Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1940results about "Grinding wheel securing apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

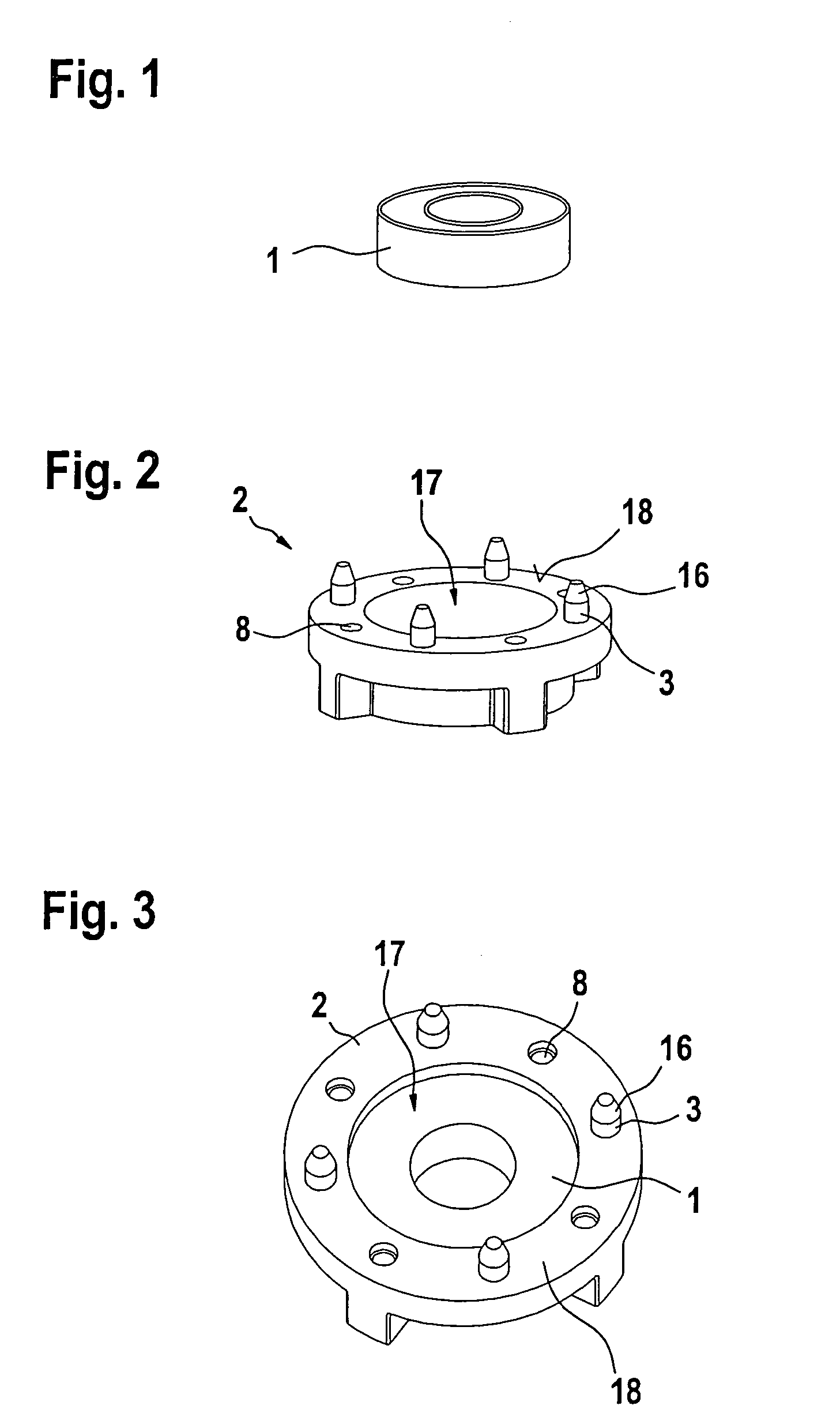

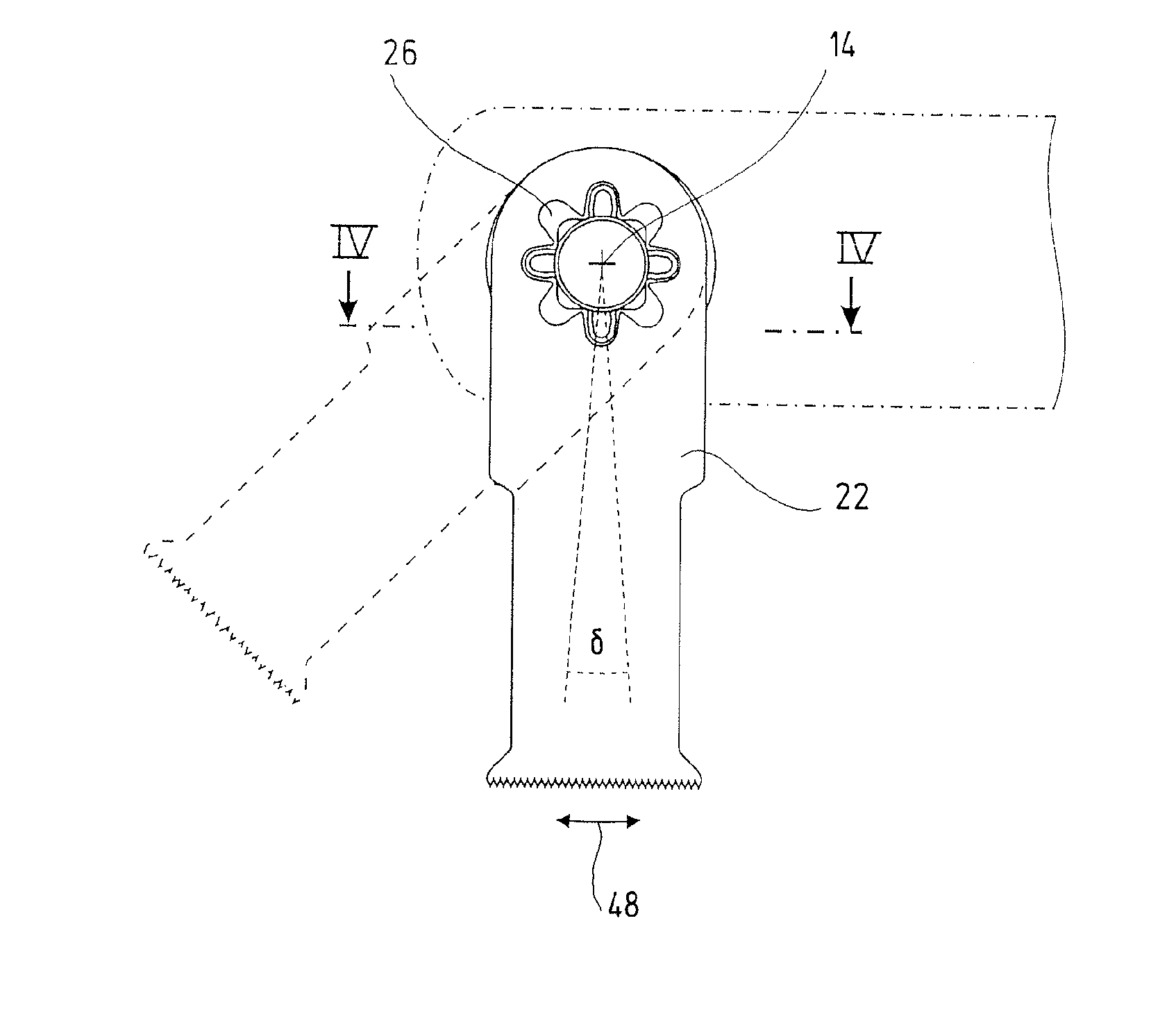

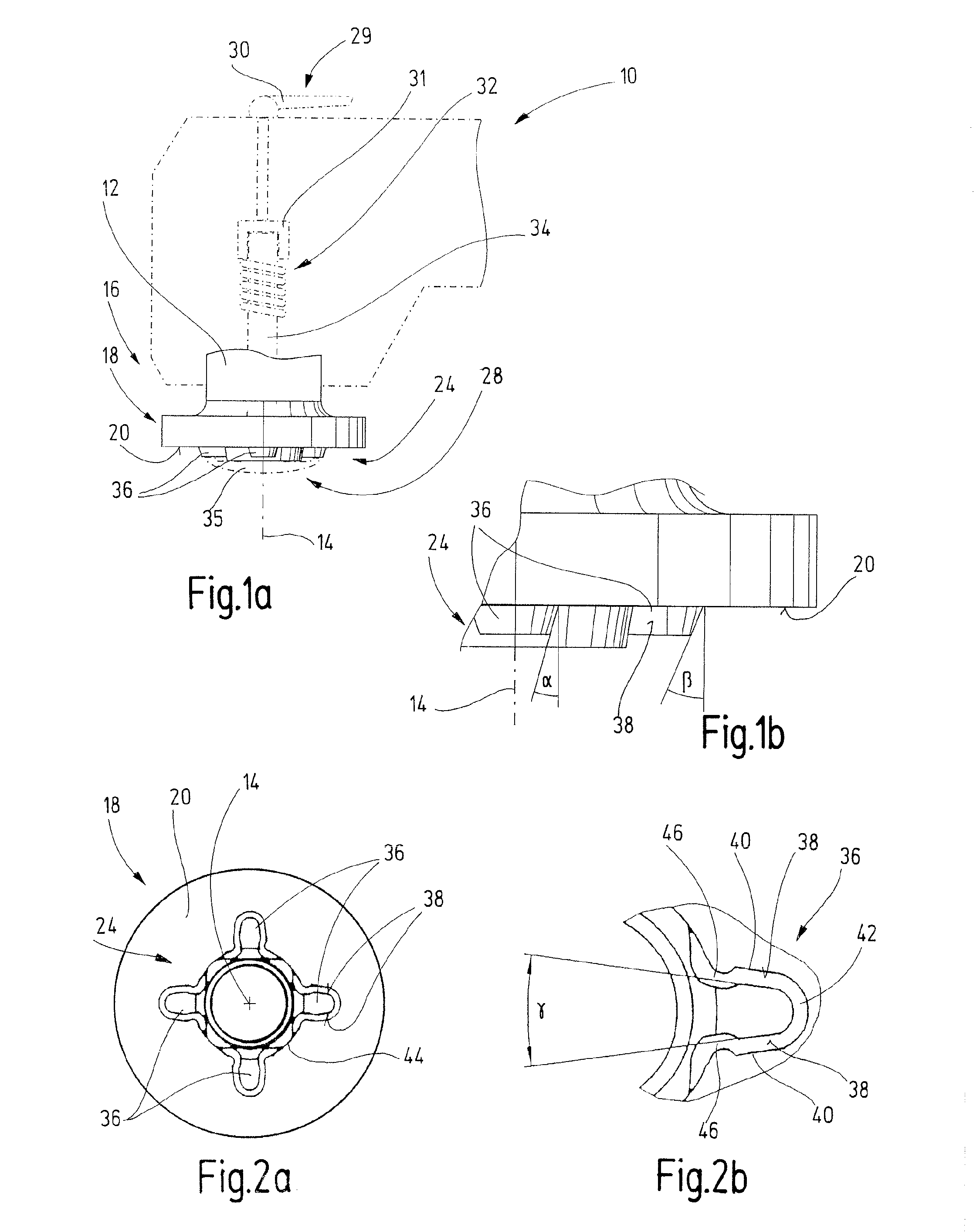

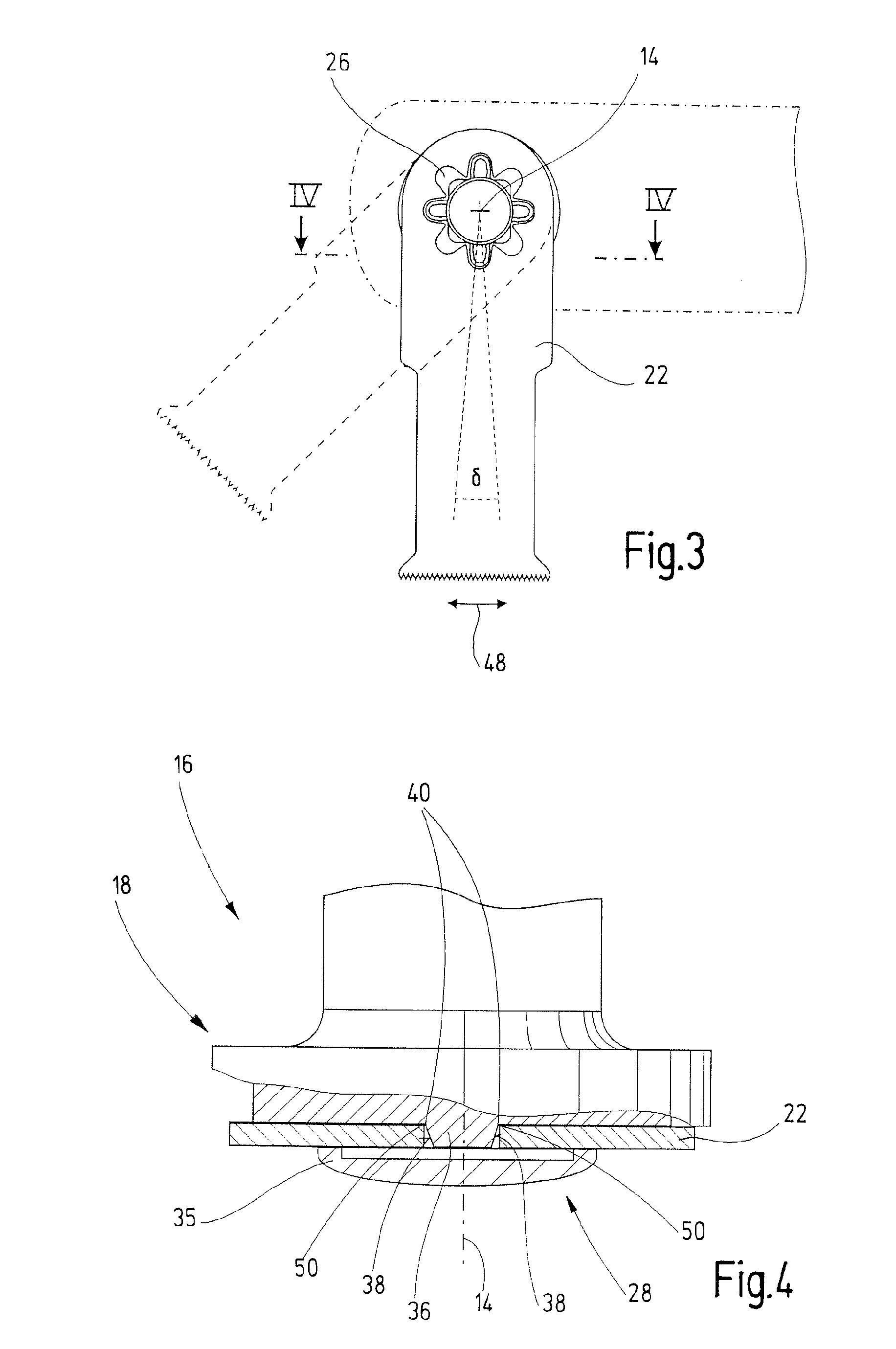

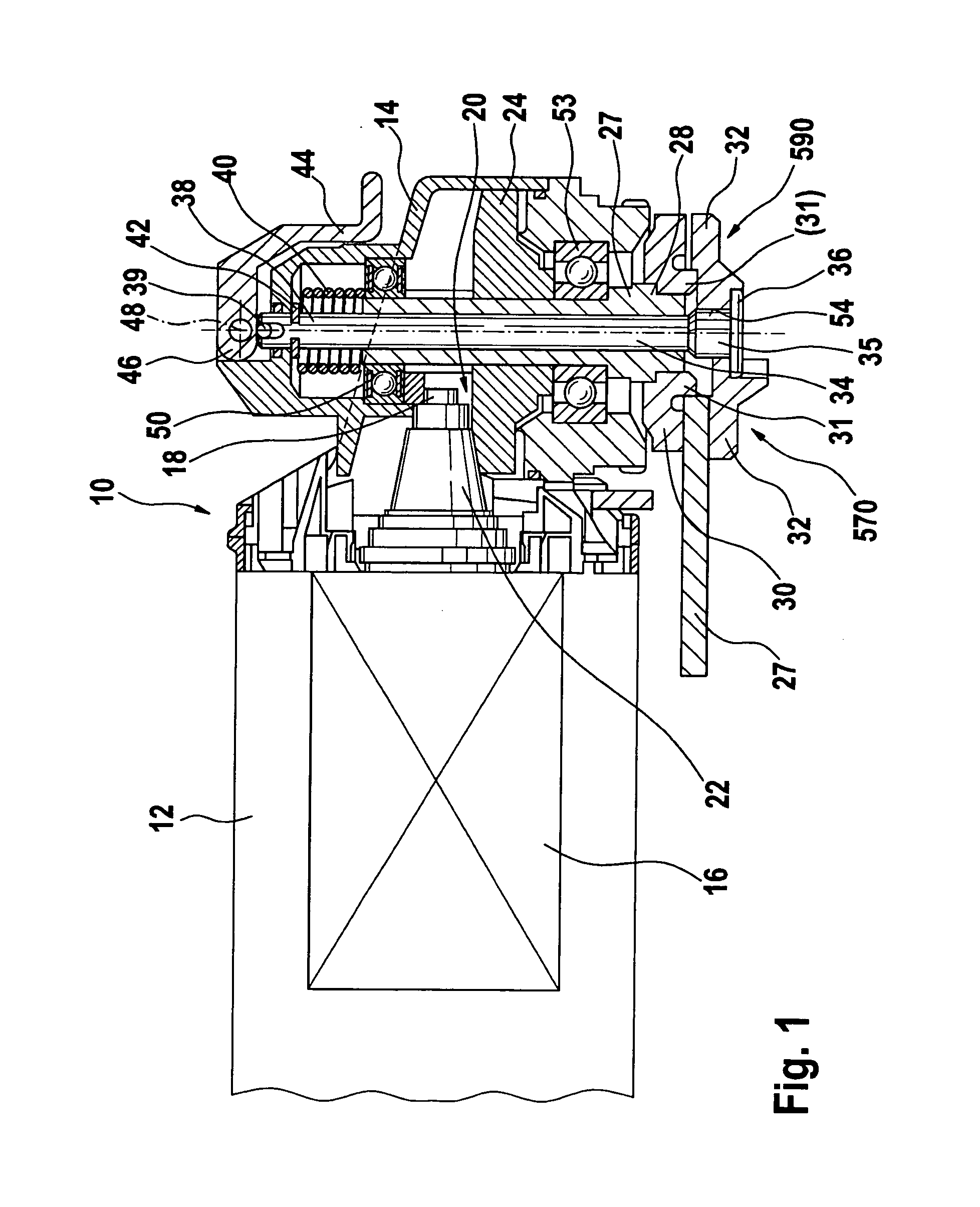

Power tool having a receptacle for securing a tool

InactiveUS6945862B2Reduce riskImprove transmittanceGrinding wheel securing apparatusMetal sawing toolsDrive shaftPower tool

