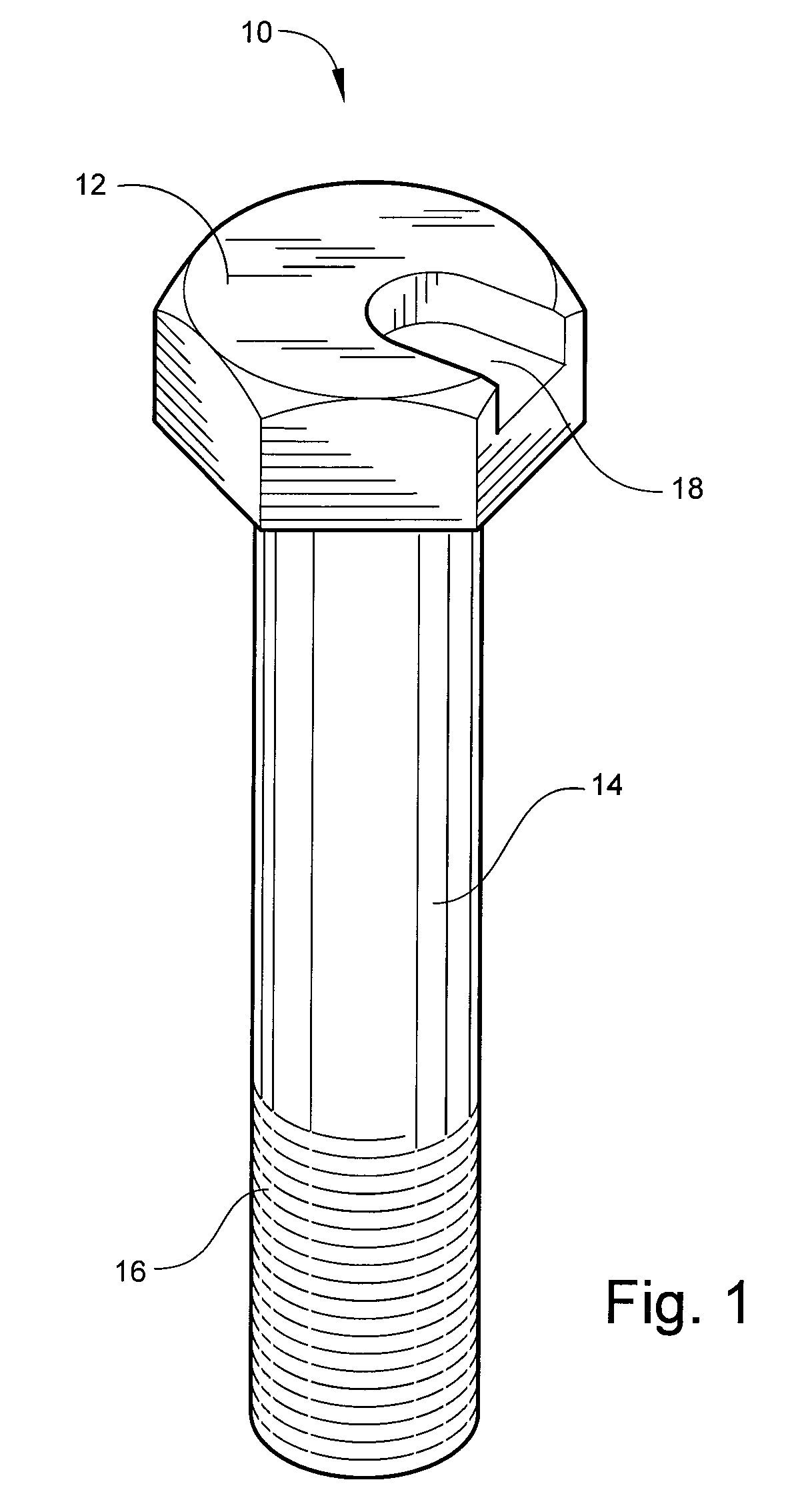

Threaded fastener with determinable clamp load

A threaded fastener for securing workpieces with a determinable desired clamp load and including a nut assembly and a bolt with the nut assembly including a nut member with a lock base having a load ring portion and a boss portion with the boss portion adapted to be located in a retention counterbore in the nut member and being of a length to provide a gap between the load ring portion and nut and at a predetermined load to collapse and close the gap and be deformed radially into compressive engagement with the threads of the bolt to provide prevailing torque type lock structure resisting loosening of the nut assembly from the bolt with the predetermined collapse load providing the desired clamp load and with the gap closure visibly indicating attainment of the desired clamp load.

