Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2837results about How to "For quick replacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

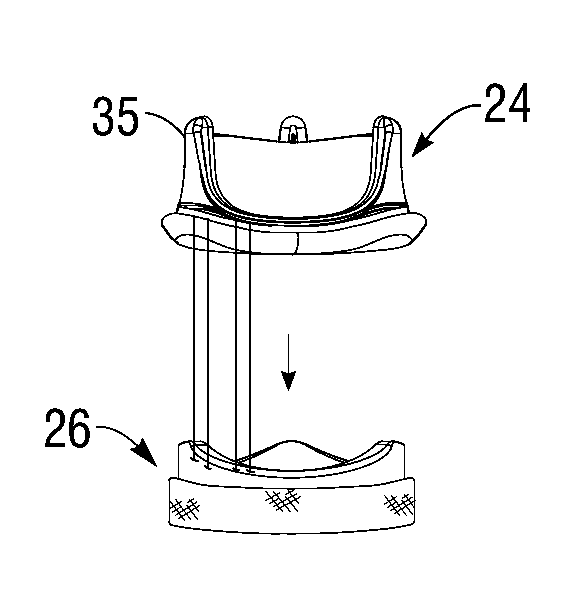

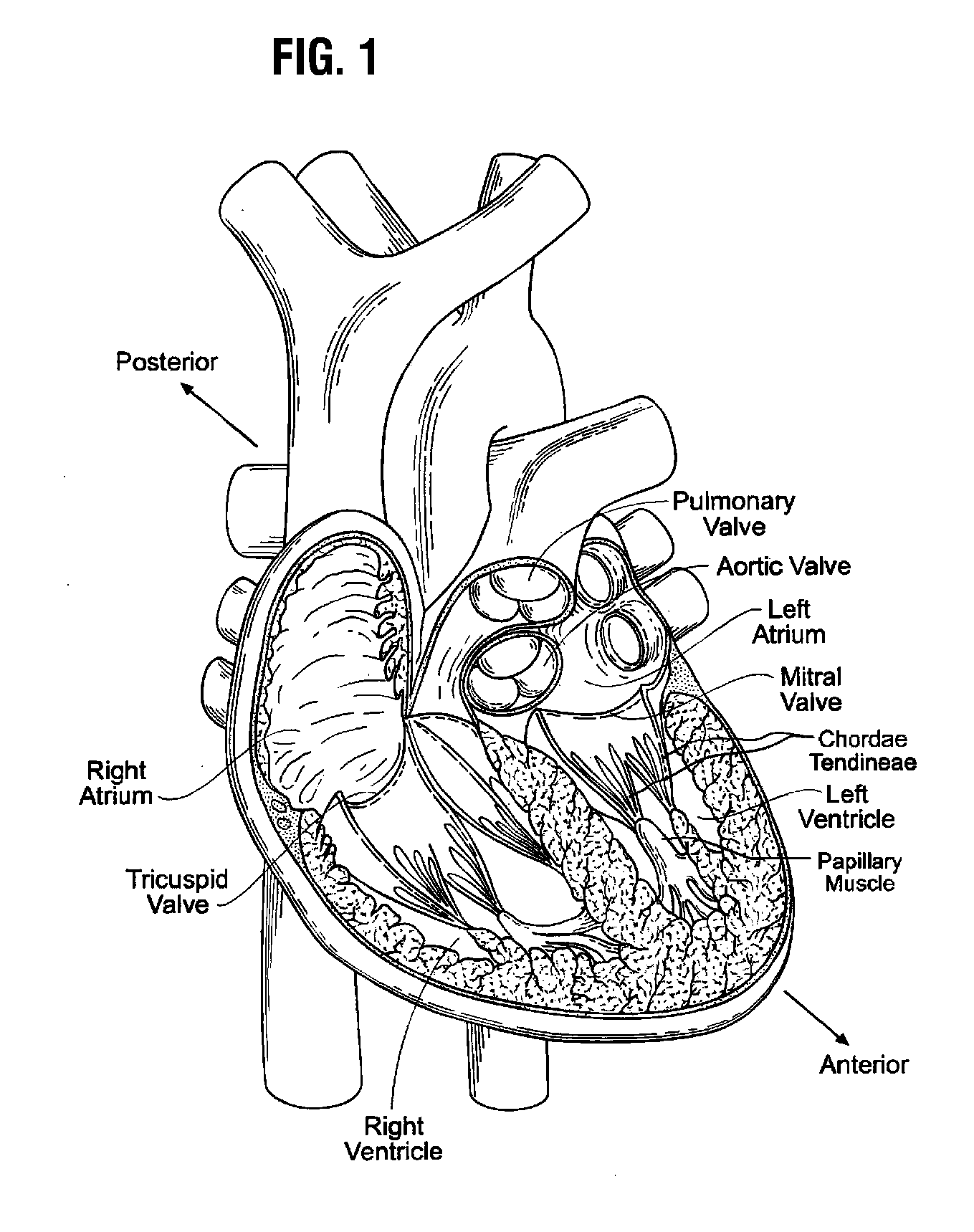

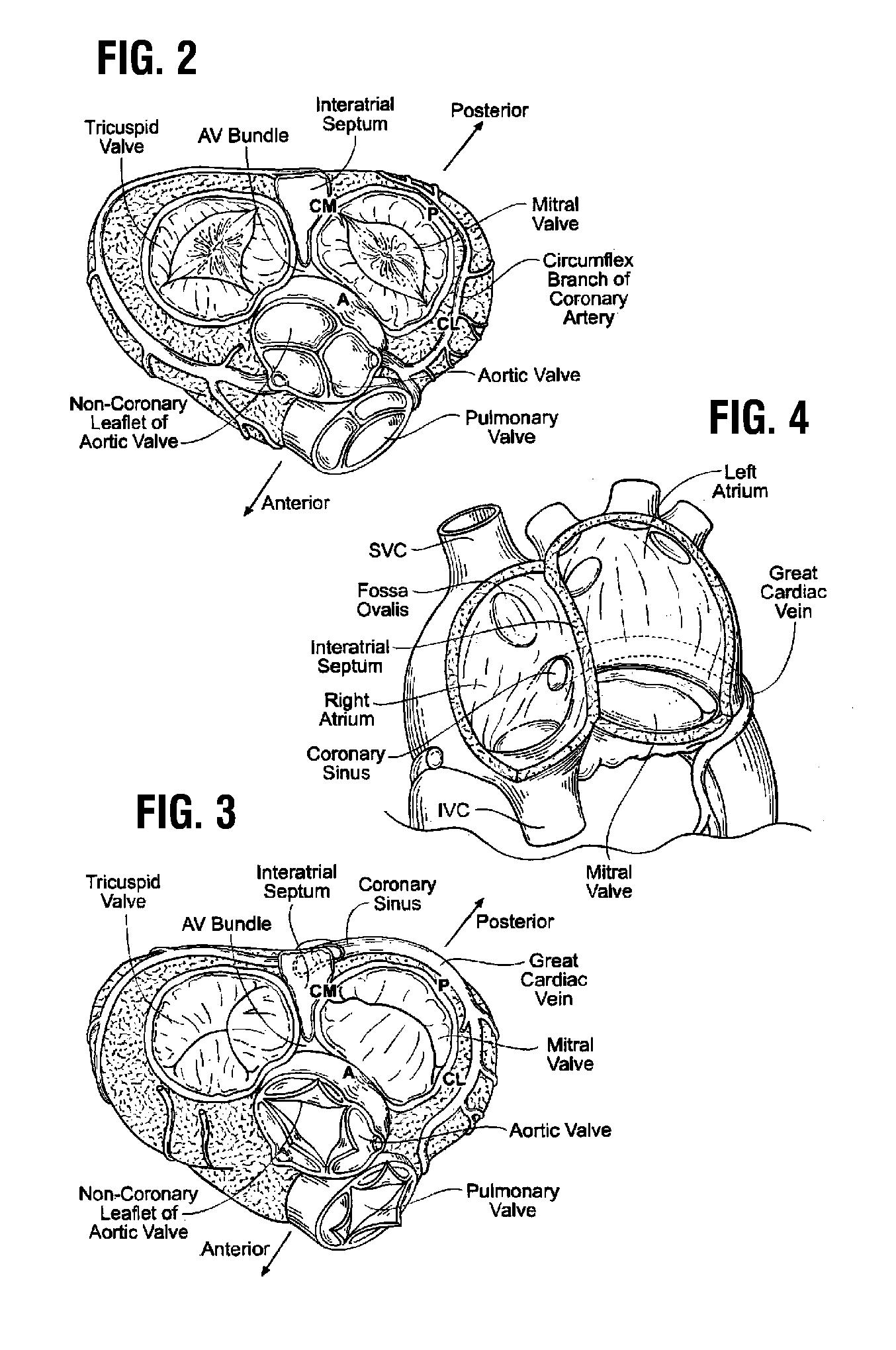

Unitary Quick Connect Prosthetic Heart Valve and Deployment System and Methods

ActiveUS20100331972A1For quick replacementMinimize timeBalloon catheterHeart valvesProsthetic valveProsthetic heart

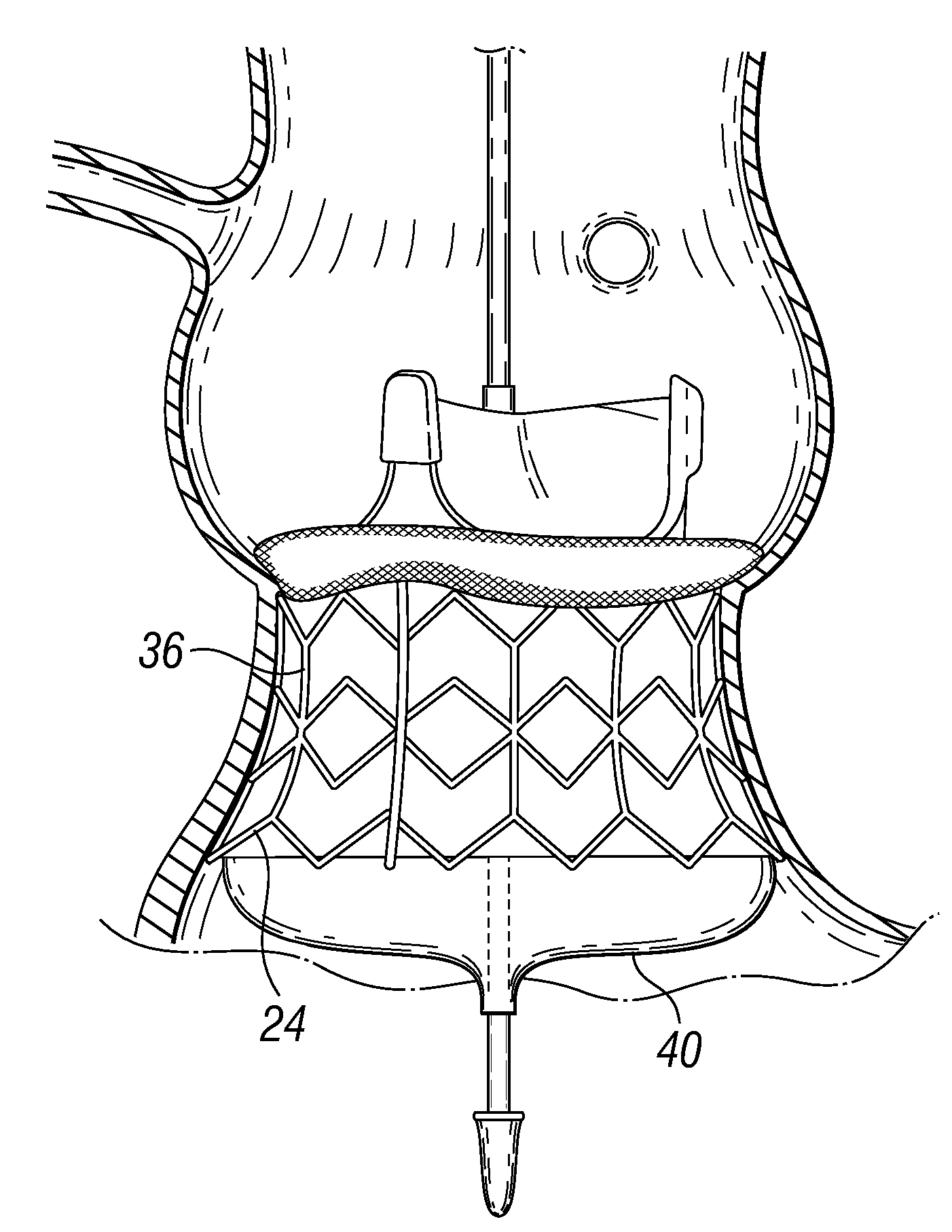

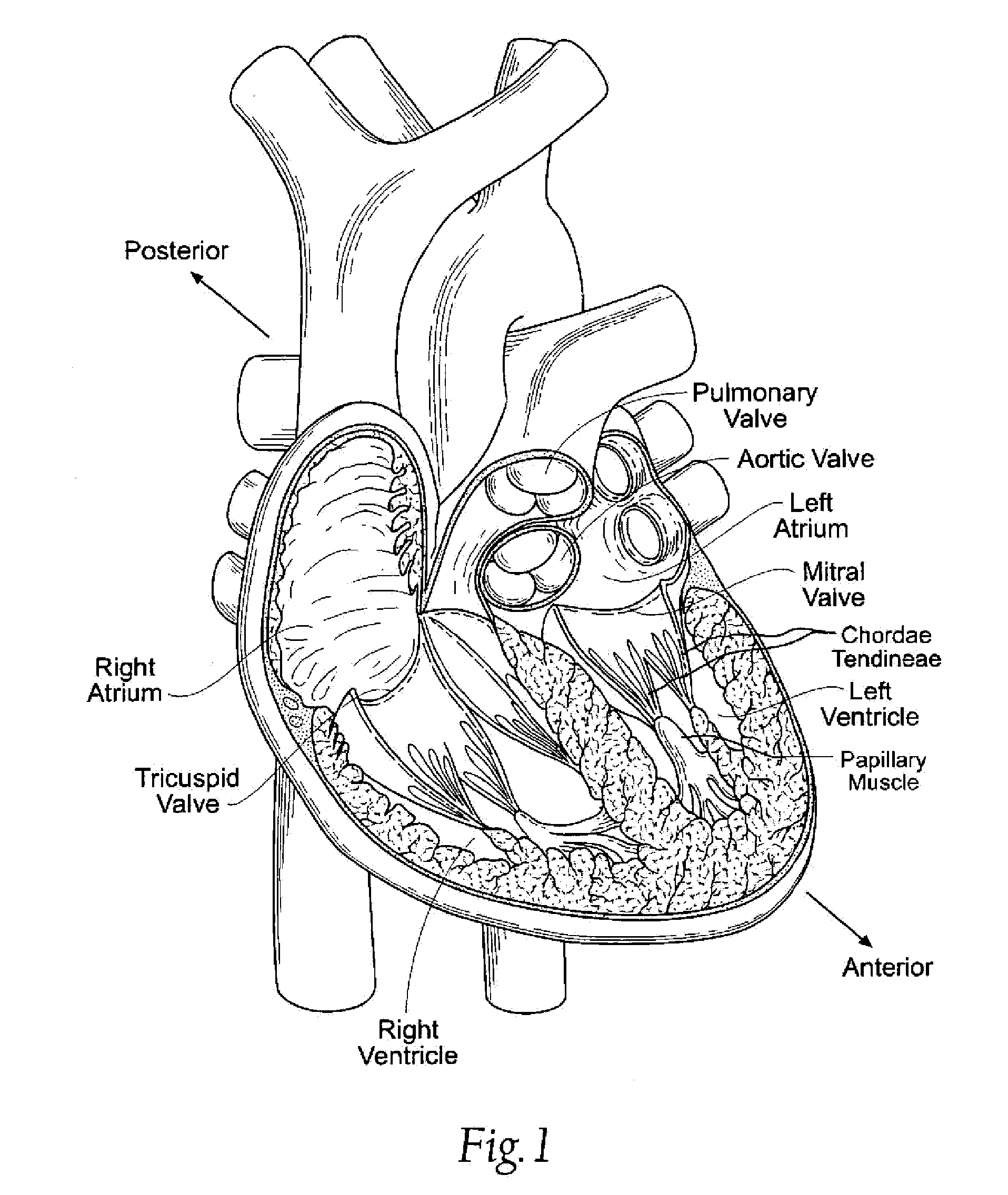

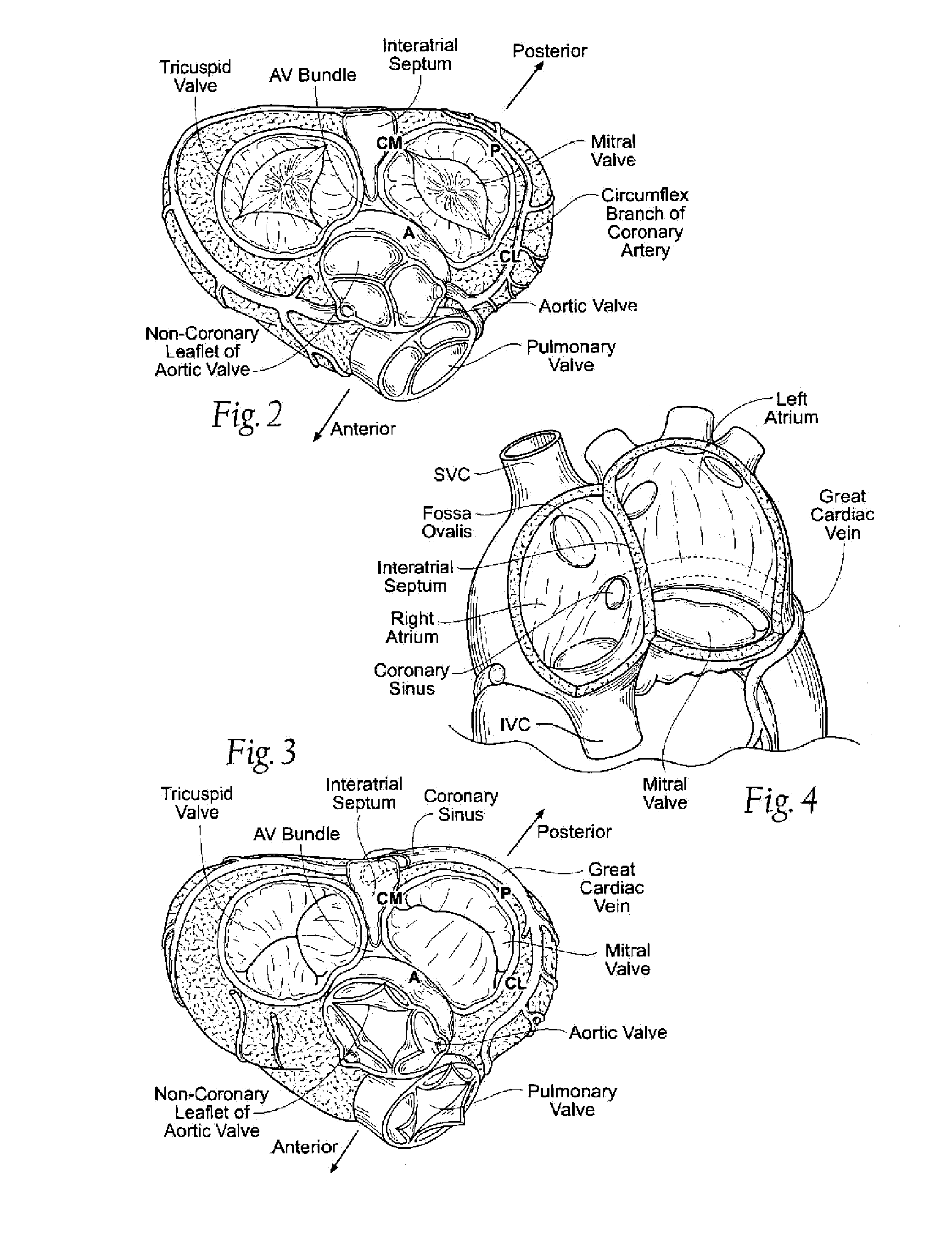

A quick-connect heart valve prosthesis that can be quickly and easily implanted during a surgical procedure is provided. The heart valve includes a substantially non-expandable, non-compressible prosthetic valve and a plastically-expandable coupling stent, thereby enabling attachment to the annulus without sutures. A small number of guide sutures may be provided for aortic valve orientation. The prosthetic valve may be a commercially available valve with a sewing ring with the coupling stent attached thereto. The coupling stent may expand from a conical deployment shape to a conical expanded shape, and may include web-like struts connected between axially-extending posts. A system and method for deployment includes a hollow two-piece handle through which a balloon catheter passes. A valve holder is stored with the heart valve and the handle easily attaches thereto to improve valve preparation steps.

Owner:EDWARDS LIFESCIENCES CORP

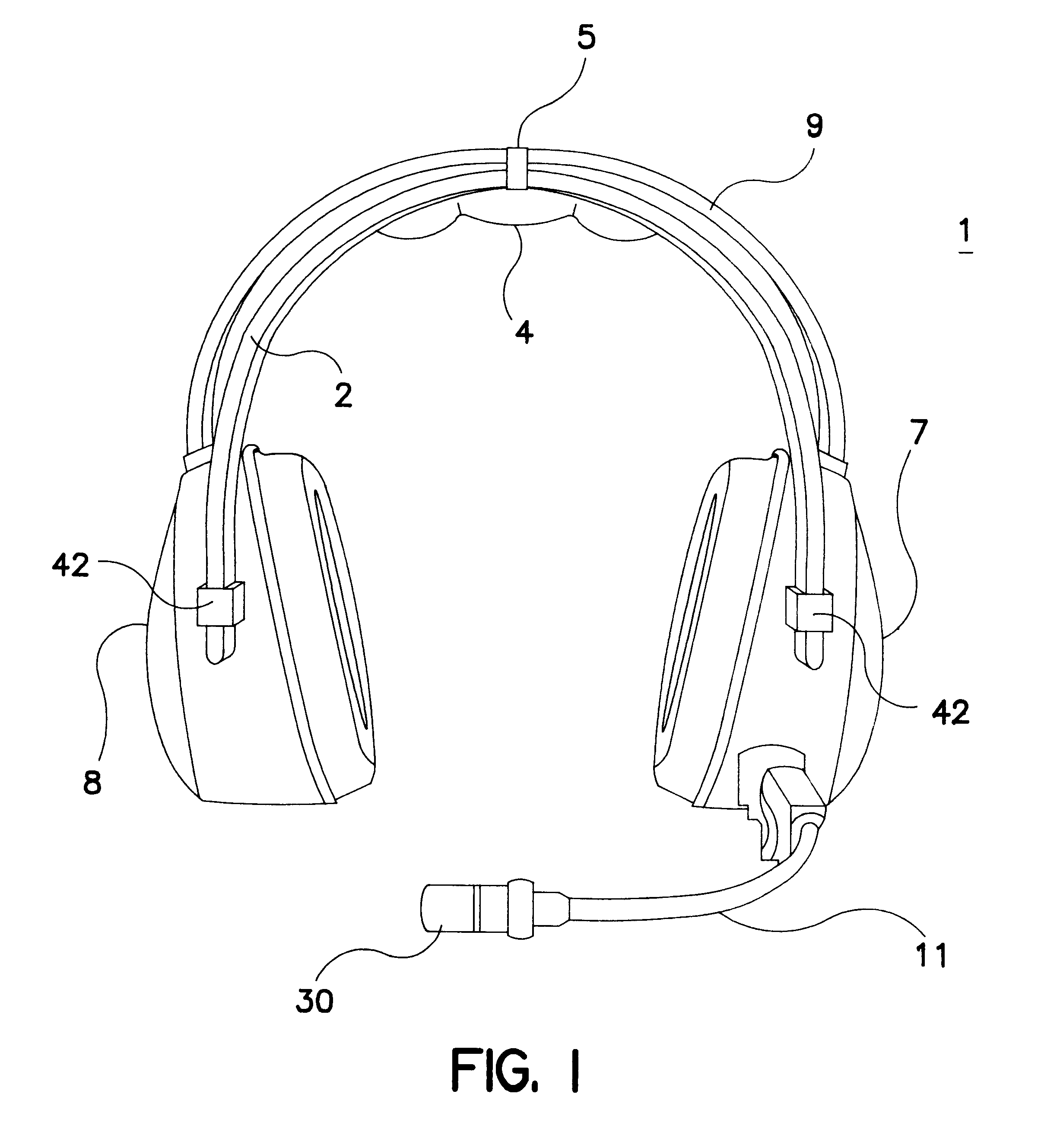

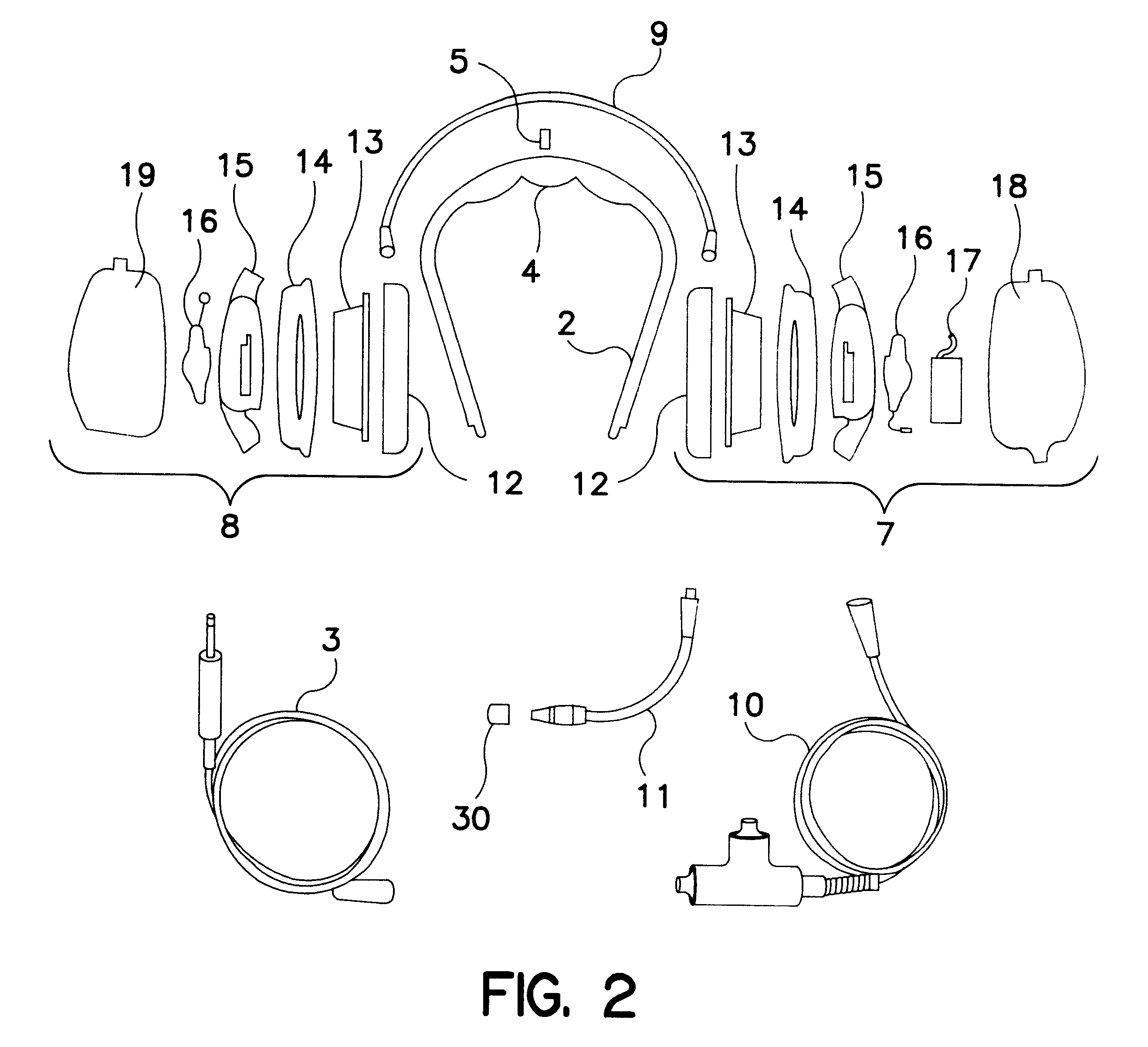

Weather resistant sound attenuating modular communications headset

InactiveUS6466681B1SanitationSimple procedureHeadphones for stereophonic communicationSupra/circum aural earpiecesField conditionsModularity

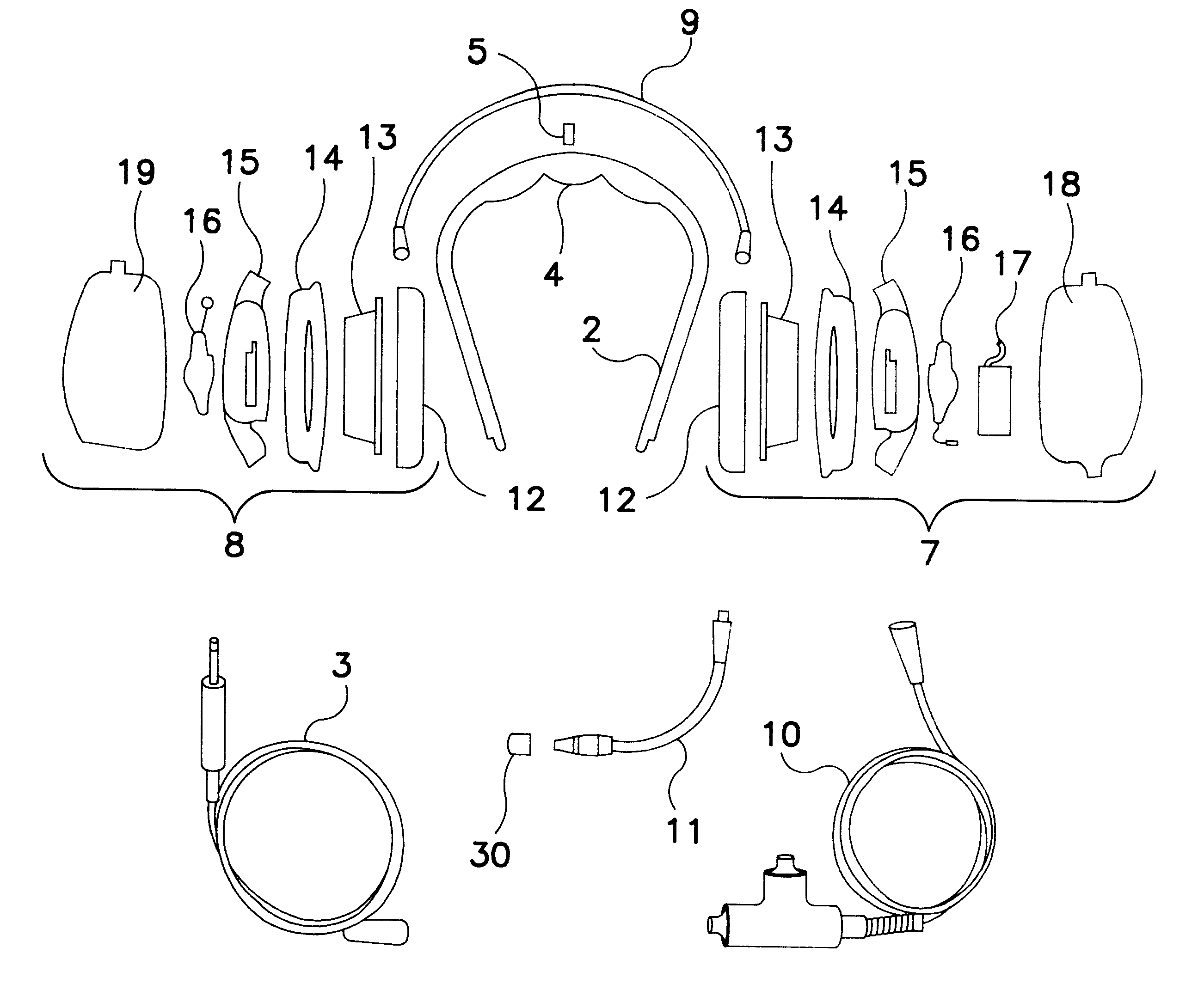

A weather resistant sound attenuating communications headset of modular construction includes two ear cup modules, a microphone boom module, a head band module, a headband cable module, and a termination cable module. The modular construction allows easy replacement of modules as well as selected components of the modules under field conditions without the need for tools. Replaceable water resistant thin film membranes are employed to provide weather protection as well as hygienic protection for the microphone, speaker and amplification electronics. The thin film membranes which cover areas which come into intimate contact with the wearer are easily replaceable under field conditions. Thus a headset that is shared by more than one user can be hygienically cleansed by simple replacement of the microphone and ear cup membranes.