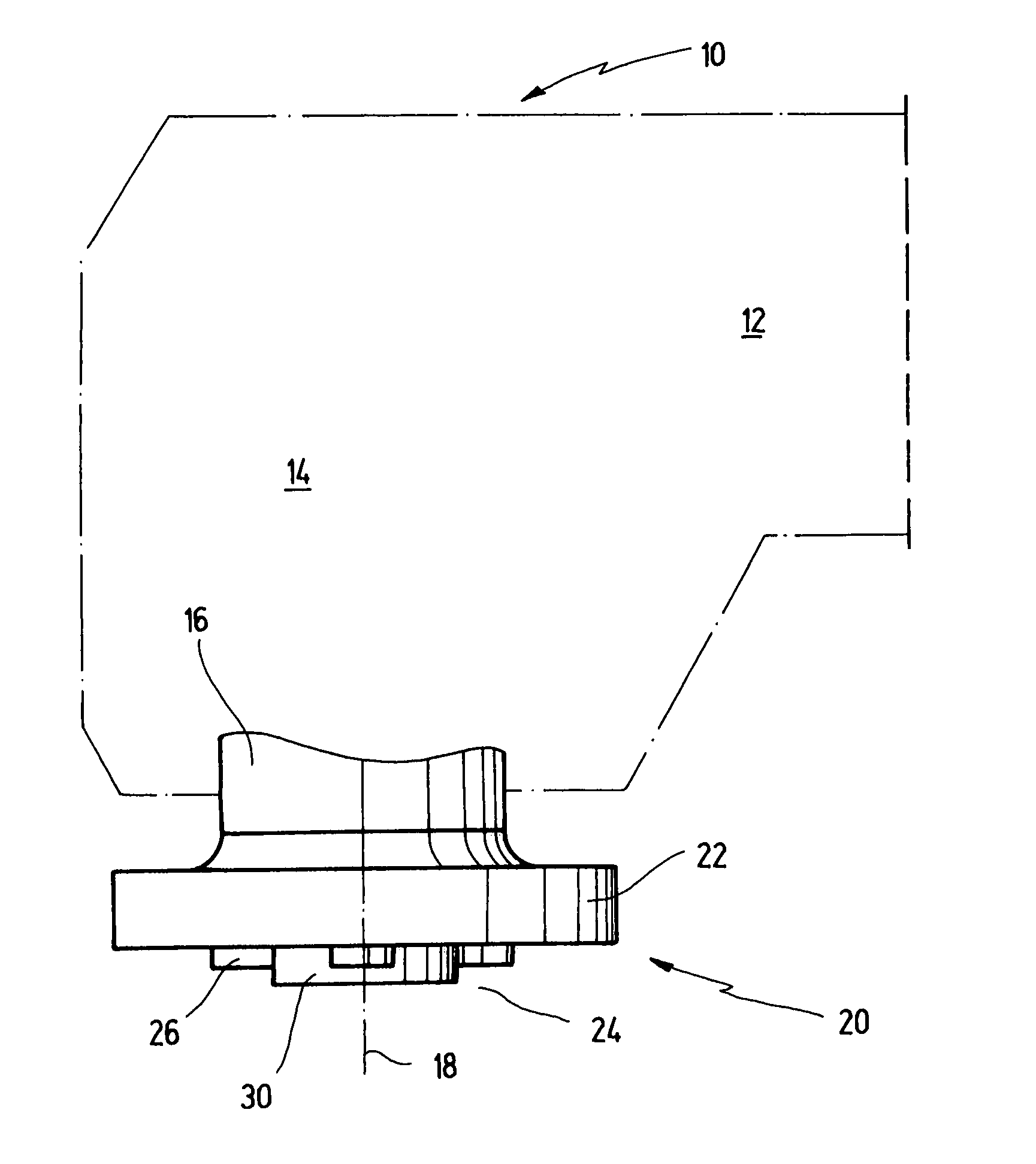

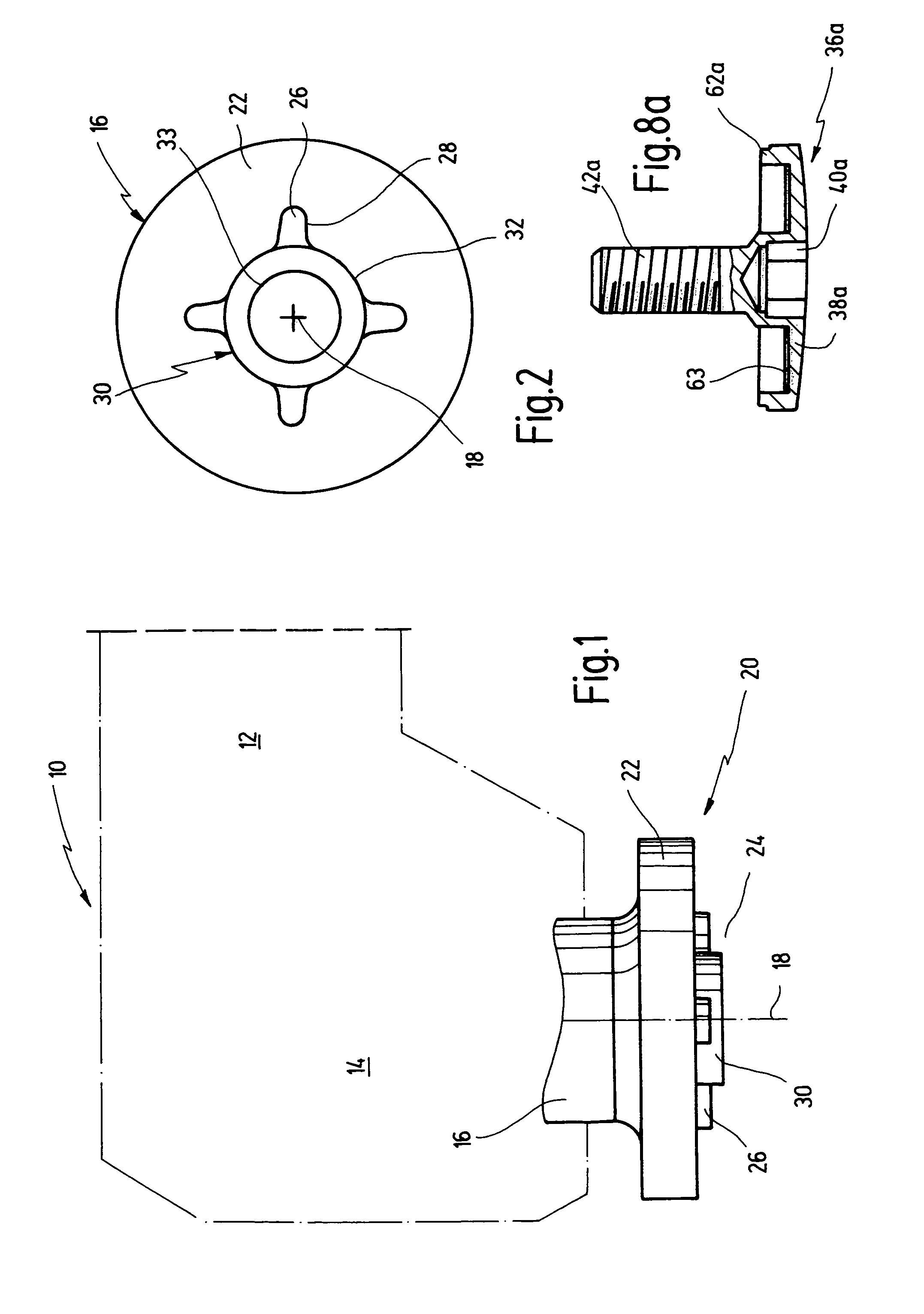

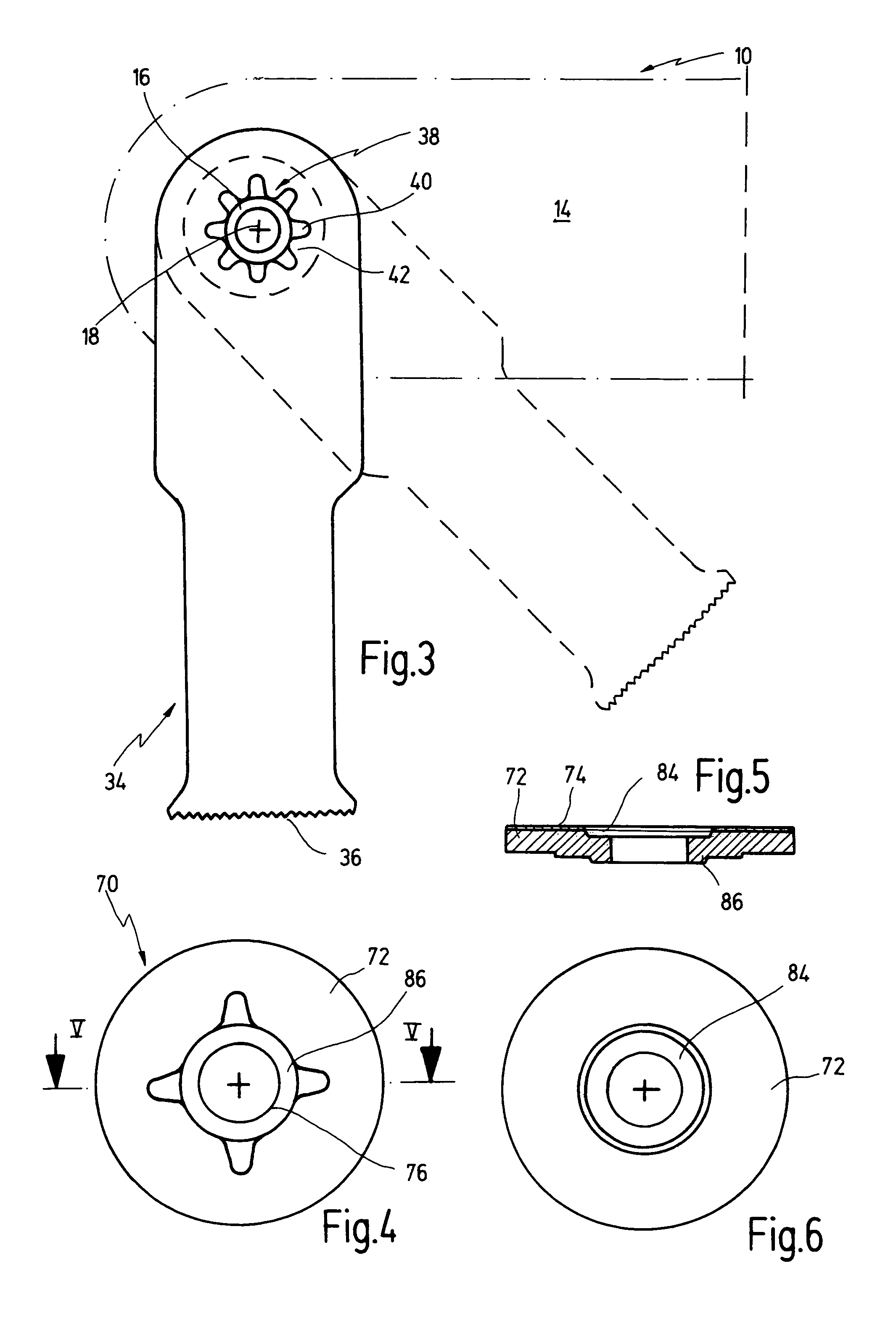

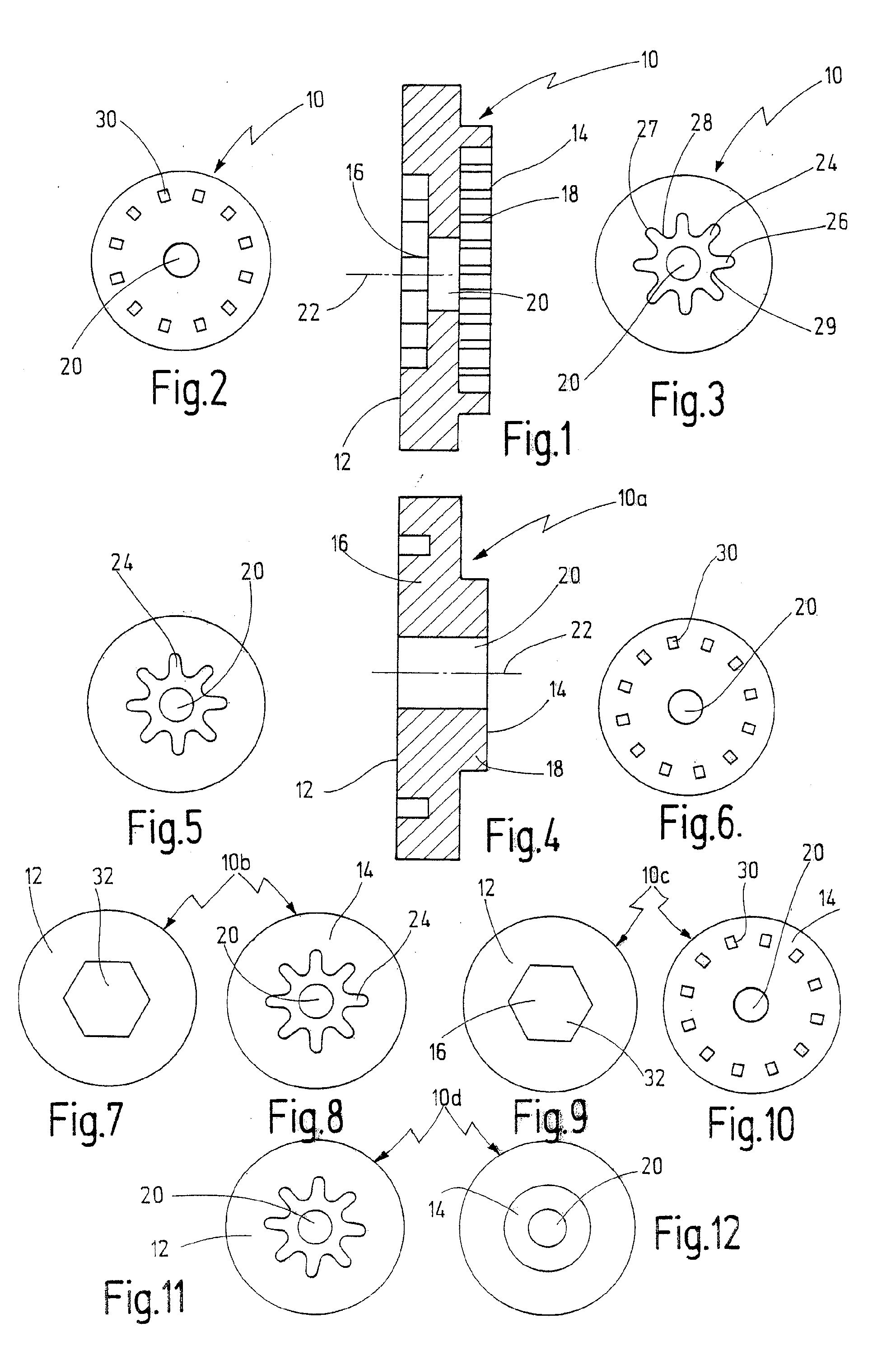

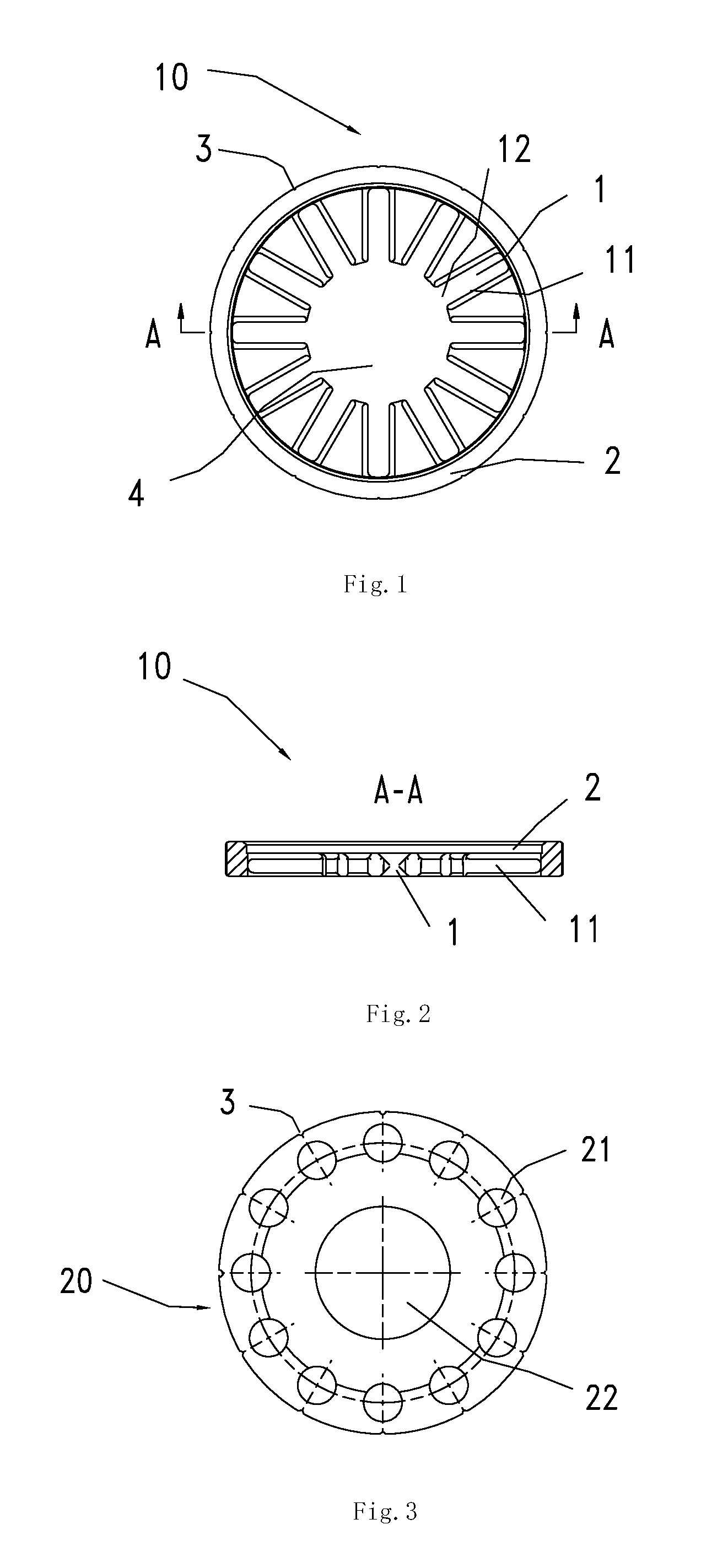

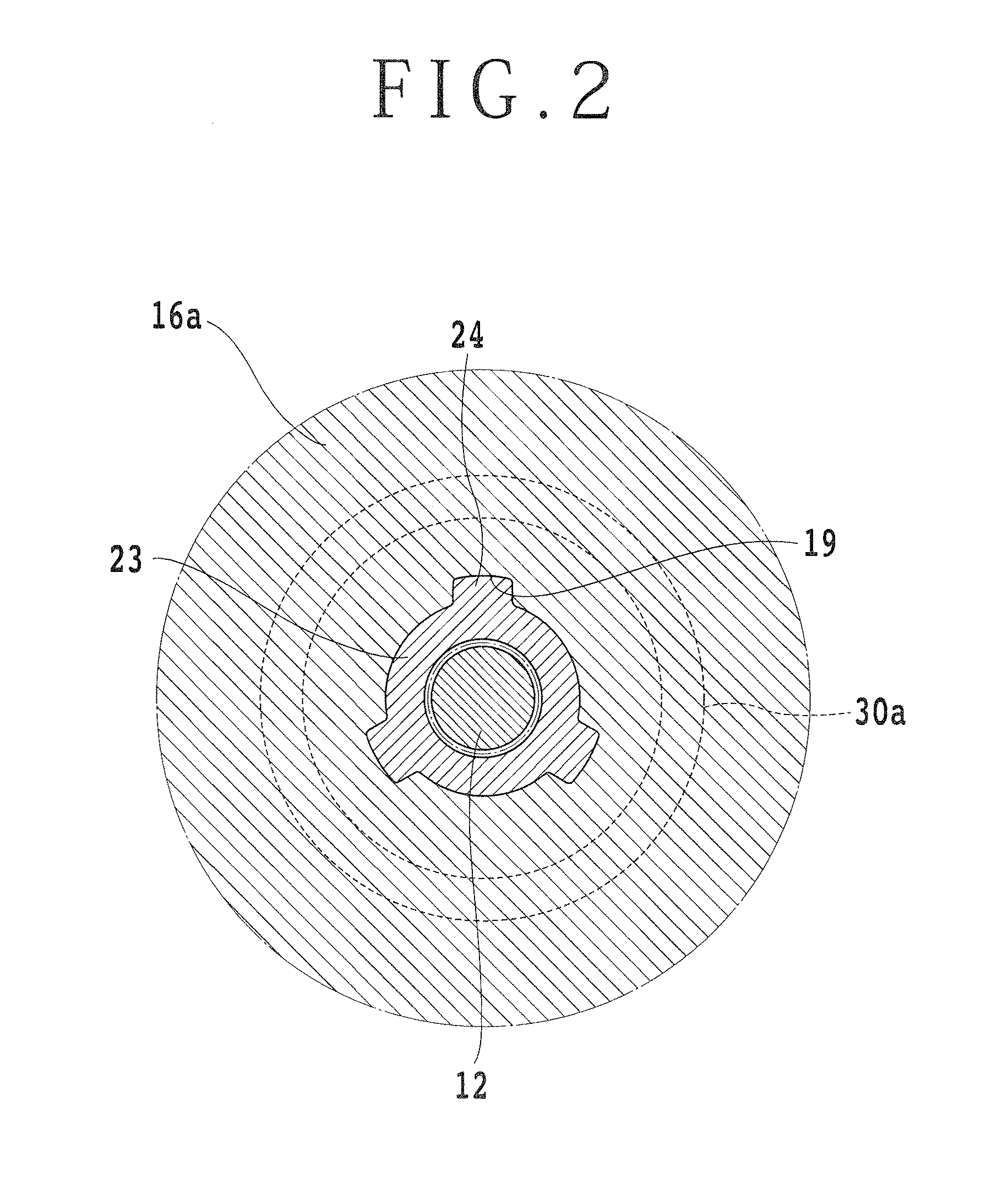

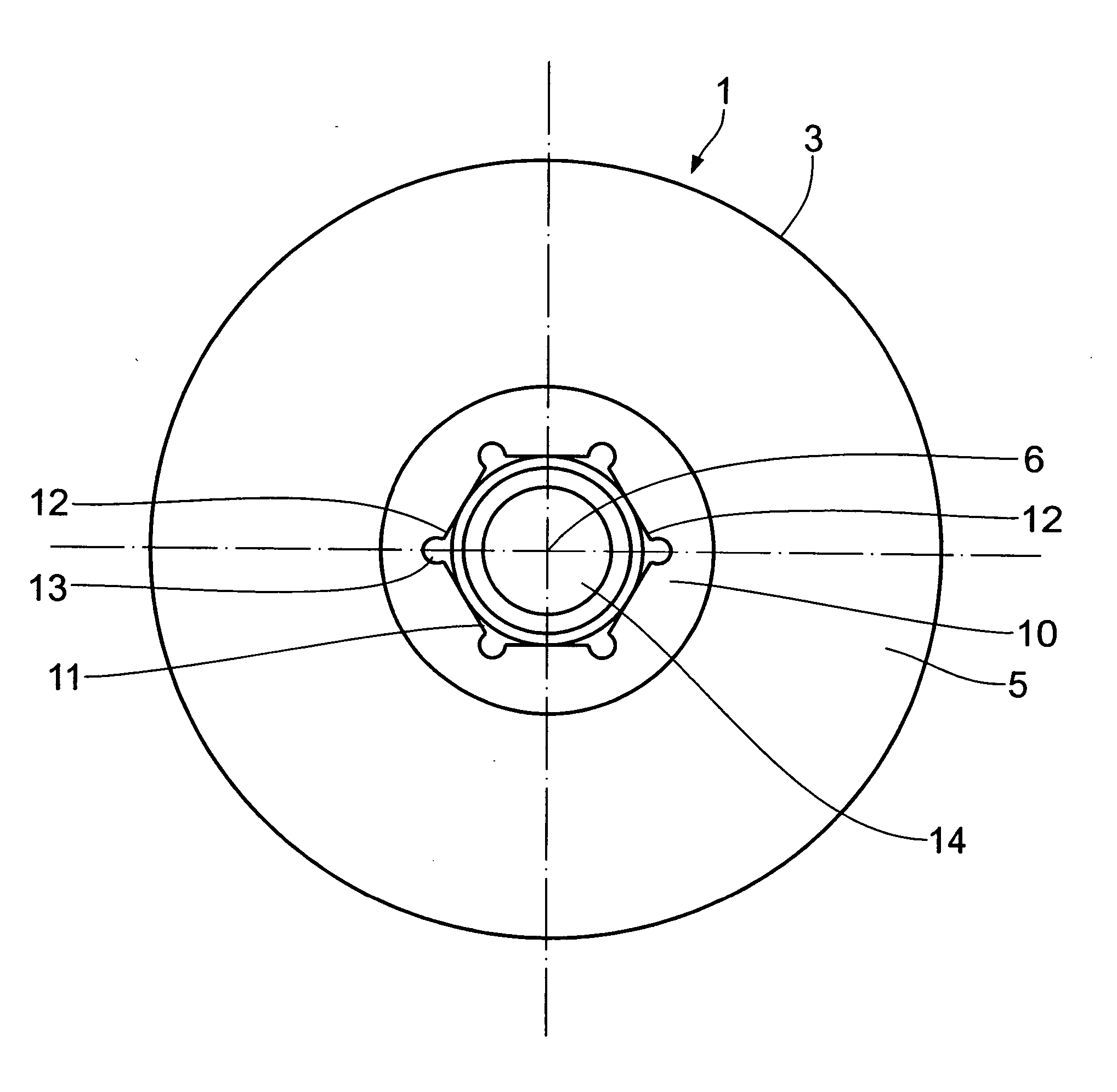

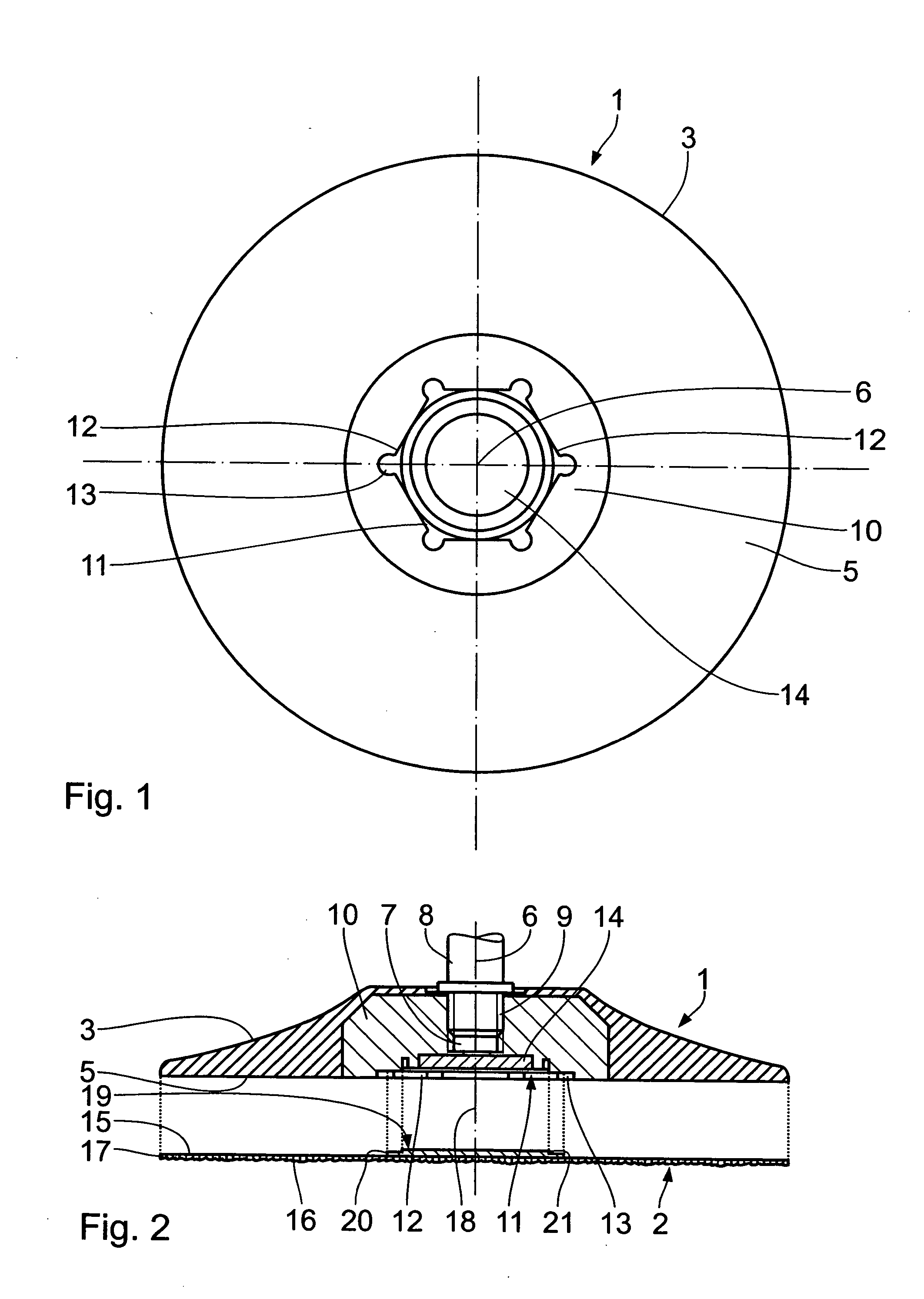

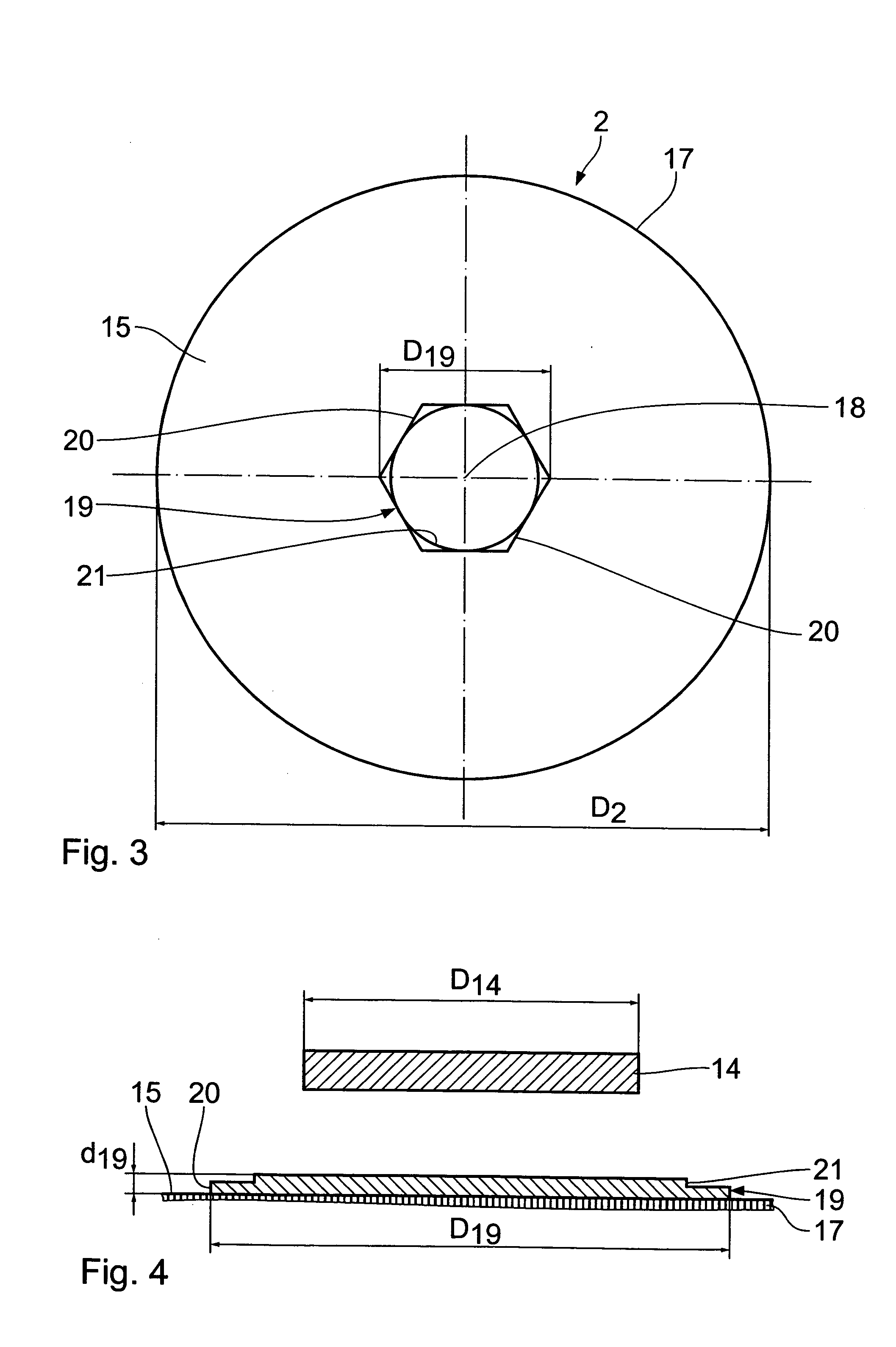

A power tool having a receptacle for securing a tool to a drive shaft thereof is disclosed. The receptacle comprises a receiving opening, preferably being arranged on the tool. The receiving opening engages a securing section preferably being provided in a raised fashion on the drive shaft of the power tool, thereby effecting a positive fit. The securing section comprises a plurality of rounded tips arranged at even radial distances from said longitudinal axis, at angular intervals between each other, each rounded tip having a pair of lateral flanks extending from a common apex toward an intermediate section connecting lateral flanks of a pair of adjacent rounded tips. Preferably the receiving opening comprises a number of rounded tips which is twice the number of rounded tips provided on the raised section.

Owner:C & E FEIN GMBH & CO KG

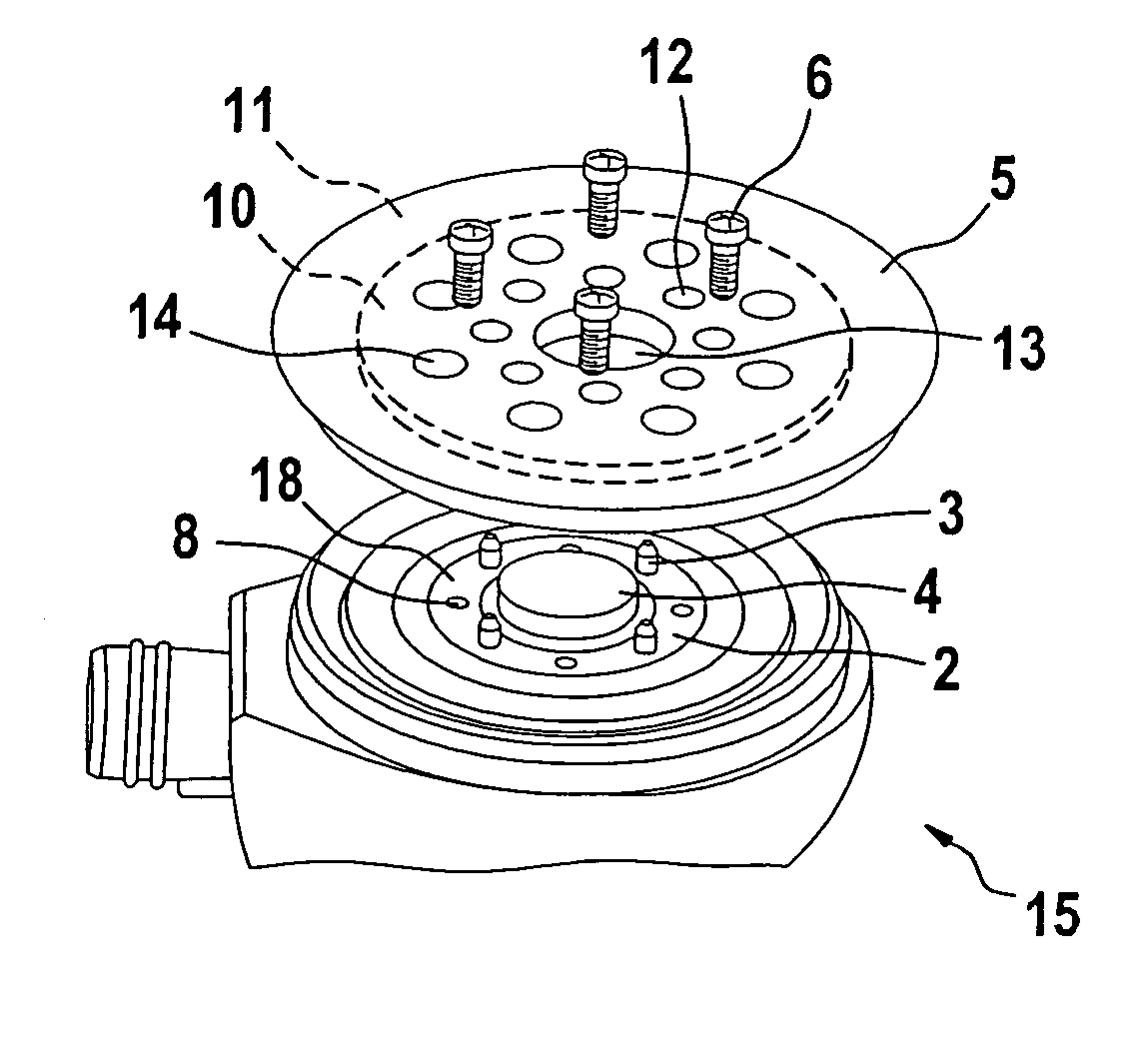

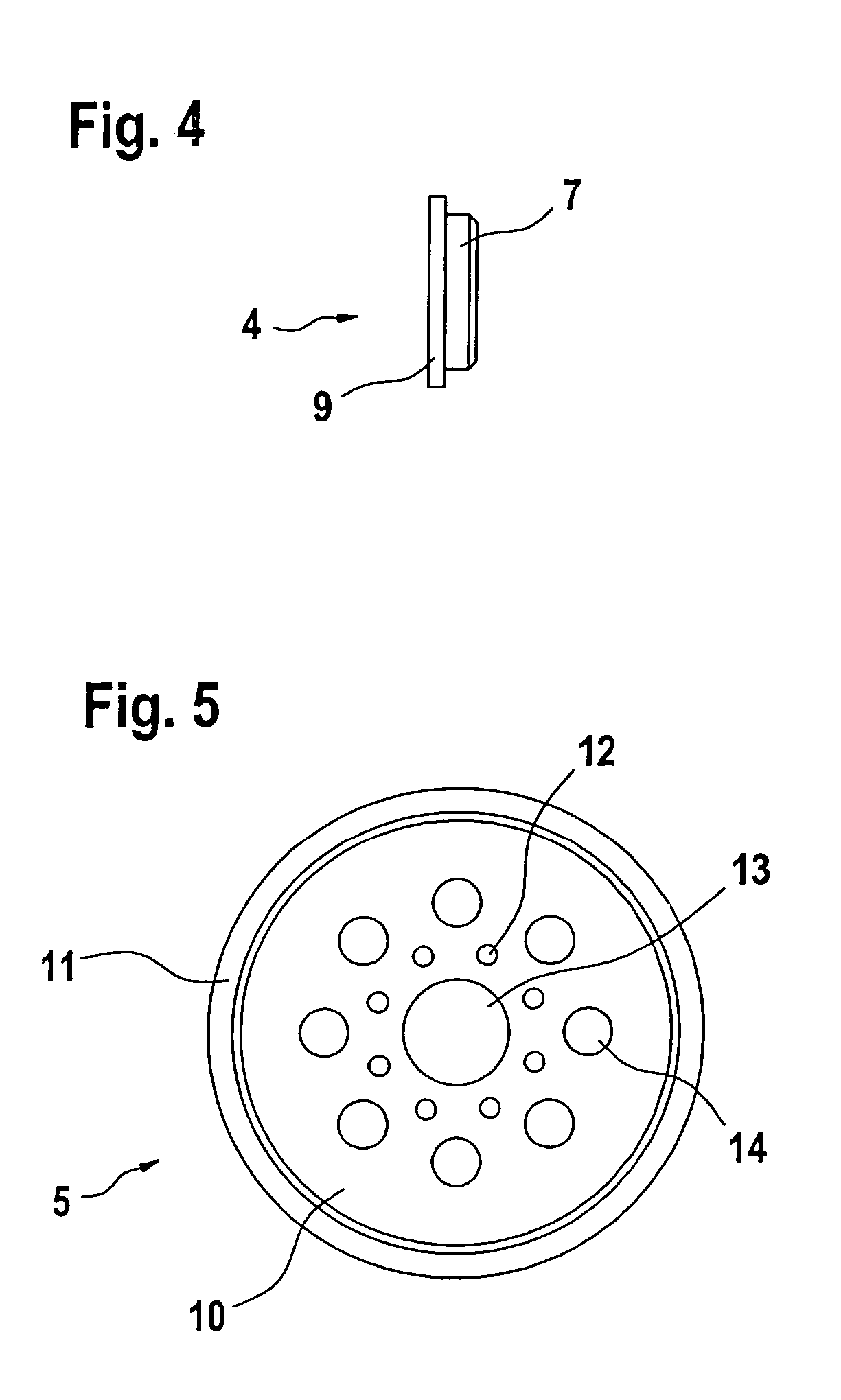

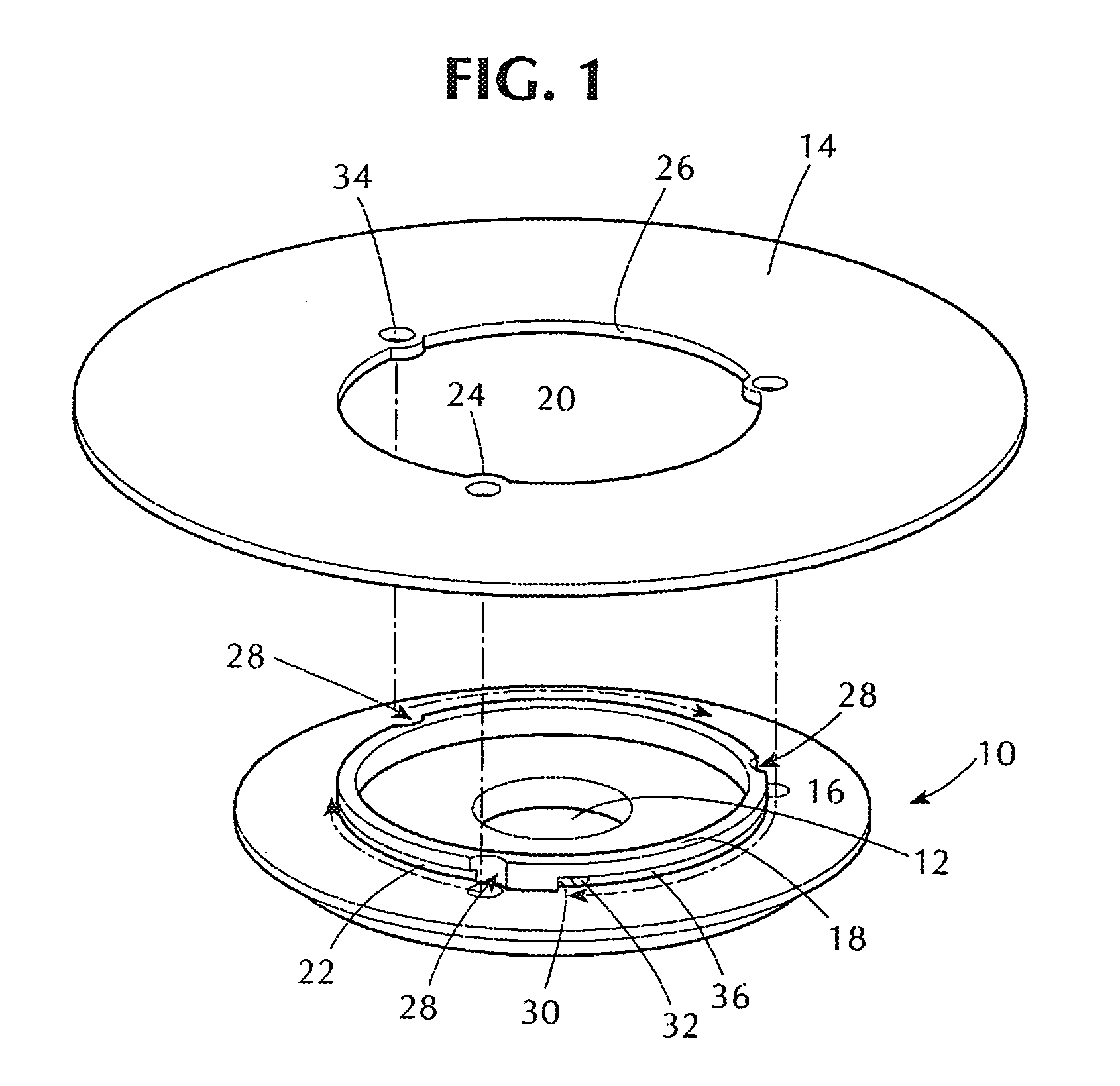

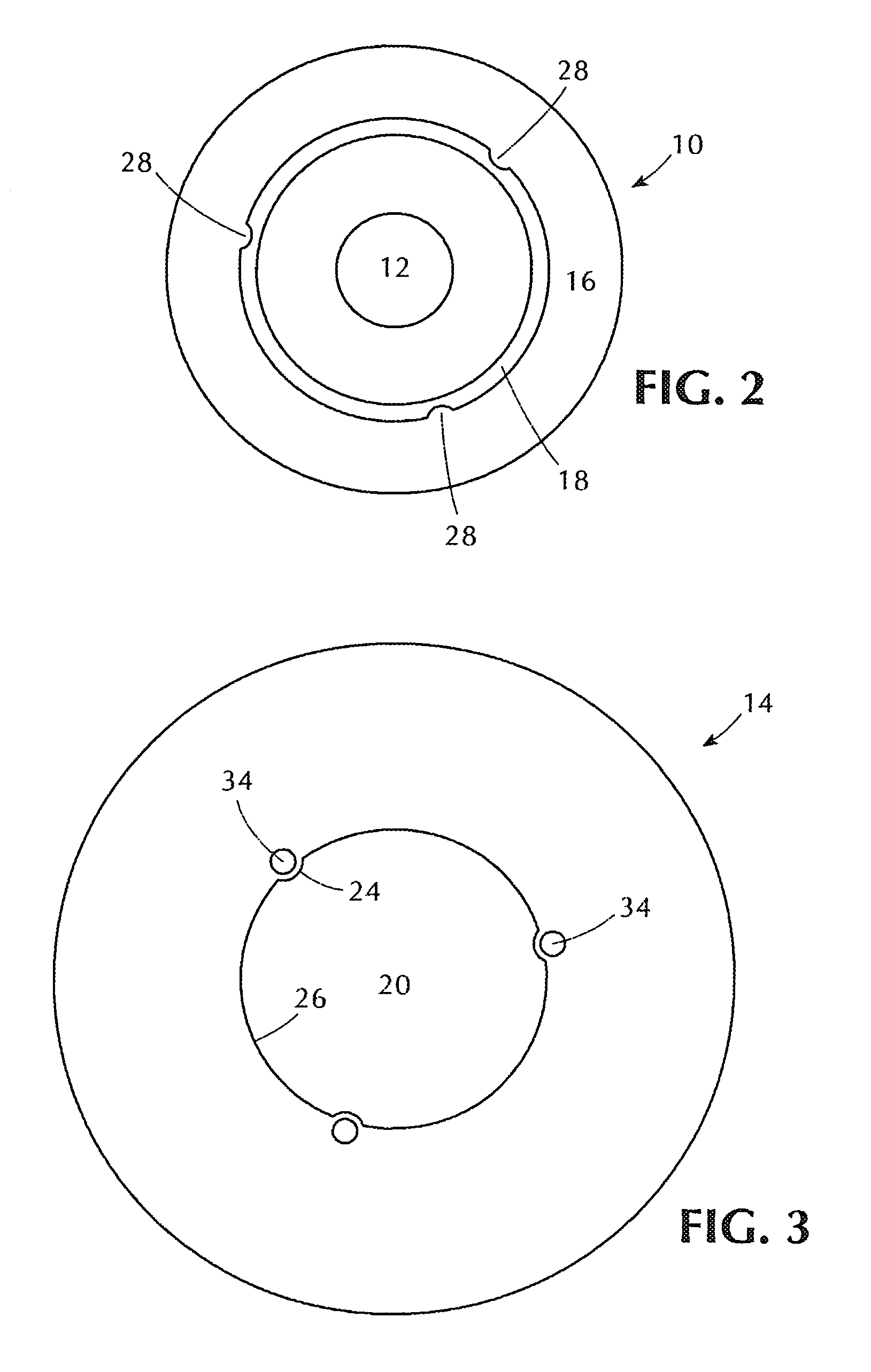

Adapter For Mounting A Tool On An Oscillating Drive

ActiveUS20100056029A1Reduce tool typesLow costGrinding wheel securing apparatusGrinding drivesMating connectionDrive shaft

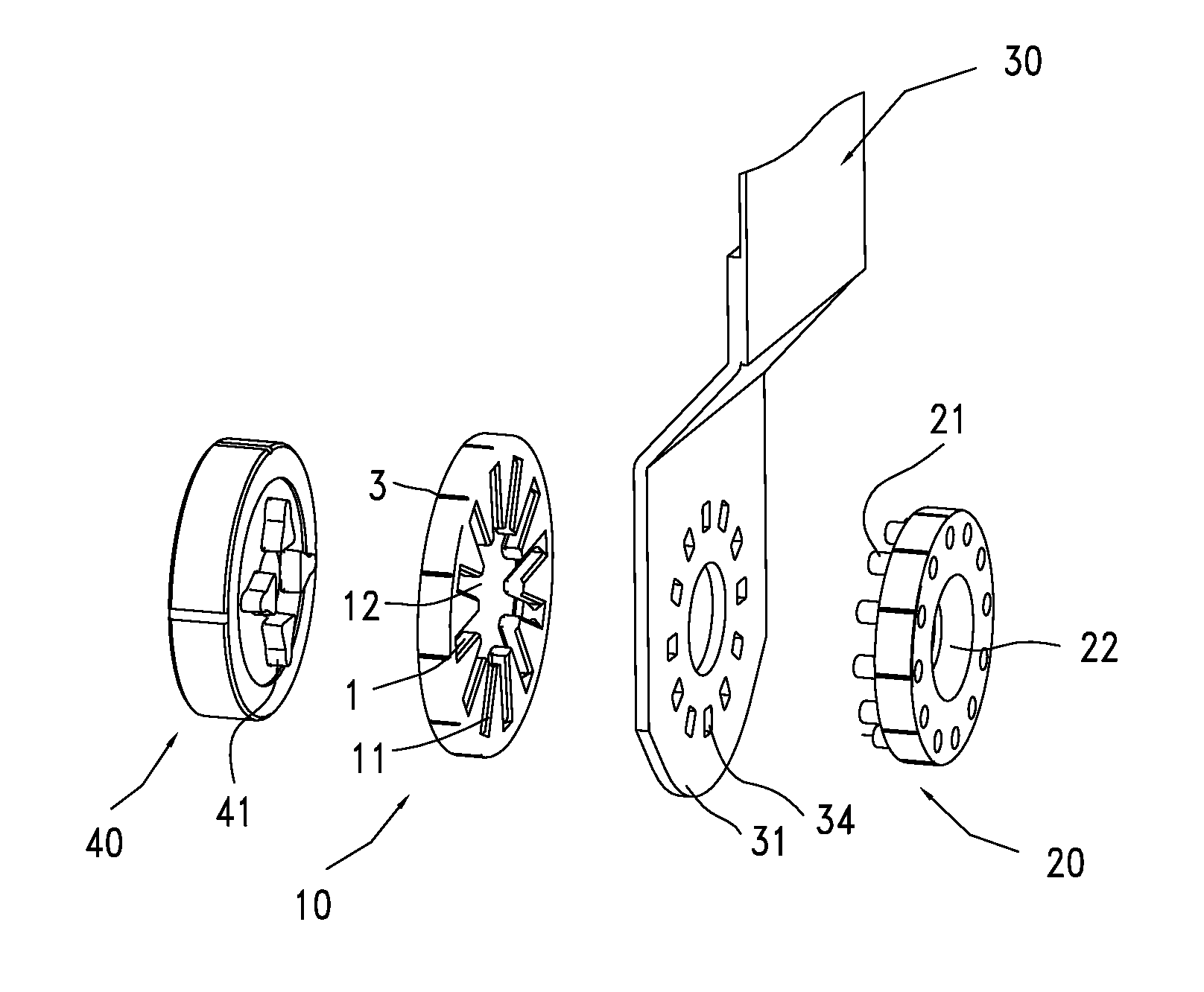

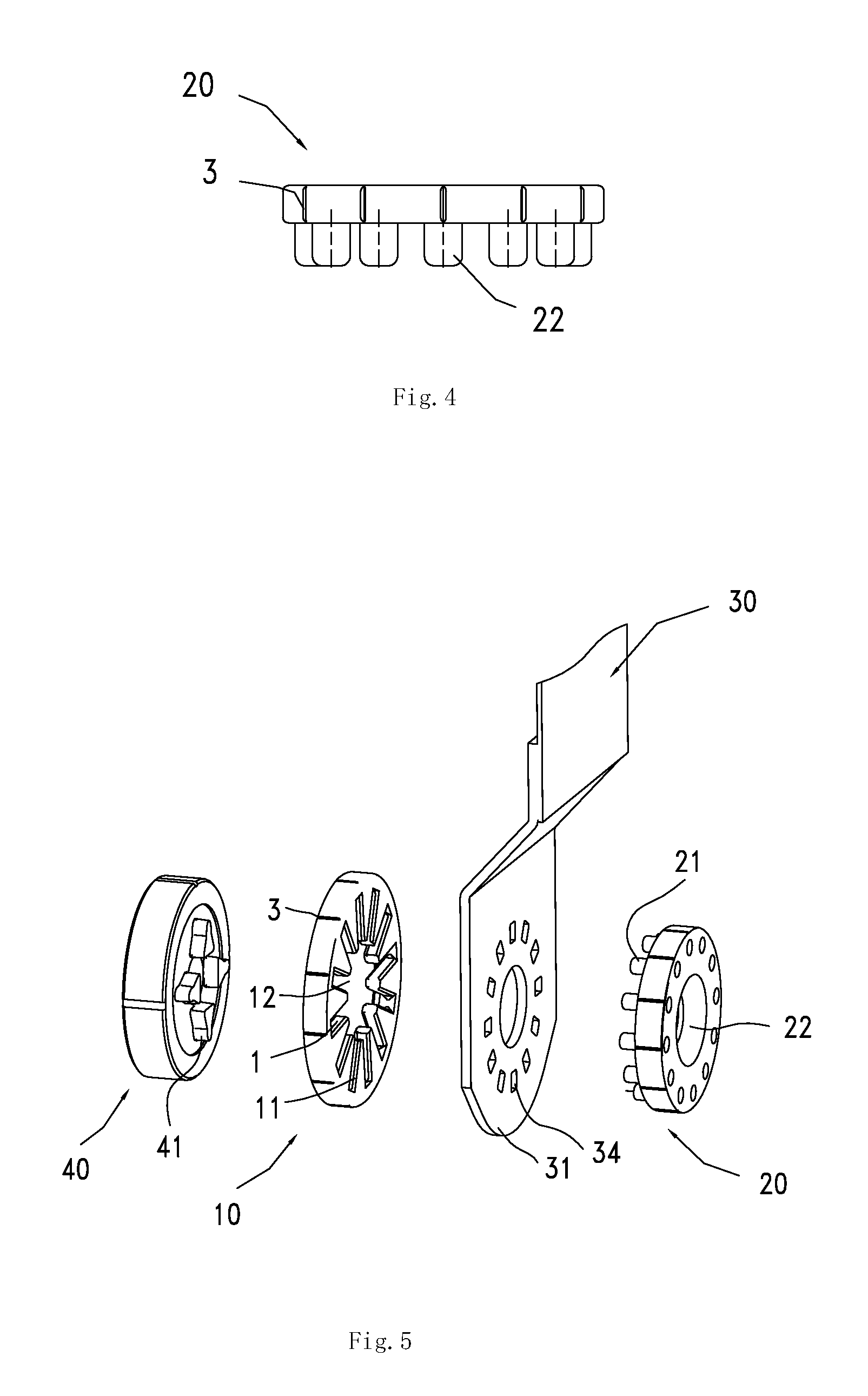

An adapter is disclosed for mounting a tool on an oscillating drive having a drive shaft that can be driven to oscillate about its longitudinal axis, wherein the adapter is passed by a central opening, and has at its drive end at least one positive-locking element for positive connection with the tool, the positive-locking element having the shape of a regular polygon, or a plurality of positive-locking elements arranged on a circle concentric to the center axis, or a plurality of outwardly extending convex projections having rounded tips and being connected with neighboring projections via rounded concave lateral flanks, wherein the positive-locking elements on the drive end are configured for positive-locking connection with a matching positive-locking counter-element on the drive shaft, and wherein the adapter has a second receptacle on its tool end for effecting connection with a tool having a shape different from the first receptacle and being configured as a circle, or as a plurality of positive-locking elements arranged along a circle concentric to the center axis, or as plurality of outwardly extending convex projections with rounded tips and being connected with neighboring projections via rounded concave lateral flanks.