Owner:HUCK INT INC

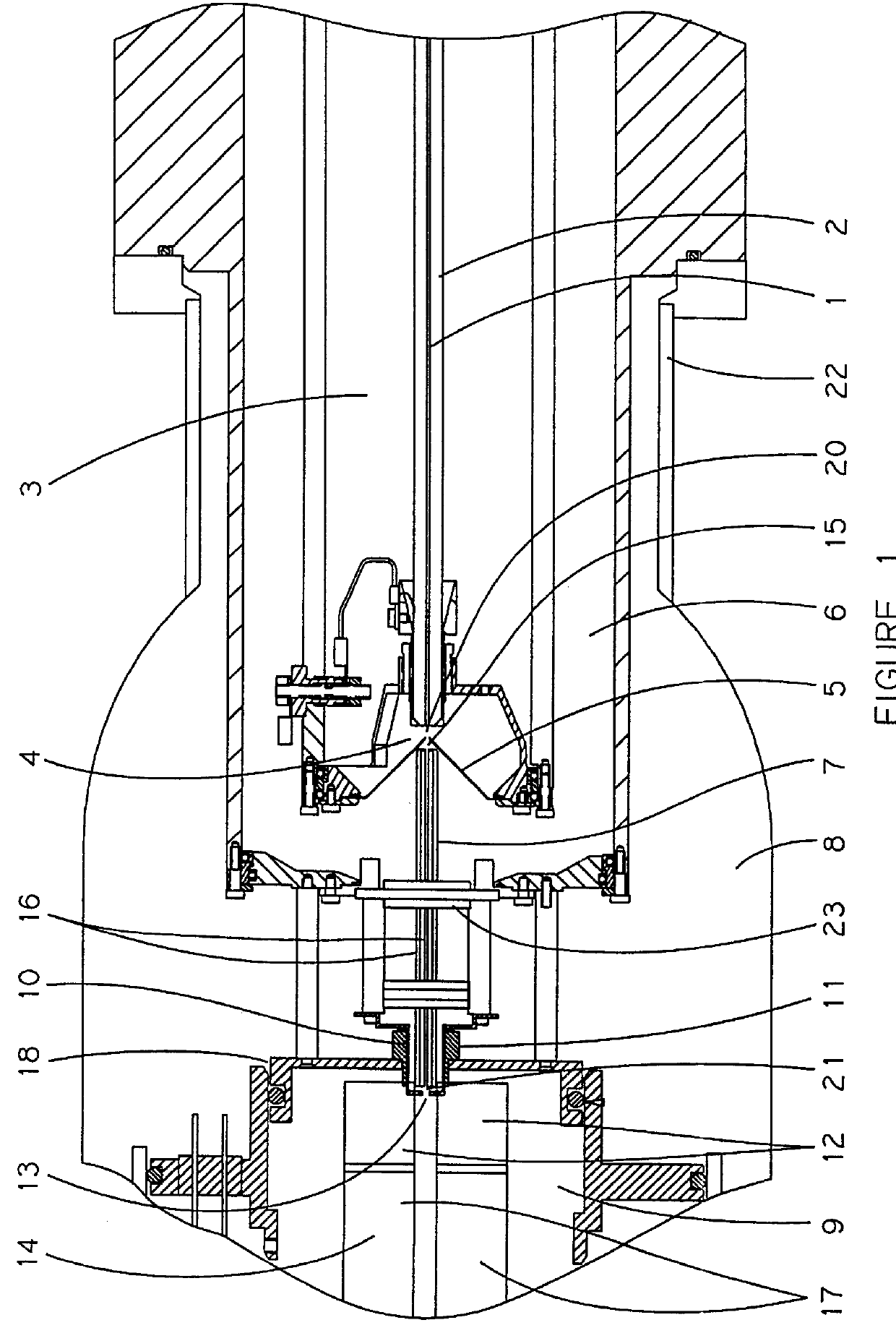

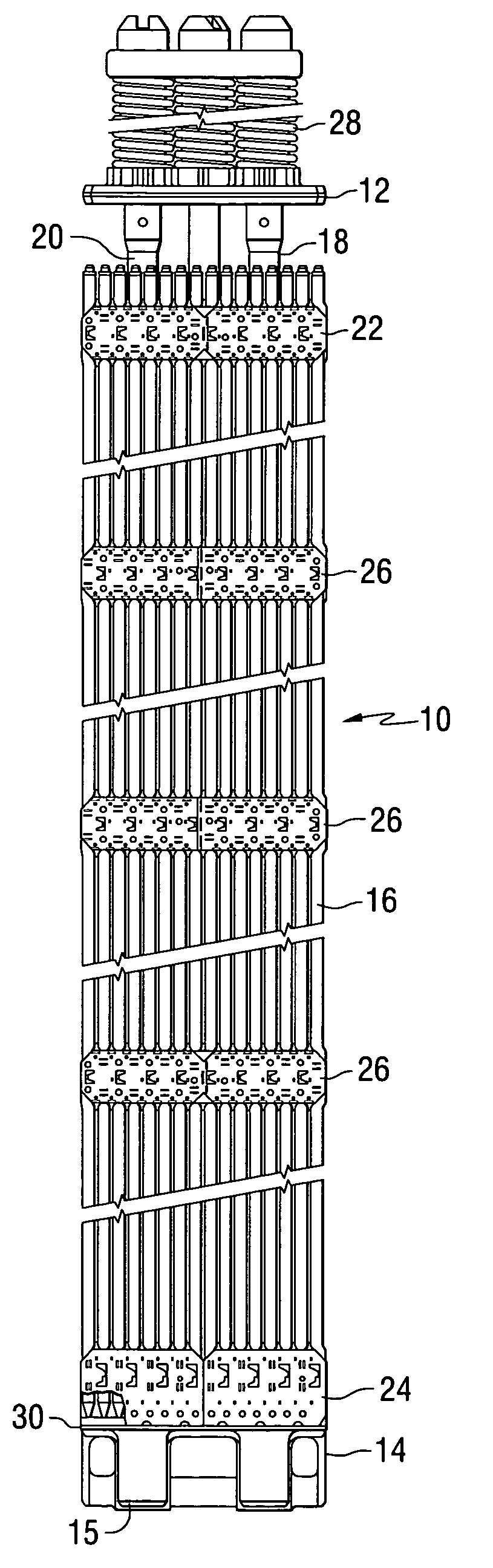

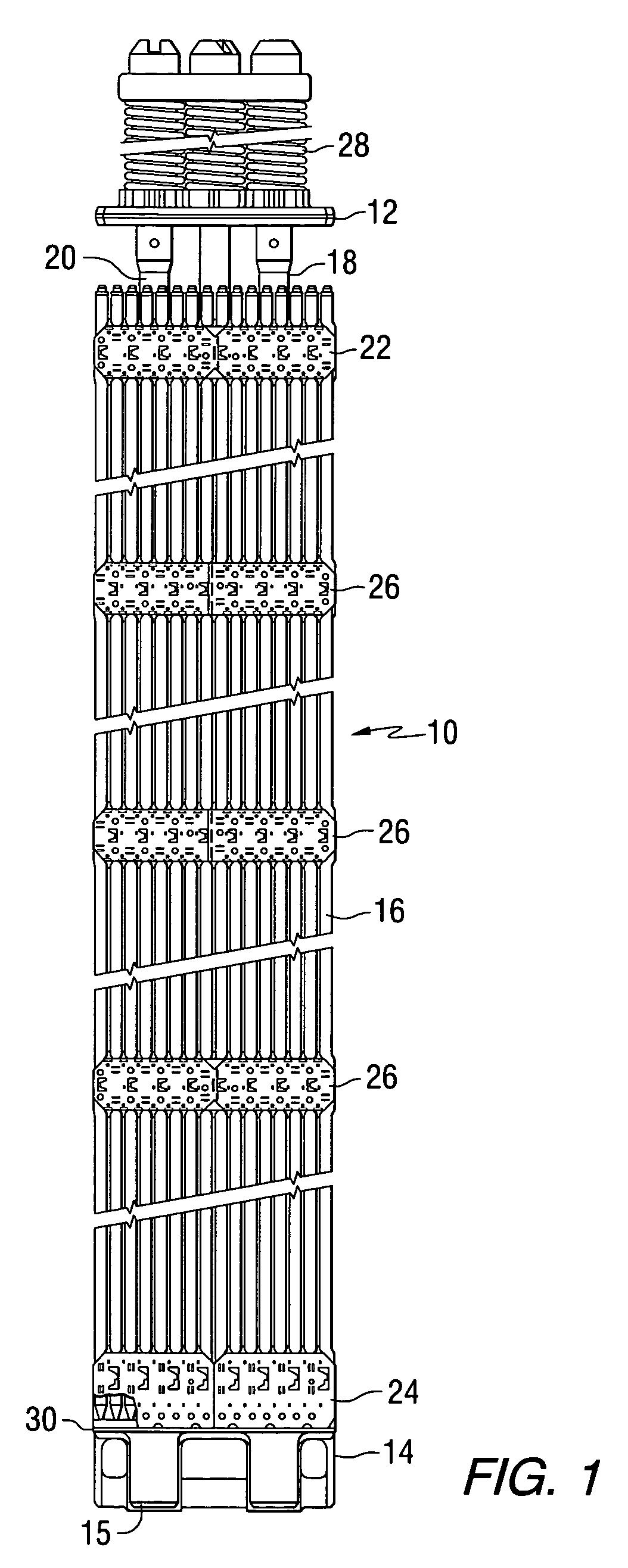

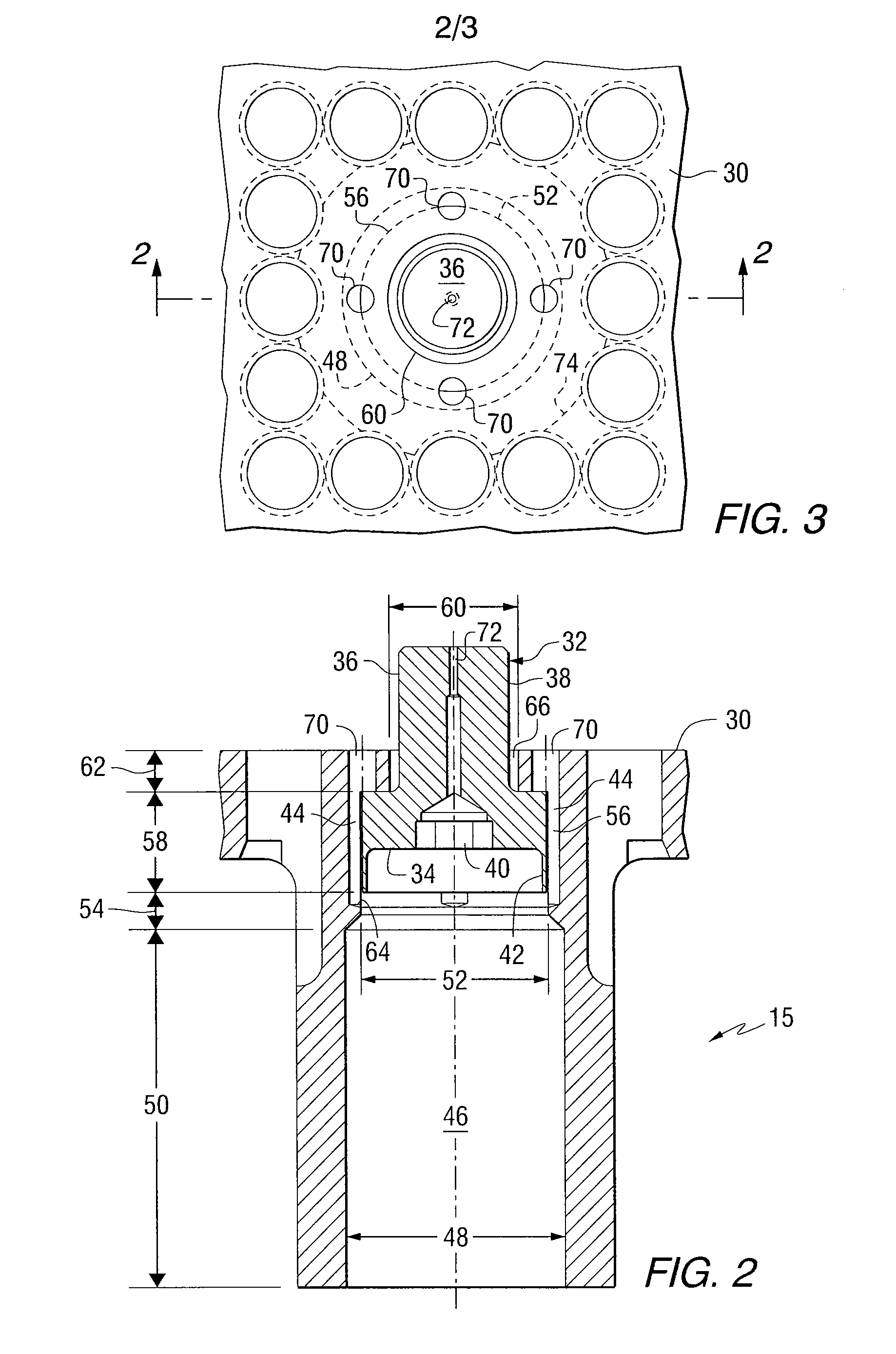

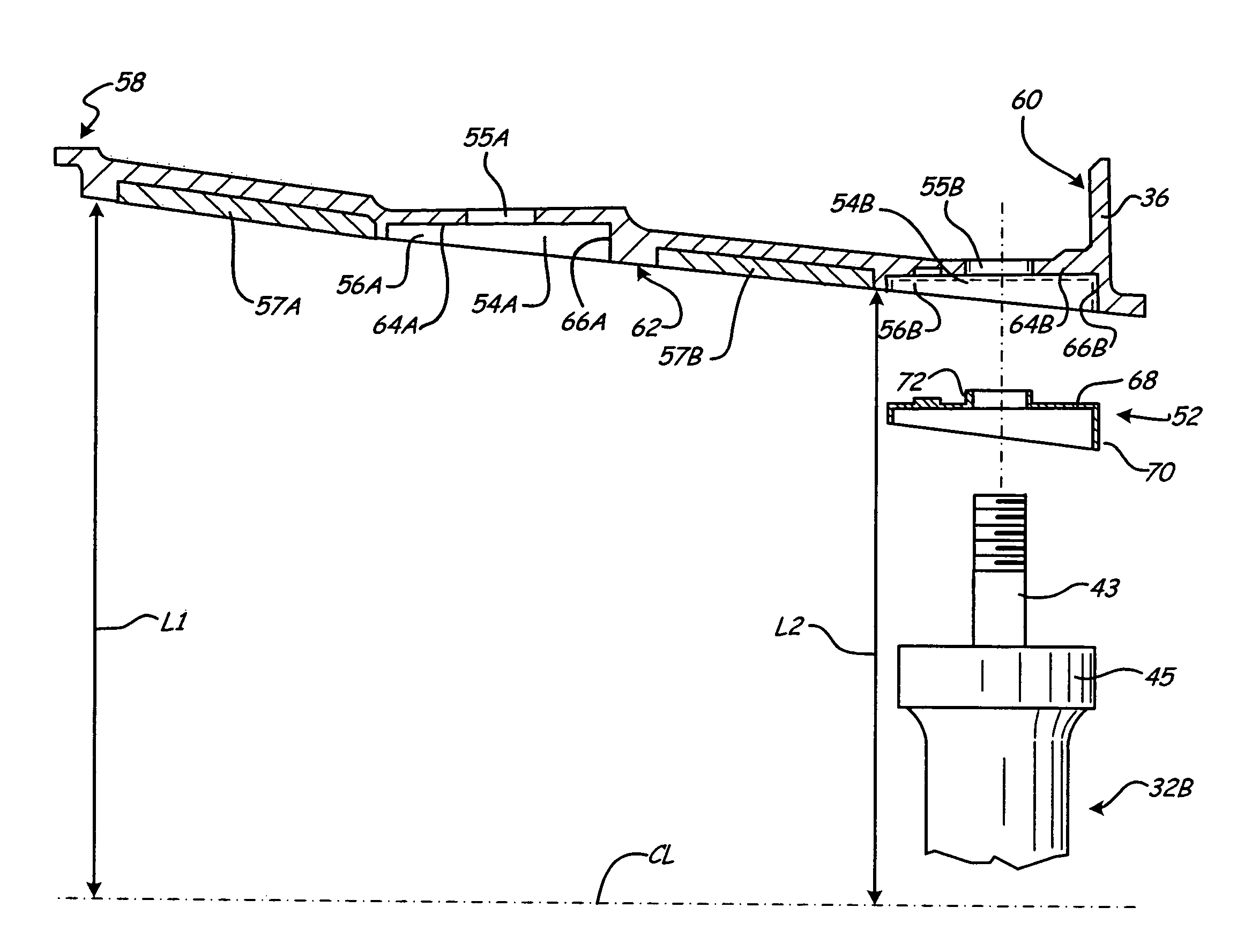

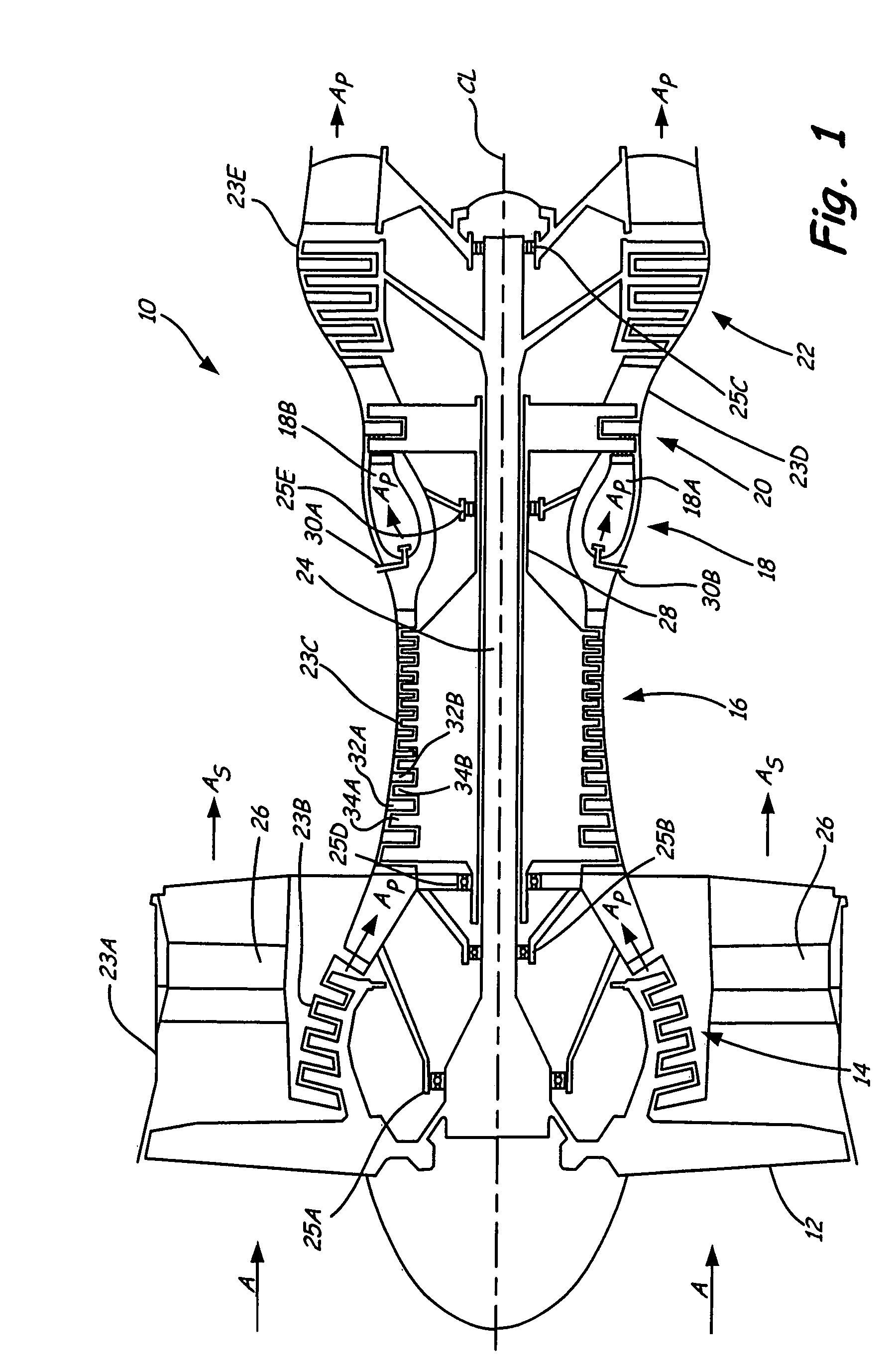

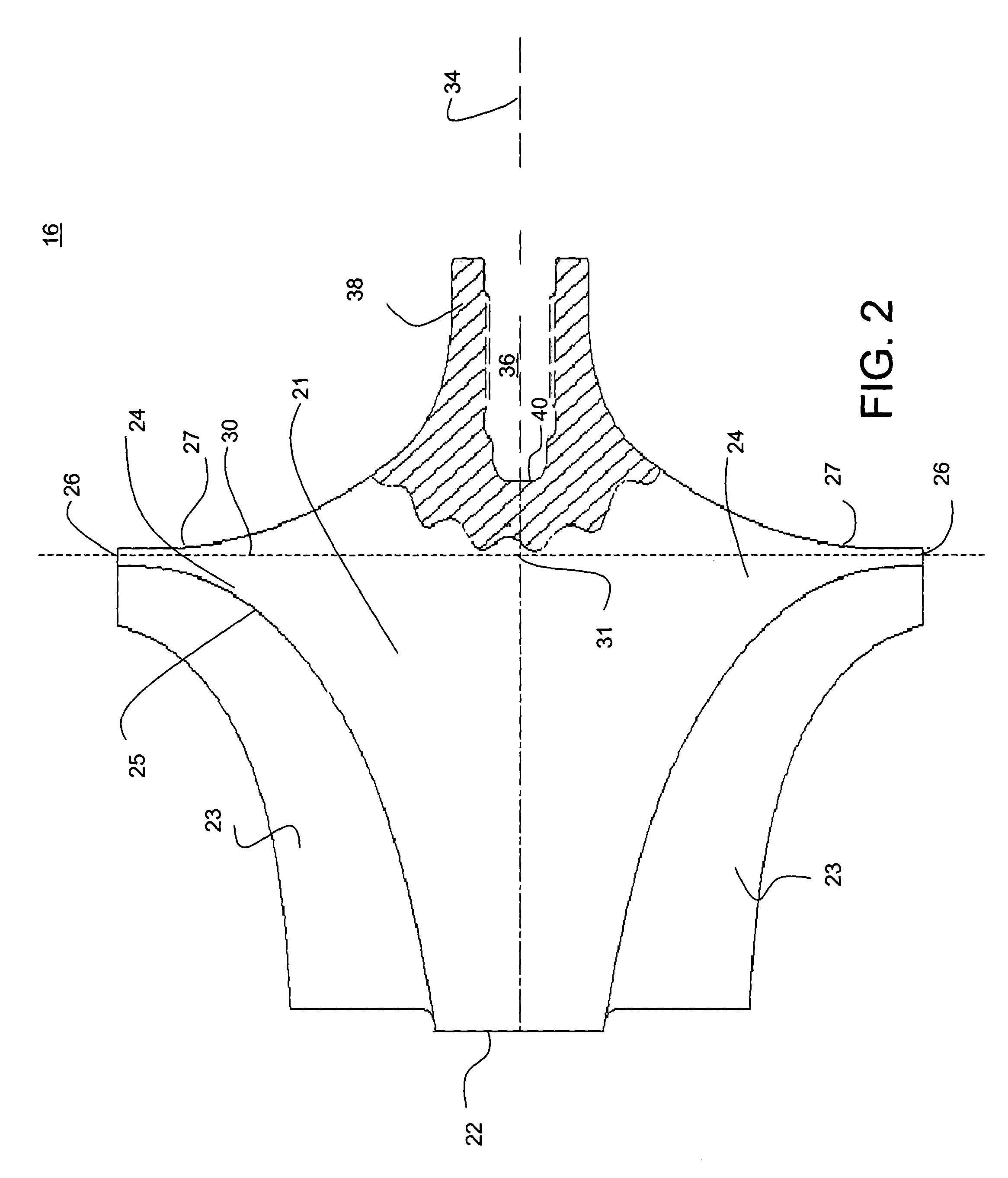

Nuclear fuel assembly control rod drive thimble to bottom nozzle connector

ActiveUS7453972B2Easy to implement and re-work and inspectLess componentsNuclear energy generationFuel element assembliesEngineeringPneumatic tool

A secure connection between the bottom nozzle of a nuclear fuel assembly and the control rod guide thimbles having two or four crimped pockets in the side wall of a bottom nozzle leg counterbore which are formed by drilling two or four blind holes through the top surface of the bottom nozzle. After attaching the bottom nozzle to the fuel assembly with a crimp bolt a pneumatic tool is then inserted into a flanged cup feature on the crimp bolt head and the flanged portion of the cup feature of the crimp bolt is deformed into the crimp pockets. The crimp pockets are contained within the leg counterbore and prevent the screw from rotating or falling out of the assembly in the event of preload loss or screw fracture.

Owner:WESTINGHOUSE ELECTRIC CORP

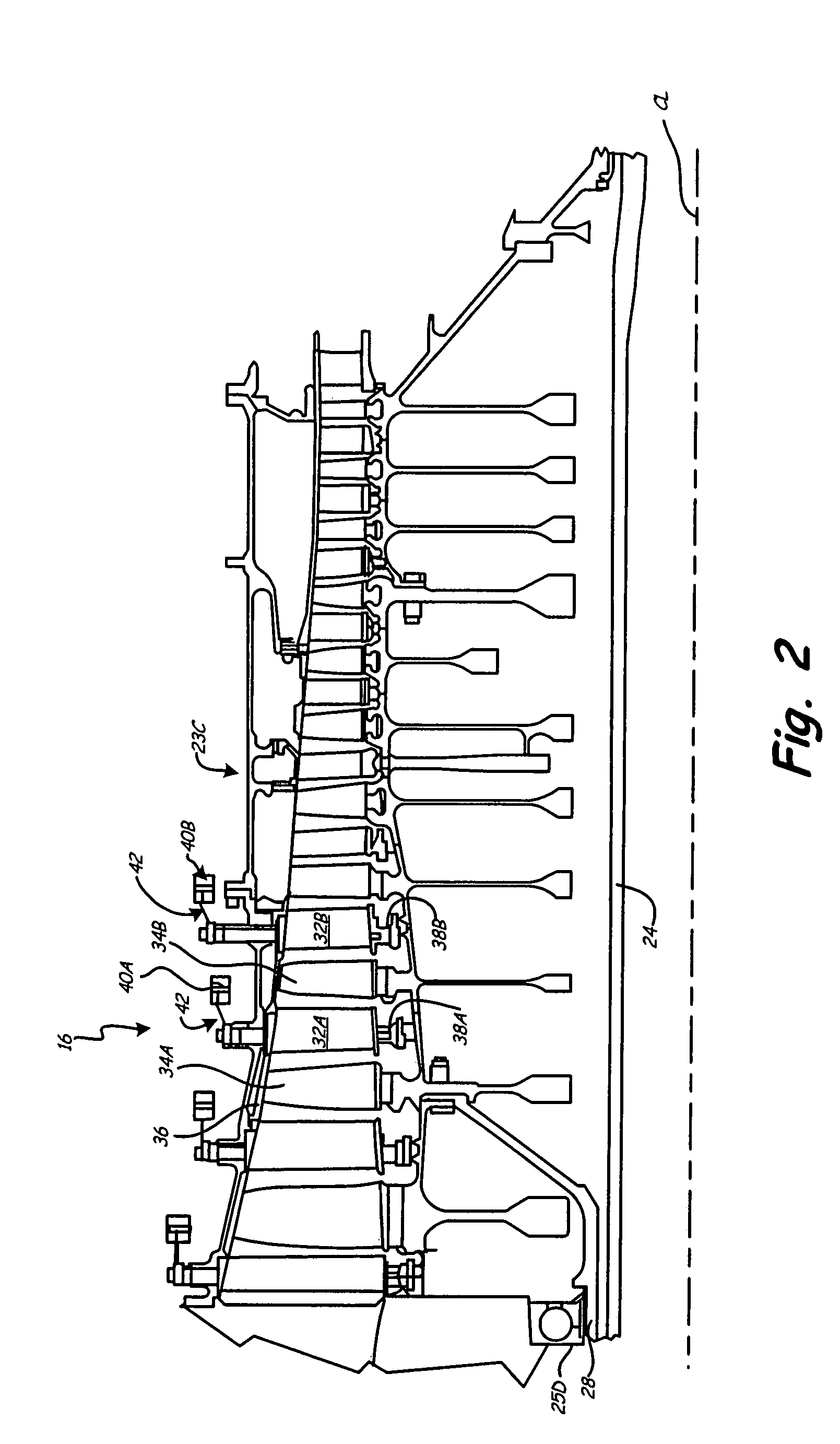

Hole liners for repair of vane counterbore holes

A variable vane shroud for a gas turbine engine comprises a cylindrically shaped body, a hole arranged at a circumference of the body, and a counterbore arranged concentrically around the hole on a radially inward facing surface of the body. The hole is for receiving a trunnion from a variable vane and the counterbore is for receiving a hub from the variable vane. A liner is inserted into the hole and counterbore such that the trunnion and hub are provided with a contact surface. The invention also provides a method for repairing a damaged counterbore in a variable vane shroud. A liner having a shape corresponding to a layer of material removed from the shroud is inserted into the void left by removing damaged material such that the counterbore is restored to pre-damaged dimensions.