Owner:COMPREHENSIVE TECHN SOLUTIIONS

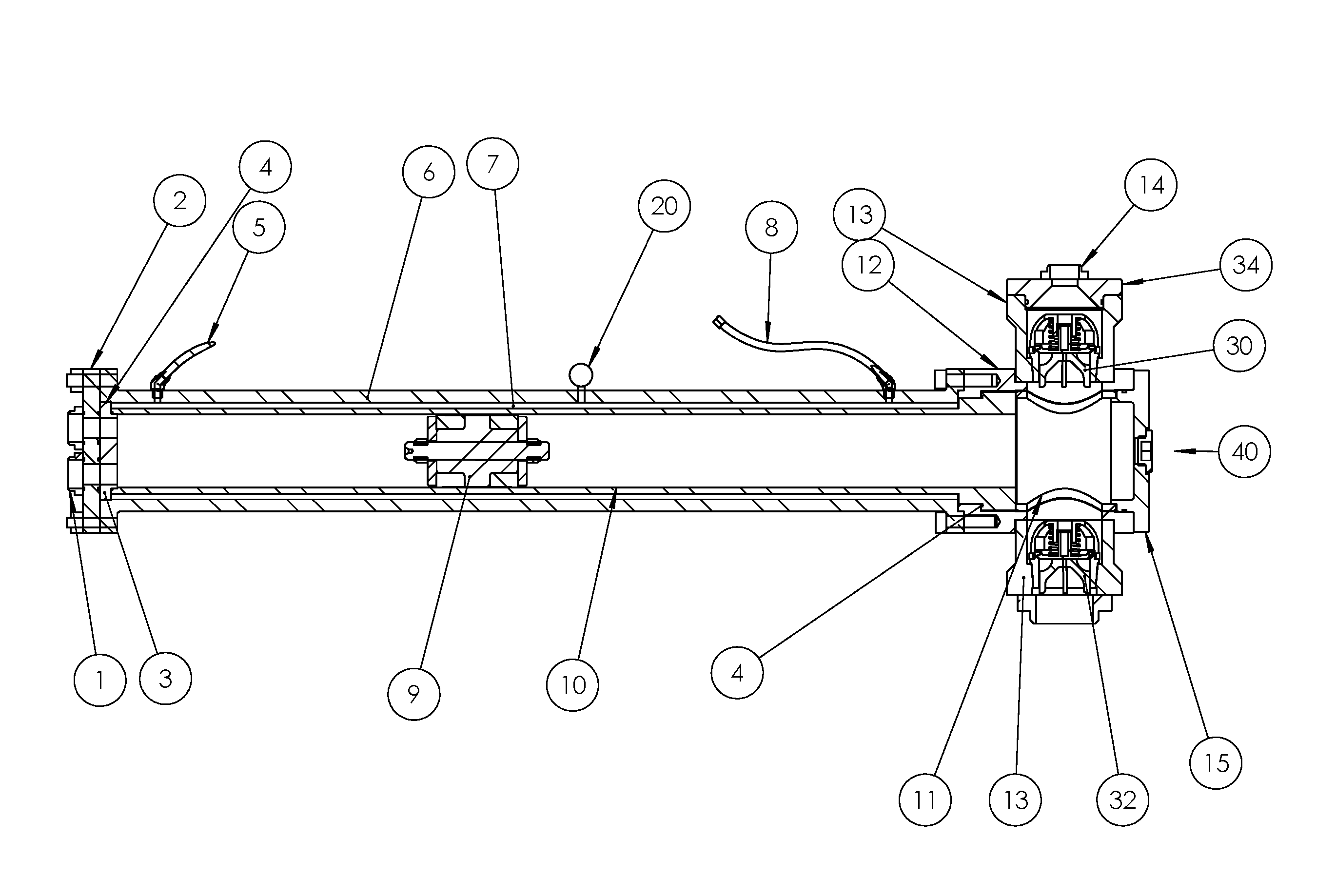

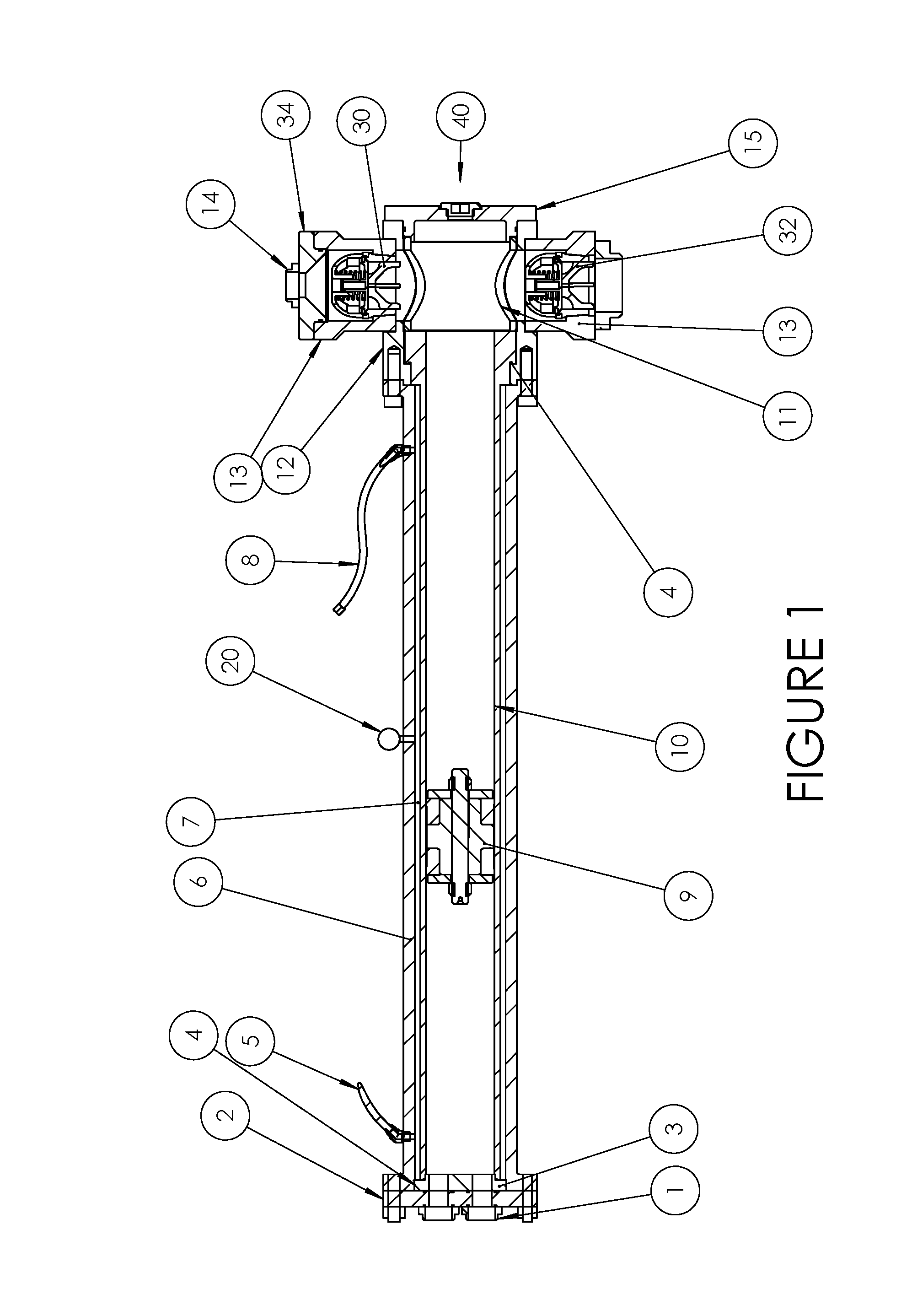

Economical High Pressure Wear Resistant Cylinder That Utilizes A High Pressure Field For Strength

InactiveUS20160215774A1Easy to transportLighter and cheap materialPositive displacement pump componentsFluid removalWear resistantHydraulic fracturing

A high-pressure wear resistant cylinder that utilizes a high-pressure field for strength is an economical method of, or device for, handling very high pressures and the pumping of abrasive and corrosive fluids. The economic considerations are so favorable, that the invention may be considered a replacement part. The invention is suitable for a variety of applications, particularly a reciprocating flow work exchanger in the well stimulation or hydraulic fracturing industry. Using a high pressure field to strengthen the external surface (outside) of a pipe that is precision honed and plated or sleeved internally (inside), it is now possible to construct various high pressure machines in a relatively inexpensive manner. This invention makes it possible to use pipe with internal operating pressures greater than their nominal operating pressure ratings permit. This invention will be used in various high pressure piping and machinery applications.