Owner:C & E FEIN GMBH & CO KG

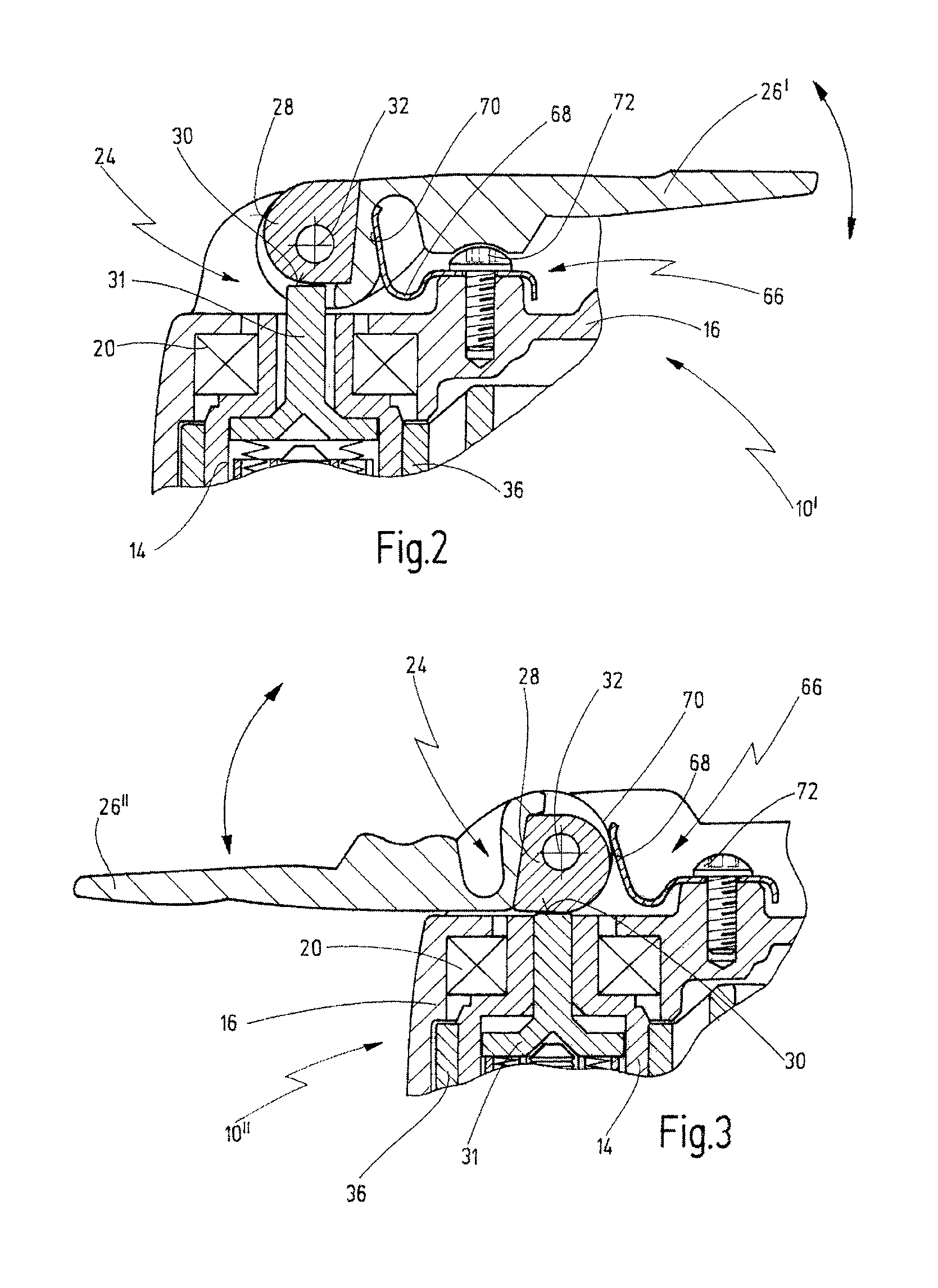

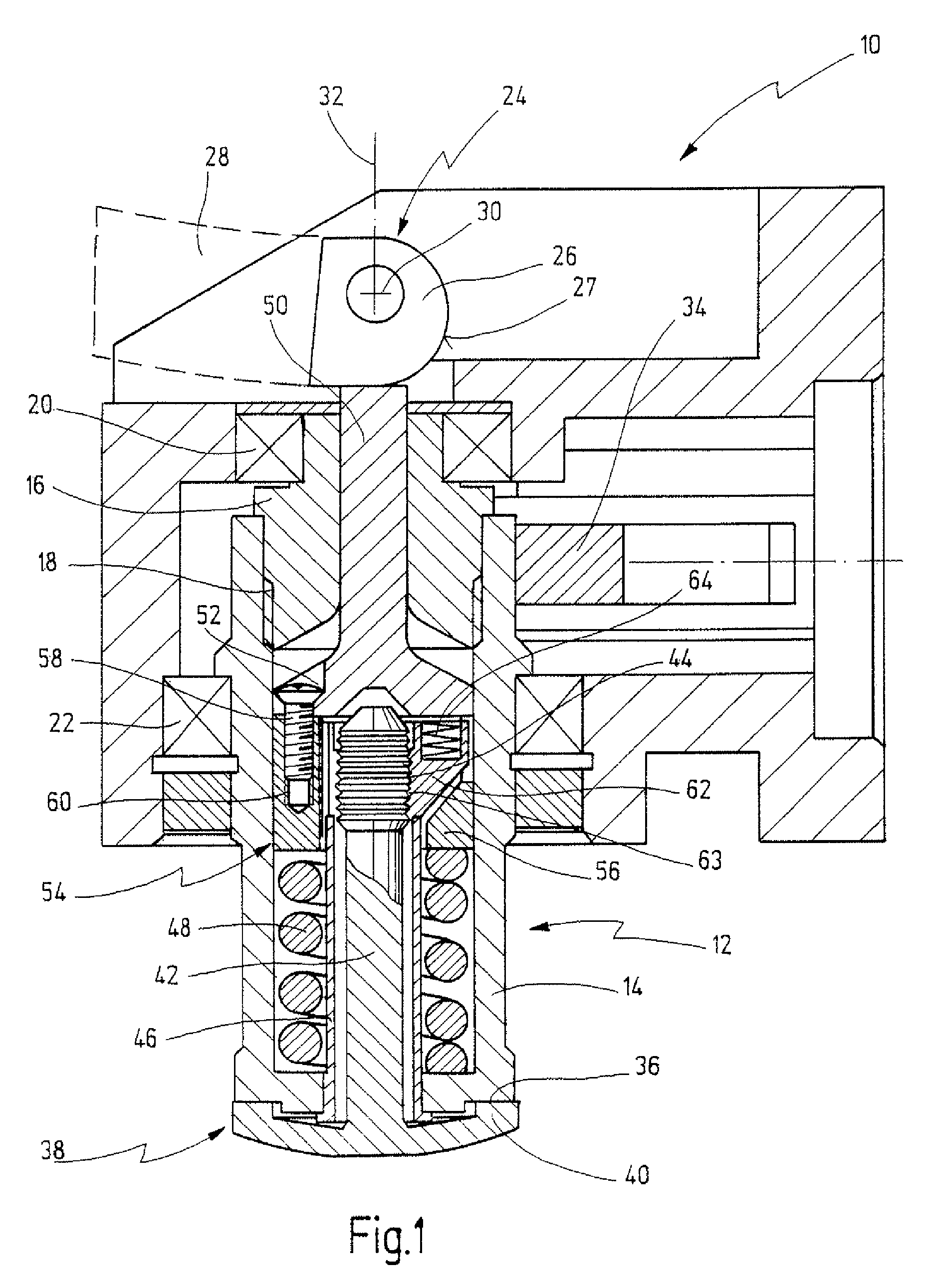

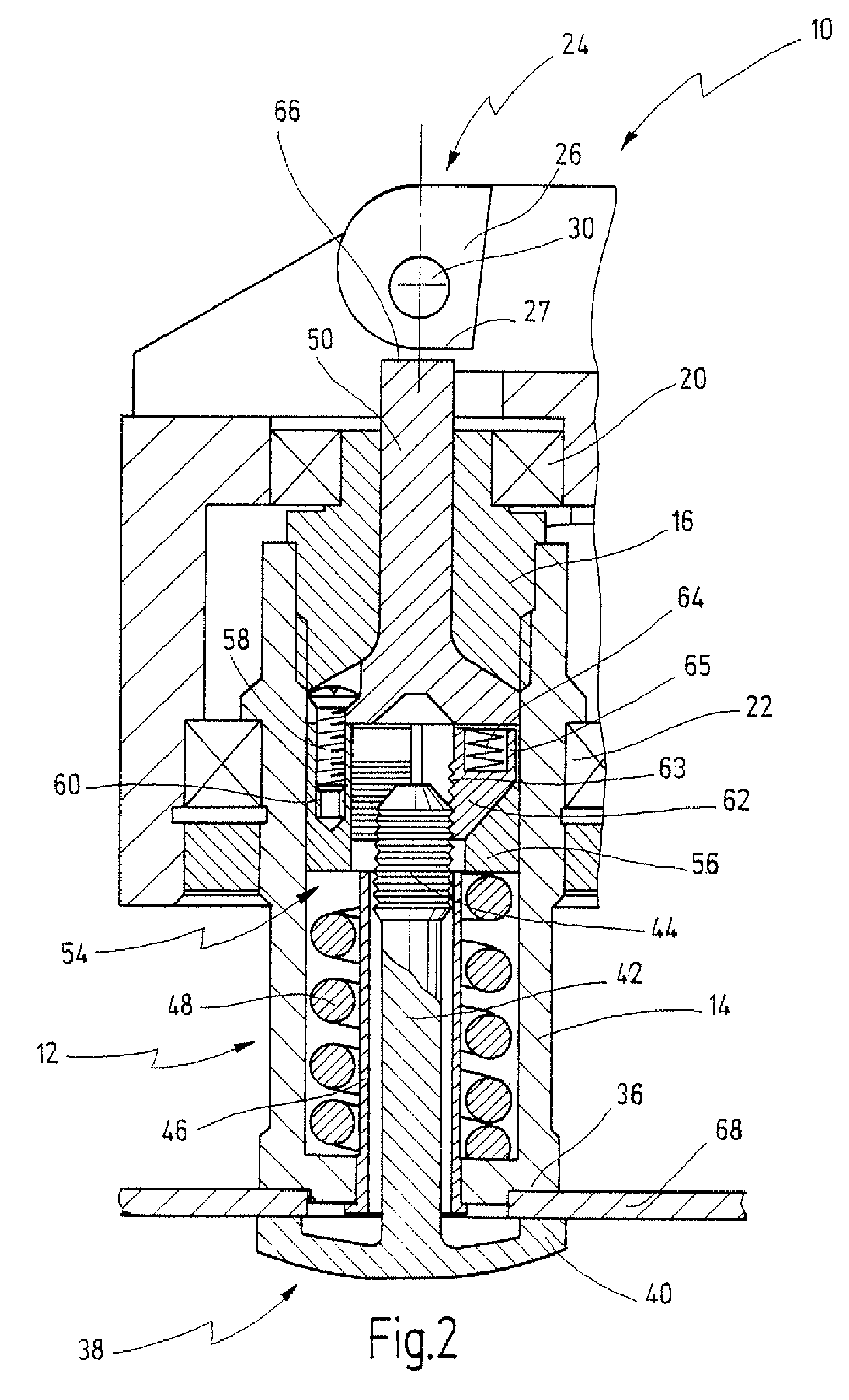

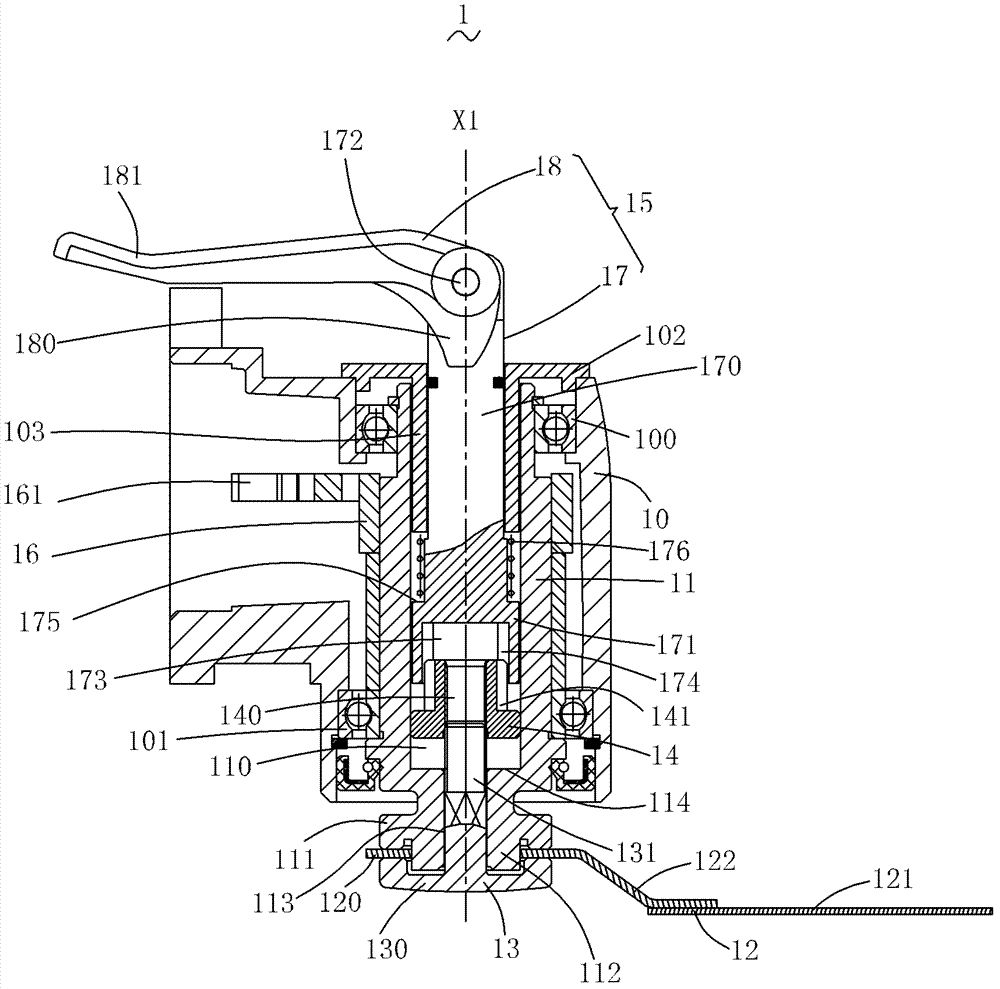

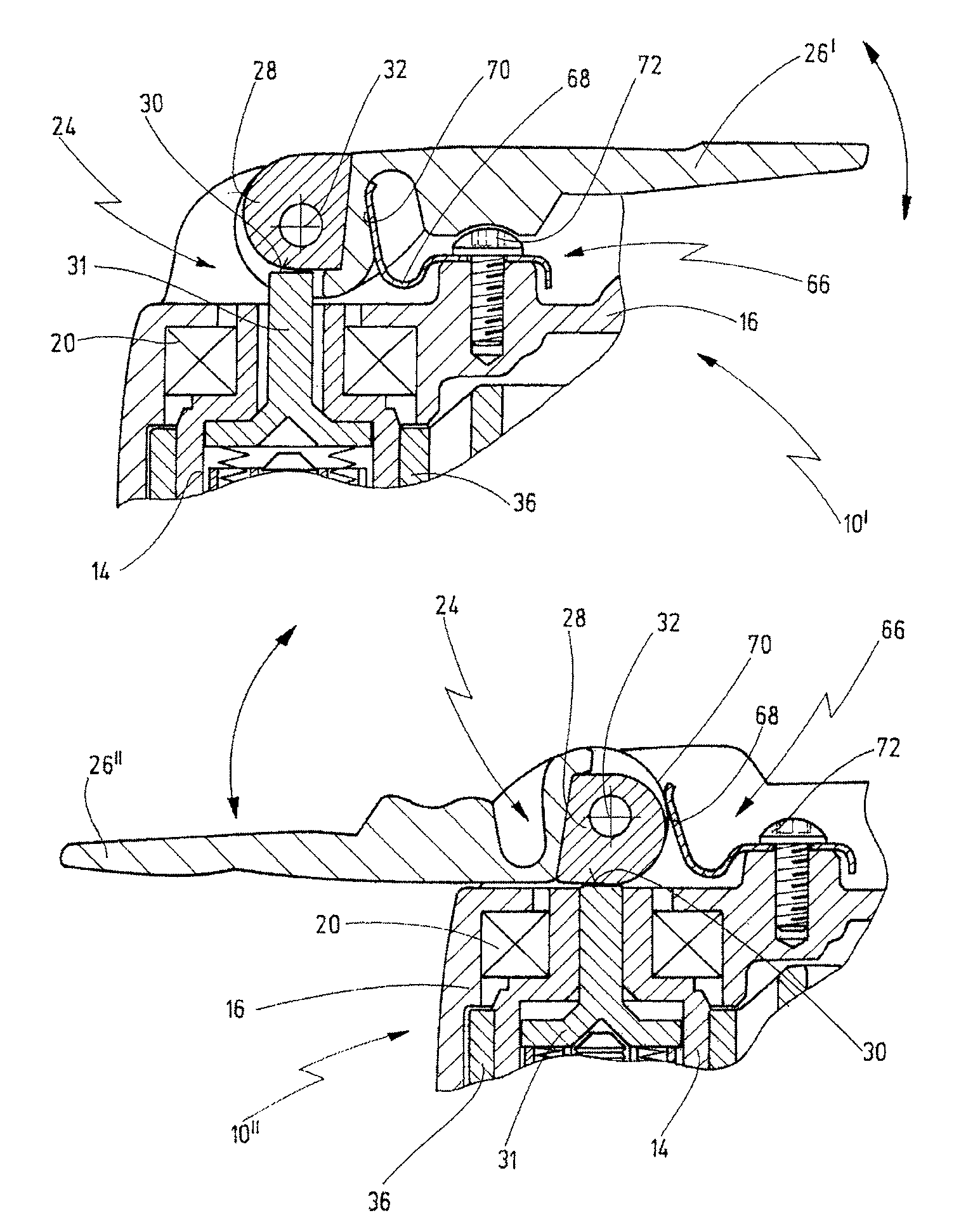

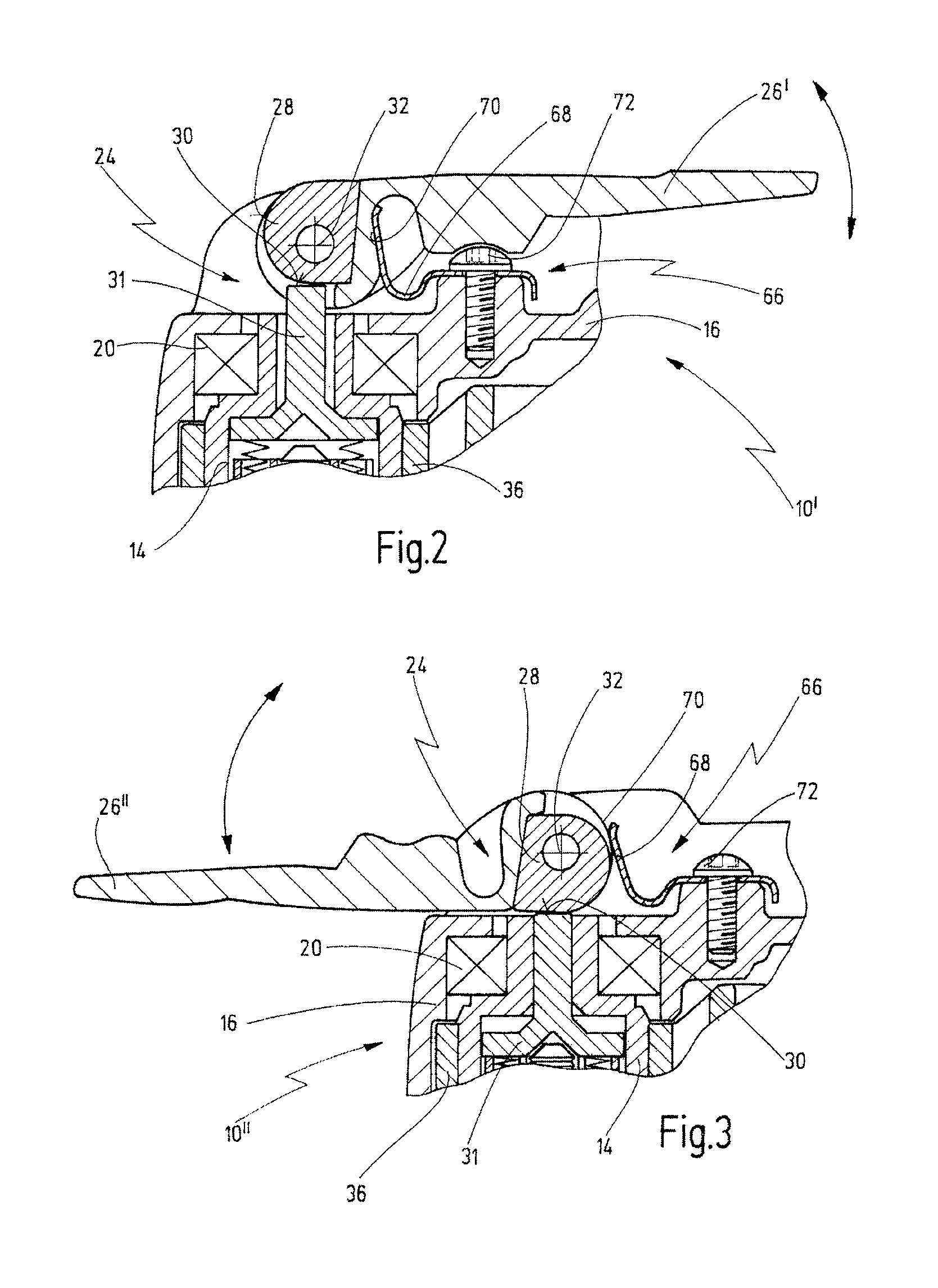

Power-Driven Hand Tool With Clamping Fixture For A Tool

InactiveUS20100197208A1Easy to handleEasy to installGrinding wheel securing apparatusPortable grinding machinesEngineeringHand tool

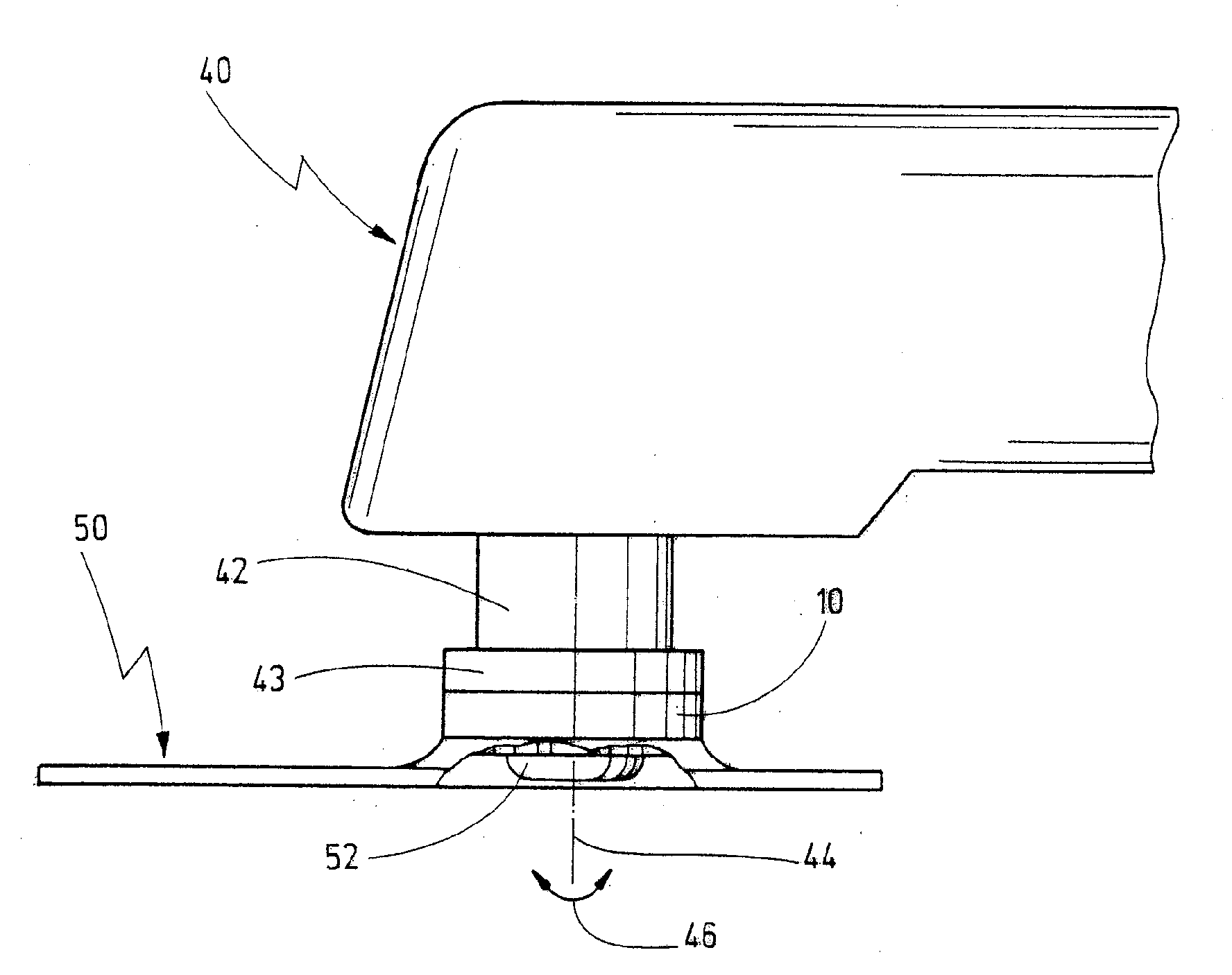

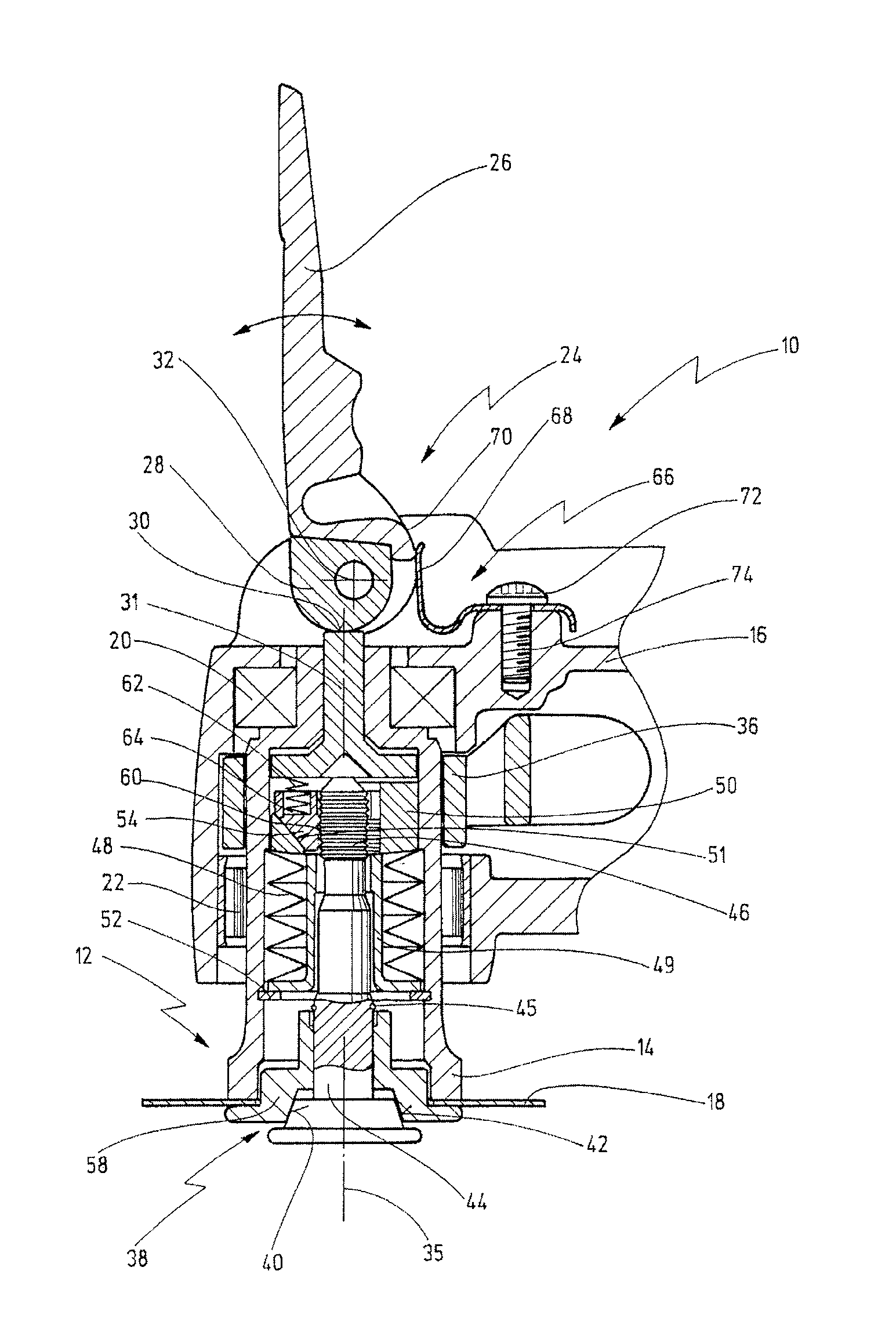

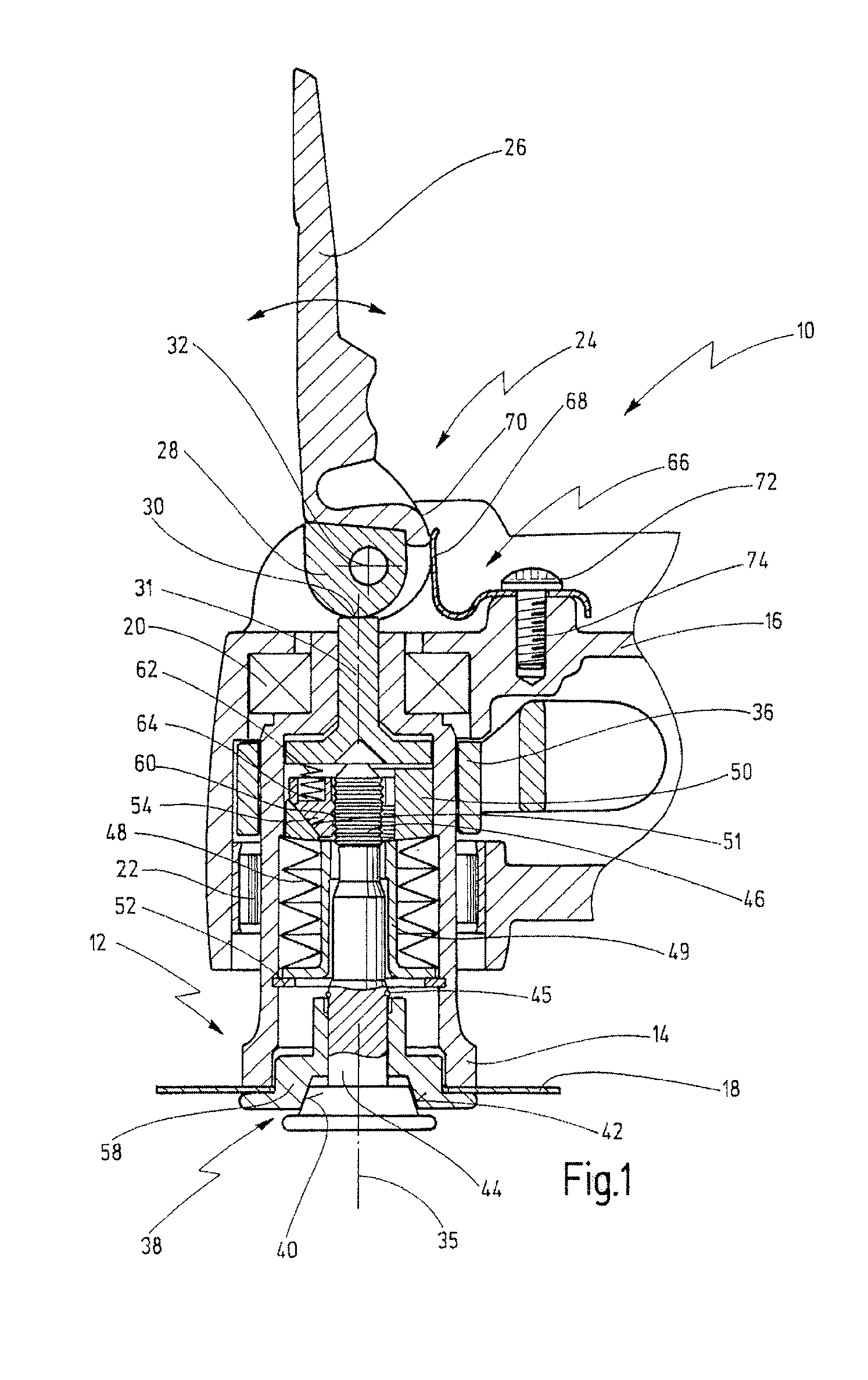

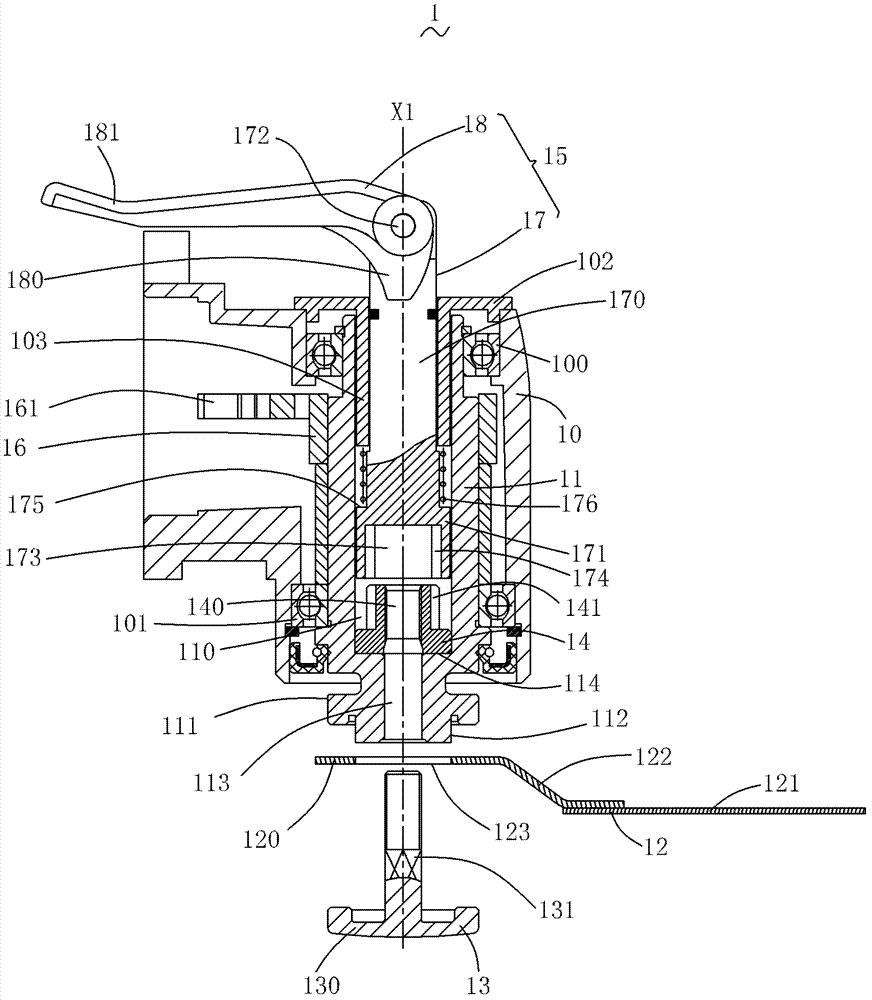

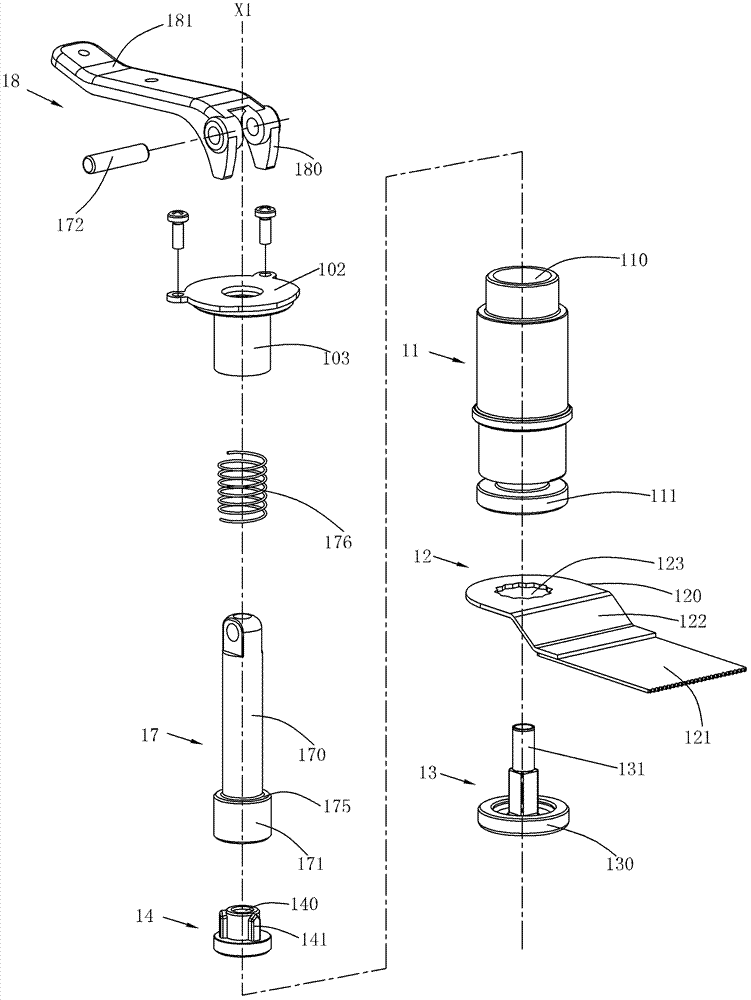

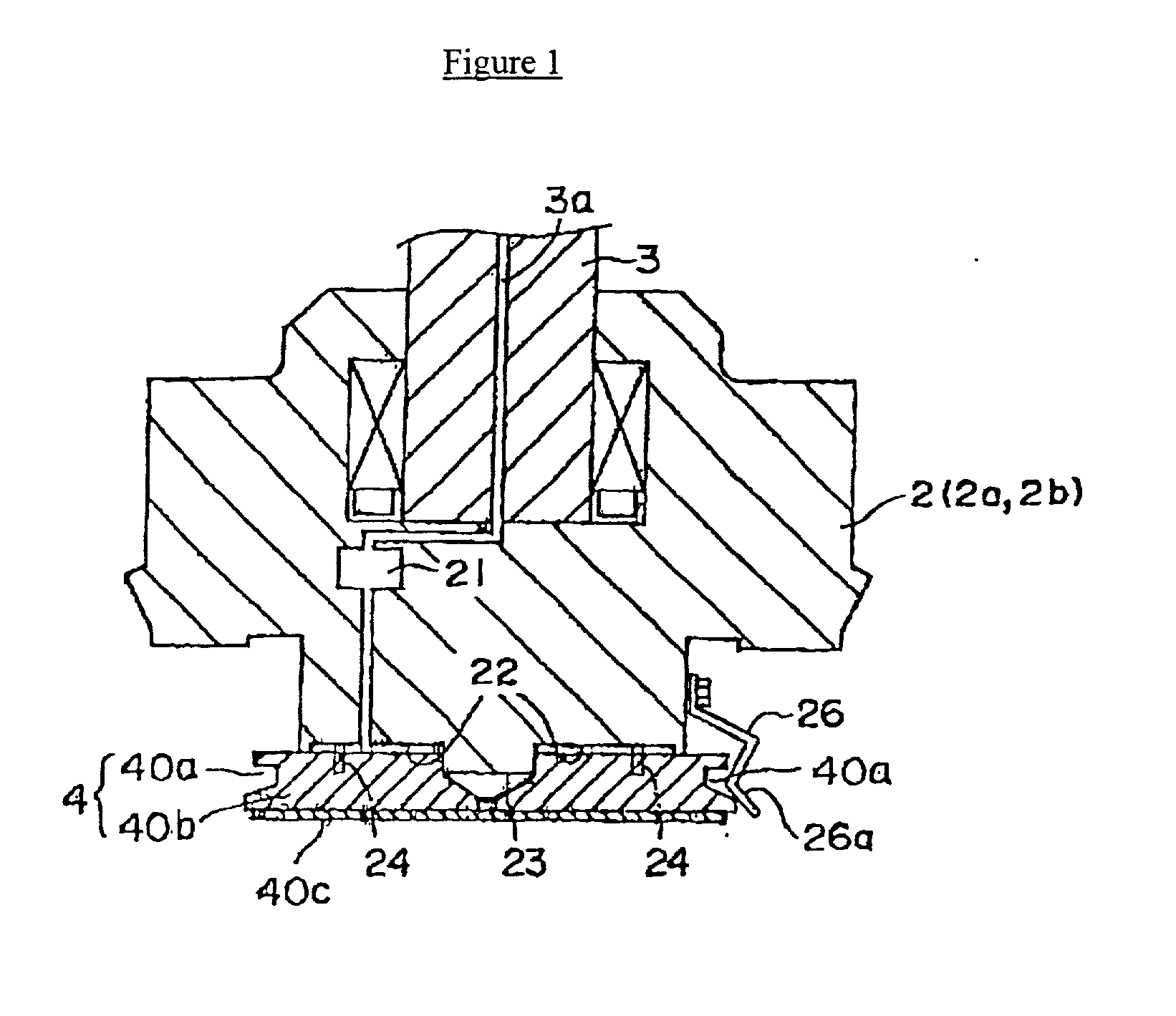

A power-driven hand tool is disclosed comprising a housing, a work spindle for driving a tool, which tool can be located between a tool end of the work spindle and a fixing mechanism, further comprising a displacing mechanism with a clamping lever, adapted to pivot about a pivot axis for displacing the fixing mechanism between a releasing position, in which the fixing mechanism can be released from the work spindle, and a clamping position in which the fixing mechanism is clamped on the work spindle by a spring. An impeding mechanism is provided that interacts with the clamping lever for impeding the pivoting movement of the clamping lever between the releasing position and the clamping position.