Owner:RTX CORP

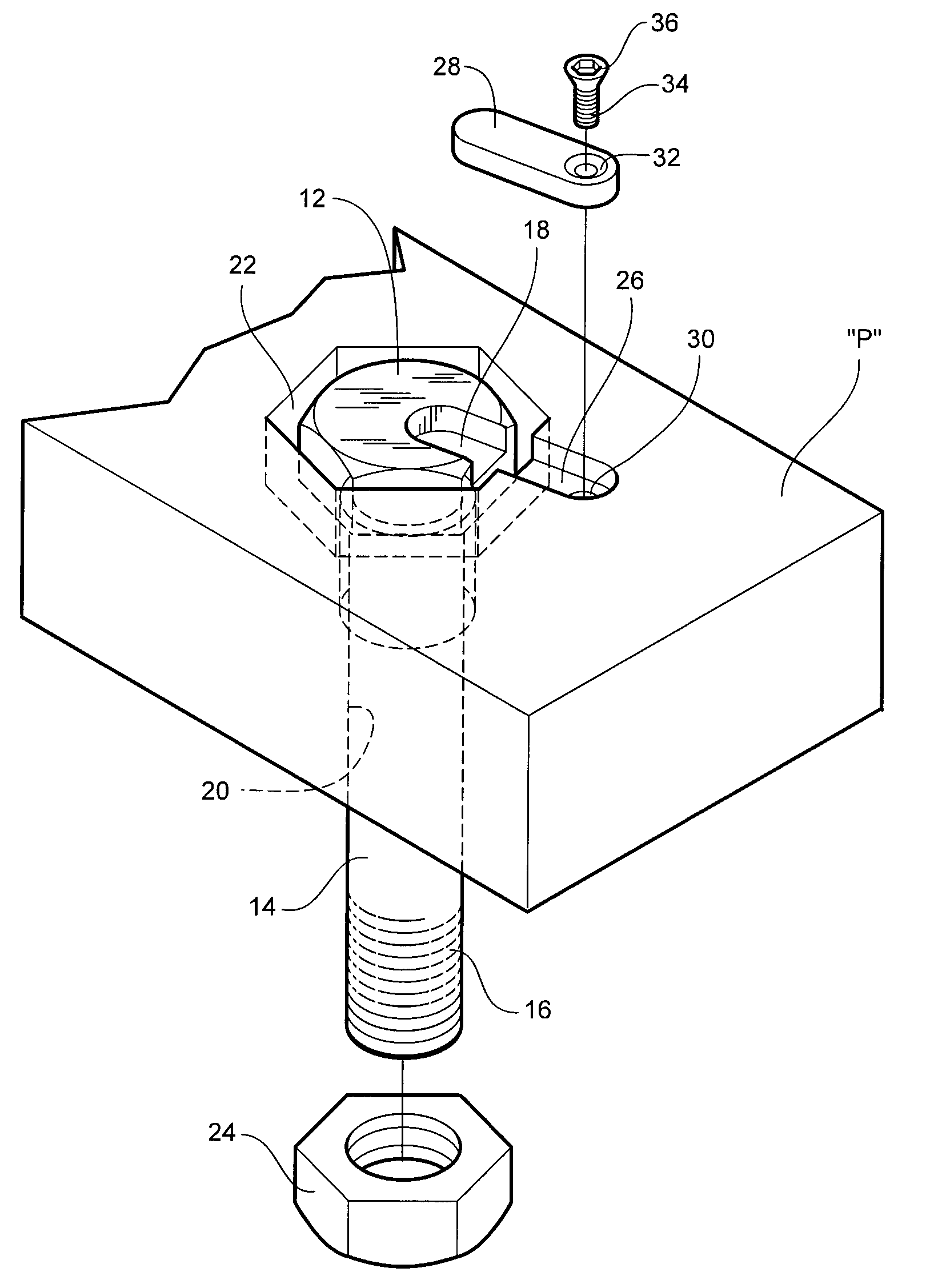

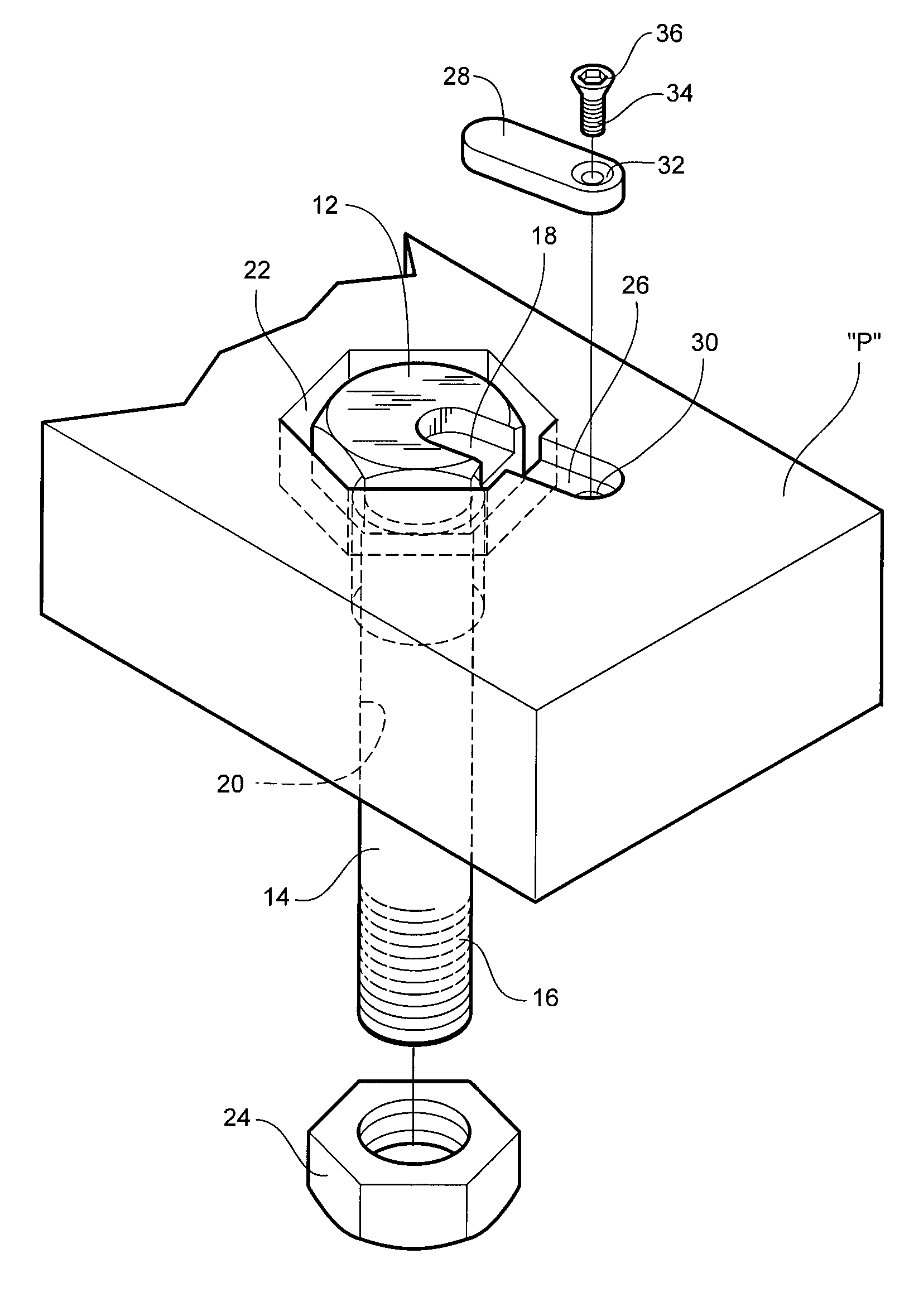

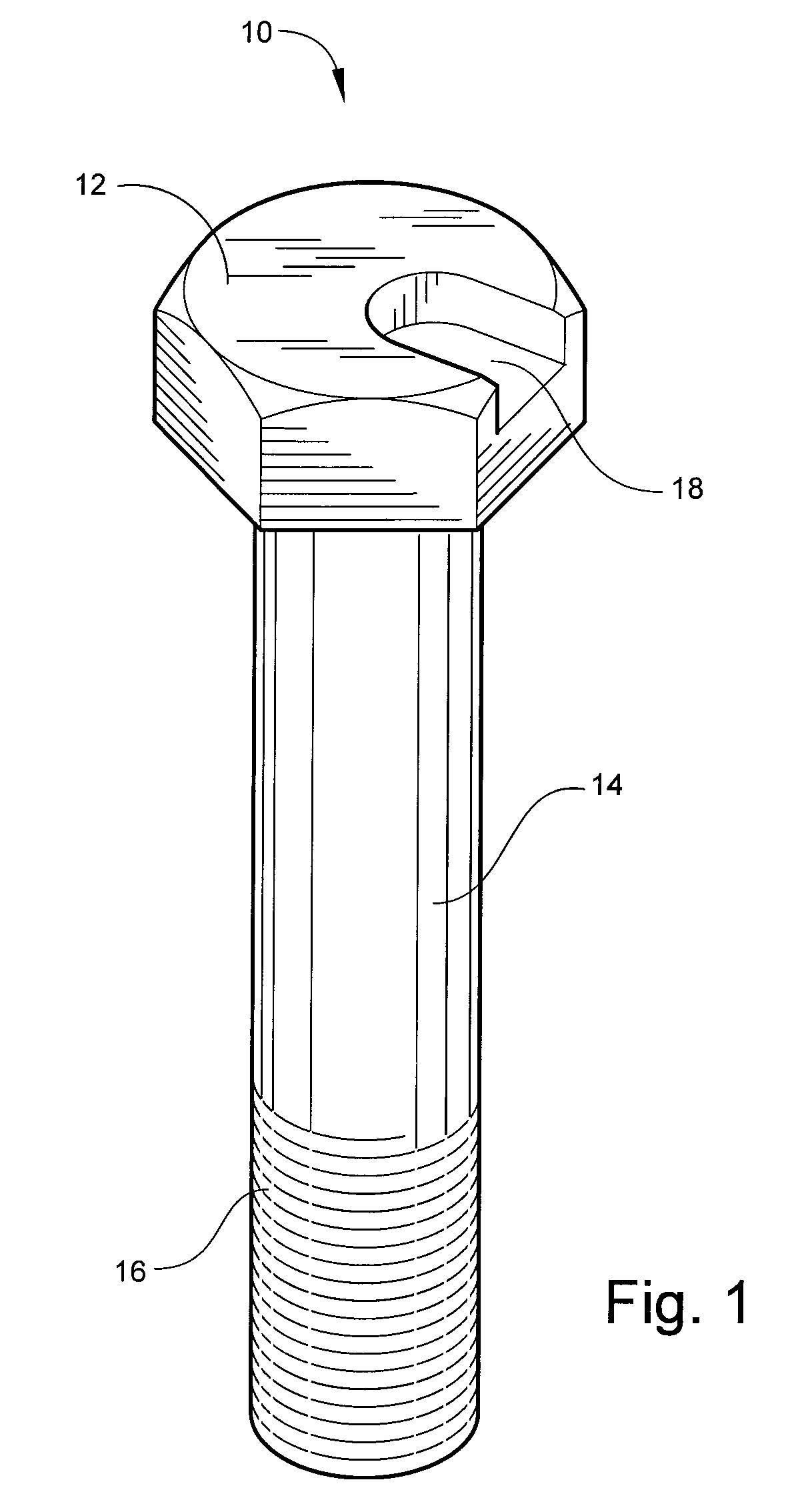

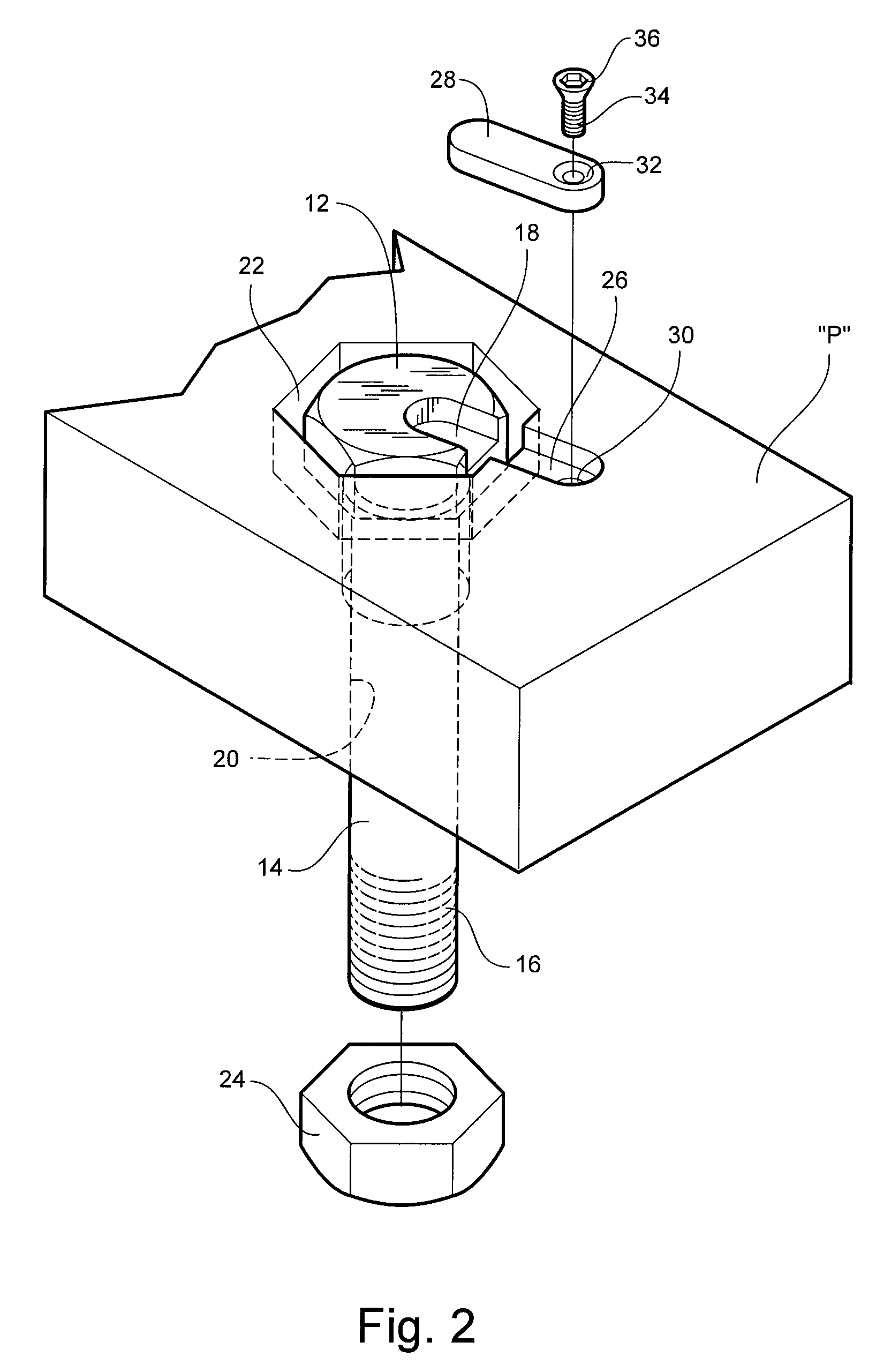

Fastener system, fastener system article, and method

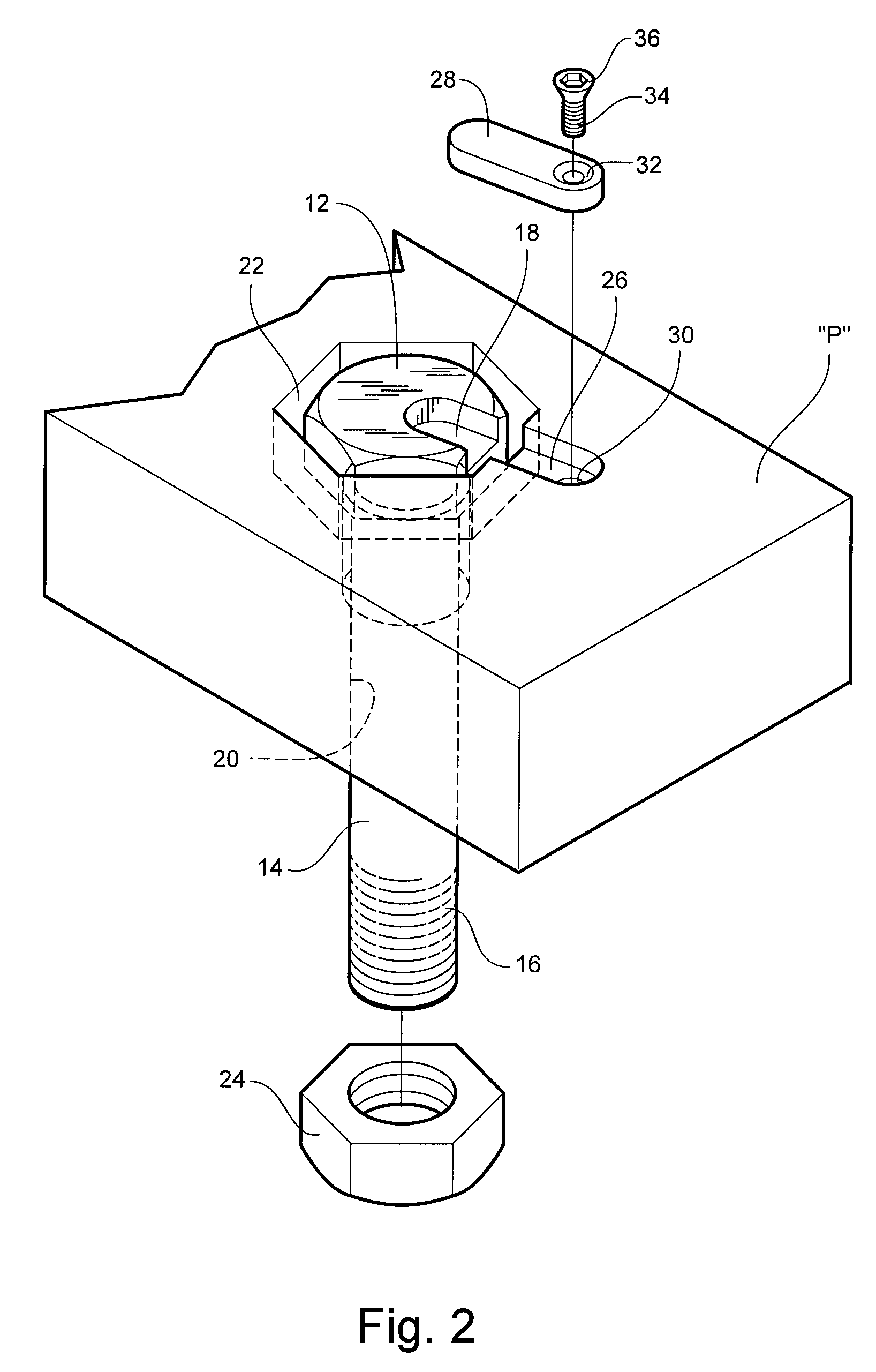

A fastener system for retaining a loose elongate fastener in a counterbore, including an elongate fastener, such as a bolt, having a head for being received and retained in a counterbore in a structure and in generally flush relation to a surface of the structure surrounding the counterbore, and a retaining member for being secured to the structure proximate the counterbore and overlapping the counterbore to trap the loose fastener in the counterbore.