Owner:TRINITY PUMPWORKS LLC

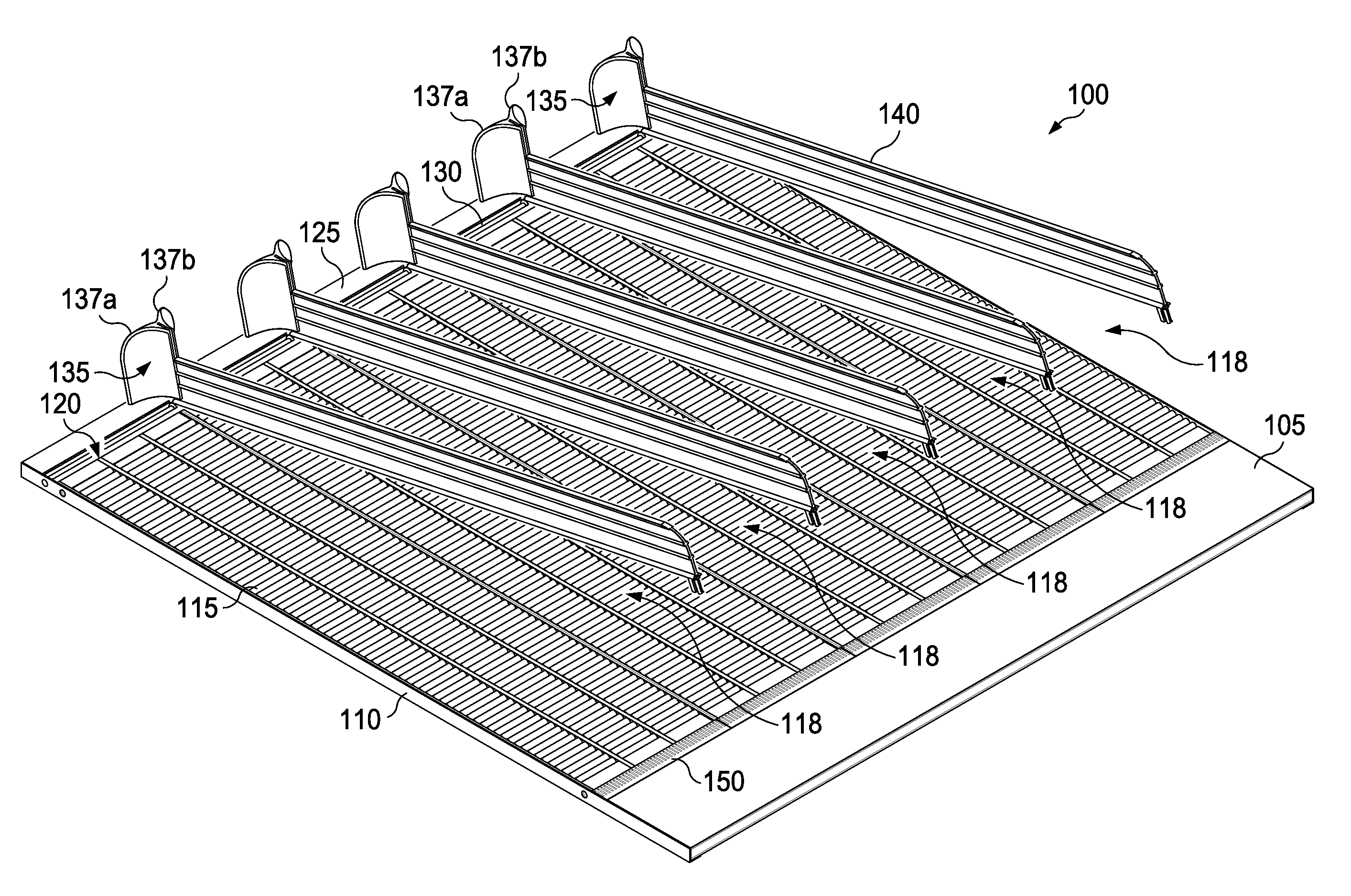

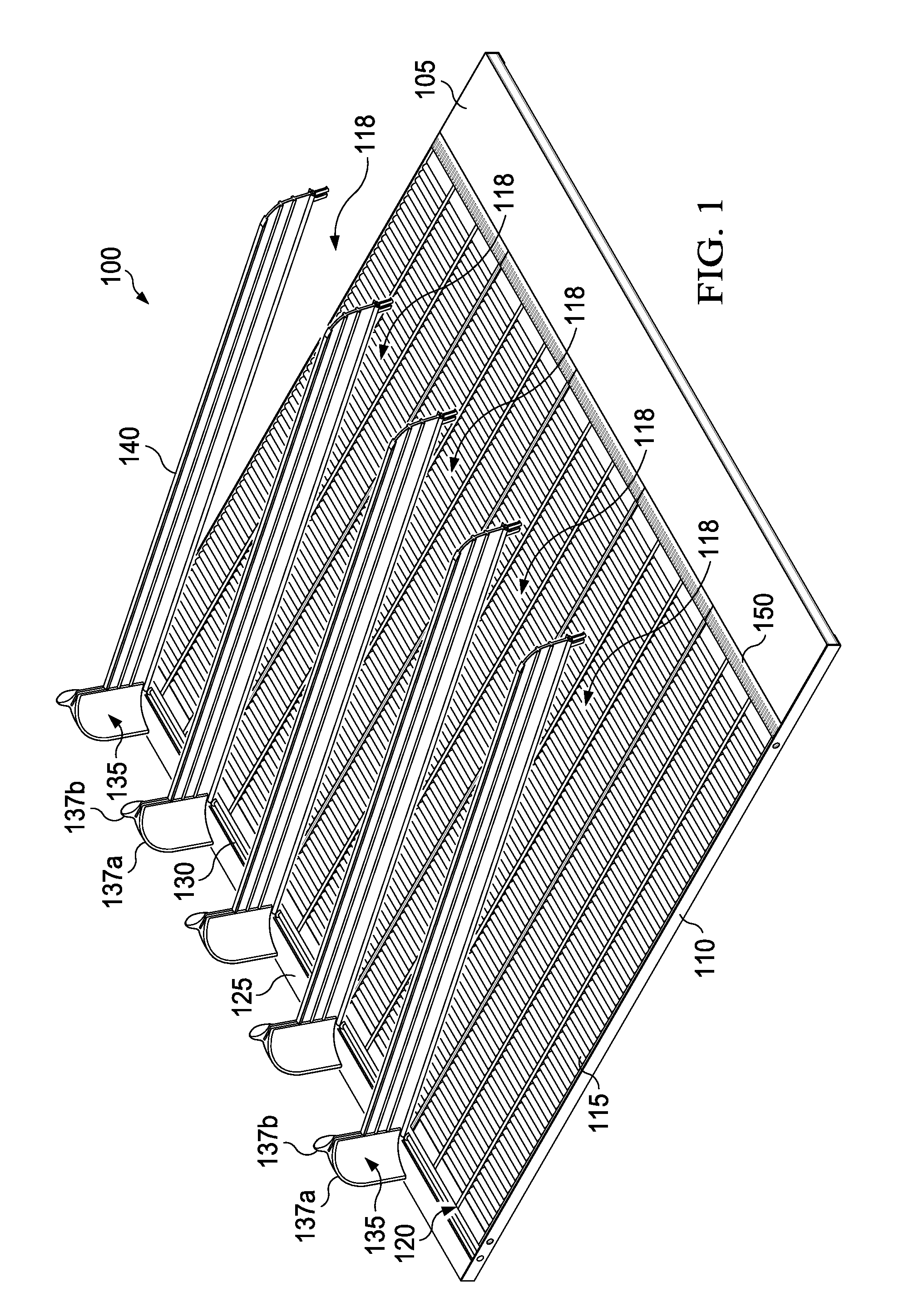

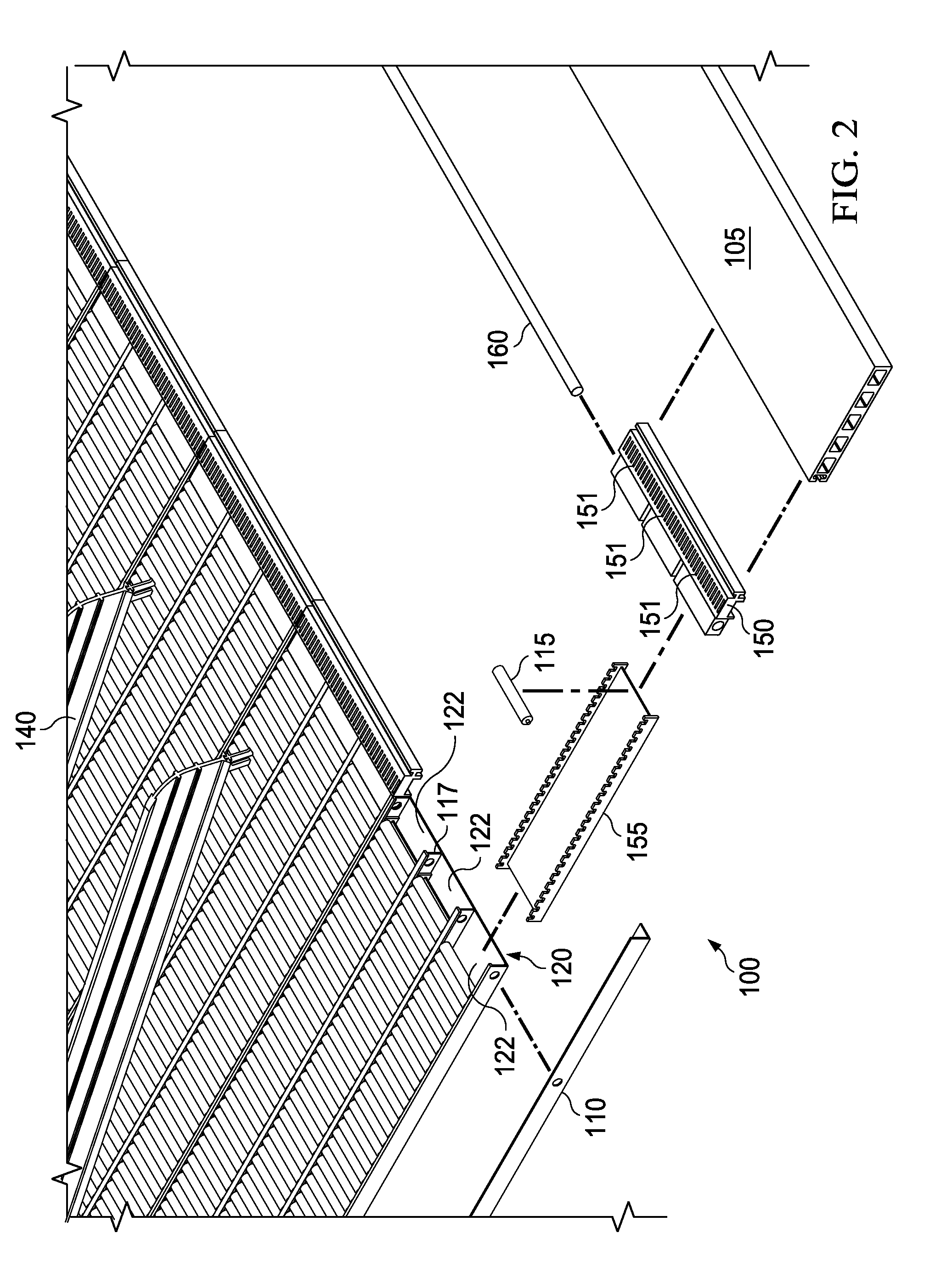

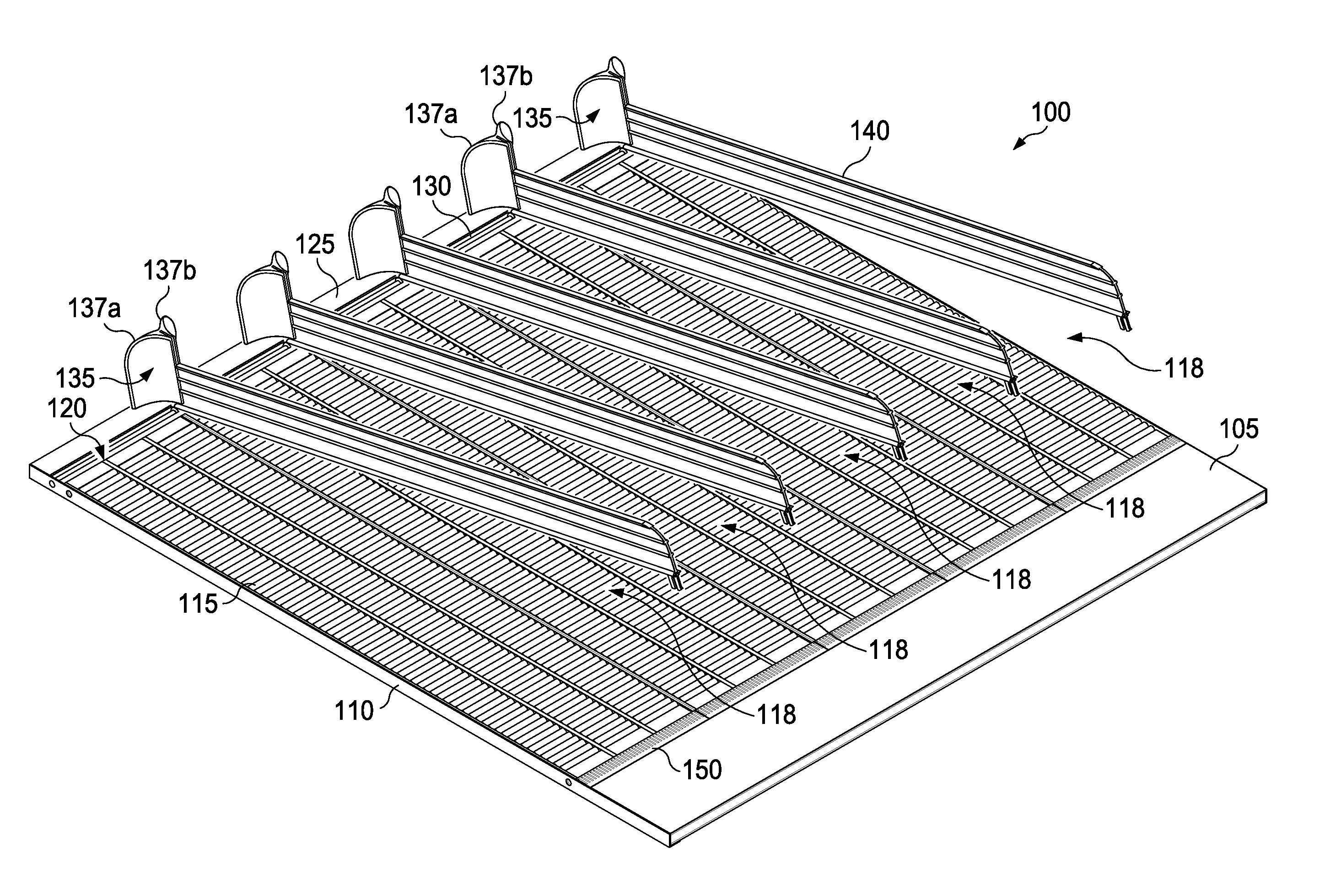

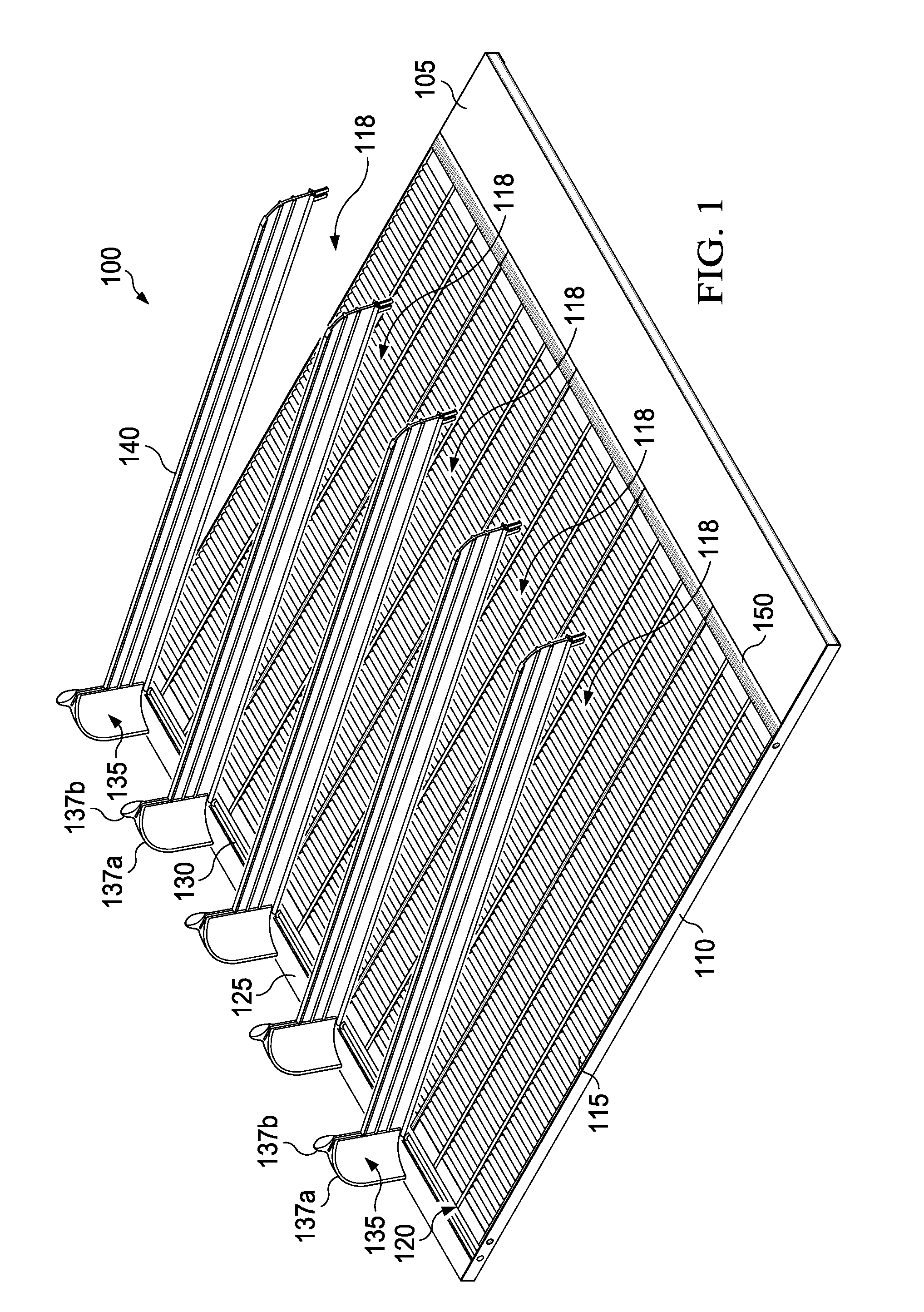

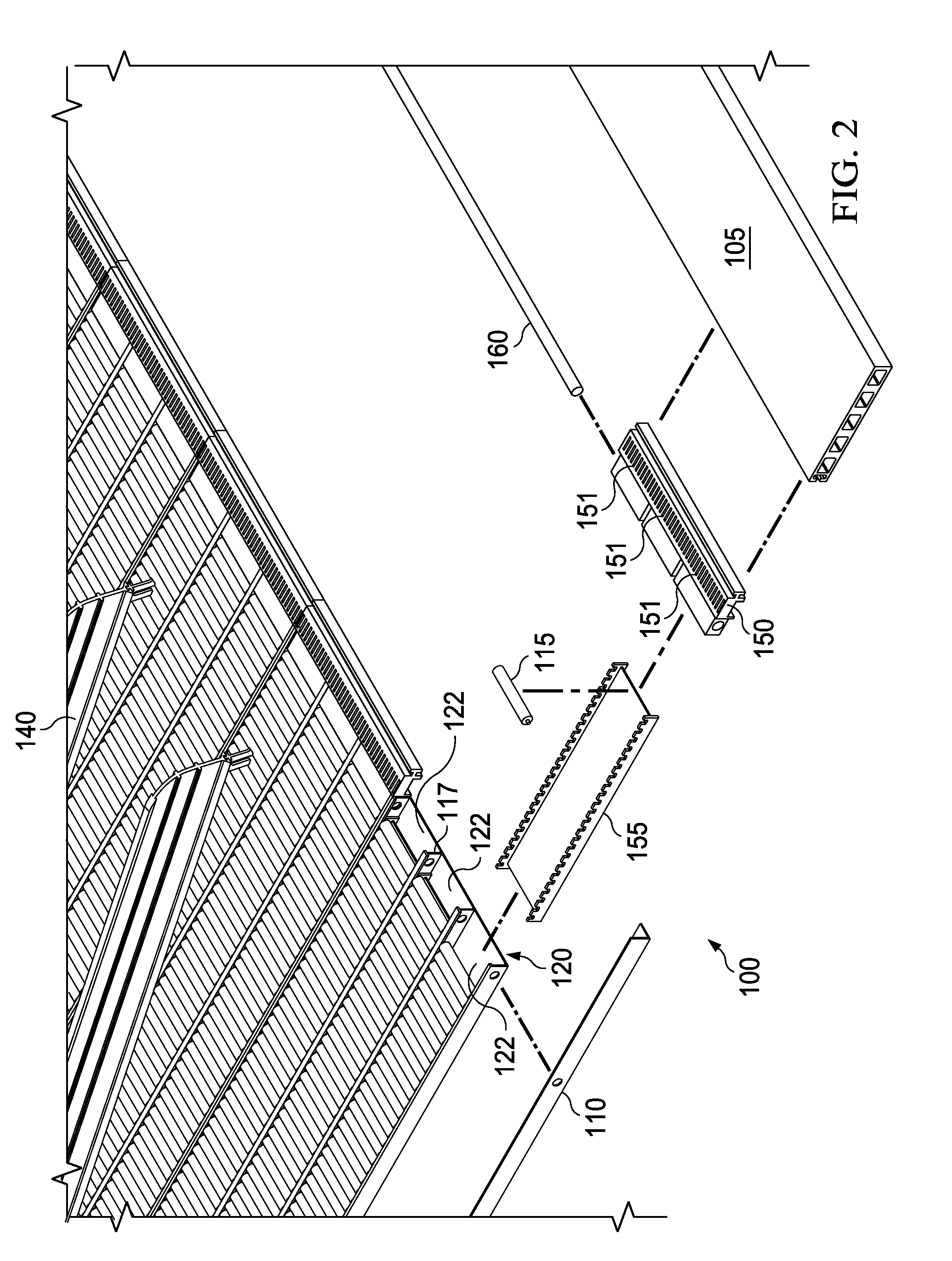

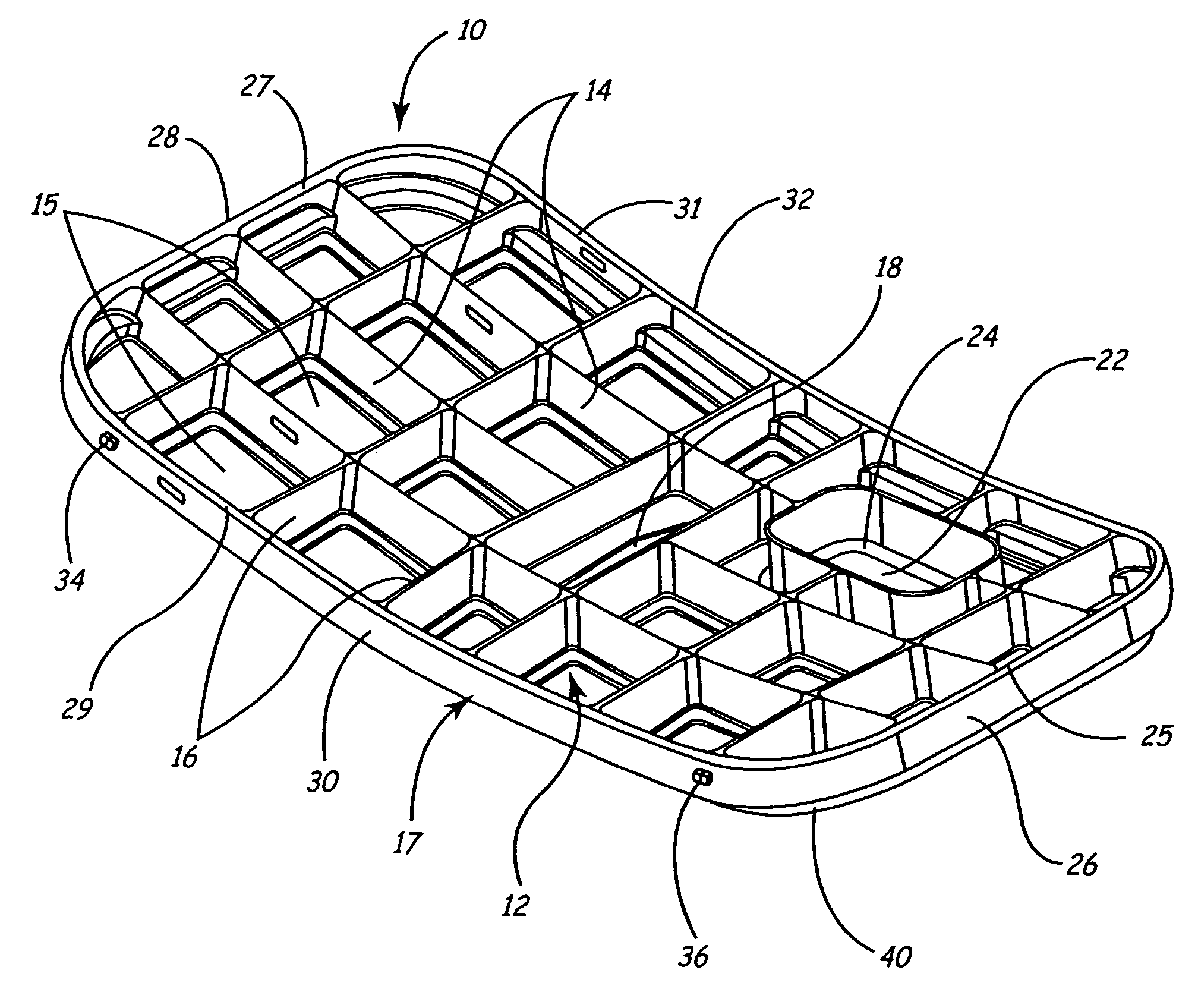

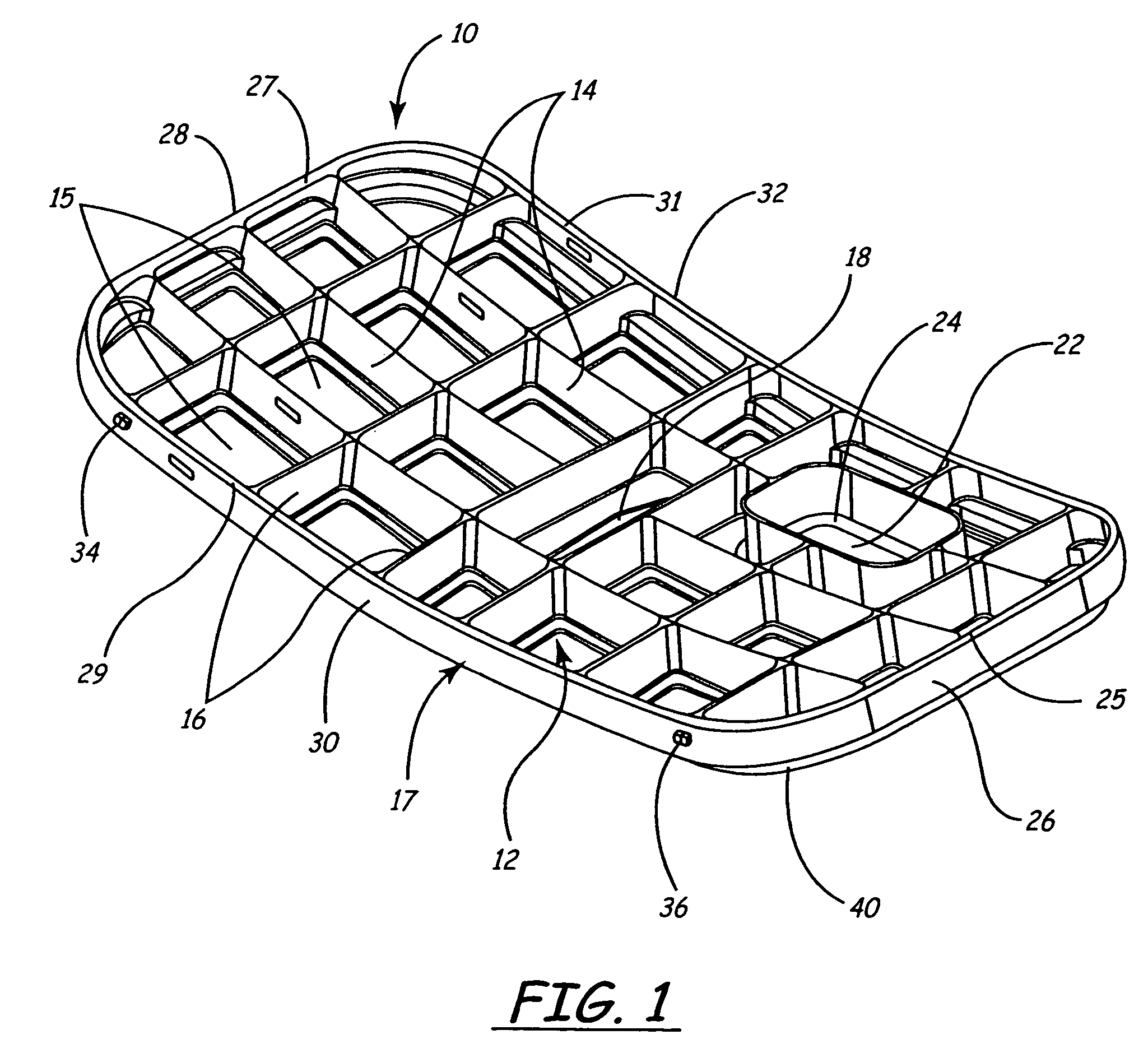

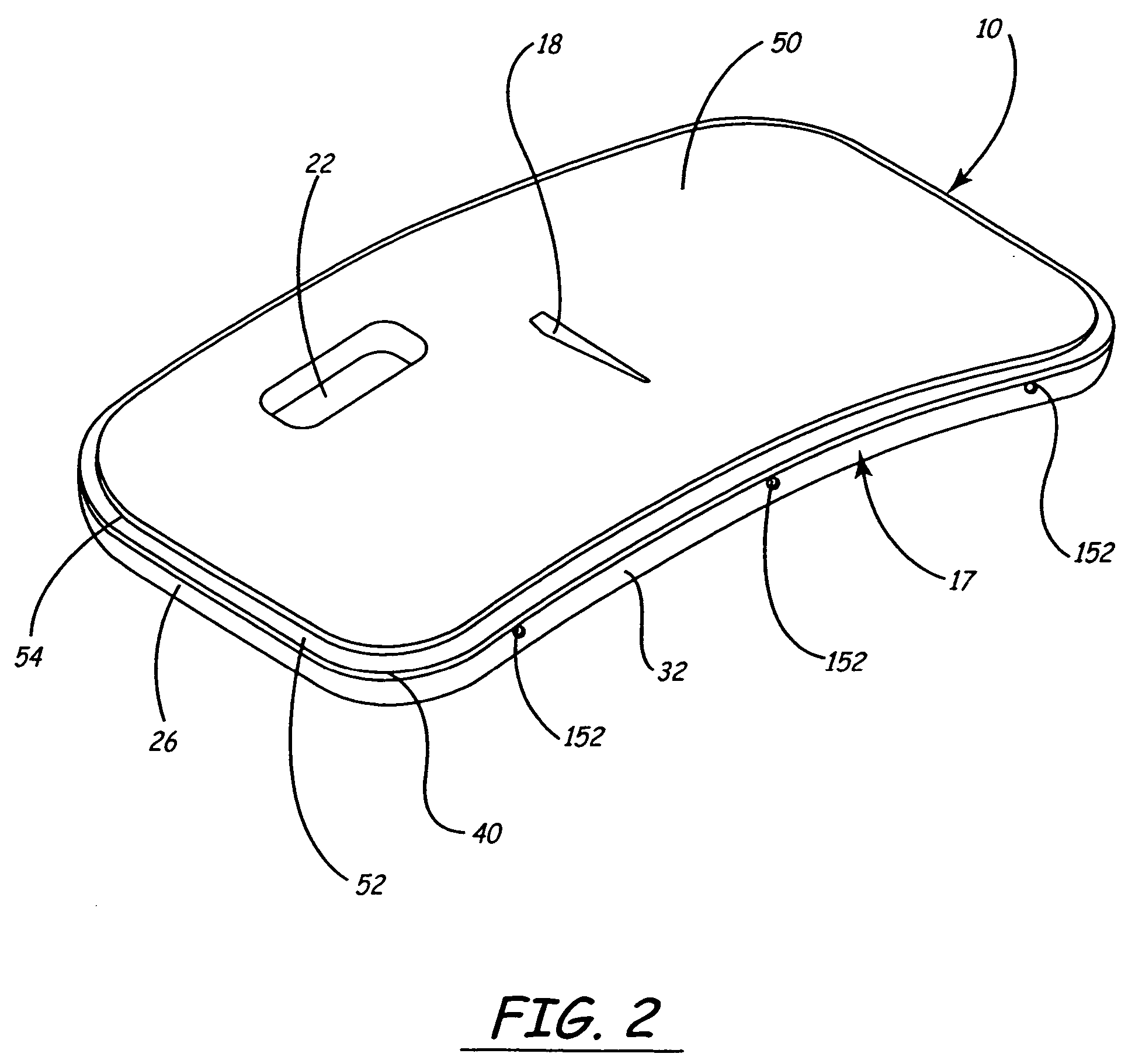

Shelving glide

A shelving glide includes a deck having a plurality of dividers; a first trough having a first index arranged along at least a portion of a width of the deck; a second trough having a second index arranged along at least a portion of the width of the deck; and a plurality of partitions defining a plurality of pathways. A partition includes a first clip securable to the first index; and a second clip securable to the second index. The partition is adjustable along the width of the deck from a first position to a second position upon disengagement of the second clip from the second index. The first clip is adapted to disengage from the first index upon disengagement of the second clip from the second index. The partition is secured to the deck at the second position upon reengagement of the second clip to the second index.

Owner:ADCO IND TECH

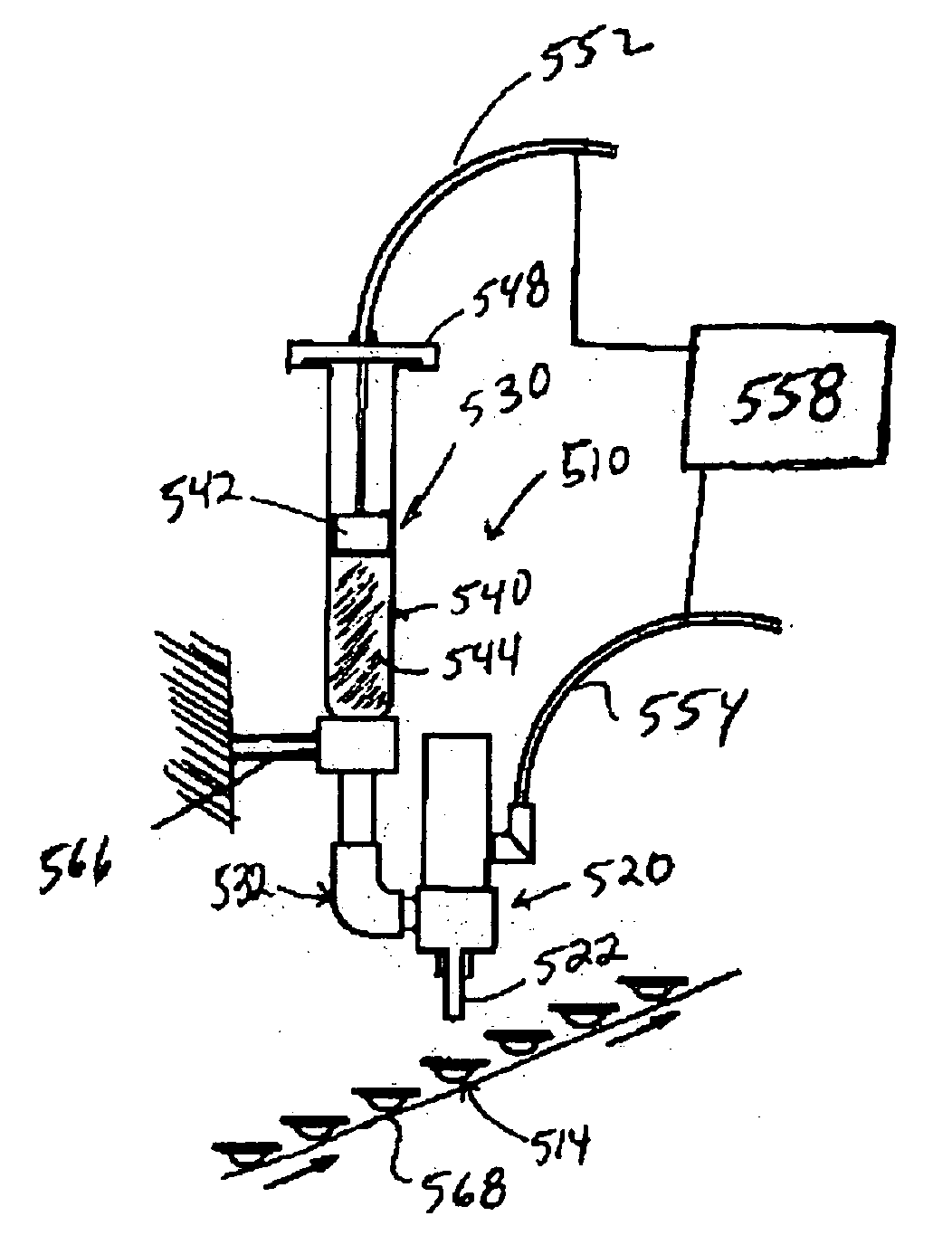

Systems and methods for rapidly deploying surgical heart valves

ActiveUS20120065729A1For quick replacementMinimize timeStentsBalloon catheterProsthetic valveProsthesis

A quick-connect heart valve prosthesis that can be quickly and easily implanted during a surgical procedure is provided. The heart valve includes a substantially non-expandable, non-compressible prosthetic valve and a plastically-expandable frame, thereby enabling attachment to the annulus without sutures. A small number of guide sutures may be provided for aortic valve orientation. The prosthetic valve may be a commercially available valve with a sewing ring with the frame attached thereto. The frame may expand from a conical deployment shape to a conical expanded shape, and may include web-like struts connected between axially-extending posts. A system and method for deployment includes an integrated handle shaft and balloon catheter. A valve holder is stored with the heart valve and the handle shaft easily attaches thereto to improve valve preparation steps.

Owner:EDWARDS LIFESCIENCES CORP

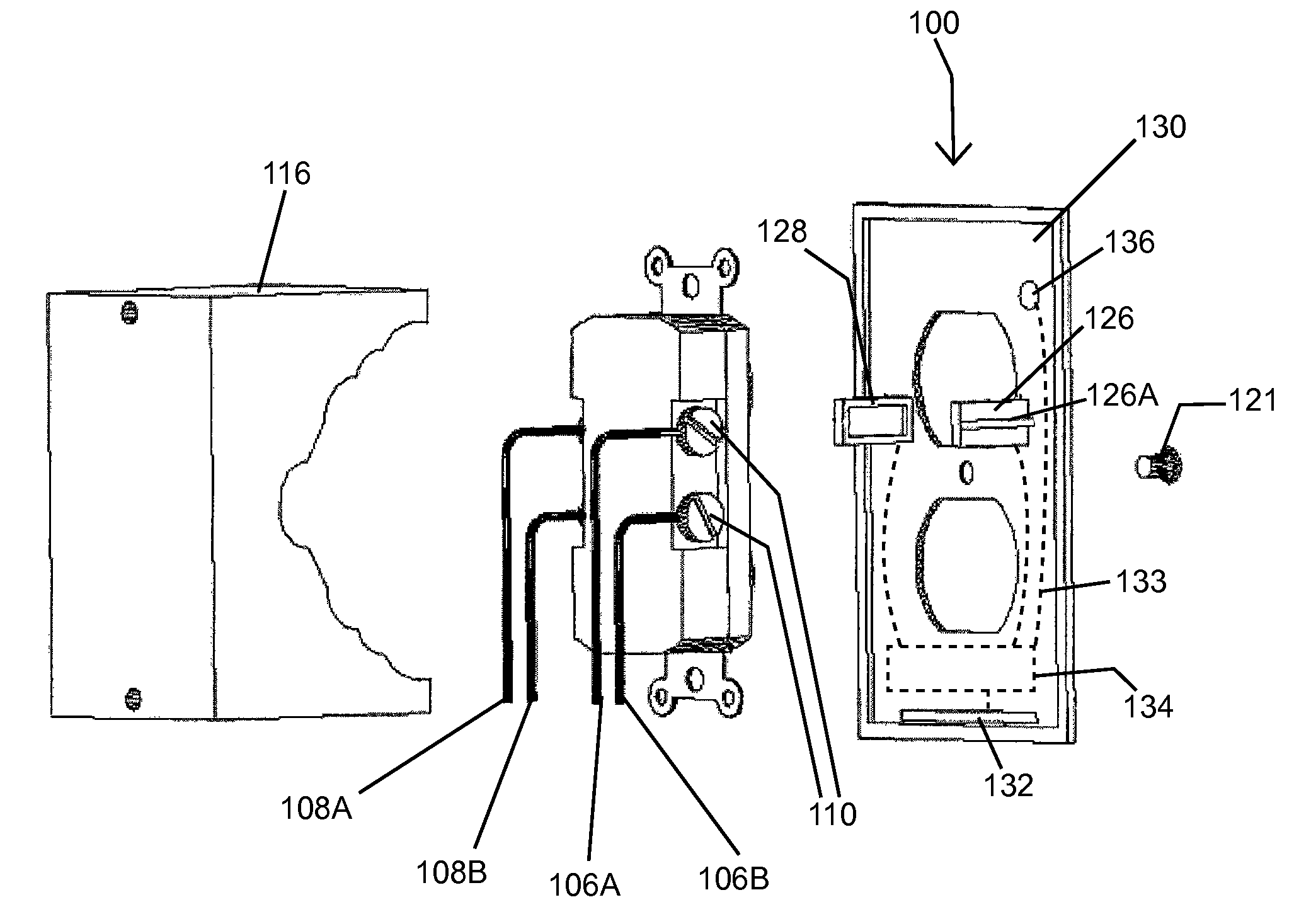

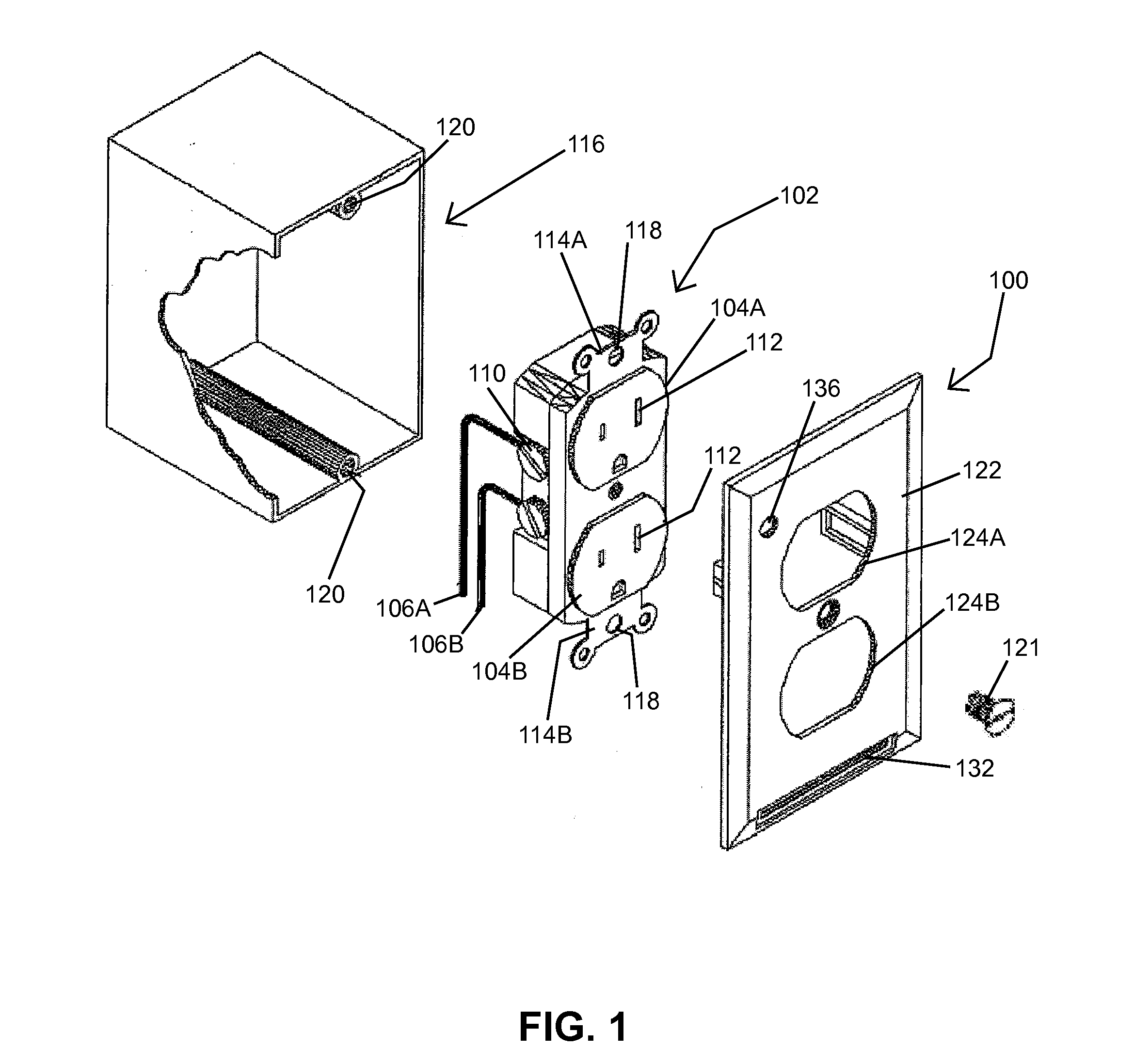

Receptacle cover

ActiveUS8668347B2Lower potentialImprove securityTwo pole connectionsLighting support devicesElectricityEngineering

A cover for an electrical receptacle including a faceplate. The cover also includes a first transmission tab configured to be electrically connected to a first power line of the electrical receptacle and a second transmission tab configured to be electrically connected to a second power line of the electrical receptacle. Additionally, the cover includes a device (such as a light source, circuit, port, or sensor) in communication with the first transmission tab and the second transmission tab.

Owner:LIGHTING DEFENSE GRP LLC

Shelving glide

A shelving glide includes a deck having a plurality of dividers; a first trough having a first index arranged along at least a portion of a width of the deck; a second trough having a second index arranged along at least a portion of the width of the deck; and a plurality of partitions defining a plurality of pathways. A partition includes a first clip securable to the first index; and a second clip securable to the second index. The partition is adjustable along the width of the deck from a first position to a second position upon disengagement of the second clip from the second index. The first clip is adapted to disengage from the first index upon disengagement of the second clip from the second index. The partition is secured to the deck at the second position upon reengagement of the second clip to the second index.

Owner:ADCO IND TECH

High-pressure plug valve with replaceable inserts and method of refurbishing same

ActiveUS20060027779A1Improve wear resistanceQuickly and easily refurbishedPlug valvesThin material handlingPlug valveBung

A plug valve has a valve body, a cage fitted within the valve body and a rotatable plug housed within a cylindrical cavity in the cage, for controlling fluid flow through the valve. The cage has first and second opposed flat side surfaces, each side surface has a port for receiving a replaceable flow-path insert in a fluid-tight seal. In one embodiment, the plug also includes at least one inset seal for sealing the at least one of the ports when the plug is in a closed position to inhibit leakage through the valve at low fluid pressures.

Owner:WELLS FARGO BANK NAT ASSOC +1

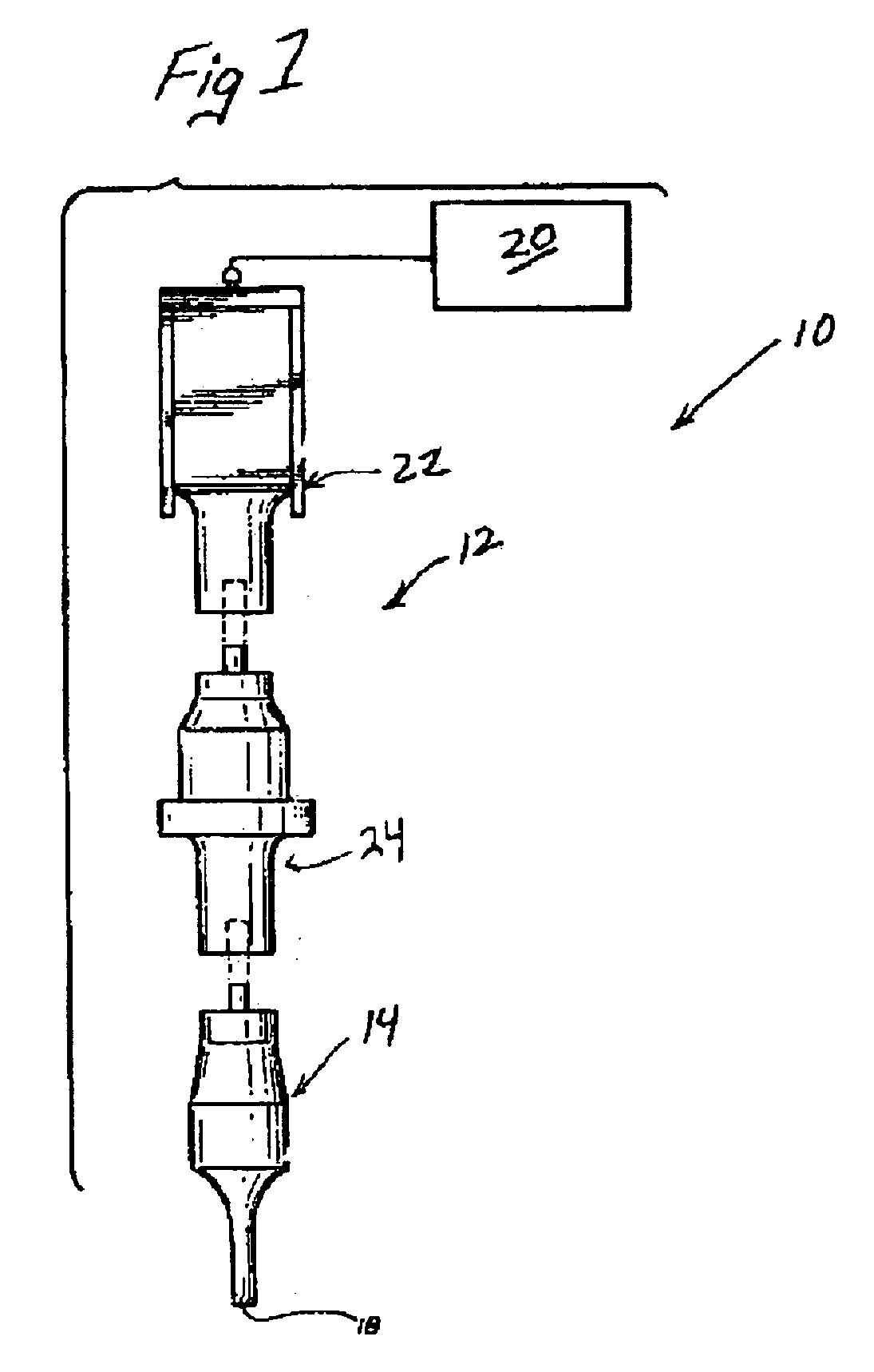

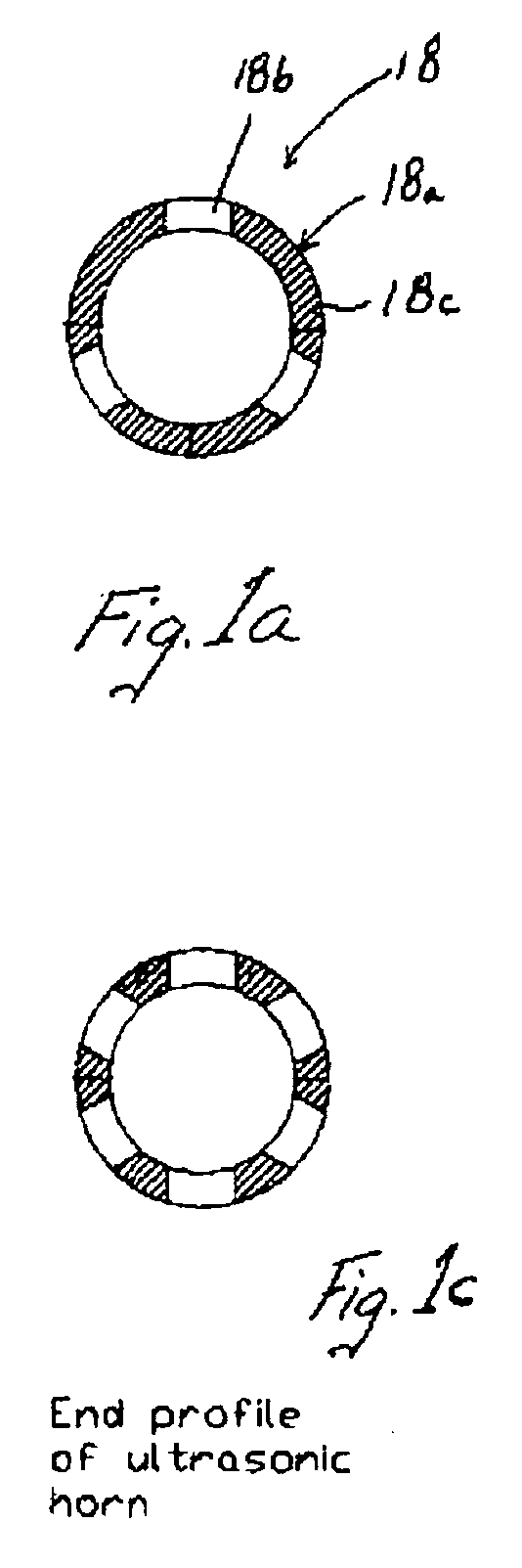

Contact lens mold assemblies and systems and methods of producing same

ActiveUS20070035051A1Prevent materialEnhanced cavitationOptical articlesStereotype platesEngineeringContact lens

Methods and apparatus are provided for making an ophthalmic lens. Apparatus are provided for filling contact lens shaped cavities of contact lens molding assemblies. Methods of coupling and fusing contact lens mold sections are also provided and generally include providing first and second mold sections which when coupled together are effective to form a lens-shaped cavity and contact regions between the mold sections. One or both of the mold sections may include one or more recessed regions or projections which provide areas of non-fusion and areas of fusion, respectively, when the mold sections have been filled with a contact lens precursor material and are fused together, for example, by means of focused ultrasound energy.

Owner:COOPERVISION INT LTD

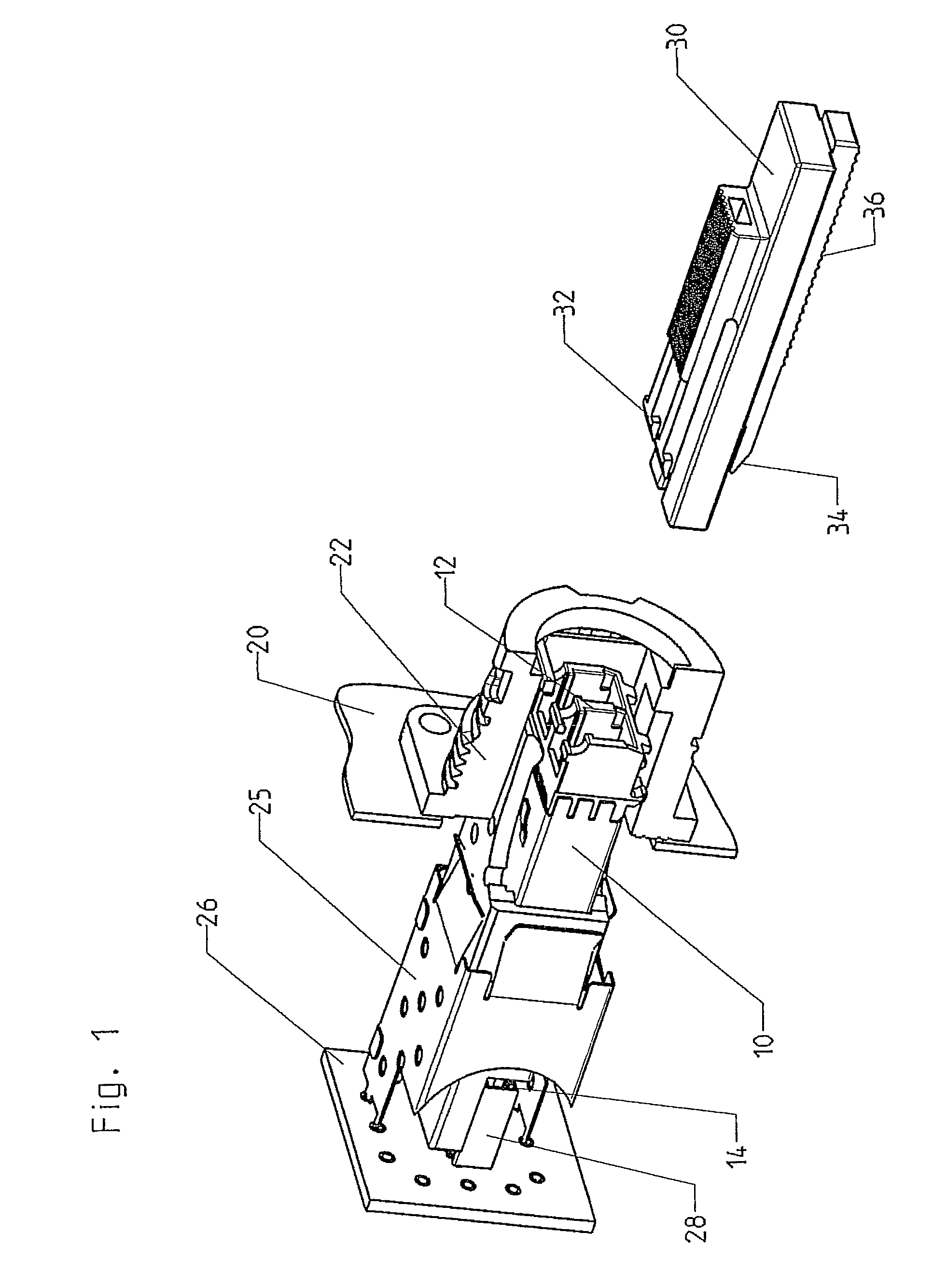

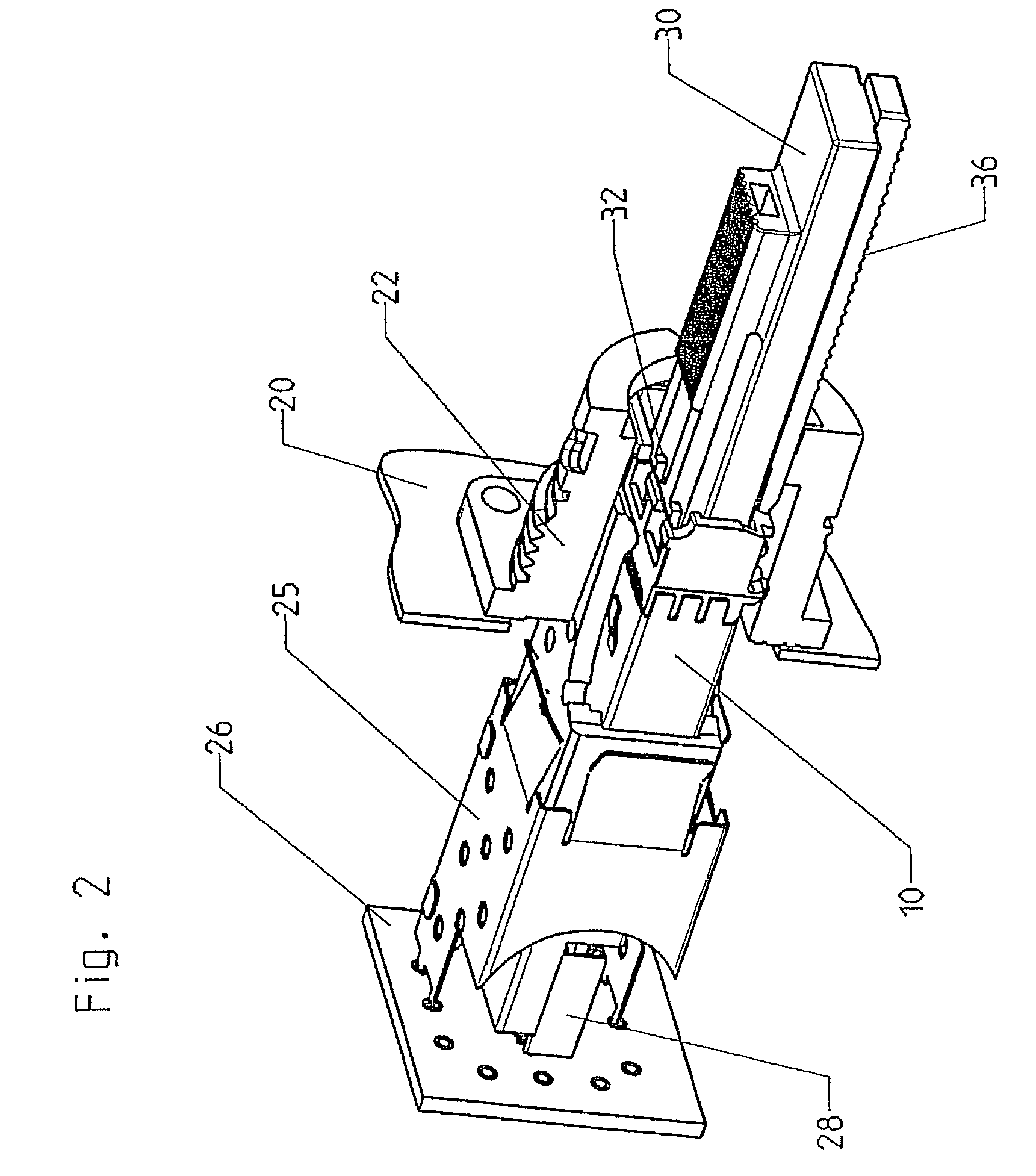

Device for releasing a transceiver fixed in a housing via a connection from the housing

ActiveUS8956058B2For quick replacementFacilitated releaseBottle/container closurePower operated devicesTransceiver

The invention concerns a device for releasing a transceiver, fixed in a housing via a connection, from the housing, wherein the device is releasably connectable and insertable into a plug contour of the transceiver via first means and wherein the device has second means for releasing the connection between the transceiver and the housing.