Owner:C & E FEIN GMBH & CO KG

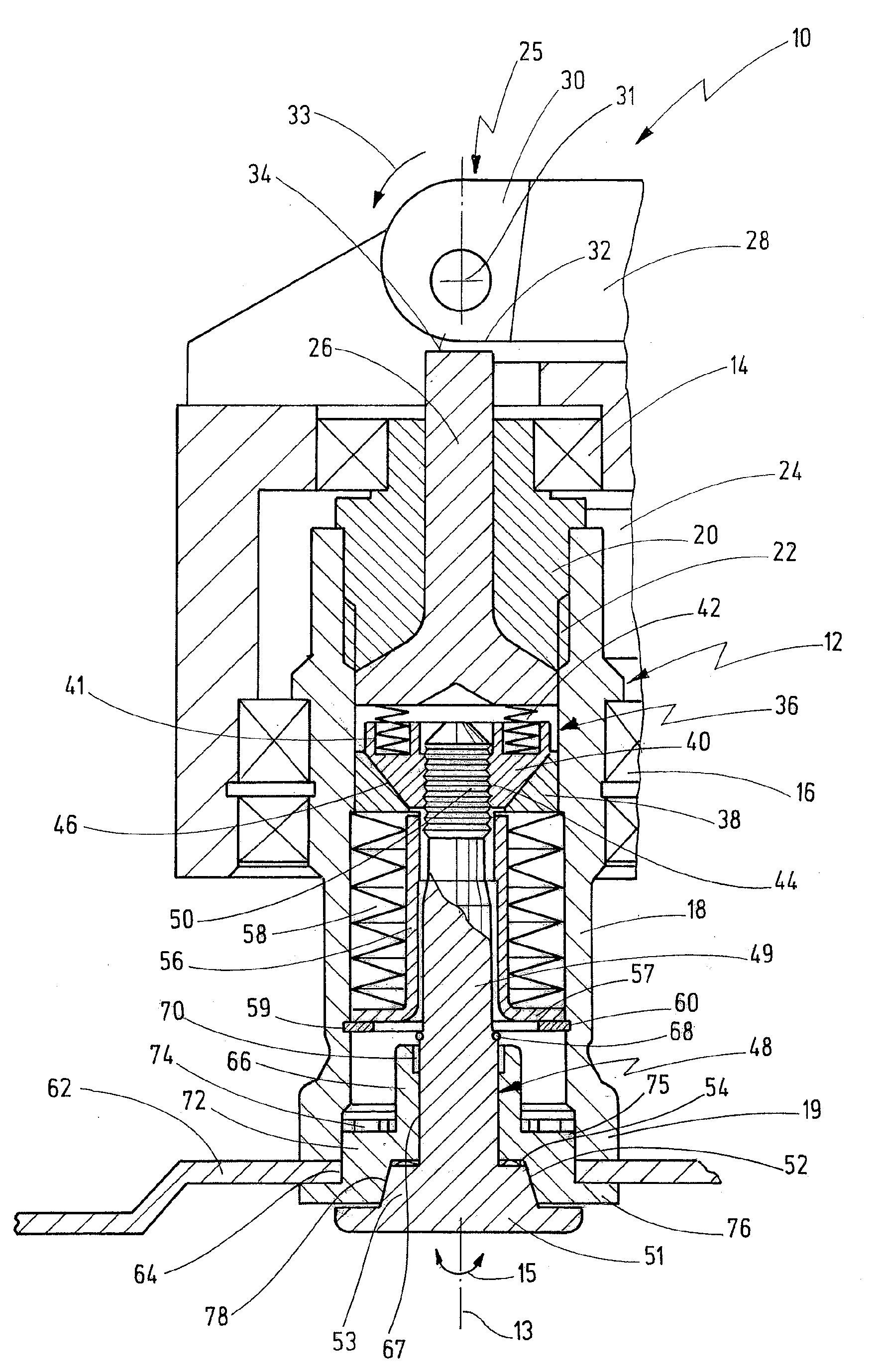

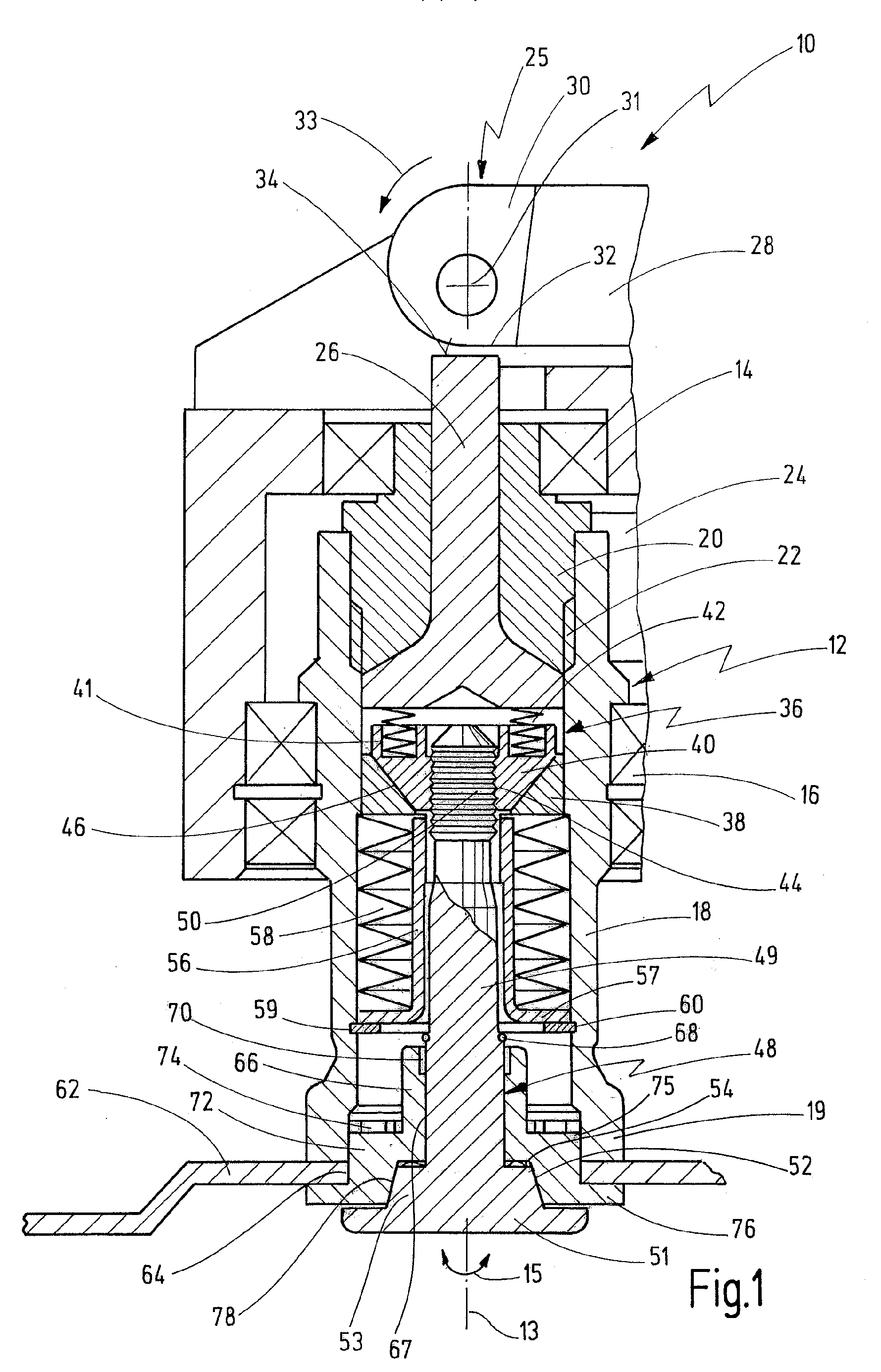

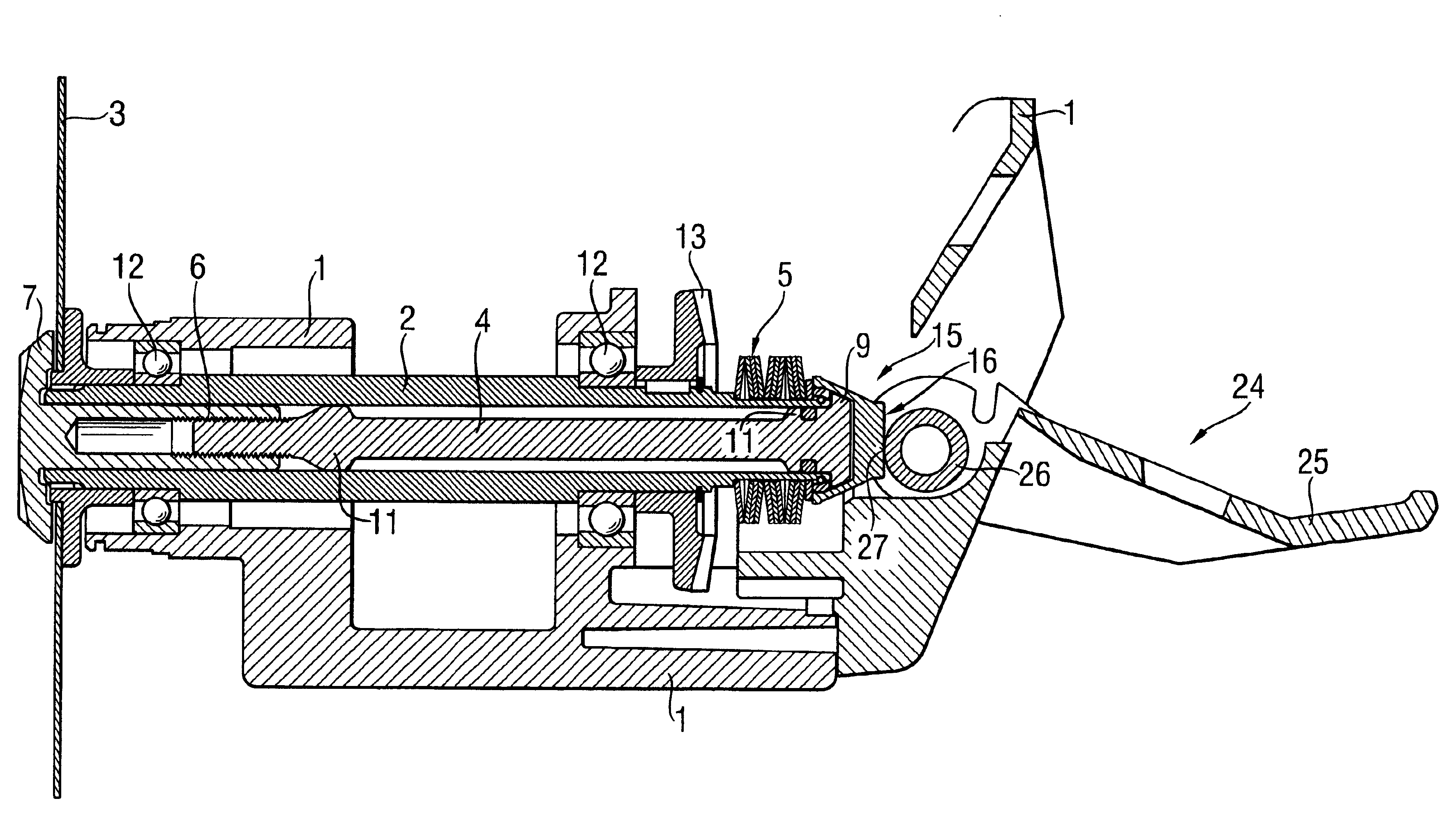

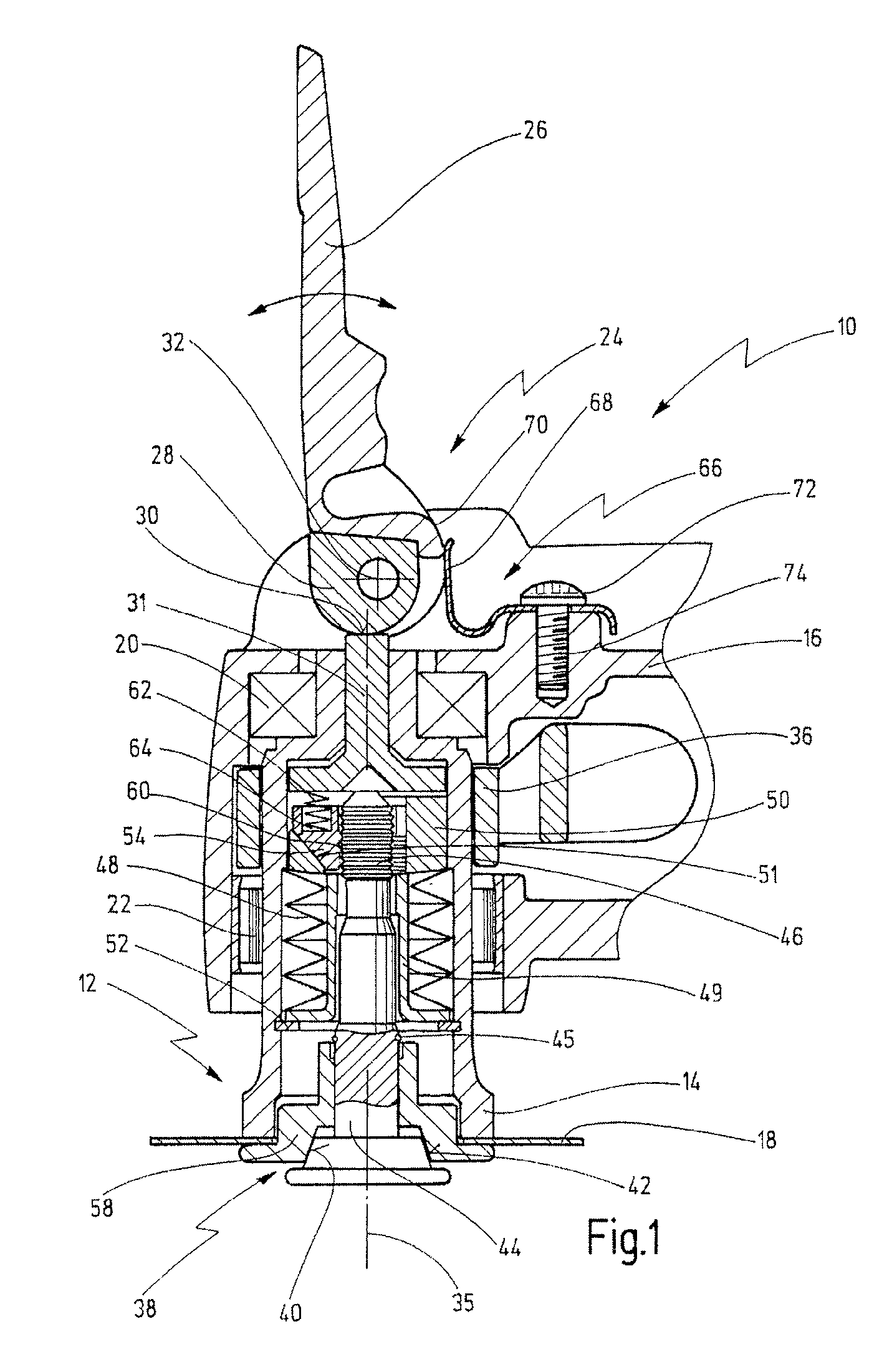

Power-Driven Hand Tool

ActiveUS20090023371A1Closer form-locking connectionFirmly connectedGrinding wheel securing apparatusPortable grinding machinesEngineeringHand tool

A power-driven hand tool comprises a drive spindle adapted to drive a tool, that can be driven to oscillate about its longitudinal axis, which tool can be fixed on a retaining section of the dive spindle by a securing element, and further comprises a displacing device that serves to displace the securing element between a releasing position in which the securing element can be released from the drive spindle and a clamping position in which the securing element is clamped on the retaining section by a spring element, the securing element comprising a clamping shaft adapted to be inserted into the securing element, which is axially fixed in the drive spindle for clamping the tool in the clamping position, and which can be detached in the releasing position. For clamping of the tool a split chuck is provided which is clamped on the retaining section by the securing element in the clamped position and is connected with the retaining section in form-locking engagement.

Owner:C & E FEIN

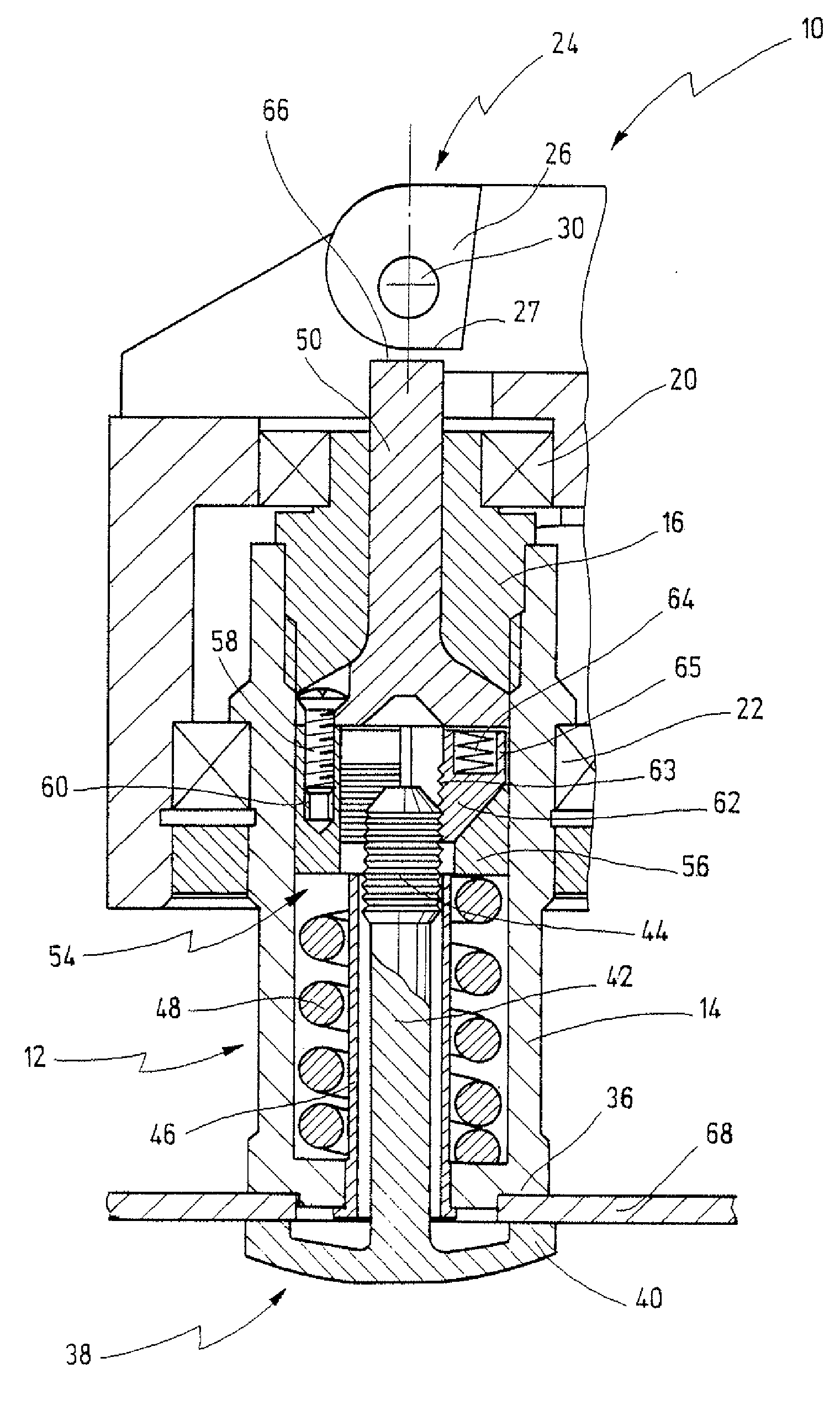

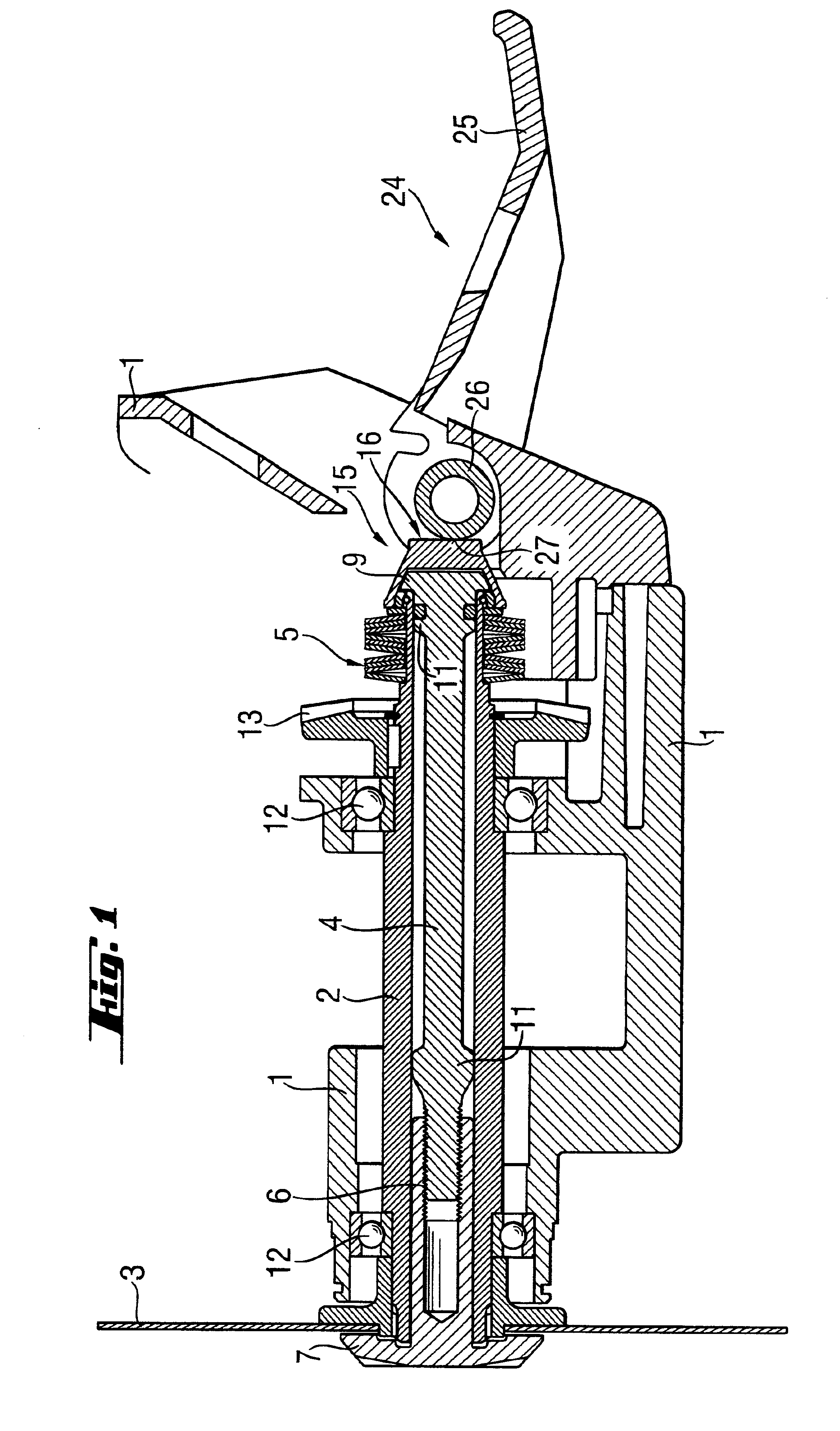

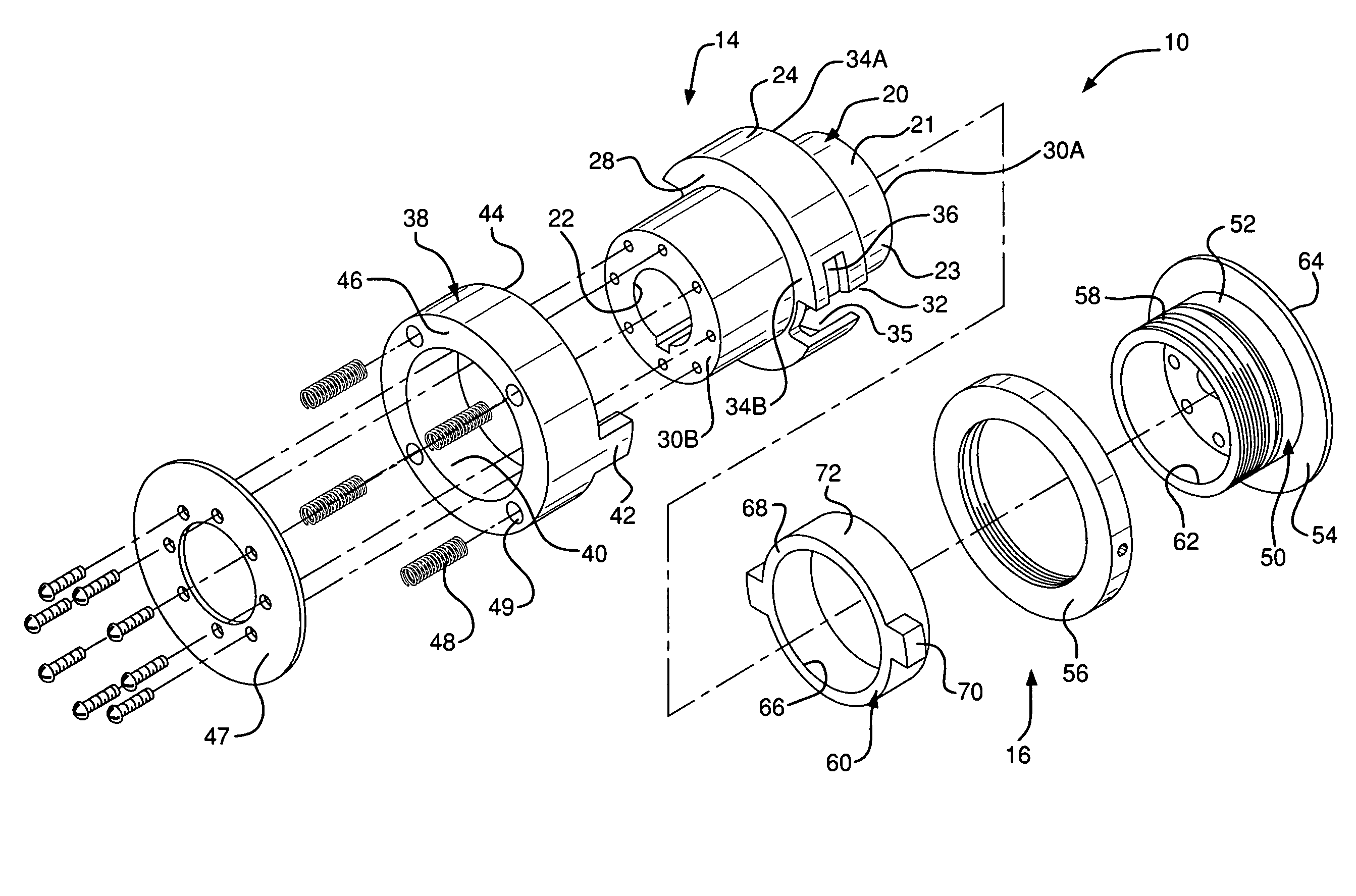

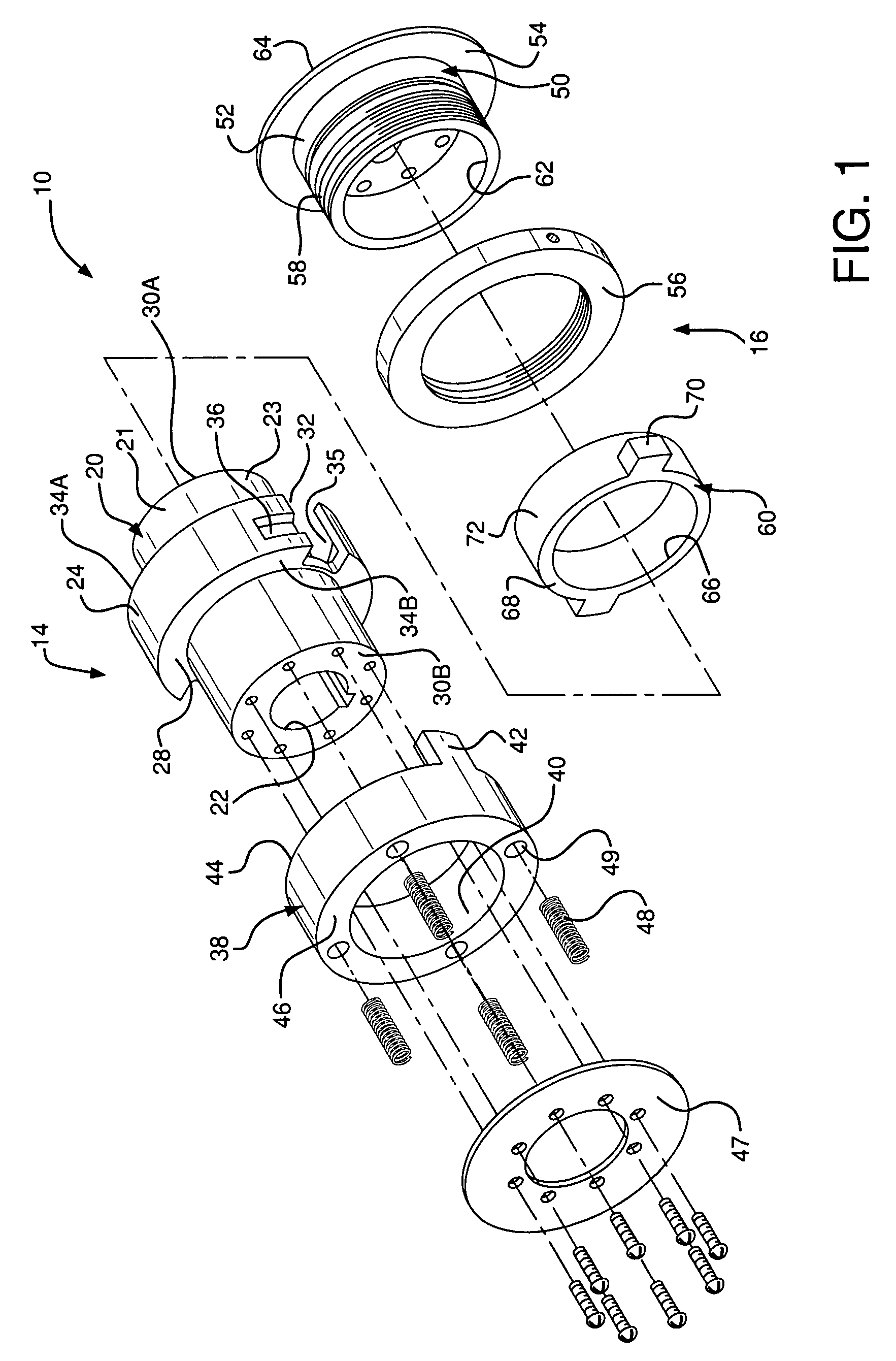

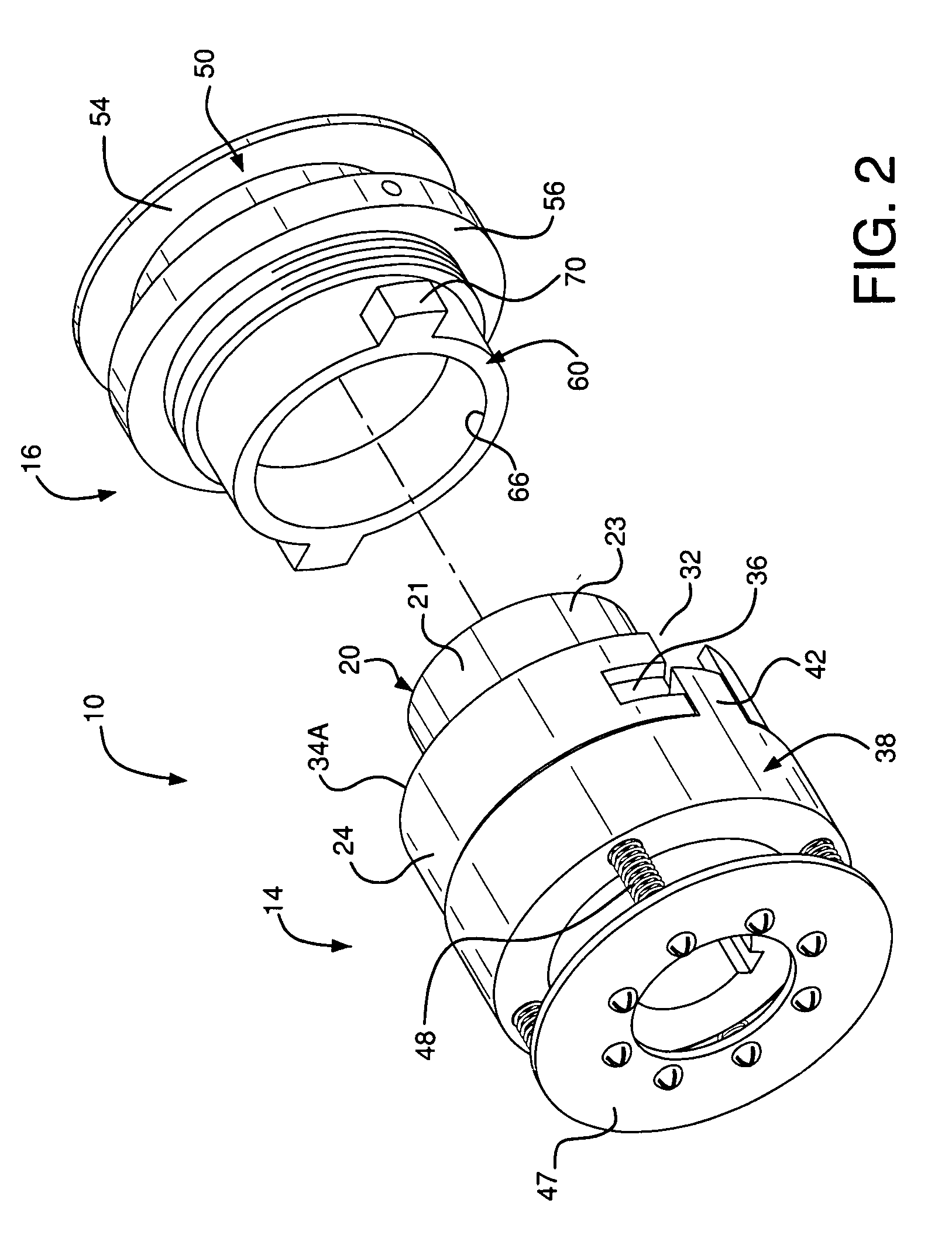

Hand-held power tool with clamping device for a tool

ActiveUS7344435B2The method is simple and reliableStrong clamping forceGrinding wheel securing apparatusPortable grinding machinesHand heldEngineering