Owner:REIMLER JAMES L

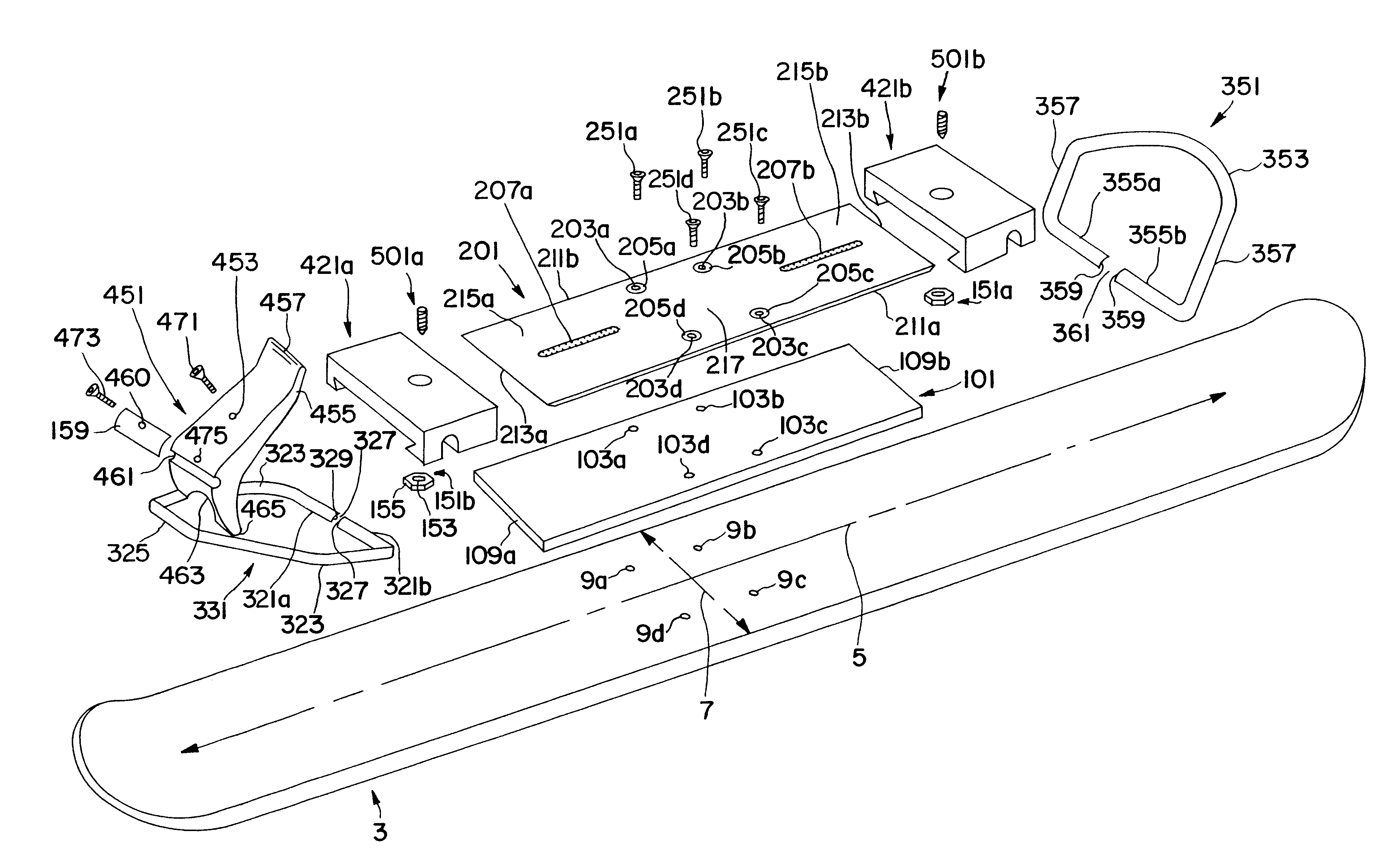

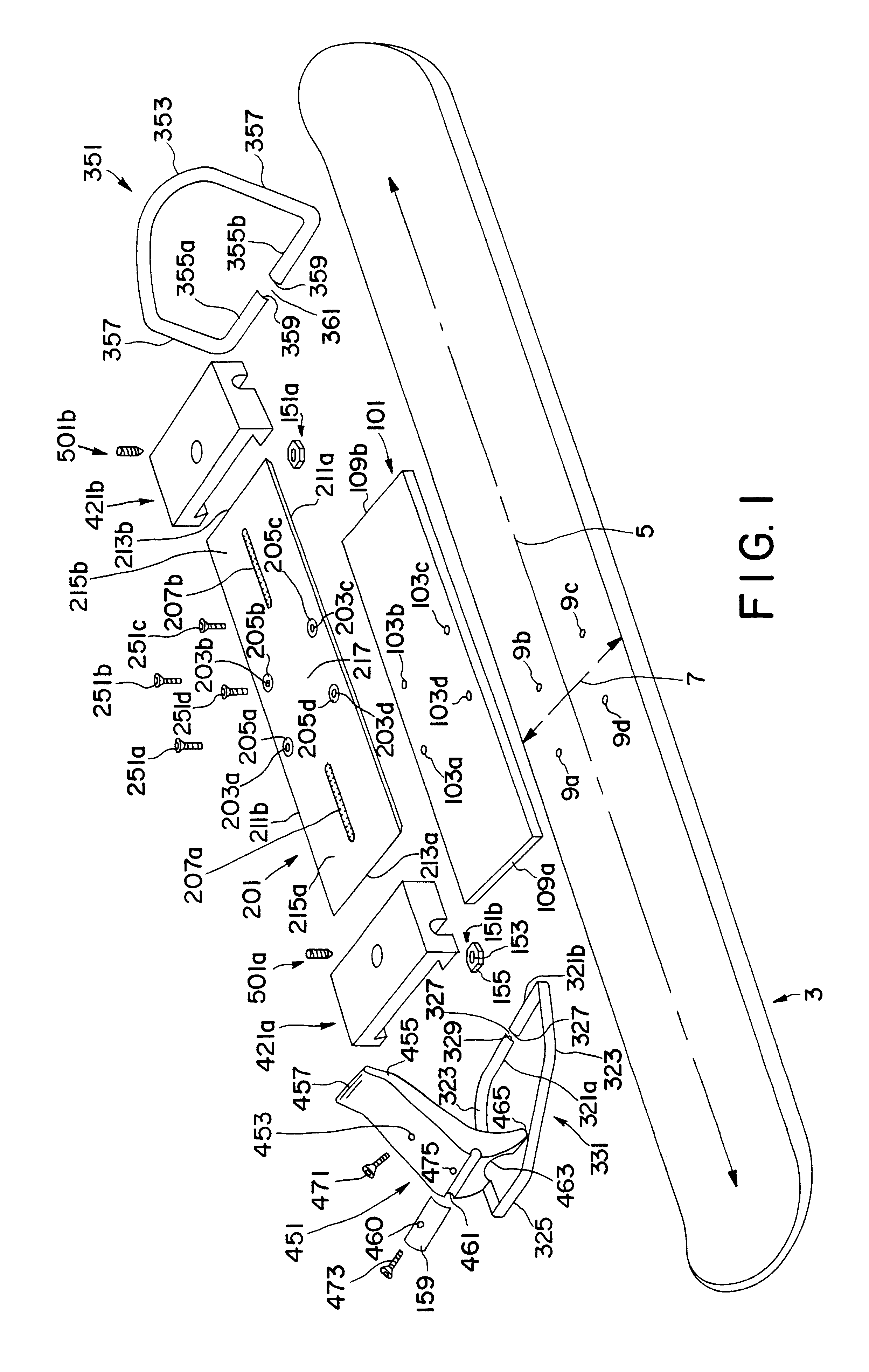

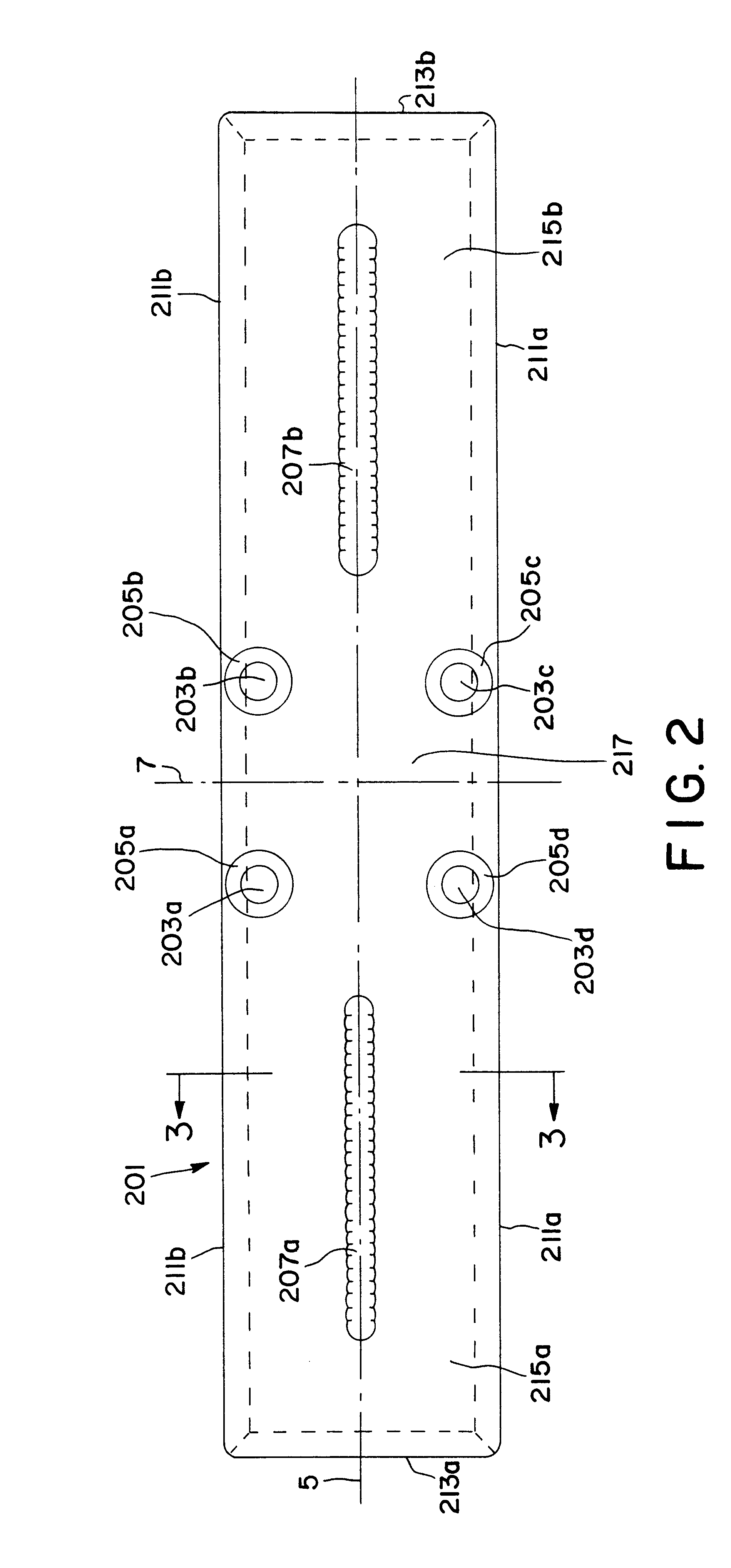

Boot binding system

A boot binding system is shown for use especially on skiboards, having a binding plate, boot supports, bails, a lever, a resilient material, and a size adjustment locking mechanism. Boot supports and binding plate are complimentary shaped for slideable affixation to each, without requiring additional fasteners. A simple fastener locks the relative position of the boot support on the binding plate while also immobilizing any boot support motion. In the locked position, the fastener mates with counterbores in the binding plate's surface. The binding plate is rectangular in top view and its longitudinal edges have a chamfer, which complements a chamfer on the boot supports. The binding plate has mounting holes in its central region, which are used to affix the binding to a skiboard. Resilient material exists between the binding plate and the skiboard, thereby allowing the skiboard to flex more freely. The boot supports have slots to retain the bails. The lever also has a slot to accept a bail. The binding is simple to manufacture and assemble making it cost competitive for production. An alternate embodiment includes a version that eliminates the need for resilient material. A second alternate embodiment eliminates the central mount and mounts to the skiboard in the region of the boot supports.

Owner:CARON ALPINE TECH

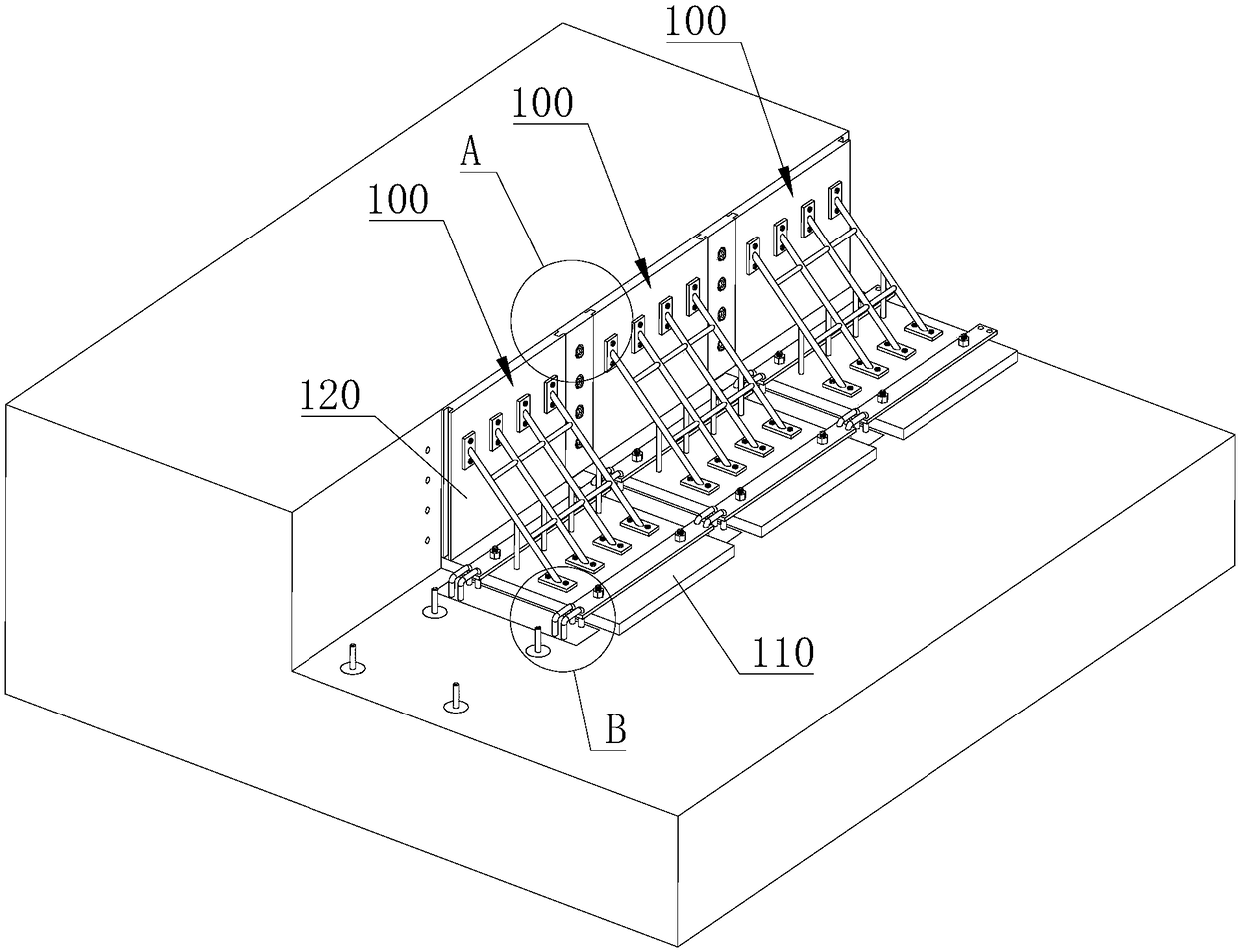

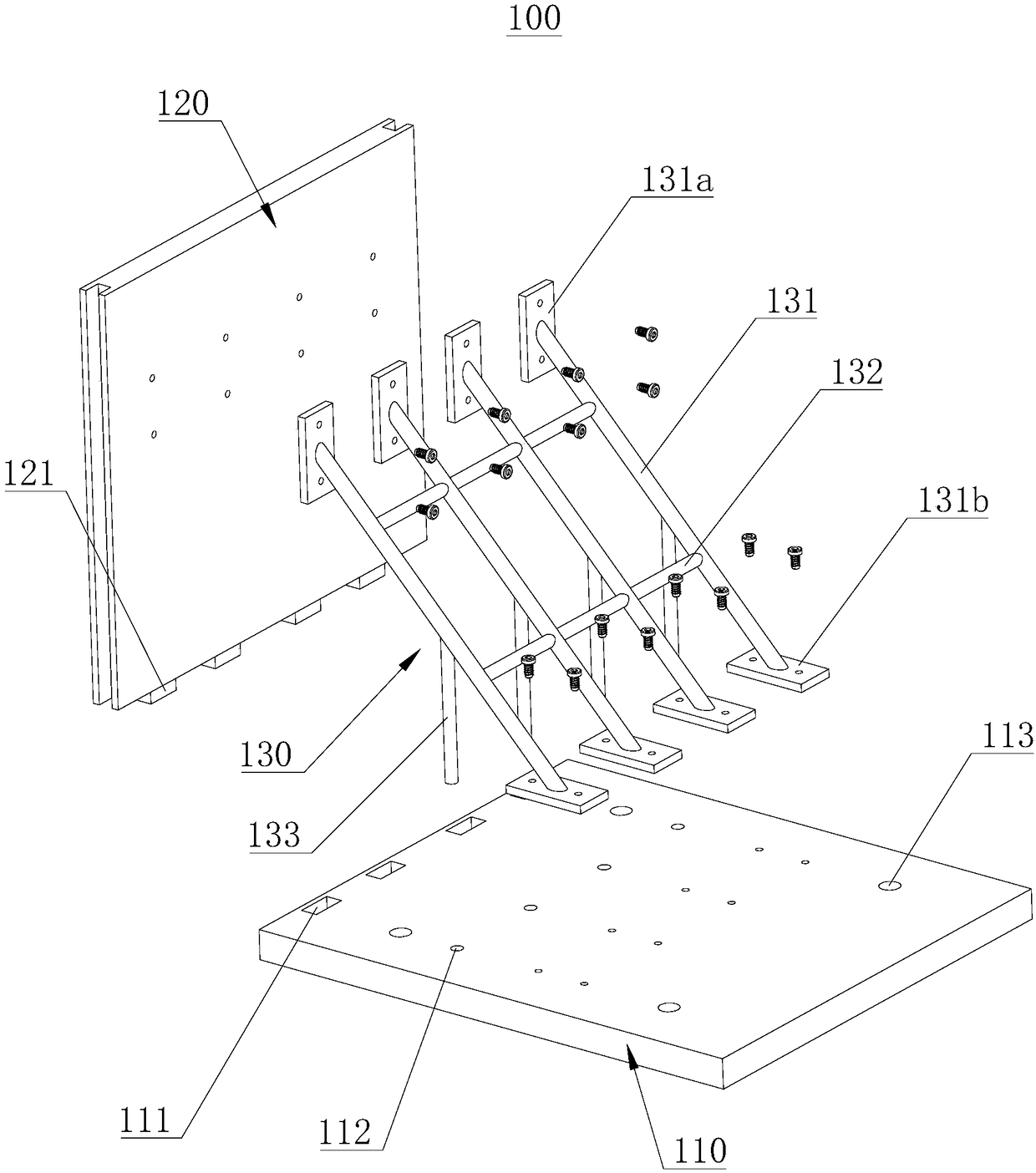

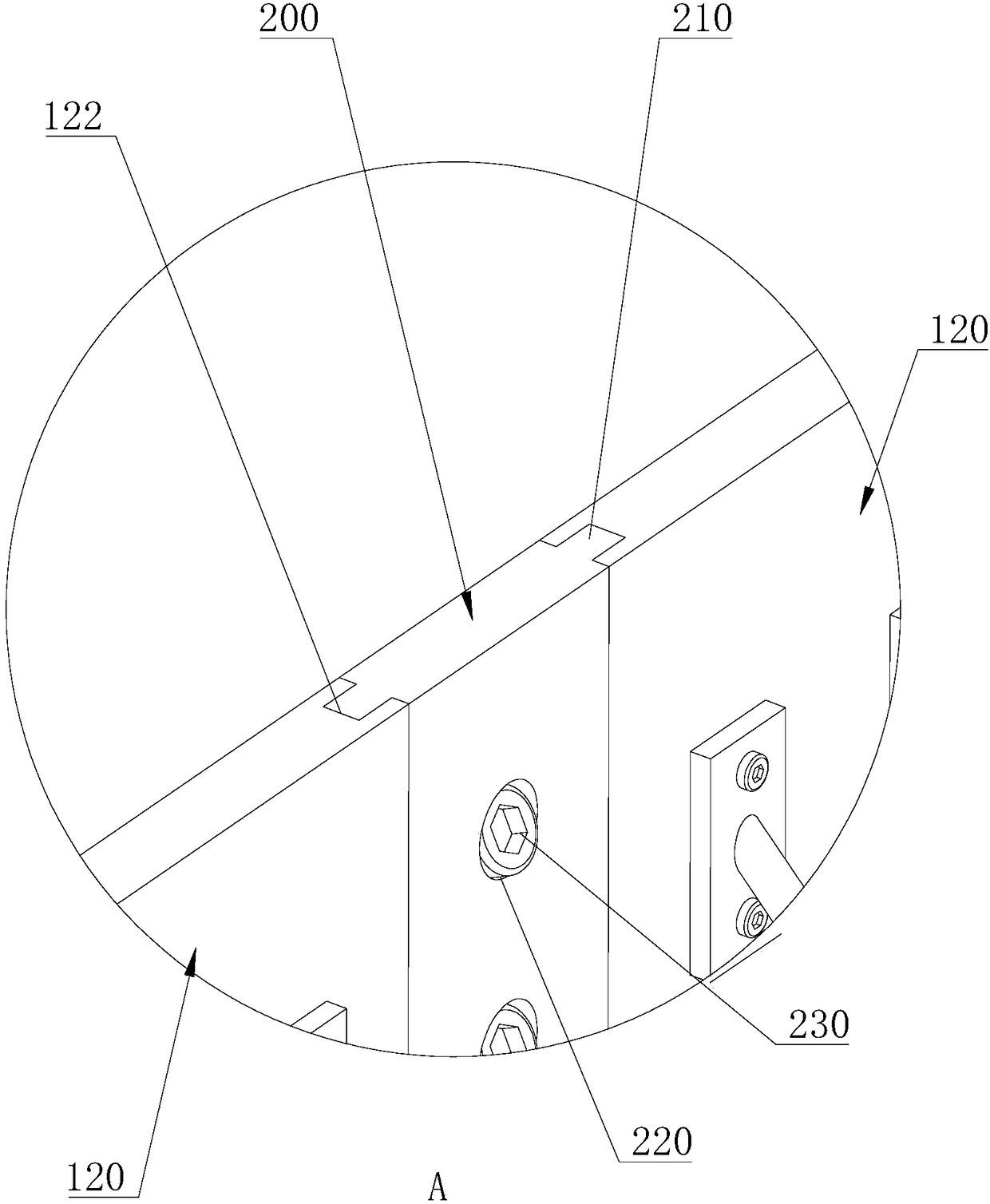

Support structure of foundation pit

The invention discloses a support structure of a foundation pit, which solves the problem of complex disassembly and assembly of an existing support structure of the foundation pit. The support structure of the foundation pit adopts the technical scheme that the support structure comprises a plurality of support assemblies, wherein the plurality of support assemblies are arranged along the side wall of the foundation pit, the support assemblies comprise bottom plates which are fixed to the bottom of the foundation pit, protective plates which are used for supporting the side wall of the foundation pit and support assemblies which are used for connecting the bottom plates and the protective plates, clamping grooves are formed in both sides of the protective plates in a height direction, connecting baffles of which the edges of both sides are respectively clamped into the clamping grooves are arranged between the adjacent protective plates, fixed counterbores are formed in one side, which is far from the side wall of the foundation pit, of the connecting baffles, support rods which are used for tightly pressing the connecting baffles on the side wall of the foundation pit and are inserted into the side wall of the foundation pit are installed in the fixed counterbores, and the support structure of the foundation pit is simple and convenient to install and remove in the foundationpit.