Owner:MC TECH GMBH (DE)

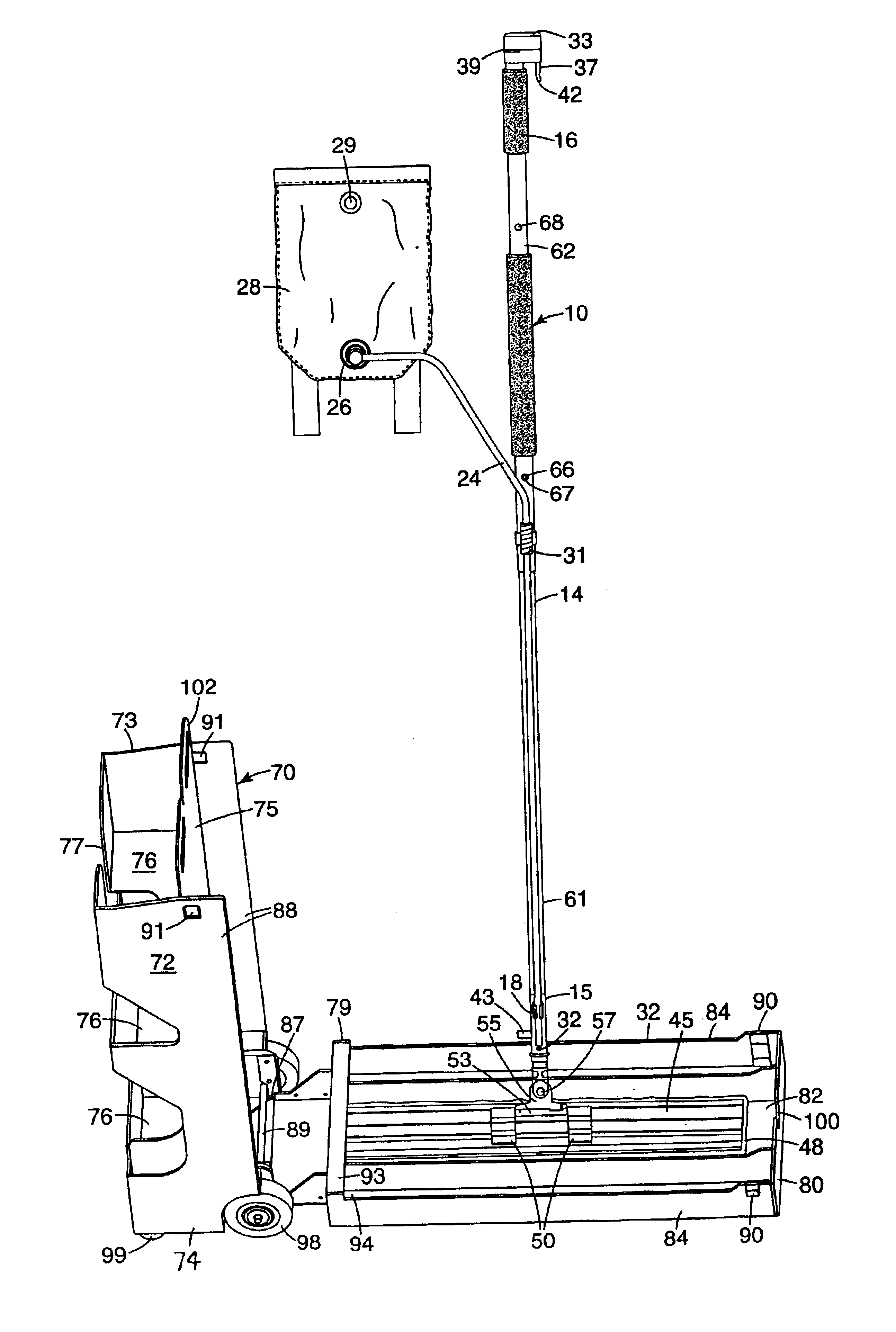

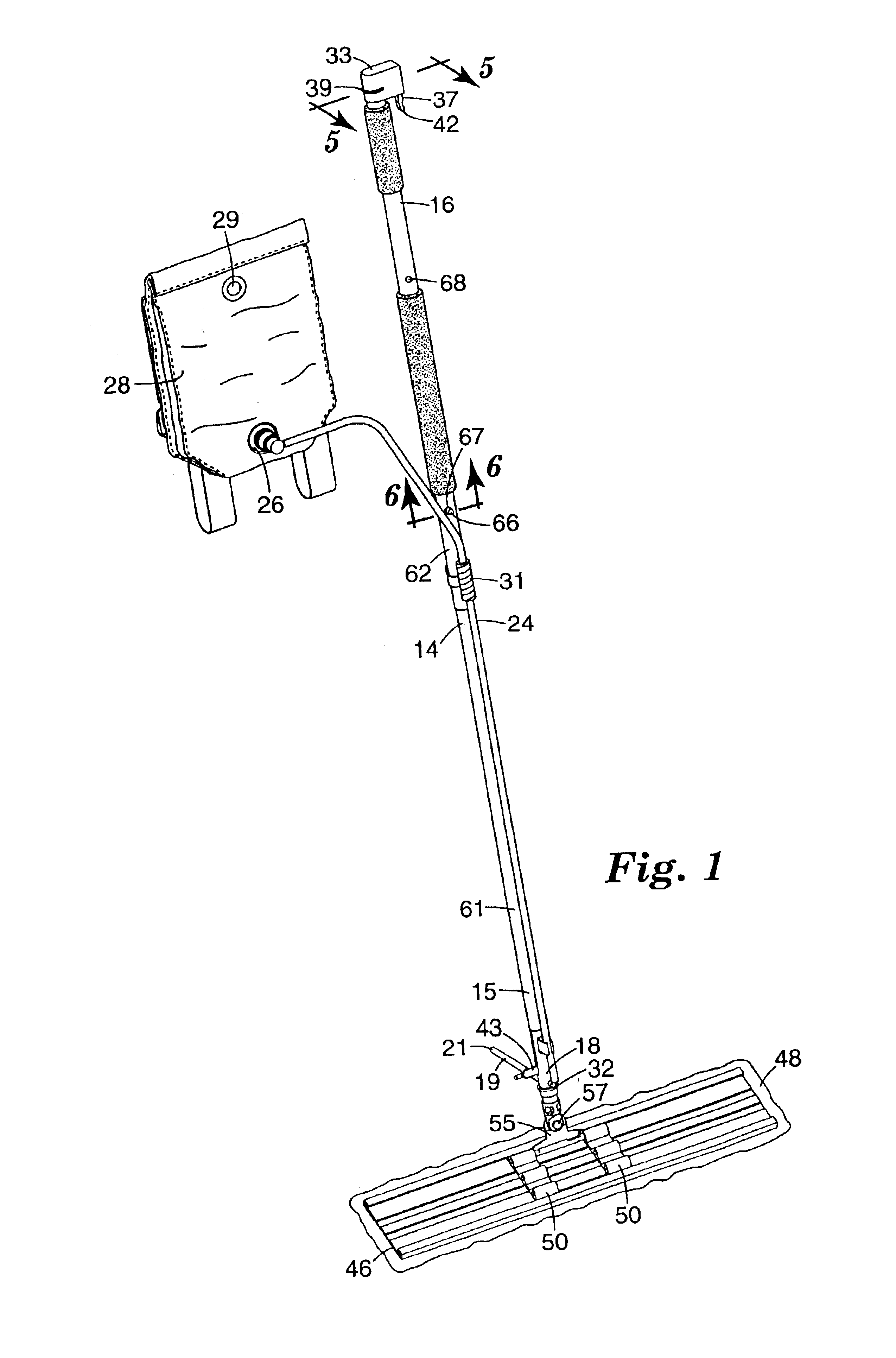

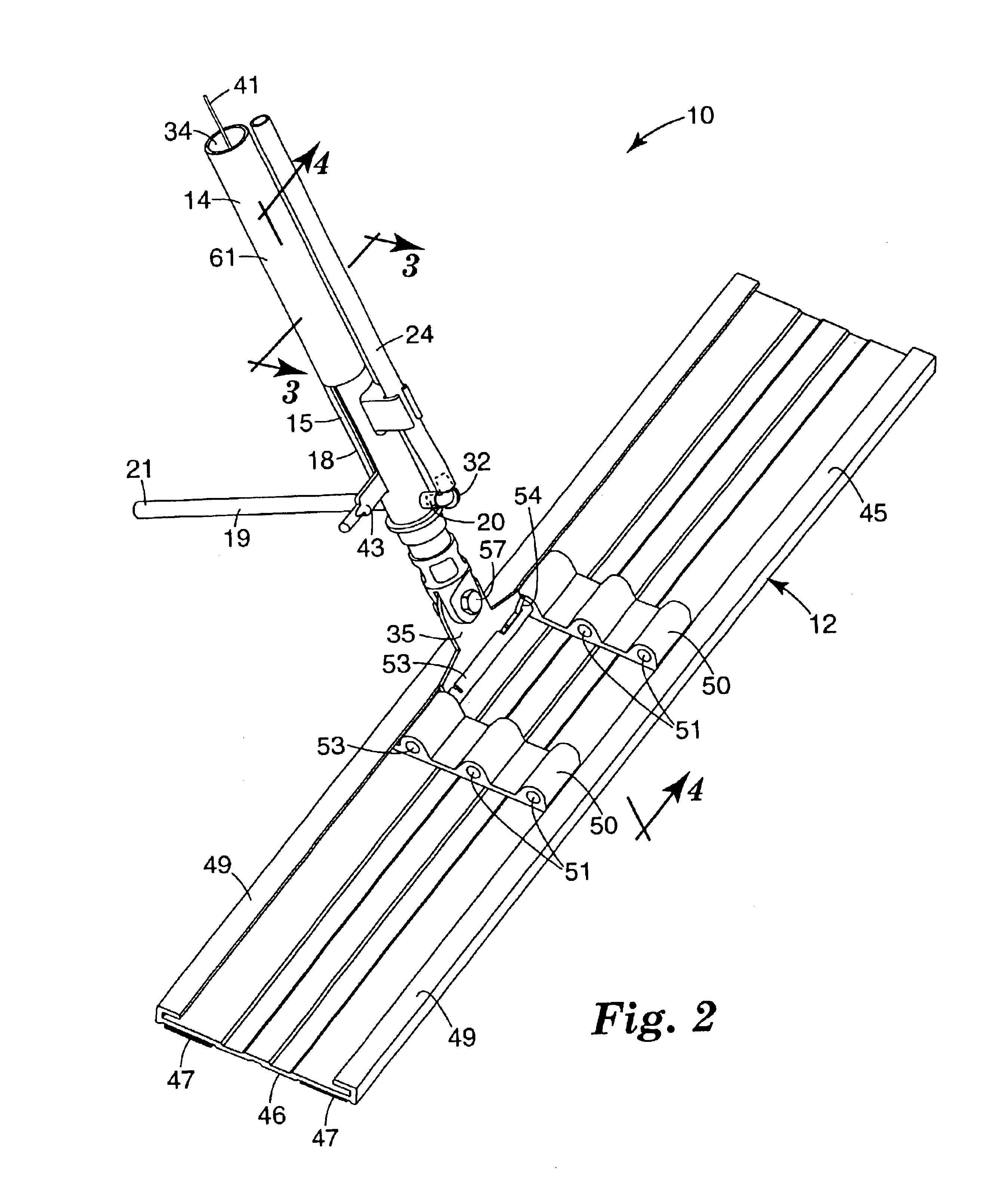

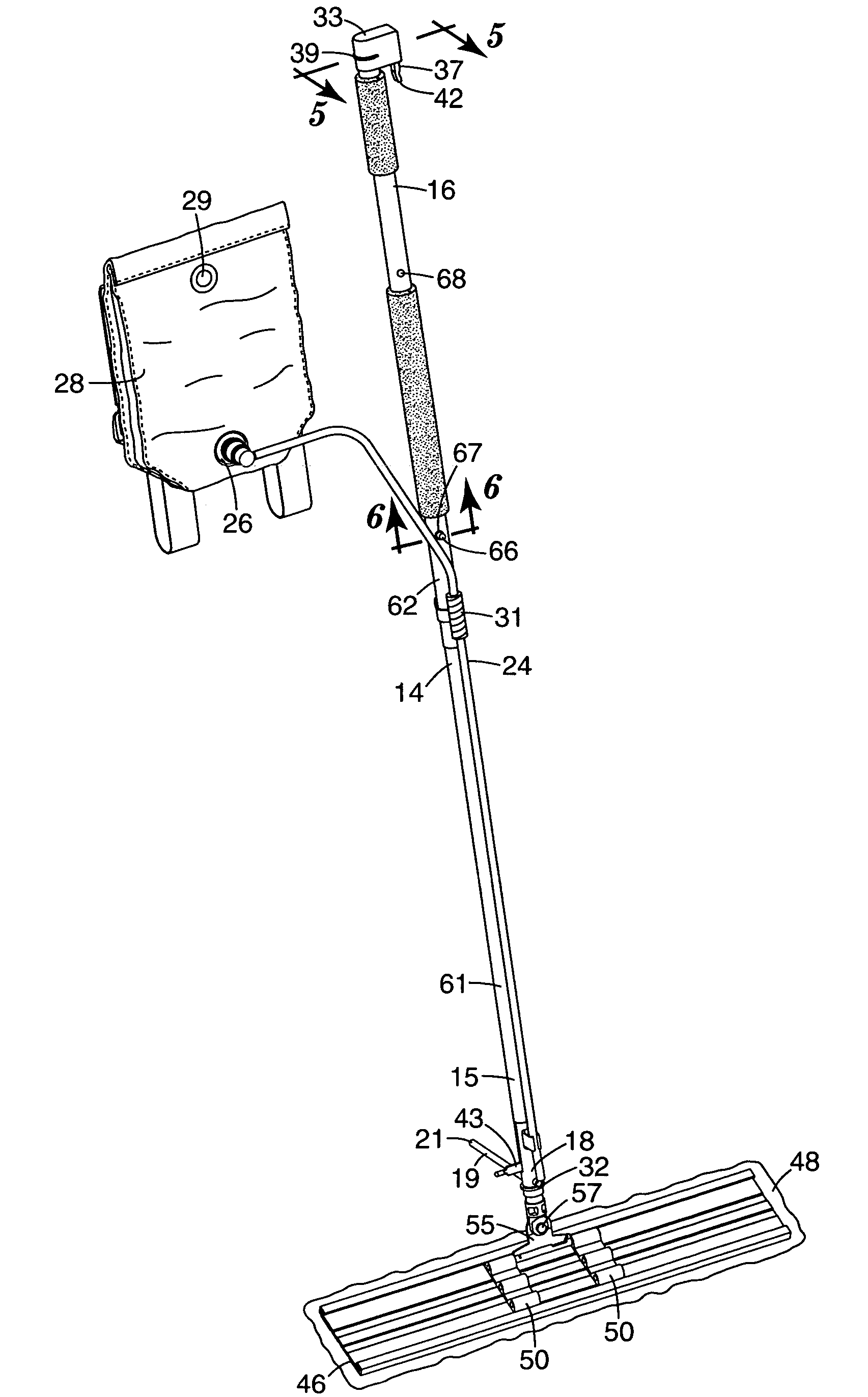

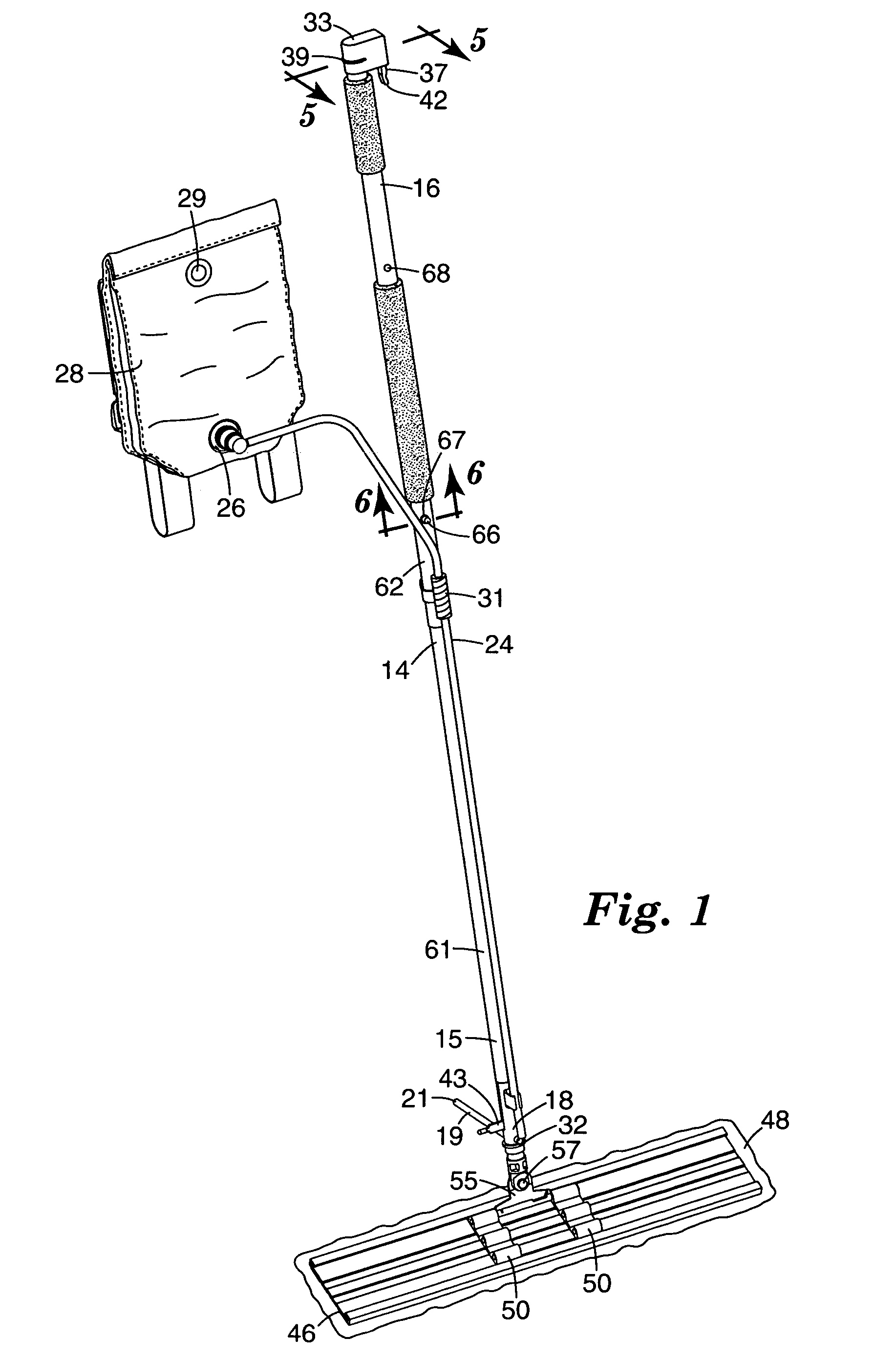

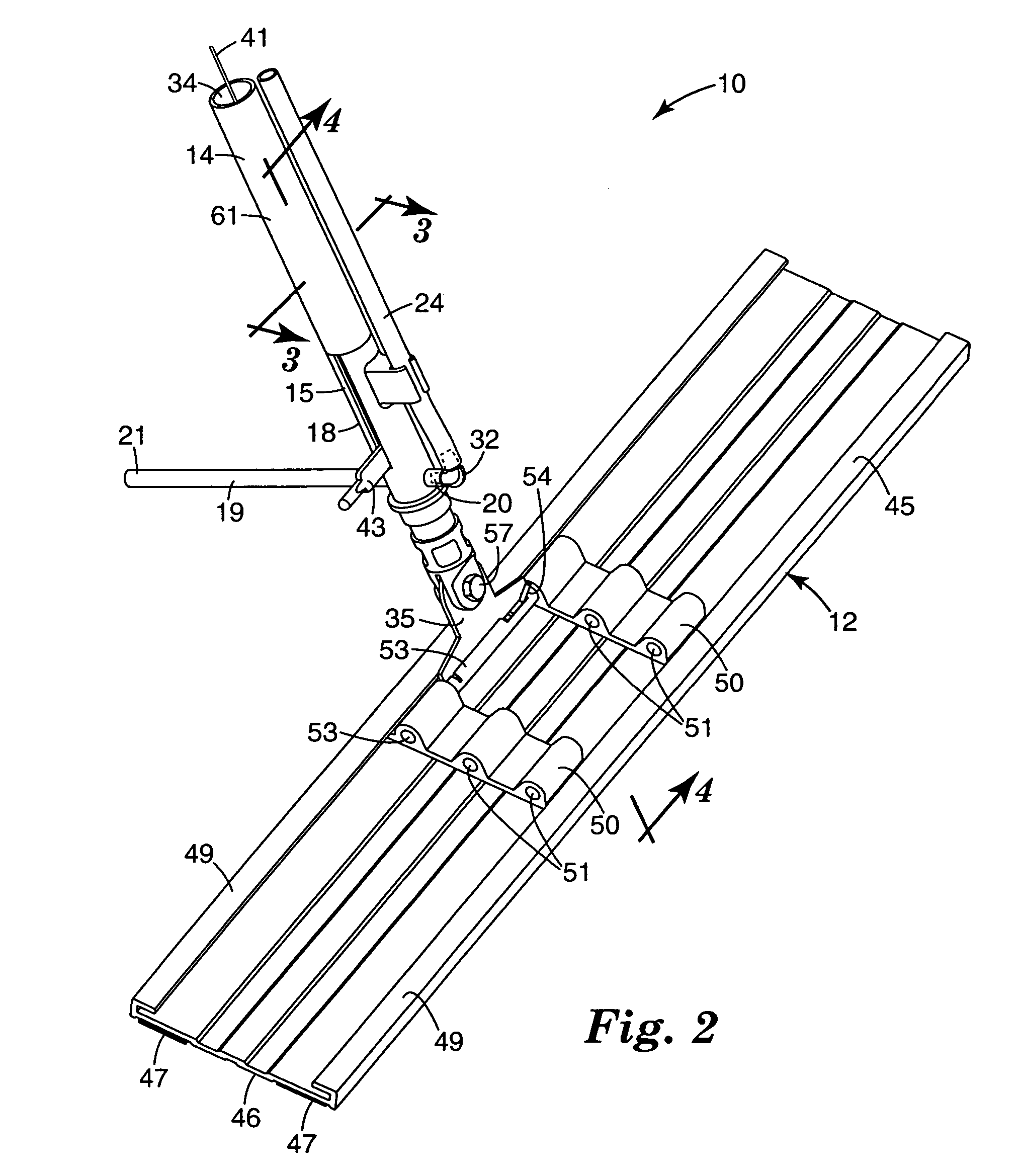

Mop assembly and cart

InactiveUS6854912B2Quick and easy changeFor quick replacementCarpet cleanersWriting connectorsSurface cover

A mop assembly including a mop head and handle, and a supply of liquid connected to a valve assembly on the handle adjacent the mop head. The valve assembly includes a length of resiliently flexible tubing that has a portion extending transversely through the handle and first and second members on opposite sides of the length of tubing that are relatively movable between a closed position at which the first and second members pinch together opposite sides of the length of tubing to stop the flow of liquid through it, and an open position at which the first and second members are spaced apart to afford flow of liquid through it. Should the tubing become plugged, it can easily be replaced by disconnecting one end from a liquid supply length of tubing, withdrawing the tubing from between the first and second members, and then installing a new length of tubing. A storage cart for use with the mop assembly includes an elongate upwardly projecting main portion having walls providing a side surface, and an elongate tray portion that provides a receptacle adapted to receive the mop head. The tray portion is mounted on a bottom end of the main portion for relative movement between a closed position at which the side surface covers an open side of the receptacle to thereby afford retention of the mop head in the receptacle; and an open position with the tray portion disposed at about a right angle with respect to the main portion so that the mop head can be inserted into or removed from the receptacle and so that the bottom wall can be supported along a horizontal surface such as a floor surface with side walls of the receptacle projecting upwardly.

Owner:3M INNOVATIVE PROPERTIES CO

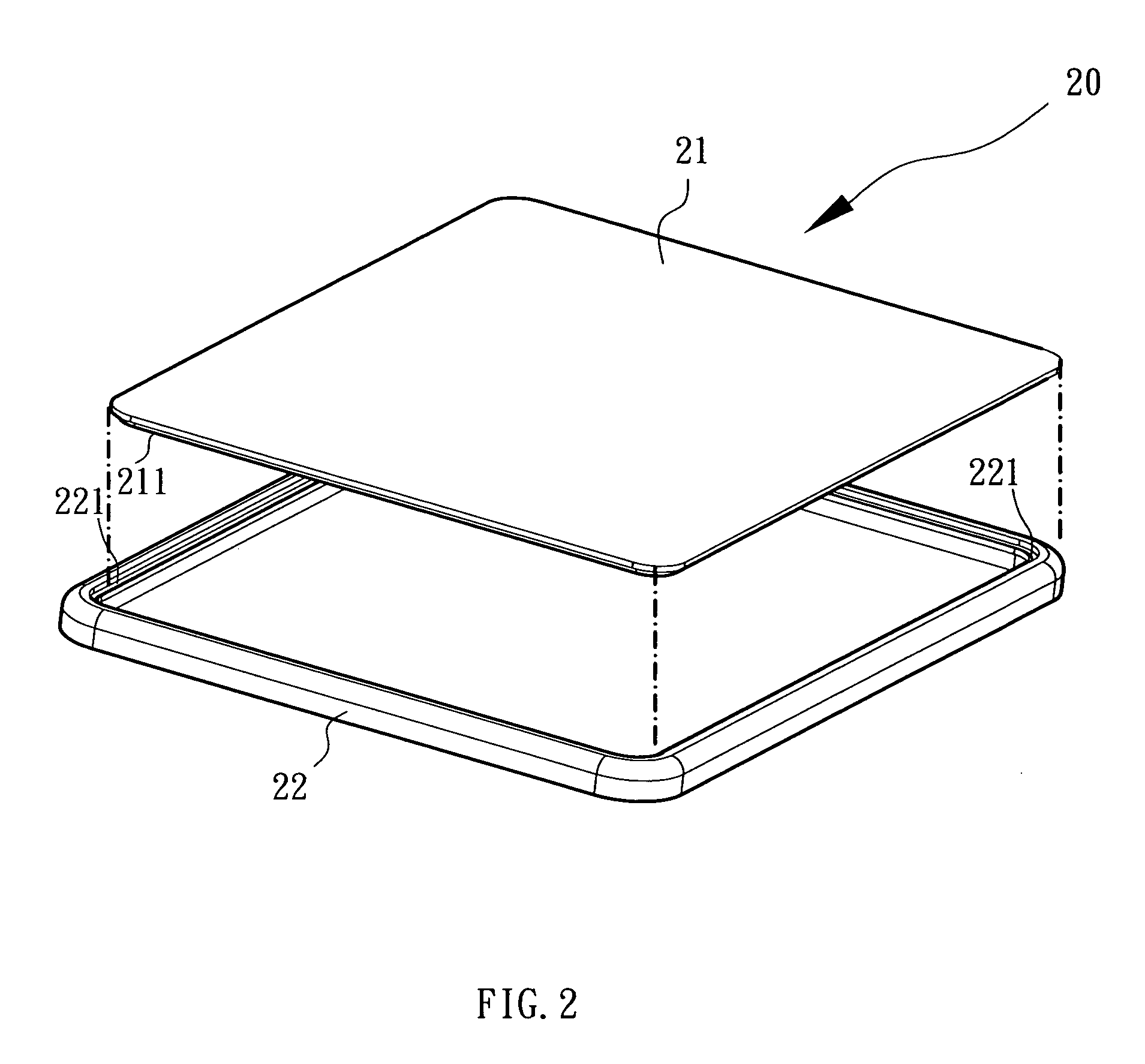

Replacing-type upper cover plate structure of notebook computer

InactiveUS7236357B2Quick releaseEffectively stimulatedClosed casingsFurniture partsAgricultural engineering

A replacing-type upper cover plate structure of notebook computer is disclosed. It includes a cover plate having an embedded element, and a containing frame having a groove bonding with the embedded element. The replacing-type upper cover plate structure, through a preferred module bonding mode, makes the upper and the lower shell tight-fit to bond for achieving the efficacy of protecting the interior and exterior elements of the cover plate. In the meantime, since the replacing mode of the cover plate is simple, convenient, and fast, thereby, the invention can improve the users' working efficiency to meet the humanized requirement.

Owner:INVENTEC CORP

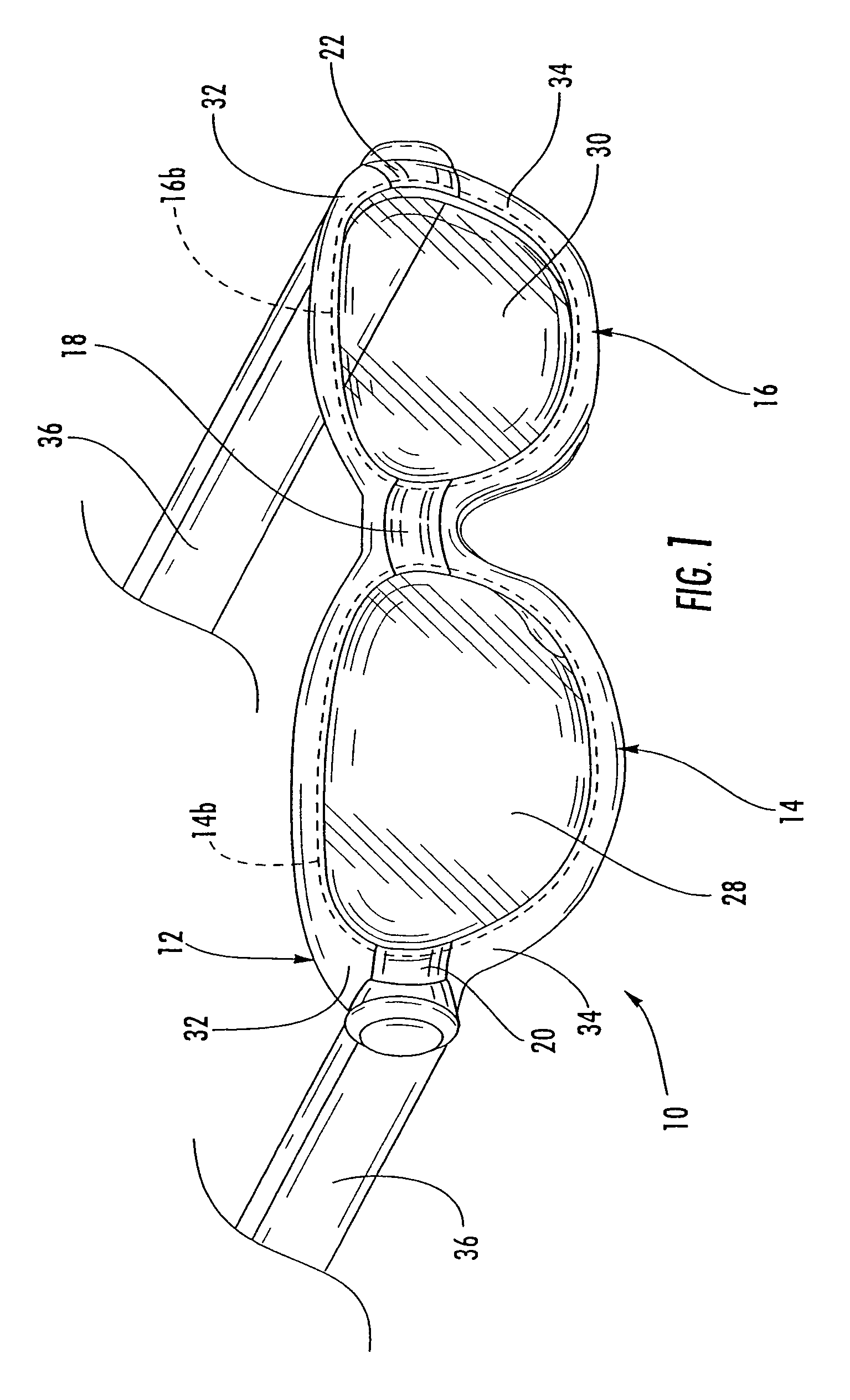

Safety glasses with flexible frame and interchangeable dual-lenses

Safety eyewear (10) having interchangeable lens(es) (28,30) is provided. To provide for interchange of the lenses (28,30) in the frame (12), upper and lower frame members (32,34) are molded from a harder, more rigid plastic while lateral temple portions (20,22), and a central nose bridge portion (18) are molded from a softer, more elastic material. The entire frame structure (12) is preferably molded as a unitary piece to form a unitary frame having rigid upper and lower frame portions (32,34) joined by flexible intermediate portions (18,20,22). In this regard, the upper and lower frame portions (32,34) can be flexed or stretched relative to each other to temporarily separate the frame portions (32,34) and open up the lens openings (24,26).