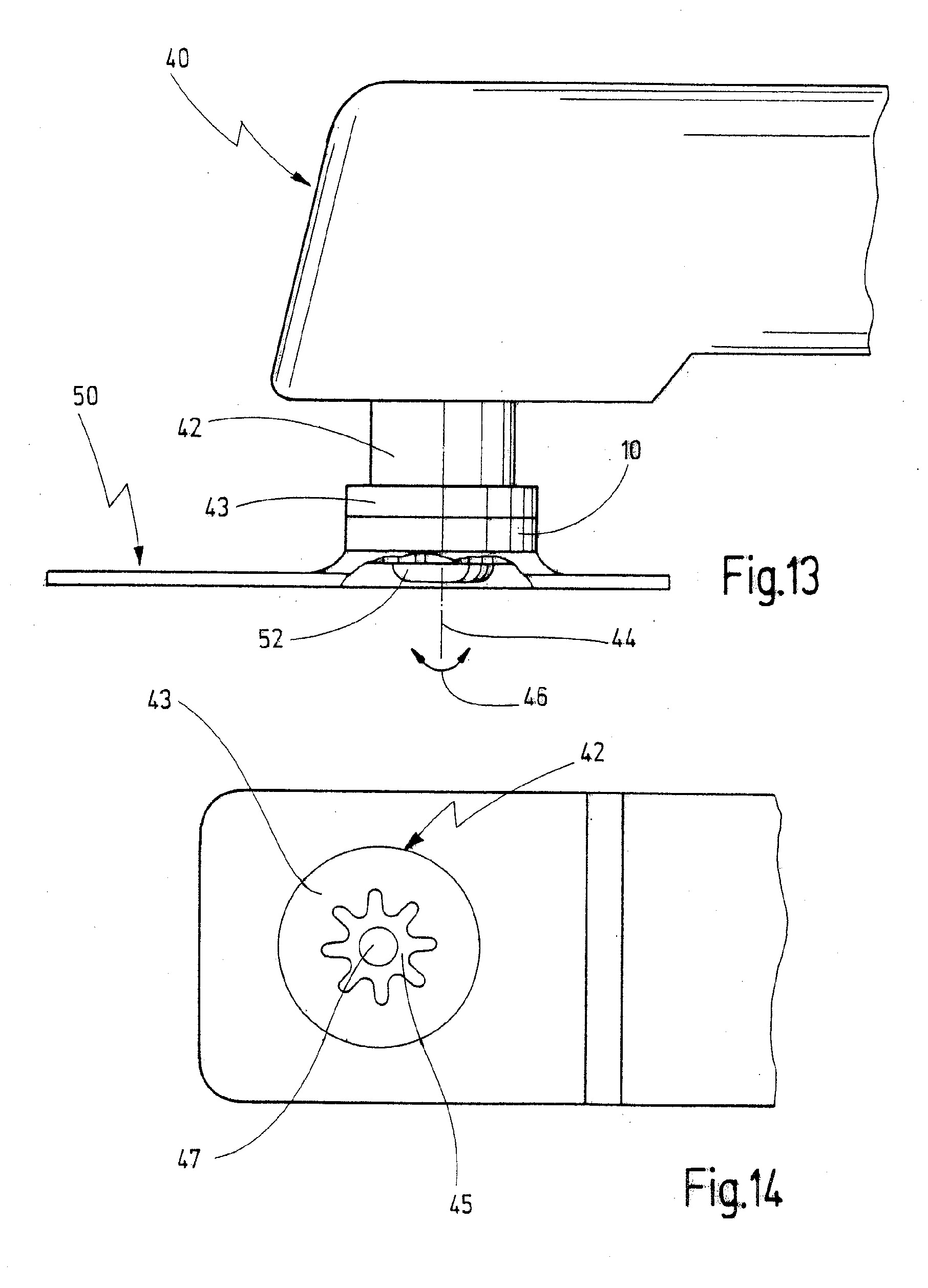

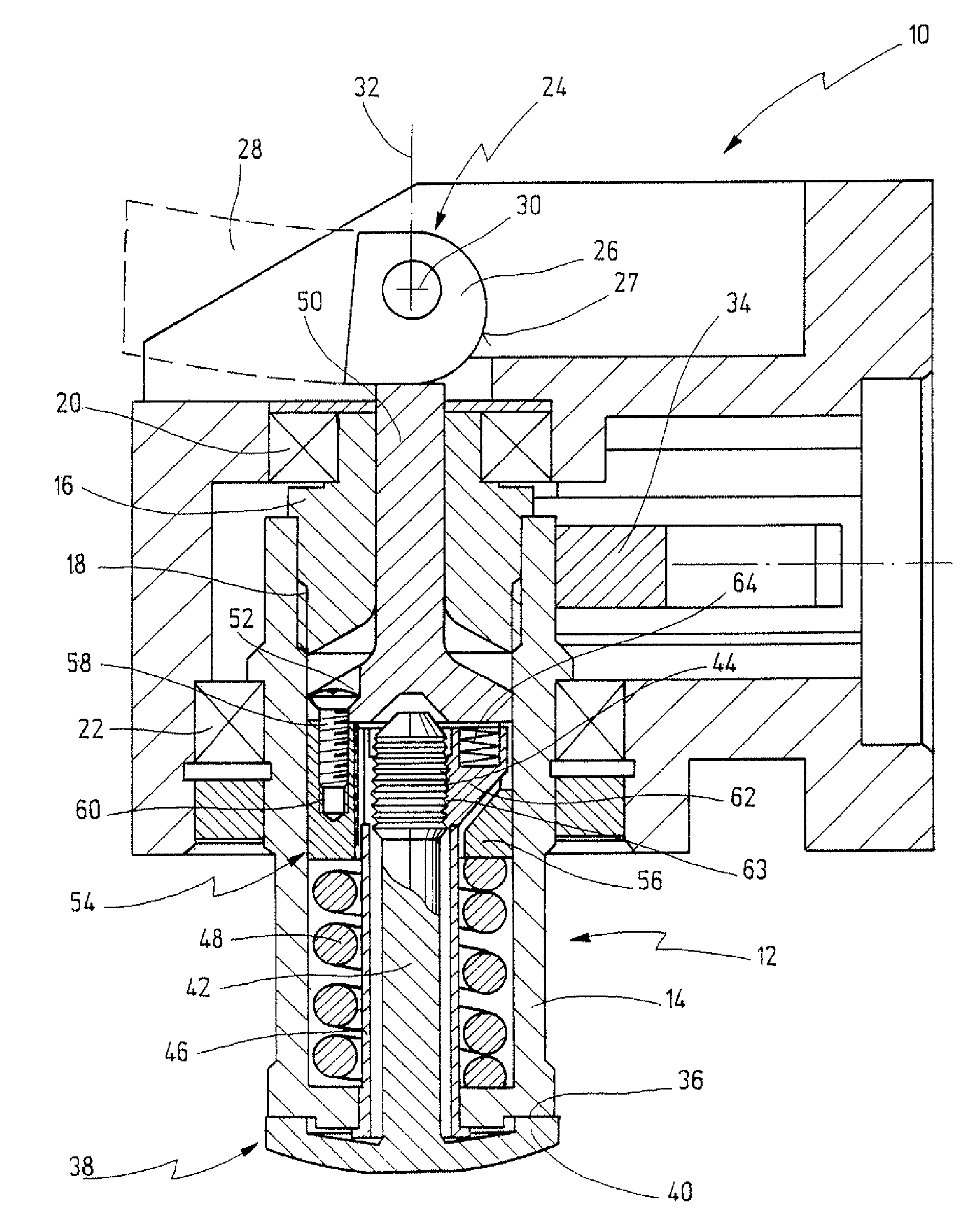

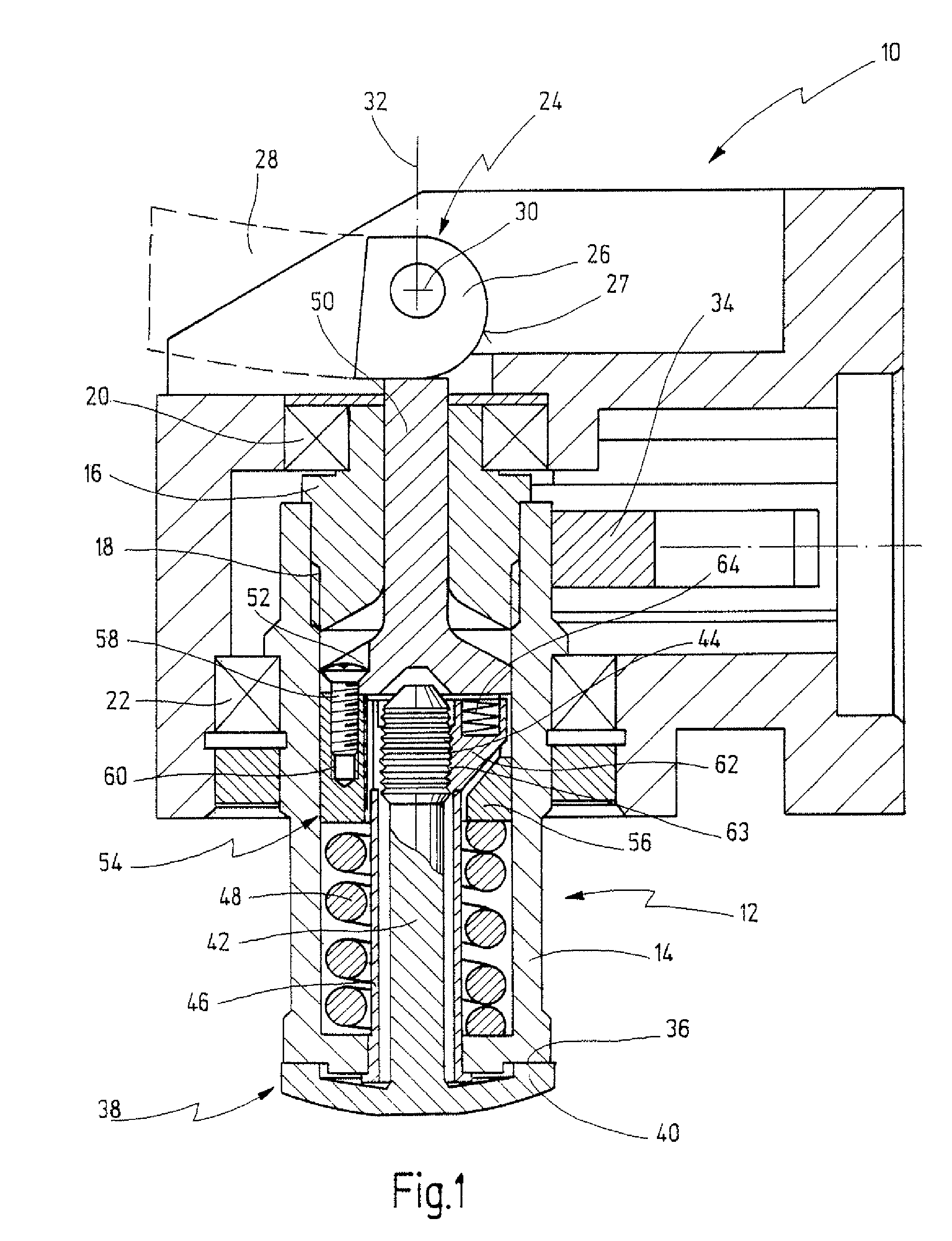

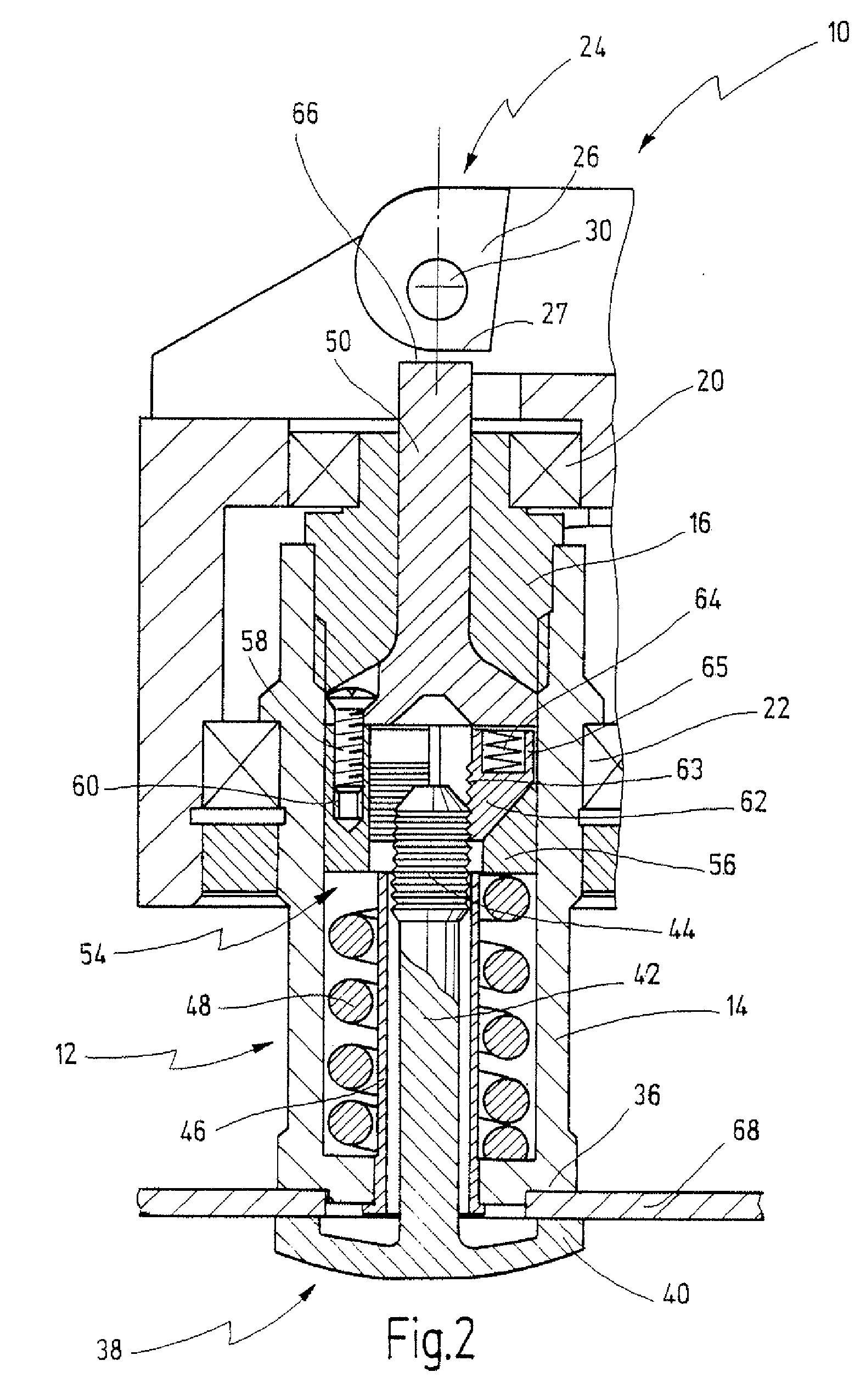

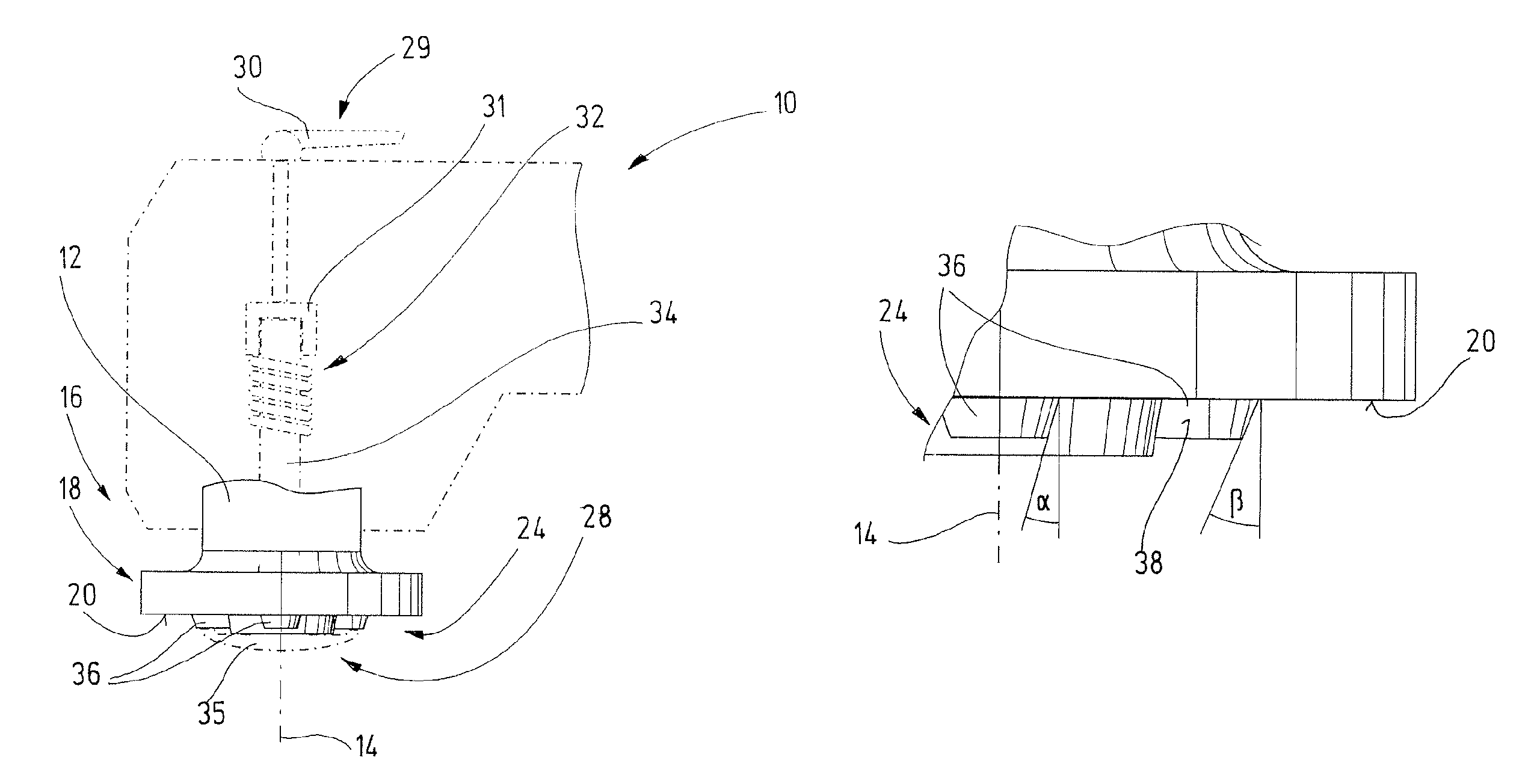

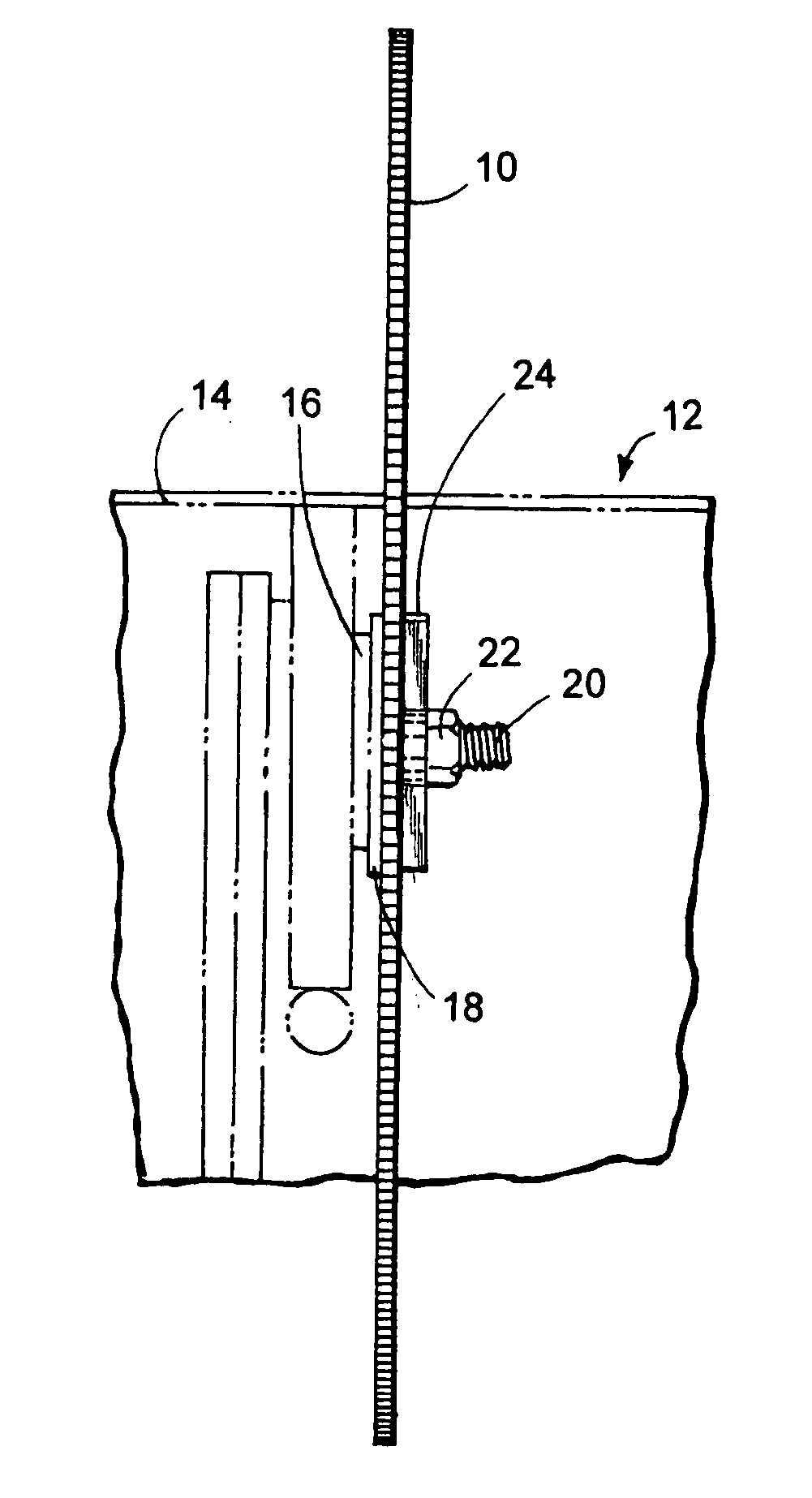

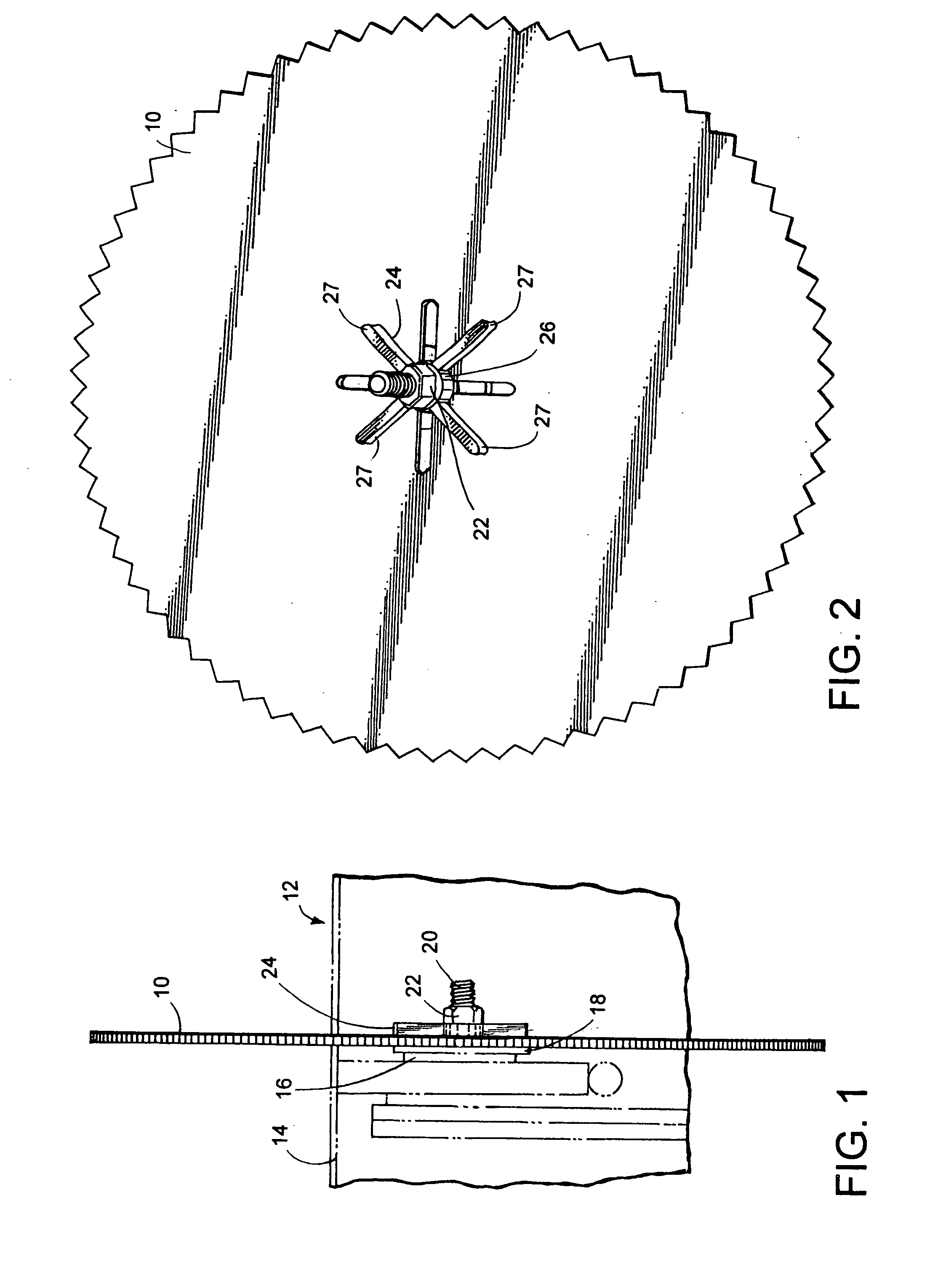

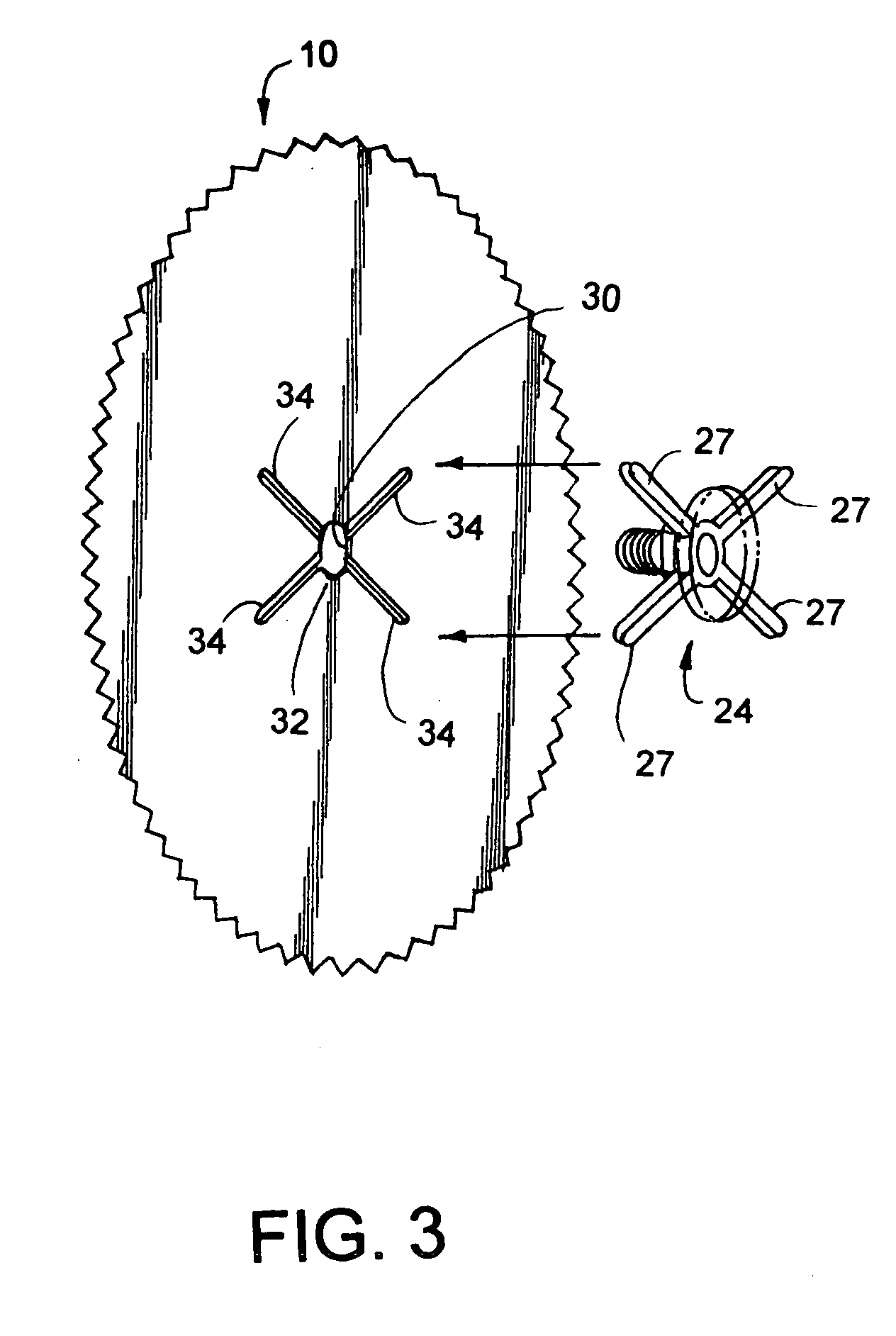

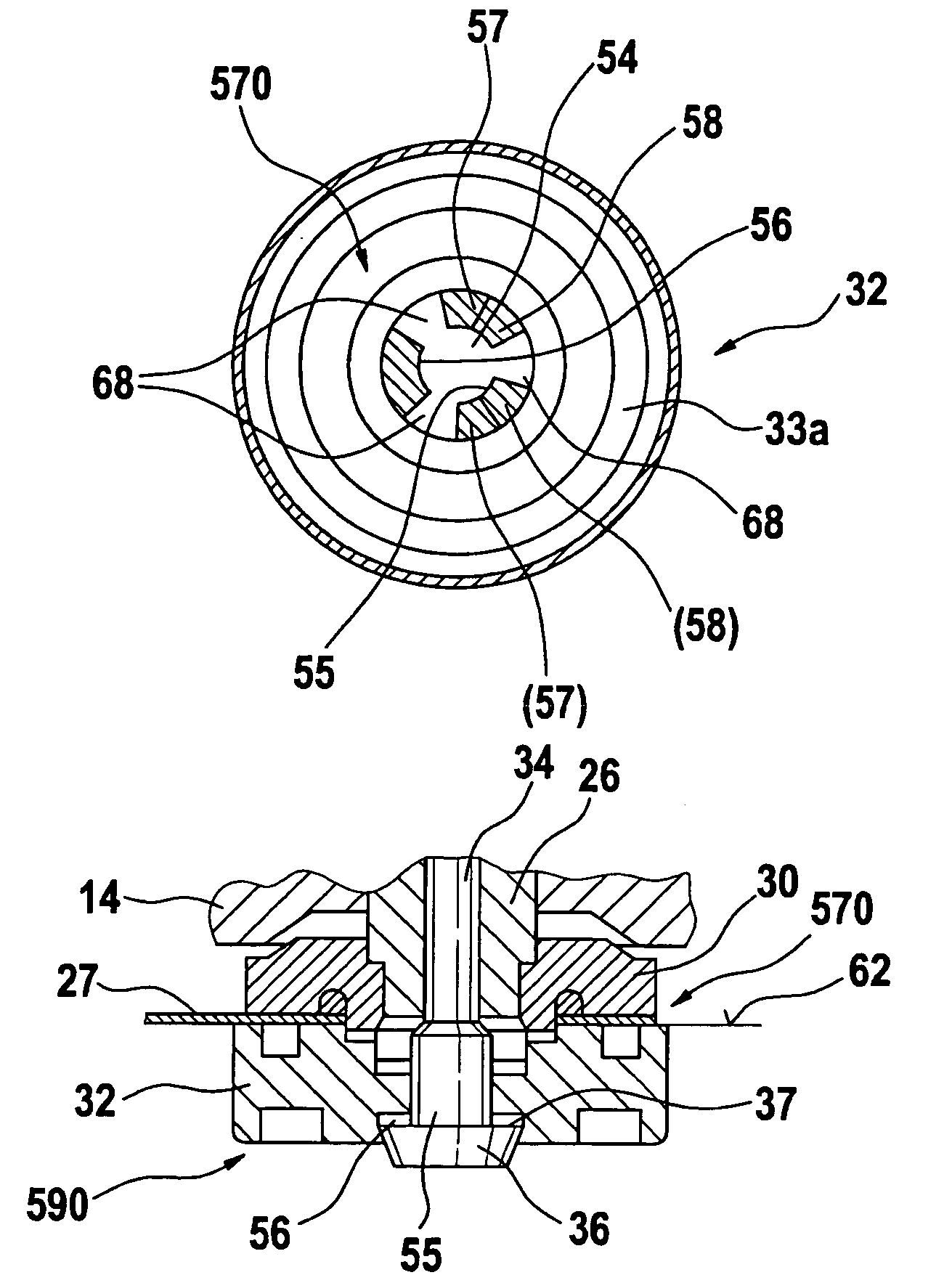

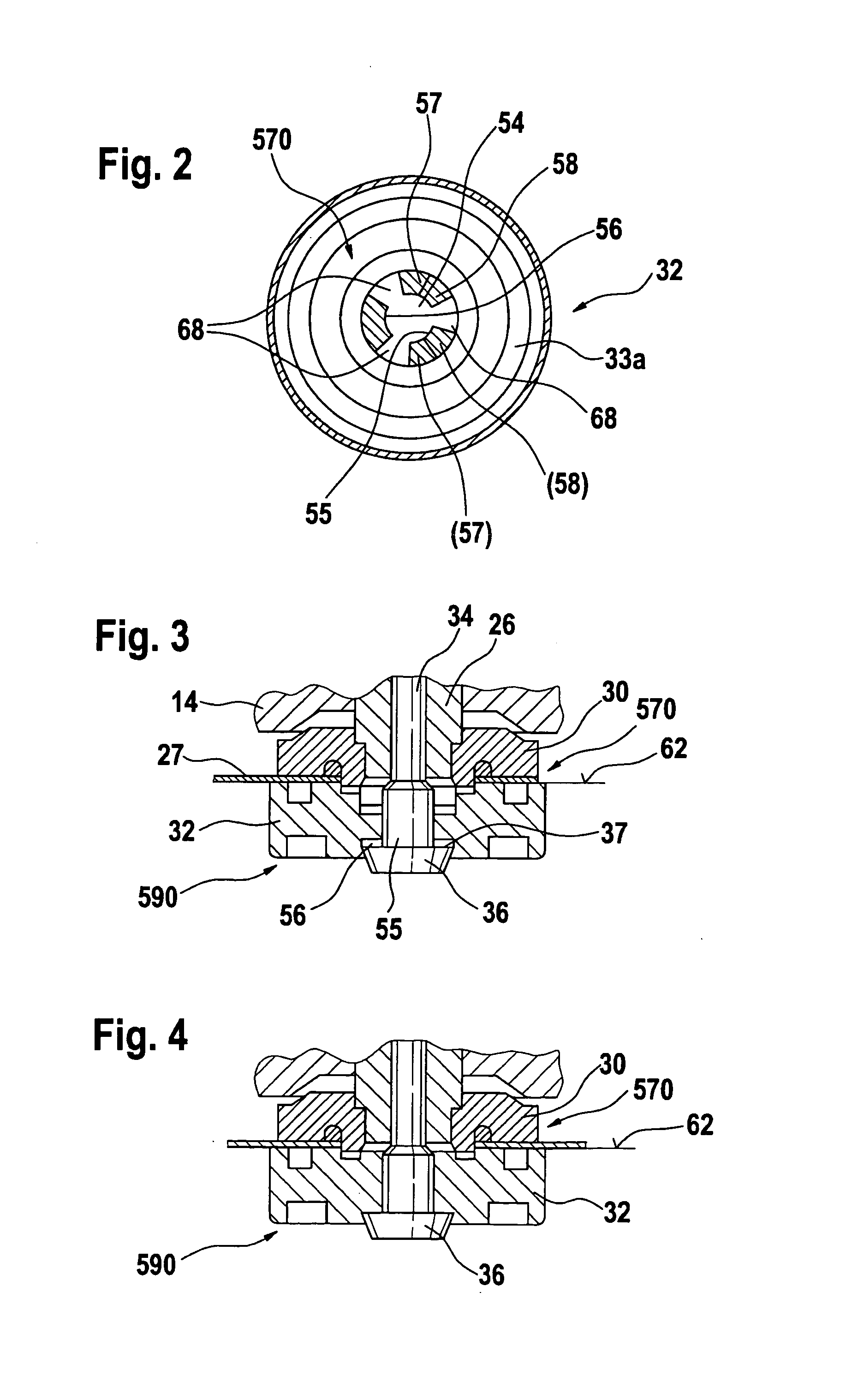

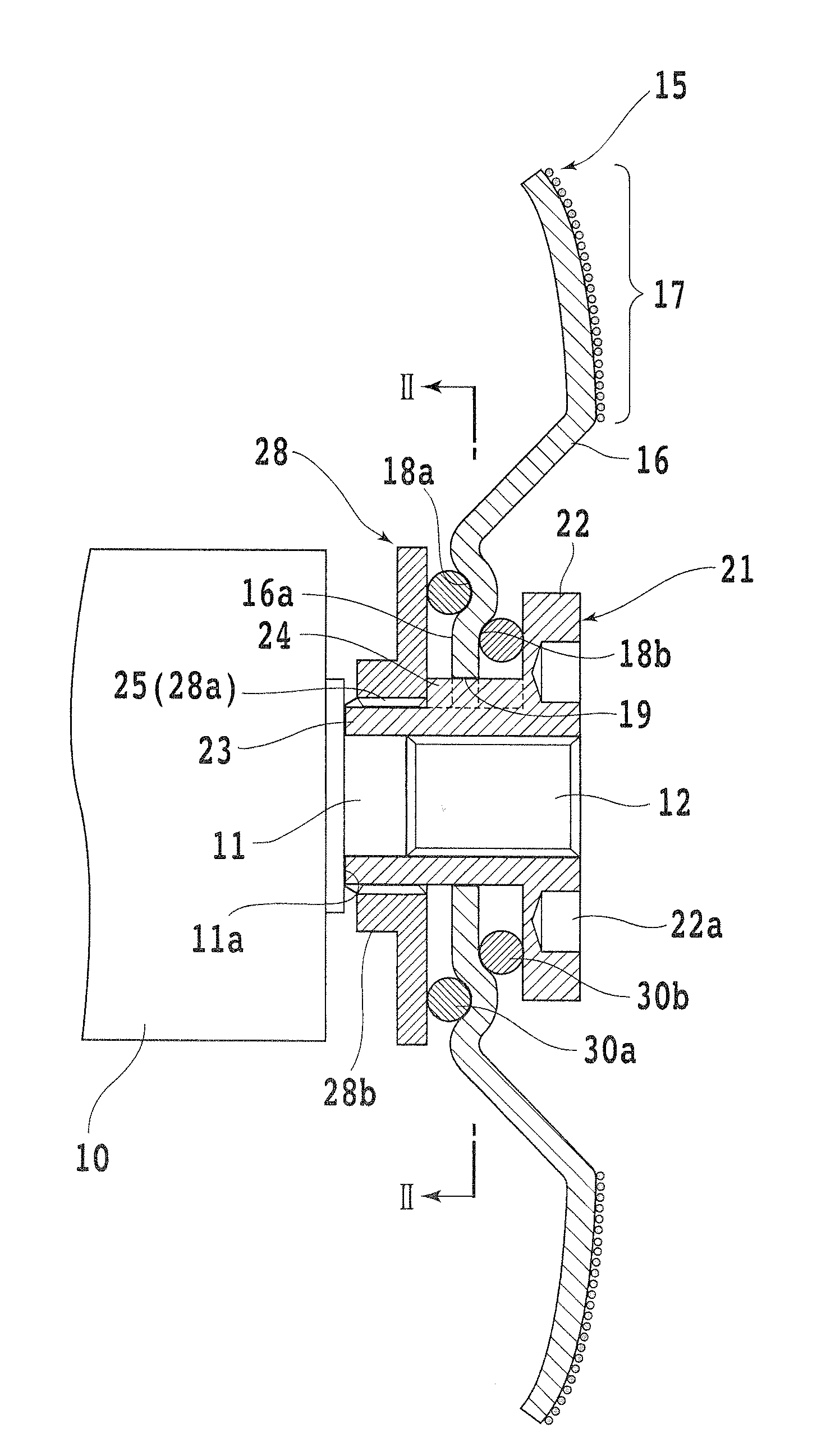

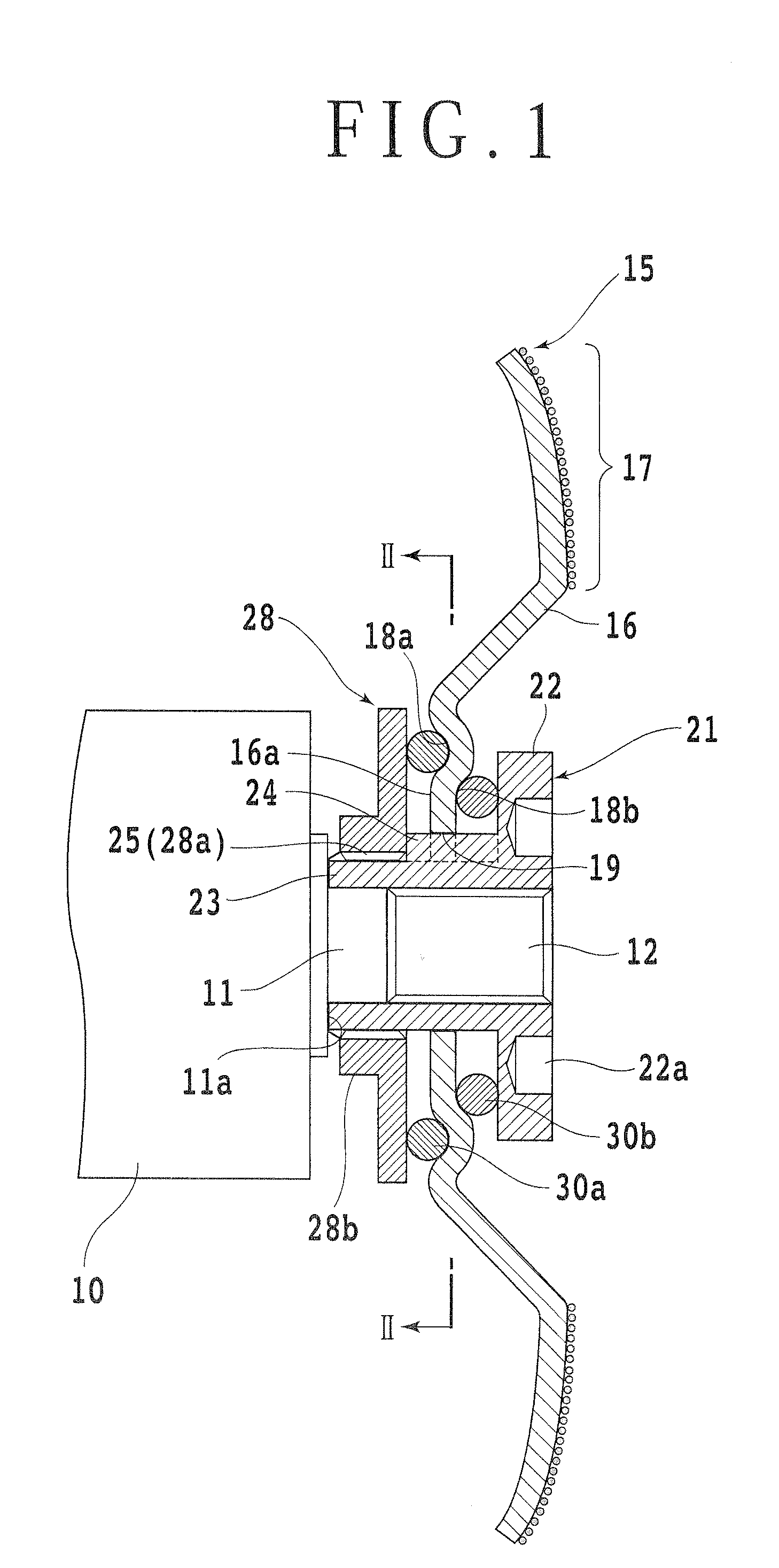

A hand-held power tool (10) is specified, comprising a work spindle (12) for driving a tool (68), said tool (68) being fastenable between a fastening element (38) and a holding portion (36) on a tool end of the work spindle (12), and a displacement device (24) for sliding the fastening element (38) between a released position in which the fastening element (38) can be detached from the work spindle (12) and a clamped position in which the fastening element (38) is clamped against the holding portion (36) by a spring element (48). The fastening element (38) includes a clamping shaft (42) that is insertable into the work spindle (12) and held in the clamped position by a lock assembly (54) inside the work spindle (12), and which can be removed when in the released position (FIG. 2).