Owner:浙江立鹏建设有限公司

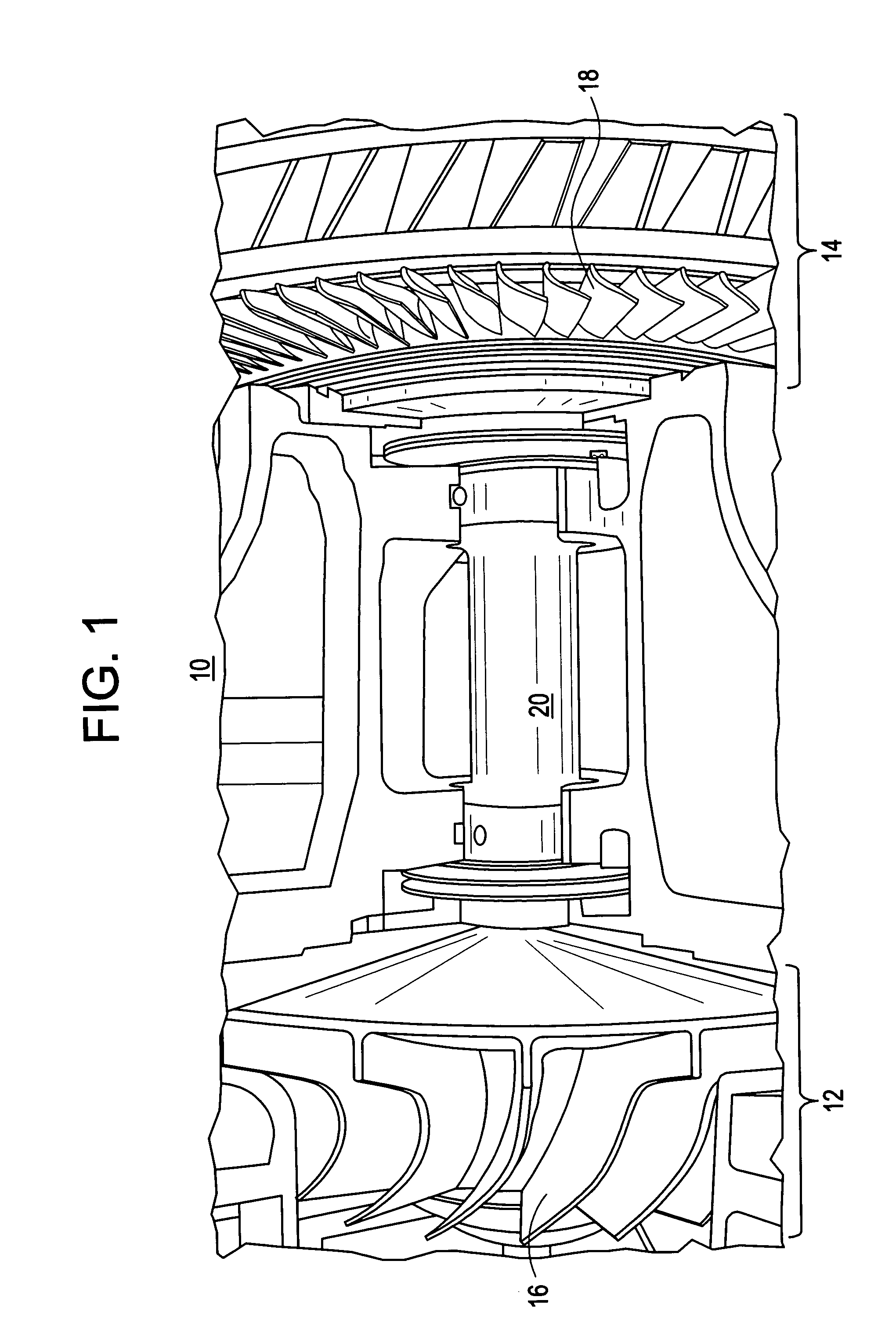

Turbocharger compressor wheel having a counterbore treated for enhanced endurance to stress-induced fatigue and configurable to provide a compact axial length

InactiveUS6994526B2Avoiding and reducing overhangProlong lifePropellersPump componentsImpellerStress induced

Owner:GENERAL ELECTRIC CO

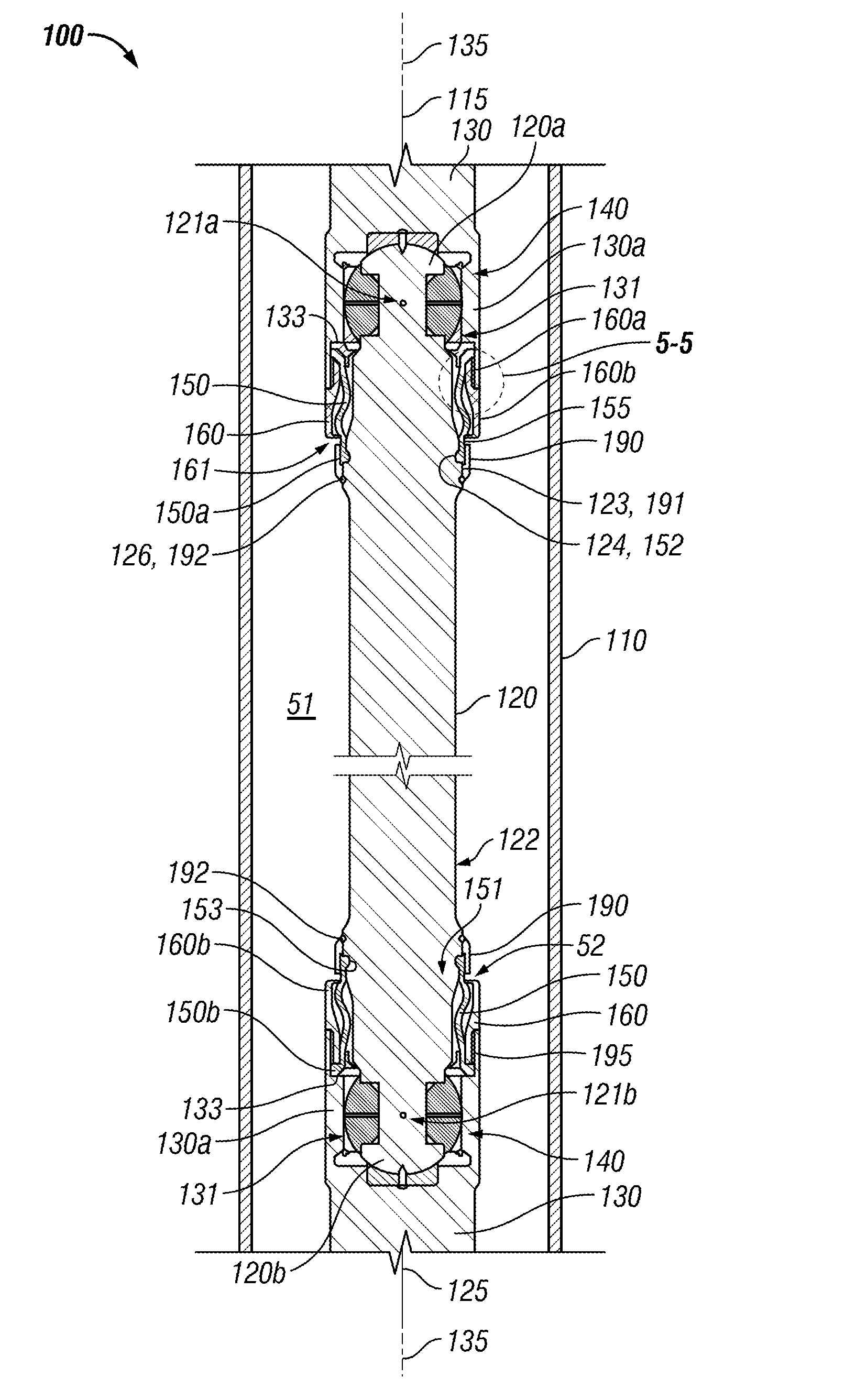

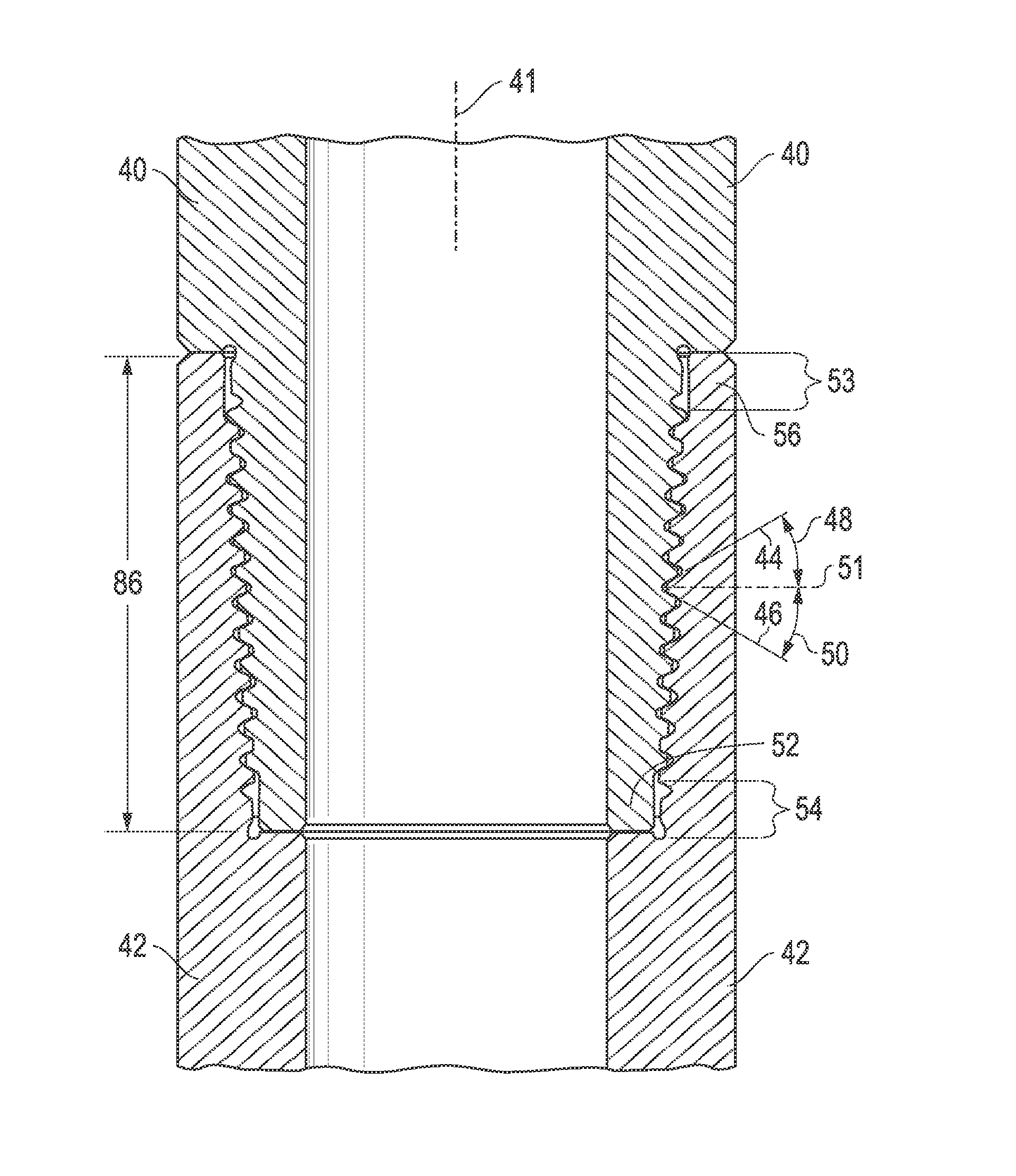

Retention Means for a Seal Boot Used in a Universal Joint in a Downhole Motor Driveshaft Assembly

A driveshaft assembly for a downhole motor comprises a housing and a driveshaft rotatably disposed within the housing. The driveshaft has a central axis and a first end. Further, the driveshaft assembly comprises a driveshaft adapter having a first end coupled to the first end of the driveshaft with a universal joint. The first end of the driveshaft adapter includes a counterbore. The first end of the driveshaft and the universal joint are disposed in the counterbore. Still further, the driveshaft assembly comprises an end cap disposed about the driveshaft and coaxially coupled to the adapter. Moreover, the driveshaft assembly comprises a seal boot disposed about the driveshaft and adapted to restrict fluid flow through a annular gap positioned between the driveshaft and the end cap. The driveshaft assembly also comprises a locking assembly adapted to restrict the end cap from moving axially relative to the adapter.