Owner:SPERIAN EYE & FACE PROTECTION

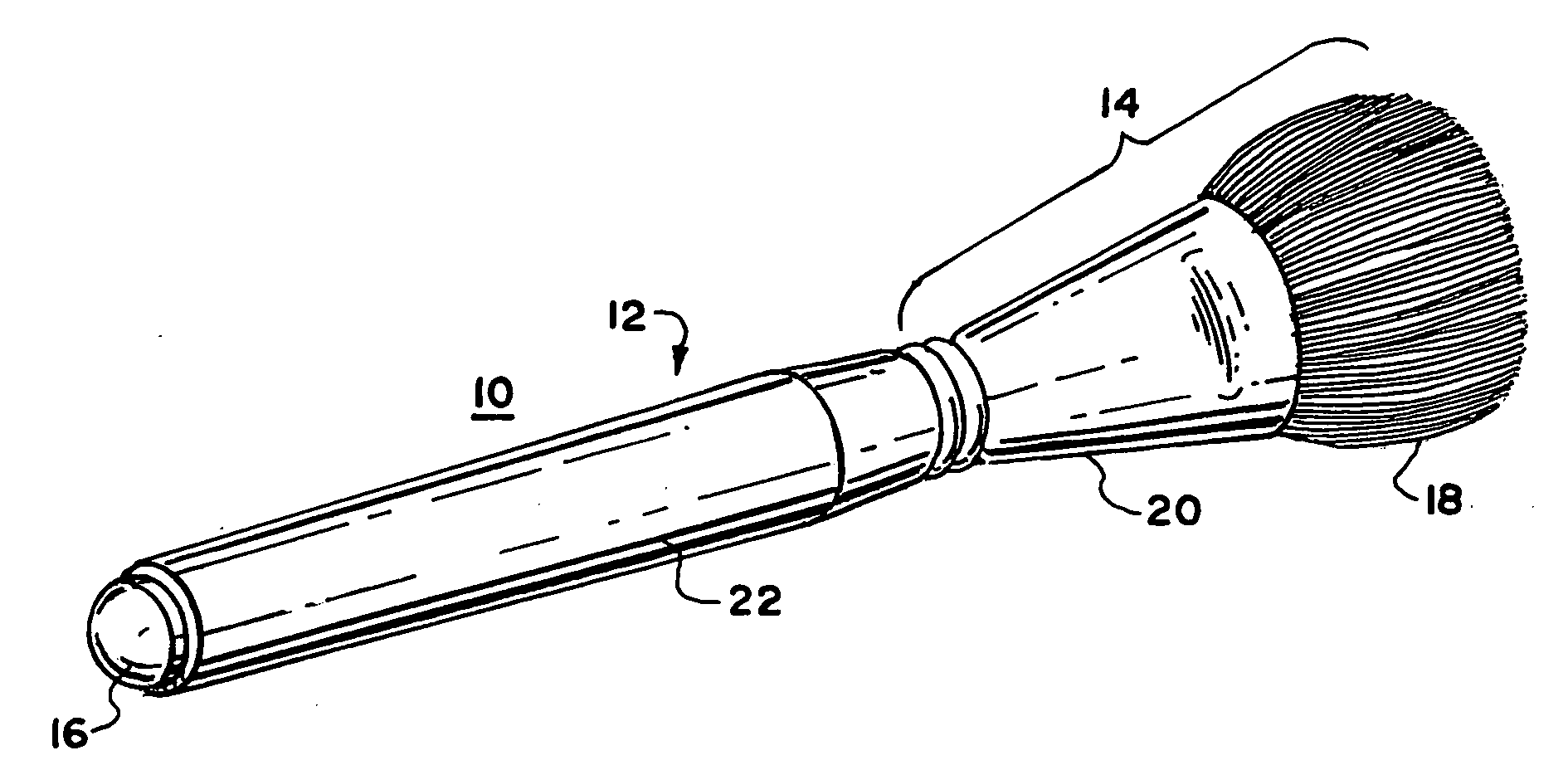

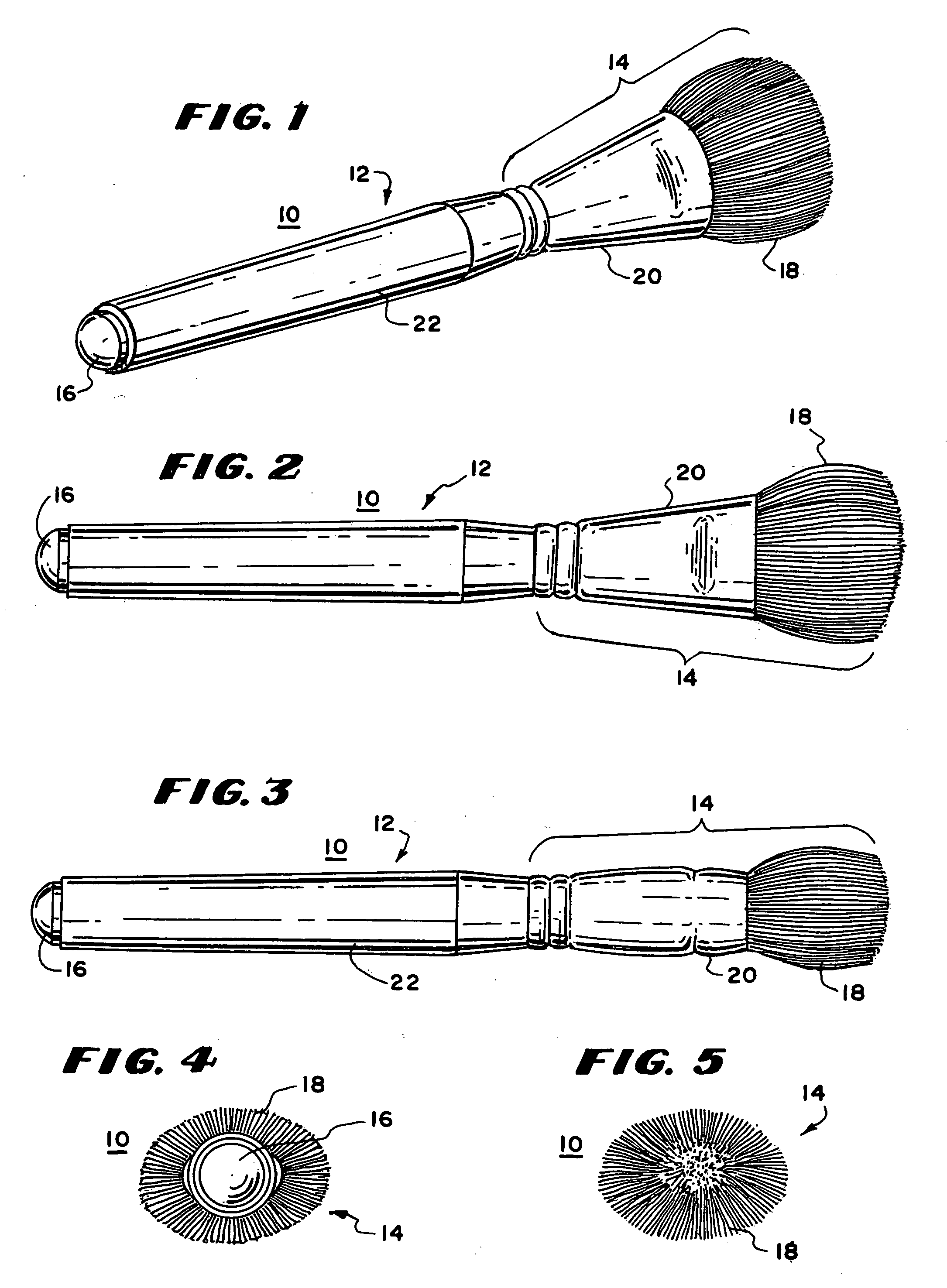

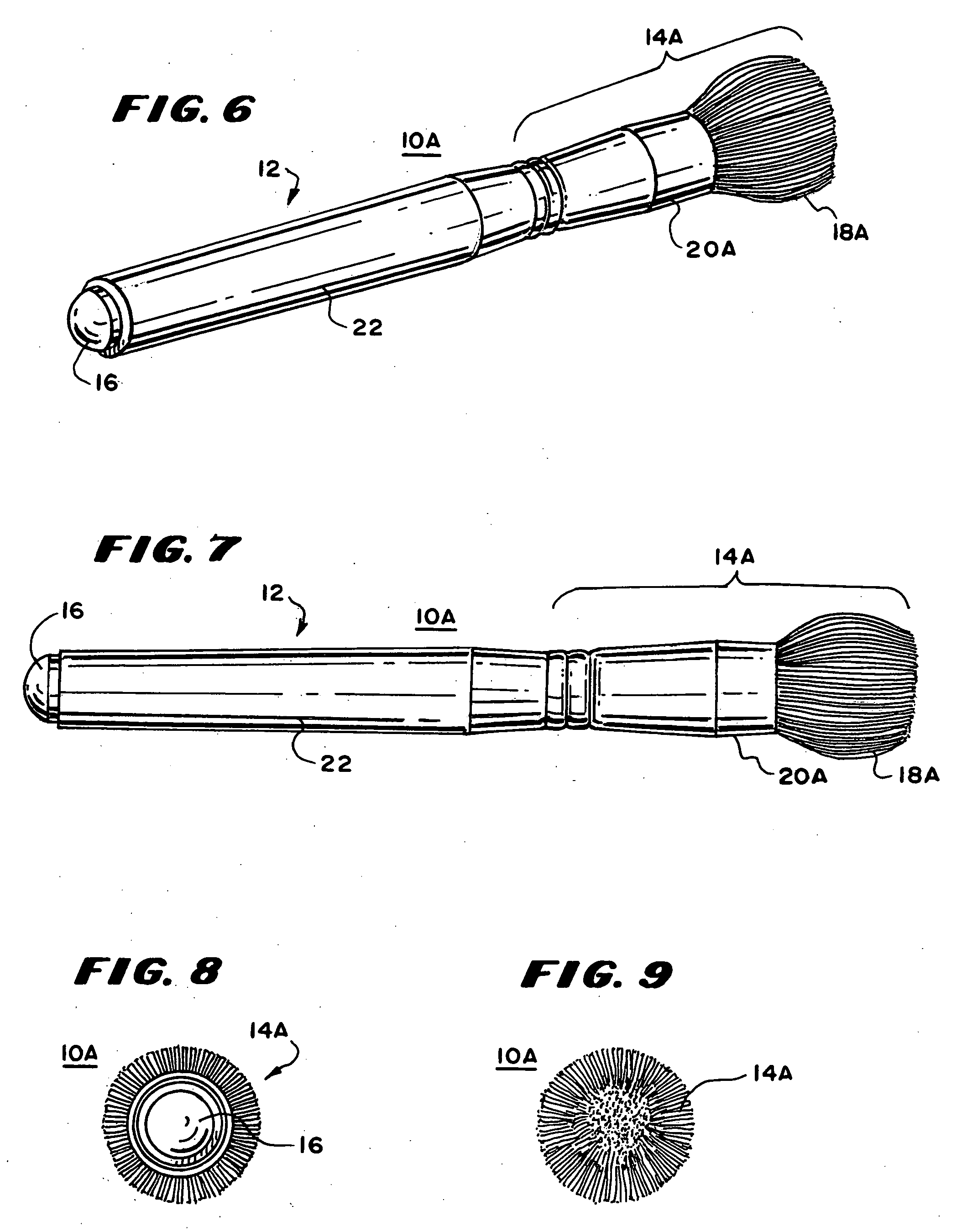

Make-up brushes, their components and methods of using them

InactiveUS20100095973A1Easy to removeFor quick replacementCarpet cleanersBrush bodiesBiomedical engineeringFastener

An ornamental design of a make-up brush with a replaceable brush head includes a handle portion having an elongated central axis and a snap fastener. A first portion of the snap fastener is fastened to the handle portion and a second portion of the snap fastener is fastened to a replaceable head. A third portion of the snap fastener includes a push button aligned with the snap fastener along an elongated central axis, wherein the decorative make-up brush is symmetrical. The replaceable head and handle portion are wobble free secured.

Owner:SHRIER LINDA FAYE

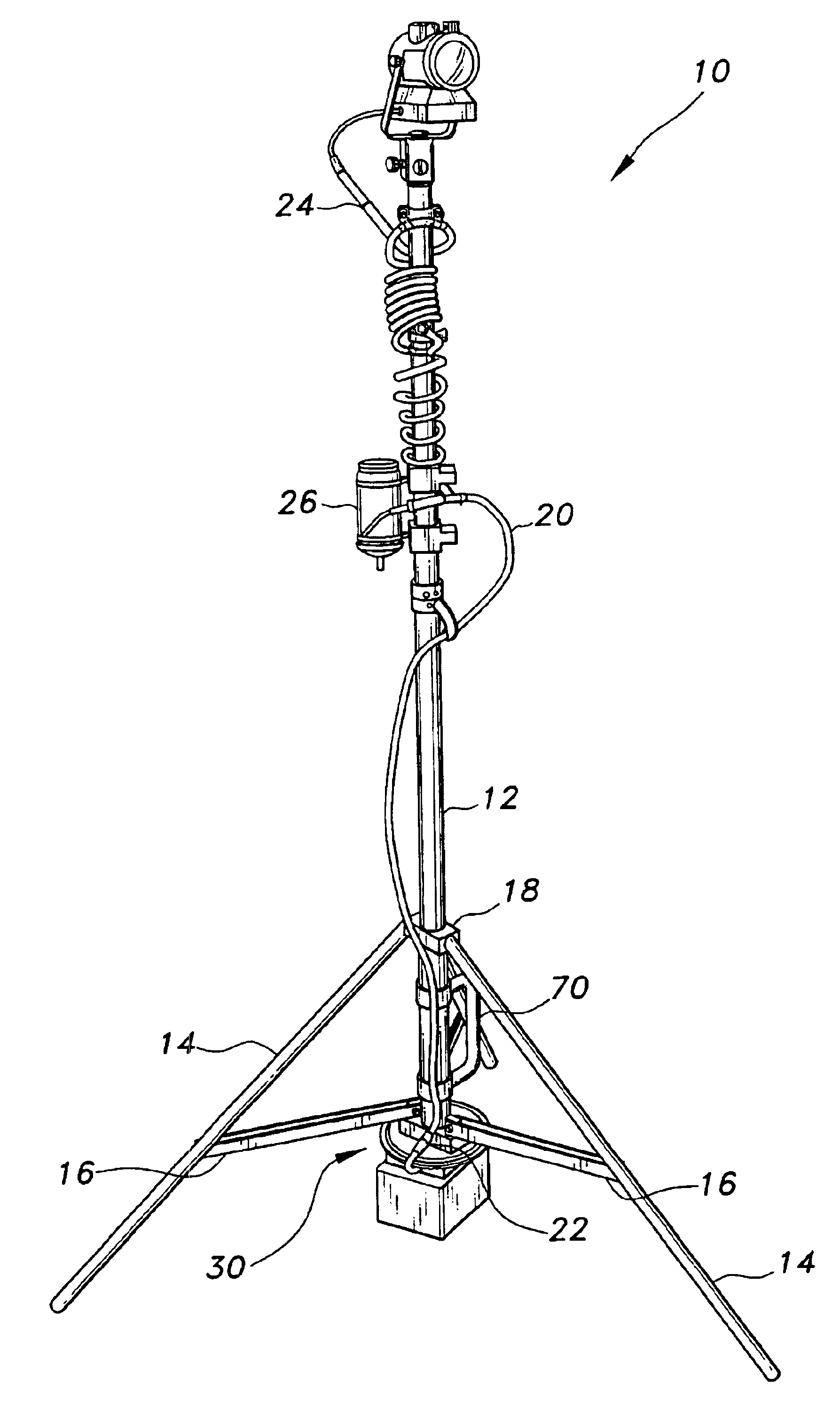

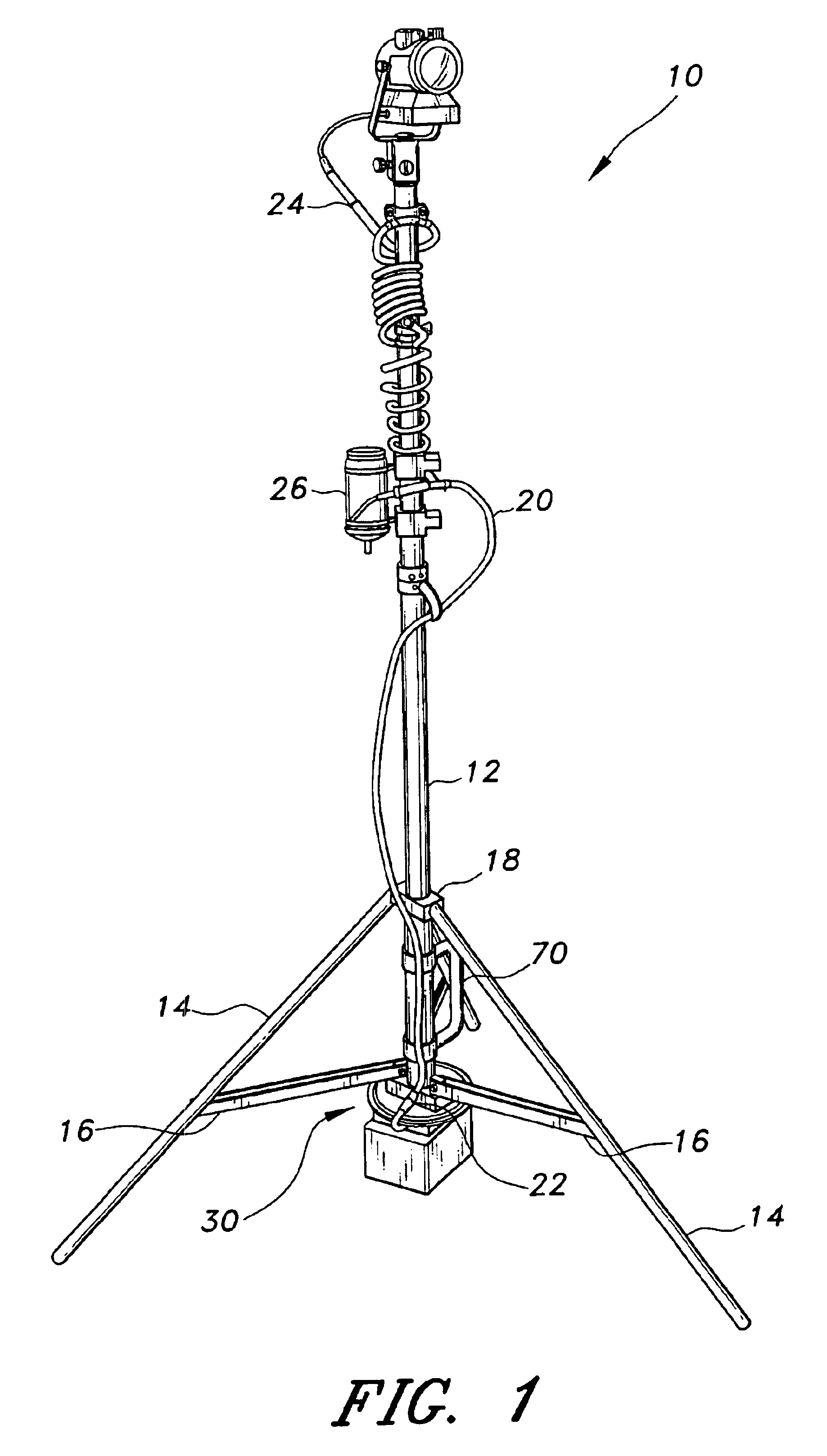

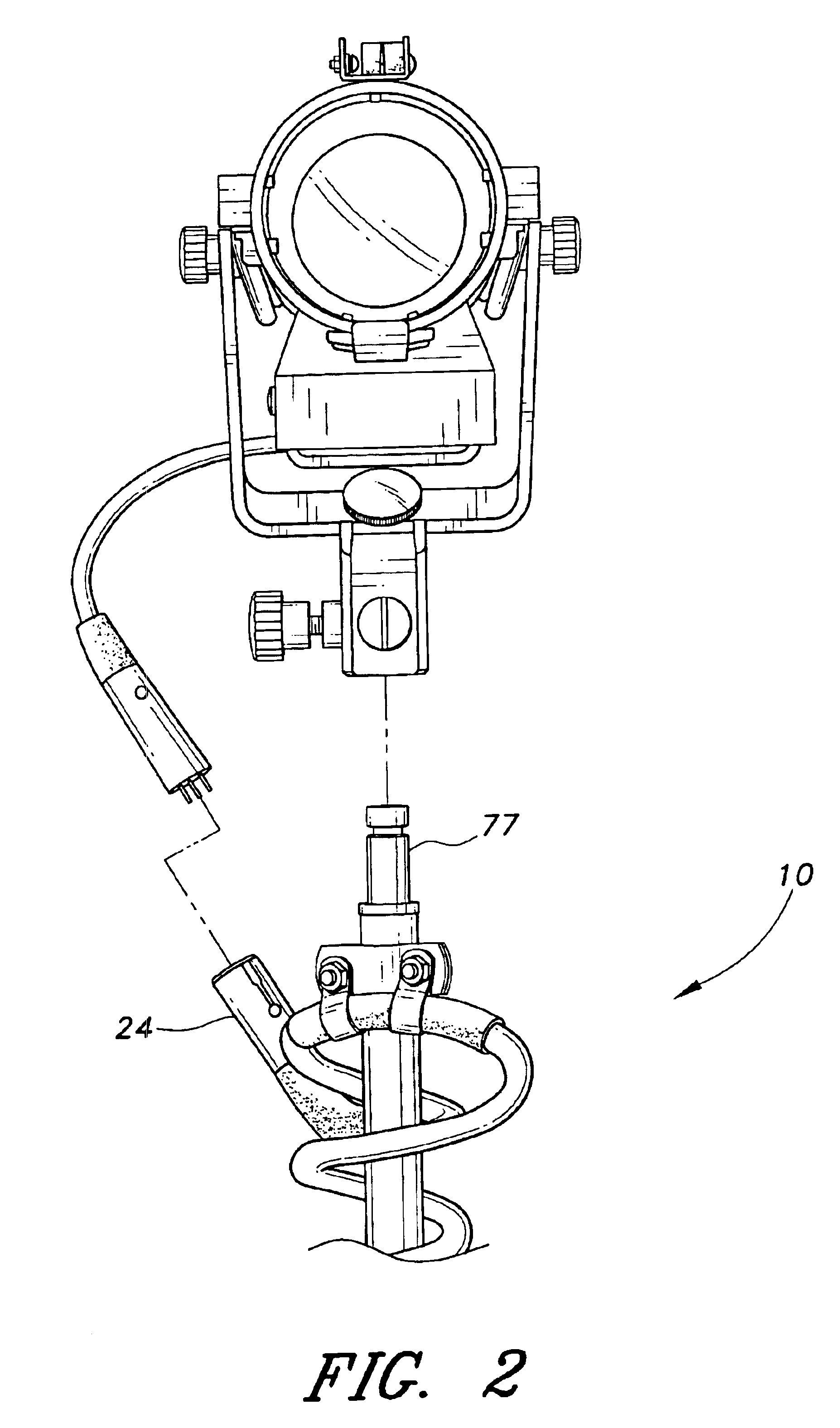

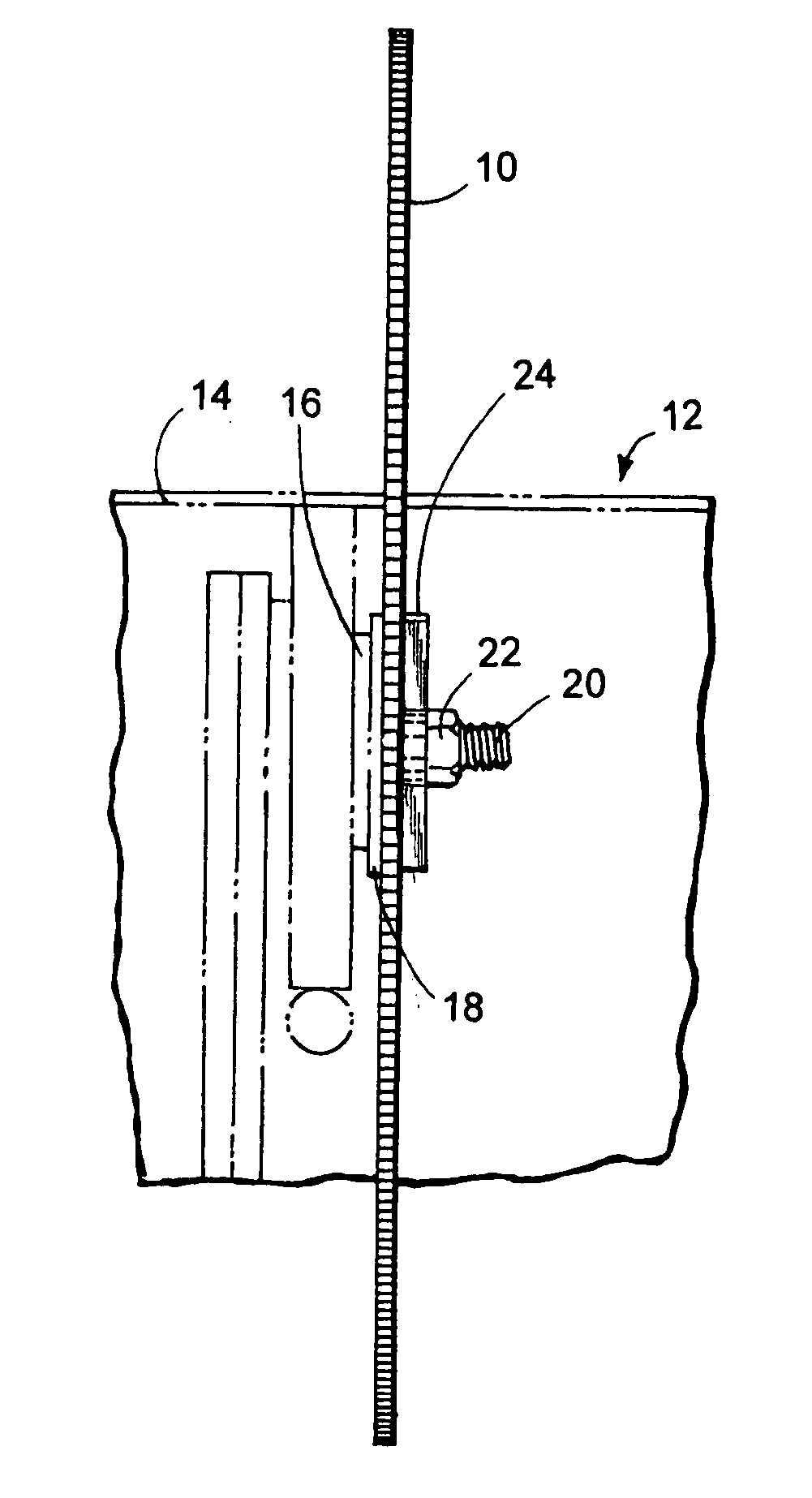

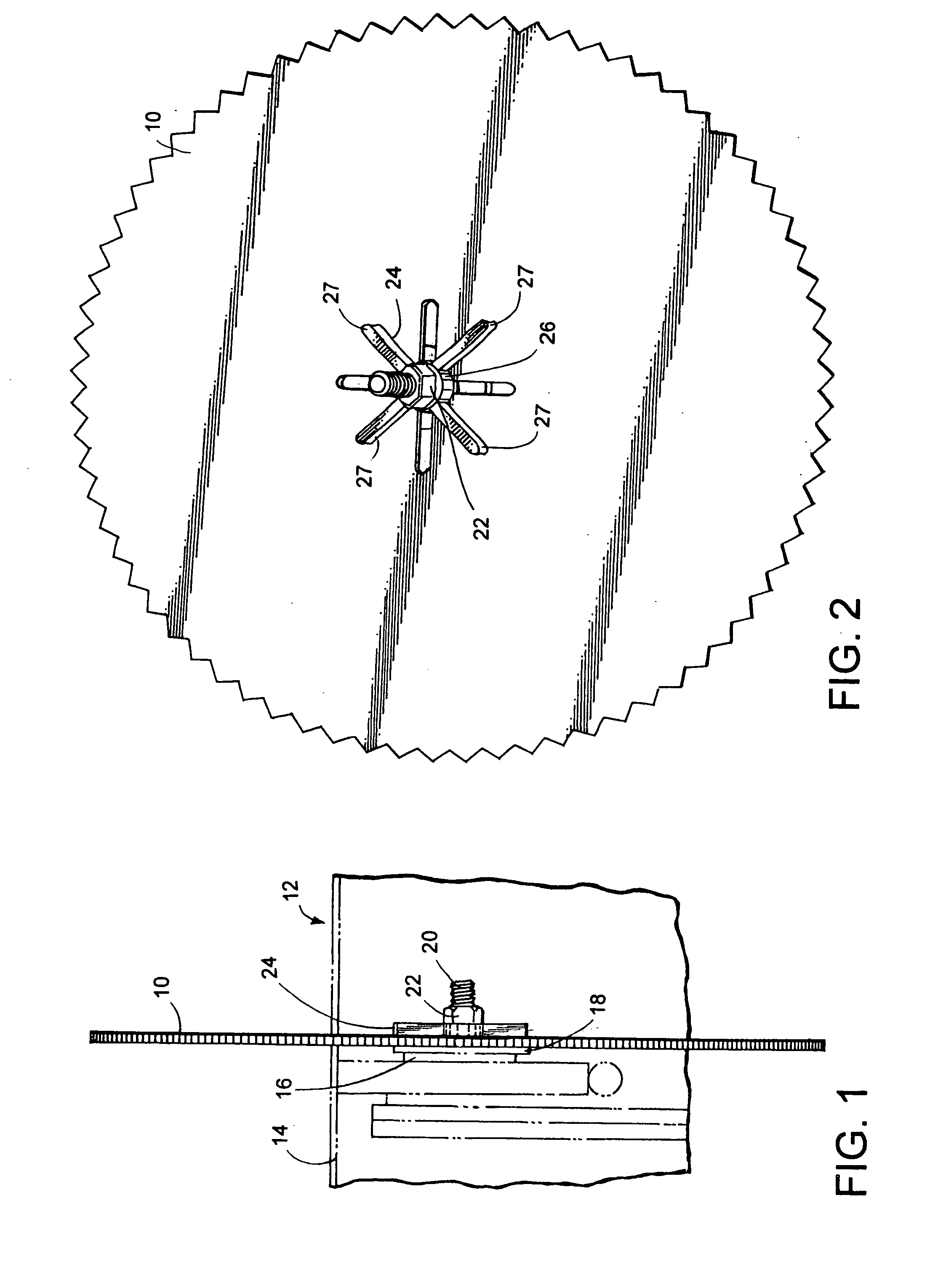

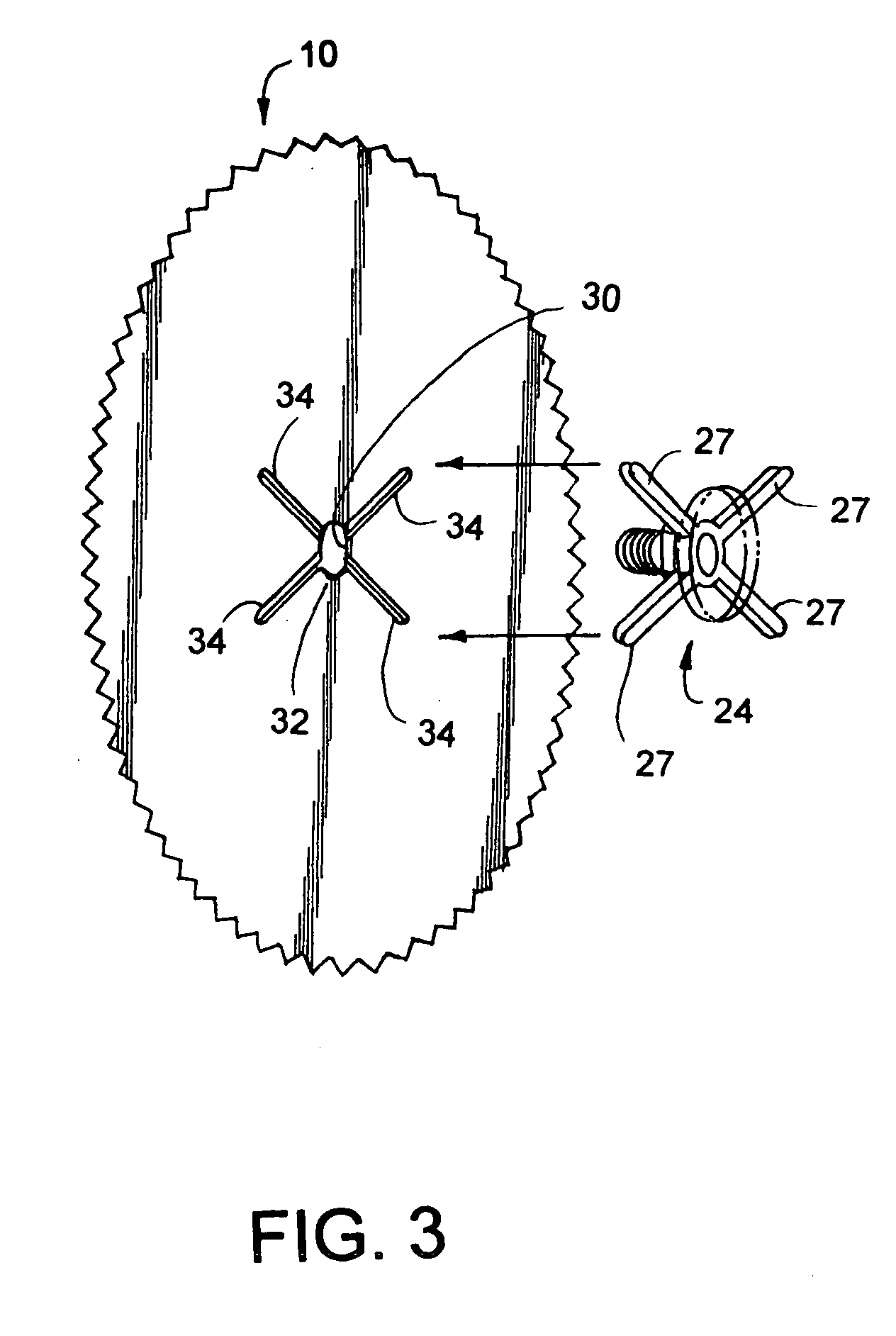

Light stand

InactiveUS6902294B2Reducing the tendency of the light stand to be tipped or knockedFor quick replacementNon-electric lightingLighting support devicesElectrical batteryRechargeable cell