Owner:C & E FEIN GMBH & CO KG

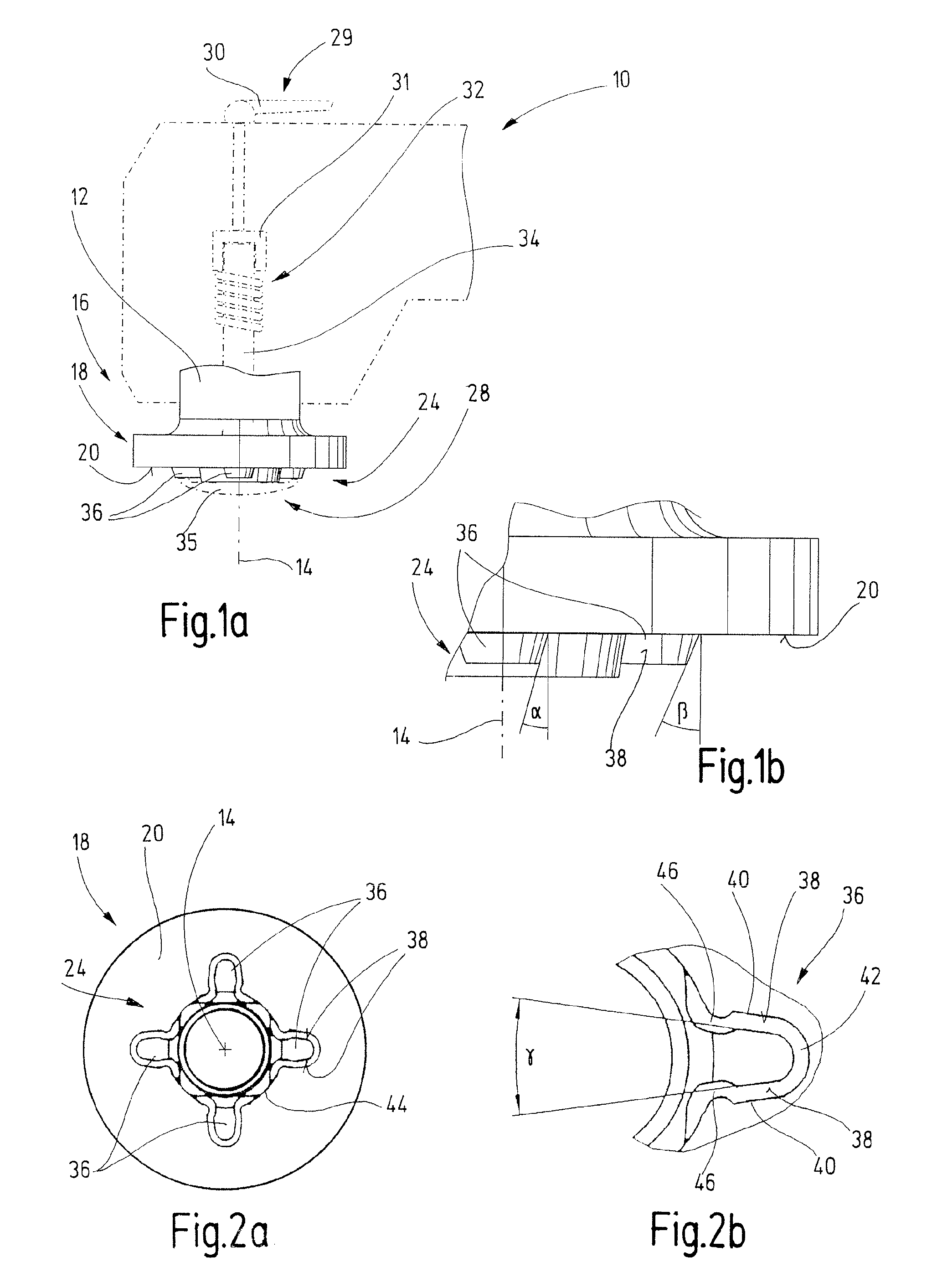

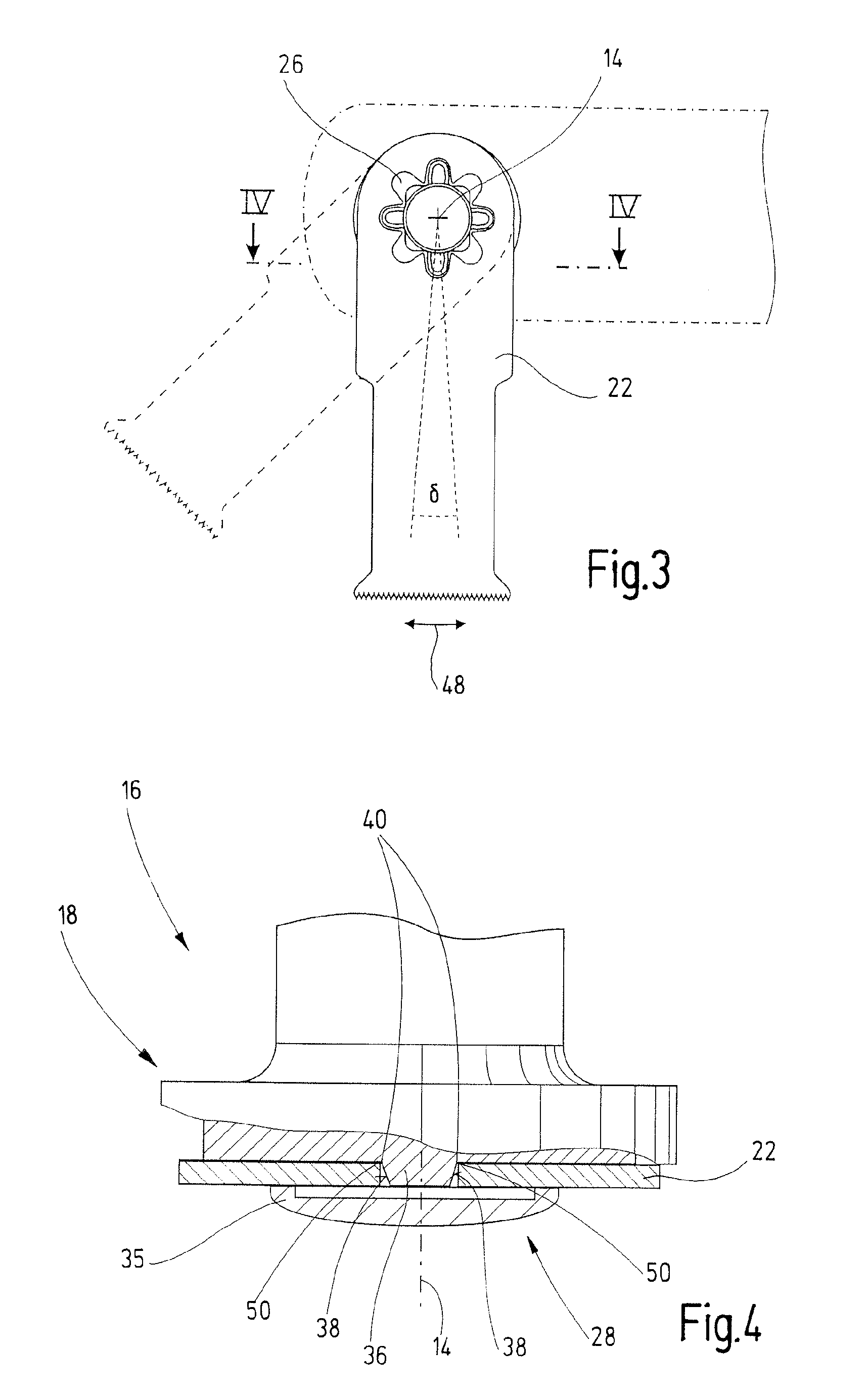

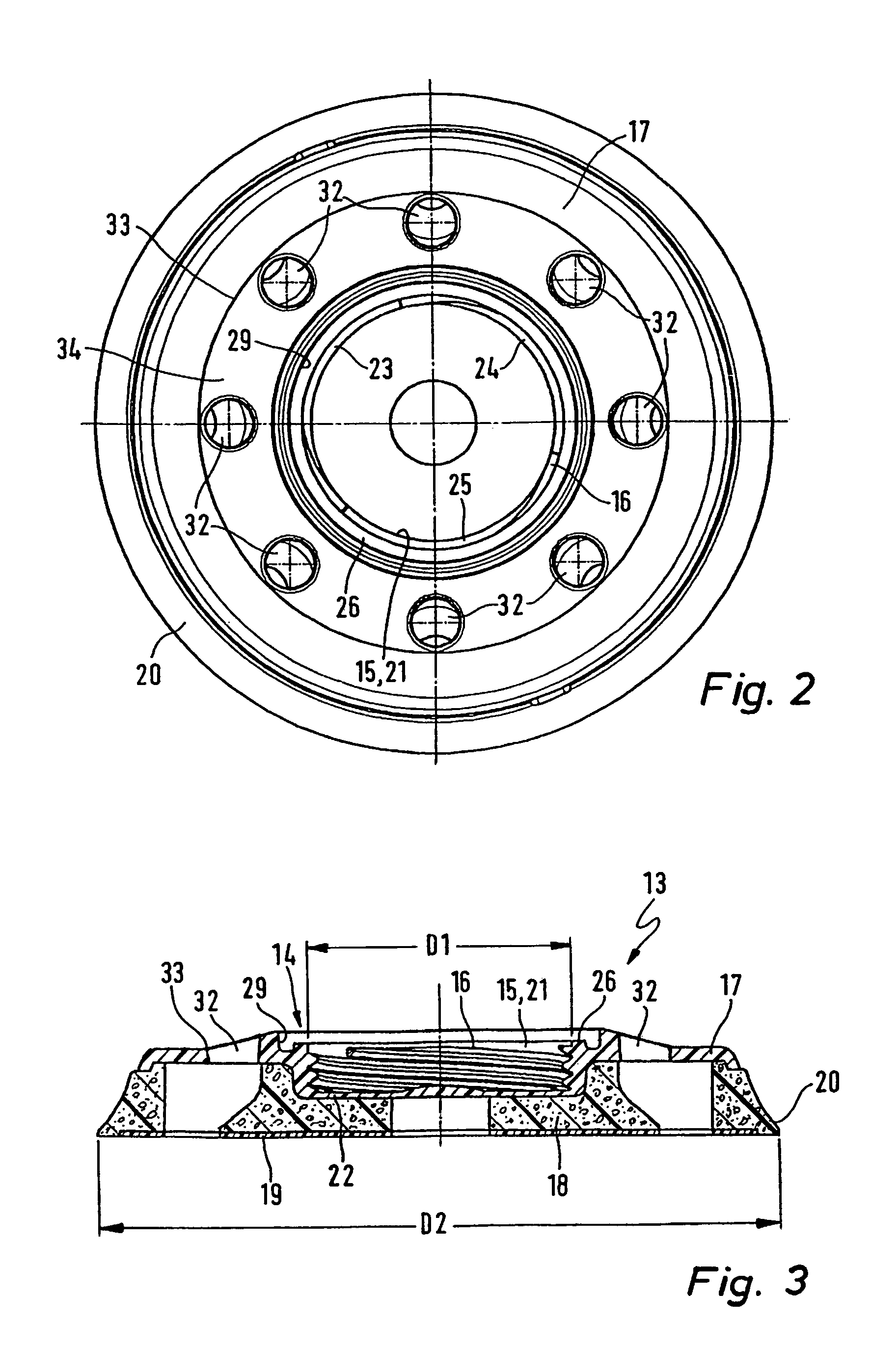

Grinding-disk receiving element especially for a hand-guided electric grinding tool

ActiveUS7217177B2Easy to installEasy to driveGrinding wheel securing apparatusSupport wheelsSanderEngineering

Owner:ROBERT BOSCH GMBH

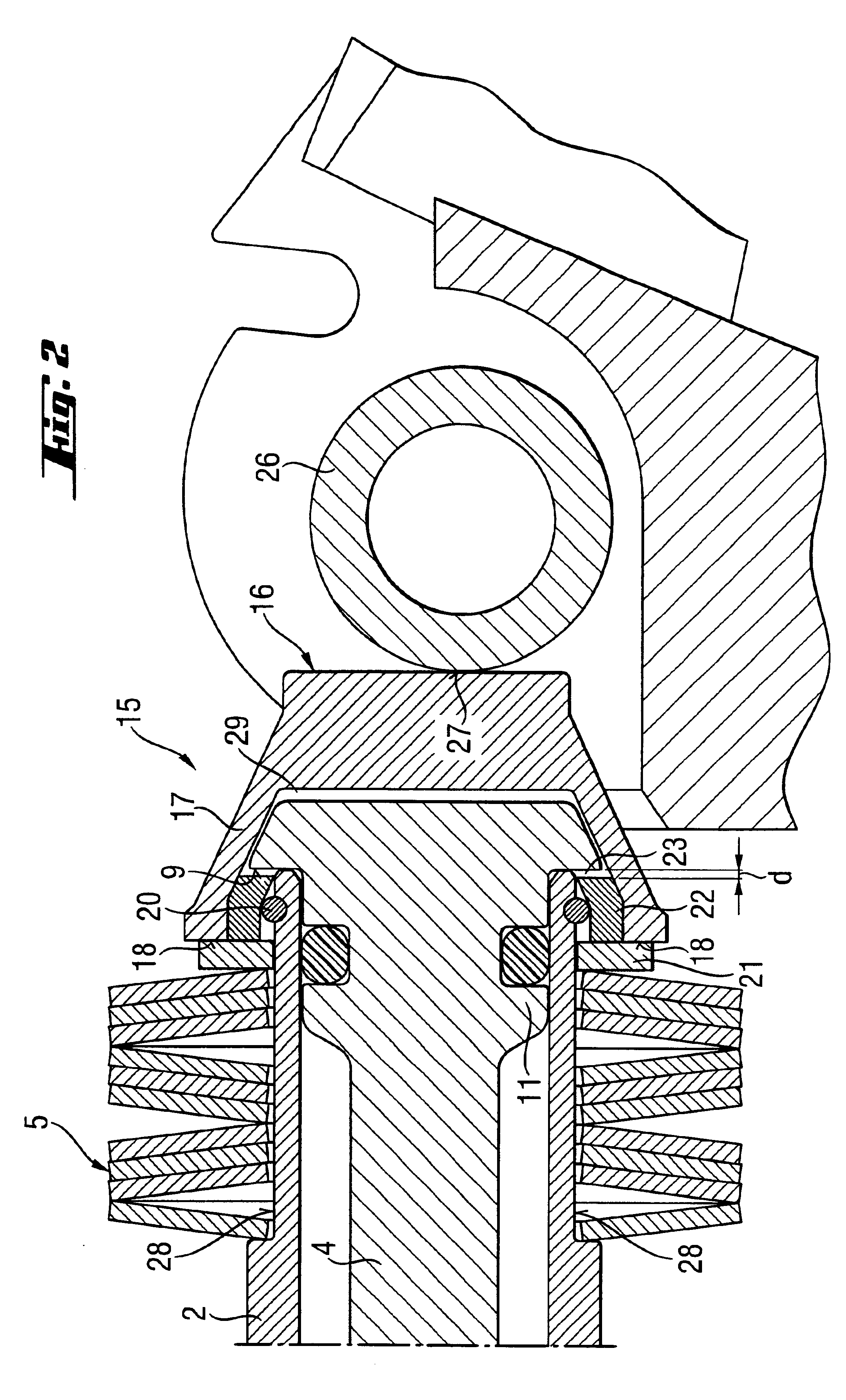

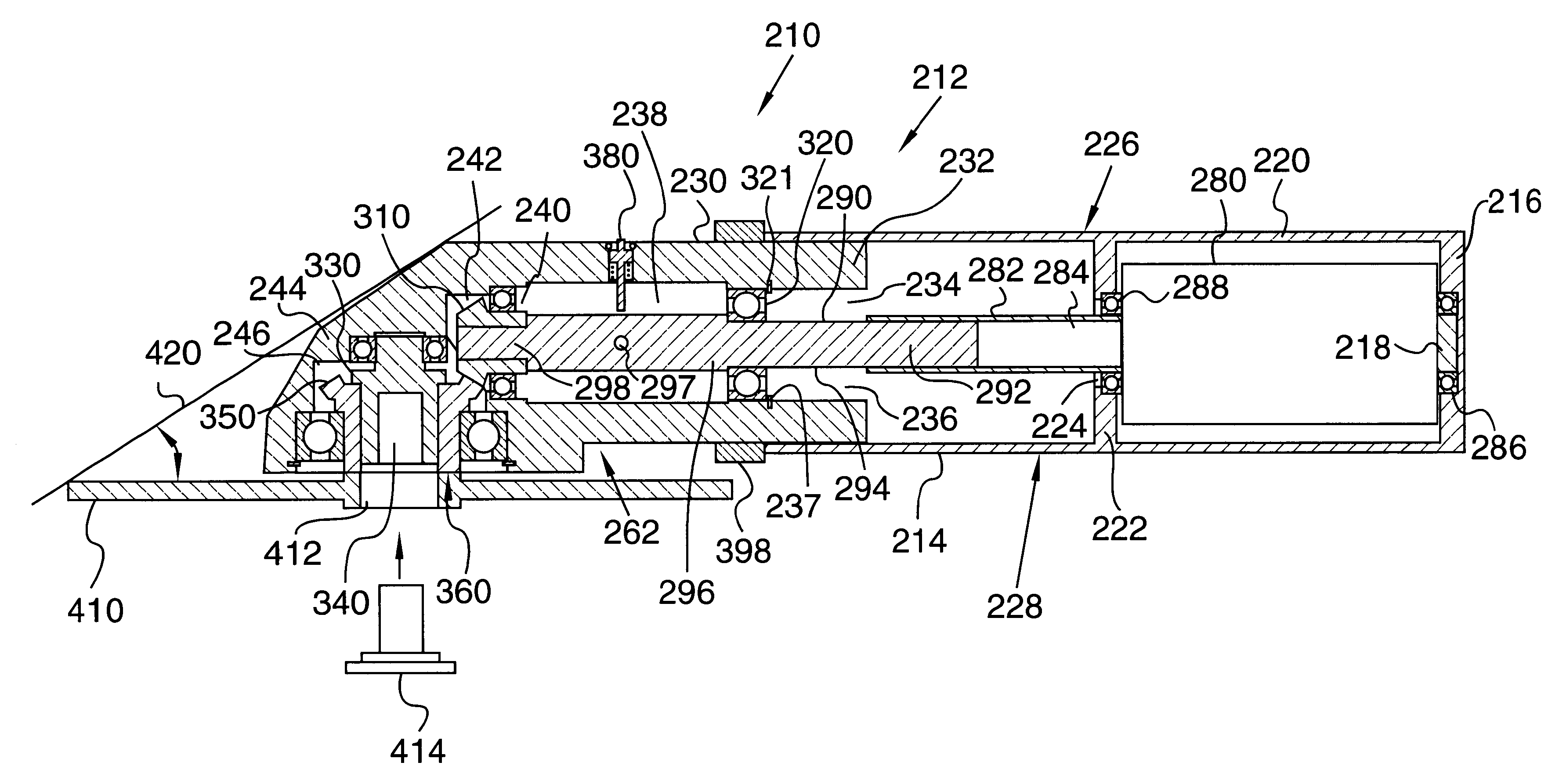

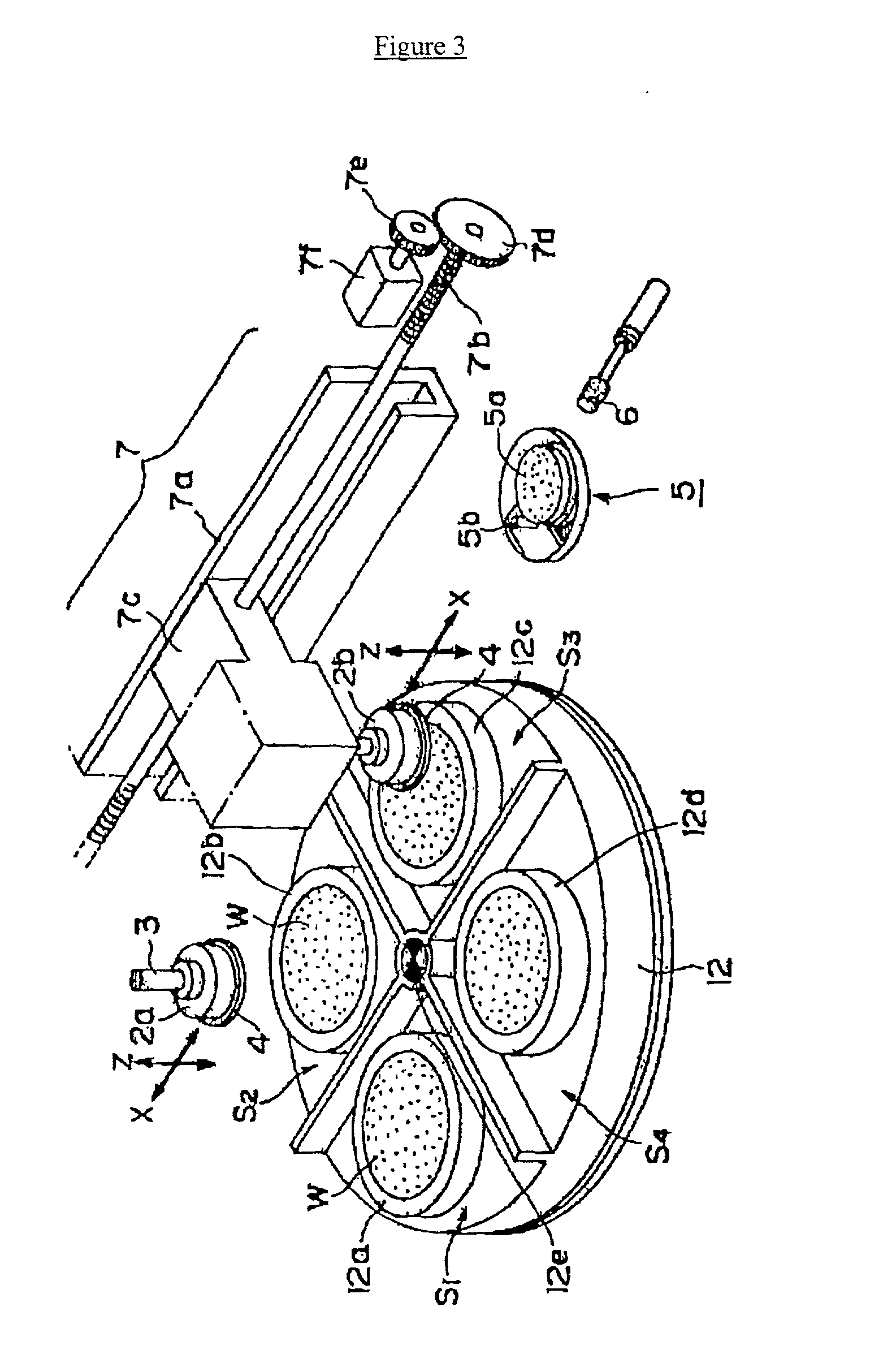

Oscillatory Drive

ActiveUS20070295156A1Reduce disadvantagesImprove transmittanceGrinding wheel securing apparatusTurning machine accessoriesPre stressPre stressing

The invention relates to an oscillatory drive having an output shaft that can be driven to perform a rotationally oscillating movement about its longitudinal axis and that comprises a free end, a holding fixture at the free end of the output shaft comprising a contact surface for attachment of a tool, a mounting section on the holding fixture, raised relative to the contact surface, that projects to the outside in the direction of the longitudinal axis and that is designed for form-locking connection with a mounting opening of a tool placed in contact with the contact surface, and having a securement for fixing the tool with its mounting opening on the holding fixture, the securement permitting the tool to yield in axial direction under the action of a torque, against a pre-stress, and the mounting section permitting the tool to rotate by a certain angle of rotation when the tool gives way axially.

Owner:C & E FEIN

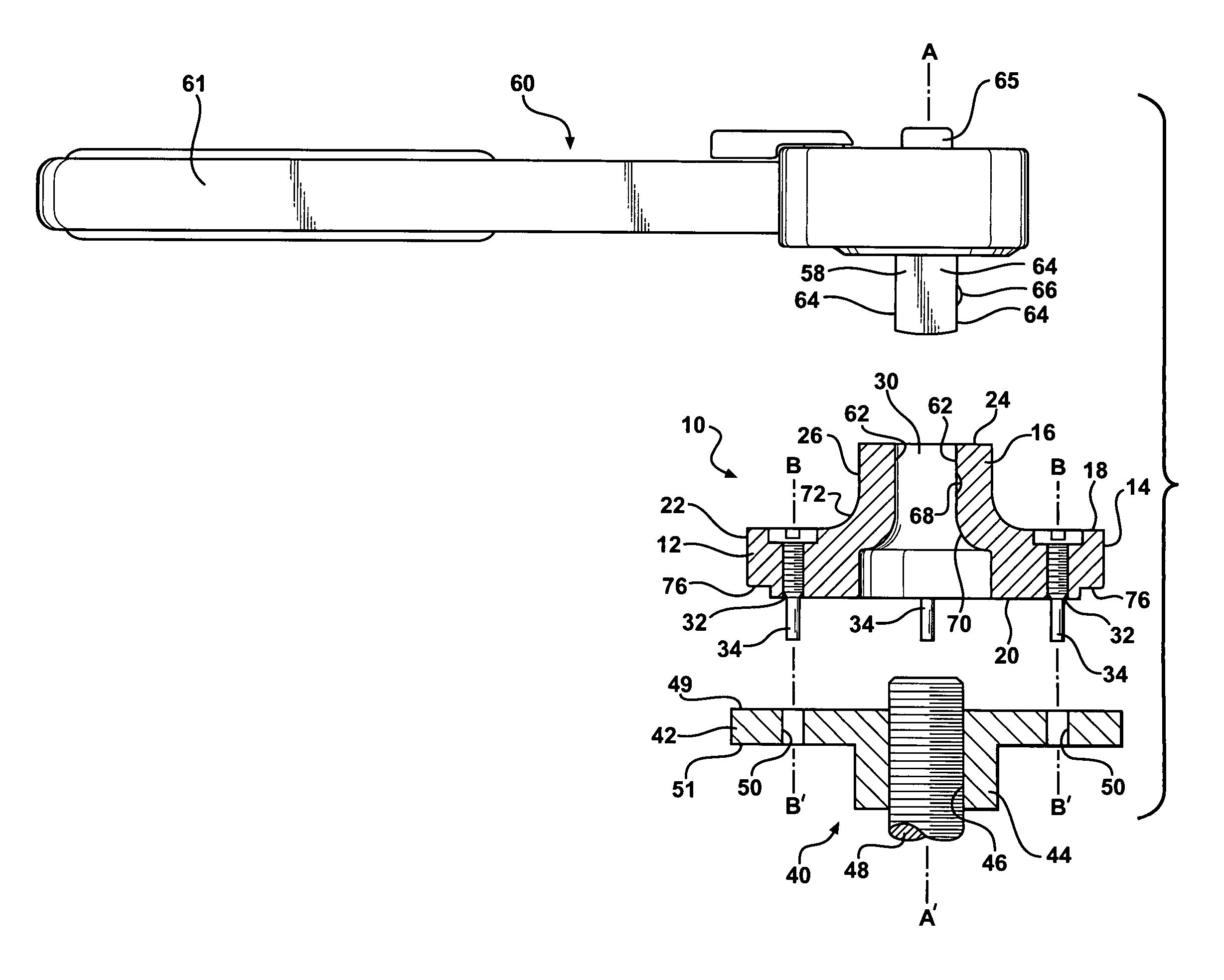

Hand-Held Power Tool With Clamping Device For A Tool

ActiveUS20070060030A1The method is simple and reliableStrong clamping forceGrinding wheel securing apparatusPortable grinding machinesHand heldEngineering

A hand-held power tool (10) is specified, comprising a work spindle (12) for driving a tool (68), said tool (68) being fastenable between a fastening element (38) and a holding portion (36) on a tool end of the work spindle (12), and a displacement device (24) for sliding the fastening element (38) between a released position in which the fastening element (38) can be detached from the work spindle (12) and a clamped position in which the fastening element (38) is clamped against the holding portion (36) by a spring element (48). The fastening element (38) includes a clamping shaft (42) that is insertable into the work spindle (12) and held in the clamped position by a lock assembly (54) inside the work spindle (12), and which can be removed when in the released position (FIG. 2).

Owner:C & E FEIN GMBH & CO KG

Oscillatory drive

ActiveUS7997586B2Reduce disadvantagesImprove balanceGrinding wheel securing apparatusControlling membersPre stressPre stressing

The invention relates to an oscillatory drive having an output shaft that can be driven to perform a rotationally oscillating movement about its longitudinal axis and that comprises a free end, a holding fixture at the free end of the output shaft comprising a contact surface for attachment of a tool, a mounting section on the holding fixture, raised relative to the contact surface, that projects to the outside in the direction of the longitudinal axis and that is designed for form-locking connection with a mounting opening of a tool placed in contact with the contact surface, and having a securement for fixing the tool with its mounting opening on the holding fixture, the securement permitting the tool to yield in axial direction under the action of a torque, against a pre-stress, and the mounting section permitting the tool to rotate by a certain angle of rotation when the tool gives way axially.

Owner:C & E FEIN GMBH & CO KG

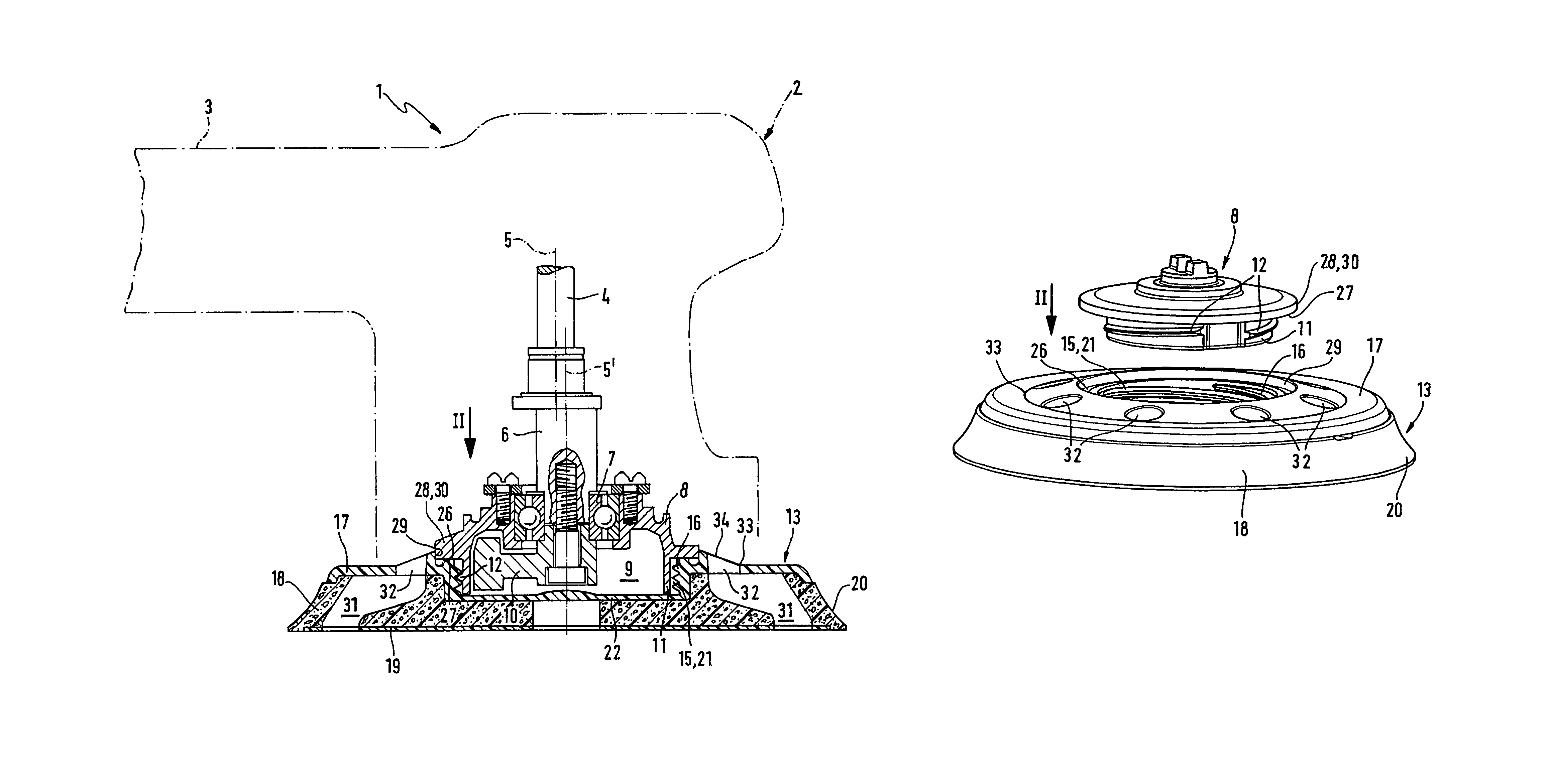

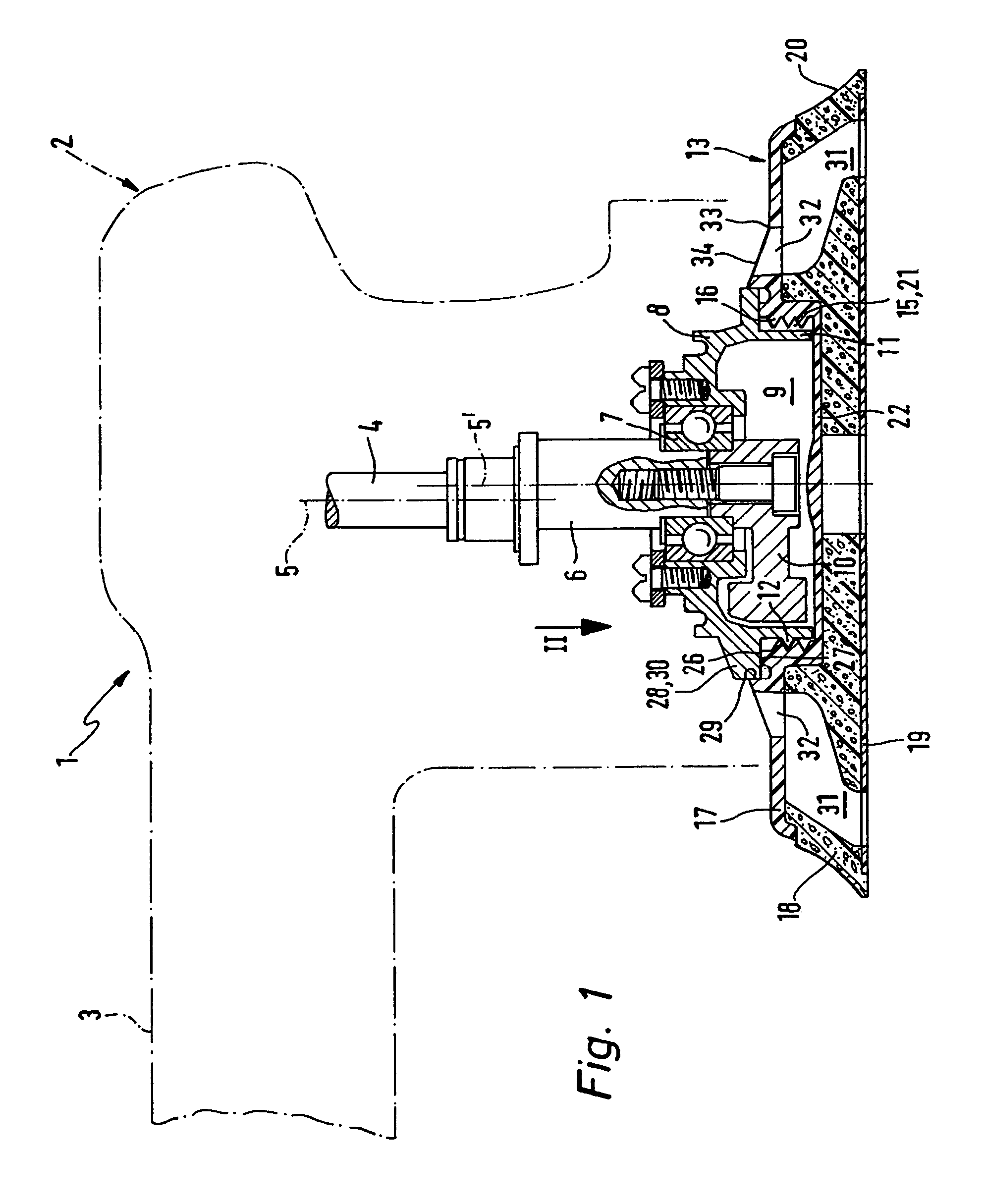

Grinding disk

ActiveUS7029384B2High torqueFine pitchGrinding wheel securing apparatusRevolution surface grinding machinesDiameter ratioEngineering

A grinding disk (13) for manually held, motor-driven grinders (1) has a centrally arranged fastening recess (15) open at the grinding disk upper side with an internal thread arrangement (16), with which the grinding disk (13) can be screwed onto a connecting part (8), which is arranged on the side of the grinder and is driven for the grinding motion during operation, and which connecting part has a thread section (11) with an external thread arrangement (12), which is associated with the internal thread arrangement (16) of the grinding disk (13). The internal thread arrangement (16) is formed by a multiple thread with at least two thread courses, which are arranged angularly offset to one another. The diameter ratio between the diameter of the internal thread arrangement (16) and the outside diameter of the grinding disk (13) is at least approximately 0.25.