Owner:NAT OILWELL VARCO LP

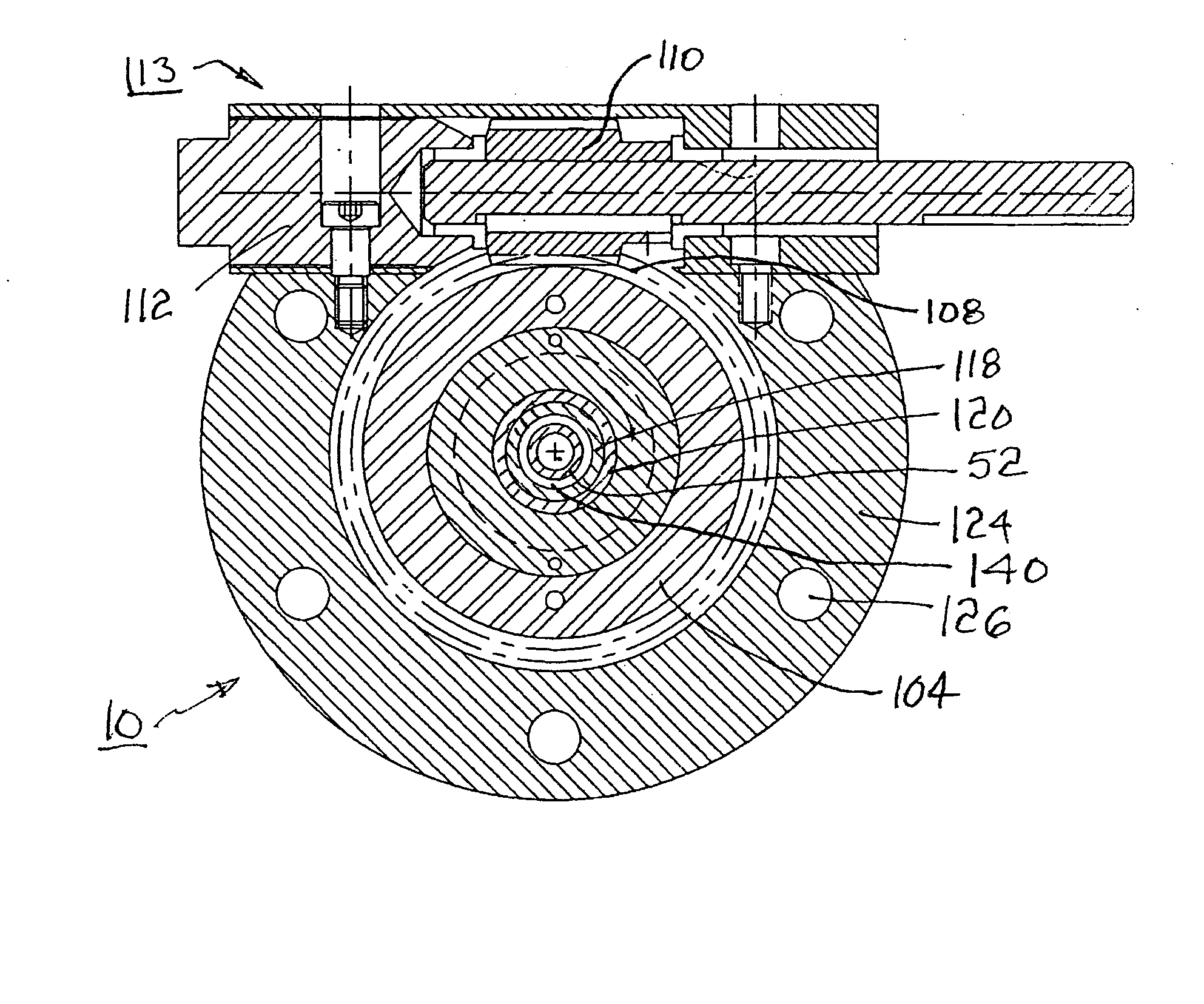

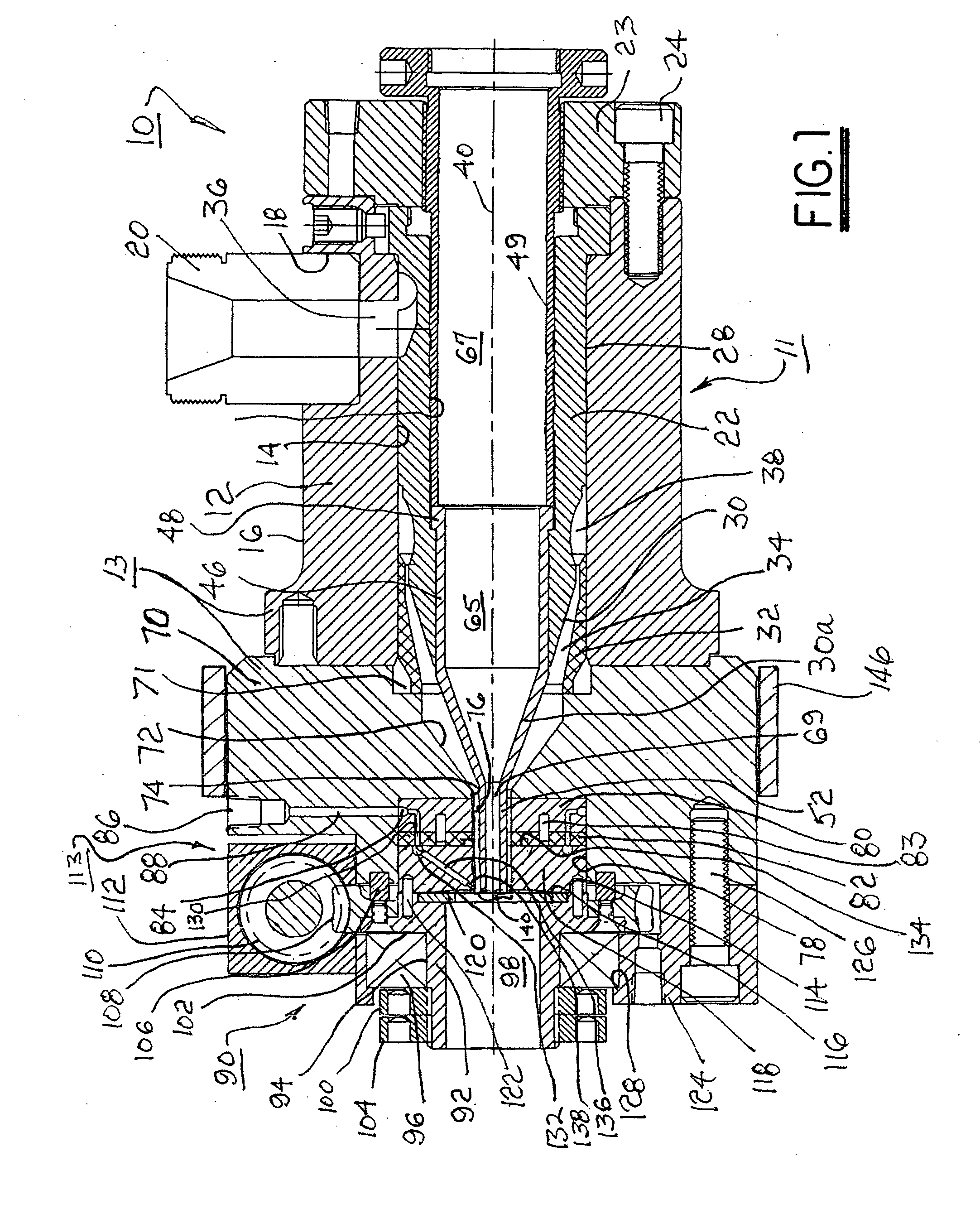

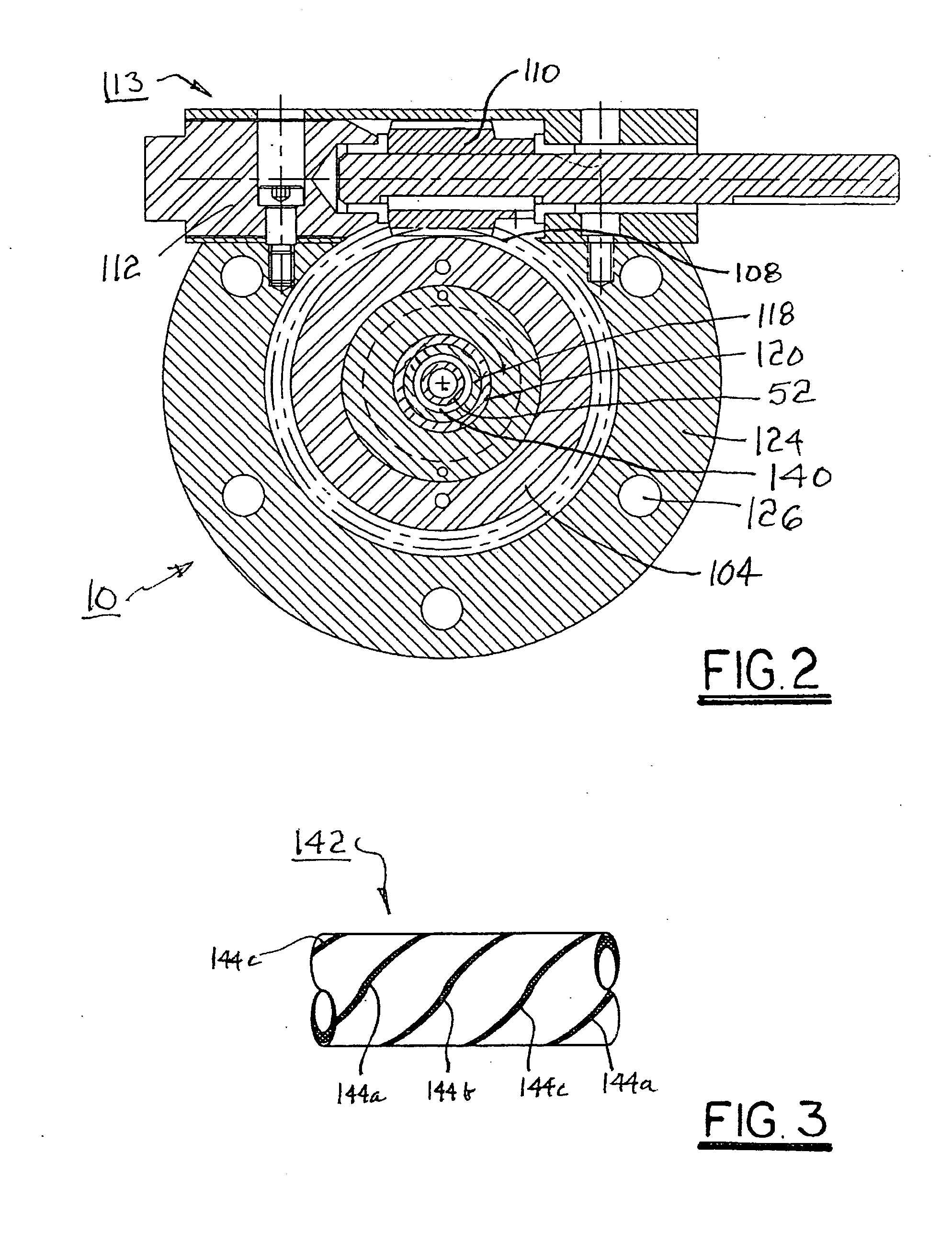

Rotatable head for forming spiral extrusions

InactiveUS20050260408A1Increase sealing forceAvoid pollutionConfectioneryFilament/thread formingEngineeringCounterbore

A polymer extrusion crosshead assembly for forming a spirally-striped extrusion. The assembly includes conventional components for admitting, turning, and accelerating primary molten polymer toward a novel rotating die sub-assembly. A body element includes an axial counterbore for receiving a manifold supply block in communication with a source of secondary striping polymer. A wear plate is attached to the manifold block. The die sub-assembly includes a striping die having an annular passage for conveying the primary polymer to form an extruded tube or a core material coating. The die is loaded against the wear plate by a Belleville washer. The die includes one or more striping nozzles in communication with the manifold block for injecting secondary striping polymer into the annular stream of primary polymer flowing through the die, creating a longitudinal stripe of striping polymer. Rotating the die while extruding both polymers yields a helically striped (spiral) extrusion.

Owner:CANGEN HLDG

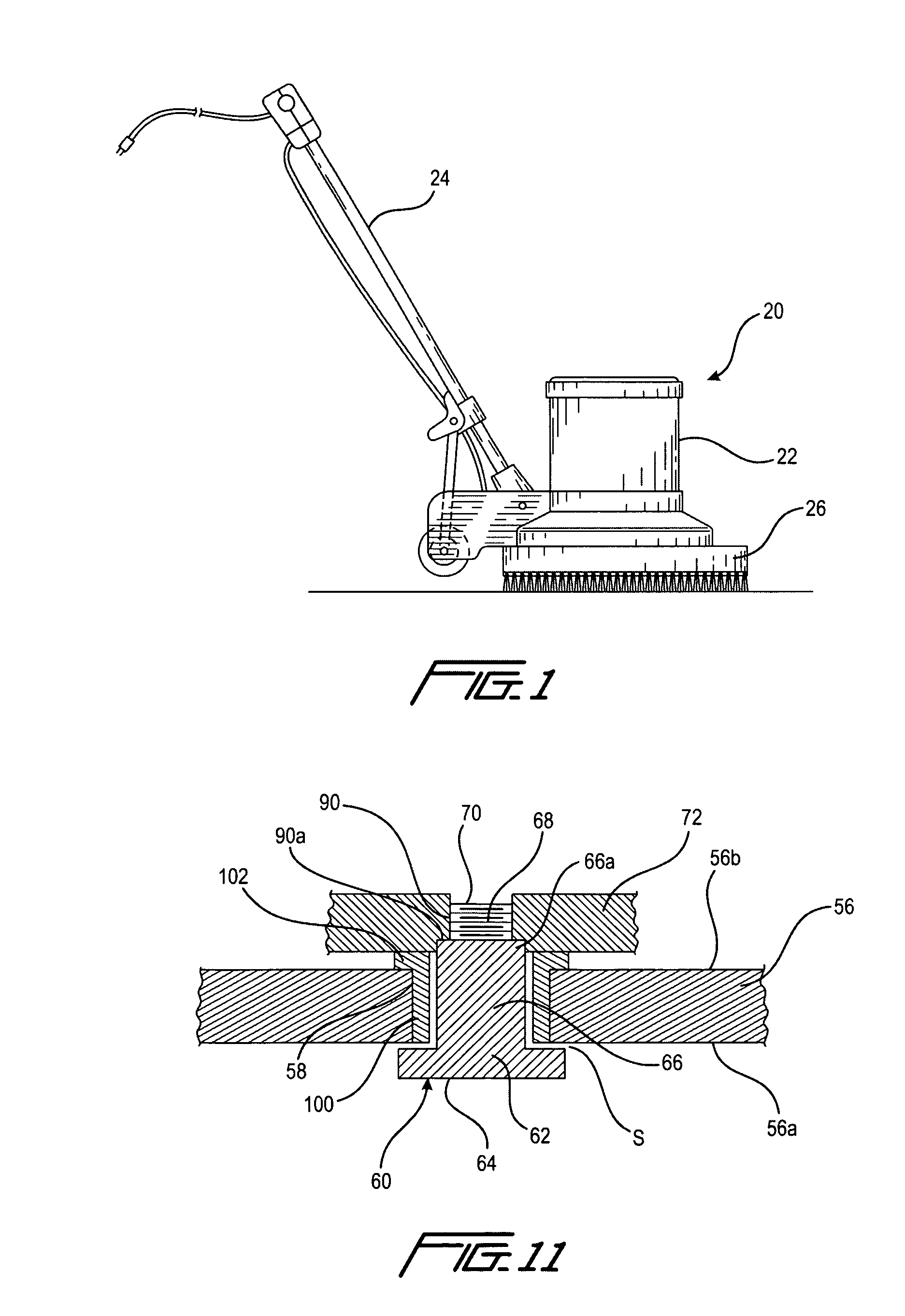

Mounting adapter for concrete surface processing tool

InactiveUS7815393B2Increase capacityFor quick replacementGrinding wheel securing apparatusCarpet cleanersMotor driveEngineering

A mounting assembly for rotatably mounting a surface processing tool holder on at least one motor driven rotatable arm of a surface processing apparatus, such that the tool can spin freely as the arm is driven by the motor, includes an elongate shank having a smooth surfaced, cylindrical portion intermediate its ends adapted for positioning within an aperture in the tool holder with one threaded end portion projecting through the aperture for attachment to an elongate mounting bar adapted for attachment to the arm. A bearing supported by the tool body and surrounding the smooth surfaced portion of the shank is rotatable relative to the shank. The mounting bar includes a threaded aperture for receiving the threaded end portion of the shank and the threaded aperture includes a counterbore for receiving the end portion of the smooth surfaced shank portion which is adjacent the threaded end portion.

Owner:WAGMAN METAL PRODS

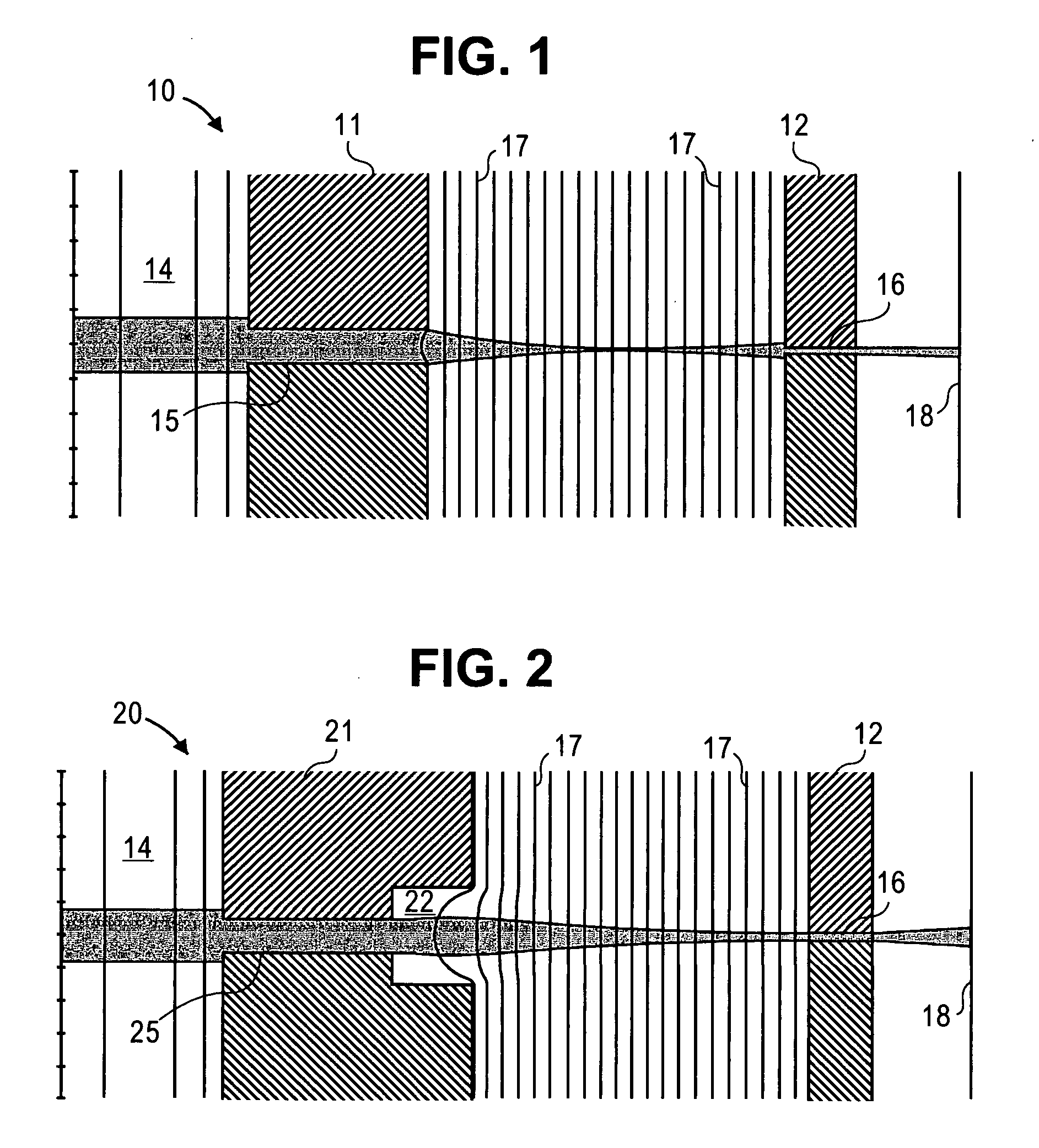

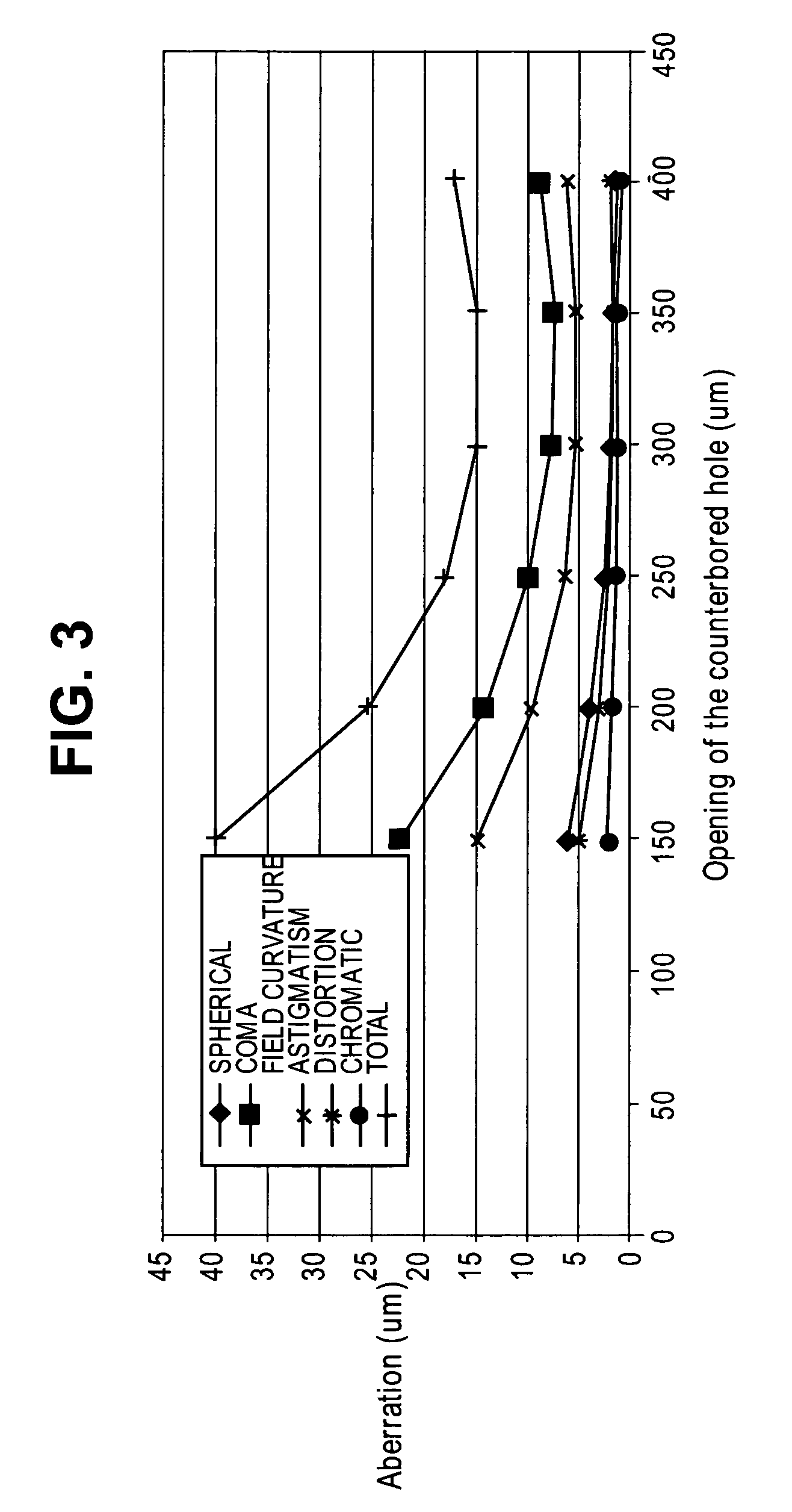

Ion beam extractor with counterbore

InactiveUS7084407B2Improve concentrationReduce aberrationElectric arc lampsMaterial analysis by optical meansIon beamCounterbore

An extractor system for a plasma ion source has a single (first) electrode with one or more apertures, or a pair of spaced electrodes, a first or plasma forming electrode and a second or extraction electrode, with one or more aligned apertures. The aperture(s) in the first electrode (or the second electrode or both) have a counterbore on the downstream side (i.e. away from the plasma ion source or facing the second electrode). The counterbored extraction system reduces aberrations and improves focusing. The invention also includes an ion source with the counterbored extraction system, and a method of improving focusing in an extraction system by providing a counterbore.

Owner:RGT UNIV OF CALIFORNIA

Fastener system, fastener system article, and method

A fastener system for retaining a loose elongate fastener in a counterbore, including an elongate fastener, such as a bolt, having a head for being received and retained in a counterbore in a structure and in generally flush relation to a surface of the structure surrounding the counterbore, and a retaining member for being secured to the structure proximate the counterbore and overlapping the counterbore to trap the loose fastener in the counterbore.