Owner:WRIGHT MICHAEL N

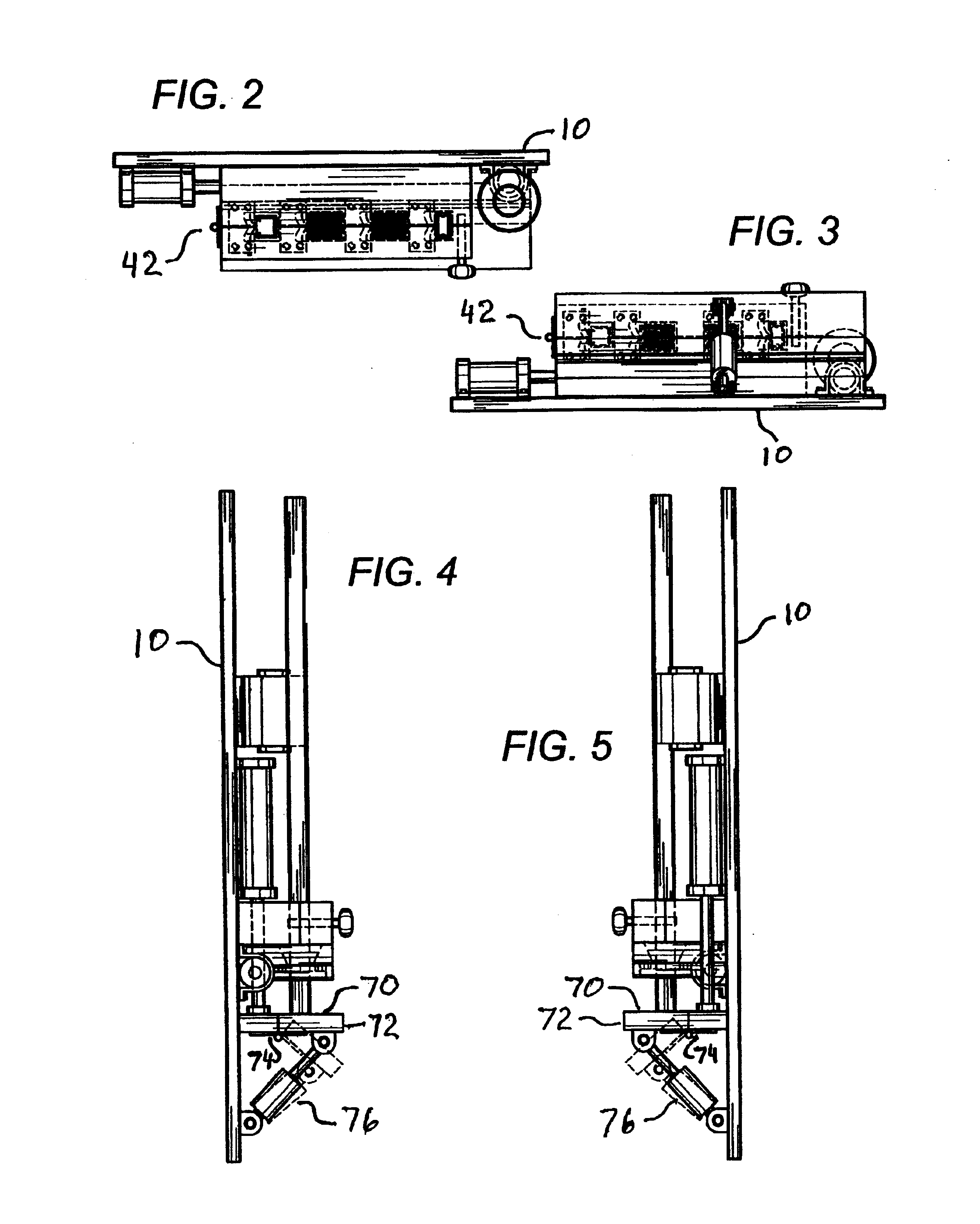

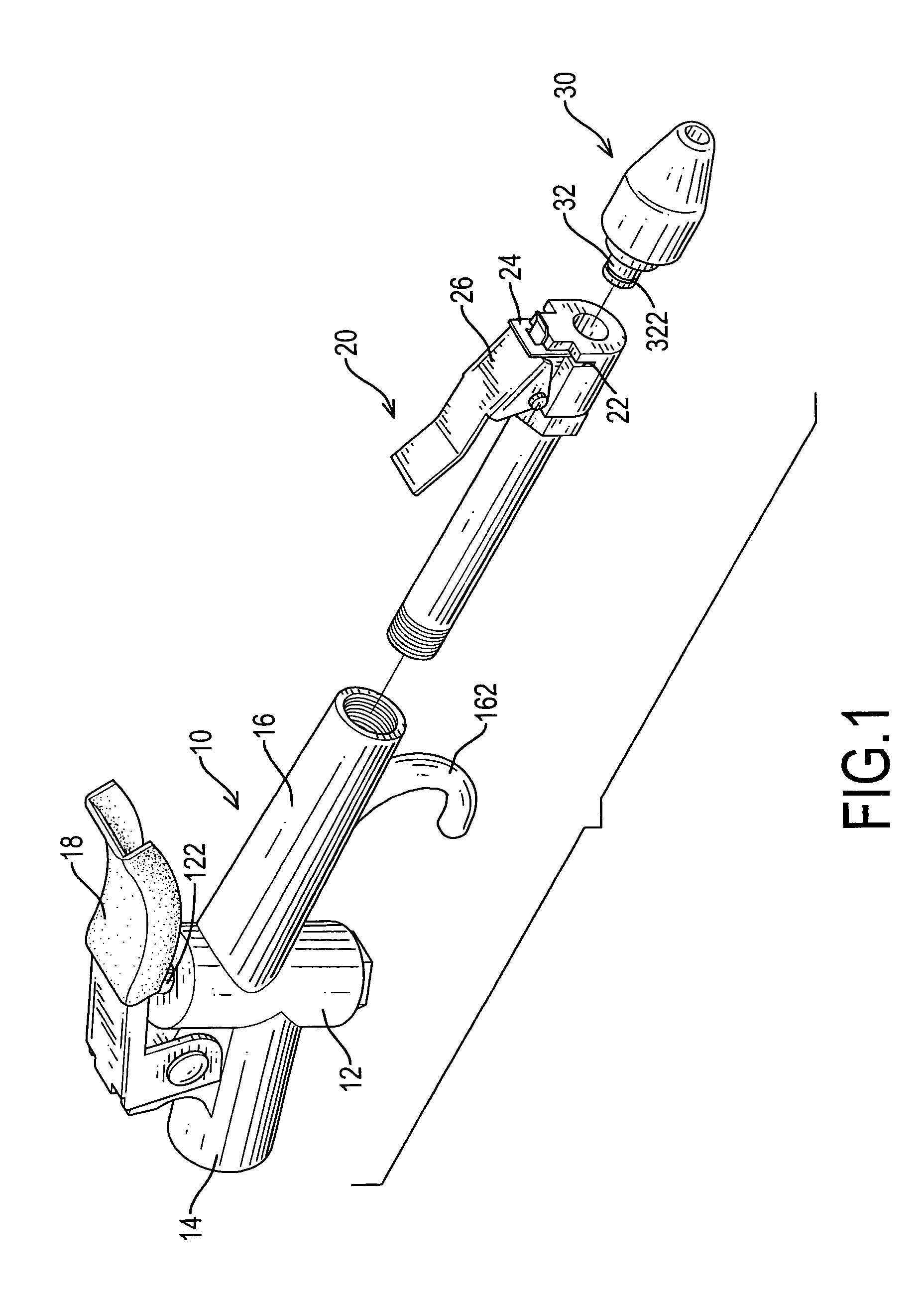

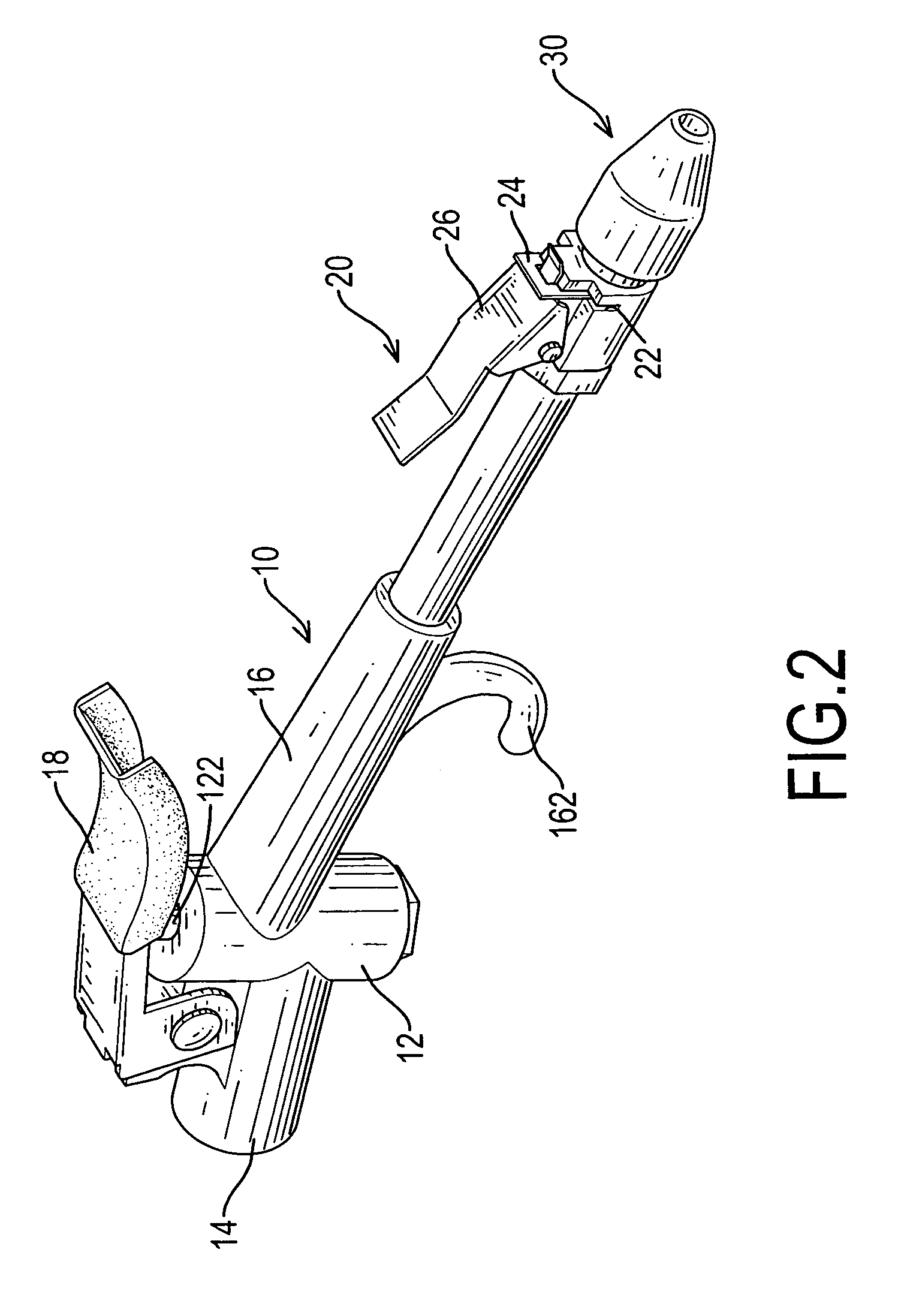

Quick-change tools

InactiveUS20060150428A1Simple and safe and reliableQuick tool changeMetal sawing devicesGrinding wheel securing apparatusEngineeringScrew thread

A tool having a quick-change mechanism for replacing tool implements on a shaft, post or handle comprising a shaft, post or handle having a flange and a threaded connector. The tool further includes a tool implement adapted to be received on the shaft, post or handle adjacent thc flange. The tool also includes a stabilizer washer adapted to be received on the shaft, post or handle adjacent the work implement. A threaded fastener is adapted to be threaded onto the threaded connector of the shaft, post or handle whereby the tool implement and the stabilizer washer are retained on the shaft, post or handle by the fastener, and wherein the tool implement and the stabilizing washer are configured to allow removal of the tool implement without removing the fastener from the shaft, post or handle.

Owner:BACULY ERIC J

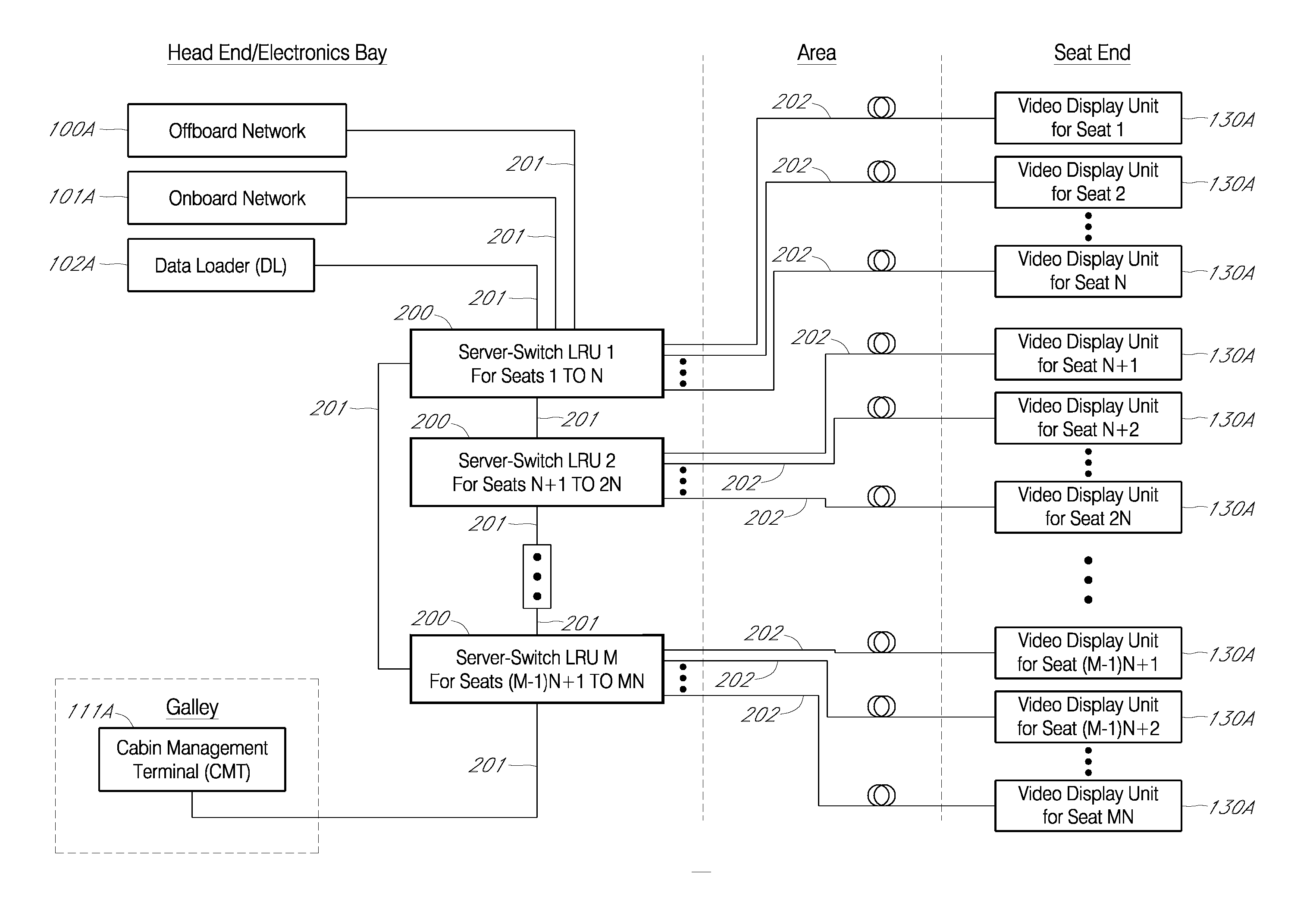

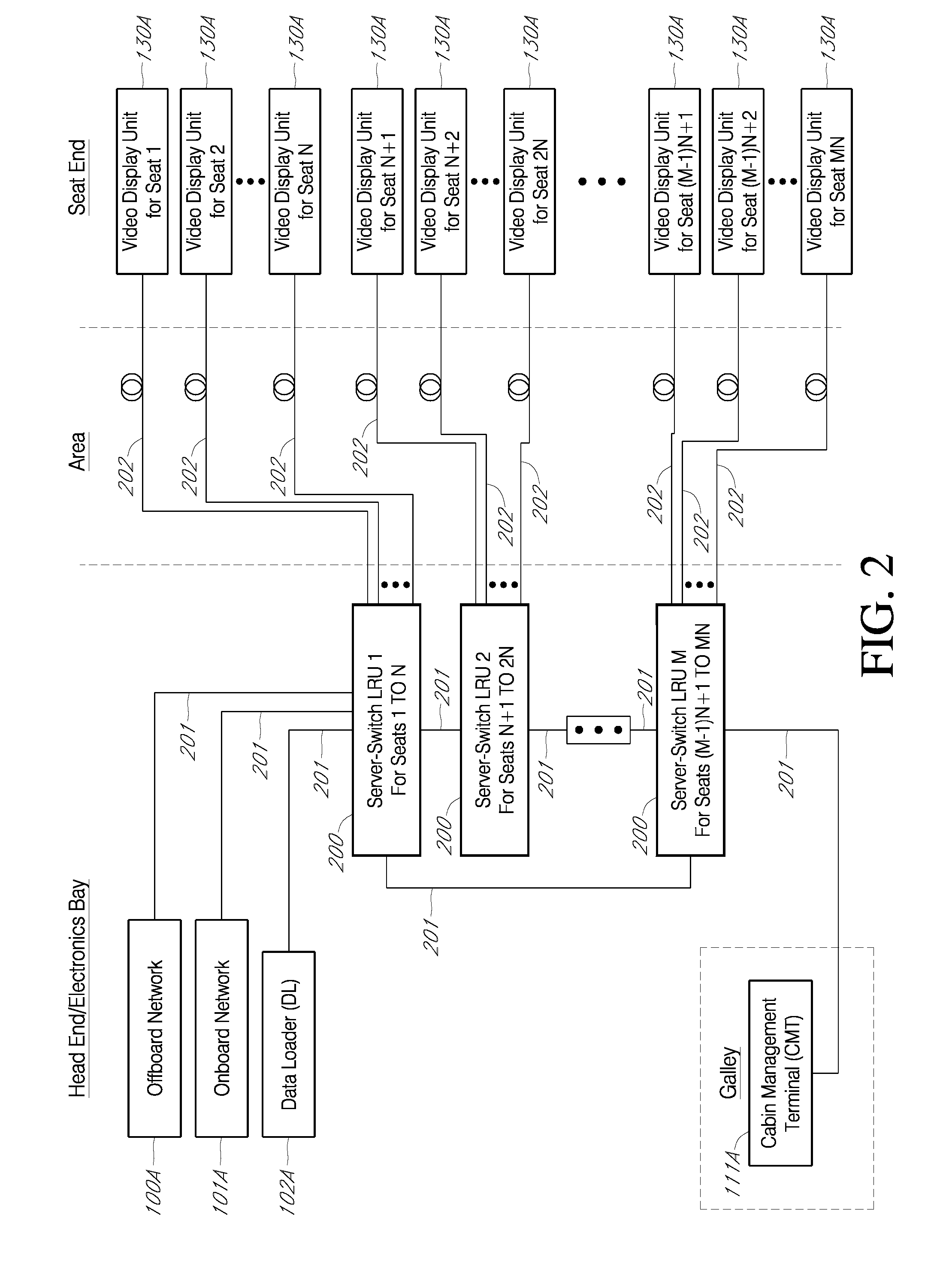

Fiber-to-the-seat in-flight entertainment system

InactiveUS20070077998A1Reduce in quantityFor quick replacementBroadcast specific applicationsOptical transmission adaptationsFiberCommunications system

A modular, scalable, extensible, In-Flight Entertainment (IFE) data communication system is described. In one embodiment, a server / switch line replaceable unit including at least one server, at least one switching element and a plurality of fiber optic transceivers communicates with a plurality of passenger seat video display units over fiber optic cables. A server, such as, for example, an audio server, a video server, an audio / video server, a game server, an application server, a file server, etc, provides data (e.g., entertainment programming, internet file data, etc.) to the video display unit. In one embodiment, a hybrid switch unit provides flexible communication between one or more servers and the passenger seats.

Owner:GLOBAL EAGLE ENTERTAINMENT

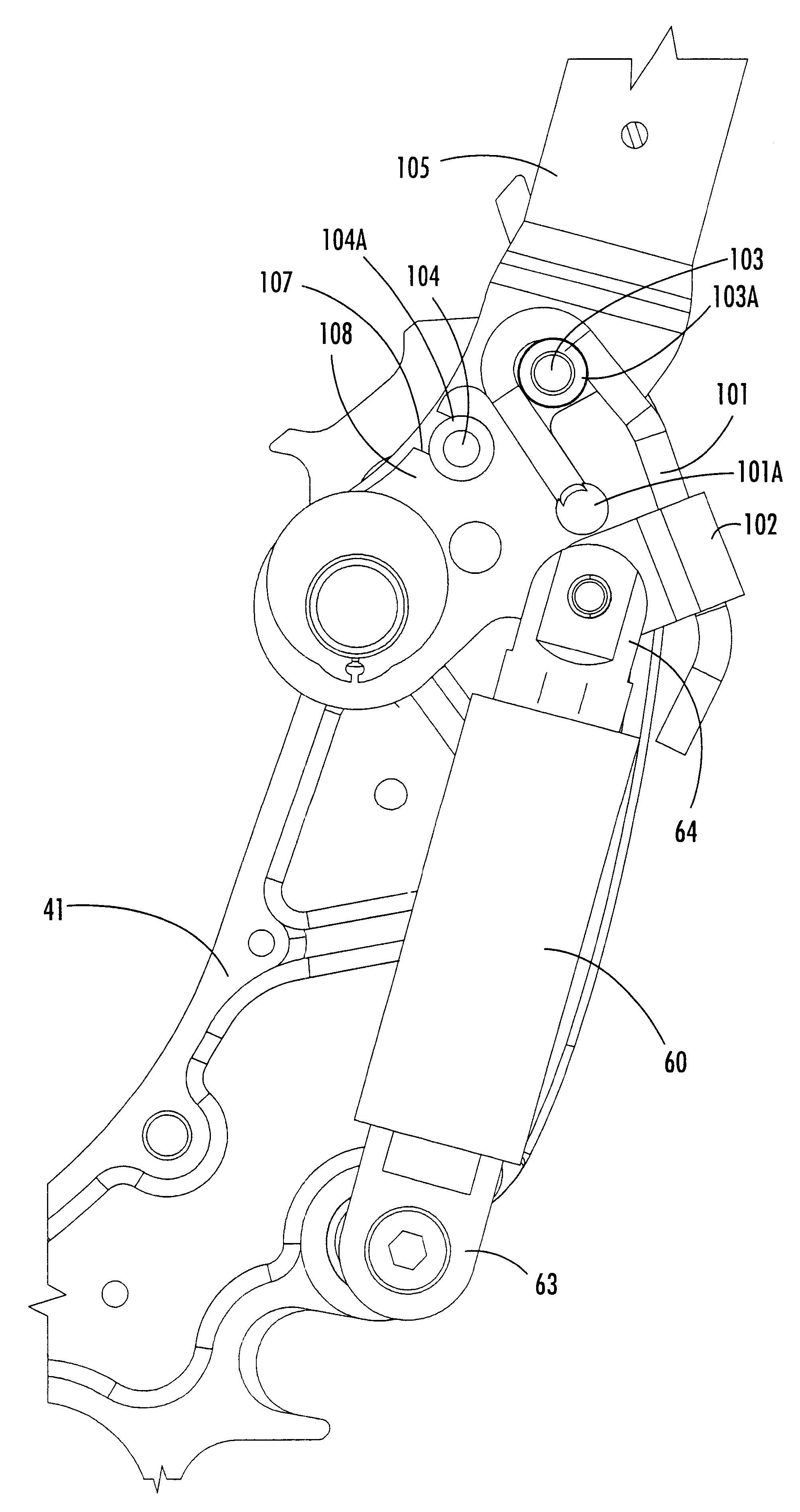

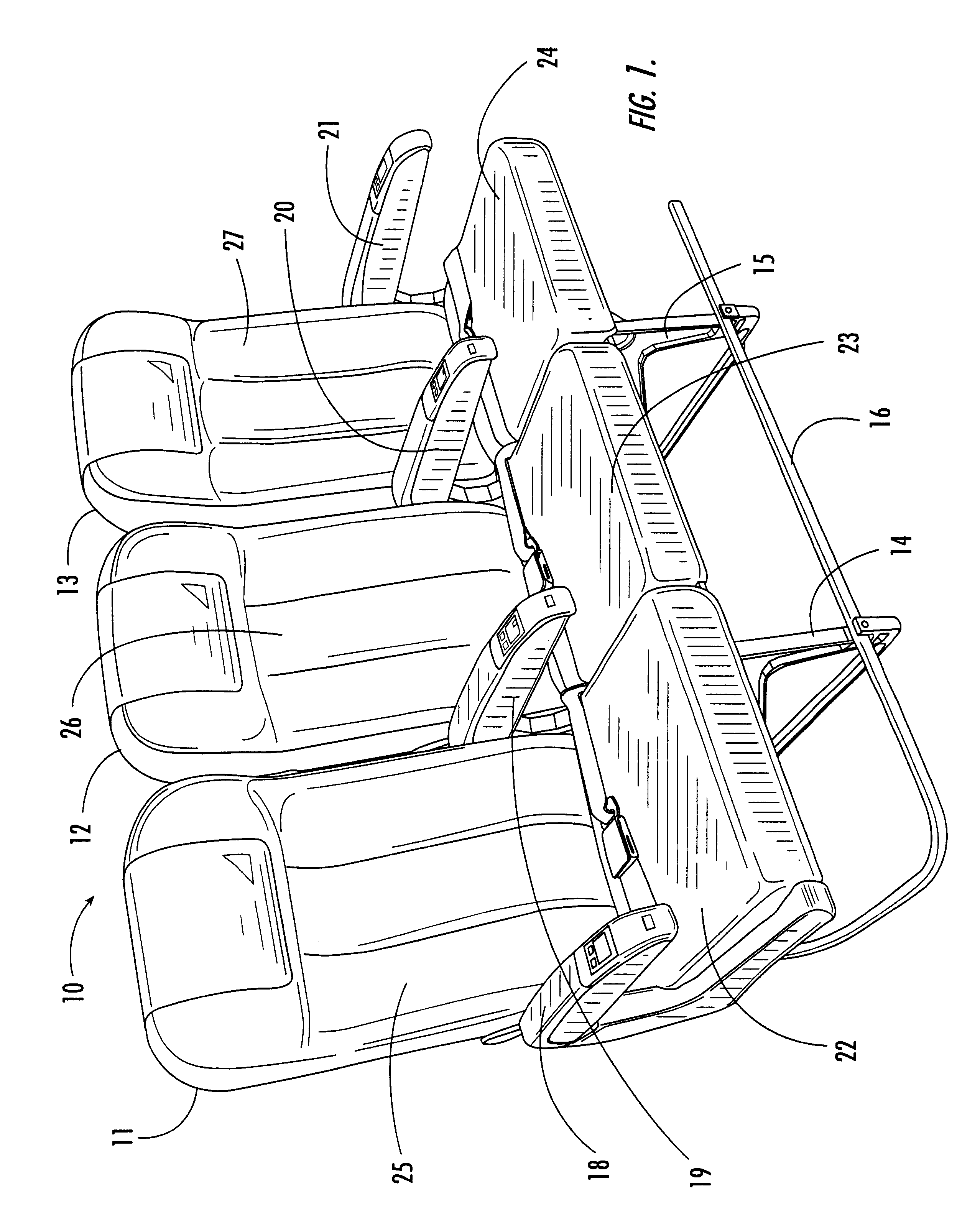

Passenger seat with seat back breakover assembly and method

InactiveUS6478256B1Reduce harmFor quick replacementSupports/holding devicesSeating arrangementsBack restsEngineering

A passenger seat is with a seat back breakover assembly for preventing movement of the seat back unit forwardly past an upright position during normal use and for permitting forward movement of the seat back past an upright position in response to a predetermined abnormal load applied in a forward direction. The breakover assembly includes a controlled deformation member having a bend in one end thereof and positioned intermediate one a section assembly module of the seat and the seat back unit. The bend of the deformation member captures therein an attachment member fixed to and movable forwardly and rearwardly in unison with the seat back unit. An end of the deformation member remote from the bend is restrained for restricted and controlled movement relative to the section assembly module. The deformation member has a resistance to deformation in response to a normal forwardly-applied force sufficient to prevent forward movement of the seat back unit beyond the upright position. The deformation member is deformable in response to an abnormal forwardly-applied force along its length whereby the bend in the deformation member is translated rearwardly along the length of the deformation member to thereby dissipate the abnormal force without damage to the seat back unit.

Owner:BE AEROSPACE INCORPORATED

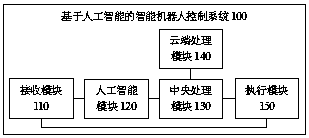

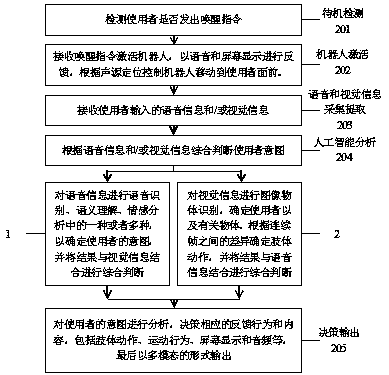

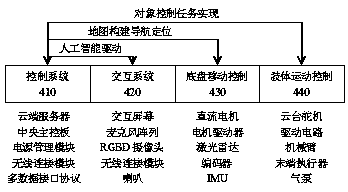

Control system and method of artificial intelligence drive robot

InactiveCN108297098AFor quick replacementEasy to replaceProgramme-controlled manipulatorCloud processingMultiple modes

The invention provides a control system and method of an artificial intelligence drive robot. The system comprises a receiving module, an artificial intelligence module, a central processing unit, a cloud processing module and an executing module. The method comprises the steps that scene information of the surrounding and voice and / or visual information of a user are acquired; a comprehensive decision is made after recognition and understanding according to voice and / or visual information; the intention of the user is confirmed, and the robot gives a response; and a treatment result is outputin multiple modes including one or more of moving of the intelligent robot, action of a mechanical arm and / or a head, expression video image display on a screen, and audio playing. According to the method, artificial intelligence analysis and decision can be carried out locally or through cloud uploading according to acquired voice and / or visual information, the robot is automatically controlledto be in interactive feedback with the user in multiple manners, much hardware can be arranged outside, a designer quickly expands a machine body, and an artificial intelligence result can be intuitively and effectively achieved on the robot.

Owner:SHANGHAI UNIV +1

Receptacle cover

ActiveUS20120068612A1Lower potentialImprove securityTwo pole connectionsLighting support devicesElectricityEngineering

A cover for an electrical receptacle including a faceplate. The cover also includes a first transmission tab configured to be electrically connected to a first power line of the electrical receptacle and a second transmission tab configured to be electrically connected to a second power line of the electrical receptacle. Additionally, the cover includes a device (such as a light source, circuit, port, or sensor) in communication with the first transmission tab and the second transmission tab.