Owner:FESTOOL GMBH

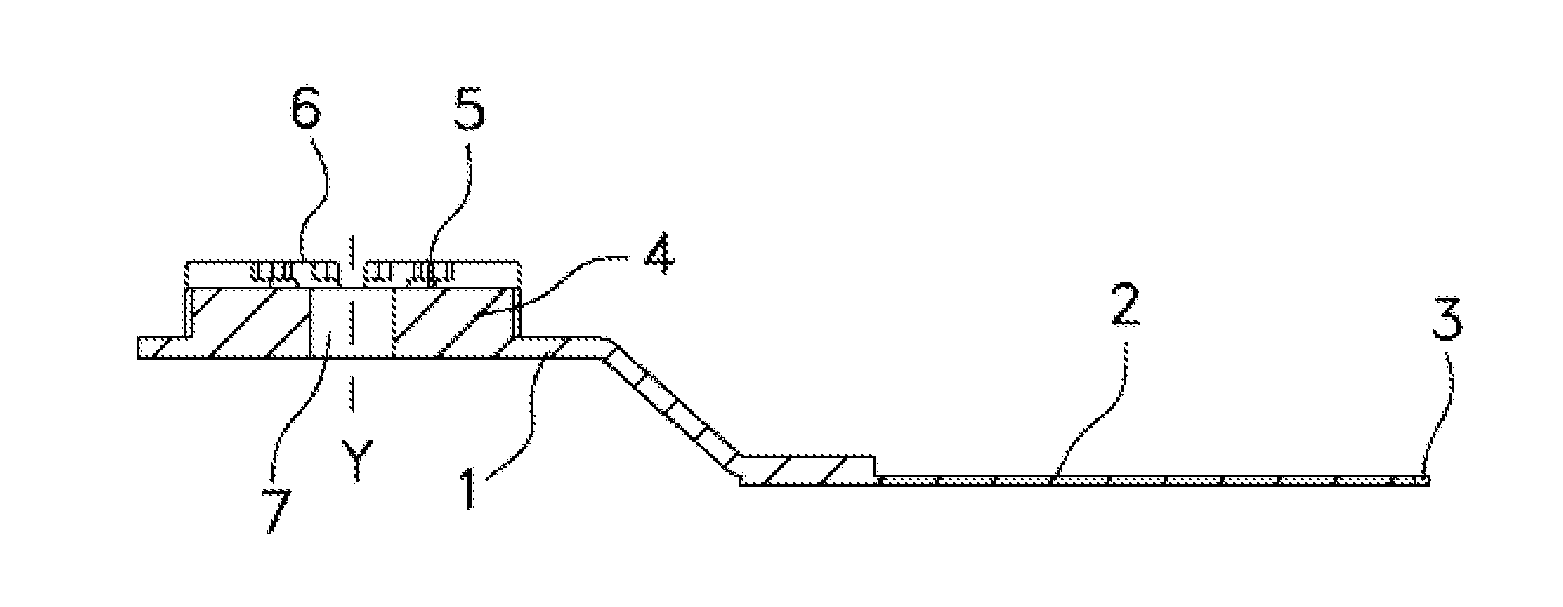

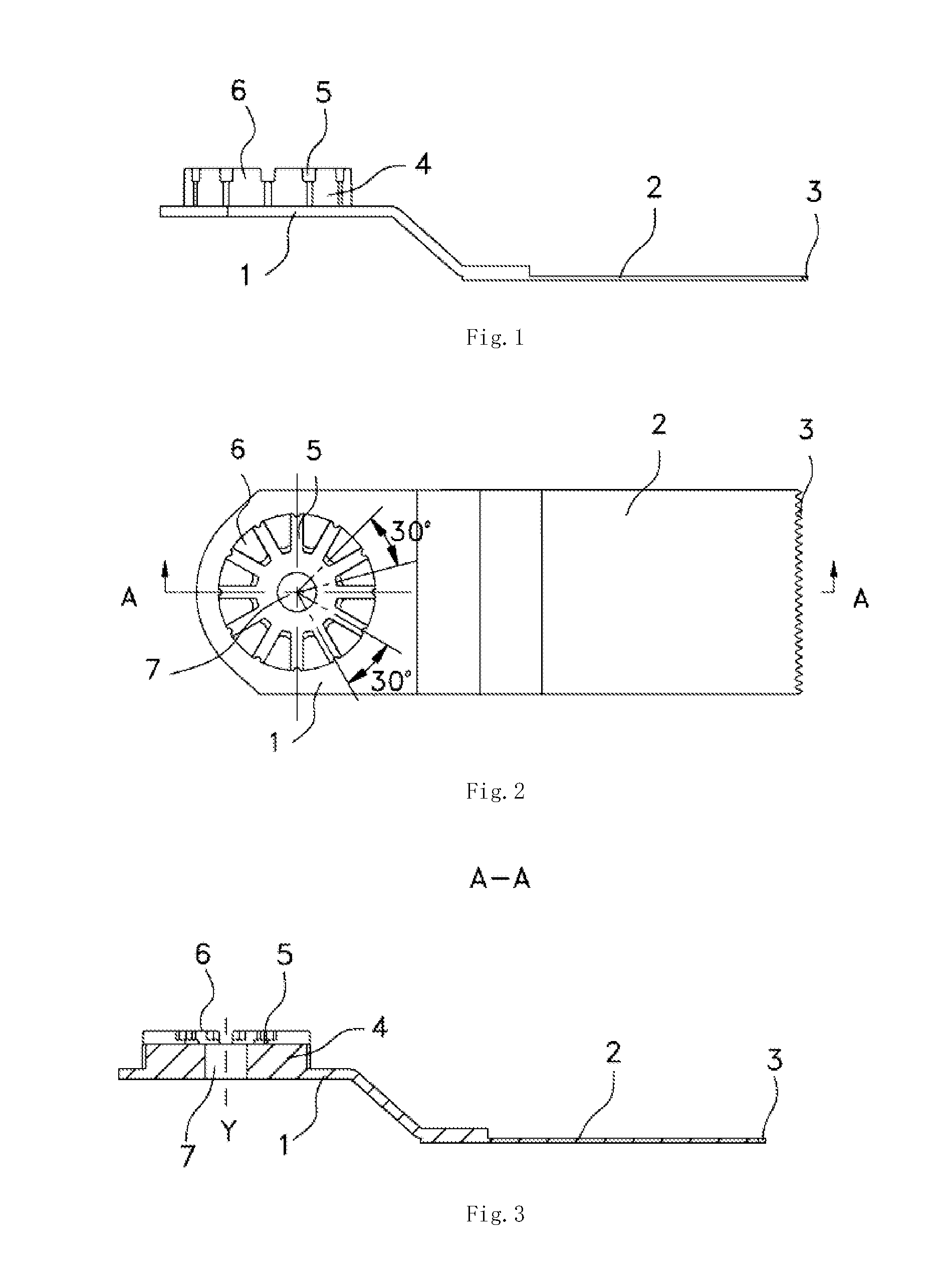

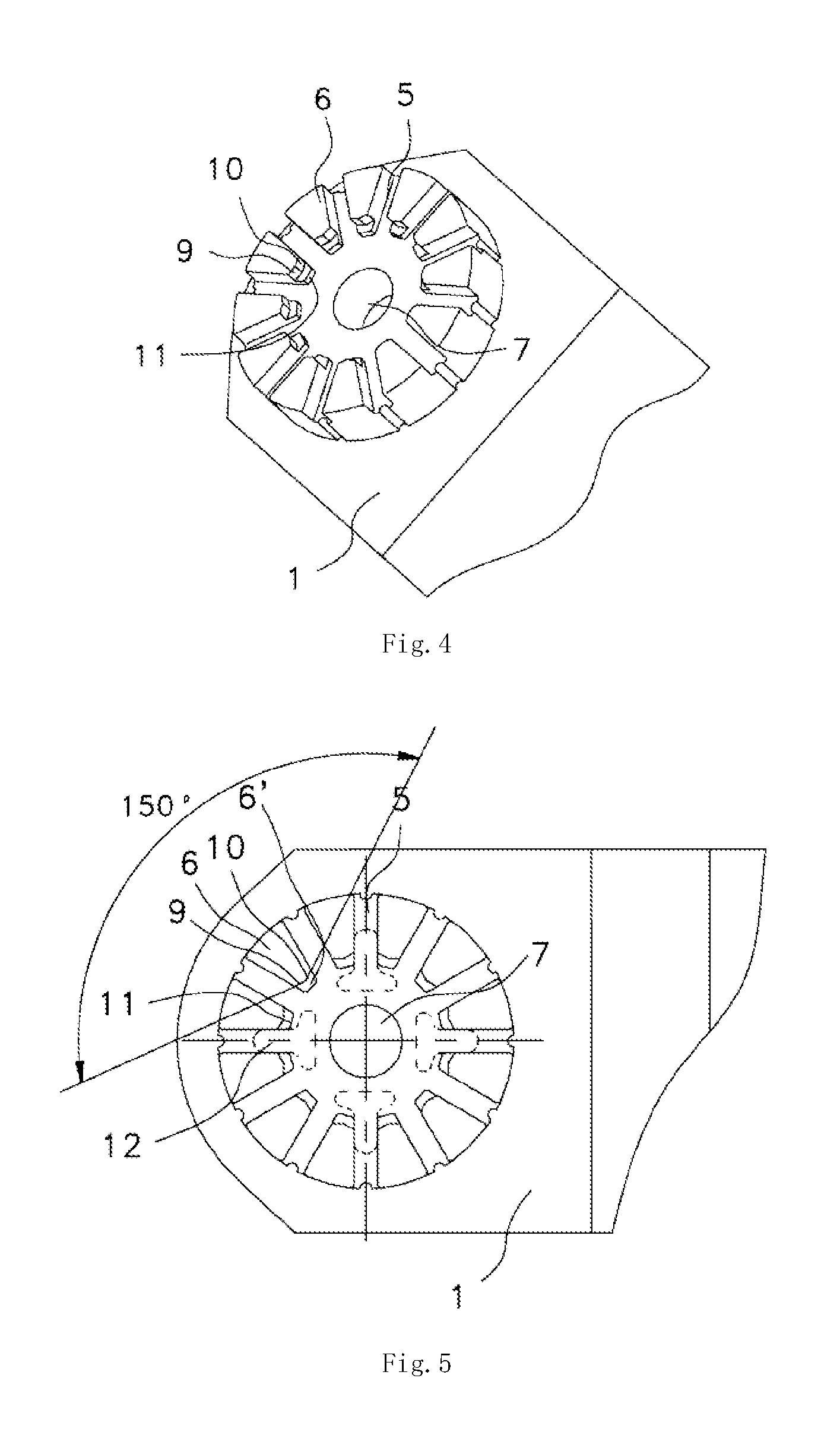

Working component for mating with multiple shaft ends

ActiveUS20110316241A1Reduce in quantityImprove portabilitySleeve/socket jointsGrinding wheel securing apparatusMechanical engineeringPhysics

A working component for mating with multiple shaft ends includes a body portion and a clamping portion which is connected to the body portion and suitable for mounting the working component to the shaft ends. The body portion has a work piece processing area for acting on the work piece to be processed and the clamping portion has a mounting hole with a longitudinal axis Y. The clamping portion includes a support portion and a mating portion which are overlapped along the direction of the longitudinal axis Y.

Owner:CHERVON HK LTD WANCHAI

Quick-change tools

InactiveUS20060150428A1Simple and safe and reliableQuick tool changeMetal sawing devicesGrinding wheel securing apparatusEngineeringScrew thread

A tool having a quick-change mechanism for replacing tool implements on a shaft, post or handle comprising a shaft, post or handle having a flange and a threaded connector. The tool further includes a tool implement adapted to be received on the shaft, post or handle adjacent thc flange. The tool also includes a stabilizer washer adapted to be received on the shaft, post or handle adjacent the work implement. A threaded fastener is adapted to be threaded onto the threaded connector of the shaft, post or handle whereby the tool implement and the stabilizer washer are retained on the shaft, post or handle by the fastener, and wherein the tool implement and the stabilizing washer are configured to allow removal of the tool implement without removing the fastener from the shaft, post or handle.

Owner:BACULY ERIC J

Adapter for multifunctional tool

InactiveUS20110227300A1Grinding wheel securing apparatusSleeve/socket jointsEngineeringMechanical engineering

An adapter for a multifunctional tool includes a converter with a first form-locating component mating with an output shaft end of the multifunctional tool and a fixer with a form-fit component mateable with the converter.

Owner:CHERVON LIMITED

Power tool and operation method thereof

ActiveCN102896619AQuick lockQuick releaseGrinding wheel securing apparatusPortable grinding machinesEngineeringPower tool

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

Electrical tool with a quick-action clamping device

InactiveUS6910694B2Action be interruptEasy constructionGrinding wheel securing apparatusCircular sawsEngineeringPower tool

A quick-action clamping device for a power tool includes a clamping spindle (4) arranged in the hollow spindle (2) of the power tool, an elastic member (5) for biasing the clamping spindle (4) into its clamping poition, in which the working tool is claming between a claming flange (7) provided on a working tool-side end of the claming spindle (4) and the hollow spindle (2), an actuation element (24) for displacing the claming spindle (4) against the biasing force of the elastic member and into its exchange position in which the working tool (3) is released, and a compansator (15) for interrupting action of the elastic member (5) on the clamping spindle (4) in the exchange position of the clamping spindle (4).

Owner:HILTI AG

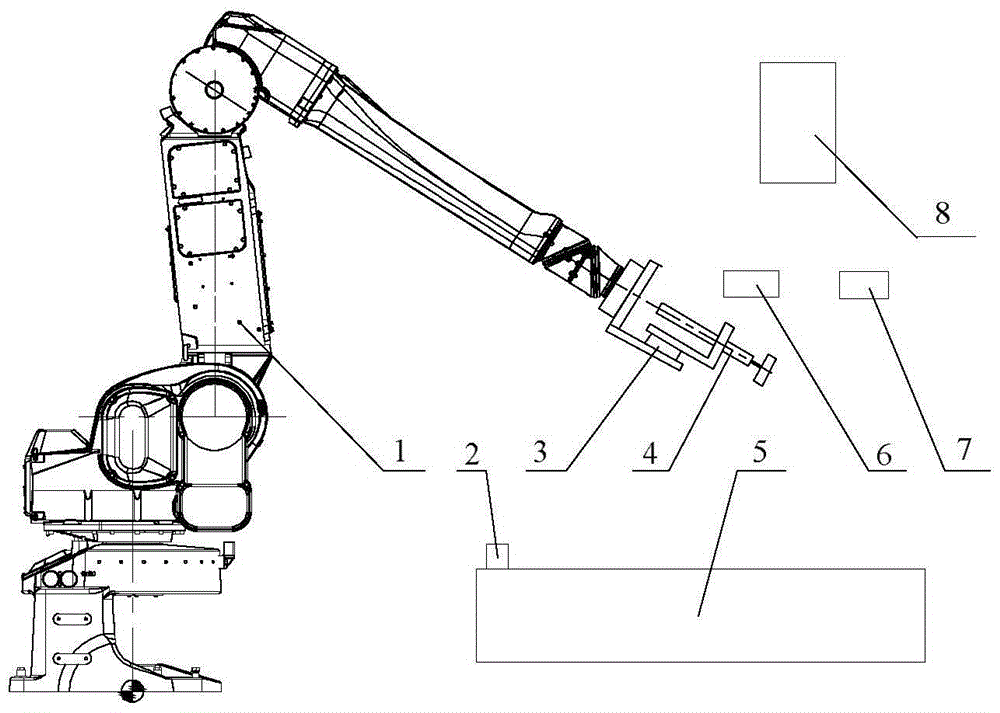

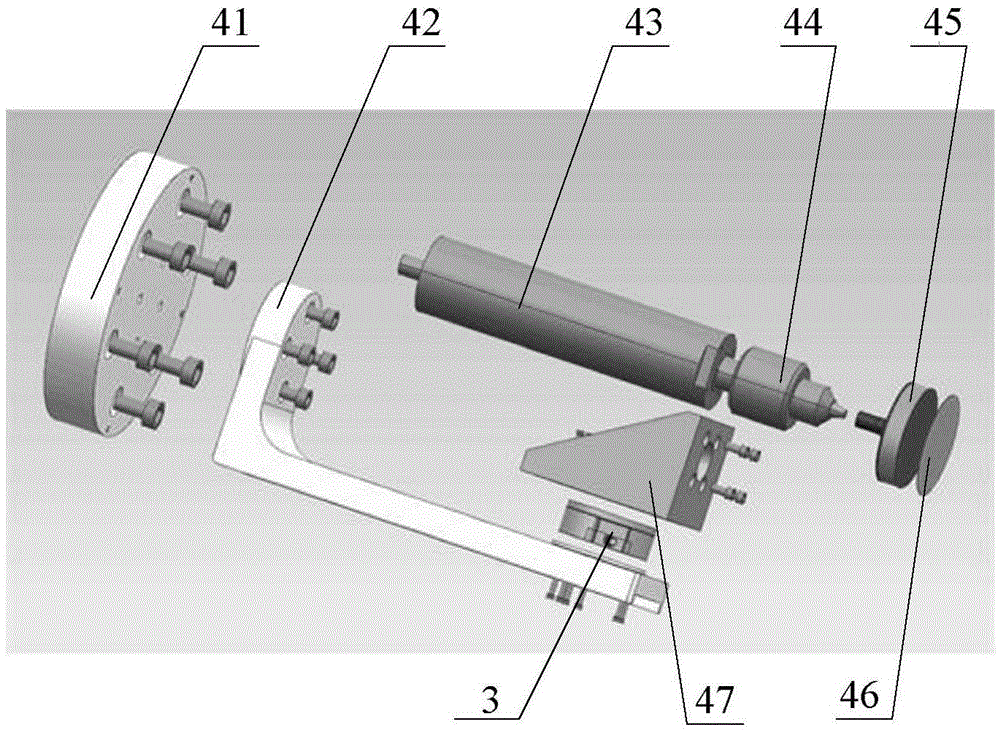

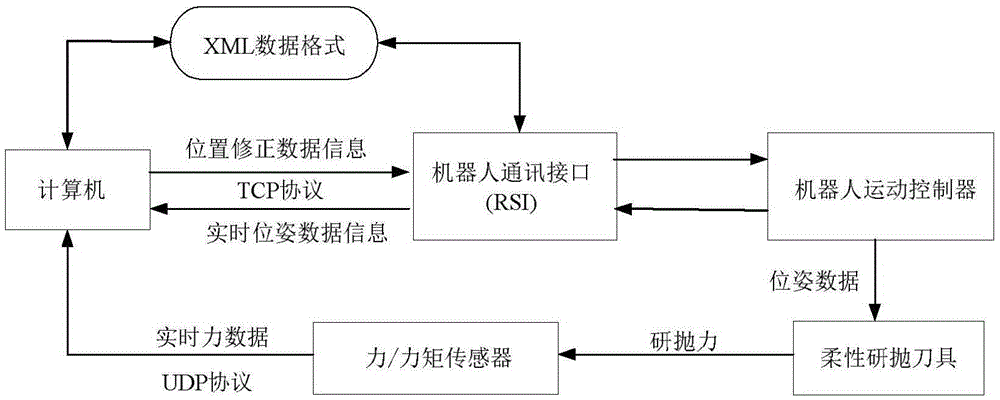

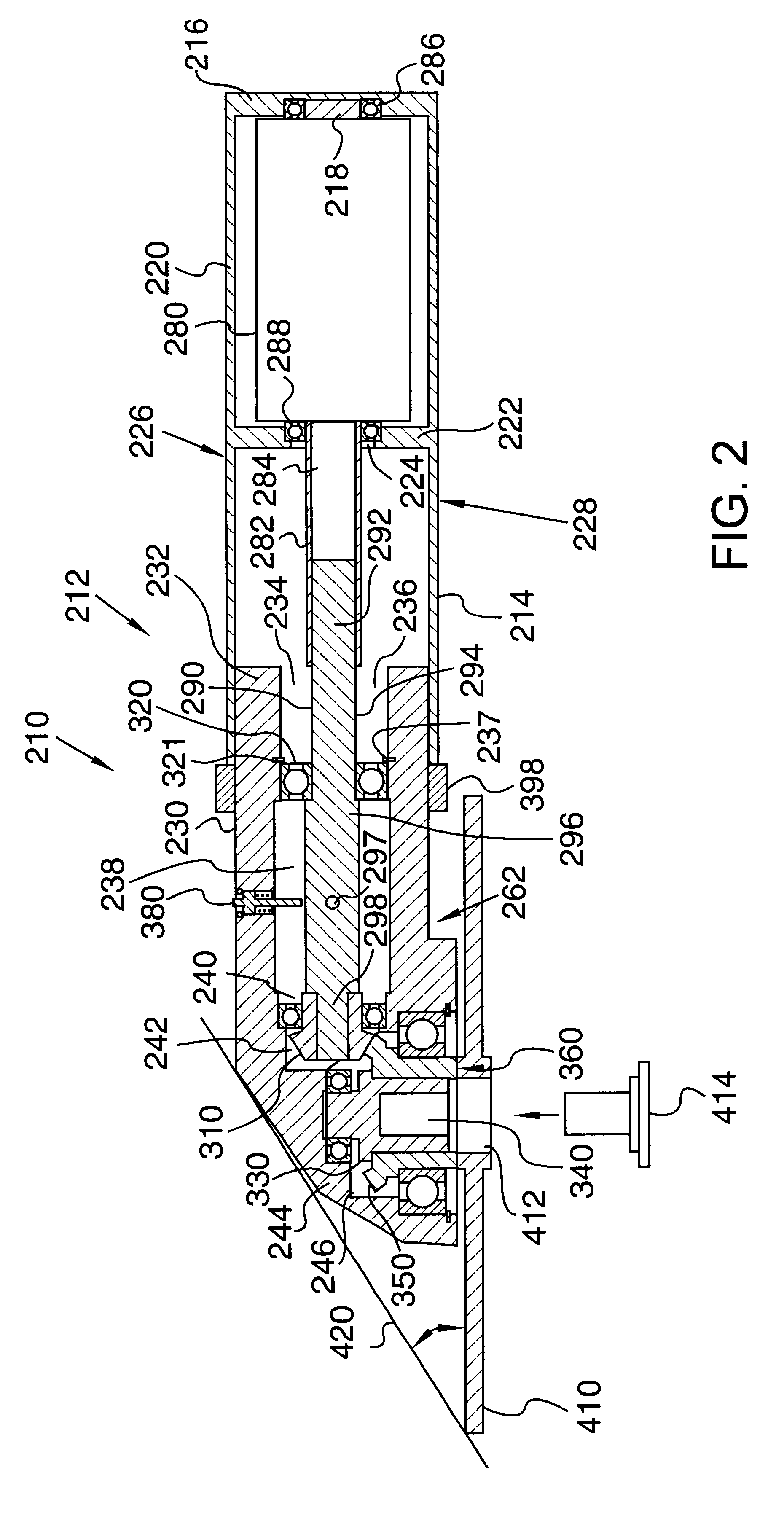

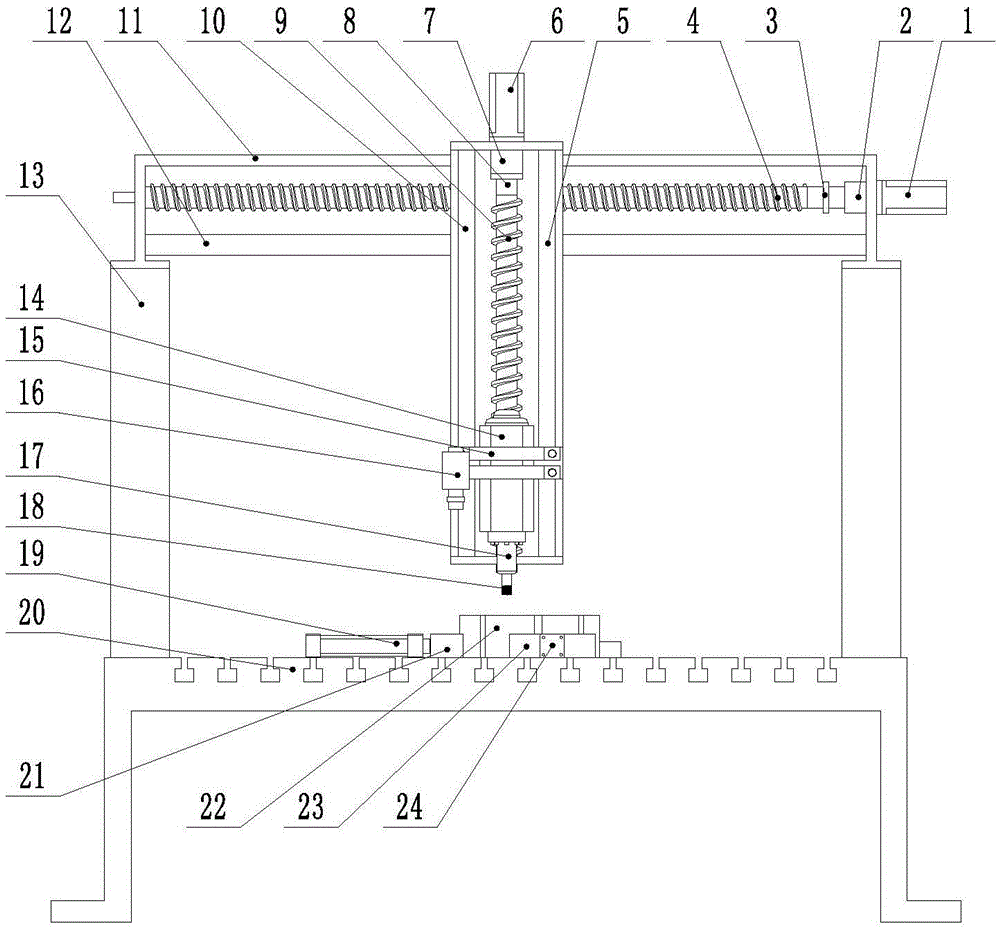

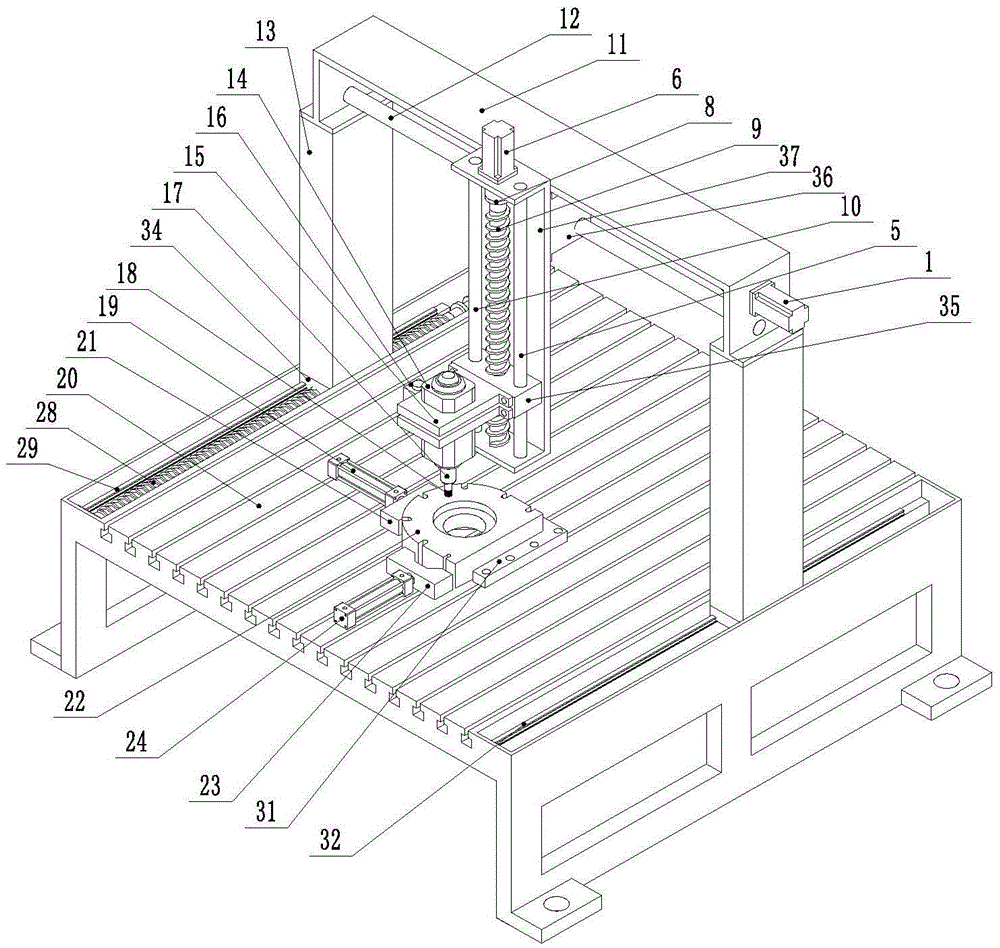

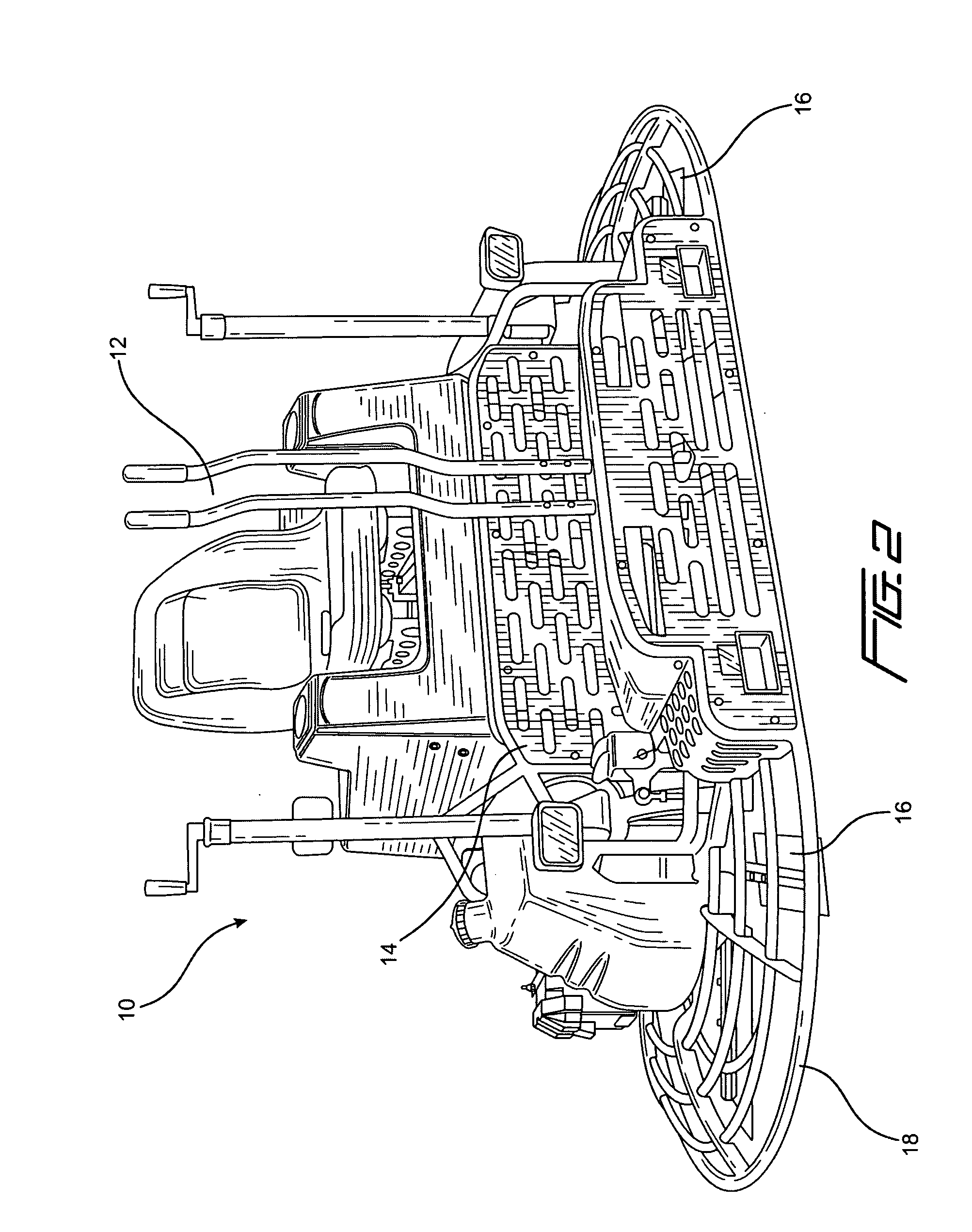

Automatic lapping and polishing system for complex surface of compliant control-based robot and machining method

InactiveCN105643399AReduce manual labor intensityReduce processing costsGrinding wheel securing apparatusGrinding drivesProcess systemsAudio power amplifier

The invention relates to an automatic lapping and polishing system for a complex surface of a compliant control-based robot and a machining method. The automatic lapping and polishing system comprises an industrial robot, a worktable, a force sensor, a flexible lapping and polishing cutter, a signal conversion amplifier, a computer and a robot controller; the method comprises the following steps: performing machining trace planning before lapping and polishing a complex surface workpiece to obtain cutter contact point trace of the lapping and polishing cutter to obtain a surface machining cutter location point trace; converting the surface machining cutter location point trace into a code format program file which can be identified by the robot controller, and inputting the code format program file into the robot controller; positioning and clamping the workpiece to complete coordinate labeling and unification of a process system; and driving the robot to move according to a machining trace planning program file to drive the lapping and polishing cutter arranged on an end executor of the robot to perform contact machining on a machined surface. According to the automatic lapping and polishing system and the machining method disclosed by the invention, manual operation at a finish machining stage of the complex surface workpiece, especially a large-sized complex surface workpiece, can be replaced; labor strength and machining cost are reduced; and quality stability and quality consistency of a machined molded surface are increased.

Owner:SHENYANG LIGONG UNIV

Hand machine tool with clamping device

InactiveUS7207873B2Avoid insufficient clamping forceIncrease clamping forceGrinding wheel securing apparatusFlexible-parts wheelsHand heldPower tool

A hand power tool has a disk-shaped tool, and a clamping device for clamping the tool, the clamping device including at least one flange and a clamping unit for clamping the tool to the at least one flange and passing through the tool, the clamping unit and the at least one flange being configured on a key-end-keyhole principle, so that after passing axially through one another and subsequently being rotated counter to one another, the clamping unit and the at least one flange axially fix one another at least in one axial direction.

Owner:ROBERT BOSCH GMBH

Hand held grinder

InactiveUS6386961B1Adds to compact designCompact designGrinding wheel securing apparatusPortable grinding machinesDrive shaftGear wheel

A hand-held grinder includes a motor and a mounting surface coupled to the motor. A housing supports the mounting surface and the motor. A grinding wheel abuts and is secured to the mounting surface, and the grinding wheel extends beyond an end of the housing. A line that is tangential with the grinding wheel distal from the housing, and that is tangential with the end of the housing, may be at an angle of less than about 45° relative to a plane of rotation of the grinding wheel. The grinder may also include a drive shaft coupled to the motor, a driving gear coupled to the drive shaft, and a driven gear engaging the driving gear and fixed to the mounting surface. The driven gear and the mounting surface may be part of a unitary member. The housing may define a bottom housing surface that is substantially coplanar with the mounting surface. The housing may also define a tapered end. The grinder may also include a telescoping feature wherein the housing includes a first member that is moveable relative to a second member to change a length of the grinder. The grinder may include a lock pin that may be selectively forced into engagement with the drive shaft, thereby preventing rotation of the drive shaft relative to the housing.

Owner:CURETON THOMAS D

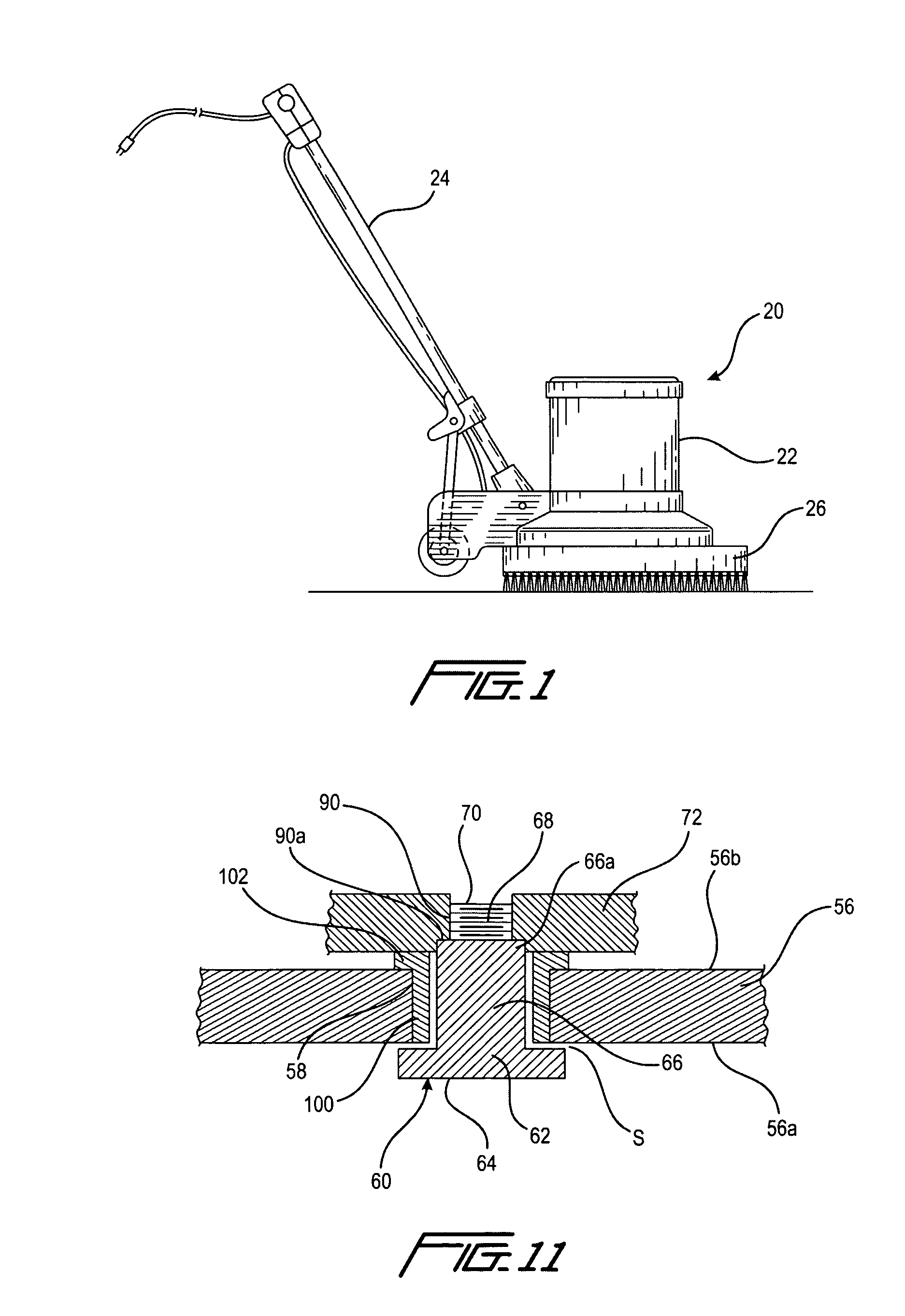

Quick change adapter for mounting brushes

A quick change adapter for removeably mounting a finishing tool to a rotary drive shaft. The quick change adapter includes a shaft hub mount designed to be mounted to a rotary drive shaft, and a tool hub mount designed to hold a finishing tool and to be removably secured to the shaft hub mount. The shaft hub mount includes a shaft sleeve with an annular sleeve ring on it. An annular locking ring is biased against the sleeve ring and includes a locking tab that slides into a locking slot in the sleeve ring. The tool adapter includes a lock sleeve adapted to slide between the annular locking ring and the shaft sleeve. The lock sleeve has a locking finger this slides into a recess slot in the locking slot when the tool adapter mount is engaged with the shaft hub mount.

Owner:WEILER BRUSH CO INC

Mounting device for disk-shaped rotating tool

InactiveUS20110086582A1Reduce vibrationSimple structureGrinding wheel securing apparatusGrinding carriagesCushioningRotary machine

An annular retaining groove is formed on the inner circumferential portion of the disk-shaped rotating tool, and a ringlike cushioning member is fitted in this annular retaining groove so as to be partially exposed. Both sides of the inner circumferential portion of the disk-shaped rotating tool are held by first and second holding members through the annular cushioning member. An axial portion of the first holding member is engaged with an output shaft of an electric rotary machine so that the disk-shaped rotating tool is rotated through the first holding member by the output shaft.