Owner:REIMLER JAMES L

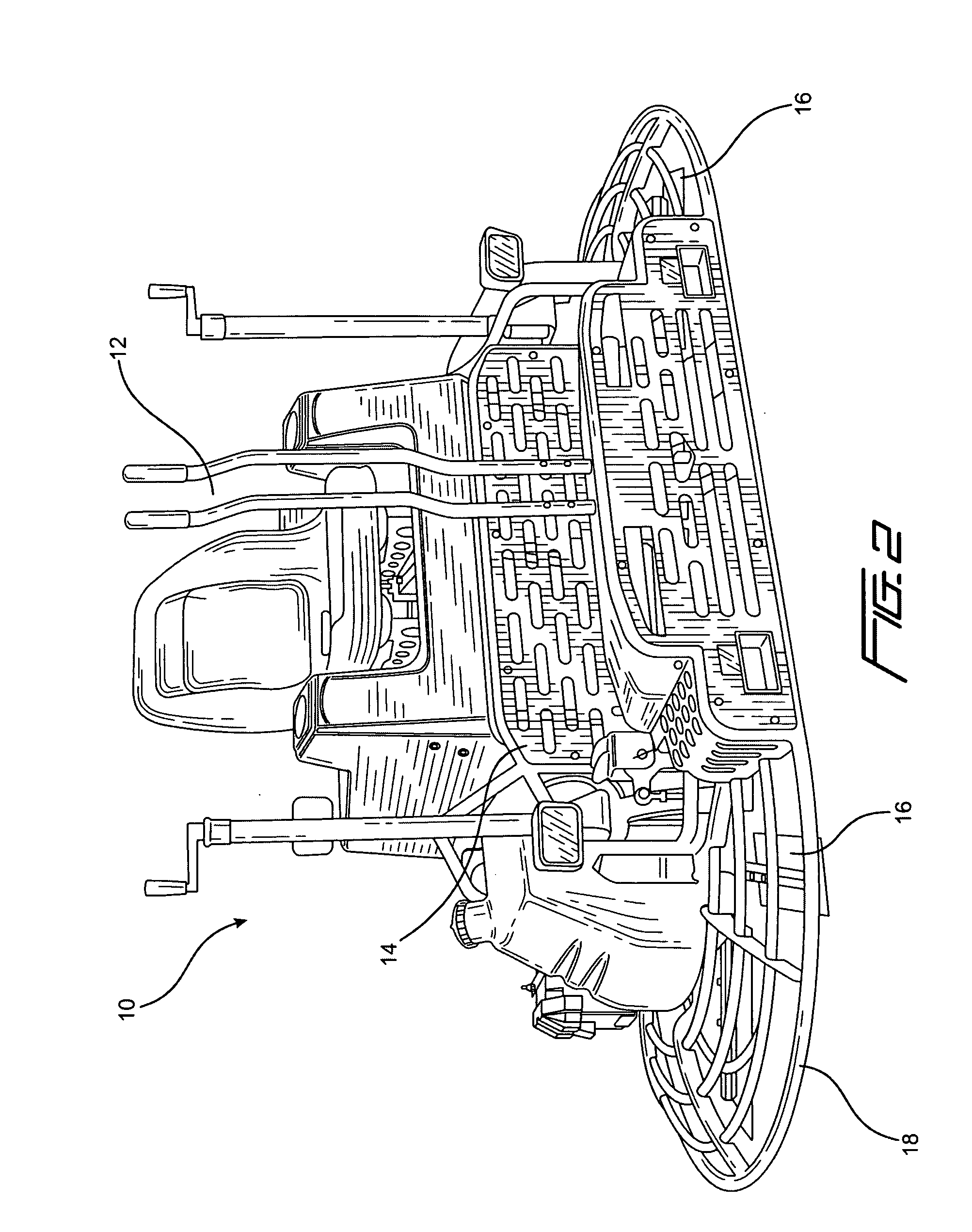

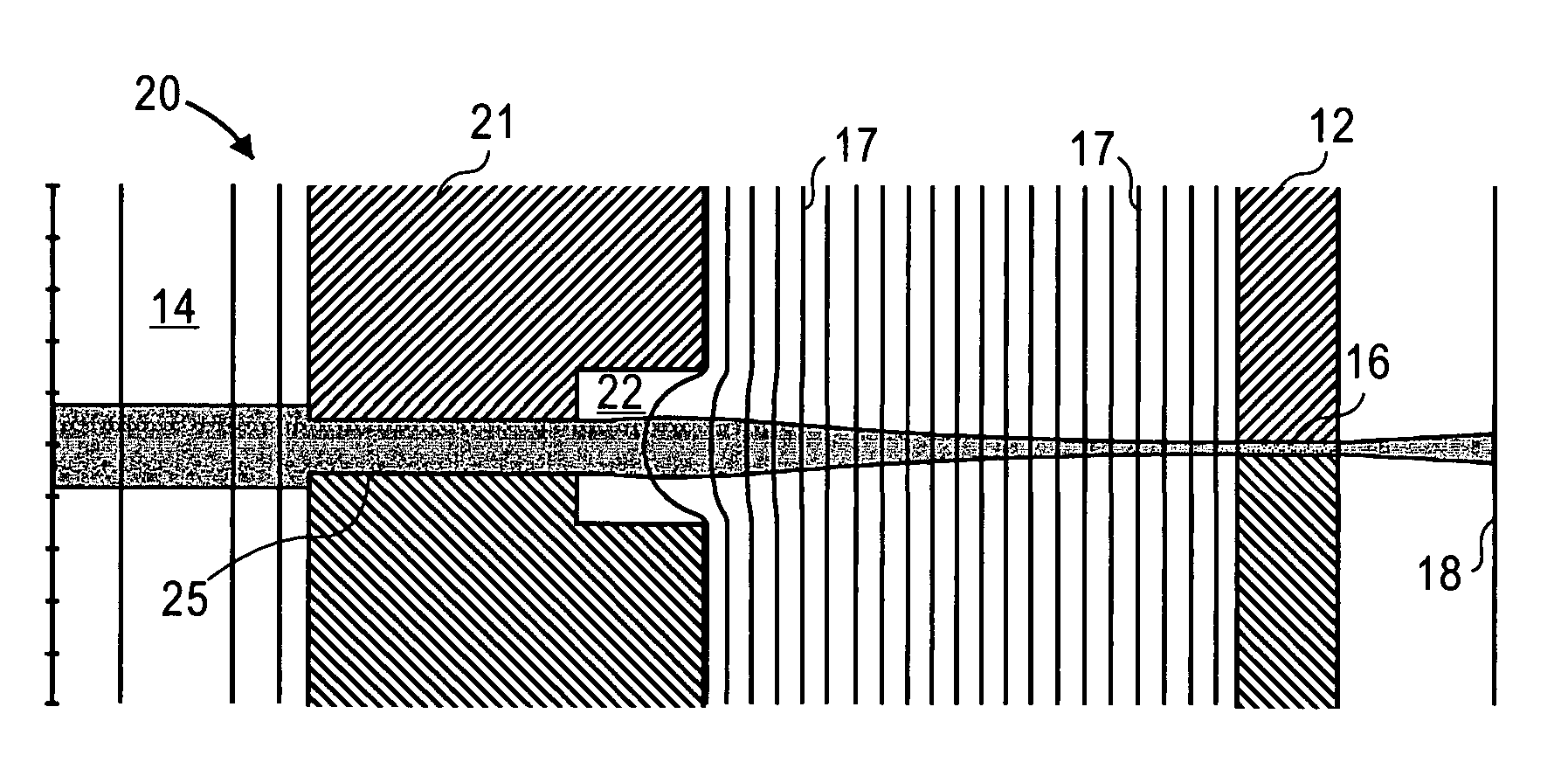

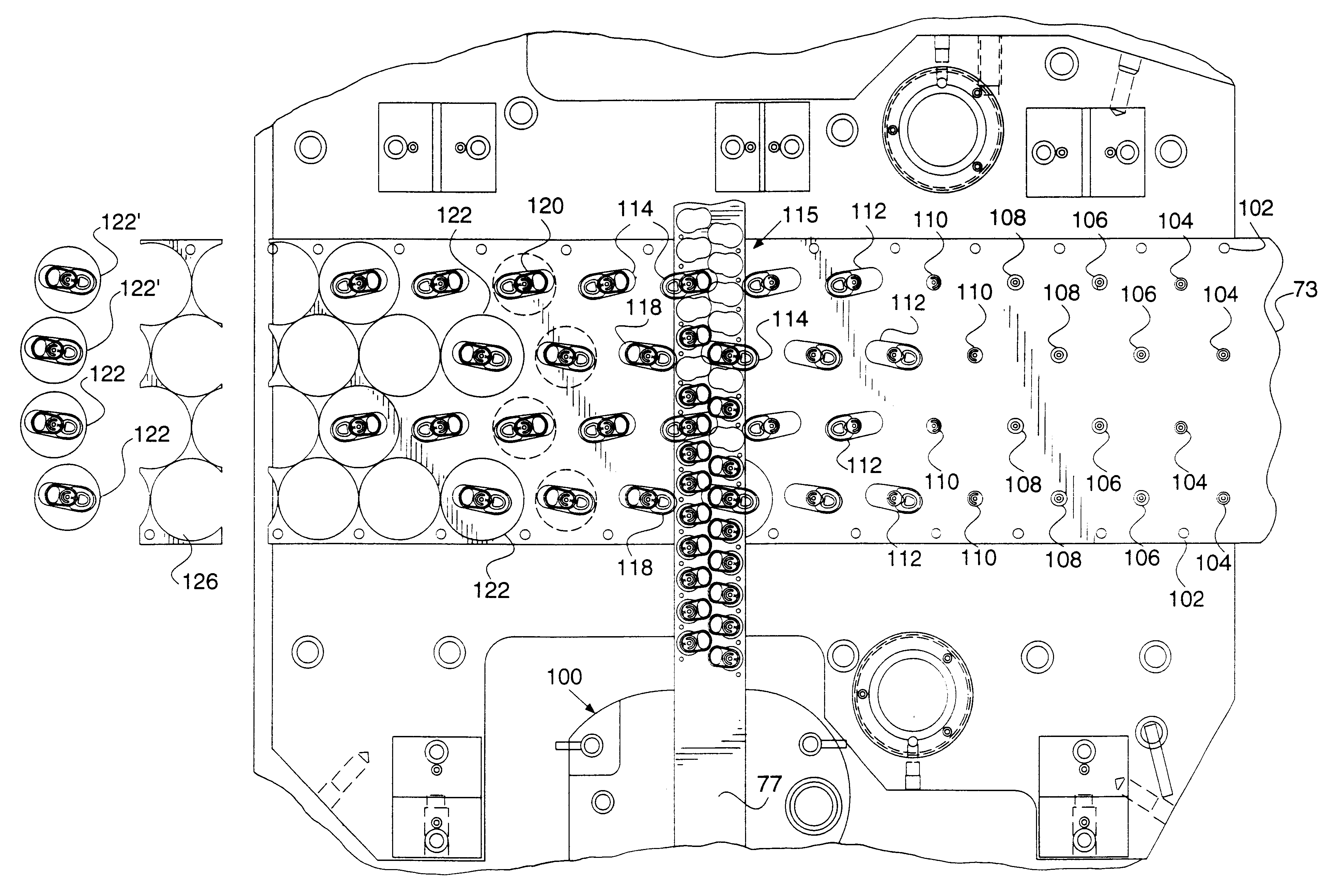

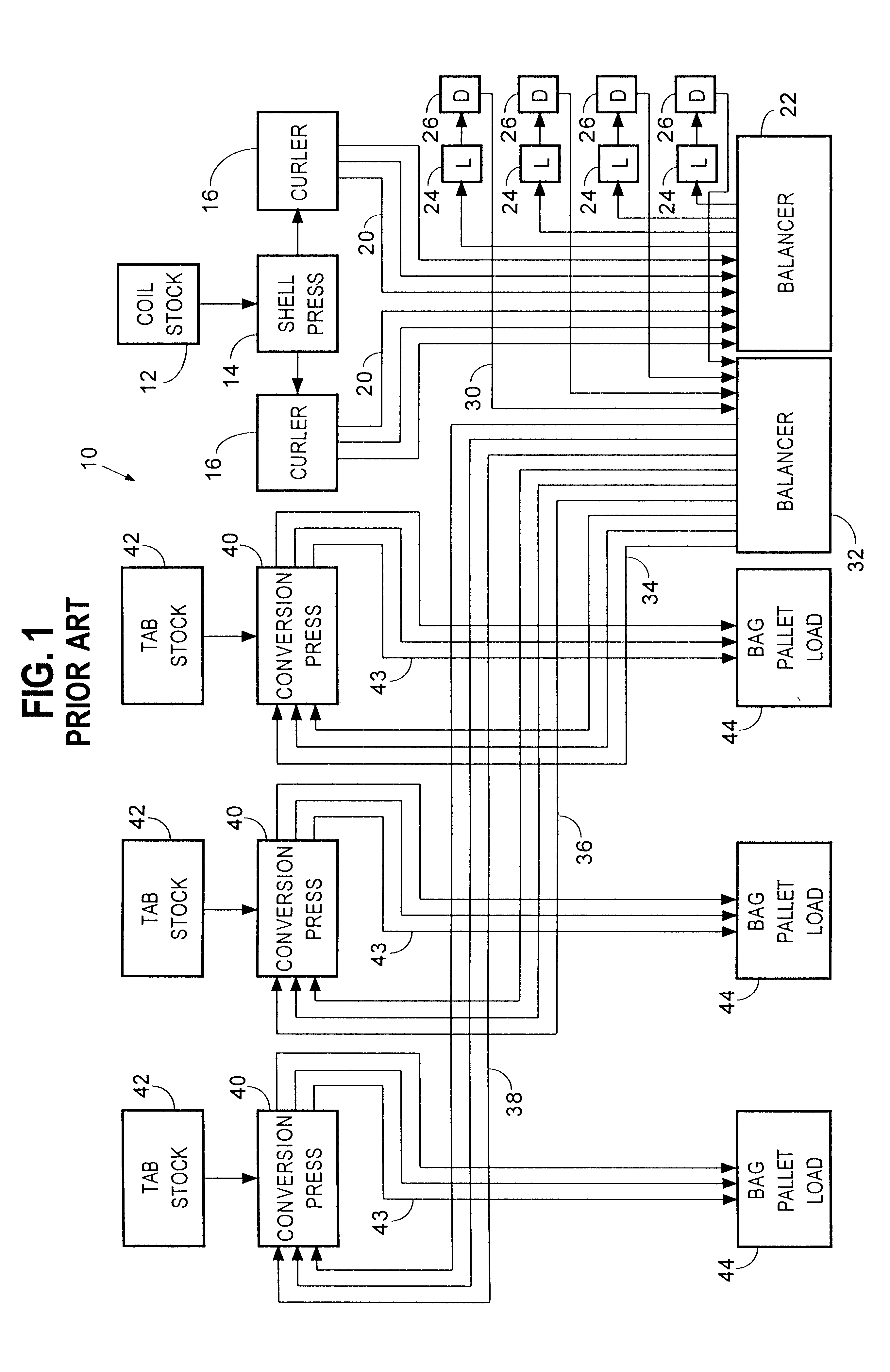

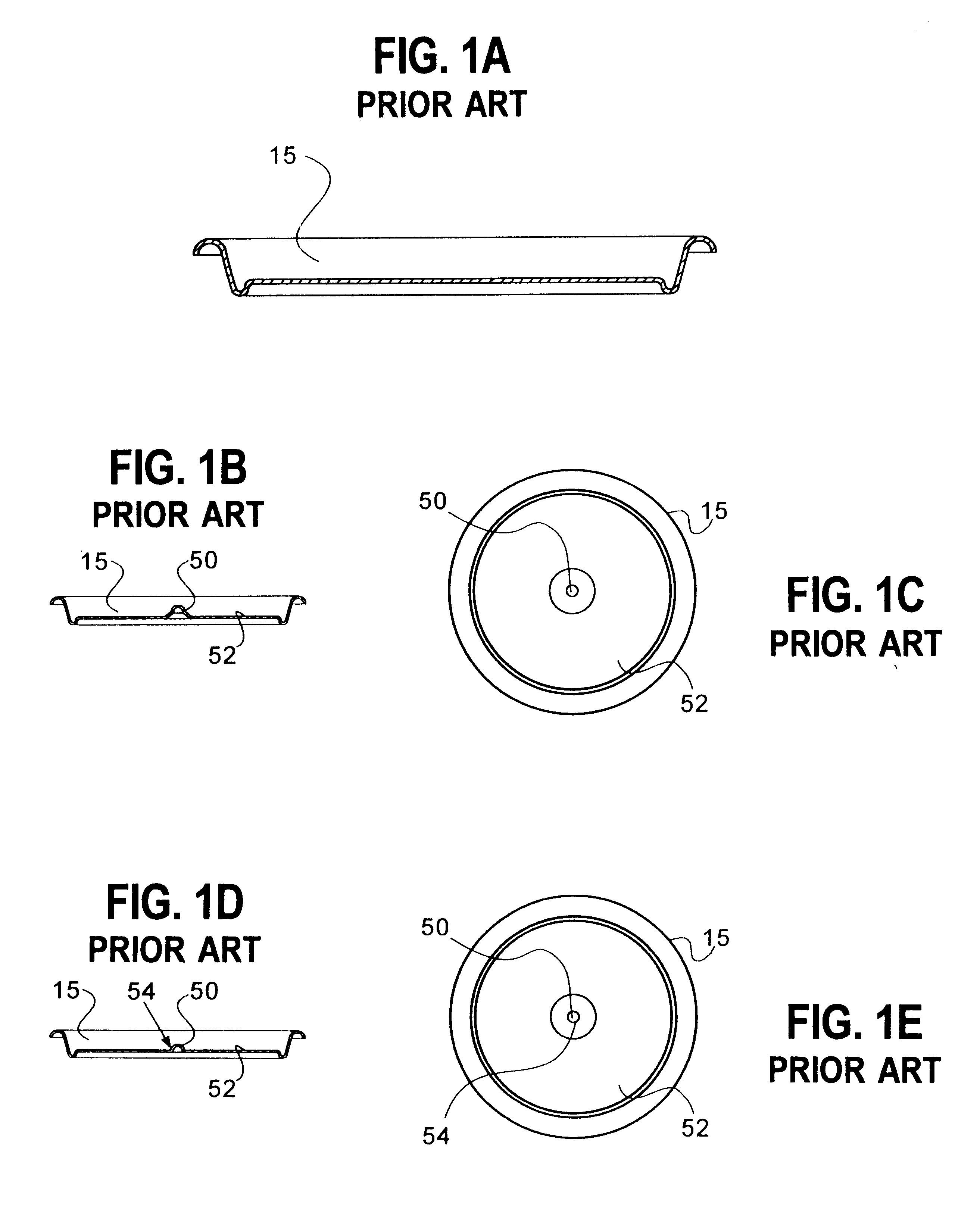

Can end manufacturing system and press therefor

Ends for cans are made in a single press, eliminating the need for separate shell and conversion presses, balancers, track work, and other equipment, as compared to existing can end manufacturing systems, while reducing floor space and capital investment requirements for installation of a new can end line. A sheet of end material or stock is introduced into the press and fed to a series of work stations. The sheet is maintained in a substantially continuous and void free state as the work stations perform forming operations on the sheet of material to form one or more ends therein. After the forming operation is complete, the end is ejected from the press. The maintenance of the sheet of material in a substantially continuous and void free state permits precise movement of the sheet through the press, and registration of the sheet relative to the tooling in the press. This precise movement and maintenance of registration results in a single press capable of operation at high speeds to produce large volumes of ends, while doing so in a reliable and cost-effective manner. In a preferred embodiment, the typical shell conversion operations are performed first on the sheet of end material, while maintaining the sheet in a substantially planar and void free state, followed by a shell forming operation in which the panel and countersink features are formed and the completed end blanked in a single stroke at the very end of the forming operations.