Owner:LIGHTING DEFENSE GRP LLC

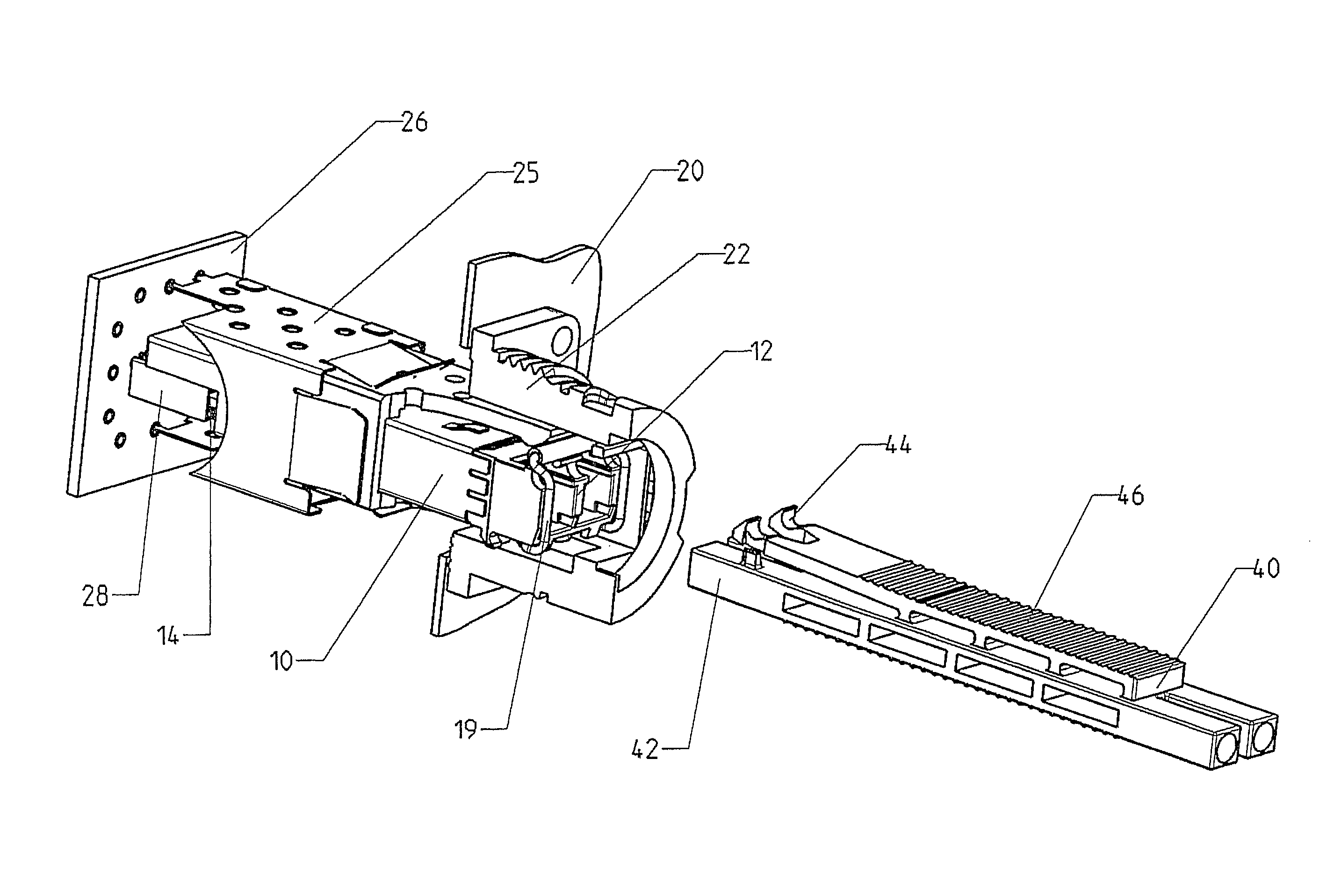

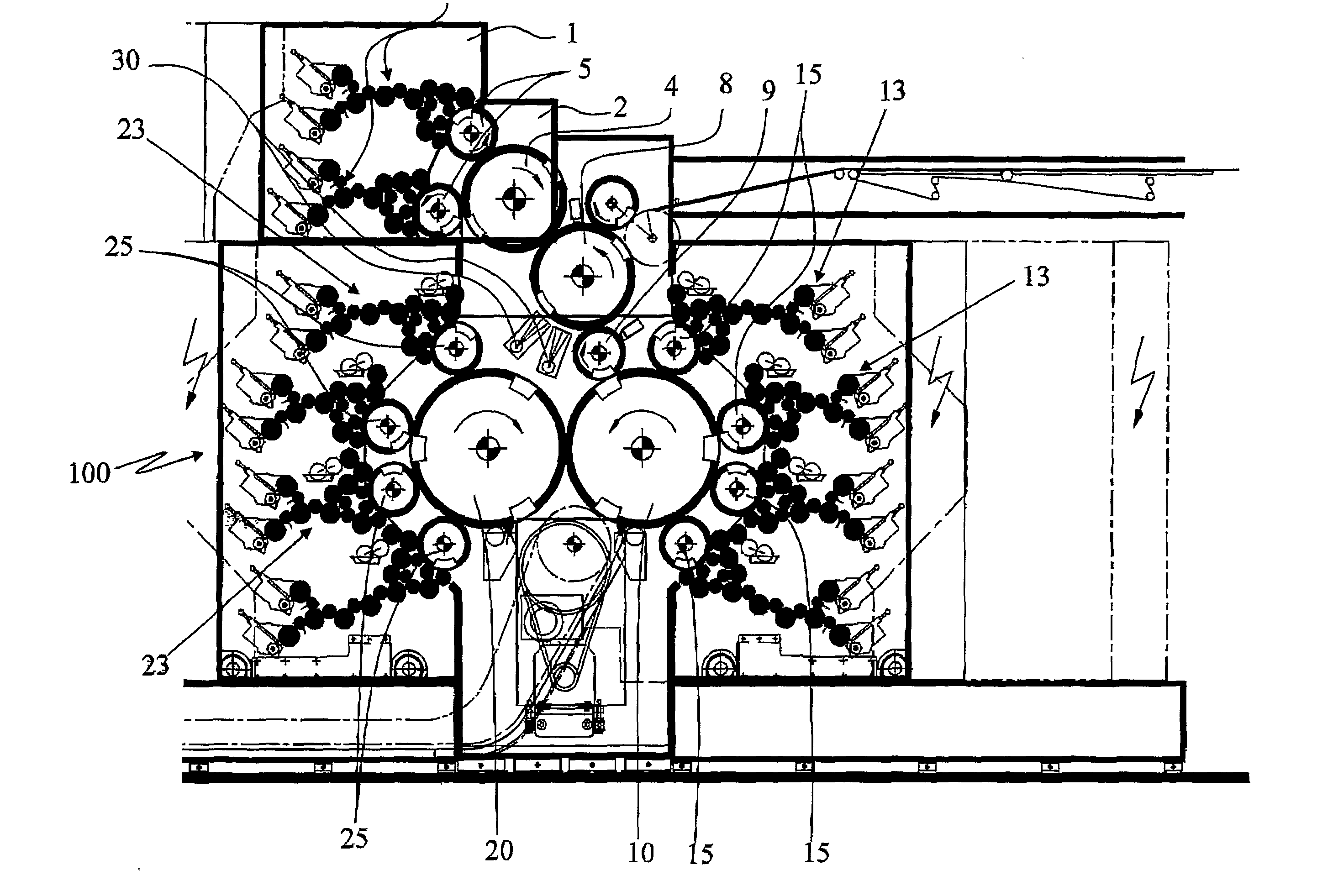

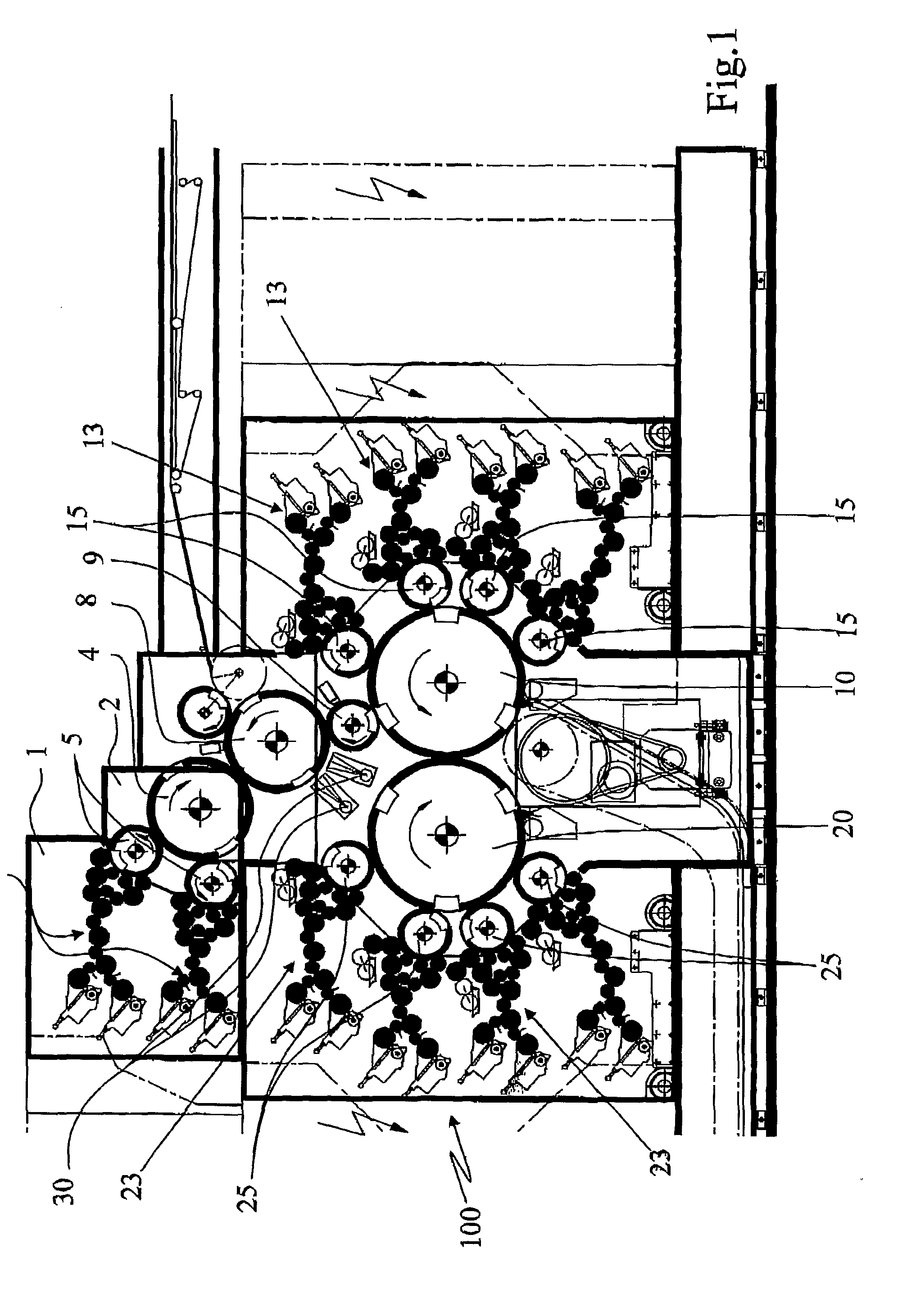

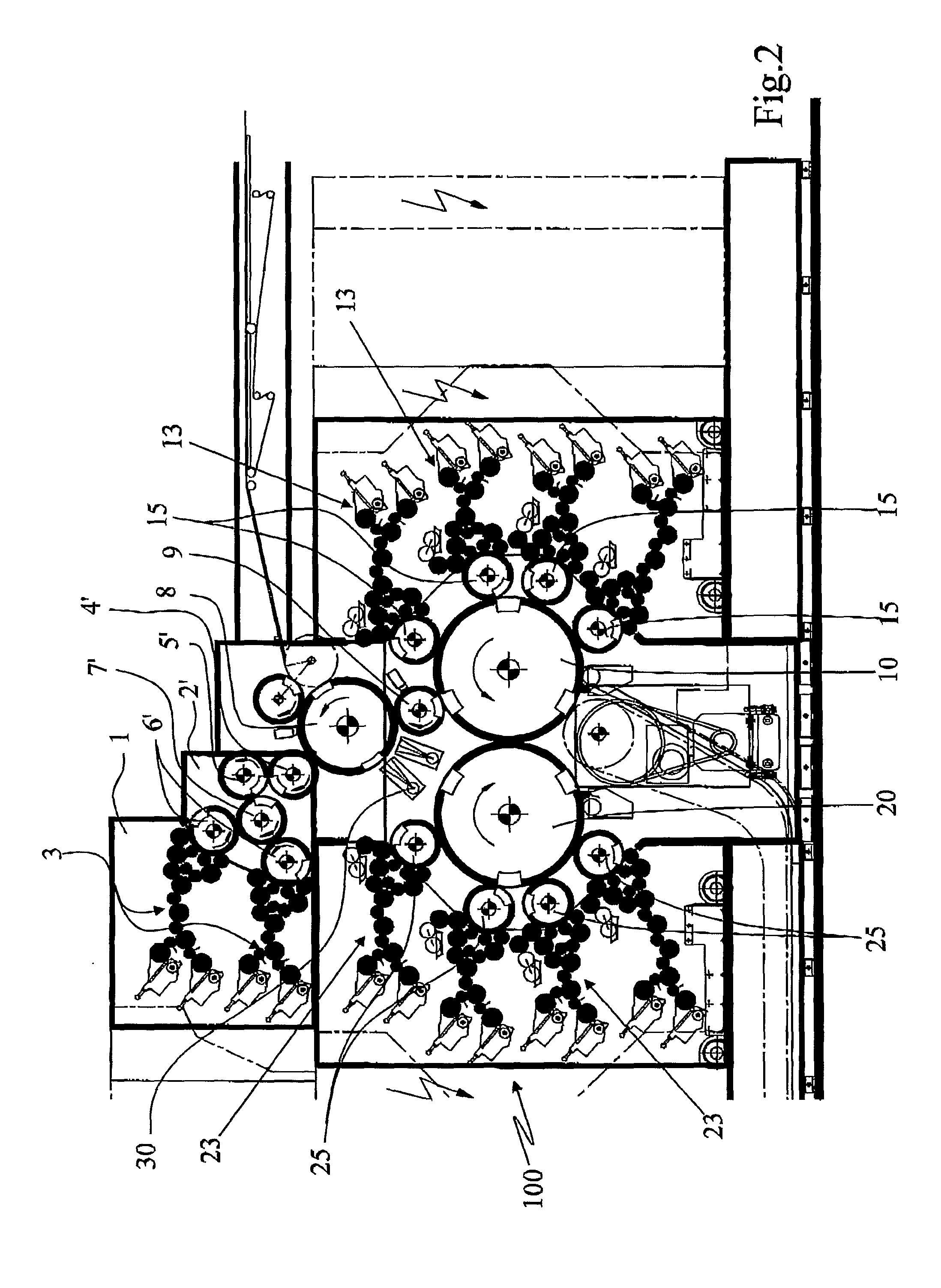

Printing Machine with Modular Additional Printing Group

InactiveUS20080271620A1Improve abilitiesIncrease flexibilityOther printing apparatusRotary letterpress machinesEngineeringPrinting press

There is described a web-fed or sheet-fed printing machine for security papers, in particular banknotes, comprising a machine frame in which is located a main printing group, the printing machine further comprising an additional printing group, independent of the main printing group, placed upstream of the main printing group with respect to a direction of displacement of the web or sheets for performing additional printing of the security papers prior to printing by said main printing group. The additional printing group comprises an inking module containing at least one inking device, and a printing module comprising a cylinder arrangement including a plurality of cylinders, the printing module being interposed between the inking module and the machine frame of the printing machine. The additional printing group is constructed in such a manner that the printing module can be decoupled from the inking module and the machine frame for replacement by another printing module without this requiring removal of said inking module from the printing machine.

Owner:KBA NOTASYS SA

Strap attachment assembly

ActiveUS7526840B2For quick replacementImprove reliabilitySnap fastenersElectrical apparatusEngineeringMechanical engineering

An assembly is disclosed for mounting a strap to a sports instrument, the assembly includes a mounting element situated in the strap, a slot situated in the sports instrument for accommodating the mounting element and fixing member for securing the mounting element in the slot. The fixing member includes a spring-loaded locking element capable of reaching into the slot and, cooperating with the same, a retaining element, whereby the locking element functions in conjunction with the sports element while the retaining element functions in conjunction with the mounting element.

Owner:SUUNTO OY

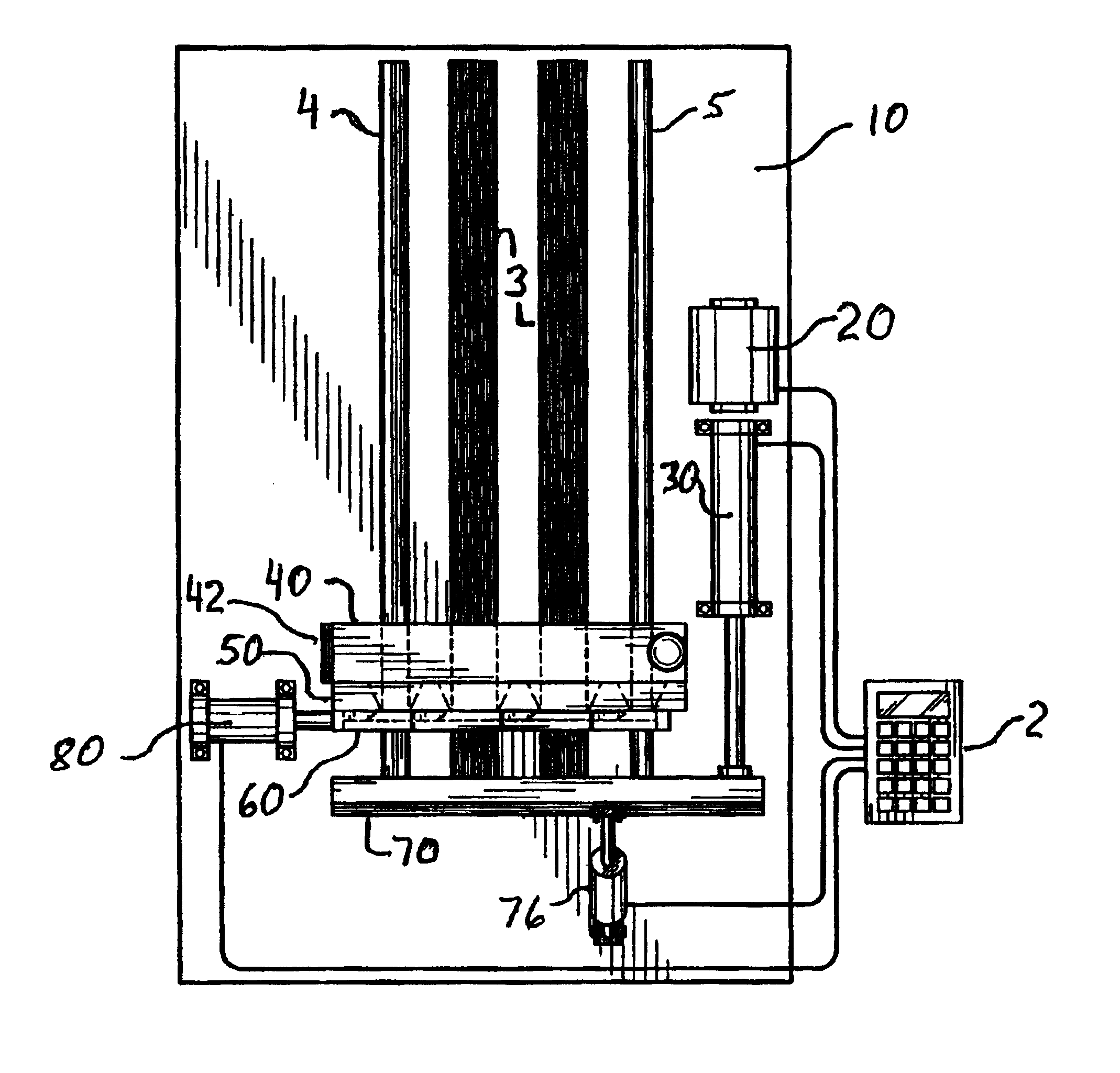

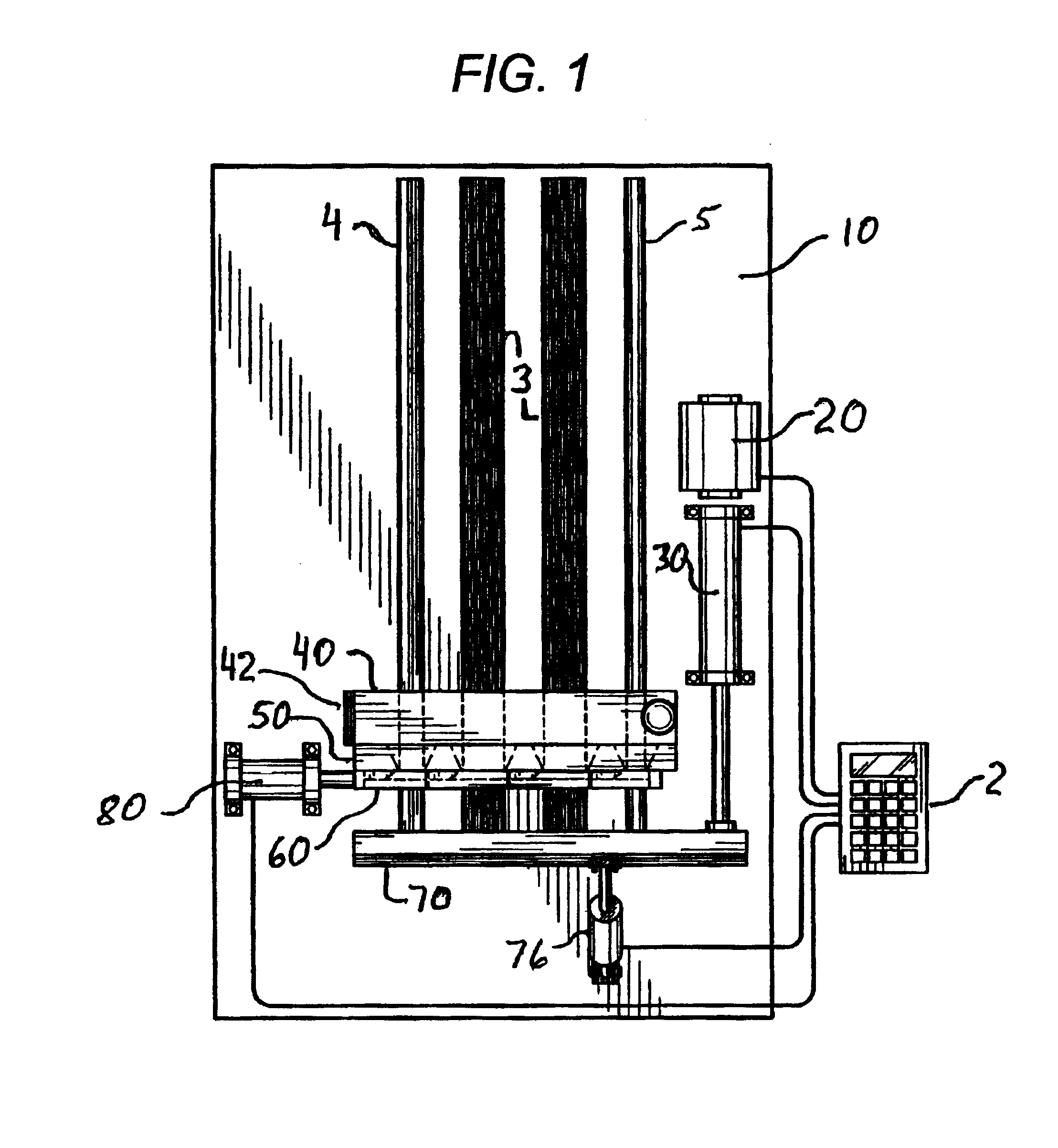

Automated blind cutting machine

InactiveUS6945152B2Reduce the amount requiredEasy to useLight protection screensStock shearing machinesElectrical controlEngineering

The present invention is a method and apparatus for automatically cutting a blind. The blind cutting apparatus comprises a framework, a die assembly, a cutting assembly, a clamp assembly, a blind support base, an integral measuring assembly, an electrical control assembly, and a displacement mechanism. The blind is cut to the exact dimensions by the operator who inputs the dimensions of the window and the size of the blind.

Owner:JABBARI ABBAS +1

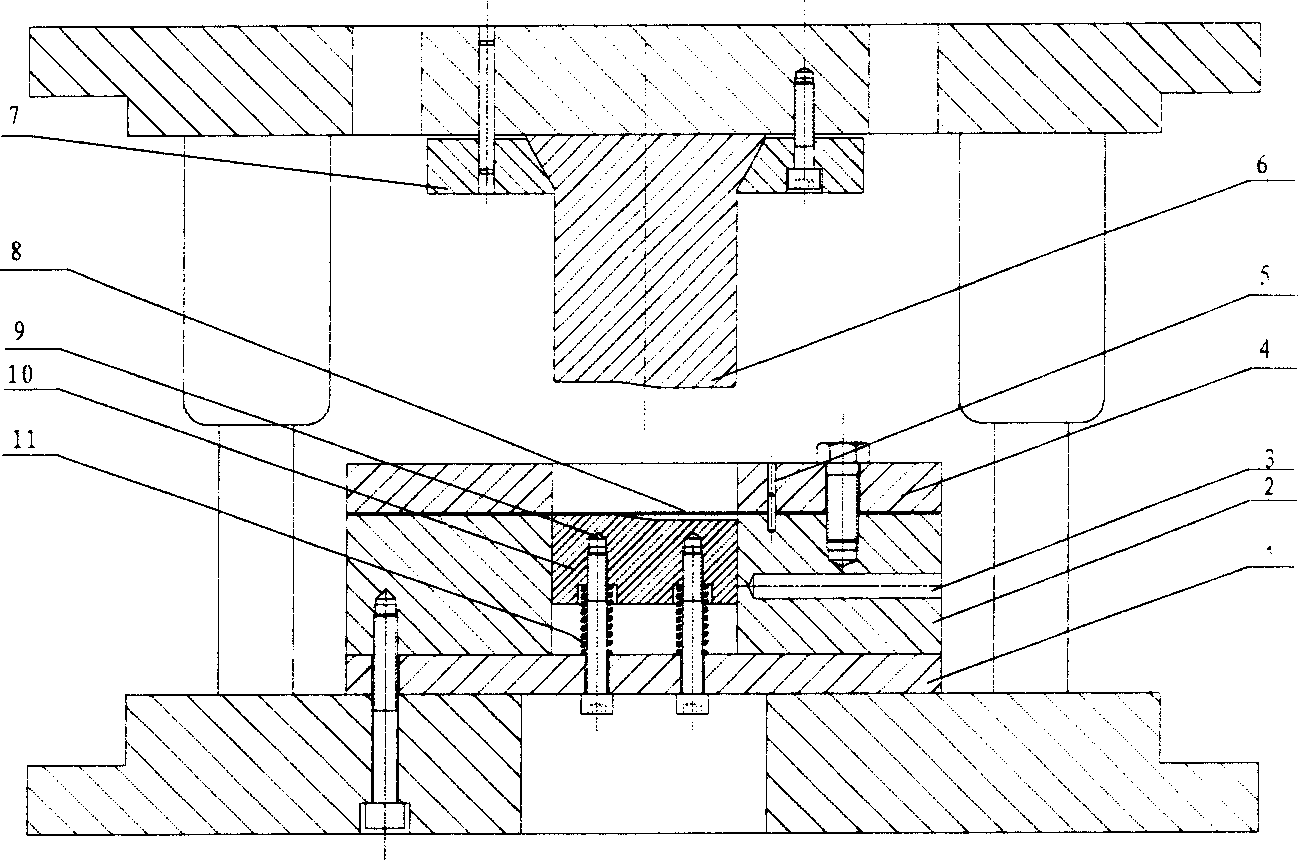

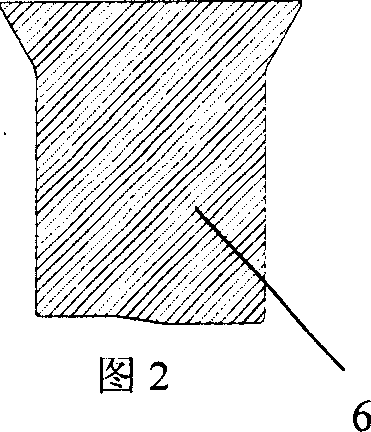

Mild hot formation method for making magnesium alloy shell of cell phone and mould specially for the same

A thermal shaping method for the Mg-alloy shell of mobile telephone features use of draw technology with a dedicated die set, which includes such steps as heating edge pressing ring and female die to 170-180 deg.C, coating lubricant onto die set and raw black of said Mg-alloy shell, heating the raw black, pre-heating the male die to 70-100 deg.C, and die pressing at 170-180 deg.C for drawing.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Mop assembly and cart

InactiveUS7160044B2For quick replacementCarpet cleanersWriting connectorsEngineeringMechanical engineering

Owner:3M INNOVATIVE PROPERTIES CO

Aircraft door system and method of making and installing the same

InactiveUS20070007390A1Quickly and easily coupledFor quick replacementAircraft assemblyAircraft doorsEngineeringFuselage