Owner:TENRYU SAW MFG

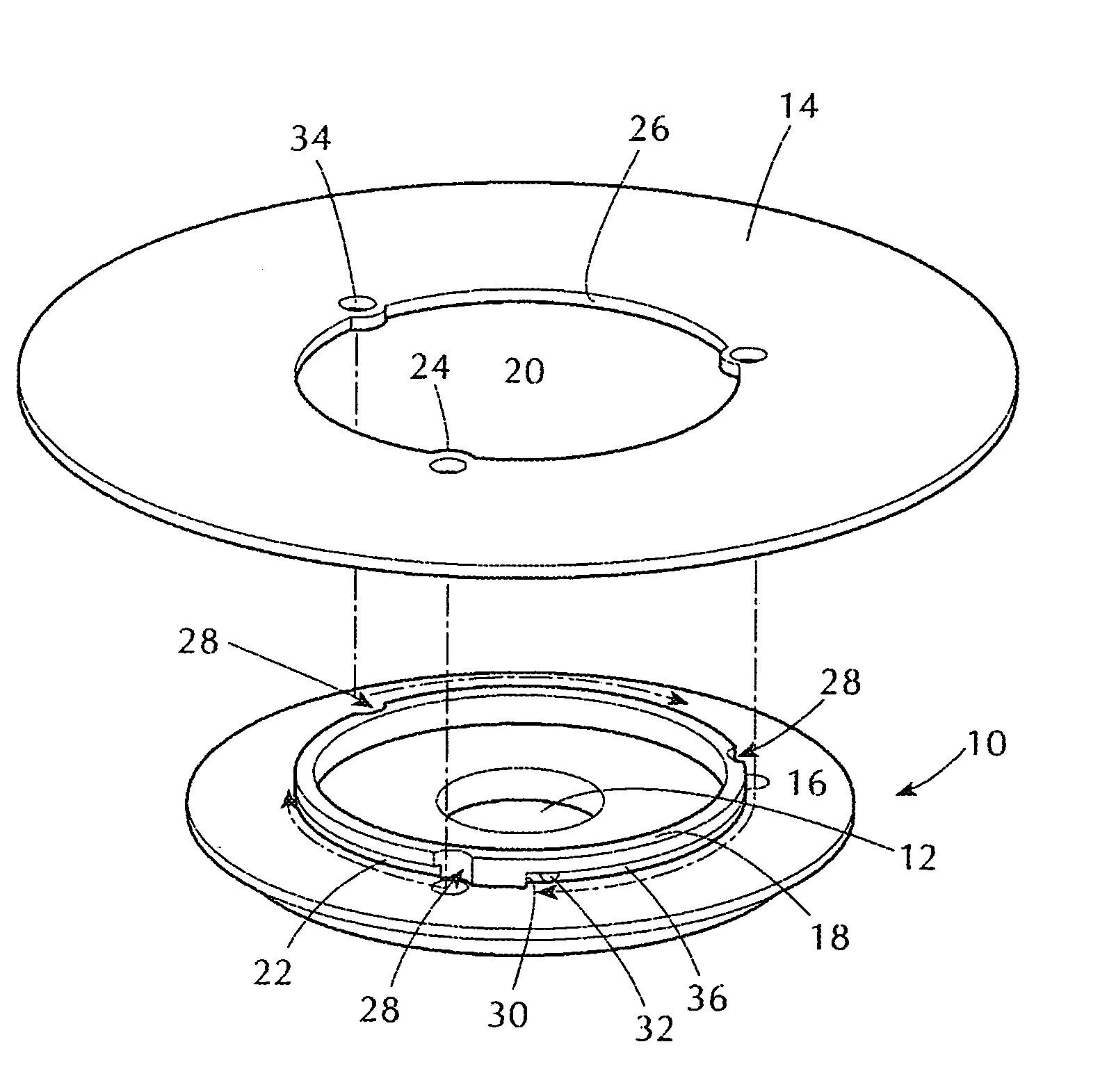

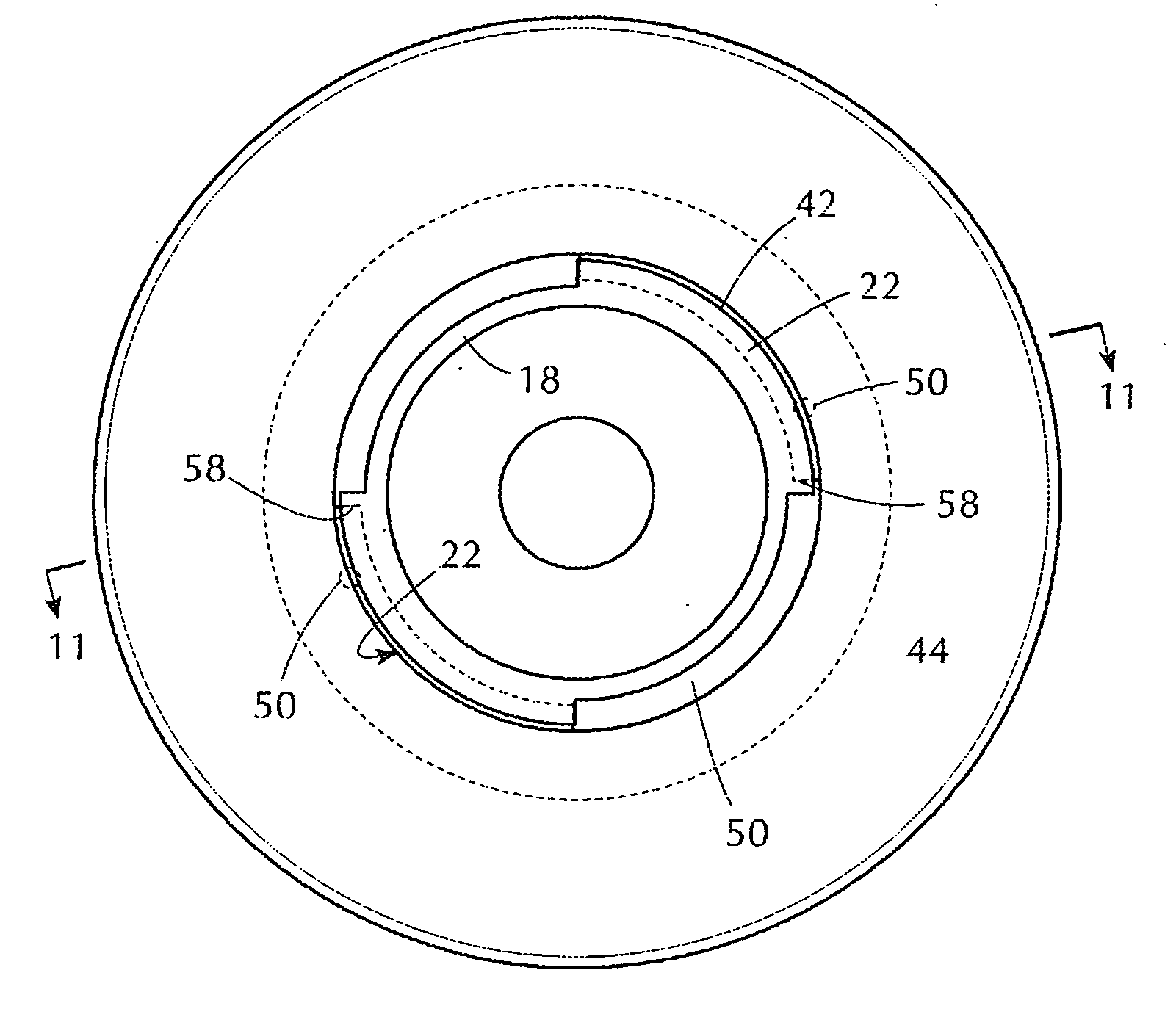

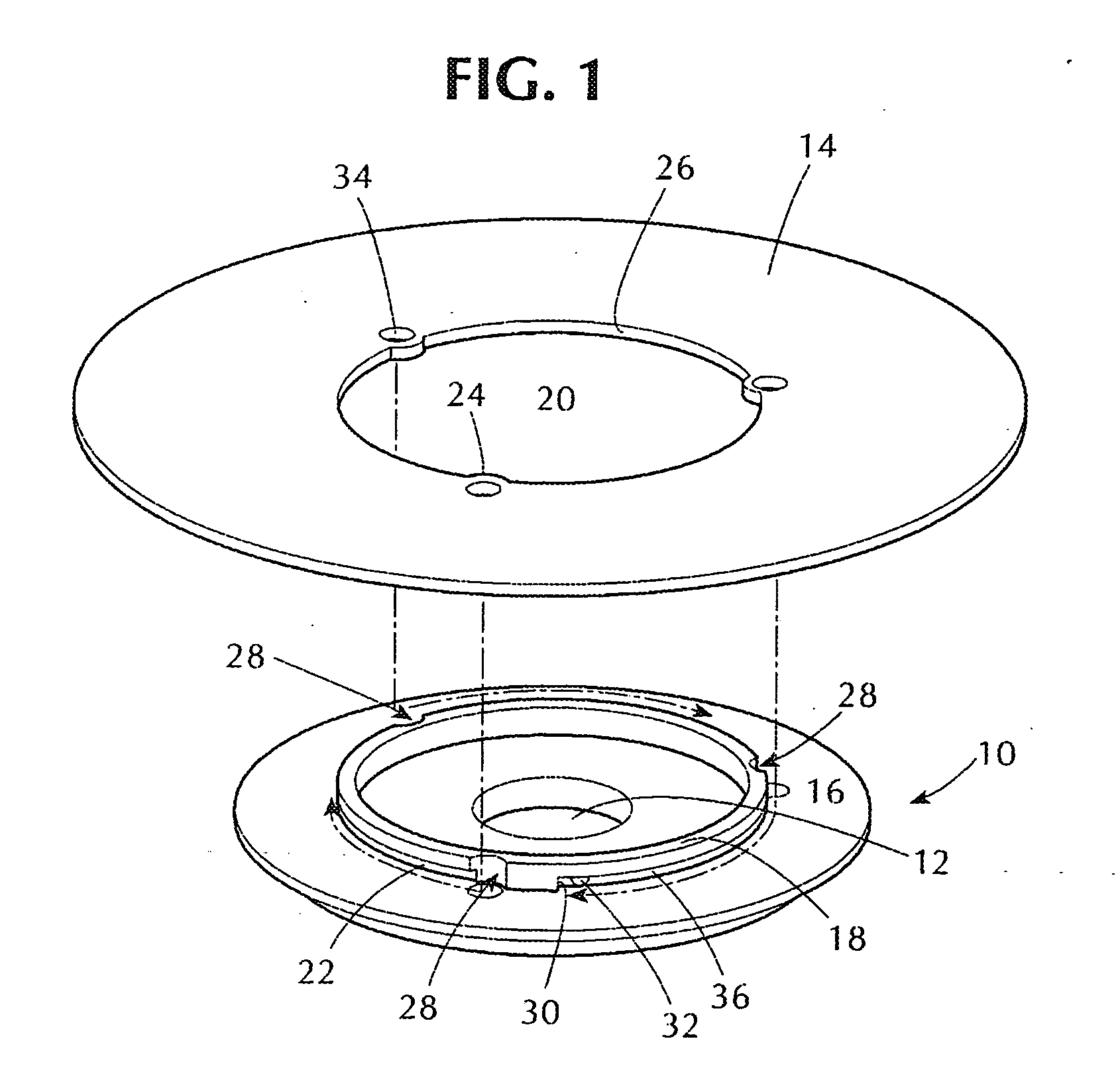

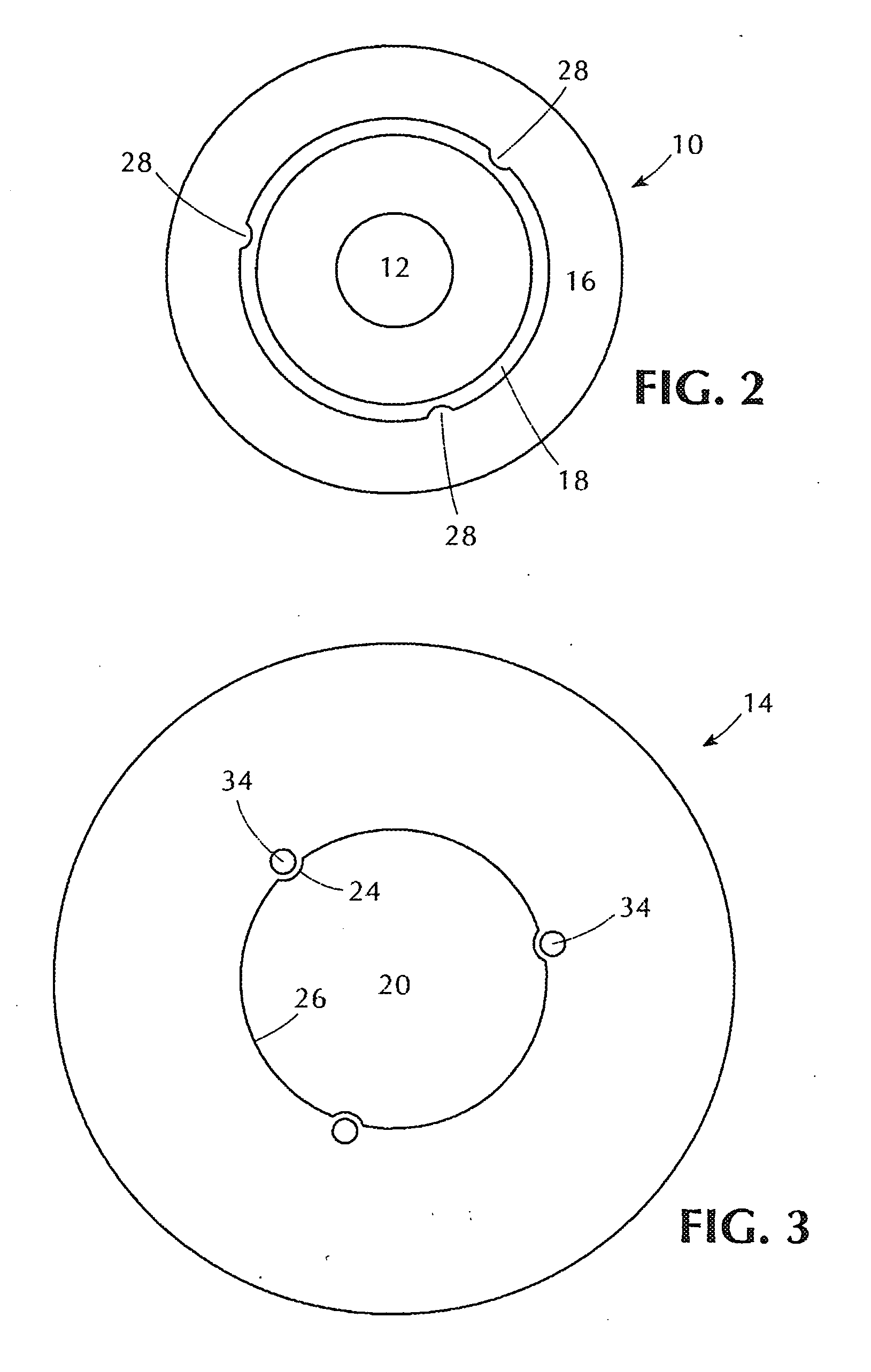

Mounting system for grinding wheels and the like

A mounting system for rotating tools such as grinding wheels in a hand-held power tool, includes a hub mountable to the tool drive shaft and a rotating tool element removably affixable to the hub. The tool has at least one flange that engages a corresponding circumferential groove in a hub wall. Both the hub and tool have complimentary lock elements to frictionally retain the tool in a releasably fixed orientation upon the hub. One of the lock elements is in the form of a depression, while a mating element located on the other ports is a complimentary projection.

Owner:NAO ENTERPRISE

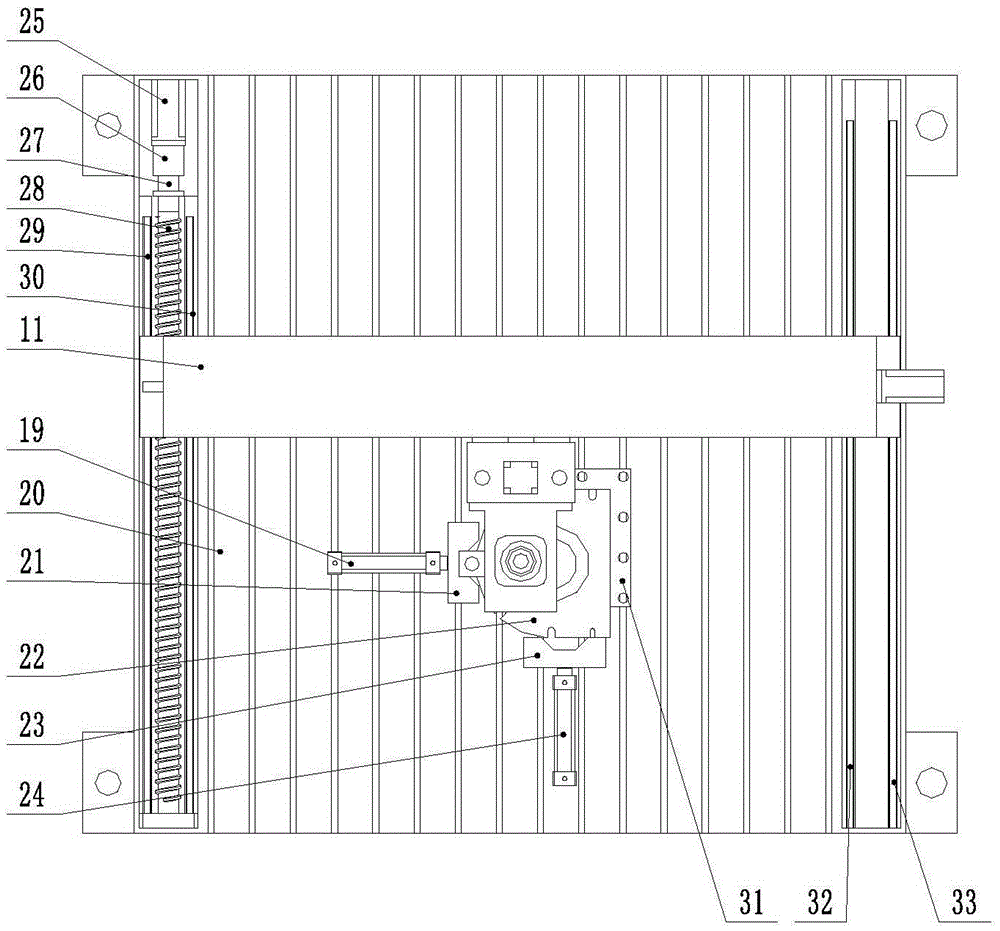

Workpiece clamping structure for grinding tool, and tracking type casting edging machine and method

InactiveCN105598777ASo as not to damageImprove uneven lightingEdge grinding machinesGrinding wheel securing apparatusProduction drawingControl system

The invention discloses a workpiece clamping structure for a grinding tool, and a tracking type casting edging machine and method. The workpiece clamping structure comprises a workbench, the workbench is provided with a plurality of positioning devices, at least one positioning device comprises a cylinder and a clamping block, and the clamping blocks clamp or leave a workpiece to be machined, under the action of cylinder piston rods. The tracking type casting edging machine comprises a bed, a moving mechanism, a grinding head assembly, the above-mentioned workpiece clamping structure, an industrial camera, a visual recognition system and a control system. The edging machine can quickly grind flash and burrs on a casting according to the requirements of a production drawing and the shape and size of the casting, without programming and equipment adjusting during casting replacement, the production efficiency is high, and machining error is small.

Owner:UNIV OF JINAN

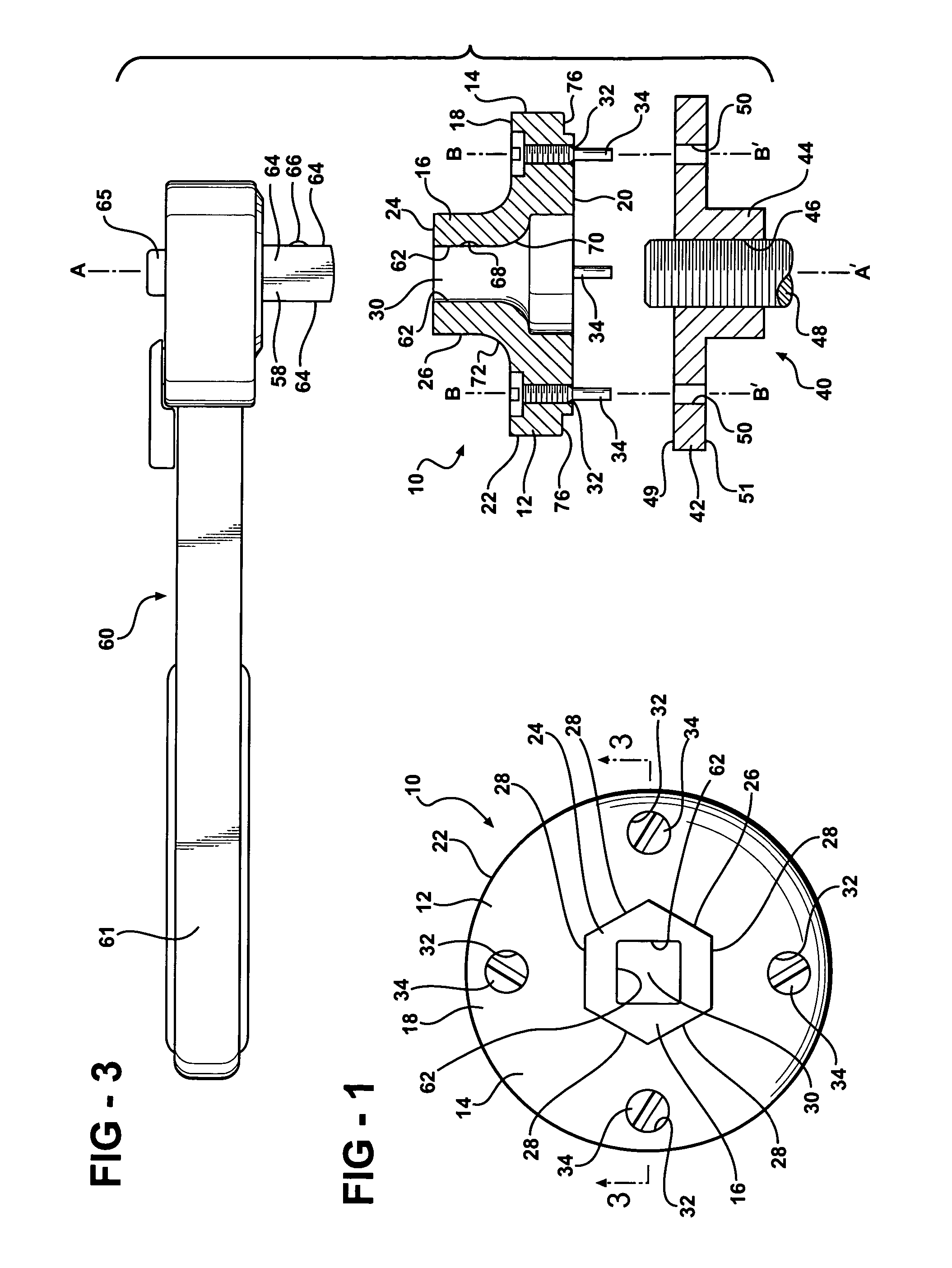

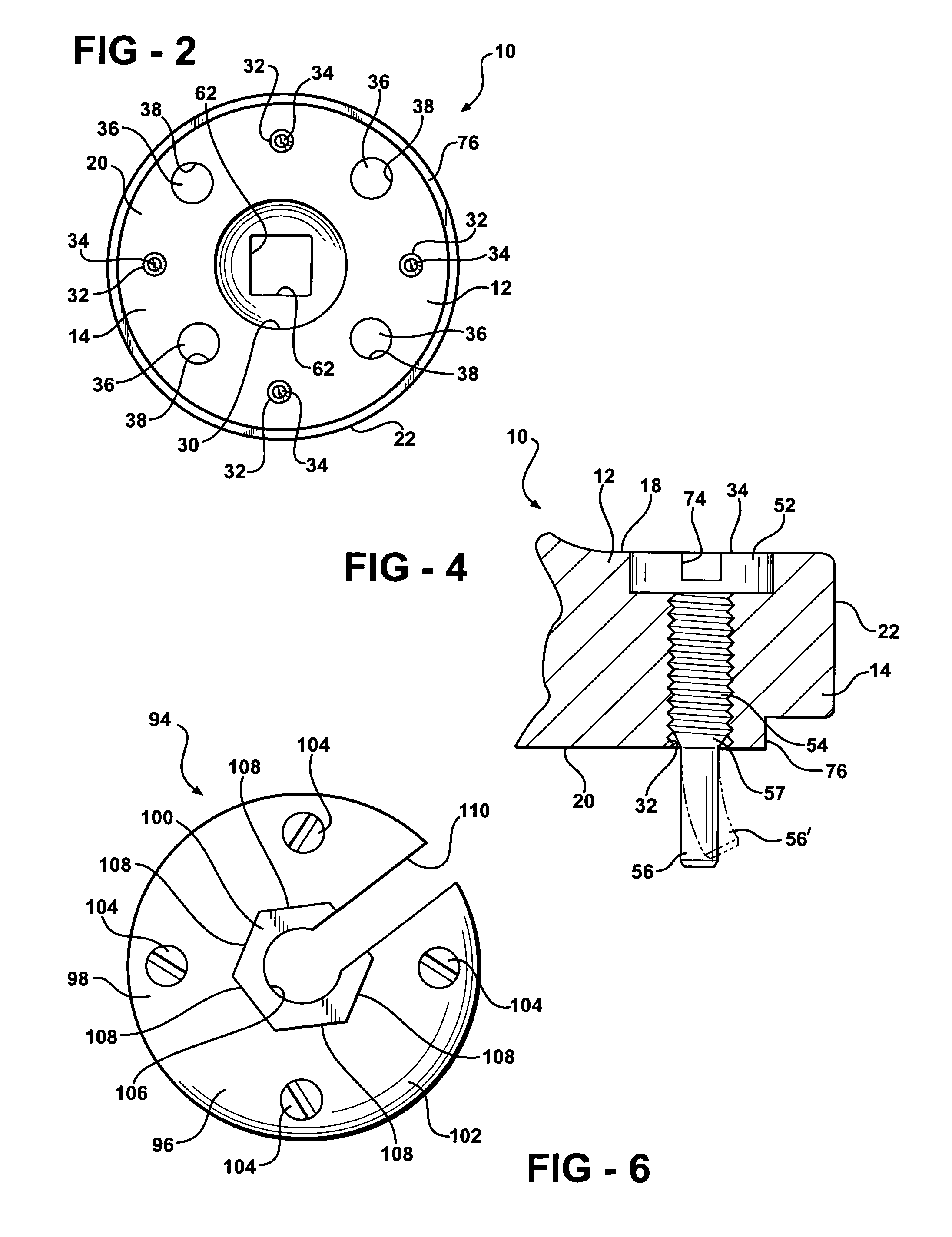

Mounting system for grinding wheels and the like

InactiveUS20070167119A1Grinding wheel securing apparatusPortable grinding machinesDrive shaftHand held

A mounting system for rotating tools such as grinding wheels in a hand-held power tool, includes a hub mountable to the tool drive shaft and a rotating tool element removably affixable to the hub. The tool has at least one flange that engages a corresponding circumferential groove in a hub wall. Both the hub and tool have complimentary lock elements to frictionally retain the tool in a releasably fixed orientation upon the hub. One of the lock elements is in the form of a depression, while a mating element located on the other ports is a complimentary projection.

Owner:NAO ENTERPRISE

Composition and method for temporarily fixing solid

InactiveUS20040185187A1Promote repairEasy to disassembleLiquid crystal compositionsAdhesive processesSemiconductorLiquid crystal

The present invention relates to a method of temporarily and firmly fixing two solids to each other and to a composition used in the method, which is a method of temporarily fixing, comprising temporarily fixing the two solids to each other with a liquid crystal compound or a composition comprising the liquid crystal compound. This method is used for a method of temporarily fixing a pad for chemical mechanical polishing, for example, to polish a wafer for a semiconductor device fixed on a surface of a base plate, when one solid is a pad for chemical mechanical polishing of a wafer for a semiconductor device and the other is a base plate to fix the pad.

Owner:JSR CORPORATIOON

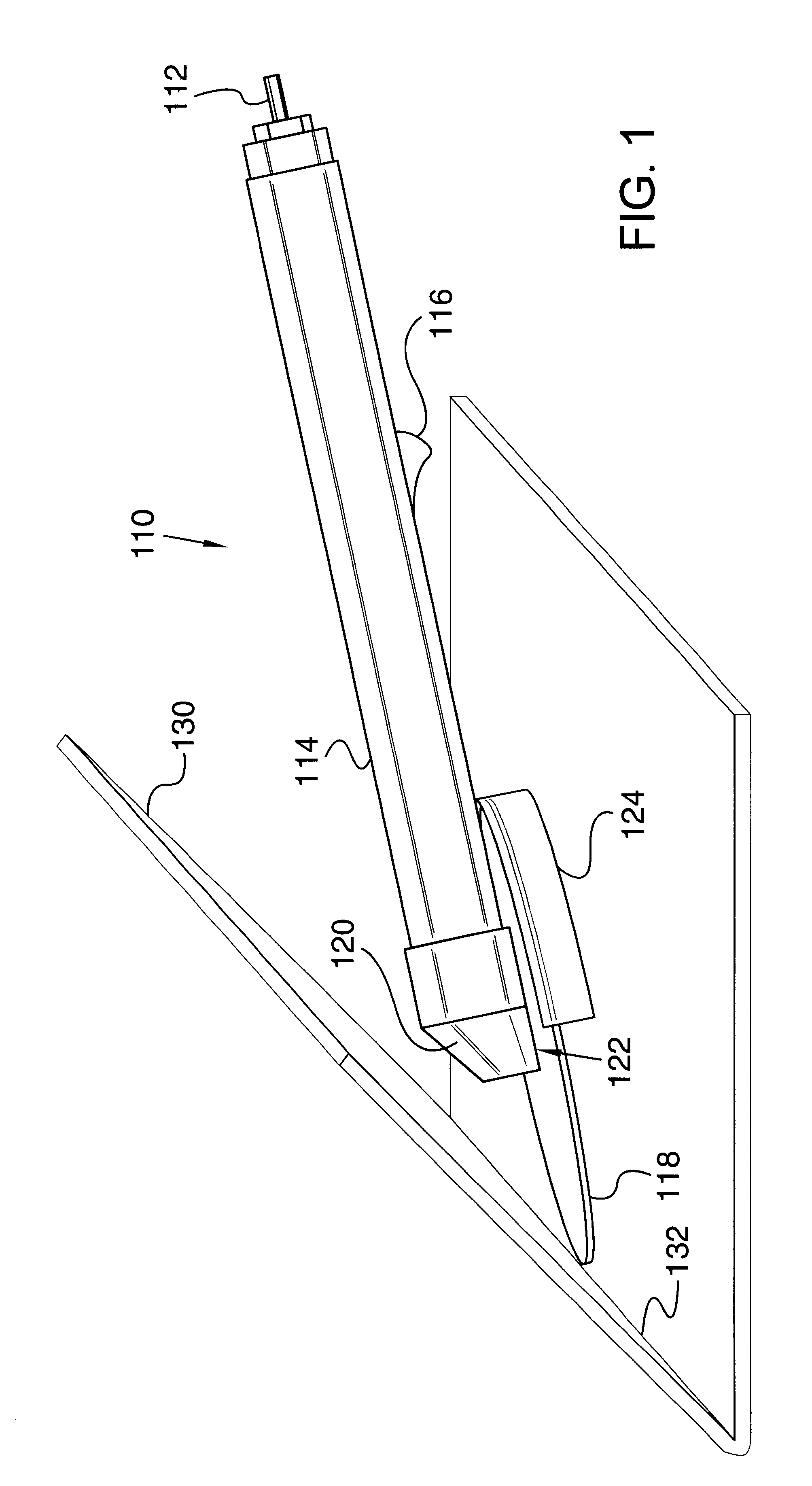

Tool

InactiveUS20050153640A1Releasing connectionProducing releasingGrinding wheel securing apparatusSupport wheelsEngineeringMagnet

In a tool comprising a supporting part and a disk-shaped working part for machining operation, the supporting part comprises a supporting face for the working part and a permanent magnet within the supporting face. The working part comprises a coupling member of ferromagnetic material which is movable into magnetically clinging connection with the permanent magnet upon application of a counterpart supporting face to the supporting face.

Owner:FA AUGUST RUGGEBRERG

Polishing device and polishing pad component exchange device and method

InactiveUS20010041650A1High frequencyEasy to operateGrinding wheel securing apparatusSupport wheelsRelative displacementMechanical engineering

A polishing device includes a wafer chuck mechanism which retains a wafer while its plane to be polished faces upward, a polishing pad component which possesses a polishing plane which polishes the wafer, a polishing head, and a shift mechanism which enables a relative displacement of said polishing pad component in relation to the wafer. A fixation and retention mechanism fixes and retains said polishing pad component to the polishing head in a detachable fashion while its polishing plane faces downward. The displacement distance of the shift mechanism ranges from the polishing position of the wafer to the exchange position of the polishing pad component, so that the polishing pad component is automatically exchanged.

Owner:NIKON CORP

Power-driven hand tool with clamping fixture for a tool

InactiveUS8317574B2Easy to handleEasy to installGrinding wheel securing apparatusPortable grinding machinesEngineeringHand tool

A power-driven hand tool is disclosed comprising a housing, a work spindle for driving a tool, which tool can be located between a tool end of the work spindle and a fixing mechanism, further comprising a displacing mechanism with a clamping lever, adapted to pivot about a pivot axis for displacing the fixing mechanism between a releasing position, in which the fixing mechanism can be released from the work spindle, and a clamping position in which the fixing mechanism is clamped on the work spindle by a spring. An impeding mechanism is provided that interacts with the clamping lever for impeding the pivoting movement of the clamping lever between the releasing position and the clamping position.

Owner:C & E FEIN GMBH & CO KG

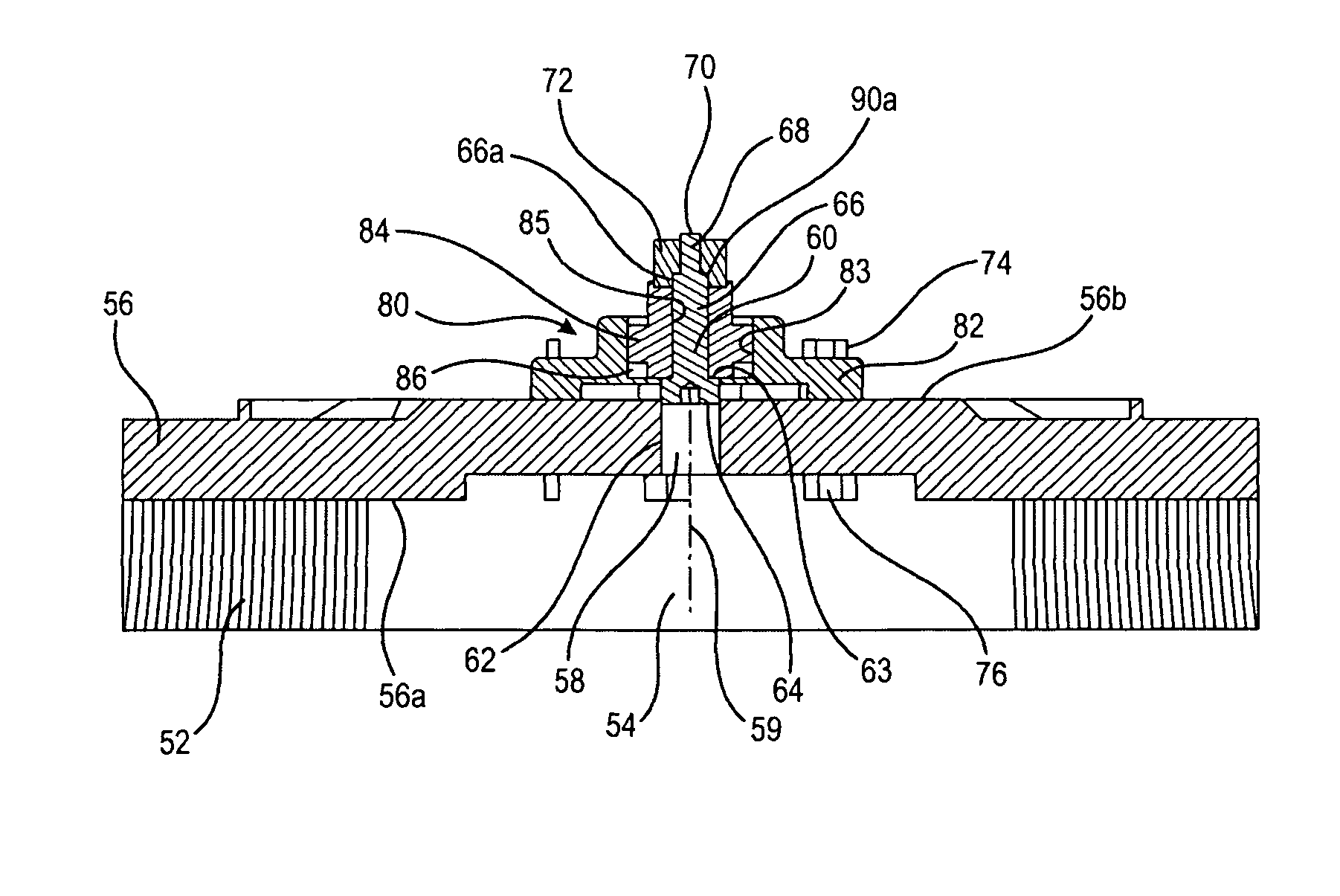

Mounting adapter for concrete surface processing tool

InactiveUS7815393B2Increase capacityFor quick replacementGrinding wheel securing apparatusCarpet cleanersMotor driveEngineering

A mounting assembly for rotatably mounting a surface processing tool holder on at least one motor driven rotatable arm of a surface processing apparatus, such that the tool can spin freely as the arm is driven by the motor, includes an elongate shank having a smooth surfaced, cylindrical portion intermediate its ends adapted for positioning within an aperture in the tool holder with one threaded end portion projecting through the aperture for attachment to an elongate mounting bar adapted for attachment to the arm. A bearing supported by the tool body and surrounding the smooth surfaced portion of the shank is rotatable relative to the shank. The mounting bar includes a threaded aperture for receiving the threaded end portion of the shank and the threaded aperture includes a counterbore for receiving the end portion of the smooth surfaced shank portion which is adjacent the threaded end portion.

Owner:WAGMAN METAL PRODS

Pneumatic grinder with improved muffling structure

InactiveUS7238095B1Simple structureReduce noiseGrinding wheel securing apparatusConstructionsEngineeringGrinding wheel

A pneumatic grinder with improved muffling structure primarily comprises a driving portion, a grinding wheel fixing portion provided at one end of the driving portion, a first housing connected to the other end of the driving portion by means of a combining portion, a second housing mounted onto the first housing, and a plurality of first and second exhaust openings arranged in staggered fashion respectively on the first and second housings. Said structure allows the pneumatic grinder to discharge waste air through foresaid two layers of exhaust openings in staggered fashion arranged in order to reduce noise during air exhaust.

Owner:STORM PNEUMATIC TOOL CO LTD

Spanner socket

InactiveUS7272996B2Low costIncrease flexibilityGrinding wheel securing apparatusSpannersRotational axisWrench

A spanner socket for application with conventional hand tools such as ratchet drivers and fixed wrenches employed for imparting torque to a work piece about an axis of rotation includes a generally cylindrical shaped base member which defines a predetermined number of engagement surfaces which are circumferentially arranged around the axis of rotation. The engagement surfaces are employed for releasably coupling with the associated hand tool. Two or more elongated drive pins are carried by the base member for rotation therewith about said axis of rotation. Each drive pin defines an axis of elongation, which is parallel to the axis of rotation and spaced from the axis of rotation for engagement with the work piece for the application of torque thereto.

Owner:PONTIERI JAMES MATTHEW

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com