Owner:REXAM BEVERAGE CAN

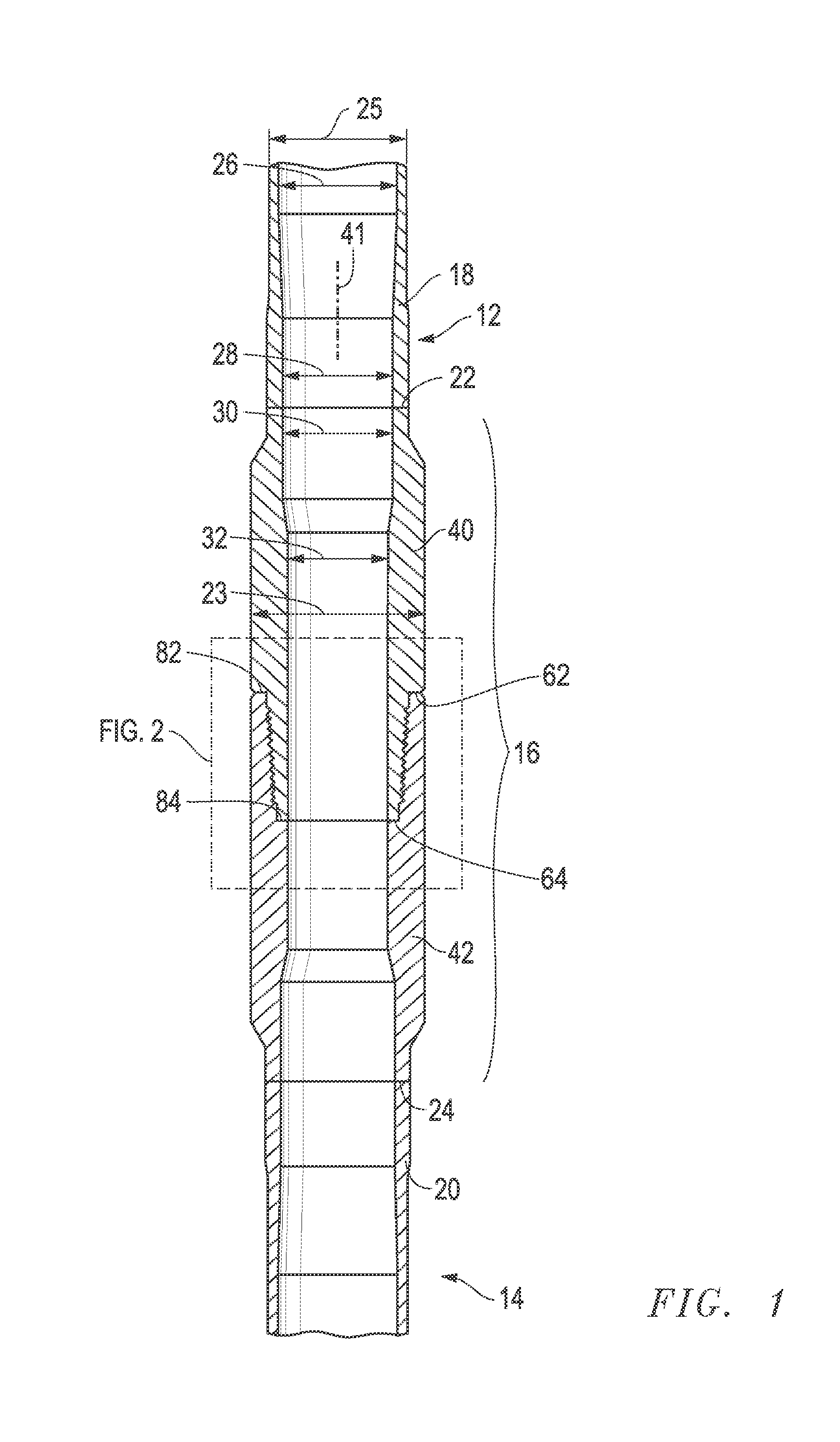

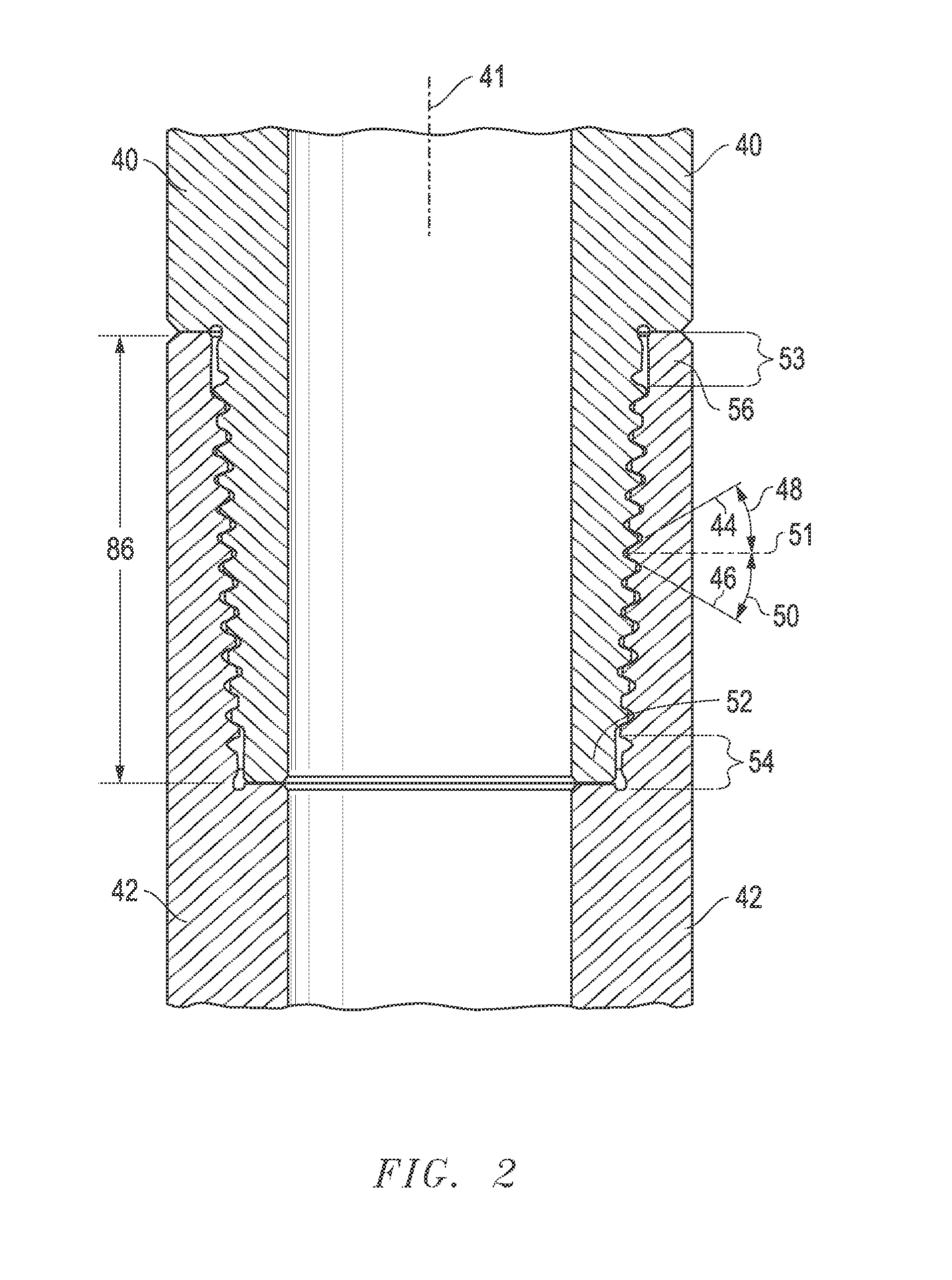

Threaded Tool Joint Connection

In a double-shoulder threaded tool joint connection, the pin external threads and the box internal threads have a thread taper between 0.75 inch per foot and 1.0 inch per foot. The pin external threads and the box internal threads have equal stab flank and load flank angles, and are in a range from thirty-three to thirty-nine degrees. Both the pin external threads and the box internal threads have roots formed in a shape of a portion of a circle tangent to both thread flanks with a minimum radius of 0.063 inch. The pin external threads and the box internal threads are in the range of two to three per inch. The box counterbore has a length of 0.750 or less. The pin nose has a length in a range of 30% to 90% of the length of the box counterbore.

Owner:TEXAS STEEL CONVERSION INC

Self loading firearm bolt carrier with integral carrier key and angled strike face

A bolt carrier for use with the AR15 / M16 family of firearms is provided. The bolt carrier includes an integrally formed carrier key and spherical strike face surrounded by a cylindrical counterbore made with a downward angle to act against the tilting force imparted by the operating rod of the firearm's gas operating system. The outer surface of the carrier includes upper and lower running rails that all extend fully to the front face of the carrier to lengthen the carrier's rail support or bearing surfaces against the receiver. To improve the robust operation of the firearm in over the beach operations, the bottom and rear of the receiver extension has drain holes formed through which water is forced out of the receiver extension by the reciprocating action of the bolt carrier when the weapon is fired.

Owner:LWRC INTERNATIONAL

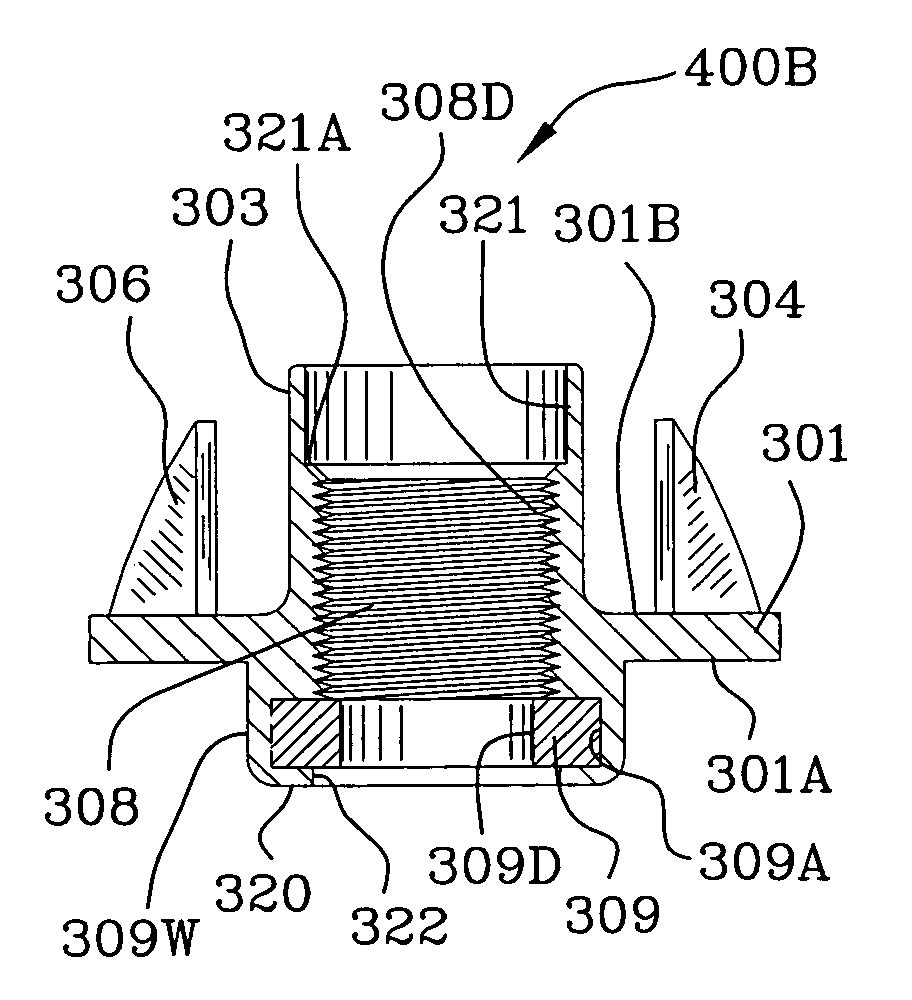

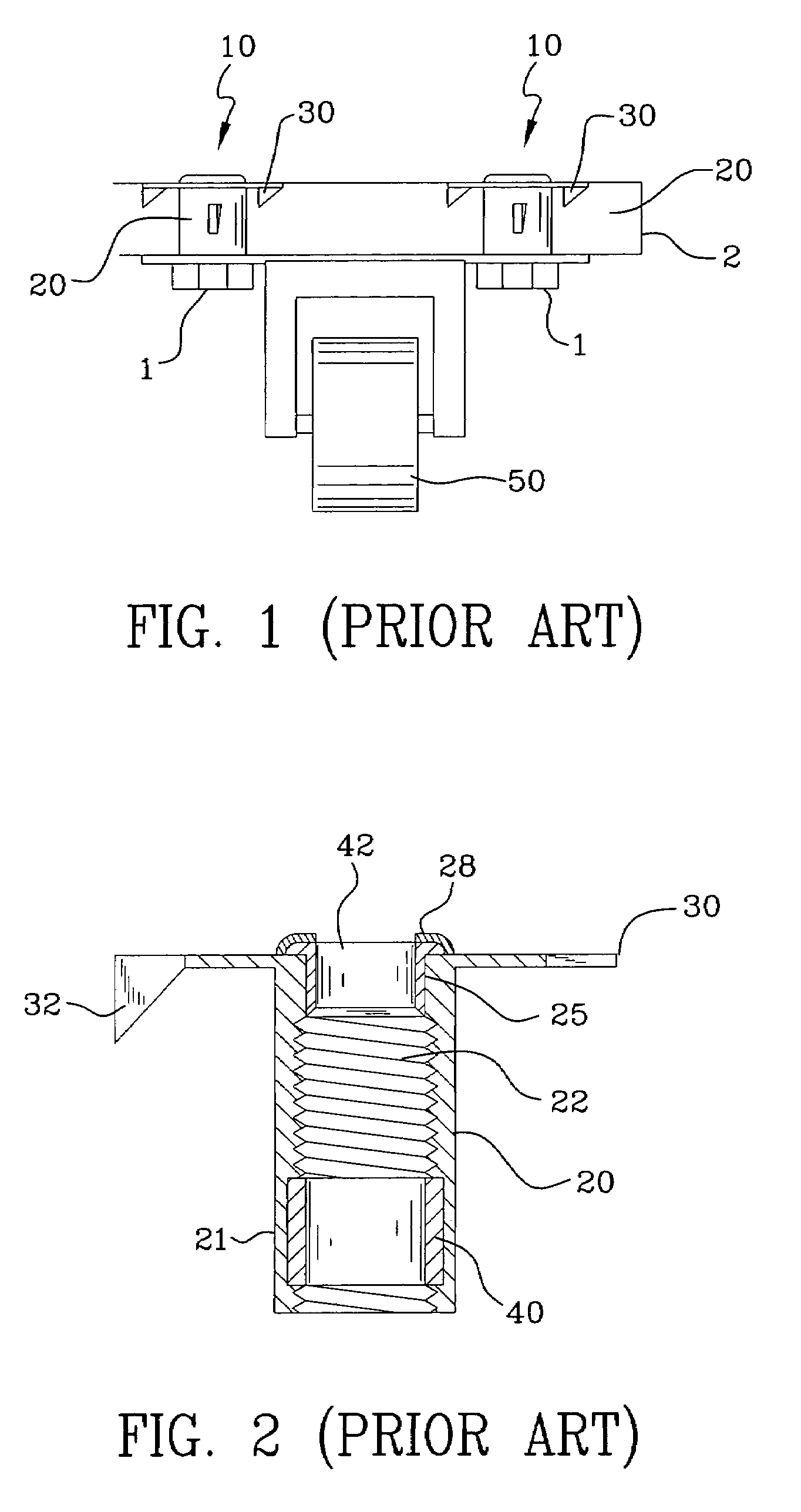

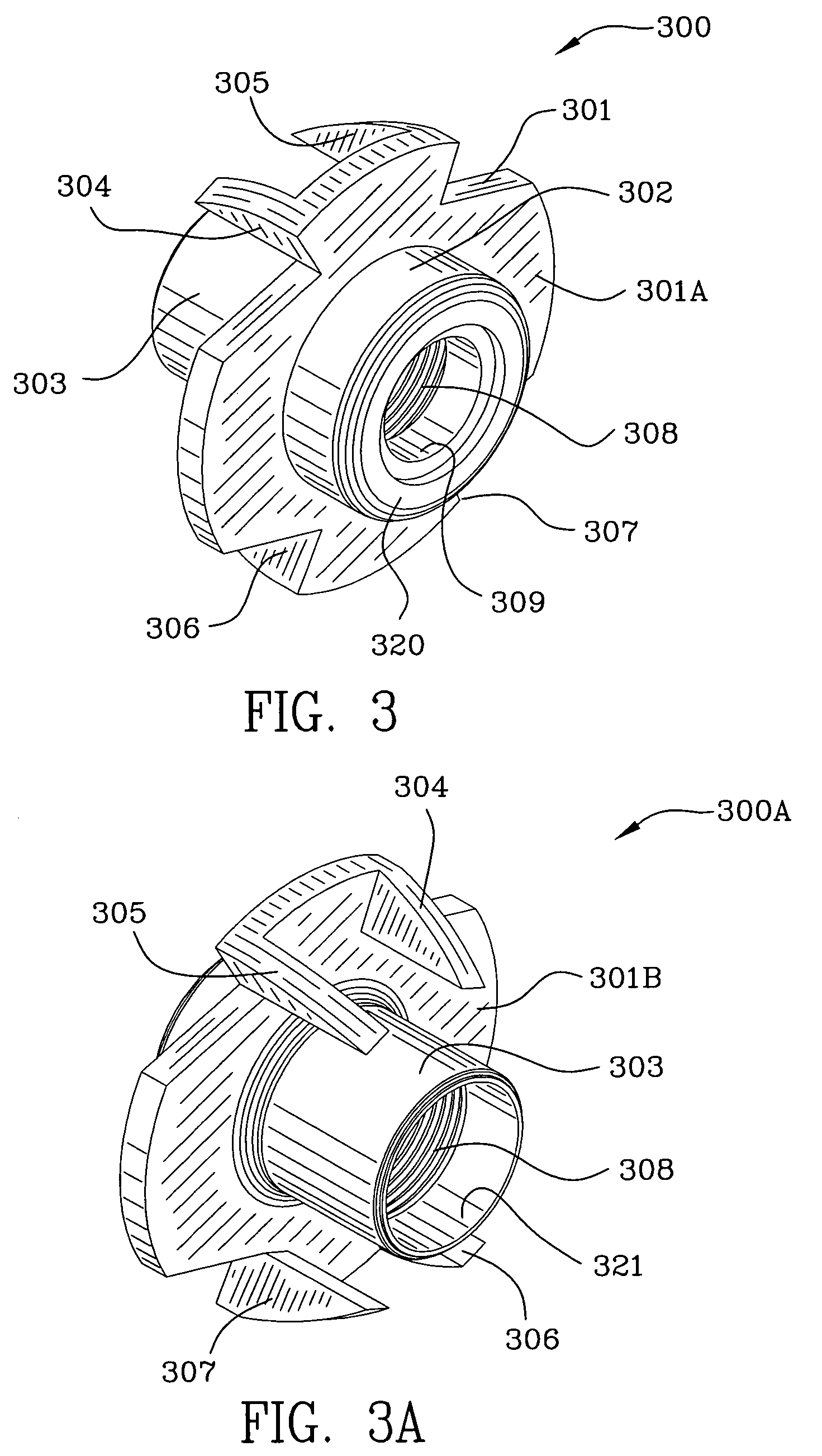

Hopper fed tee-nut having counterbore with nylon lock

A tee-nut fastener which includes a nylon locking ring located distally from the entrance to a passageway ensures proper fastening upon coupling with a threaded stud. The tee-nut is used use in combination with a track for efficient delivery. The track comprises an upper guide spaced apart relatively farther than a lower guide. The process for making the tee nut uses a cold heading process. The tee-nut includes a flange having an upper portion and a lower portion. A shank extends perpendicularly from the upper portion and a head extends oppositely from the shank and perpendicularly from the lower portion. The flange includes at least two teeth extending in the direction of the shank and a passageway through the shank, flange and head. The passageway includes a bore countersunk at both ends thereof, a cavity, and threads therein. A locking ring resides in the cavity and is relatively thin compared to the length of the teeth to ensure that the tee-nut is not extricated from a substrate in which the prongs or teeth are embedded upon coupling with a threaded stud.

Owner:STAFAST PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com