Owner:REMMELE ENG

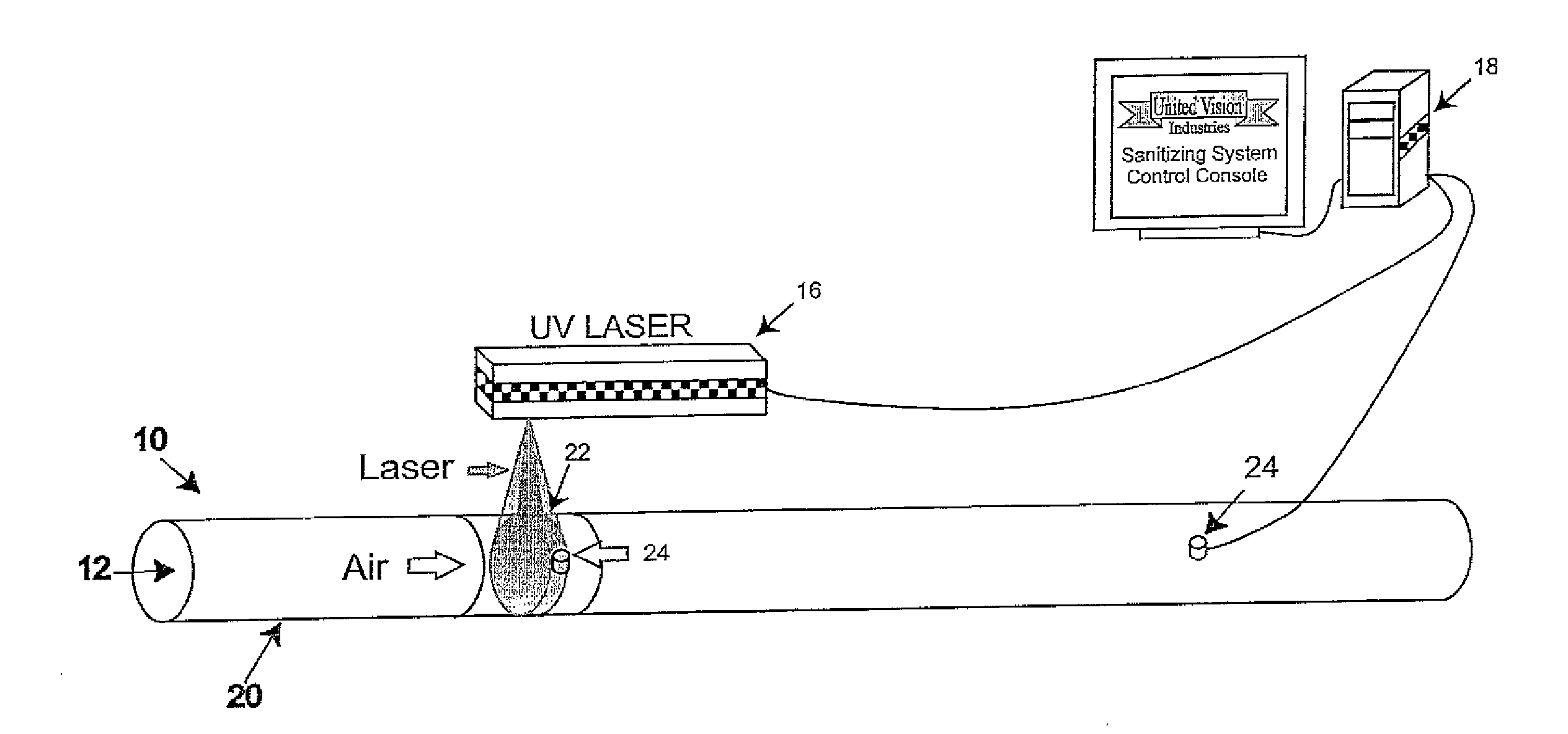

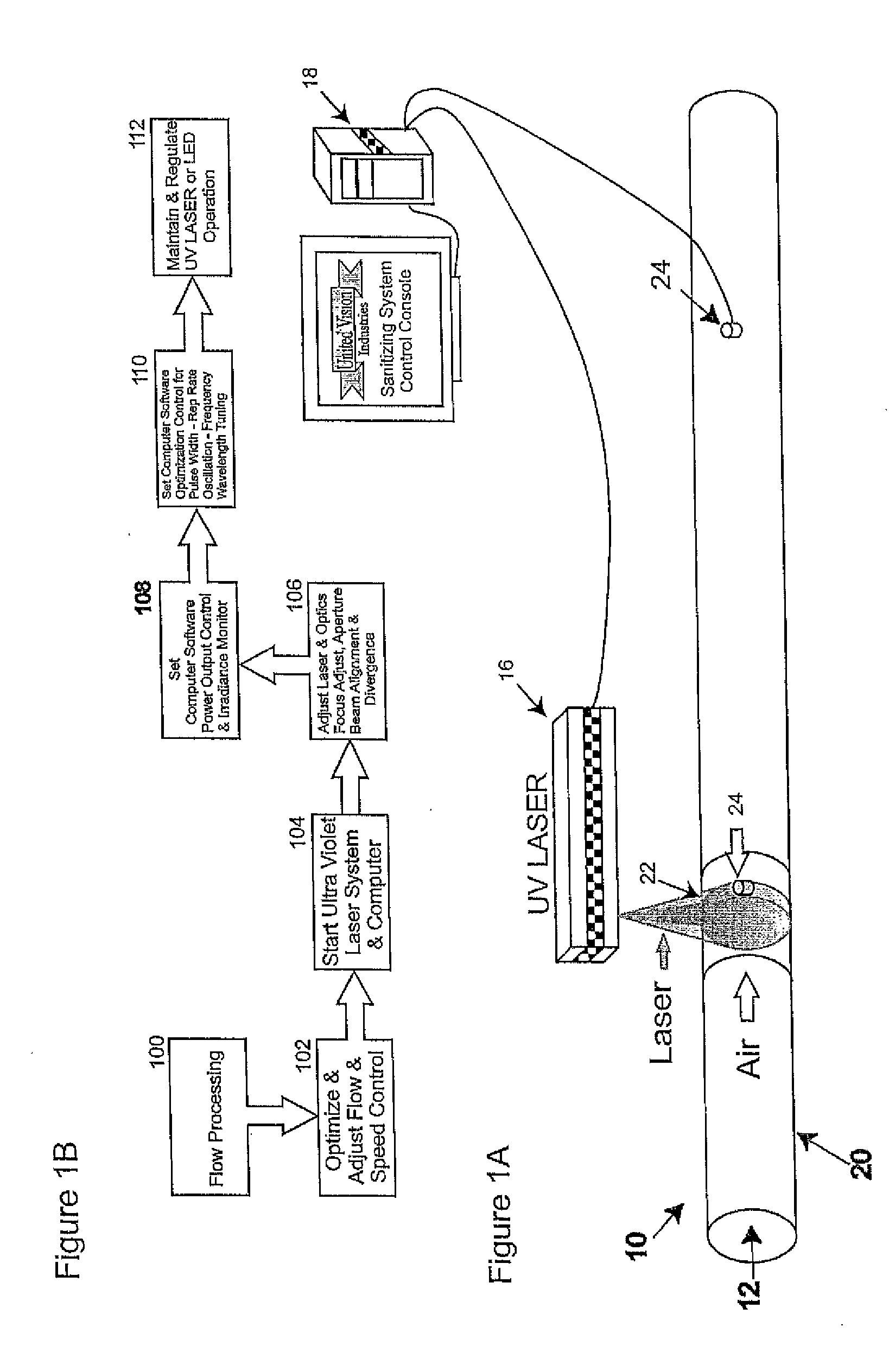

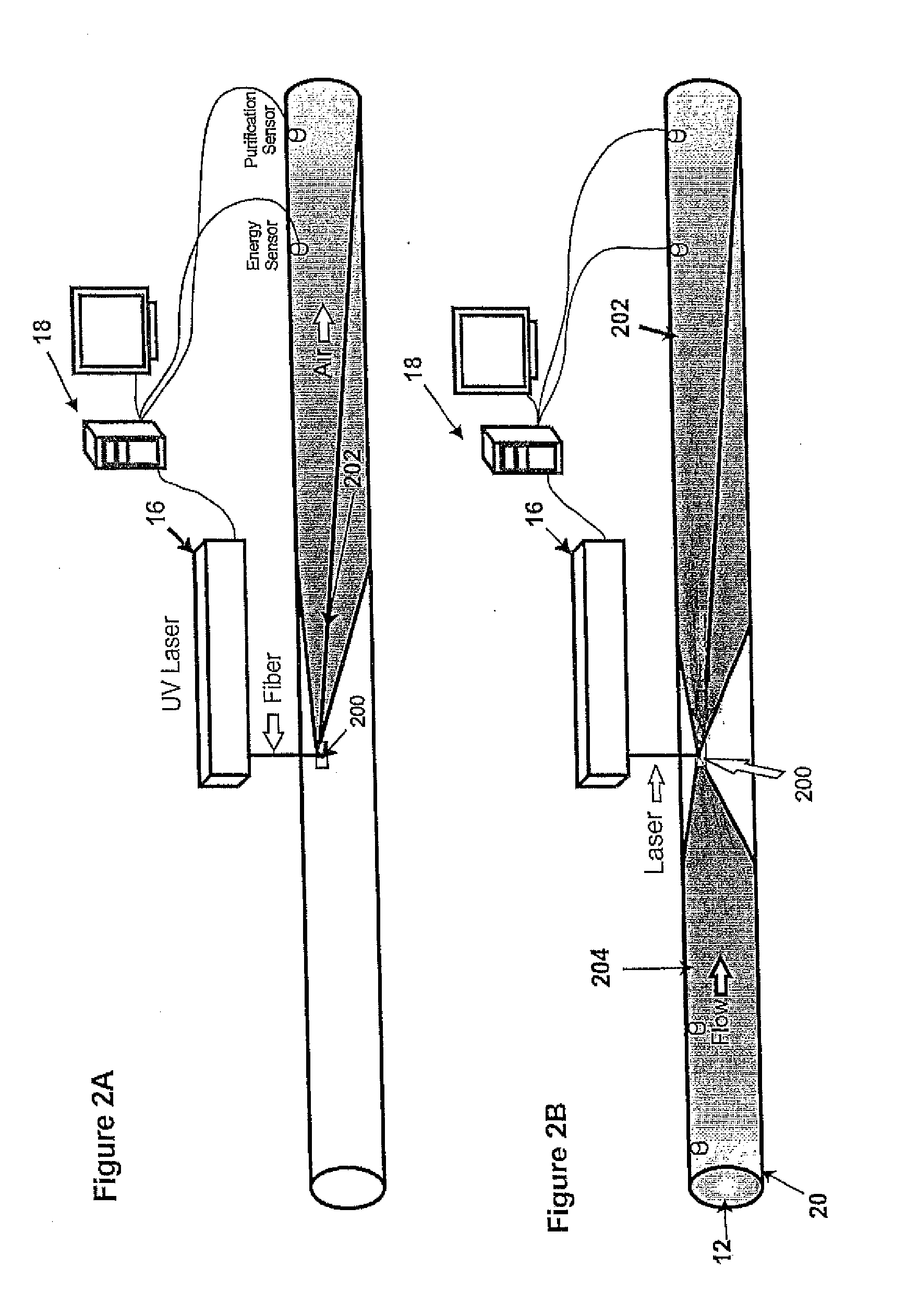

Method & apparatus for sanitizing air in aircraft, commercial airliners, military vehicles, submarines, space craft, cruise ships , passenger vehicles, mass transit and motor vehicles by integration of high density high efficiency ultra violet illumination apparatus within air conditioning, ventilation and temperature control systems

InactiveUS20120273340A1Small sizeReduce energy outputCombination devicesGas treatmentSubmarinePublic transport

The present invention provides a method and apparatus for sanitizing air within a ventilation system using ultraviolet light. The air is exposed to the ultraviolet light for a preselected duration of time and at a desired power level to achieve a desired level of sanitization.

Owner:FELIX PERRY

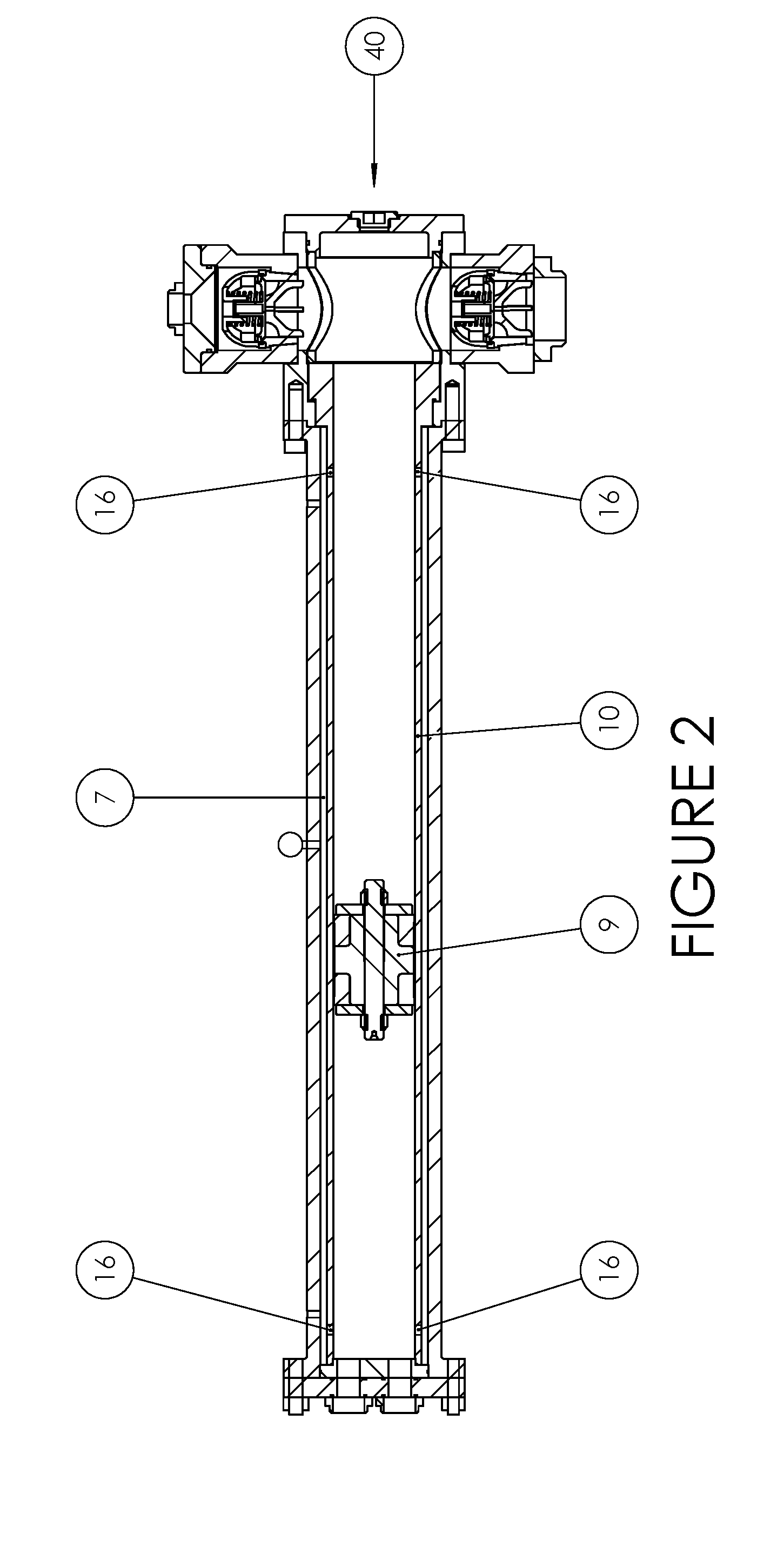

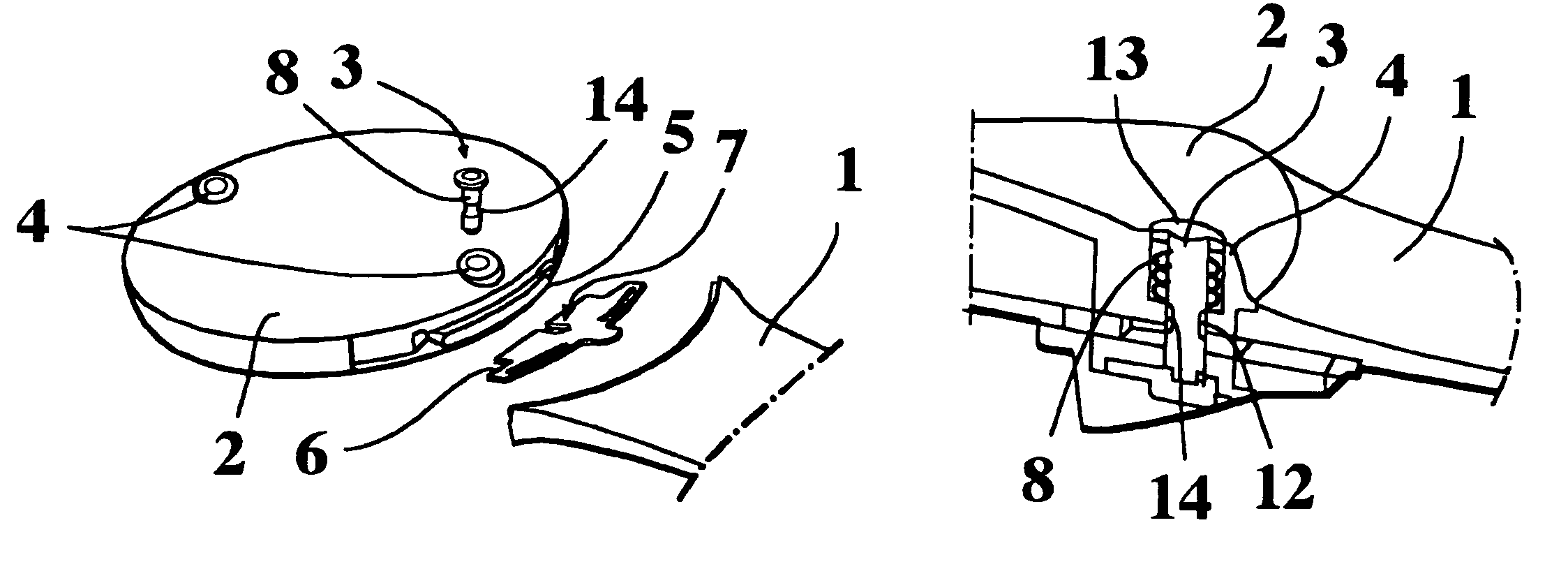

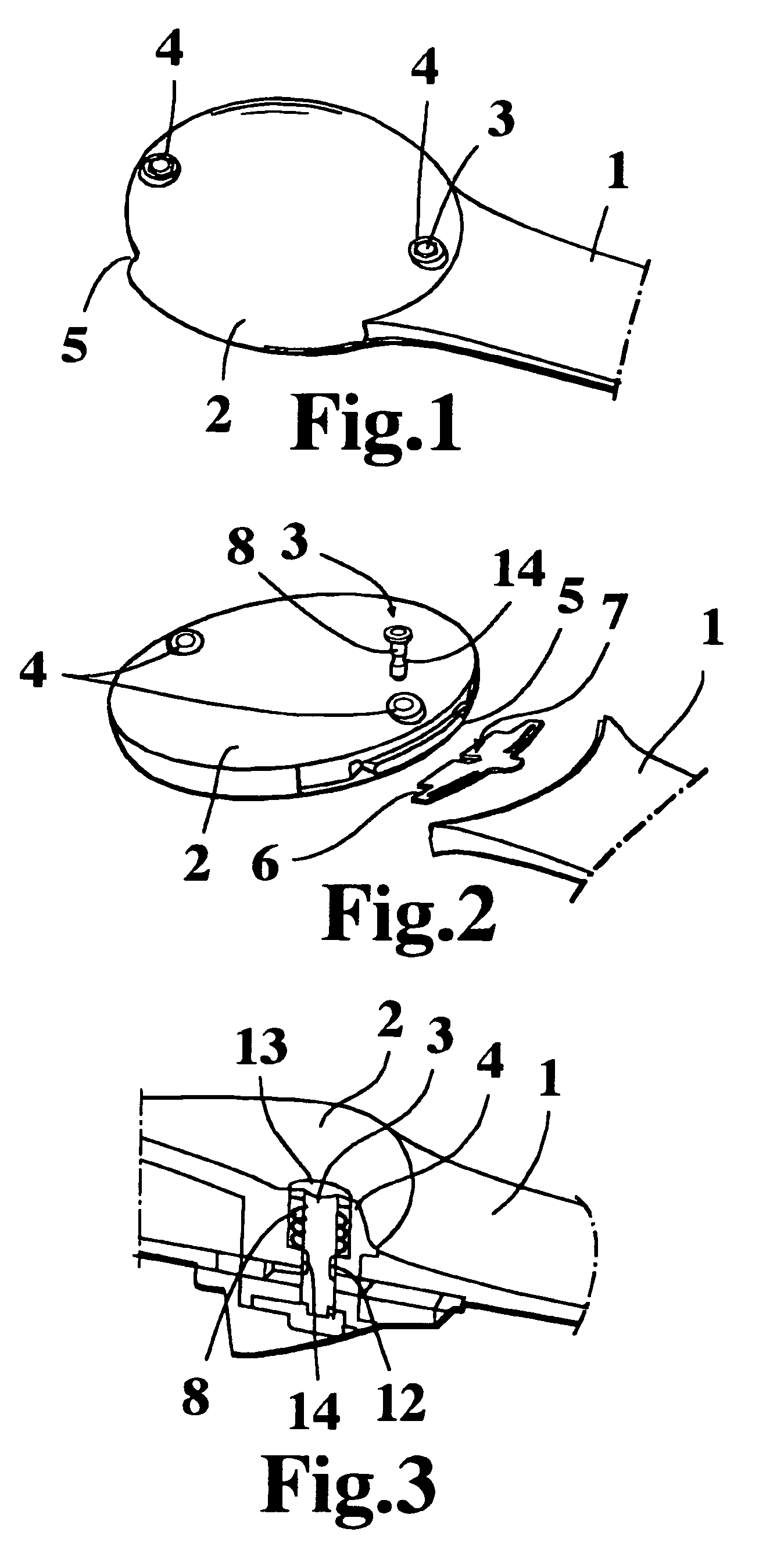

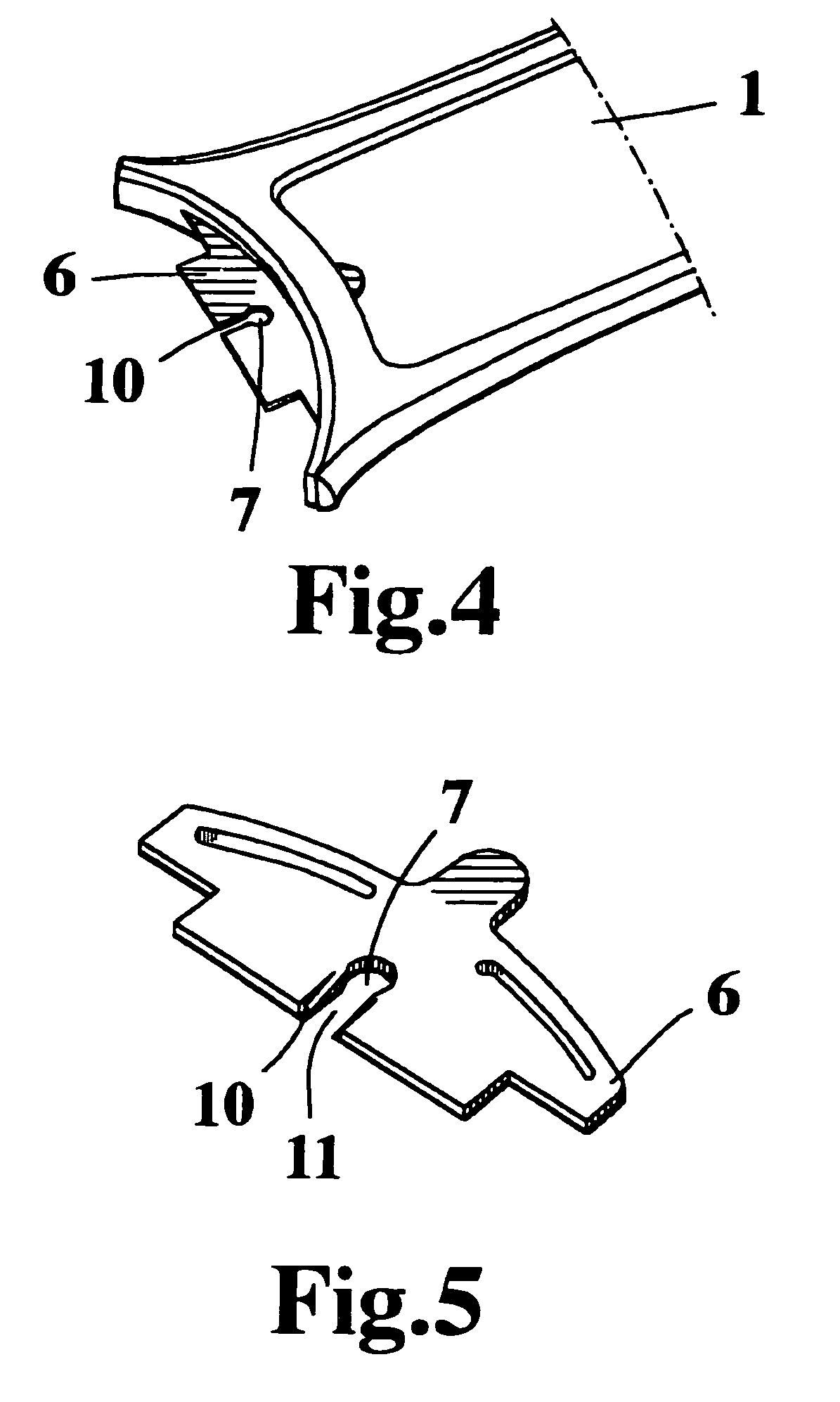

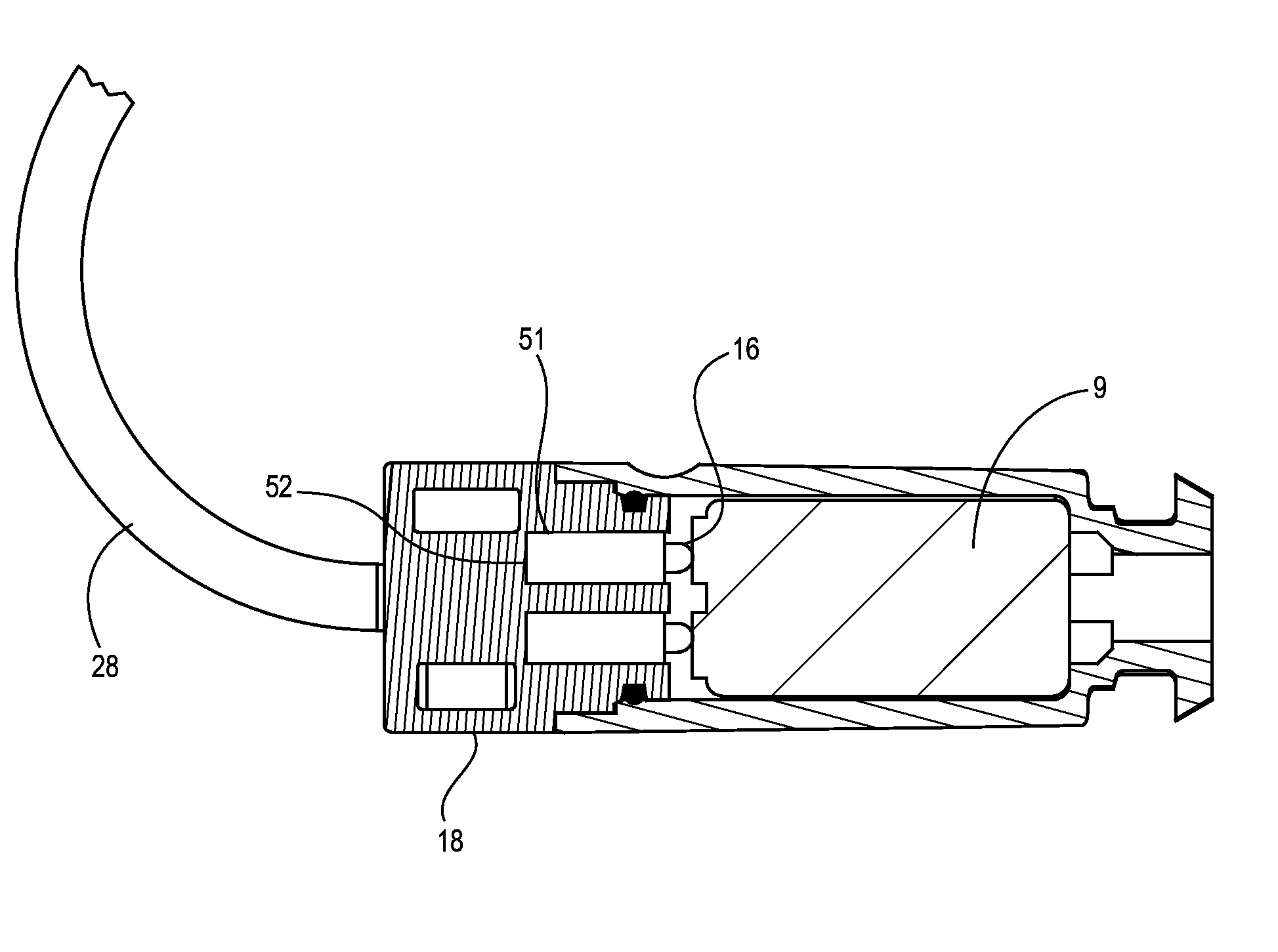

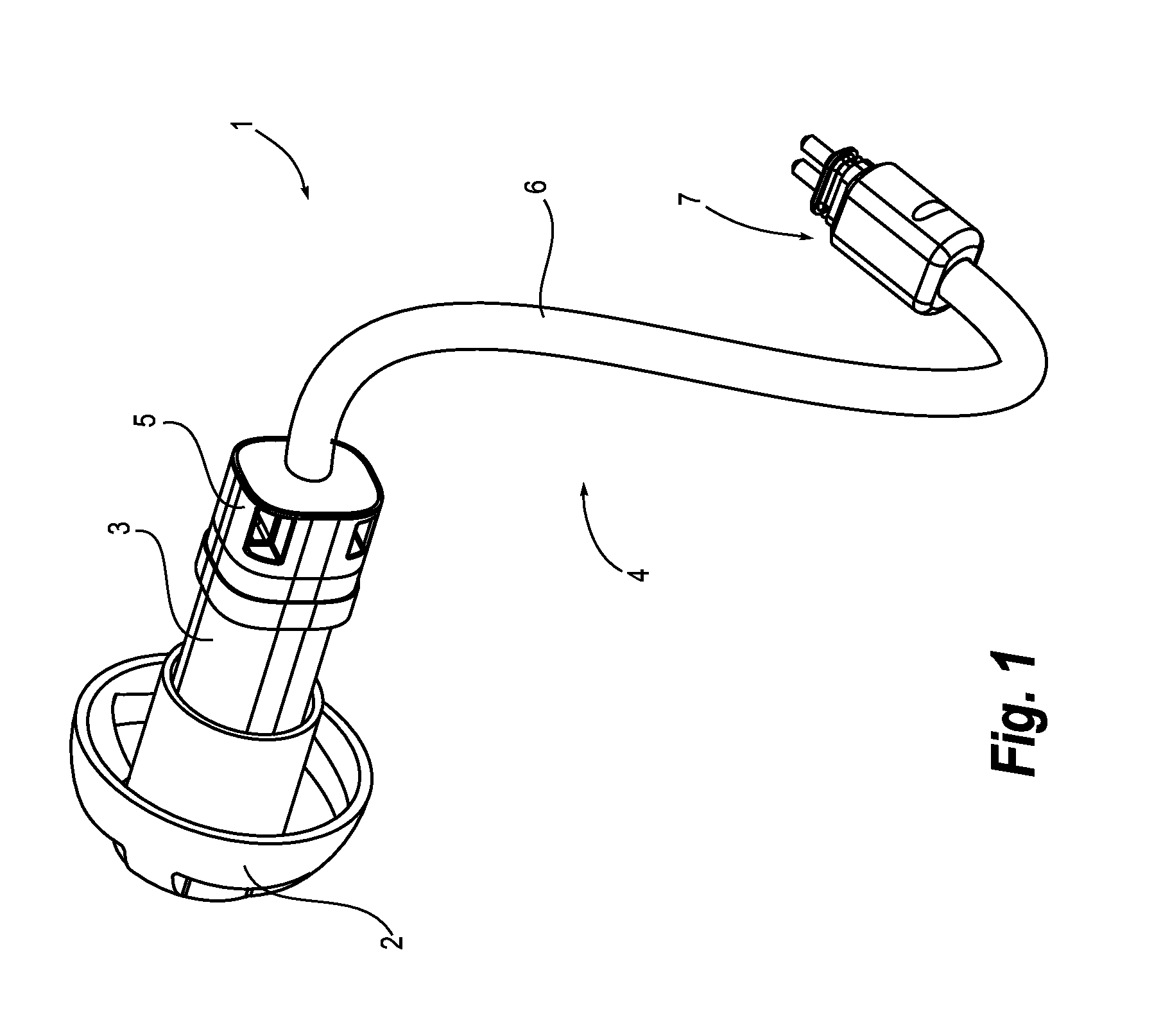

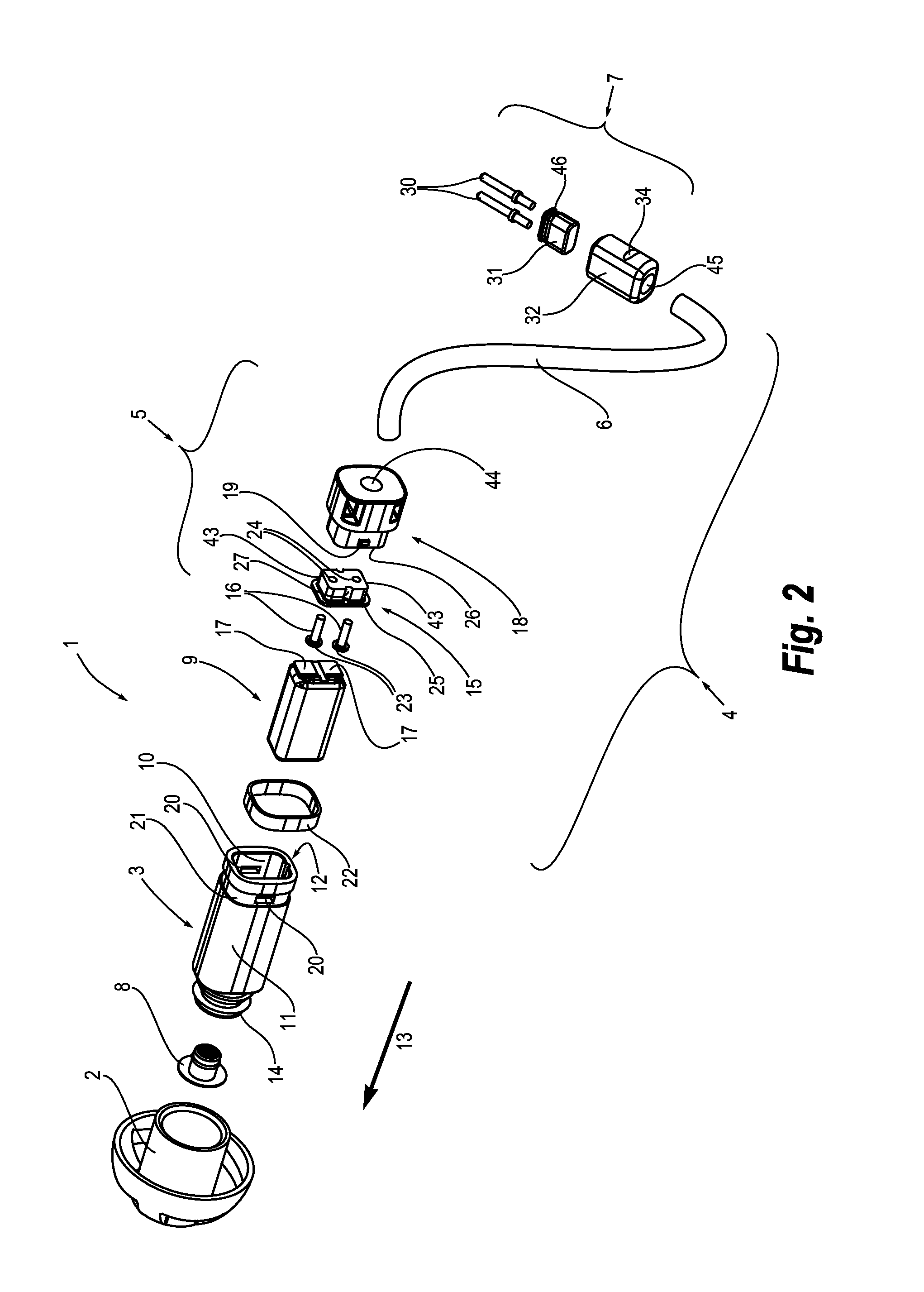

Receiver in the ear (RITE) component for a hearing aid

InactiveUS20090304216A1Simple configurationIncreased durabilityBehind the ear hearing aidsHearing aids mounting/interconnectionCouplingEngineering

A receiver in the ear (RITE) component (1) for a hearing aid, said RITE component comprising a receiver (9) and a receiver housing (3), and a connector (4) comprising coupling means (7) for coupling the RITE component to a BTE housing component of said hearing aid, and said connector (4) comprising an electrically conductive means (6). The RITE component (1) further comprises a fixture (5) to connect the receiver (9) in the receiver housing (3) and the connector (4), said fixture (5) comprising a spring element (15) and at least one contact terminal (16) adapted for abutting contact with at least one corresponding contact terminal (17) on said receiver (9).

Owner:WIDEX AS

Air gun with a quick-releasing device

Owner:CHEN KUO LIANG

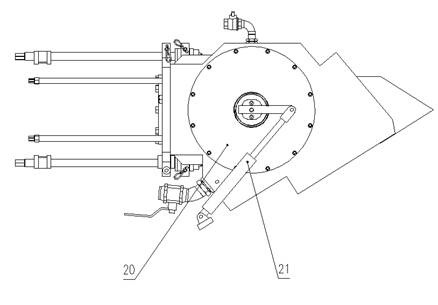

Tool pan back-loading type device for changing tool of slurry-balanced shield machine under normal pressure

The invention relates to a tool pan back-loading type device for changing a tool of a slurry-balanced shield machine under normal pressure, which is applied to the technical field of shield machine engineering machinery. The tool pan back-loading type device for changing the tool of the slurry-balanced shield machine under normal pressure comprises a tool bit, a first seal ring, a tool post, a tool bit fixing sleeve, a tool bit fixing bolt, a tool bar, a cylindrical gate, a grease injection valve, a flushing valve, a third seal ring, a fourth seal ring, a bearing, a large end cover, an oil cylinder and the like; when the tool is in the working state, the tool bit is fixed on the tool bar through the tool bit fixing sleeve and the tool bit fixing bolt; the first seal ring is mounted at thefront end of the tool bar, and the tool bar is matched with the front end of the tool post and is sealed through the first seal ring; the tool bar is fixed on the tool post by the rear end of the tool bar and the tool post through a first fixing screw; the cylindrical gate is fixed on the tool post through the bearing and the large end cover; the grease injection valve and the flushing valve are installed on the tool post; and a serial number is arranged between the cylindrical gate and the tool post. The tool pan back-loading type device for changing the tool of the slurry-balanced shield machine under normal pressure has the advantages of simple structure, reliable working, and capability of conveniently and quickly changing a worn tool under normal pressure (atmospheric pressure) in the shield construction process.

Owner:SHENYANG HEAVY MACHINERY GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com